Patents

Literature

202results about How to "Reduce bouncing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

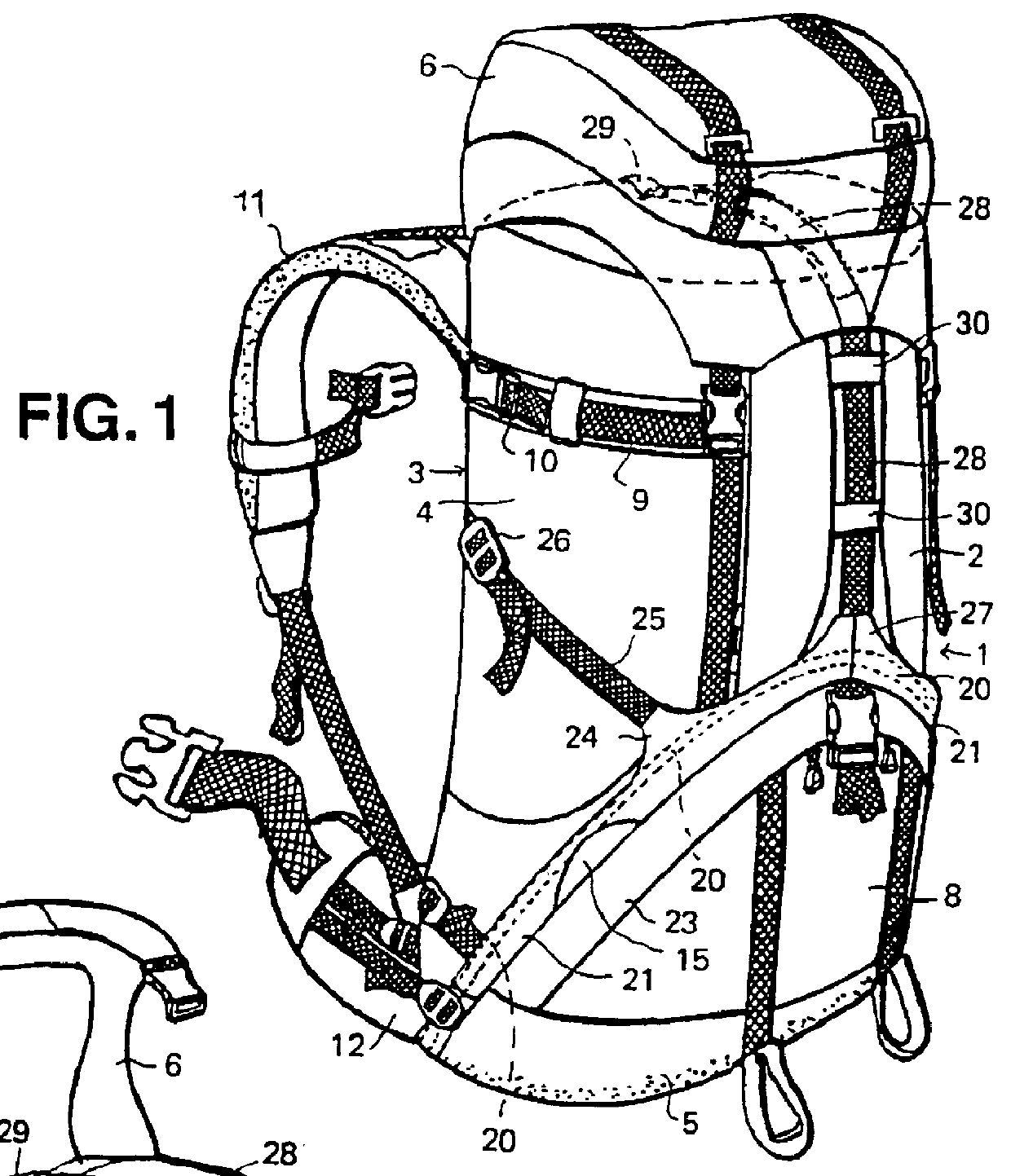

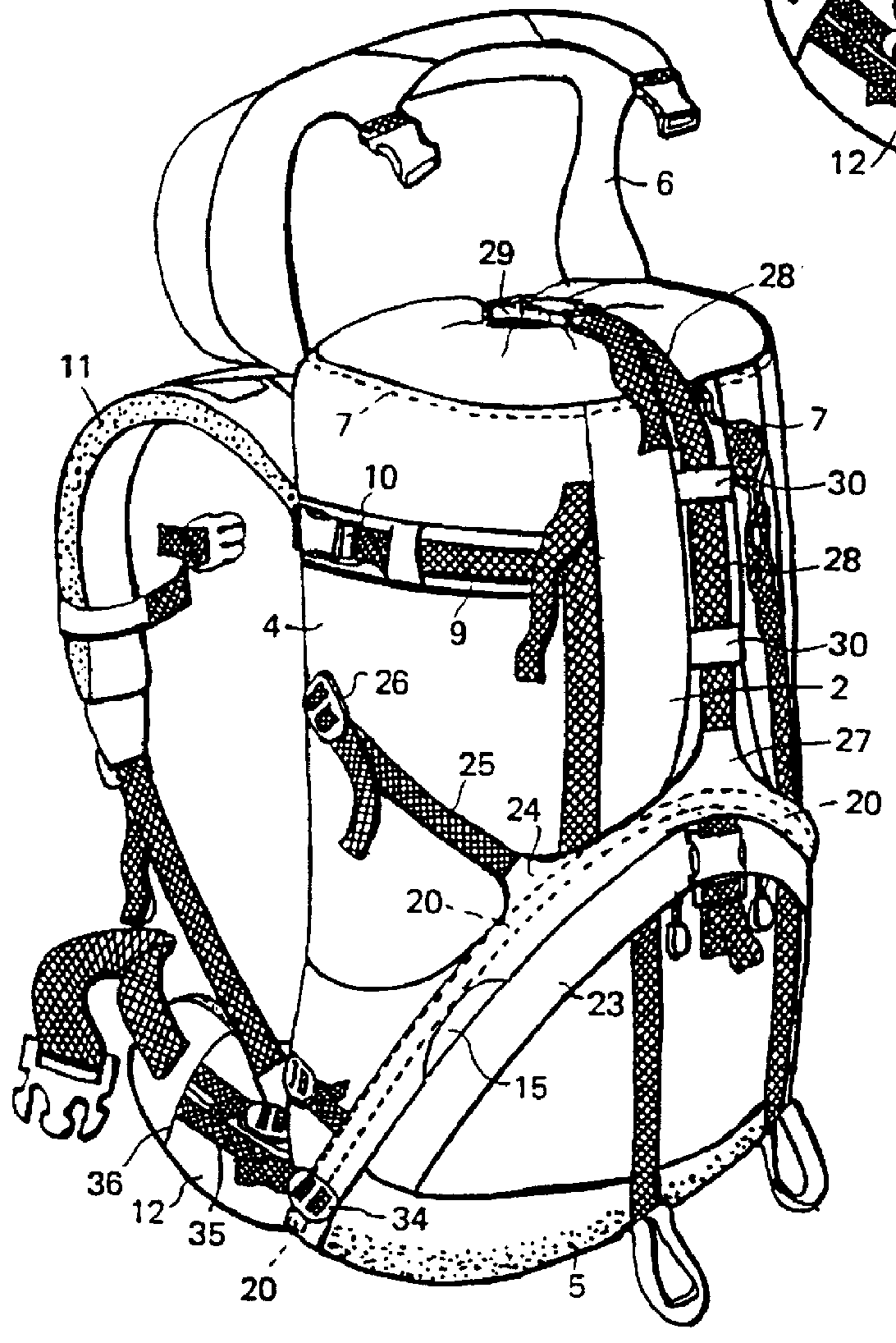

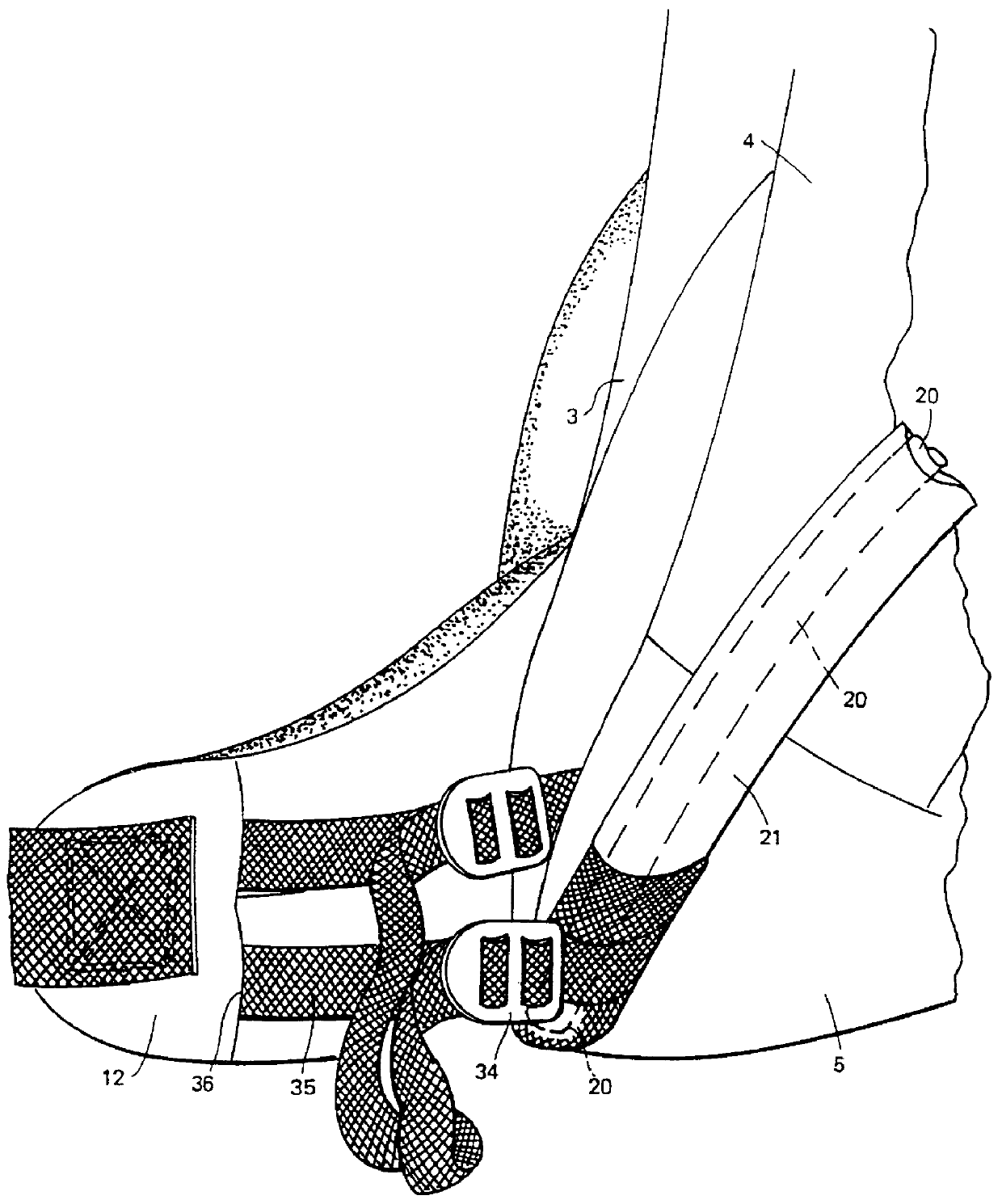

Rucksack

Owner:LOWE ALPINE HLDG

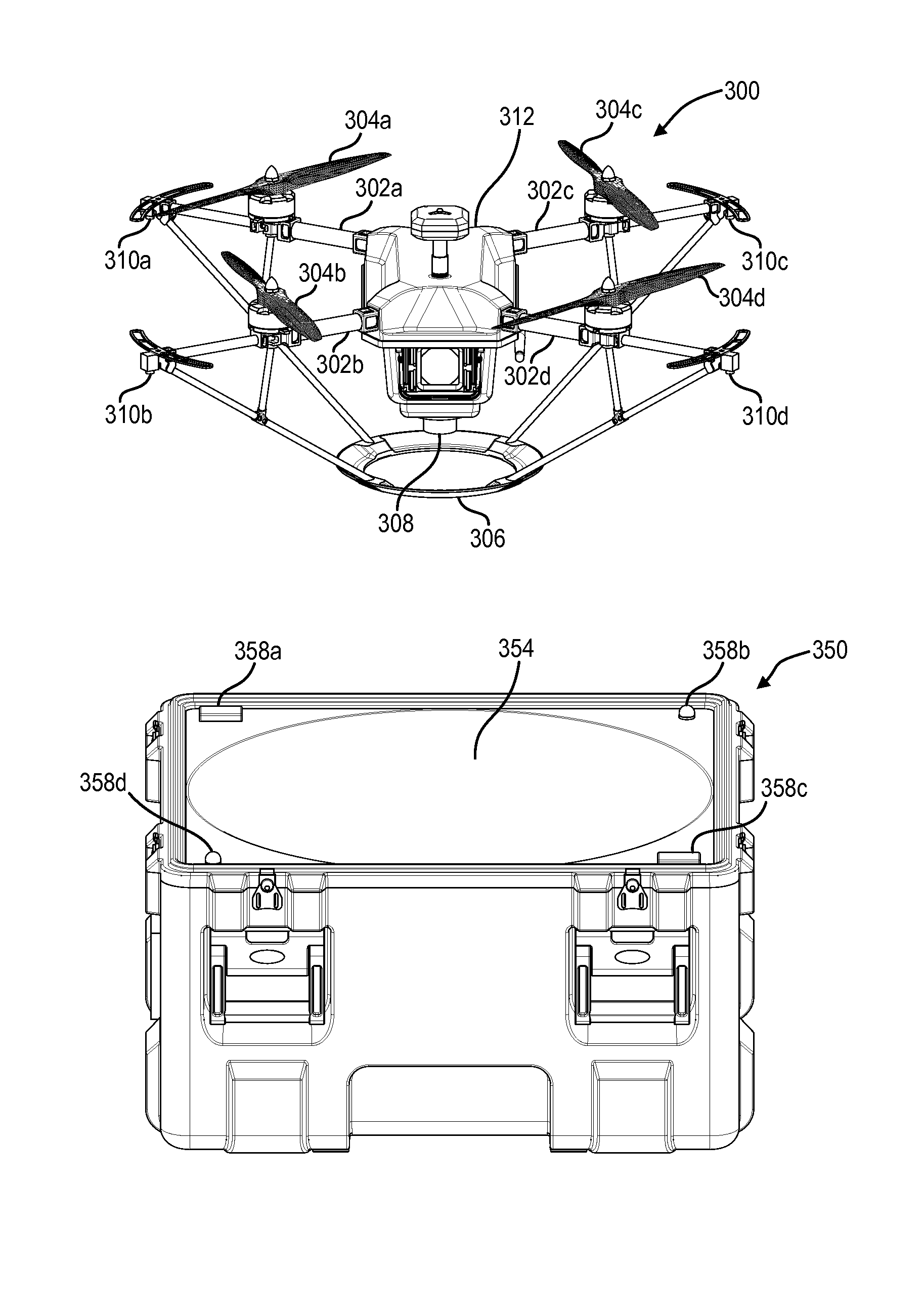

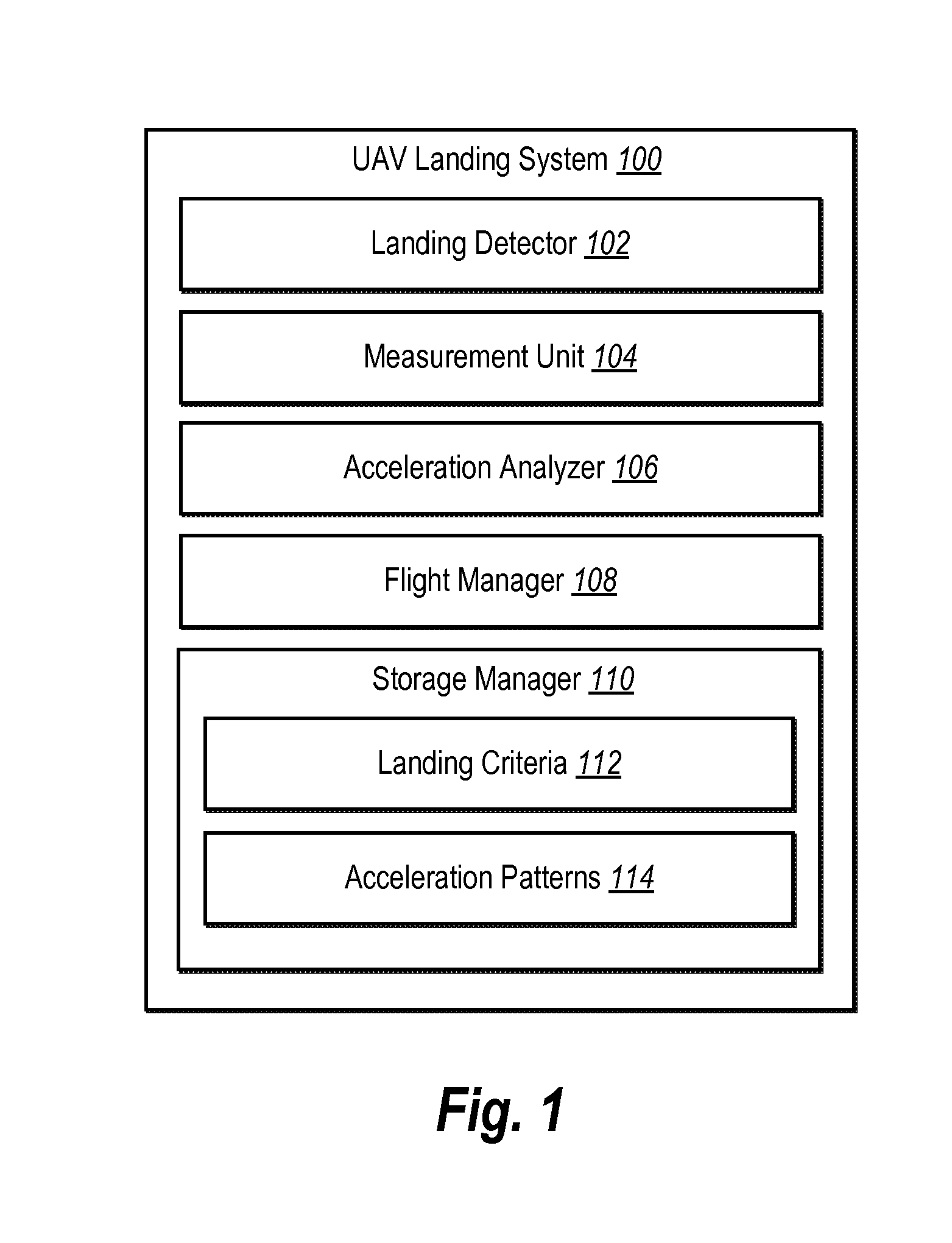

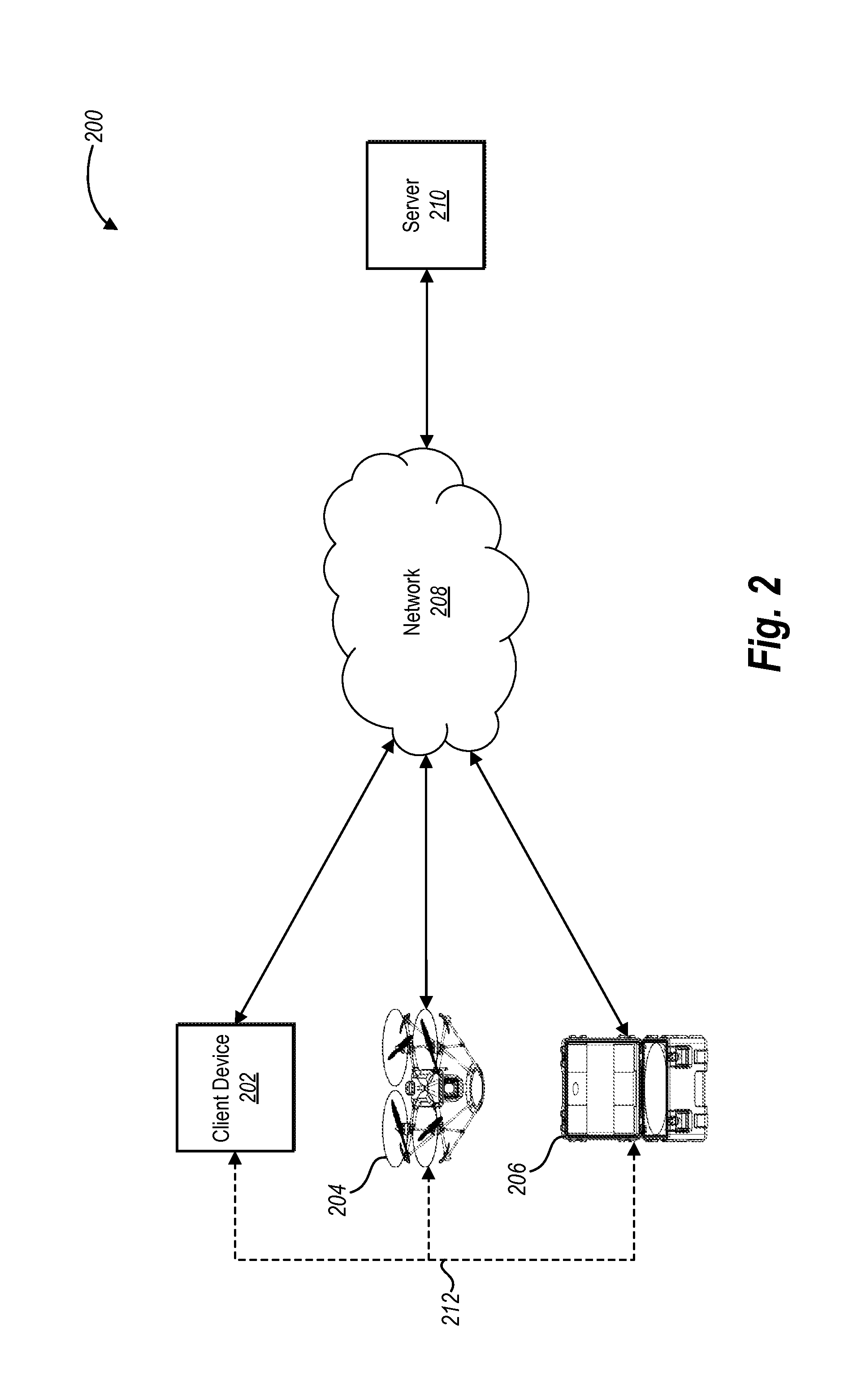

Utilizing acceleration information for precision landing of unmanned aerial vehicles

ActiveUS9448562B1Reduce “ bouncing ”Reduce gyrationUnmanned aerial vehiclesRemote controlled aircraftLand basedEngineering

