Patents

Literature

7845results about How to "Reduce defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

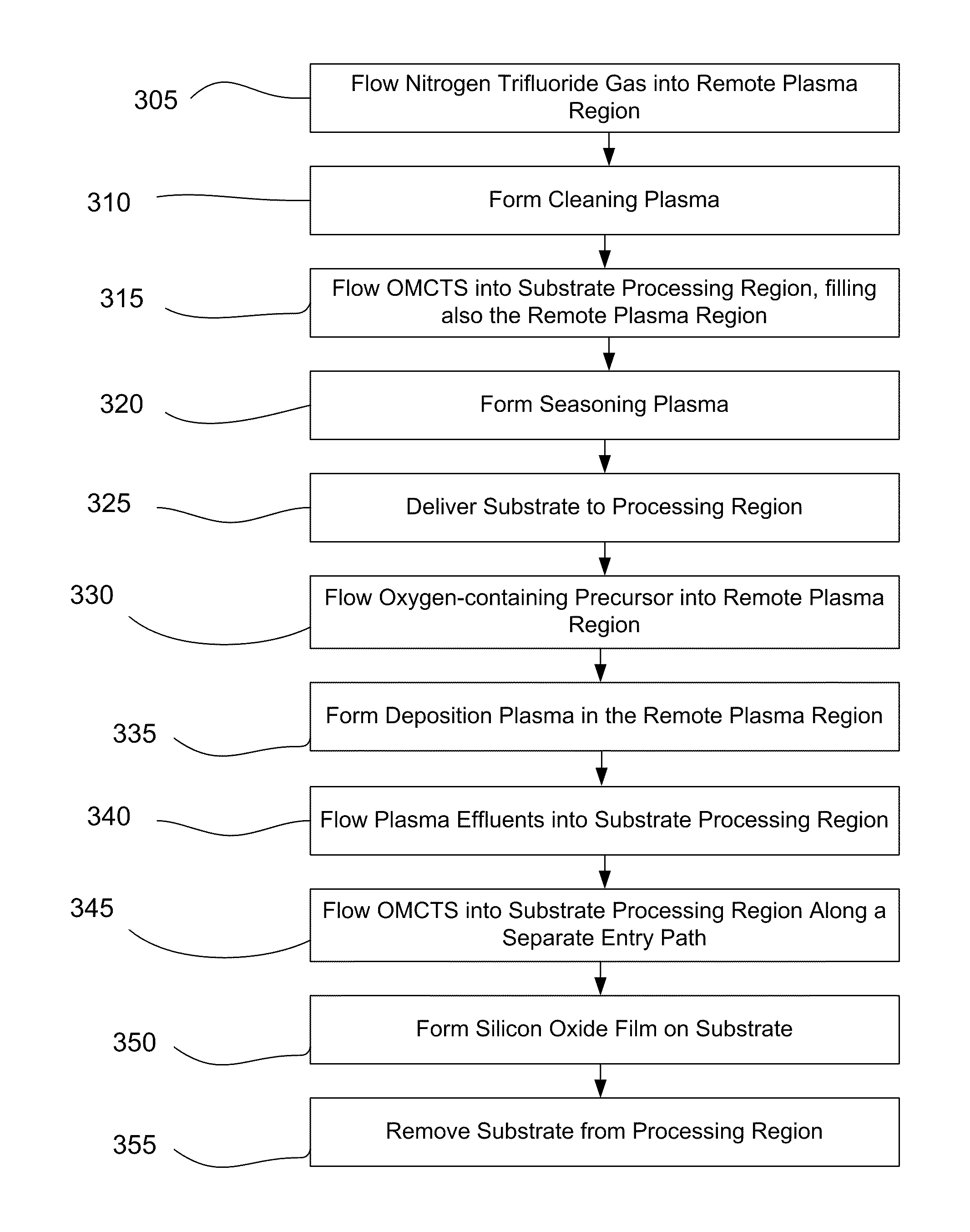

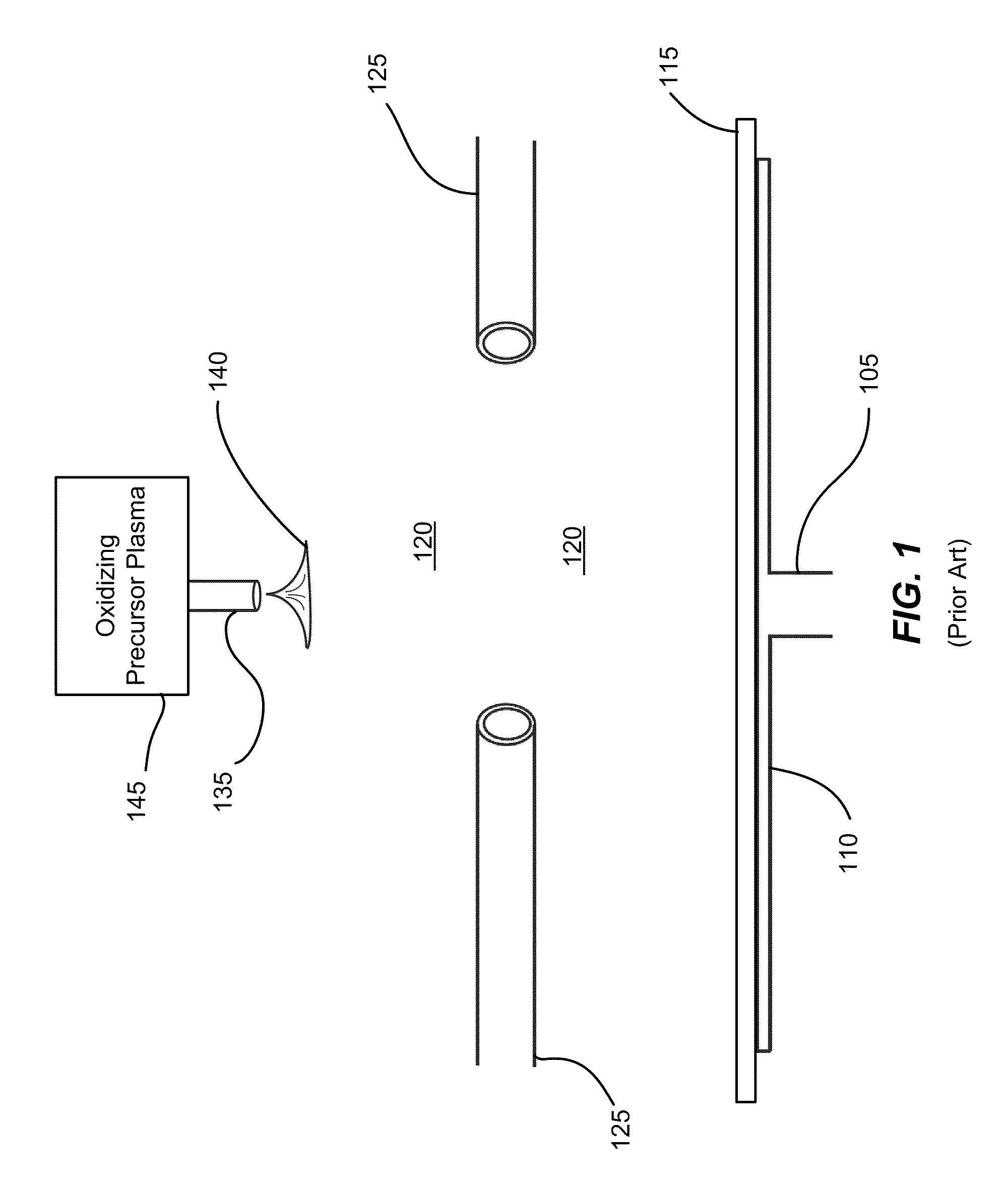

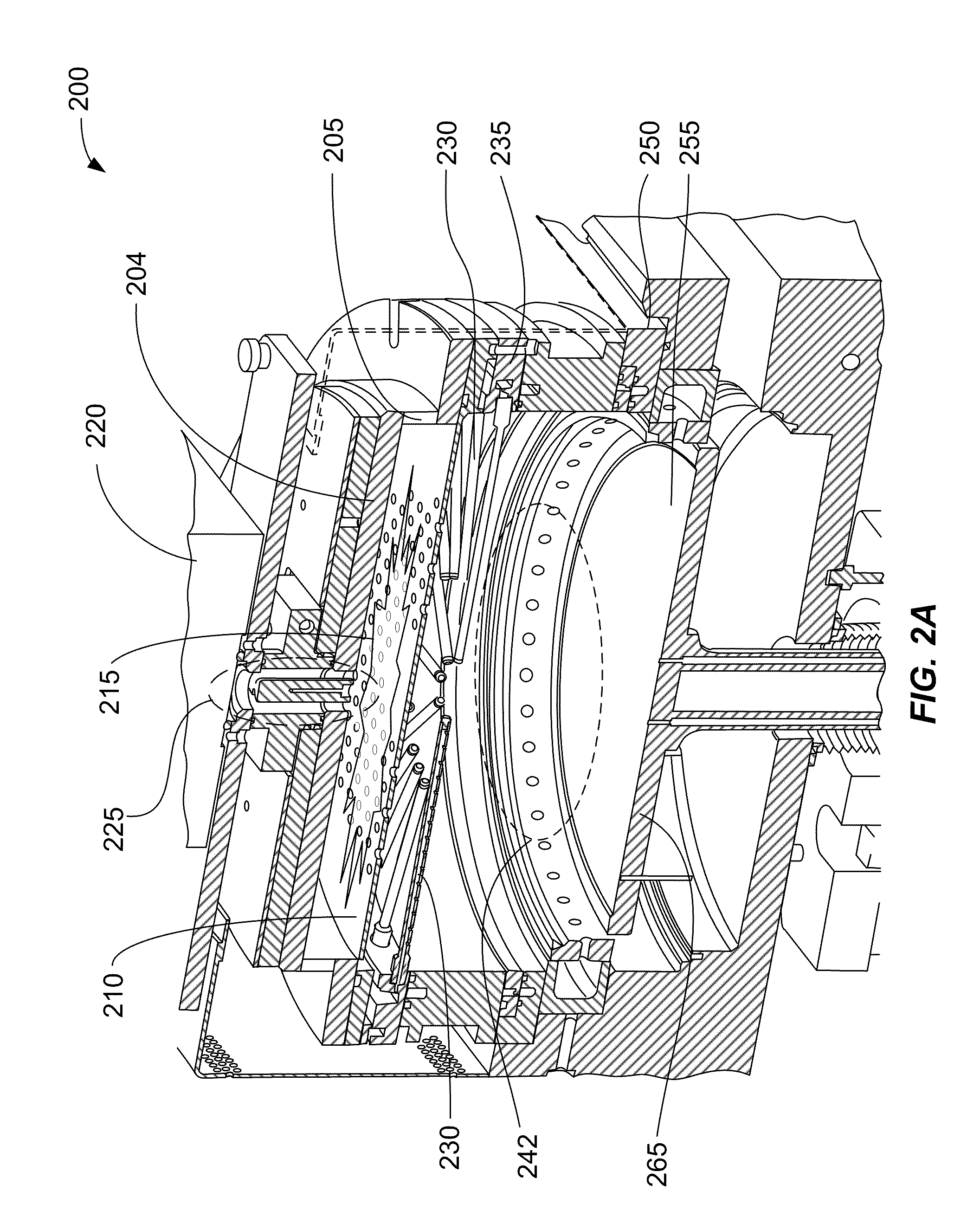

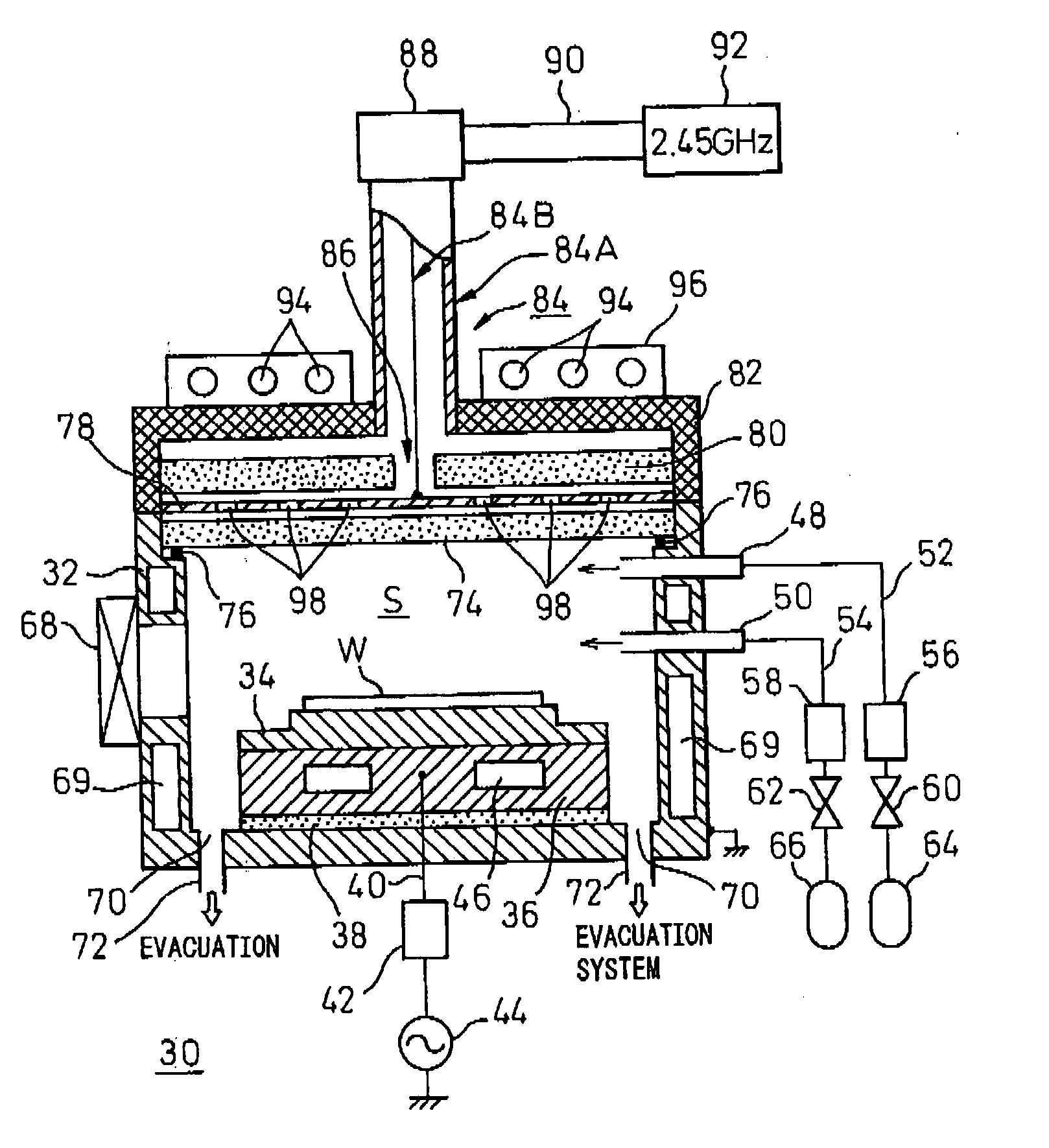

Remote plasma source seasoning

ActiveUS7989365B2Increase deposition rateImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaDeposition process

Methods of seasoning a remote plasma system are described. The methods include the steps of flowing a silicon-containing precursor into a remote plasma region to deposit a silicon containing film on an interior surface of the remote plasma system. The methods reduce reactions with the seasoned walls during deposition processes, resulting in improved deposition rate, improved deposition uniformity and reduced defectivity during subsequent deposition.

Owner:APPLIED MATERIALS INC

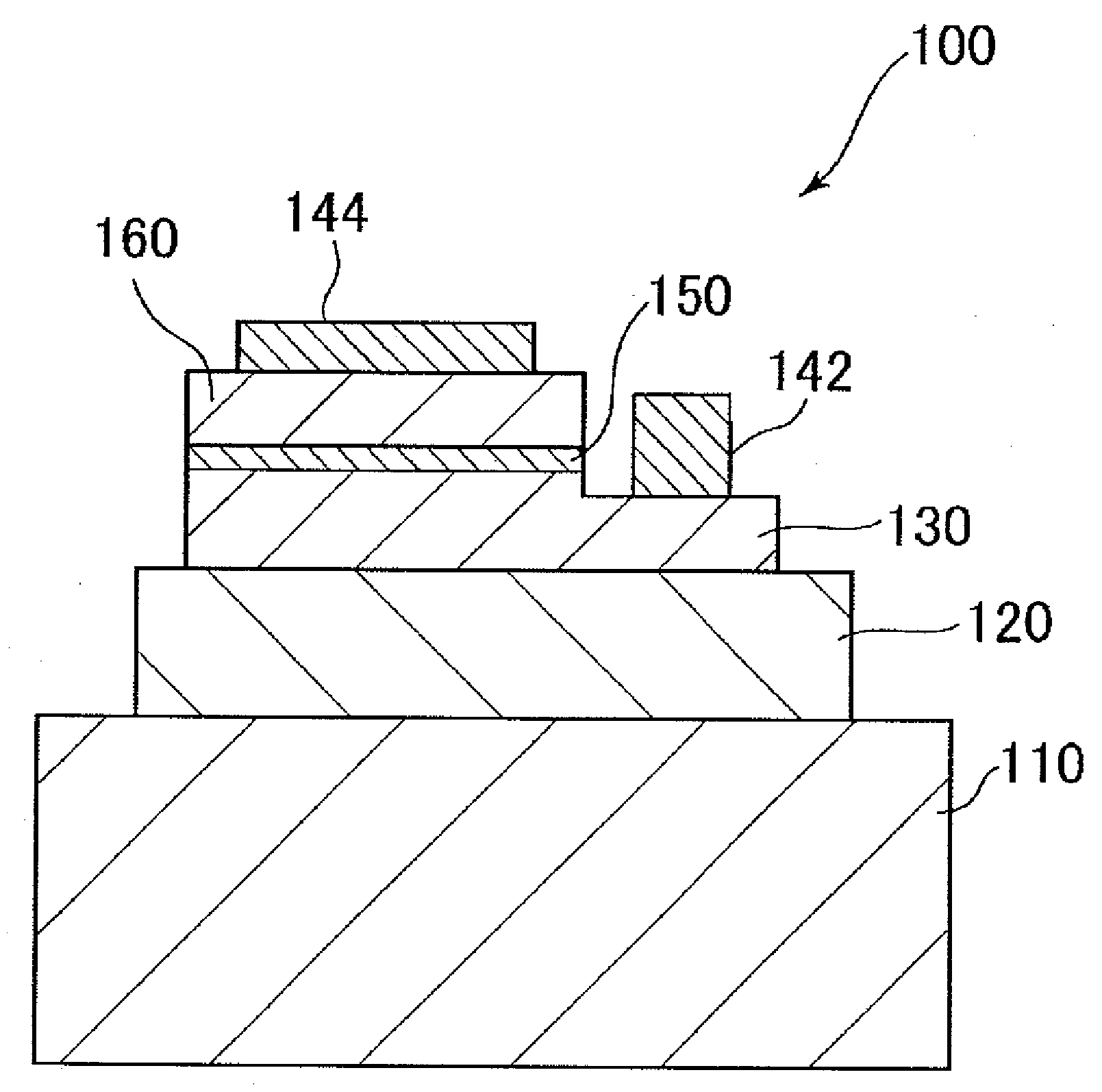

Method for Growth of Gan Single Crystal, Method for Preparation of Gan Substrate, Process for Producing Gan-Based Element, and Gan-Based Element

InactiveUS20080261378A1Reduce defectsEasy to operatePolycrystalline material growthSemiconductor/solid-state device manufacturingEtchingGas phase

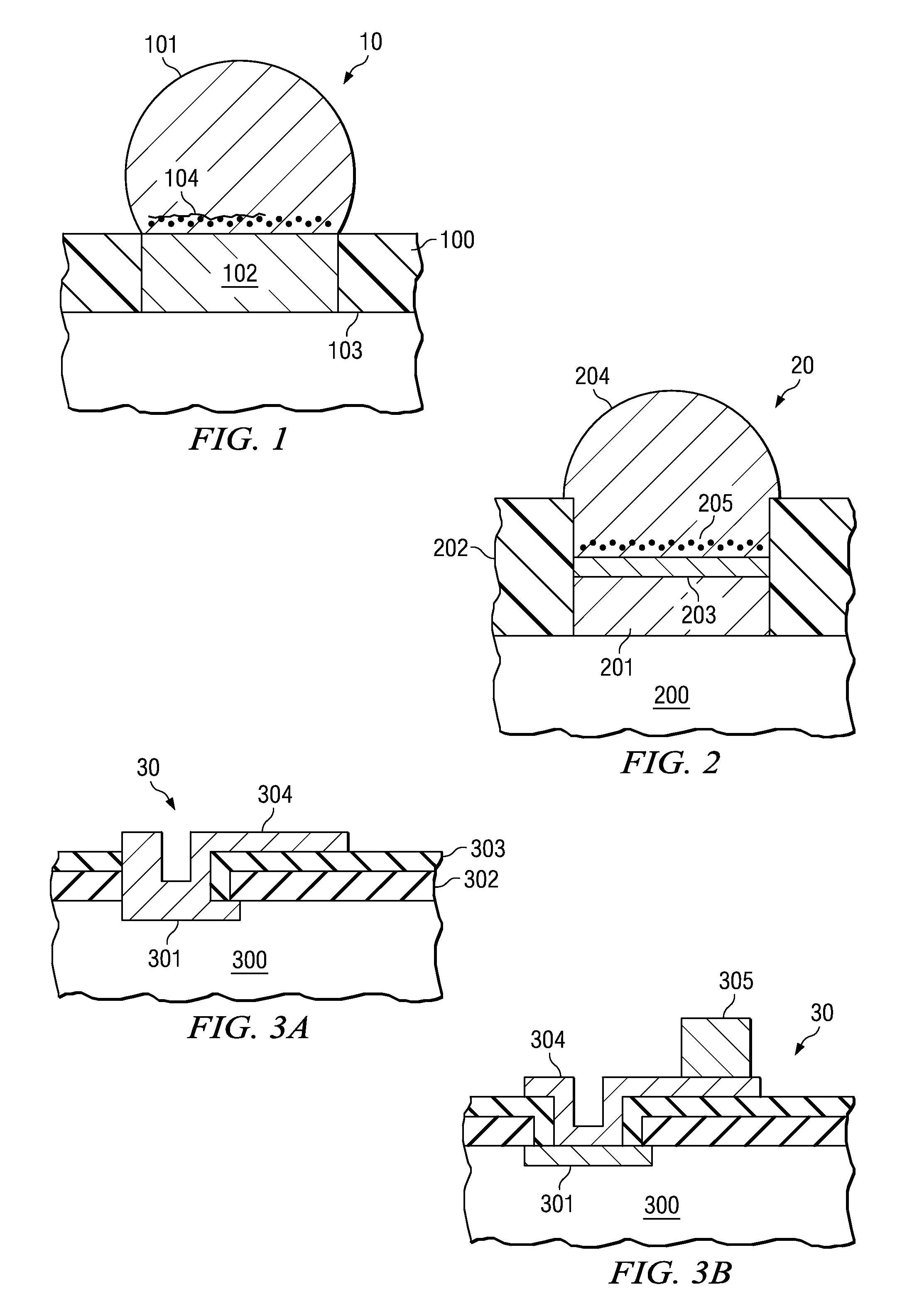

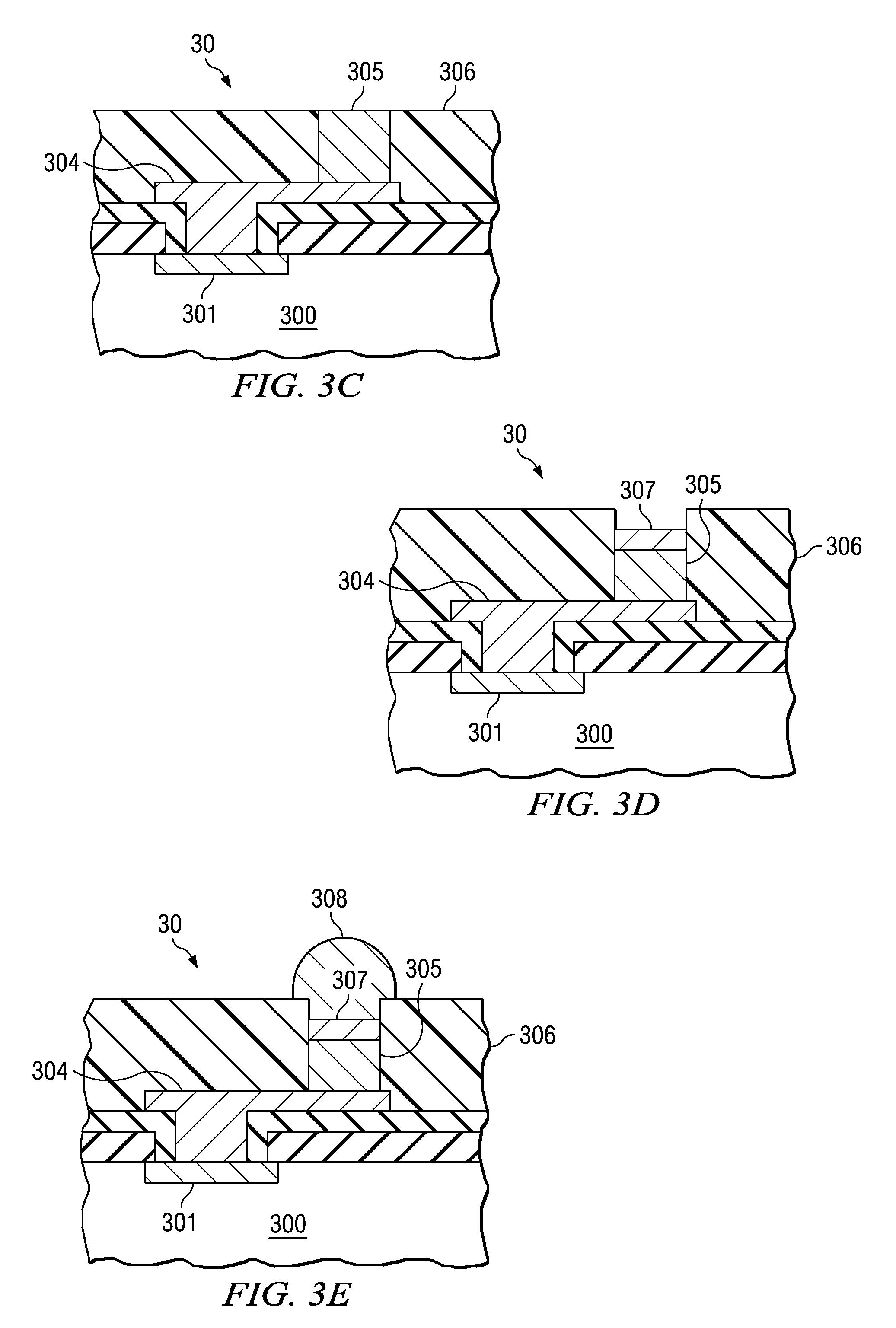

A GaN-based thin film (thick film) is grown using a metal buffer layer grown on a substrate. (a) A metal buffer layer (210) made of, for example, Cr or Cu is vapor-deposited on a sapphire substrate (120). (b) A substrate obtained by vapor-depositing the metal buffer layer (210) on the sapphire substrate (120) is nitrided in an ammonia gas ambient, thereby forming a metal nitride layer (212). (c) A GaN buffer layer (222) is grown on the nitrided metal buffer layers (210, 212). (d) Finally, a GaN single-crystal layer (220) is grown. This GaN single-crystal layer (220) can be grown to have various thicknesses depending on the objects. A freestanding substrate can be fabricated by selective chemical etching of the substrate fabricated by the above steps. It is also possible to use the substrate fabricated by the above steps as a GaN template substrate for fabricating a GaN-based light emitting diode or laser diode.

Owner:FURUKAWA COMPANY +4

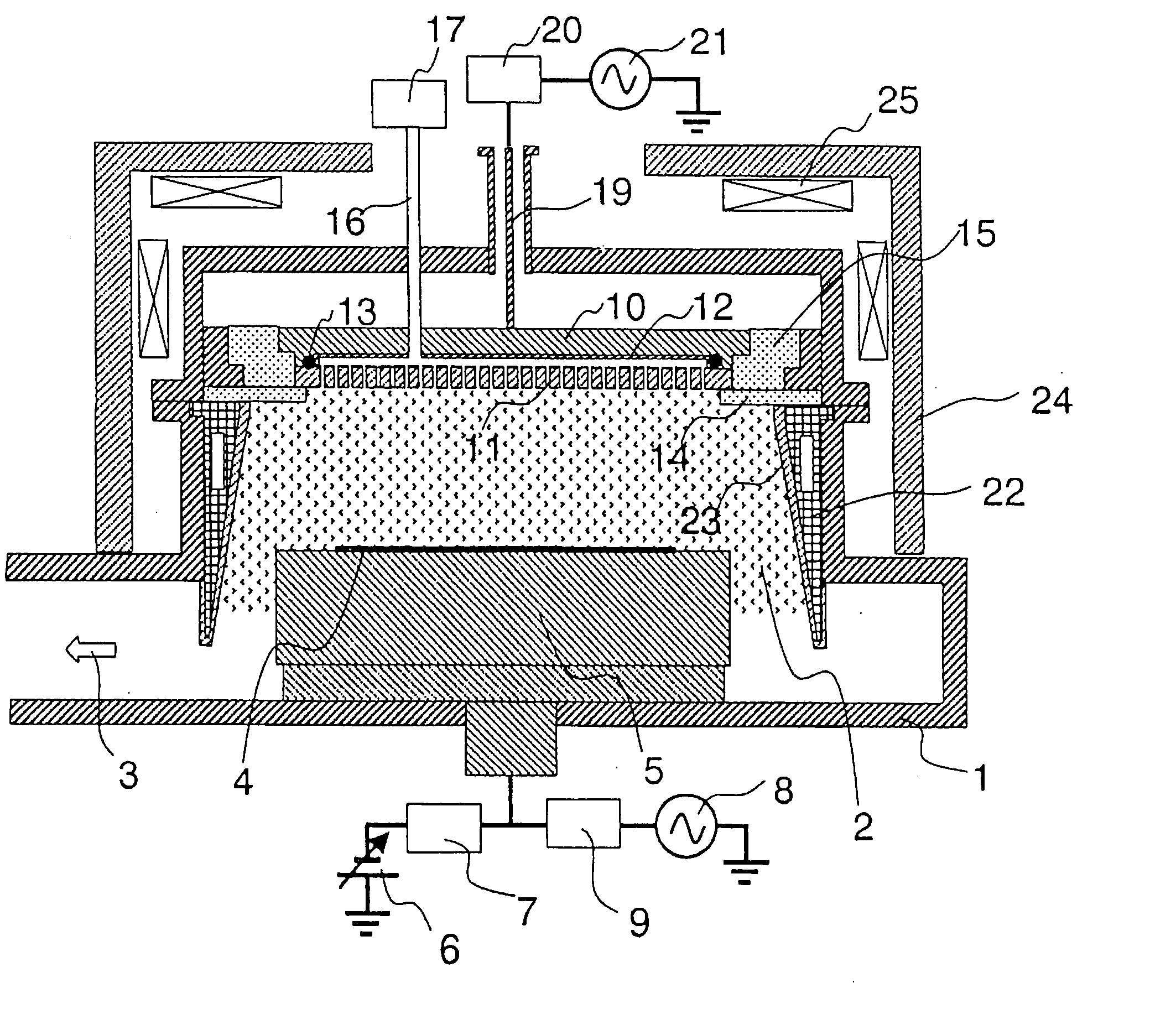

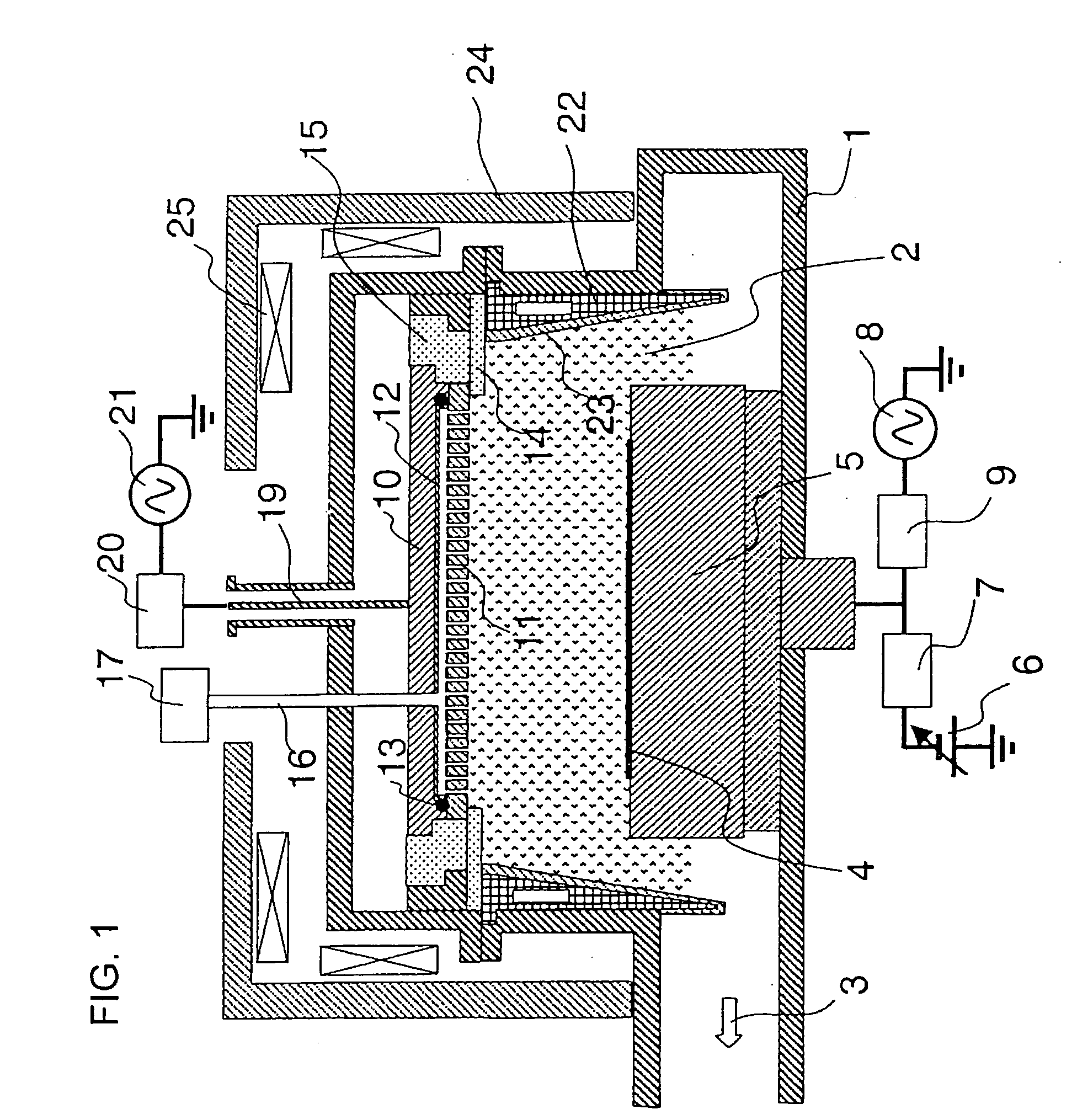

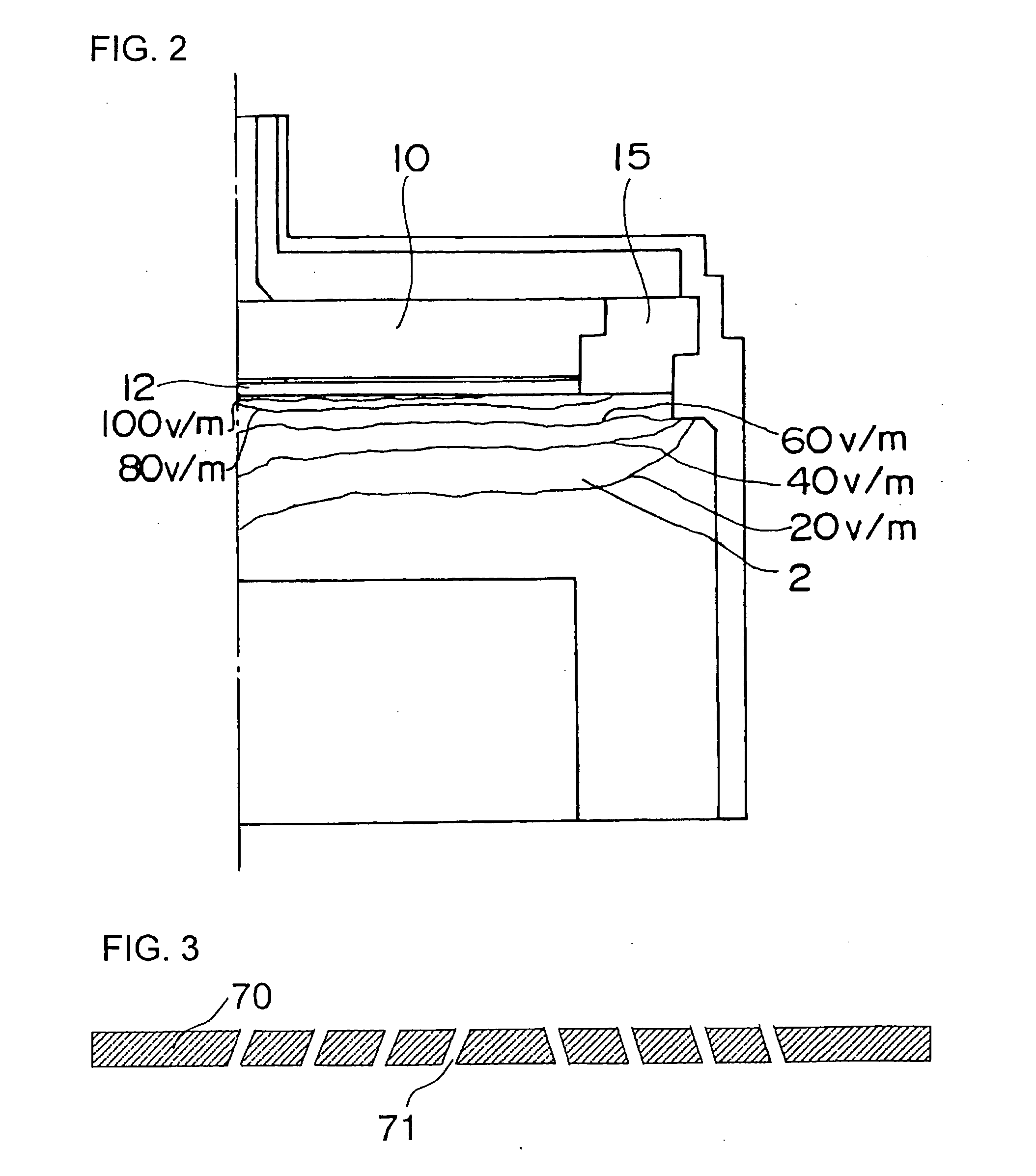

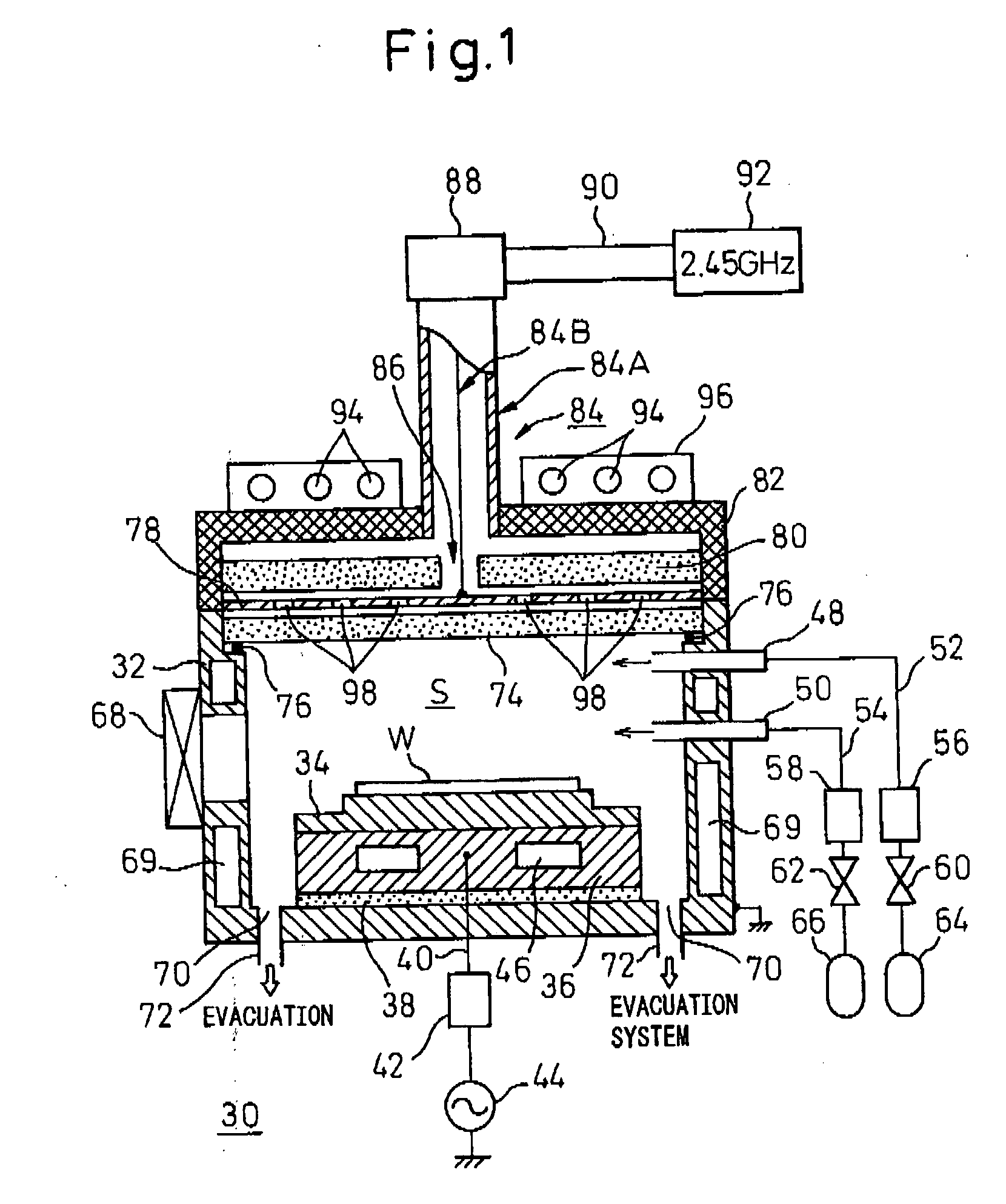

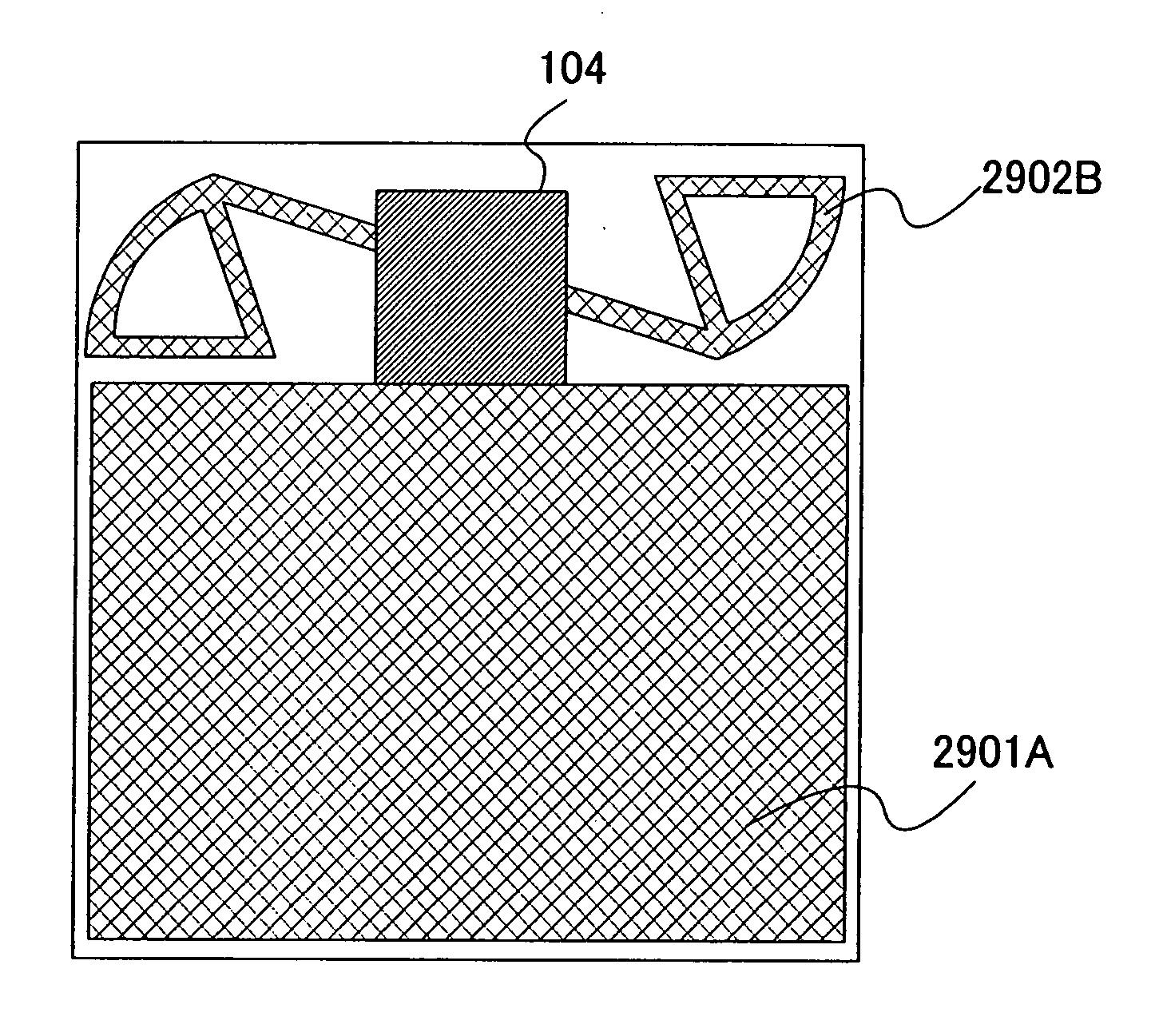

Plasma processing apparatus

ActiveUS20070044716A1Free from pollutionAvoid damageElectric discharge tubesChemical vapor deposition coatingTectorial membraneElectrical conductor

The invention provides a plasma processing apparatus aimed at suppressing the corrosion caused by reactive gas and heavy-metal contamination caused by plasma damage of components constituting the high-frequency electrode and gas supply unit. The plasma processing apparatus comprises a processing chamber 1 for subjecting a processing substrate 4 to plasma processing, gas supply means 17, 16 and 11 for feeding gas to the processing chamber 1, and an antenna electrode 10 for supplying high-frequency radiation for discharging the gas to generate plasma, wherein the gas supply means includes a gas shower plate 11 having gas discharge holes on the surface exposed to plasma, and a portion of or a whole surface of the conductor 10 exposed to gas constituting the antenna-electrode side of the gas supply means is subjected to ceramic spraying containing no heavy metal to form a protecting film 12.

