Patents

Literature

178results about How to "Even energy distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrosurgical system

InactiveUS6893435B2Sufficient powerImproving impedanceSurgical instruments for heatingSurgical forcepsEngineeringRadio frequency

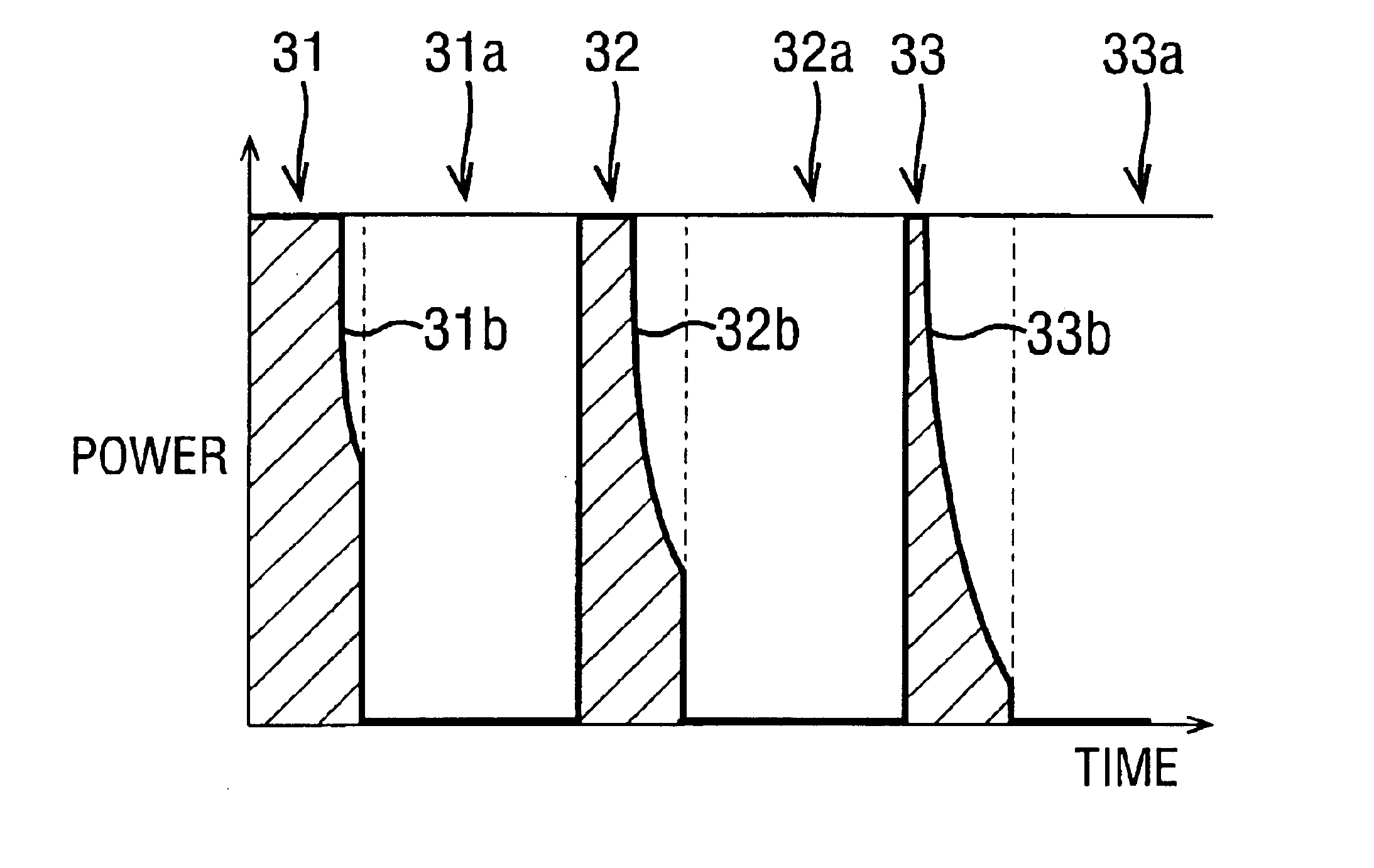

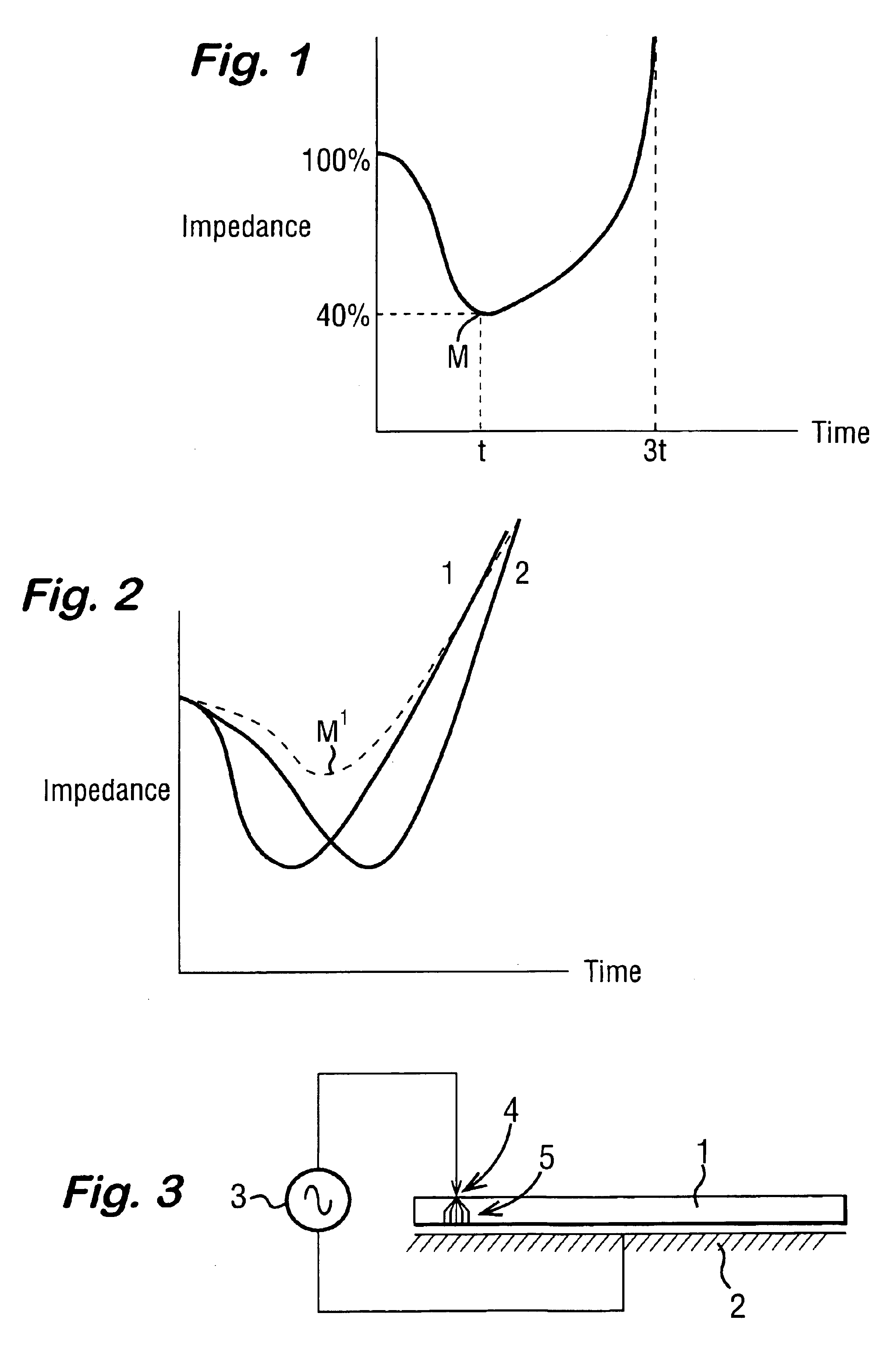

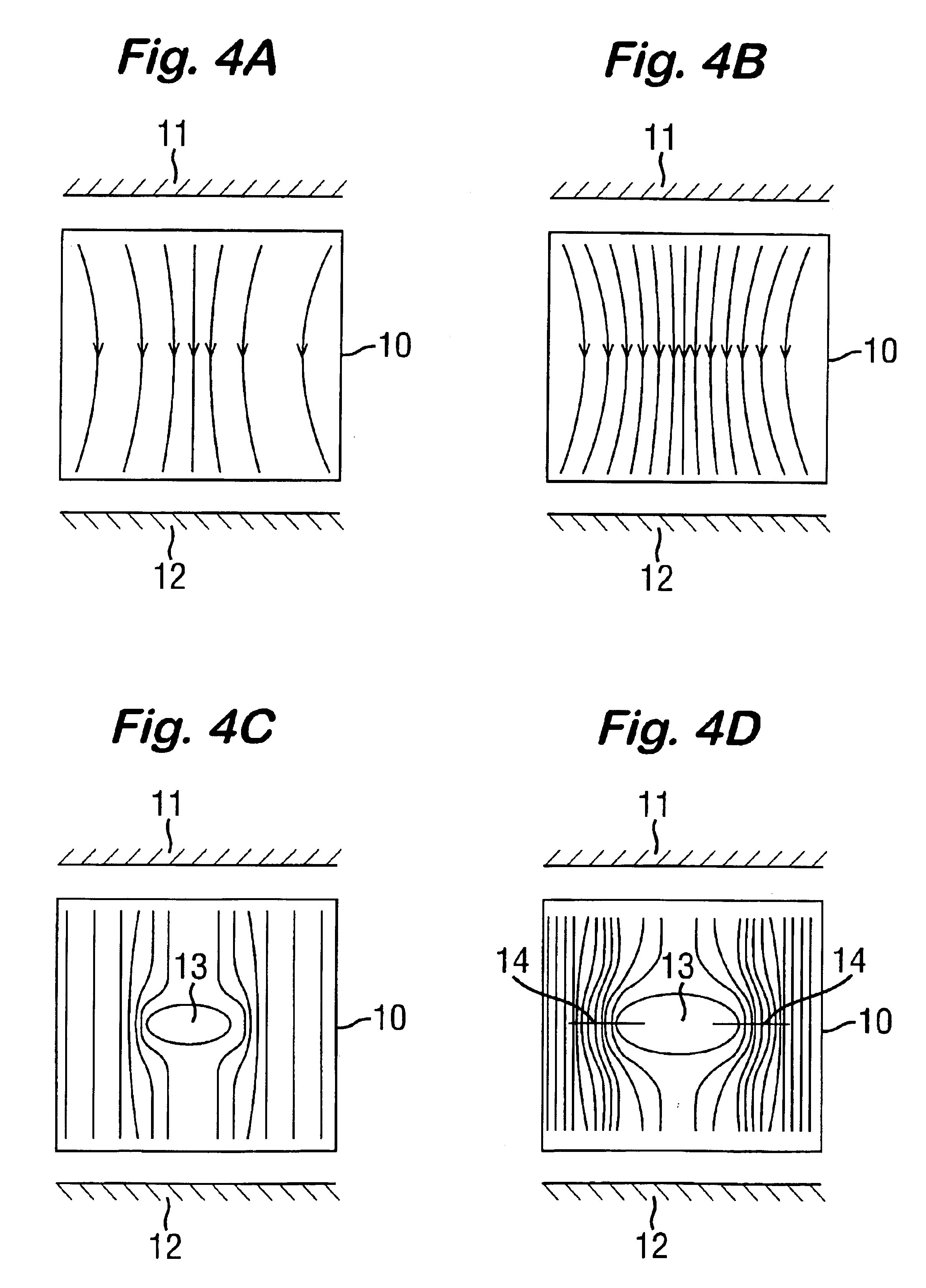

An electrosurgical system has an electrosurgical generator and a bipolar electrosurgical instrument, the generator being arranged to perform a treatment cycle in which radio frequency energy is delivered to the instrument as an amplitude-modulated radio frequency power signal in the form of a succession of pulses characterized by periods of a least 100 milliseconds between successive pulses and by a predetermined pulse mark-to-space ratio. Energy delivery between pulses is substantially zero and the mark-to-space ratio is typically 1:4 or less. Each burst is of sufficiently high power to form vapor bubbles within tissue being treated and the time between successive pulses is sufficiently long to permit condensation of the vapor. The treatment cycles may each include an initial period and a subsequent period, the pulse duty cycle being increased or energy being delivered continuously in the subsequent period in order that tissue coagulation can be achieved quickly despite increasing tissue impedance.

Owner:GYRUS MEDICAL LTD

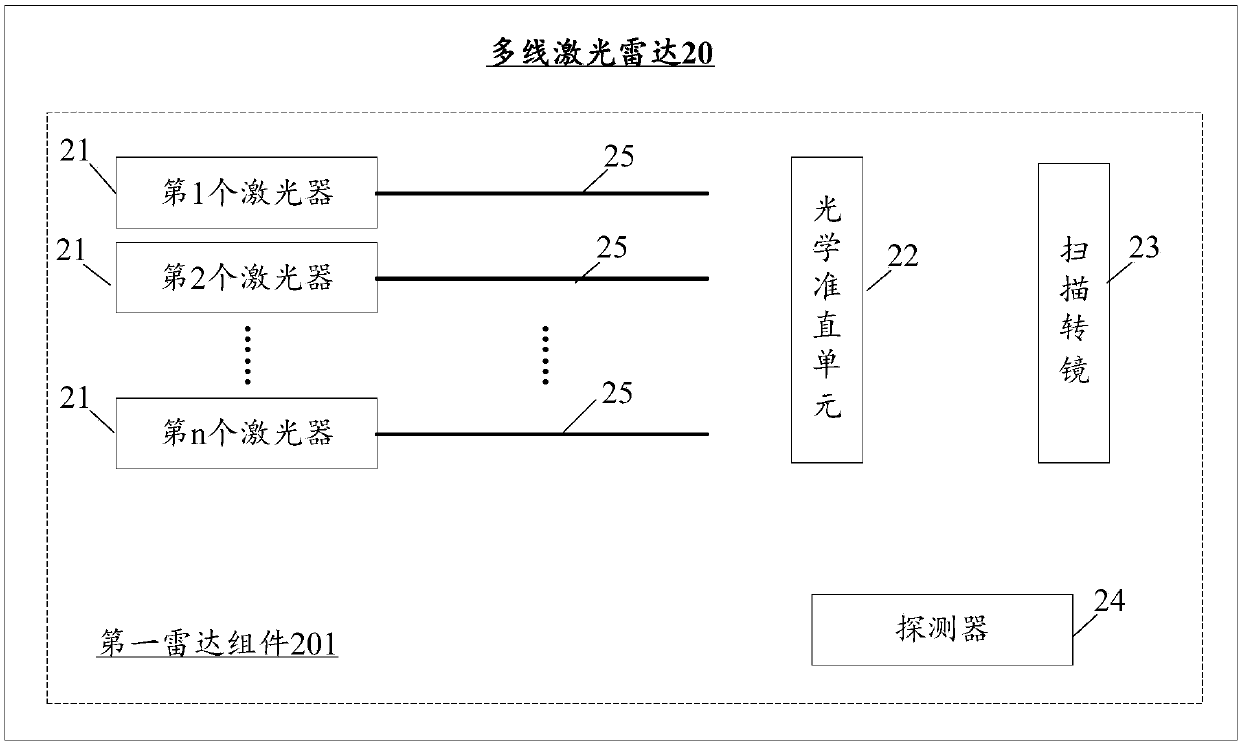

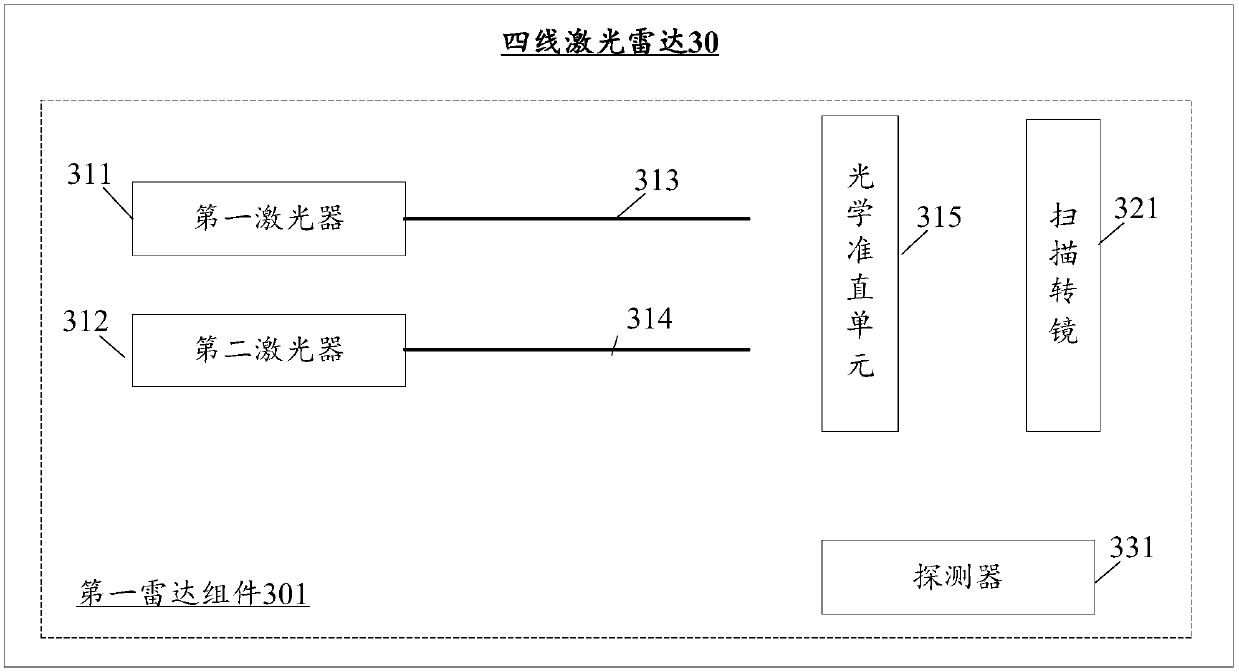

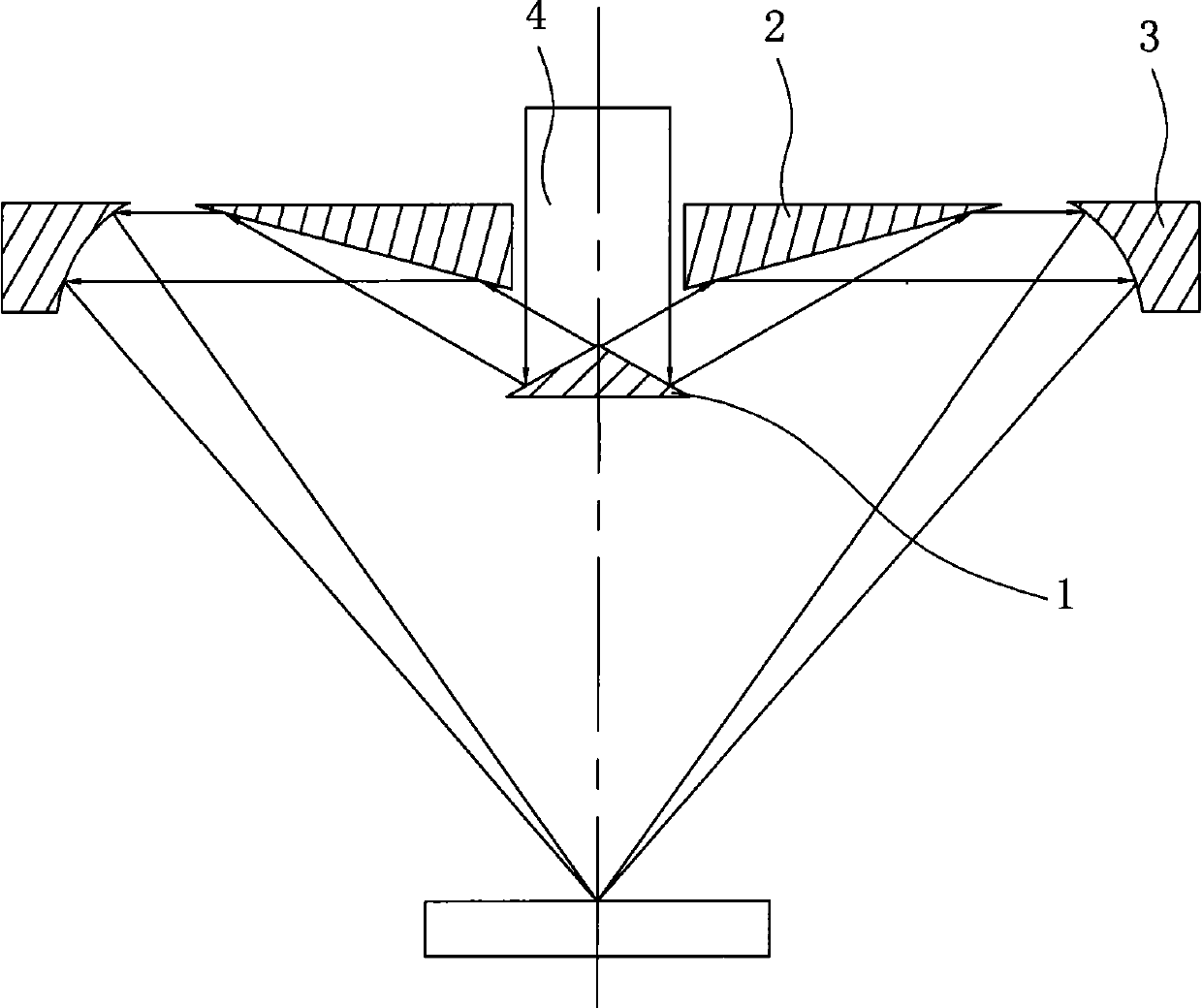

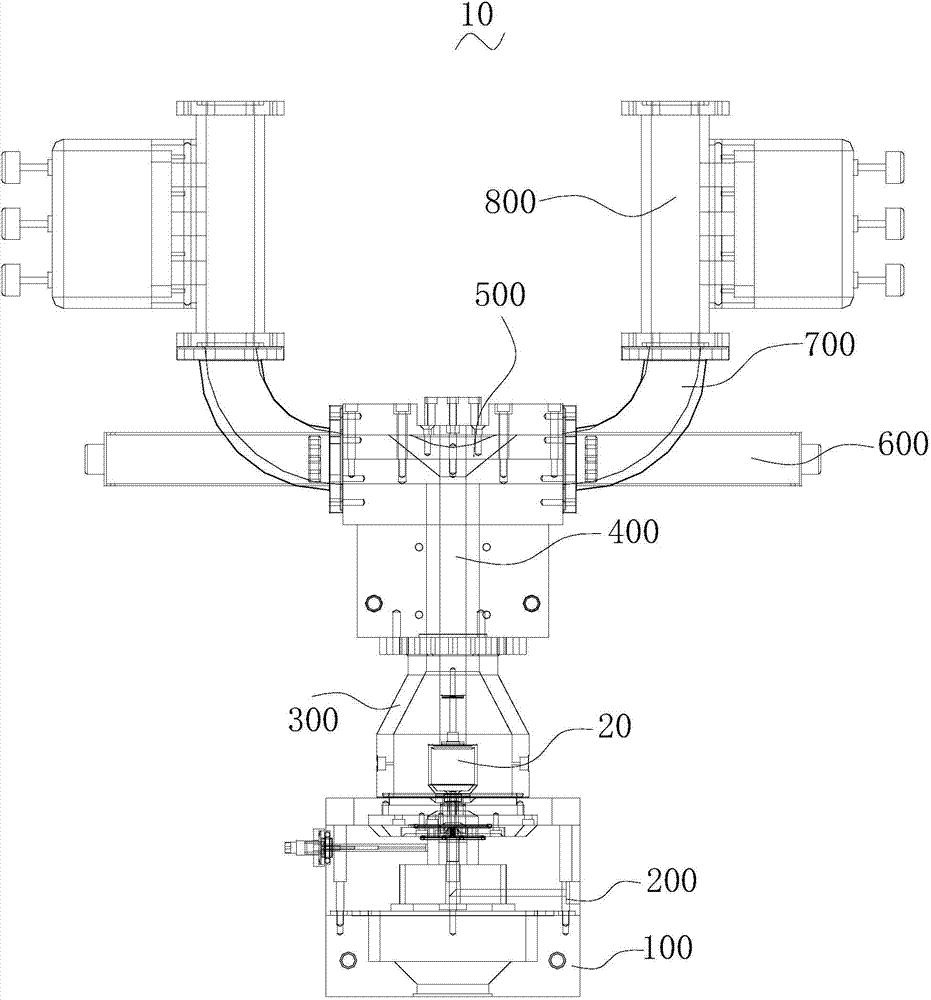

Multi-line laser radar

ActiveCN108061904AImprove work performanceReduce hardware costsElectromagnetic wave reradiationOptical elementsRadarLight beam

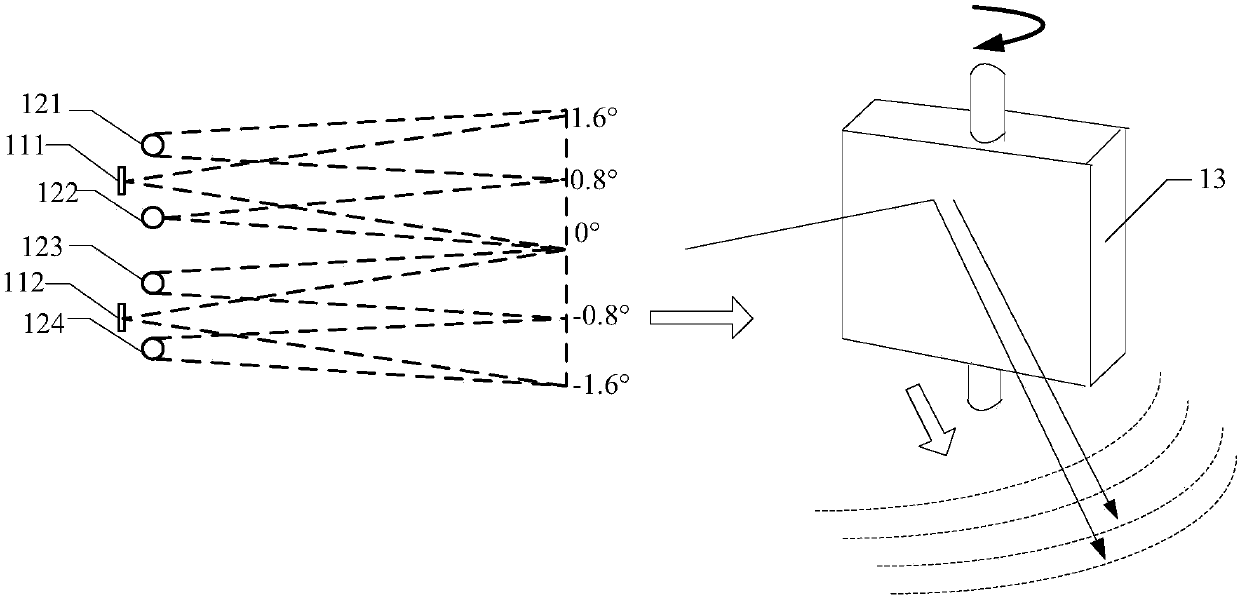

A multi-line laser radar comprises a first radar assembly, and the first radar assembly comprises n laser devices, an optical alignment unit, a scanning rotating mirror and a detector, wherein n is larger than 1. Each laser device is used for emitting one way of laser beam to the optical alignment unit; the optical alignment unit is used for aligning the n ways of laser beams, and the aligned n ways of laser beams are shot towards target reflection mirrors of the scanning rotating mirror; the scanning rotating mirror comprises the m reflection mirrors rotating around a rotary shaft, and the rotating plane of the rotary shaft is perpendicular to the arrangement direction of the aligned n ways of laser beams, wherein m is larger than 1; the target reflection mirrors are used for reflecting the received aligned n ways of laser beams to a detection area of the first radar assembly; and the detector is used for receiving reflected echo signals of the n ways of laser beams in the detection area. The multi-line laser radar is of a multi-emit and one-receive structure, signal crosstalk among different detectors is avoided, the working performance is improved, and the cost is lowered.