Owner:SKYCATCH

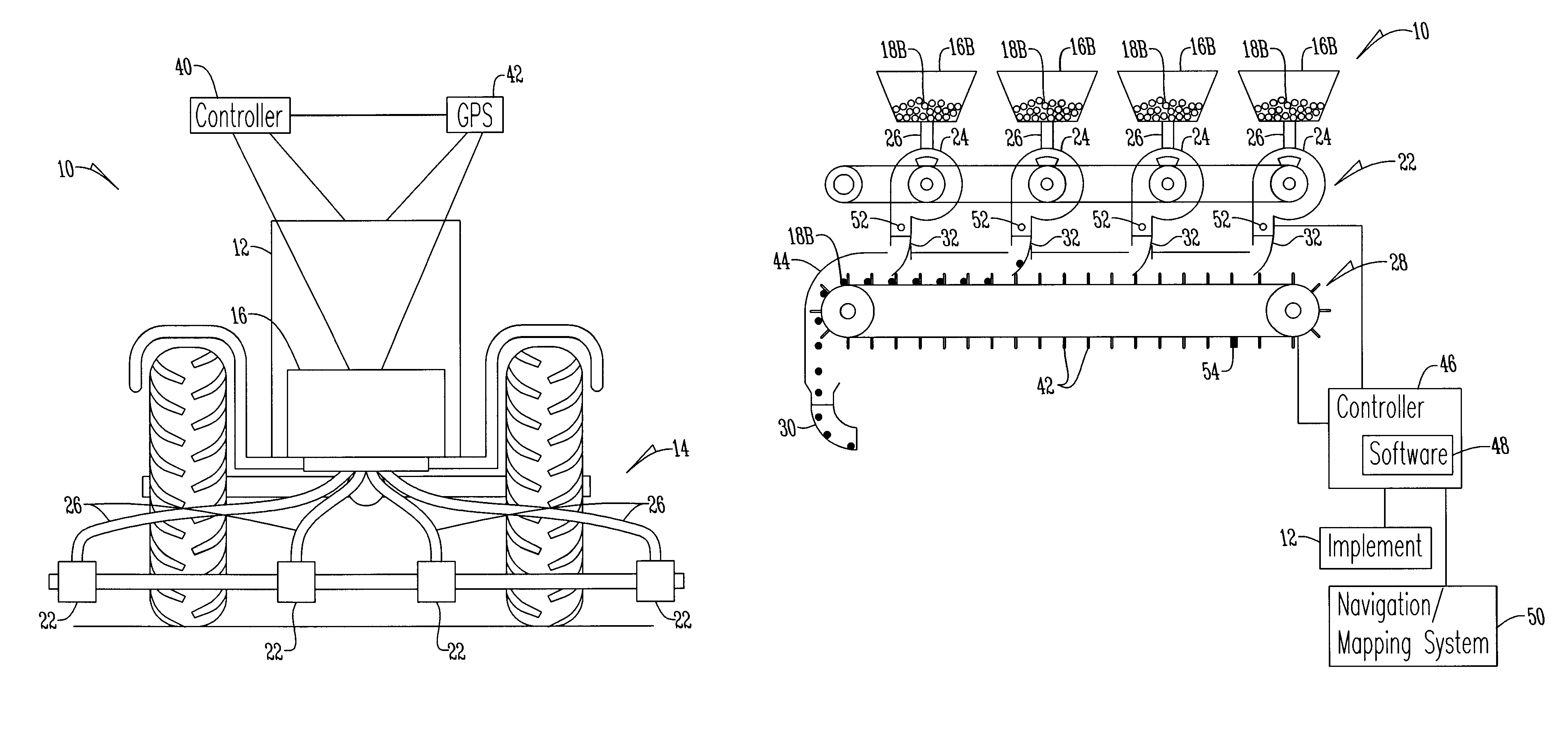

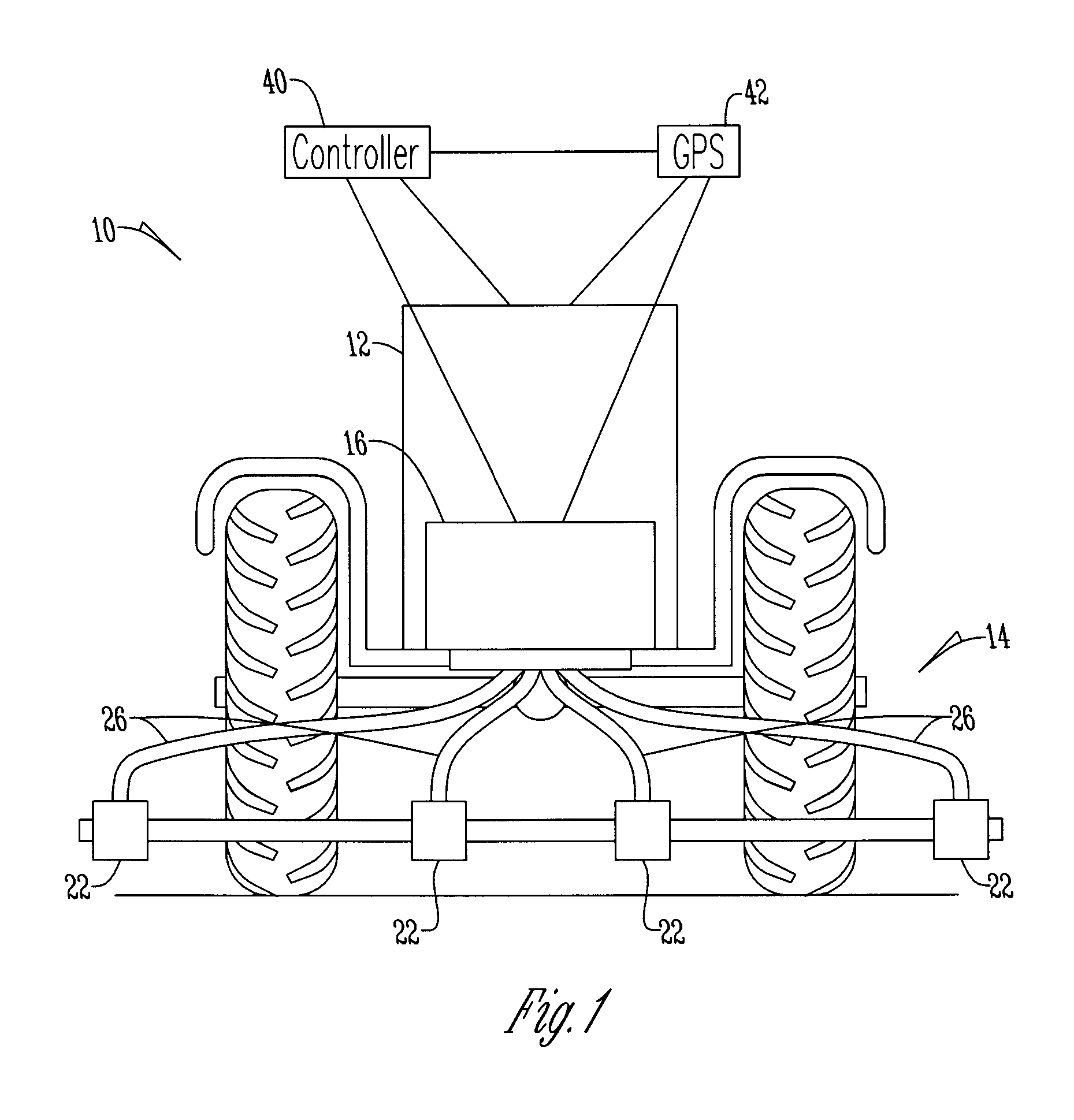

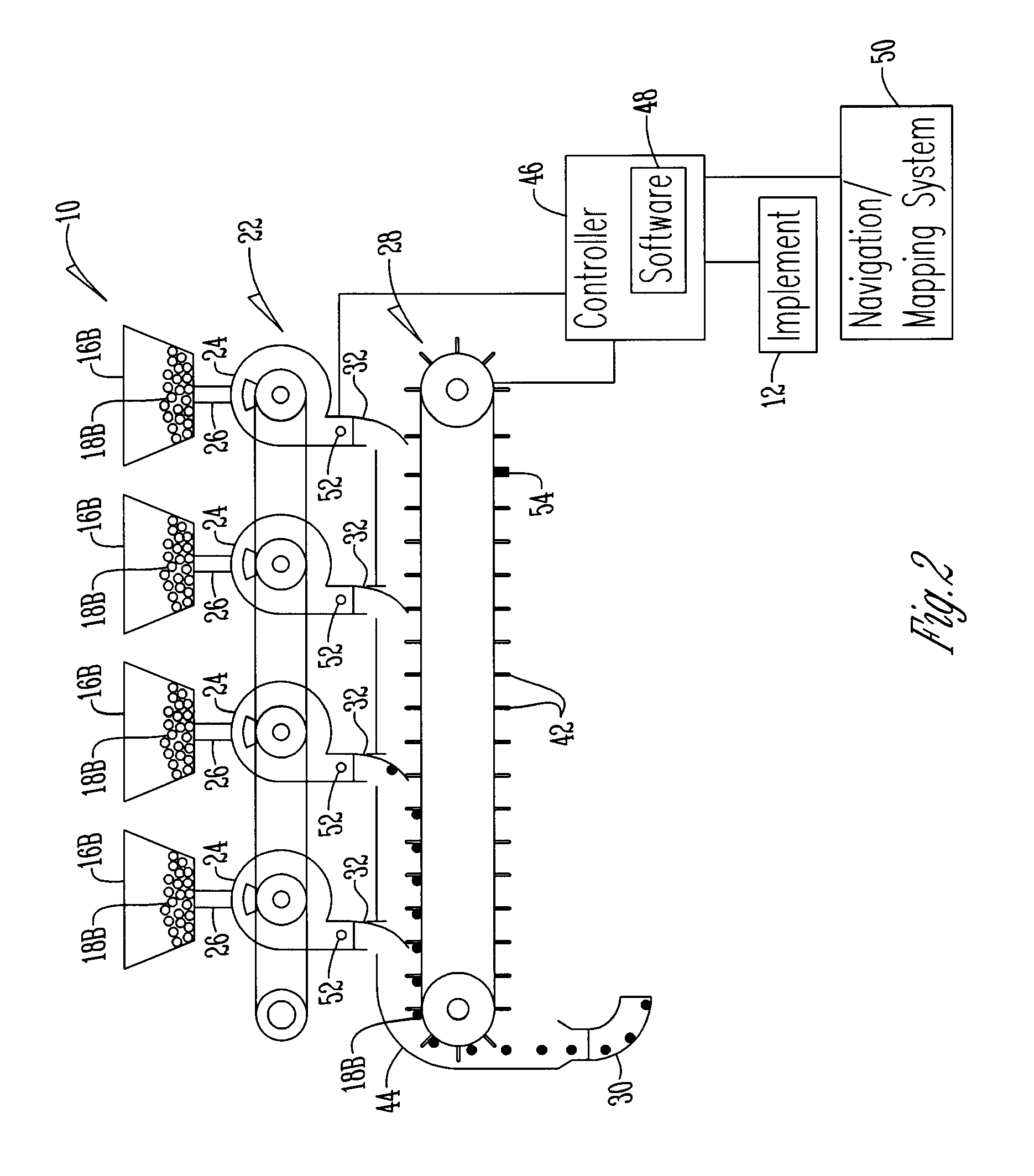

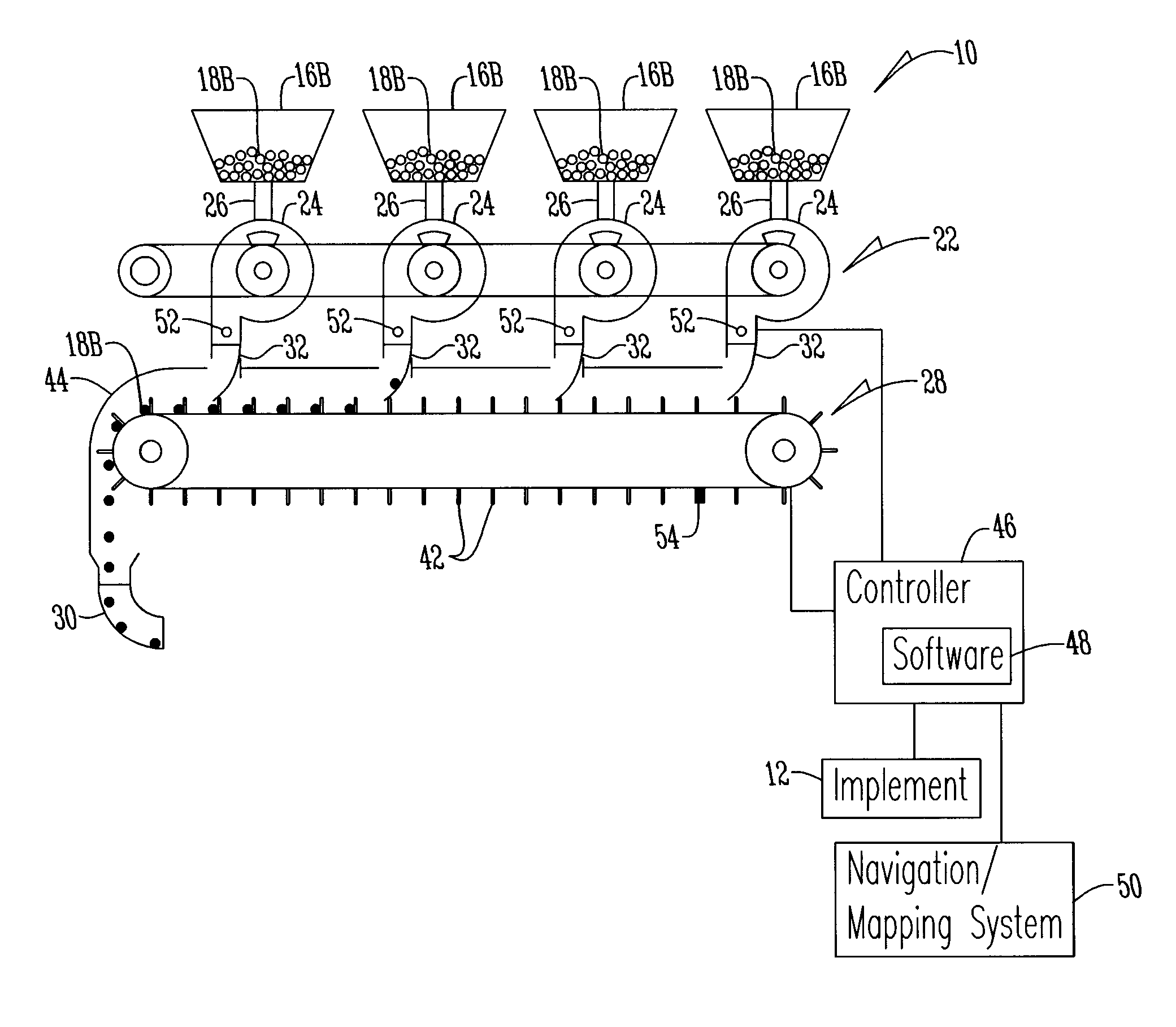

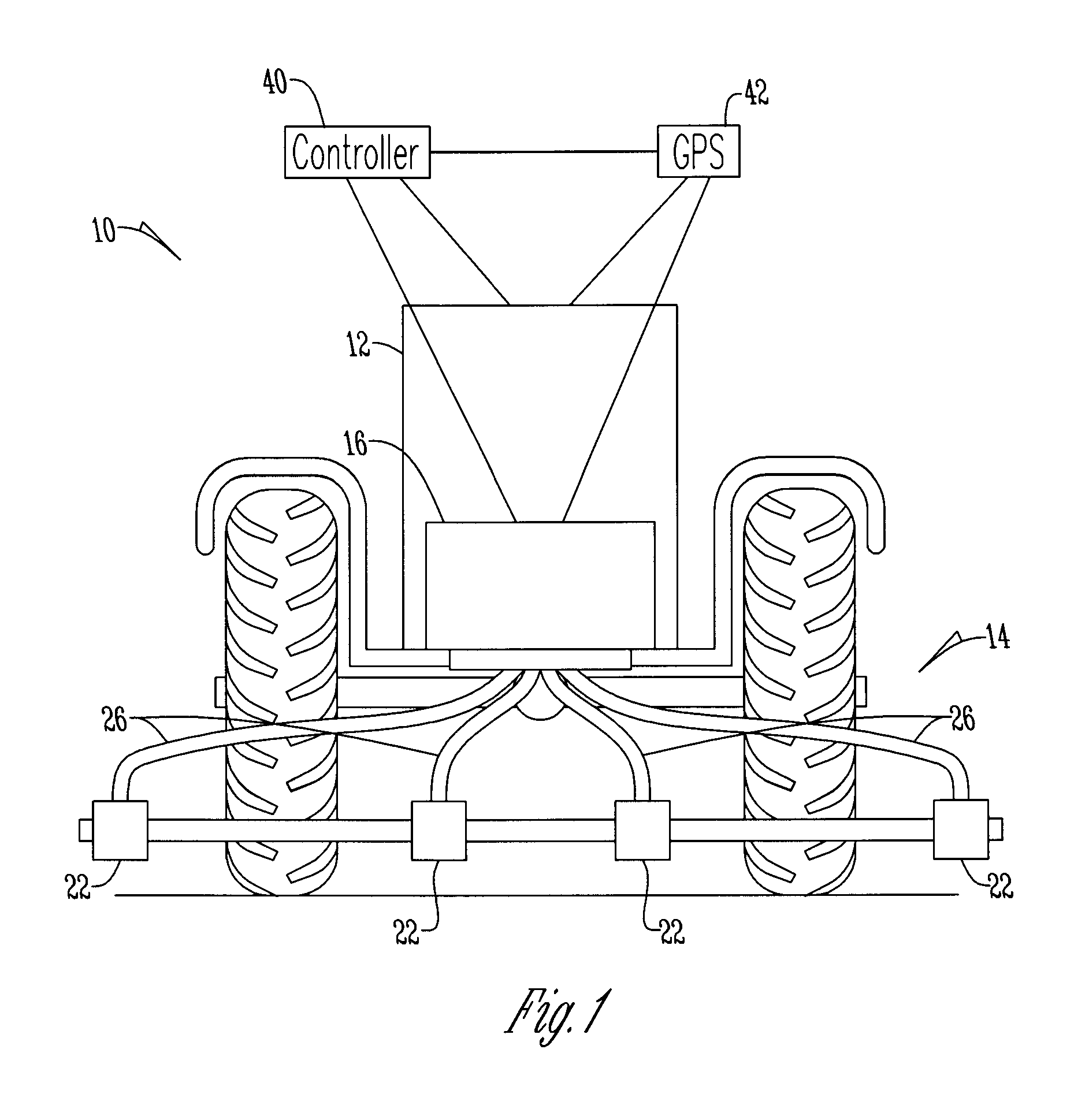

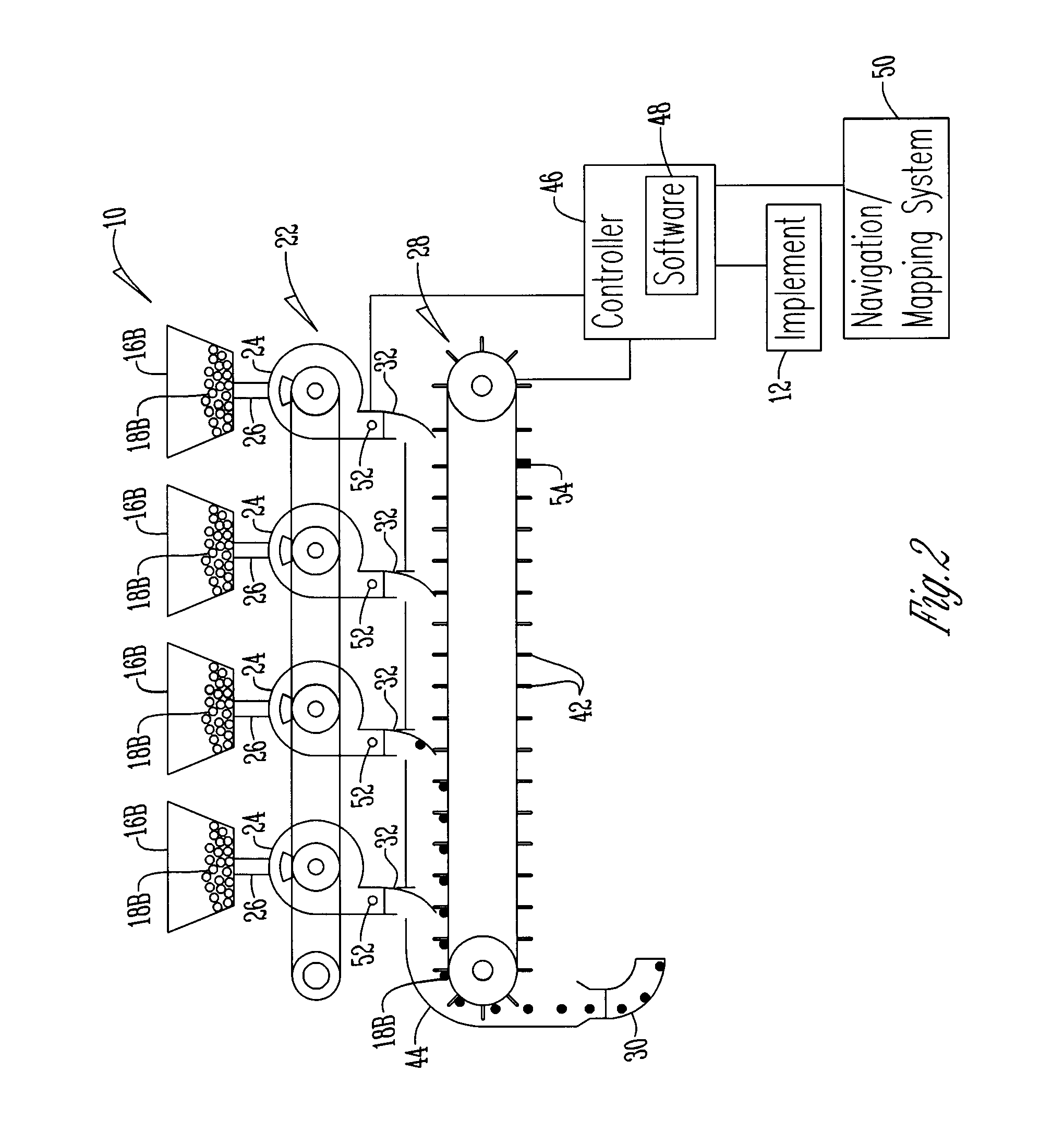

Seed variety changer for a planter

ActiveUS9148992B2Reduce bouncingEasy to switchDigital data processing detailsFertilising methodsActuator

A system for changing seed variety on a planter includes a plurality of row units with each row unit having a plurality of seed meters. Each seed meter has a guide for delivering seed to a transport belt and a switch that is activated and deactivated by a switch actuator on the belt. The belt has adjustable sidewalls, cover, and lugs.

Owner:KINZE MFG INC

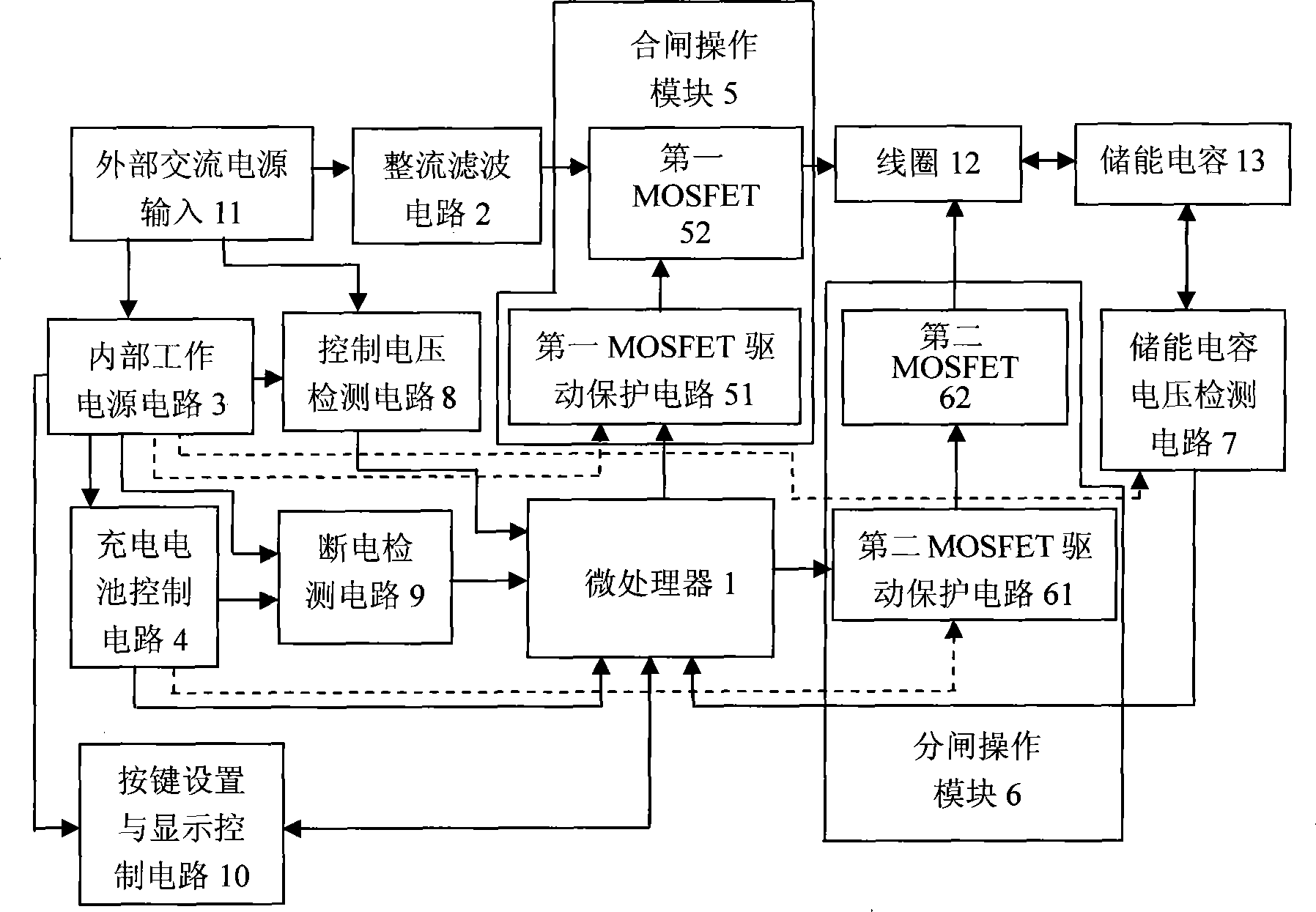

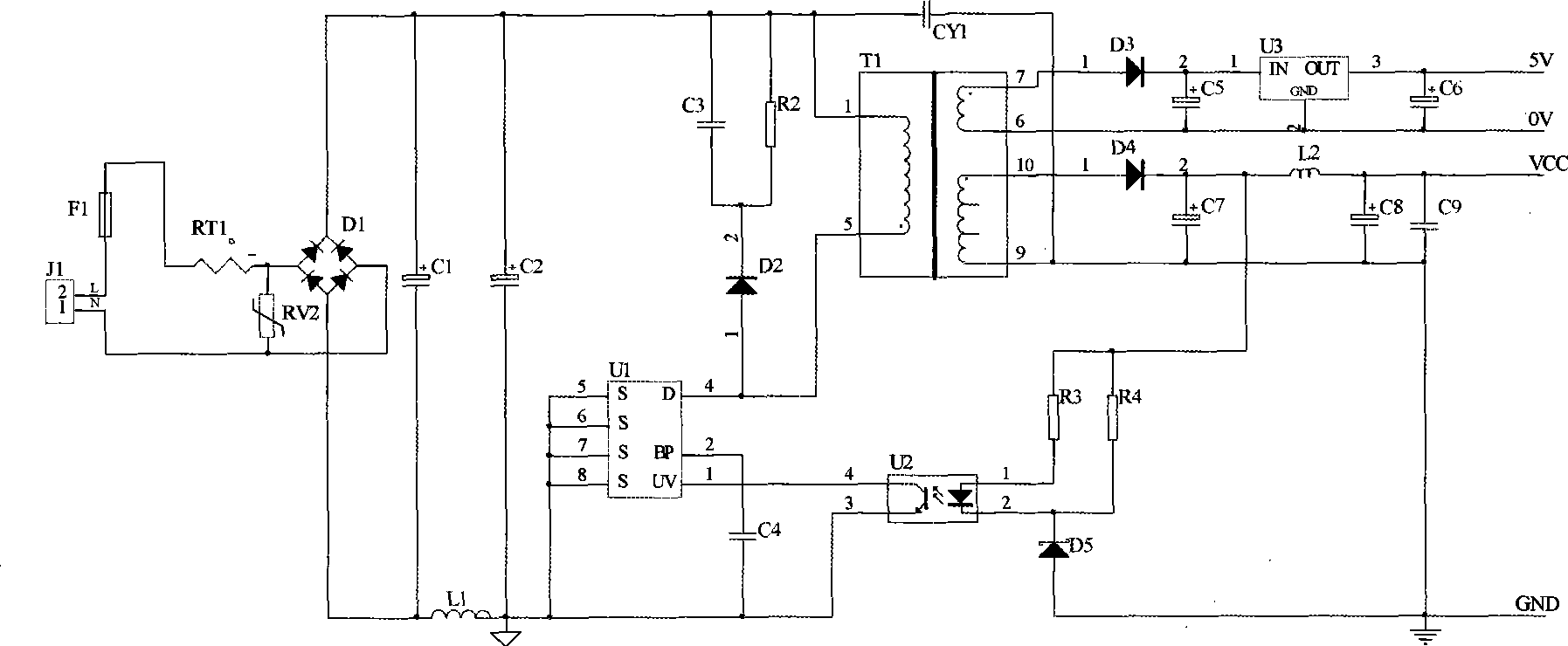

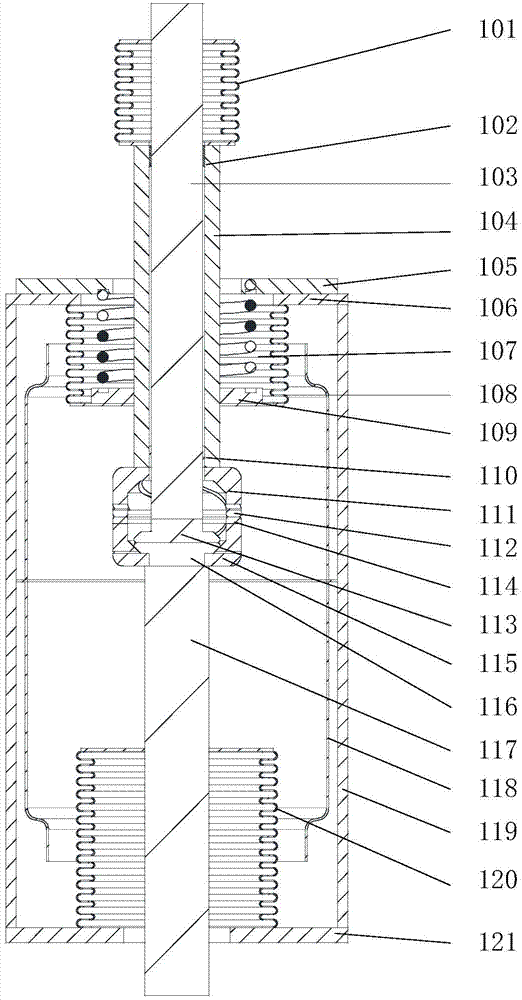

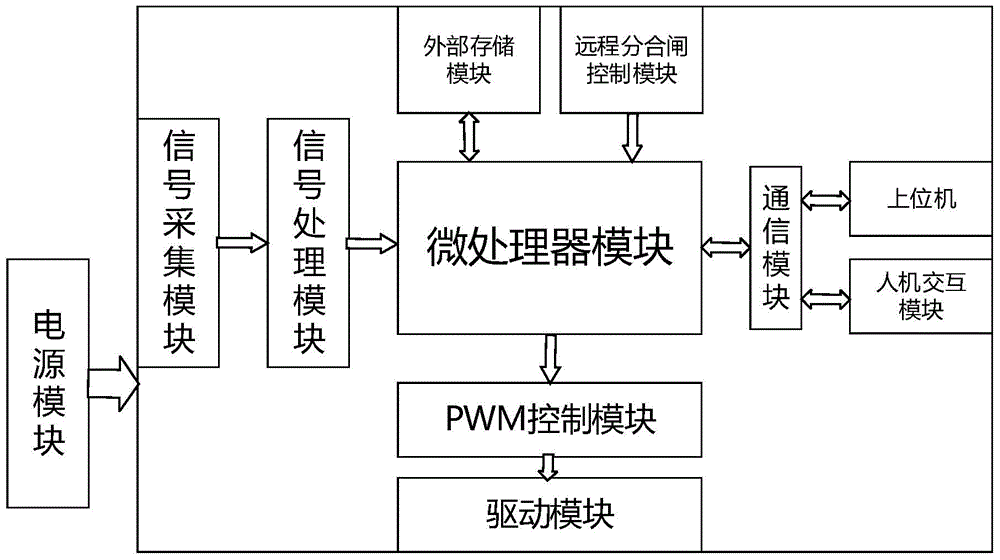

Intelligent control module for permanent magnet contactor

InactiveCN101477919AGuaranteed continuous operationEnsure safetyEmergency protective arrangements for automatic disconnectionRelaysContactorCapacitance

