Patents

Literature

319results about How to "Reduce ablation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

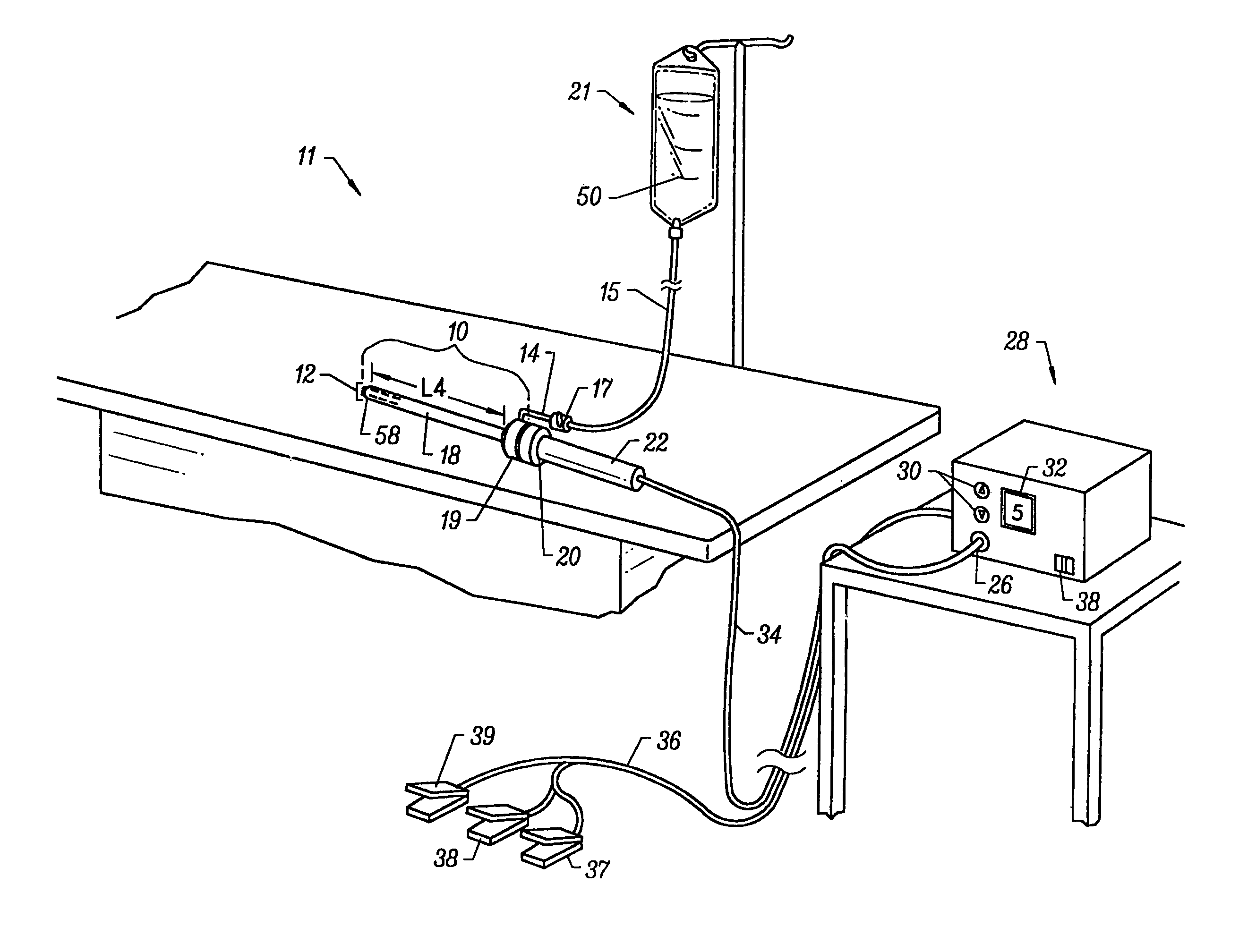

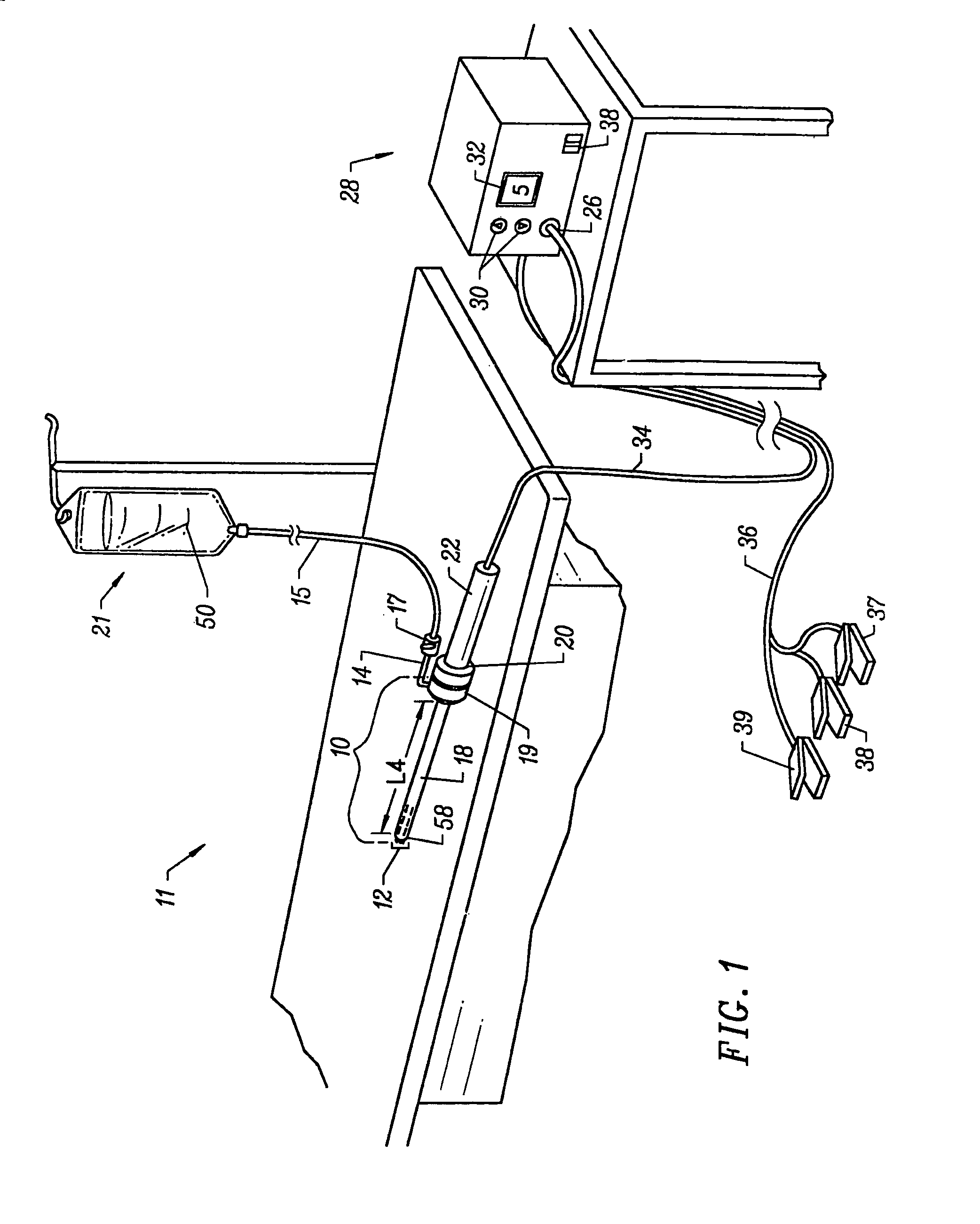

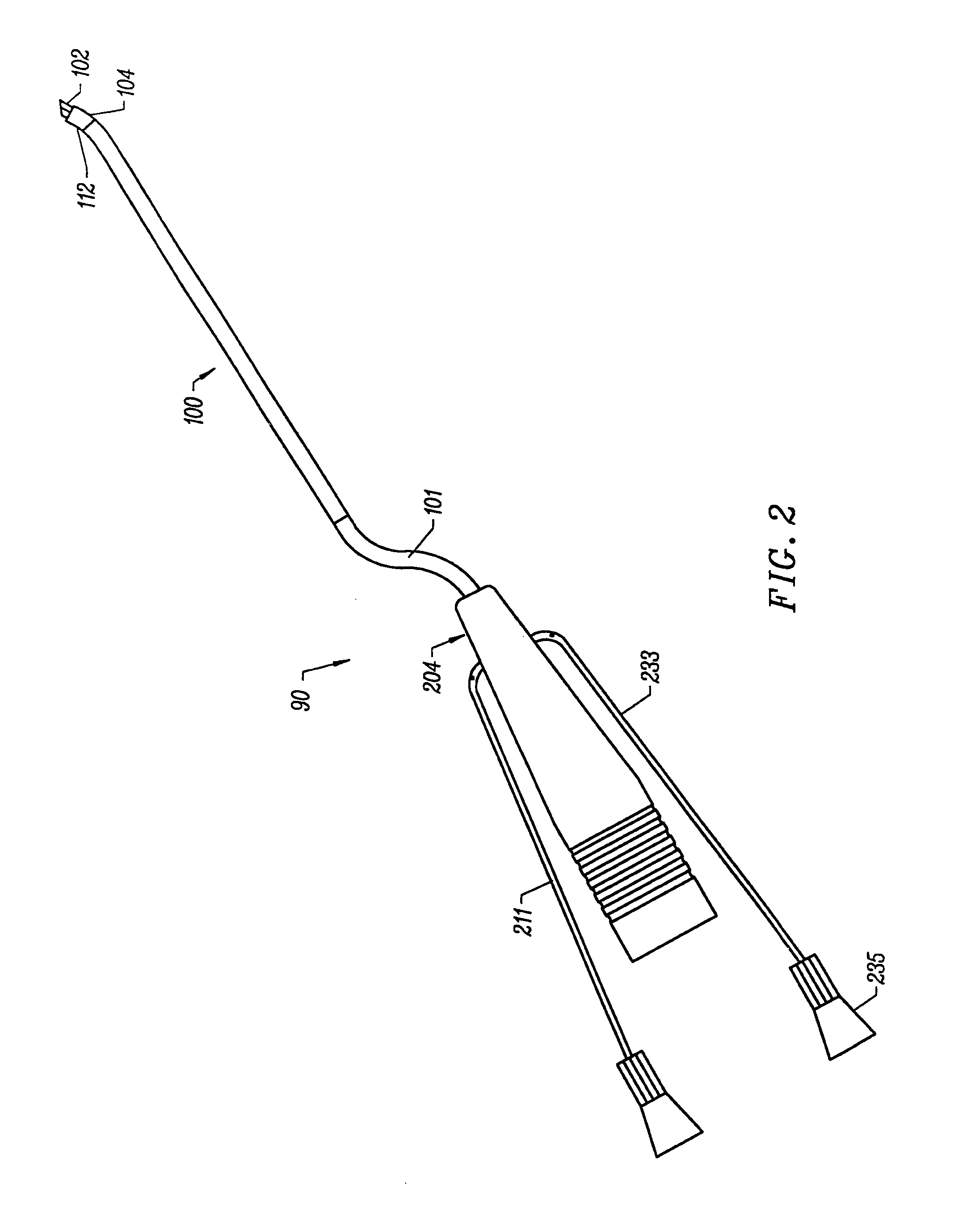

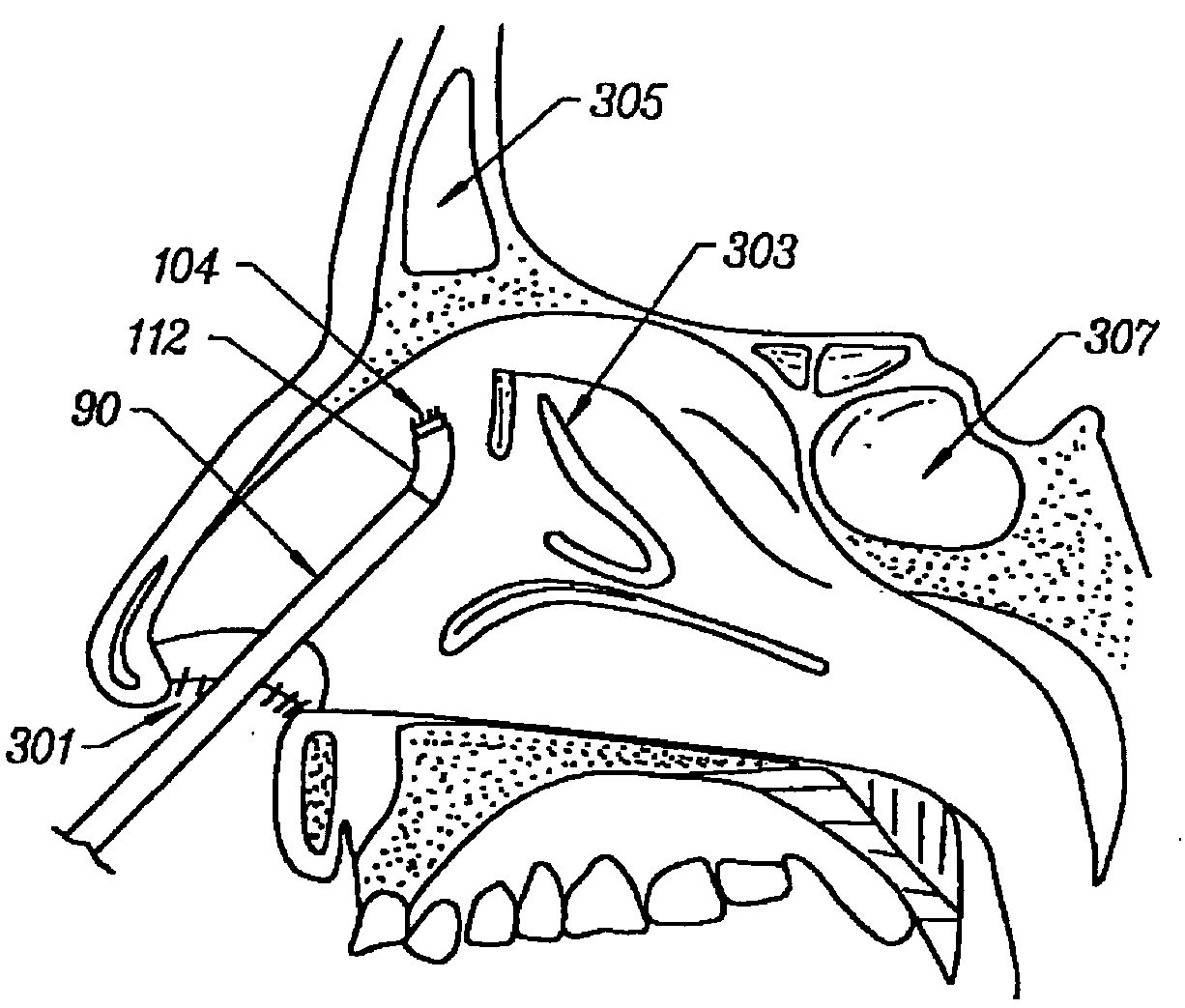

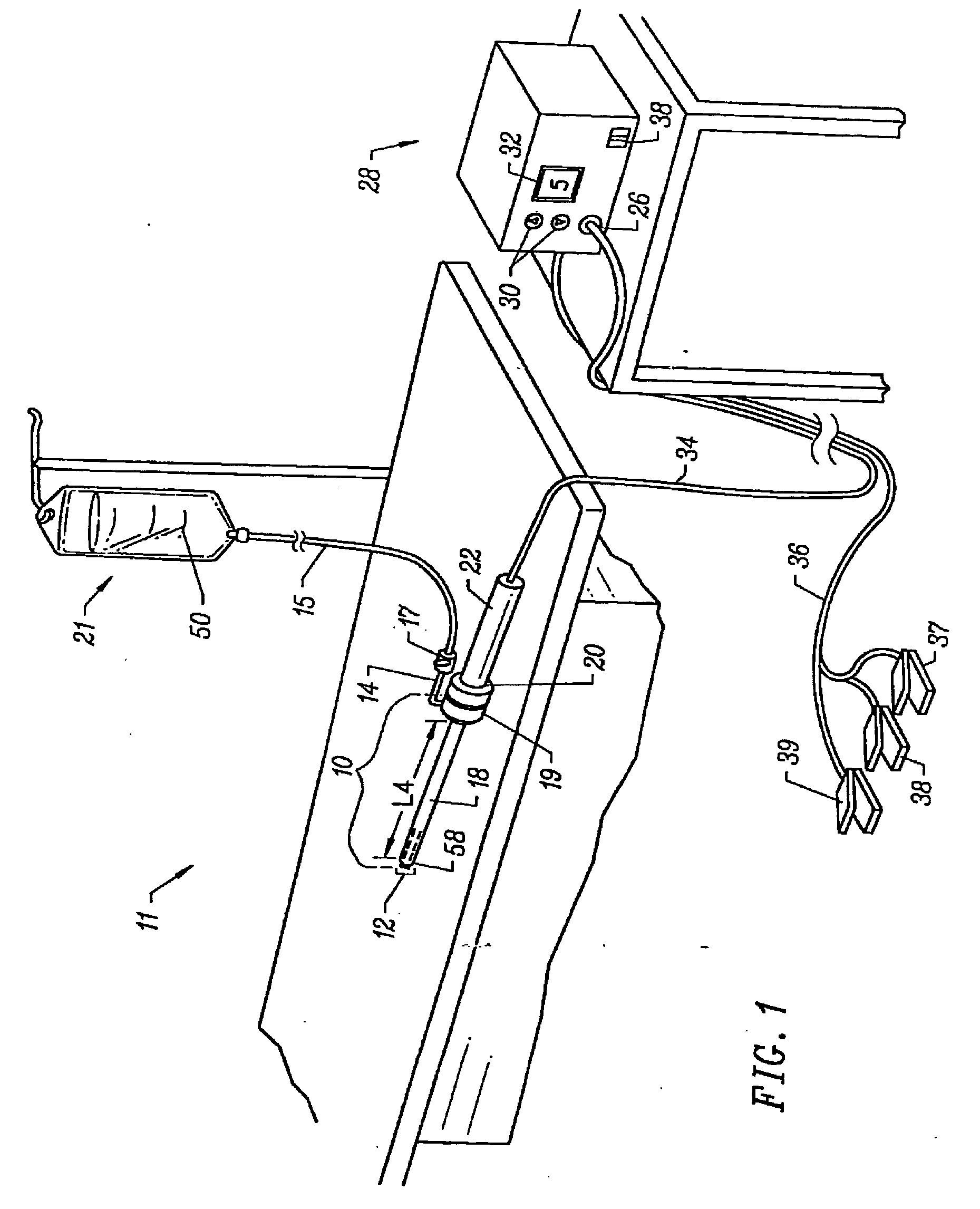

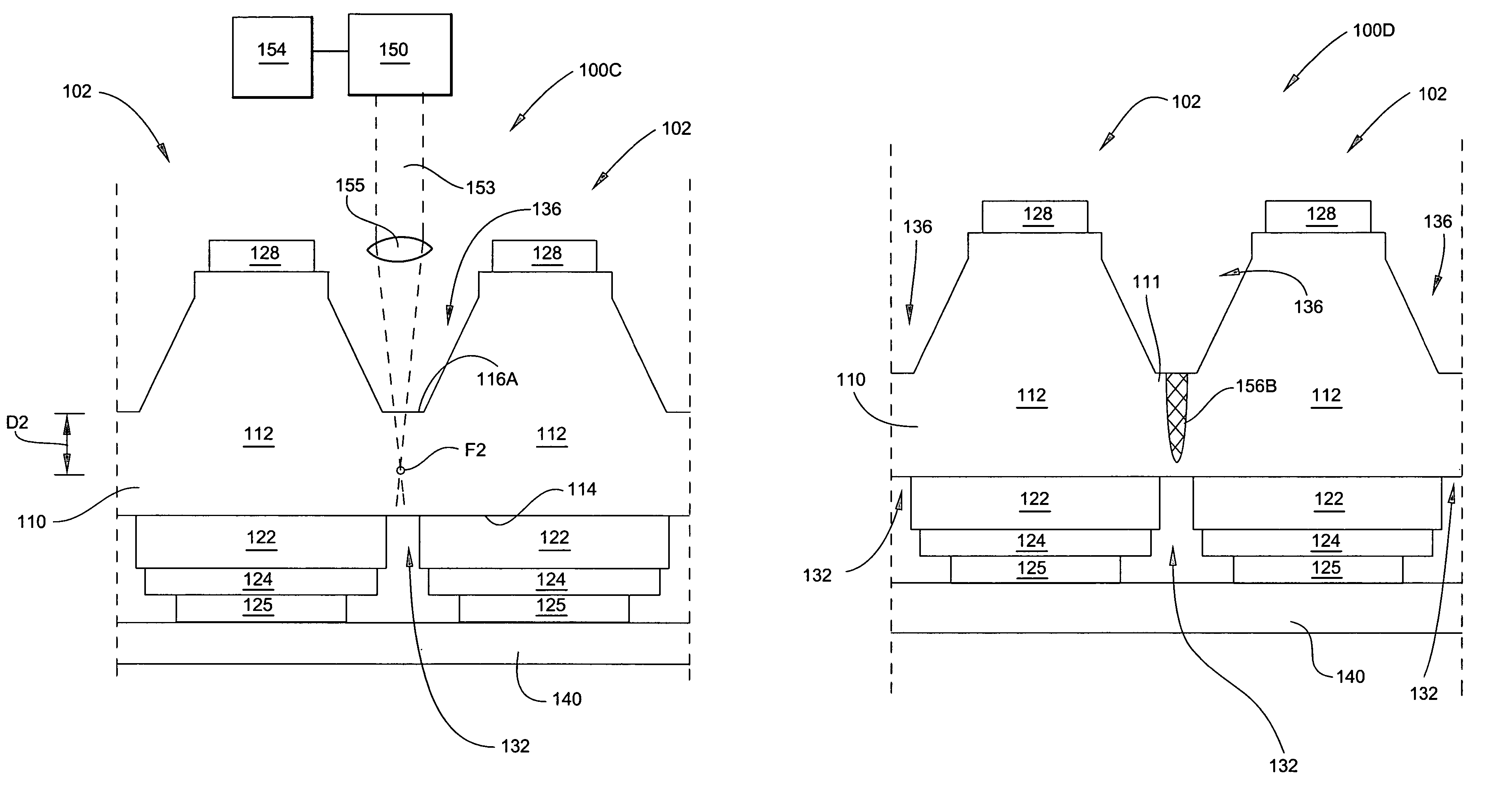

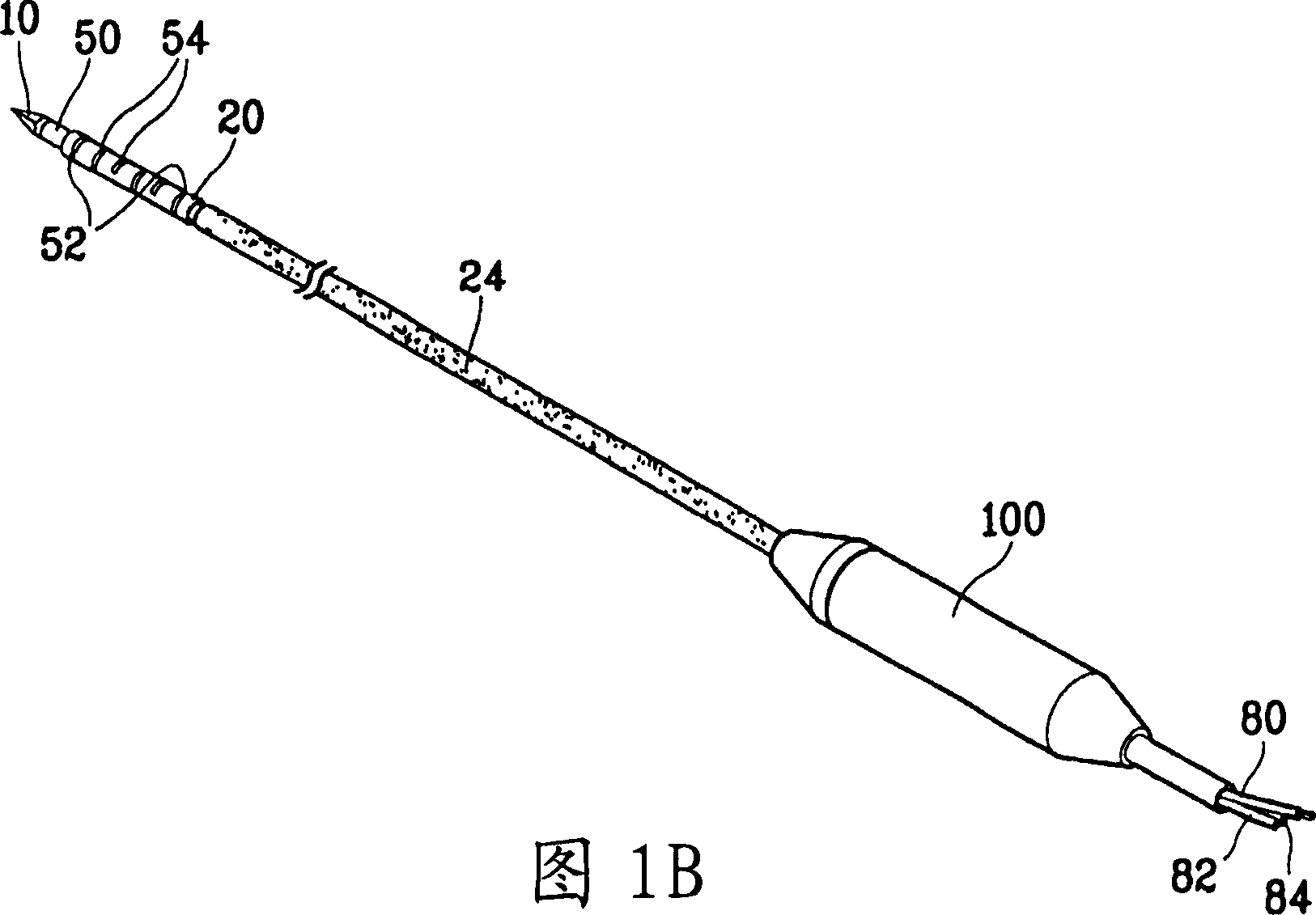

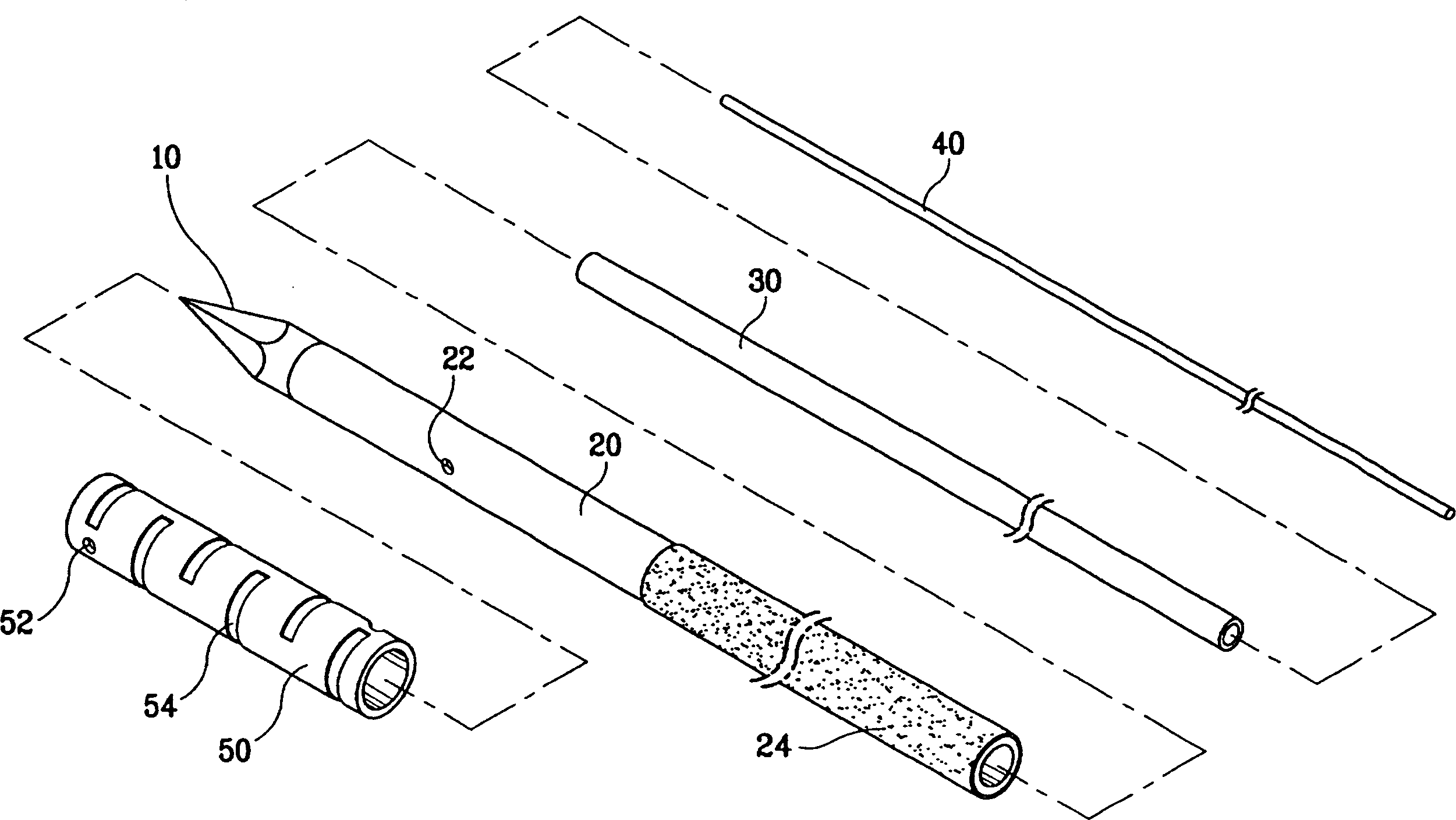

Systems and methods for electrosurgical treatment of obstructive sleep disorders

InactiveUS7131969B1Increase surface areaImprove sealingCannulasEnemata/irrigatorsThroatSleeping disorders

The present invention provides systems and methods for selectively applying electrical energy to a target location within the head and neck of a patient's body, particularly including tissue in the ear, nose and throat. The present invention applies high frequency (RF) electrical energy to one or more electrode terminals in the presence of electrically conductive fluid to remove and / or modify the structure of tissue structures. The present invention is particularly useful for treating sleep obstructive disorders, such as sleep apnea and snoring.