Owner:HITACHI HIGH-TECH CORP

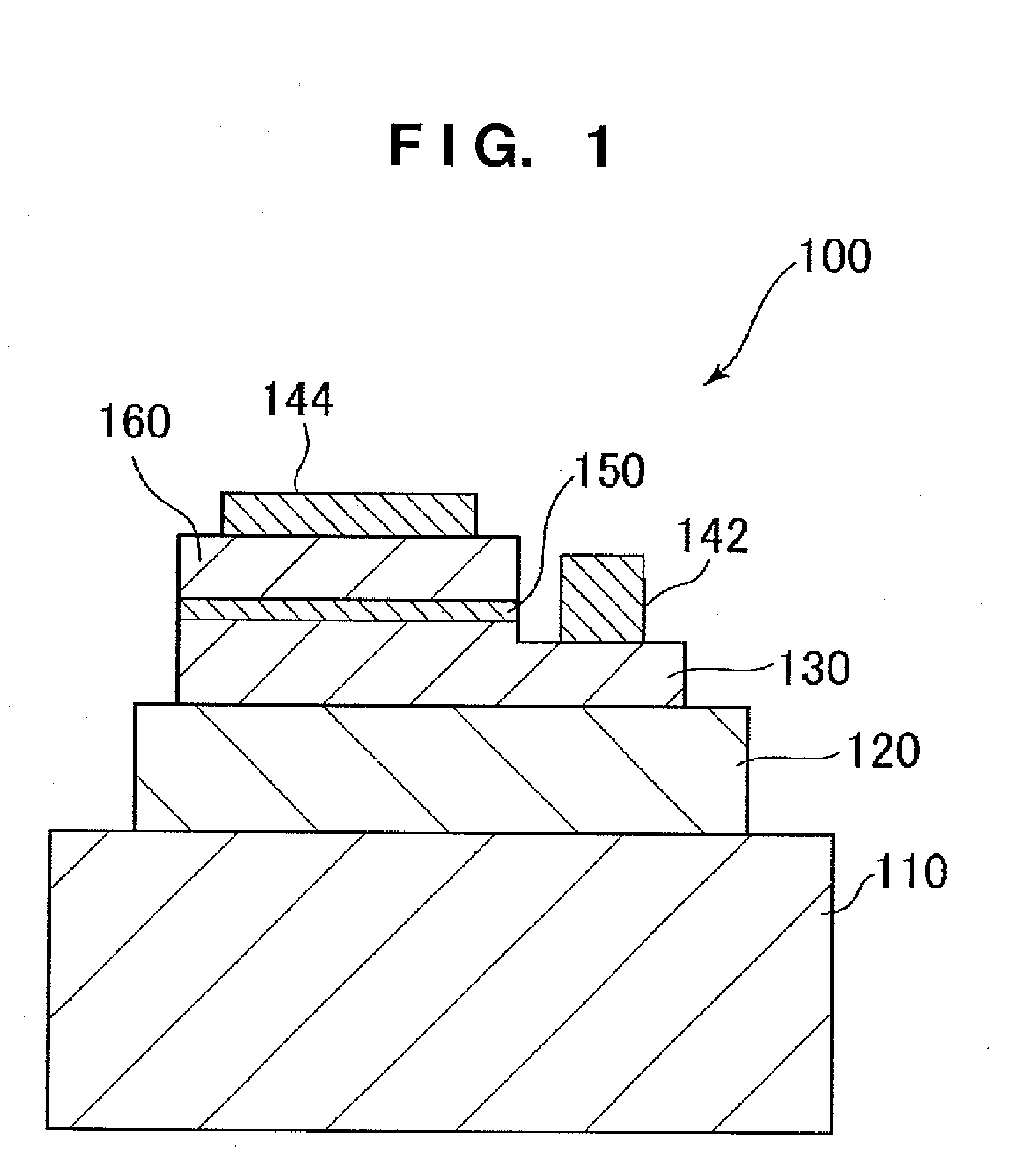

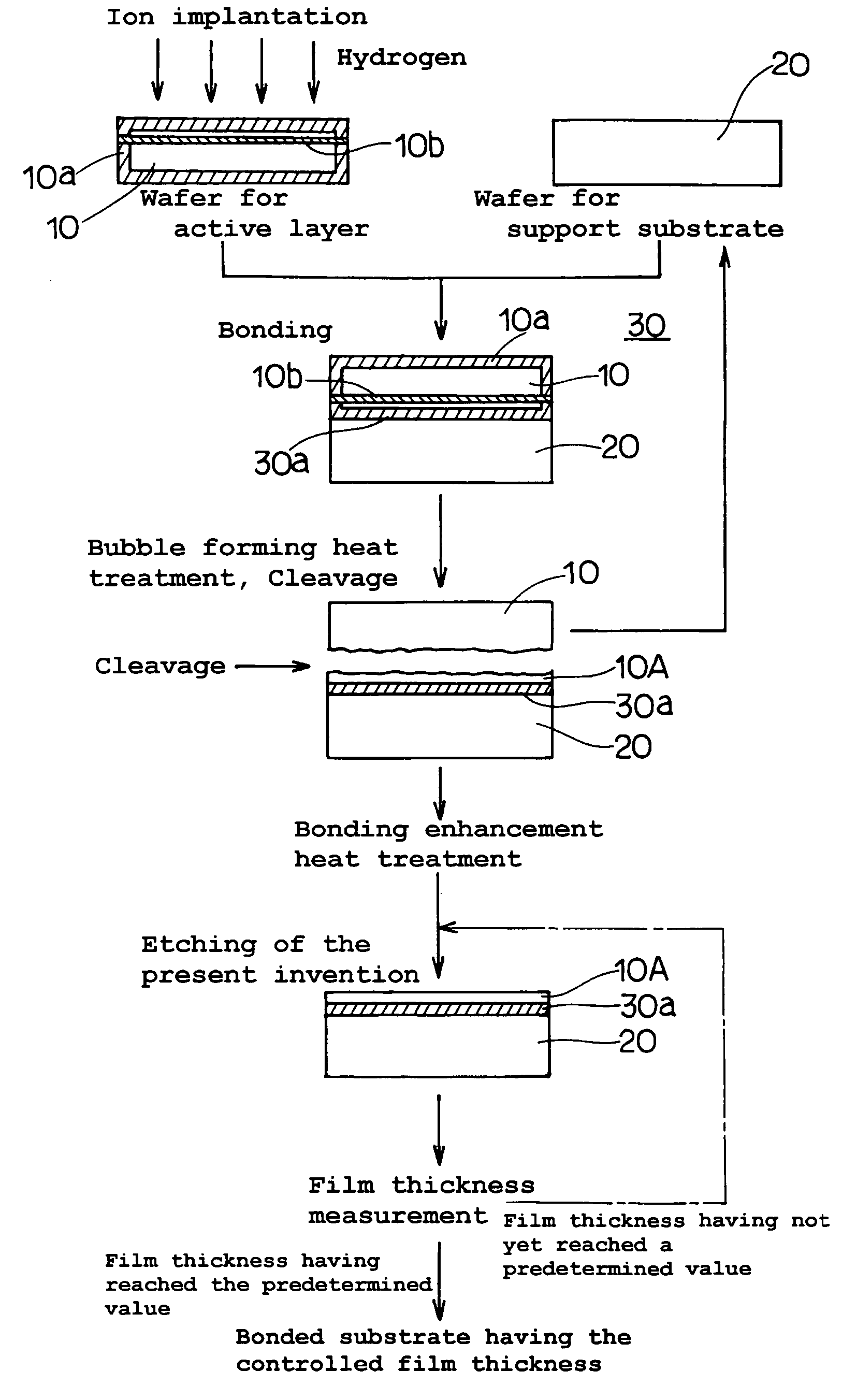

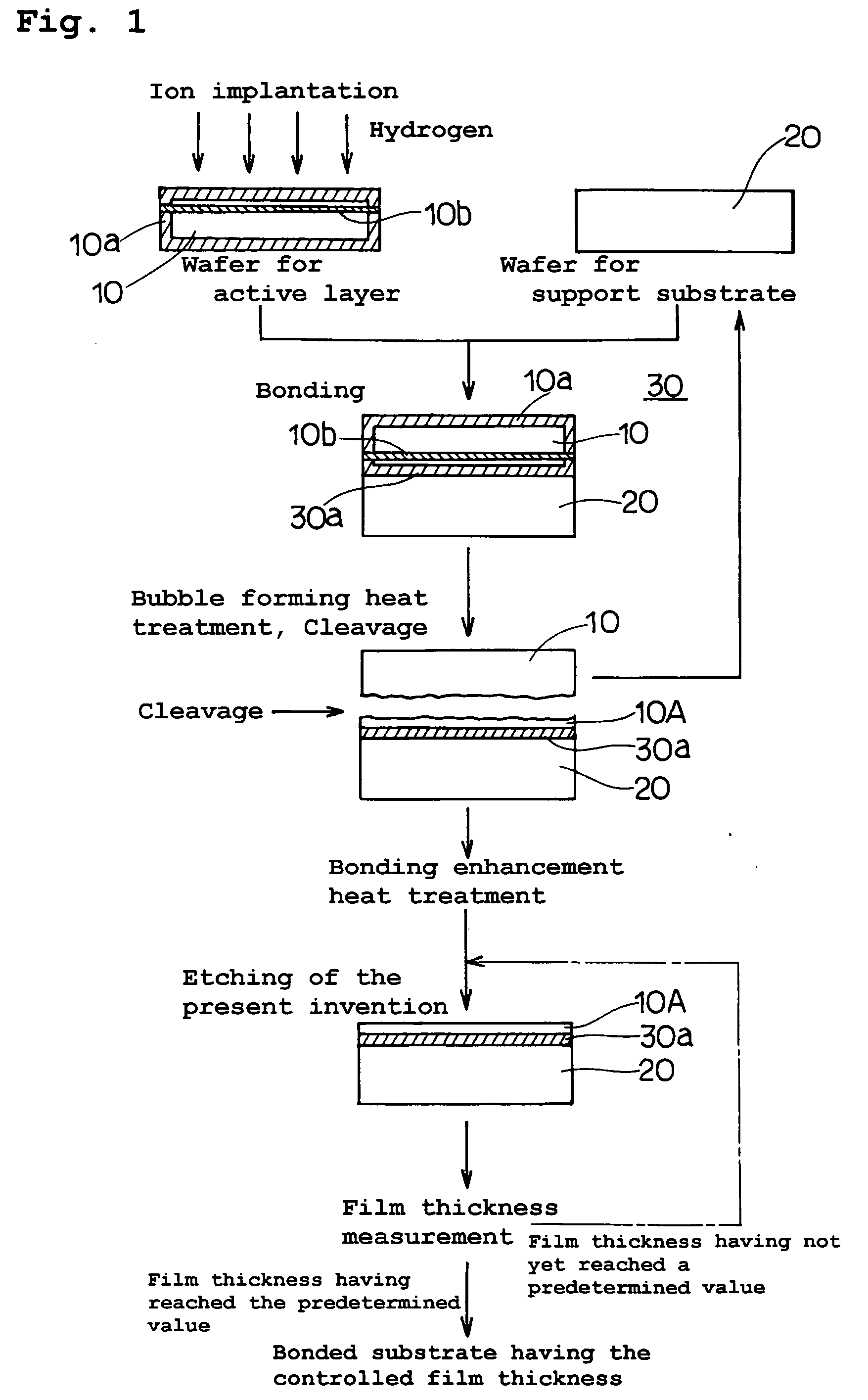

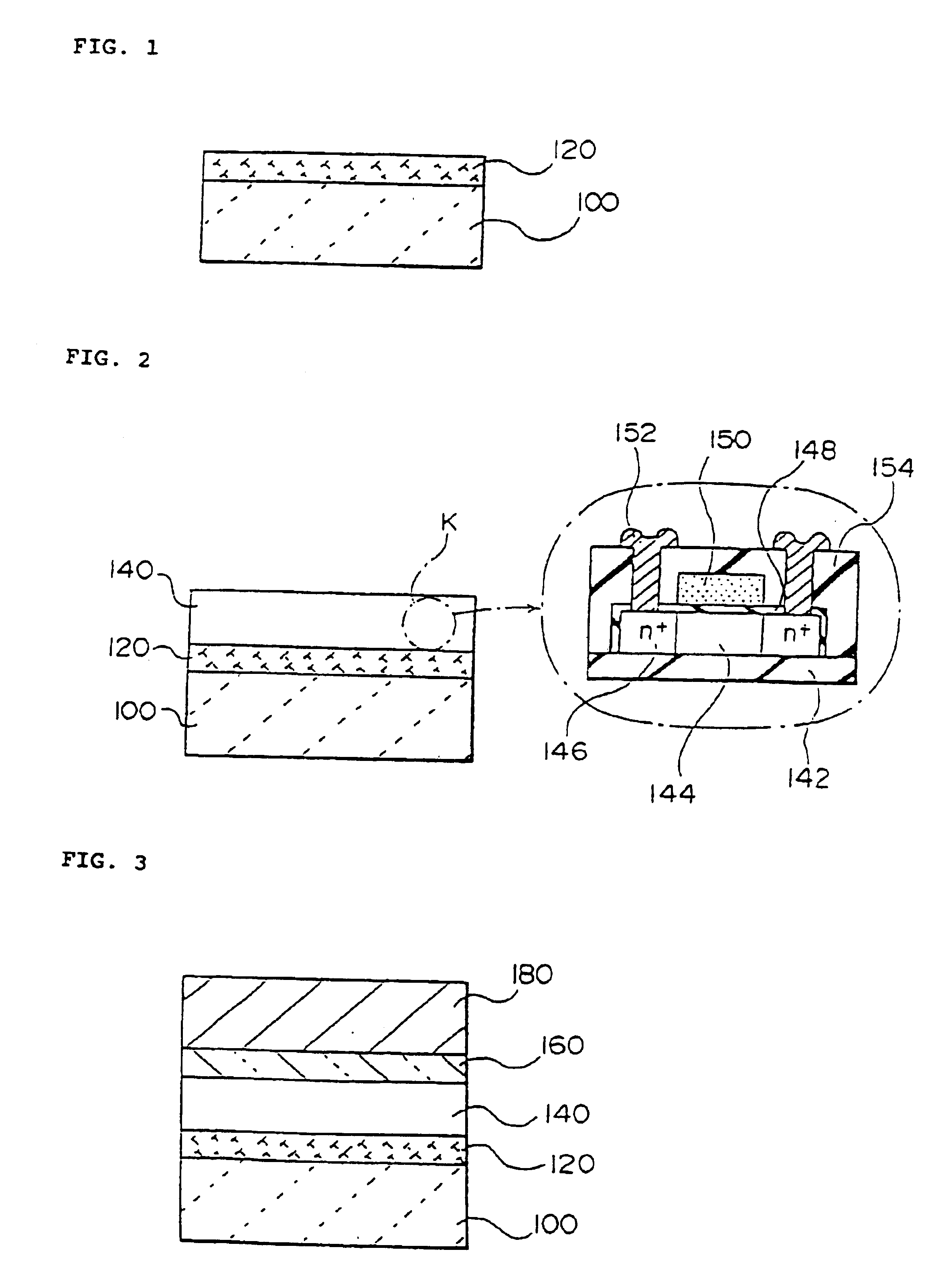

Laminated semiconductor substrate process for producing the same

InactiveUS20060118935A1Simple processReduce surface roughnessDecorative surface effectsSemiconductor/solid-state device detailsEtchingSurface roughness

The present invention provides a bonded substrate fabricated to have its final active layer thickness of 200 nm or lower by performing the etching by only 1 nm to 1 μm with a solution having an etching effect on a surface of an active layer of a bonded substrate which has been prepared by bonding two substrates after one of them having been ion-implanted and then cleaving off a portion thereof by heat treatment. SC-1 solution is used for performing the etching. A polishing, a hydrogen annealing and a sacrificial oxidation may be respectively applied to the active layer before and / or after the etching. The film thickness of this active layer can be made uniform over the entire surface area and the surface roughness of the active layer can be reduced as well.

Owner:SUMCO CORP +1

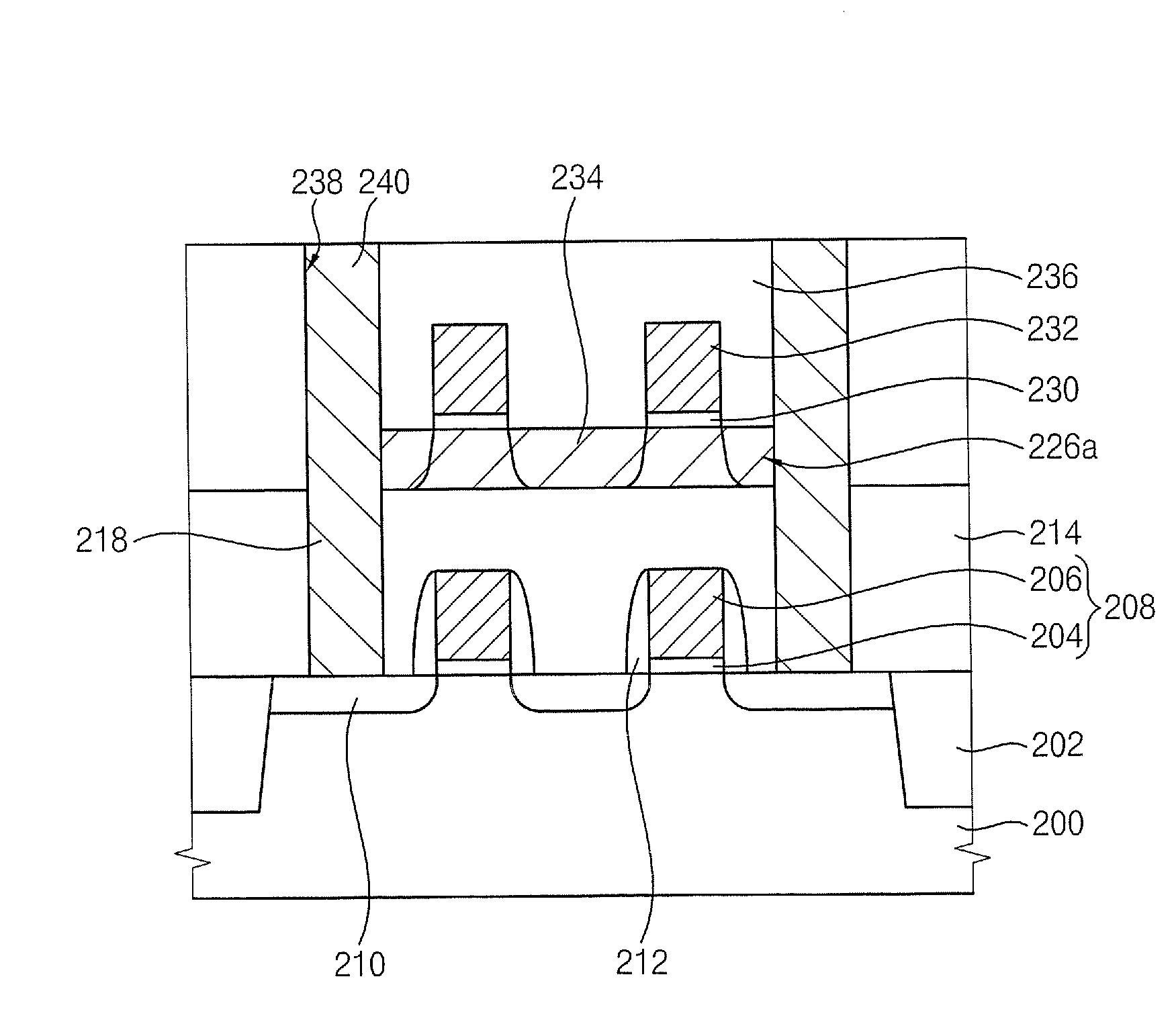

Methods of fabricating semiconductor devices including channel layers having improved defect density and surface roughness characteristics

ActiveUS20080160726A1Improved surface roughness characteristicUniform thicknessSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingSurface roughnessSingle crystal

A method of fabricating a semiconductor device including a channel layer includes forming a single crystalline semiconductor layer on a semiconductor substrate. The single crystalline semiconductor layer includes a protrusion extending from a surface thereof. A first polishing process is performed on the single crystalline semiconductor layer to remove a portion of the protrusion such that the single crystalline semiconductor layer includes a remaining portion of the protrusion. A second polishing process different from the first polishing process is performed to remove the remaining portion of the protrusion and define a substantially planar single crystalline semiconductor layer having a substantially uniform thickness. A sacrificial layer may be formed on the single crystalline semiconductor layer and used as a polish stop for the first polishing process to define a sacrificial layer pattern, which may be removed prior to the second polishing process. Related methods of fabricating stacked semiconductor memory devices are also discussed.

Owner:SAMSUNG ELECTRONICS CO LTD

Plasma processing apparatus and plasma processing method

InactiveUS20060108331A1Reduce defectsPollution suppressionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingPre treatment

A plasma processing apparatus comprising at least a plasma processing chamber for plasma-processing an object; object-holding means for disposing the object in the plasma processing chamber; and plasma-generating means for generating a plasma in the plasma processing chamber. The inner wall of the plasma processing chamber is at least partially covered with an oxide film based on a pre-treating plasma. A plasma processing apparatus and a plasma processing method effectively prevent the spluttering and the etching of the inner wall of the plasma processing chamber while suppressing contamination to the object.

Owner:TOKYO ELECTRON LTD

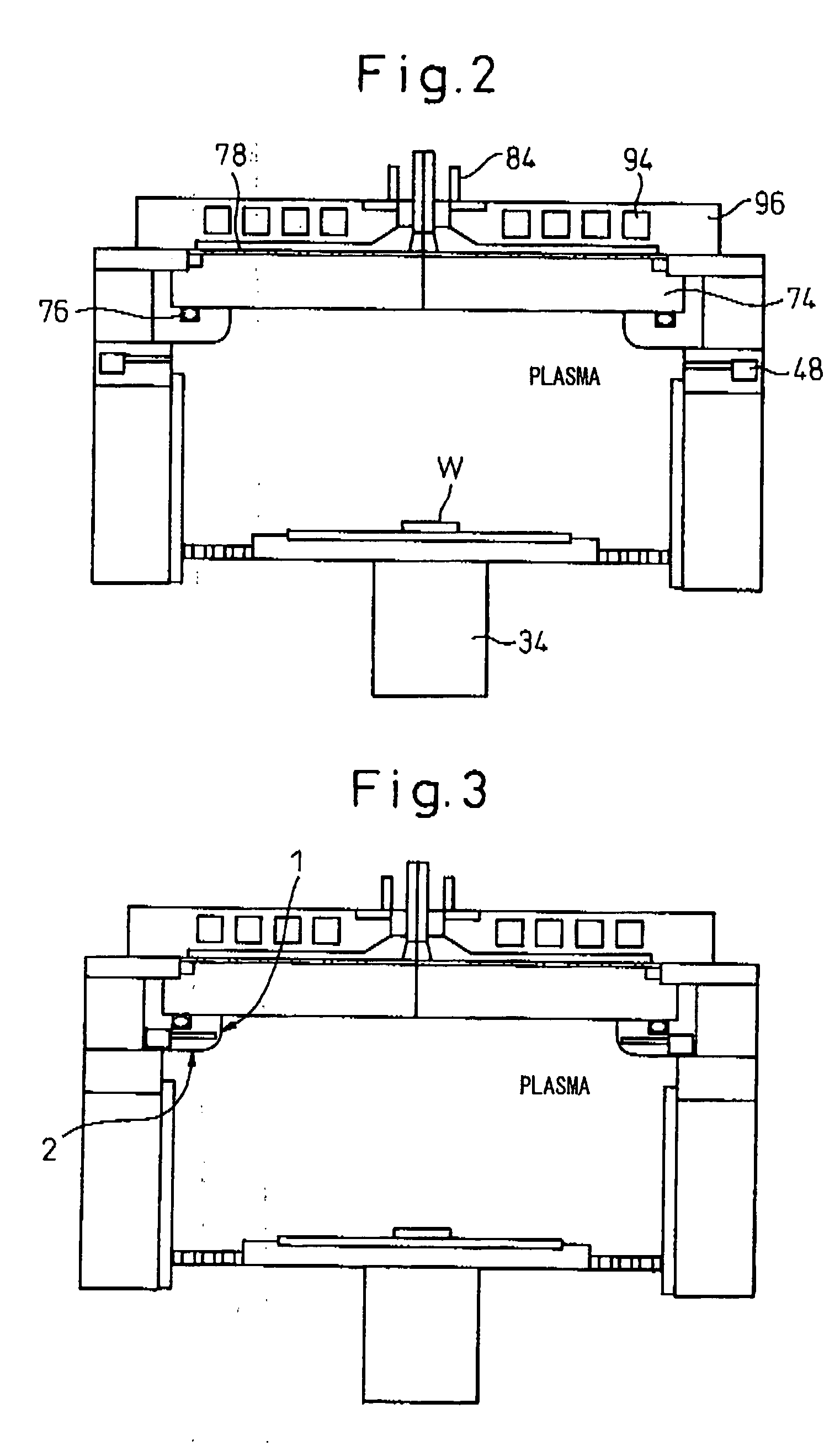

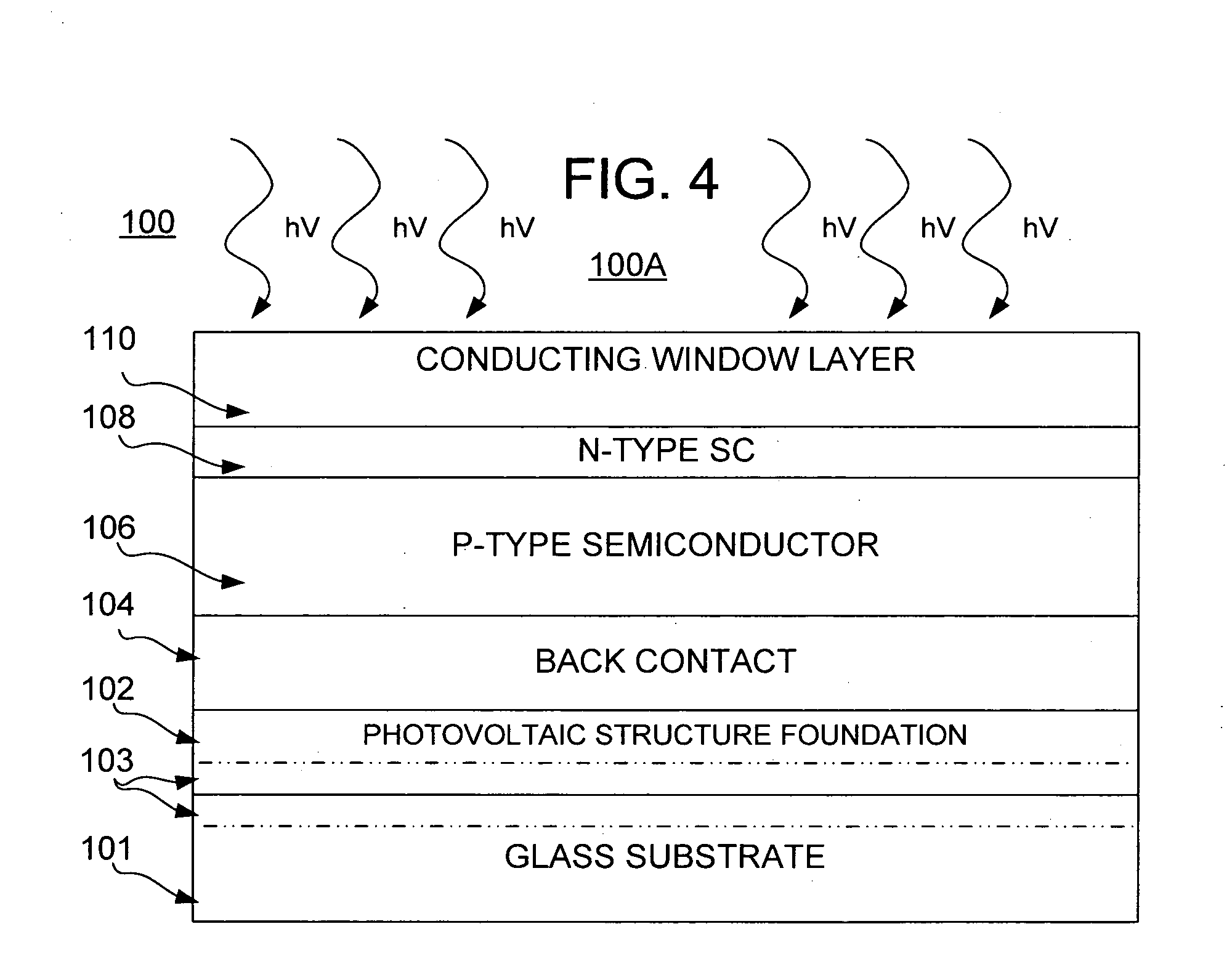

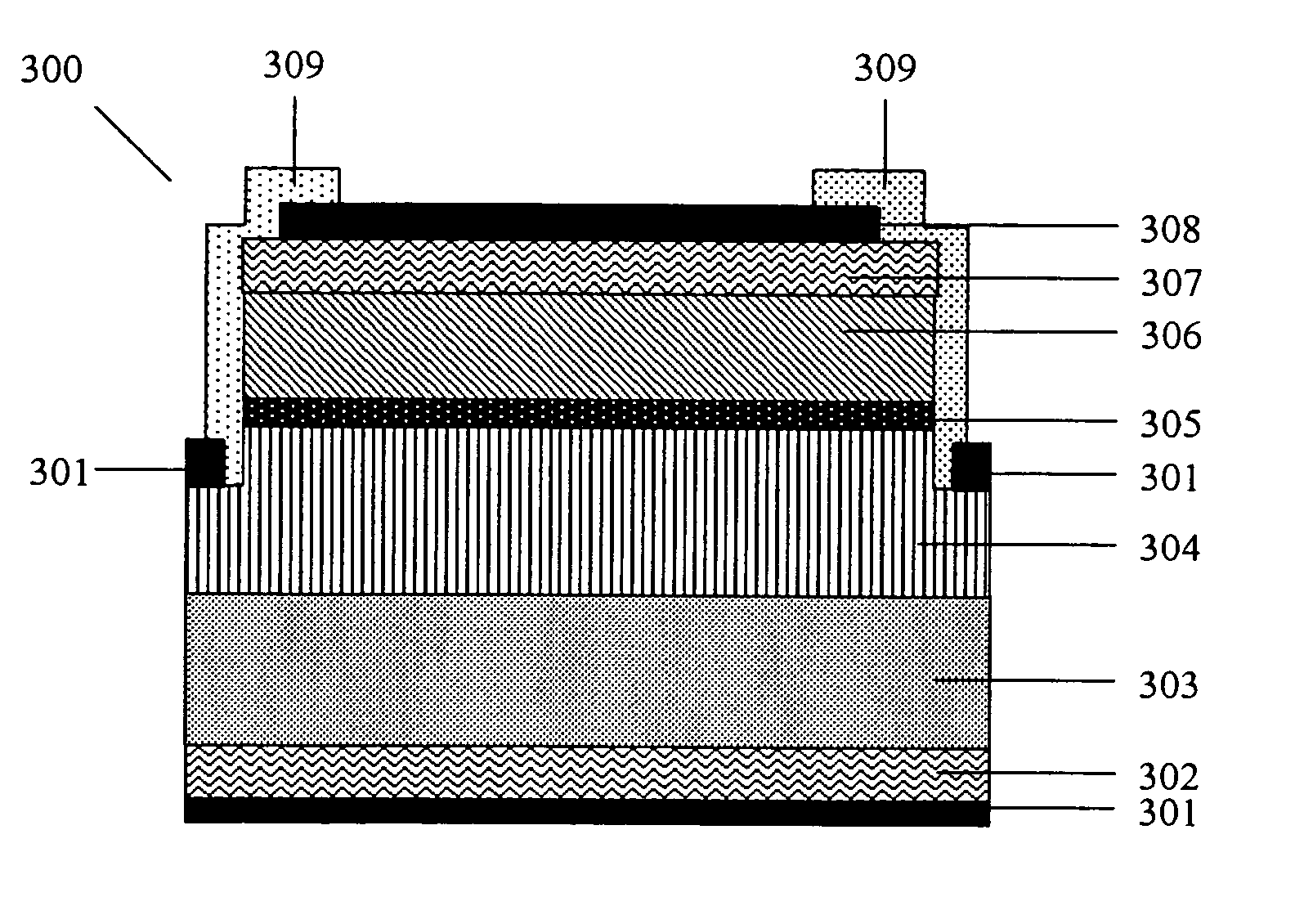

Thin film photovoltaic structure

InactiveUS20070277874A1Faster throughputReduce needSemiconductor/solid-state device manufacturingPhotovoltaic energy generationAnodic bondingVoltage

Systems and methods of production of a photovoltaic device include creating on a donor semiconductor wafer an exfoliation layer and transferring the exfoliation layer to an insulator substrate. One or more finishing processes may be performed before and / or after transferring the exfoliation layer, such as to create a plurality of photovoltaic structure layers. Production of the photovoltaic device further may include subjecting the donor semiconductor wafer to an ion implantation process to create the exfoliation layer, bonding the exfoliation layer to the insulator substrate, and separating the exfoliation layer from the donor semiconductor wafer. Transferring may include forming an anodic bond via electrolysis, such as through the application of heat, pressure and voltage to the exfoliation layer and the insulator structure.

