Patents

Literature

522 results about "Fiber type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

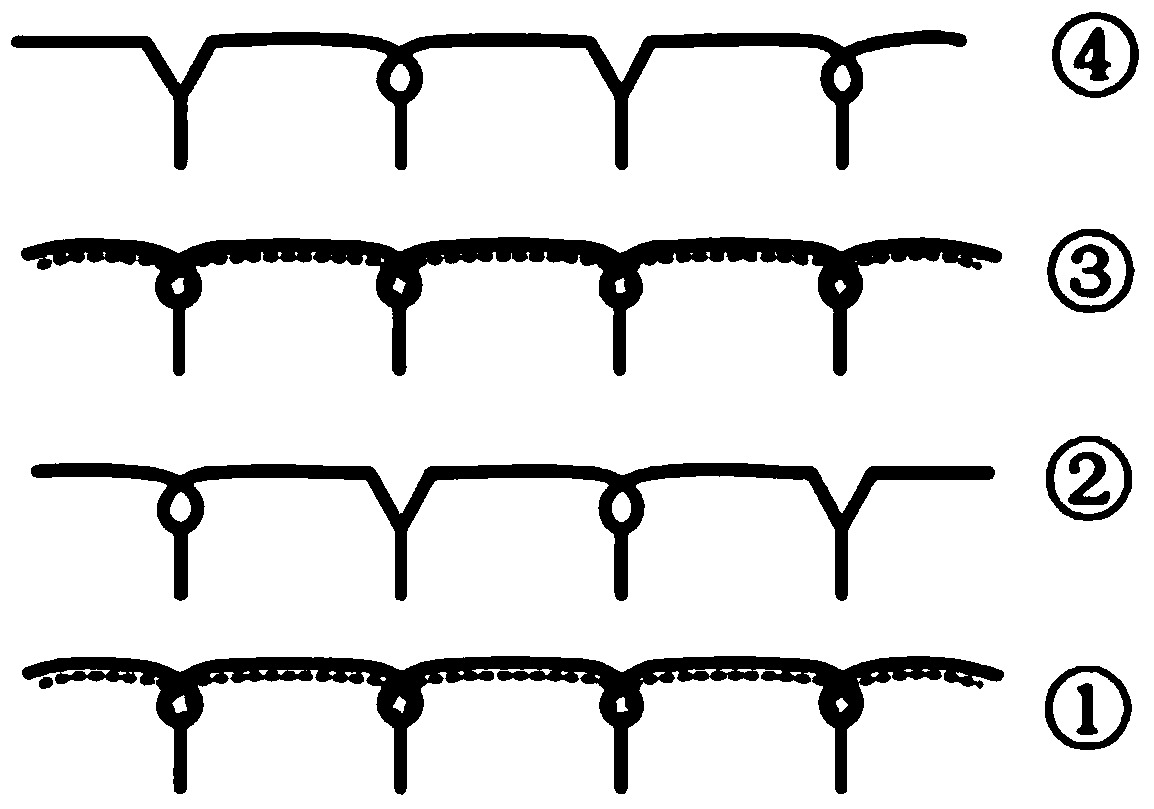

There are two main types of fiber that have different functions and distinctive health benefits. The two types of fiber are “soluble fiber" and "insoluble fiber," but within each category there are many different fibers. There are two types of fiber:

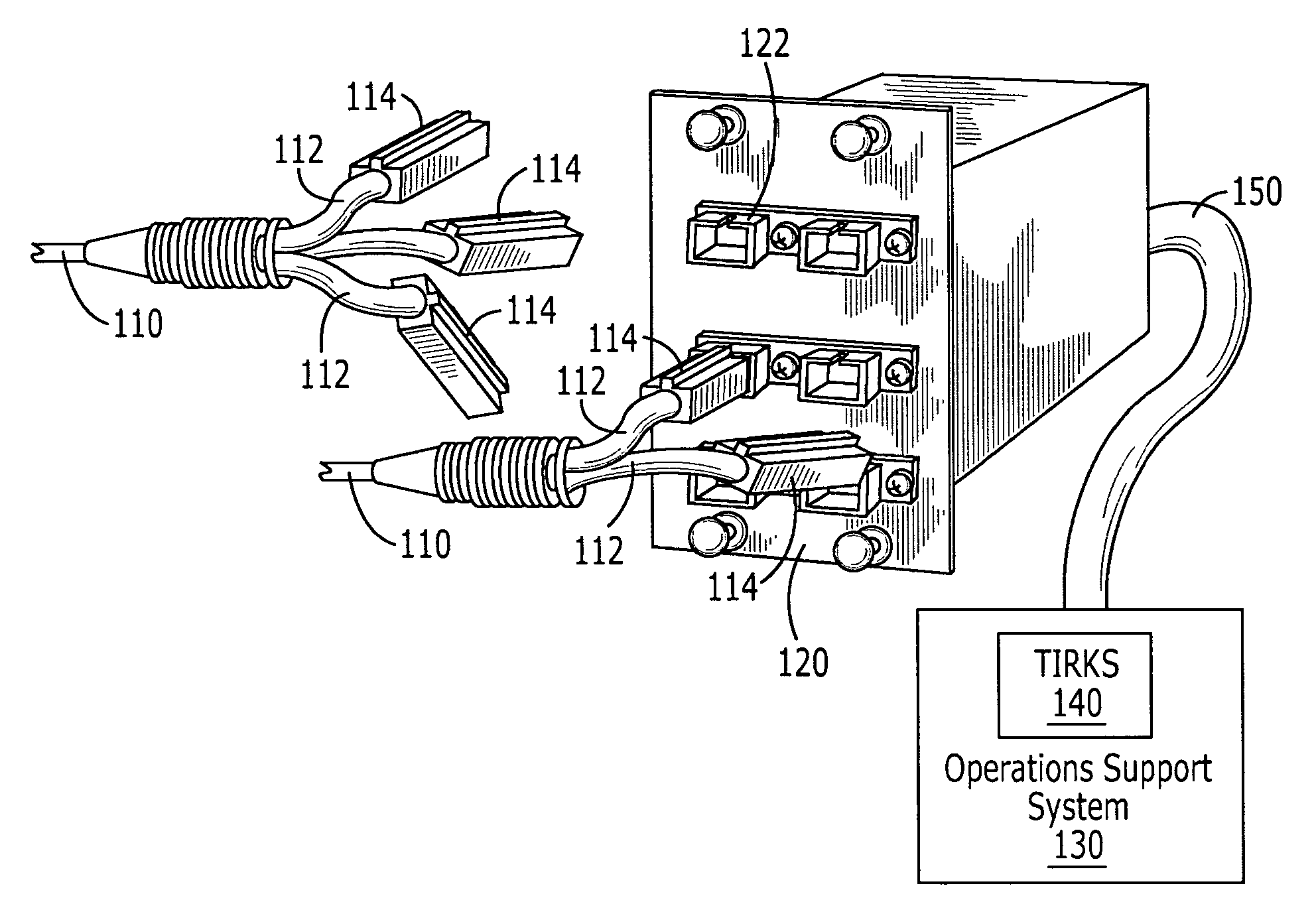

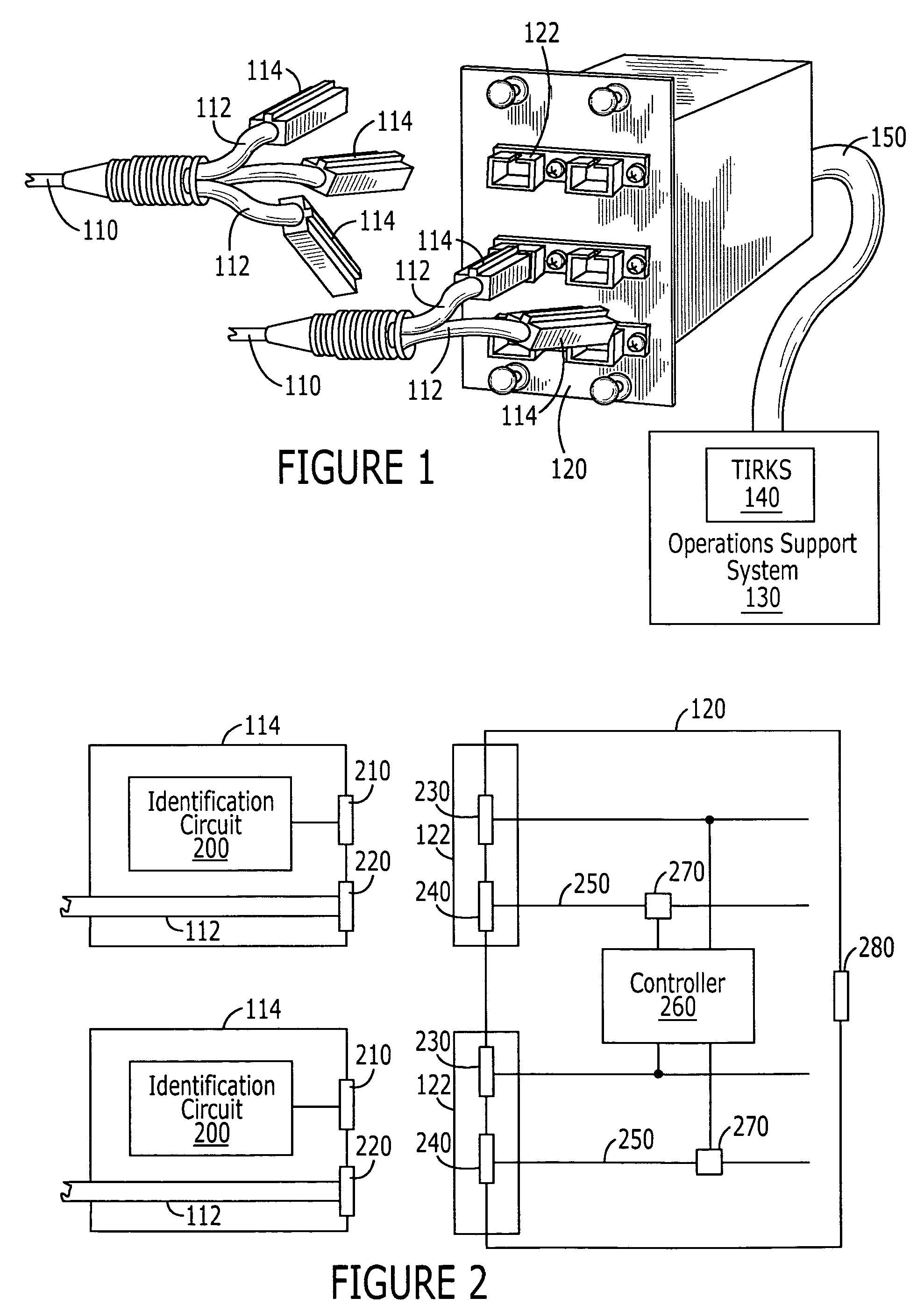

Optical fiber connectors with identification circuits and distribution terminals that communicate therewith

An optical fiber connector can include an optical fiber interface, an identification circuit, and an electrical interface that is communicatively connected to the identification circuit. The identification circuit may be a non-volatile memory such as, for example, a read only memory, a magnetic random access memory and / or a flash-random access memory. The identification circuit may include a housing that can be releasably connected to a Light Guide Cross Connect (LGX). The identification circuit may generate an electrical signal that identifies a fiber, a fiber bundle, a fiber type, a connector type, who manufactured an optical fiber, when an optical fiber was manufactured, and / or when an optical fiber was installed.Related optical fiber distribution terminals are also discussed.

Owner:BELLSOUTH INTPROP COR

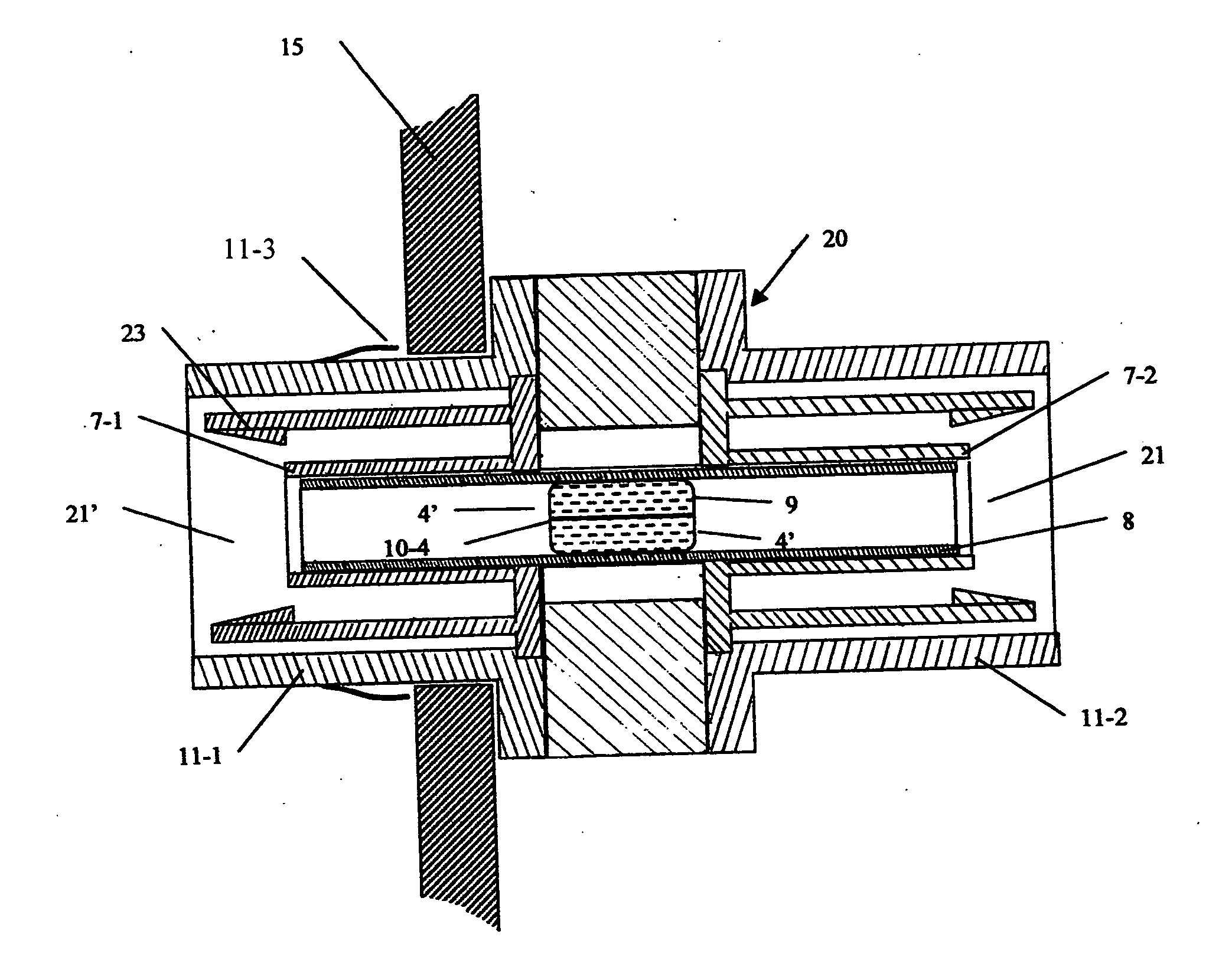

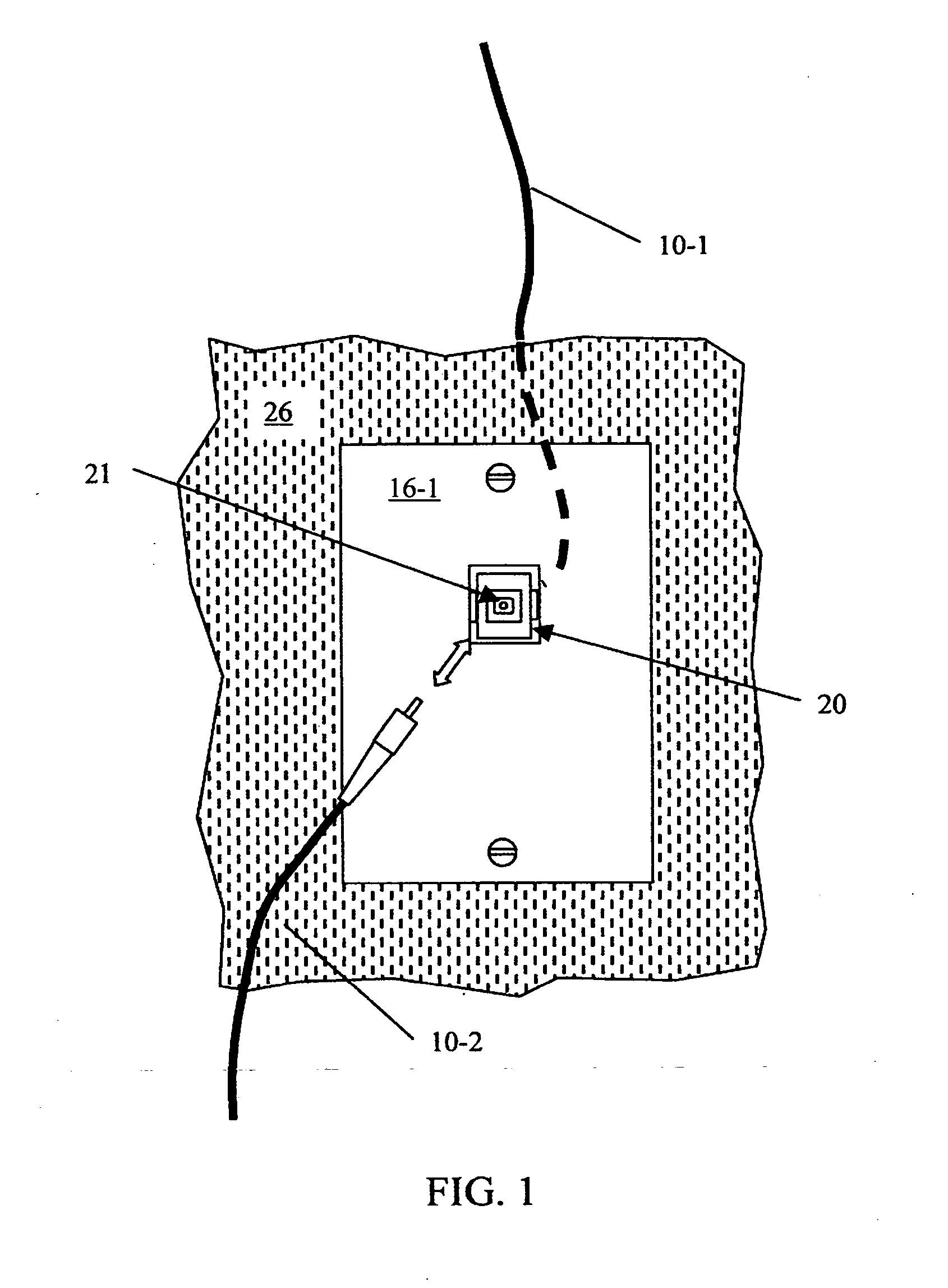

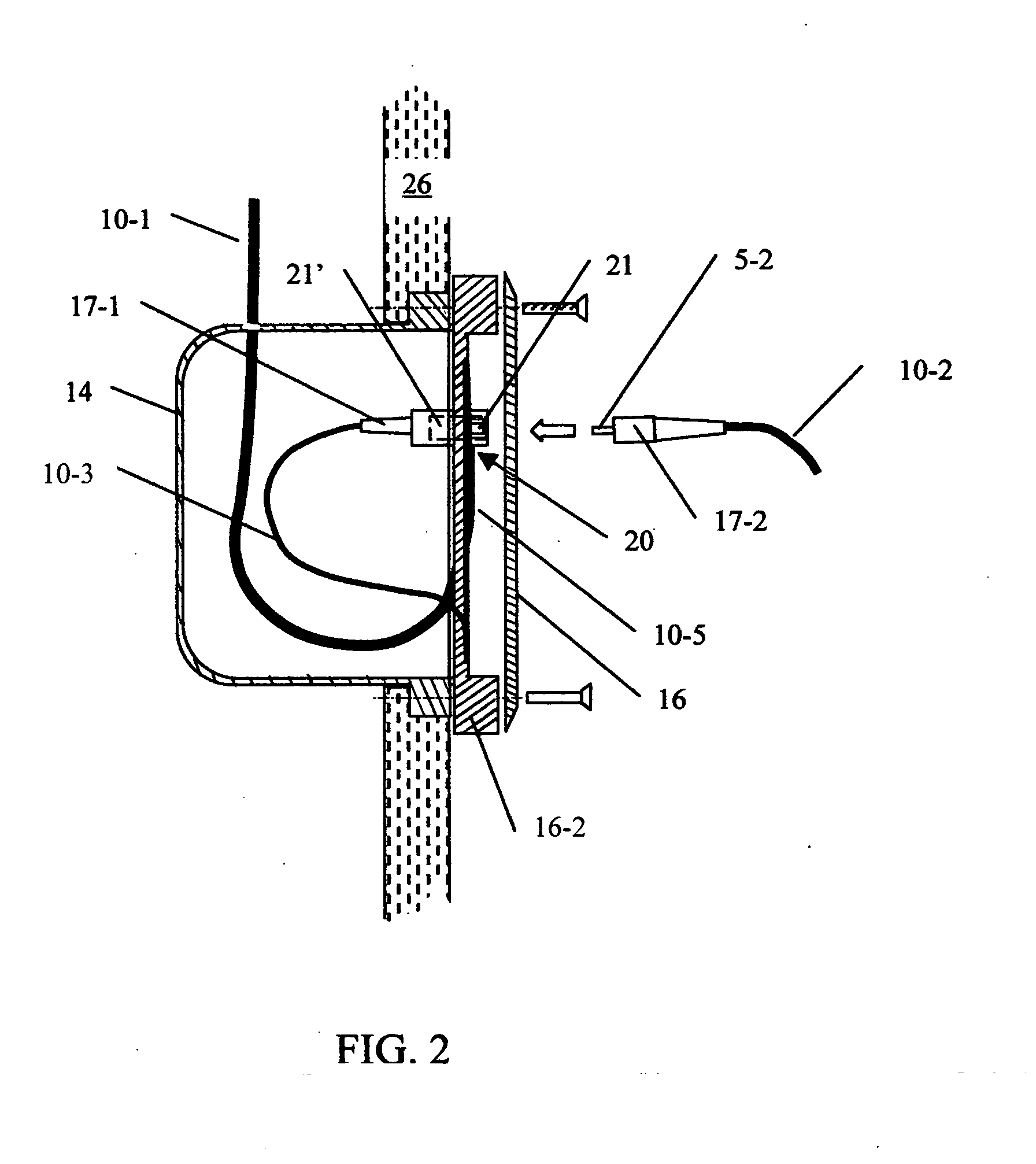

Isolated Fiber Optic Union Adapters

InactiveUS20070196053A1Reduce the possibility of damageLow costCoupling light guidesEngineeringInterconnection

Devices to enhance the reliability of optical networks and to reduce the cost of repair are disclosed in this invention. In particular, fiber optic union adapters with built-in protective isolation prevent a damaged, connectorized fiber optic cable from degrading other fiber optic terminations within the network should they be physically connected. The fiber optic union comprises a split sleeve with an interior channel and a fiber stub centrally located within the interior channel. The fiber stub prevents the ferrules of two different cables from making direct physical exchange but allows them to make efficient optical exchange. Opposite ends of the fiber stub are optically polished to enable physical contact to the ferrules of fiber optic cables with low insertion loss and low backreflection. Devices to achieve low loss isolated interconnection between cables containing dissimilar fiber types by use of a fiber taper are further disclosed.

