Patents

Literature

178 results about "Pulse microwave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

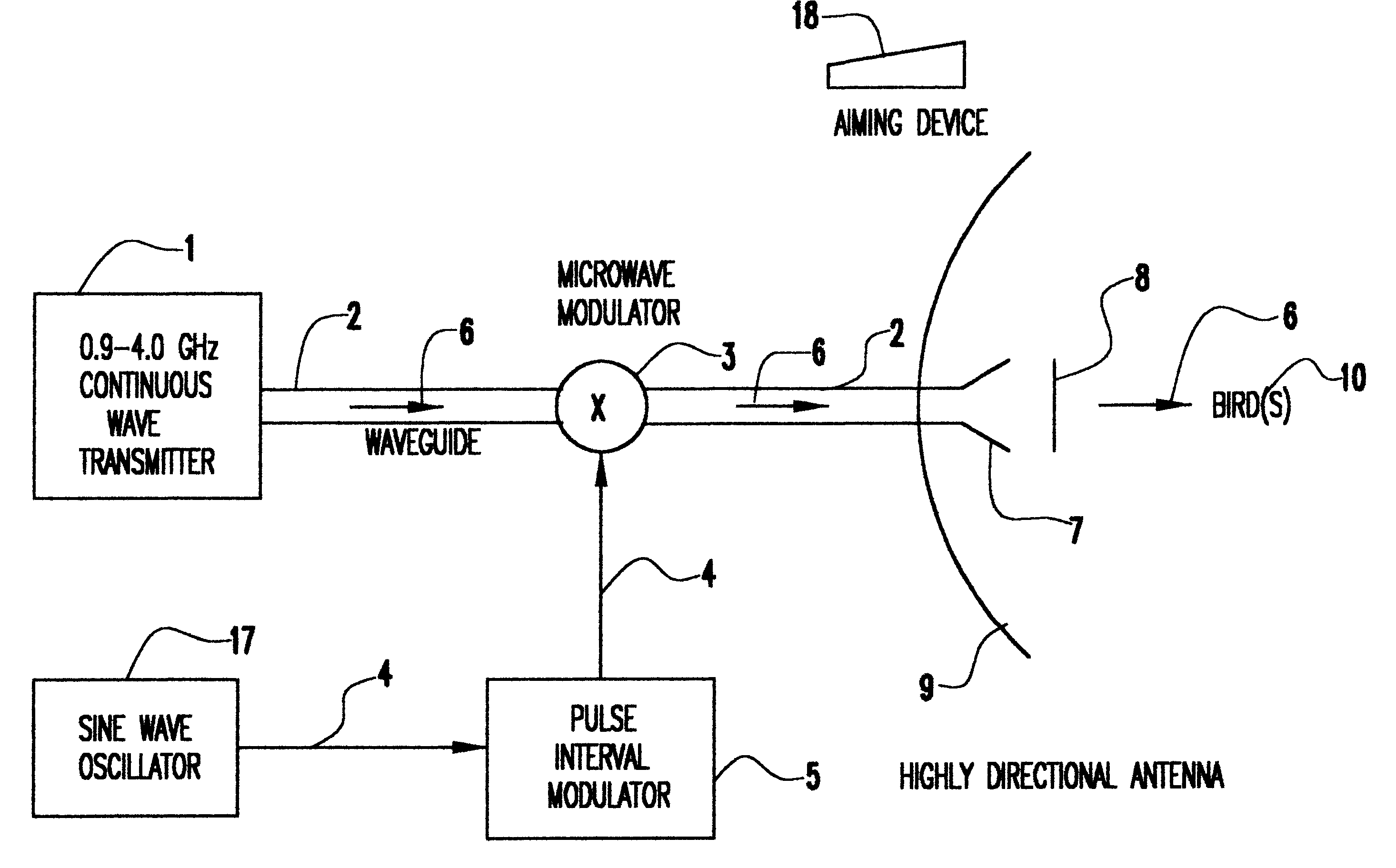

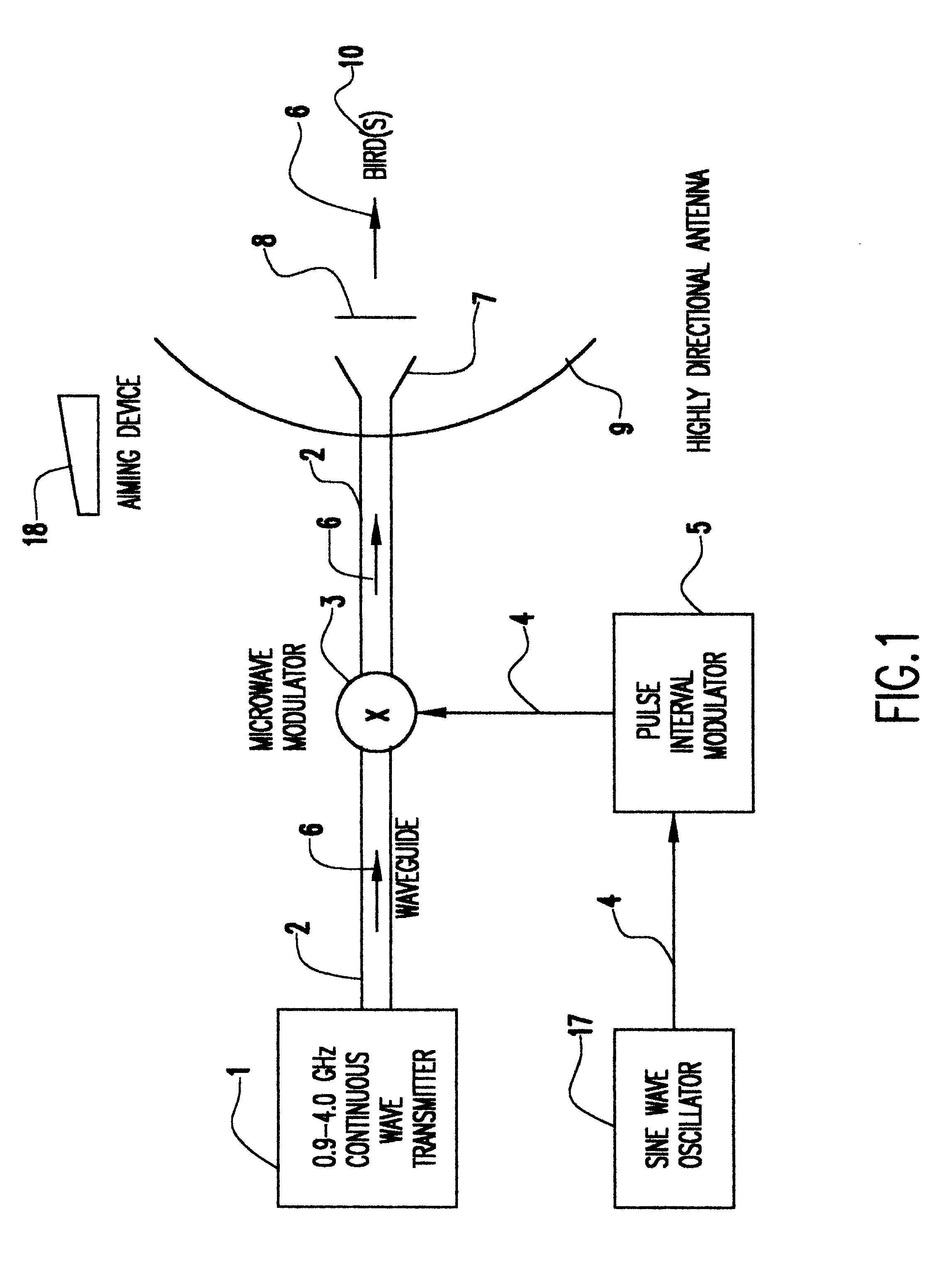

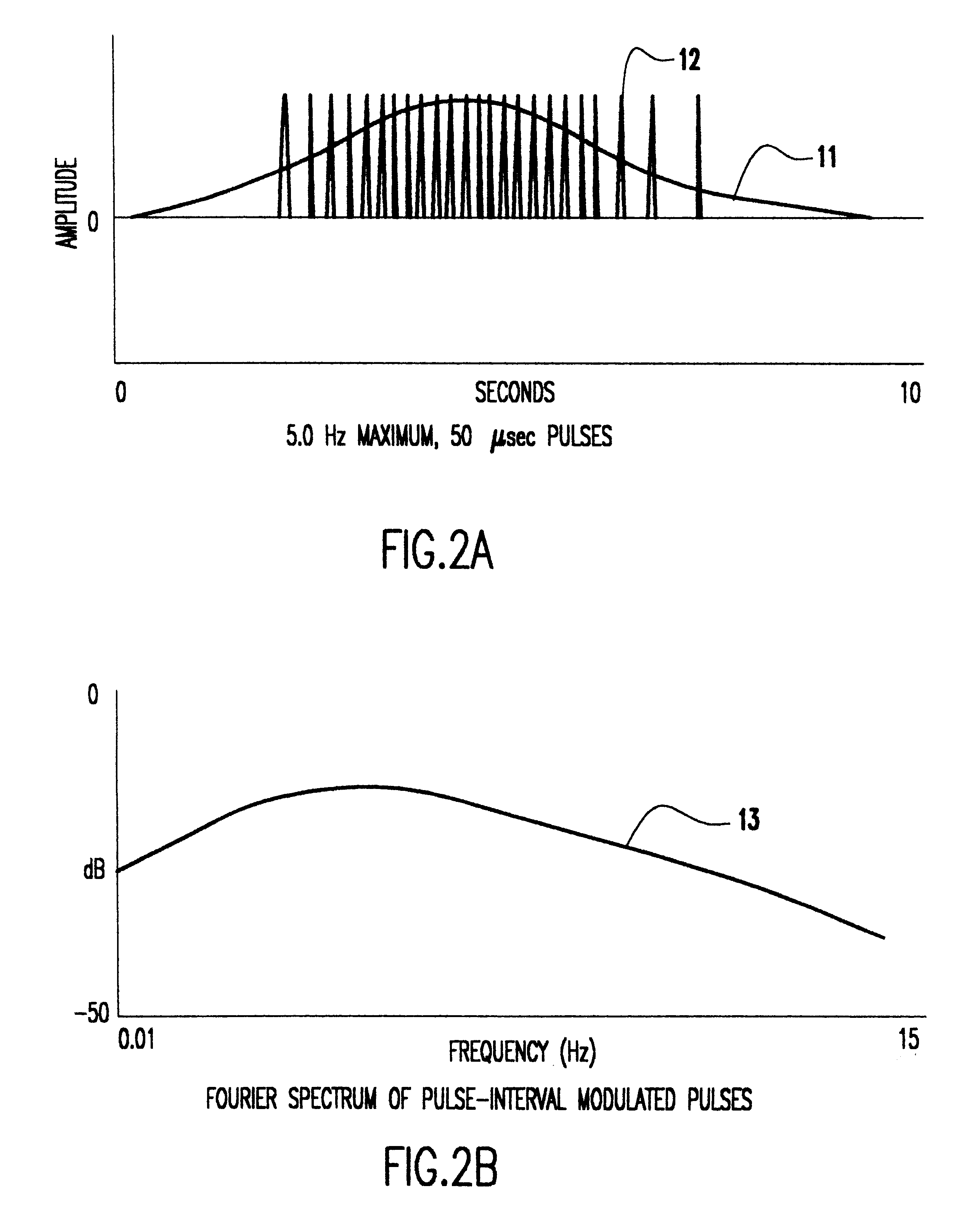

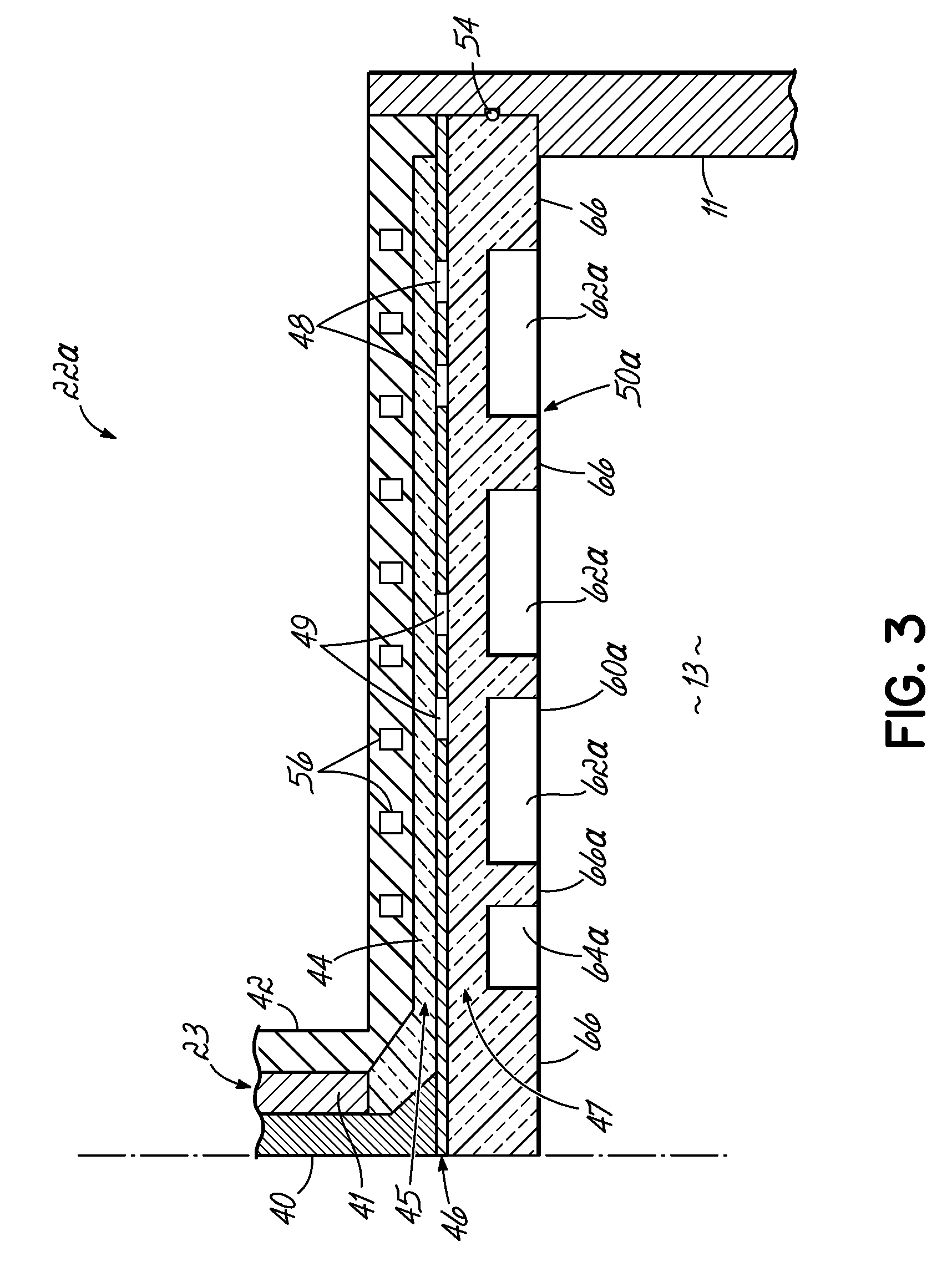

Methods and apparatus for alerting and/or repelling birds and other animals

InactiveUS6250255B1Power Loss MinimizationIncrease powerAvicultureAnimal repellantsPulse microwaveUnpleasant sensation

An external stimuli is provided that alerts animals to danger and / or repels the animals from certain areas. More specifically, the system and method of the present invention uses an external stimuli, such as, for example, pulsing microwaves, vibration or supersonic sound waves, in order to alert birds or other animals of danger and / or repel these same birds or animals from specific areas. These produced external stimuli may provide a reversible unpleasant sensation to the birds and other animals so that they will not only be repelled from a specific area, such as an airport, but also will avoid returning to such area. One such unpleasant sensation that is virtually harmless to the birds and other animals is the sensation of dizziness.

Owner:VIRGINIA COMMONWEALTH UNIV

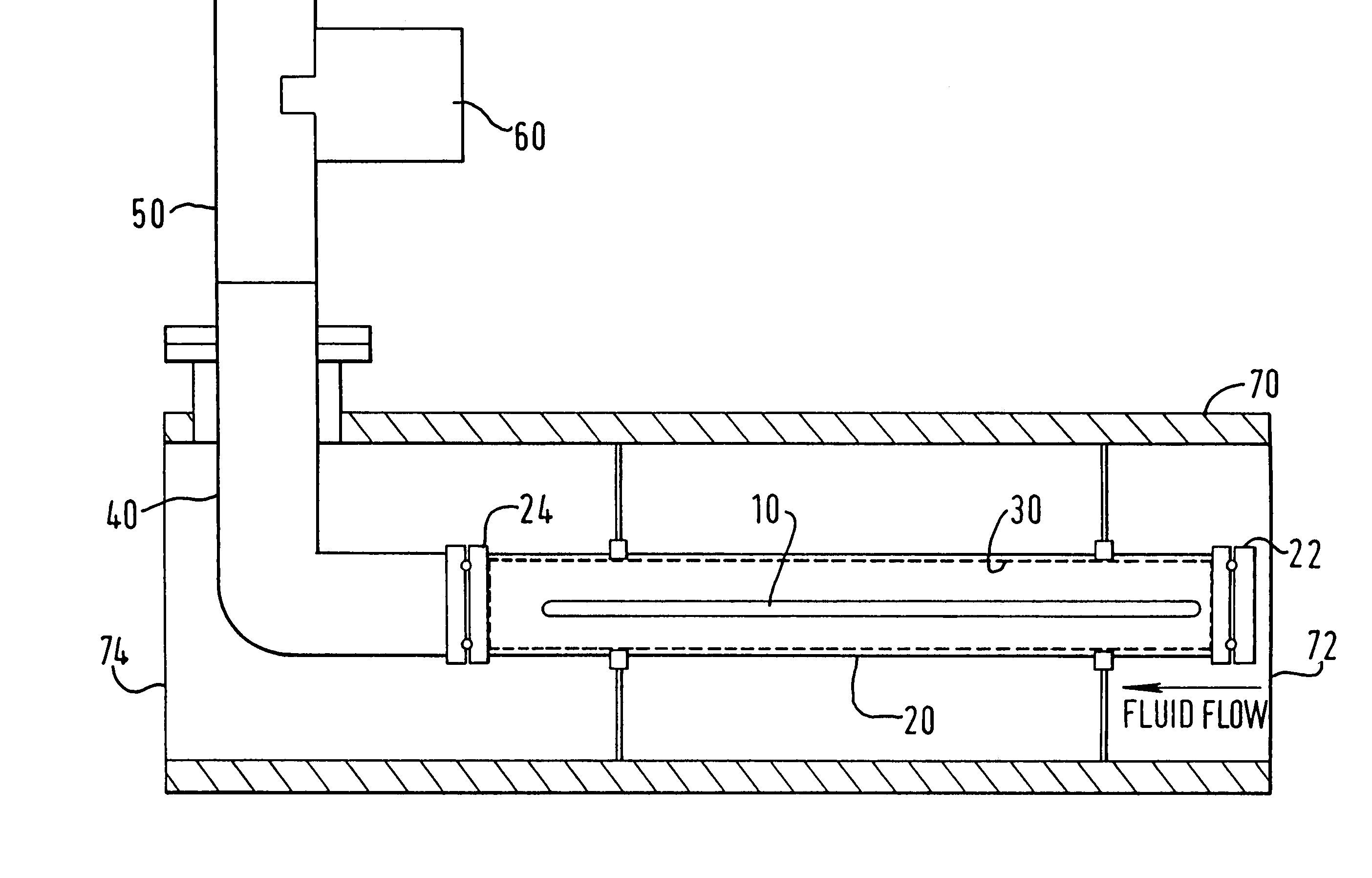

Pulsed UV light source

InactiveUS7081636B2Prevent DNA recoveryInhibition releaseOptical radiation measurementDeodrantsChemical reactionUltraviolet lights

There is described an ultraviolet light source comprising an ultraviolet bulb, a pulsed microwave energy source for exciting said ultraviolet bulb and an enclosure for enclosing the ultraviolet lamp, the enclosure comprising an optically transparent waveguide. The optically transparent waveguide wholly surrounds the bulb. The ultraviolet light source is particularly suitable for use in the sterilisation of substances; the promotion of photochemical reactions; and the promotion of molecular dissociation in liquids.

Owner:SEVEN TRENT WATER PURIFICATION INC

Method of determining the presence of a mineral within a material

InactiveUS8100581B2Improve efficiencyVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesPulse microwaveRock fragment

The invention relates generally to a method of determining the presence of a mineral within a material, such as a rock, a rock fragment, soil, sand or other geological material including: applying pulsed microwave radiation to the material; detecting radiation emitted from the material after the application of the pulsed microwave radiation; and analysing the detected radiation to determine the presence of mineral within the material. The invention also provides a method of sorting rock fragments into at least two streams using this method and an apparatus for carrying out the method.

Owner:THE UNIV OF QUEENSLAND

Method for improving brittleness of crispy fruit slices and preventing adhesion through combining high vacuum with negative pressure pulse microwave drying

InactiveCN102894303AMaintain nutrientsNot easy to stickFood preparationPulse microwaveMoisture absorption

The invention provides a method for improving the brittleness of crispy fruit slices and preventing the adhesion through combining high vacuum with negative pressure pulse microwave drying, and belongs to the technical field of fruit and vegetable food processing. According to the method, the processes for processing the high-vacuum drying crispy fruit slices comprise the steps of fresh fruit selection, cleaning, peeling, denucleation, slicing, color protection, brittleness protection, adhesion prevention, high-vacuum drying, negative pressure pulse microwave later-period short-time drying and package. A recipe adopted in the brittleness protection work procedure comprises 0.01 percent to 6.0 percent of white granulated sugar, 0.01 percent to 5.0 percent of calcium chloride, 0.01 percent to 2.0 percent of pectin and 0.01 percent to 2.0 percent of xanthan gum, the materials are subjected to vacuum osmosis in the combined water solution, and then, the negative-pressure pulse miciowave later-stage short-time drying is combined. A recipe adopted in the adhesion prevention work procedure comprises 0.01 percent to 10 percent of maltodextrin and 0.01 percent to 10 percent of lactose, the materials are soaked for 10 to 300 minutes in combined water solution, and then, the later-stage short-time microwave surface drying is combined. The improved crispy slices have the advantages that the mouth feeling is crispy, the nutrition content is high, the moisture absorption of products during the eating is avoided, and the eating time of the high-vacuum drying crispy fruit slice product is prolonged.

