Patents

Literature

2055 results about "Polysulfone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

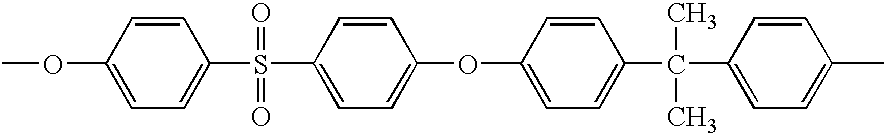

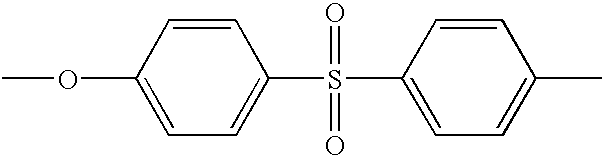

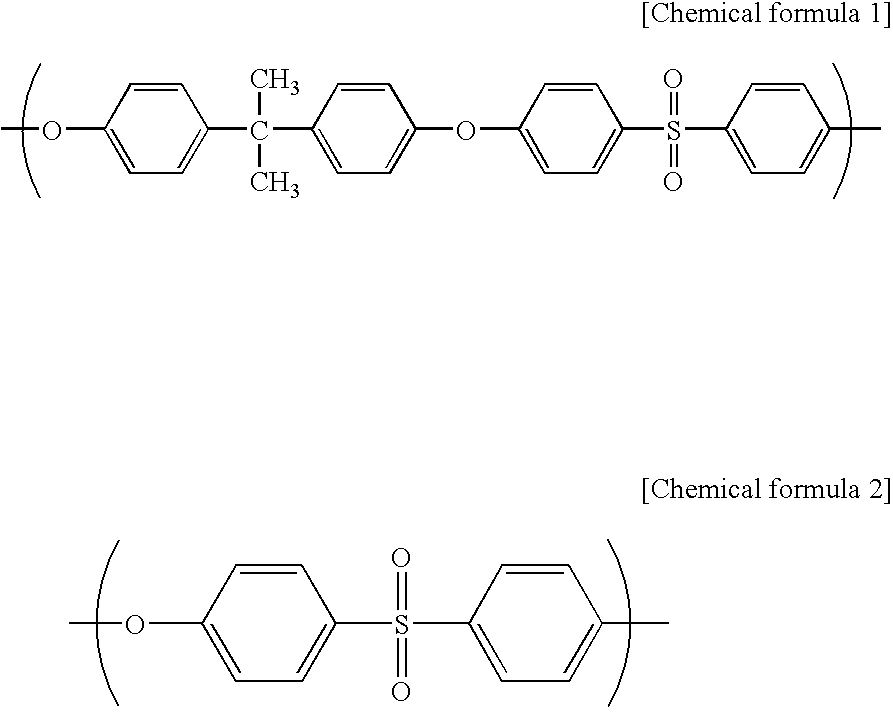

Polysulfones are a family of thermoplastic polymers. These polymers are known for their toughness and stability at high temperatures. They contain the subunit aryl-SO₂-aryl, the defining feature of which is the sulfone group. Polysulfones were introduced in 1965 by Union Carbide. Due to the high cost of raw materials and processing, polysulfones are used in specialty applications and often are a superior replacement for polycarbonates.