Owner:KEWITSCH ANTHONYS

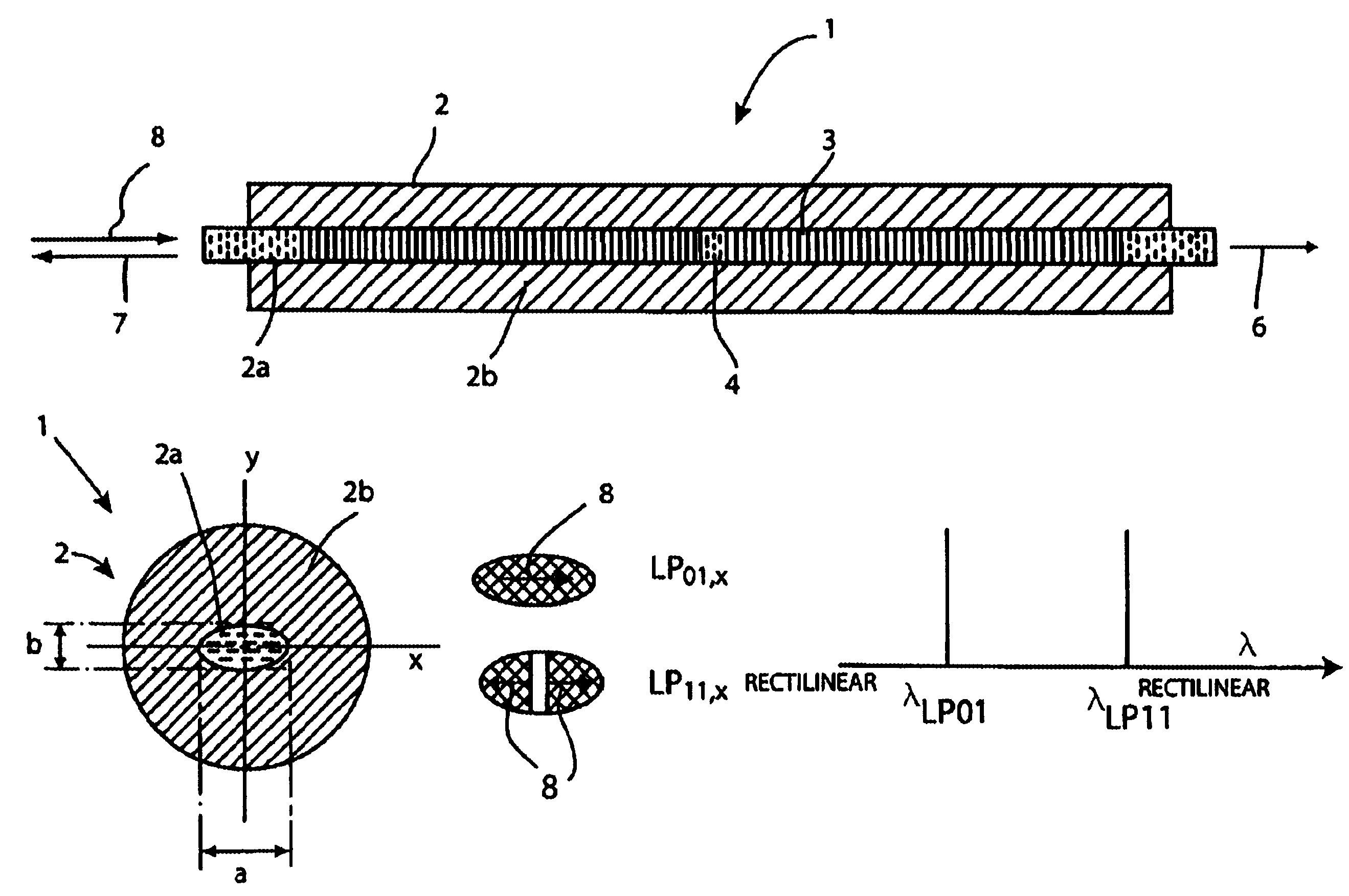

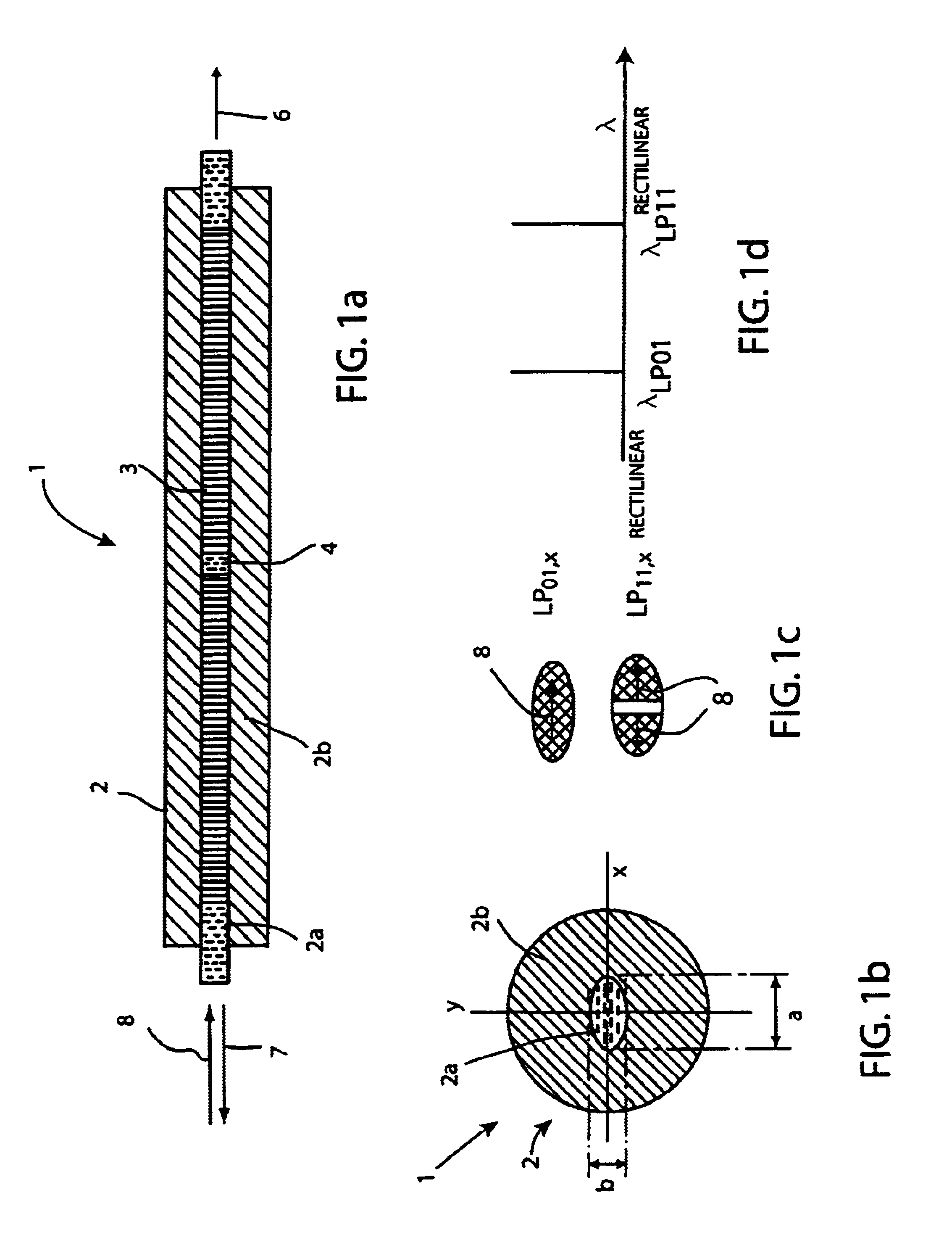

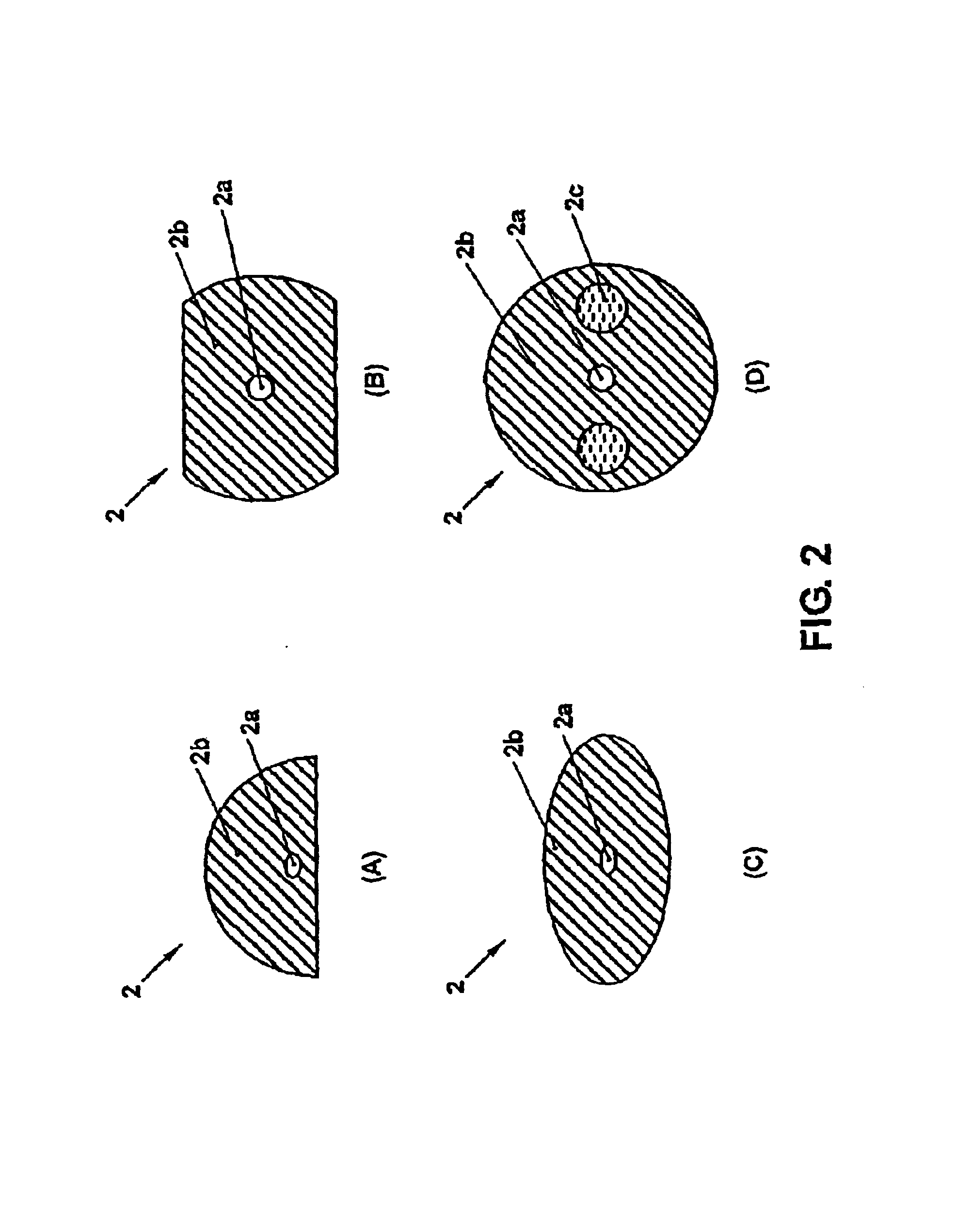

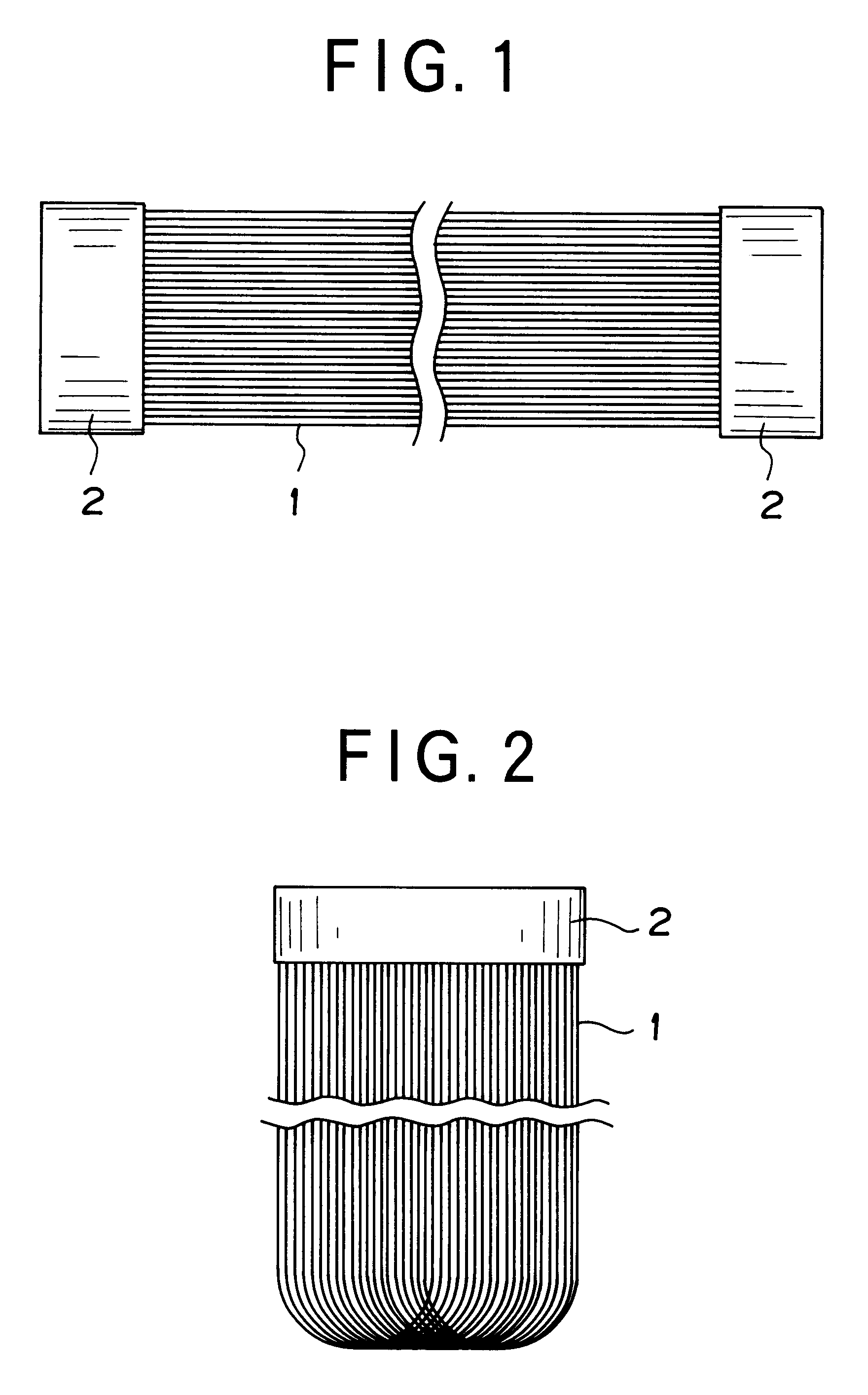

Anisotropic distributed feedback fiber laser sensor

The invention relates to a DFB fiber laser sensor (1). A measurement quantity makes it possible to induce a linear birefringence between mode pairs of the laser-amplifying fiber (2) and to measure an associated beat frequency (Δν1, Δν2, Δν3). According to the invention, the laser-amplifying fiber (2) has a nonrotationally symmetrical structure, so that it is possible to detect isotropic pressures p, acoustic waves or chemical substances that can be added radially to the laser-amplifying fiber (2). In a second aspect of the invention, an emission wavelength range and parameters (a, b, ΔN) of the laser-amplifying fiber (2) and also a grating period L of the fiber Bragg grating resonator (3) are coordinated with one another such that at least two different spatial modes (LP01, LP11even, LP11odd, LP21even) are propagatable and it is possible to measure beat frequencies (Δν1, Δν2, Δν3) between oscillatory longitudinal laser modes assigned to them. Exemplary embodiments relate to: rotationally asymmetrical fiber types, a choice of special spatial modes (LP11odd, LP21even) and / or multiple fiber Bragg gratings (3) for reducing the beat frequencies (Δν1, Δν2, Δν3) below 100 GHz; and elimination of temperature influences e.g. by the detection of a plurality of beat frequencies (Δνa, Δνb, Δνc, Δνd) between different pairs of spatial modes (LP01, LP11even, LP11odd, LP21even) and / or polarization modes (X, Y).

Owner:GE OIL & GAS UK LTD

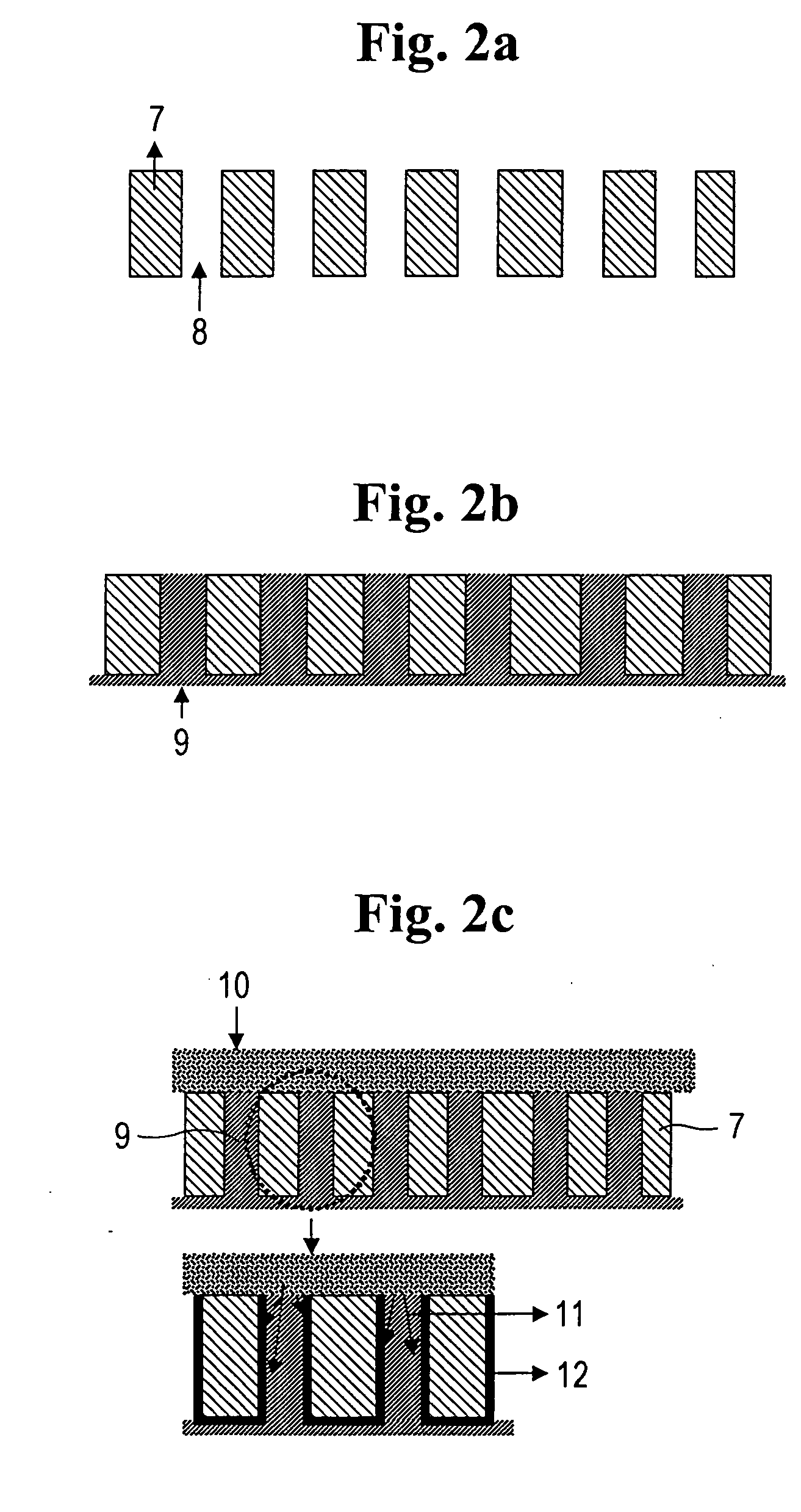

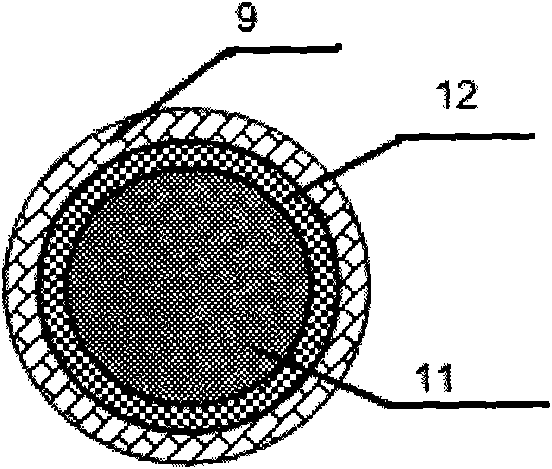

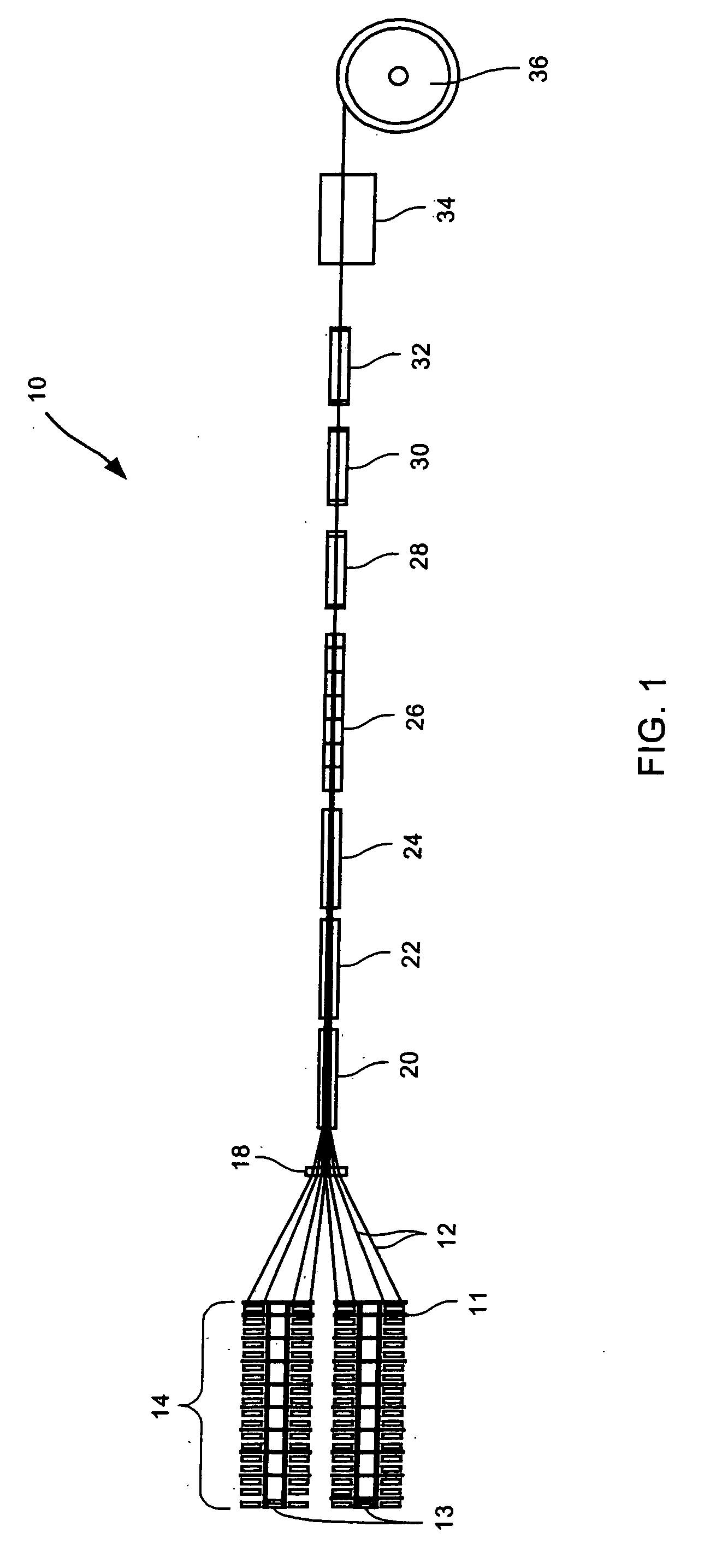

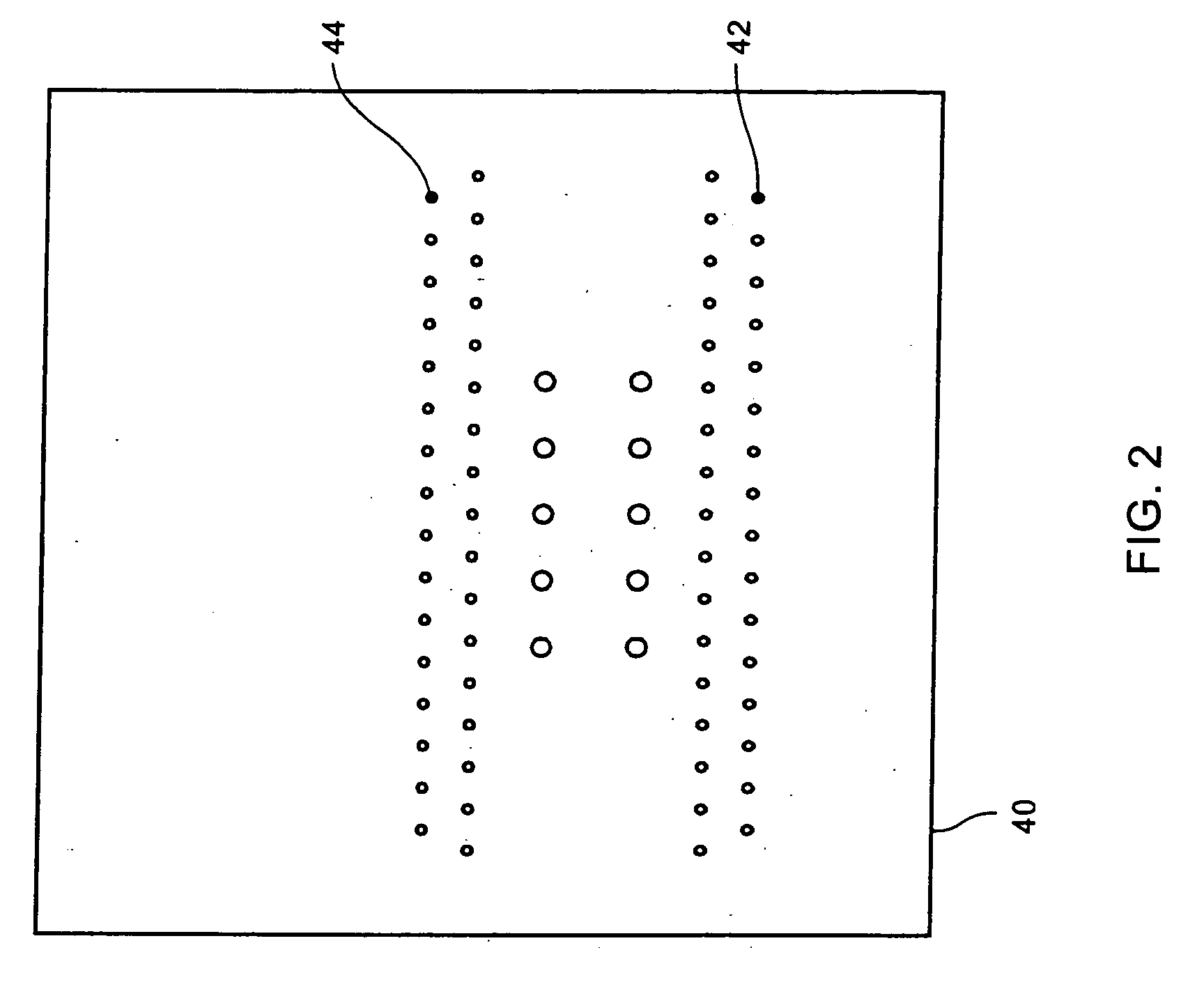

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS7179522B2Change in weightMaintain stable propertiesNon-insulated conductorsSynthetic resin layered productsElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about −45° C. to about 240° C. or higher, at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about −0.6×10−6 per deg. C. to about 1.0×10−5 per deg. C. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

