Patents

Literature

104results about How to "Improve processing rheology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste PVC (Polyvinyl Chloride) and fly ash composite material and preparation method thereof

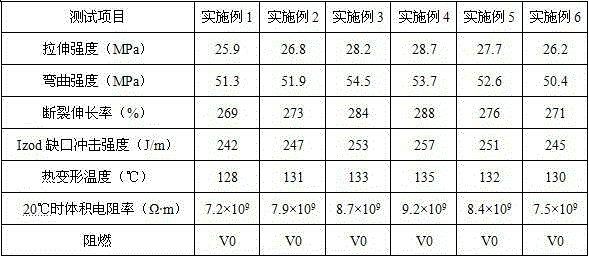

The invention relates to the technical field of PVC (Polyvinyl Chloride) composite materials and particularly relates to a waste PVC and fly ash composite material and a preparation method thereof. The waste PVC and fly ash composite material comprises the following raw materials according to parts by weight: 80-120 parts of waste PVC, 35-55 parts of fly ash, 3-10 parts of plasticizer, 1-2 parts of flame retardant, 0.5-2 parts of stabilizer, 0.5-2 parts of impact modifier, 0.3-1 part of lubricant and 0.1-0.5 part of antioxidant. The preparation method comprises the following steps of: weighing all the raw materials according to the parts by weight, mixing, stirring, extruding through a twin-screw extruder for granulation, chopping and air-cooling to obtain the waste PVC and fly ash composite material. The waste PVC and fly ash composite material prepared by the preparation method has excellent heat resistance, high strength, good flame retardant effect, high compression performance and toughness, and excellent processing performance and comprehensive performance; and the additive amount of renewable resources in the waste PVC and fly ash composite material reaches 90%-95%, thus lowering the production cost, reducing the environmental pollution, and bringing good economic benefit and social benefit.

Owner:广东祺龙科技有限公司

Composite of polyethylene with low viscosity ultra high moleculer weight and preparation process thereof

The invention is a low-viscosity ultrahigh molecular weight polyethylene combination and its preparing method, and its character: adding ultrahigh molecular weight polyethylene 70-90 weight shares, polypropylene 30-10 weight shares, antioxidant 0.03-0.8 weight share, lubricant 0.2-2.0 weight shares and compound assistant 1-15 weight shares in a high-speed mixer to mix at a high speed for 2-5 minutes, mixing uniformly and then making particles by a double-screw extruder, and the extruding temperature is 180 deg.C-230 deg.C. The viscosity of the combination is reduced remarkably, the critical cutting speed is increased, and the combination can be processed into products by general die forming, extrusion molding and injection molding, the synthetic properties are good and especially, the shock-resistant property does not change.

Owner:SICHUAN UNIV

Low-smoke halogen-free flame-retarding ceramizable thermoplastic polyurethane elastomer composite material, preparation method and application thereof

The invention relates to the technical field of polyurethane elastomers and particularly relates to a low-smoke halogen-free flame-retarding ceramizable thermoplastic polyurethane elastomer composite material, a preparation method and an application thereof. The composite material comprises, by weight, 25-85 parts of thermoplastic polyurethane, 10-70 parts of a halogen-free flame retardant, 1-10 parts of a smoke inhibitor, 20-80 parts of a ceramization powder, 0.5-5 parts of a compatilizer, 0.02-0.1 parts of an antioxidant, and 0.02-0.1 parts of a hydrolysis inhibitor. The thermoplastic polyurethane elastomer composite material has excellent flame-retarding effect, low smoke density, high strength, good flexibility and high break elongation, can form a compact ceramized product at the temperature range of 600-1000 DEG C, is low in ceramization temperature and can form compact ceramic. The formed ceramized product has high high-temperature strength and anti-heat-flow-impact capability.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Antistatic and antibacterial color masterbatch and preparation method thereof

The invention relates to the technical field of color masterbatches and specifically relates to an antistatic and antibacterial color masterbatch and a preparation method thereof. The color masterbatch is prepared from the following raw materials in parts by weight: 48-63 parts of polypropylene resin, 19-36 parts of toner, 2-7 parts of dispersant, 0.5-1.5 parts of antistatic agent and 0.5-1.5 parts of antibacterial agent, wherein the polypropylene resin is metallocene polypropylene of which the melt index is 5-25g / 10min and the density is 0.886-0.924g / cm<3>; the antistatic agent is a mixture of octadecylamine polyoxyethylene ether, dodecylamine polyoxyethylene ether and monoglyceric stearate in the weight ratio of (0.5-1.5) to 1 to (2.4-3.2); the antibacterial agent is a mixture of silver-loaded zeolite and silver-loaded cobalt phosphate in the weight ratio of (1.5-2.5) to 1. The antistatic and antibacterial color masterbatch is good in antistatic effect, and has a relatively high safety coefficient, good antibacterial function and low harm.

Owner:ZHEJIANG JINCAI NEW MATERIAL

Modification method of phosphogypsum for PVC material production

InactiveCN105482503AImprove processing rheologyHigh strengthPigment treatment with non-polymer organic compoundsFilling materialsParaffin oils

The invention relates to the technical field of PVC production filling materials and especially relates to a modification method of phosphogypsum for PVC material production. The method comprises mixing fresh phosphogypsum and quicklime until pH is in a range of 6-8 so that phosphogypsum free water content is reduced, carrying out heating treatment through a stirring heater, controlling the temperature in a range of 150-180 DEG C so that the fresh phosphogypsum is transformed into semi-hydrated phosphogypsum, adding paraffin into the semi-hydrated phosphogypsum so that phosphogypsum plasticity and rheological properties are improved and the dry phosphogypsum adsorbs water to form crystal water with an unstable structure, carrying out dry grinding and screening so that crystal water in the phosphogypsum is exposed, related content of phosphogypsum impurities in unit volume is reduced and phosphogypsum whiteness is improved, and carrying out stir-frying at a temperature of 180-200 DEG C so that a part of crystal water in phosphogypsum is lost. The prepared phosphogypsum is a mixture of semi-hydrated gypsum, III-type anhydrite and II-type anhydrite, has high rheological properties and plasticity and improves PVC quality.