Owner:JIANGNAN UNIV +1

Microwave hemorrhagic stroke detector

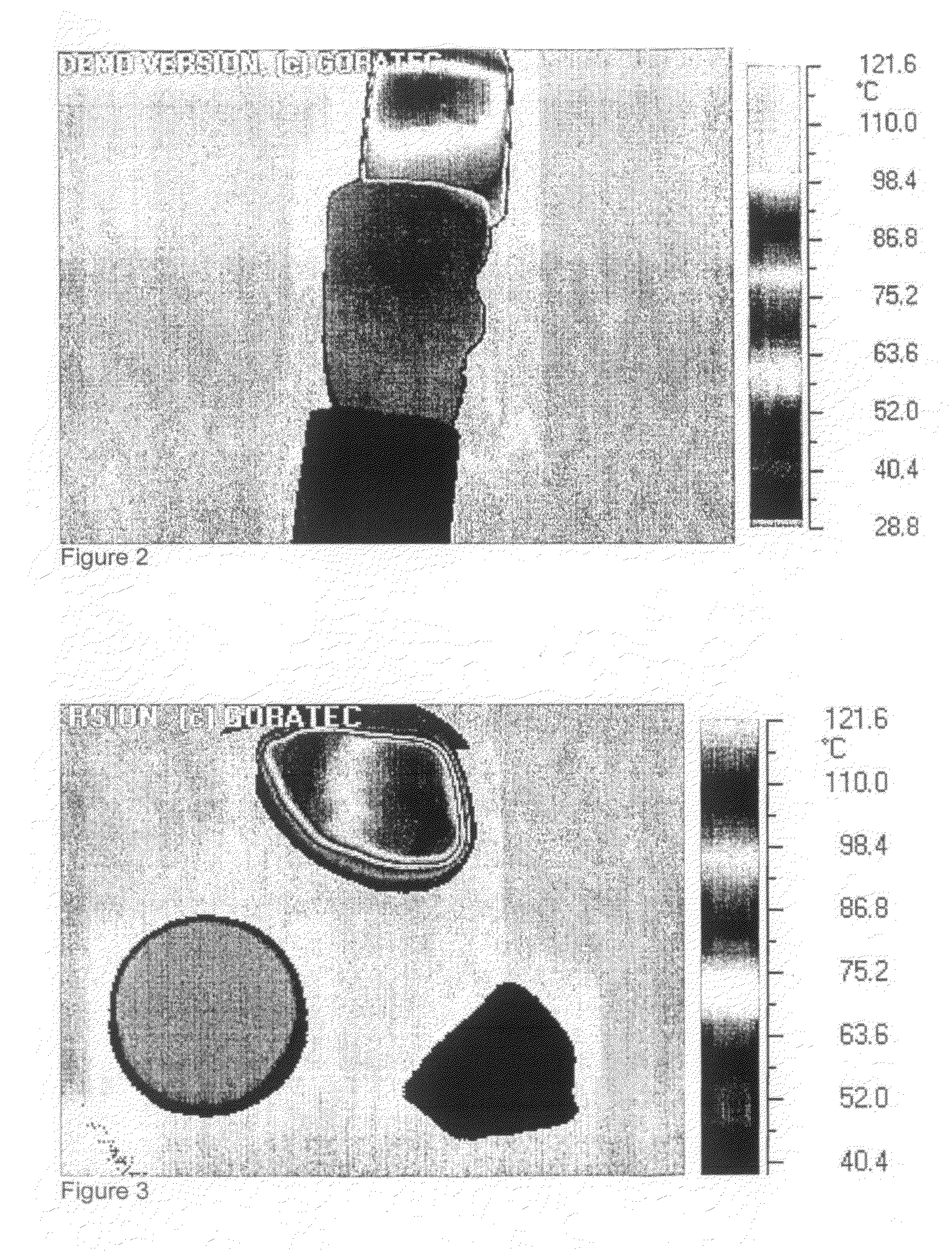

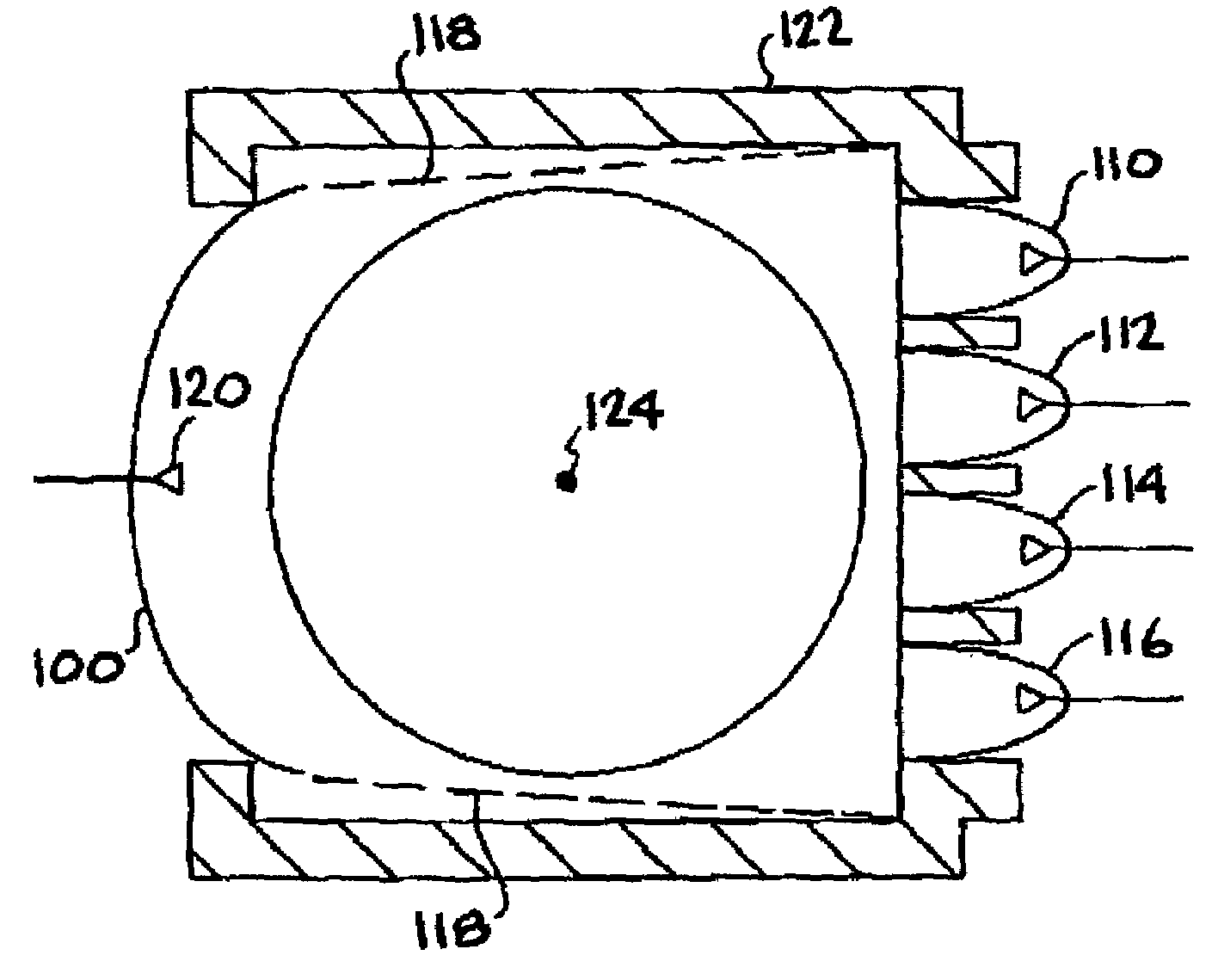

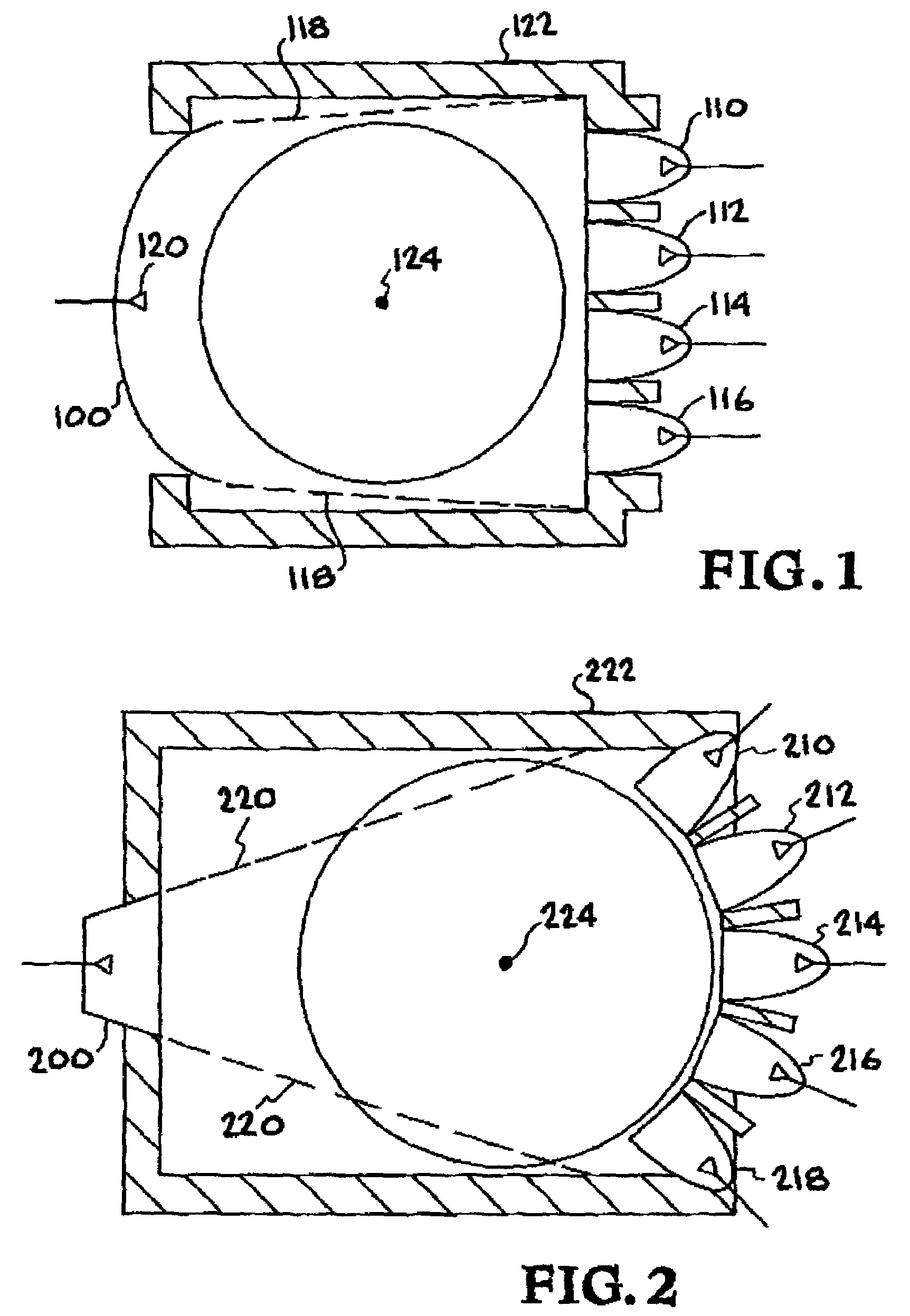

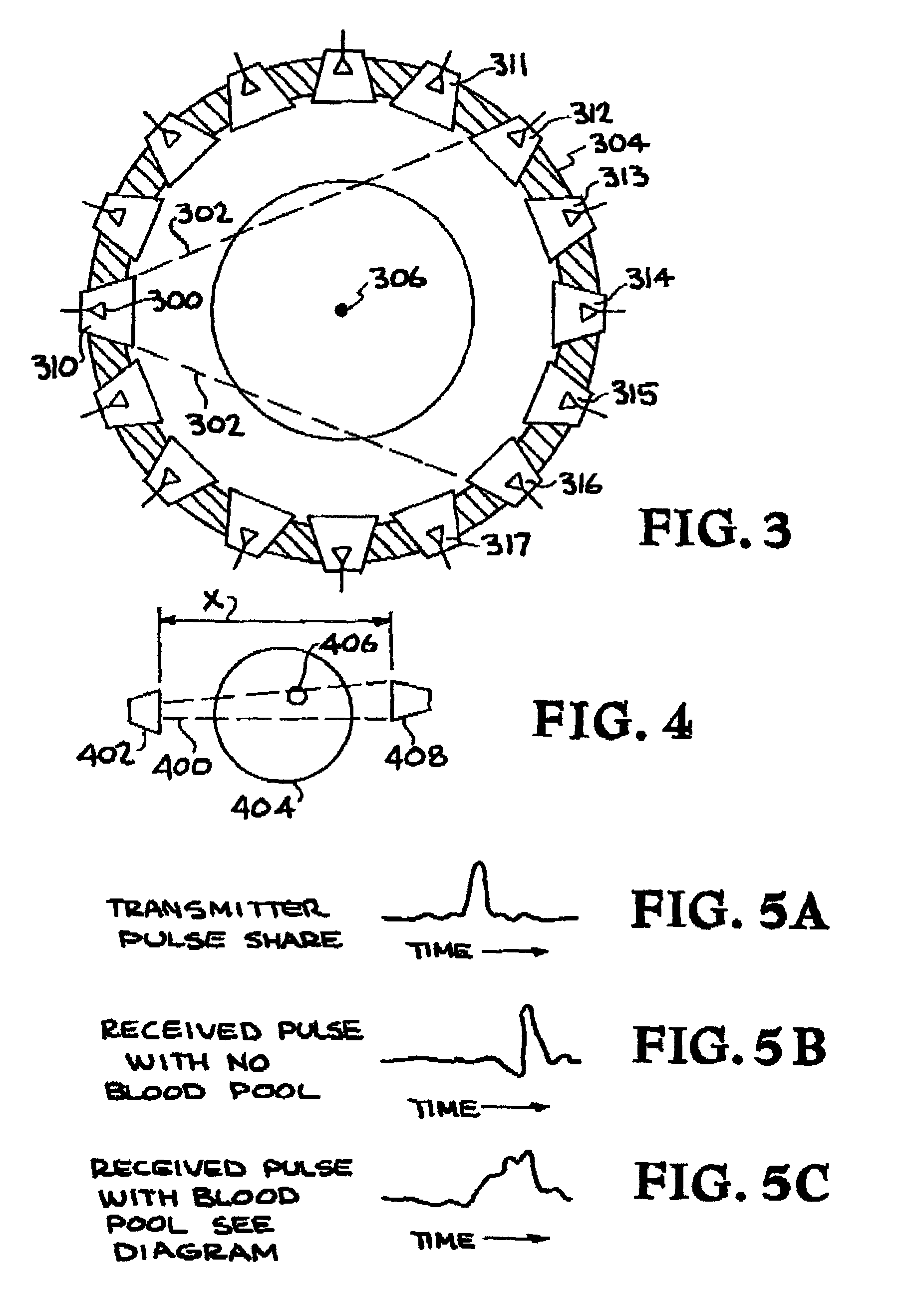

InactiveUS7226415B2Eliminating unnecessary scanSave livesCatheterRespiratory organ evaluationPulse microwaveNon invasive

The microwave hemorrhagic stroke detector includes a low power pulsed microwave transmitter with a broad-band antenna for producing a directional beam of microwaves, an index of refraction matching cap placed over the patients head, and an array of broad-band microwave receivers with collection antennae. The system of microwave transmitter and receivers are scanned around, and can also be positioned up and down the axis of the patients head. The microwave hemorrhagic stroke detector is a completely non-invasive device designed to detect and localize blood pooling and clots or to measure blood flow within the head or body. The device is based on low power pulsed microwave technology combined with specialized antennas and tomographic methods. The system can be used for rapid, non-invasive detection of blood pooling such as occurs with hemorrhagic stoke in human or animal patients as well as for the detection of hemorrhage within a patient's body.

Owner:RGT UNIV OF CALIFORNIA

Method for preparing blueberry fruit wine

ActiveCN103114020AAvoid influenceImprove product qualityAlcoholic beverage preparationMicroorganism based processesPectinaseFiltration

The invention discloses a method for preparing blueberry fruit wine and belongs to the technical field of deep-processing of agricultural products. The method comprises the following steps: juicing blueberries, performing instantaneous high-power pulse microwave treatment and composite pectinase enzymolysis, inoculating brewer's yeast, fermenting at controlled temperature, performing vacuum drum datomite filtration, composite flocculation clarification treatment, diatomite filtering, microfiltration and pulse microwave treatment and filling. According to the method, instantaneous high-power pulse microwave treatment is performed before fermentation, infectious microbes in the blueberry juice are killed under normal temperature conditions, polyphenol oxidase in the blueberry juice is passivated, sulfur dioxide is not required to be added, and pure fermentation is performed through inoculation of a good fermentation agent, so that high-quality blueberry fruit wine is produced, and the economic value of blueberries is obviously improved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

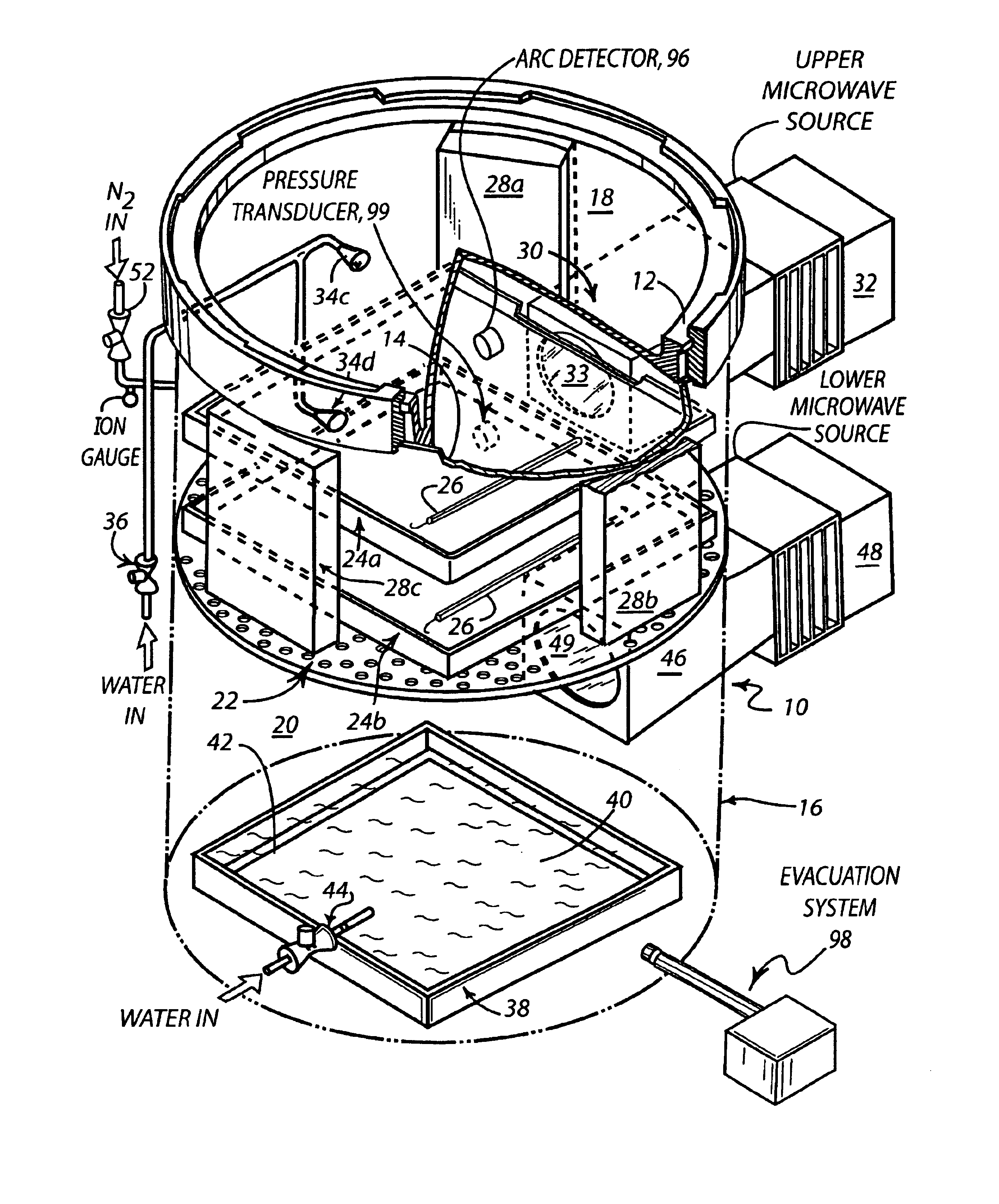

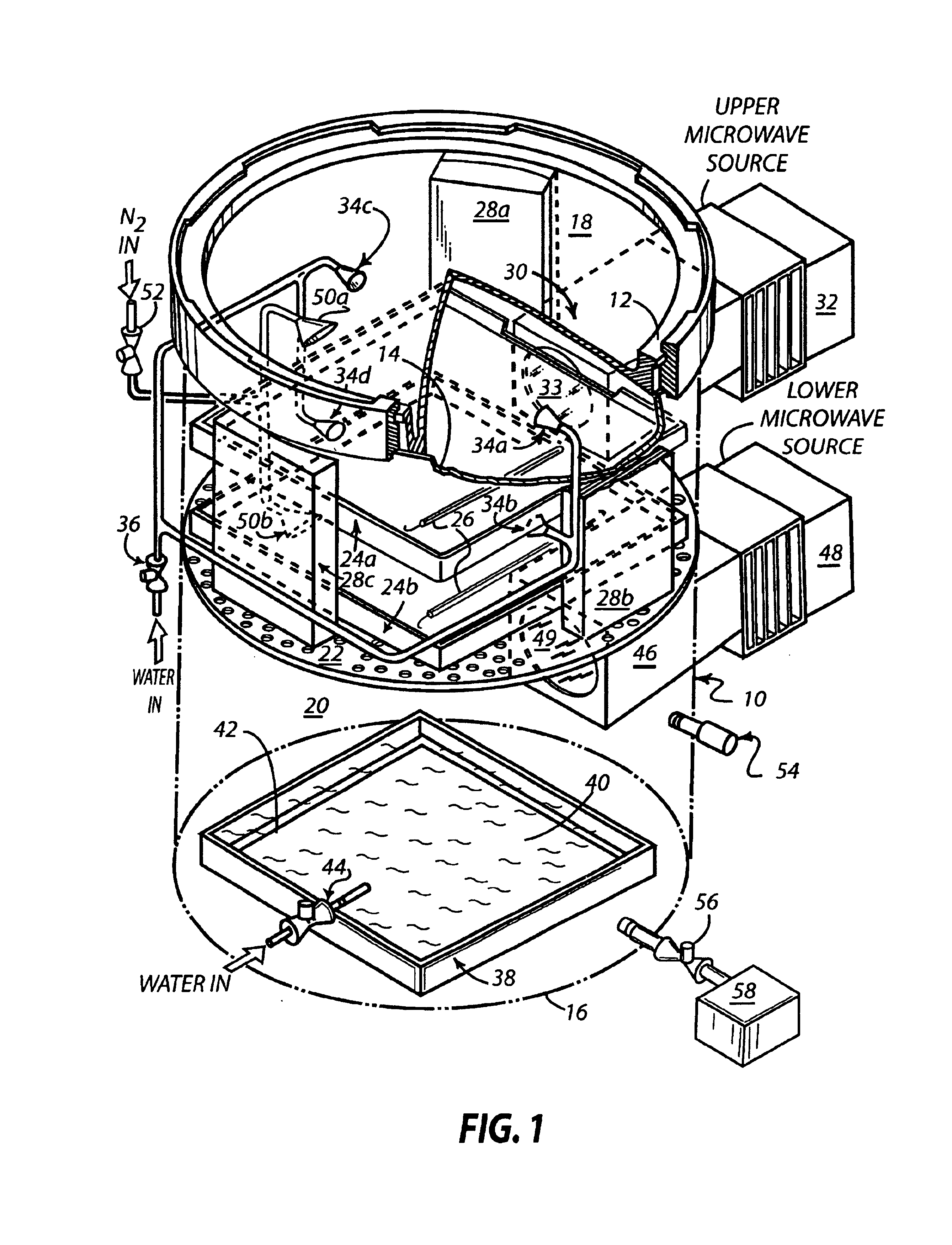

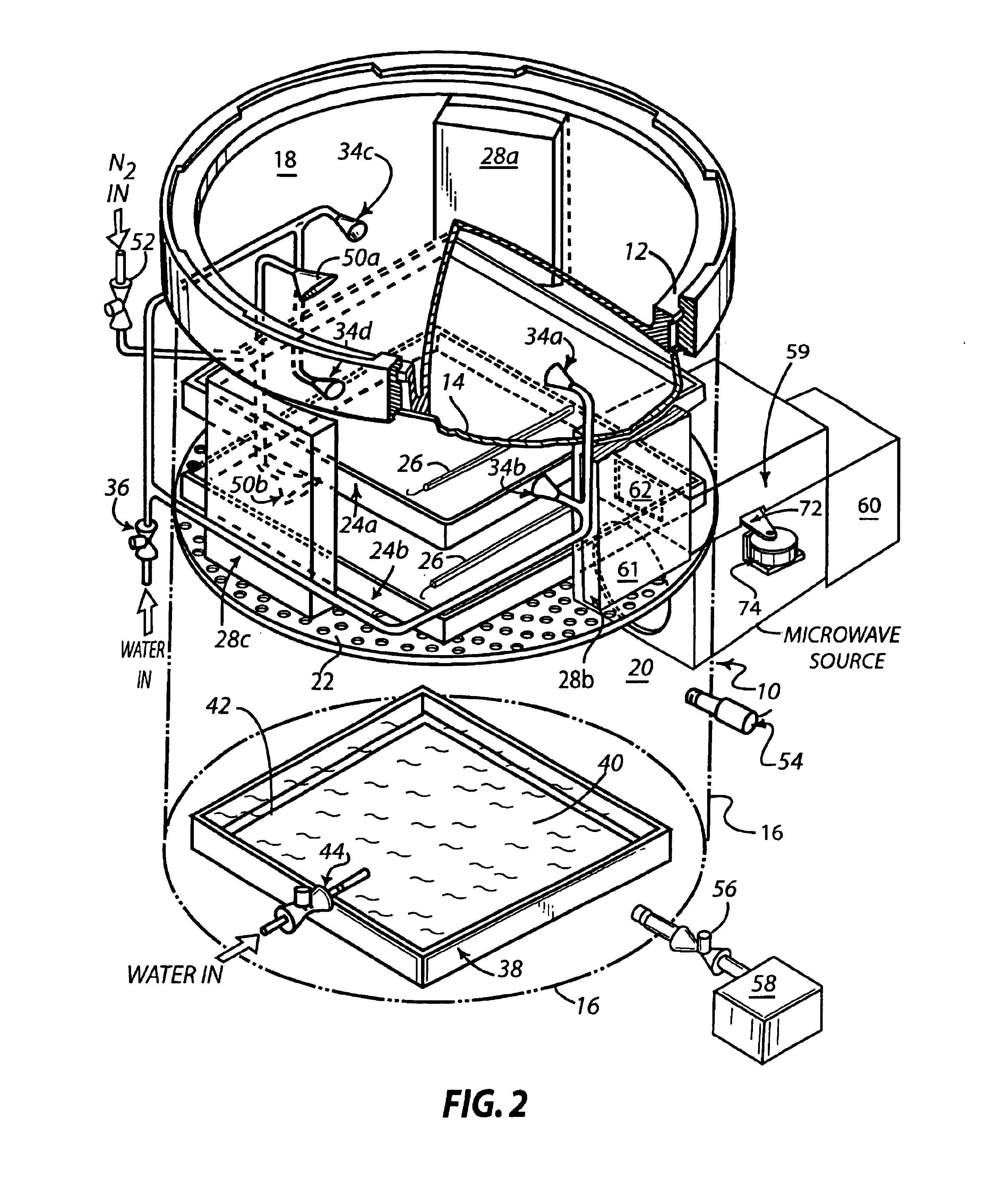

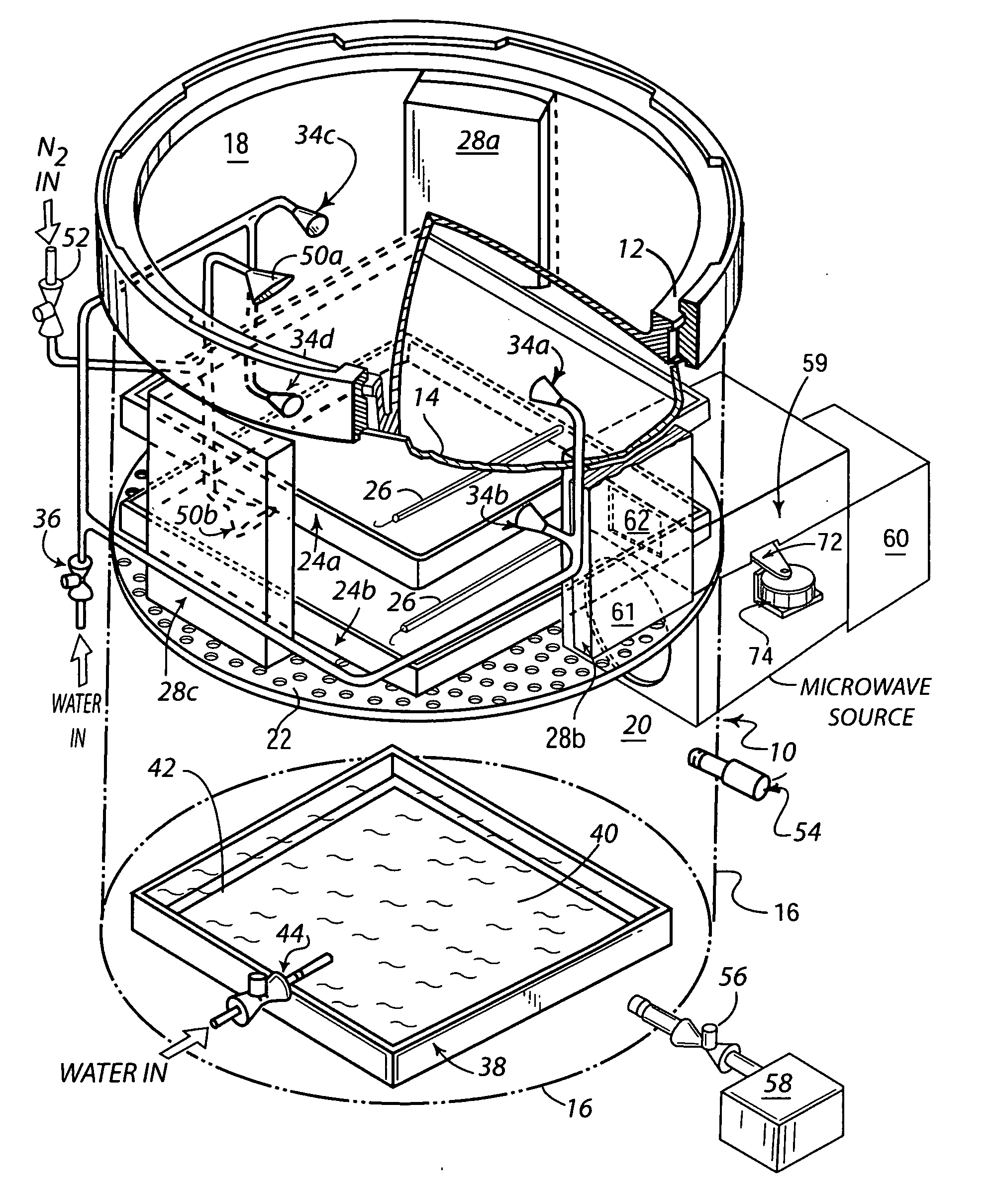

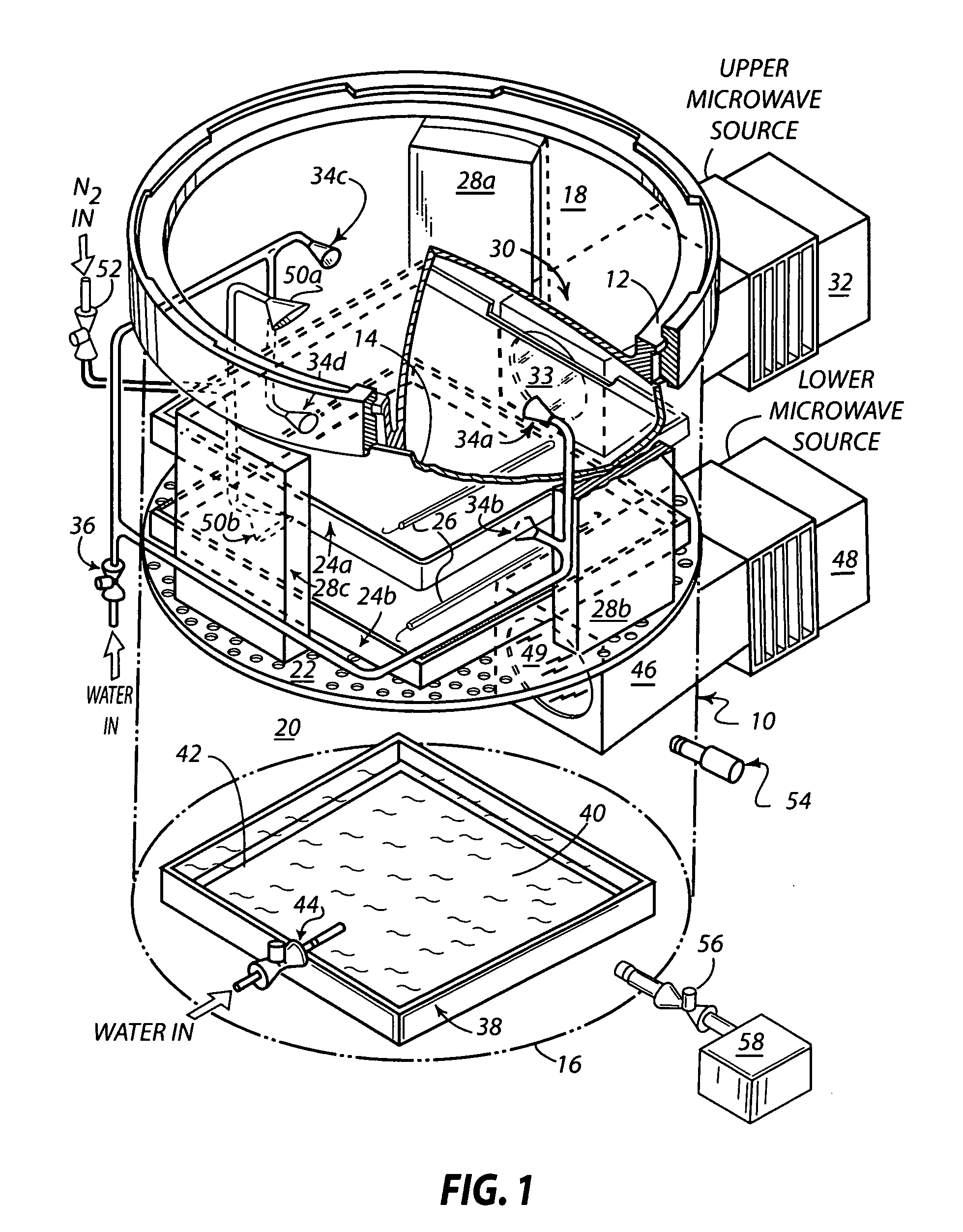

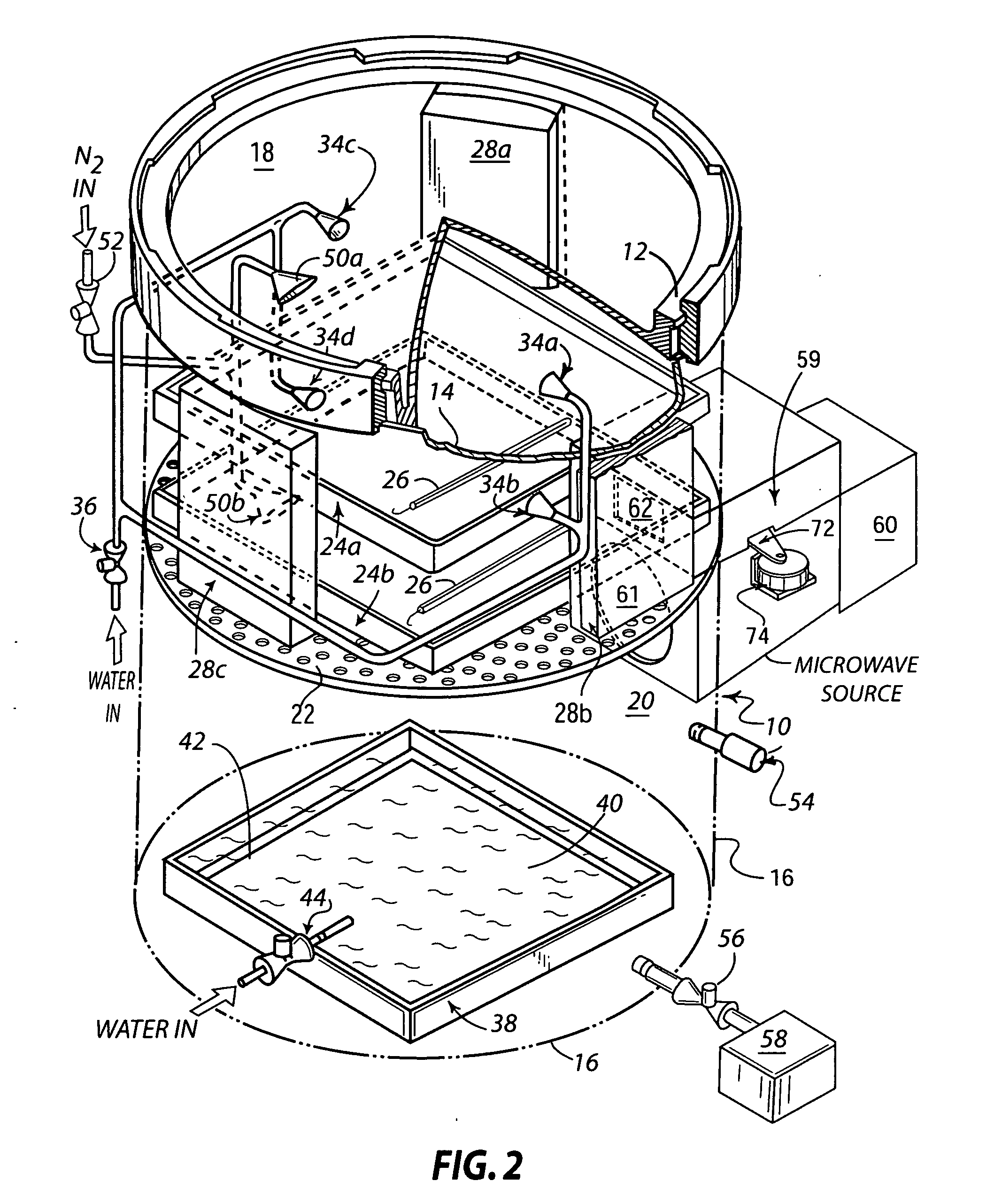

Microwave-assisted steam sterilization of dental and surgical instruments

InactiveUS6900421B2Rapid and complete sterilizationDielectric heating circuitsDentistrySteam pressureLiquid water

A surgical and dental instrument sterilizer is described. Liquid water is rapidly vaporized by microwave heating and steam is generated to attain a steam pressure of approximately 47 psi and a temperature of approximately 135° C. in the region of the articles to be sterilized. Micron-size water-droplets are intermittently sprayed onto the articles which are arranged on a tray, from both the top and from underneath thereof so as to thoroughly wet the surfaces. A 30-90 s duration of droplet spray is followed by pulsed microwave irradiation of the top and underneath surfaces for a similar period, as an example; this is followed by a plurality of spray / microwave cycles. Sterilizing conditions in the sterilizer chamber are maintained in the presence of the water spray / microwave flashing cycles since introducing small aliquots of water will not affect the desired sterilizing condition provided by superheated steam augmented by microwave radiation necessary to kill microbes including spores; however arcing from metal instruments when subjected to microwave radiation is substantially reduced.