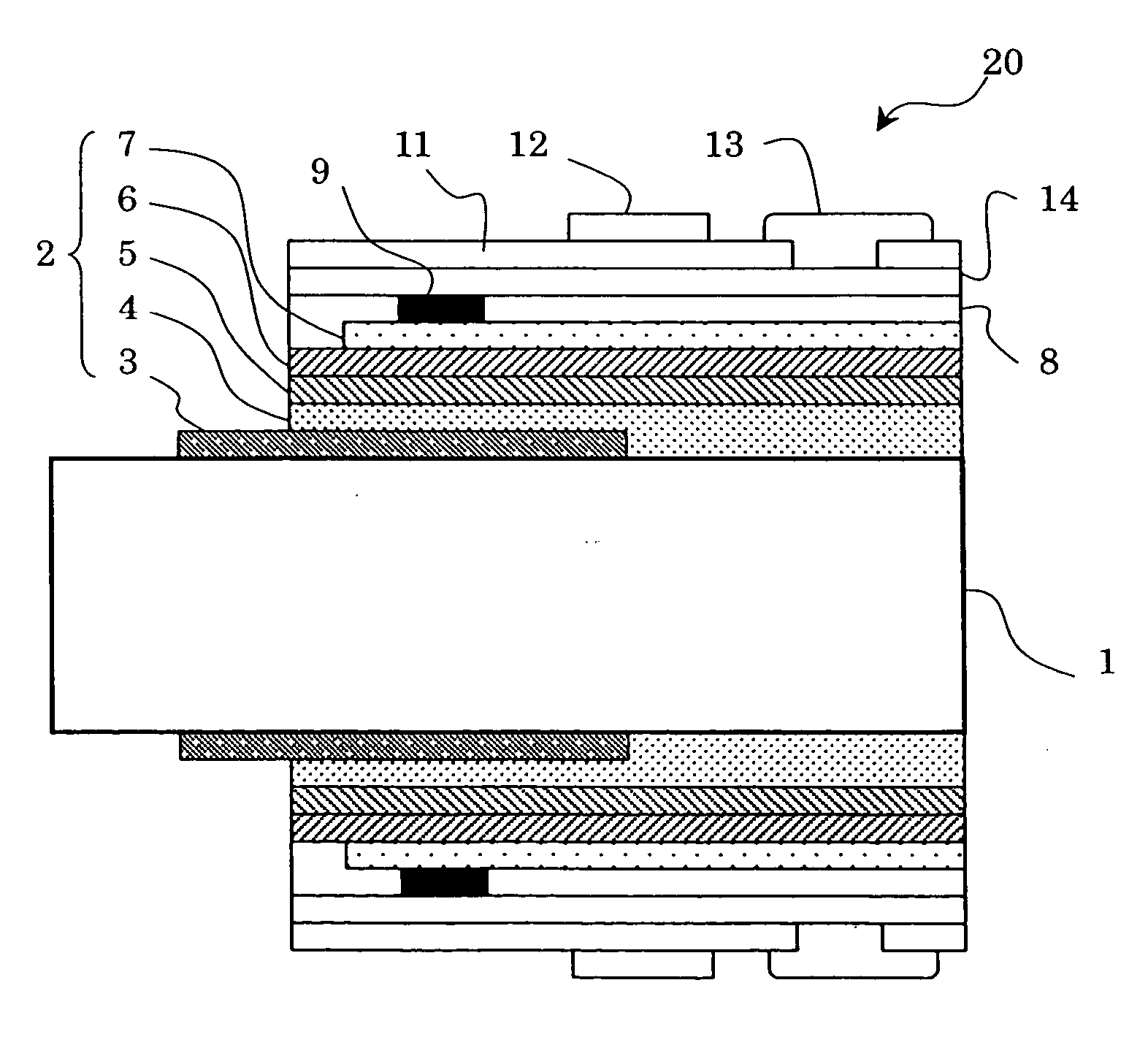

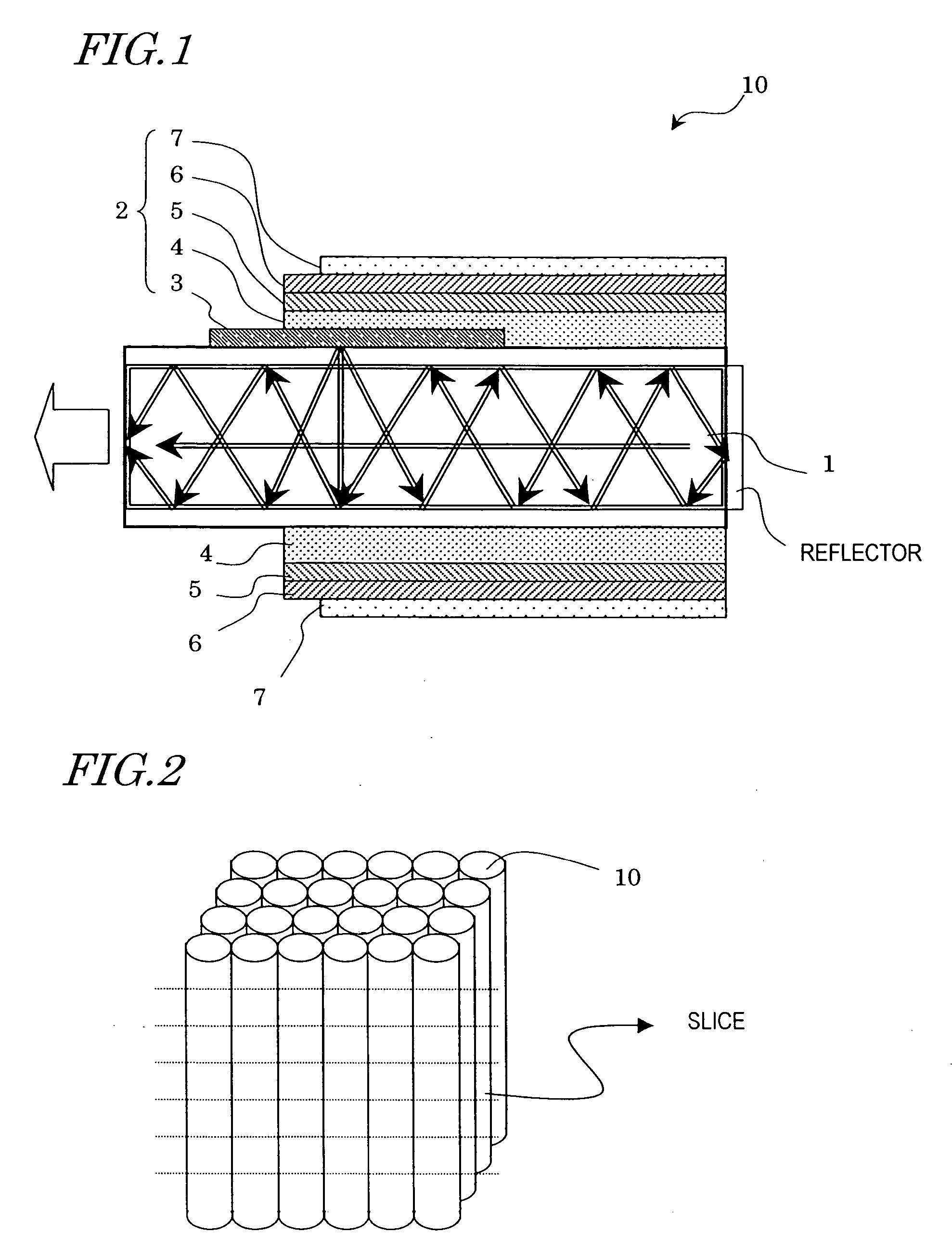

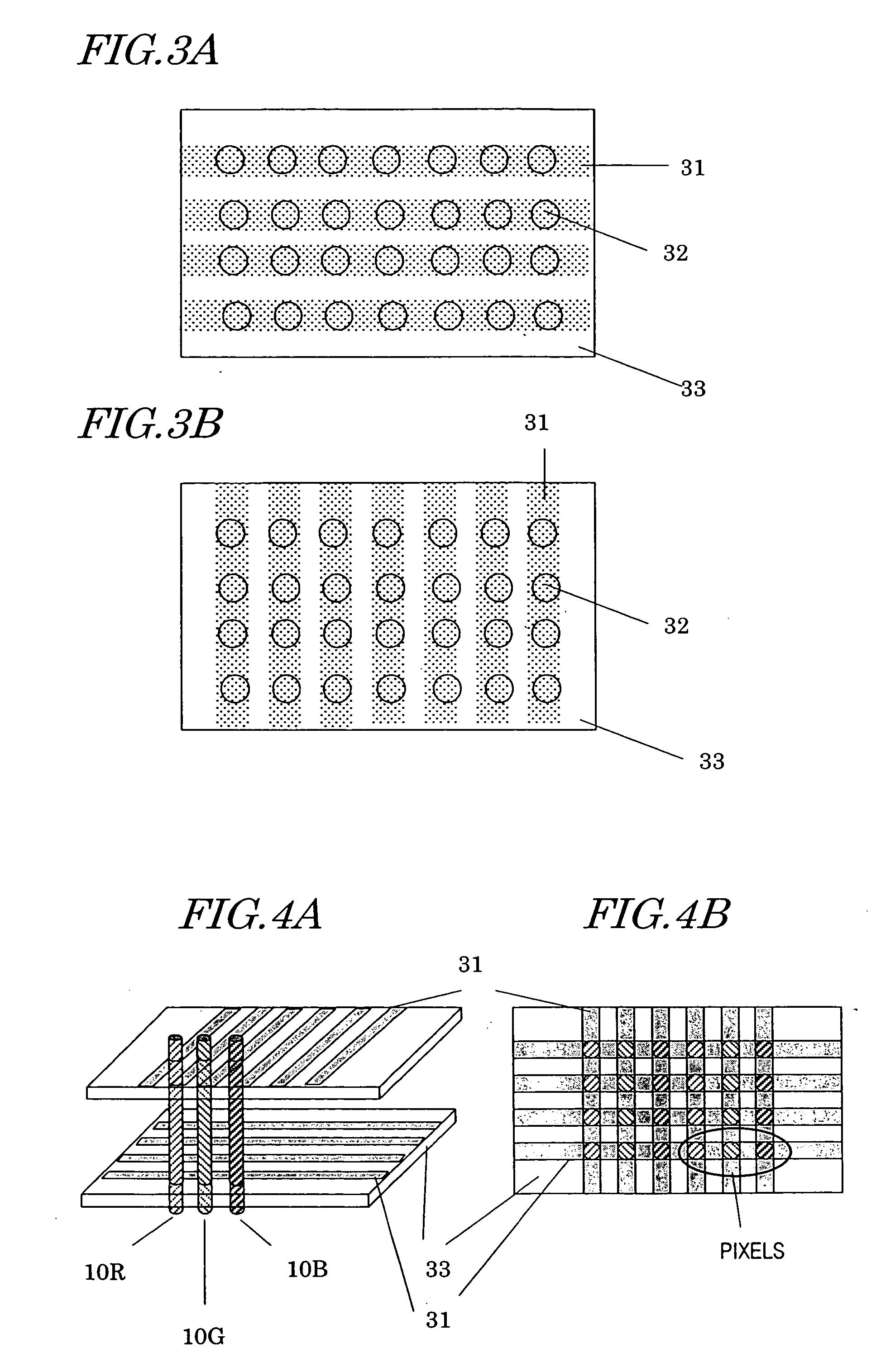

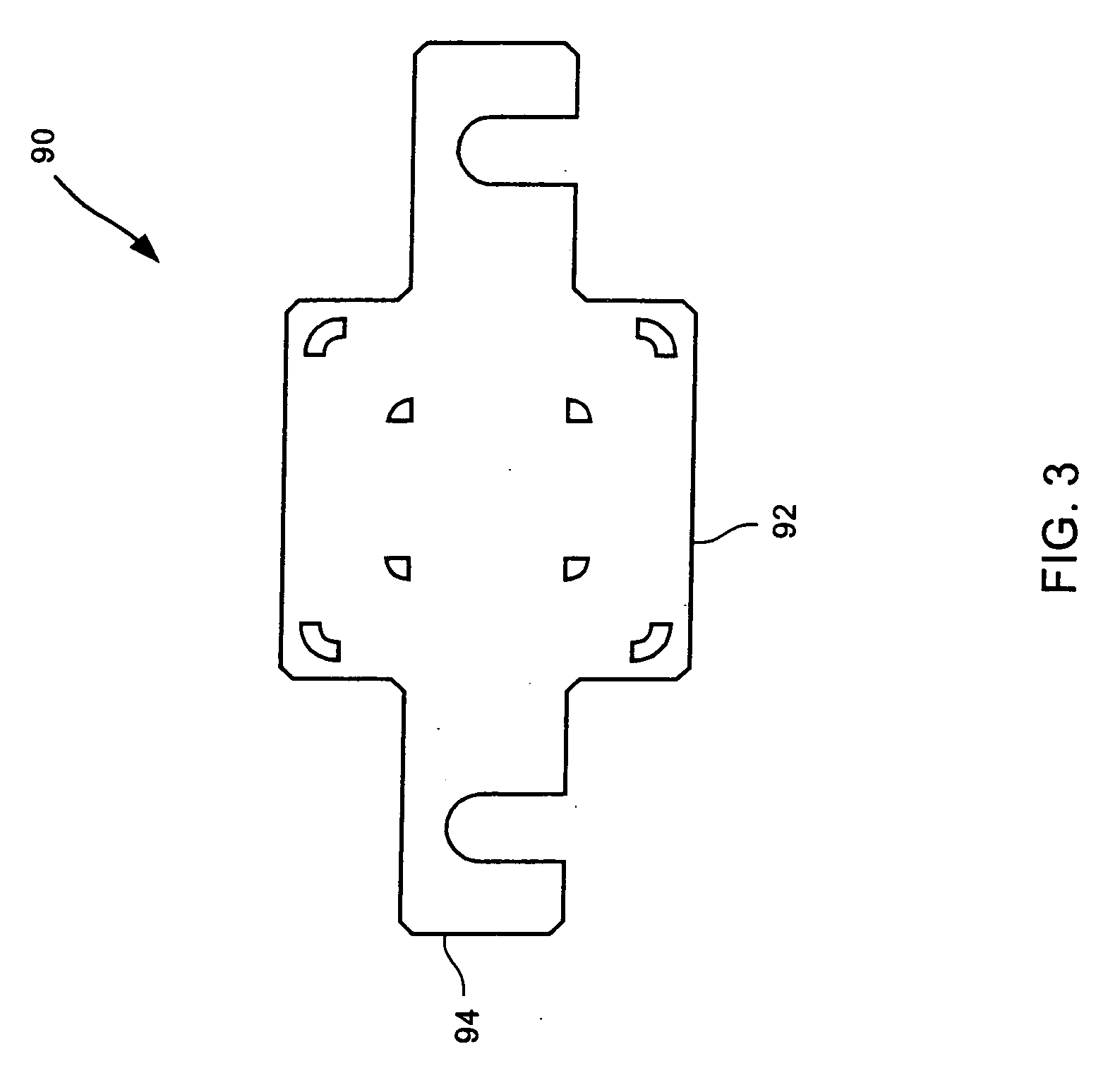

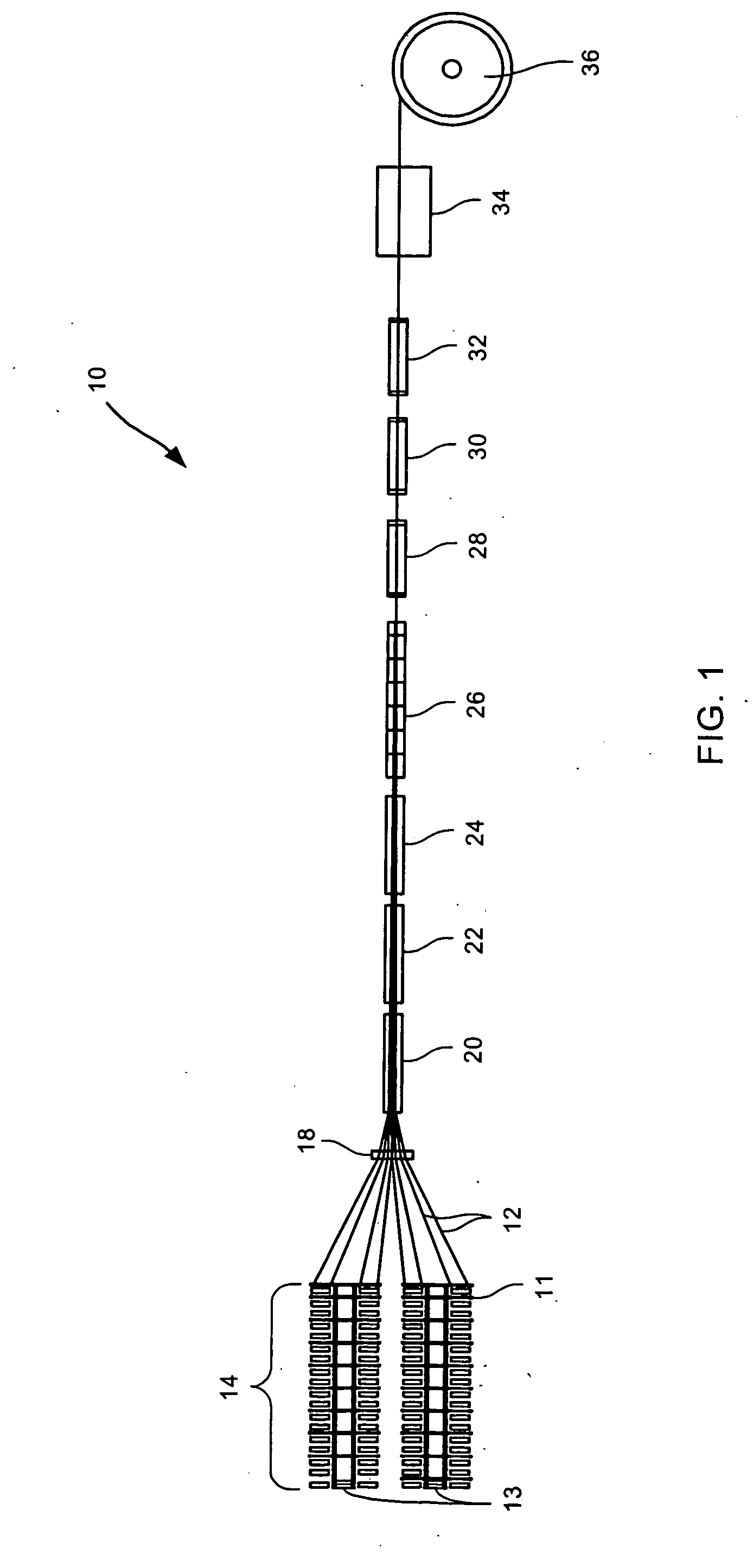

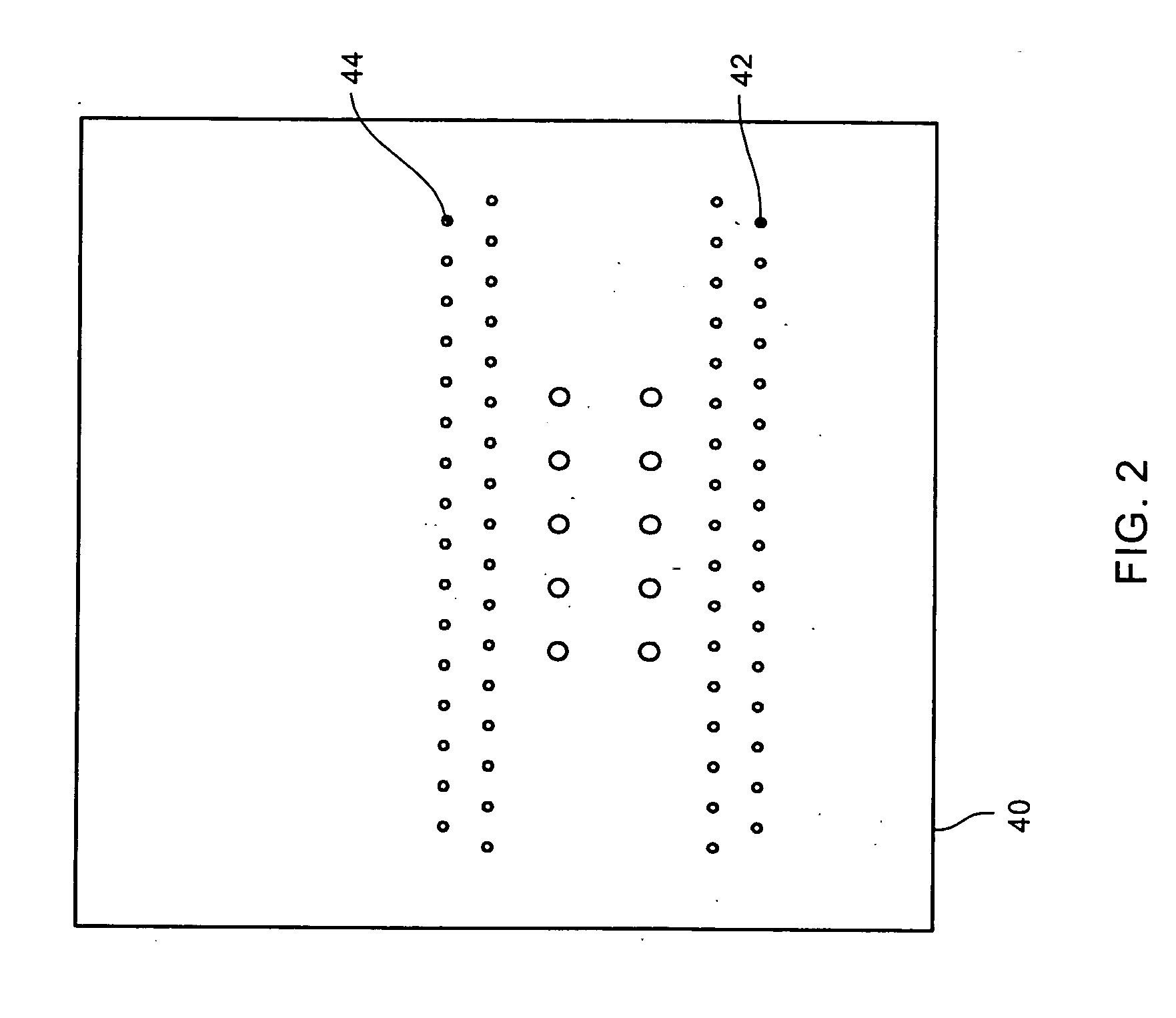

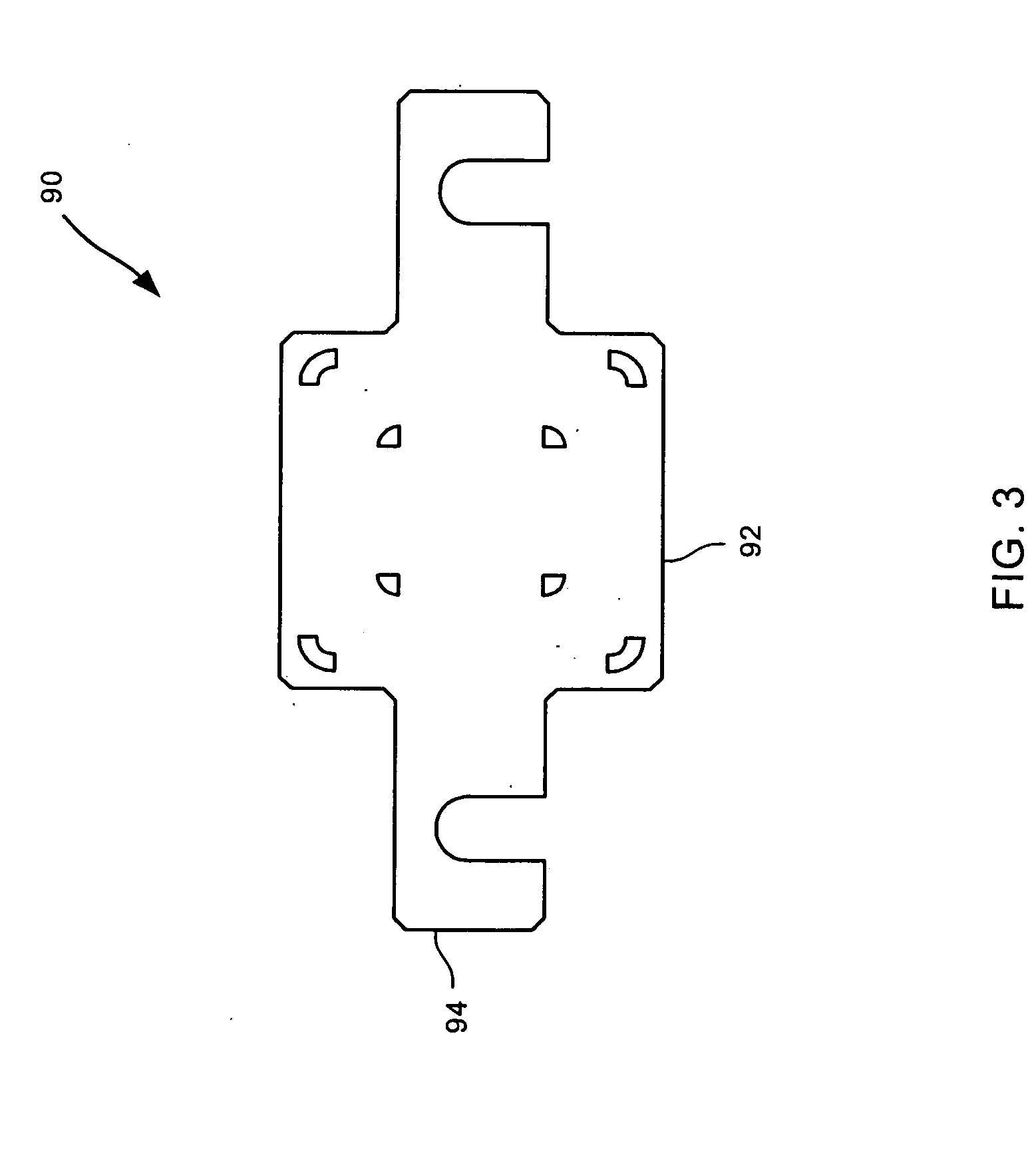

Display apparatus and method for producing the same

A display apparatus includes an array of fiber-type semiconductor light-emitting elements. Each of the fiber-type semiconductor light-emitting elements includes a layered structure having a first electrode layer, a second electrode layer, and a semiconductor light-emitting layer at least part of which is sandwiched by the first and second electrode layers, and a fiber for supporting the layered structure and for propagating light emitted from the light-emitting layer. The display apparatus also includes driving connectors including a switching element or a plurality of first and second conductive lines, which are electrically connected to the first and second electrode layers, respectively, for driving the plurality of the fiber-type semiconductor light-emitting elements.

Owner:SHARP KK

High performance fiber blend and products made therefrom

A blended yarn is provided having at least one component fiber type being made of stretch broken fibers, preferably of a stretch broken high performance fiber, along with multi-end yarns containing the blended yarn, composite yarns having at least one component being the blended yarn, and articles made from the blended, multi-end or composite yarn.

Owner:SUPREME ELASTIC

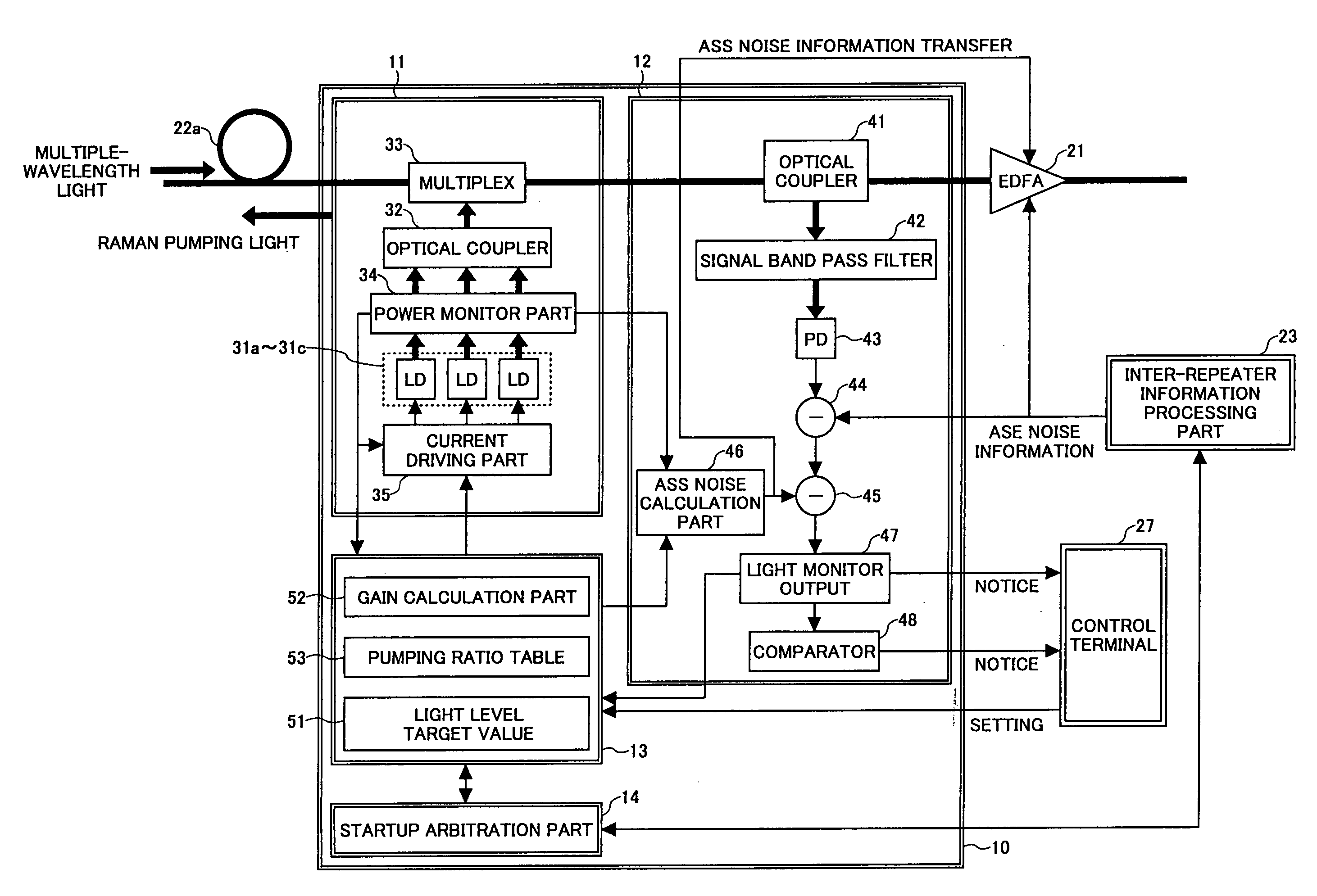

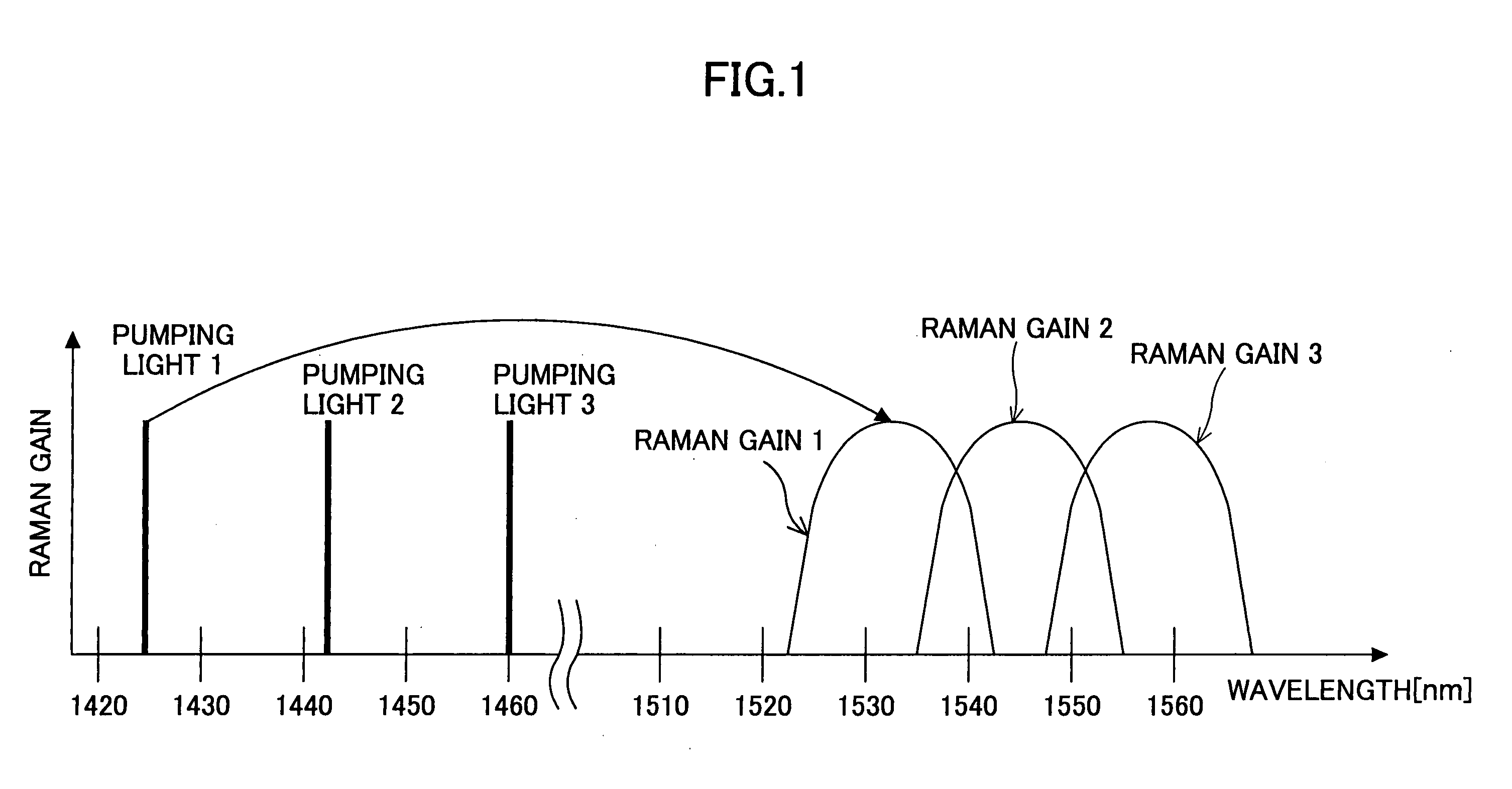

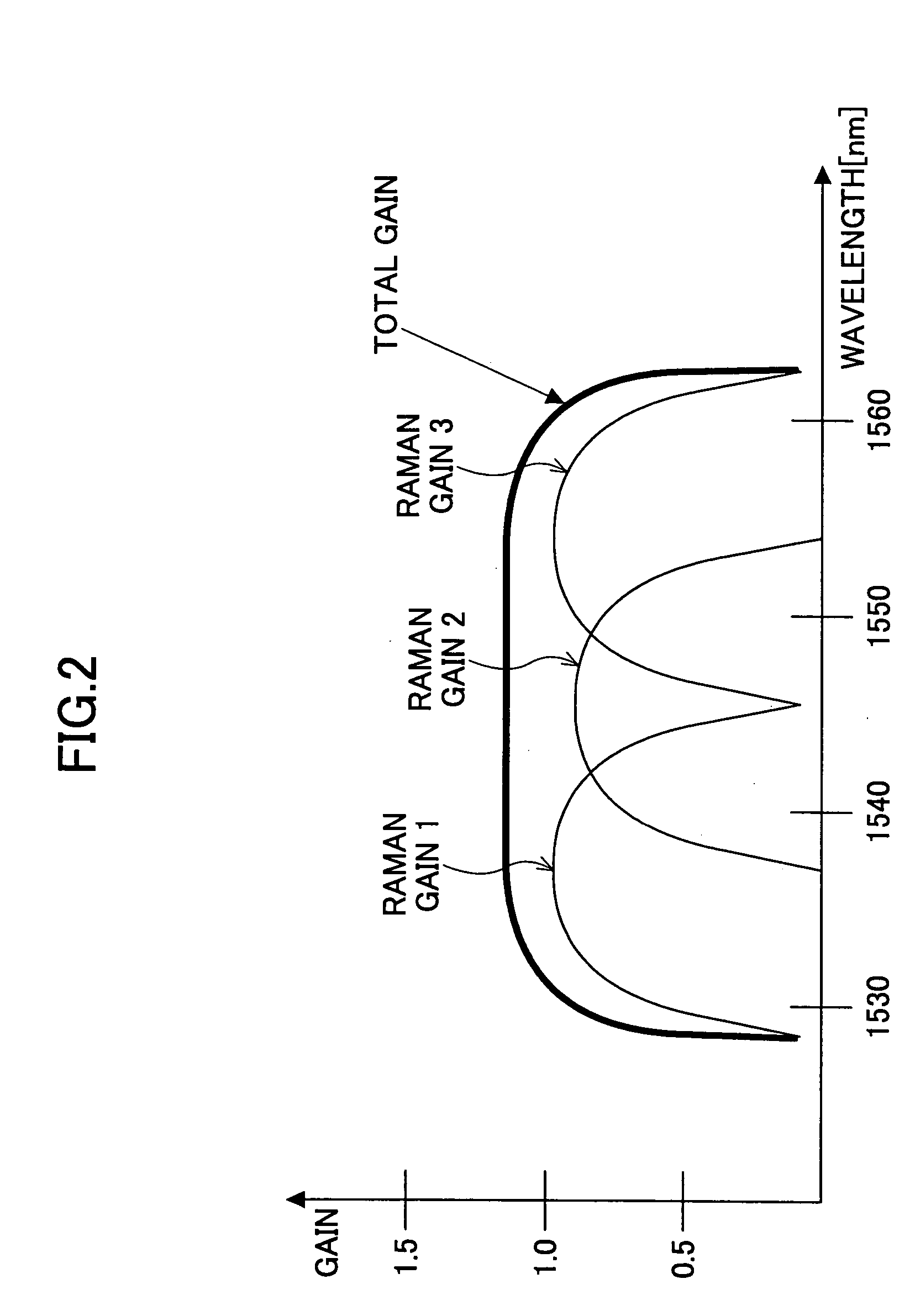

Raman amplifier and raman amplifier adjustment method

ActiveUS20050024712A1Accurate detectionImprove featuresLaser using scattering effectsActive medium materialOptical propertyRaman amplifiers

A pumping unit supplies pumping light to a fiber connecting medium; a light monitoring unit detects light power of multiple-wavelength light; and a control unit controls the pumping light based on light power detected by the light monitoring unit and connecting medium information indicating optical characteristics in the connecting medium. The connecting medium information includes information indicating a fiber type of the fiber connecting medium, information indicating a length of the fiber connecting medium, an average fiber loss coefficient of the fiber connecting medium and an intra-station loss value.

