Patents

Literature

783 results about "Crown ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

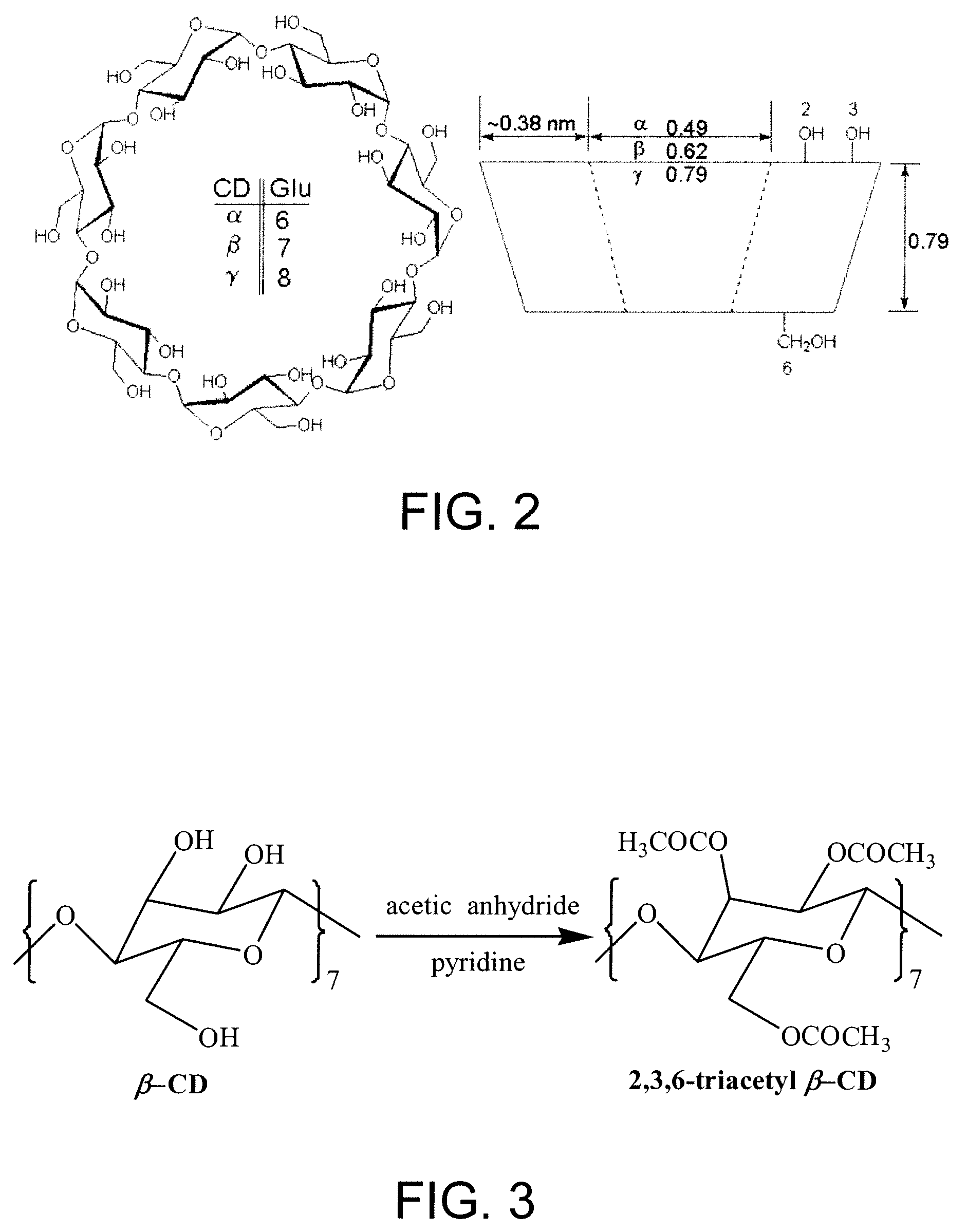

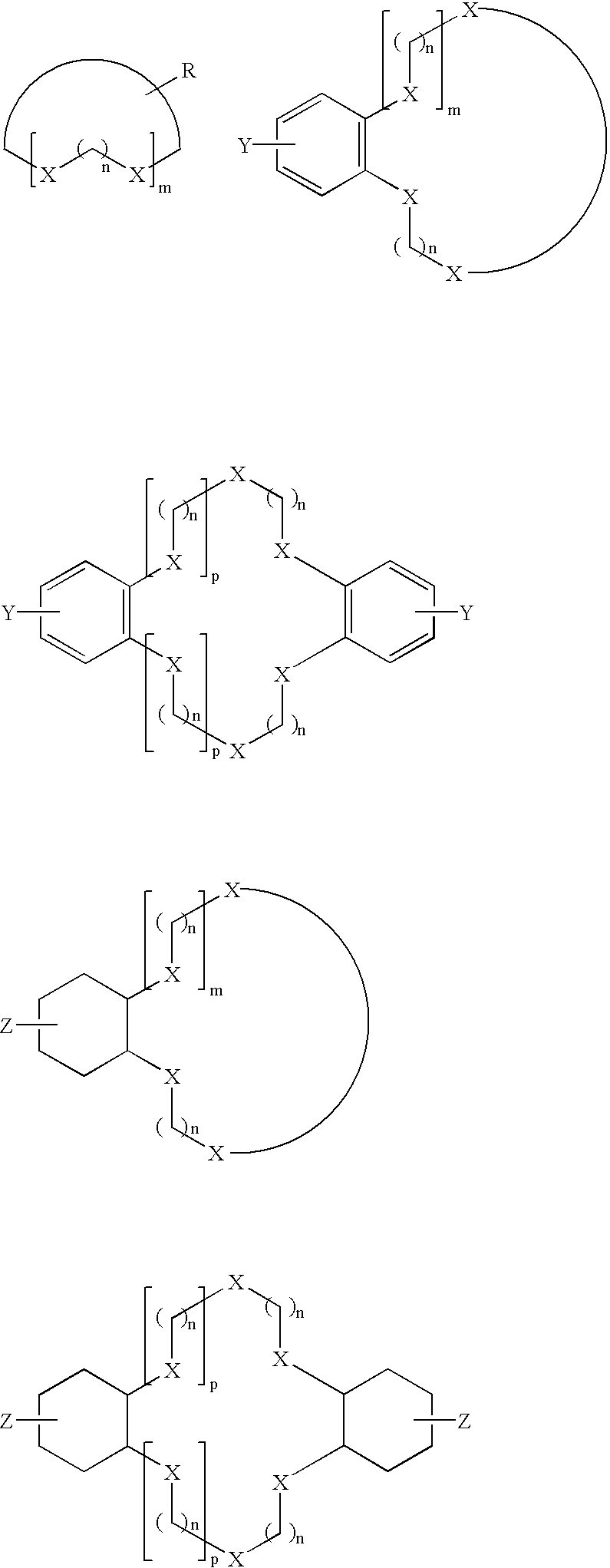

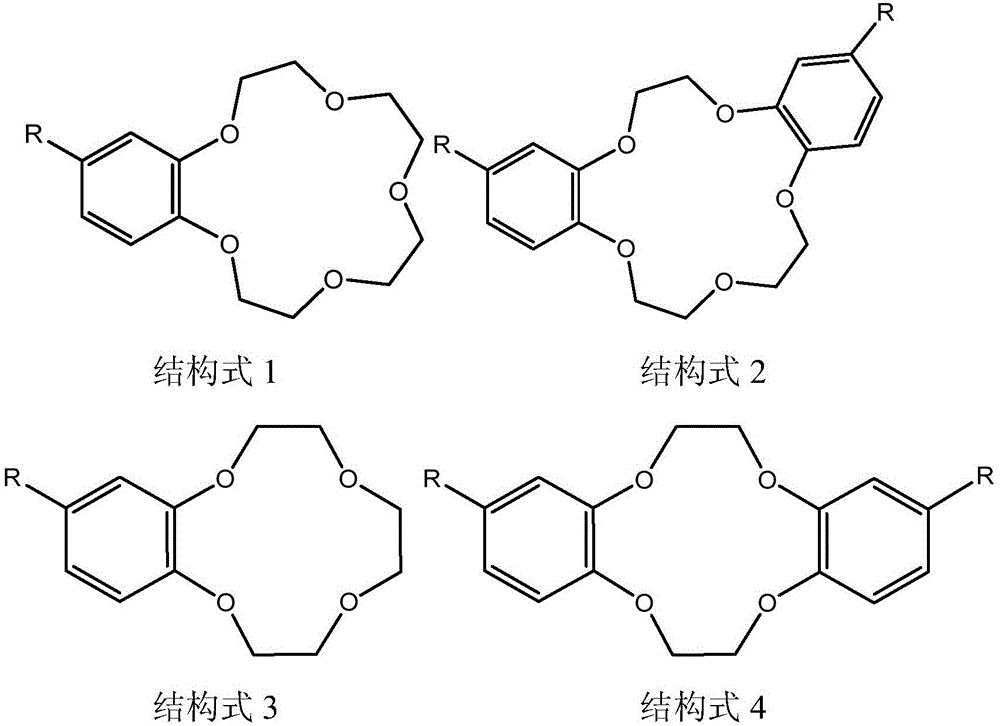

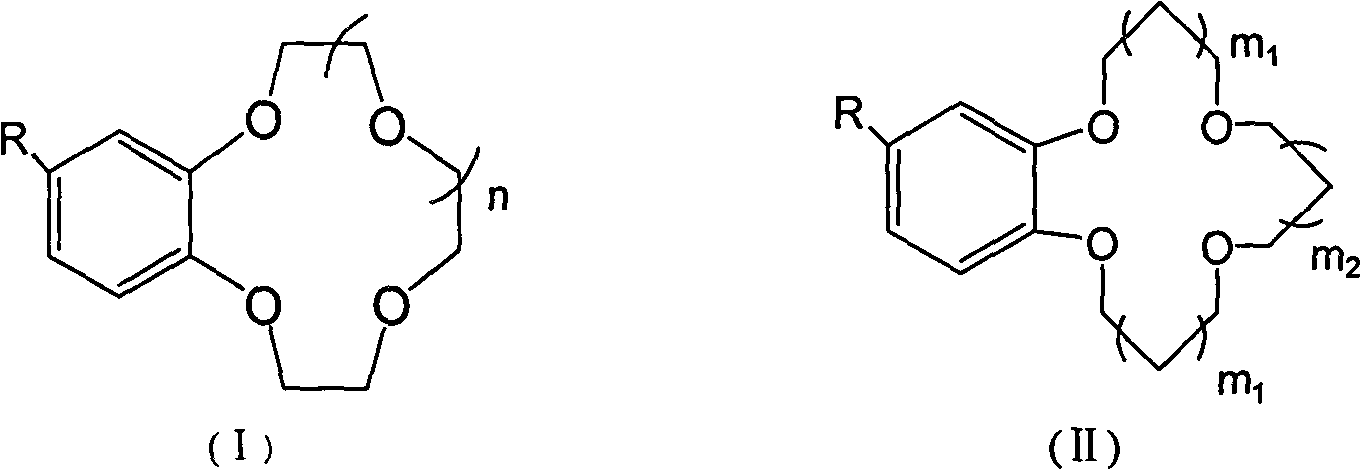

Crown ethers are cyclic chemical compounds that consist of a ring containing several ether groups. The most common crown ethers are cyclic oligomers of ethylene oxide, the repeating unit being ethyleneoxy, i.e., –CH₂CH₂O–. Important members of this series are the tetramer (n = 4), the pentamer (n = 5), and the hexamer (n = 6). The term "crown" refers to the resemblance between the structure of a crown ether bound to a cation, and a crown sitting on a person's head. The first number in a crown ether's name refers to the number of atoms in the cycle, and the second number refers to the number of those atoms that are oxygen. Crown ethers are much broader than the oligomers of ethylene oxide; an important group are derived from catechol.

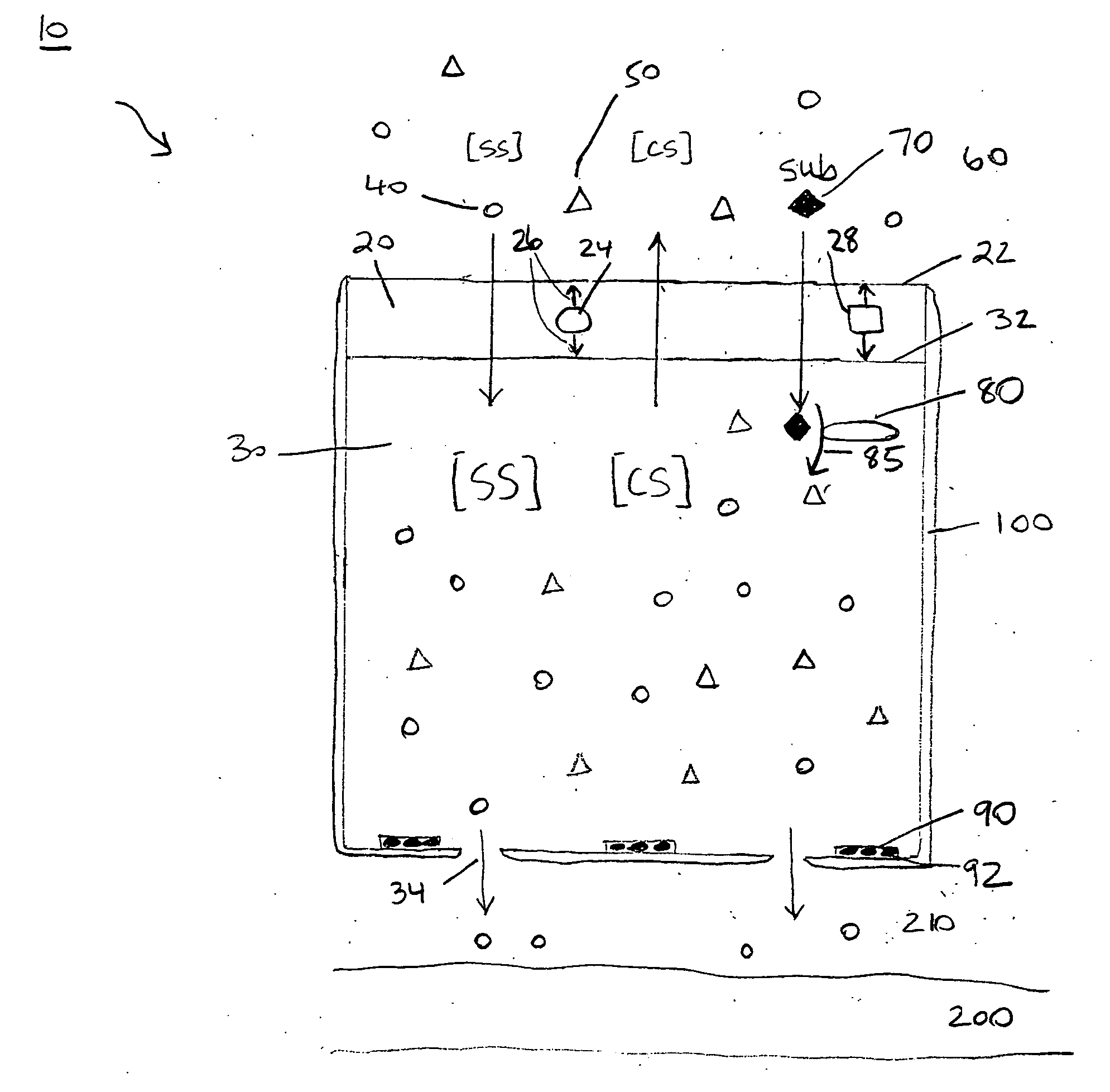

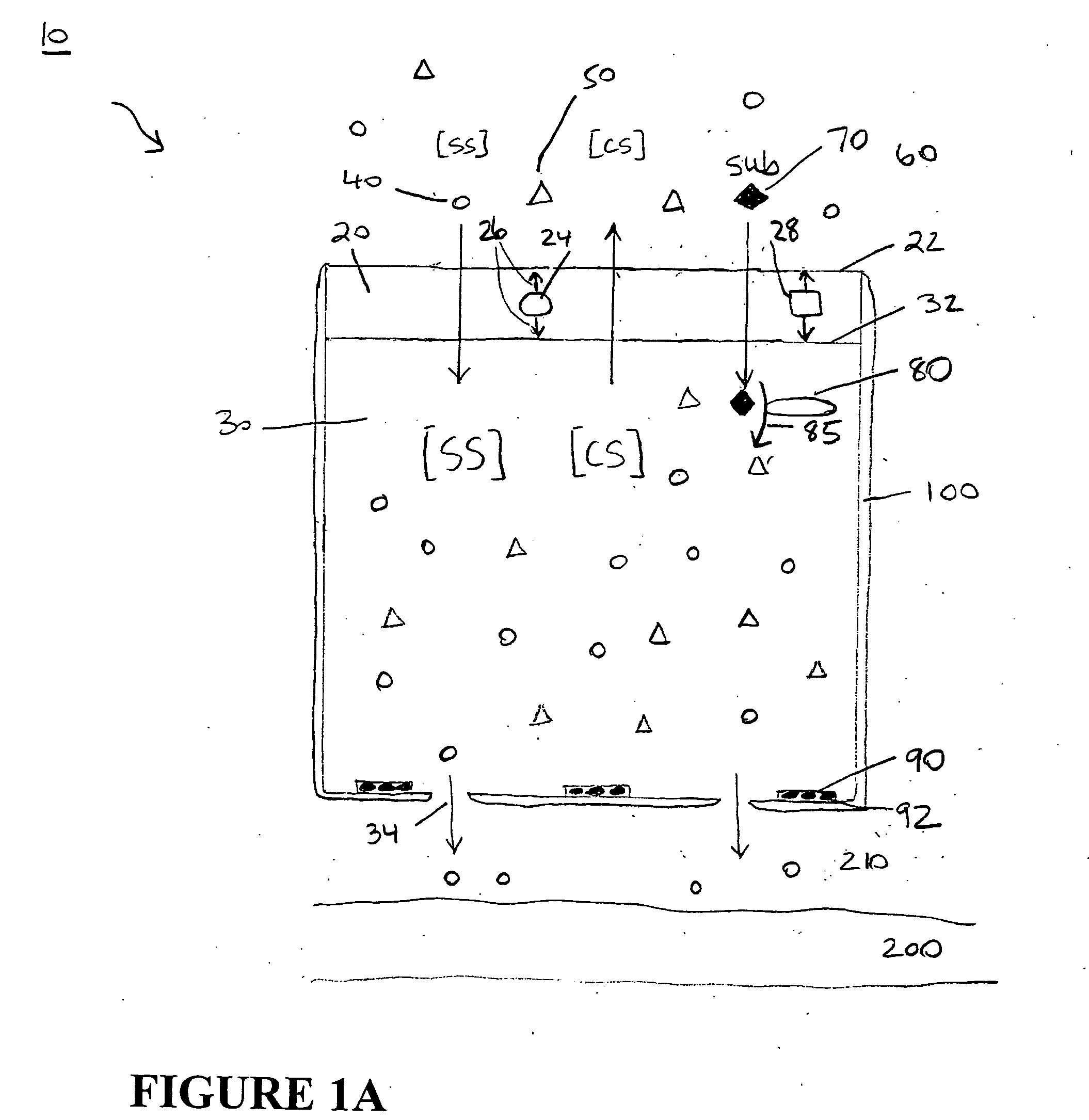

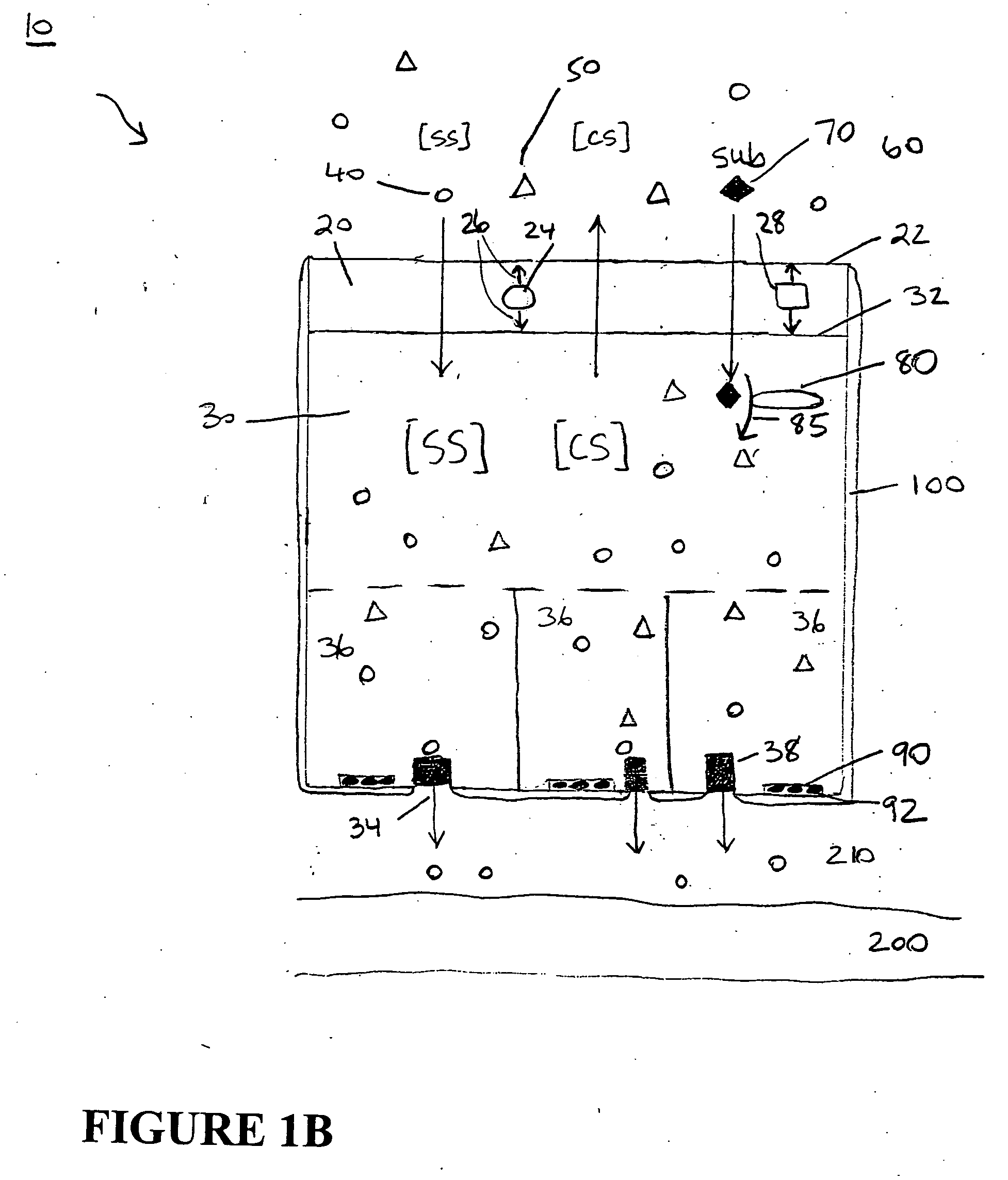

Neural stimulation device employing renewable chemical stimulation

A variety of neural stimulation devices are disclosed. The devices comprise an uptake component comprising means for selectively transporting a stimulating species into the device; a release component comprising means for releasing the stimulating species; and means for producing a concentration gradient of a second species. The concentration gradient of the second species provides energy to transport the stimulating species into the device. The stimulating species may be an ion, e.g., a potassium ion, or a neurotransmitter. In a preferred embodiment of the invention the stimulating species is a potassium ion. In a second preferred embodiment the stimulating species is dopamine. In certain embodiments of the invention countertransport across an uptake component comprising a synthetic ABA polymer membrane is achieved using a carboxylic acid crown ether. The gradient of the second species may be provided by means of a chemical reaction that takes place inside the device. The substrate for the chemical reaction is transported into the device from the external environment. In certain embodiments the neural stimulation device comprises light-sensitive elements that comprise light-sensitive proton pumps. The proton pumps translocate protons into the device in response to light, thereby triggering release of the stimulating species. In certain embodiments the neural stimulation device comprises electronic components that receive a signal and send an activating input to the device, thereby triggering release of the stimulating species.