Owner:ECOFRIEND TECH

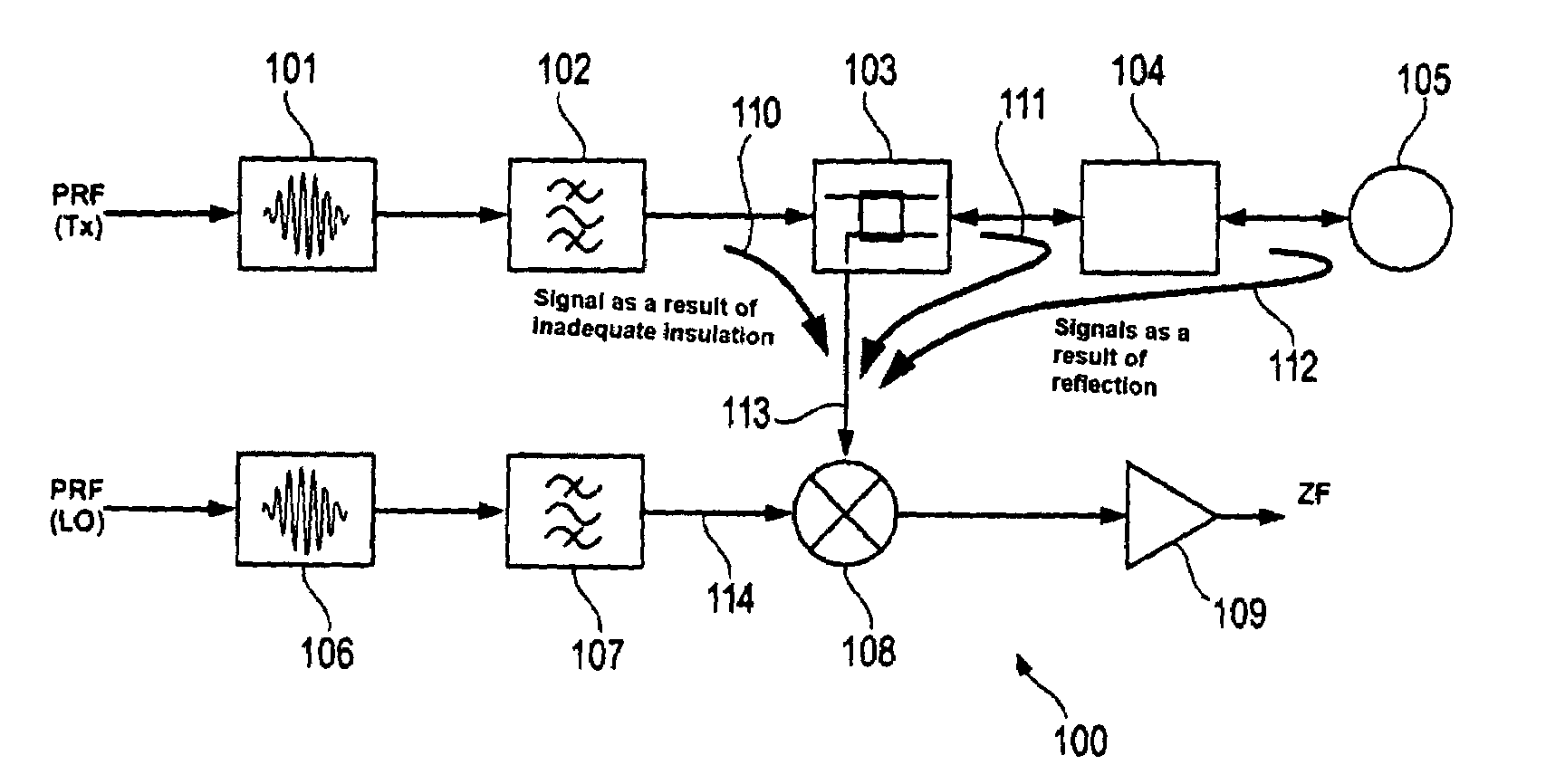

Independent Reference Pulse Generation

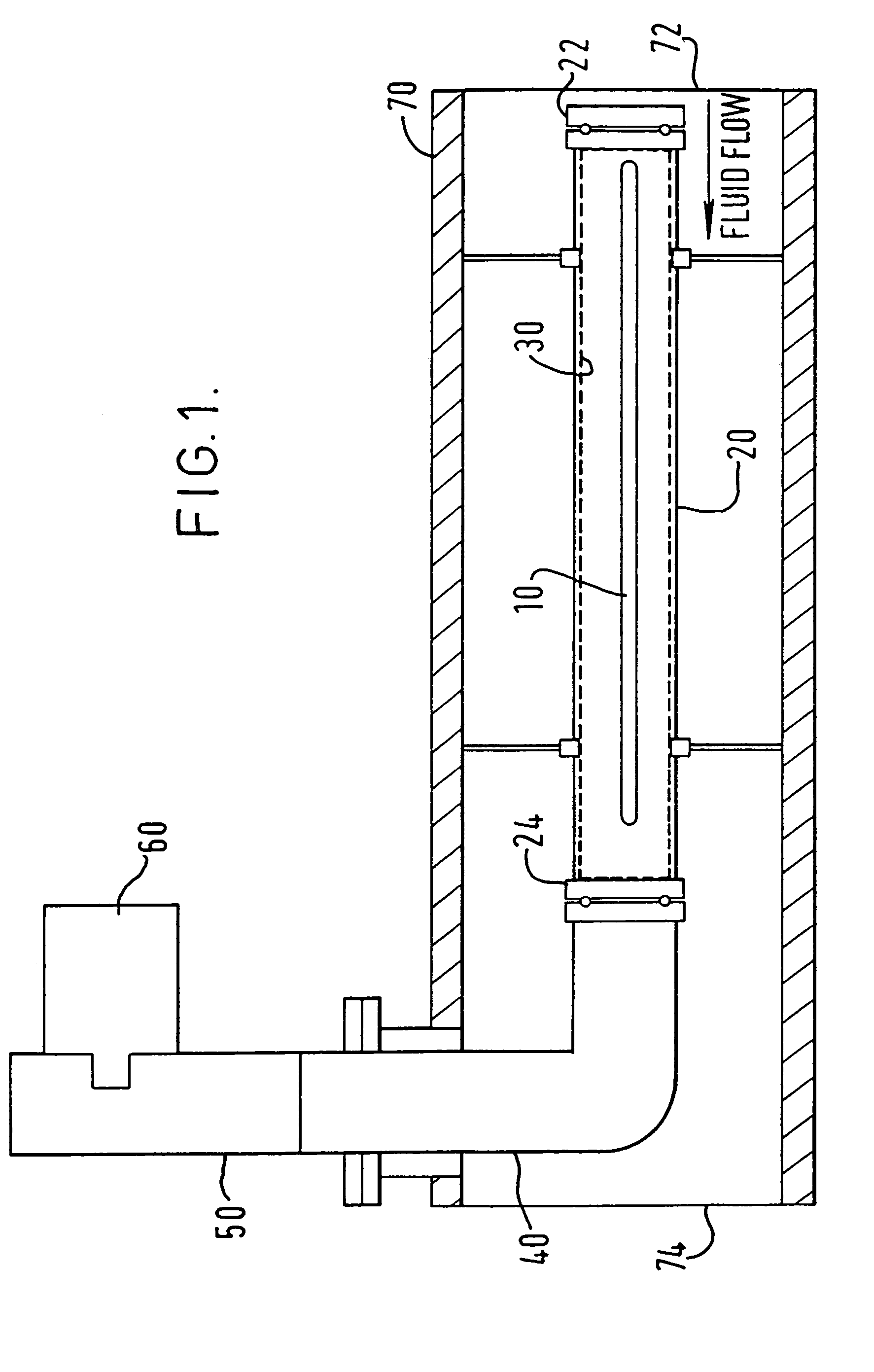

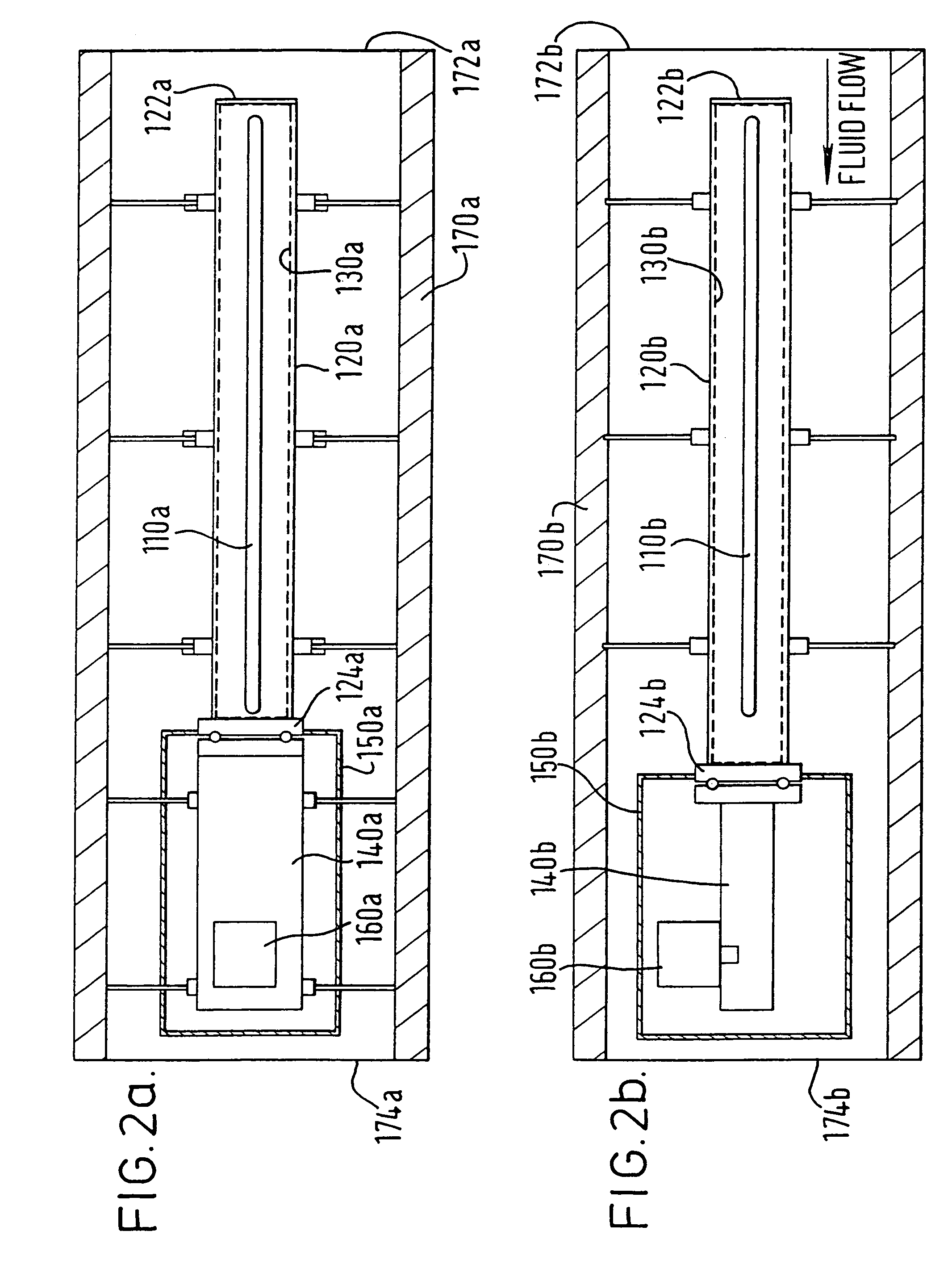

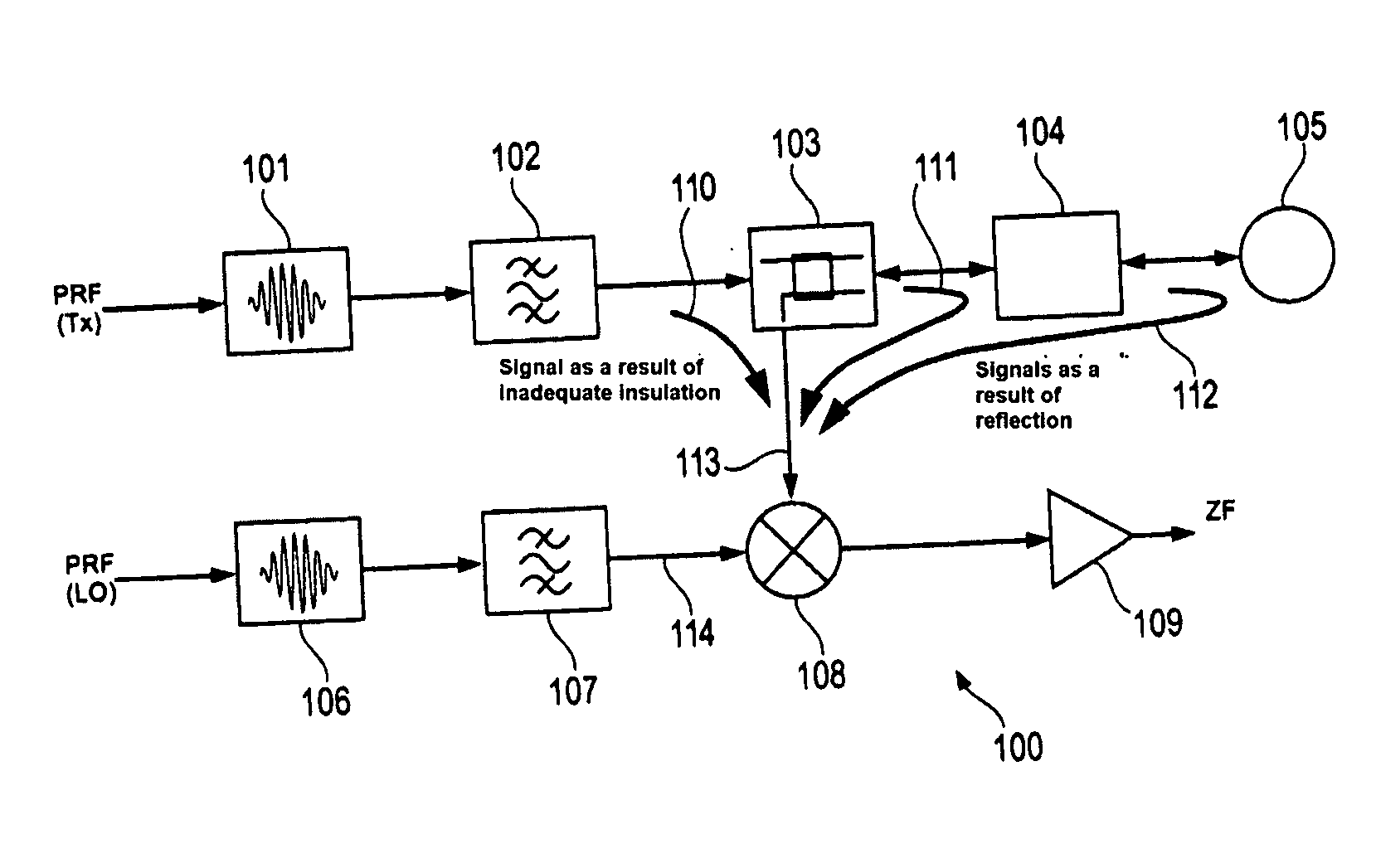

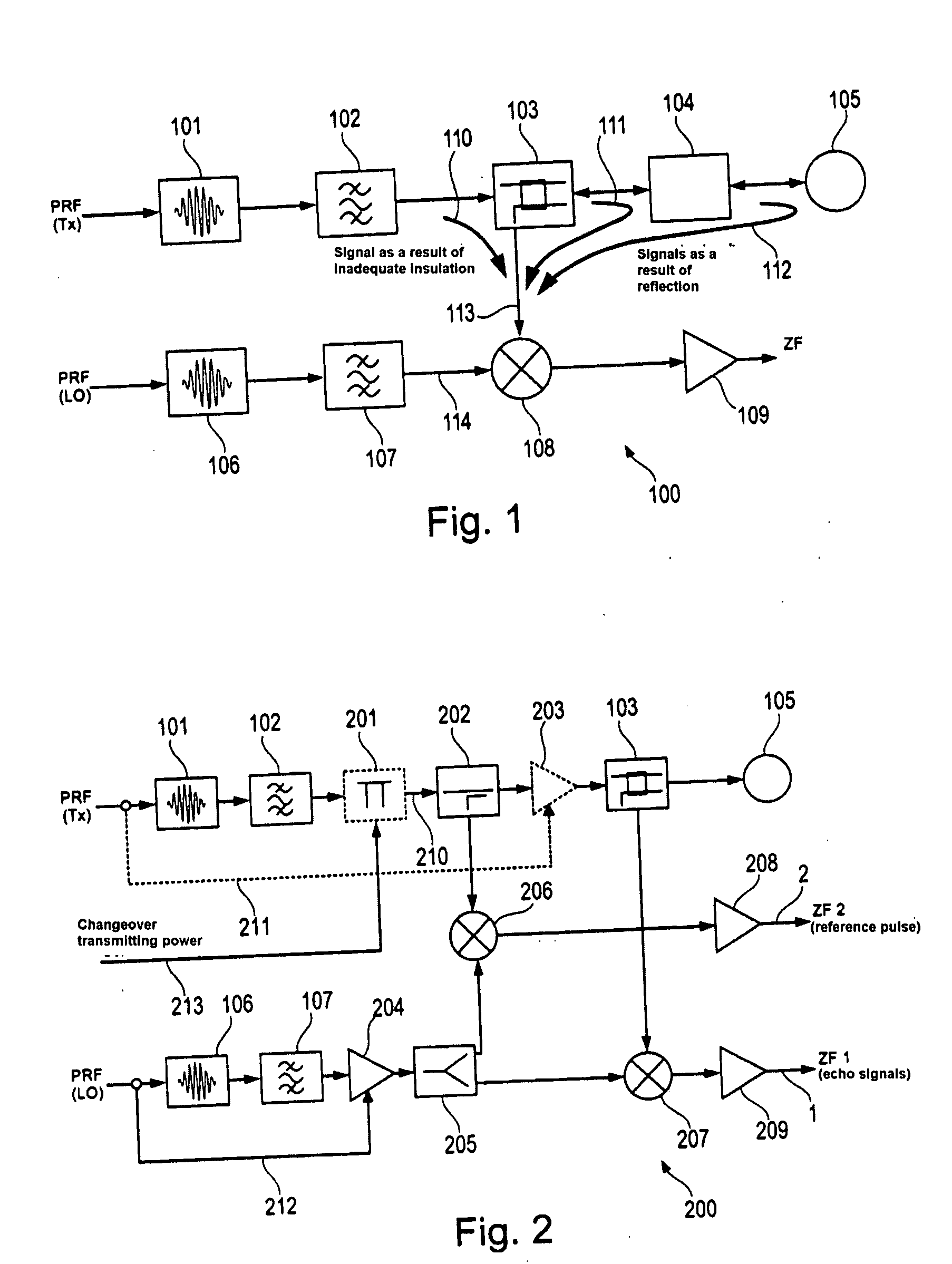

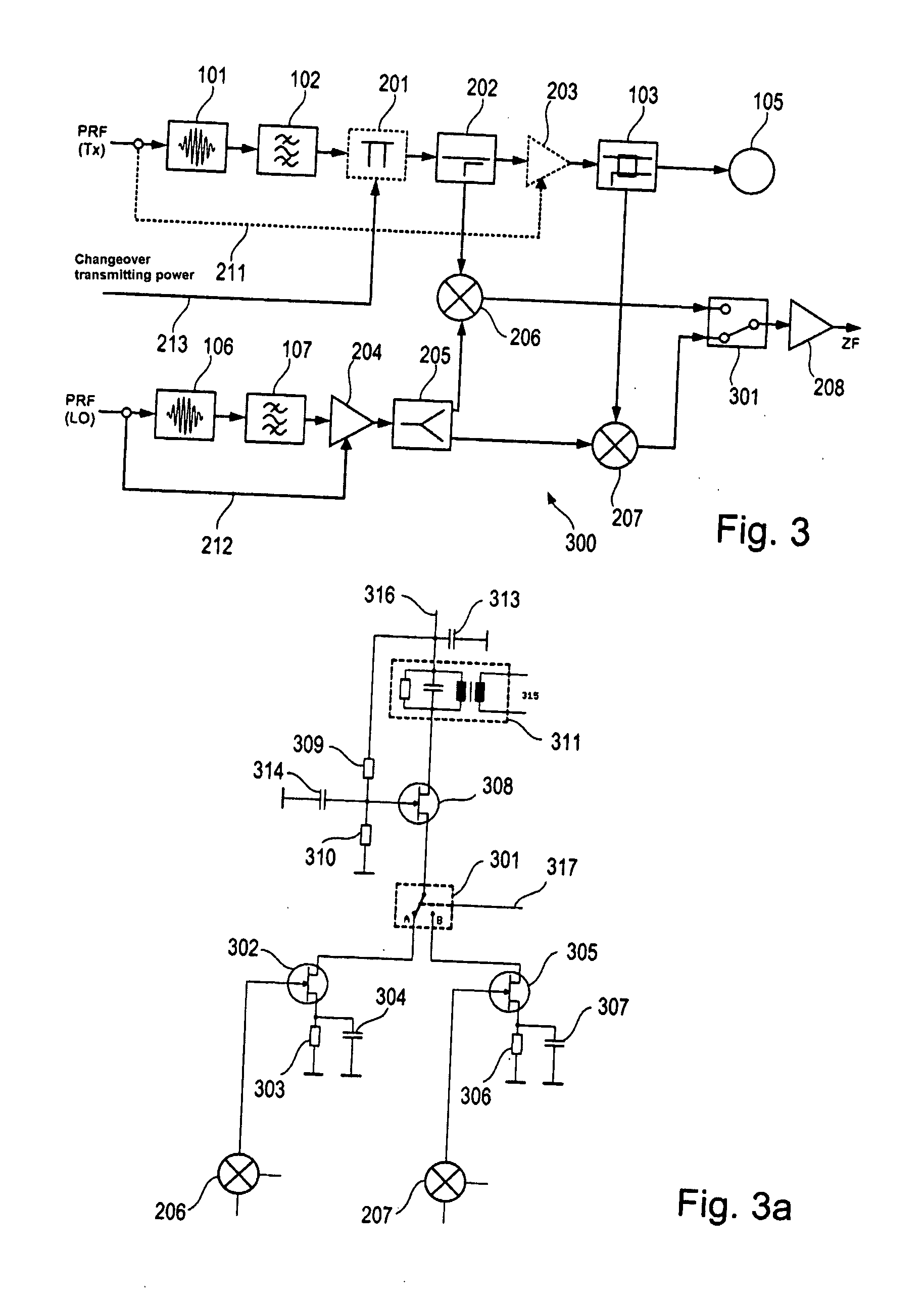

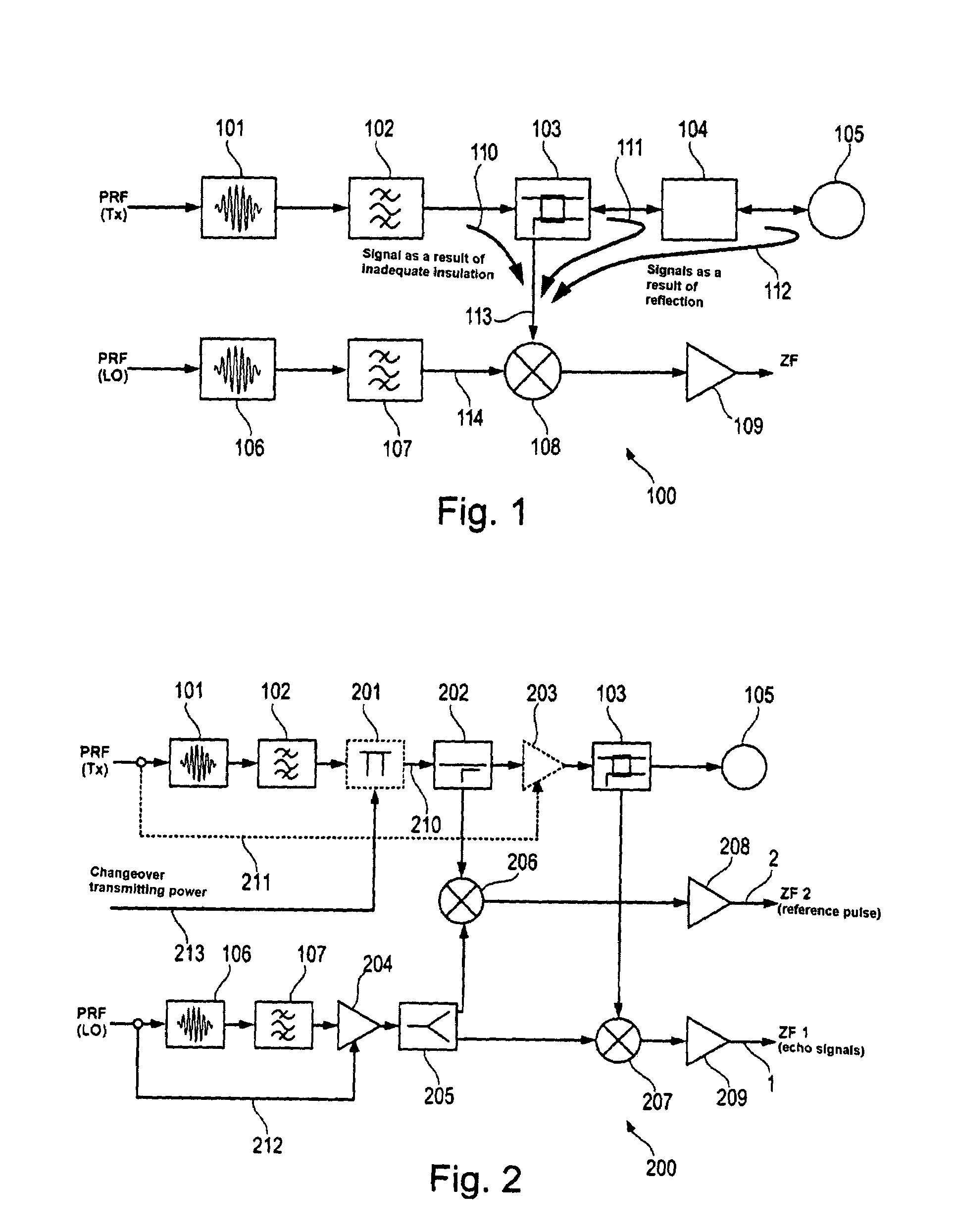

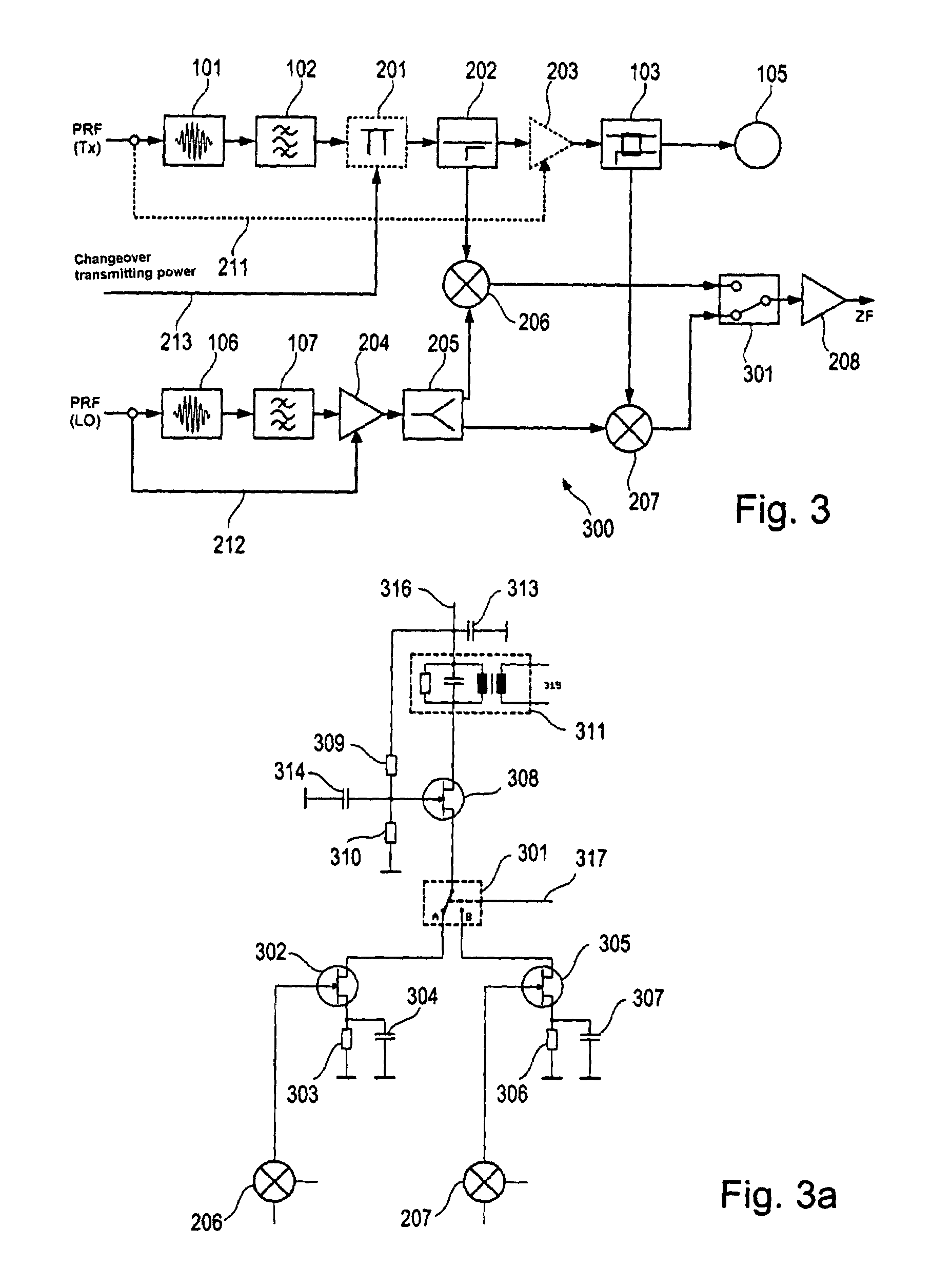

ActiveUS20080024145A1Efficiency sometimes variesSimple designResistance/reactance/impedenceLevel indicatorsFrequency mixerPulse microwave

In fill-level measuring devices according to the pulse-transit-time method, a reflection that is generated internally in a microwave module is used as a reference for transit time measuring. For generating the reference pulse, the microwave module comprises its own sampling mixer or its own oscillator. Subsequently, the echo signal and the reference pulse can be further processed separately or together. No delay line is necessary on the transmission frequency of the radar sensor. Interference as a result of leakage signals is largely prevented.

Owner:VEGA GRIESHABER GMBH & CO

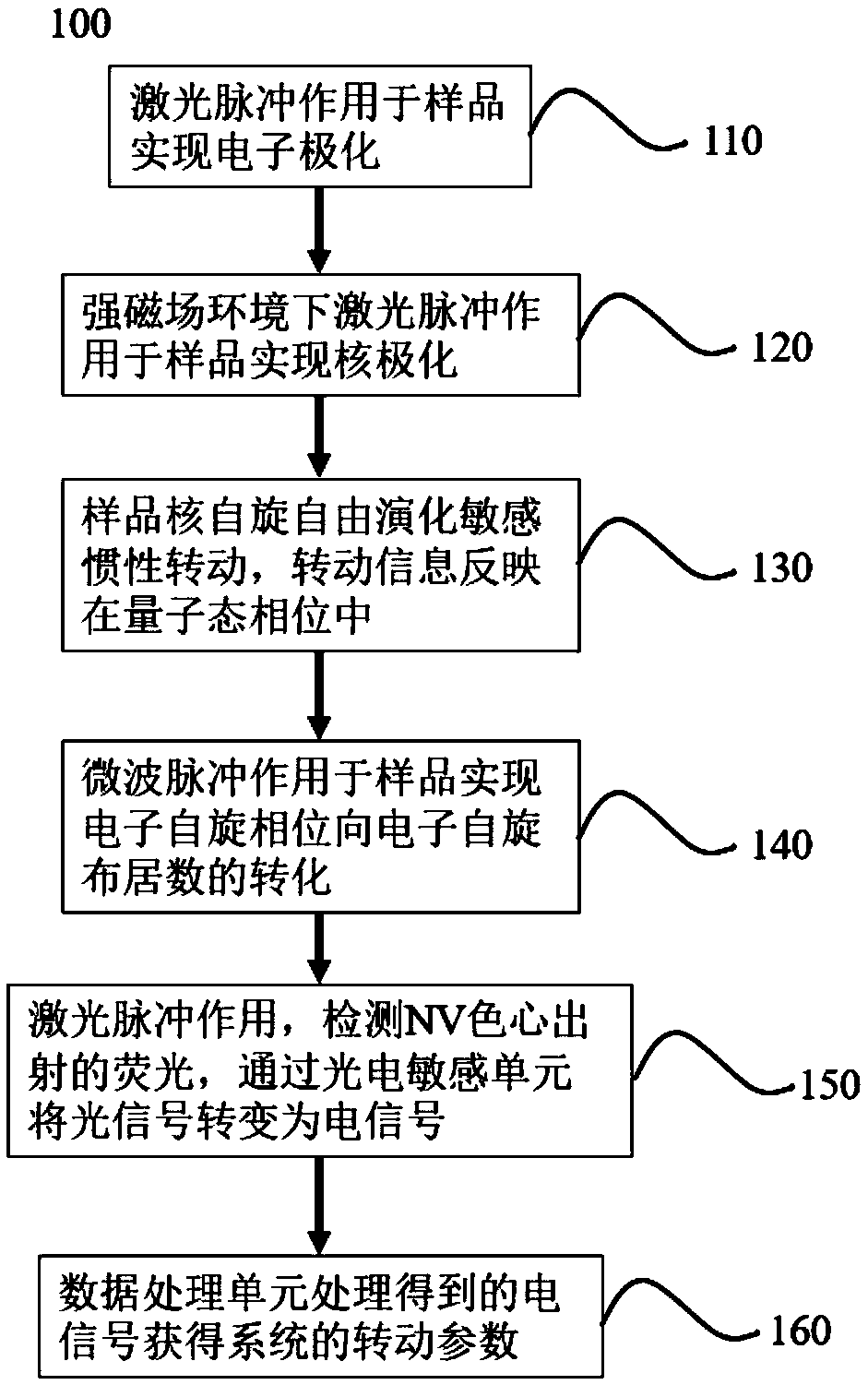

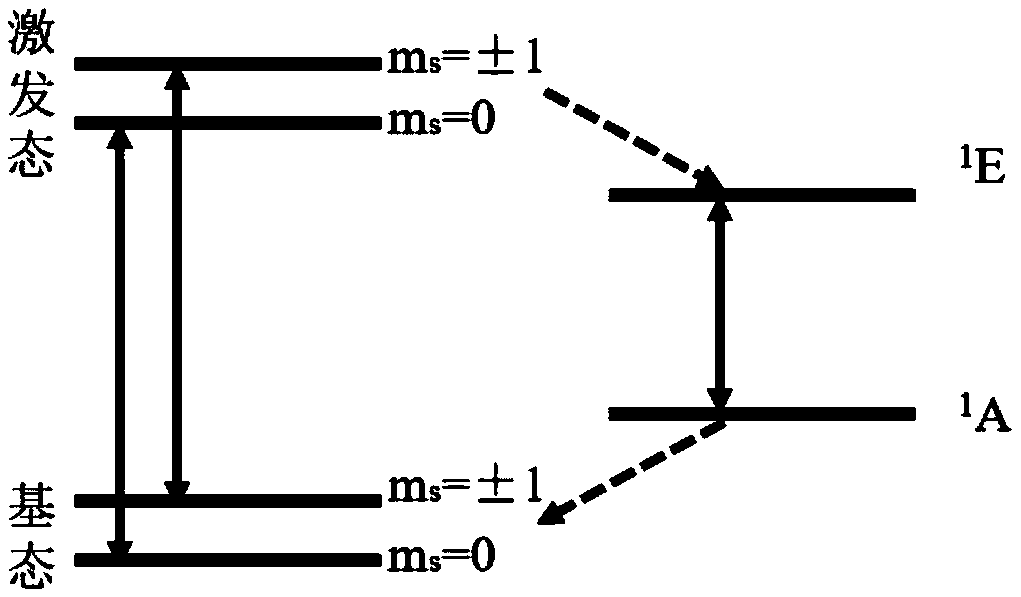

Inertia measurement device and method based on diamond NV color center under high magnetic field

ActiveCN108759810AAchieve nuclear polarizationSimple structureTurn-sensitive devicesHigh concentrationMeasurement device

The invention discloses an inertia measurement device and method based on a diamond NV color center under a high magnetic field. The method adopts a diamond material containing a high-concentration nitrogen-vacancy (NV) color center as a sensitive element, laser and the about 500 gauss of high magnetic field are used for achieving the polarization of nuclear angular momentum, and pulse laser and pulse microwave are used for achieving the operation, control and detection of the diamond NV color center, thereby achieving the measurement of inertial rotation. Compared with the inertial rotation measurement by using electron spin, the measurement sensitivity is significantly improved through nuclear polarization, it is of great value for the development of an inertial measurement system basedon a quantum theory, and the device serves for various fields in the future, especially for civil miniaturized inertial navigation and attitude determination systems.

