Process and device of forming multilayer insulating thin film on inner wall of glass container

A glass container and barrier technology, which is applied in the field of process and equipment for forming multi-layer barrier films on the inner wall of glass containers, can solve the problems of failure to meet barrier requirements, uneven deposition, and no orientation, etc., to improve the use of life, increase deposition efficiency, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

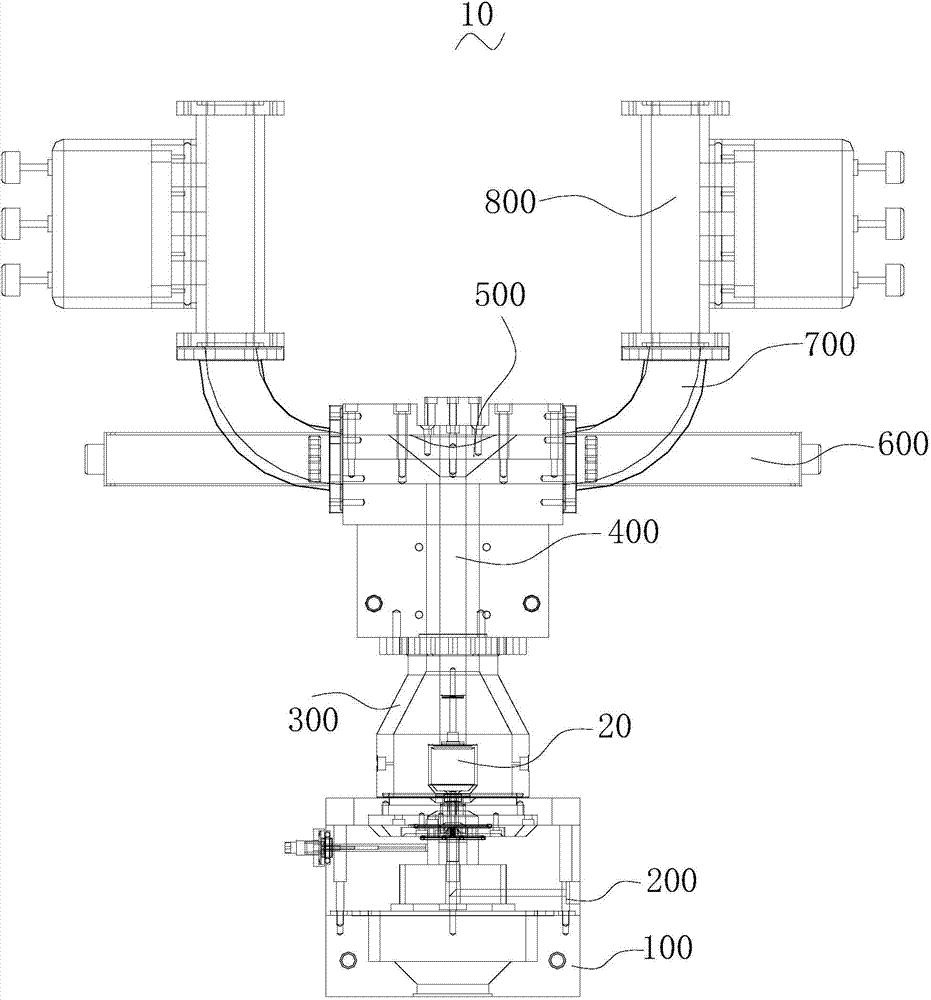

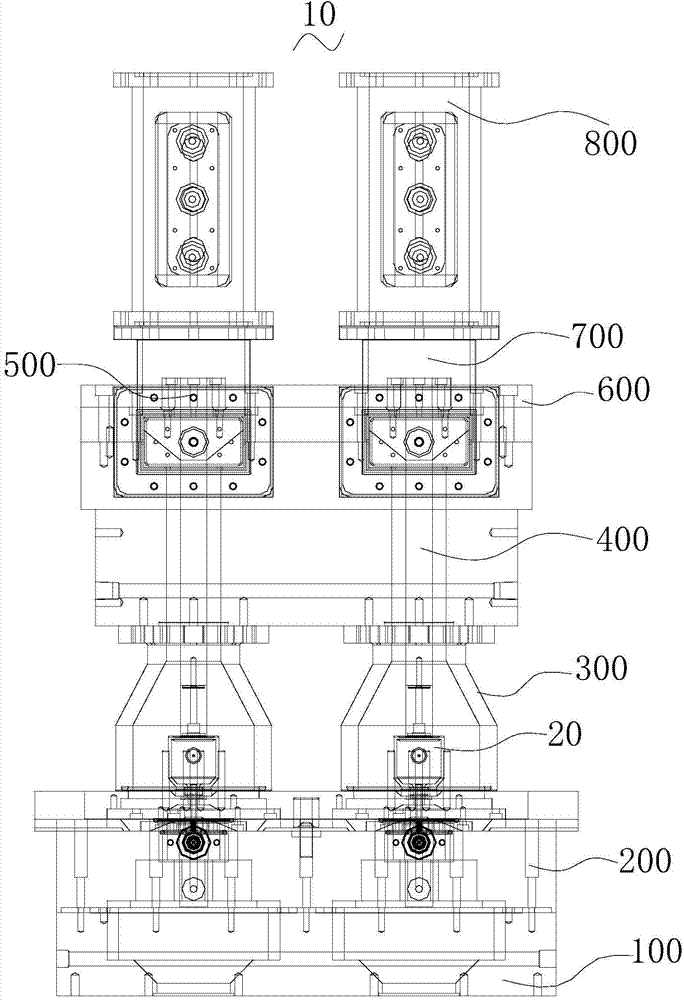

[0026] Such as figure 1 As shown, it is a front view of an apparatus 10 for forming a multilayer barrier film on the inner wall of a glass container according to an embodiment of the present invention. Please also refer to figure 2 , which is figure 1 A side view of an apparatus 10 for forming a multilayer barrier film on the inner wall of a glass container is shown.

[0027] This equipment 10 for forming a multilayer barrier film on the inner wall of a glass container is used to form a multilayer barrier film on the inner wall of a glass container 20, which includes: a machine base 100, a gas pipeline 200, a microwave sealing cover 300, an antenna 400, A mode converter 500 , an adjuster 600 , a waveguide 700 , and a pulsed microwave source 800 .

[0028] The glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com