The invention discloses an intelligent control module of a permanent magnet contactor, which mainly comprises a microprocessor, a rectifier and filter, an internal working power circuit, a rechargeable battery control circuit, a closing operation module, an opening operation module, an energy-storage capacitor voltage detection circuit, a control voltage detection circuit, a power off detection circuit, and a key-press setting and display control circuit; wherein, the closing operation module consists of a first MOSFET driving protection circuit and a first MOSFET; and the opening operation module consists of a second MOSFET driving protection circuit and a second MOSFET. The intelligent control module can set delay time parameters of transient interference electricity through key-presses according to requirements of a customer, realizes delay disconnection of the permanent magnet contactor and can ensure the stable and continuous operation of equipment through staying away from influences of interference electricity; and as for conditions of requiring urgent opening operation, the intelligent control module can immediately cut off the contactor through key-press control, so as to ensure the safety of the operating equipment.

Owner:SOUTHEAST UNIV

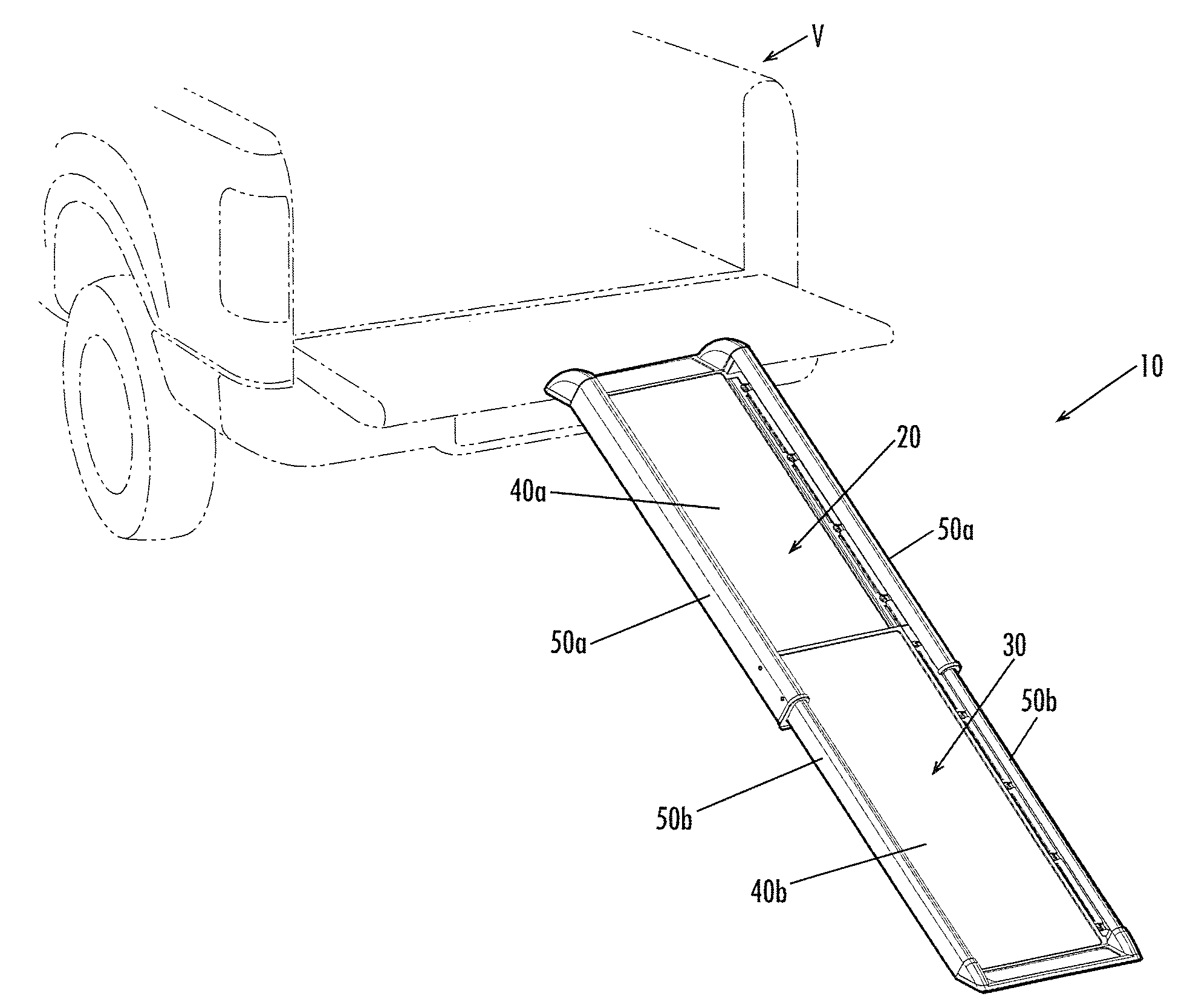

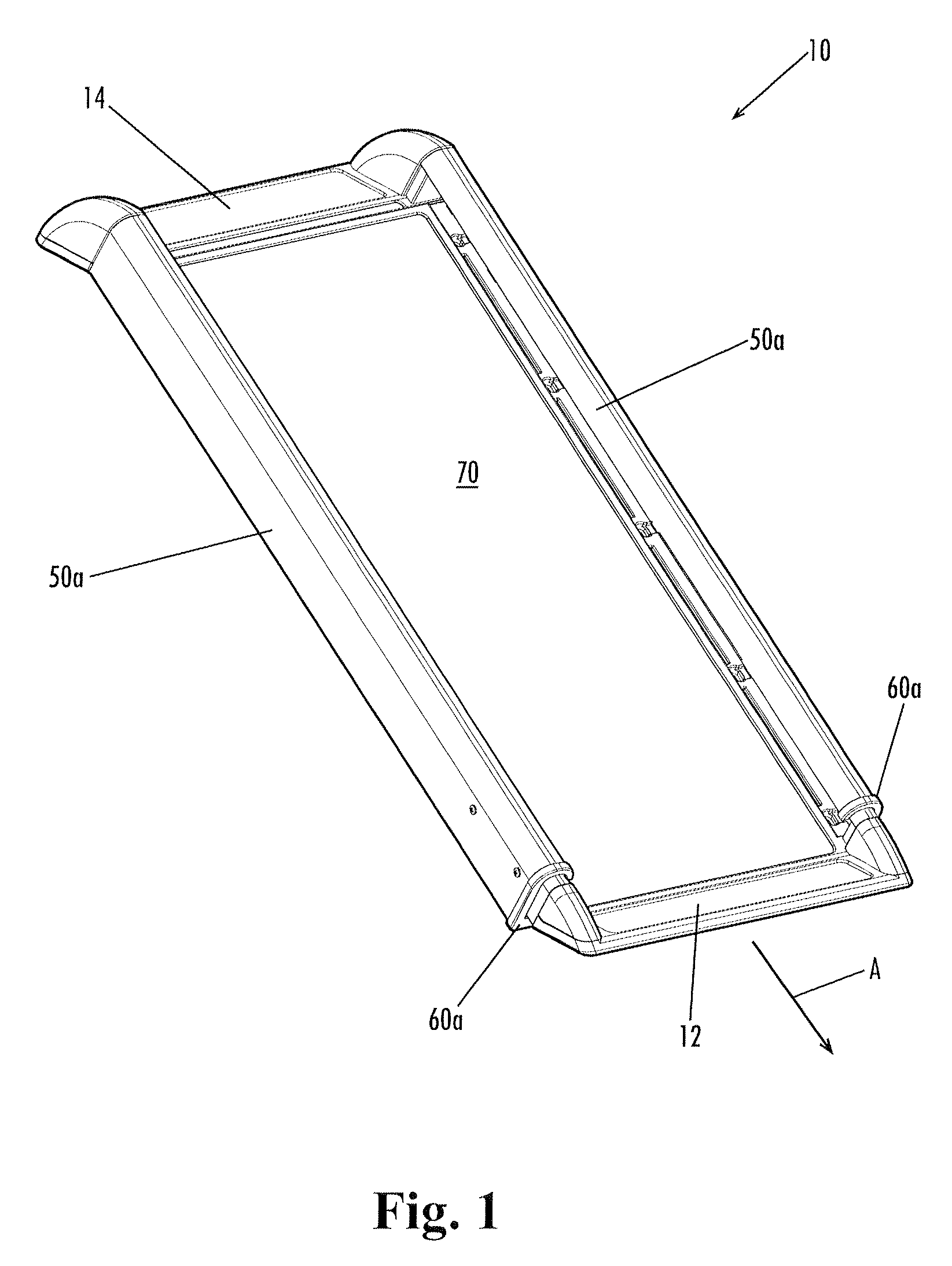

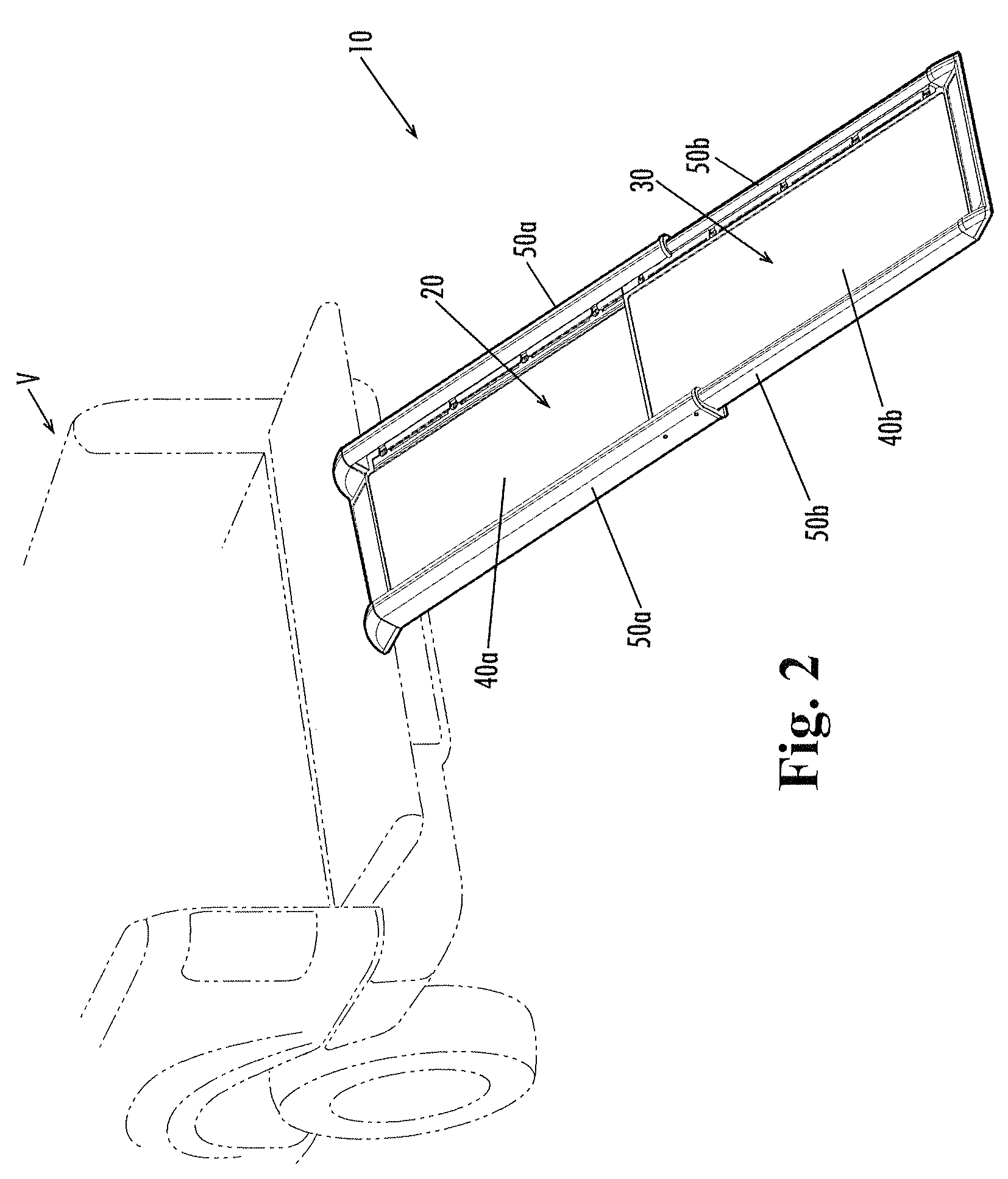

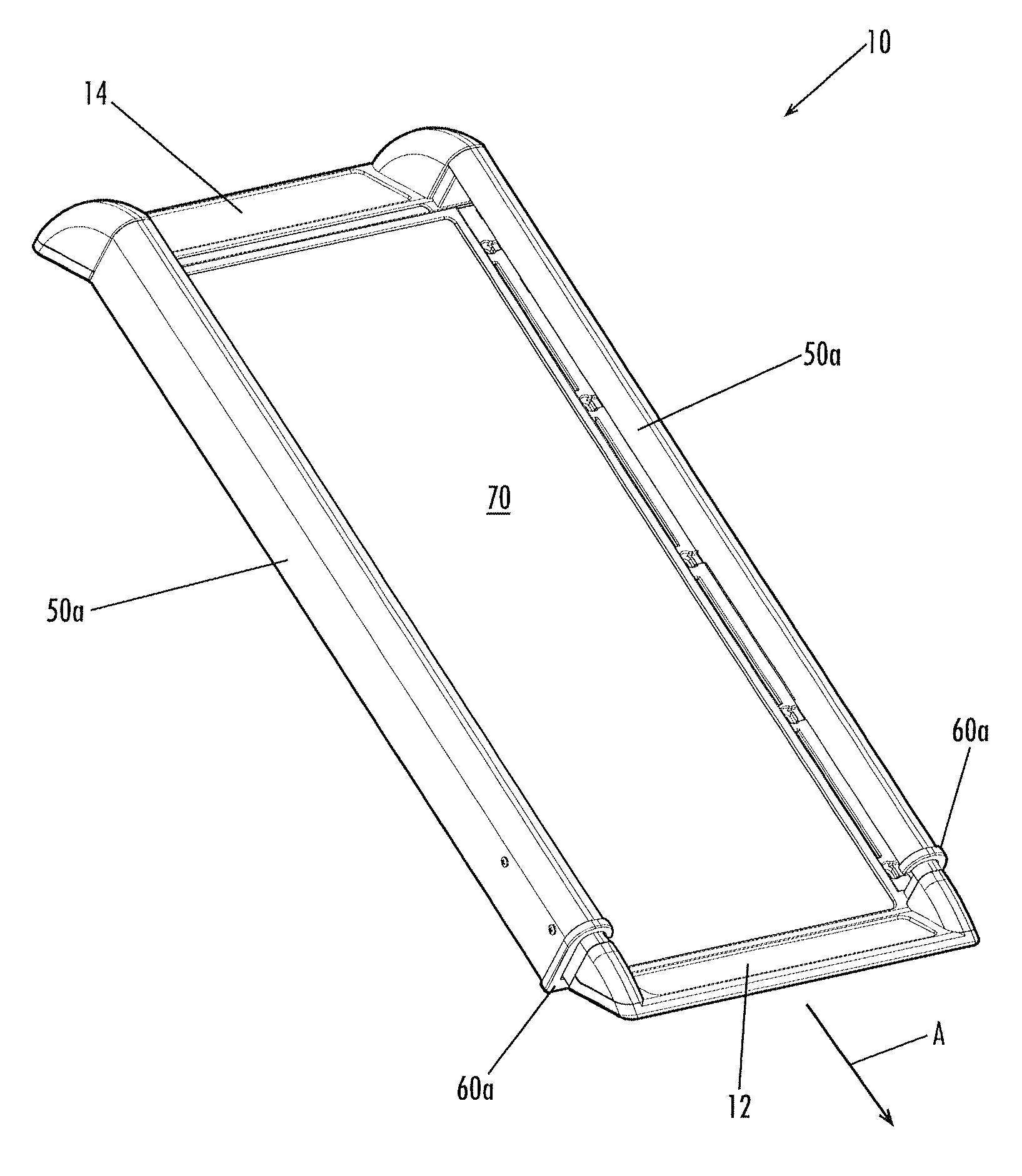

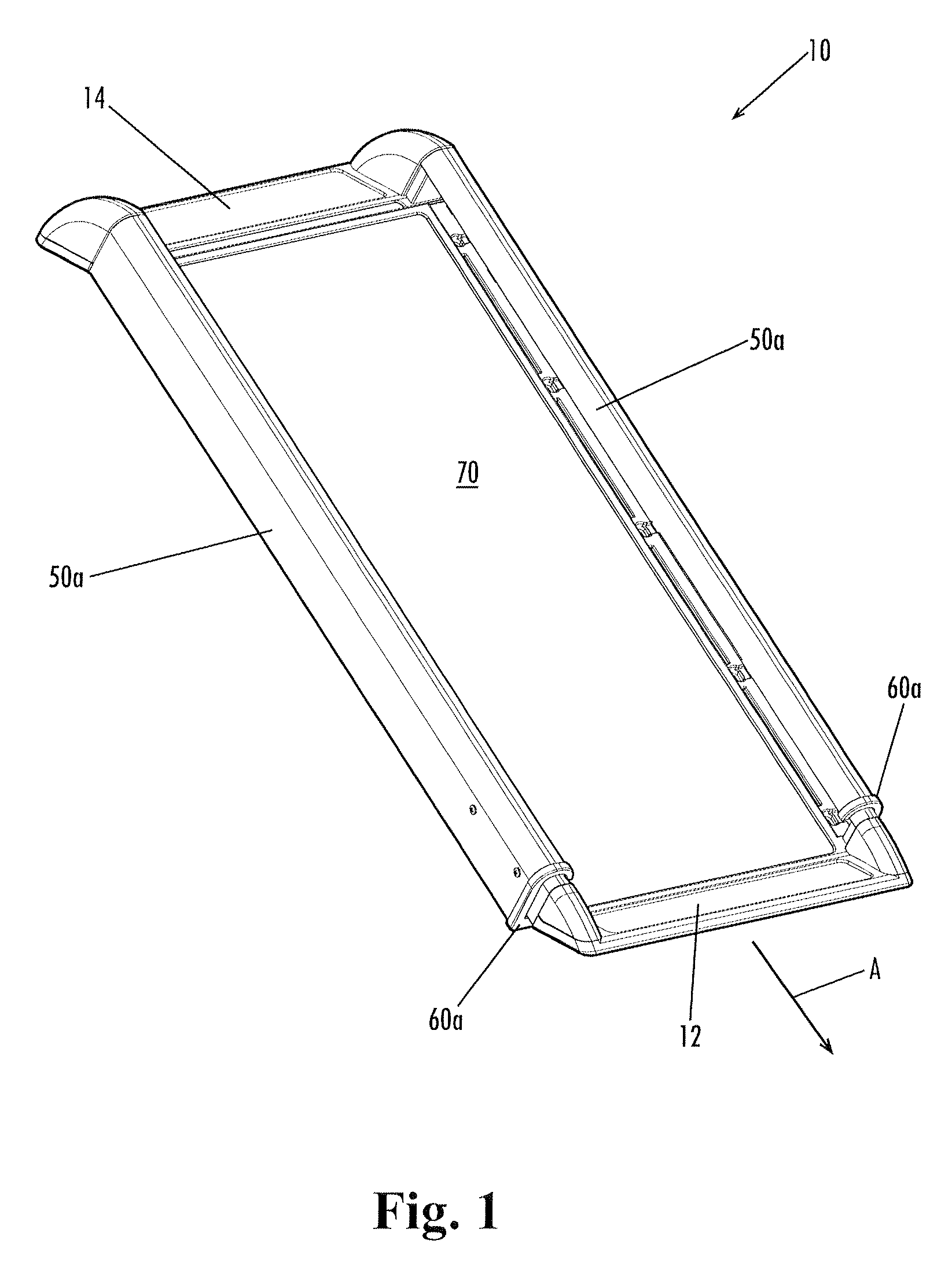

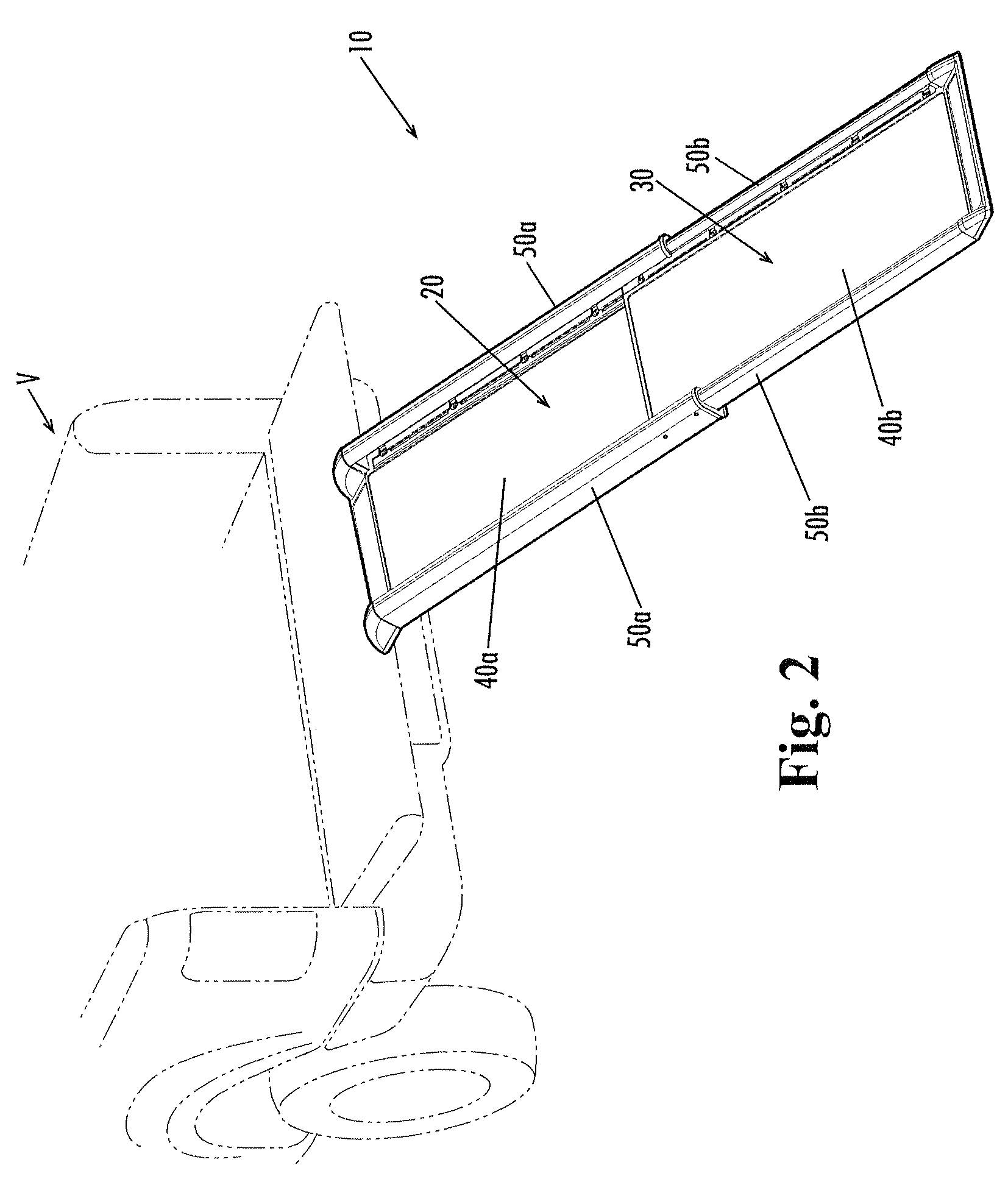

Telescoping pet ramp

ActiveUS20080105215A1Improve rigidityReduce bouncingAnimal housingLoading/unloadingEngineeringElectrical and Electronics engineering

A telescoping pet ramp having first and second ramp segments telescopically extendable from a compact state to an extended state. Side rails of the panels include end caps with abutment members for preventing the first floor panel and second floor panel from being separated when the pet ramp is fully extended, and including interlocking angled contact faces that frictionally engage one another when the ramp is fully extended.