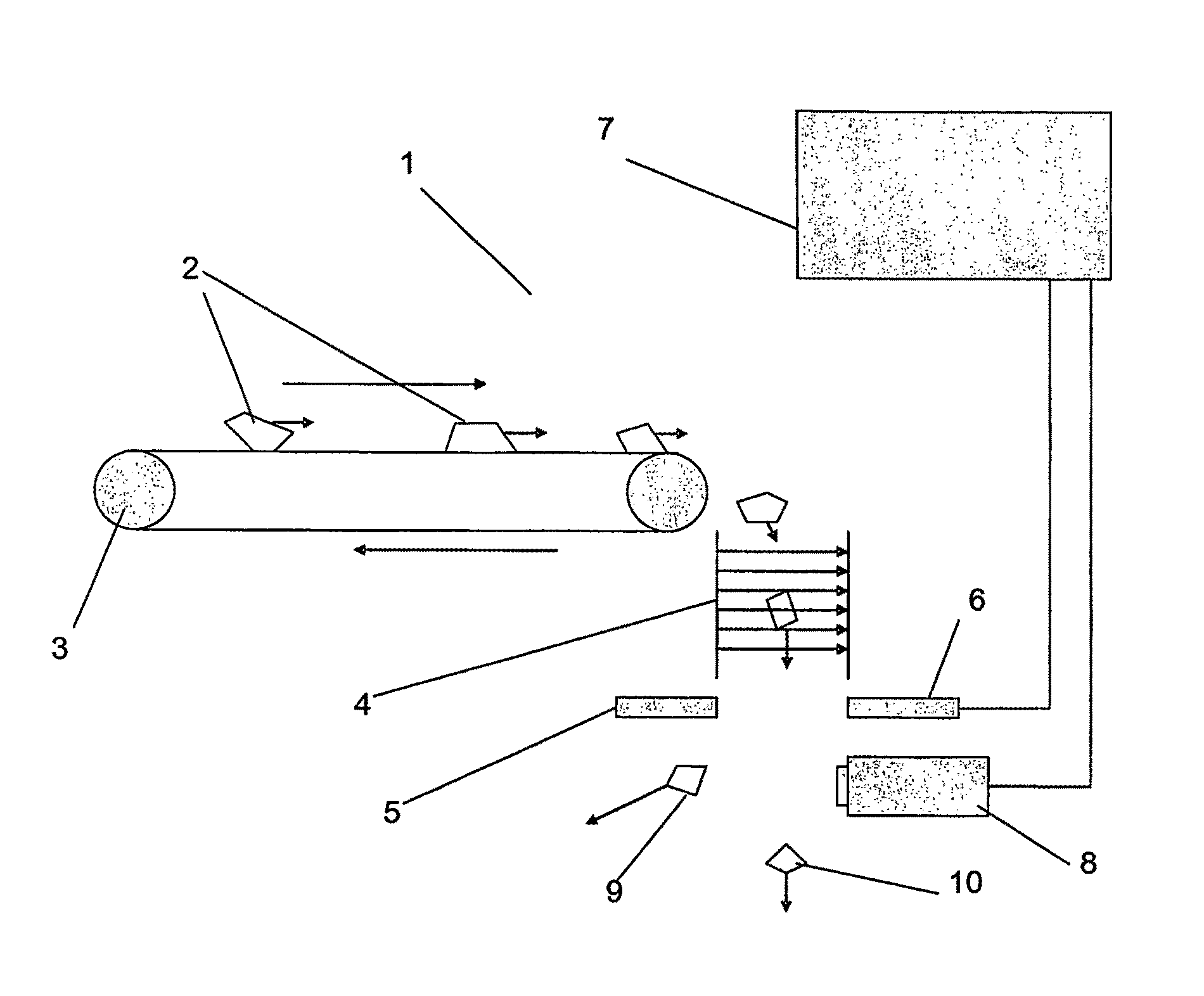

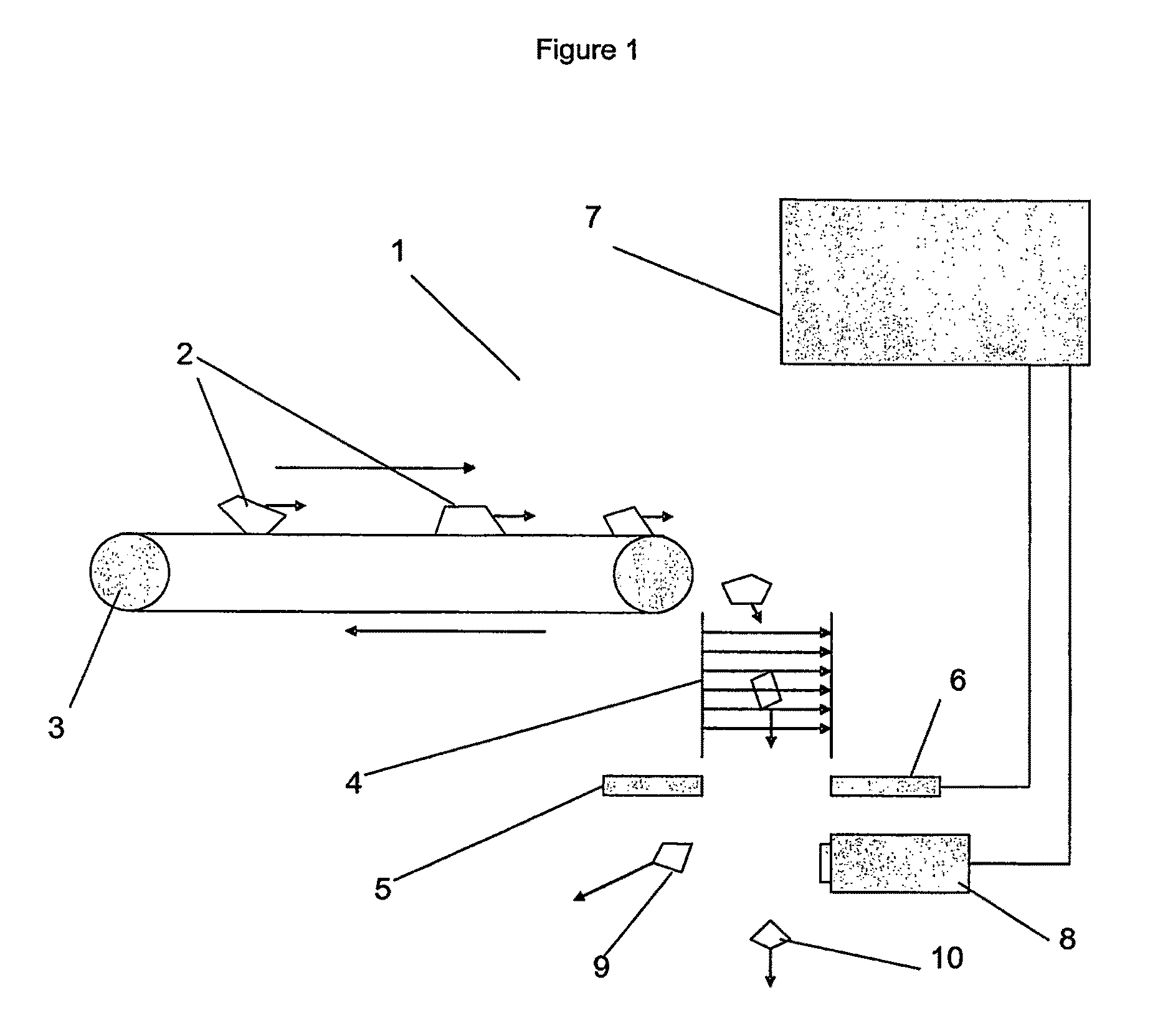

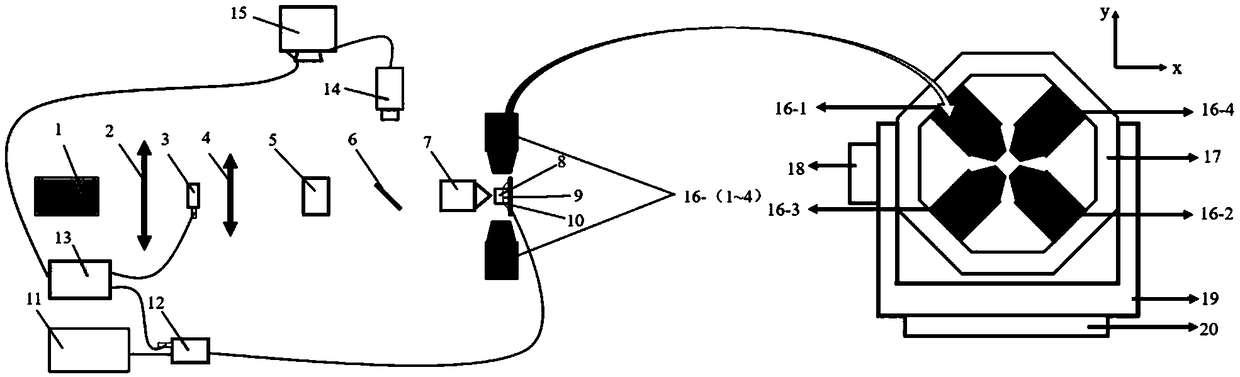

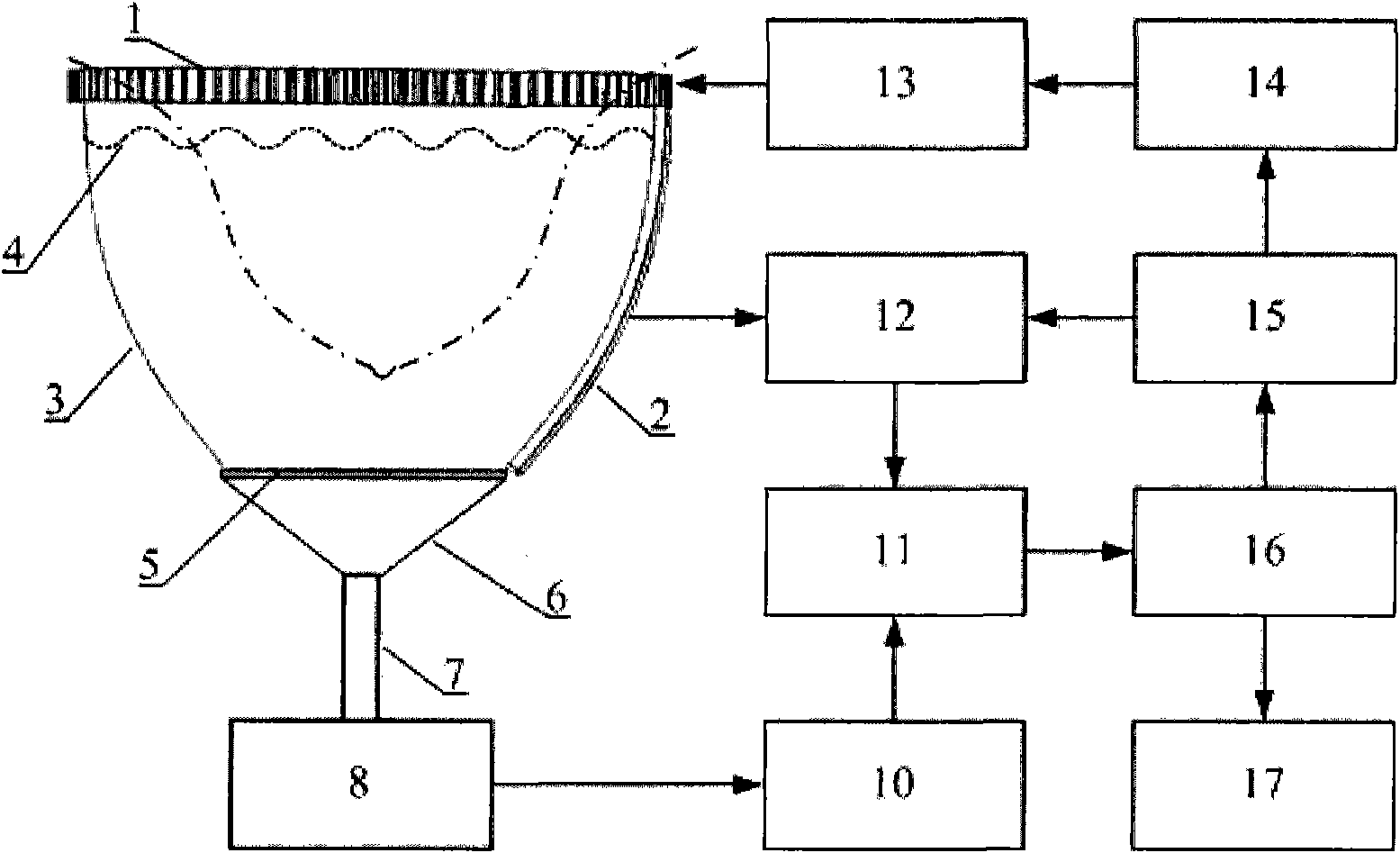

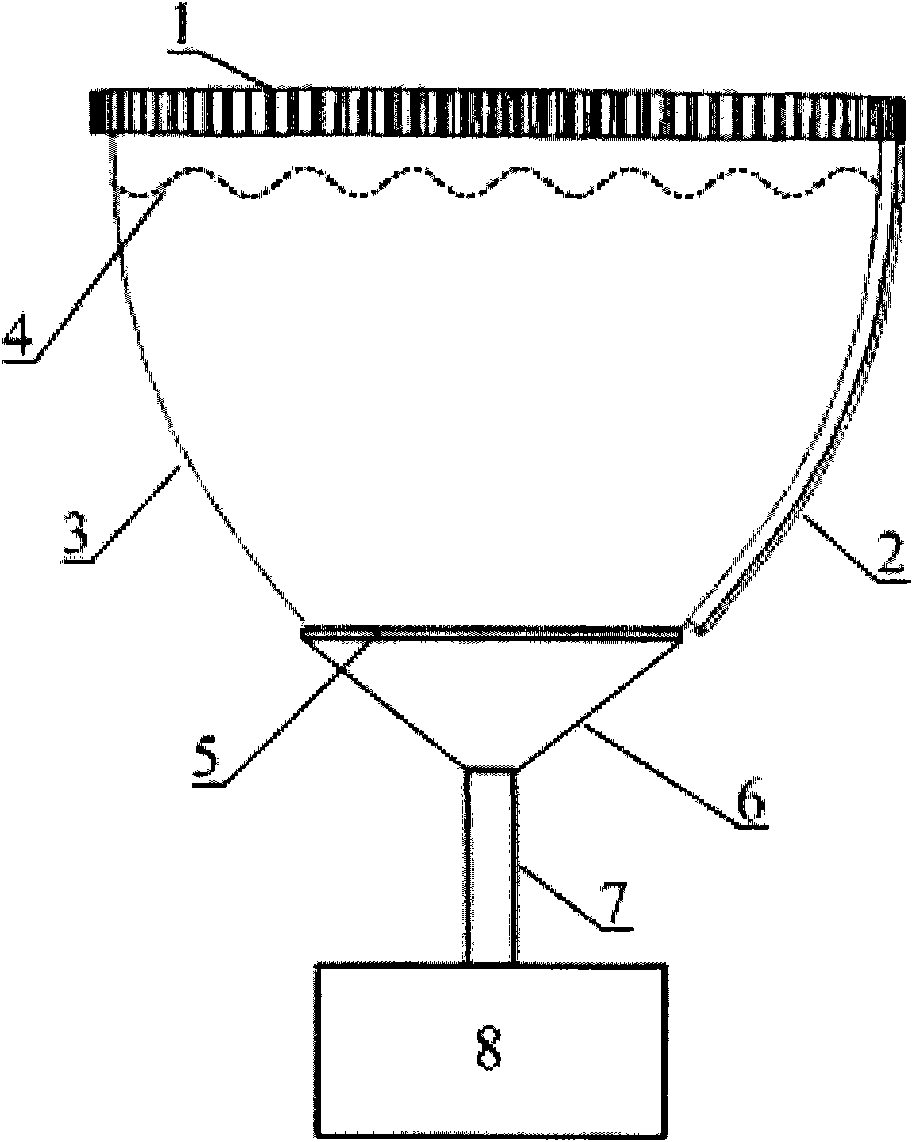

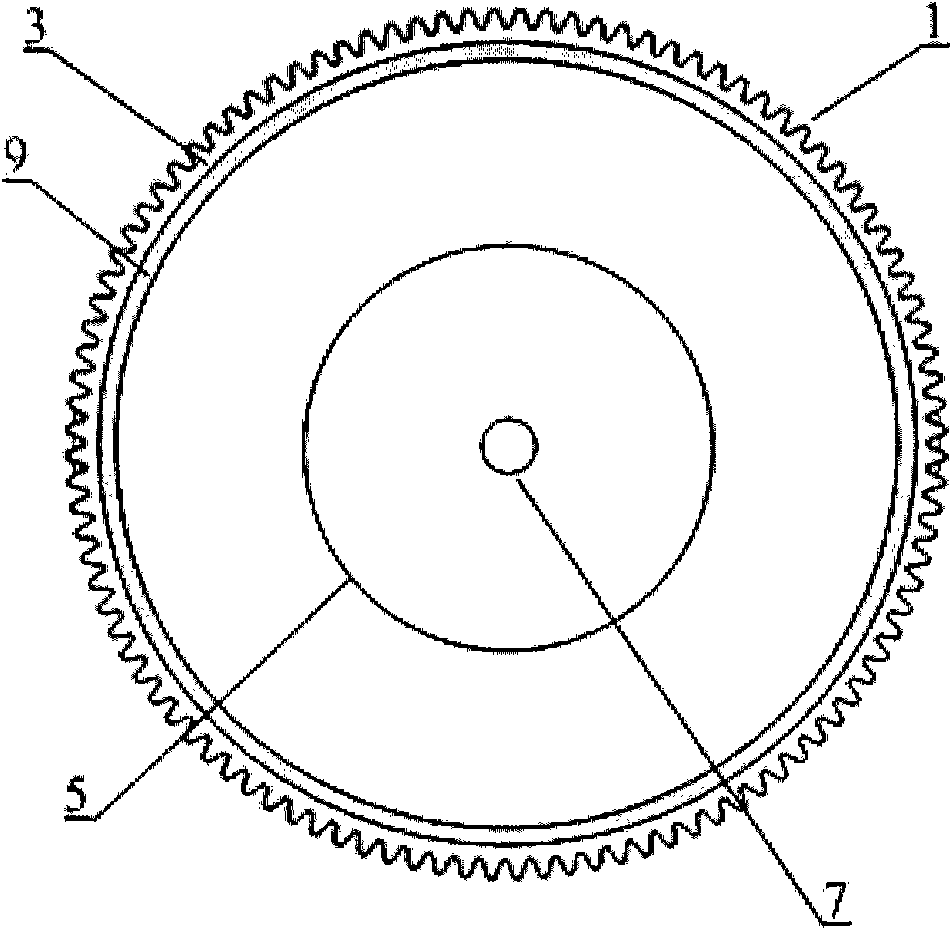

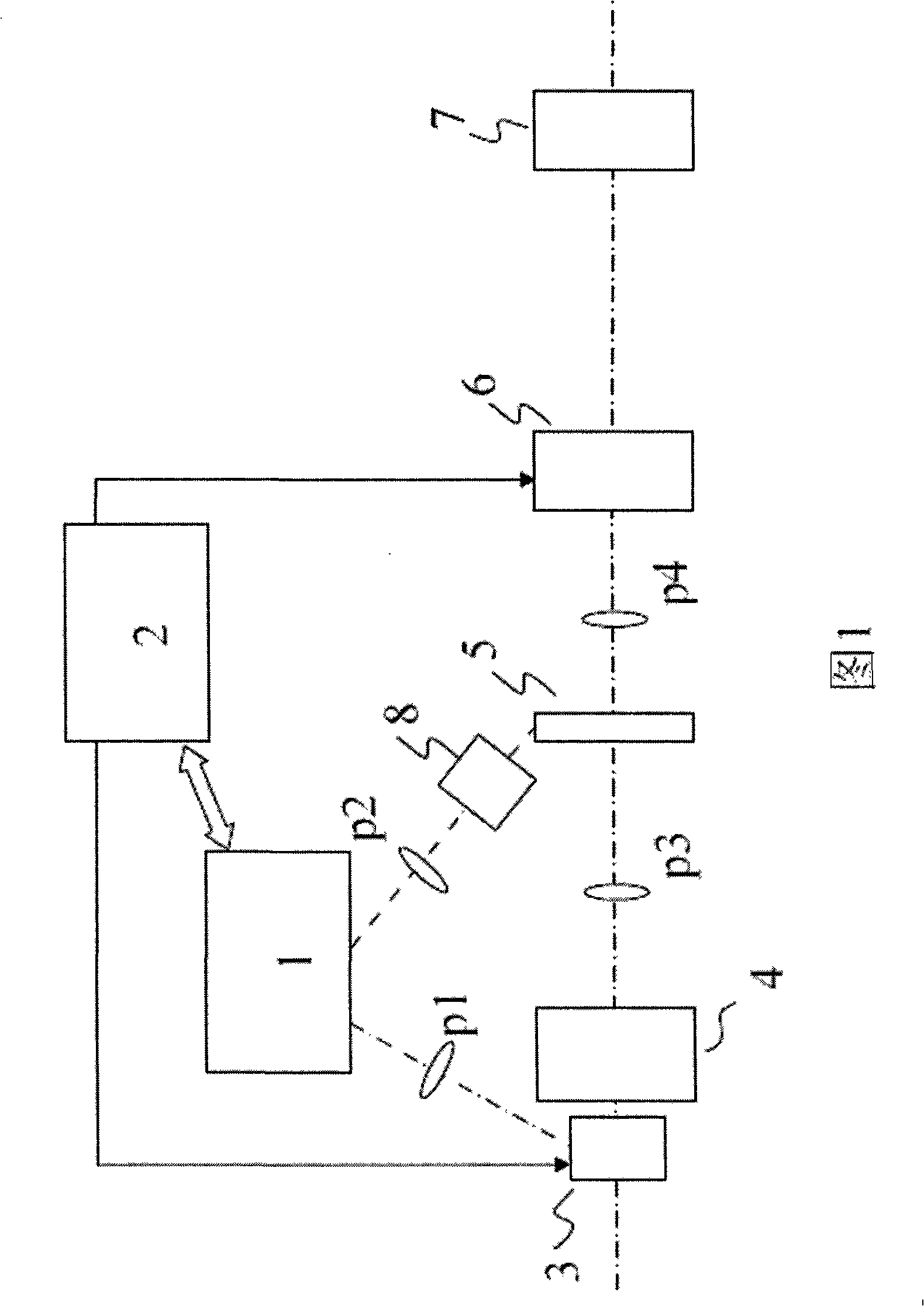

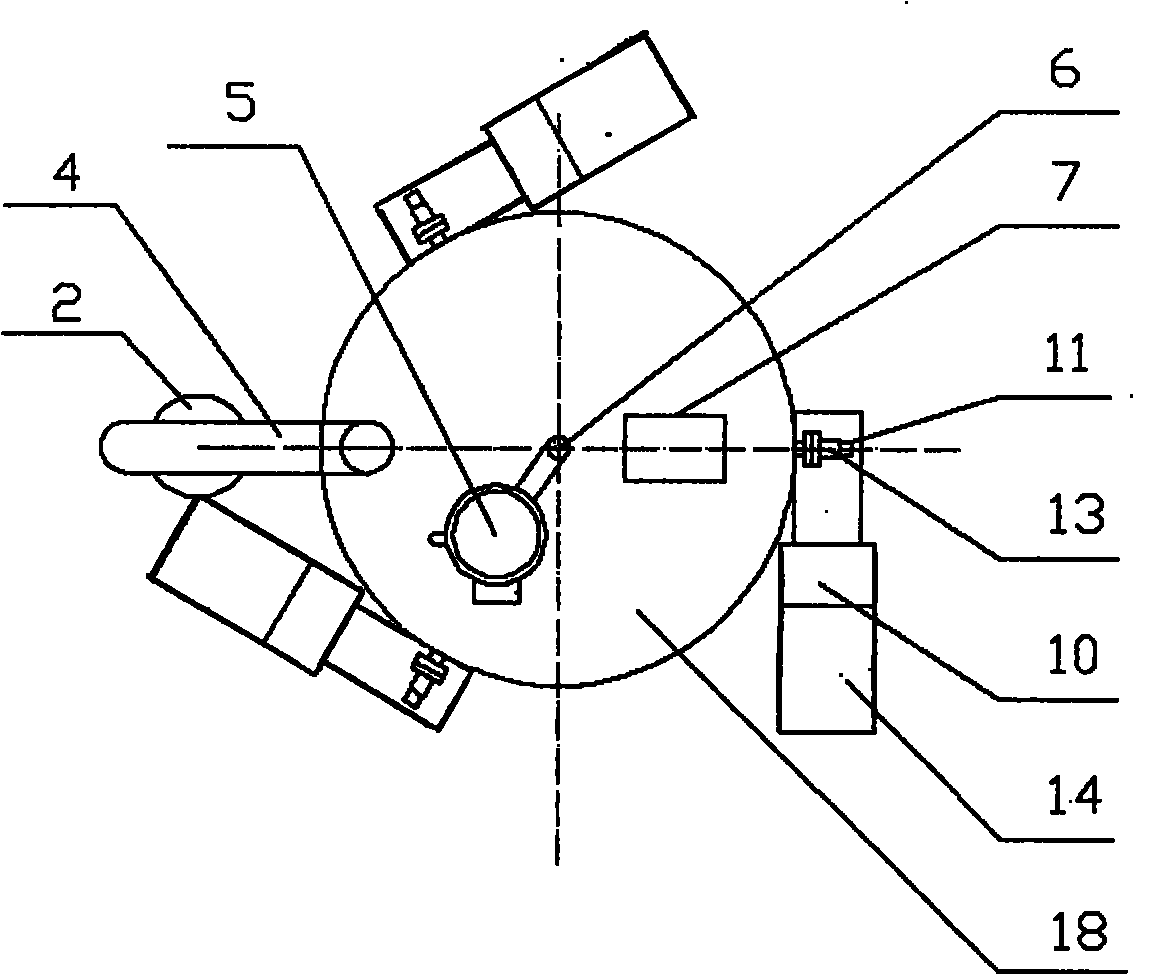

Early-stage breast cancer nondestructive screening and imaging system

InactiveCN101816572AMiniaturizationImprove practicalityUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsEarly breast cancerPulse microwave

The invention discloses an early-stage breast cancer nondestructive screening and imaging system, which mainly comprises circular gears, an annular ultrasonic array, a bowl-shaped annular shell, ultrasonic coupling liquid, a protective film, a horn antenna, a waveguide tube, a microwave generator, a frequency divider, a data acquisition circuit, a preprocessing circuit, a stepping motor, a driver, a digital I / O card, a computer and a display. The working process of the system is that: detected mammary glands are radiated by pulse microwaves to generate thermo-acoustic signals which are received by the annular ultrasonic array and are finally acquired by the computer; the driver drives the annular ultrasonic array to rotate to a next position around detected biological tissues; and the steps of acquisition and rotation are repeated until the thermo-acoustic signals of enough positions are received, and the computer re-establishes three-dimensional thermo-acoustic images of the detectedtissues. The early-stage breast cancer nondestructive screening and imaging system can quickly and nondestructively realize the three-dimensional thermo-acoustic imaging of the detected mammary glands to provide one of important bases for the diagnosis of early-stage breast cancer.