Owner:HUAWEI TECH CO LTD

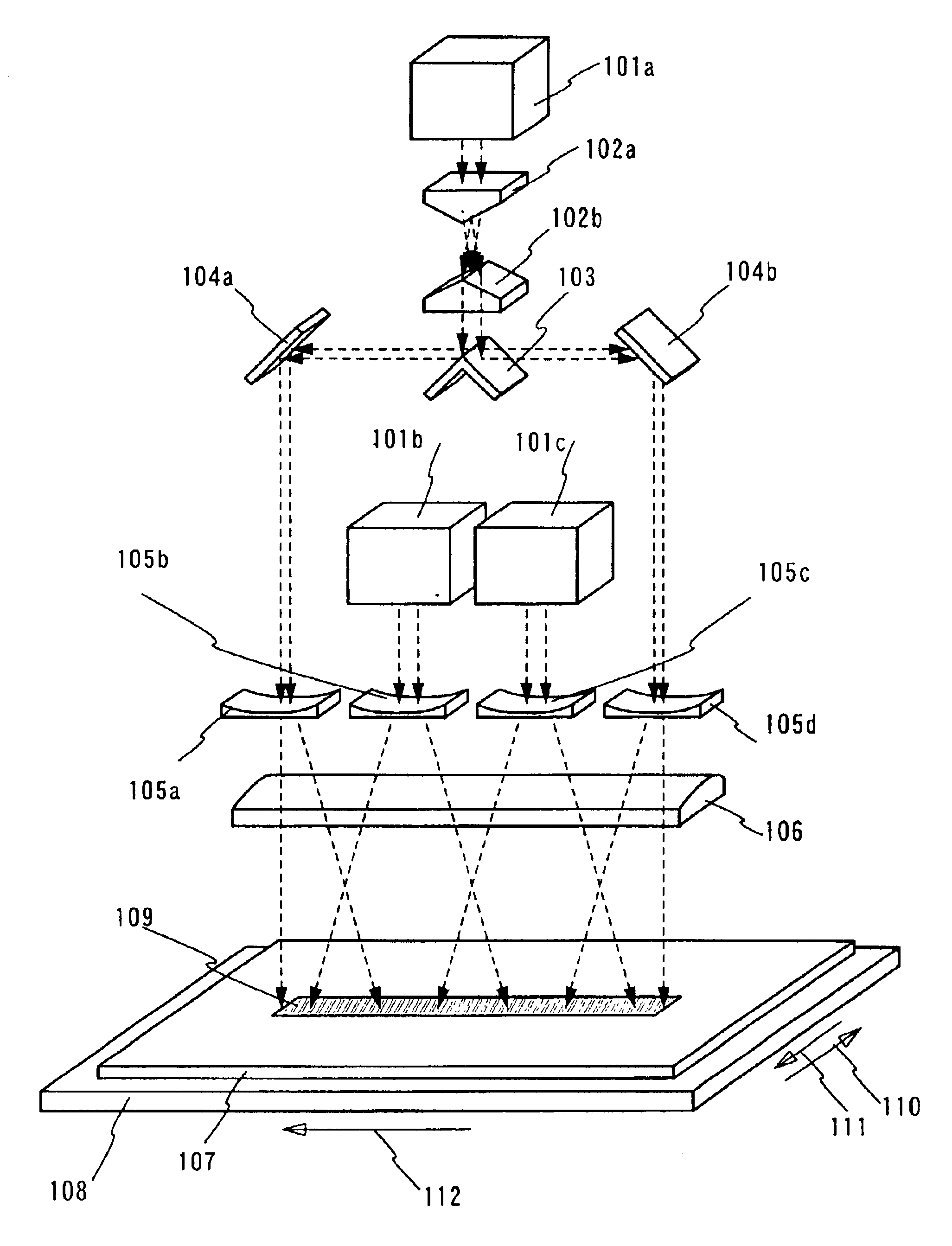

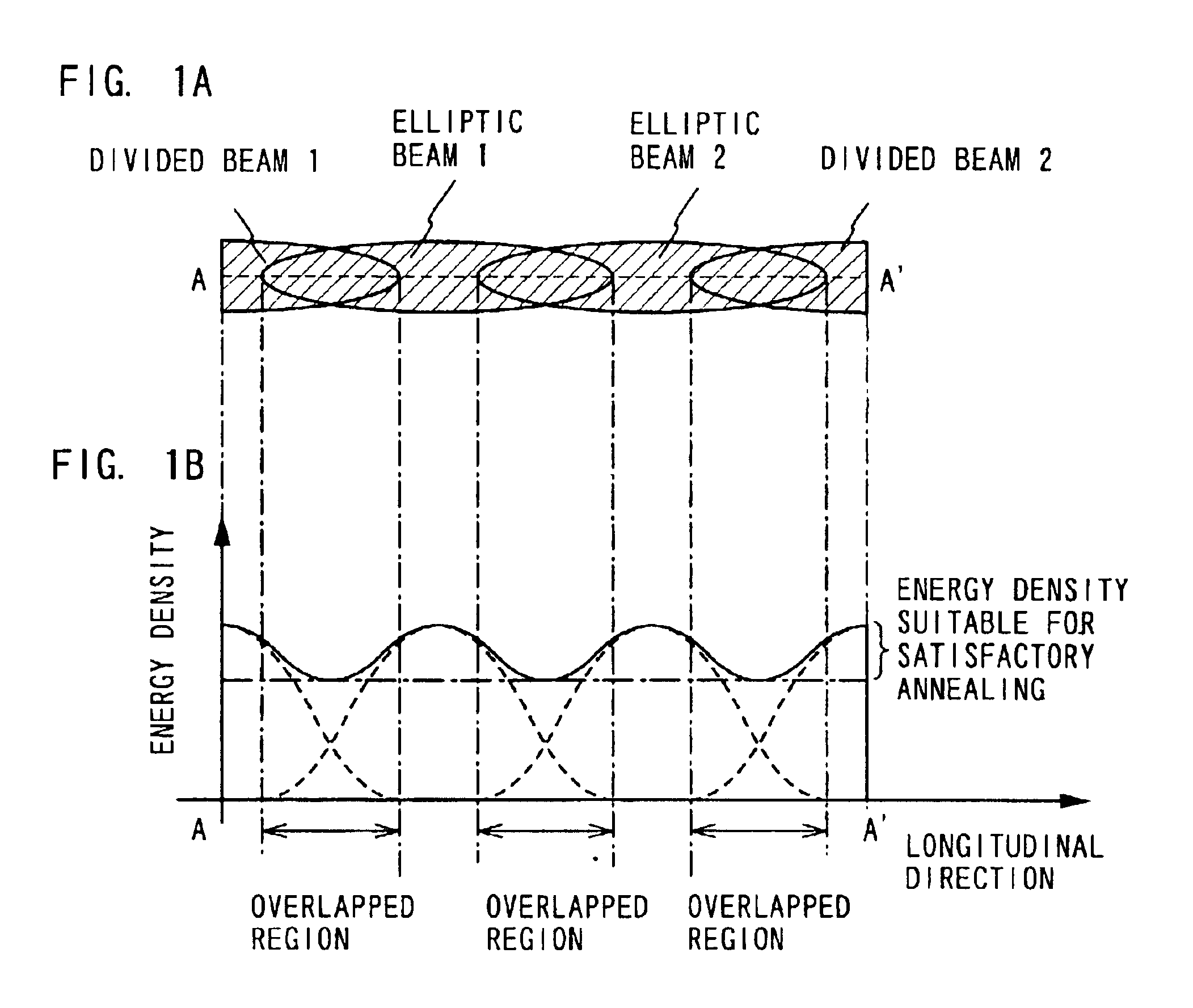

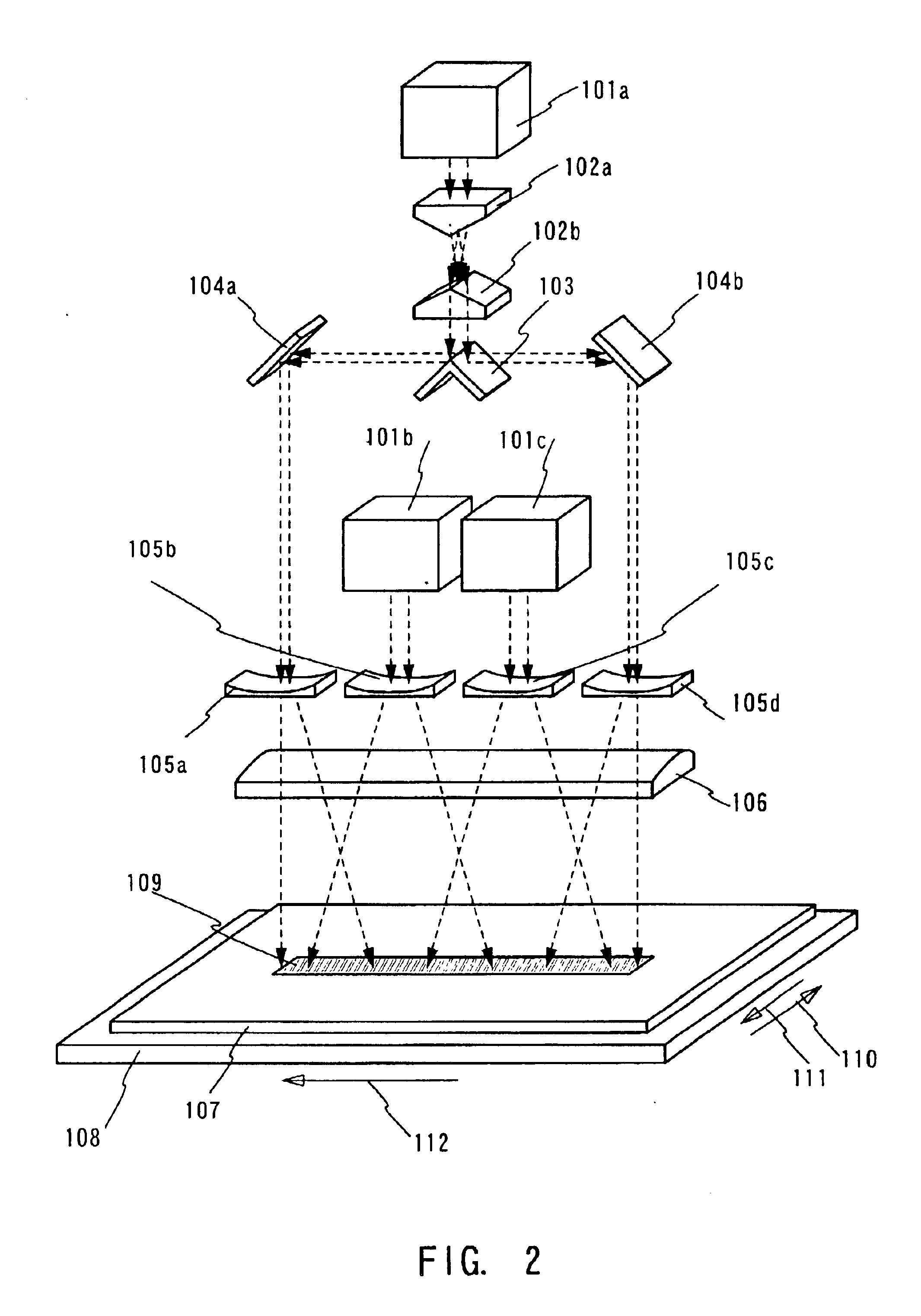

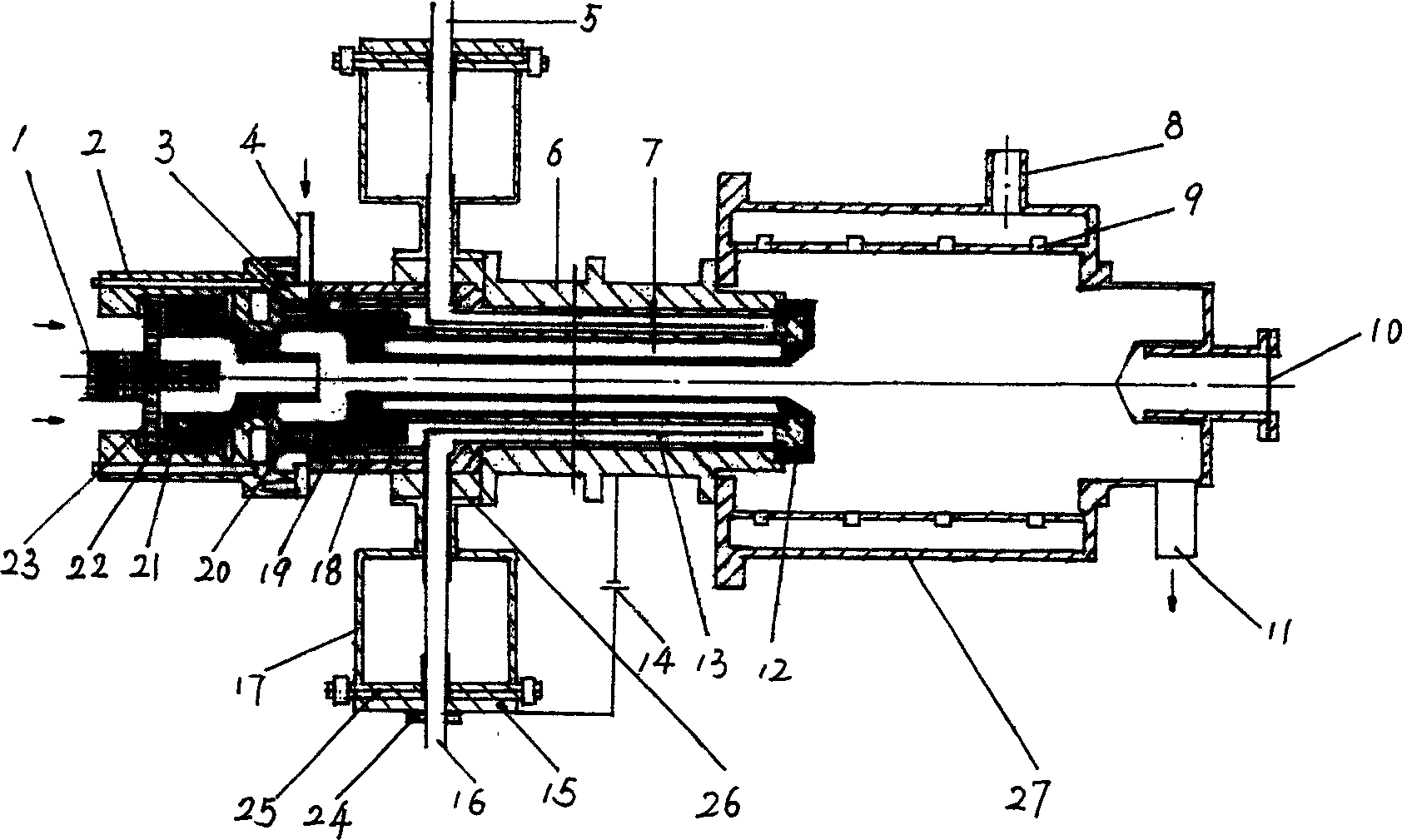

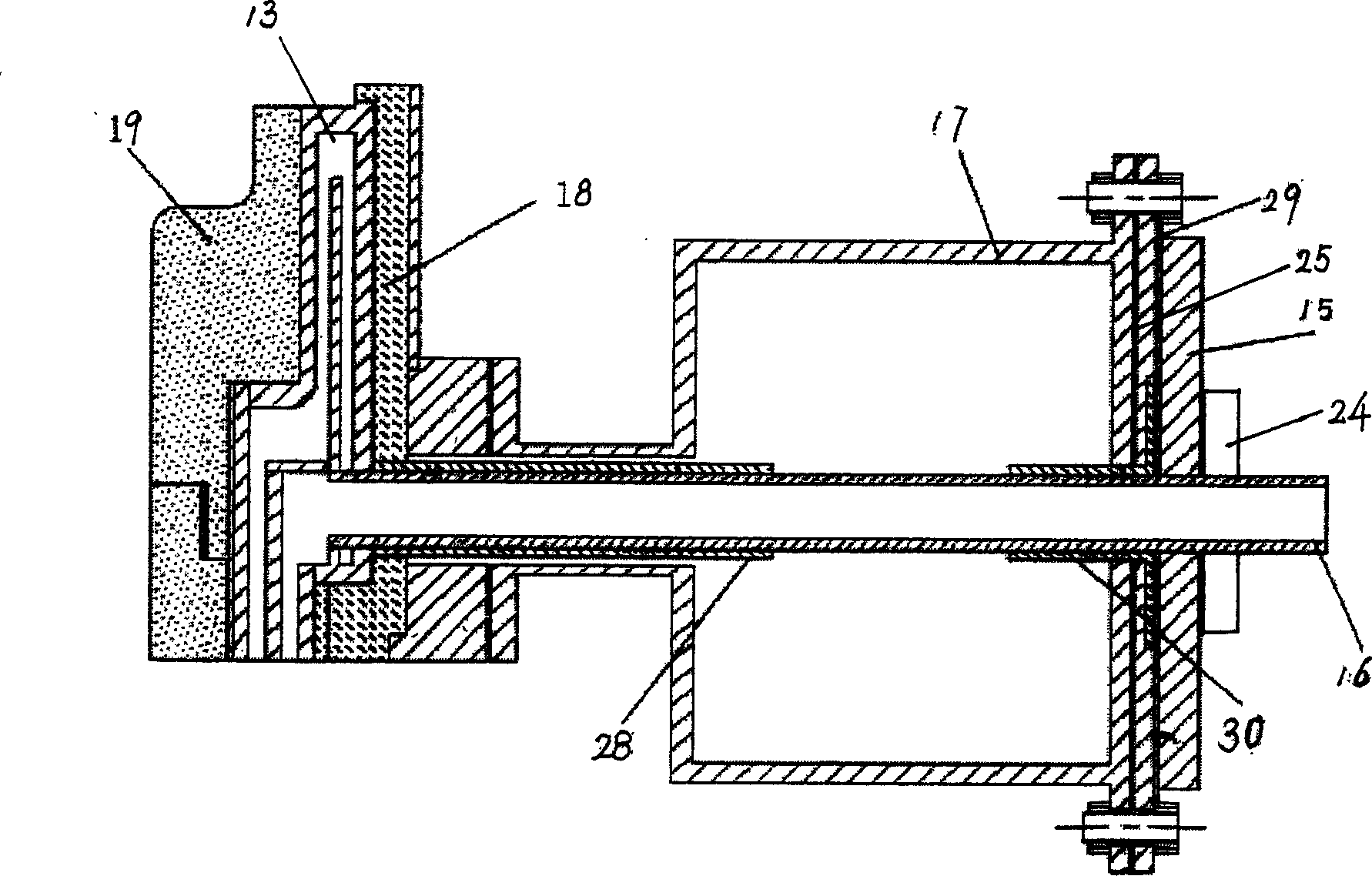

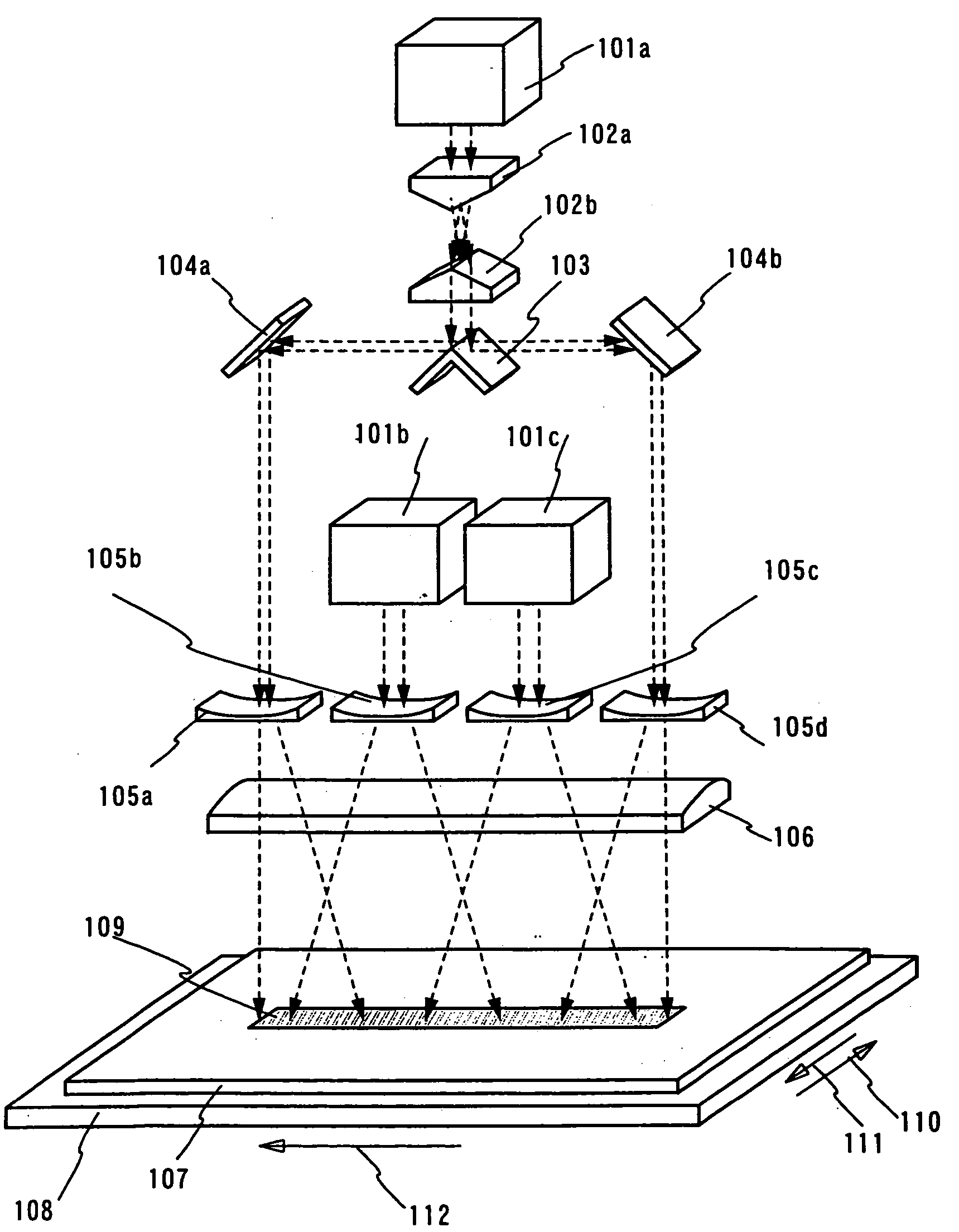

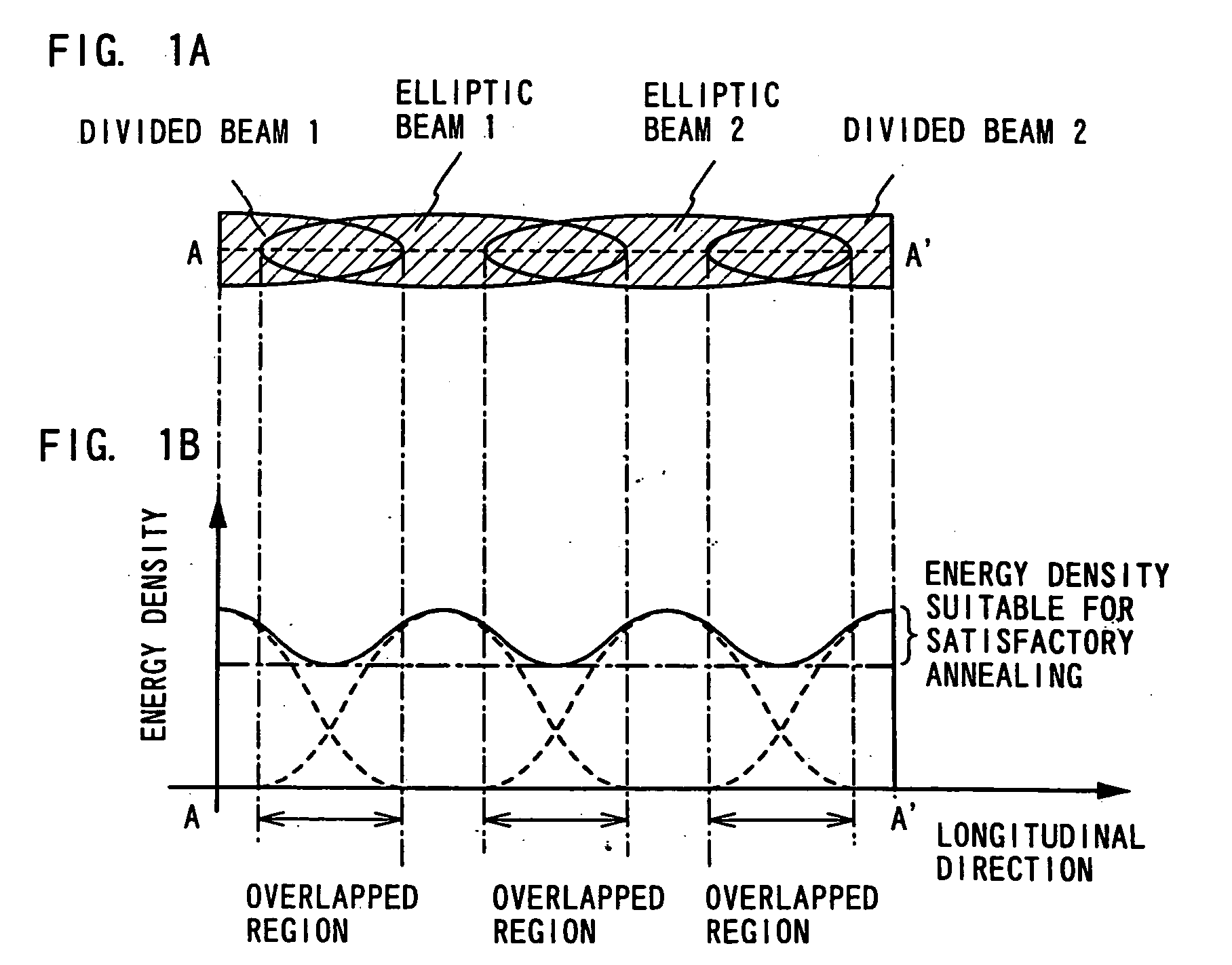

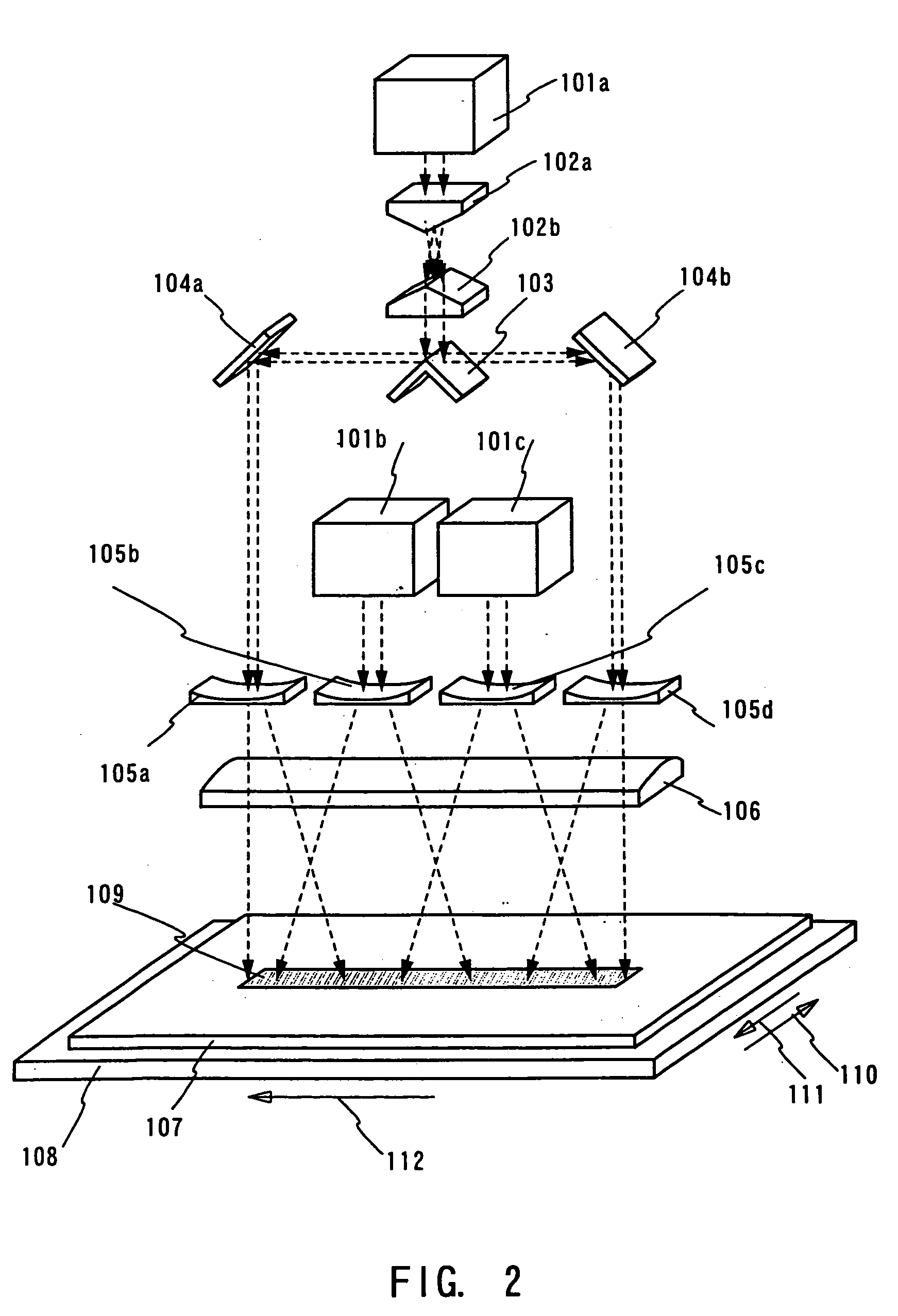

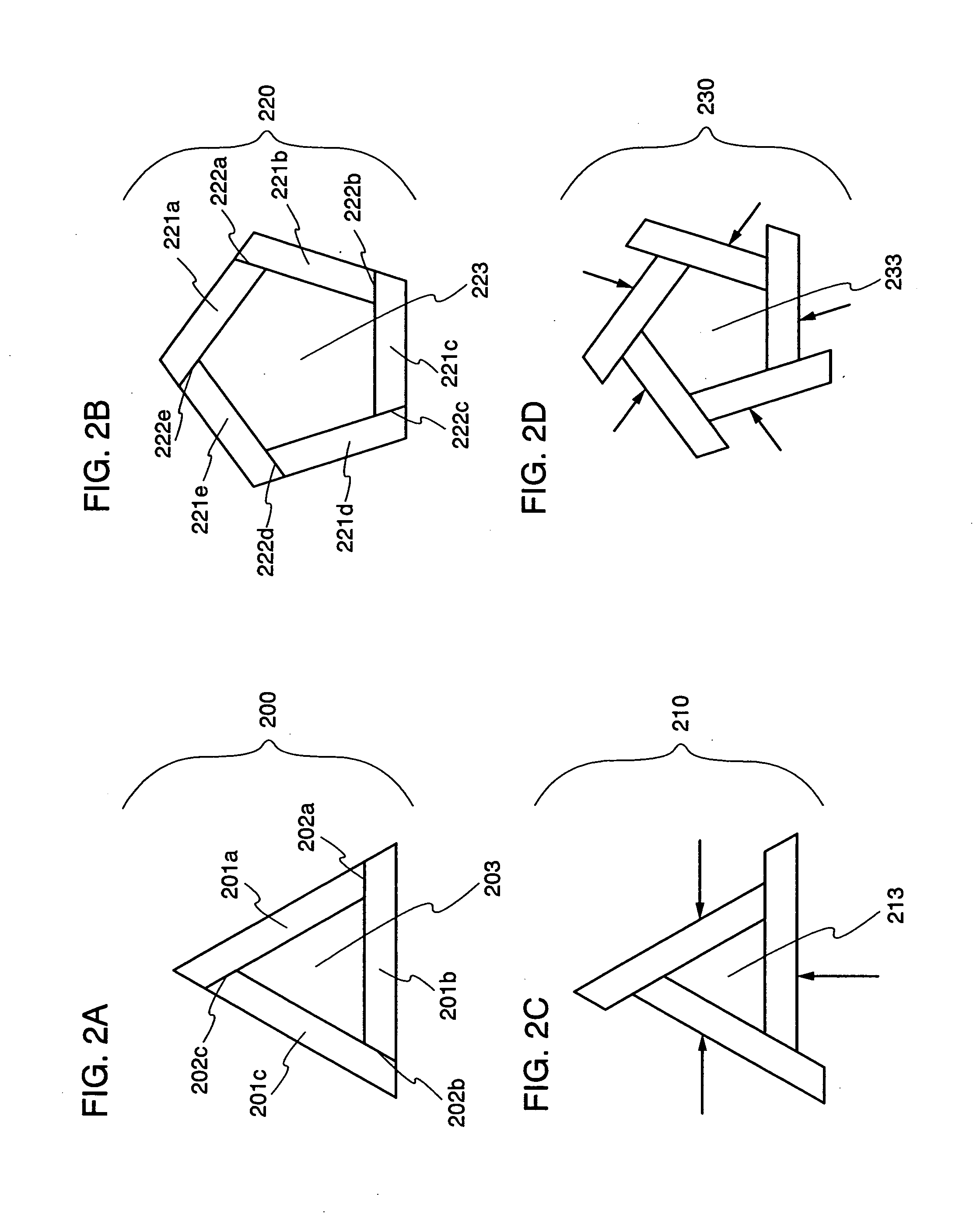

Laser irradiation apparatus, laser irradiation method, and method of manufacturing a semiconductor device

InactiveUS6852947B2Reduce weightIncreased durabilityTransistorLaser detailsUltrasound attenuationLaser light

