Nano-silver antibacterial composite decorated by modified chitosan, preparing method and application

A nano-silver antibacterial and composite material technology, which is applied in the fields of nanotechnology, nanotechnology, nanotechnology and other fields for materials and surface science, can solve the problems of poor stability, limited antibacterial effect, and synthesis of chitosan nanosilver composites. The process is cumbersome and other problems, and the effects of good water solubility, low price and simple preparation process are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

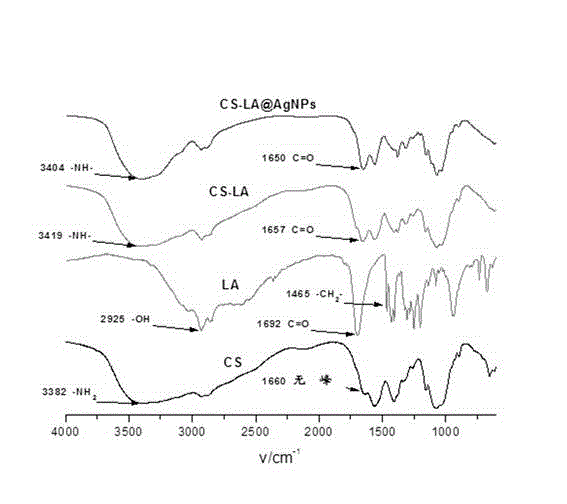

[0051] (1) Preparation of modified chitosan CS-LA

[0052] Fully dissolve chitosan in water to make an aqueous solution with a chitosan concentration of 0.02 mol / L; weigh lipoic acid with 5% chitosan amino molarity, dissolve it in ethanol, and then add an equal molar amount of lipoic acid EDC and NHS were used to activate the carboxyl group of lipoic acid, mixed and added to the chitosan solution, and reacted for 4 hours at 30 °C; after the reaction was completed, the unreacted lipoic acid and EDC / NHS activator were removed by dialysis, and the reaction solution was freeze-dried to obtain improved The natural chitosan product CS-LA has the following chemical structural formula:

[0053] The modified chitosan contains disulfide bond groups, which can be used to covalently modify nano silver.

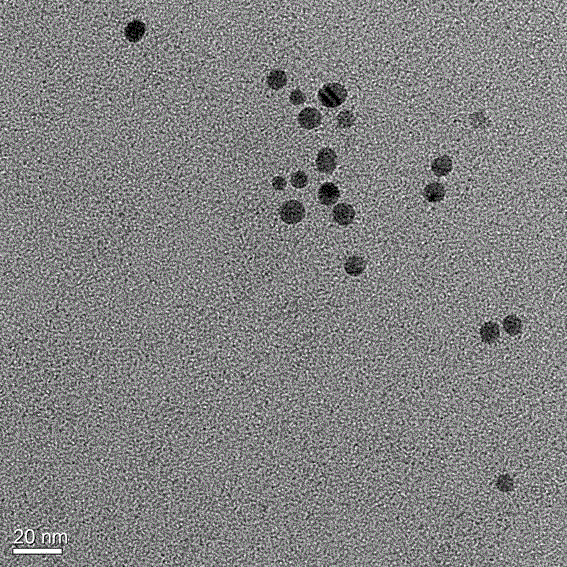

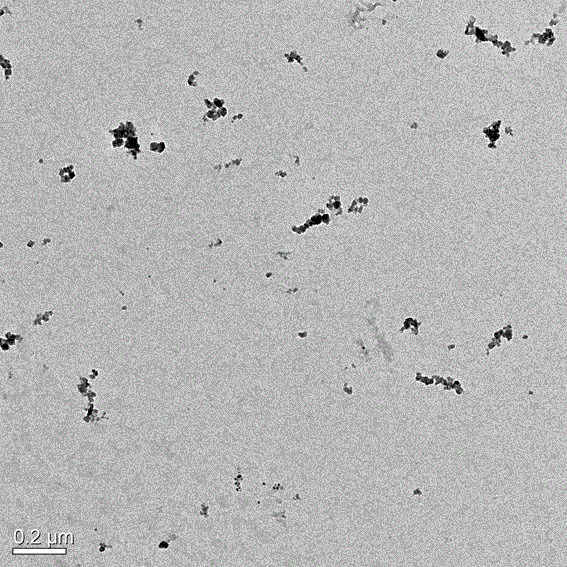

[0054] (2) Preparation of nano silver

[0055] Add 30 ml of reducing agent sodium borohydride with a concentration of 0.067 mol / L to 10 ml of a silver nitrate solution with a concent...

Embodiment 2

[0059] (1) Preparation of modified chitosan CS-LA

[0060] Fully dissolve chitosan in water to make an aqueous solution with a chitosan concentration of 0.02 mol / L; weigh lipoic acid with 50% chitosan amino molarity, dissolve it in ethanol, and then add an equal molar amount of lipoic acid EDC and NHS were used to activate the carboxyl group of lipoic acid, mixed and added to the chitosan solution, and reacted for 24 hours at 80 °C; after the reaction was completed, the unreacted lipoic acid and EDC / NHS activator were removed by dialysis, and the reaction solution was freeze-dried to obtain the same The same modified chitosan product CS-LA of step (1) in embodiment 1;

[0061] (2) The modified chitosan CS-LA is dissolved in the aqueous solution, and the silver nitrate solution is added dropwise to the above solution. The amino groups and hydroxyl groups on the polysaccharide stabilize and disperse silver nitrate, then add sodium borohydride, a reducing agent with an equal mol...

Embodiment 3

[0064] (1) Preparation of gallic acid modified chitosan CS-GA

[0065] Fully dissolve chitosan in water to make an aqueous solution with a chitosan concentration of 0.02 mol / L; weigh gallic acid with 25% chitosan amino molar number, dissolve it in ethanol, and add an equimolar amount of gallic acid EDC and NHS were used to activate the carboxyl group of gallic acid, mixed and added to the chitosan solution, and reacted at 50 °C for 24 h; after the reaction was completed, the unreacted gallic acid and EDC / NHS activator were removed by dialysis, and the reaction solution was freeze-dried to obtain The modified chitosan product CS-GA has the following chemical structural formula:

[0066]

[0067] (2) Preparation of nano silver

[0068] Add 30 ml of reducing agent sodium thiosulfate with a concentration of 0.067 mol / L to 10 ml of silver nitrate solution with a concentration of 0.1 mol / L, and use 1 mmol of sodium citrate as a stabilizer, in dark conditions and a stirring sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com