Owner:CORNING INC

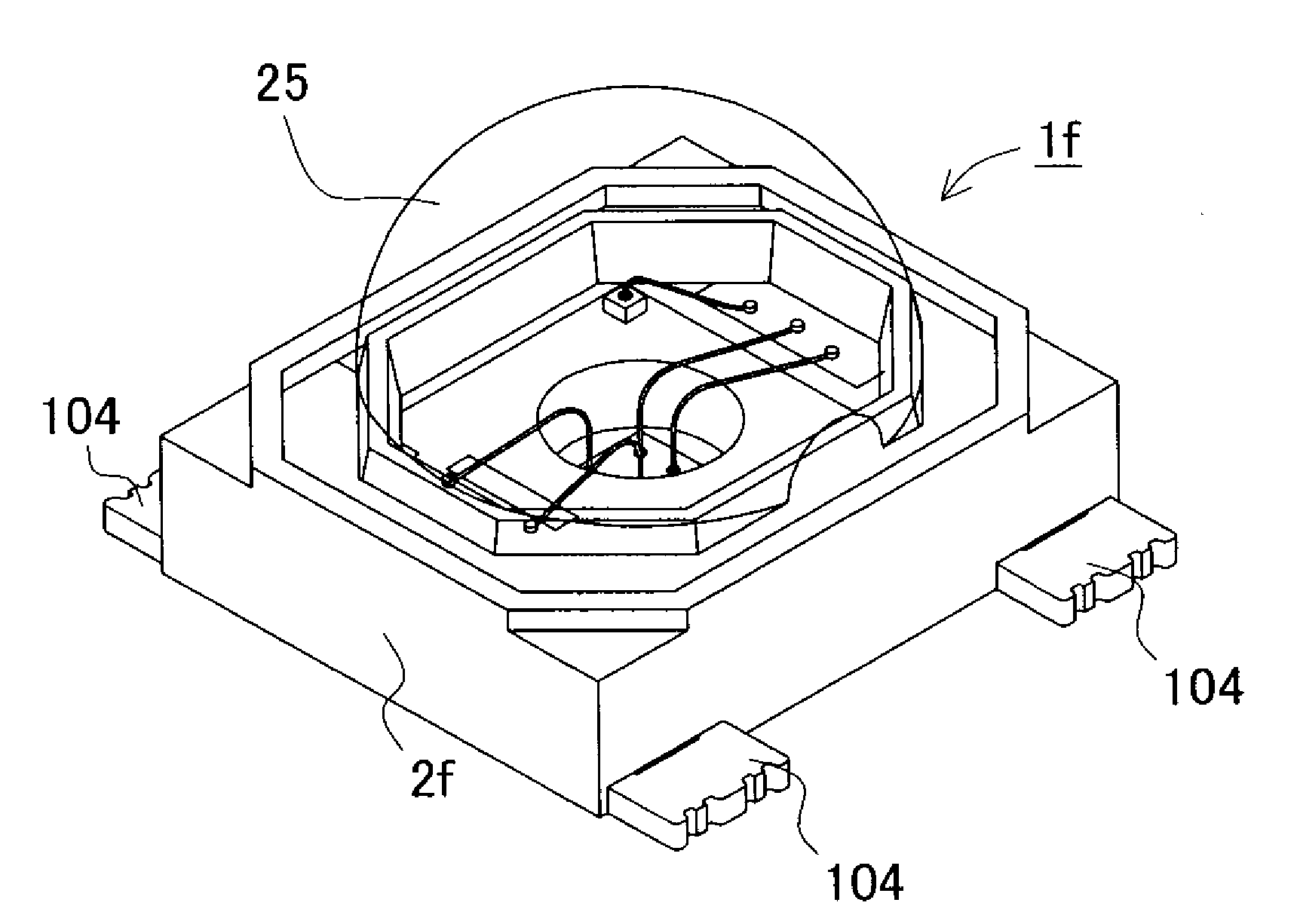

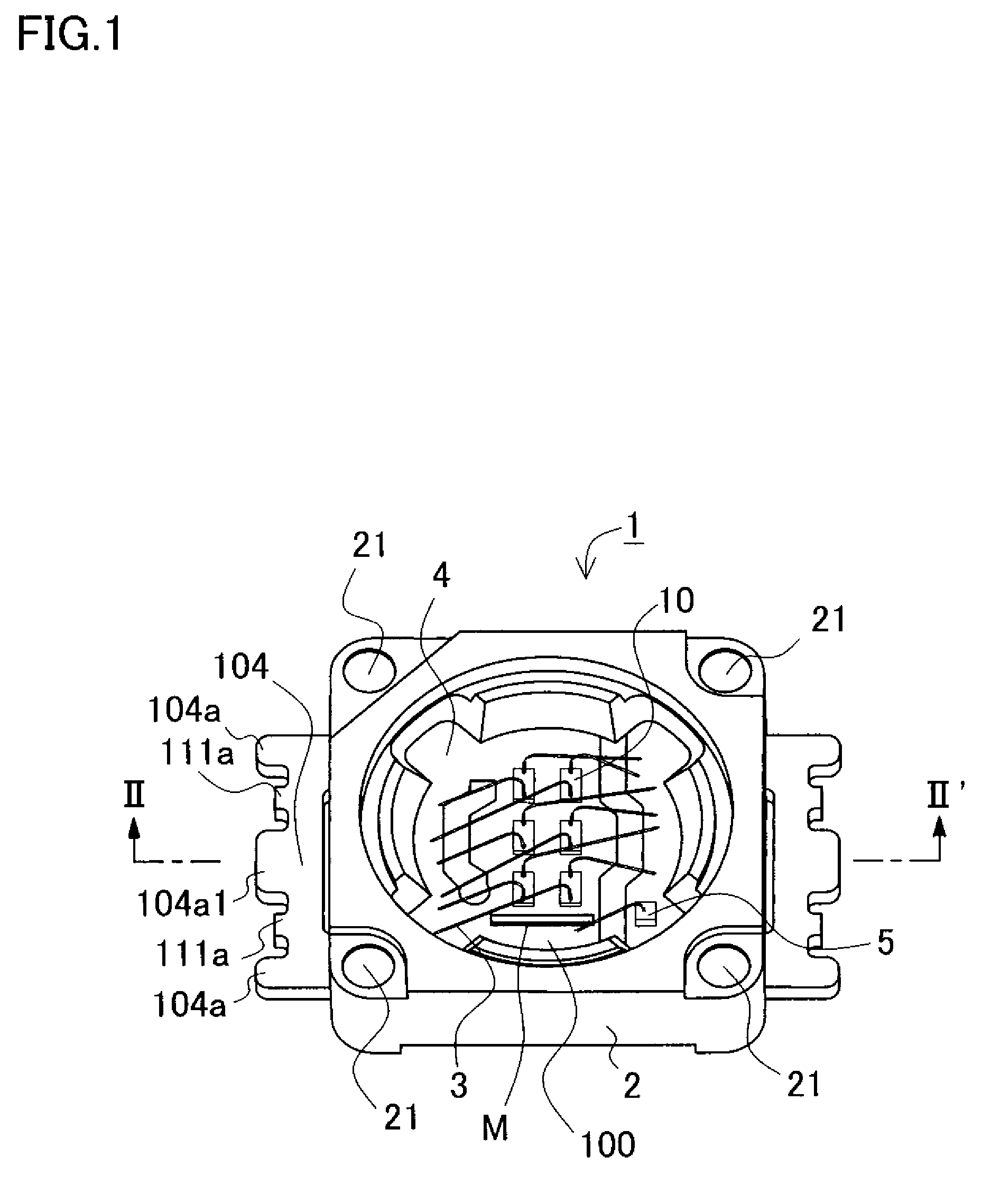

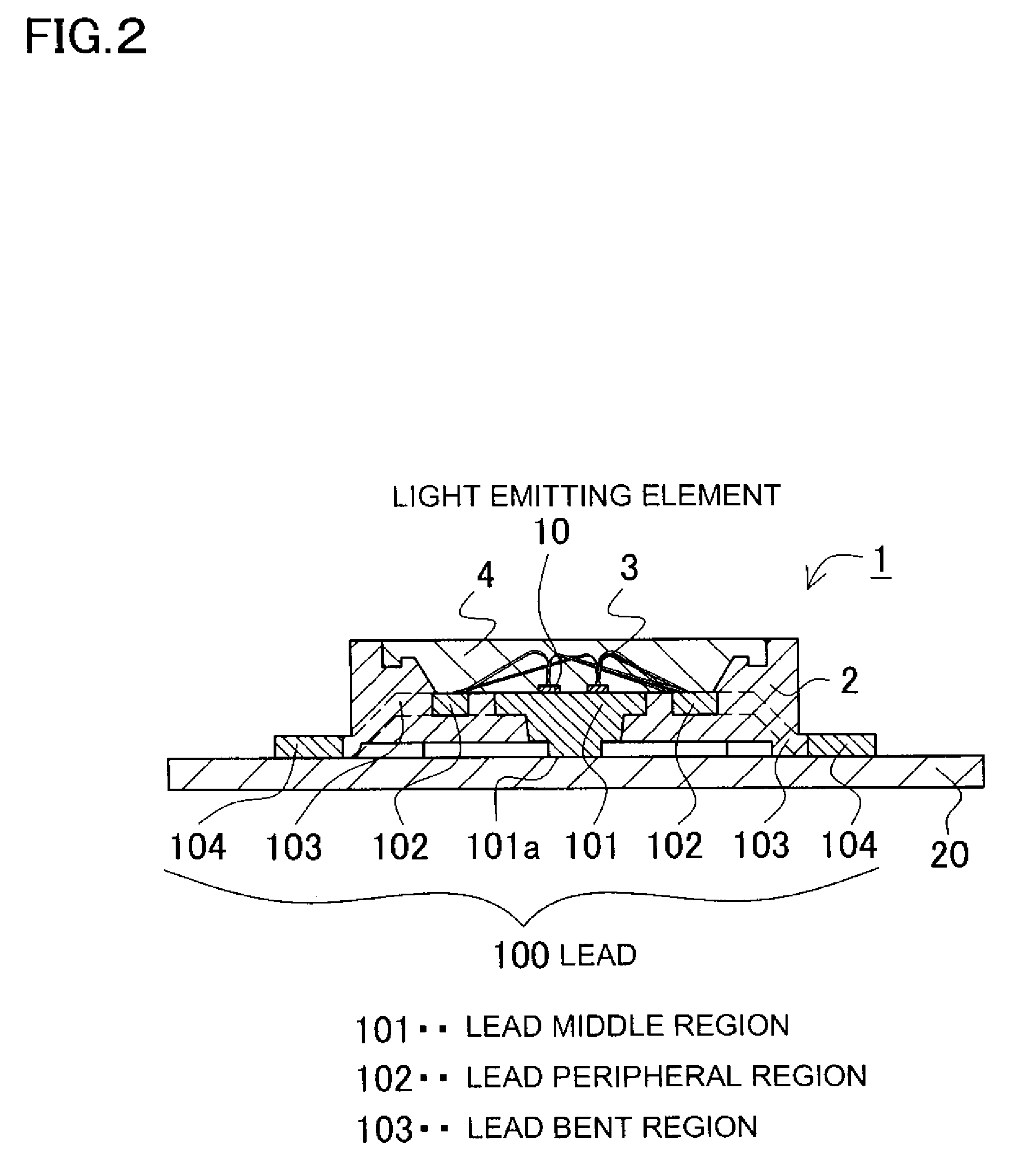

Semiconductor light emitting device and a method for producing the same

ActiveUS20070262328A1Avoid damageReduce the possibility of damageSolid-state devicesSemiconductor devicesEngineeringLight emitting device

Both ends of the lead arrangement project outward from side surfaces of a package to form outer lead regions. Each of the outer lead regions includes a pair of outer lead projections and lead terminal smaller projections that are located between the outer lead projections. The outer lead projections and lead terminal smaller projections project outward. Adjustment is made to the projection amount of end surfaces of the lead smaller projections lying in a plane perpendicular to a longitudinal direction of the lead arrangement, whereby the end surfaces projecting less than end surfaces of the outer lead projections. Thus, cut surfaces of lead connection portions with edged corners are not exposed. This arrangement prevents that the cut surfaces damage other devices.

Owner:NICHIA CORP

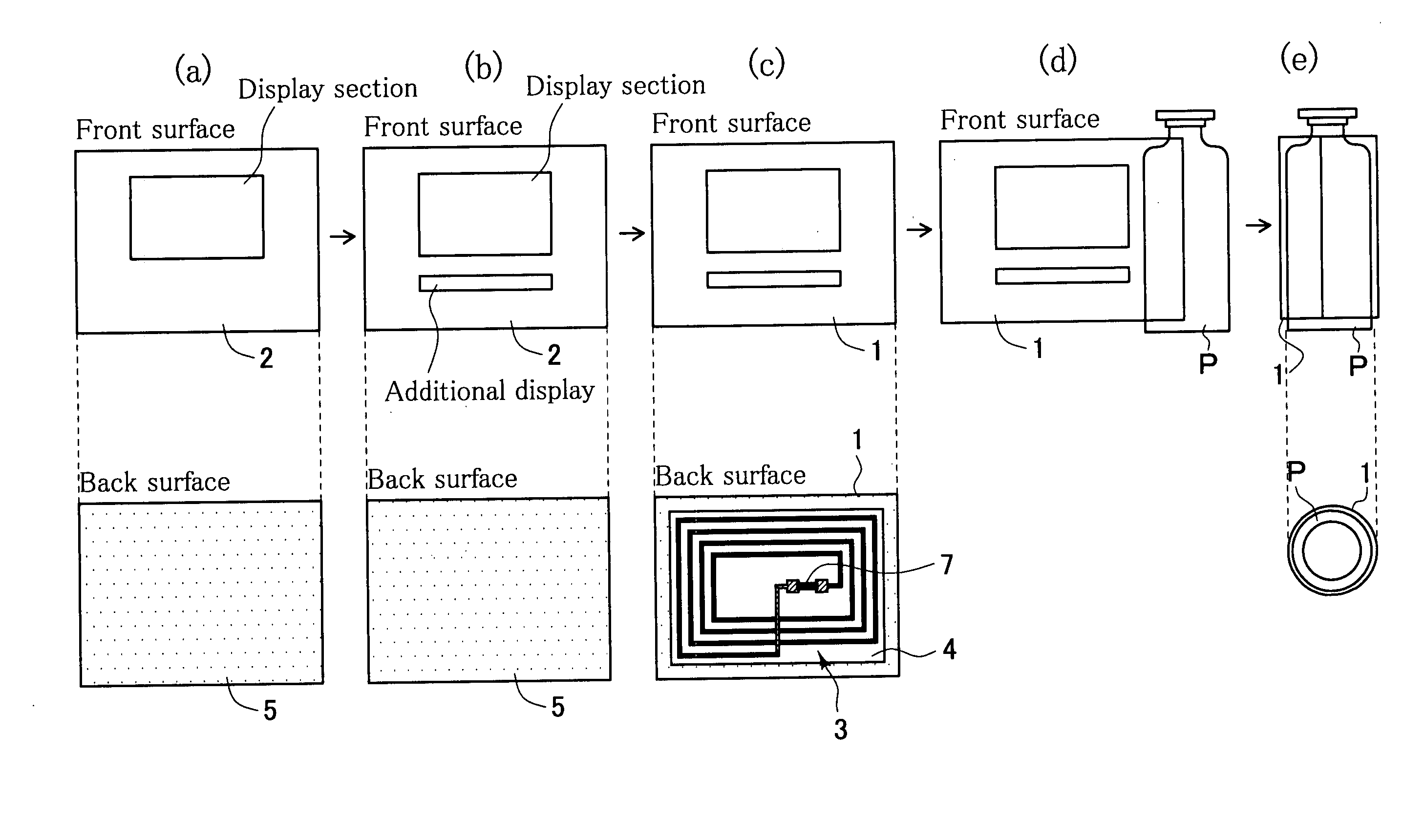

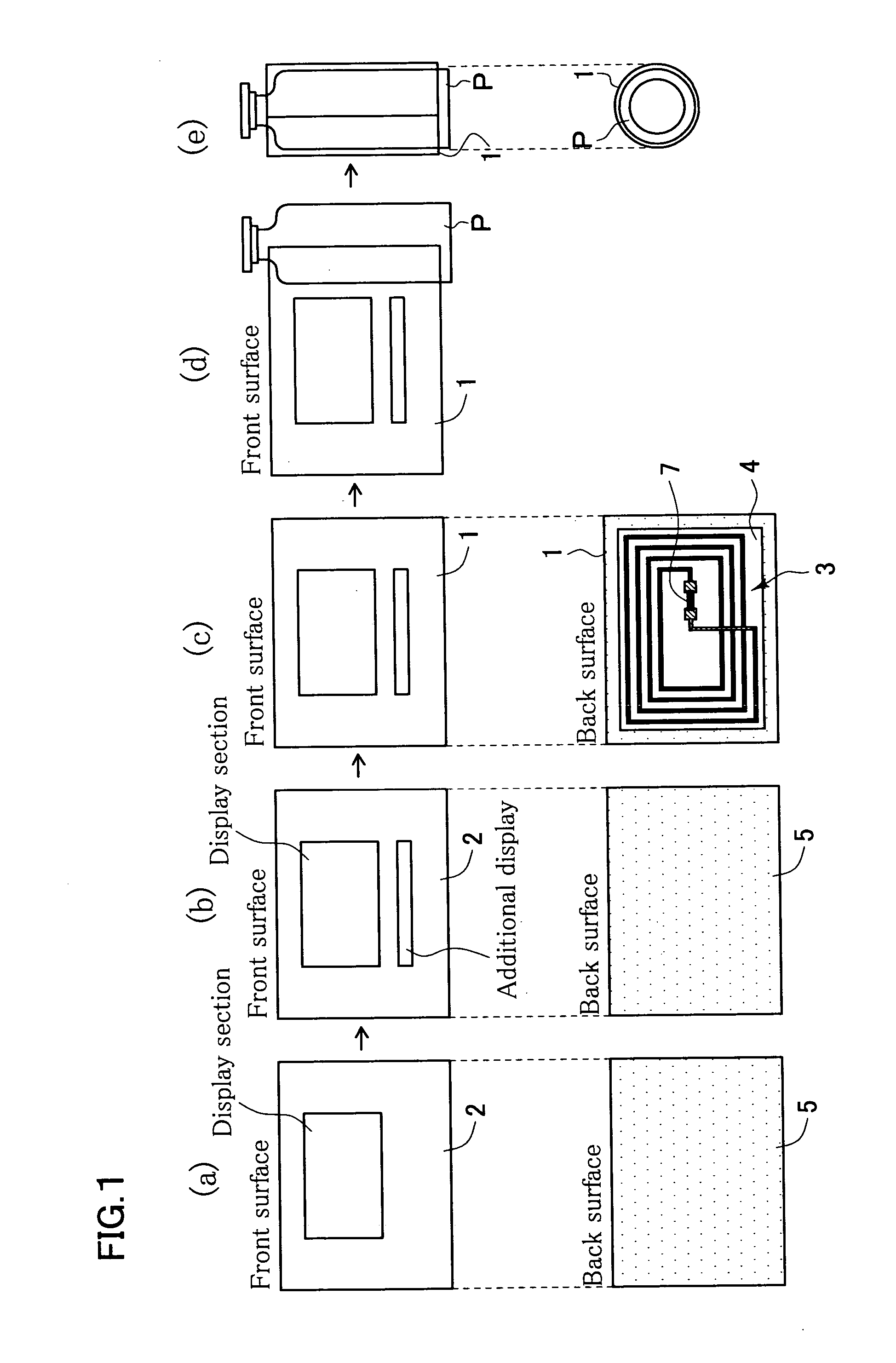

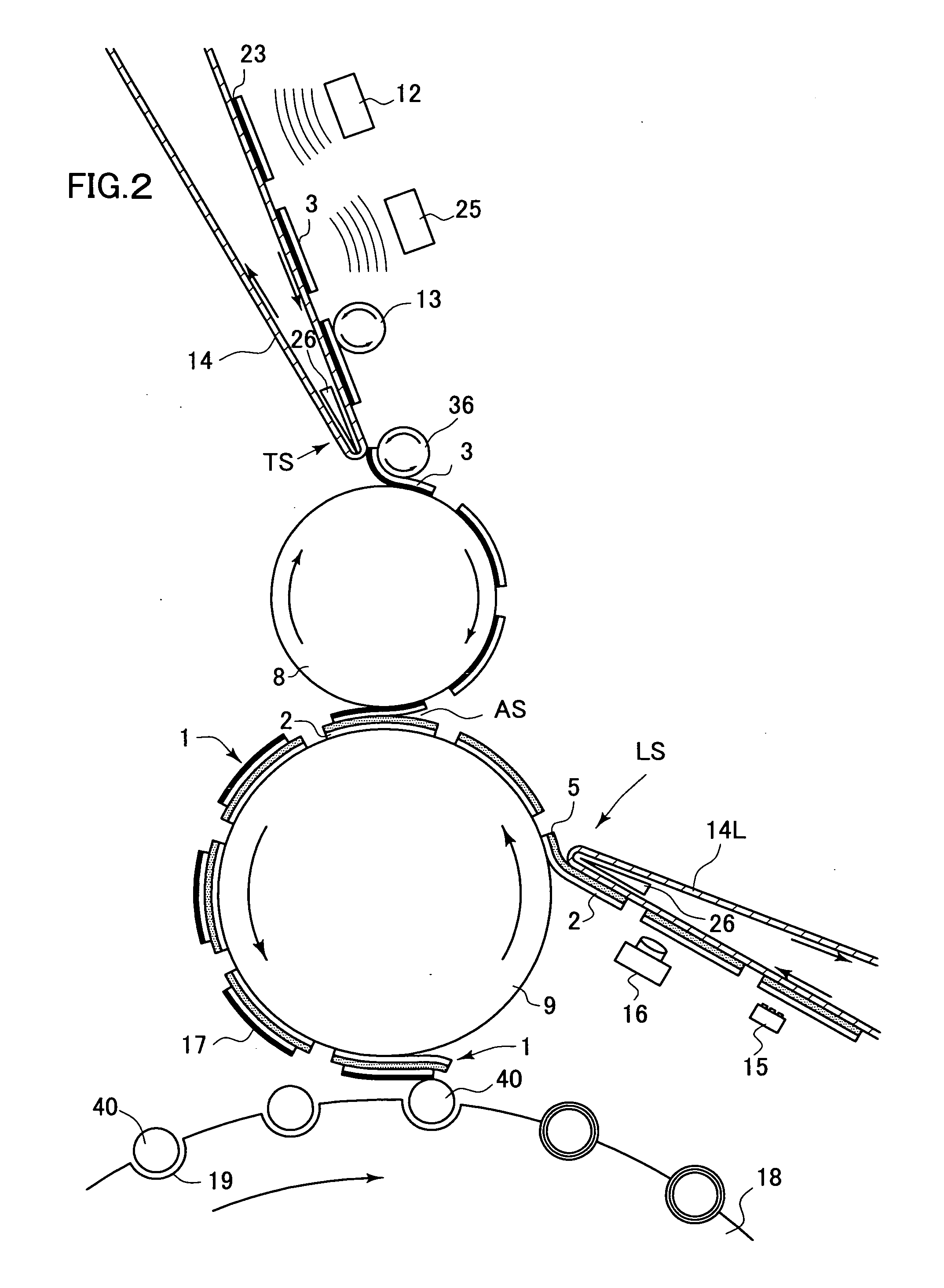

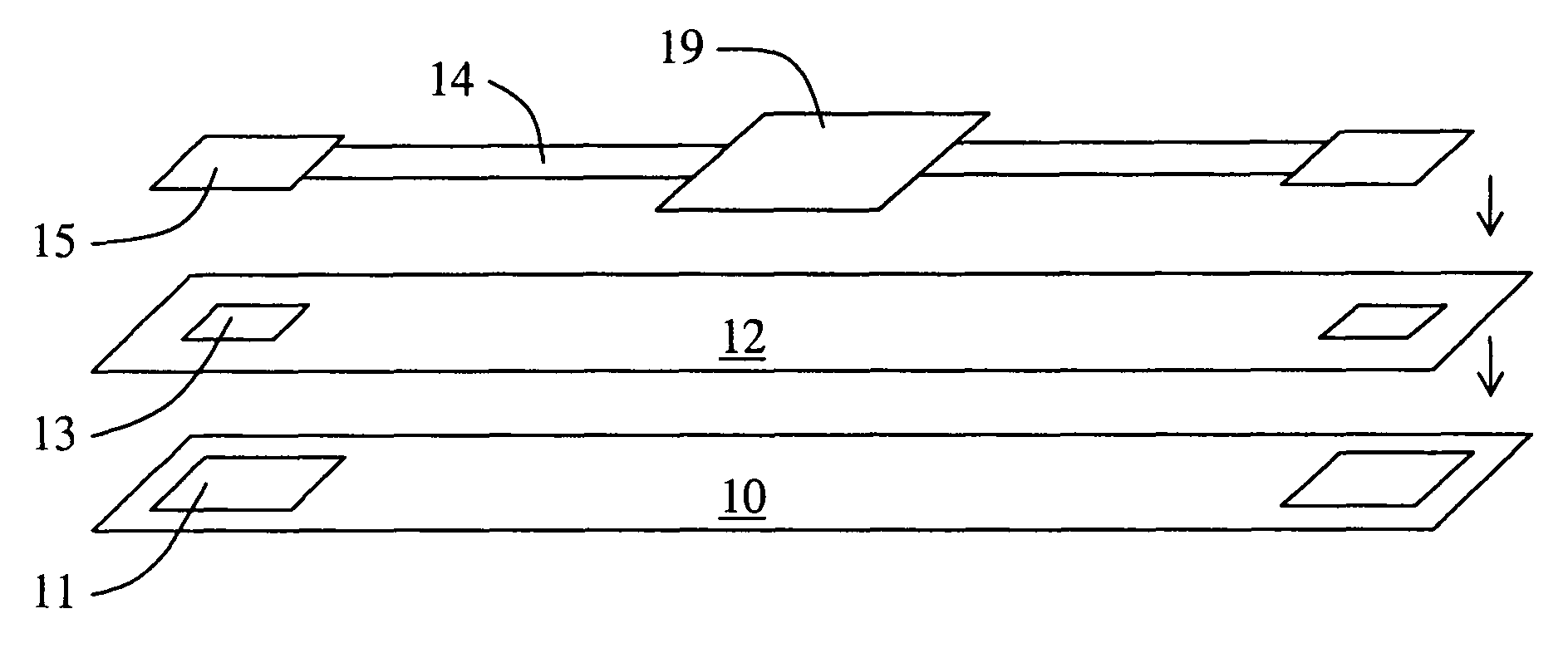

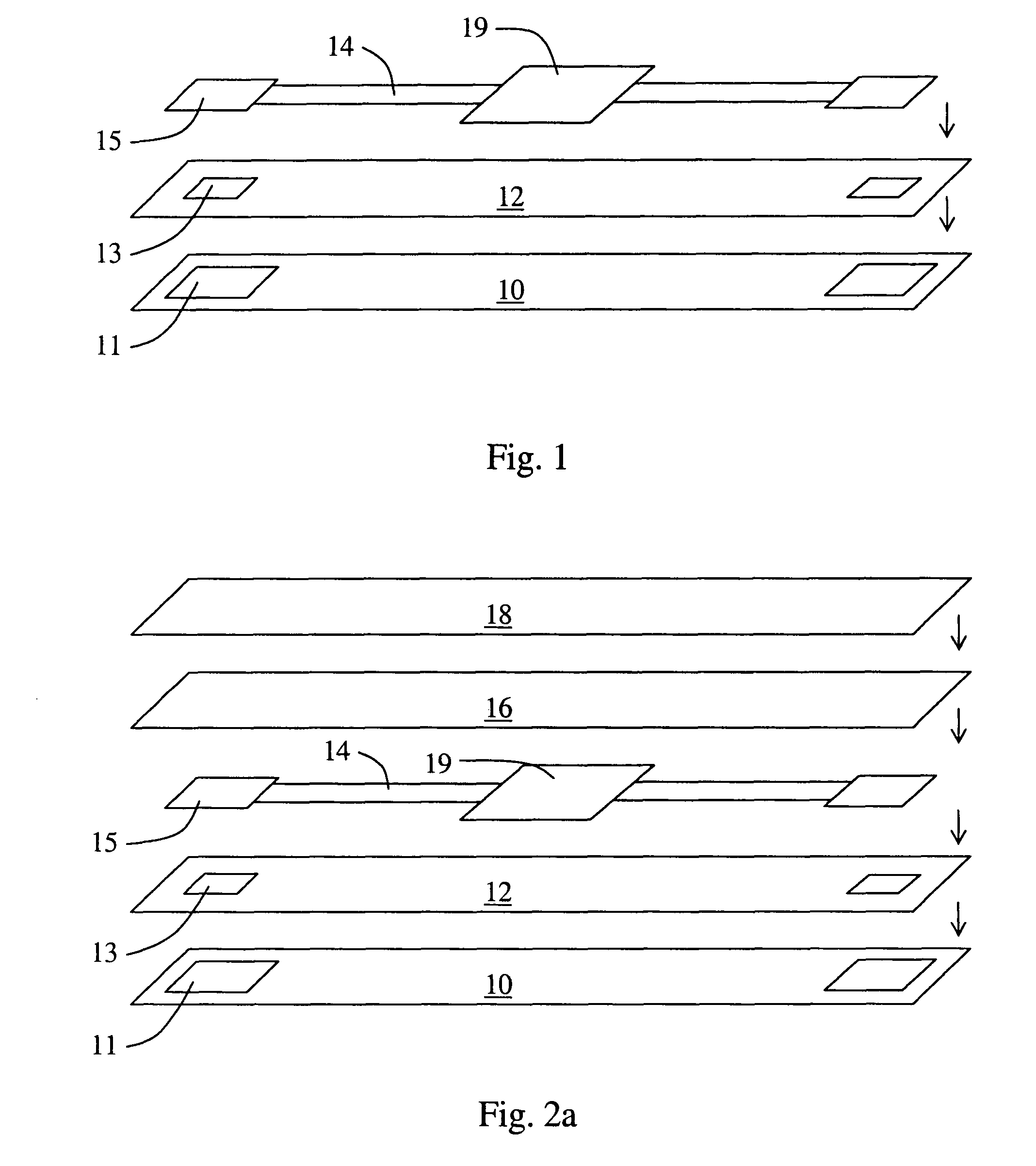

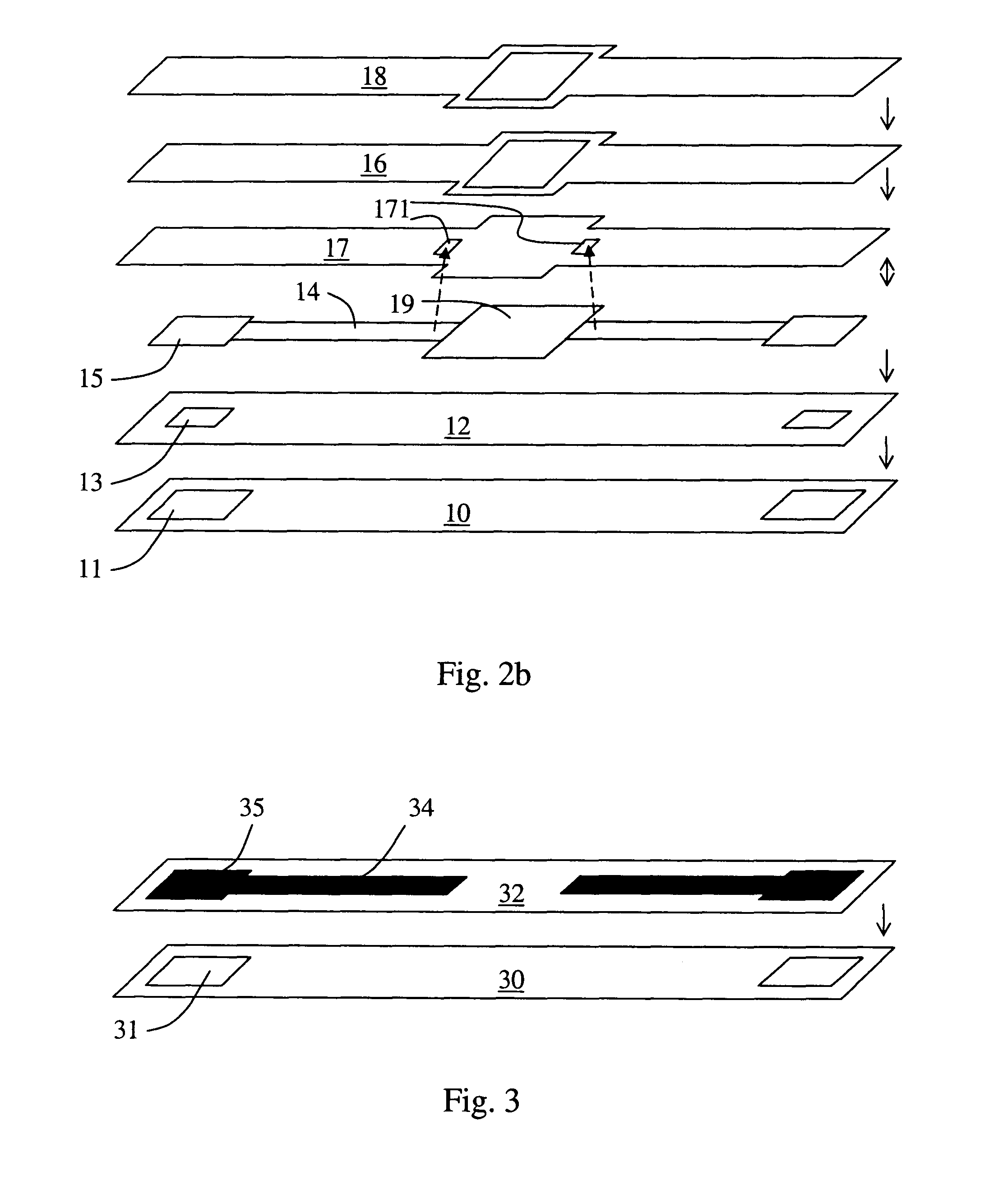

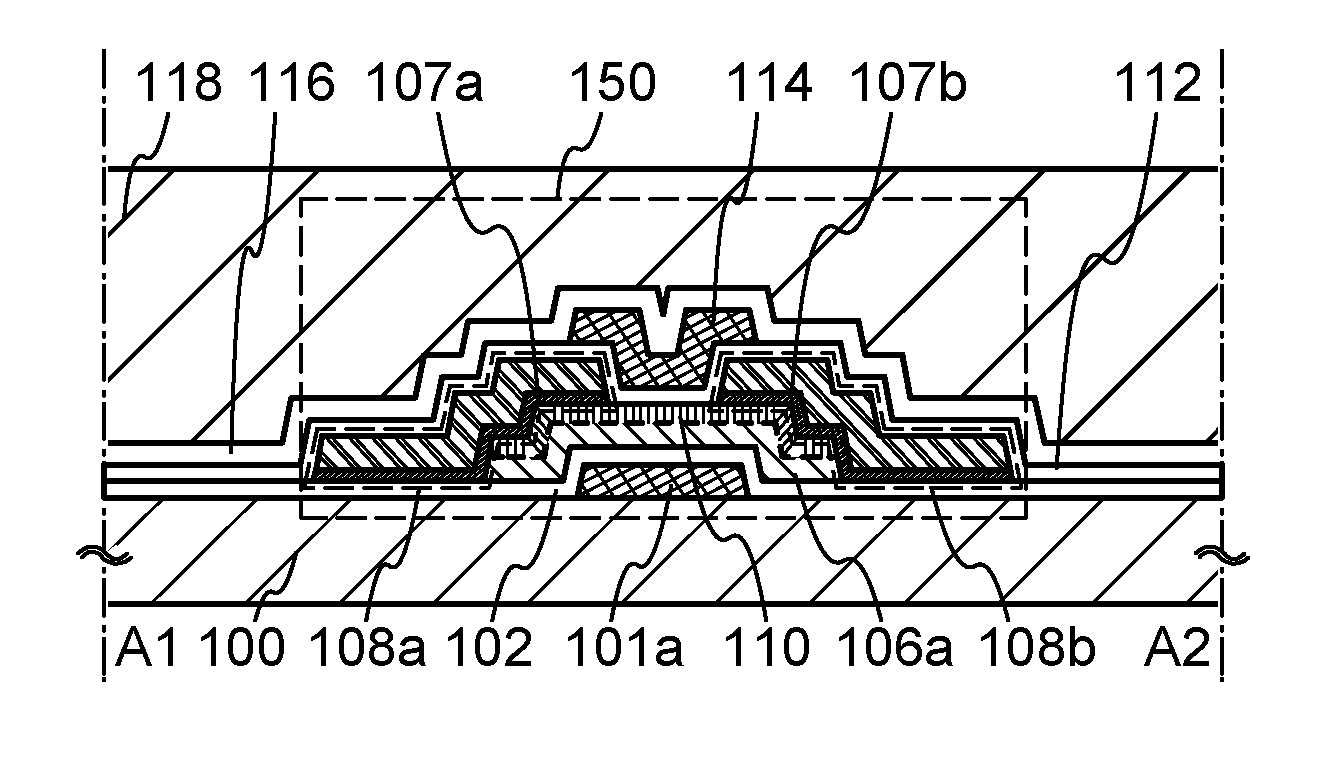

Affixing Method of Rfid Label and its Affixing Apparatus

InactiveUS20070252700A1Low costEliminate the problemSemiconductor/solid-state device manufacturingSubscribers indirect connectionEngineeringElectrical and Electronics engineering

A display label, having a display section on a surface thereof and an adhesive surface on a back surface thereof, and an IC tag, provided with an antenna coil and an IC chip so as to transmit information through non-contact communication, are prepared. After writing information on the IC chip, reading test is applied, so as to separate non-defective ID tags and defective ID tags. After printing addition display on the surface of the display label, a non-defective ID tag is adhered on an adhesive surface thereof, so as to form an RFID label. Then the RFID label is affixed to an object-to-affix such as a container. An affixing method of an RFID label and its affixing method are provided, wherein an ID tag is less likely to be damaged, since the ID tag is not adhered on a display label while printing additional display.

Owner:IWATA LABEL CO LTD +1

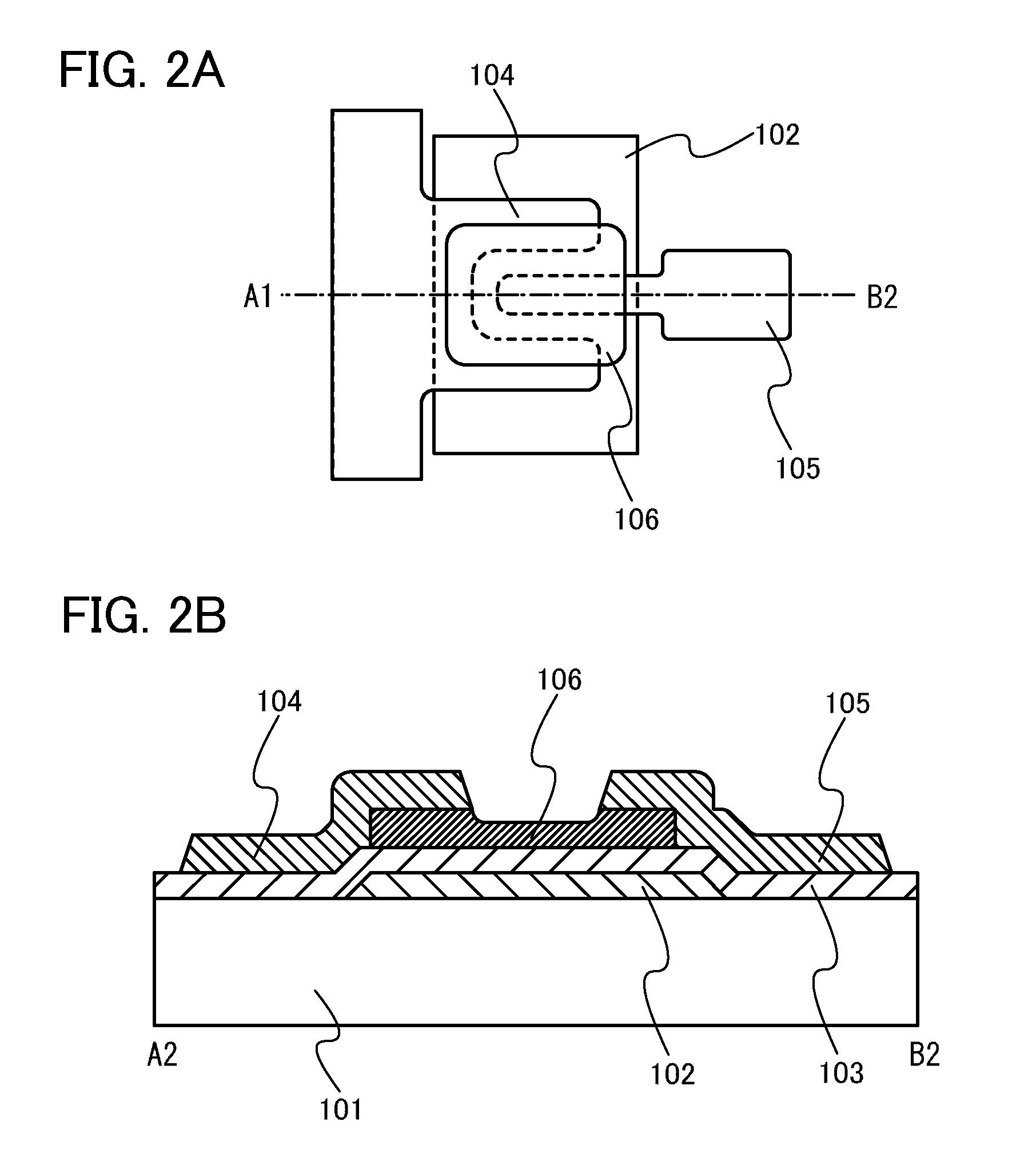

Oxide semiconductor, thin film transistor, and display device

ActiveUS20100102312A1Reduce defectsReduce carrier concentrationTransistorSolid-state devicesHydrogenDisplay device

An object is to control composition and a defect of an oxide semiconductor. Another object is to increase field effect mobility of a thin film transistor and to obtain a sufficient on-off ratio with off current suppressed. The oxide semiconductor is represented by InMO3(ZnO)n (M is one or a plurality of elements selected from Ga, Fe, Ni, Mn, Co, and Al, and n is a non-integer number of greater than or equal to 1 and less than 50) and further contains hydrogen. In this case, the concentration of Zn is made to be lower than the concentrations of In and M (M is one or a plurality of elements selected from Ga, Fe, Ni, Mn, Co, and Al). In addition, the oxide semiconductor has an amorphous structure. Here, n is preferably a non-integer number of greater than or equal to 50, more preferably less than 10.