Owner:JIANGXI SCI & TECH NORMAL UNIV

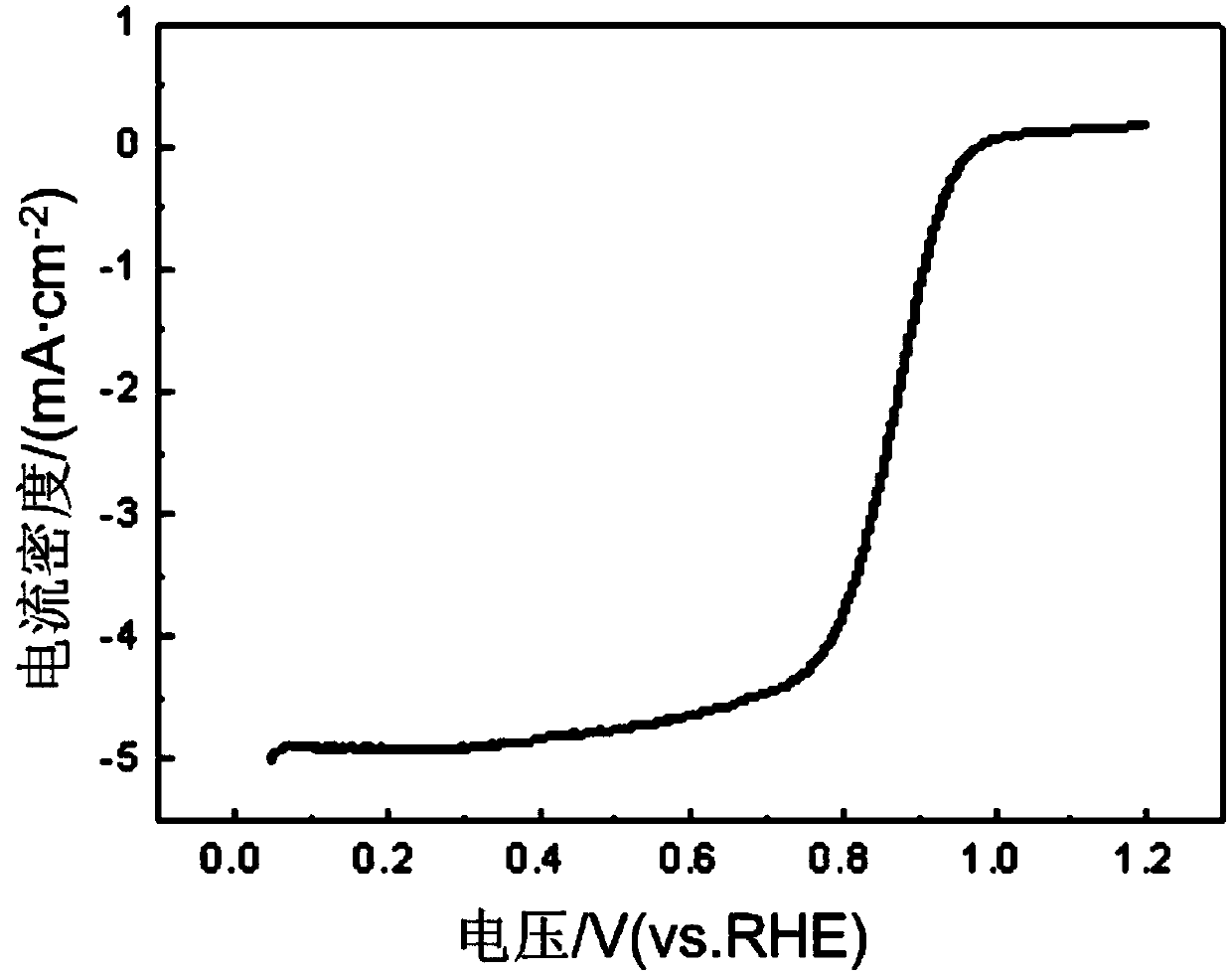

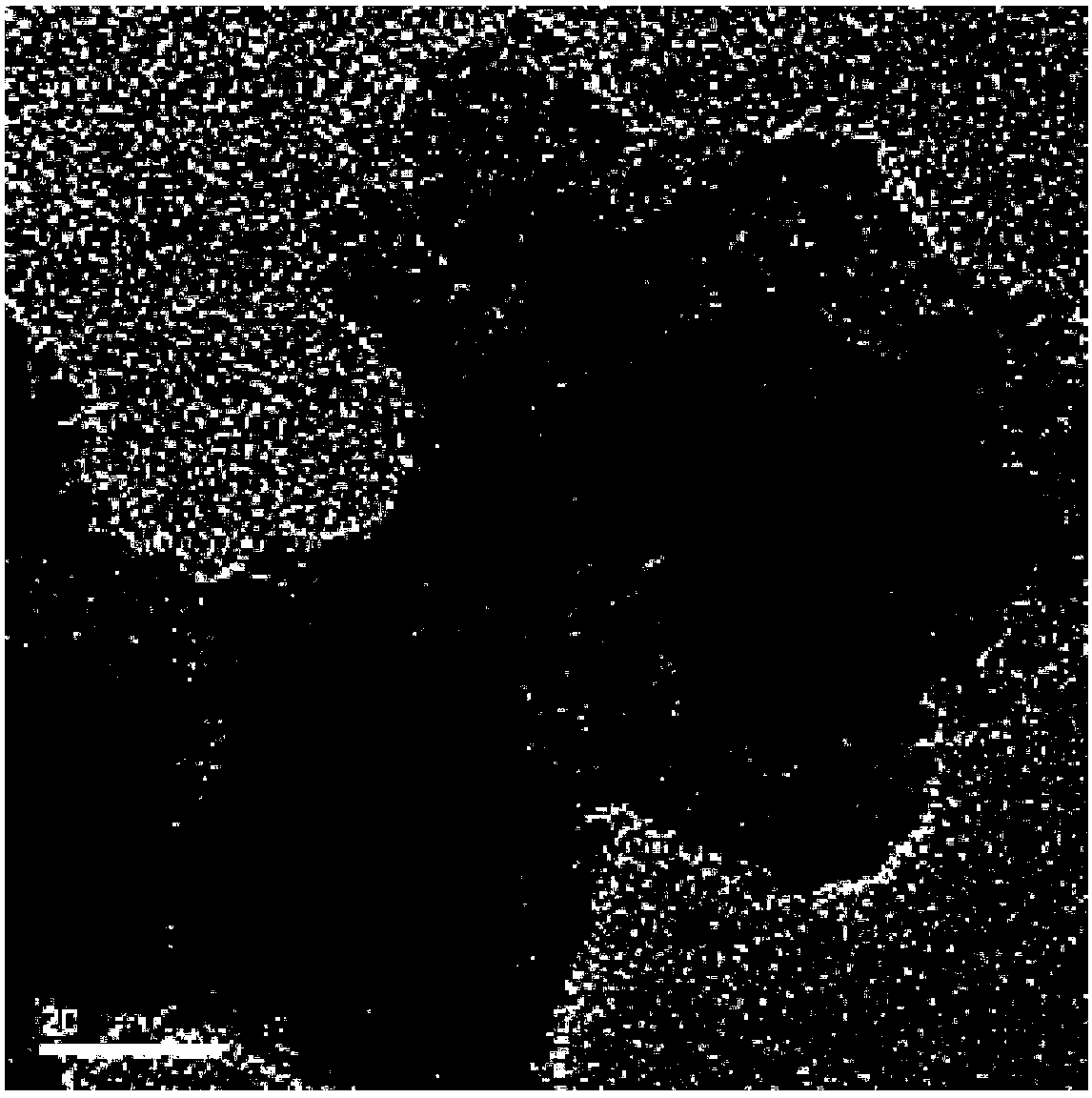

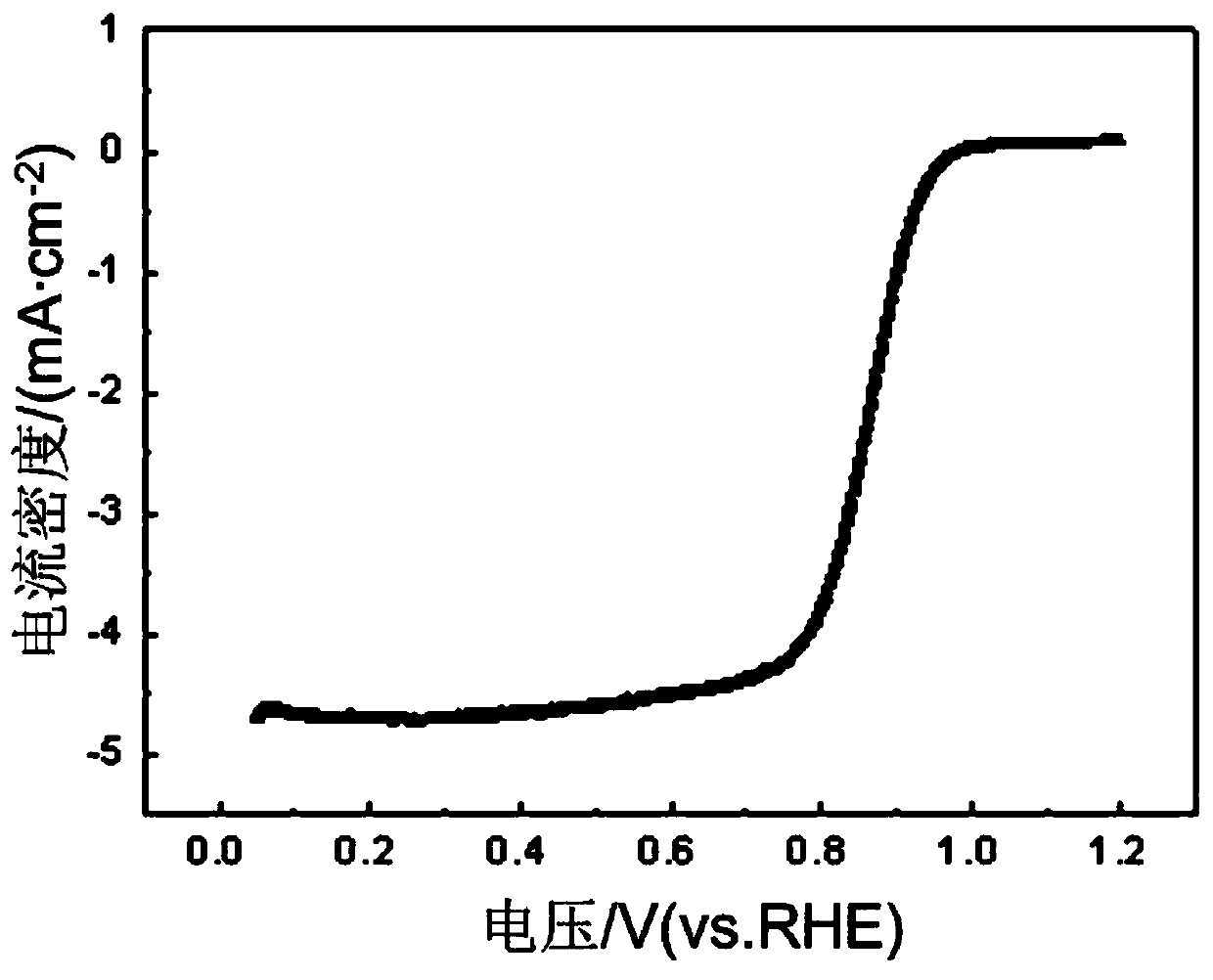

PtM/C electrocatalyst for fuel cell and preparation method of PtM/C electrocatalyst for fuel cell

The invention relates to a PtM / C electrocatalyst for a fuel cell. The PtM / C electrocatalyst comprises the following components by mass percent: 18.16-36.52% of active components, 1.74-3.68% of auxiliary agents and the balance being a conductive carrier. The PtM / C electrocatalyst is prepared by the steps of feeding precursors of the active components and precursors of the auxiliary agents into a mixed suspension liquid of the conductive carrier and a reducing agent in one step; loading metal Pt and M onto the conductive carrier by adopting a pulse microwave-assisted chemical reduction method; and after that, precipitating, filtering, washing and carrying out vacuum drying to obtain the PtM / C electrocatalyst. Compared with the prior art, the preparation method is simple; the prepared PtM / C electrocatalyst is uniform in particle distribution, small in size and high in catalytic activity of oxygen reduction reaction, and can be used in the field of the fuel cell.

Owner:TONGJI UNIV

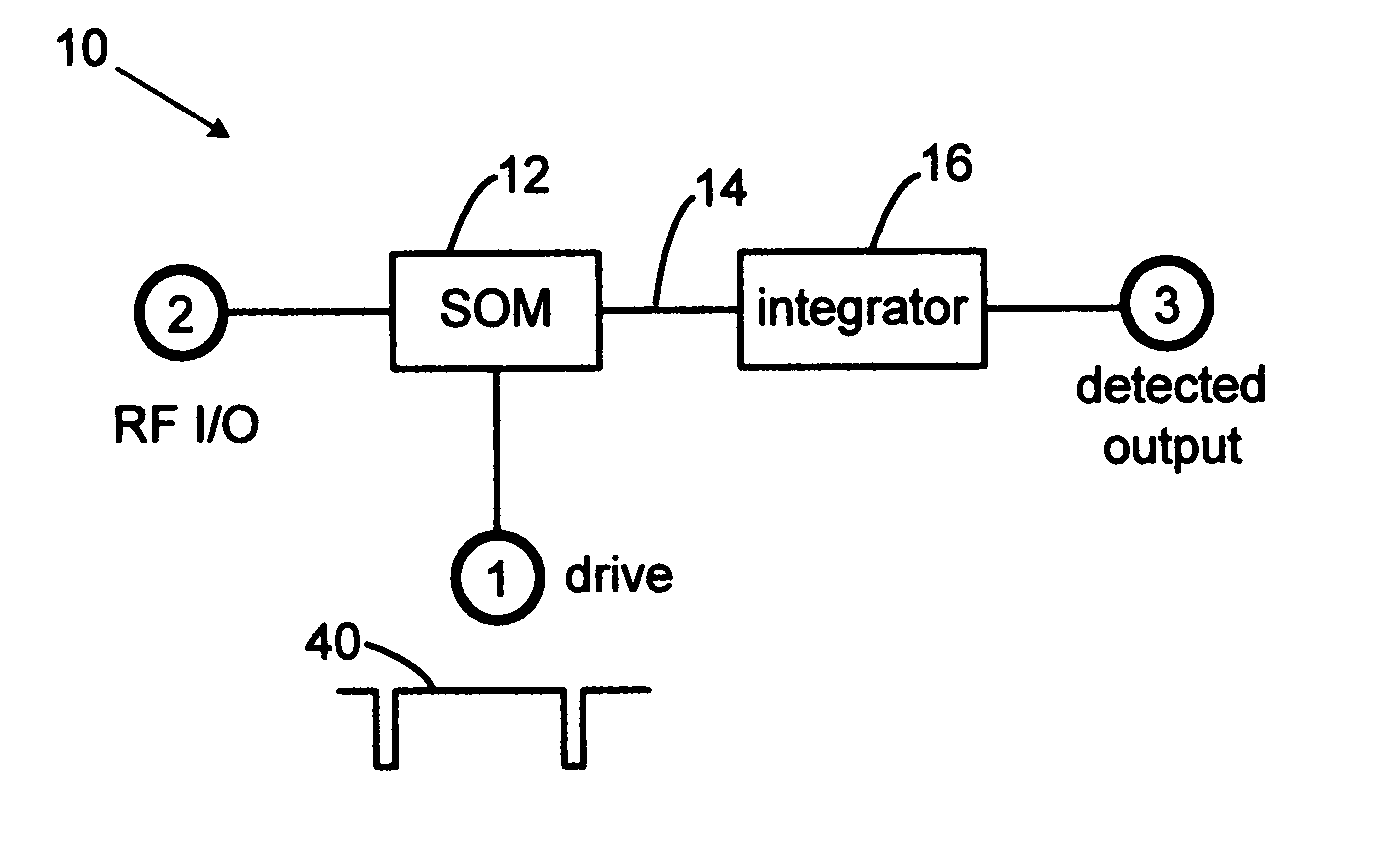

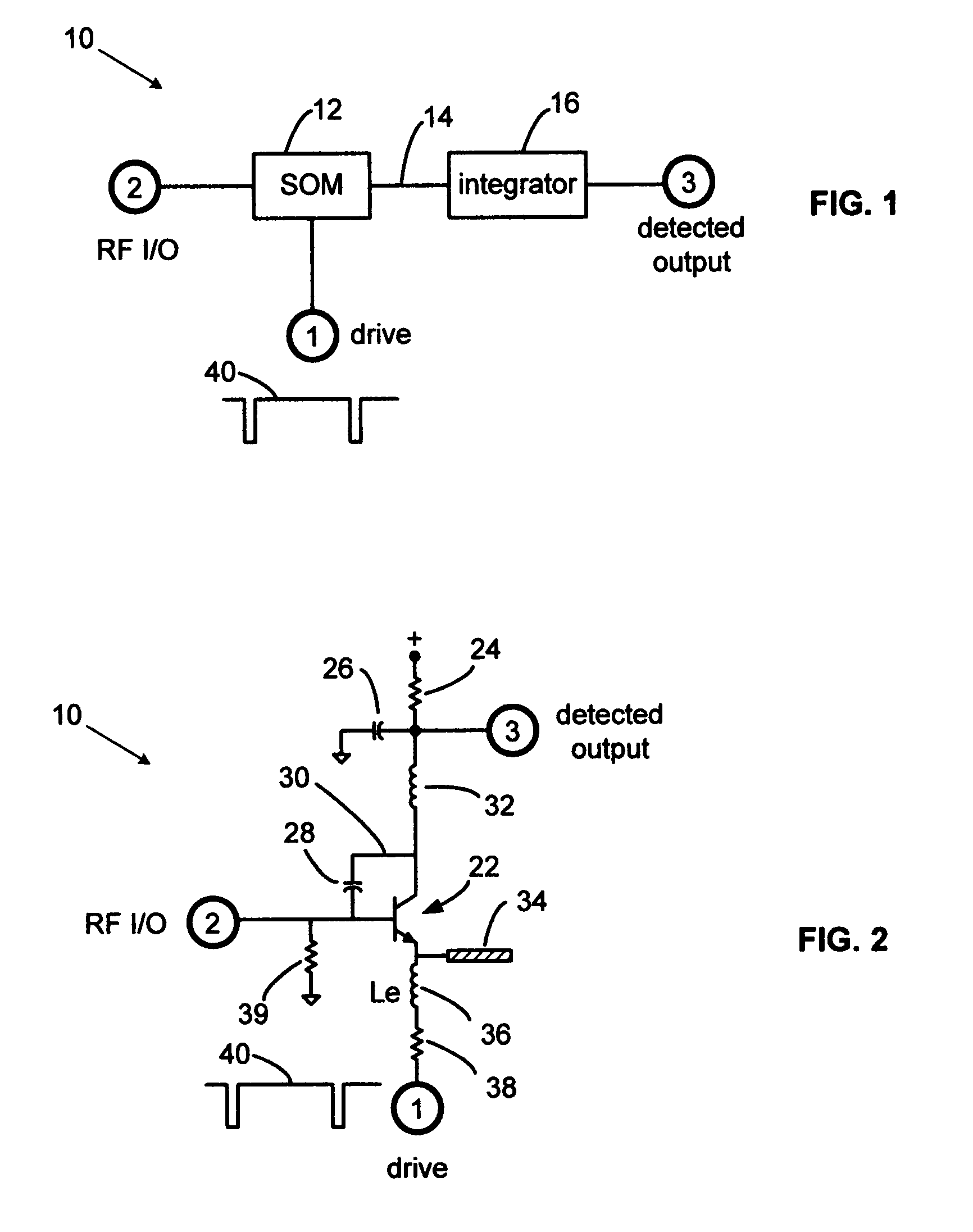

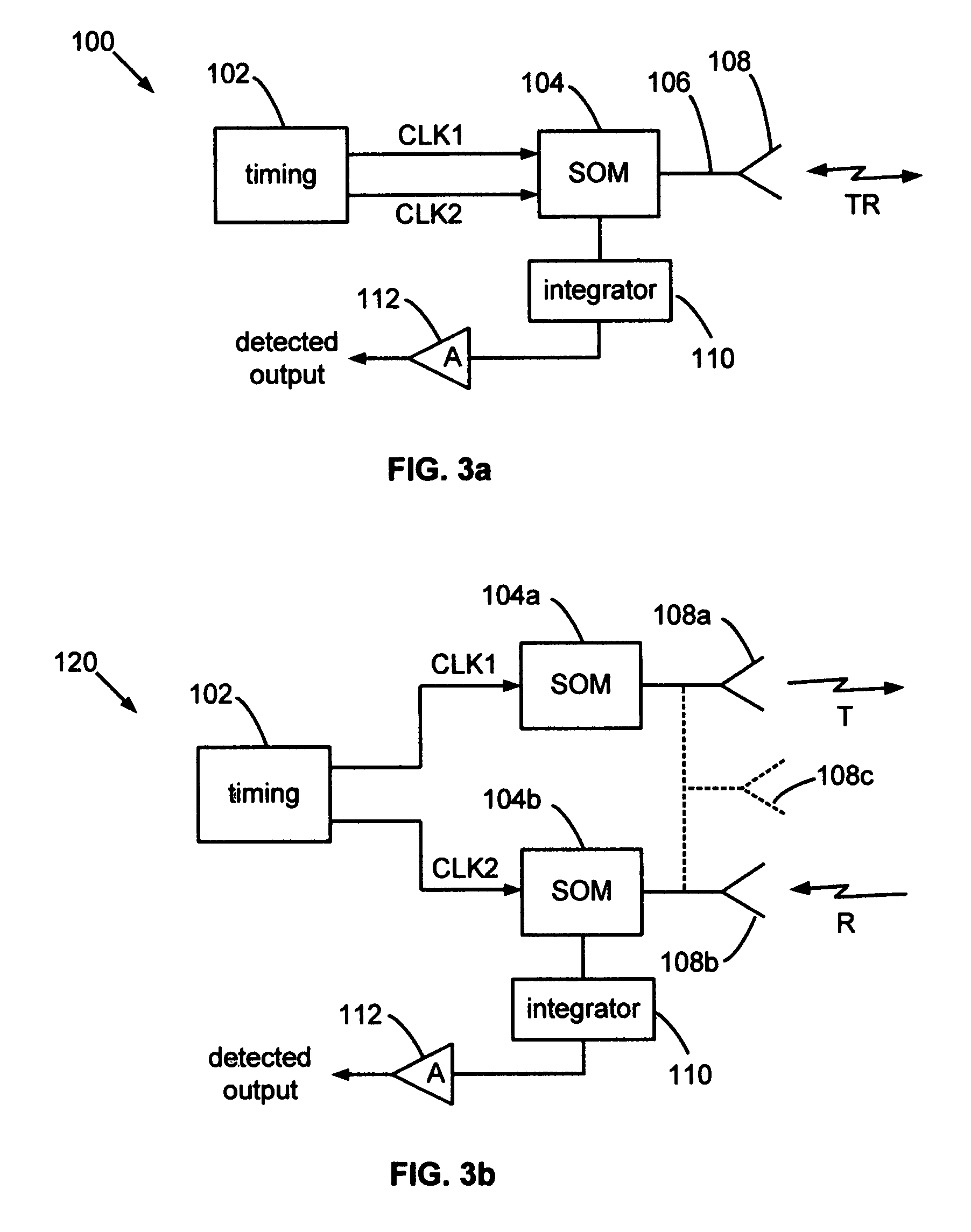

Self-oscillating UWB emitter-detector

ActiveUS8115673B1Reduce noiseModulation transference by semiconductor devices with minimum 2 electrodesAmplitude demodulation by non-linear multiple-pole elementsLow noiseIntegrator

A UWB RF detector employs a pulsed self-oscillating mixer (SOM) and an output integrator to provide low-noise preamplification, mixing and sampling. The SOM produces short-burst, microwave self-oscillations that are phase-locked to a clock. The self-oscillations are used for mixing. The SOM can also radiate UWB RF pulses. A one-transistor SOM can simultaneously implement both a UWB emitter and a UWB detector in a radar transceiver. A control loop can stabilize the self-oscillations at nanowatt levels. Nanowatt UWB radars and radios can be realized, thereby opening new spectral bands beyond those formally designated for UWB operation.

Owner:MCEWAN TECH

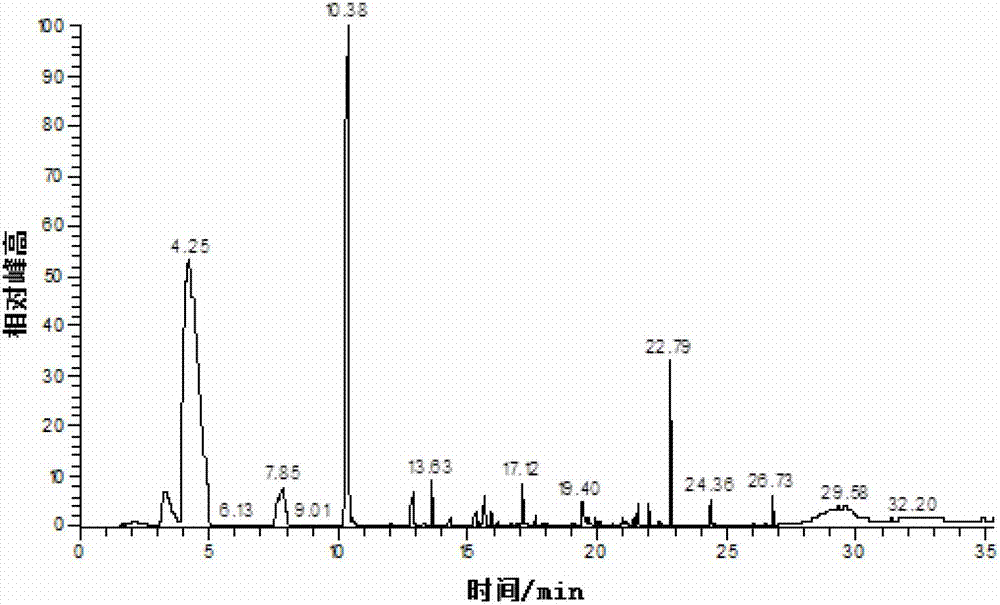

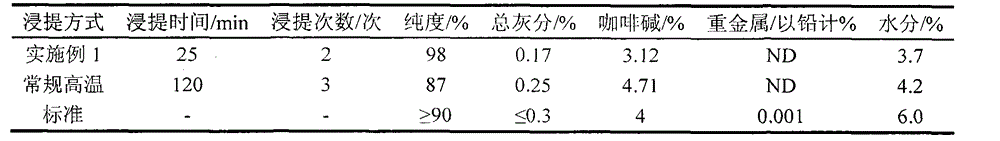

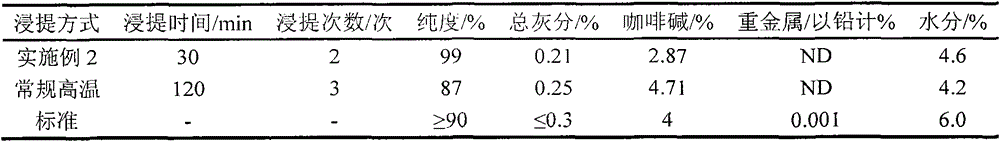

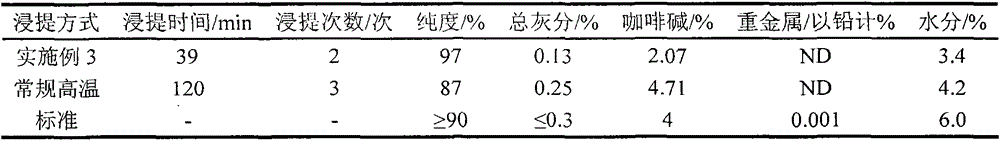

Microwave-assisted enzymatic extraction process of tea polyphenol

InactiveCN104974193AImprove extraction efficiencyImprove solubilityOrganic chemistryChemical industryPhenolic content in teaFreeze-drying

The invention relates to a microwave-assisted enzymatic extraction process of tea polyphenol, wherein the process includes the steps of removing impurities from fresh tea, cleaning and crushing the tea, blending a solution and adding an enzyme, performing vacuum-microwave treatment, performing centrifugal separation, performing resin adsorption, performing secondary elution, vacuum-concentration to an eluant and freeze-drying the concentrated liquid to obtain tea polyphenol dry powder. The microwave is a pulse microwave. By means of strict control of pulse microwave dosage, pulse width and pulse period, biological effects of microwave are fully achieved, so that the activities of the enzymes are activated and the object of quickly and high-effectively extracting the tea polyphenol is achieved. The process is high in efficiency, is less in energy consumption and is less in extraction time. The tea polyphenol is high in purity and bio-activity, is green and environment-friendly, and is natural and pollution-free.

Owner:HUNAN FEIXIANG JINYANG BIOTECH CO LTD

Microwave-assisted steam sterilization of dental and surgical instruments

InactiveUS20050224493A1Rapid and complete sterilizationDentistryLavatory sanitorySteam pressureLiquid water

A surgical and dental instrument sterilizer is described. Liquid water is rapidly vaporized by microwave heating and steam is generated to attain a steam pressure of approximately 47 psi and a temperature of approximately 135° C. in the region of the articles to be sterilized. Micron-size water-droplets are intermittently sprayed onto the articles which are arranged on a tray, from both the top and from underneath thereof so as to thoroughly wet the surfaces. A 30-90 s duration of droplet spray is followed by pulsed microwave irradiation of the top and underneath surfaces for a similar period, as an example; this is followed by a plurality of spray / microwave cycles. Sterilizing conditions in the sterilizer chamber are maintained in the presence of the water spray / microwave flashing cycles since introducing small aliquots of water will not affect the desired sterilizing condition provided by superheated steam augmented by microwave radiation necessary to kill microbes including spores; however arcing from metal instruments when subjected to microwave radiation is substantially reduced.

Owner:VARMA RAVI

Ultrafast electron diffraction system based on X waveband photocathode microwave electronic gun

ActiveCN101403714ASave experiment timeSave sample quantityMaterial analysis using wave/particle radiationSurface/boundary effectElectron sourcePhotocathode

The invention provides an ultra-fast electronic diffraction system based on an X-waveband photocathode microwave electron gun, belonging to the technical field of ultra-fast electronic diffraction; the ultra-fast electronic diffraction system is characterized in that the X-waveband photocathode microwave electron gun replaces a DC high-voltage photocathode microwave electron gun in the existing Kev ultra-fast electronic diffraction system and is used as an electron source; and correspondingly, an X-waveband pulse microwave power unit is adopted and high-quality electron beams ranging from 0.5MeV to 1.5MeV is easily obtained, thus leading the electron number in each electron beam bunch to be improved to 2 to 3 magnitude and correspondingly saving a plurality of samples and testing time of the diffraction samples to be researched, thereby leading the obtaining of single diffraction sample spot to be possible.

