Power supply for achieving pulse microwave output employing magnetron and control method of power supply

A technology of pulsed microwave and magnetron, which is applied in the field of power supply and control of pulsed microwave output by magnetron, can solve the problems that hinder the application process of microwave "thermal effect" and "non-thermal effect, lack of high-power pulsed microwave, etc., and achieve Achieving Precisely Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

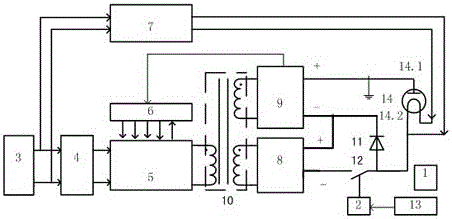

[0028] Example 1: A 2.45GHz magnetron 2M469 is used with a power of 1.05kW, an anode voltage of 4450V, an anode current of 0.25A, a filament voltage of 3.5V, and a current of 10A. The cooling method is water cooling. Using the method proposed by the invention, the negative high voltage between the cathode and the anode is powered by pulse modulation. Such as Figure 5 shown. The mains 220V is connected to the full-bridge inverter circuit composed of 4 FETs after EMI filtering and bridge rectification module. An RCD absorption circuit is connected between the drain and the source of each field effect transistor to reduce switching loss. The midpoint of the bridge arm is connected to the high-frequency step-up transformer through a DC blocking capacitor. The output of the secondary side of the transformer is divided into two windings, in which the main winding passes through 4 fast recovery high-voltage diodes 2CLG7.5K and a high-voltage capacitor to form a rectification and...

Embodiment 2

[0029] Example 2: A 2.45GHz magnetron 2M463G is used with a power of 1.5kW, an anode voltage of 4650V, an anode current of 0.3A, a filament voltage of 3.5V, and a current of 10A. The cooling method is water cooling. Using the method proposed by the invention, the negative high voltage between the cathode and the anode is powered by pulse modulation. The mains 220V is connected to the full-bridge inverter circuit composed of 4 FETs after EMI filtering and bridge rectification module. An RCD absorption circuit is connected between the drain and the source of each field effect transistor to reduce switching loss. The midpoint of the bridge arm is connected to the high-frequency step-up transformer through a DC blocking capacitor. The output of the secondary side of the transformer is divided into two windings, in which the main winding passes through 4 fast recovery high-voltage diodes 2CLG7.5K and a high-voltage capacitor to form a rectification and filtering circuit to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com