Patents

Literature

198results about How to "Increase dissociation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

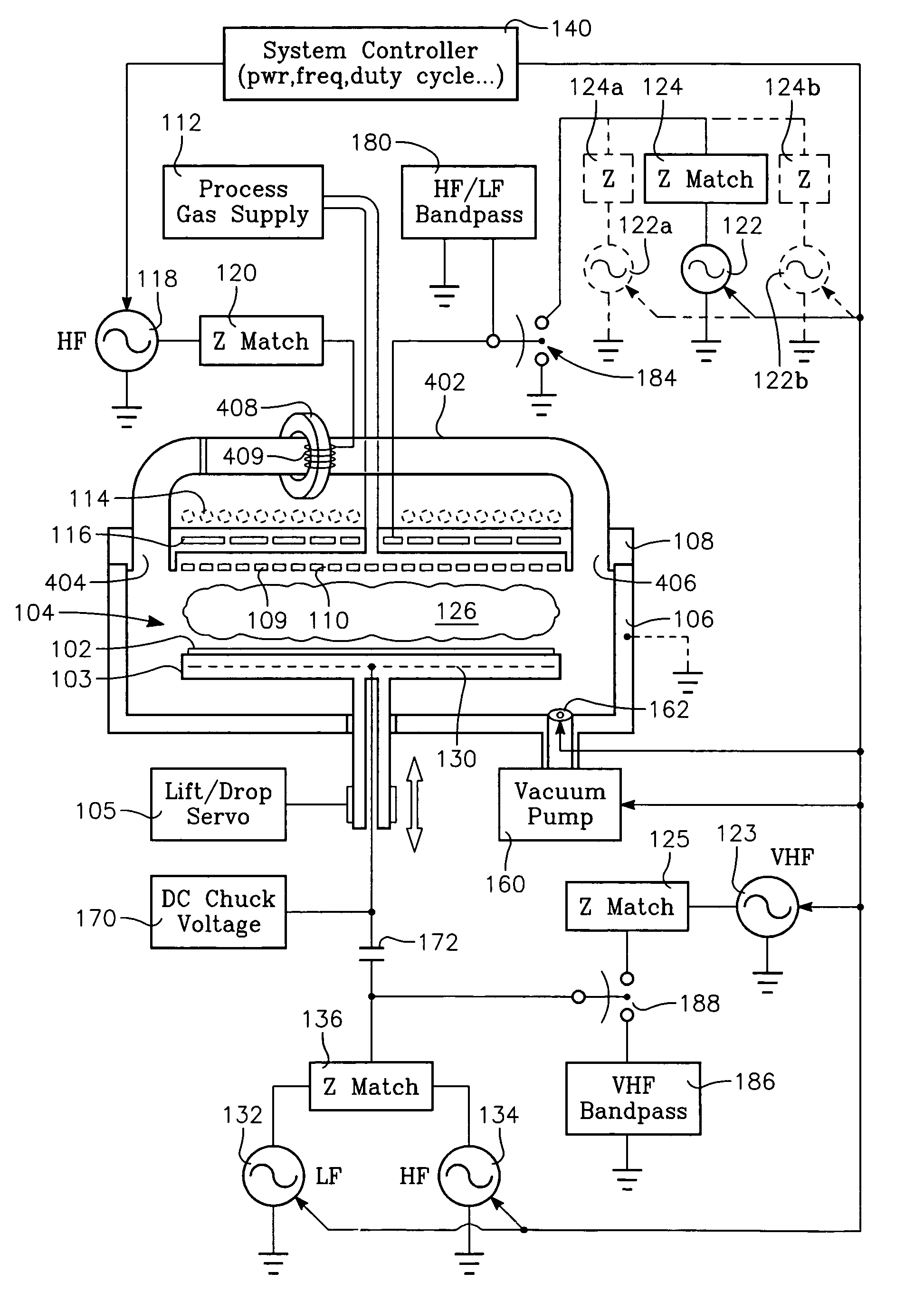

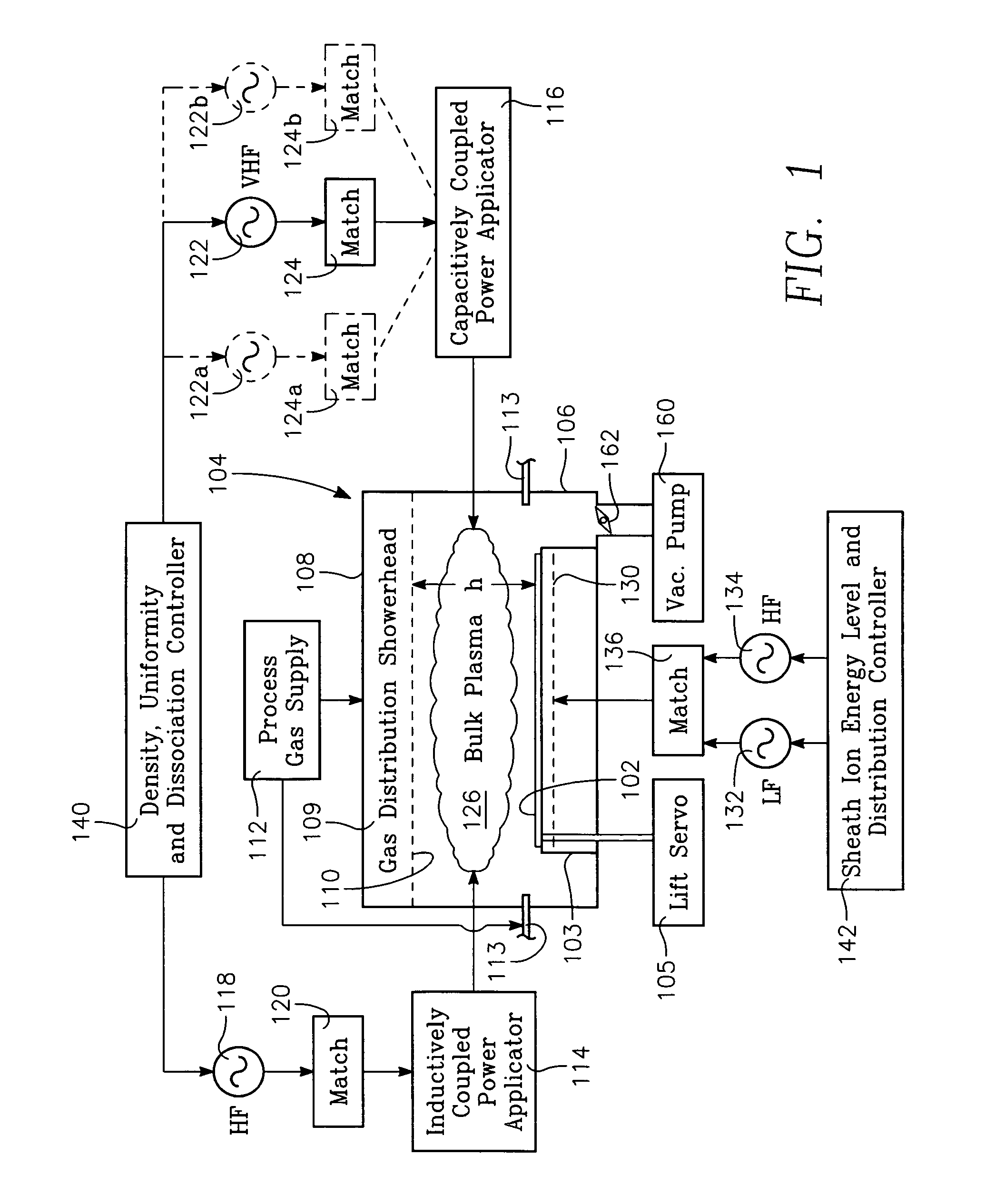

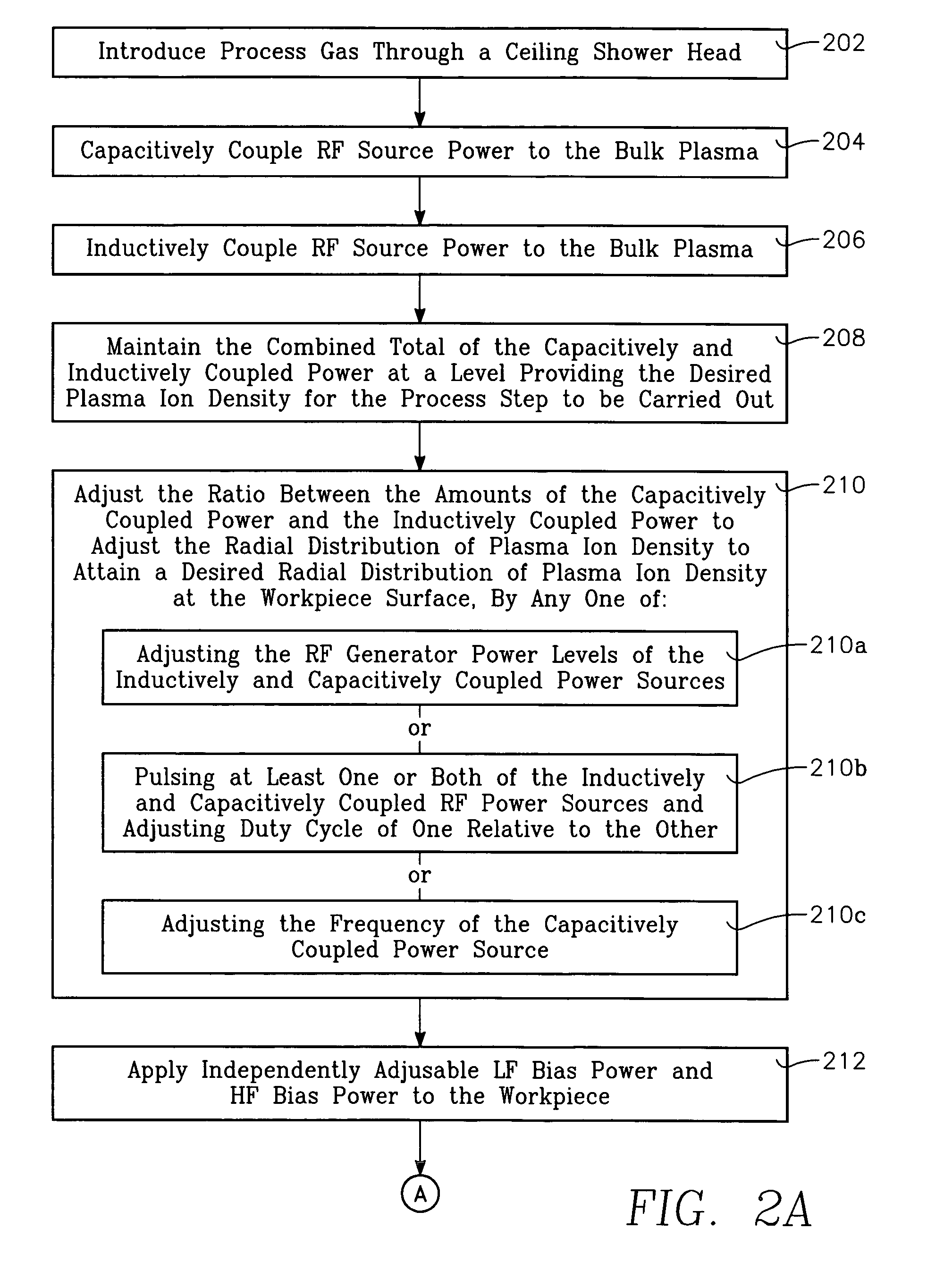

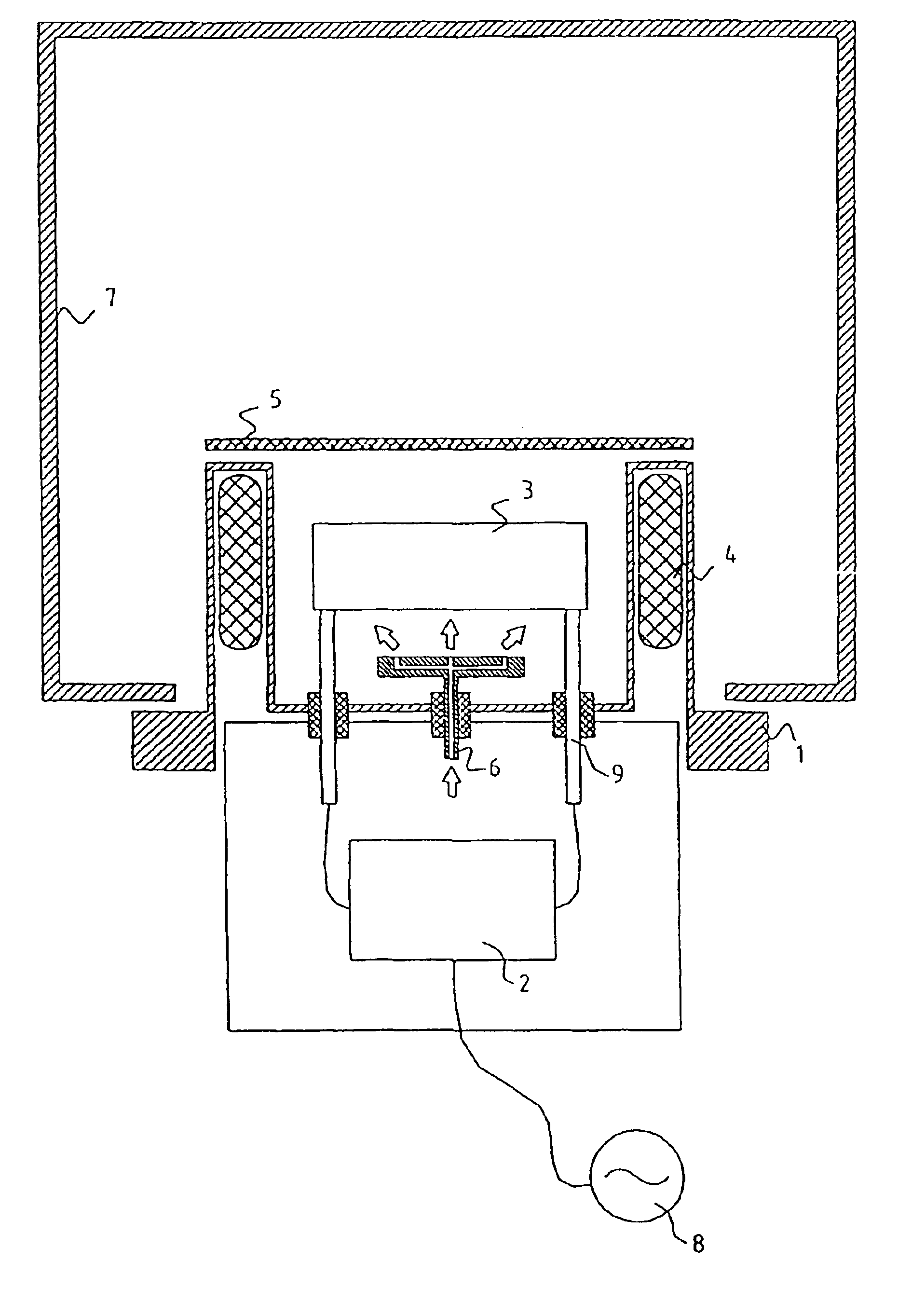

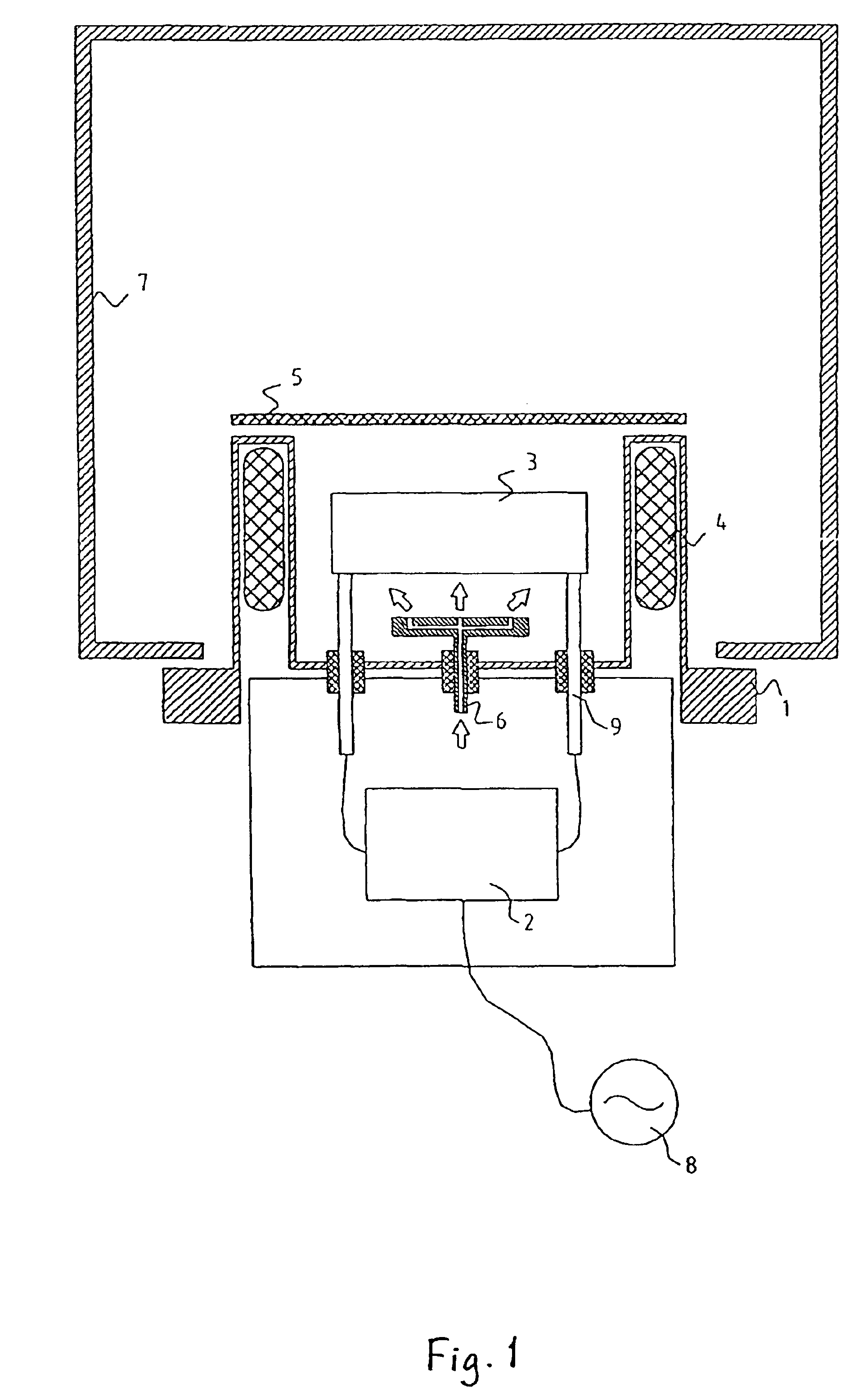

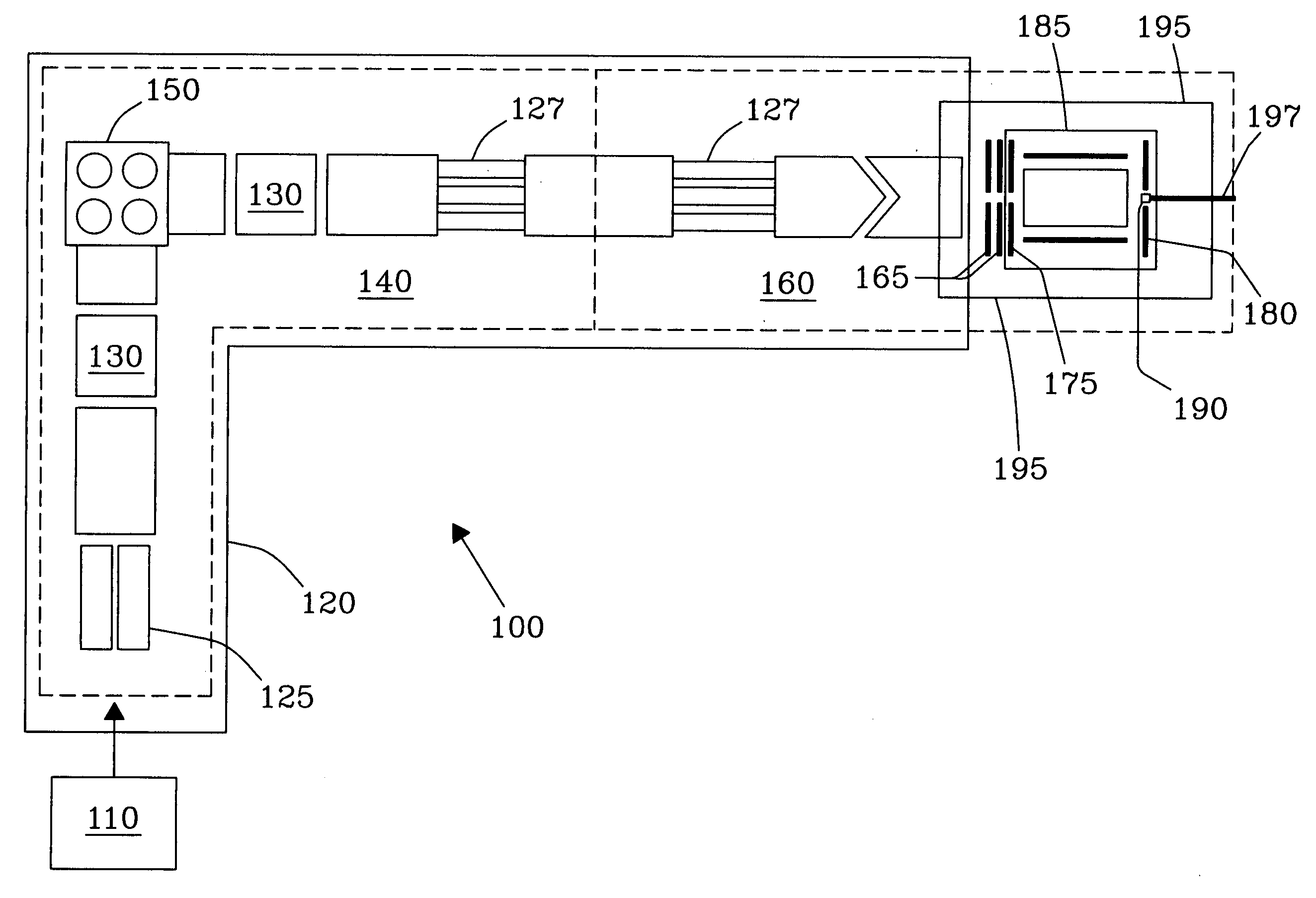

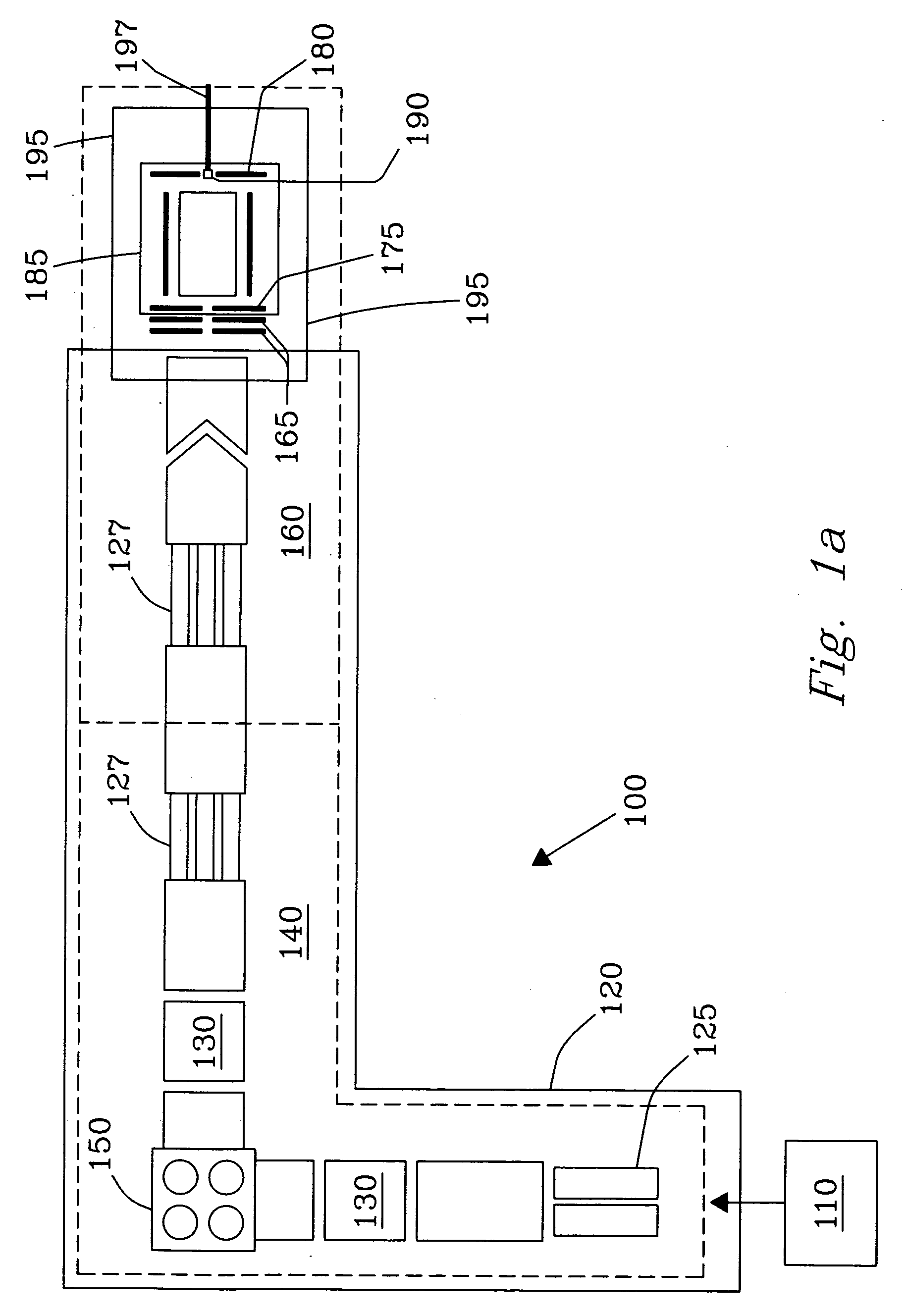

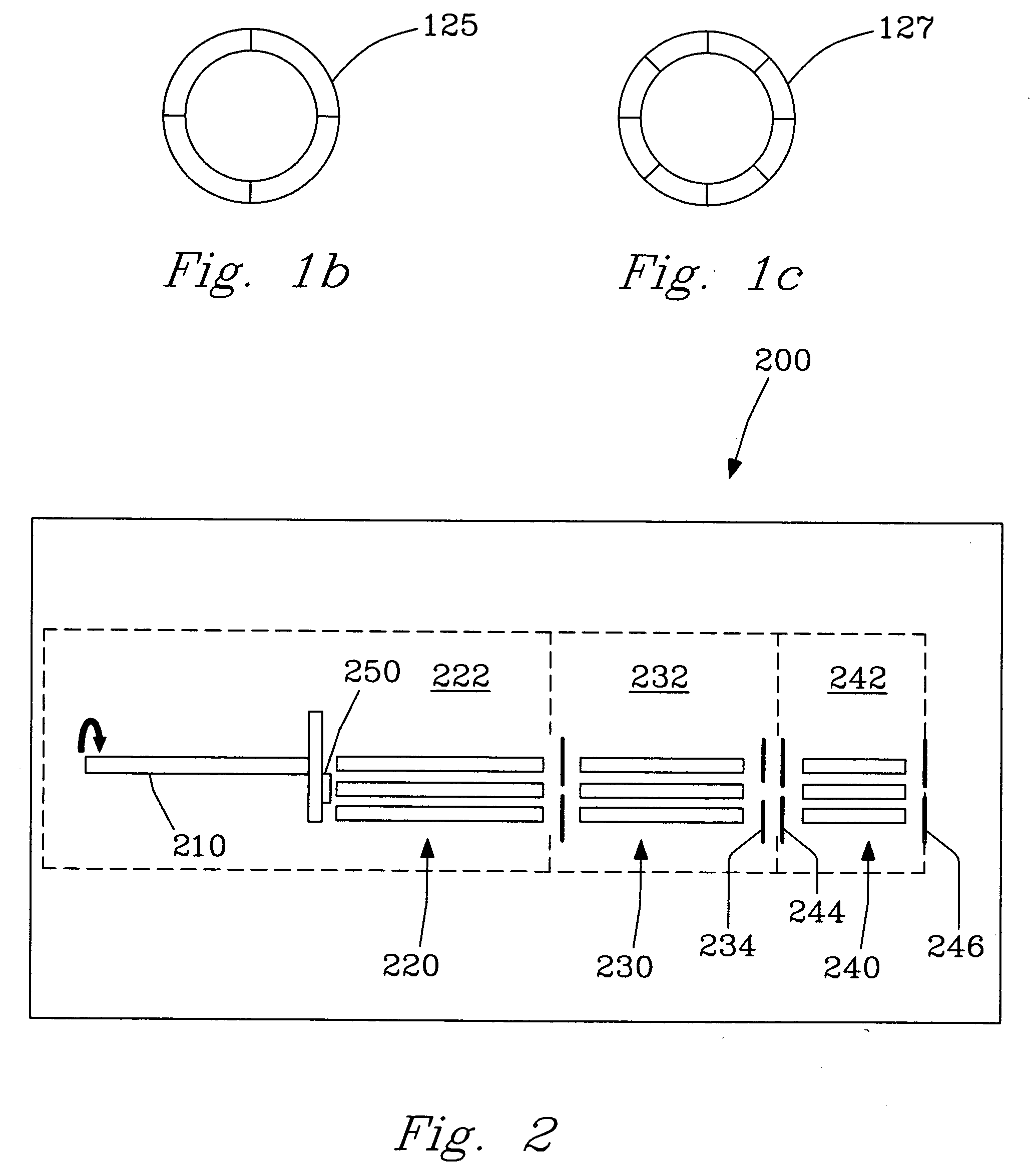

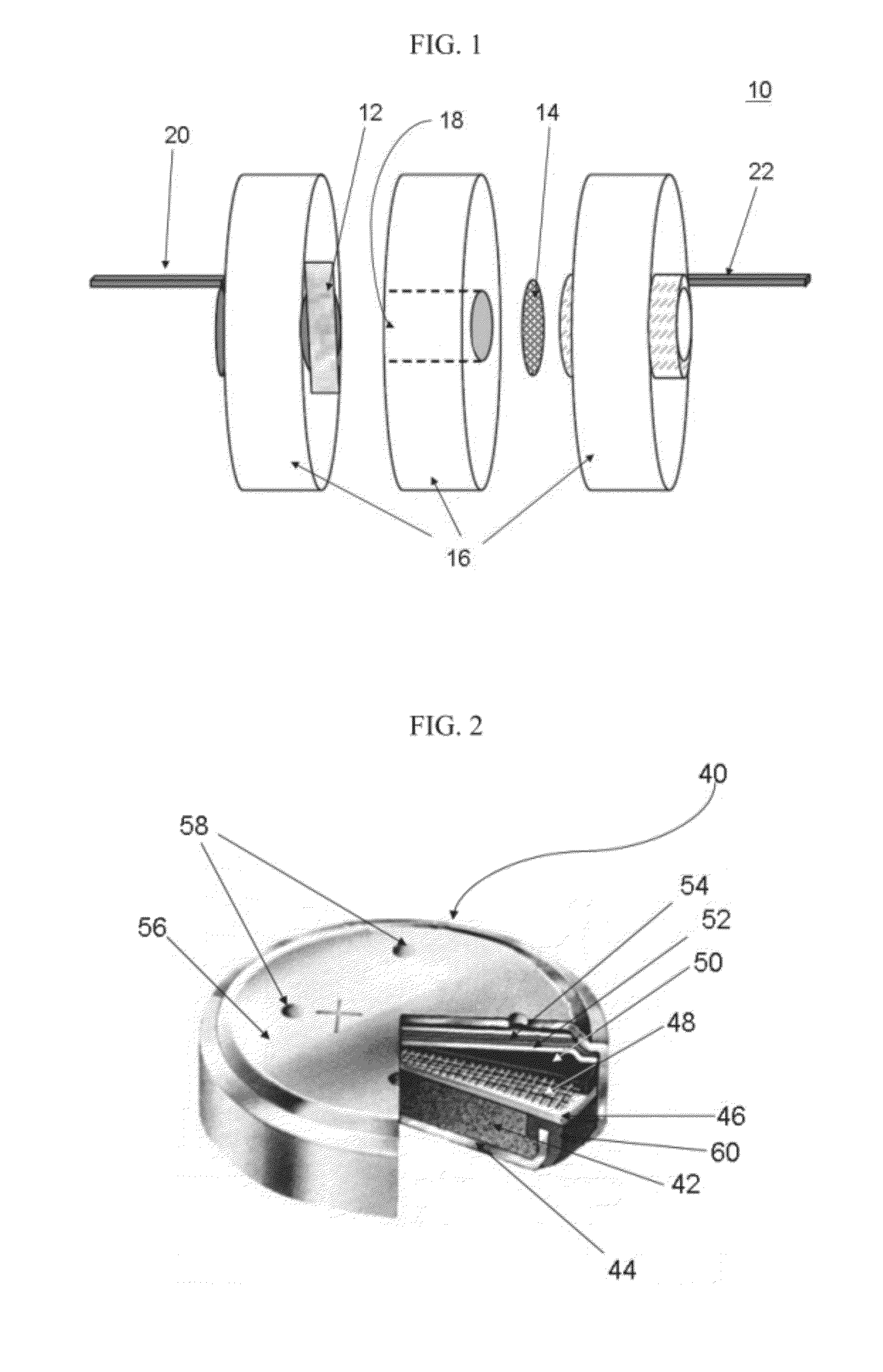

Plasma reactor apparatus with independent capacitive and toroidal plasma sources

InactiveUS7264688B1Increase ratingsIncrease ion densityElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceEngineering

A plasma reactor includes a toroidal plasma source having an RF power applicator, and RF generator being coupled to the RF power applicator. The reactor further includes a capacitively coupled plasma source power applicator or electrode at the ceiling or the workpiece support, a VHF power generator being coupled to the capacitively coupled source power applicator, a plasma bias power applicator or electrode in the workpiece support and an RF bias power generator coupled to the plasma bias power applicator. A controller adjusts the relative amounts of power simultaneously coupled to plasma in the chamber and conduit by the toroidal plasma source and by the capacitively coupled plasma source power applicator.