Owner:RADIO SYST CORP

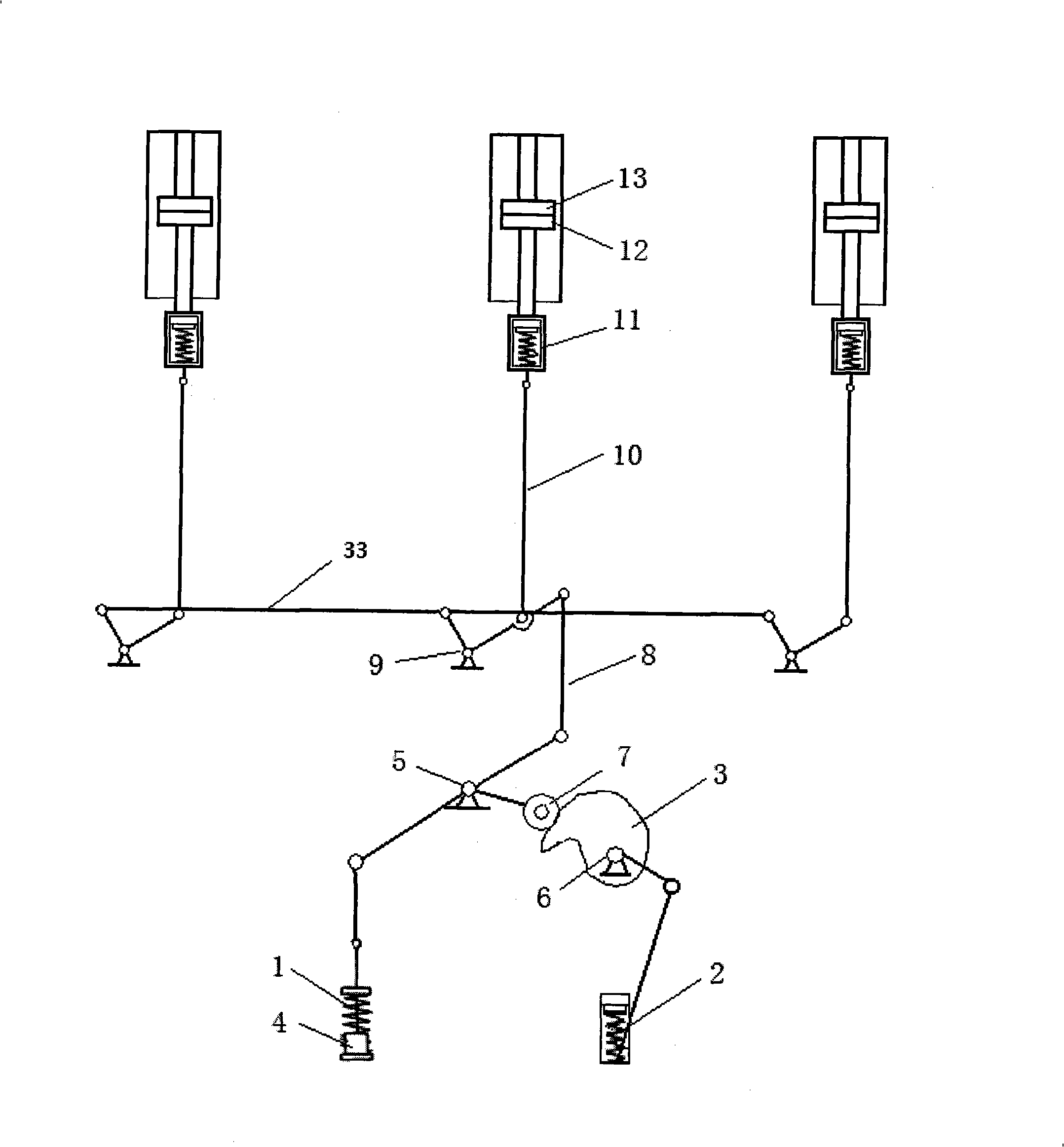

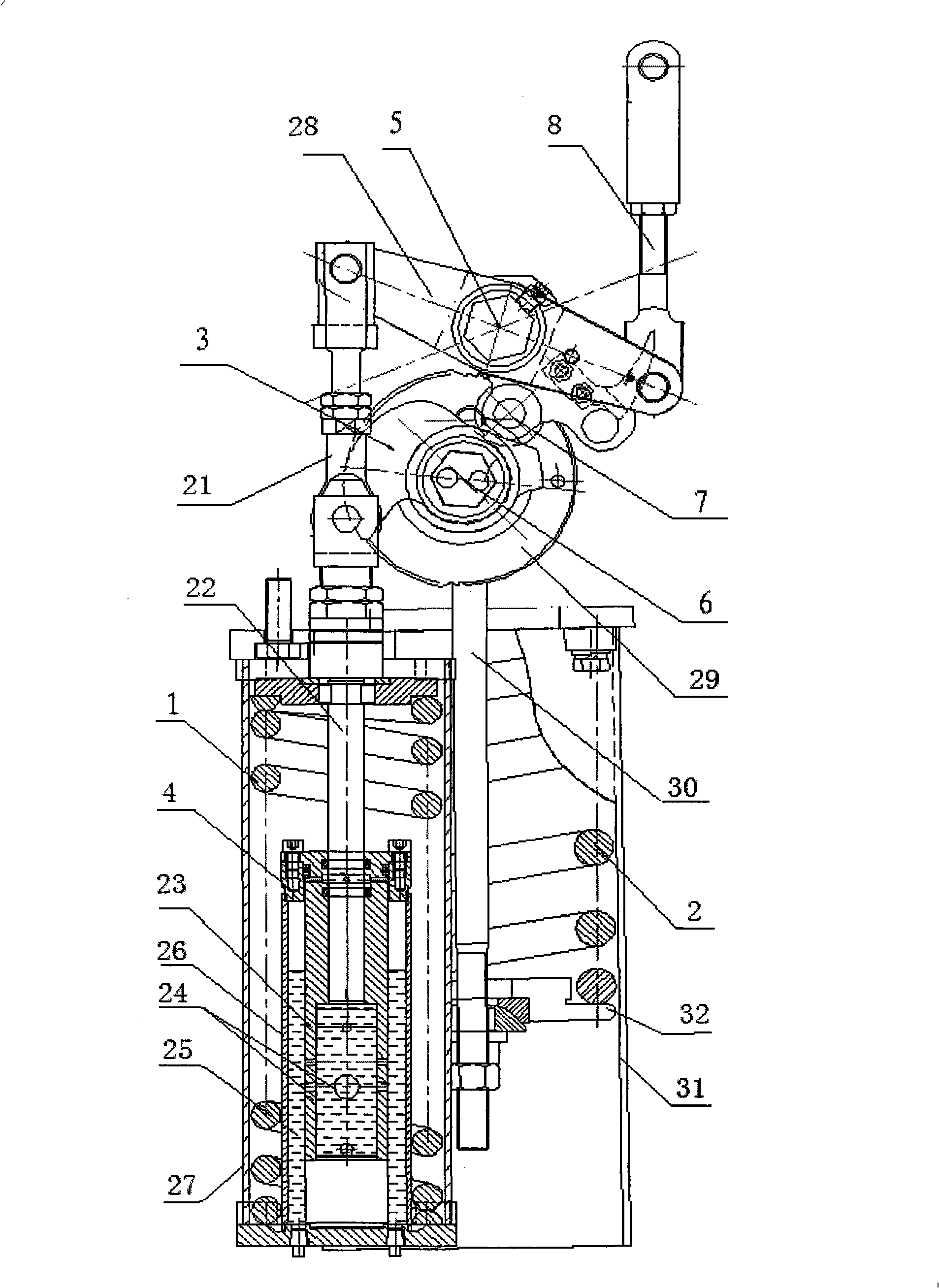

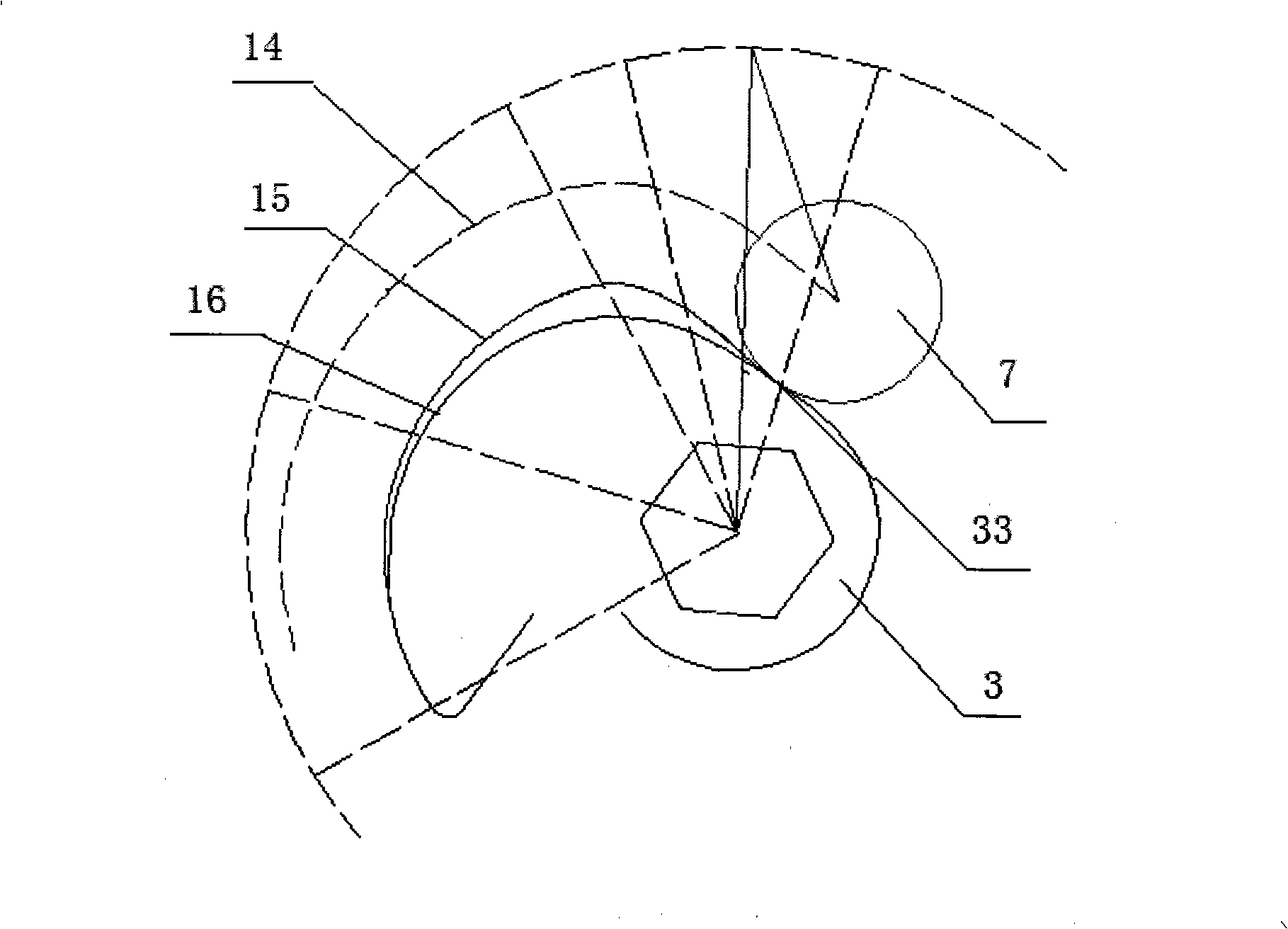

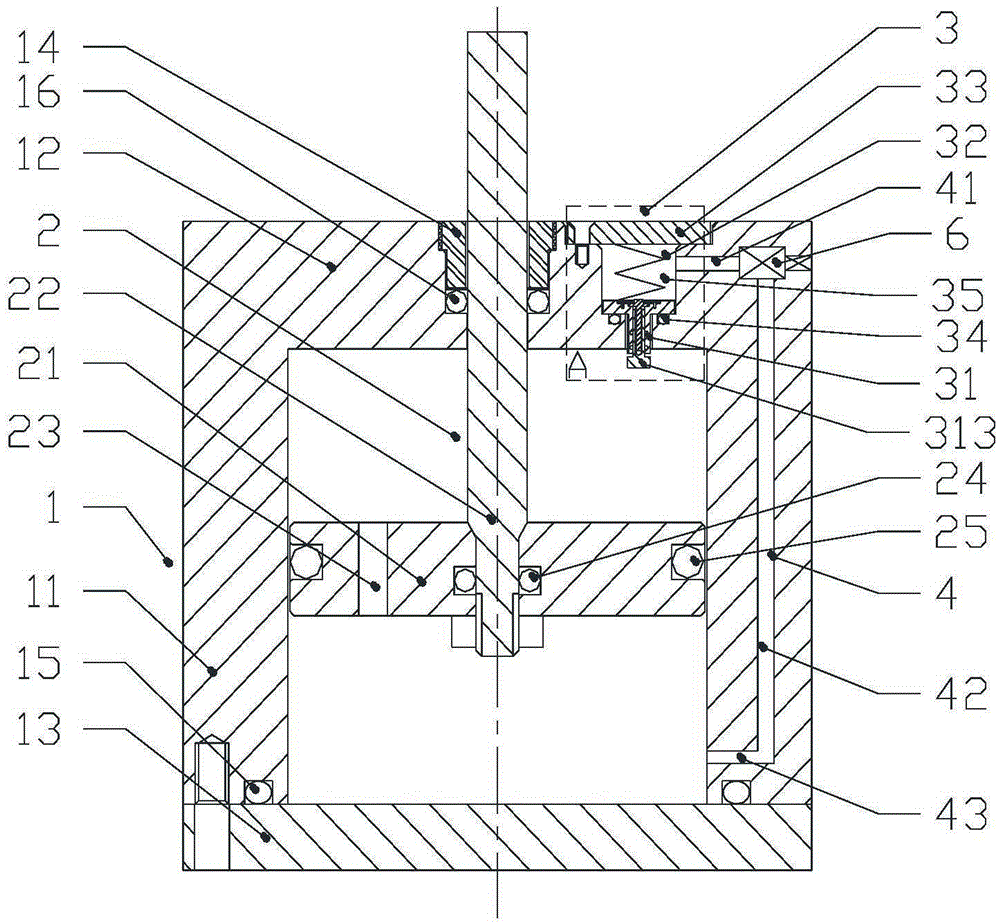

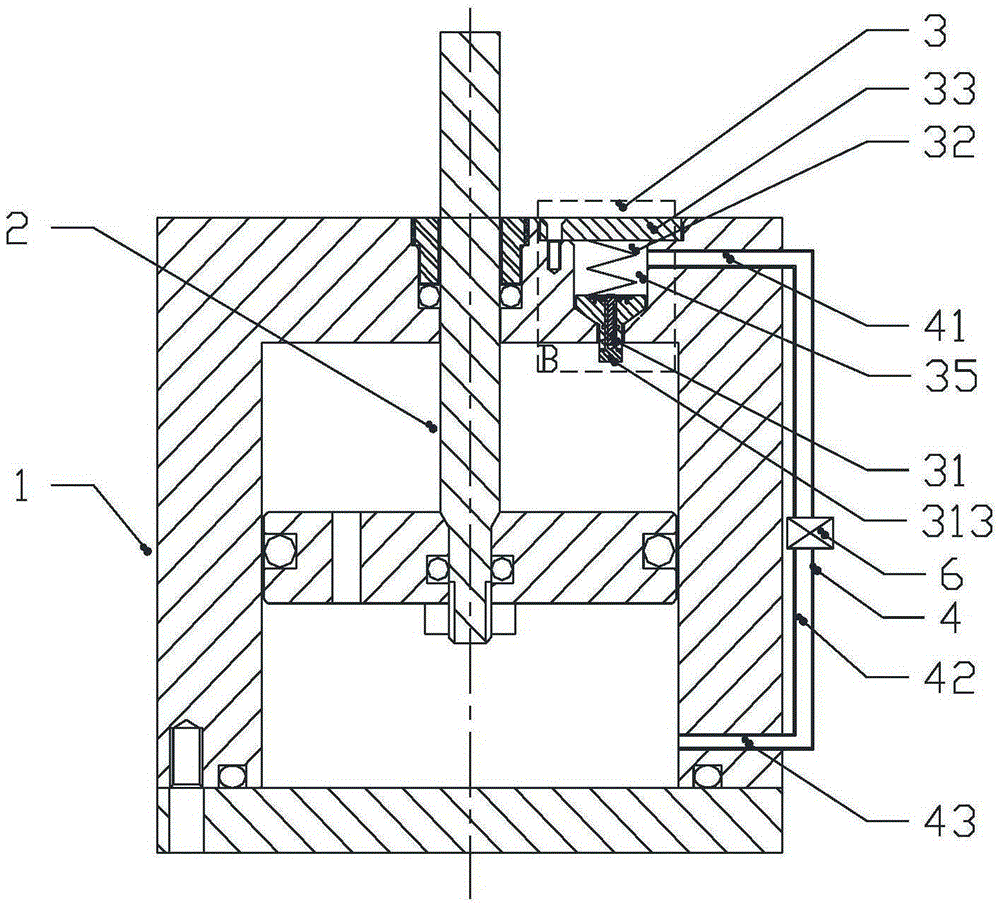

Spring operating mechanism cooperated with 126kV vacuum circuit breaker separation-integration characteristic

InactiveCN101315849AReduce bouncingReduce opening and closing workHigh-tension/heavy-dress switchesAir-break switchesEngineeringCam

The invention relates to a spring operating mechanism matched with a 126kV vacuum high-voltage circuit breaker, the invention designs the contour trajectory of a cam to achieve the best match of the output characteristics and the load characteristics; when in closing process, the speed at instant of touching is controlled in the reasonable range to effectively reduce the closing bounces, and the mechanism can also be ensured to overcome the reaction force of a contact spring at the end of the closing; the design of the size and the position of an oil drain hole on a wall of a buffer can allow the circuit breaker to ensure higher speed at instant of touching during the opening process to allow an arc-extinguishing chamber to rapidly enter the short arcing time, thus allowing the average speed to be maintained within a certain range, ensuring the long arcing time of the circuit breaker and further being conductive to the arc extinguishment; the spring operating mechanism can solve the problem of poor match of the output force of the mechanism in the past with the load characteristics of the vacuum circuit breaker, reasonably distribute energy to the overall motion process of the circuit breaker and reduce the opening and closing works of the mechanism.

Owner:XI AN JIAOTONG UNIV +1

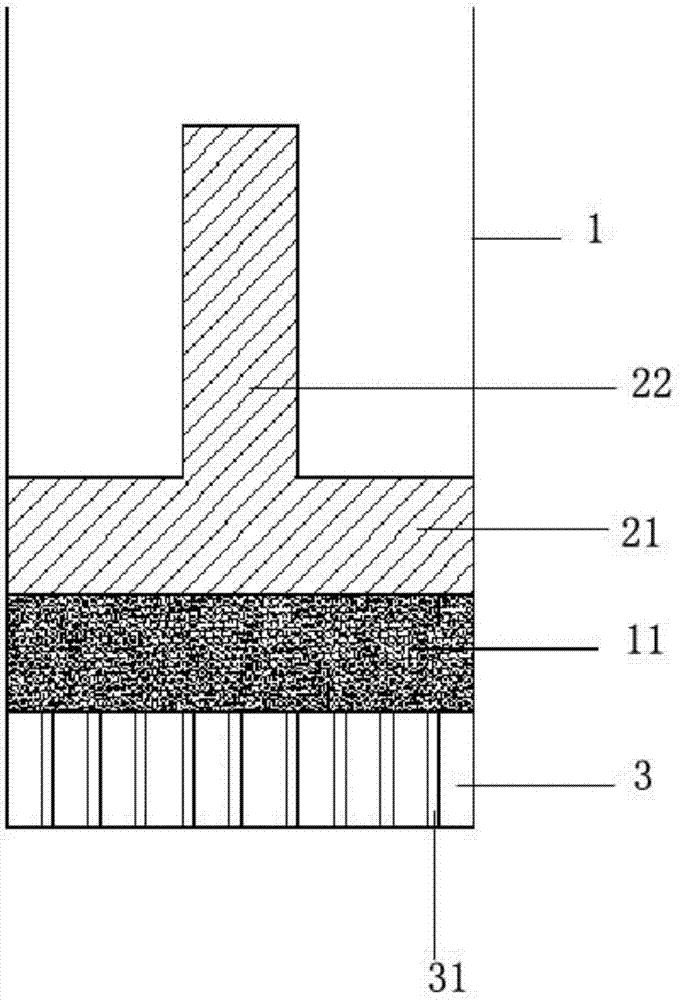

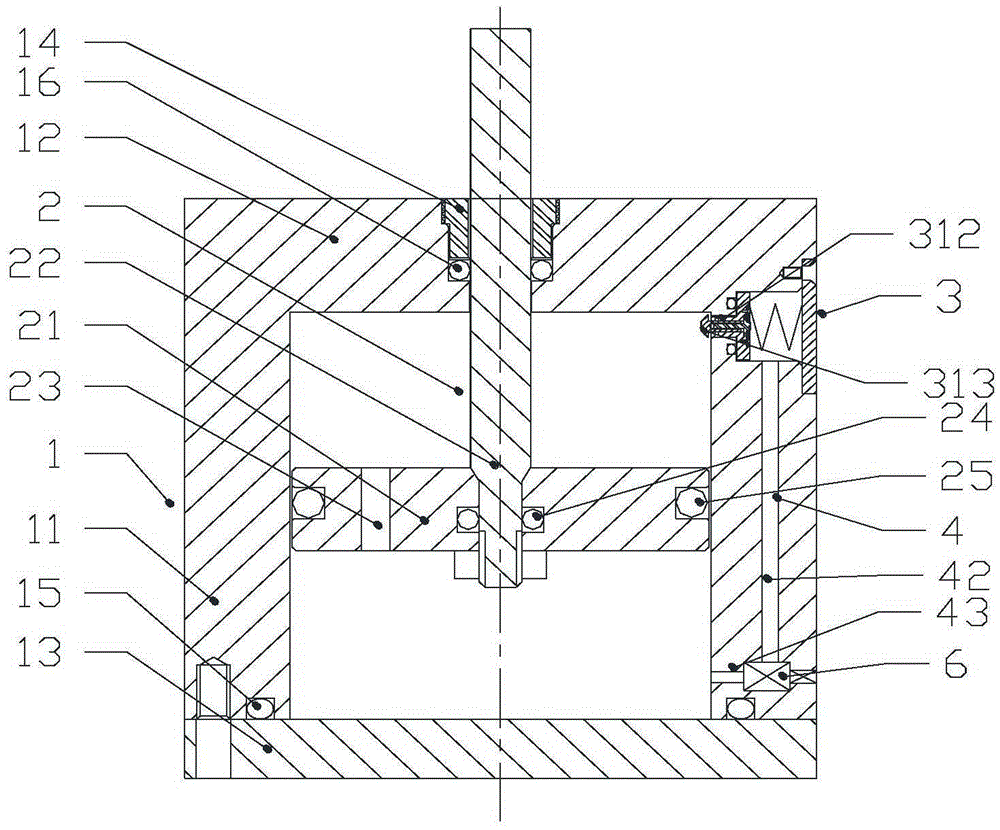

Novel composite contact vacuum arc-extinguishing chamber and vacuum circuit breaker with same

ActiveCN103594280AUniform magnetic fieldEasy to installHigh-tension/heavy-dress switchesAir-break switchesVacuum arcVacuum interrupter

The invention discloses a novel composite contact vacuum arc-extinguishing chamber and a vacuum circuit breaker with the same. The novel composite contact vacuum arc-extinguishing chamber comprises a static side structure portion, a movable side structure portion and a shell structure. The static side structure portion comprises a static side arcing current conducting rod and a static side main conducting rod which is arranged in the static side arcing current conducting rod and is in clearance fit with the static side arcing current conducting rod. A static side arcing magnetic field contact and a static side annular arcing-resisting contact material are sequentially welded at the lower end of the static side arcing current conducting rod. A static side conducting contact is welded at the lower end of the static side main conducting rod. In the arcing process, the static side conducting contact is located inside the static side arcing magnetic field contact all the time, the static side main conducting rod is connected with the static side arcing current conducting rod through a static side small-diameter corrugated pipe, the static side arcing current conducting rod is connected with a cover plate on the upper side of the arc-extinguishing chamber through a static side large-diameter corrugated pipe. A static side compression spring is installed inside the static side large-diameter corrugated pipe. According to the novel composite contact vacuum arc-extinguishing chamber, the problem that the magnetic structural design does not exist in the existing vacuum arc-extinguishing chamber contact design is solved.