Owner:U S GOVERNMENT REPRESENTED BY THE DEPT OF VETERANS AFFAIRS +2

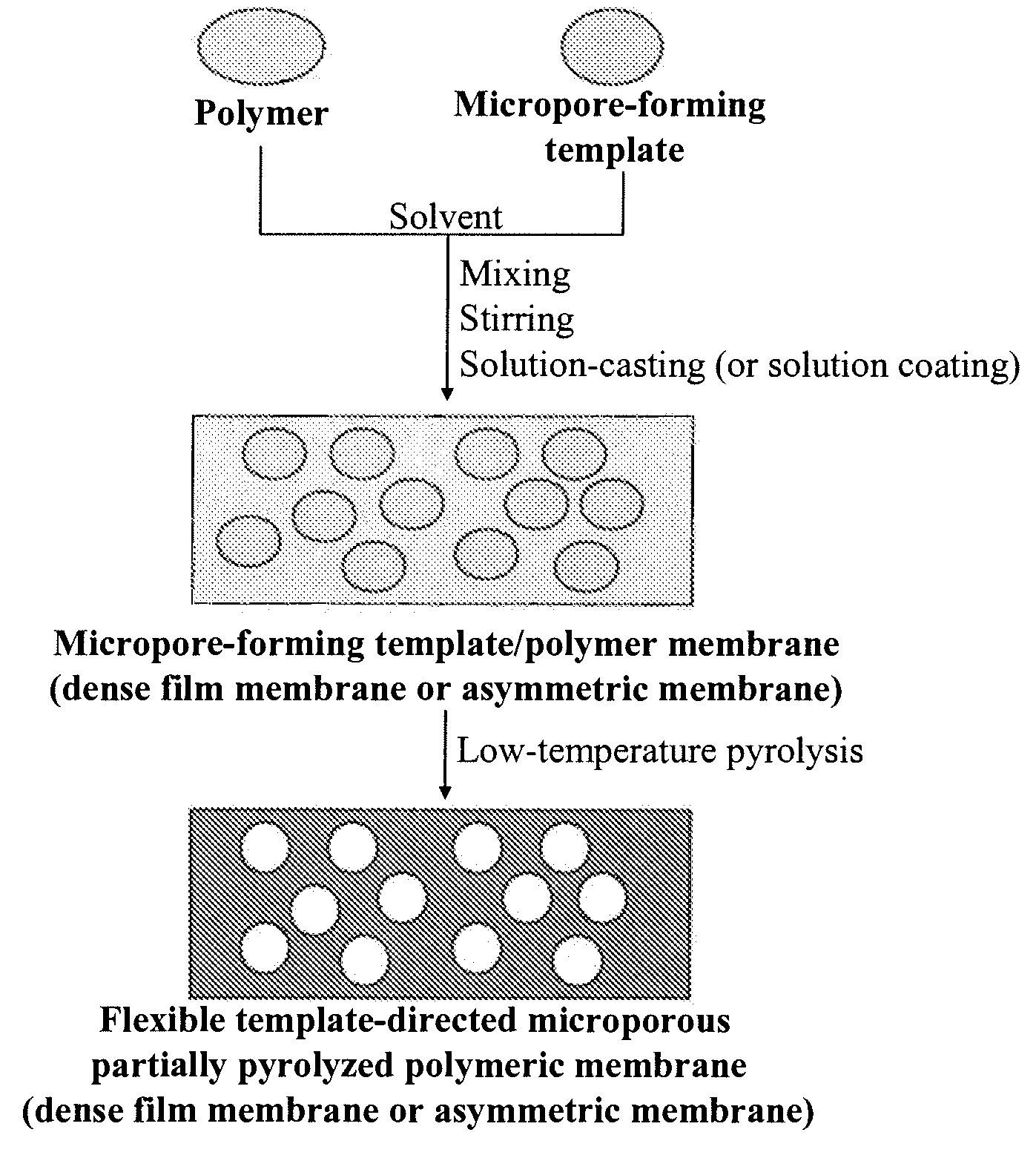

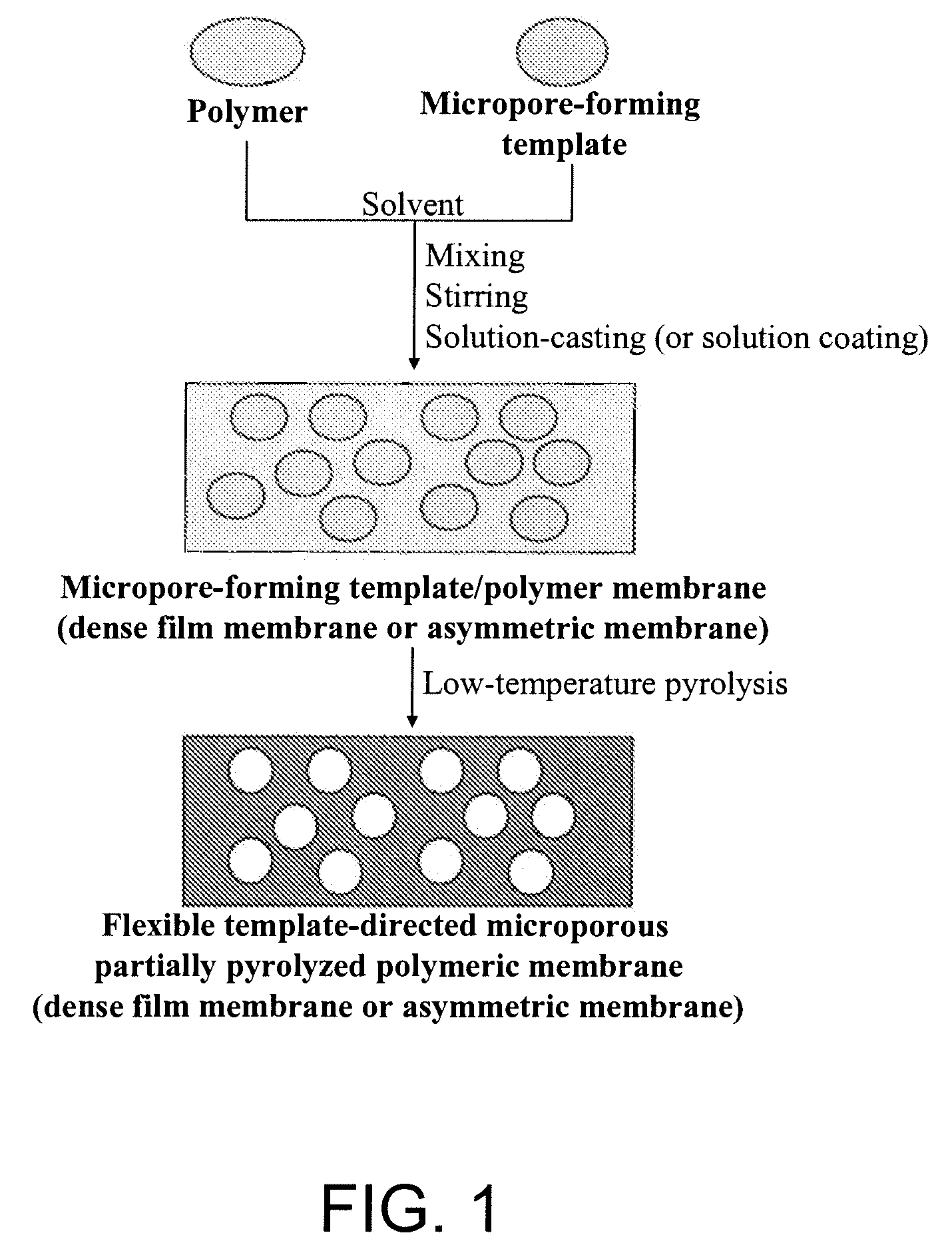

Flexible Template-Directed Microporous Partially Pyrolyzed Polymeric Membranes

InactiveUS20070209506A1High selectivityGood anti-plasticizing performanceMembranesSemi-permeable membranesCyclodextrinSolvent

This invention describes a new concept of flexible template-directed microporous partially pyrolyzed polymeric membranes which have greatly improved performance in separation of gas pairs compared to their precursor polymeric membranes. Organic hosts, such as crown ethers, cyclodextrins (CDs), calixarenes (CXs), and spherands, or polymeric additives, such as poly(ethylene glycol) (PEG) and polyvinylpyrrolidone (PVP) were used as the micropore-forming templates. Micropore-forming template / polymer blend membranes comprising organic micropore-forming templates embedded in a polymer matrix were prepared by dissolving the organic micropore-forming templates in the polymer solution followed by solution-casting and solvent evaporation or solvent exchange. Low-temperature selectively pyrolyzing micropore-forming templates in the micropore-forming template / polymer blend membranes at a nitrogen flow resulted in the formation of flexible microporous partially pyrolyzed polymeric membranes.

Owner:UOP LLC

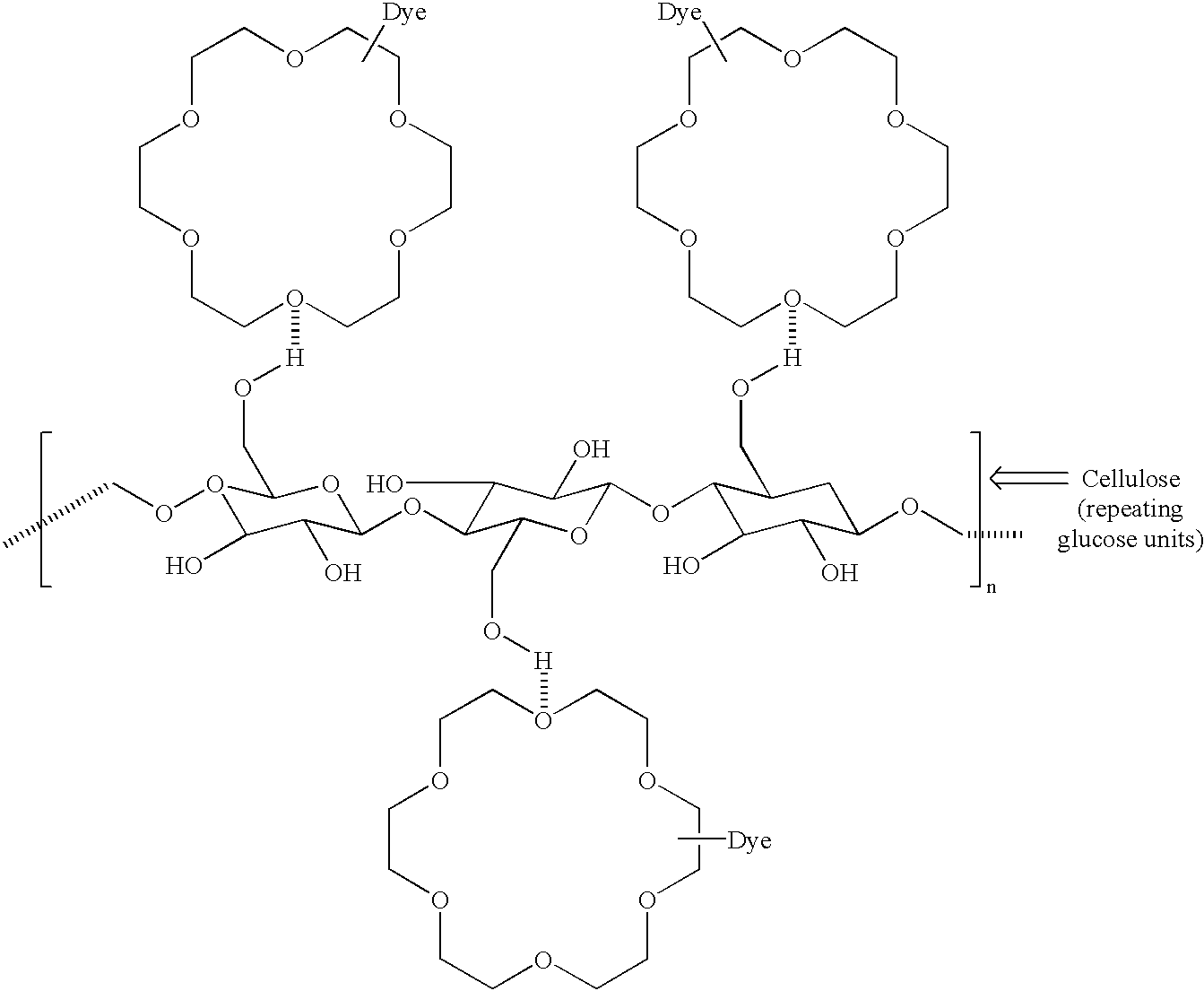

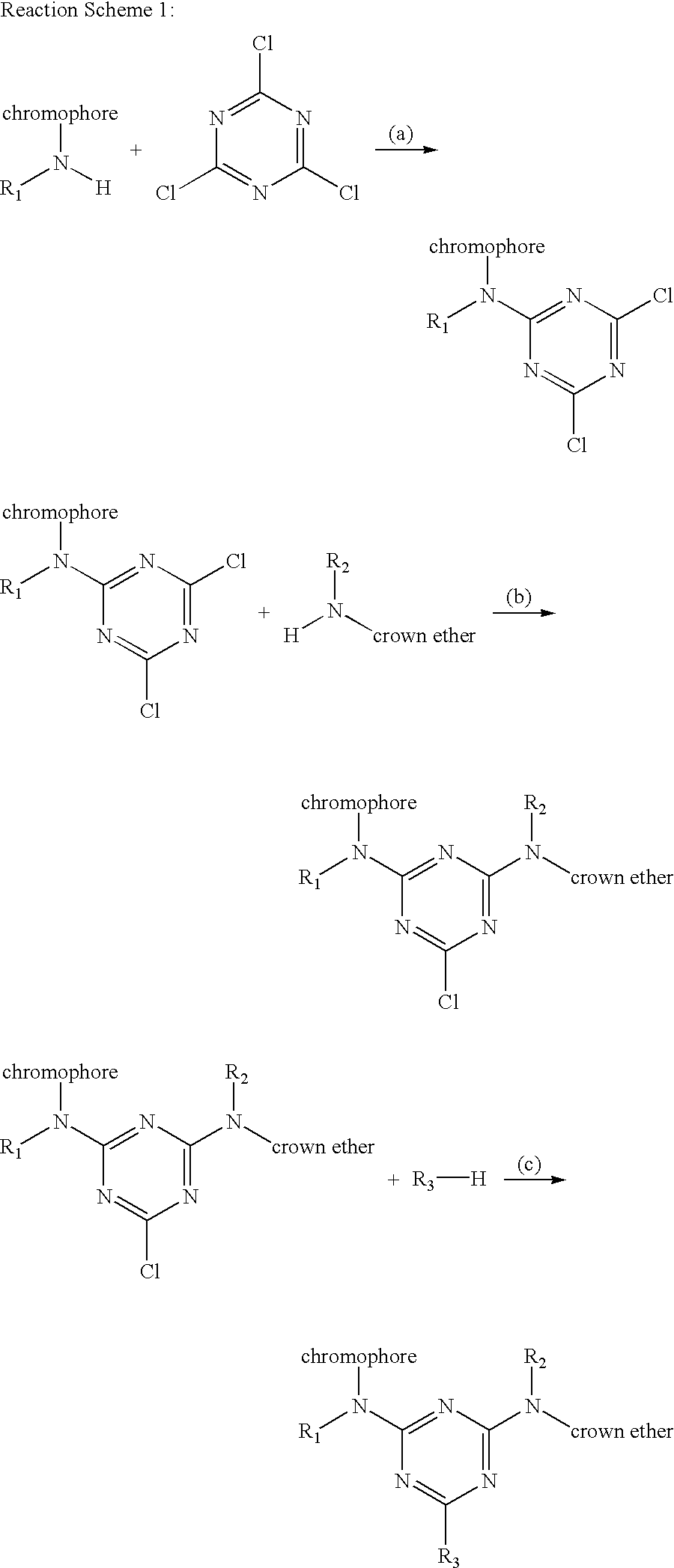

Derivatization of dyes/pigments with crown ethers and inkjet printing fluids containing the same

InactiveUS20020144626A1Improved lightfastnessImproved smearfastnessInksOrganic dyesDisperse dyeOrganic solvent

An inkjet ink is provided that employs one or more water-soluble colorants or water-insoluble colorants, such as solvent dyes, disperse dyes, or pigments. The colorant, whether water-soluble or water-insoluble, is derivatized with one or more crown ethers to render the water-insoluble colorants soluble in water and in water-miscible organic solvents commonly employed in inkjet printing, particularly thermal inkjet printing, and to impart improved properties to the colorants, such as lightfastness, smearfastness, and waterfastness. The inkjet ink comprises a vehicle and at least one crown ether derivatized colorant. The resulting inkjet ink evidences improved print quality properties, compared to inkjet inks containing colorants that are not so derivatized.