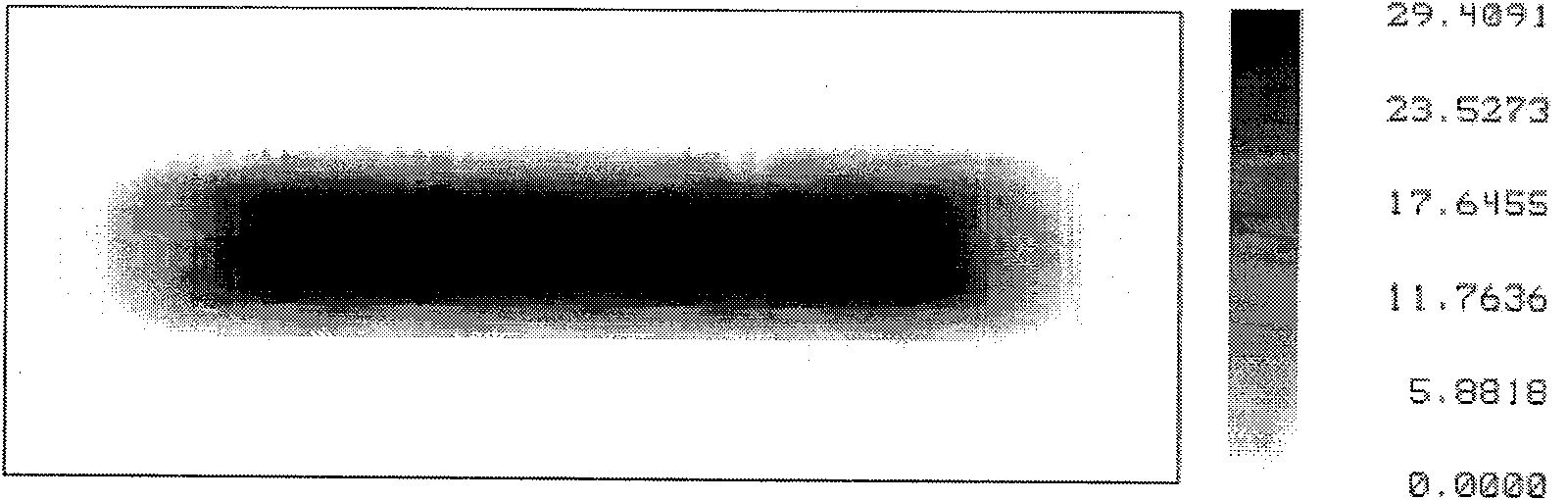

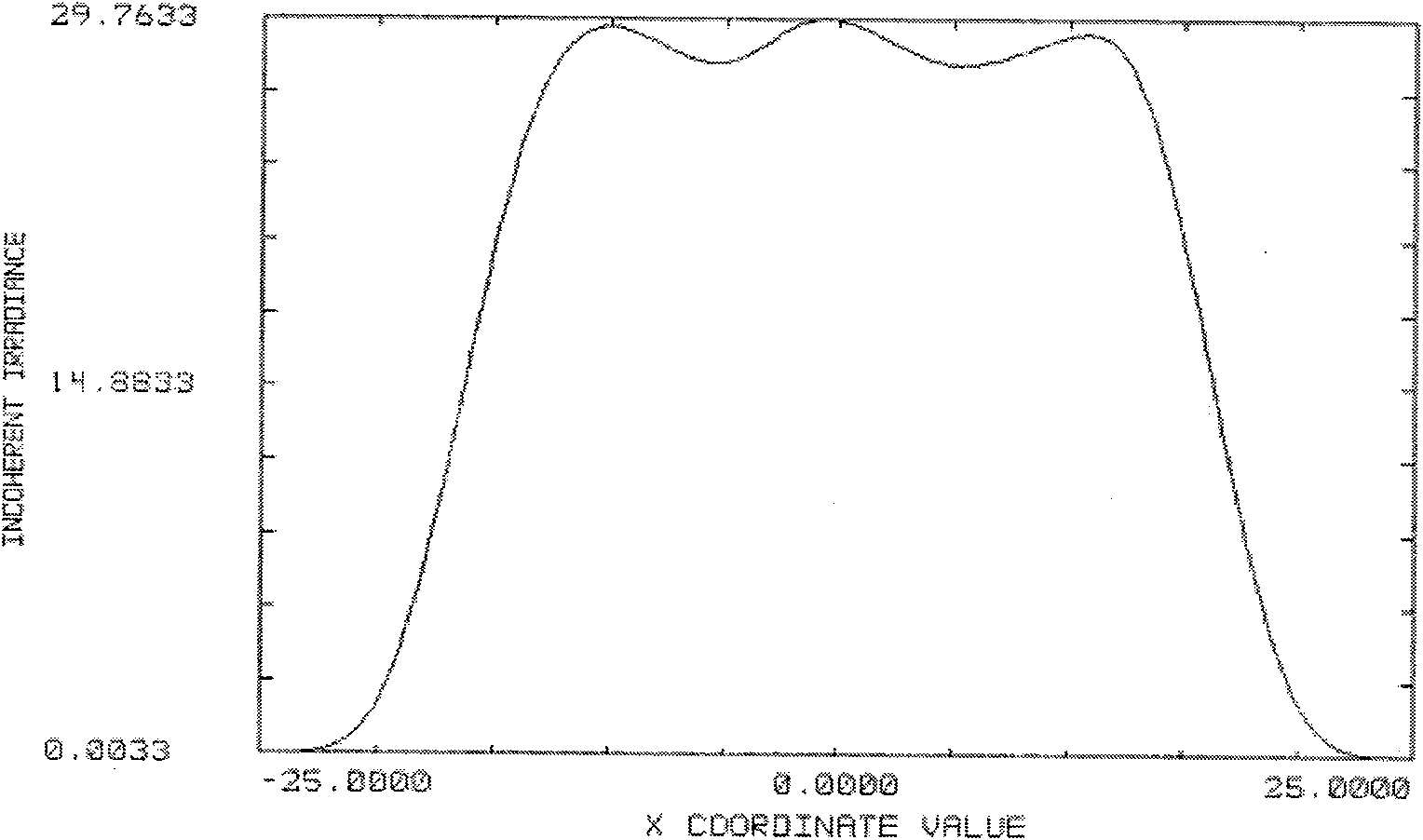

At edges of laser light on an irradiation surface or in the vicinity thereof, the energy density is attenuated gradually due to aberration of a lens or the like. Since such regions (attenuation regions) do not have enough energy density for annealing of an irradiation object, uniform annealing of the irradiation object is not possible.In the present invention, one of the plural laser beams is divided into two laser beams so that each section of the two laser beams serves as an edge of the resultant laser light. Each attenuation region of the two laser beams is synthesized with an attenuation region of another laser beam. In this way, laser light every part of which has an energy density suitable for satisfactory annealing of an irradiation object can be obtained from plural laser beams having attenuation regions.

Owner:SEMICON ENERGY LAB CO LTD

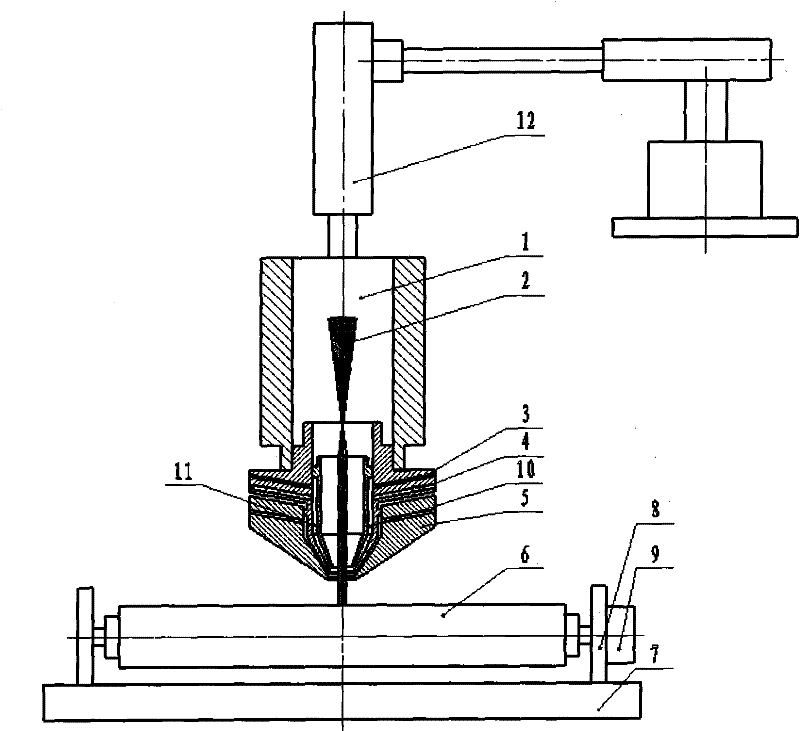

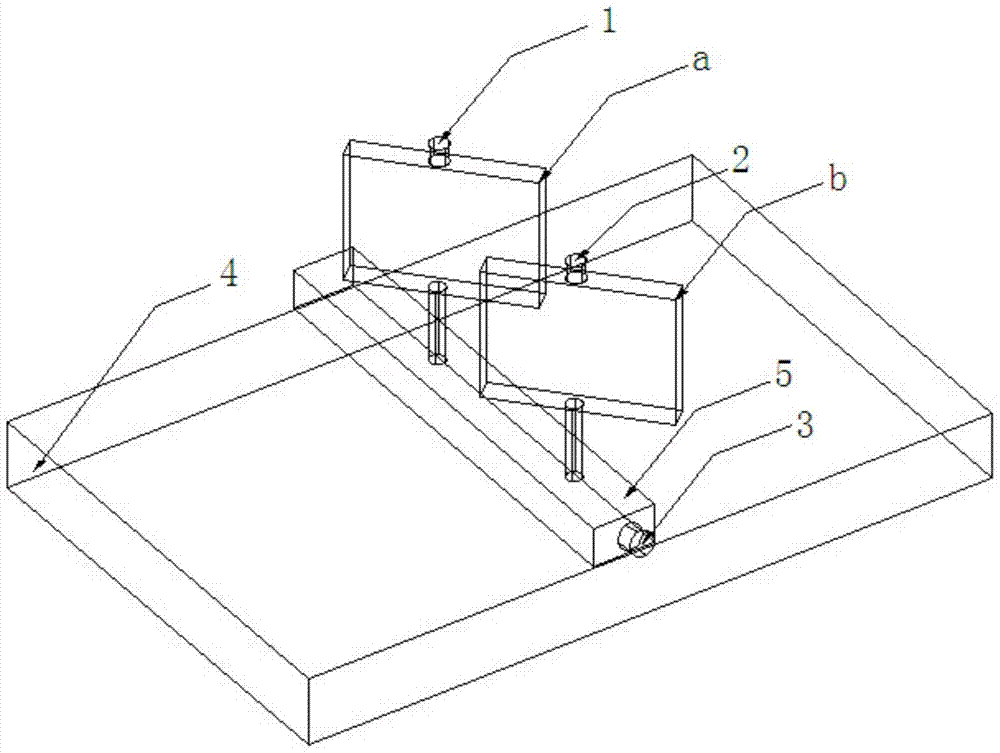

A high-performance composite roll laser injection forming manufacturing and repair method and equipment

InactiveCN102259187AEvenly distributedIncrease the area of actionIncreasing energy efficiencyRollsLaser lightRisk stroke

The invention provides a method and equipment for manufacturing and repairing a high-performance composite roll by laser spray forming, which uses laser spray forming to manufacture the transition layer and the working layer of the roll. It is characterized in that the specific method steps are as follows: A) removing the surface of the core of the roll B) Put the powder of the working layer material and the powder of the roller core into the powder feeding system respectively, and start the laser jet synchronous powder feeding through the surface of the roller whose stroke is controlled by the mechanical arm Direct metal Manufacture the intermediate transition layer of the roll; C) After one layer is deposited, the interlaced deposition is realized by changing the direction of the square spot and the movement direction of the mechanical arm; D) After the transition layer is formed, the spray forming on the surface of the transition layer is completely formed by the added The functional material constitutes the working layer. The invention uses a high-power short-wavelength laser as a processing light source and shapes the light spot of the laser into a rectangle, thereby effectively improving the quality of spray forming and increasing the processing speed.

Owner:周明

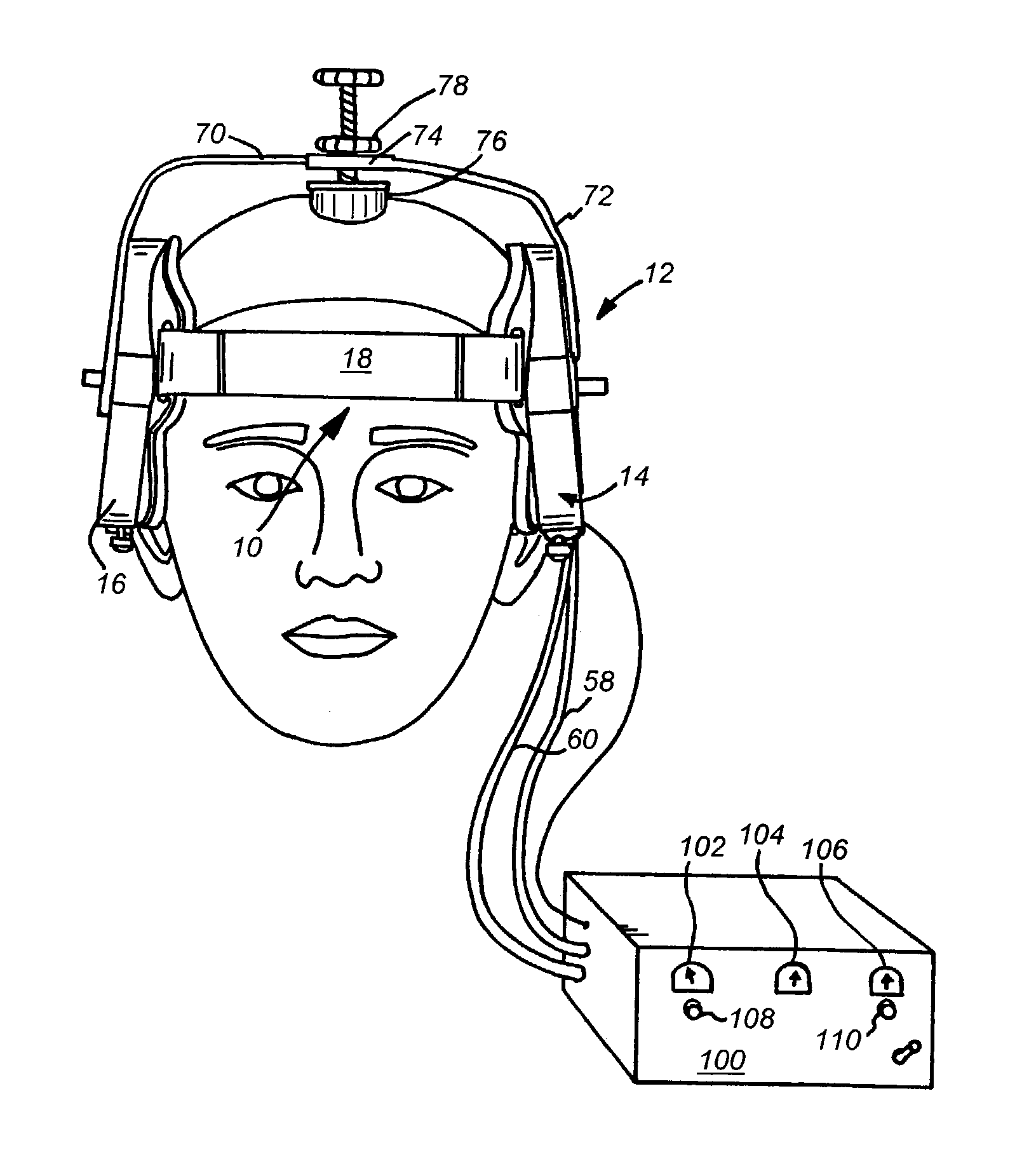

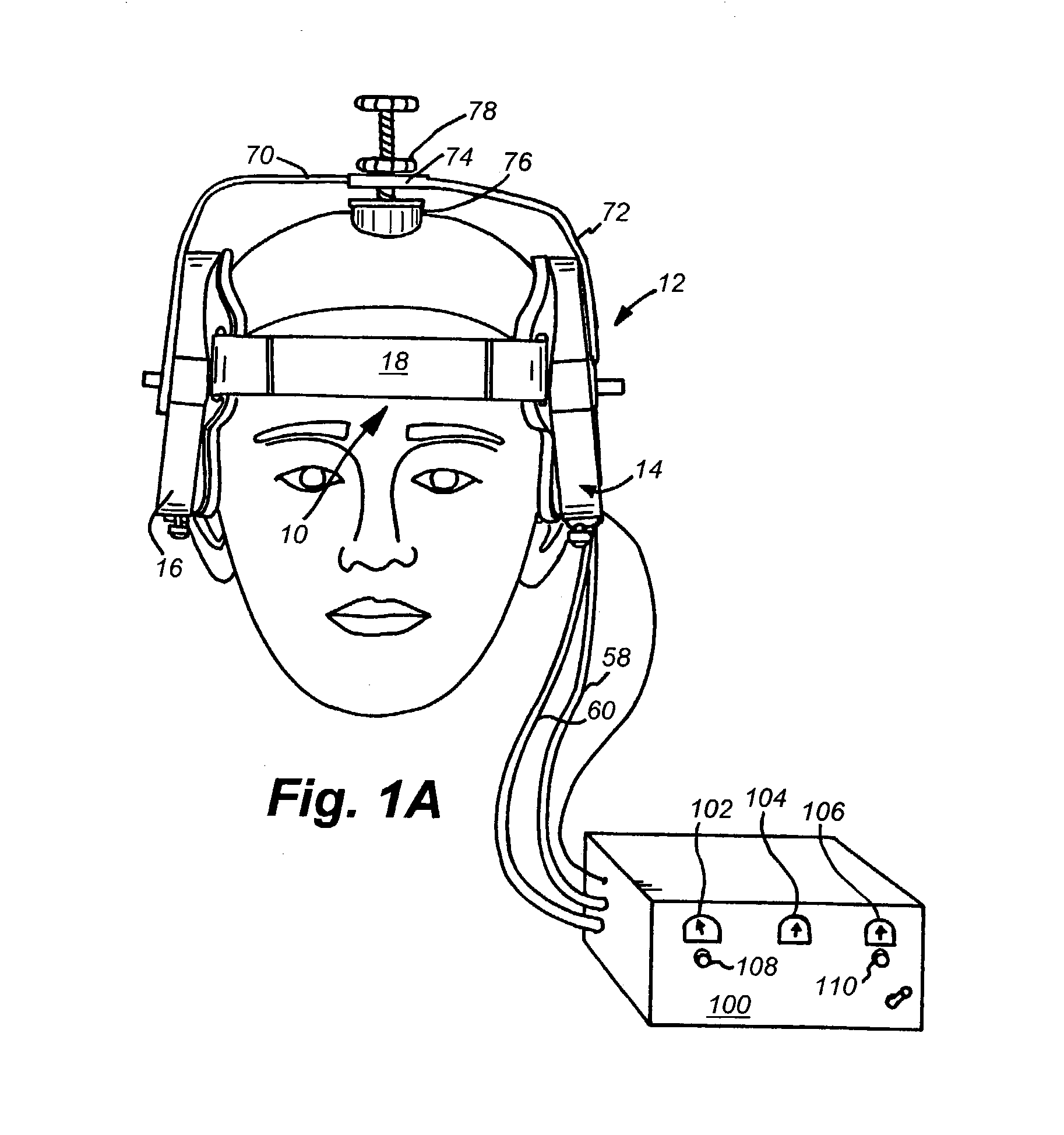

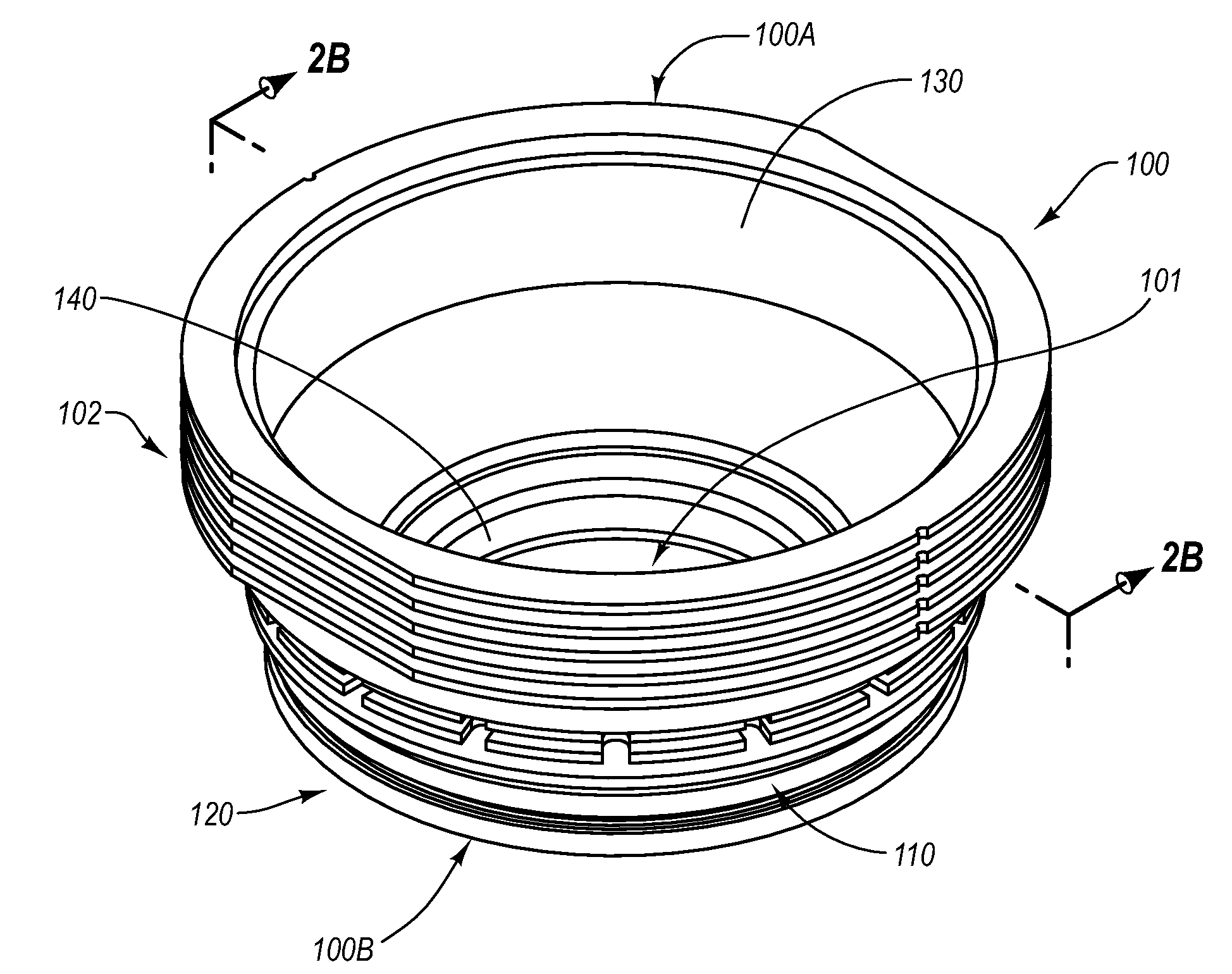

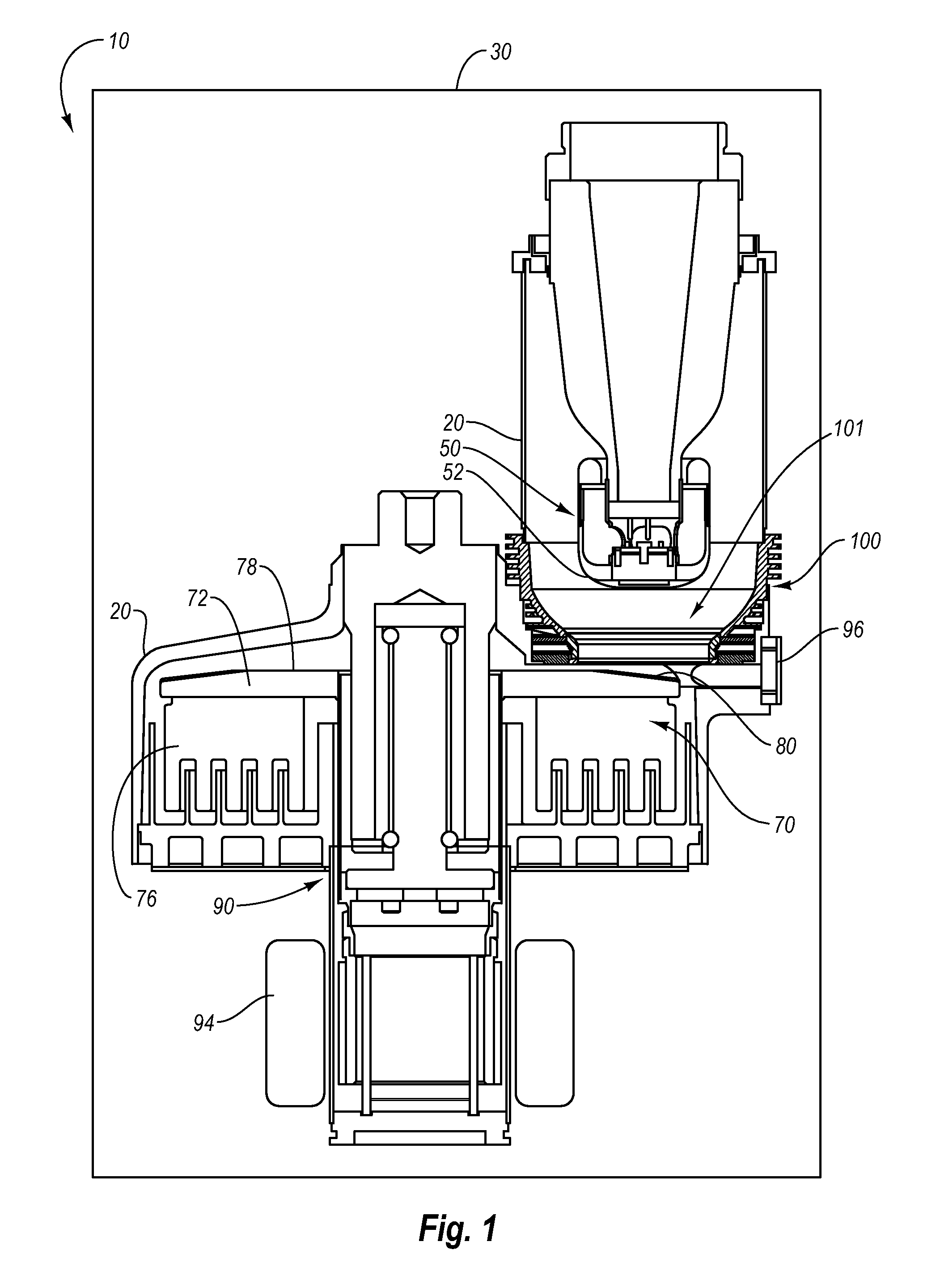

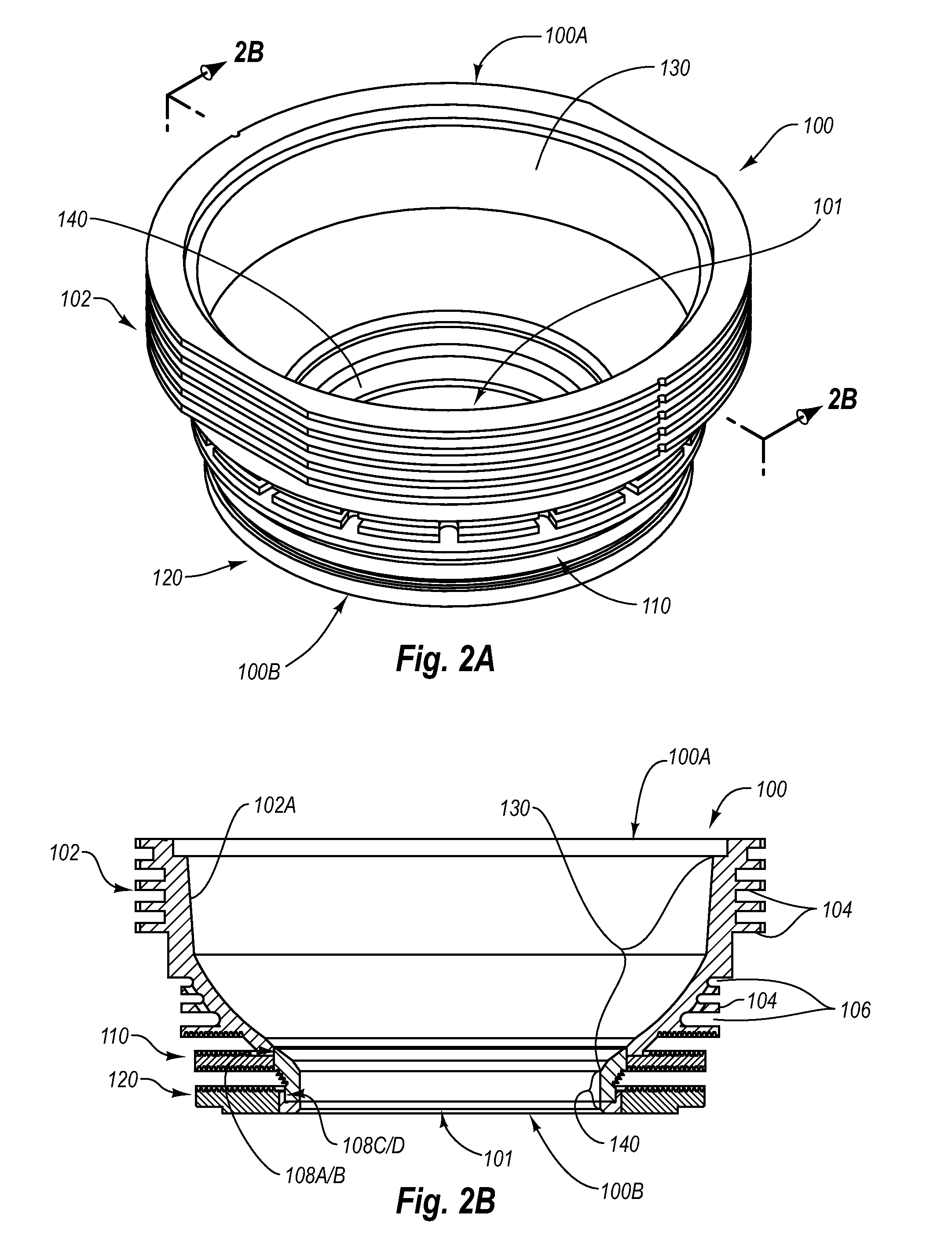

Encephalic insonication

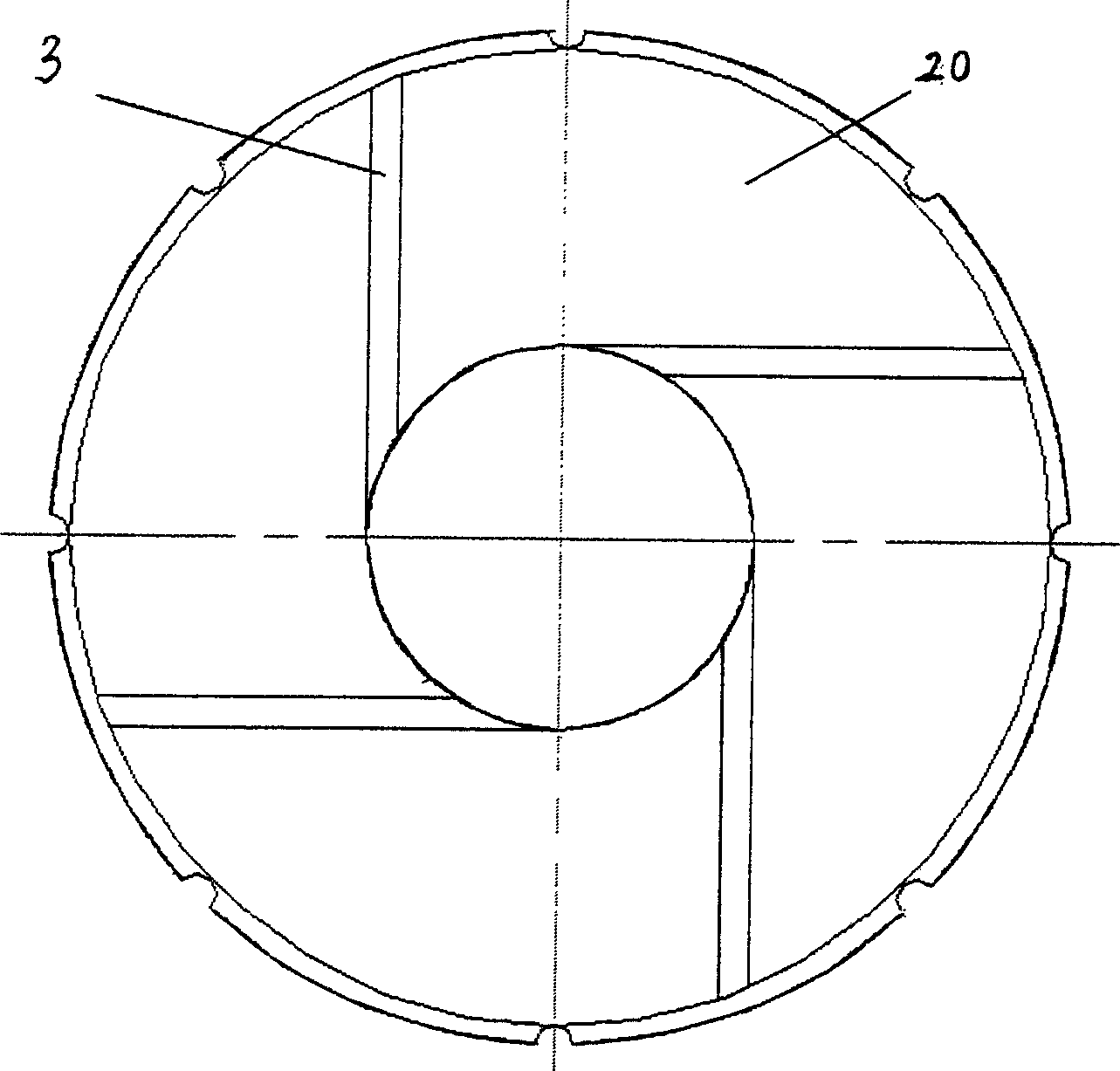

ActiveUS8353853B1Remove heat generatedImprove transmission efficiencyUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyHuman bodyTransducer

Apparatus for encephalic insonication, comprising a transducer array configured to safely insonicate a field in a human body of a size comparable to the spatial extent of the array itself. The array comprises a plurality of acoustic transducers arranged in a polygonal configuration and energized in subsets at frequencies between 200 and 400 kHz. A relatively uniform insonication of a field comparable in size to that of significant anatomical regions of the brain is obtained by driving the transducers in each subset in opposed phase relationship during at least part of the interval during which they are active. A pulsed driving scheme enables minimization of heating effects while providing significant therapeutic treatment. The apparatus is useful both with and without additional lytic agents.