Owner:XI AN JIAOTONG UNIV

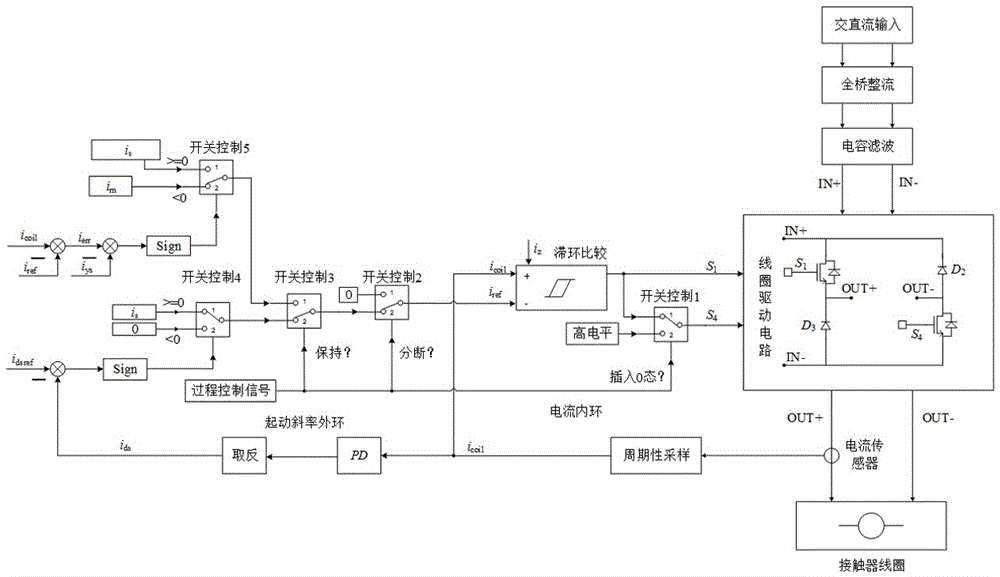

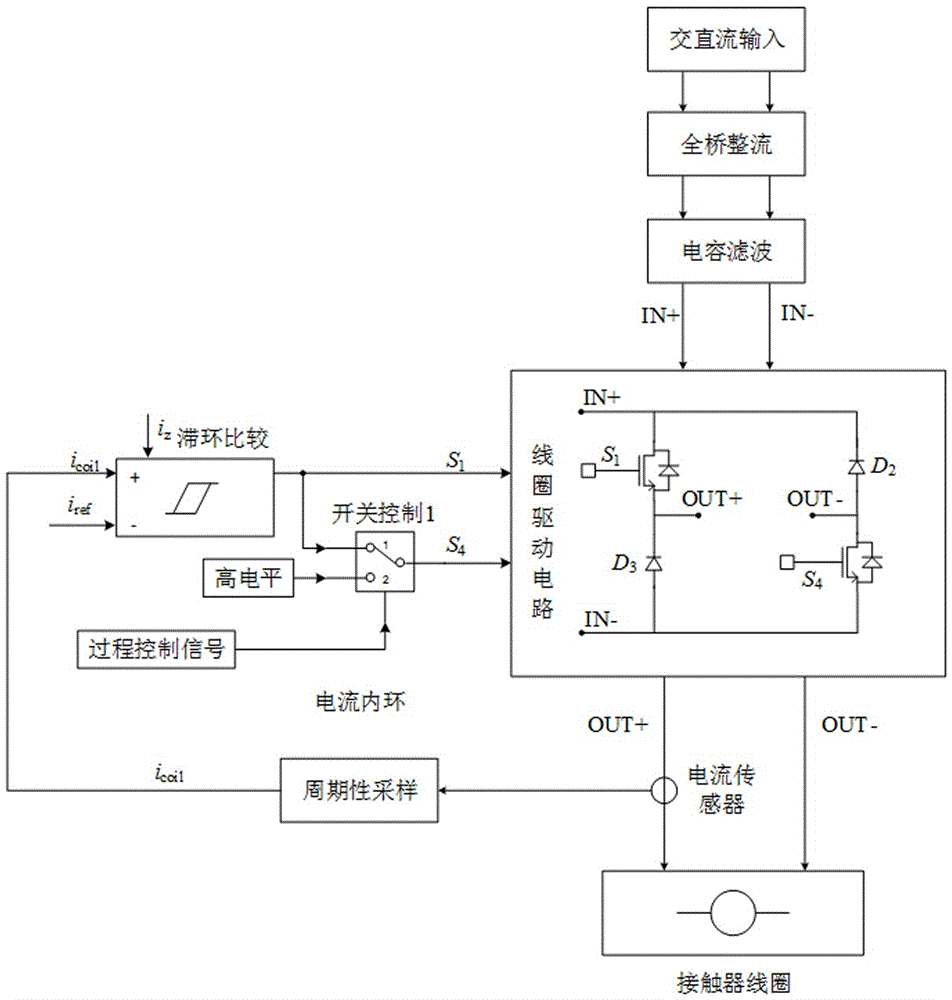

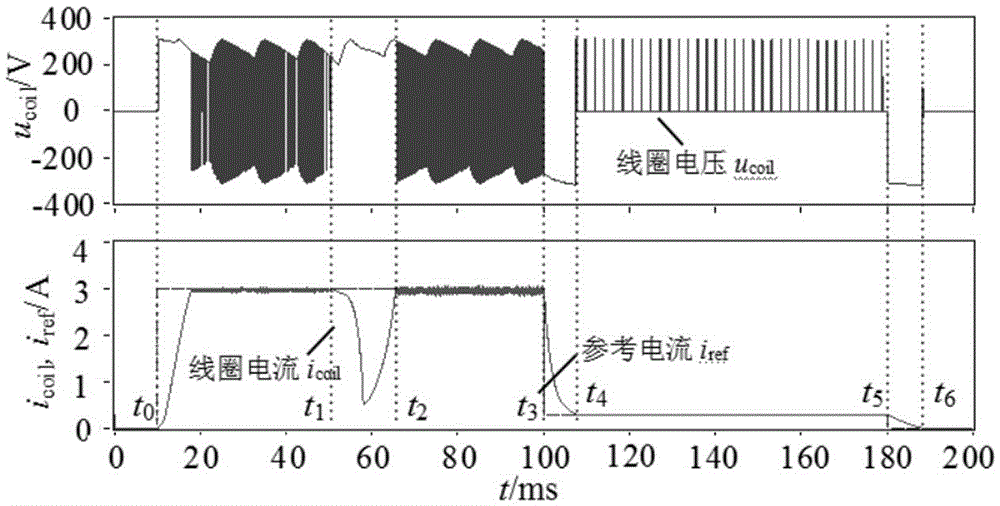

Dynamic reliable control strategy of high-capacity contactor

The invention relates to a dynamic reliable control strategy of a high-capacity contactor. The dynamic reliable control strategy comprises the following steps of: by adopting a current closed loop as a basic inner loop, controlling the current inner loop by adopting a slope outer loop in a starting process, lowering the collision speed of a movable iron core, and reducing bounce of a contact terminal in the starting process; during a maintaining process, monitoring the outer loop by adopting error breaking, predicting an error breaking fault of the contactor, and taking a measure in time to prevent the error breaking; and during a breaking process, controlling the breaking speed of the movable iron core, so that not only can the rapid breaking of the contactor be guaranteed, but also the burning of the contact terminal caused by breaking electric arc is reduced, and the impact on a contactor framework during the breaking process is also reduced.

Owner:FUZHOU UNIV

Seed variety changer for a planter

ActiveUS20140352586A1Reduce bouncingEasy to switchFertilising methodsPotato plantersEngineeringActuator

A system for changing seed variety on a planter includes a plurality of row units with each row unit having a plurality of seed meters. Each seed meter has a guide for delivering seed to a transport belt and a switch that is activated and deactivated by a switch actuator on the belt. The belt has adjustable sidewalls, cover, and lugs.

Owner:KINZE MFG INC

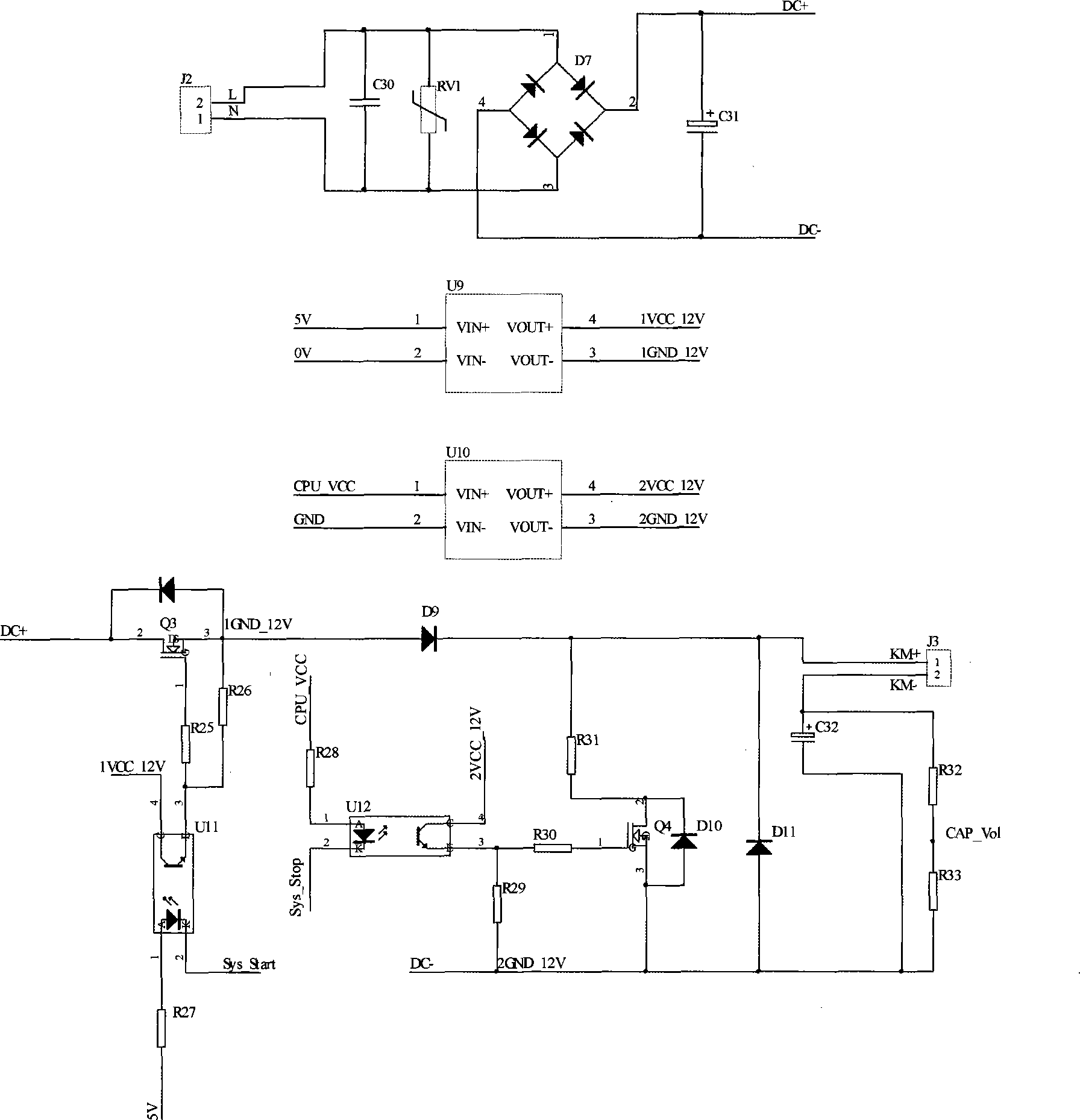

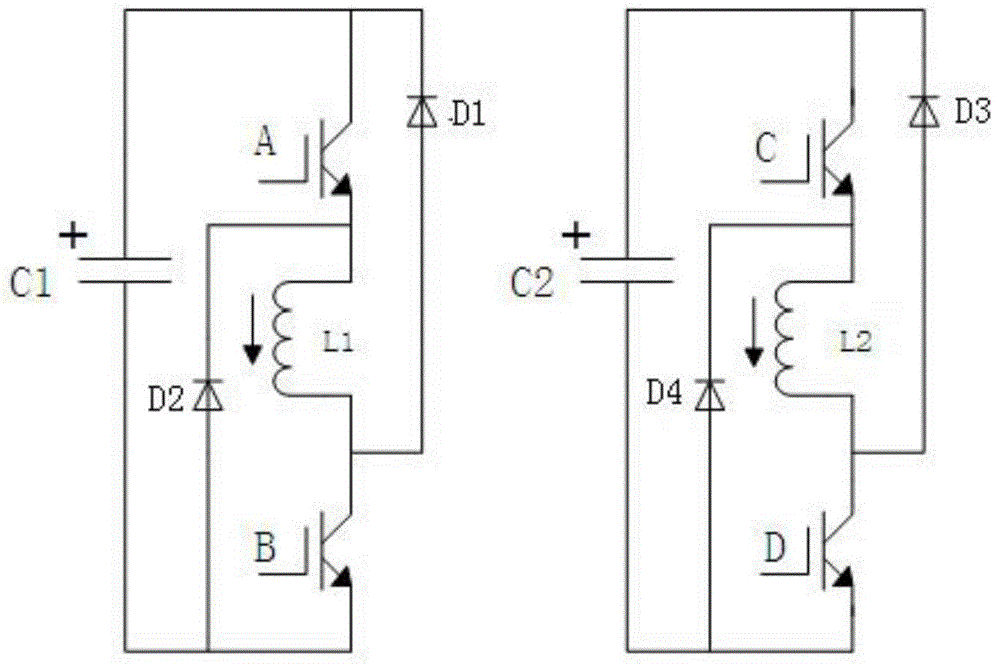

Control device and method of bistable permanent-magnet vacuum circuit breaker rapid divide-shut brake

InactiveCN104157509ASmall pressure dropAvoid generatingHigh-tension/heavy-dress switchesAir-break switchesCapacitancePeak current

The invention discloses a control device and method of a bistable permanent-magnet vacuum circuit breaker rapid divide-shut brake. The method comprises the following steps that a freewheeling diode is utilized for enabling the coils to be supplied with follow current, so that the coils can discharge to a corresponding discharge capacitor when switch tubes on the two sides of an opening coil or a closing coil are all turned off, and at the same time, the induced voltage generated by mutual inductance is counteracted with the negative voltage, namely, the voltage of a non-discharge voltage. According to the control device and method, the problem of the conventional bistable operating mechanism that the voltage drop of the capacitor is too big and the operation is influenced by the induced current is solved, the control voltage is reduced, the discharging peak current is reduced, the movement speed can be adjusted by the PWM drive control module according to requirements and the contact bounce is reduced, so that the operating characteristic is more in accordance with the arc resistance of the circuit breaker.

Owner:SOUTHEAST UNIV

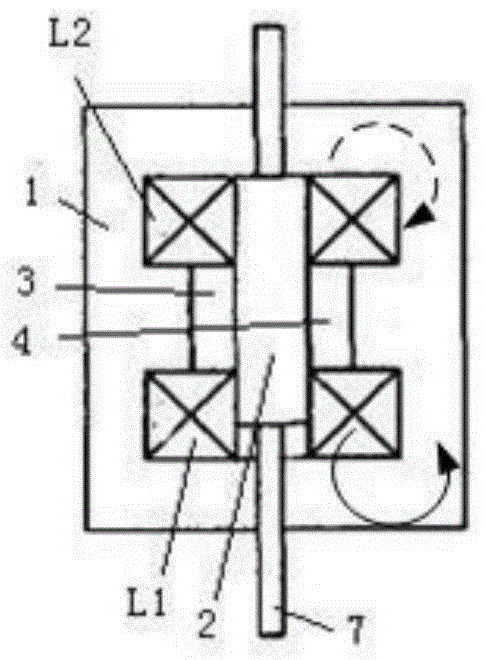

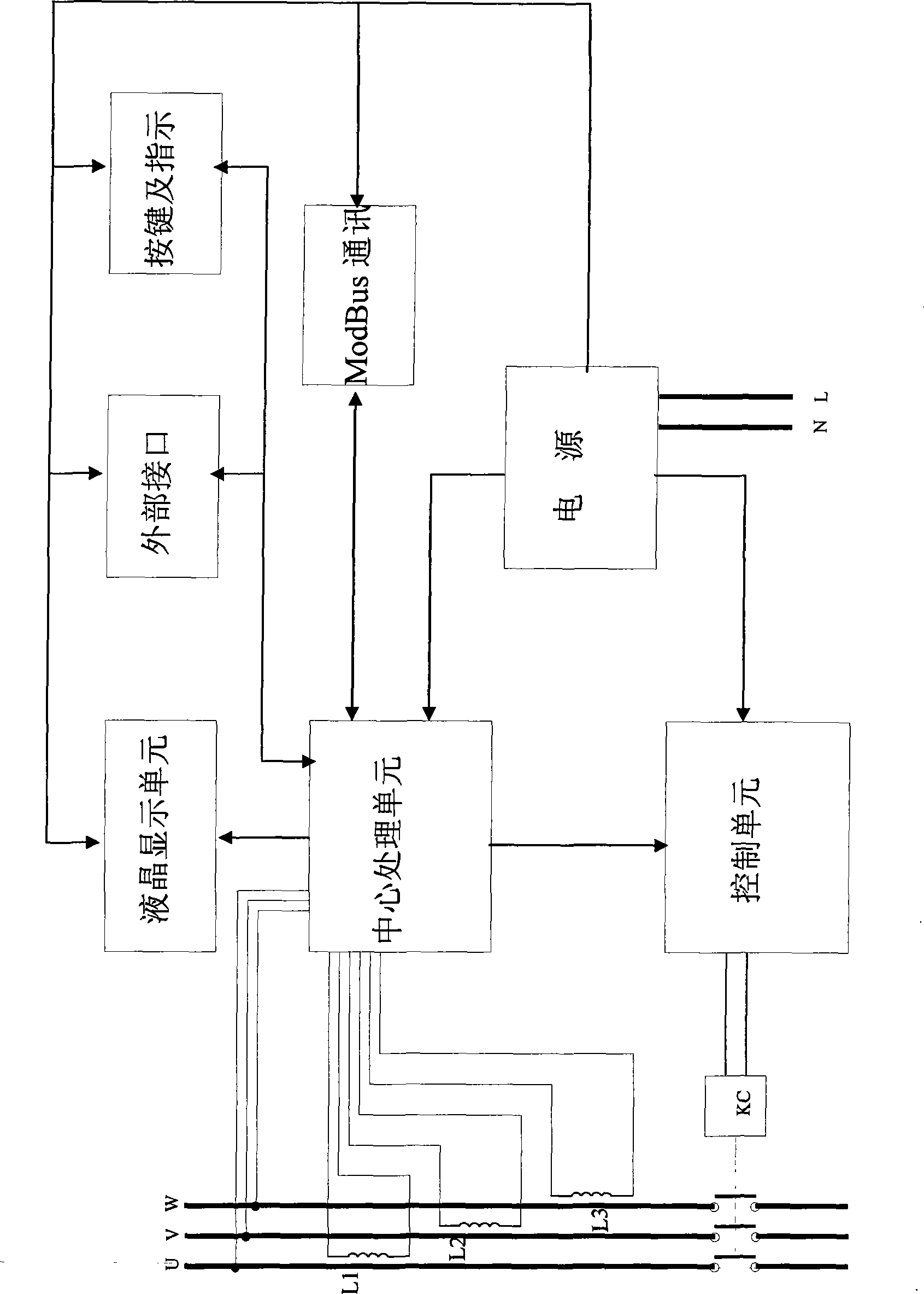

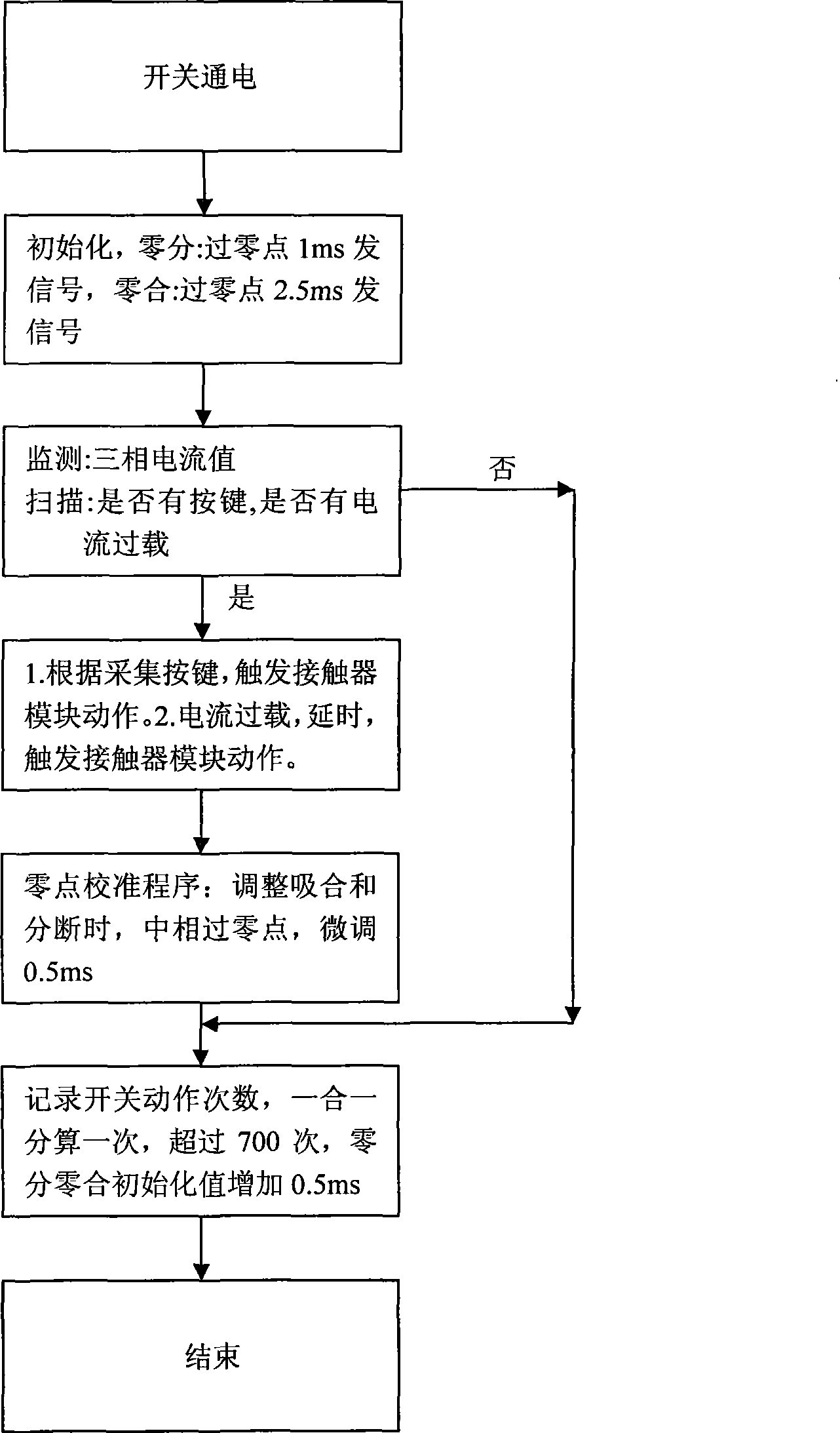

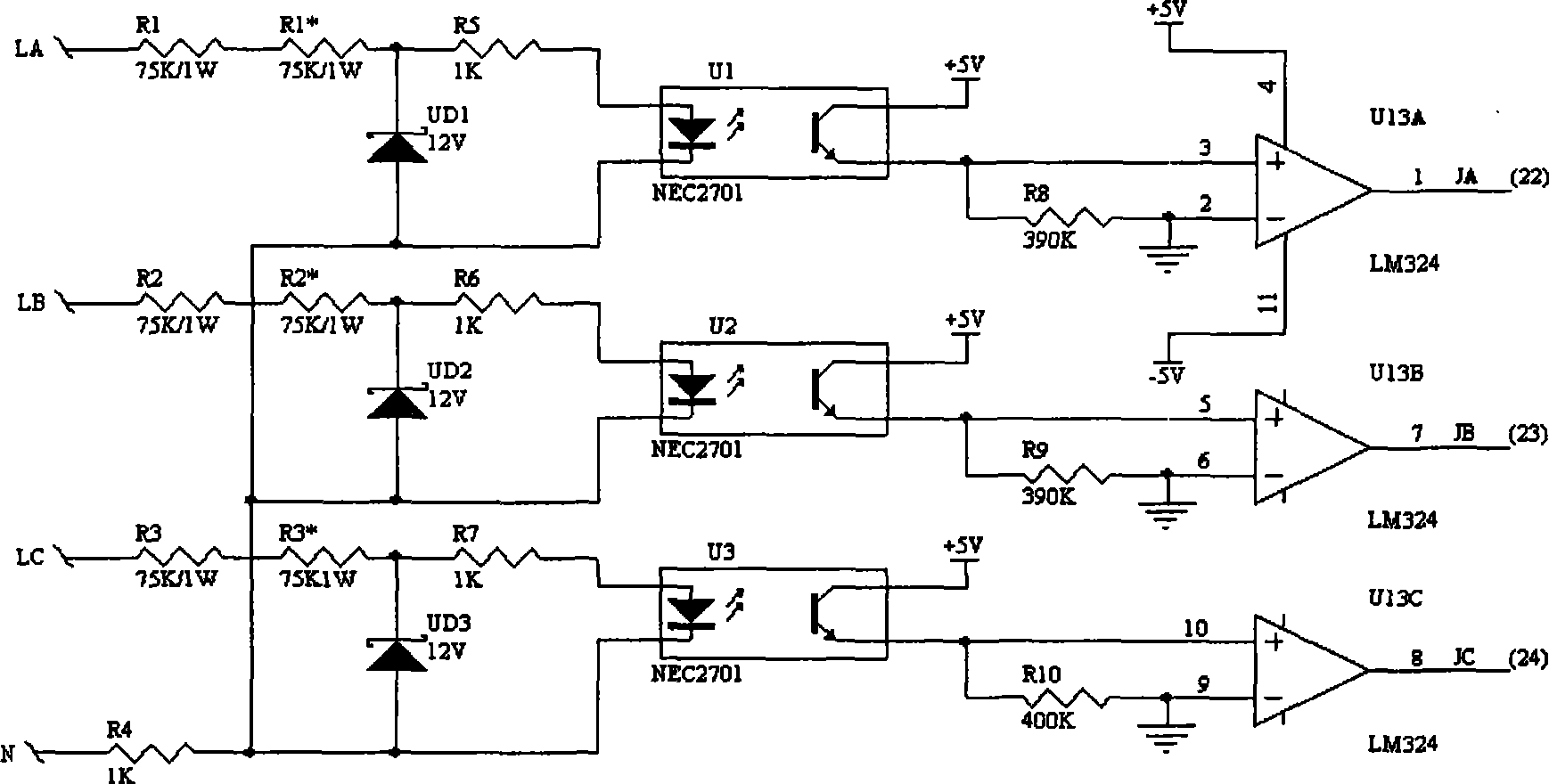

Method for implementing middle phase zero division zero sum by control protection switch

ActiveCN101505052AReduce bouncingReduce the chance of stickingEmergency protective circuit arrangementsOvervoltageElectricity

The invention relates to the technical field of motor control, in particular to a method for realizing medium phase zero-breaking and zero-closing by a control protection switch. The control protection switch is a carrier to realize the method, and comprises a central processing module and a contactor module. The method is characterized by comprising the following steps that: a main CPU singlechip of the central processing module acquires a voltage signal through a voltage signal acquisition circuit, and acquires a current signal through a current signal acquisition circuit; then a three-phase electricity zero-crossing point period is compared with electrified closing mechanical time and power off breaking mechanical time of the contactor module; and a closing or breaking signal after judgment is sent so as to close or break the contactor module of the control protection switch on the medium phase zero point of the three-phase electricity. The method is a simple and effective method for relieving the overvoltage and overcurrent impact, improves service life of the switch body, reduces abrasion of a contactor material, and reduces consumption of noble metal resources.