Owner:HEWLETT PACKARD DEV CO LP

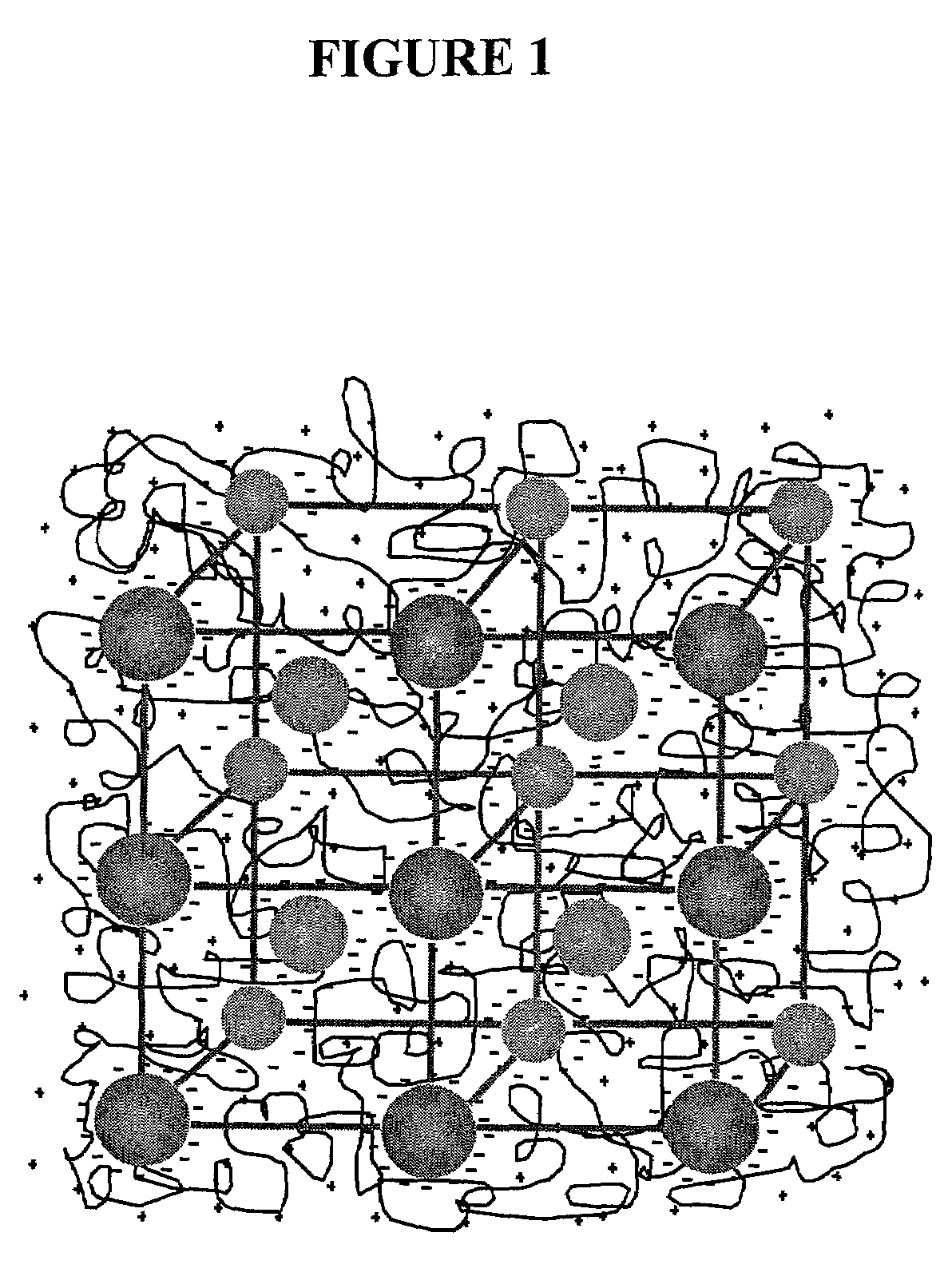

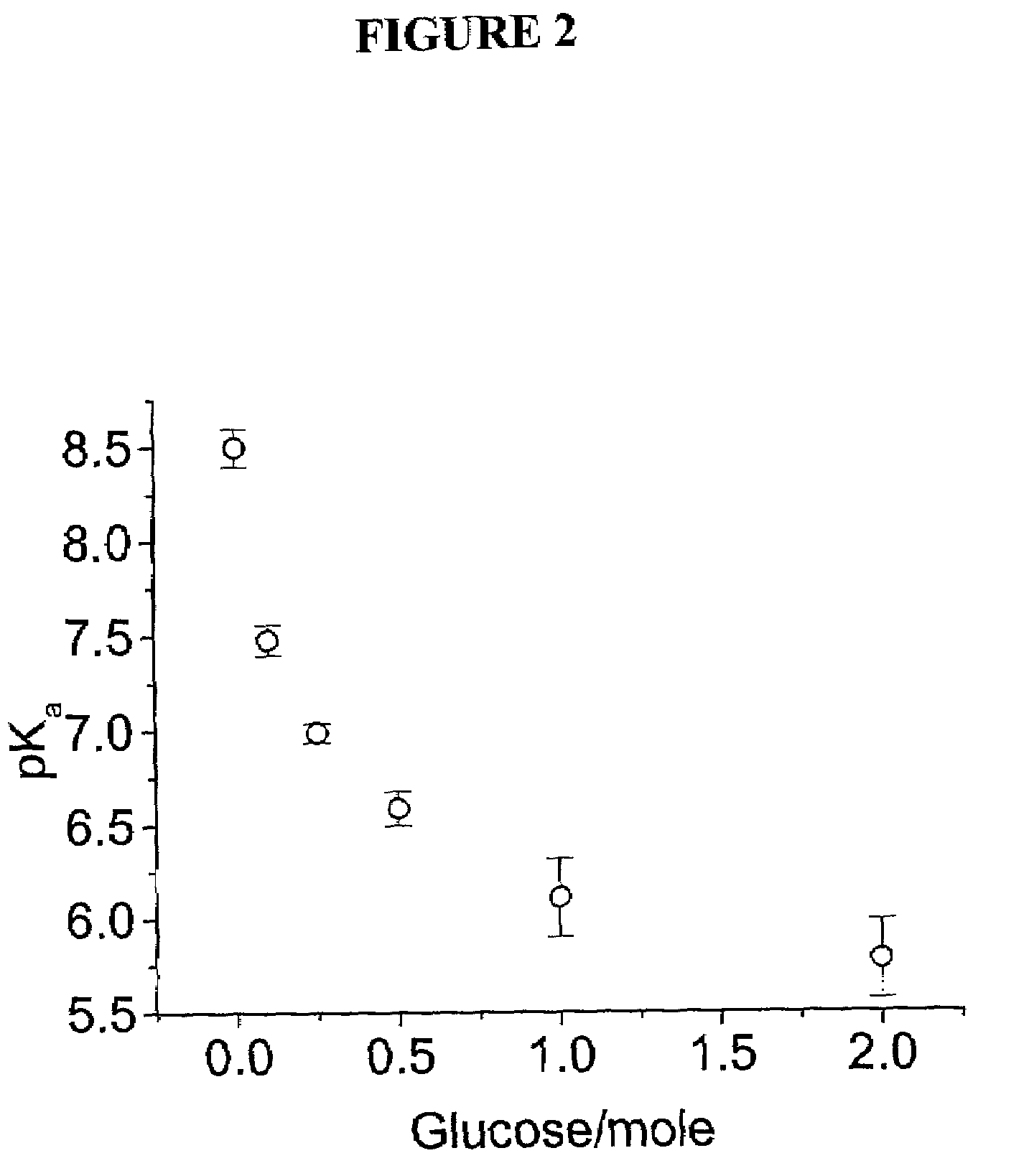

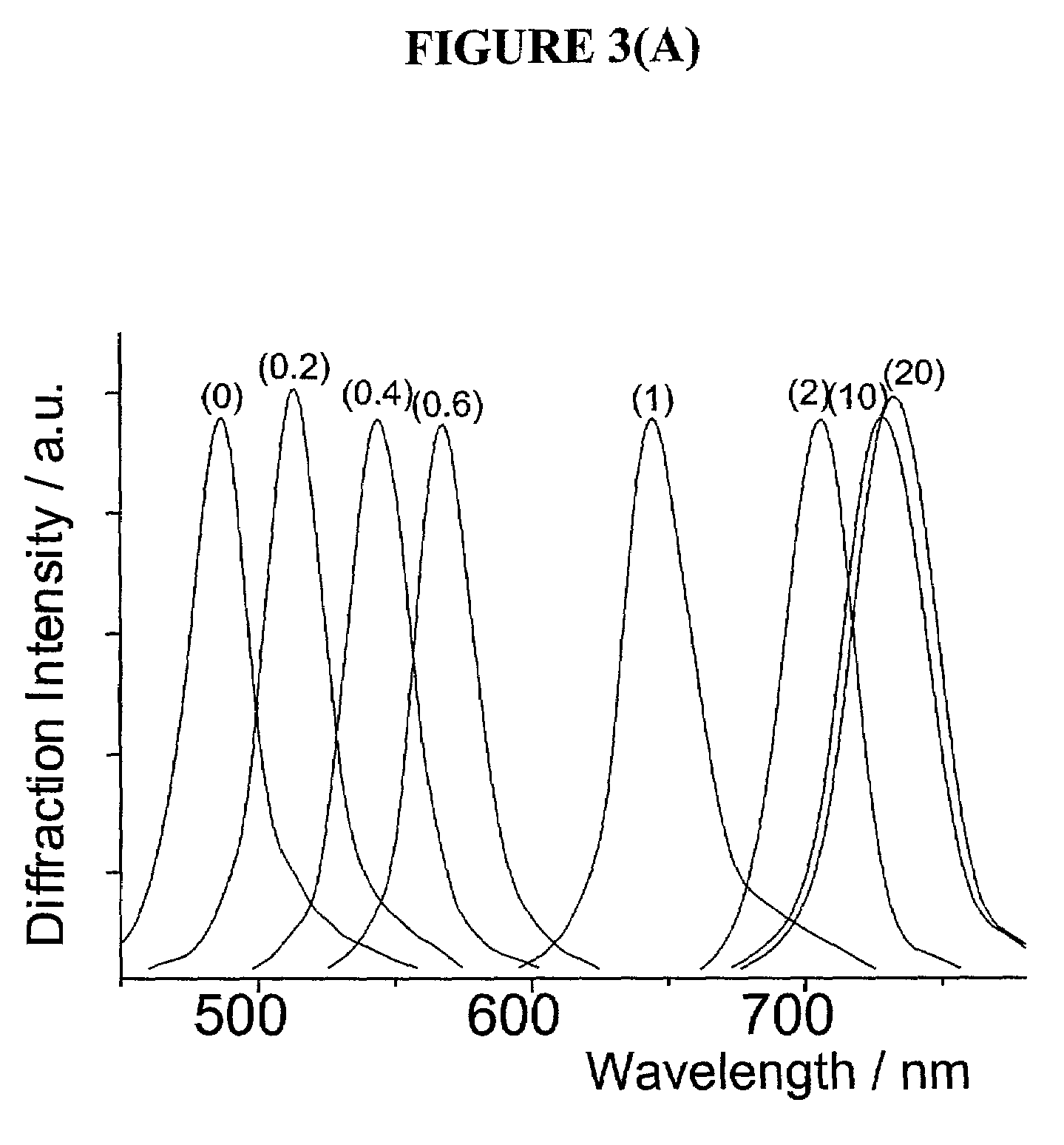

Intelligent polymerized crystalline colloidal array carbohydrate sensors

InactiveUS7105352B2Material analysis by observing effect on chemical indicatorSpectrum generation using diffraction elementsGlucose sensorsConcentrations glucose

The present invention is related to glucose sensors that are capable of detecting the concentration or level of glucose in a solution or fluid having either low or high ionic strength. The glucose sensors of the present invention comprise a polymerized crystalline colloidal array (PCCA) and a molecular recognition component capable of responding to glucose. The molecular recognition component may be a boronic acid, such as a phenylboronic acid, glucose oxidase, a combination of phenylboronic acid and poly(ethylene)glycol or crown ether, or another component capable of detecting glucose in various fluids and solutions. The glucose sensors of the present invention may be useful in the development of noninvasive or minimally invasive in vivo glucose sensors for patients having diabetes mellitus.

