Patents

Literature

543results about How to "Cold-resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature resistant flame-retardant environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

Environment-friendly cold-resistant polyvinyl chloride cable material and preparation method thereof

InactiveCN102653618AImprove performanceHeat resistantPlastic/resin/waxes insulatorsAntioxidantDioctyl terephthalate

The invention provides an environment-friendly cold-resistant polyvinyl chloride cable material and a preparation method thereof. The environment-friendly cold-resistant polyvinyl chloride cable material is prepared from the following raw materials in percentage by mass: 40-60% of polyvinyl chloride, 5-25% of dioctyl terephthalate, 5-25% of dioctyl adipate, 1-10% of chlorinated polyethylene, 5-25% of light activated calcium carbonate, 1-3% of lubricant, 2-8% of Ca-Zn composite stabilizer, 0.1-1% of antioxidant and 0.1-4% of pigment. The environment-friendly cold-resistant polyvinyl chloride cable material is mainly compounded from dioctyl terephthalate and dioctyl adipate. The cable material can be normally used in a low-temperature environment of -40 to -65 DEG C, has favorable shock resistance under low-temperature conditions, does not contain ortho-benzoic ether compounds, and is environment-friendly, thereby solving the problem that the existing polyvinyl chloride cable material is not environment-friendly and has poor shock resistance under low-temperature conditions.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD +1

Leaf fertilizer containing amino acid and its preparation method

InactiveCN1911869AFull of nutritionPromote activationOrganic fertilisersFertilizer mixturesPhosphateCopper sulfate

The present invention relates to fertilizer preparing technology, and is especially one kind of foliage fertilizer containing amino acid and with fast acting and its preparation process. The foliage fertilizer includes potassium dihydrogen phosphate 2-4 weight portions, copper sulfate 0.3-0.6 weight portions, ferrous sulfat 0.4-0.8 weight portions, magnesium sulfate 0.4-0.8 weight portions, zinc sulfate 0.3-0.6 weight portions, borax 0.4-0.8 weight portions, manganese sulfate 0.2-0.4 weight portions, calcium sulfate 0.2-0.4 weight portions, urea 2-4 weight portions, honey 0.1-0.3 weight portions, milk 0.5-1.0 weight portions, water soluble vitamins electrolyte 0.02-0.04 weight portions, amino acid 0.5-1.5 weight portions, fish liver oil 0.02-0.04 weight portions, vitamins B 0.04-0.12 weight portions. The foliage fertilizer has rich nutrients and pH 5.5-6.5 after being diluted, is suitable for foliage absorption and may be used to replace root applying organic fertilizer.

Owner:陈俊茂

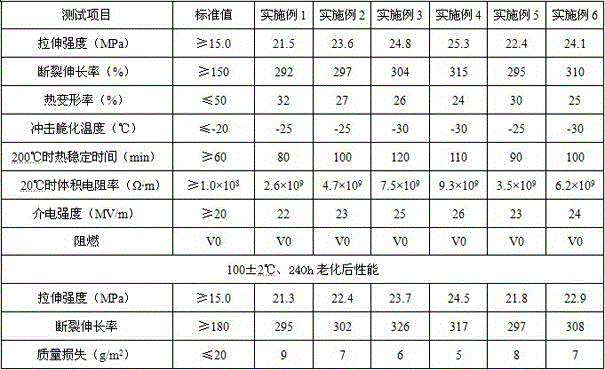

High temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and preparing method thereof

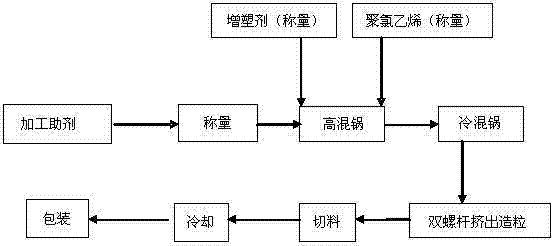

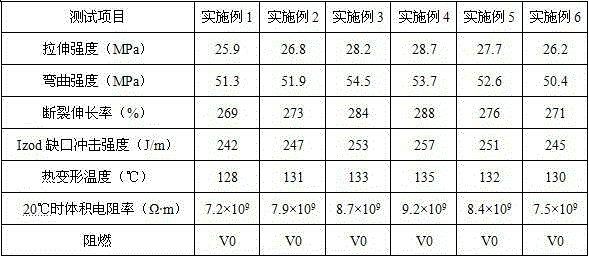

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a high temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and a preparing method thereof. The modified material comprises by weight, 80-120 parts of PVC resin, 30-70 parts of filling agent, 31-70 parts of plasticizer, 1-10 parts of hot-resistant modifying agent, 1-10 parts of fire retardant, 1-10 parts of stabilizing agent, 5-15 parts of impact modifier and 0.2-2 parts of lubricating agent. Each raw material is weighed by weight and mixed after being stirred; the raw material is squeezed out of prilling through a double-screw extruder and the modified material is available. The hot temperature resistant performance of the modified material manufactured by the preparing method is fine; the maximum usage temperature can reach up to 135 DEG C. The modified material is environment-friendly and has the advantages of high intensity, good flame retardant effects, strong compression performance and toughness, excellent processing performance and better comprehensive performance. The preparing method of the high temperature resistant environment-friendly polyvinyl chloride (PVC) modified material has the advantages of being simple in process, convenient to control and operate, stable in quality, and high in production efficiency. In addition, the preparation method of the high temperature resistant environment-friendly polyvinyl chloride (PVC) modified material can be used for a large-scale industrial production.

Owner:广东祺龙科技有限公司

Waste PVC (Polyvinyl Chloride) and fly ash composite material and preparation method thereof

The invention relates to the technical field of PVC (Polyvinyl Chloride) composite materials and particularly relates to a waste PVC and fly ash composite material and a preparation method thereof. The waste PVC and fly ash composite material comprises the following raw materials according to parts by weight: 80-120 parts of waste PVC, 35-55 parts of fly ash, 3-10 parts of plasticizer, 1-2 parts of flame retardant, 0.5-2 parts of stabilizer, 0.5-2 parts of impact modifier, 0.3-1 part of lubricant and 0.1-0.5 part of antioxidant. The preparation method comprises the following steps of: weighing all the raw materials according to the parts by weight, mixing, stirring, extruding through a twin-screw extruder for granulation, chopping and air-cooling to obtain the waste PVC and fly ash composite material. The waste PVC and fly ash composite material prepared by the preparation method has excellent heat resistance, high strength, good flame retardant effect, high compression performance and toughness, and excellent processing performance and comprehensive performance; and the additive amount of renewable resources in the waste PVC and fly ash composite material reaches 90%-95%, thus lowering the production cost, reducing the environmental pollution, and bringing good economic benefit and social benefit.

Owner:广东祺龙科技有限公司

Polyesteramide hot melt adhesive with low melting point and preparation method thereof