Owner:天津北方恒业电气技术有限公司

Telescoping pet ramp

ActiveUS7493874B2Improve rigidityReduce bouncingAnimal housingLoading/unloadingEngineeringElectrical and Electronics engineering

A telescoping pet ramp having first and second ramp segments telescopically extendable from a compact state to an extended state. Side rails of the panels include end caps with abutment members for preventing the first floor panel and second floor panel from being separated when the pet ramp is fully extended, and including interlocking angled contact faces that frictionally engage one another when the ramp is fully extended.

Owner:RADIO SYST CORP

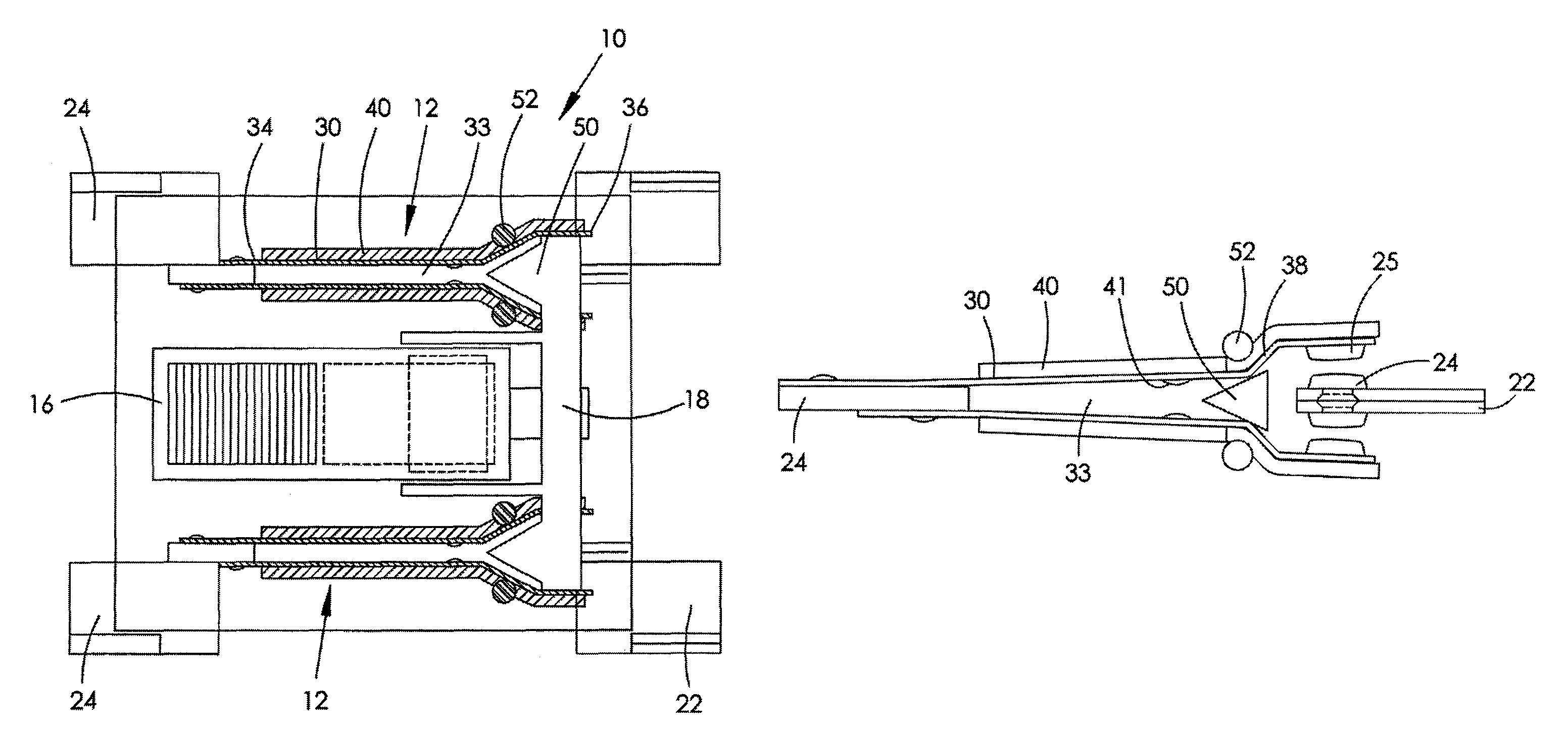

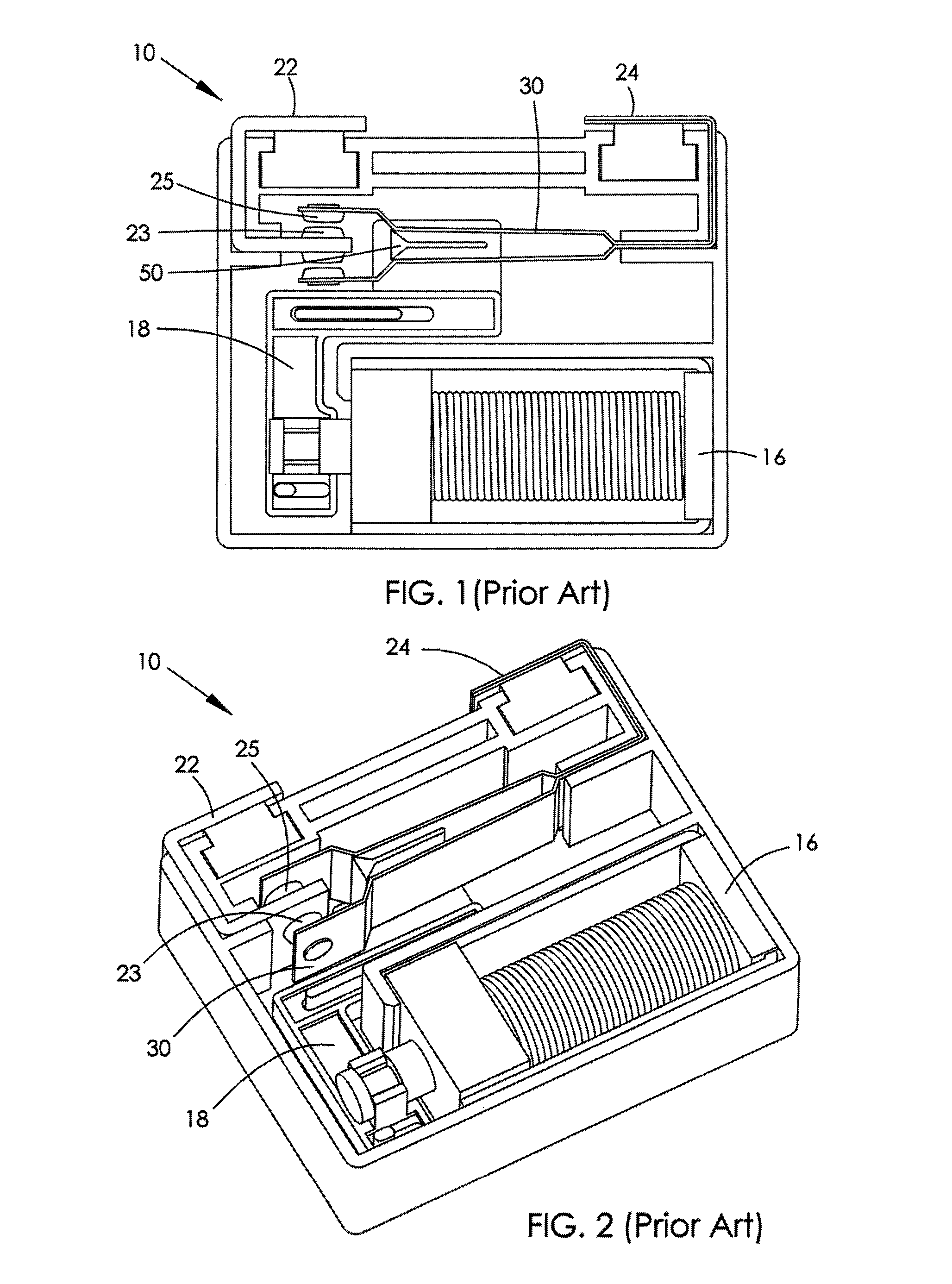

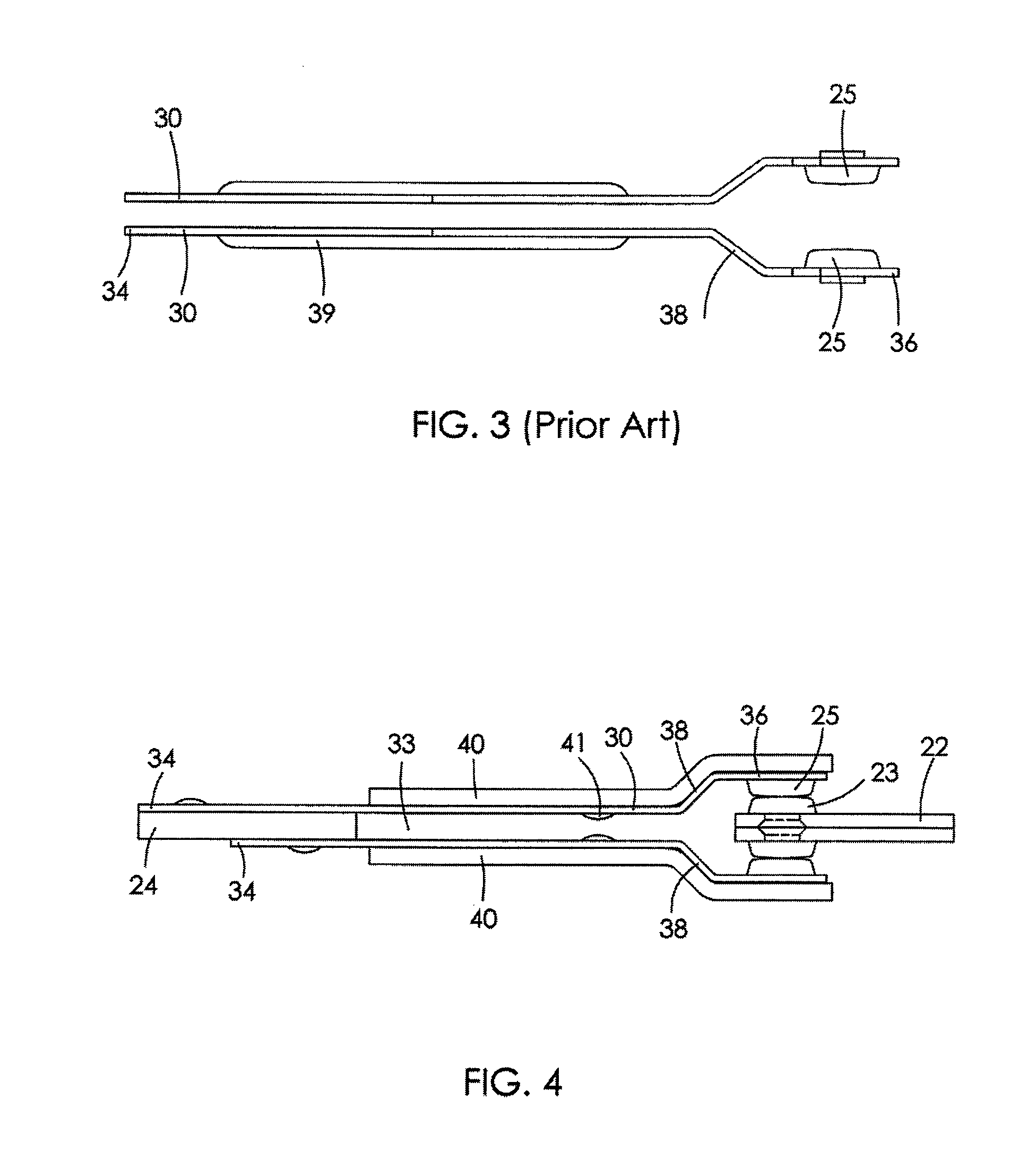

Switching contactor

ActiveUS8845350B2Increase contact pressureReduce bouncingEngagement/disengagement of coupling partsSubstation/switching arrangement detailsElectrical resistance and conductanceEngineering

A switching electrical power contactor having a bi-blade type switch, has ferrous plates attached to the blades to increase the current carrying capacity and reduce the resistance of the switch. Flexible tangs formed at the distal end of the blades cooperate with a movable member to hold the contacts closed when the contactor is in the closed state.

Owner:JOHNSON ELECTRIC INT UK

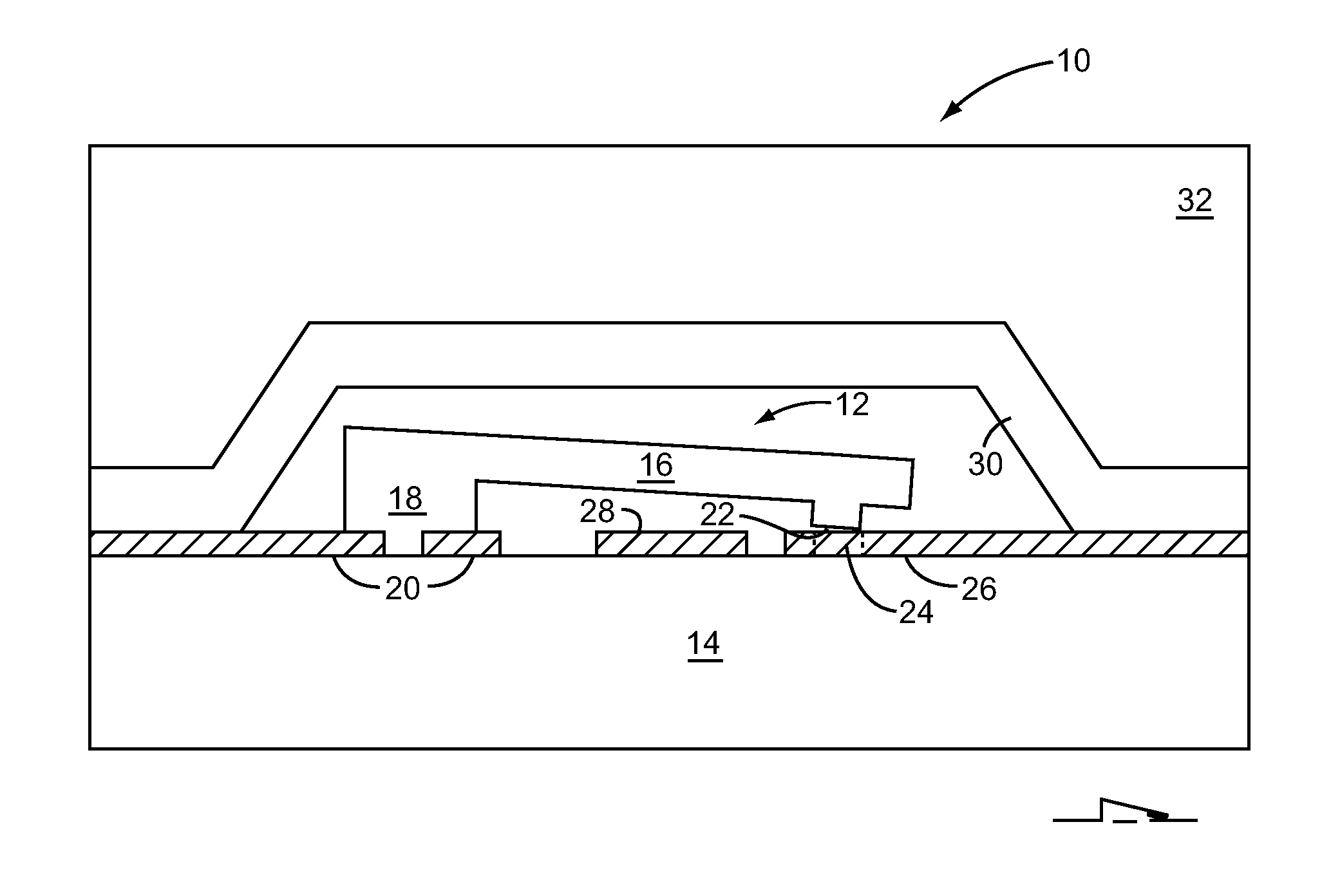

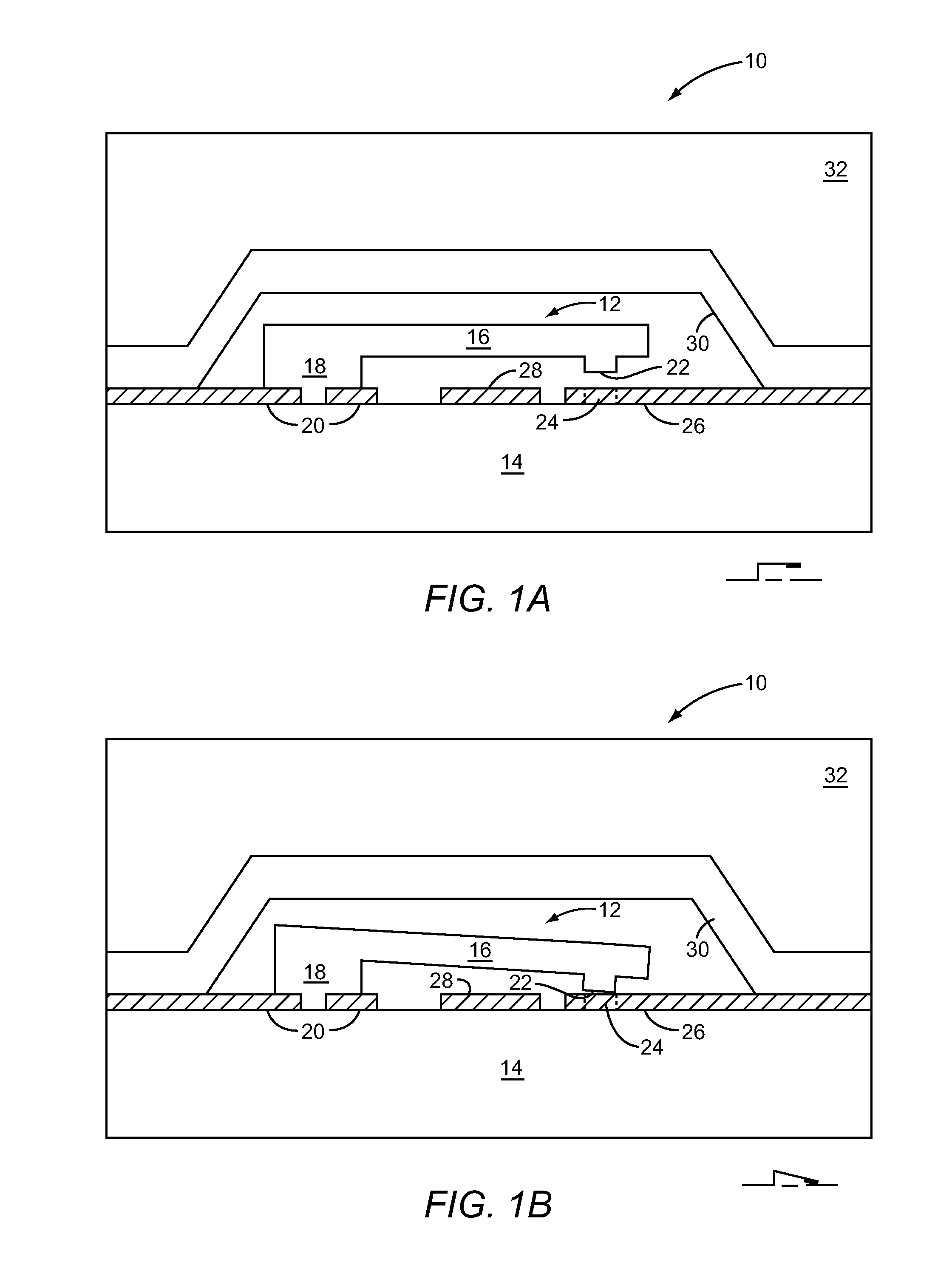

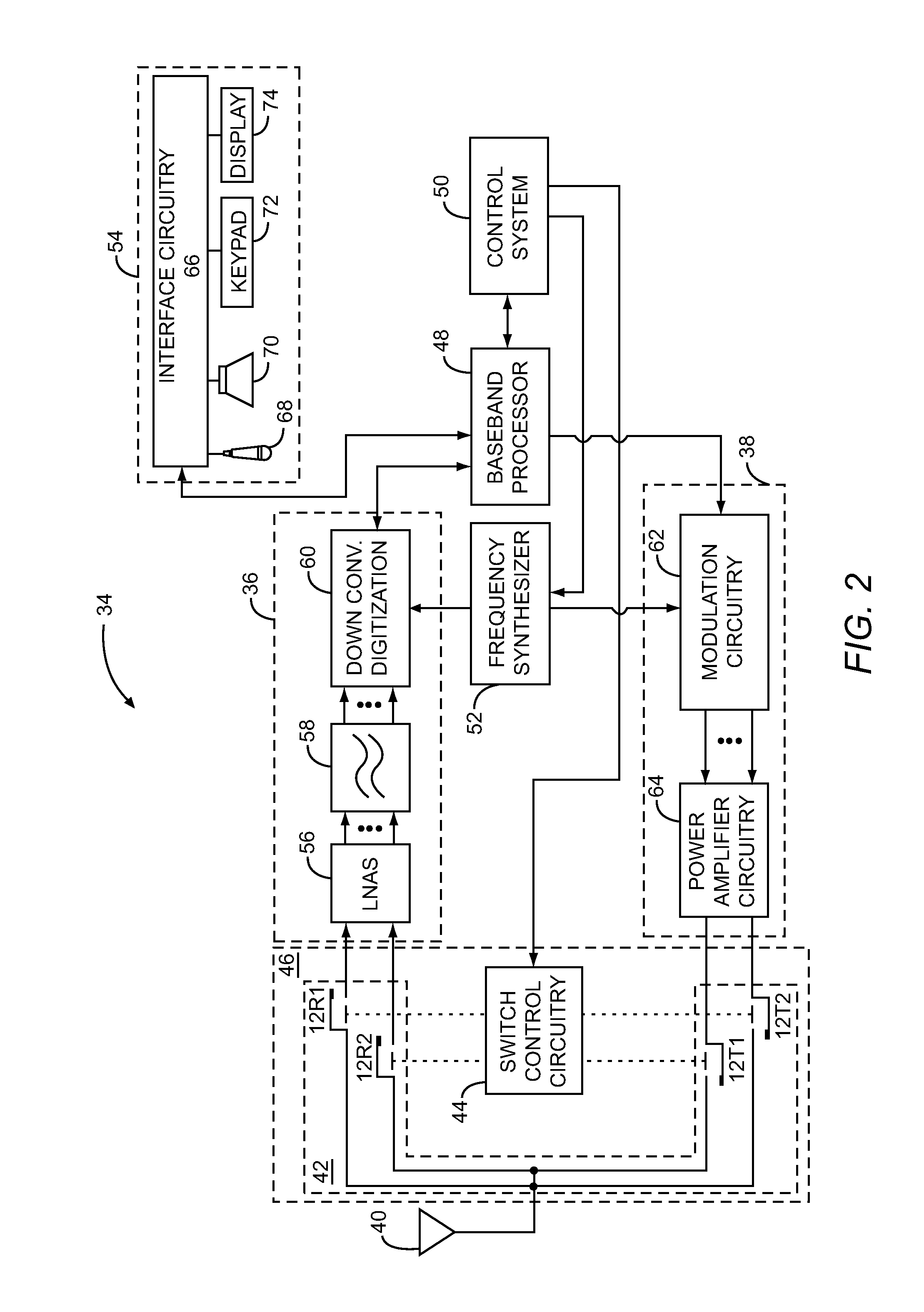

Actuation signal for microactuator bounce and ring suppression

ActiveUS20120175230A1Reduce bouncingReduced ringingElectrostatic/electro-adhesion relaysElectrostatic generators/motorsEngineeringControl circuit

The present disclosure provides a system and method for controlling positioning of a movable member of a MEMS microactuator to reduce bouncing and ringing. The system includes control circuitry in communication with the MEMS microactuator. The control circuitry is adapted to linearly increase an actuation signal from a first state to a second state to urge the movable member from a first position to a second position and hold the movable member in the second position. The control circuitry is further adapted to linearly decrease the actuation signal from the second state to the first state to release the movable member to the first position. A transition time is not less than the inverse of one quarter of a natural frequency of the movable member as the movable member moves to the first position.