Owner:BOSTON SCI SCIMED INC

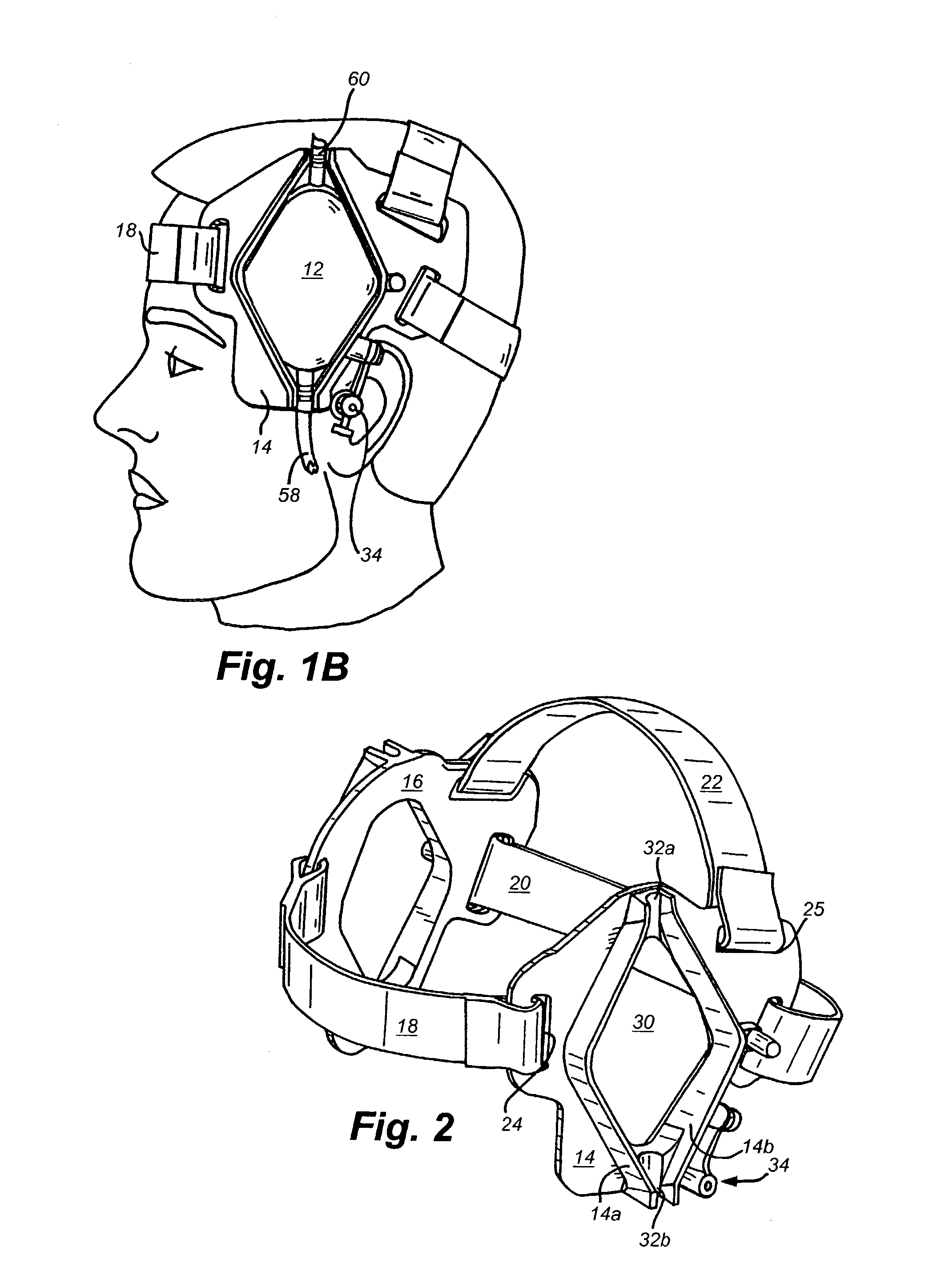

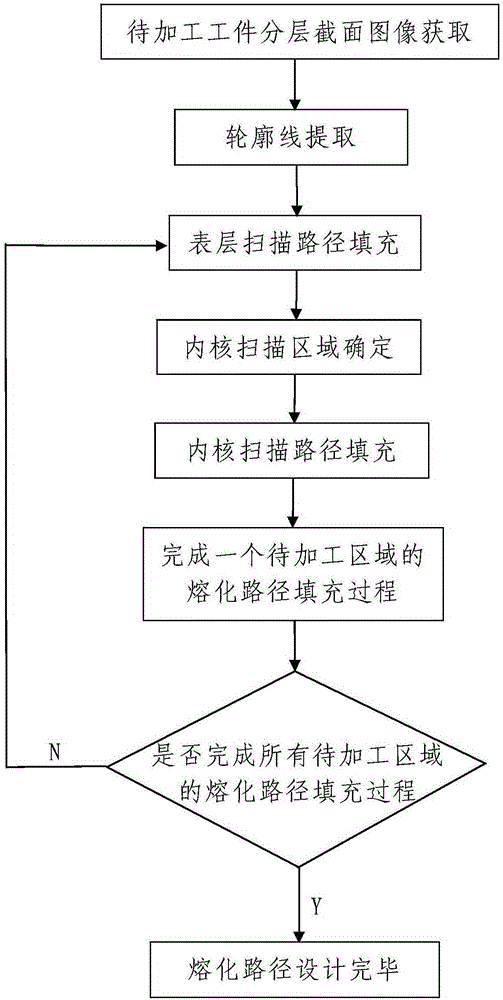

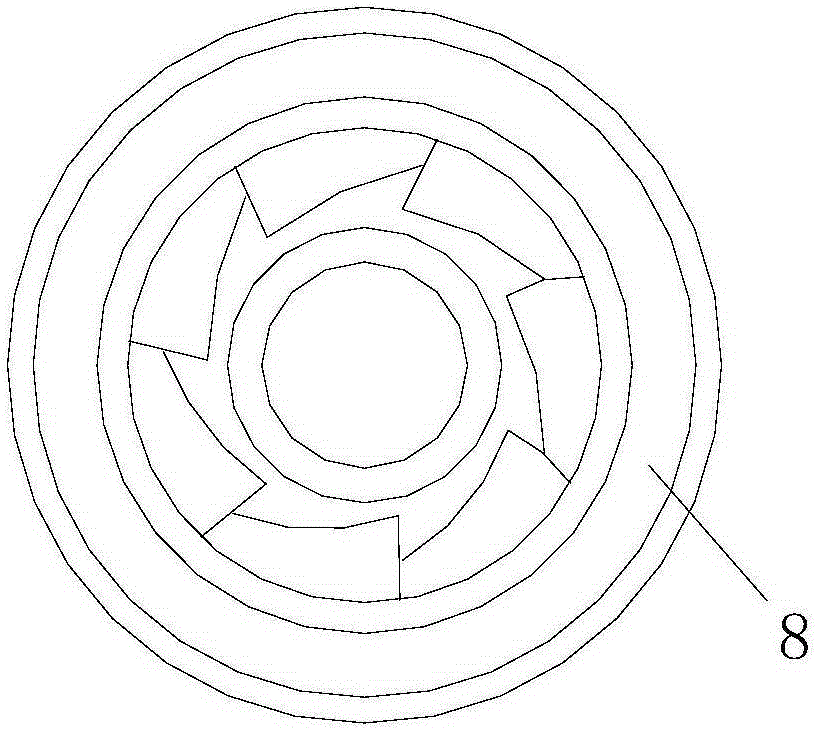

Melting path design method for high energy beam selective melting forming

ActiveCN105195742AThe method steps are simpleReasonable designAdditive manufacturing apparatusSurface layerComputer science

The invention discloses a melting path design method for high energy beam selective melting forming. The method comprises the following steps: 1, acquisition of layered section images of a to-be-machined workpiece: layered section images of multiple layers of the to-be-machined workpiece are acquired and stored, wherein the section of each layer is a to-be-machined area; 2, contour extraction: the contour of each layer of section image is extracted; 3, melting path filling: melting path filling is performed on the multiple to-be-machined areas respectively, melting path filling for any to-be-machined area comprises the following steps: surface layer scanning path filling, inner core scanning area determining and inner core scanning path filling. The method has simple steps and is reasonable in design, convenient to implement and good in use effect; a melting path for high energy beam selective melting forming can be designed simply, conveniently and rapidly, the designed melting path is reasonable, the workpiece machining precision is high, all parts of the workpiece are uniformly heated, and the workpiece has excellent mechanical properties.

Owner:西安赛隆增材技术股份有限公司

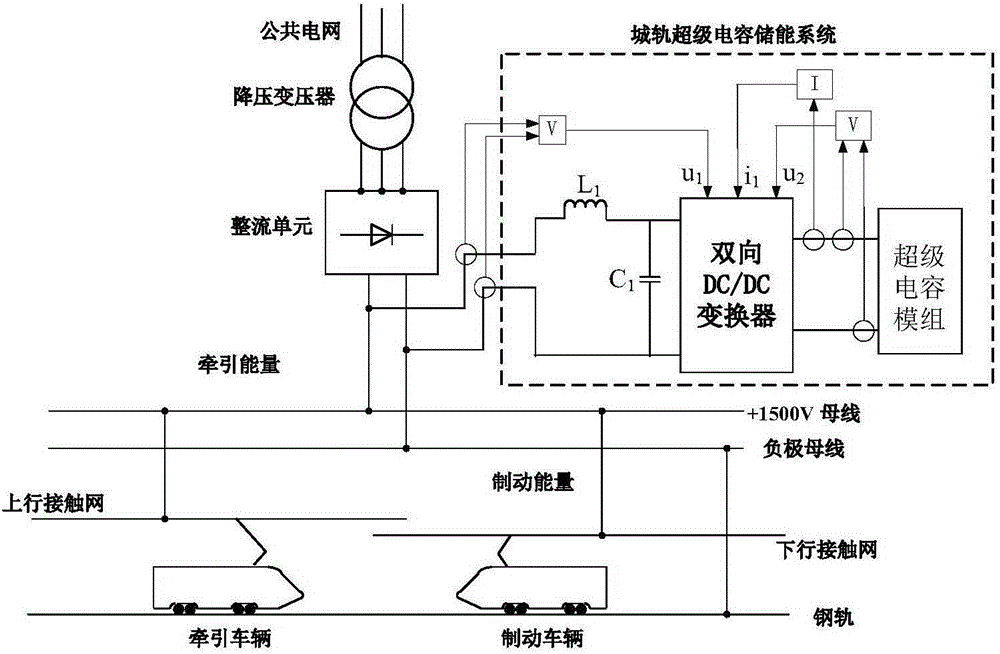

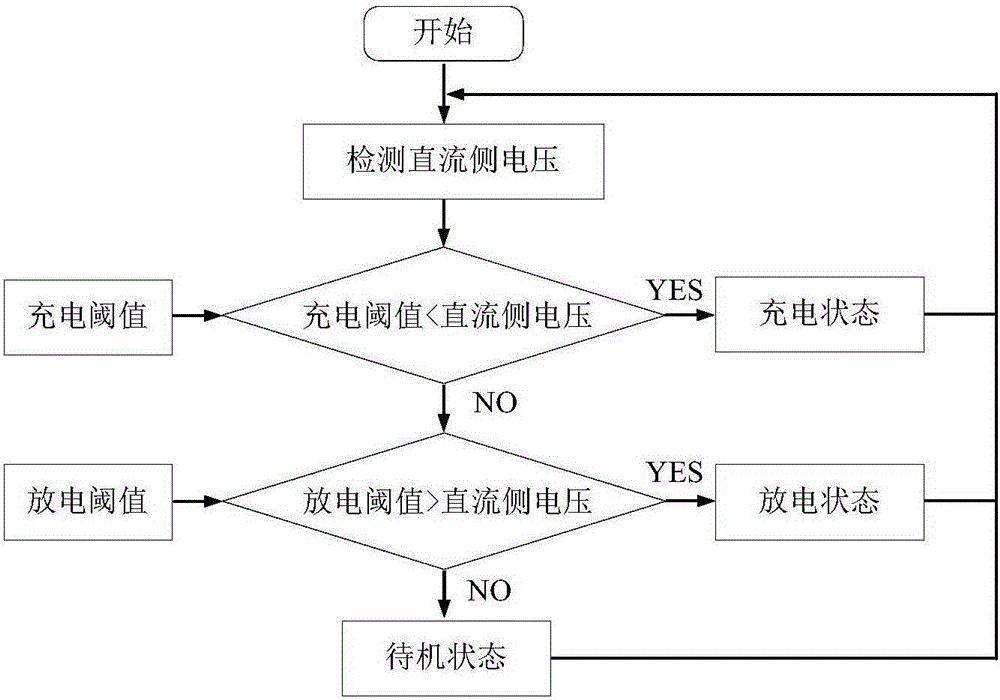

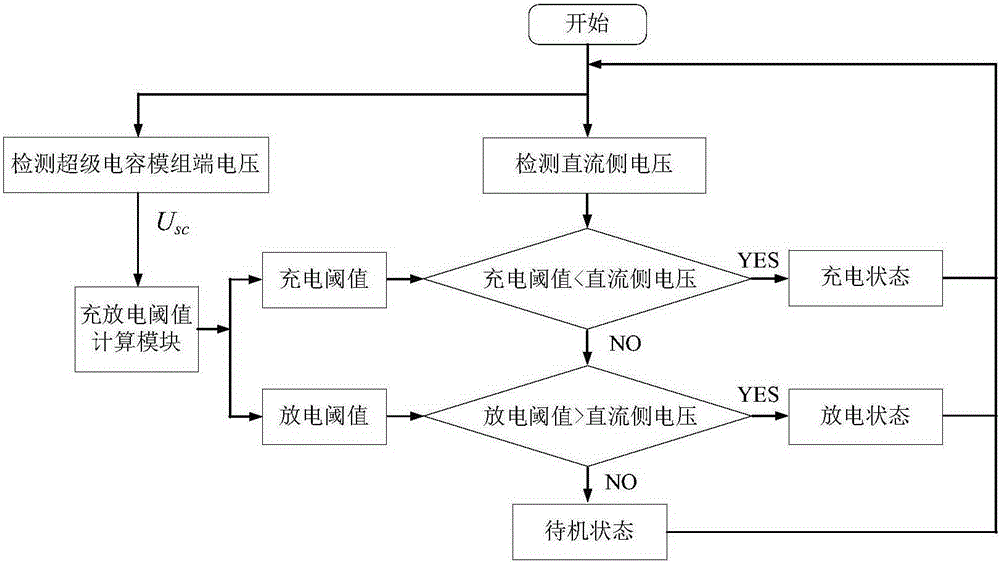

Energy control method of urban rail super capacitor storage system

ActiveCN105226790ATo achieve mutual cooperationExtended service lifeBatteries circuit arrangementsElectric powerCapacitanceTerminal voltage

The invention relates to an energy control method of an urban rail super capacitor storage system. The method comprises the following steps that: a direct-current power supply network voltage Udc and a super capacitor module group terminal voltage Usc are collected respectively and an output branch current Isc of the super capacitor module group is connected within each control period; a charging-discharging threshold calculation module outputs a charging threshold value Uchar and a discharging threshold value Udis in real time based on the super capacitor module group terminal voltage Usc within each control period; and according to a relation between the charging threshold value, the discharging threshold value, and the direct-current power supply network voltage Udc, a current control period of an urban rail super capacitor storage system is determined to be in a charging state, discharging state or a standby state. According to the energy control method provided by the invention, multiple sets of urban rail super capacitor storage systems can work in a coordinated mode and thus the urban rail super capacitor storage systems can absorb brake energy of the train fully and effectively, thereby improving the energy utilization efficiency of the urban rail power supply system. Moreover, fluctuation of the direct-current side voltage of the power supply system can be inhibited.

Owner:BEIJING JIAOTONG UNIV

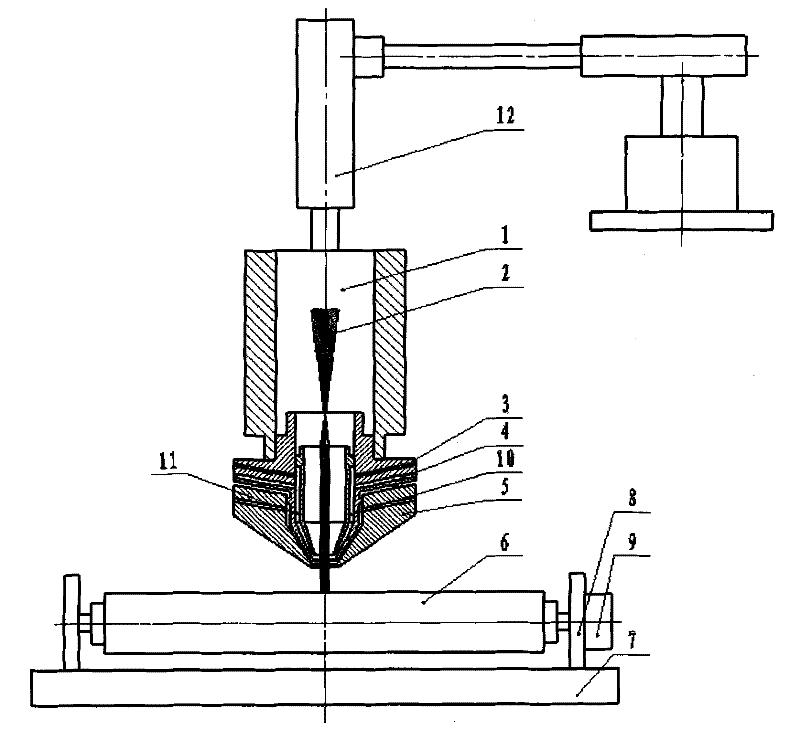

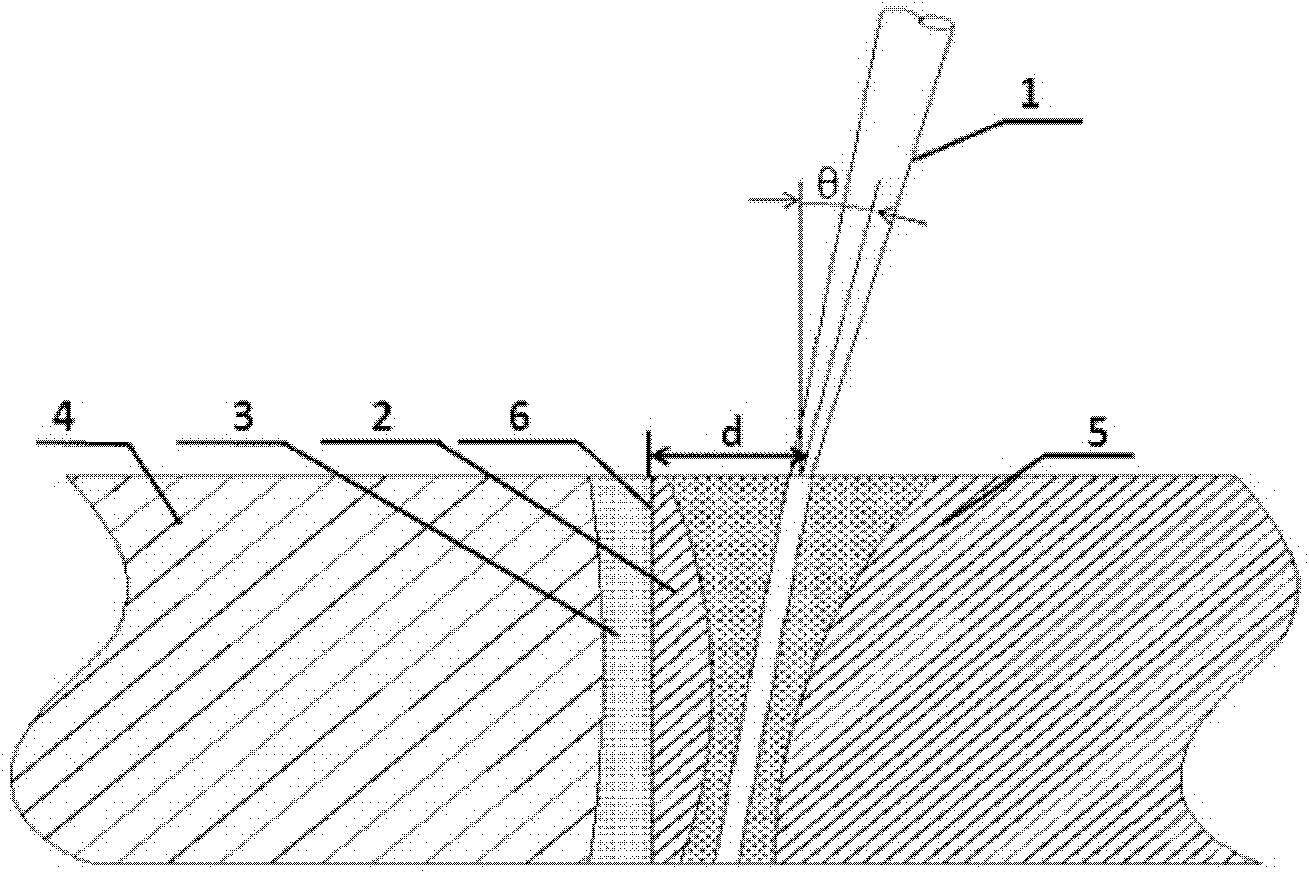

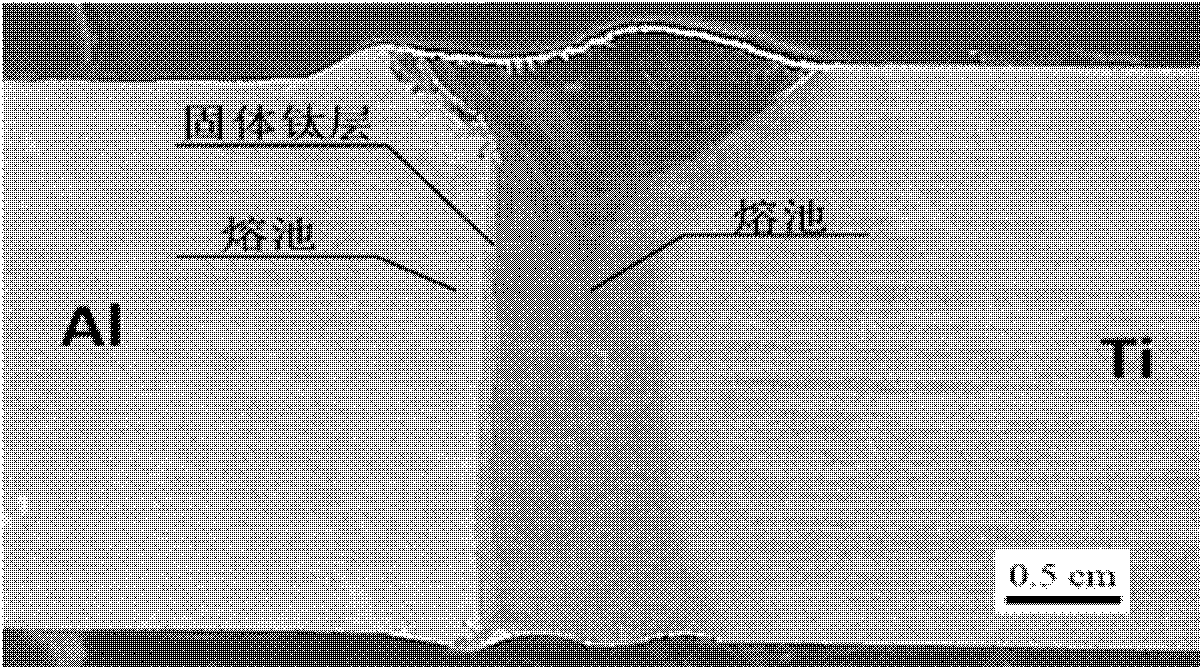

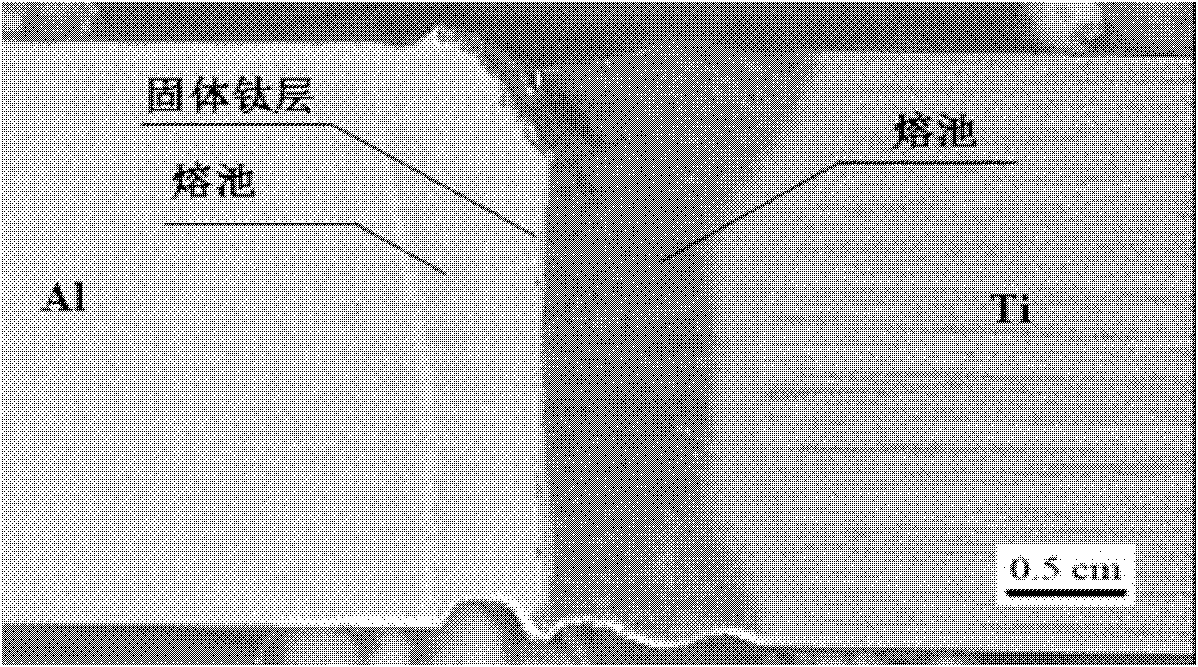

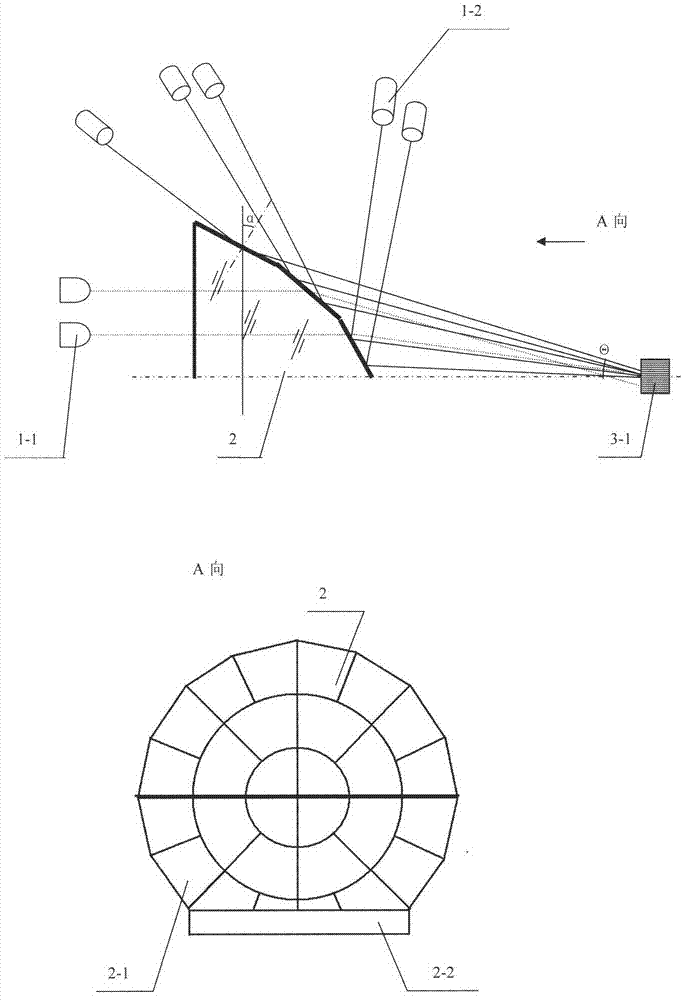

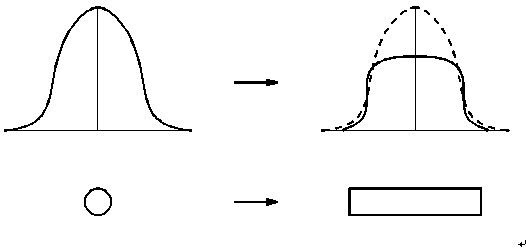

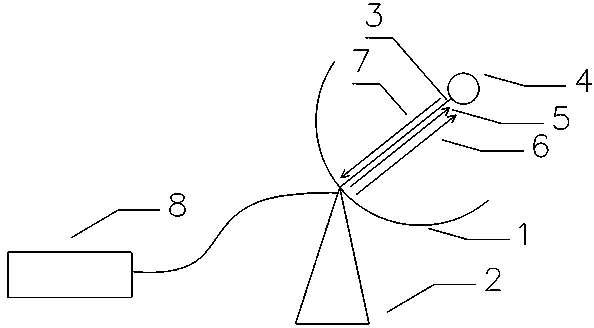

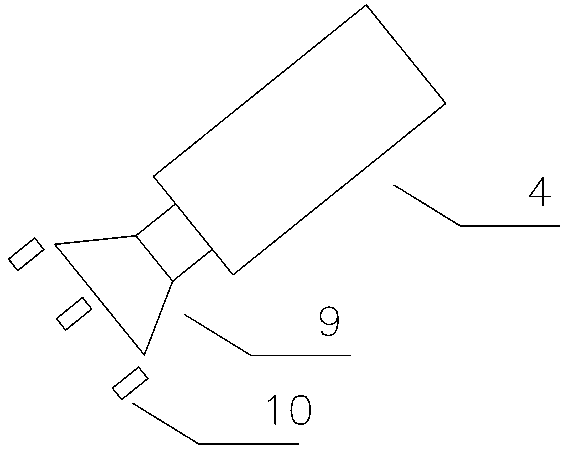

Laser penetration brazing method for dissimilar alloy

InactiveCN102145420AThe effect of improving wettabilityUncontrollable formationSoldering apparatusAlloyMaterials processing

The invention discloses a laser penetration brazing method for dissimilar alloy and belongs to the technical field of laser material processing. The method comprises the following steps of: during welding, allowing a focused laser beam (1) to act on one side of a high-melting-point parent material (5) to realize penetration fusion welding; and controlling a distance d of the laser beam (1) and an interface (6) on the surface of the high-melting-point parent material and an included angle theta between the laser beam (1) and a normal line, forming a high-melting-point parent material solid state intermediate layer (2) on the high-melting-point parent material side close to the interface (6), melting a low-melting-point parent material (4) through the heat conduction of the high-melting-point parent material solid state intermediate layer (2), and spreading and soaking the high-melting-point parent material (5) on a melted low-melting-point parent material layer (3) to realize the laser penetration brazing of the dissimilar alloy. The laser energy utilization rate and welding efficiency are obviously improved, and the welding of a dissimilar alloy plate with a certain thickness can be realized. The influence of mixing two kinds of metal liquid states at the interface to generate a complex and brittle intermetallic compound on joint quality is avoided.