Owner:SEMICON ENERGY LAB CO LTD

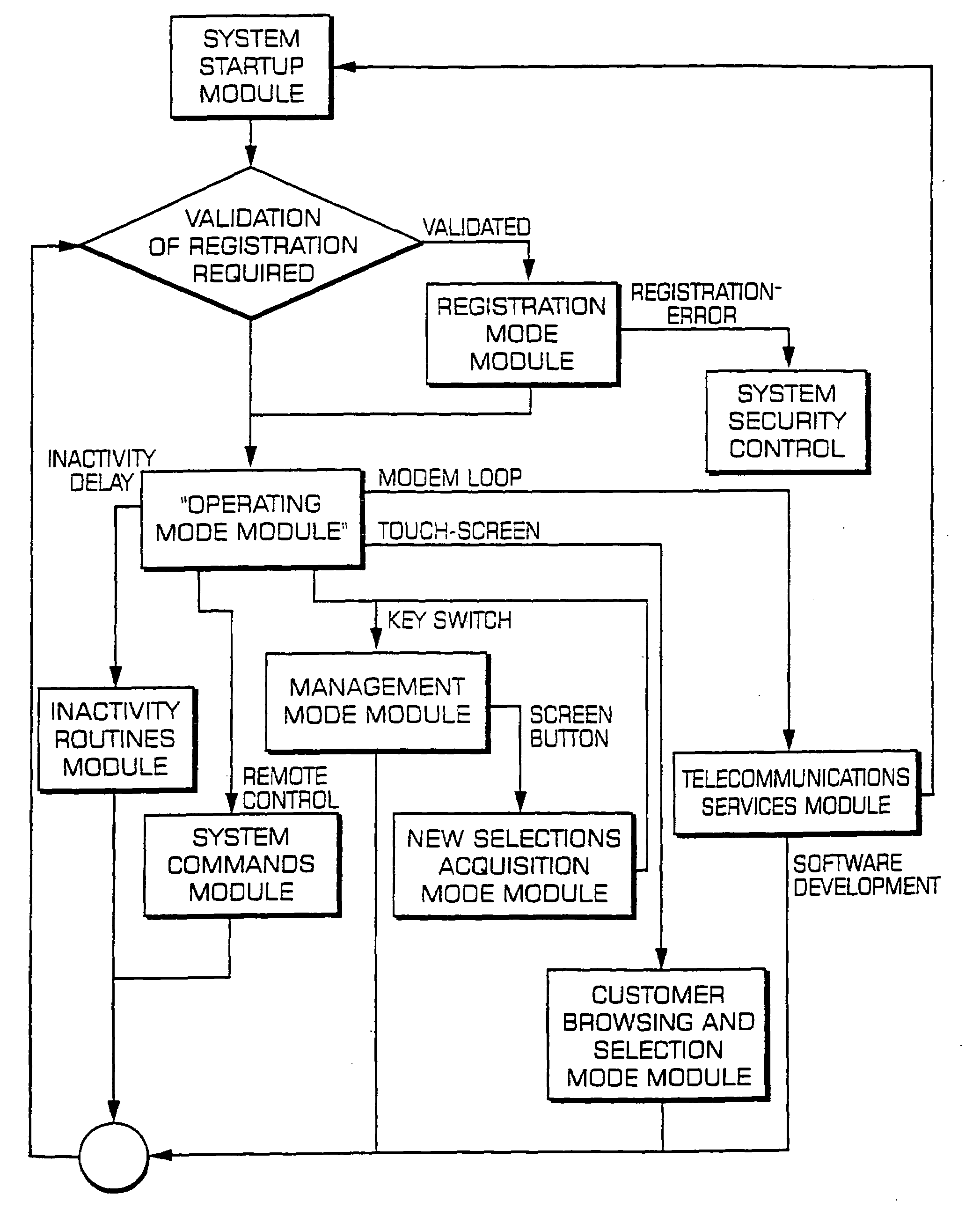

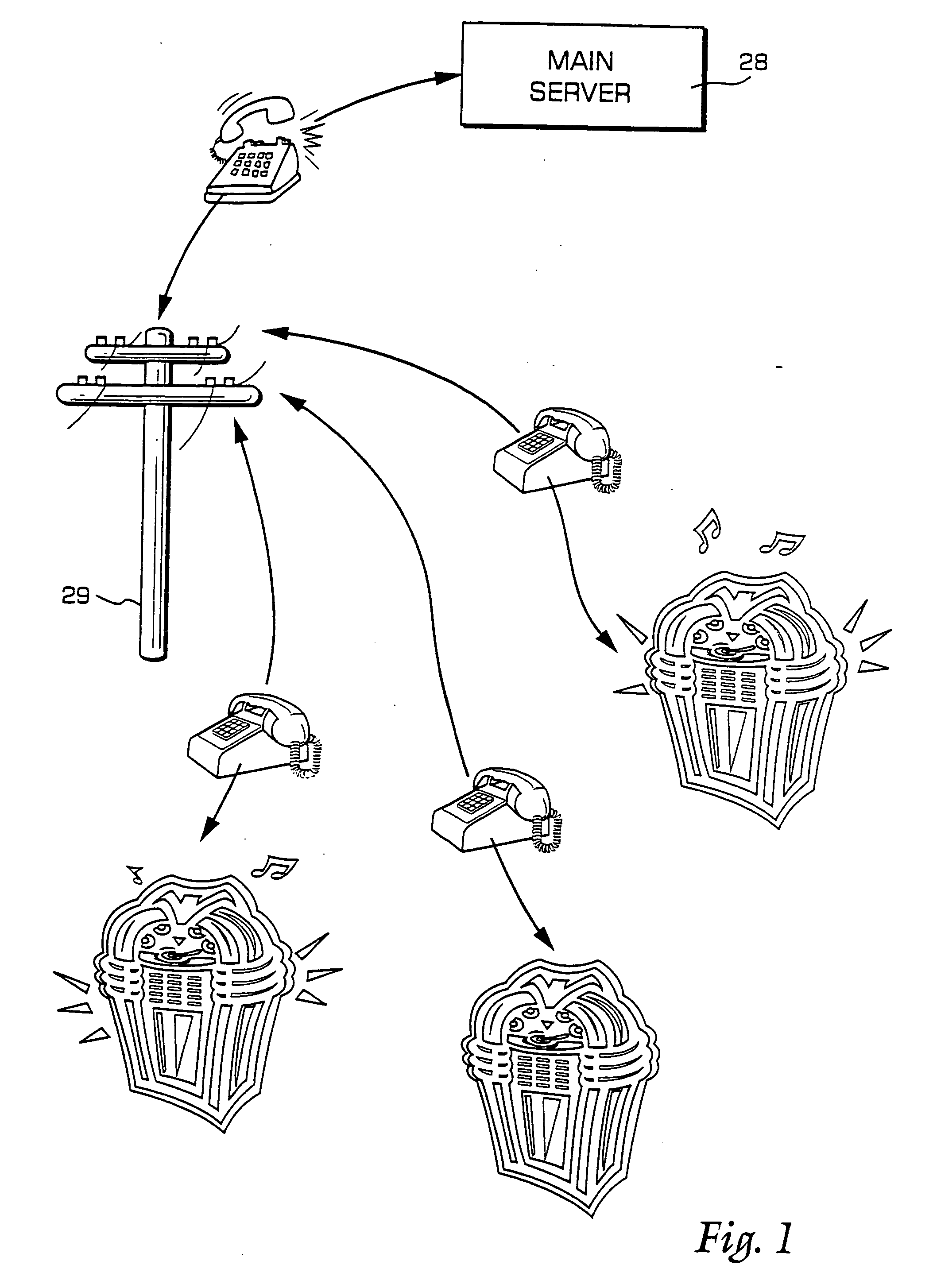

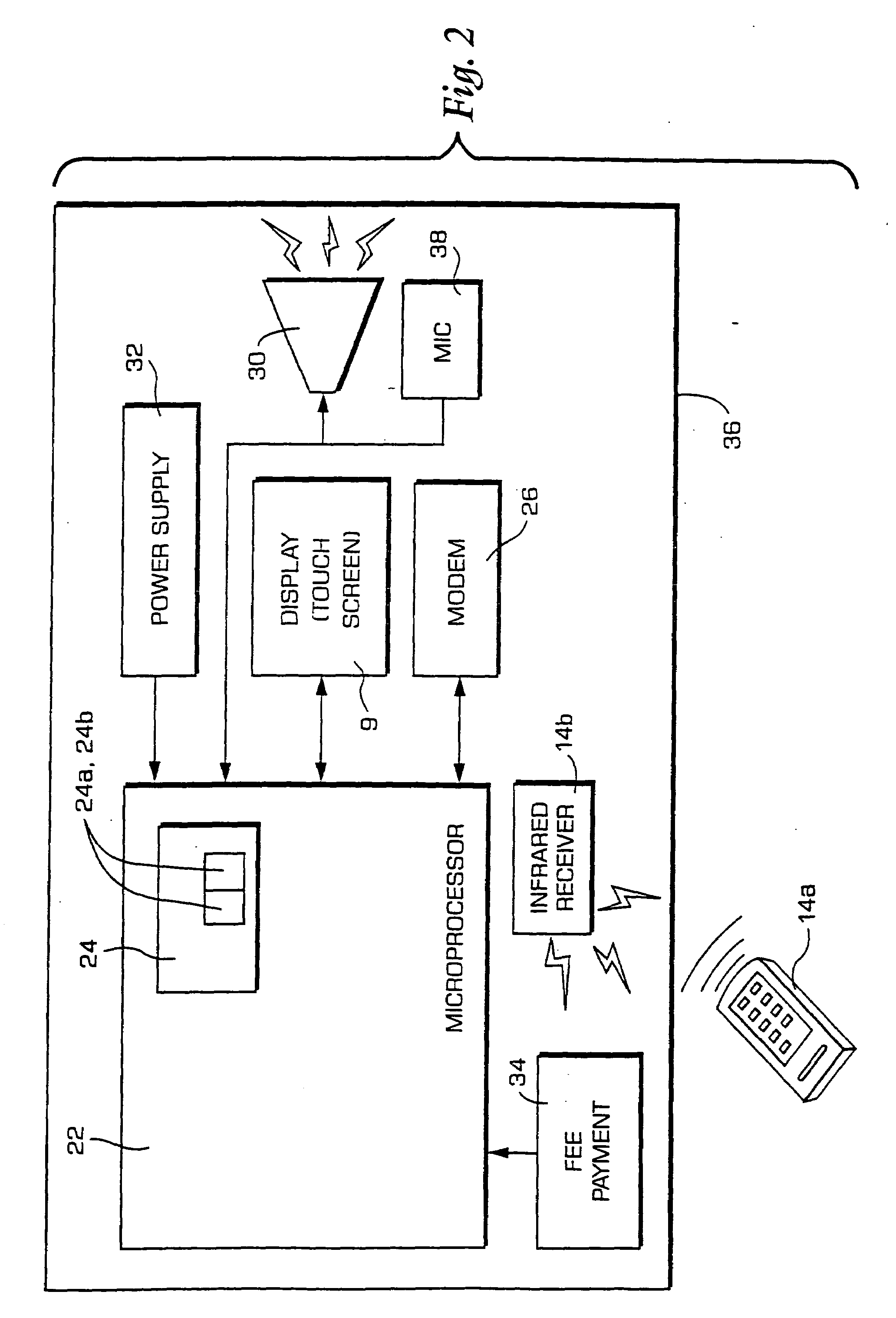

Intelligent digital audiovisual playback system

InactiveUS20090282491A1High qualityEasy deletion or insertionAcutation objectsDigital data processing detailsTelecommunications serviceTelecommunications Device

Payment-based audiovisual playback system characterized by comprising a microprocessor device associated with a payment device primarily including means for storing, inter alia, in digital format the visual and sound information to be used. The system is associated through interfaces with display means and sound playback means for providing a multimedia environment. The system is controlled by a multitask operating system including a tool and service library integrated into the storage means. The system, which is also associated through an interface with a telecommunications modem, is optionally connected to an audiovisual data distribution network by a telecommunications modem and telecommunications links, said telecommunications function also being controlled by said multitask operating system.

Owner:TOUCHTUNES MUSIC CORP

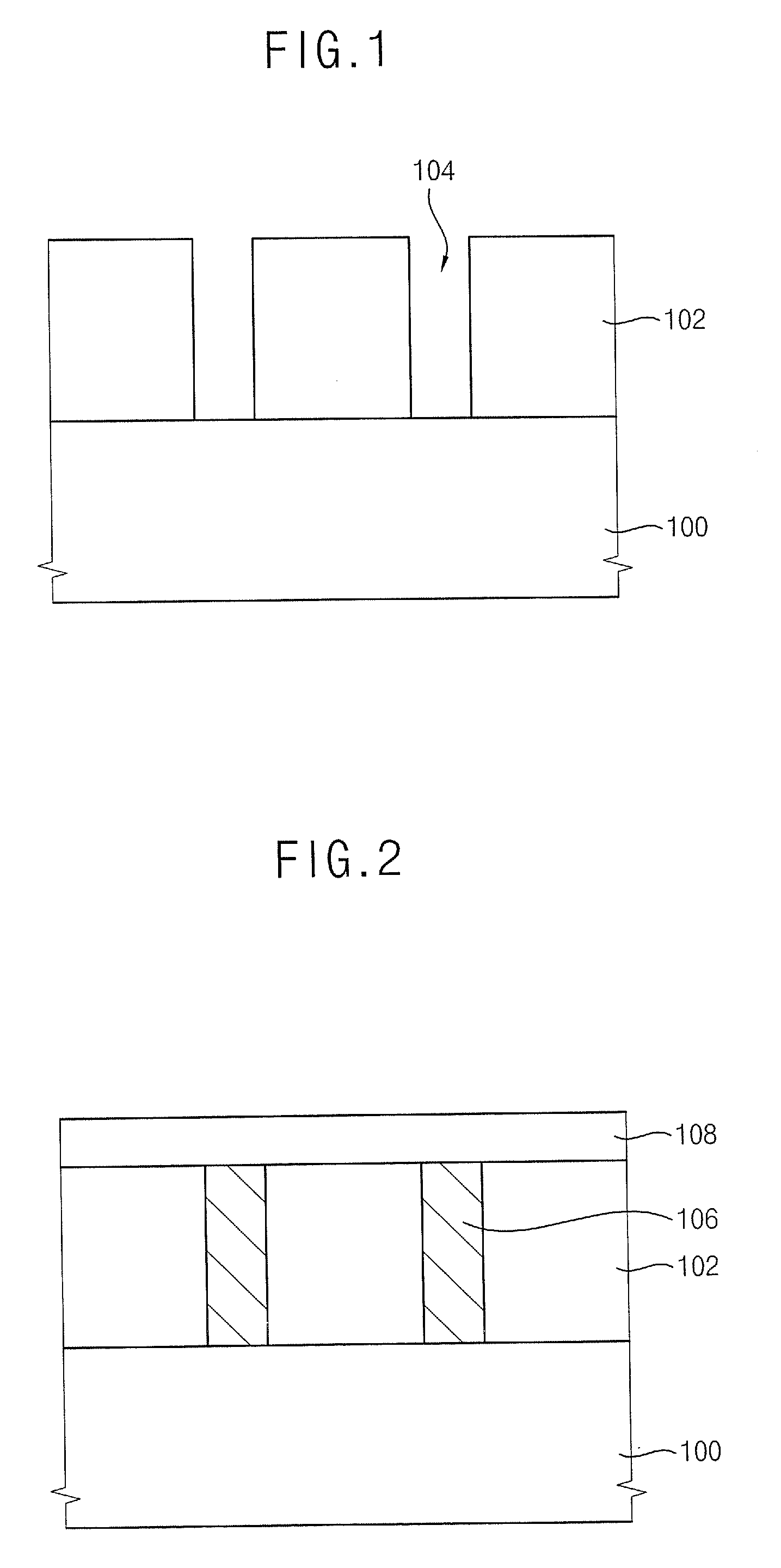

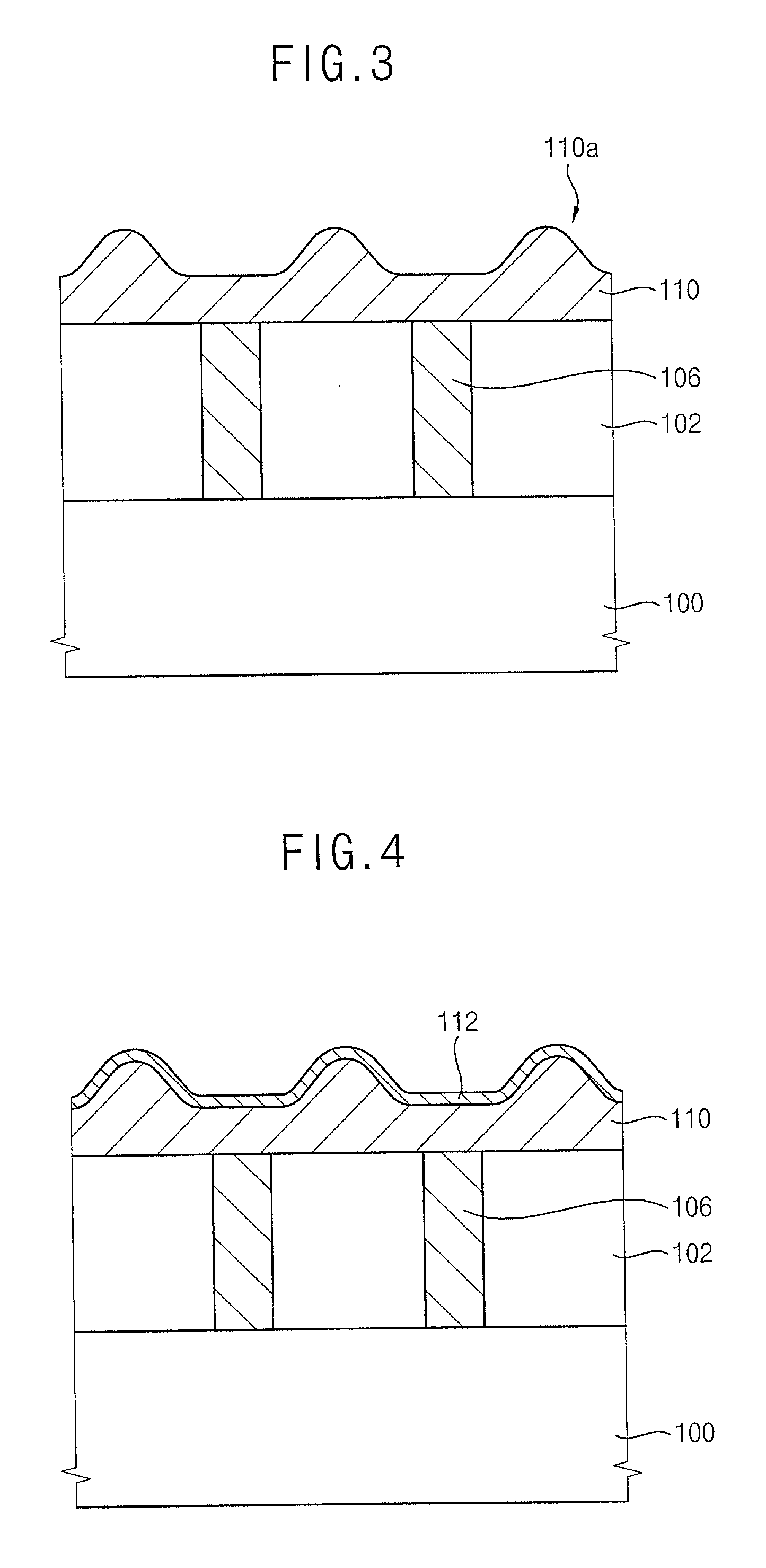

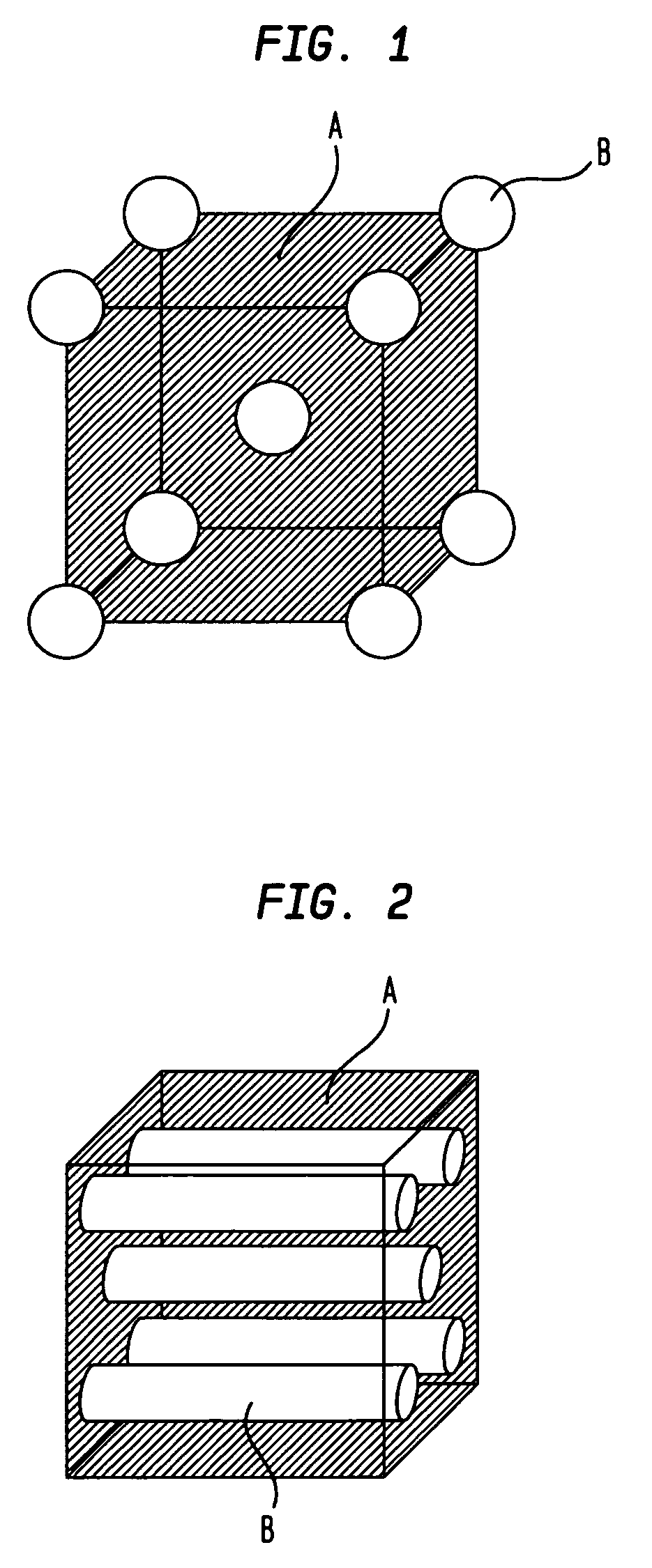

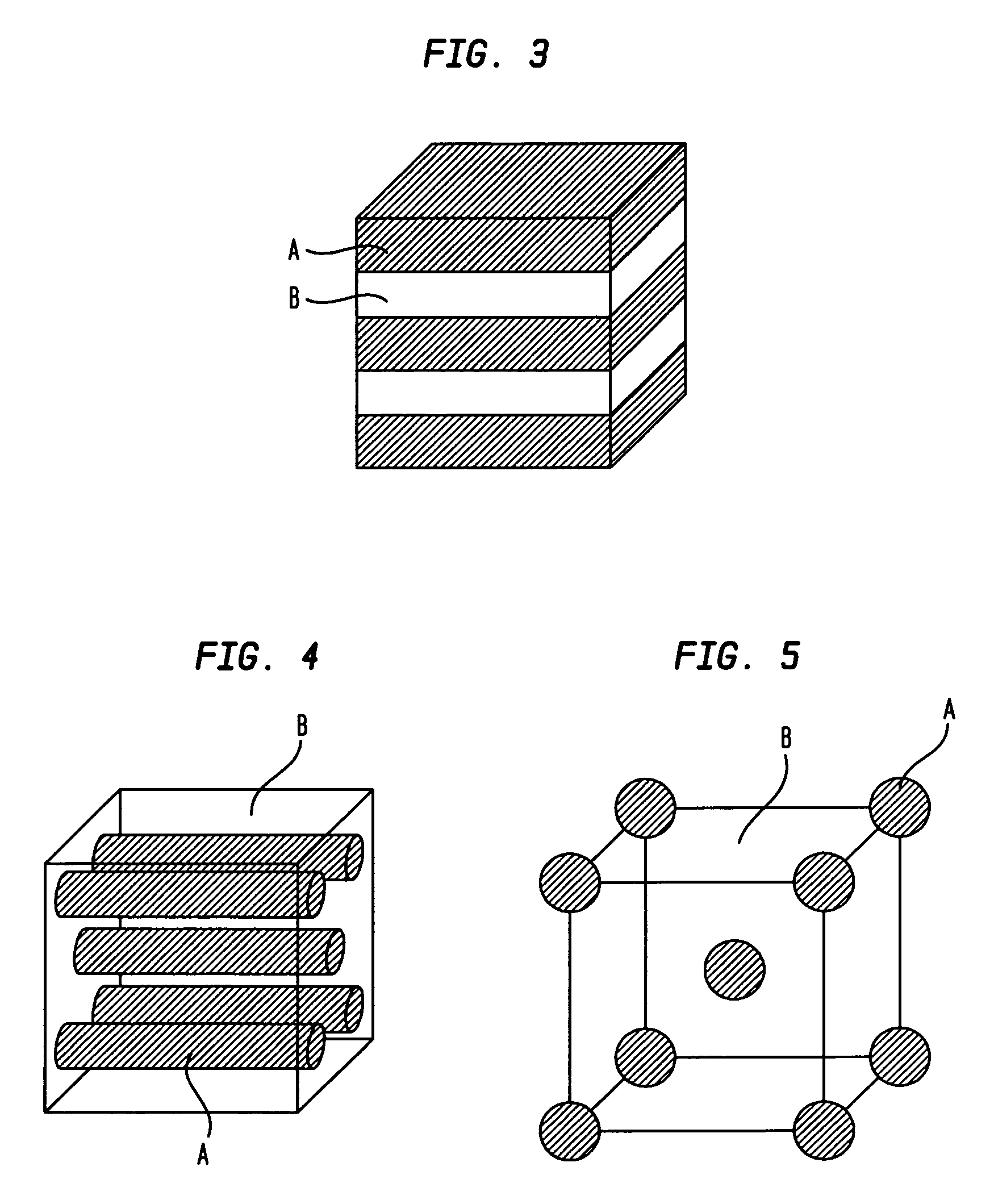

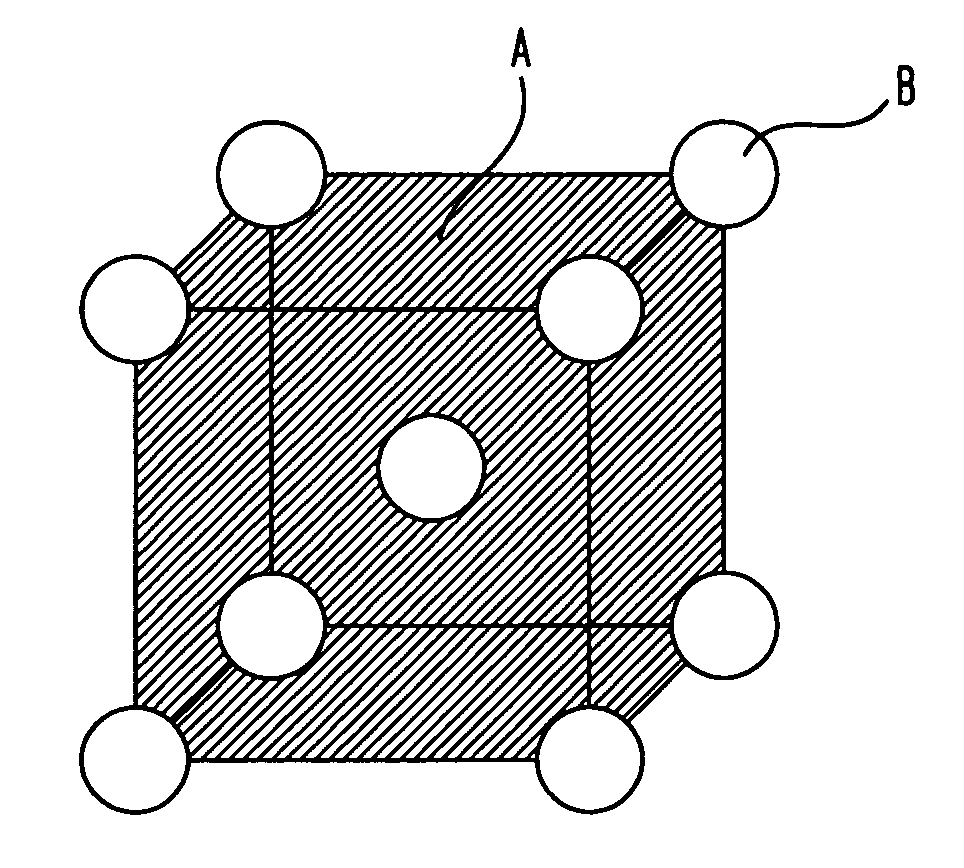

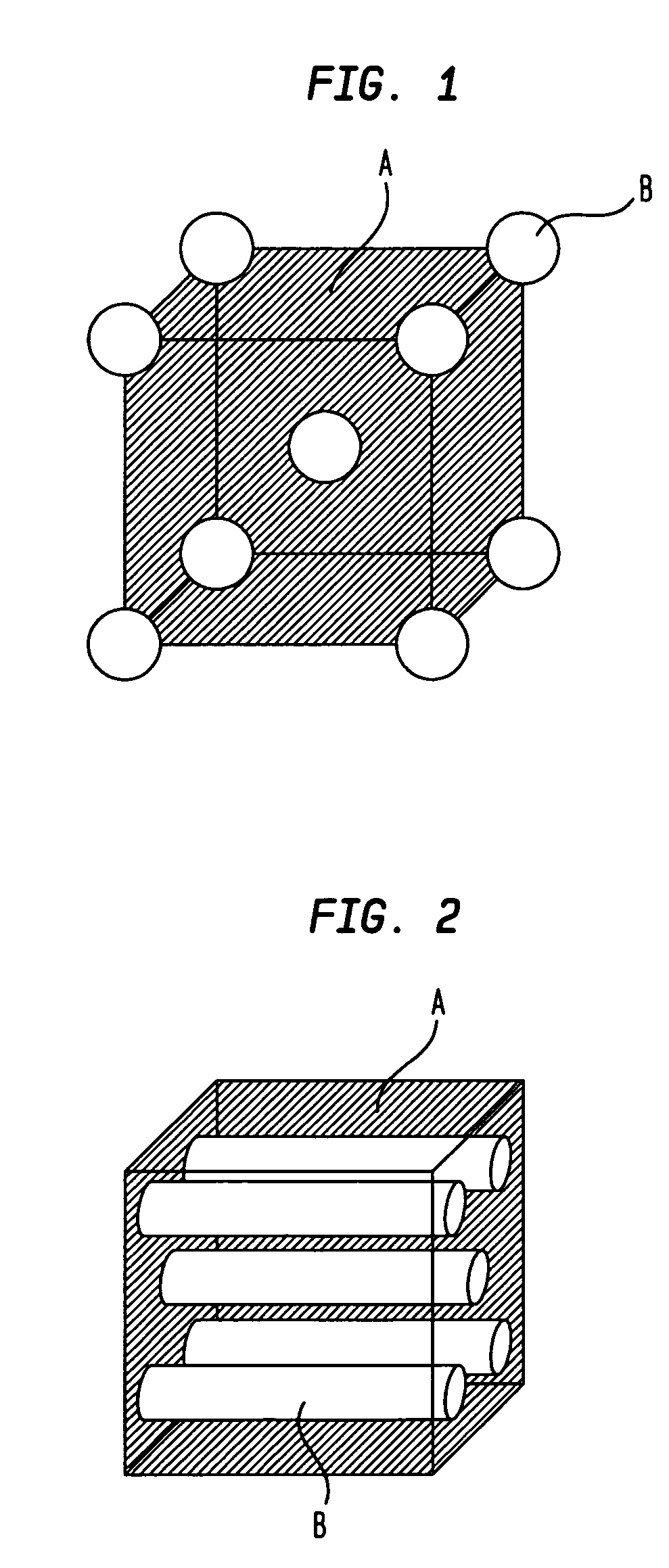

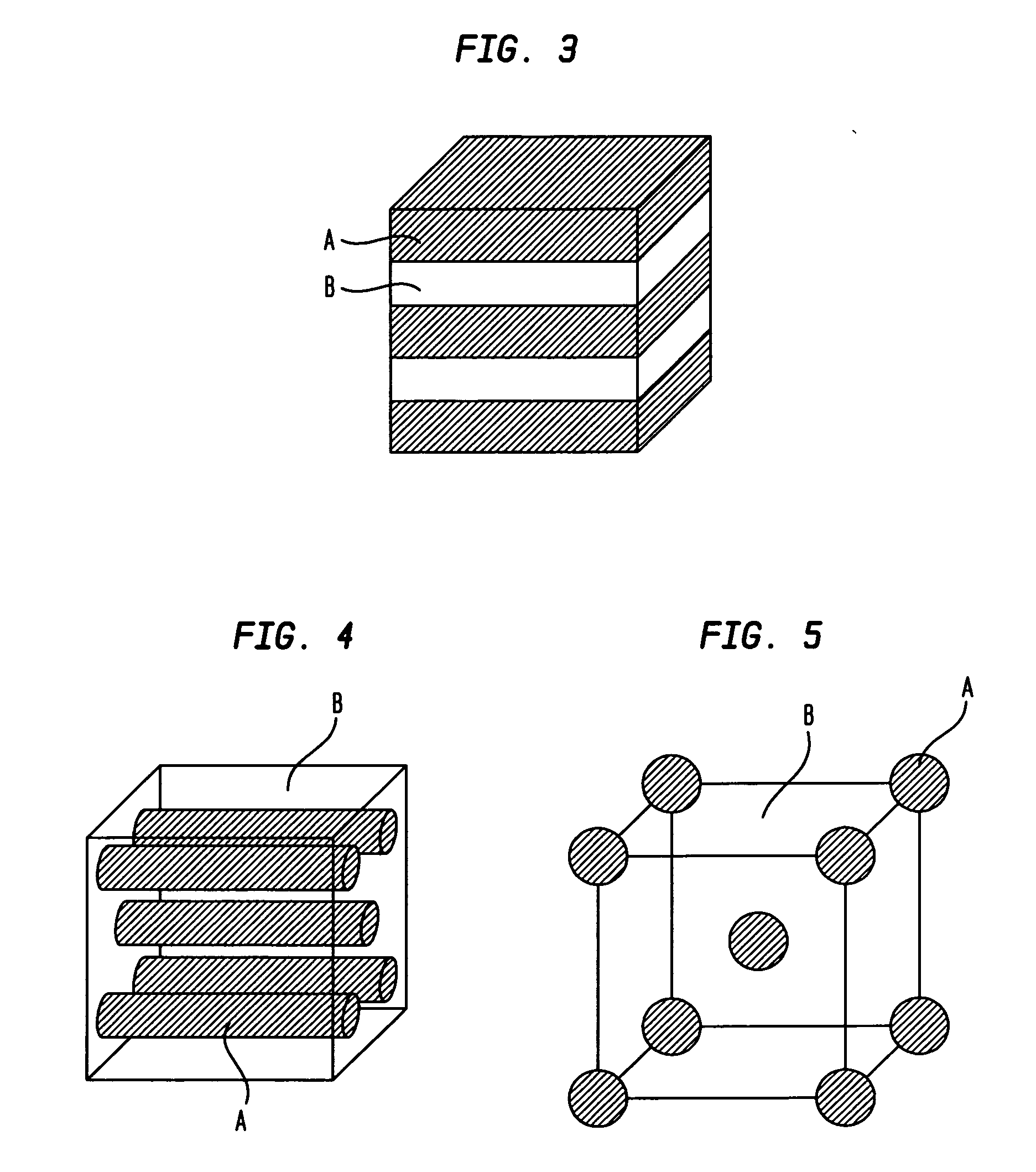

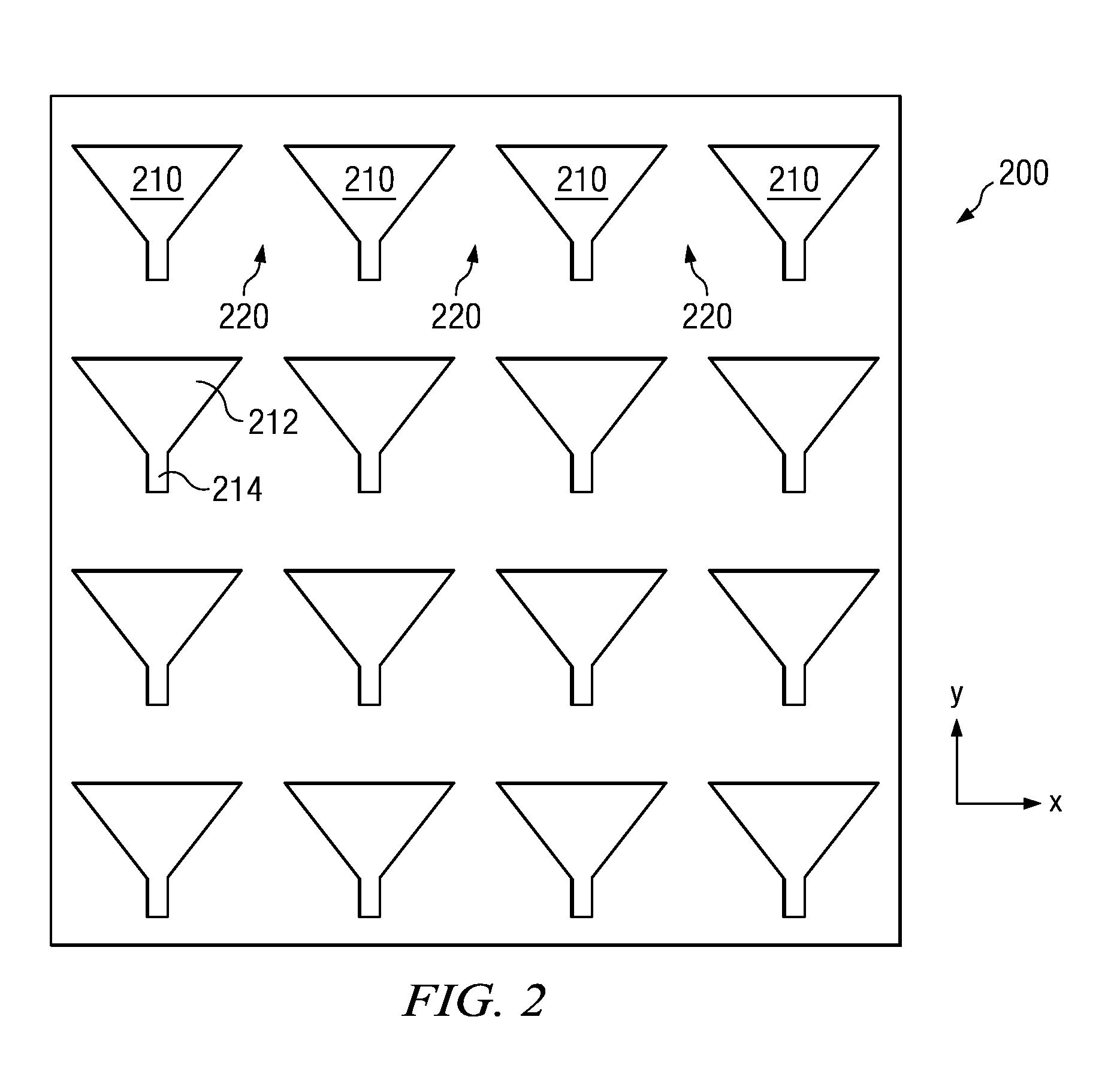

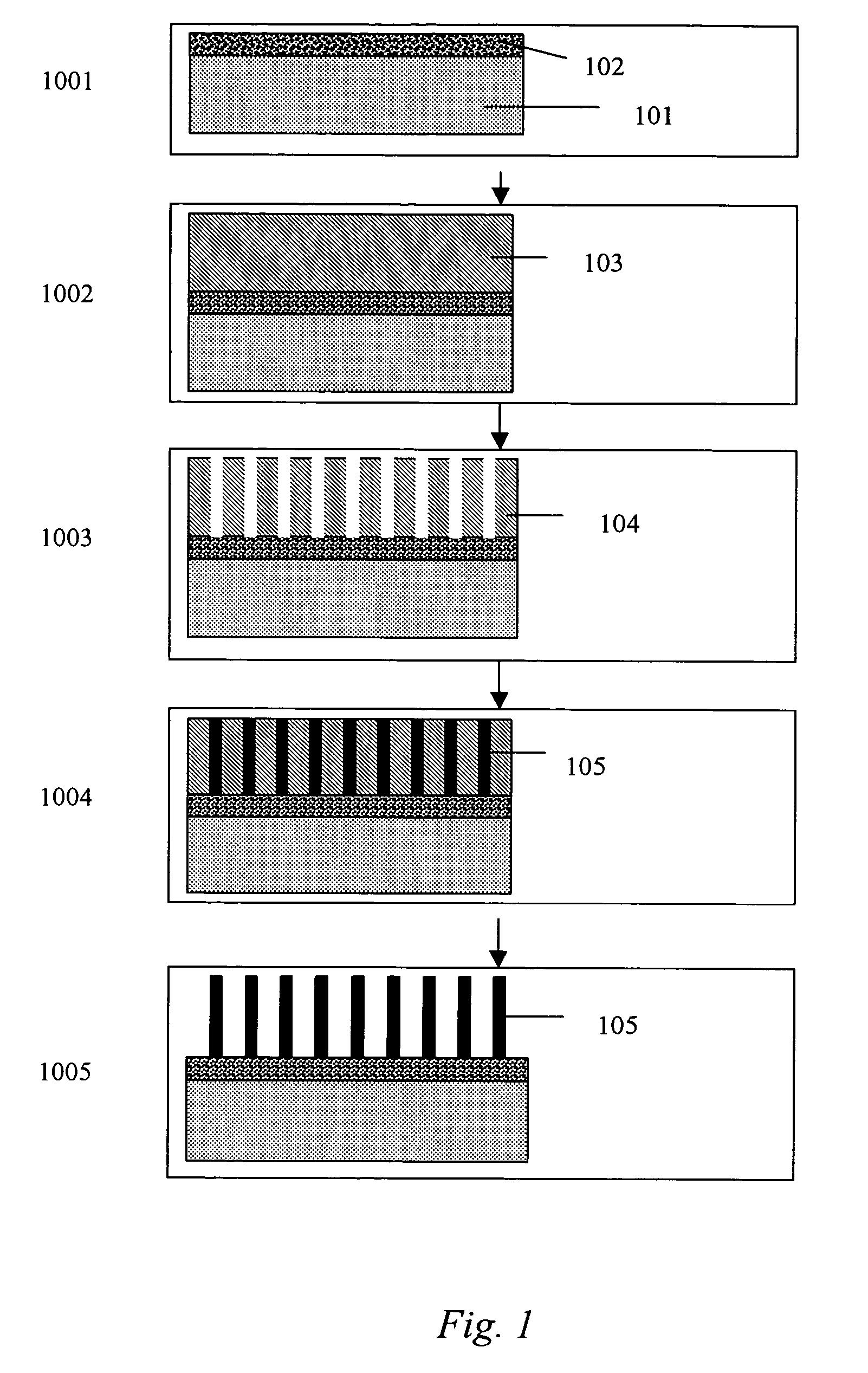

Methods for forming improved self-assembled patterns of block copolymers

ActiveUS7347953B2Easy alignmentReduce defectsMaterial nanotechnologyRadiation applicationsSemiconductor structureStructural unit

A method for forming self-assembled patterns on a substrate surface is provided. First, a block copolymer layer, which comprises a block copolymer having two or more immiscible polymeric block components, is applied onto a substrate that comprises a substrate surface with a trench therein. The trench specifically includes at least one narrow region flanked by two wide regions, and wherein the trench has a width variation of more than 50%. Annealing is subsequently carried out to effectuate phase separation between the two or more immiscible polymeric block components in the block copolymer layer, thereby forming periodic patterns that are defined by repeating structural units. Specifically, the periodic patterns at the narrow region of the trench are aligned in a predetermined direction and are essentially free of defects. Block copolymer films formed by the above-described method as well as semiconductor structures comprising such block copolymer films are also described.