Owner:UNIVERSITY OF PITTSBURGH

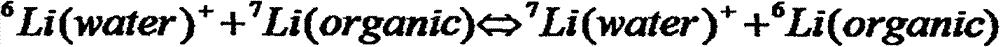

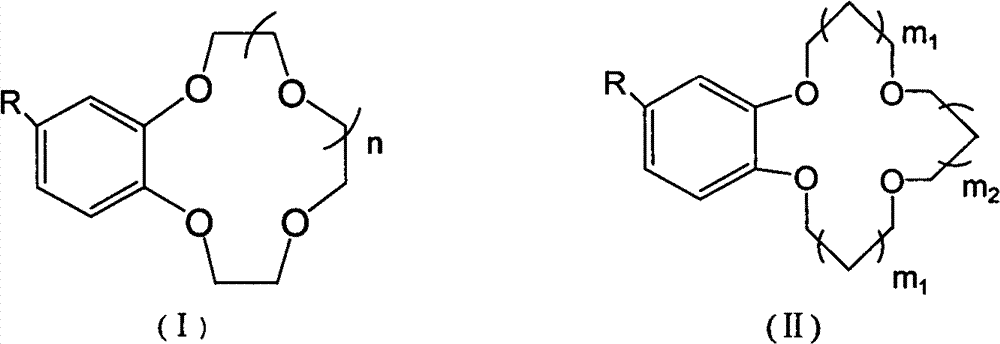

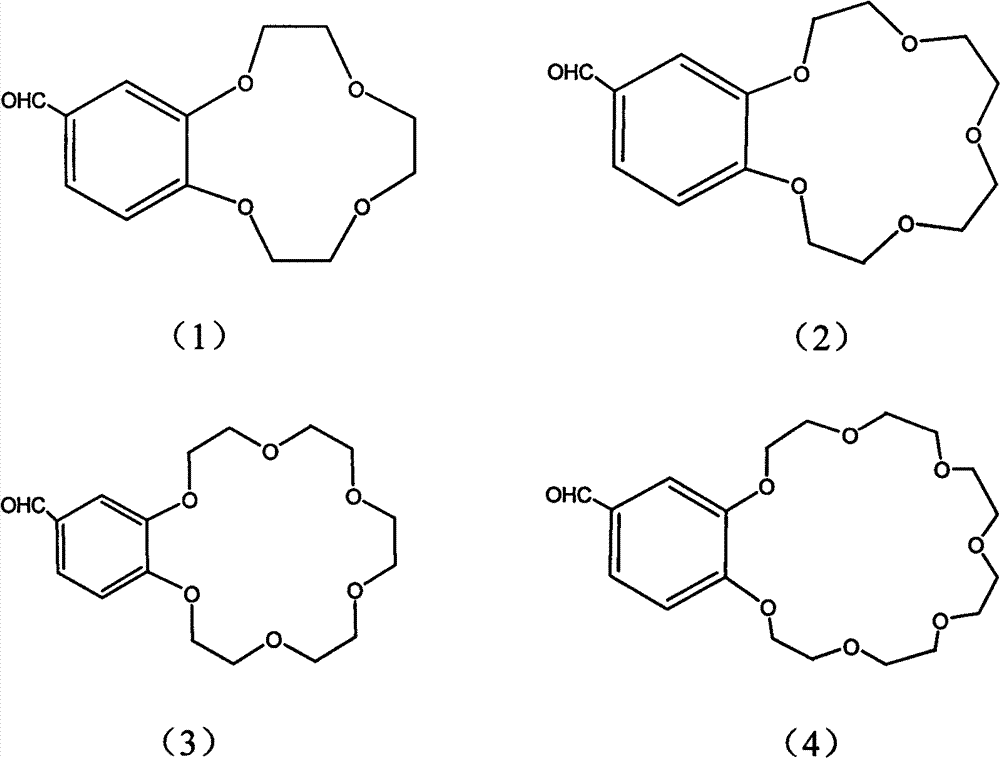

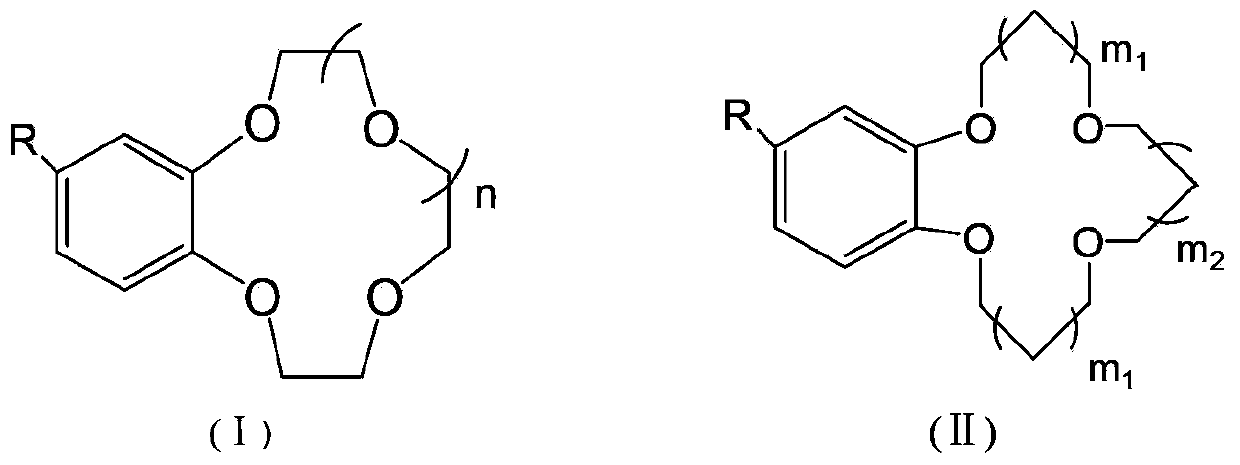

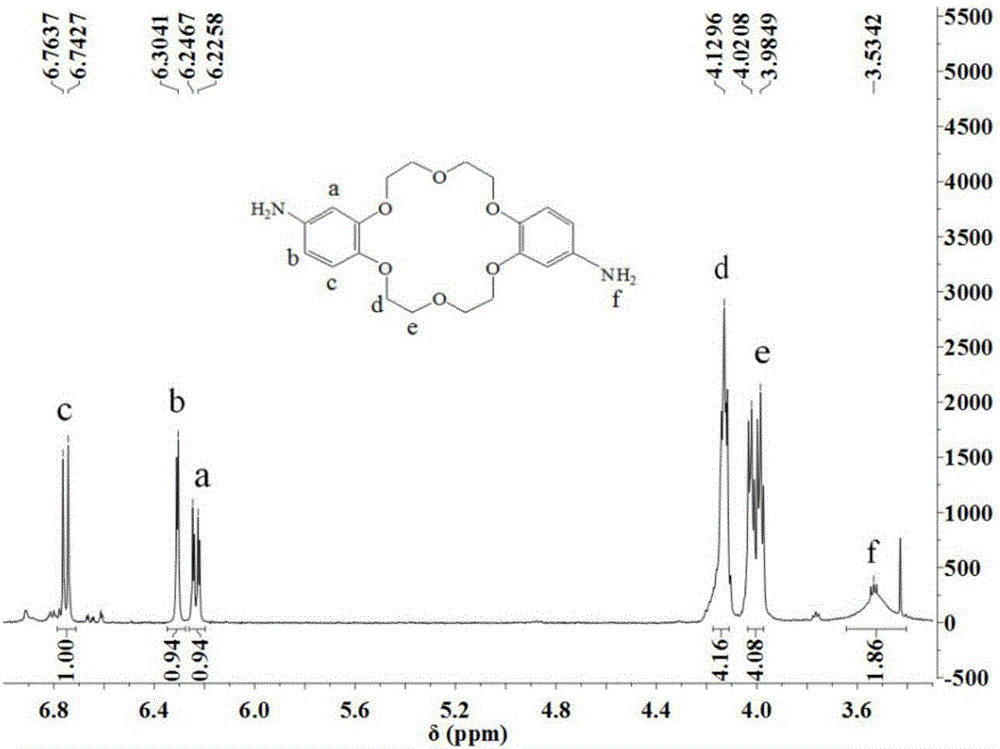

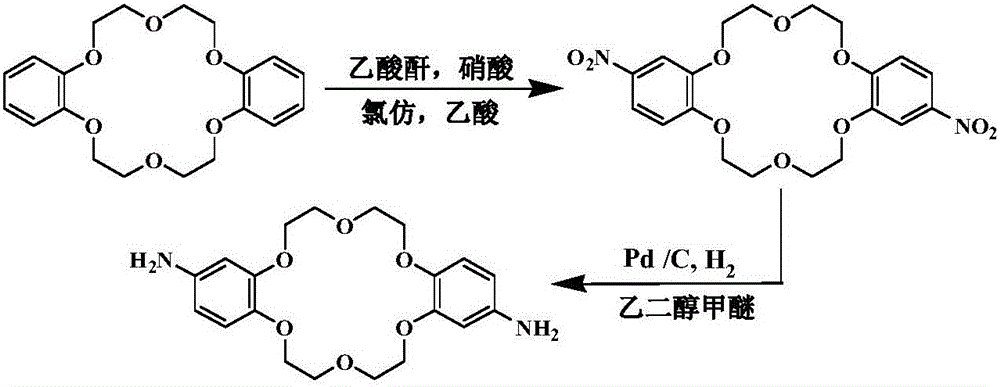

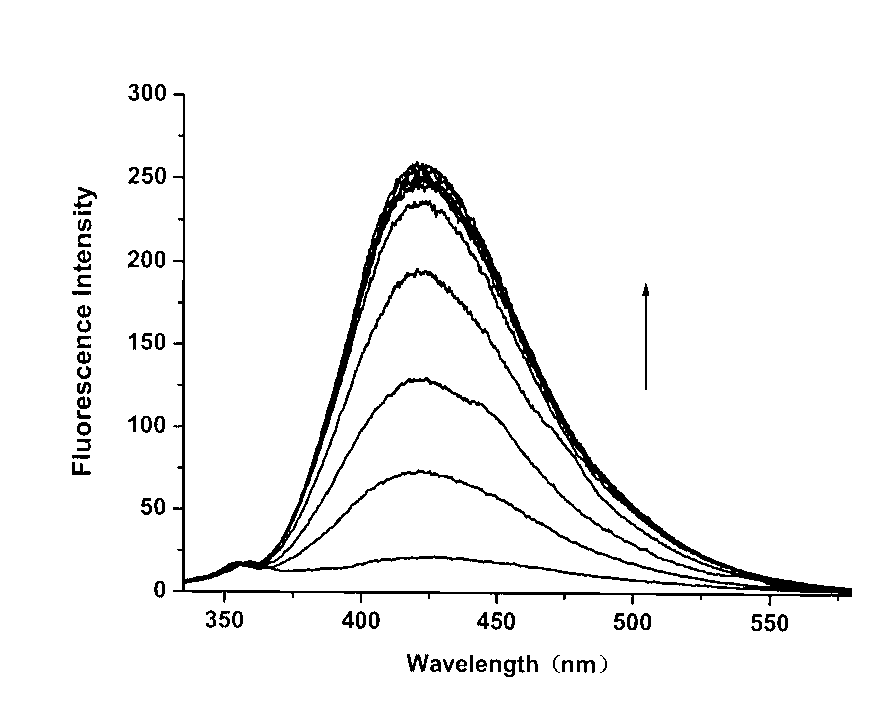

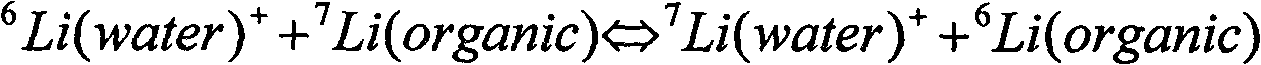

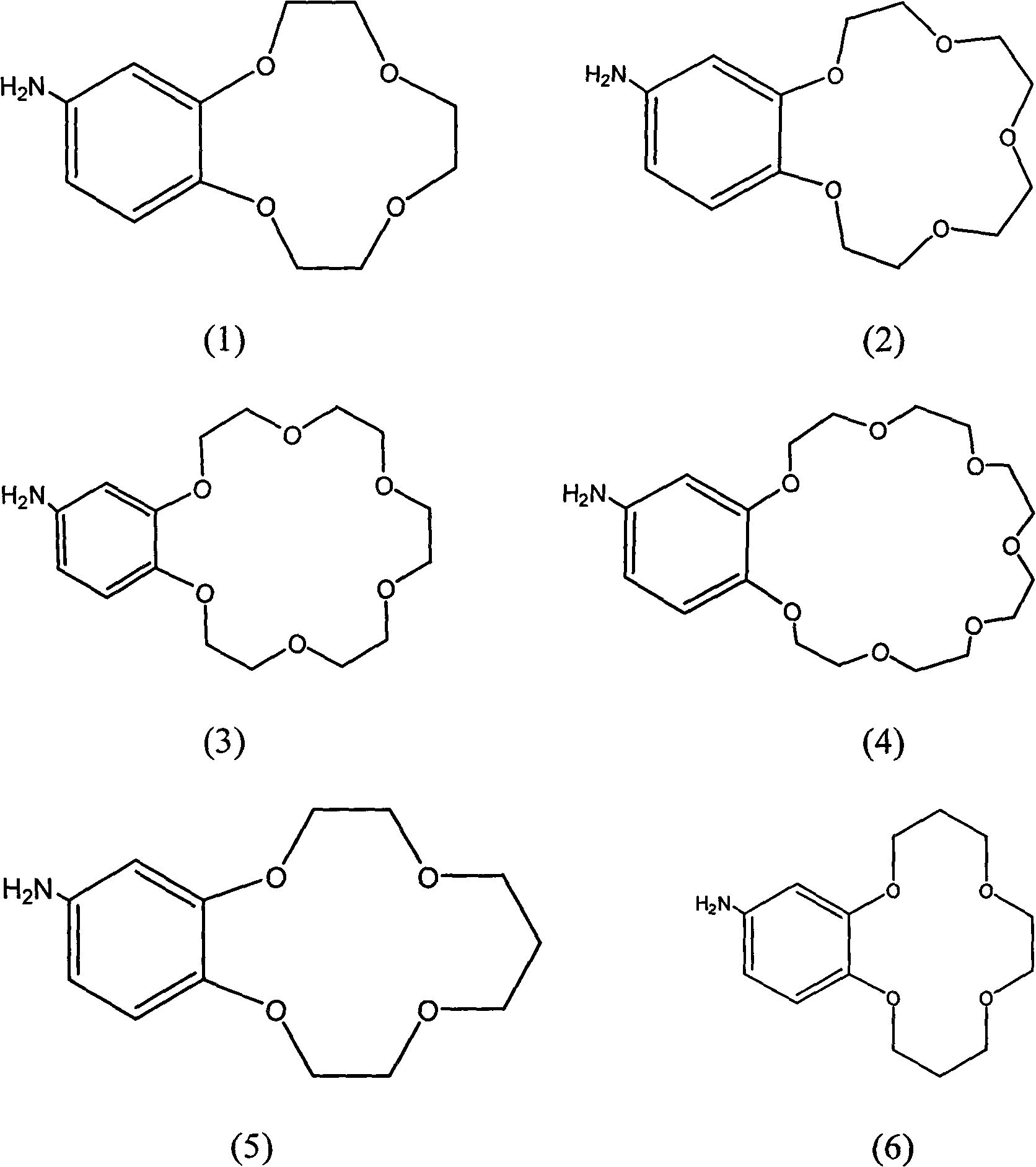

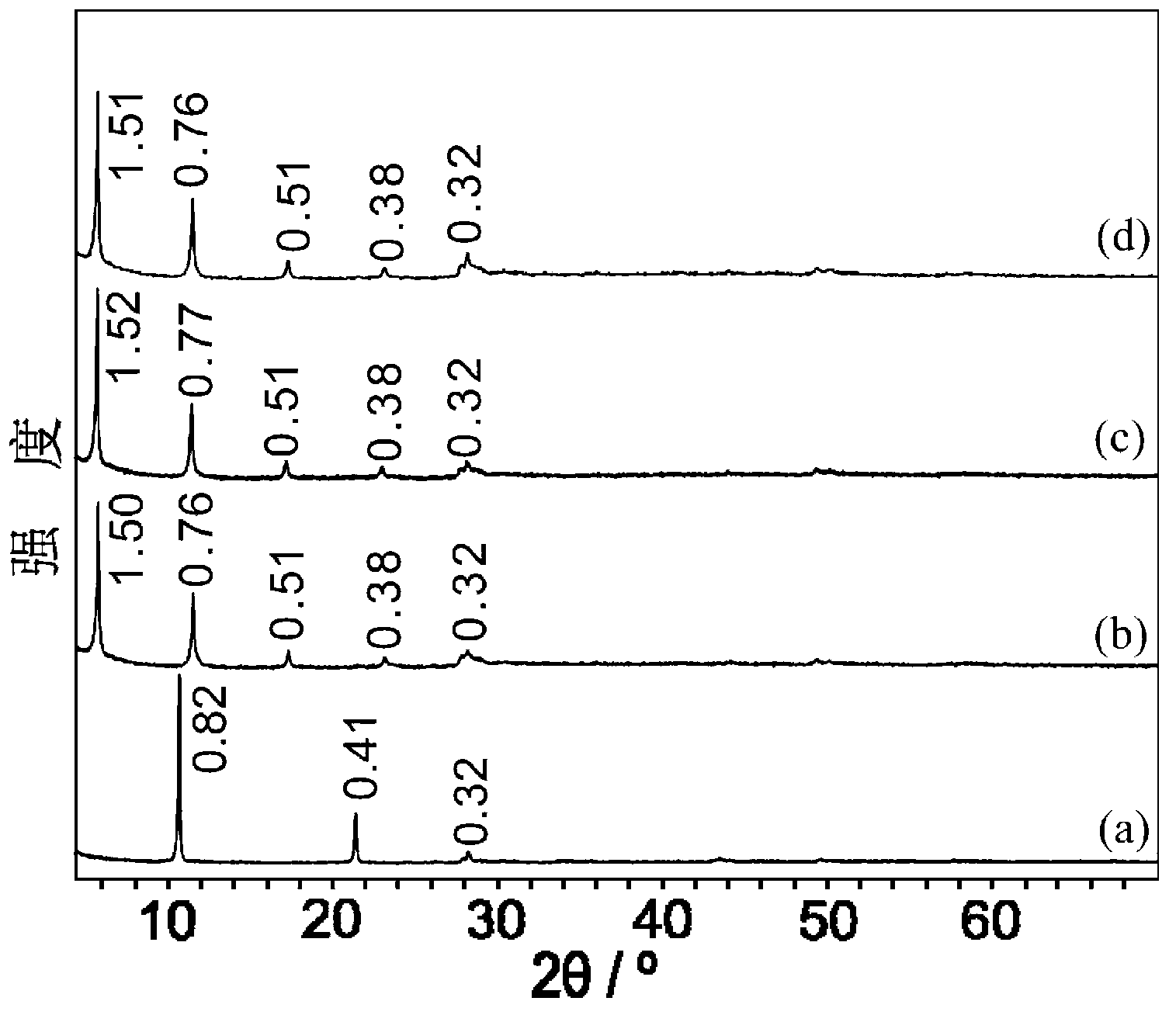

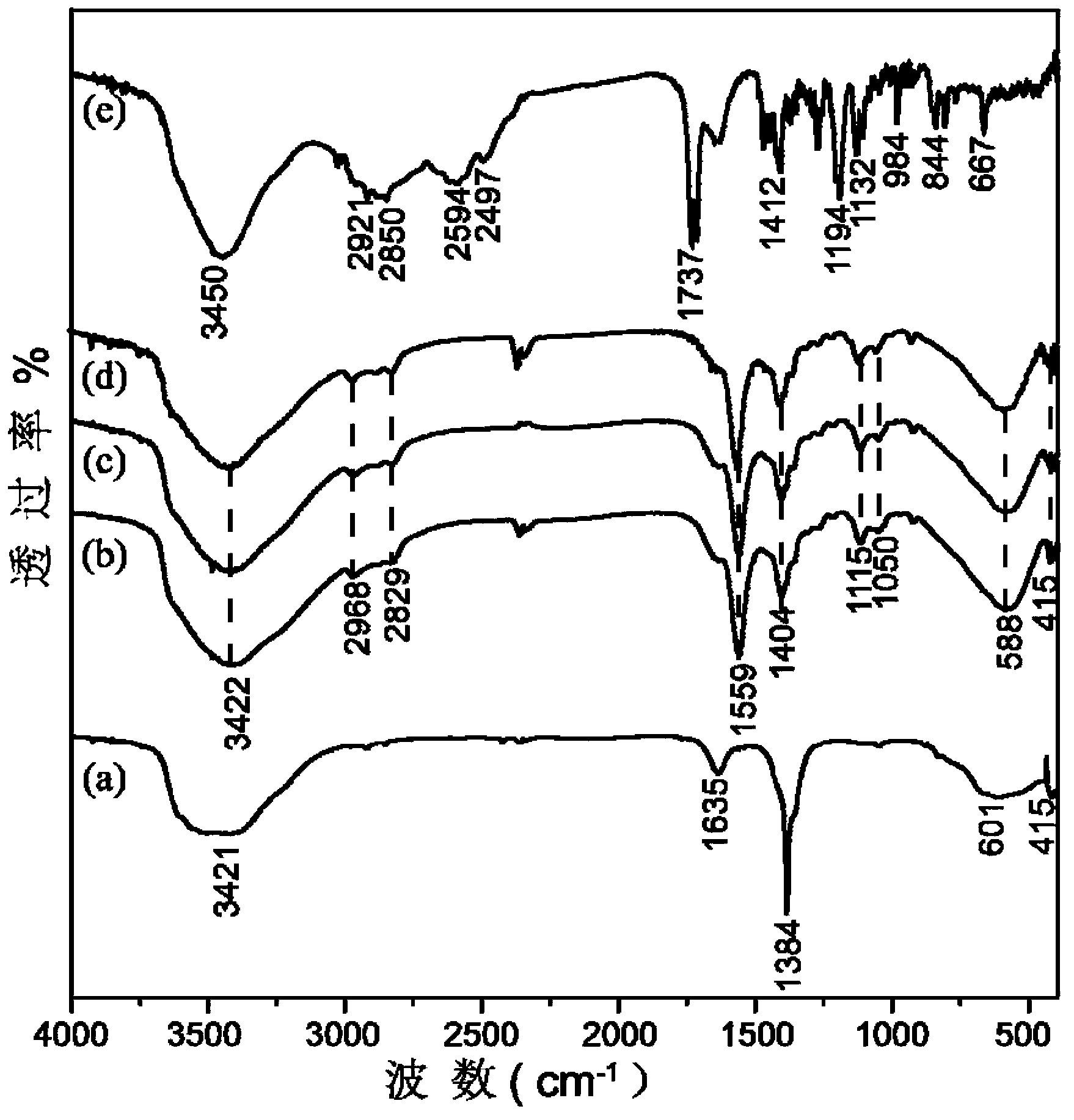

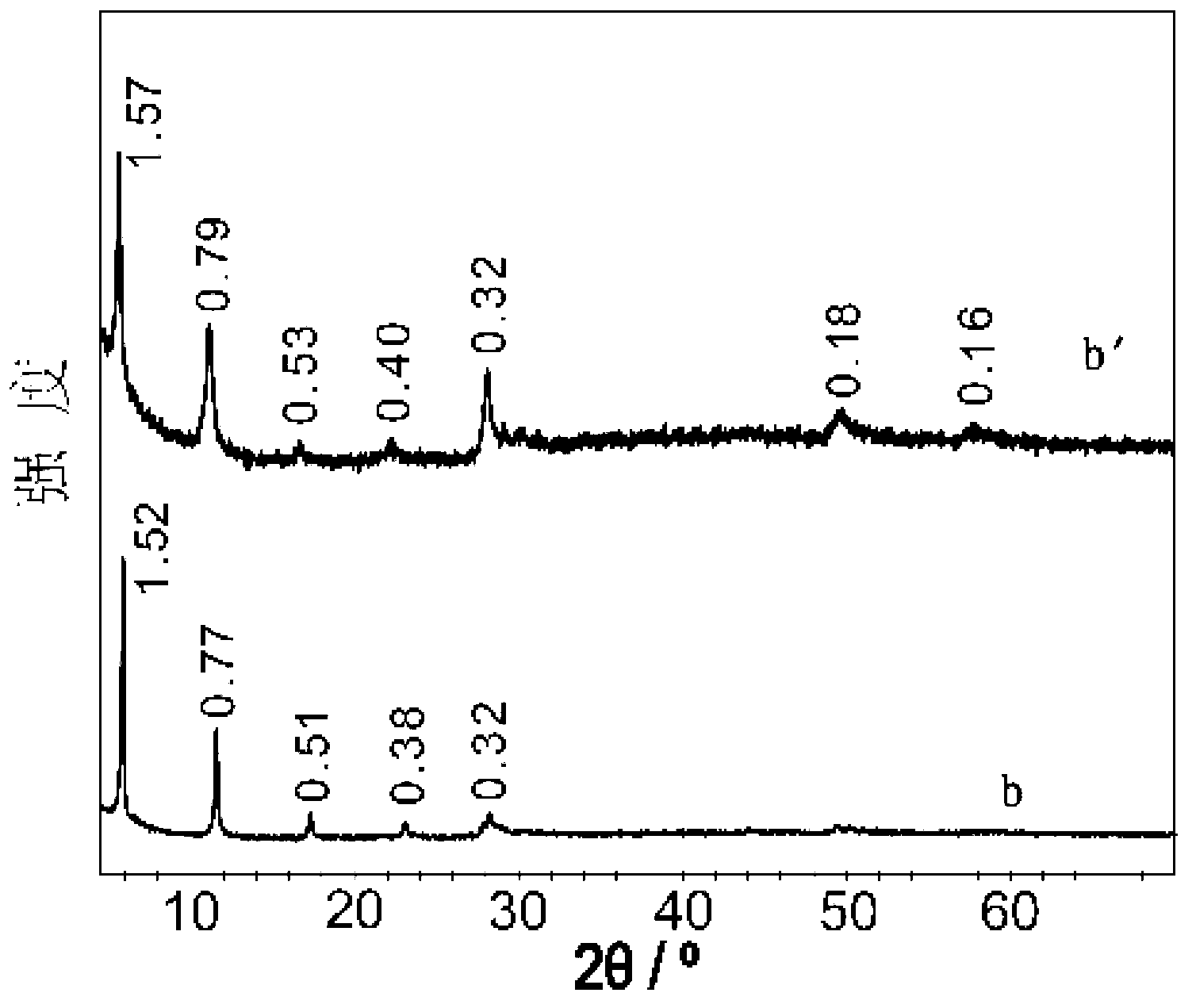

Benzocrown ether graft polymer with lithium isotopic separation effect and preparation method thereof

ActiveCN102786616AIncrease loading capacityExcellent separation factorOther chemical processesIsotope separationBackbone chainSolvent

The invention provides a benzocrown ether graft polymer with a lithium isotopic separation effect and a preparation method thereof. As for the polymer, hydroxyl-contained polyvinyl alcohol or polyethylene-vinyl alcohol is adopted to serve as a main chain; benzocrown ether is adopted to serve as a side hung group; and the main chain and the side hung group are connected together through chemical bonds so as to form the benzocrown ether graft polymer. The preparation method comprises the following steps: dissolving the active hydroxyl-contained polyvinyl alcohol or the polyethylene-vinyl alcohol and the benzocrown ether with an active carboxyl functional group or an aldehyde group in a solvent; performing esterification or aldolization under the action of a catalyst at a certain temperature; completing the chemical grafting of the benzocrown ether with the polyvinyl alcohol or the polyethylene-vinyl alcohol; and finally adding a precipitating agent so as to obtain the graft polymer through precipitation. The graft polymer provided by the invention, which contains the benzocrown ether group, has a good lithium isotopic separation effect. Moreover, through adjusting the size of the crown ether ring, the graft polymer can be used for recognition and separation of heavy metal ions, and has an extensive application prospect.

Owner:TIANJIN POLYTECHNIC UNIV

Composition for removing metal from hydrocarbon oil

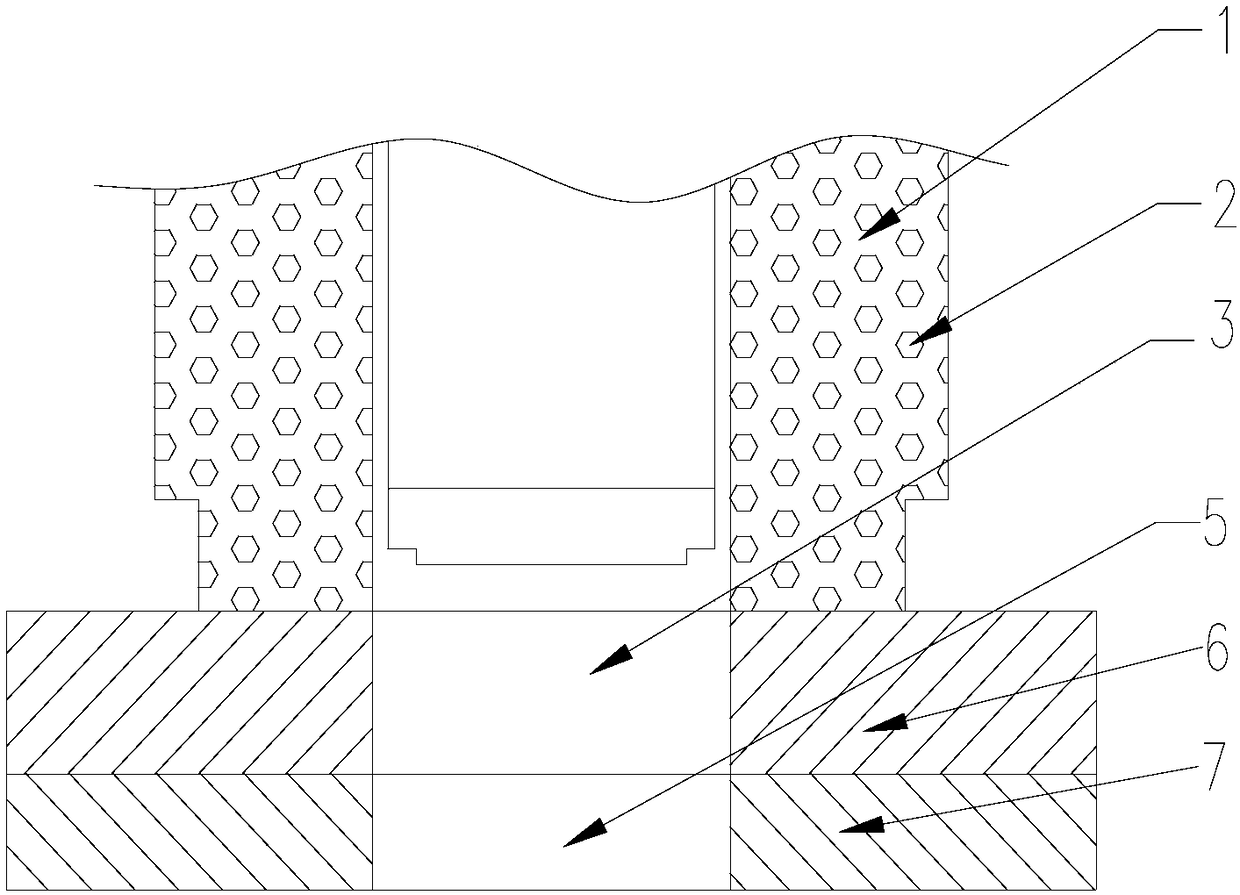

ActiveCN1657596AReduce calcium concentrationReduce consumptionDewatering/demulsification with electric/magnetic meansHydrocarbon oils refiningDemulsifierPhosphonium salt

A composition for removing metals from masrolar D contains chelating agent, precipitant, optional surfactant and demulsifier, and at least one of mono-alcohol or biol polymer, quaternary ammonium salt, quaternary phosphonium salt and crown ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

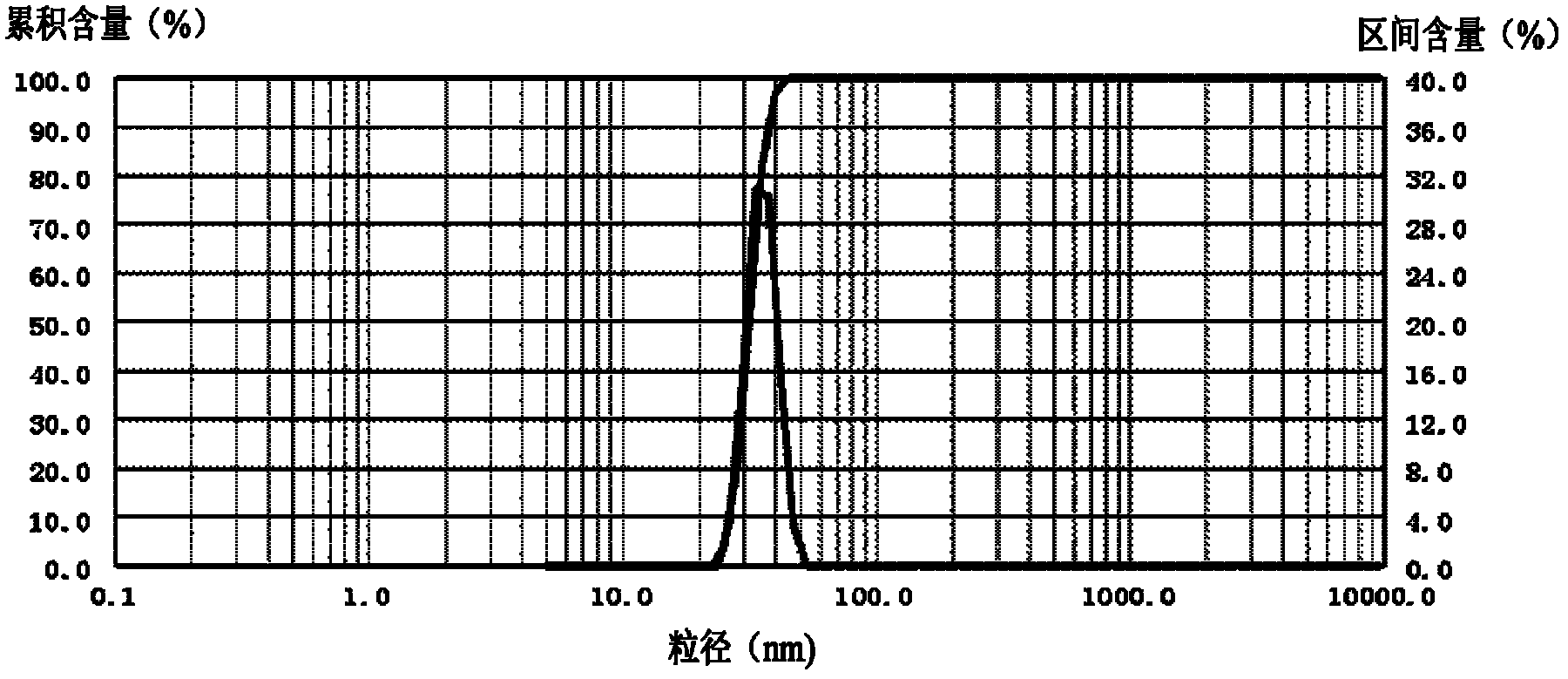

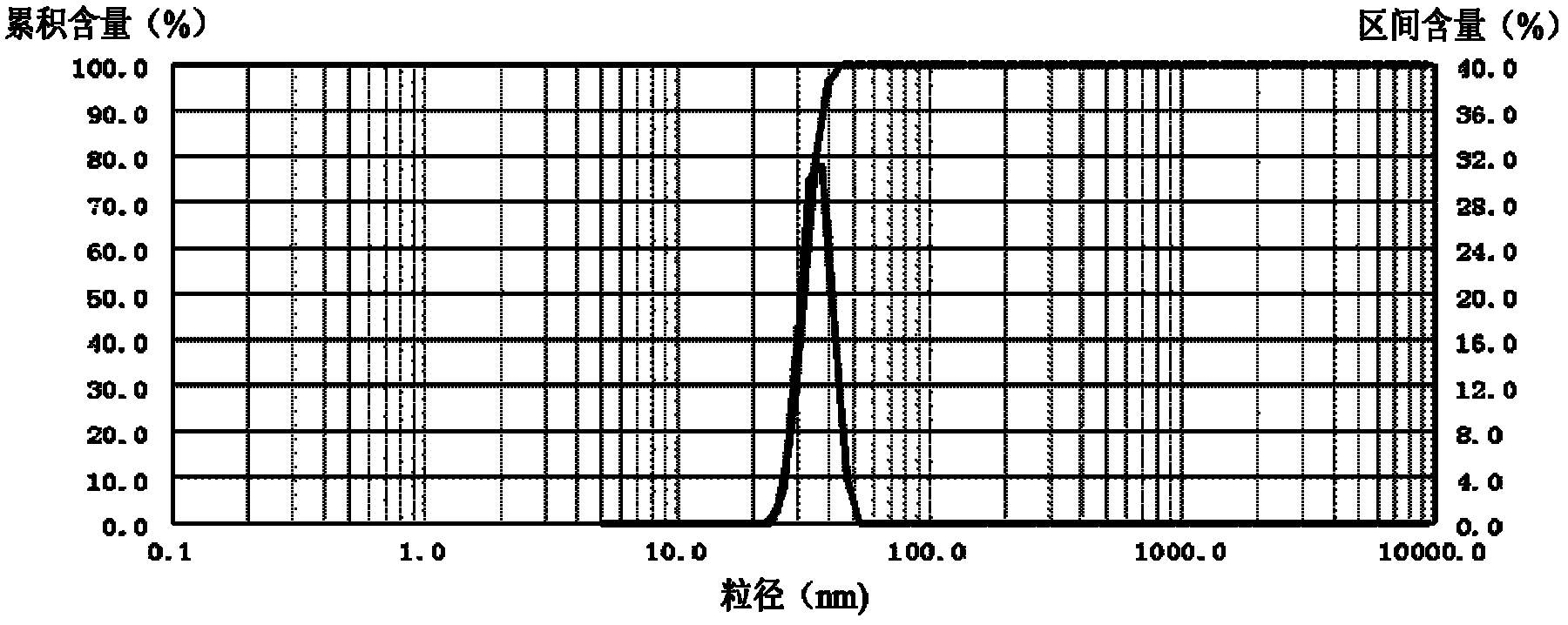

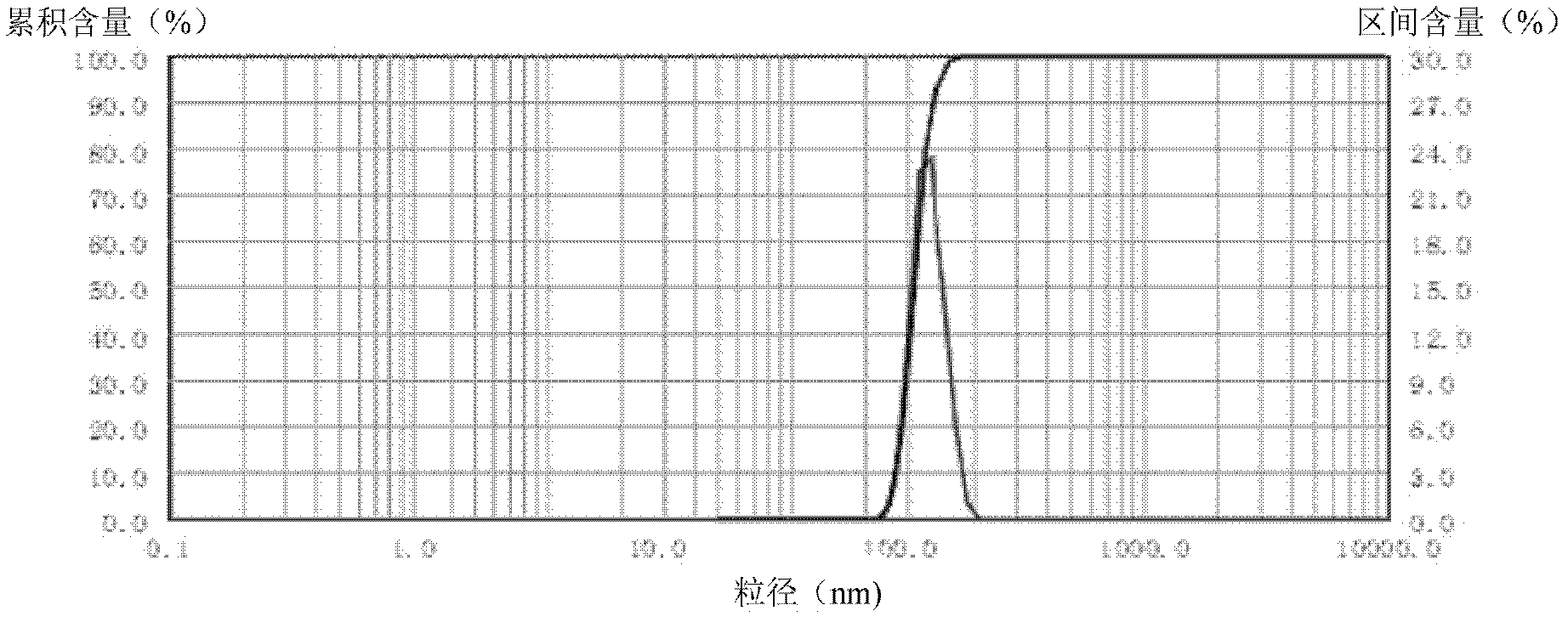

Preparation method of nanometer silver particles

The invention provides a preparation method of nanometer silver particles. The preparation method comprises the following steps of: (a) adding a silver source, a coating agent and ammonia water into water under the conditions of stirring and heating to obtain a reaction solution with the pH value being 7-12, wherein the molar ratio of the silver source to the coating agent is 1:(1-5); (b) adding crown ether into the reaction solution under a stirring state, wherein the molar ratio of the crown ether to the silver source is (1-3):1; and (c) adding a reducing agent containing alkali metal into a mixture solution obtained in (b) under a stirring state to obtain nanometer silver particles, wherein the molar ratio of the reducing agent to the silver source is (1-3):1. According to the invention, the crown ether is added into the reaction system in a reaction process, meanwhile, the reducing agent containing the alkali metal is used in a matching manner. The crown ether is added to facilitate distantiation between positive charges and negative charges in a nano-silver system, so that nano-silver can stably disperse in a water solution without agglomeration.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

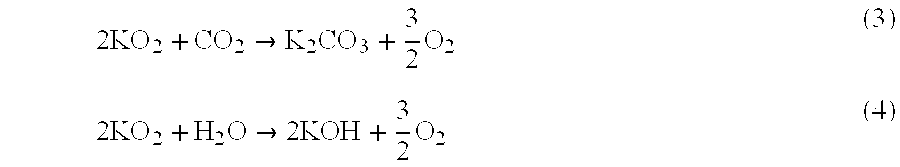

Method for the preparation of reactive compositions containing hydrogen peroxide

The subject invention provides a potentially economically viable method for the preparation of hydrogen peroxide (H2O2) in deep eutectic solvents (DES). H2O2 is then used for the destruction of small to large quantities of sulfur and nitrogen mustards and lewisite, their homologous / analogues, and similar chemical warfare agents at ambient conditions in DES without producing any toxic by-products. Furthermore, H2O2 has been used for the destruction of small to large quantities of halogenated hydrocarbons, their homologous / analogues, and similar hazardous chemicals at ambient conditions. H2O2 can be formed by either the electrochemical reduction of oxygen in DES in the presence of water or by dissolving Group 1 (alkali metals) or Group 2 (alkaline earth metals) superoxides, e.g. potassium superoxide, in DES in the presence of water, with / without chemicals used for the enhancement of the solubility of the metal superoxide in the DES, e.g. crown ethers.