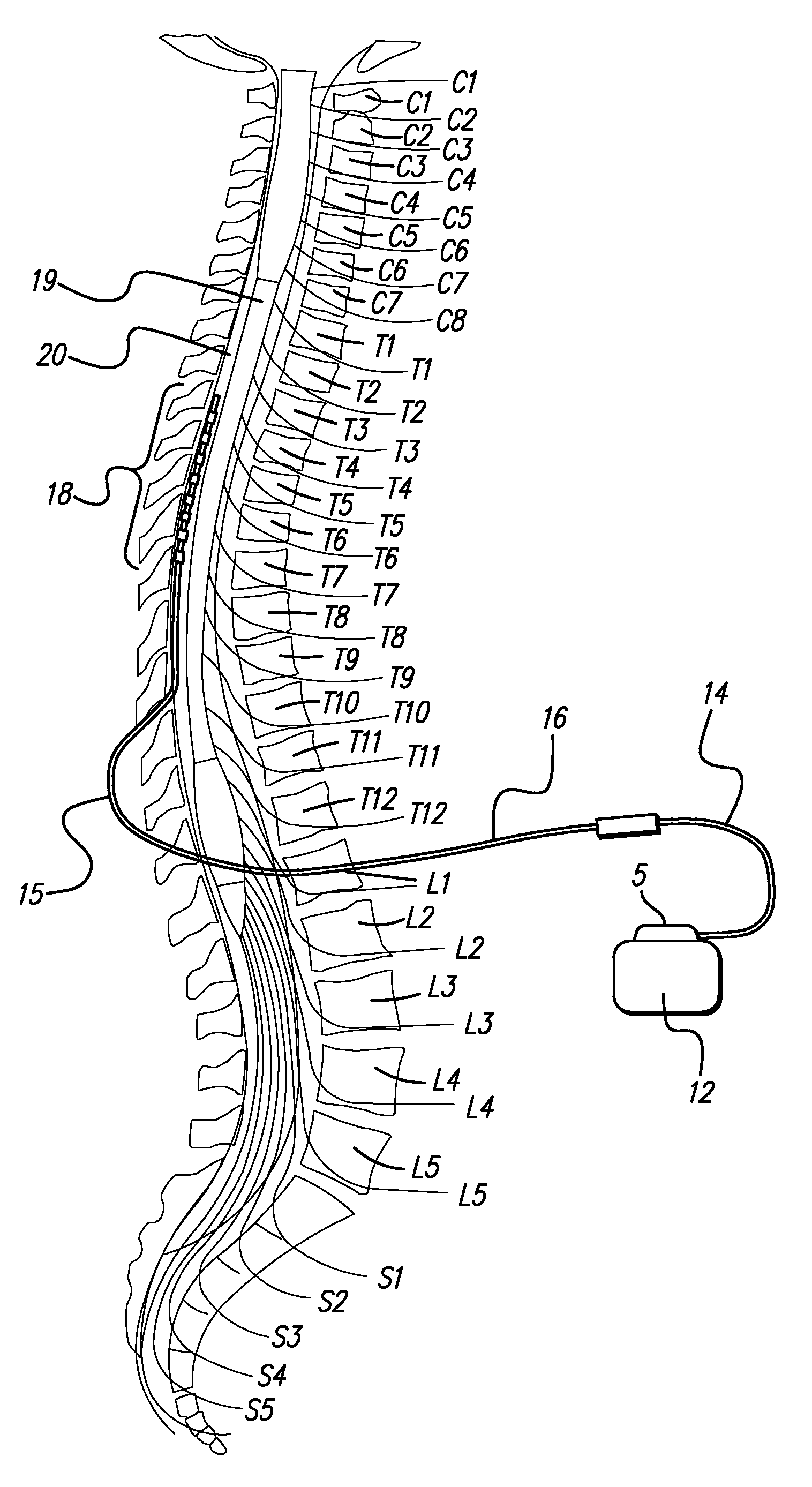

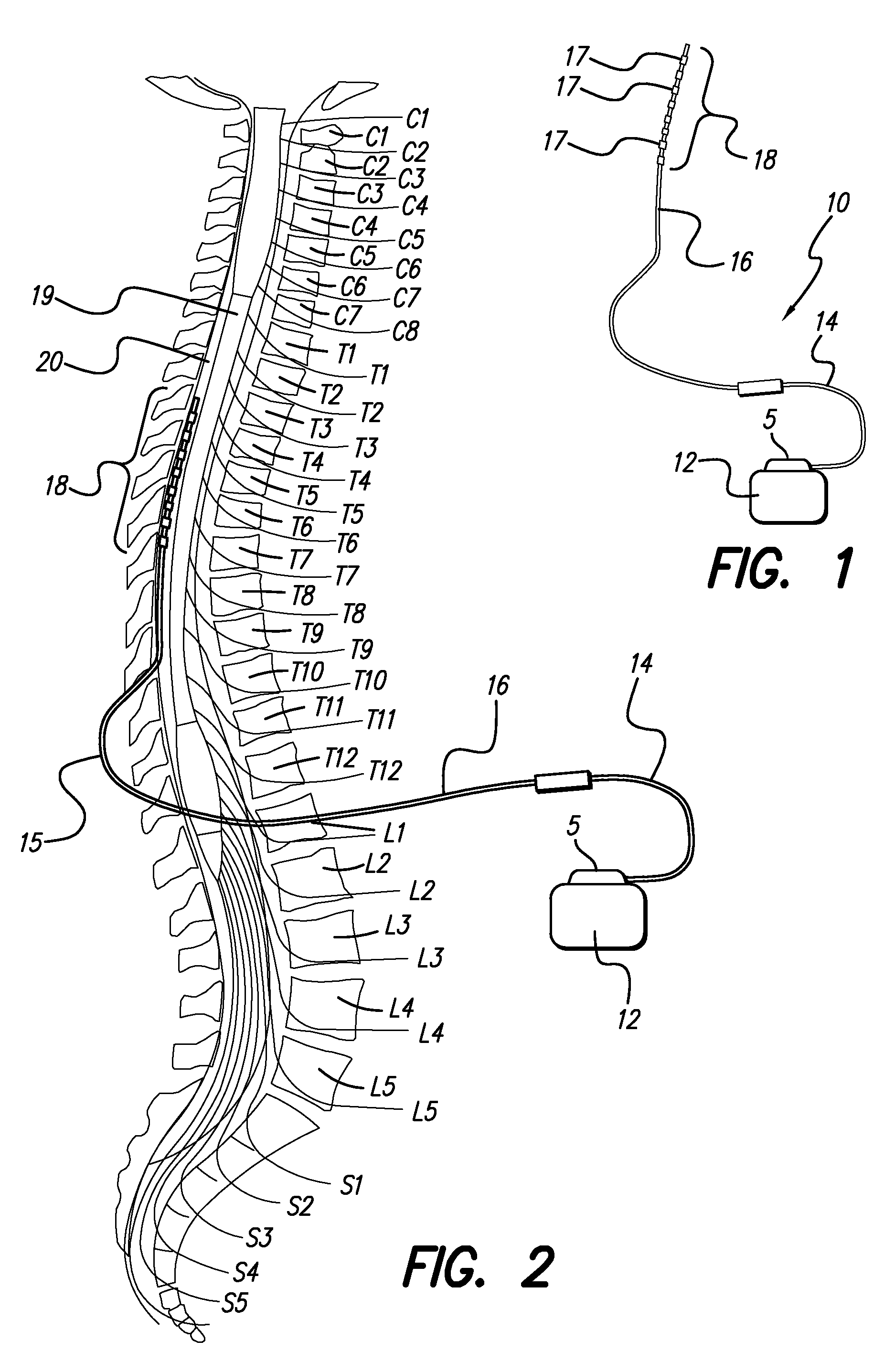

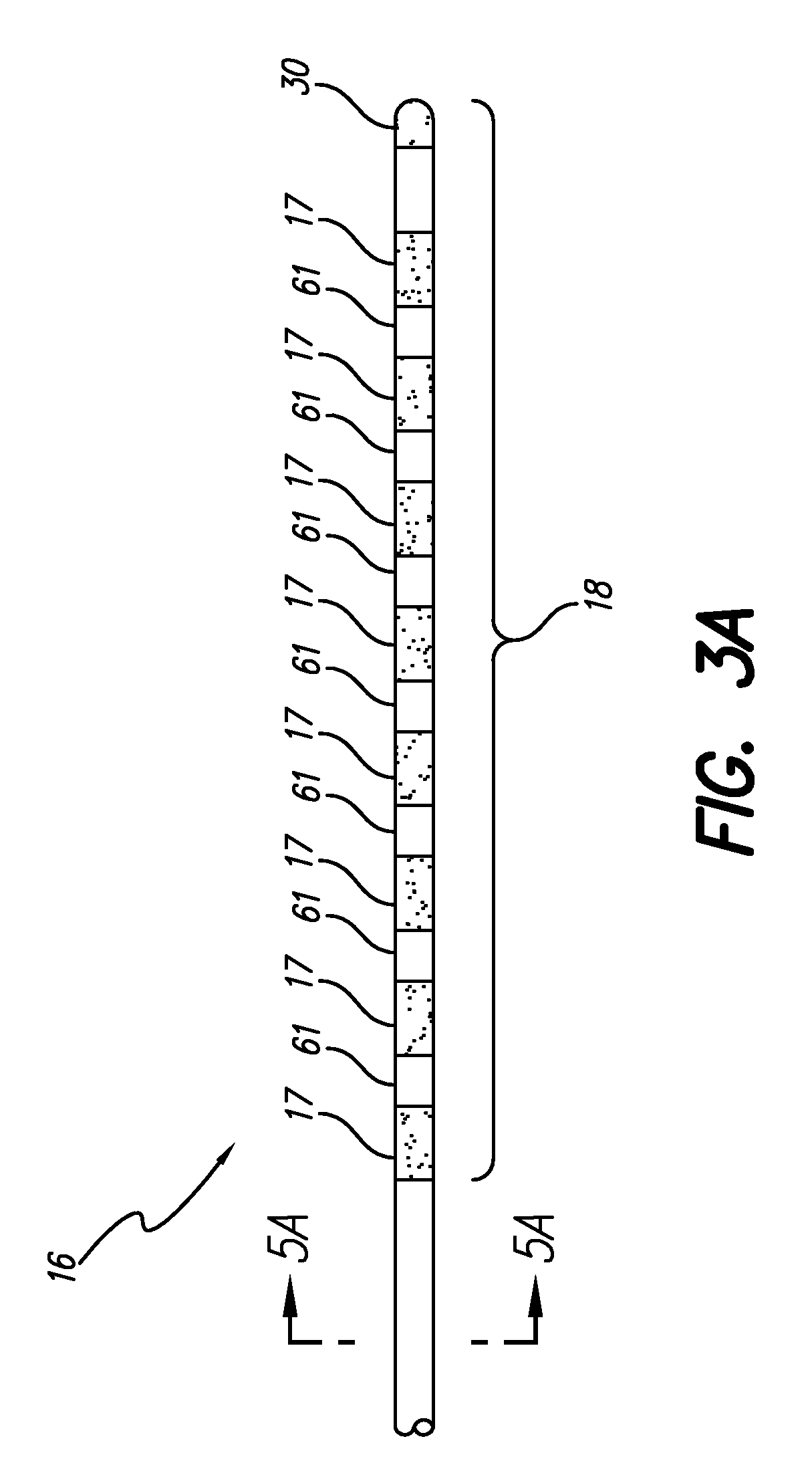

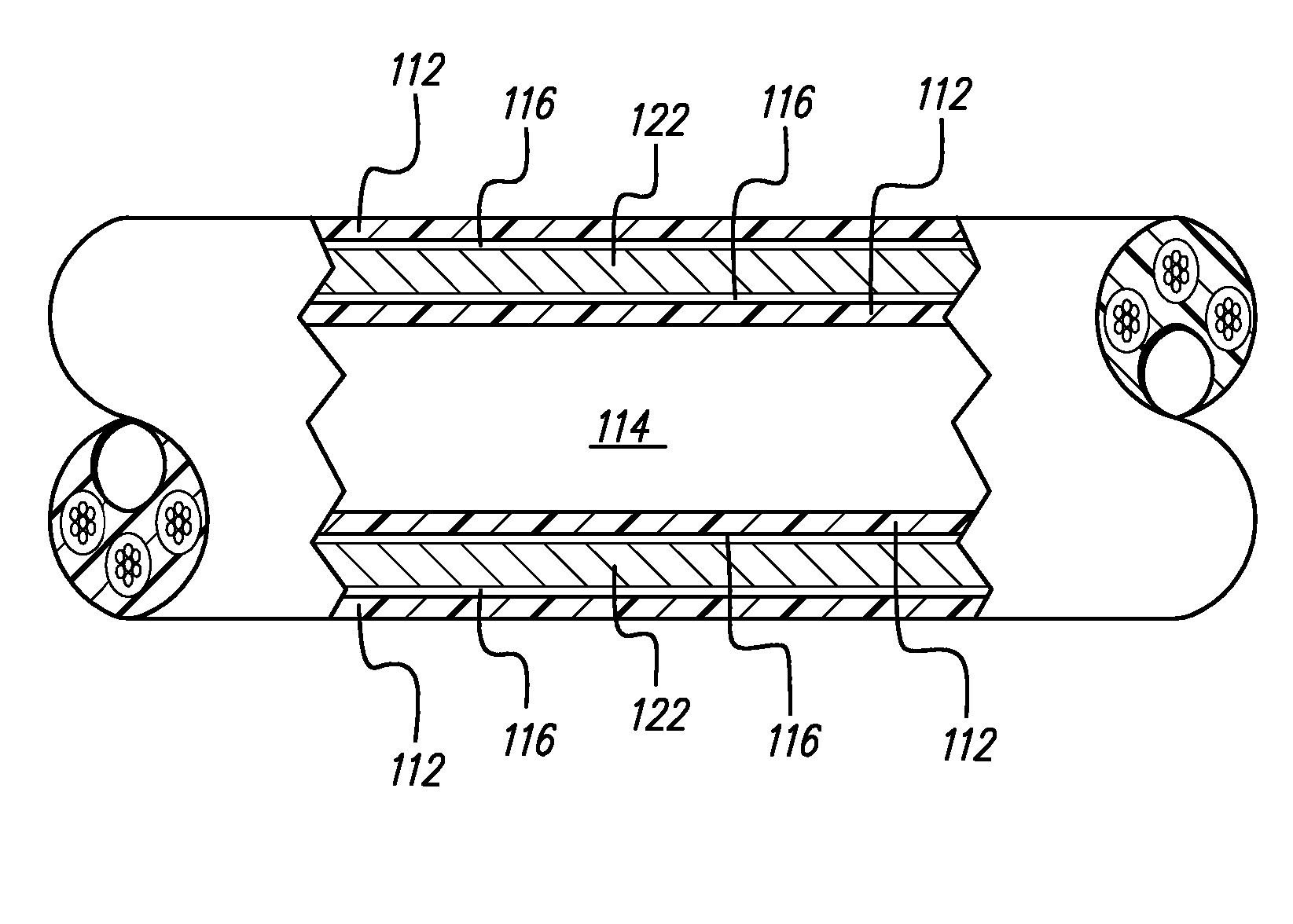

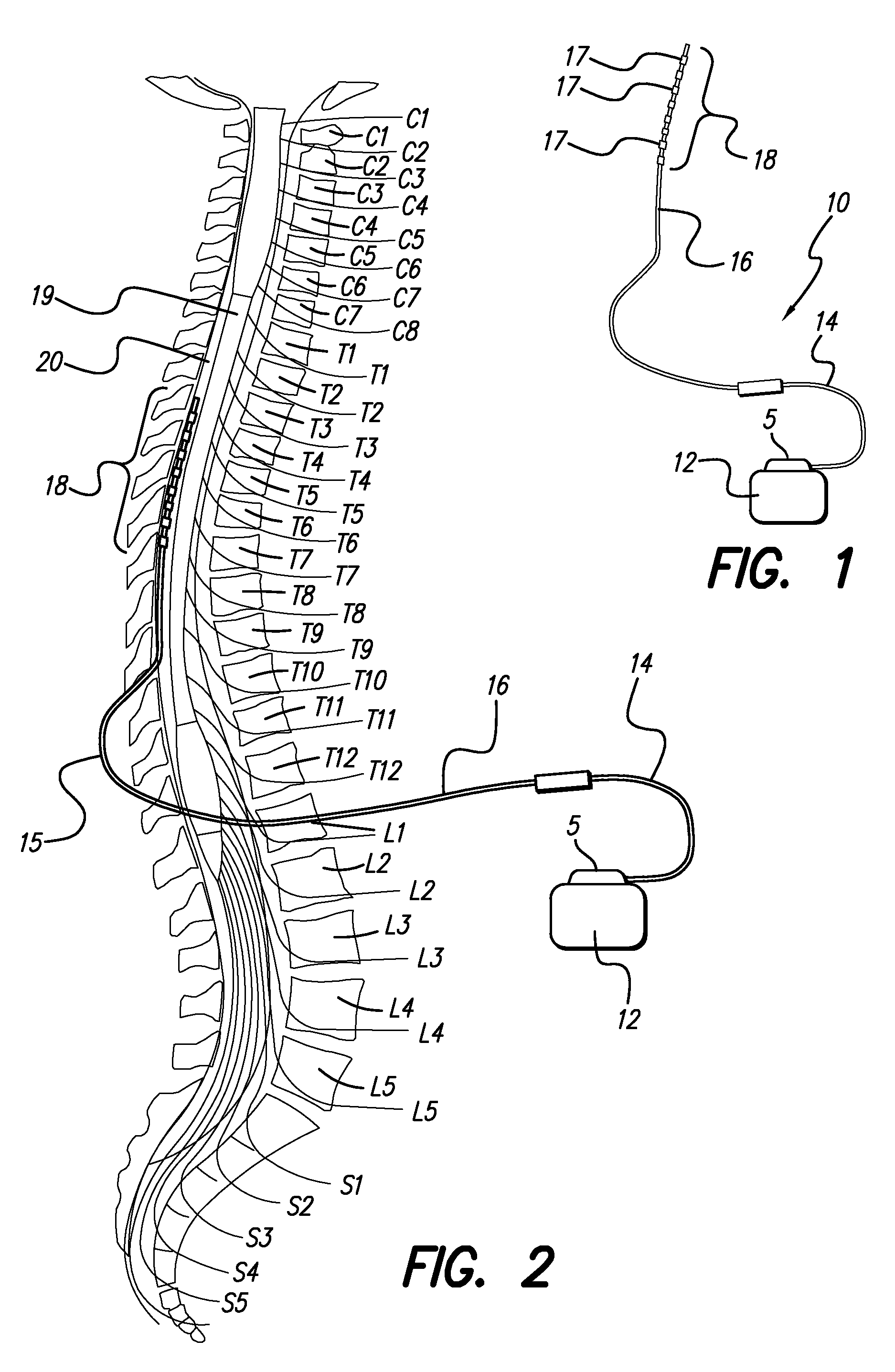

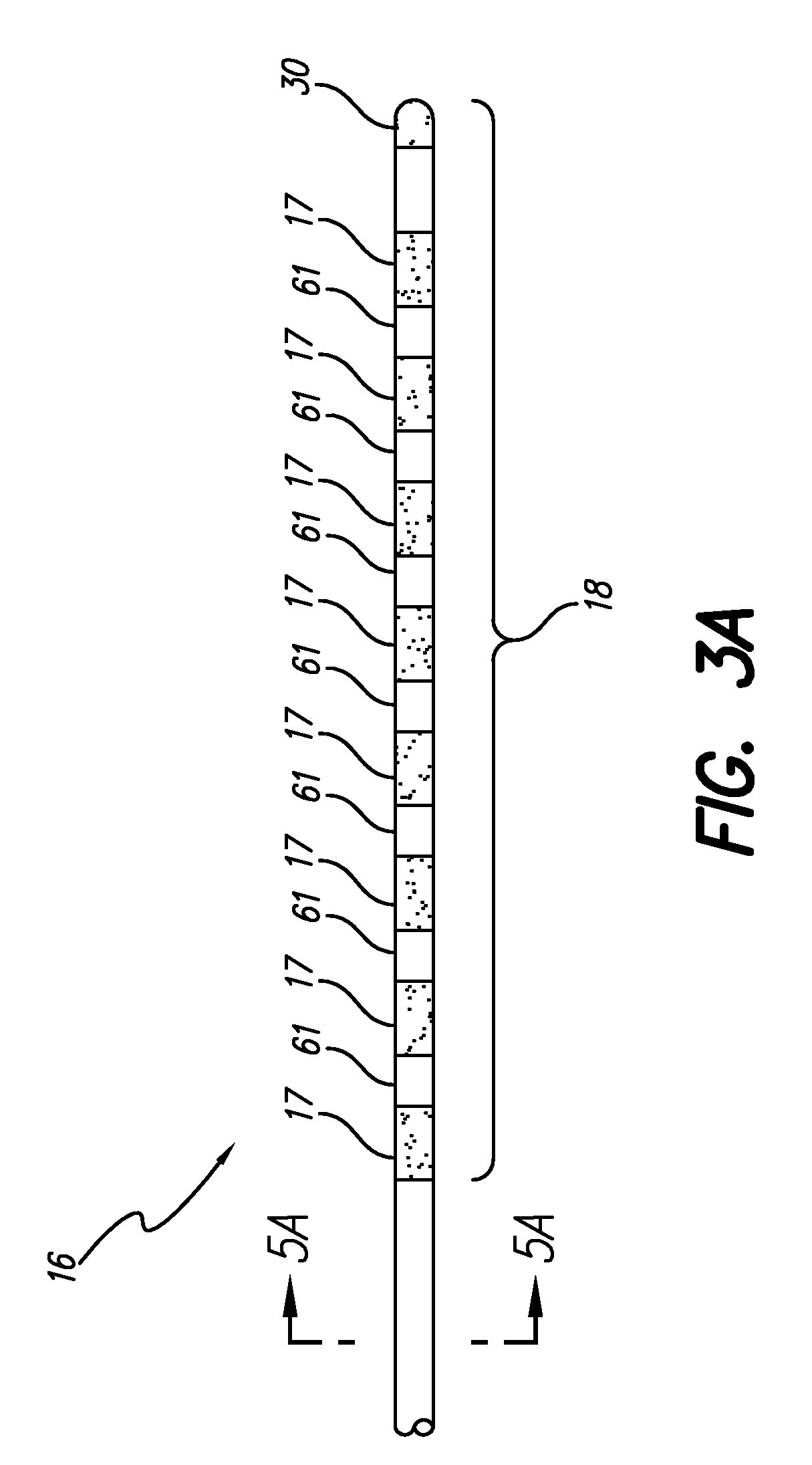

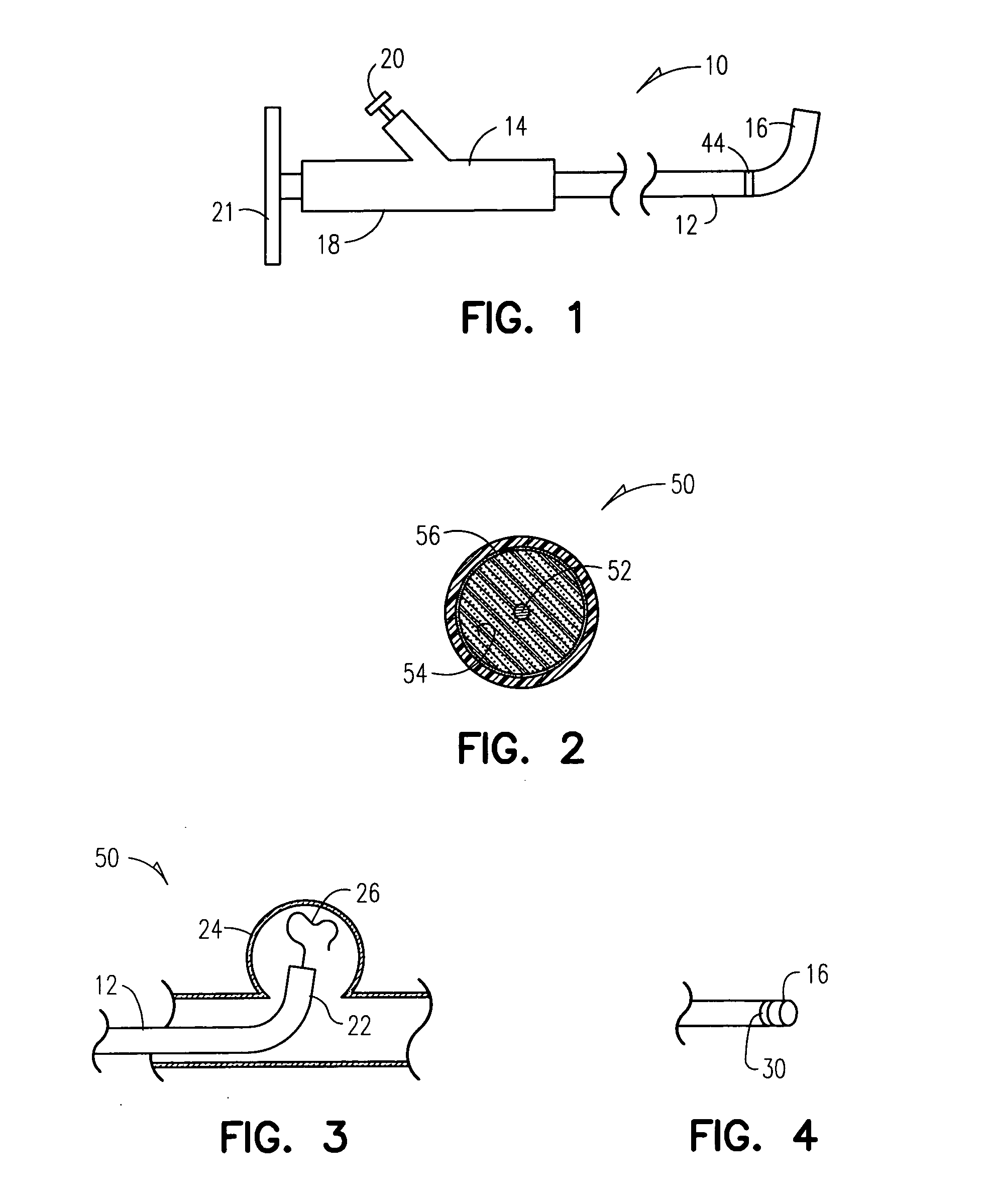

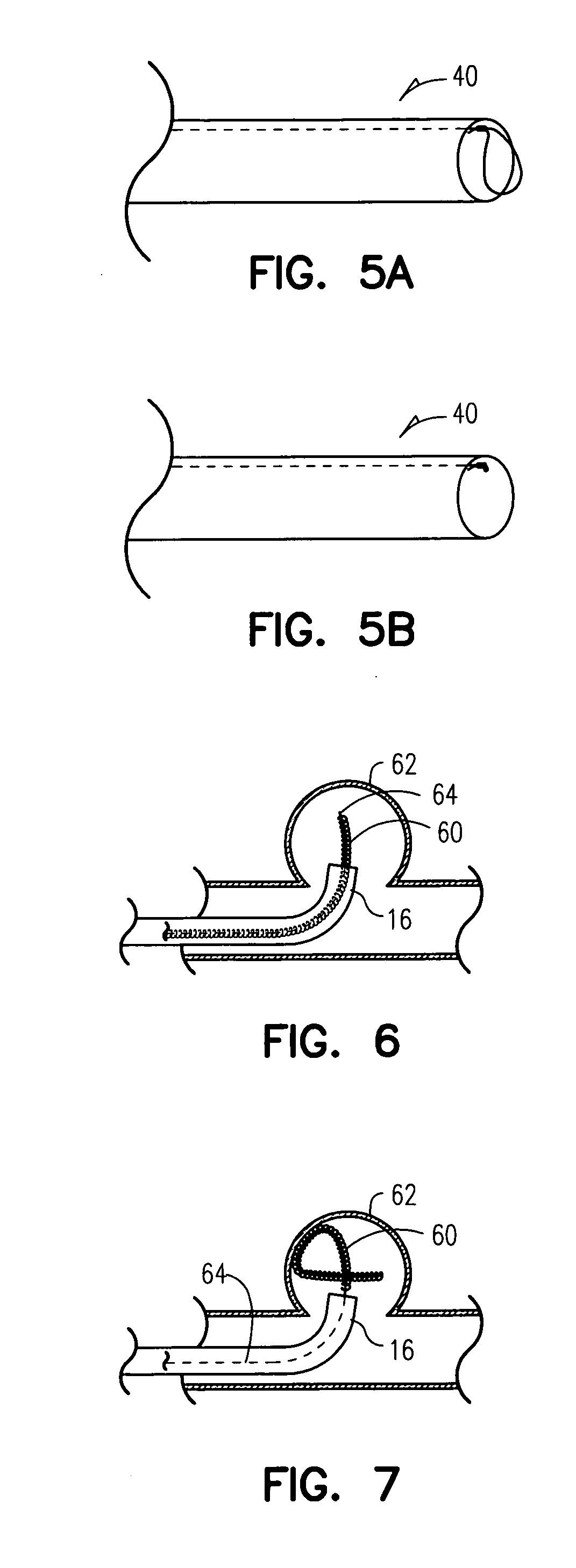

Lead Assembly and Method of Making Same

A lead assembly and a method of making a lead are provided. The lead comprises a terminal, proximal end having a plurality of terminal contacts and material separating the terminal contacts. In one embodiment of the lead, the terminal contacts are separated by a preformed spacer, that may be made from various hard materials such as polyurethane, PEEK and polysulfone. Epoxy may be used to fill spaces at the proximal lead end, including between the spacer and terminal contacts. In one embodiment of the lead, the terminal contacts are separated by epoxy only. The lead may include a plurality of conductor lumens that contain conductors. The lead may also include a stylet lumen for accepting a stylet.

Owner:BOSTON SCI NEUROMODULATION CORP

Lead assembly and method of making same

A lead assembly and a method of making a lead are provided. The lead comprises a terminal, proximal end having a plurality of terminal contacts and material separating the terminal contacts. In one embodiment of the lead, the terminal contacts are separated by a preformed spacer, that may be made from various hard materials such as polyurethane, PEEK and polysulfone. Epoxy may be used to fill spaces at the proximal lead end, including between the spacer and terminal contacts. In one embodiment of the lead, the terminal contacts are separated by epoxy only. The lead may include a plurality of conductor lumens that contain conductors. The lead may also include a stylet lumen for accepting a stylet.

Owner:BOSTON SCI NEUROMODULATION CORP

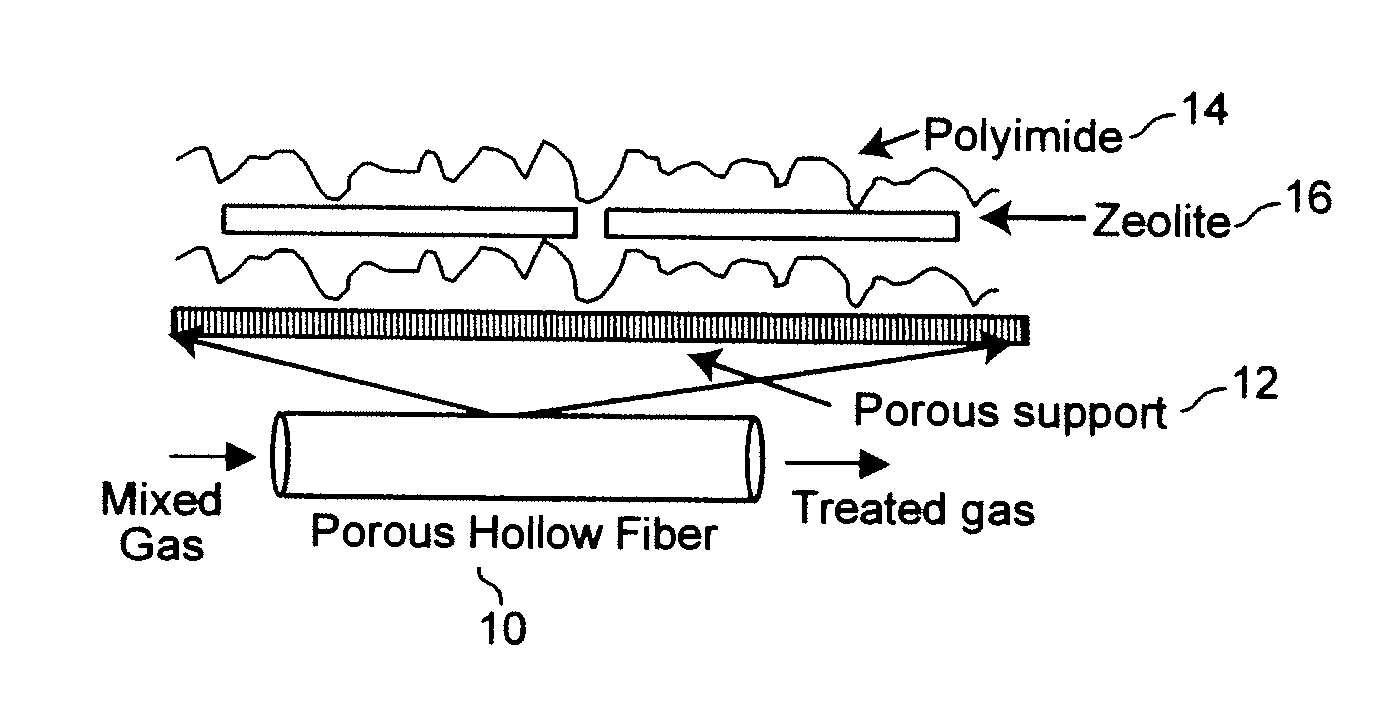

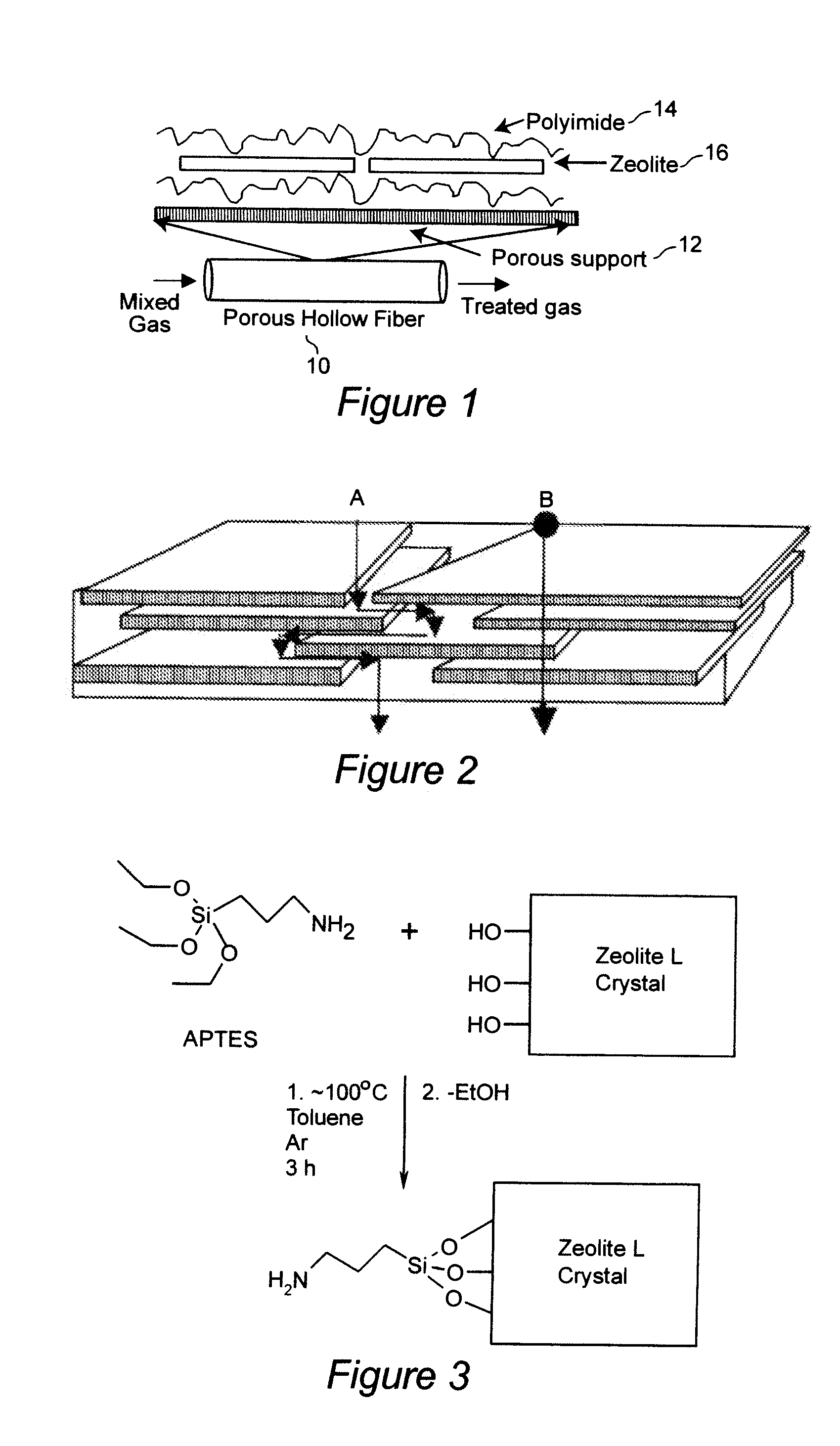

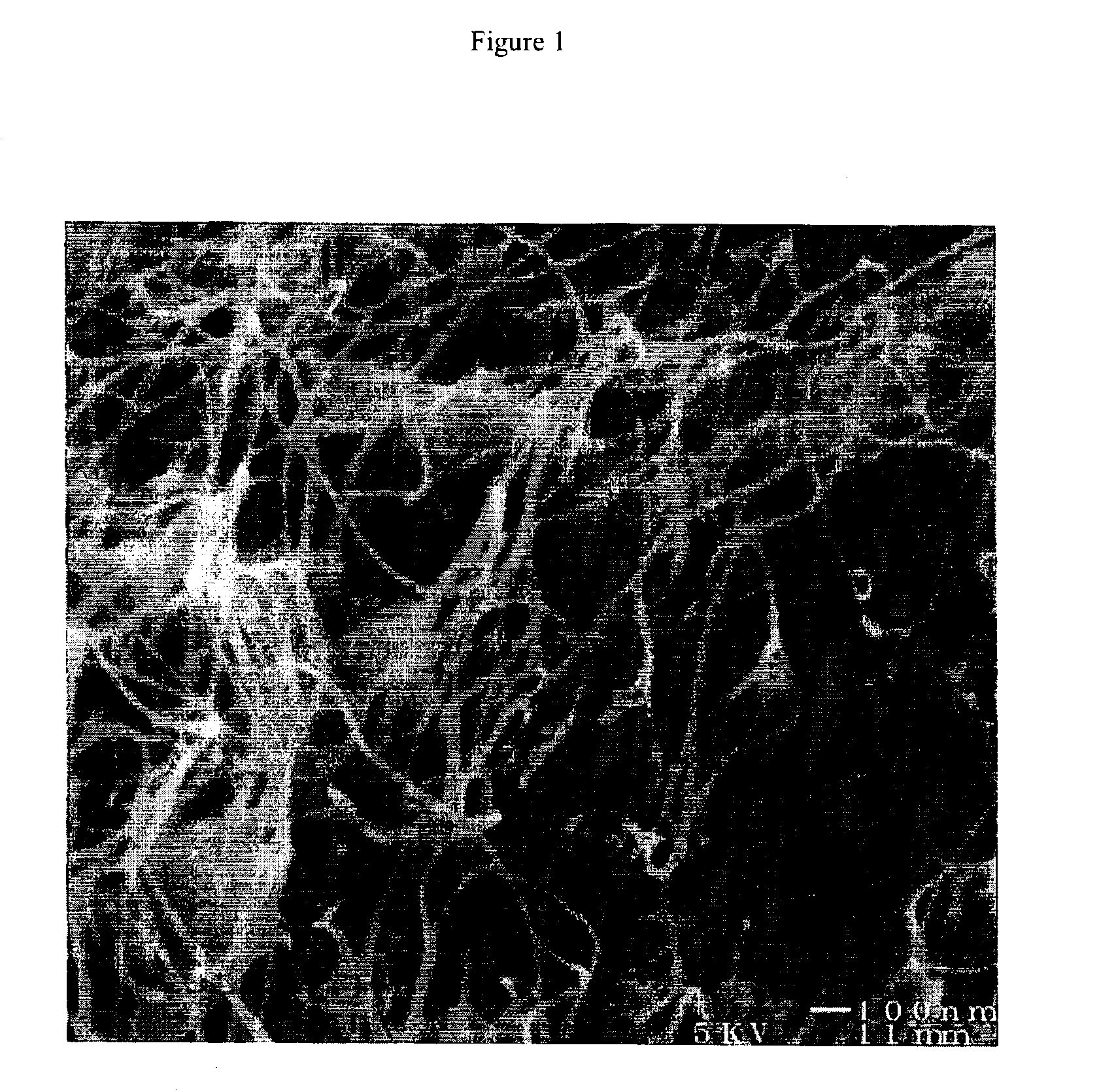

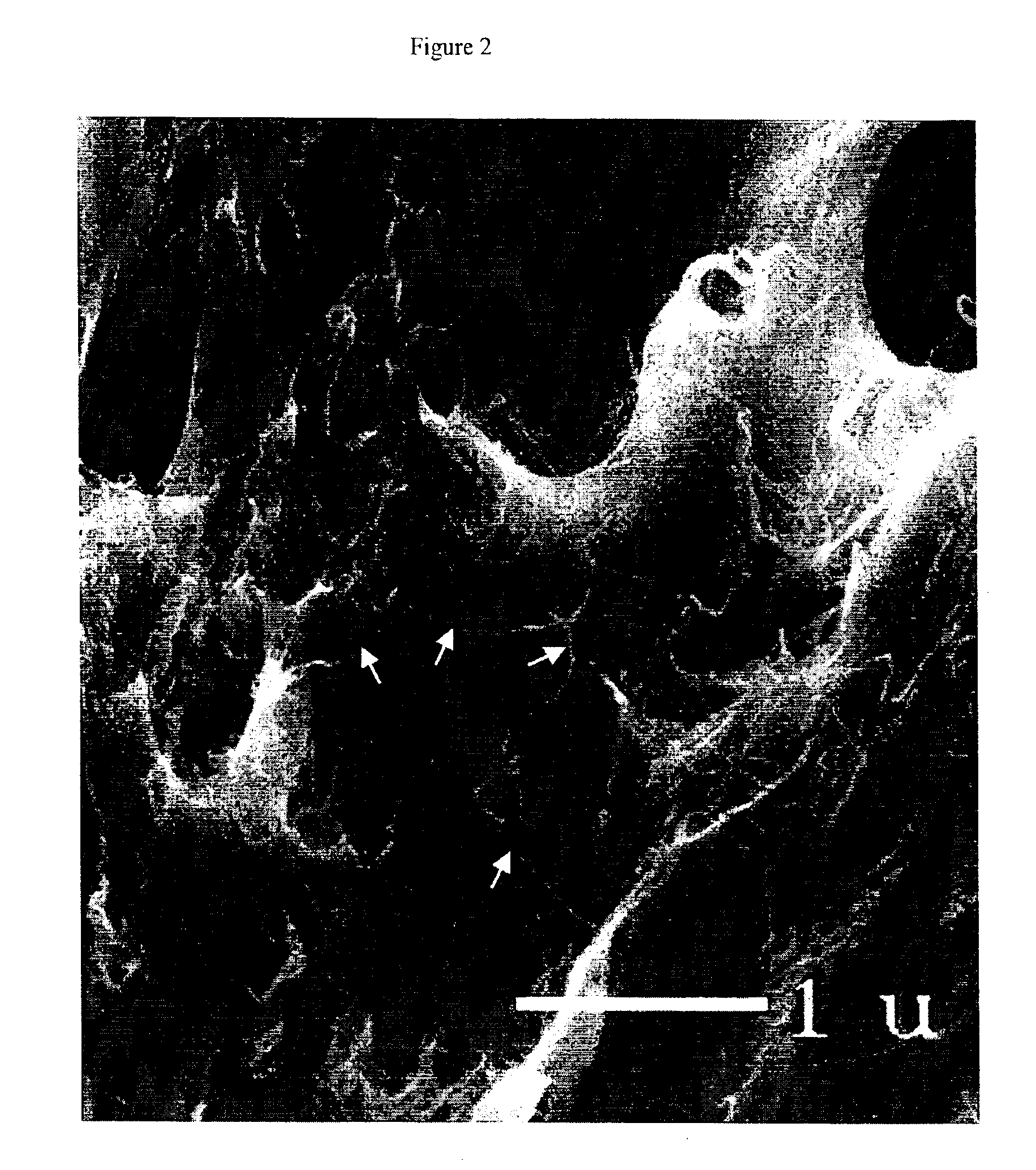

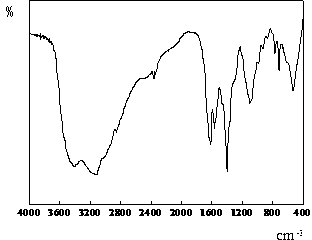

Ordered mesopore silica mixed matrix membranes, and production methods for making ordered mesopore silica mixed matric membranes

InactiveUS20070022877A1Enhanced interactionEffectively incorporated into polymer structureSemi-permeable membranesOrganic-compounds/hydrides/coordination-complexes catalystsMesoporous silicaSilicon dioxide