Owner:TSINGHUA UNIV

Microwave thermoacoustic early hepatoma detection device and method

InactiveCN107788982ARelieve painIncrease contrastMedical imagingOrgan movement/changes detectionUltrasonic sensorSonification

The invention relates to a microwave thermoacoustic early hepatoma detection device and method. The device comprises a microwave trigger, a microwave generator, a transmitting antenna, an ultrasonic transducer, a data acquisition card and a computer connected successively. The microwave generator transmits pulsed microwaves to the liver of the detected human body through the transmitting antenna under the triggering of the microwave trigger, and ultrasonic signals are generated by utilizing thermoacoustic effects; and the ultrasonic transducer converts the ultrasonic signals into electric signals, transmits the electric signals to the data acquisition card and finally inputs into the computer for image reconstruction by using a filter back projection algorithm and an ultrasonic processingtechnology. The detection device adopts a non-destructive detection technology and has the advantages of high contrast, high resolution, large visual field, easy adjustment and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

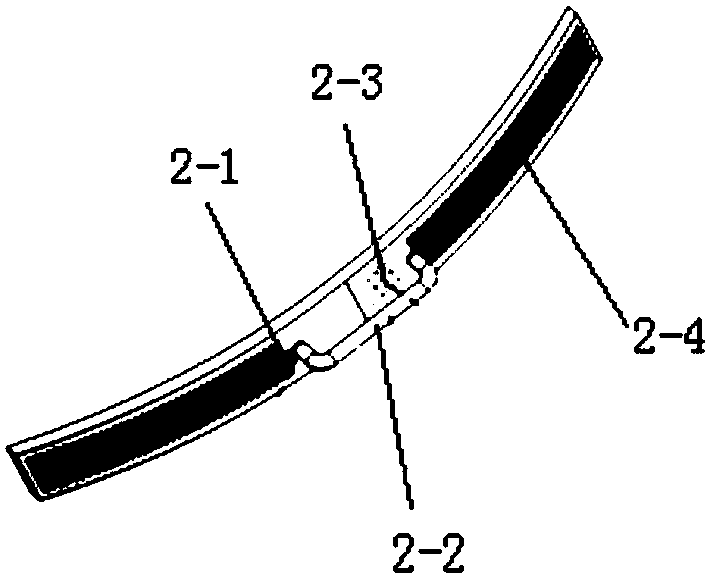

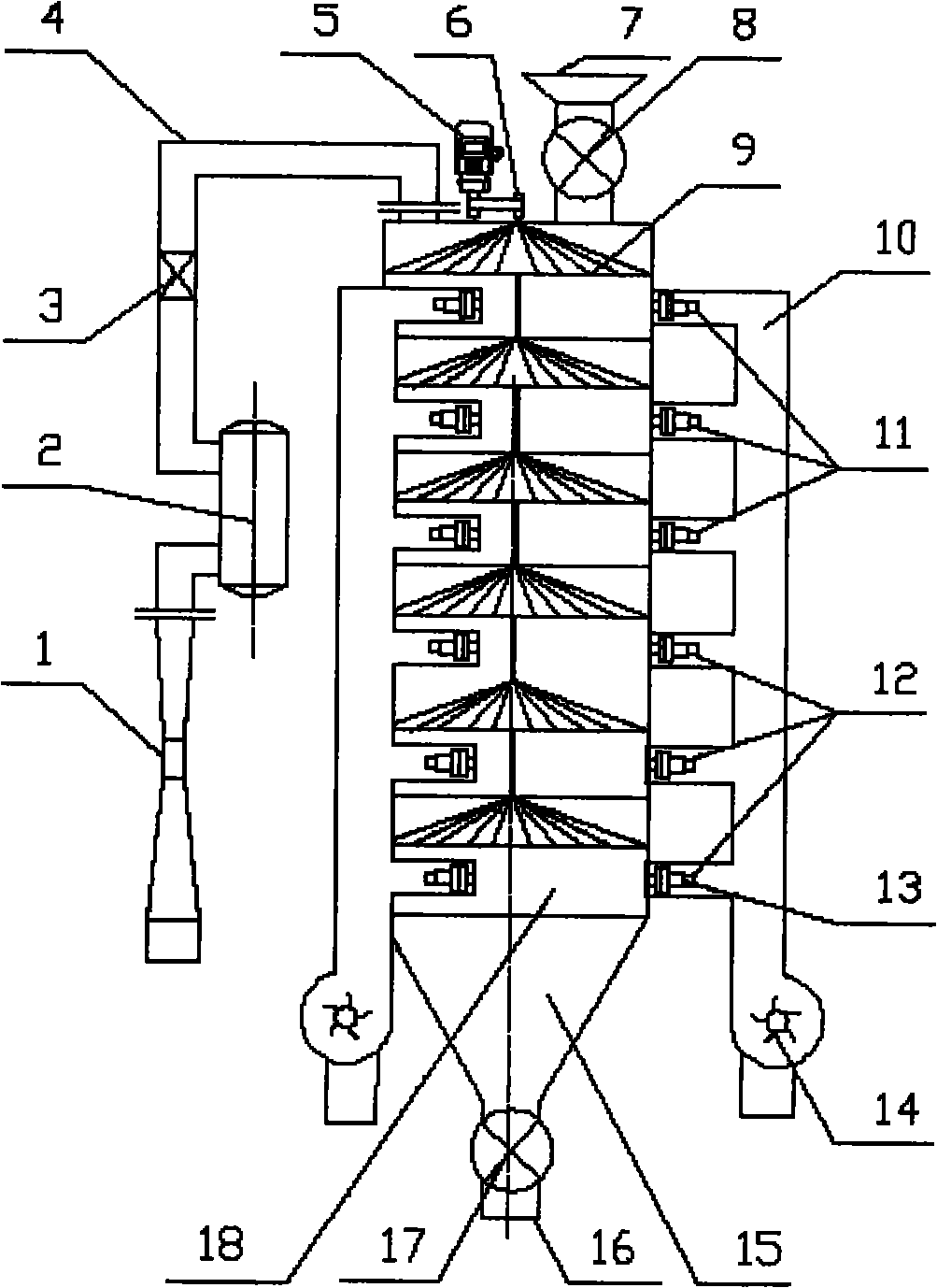

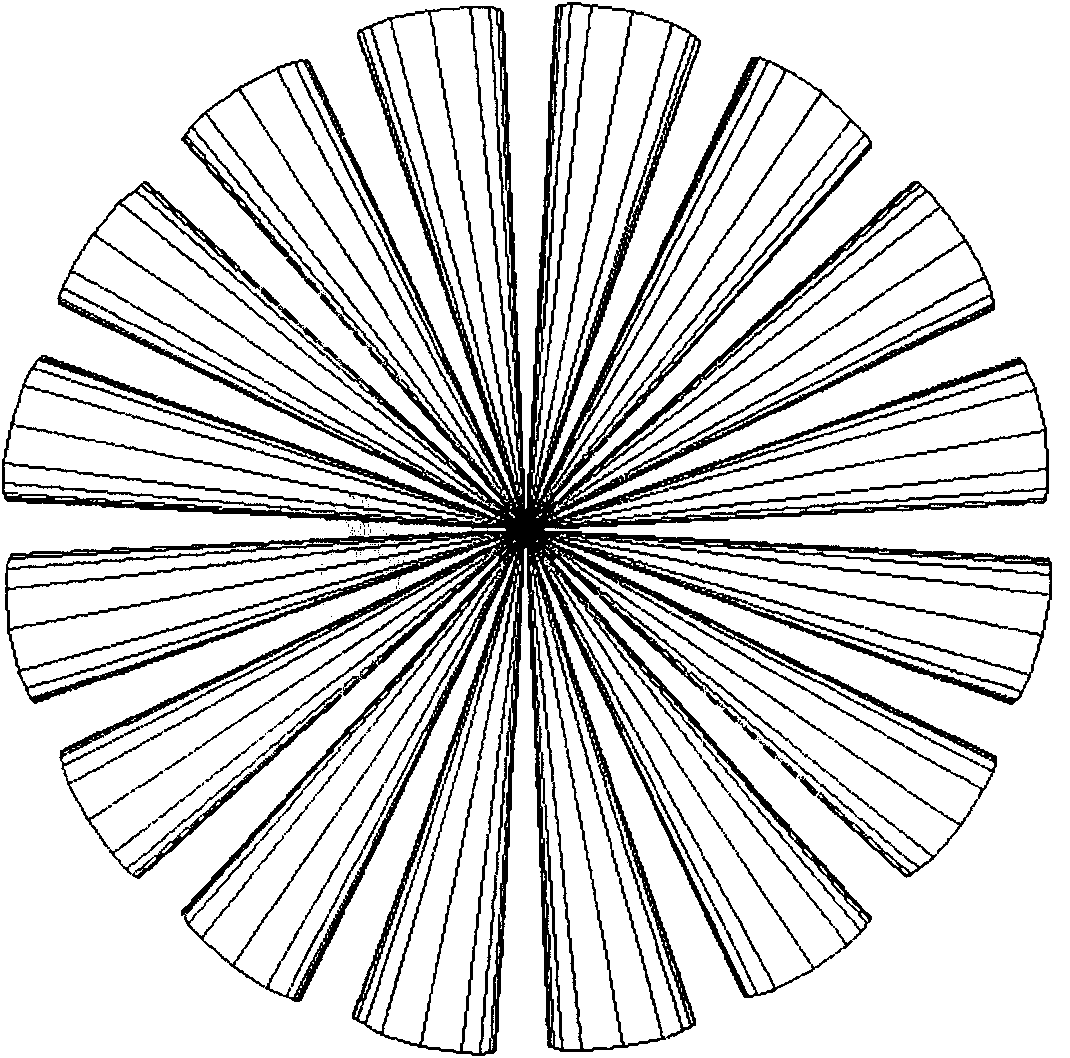

Cut leaf tobacco microwave vacuum drying equipment

ActiveCN101822415AImprove sensory qualityKeep the aromaTobacco preparationVacuum pumpingElectric machinery

Cut leaf tobacco microwave vacuum drying equipment is characterized by comprising a vertical cylinder-shaped drying cavity, a vacuum-pumping system communicated with the drying cavity, and a microwave heating system, wherein the top part and the bottom part of the drying cavity are respectively provided with a feed port and a discharge port, the drying cavity is internally provided with a material dispersion mechanism, the material dispersion mechanism comprises a spindle arranged on the axle center of the drying cavity, and multi-layer material dispersion plates arranged on the spindle, the spindle is driven to rotate by a motor, the microwave heating system is divided into a continuous microwave heating unit arranged on the upper part of the drying cavity and a pulsed microwave heating unit arranged on the lower part of the drying cavity, and the two heating units can respectively hierarchically arranged in multi groups along the shell of the drying cavity. Compared with the prior art, the invention has the advantages that the cut leaf tobacco microwave vacuum drying equipment can carry out the microwave drying in stages to the cut leaf tobacco under the a vacuum status, reduces the drying temperature of the cut leaf tobacco, keeps the fragrant of the cut leaf tobacco, improves the aesthetic quality of the cut leaf tobacco, at the same time, can realize the rapid dehydration and drying of the cut leaf tobacco, and improves the filling value of the cut leaf tobacco.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

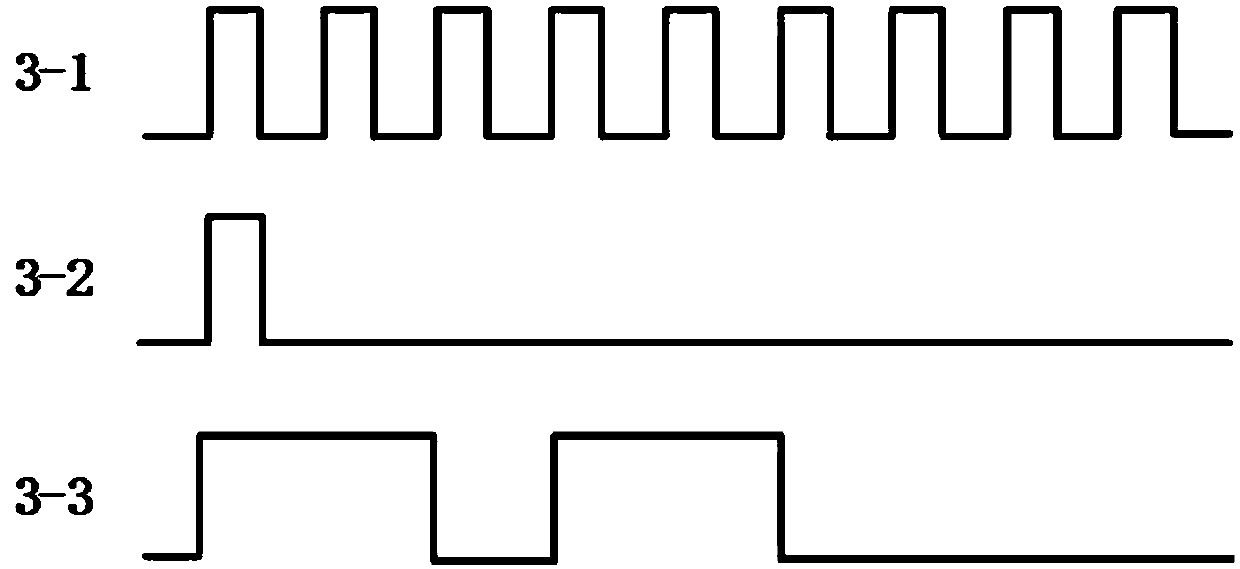

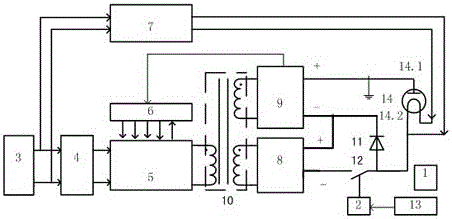

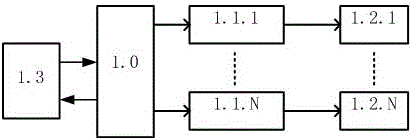

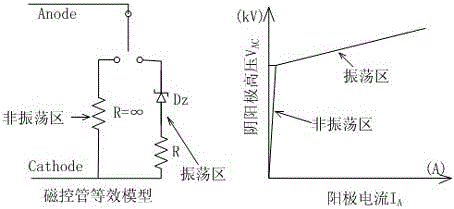

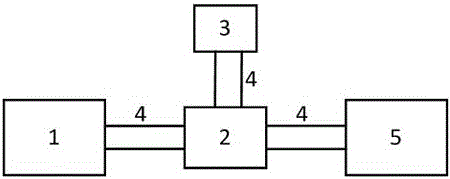

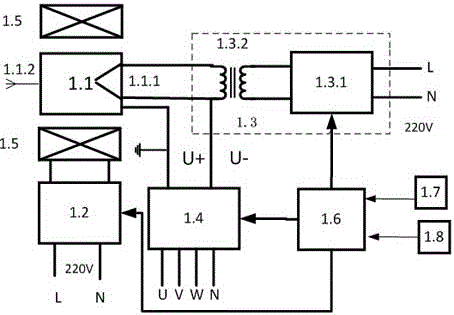

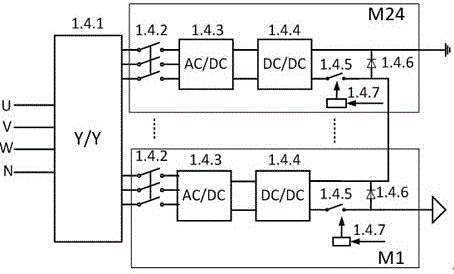

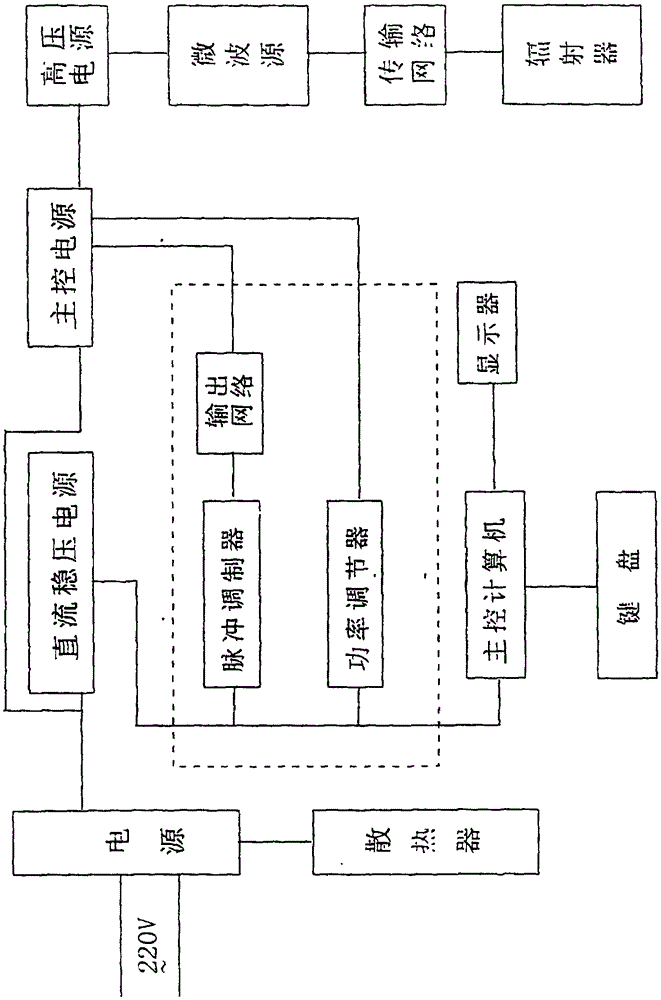

Power supply for achieving pulse microwave output employing magnetron and control method of power supply

ActiveCN105790630APrecise control of microwave working timeAmplitude stableMicrowave heatingPower conversion systemsPulse microwaveEngineering

The invention relates to a power supply for achieving pulse microwave output employing a magnetron and a control method of the power supply. The power supply for achieving the pulse microwave output employing the 2.45GHz magnetron comprises a filament power supply, an anode negative high-voltage power supply and a controller. Output of the anode-supply high-voltage power supply of the 2.45GHz magnetron at a certain pulse repetition frequency and a modulated duty ratio is achieved under the condition of not changing heat-sink cooling of the anode, so that accurate and controllable microwave generation time and the maximal output power are achieved; and synthesis of output power multi-tubes of the 2.45GHz magnetron is achieved through control to the requirements of industrial high-power microwave output.

Owner:NANHUA UNIV

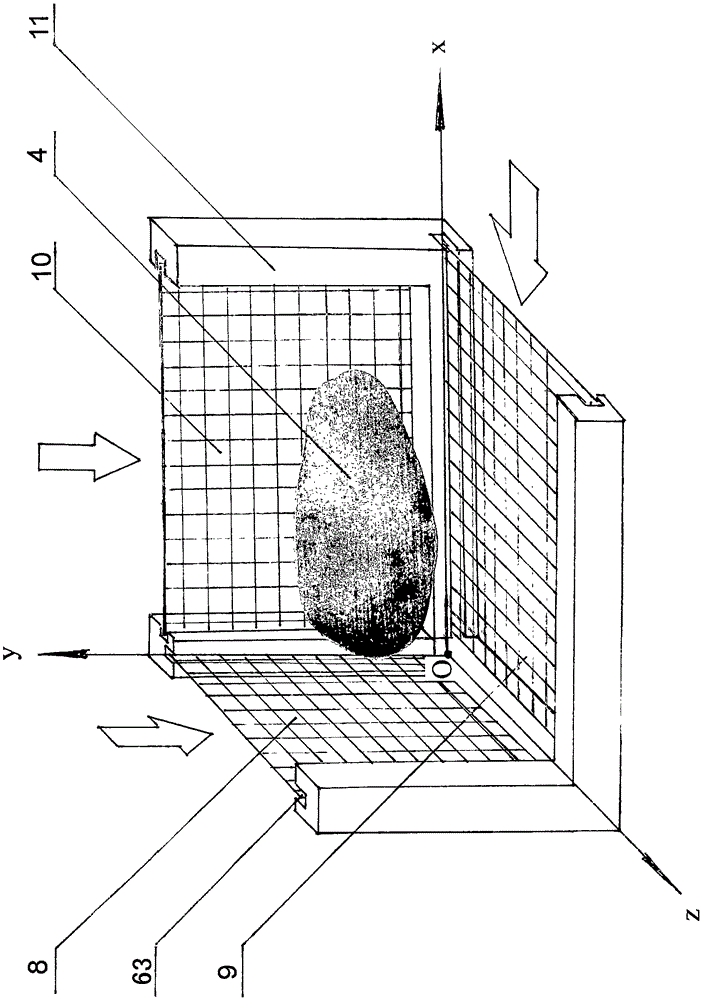

Device for crushing and grinding uranium ores through assistance of 915MHz pulse microwave irradiation and control method

ActiveCN105944810ALow mechanical strengthGood for grindingGrain treatmentsUranium orePulse microwave

The invention relates to a device for crushing and grinding uranium ores through assistance of 915MHz pulse microwave irradiation and a control method. The device comprises five main parts of: a 915MHz microwave source generator, a microwave circulator, a water load, wave guide tubes and a microwave resonant heating cavity. After the uranium ores are irradiated by high-power pulse microwave emitted by the device, the mechanical strength of the uranium ores is reduced, the dissociation degree of the uranium ores is increased, and the crushing and the grinding of the uranium ores and the leaching of uranium minerals are facilitated. Compared with traditional continuous microwave irradiation, the pulse microwave irradiation is lower in consumption and better in assistance of the crushing and grinding effect, and can effectively prevent high-temperature sintering.

Owner:NANHUA UNIV

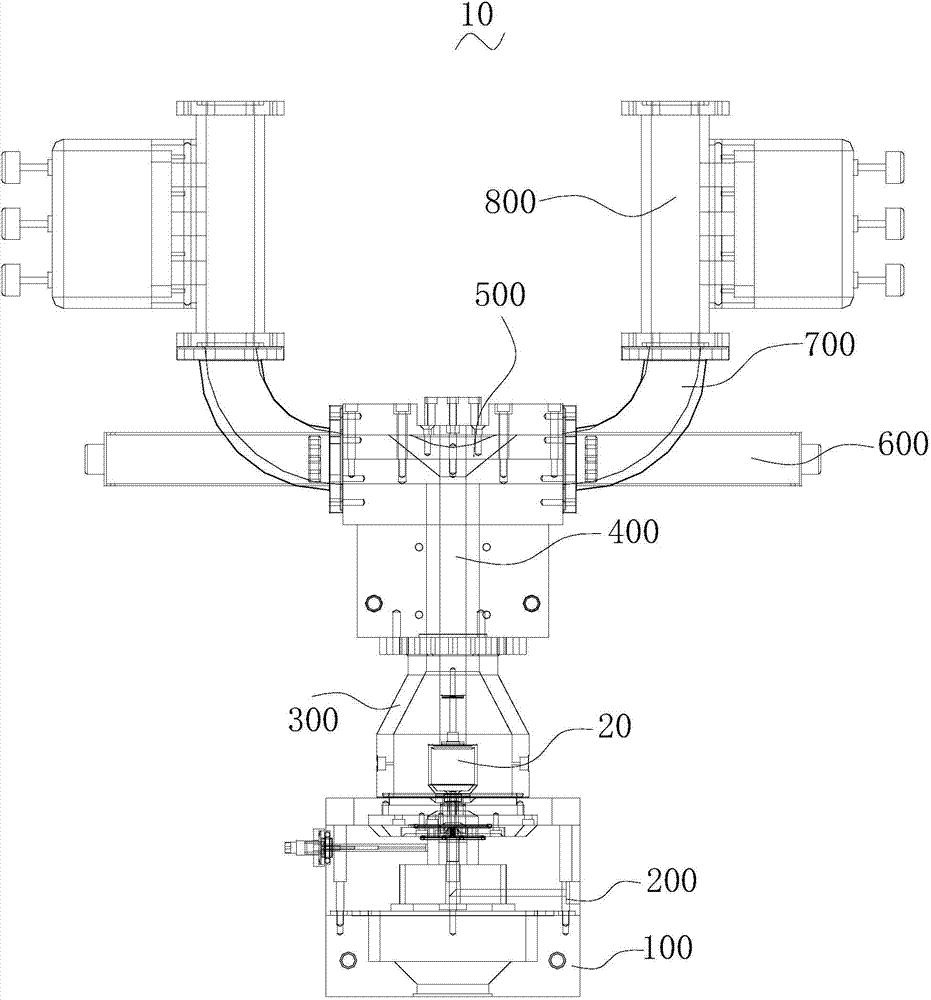

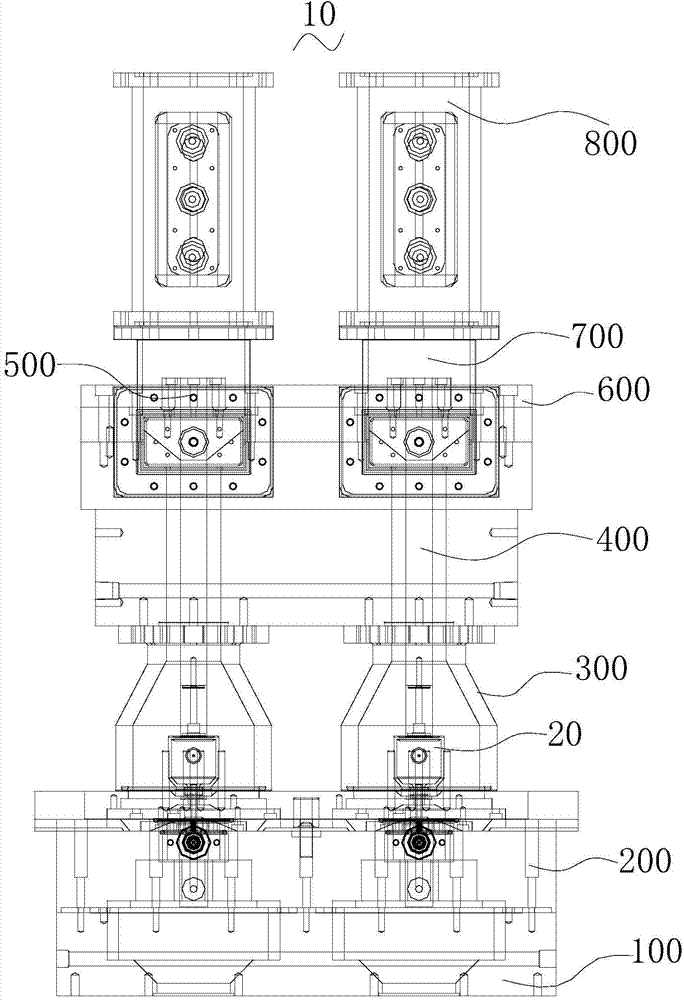

Process and device of forming multilayer insulating thin film on inner wall of glass container

InactiveCN104762609AAvoid damageBarrier stabilityChemical vapor deposition coatingPulse microwaveProduct gas

The invention relates to a process and a device of forming a multilayer insulating thin film on an inner wall of a glass container. The device includes a machine base, a gas transportation pipeline, a microwave sealing cover, an antenna, a mode convertor, a tuner, a waveguide tube and a pulse microwave generating source. The invention also provides a process corresponding to the device, comprising following steps: (1) vacuumizing the microwave sealing cover and feeding oxygen to the microwave sealing cover through the gas transportation pipeline; (2) introducing a high-power pulse microwave generated from the pulse microwave generating source to the mode convertor through the waveguide tube, tuning the high-power pulse microwave by the tuner, and enabling the high-power pulse microwave to pass through the antenna and uniformly enter into the interior of the vacuum glass container; (3) feeding various special gases successively into the vacuum glass container and ionizing the special gases to generate compact and uniform oxide thin films, wherein the thin films in different nano-scale thicknesses are alternatedly deposited onto the inner wall of the glass container. With the process and the device, the inner wall of a glass container in complex structure can be coated by the thin film, thereby increasing the service life of the product and the deposition efficiency, reducing production cost and enhancing film layer adhesive force and uniformity.