Owner:KING SAUD UNIVERSITY

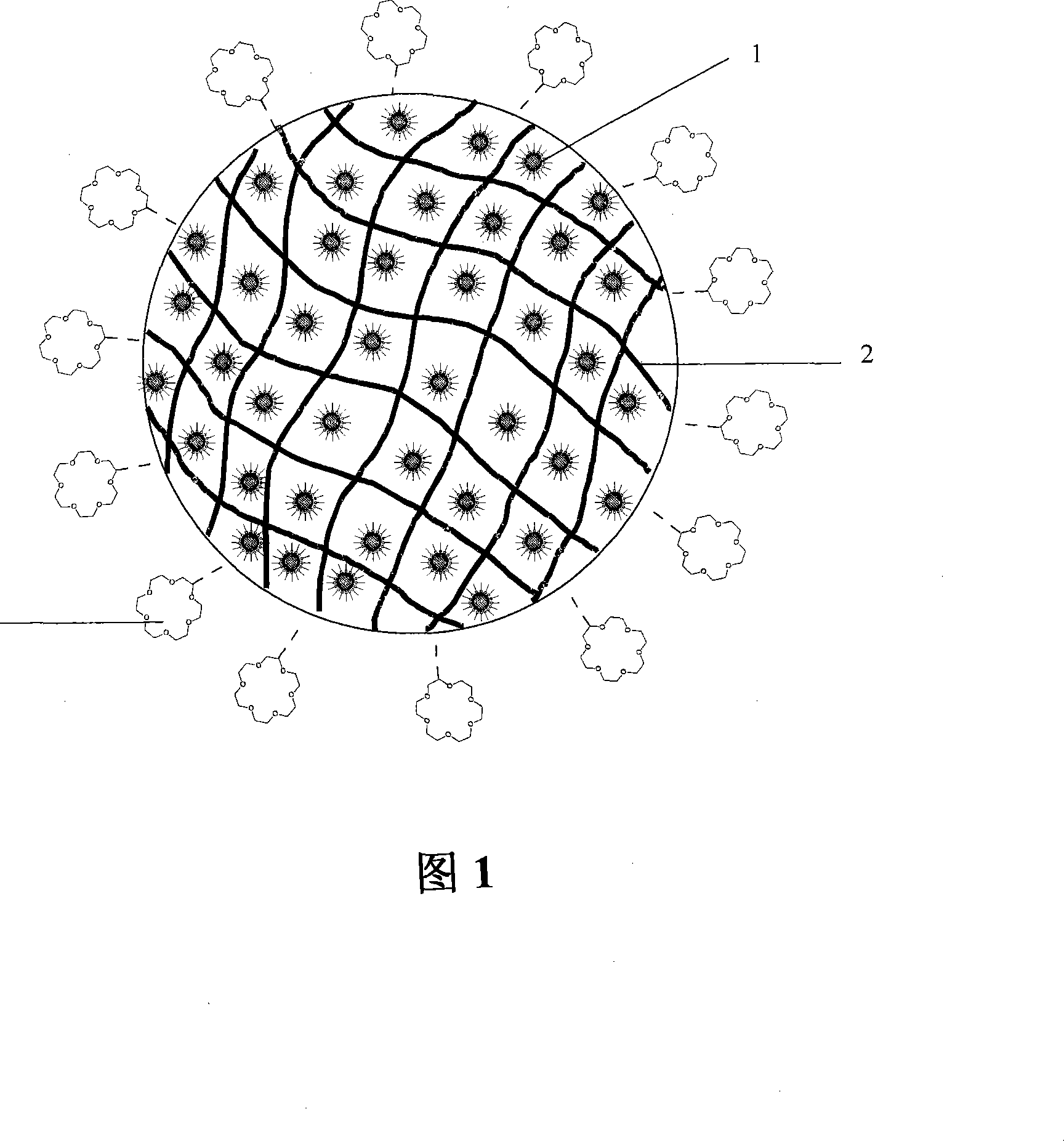

Magnetic particle extractive agent and method for isolating radionuclide

InactiveCN101231899AEasy to desorbEasy to operateOrganic/organic-metallic materials magnetismLiquid solutions solvent extractionLiquid wasteAdditive ingredient

The invention discloses finished magnetic-particle extractant combined with magnetic nanometer microspheres, a preparation method thereof and application thereof in separation of radioactive species. The extractant consists of magnetic fine particles carrying separated functional groups of radioactive species. Nanometer particles of magnetism Fe3O4 are dispersed inside a polymer. A layer of ingredients selected from crown ether and ramification thereof or neutral phosphorus (TBP, TOPO) ramification and tertiary amine (TOA) ramification connected with chemical bonds is arranged on the surface of the polymer. The magnetic particle extractant can be directly added to solution containing radioactive species, and is stirred at a room temperature. The magnetic extractant is separated out with the applied magnetic field to separate radioactive species. The invention is integrated with the advantages of simple operation of magnetic separation and high selectivity of extraction separation, and can separate target radioactive species out from complicated radioactive liquid waste containing one or a plurality of kinds of <90>Sr and actinide elements. The magnetic-particles can be desorbed easily, and can be used repeatedly without producing secondary waste. In addition, by adopting the invention, continuous large-scale separation can be completed.

Owner:NAT INST FOR RADIOLOGICAL PROTECTION & NUCLEAR SAFETY CHINESE CENT FOR DISEASE CONTROL & PREVENTION

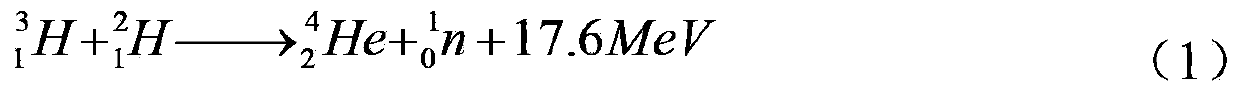

Method for extracting lithium isotope

The present invention provides a method for extracting and separating lithium isotopes 7Li and 6Li. The method comprises the steps of: preparing a first organic phase: evenly mixing a hydrophobic ionic liquid and a diluent in the volume ratio of 1-15:1-10 by stirring under closed condition; then adding an extractant to form a first organic phase; preparing a first aqueous phase of an aqueous solution of lithium salt with lithium ion concentration of 0.2-5.0mol / L; mixing the first aqueous phase and the first organic phase in the volume ratio of the 1-2:1-4 to form a first extraction system; severely shocking for 5-60 min, and enriching 7Li in the aqueous phase; and then conducting reextraction to obtain 6Li enriched in the organic phase. Compared with the crown ethers and pure ionic liquid system of the prior art, the system has the advantages of low operating costs and strong industry adaptability.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

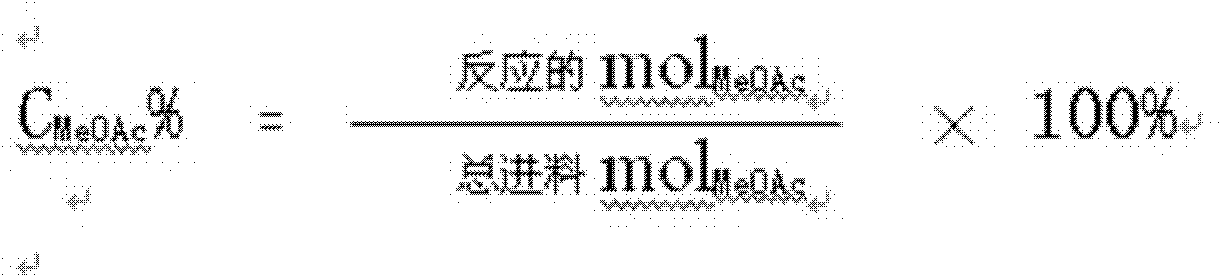

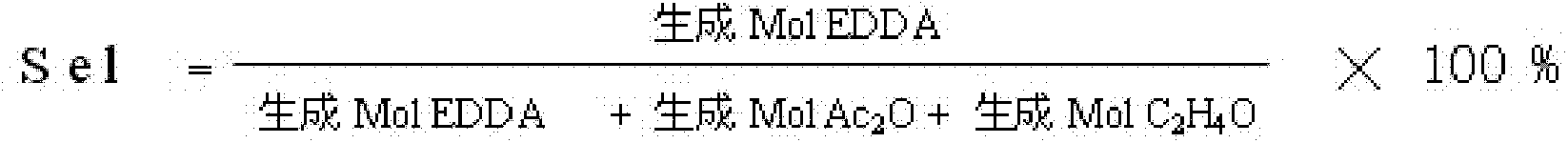

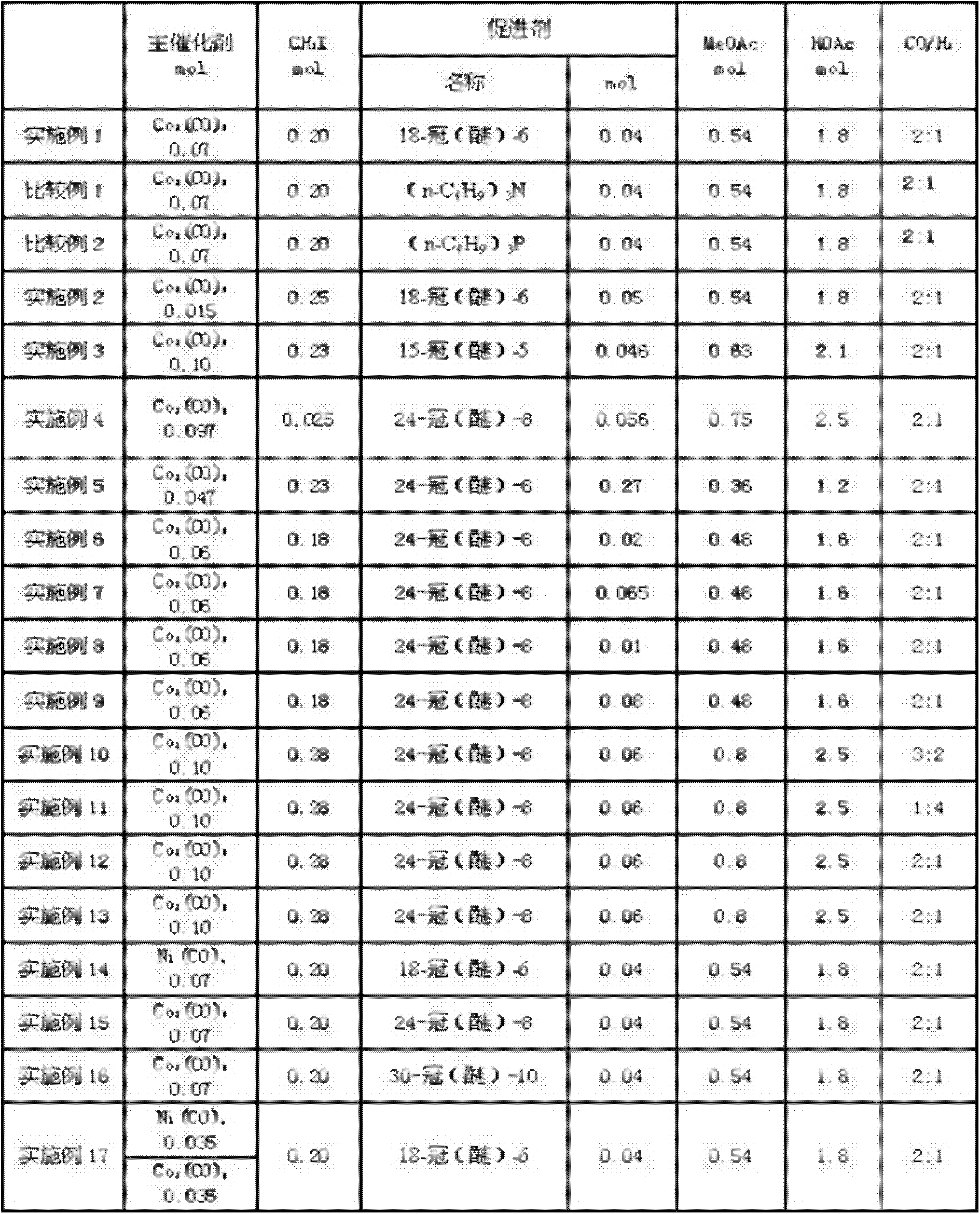

Synthetic method of ethylidene diacetate

ActiveCN103553913AHigh activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionHydrogenIodide

The invention relates to a synthetic method for synthesizing ethylidene diacetate through carbonylation of methyl acetate, mainly solving the problems that the conversion rate of reactant methyl acetate during the synthesis of ethylidene diacetate through carbonylation of methyl acetate is low and the yield and selectivity of ethylidene diacetate are low when organic nitrogen or organic phosphorus is used as an accelerant in the prior art. The technical scheme of the synthetic method is as follows: methyl acetate, carbon monoxide and hydrogen are used as raw materials, acetate acid is used as a solvent, ethylidene diacetate is synthesized under the conditions that the reaction temperature is 130-200 DEG C, the reaction pressure is 2-10MPa and the reaction time is 3-10h, a main catalyst adopts ironic series metals or compounds thereof, a catalyst promoter is iodide and the accelerant is crown ether. By adopting the synthetic method, the problems are well solved, and the synthetic method can be used for production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

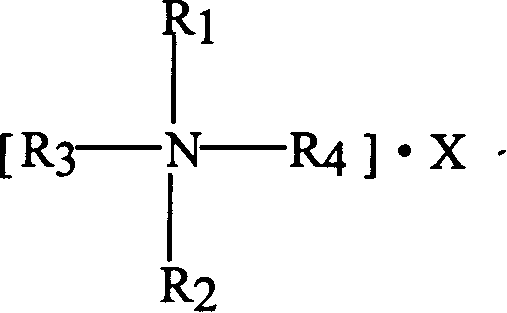

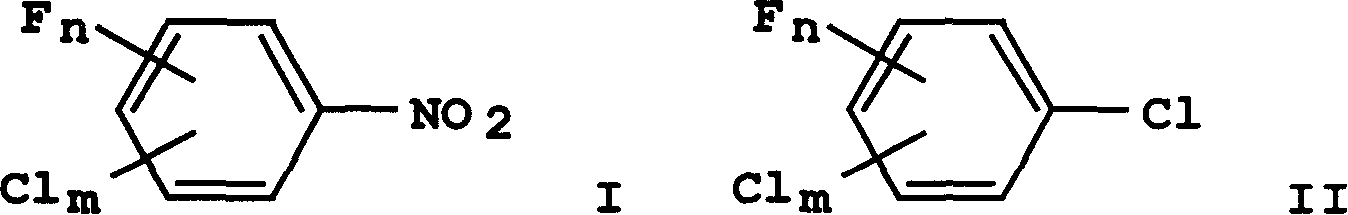

Process for producing fluoroolefins

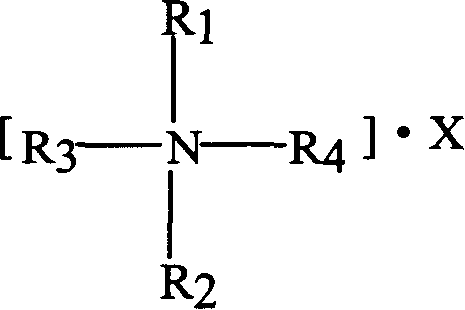

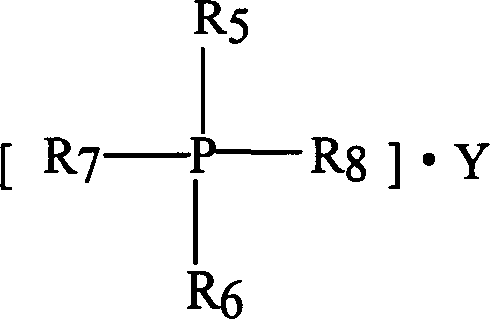

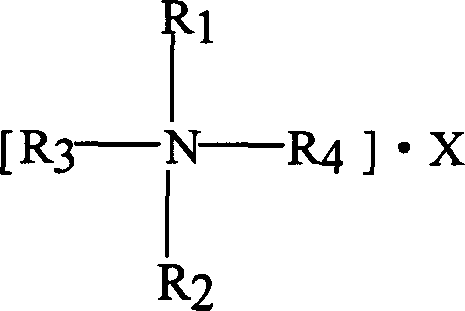

InactiveCN1589248APreparation by hydrogen halide split-offOrganic chemistry methodsPhosphonium saltPotassium

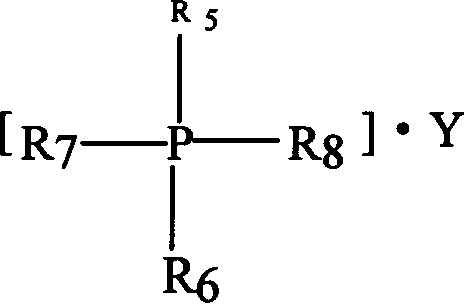

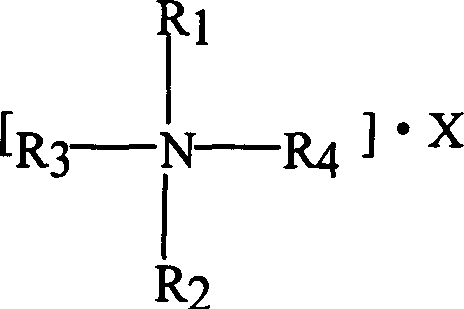

A process for producing a fluoroolefin of the formula: CF3CY=CXnHp wherein Y is a hydrogen atom or a halogen atom (i.e., fluorine, chlorine, bromine or iodine); X is a hydrogen atom or a halogen atom (i.e., fluorine, chlorine, bromine or iodine); nand p are integers independently equal to 0, 1 or 2, provided that (n + p) = 2; comprising contacting, in the presence of a phase transfer catalyst, a compound of the formula: CF3C (R<l>aR<2>b) C (R<3>CR<4>d) , wherein R<1>, R<2>, R<3>, and R<4> are independently a hydrogen atom or a halogen selected from the group consisting of fluorine, chlorine, bromine and iodine, provided that at least one of R<1>, R<2>, R<3>, and R<4> is halogen and there is at least one hydrogen and one halogen on adjacent carbon atoms; a and b are independently = 0, 1 or 2 and (a+b) = 2; and c and d are independently = 0, 1, 2 or 3 and (c+d) = 3; and at least one alkali metal hydroxide. The alkali metal hydroxide can be, for example, potassium or sodium hydroxide and the phase transfer catalyst can be, for example, at least one: crown ether such as 18-crown-6 and ls-crown-S; or onium salt such as, quaternary phosphonium salt and quaternary ammonium salt. The olefin is useful, for example, as an intermediate for producing other industrial chemicals and as a monomer for producing oligomers and polymers.