Owner:GLOBALFOUNDRIES US INC

Methods for forming improved self-assembled patterns of block copolymers

ActiveUS20070175859A1Easy alignmentReduce defectsMaterial nanotechnologyRadiation applicationsSemiconductor structureStructural unit

A method for forming self-assembled patterns on a substrate surface is provided. First, a block copolymer layer, which comprises a block copolymer having two or more immiscible polymeric block components, is applied onto a substrate that comprises a substrate surface with a trench therein. The trench specifically includes at least one narrow region flanked by two wide regions, and wherein the trench has a width variation of more than 50%. Annealing is subsequently carried out to effectuate phase separation between the two or more immiscible polymeric block components in the block copolymer layer, thereby forming periodic patterns that are defined by repeating structural units. Specifically, the periodic patterns at the narrow region of the trench are aligned in a predetermined direction and are essentially free of defects. Block copolymer films formed by the above-described method as well as semiconductor structures comprising such block copolymer films are also described.

Owner:GLOBALFOUNDRIES US INC

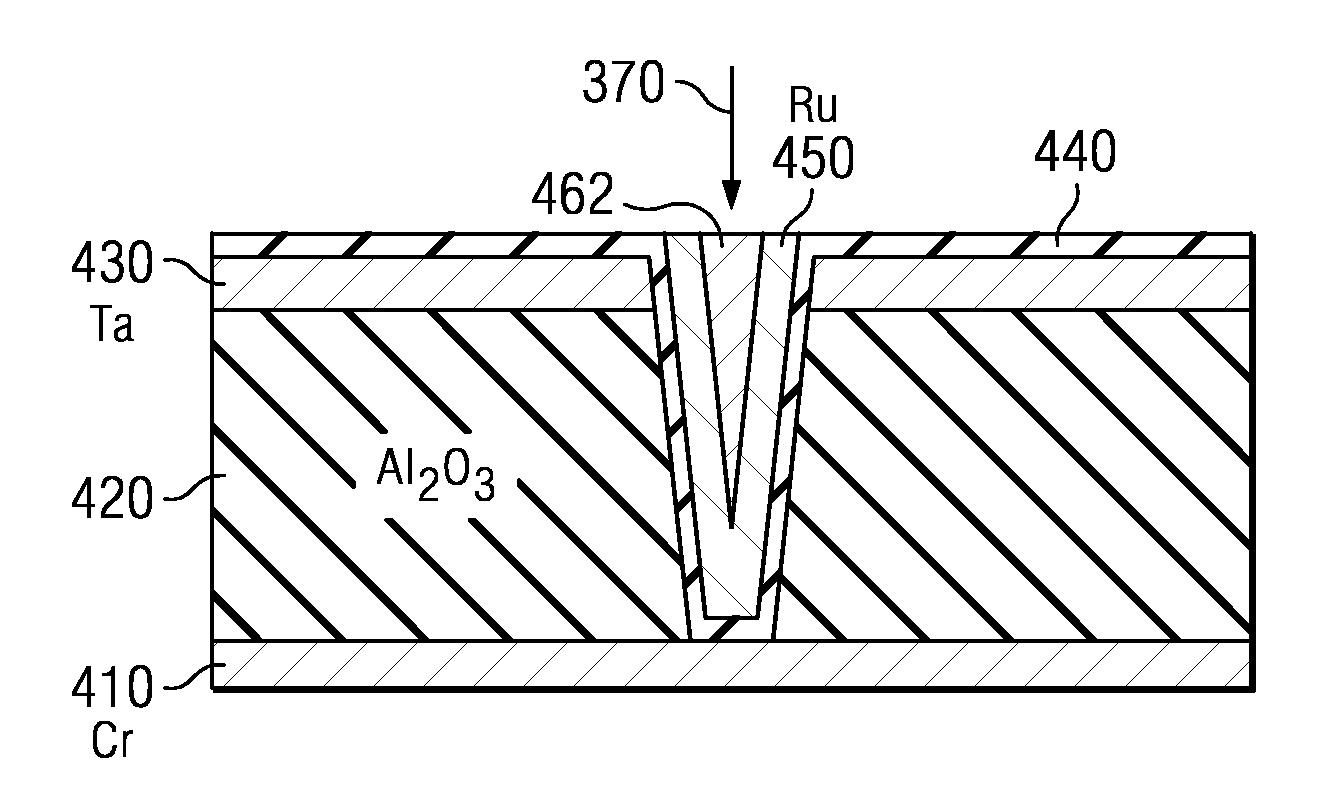

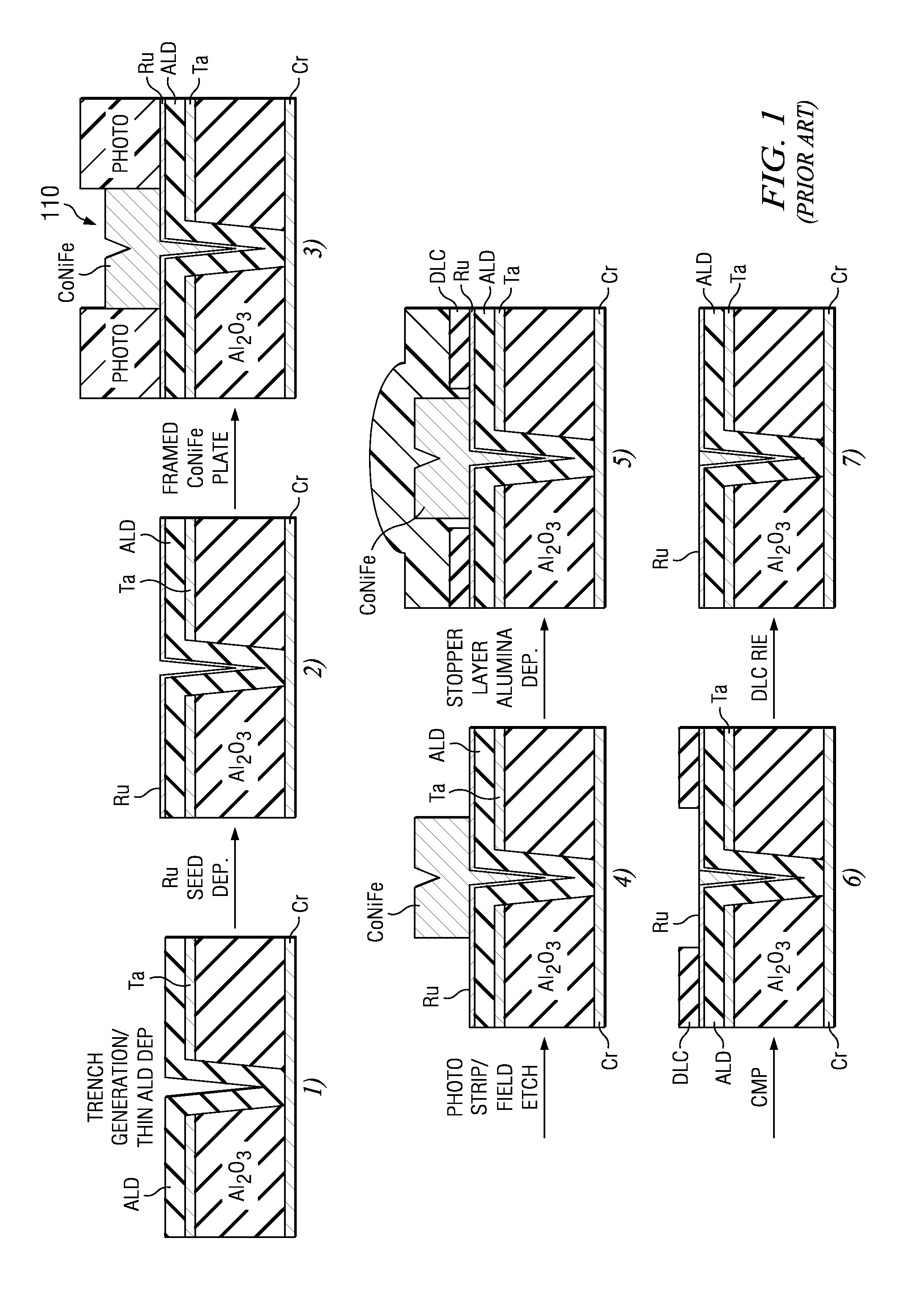

Methods of producing damascene main pole for perpendicular magnetic recording head

InactiveUS8262918B1Reduce defectsReduce complexityDecorative surface effectsRecord information storageMaterial removalEngineering

Methods of producing magnetic recording heads are disclosed. The methods can include providing a wafer comprising a substrate layer in which are disposed a plurality of damascene trenches. The method can further include depositing a pole material across the whole wafer, wherein the plurality of trenches are filled with the pole material. The methods can further include depositing a mask material over the pole material across the whole wafer. The methods can further include performing a first material removal process across the whole wafer to remove the mask material and a first portion of the pole material at a same material removal rate. The methods can further include performing a second material removal process to remove a second portion of the pole material above the substrate layer.

Owner:WESTERN DIGITAL TECH INC

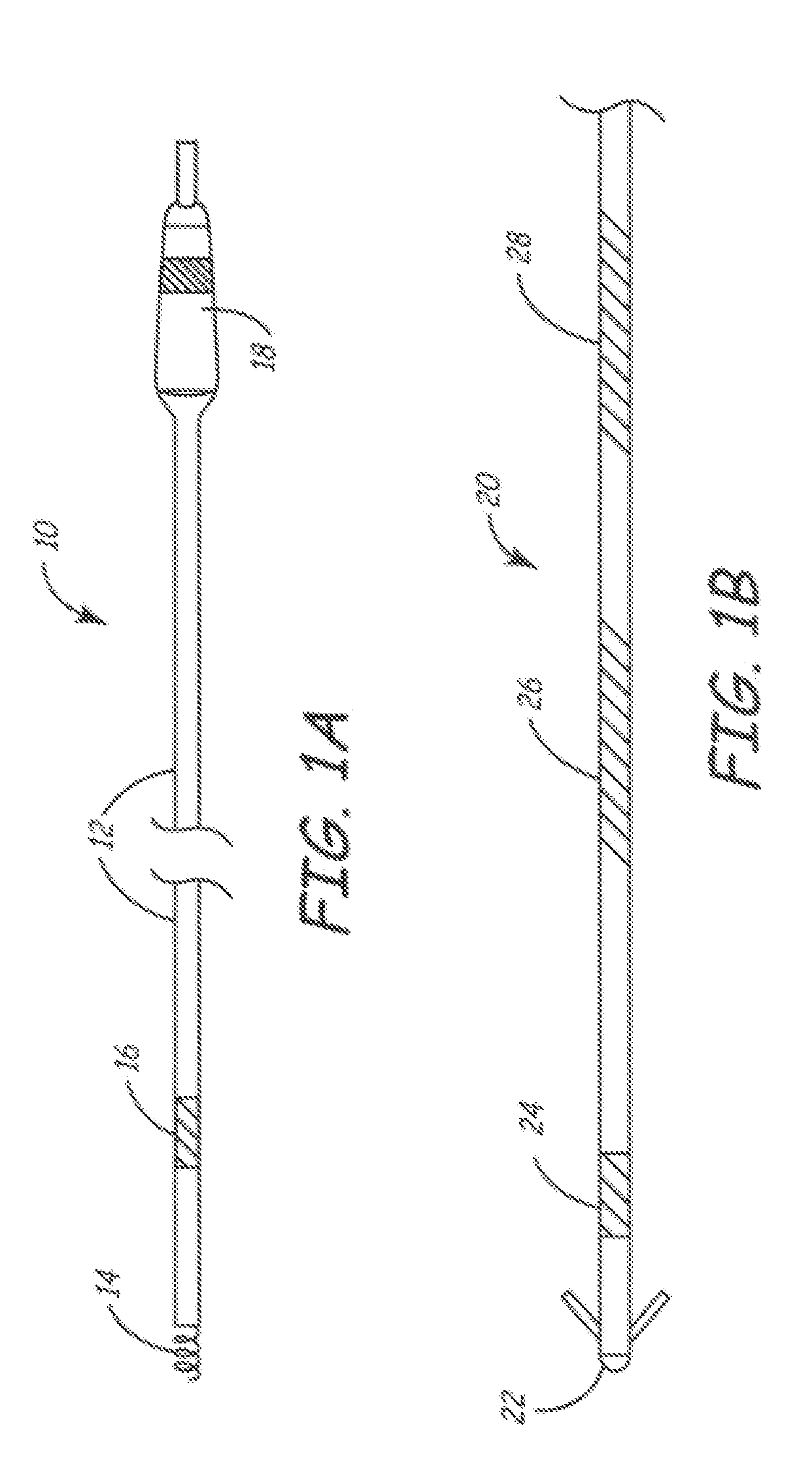

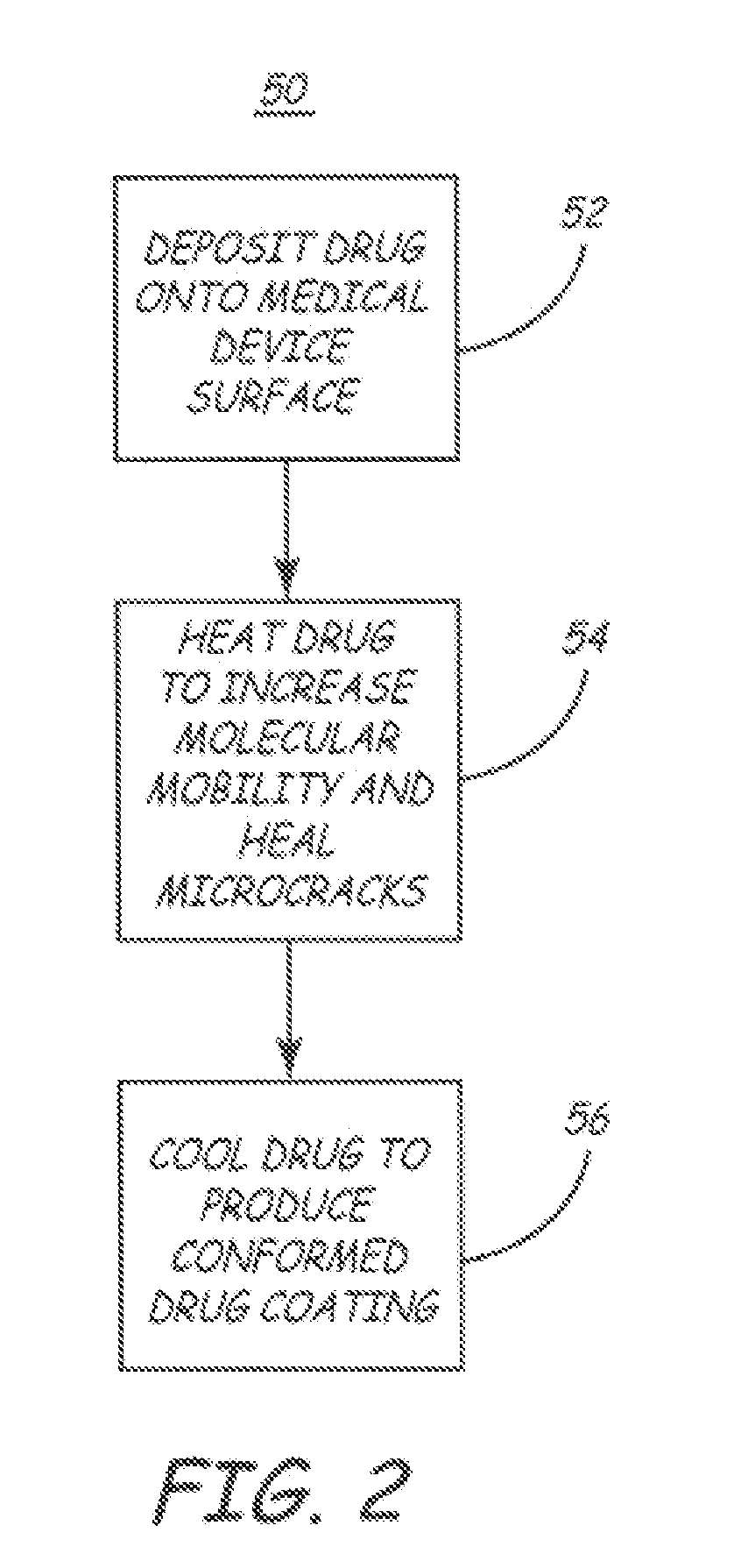

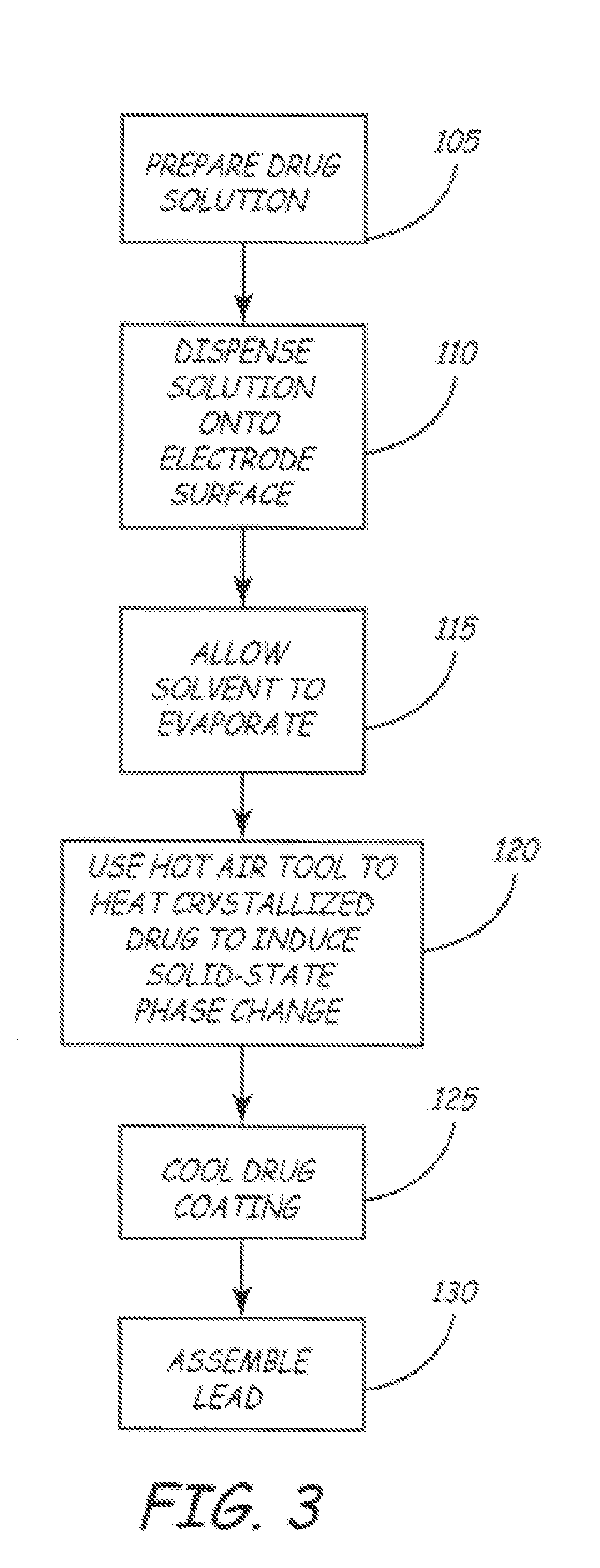

Method for applying a drug coating to a medical device

A method for coating a medical device with a drug is provided. Energy, preferably thermal energy, is applied to a crystalline deposit of a drug on the surface of a medical device to increase the molecular mobility and form a conformable drug coating with a low density of micro-cracks and other mechanical defects that can degrade the coating toughness and effective adhesion to the device surface. In a preferred embodiment, solution evaporation methods are used to deposit a crystalline coating of an anti-inflammatory steroid on a medical electrode. Heat applied at a controlled temperature, for a predetermined amount of time, induces a solid-state phase change of the drug coating providing a smooth, uniform, well-attached, conformable coating to form a layer that will elute from the electrode over time when implanted in a patient's body.

Owner:MEDTRONIC INC

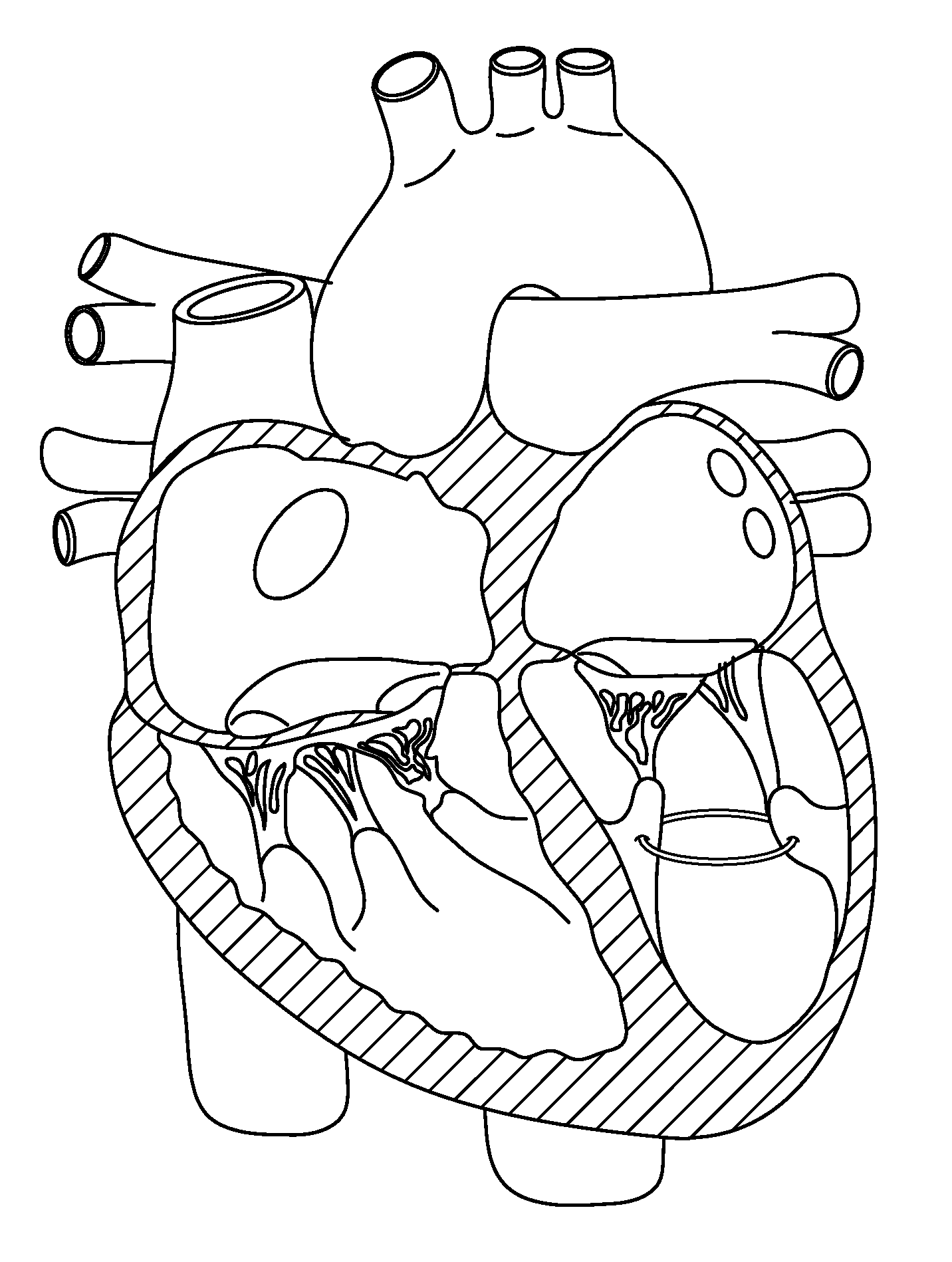

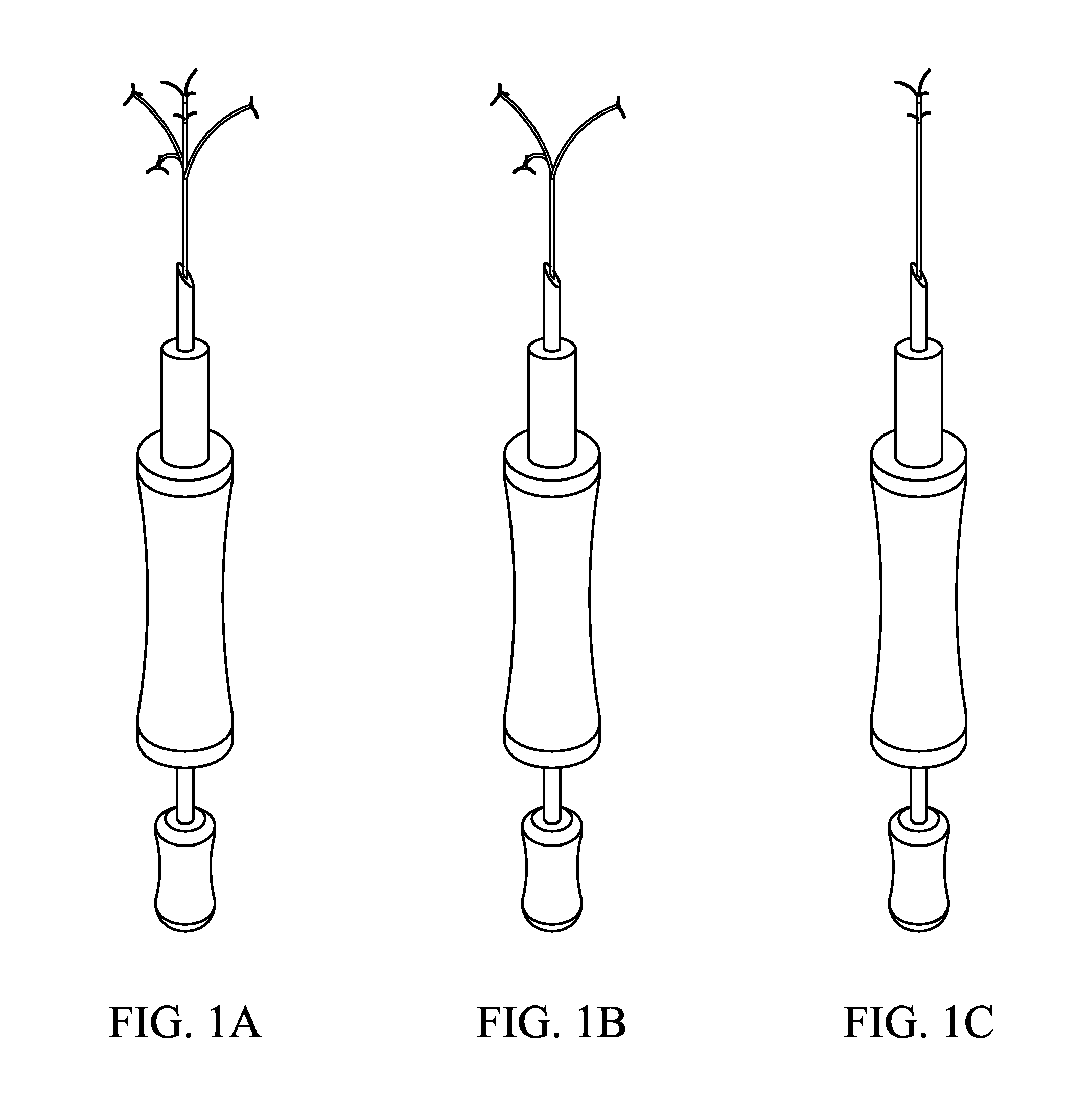

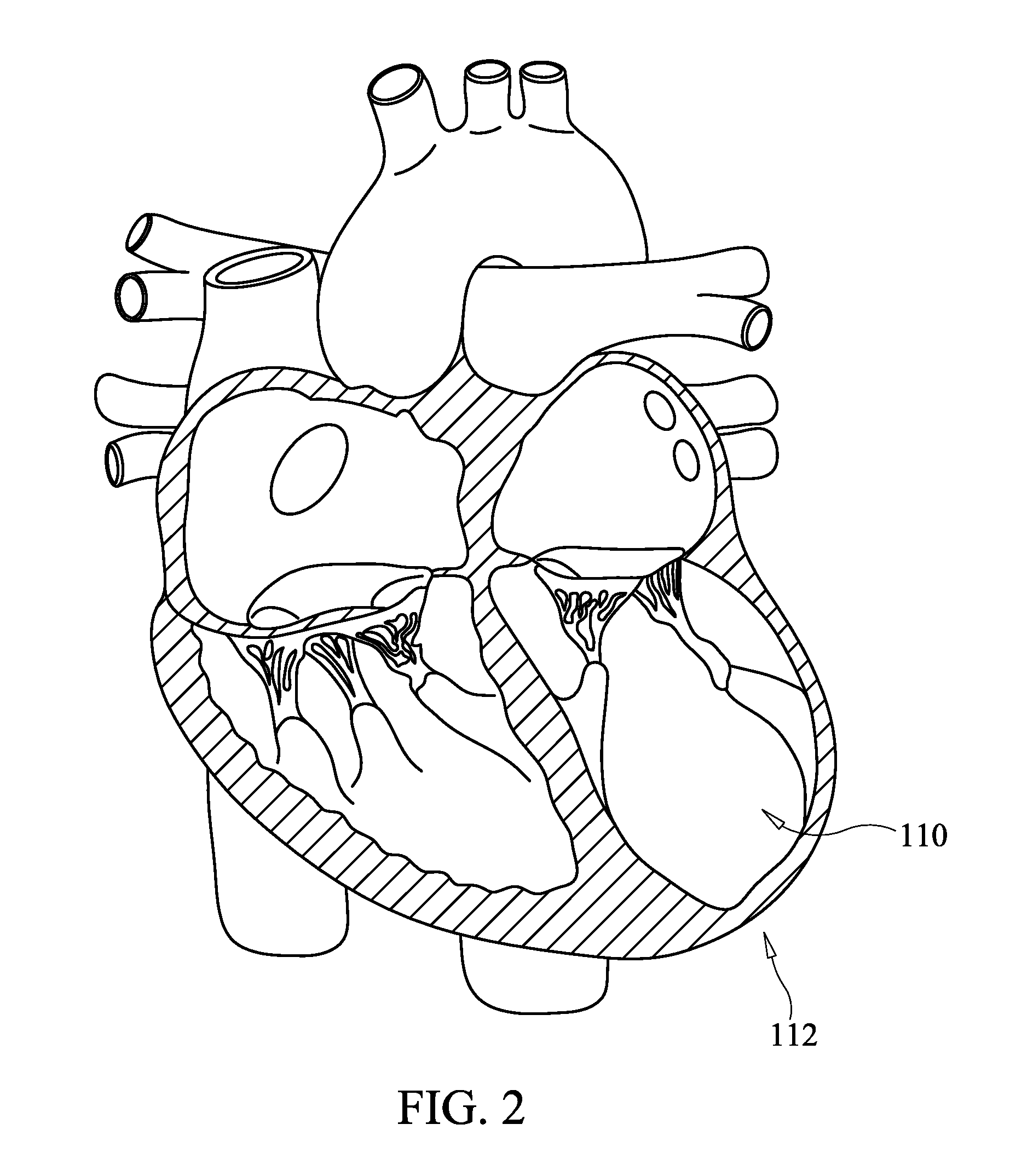

Method for percutaneous lateral access to the left ventricle for treatment of mitral insufficiency by papillary muscle alignment

InactiveUS20100210899A1Improve heart functionLower the volumeSuture equipmentsHeart valvesLeft ventricular sizePapillary muscle

This invention relates to devices and methods for the therapeutic changing of the geometry of the left ventricle of the human heart. Specifically, the invention relates to the left-ventricular lateral wall introduction of an anchoring device to align the papillary muscles.

Owner:TENDYNE MEDICAL

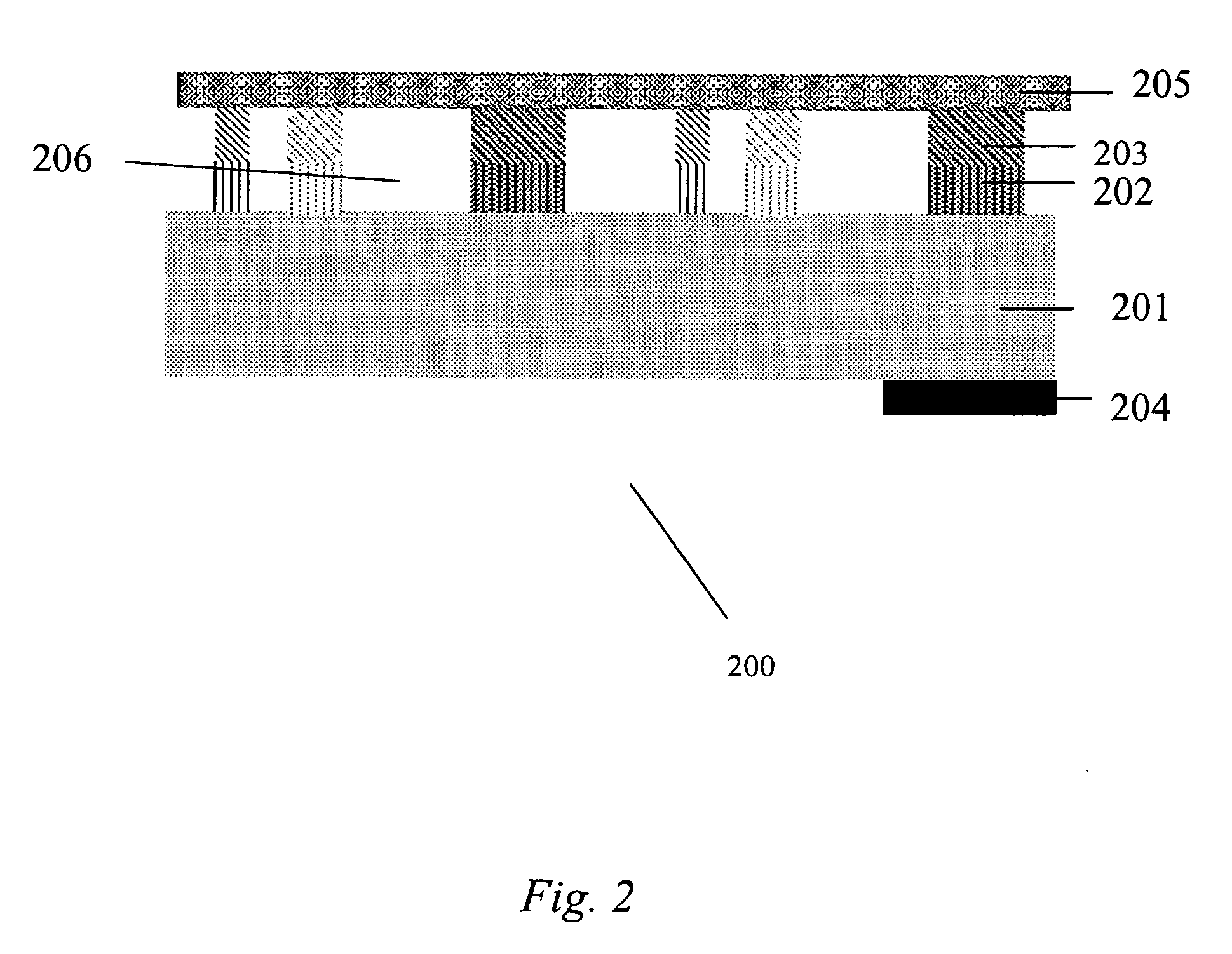

Monolithic light emitting devices based on wide bandgap semiconductor nanostructures and methods for making same

InactiveUS20050082543A1Reduce defectsSmall sizeLaser detailsLaser active region structureNanolithographyPhosphor

The present invention is directed toward a method for fabricating low-defect nanostructures of wide bandgap materials and to optoelectronic devices, such as light emitting sources and lasers, based on them. The invention utilizes nanolithographically-defined templates to form nanostructures of wide bandgap materials that are energetically unfavorable for dislocation formation. In particular, this invention provides a method for the fabrication of phosphor-less monolithic white light emitting diodes and laser diodes that can be used for general illumination and other applications.