Owner:APPLIED MATERIALS INC

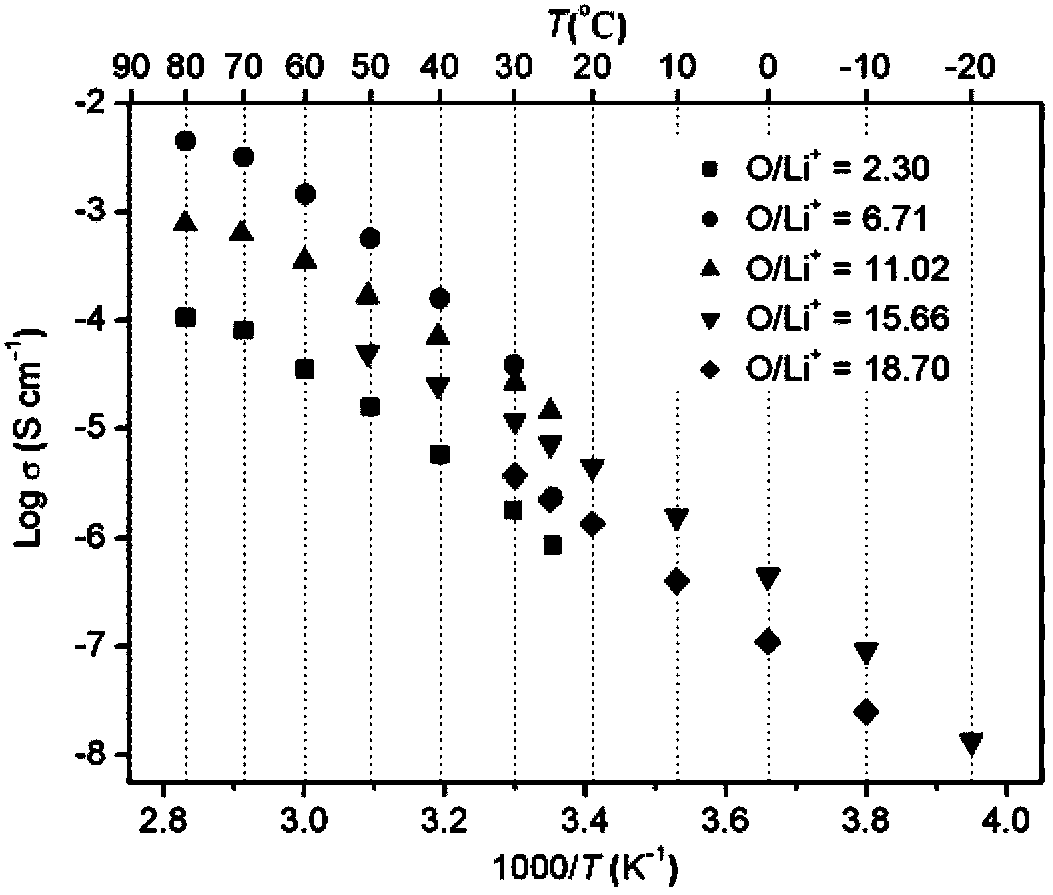

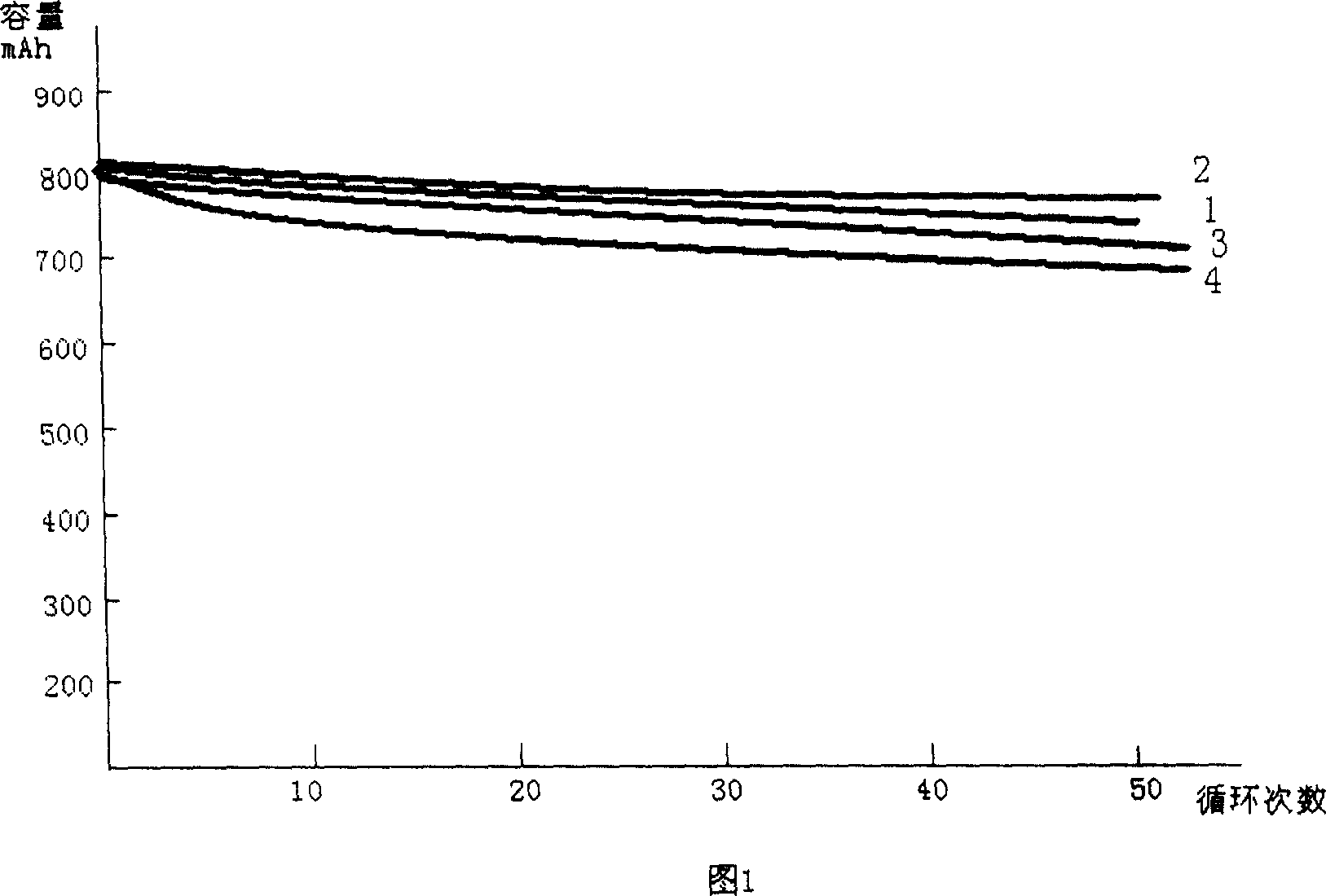

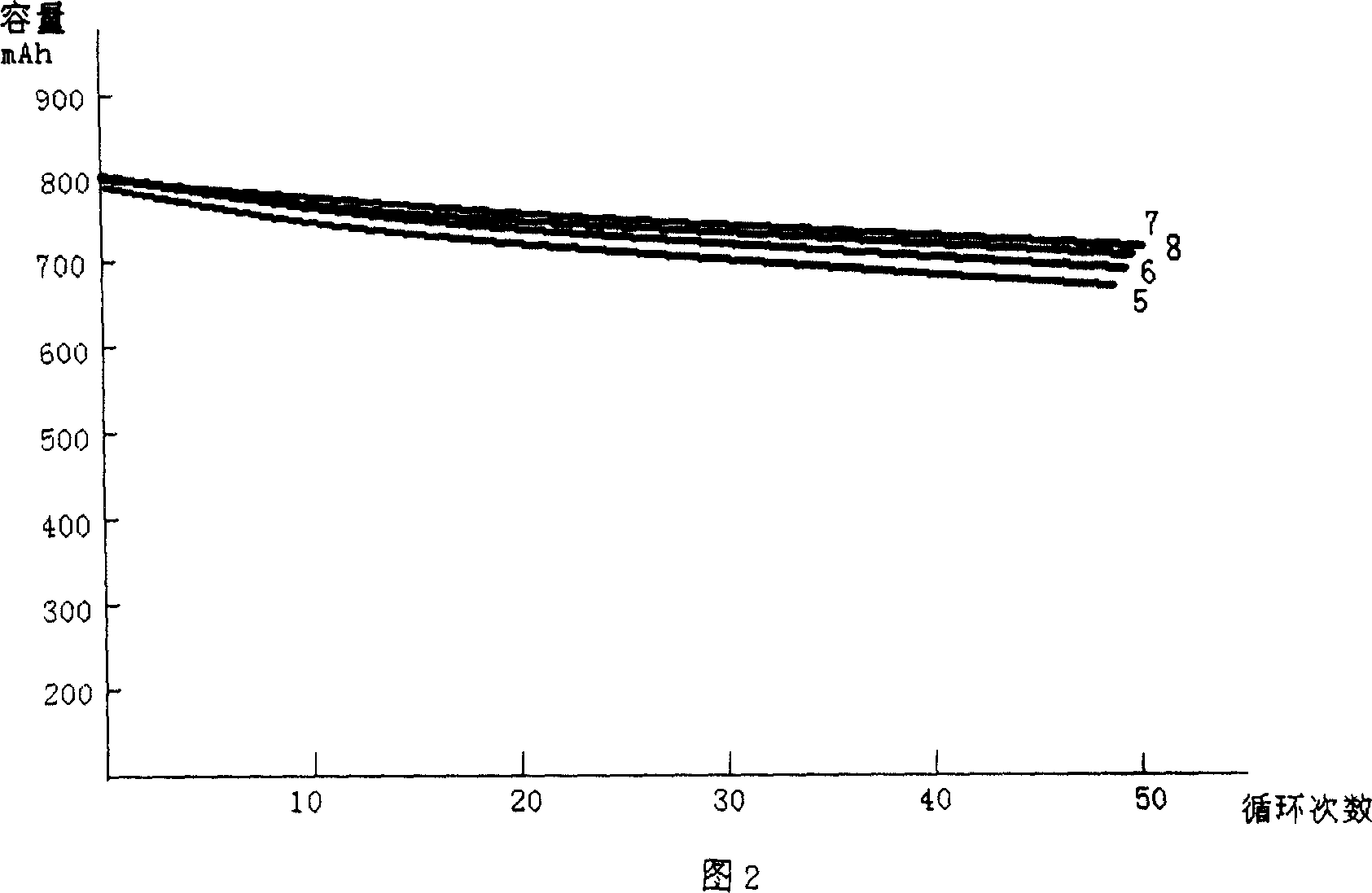

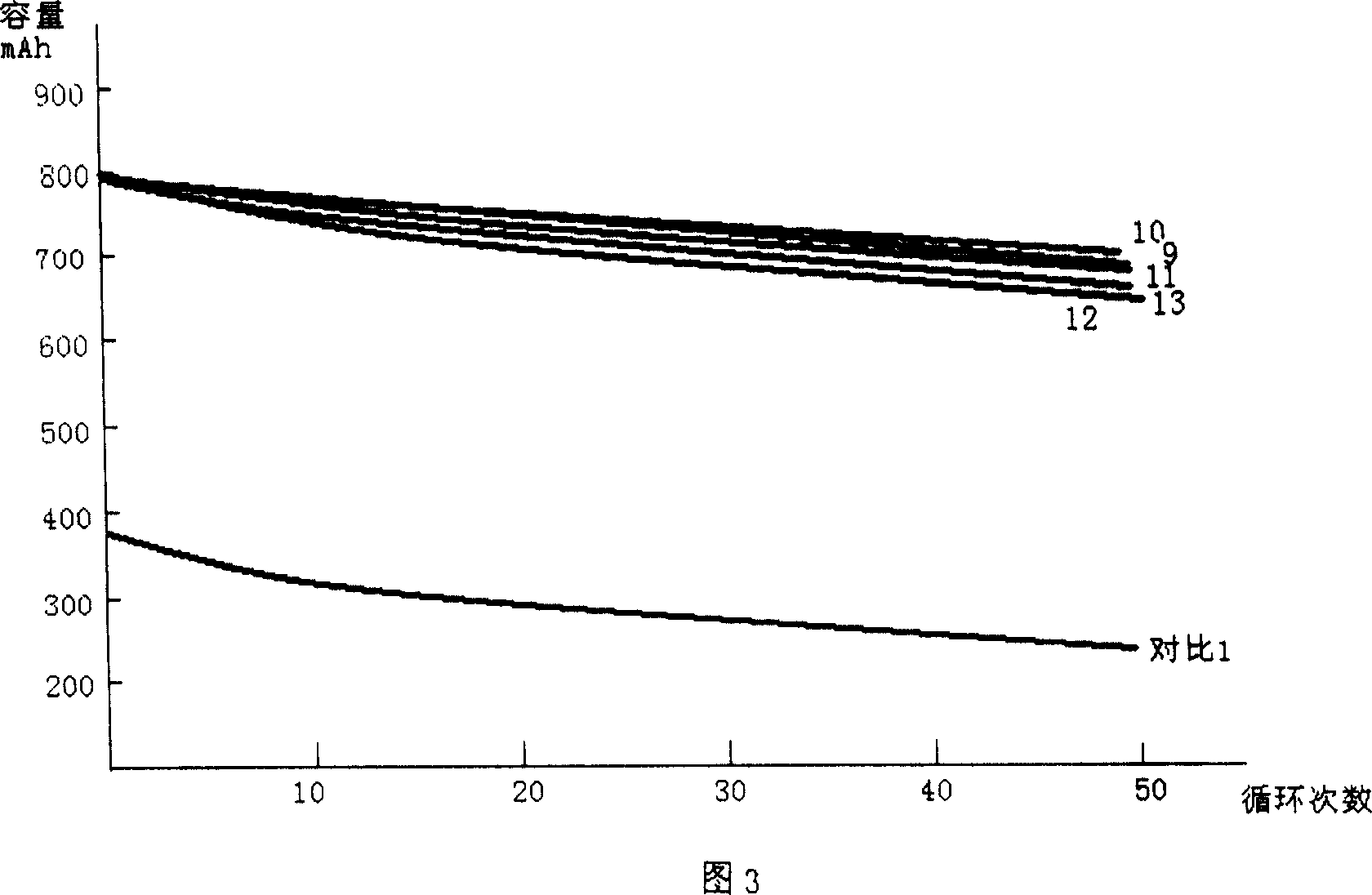

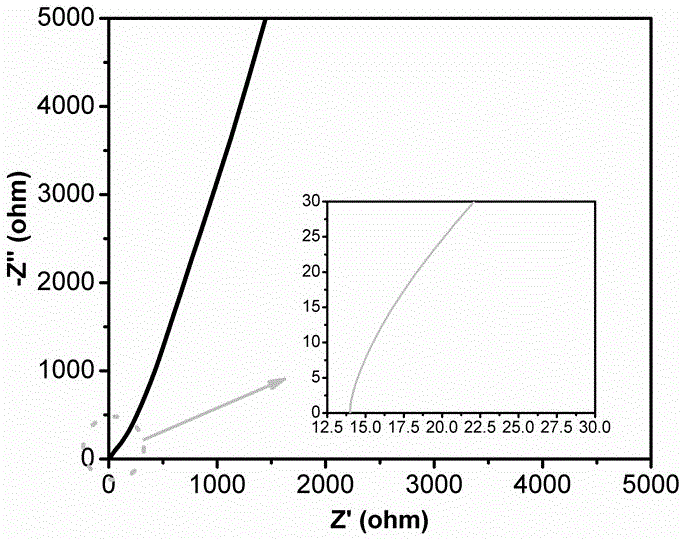

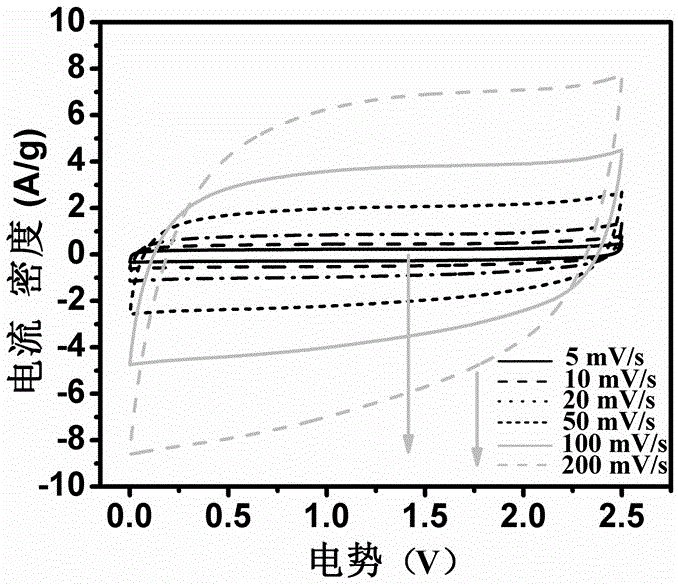

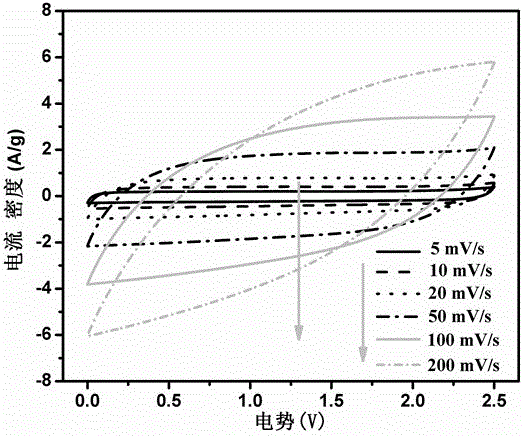

Polymer single-ion electrolyte and preparation method thereof

ActiveCN103509153AHigh conductivity at room temperatureReduce crystallinitySecondary cellsLithium imideCrystallinity

The invention discloses random copolymerization single-ion polymer electrolyte or block copolymerization single-ion polymer electrolyte which is obtained through copolymerization between a (p-vinyl phenylsulfonyl) (perfluoroalkyl sulfonyl) lithium imide monomer and a methoxyl polyethylene glycol acrylate monomer, and a preparation method of the electrolyte. The polymer single-ion electrolyte prepared by the method disclosed by the invention has the advantages of high room-temperature conductivity, high lithium ion transference number, low glass state temperature and degree of crystallinity, good mechanical strength and film-forming properties, wide electrochemical window, good thermal stability and the like, and has potential application values in the aspects of lithium (ion) batteries, carbon-based super-capacitors, solar batteries and the like.

Owner:武汉市瑞华新能源科技有限公司

Non-aqueous electrolyte for lithium iron phosphate battery

The invention discloses a non-aqueous electrolyte for a lithium iron phosphate battery. The non-aqueous electrolyte comprises 70 to 85 weight percent of carbonic ester compound, 3 to 20 weight percent of various function additives and 11 to 17 weight percent of lithium hexafluorophosphate, wherein the carbonic ester compound is one of ethylene carbonate, propylene carbonate, butylene carbonate, dimethyl carbonate and diethyl carbonate or a mixture of more of the ethylene carbonate, the propylene carbonate, the butylene carbonate, the dimethyl carbonate and the diethyl carbonate; and the additives comprise one of 0.5 to 10 percent of film-forming additive, 0.5 to 10 percent of high-temperature additive, 0.5 to 10 percent of low-temperature additive, 0.5 to 10 percent of overcharge-preventing additive and 0.001 to 2 percent of stability additive, and a mixture of more of the additives. The non-aqueous electrolyte for the lithium iron phosphate battery has the advantages that the solubility and dissociation of the lithium hexafluorophosphate are improved, and electric conductivity is improved; the low temperature resistance of a solid electrolyte interphase (SEI) is reduced; the overall stability of the battery is improved, the overall service life of the battery is prolonged, the compatibility of an electrolyte and a cathode is improved, circulation of the battery is improved, and the service life is prolonged; and the non-aqueous electrolyte can have high performance at high temperature.

