Apparatus and process for producing acetylene by low-temperature plasmochemical pyrolysis of natural gas

A low-temperature plasma and plasma technology, applied in the field of ion chemistry, can solve problems such as low natural gas conversion rate, and achieve the effects of reducing local ablation, improving stability and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

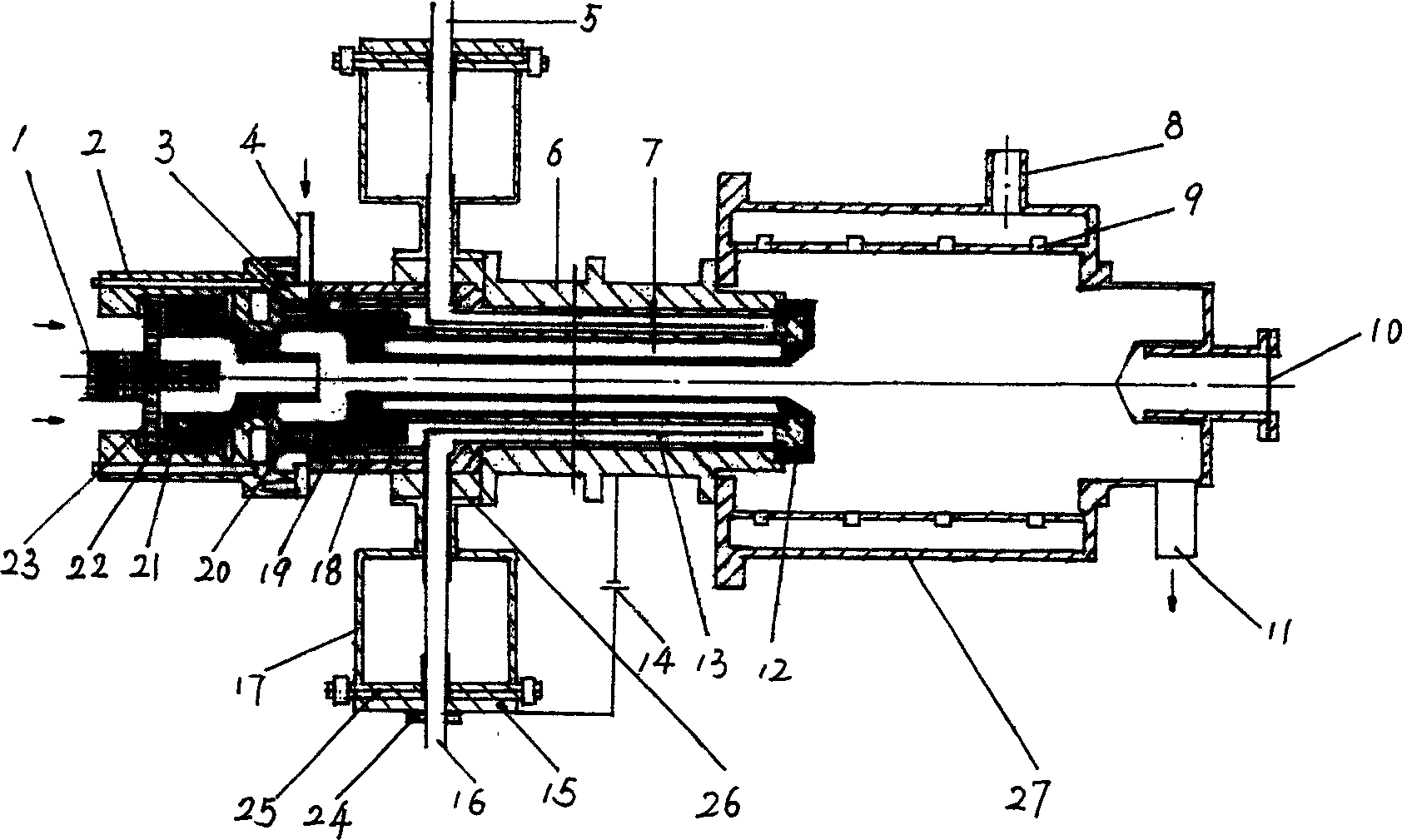

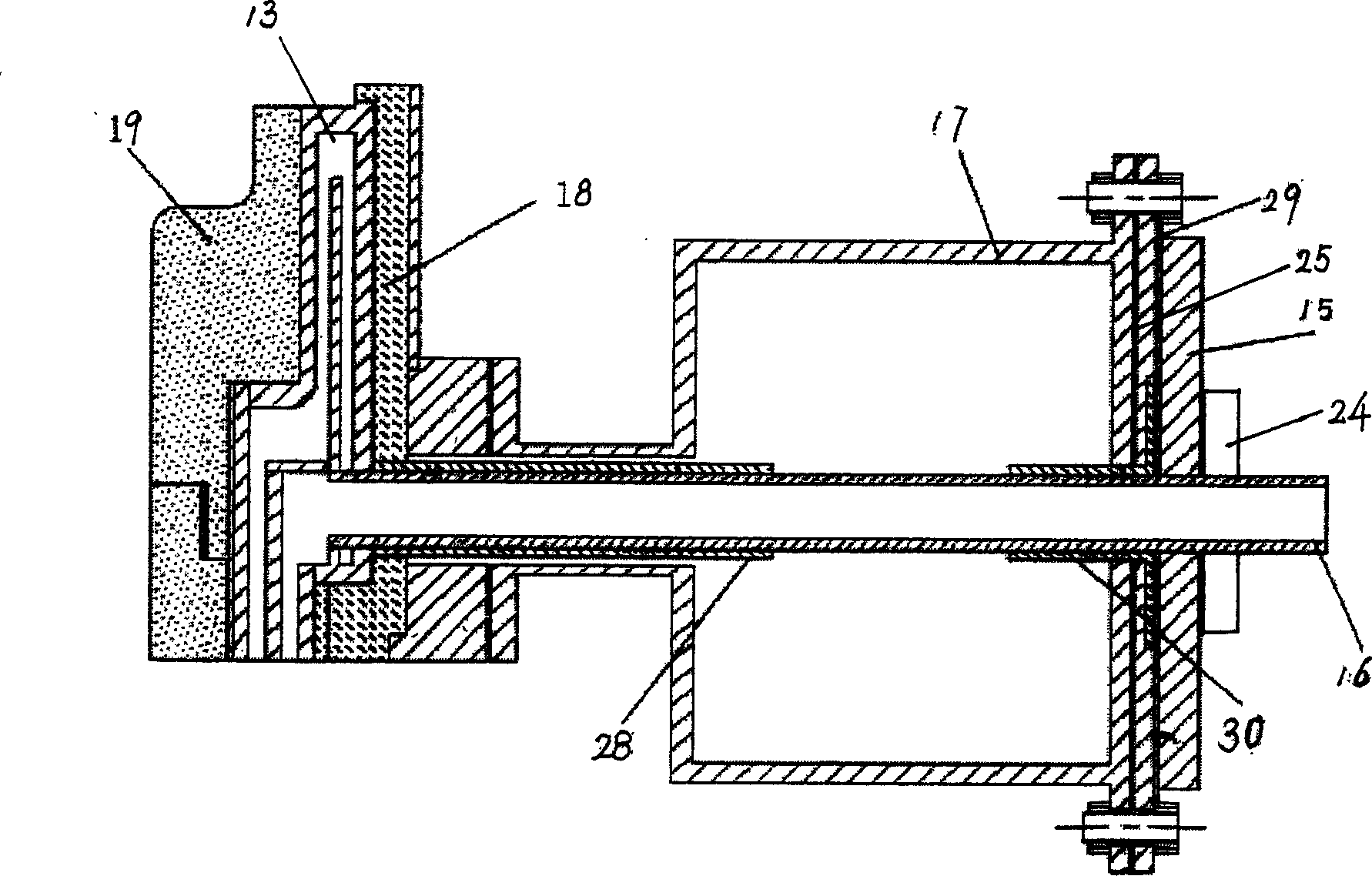

Method used

Image

Examples

Embodiment 1

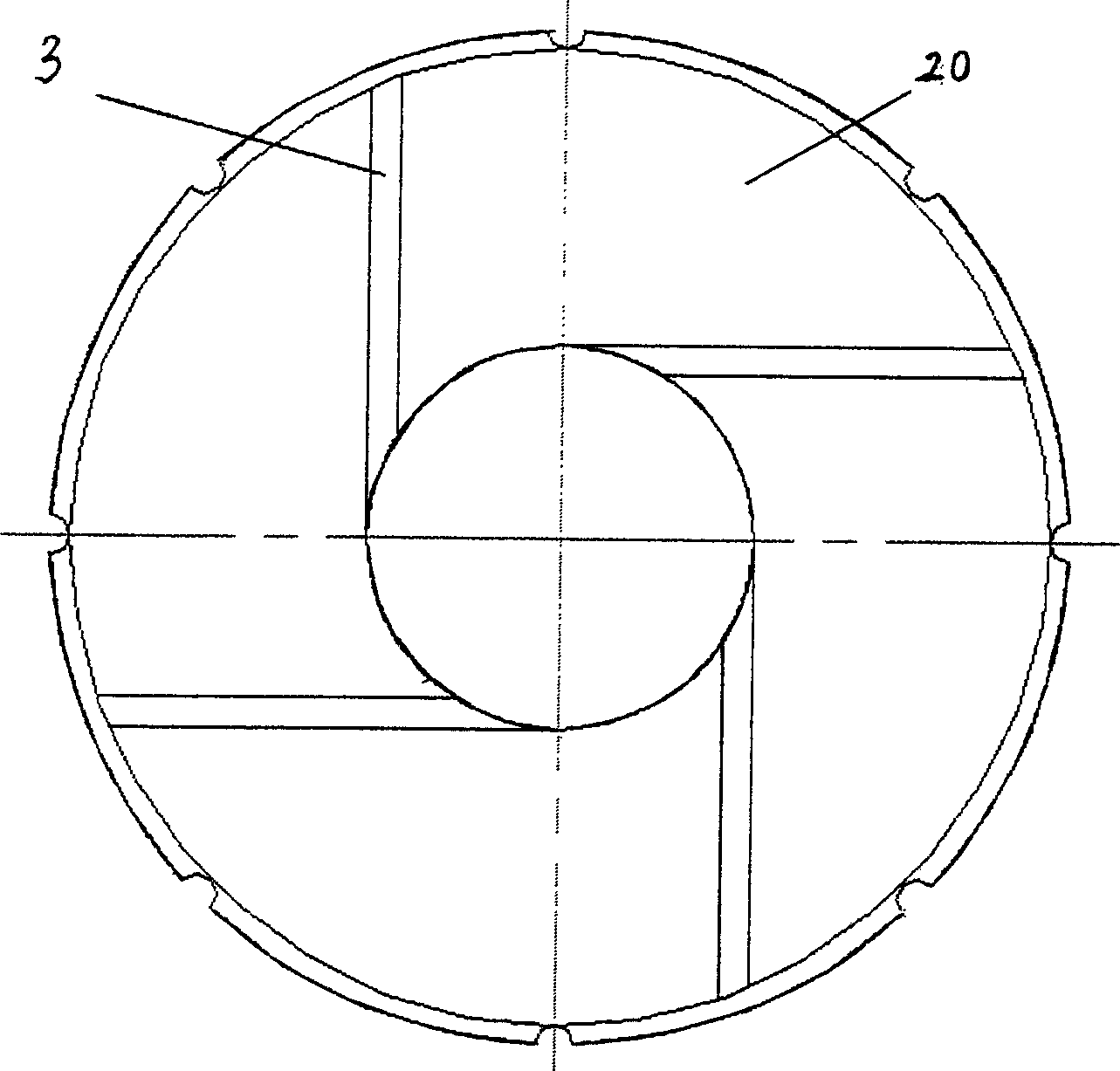

[0039] Example 1 Effect of Reaction Chamber Size on Plasma Operating Voltage and Power Supply Efficiency

[0040] Under the condition of constant arc current, as the diameter of the reaction chamber increases, the plasma operating voltage increases significantly, and at the same time, the power supply efficiency also increases due to the increase of the operating voltage. When the hydrogen flow rate