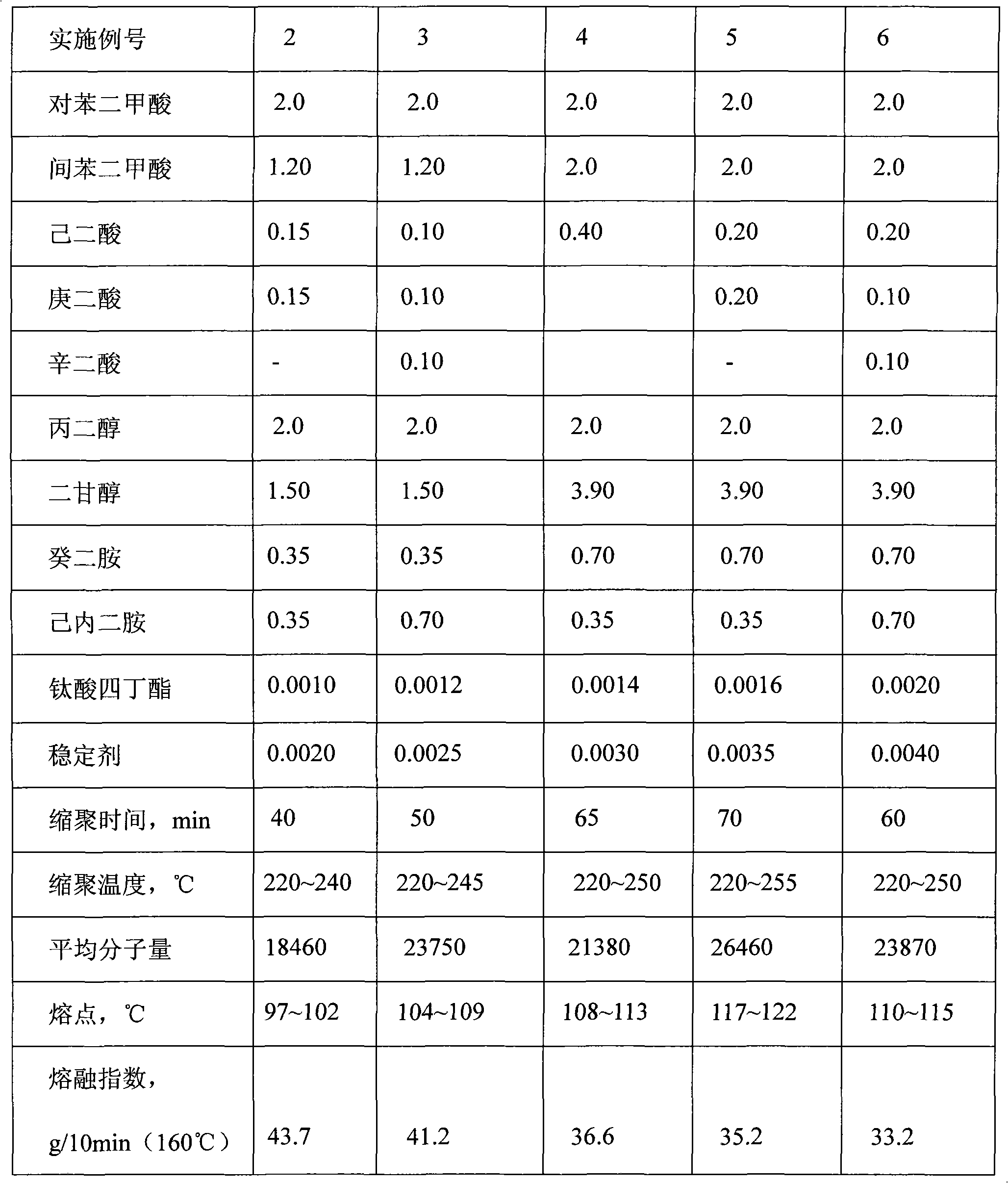

The invention provides a preparation method of a polyesteramide hot melt adhesive with a low melting point, which mainly comprises the following steps of: (1) carrying out an esterification reaction on terephthalic acid, propylene glycol and diglycol under the action of a tetrabutyl titanate catalyst; (2) adding isophthalic acid, aliphatic dicarboxylic acid, decamethylene diamine and caprolactam into the products of the step (1) to carry out esterification and amidation reactions; and (3) adding 2,6-tertiary butyl-4-methylphenol as a polycondensation stabilizer into the reaction system, and carrying out copolycondensation under reduced pressure to obtain a copolymer. The obtained polyesteramide hot melt adhesive has the advantages of good heat stability, heat resistance, cold resistance, quick solidification and the like, is widely applied to the adhesion of synthetic fiber and is especially applicable to nylon products.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +1

High-resolution remote sensing image road information extraction method

InactiveCN106295562AImprove adhesionWith tenacityCharacter and pattern recognitionRgb imageImage segmentation

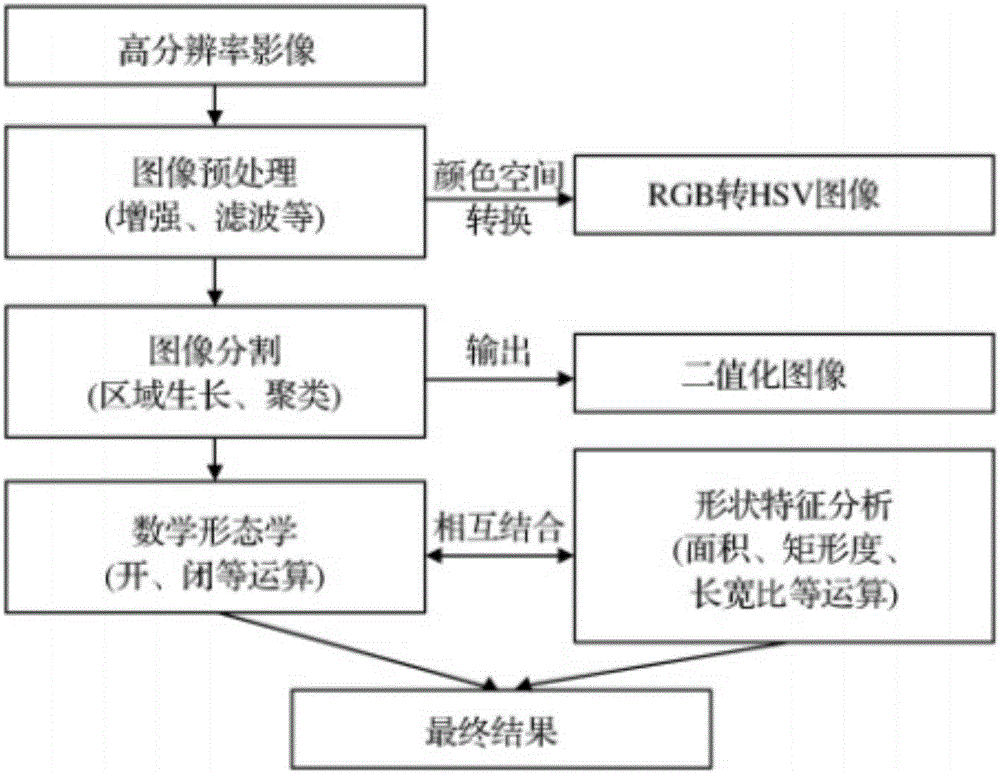

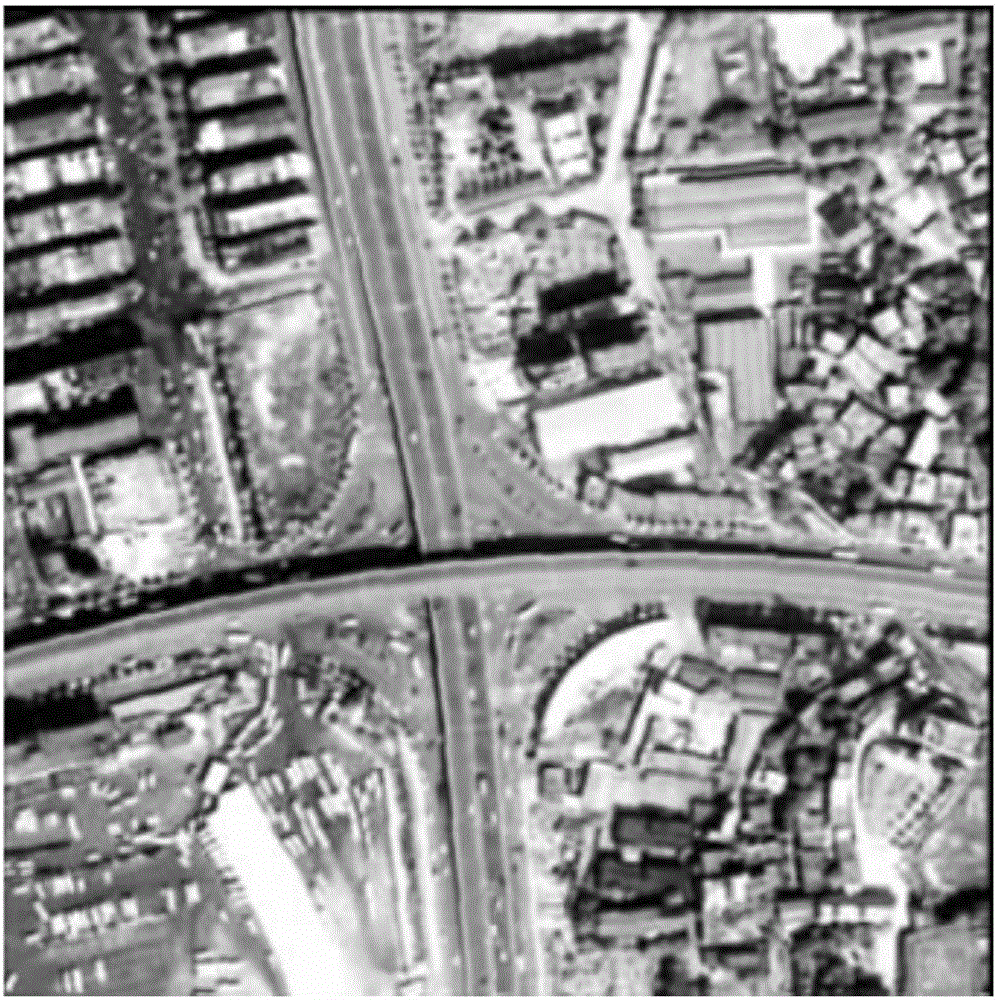

The present invention discloses a high-resolution remote sensing image road information extraction method. The method comprises the following steps: image preprocessing: employing an enhanced and filtering method to realize the purpose of the difference of a road image and a background image; a road image segment method: improving the traditional area growth algorithm and adding a secondary cluster method after growth to remove the complex small plates distributed in the image as much as possible so as to allow the ground object connected with the road to be separated from each other as far as possible; image analysis and identification: and employing a mathematical morphology method and structural elements with a certain shape to measure and extract the corresponding shaped in the image to reach the purpose of the analysis and identification of the image, convert the RGB image to an HSV image in the image processing process and improve the area growth algorithm to adapt for the extraction road so as to greatly improve the quality of the road segment, have high precision of the extraction of the city road, and especially adapt for the extraction of the city main road.