Owner:广东金光高科股份有限公司

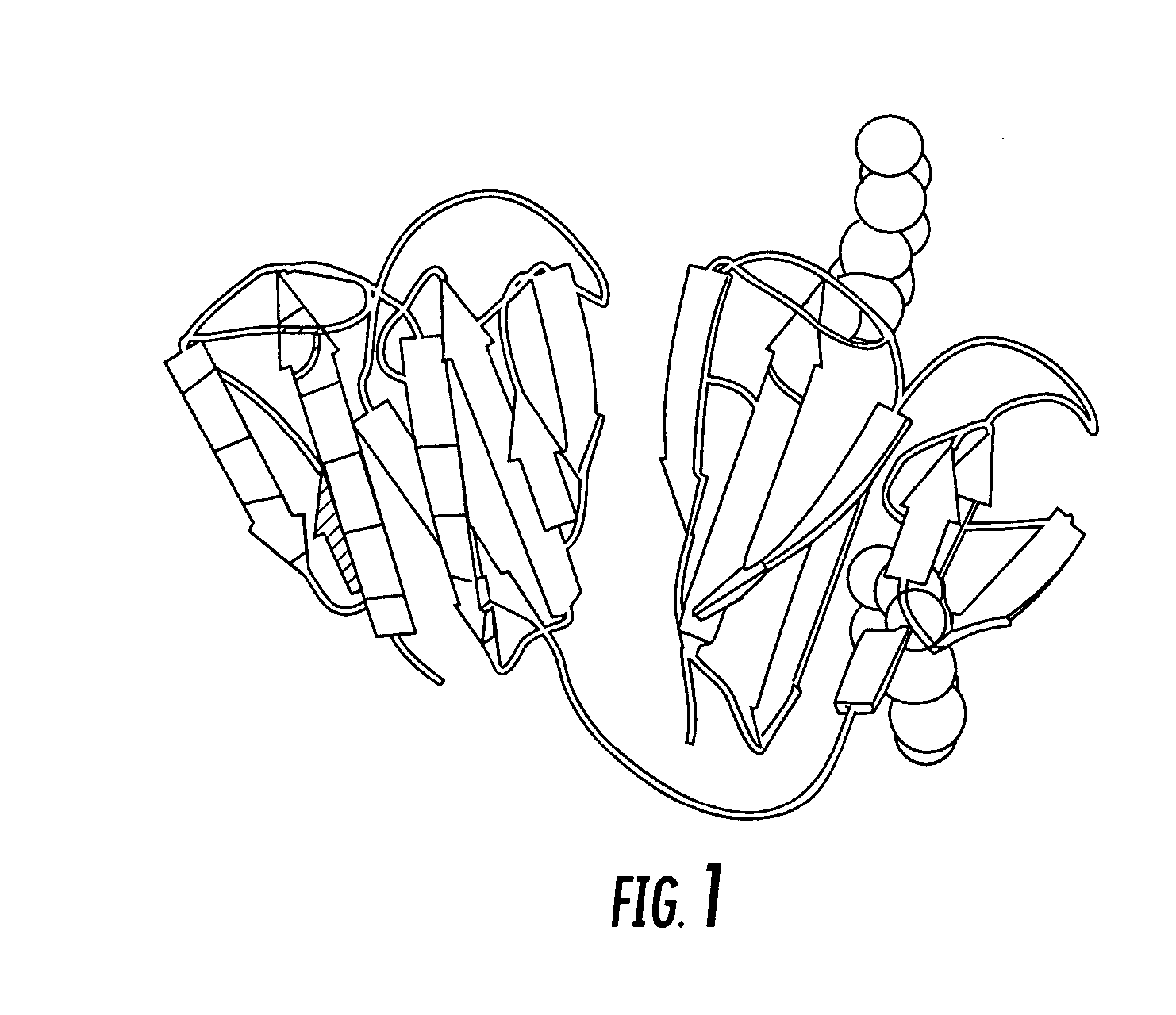

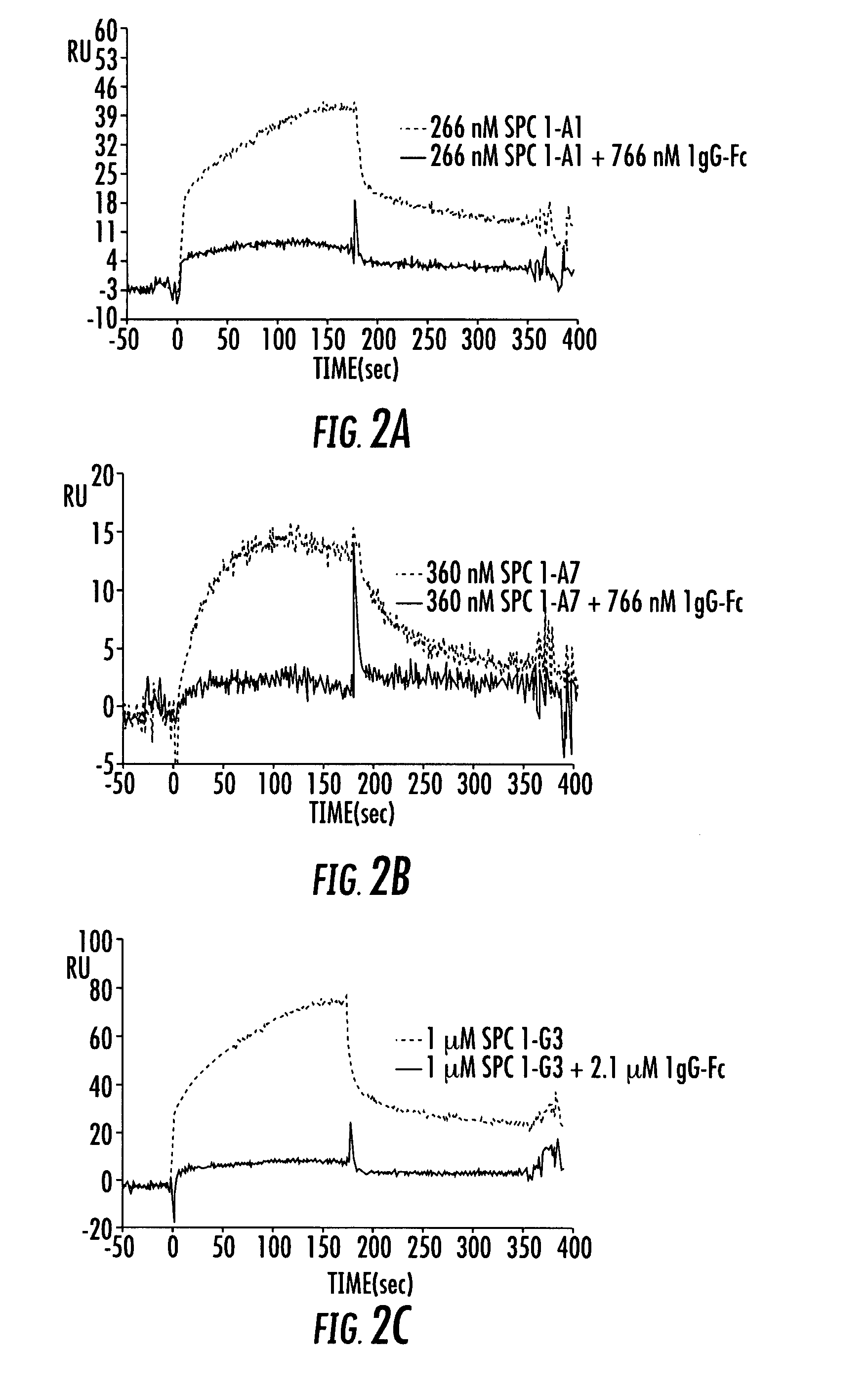

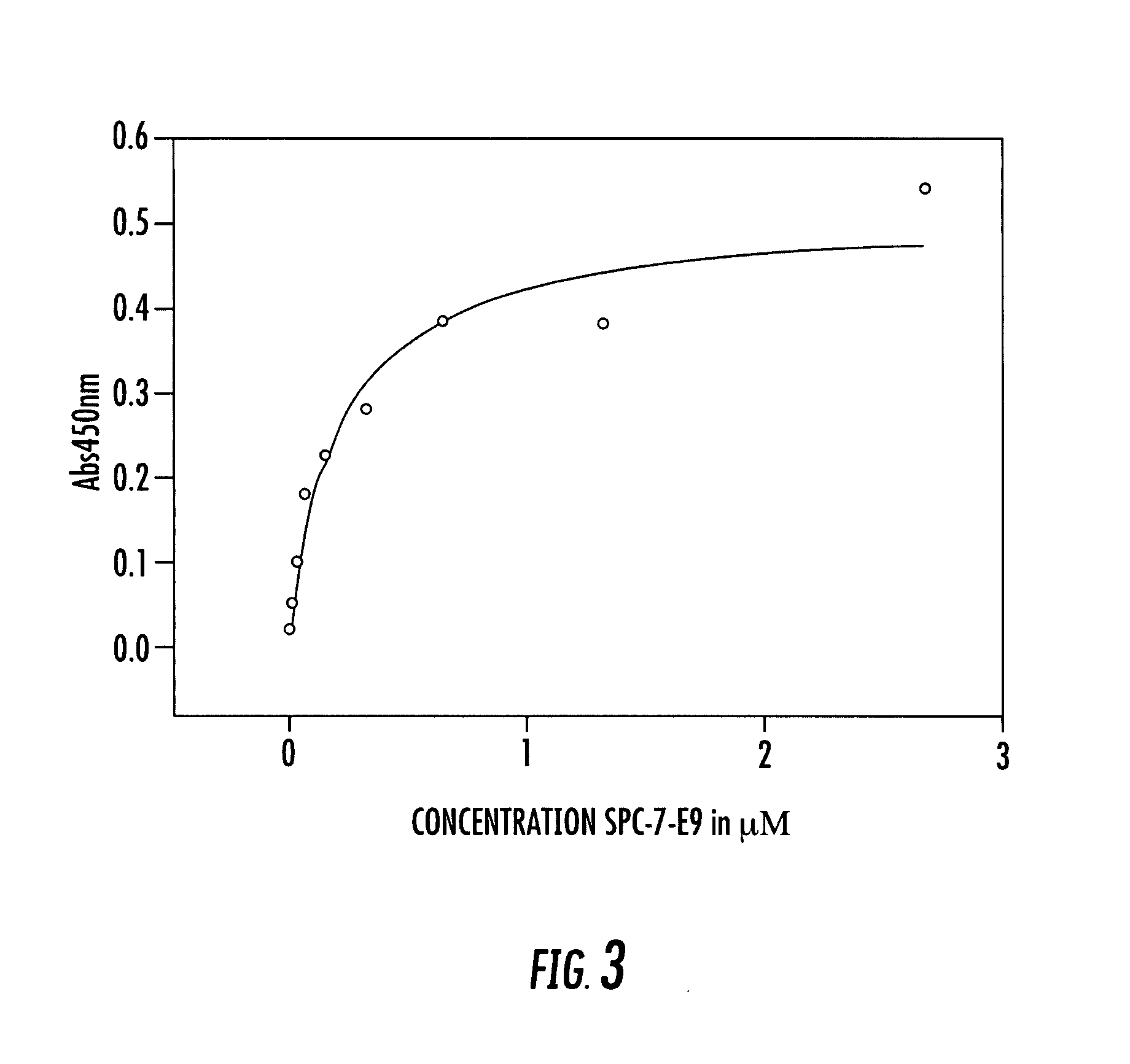

Ubiquitin or gamma-crystalline conjugates for use in therapy, diagnosis and chromatography

ActiveUS20070248536A1Lower capability requirementsIncrease dissociationImmunoglobulins against bacteriaFermentationUbiquitinsDiagnosis treatment

The present invention relates to conjugates containing a covalent linkage between one or more polypeptide molecules based on gamma-crystallin or ubiquitin and one or more functional components. Furthermore, the present invention relates to a method for the preparation of such a conjugate as well as to the use of the conjugate in diagnostics, therapy and chromatography.

Owner:NAVIGO PROTEINS GMBH

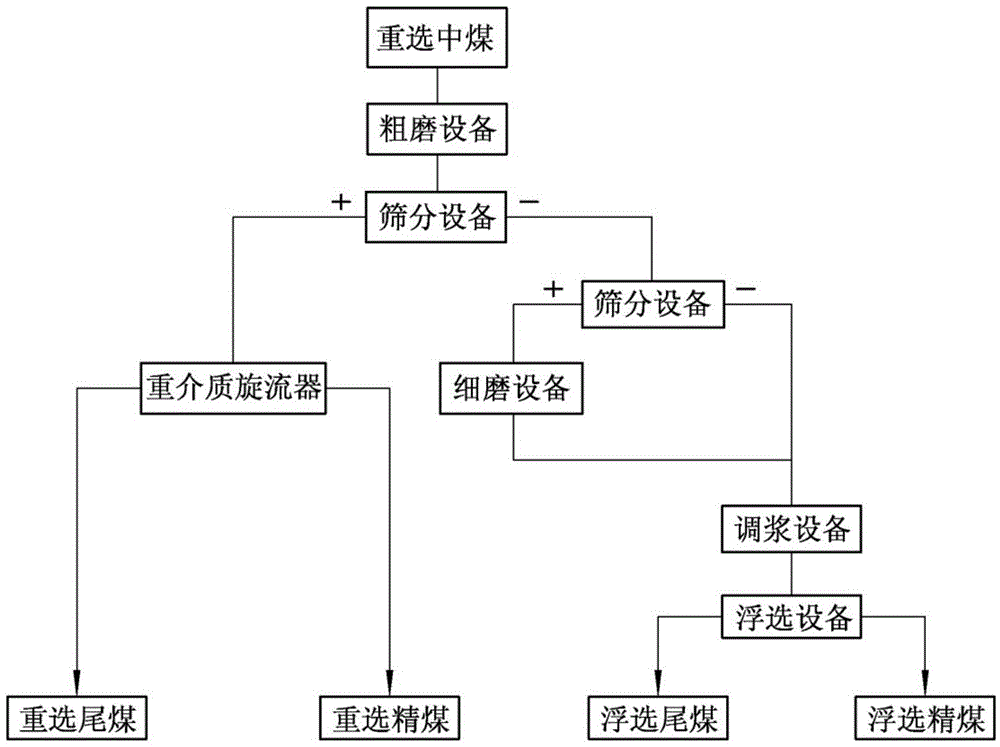

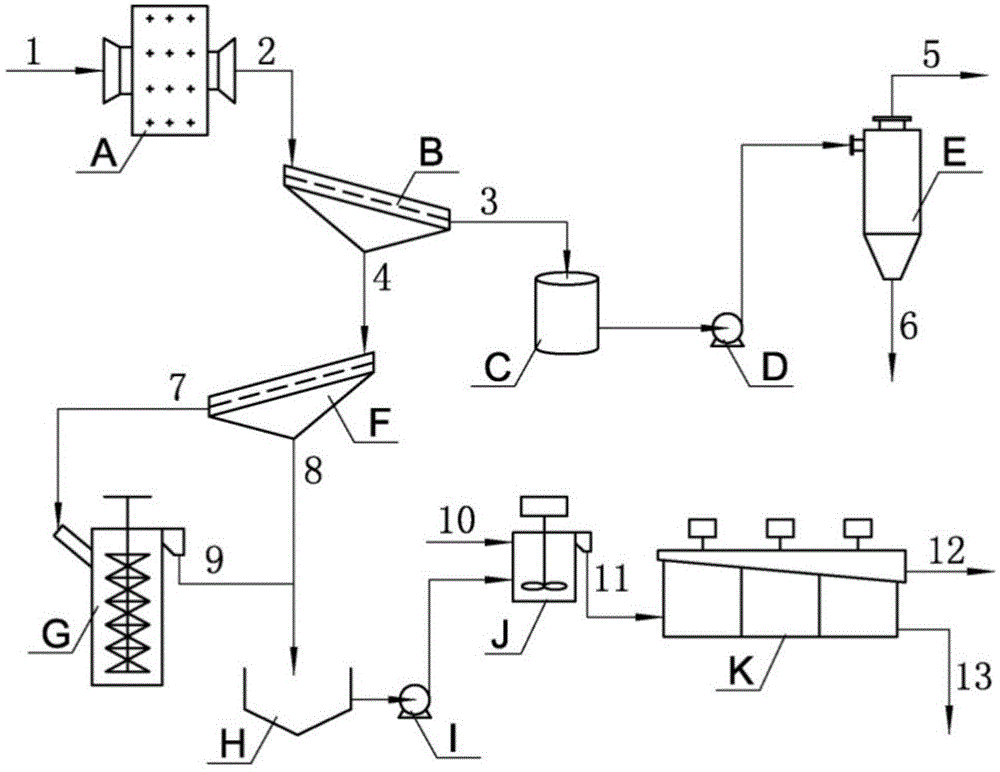

Gravity separation middling coal separation technology

InactiveCN104437831AReduce over-crushingImprove equipment sorting efficiencyGrain treatmentsWet separationGravity separationEngineering

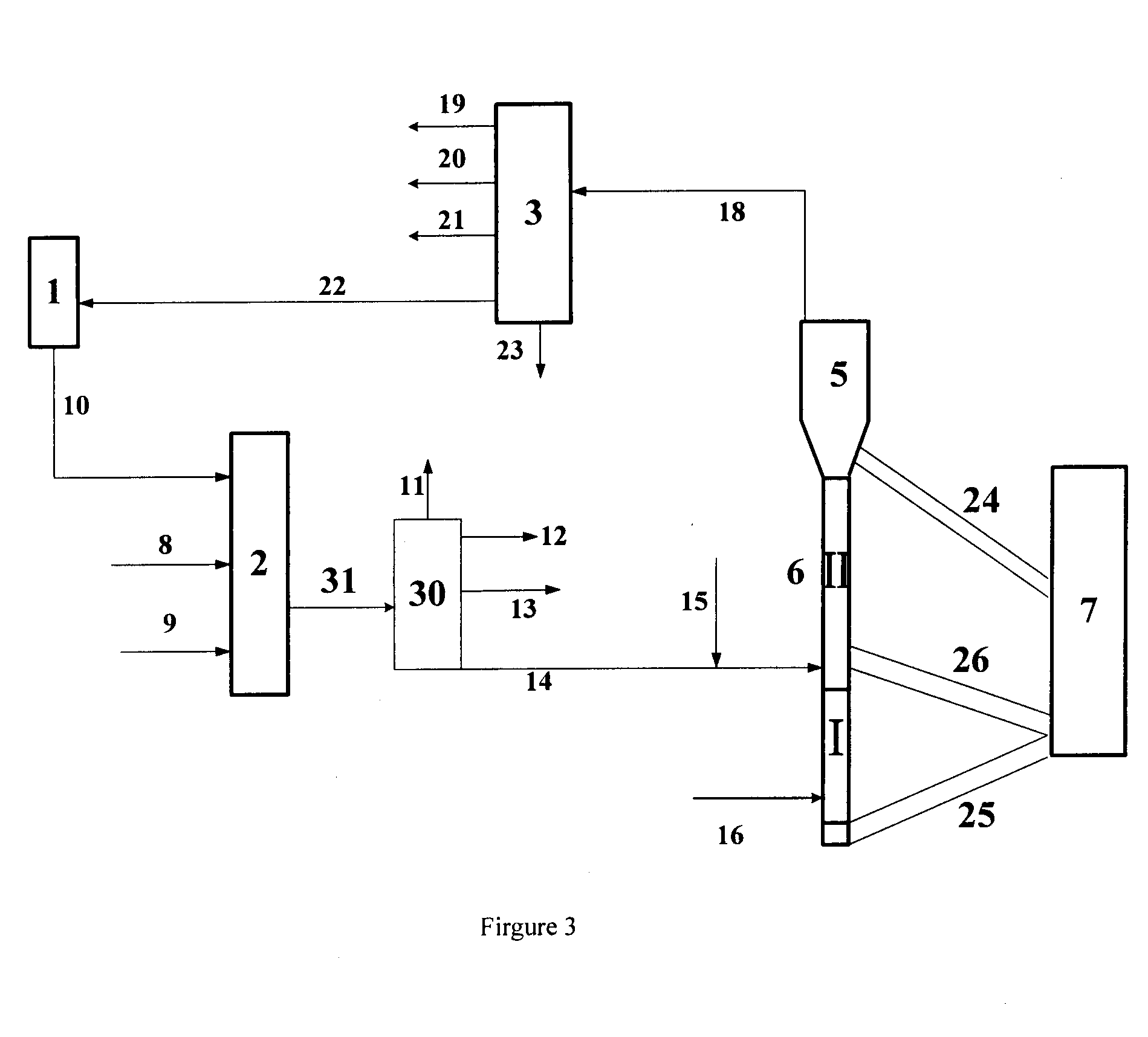

The invention belongs to a coal washing method and discloses a gravity separation middling coal separation technology. Gravity separation middling coal is fed into rough grinding equipment. Products obtained after rough grinding is fed into screening equipment for primary classifying, and primary plus-sieve products and primary minus-sieve products are obtained. The primary plus-sieve products are fed into a dense medium cyclone for separation. The primary minus-sieve products are fed into separation equipment for secondary classification, and secondary plus-sieve products and secondary minus-sieve products are obtained. The secondary plus-sieve products are fed into fine grinding equipment for fine grinding. Products obtained after fine grinding and the secondary minus-sieve products are fed into size mixing equipment together for completing flotation. Two-time ore grinding, gravity separation and floatation combination and classifying separation are combined to separate gravity separation middling coal, under the premise that the middling coal dissociation degree is improved, the phenomena of over crushing are reduced, equipment separation efficiency is obviously improved, clean coal in the middling coal is recycled to the maximum degree, the coal preparation plant clean coal productivity is increased, and enterprise economical benefit is improved.

Owner:CHINA UNIV OF MINING & TECH

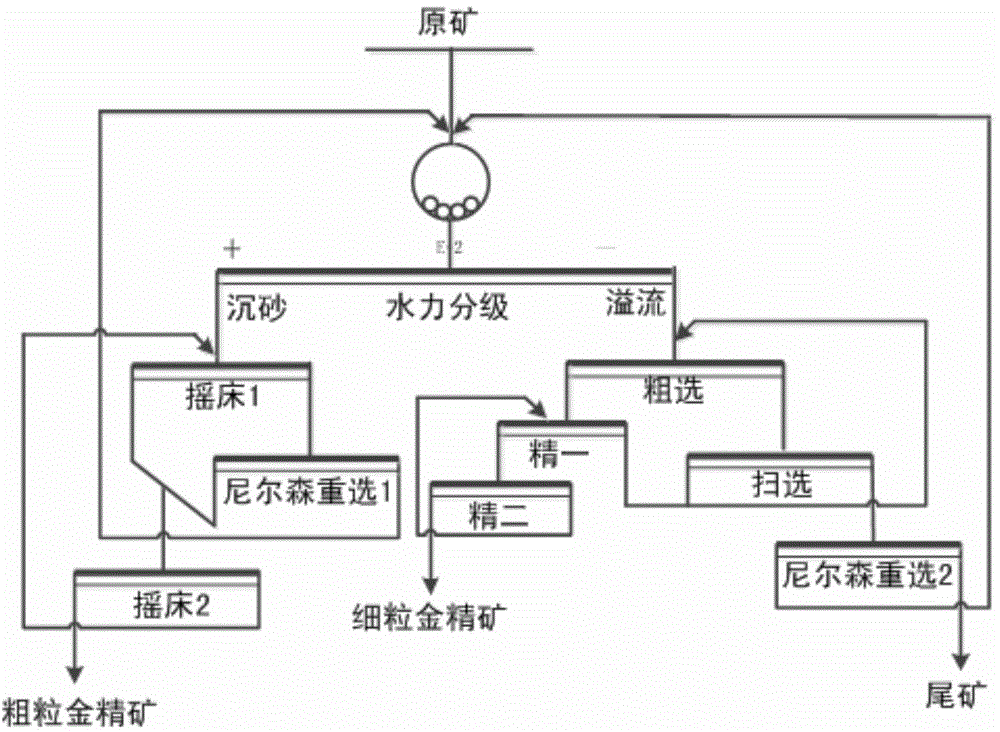

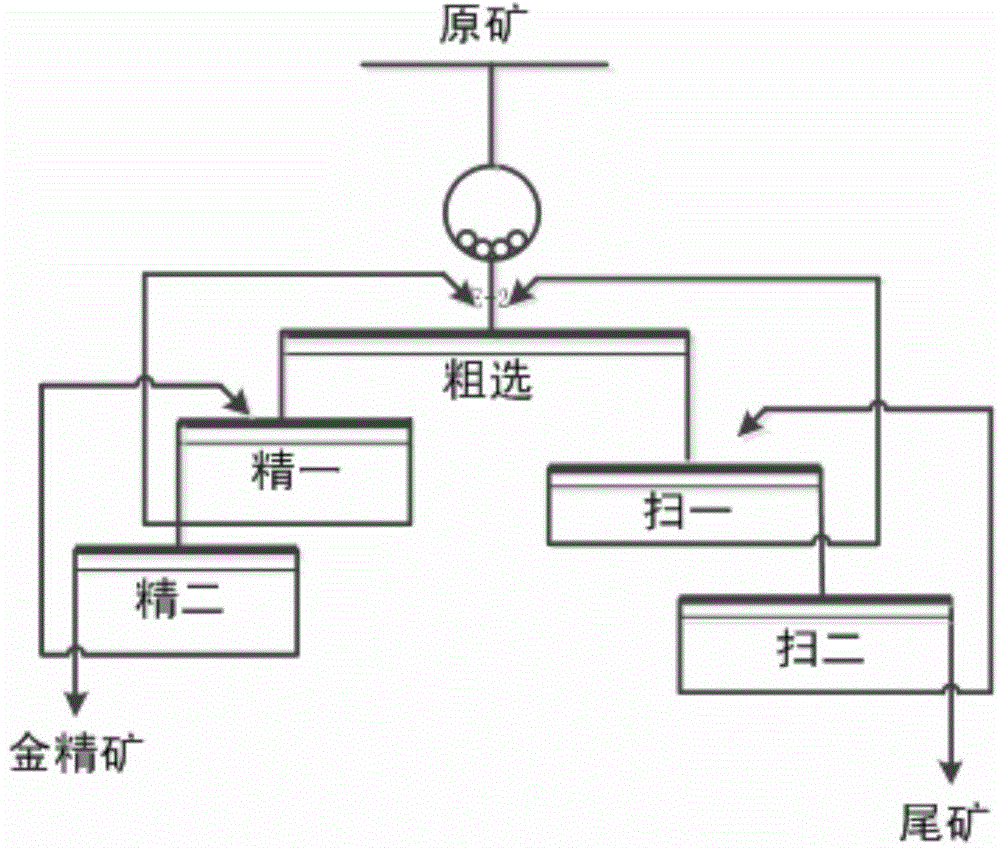

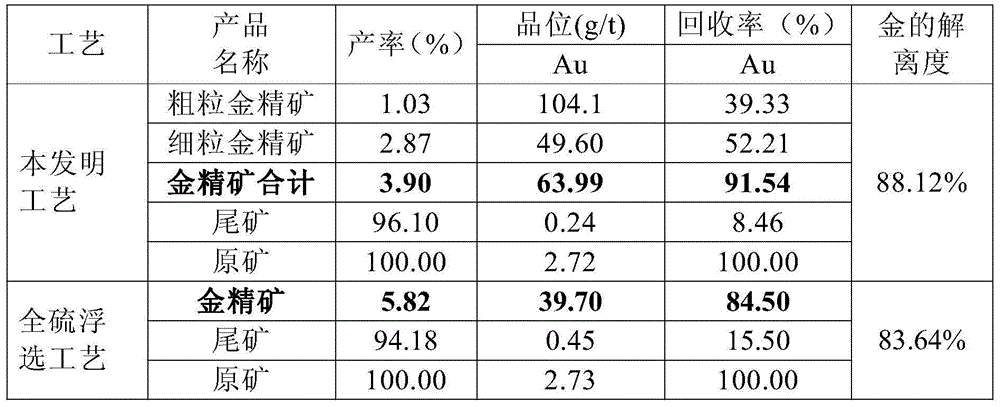

Beneficiation process for increasing recovery rate of gold of refractory gold ores

The invention relates to a beneficiation process for increasing the recovery rate of gold of refractory gold ores. According to the process, a reselection-floatation-reselection combined procedure is adopted to increase the recovery rate of the gold, and in other words, ores are ground till the particle size is -0.074 mm(60-80)%; a hydraulic power classifier is firstly utilized for classification, coarse gold concentrate is obtained from classified setting sand through a reselection method, and reselected tailings return to a ball mill to be ground gain; and classified overflow adopts a total-sulfur flotation method to recycle the gold, mustard gold concentrate is obtained, flotation tailings are reselected through a Nilson centrifugal ore separator, and obtained reselected concentrate returns to the ball mill to be ground gain. Early recovery and much recovery of the gold can be achieved through the process, gold which cannot be recycled because the particle size is too large or too small in total-sulfur flotation is effectively recycled, the purpose of selective ore grinding is achieved through reselection-ball mill closed cycle, the dissociation degree of the ores can be improved easily, the grade of the gold concentrate is remarkably improved, the metal recovery rate is remarkably increased, and good economic benefits can be brought to enterprises.