Owner:ARTHROCARE

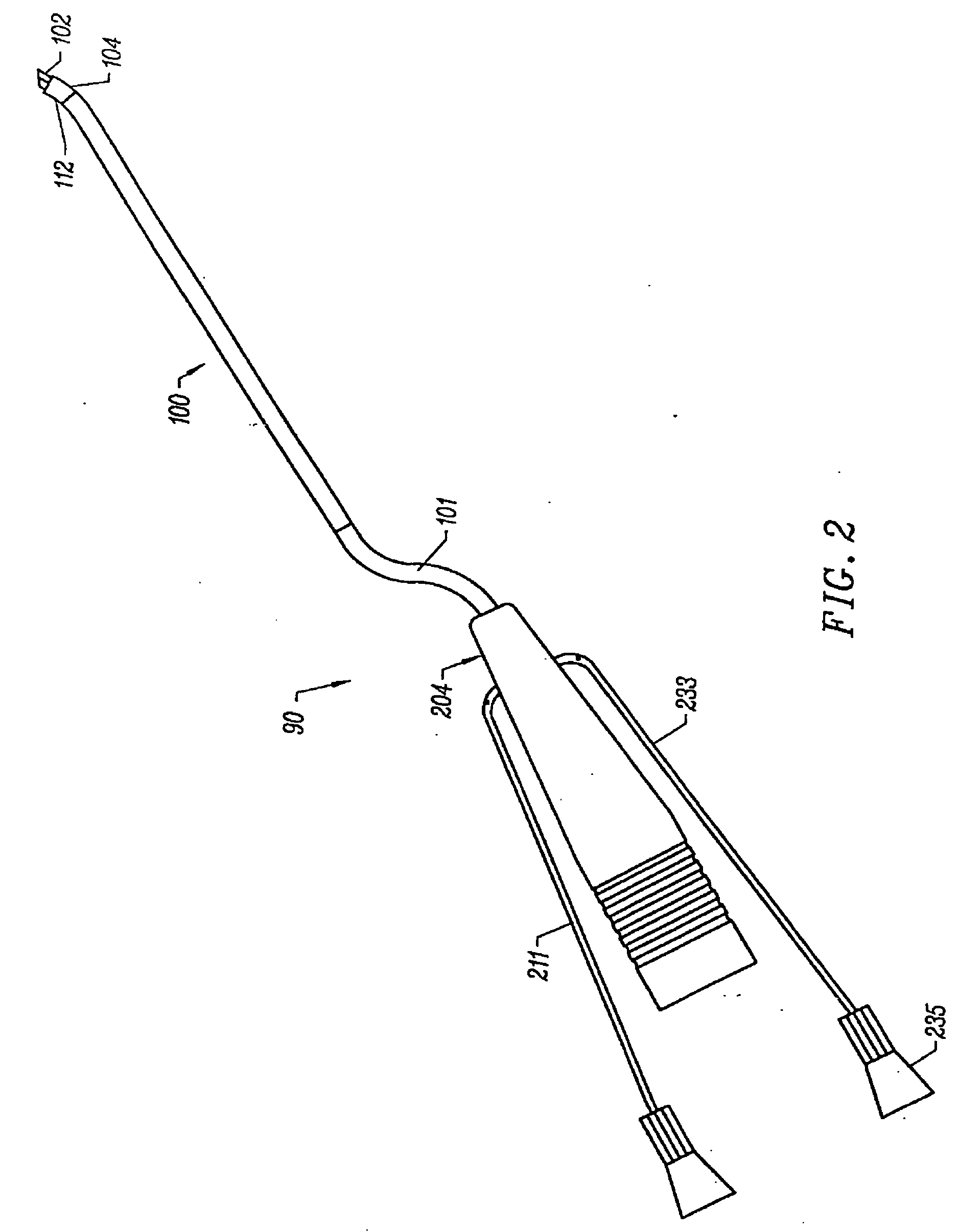

Systems and methods for electrosurgical treatment of obstructive sleep disorders

InactiveUS20060253117A1Less tissue damageReduce postoperative painCannulasEnemata/irrigatorsThroatSleeping disorders

Owner:ARTHROCARE

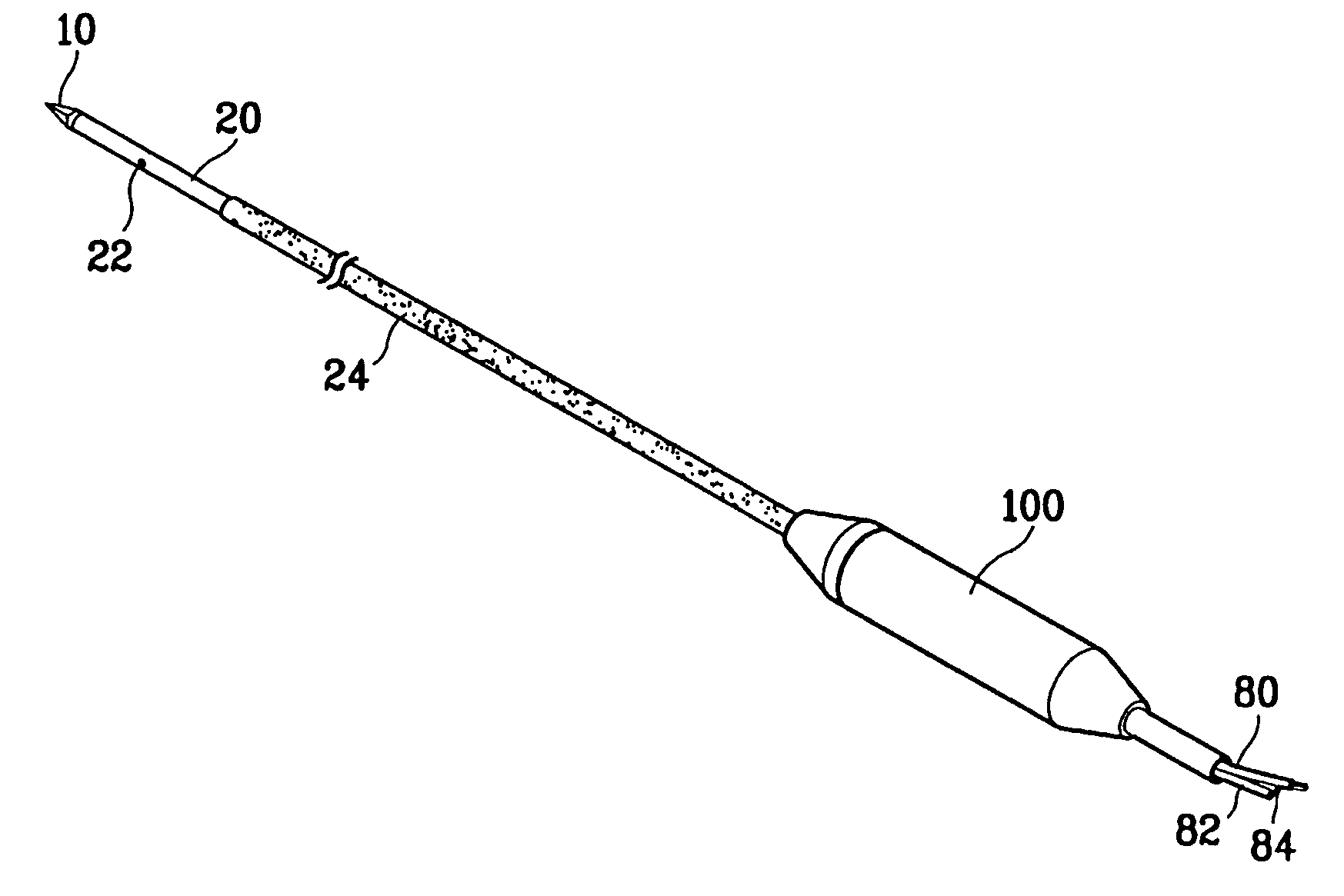

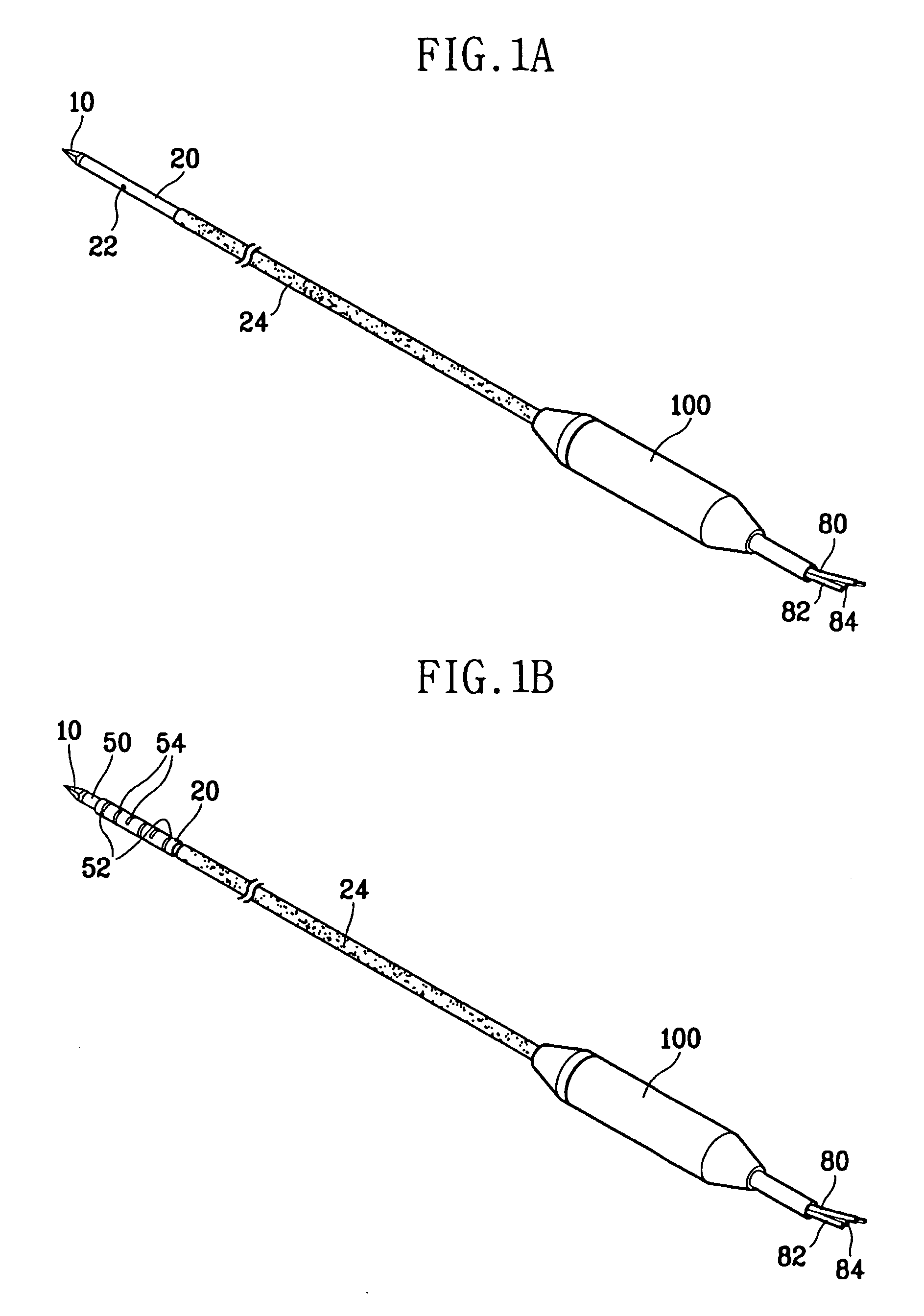

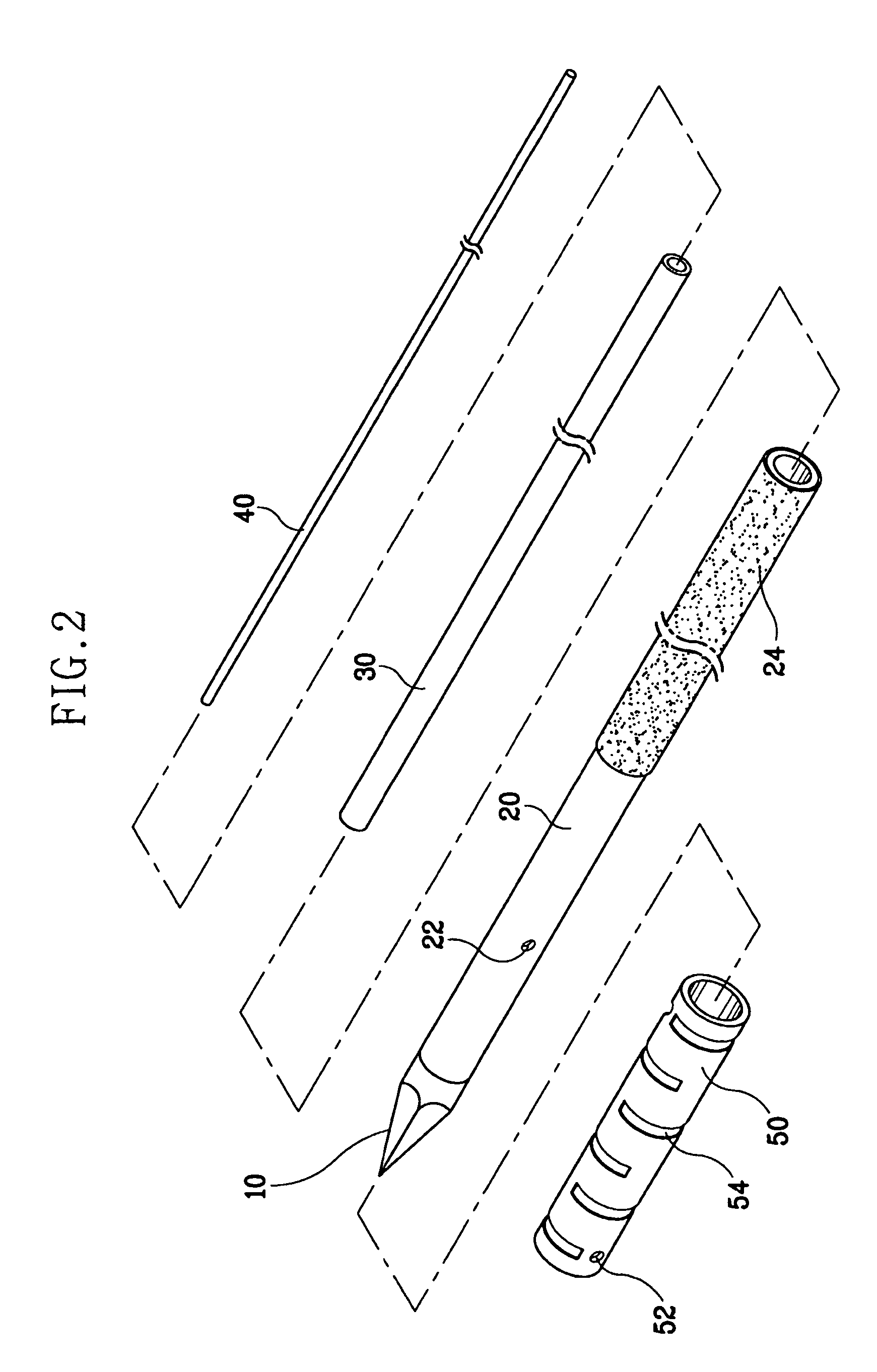

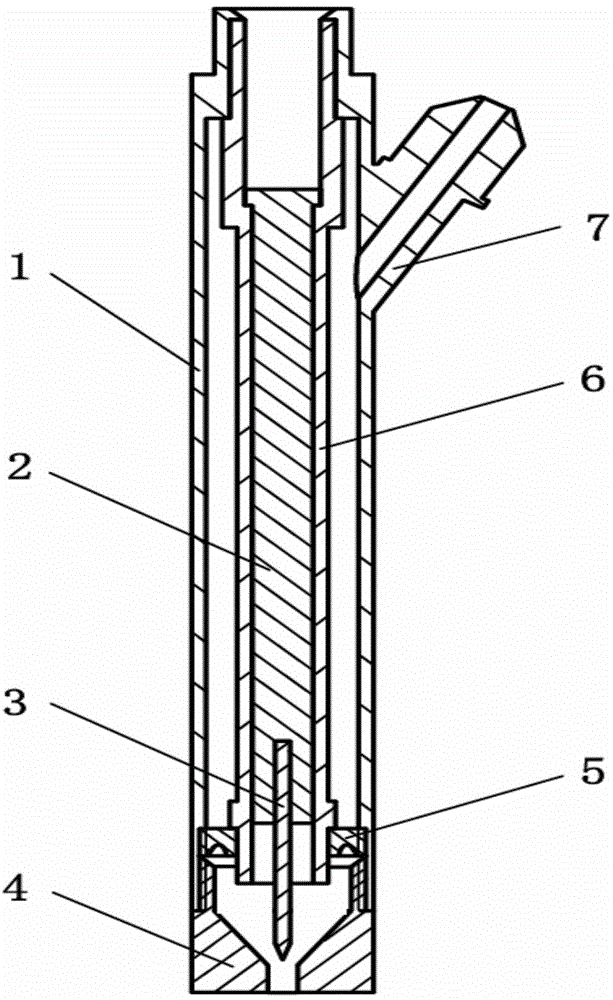

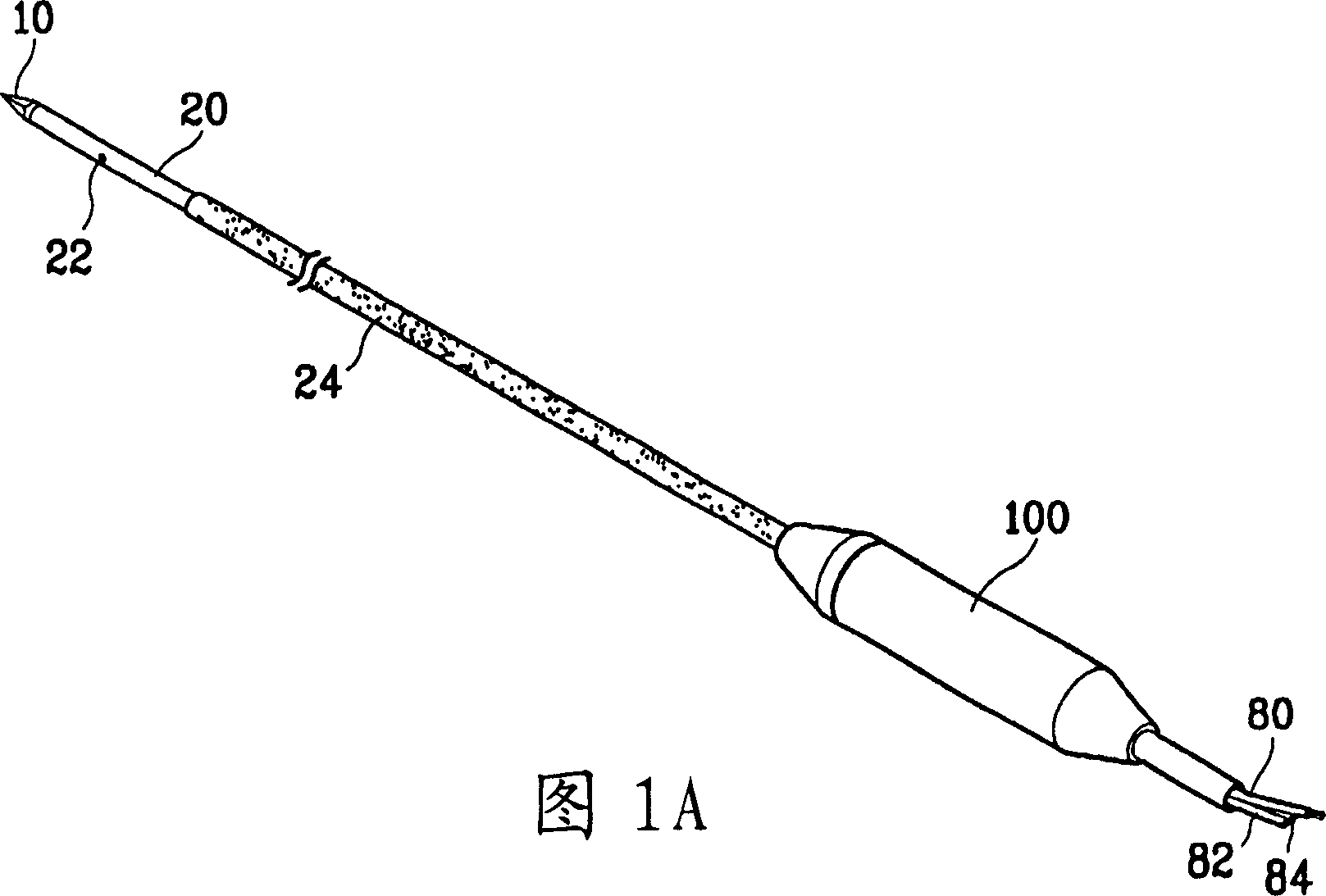

Electrode for radiofrequency tissue ablation

InactiveUS20060122593A1Facilitate ablationReduce ablationSurgical needlesSurgical instruments for heatingSaline solutionsRefrigerant

The present invention discloses an electrode for an electric operation device including a hollow electrode being formed in a hollow tube shape extended long from a closed tip, and having an insulation-coating on the outside surface except a predetermined length of the closed tip side, a refrigerant tube having a smaller diameter than a diameter of the hollow electrode, and being inserted into the hollow electrode, the refrigerant tube supplying refrigerants for cooling a living tissue contacting the closed tip and the hollow electrode into the hollow electrode, and externally discharging the heat-exchanged refrigerants from the living tissue through the gap between the refrigerant tube and the hollow electrode, at least one first hole formed on the outside surface of the hollow electrode where the insulation coating has not been formed, for externally discharging some of the refrigerants supplied through the refrigerant tube from the hollow electrode, and a flow control means formed on the outside surface of the hollow electrode where the insulation coating has not been formed, and operated as a discharge resistance to the refrigerants discharged from the first hole, for controlling a flow of the refrigerants, whereby supplying an electrode structure using both a method for water-cooling the inside of the electrode and a method for discharging the saline solution.