Owner:GENERAL ELECTRIC CO

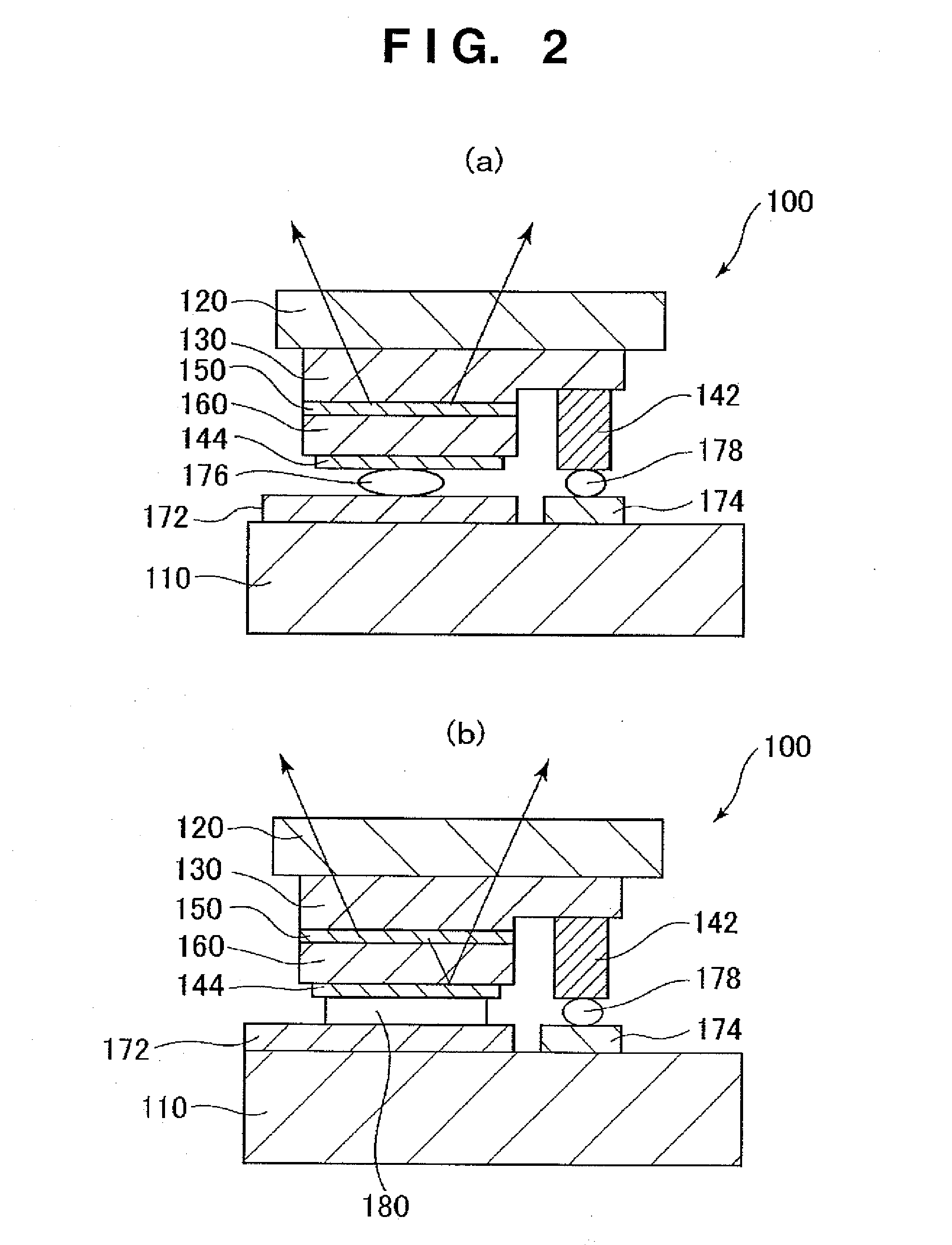

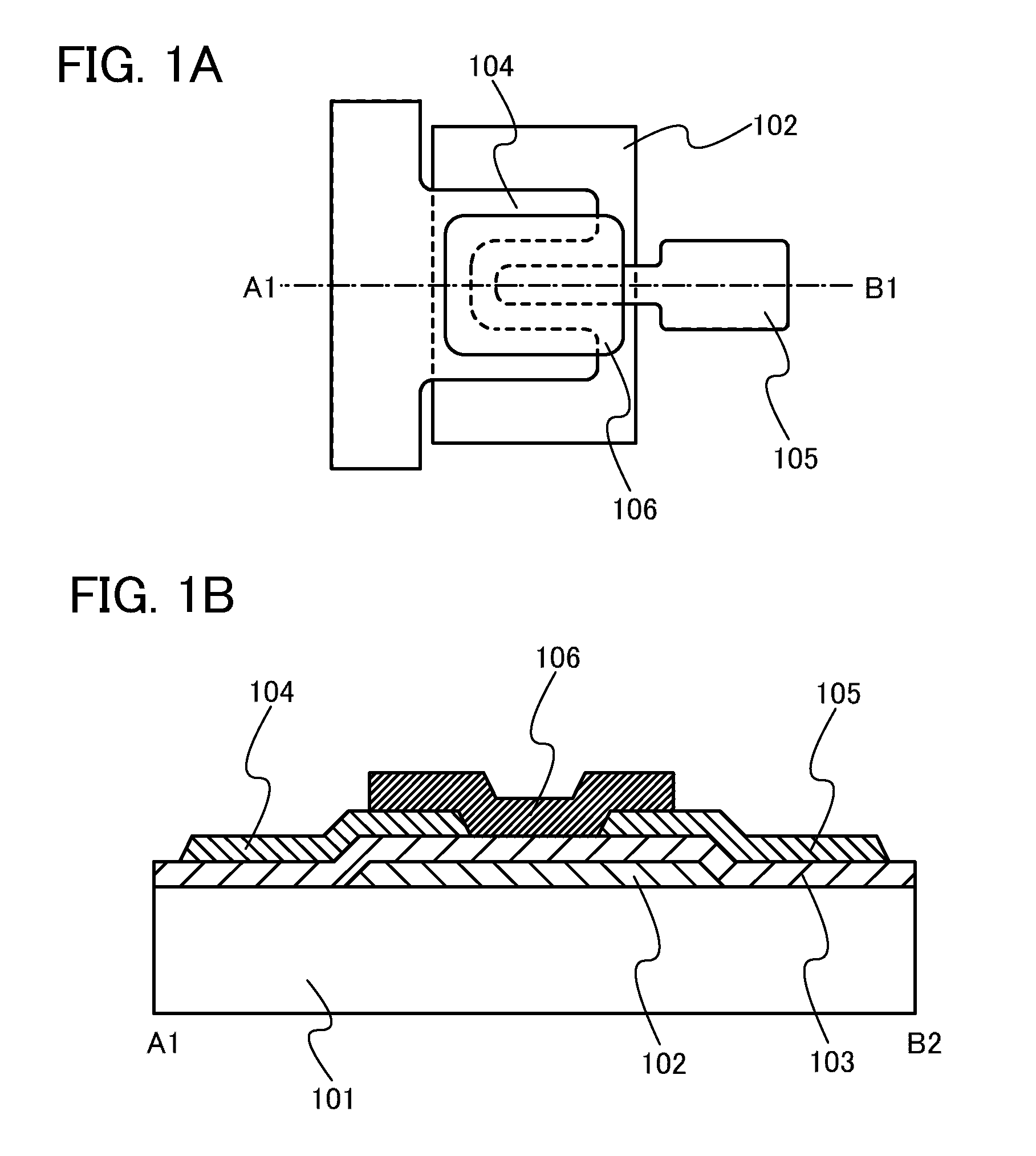

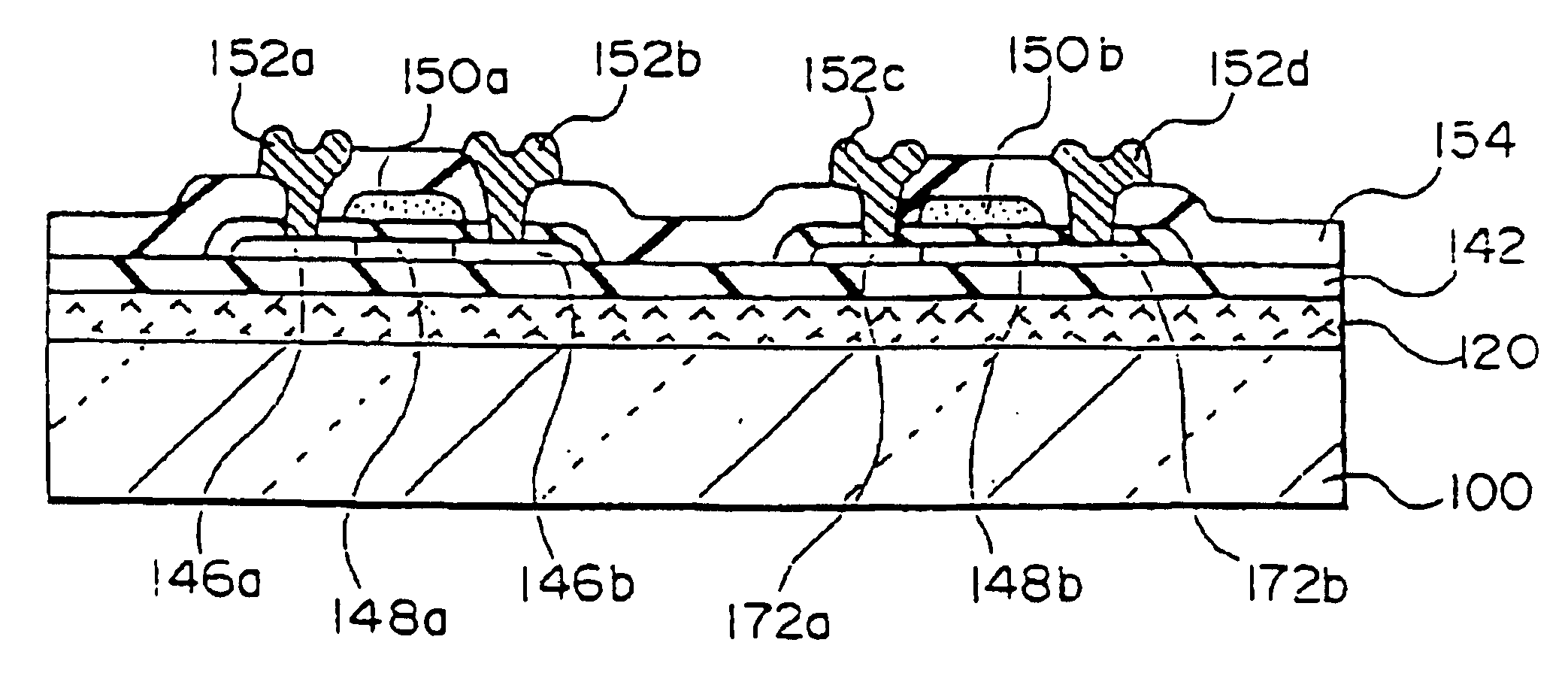

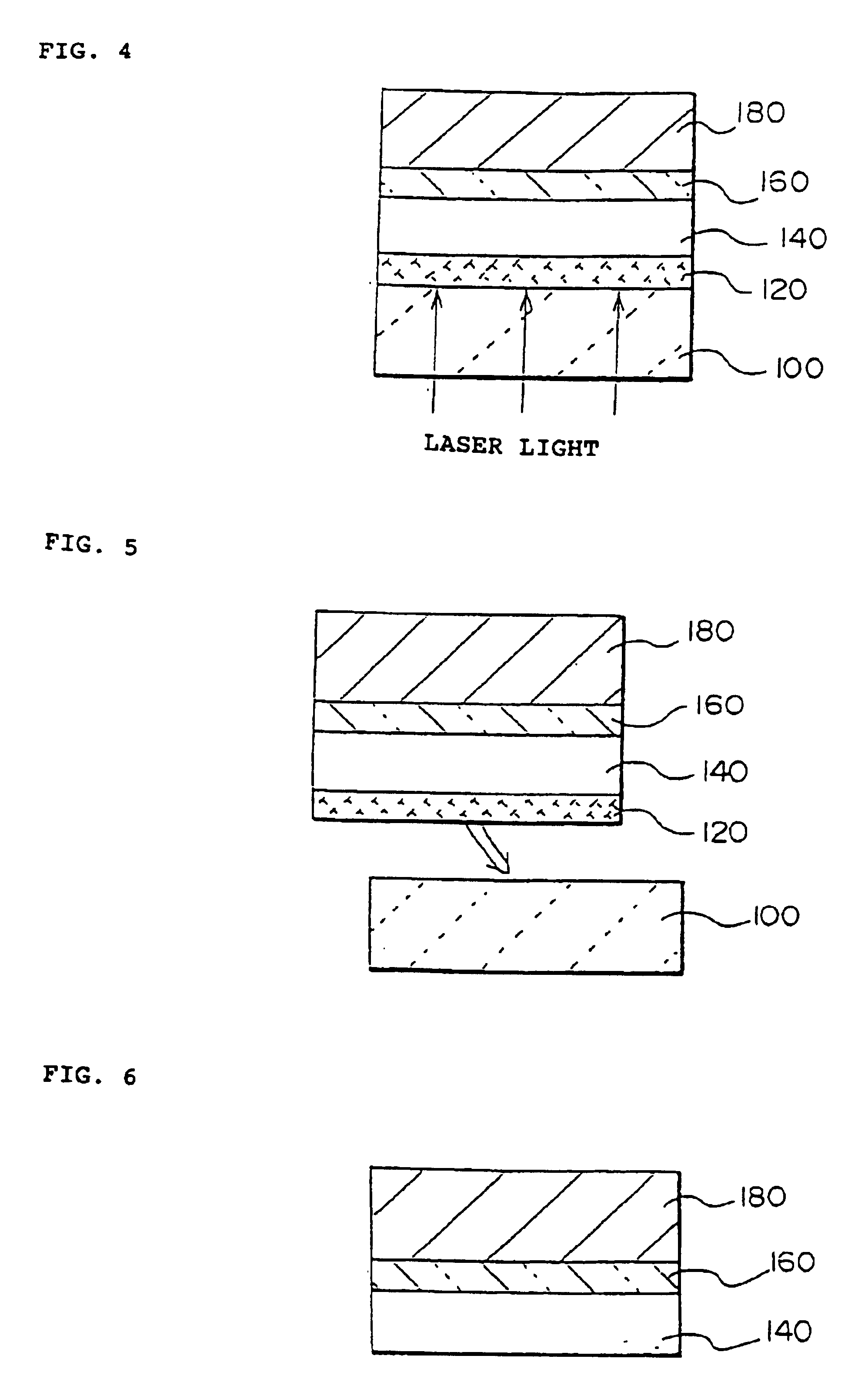

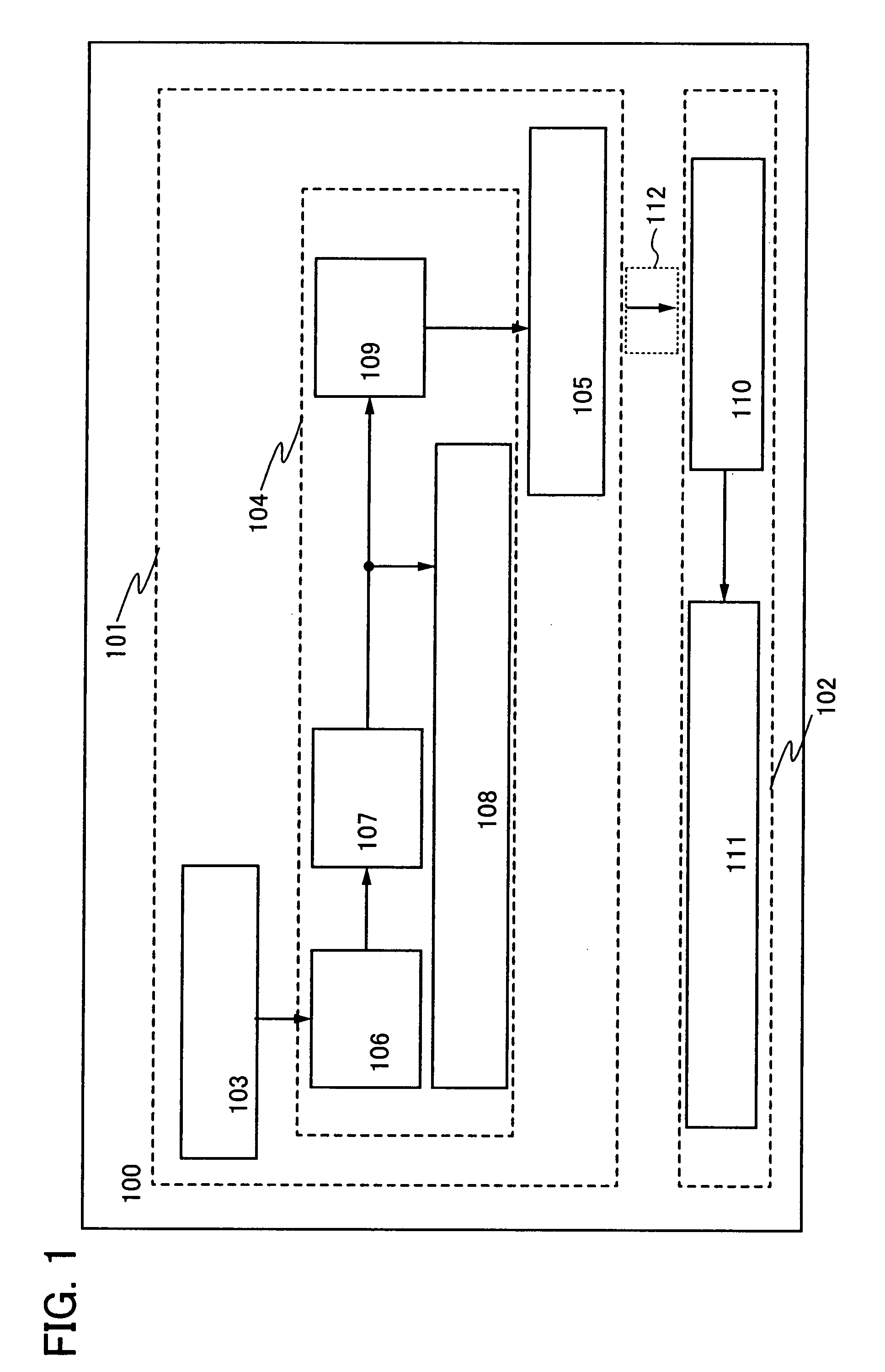

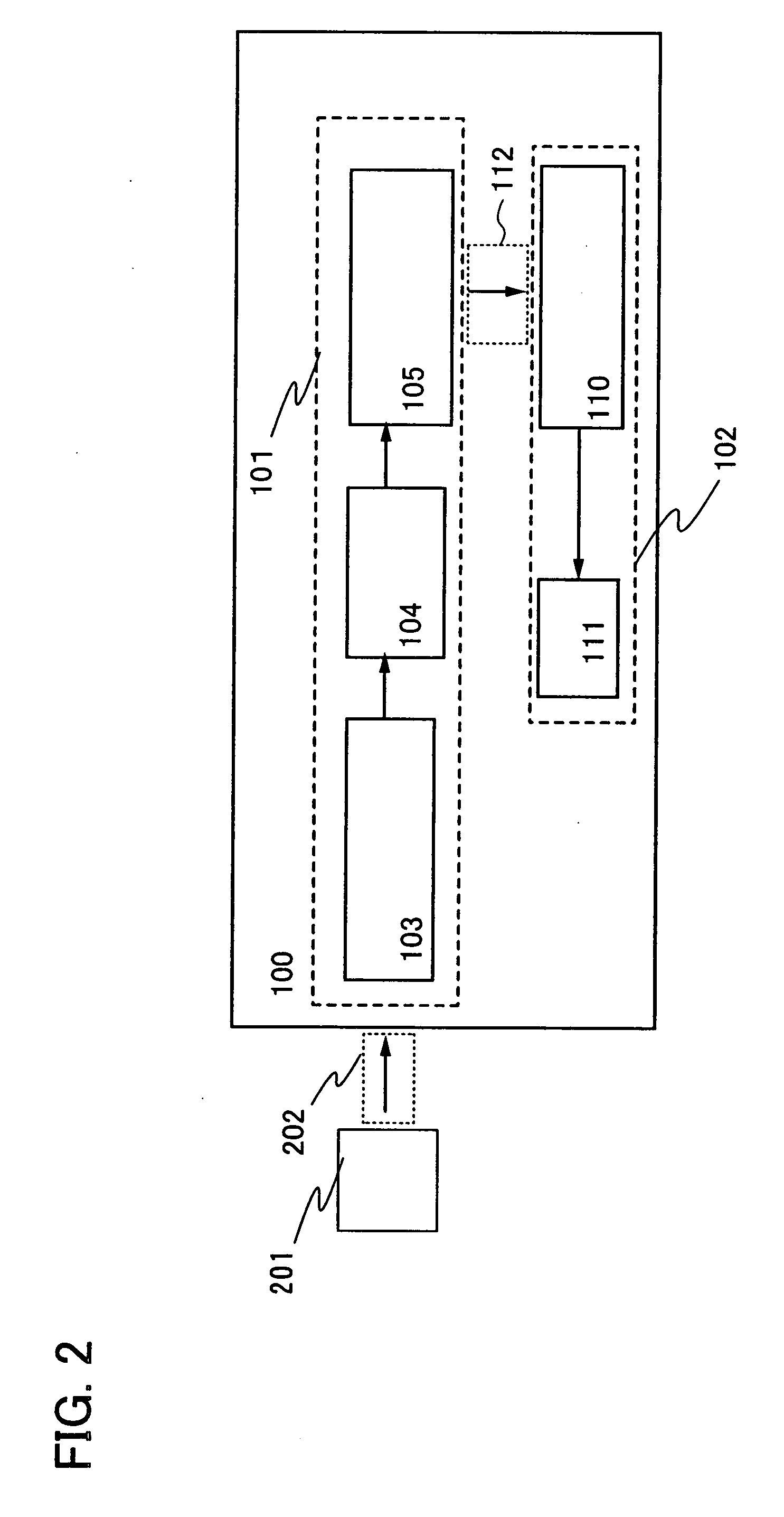

Method of separating thin film device, method of transferring thin film device, thin film device, active matrix substrate and liquid crystal display device

InactiveUS6885389B2Quantity of light is reducedInhibit deteriorationTransistorSolid-state devicesHydrogenLiquid-crystal display

A separation layer is provided on a substrate, and a thin film device, such as TFT, is formed thereon. Separation accelerating ions such as hydrogen ions are implanted into the separation layer in the course of the process for forming the thin film device. After the formation of the thin device, the thin film device is preferably joined to a transfer material through an adhesive layer, and irradiated with laser light from the substrate side. This causes separation in the separation layer by also using the action of the separation acceleration ions. The thin film device is separated from the substrate. This permits transfer of a desire thin film device to any substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

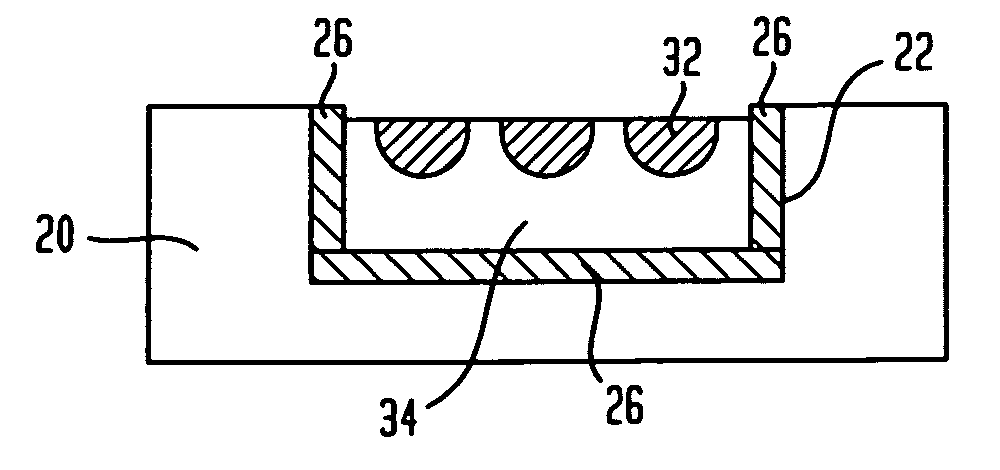

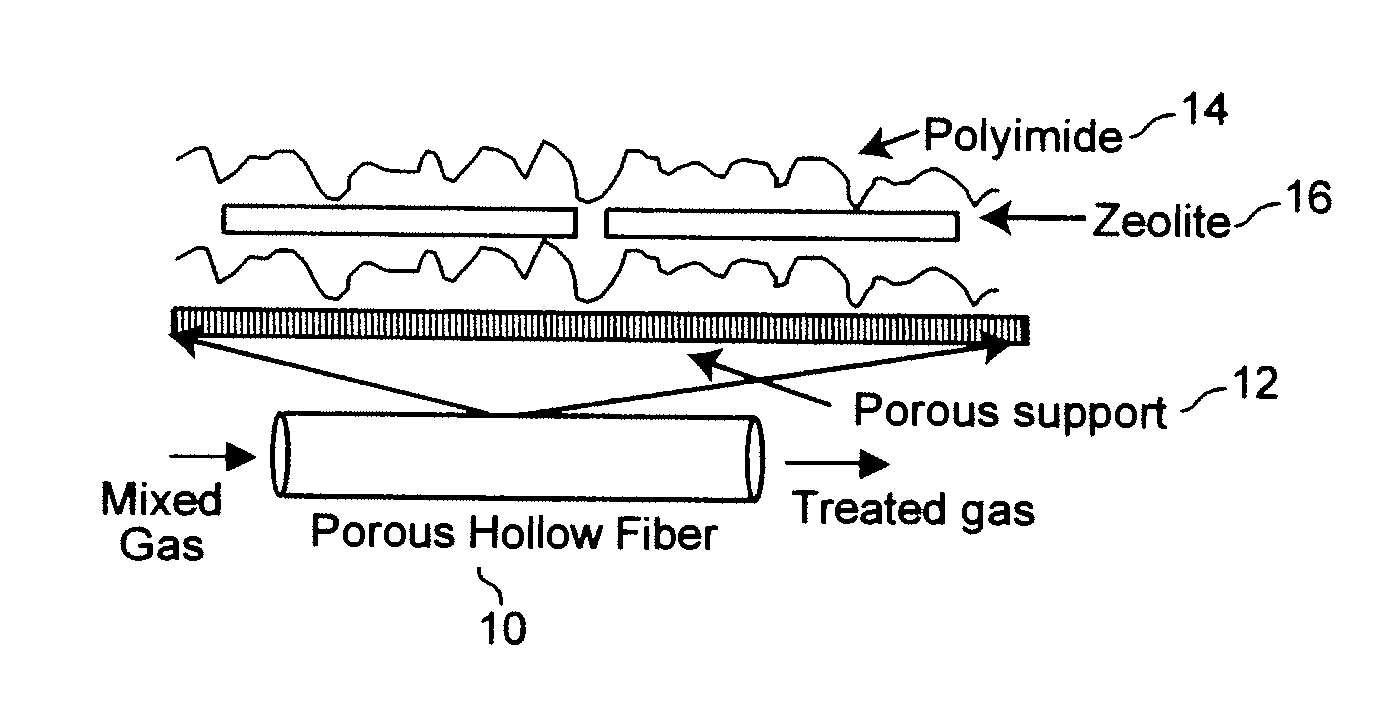

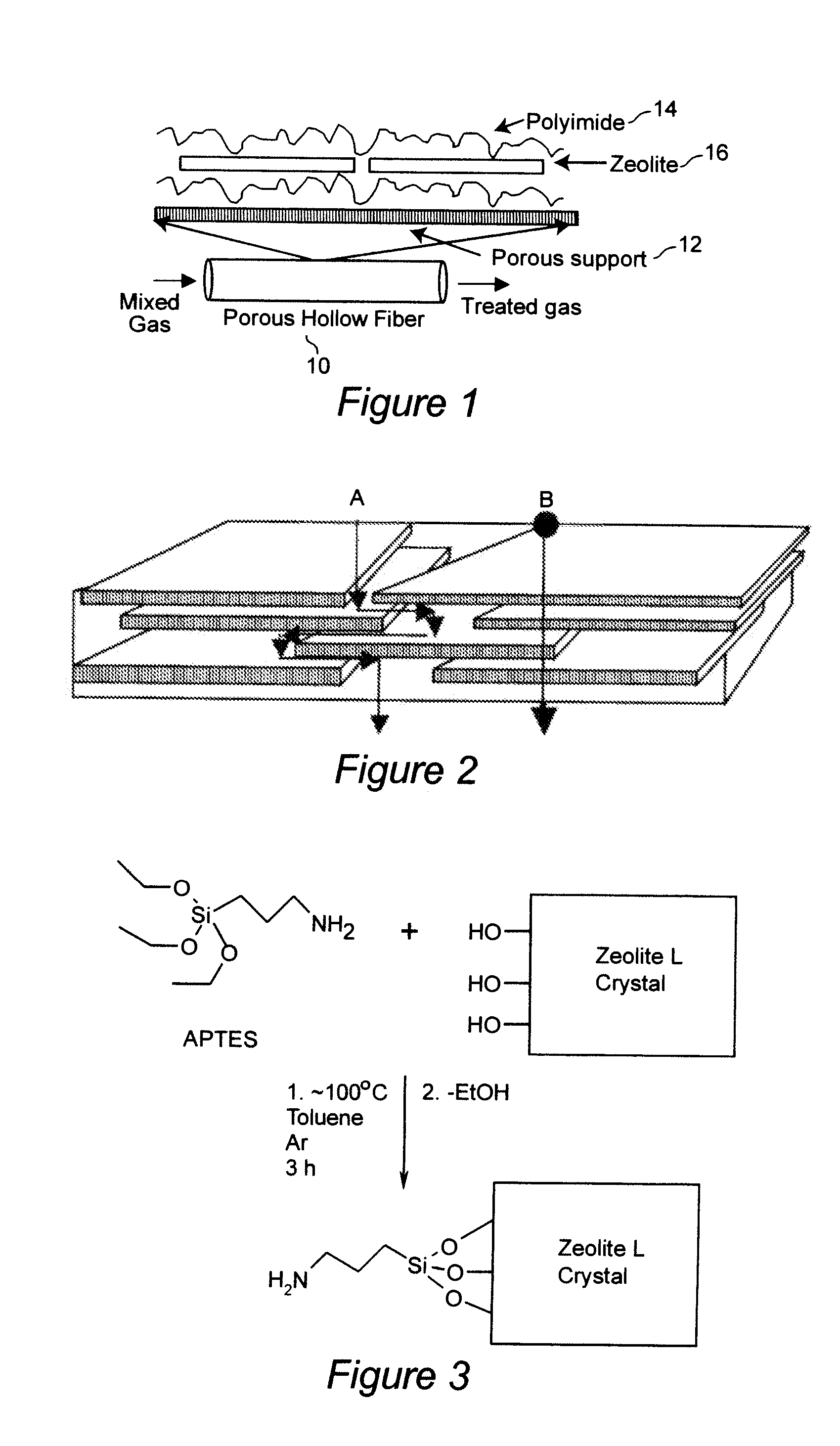

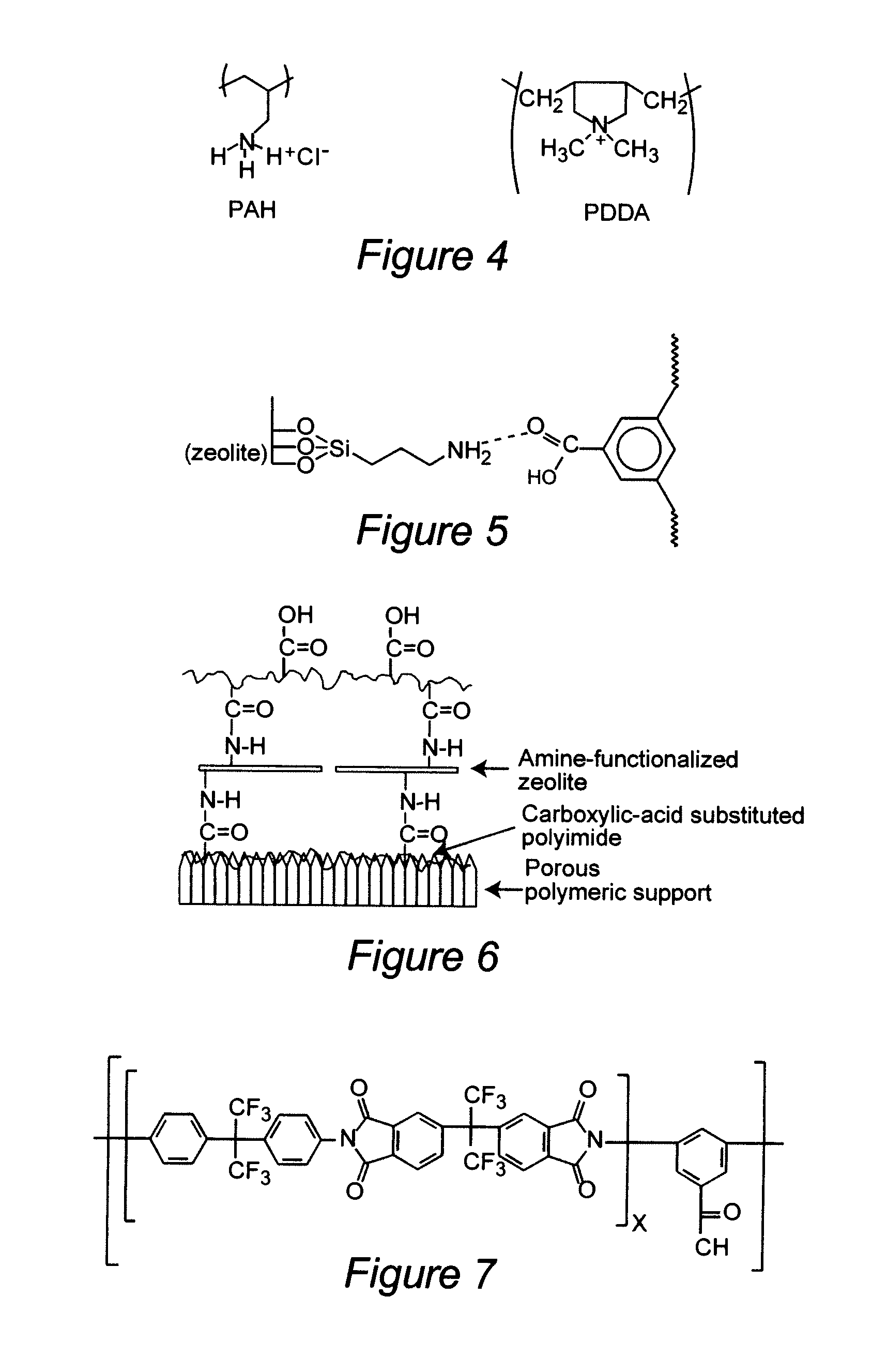

Ordered mesopore silica mixed matrix membranes, and production methods for making ordered mesopore silica mixed matric membranes

InactiveUS20070022877A1Enhanced interactionEffectively incorporated into polymer structureSemi-permeable membranesOrganic-compounds/hydrides/coordination-complexes catalystsMesoporous silicaSilicon dioxide

Mixed matrix membranes are prepared from mesoporous silica (and certain other silica) and membrane-forming polymers (such as polysulfone), in a void free fashion where either no voids or voids of less than 100 angstroms are present at the interface of the membrane-forming polymer and the silica. Such silica-containing mixed matrix membranes are particularly useful for their selectivity (such as carbon dioxide selectivity) and permeability. Methods for separating carbon dioxide are provided.

Owner:VIRGINIA TECH INTPROP INC

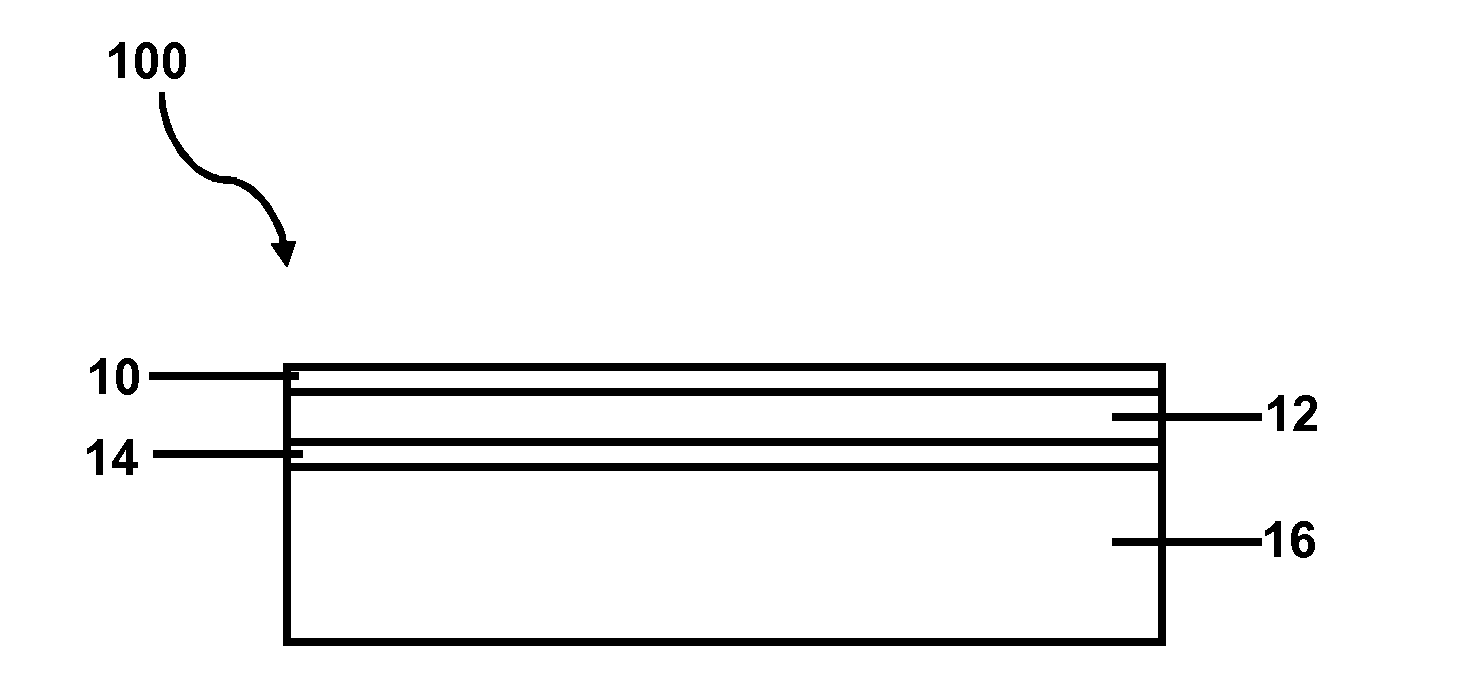

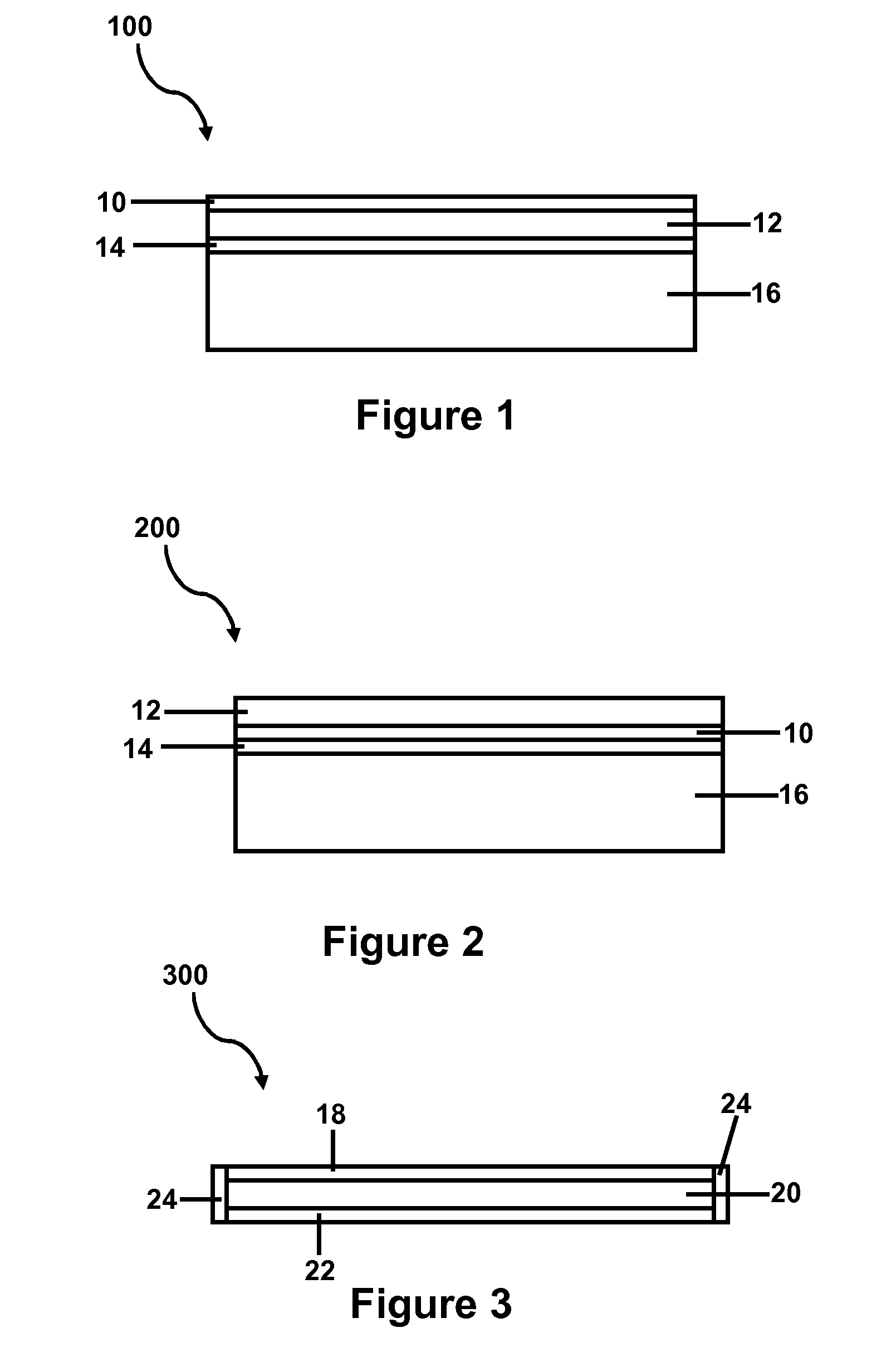

Glass laminated articles and layered articles

ActiveUS20090297806A1Reduce defectIncrease clarityRecord information storageLight beam reproducingElectrochromic devicesPolymer science

Laminated articles and layered articles, for example, low alkali glass laminated articles and layered articles useful for, for example, electrochromic devices are described.

Owner:CORNING INC

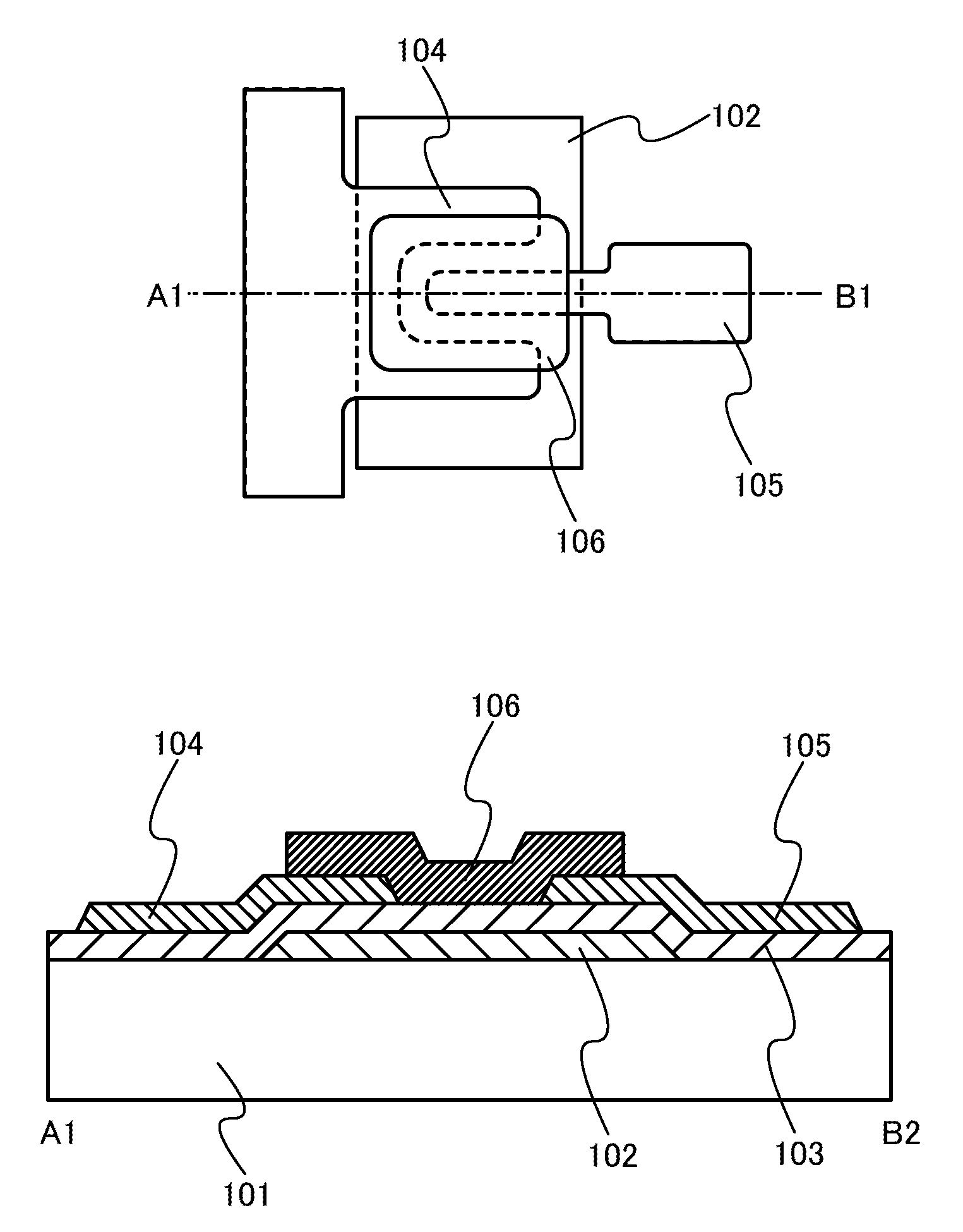

Sensor arrangement

ActiveUS8386009B2Easy to manufactureReduce defectsElectrotherapyBioelectric signal measurementElectrical conductorEngineering

A sensor for measuring a physiological signal and a method for manufacturing such a sensor. Such a sensor includes a flexible substrate and at least one electrode, which has a signalling surface, which faces in the same direction as the first surface of the flexible substrate. In addition, the sensor includes a signal transmission conductor, which is connected electrically to the electrode. The signal transmission conductor is attached in a watertight manner to the second surface of the substrate. The sensor is reliable, economical to manufacture, and comfortable to the user.