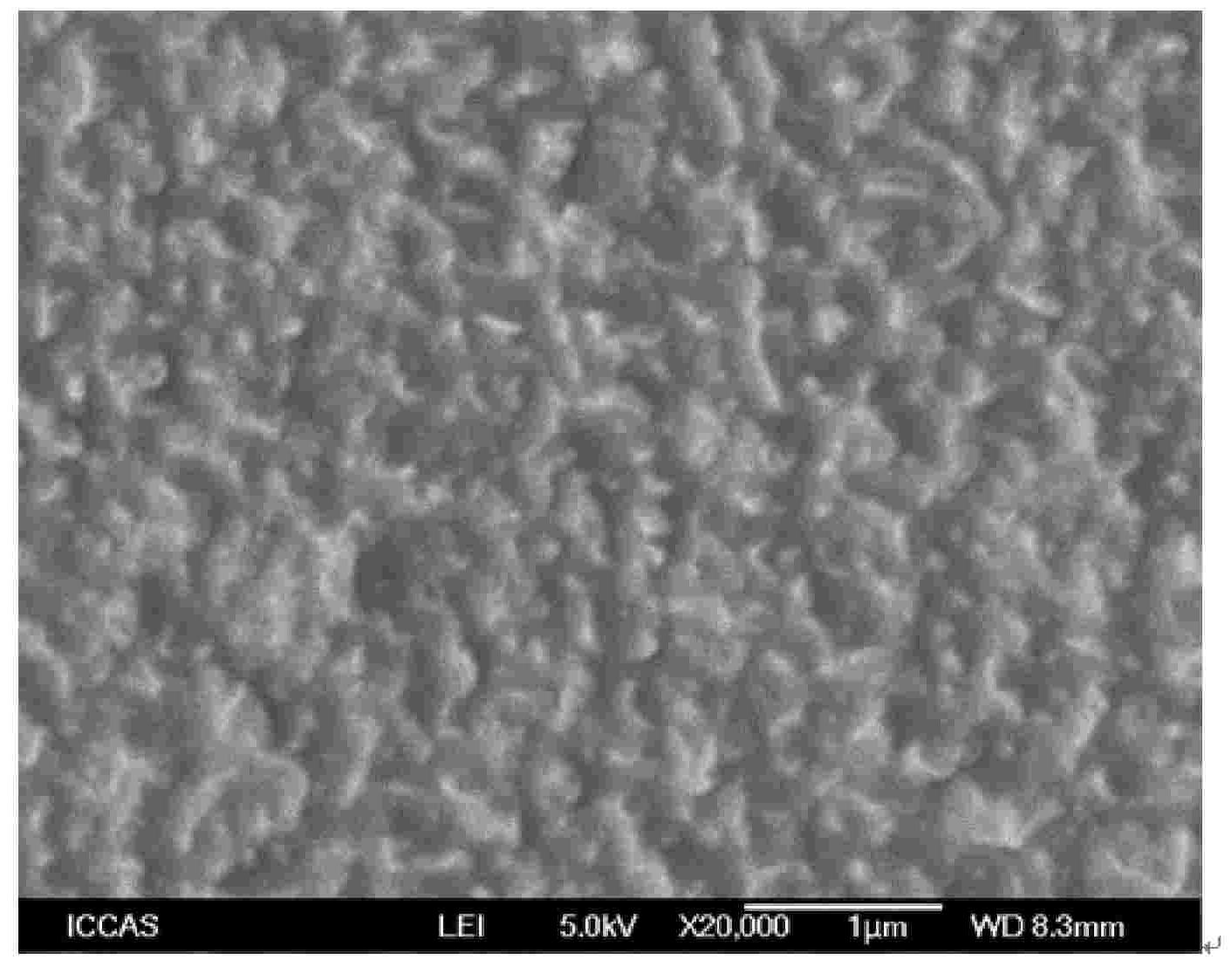

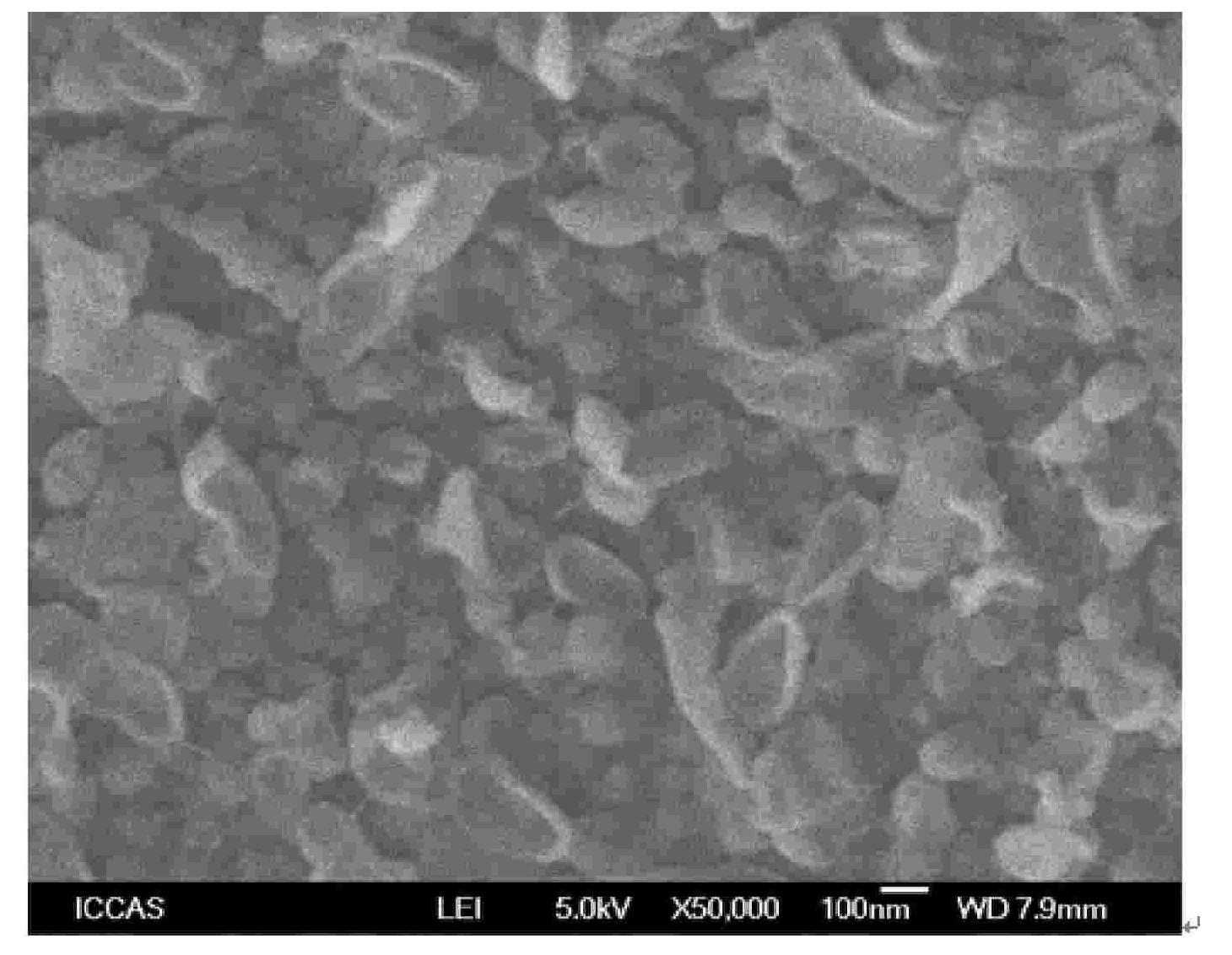

Mixed matrix membranes are prepared from mesoporous silica (and certain other silica) and membrane-forming polymers (such as polysulfone), in a void free fashion where either no voids or voids of less than 100 angstroms are present at the interface of the membrane-forming polymer and the silica. Such silica-containing mixed matrix membranes are particularly useful for their selectivity (such as carbon dioxide selectivity) and permeability. Methods for separating carbon dioxide are provided.

Owner:VIRGINIA TECH INTPROP INC

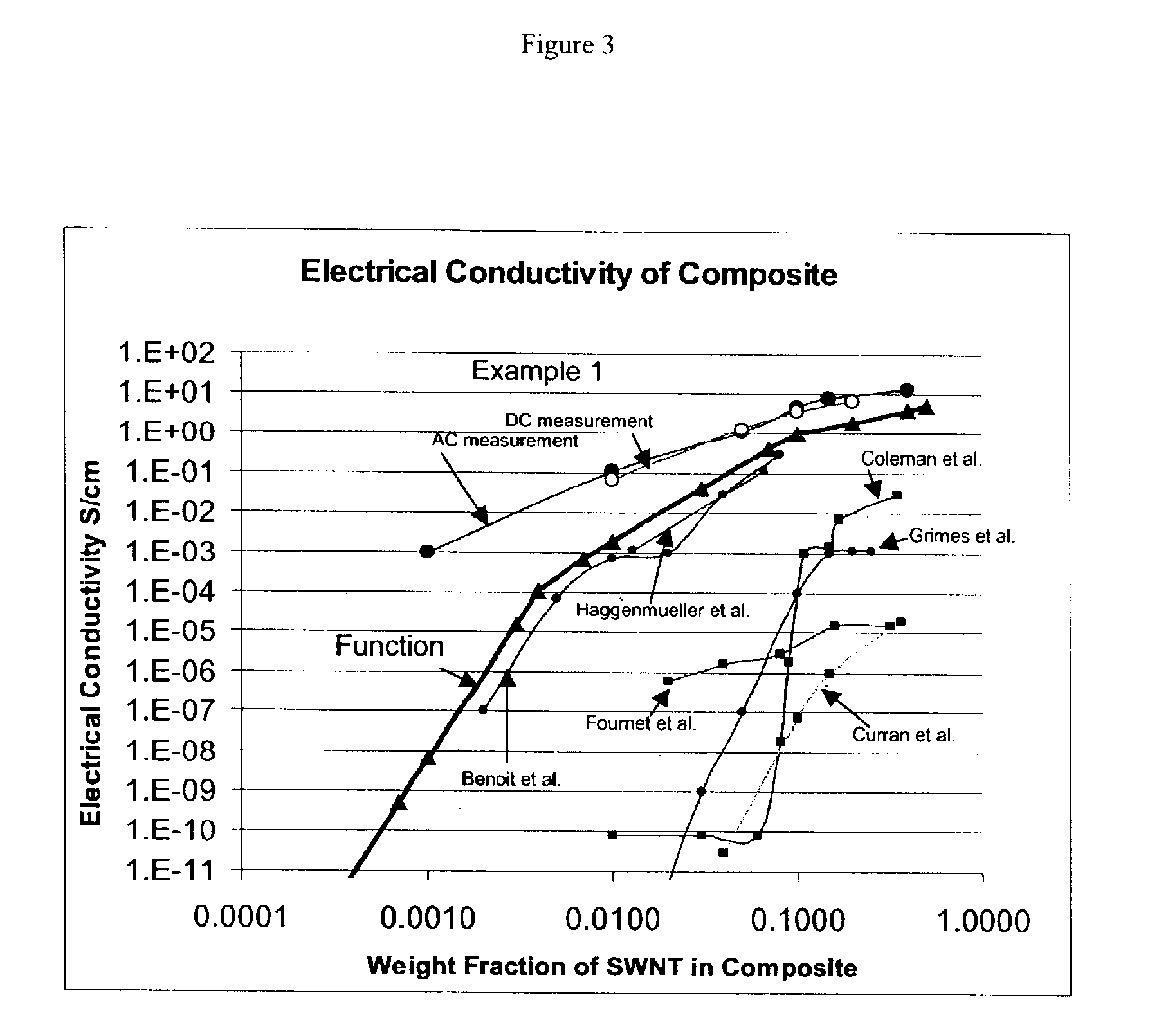

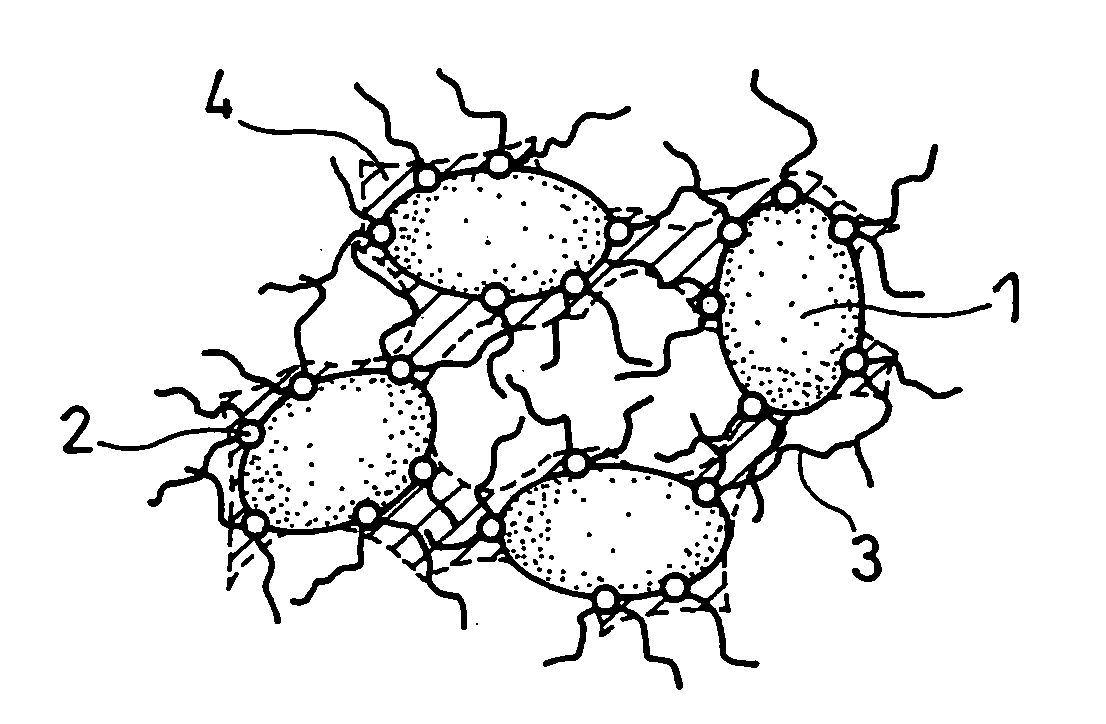

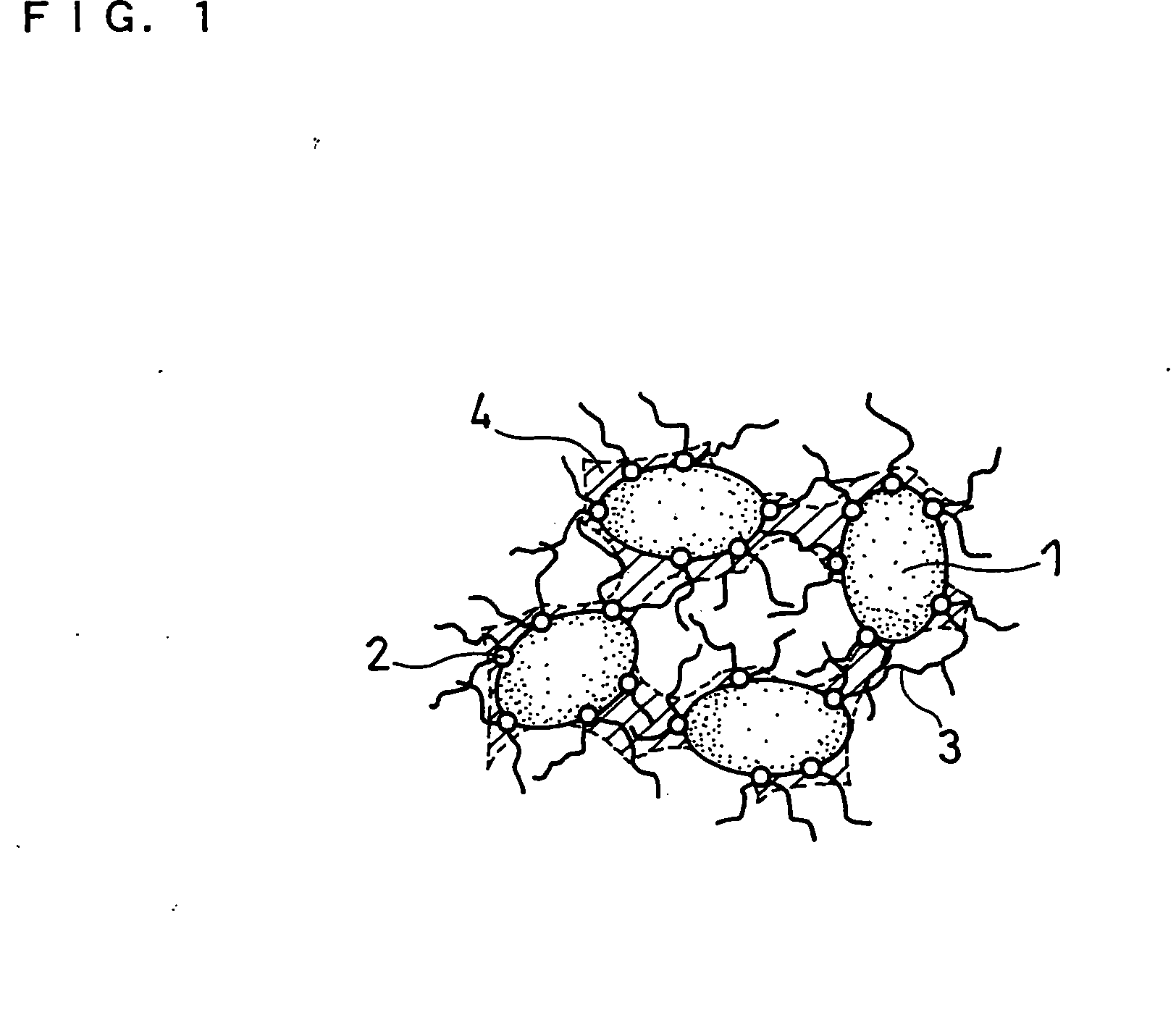

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

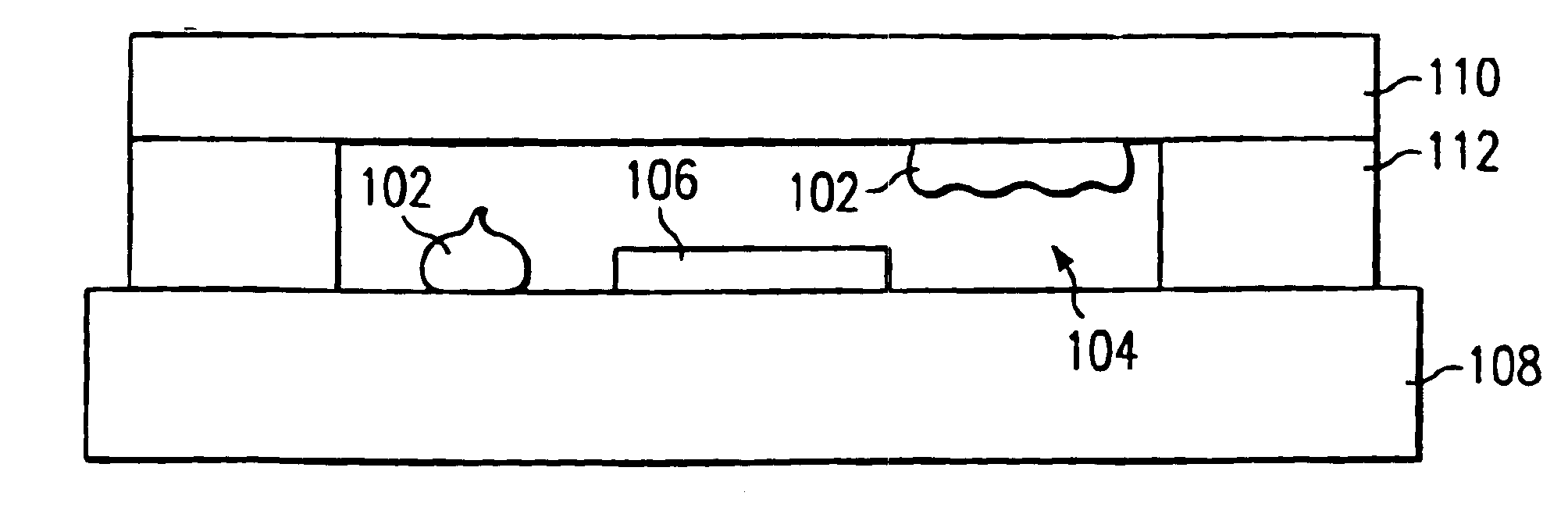

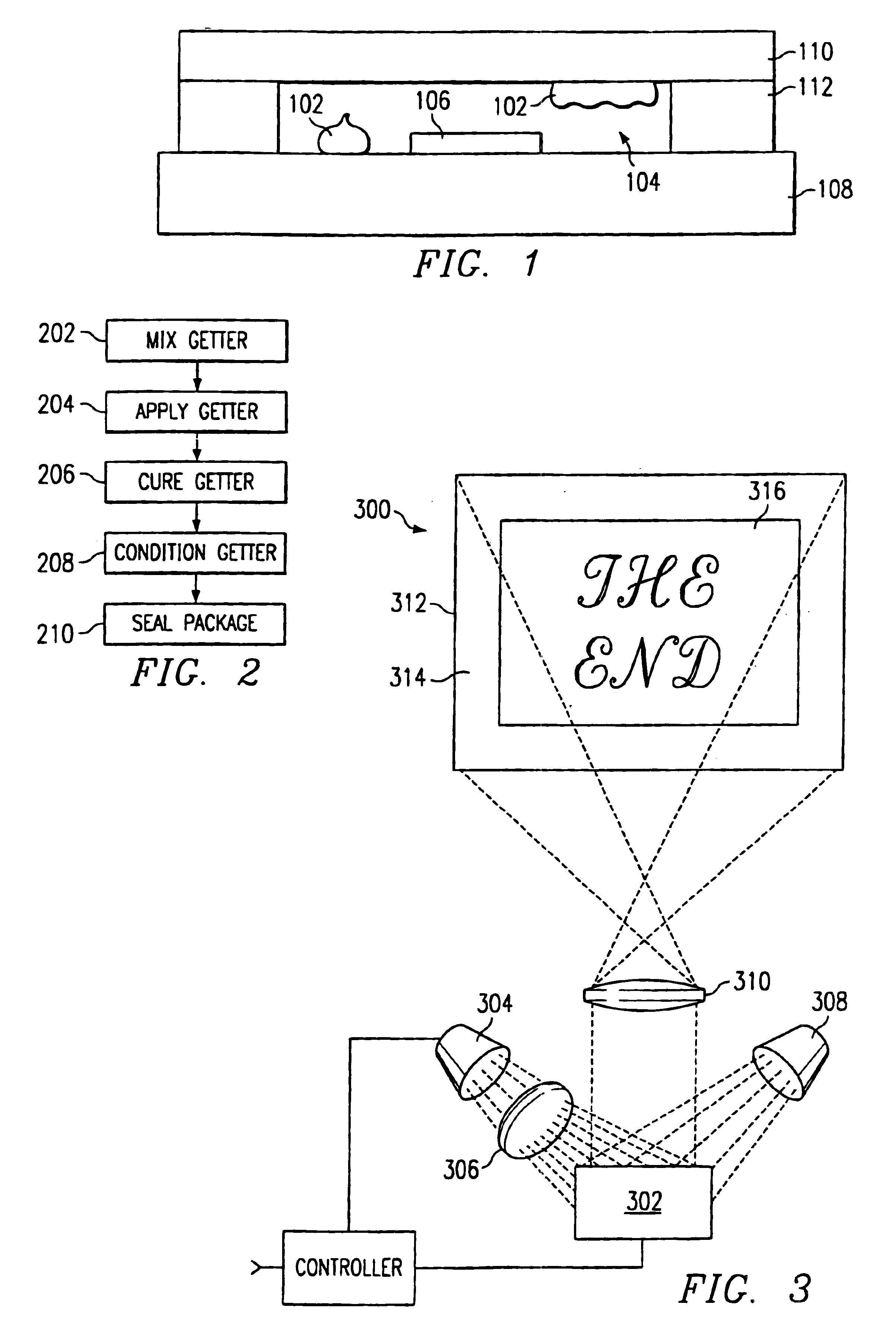

Getter for enhanced micromechanical device performance

A desiccant compound, image projection system using the desiccant compound, and a method for utilizing the desiccant compound. The desiccant compound formed by mixing (202) a polymer binder selected from the group consisting of polysaccharides (including without limitation structural polysaccharides such as cellulose, chitin, and their functionalized derivatives), polyamines, polysulfones, and polyamides with a drying agent, typically a zeolite, at a polymer to drying agent weight ratio of 1:2.1 to 1:100, or 1:4 to 1:10. After the desiccant compound is mixed (202) it is applied (204) to a surface and cured (206), often through the application of heat and vacuum. The cured desiccant compound is conditioned (208) and the it package is sealed (210).