Owner:JUN MYONG KI

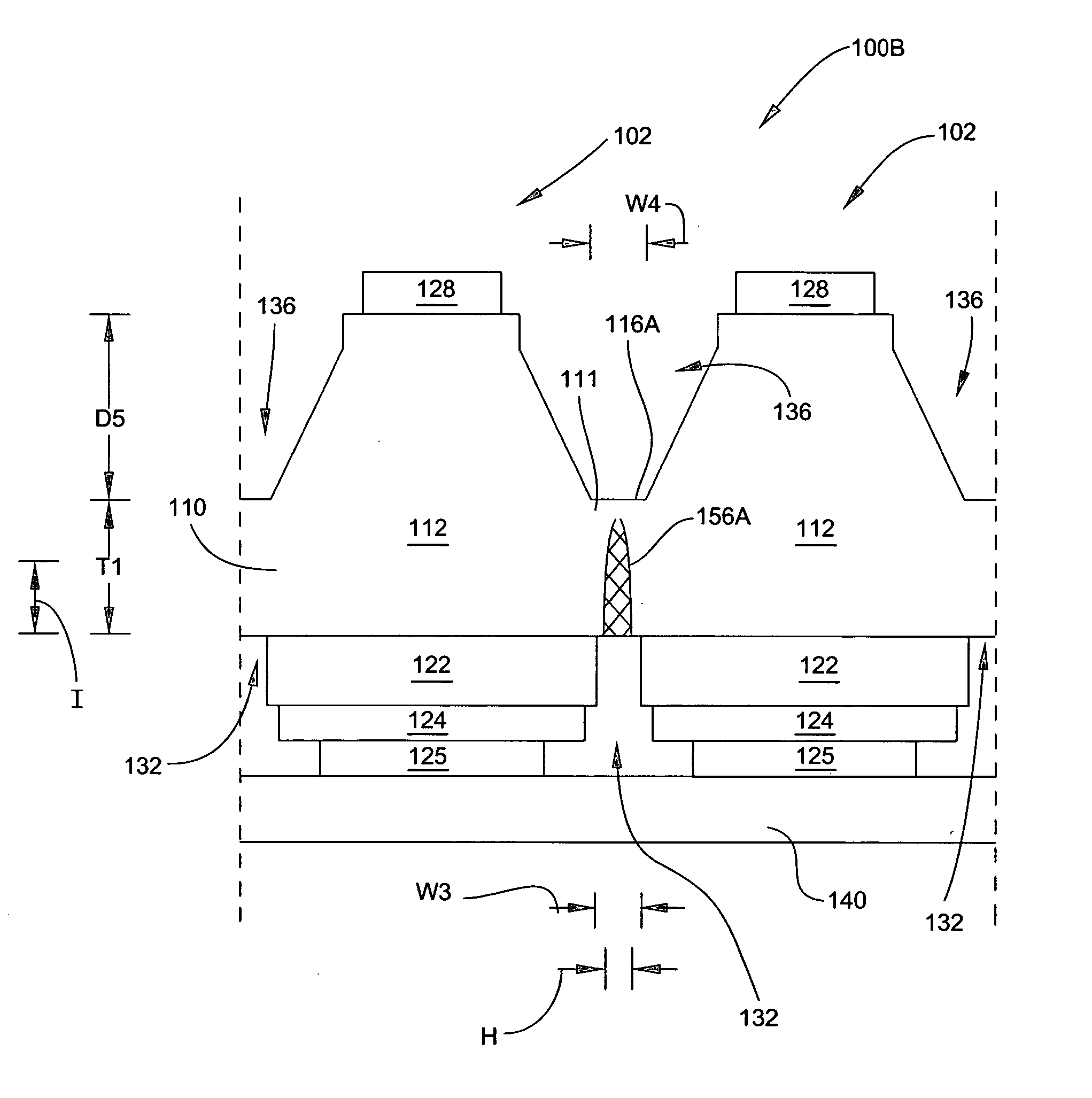

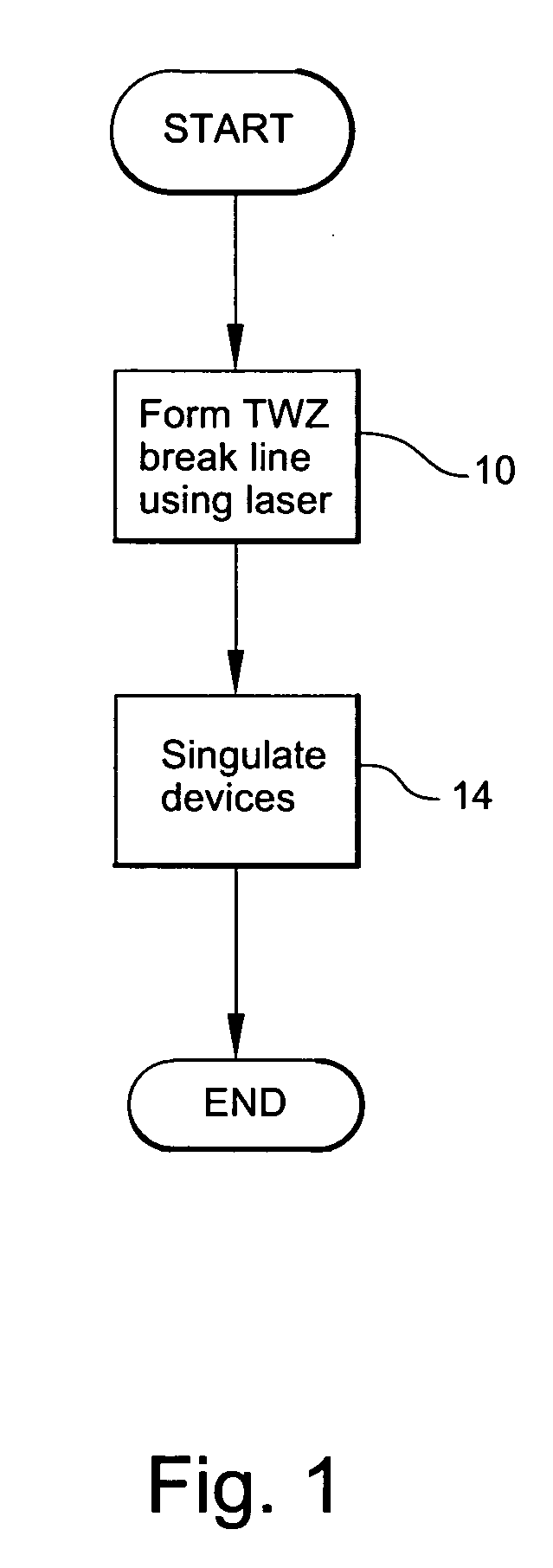

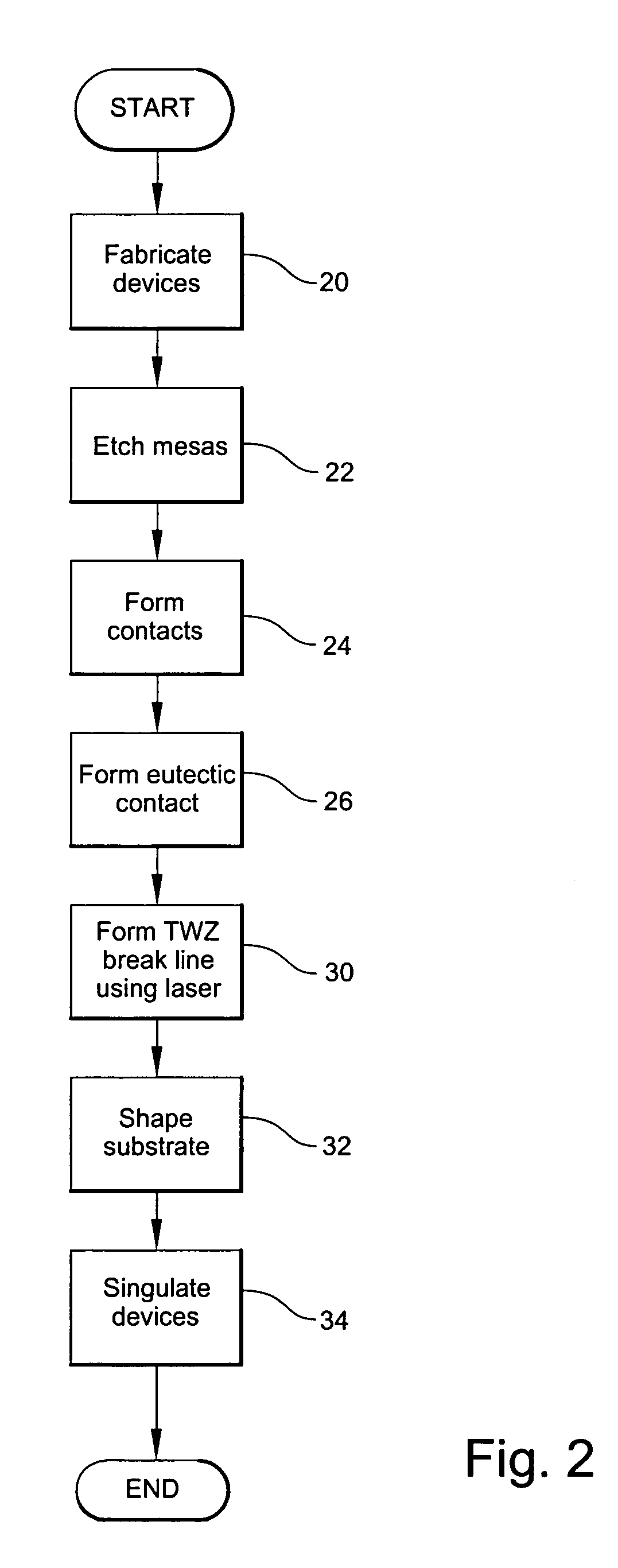

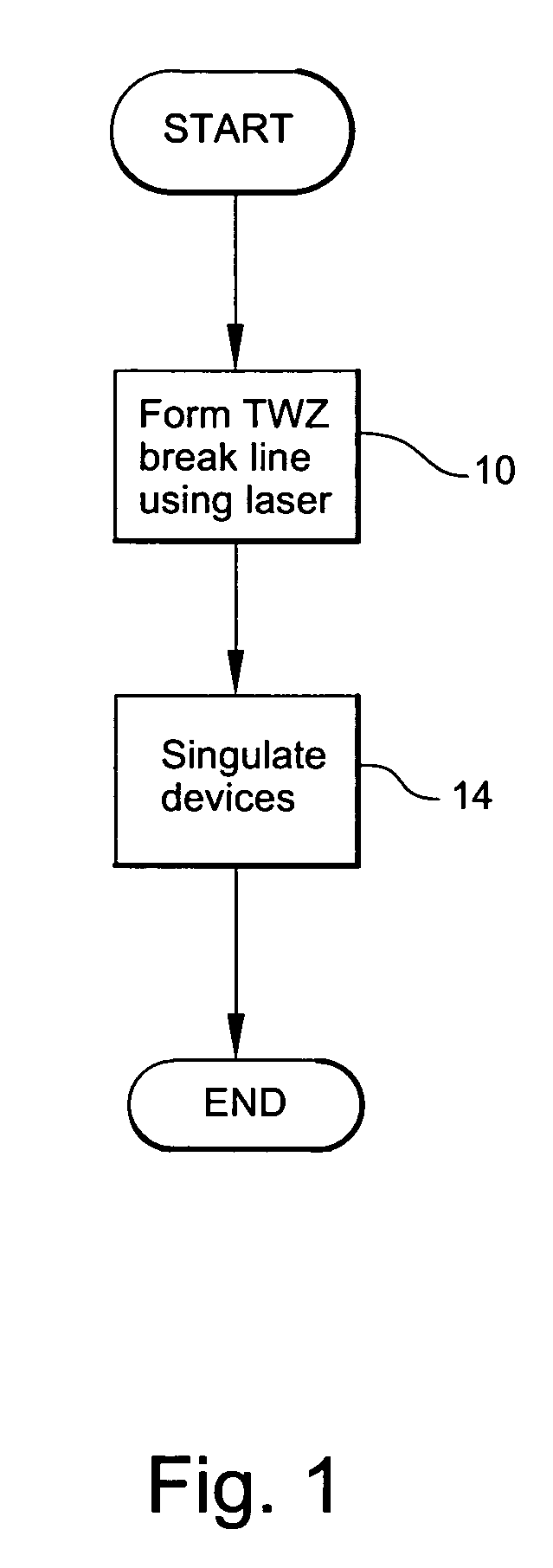

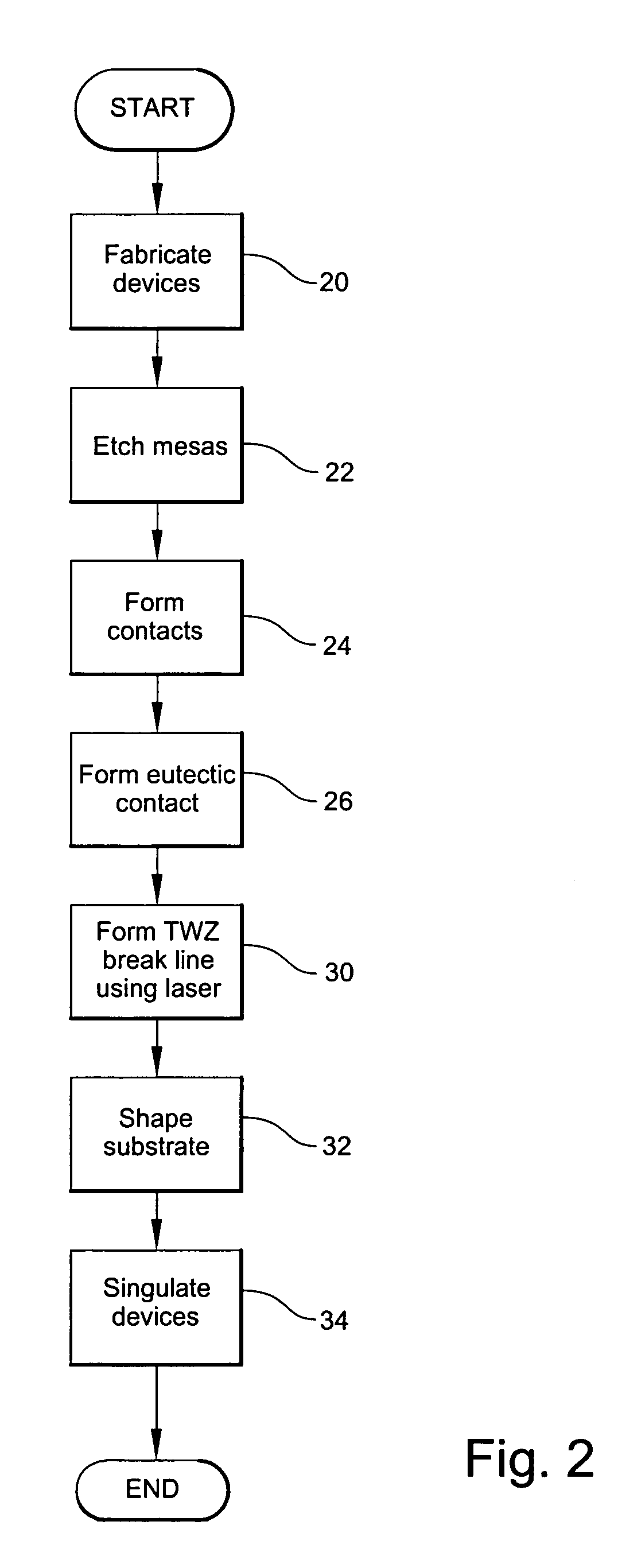

Semiconductor substrate assemblies and methods for preparing and dicing the same

ActiveUS20050130390A1High densityReduce ablationSemiconductor/solid-state device detailsSolid-state devicesLaser lightLaser beams

A method for forming semiconductor devices using a semiconductor substrate having first and second opposed surfaces and including first and second device regions includes directing a beam of laser light at the substrate such that the beam of laser light is focused within the substrate between the first and second surfaces thereof and the beam of laser light forms a thermally weakened zone (TWZ) in the substrate. The TWZ extends between the first and second device regions and defines a break line.

Owner:CREE INC

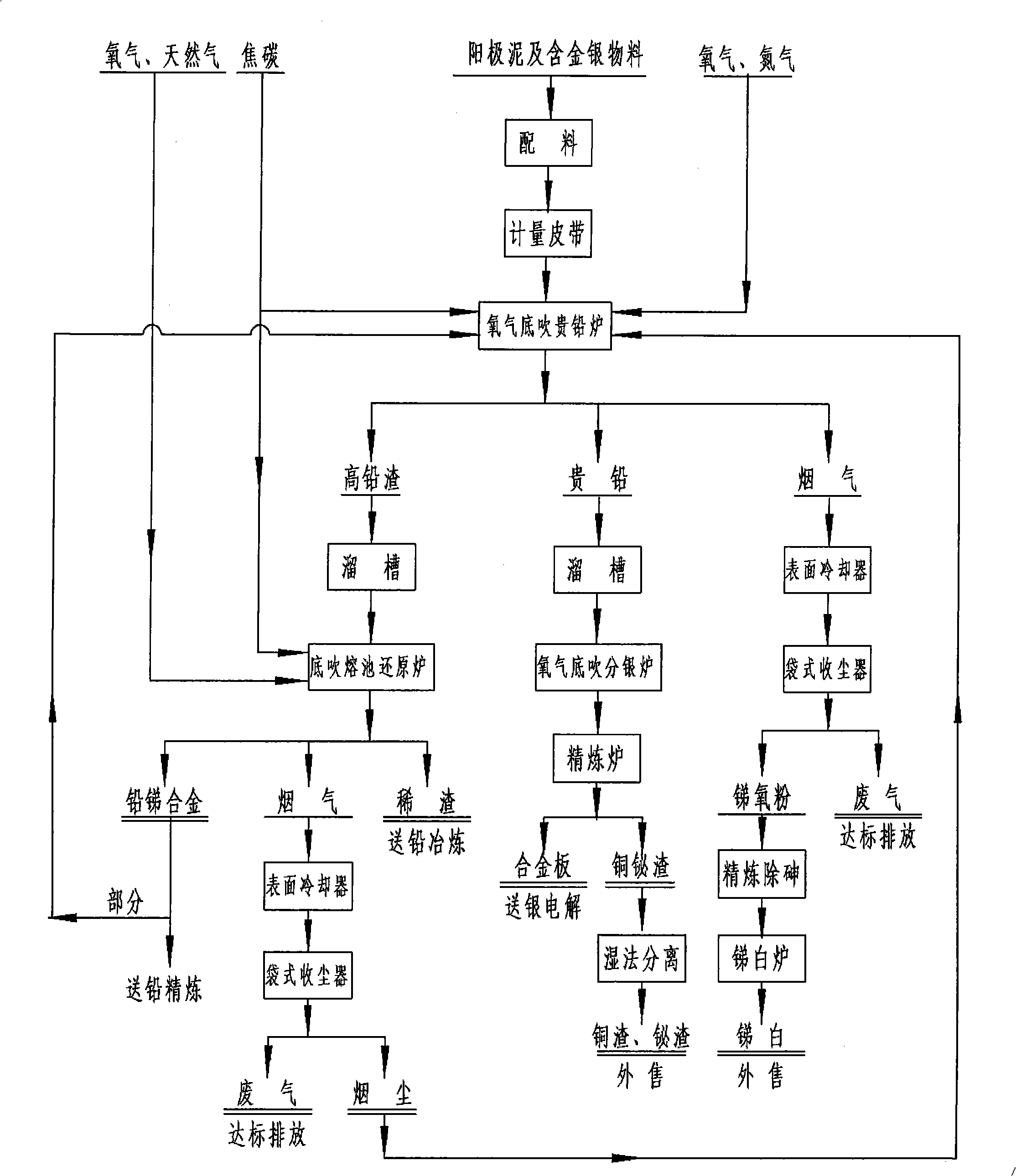

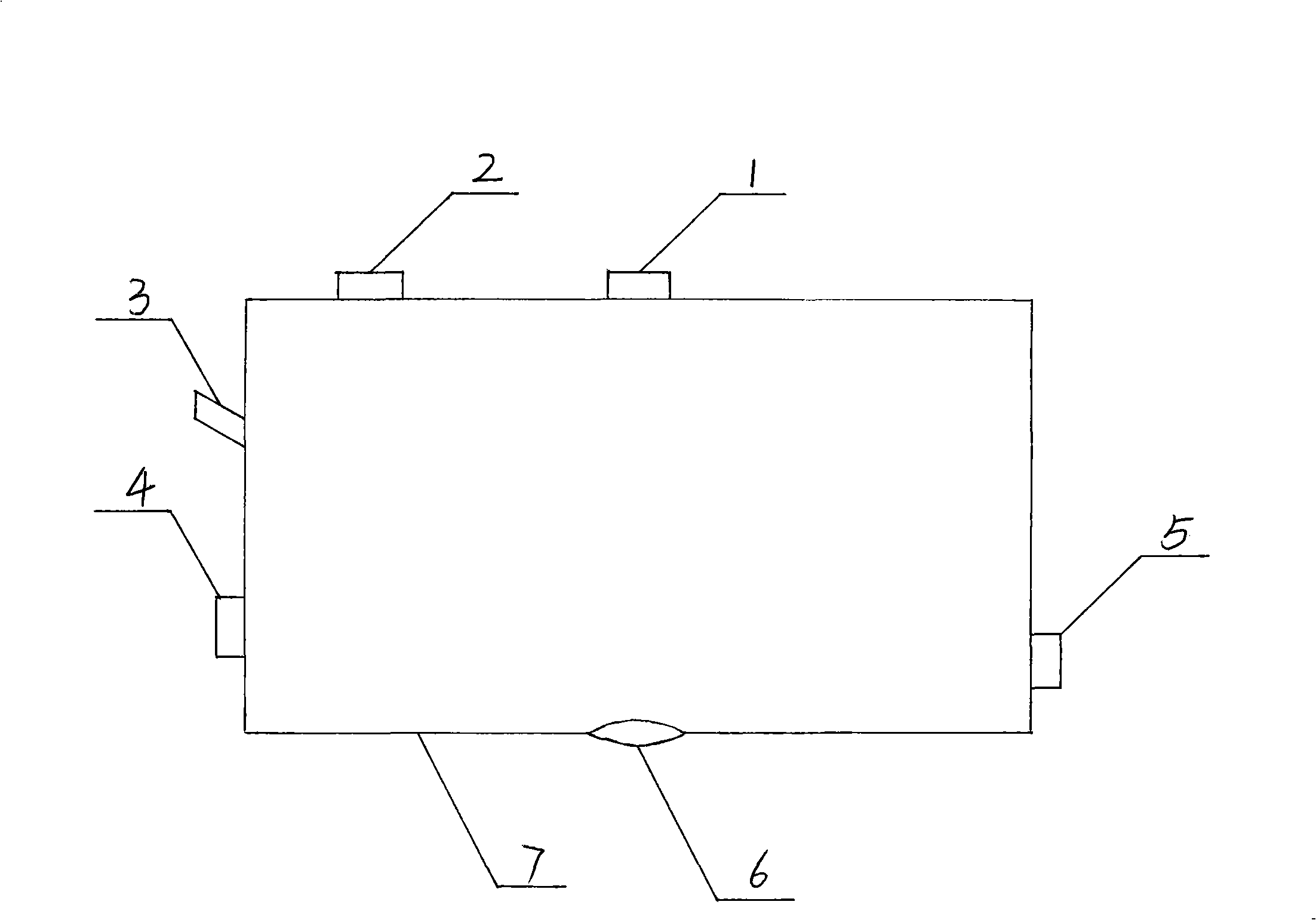

Smelting method for separating value metals from anode mud by firing process and device thereof

The present invention relates to a smelting method for separating and extracting noble and base metals during anode mud pyrogenic attack process and the device thereof, belonging to the field of nonferrous metallurgical industry. The smelting compositions only includes anode mud and nut coke, continuous oxidation-reduction smelting is carried out on the anode mud by oxygen bottom blown smelting method, gold, silver, copper and bismuth are enriched, arsenic and stibium are volatilized, silicon and lead are slagged, the smelting process is divided into two processes: one is the process of bottom oxidative slagging of oxygen and noble lead or bottom lead; the other is the process of reducing volatilization of coke on the slag surface, the two processes are two continuous combined cycle smelting processes finished in a same furnace and during the same time, the smelting process is non-alkali low-silicon high-lead-slag type, the mass ratio of the SiO2 to PbO is 0.2 to 0.5. The invention has the advantages of low cost, large handling capacity, low energy comsuption, long using period of refractory lining, high direct recovery rate of gold, silver, copper, stibium and bismuth, strong adaptability to raw materials, high automation level, etc.