Owner:QORVO US INC

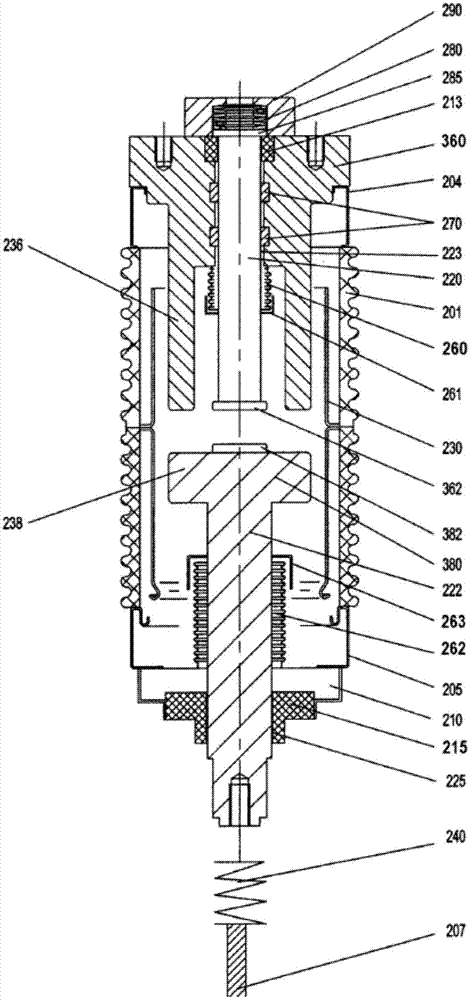

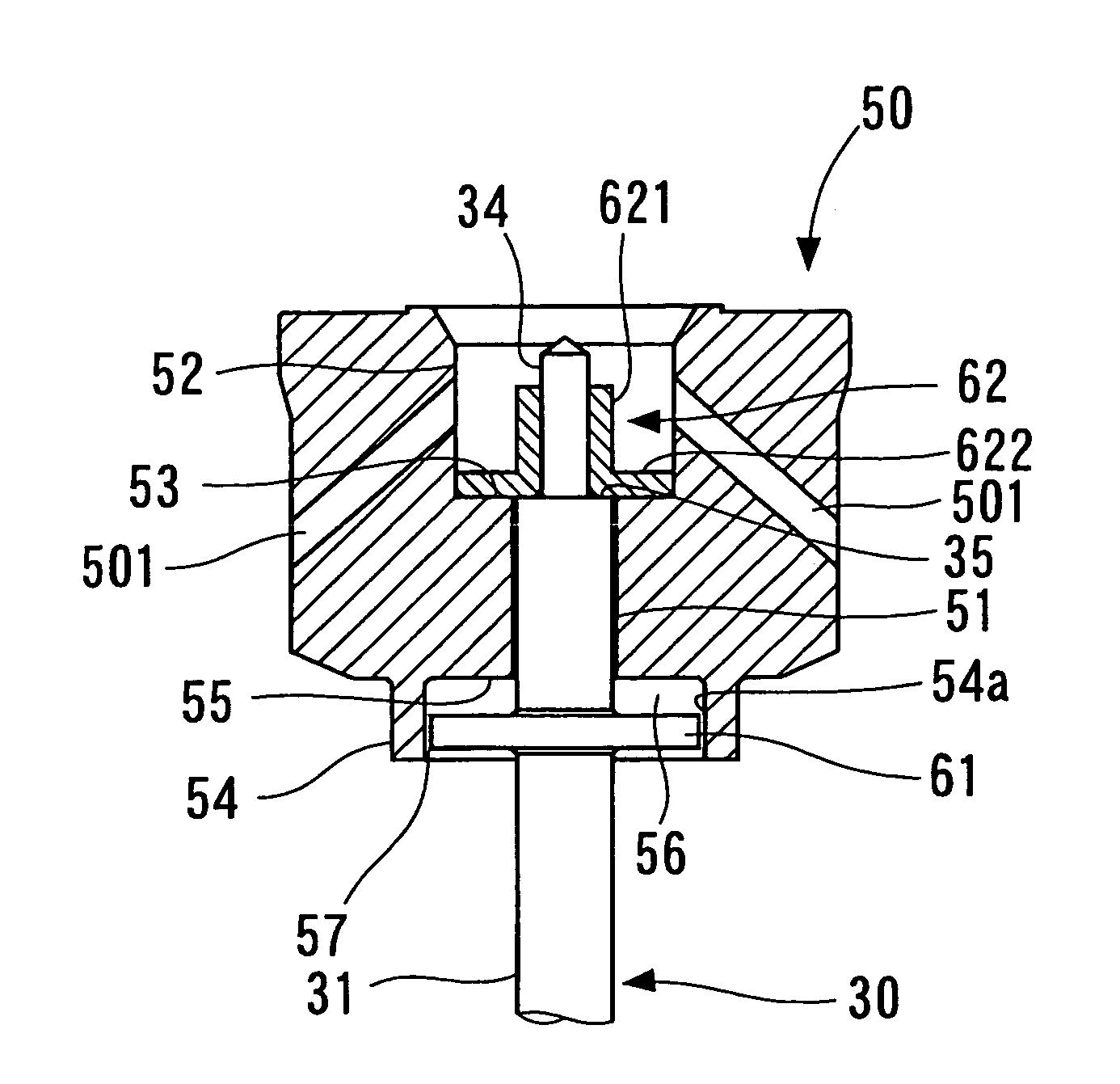

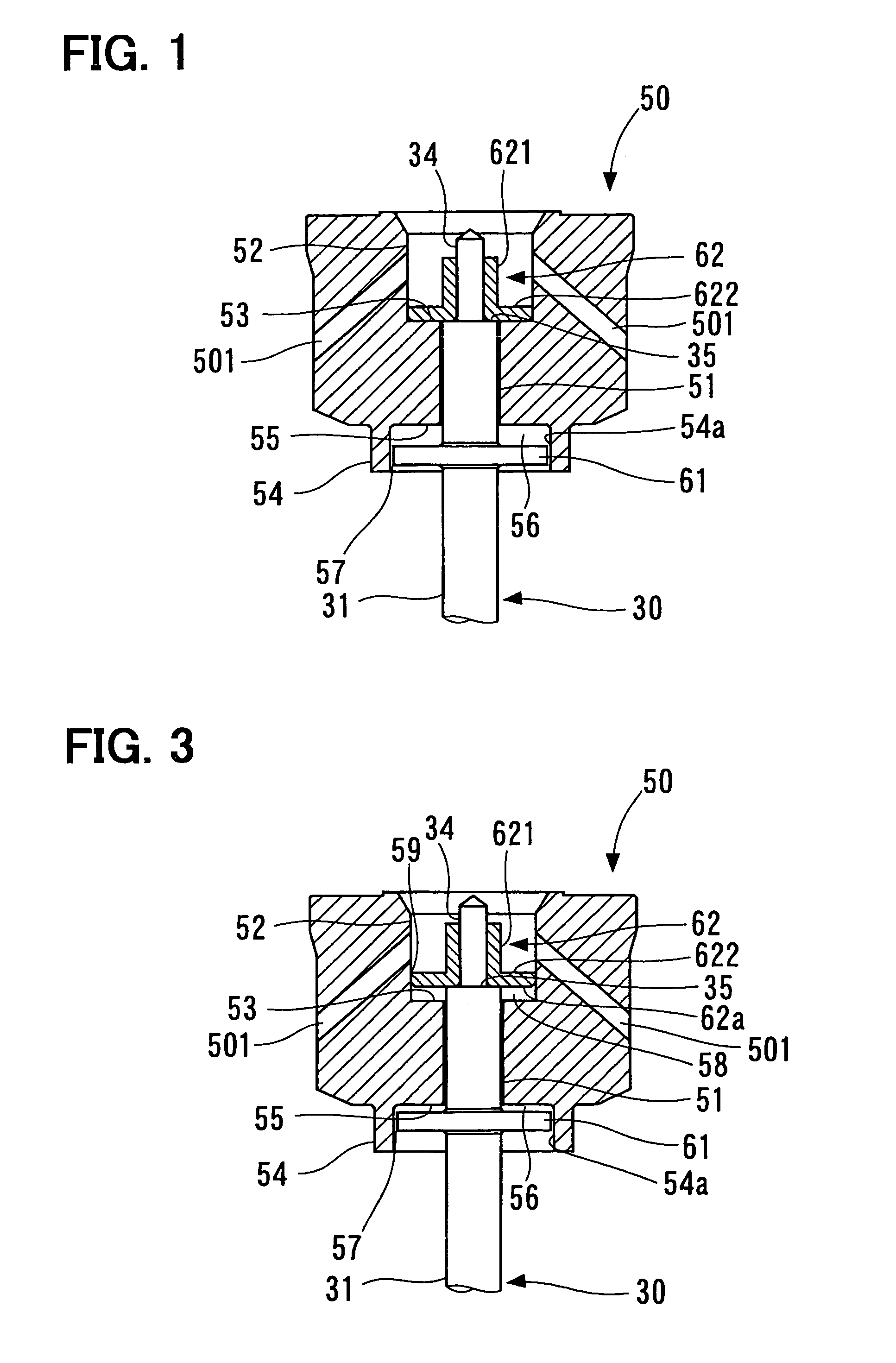

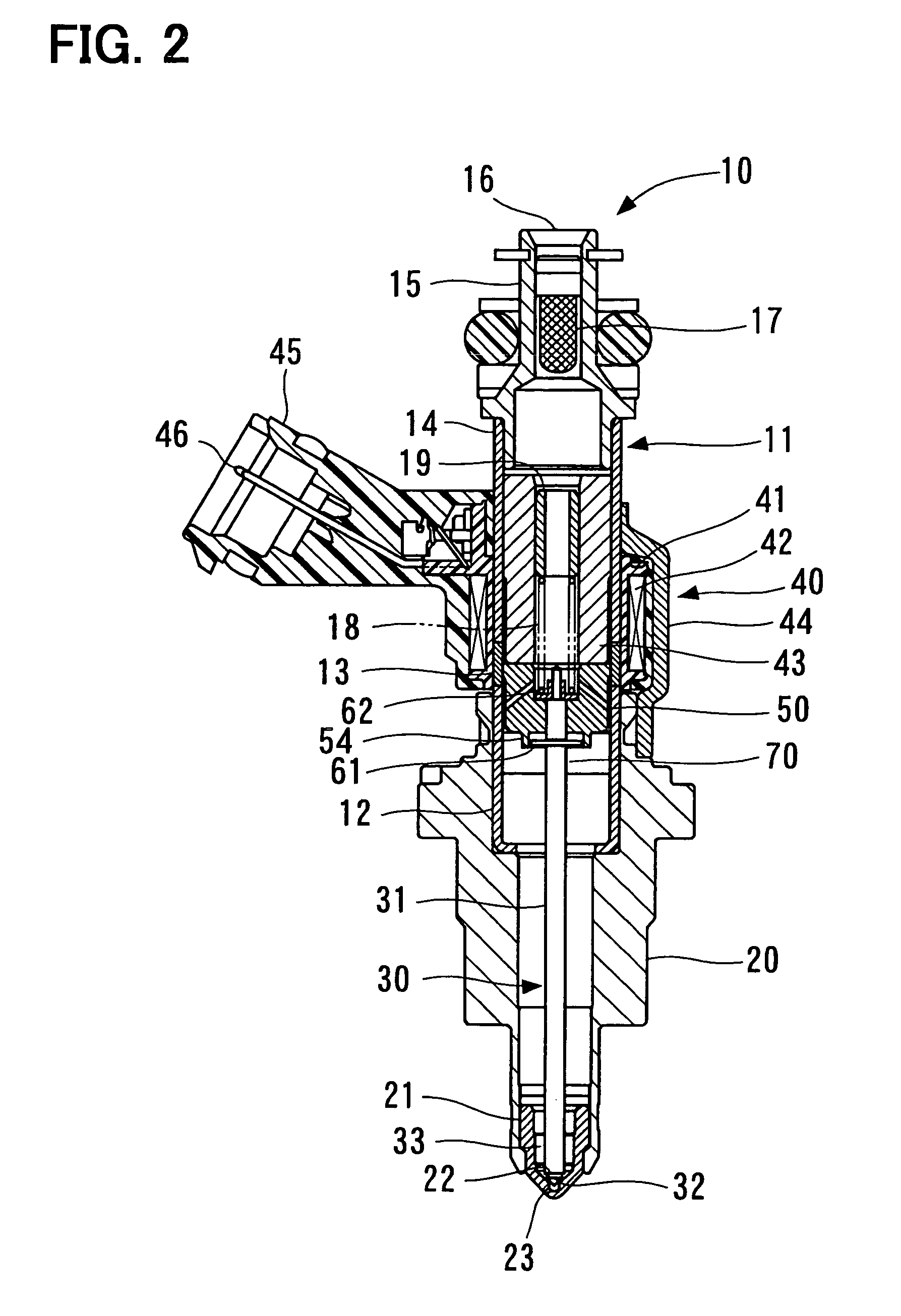

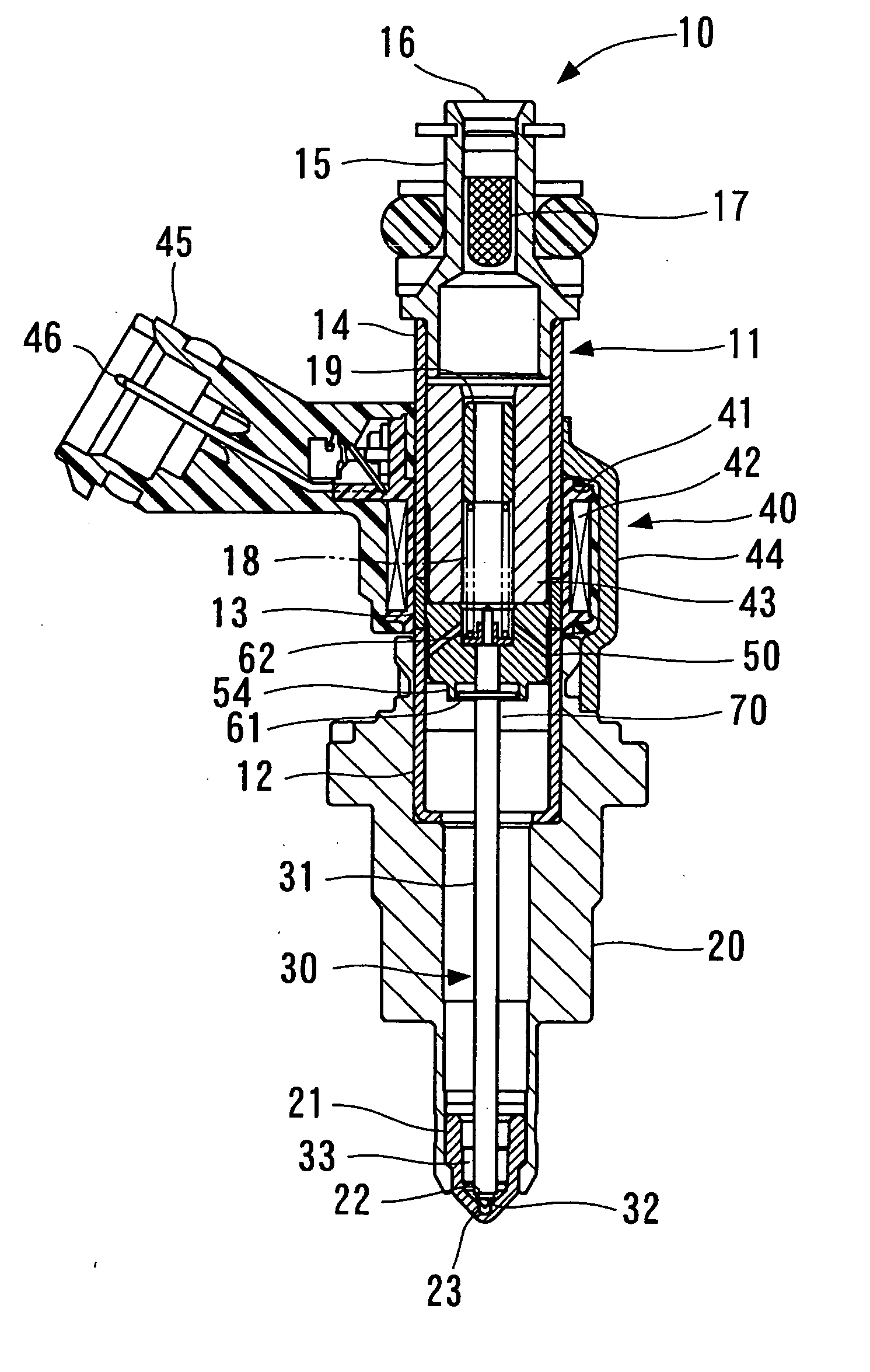

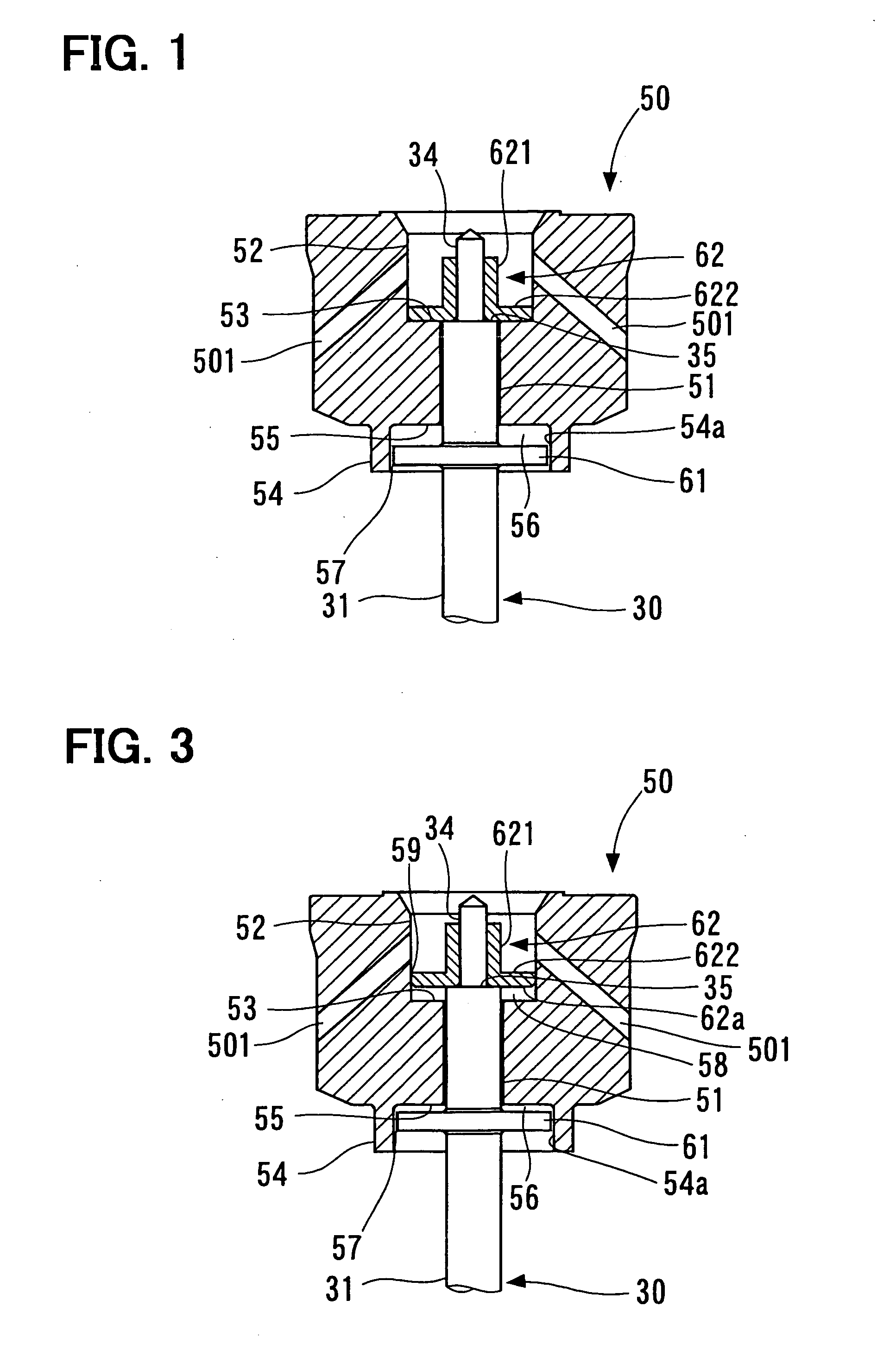

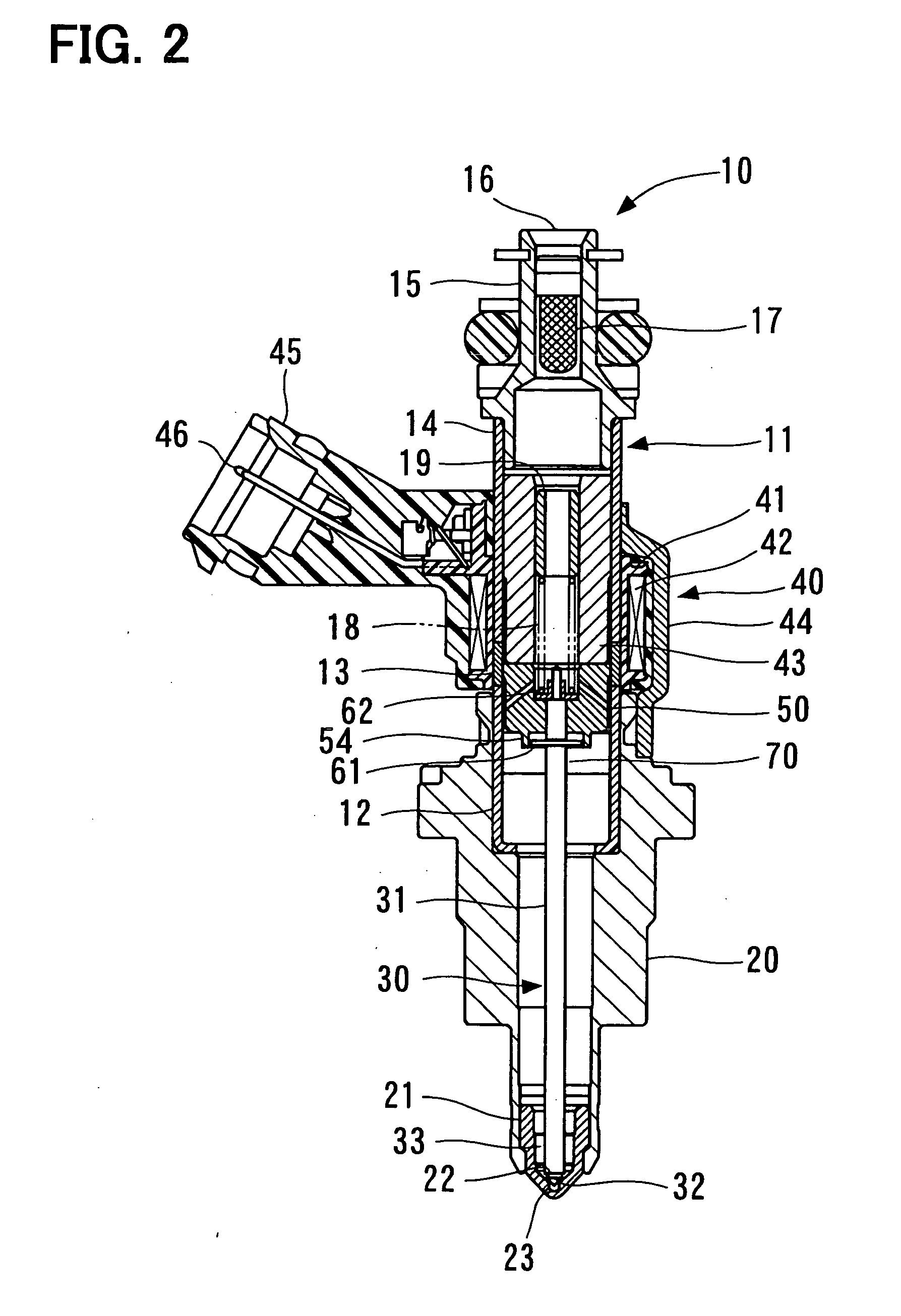

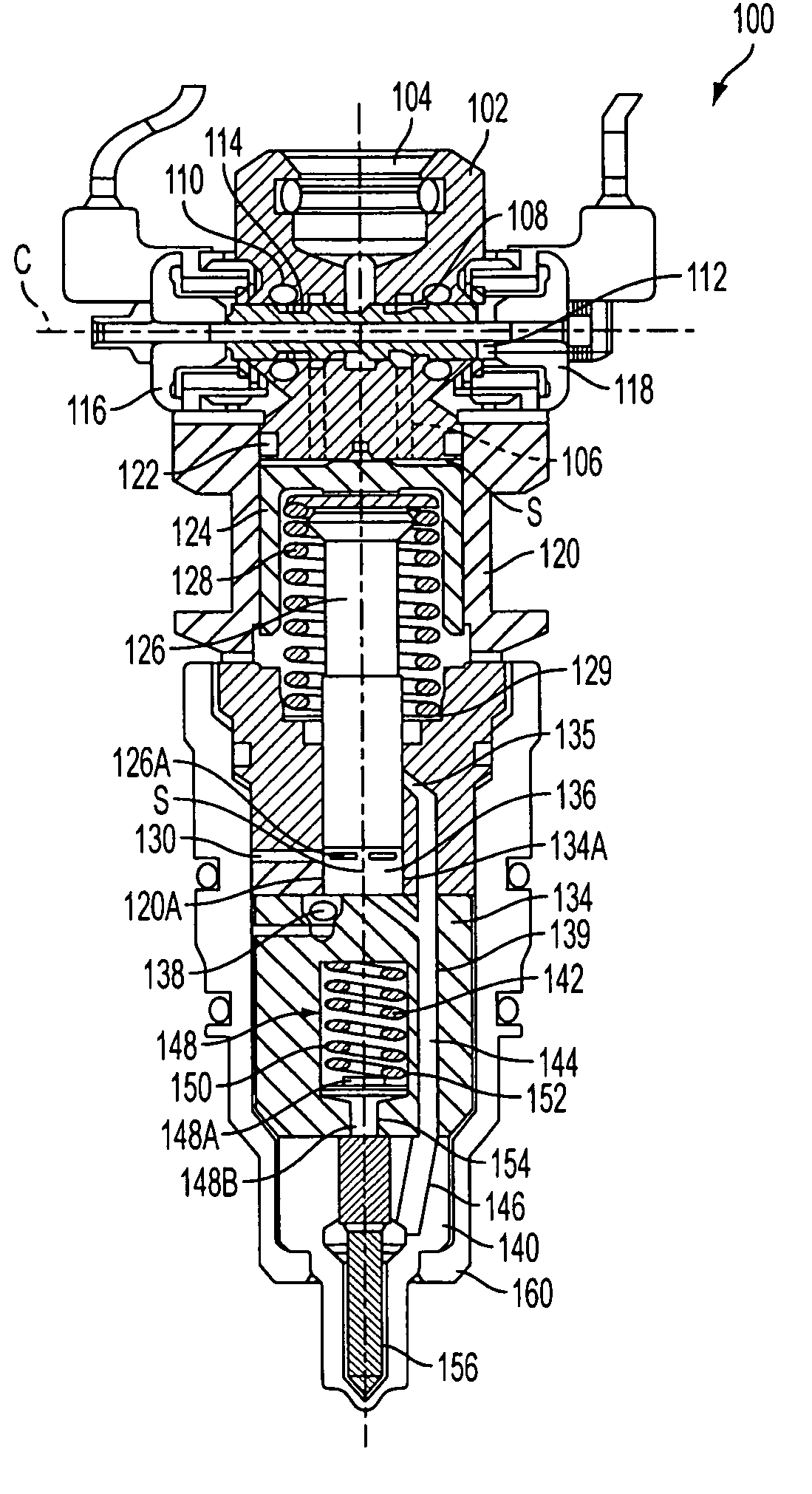

Fuel injection valve

InactiveUS7252245B2Reduce bouncingIncrease the number ofOperating means/releasing devices for valvesSpray nozzlesAxial displacementEngineering

A fuel injection valve includes a valve member, a first stop member, a second stop member, a movable core, a fixed core, and a coil. The valve member opens and closes an injection nozzle. The first stop member protrudes radially outward from said valve member. The second stop member protrudes radially outward from said valve member. The movable core is sandwiched between said first and second stop members. The movable core and one of said first and second stop members defines a fuel chamber. The fixed core is axially displaced from said movable core. The coil causes reciprocal axial displacement of said valve member such that said movable core axially reciprocates toward and away from said fixed core therewith.