Owner:有研资源环境技术研究院(北京)有限公司

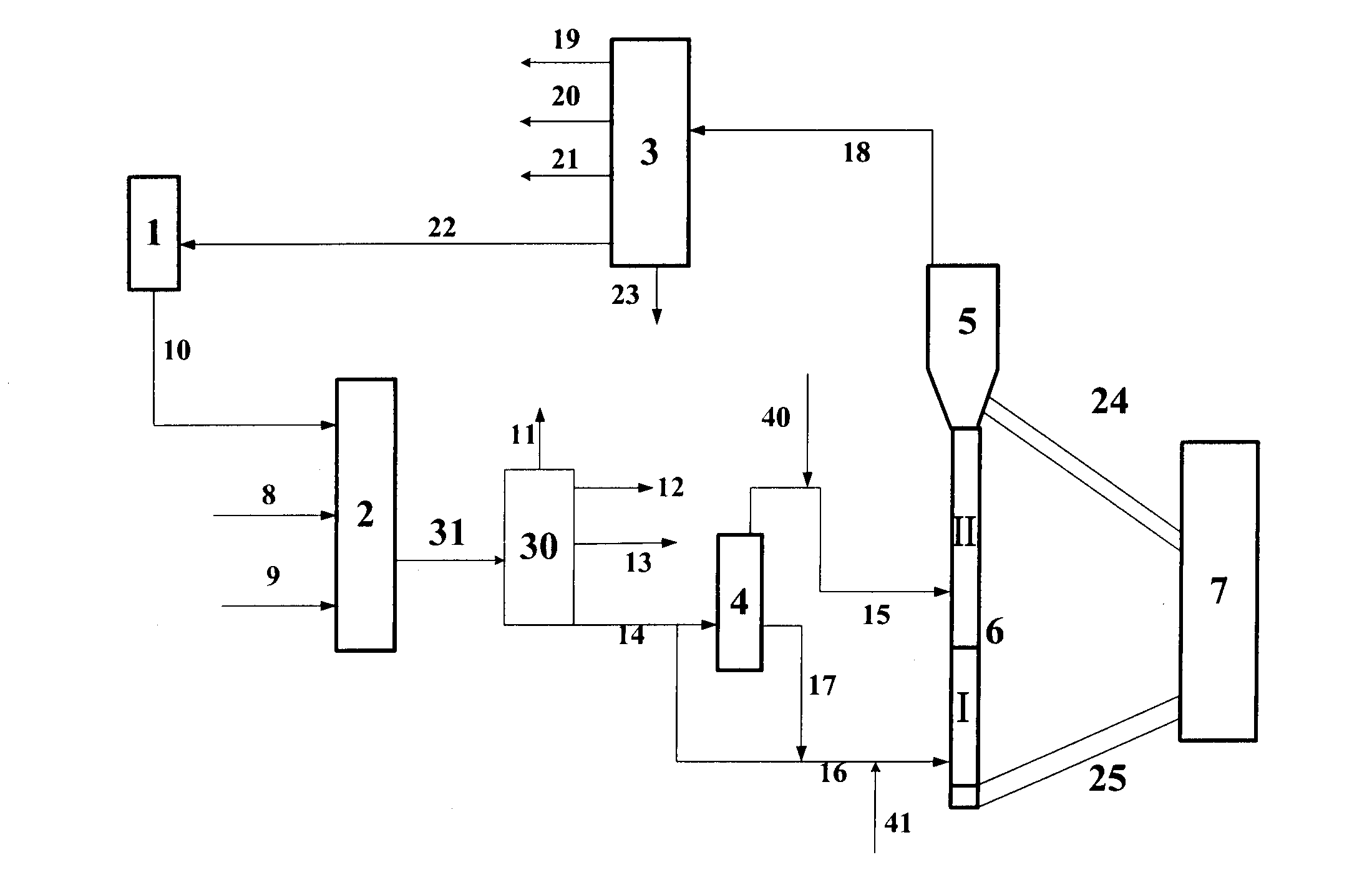

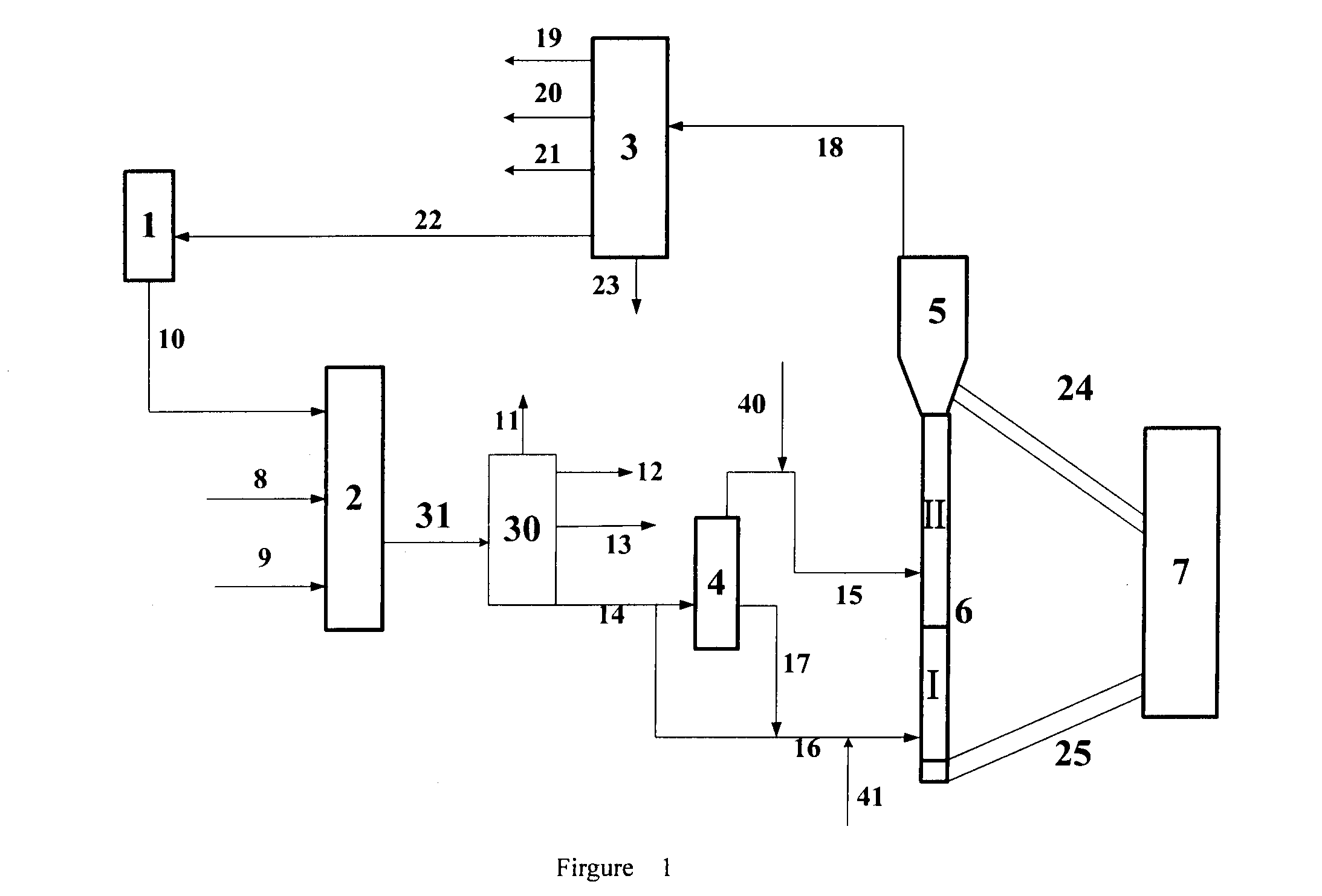

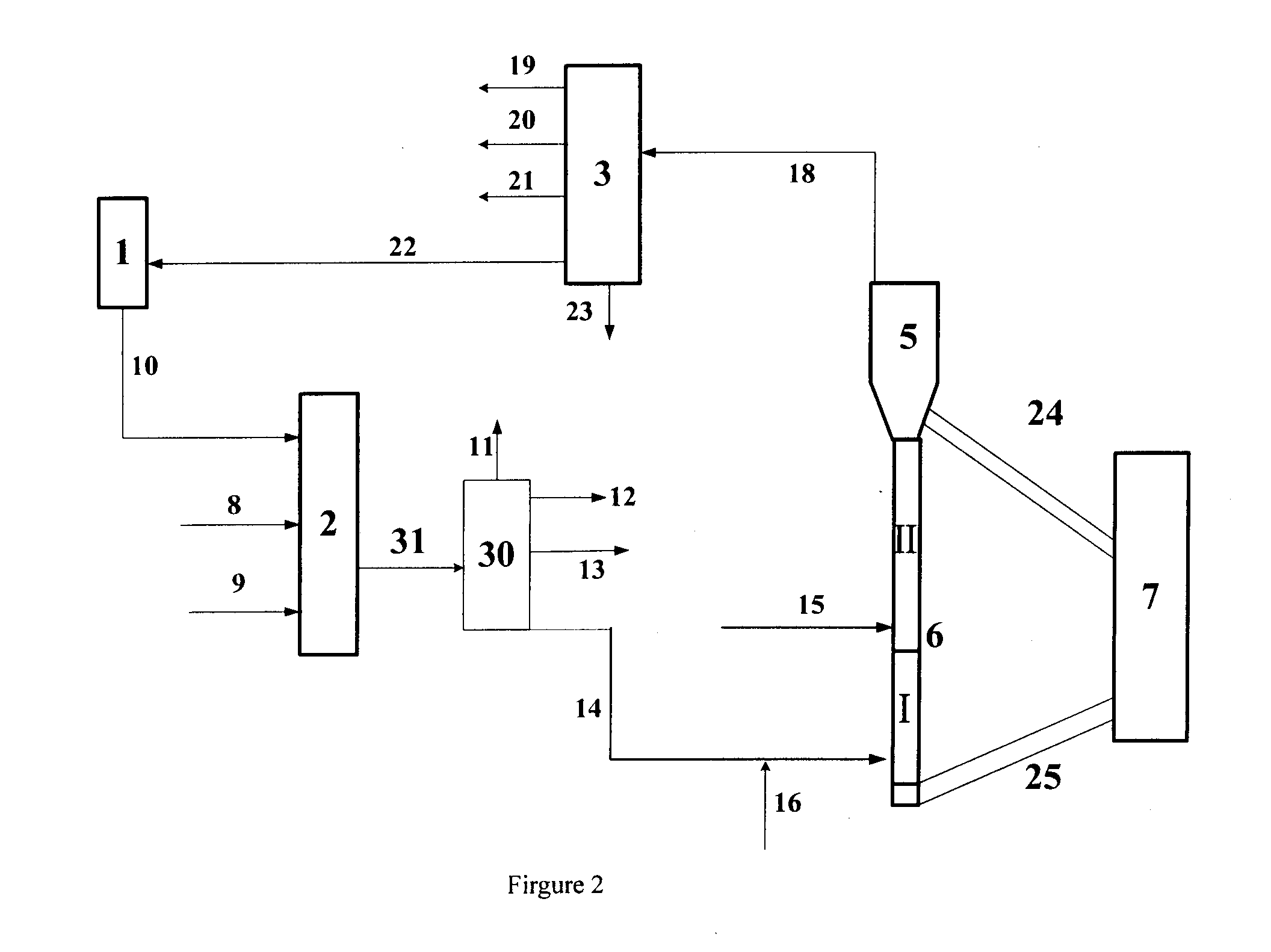

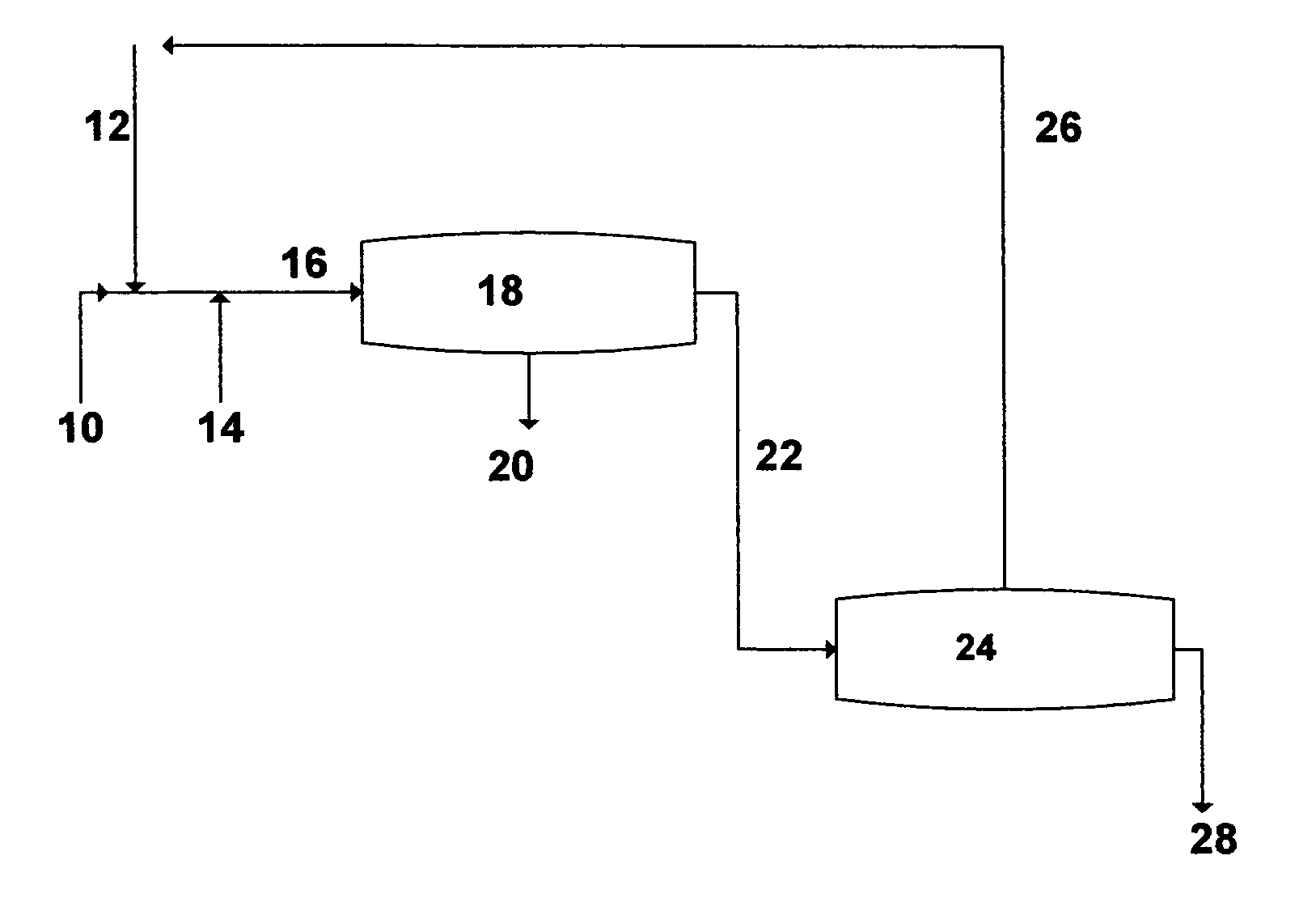

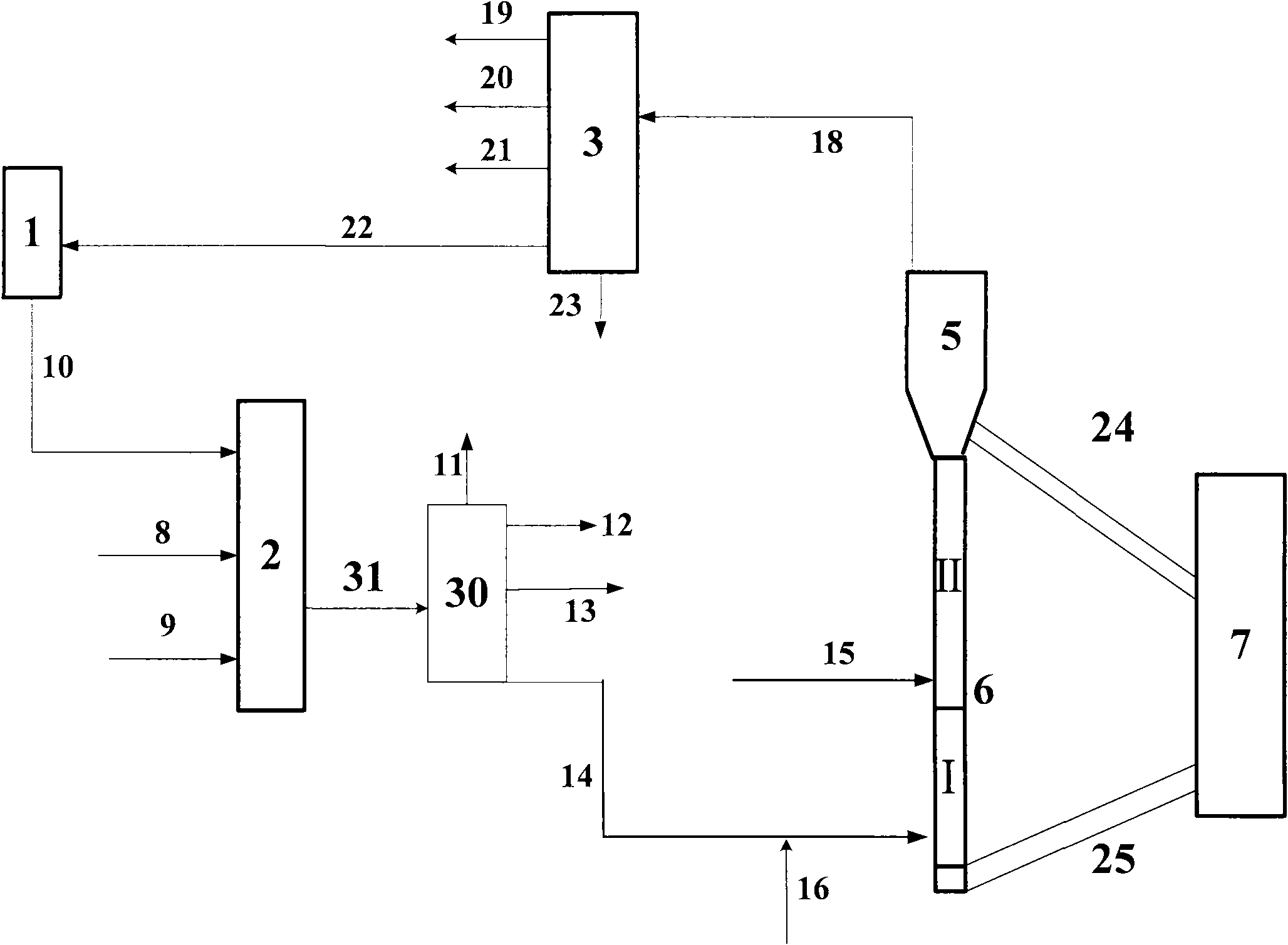

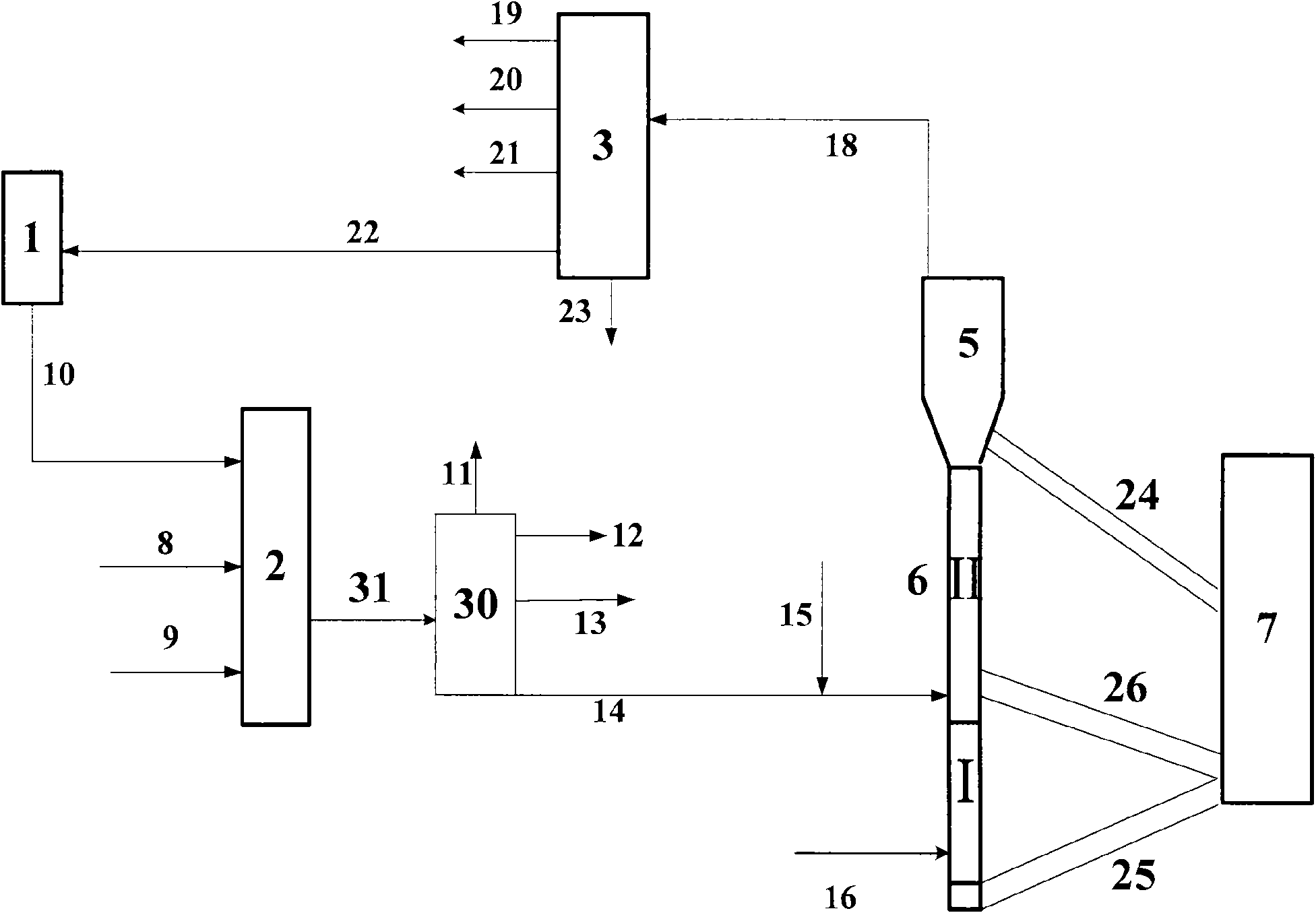

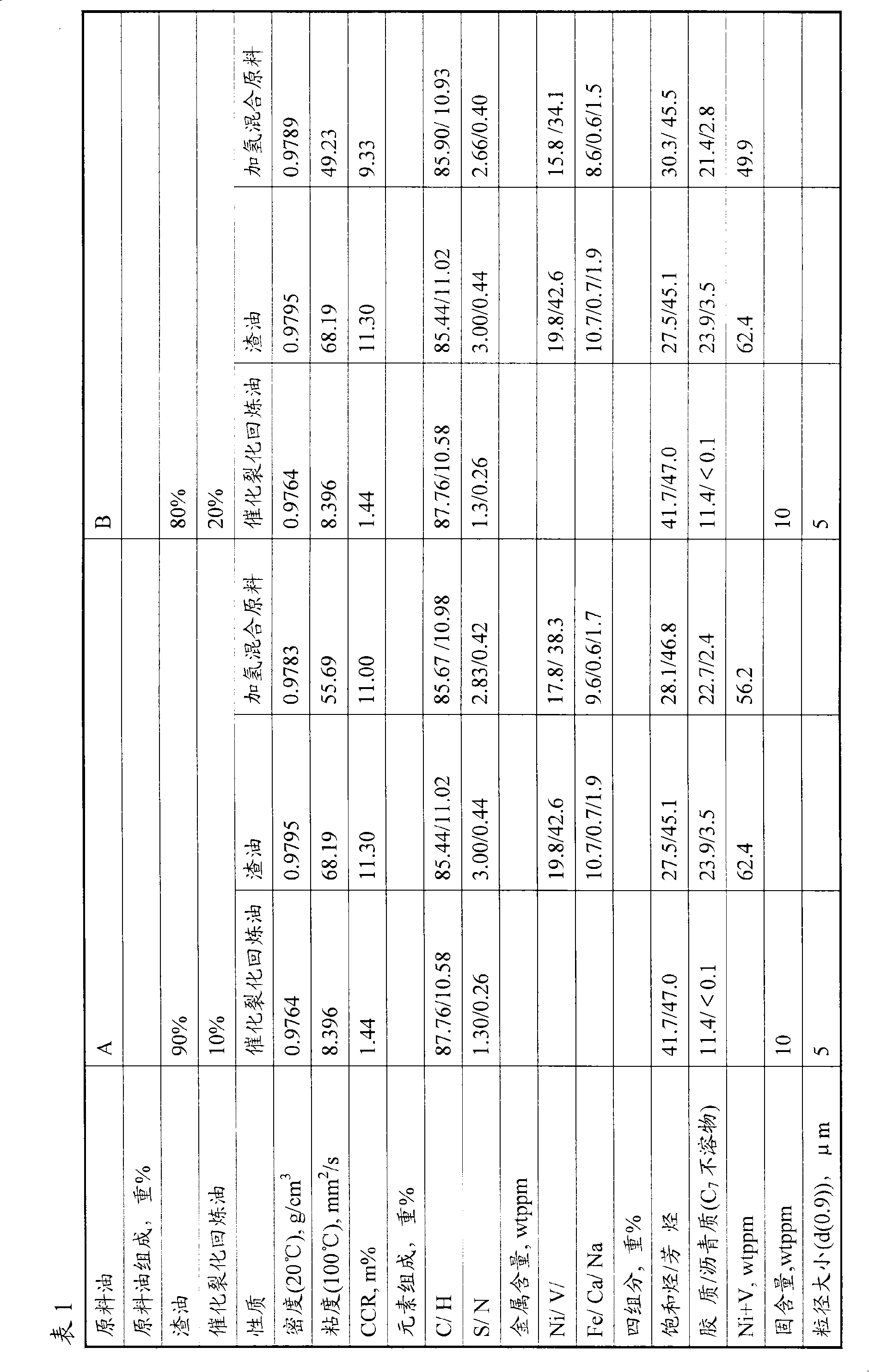

Improved integrated process for hydrogenation and catalytic cracking of hydrocarbon oil

ActiveUS20110062054A1Improve conversion depthIncrease productionCatalytic crackingTreatment with plural parallel cracking stages onlyQuantum gasNatural gas

Disclosed is a combination process for improved hydrotreating and catalytic cracking of hydrocarbon oils, including: contacting residual oil, catalytic cracking cycle oil, and optional distillate oil with a hydrotreating catalyst under hydrotreating conditions in the presence of hydrogen followed by separation of the reaction products to obtain gas, hydrogenated naphtha, hydrogenated diesel oil, and hydrogenated tail oil; contacting the hydrogenated tail oil and optional normal catalytic cracking feedstock oil with a cracking catalyst under catalytic cracking conditions followed by separation of the reaction products to obtain dry gas, hydrogenated naphtha, liquefied petroleum gas, catalytic cracked gasoline, catalytic cracked diesel oil, and catalytic cracking cycle oil; wherein the hydrogenated tail oil and / or normal catalytic cracking feedstock oil are separated into at least two fractions, the light and the heavy fractions or normal catalytic cracking heavy feedstock oil and normal catalytic cracking light feedstock oil, prior to contacting the hydrogenated tail oil and / or normal catalytic cracking feedstock oil with the cracking catalyst. The process according to the present invention is especially suitable for conversion of hydrocarbon oils to produce more products of gasoline or diesel oil.

Owner:CHINA PETROCHEMICAL CORP +1

Ink-jet recording method

InactiveUS6786586B2Increase speedIncrease dissociationMeasurement apparatus componentsDuplicating/marking methodsFiberComputer printing

An ink-jet recording method is provided in that upon carrying out printing at a high speed as equivalent to laser printers by using the plain paper, the optical density and the coloring property of the image are high with less occurrence of intercolor breed and feathering, and the image has high water resistance. The method contains a step of printing on recording paper having base paper mainly containing pulp fibers and a filler by using a pigment ink of at least one color at a scanning speed of a printing head of 25 cm / sec or more and a maximum ink injection amount in a range of from 6 to 30 mL / m<2>, the ink having a surface tension in a range of from 20 to 35 mN / m, and an aggregation degree of a pigment contained in the ink in contact with a surface of the recording paper being 5 or more.

Owner:FUJIFILM BUSINESS INNOVATION CORP

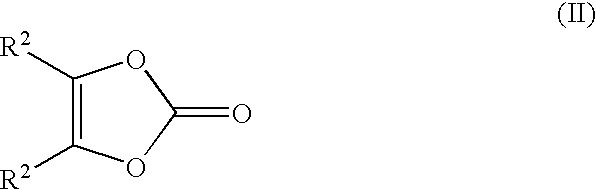

High rate electrolyte for lithium ion battery

ActiveCN1925207AIncrease dissociationImprove mobilityOrganic electrolyte cellsSecondary cellsHigh ratePhysical chemistry

This invention relates to lithium ion battery electrolyte with high times and discloses the main components as following: vinylene carbonate for 10 to 30 percentage; propylene carbonate for 4 to 20 percentage; dimethyl carbonate for 35 to 50 percentage; methyl carbonate for 10 t0 20 percentage; lithium salt for 12.5 to 16 percentage and B(OR)<3> with R representing carbon atoms less than 4 or crown ether of one or more function addictives for 0.1 to 5.0 percentage.

Owner:GUANGZHOU TINCI MATERIALS TECH

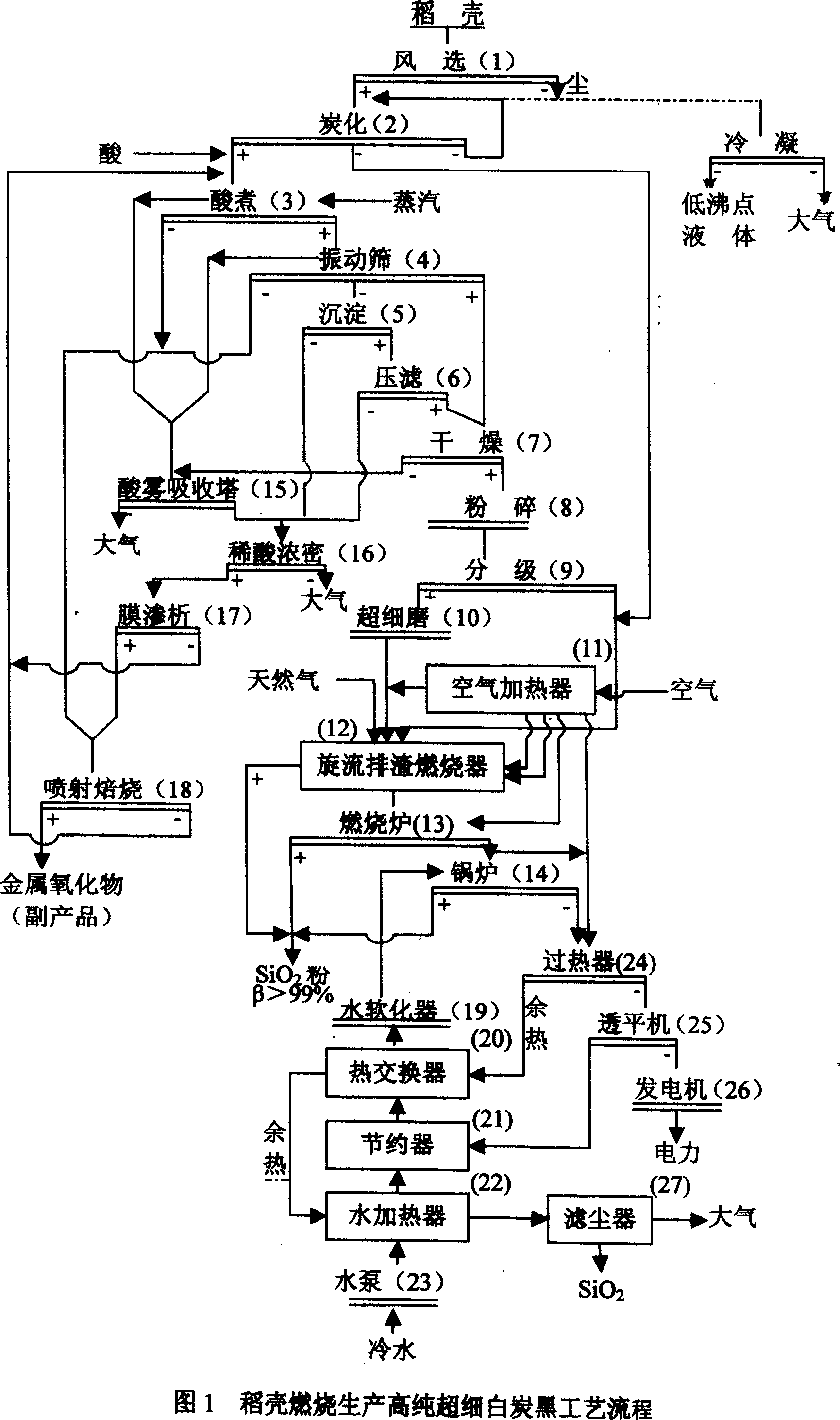

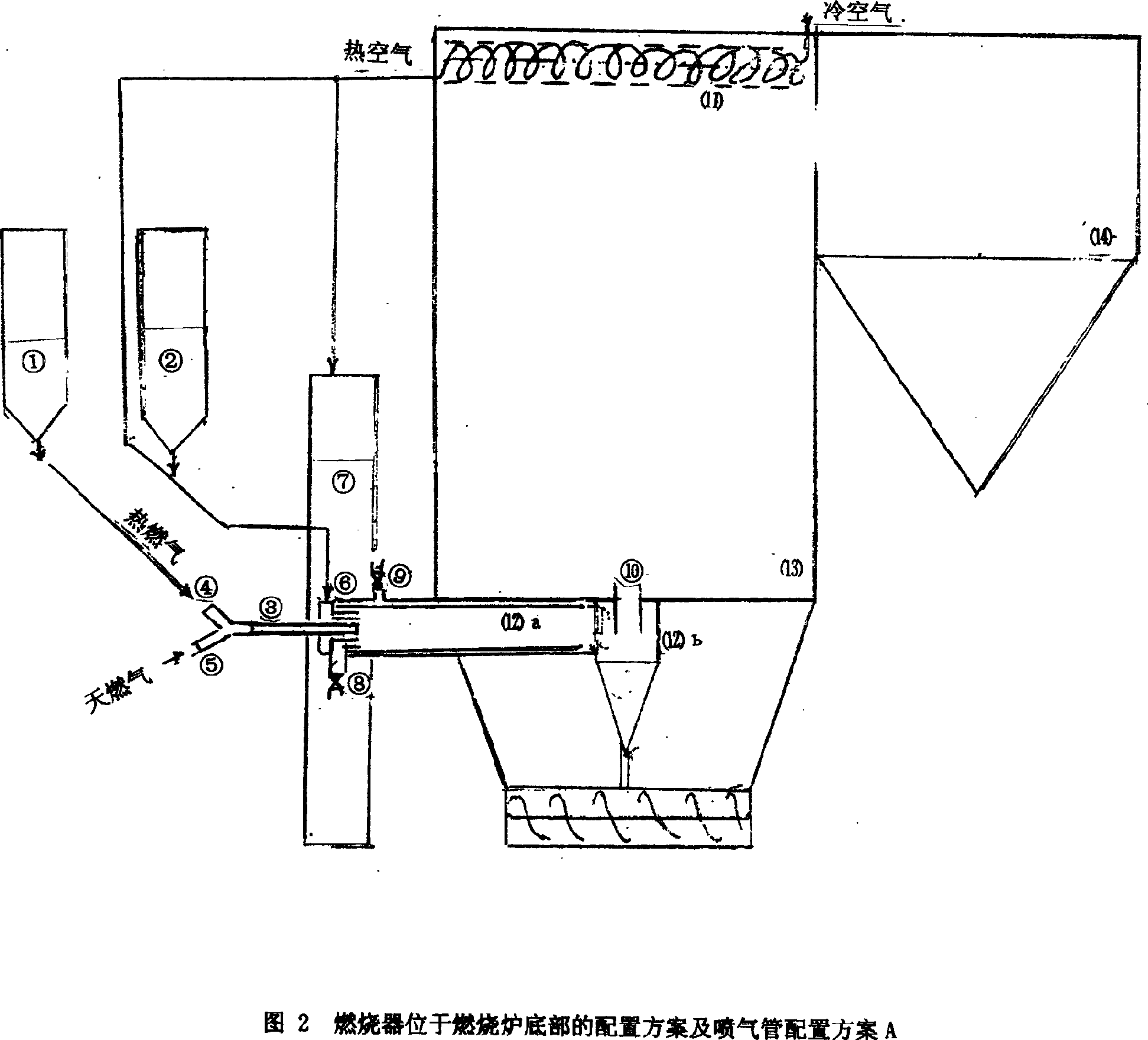

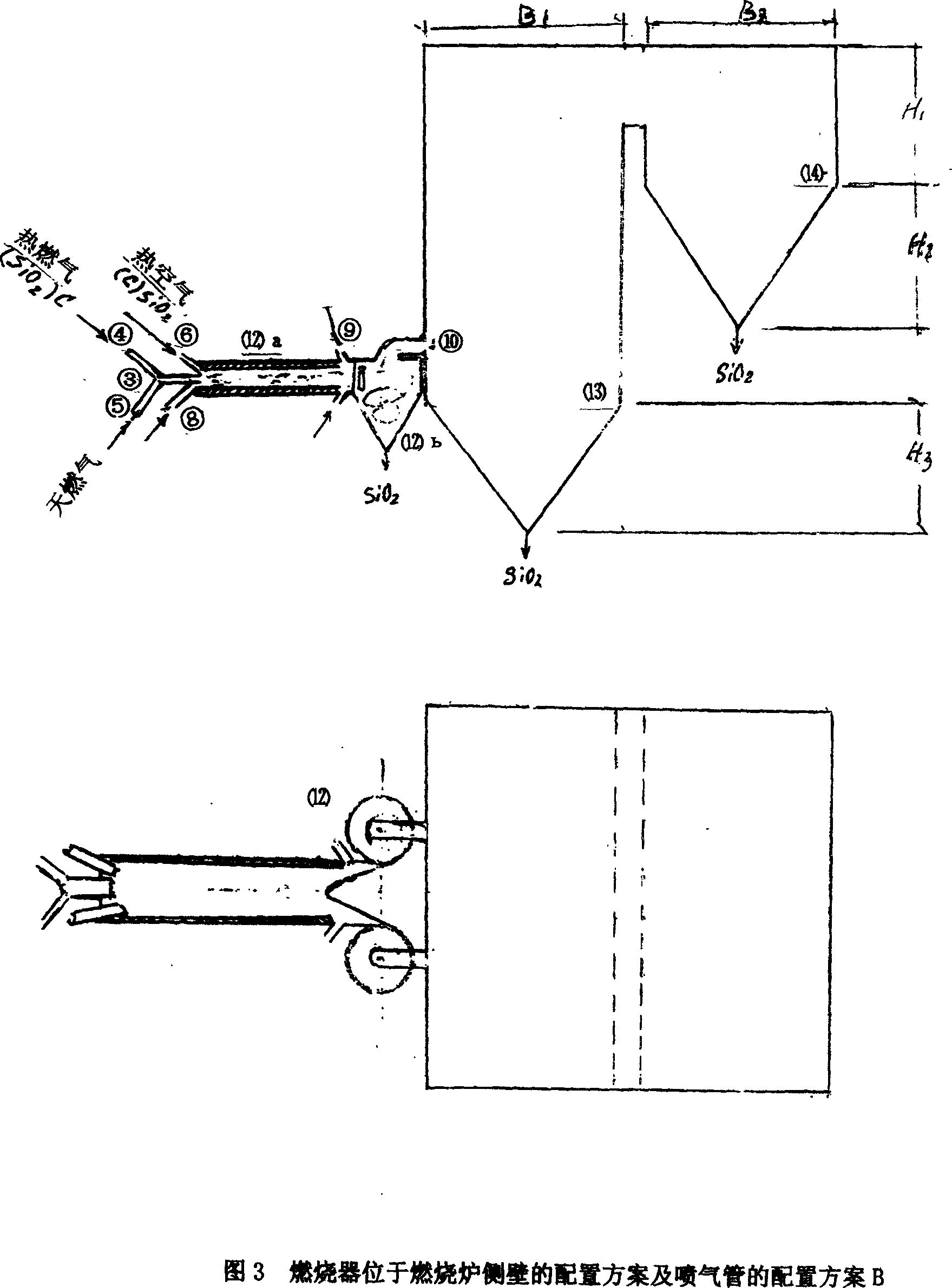

Process for producing super-fine high-purity white carbon from rice hull and burning heat

InactiveCN101028926AIncrease dissociationImprove product qualitySilicaCombustion systemProcess engineering

A process for preparing high-purity superfine white carbon black from rice husk by the heat generated by burning the rice husk includes such steps as charring, acid treating, pulverizing, sieving, burning in a serial combustion system to obtain white carbon black and waste acid, and treating the waste acid for reuse.