Owner:HENAN YUGUANG GOLD & LEAD

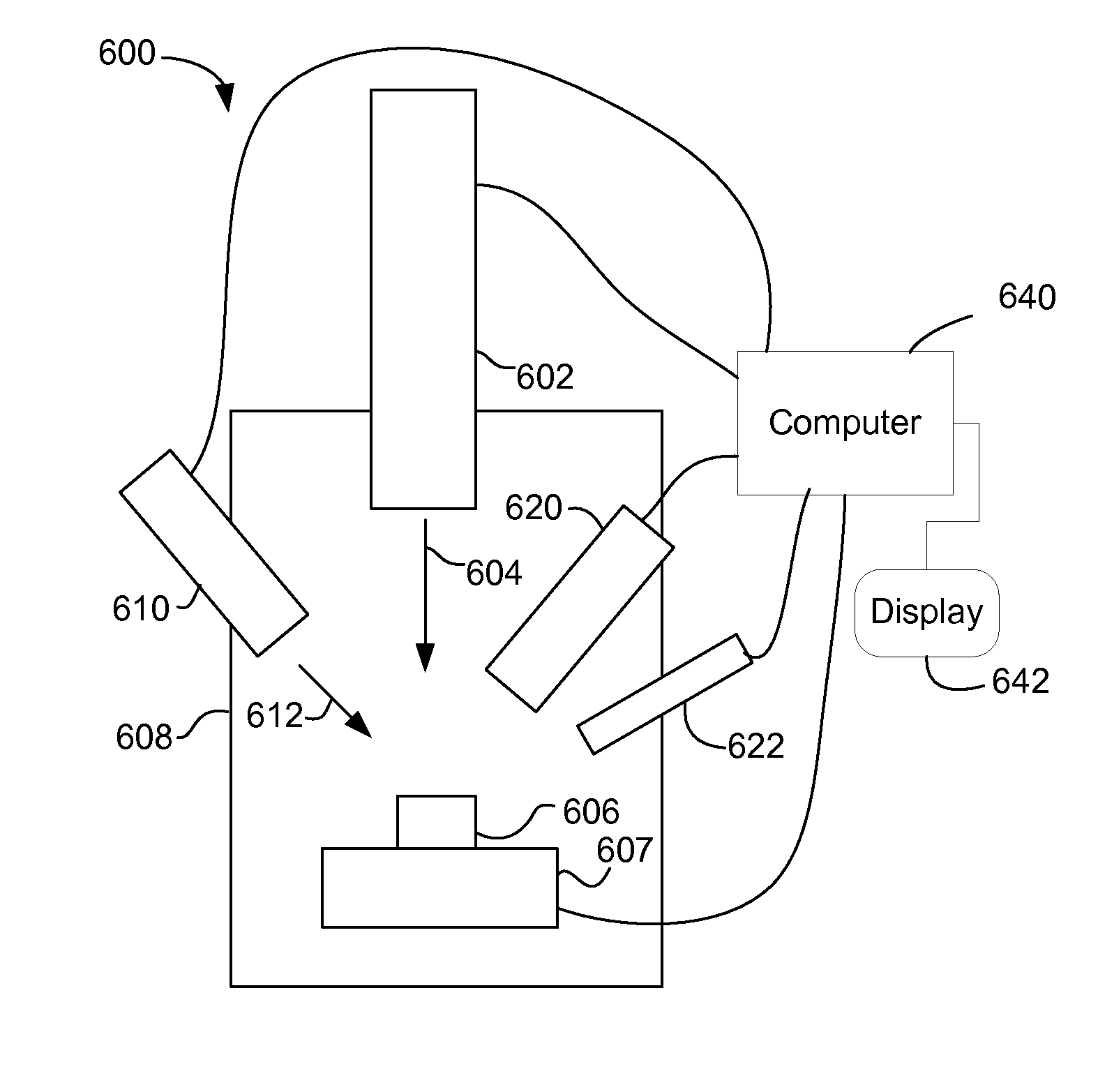

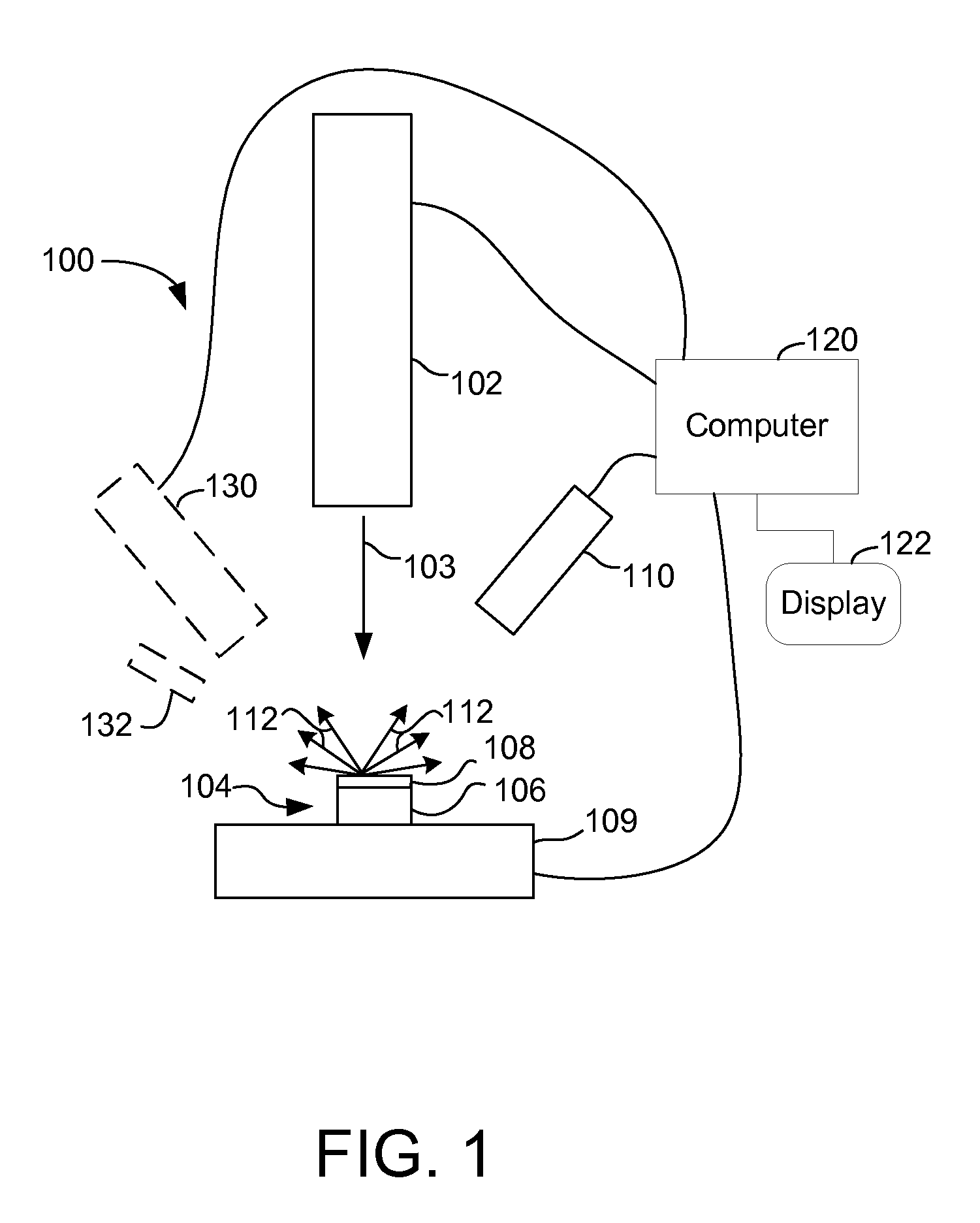

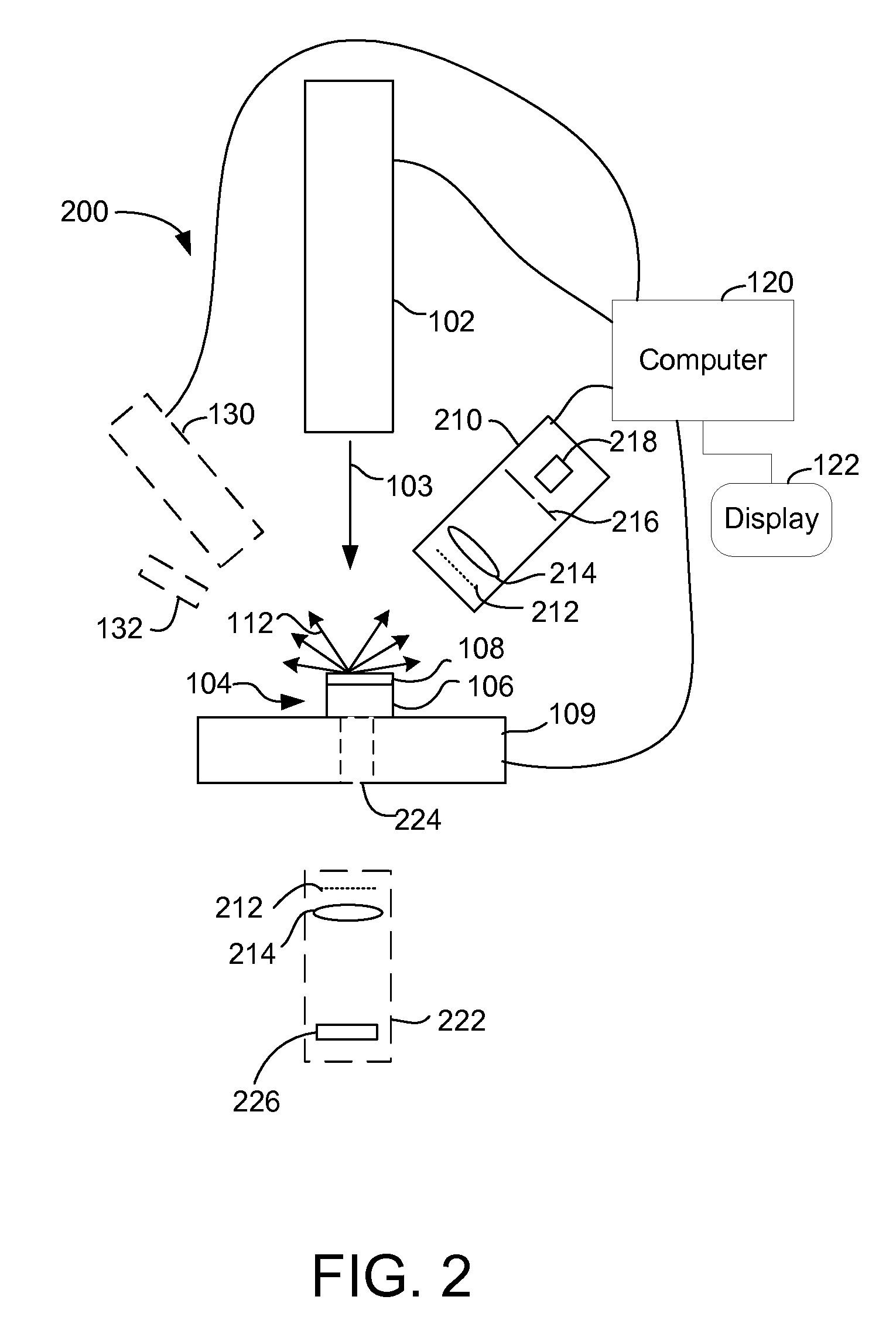

Method and Apparatus for Laser Machining

ActiveUS20110115129A1Improve micromachiningSpeed up the processElectric discharge tubesLaser beam welding apparatusLaser processingIon beam

A charged particle beam and a laser beam are used together to micromachine a substrate. A first beam alters the state of a region of the work piece, and the second beam removes material whose state was altered. In one embodiment, an ion beam can create photon absorbing defects to lower the local ablation threshold, allowing the laser beam to remove material in a region defined by the ion beam. The combination of laser beam and charged particle beam allows the creation of features similar in size to the charged particle beam spot size, at milling rates greater than charged particle processing because of the increased energy provided by the laser beam.

Owner:FEI CO

Method for preparing high specific surface area granular activated carbon by physical activation process

The invention provides a method for preparing grain active carbon with high specific surface area by a physical activation method, comprising the steps as follows: firstly, coconut shell is carbonized under high temperature; subsequently, the crushed and screened carbonization material is arranged in a microwave radiation device; by controlling activation temperature and adjusting activation time and activation gas flux, the raw material is activated so as to gain the grain active carbon product with the specific surface area more than 2200m<2> / g. The method utilizes high-temperature carbonization to improve the micro-pore structure of the carbonization material of the coconut shell, is beneficial for improving the orderly structure of the carbonization material of the coconut shell, reduces the burning of the carbon during the carbonization process and improves the yield of the active carbon product; the prepared active carbon is the grain active carbon, and the applicable range is improved.

Owner:KUNMING UNIV OF SCI & TECH

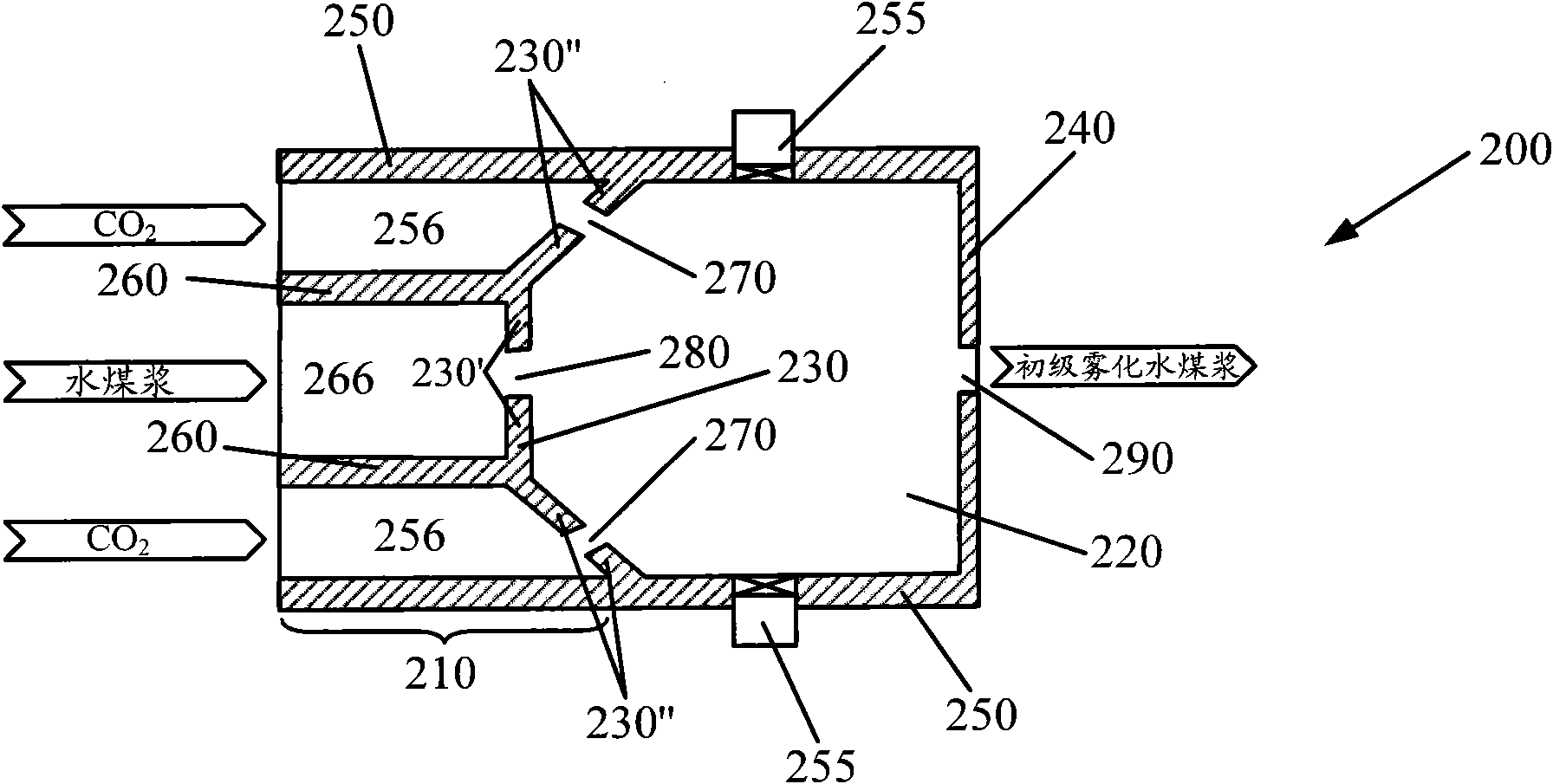

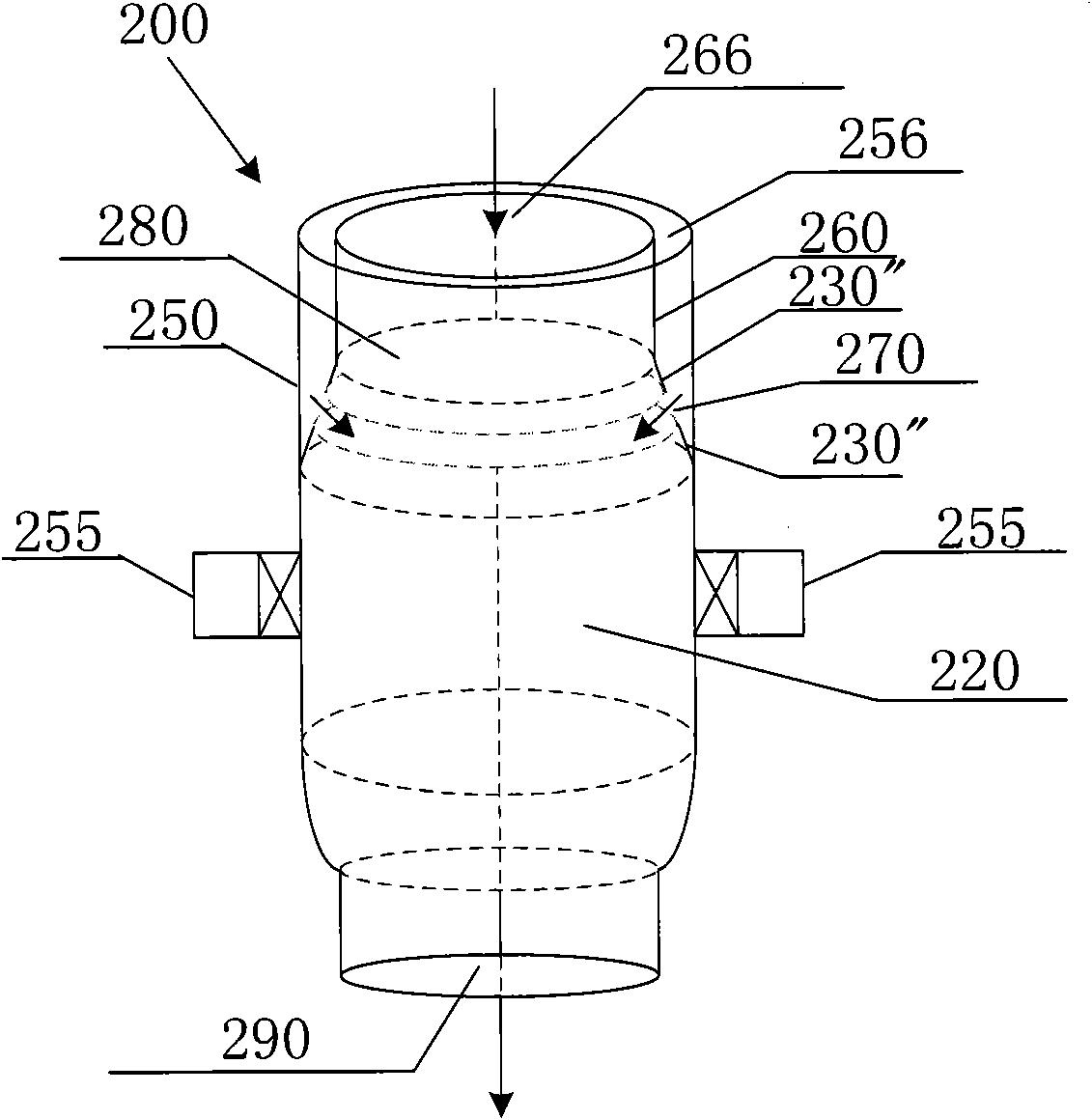

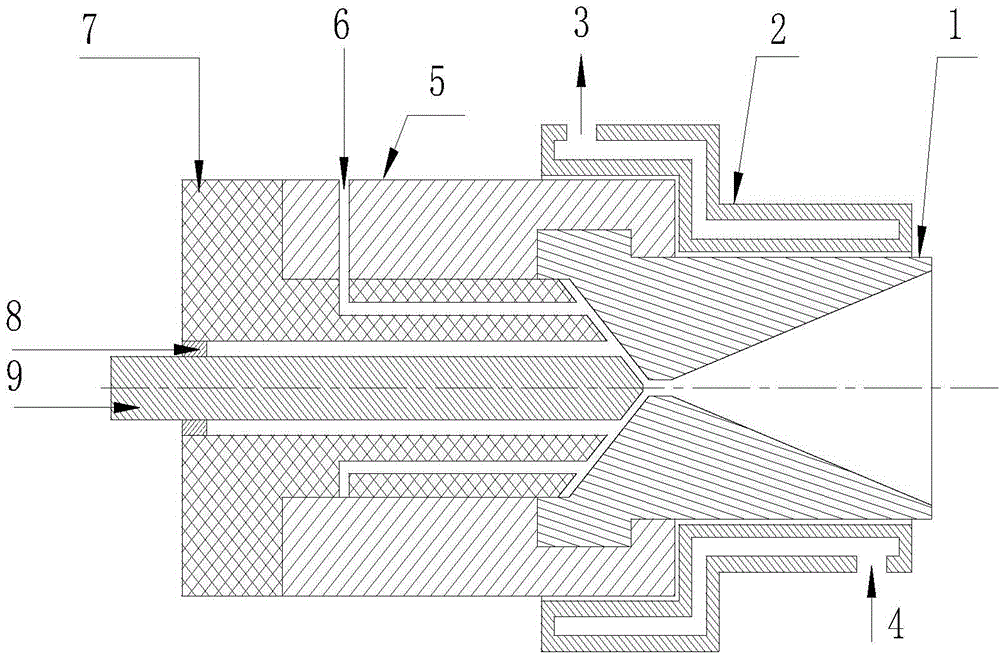

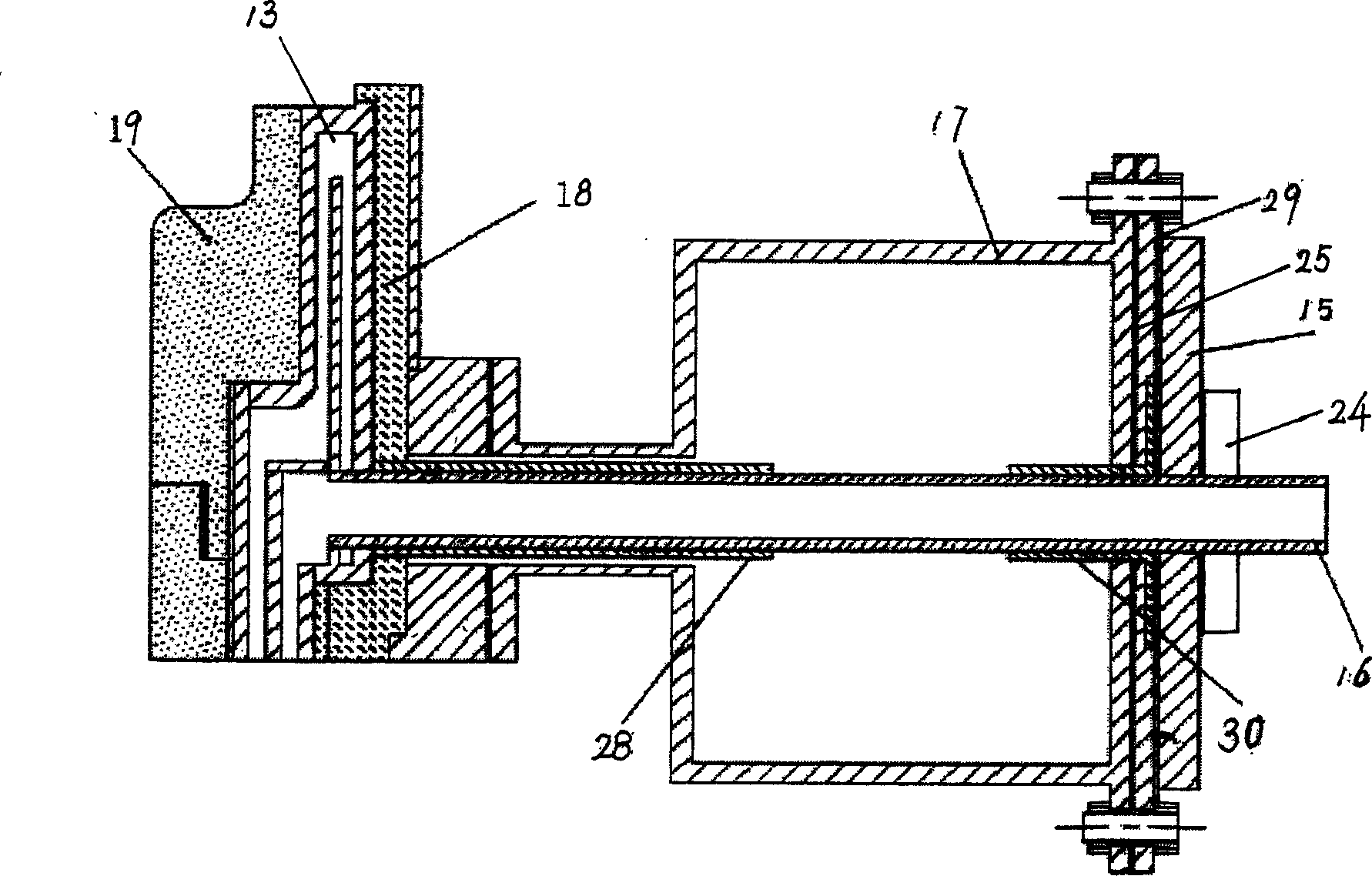

Process nozzle and system for gasifying water coal slurry and application thereof

ActiveCN102031152AEffective protectionImprove cooling effectLiquid spraying apparatusGranular/pulverulent flues gasificationCoal slurryWater jacket

The invention provides a process nozzle and a system for gasifying water coal slurry. The process nozzle comprises a first oxygen channel, a water coal slurry channel, a second oxygen channel, a first cooling water jacket and a cooling water coil, wherein the first oxygen channel comprises a first oxygen channel inlet and a first oxygen channel outlet; the water coal slurry channel comprises at least one water coal slurry channel inlet and a water coal slurry channel outlet; the second oxygen channel comprises a second oxygen channel inlet and a second oxygen channel outlet; the first cooling water jacket comprises a first cooling water jacket inlet and a first cooling water jacket outlet; and the cooling water coil comprises a cooling water coil inlet and a cooling water coil outlet. The process nozzle is characterized in that: the first oxygen channel is positioned at the central position of the process nozzle; the water coal slurry channel is positioned between the first oxygen channel and the second oxygen channel and surrounds the periphery of the first oxygen channel; and the second oxygen channel surrounds the periphery of the water coal slurry channel. The process nozzle reduces the length of combustion flame more effectively, reduces the ablation of flame on a refractory brick, promotes the mixing and atomization of water coal slurry and oxygen and improves gasification efficiency.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