Owner:FUJITSU LTD

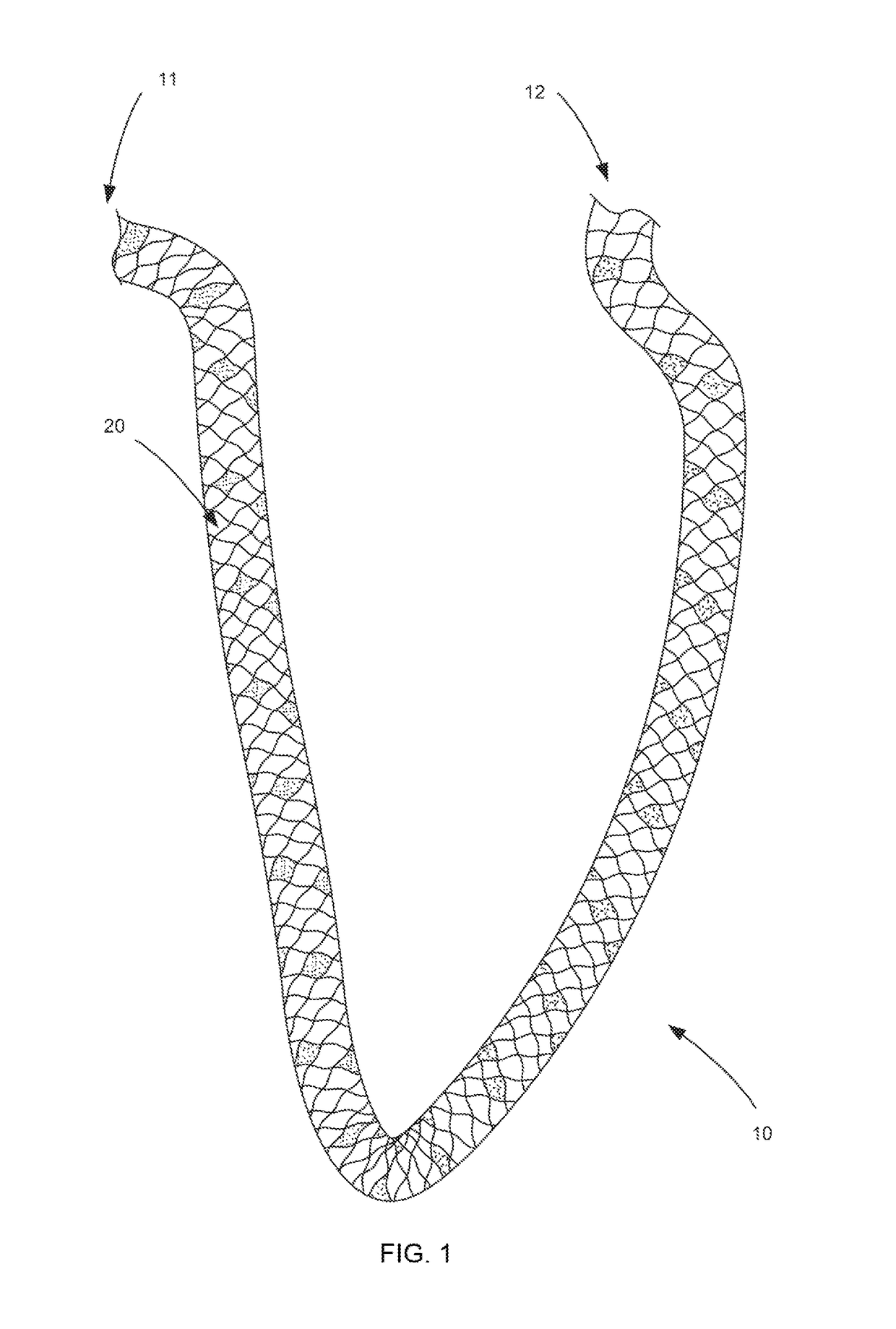

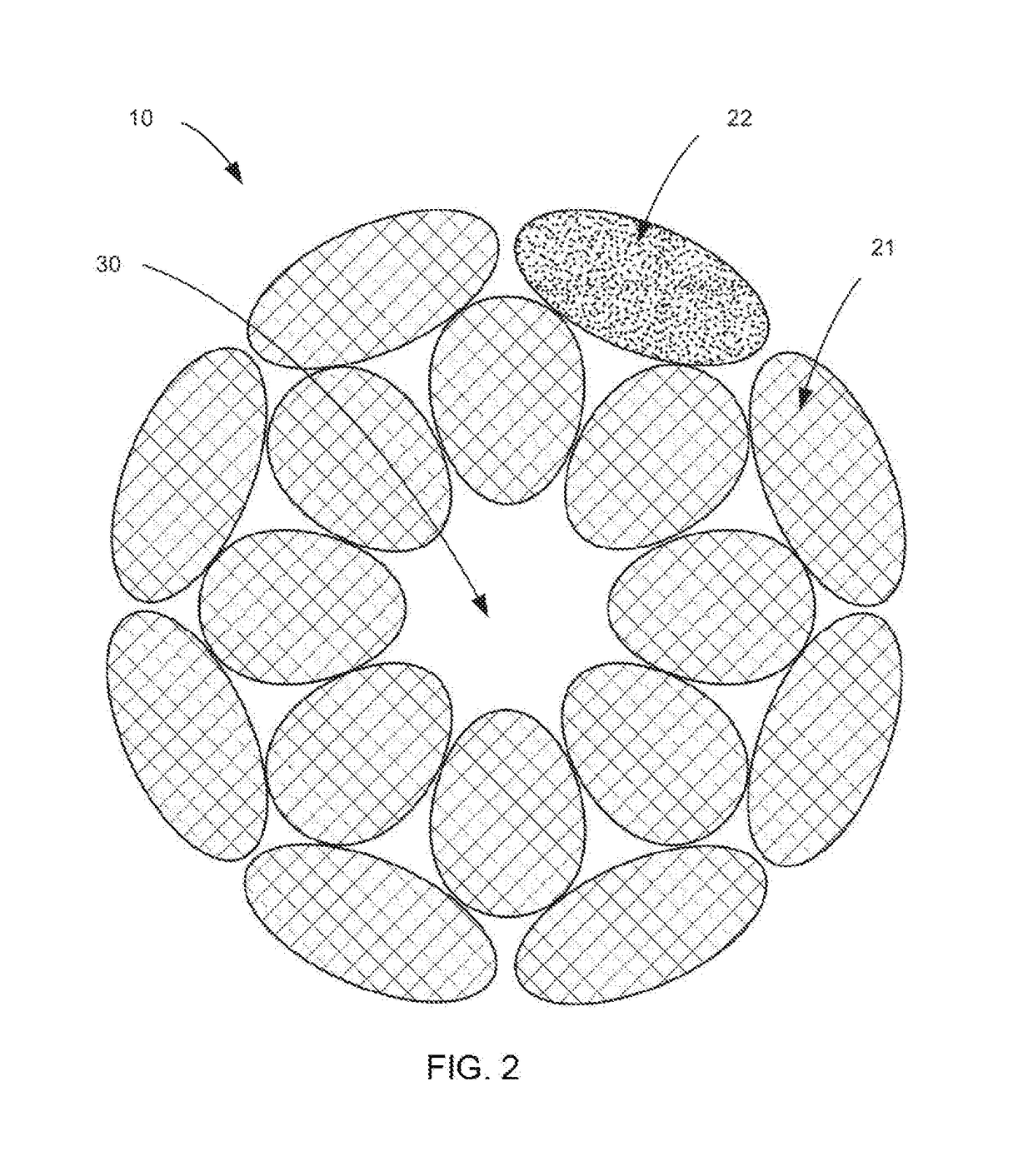

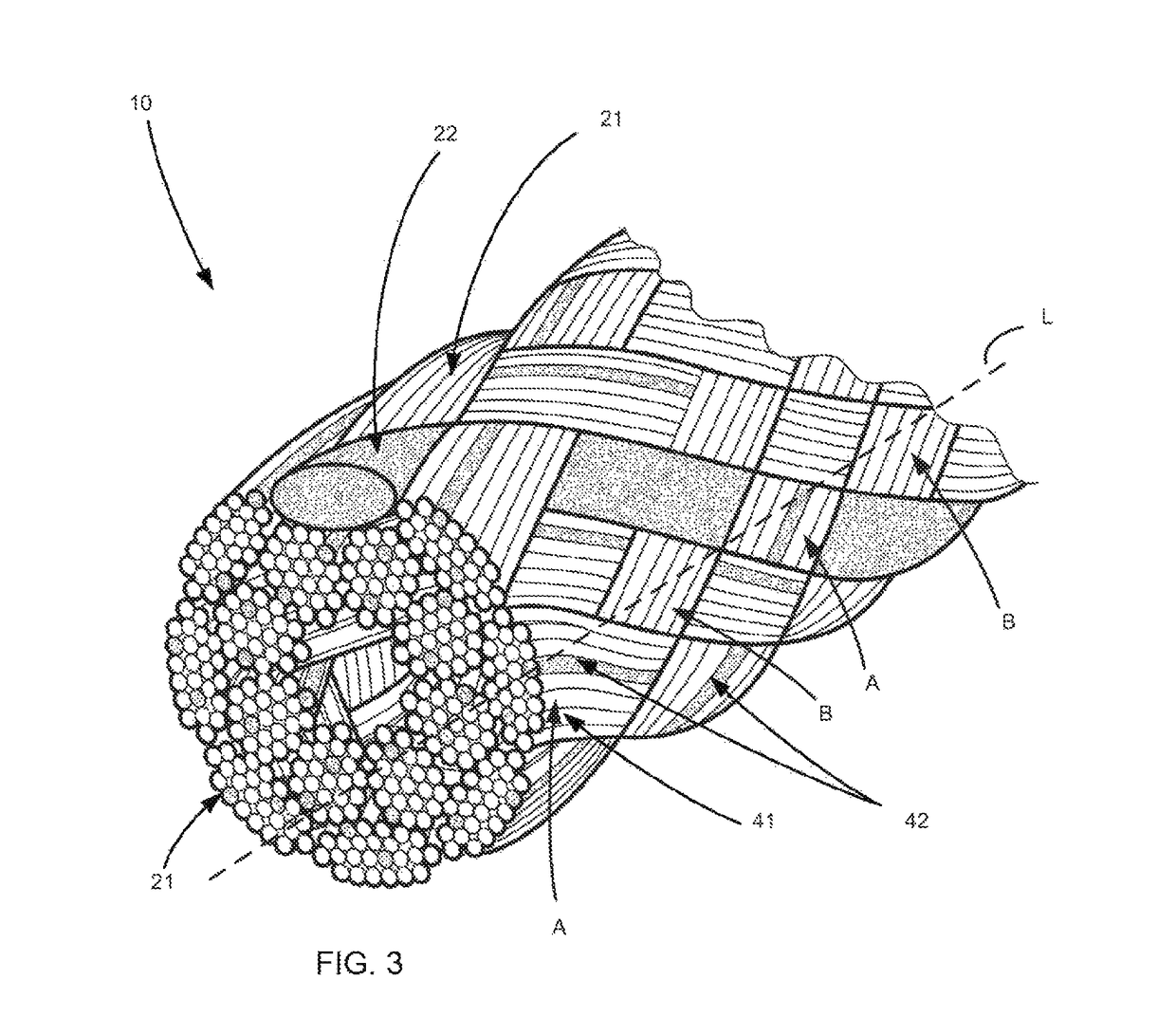

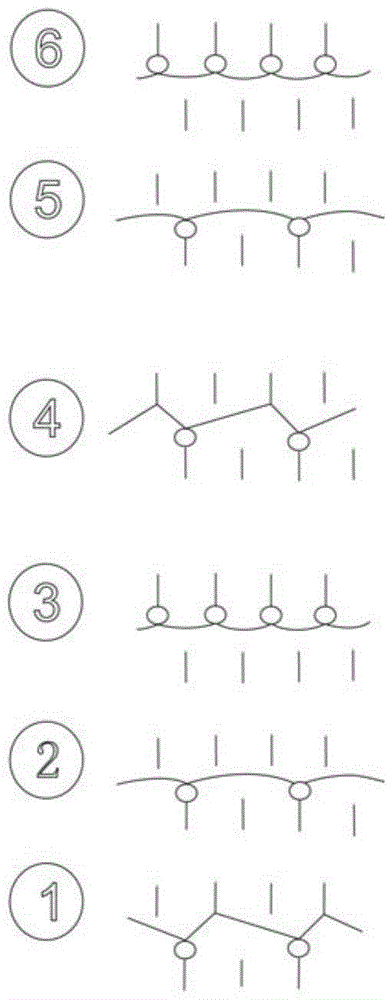

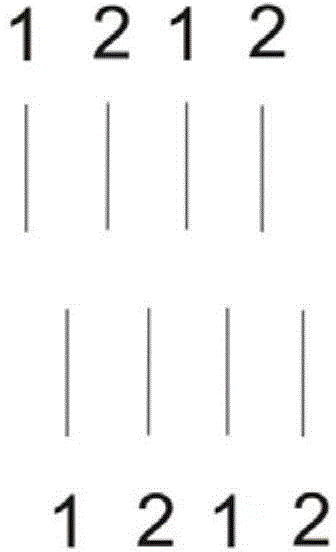

Braided filament with particularized strand compositions and methods of manufacturing and using same

In one embodiment, the present invention is a braided filament including a plurality of strands each having at least one ultrahigh molecular weight polyethylene fiber and at least one polyester fiber wherein the quantity of certain types of fibers in a first strand is the same as the quantity of the same type of fibers in a second strand. In a variant, one additional strand of the braided filament is a monofilament strand. In another variant, each strand is homogeneous with respect to the other strands and is made exclusively from ultrahigh molecular weight polyethylene fibers and polyester fibers such that each strand has the same distribution and quantity of fiber types.

Owner:STRYKER CORP +1

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20050129942A1Change in weightMaintain stable propertiesNon-insulated conductorsSynthetic resin layered productsProduction rateElectrical conductor

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about −45° C. to about 240° C. or higher, at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about −0.6×10−6 per deg. C. to about 1.0×10−5 per deg. C. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

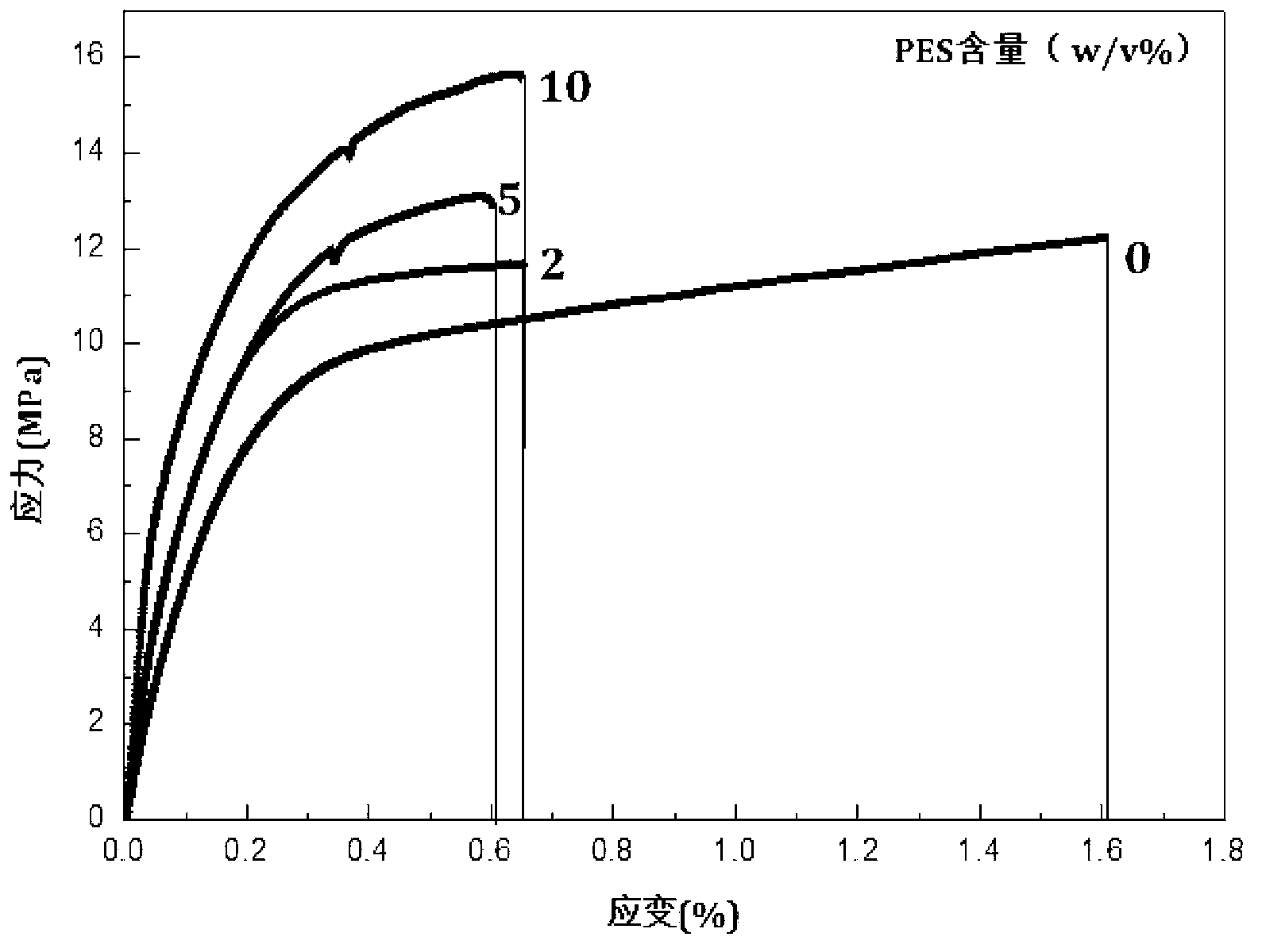

Preparation of hydrophilic polyvinylidene fluoride microporous membrane

InactiveCN1704152AImprove hydrophilicitySimple processSemi-permeable membranesPhysical chemistryFiber type

The invention relates to a method for preparing hydrophilic PVDF microporous barrier. The principal raw material is polyvinylidene fluoride with the range of molecular weight: 5000 to 50000. It prepares hydrophilic PVDF microporous barrier by the method of separating solution and compounding dip-coating modification. It especially suits the occasion of effluent treatment, medicine separation and biochemy. The technology can prepare microporous barriers with plate type and hollow fiber type.

Owner:杨虎

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20040131834A1High strengthIncrease ampacityNon-insulated conductorsApparatus for heat treatmentElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about -45° C. to about 230° C., at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about -0.7x10<-6 >m / m / ° C. to about 6x10<-6 >m / m° C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 60 ft / min.

Owner:CTC GLOBAL CORP

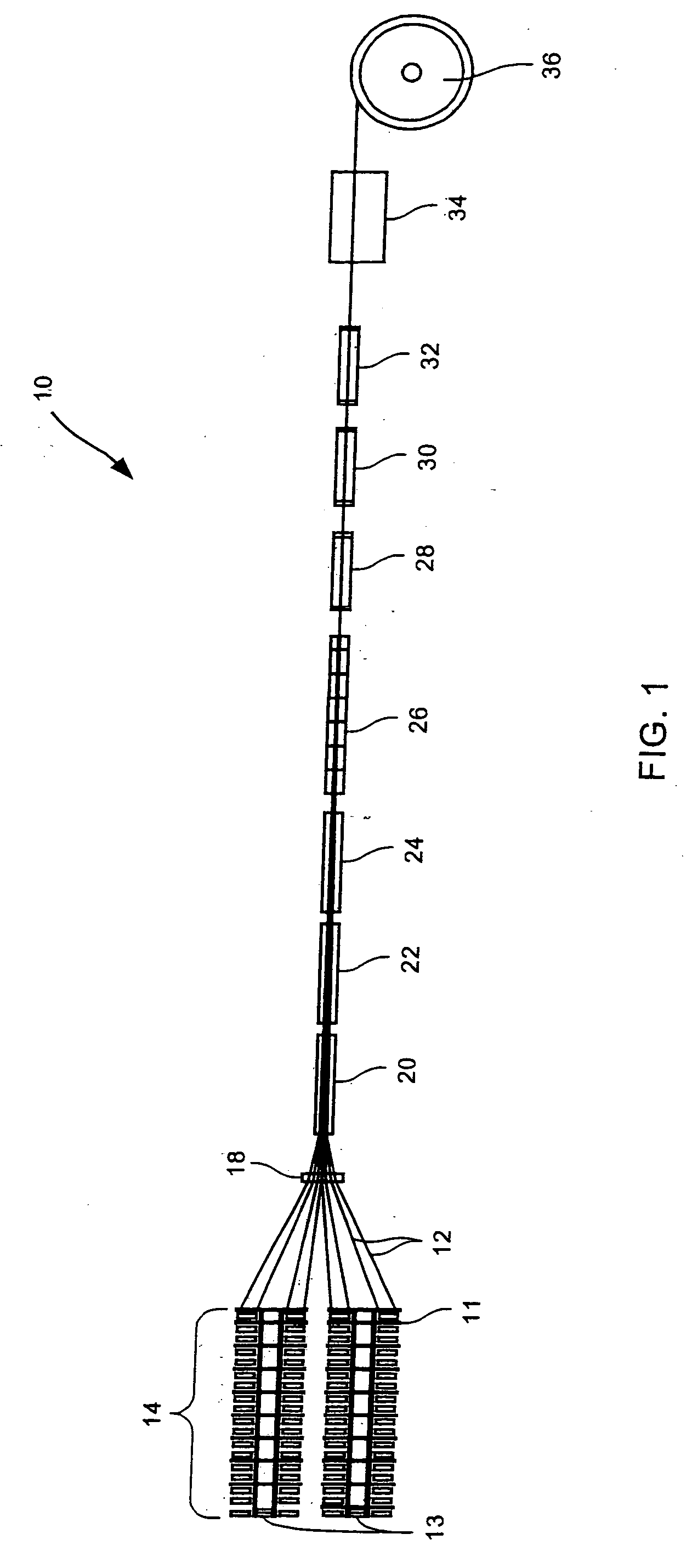

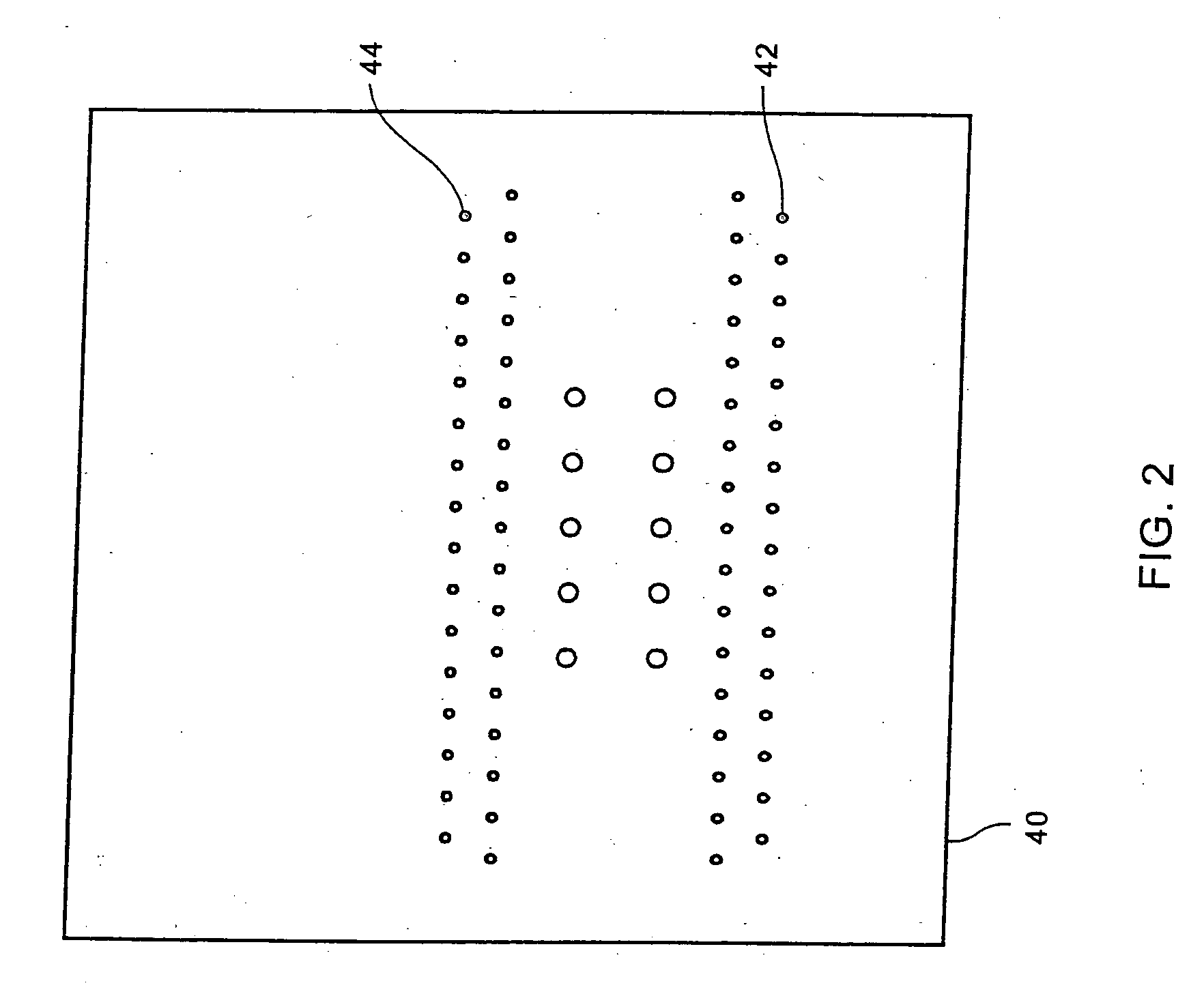

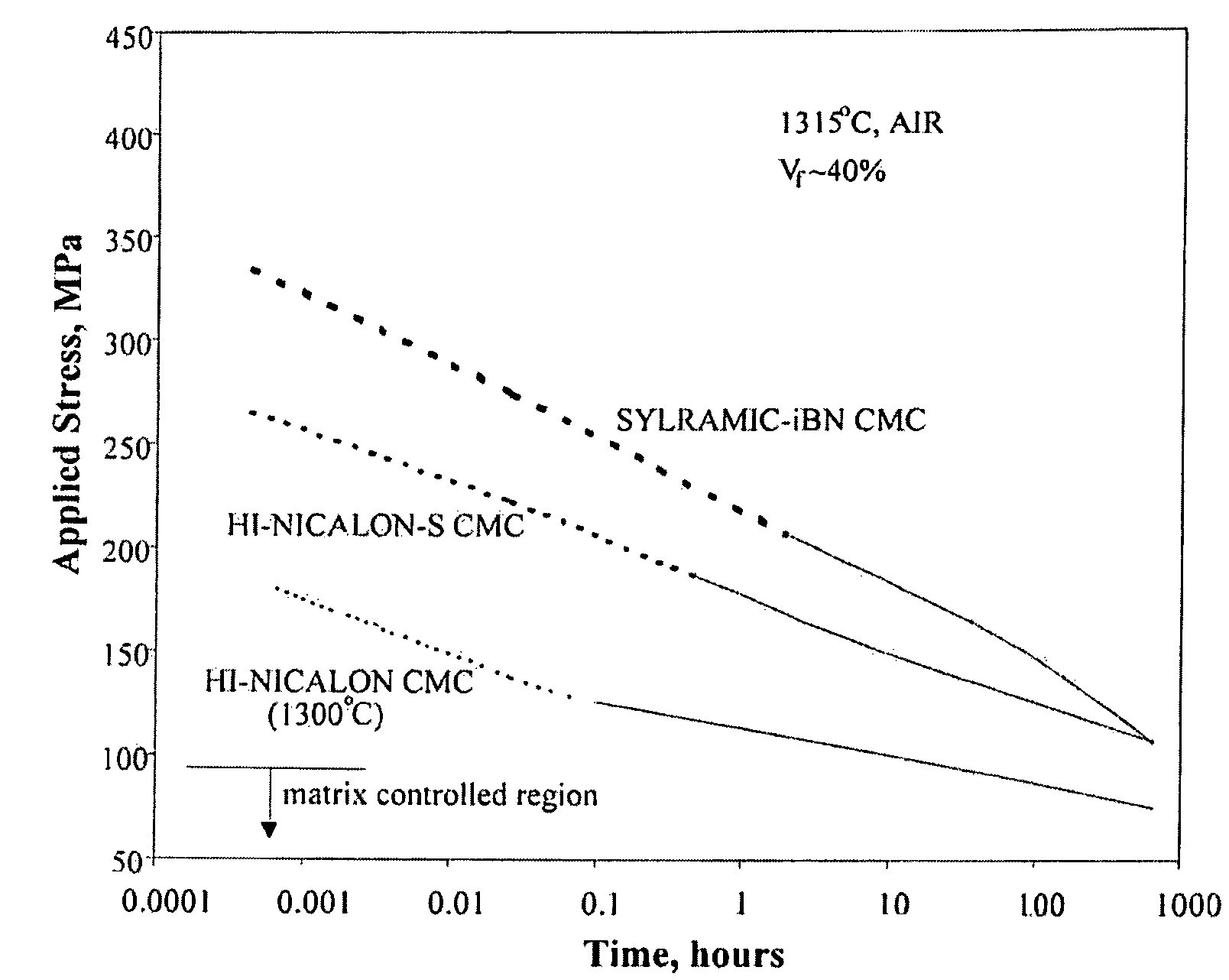

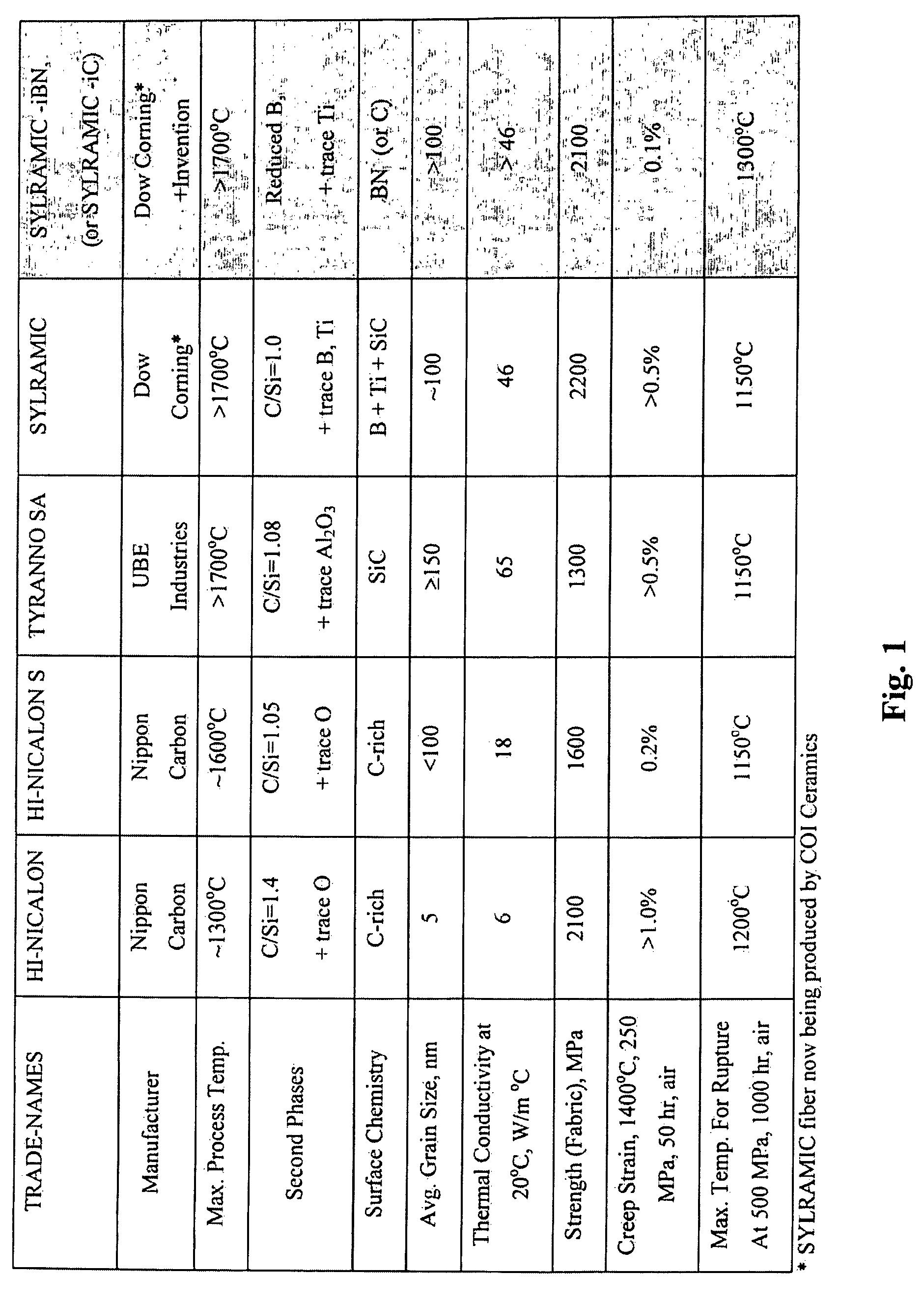

Methods for producing silicon carbide architectural preforms

ActiveUS7687016B1Reducing fiber stressMinimal lossCeramic shaping apparatusClaywaresFiber typeHigh intensity