Owner:TEXAS INSTR INC

Modified membranes

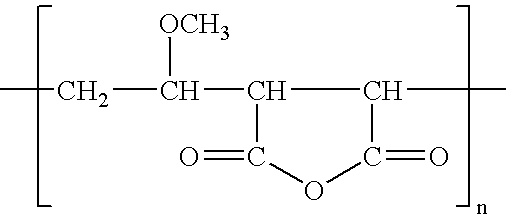

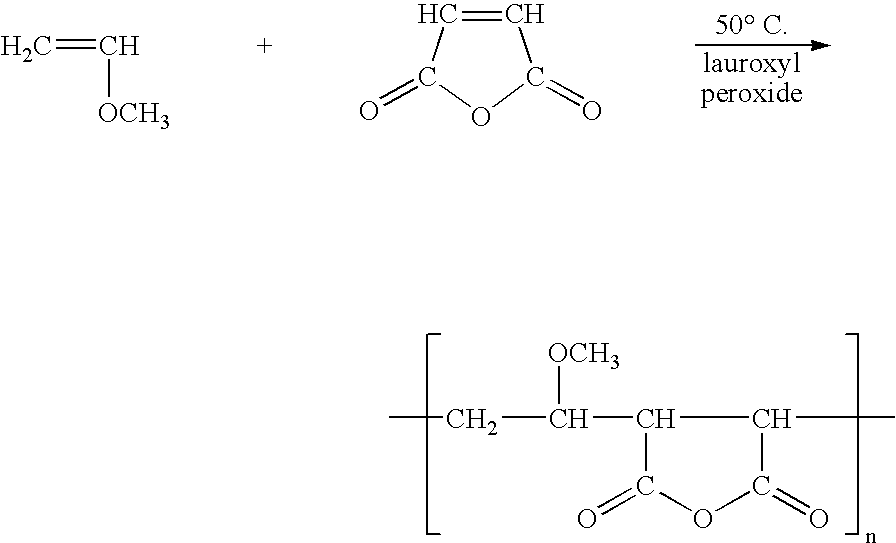

InactiveUS20050029186A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

InactiveUS6884350B2Reduce dirtEssential mechanical properties of the membranesMembranesSemi-permeable membranesVinyl etherPolyamide

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

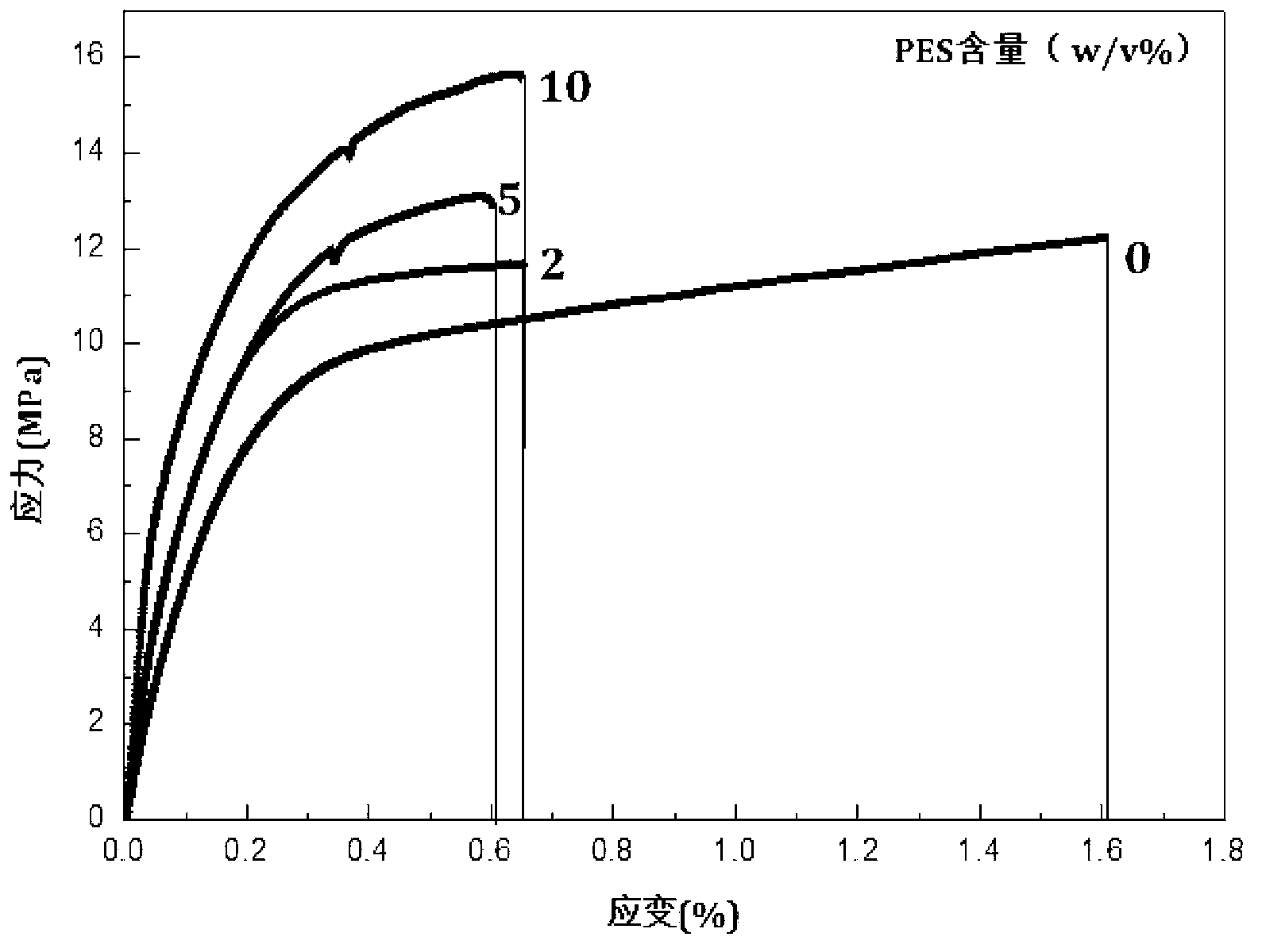

Composite thermotropic phase separation film-making method

The invention relates to a composite thermotropic phase isolated membrane preparation method which is characterized in that used composite diluent is the mixture of water-soluble good solvent and water-soluble additive of polymers. The membrane forming separation is a composite process which mainly takes the thermotropic membrane phase separation as the dominant role and non-solvent induced phaseseparation as the subsidiary role. The membrane prepared through the method has the advantages of high abruption strength, high abruption elongation and high water flux. The method is applicable to the preparation of membranes which are made of a plurality of polymers, including polyvinylidene fluoride, polysulfone, polyether sulfone, polyvinyl chloride and polyacrylonitrile. The performances of the membranes are improved greatly. Thus, the membranes can be widely applied to the fields of drinking water advanced treatment, pretreatment before reverse permeation, membrane bioreactor wastewatertreatment, reclaimed water reuse, etc.

Owner:湖南坎普尔环保技术有限公司

Modified membranes

InactiveUS20050032982A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:MULLER HEINZ JOACHIM

Modified membranes

InactiveUS20050029185A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Protective coating materials for electrochromic devices

InactiveUS6261641B1Free from mechanical damagePretreated surfacesLiquid/solution decomposition chemical coatingCell layerEther

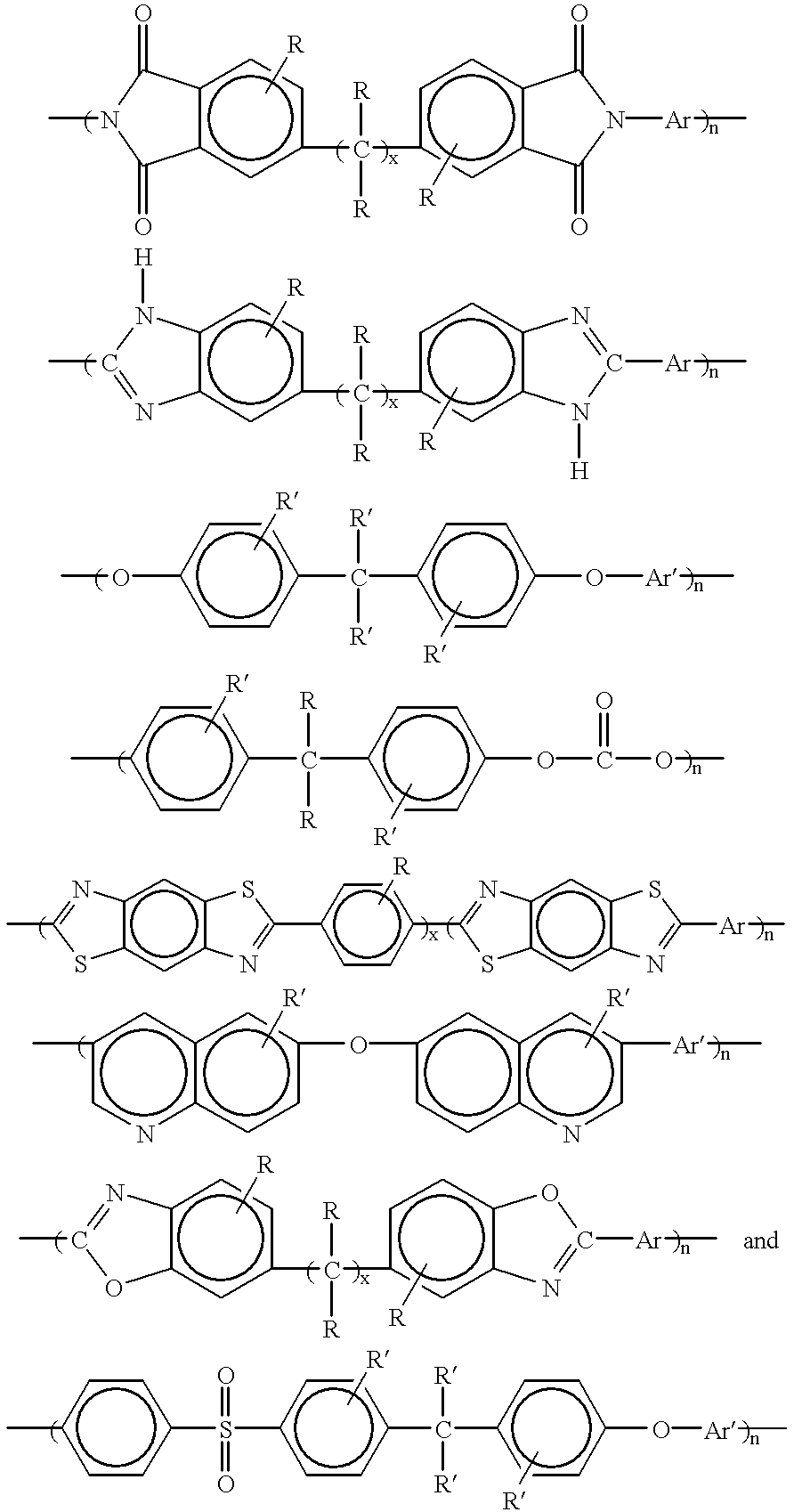

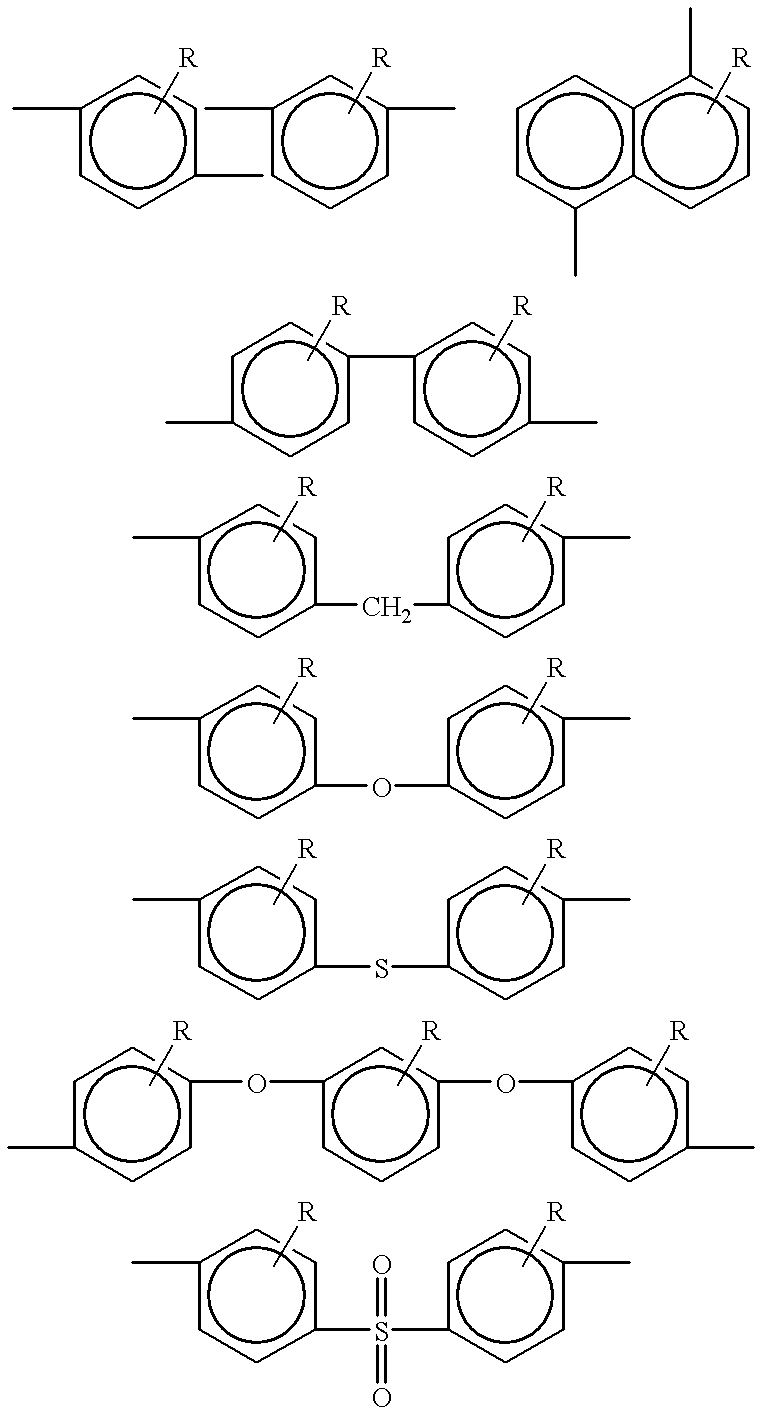

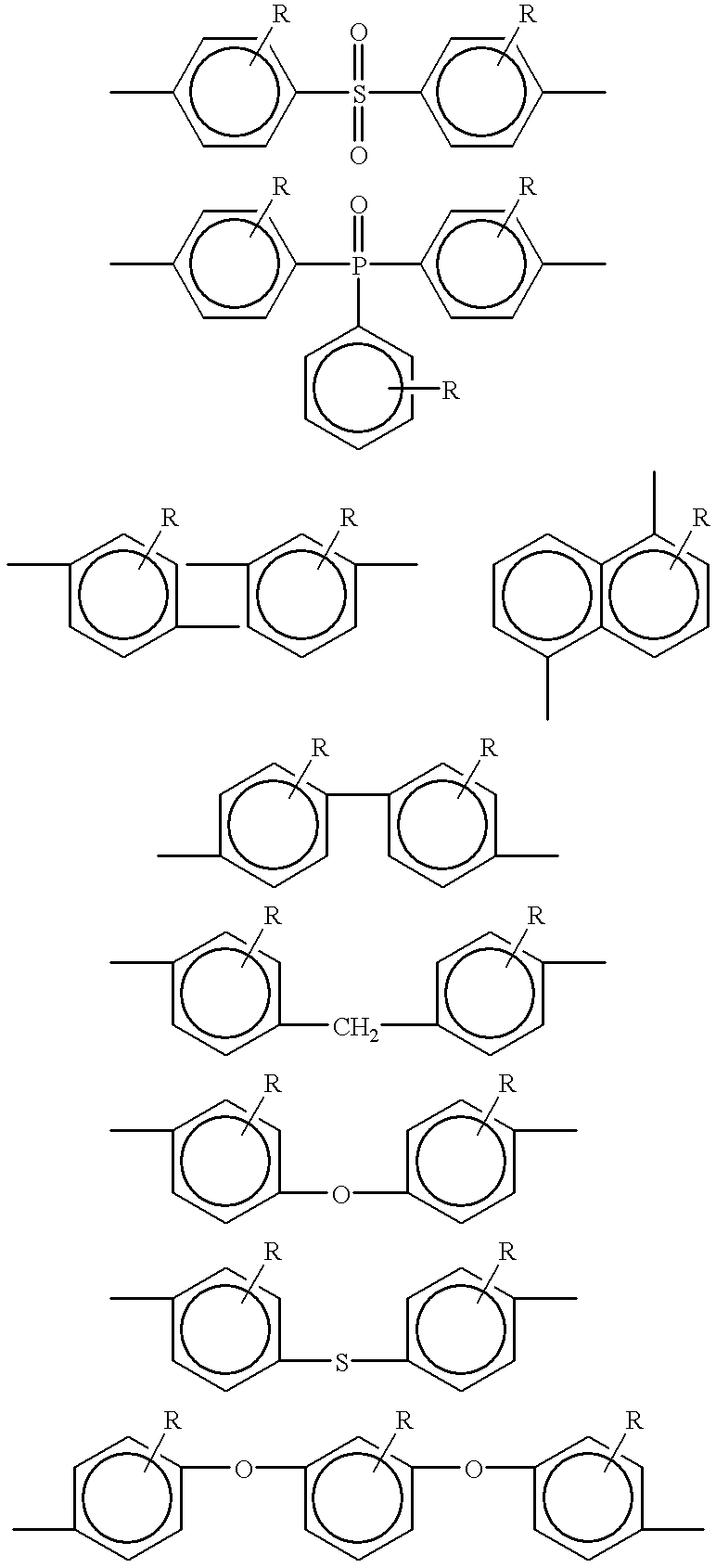

Polymeric coating materials used to protect electrochromic devices from environmental and mechanical damage arc provided. The protective polymeric coating materials are physically, chemically and optically compatible with the electrochromic cell layers of electrochromic devices. The polymeric coating materials are polymers having generic polymer back-bones selected from the group of polyimides, polybenzimidazoles, polybenzothiazoles, polybenzoxazoles, poly(phenylene ethers), polyquinolines, polycarbonates, and polysulfones.