Owner:HUIZHOU OBOLAND OPTOELECTRONICS TECH

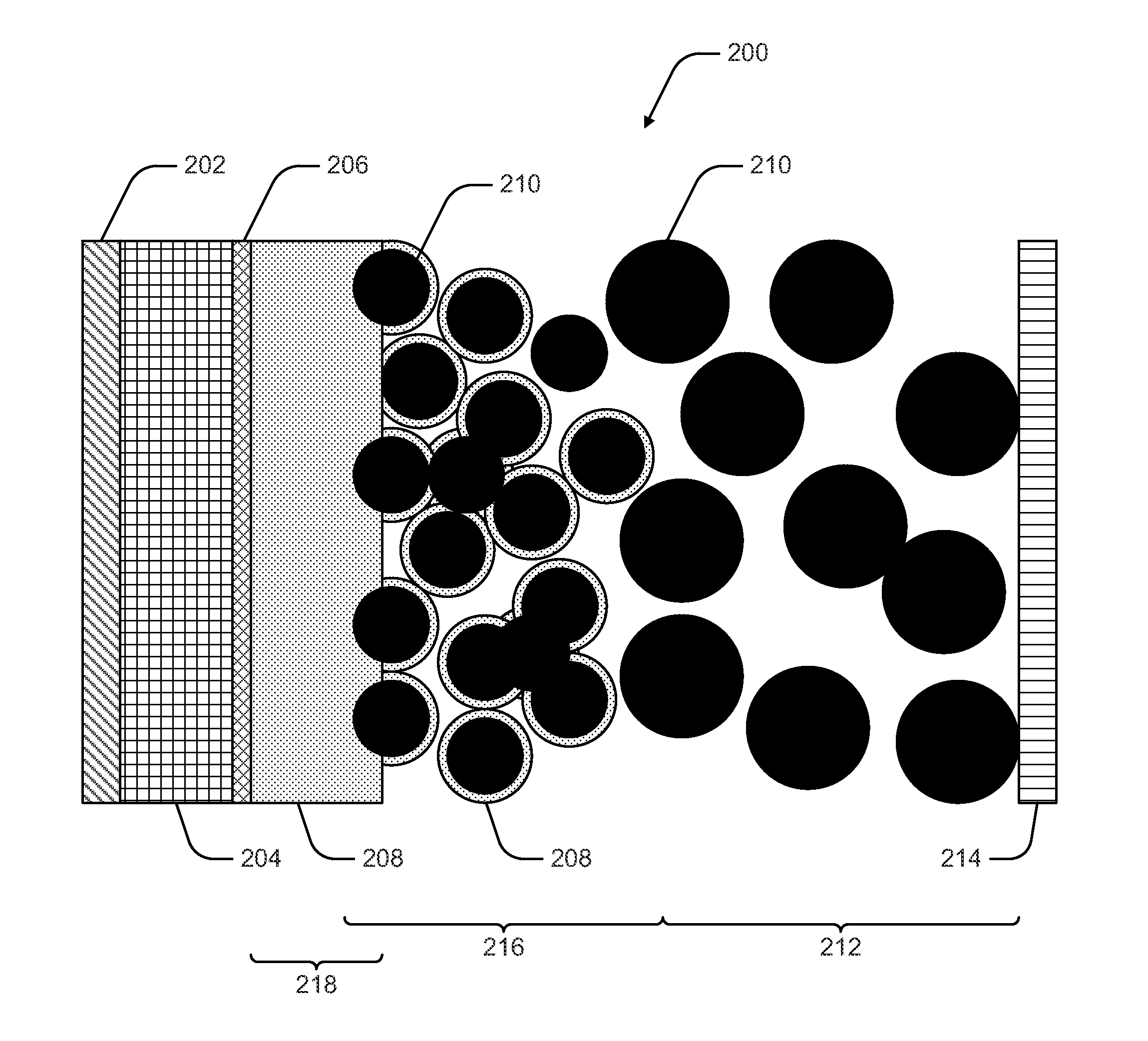

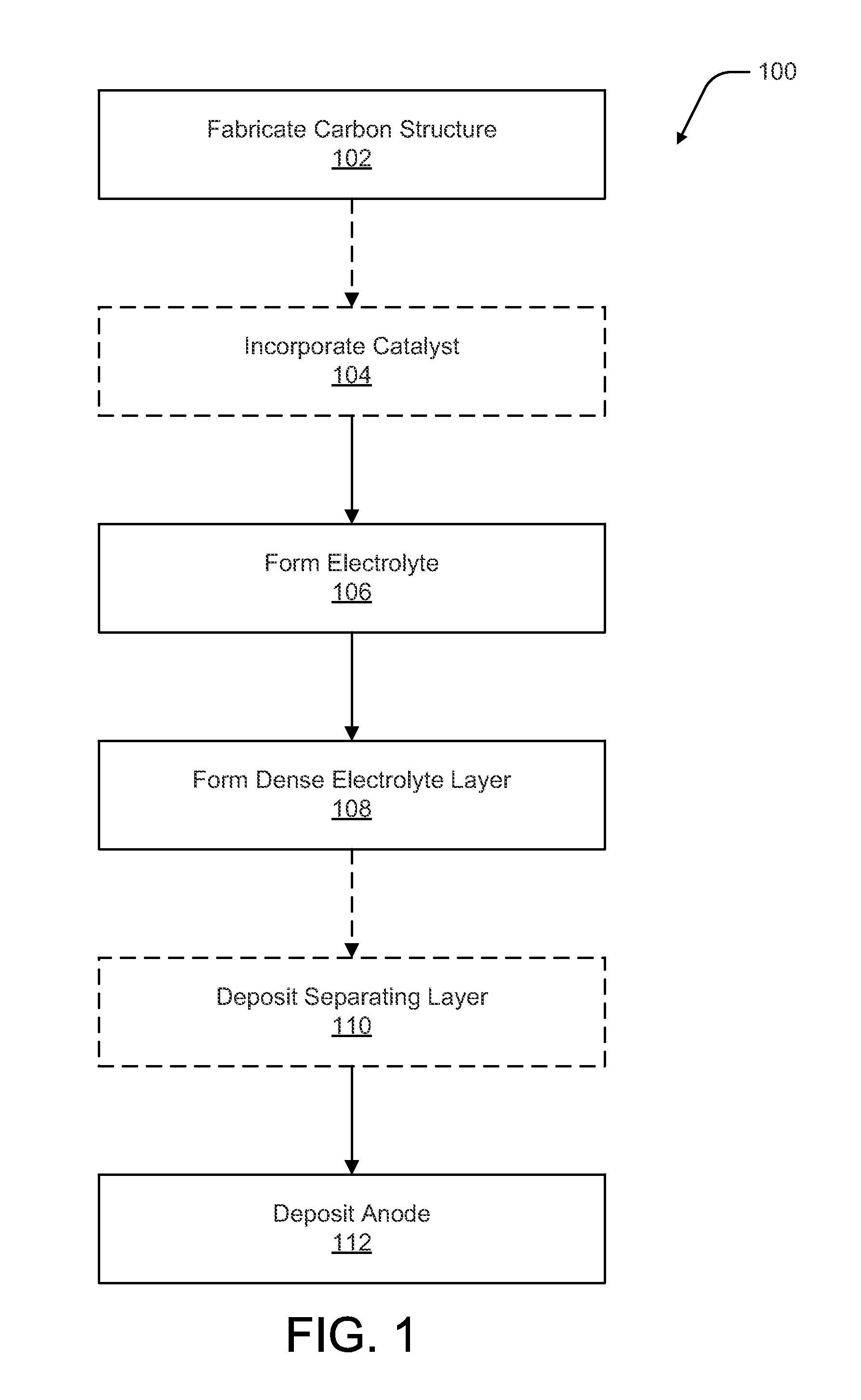

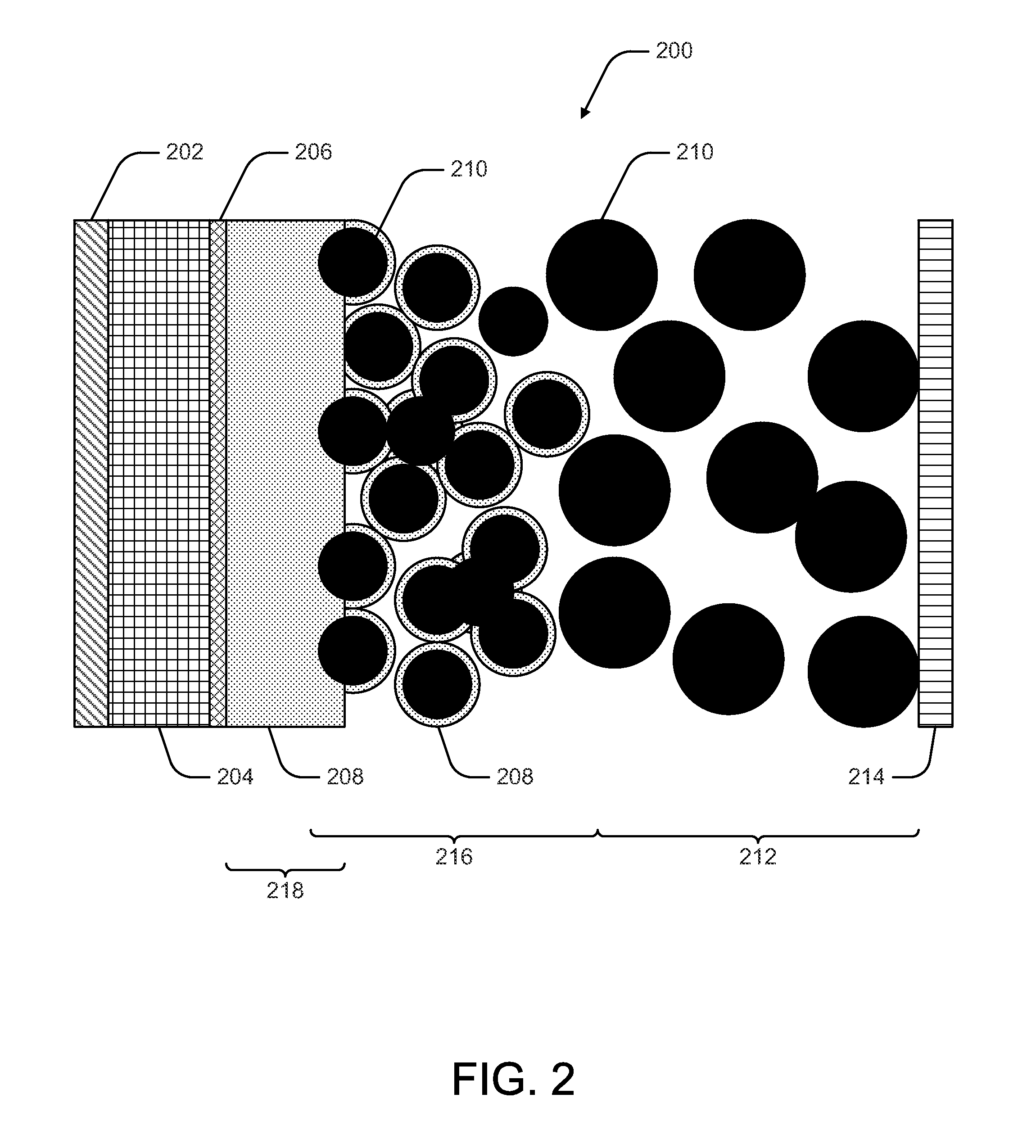

Rechargeable, thin-film, all solid-state metal-air battery

Owner:ITN ENERGY SYST INC

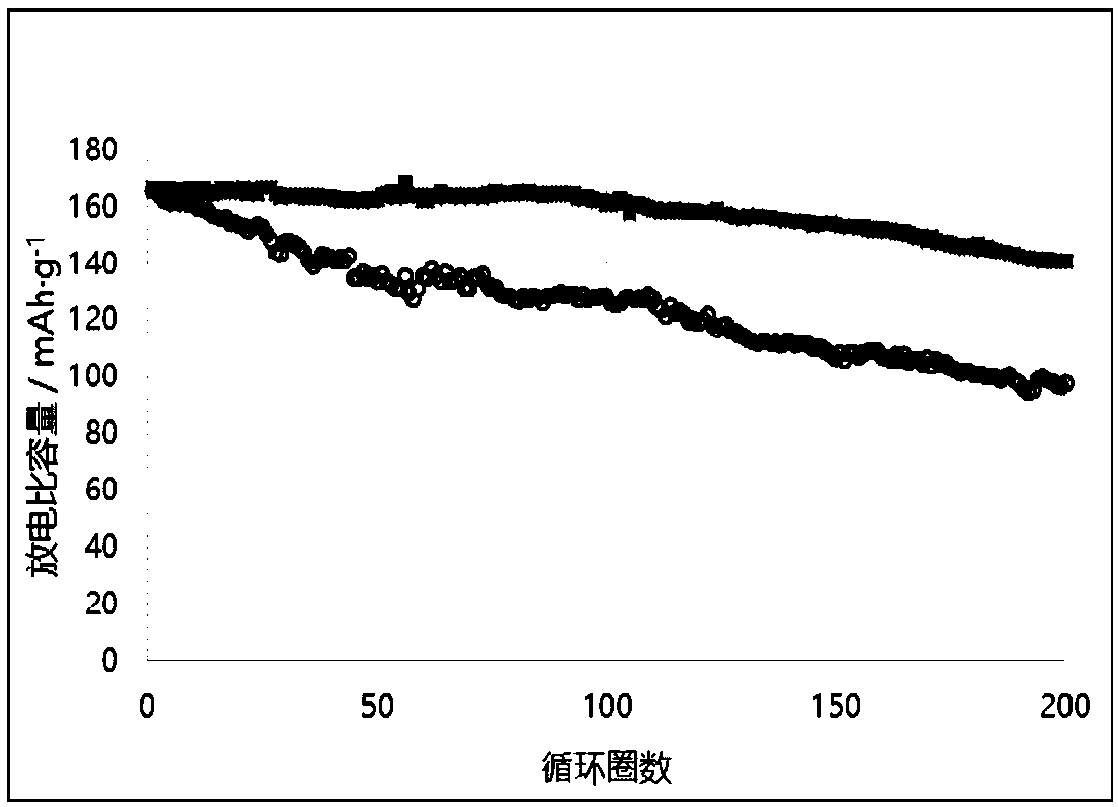

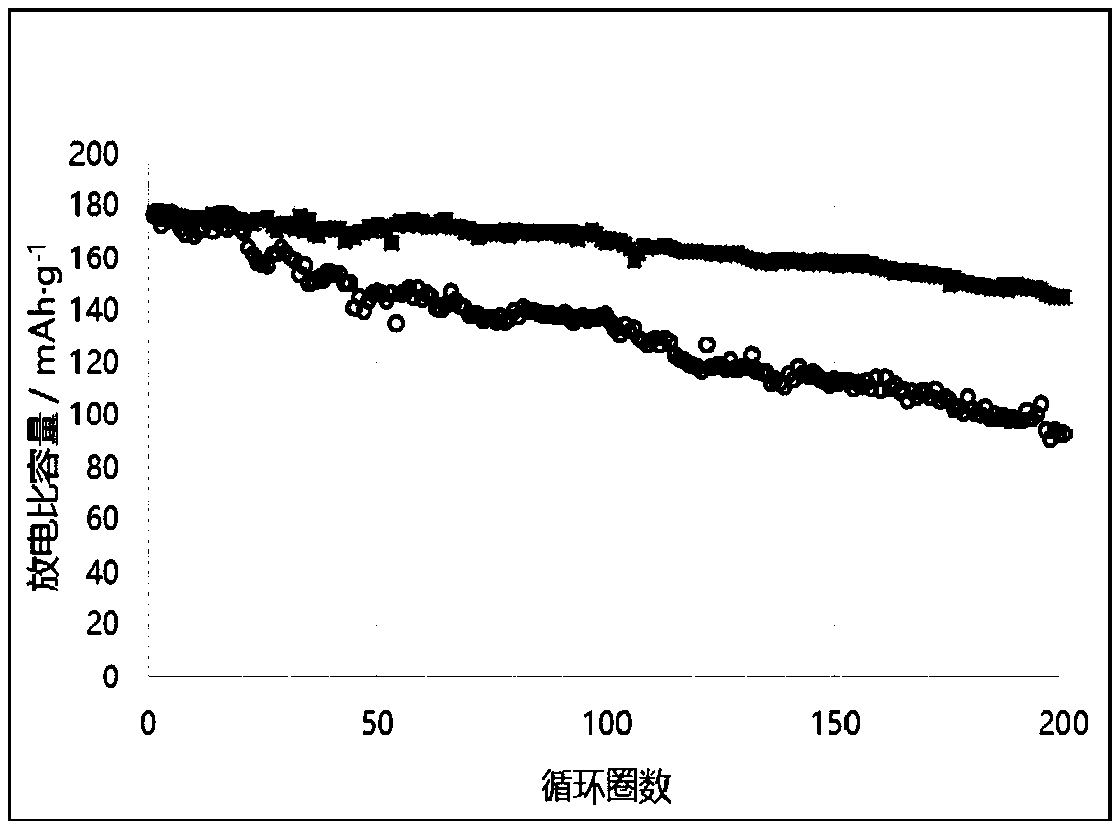

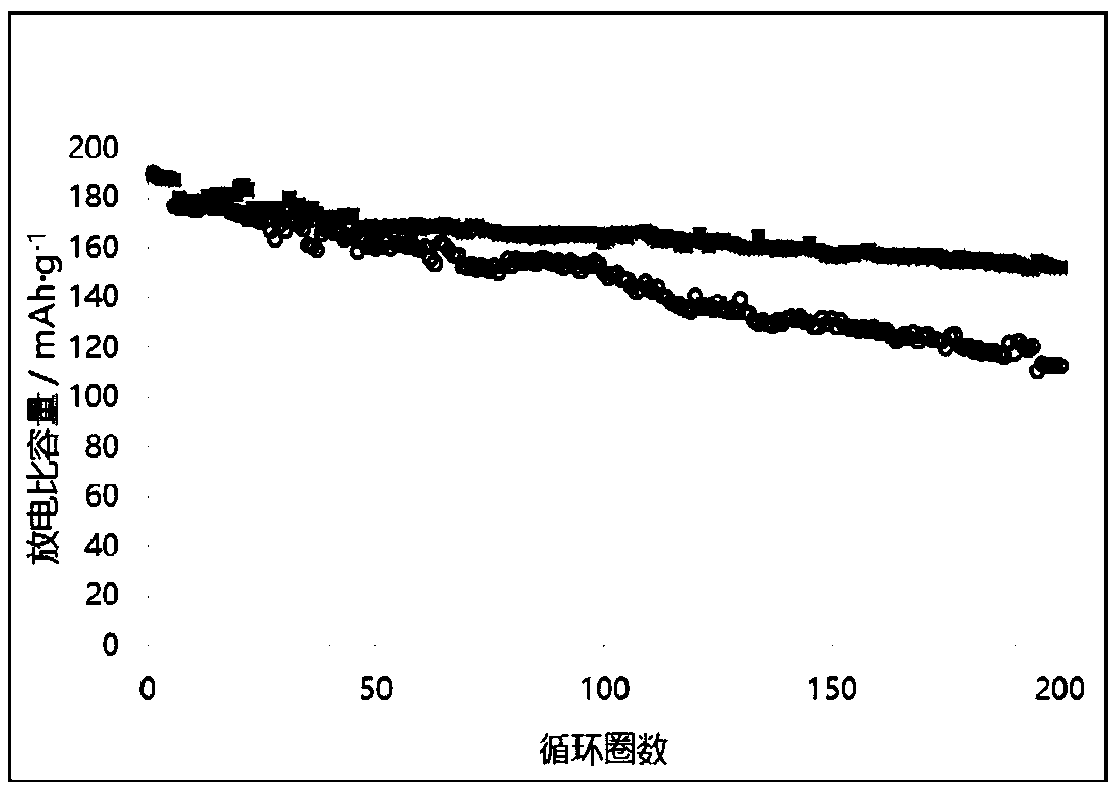

Titanium dioxide coated lithium nickel cobalt manganate cathode material and preparation method thereof

ActiveCN108963239AImprove uniformityThickness is easy to controlSecondary cellsPositive electrodesPulse microwaveCobalt

The invention discloses a titanium dioxide coated lithium nickel cobalt manganate cathode material, the thickness of the titanium dioxide layer coated on the surface of the lithium nickel cobalt manganate powder is 10 nm to 1 mum, Lithium nickel cobalt manganate powder was deposited on the surface of lithium nickel cobalt manganate powder by pulsed microwave excitation, and titanium dioxide coatedlithium nickel cobalt manganate cathode material was prepared. The titanium dioxide coating layer formed on the surface of the lithium nickel cobalt manganate powder has good uniformity, controllablethickness, convenient operation and implementation of the preparation method, low coating temperature required in the preparation process, short time and easy industrial production; The cathode material prepared by the invention brings excellent electrochemical cycling performance to the lithium ion battery, and the capacity retention rate is greatly improved.

Owner:利信(江苏)能源科技有限责任公司

Microwave plasma atomic fluorescence mercury analysis system

InactiveUS20120224175A1Great contributionRadiation pyrometrySpectrum investigationAtomic elementFluorescence

A method for the detection of mercury or other heavy metals in a gas stream comprises the steps of: providing a pulsed microwave power supply;supplying a microwave generator with power from the pulsed microwave power supply; using the microwave generator to power a short circuited waveguide to create a plasma torch located in a chamber; feeding a sample of the gas stream to the plasma torch; using the plasma torch to transform oxidized elements in the gas stream to atomic elements; and analyzing by atomic fluorescence of the gas stream having the atomic elements with an excitation lamp for the presence of at least one metal.

Owner:MINGHETTI PHILIPPE

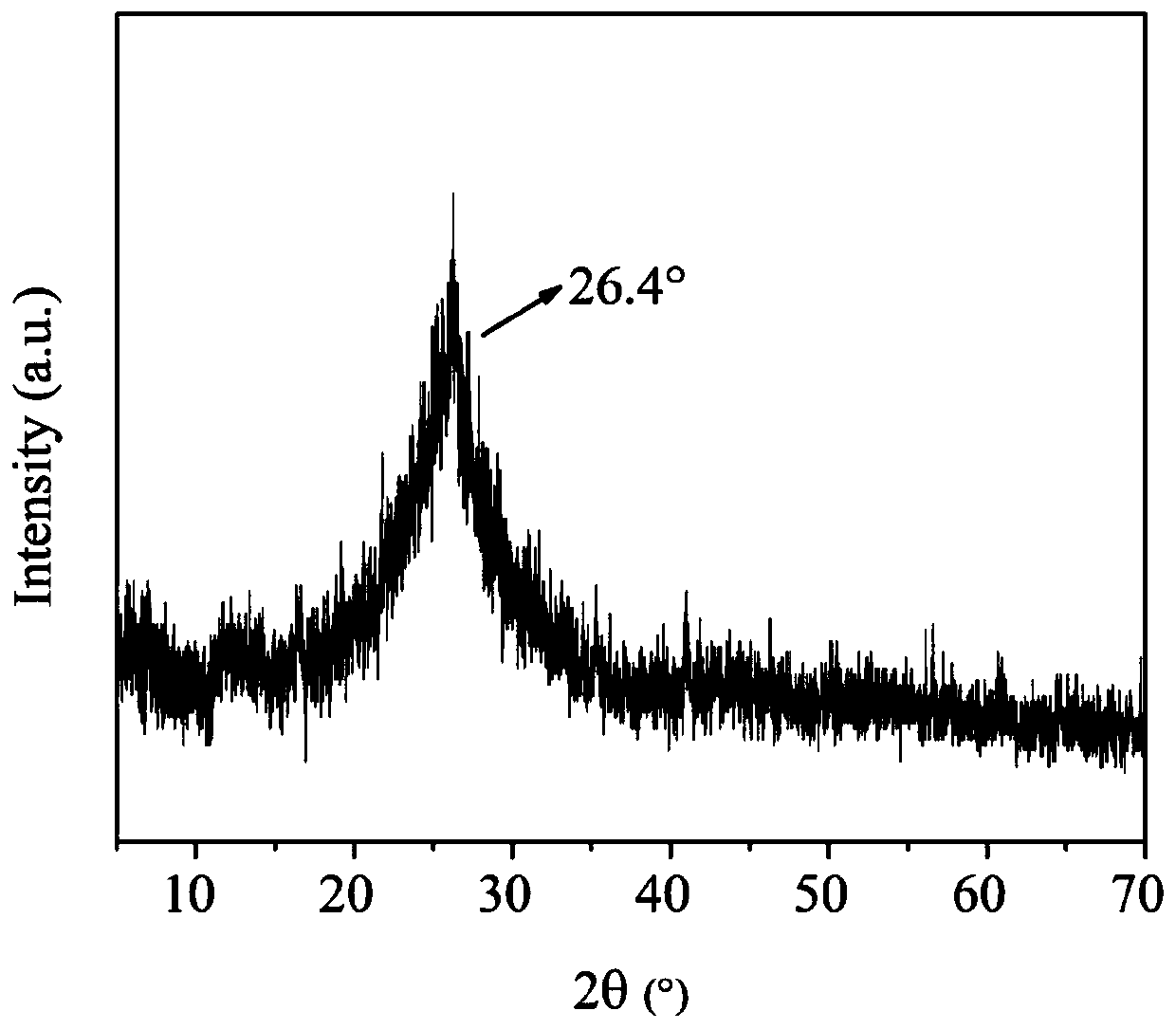

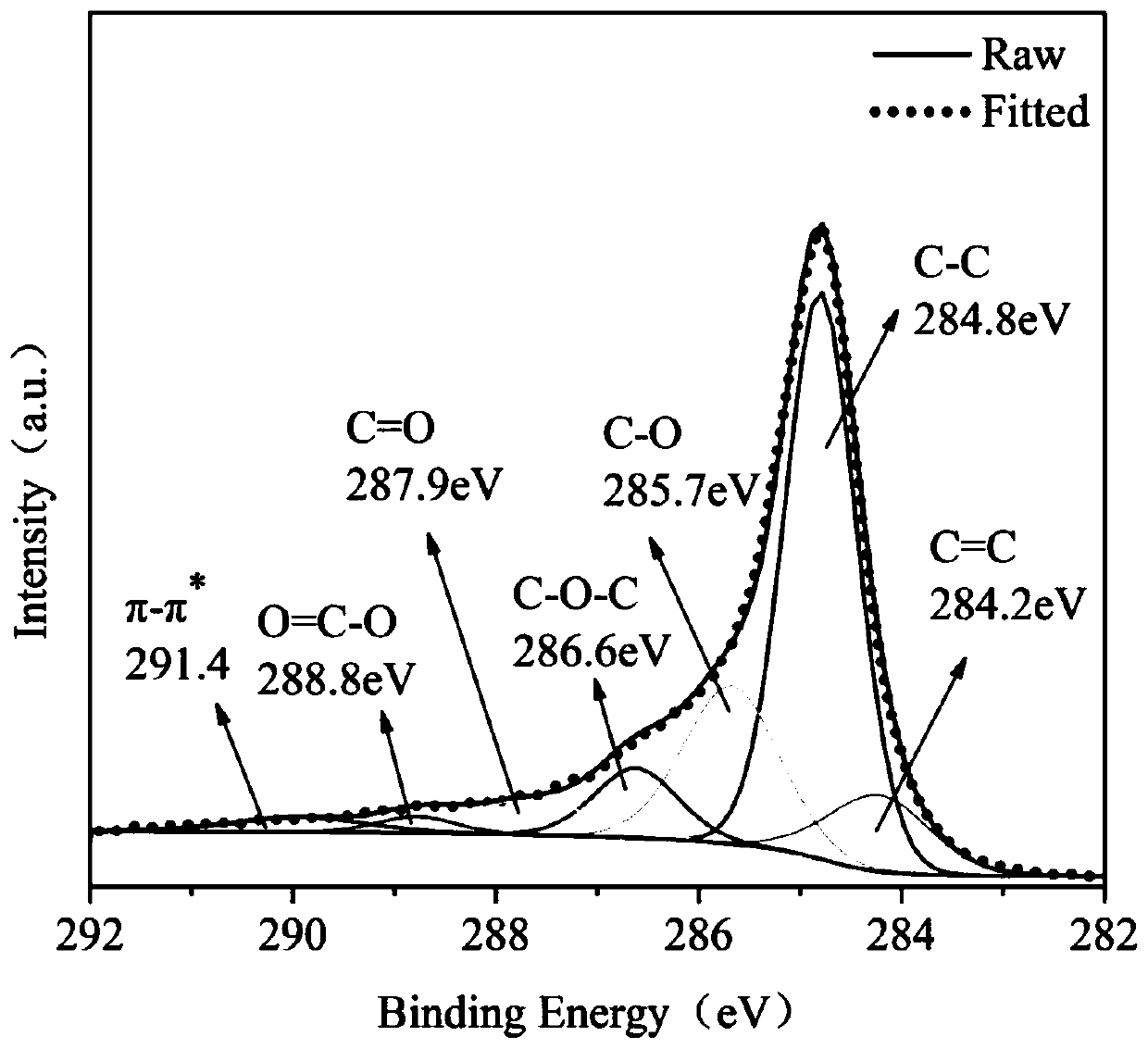

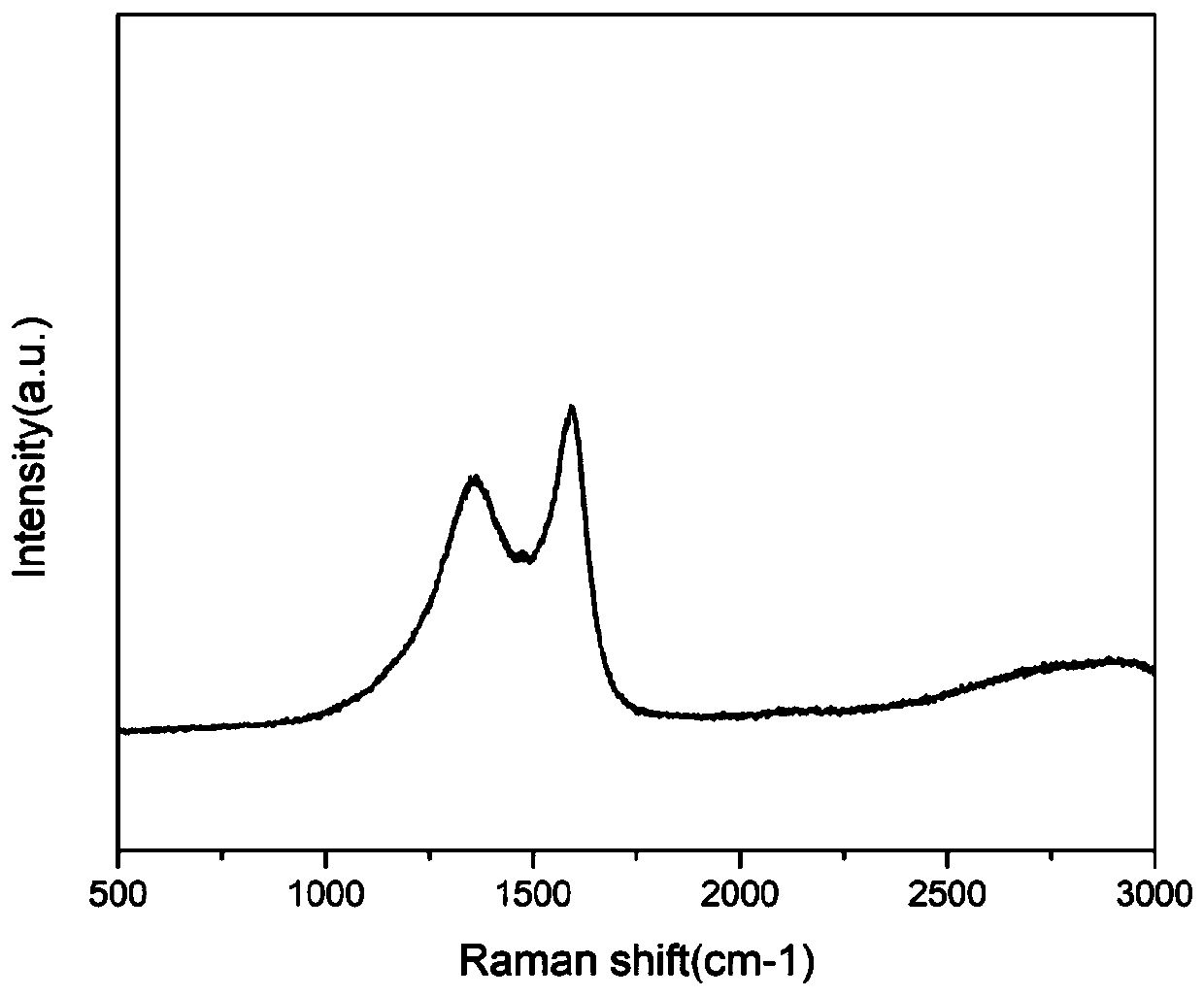

Method for preparing high-quality reduced graphene through high-energy-pulse microwave rapid recovery

The invention provides a method for preparing high-quality reduced graphene through high-energy-pulse microwave rapid recovery. The method comprises the main steps that crystalline flake graphite is added into fuming nitric acid under ice-water bath, hydrogen peroxide is added for a reaction for a certain time, washing and drying are conducted, and expanded graphite is obtained through microwave puffing; the expanded graphite and potassium permanganate are sequentially added in a mixed-acid system of 0-DEG C concentrated sulfuric acid and phosphoric acid, the strong oxidizing performance of the potassium permanganate is used, and the graphene is oxidized into graphene oxide under the low temperature of 0 DEG C; the graphene oxide is placed in a tube furnace to be subjected to insulation treatment, and pre-reduced graphene oxide powder is obtained; and finally, the pre-reduced graphene oxide powder is placed in a high-energy-pulse microwave cavity, microwave is opened, and a high-quality reduced graphene product is obtained. According to the high-quality reduced graphene prepared through the method, the lamellar structure is complete, the reduced graphene finally obtained through high-energy-pulse microwave rapid recovery is high in quality, and a good foundation is provided for preparation of graphene oxide, and graphene-based nanocomposite materials.

Owner:徐州宇帆机电科技有限公司 +1

Independent reference pulse generation

ActiveUS7710125B2Efficiency sometimes variesSimple designResistance/reactance/impedenceLevel indicatorsFrequency mixerPulse microwave

In fill-level measuring devices according to the pulse-transit-time method, a reflection that is generated internally in a microwave module is used as a reference for transit time measuring. For generating the reference pulse, the microwave module comprises its own sampling mixer or its own oscillator. Subsequently, the echo signal and the reference pulse can be further processed separately or together. No delay line is necessary on the transmission frequency of the radar sensor. Interference as a result of leakage signals is largely prevented.

Owner:VEGA GRIESHABER GMBH & CO

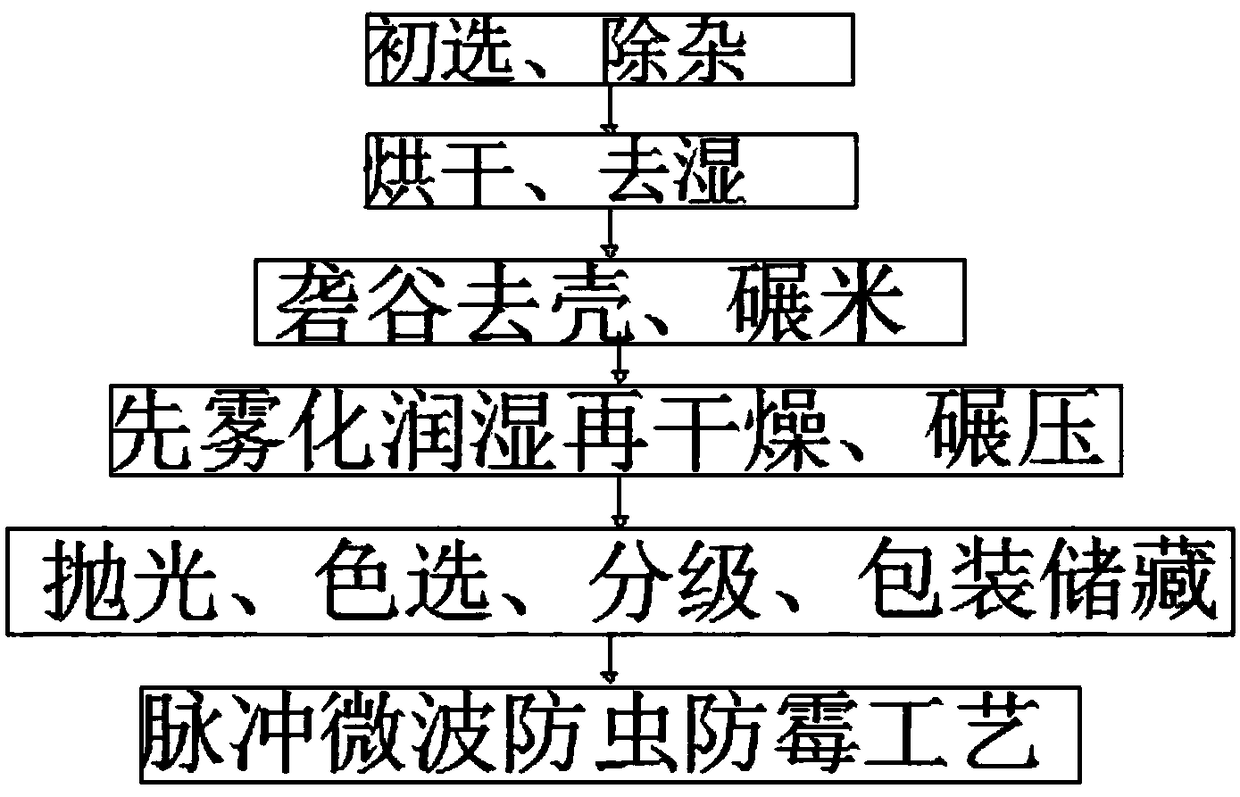

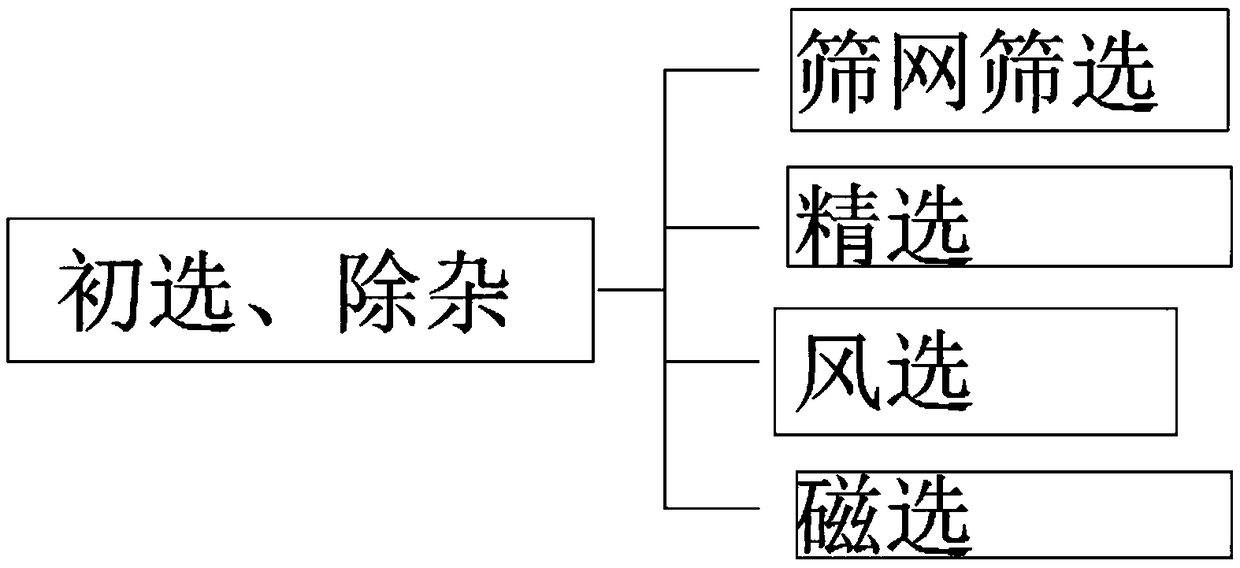

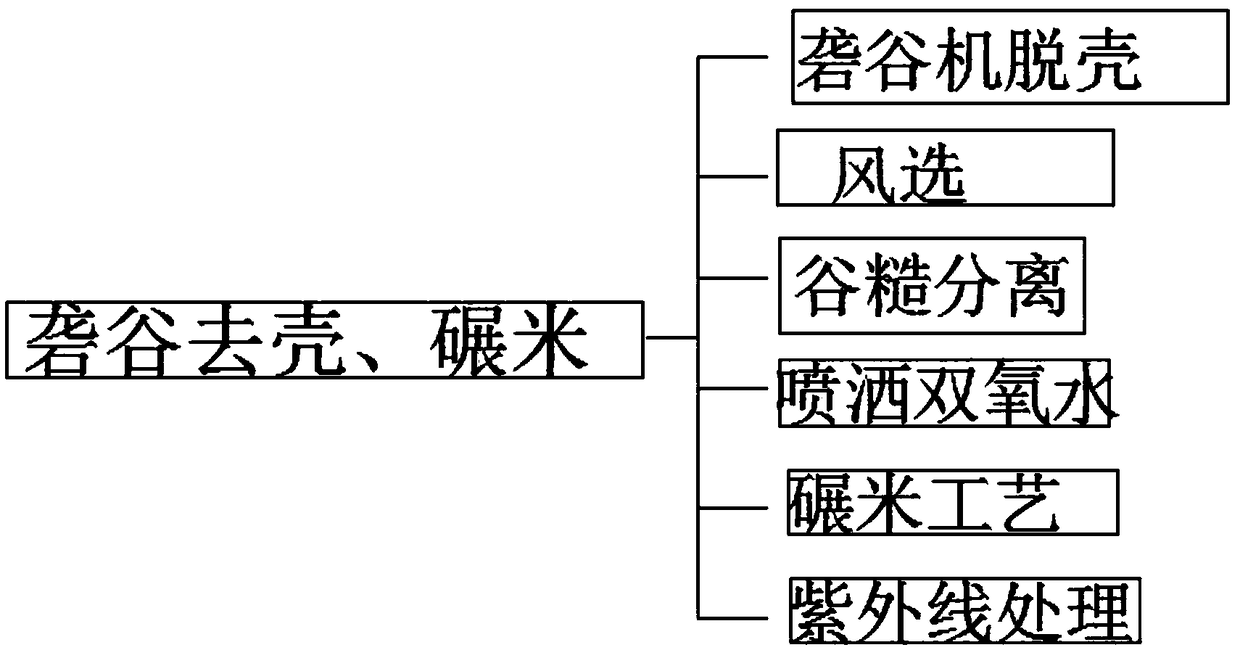

Rice processing method with essential oil mist spraying and pulse microwave action

InactiveCN109092398ALight in massReduce healthSeed preservation by irradiation/electric treatmentGrain millingPulse microwaveFatty acid

The invention discloses a rice processing method with essential oil mist spraying and pulse microwave action. The rice processing method comprises the following steps of preliminary screening, impurity removal, drying, dehumidification, husking shelling, rice milling, atomization and wetting and then drying, milling, polishing, color sorting, grading, packaging and storage and a pulse microwave anti-insect and anti-mould process, specifically, harvested rice is screened, firstly, a screening machine with appropriate sieve meshes is selected for screening out impurities with a different size from grains according to the different widths and thicknesses of rice and the impurities, then fine selection is performed, the rice is separated from the impurities according to the difference in lengths of the rice and the impurities, then air separation is continued to be performed, and the light impurities (such as chaff, rice straws and false grains) are taken away by wind force to be separatedfrom the rice in ascending or horizontal airflow. The rice processing method has good antibacterial and delay aging effects, can inhibit generation of colonies and formation of fatty acids in the rice and has a high fatality rate to pests and aspergillus parasiticus, and pulse microwave treatment reduces the hatching rate of pest eggs and reduces the viability of the pests.