Owner:GUIZHOU KAILIN GRP CO LTD

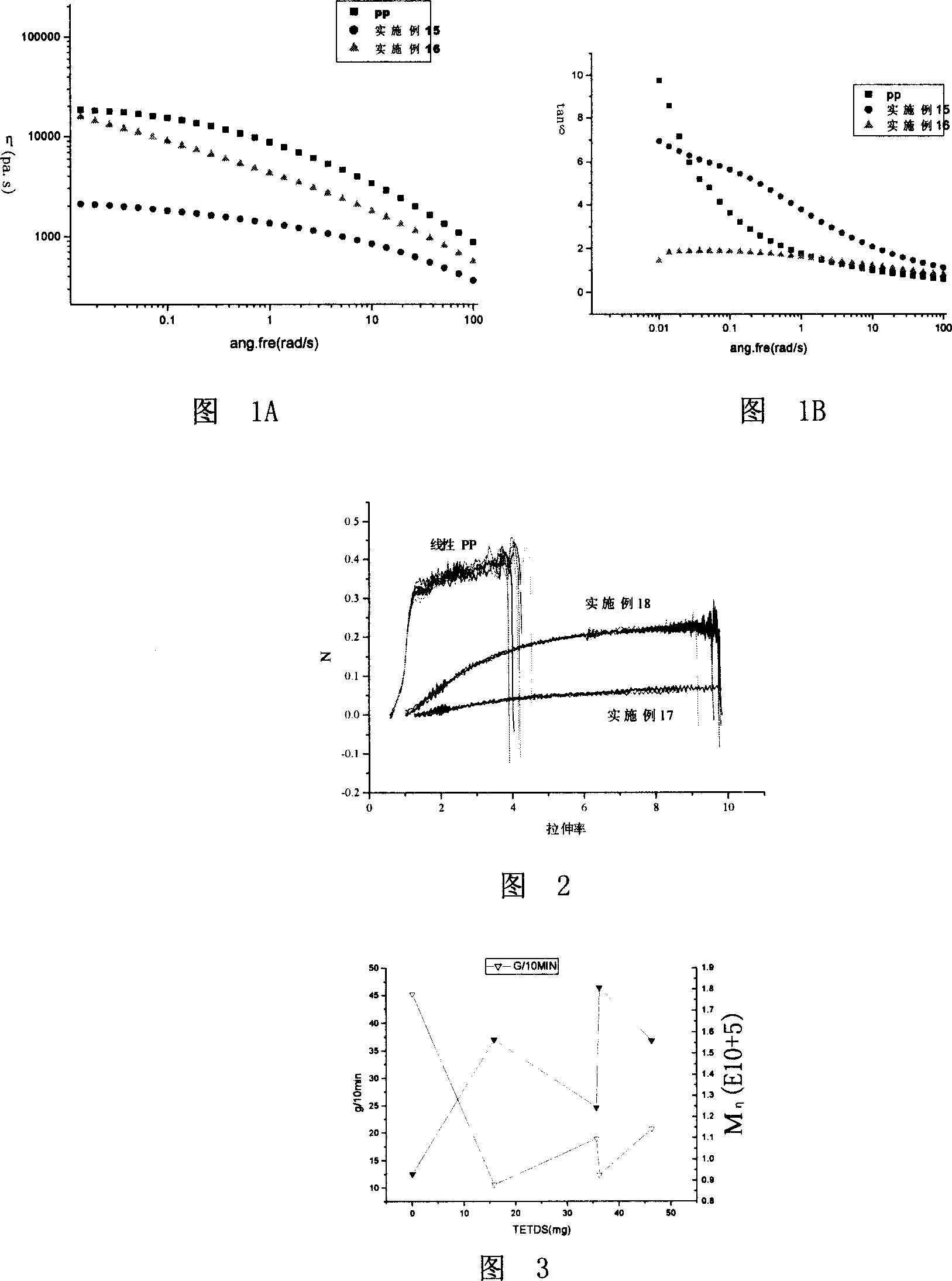

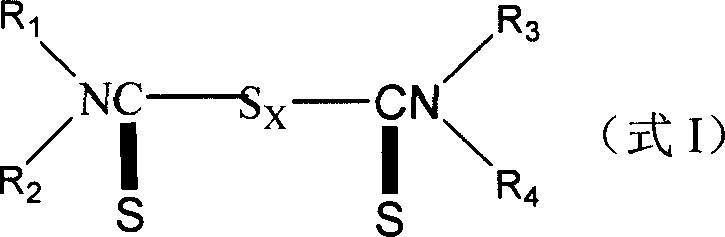

Branched polypropylene and its preparation method

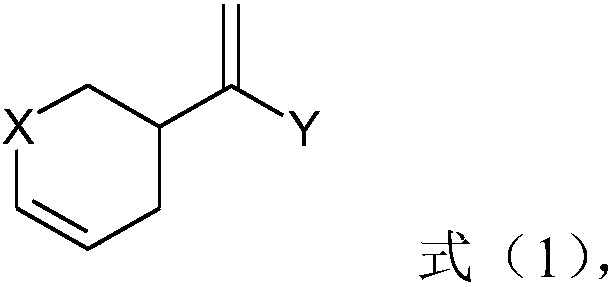

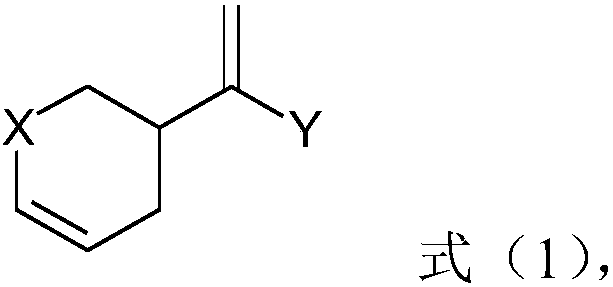

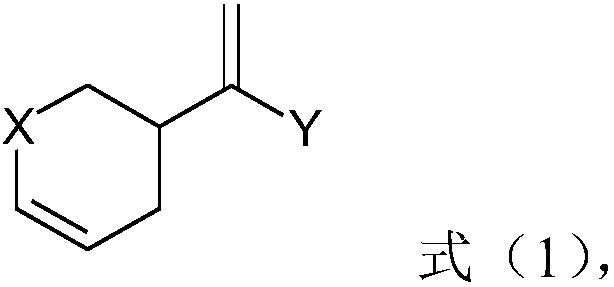

InactiveCN1962707AGood processing rheologyInhibition of beta scission responseArylEthylene Homopolymers

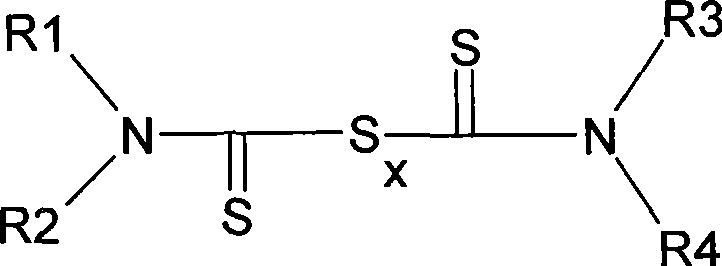

The invention discloses a branched polypropylene and preparing method, which comprises the following parts: 88.9-99.978% polypropylene, 0.01-10% polyfunctional monomer, 0.01-1% initiator and 0.002-0.1% branched accelerant, wherein the branched accelerant possesses the structure in the formula I; X is 1 or 2; R1, R2, R3 and R4 is alkyl or aryl with carbon atom number at 1-10; the third monomer and branched accelerant are induced into propylene homopolymer or copolymer through oxidizing, which possesses obvious hardening chain to inhibit beta-fracture to synthesize non-crosslinking branched polypropylene.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polyester/mesoporous molecular sieve composite material and its preparing material

This invention relates to polyester / mesoporous molecular sieve composite material and its preparing method. Using mesoporous molecular sieve fine particles with definite grain size, aperture and acid-base value, after drying, mixing with liquid polyesters, esterifying to obtain esterified mixed product, during reaction combining with ultrasonic dispersion technology to make monomer and molecular sieve fine partticles mix uniformly, by precondensation and endcondensation under constant temperature and pressure esterified product to obtain a product, by granulating and drying to be agglomerates. During prparation, under vacuum and ultrasonic action, monomer can enter to particle aperture, by in-situ polymerization, particles inside and outside is coated with polymer, bonding polyester and molecular sieve interface well to form polyester / mesoporous molecular sieve composite material with inorganic-organic interpenetrating network structure. The material properties, such as melt crystallization temperature, crystallinity, glass-transition temperature and bending strength, storage modulus elasticity modulus are obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

High melt strength polypropylene blend and method of preparing same

The invention relates to a product. The product is prepared by the following steps: mixing 18 to 99.979 weight portions of polypropylene, 0.01 to 80 weight portions of filler, 0.01 to 1 weight portion of initiator, and 0.001 to 1 weight portion of branching promoter; and carrying out the reaction of the mixed raw materials in a Banbury mixer or a screw extruder at the reaction temperature of between 140 and 250 DEG C. Compared with the prior art, the obtained branched high bath strength polypropylene co-mixture has a simple process and good product processing rheological performance.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Polyurethane adhesive and preparation method thereof

ActiveCN107858133AExcellent reworkabilityReduce tanglingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane elastomerMasterbatch

The invention provides a polyurethane adhesive and a preparation method thereof. The polyurethane adhesive is prepared from the following components in percentage by mass: 1.6 to 11.4 percent of hydroxyl polyurethane elastomer, 0 to 3.5 percent of flexibilizer, 0 to 2.8 percent of polymer modifier, 0.1 to 2.8 percent of reinforcing agent, 0 to 1.5 percent of aid and 88 to 97 percent of organic solvent. The adhesive has the advantages of low solid content, good rework ability, high initial viscosity, high peel strength, high shearing strength, good wettability and low cost of a substrate and the like; in addition, the adhesive has good high-temperature washing resistance, bending resistance and heat-resisting aging when being used for adhering shoe soles to vamps. The invention also provides the preparation method of the polyurethane adhesive; the preparation method comprises the steps of preparing polyurethane elastomer masterbatch, dissolving and the like; the process is simple.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Ultraviolet-resistant oxidation-resistant color master batch and preparation method thereof

The invention relates to the technical field of color master batches, particularly an ultraviolet-resistant oxidation-resistant color master batch and a preparation method thereof. The color master batch is prepared from the following raw materials in parts by weight: 45-60 parts of polypropylene resin, 37-49 parts of toner, 2-7 parts of dispersing agent, 0.5-1.5 parts of antioxidant and 0.1-0.5 part of ultraviolet-resistant agent. The polypropylene resin is a mixture composed of a polypropylene resin reclaimed material and a polypropylene fresh material in a weight ratio of 1:(4-6). The antioxidant is a mixture composed of an antioxidant 1010 and an antioxidant 168 in a weight ratio of 1:(1-2). The ultraviolet-resistant agent is a mixture composed of 4-benzoyloxy-2,2,6,6-tetramethylpiperidine and 2-hydroxy-4-n-octyloxydiphenyl ketone in a weight ratio of 1:(1.8-2.6). The color master batch has the advantages of favorable ultraviolet resistance, favorable oxidation resistance, small influence on mechanical properties of plastic products, and long service life.

