Environment-friendly cable for automobile charging pile

A car charging and environment-friendly technology, which is applied in the direction of power cables, power cables including electronic control, and power cables including electrical communication lines, to achieve good low temperature resistance, good mechanical properties, and improved dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

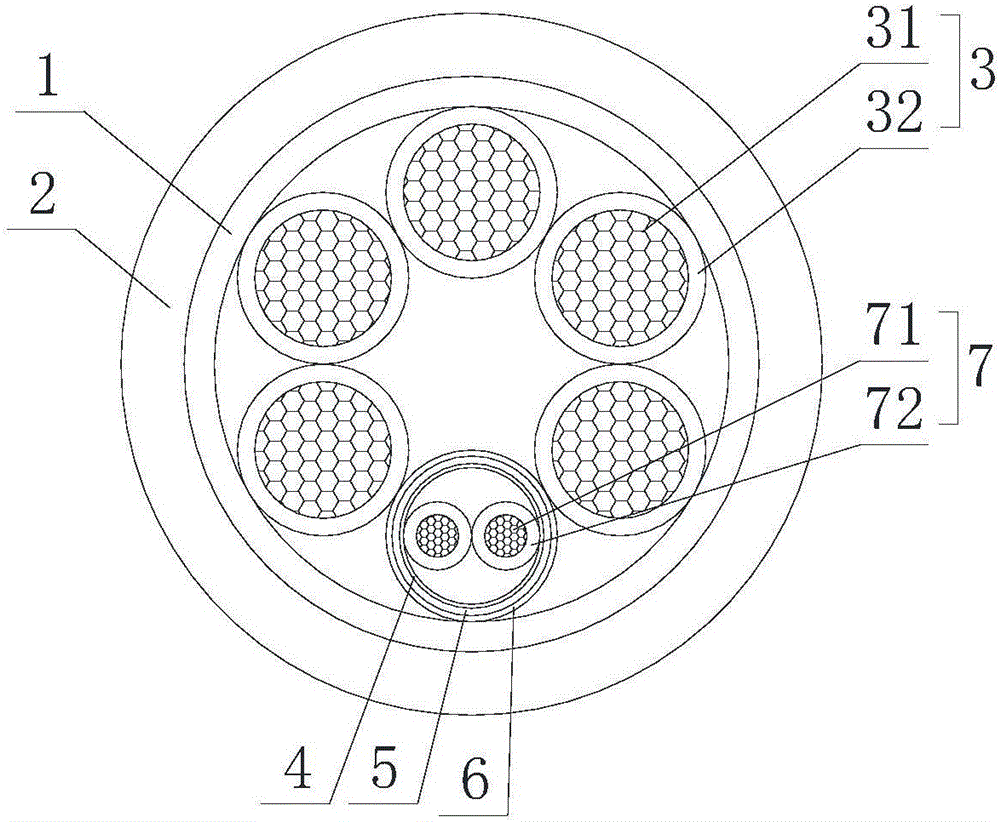

[0030] An environmentally friendly cable for automobile charging piles, comprising: a cable core, a total wrapping layer 1, a total sheath layer 2;

[0031] The cable core is formed by twisting a plurality of power core wires 3 and a control core wire. The power core wire 3 includes a first conductor 31 in the middle and a first insulating layer 32 covering the outside of the first conductor 31. The core wire includes a control wire core, a sub-winding layer 4, a shielding layer 5, and a sub-sheath layer 6. The control wire core is twisted by two control wires 7, each of which includes a second conductor 71 located in the middle. And the second insulating layer 72 covering the outside of the second conductor 71, the sub-winding layer 4 is covering the outside of the control wire core, the shielding layer 5 is covering the outside of the sub-winding layer 4, and the sub-sheathing layer 6 is covering Outside the shielding layer 5;

[0032] The total wrapping layer ...

Example Embodiment

[0035] Example 2

[0036] An environmentally friendly cable for automobile charging piles, comprising: a cable core, a total wrapping layer 1, a total sheath layer 2;

[0037] The cable core is formed by twisting a plurality of power core wires 3 and a control core wire. The power core wire 3 includes a first conductor 31 in the middle and a first insulating layer 32 covering the outside of the first conductor 31. The core wire includes a control wire core, a sub-winding layer 4, a shielding layer 5, and a sub-sheath layer 6. The control wire core is twisted by two control wires 7, each of which includes a second conductor 71 located in the middle. And the second insulating layer 72 covering the outside of the second conductor 71, the sub-winding layer 4 is covering the outside of the control wire core, the shielding layer 5 is covering the outside of the sub-winding layer 4, and the sub-sheathing layer 6 is covering Outside the shielding layer 5;

[0038] The total wrapping layer ...

Example Embodiment

[0041] Example 3

[0042] An environmentally friendly cable for automobile charging piles, comprising: a cable core, a total wrapping layer 1, a total sheath layer 2;

[0043] The cable core is formed by twisting a plurality of power core wires 3 and a control core wire. The power core wire 3 includes a first conductor 31 in the middle and a first insulating layer 32 covering the outside of the first conductor 31. The core wire includes a control wire core, a sub-winding layer 4, a shielding layer 5, and a sub-sheath layer 6. The control wire core is twisted by two control wires 7, each of which includes a second conductor 71 located in the middle. And the second insulating layer 72 covering the outside of the second conductor 71, the sub-winding layer 4 is covering the outside of the control core, the shielding layer 5 is covering the outside of the sub-winding layer 4, and the sub-sheathing layer 6 is covering Outside the shielding layer 5;

[0044] The total wrapping layer 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com