is 200L / min, the methane flow rate is 400L / min, and the arc current is maintained at 40A, the diameter of the reaction chamber is increased from 10mm to 20mm, and the plasma operating voltage can be increased from 1050V to 1700V. At the same time, the power supply efficiency is also increased from 75%. increased to 85%.

Embodiment 2

[0041] Embodiment 2 The influence of plasma working gas composition and gas flow rate on voltage and power supply efficiency

[0042] With the increase of the proportion of methane in the plasma working gas or the increase of the total flow rate of the gas, the arc voltage increases obviously. For a reaction chamber with a diameter of 15mm, the hydrogen flow rate of the microwave plasma working gas is 200L / min, the microwave power is 12kW, and the total flow rate of the conventional plasma working gas is 400L / min. If the methane flow rate in the conventional plasma working gas is increased from 0L / min to 400L / min, when the arc current is 30A, the voltage increases from 850V to 1700V, and when the arc current is 50A, the voltage increases from 650V to 1400V.

[0043] Also for a reaction chamber with a diameter of 15mm, using hydrogen as the plasma working gas, the flow rate of the microwave plasma gas remains unchanged at 200L / min, the flow rate of the conventional plasma work...

Embodiment 3

[0044] Example 3 Effect of Microwave Power on Electrode Ablation Rate

[0045] When other working conditions remain unchanged, the combined use of microwave plasma and conventional plasma can significantly reduce the ablation rate of the anode, and at the same time make the ablation of the anode more uniform, thereby further improving the service life of the anode. When the ratio of microwave power to conventional power is 1:10, the anode ablation rate can be reduced from 5.8g / hr to 3.7g / hr.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com