Owner:BEIJING UNIV OF TECH

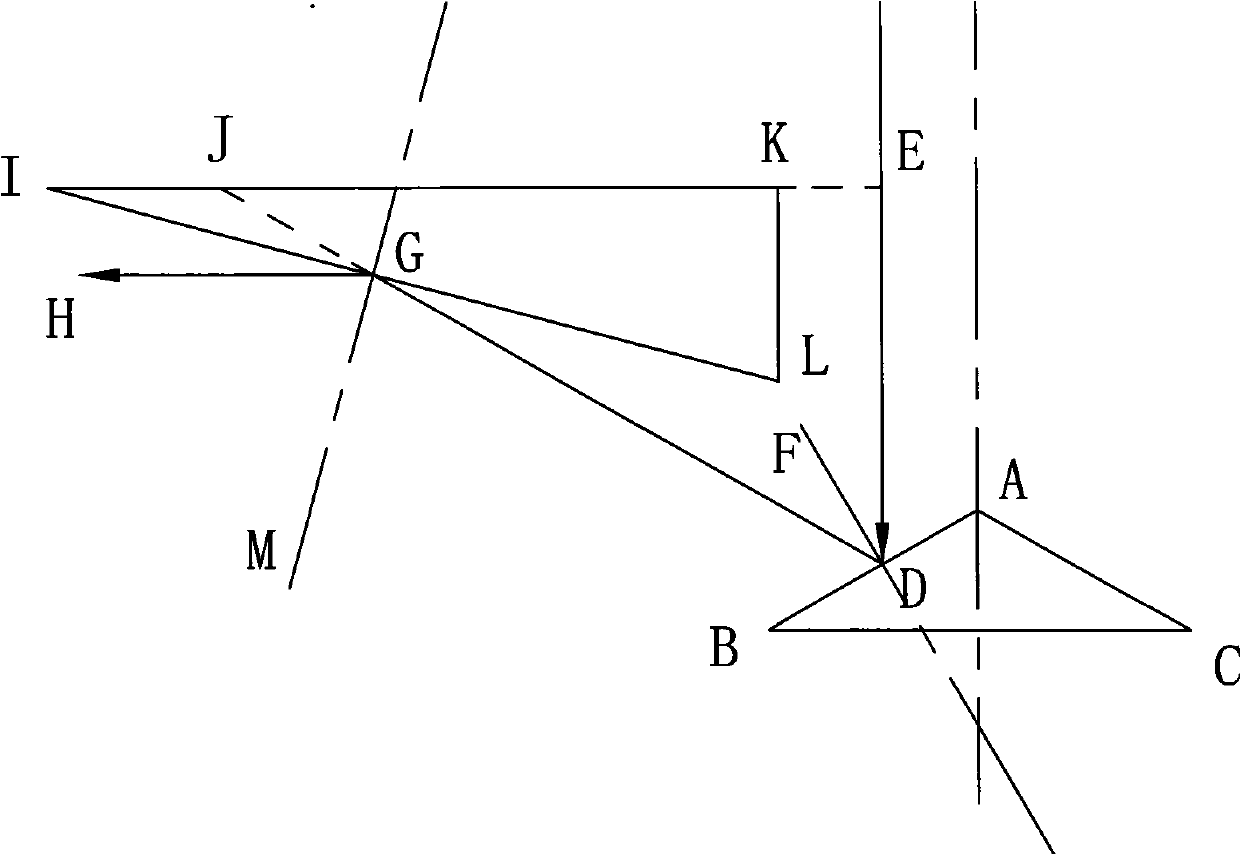

Method and device for realizing laser focusing

InactiveCN101770076APlay a focal roleFocusLaser beam welding apparatusOptical elementsLight spotLight beam

The invention discloses a method for realizing laser focusing, which utilizes reflection of a reflector and focusing of a focus lens to exchange an inner position and an outer position of a light spot of a laser beam in rings along the radial direction and to focalize. The method is characterized by comprising the following steps: the laser beam is reflected to a turbinate annular beam; the turbinate annular beam is converted into an annular beam; the annular beam is focused, so as to form an annular conical beam, and a hollow conical dark area is formed in the middle of the annular conical beam, thus obtaining a focusing spot of hollow annular light. The method solves the defects of laser focusing in the prior art and obtains a focusing spot with strong light encompassing weak light, almost uniform energy distribution and small gradient, thus improving the processing effect.

Owner:SUZHOU LEAD LASER TECH

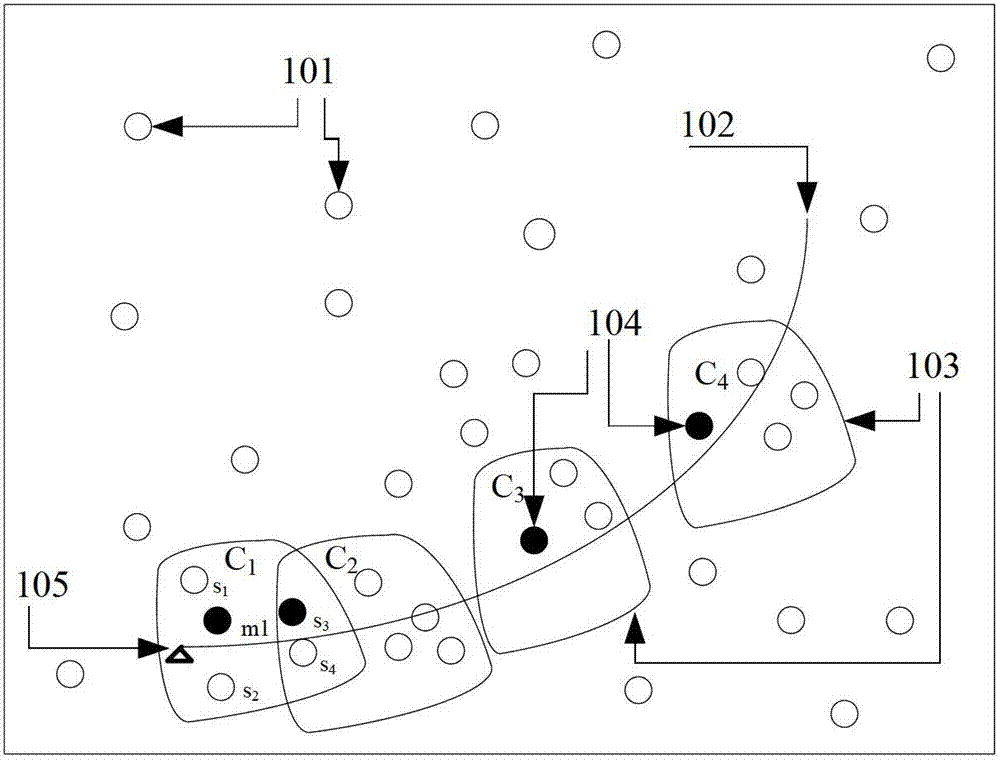

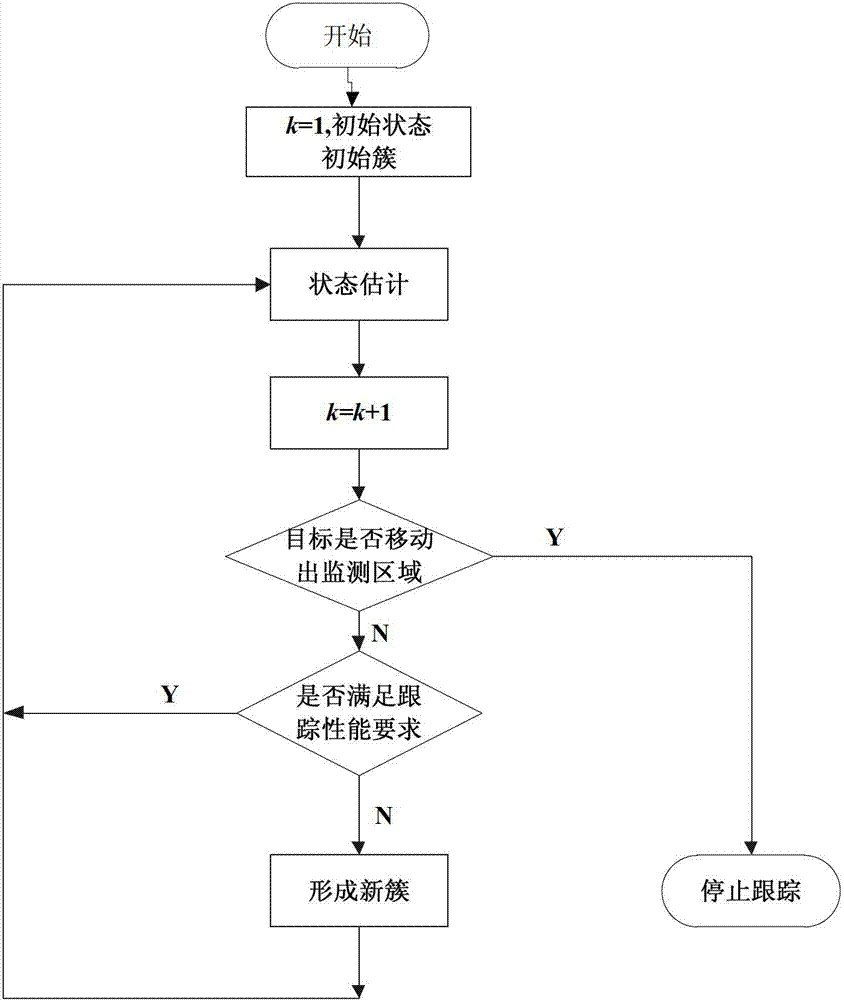

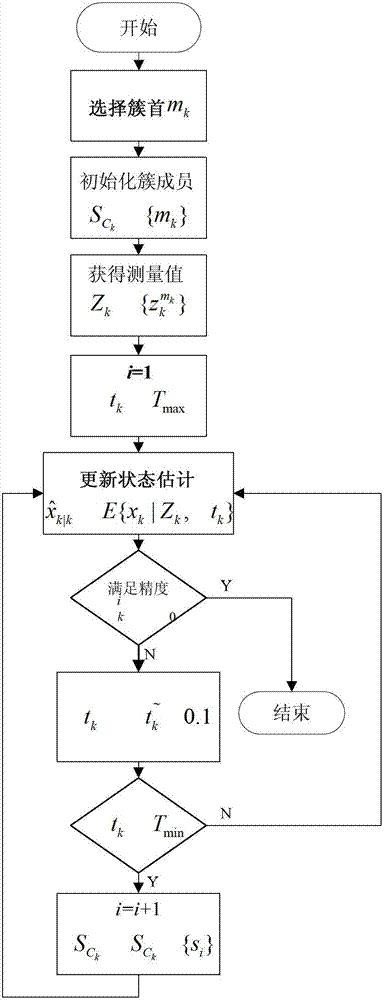

Wireless sensor network-based energy-efficient collaborative scheduling method

InactiveCN103052128AImprove tracking accuracyImprove network reliabilityPower managementHigh level techniquesWireless sensor networkingPerformance index

The invention discloses a wireless sensor network-based energy-efficient collaborative scheduling method, which is characterized by comprising the following steps of: (1) initializing a target; (2) estimating a state; (3) selecting a sampling interval; (4) dynamically forming a next cluster; and (5) dynamically updating a cluster head, i.e., judging whether a moving target moves out of a monitoring region of a wireless sensor network, stopping tracking if the moving target moves out of the monitoring region of the wireless sensor network, otherwise transferring state estimation information of the cluster head at the current moment to a cluster head of a next moment by the cluster head, changing the cluster head of the next moment into a working cluster head and turning to the step (2). According to the wireless sensor network-based energy-efficient collaborative scheduling method, various performance indexes are considered, the performance indexes are optimized on line to select the cluster head, the cluster is dynamically generated and the sampling interval is adaptively determined, and accurate tracking of a target is realized through collaborative sensing and information fusion of a sensor node in the cluster. The wireless sensor network-based energy-efficient collaborative scheduling method has the advantages that communication energy is saved, energy distribution and calculation resources in a network are balanced, the life cycle of the network is prolonged, the reliability of the network is improved and the like.

Owner:SOUTH CHINA UNIV OF TECH

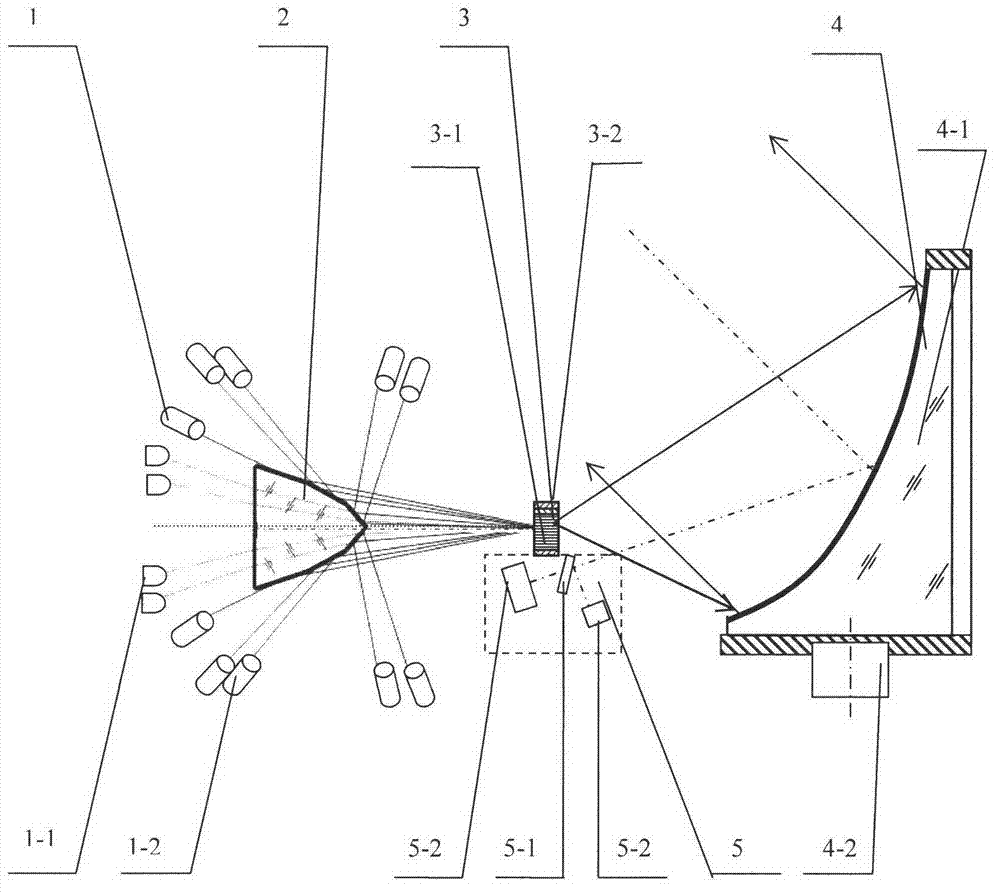

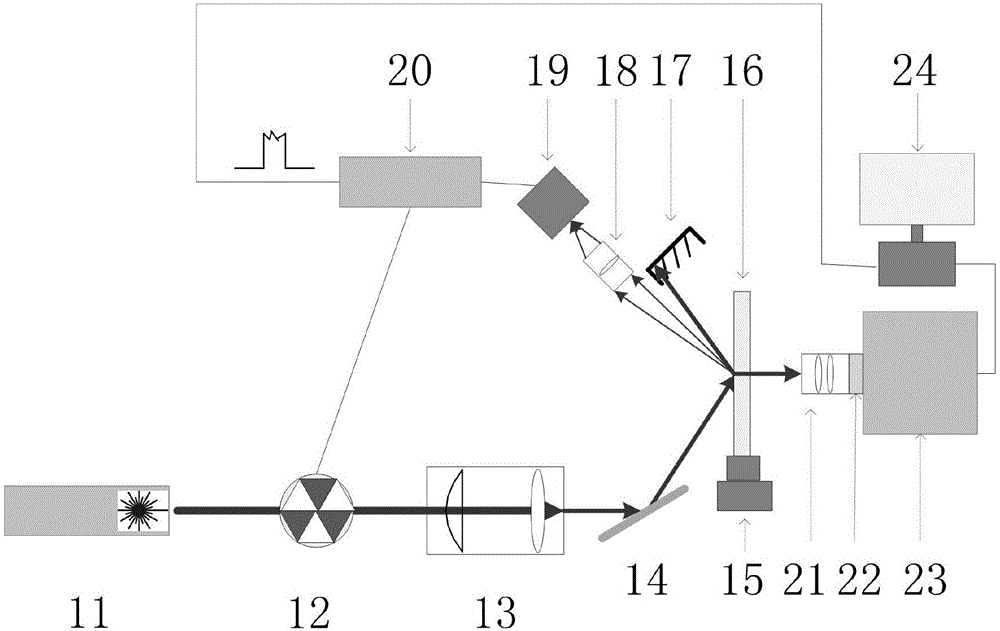

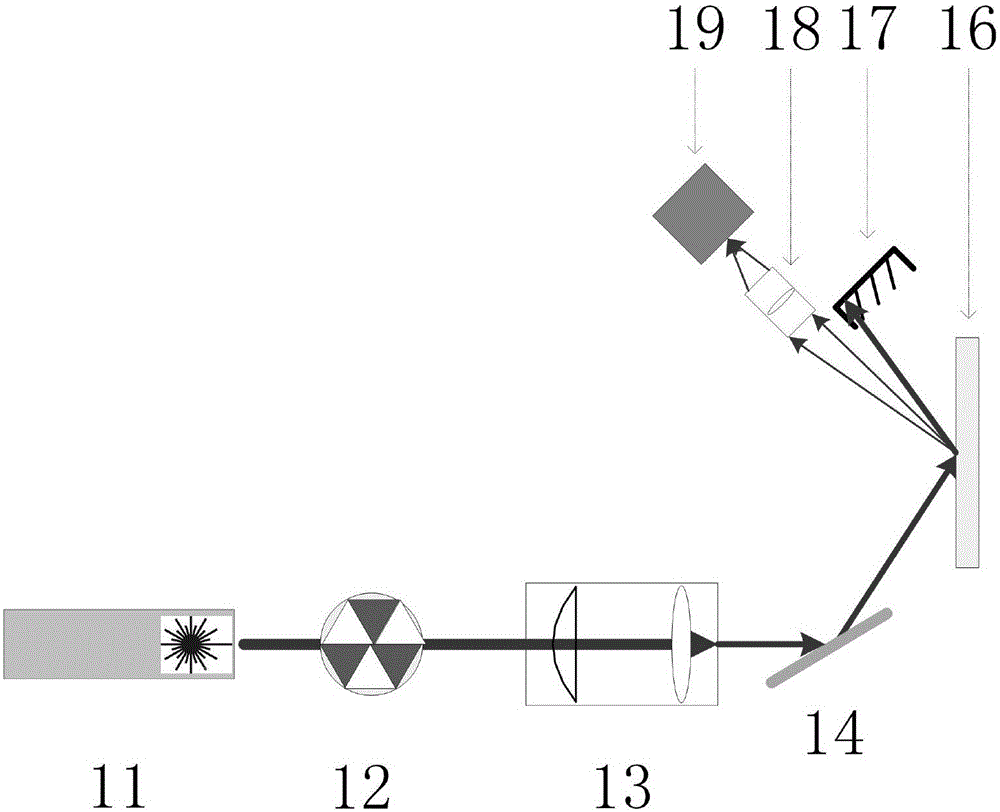

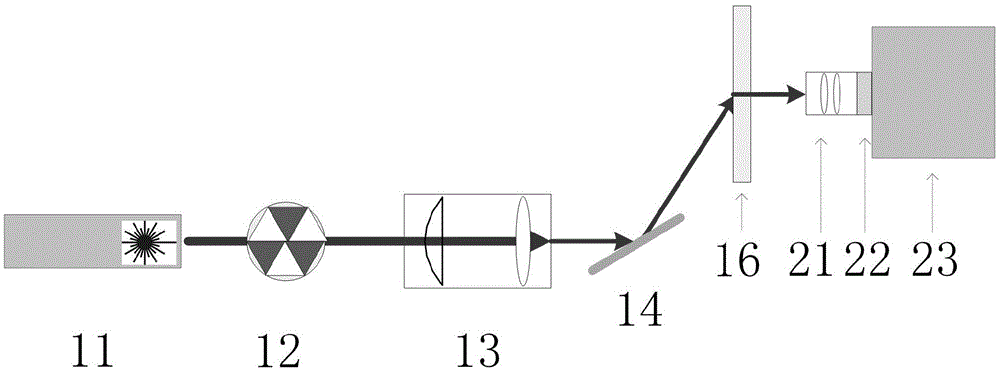

Beam combining, irradiating and receiving system of lasers

The invention discloses a beam combining, emitting and receiving method of lasers and a system, which belong to the technical field of photoelectricity and are used for carrying out beam combination, emission and reception on multi-beam multi-band high-power lasers. The beam combination, the emission and the reception of lasers in incidence in a plurality of directions are realized by adopting the reflection of a film at the side face of a prism, the incidence and the penetration of an end face, an optical fibre bar and a collimating mirror. The system contains a plurality of laser light sources, a multi-dimensional beam combiner, a shaper, a collimating mirror, a receiving and detecting unit and a computer system. The multi-dimensional beam combiner contains a multi-face prism and a prism holder, wherein the multi-face prism is provided with an end face and a plurality of reflecting mirror faces. A plurality of lasers are irradiated on the end face and the reflecting mirror faces of the multi-dimensional beam combiner from the periphery, the lasers of which the beams are combined are gathered on the input end face of the shaper at an aperture angle smaller than the numerical value of optical fibers, the output lasers are collimated into quasi-parallel light by the collimating mirror for irradiating a target, and the diffuse reflection lasers and the laser-induced radiation patterns of the target are received by the receiving and detecting unit positioned at the position of the focal point of the collimating mirror so as to realize the detection of the target and the acquisition of images.

Owner:中国兵器工业第二0五研究所

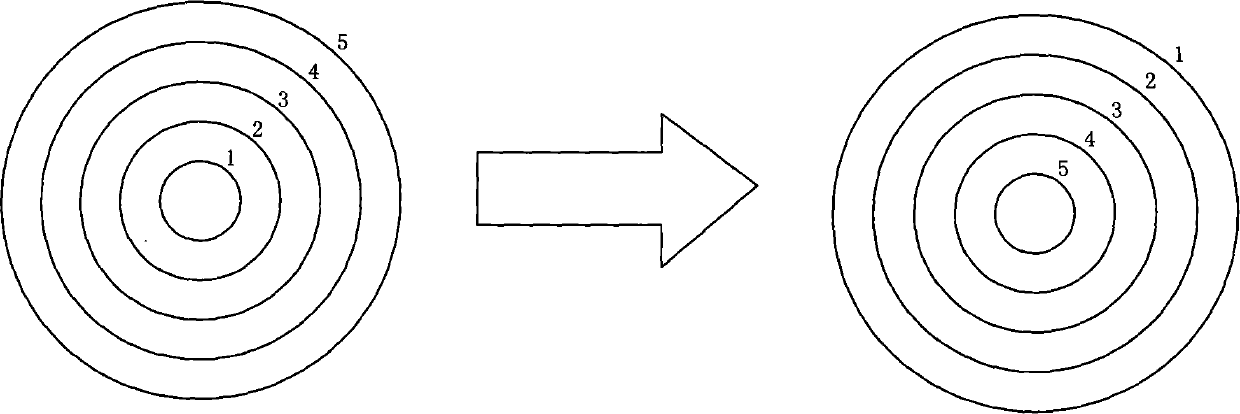

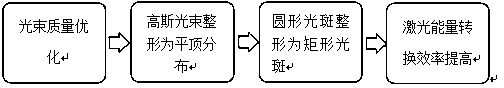

Method of improving laser processing efficiency by optimizing light beam quality

InactiveCN103513426AOptimize energy distributionEven energy distributionOptical elementsLaser processingLight beam

The invention discloses a method of improving laser processing efficiency by optimizing light beam quality, and relates to the technology application field of optical systems and laser processing systems. The method is characterized in that light beams of an Nd: YAG laser device are optimized and shaped from two aspects, wherein a step A is that a shaping system of a Galileo-type aspherical mirror set is used for optimizing and shaping round laser spots in a Gaussian distribution pattern into round laser spots in an ultra Gaussian flat-topped distribution pattern; a step B is that the round laser spots in the ultra Gaussian flat-topped distribution pattern in the step A pass through a spot conversion device and are converted into linear spots in the ultra Gaussian flat-topped distribution pattern under the action of the spot conversion device. Laser beams obtained through the method are uniform in energy distribution and optimized in quality, and energy conversion efficiency of laser is improved. The method has the advantages that the technique is simple, and since two sets of devices are both composed of various lenses, cost and power consumption are low, and the method is easy to implement.

Owner:JIANGSU UNIV

Optical fiber temperature sensor

ActiveCN103175628AHigh sensitivityEven energy distributionThermometers using physical/chemical changesBroadband light sourceFiber optic sensor

The invention relates to the technical field of optical fiber sensors, in particular to an optical fiber temperature sensor which comprises a broadband light source, a first single-mode fiber, a second single-mode fiber and a multi-core fiber. The broadband light source is connected with the second single-mode fiber sequentially through the first single-mode fiber and the multi-core fiber. The connections on the first single-mode fiber, the second single-mode fiber and the multi-core fiber are all of recess structures formed by arc discharge. The optical fiber temperature sensor is high in temperature sensitivity, low in stress-temperature cross sensitivity and widely applicable to high-precision temperature measurementunder stress interference.