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI

Aqueous PU fog face rubbing surface treatment agent for synthetic leather and preparation method thereof

The invention discloses an aqueous PU fog face rubbing surface treatment agent for synthetic leather, comprising the following components by weight percentage: 40-50% of aqueous polyurethane resin, 30-40% of water, 3-6% of matting agent, 1-5% of organic silicon antifoaming agent, 0.5-5% of organic silicon flatting agent and 0.5-5% of aqueous polyurethane thickener. The surface treatment agent provided by the invention takes water as solvent which replaces poisonous solvents such as dimethylformamide and butanone and has the performances of non-combustion, safety, environmental protection and less cost; after being treated by the surface treatment agent provided by the invention in a wiping manner, the prepared leather has good fog face rubbing effect, sharp contrast between colours of a surface layer and a rubbing layer, good visual effect and excellent general effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

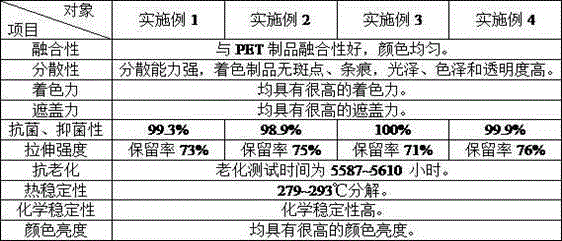

Preparing technology for color master batches

The invention relates to the technical fields of color master batches and preparing technologies thereof, in particular to a preparing technology for color master batches, and particularly discloses a preparing technology for color master batches for high-speed spinning fibers. The preparing technology includes the steps of carrier grinding, coloring material grinding, matched material grinding, assistant grinding, mixed grinding, high-speed grinding, extrusion prilling and drying. The color master batches prepared with the technology can be easily mixed with PET product plastic, and the even coloring effect can be achieved. Dispersibility, coloring strength and covering power are improved, weather resistance, acid resistance, heat resistance and cold resistance are achieved, the chemical stability of pigment is kept, and the color master batches are more environmentally friendly and healthier in the use process.

Owner:JIEDONG PARIS WANZHU SHAHUA TEXTILES CO LTD

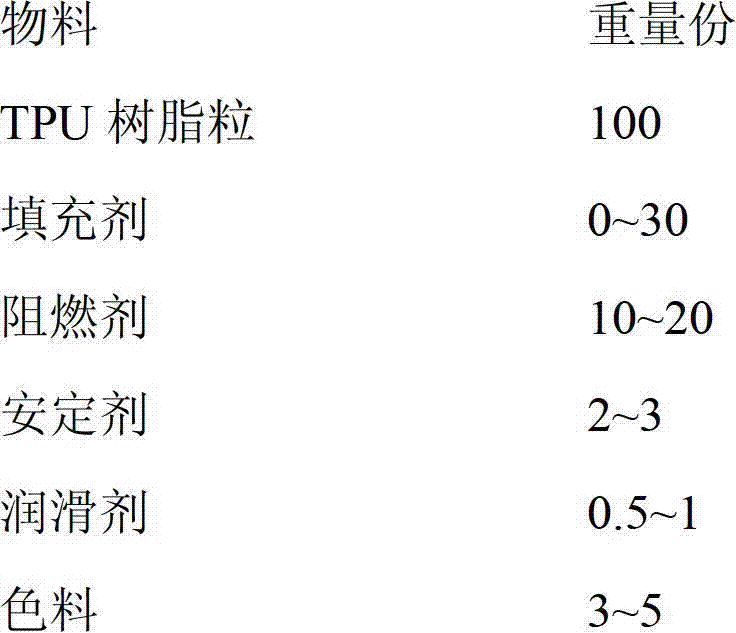

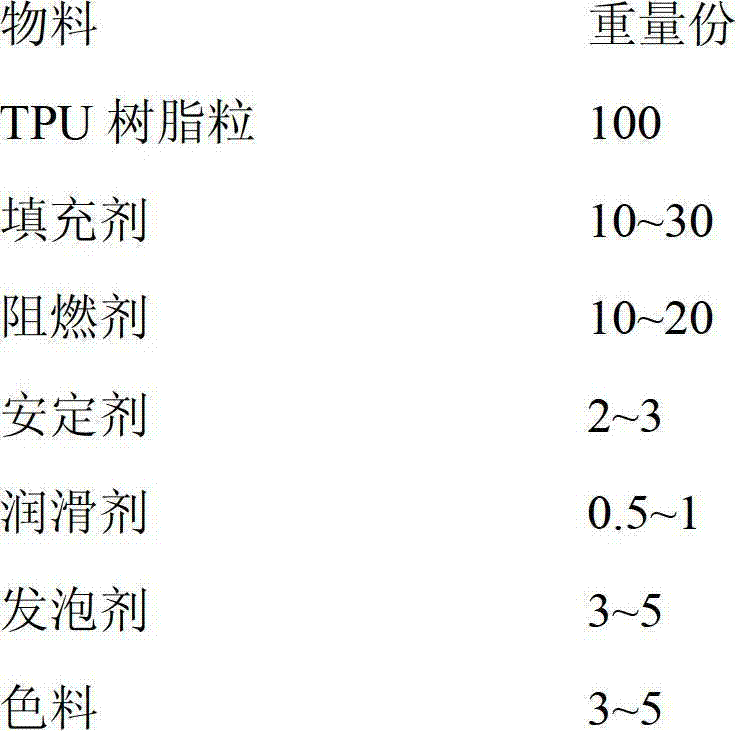

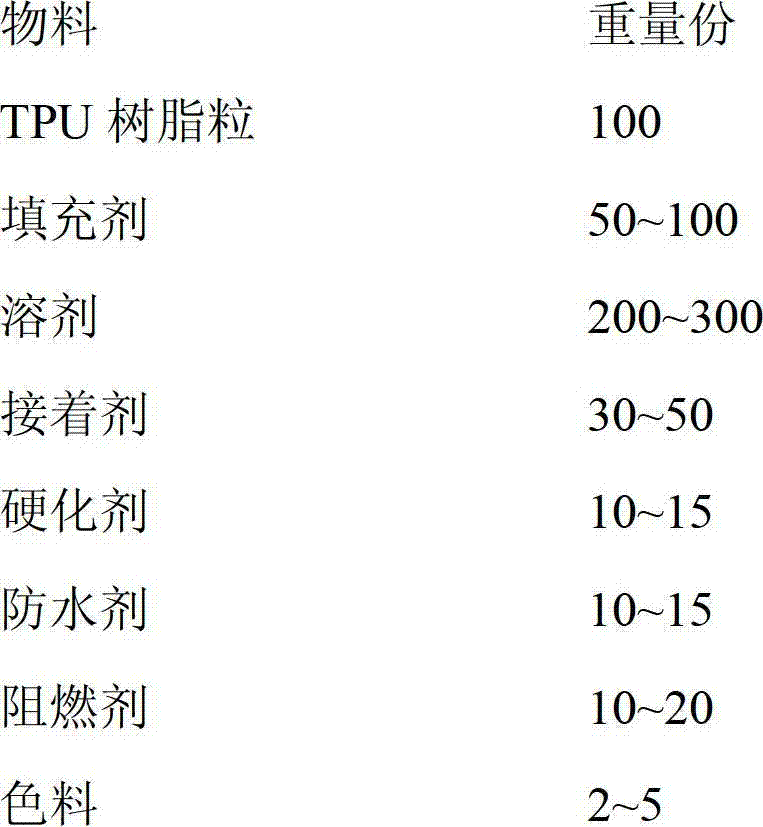

Thermoplastic foaming polyurethane fiber board, production method and uses thereof