Owner:HONEYWELL INT INC

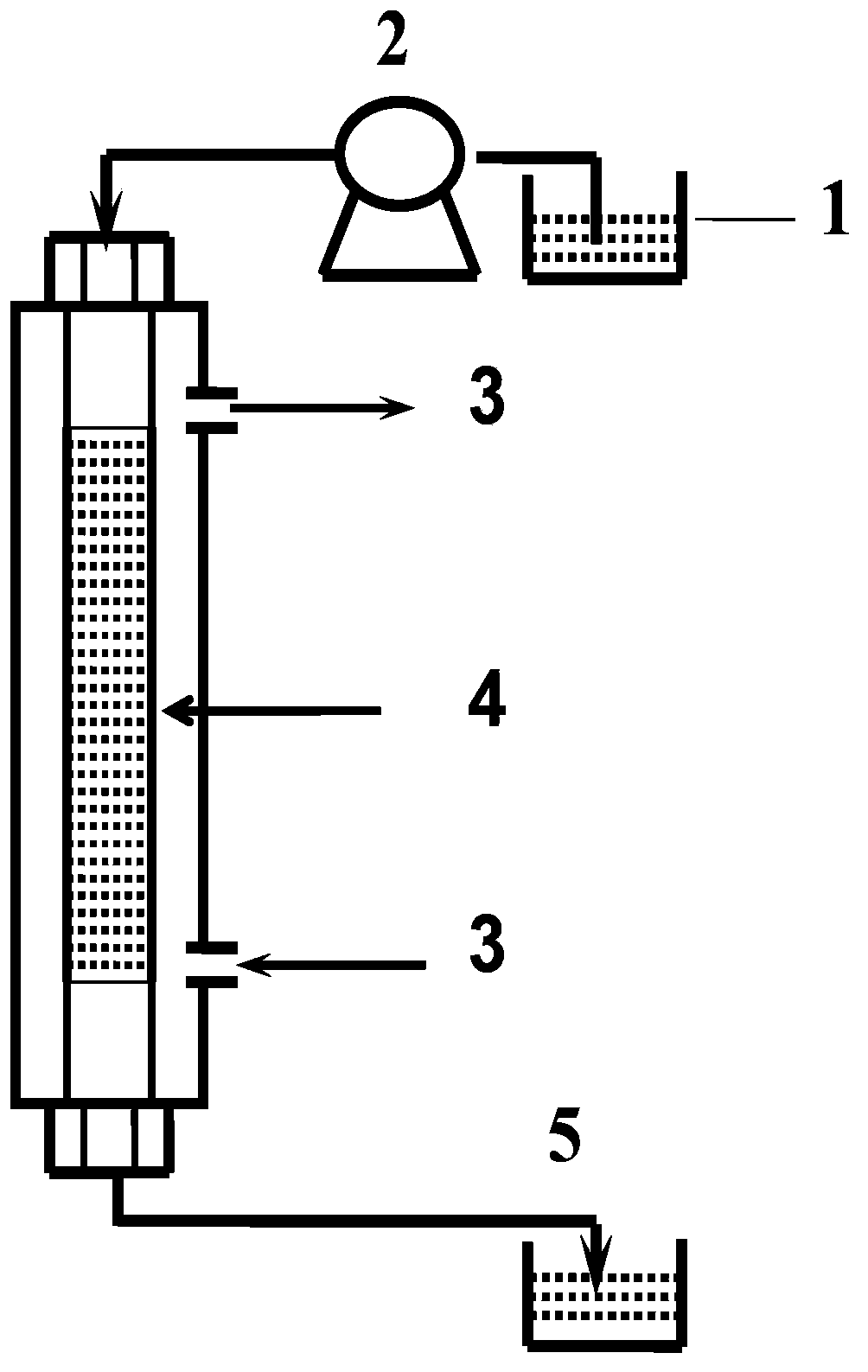

Non-woven base composite membrane for lithium isotope separation, and preparation method thereof, as well as lithium isotope separation method by using membrane chromatography

InactiveCN103386299AAchieve serializationSerialization is easy to implementOther chemical processesSolid sorbent liquid separationChromatographic separationPolymer solution

The invention provides a non-woven base composite membrane for lithium isotope separation and a preparation method thereof, as well as a lithium isotope separation method by using a membrane chromatography. The non-woven base composite membrane takes a non-woven fabric as a porous support body or a micropore membrane, a coating is prepared on the non-woven fabric by taking a crown ether graft polymer or a Kryptofix graft polymer with a lithium isotope separation effect as a film forming matter, or a coating can be prepared on the non-woven fabric by blending crown ether or Kryptofix and derivates of the crown ether or the Kryptofix into a film-formation polymer solution, and the coating and a base membrane are combined to form a composite separated membrane; the composite separated membrane is taken as a membrane chromatography medium stationary phase, so as to separate lithium isotopes by using the membrane chromatography. The non-woven base composite membrane or the lithium isotope separation method by using the membrane chromatography can effectively improve the contact and coupling efficiency of crown ether molecules and Lithium Ions in the separation process for solid-liquid extraction lithium isotopes, and realize the greenization, serialization and high efficient of the process of lithium isotope separation.

Owner:TIANJIN POLYTECHNIC UNIV

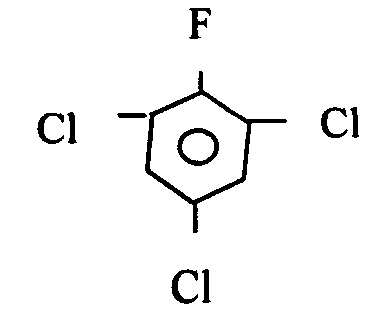

Method for preparing 2,4,6-trichloro-fluorobenzene

InactiveCN101177379ALow costLower requirementOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationState of artSocial benefits

The invention relates to a preparation method for the two, four, six-three-chlorine fluorobenzene, belonging to fluorin chemical engineering technical field. The invention is characterized in that three and five-two chlorine and four fluorin are used as the materials, which are catalyzed and chlorinated with the chlorine under the action of a catalyst in order to make the two, four and six-three-chlorine fluorobenzene; the reaction temperature ranges from one hundred and fifty and two hundred and fifty DEG C; the catalyst is chosen from oxidation benzoyl, azobisisobutyronitrile, and crown ether; the dosage accounts for zero point zero three percent to one percent of the three and five-two-chlorine-four-nitrobenzene. The invention has the advantages that the defects of the preparation method in the prior art such as low yield, high reaction temperature and the rigorous equipment condition are overcome; the preparation method enables the reaction to be completed below two hundred and twenty DEG C; the reaction equipment and the corresponding matched auxiliary equipment has low cost; the material transformation rate and the yield are increased; the purity of the products can reach ninety-nine point eight percent; the materials of the invention can be chosen from the leftovers which can be seen commonly in chemical enterprises and the rectifying remaining, which can save the prior resources with good economic benefit, environmental benefits and social benefits.

Owner:ZHEJIANG FUSHENG HLDG GROUP

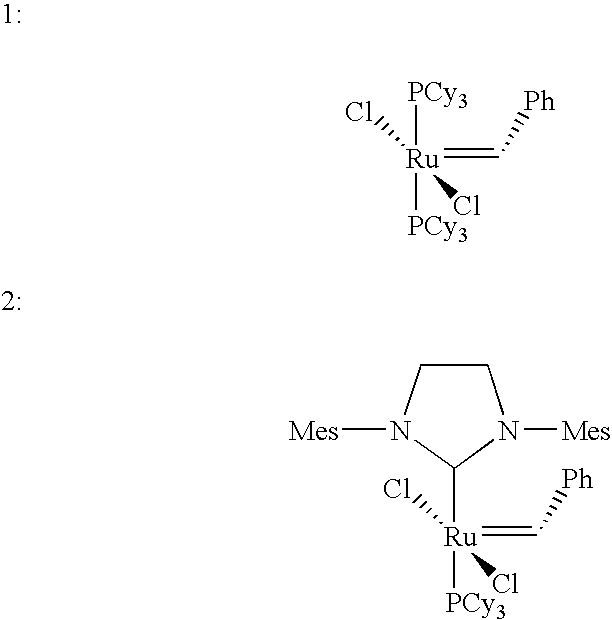

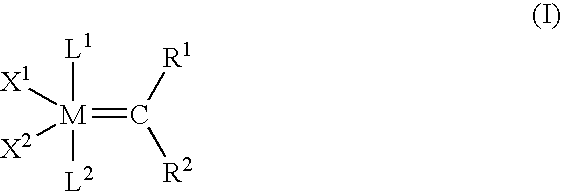

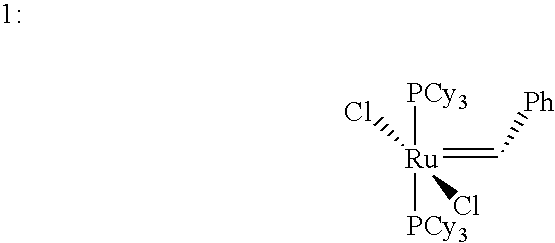

Ring-expansion of cyclic olefins metathesis reactions with an acyclic diene

InactiveUS7034096B2Group 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryOrganic synthesis

This invention relates generally to synthetic procedures that include the step of ring-opening metathesis of cyclic olefins and reaction with an acyclic diene co-reactant to produce olefin macrocycles by ring expansion, or alternatively. The ring expansion of the cyclic olefin is provided by three types of sequential olefin metathesis (ring-opening, cross, and ring-closing olefin metathesis). More particularly, the invention pertains to synthesis of olefin macrocycles via olefin metathesis reactions using a Group 8 transition metal complex as the metathesis catalyst. Macrocycles provided herein have a variety of uses in the pharmaceutical, biomedical, organic synthesis and chemical industries, such as the production of crown ethers that are useful as metal complexing species.

Owner:CALIFORNIA INST OF TECH

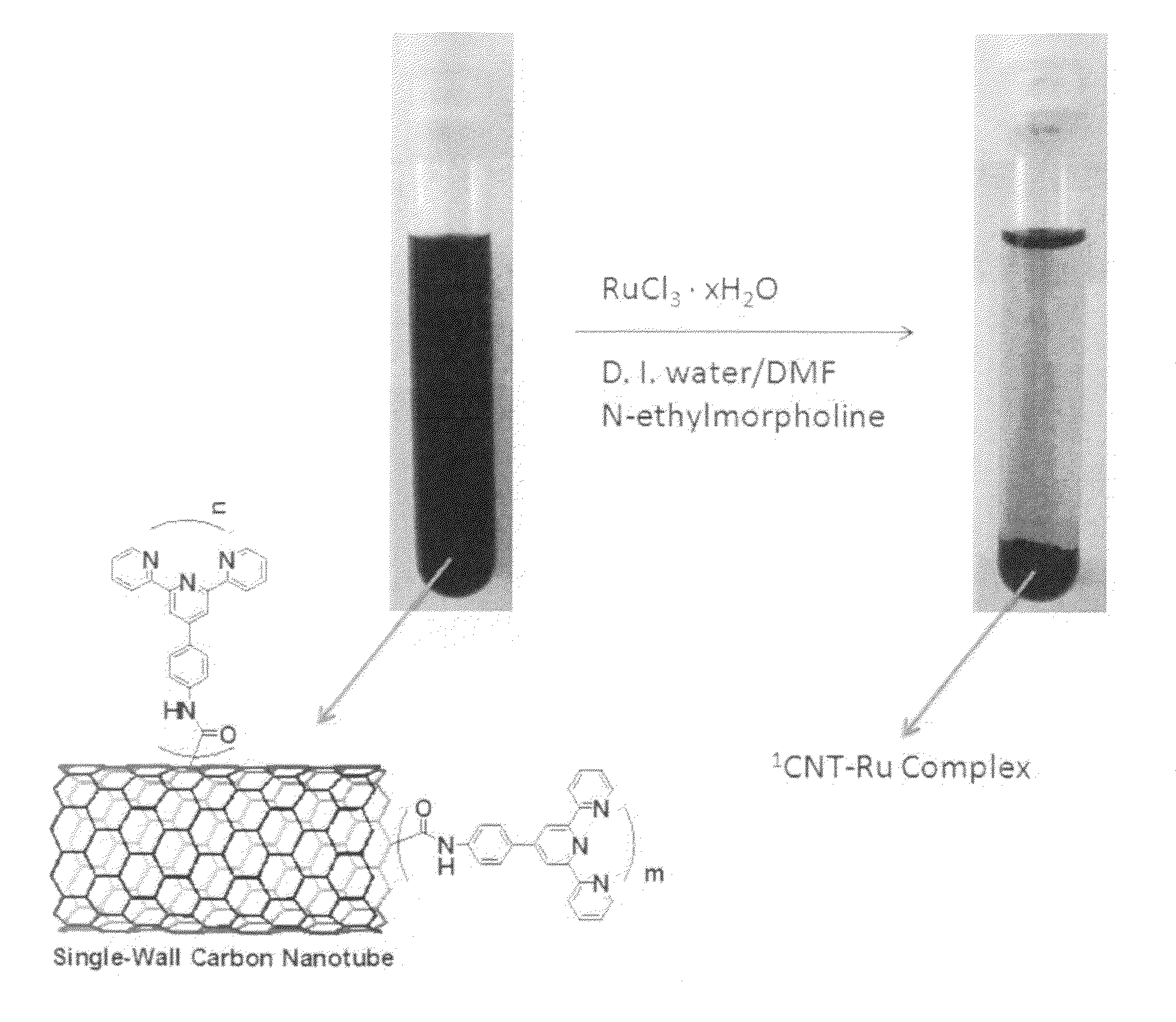

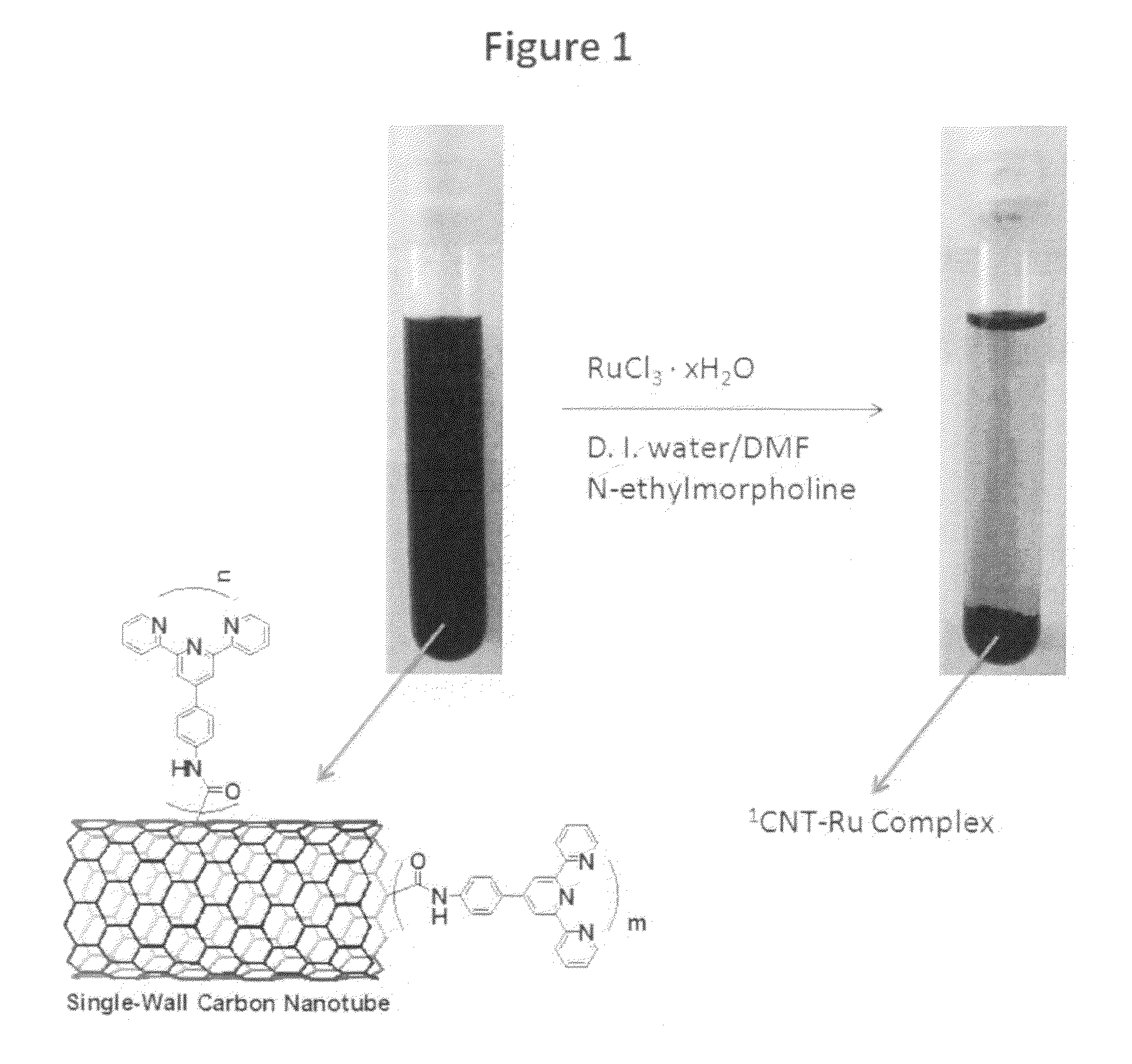

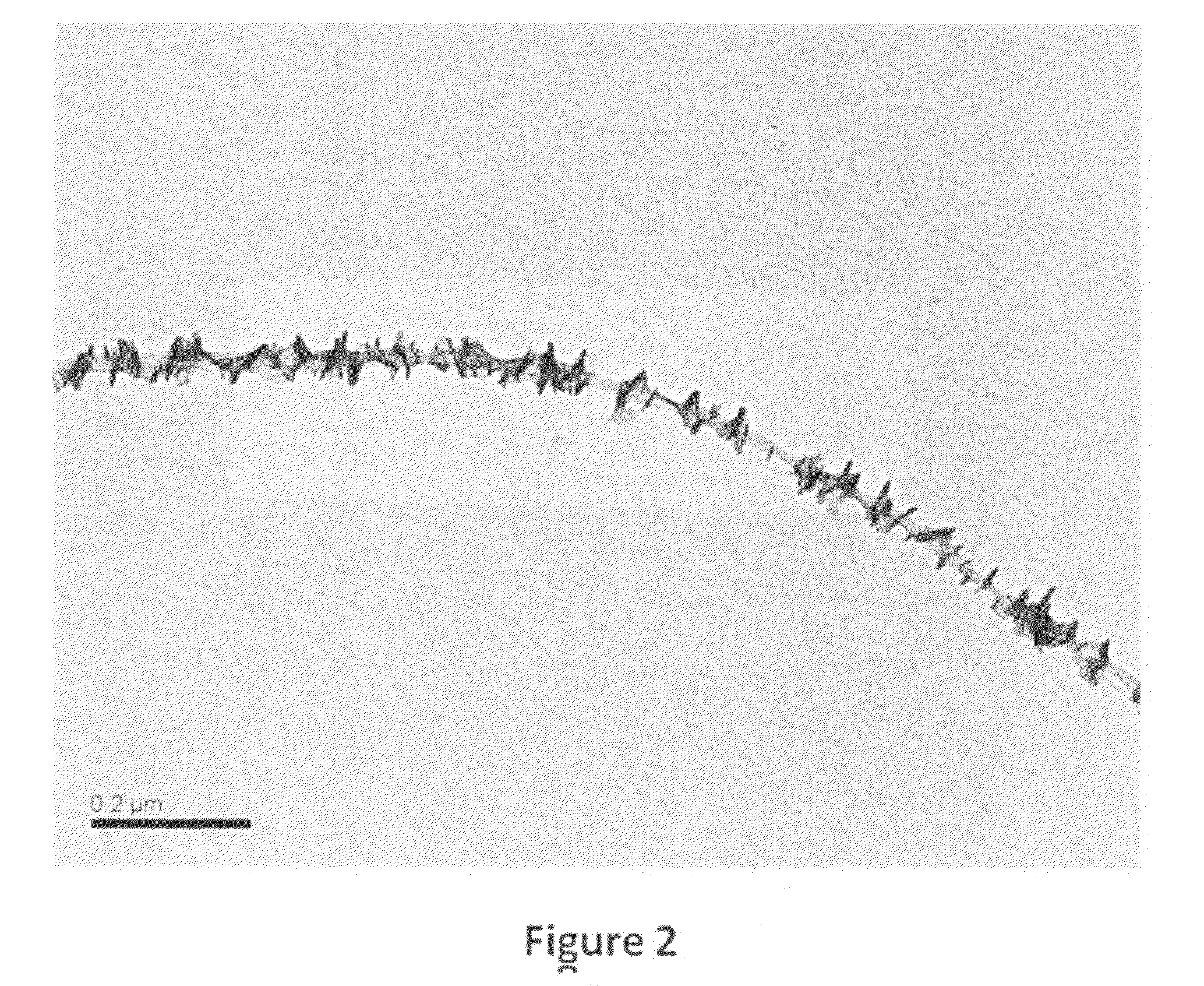

Carbon nanotubes using for recovery of radionuclides and separation of actinides and lanthanides

ActiveUS20090093664A1High mechanical strengthExcellent chemical/physical stabilityFibre chemical featuresPhosphorus organic compoundsNuclear powerPhosphate

Methods and compositions to extract radionuclides such as various actinides and lanthanides from organic and / or aqueous solutions by utilizing extractant functionalized carbon nanotubes are disclosed. More particularly, phosphorous-containing (such as phosphine oxides, phosphoric acids or phosphates) organic extractants and other predesigned extractants (such as crown ethers, calncrown derivatives, malonamide and diglycolamide derivatives, polyethylene glycol derivatives, cobalt dicarbollite derivatives, and N-donating heterocyclic ligands) can be covalently and / or non-covalently employed on the surfaces and / or ends (tips) of carbon nanotubes for the purpose of removal radionuclides such as various actinides and lanthanides from organic and / or aqueous solutions. Extractant functionalized carbon nanotubes can be used for extracting radioactive nuclides from nuclear waste or spent nuclear fuel, which are produced and / or reprocessed from the nuclear power generation or other nuclear application. The invention also relates to the solid-liquid separation process based on the contact of liquid radioactive waste by using the invention extracting agents as the solid phase.

Owner:CHEMNANO MATERIALS

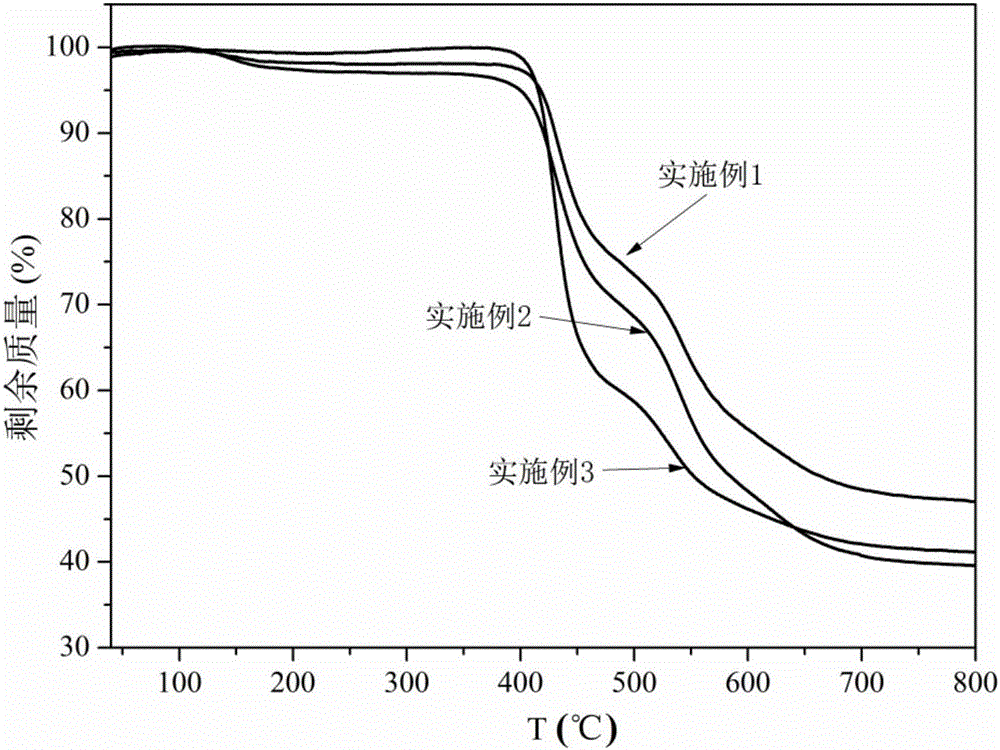

Crown ether micropore containing polyimide intrinsic microporosity polymer membrane and preparation method thereof

ActiveCN106674560AImprove screening selectivityIncreased free volumeUltrafiltrationPolymer scienceOrganic solvent

The invention relates to a crown ether micropore containing polyimide intrinsic microporosity polymer membrane and a preparation method thereof. The preparation method comprises the following steps of: firstly, preparing a diamine solution from aromatic diamine; adding aromatic dianhydride into the diamine solution, and stirring for 9-13 hours at the room temperature; further adding a dehydration agent and a catalyst, stirring for 3-6 hours at 40-65 DEG C, removing the solvent, and drying, so as to obtain a crown ether micropore containing polyimide intrinsic microporosity polymer; and dissolving the polymer by using an organic solvent so as to obtain a membrane casting liquid, and performing membrane casting and drying, thereby obtaining the crown ether micropore containing polyimide intrinsic microporosity polymer membrane. As crown ether micropores are introduced into the polymer membrane provided by the invention, dense accumulation of polymer chain segments can be effectively prevented by virtue of steric hindrance of a cyclic structure of crown ether, an intrinsic microporosity polymer membrane material has a relatively large free volume, and in addition ether bonds of the crown ether have very good affinity with CO2, so that the prepared crown ether micropore containing polyimide intrinsic microporosity polymer membrane is relatively high in gas permeability coefficient and good in selectivity.

