Weatherable irradiation crosslinking cable material

A cable material and weather resistance technology, applied in the direction of organic insulators, etc., can solve the problems of decomposition and embrittlement, low flame retardancy, low notched impact strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

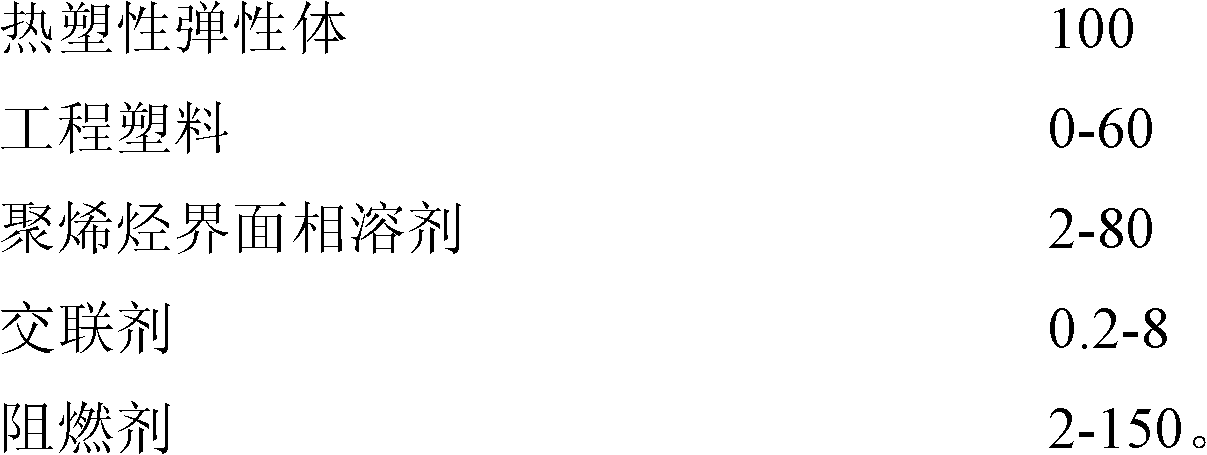

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with specific embodiments.