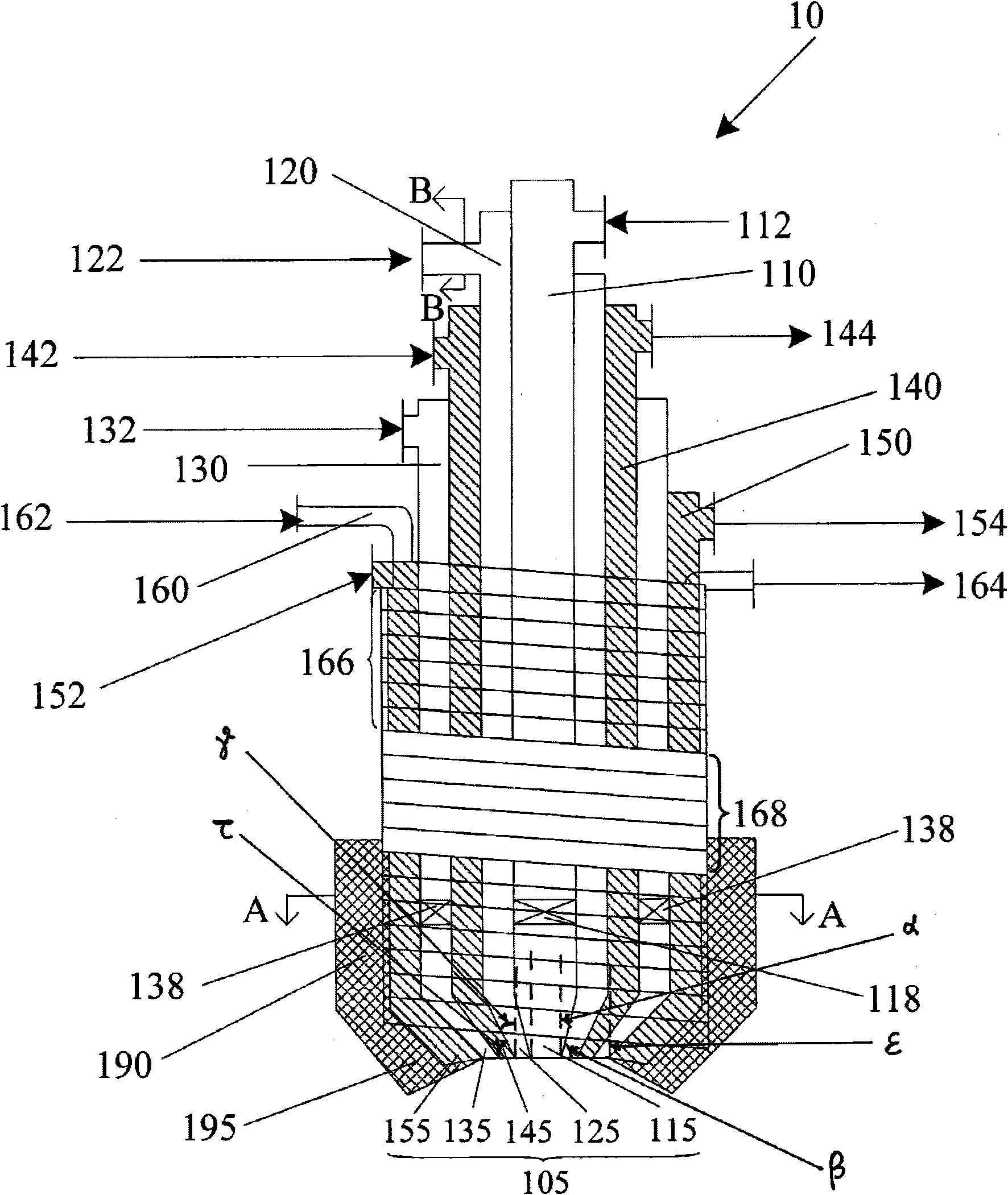

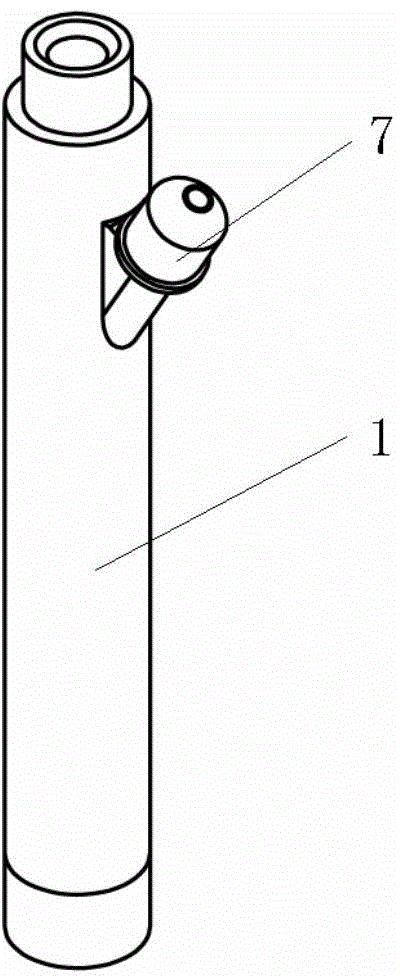

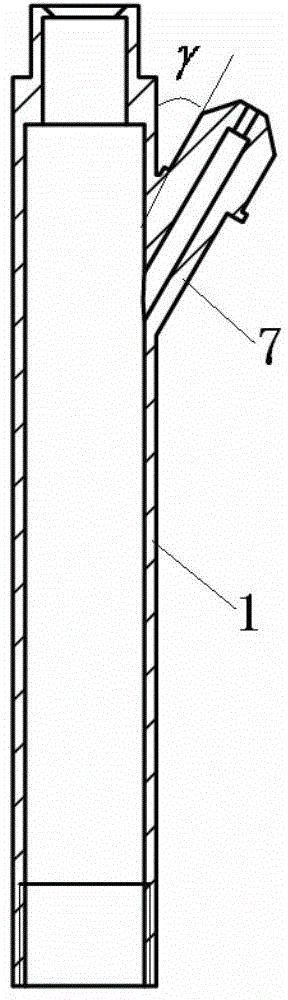

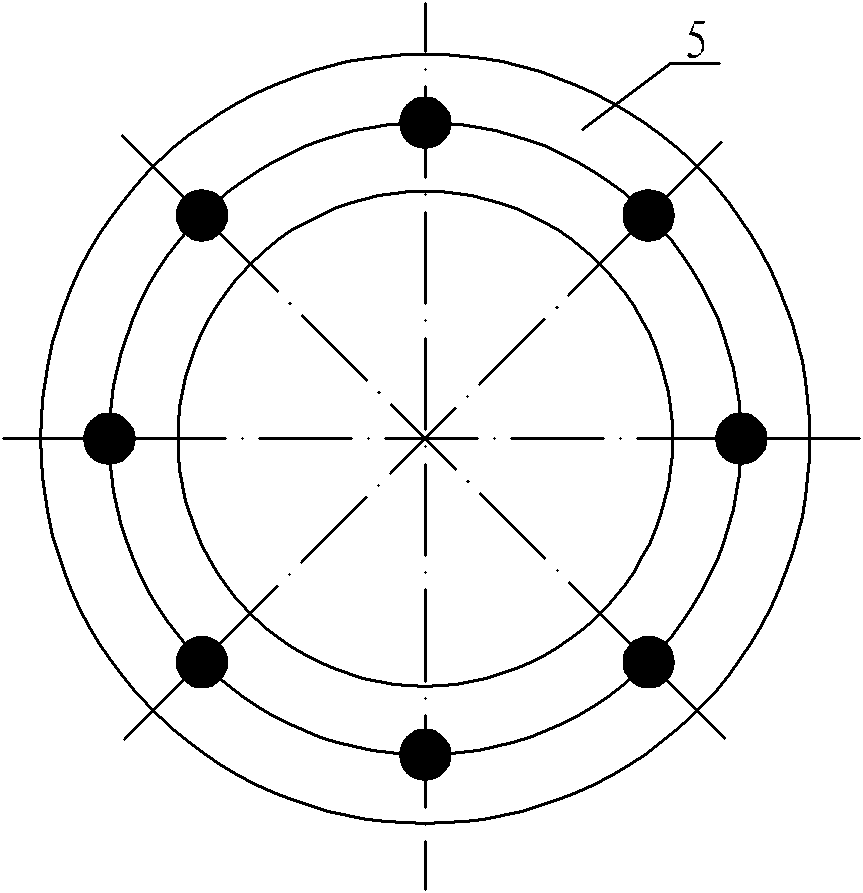

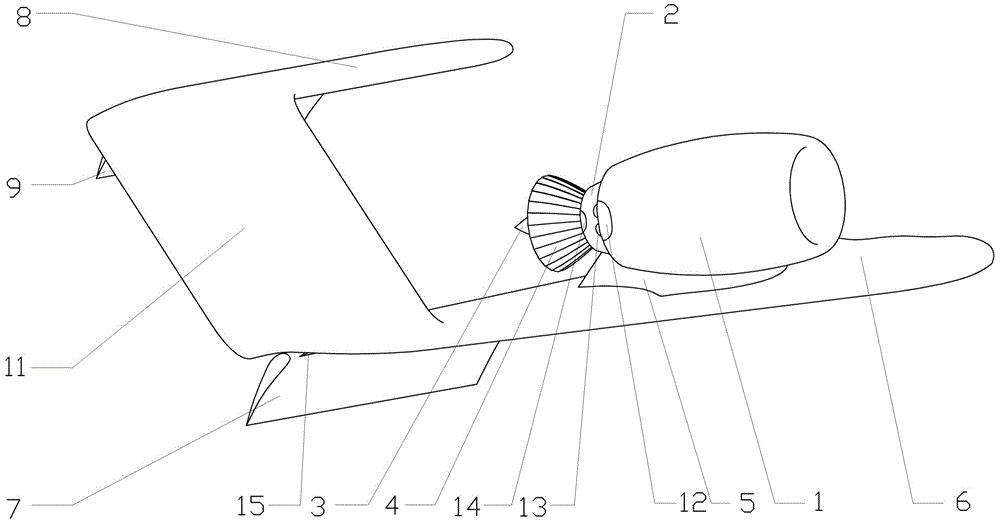

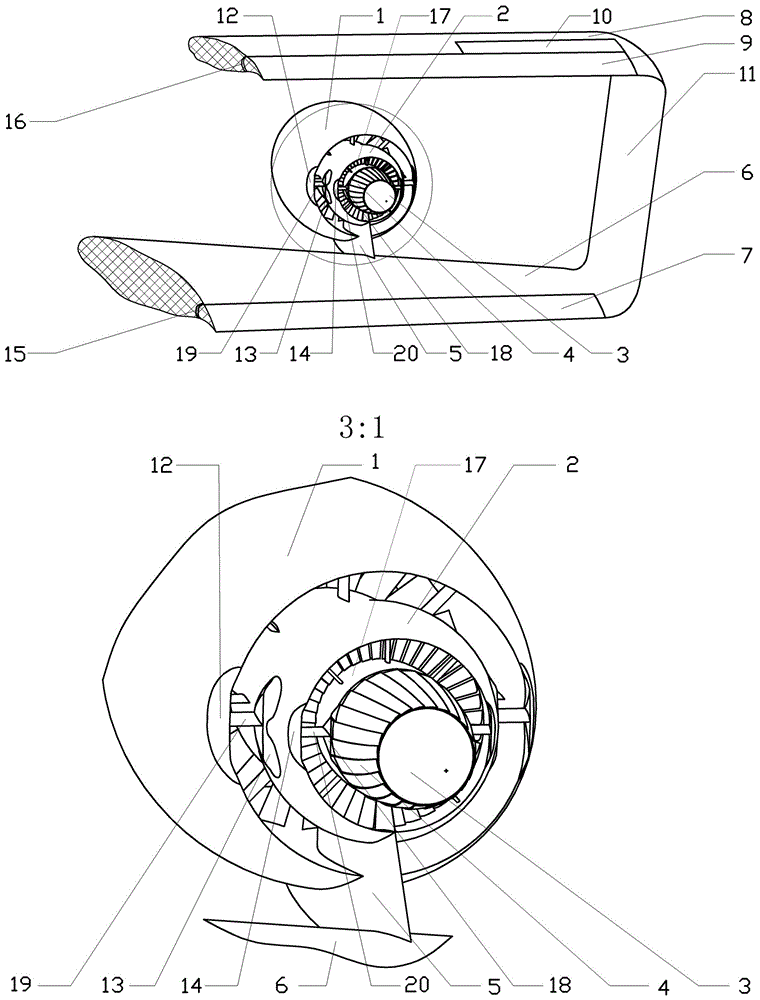

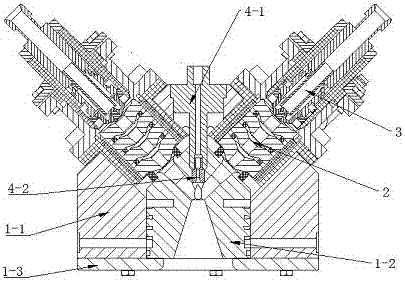

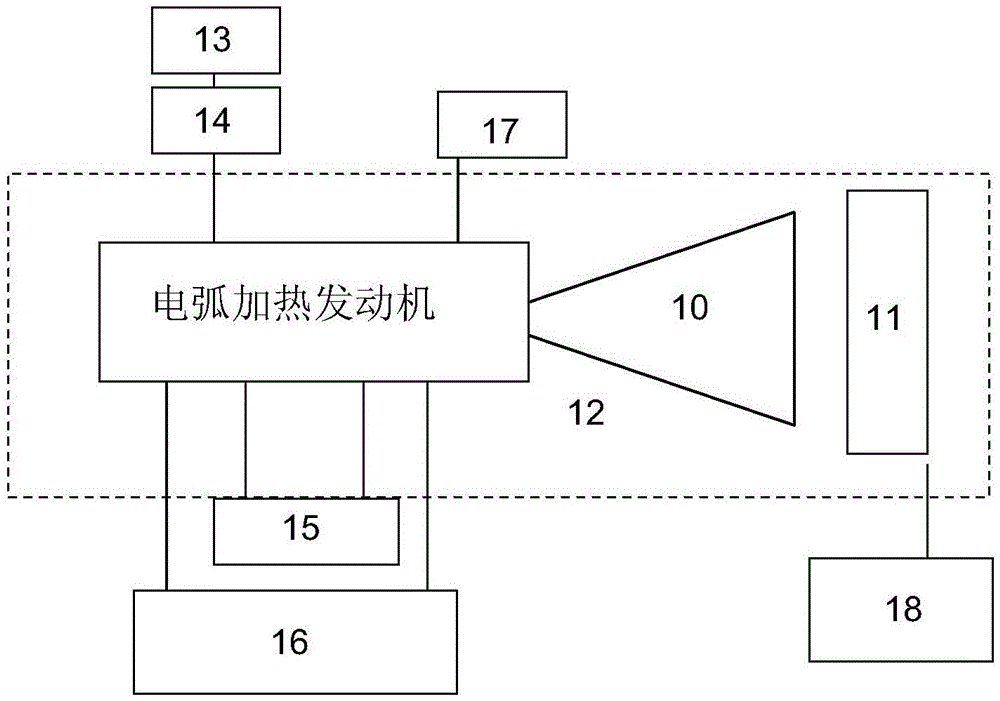

Elongating arc plasma jet ignition device

ActiveCN104454290AIncrease the speed of flame spreadStrong penetrating powerMachines/enginesEngine ignitionPlasma jetFlame spread

Disclosed is an elongating arc plasma jet ignition device. A swirler is fixed to the bottom of an inner cavity of a shell; a positive pole is located in the shell and fixedly connected with the swirler; the lower end of an insulation sleeve is installed in a central hole of the swirler, and an air chamber is formed in the gap between the outer peripheral surface of the middle of the insulation sleeve and the inner surface of the shell. A negative pole is embedded on a negative pole installation base, and the arc end of the negative pole extends out of the lower end of the insulation sleeve to be located in the positive pole. An arcing distance 2-8 mm long is kept between the arc end of the negative pole and a nozzle of the positive pole; an air inlet pipe is located at the upper end of the shell and communicated with the space of the air chamber formed between the insulation sleeve and the shell. The taper angle beta of the arc end of the negative pole is 40 degrees. The taper angle alpha of a contraction section of the positive pole is 60-90 degrees. Eight swirling holes with the spiral angle of 45 degrees are evenly distributed in an end surface of the swirler, and work media passing through the swirler generate swirling flow. The elongating arc plasma jet ignition device has the advantages of being high in flame spreading speed, high in penetrating power and rich in active air plasma.

Owner:AIR FORCE UNIV PLA

Silver-copper-based metal oxide electrical contact material containing additive elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

Semiconductor substrate assemblies and methods for preparing and dicing the same

ActiveUS7008861B2High densityReduce ablationSemiconductor/solid-state device detailsSolid-state devicesLaser lightLaser beams

A method for forming semiconductor devices using a semiconductor substrate having first and second opposed surfaces and including first and second device regions includes directing a beam of laser light at the substrate such that the beam of laser light is focused within the substrate between the first and second surfaces thereof and the beam of laser light forms a thermally weakened zone (TWZ) in the substrate. The TWZ extends between the first and second device regions and defines a break line.

Owner:CREE INC

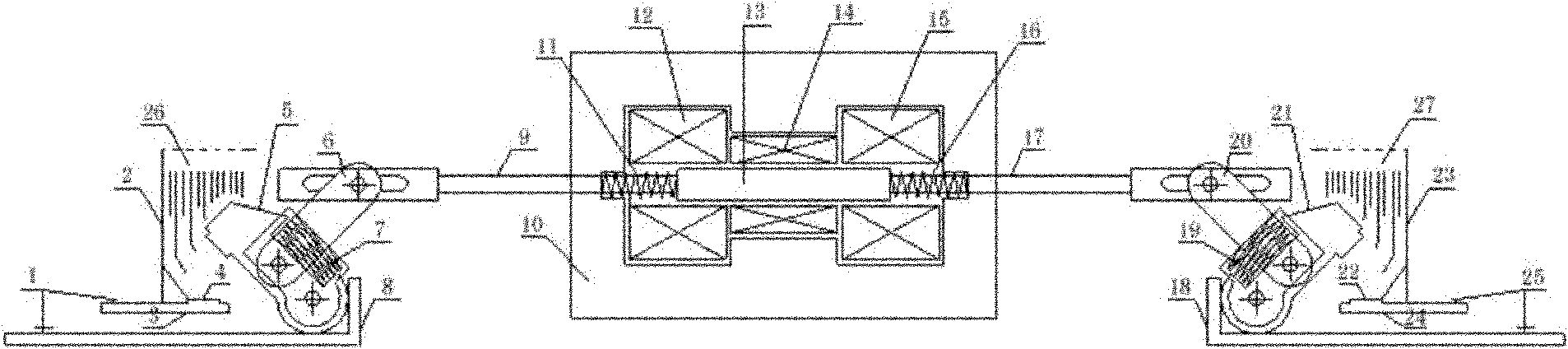

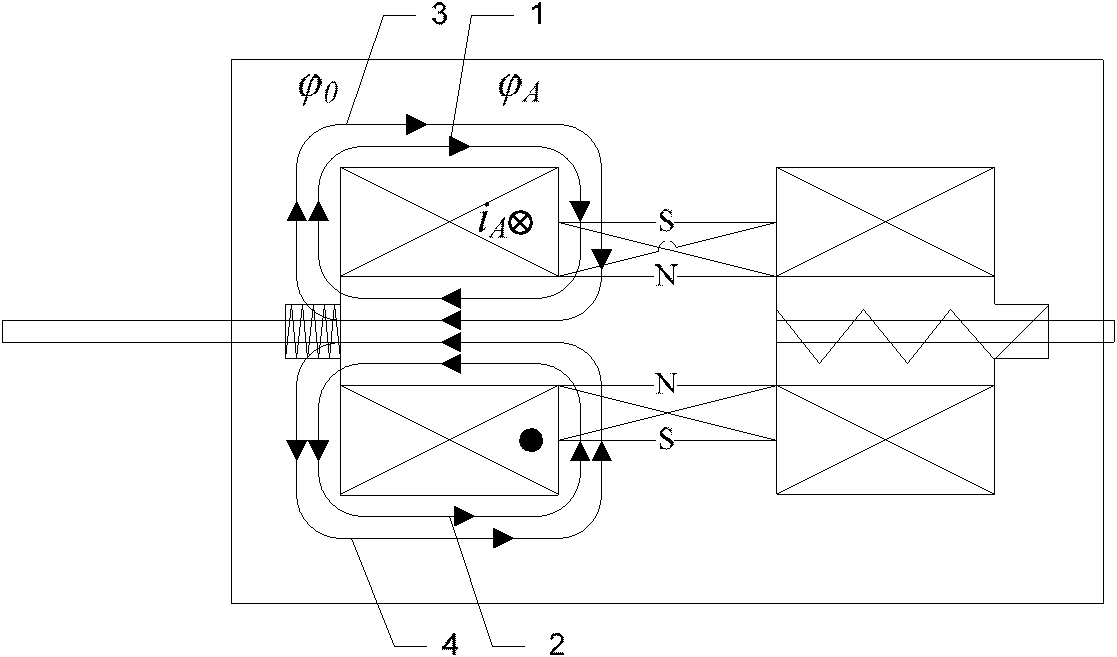

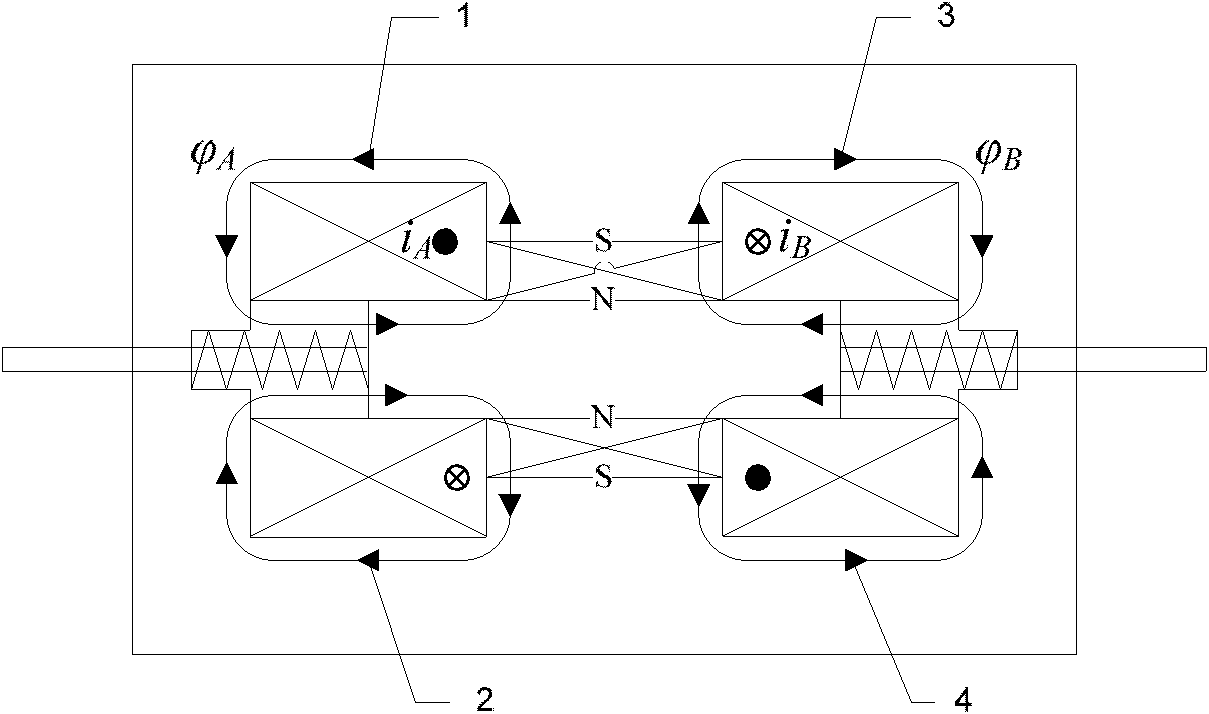

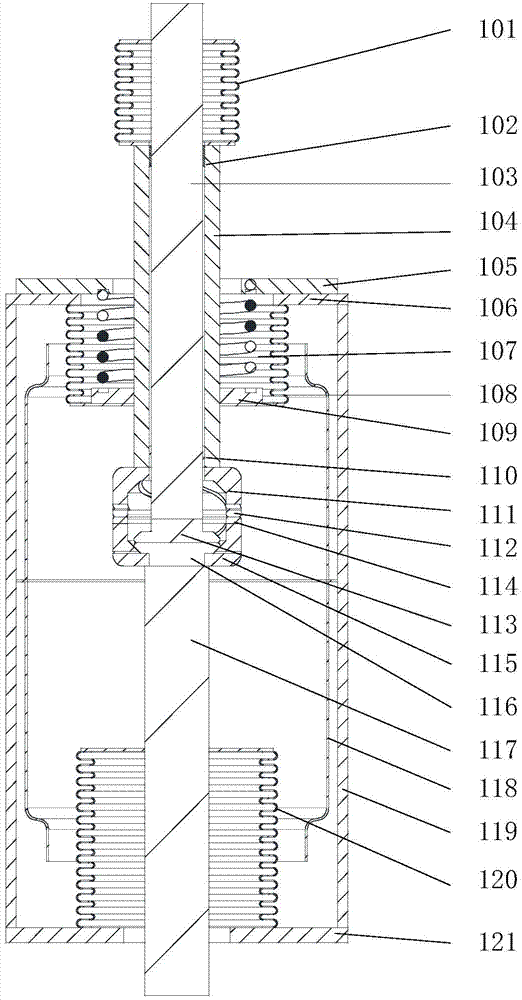

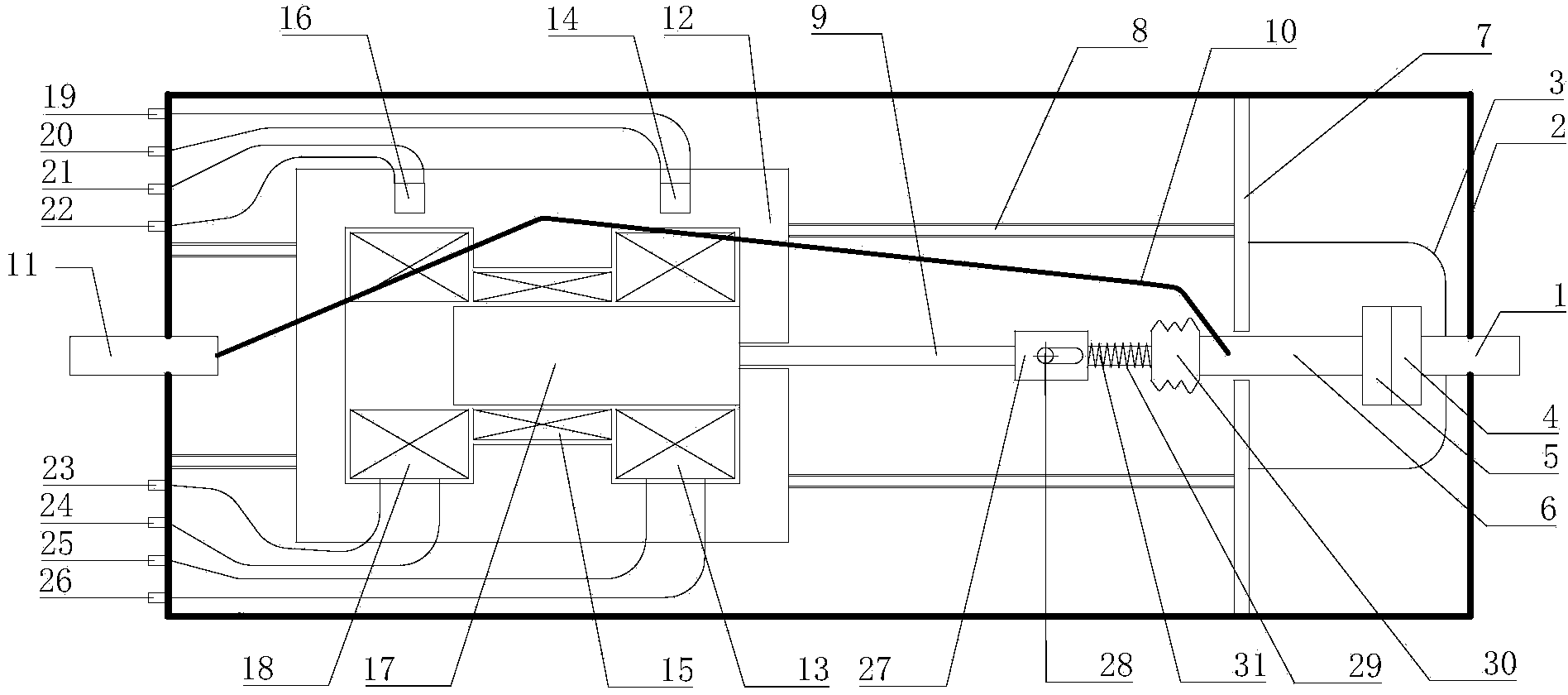

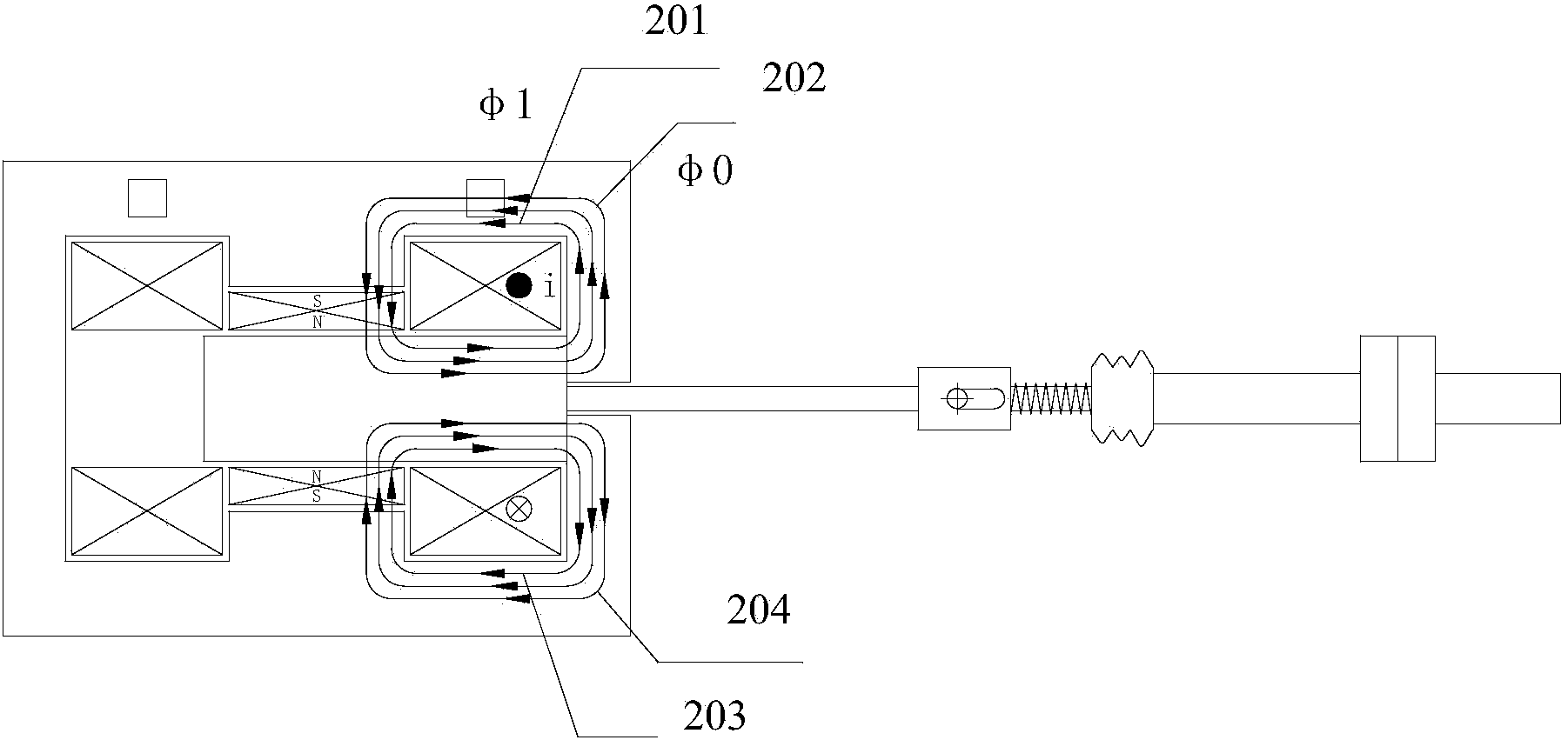

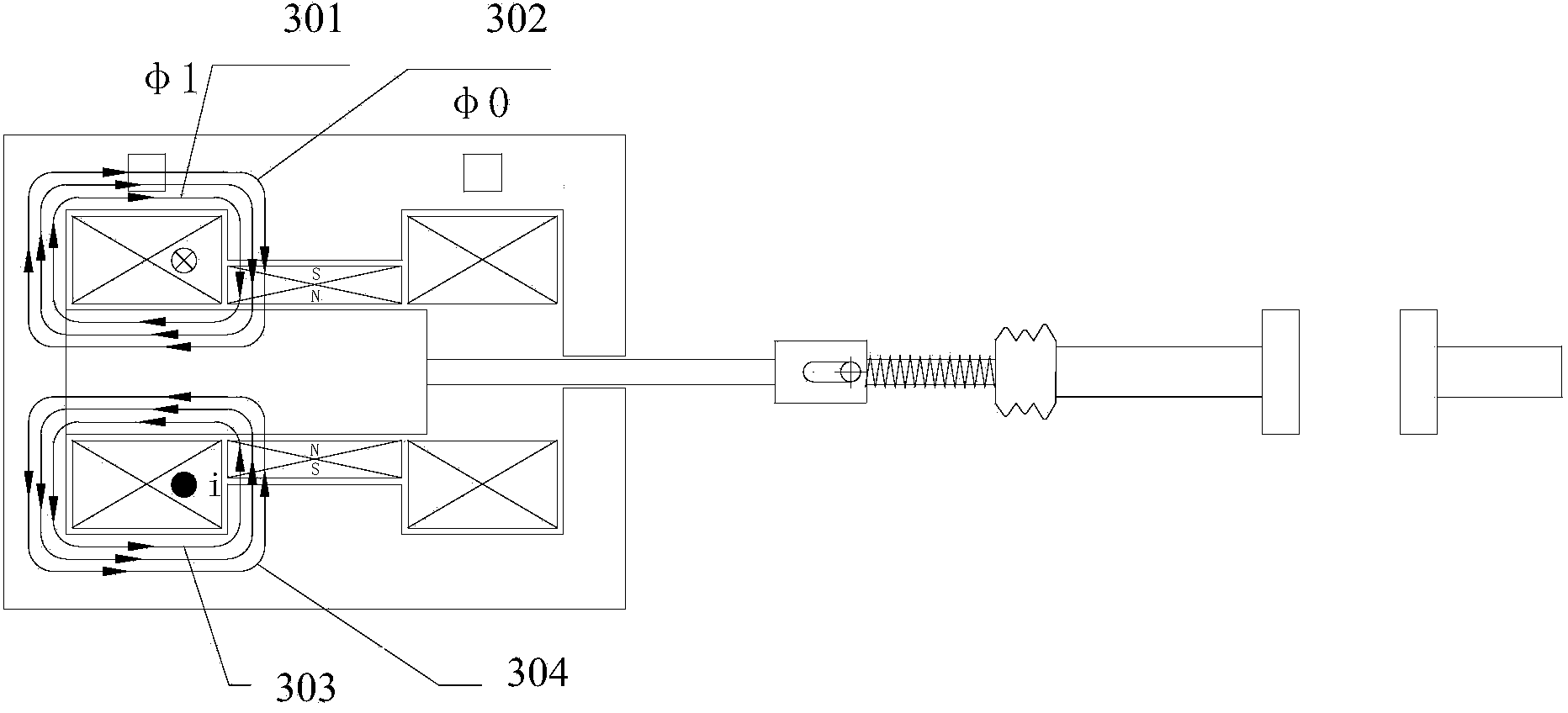

Permanent magnet mechanism automatic changeover switch

ActiveCN102034619AImprove electrical lifeReduce ablationSwitch power arrangementsEmergency protective devicesLow voltageEngineering

The invention belongs to low voltage electrical equipment, and relates to an operation mechanism and an arc extinguish chamber structure of an automatic changeover switch, in particular to a permanent magnet mechanism automatic changeover switch. The permanent magnet mechanism automatic changeover switch comprises two groups of dynamic and static contacts and arc extinguish chambers, a set of permanent magnet mechanism, and corresponding driving connecting rods and conducting rods, and is characterized in that: the permanent magnet mechanism is provided with three stable working positions andcan realize changeover control over the three working states of the automatic changeover switch; when the two groups of contacts are closed respectively, a permanent magnet provides holding force; when the two groups of contacts are opened at the same time, two opening springs provide the holding force; and an electromagnetic coil is electrified to work only during state changeover, so that the electric energy consumption of an electromagnetic mechanism is greatly reduced. When a three-phase system is formed, every phase adopts independent mechanism control so as to realize phase-separated operation, and arc-free break can be realized by phase-selected control; and the operation mechanism has a few parts, a simple structure and high reliability.