ActiveCN103072346AAntifoulingWaterproofCovering/liningsSynthetic resin layered productsFiberThermoplastic

The present invention relates to a thermoplastic foaming polyurethane fiber board, a production method and uses thereof. The thermoplastic foaming polyurethane fiber board comprises an A surface layer, a B middle layer and a C bottom layer, wherein the A surface layer, the B middle layer and the C bottom layer are integratedly compounded from top to bottom, the A surface layer is a sheet material prepared by carrying out mixing calendaring on a TPU resin, a filler, a fire retardation agent, a stabilizer, a lubricant and a colorant according to a certain ratio, the B middle layer is a layer prepared by foaming the sheet material prepared by carrying out mixing calendaring on a TPU resin, a filler, a fire retardation agent, a stabilizer, a lubricant and a colorant according to a certain ratio, and the C bottom layer is a layer prepared by drying a fiber cloth impregnated with a TPU composition. The thermoplastic foaming polyurethane fiber board can be used as flooring boards, wall panels, roof hanging plates and indoor partition boards, and can be used for production of furniture materials and various building materials.

Owner:JIANGSU BIDE SCI & TECH CO LTD

Aqueous PU velvet resin used for synthetic leather

InactiveCN101634109ALow costThe ratio is scientific and reasonableFibre treatmentDimethyl formamideChemistry

The invention discloses an aqueous PU velvet resin used for synthetic leather, which comprises the following raw materials by weight percent: 40-50% of aqueous polyurethane resin, 40-50% of water, 2-5% of low-temperature sheep bar powder, 2-4% of silicon dioxide velvet powder, 1-3% of organic silicone oil smoothing agent, 1-4% of extinction powder, 0.5-1% of organic silicon flatting agent, 2-5% of organic silicon antifoaming agent and 0.5-2% of aqueous polyurethane thickening agent. The aqueous PU velvet resin used for synthetic leather of the invention takes water as solvent to replace toxic solvent, such as dimethyl fomamide, butanone and the like and has the advantages of being non-combustible, safe and environment-friendly, saving cost and the like. The aqueous PU velvet resin also has the advantages of good film-forming resistance, firm bonding, coating solvent resistance, cold resistance, hydrolysis resistance and heat-proof aging. Products fabricated by using the resin have the characteristics of plump feel, unique velvet effect, strong real leather quality, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

High-wear-resistance transparent TPU spherical film and preparation method thereof

The invention provides a high-wear-resistance transparent TPU spherical film and a preparation method thereof. The high-wear-resistance transparent TPU spherical film is prepared by mixing and tape-casting the following components in parts by weight: 60-90 parts of polyurethane-nanopowder complexing agent, 2-10 parts of chain extender, 0.3-2 parts of antioxidant, 1-4 parts of hydrolysis stabilizer, 0.8-3 parts of slipping agent, 0.8-3 parts of antiblocking agent, 1-10 parts of filling agent and 1-3 parts of flame retardant. The TPU spherical film material prepared by modifying and creating all components and preparation proportion of the TPU spherical film has unique technological advantages of being high in wear resistance, transparency and hydrolysis resistance properties, good in elasticity, cold-proof, durable, environment-friendly in materials, free from any hidden injury to a human body, printable, and capable of performing high-frequency welding and the like, the wide use of the TPU special film material in a plurality of fields can be promoted, and the TPU spherical film material has wide market prospects.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH +1

Multi-resistant nutrient for plant growth and preparation method thereof

The invention provides a multi-resistant nutrient for plant growth and a preparation method of the multi-resistant nutrient for plant growth. The multi-resistant nutrient comprises the components in parts by weight as follows: 6-10 parts of compound amino acids, 0.5-1.5 parts of mushroom protein polysaccharide, 0.5-1.5 parts of water soluble chitosan, 2-4 parts of zinc sulfate, 1-3 parts of boric acid and 90-180 parts of water. The preparation method comprises the steps of: heating part of water and dissolving zinc sulfate and boric acid; then heating the residual water and dissolving compound amino acids, mushroom protein polysaccharide and water soluble chitosan; then heating while agitating, and uniformly mixing with zinc sulfate and boric acid; and cooling after insulating so as to obtain the multi-resistant nutrient for plant. The multi-resistant nutrient for plant is rich in various amino acid trace elements which prompt growth of the plant, has remarkable effects of enhancing the immunologic function of the plant and preventing diseases and insect pests, has various biological adjusting functions, and is stress resistant, cold resistant, draught resistance and prevents diseases and insect pests.