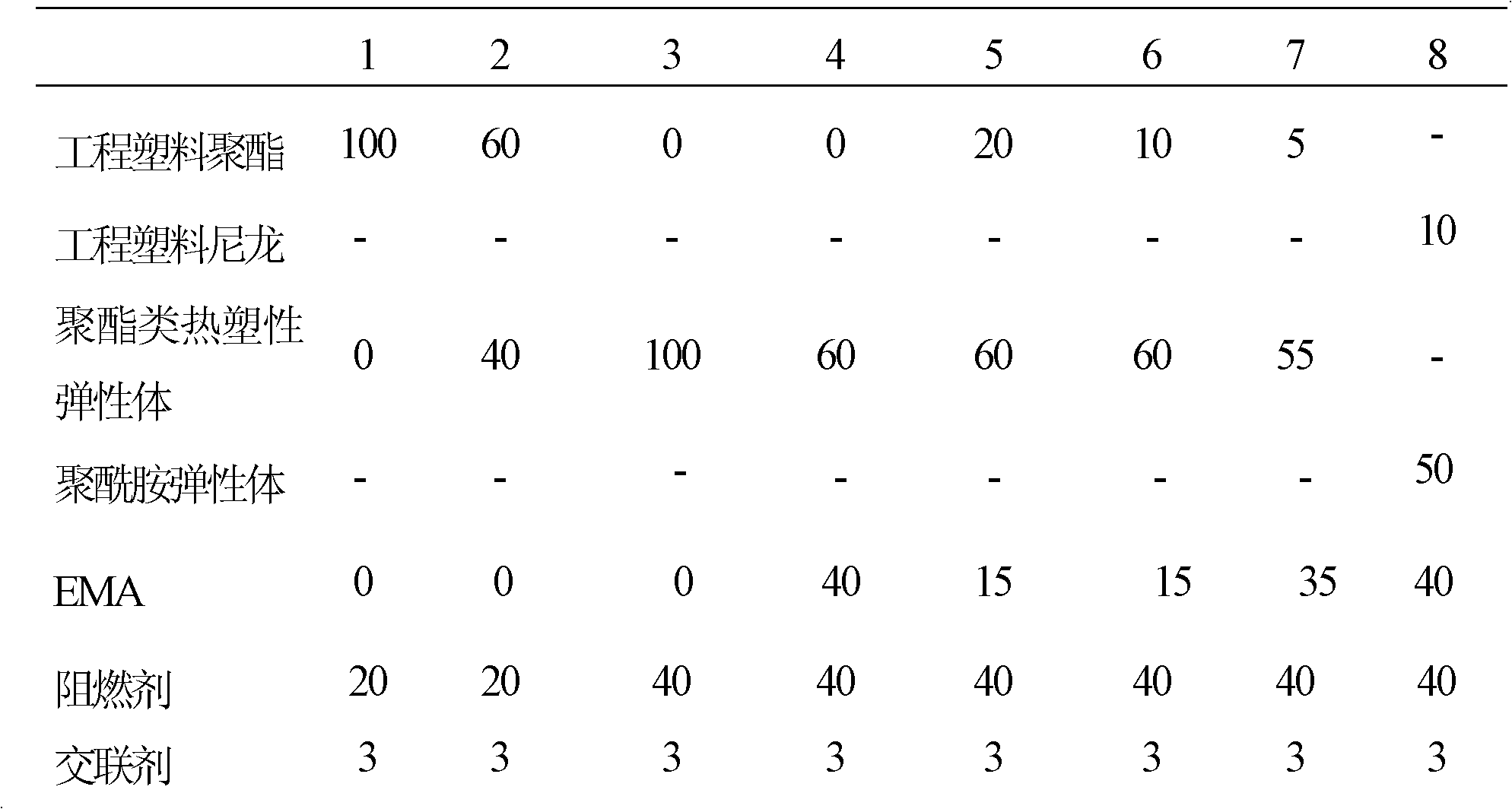

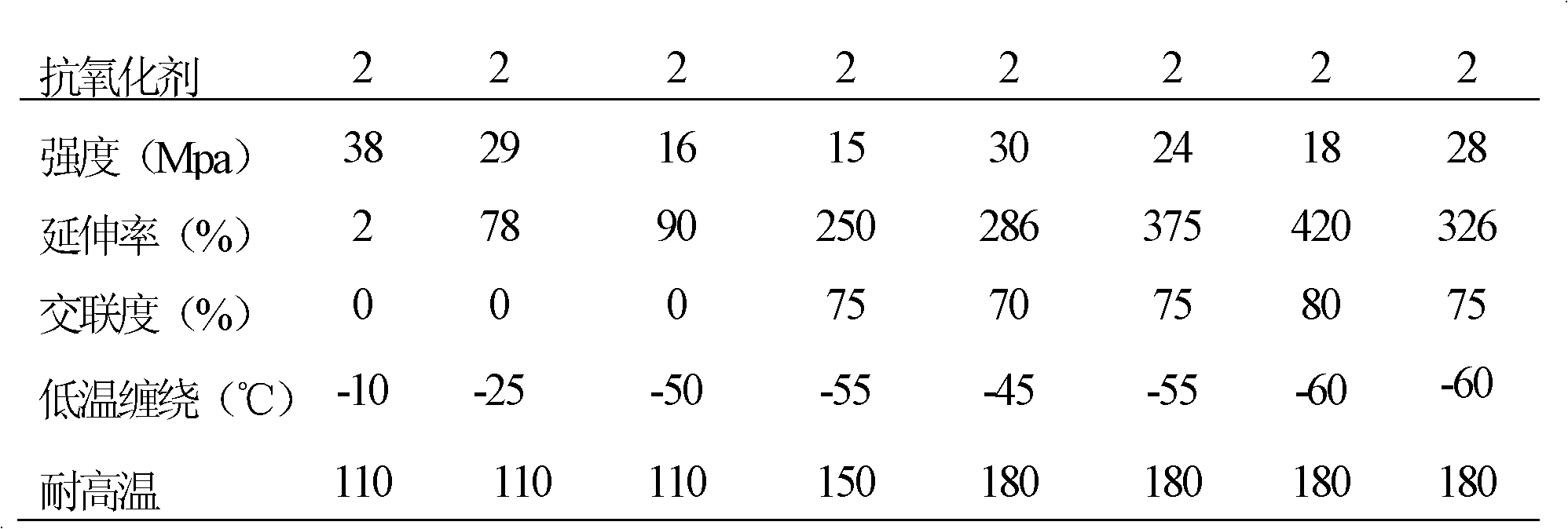

[0026] In the following examples: the polyester engineering plastic PBT is the American Shabitt brand Valox*325, and the melt index is 15g / 10min (250℃ / 2.16kg); the polyester block copolymer thermoplastic elastomer is the American Riteflex brand 655, the melt index 20g / 10min (250℃ / 2.16kg); polyolefin interfacial solvent EMA is French Ato’s brand 29MA03, melt index is 3 (190℃ / 2.16kg); engineering plastic nylon adopts American Baffle nylon PA-6 brand B29 ; Nylon-polyether block copolymer adopts French Atto PEBAX5533; flame retardant adopts magnesium hydroxide low-smoke halogen-free flame retardant; antioxidant adopts airbus brand Irgnox 1010 and modified aromatic diphenylamine brand Naugard445; The linking agent is Taic crosslinking agent.

[0027] Mix the main materials uniformly according to the comparative examples 1, 2, 3 listed in Table 1 and the raw material ratios of Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com