Owner:SUUNTO OY

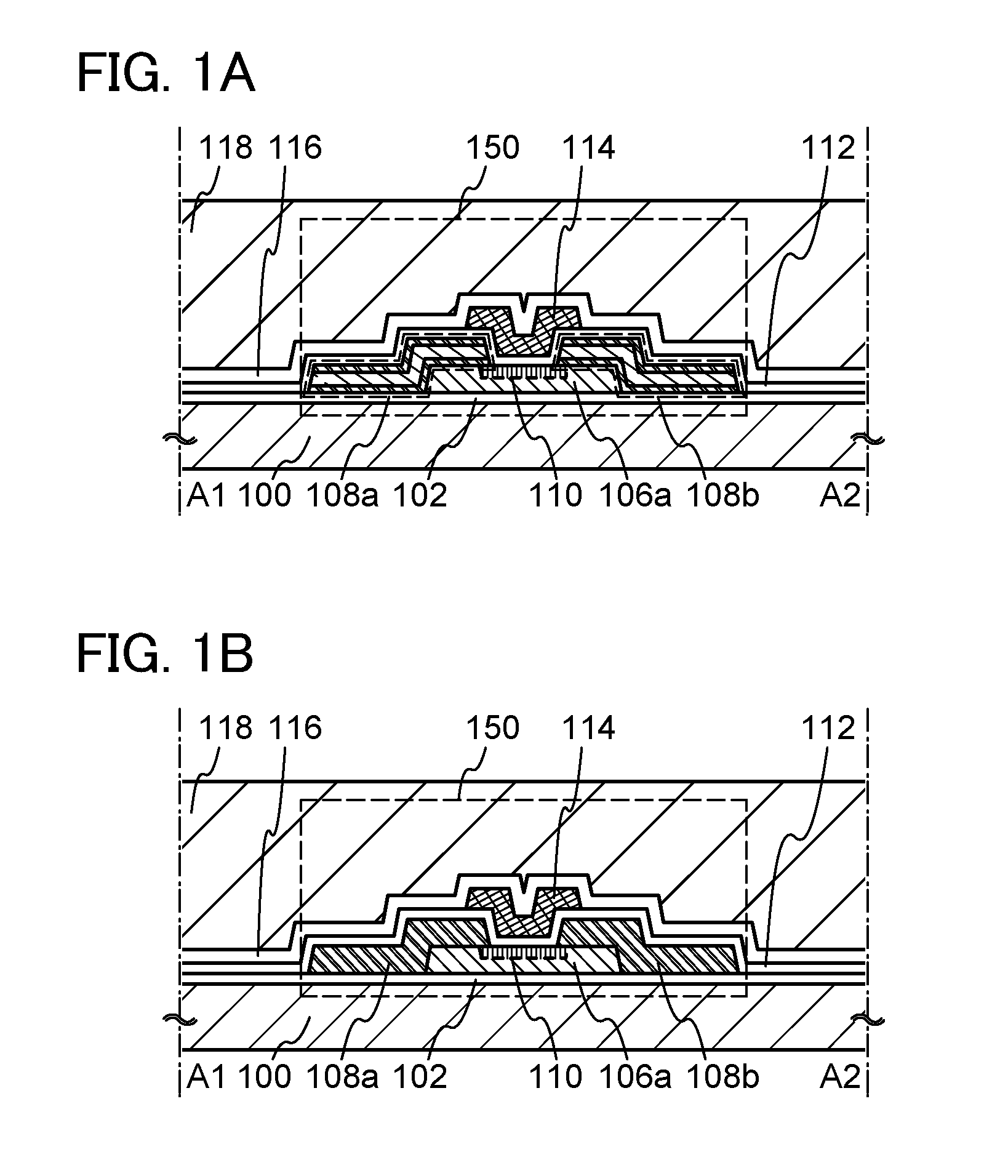

Semiconductor device and manufacturing method thereof

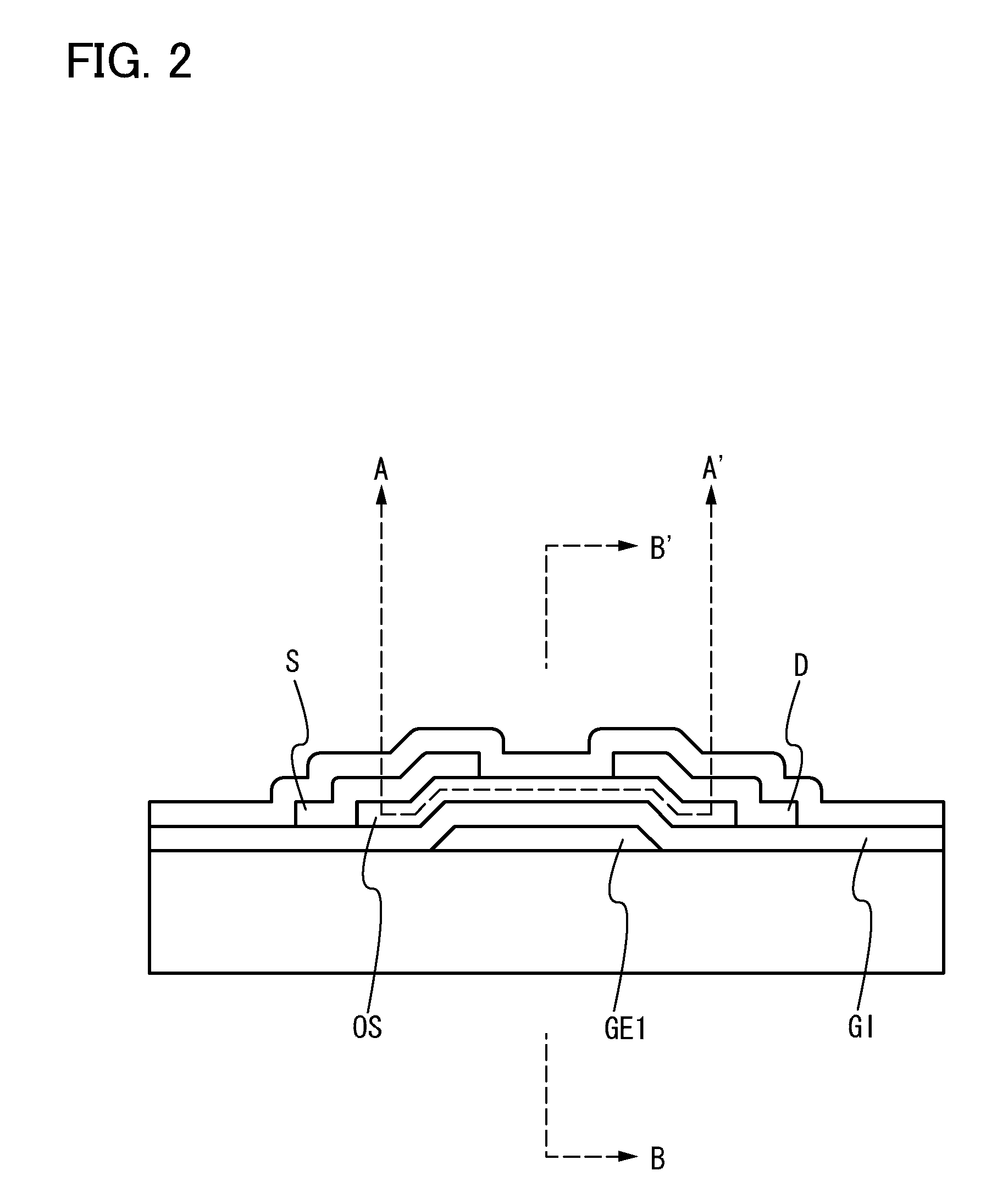

ActiveUS20110133191A1Improve insulation performanceExcellent electrical propertiesTransistorSolid-state devicesDevice materialSemiconductor

A semiconductor device includes an oxide semiconductor layer including a crystalline region over an insulating surface, a source electrode layer and a drain electrode layer in contact with the oxide semiconductor layer, a gate insulating layer covering the oxide semiconductor layer, the source electrode layer, and the drain electrode layer, and a gate electrode layer over the gate insulating layer in a region overlapping with the crystalline region. The crystalline region includes a crystal whose c-axis is aligned in a direction substantially perpendicular to a surface of the oxide semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

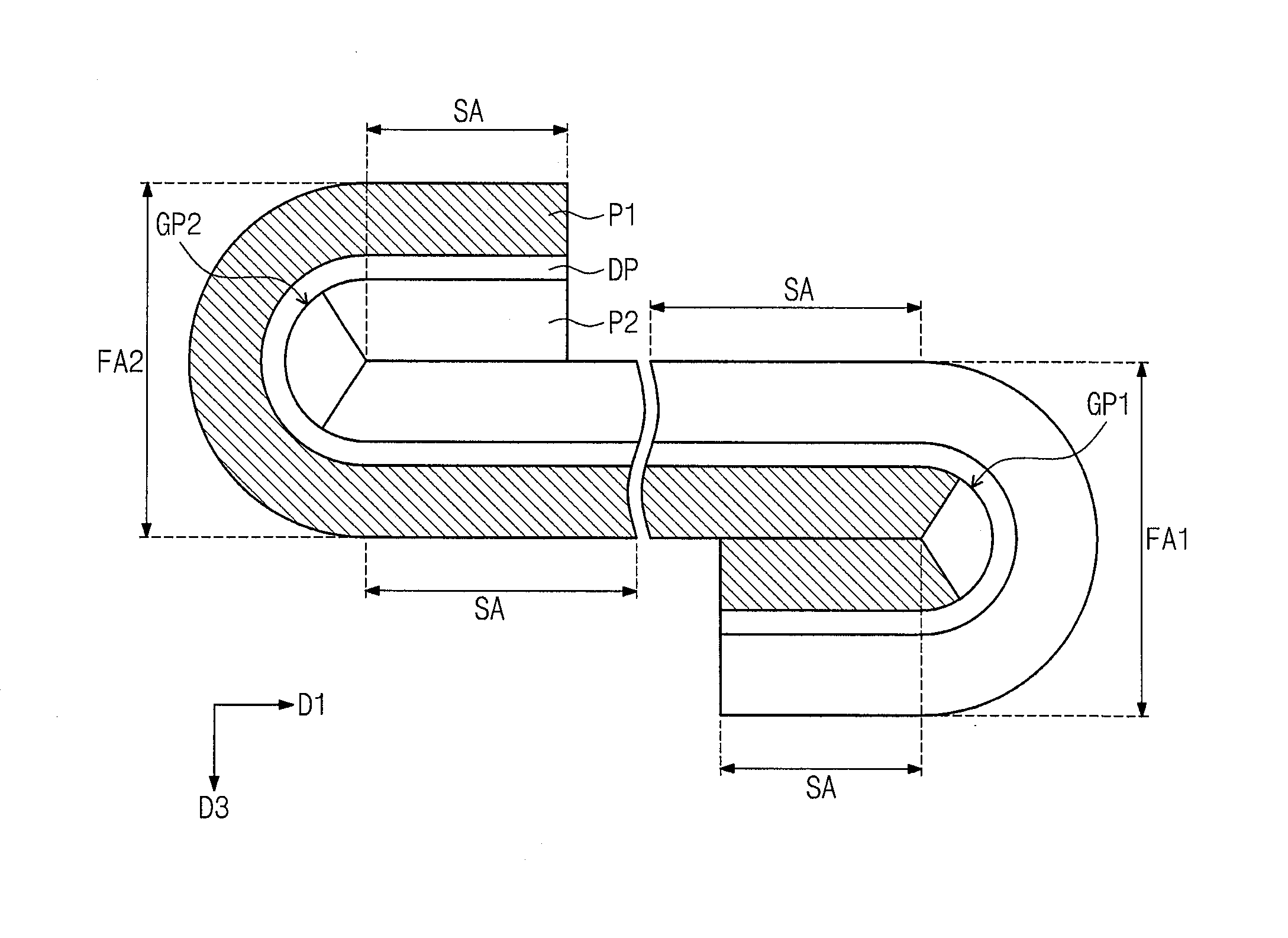

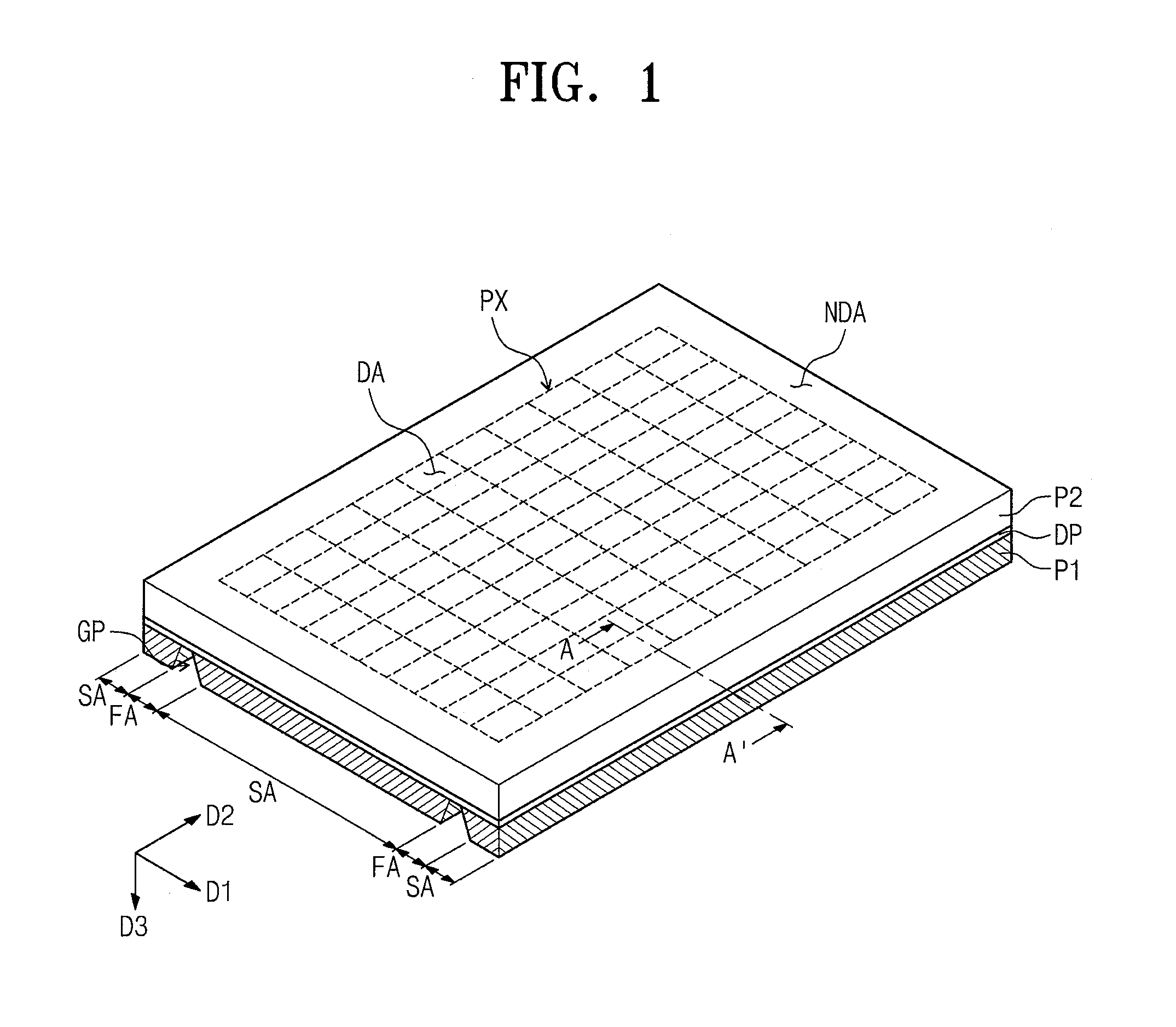

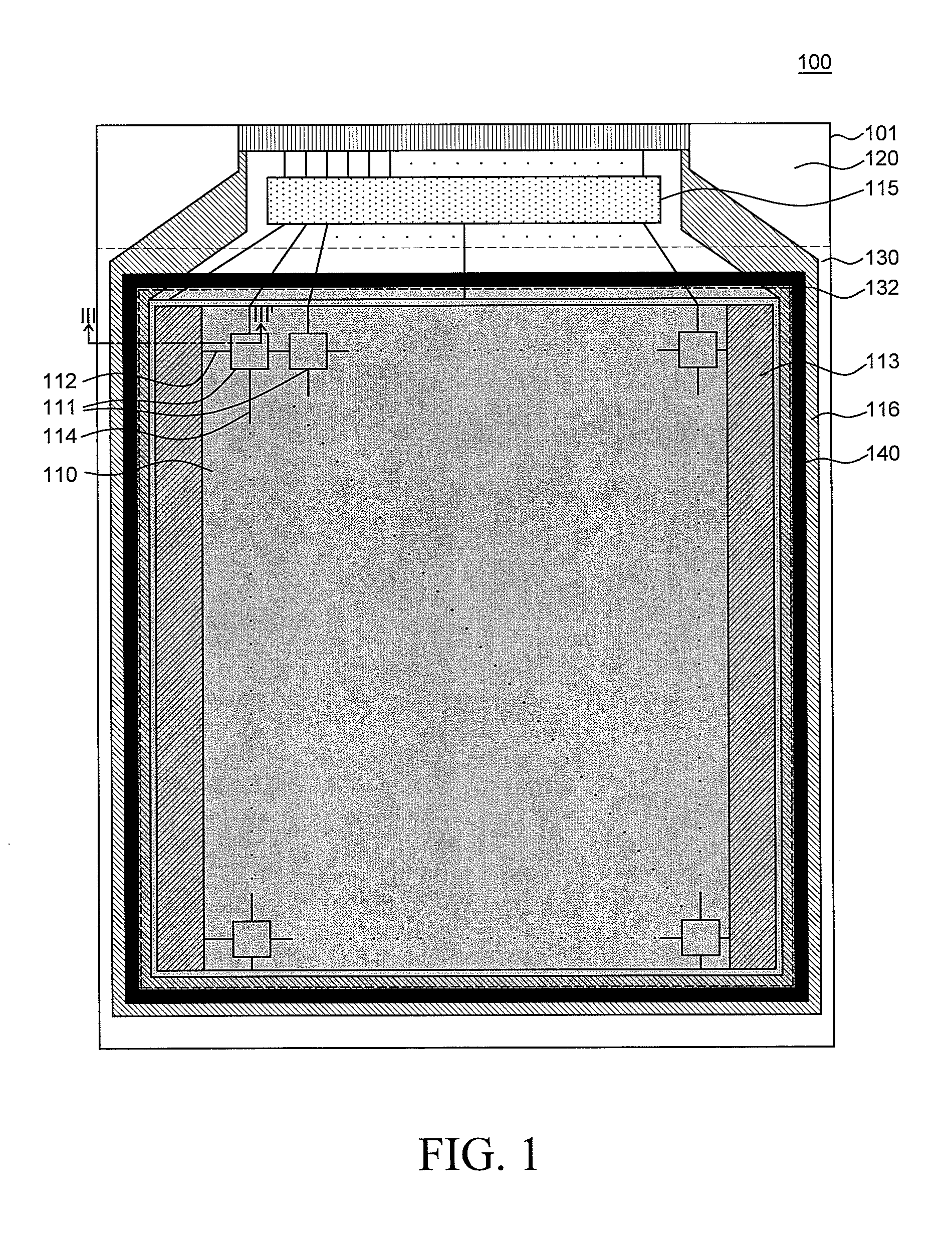

Flexible display device

ActiveUS20150146386A1Avoid crackingReduce the amount requiredPrinted circuit detailsPrinted circuit aspectsEngineeringFlexible display

A flexible display device including a flexible display panel including a folding area and a peripheral area, and a first outer member including a groove pattern is disclosed. The groove pattern includes a flat surface and inclined portions connected to the flat surface and symmetrical with each other about the flat surface.

Owner:SAMSUNG DISPLAY CO LTD

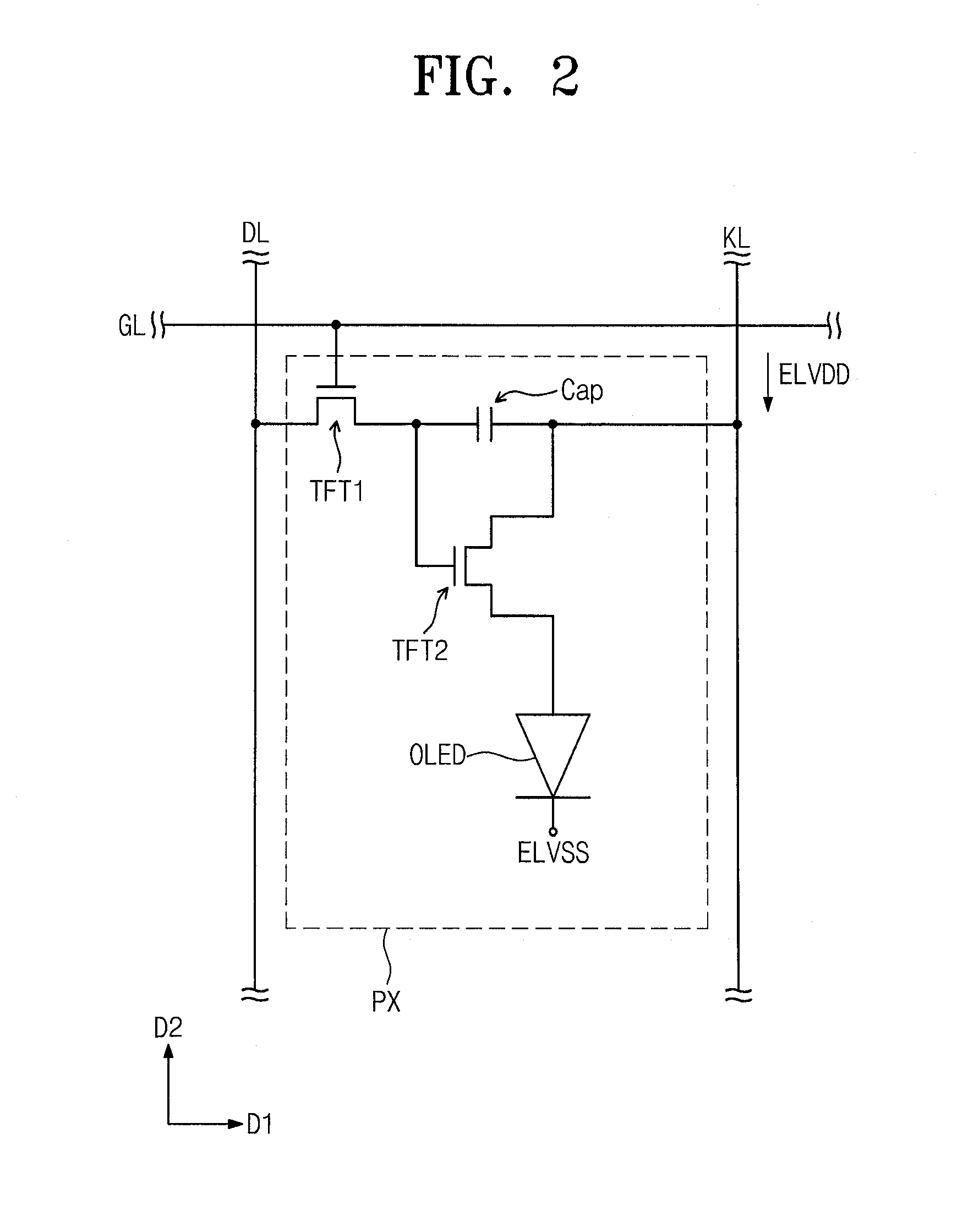

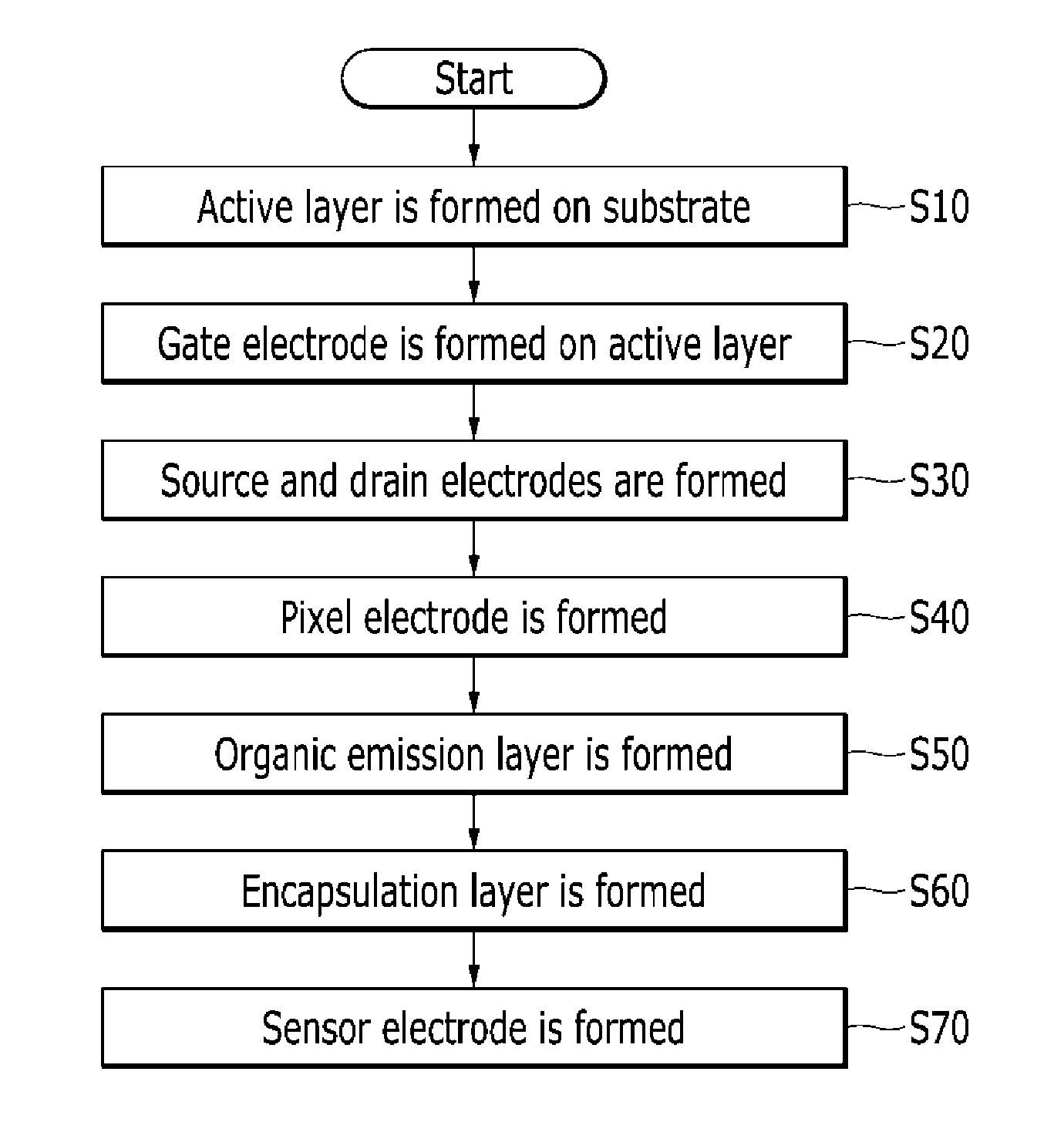

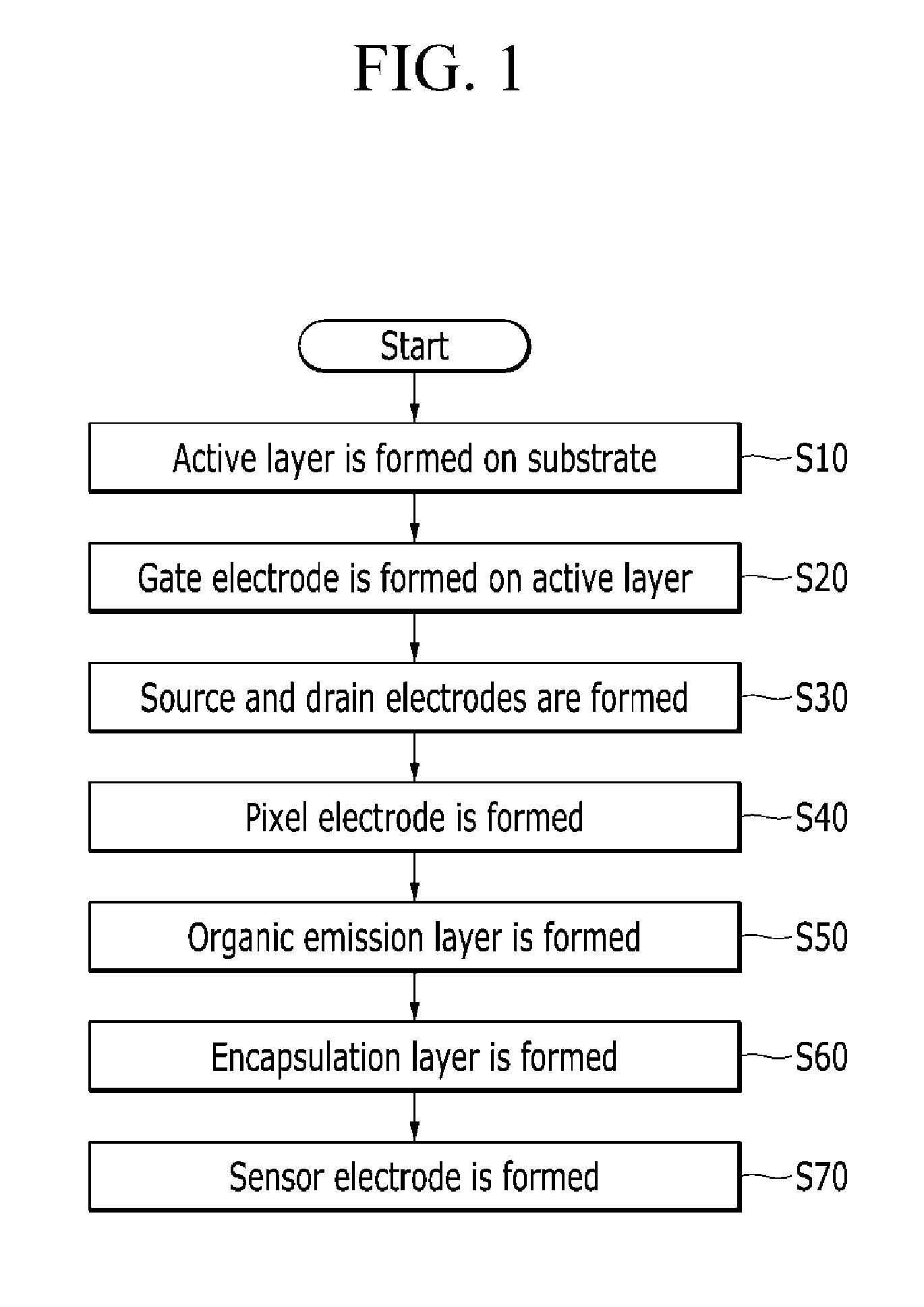

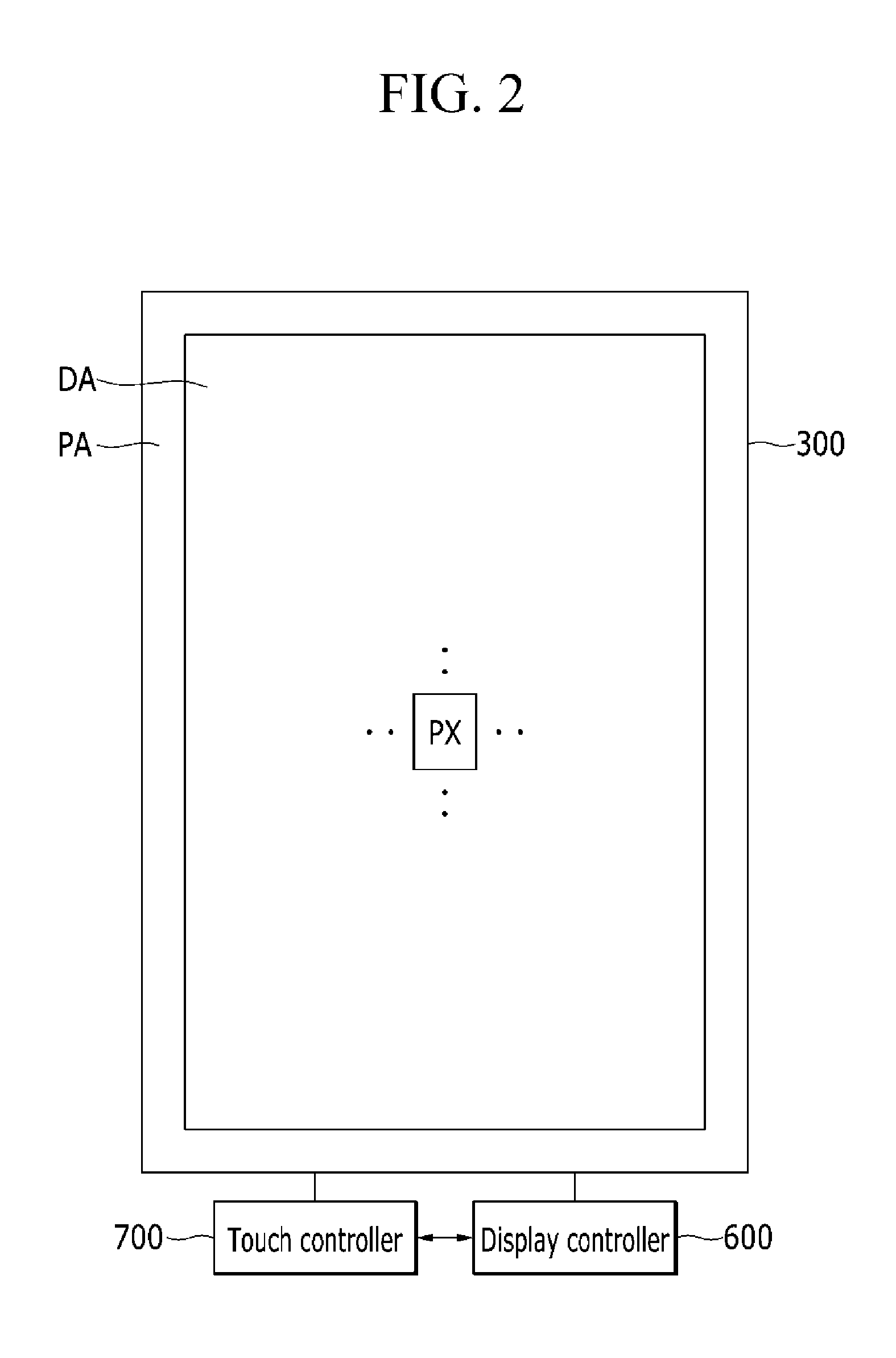

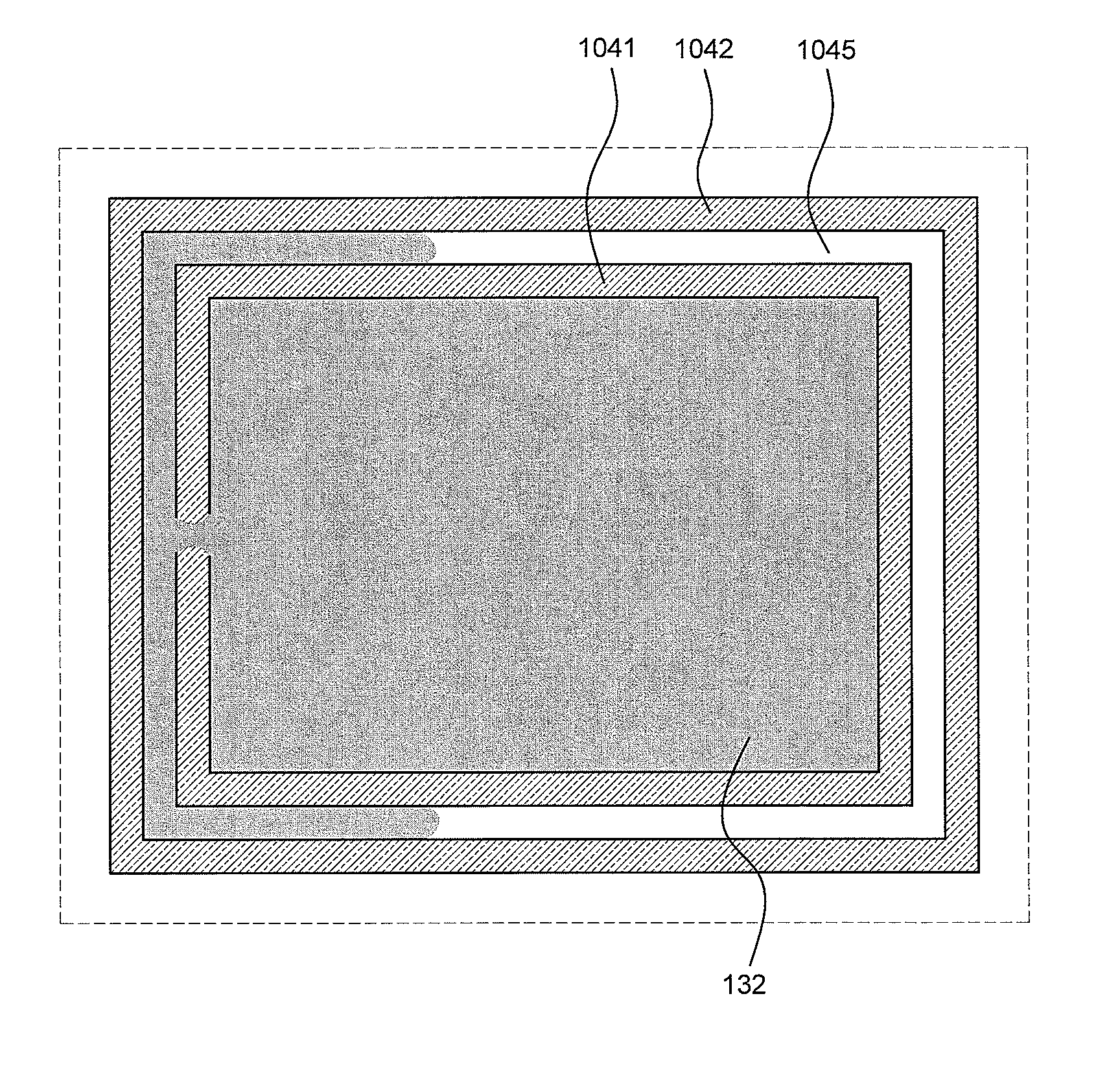

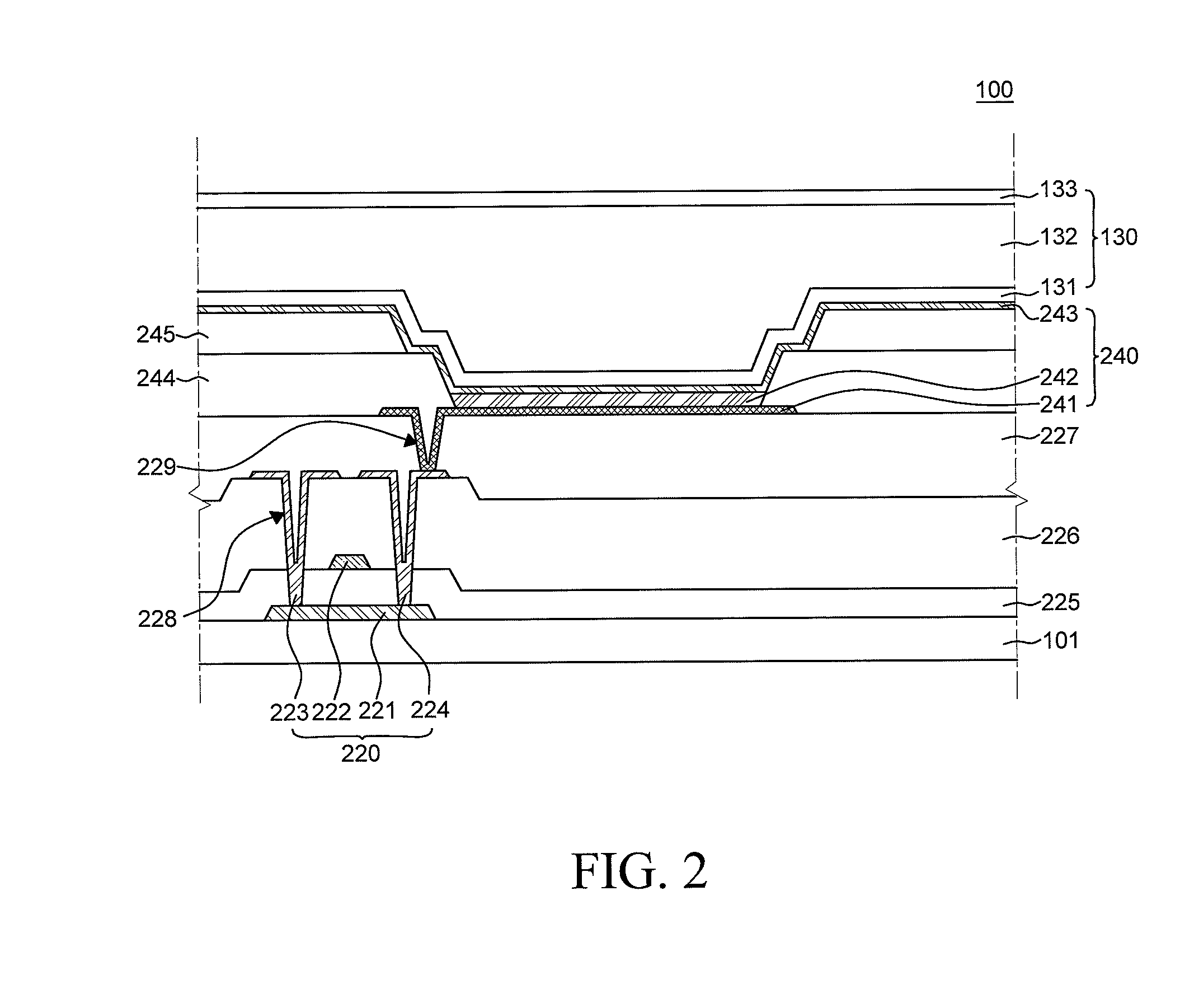

Display device including touch sensing sensor

ActiveUS20160154499A1Simple manufacturing processReduce manufacturing costInput/output processes for data processingTouch SensesDisplay device

A display device includes: a substrate; a pixel driving circuit disposed in a first region on the substrate; an encapsulation layer disposed on the pixel driving circuit; a touch sensing layer formed on the encapsulation layer and including a touch sensing sensor; and a touch-driving layer including a touch driving circuit disposed in a second region on the substrate, integrally formed with the pixel driving circuit, and electrically connected to the touch sensing sensor to apply a signal thereto.