Owner:XI AN JIAOTONG UNIV

Multifunctional bio-charcoal and preparation method thereof

The invention relates to a multifunctional bio-charcoal and a preparation method thereof. According to the technical scheme, the preparation method comprises the steps of dipping biomass into 1-15wt% caustic alkali solution for 1-50h, washing with water to be neutral, and drying to obtain treated biomass; then charring the treated biomass in a tube furnace in mixed gas at 300-900 DEG for 1-130h to obtain the multifunctional bio-charcoal. The biomass is one of rice straw, wheat straw, sawdust, wood, green grass, fruit peel and animal tissue waste; the biomass contains 30-60wt% of volatile organic carbon of charcoal, 10-40wt% of fixed carbon, 1-30wt% of ash and 10-60wt% of water. The preparation method disclosed by the invention has the characteristics of low production cost, high yield, simple process, controllable production process and environment friendliness, and the prepared multifunctional bio-charcoal has a good adsorption effect on heavy metals and high stability and can be used for repairing water bodies, solid matrixes and soil which are polluted by heavy metals.

Owner:WUHAN UNIV OF SCI & TECH

Electric arc preheating repair welding method for stir friction plug

InactiveCN101966621AFull plastic flowSufficient plastic flow, the stirring needle is not easy to breakNon-electric welding apparatusFriction weldingPore diameter

The invention discloses an electric arc preheating repair welding method for a stir friction plug, relates to a repair welding method for the stir friction plug and aims to solve the problem of poor continuous flowability of a material because a stirring needle is broken before complete plastic deformation and flow under the action of strong resisting force of a material at a repair welding position of the stir friction plug. The method comprises the following steps of: 1, performing electric arc preheating on a key hole left by friction stir welding or secondary friction stir welding repairing, namely, putting a circular ring at a key hole position until the center of the circular ring is coincided with that of the key hole, performing electric arc heating on the circular ring by using a tungsten electrode argon arc welding machine at the temperature of between 180 and 200 DEG C and transferring heat to a region needing repair welding after the circular ring is heated so as to preheat the key hole in the region needing repair welding, wherein the central pore diameter of the circular ring is greater than that of the key hole; and 2, performing repair welding on the key hole, namely, during repair welding, moving a welding tool towards a welding direction by 1 to 5 millimeters and allowing the stirring needle to undergo plastic deformation and flow so as to fill the key hole. The method is used for performing repair welding on the weld defects of the stir friction welding and the key hole.

Owner:HARBIN INST OF TECH

Method of direct Coulomb explosion in laser ablation of semiconductor structures

InactiveUS7759607B2Generate efficientlyReduce ablationSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesSemiconductor materialsMaterial removal

A new technique and Method of Direct Coulomb Explosion in Laser Ablation of Semiconductor Structures in semiconductor materials is disclosed. The Method of Direct Coulomb Explosion in Laser Ablation of Semiconductor Structures provides activation of the “Coulomb explosion” mechanism in a manner which does not invoke or require the conventional avalanche photoionization mechanism, but rather utilizes direct interband absorption to generate the Coulomb explosion threshold charge densities. This approach minimizes the laser intensity necessary for material removal and provides optimal machining quality. The technique generally comprises use of a femtosecond pulsed laser to rapidly evacuate electrons from a near surface region of a semiconductor or dielectric structure, and wherein the wavelength of the laser beam is chosen such that interband optical absorption dominates the carrier production throughout the laser pulse. The further application of a strong electric field to the semiconductor or dielectric structure provides enhancement of the absorption coefficient through a field induced redshift of the optical absorption. The use of this electric field controlled optical absorption is available in all semiconductor materials and allows precise control of the ablation rate. When used in conjunction with nanoscale semiconductor or dielectric structures, the application of a strong electric field provides for laser ablation on sub-micron lateral scales.

Owner:OPTICAL ANALYTICS

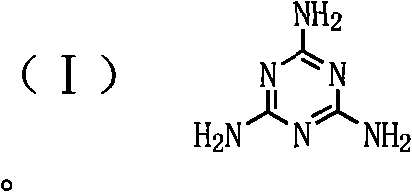

Preparation method of high flame retardant expansible graphite

The invention relates to a preparation method of high flame retardant expansible graphite, which comprises the following steps: dissolving the graphite into a mixing solution of perchloric acid and concentrated nitric acid, wherein the dosage of the solution is 100-600% of the mass of the solution; oxidizing the graphite by using solid oxidant of which the dosage is 0.5-50% of the mass of the oxidant to obtain the primary expansible graphite, wherein the temperature of the expansible graphite is 20-80 DEG C, and the reaction time is 20-300min; dissolving tripolycyanamide or the derivants thereof and the solid oxidant into phosphoric acid of which the mass fraction is 85+ / -10% to form a phosphoric acid solution, wherein the dosage of the solid oxidant is 0.5-50% of the mass thereof, and the mass concentration of the tripolycyanamide or the derivants thereof of the formed phosphoric acid solution is 0.02-2g / ml; carrying out reaction of the primary expansible graphite and the phosphoric acid solution at the temperature of 20-80 DEG C for 20-300min to prepare the high flame retardant expansible graphite. The method has the advantages that the tripolycyanamide or the derivants thereof are inserted between the expansible graphite layers, thereby improving the expansibility, start expansion temperature and fire resistance of the expansible graphite, and can be widely used for the flame retardant of multiple materials such as plastic, rubber, paint, foam and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

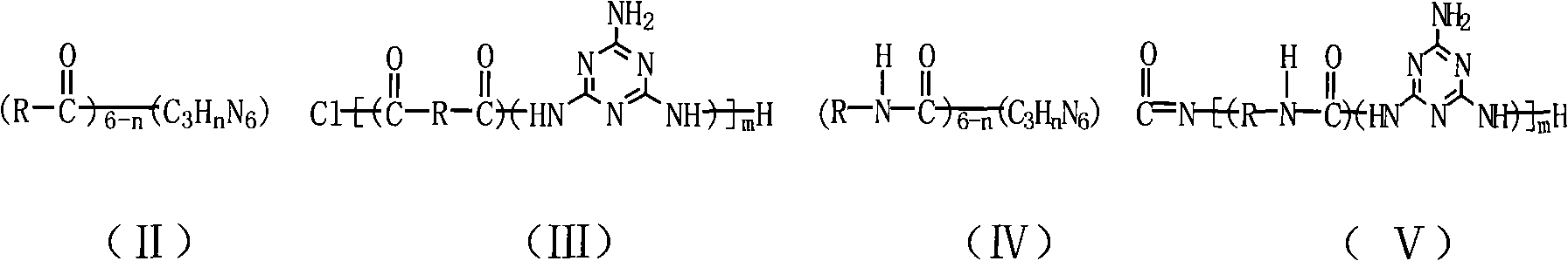

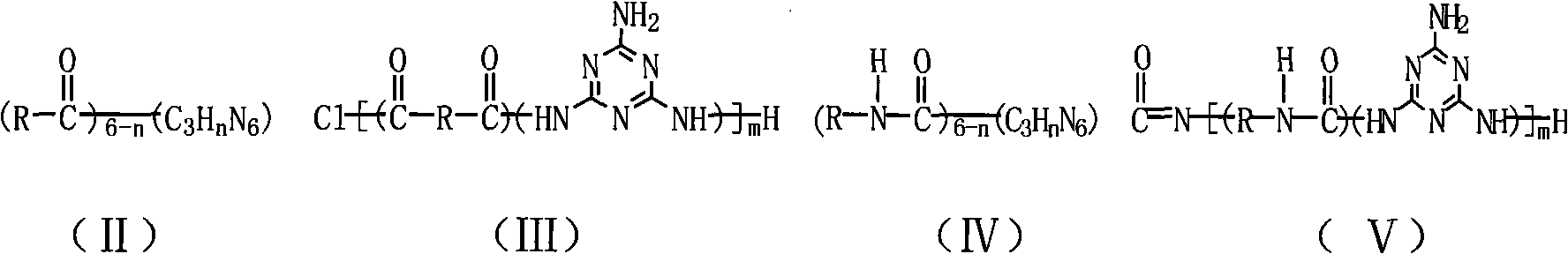

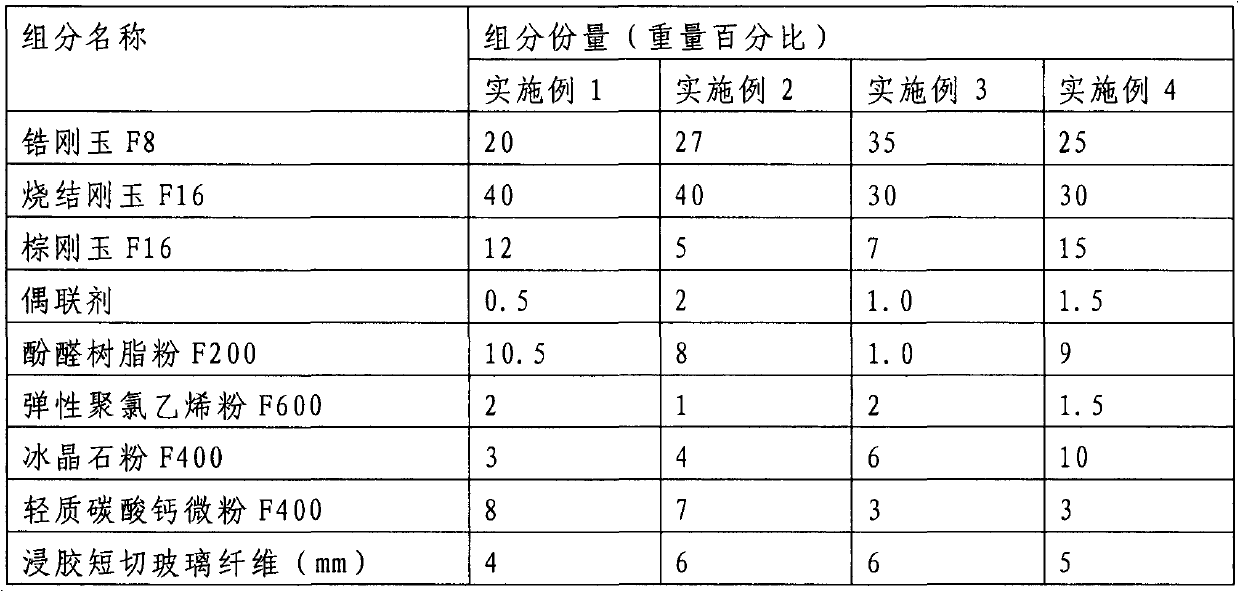

Heavy-load grinding wheel and preparation method thereof

InactiveCN103144047APlay the role of cushioning and dampingImprove flame retardant performanceAbrasion apparatusGrinding devicesPolyvinyl chlorideGrinding wheel

The invention discloses a heavy-load grinding wheel. The heavy-load grinding wheel comprises the following components in percentage by weight: sintered corundum, fused alumina zirconia, brown fused alumina, a coupler, phenol-formaldehyde resin powder, elastic polyvinyl chloride powder, cryolite powder, light calcium carbonate micro powder and impregnation chopped glass fibers and is prepared by a hot pressing molding process. The elastic polyvinyl chloride resin powder is mixed in a grinding material, so that the tenacity and the shock absorbing effect of the grinding wheel are improved, and the probability of sheet blasting is greatly reduced. On the other hand, elastic polyvinyl chloride has excellent flame resistance, so that burning of grinding heat to phenol-formaldehyde resin is reduced, the bonding ability of the phenol-formaldehyde resin to the grinding material is improved, and the grinding ratio of the grinding wheel is improved. The coupler is used for modifying the surface of the phenol-formaldehyde resin, so that the interface bonding force between the organic resin and the inorganic grinding material is stronger, and the rotation strength of the grinding wheel is improved. Furthermore, due to the adoption of the impregnation chopped glass fibers, the dissolving ability of the phenol-formaldehyde resin is favorably enhanced, and the rotation strength of the grinding wheel is further improved.

Owner:泰州苏蒙砂轮有限公司

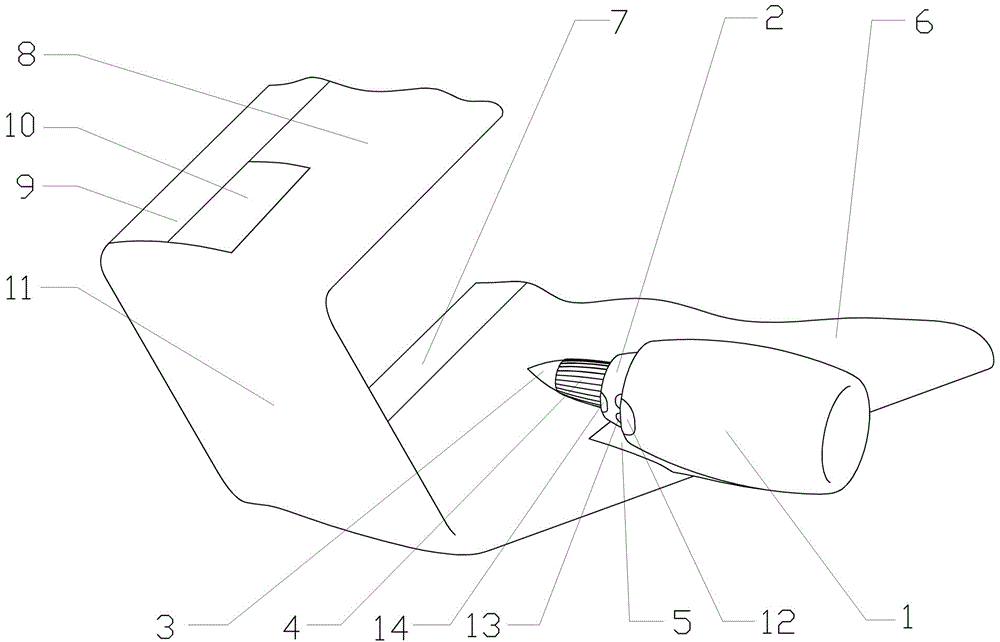

Jet-propelled flap lift augmentation joined wing system and aircraft thereof

The invention discloses a jet-propelled flap lift augmentation joined wing system. The jet-propelled flap lift augmentation joined wing system comprises a turbofan engine, an airfoil, a hanger and a turbine shaft rectifying cone, wherein the airfoil is provided with a rear-edge flap, the turbine shaft rectifying cone extends backwards for a given length and is provided with a plurality of scale-type convergence dispersion spray pipes, the left side and the right side of an outer duct spray opening are respectively provided with an airflow convergence dispersion apparatus consisting of an outer front edge and two outer convergence dispersion sheets, the left side and the right side of an inner duct spray opening are respectively provided with an airflow convergence dispersion apparatus consisting of an inner front edge and two inner convergence dispersion sheets, the airfoil is a joined wing. When the jet-propelled flap lift augmentation joined wing system takes off and lands perpendicularly, an upward lift resultant force can be generated; when the jet-propelled flap lift augmentation joined wing system flies in a level cruising manner, a thrust force and a lift force can be generated; an aircraft utilizing the jet-propelled flap lift augmentation joined wing system disclosed by the invention can vertically take off and land and fly at a high speed and can be stably switched between the vertical taking-off and landing and high-speed flight.

Owner:江苏中孚动力产业链有限公司

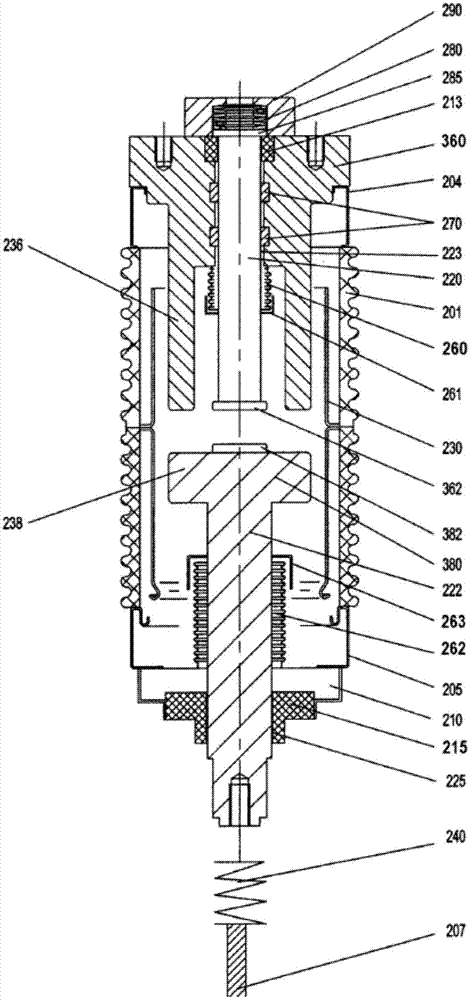

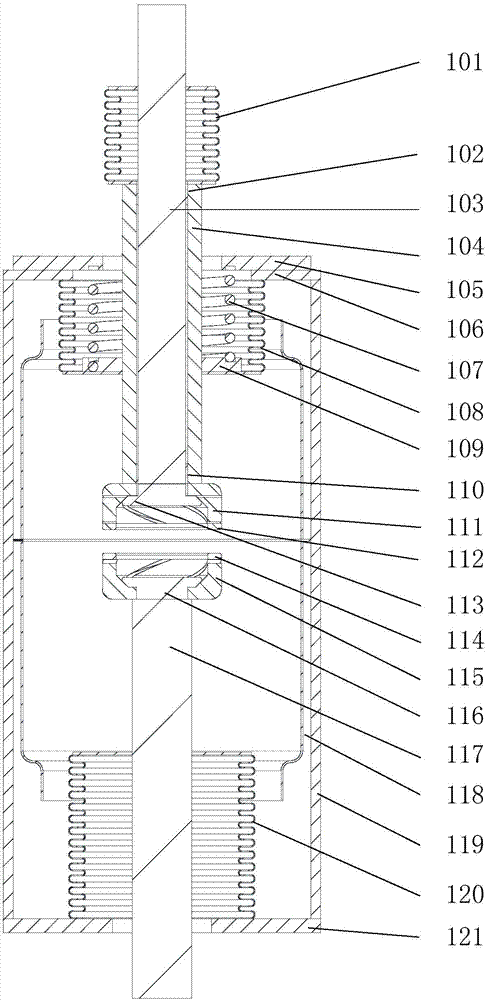

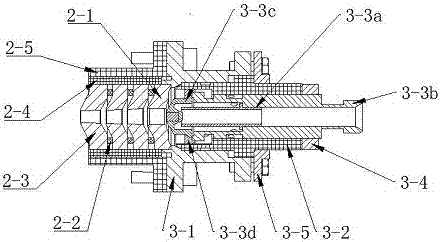

Electrode for radiofrequency tissue ablation

InactiveCN1777396AIncrease the ablation areaReduce ablationSurgical needlesSurgical instruments for heatingSalt solutionTissue ablation

The present invention discloses an electrode for an electric operating device, comprising: a hollow electrode in the shape of a hollow tube extending from a closed top end and having an insulating coating on the outer surface except for a predetermined length of the closed top end side; a refrigerant tube , whose diameter is smaller than that of the hollow electrode and inserted into the hollow electrode, the refrigerant tube supplies the refrigerant that cools the living tissue in contact with the closed top end and the hollow electrode into the hollow electrode, and transfers the heat through the gap between the refrigerant tube and the hollow electrode The exchanged refrigerant is discharged outward from the living tissue; at least one first hole is formed on the outer surface of the hollow electrode on which the insulating coating is not formed, and discharges some of the refrigerant supplied through the refrigerant tube from the hollow electrode; and a flow rate The control device is formed on the outer surface of the hollow electrode without an insulating coating, and acts as a discharge resistance to the refrigerant discharged from the first hole to control the flow of the refrigerant. It provides two types of water cooling inside the electrode and discharge of saline solution. The electrode structure of the method.