Owner:郭梦雄

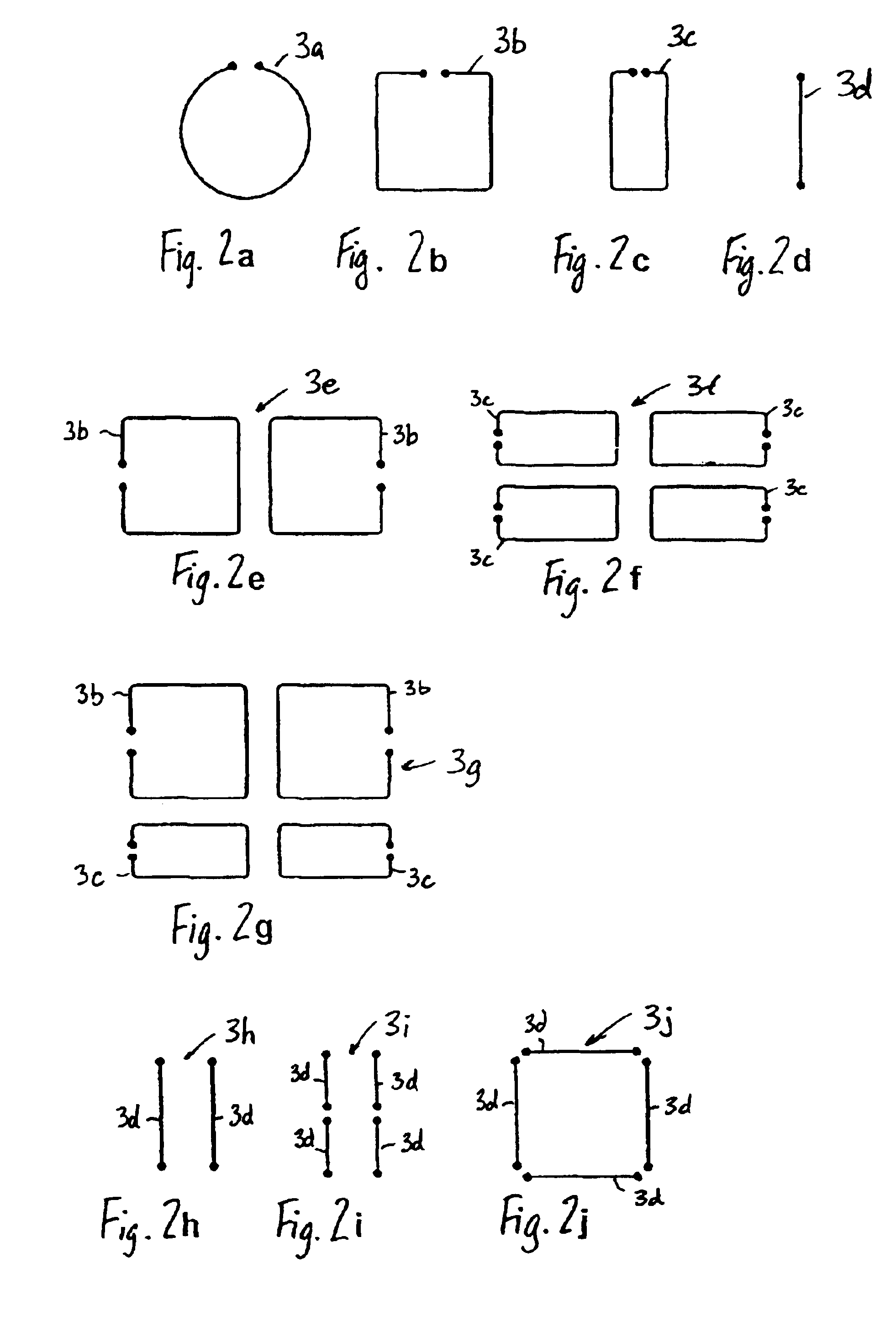

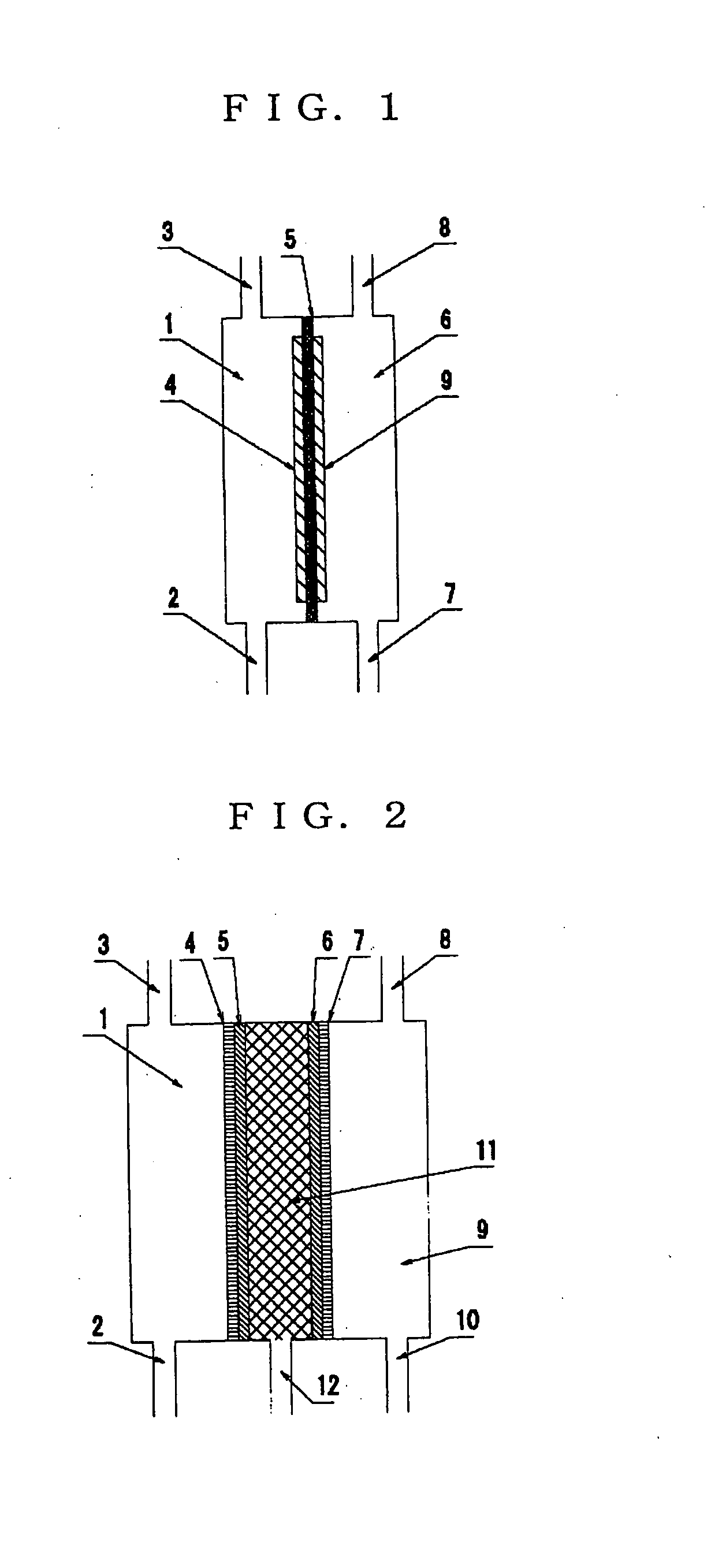

High frequency plasma source

InactiveUS6936144B2Improve versatilityImprove functionalityCellsElectric discharge tubesDistribution systemField coil

A high frequency plasma source includes a support element, on which a magnetic field coil arrangement, a gas distribution system and a unit for extraction of a plasma beam are arranged. Additionally a high frequency matching network is arranged within the plasma source.

Owner:CCR GMBH BESCHICHTUNGSTECH

Non-Aqueous Electrolyte for Battery and Non-Aqueous Electrolyte Secondary Battery Comprising the Same

InactiveUS20080254361A1Improve conductivity stabilityImprove conductivityElectrolytesLi-accumulatorsAlkoxy groupPhysical chemistry

This invention relates to a non-aqueous electrolyte for a battery capable of simultaneously establishing a high flame retardance and excellent battery performances, and more particularly to a non-aqueous electrolyte for a battery comprising a non-aqueous solvent and a support salt, characterized in that the non-aqueous electrolyte for the battery further contains a fluorophosphate compound represented by the following general formula (I):[wherein R1s are independently fluorine, an alkoxy group or an aryloxy group and at least one of two R1s is the alkoxy group or the aryloxy group, provided that two R1s may be bonded with each other to form a ring].

Owner:BRIDGESTONE CORP

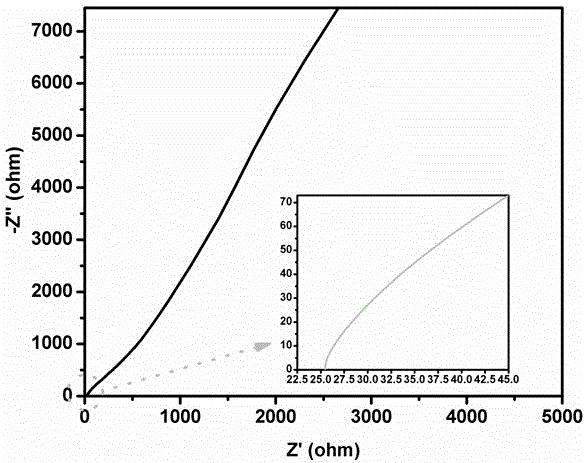

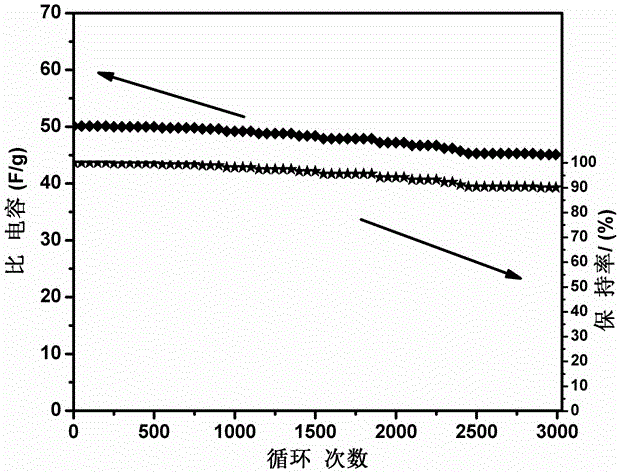

Boron-containing gel polymer electrolyte and preparation method and application thereof

ActiveCN106432608AImprove mechanical propertiesIncrease dissociationSecondary cellsElectrolyte immobilisation/gelificationIon transport numberPolymer science

The invention belongs to the technical field of polymer electrolytes, and particularly relates to a boron-containing gel polymer electrolyte and a preparation method and application thereof. The gel polymer electrolyte is prepared from lithium salt, an organic solvent, a photoinitiator, boron-containing heterocyclic photosensitive monomers and acrylate monomers in a copolymerization mode. The preparation method of the gel polymer electrolyte includes the steps that a compound containing boric acid groups and an alkene compound with a diol structure are esterified to obtain boron-containing heterocyclic alkene monomers, and the boron-containing heterocyclic alkene monomers, the acrylate monomers, the photoinitiator, the lithium salt and the organic solvent are uniformly dispersed; a mould containing the mixed solution is irradiated by an LED lamp for surface photo-initiated polymerization, and the boron-containing gel polymer electrolyte is obtained. The boron-containing gel polymer electrolyte has high ionic conductivity and a high cationic transference number, effectively solves the problems of liquid leakage, corrosion, poor mechanical performance and the like of a liquid electrolyte in traditional lithium-ion batteries and can be applied to preparation of supercapacitors, lithium-ion batteries, hybrid supercapacitors and the like.

Owner:FUDAN UNIV

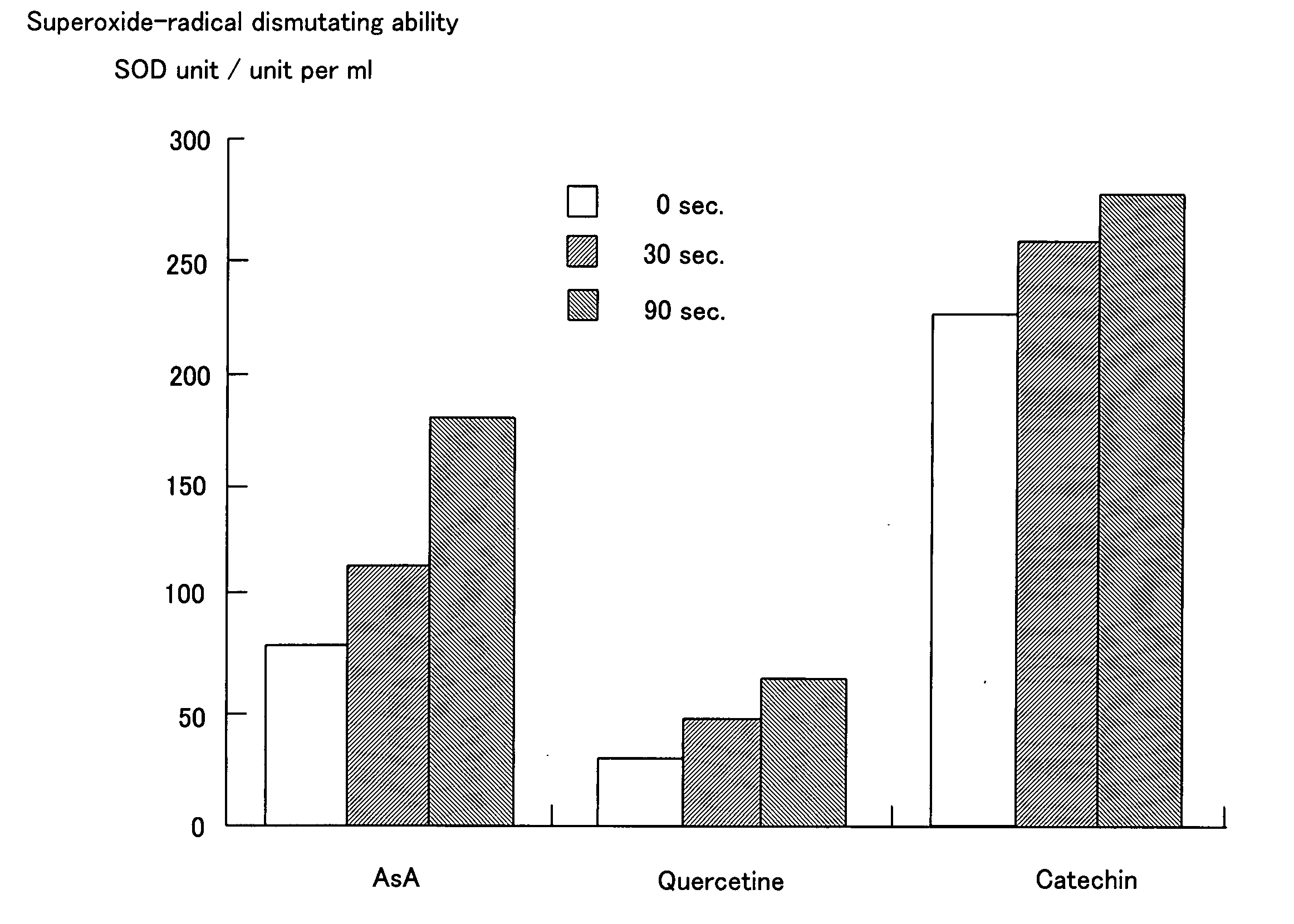

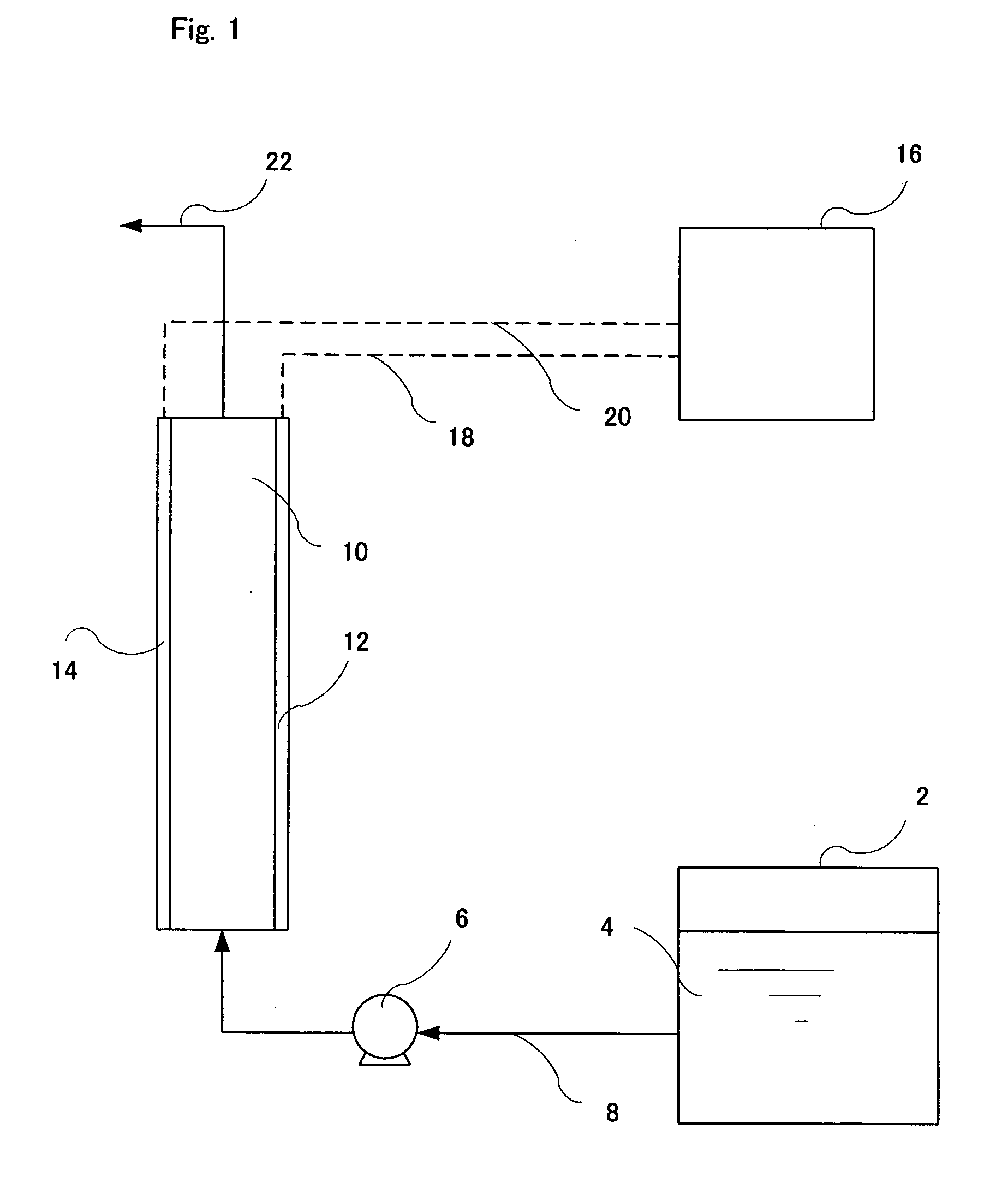

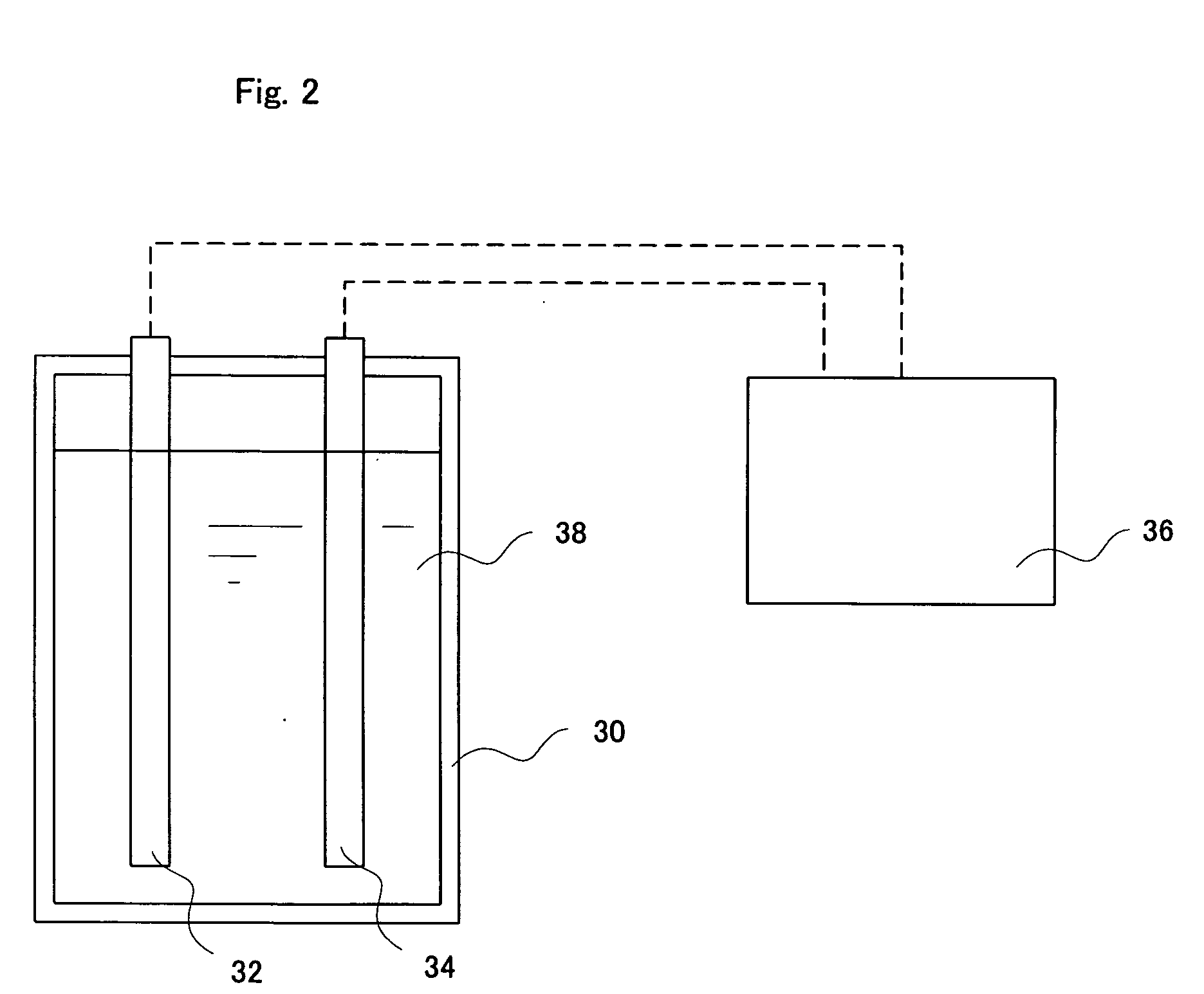

Process for preducing mixed electrolyzed water

InactiveUS20060065544A1Efficient mixingImprove abilitiesWater treatment parameter controlPhotography auxillary processesInorganic saltsElectrolysis

This invention discloses a process for preparing a mixed electrolyzed water consisting of a cathodic and an anodic electrolyzed waters comprising the step of electrolyzing an aqueous solution of an organic electrolyte containing a water-soluble inorganic salt in less than 0.1 mM and an organic electrolyte in 1 to 50 mM which is fed into a non-diaphragm electrolytic bath comprising at least a pair of inactive electrodes separated from each other by an inter-electrode distance of 2 mm or less, wherein the aqueous solution of an organic electrolyte with pH equal to that of the mixed electrolyzed water prepared by electrolysis is neutralized with a titration volume less than that for the raw aqueous solution in neutralization titration with an aqueous solution of sodium hydroxide or has a higher dismutation activity to superoxide radical per mole than the raw aqueous solution.