Owner:HUAZHONG UNIV OF SCI & TECH

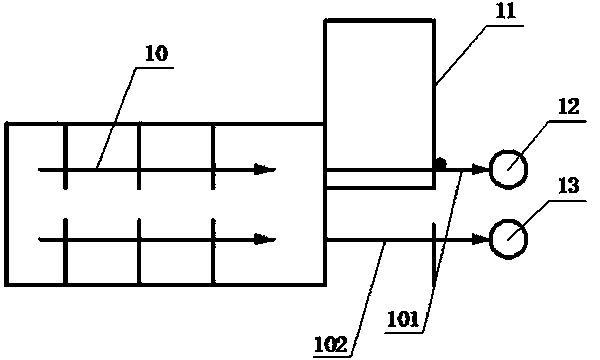

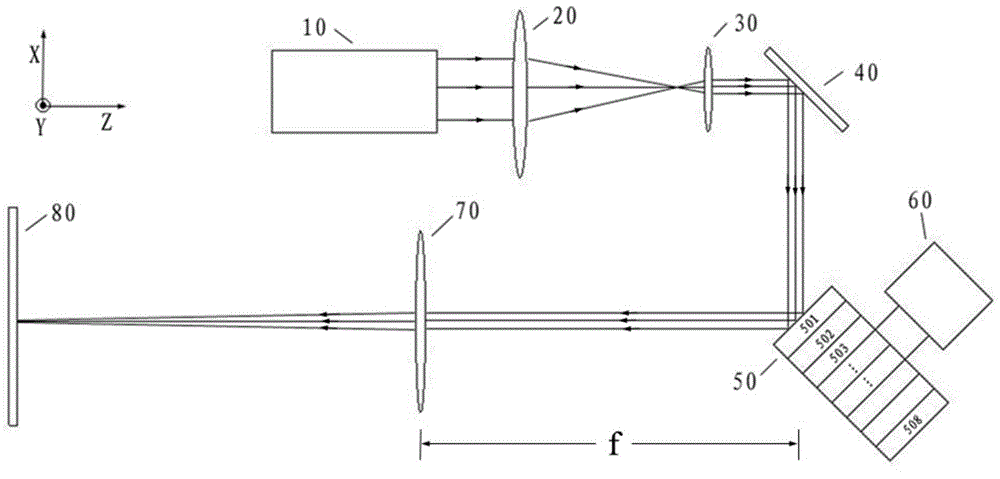

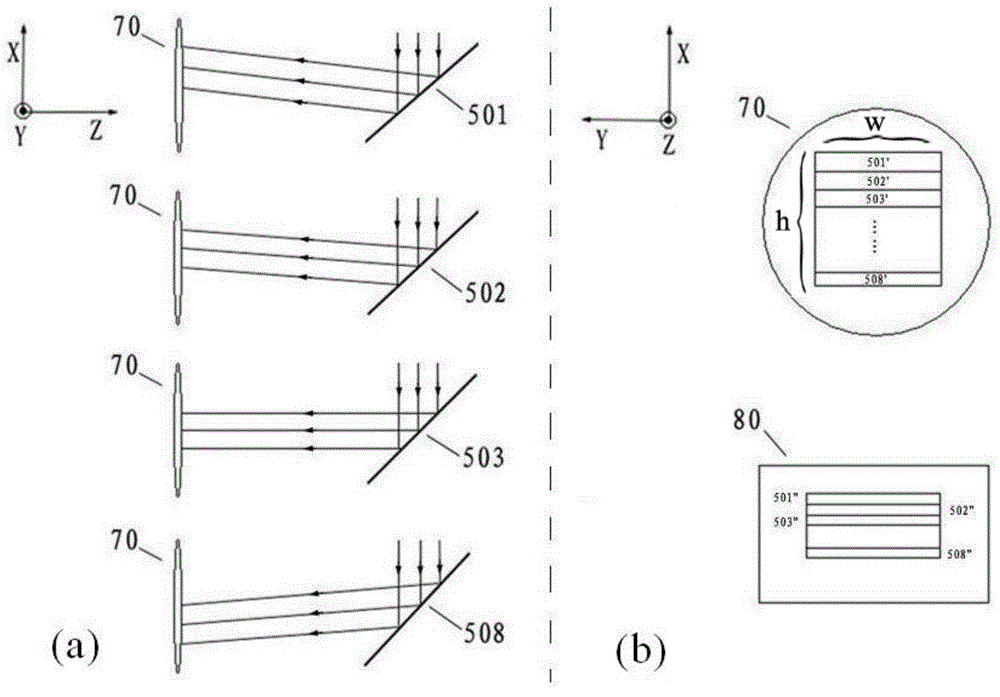

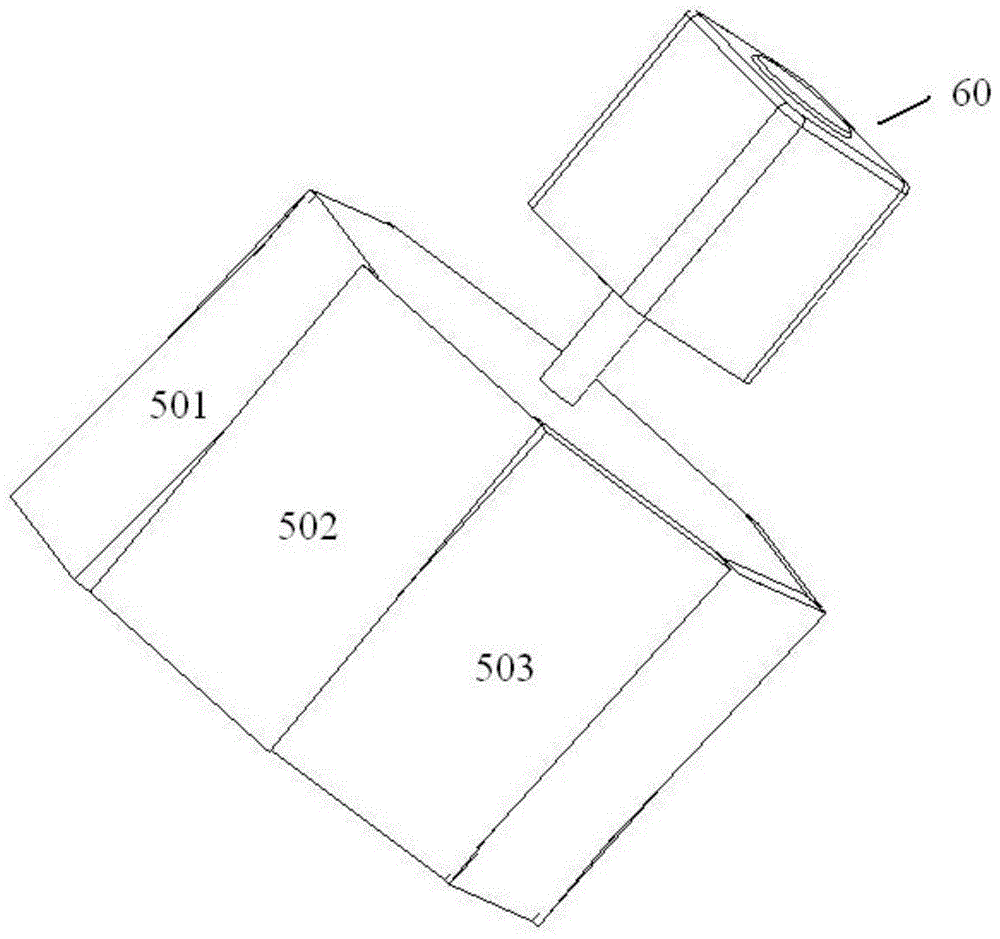

Uniform light spot surface scanning device of laser cleaning machine

A uniform light spot surface scanning device of a laser cleaning machine comprises a laser output module (10), a gauss-flat top system, a gradually-changing rotating polygonal mirror (50), a drive motor (60) and a collimation focusing lens (70). The gauss-flat top system redistributes the energy of a gaussian laser beam emitted by the laser output module (10) and compresses the diameter of the laser beam at the same time, so that a laser beam with uniform energy is formed; the laser beam irradiates the gradually-changing rotating polygonal mirror (50); the gradually-changing rotating polygonal mirror (50) is driven by the drive motor (60) to rotate so as to make the laser beam form a space angle scanning beam; the space angle scanning beam is refracted by the collimation focusing lens (70) and then forms surface light spots on an object (80) to be cleaned.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

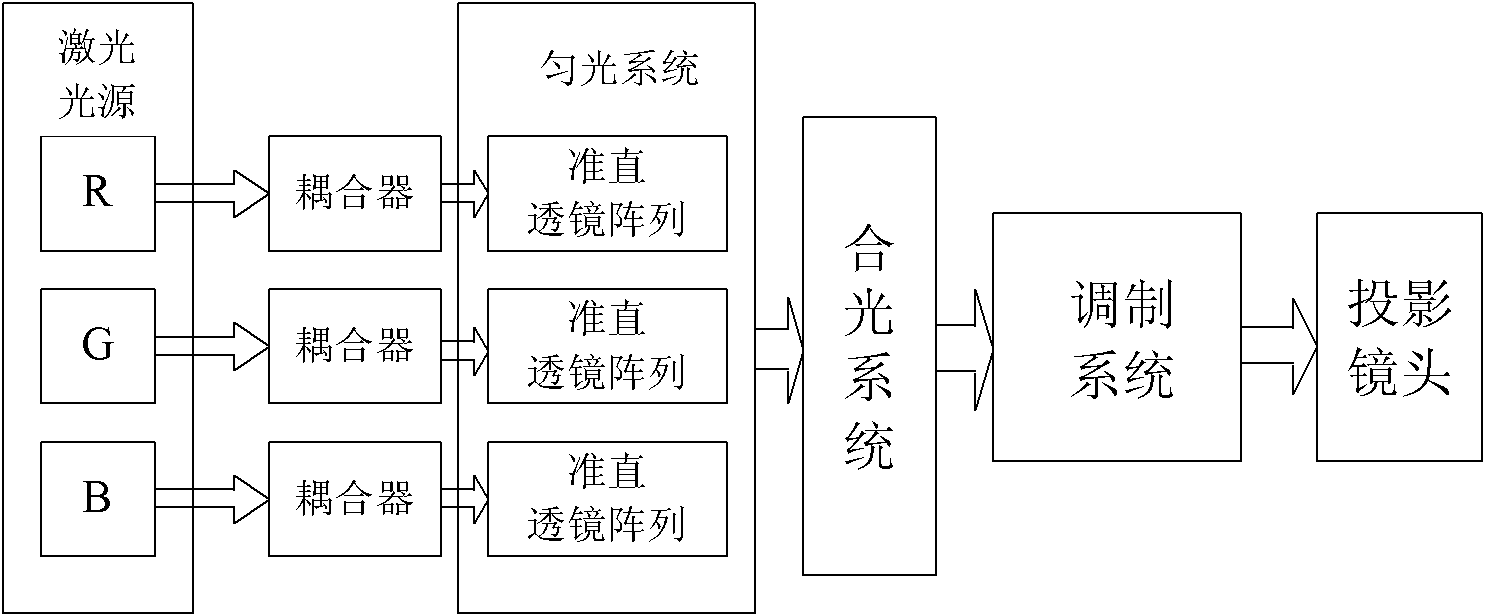

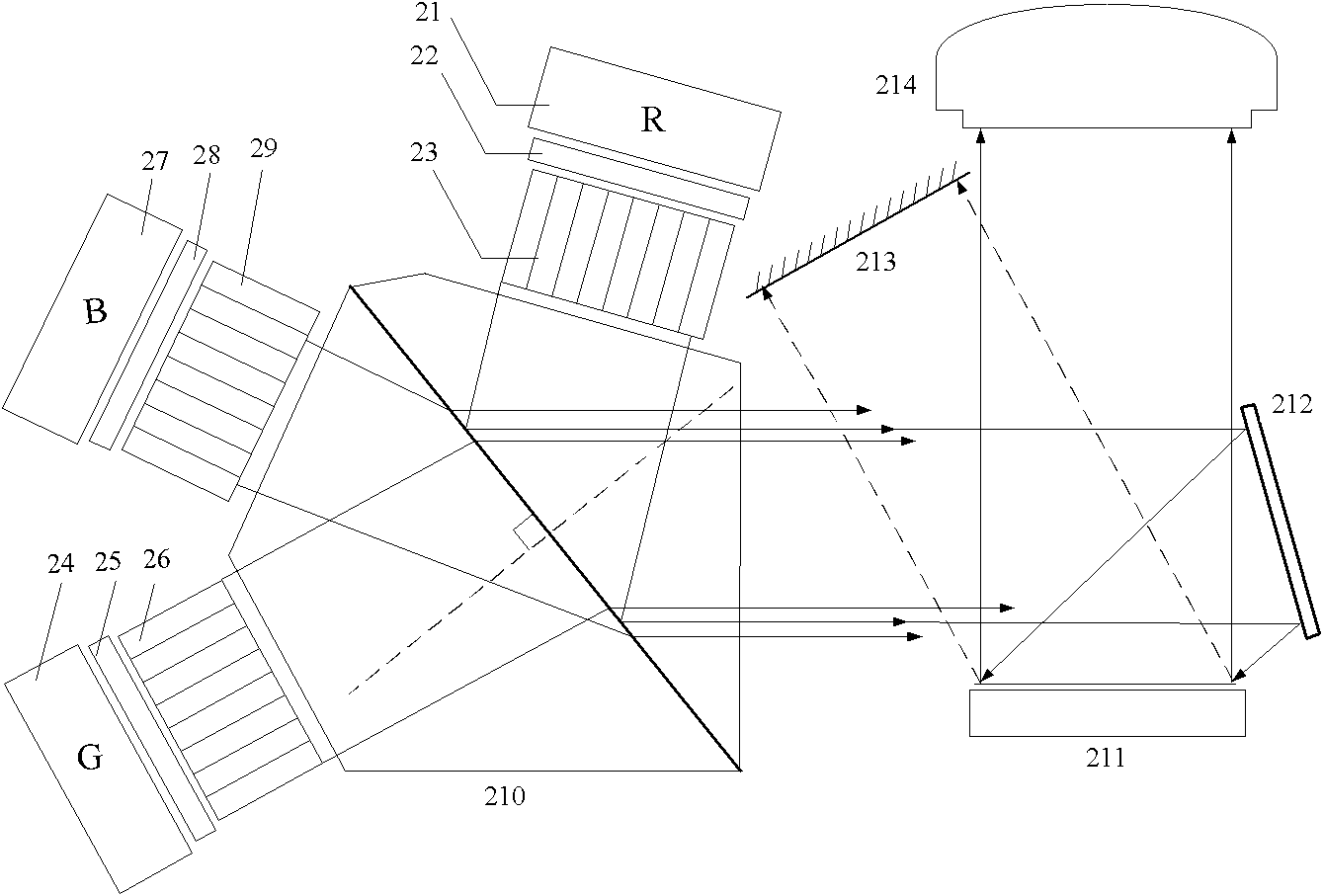

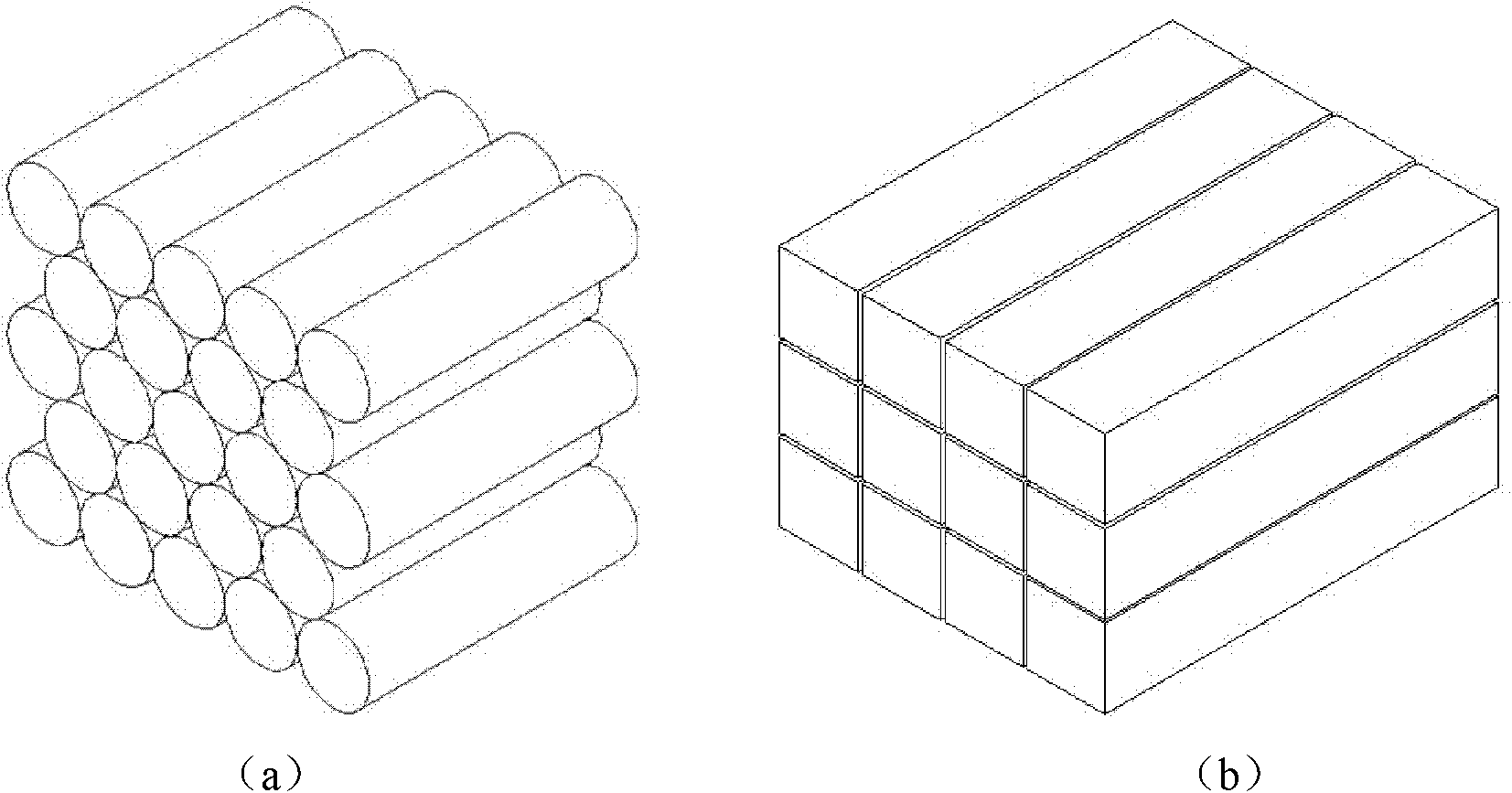

Optical engine for projector

The invention relates to an optical engine for a projector, belonging to the technical field of projection display. Three light beam couplers respectively output three groups of array light by processing laser light generated by an RGB (three primary colors: red, green and blue) laser light source; a light-equaling system comprises three collimation lens arrays; each collimation lens array consists of gradient reflective index lens units with a quarter of pitch of optical length; the three groups of array light are respectively output by the three collimation lens arrays to form three groups of parallel light with even energy distribution; and the parallel light can be merged by a merging and modulating system, and then can be output to a projection lens. In the optical engine, the light-equaling system adopts the collimation lens arrays consisting of the gradient reflective index lens units and can simultaneously realize light equaling, reshaping and collimation; the energy of emergent light spots of the light-equaling system are equally distributed, so as to realize higher utilization rate of light energy; simultaneously, the light-equaling system has the characteristic of a simple structure, is beneficial to reducing the volume of the optical engine and realizes miniaturization of a complete machine. A light merging system can adopt a Wollaston prism; based on related principles of crystal optics and polarization optics, the light merging structure is innovated, so as to further increase the utilization rate of light energy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

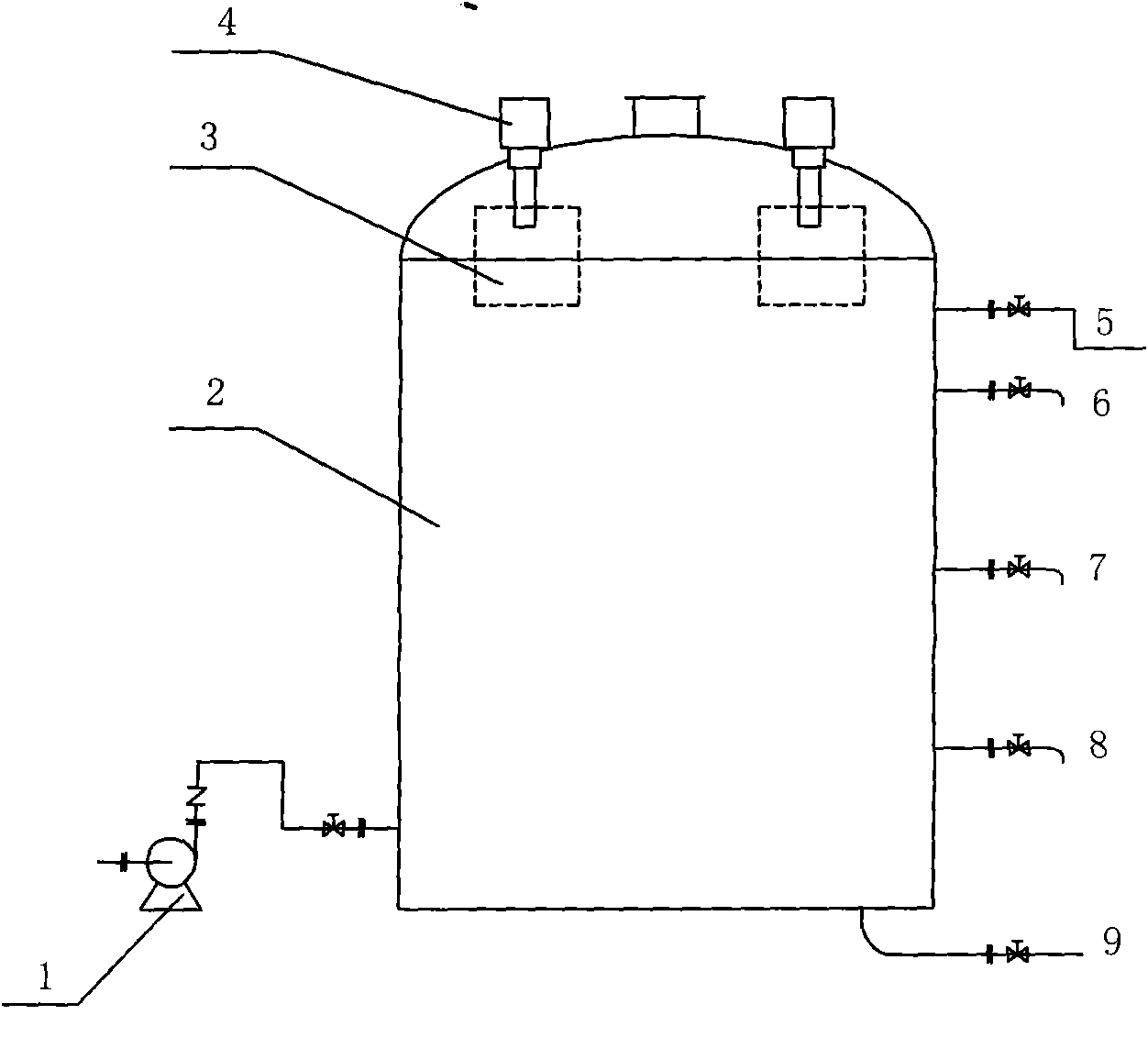

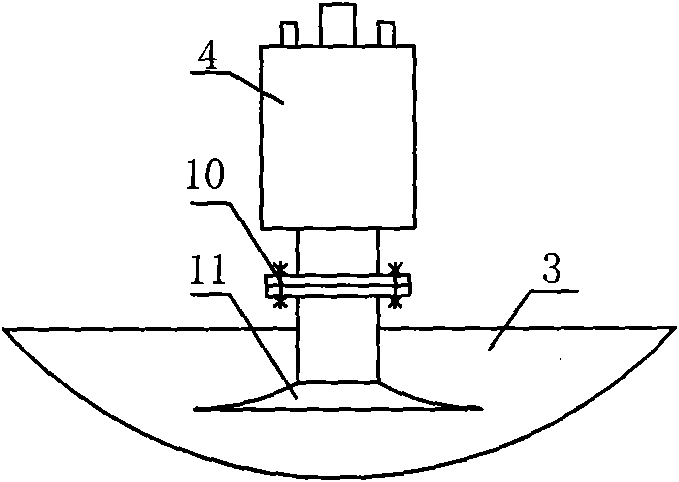

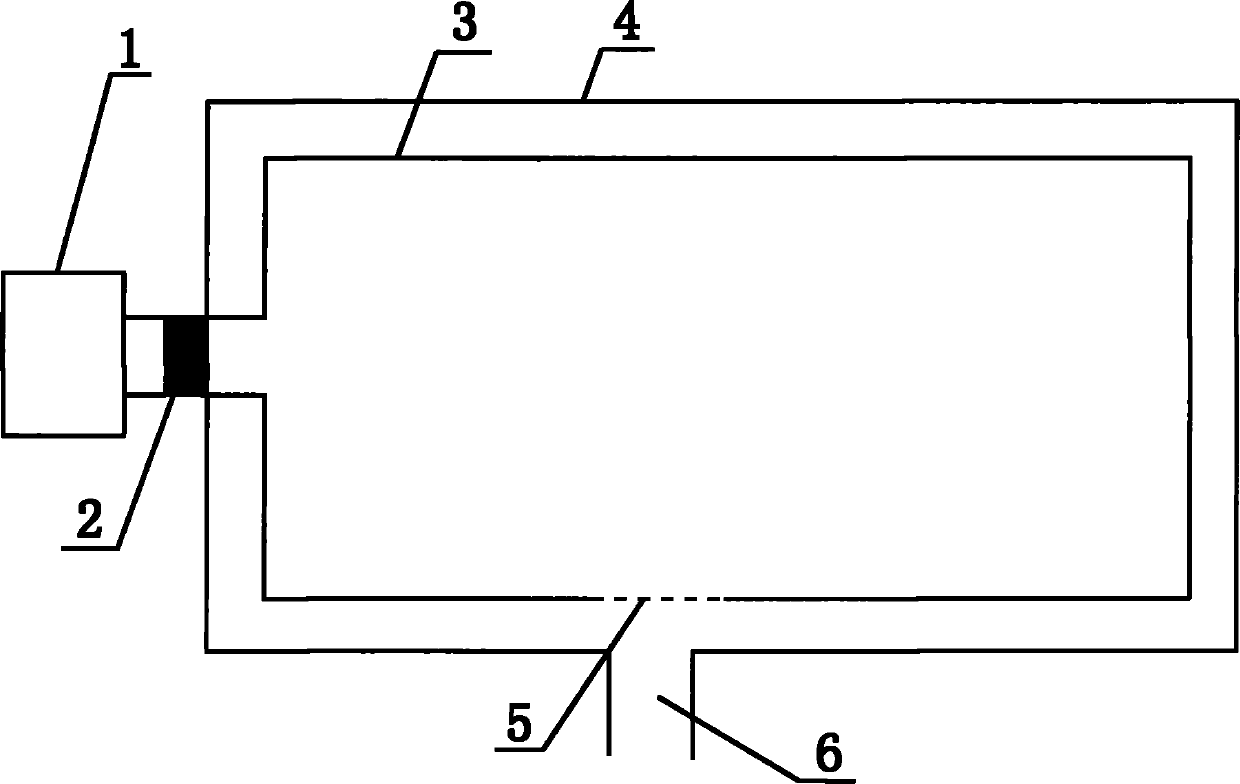

Method and device for performing emulsion breaking on oil-water emulsion by ultrasonic wave

InactiveCN102051201ASimple structureSettling fastDewatering/demulsification with electric/magnetic meansUltrasonic radiationOil water

The invention relates to a method for performing emulsion breaking on an oil-water emulsion by an ultrasonic wave. In the method, one or more ultrasonic generators are arranged in a raw material storage tank or a settlement tank in the gravity settling direction, only one ultrasonic generator acts in the direction of the same vertical line. An emulsion breaking device for implementing the method comprises the raw material storage tank or the settlement tank, and one or more ultrasonic generators are arranged at the bottom or / and top of the raw material storage tank or the settlement tank. The ultrasonic generators are distributed reasonably according to structural size and ultrasonic radiation areas, so that the ultrasonic generators cover comprehensively, and are prevented from being overlapped. The ultrasonic generators are connected with ultrasonic distributors, and one ultrasonic generator is arranged in one ultrasonic distributor. The action direction of the ultrasonic wave is the vertical direction and is consistent with the gravity settling direction, so the driving force is added in the oil-water settling direction, and the oil-water settling speed is accelerated. The device is uniform in ultrasonic wave energy distribution, excellent in emulsion breaking effect, simple in operation, convenient to run and maintain and low in running cost.

Owner:CHINA PETROLEUM & CHEM CORP

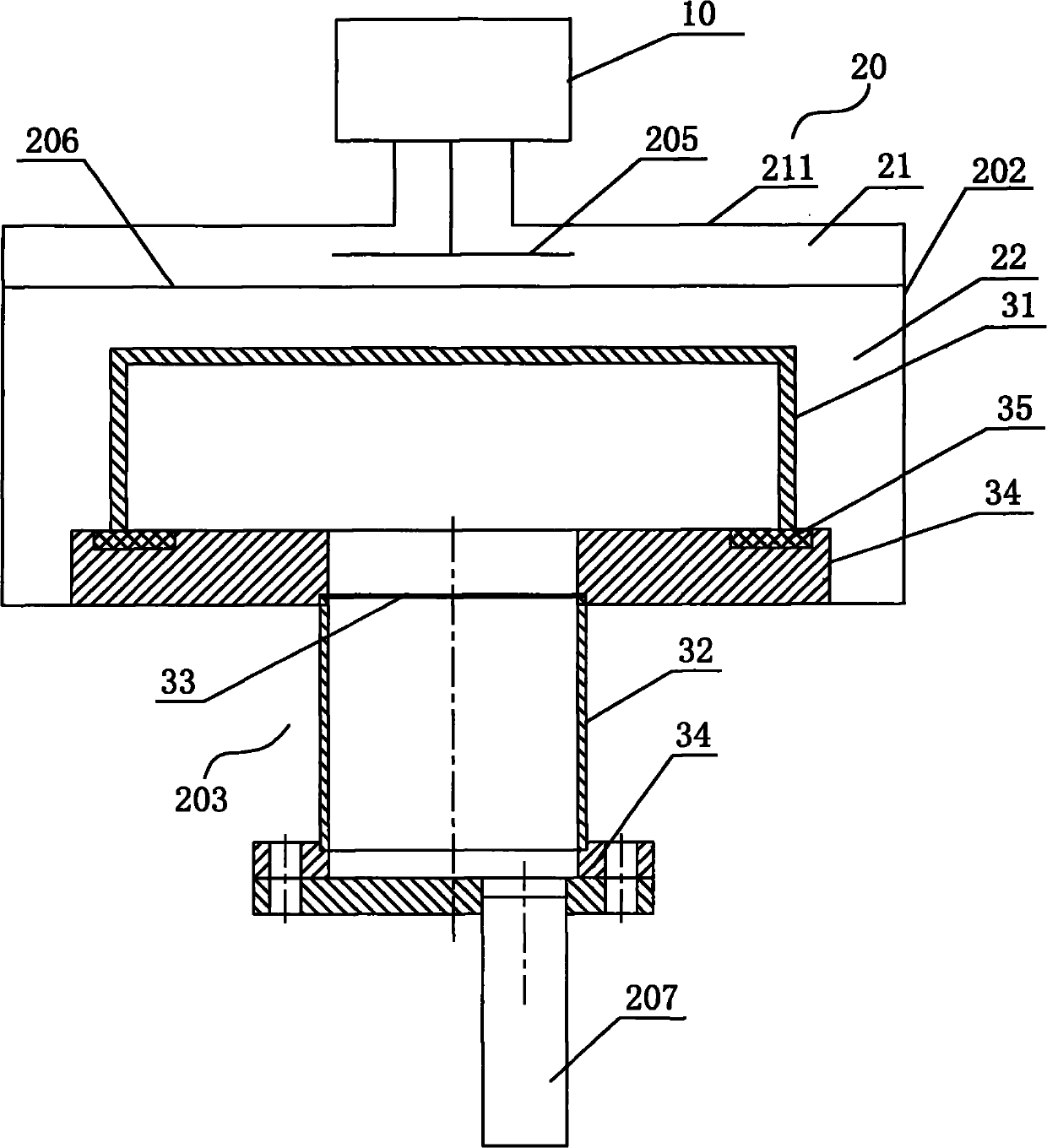

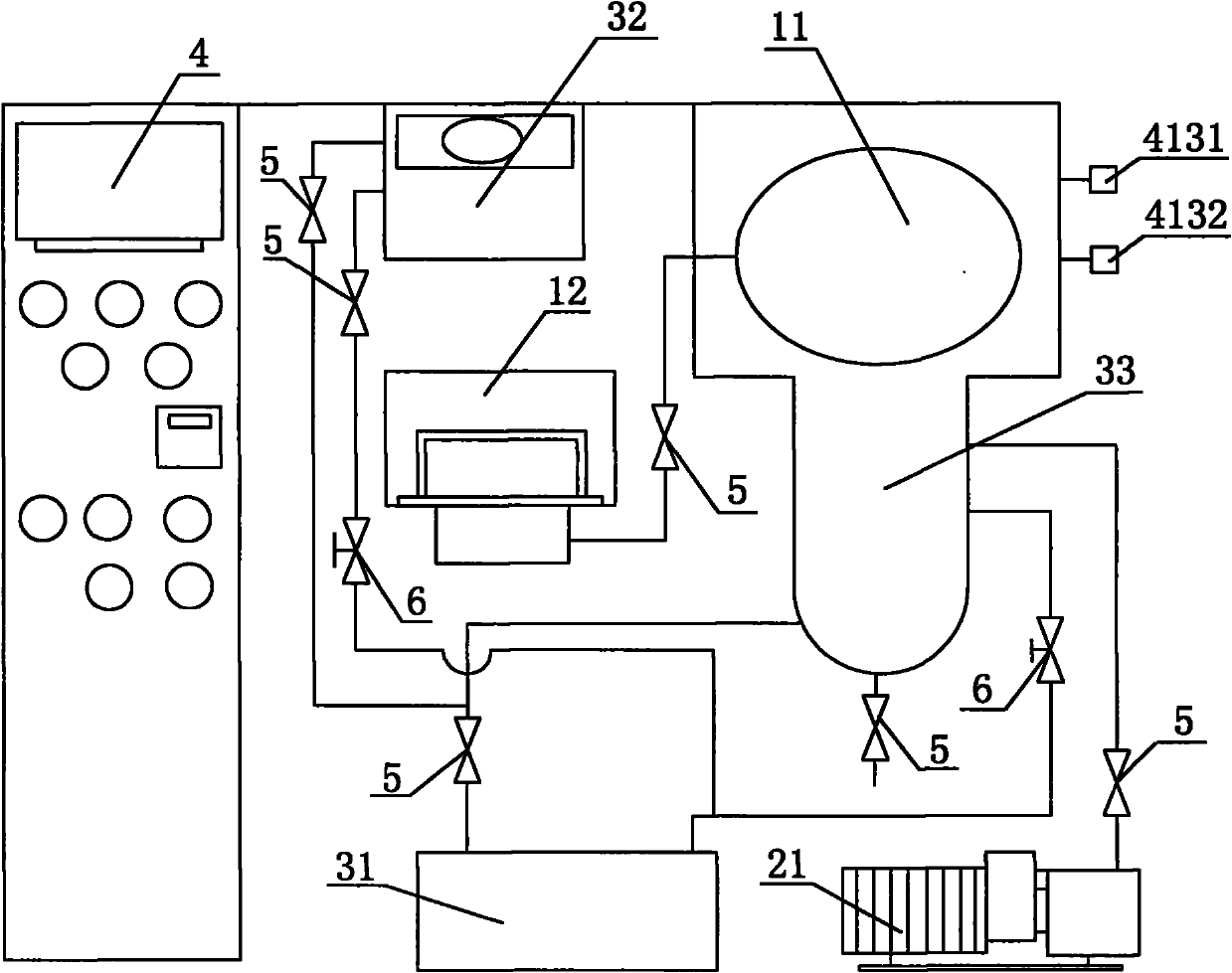

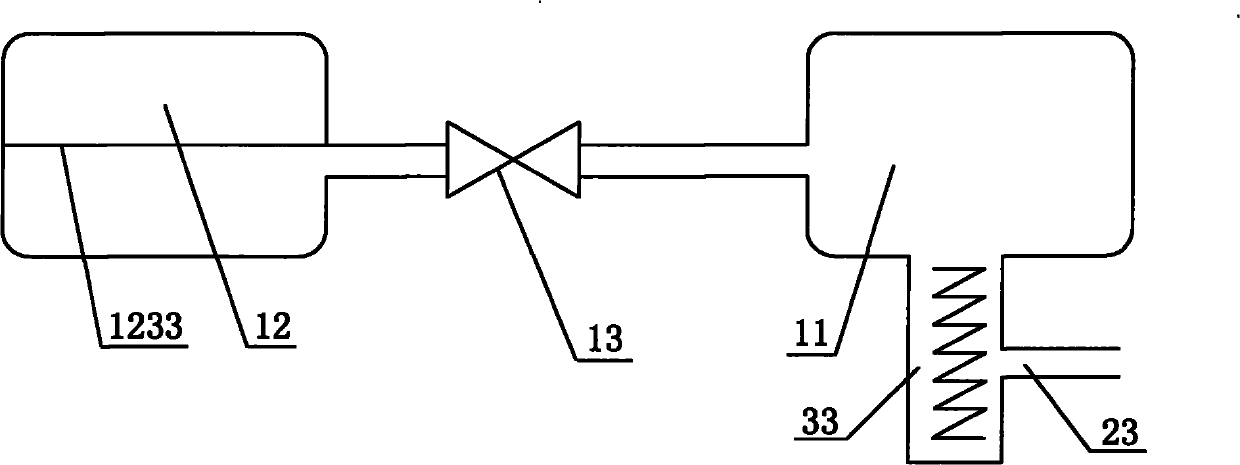

Micro-wave vacuum freeze-drying equipment

ActiveCN102200372AReduce the probability of microwave low voltage dischargeAvoid sparking discharge phenomenonDrying using combination processesResonant cavityFreeze-drying