Owner:JDS UNIPHASE CORP

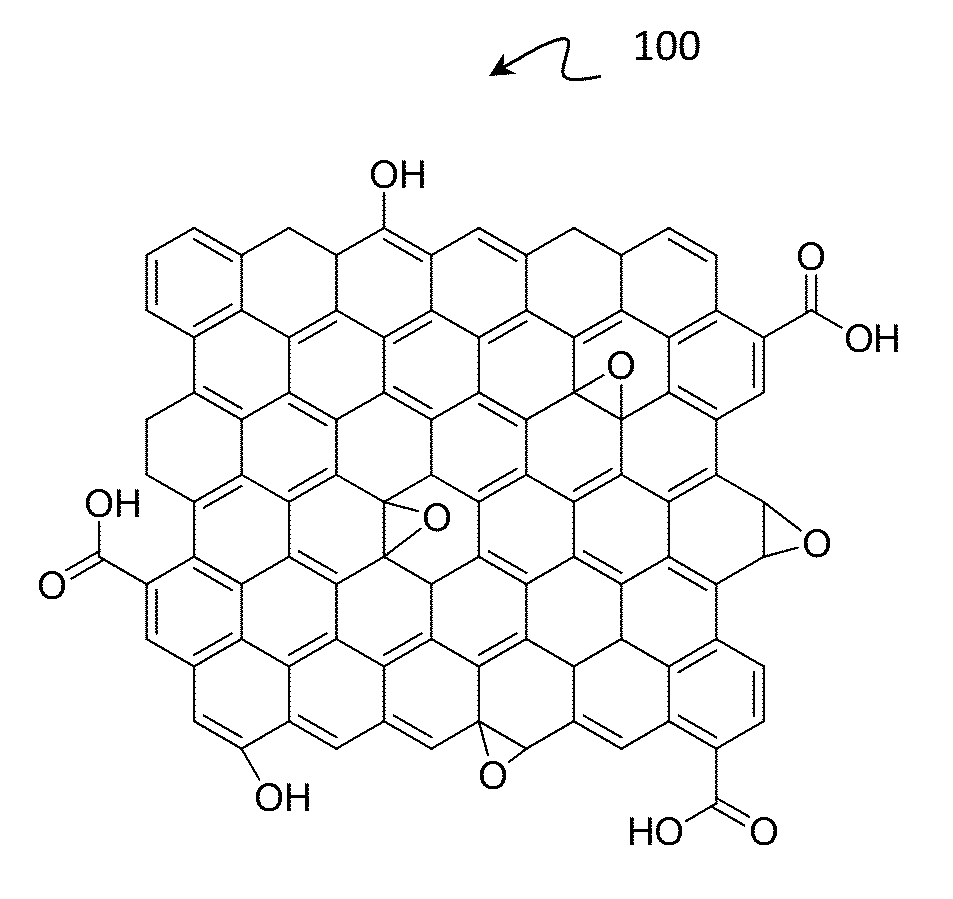

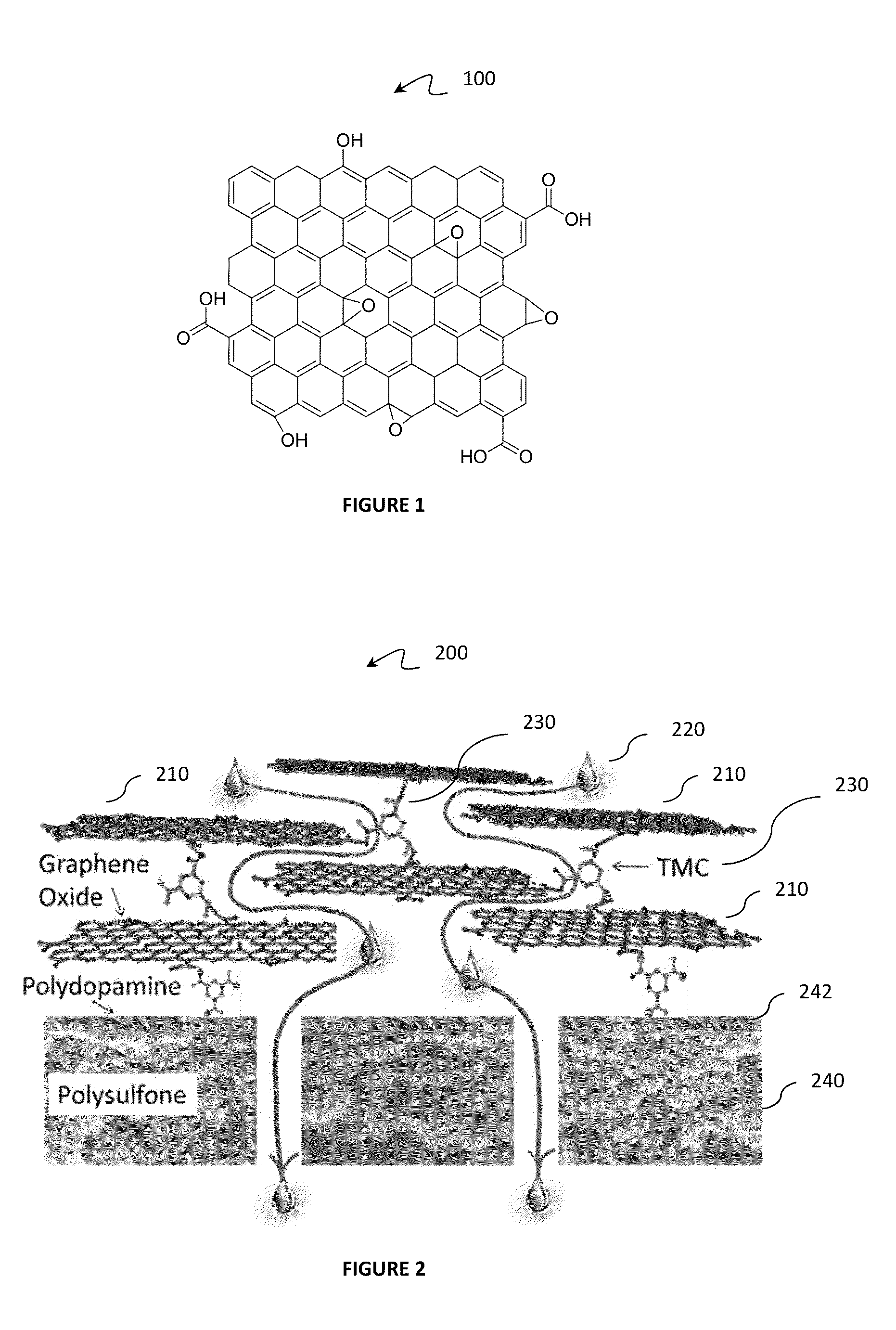

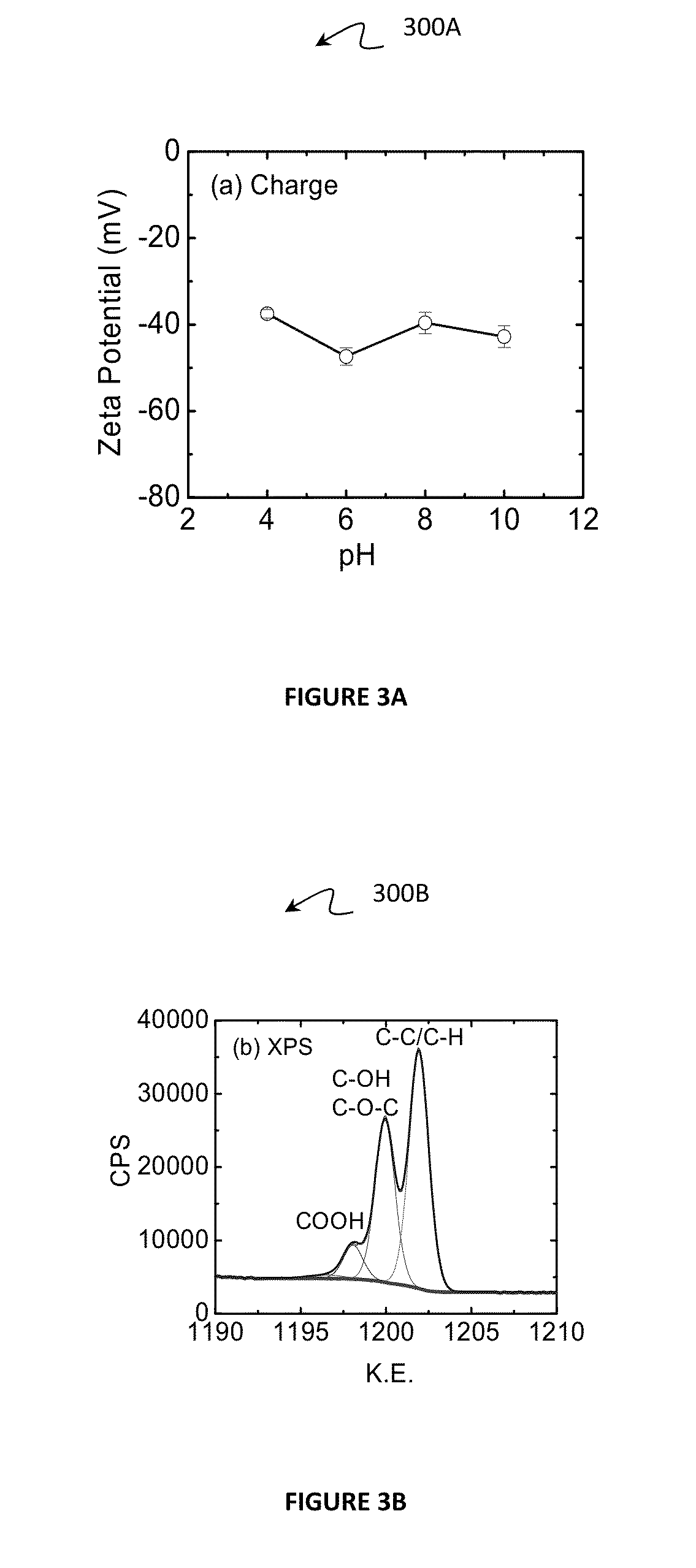

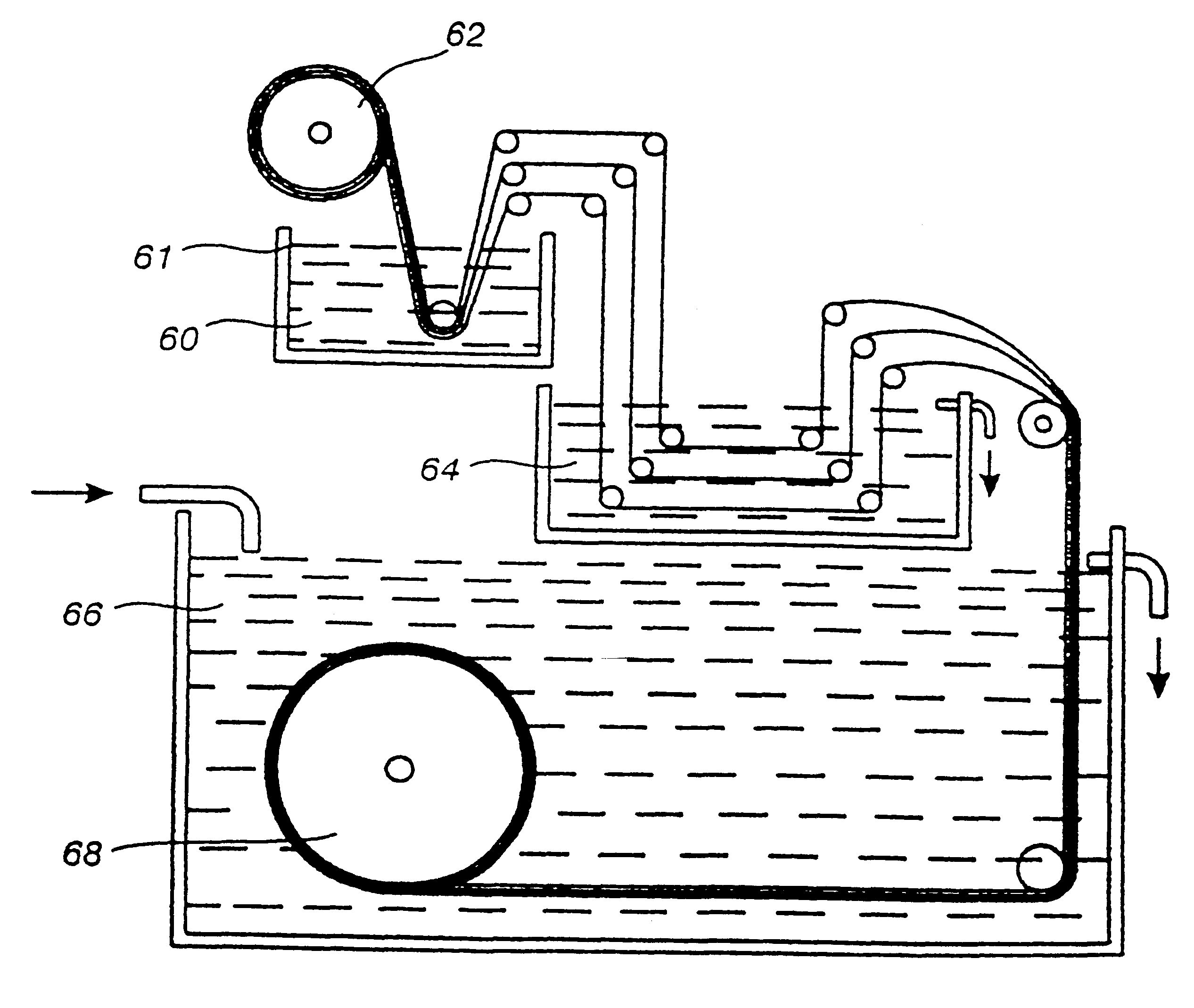

Layer-by-layer assembly of graphene oxide membranes via electrostatic interaction and eludication of water and solute transport mechanisms

A method for synthesizing a water purification membrane is presented. The method includes stacking a plurality of graphene oxide (GO) nanosheets to create the water purification membrane, the stacking involving layer-by-layer assembly of the plurality of GO nanosheets and forming a plurality of nanochannels between the plurality of GO nanosheets for allowing the flow of a fluid and for rejecting the flow of contaminants. The method further includes cross-linking the plurality of GO nanosheets by 1,3,5-benzenetricarbonyl trichloride on a polydopamine coated polysulfone support.

Owner:UNIV OF MARYLAND

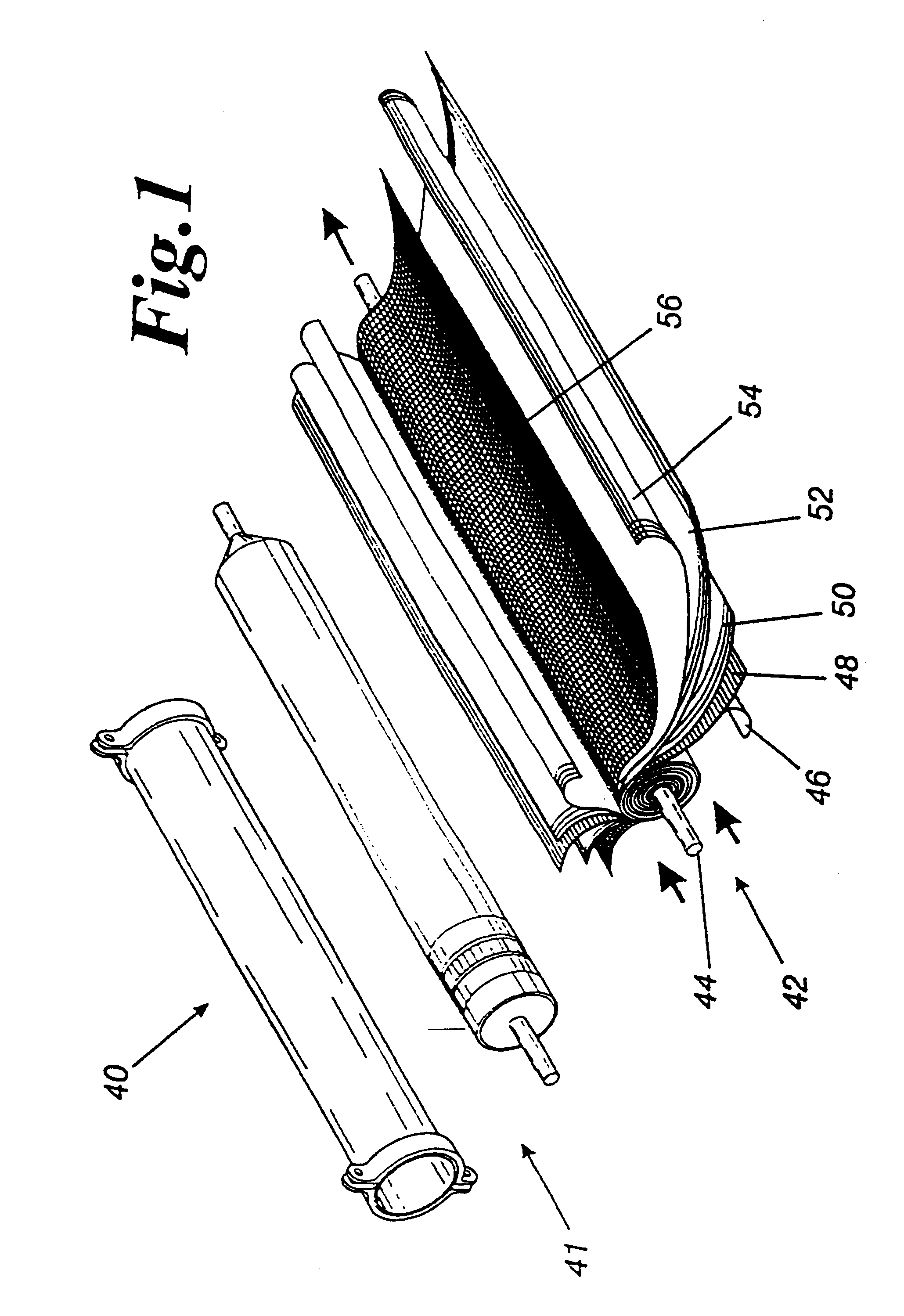

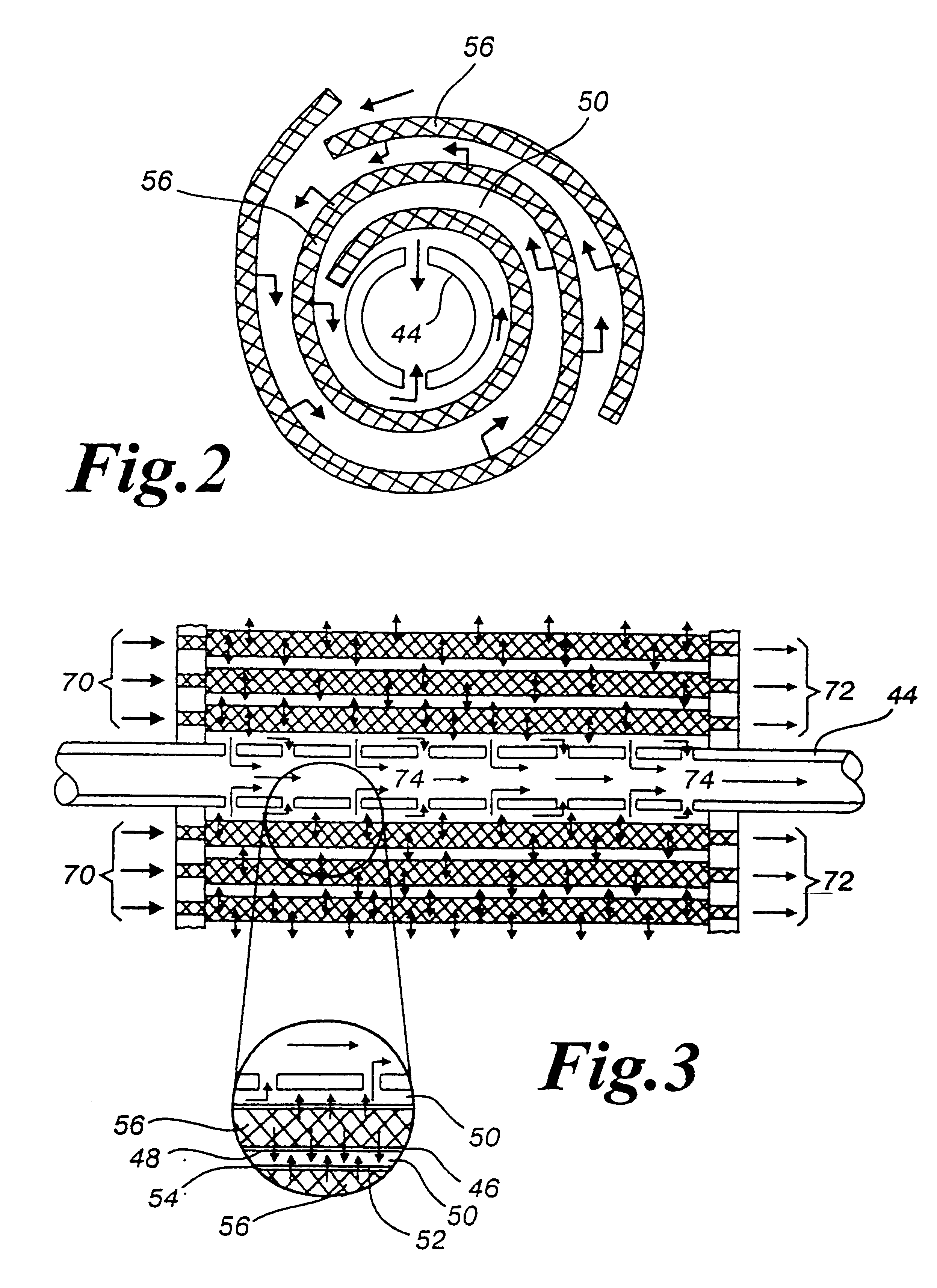

Antimicrobial semi-permeable membranes

Cast semi-permeable membranes made from synthetic polymer used in reverse osmosis, ultrafiltration and microfiltration are treated with a non-leaching antimicrobial agent to prevent its bio-fouling and bacterial breakthrough. The semi-permeable membranes include a polymeric material and a non-leaching antimicrobial agent that is incorporated into and homogeneously distributed throughout the polymeric material. The polymeric material, in the case of one membrane, may be cellulose acetate. In the case of thin film composite polyamide membranes, the antimicrobial agent is incorporated in a microporous polysulfone layer that is sandwiched between a reinforcing fabric and an ultrathin polyamide material. The invention also includes a treatment of flat and hollow fiber semipermeable membranes made with polysulfones and polyvinylidene fluoride.

Owner:MICROBAN PROD CO INC

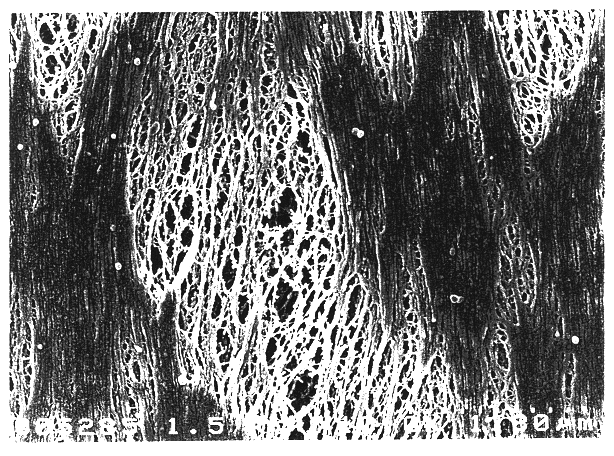

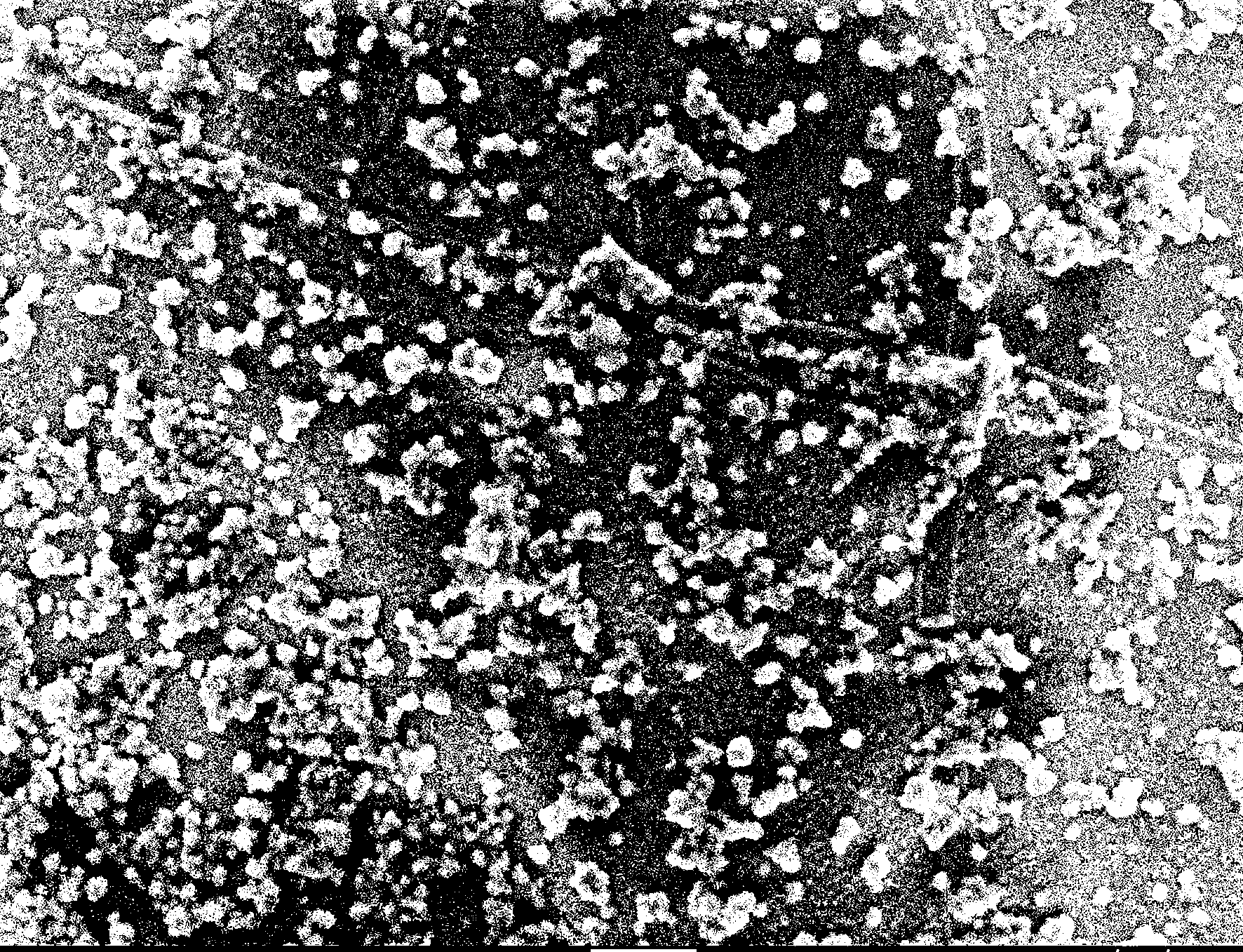

Polysulfone-base hollow-fiber hemocathartic membrane and processes for the production thereof

InactiveUS6432309B1Good blood compatibilityEasy to separateSemi-permeable membranesMembranesFiberHollow fibre membrane

Provided are a polysulfone type blood-purifying membrane which is improved in blood compatibility and separation properties and less in polyvinyl pyrrolidone eluting in the internal surface of the hollow fiber membrane, as well as a process for producing the same.