Owner:ZHEJIANG JINCAI NEW MATERIAL

Highly cold-resistant and toughening color masterbatch and preparation method thereof

The invention relates to the technical field of color masterbatches, and in particular relates to a highly cold-resistant and toughening color masterbatch and a preparation method thereof. The color masterbatch comprises the following raw materials in parts by weight: 45-61 parts of polypropylene resin, 32-53 parts of toner, 2-7 parts of a dispersing agent and 1-5 parts of a cold-resistant and toughening agent, wherein polypropylene is a mixture of co-polypropylene and homo-polypropylene which are in a weight ratio of 1 to 1.4-2.2, and the cold-resistant and toughening agent is a mixture of an amide Beta crystal form nucleating agent and a dicarboxylate Beta crystal form nucleating agent which are in a weight ration of 1 to 1.2-1.8. The highly cold-resistant and toughening color masterbatch has an obvious toughening effect and higher impact strength at a low temperature of -20 DEG C than normal temperature; in addition, the rigidity of the highly cold-resistant and toughening color masterbatch is improved obviously at normal temperature; the addition of the color masterbatch is small; the color masterbatch is convenient and flexible to use and add. The preparation method of the color masterbatch and materials provided by the invention are used together so that the materials can take full effect; the process is simple and convenient to operate and control; the quality is stable, the production efficiency is high, and large-scale industrial production can be realized.

Owner:DONGGUAN GOLDCOLOR MASTERBATCH

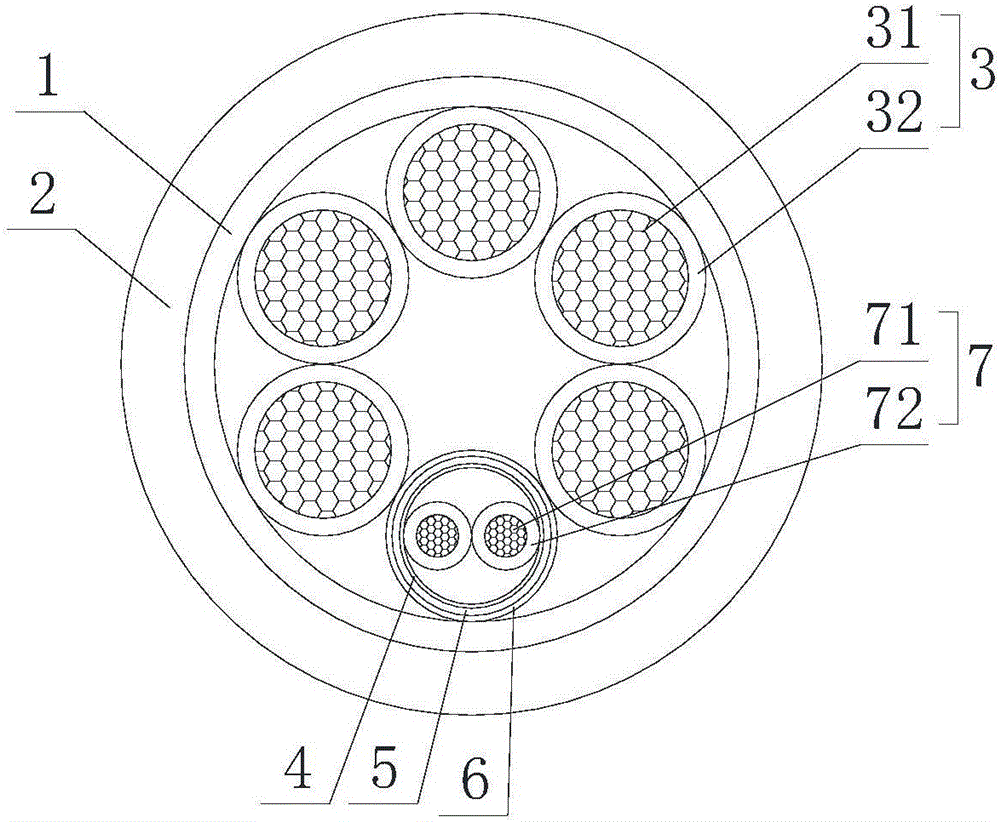

Flame-retardant power cable

InactiveCN105602252AImprove tear resistanceImprove impact resistanceRubber insulatorsInsulated cablesDicumyl peroxideInsulation layer

The invention discloses a flame-retardant power cable which comprises a wire, a high-temperature-resistant insulation layer coated on the wire, a shielding layer coated on the high-temperature-resistant insulation layer and a protective layer coated on the shielding layer. The protective layer is prepared from the following raw materials in parts by weight: 40-60 parts of silicon rubber, 40-60 parts of ethylene propylene diene monomer rubber, 20-25 parts of modified carbon fiber, 30-50 parts of nano kaolin, 1-3 parts of trioctyl trimellitate, 2-4 parts of epoxy soybean oil, 15-25 parts of microcapsulated red phosphorus, 10-15 parts of melamine, 1-3 parts of Si69, 0.5-1 part of dicumyl peroxide, 0.5-1 part of di-tert-butyl peroxide, 0.4-0.6 part of accelerator TMTD, 0.3-0.5 part of accelerator BZ, 2-4 parts of Ca / Zn composite stabilizer, 1-2 parts of butyl tin mercaptide, 0.4-0.6 part of antioxidant 1076, 0.2-0.3 part of anti-aging agent and 2-4 parts of silicone powder.

Owner:ANHUI WUZHOU SPECIAL CABLE GRP

Environment-friendly plastic bag

The invention discloses an environment-friendly plastic bag. The environment-friendly plastic bag is prepared from modified plant starch, polylactic acid, nano-bentonite, soybean oil, bagasse, tetrabutyl titanate, polyvinyl alcohol, glycerol, vinyltriethoxysilane, carboxymethylcellulose polycyclic lactone, polyhydroxybutyrate-hydroxyvalerate and nano-titania. According to the plastic bag easy to degrade, adopted corn starch, cassava starch and water chestnut starch are fast-growing and renewable resources which are abundant, low in unit cost and good in substitutability, and thus the plastic bag has significant economic benefits and ecological benefits; the plastic bag is excellent in biodegradability, and the mass can be reduced by 9-11% within 120 days after the plastic bag is buried. The longitudinal tensile strength of the plastic bag can reach 16.8 MPa, and the transverse tensile strength of the plastic bag can reach 15.6 MPa; the plastic bag easy to degrade is bright in color and luster, high in transparency, bearing capacity, water resistance and wet strength, and capable of meeting the requirements of customers for a larger capacity and reusability.

Owner:BENGBU WEIGUANG PLASTIC PRODS

Ultrahigh molecular weight polyethylene composition capable of being extrusion molded and its prepn process

InactiveCN1847299AIncrease the critical shear rateImprove processing rheologyPolymer sciencePolypropylene

The ultrahigh molecular weight polyethylene composition capable of being extrusion molded is prepared with ultrahigh molecular weight polyethylene in 10-30 weight portions, composite machining assistant in 1-5 weight portions, antioxidant in 0.1-1 weight portion, nucleating agent in 0.1-1 weight portion, and lubricating agent in 0.1-1 weight portion, and through mixing inside a high speed mixer at 70-90 deg.c for 2-5 min and extruding in a double screw extruder at 170-220 deg.c. The ultrahigh molecular weight polyethylene composition has improved machining performance.

Owner:SICHUAN UNIV

PVC (Polyvinyl Chloride) modifying material for curtains and preparation method thereof

The invention relates to the technical field of PVC (Polyvinyl Chloride) materials, in particular to a PVC (Polyvinyl Chloride) modifying material for curtains and a preparation method thereof. The PVC modifying material for the curtain is prepared from the following raw materials in parts by weight: 80 to 120 parts of high-polymerization-degree PVC resin, 45 to 65 parts of plasticizer, 5 to 15 parts of ground calcium carbonate, 10 to 15 parts of light calcium carbonate, 2 to 4 parts of stabilizer, 1 to 3 parts of water-proofing agent, 0.5 to 1.5 parts of modifying agent, 0.6 to 1.0 part of anti-ultraviolet agent, 0.3 to 0.7 part of antioxidant, 0.3 to 0.7 part of anti-blushing agent and 0.4 to 0.8 part of outer lubricant. The PVC modifying material for curtains disclosed by the invention has the advantages of good water-proofing and anti-aging effects, environmental friendliness, excellent temperature resistance and weather resistance, high strength, excellent impact resistance, good flame retarding effect, excellent machining performance and superior comprehensive performance.