Owner:全明基

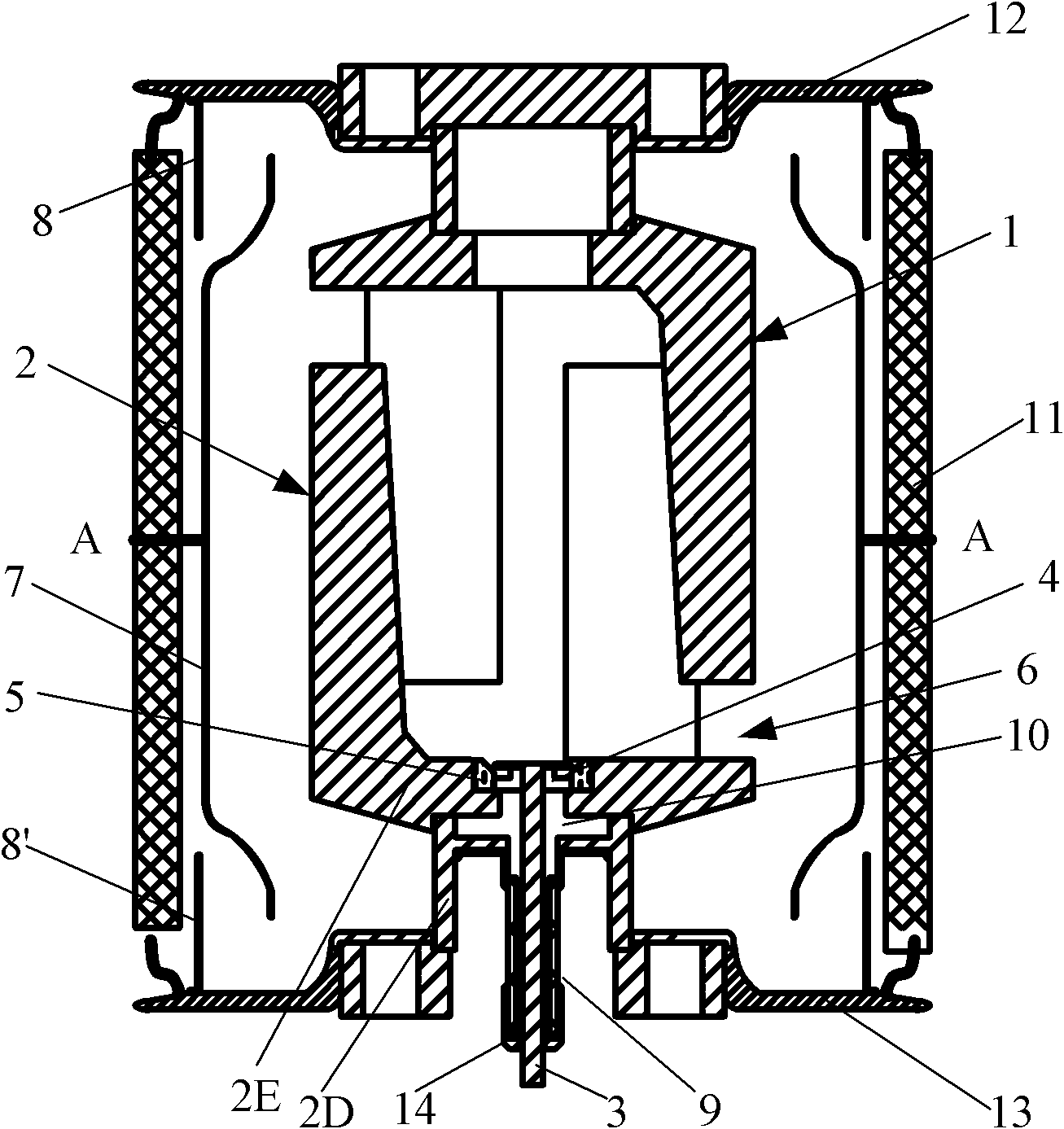

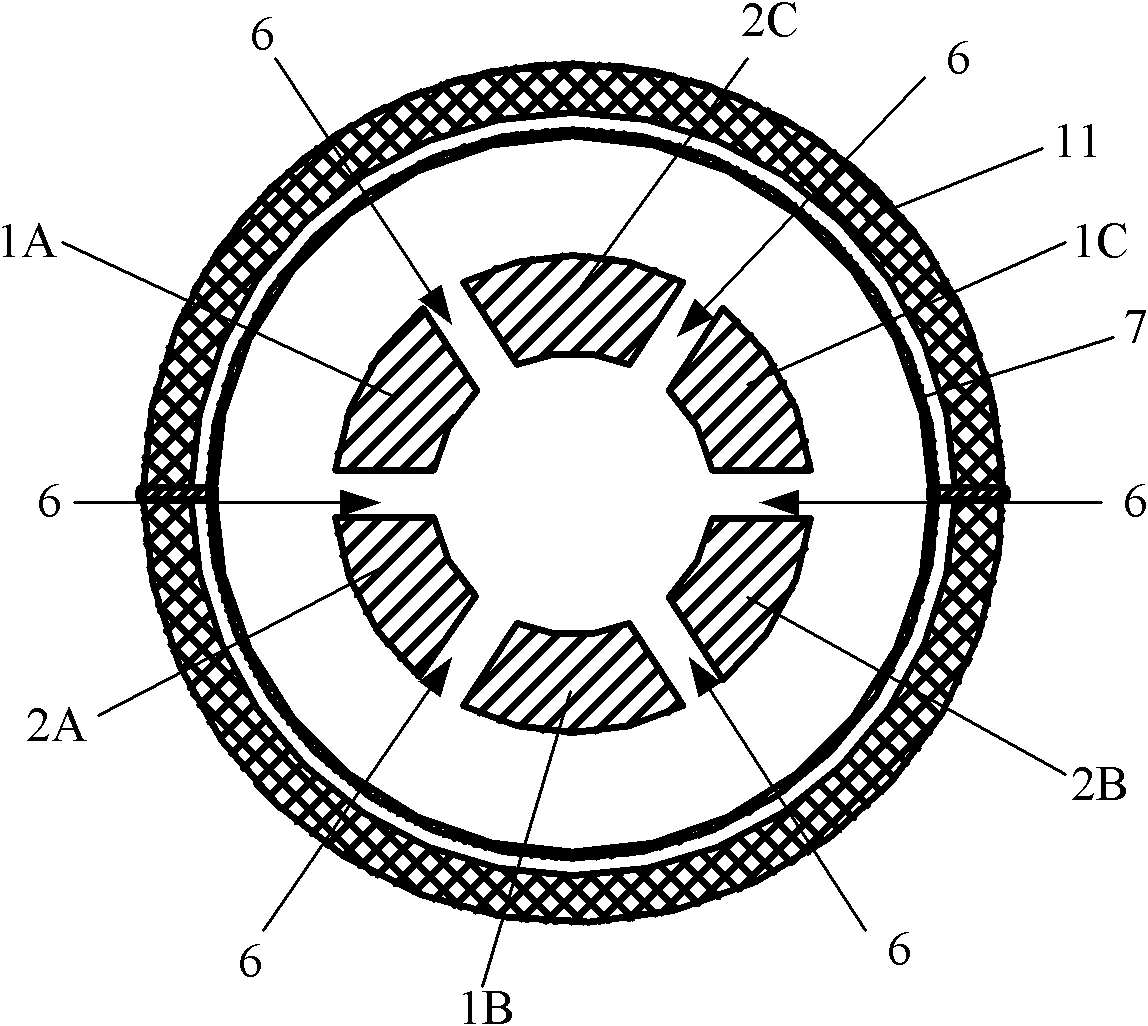

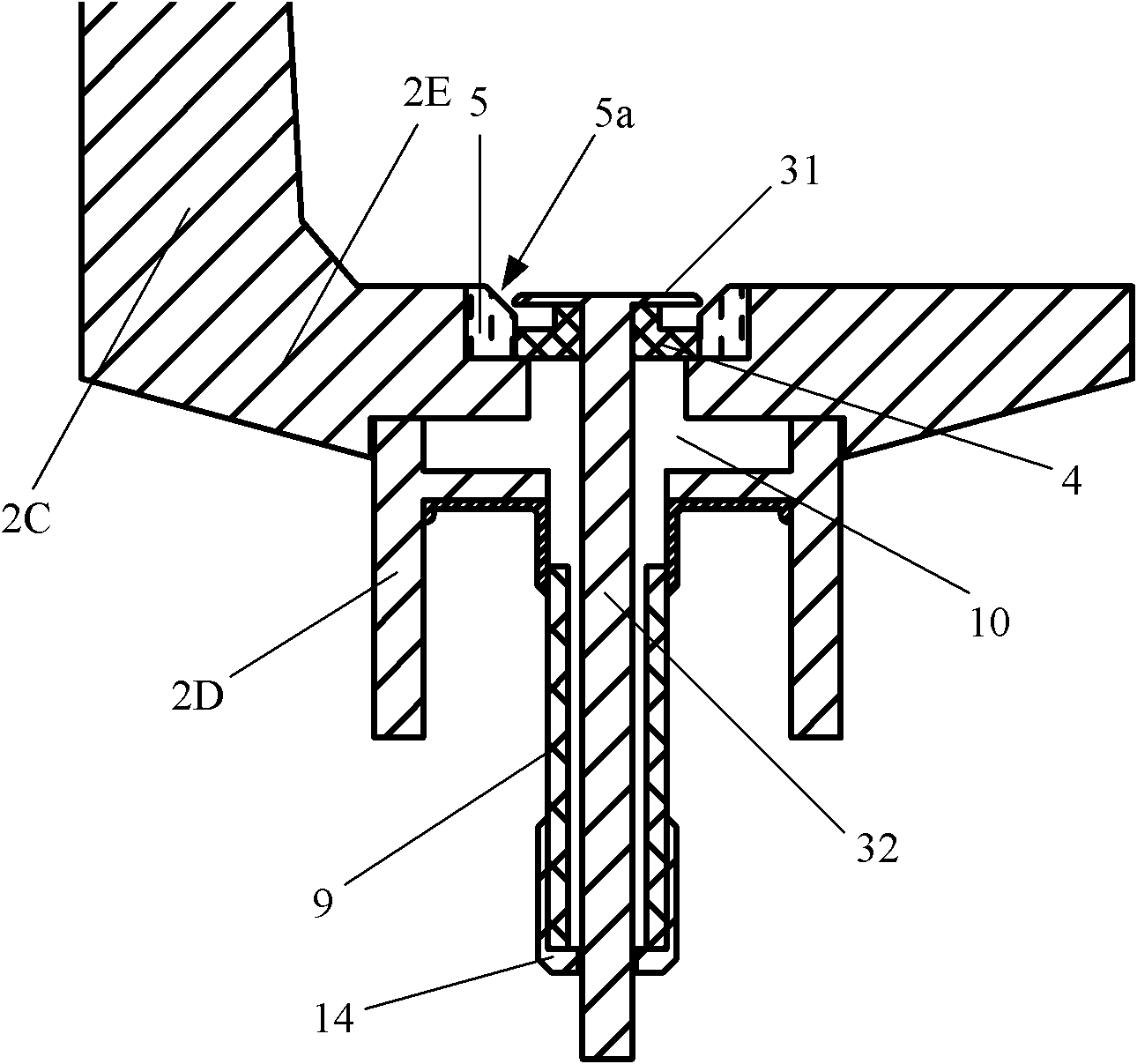

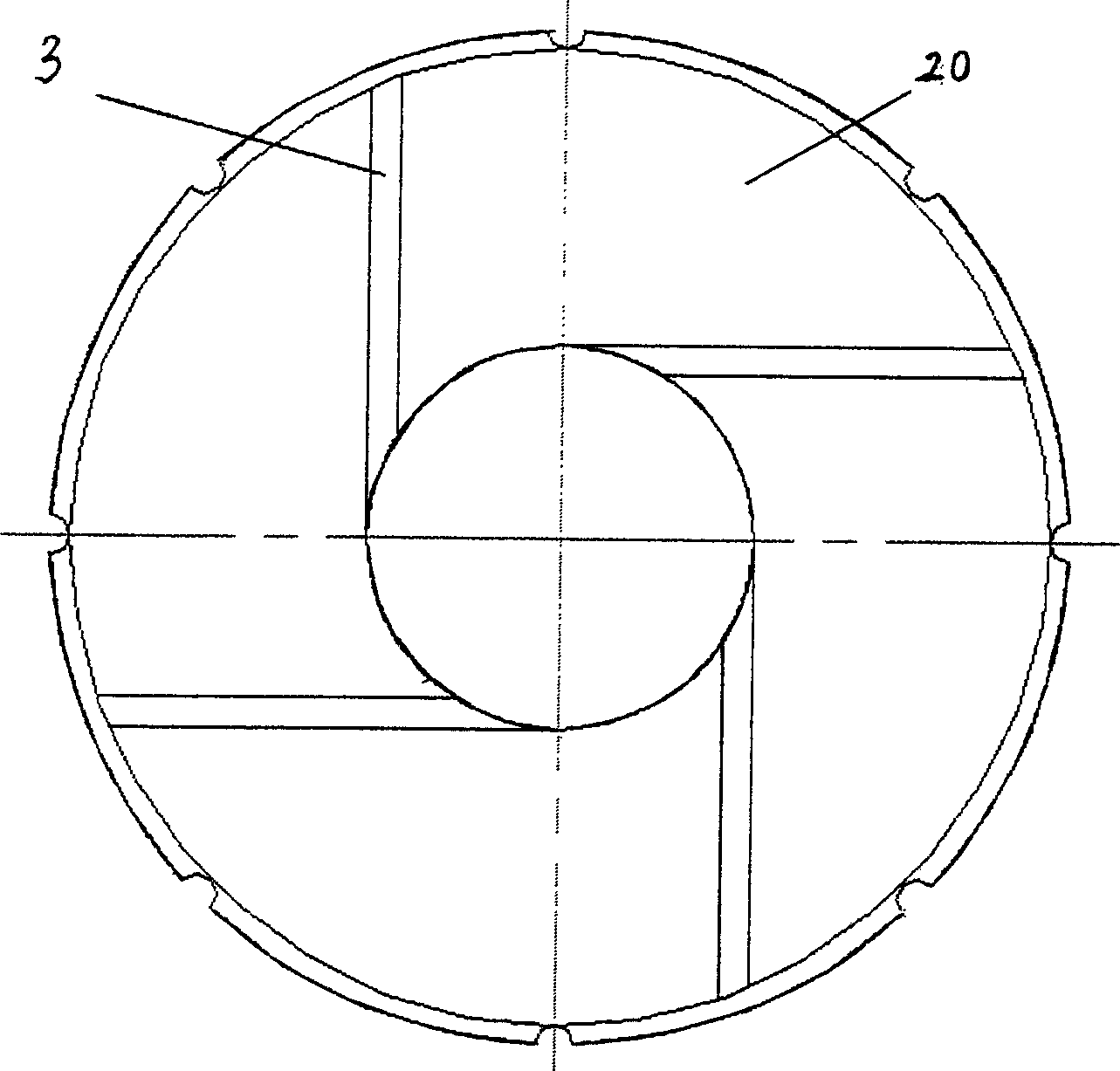

Novel composite contact vacuum arc-extinguishing chamber and vacuum circuit breaker with same

ActiveCN103594280AUniform magnetic fieldEasy to installHigh-tension/heavy-dress switchesAir-break switchesVacuum arcVacuum interrupter

The invention discloses a novel composite contact vacuum arc-extinguishing chamber and a vacuum circuit breaker with the same. The novel composite contact vacuum arc-extinguishing chamber comprises a static side structure portion, a movable side structure portion and a shell structure. The static side structure portion comprises a static side arcing current conducting rod and a static side main conducting rod which is arranged in the static side arcing current conducting rod and is in clearance fit with the static side arcing current conducting rod. A static side arcing magnetic field contact and a static side annular arcing-resisting contact material are sequentially welded at the lower end of the static side arcing current conducting rod. A static side conducting contact is welded at the lower end of the static side main conducting rod. In the arcing process, the static side conducting contact is located inside the static side arcing magnetic field contact all the time, the static side main conducting rod is connected with the static side arcing current conducting rod through a static side small-diameter corrugated pipe, the static side arcing current conducting rod is connected with a cover plate on the upper side of the arc-extinguishing chamber through a static side large-diameter corrugated pipe. A static side compression spring is installed inside the static side large-diameter corrugated pipe. According to the novel composite contact vacuum arc-extinguishing chamber, the problem that the magnetic structural design does not exist in the existing vacuum arc-extinguishing chamber contact design is solved.

Owner:XI AN JIAOTONG UNIV

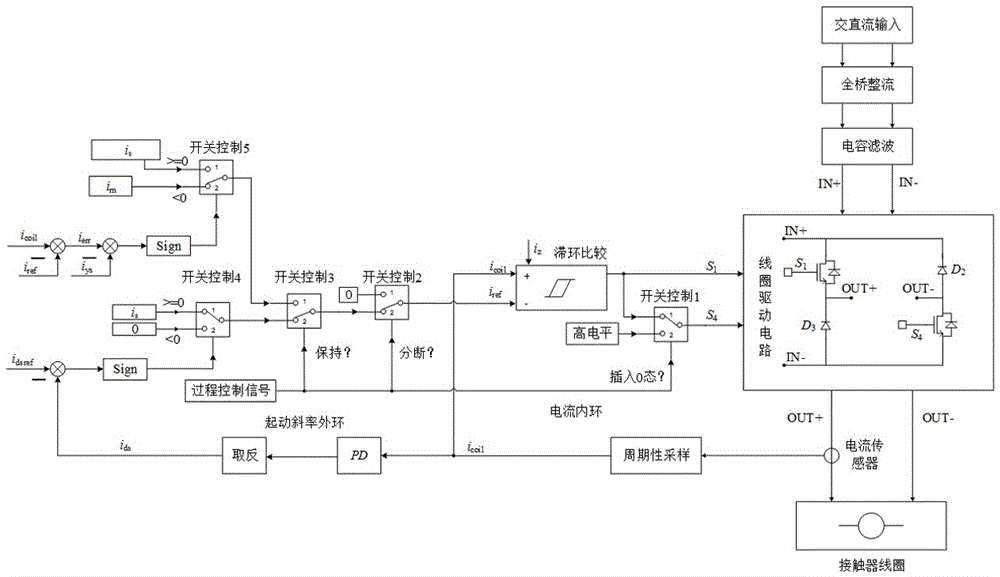

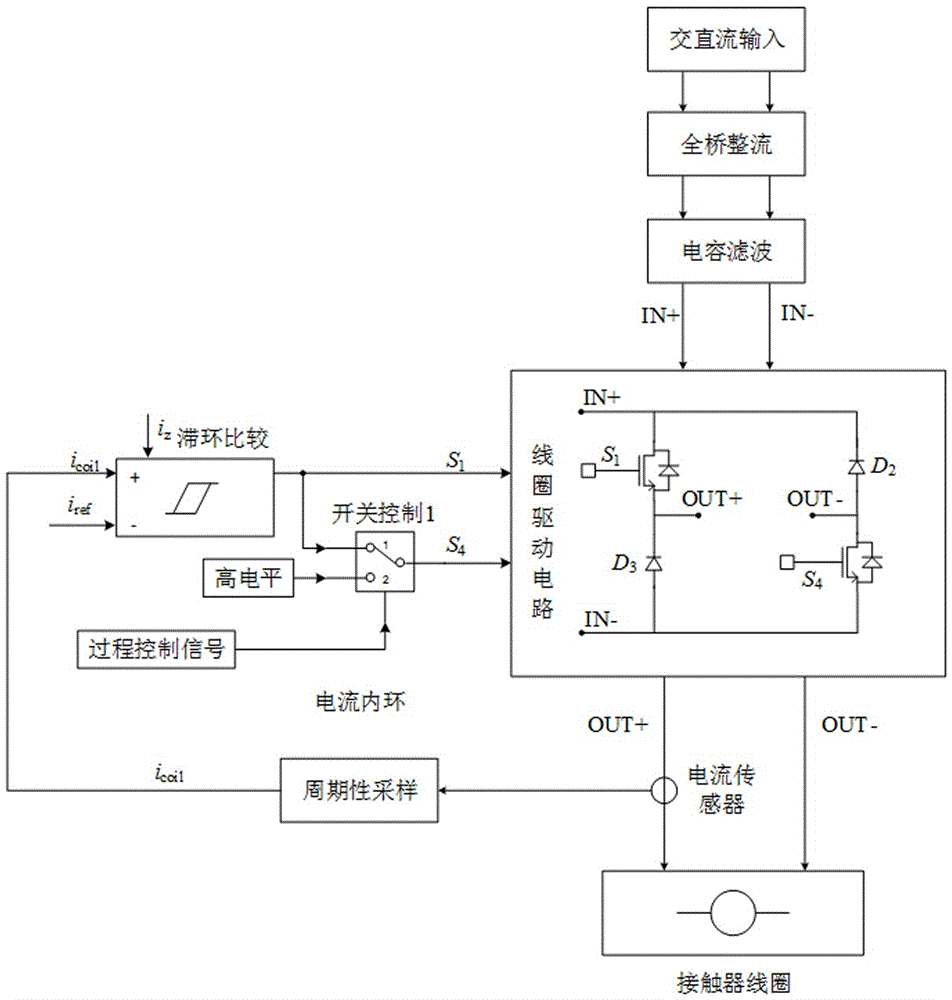

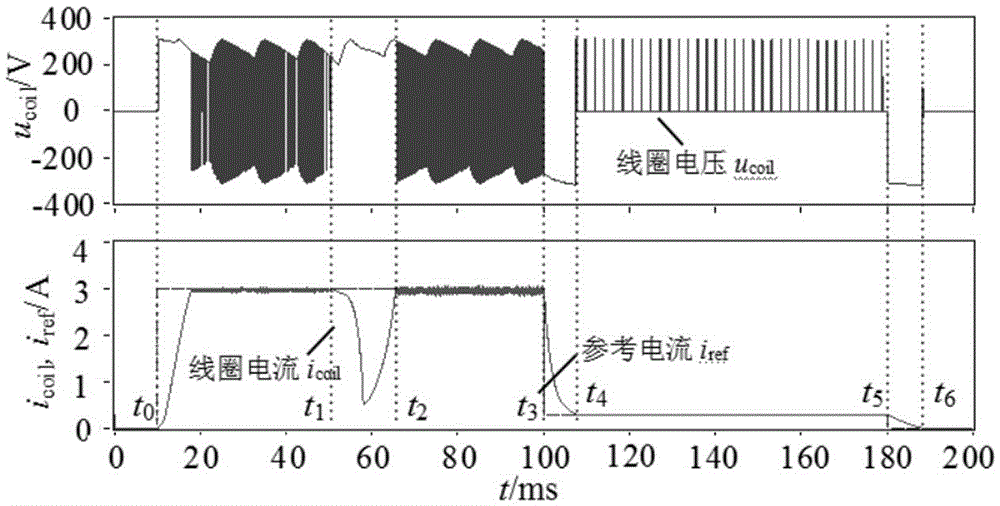

Dynamic reliable control strategy of high-capacity contactor

The invention relates to a dynamic reliable control strategy of a high-capacity contactor. The dynamic reliable control strategy comprises the following steps of: by adopting a current closed loop as a basic inner loop, controlling the current inner loop by adopting a slope outer loop in a starting process, lowering the collision speed of a movable iron core, and reducing bounce of a contact terminal in the starting process; during a maintaining process, monitoring the outer loop by adopting error breaking, predicting an error breaking fault of the contactor, and taking a measure in time to prevent the error breaking; and during a breaking process, controlling the breaking speed of the movable iron core, so that not only can the rapid breaking of the contactor be guaranteed, but also the burning of the contact terminal caused by breaking electric arc is reduced, and the impact on a contactor framework during the breaking process is also reduced.

Owner:FUZHOU UNIV

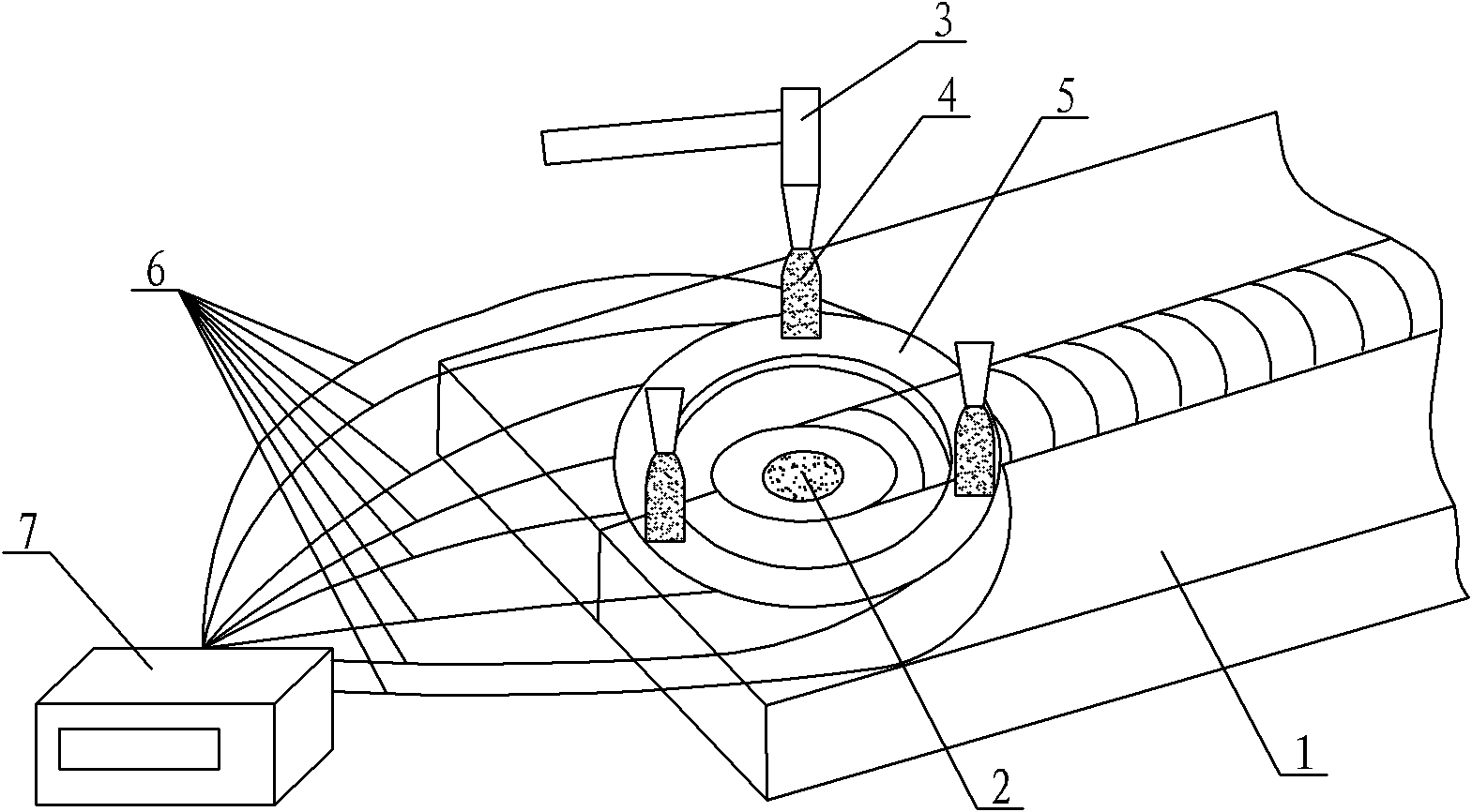

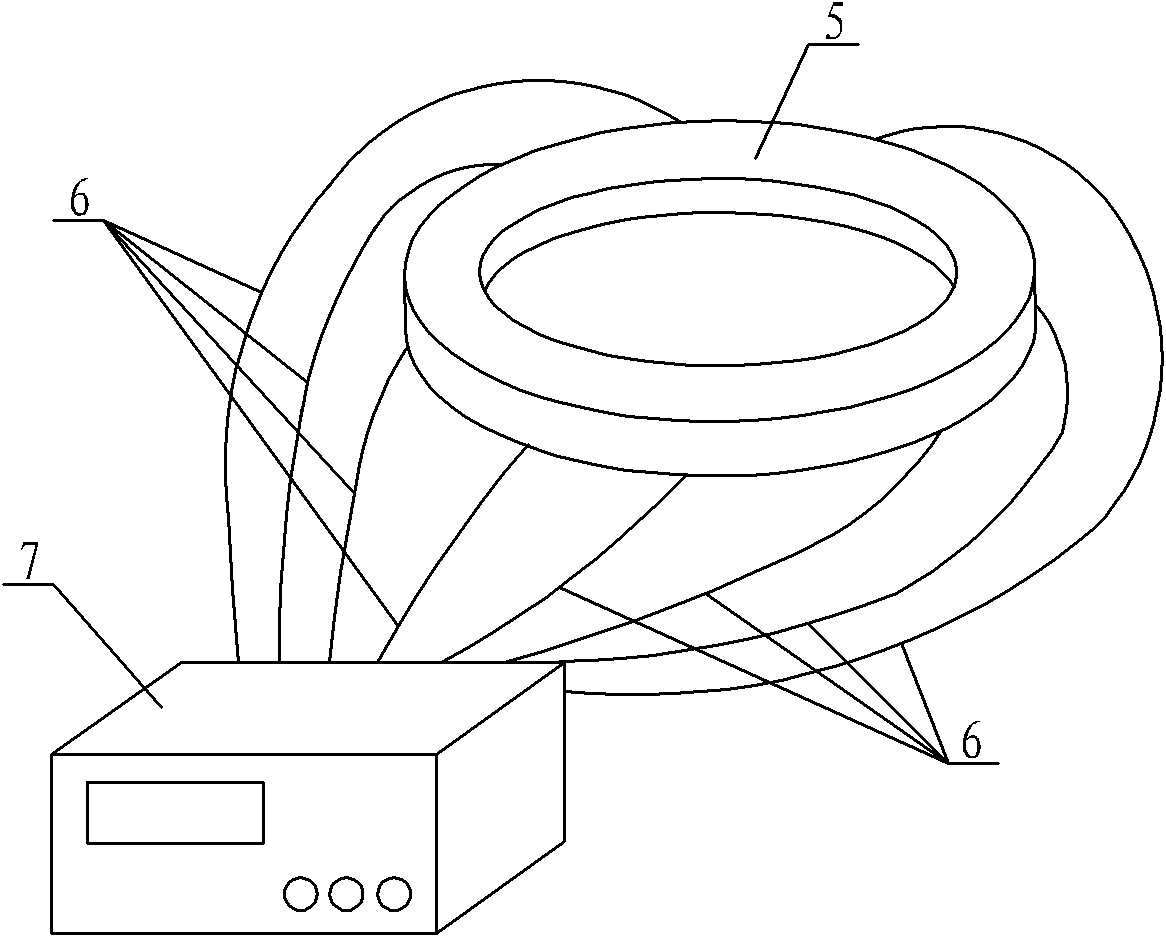

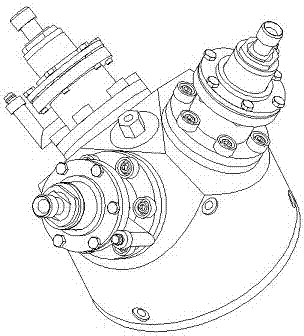

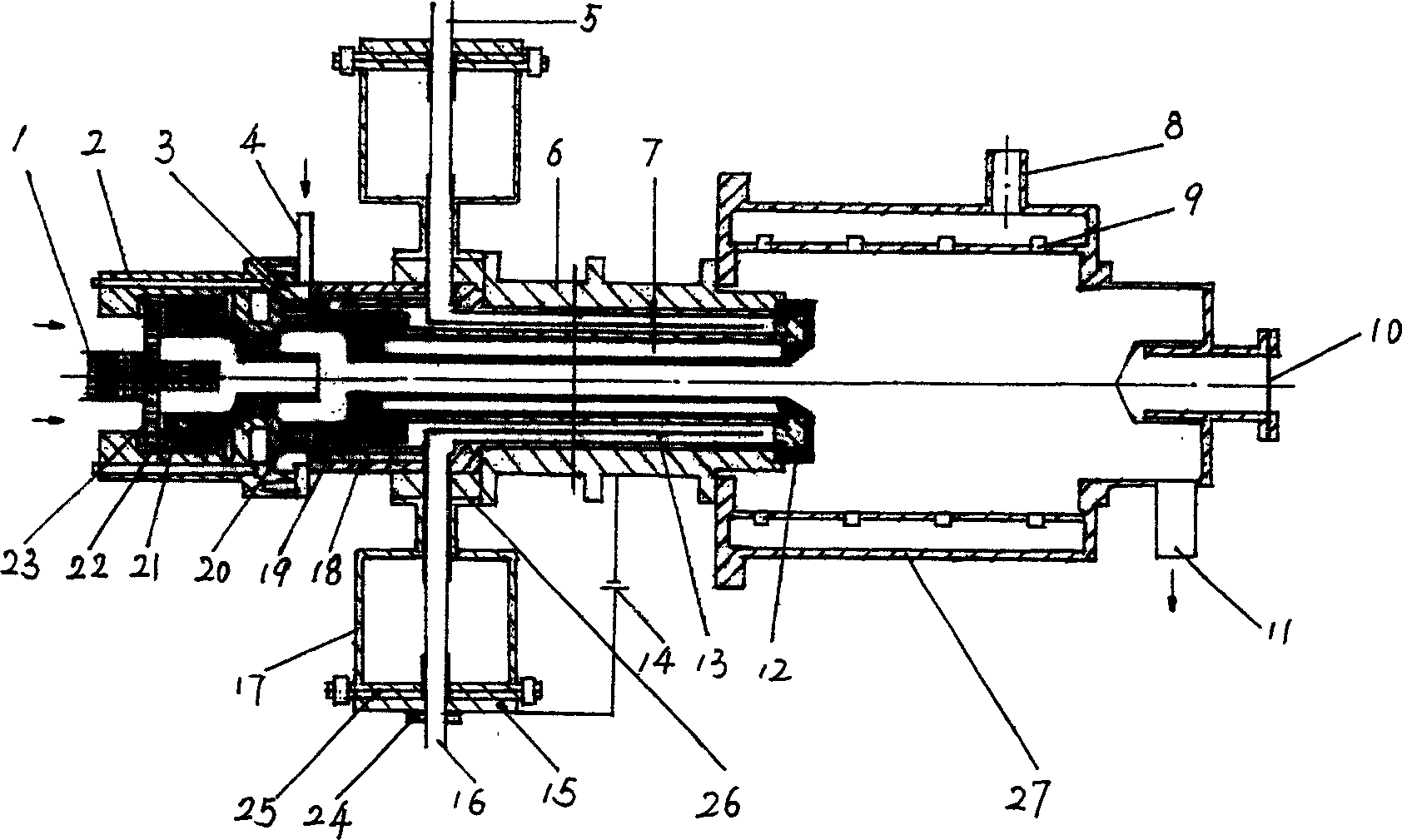

Multi-cathode laminar flow plasma powder spheroidization device

PendingCN107124814AReduce volatilityReduce ablationTransportation and packagingMetal-working apparatusJet flowControllability

The invention provides a multi-cathode laminar flow plasma powder spheroidization device, which consists of an anode part, an interpole part, a cathode part, a power feeding part and an accessory, wherein the anode electrode part consists of an anode casing, an anode, a compression cover and the like. Each part is compressed and connected through screw bolts; the interpole part consists of an arcing ring, an insulation ring, an interpole, an interpole inner sleeve, an interpole outer sleeve and the like; the cathode part and the anode part are simultaneously compressed; the cathode part consists of a cathode case, a cathode sleeve, a cathode and a cathode fastening ring; each part is sequentially connected; the cathode compression ring is in contact with the cathode sleeve and is fixedly connected with the cathode case; the powder feeding part consists of a power feeding pipe and a powder feeding spray nozzle which are sequentially and fixedly connected. The excellent characteristics of good jet flow controllability, high enthalpy value, long jet flow length and the like of the laminar plasma are utilized for realizing the spheroidization on powder; the treated powder has the advantages of high spheroidization rate, high uniformity and the like.