Owner:ASAHI KASEI MEDICAL CO LTD

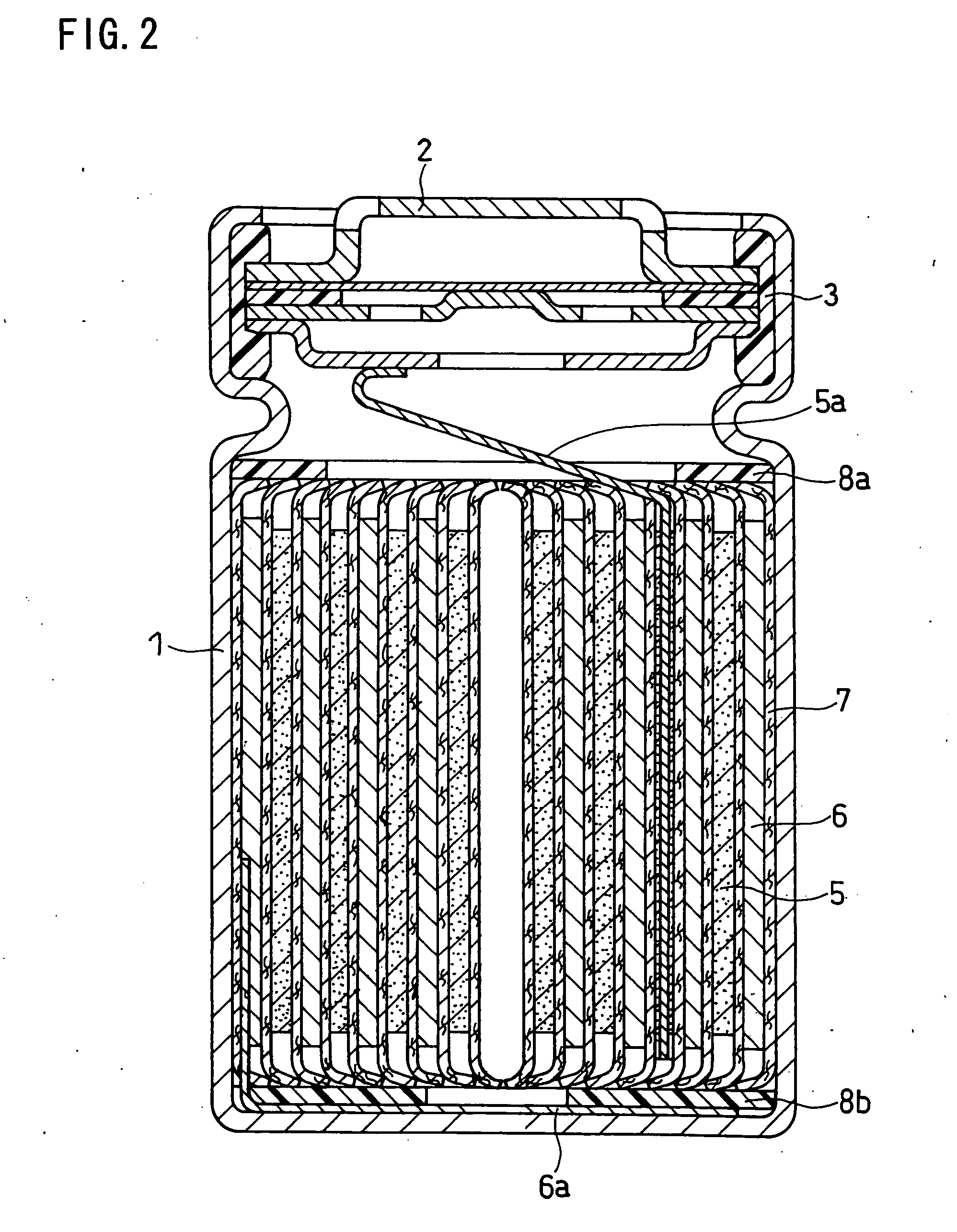

Non-aqueous electrolyte secondary battery

InactiveUS20070099081A1Improve reliabilityHigh charge and discharge capacityMaterial nanotechnologyNon-aqueous electrolyte accumulatorsPolyetherimidePolyamide

A non-aqueous electrolyte secondary battery including a positive electrode, a negative electrode, a separator interposed between the positive and negative electrodes, and a non-aqueous electrolyte. The negative electrode includes composite particles and a binder. Each of the composite particles includes: a negative electrode active material including an element capable of being alloyed with lithium; carbon nanofibers that are grown from a surface of the negative electrode active material; and a catalyst element for promoting the growth of the carbon nanofibers. The binder comprises at least one polymer selected from the group consisting of polyimide, polyamide imide, polyamide, aramid, polyarylate, polyether ether ketone, polyether imide, polyether sulfone, polysulfone, polyphenylene sulfide, and polytetrafluoroethylene.

Owner:PANASONIC CORP

Microbial contamination resistance composite reverse osmosis membrane and preparation method thereof

ActiveCN101874989AEasy to manufactureEasy to operateSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSurface layerReverse osmosis

The invention discloses a microbial contamination resistance composite reverse osmosis membrane and a preparation method thereof. The microbial contamination resistance composite reverse osmosis membrane comprises a nonwoven fabric layer, a polysulfone supporting layer and two polyamide surface layer, wherein a second polyamide surface layer which is prepared by reacting nano inorganic antibacterial particle-modified polyamine solution with poly(acylchloride) is formed above a first polyamide surface layer. Compared with the prior art, the composite reverse osmosis membrane prepared by the invention is improved in microbial contamination resistance, surface thickness, mechanical damage resistance and service life for a layer of nano inorganic antibacterial particle-modified polyamide membrane is formed on the surface of the polysulfone supporting layer besides the layer of complete and uniform polyamide membrane. The composite reverse osmosis membrane of the invention has the characteristics of easy preparation and operation and high salt rejection rate and water permeability.

Owner:VONTRON TECH CO LTD

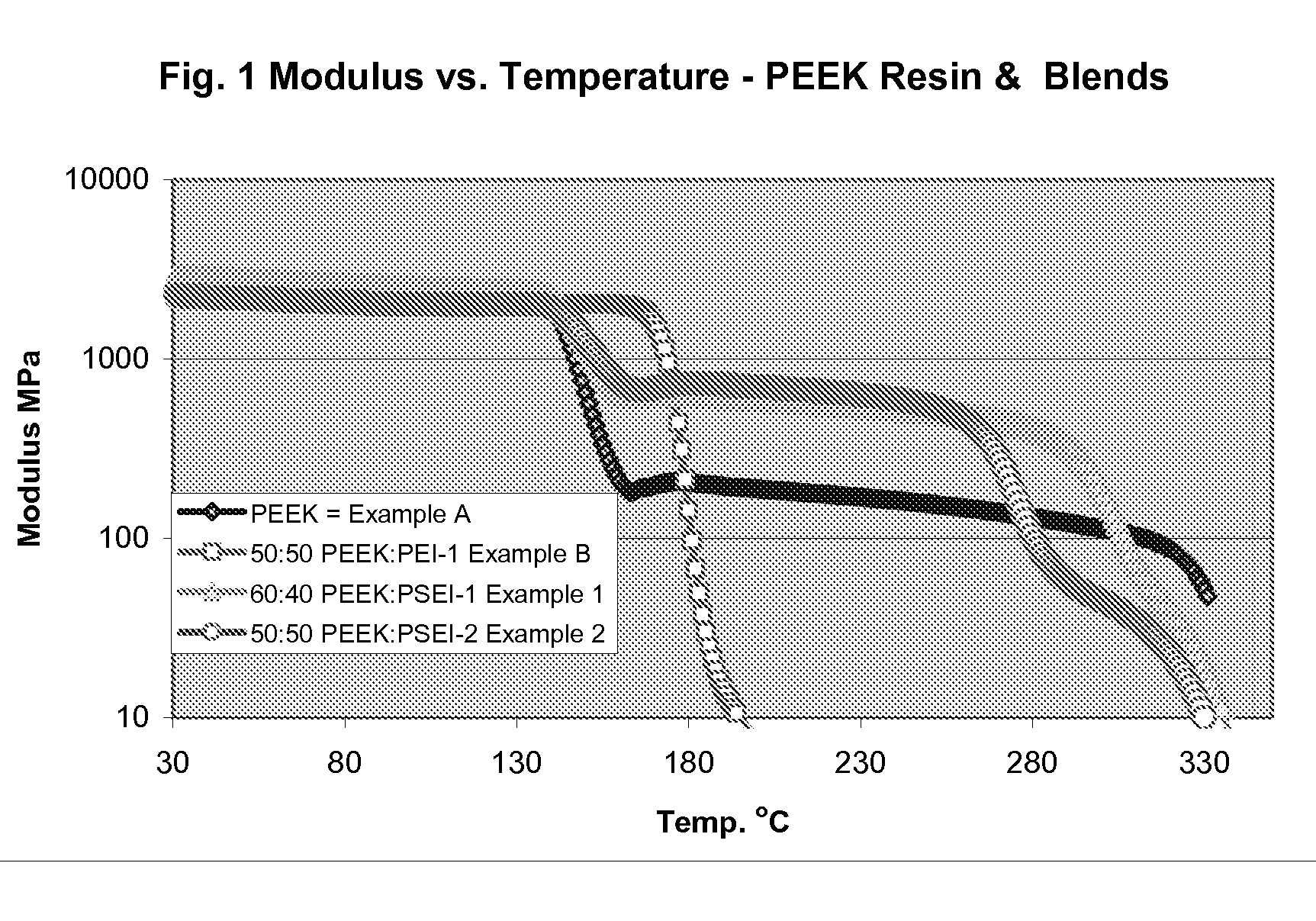

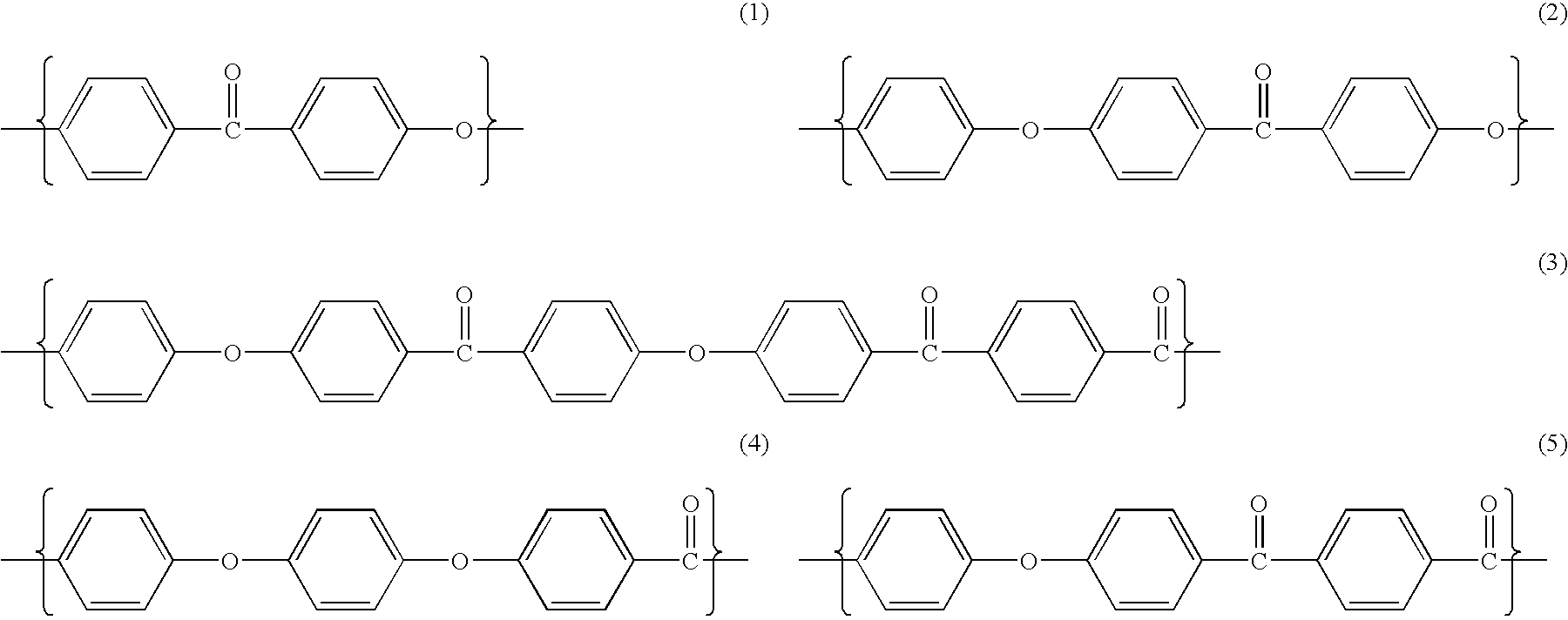

Poly aryl ether ketone polymer blends

Filled phase-separated blends of polyaryl ether ketones, polyaryl ketones, polyether ketones, polyether ether ketones and mixtures thereof with at least one polysulfone etherimide, wherein the polysulfone etherimide has greater than or equal to 50 mole % of the polymer linkages contain at least one aryl sulfone group are described. Such filled blends have improved load-bearing capability at high temperature. In another aspect the filled blends have a higher crystallization temperature, especially at fast cooling rates.

Owner:SABIC GLOBAL TECH BV

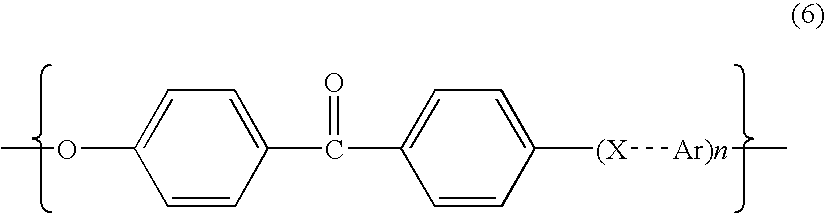

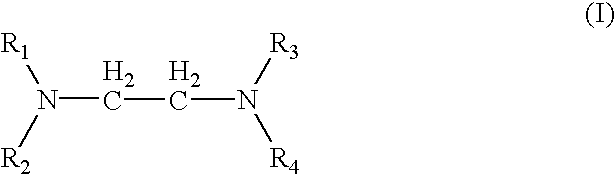

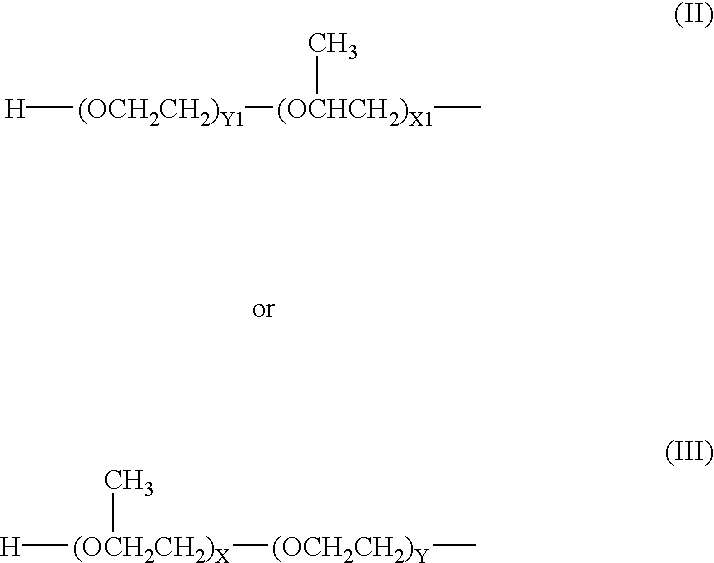

Membrane which comprises a blend of a polysulphone or a polyether sulphone and polyethylene oxide/polypropylene oxide substituted ethylene diamine

A membrane which can be used in membrane filtration processes and which has a reduced tendency to fouling is a polysulphone or a plyether sulphone and a polyethylene oxide / polypropylene oxide substituted diamine and can be made by a phase inversion process in the presence of pore modifying agents such as an alcohol, glycerol or glycol to give a membrane which has a pore size of 0.1.mu. to 1 micron and is hydrophilic.

Owner:HYDRANAUTICS

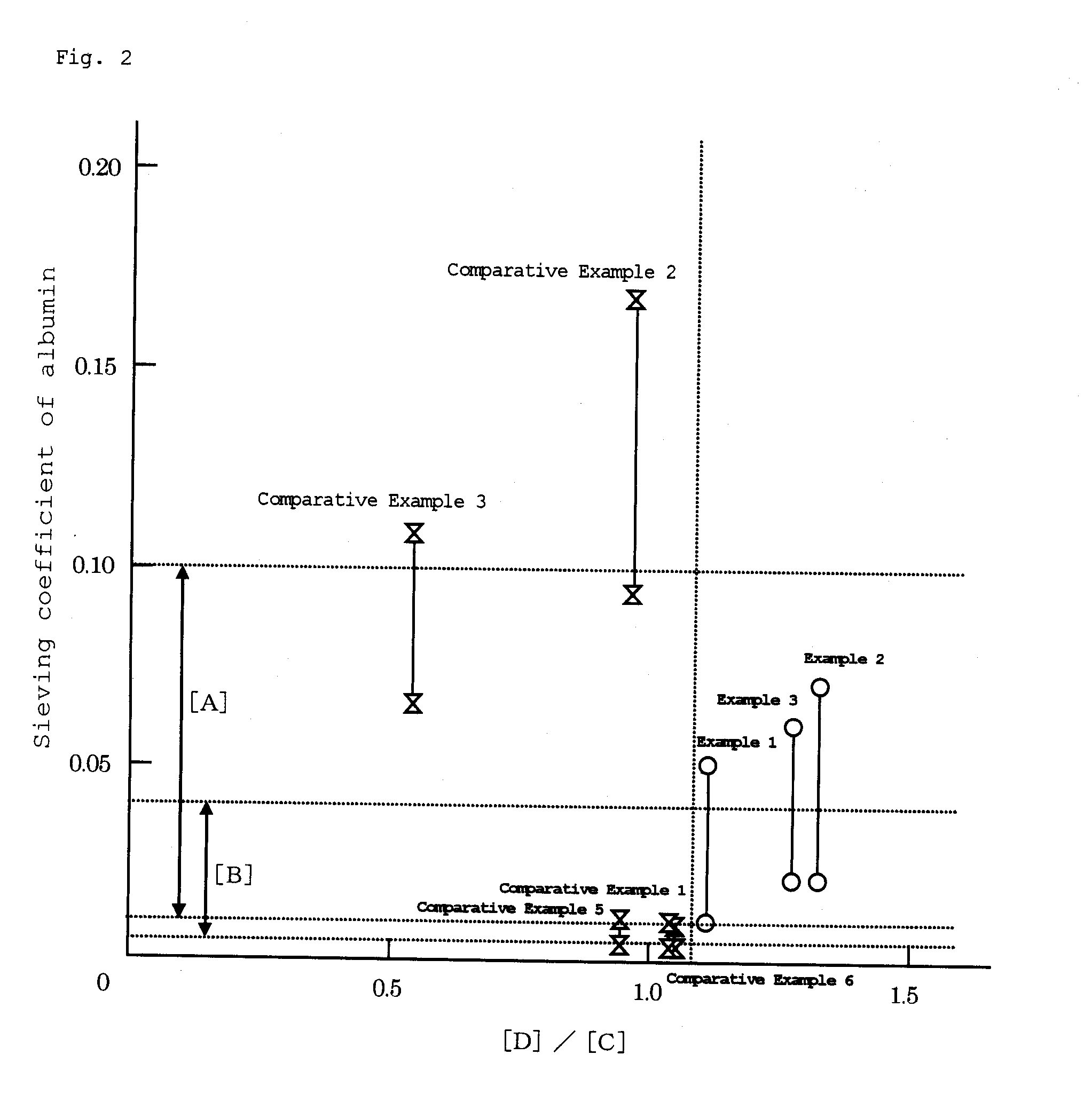

Separation Membrane With Selective Permeability And Process For Producing The Same

ActiveUS20070199891A1Accelerates oxide degradationStorage stability is degradedMembranesUltrafiltrationMembrane configurationChromatography

The present invention relates to a permselective separation membrane that can be used in blood purifying treatment. More particularly, the present invention relates to a polysulfone-based permselective separation membrane which has well-balanced separation properties, highly stable safety and performance, and also can be smoothly assembled into a module, and a method for producing the same.