Owner:YONGREN YUANNAN AGRI COMPREHENSIVE DEV CO LTD

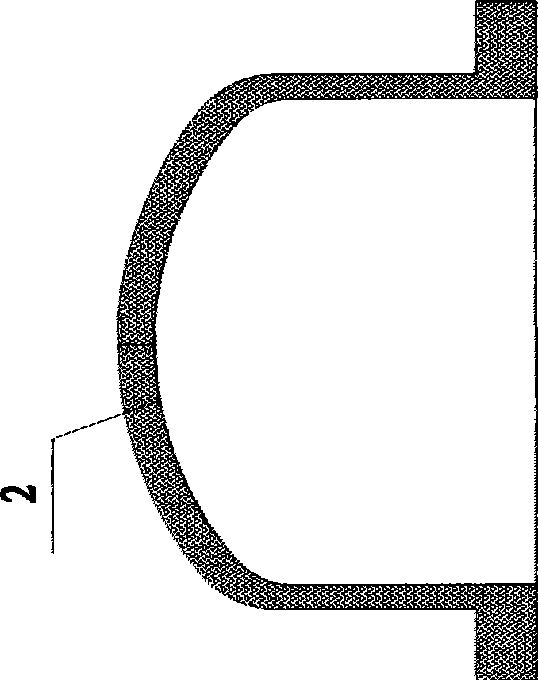

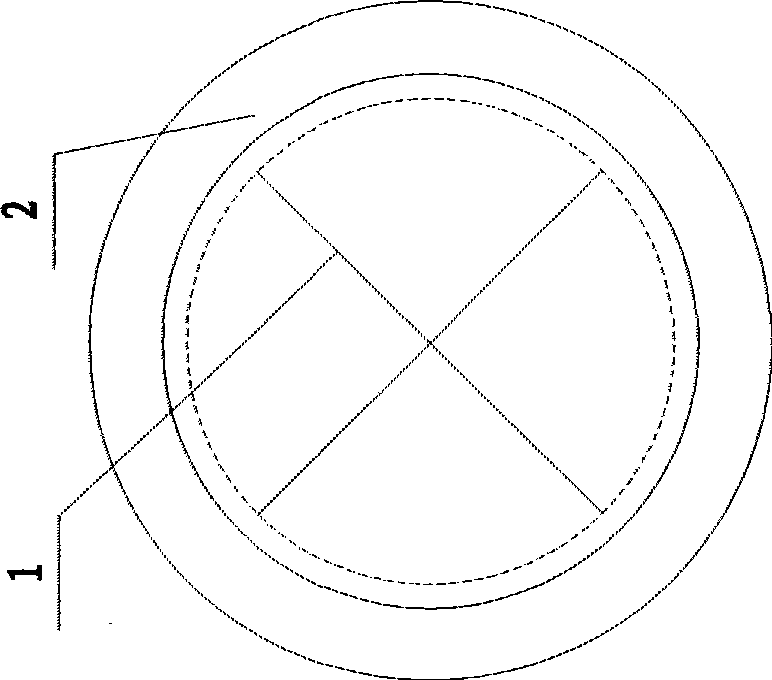

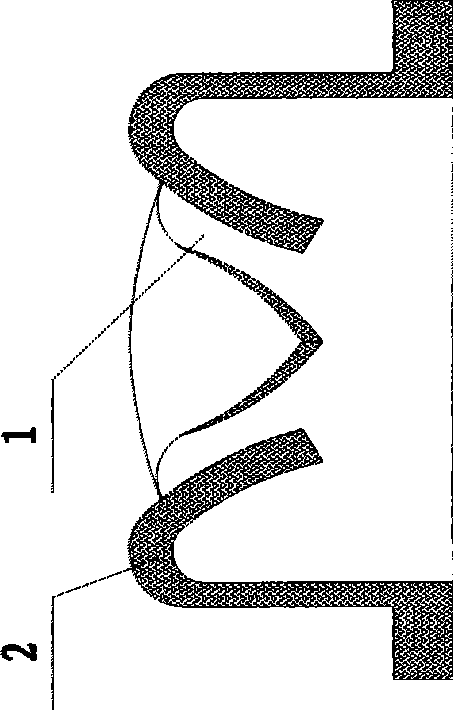

Multipurpose thimbleshaped valve respiration valve

The invention discloses a multipurpose cap-shape valve respiratory valve, comprising a valve seat, a valve core and a fixed sleeve; the valve core is of cap shape and made of elastic rubber; the cap rim of the valve core is fixed between the valve seat and the fixed sleeve; the cap body is sheathed in the central hole of the valve seat or the fixed sleeve; furthermore, the top of the cap of the valve core is provided with at least two lancings so that at least one valve clack is formed at the top of the cap. the lancings are distributed all around in a radial pattern from the axle center projected at the top of the cap to form a taper angle shape valve clack, or a C shape, V shape, U shape or opening polygon shape valve clack to cause the end part projected at the top of the cap to form a flip-shell valve clack or cause the lateral side projected at the top of the cap to form at least two valve clacks. The invention has the advantages of simple structure, few faults, long service life, low manufacturing cost, multiple functions and extensive usage, is favorable for environment protection, and has good social and economical benefits.

Owner:刘景福

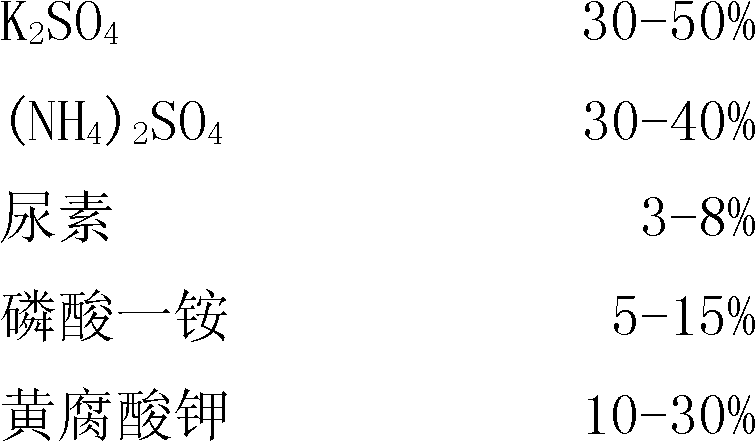

Fully-water soluble fertilizer

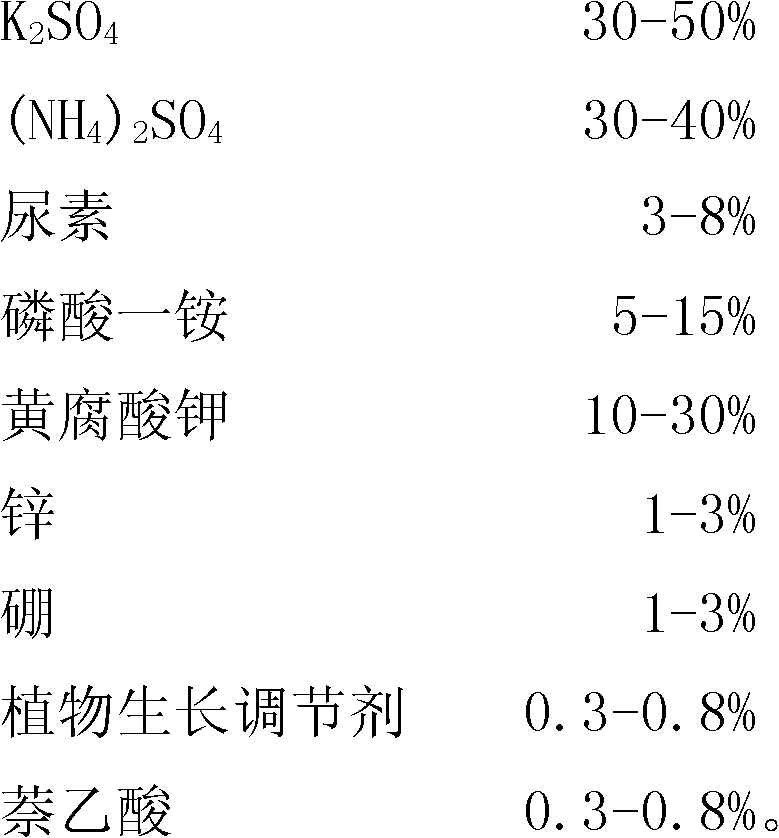

InactiveCN102674959APromote photosynthesisPromote growth and developmentFertilizer mixturesPhosphatePlant growth

The invention provides a fully-water soluble fertilizer and relates to a fertilizer. The fully-water soluble fertilizer consists of K2SO4, (NH4)2SO4, urea, monoammonium phosphate, fulvic acid potassium, zinc, boron, a plant growth regulator and naphthylacetic acid, and the mass percentage occupied by the components is shown as follows: 30-50 percent of K2SO4, 30-40 percent of (NH4)2SO4, 3-8 percent of urea, 5-15 percent of monoammonium phosphate, 10-30 percent of fulvic acid potassium, 1-3 percent of zinc, 1-3 percent of boron, 0.3-0.8 percent of plant growth regulator and 0.3-0.8 percent of naphthylacetic acid. The fully-water soluble fertilizer has the beneficial effects that the fully-water soluble fertilizer is formed by adopting high-quality imported N, O and K as main materials, adding trace elements, i.e. zinc and boron, mixing auxin DA-6, and refining and processing; the fully-water soluble fertilizer has the effects of cold resistance and drought resistance, enhances the photosynthesis of crops, is a necessary nutrient element for maintaining a chloroplast structure, has remarkable effect on paper plant growth metabolism and facilitates the growth and the development of the crops; the infection risk of cottons, wheat, melons and fruits, and other virus and diseases can be reduced; and the fully-water soluble fertilizer is the high-quality fertilizer for supplanting crop nutrition and has the characteristics of fast dissolution, full dissolution, yield increment, efficiency increment and the like.