The invention discloses micro-wave vacuum freeze-drying equipment, which comprises a micro-wave power source and a micro-wave vacuum freeze-drying device, wherein the micro-wave power source is connected with the micro-wave vacuum freeze-drying device; the micro-wave vacuum freeze-drying device comprises a micro-wave resonant cavity and a vacuum bin; the vacuum bin is arranged in the micro-wave resonant cavity; and the vacuum bin can realize double functions of micro-wave screening and vacuum sealing to ensure freeze-drying conditions of micro-wave vacuum freeze-drying. In the invention, on the basis of the conventional freeze-drying technology, a providing mode of latent heat of sublimation is changed from infrared heating to micro-wave heating, so materials are heated internally and externally, heat transfer resistance in a freeze-drying process is avoided, energy loss is reduced, sublimation efficiency is improved, freeze-drying time is shortened, and drying cost is reduced.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

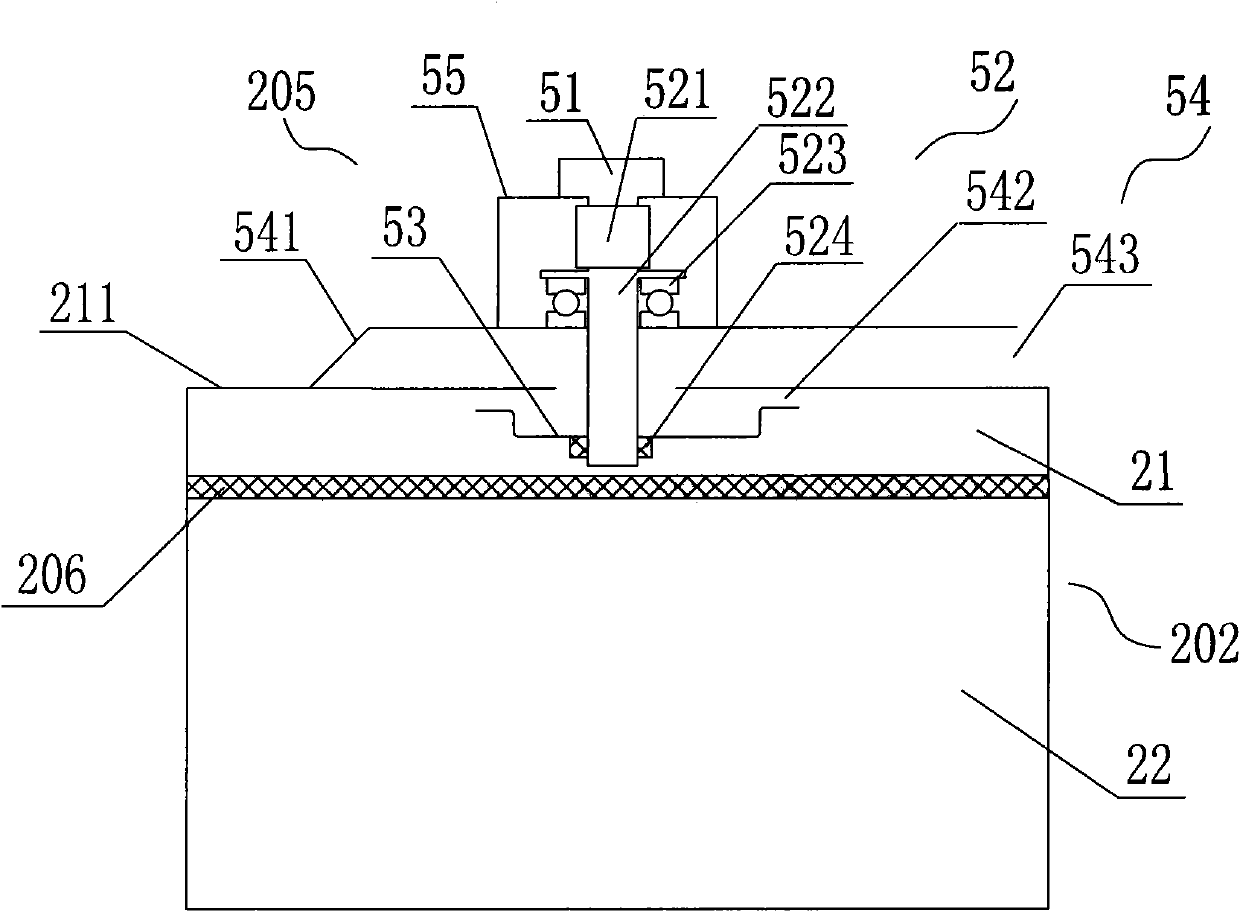

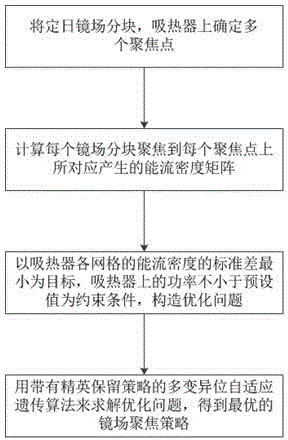

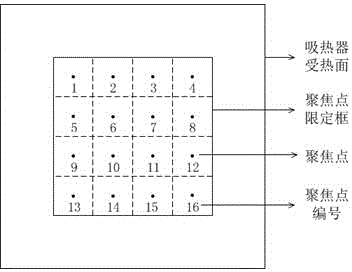

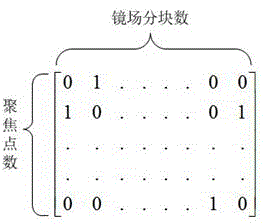

Focusing strategy optimizing method for mirror fields of tower type solar thermoelectric power system

ActiveCN104408527AEven energy distributionAvoid temperature gradientsSolar heating energySolar heat devicesGenetic algorithmSolar thermal electricity

The invention discloses a focusing strategy optimizing method for mirror fields of a tower type solar thermoelectric power system. The focusing strategy optimizing method comprises the following steps: (1) blocking heliostats fields and determining a plurality of focusing points on a heat absorber; (2) calculating an energy flow density matrix produced by focusing each mirror field block to each focusing point; (3) constructing an optimizing problem by taking the smallest standard deviation of the energy flow density of each grid of the heat absorber as a target and adopting a constraint condition that the power of the heat absorber is not smaller than a preset value; and (4) solving the optimizing problem by adopting a multi-variable-site adaptive genetic algorithm with the elitism strategy to obtain the optimal mirror field focusing strategy. The focusing strategy optimizing method for mirror fields of the tower type solar thermoelectric power system disclosed by the invention can be used for enabling the energy on the heating surface of the heat absorber to be uniformly distributed on the premise of ensuring as much as energy received by the heat absorber as possible, is beneficial to protecting the heat absorber, the improving the heat exchange efficiency and strengthening the system performance, so that reference is provided for the operation of the tower type solar heating and power plant.

Owner:ZHEJIANG UNIV

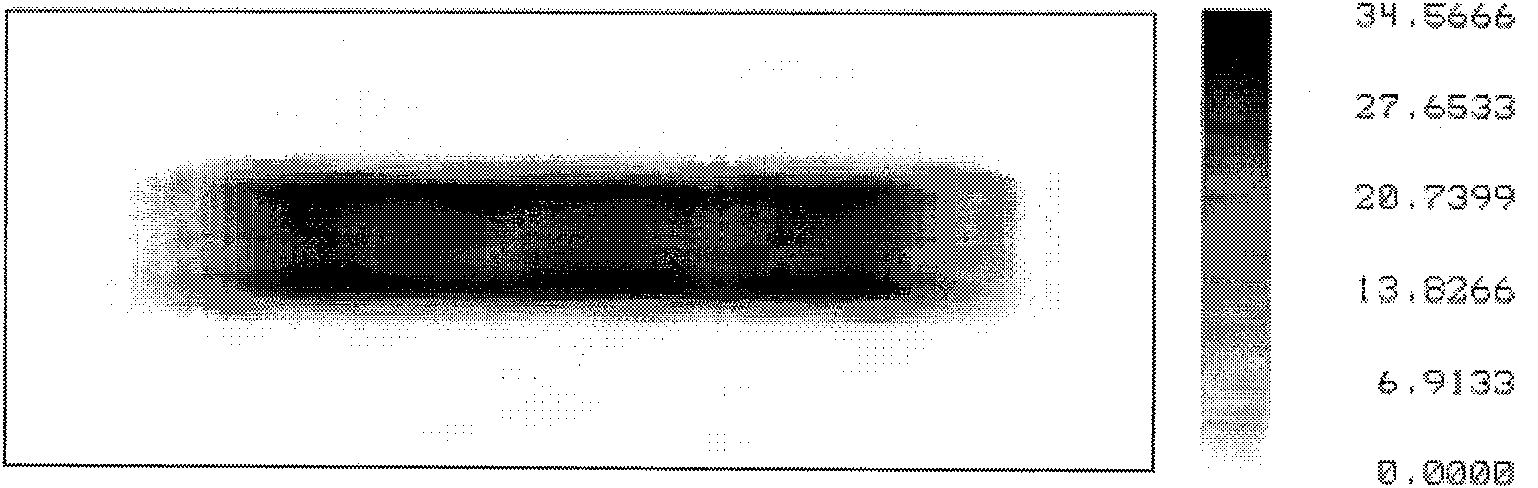

High-sensitivity fast on-line detection method of optical thin film and element surface laser-induced damage

ActiveCN105021627AImprove reliabilityIncrease contrastOptically investigating flaws/contaminationTest sampleImage detection

The invention discloses a high-sensitivity fast on-line detection method of optical thin film and element surface laser-induced damage and relates to the field of optical thin film and element surface laser-induced damage and life detection. The method utilizes a He-Ne light scattering detection method as a main detection method and utilizes a microscopic CCD imaging detection method as an auxiliary detection method. Aiming at each one test sample point, the high-sensitivity fast on-line detection method comprises carrying out detection by the He-Ne light scattering detection method as an optical thin film and element surface laser-induced damage determination basis, if the He-Ne light scattering detection result shows the optical thin film and element surfaces produce laser-induced damage, suspending the He-Ne light scattering detection, recording radiation laser pulse number, determining the He-Ne light scattering detection result by the microscopic CCD imaging detection method, and testing the next test point by the same methods so that detection of laser-induced damage on the whole surface is finished. The high-sensitivity fast on-line detection method realizes effective combination of the He-Ne light scattering detection method and the microscopic CCD imaging detection method and greatly improves sensitivity and reliability of optical thin film and element surface laser-induced damage on-line detection.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

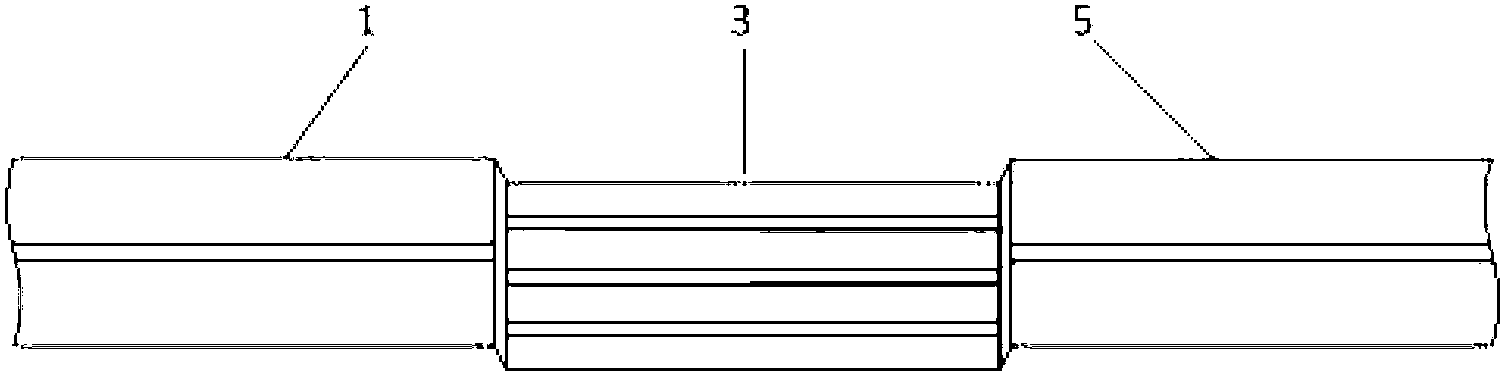

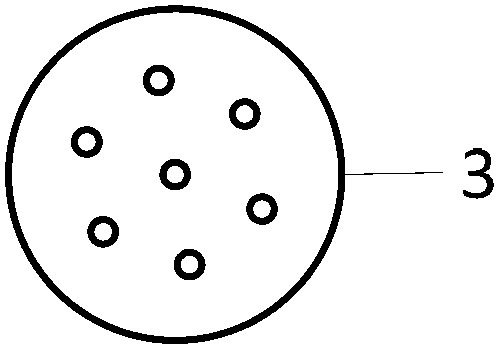

Semiconductor laser side pump module

ActiveCN101834402ALow costReduce in quantityActive medium materialSemiconductor lasersBeam expanderLaser array

The invention relates to a semiconductor laser side pump module comprising one or more side pump module units and a crystal bar, wherein each side pump module unit comprises a baseplate, a semiconductor laser module fixed on the baseplate, a fast axis collimator arranged at the front end of the semiconductor laser module and a beam expander arranged behind the fast axis collimator, and the crystal bar is arranged behind the beam expander; the semiconductor laser module comprises a bar; and the side pump module unit also comprises a homogenizing mirror arranged between the beam expander and the crystal bar. The side pump module can ensure that the beam homogeneity and the energy density of a pumping semiconductor laser satisfy the operating requirement by utilizing fewer high-power semiconductor laser arrays as the pumping source after beam expansion and homogenization.

Owner:FOCUSLIGHT TECH

Apparatus and process for producing acetylene by low-temperature plasmochemical pyrolysis of natural gas

InactiveCN1613838AReduce ablationReduced localized point ablationHydrocarbon by hydrocarbon crackingElectrical conductorEngineering

A low-temperature plasma chemical reactor for producing ethyne by cracking natural gas and its process are disclosed. The reactor consists of microwave plasma torch and DC plasma exciting mechanism. The external conductor of the microwave plasma torch is of hollow structure, of which outlet forms a nozzle, the DC plasma exciting mechanism consists of external conductor, conductive pipe corresponding to the external conductor nozzle, the cavity of the conductive pipe as reacting chamber , the external conductor as cathode, the conductive pipe as anode, with the conductive pipe connected with DC electric source by choking structure. The process is carried out by: microwave plasma entering into DC plasma exciting mechanism; 2) microwave plasma forming normal DC plasma under the action of the DC electric source, and natural gas cracking to obtain ethyne. It achieves long life and high efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Laser irradiation apparatus, laser irradiation method, and method of manufacturing a semiconductor device

InactiveUS20050111339A1Efficient executionReduce weightTransistorCombination recordingUltrasound attenuationDevice material

At edges of laser light on an irradiation surface or in the vicinity thereof, the energy density is attenuated gradually due to aberration of a lens or the like. Since such regions (attenuation regions) do not have enough energy density for annealing of an irradiation object, uniform annealing of the irradiation object is not possible. In the present invention, one of the plural laser beams is divided into two laser beams so that each section of the two laser beams serves as an edge of the resultant laser light. Each attenuation region of the two laser beams is synthesized with an attenuation region of another laser beam. In this way, laser light every part of which has an energy density suitable for satisfactory annealing of an irradiation object can be obtained from plural laser beams having attenuation regions.

Owner:SEMICON ENERGY LAB CO LTD

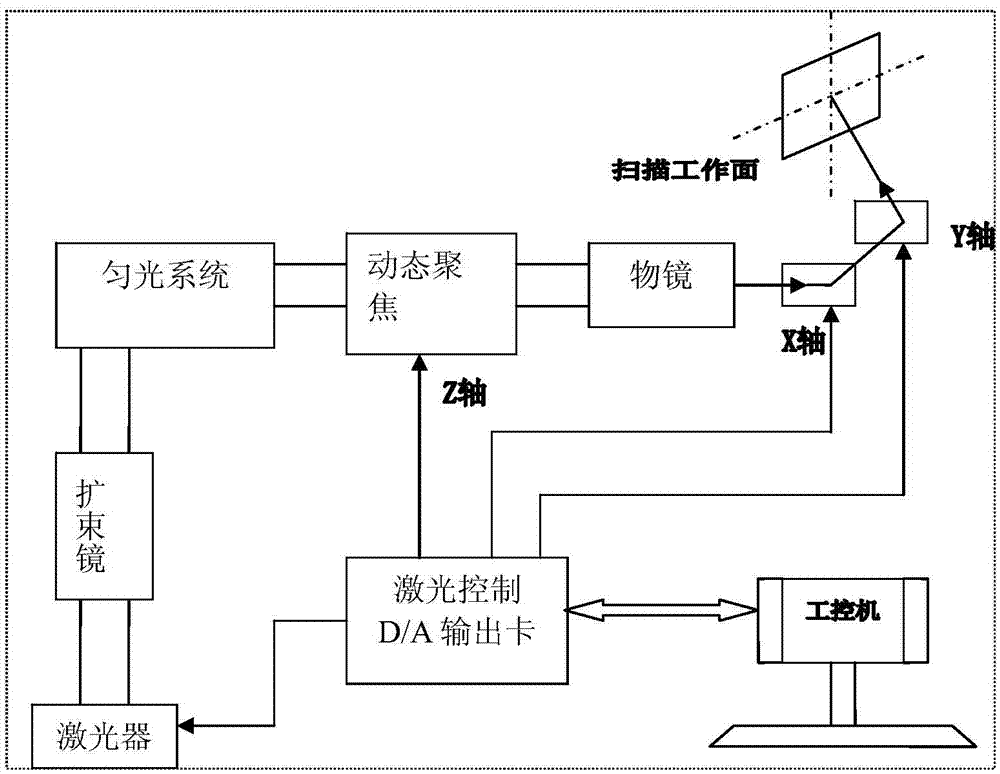

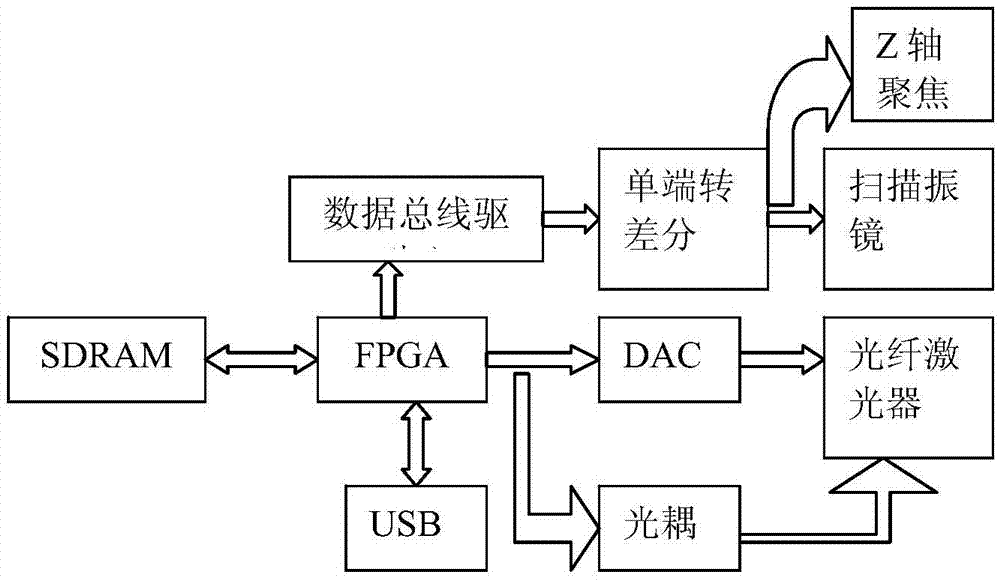

Optical path design control system and control method of laser etching machine

InactiveCN106903438AEven energy distributionGood collimationLaser beam welding apparatusLaser etchingBeam expander

The invention relates to an optical path design control system and a control method of a laser etching machine. The optical path design control system comprises a laser device, a beam expander, a uniform light system, a dynamic focusing system, an objective lens, a galvanometer scanning system, an industrial personal computer and a laser control D / A output card, wherein a laser beam output from the laser device is expanded by the beam expander and then transformed by the uniform optical system, so that the laser beam is distributed more uniformly, and the uniform light system is behind the beam expander in the optical path; the dynamic focusing system is behind the uniform light system in the optical path; the objective lens is behind the dynamic focusing system in the optical path; the galvanometer scanning system is behind the uniform light system, and the industrial personal computer is connected with the laser control D / A output card for controlling the laser control D / A output card; and the laser control D / A output card is connected with the laser device, the dynamic focusing system and the galvanometer scanning system correspondingly. The scanning width of the optical path design control system is large, the energy of the processing beam is uniform, so that the laser etching machine produces a higher yield, and the processing range is larger.

Owner:WUHAN MIRACLE LASER SYST

Process and device of forming multilayer insulating thin film on inner wall of glass container

InactiveCN104762609AAvoid damageBarrier stabilityChemical vapor deposition coatingPulse microwaveProduct gas

The invention relates to a process and a device of forming a multilayer insulating thin film on an inner wall of a glass container. The device includes a machine base, a gas transportation pipeline, a microwave sealing cover, an antenna, a mode convertor, a tuner, a waveguide tube and a pulse microwave generating source. The invention also provides a process corresponding to the device, comprising following steps: (1) vacuumizing the microwave sealing cover and feeding oxygen to the microwave sealing cover through the gas transportation pipeline; (2) introducing a high-power pulse microwave generated from the pulse microwave generating source to the mode convertor through the waveguide tube, tuning the high-power pulse microwave by the tuner, and enabling the high-power pulse microwave to pass through the antenna and uniformly enter into the interior of the vacuum glass container; (3) feeding various special gases successively into the vacuum glass container and ionizing the special gases to generate compact and uniform oxide thin films, wherein the thin films in different nano-scale thicknesses are alternatedly deposited onto the inner wall of the glass container. With the process and the device, the inner wall of a glass container in complex structure can be coated by the thin film, thereby increasing the service life of the product and the deposition efficiency, reducing production cost and enhancing film layer adhesive force and uniformity.

Owner:HUIZHOU OBOLAND OPTOELECTRONICS TECH

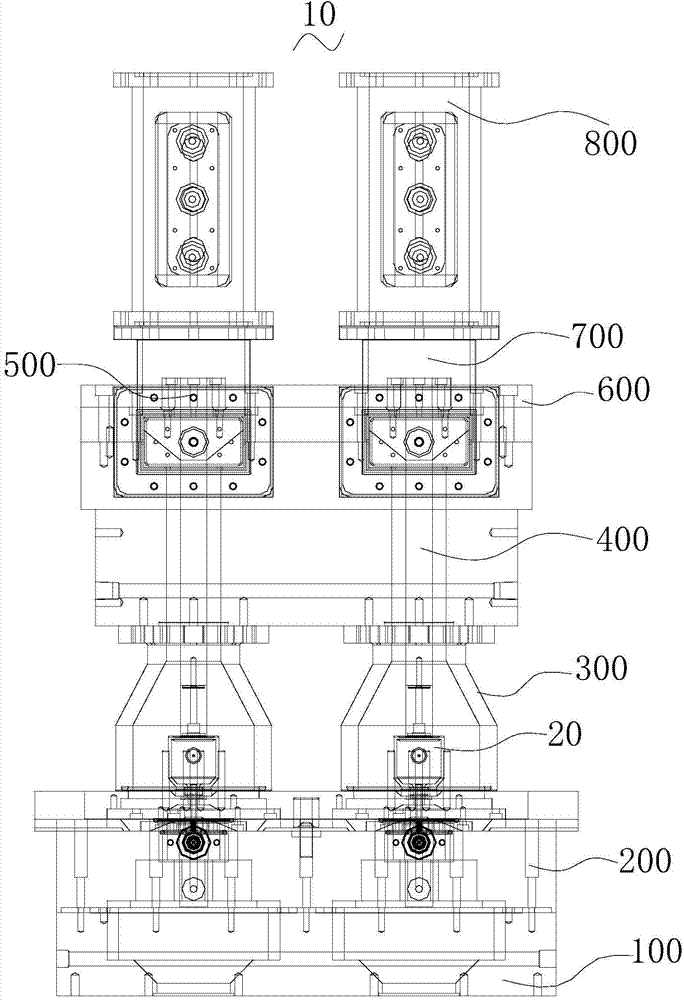

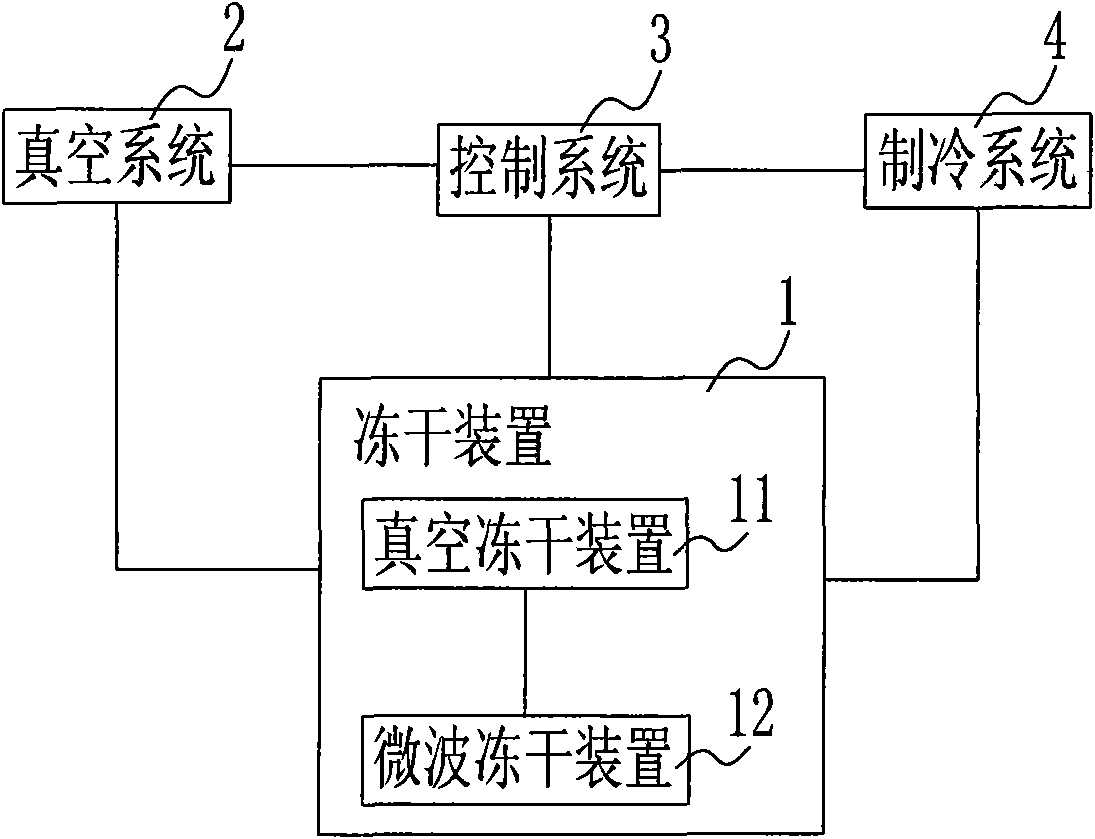

Vacuum freeze-drying tester

ActiveCN102200373AEasy to compare and analyzeEasy to compareDrying using combination processesHeating arrangementFreeze-dryingControl system