Methods are disclosed for producing architectural preforms and high-temperature composite structures containing high-strength ceramic fibers with reduced preforming stresses within each fiber, with an in-situ grown coating on each fiber surface, with reduced boron within the bulk of each fiber, and with improved tensile creep and rupture resistance properties for each fiber. The methods include the steps of preparing an original sample of a preform formed from a pre-selected high-strength silicon carbide ceramic fiber type, placing the original sample in a processing furnace under a pre-selected preforming stress state and thermally treating the sample in the processing furnace at a pre-selected processing temperature and hold time in a processing gas having a pre-selected composition, pressure, and flow rate. For the high-temperature composite structures, the method includes additional steps of depositing a thin interphase coating on the surface of each fiber and forming a ceramic or carbon-based matrix within the sample.

Owner:NASA

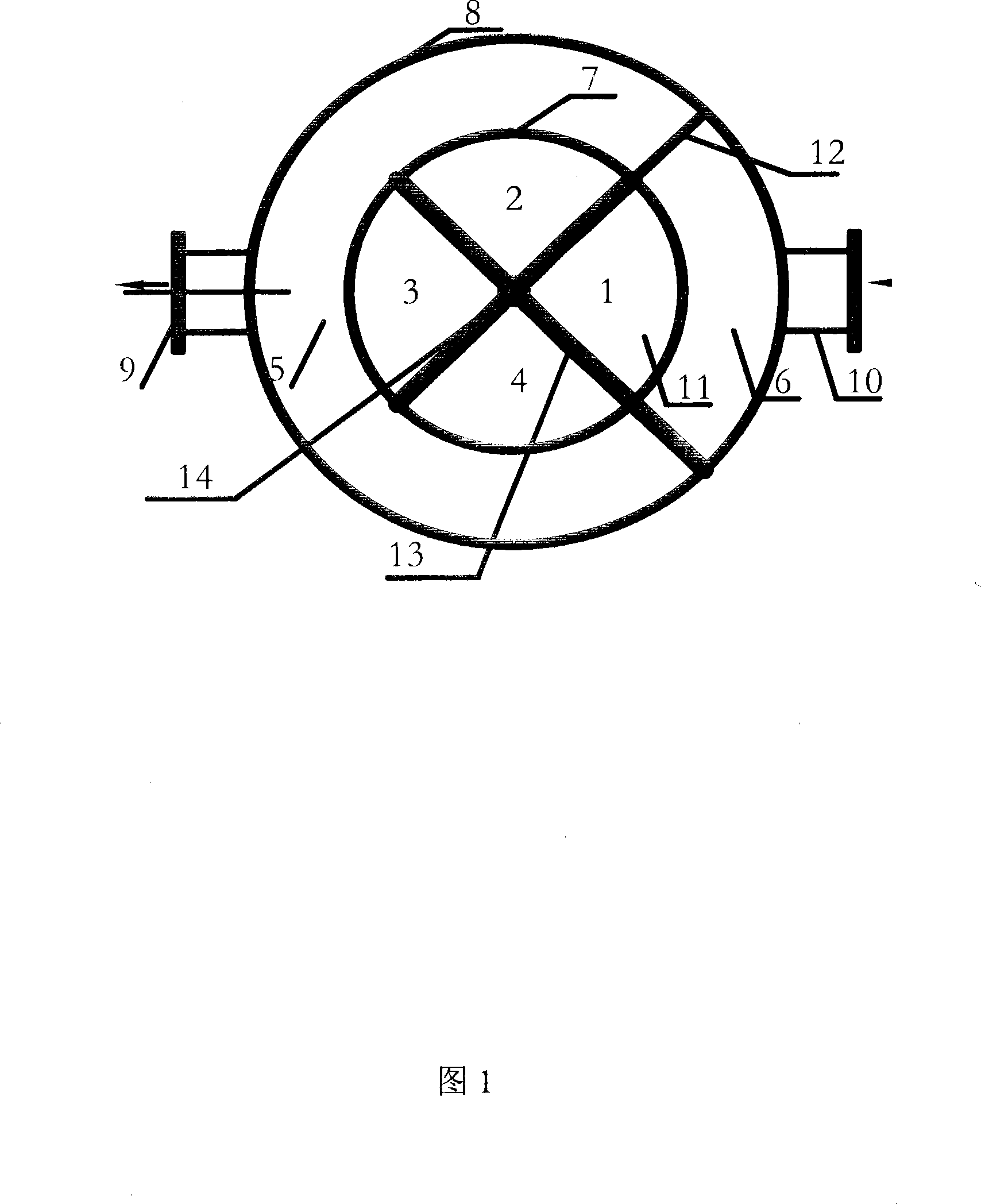

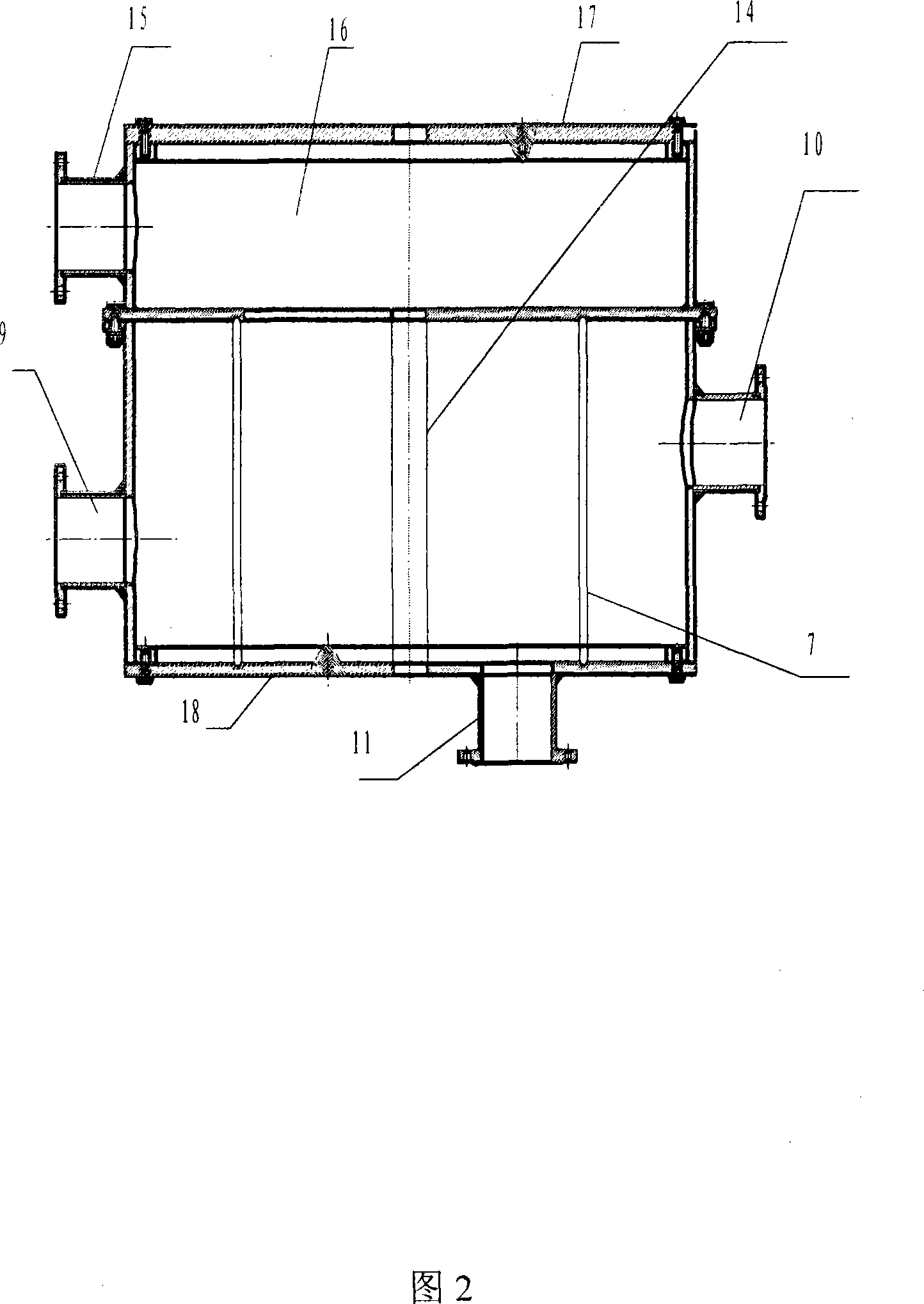

Sewage full-automatic sewage-removing machine

InactiveCN101143279AThere will be no accumulation of dead endsRealize automatic decontamination functionMoving filtering element filtersFiber typeSewage

The invention relates to a full automatic pollutant remover of sewage, which is used in sewage filtrating process of sewage source heat pump system. The invention is mainly composed of a cylinder shaped filter screen, a pollutant removal scraper, a shaft, a pollutant removal machine casing, a sewage segregator, an upper cover board, a lower cover board, a separator and so on. The pollutant removal scraper can rotate, which can ensure that no pollutant sundries dead angle can be found, and ensure to scrape off fiber typed pollutant sundries like the animal hair and so on. The sewage segregator is arranged to match the rotating of the pollutant removal scraper, in order to realize the impurity contained sewage feed water inside the cylinder filter screen. After being removed pollutant, the water is fed from outside of the cylinder. After being exchanged heat, the sewage backs into cylinder filter screen. After being backwashed, the impurity contained sewage is drained out of the cylinder filter screen. On working process, the invention needs no manual work to remove the pollutant every a fixed period, which can realize full automatic pollutant remove function.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

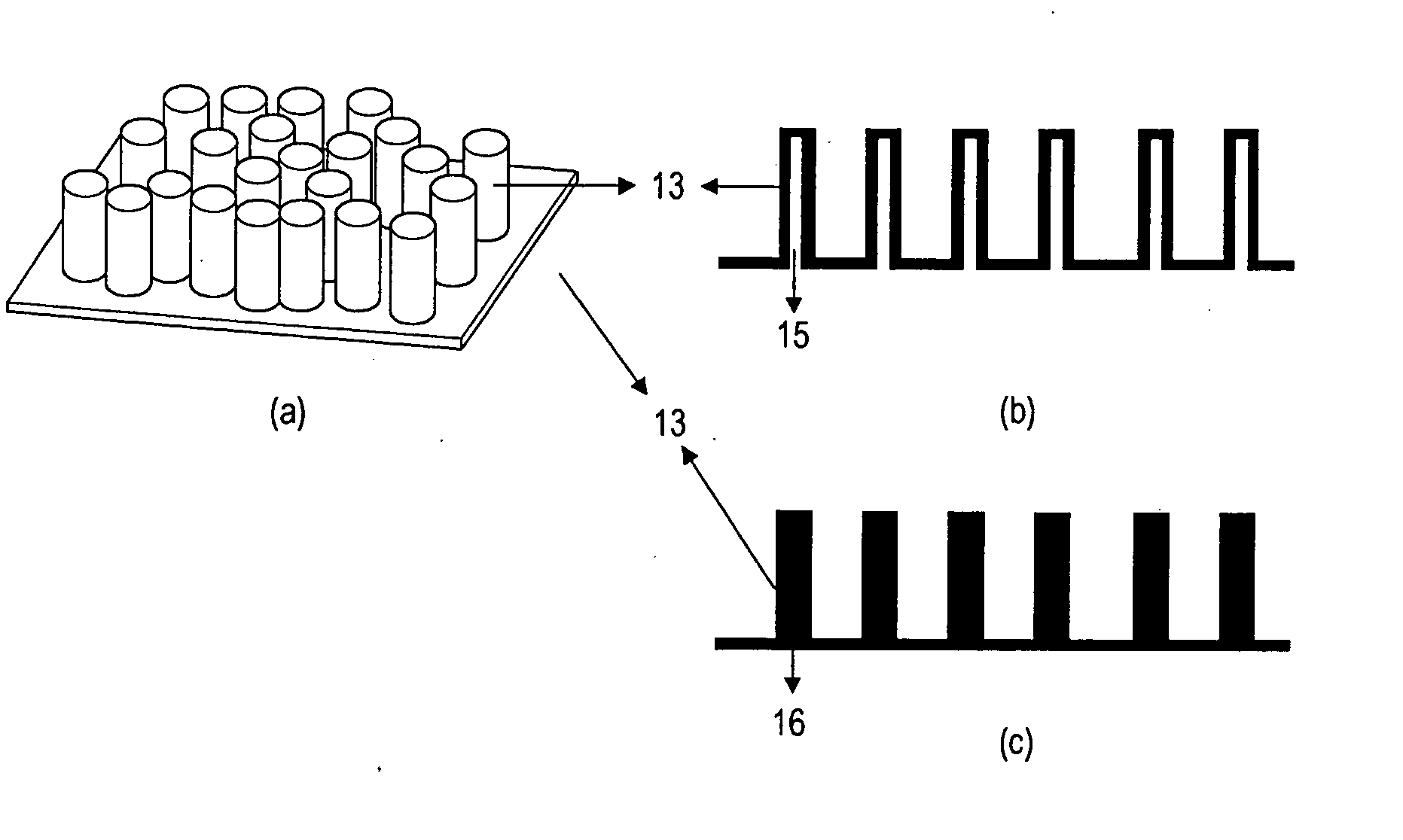

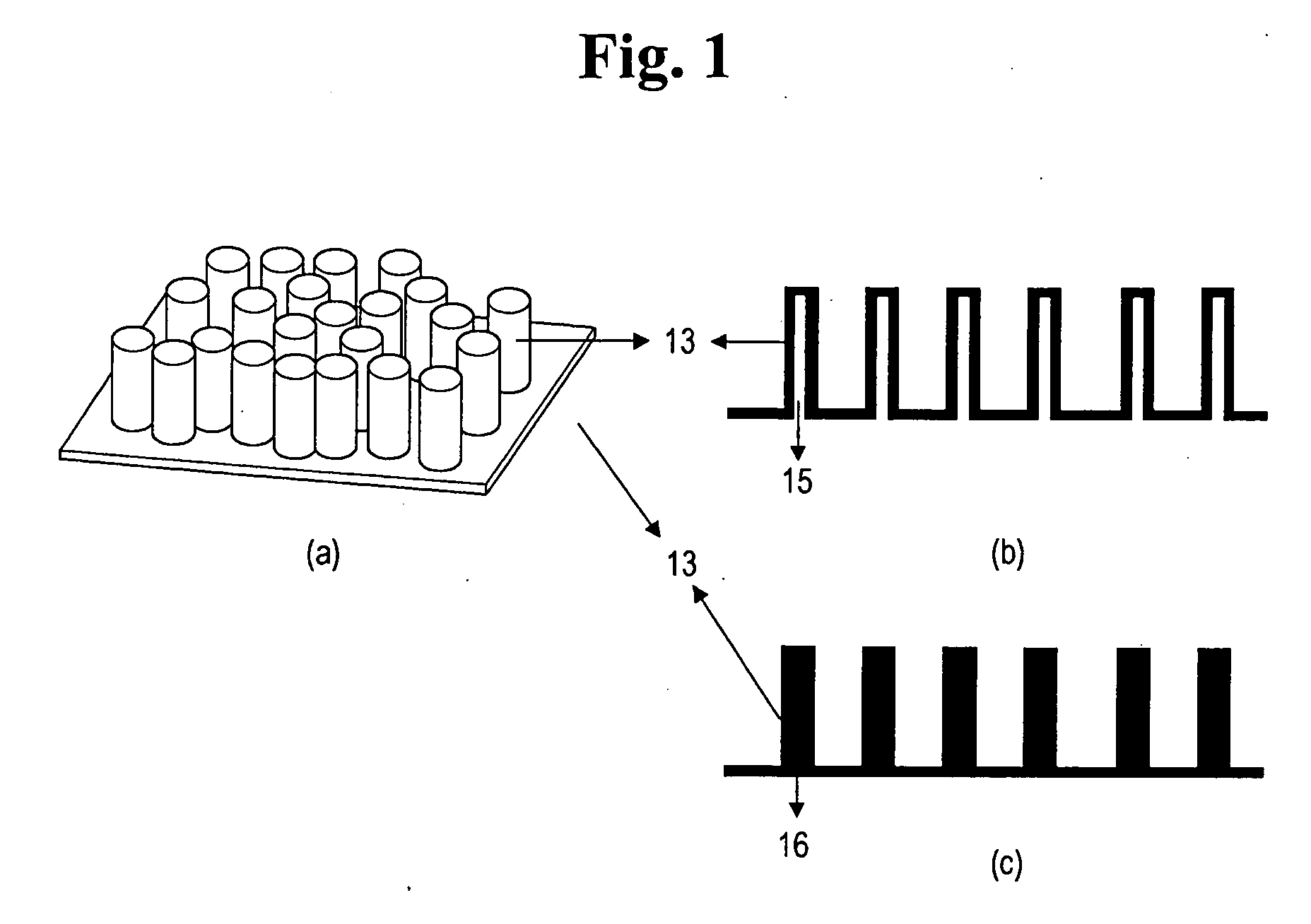

Method of fabricating a three-dimensional nanostructure

InactiveUS20070100086A1Rapid and reliable mannerManufactured rapidly and reliablyMaterial nanotechnologyNanostructure manufactureInterfacial reactionMicrometer

There is provided a rapid and reliable method of fabricating a three-dimensional organic / inorganic nanostructure of a well-arranged shape wherein tubes or fibers of several nanometer to several micrometer size have horizontal and vertical orientations. The method of the present invention comprises the following steps: A) forming a tube- or fiber-type structure of an organic or inorganic nanometer / micrometer size by an interfacial polymerization method or interfacial reaction method; and B) obtaining the organic / inorganic composite three-dimensional nanostructure.