Owner:安徽天之野生物科技有限公司

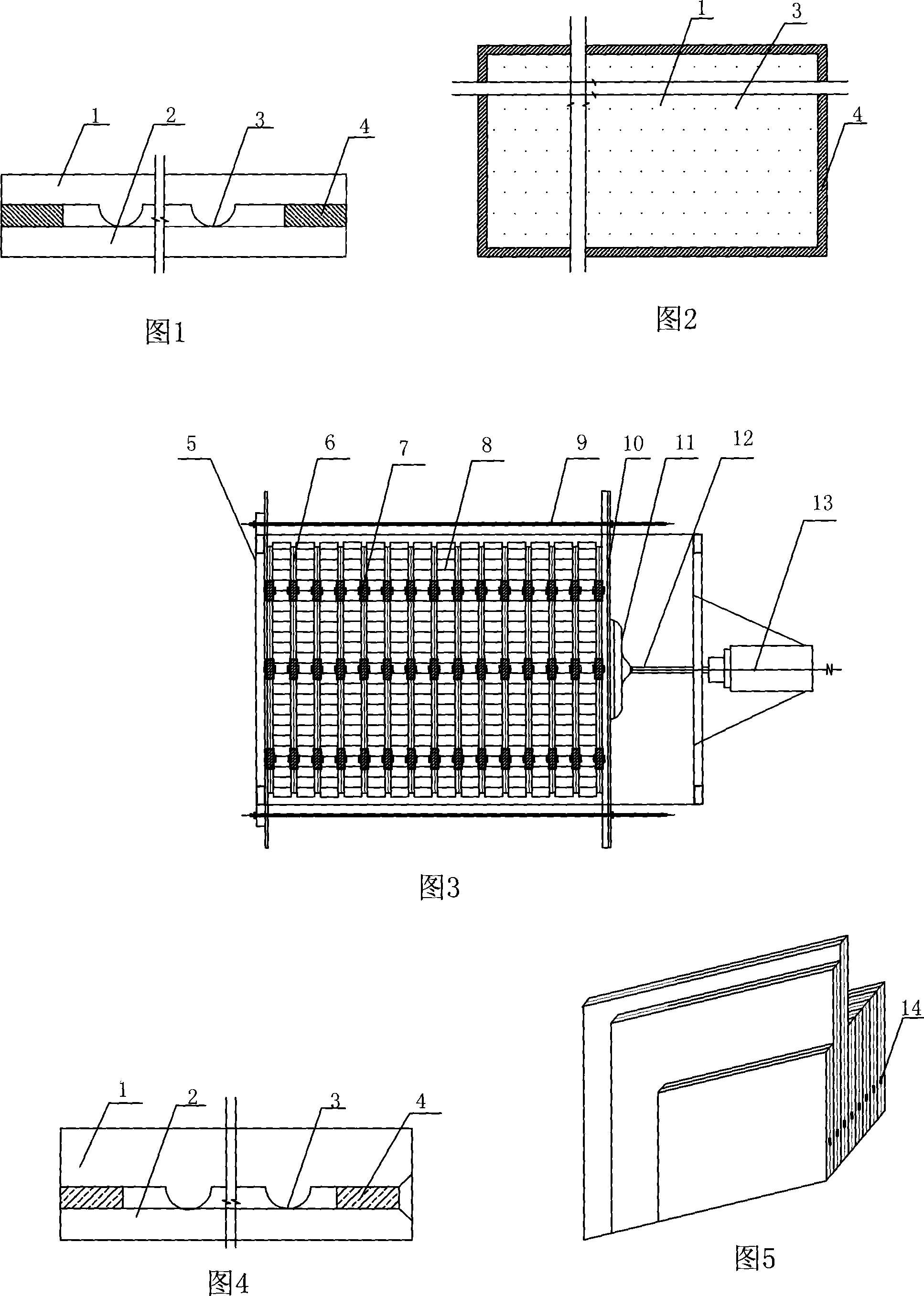

Method for manufacturing vacuum glass

A manufacture method of vacuum glass belongs to the glass manufacturing technology field, including steps as follows: a piece of sheet glass and a piece of convex glass are cut according to requirement, and edging process is implemented according to requirement; a lined adhesive glass film is adopted to overlap the surrounding edges of the sheet glass and the convex glass and then is put on a glass fixture into a vacuum lined adhesive furnace, which is pumped to be vacuum. The furnace is heated for 1-3h at 140-160 degree Celsius to fuse the glass and the film; the glass is taken out of the furnace after being cooled naturally, and protective sealant is used to seal and reinforce the vacuum glass. The production process of the invention is easy to be operated and is constructed through connecting the convex glass and the sheet glass directly, which leads to the more stable support in the hollow region of the two-layer glass. The lined adhesive glass film adopted for the sealing of the surrounding edges has the advantages of strong heat resistance and cold resistance and high mechanical strength and can keep various physical performance indexes within the range of 40 degree Celsius subzero to 120 degree Celsius above aero stable. Vacuum glass can be pumped sealed in batches to realize the highly efficient production.

Owner:刘华俊

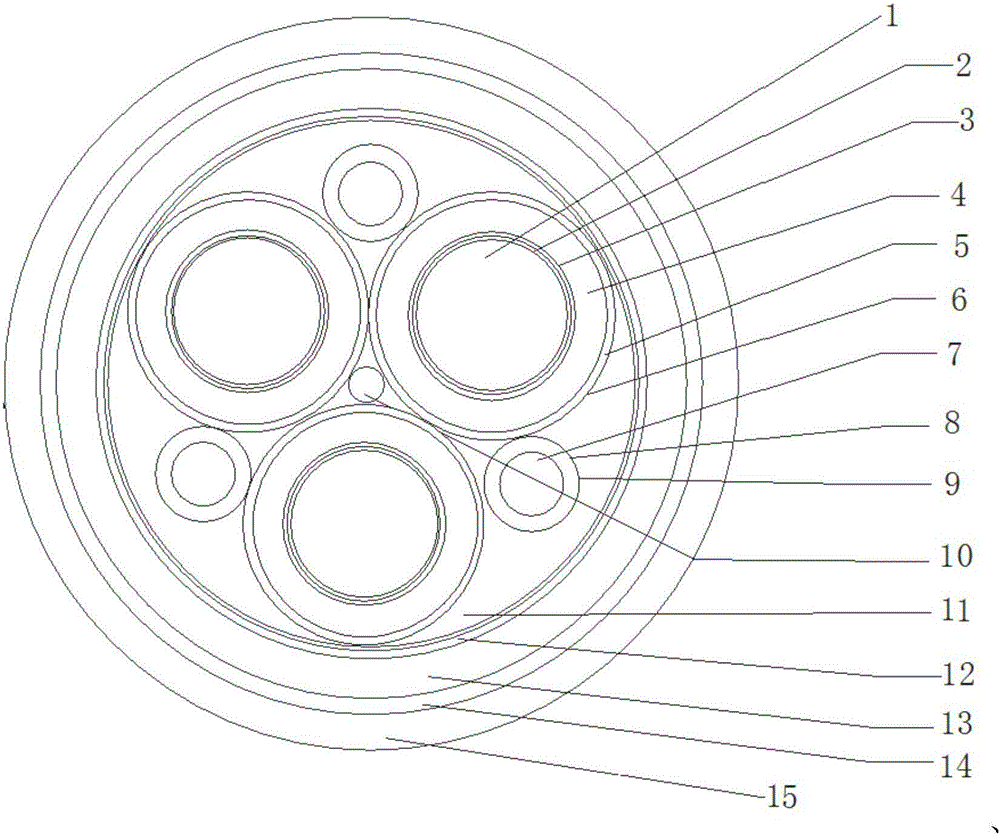

Wear-resistant, drag-resistant and low-temperature resistant flexible cable and fabrication method thereof

ActiveCN106373646AStable structureStructural symmetryPower cables with screens/conductive layersFlexible cablesCopper conductorCross-link

The structure of a wear-resistant, drag-resistant and low-temperature resistant flexible cable comprises a cable core, wherein the cable core is formed by twisting three main wire cores, three ground wire cores and a cable core gap semiconductive filler, each main wire core comprises a cross-linking wire core formed by co-extruding a conductor, a semiconductive nylon strap, a conductor shielding layer, an insulation layer and an insulation shielding steam continuous vulcanization layer, each ground wire core comprises a conductor and a semiconductive material steam continuous vulcanization extruded on a surface of the conductor, an isolation strip, an inner sheath, a fiber weaving reinforcement piece and an outer sheath are sequentially applied outside the cable core to form a finished cable, the conductors adopt tin-plated annealed copper conductors, filaments of the tin-plated annealed copper conductors are more slim, and the diameter ranges of the filaments are 0.1-0.41 millimeter. A cable fabrication method comprises the steps of fabricating the main wire cores and the ground wire cores; fabricating the cable core; winding an isolation strip; extruding the inner sheath; weaving the reinforcement layer; and performing steam continuous vulcanization extruding or radiating the cross-linking outer sheath. The cable fabricated according to the method can conform to the design and application requirements, and meanwhile, the qualified rate reaches over 99%.

Owner:JIANGSUSNGSHANG CABLE GROUP

Middle layer material for latching floors and preparation method thereof

The invention relates to a PVC (Polyvinyl Chloride) plastic floor, and discloses a middle layer material for latching floors and a preparation method thereof. The middle layer material consists of the following raw materials in parts by weight: 100-200 parts of PVC, 1-5 parts of stabilizer, 20-40 parts of plasticizer, 0.1-1 part of carbon black, 400-600 parts of calcium carbonate and 5-10 parts of nitrile rubber. According to the preparation method, the nitrile rubber is added, so that the mixing processing is convenient, the toughness of the middle layer material is improved and the strength of the latching tension between products is improved at the same time. Compared with the existing plastic floors, a floor product obtained by thermal compounding between the middle layer material and a wearing layer, a printing color films and a bottom layer material has strength, heat resistance and cold resistance.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

Rubber foaming shoe bottom, rubber foaming plates and pieces, and fabricating method of molding with cloth being added

InactiveCN1872531AModerate weightLow costFlat articlesMetal working apparatusPolymer scienceFoam rubber

Owner:珠海经济特区珠瑞橡胶化学工业有限公司

High-abrasion-resistance transparent thermoplastic polyurethane elastomer for ball film and manufacturing method thereof