Owner:江苏育龙粮油有限公司

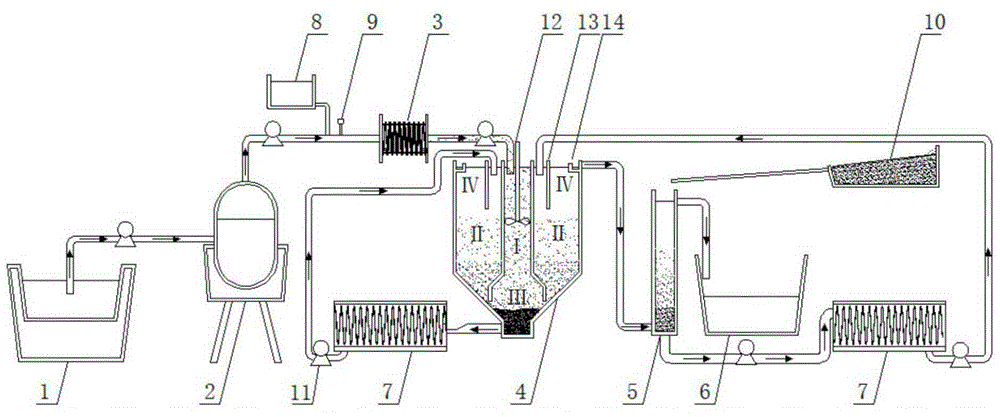

Method for resource recycling of phosphorus in breeding waste

The invention provides a method for resource recycling of phosphorus in breeding waste. The method comprises the following steps that (1) pulse ultrasonic treatment is conducted on the breeding waste; (2) the breeding waste treated in the step (1) is introduced into a wet type chemical oxygenizer and oxidized under the action of an oxidizing agent; (3) a magnesium solution and a pH value regulating agent are added into supernate of the breeding waste treated in the step (2), and pulse microwaves are applied to the mixed solution; (4) the mixed solution treated in the step (3) is introduced into a crystallizing bed, bird dung crystal mud and supernate are obtained after the mixed solution is crystallized, and the bird dung crystal mud is collected; and (5) the supernate obtained in the step (4) is introduced into an adsorption column, and ferric oxide hydrate-carried charcoal after adsorption is collected with ferric oxide hydrate-carried charcoal as an adsorbent. According to the method, the pulse ultrasonic and advanced oxidation coupling technique is adopted, and the phosphorus release rate and the organophosphorus conversion rate are high; the bird dung crystal and ferric oxide hydrate-carried charcoal adsorption coupling technique is adopted, and thus phosphorus loss rate is low.

Owner:CHINA AGRI UNIV

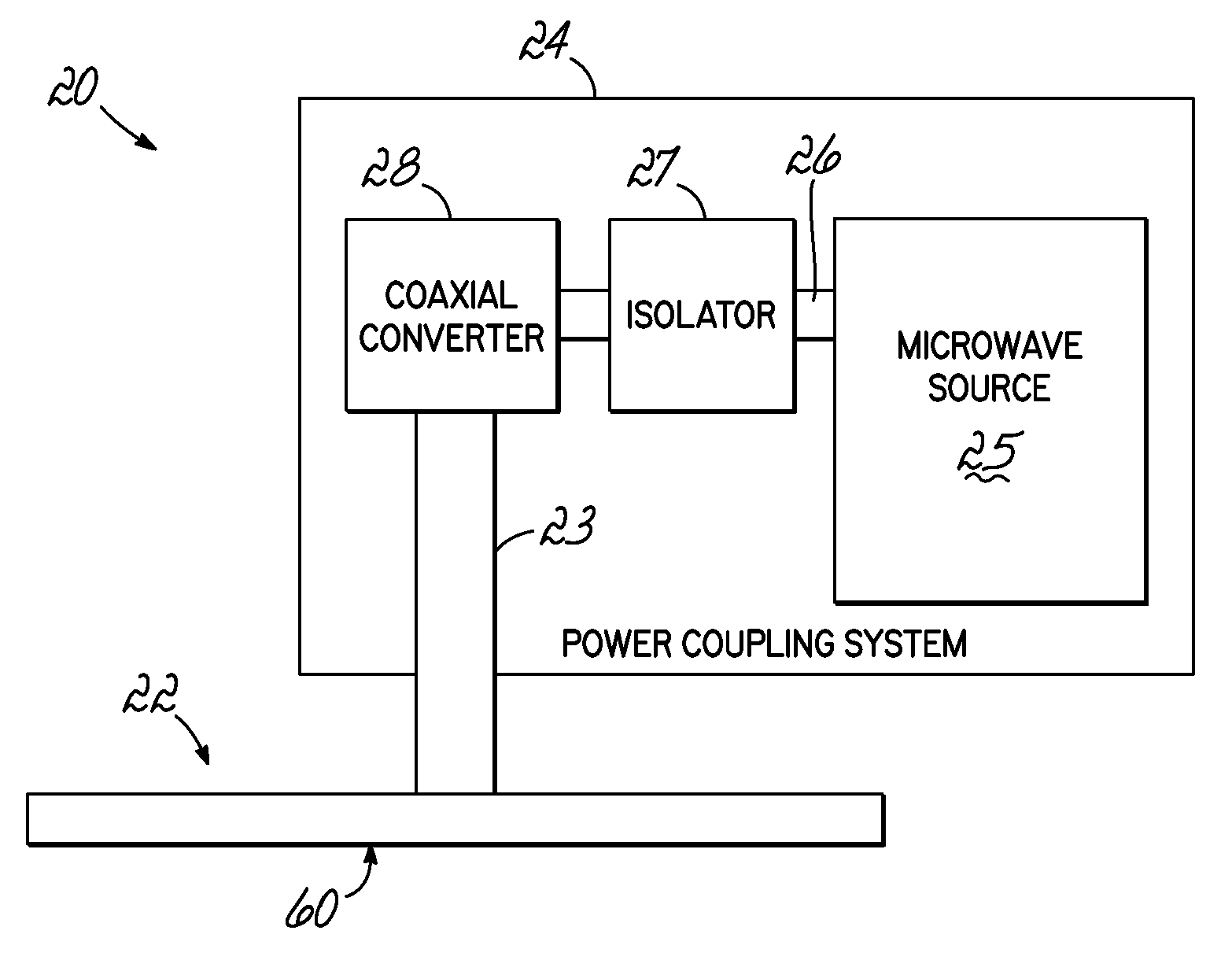

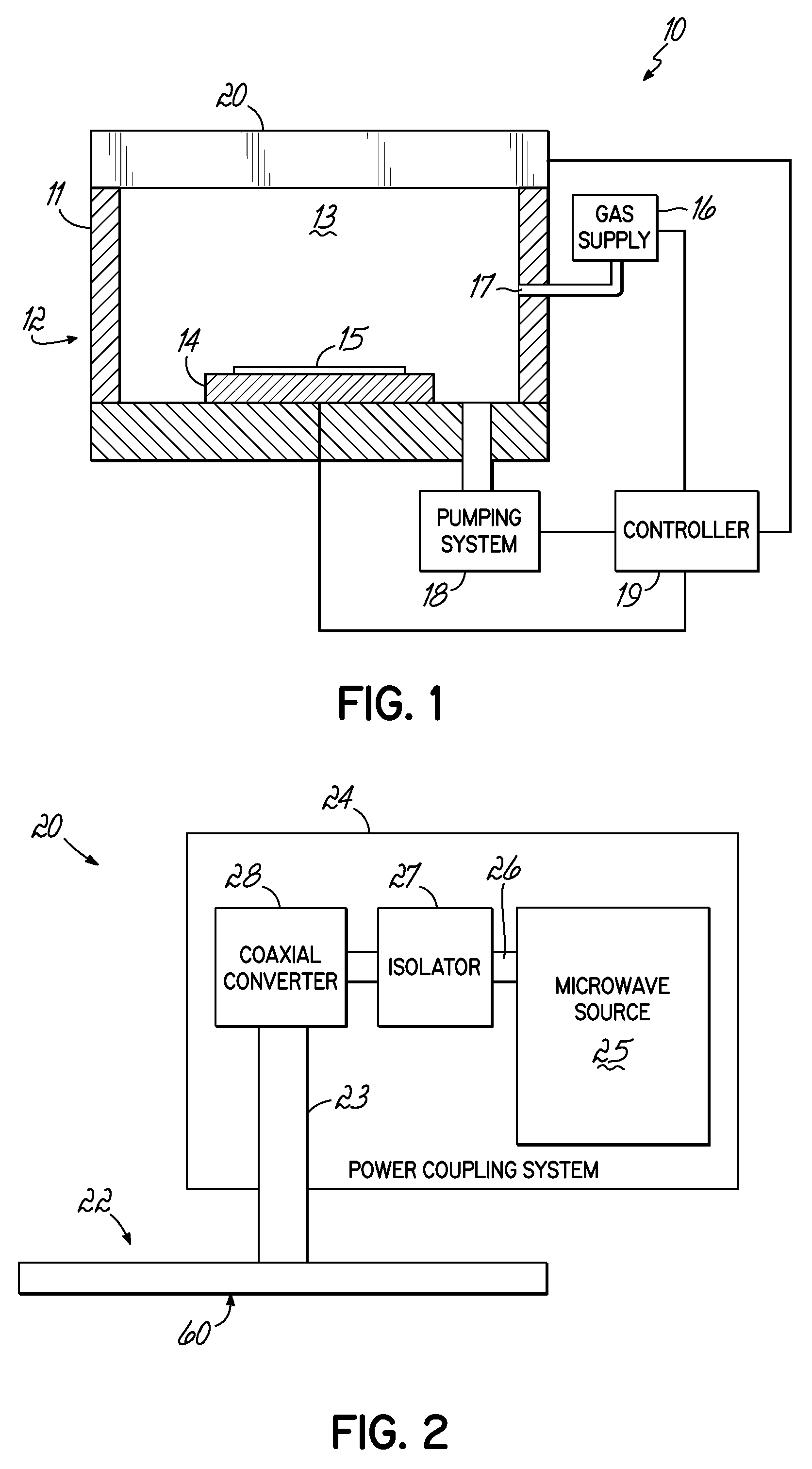

Low electron temperature microwave surface-wave plasma (SWP) processing method and apparatus

ActiveUS20130256272A1High degree of ionizationImprove uniformityLiquid surface applicatorsElectric discharge tubesElectron temperaturePlasma density

A surface wave plasma (SWP) source couples pulsed microwave (MW) energy into a processing chamber through, for example, a radial line slot antenna, to result in a low mean electron energy (Te). To prevent impingement of the microwave energy onto the surface of a substrate when plasma density is low between pulses, an ICP source, such as a helical inductive source, a planar RF coil, or other inductively coupled source, is provided between the SWP source and the substrate to produce plasma that is opaque to microwave energy. The ICP source can also be pulsed in synchronism with the pulsing of the MW plasma in phase with the ramping up of the MW pulses. The ICP also adds an edge dense distribution of plasma to a generally chamber centric MW plasma to improve plasma uniformity.

Owner:UNIV HOUSTON SYST +1

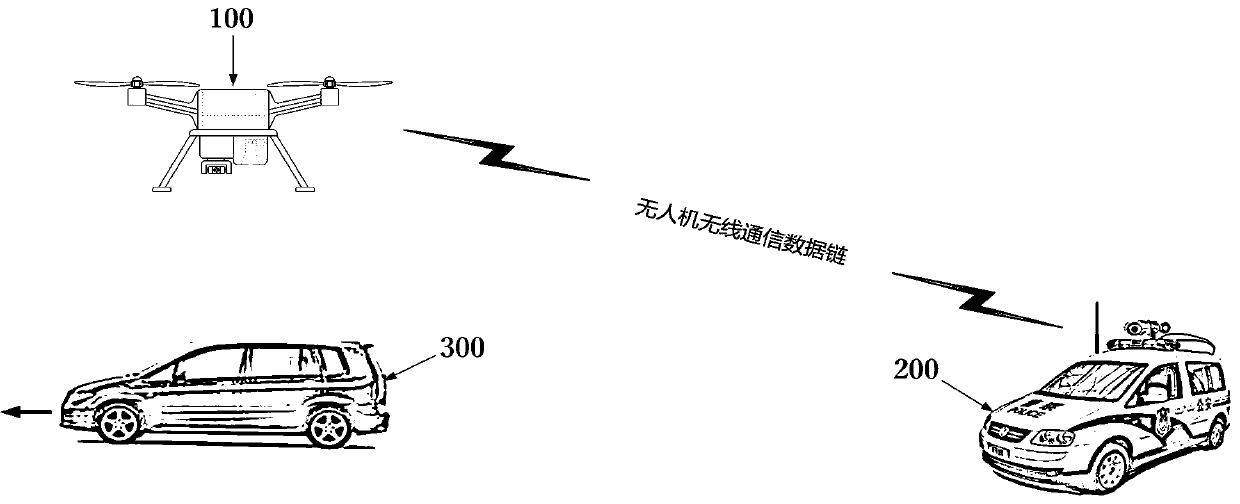

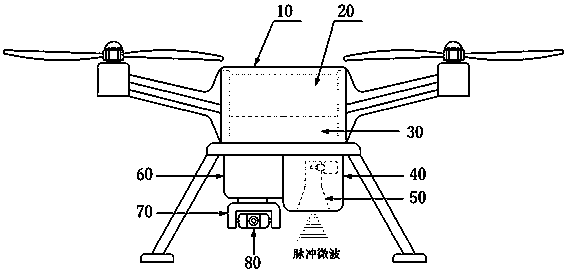

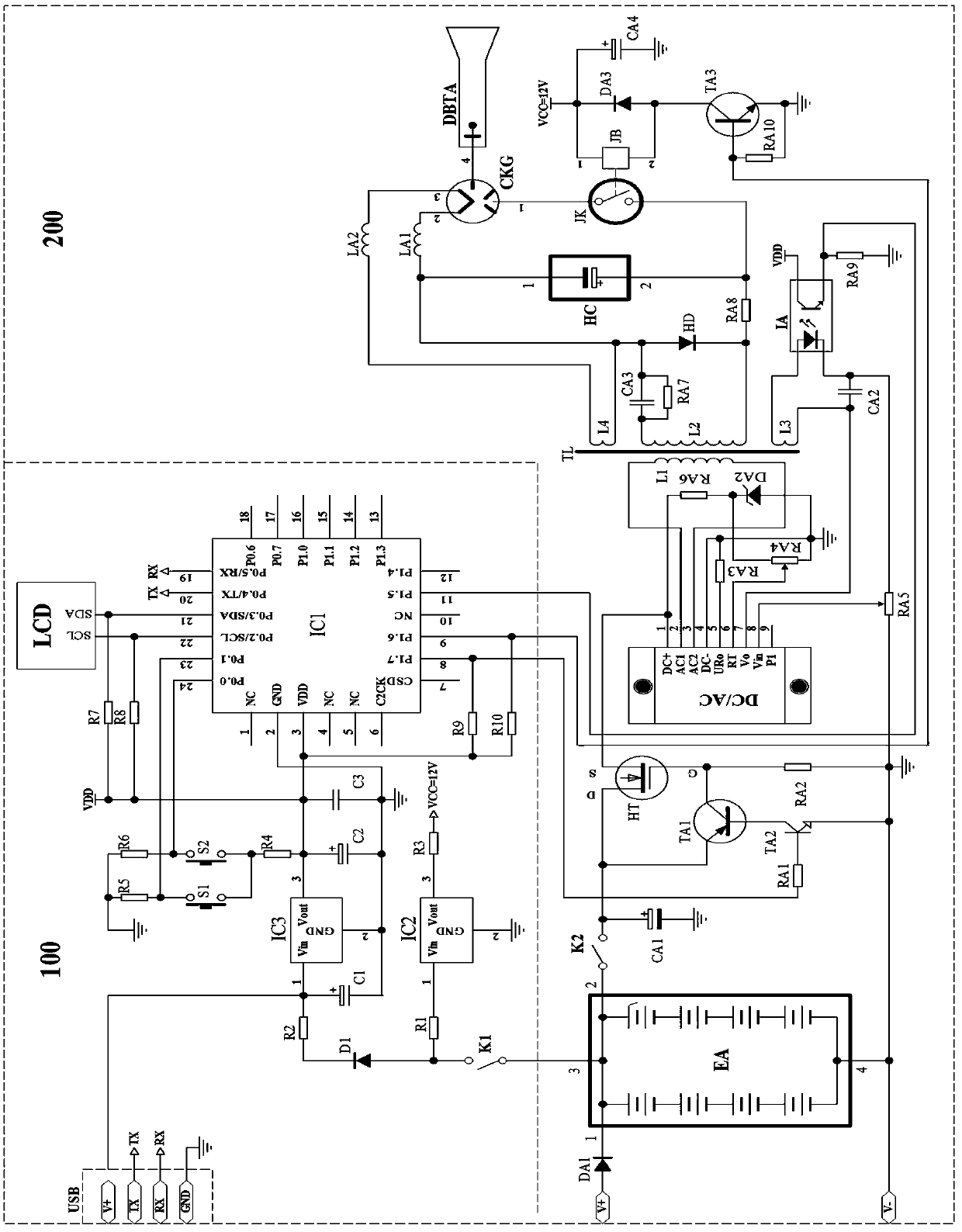

Police high-power pulse microwave emission vehicle forced stopping device

PendingCN111130575AImprove social management and control capabilitiesImprove public safetyAircraft componentsTransmissionPulse microwaveUncrewed vehicle

The invention relates to a police high-power pulse microwave emission vehicle forced stop device which comprises an unmanned aerial vehicle and a microwave emitter carried on the unmanned aerial vehicle. The unmanned aerial vehicle is provided with a camera holder and a camera. The microwave emitter comprises a lithium battery pack, a control circuit and a pulse microwave emitting circuit. The invention provides a police high-power pulse microwave emission vehicle forced stopping device. The police high-power pulse microwave emission vehicle forced stopping device is composed of a micro-processing control circuit and a high-power pulse microwave emission circuit. The miniaturized police high-power pulse microwave emission vehicle forced stopping device can be installed on an unmanned aerial vehicle, a police motorcycle and a police automobile. Under the non-contact (within a certain distance) and non-fatal conditions, high-power pulse microwaves are emitted to a target vehicle, so thatan ignition system of a vehicle engine is disordered, the engine is shut down, the vehicle is forced to stop due to power loss, the social management and control capacity of the government is improved, and the public safety level of China is improved.

Owner:深圳市思博克科技有限公司

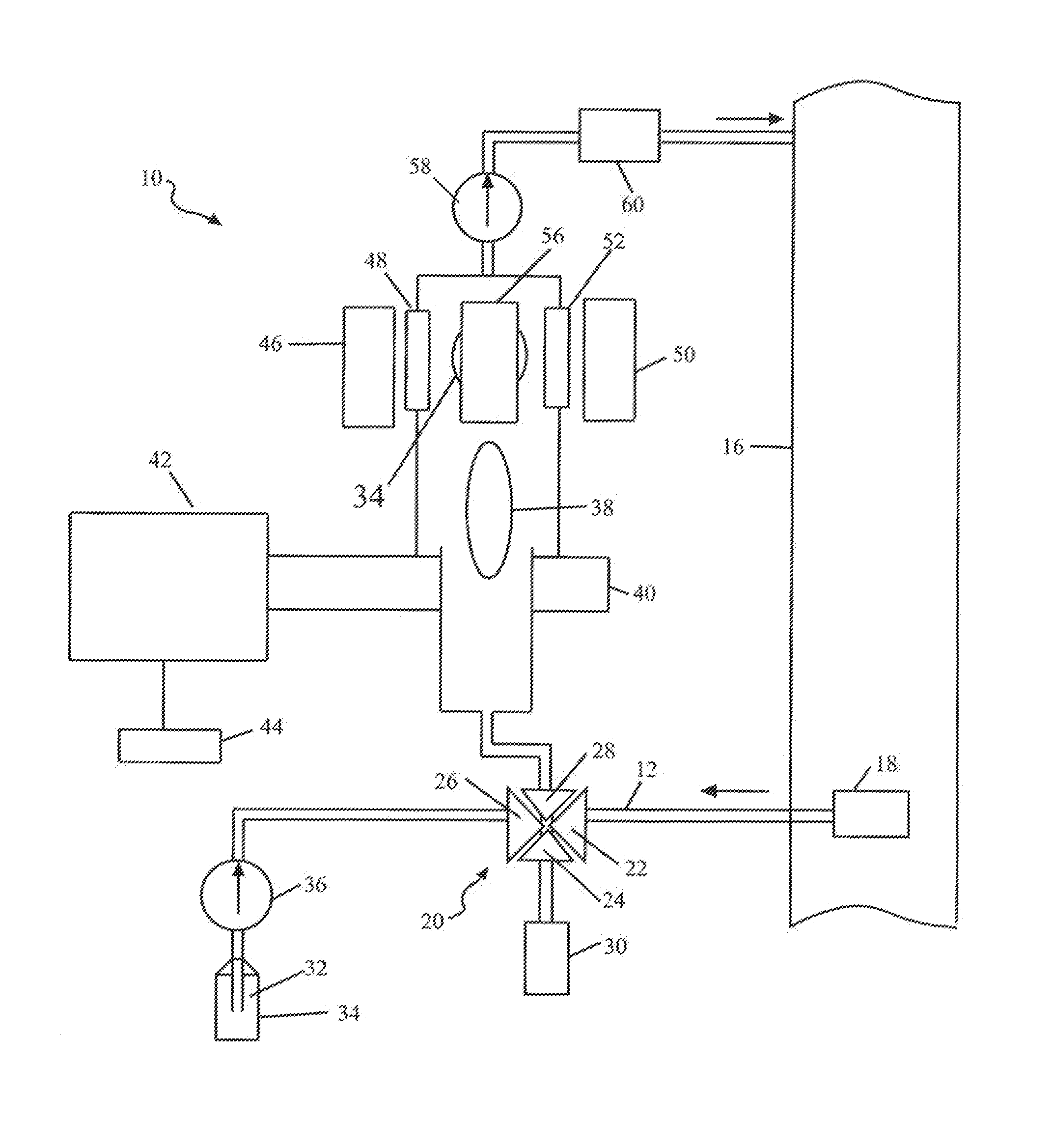

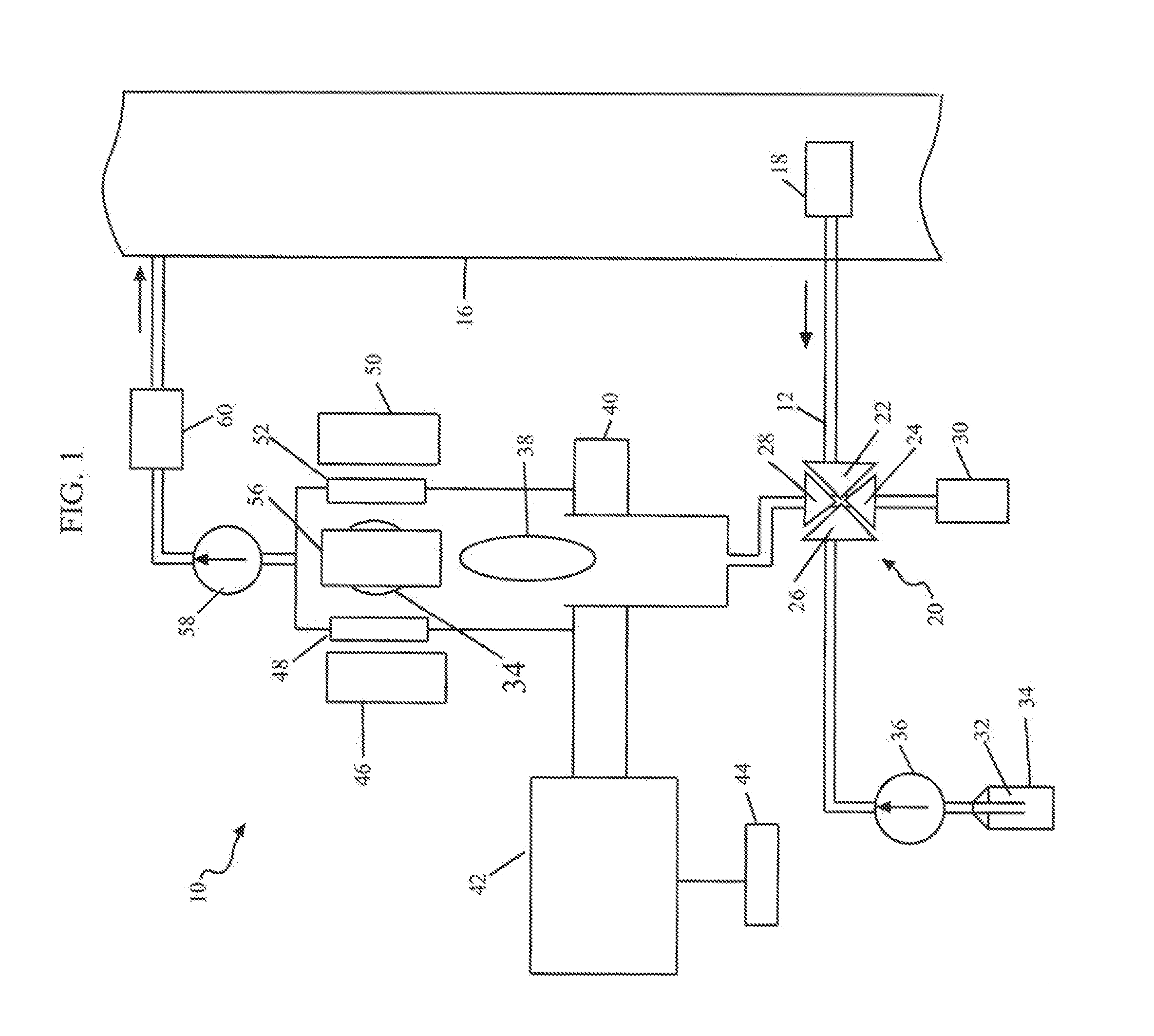

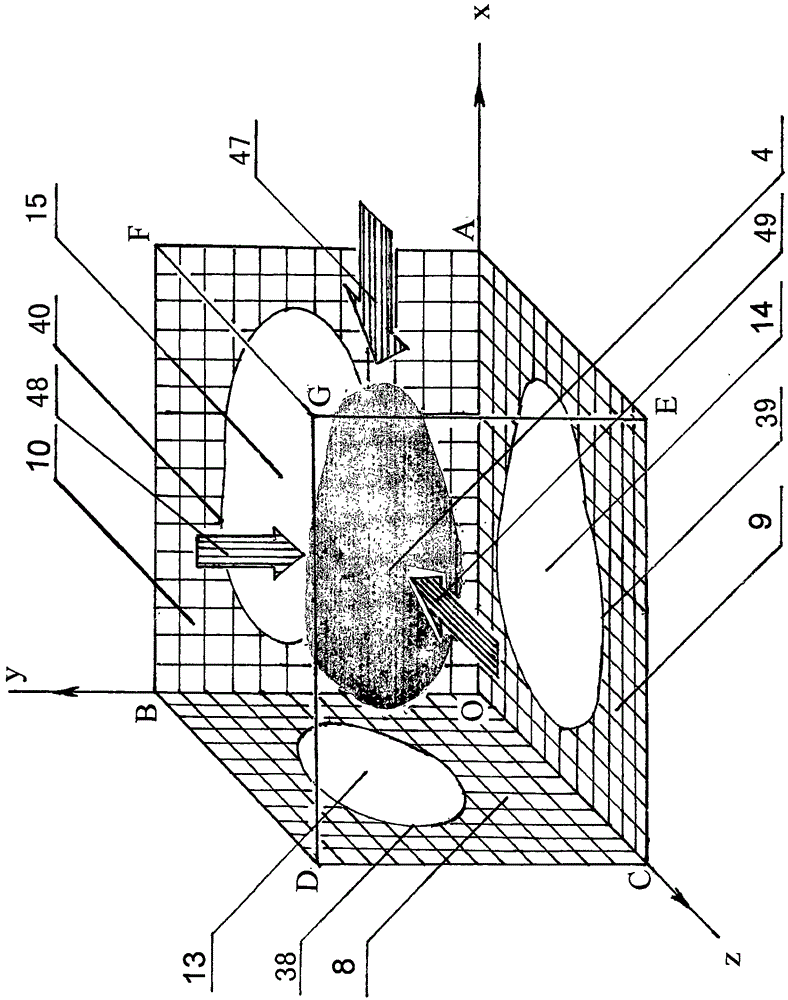

Microwave treatment method and microwave treatment device

InactiveCN105344018ANo painThe temperature field has a clear boundaryMicrowave therapyCancer cellPulse microwave

The invention relates to a device and a method for using microwaves for removing tumors, stopping bleeding, clotting, relieving pains and improving blood circulation. The method includes: using a camera 28 for shooting a lesion 4, enabling a computer 32 to control a scribing machine 31 to scribe voids 13, 14 and 15 of metal stencils 8, 9 and 10 of a three-dimensional lesion projection, radiating microwave beams 19, 20 and 21 penetrating the voids of the stencils in turns from an opposite three-dimensional direction of the projection direction onto the lesion, and enabling the microwave beams to form a high-temperature microwave radiation area 26 coincident with the three-dimensional projection, wherein the temperature of the high-temperature microwave radiation area 26 is higher than a withstanding temperature 43 DEG C of cancer cells; enabling a normal cell tissue 53 to be positioned in a temperature area 25 formed by radiation of nonoverlapped one-dimensional wave beams, wherein the temperature of the temperature area 25 is lower than 40 DEG C. The metal stencils define radiation ranges and positions, a pulse microwave generator and a lens antenna transmit parallel microwave beams 44, 45 and 46, running water controls radiation sequence, and a pyroelectric infrared thermometer and an overtemperature power cut circuit control the radiation temperature. Accurate heating position and range, safety in treatment, painlessness, quickness, one-time completion and thoroughness in killing of cancer cells and low cost are realized.

Owner:杨富云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com