Owner:SAMSUNG DISPLAY CO LTD

Organic light emitting display apparatus

ActiveUS20150380685A1Reduce liquidityEasy to crackSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsGate driver

An organic light-emitting display (OLED) device includes: a pixel area defined by a plurality of pixels on a flexible substrate; a non-pixel area around the pixel area; a gate driver in the non-pixel area; a structure in the non-pixel area configured to surround the pixel area; a first encapsulation layer covering the plurality of pixels, the gate driver and the structure; and a particle cover layer covering the pixel area and suppressed from being excessively spread by the structure.

Owner:LG DISPLAY CO LTD

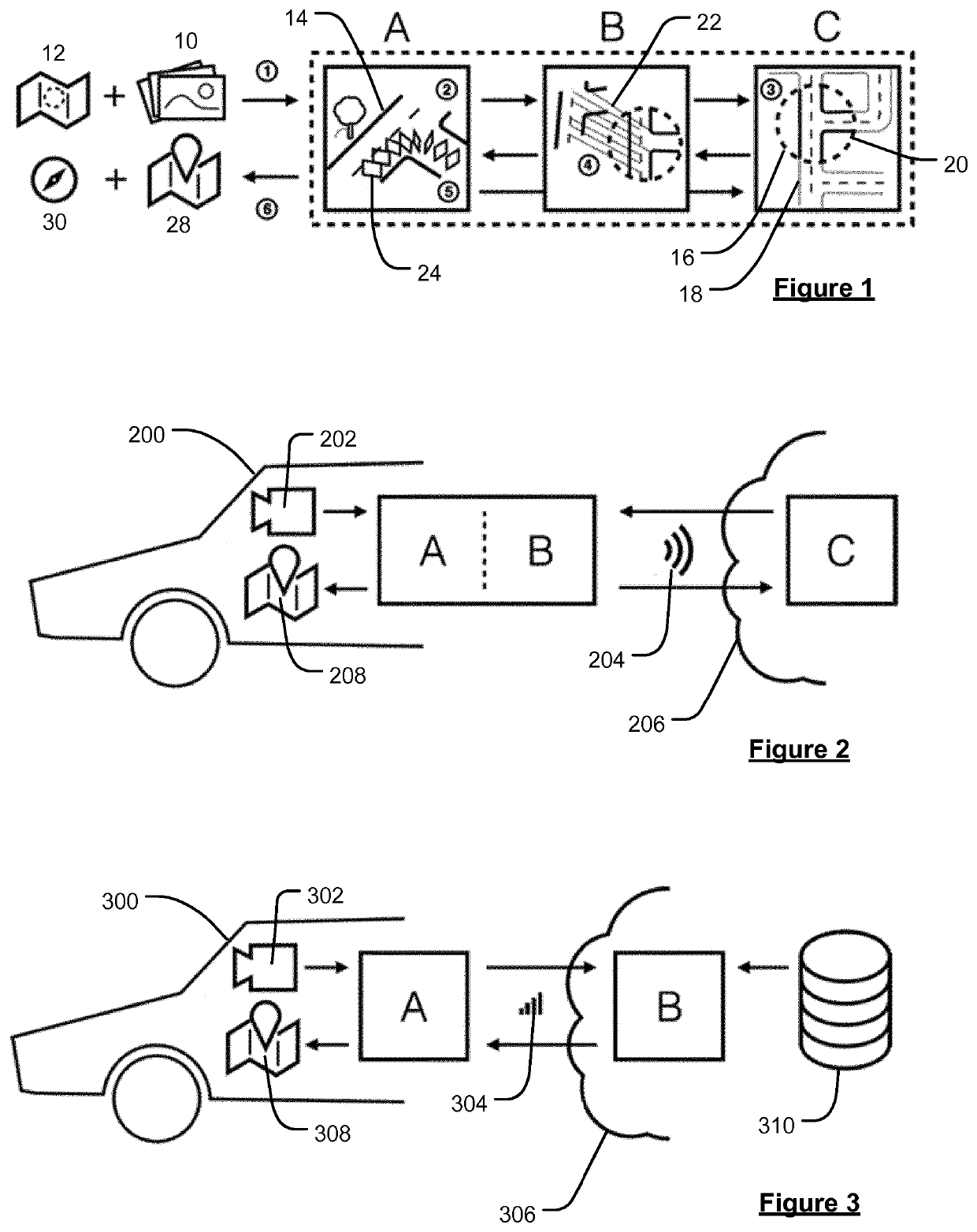

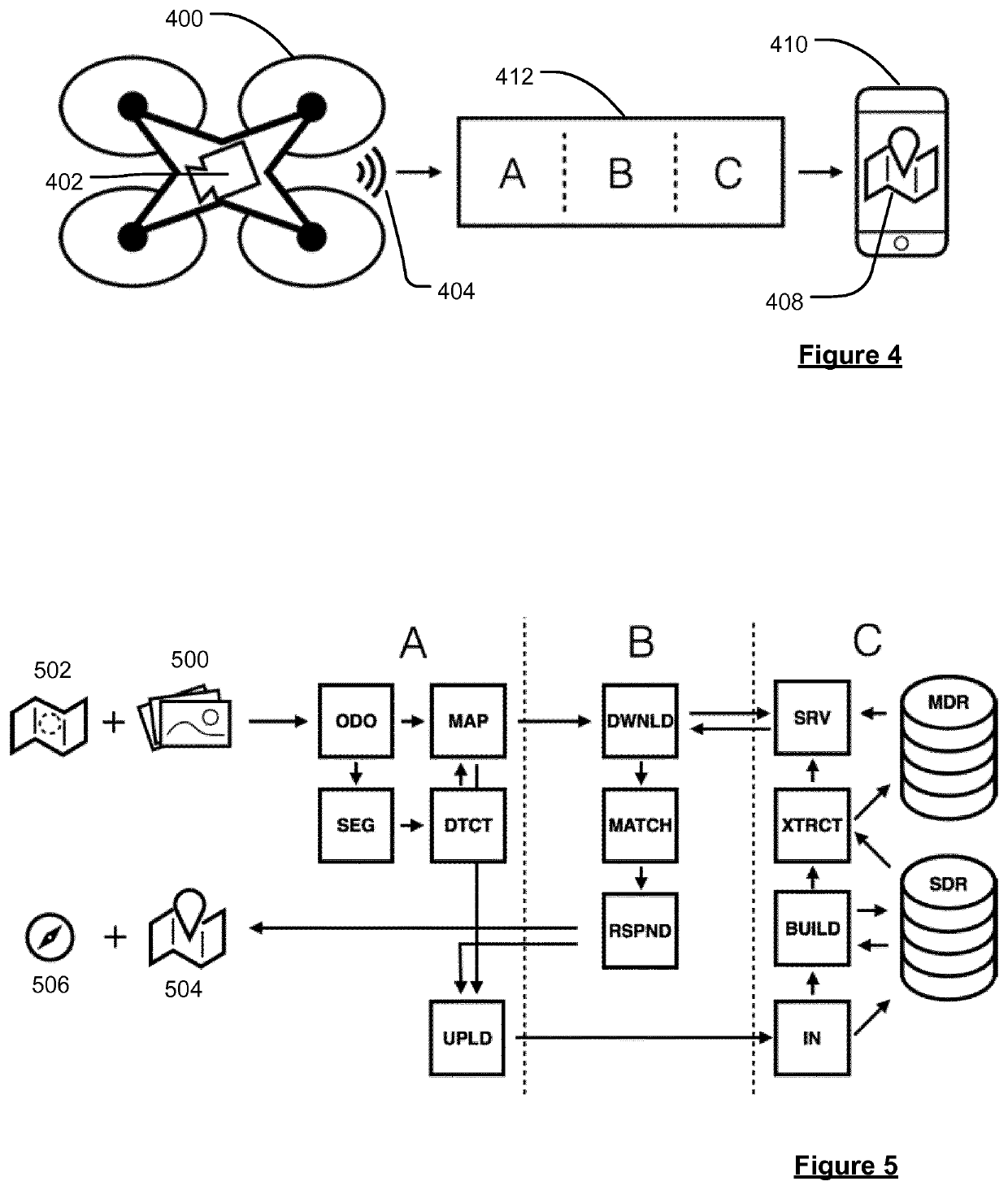

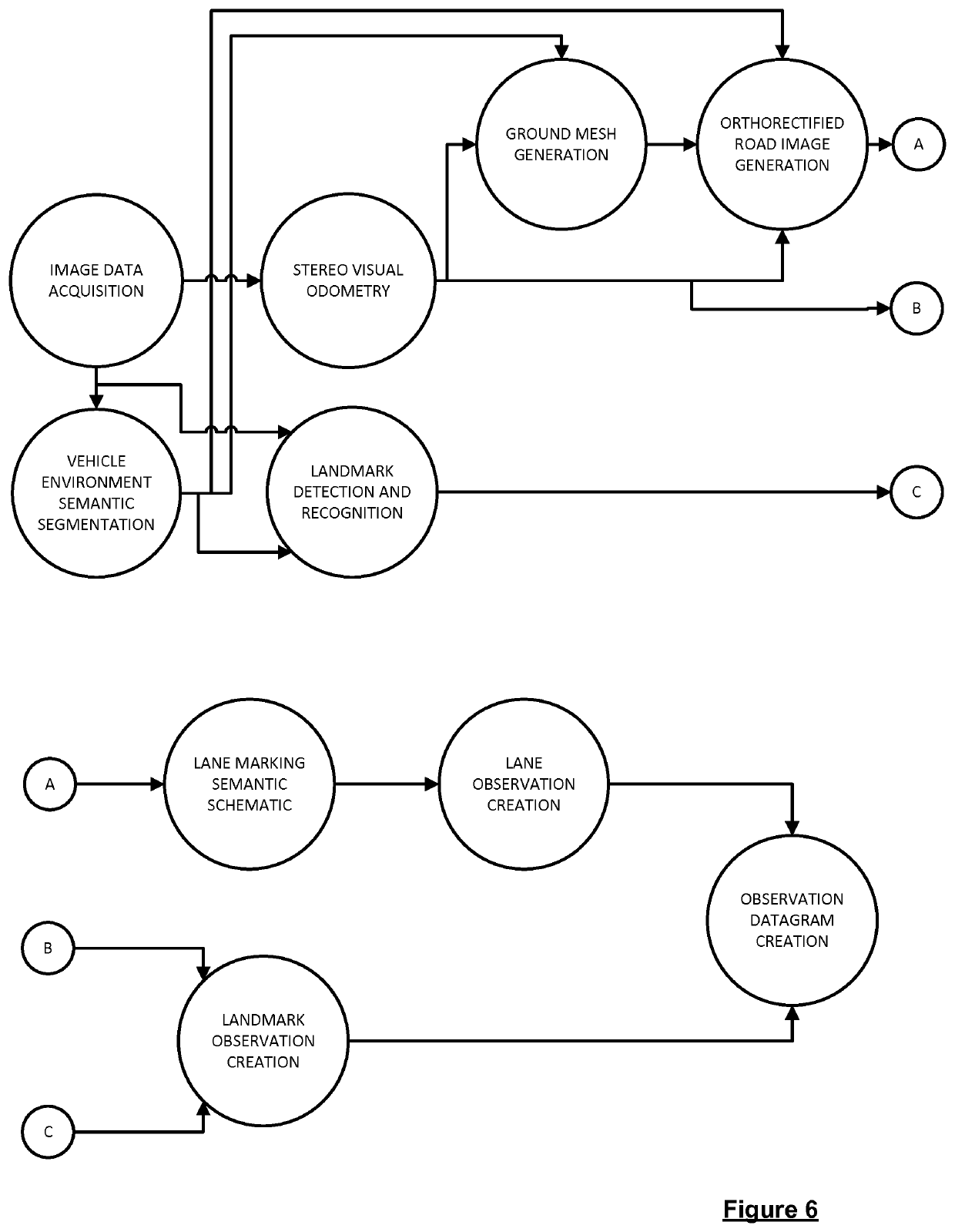

Method and System for Video-Based Positioning and Mapping

PendingUS20200098135A1Accurately identifyReliably detectImage enhancementInstruments for road network navigationImage representationElectronic map

A method and system for determining a geographical location and orientation of a vehicle (200, 300) travelling through a road network is disclosed. The method comprises obtaining, from one or more cameras (202, 302) associated with the vehicle (200, 300) travelling through the road network, a sequence of images (500) reflecting the environment of the road network on which the vehicle (200, 300) is travelling, wherein each of the images has an associated camera location at which the image was recorded. A local map representation representing an area of the road network on which the vehicle (200, 300) is travelling is then generated using at least some of the obtained images and the associated camera locations. The generated local map representation is compared with a section of a reference map, the reference map section covering the area of the road network on which the vehicle (200, 300) is travelling, and the geographical location and orientation of the vehicle (200, 300) within the road network is determined based on the comparison. Methods and systems for generating and / or updating an electronic map using data obtained by a vehicle (200, 300) travelling through a road network represented by the map are also disclosed.

Owner:TOMTOM LOCATION TECH GERMANY GMBH +1

Wireless power receiving device

ActiveUS20090308933A1Low costLow production costBatteries circuit arrangementsAntenna supports/mountingsElectric power transmissionElectricity

To provide a wireless power receiving device and an electronic device having the wireless power receiving device whose production costs do not increase even when frequency of electromagnetic waves received for power supply varies. Further, to provide a wireless power receiving device capable of power transmission without disconnection or poor connection when a load supplied with electricity and a battery connected to an antenna are manufactured in different steps. A power transmitter and receiver portion having first and second antenna circuits and a battery portion and a load portion having a third antenna circuit are provided to charge a battery of the battery portion with a first radio signal received at the first antenna circuit and transmit electricity stored in the battery portion as a second radio signal from the second antenna circuit to the third antenna circuit so that the third antenna circuit supplies electricity to the load.

Owner:SEMICON ENERGY LAB CO LTD

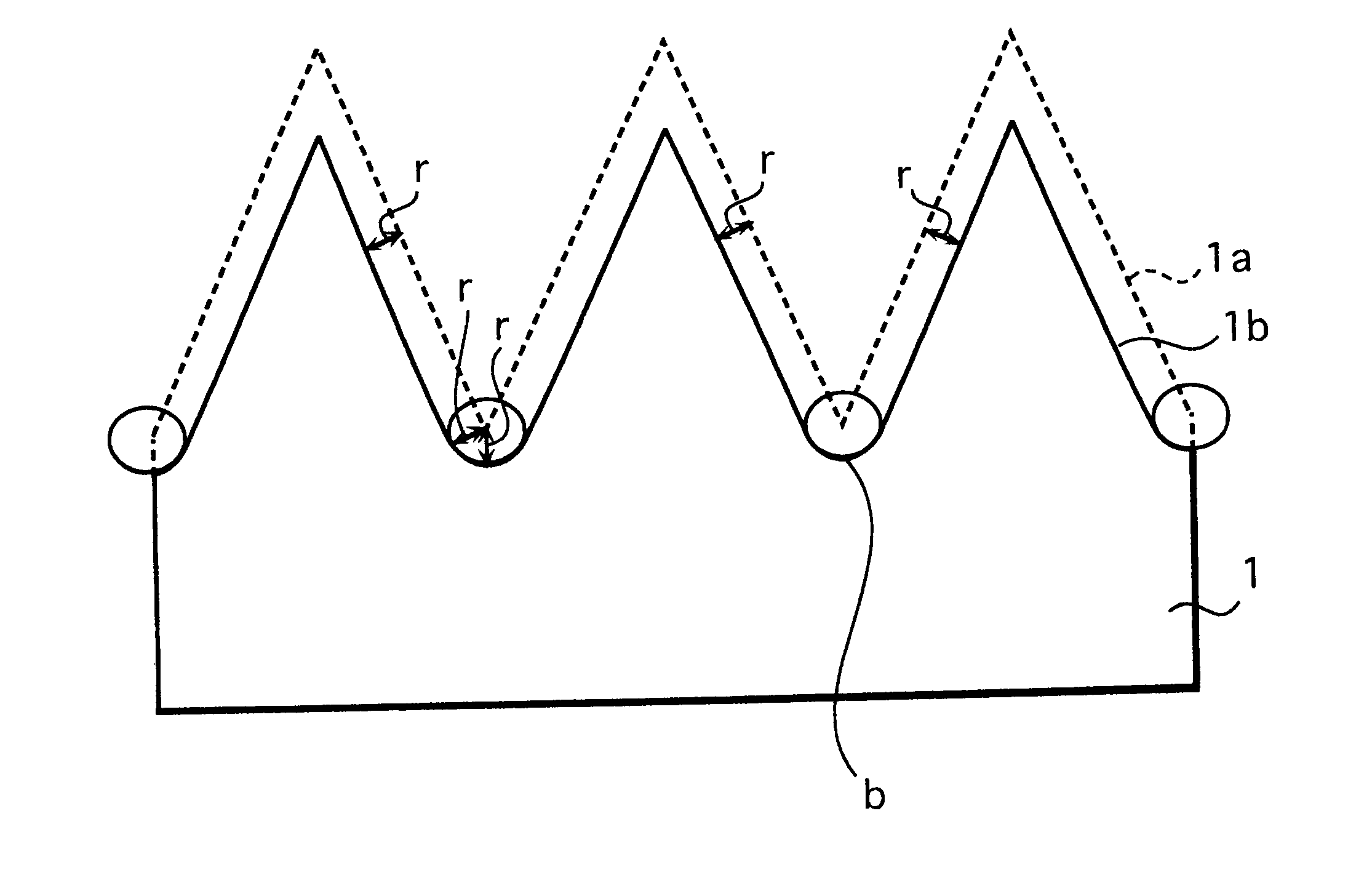

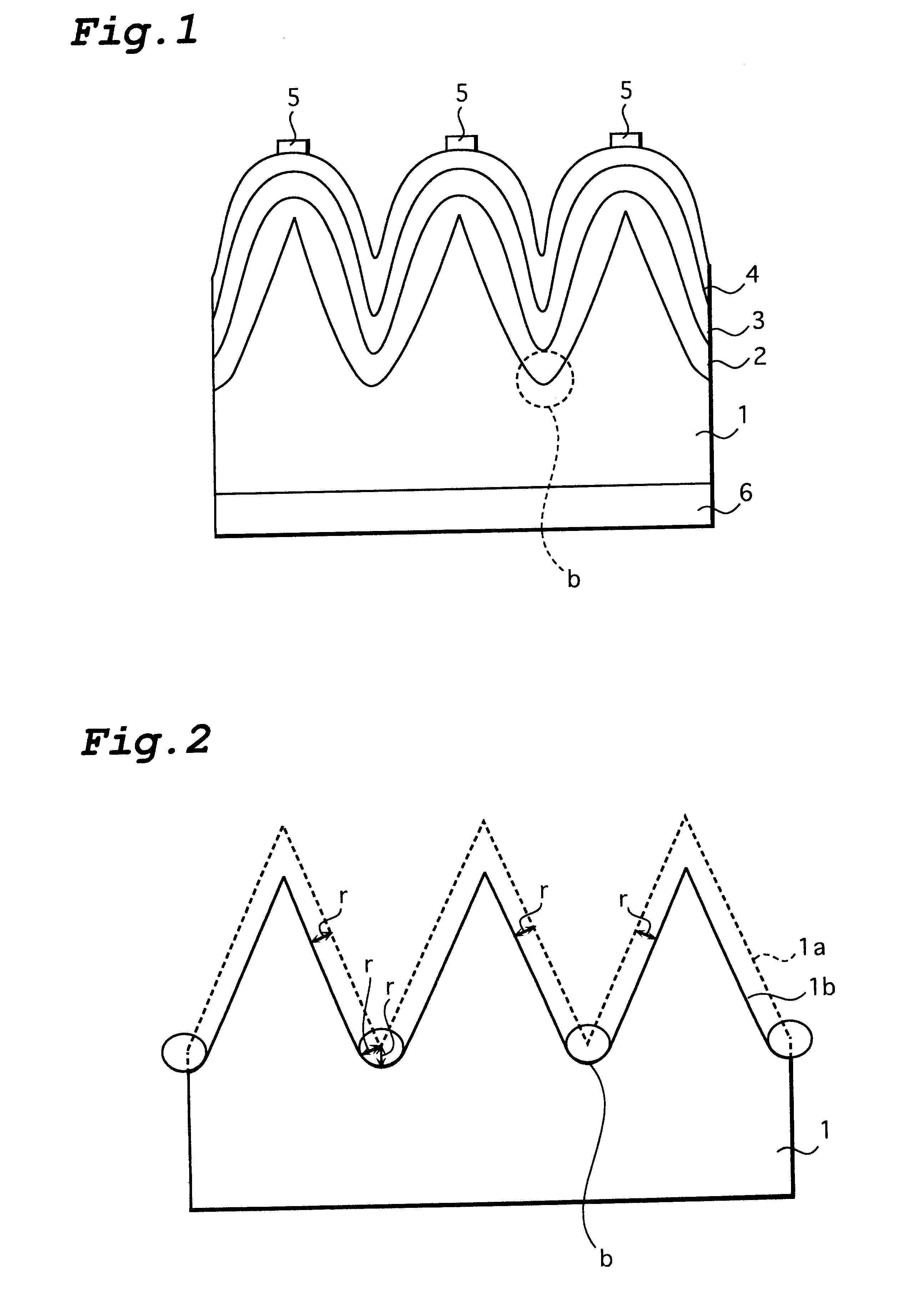

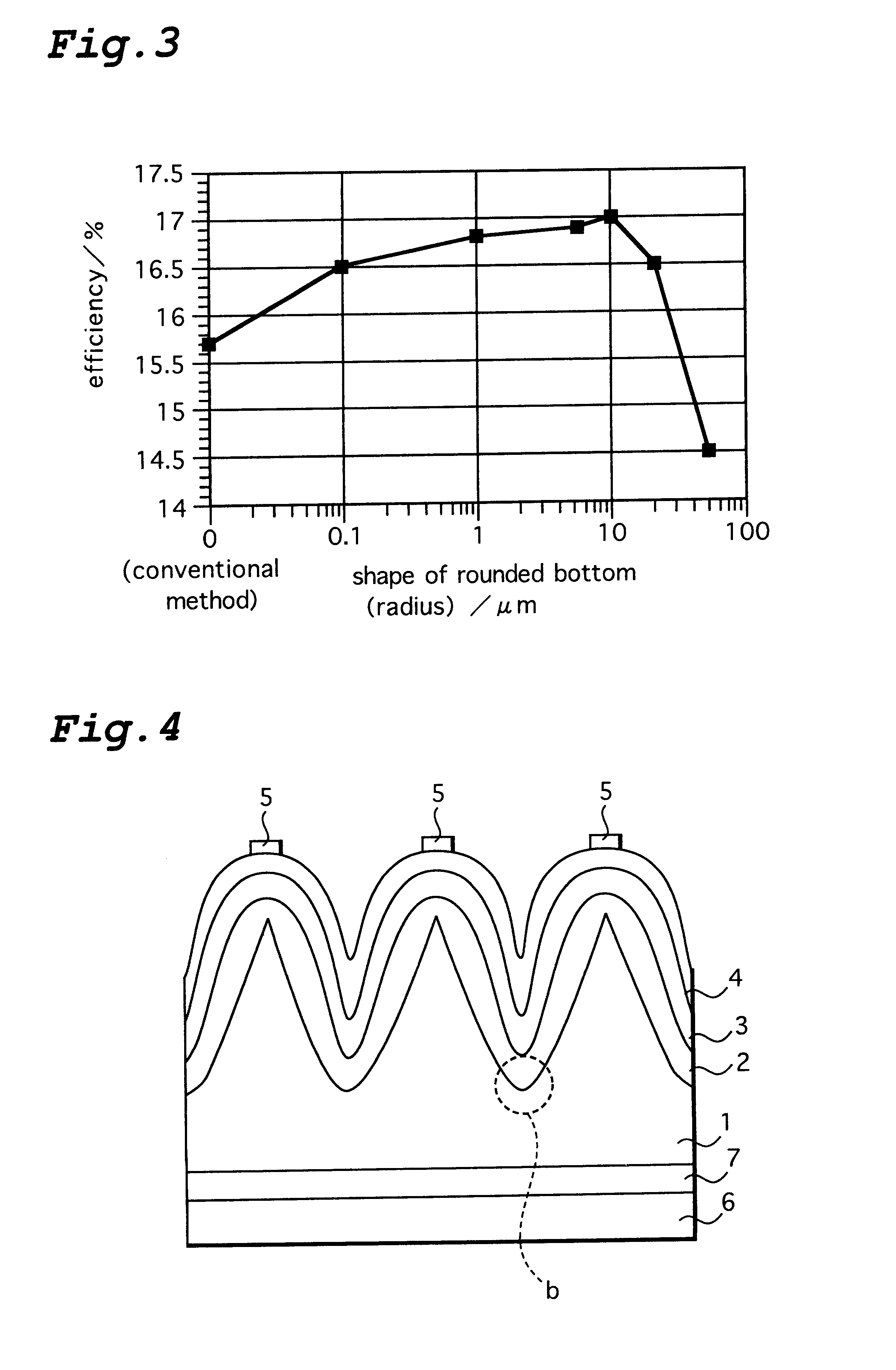

Photovoltaic element and method for manufacture thereof

InactiveUS6207890B1Lowered open circuit voltage circuitLowered circuit short circuitPV power plantsSolid-state devicesSolar lightAmorphous silicon

A photovoltaic element which directly converts an optical energy such as solar light into an electric energy. After many uneven sections are formed on the surface of an n-type crystalline silicon substrate (1), the surface of the substrate (1) is isotropically etched. Then the bottoms (b) of the recessed sections are rounded and a p-type amorphous silicon layer (3) is formed on the surface of the substrate (1) through an intrinsic amorphous silicon layer (2). The shape of the surface of the substrate (1) after isotropic etching is such that the bottoms of the recessed sections are slightly rounded and therefore the amorphous silicon layer can be deposited in a uniform thickness.

Owner:SANYO ELECTRIC CO LTD

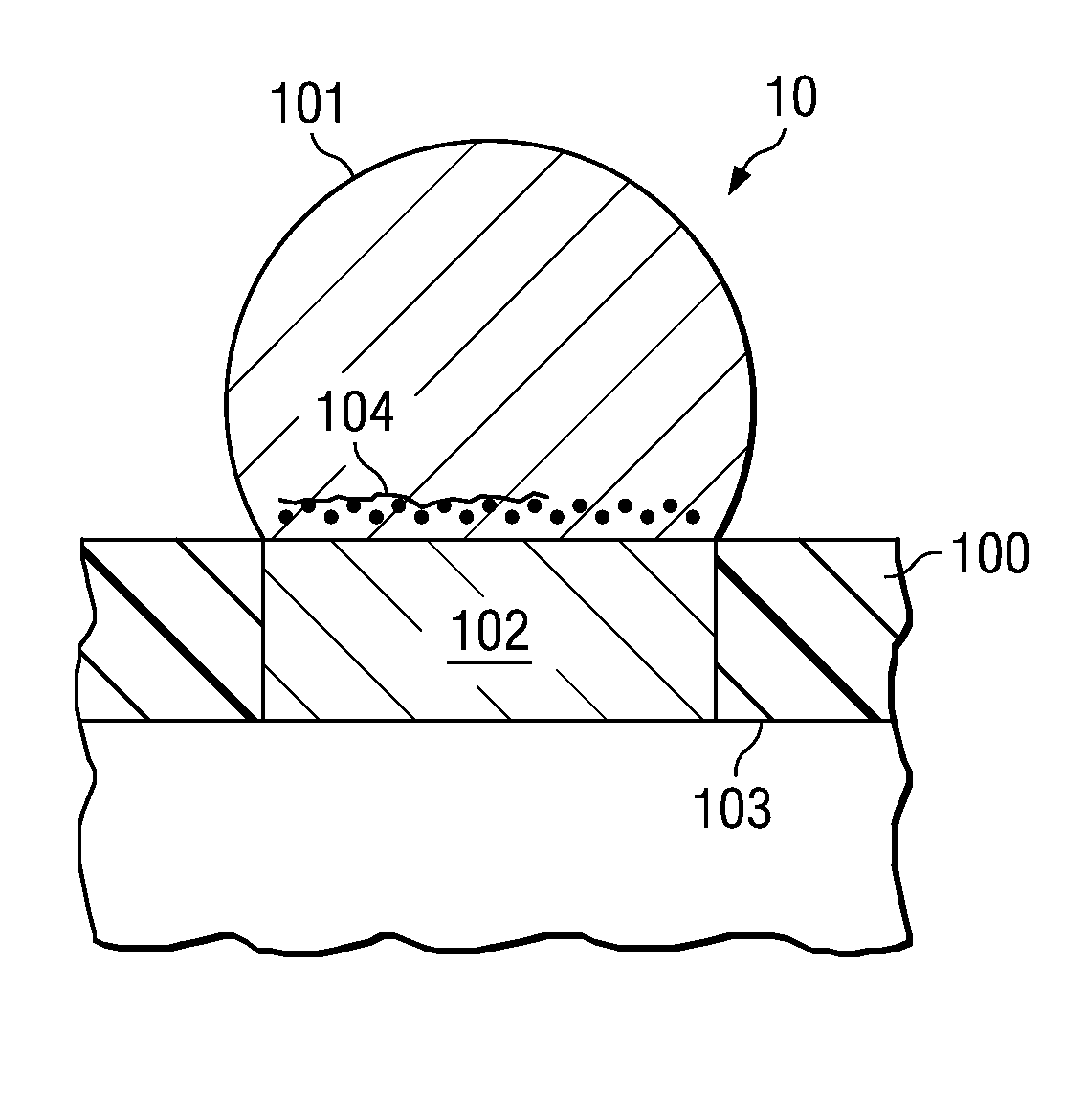

Protected Solder Ball Joints in Wafer Level Chip-Scale Packaging

ActiveUS20090130840A1High strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical connectionSolder ball

Owner:TAIWAN SEMICON MFG CO LTD

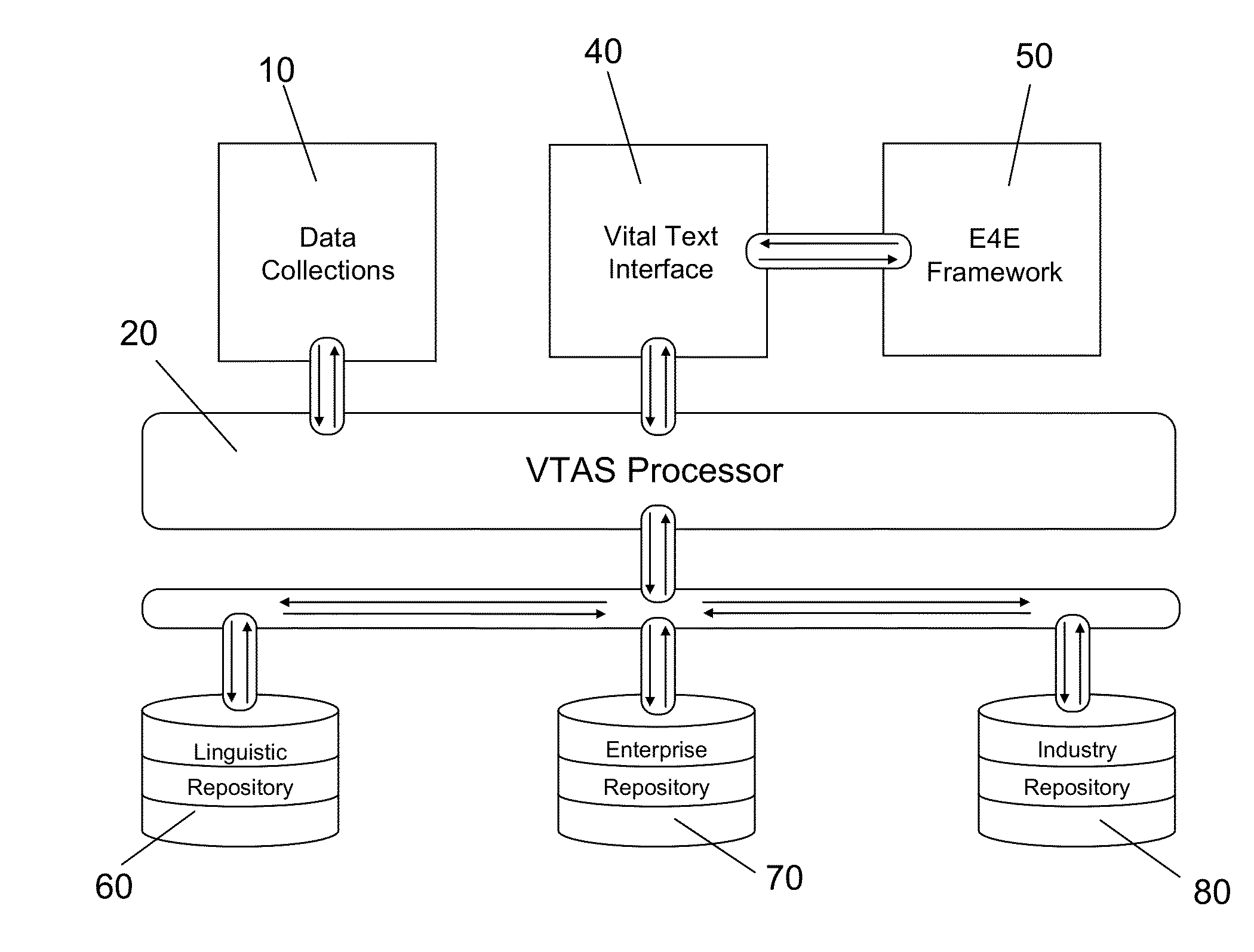

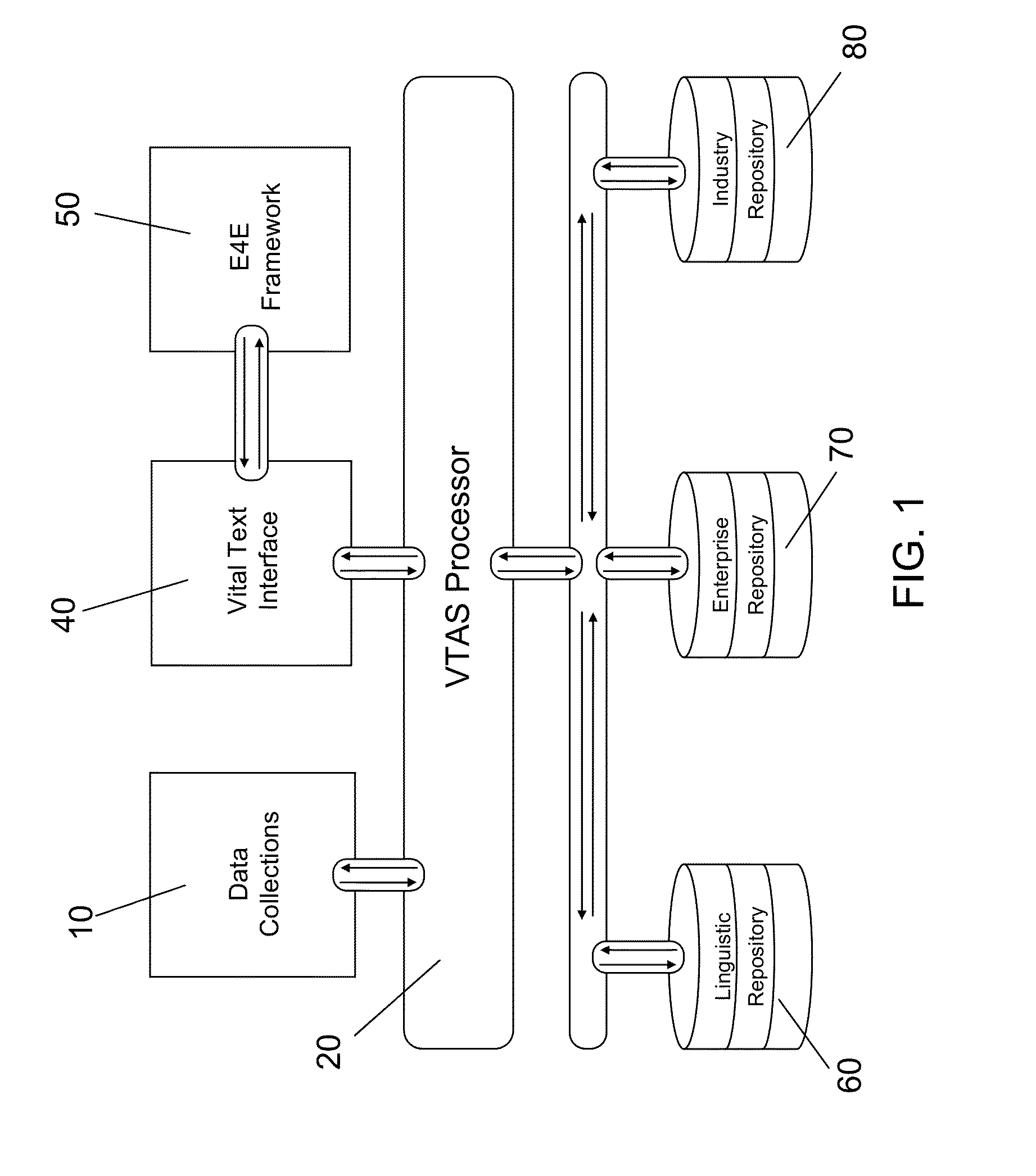

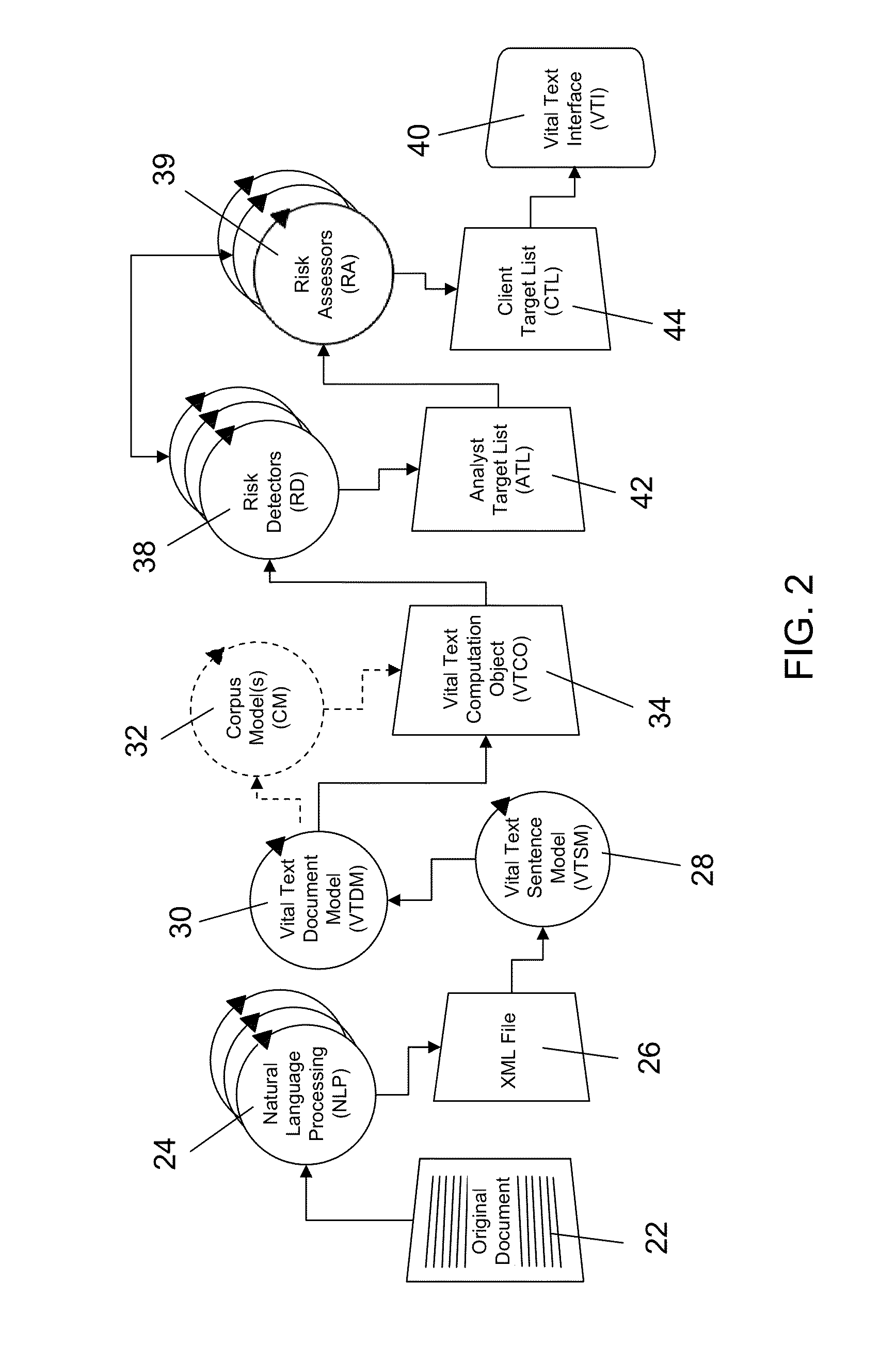

Vital text analytics system for the enhancement of requirements engineering documents and other documents

ActiveUS20140172417A1Improve efficiencyReduce defectsSemantic analysisSpecial data processing applicationsDocumentation procedureTechnical specifications

A Vital Text Analytics System (VTAS), incorporating a repository of enterprise terms or concepts, is one that improves the readability and fidelity of technical specifications, instructions, training manuals requirements engineering documents and other related engineering documents, typically from a single organization or workgroup. The system stresses ontological analysis of a corpus of related documents, and applies a suite of computational tools that supports the identification and assessment of risk in evaluating the content of the documents, as well as providing statistical measures reflecting the frequency and severity of document features that threaten comprehension.

Owner:CLOUD 9 LLC DBA VITAL TEXT SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com