Owner:MIKUNI CORP +1

Combined process of hydrotreating and catalytic cracking of hydrocarbon oils

ActiveUS20130062250A1Big ratioIncrease productionCatalytic crackingTreatment with plural parallel cracking stages onlyHydrogenResidual oil

Disclosed is a combination process for improved hydrotreating and catalytic cracking of hydrocarbon oils, including: contacting residual oil, catalytic cracking cycle oil, and optional distillate oil with a hydrotreating catalyst under hydrotreating conditions in the presence of hydrogen followed by separation of the reaction products to obtain hydrogenated tail oil and other products; contacting the hydrogenated tail oil and optional normal catalytic cracking feedstock oil with a cracking catalyst under catalytic cracking conditions followed by separation of the reaction products; wherein the hydrogenated tail oil and / or normal catalytic cracking feedstock oil are separated into at least two fractions prior to contacting the hydrogenated tail oil and / or normal catalytic cracking feedstock oil with the cracking catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

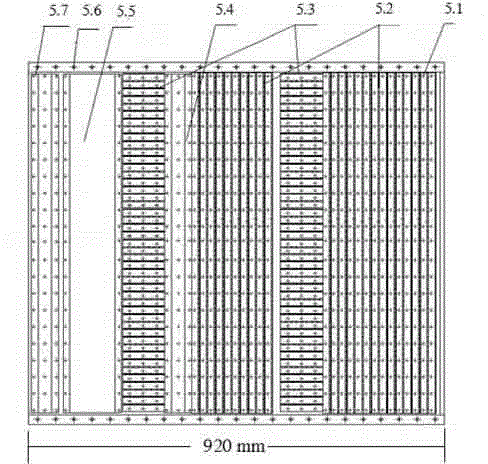

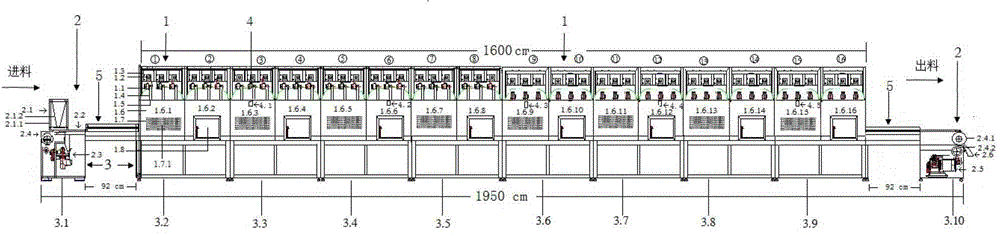

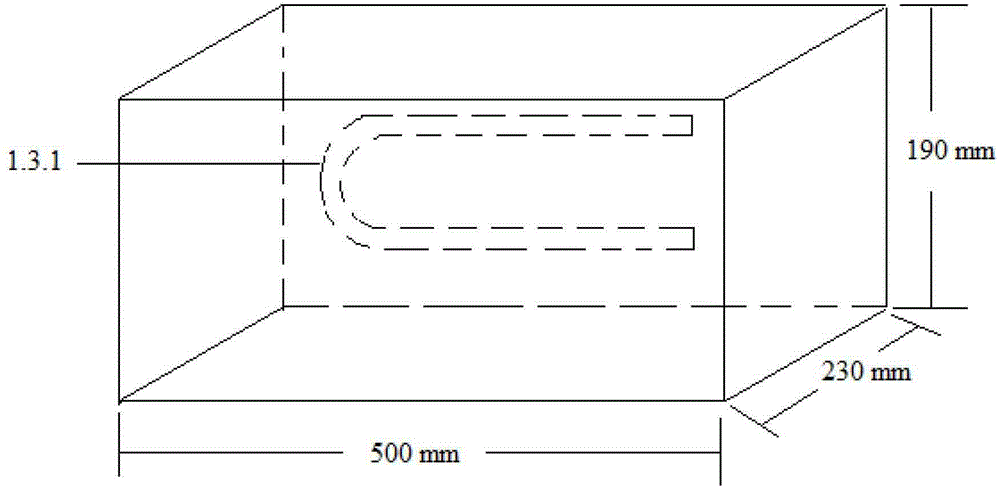

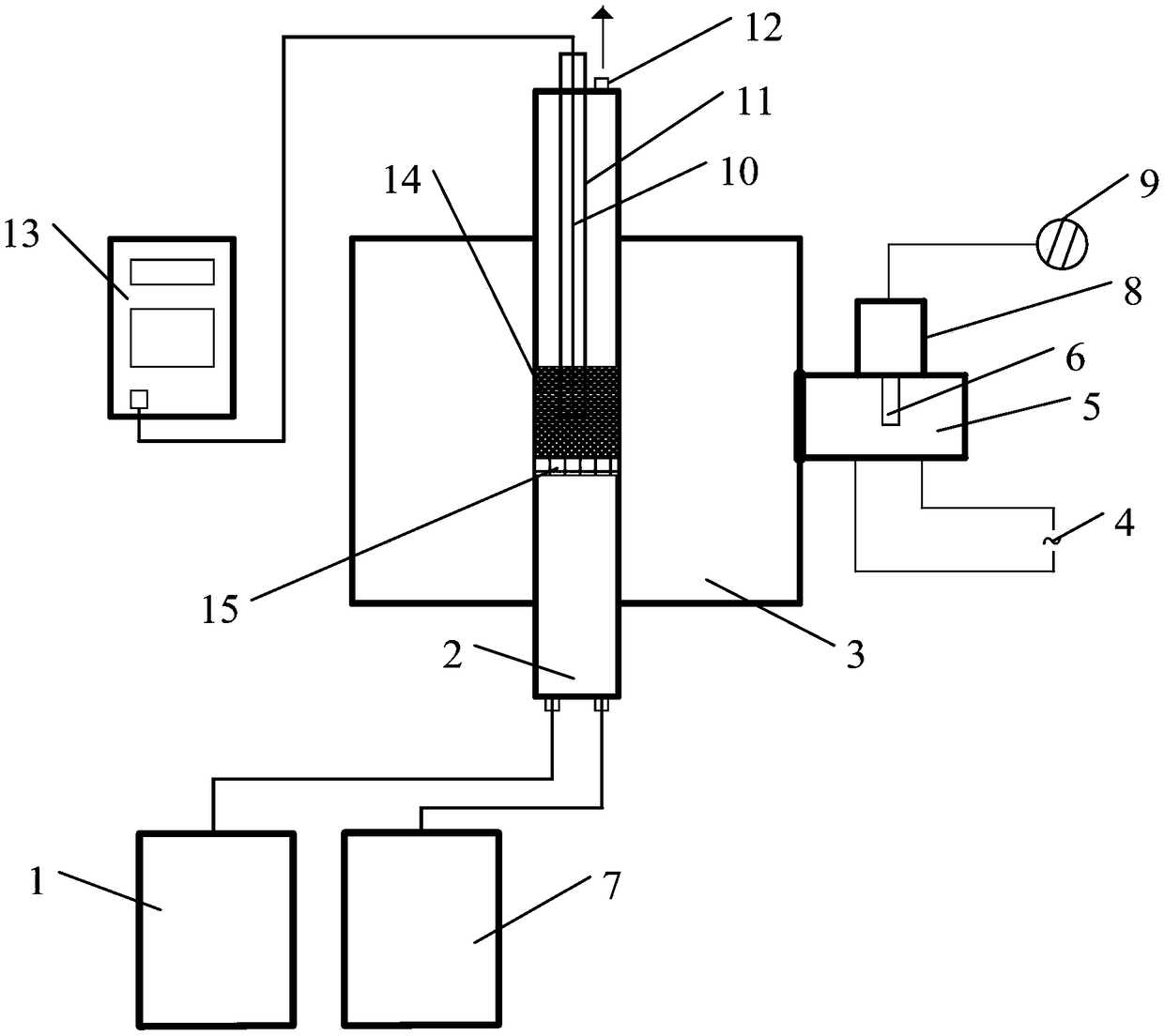

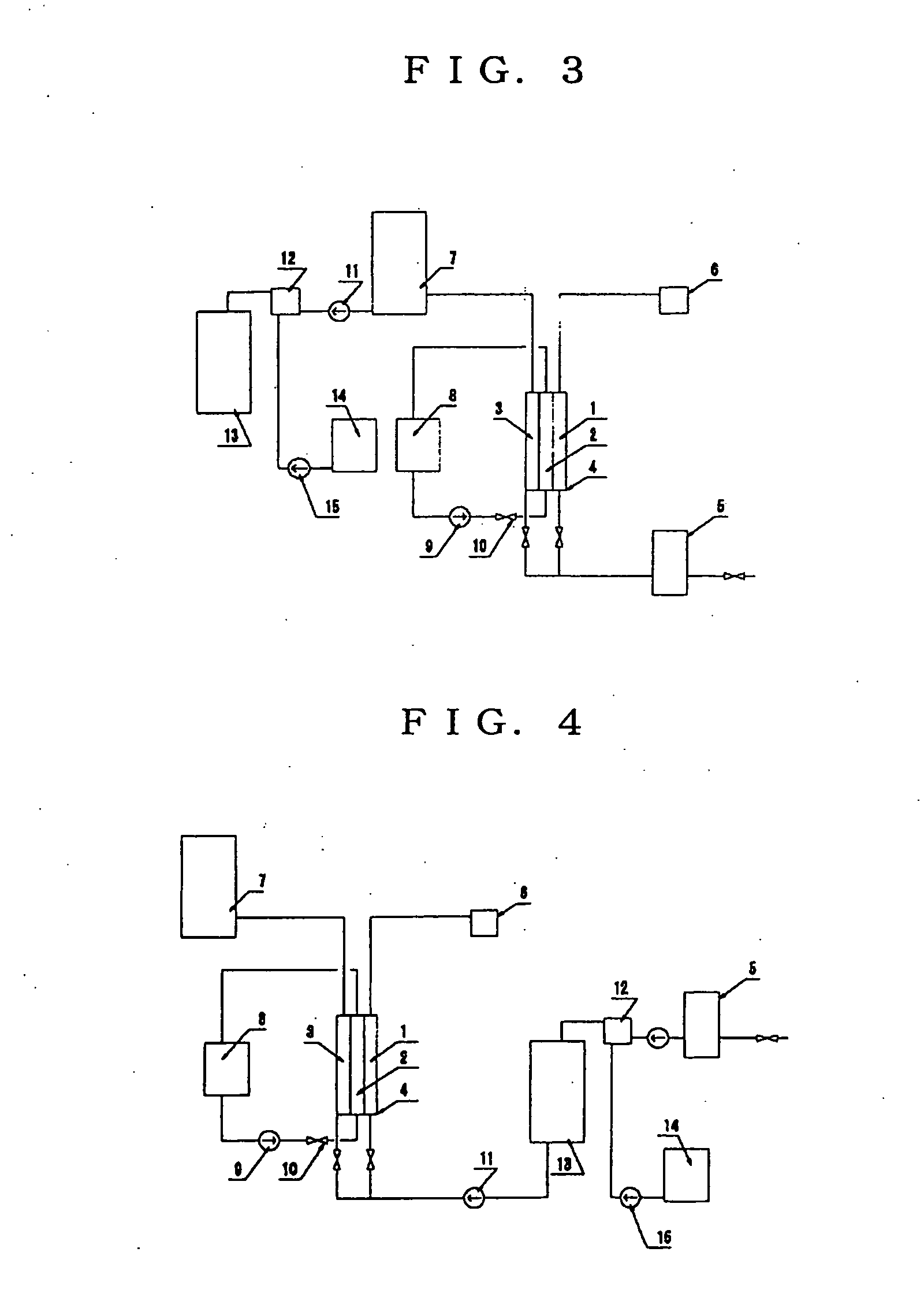

Microwave processing device for dump leaching uranium ores

The invention discloses a microwave processing device for the dump leaching uranium ores. The device uses microwave to carry out irradiation to dump leaching uranium ores, due to the fact that differences exist among the microwave temperature rising effects of different minerals inside the uranium ore particles, heat stress differences are generated among the different minerals inside the uranium ore particles, the grain boundaries of the different minerals inside uranium ore particles break and the cracks inside the particles extend, therefore the poriness of the uranium ore particles is increased, the permeability of the inner portions of the uranium ore particles is improved, the dissociation degree of the uranium ores is improved, the leaching efficiency of the dump leaching of the uranium ores is improved, and a leaching period is shortened. The whole equipment comprises 16 microwave units, a material conveying system, a support, a temperature detecting and controlling system and a microwave suppressor. When the microwave processing device for the dump leaching uranium ores is used to process the dump leaching uranium ores, the microwave processing device has the advantages of being good in the matching of microwave power and the uranium ores, low in processing energy consumption, large in processing quantity, stable in material conveying, and small in microwave leakage, the poriness of the uranium ores and the dissociation degree of the uranium ores are further improved, the leaching efficiency is further improved, and the leaching period is further shortened and the like. The microwave processing device for the dump leaching uranium ores is also suitable for the processing of dump leaching gold ores, dump leaching copper ores and other dump leaching ores, and has obvious effect in increasing poriness of ore particles, improving the permeability of the inner portion of the ore particles, improving the dissociation degree of useful ores, improving leaching efficiency, and shortening leaching efficiency.

Owner:NANHUA UNIV

Boron-containing solid polymer electrolyte and preparation method and application thereof

InactiveCN106229547AHigh lithium ion transfer numberIncrease dissociationHybrid capacitor electrolytesSecondary cellsPolymer scienceIon transport number

The invention belongs to the technical field of an electrolyte material, especially a boron-containing solid polymer electrolyte and a preparation method and application thereof. The polymer electrolyte provided by the invention comprises high molecular polymer matrix and electrolyte salt. The preparation method comprises the steps of esterifying boric acid-containing compounds and alkene compounds with diol structures, thereby obtaining boron heterocycle-containing vinyl monomer, uniformly dispersing the boron heterocycle containing vinyl monomer, initiator, the electrolyte salt and organic solvent, carrying out free radical polymerization, and drying obtained mixture, thereby obtaining the boron-containing solid polymer electrolyte. The boron-containing solid polymer electrolyte has the advantages of high ion conductivity, high cation transference number, good mechanical property and excellent electrode / electrolyte interface interaction and can be applied to fields such as a supercapacitor, a lithium ion battery, a hybrid supercapacitor and a fuel battery. The supercapacitor assembled with the polymer electrolyte has the advantages of wide electrochemical window, long cycle life and high security.

Owner:FUDAN UNIV

Microwave-fluid bed roasting method for intensifying separation of complex refractory iron ore

A microwave-fluid bed roasting method for intensifying separation of complex refractory iron ore comprises the following steps of (1) fine grinding the complex refractory iron ore to obtain iron ore powder, then putting the iron ore powder on a quartz mesh in a reaction chamber, and plugging into a thermocouple; (2) introducing protective gas into the reaction chamber to make the iron ore powder be in a fluidized state; (3) generating a microwave by a magnetron of a microwave cavity outside the reaction chamber to heat the iron ore powder; (4) when the temperature of the iron ore powder risesto reaction temperature, introducing reducing gas to make the iron ore powder have a microwave-fluid bed roasting reaction; and (5) cooling to normal temperature after the reaction is ended, taking out microwave roasted ore, and performing low intensity magnetic separation after ore grinding. According to the method disclosed by the invention, through the specific selective heating advantage of the microwave, single separation degree and grindability of the ore are obviously improved, and resource recovery and efficient development and utilization of the complex refractory iron ore are realized.

Owner:NORTHEASTERN UNIV

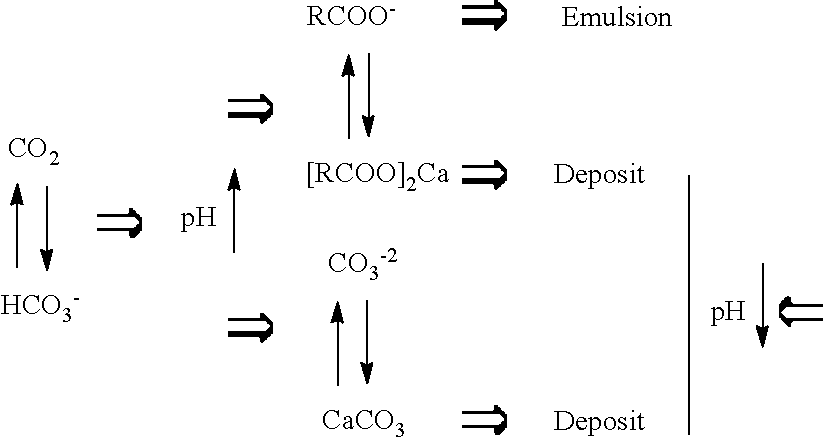

Method and apparatus for enhanced sequencing of complex molecules using surface-induced dissociation in conjunction with mass spectrometric analysis

InactiveUS20060043285A1Increase dissociationLow quantity requiredParticle separator tubesIsotope separationBiologyMass spectrometric

The invention relates to a method and apparatus for enhanced sequencing of complex molecules using surface-induced dissociation (SID) in conjunction with mass spectrometric analysis. Results demonstrate formation of a wide distribution of structure-specific fragments having a wide sequence coverage useful for sequencing and identifying the complex molecules.

Owner:BATTELLE MEMORIAL INST

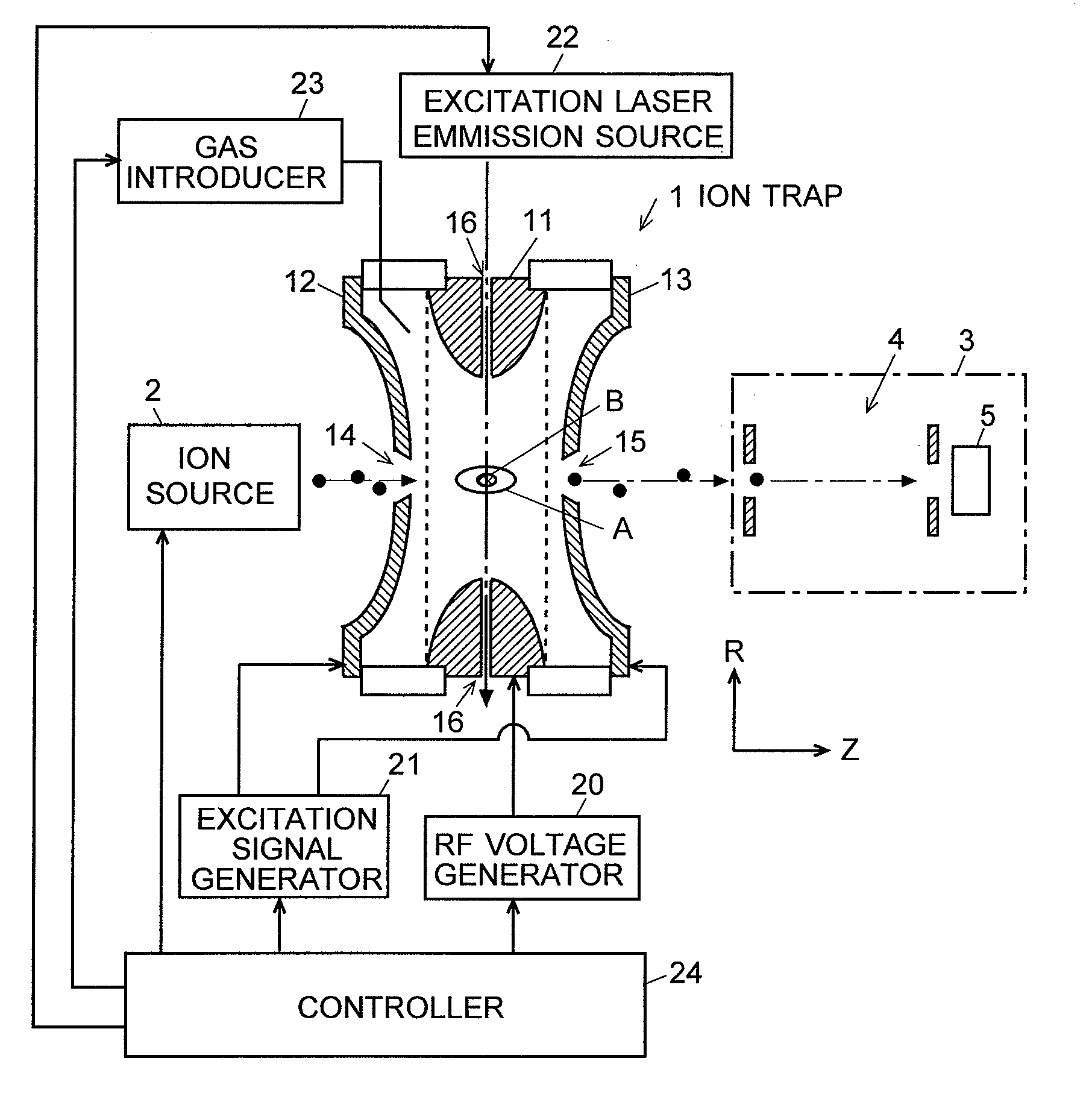

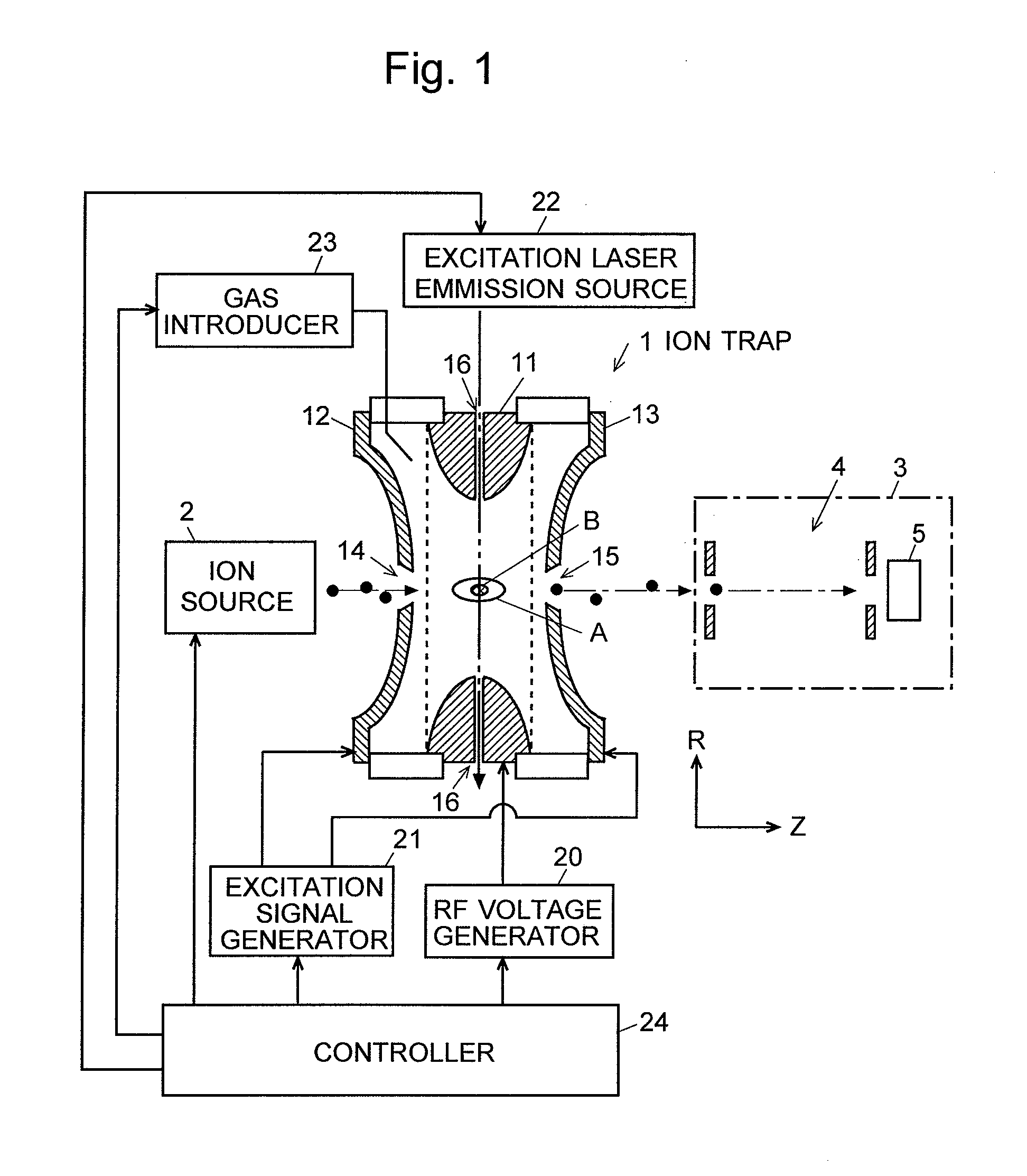

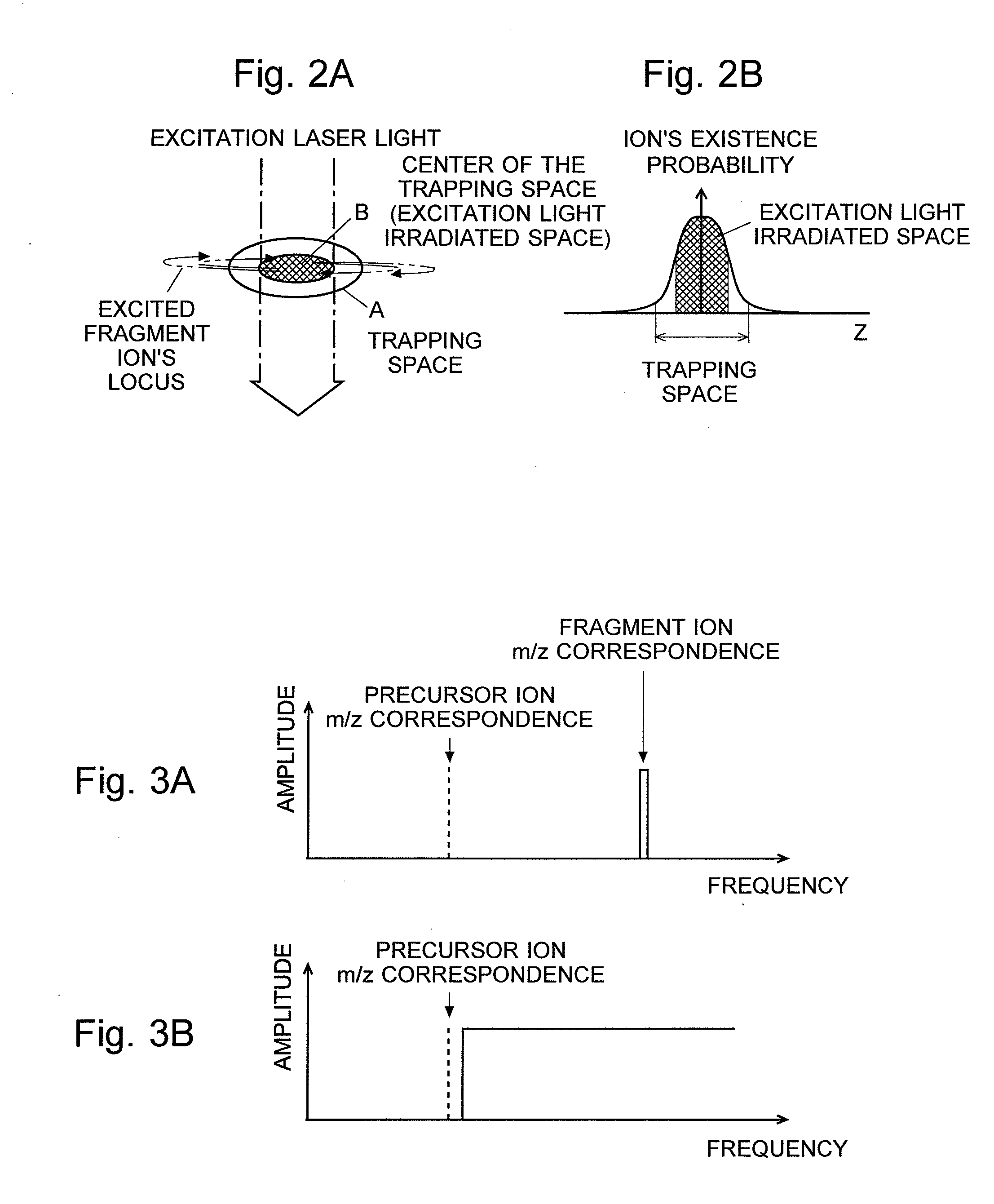

Mass spectrometer

InactiveUS20110168883A1Improve signal-to-noise ratioIncrease dissociationIsotope separationMass spectrometersIon trap mass spectrometryTrapping

A mass spectrometer is provided that restrains the signal intensity of an MS / MS spectrum from decreasing according to the secondary dissociation of a primary fragment ion generated by a photodissociation. An excitation laser light for causing a photodissociation is irradiated to the trapping space A in the ion trap 1. At the same time, an excitation signal that does not excite a precursor ion but excites fragment ions is applied to the end cap electrodes 12 and 13. Since the selected precursor ions gather around the center of the trapping space A, they are irradiated by the excitation laser light and efficiently dissociated. The fragment ions generated by this are immediately excited by the excitation electric field's effect, and are vibrated wildly to be out of the excitation light irradiated space B. Therefore, the fragment ions are not easily irradiated by the excitation laser light and the secondary dissociation does not easily occur.