Owner:广东祺龙科技有限公司

Uvioresistant and antioxidant ground mat and preparation method thereof

InactiveCN106928596AImprove thermal stabilityEfficient weather resistanceSynthetic resin layered productsLaminationAntioxidantPlasticizer

The invention relates to the technical field of floor mats, in particular to an anti-ultraviolet and anti-oxidation floor mat and a preparation method thereof. The anti-ultraviolet and anti-oxidation floor mat includes a PVC base material layer and a silk braided layer attached to the upper surface of the PVC base material layer. The PVC substrate layer includes the following raw materials in parts by weight: 85-105 parts of PVC resin, 30-40 parts of plasticizer, 20-30 parts of filler, 3-7 parts of stabilizer, 4-8 parts of impact modifier 0.5-1.5 parts of anti-ultraviolet agent, 0.5-1.5 parts of antioxidant, 1.0-1.4 parts of lubricant. The anti-ultraviolet and anti-oxidation floor mat of the present invention has good anti-ultraviolet and anti-oxidation effects, is environmentally friendly and non-toxic, has good strength, toughness and flame retardancy, and has excellent comprehensive performance.

Owner:广东雅丽斯佳新材料有限公司

PVC modified material used for antiskid carpets, and preparation method thereof

The invention relates to the technical field of PVC materials, and concretely to a PVC modified material used for antiskid carpets, and a preparation method thereof. The PVC modified material used for anti-skid carpets comprises, by weight, 80-120 parts of PVC resin, 40-60 parts of a plasticizer, 10-15 parts of heavy calcium carbonate, 5-15 parts of light calcium carbonate, 3-7 parts of a high composite stabilizer, 1-3 parts of chlorinated polyethylene, 1-3 parts of a wear resistant modifier, 0.3-0.7 parts of an antiskid agent, 0.6-1.0 part of an ultraviolet resisting agent, 0.3-0.7 parts of an antioxidant and 0.3-0.7 parts of a lubricant. The PVC modified material used for antiskid carpets has the advantages of good wear resistance, good antiskid and anti-aging effect, environmental protection, excellent resistance to temperature and weather, high strength, excellent impact resistance, good flame retardation effect, excellent processability and excellent comprehensive performances.

Owner:广东祺龙科技有限公司

Damping rubber material

InactiveCN105440464AImprove mechanical propertiesImprove shock absorptionRubber materialParaffin wax

The invention discloses a damping rubber material. Raw materials of the damping rubber material comprise, by weight, 50-70 parts of butyl rubber, 30-50 parts of butadiene-acrylonitrile rubber, 50-70 parts of a composite filler, 15-25 parts of micro-encapsulation red phosphorus, 10-15 parts of melamine phosphate, 5-8 parts of tributyl phosphate, 10-15 parts of epoxidized soybean oil, 15-25 parts of tributyl citrate, 0.5-0.8 part of sulphur, 0.1-0.2 part of stearic acid, 0.1-0.15 part of zinc oxide, 0.2-0.4 part of a promoter DM, 2-4 parts of a Ca / Zn compound stabilizer, 2-4 parts of dibutyltin dilaurate, 0.1-0.3 part of an anti-aging agent RD, 0.1-0.2 part of an anti-aging agent 445, 0.2-0.4 part of an anti-fatigue agent PL and 3-5 parts of paraffin. Raw materials of the composite filler contain modified nano-white carbon black and beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic octadecanol. The damping rubber material of the invention has good damping performance.

Owner:宁国市开源橡塑汽车零部件有限公司

High melt strength polypropylene and preparation thereof

ActiveCN101503538AImprove processing rheologyInhibition of beta scission responsePolypropyleneMonomer

The invention provides a high-melt-strength polypropylene composition. The composition is made from the following compositions in parts by weight: 48-99.989 parts of polypropylene, 0.01-1 part of an initiator and 0.001-1 part of a branching accelerant. The high-melt-strength polypropylene composition can be made into high-melt-strength polypropylene with satisfactory overall properties including satisfactory melt strength without adding polyfunctional monomers.

Owner:宁波帕斯卡新材料有限公司

Tear-resistant heat-insulating rubber cable material and preparation method thereof

PendingCN105585754AImprove heat resistanceImprove corrosion resistanceRubber insulatorsPolymer scienceButadiene-styrene rubber

The invention discloses a tear-resistant heat-insulating rubber cable material which is prepared from the following raw materials in parts by weight: 20-30 parts of epoxidized natural rubber, 40-60 parts of styrene-butadiene rubber, 30-50 parts of ethylene propylene diene monomer rubber, 50-80 parts of modified montmorillonite, 25-35 parts of dioctyl phthalate, 25-35 parts of epoxy soybean oil, 20-40 parts of aluminum hydroxide, 10-15 parts of melamine, 10-15 parts of sodium metaborate, 1-3 parts of bis-[gamma-(triethoxysilyl)propyl]tetrasulfide, 1-2 parts of sulfur, 0.6-0.8 part of accelerator M, 0.4-0.6 part of accelerator D, 2-4 parts of Ca / Zn composite stabilizer, 1-2 parts of bis-butyl tin dichloride, 0.2-0.4 part of antioxidant BHT, 0.1-0.2 part of anti-aging agent and 2-4 parts of montanin wax. The invention also discloses a preparation method of the tear-resistant heat-insulating rubber cable material. The tear-resistant heat-insulating rubber cable material has the advantages of favorable tear resistance and favorable heating insulating property.

Owner:繁昌县菲德通讯材料设计有限公司

Fire-resistant plastics-wood composite capable of purifying air and preparation method thereof

The invention provides a fire-resistant plastics-wood composite capable of purifying air and a preparation method thereof, and relates to the technical field of plastics-wood composite materials. The fire-resistant plastics-wood composite capable of purifying the air is prepared from, by weight, 15-23 parts of bamboo sawdust, 13-21 parts of rice husks, 13-19 parts of bagasse, 7-29 parts of ammonium polyphosphate, 15-27 parts of waste polyethylene foamed plastics, 5-21 parts of diatom ooze, 15-21 parts of activated carbon, 12-16 parts of urea resin, 21-37 parts of calcium oxide, 18-30 parts of phenolic foam, 13-19 parts of bamboo charcoal, 15-23 parts of attapulgite, 0.6-1.2 parts of flame retardant, 0.3-0.7 part of a heat stabilizer, 0.4-0.8 part of an antioxidant and 0.7-1.3 parts of compatilizer. The preparation method comprises the following steps of 1 raw material weighing, 2 crushing, 3 mixing, 4 stirring and 5 granulating. The prepared fire-resistant plastics-wood composite capable of purifying the air has the advantages of being resistant to flame and capable of purifying the air.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

