Branched polypropylene and its preparation method

A branched polypropylene and polypropylene technology, applied in the field of branched polypropylene and its preparation, can solve the problems of limiting the application of polypropylene, decrease in melt strength, deterioration of sag resistance, etc. The effect of good processing rheology and high melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

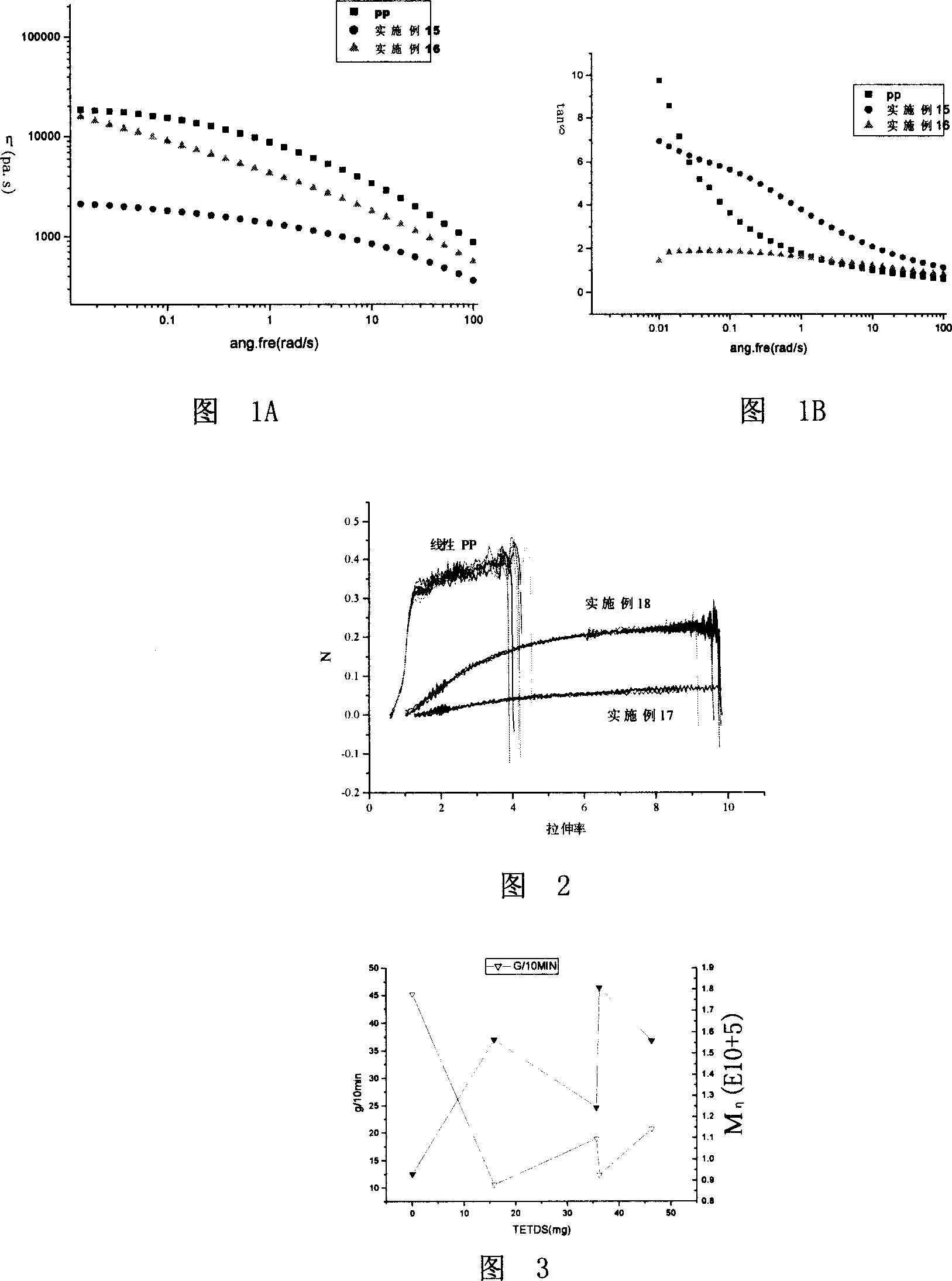

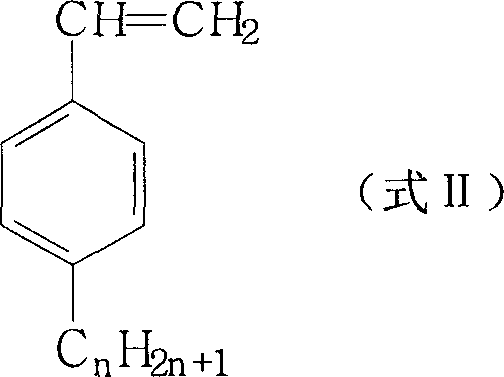

[0033] 50g of propylene copolymer of 4-methylstyrene and propylene (MFR=0.883, the molar content of 4-methylstyrene unit is 1.55*10 -2 %) into the internal mixer at a temperature of 210°C, stirring for 2 minutes, adding 0.77 g of trimethyl alcohol hydroxypropane triacrylate, stirring for 1 minute, and then simultaneously adding 0.0352 g of 2,5-dimethyl-2,5-di-tert- Butylperoxyhexane and 15mg tetraethylthiurab dithioester (TETDS) were reacted for 7 minutes and discharged to obtain branched polypropylene with a branching ratio of 0.3 / 1000°C and a melt strength of 223mN.

Embodiment 2

[0035] 50g of propylene copolymer of 4-methylstyrene and propylene (MFR=0.847, 4-methylstyrene unit molar content is 2.74*10 -2 %) into the internal mixer at a temperature of 210°C, stirring for 2 minutes, adding 0.88 g of trimethyl alcohol hydroxypropane triacrylate, stirring for 1 minute, and then simultaneously adding 0.0352 g of 2,5-dimethyl-2,5-di-tert-butyl Hexyl peroxide reacted with 15mg tetraethylthurium dithioester for 7min and then discharged to obtain branched polypropylene with a branching ratio of 0.43 / 10000C and a melt strength of 235mN.

Embodiment 3

[0037] 50g of propylene copolymer of 4-methylstyrene and propylene (MFR=0.297, the molar content of 4-methylstyrene unit is 3.71*10 -2 %) into the internal mixer at a temperature of 210°C, stirring for 2 minutes, adding 0.99 g of trimethyl alcohol hydroxypropane triacrylate, stirring for 1 minute, and then simultaneously adding 0.0352 g of 2,5-dimethyl-2,5-di-tert-butyl Hexyl peroxide and 15mg of tetraethylthiurabdithioester reacted after 7min to obtain branched polypropylene, and its branching rate was 0.45 / 10000C, and the melt strength of gained branched polypropylene was 237mN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt strength | aaaaa | aaaaa |

| Melt strength | aaaaa | aaaaa |

| Melt strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com