Owner:TOYO TOYOBO CO LTD

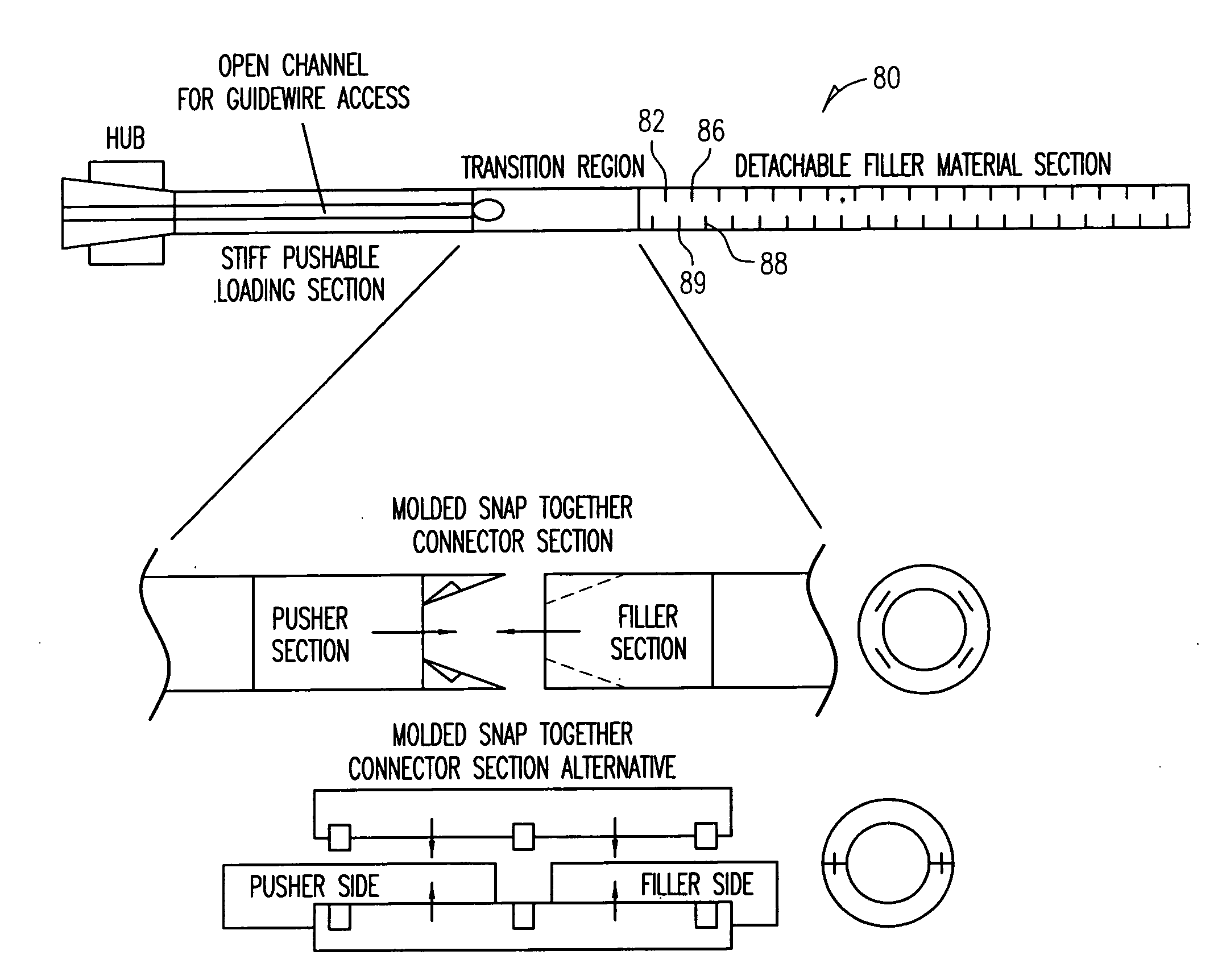

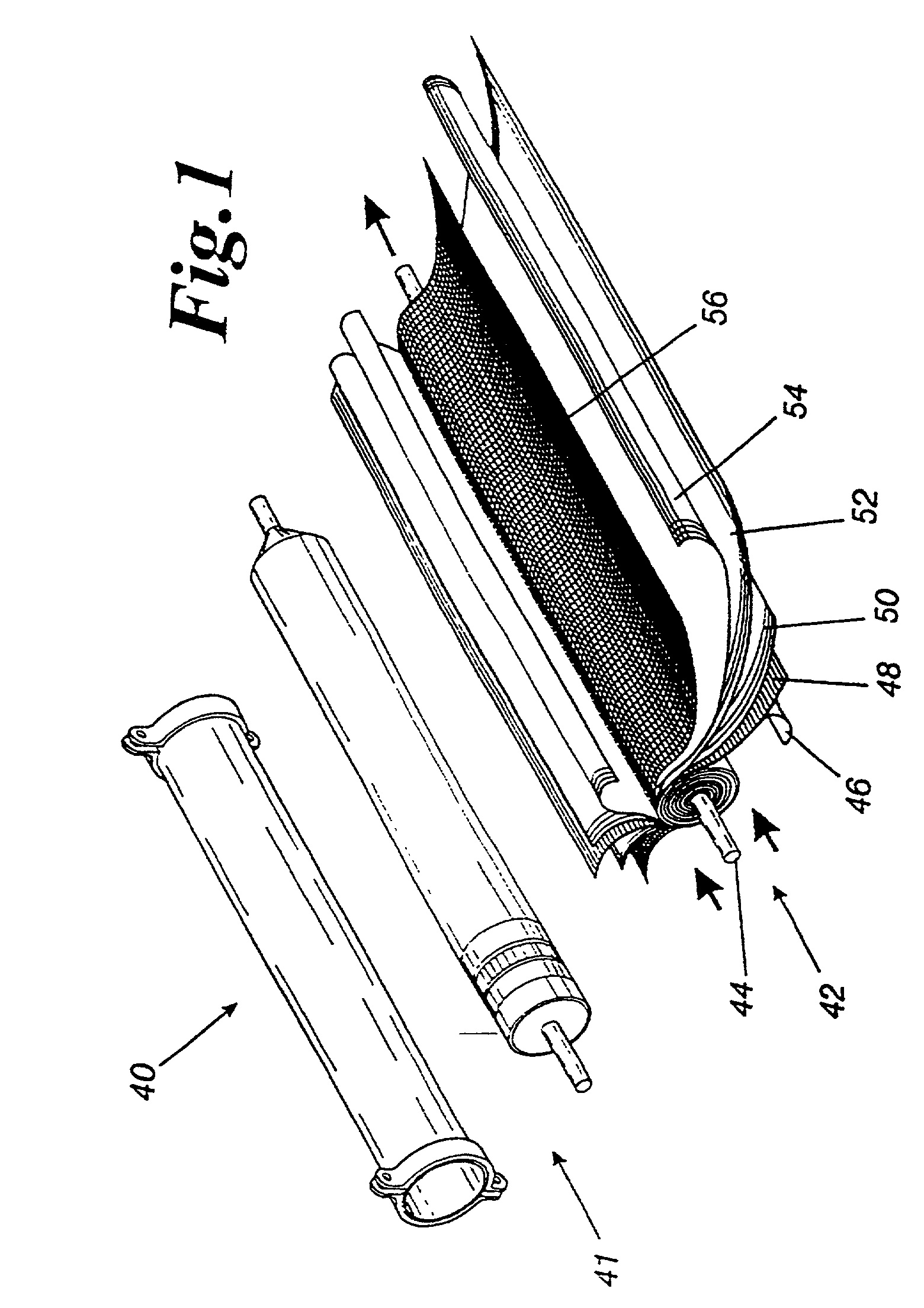

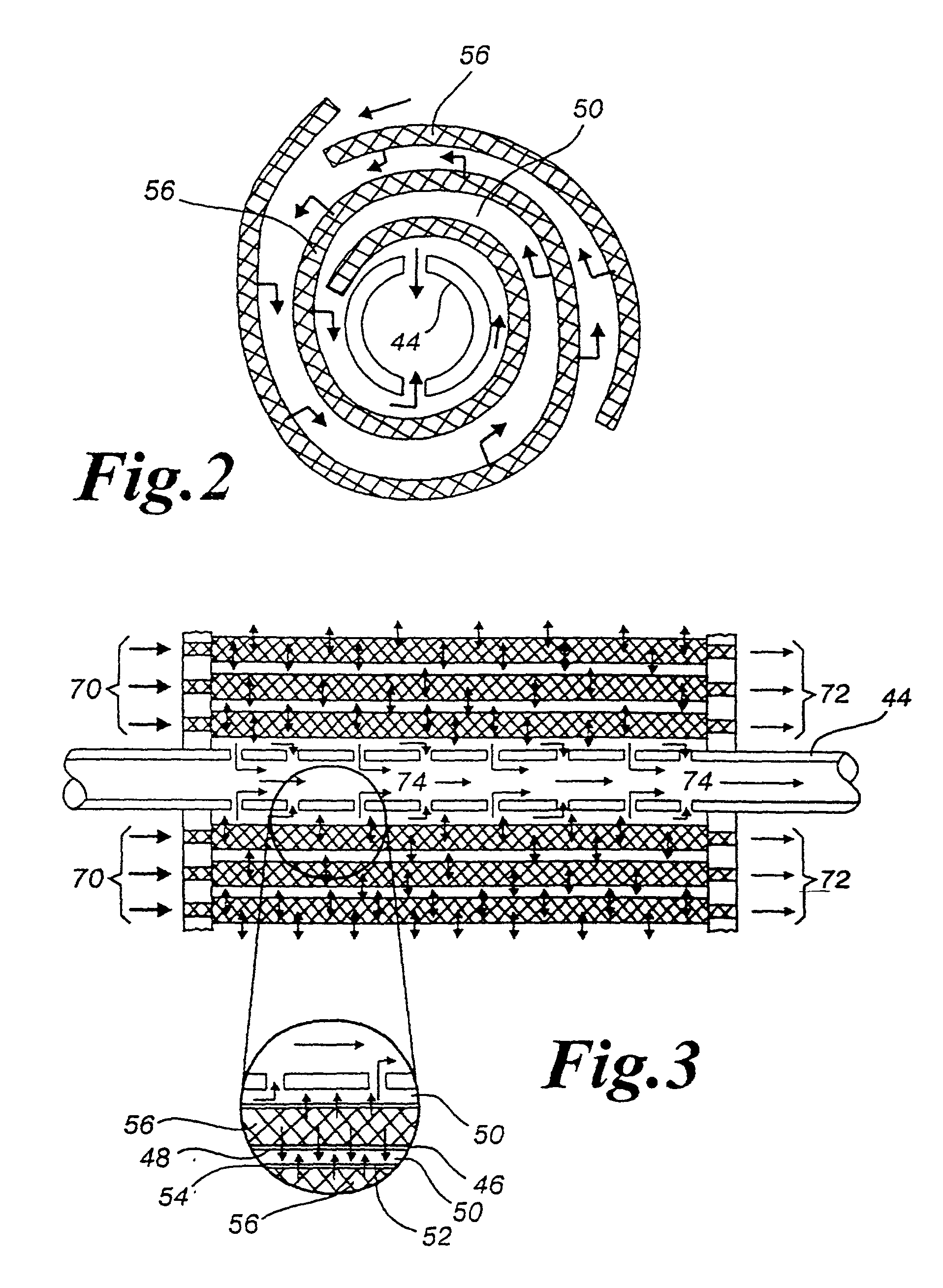

Multiple point detacher system

Embodiments of the invention include a method for treating an aneurysm, comprising: providing a biocompatible polymeric sleeve, string or coil or combination of sleeve, string or coil, made from a material selected from one or more of a group consisting of an acrylamide, a methacrylate, cyclodextran, synthetic elastin polymer, poly chelating amphiphilic polymers, hydrogels, hyaluronic acid conjugates, polyanhydrides, glycolipids, polysaccharides, and halamines, natural hydrogel, a synthetic hydrogel, silicone, polyurethane, polysulfone, cellulose, polyethylene, polypropylene, polyamide, polyimide, polyester, polytetrafluoroethylene, polyvinyl chloride, epoxy, phenolic, neoprene, polyisoprene, and a combination thereof; transporting the sleeve, string or coil to an aneurysm; filling the aneurysm with the sleeve, coil, or string; and detaching the sleeve, string or coil

Owner:NEUROVASX

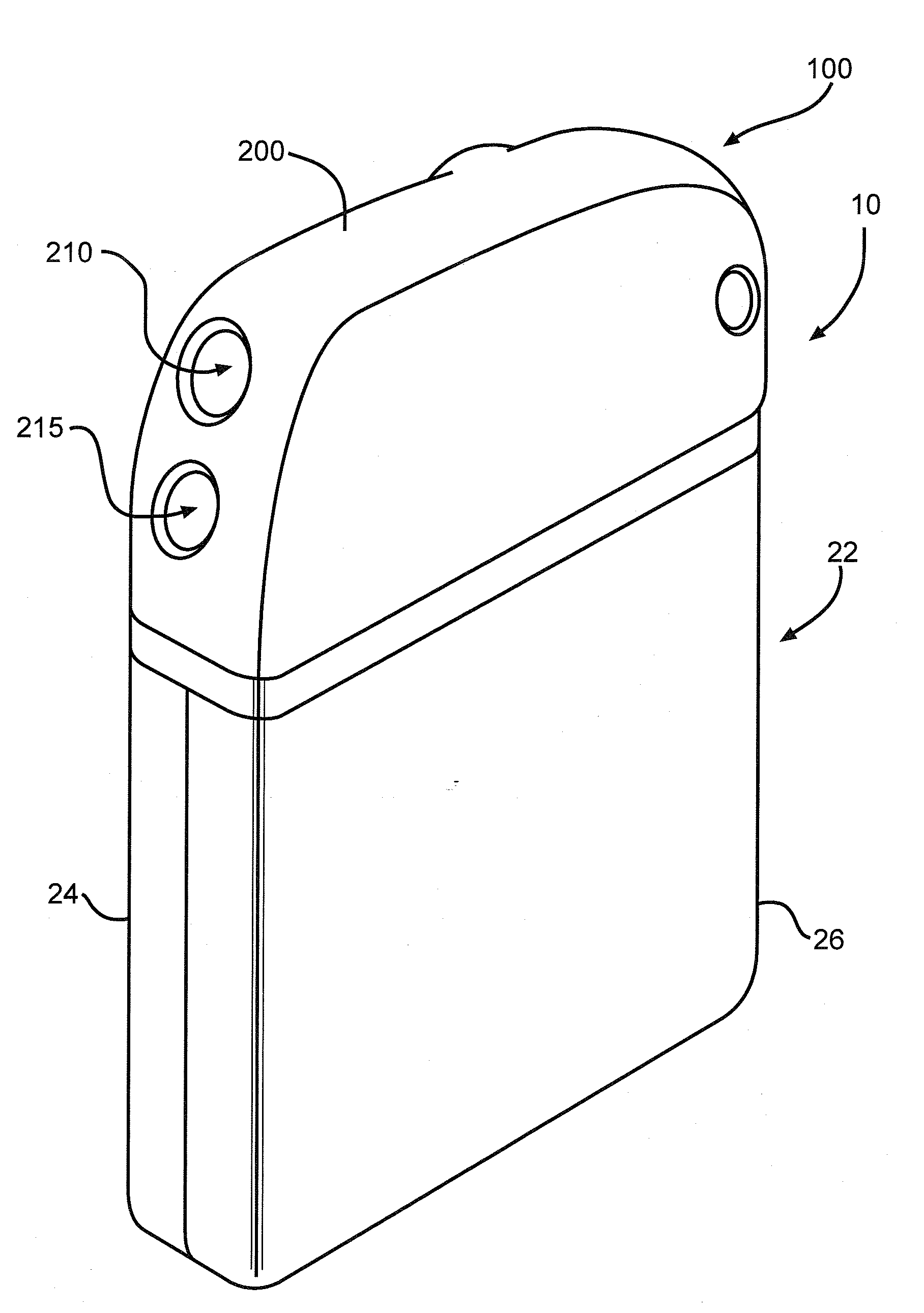

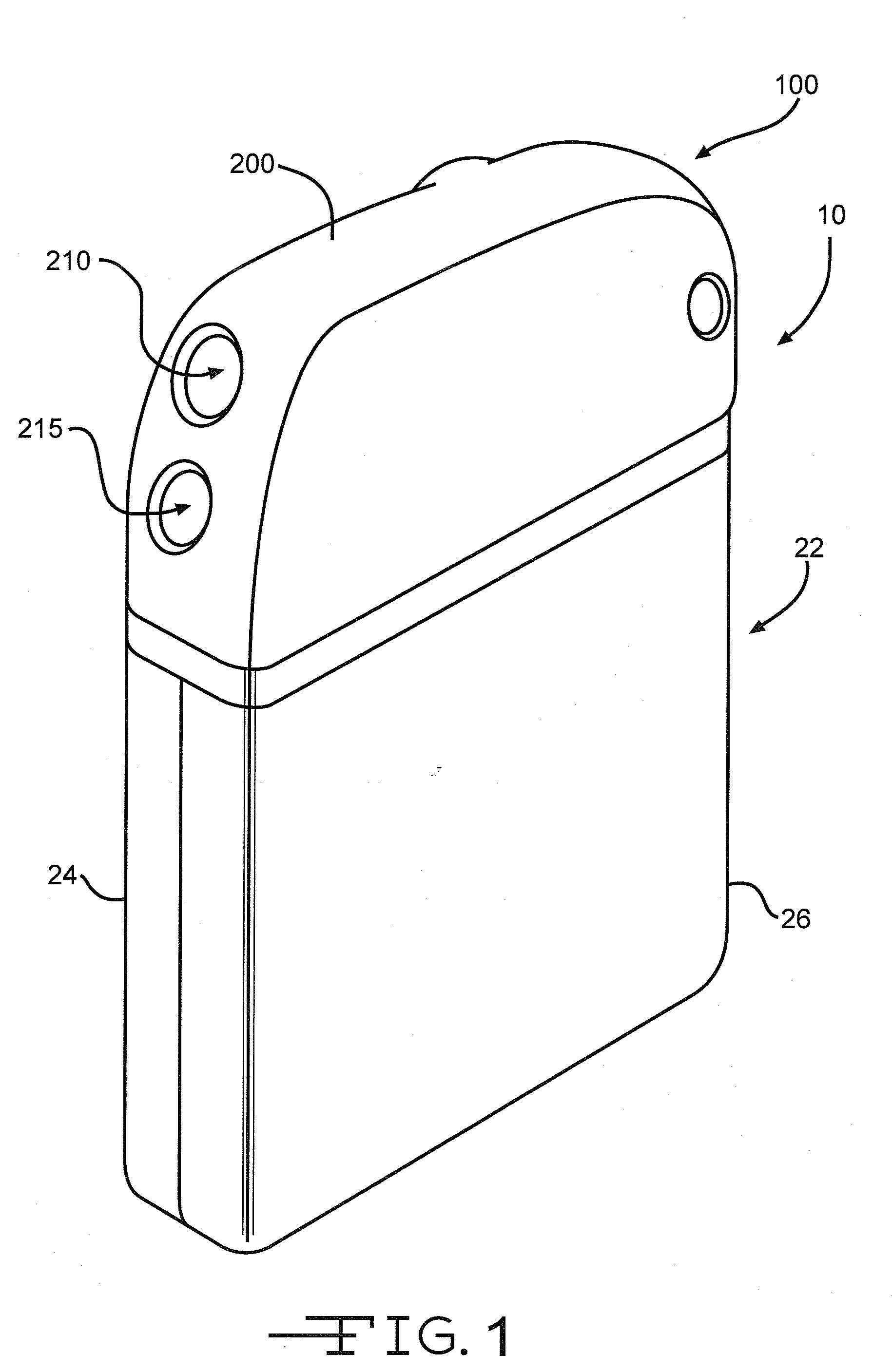

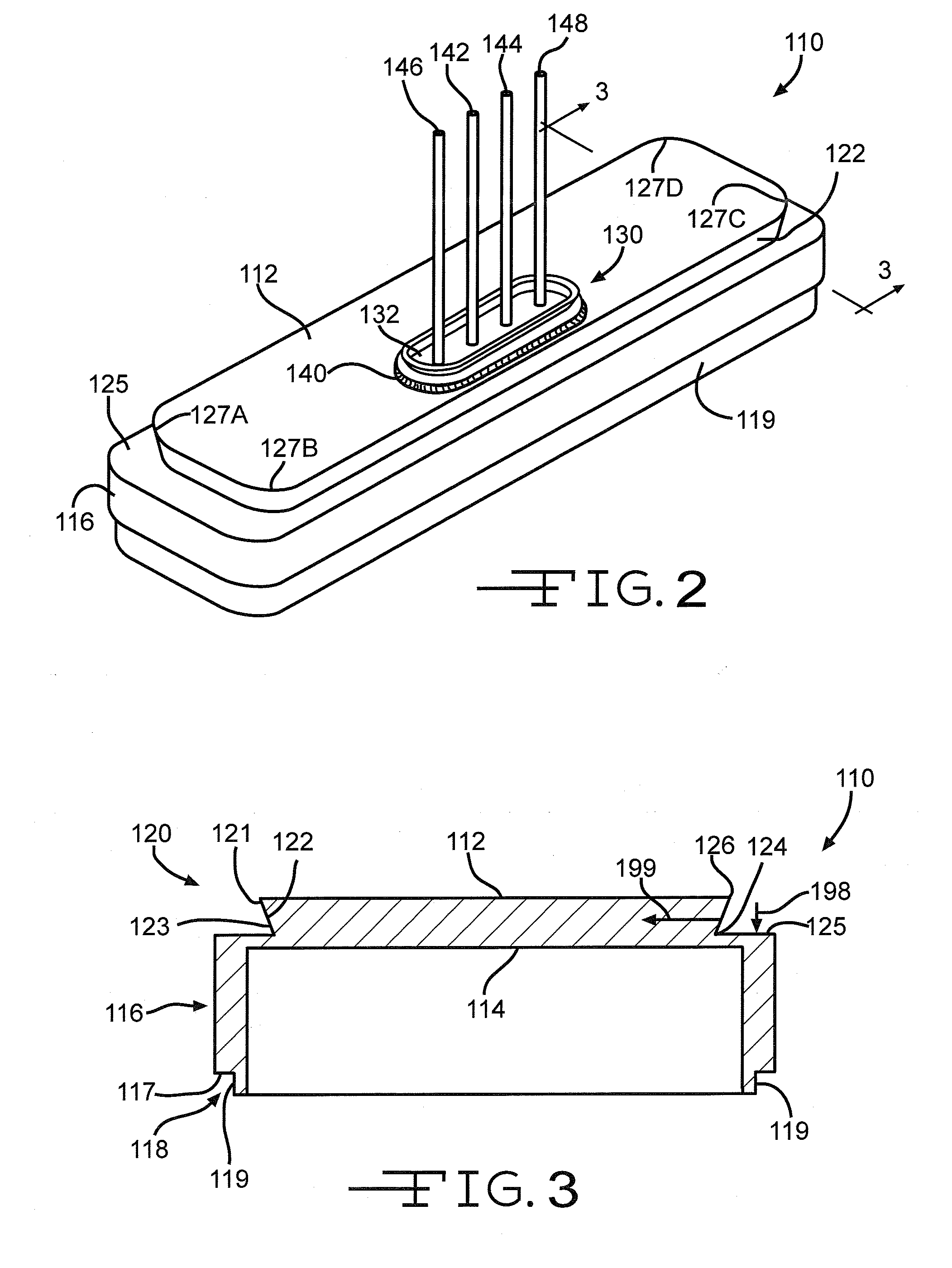

Header over-molded on a feedthrough assembly for an implantable device

A header assembly for connecting a conductor terminating at a body organ with an implantable medical device is described. The header assembly comprises a base plate, a feedthrough subassembly disposed in the base plate and comprising a ceramic-to-metal seal with first and second feedthrough wires passing through the ceramic-to-metal seal; a first electrically conductive terminal connected to a distal end of the first feedthrough wire and having a first lead opening sized to receive a first portion of a lead for the conductor; a second electrically conductive terminal connected to a distal end of the second feedthrough wire and having a second lead opening sized to receive a second portion of the lead for the conductor; a body of polymeric material molded in a two-part construction to encase the conductive terminals and their feedthrough wires except for a first bore communicating from outside the polymeric body to the first and second lead openings aligned in a first co-axial relationship. Preferably, the polymeric body comprises a first polymeric material such as Techothane® or Polysulfone® encasing the terminals except the bore and an epoxy as a second polymeric material molded over the first polymeric material.

Owner:WILSON GREATBATCH LTD

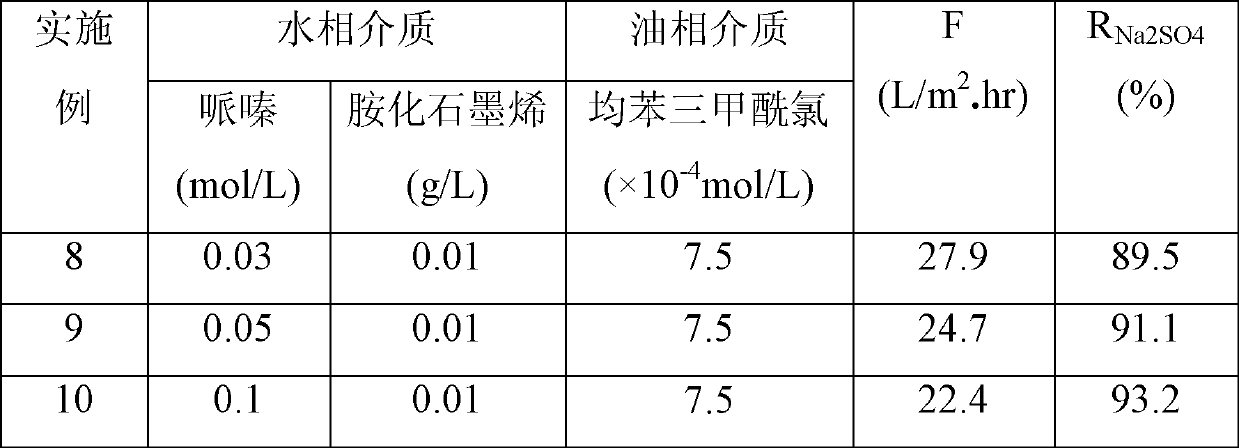

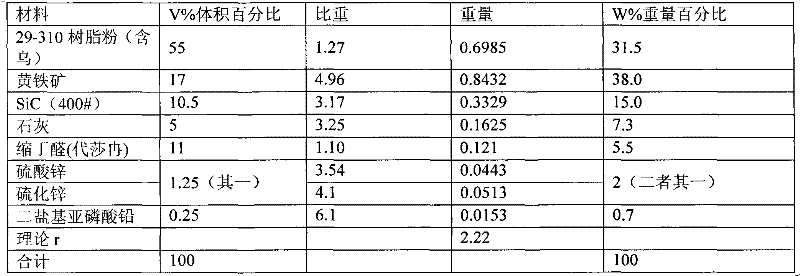

Preparation method of positively charged composite nanofiltration membrane

The invention discloses a preparation method of a positively charged composite nanofiltration membrane, belonging to the technical field of the membrane. The key technology comprises the processes of utilizing polyethyleneimine (PEI), chitosan quaternary ammonium salt, and nano TiO2 as water-phase film-forming materials; taking trimesoyl chloride (TMC) as an organic-phase film-forming material; taking ultrafiltration membranes such as polysulfone, polyether sulfone and sulfonated polyethersulfone as supported base membranes, and preparing the PEI / chitosan quaternary ammonium salt / TiO2 / TMC composite nano-filtration membranes by an interfacial polymerization method. The membrane has the advantages of high flux, high dye intercept rate, and low intercept rate of inorganic salt such as sodium sulfate and sodium chloride, can generate negative intercept phenomenon of salt when dye / salt system is separated, is high in dye and inorganic salt separating efficiency, and is suitable for desalination and purification of coarse liquid dye, especially the preparation of high-purity liquid dye for digital ink-jet printing.

Owner:ZHENGZHOU UNIV

Process for preparing composite hollow fiber membrane

A preparation of composite hollow fiber membrane adopts solution phase transfer hollow fiber spinning process, makes poly(ethylene terephthalate) or polysulfone, solvent and pore-forming agent into a base membrane spinning solution of composite hollow fiber membrane, makes polyvinylidene fluoride or other copolymers or mixture of same, solvent and pore-forming agent into composite layer spinning solution of composite hollow fiber membrane and simultaneously extrudes the said two spinning solution and core solution in the hole of the spinneret central pipe through the spinneret for outside condensation bath. The solvents and pore-forming agents in the two kinds of spinning solutions prepared in said step (1) and (2) enters condensation solution phase and the polymers, as the composite layer and the base membrane materials, precipitates into polymer hollow fiber membrane due to phase transfer, producing high-strength and high-flux hydrophilic composite hollow fiber membrane.