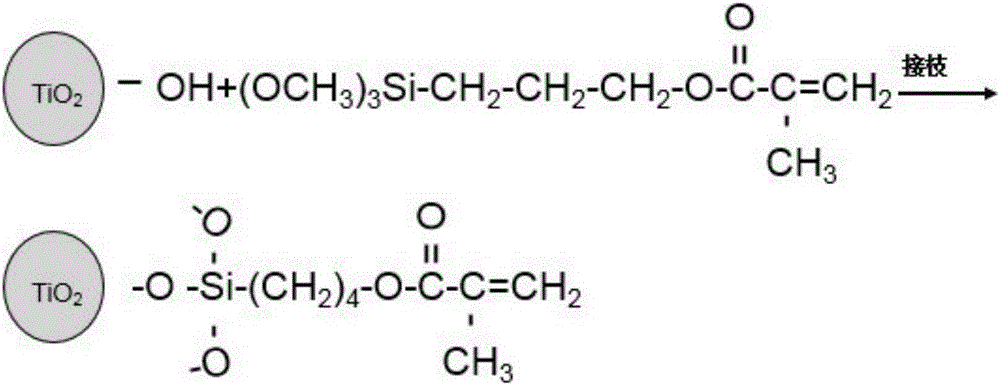

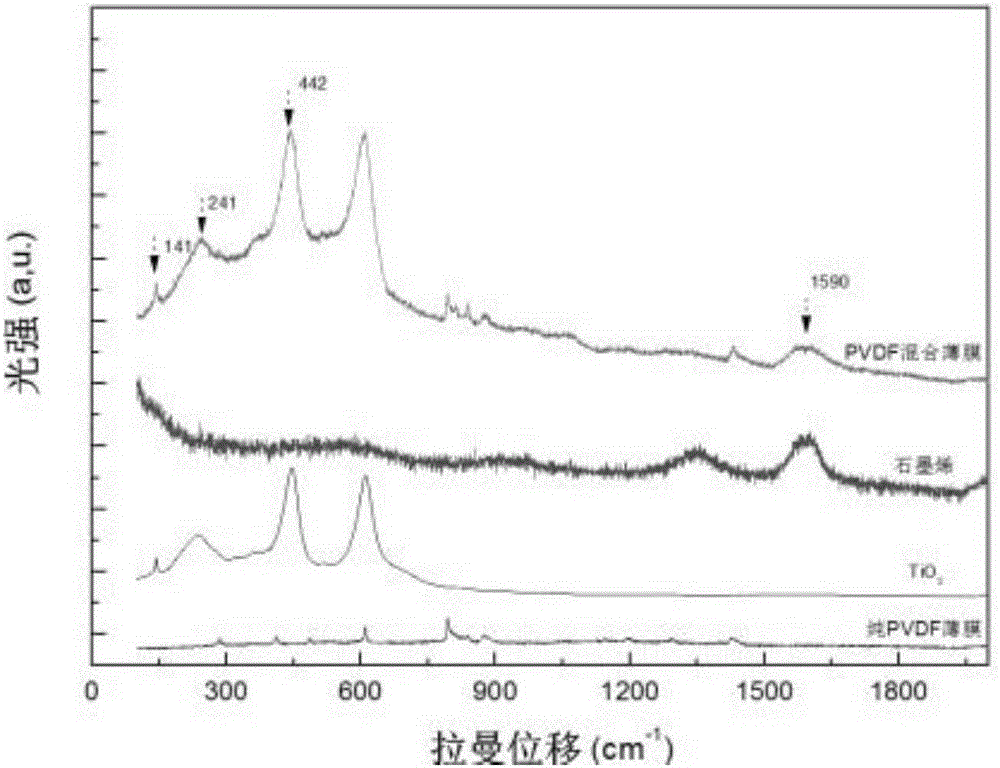

Blend film containing graphene and preparation method thereof

InactiveCN105218987AGood anti-light aging performanceHigh thermal conductivityPhotovoltaic energy generationSemiconductor devicesAging resistanceSolar cell

The invention is suitable for preparing a solar cell back film, and provides a blend film containing graphene and a preparation method thereof. The blend film is a blend membrane of titanium dioxide graft, PVDF, PMMA, PPA and graphene, and the titanium dioxide graft is modified titanium dioxide with a silane coupling agent KH570 grafted on the surface. In the existence of the graft, the titanium dioxide has non-uniformity phenomenon in the blend membrane, so that when the blend membrane is used as the solar cell back film, the cohesive force between the film and other backboard base materials is greatly increased, and the existence of the PMMA, PPA and graphene also improves the aging resistance, heat conductivity and surface smoothness of the solar cell back membrane. The preparation method comprises the following steps: first grafting the silane coupling agent KH570 onto the surface of the titanium dioxide, mixing weighted TiO2 graft, PVDF, PMMA, PPA and graphene, uniformly mixing, extruding to form strips, cutting the strips into granules, drying the granules, extruding the granules by virtue of a single screw, and tape casting to obtain the blend film.

Owner:SHENZHEN UNIV

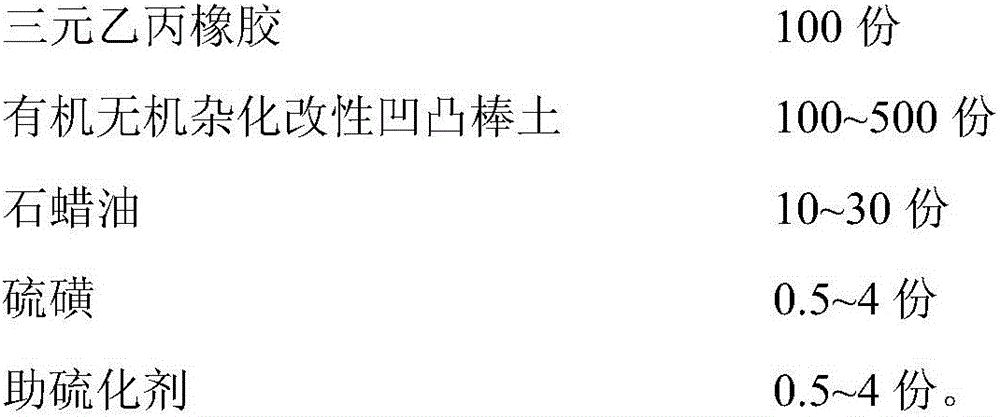

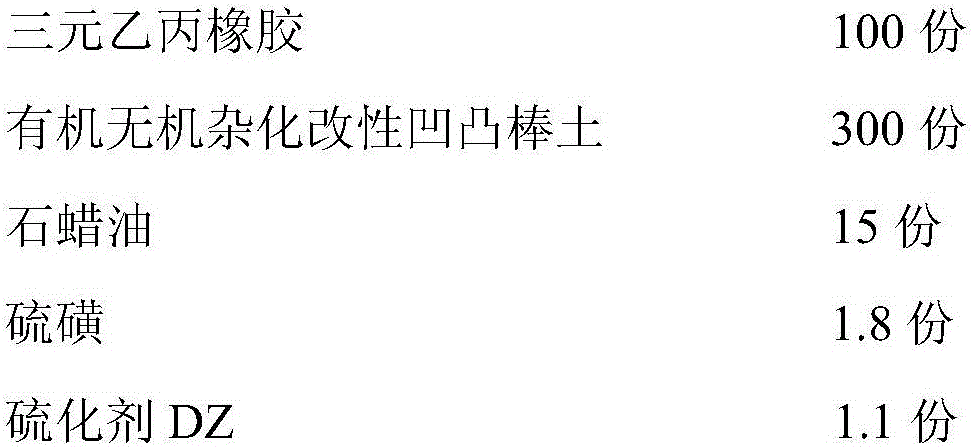

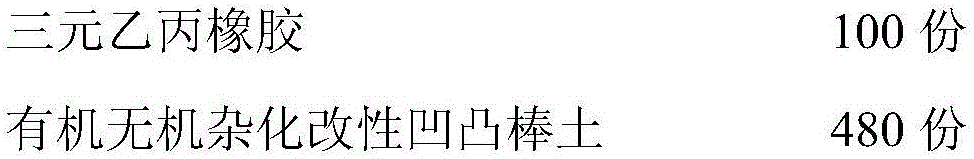

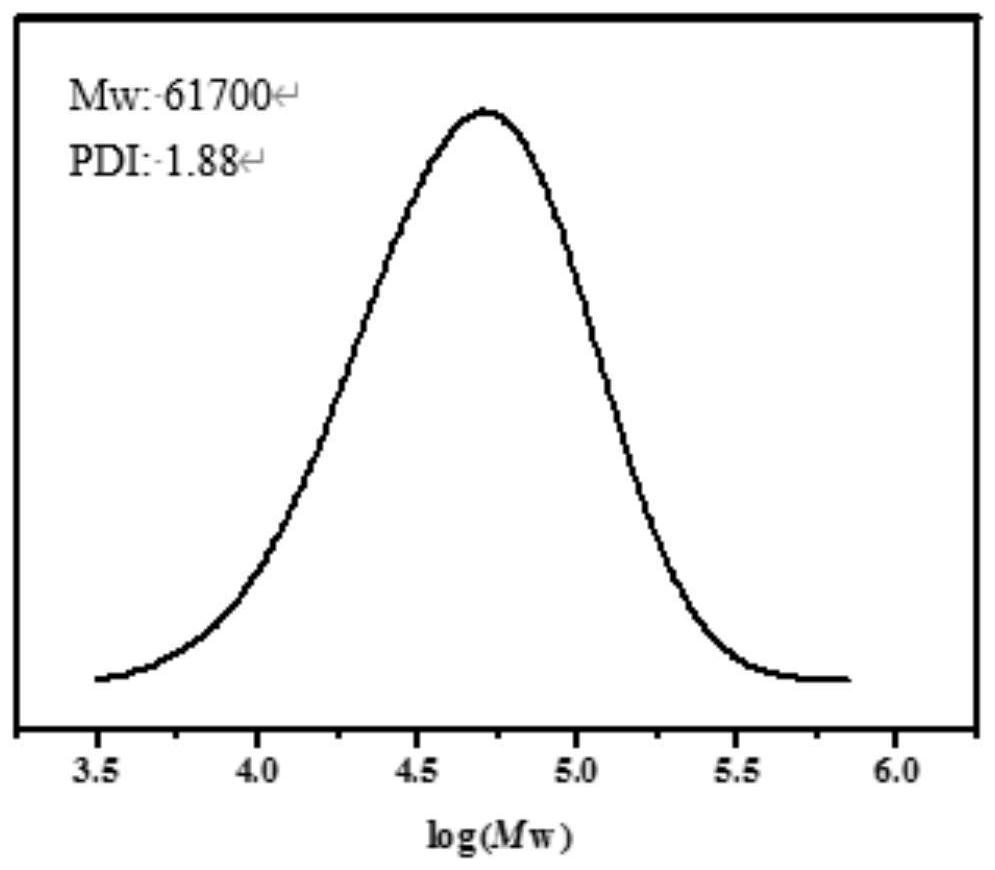

Organic inorganic hybridized modified attapulgite ethylene propylene terpolymer composite

InactiveCN106832612AIncrease filling volumeGood compatibilityEthylene-propylene-diene-monomerSilicon

The invention discloses an organic inorganic hybridized modified attapulgite ethylene propylene terpolymer composite. The invention develops a novel organic silicon coupling reagent which is combined with a silicon sol and an organic inorganic hybridized surface modified attapulgite. The novel organic silicon coupling reagent is used for filling and modifying ethylene propylene terpolymer, so that the organic inorganic hybridized modified attapulgite ethylene propylene terpolymer composite with high performance can be acquired. The organic inorganic hybridized modified attapulgite ethylene propylene terpolymer composite provided by the invention is prepared from the following raw materials in parts by weight: 100 parts of ethylene propylene terpolymer, 100-500 parts of organic inorganic hybridized modified attapulgite, 10-30 parts of paroline, 0.5-4 parts of sulphur and 0.5-4 parts of vulcanizing agent.