Owner:SHIMADZU CORP

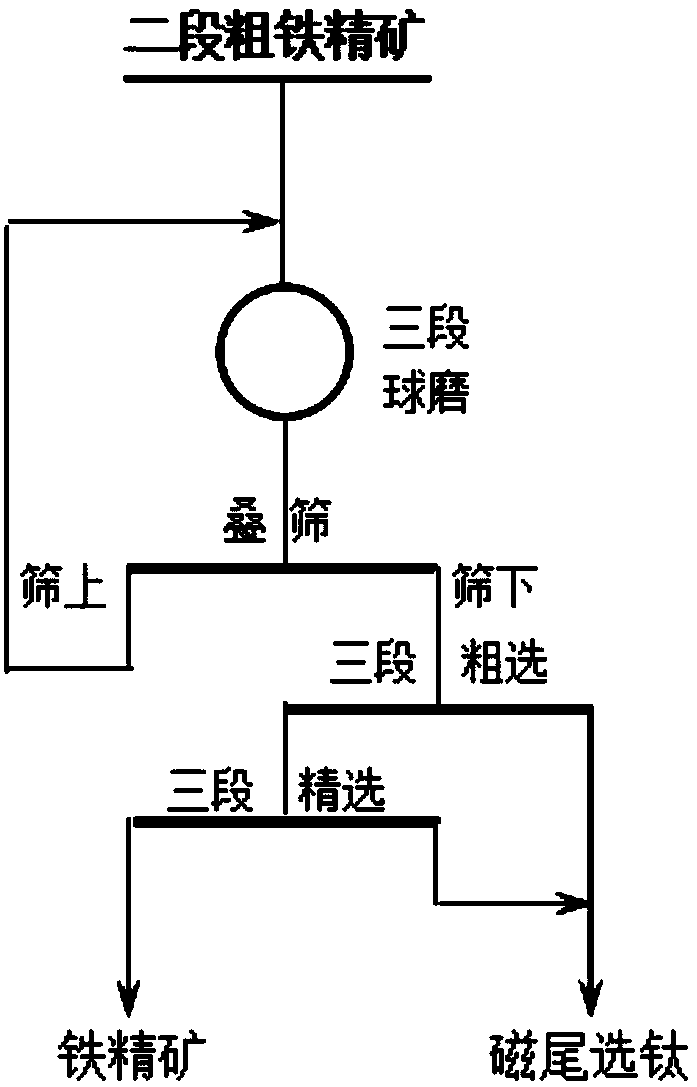

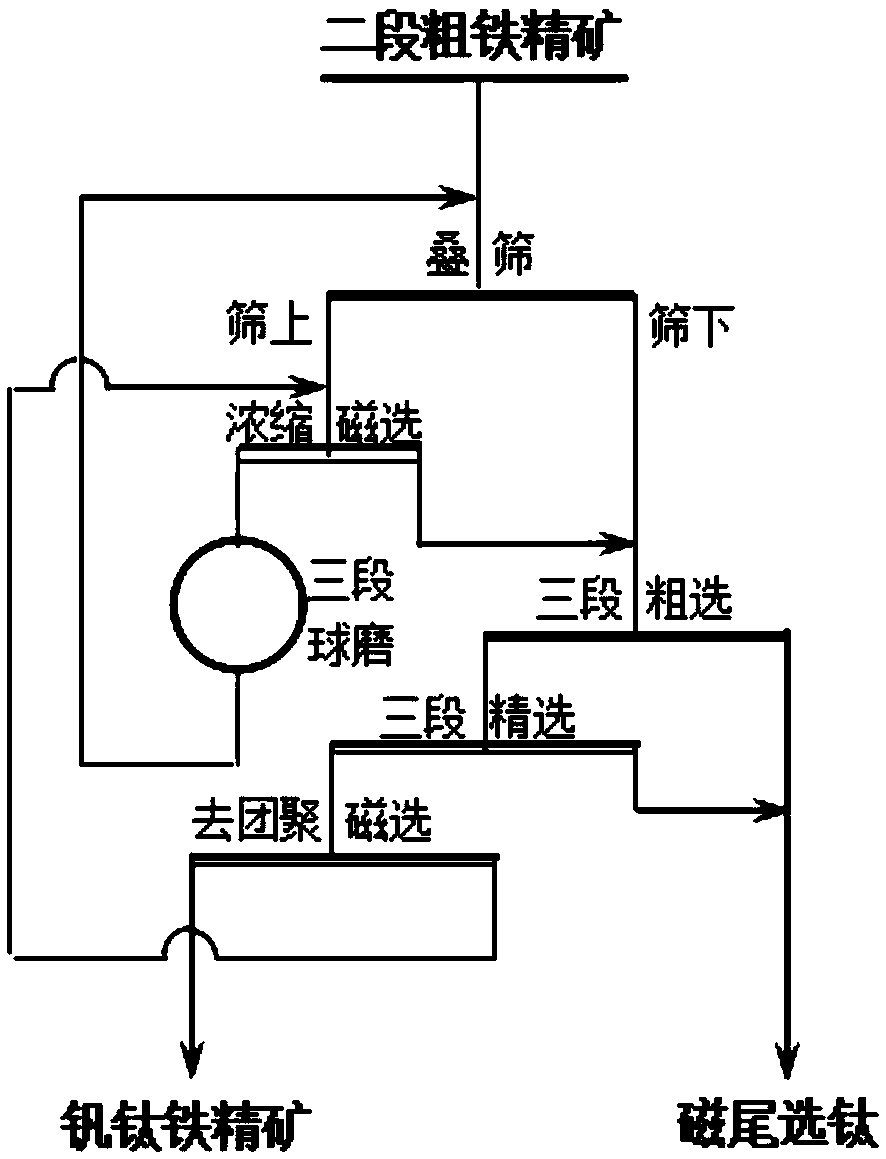

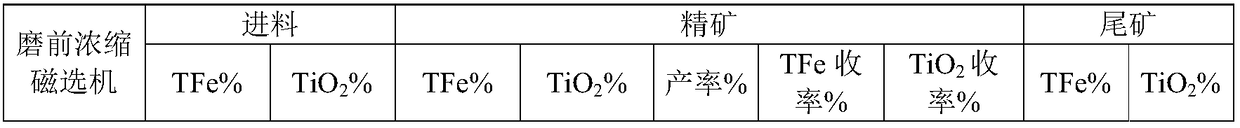

Technological method for improving quality of vanadium-titanium iron concentrates

InactiveCN109395873AReduce overgrindingImprove processing powerGrain treatmentsWet separationTitaniumMaceral

The invention relates to a technological method for improving the quality of vanadium-titanium iron concentrates. Various techniques are integrated. The technological method includes preliminary classification, fine screening classification, three-section ore grinding, concentration magnetic separation and stair magnetic separation. In preliminary classification, a qualified fraction part good indissociation in rough iron concentrates can be effectively classified out, the treatment capability of a mill is improved, and energy consumption of the product is lowered. In fine screening classification, a fine screening closed loop is adopted for cyclic ore grinding, compared with common rotational flow classification, classification is conducted strictly according to the particle size, meanwhile, the classification efficiency reaches up to 70% or higher, the qualified fraction is better classified out in time, excessive grinding is reduced, and cyclic loads are reduced. In concentration magnetic separation, concentration magnetic section is adopted before ore grinding, part of weak magnetic titanium ore and gangue can be removed out, excessive grinding of the titanium ore is reduced,and the titanium iron ore recycling rate is increased; and meanwhile, the ground ore grade is improved, the yield is increased, and the product cost is reduced. In stair magnetic separation, iron andtitanium separation is well achieved, and the iron concentrate grade is improved step by step.

Owner:SICHUAN LOMON MINING & METALLURGY

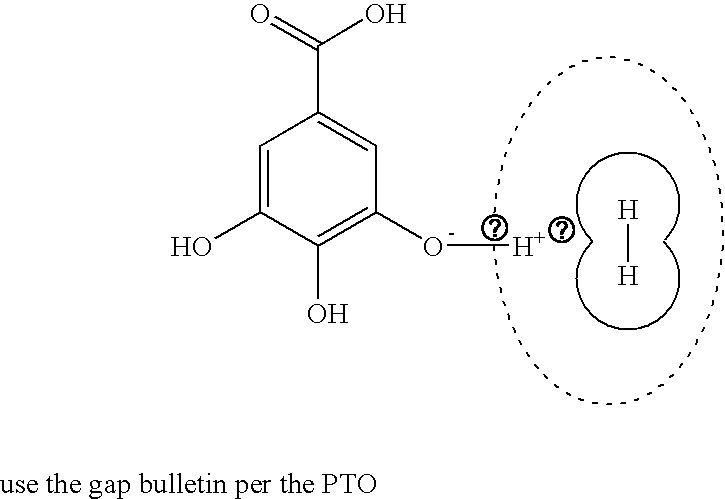

Hydrogen-dissolved aqueous solution and method for prolonging the life duration of hydrogen dissolved in the aqueous solution

InactiveUS20100062113A1Helpful to maintenance/promotion of healthLong life durationDispersion deliveryInorganic active ingredientsHydrogenGlycoside formation

Provided is an aqueous solution in which hydrogen dissolved therein has a long life duration at low cost. Specifically disclosed is an aqueous solution having hydrogen dissolved therein at a concentration of not less than 0.01 ppm and not higher than the saturated concentration, wherein the aqueous solution contains a substance having a reducing aldehyde group and / or a glycoside hydroxyl group in an amount of 10 to 300000 ppm.

Owner:SPRING

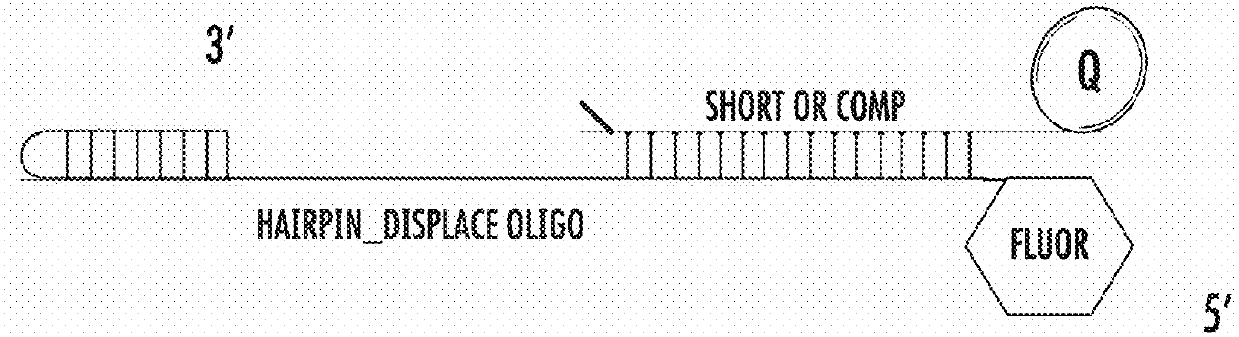

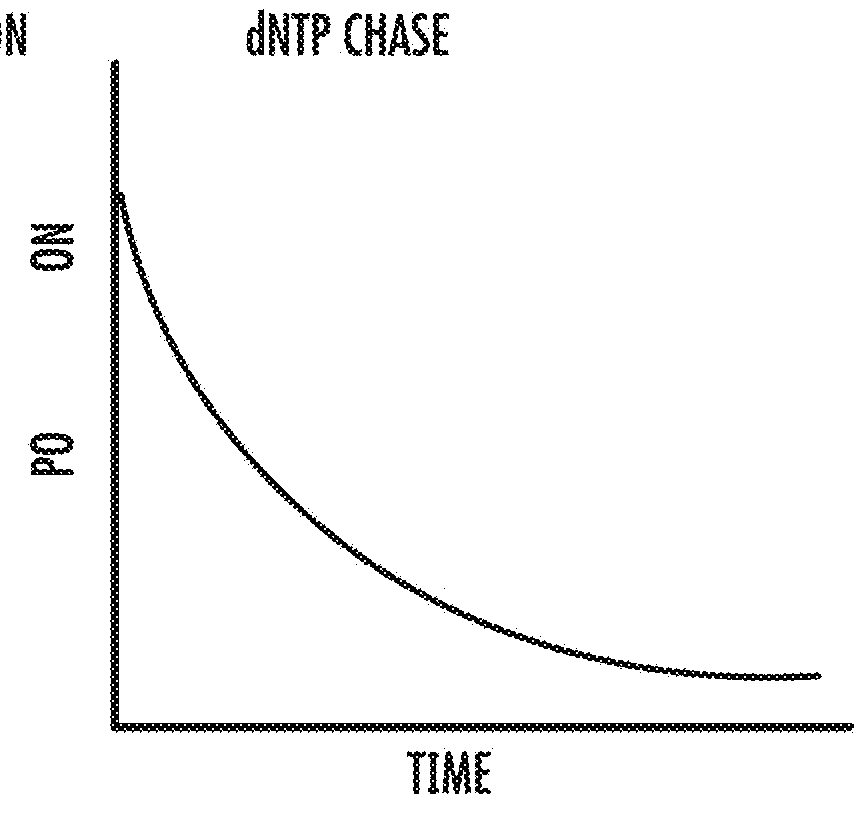

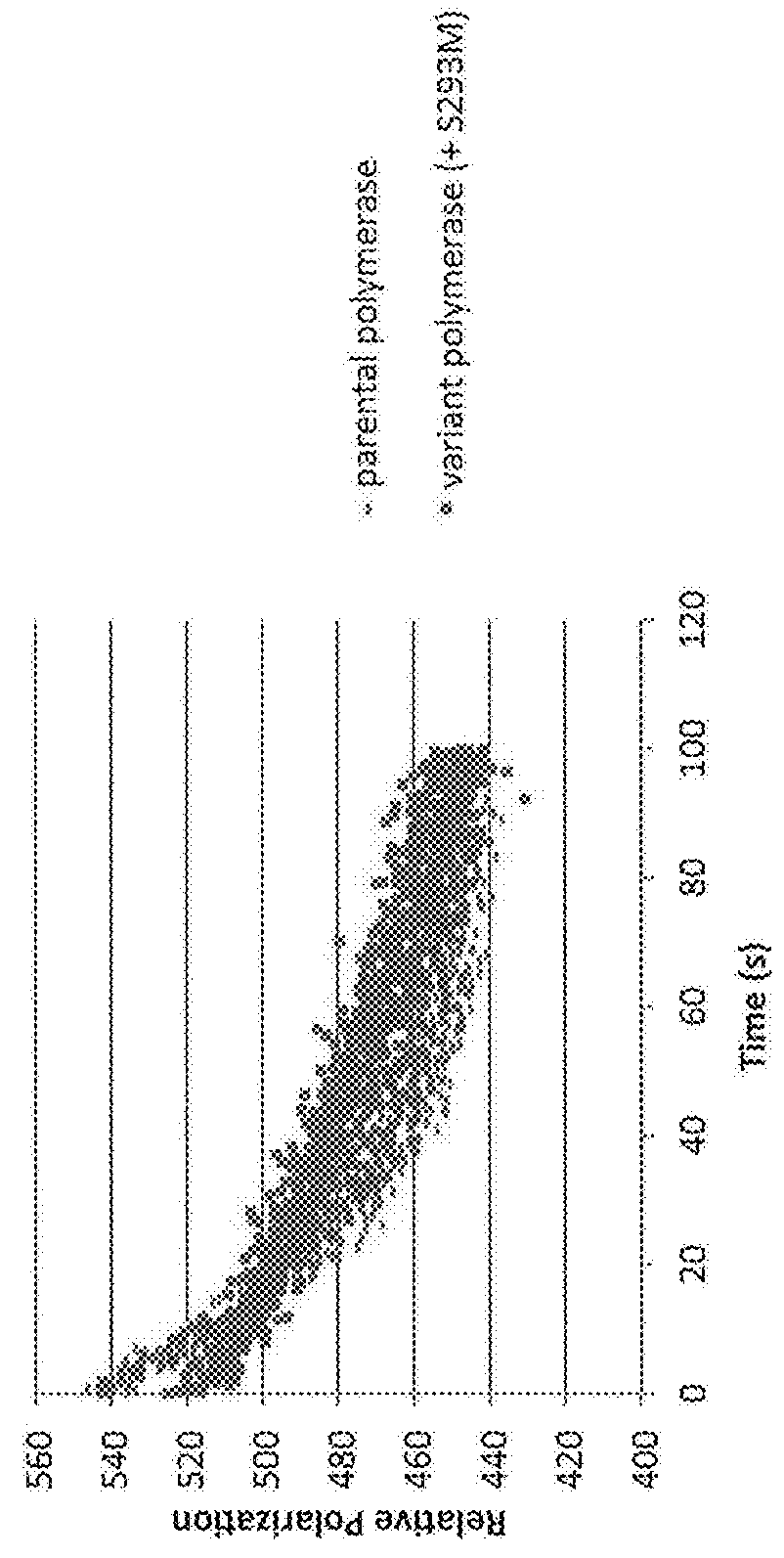

Polymerase Variants

ActiveUS20180094249A1Improved strand displacementCharacteristic can be alteredMicrobiological testing/measurementTransferasesBiotechnologyPolymerase L

The present disclosure provides variant Pol6 polymerase polypeptides, compositions comprising the Pol6 variant polypeptides, and methods for using the variant Pol6 polypeptides for determining the sequencing of nucleic acids, for example, by nanopore sequencing. The variant Pol6 polymerases possess decreased rates of dissociation of template from the polymerase-template complex, which result in increased processivity relative to the parental Pol6 polypeptides from which they are derived.

Owner:ROCHE SEQUENCING SOLUTIONS INC +1

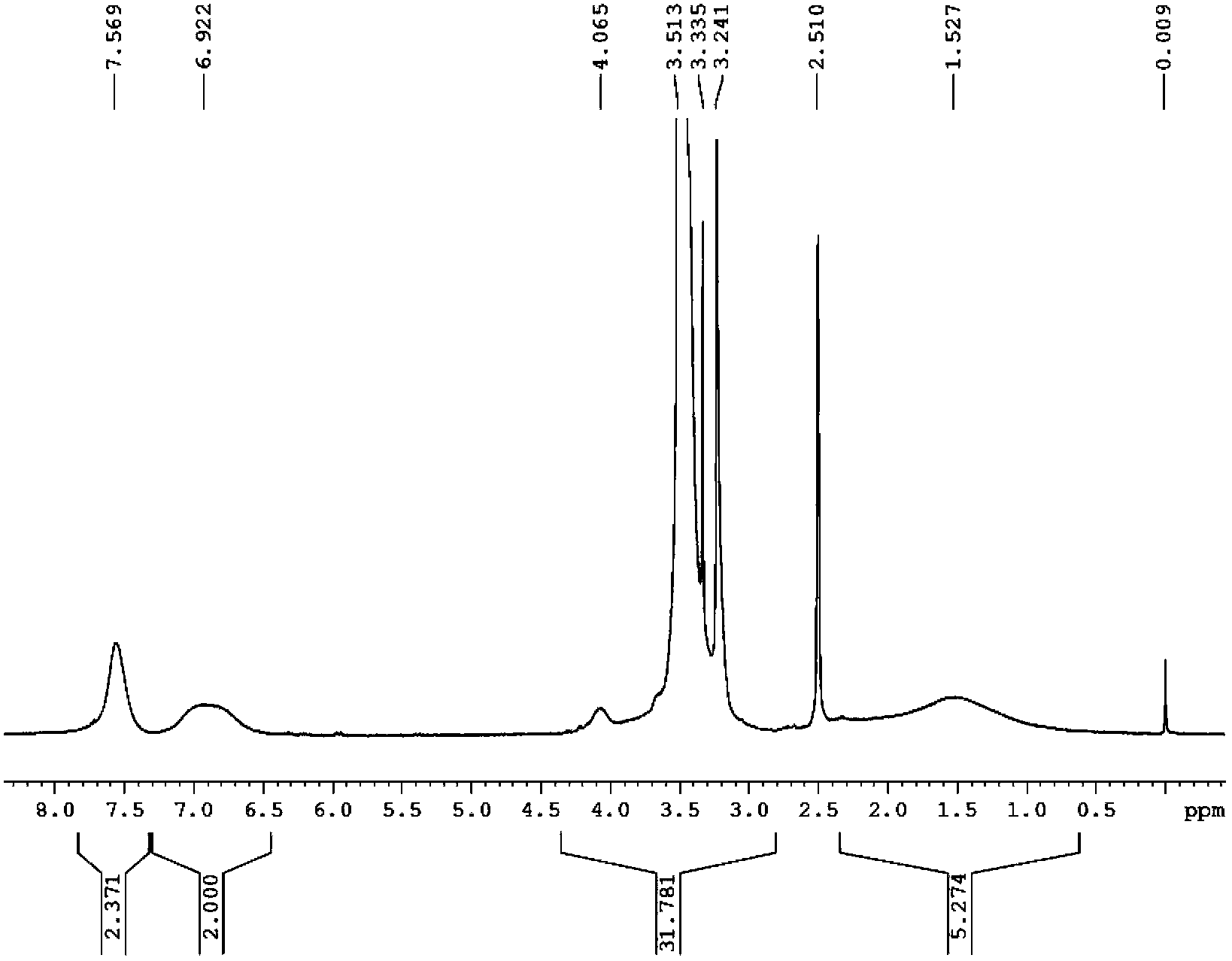

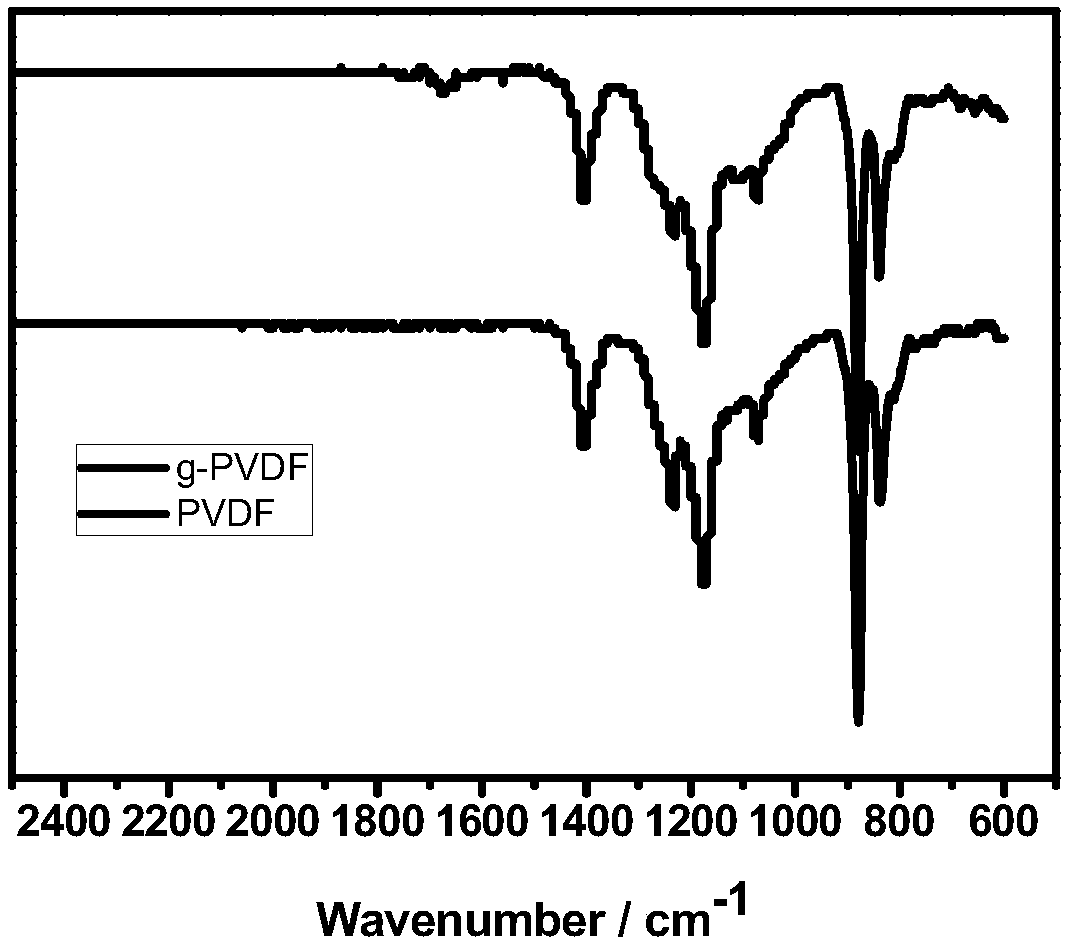

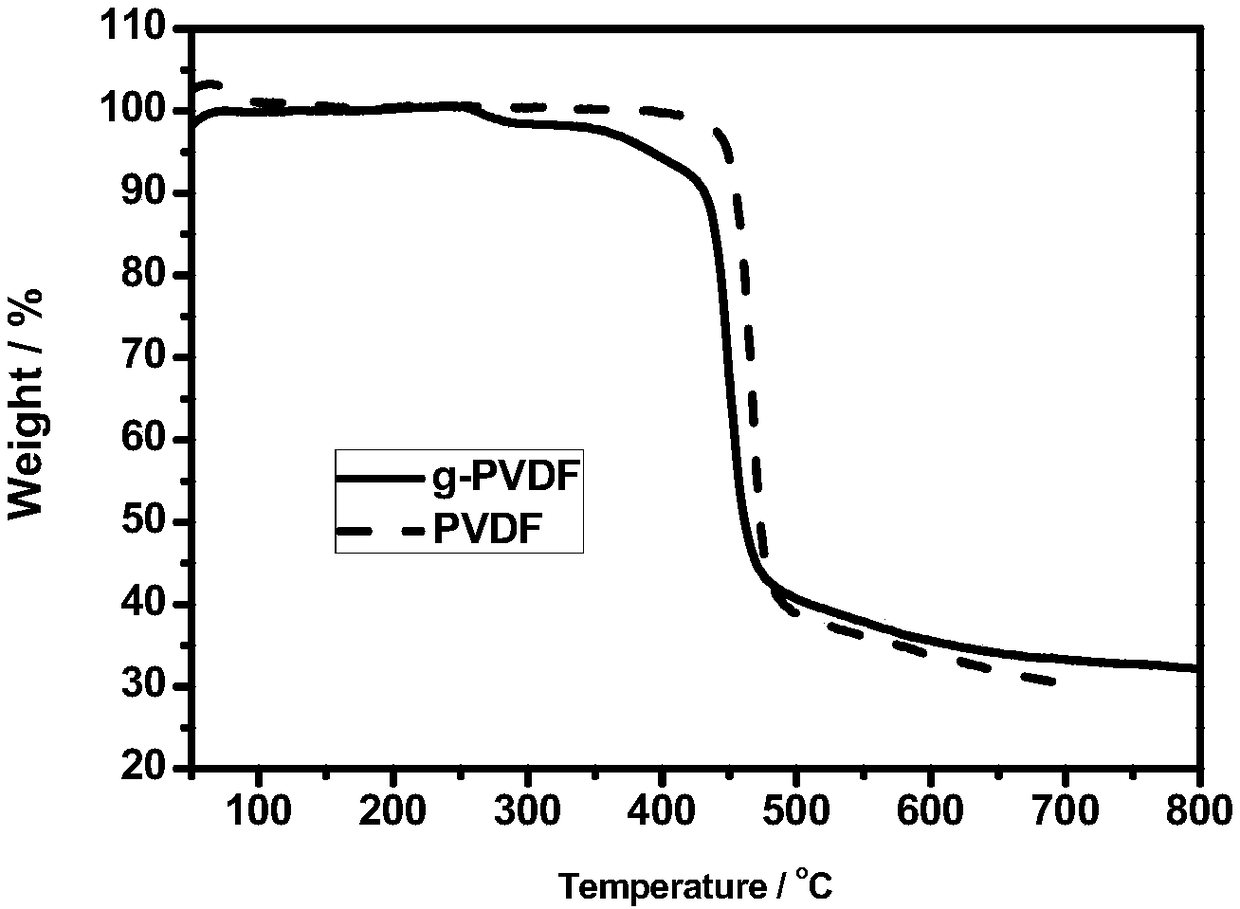

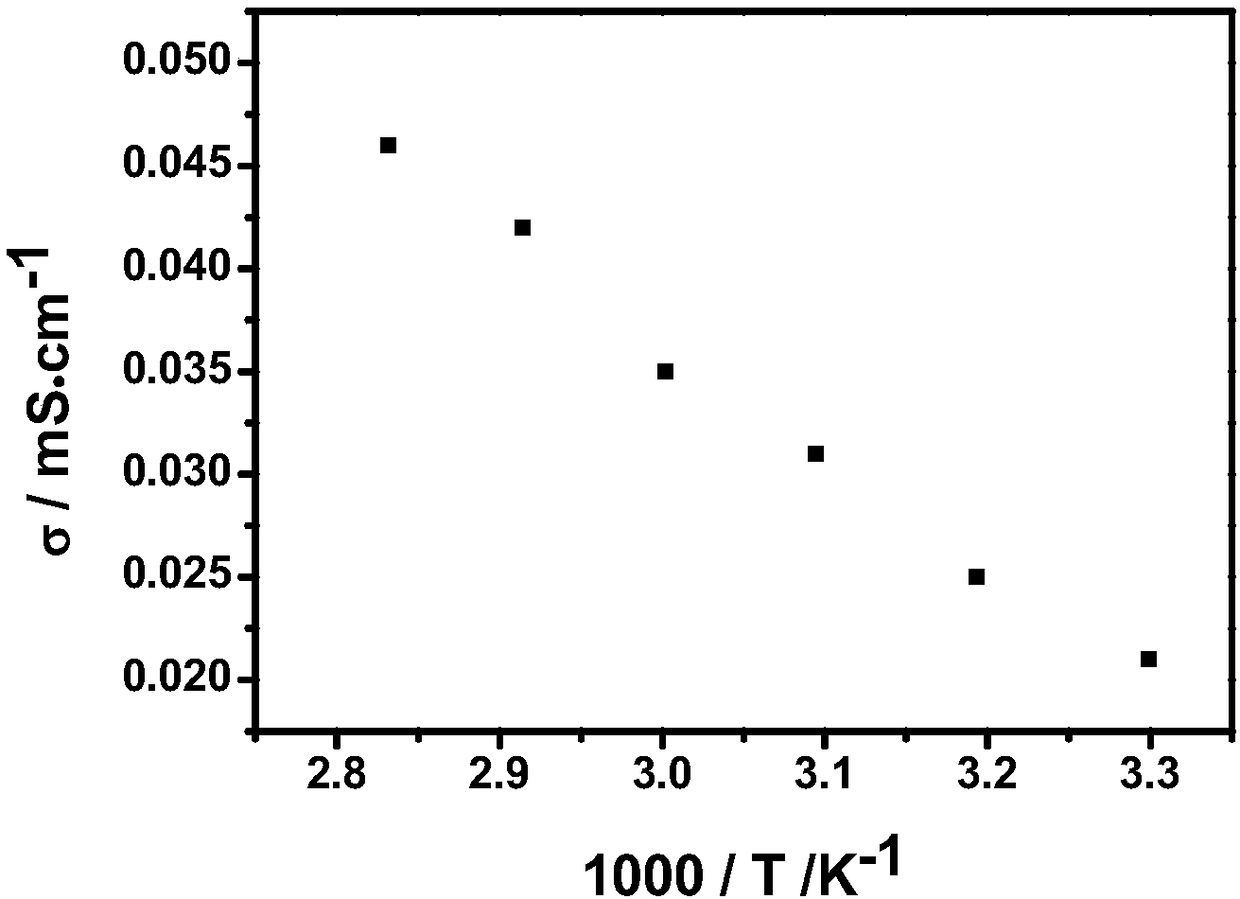

Novel single ion polymer electrolyte and preparation method and application thereof

The invention discloses a novel single ion polymer electrolyte and a preparation method and an application of the novel single ion polymer electrolyte. A radiation grafting method is used to synchronously graft two functional monomers on a powder substrate, wherein one monomer is a fluorine-containing monomer, and the other grafted monomer is a monomer comprising a lithium salt ion pair. The powder substrate is selected, the proportion of the monomers is regulated through the radiation grafting method without adding an initiator or a catalyst, and an evenly grafted pure double-monomer graftingmembrane is conveniently obtained. The grafting membrane is applied to a lithium ion battery, the lithium salt is not additionally added, only a small quantity of plasticizer is needed, and the grafting membrane has a prominent electrochemical performance. Meanwhile, the grafting membrane has the advantages of heat stability, size stability and mechanical property. The method is novel and effective, is simple, is low in cost and strong in operability, and is quite suitable for commercial production.