Owner:江苏美能膜材料科技有限公司

Method for preparing composite nanofiltration membrane

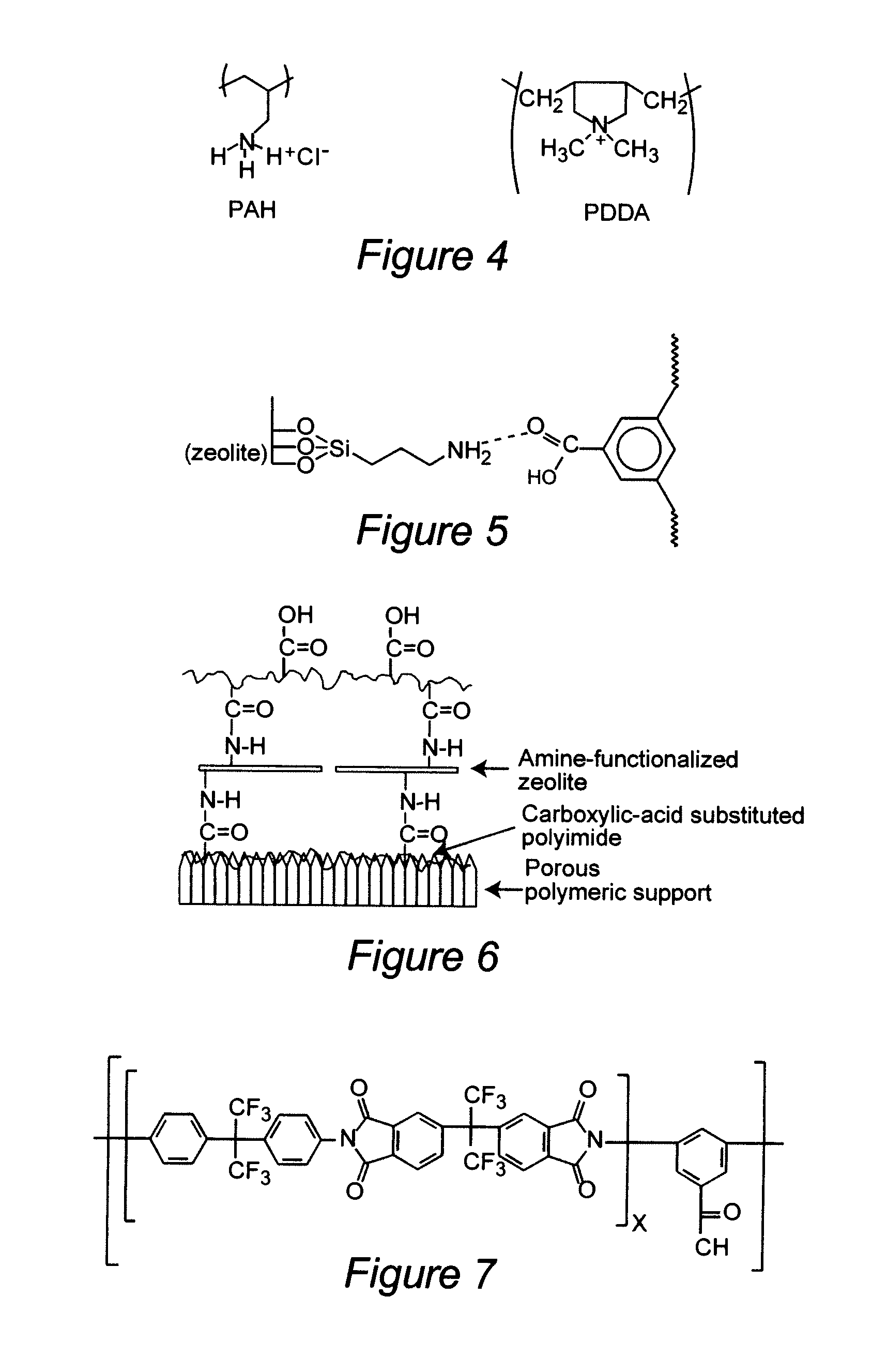

The invention relates to a method for preparing composite nanofiltration membrane, to the field of film separating technology. The electrolyte multilayer film is assembled on the substrate film as an ultrathin separating film using layers static self-assembly technology, to obtain the composite nanofiltration membrane. The preparation method alternately immerges the substrate film into the polyanion solution and the polycation solution to alternately and repeatedly aggrade on the surface of the substrate film to get the composite nanofiltration membrane ultrathin separating layer after the assemble of a certain layers. The said polyanion solution is sodium polystyrene sulfonate or sodium polyacrylate; the said polycation solution is poly dimethyl diallyl ammonium chloride or polyallyl ammonium chloride, and the said substrate film is polyethersulfone ultrafiltration film or polysulfone ultrafiltration film. The method of the invention has a simple process, and the thickness of ultrathin separating layer is controlled. The compositenanofiltration membrane has a using foreground in the field of sea water and bitter desalination, sewage disposal and callback, ultra pure water preparation and so on.

Owner:SHANGHAI UNIV

Antimicrobial semi-permeable membranes

Cast semi-permeable membranes made from synthetic polymer used in reverse osmosis, ultrafiltration and microfiltration are treated with a non-leaching antimicrobial agent to prevent its bio-fouling and bacterial breakthrough. The semi-permeable membranes include a polymeric material and a non-leaching antimicrobial agent that is incorporated into and homogeneously distributed throughout the polymeric material. The polymeric material, in the case of one membrane, may be cellulose acetate. In the case of thin film composite polyamide membranes, the antimicrobial agent is incorporated in a microporous polysulfone layer that is sandwiched between a reinforcing fabric and an ultrathin polyamide material. The invention also includes a treatment of flat and hollow fiber semipermeable membranes made with polysulfones and polyvinylidene fluoride.

Owner:MICROBAN PROD CO INC

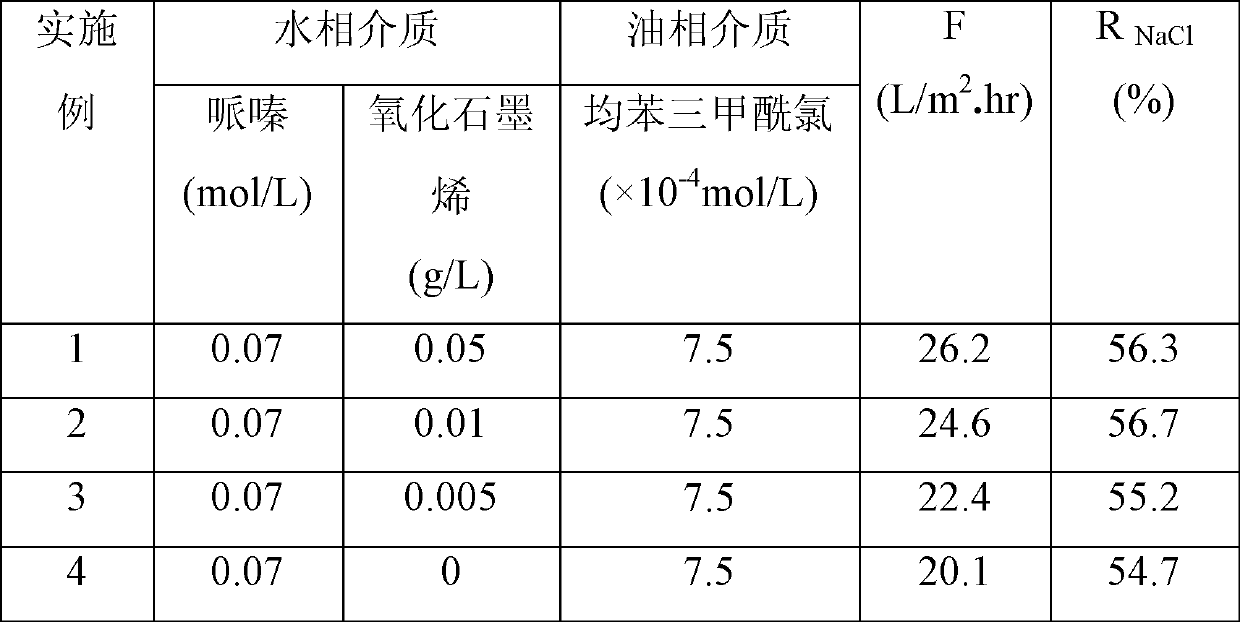

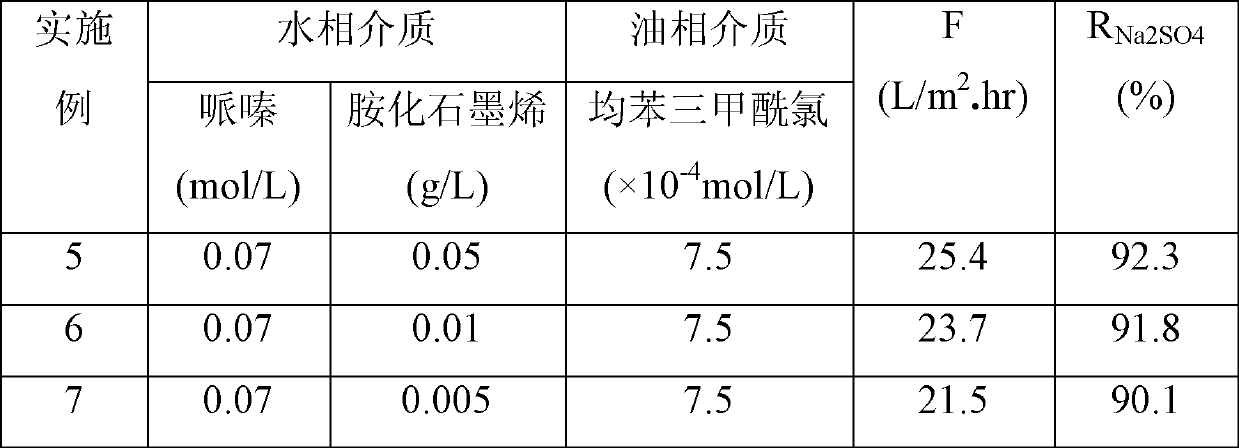

Polymer/graphene hybridization nanofiltration composite membrane and preparation method thereof

The invention discloses a polymer / graphene hybridization nanofiltration composite membrane and a preparation method of the polymer / graphene hybridization nanofiltration composite membrane. The nanofiltration composite membrane is formed by forming a layer of polymer functional cortex containing graphene on a polysulfone porous support membrane through an interface polymerization technique. The graphene is effectively introduced into the functional cortex of the nanofiltration membrane by using the unique two-dimensional nanopore structure and good molecular mass transfer channel effect of the graphene, so that the performance of the nanofiltration composite membrane can be improved.

Owner:浙江欧托电气有限公司

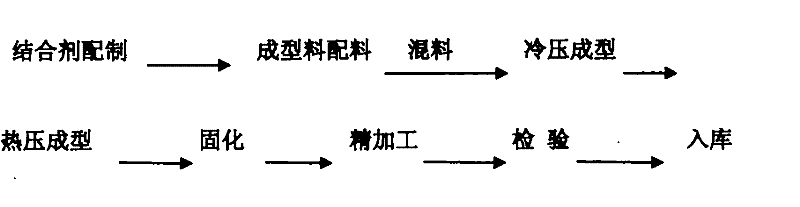

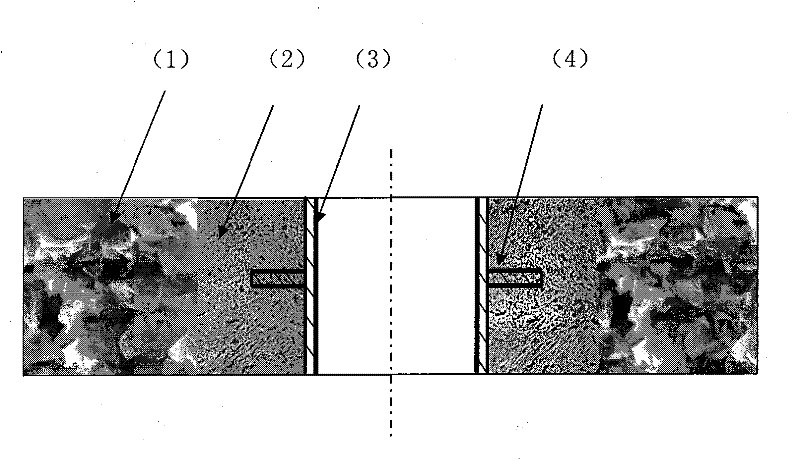

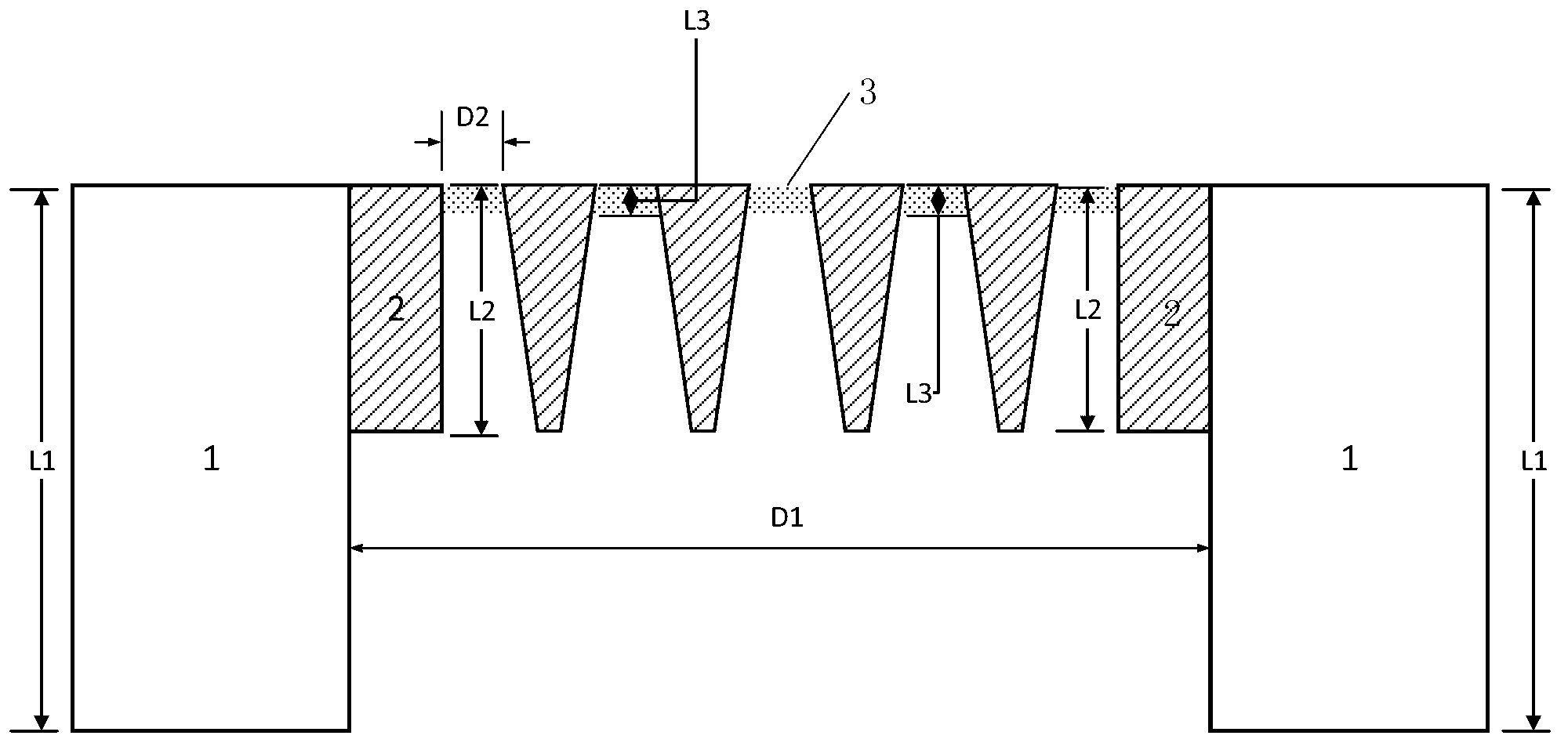

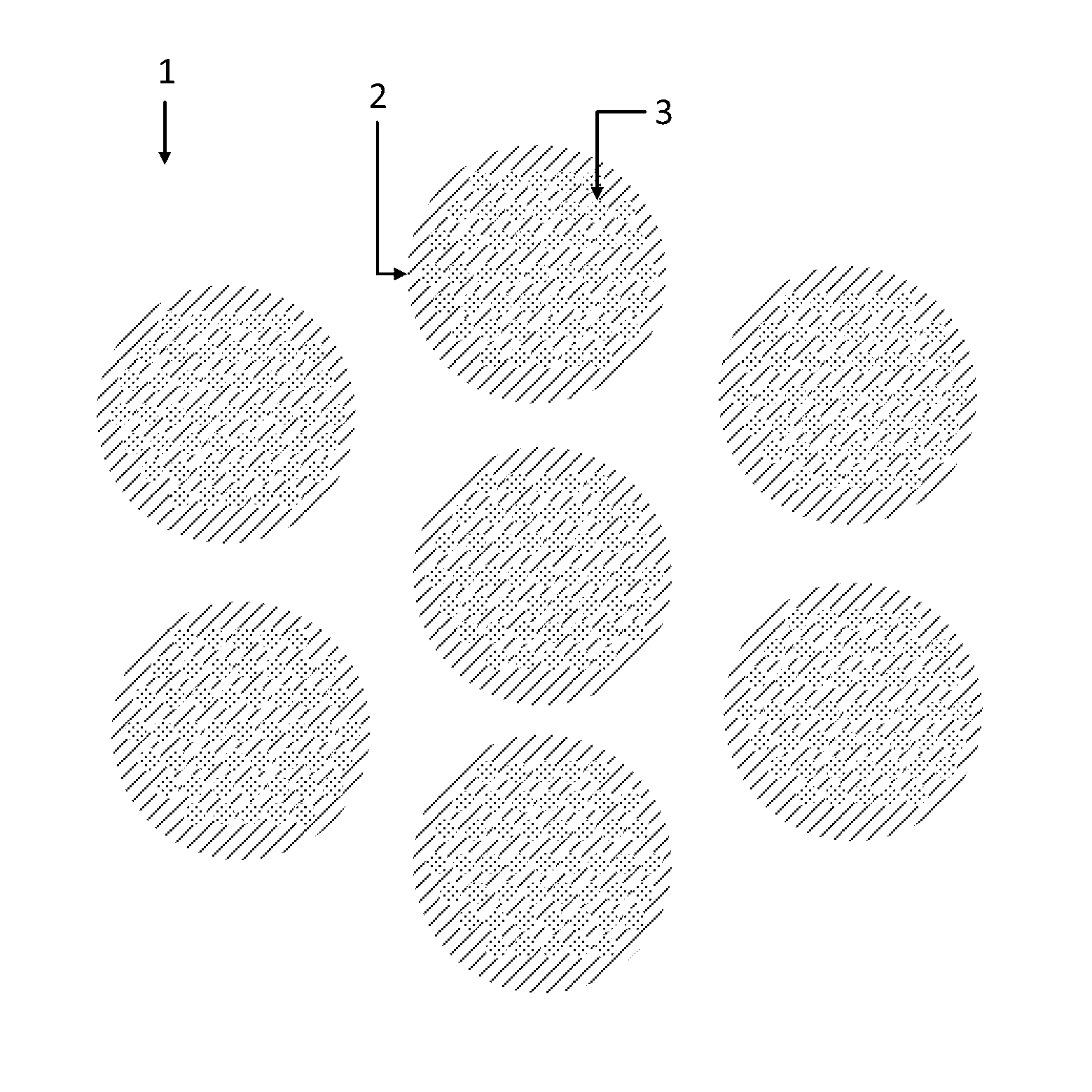

High-speed resin heavy-load grinding wheel

InactiveCN102161183AImprove mechanical propertiesImprove automationAbrasion apparatusGrinding devicesFiberZirconia alumina

Owner:江苏华东砂轮有限公司

Low-pollution compound reverse osmosis membrane

ActiveCN101130444AOvercome the disadvantage of easy falling offImprove anti-pollution performanceGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisWide areaReverse osmosis

The invention discloses a low-pollution compound reverse osmosis film, which comprises the following parts: nonwoven layer, polysulfone support layer and polyamide layer on the polysulfone support layer, wherein the crosslinked PVA layer is set on the polyamide layer, which is crosslinked by one of aliphatic dialdehydes, hydroxy fatty acid, acid anhydride or polyvalent anion salt compound and PVA solution. The invention overcomes the defect of easy stripping of PVA layer to improve the anti-pollution property of composite osmosis reverse film to lengthen the using life, which is easy to prepare and operate with high desalinization rate and large water flux, therefore fitting for water disposing course in wider domain to expand the application of the reverse osmosis film.

Owner:VONTRON TECH CO LTD

Hollow fiber type composite nano-filtration membrane and preparation method thereof

ActiveCN103223300AHigh strengthImprove anti-scourSemi-permeable membranesHollow fibreFiltration membrane

The invention relates to a hollow fiber type composite nano-filtration membrane and a preparation method thereof. The hollow fiber type composite nano-filtration membrane comprises a hollow fiber microporous base membrane adopted as a supporting layer, a polysulfone transition layer, and a polyamide composite layer, wherein the polysulfone transition layer is positioned inside membrane holes of the hollow fiber microporous base membrane, and the polyamide composite layer is positioned inside membrane holes of the polysulfone transition layer. The preparation method comprises: adopting a thermally induced phase separation method to obtain an asymmetric microporous base membrane, adopting an impregnation phase transformation method to obtain the polysulfone transition layer in the micro holes, and adopting pressure control and an interface condensation polymerization reaction to obtain the polyamide composite layer. The hollow fiber type composite nano-filtration membrane provides a sodium chloride salt solution entrapment rate of more than 90%, a divalent salt ion entrapment rate of more than 95%, and a pollutant entrapment rate of more than 99% under 0.2-0.8 MPa, such that the hollow fiber type composite nano-filtration membrane has characteristics of high strength, washing resistance, large flux and the like, wherein the pollutants have a molecular weight of 300-200,000 Daltons.

Owner:TSINGHUA UNIV

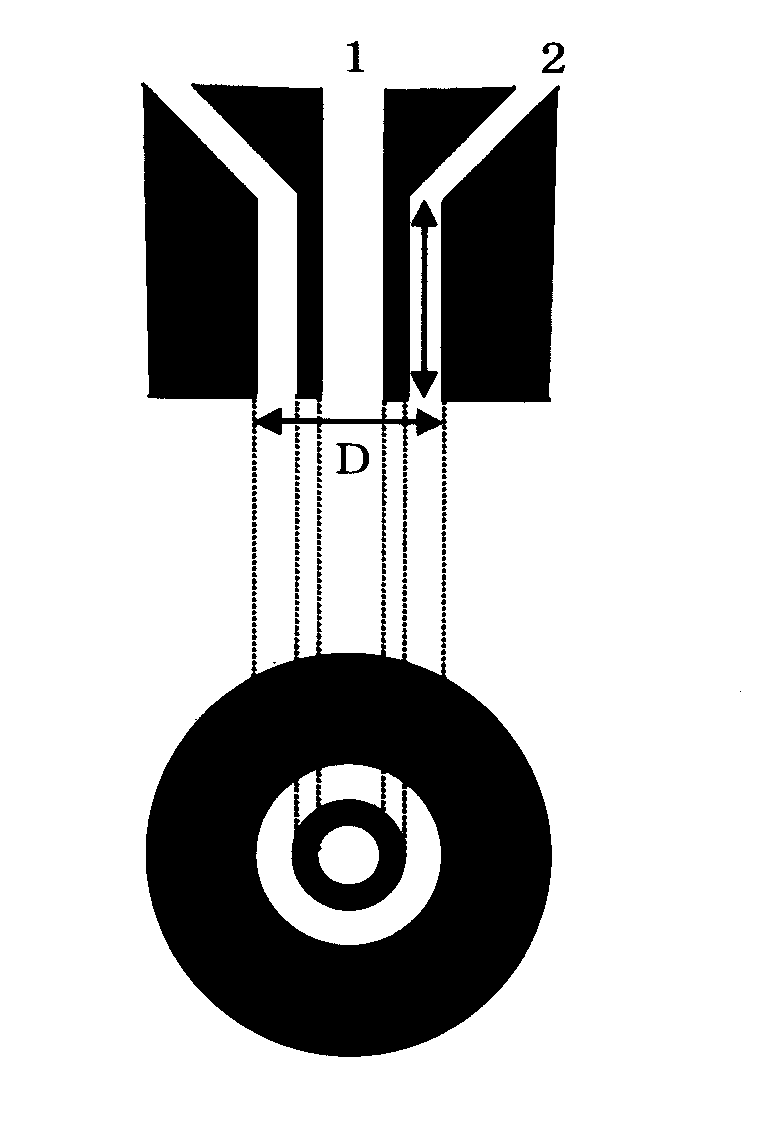

Polysulfone Type Selectively Permeable Hollow Fiber Membrane Module and Process for Manufacturing the Same

ActiveUS20080044643A1Light weightImprove performance stabilityMembranesSemi-permeable membranesPolymer scienceHydrophilic polymers

The invention relates to a hollow fiber membrane module comprising polysulfone type selectively permeable hollow fiber membranes which contain a polysulfone-based resin and a hydrophilic polymer as main components, wherein (A) the content of the hydrophilic polymer in the uppermost layer of the inner surface of the hollow fiber membrane is at least 1.1 times larger than the content of the hydrophilic polymer in the proximate layer of the inner surface of the membrane, and (B) the content of the hydrophilic polymer in the uppermost layer of the outer surface of the hollow fiber membrane is at least 1.1 times larger than the content of the hydrophilic polymer in the uppermost layer of the inner surface of the membrane. The hollow fiber membrane module is exposed to a radioactive ray, on condition that the oxygen concentration of an ambient atmosphere around the hollow fiber membrane is from 0.001 to 0.1%, and that the moisture content of the hollow fiber membrane to the weight thereof is from 0.2 to 7 mass %.

Owner:NIPRO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com