High melt strength polypropylene and preparation thereof

A technology with high melt strength and melt strength, applied in the field of high melt strength polypropylene and its preparation, can solve the problem that it is difficult to control only the formation of long chain branching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

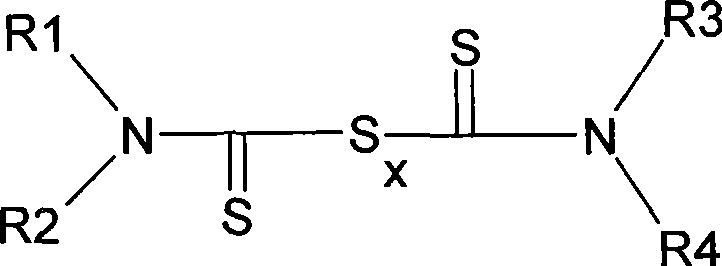

Method used

Image

Examples

Embodiment 1

[0087] The parts by mass of each component are:

[0088] Polypropylene (MFR=4.50g / 10min) 99,

[0089] Dicumyl peroxide 0.5,

[0090] Tetraethylthiuram dithioester 0.5,

[0091] In a twin-screw extruder with L / D=60, D=35mm, the feed rate is 10kg / h, and the speed is 100rpm. The temperature setting is divided into three sections, the conveying section is 160°C, the reaction section is 200°C, and the extrusion section is 190°C ℃. The melt strength of the resulting polypropylene was 305.8 mN and the melt index was 2.10 g / 10 min.

Embodiment 2

[0093] The parts by mass of each component are:

[0094] Polypropylene (MFR=4.50g / 10min) 99.4,

[0095] Dicumyl peroxide 0.5,

[0096] Tetraethylthiuram dithioester 0.1,

[0097] In a twin-screw extruder with L / D=60, D=35mm, the feed rate is 10kg / h, and the speed is 100rpm. The temperature setting is divided into three sections, the conveying section is 160°C, the reaction section is 200°C, and the extrusion section is 190°C ℃. The resulting polypropylene had a melt strength of 258.4 mN and a melt index of 2.64 g / 10 min.

Embodiment 3

[0099] The parts by mass of each component are:

[0100] Polypropylene (MFR=4.50g / 10min) 98.9,

[0101] Dicumyl peroxide 1,

[0102] Tetraethylthiuram dithioester 0.1,

[0103] In a twin-screw extruder with L / D=60, D=35mm, the feed rate is 10kg / h, and the speed is 100rpm. The temperature setting is divided into three sections, the conveying section is 160°C, the reaction section is 200°C, and the extrusion section is 190°C ℃. The resulting polypropylene had a melt strength of 275.6 mN and a melt index of 2.40 g / 10 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt strength | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Melt strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com