Owner:XIAMEN UNIV

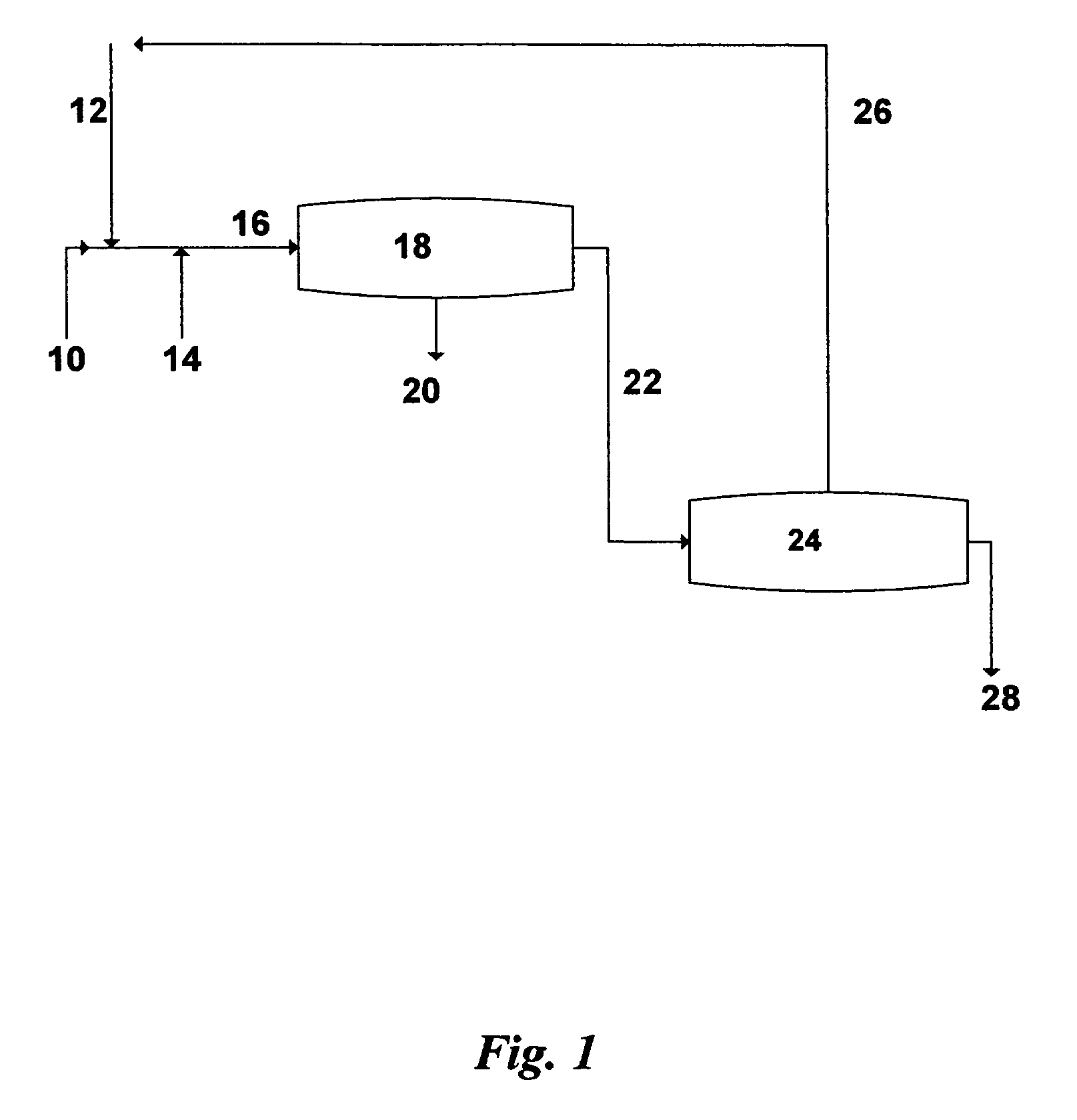

Methods to properly use saline water for oil reservoirs injection operations

ActiveUS7934551B1Increase dissociationGeneral water supply conservationSeawater treatmentSaline waterOil field

This invention presents innovative and off the beaten path methods to mainly produce suitable saline streams for oil-fields water injection operations. The production of such suitable saline streams can: (1) be achieved economically; and (2) meet the actual stringent requirements for injection operations to steadily enhance oil production from depleted and plugged wells.

Owner:BADER MANSOUR S

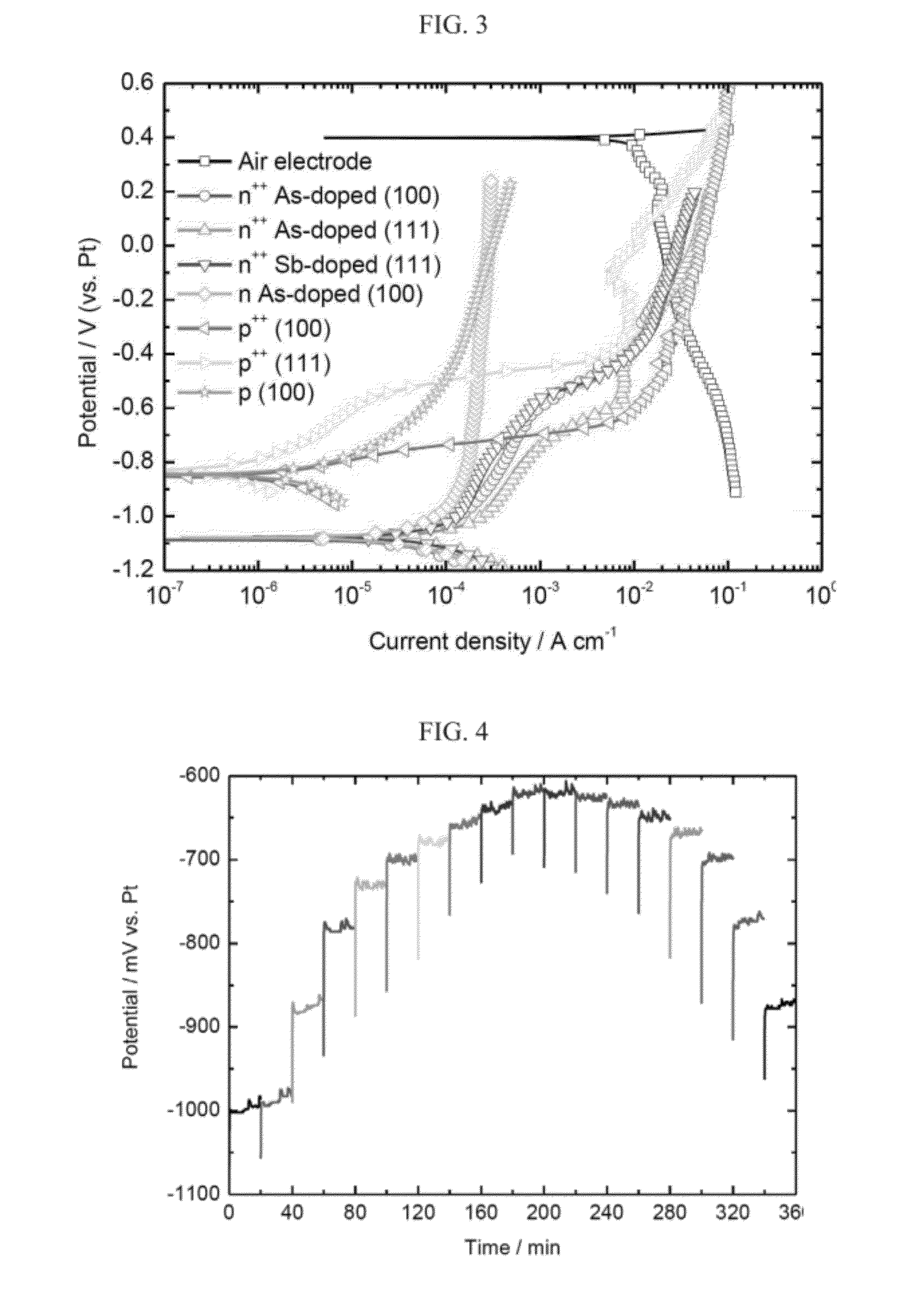

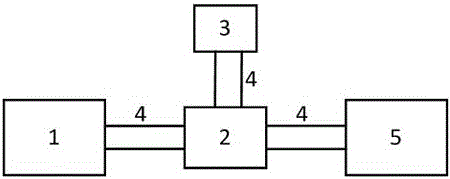

Silicon-air batteries

InactiveUS20120299550A1Increase oxygen flowIncrease dissociationFuel and primary cellsBatteries circuit arrangementsSilicon–air batterySilicon oxygen

Owner:PENN STATE RES FOUND +1

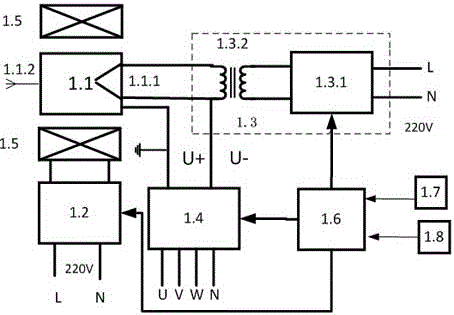

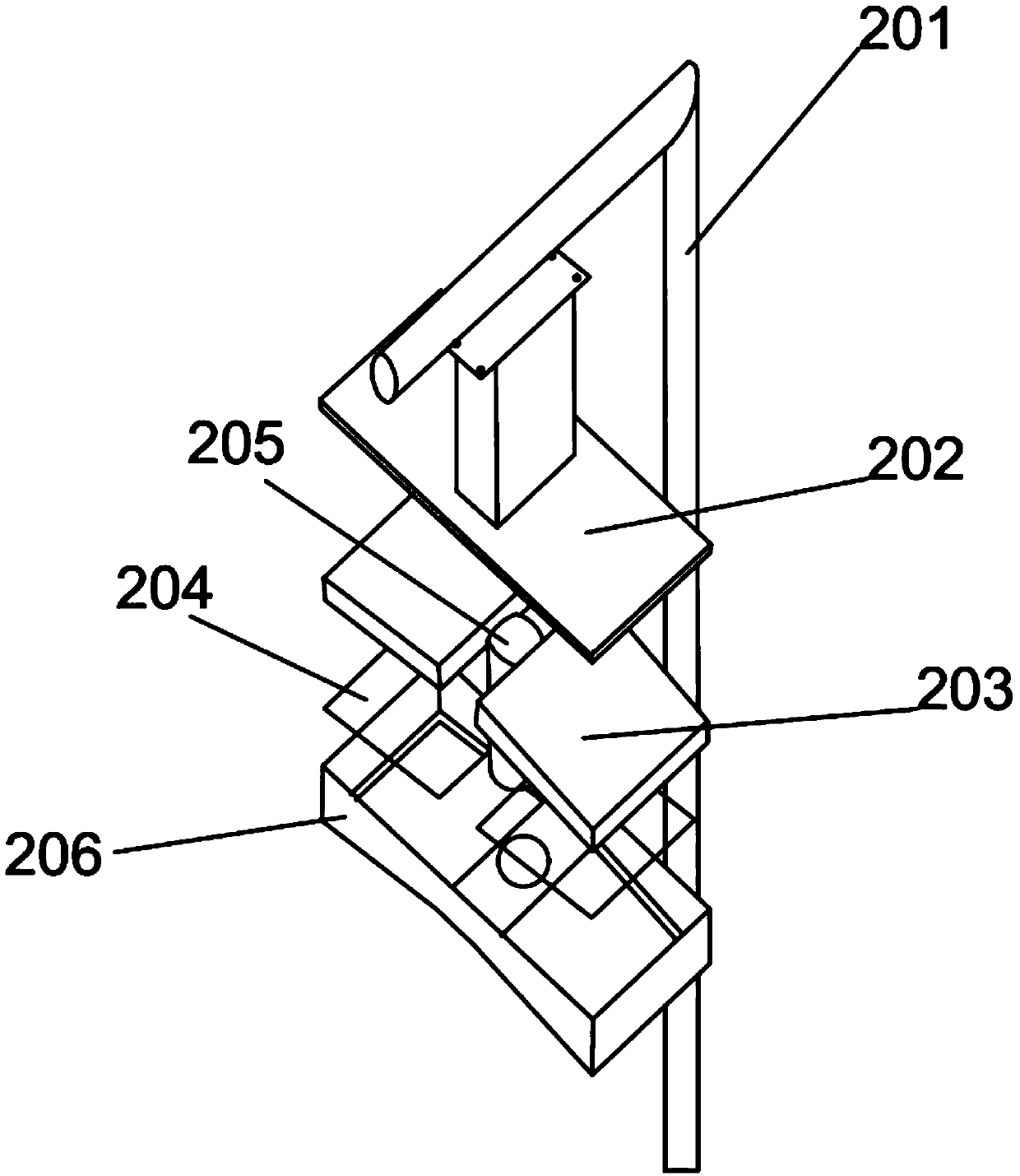

Device for crushing and grinding uranium ores through assistance of 915MHz pulse microwave irradiation and control method

ActiveCN105944810ALow mechanical strengthGood for grindingGrain treatmentsUranium orePulse microwave

The invention relates to a device for crushing and grinding uranium ores through assistance of 915MHz pulse microwave irradiation and a control method. The device comprises five main parts of: a 915MHz microwave source generator, a microwave circulator, a water load, wave guide tubes and a microwave resonant heating cavity. After the uranium ores are irradiated by high-power pulse microwave emitted by the device, the mechanical strength of the uranium ores is reduced, the dissociation degree of the uranium ores is increased, and the crushing and the grinding of the uranium ores and the leaching of uranium minerals are facilitated. Compared with traditional continuous microwave irradiation, the pulse microwave irradiation is lower in consumption and better in assistance of the crushing and grinding effect, and can effectively prevent high-temperature sintering.

Owner:NANHUA UNIV

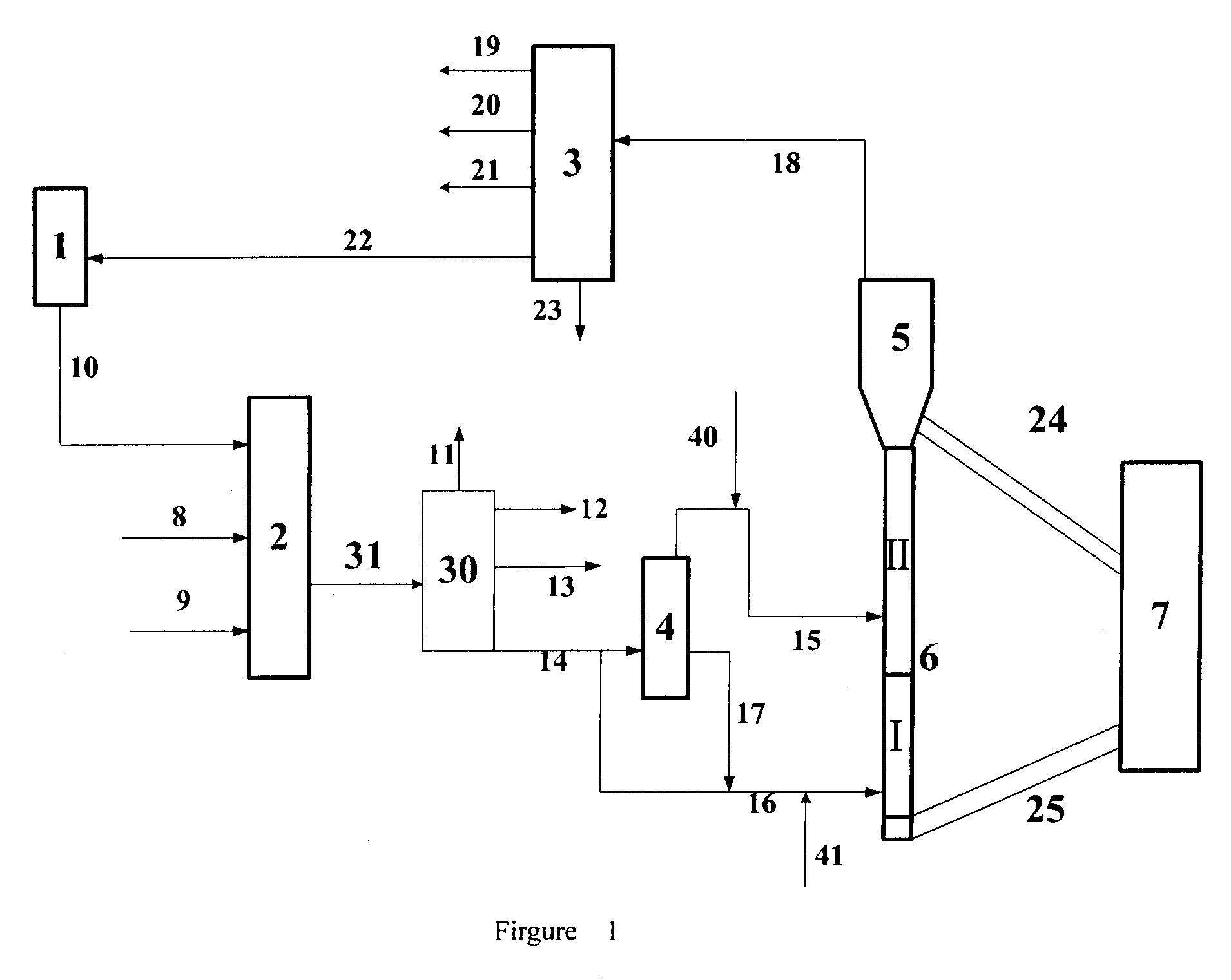

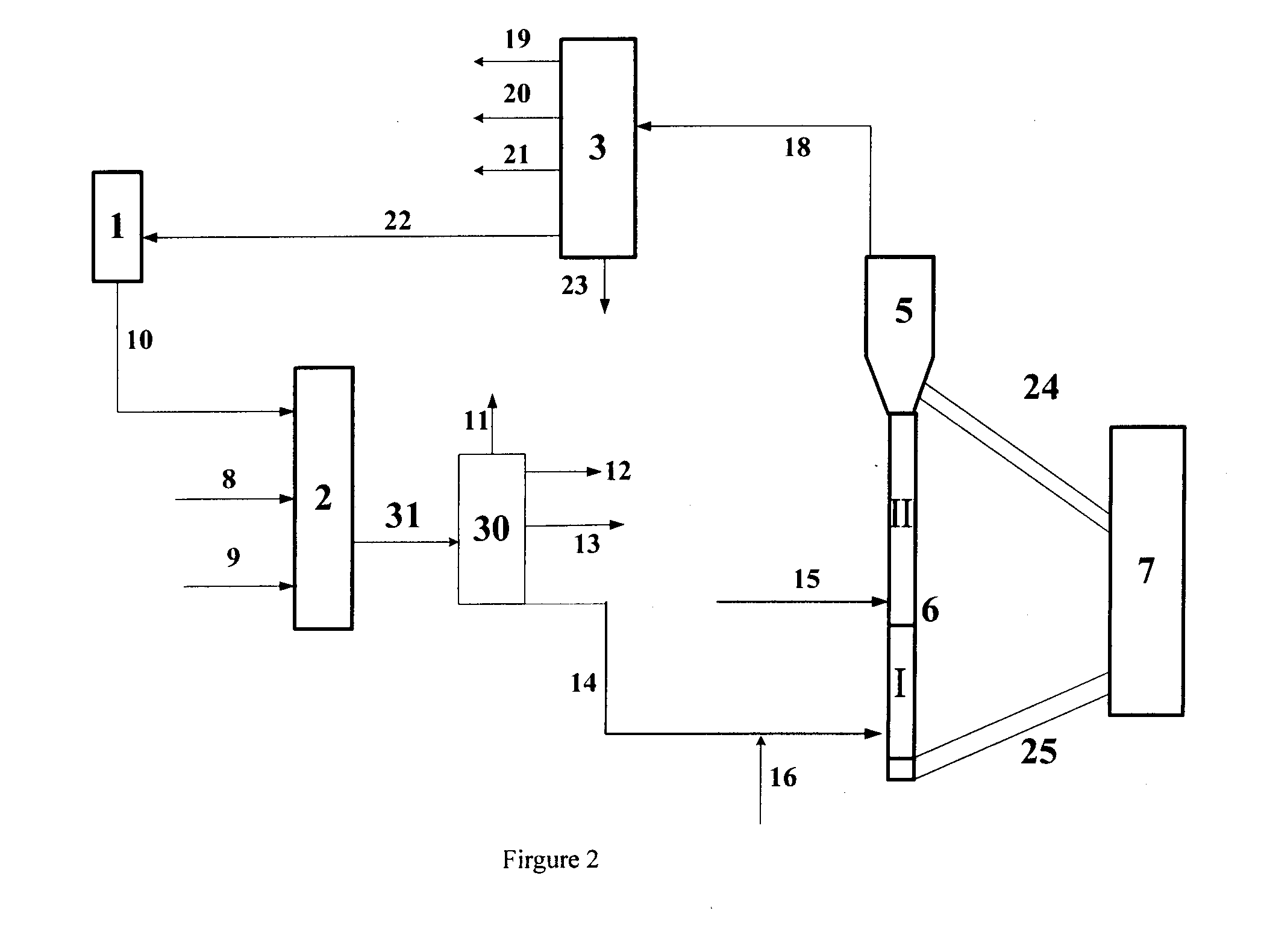

Improved hydrotreatment and catalytic cracking combination method for hydrocarbon oil

ActiveCN101538481AEnhanced dissociationImprove efficiencyTreatment with hydrotreatment processesCycle oilChemistry

The invention discloses an improved hydrotreatment and catalytic cracking combination method for hydrocarbon oil, which comprises the following steps that: under reaction conditions of the presence of hydrogen and the hydrotreatment, the contact reaction of residual oil, catalytic cracking cycle oil, optional distillate oil and a hydrotreating catalyst is performed, and gas, hydrogenerated naphtha, hydrogenerated diesel oil and hydrogenerated tail oil are obtained after a reaction product is separated; under catalytic cracking reaction conditions, the contact reaction of the optional conventional catalytic cracking raw oil, the hydrogenerated tail oil and a catalytic cracking catalyst is performed, and dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking cycle oil are obtained after a reaction product is separated; and the conventional catalytic cracking raw oil is light or heavy distillate oil, and the contact reaction with the catalytic cracking catalyst is that the heavy raw oil and light raw oil are optionally and orderly performed along with the hydrogenerated tail oil in a reactor comprising at least two reaction regions (I and II) along the flowing direction of reaction materials respectively. The method is suitable for hydrocarbon oil conversion to produce more gasoline and diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

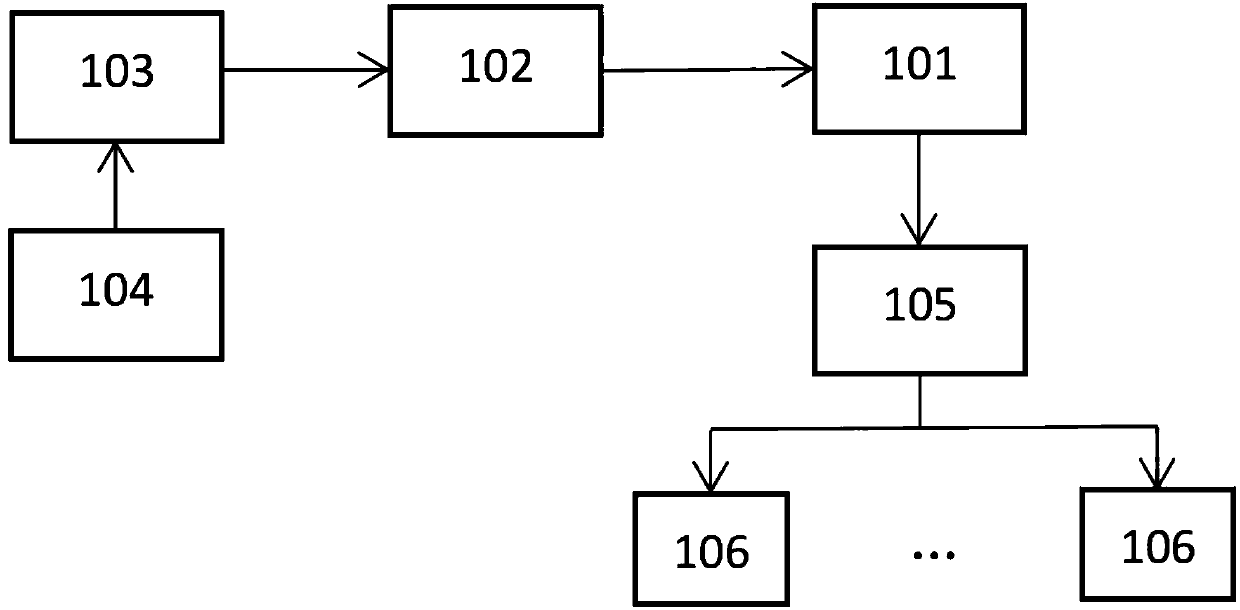

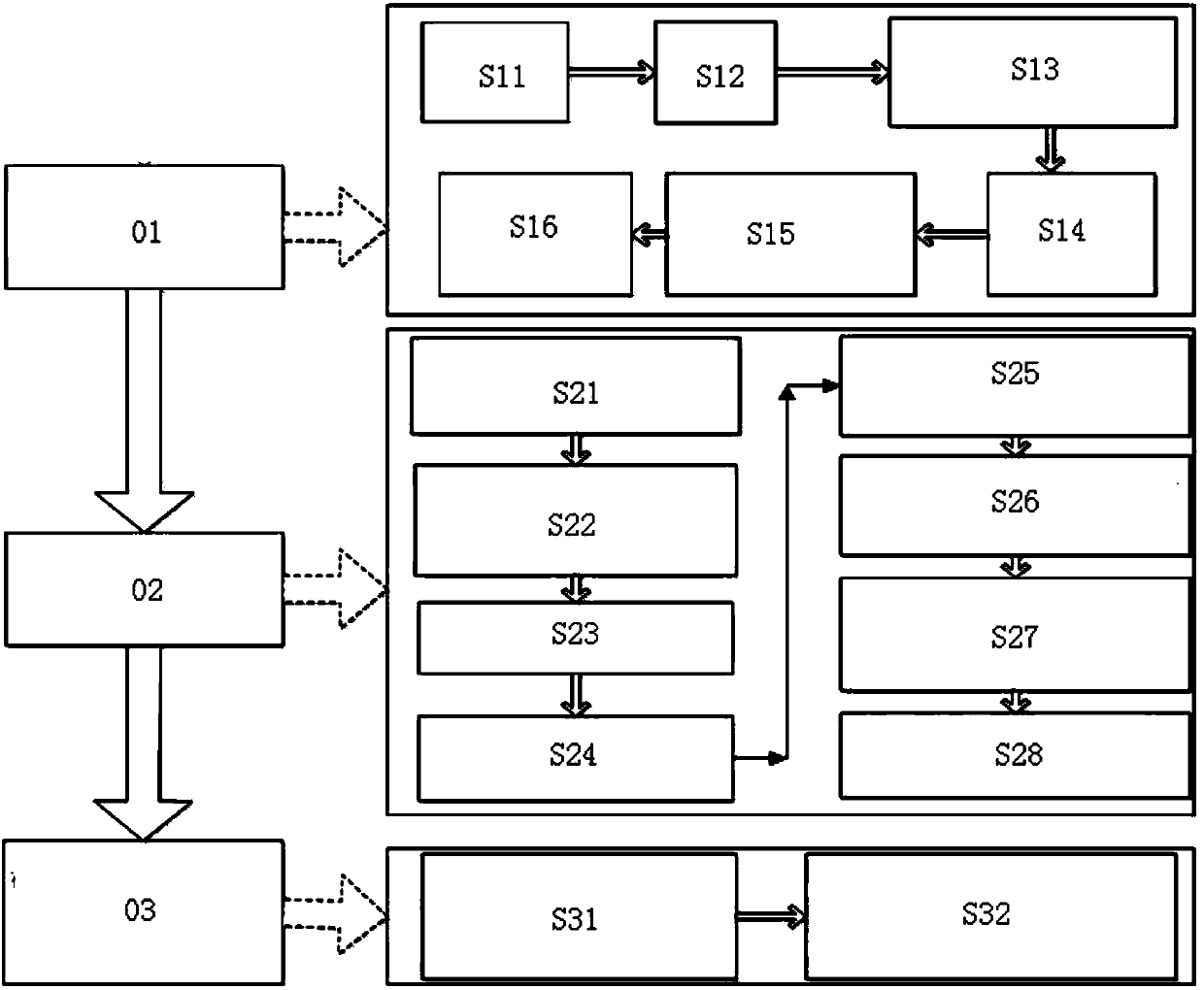

Online detection equipment for ore granularity based on a map image algorithm analysis technology

ActiveCN109785378AIncrease dissociationOptimize the beneficiation processImage enhancementImage analysisGranularityImaging algorithm

The invention discloses an online ore granularity detection device based on a map image algorithm analysis technology. The online ore granularity detection device is characterized by comprising an oregranularity analyzer and an industrial personal computer, The ore particle size analyzer is connected with the industrial personal computer through a special local area network; The industrial personal computer is connected into the Internet, and a plurality of clients are further connected into the local area network. The ore particle size analyzer is mounted above the ore conveying belt and isused for photographing ores on the conveying belt and continuously collecting ore particle size images on the conveying belt in real time; An ore particle size analysis system is installed in the industrial personal computer and comprises an image preprocessing module, an image segmentation module and an ore particle size calibration and analysis module. According to the method, conveyor belt oreimages are collected online, multi-stage image algorithm processing is carried out, the ore granularity is continuously analyzed online in a high-precision and real-time mode, analysis results are automatically counted and output, the ore dissociation degree is improved in cooperation with optimization of the ore dressing technological process, and the production efficiency is improved.

Owner:威海晶合数字矿山技术有限公司

Fine ferric oxide desulfurizing agent and preparation method and application method thereof

ActiveCN106268219AHigh precisionHigh sulfur capacityDispersed particle separationSodium BentoniteCopper sulfate

The invention discloses a fine ferric oxide desulfurizing agent and a preparation method and an application method thereof. The fine ferric oxide desulfurizing agent is prepared from ferrous sulfate septihydrate, calcium hydroxide, copper sulfate pentahydrate, sodium hydroxide, bentonite and sodium carboxymethylcellulose through mixing, strip extrusion and drying, and comprises, by mass, 57%-68% of ferrous sulfate septihydrate, 18%-25% of calcium hydroxide, 3%-8% of copper sulfate pentahydrate, 6.5%-18% of sodium hydroxide, 3%-10% of bentonite and 1%-3% of sodium carboxymethylcellulose. The fine ferric oxide desulfurizing agent is applied to removal of natural gas, coke-oven gas, oil field gas, synthesis gas, methane, carbon dioxide and organic sulfur such as H2S, COS and mercaptan in liquid hydrocarbon feed gas under the normal-temperature anaerobic condition and is high in desulfurization precision and sulfur capacity. The environment-friendly fine ferric oxide desulfurizing agent is prepared without washing and filtering, and the preparation method has the advantages of simple production technology, low equipment investment and maintenance cost and suitability for large-scale industrial production.

Owner:HUNAN HUANDA ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com