The invention discloses a vacuum freeze-drying tester, which comprises a freeze-drying device, a vacuum system, a refrigerating system and a control system, wherein the control system is respectively connected with the vacuum system, the refrigerating system and the freeze-drying device; the vacuum system and the refrigerating system are respectively connected with the freeze-drying device; the freeze-drying device comprises a vacuum freeze-drying device and a micro-wave freeze-drying device; the vacuum freeze-drying device is connected with the micro-wave freeze-drying device by a freeze-drying cut-off value; and the freeze-drying cut-off value is used for switching between vacuum freeze-drying and micro-wave freeze-drying to separately / simultaneously perform vacuum drying and micro-wavevacuum drying or separately / simultaneously perform vacuum freeze-drying and micro-wave freeze vacuum drying.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

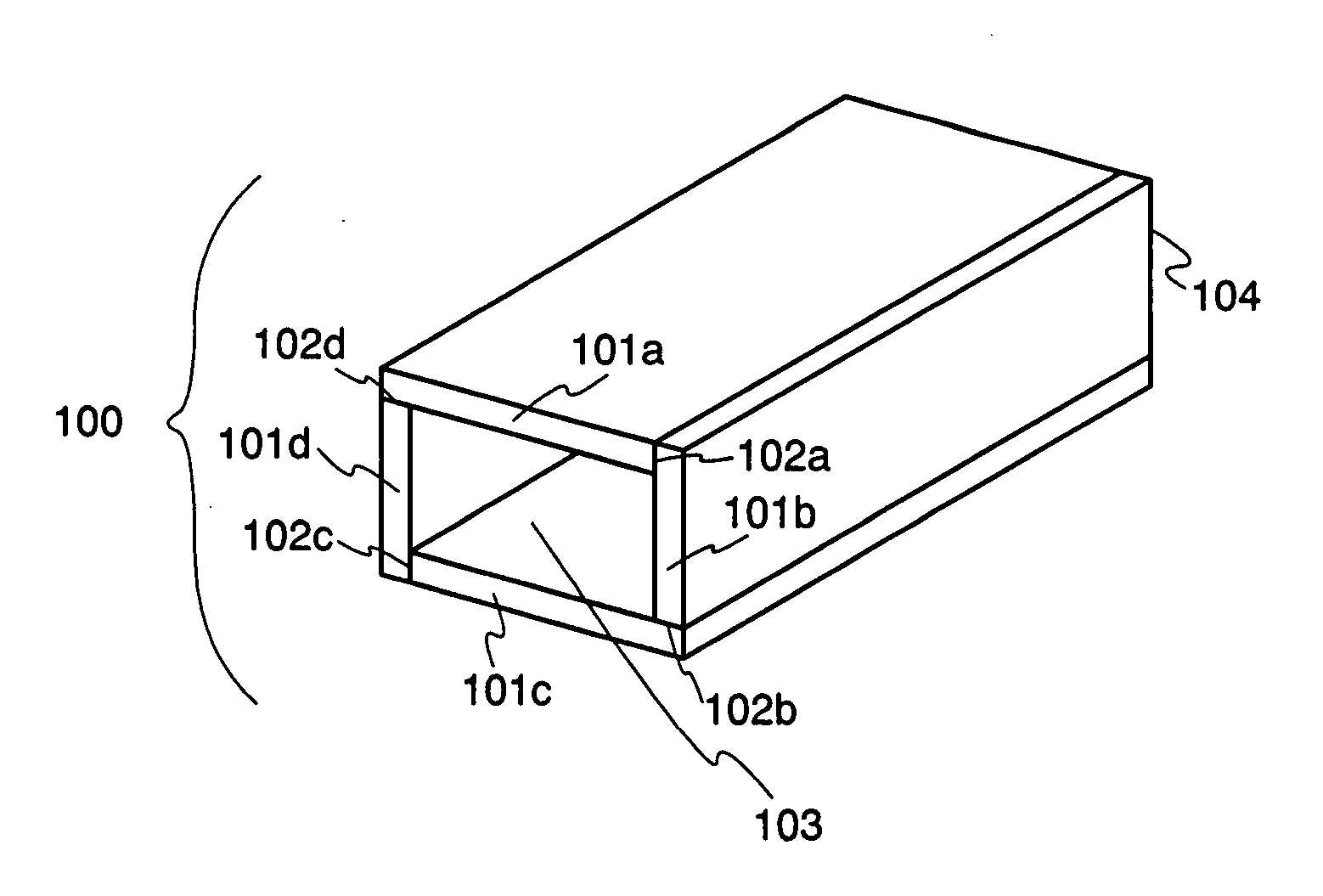

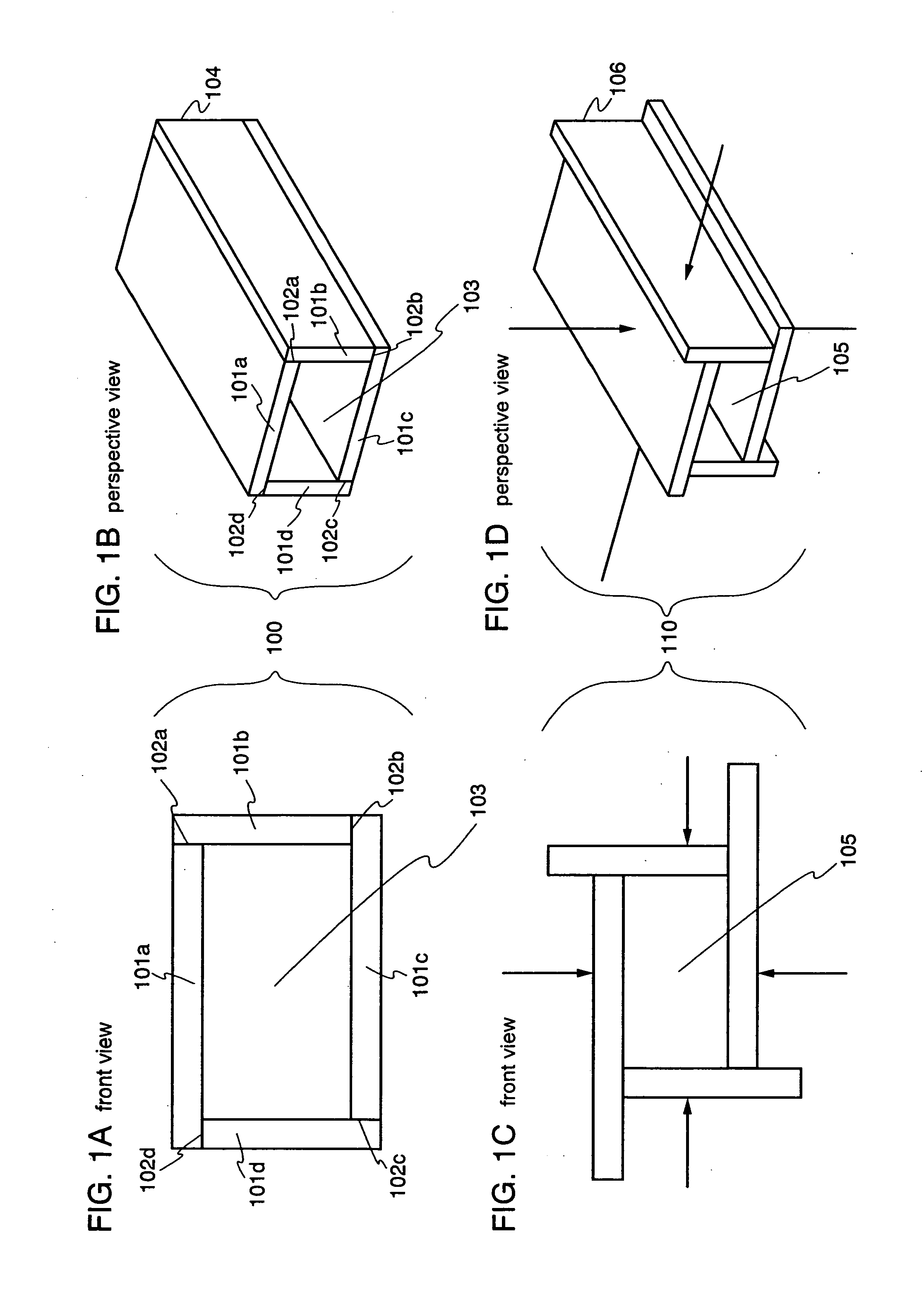

Optical element and light irradiation apparatus

InactiveUS20060227676A1Improves strength uniformityEven energy distributionPhotomechanical apparatusRecord information storageLight irradiationDevice material

It is an object of the present invention to provide an optical element which forms a beam spot with homogeneous energy distribution on an irradiated surface, and a light irradiation apparatus. It is another object of the invention to provide a manufacturing method of a semiconductor device using a beam spot with homogeneous energy distribution. One feature of the invention is to homogenize energy distribution of a beam spot on an irradiated surface by forming the optical element provided with a polygonal entrance and exit using a plurality of reflectors as side walls and introducing a beam to the optical element. Further, a beam spot with a desired size or shape can be obtained by making the reflectors movable. Furthermore, by using a light irradiation apparatus using the optical element, failure in manufacturing a semiconductor device can be reduced.

Owner:SEMICON ENERGY LAB CO LTD +1

Aperture shield incorporating refractory materials

ActiveUS20090080617A1Reduce failure rateReduce thermal stressStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsThroatX-ray

An x-ray tube electron shield is disclosed for interposition between an electron emitter and an anode configured to receive the emitted electrons. The electron shield is configured to withstand the elevated levels of heat produced by electrons backscattered from the anode and incident on the electron shield. This in turn equates to a reduced incidence of failure in the electron shield. In one embodiment the electron shield includes a body that defines a bowl-shaped aperture having a narrowed throat segment. The body of the electron shield includes a first body portion, a second body portion, and a disk portion. These portions cooperate to define the bowl and the throat segment. The throat segment and the lower portion of the bowl are composed of a refractory material and correspond with the regions of the electron shield that are impacted by relatively more backscattered electrons from the anode surface.

Owner:VAREX IMAGING CORP

Disc-type solar power generation system and power generation method

PendingCN108757356AImprove reliabilityImprove energy efficiencyFrom solar energyMachines/enginesEngineeringSolar power

The invention relates to a disc-type solar power generation system and a power generation method, and belongs to the technical field of solar heat utilization. The power generation method is particularly applied to the improvement of the disc-type solar power generation system and the comprehensive utilization of energy. The disc-type solar power generation system comprises a disc-type reflectingmirror, a vertical column, a supporting arm, a Stirling generator and a heat absorber, wherein the disc-type reflecting mirror is mounted on the vertical column; the Stirling generator is mounted on the disc-type reflecting mirror through the supporting arm; and the heat absorber is mounted on the Stirling generator. The disc-type solar power generation system is structurally characterized by further comprising an afterburner, a cooling fluid circulation device and a waste heat utilization device; the afterburner comprises gas pipelines and nozzles; the gas pipelines communicate with the nozzles; the nozzles are mounted on the heat absorber; the cooling fluid circulation device comprises an upper flow tube and a lower flow tube; both the upper flow tube and the lower flow tube are in contact with the Stirling generator; the upper flow tube communicates with the lower flow tube; and the lower flow tube communicates with the waste heat utilization device.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

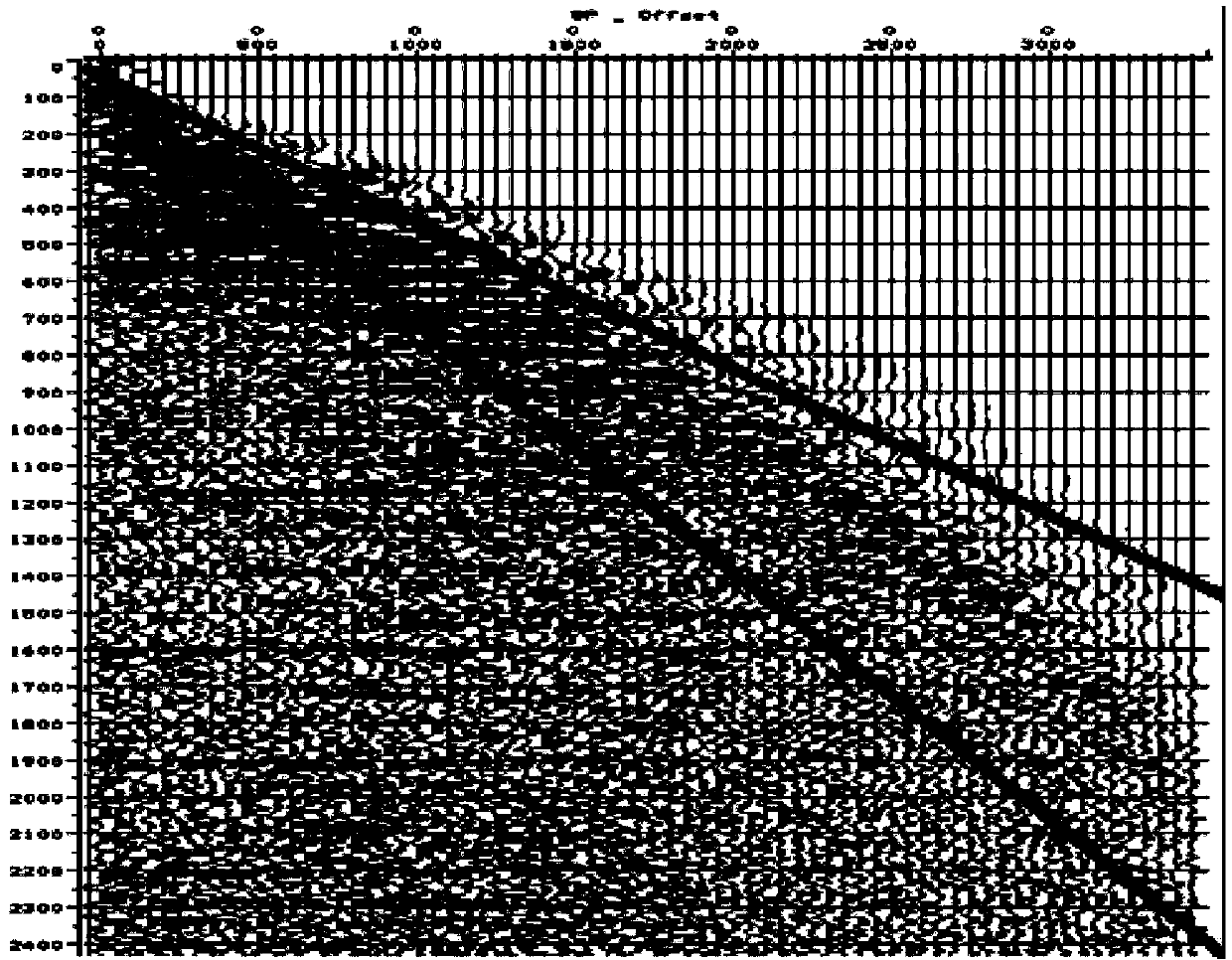

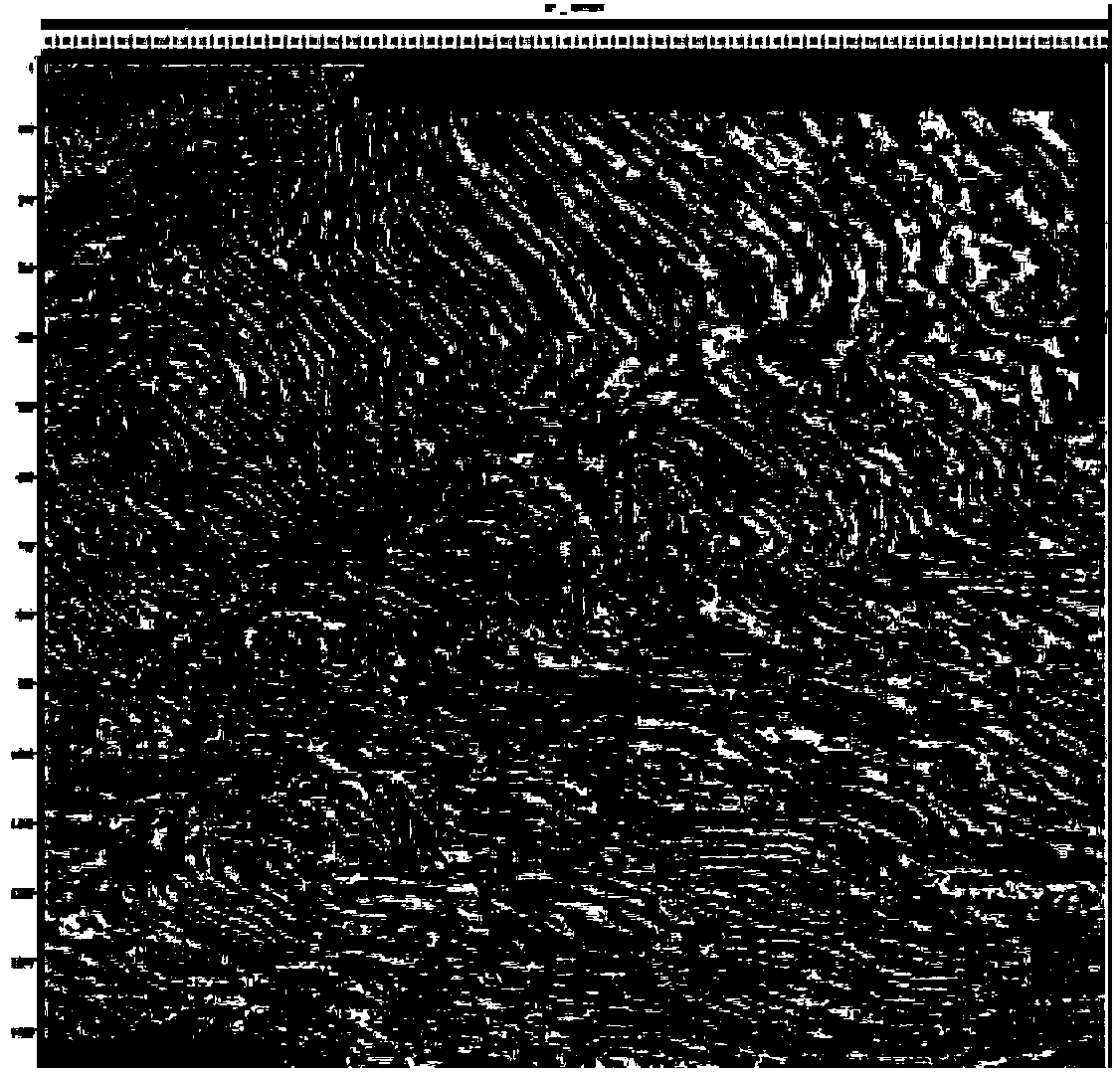

Method for solving energy nonuniform problem during multiple three-dimensional seismic data fusion processing before stacking

InactiveCN103913767AEliminate offset arcing phenomenonLow costSeismic signal processingCorrelation functionEngineering

The invention relates to a method for solving an energy nonuniform problem during multiple three-dimensional seismic data fusion processing before stacking. Firstly, movable correction and cutting are carried out on CMP gathers before stacking, the signal to noise ratio and the effective covering times of each CMP surface element are calculated, energy adjustment factors are calculated according to the signal to noise ratio and relative functions of the effective covering times, then smooth filtering is carried out on the energy adjustment factors, the energy adjustment factors are applied to the CMP gathers for energy adjustment, and ultimately, deviation processing is carried out before stacking. The method solves the arc drawing deviation problem in the prior art caused due to the fact that energy is nonuniform during multiple three-dimensional seismic data fusion processing.

Owner:CHINA PETROLEUM & CHEM CORP +1

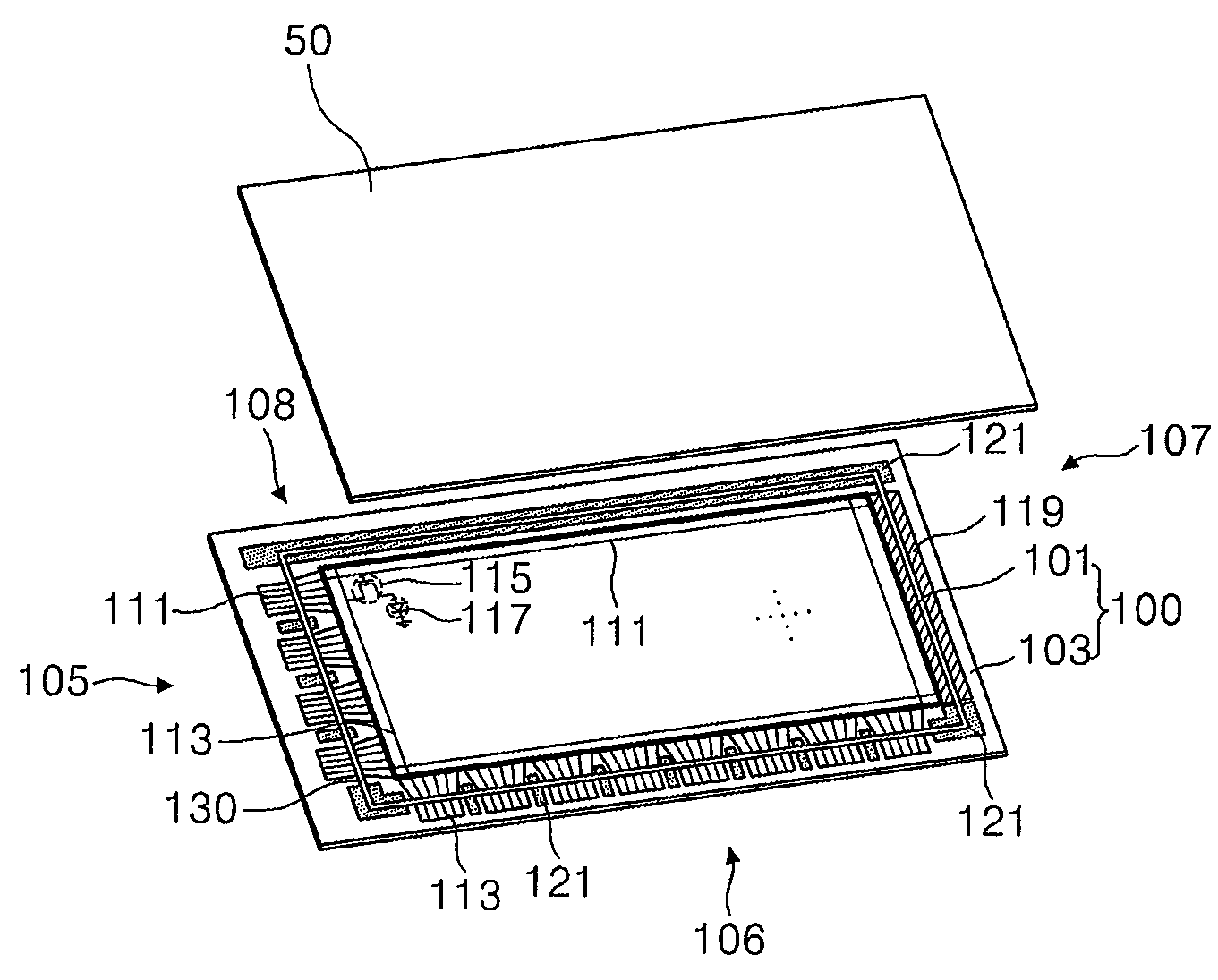

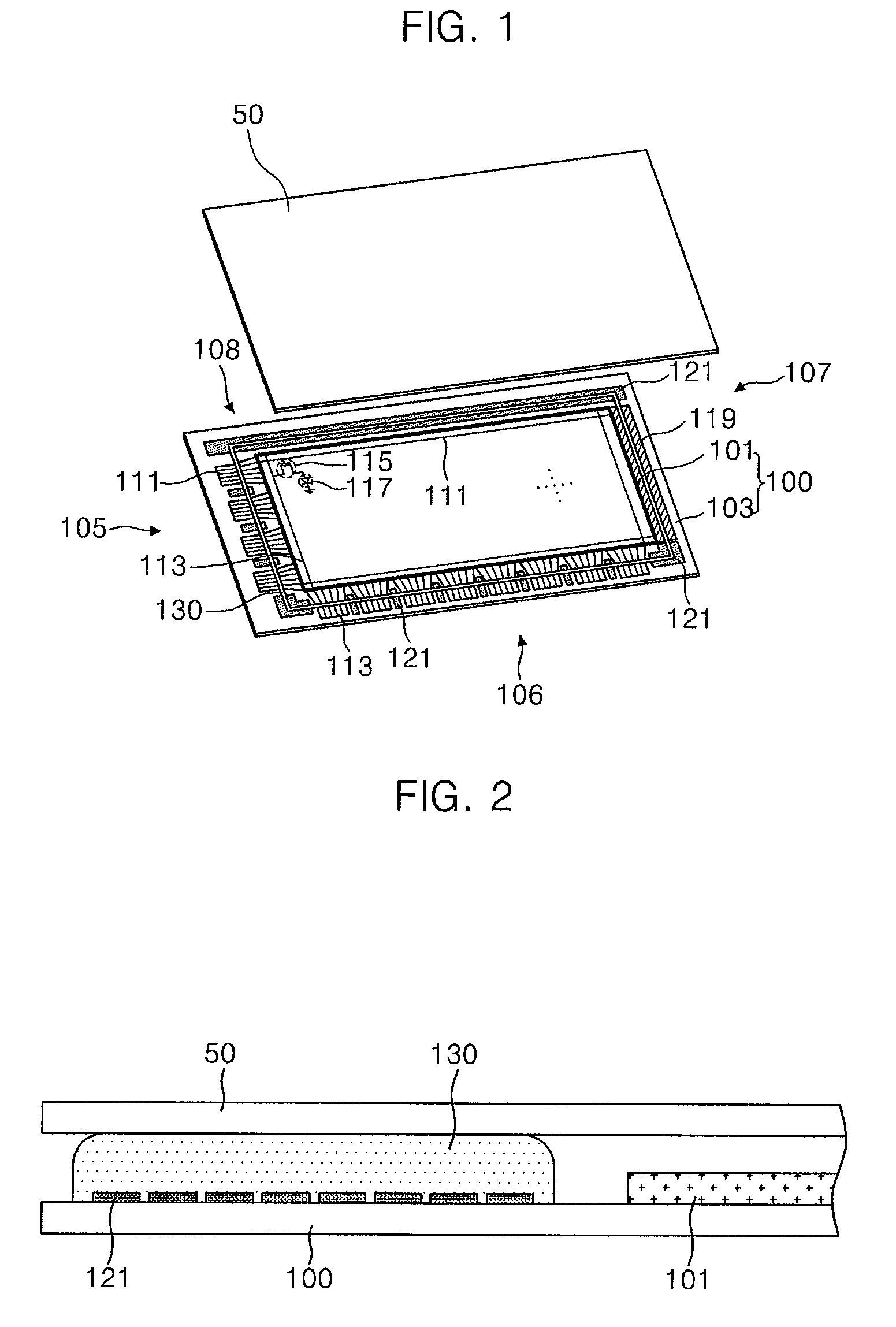

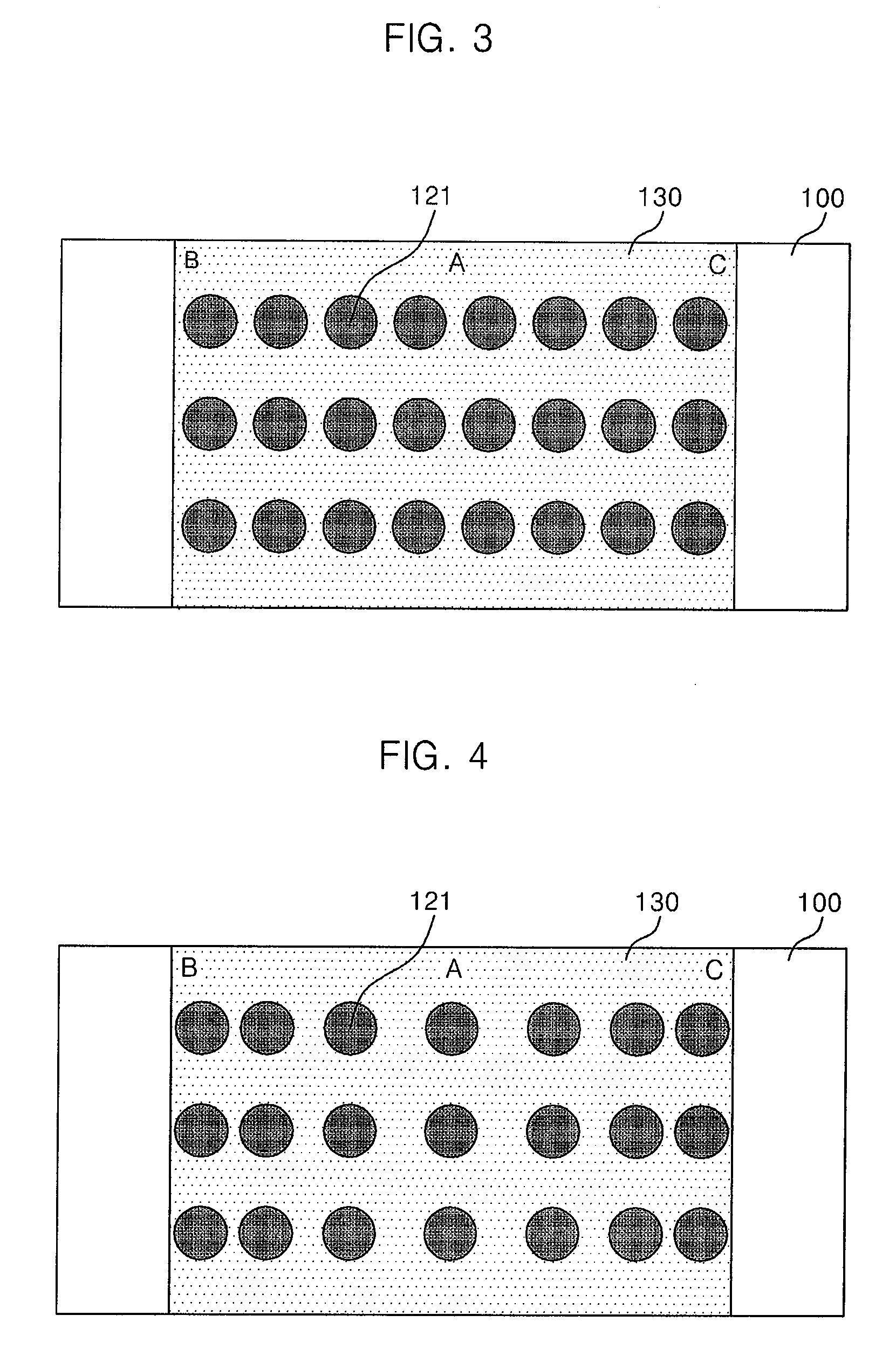

Organic light emitting device

InactiveUS20090128015A1Improve adhesionPrevent changeDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringMetal

An organic light-emitting device (“OLED”) improving adhesion of a frit is disclosed. The organic light-emitting device includes a first substrate, an auxiliary metallic layer disposed on a surface of the first substrate, a second substrate, a frit formed in overlapping relationship with the auxiliary metallic layer and interposed between the first and the second substrates to adhere the first and the second substrates together and wherein the auxiliary metallic layer is overlapped by the frit on the first substrate and formed separately from a wiring.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com