Owner:XI AN JIAOTONG UNIV

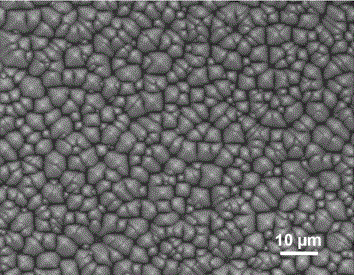

Monocrystalline silicon wafer texture surface making additive and application

ActiveCN106119977ATexture fastFast response to texturingPolycrystalline material growthAfter-treatment detailsEtherPyramid

The invention provides a monocrystalline silicon wafer texture surface making additive. The monocrystalline silicon wafer texture surface making additive comprises the following components in percentages by mass: 0.1%-3% of a component A, 0.01%-10% of a component B and the balance of water. The component A is selected from one or more of crown ether, crown ether derivatives and alkali metal complex of the crown ether; and the component B is alcohol ether. The invention further provides texture surface making liquid for monocrystalline silicon wafer texture surface making. The texture surface making liquid contains an alkali solution and the monocrystalline silicon wafer texture surface making additive. The invention further provides a monocrystalline silicon wafer texture surface making method. Texture surface making on a monocrystalline silicon wafer is carried out by the texture surface making liquid. The additive is added in the monocrystalline silicon wafer texture surface making liquid, so that texture surface making reaction becomes fast, quick texture surface making on the monocrystalline silicon wafer cut by a diamond wire can be carried out, the capacity is improved, uniform and compact texture surface pyramids can be obtained, the reflectivity is reduced, and the efficiency of a battery is improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

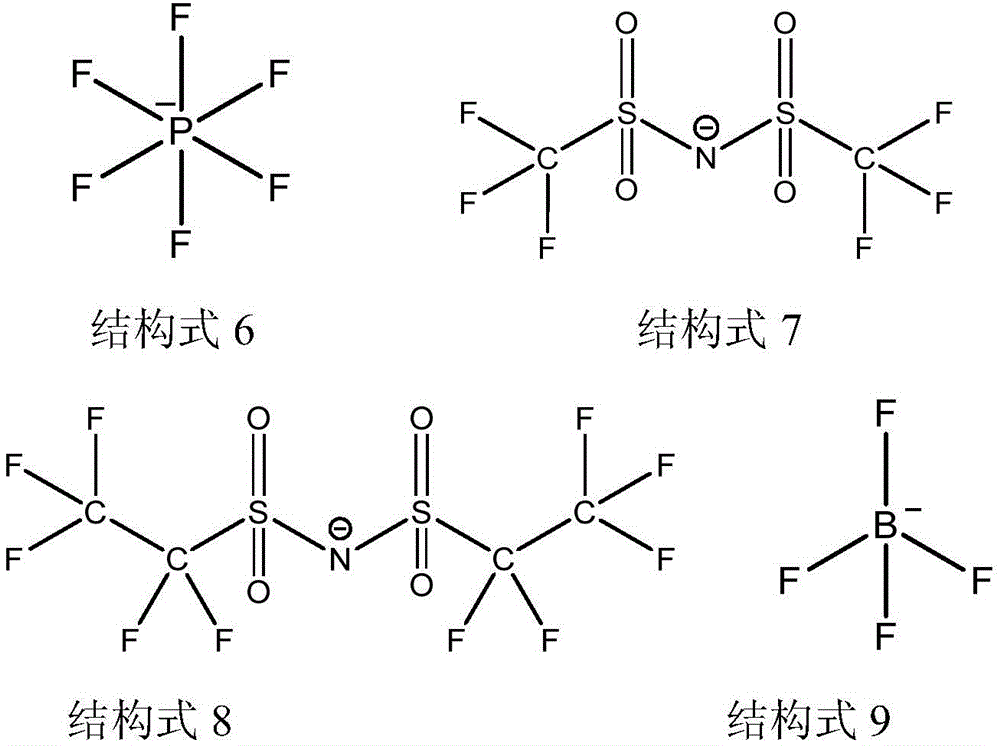

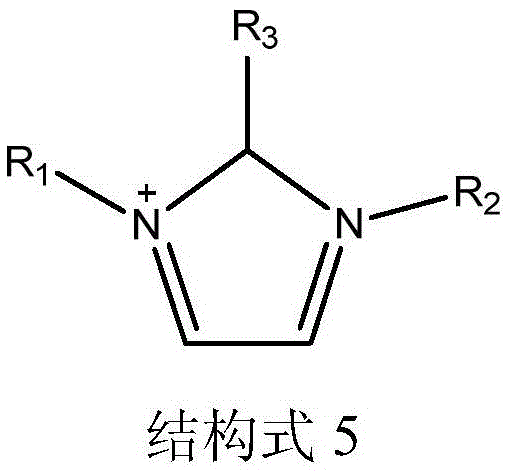

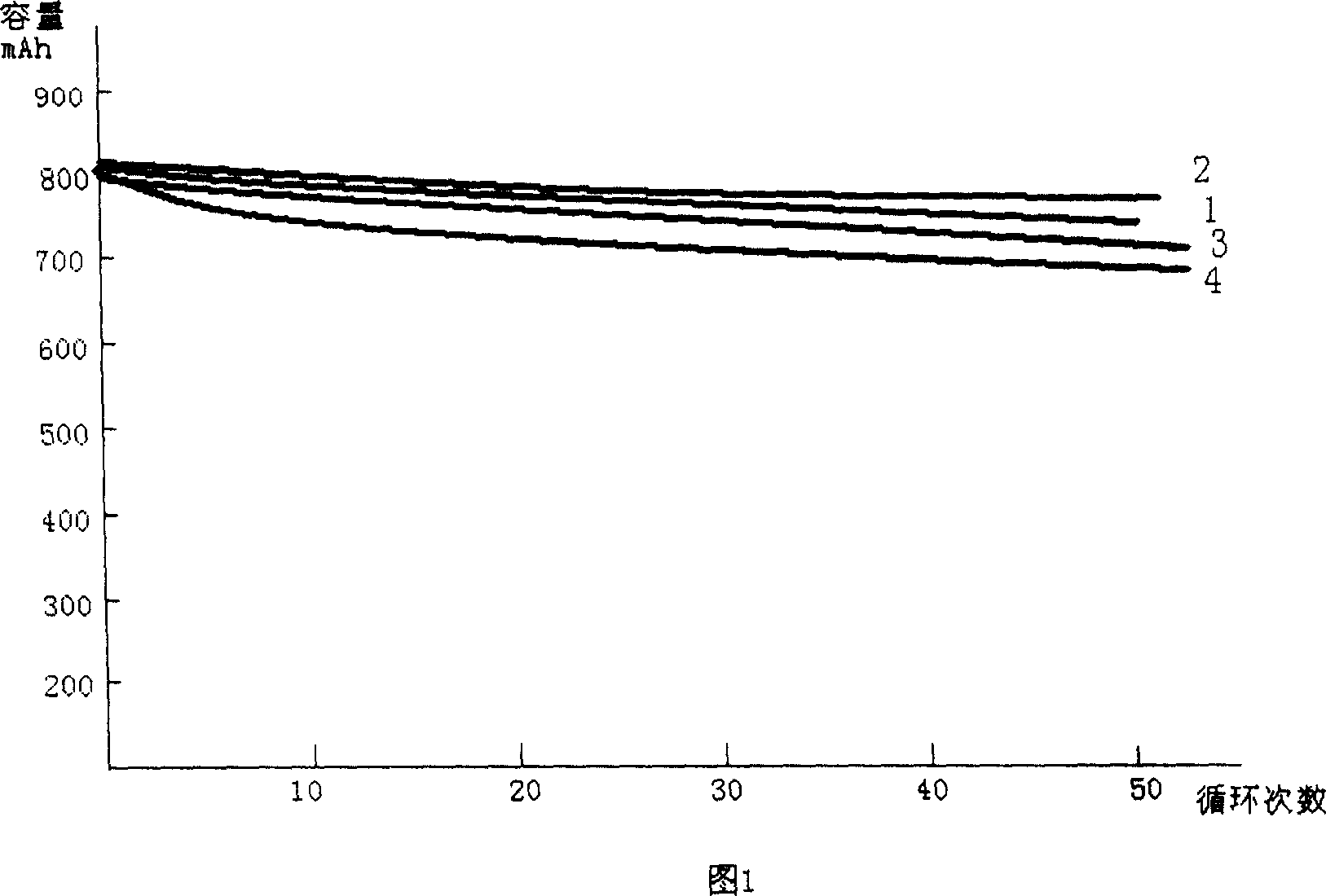

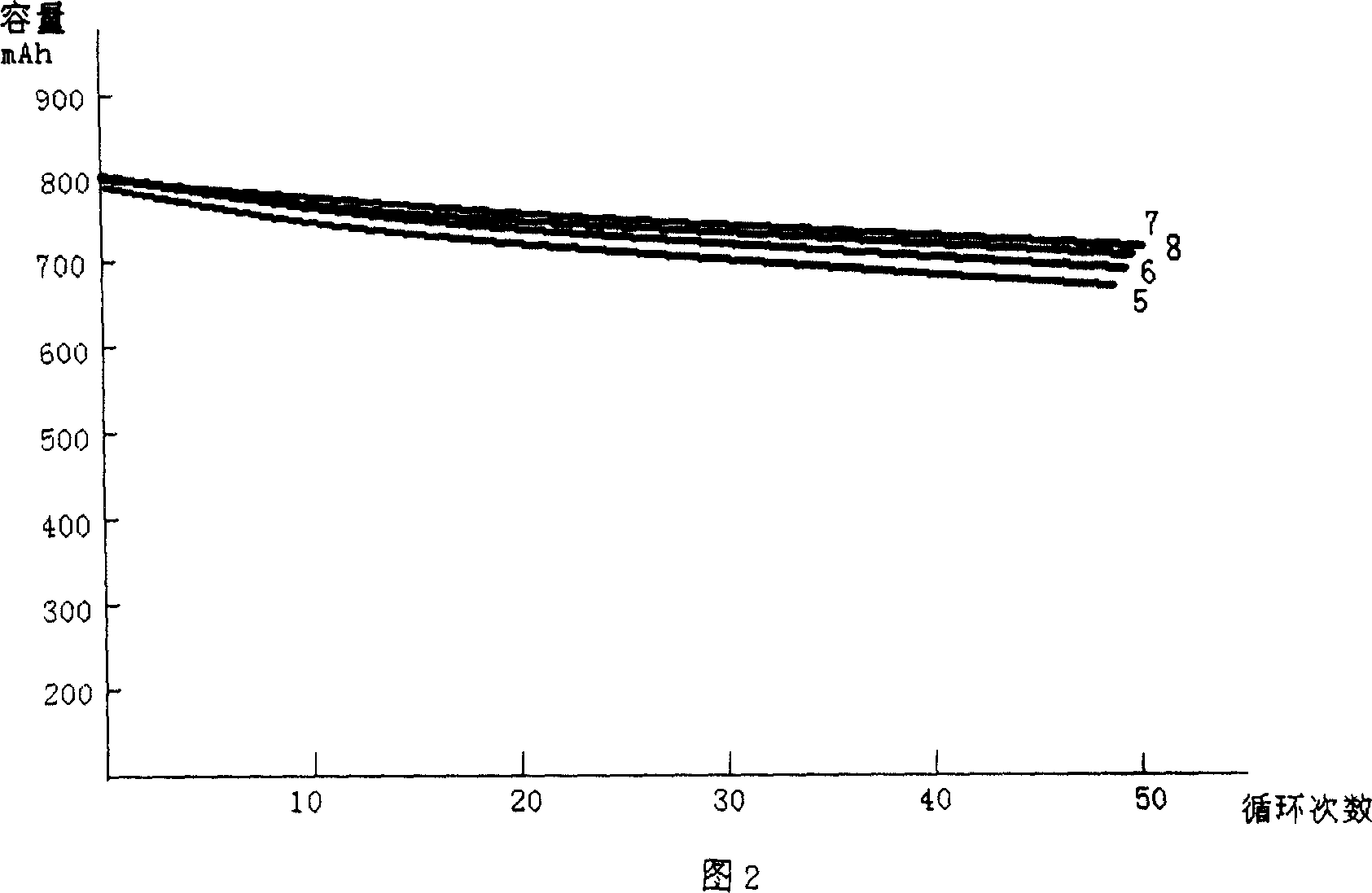

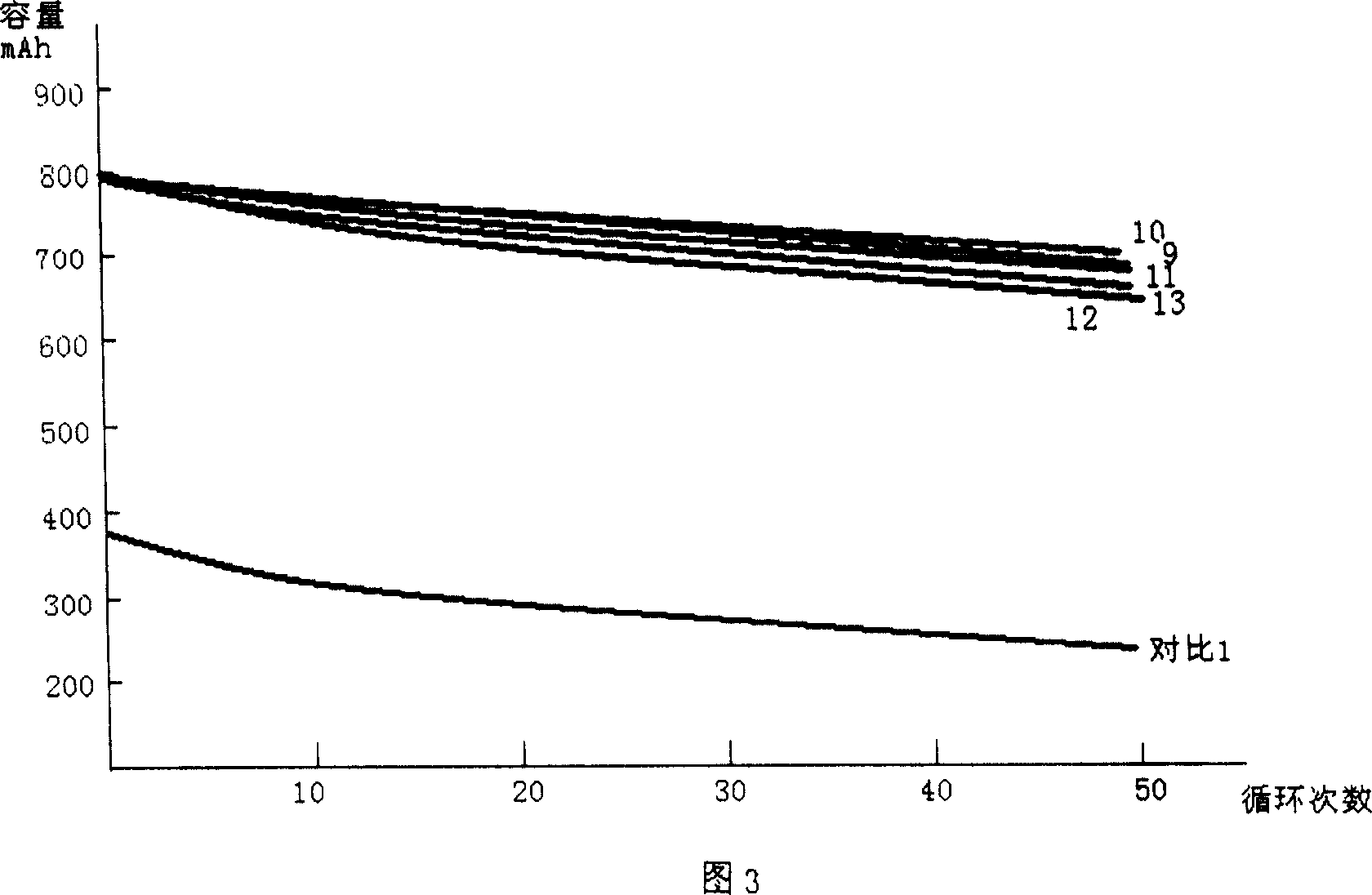

High rate electrolyte for lithium ion battery

ActiveCN1925207AIncrease dissociationImprove mobilityOrganic electrolyte cellsSecondary cellsHigh ratePhysical chemistry

This invention relates to lithium ion battery electrolyte with high times and discloses the main components as following: vinylene carbonate for 10 to 30 percentage; propylene carbonate for 4 to 20 percentage; dimethyl carbonate for 35 to 50 percentage; methyl carbonate for 10 t0 20 percentage; lithium salt for 12.5 to 16 percentage and B(OR)<3> with R representing carbon atoms less than 4 or crown ether of one or more function addictives for 0.1 to 5.0 percentage.

Owner:GUANGZHOU TINCI MATERIALS TECH

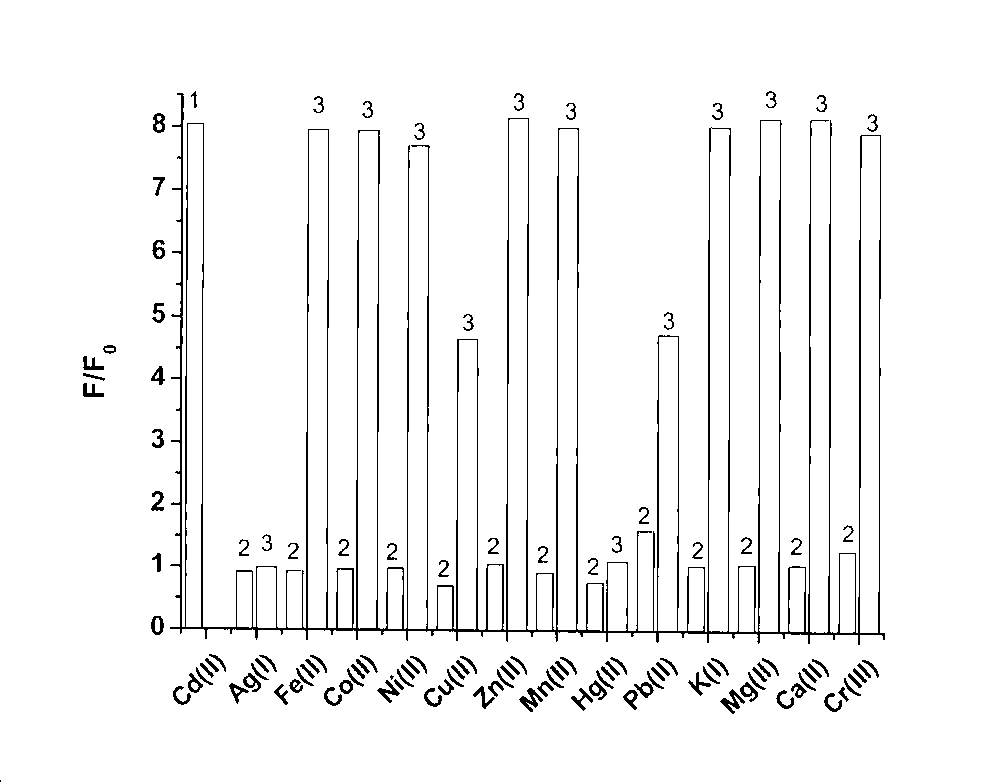

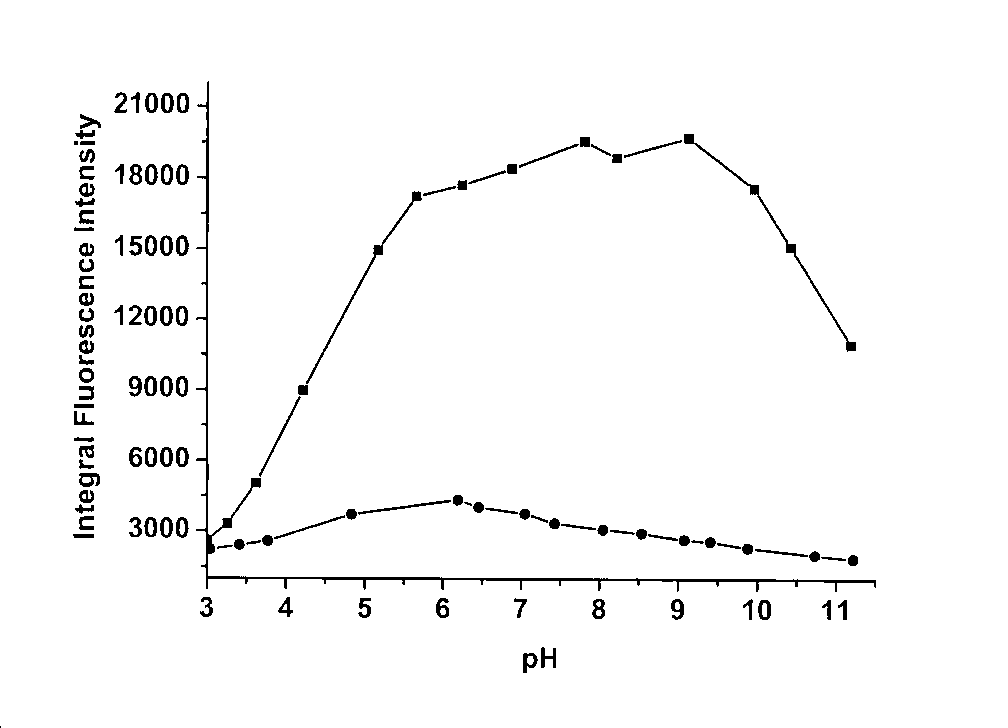

Cadmium ion fluorescence probe, preparation method and application

InactiveCN102876323ASensitive detectionHigh detection sensitivityOrganic chemistryFluorescence/phosphorescenceFluorescenceQuinoline

The invention relates to a cadmium ion fluorescence probe and a preparation method thereof. The cadmium ion fluorescence probe consists of a derivative of quinoline with a position 2 which is modified by aza-crown ether. An aza-crown ether group is bonded onto a quinoline chromophoric group with an auxiliary coordination function to synthesize the cadmium ion fluorescence probe with a specific response function. As homologous transition metal ions, the interaction of cadmium and zinc with S, O and N donors is very close. Comparatively, the connection of the cadmium with the S and N donors is closer than the connection of the zinc with the S and N donors. The novel fluorescence probe is designed by using the characteristics. The influence of zinc ions on the unique response of the cadmium ion fluorescence probe is overcome. The fluorescence probe can be used for the selective rapid fluorescence detection of the cadmium ions in water bodies, the selectivity is very good, the resistance to interference of other metal ions is strong and the cadmium ion fluorescence probe consists of ideal sensing molecules for the field detection of the cadmium ions.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Benzo crown ether graft polymer material with lithium isotope separation effect and preparation method thereof

InactiveCN102911372AHigh crown ether immobilization capacityExcellent separation factorMethyl groupPolymer chemistry

Owner:TIANJIN POLYTECHNIC UNIV

Lamellar hydroxide composite material and preparation method thereof

InactiveCN103230776ALarge specific surface areaHigh porosityOther chemical processesPorosityRare earth

The invention provides a lamellar rare earth hydroxide composite material. The lamellar rare earth hydroxide composite material is prepared by carrying out a reaction on lamellar rare earth hydroxide and crown ether carboxylic acid derivatives. In comparison with the prior art, the lamellar hydroxide composite material is compounded from the lamellar rare earth hydroxide and a crown ether compound. Firstly, the lamellar rare earth hydroxide composite material has the advantages of high specific surface area, porosity and high stability of the lamellar rare earth hydroxide, so that heavy metal ion in water can be absorbed; and secondly, the lamellar rare earth hydroxide composite material has the characteristics of softness and high selectivity to object ions of the organic macrocyclic crown ether compound. Thus, the lamellar rare earth hydroxide composite material can overcome the defects and develop the advantages, and has high adsorption capacity and selectivity to heavy metal ions.