The invention provides high-abrasion-resistance transparent thermoplastic polyurethane elastomer for a ball film and a manufacturing method of the high-abrasion-resistance transparent thermoplastic polyurethane elastomer. The thermoplastic polyurethane elastomer is made of nano-modification TPU composite materials, and the nano-modification TPU composite materials are formed by mixing, by weight, 70-90 parts of polyurethane-nano-powder composite components, 3-10 parts of chain extenders, 0.5-2 parts of antioxidants, 1.2-4 parts of hydrolytic stabilizers, 1-3 parts of slipping agents, 1-3 parts of antiblocking agents, 3-20 parts of fillers and 0.8-3 parts of fire retardant. The nano-modification TPU composite materials manufactured by modifying and innovating all raw material components and the configuration proportion of the TPU composite materials have the unique advantages of being high in hardness and abrasion resistance, strong in elasticity and toughness, high in transparency, high in hydrolysis resistance, good in environmental protection, capable of achieving high-frequency welding and the like, the wide application of the TPU materials is promoted, and the wide market prospect is achieved.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH +1

Waterborne PU high smooth wax resin for synthetic leather

The invention discloses a waterborne PU high smooth wax resin for synthetic leather and the resin comprises the following raw materials by weight percent: 30-40% of waterborne silicon-fluorine resin,20-30% of waterborne polyurethane, 10-30% of water, 0.2-0.8% of waterborne wax emulsion, 1-3% of organic silicone oil smoothing agent, 0.5-1% of organic silicone flatting agent, 2-5% of organic silicone defoamer and 0.5-2% of waterborne polyurethane thickener. The waterborne PU high smooth wax resin for synthetic leather provided by the invention uses water as solvent instead of toxic solvents such as dimethyl formamide, butanone and the like and has the advantage of noninflammability, safety, environmental protection, cost-saving and the like. The finished product prepared from the waterbornePU high smooth wax resin for synthetic leather provided by the invention has full hand feeling, high luster and high luminance, extremely smooth waxy feeling, delicate texture and good air permeability; and the prepared synthetic leather has good comprehensive effect in hand feeling, smoothness, water resistance, waxy feeling and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Ginger crystal and production technology thereof

The invention discloses a ginger crystal and a production technology thereof. The ginger crystal comprises dry ginger powder, brown sugar and honey. The production technology comprises the following steps: milling the brown sugar, adding honey to the milled brown sugar, mixing, drying for 2h at 90DEG C in a drying room, mixing with the dry ginger powder, drying, milling, and packaging. The ginger crystal of the invention, which has the advantages of abundant nutrition and good taste, has a wide market.

Owner:兴义市东泰天然果蔬开发有限公司

Tanning method for fish skin and after finishing method for fish skin leather

InactiveCN1492057AFeel goodImprove tensile propertiesTanning treatmentSpecial leather manufactureFiberNitrocellulose

The fish skin leather processing method includes painting acrylic resin onto tanned fish skin, the first ironing and shaping in leather ironing machine after drying, spraying the mixture of polyurethane and acrylic resin onto the fish skin, the second ironing and shaping in leather ironing machine after drying, spraying the mixture of nitrocellulose brightener and slip agent onto the fish skin, the third ironing and shaping in leather ironing machine after drying, and spraying the mixture of feeling agent and waterproof agent onto the fish skin. The advantages include good feeling, high tensile strength, cold resistance, water proofing, no delaminating, high penetrating and beautiful grain of the processed fish leather; low processing cost, less pollution, etc. The skin leather is suitable for making various leather products.

Owner:沈玉良

Bee breeding method

InactiveCN106172250AImprove reproductive efficiencyIncrease productivityBiocideAnimal feeding stuffItalian beePollen

The invention provides a honeybee breeding method and belongs to the technical field of animal husbandry. The breeding method includes the following steps: firstly, select a bee breeding place, set up a beehive, and regularly apply acaricide to the beehive to remove bee mites; then, select North China bee, Italian bee and Northeast black bee as parents, Breeding bees with stable and excellent properties as bee species; and feeding feed a made of honey, white sugar, orange juice, tomato juice, longan juice, grape juice, citric acid, edible salt, water, and natural pollen, Feed b made of defatted soybean flour, white sugar and appropriate amount of water. The invention provides a honeybee breeding method. The breeding method is safe and reliable. The North China honeybee, Italian honeybee and Northeast honeybee are scientifically bred to obtain a honeybee with high yield, cold resistance, mite resistance and disease prevention. species, and then fed scientifically and rationally to promote the healthy development of bees, reduce the incidence of morbidity, and improve the quality and food safety of honey.

Owner:陆川县乌石镇万意养蜂专业合作社

Water-soluble PU nubuck low-temperature foamex for synthetic leather

InactiveCN101666039ALow costThe ratio is scientific and reasonableFibre treatmentSolventWater soluble

The invention discloses water-soluble PU nubuck low-temperature foamex for synthetic leather, prepared by the following raw materials in percentage by weight: 30-40 percent of water-soluble polyurethane, 40-50 percent of water, 2-10 percent of low-temperature nubuck foam powder, 2-5 percent of organosilicon levelling agent, 2-5 percent of organosilicon antifoaming agent and 0.5-2 percent of water-soluble polyurethane thickener. The mixture ratio of each component of the water-soluble PU nubuck low-temperature foamex for synthetic leather is scientific and reasonable, and the components mutually coordinate and jointly act. The nubuck low-temperature foamex has the advantages of good film reforming property and firm adhesion, and coating is resistant to solvent, cold, hydrolysis and thermalageing. The original effect of the leather surface of a finished product prepared from the water-soluble PU nubuck low-temperature foamex can not be influenced; after the leather surface is treated bythe foamex, low-temperature foaming is carried out to produce nubuck leather, and therefore, the effect of the leather surface is unique; moreover, the synthetic leather has exquisite texture, good air permeability and excellent resultant effect of hand feeling, water proofing, adhesion and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU high solid resin combination for synthetic leather

The invention discloses a water-based PU high solid resin combination for synthetic leather, which comprises the following materials by weight percent: 25 to 35 percent of water-based polyurethane resin, 45 to 55 percent of water, 10 to 20 percent of modified organic silicon polymer, 0.5 to 1.5 percent of organic silicon flatting agent, 1 to 3 percent of organic silicon foam killer and 1.5 to 4.5 percent of water-based polyurethane thickening agent. The water-based PU ironing finishing agent has the advantages that the mixture ratio of the component is scientific and reasonable, and the components are coordinated with each other and act together; the high solid resin combination has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating; the finished product made of the synthetic leather, the surface of which is treated by the high solid resin combination, has the advantages that the original effect of the leather surface is not affected, raised patterns on the leather surface are sufficient in contrast to the leather sole after the leather surface is treated and modified, and the leather surface has unique high solid effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Method for catalytic conversion preparation of hexahydric alcohol from jerusalem artichoke as raw material

ActiveCN102746117AReduce the requirements of natural conditionsResistant to barrennessOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingIridiumHydrogen pressure

The invention relates to a method for catalytic conversion preparation of a hexahydric alcohol from jerusalem artichoke as a raw material. The method is characterized in that a raw material of natural biomass jerusalem artichoke (mainly comprising fructose-based polysaccharide carbohydrates) undergoes a reaction at a temperature above 20 DEG C under hydrogen pressure of 1 to 13MPa in the presence of water as a solvent and a catalyst or a mixed catalyst for at least 5 minutes, wherein the catalyst comprises acidic carriers and one or more of transition metals of iron, cobalt, nickel, copper, ruthenium, rhodium, palladium, iridium and platinum loaded on the acidic carriers; and the mixed catalyst comprises solid acids and a metal hydrogenation catalyst comprising carriers and one or more of transition metals of iron, cobalt, nickel, copper, ruthenium, rhodium, palladium, iridium and platinum loaded on the carriers. Through one-step catalytic conversion, high-efficiency, high-selectivity and high-yield preparation of a hexahydric alcohol such as mannitol and sorbitol from jerusalem artichoke as a raw material is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Chromatophilous polyurethane resin for synthetic leather and preparation method of polyurethane resin

The invention relates to chromatophilous polyurethane resin for synthetic leather and a preparation method of the polyurethane resin. The polyurethane resin comprises the following components by mass percentage: 15-20% of polyester polyol EG1000, 3-5% of polyester polyol PCL2000, 15-20% of diphenyl-methane-diisocyanate (MDI), 0.1-0.2% of epoxy resin, 0.05% of triphenyl phosphite, 0.02% of dibutyltin dilaurate, 0.01% of silicone oil, 0.8-1.5% of glycol, 2-3% of 1,4-butanediol, 0.4-0.6% of alcohol, and the balance of solvent, wherein the solvent comprises the following components by mass percentage: 20-25% of dimethyl formamide (DMF), 15-20% of butanone, and the balance of methylbenzene. The chromatophilous polyurethane resin for the synthetic leather and the preparation method have the benefits that the polyurethane resin synthesized by the preparation method is chromatophilous, high in fixation, and uniform in coloring, and has good mechanical properties such as water resistance, solvent resistance, cold resistance and folding resistance after being produced into the leather.