Owner:KOREA INST OF SCI & TECH

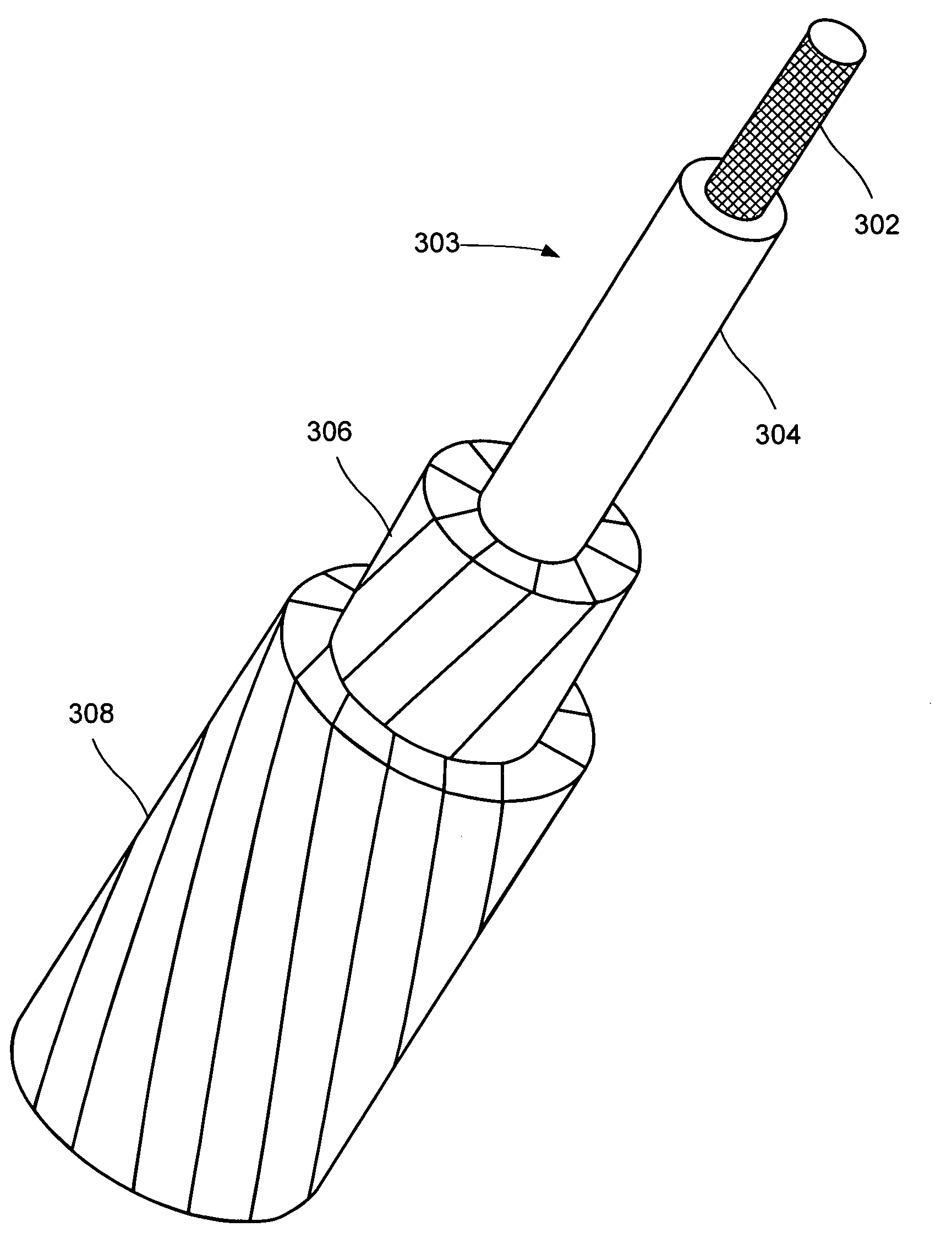

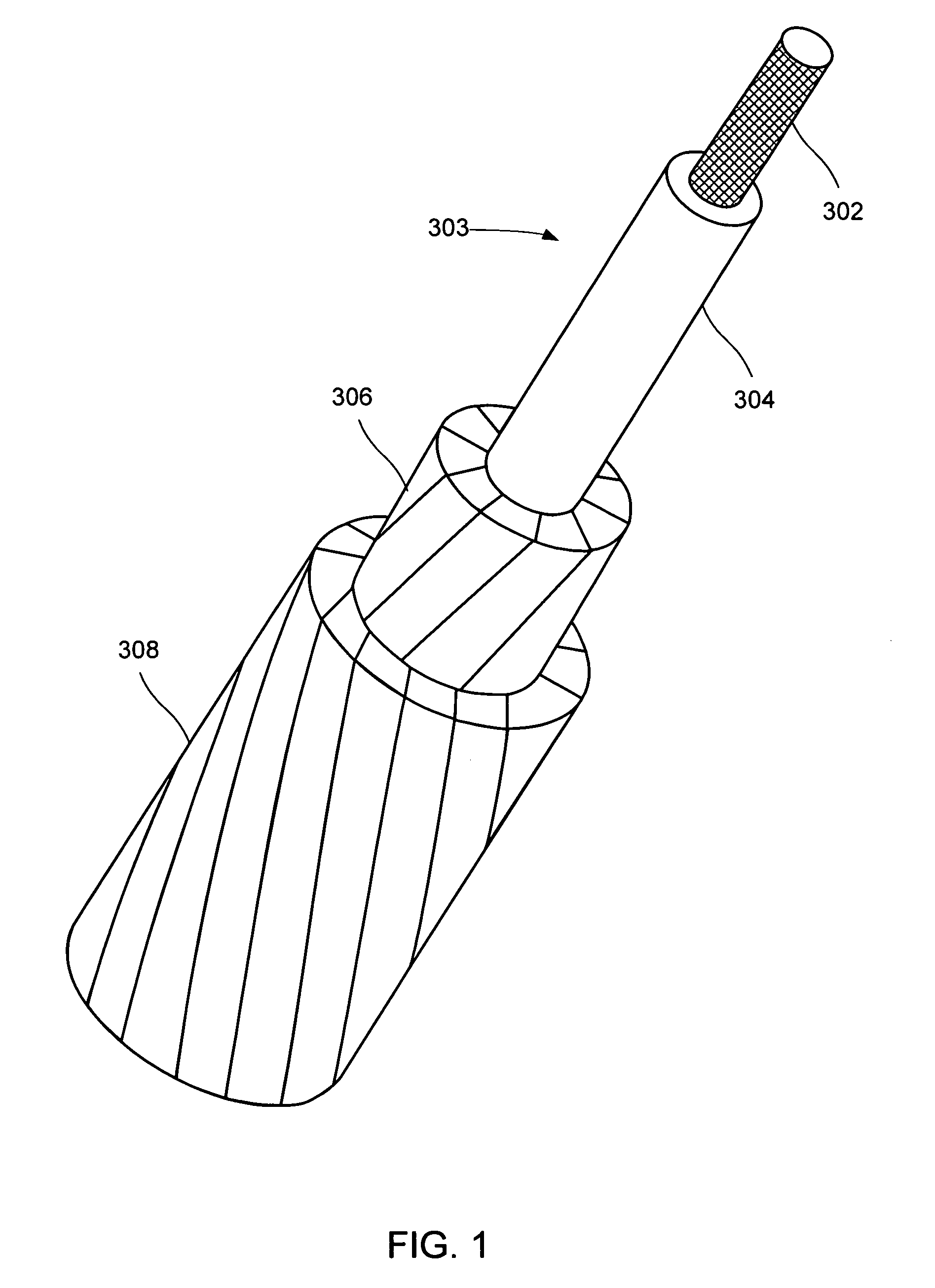

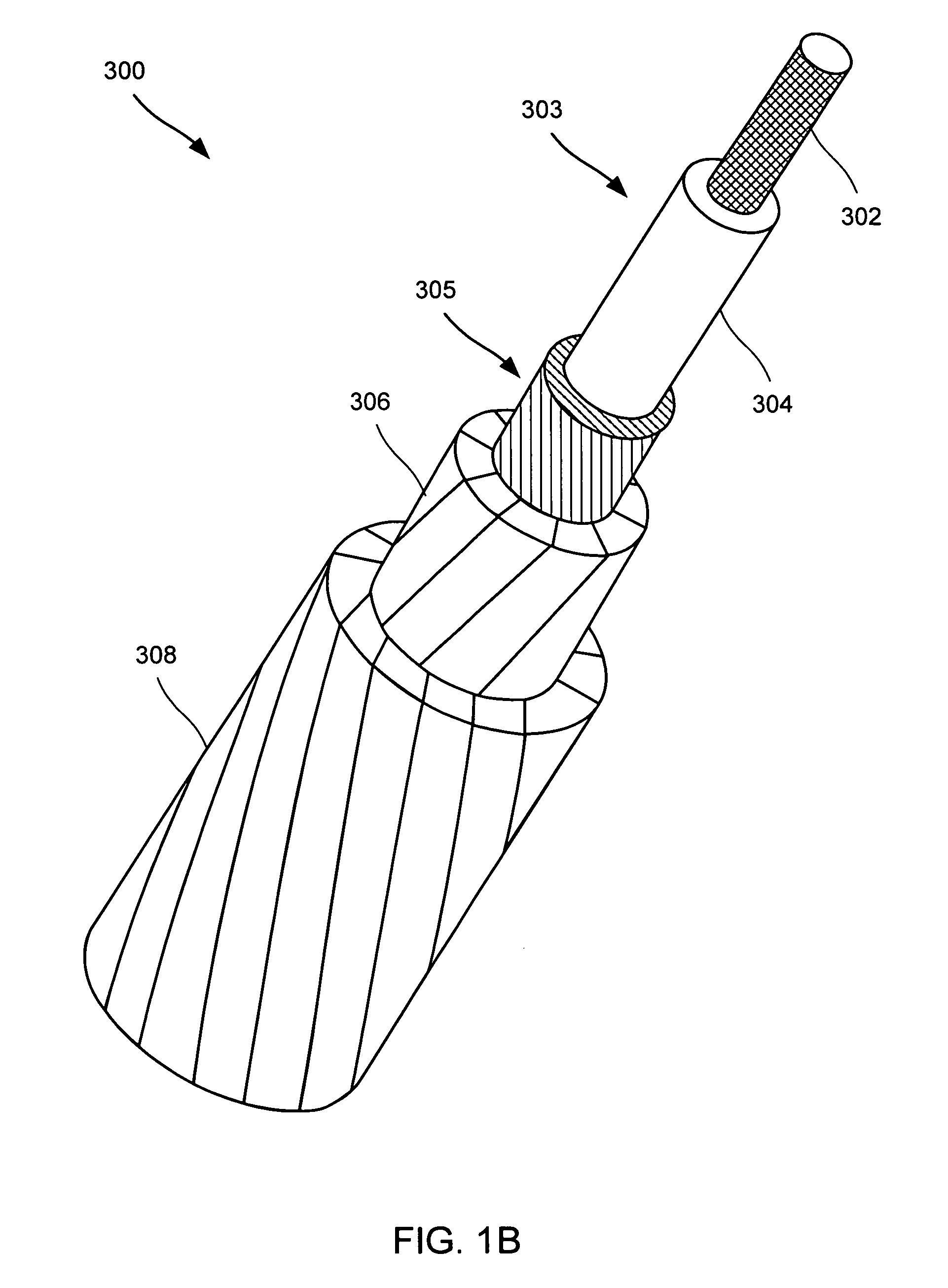

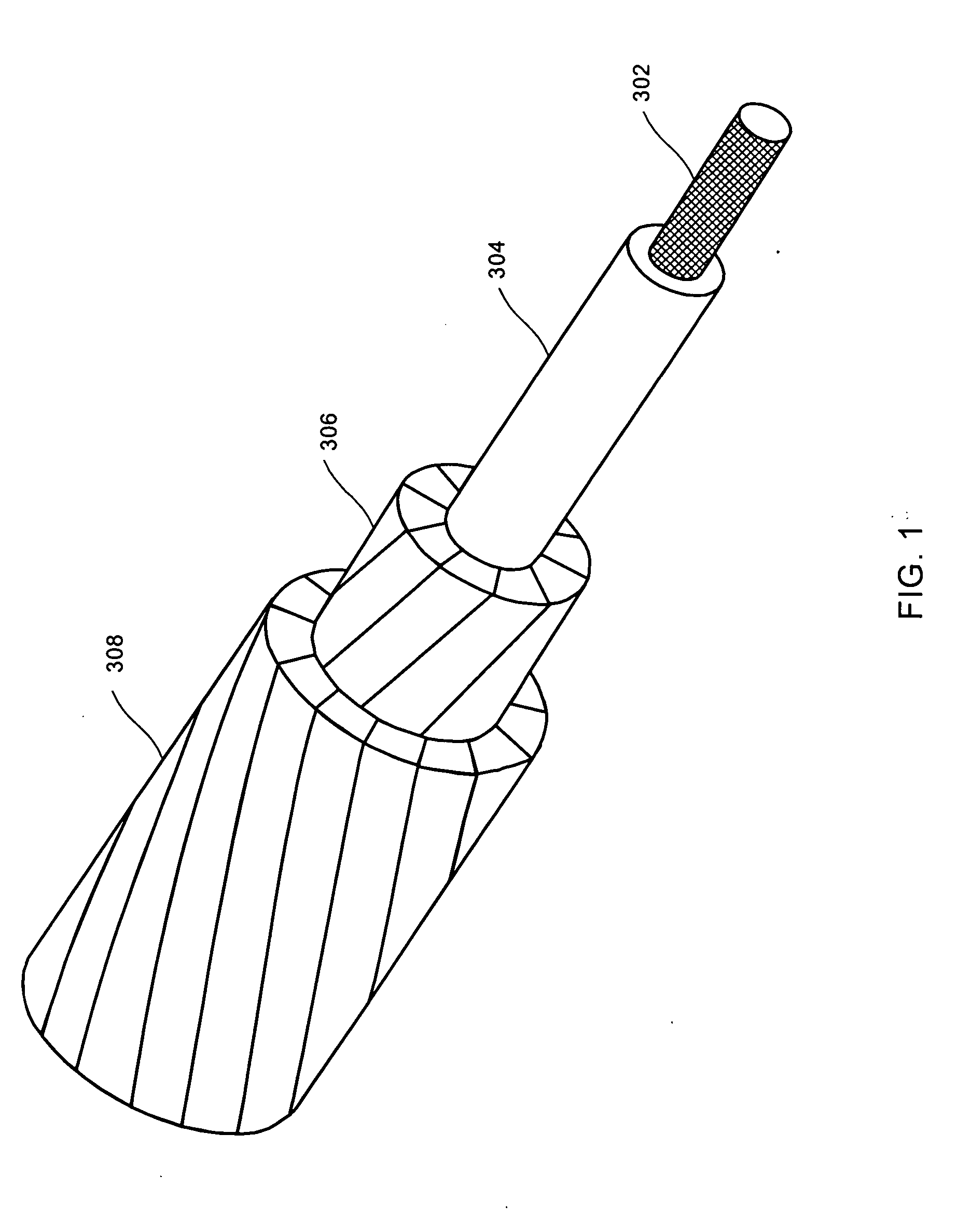

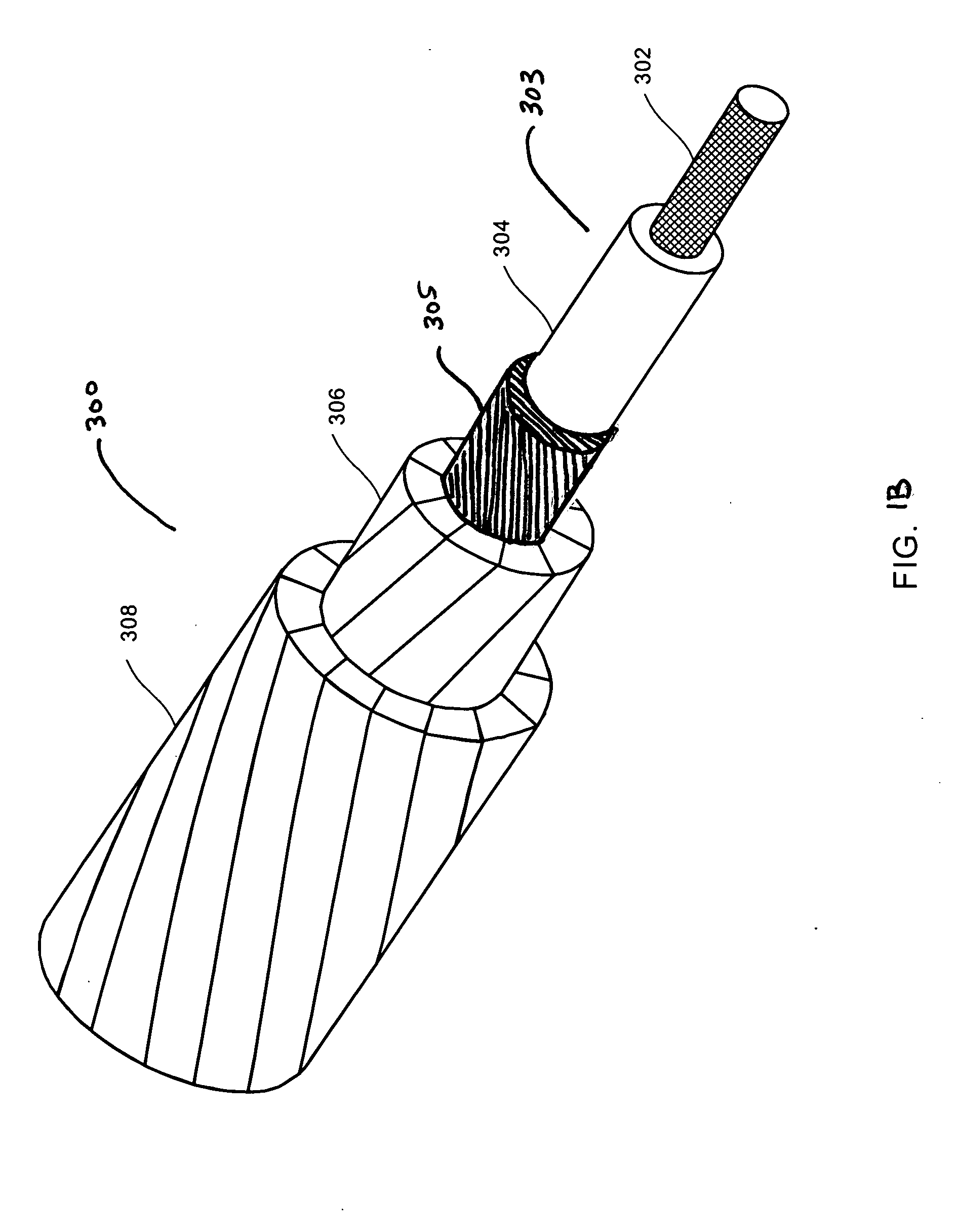

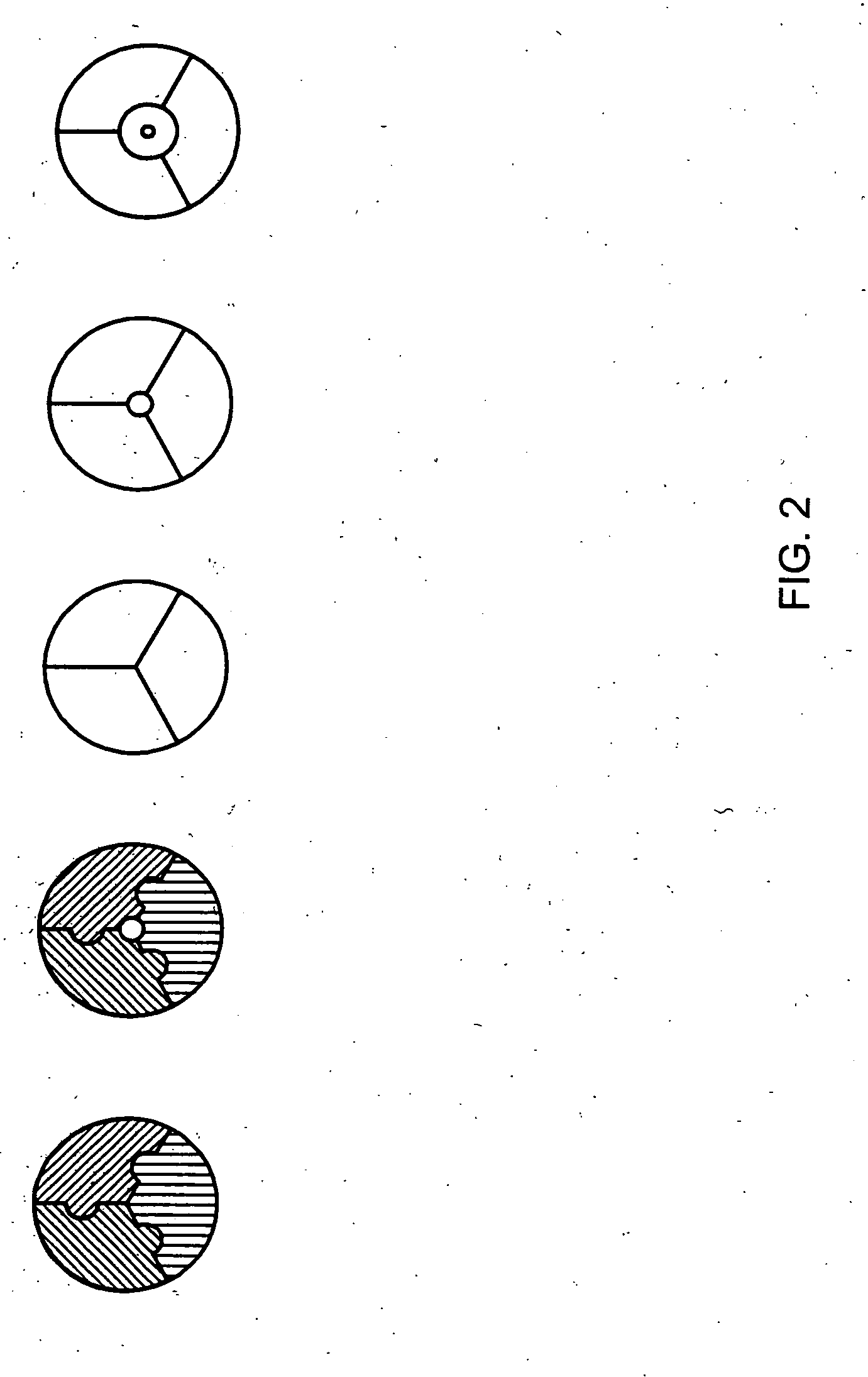

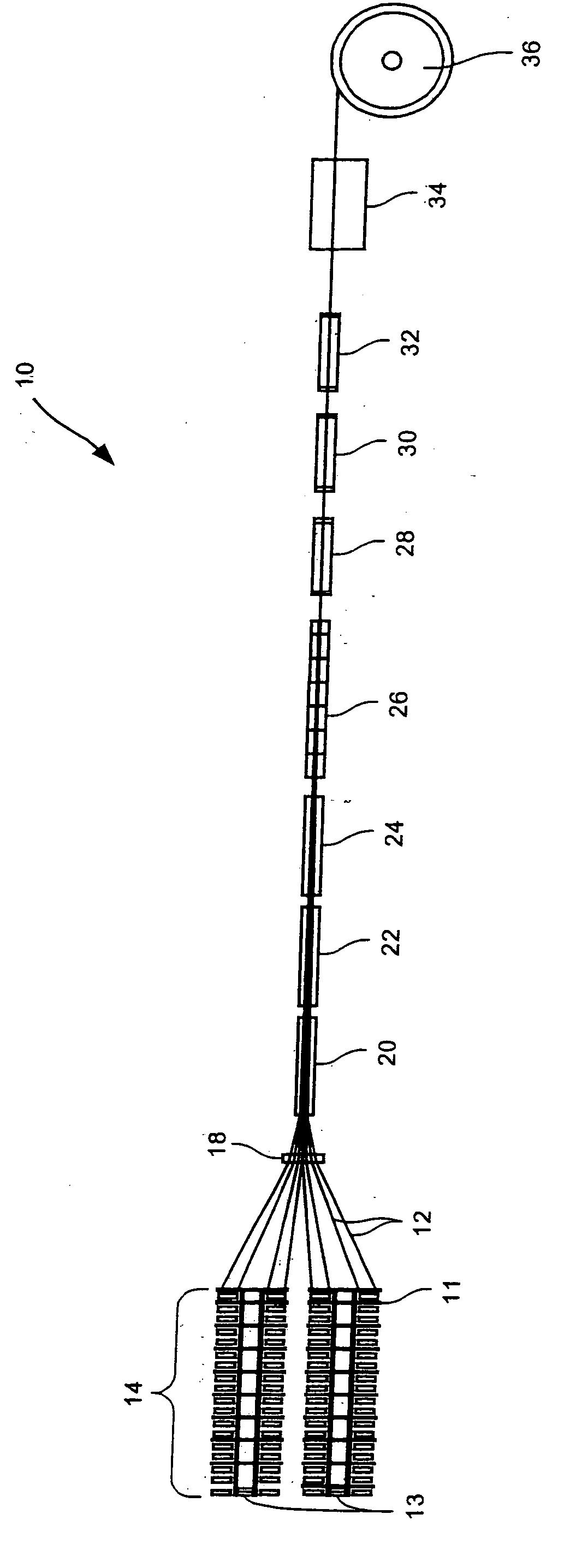

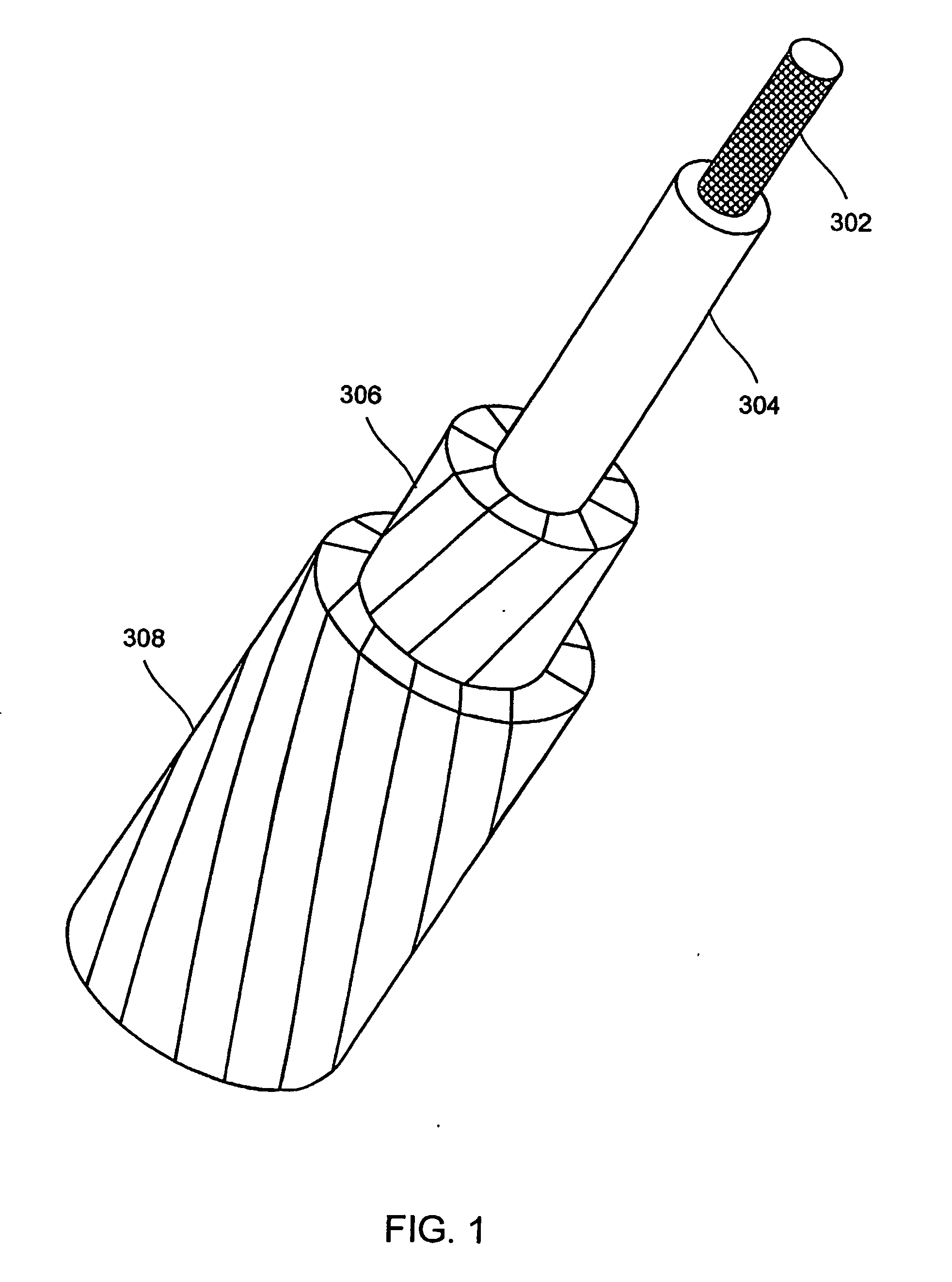

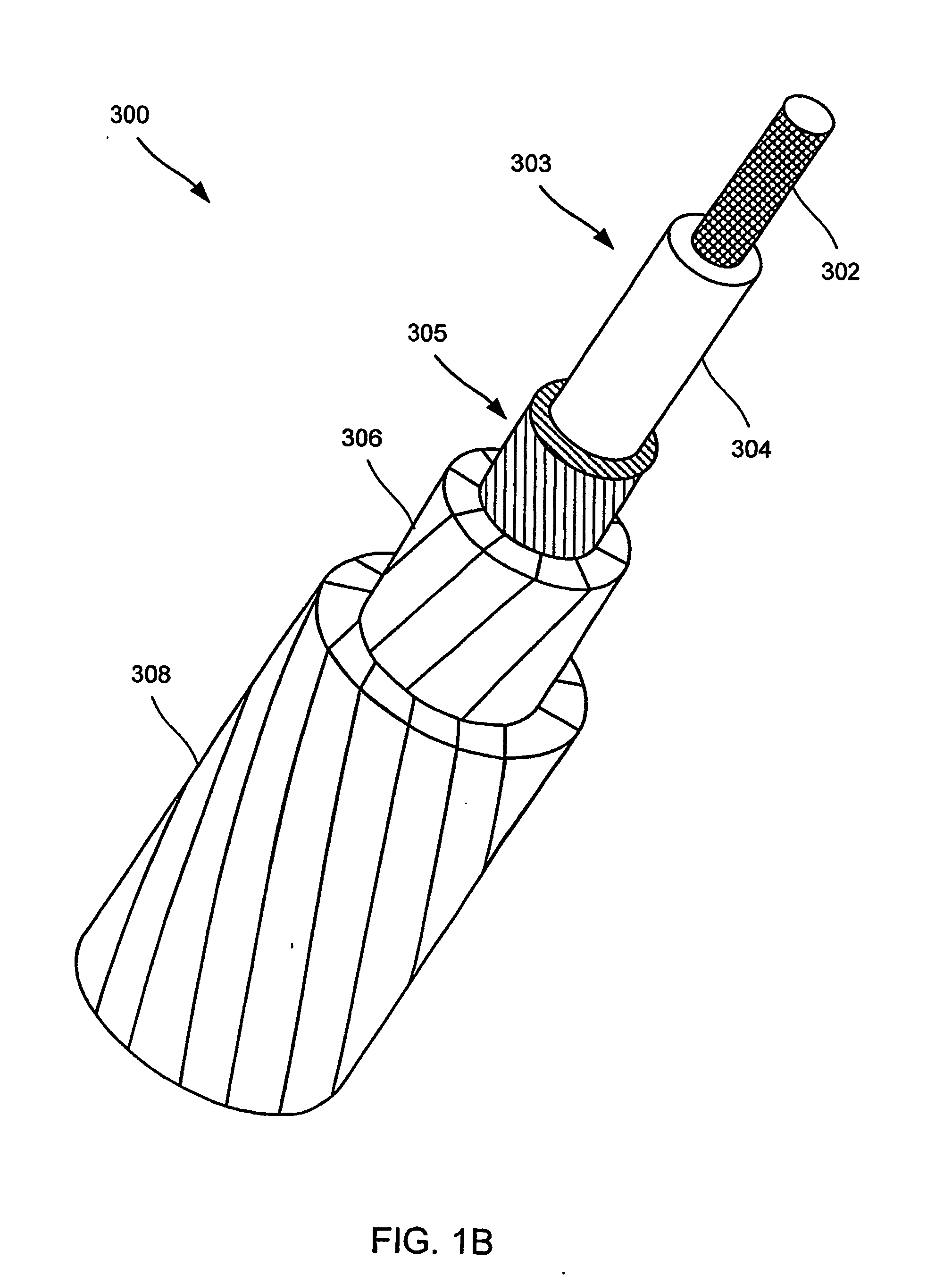

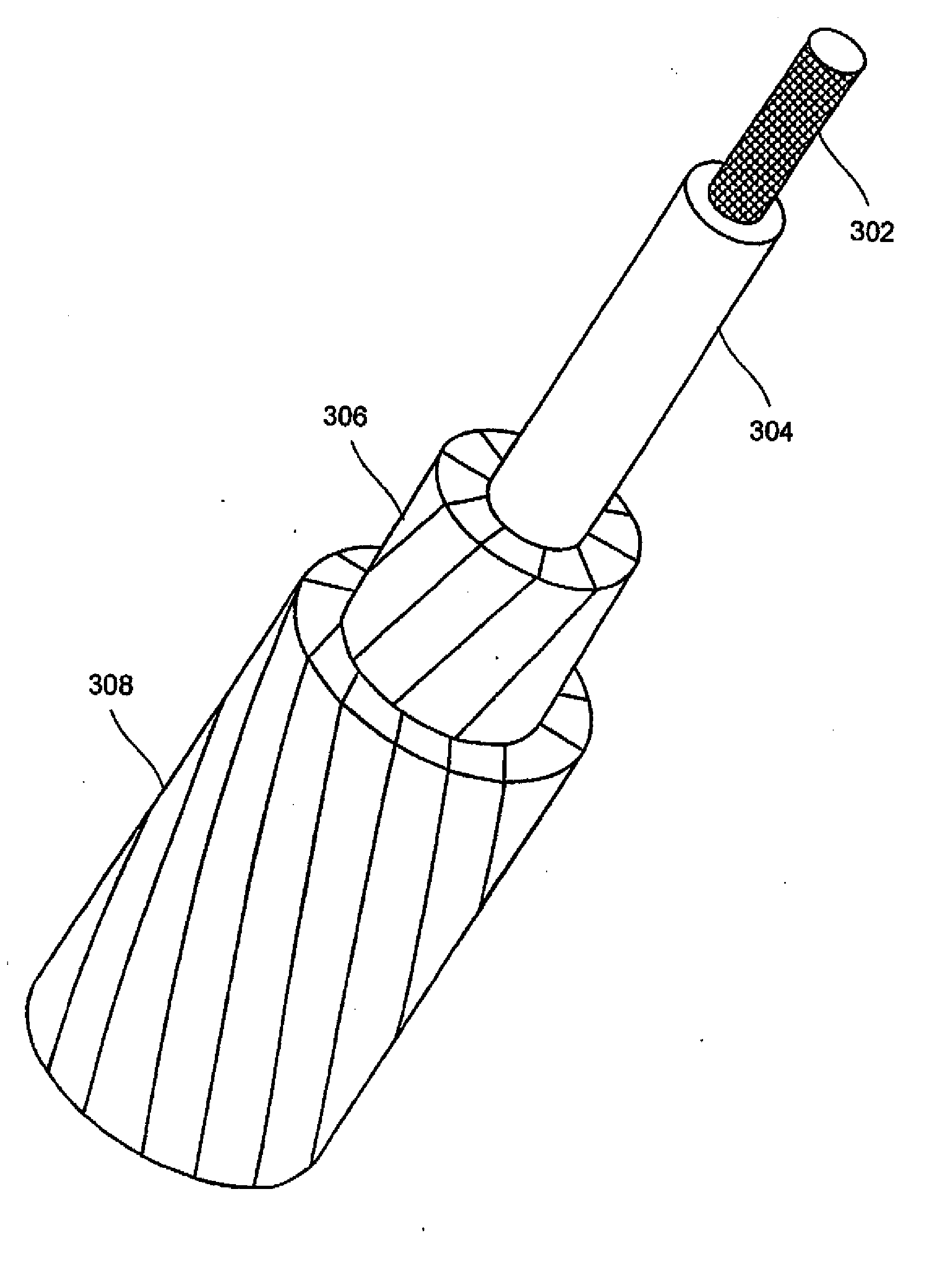

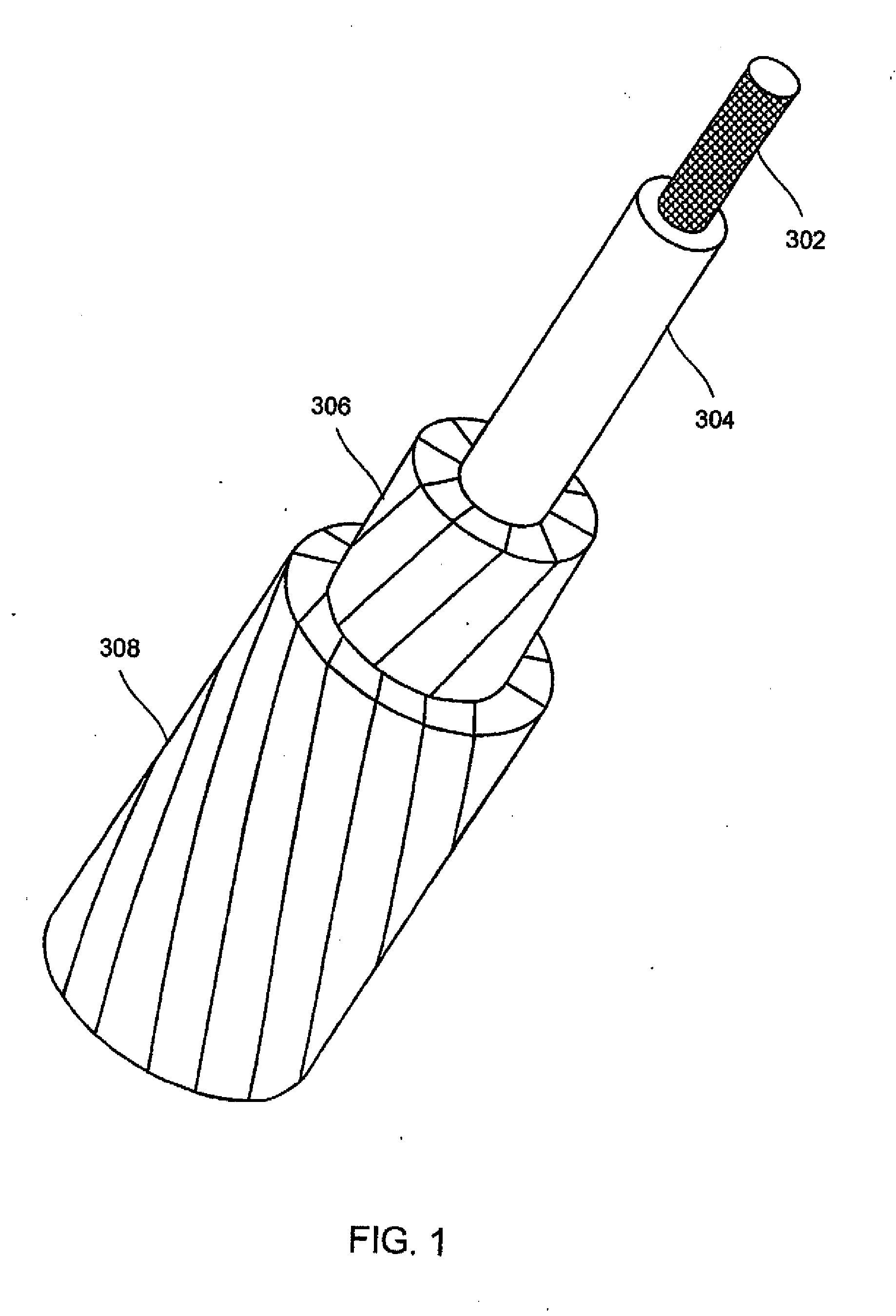

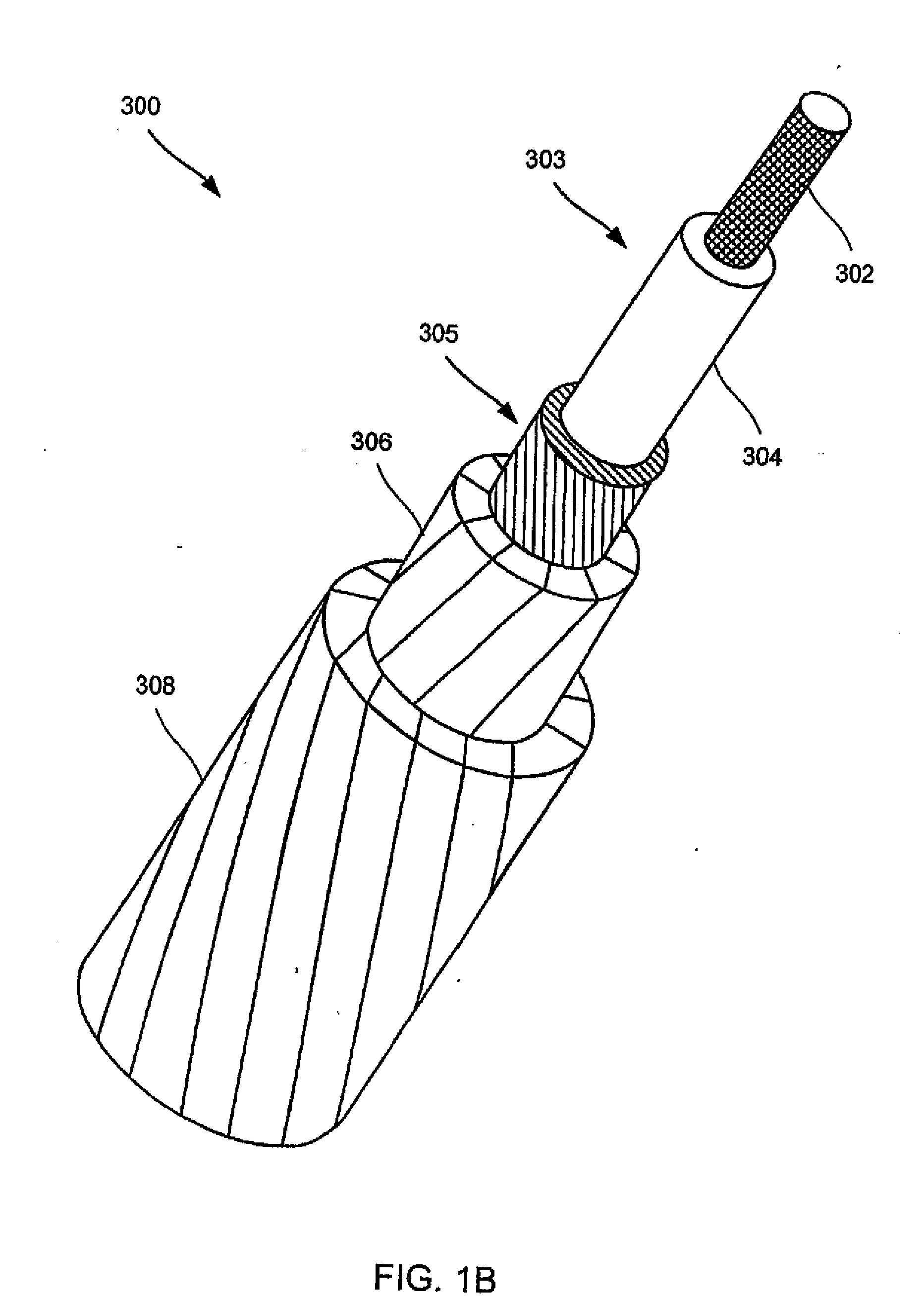

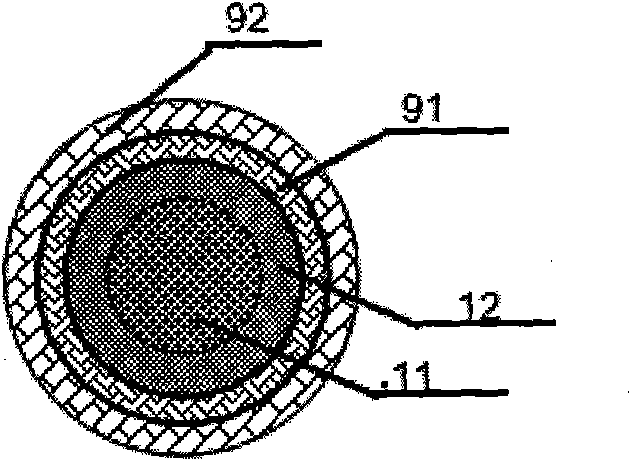

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20070128435A1Change in weightMaintain stable propertiesMaterial nanotechnologyNon-insulated conductorsProduction rateFiber type

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC 303 cable (300) has a composite core surrounded by an outer film (305) and at least one layer of aluminum conductor (306). The composite core (303) comprises a plurality of fibers from at least one fiber type in one or more matrix materials. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

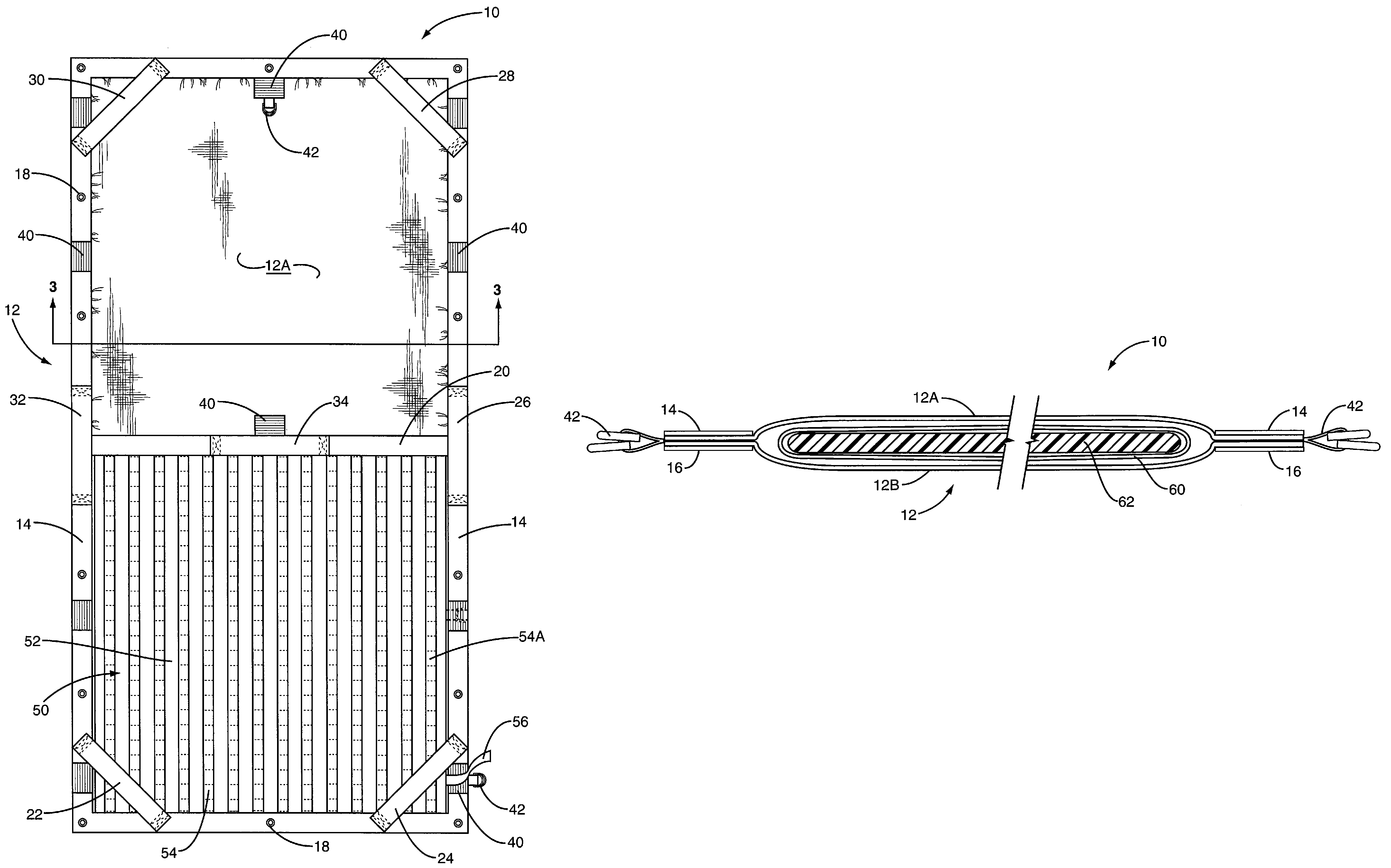

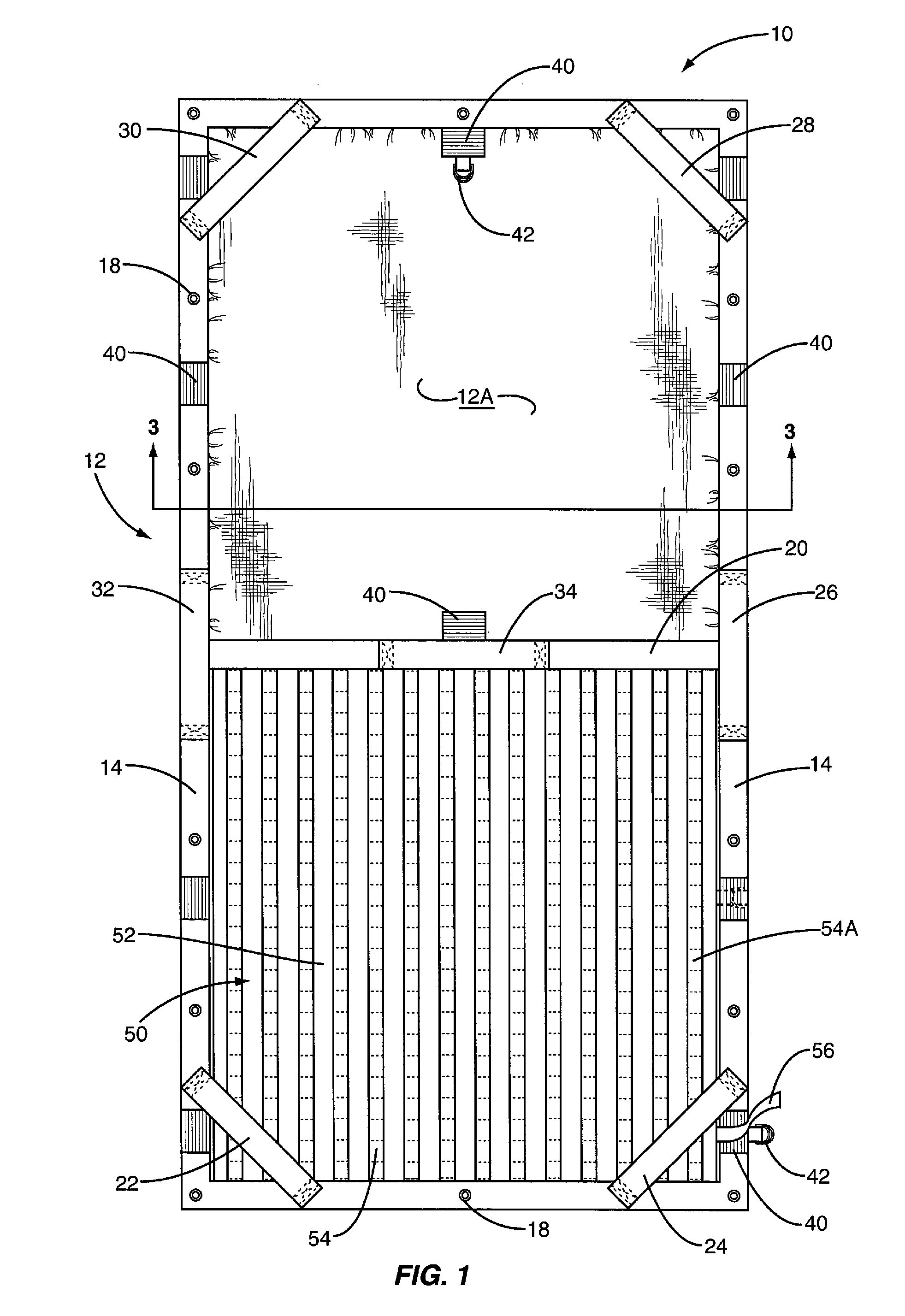

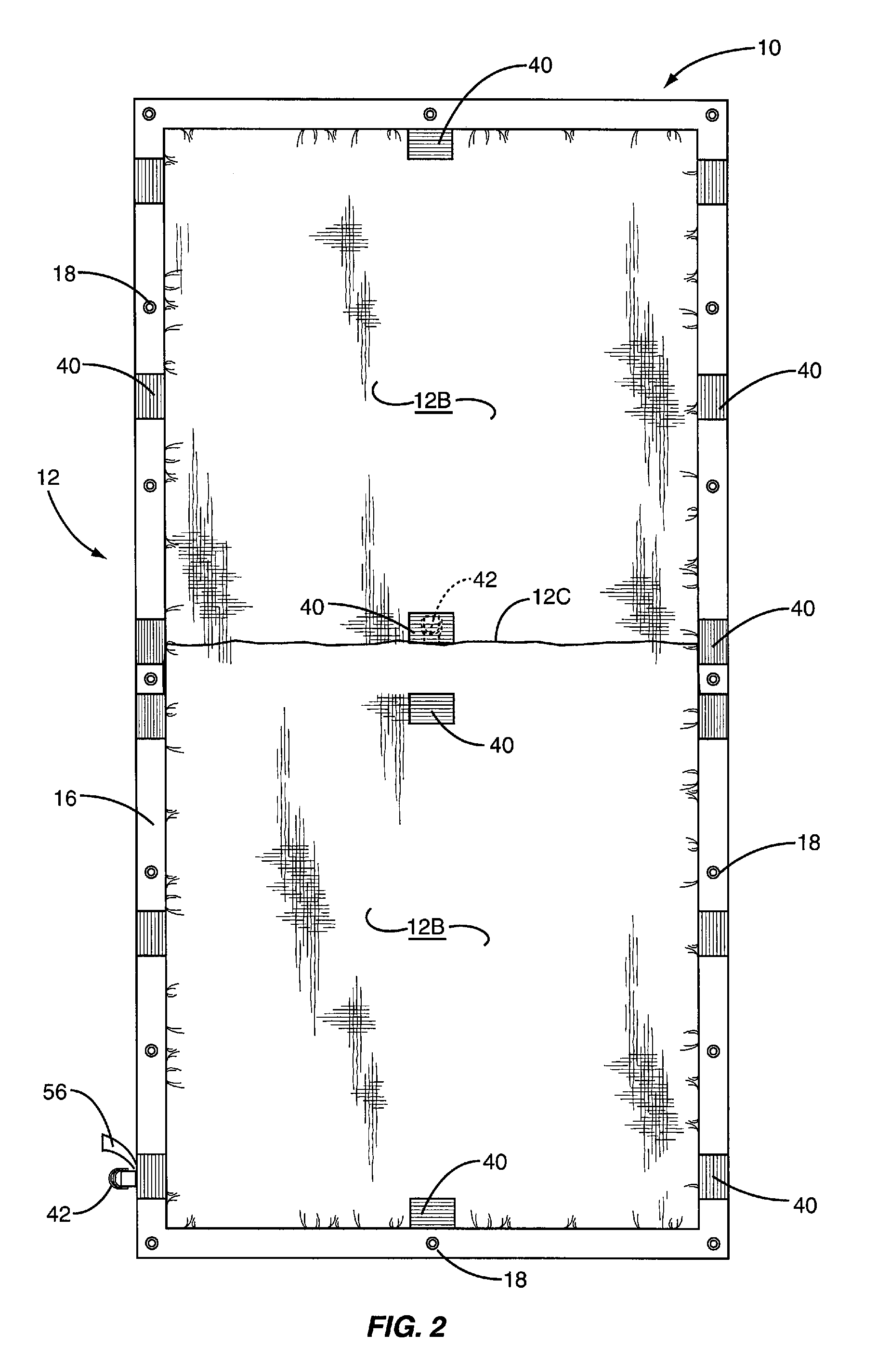

Ballistic blanket

A ballistic blanket is provided and includes a pliable outer shell or housing that encompasses an inner ballistic core which is housed or contained within an inner shell or housing. Secured to exterior portions of the ballistic blanket are a series of handles and one or more attaching straps or buckles that facilitate the securement of devices such as a carrier panel. In one design, the interior ballistic core comprises a high performance fiber such as an aramid fiber, high molecular weight polyethylene, a combination of high performance fiber types, or a non-woven thermoplastic composite.