Owner:BEIJING NORMAL UNIVERSITY +1

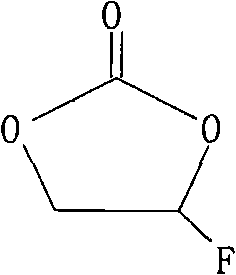

Method for synthesizing fluoroethylene carbonate by phase-transfer catalysis

InactiveCN101870687AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHalogenPotassium fluoride

The invention relates to a method for synthesizing fluoroethylene carbonate by phase-transfer catalysis. The fluoroethylene carbonate is produced by performing halogen exchange reaction on chloroethylene carbonate and potassium fluoride under the catalysis of crown ether serving as a phase-transfer catalyst in aprotic solvent.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

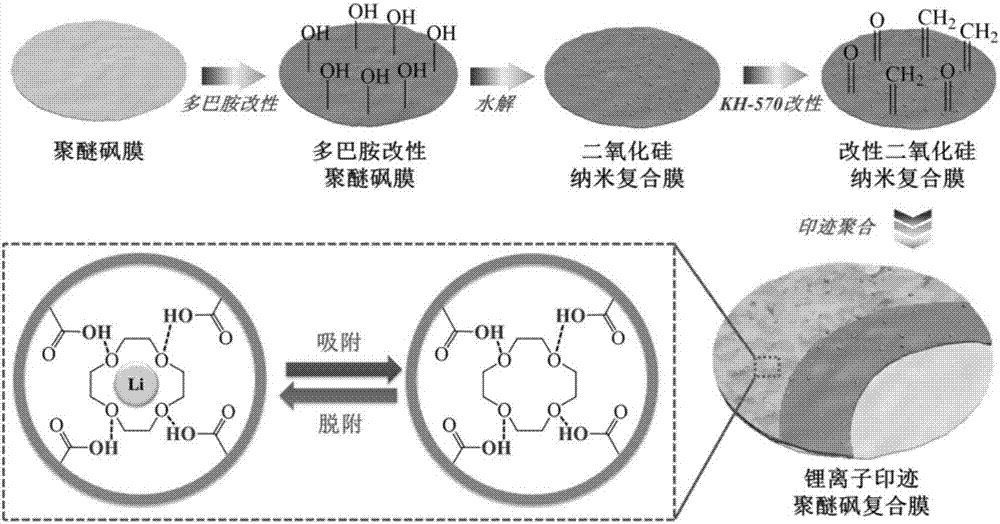

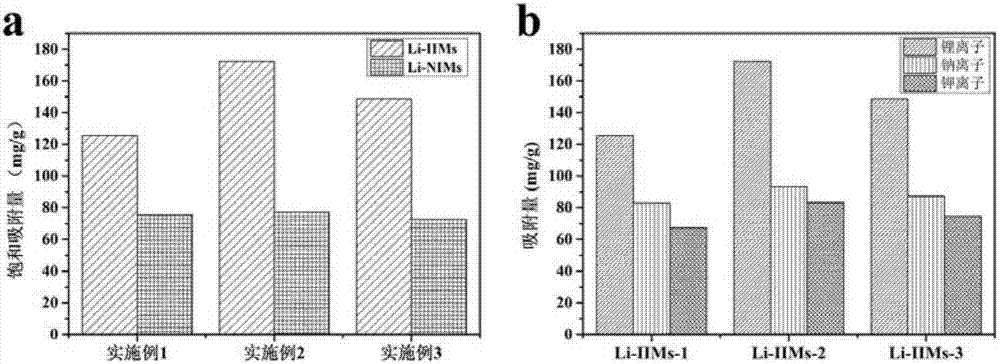

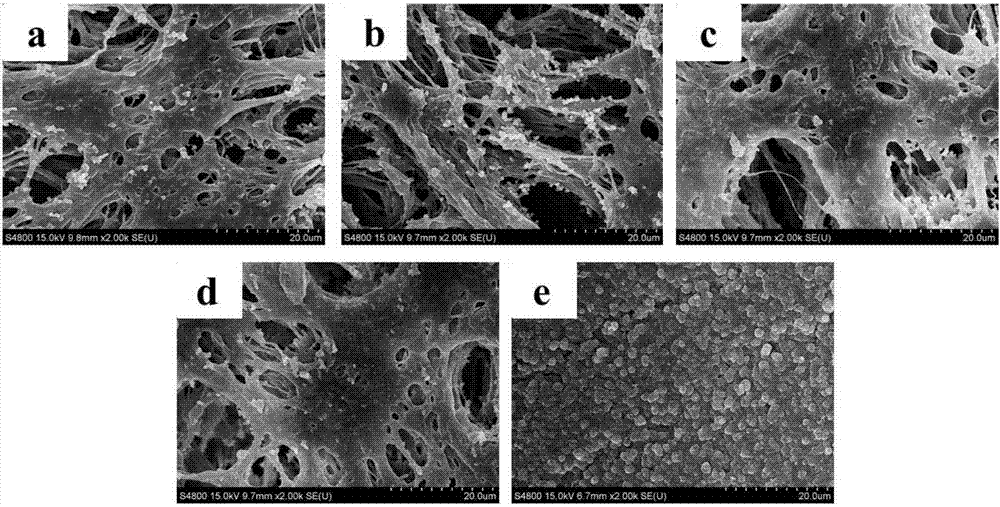

Preparation method and application of lithium-ion-imprinted polyethersulfone composite membrane

ActiveCN106902654AAchieving identifiabilityAchieve adsorptionSemi-permeable membranesOther chemical processesCross-linkFunctional monomer

The invention provides a preparation method and application of a lithium-ion-imprinted polyethersulfone composite membrane, belonging to the technical field of preparation of functional materials. The lithium-ion-imprinted polyethersulfone composite membrane is prepared with a polyethersulfone membrane as a substrate membrane material, lithium ions as a template, 12-crown-4-ether as a binding site, methacrylic acid as a functional monomer, ethylene glycol dimethacrylate as a cross-linking agent and azodiisobutyronitrile as an initiator by using a combination of dopamine surface modification technology, silica nanometer compounding technology and imprinted polymerization technology. Static adsorption experiments are conducted to research the adsorption equilibrium, kinetic performance and selective recognition performance of the prepared lithium-ion-imprinted polyethersulfone composite membrane; and selective permeation experiments are carried out to research the permeation action of the prepared lithium-ion-imprinted polyethersulfone composite membrane on target ions (lithium ions) and non-target ions (sodium ions and potassium ions). The lithium-ion-imprinted polyethersulfone composite membrane prepared in the invention has high specific lithium ion adsorption capability and lithium ion recognition and separation capability.

Owner:JILIN NORMAL UNIV

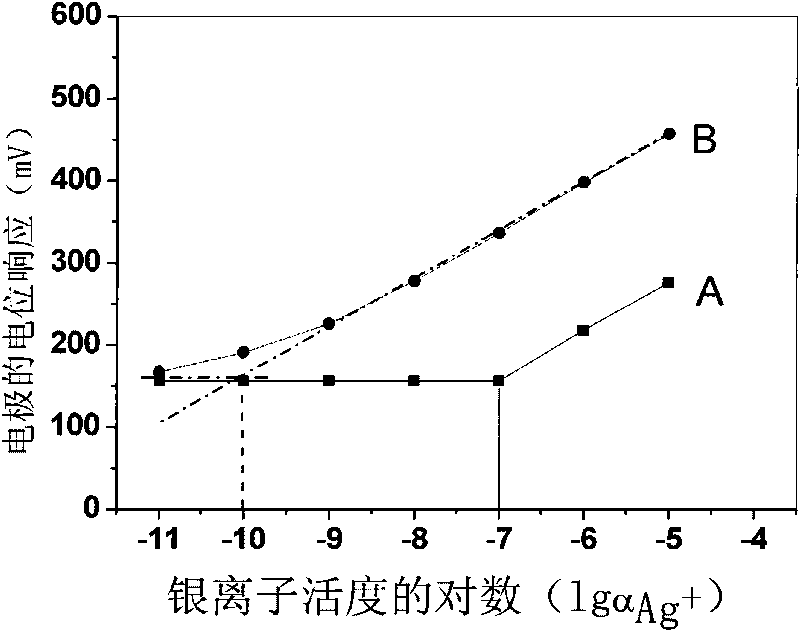

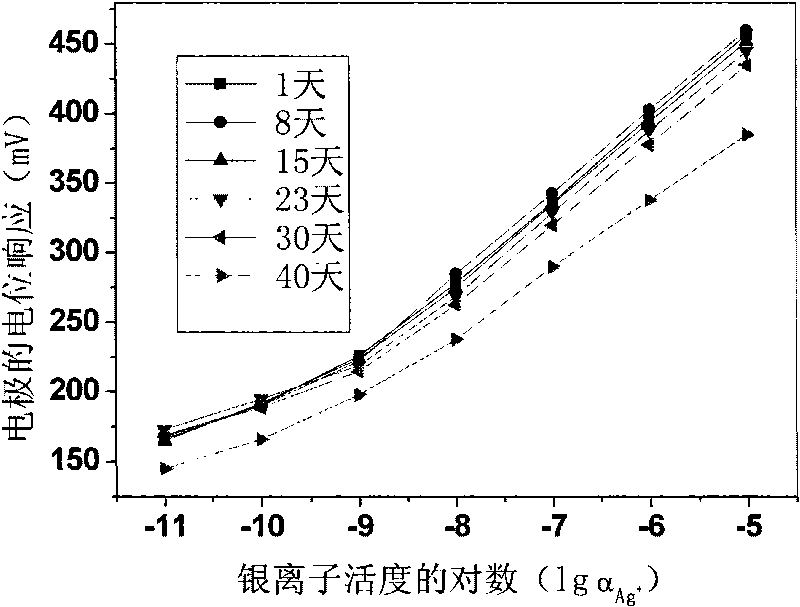

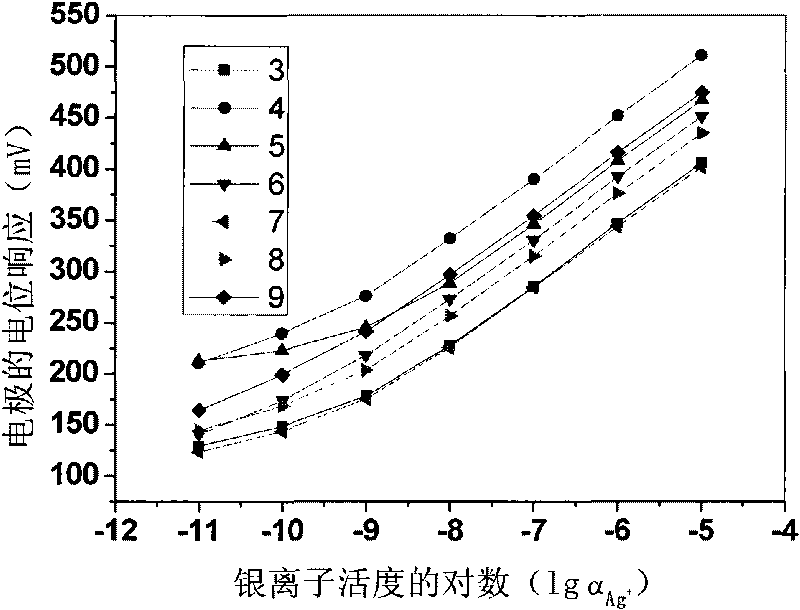

Method for producing polymer membrane silver ion selective electrode

InactiveCN101750444ASolution to short lifeLow detection limitMaterial analysis by electric/magnetic meansPolyvinyl chlorideIon exchange

The invention discloses a method for producing a polymer membrane silver ion selective electrode. Crown ether compound which comprises amide groups and sulfur heteroatoms is used as silver ion carrier and is mixed with polyvinyl chloride, plasticizer and ion exchanging agent according to a certain proportion. Inorganic salt which comprises anions which can form slightly soluble matters with silver ions is used to adjust the concentration of interfering ions and main ions in internally filled liquid. The polymer membrane silver ion selective electrode membrane forming and activating conditions are optimized, the seepage of main irons of an inner membrane phase to sample solution is effectively reduced, and the polymer membrane silver ion selective electrode detection limit is made to comply with theoretical prediction value (less than 10-10mol / L). The polymer membrane silver ion selective electrode has good silver ion nernst response and silver ion selectivity. The method for producing the polymer membrane silver ion selective electrode overcomes the defect that the complexing agent used for the internally filled liquid of a polymer membrane electrode of low detection limit is easy to seep into a polymer membrane and the iron exchange resin is hard to miniaturize. The performance of the polymer membrane silver ion selective electrode can not be reduced in one month.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Low-shrinkage high-strength polyester industrial yarn and preparation method thereof

ActiveCN108385189AIncrease the cross-sectional areaReduce the temperatureSpinnerette packsFibre typesYarnThermal insulation

The invention relates to a low-shrinkage high-strength polyester industrial yarn and a preparation method thereof. The preparation method comprises: carrying out solid phase condensation polymerization tackifying on a modified polyester, melting, metering, extruding, cooling, oiling, drawing, carrying out heat setting, and winding, wherein the unchanged longitudinal height is maintained during thecooling, the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method, and the oil agent for oiling contains 67.30-85.58 wt% of crown ether. According to the present invention, the preparation method is simple; the material of the prepared low-shrinkage high-strength polyester industrial yarn is the modified polyester with the molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the fracture strength is more than or equal to 7.3 cN / dtex, and the dry heat shrinkage rates at the conditions comprising 177 DEG C, 10 min and 0.05 cN / dtex and the conditions comprising 190 DEG C, 15 min and 0.01 cN / dtex respectively are 1.8+ / -0.5% and 3.5+ / -0.5%.

Owner:JIANGSU HENGLI CHEM FIBER

Decalcification agent for crude oil

ActiveCN1657594AReduce calcium concentrationReduce consumptionHydrocarbon oils refiningQuaternary ammonium cationPhosphonium salt

A decalcification agent for crude oil contains at least one chelating agent chosen from monocarboxylic acid, binary carboxylic acid, organic phosphonic acid, amino acid or its derivative, polyphosphoric acid and hydroxy quinoline, optional surfactant and demulsifier, and at least one of monoalcohol or biol polymer quaternary ammonium salt, quaternary phosphonium salt and crown ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

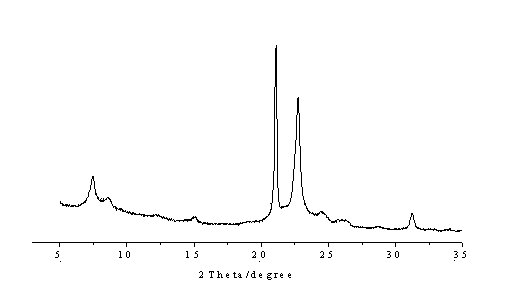

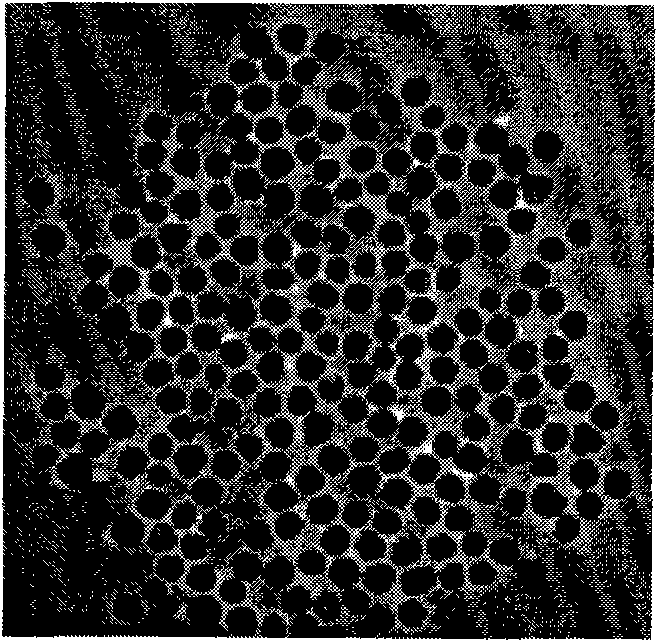

ZSM-48 molecular sieve with low silica-alumina ratio and preparation method thereof

ActiveCN103803576AIncrease acidityReduce the ratio of silicon to aluminumCrystalline aluminosilicate zeolitesMolecular sieveMass ratio

The invention discloses a ZSM-48 molecular sieve with a low silica-alumina ratio and a preparation method thereof. The molecular sieve has the following properties: the molar ratio of silica to alumina is 25-50; the specific surface is 250-400 m2 / g; the pore volume is 0.25-0.35 cm3 / g; the average pore size is 3-5 nm. The preparation method comprises the following steps: (1) well mixing a seed crystal S, a template R, a silicon source, an aluminium source, sodium hydroxide and water to prepare a reaction mixture, wherein the composition of the reaction mixture is as follows: on a basis of oxide, the molar ratio of R to SiO2 is 0.05-0.2, the molar ratio of SiO2 to Al2O3 is 30-50, the molar ratio of Na2O to SiO2 is 0.06-0.1, the molar ratio of H2O to SiO2 is 15-23, the mass ratio of S to SiO2 is 0.05-0.5, S is the ZSM-48 molecular sieve, and R is 12-crown ether-4; (2) performing hydrothermal crystallization of the reaction mixture prepared in step (1) at 150-170 DEG C for 4-8 days, performing filtration, washing, drying, and roasting of the crystallization product to obtain the ZSM-48 molecular sieve with a low silica-alumina ratio. The ZSM-48 molecular sieve prepared by the method of the invention has a low silica-alumina ratio, and has good application prospects in technical fields of isodewaxing and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

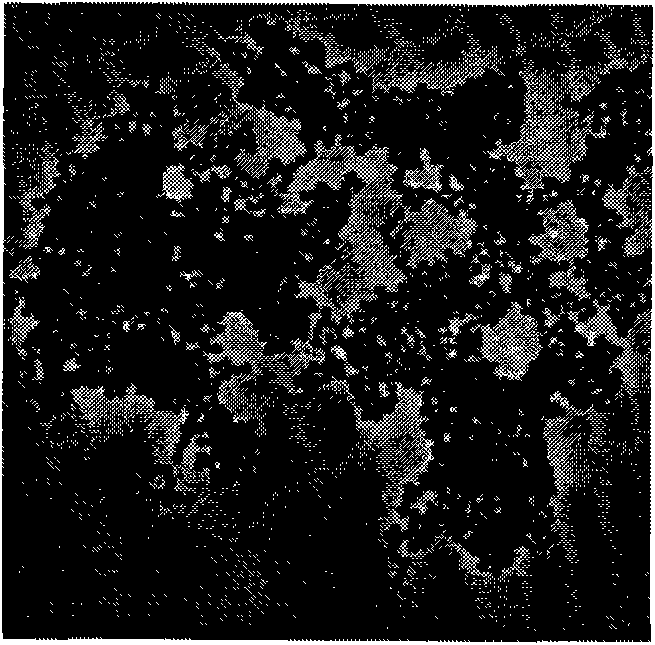

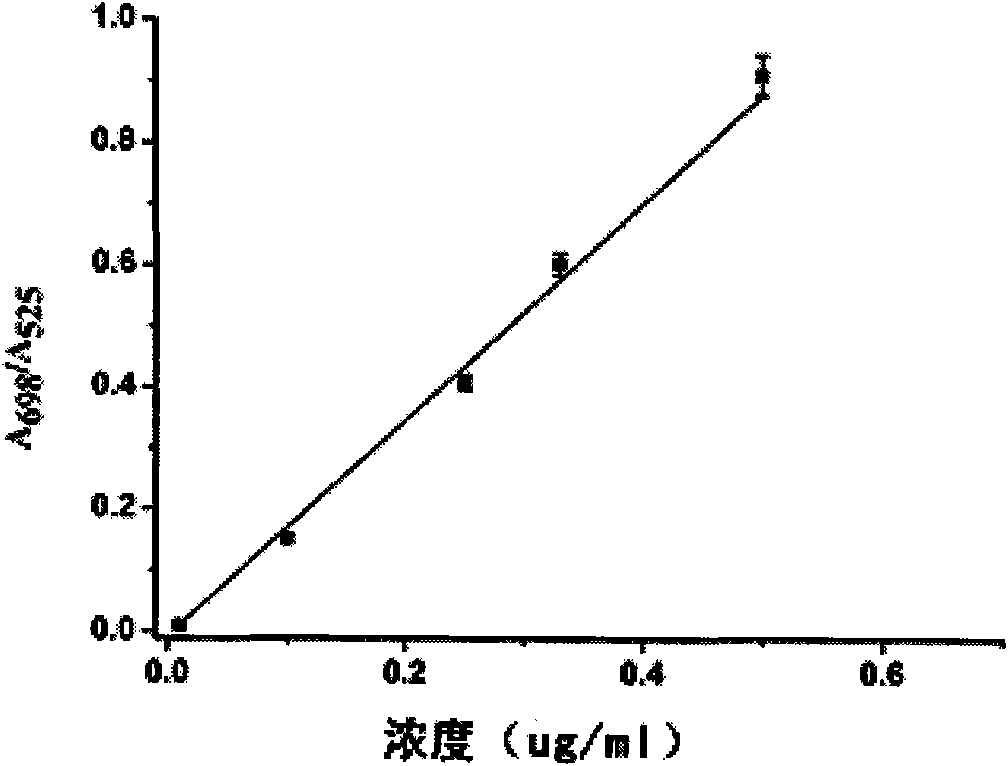

Method for quickly testing melamine content in milk powder by using gold nanoparticle colorimetric method

InactiveCN101846631AEasy to detectQuick checkMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationHigh fluxColor changes

The invention discloses a method for quickly testing melamine content in milk powder by using a gold nanoparticle colorimetric method, which belongs to the technical field of analytical chemistry. The invention comprises the steps of preparing gold nanoparticles (AuNPs), derivatizing crown ether, conjugating gold nanoparticle and crown ether, self assembling by applying the gold nanoparticles, detecting melamine by molecular recognition, detecting the practical sampling and the like. The invention prepares a gold nanoparticle self-assembly material, can simply, quickly and flexibly detect the melamine content in the milk powder according to the color change of a gold nanoparticle system, simultaneously improves the detection sensitivity greatly, achieves the purpose of high flux, and provides convenience for the subsequent research, production, supervision and the like.

Owner:JIANGNAN UNIV

New method for the preparation of reactive compositions containing superoxide ion

InactiveUS20090008262A1Photography auxillary processesElectrolysis componentsSolubilityAlkaline earth metal

The subject invention provides a potentially economically viable method for the preparation of reactive superoxide ion in deep eutectic solvents (DES). The superoxide ion can be used for many applications, e.g. the degradation of hazardous chemicals at ambient conditions or in the synthesis of some special chemicals, e.g. carboxylic acids, aldehydes, and ketones from the corresponding alcohols. The superoxide ion can be formed by either the electrochemical reduction of oxygen in DES or by dissolving Group 1 (alkali metals) or Group 2 (alkaline earth metals) superoxides, e.g. potassium superoxide, in DES, with / without chemicals used for the enhancement of the solubility of the metal superoxide in the DES, e.g. crown ethers.

Owner:KING SAUD UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com