Owner:JIANDE BAISHA CHEM

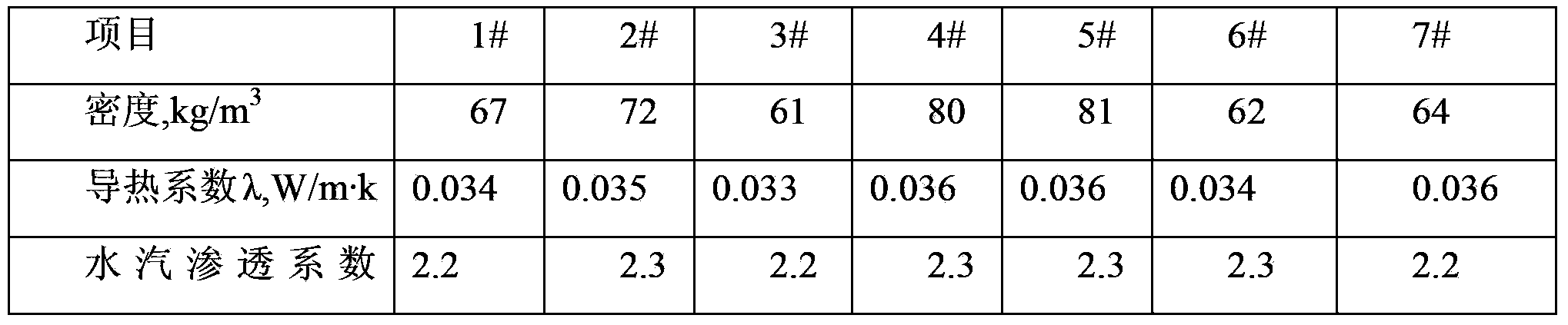

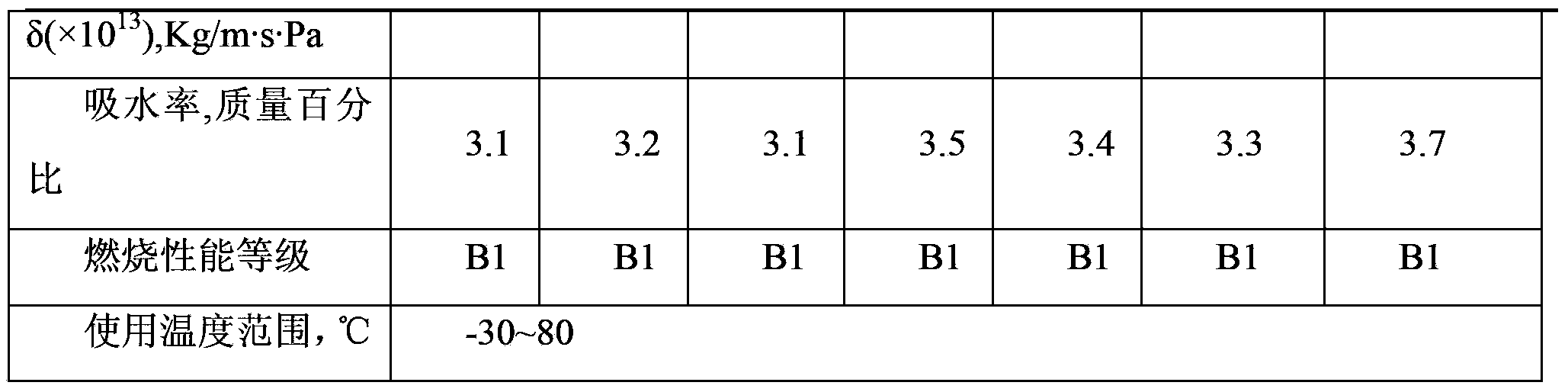

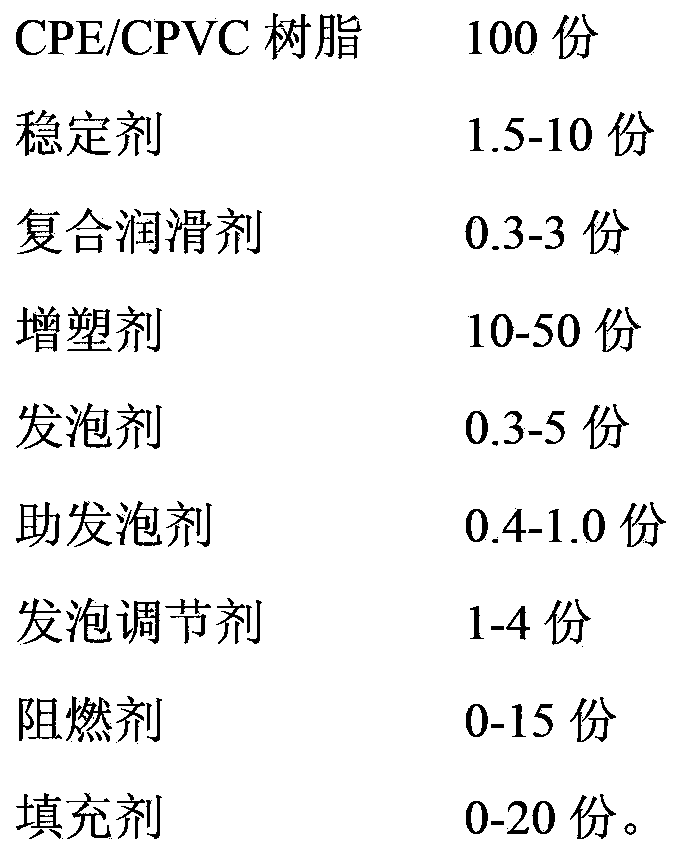

CPE/CPVC rubber-plastic thermal-insulation material and preparation method thereof

The invention relates to a CPE / CPVC rubber-plastic thermal-insulation material and a preparation method thereof and belongs to the field of polymer synthesis and processing application. The CPE / CPVC rubber-plastic thermal-insulation material is prepared from 100 parts by mass of CPE / CPVC resin, 1.5-10 parts by mass of a stabilizing agent, 0.3-3 parts by mass of a composite lubricant, 10-50 parts by mass of a plasticizer, 0.3-5 parts by mass of a foaming agent, 0.4-1.0 part by mass of a foaming aid, 1-4 parts by mass of a foaming adjustment agent, 0-15 parts by mass of a fire retardant and 0-20 parts by mass of a filling material. The CPE / CPVC rubber-plastic thermal-insulation material has excellent performances such as softness, flexing damage resistance, cold resistance, heat resistance, flame retardation, water resistance, low heat-conduction coefficient, cushioning effect and sound absorption and has ideal use effects in the aspect of thermal insulation for heat loss prevention. The preparation method of the CPE / CPVC rubber-plastic thermal-insulation material is simple and continuous, has high production efficiency, is suitable for streamline batch production and can be widely used in industries of building, light textile, medicine, chemical engineering, metallurgy and ship-building.

Owner:CHINA PETROLEUM & CHEM CORP

Corrosion resistant ceramic and preparation method thereof

The invention discloses corrosion resistant ceramic and a preparation method thereof. The corrosion resistant ceramic is prepared from the following raw materials in parts by weight: 12-14 parts of quartz, 11-13 parts of forsterite, 3.5-3.8 parts of sodium oxide, 4-6 parts of titanium dioxide, 1-3 parts of red stoneware ore, 40-45 parts of clay, 18-20 parts of deionized water, 8-10 parts of kaolinite, 16-18 parts of feldspar, 5-7 parts of magnesium oxide, 3-5 parts of tetraethyl orthosilicate, 1-3 parts of zinc tetroxy chromate, 15-20 parts of nickel powder, 8-15 parts of copper powder and 13-15 parts of an assistant. The assistant is prepared from the following components in parts by weight: 5-7 parts of zirconite, 12-18 parts of kaolinite, 4-6 parts of clay, 10-15 parts of deionized water, 2-4 parts of graphite powder, 1-3 parts of feldspar, 7-9 parts of polyethylene glycol and 0.3-0.8 part of nano boron fiber.

Owner:SUZHOU TONGMING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com