Owner:CARTER GERALD D +1

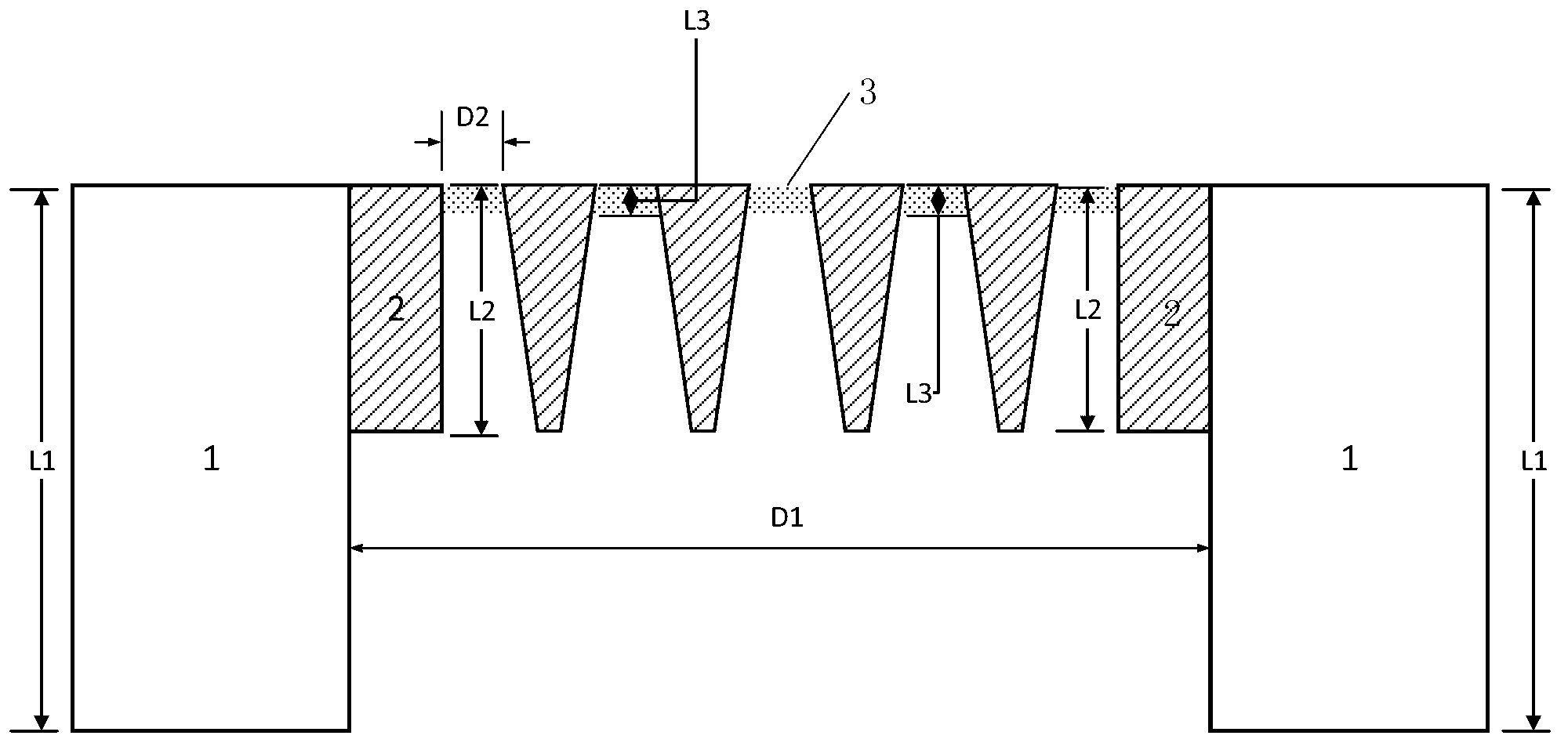

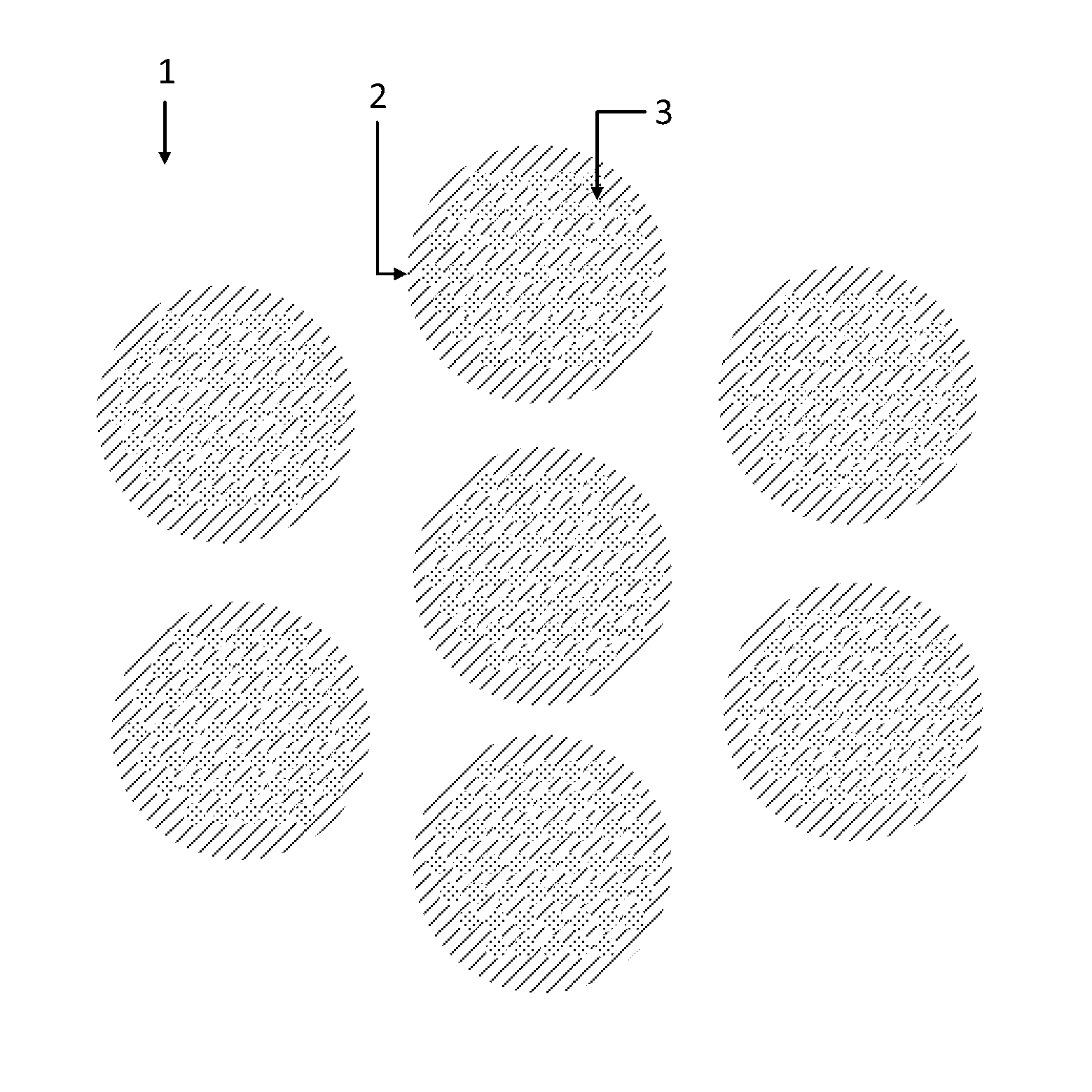

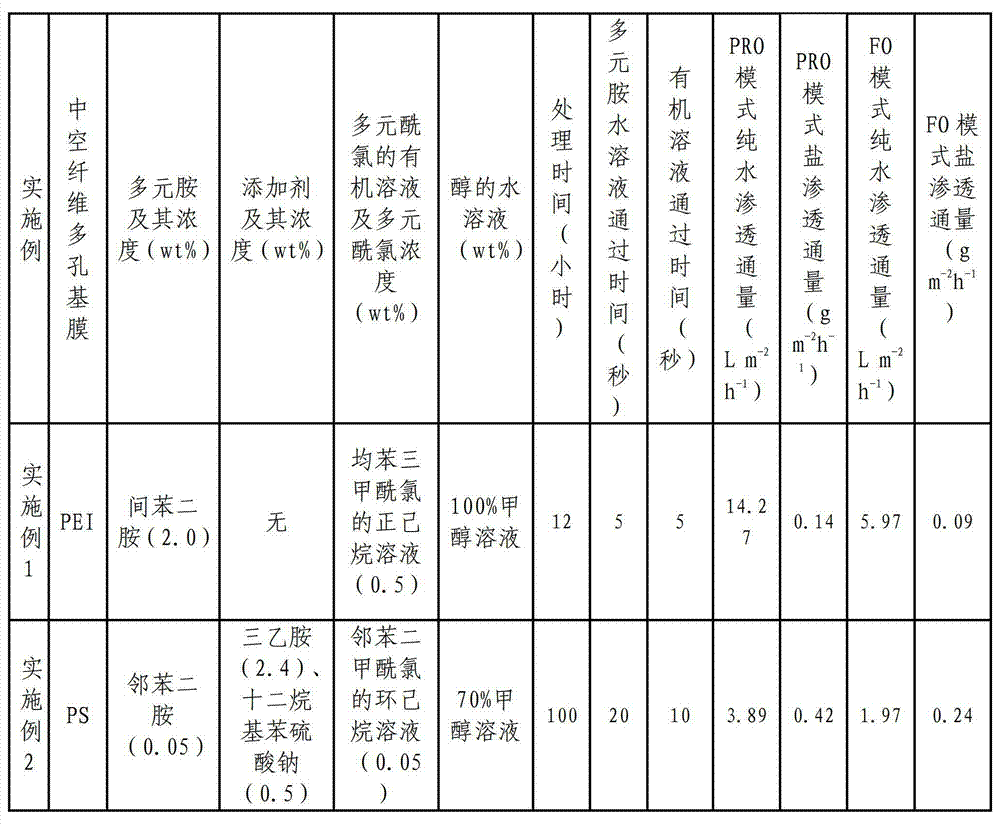

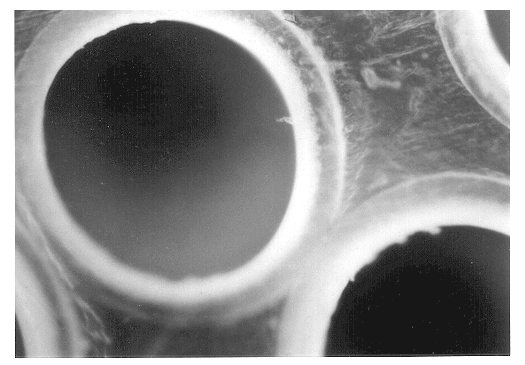

Hollow fiber type composite nano-filtration membrane and preparation method thereof

ActiveCN103223300AHigh strengthImprove anti-scourSemi-permeable membranesHollow fibreFiltration membrane

The invention relates to a hollow fiber type composite nano-filtration membrane and a preparation method thereof. The hollow fiber type composite nano-filtration membrane comprises a hollow fiber microporous base membrane adopted as a supporting layer, a polysulfone transition layer, and a polyamide composite layer, wherein the polysulfone transition layer is positioned inside membrane holes of the hollow fiber microporous base membrane, and the polyamide composite layer is positioned inside membrane holes of the polysulfone transition layer. The preparation method comprises: adopting a thermally induced phase separation method to obtain an asymmetric microporous base membrane, adopting an impregnation phase transformation method to obtain the polysulfone transition layer in the micro holes, and adopting pressure control and an interface condensation polymerization reaction to obtain the polyamide composite layer. The hollow fiber type composite nano-filtration membrane provides a sodium chloride salt solution entrapment rate of more than 90%, a divalent salt ion entrapment rate of more than 95%, and a pollutant entrapment rate of more than 99% under 0.2-0.8 MPa, such that the hollow fiber type composite nano-filtration membrane has characteristics of high strength, washing resistance, large flux and the like, wherein the pollutants have a molecular weight of 300-200,000 Daltons.