Owner:SICHUAN UNIV

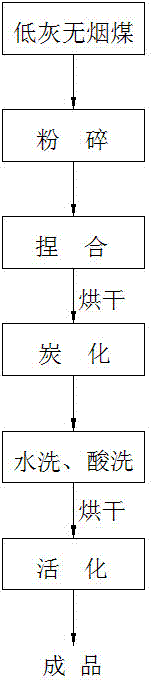

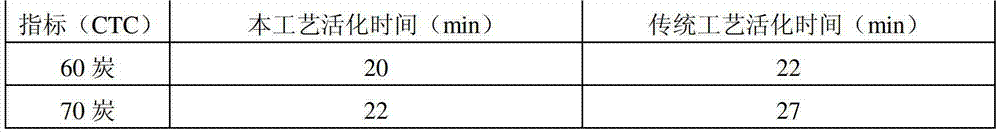

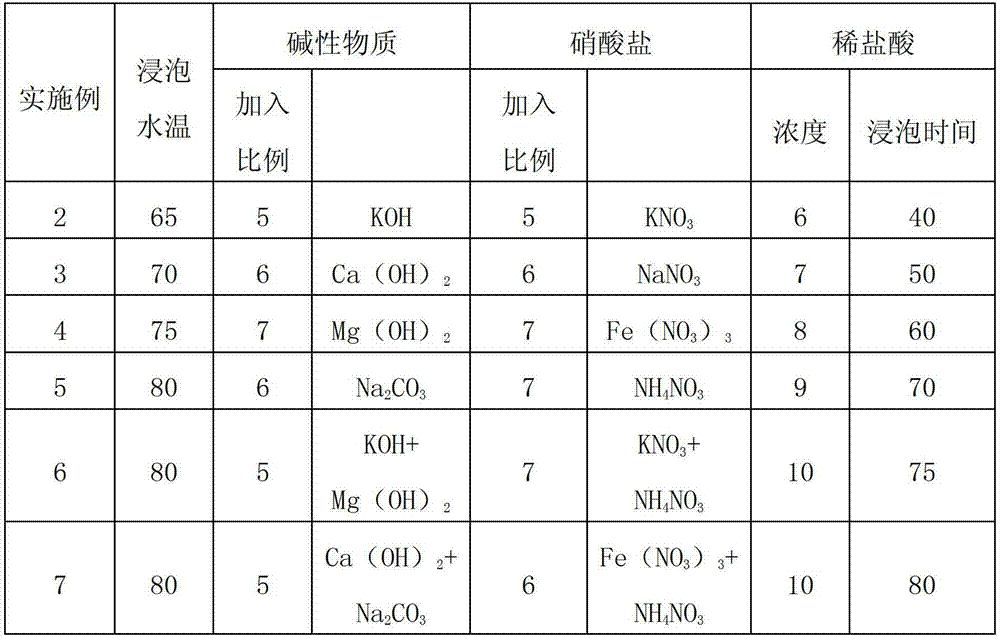

Low-ash coal-based activated carbon quick activation production technology

The invention relates to an active carbon production technology, and in particular relates to a low-ash coal-based activated carbon quick activation production technology which comprises the following steps of grinding, kneading, carbonizing, washing, acid washing and activation to obtain a finished product. Through the technology improvement, the activation time, the activation energy consumption and the ablation of carbonized material can be reduced by about 10%; meanwhile, the ash content of the finished product of active carbon can be reduced by 2-4%, and the carbon tetrachloride adsorption rate (CTC), the iodine adsorption value and the methylene blue adsorption value are increased; for an active carbon production enterprise, by only adding a trace amount of alkaline substance and nitrate, the cost per ton is only increased by *-* yuan, the energy use and product quality can be effectively reduced, and the energy saving and emission reducing effect is obvious; and the cost per ton can be reduced by about ** yuan, and the production cost can be reduced by *** thousand yuan per year for an active carbon enterprise with annual output of 10 thousand tons.

Owner:NINGXIA UNIVERSITY

Arcjet thruster capable of improving operation stability

InactiveCN104454418AAvoid excessive heatReduce ablationLiquid coolingMachines/enginesEngineeringCathode

The invention provides an arcjet thruster capable of improving operation stability. The arcjet thruster comprises a cathode, a sealing piece, an insulating piece, a metal sleeve and an anode spraying pipe which are sequentially connected. The cathode, the sealing piece and the insulating piece are fixedly connected in sleeving mode in sequence. One end of the metal sleeve is connected with the insulating piece in a sleeving mode. The other end of the metal sleeve is clamped to the anode spraying pipe. The arcjet thruster further comprises a water cooling sleeve adaptive to the anode spraying pipe. The water cooling sleeve is additionally arranged on the outer wall face of the anode spraying pipe. A through way allowing cooling water to pass through is arranged in the water cooling sleeve. According to the arcjet thruster, the water cooling sleeve is additionally arranged near the outer wall face of the anode spraying pipe of the arcjet thruster, it is avoided that the temperature of the anode spraying pipe is excessively high, ablation of the inner wall face of the anode spraying pipe is lowered accordingly, and the operation stability of the arcjet thruster is improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Multipole field breakdown type vacuum trigger switch

InactiveCN102130670AIncrease surface areaReduce ablationElectronic switchingBiomedical engineeringOperating life

The invention discloses a multipole field breakdown type vacuum trigger switch. In the invention, a top electrode and a bottom electrode of the trigger switch respectively comprise electrode bottom columns, electrode platforms and a plurality of columnar electrodes; the columnar electrodes of the top electrode and the bottom electrode extend in opposite directions and are staggered; gap widths between every two adjacent columnar electrodes are equal and are same as the gap widths between the tops of the columnar electrodes and the corresponding electrode platforms; the electrode platform of the bottom electrode is provided with a notch and a trigger electrode; the trigger electrode comprises a trigger needle and a trigger insulation sleeve ring; the axial section of the trigger needle is T-shaped; the trigger insulation sleeve ring is of a boss structure and embedded in the notch; the trigger needle comprises a trigger needle head and a trigger needle rod; one end of the trigger needle rod is connected with the trigger needle head, and the other end of the trigger needle rod passes through the trigger insulation sleeve ring and the electrode platform; the upper surface of the trigger needle head is lower than the upper surface of the electrode platform of the bottom electrode; and gaps exist between corners and the electrode platform of the bottom electrode. The trigger switchhas long service life and strong through-current capability under the condition of big current.

Owner:HUAZHONG UNIV OF SCI & TECH

Apparatus and process for producing acetylene by low-temperature plasmochemical pyrolysis of natural gas

InactiveCN1613838AReduce ablationReduced localized point ablationHydrocarbon by hydrocarbon crackingElectrical conductorEngineering

A low-temperature plasma chemical reactor for producing ethyne by cracking natural gas and its process are disclosed. The reactor consists of microwave plasma torch and DC plasma exciting mechanism. The external conductor of the microwave plasma torch is of hollow structure, of which outlet forms a nozzle, the DC plasma exciting mechanism consists of external conductor, conductive pipe corresponding to the external conductor nozzle, the cavity of the conductive pipe as reacting chamber , the external conductor as cathode, the conductive pipe as anode, with the conductive pipe connected with DC electric source by choking structure. The process is carried out by: microwave plasma entering into DC plasma exciting mechanism; 2) microwave plasma forming normal DC plasma under the action of the DC electric source, and natural gas cracking to obtain ethyne. It achieves long life and high efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

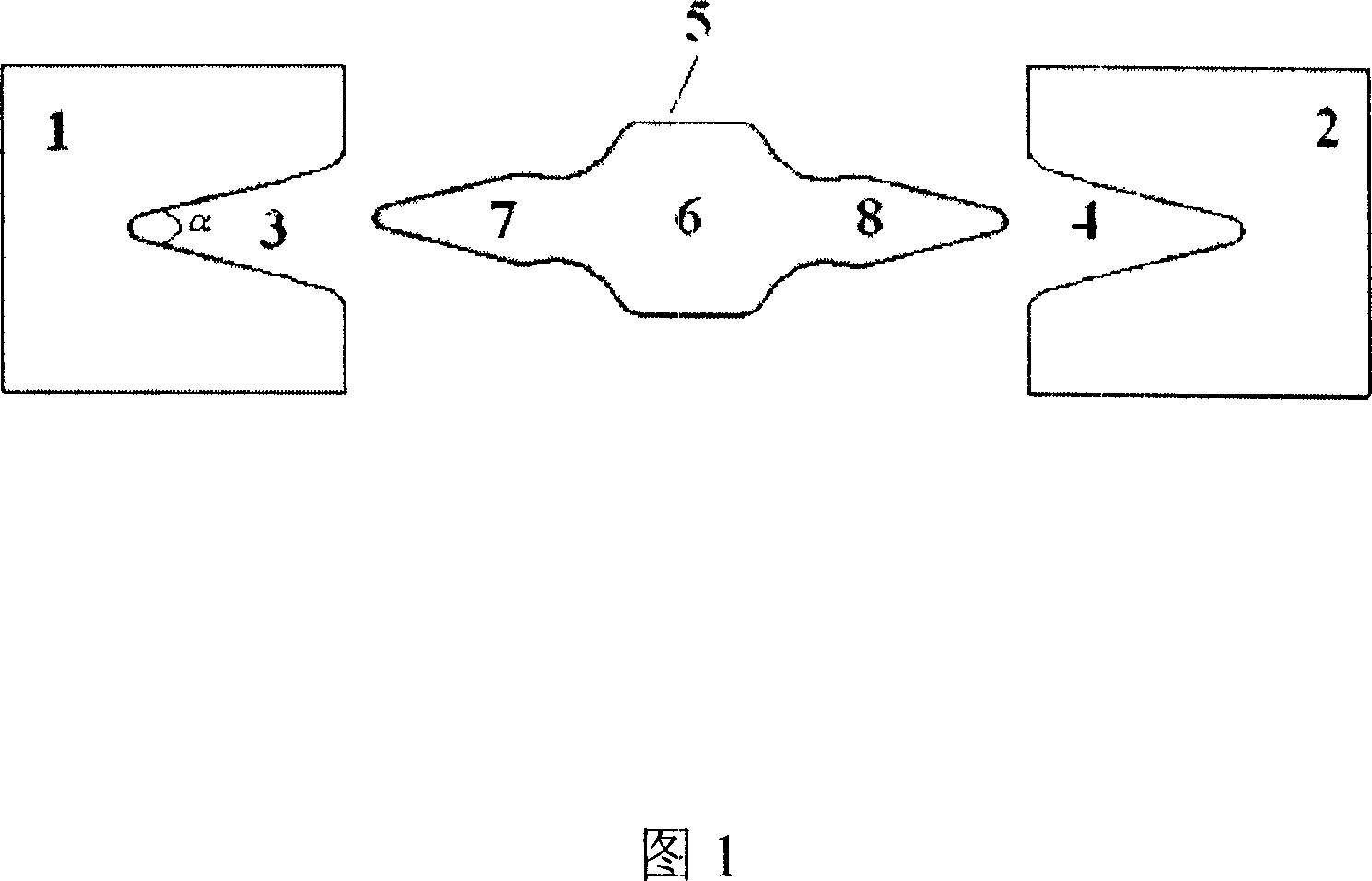

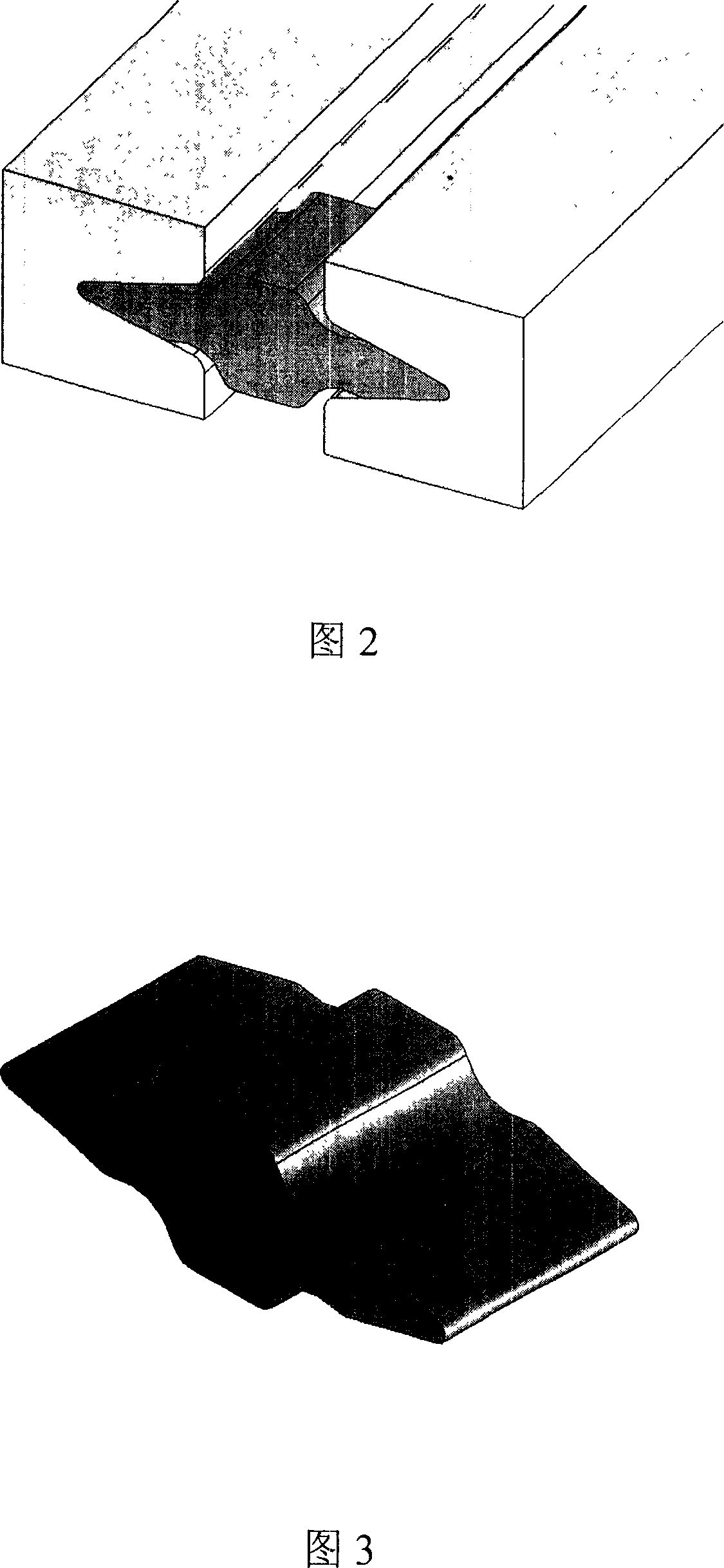

Electromagnetic railgun

InactiveCN101021396AExtended service lifeIncrease electrical contact areaElectromagnetic launchersElectricityEngineering

The invention discloses an electromagnetism rail gun which the structure is: the insulation material is between the first rail and second guide rail which are all opened with the symmetrical 'V' slot. The angle of the slot is 30-60degree. The solid armature is set between the first and second guide rail. The two symmetrical side wings extend to both sides from the body which the shape and size is matched to the 'V' slot. The upper and lower surface of the two side wing front contacts with the 'V' slot to form the electrical contact surface of the solid armature and the guide rail; the back end of the two side wings are separate with the two guide rail. The invention can control the damage of the transitional voltaic arc, so it can prolong the gun using life but getting the higher shooting speed (>3kms), so it has the widely future.

Owner:HUAZHONG UNIV OF SCI & TECH

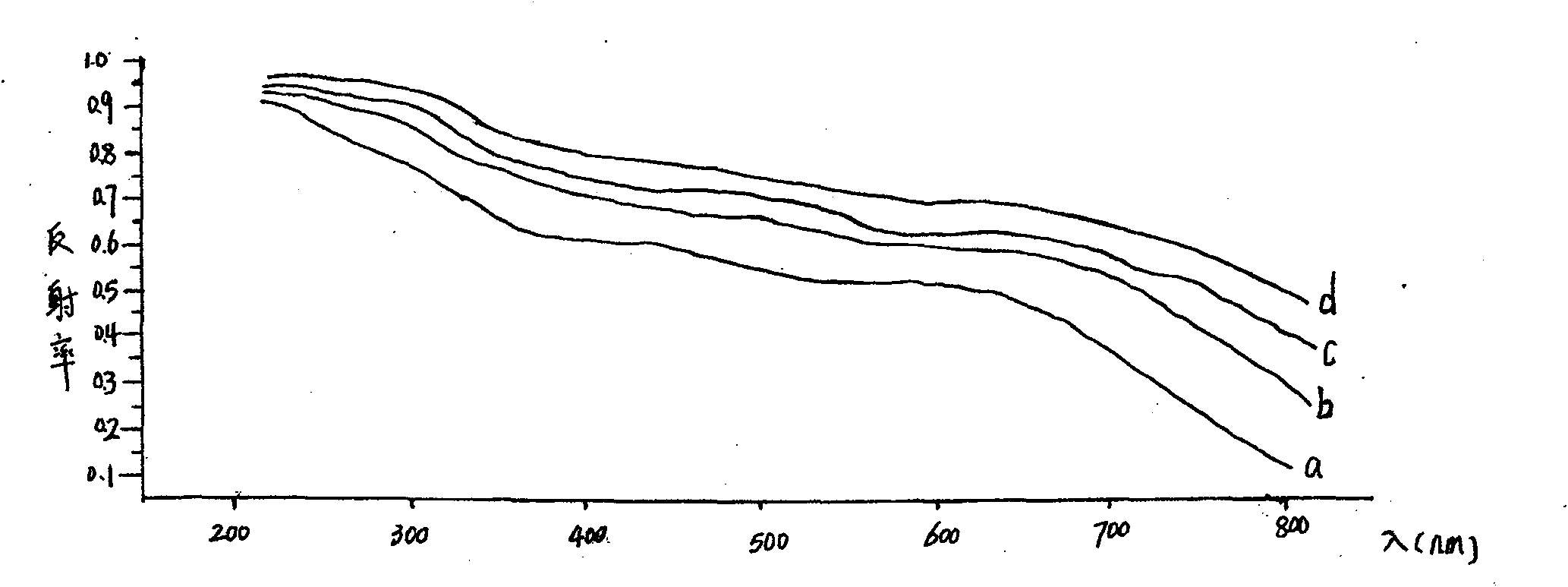

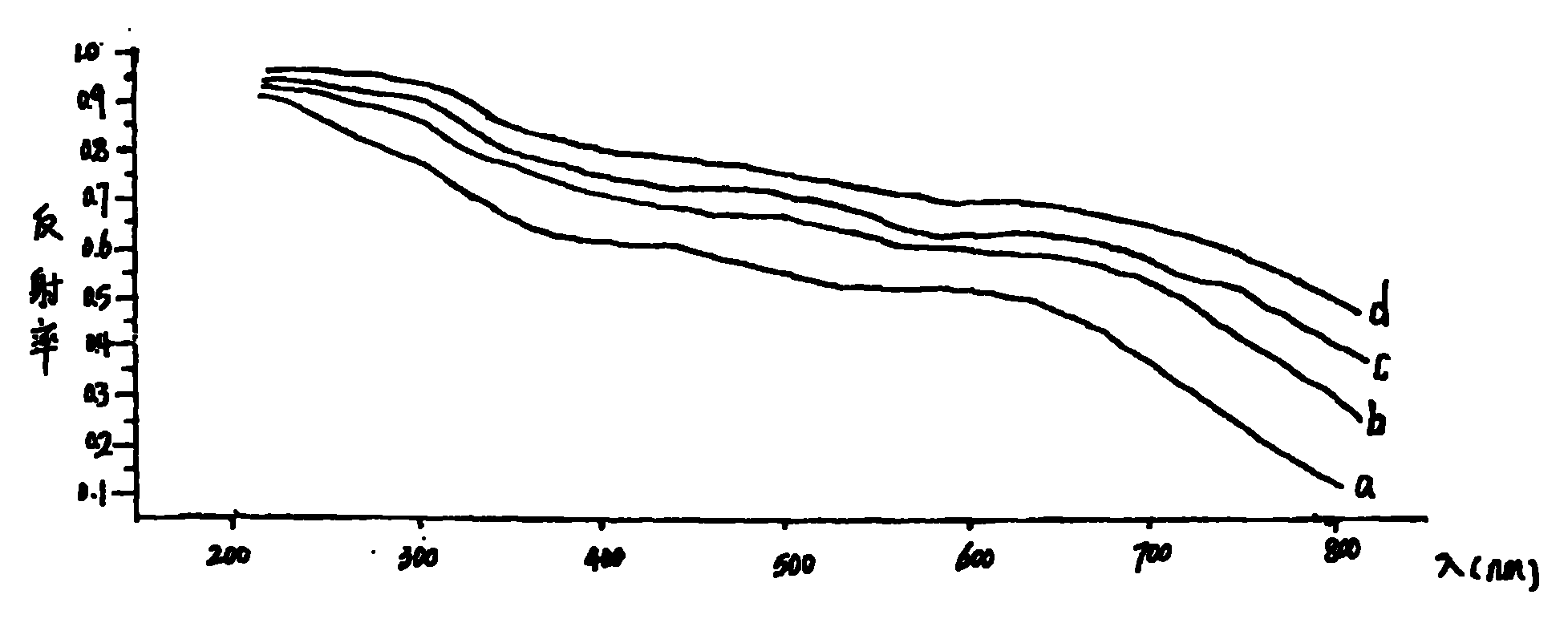

Method for manufacturing nozzle for circuit breaker

The invention discloses a method for manufacturing a nozzle for a circuit breaker. Inorganic materials such as boron nitride and the like are added based on a pure polytetrafluoroethylene (PTFE) material of the nozzle in the prior art, so the light reflectivity of the nozzle is greatly improved, the ablation caused by electric arc radiation to the nozzle is reduced, serious decomposition and internal explosion due to that the nozzle is subjected to optothermal and electric arc radiation are avoided, and electric arc ablation resistance of the nozzle is greatly improved.

Owner:江苏常新密封材料有限公司

Integrated permanent magnet mechanism vacuum switch

ActiveCN103779137AMake electrical connectionsRealize detectionHigh-tension/heavy-dress switchesAir-break switchesElectrical connectionRelative motion

The invention discloses an integrated permanent magnet mechanism vacuum switch. The structure of a traditional permanent magnet mechanism vacuum switch is redegined, the bellows is removed, components, such as the permanent magnet mechanism, moving and fixed contacts, a drive rod, an arc extinguishing system, etc., are all placed in the vacuum environment surrounded by a ceramic housing (all moving components are integrated in the ceramic vacuum housing), and wire connection terminals on two ends are fixedly connection with the ceramic vacuum housing (no relative movement exists), wherein one wire connection terminal is connected with the fixed contact, and the other wire connection terminal is in electrical connection with a conductive rod of the moving contact end through soft connection.

Owner:XI AN JIAOTONG UNIV

Preparation method of high-flame-retardancy expandable graphite

The invention relates to a preparation method of high-flame-retardancy expandable graphite, which comprises the following steps: oxidizing graphite by using concentrated sulfuric acid / nitric acid mixture, nitric acid / phosphoric acid mixture, fuming nitric acid or concentrated sulfuric acid together with a solid strong oxidizer which accounts for 5-60 wt% of graphite, wherein the reaction temperature is 15-50 DEG C, and the reaction time is 10-100 minutes; after the reaction finishes, filtering, and washing with water until the pH value is 4-7, thereby obtaining the primary expandable graphite; and reacting the primary expandable graphite with guanidine salt solution at 20-80 DEG C for 20-200 minutes, carrying out repeated vacuum filtration, washing with water until the pH value is 6-7, and baking at 40-80 DEG C for 10-72 hours to obtain the high-flame-retardancy expandable graphite. The method provided by the invention intercalates guanidine salts into the interlayer of the expandable graphite, enhances the expansion ratio and flame retardancy, and can be widely used for flame retardancy for plastics, rubber, paint, foam and various other materials.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com