Owner:江苏中业登泰新材料科技有限公司

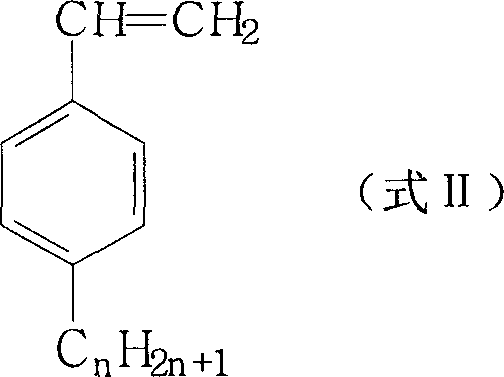

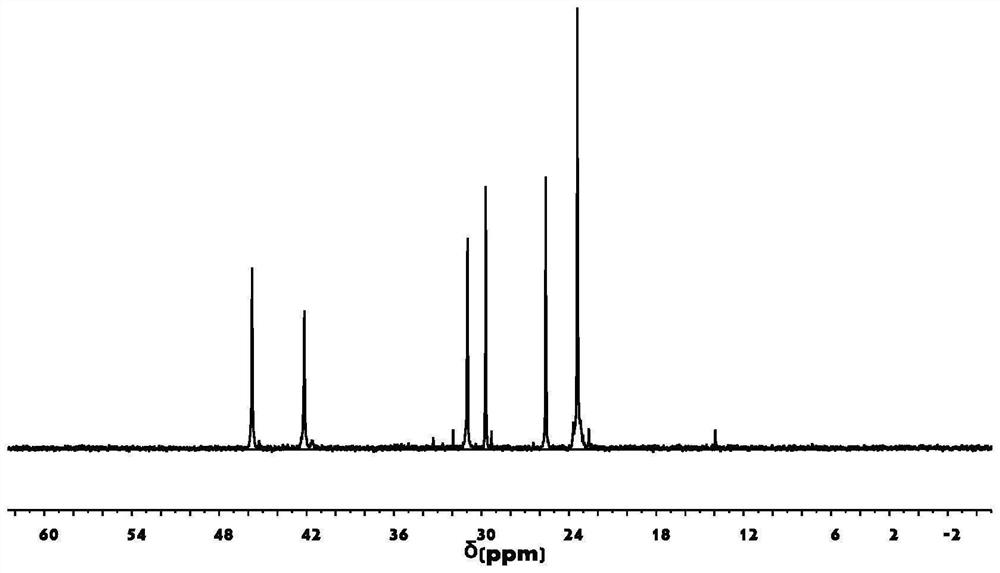

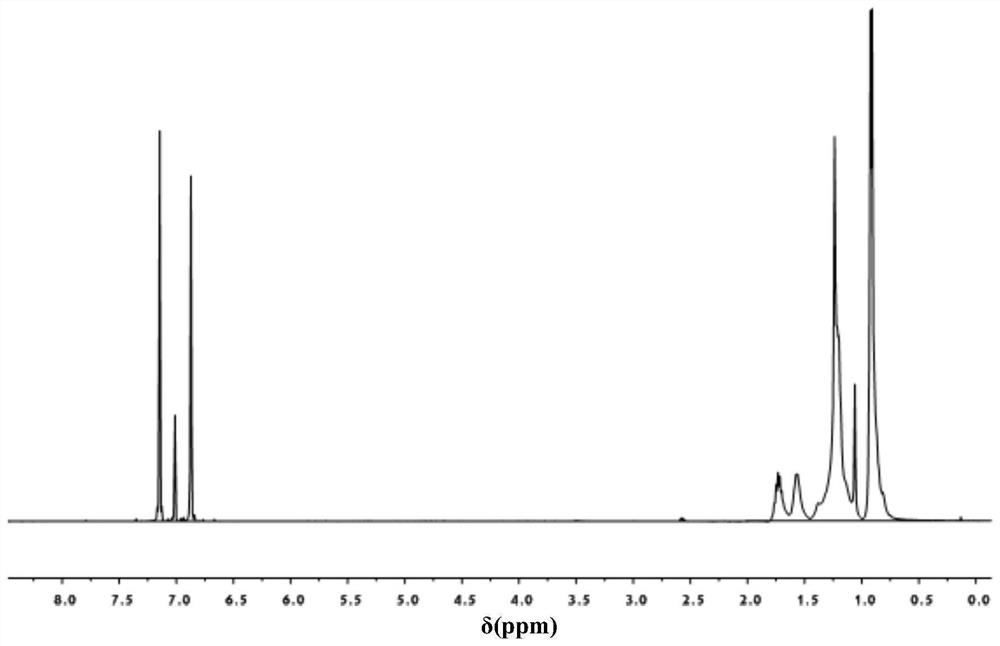

PMP copolymer and preparation method thereof

The invention discloses a PMP copolymer and a preparation method thereof, and belongs to the technical field of PMP copolymerization. The PMP side chain of the polymer contains a long-chain polyethylene structure. The preparation method of the polymer comprises the following steps: preparing long-chain polyethylene from a component A catalyst system; and under the catalytic action of the component B catalyst, copolymerizing ethylene and PMP to prepare the PMP copolymer. On the basis of maintaining excellent mechanical properties, thermal properties, transparency and the like of PMP, the polyPMP is endowed with the characteristics of controllable molecular weight and structure, increased toughness, good processing rheological property and the like, further processing and application of the polyPMP are facilitated, meanwhile, the preparation method is simple, and conditions are provided for wide application of the novel material.

Owner:TIANJIN UNIV

Water antistatic synthetic leather and preparation method thereof

InactiveCN104562726AImprove mechanical propertiesHigh tensile strengthSynthetic resin layered productsTextiles and paperAntistatic agentSURFACTANT BLEND

The invention discloses water antistatic synthetic leather and a preparation method thereof. The synthetic leather is prepared from an antistatic sizing agent by adopting a rolling process, wherein the antistatic sizing agent is prepared by following components in parts by weight: 100 parts of water polyurethane resin, 5 to 10 parts of antistatic agent, 0.5 to 1 part of antifoaming agent, 0.5 to 1 part of flatting agent, 0.5 part of organic silicon dry sliding agent and 0.3 to 0.5 part of compatilizer, and the antistatic agent is a complex consisting of a quaternary ammonium cationic surfactant and a nonionic surfactant. The synthetic leather is not only relatively good in mechanical property and capable of improving tensile strength and impact strength of the product, realizing high filling and improving the processing rheological property, but also relatively excellent in antistatic characteristic.

Owner:JIANGSU GUOXIN SYNTHETIC LEATHER

Environment-friendly cable for automobile charging pile

InactiveCN105801937AImprove low temperature resistanceImprove corrosion resistancePower cables including communication wiresInsulated cablesAmmonium polyphosphateCorrosion

Owner:安徽华海特种电缆集团有限公司

Inorganic powder highly filled polyolefin fiber paper and production method thereof

PendingCN108864521AEasy to distributeHigh surface glossWater-repelling agents additionPaper-making machinesSurface finishPolymer science

The invention discloses inorganic powder highly filled polyolefin fiber paper and a production method thereof. The polyolefin fiber paper is prepared from the raw materials in proportion: 10% to 20% of polyolefin, 0.1% to 2% of coupling agent, 0.1% to 1% of dispersing agent, 1% to 10% of compatibilizer, 0.1% to 2% of plasticizer, 1 to 5% of hot-melt type adhesive, 0.1% to 2% of surface active agent, 0.1% to 1.5% of rheology modifier and 75% to 85% of inorganic powder. The production method comprises the steps of evenly mixing and stirring polyolefin and the rheology modifier under the assistance of a technology to improve a melt index and fluidity of polyolefin; sequentially adding the compatibilizer and the plasticizer to be evenly stirring and mixed; then sequentially adding the activated inorganic powder and the activated hot-melt type adhesive and evenly mixing and stirring; processing through the work procedures of mixing, kneading, drawing fiber, preparing a finished product fromfiber stuff and the like to obtain the inorganic powder highly filled polyolefin fiber paper. According to the inorganic powder highly filled polyolefin fiber paper disclosed by the invention high filling of inorganic powder is achieved, a resin use amount is reduced, tensile strength, impact strength and surface smoothness of the product are enhanced, and a filler retention rate is improved.