Owner:TSINGHUA UNIV

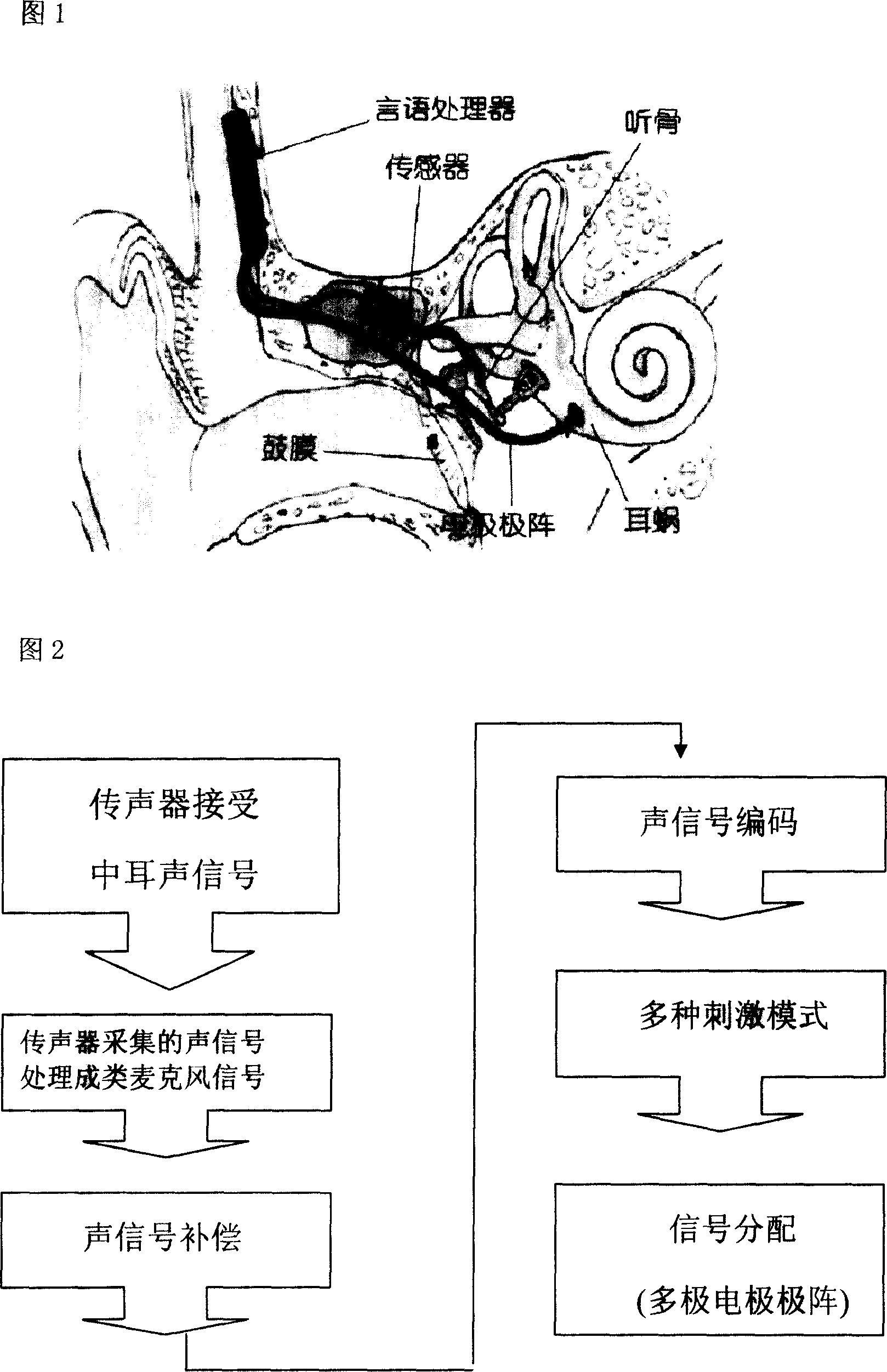

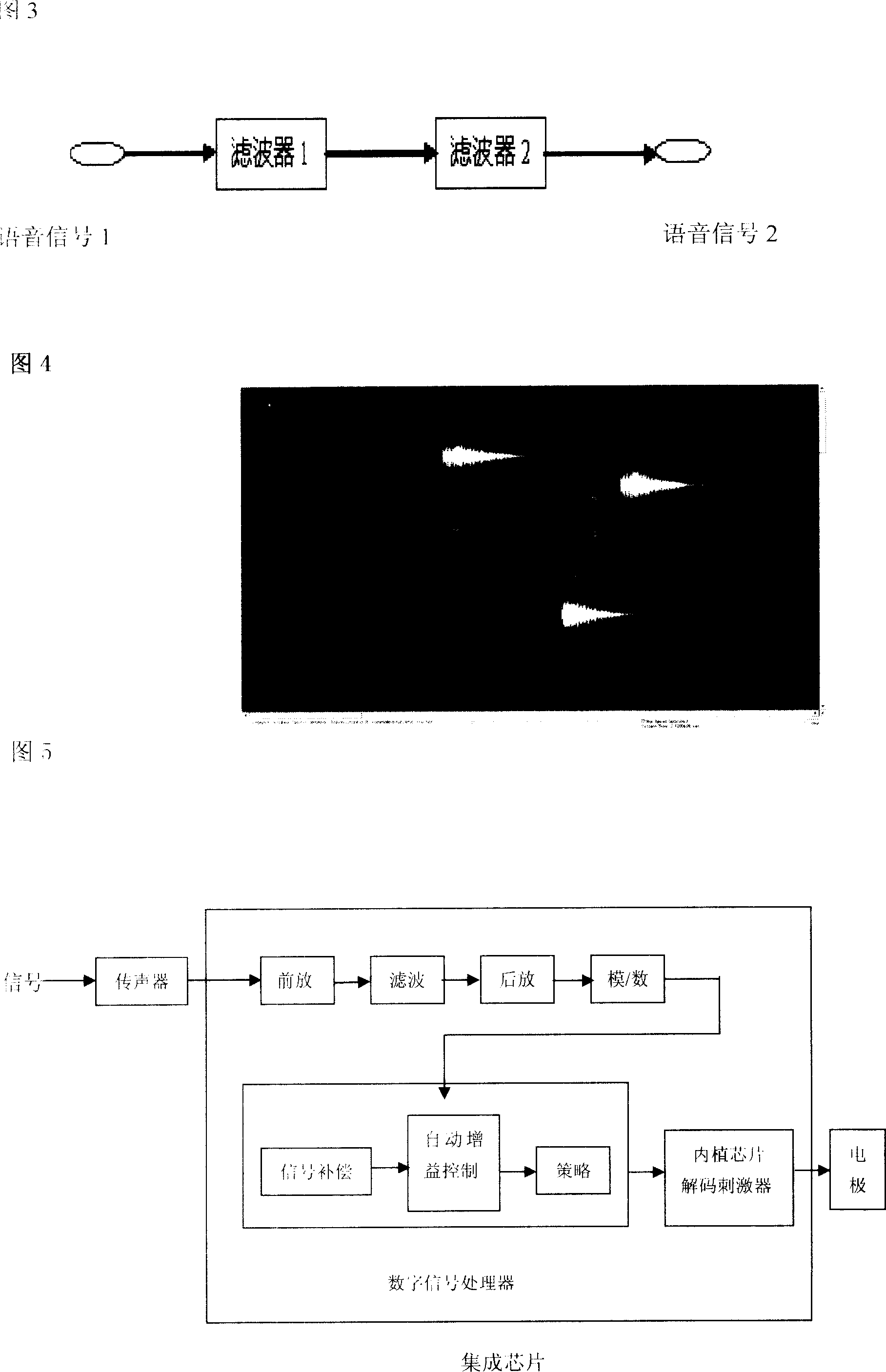

Full-implanting type artificial cochlea and method for making same

The present invention relates to biomedicine engineering and bionics, and is especially one new type of implanted artificial cochlea and its making process. The implanted artificial cochlea consists of one implanted piezoelectric or fiber type microphone, one signal amplifier, one phonetic processor and one decoding stimulator. It has optimized MSPR mixed coding mode and multiple stimulating modes. Experiment shows that the implanted artificial cochlea has high sensitivity and good frequency characteristic, and is suitable for sufferer, especially children sufferer, of deafness.

Owner:EYE & ENT HOSPITAL SHANGHAI MEDICAL SCHOOL FUDAN UNIV

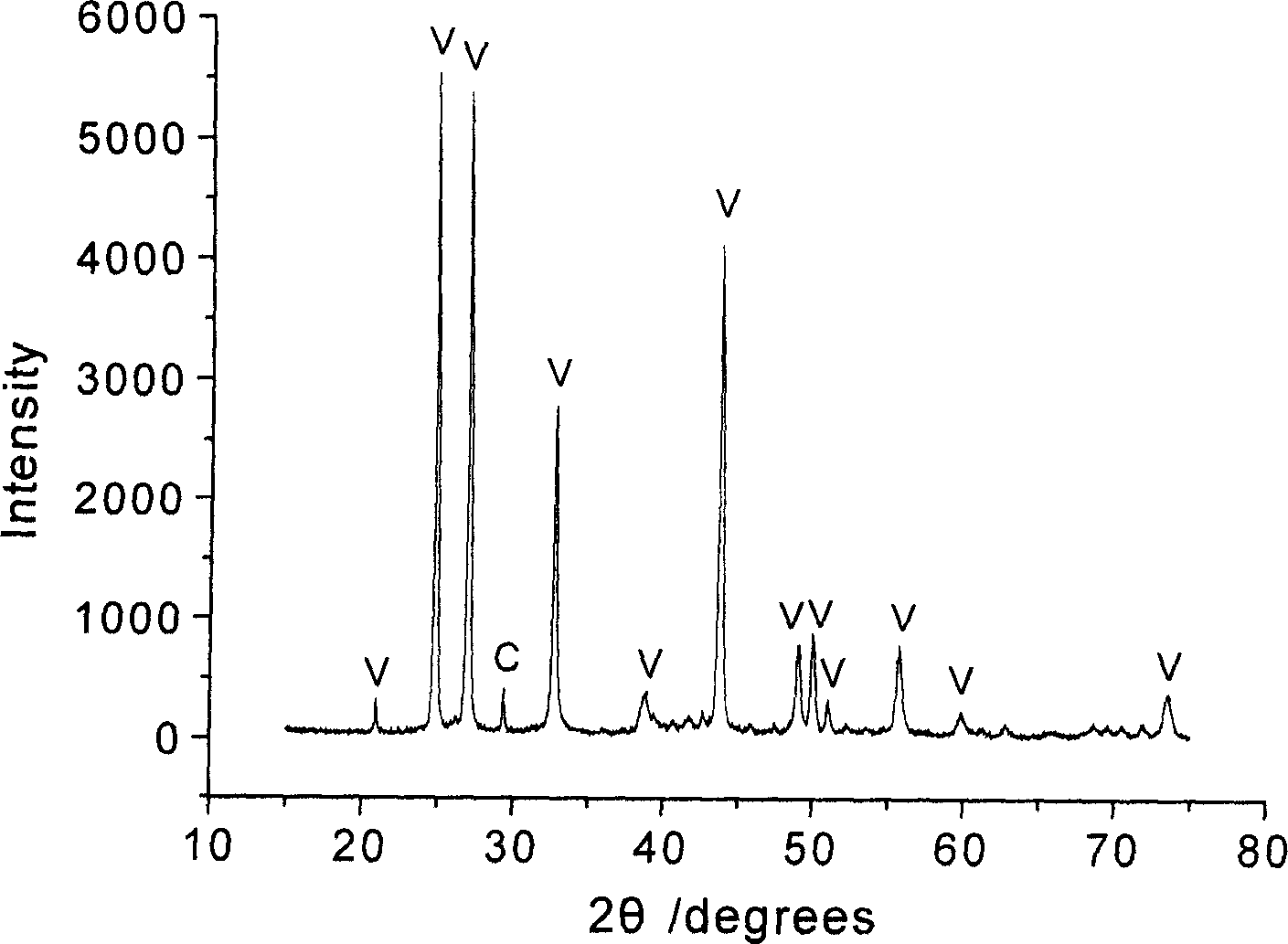

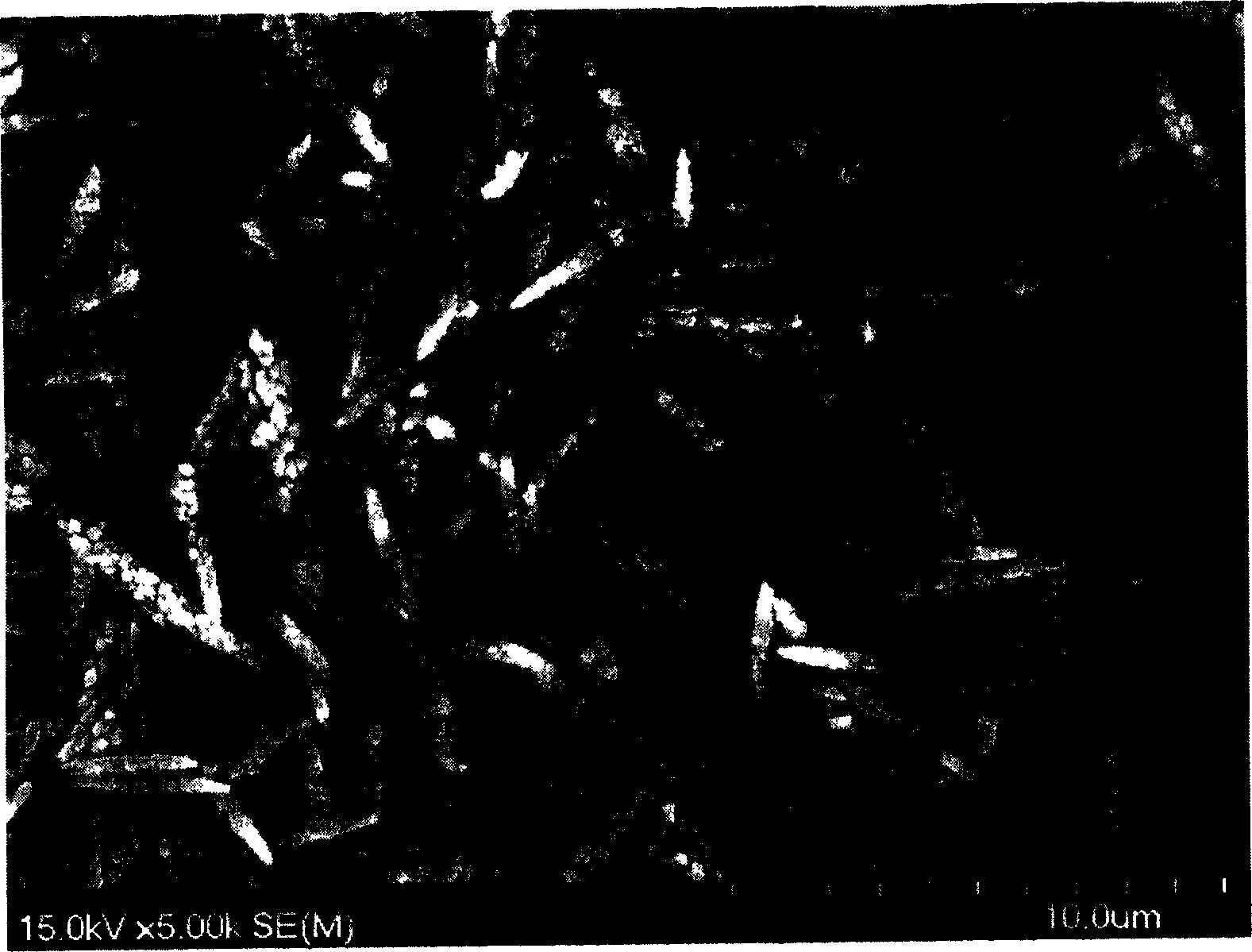

Single dispersing micron chopped fiber-like aragonite type calcium carbonate and preparation method thereof

InactiveCN1631792ASimple methodThe method is simple and controllableCalcium/strontium/barium carbonatesSolubilityPrinting ink

The invention relates to a single-distributive micron short fiber-typed vaterite calcium carbonate and its preparing method. The calcium carbonate crystal is needle short fiber-typed, its length is 2-8 micron and width is 0.3-1.5 micron, the ratio of length and diameter is 5-10, its content of vaterite calcium carbonate is larger than 90% with small particle on the surface of. The preparing method includes mix the aqueous solution of carbonate containing water soluble organic solvent with aqueous solution of calcium salt also containing that, make use of the different dissolubility of carbonate and calcium salt in water soluble organic solvent and water, and the different solvation to calcium ion, compound the product. The calcium carbonate has remarkable single distribution, large ratio of length and diameter, high activity of surface, suitable for coating on paper, filling plastic, coating, printing ink and paper, as well as the raw material for calcium preparations.

Owner:ZHEJIANG UNIV

Antibacterial, safe, moisture absorbing and quick-drying fabric and production method thereof

ActiveCN104278421AGood skin affinityBump effect is prominentWeft knittingFibre treatmentYarnPolyester

The invention discloses an antibacterial, safe, moisture absorbing and quick-drying fabric and a production method thereof. The fabric is woven from first yarns, second yarns and third yarns, wherein the first yarns are pure cotton fiber yarns or cotton fiber type blended yarns, and the cotton fiber type blended yarns are yarns formed by blending of cotton fibers and one or several of jute fibers, polyester fibers, polyacrylonitrile fibers and polyarmide fibers; the second yarns are modified polyester fiber yarns with non-circular cross sections where nano silver ions are guided or modified polyester fiber type blended yarns with non-circular cross sections, and the modified polyester fiber type blended yarns are yarns blended by the modified polyester fibers with nano silver ions guided in and regenerated cellulose fibers; the third yarns are polyurethane fiber yarns. The fabric is good in antibacterial, moisture absorbing and quick-drying performance and excellent in safety. Meanwhile, the production method is simple in operation and applicable to large-scale industrial production.

Owner:武汉爱帝针纺实业有限公司

Composite core for an electrical cable

InactiveUS20100163275A1Change in weightMaintain stable propertiesMaterial nanotechnologyNon-insulated conductorsProduction rateElectrical conductor

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable (300) has a composite core and at least one layer of aluminum conductor (306). The composite core (303) comprises a plurality of fibers from at least one fiber type in one or more matrix materials. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

Moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and preparation method thereof

ActiveCN103952845AImprove hydrophilicityGood wicking and moisture-wicking functionSucessive textile treatmentsWeft knittingYarnPolyester

The invention discloses a moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and a preparation method thereof. The fabric is formed by weaving first yarns, second yarns, third yarns and fourth yarns, wherein the first yarns are regenerated cellulose fiber type blended yarns formed by blending linen, wool or cashmere, one or more types of cotton fibers and regenerated cellulose fibers, or regenerated cellulose multi-filaments, or regenerated cellulose staple fiber yarns; the second yarns are modified polyester fiber yarns with non-circular cross sections; the third yarns are cotton fiber type blended yarns formed by blending one or two of polyester staple fiber yarns or polyacrylonitrile fibers and cotton fibers, or all cotton yarns; the fourth yarns are polyurethane fiber yarns. The moisture absorption and heat-generating value of the fabric exceeds national standards, the moisture absorption and quick-drying performance is excellent, and the thermal insulation rate meets national standards; the fabric also has comfortable elasticity and soft and smooth hand feeling of one surface next to the skin. Meanwhile, the preparation method is simple in process, and convenient to operate.

Owner:武汉爱帝针纺实业有限公司

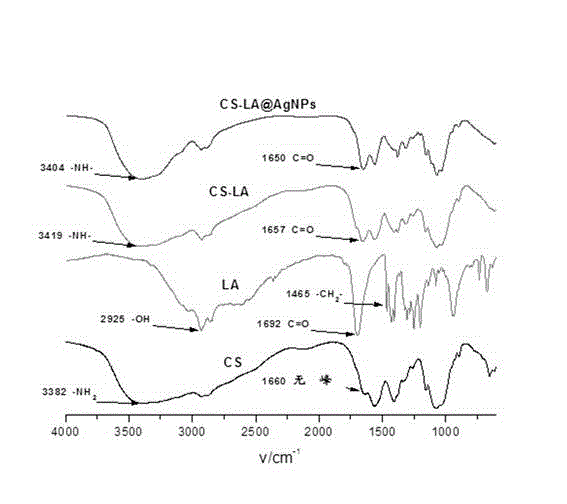

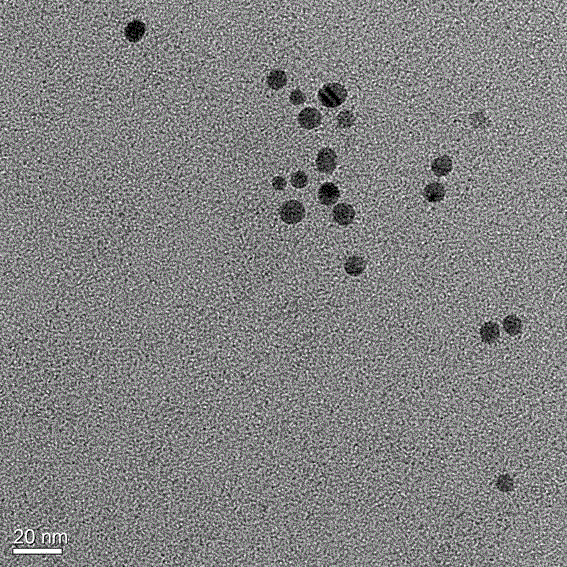

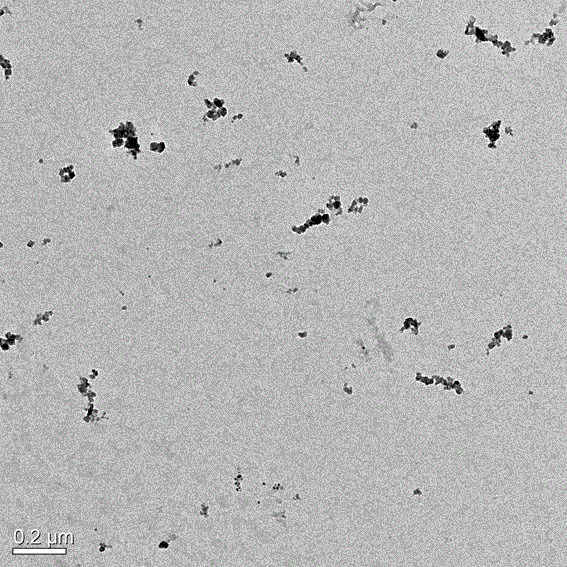

Nano-silver antibacterial composite decorated by modified chitosan, preparing method and application

ActiveCN104128602AWide variety of sourcesLow priceMaterial nanotechnologyAntimicrobial actionCovalent modification

The invention discloses a nano-silver antibacterial composite modified by modified chitosan and a preparing method of the nano-silver antibacterial composite. According to the nano-silver antibacterial composite and the preparing method of the nano-silver antibacterial composite, the chitosan with the small molecule quantiy and good water solubility is selected and used as a raw material, chemical modification is conducted on the chitosan by using small molecules which are capable of having chelation with nano-silver particles, the modified chitosan is arranged on the surfaces of the nano-silver particles in a covalent modification mode, and the novel nano-silver antibacterial composite is prepared. The prepared nano-silver antibacterial composite modified by the modified chitosan has good water solubility and dispersibility and can be stably dispersed in a water solution in a long term without aggregation under the conditions of high salinity and wide pH. The prepared nano-silver antibacterial composite modified by the modified chitosan enables the antibacterial property of the chitosan and the antibacterial property of nano-silver to be in effective synergy, the antibacterial performance is good, and the nano-silver antibacterial composite can serve as a water coating agent to perform the surface antibacterial function on the surfaces of materials and can also permeate into fiber type materials to perform the deep internal antibacterial function.

Owner:SICHUAN UNIV

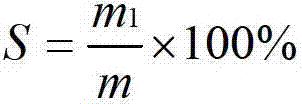

Hollow fiber type filtration membrane

InactiveUS6165363AHigh enough strengthHigh strengthSemi-permeable membranesMoving filtering element filtersHollow fibreFiltration membrane

PCT No. PCT / JP96 / 03677 Sec. 371 Date Jun. 18, 1998 Sec. 102(e) Date Jun. 18, 1998 PCT Filed Dec. 17, 1996 PCT Pub. No. WO97 / 22405 PCT Pub. Date Jun. 26, 1997A hollow fiber filter membrane where the inner surface comprises a three-dimensional network structure having thick trunks of 10-30 mu m in maximum diameter and the average pore diameter of a minimum pore diameter layer of the membrane is 0.01 mu m or more and less than 1 mu m.

Owner:ASAHI KASEI KK

Novel electric cable reinforced core and preparation method thereof

InactiveCN101740161ASmall sagHigh tensile strengthNon-insulated conductorsPlastic/resin/waxes insulatorsFiber-reinforced compositeFiber type

The invention discloses a novel electric cable reinforced core, which is composed of a fiber reinforced composite material, the fiber reinforced composite material comprises at least a reinforced fiber type which has longitudinal orientation in the resin and is basically continuous and is used as an inner layer composite material core; the fiber reinforced composite material further comprises a braided or twined reinforced protective outer layer around the inner layer composite material core, the reinforced protective outer layer comprises at least a reinforced fiber type which is braided in the resin and is basically continuous. The longitudinal fiber and the braided fiber are composited in the invention, thereby having the advantages that the longitudinal tensile strength, the resist compression strength, the bending resistance and the shearing resistance of the electric cable reinforced core in the longitudinal direction are increased, and the safety factor are increased, and the loss of the mechanical performance caused by defects owning to external abrasion or impact in the transportation process, the laying and installing process and the operation process is avoided.

Owner:SHANGHAI ELECTRIC CABLE RES INST

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20040131851A1High strengthIncrease ampacityNon-insulated conductorsApparatus for heat treatmentElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about 45° C. to about 230° C., at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about -0.7x10<-6 >m / m / ° C. to about 6x10<-6 >m / m / ° C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 60 ft / min.

Owner:CTC GLOBAL CORP

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20050227067A1Increase ampacityMaintain stable propertiesNon-insulated conductorsApparatus for heat treatmentElectrical conductorResin matrix

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable having a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises at least one longitudinally oriented substantially continuous reinforced fiber type in a thermosetting resin matrix having an operating temperature capability within the range of about 90 to about 230° C., at least 50% fiber volume fraction, a tensile strength in the range of about 160 to about 240 Ksi, a modulus of elasticity in the range of about 7 to about 30 Msi and a thermal expansion coefficient in the range of about 0 to about 6×10−6 m / m / C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 50 ft / min.

Owner:CTC GLOBAL CORP

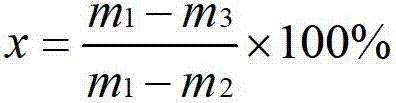

Method for preparing hollow fiber type forward osmotic membrane

ActiveCN102773024AUnique cross-network pore structureImprove fill rateSemi-permeable membranesFiltrationGlycerol

The invention discloses a method for preparing a hollow fiber type forward osmotic membrane, which specifically comprises the following steps that: 1, a hollow fiber substrate membrane is made into a membrane component, and the membrane component is put in a membrane filtration device; 2, the residual glycerol on the surface of the membrane component is washed with water, the residual water of the membrane component is removed, and the hollow fiber substrate membrane is dried; 3, a polyamine aqueous solution is prepared and is enabled to pass through the internal surface of the membrane component, and then, the residual water on the surface of the membrane component is removed; 4, an organic solution which contains multi-acyl chloride is prepared, and is enabled to pass through the internal surface of the membrane component to react for a certain while; and 5, after the reaction is completed, the aqueous solution which contains alcohol is used to treat the membrane which is obtained from the reaction, so the hollow fiber type forward osmotic membrane is obtained. The hollow fiber composite forward osmotic membrane which is prepared by the method for preparing the hollow fiber type forward osmotic membrane has high filling rate and pollution resistance, is easy to clean, has a large effective filter area compared with components of the same size, and is suitable for a forward osmotic separation process.

Owner:SUZHOU FAITH HOPE MEMBRANE TECH

Filter element

A filter element includes a bundle of hollow fiber type separation membranes made of a natural or synthetic macromolecular material and a sealed part made of a thermoplastic resin. The bundle has an opening in at least one terminal part thereof. The sealed part is bonded to the bundle at a temperature not higher than the melting or decomposing temperature of the macromolecular material and adapted to seal watertightly the opening of the bundle in a half-bonded state showing no compatibility with the macromolecular material and permitting persistence of the mutual interface of bondage.

Owner:KITZ CORP

Ultralow-permeation plugging anti-sloughing oil layer protective agent for drilling fluid and preparation method of protective agent

InactiveCN103045184ASimple production processLow costDrilling compositionDispersion stabilityCellulose

The invention relates to an ultralow-permeation plugging anti-sloughing oil layer protective agent for a drilling fluid. The ultralow-permeation plugging anti-sloughing oil layer protective agent is characterized by consisting of the following components in percentage by weight: 10%-50% of a mineral fiber type material, 10%-50% of lignin fiber, 0%-15% of asphalt fiber, 20%-60% of low-softening point asphalt powder, 5%-10% of cellulose modified starch, 0%-5% of walchowite, 0%-5% of superfine calcium carbonate and 2%-8% of a modifying agent. The invention further relates to a preparation method of the plugging anti-sloughing oil layer protective agent. A sample obtained in the invention contains a plurality of deformable particles, including a high-temperature softening material, a bridge plug material, a water-swellable and fiber-deformation material and the like; and the sample has wide grain size distribution range, can plug fissures and holes in wide size range, can quickly form an ultralow-permeation shielding film, can reduce the amount of the drilling fluid flowing into the ground layer, can simultaneously protect storage layers, achieves good water dispersion stability, can be matched with a plurality of drilling fluids, simultaneously is simple in production technique, can satisfy the current environment, human body health and safety requirements, is low in cost and causes no adhesion problem in transportation.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com