Owner:福建省大投科技有限公司

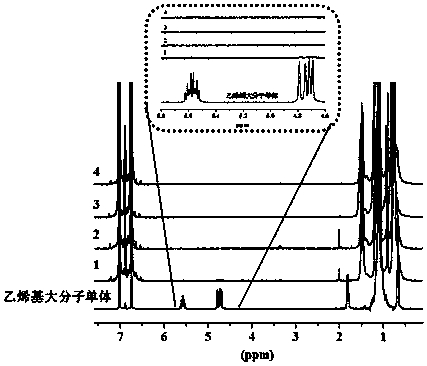

Propylene copolymer and preparation method thereof

ActiveCN109748988AImprove mechanical propertiesImprove thermal performanceAcrylic resinPolypropylene

The invention discloses a propylene copolymer and a preparation method thereof. According to the method, a vinyl macromonomer is prepared from a first component catalyst system; polymeric propylene and the vinyl macromonomer are copolymerized through catalysis of a second component catalyst system to obtain the propylene copolymer. On the basis of retaining the excellent mechanical properties, thermal properties, chemical stability and electrical insulating properties of polypropylene, the propylene copolymer has the advantages of controllable molecular weight and structure, high impact resistance, high melt strength, good rheological property in processing and the like, so that acrylic resin is conveniently further processed and applied, and conditions are provided for wide application ofthe novel material.

Owner:TIANJIN UNIV +1

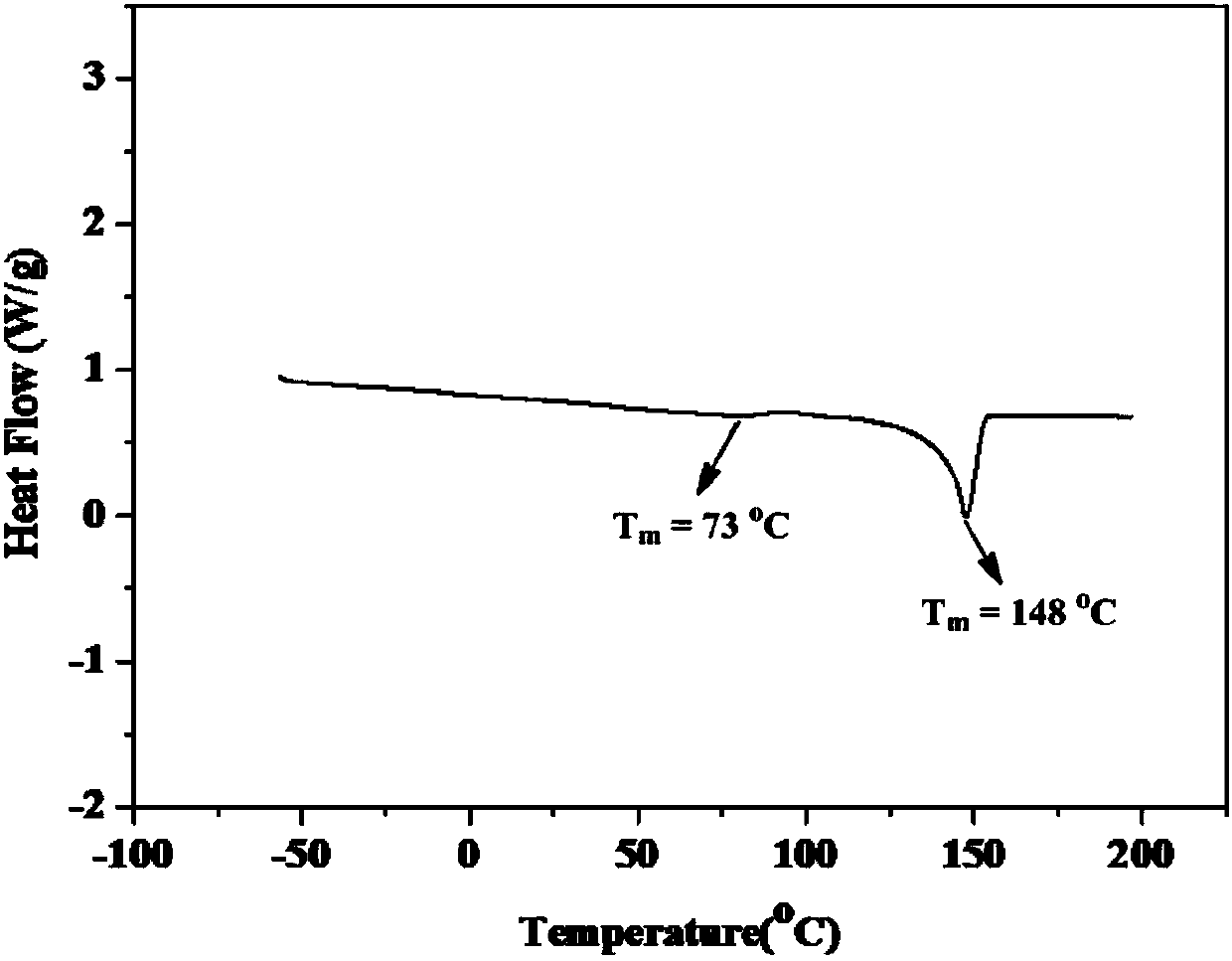

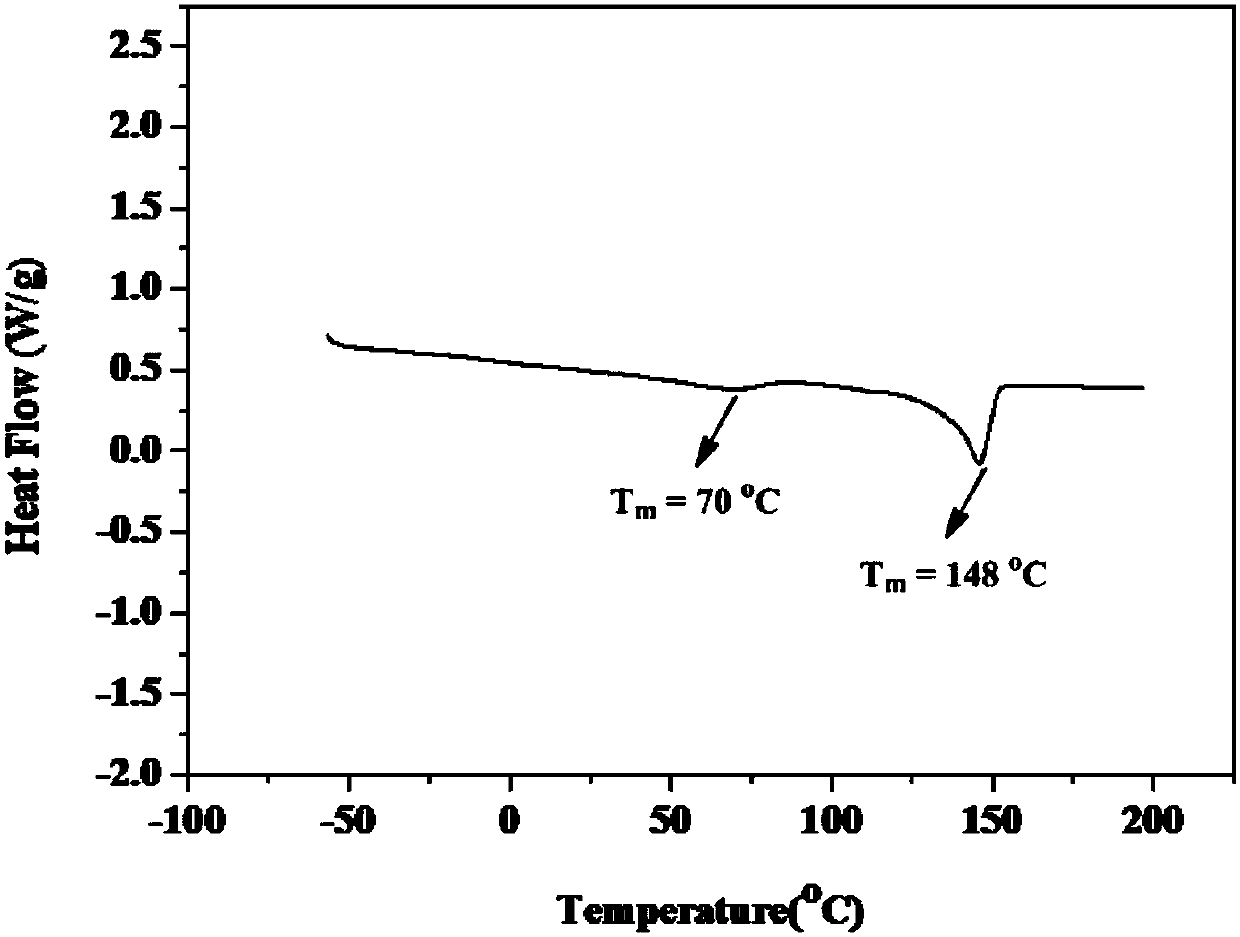

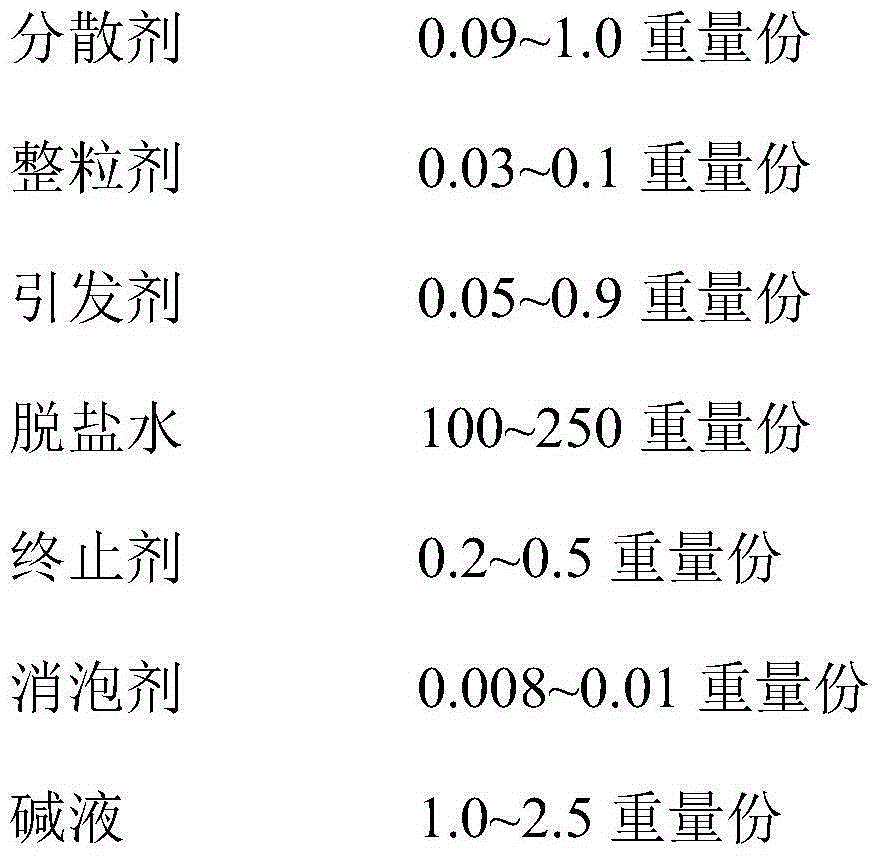

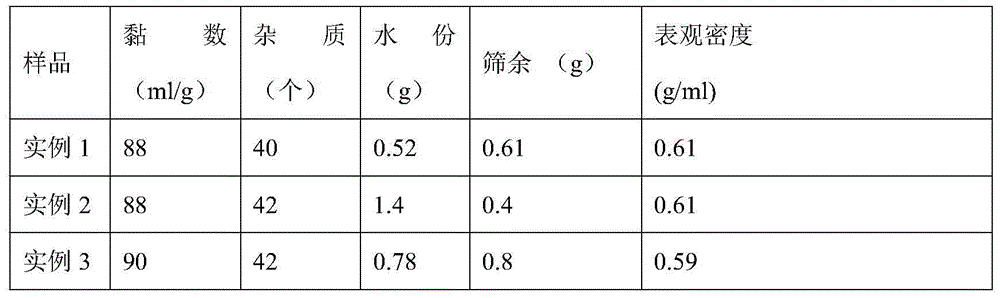

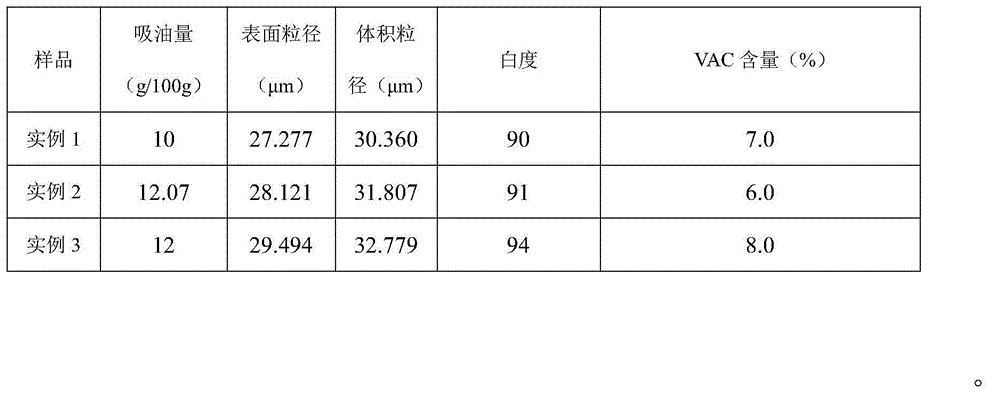

Polymerization method used for reducing vinyl chloride/vinyl acetate copolymer blending resin glass transition temperature

InactiveCN105273120ALower glass transition temperatureImprove processing rheologySlurryEthyl Chloride

The invention discloses a polymerization method used for reducing vinyl chloride / vinyl acetate copolymer blending resin glass transition temperature. The polymerization method comprises following steps: vinyl chloride monomer, vinyl acetate monomer, a dispersing agent, a size stabilization agent, an initiating agent, and desalted water are delivered into a polymerization kettle for reaction; temperature is increased to 48 to 52, and is maintained for 1 to 2h, and then is increased naturally to 60 to 65 DEG C; when reaction pressure is reduced to 200 to 300KPa, a terminating agent and an antifoaming agent are added to end the reaction so as to obtain a vinyl chloride / vinyl acetate copolymer blending resin slurry emulsion; an alkaline liquor is added, and the vinyl chloride / vinyl acetate copolymer blending resin is collected from a reaction product. According to the polymerization method, the vinyl chloride / vinyl acetate copolymer blending resin is relatively low in glass transition temperature Tg, excellent in fluidity, flexibility, toughness, and thermoplasticity, is convenient to process, can be adhered with metal surfaces easily, and can be widely used for preparing plastic floor, transparent packaging sheets, artificial leather, protective paint, magnetic binders, and printing plates.

Owner:SHANGHAI CHLOR ALKALI CHEM

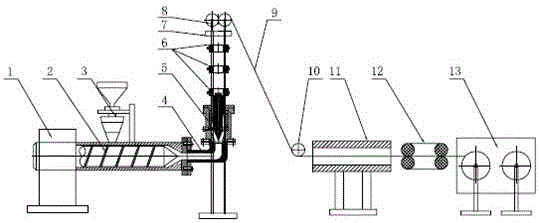

Production process of special large-pipe-diameter PE branch pipe for low-pressure drip irrigation

The invention relates to a production process of a special large-pipe-diameter PE branch pipe for low-pressure drip irrigation. The process comprises the following steps: (1) preparing a polyethylene mixture; (2) adding the polyethylene mixture into a hopper of an extruding machine, and starting a transmission device; (3) melting and plastifying the polyethylene mixture through a screw cylinder of the extruding machine, enabling the polyethylene mixture to enter a mandril in a head die through a machine neck transitioning body, and carrying out gas feeding and exhausting through compressed air and extruding forming to obtain a pipe blank; and (4) enabling the inner diameter of the pipe blank to be increased under the action of the compressed air, carrying out stretching along the axial direction of the pipe blank under the action of a pulling wheel and a pulling device, so as to enable a PE macromolecular chain and a chain section inside the pipe blank to form biaxial stretching orientation along the axial direction and the circumferential direction of the pipe blank, enable the pipe blank to penetrate through three layers of perpendicularly stacked cooling air rings in sequence and enter a secondary cooling device after an infrared diameter sizing device controls the pipe diameter, and finally enable the pulling device to pull the pipe blank to form the special large-pipe-diameter PE branch pipe for low-pressure drip irrigation, and putting the product into a winding device. The production process is low in cost and easy to implement, and the obtained product is excellent in product performance.

Owner:GANSU DAYU WATER SAVING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com