Owner:DENSO CORP

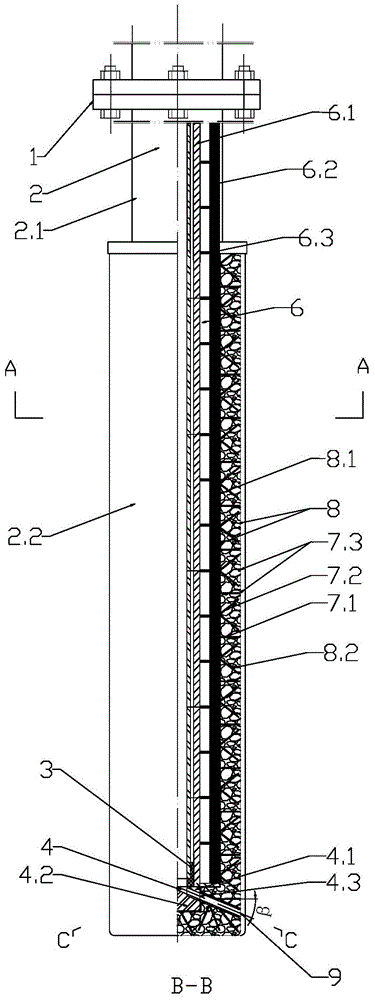

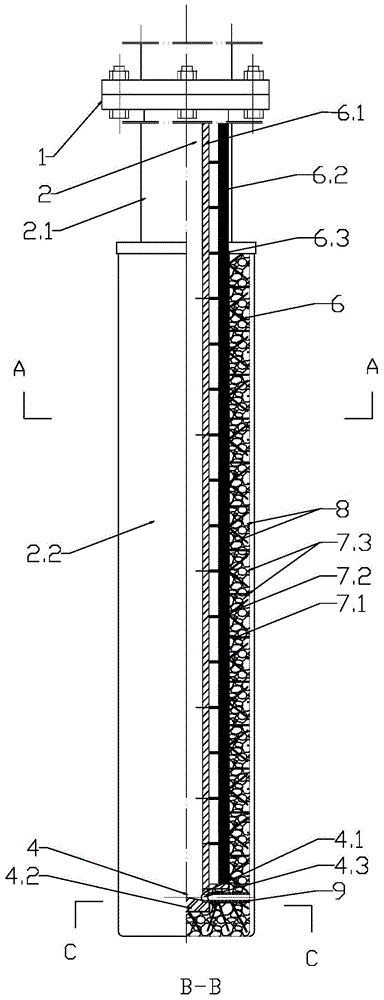

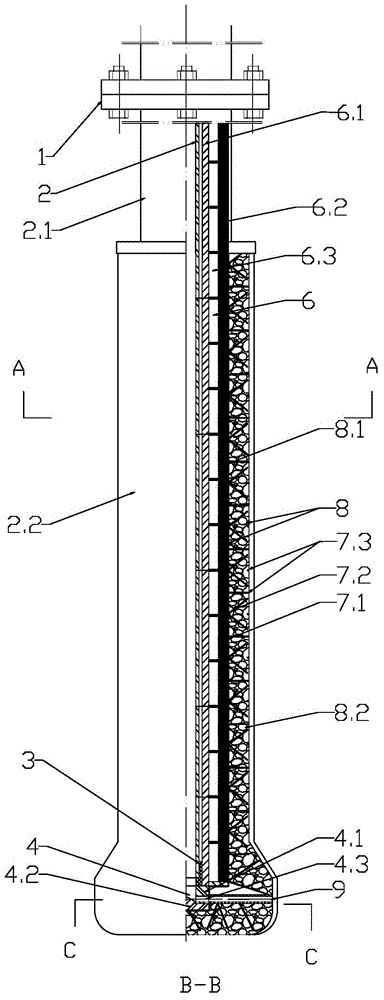

Direct injection molten iron desulphurization spray gun

The invention discloses a direct injection molten iron desulphurization spray gun for a metal particle magnesium or magnesium-based or calcium-based desulphurization agent. The direct injection molten iron desulphurization spray gun comprises a connecting flange and a gun barrel which are sequentially connected and communicated, wherein the gun barrel comprises a connecting section gun barrel and a gun body section gun barrel; the connecting section gun barrel comprises a gun core; a distributor is connected with the lower end of the gun core of the gun body section gun barrel; the distributor comprises an upper end short connecting pipe, a lower end plug platform and a plurality of through holes formed in the wall of the short connecting pipe; and each through hole is communicated with a jetting pipe, and the jetting pipes are distributed in a fire-proof pouring material liner positioned outside the side wall of the distributor. The direct injection molten iron desulphurization spray gun disclosed by the invention can be used for enhancing the jetting strength, extending the desulphurization reaction area and intensifying the gasification and dissolution of metal particle magnesium through structural design, and can be used for enhancing the adaptability on low-quality metal particle magnesium and jetting desulphurization of molten iron tanks with different sizes, extending the adaptive capacity of a process and reducing the consumption cost of the molten iron desulphurization metal particle magnesium through the improvement of desulphurization process steps.

Owner:武汉钢铁有限公司

Fuel injection valve

InactiveUS20050269432A1Reduce bouncingIncreasing minimum number of componentOperating means/releasing devices for valvesSpray nozzlesAxial displacementReciprocating motion

A fuel injection valve includes a valve member, a first stop member, a second stop member, a movable core, a fixed core, and a coil. The valve member opens and closes an injection nozzle. The first stop member protrudes radially outward from said valve member. The second stop member protrudes radially outward from said valve member. The movable core is sandwiched between said first and second stop members. The movable core and one of said first and second stop members defines a fuel chamber. The fixed core is axially displaced from said movable core. The coil causes reciprocal axial displacement of said valve member such that said movable core axially reciprocates toward and away from said fixed core therewith.

Owner:DENSO CORP

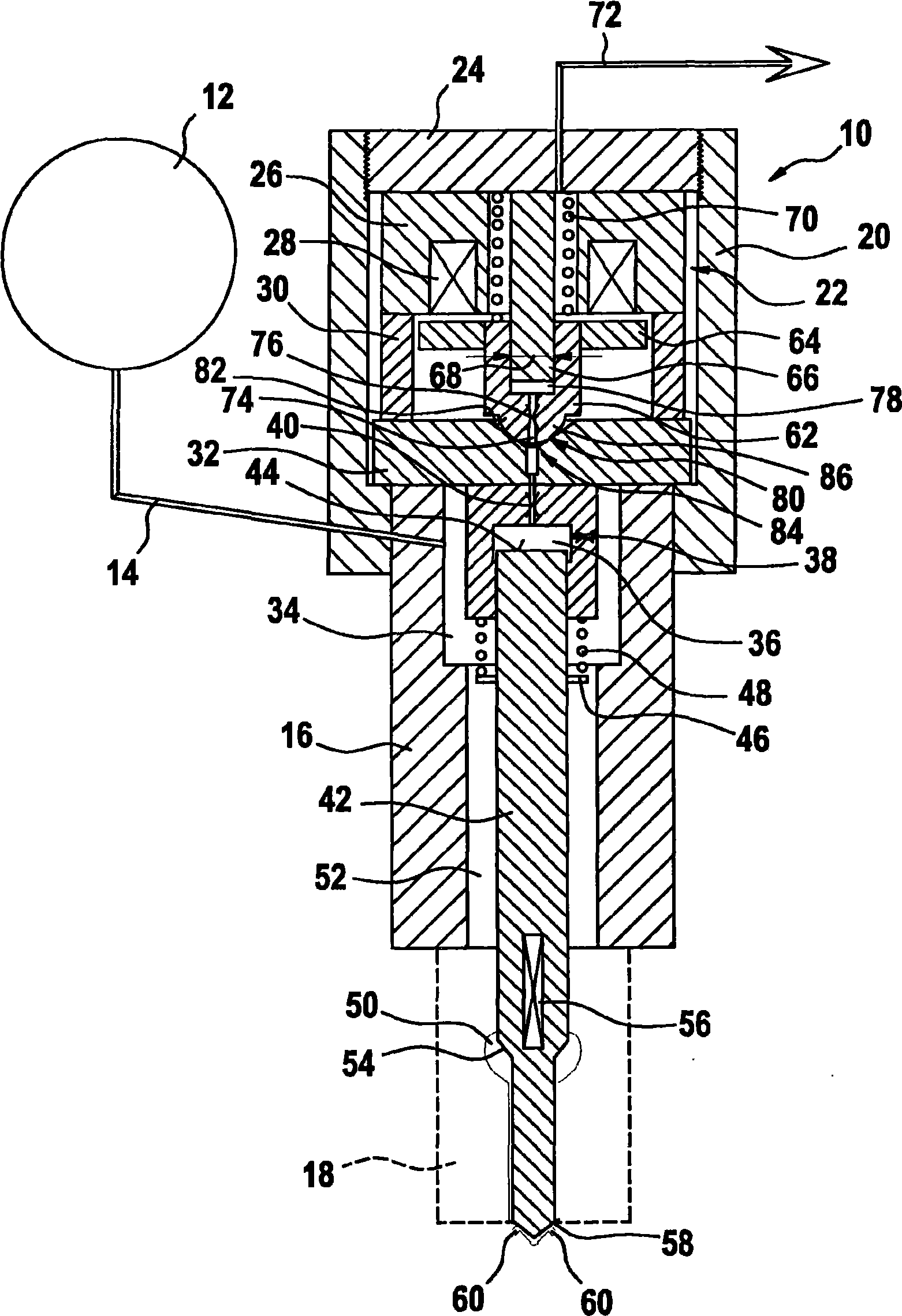

Fuel injector having a solenoid valve with a spherical seat

InactiveCN101548092AReduce bouncingImprove coordinationMachines/enginesSpecial fuel injection apparatusCombustion chamberCombustor

The invention relates to a fuel injector (10) for injecting fuel into a combustion chamber of an internal combustion engine. An injection valve element (42) is actuated via pressure relief of a control space (36). Said control space (36) is loaded by a system pressure Rhosys. The control space (36) is relieved of pressure via a solenoid valve (22) of pressure-equalized configuration, the valve element (62) of which opens or closes a valve seat (80). The valve seat (80) comprises a spherical surface (86).

Owner:ROBERT BOSCH GMBH

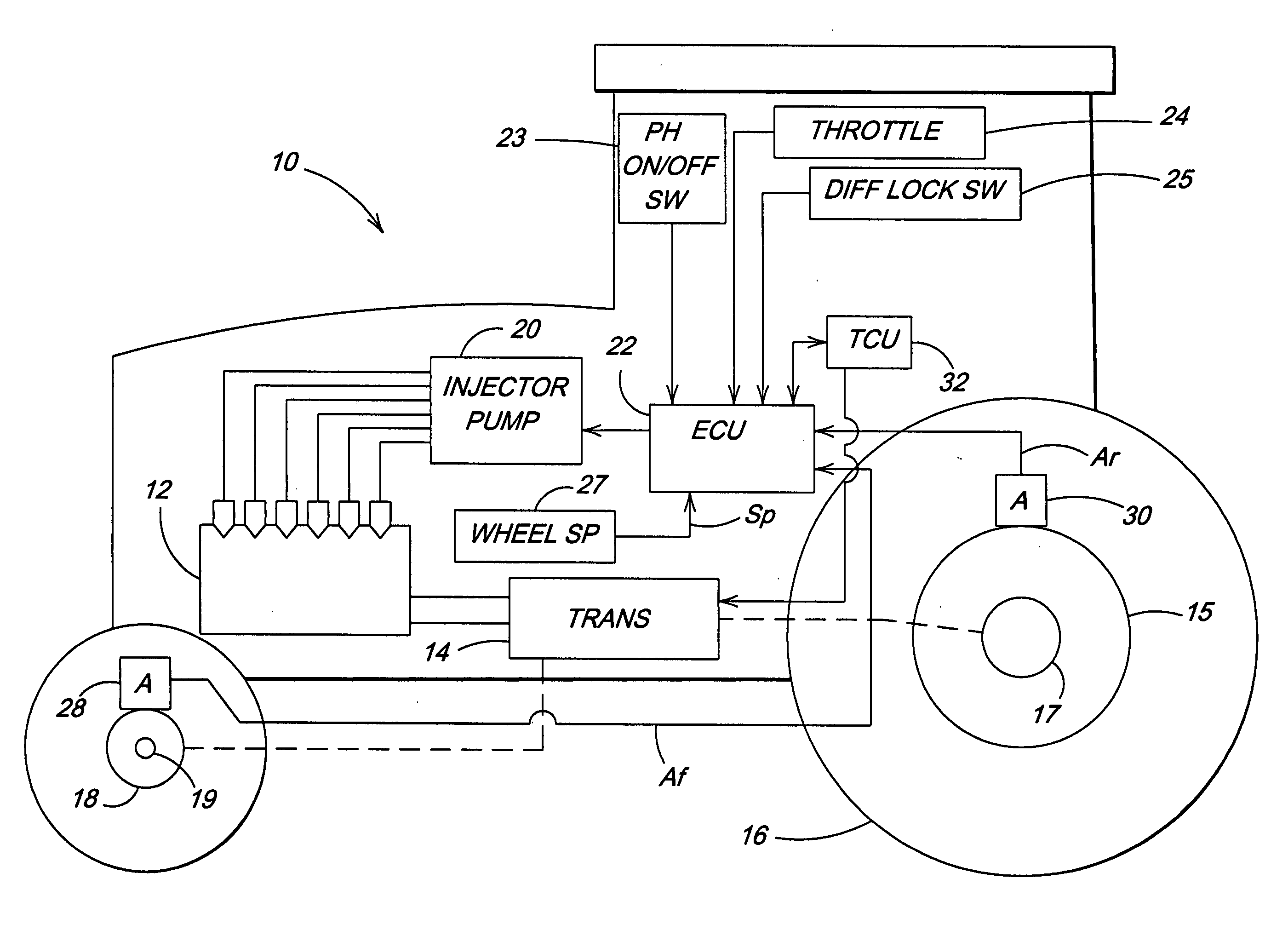

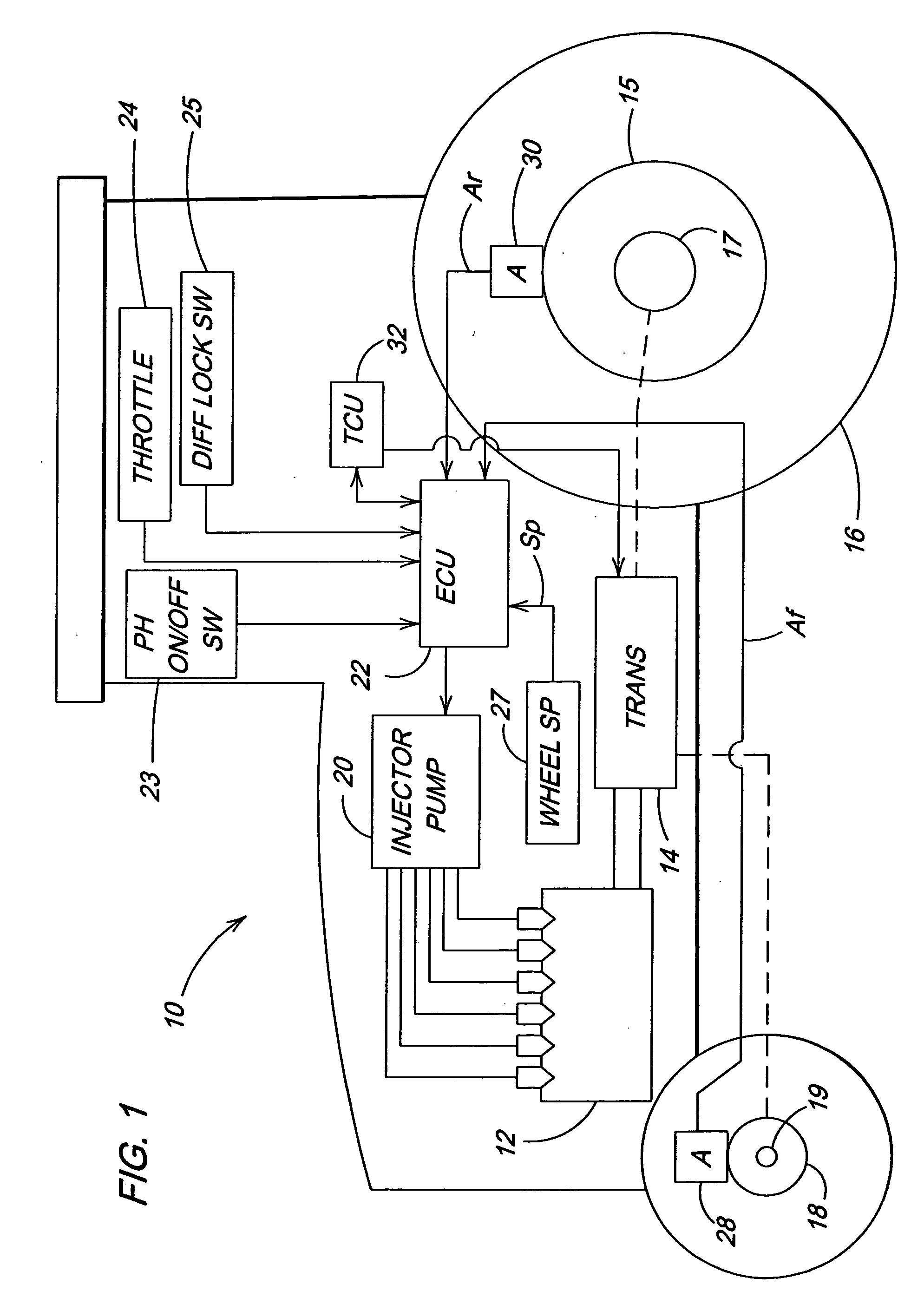

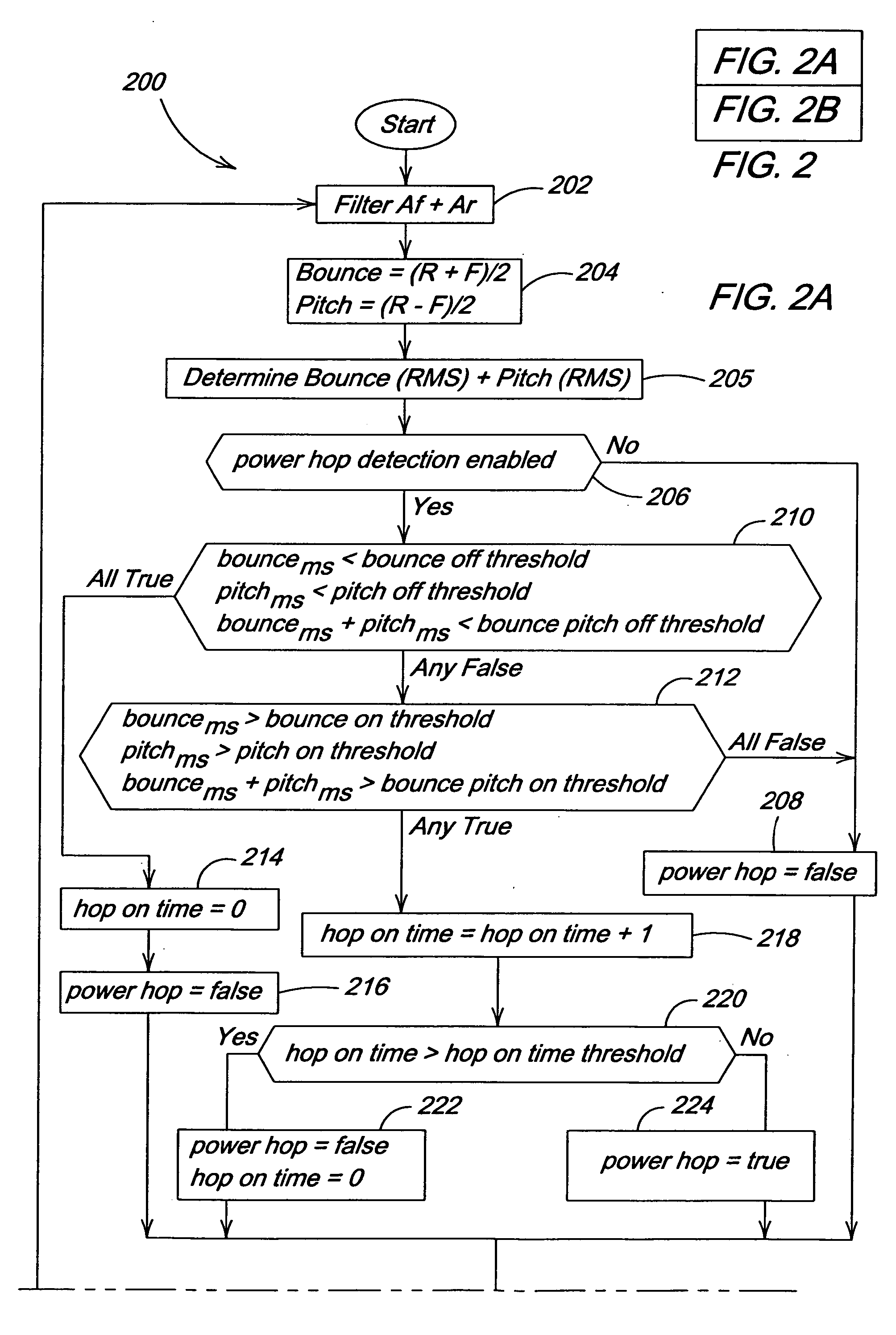

Tractor power hop control system and method

ActiveUS20060009897A1Decrease pitchReduce bouncingElectrical controlAnalogue computers for trafficDrive wheelControl signal

A control system performs a method for controlling pitching and bouncing of a vehicle having an engine driving wheels through a transmission, and having a fuel control unit for supplying a variable amount of fuel to the engine in response to fuel control signals generated by an engine control unit. The method includes, from front and rear acceleration signals, generating vehicle pitch and bounce signals, converting the pitch and bounce signals to RMS pitch and bounce values, generating a fuel offset value as a function of the RMS pitch and bounce values, and modifying fuel delivered to the engine as a function of the fuel offset value. The fuel offset value is operate don by a bi-linear gain function wherein negative values are multiplied by a larger gain and positive values are multiplied by a smaller gain.

Owner:DEERE & CO

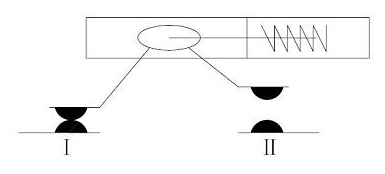

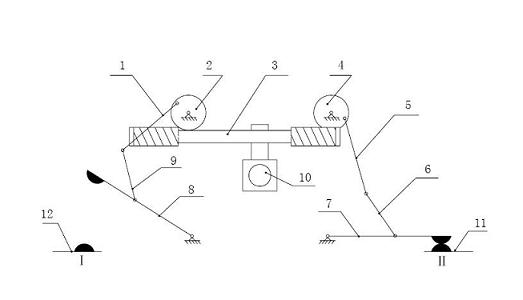

Rack-and-pinion type transmission mechanism of automatic changeover switch device

InactiveCN101866762AReduce impactSimple organizationContact driving mechanismsGear wheelReciprocating motion

The invention discloses a rack-and-pinion type transmission mechanism of an automatic changeover switch device. The transmission mechanism comprises a first gear, a second gear and a rack, wherein the two ends of the rack are provided with dentiform sections, and the middle of the rack is a flat and straight section; the first gear is rotatablely arranged on one end of a base body of the automatic changeover switch, and the second gear is rotatablely arranged on the other end of the base body; and the rack is simultaneously meshed with the fist gear and the second gear, the rack is connected with a driving mechanism which is used for pushing the rack to carry out reciprocating motion, the first gear is linked with a first moving contact of the automatic changeover switch device, and the second gear is linked with a second moving contact of the automatic changeover switch device. The rack-and-pinion type transmission mechanism of the invention has the advantages of simplicity, strong anti-shock / vibration capacity, small impact force and little bounce when the contacts are separated and connected, and great improvement on the operating reliability.

Owner:宁波伊尔特智能电器开关有限公司

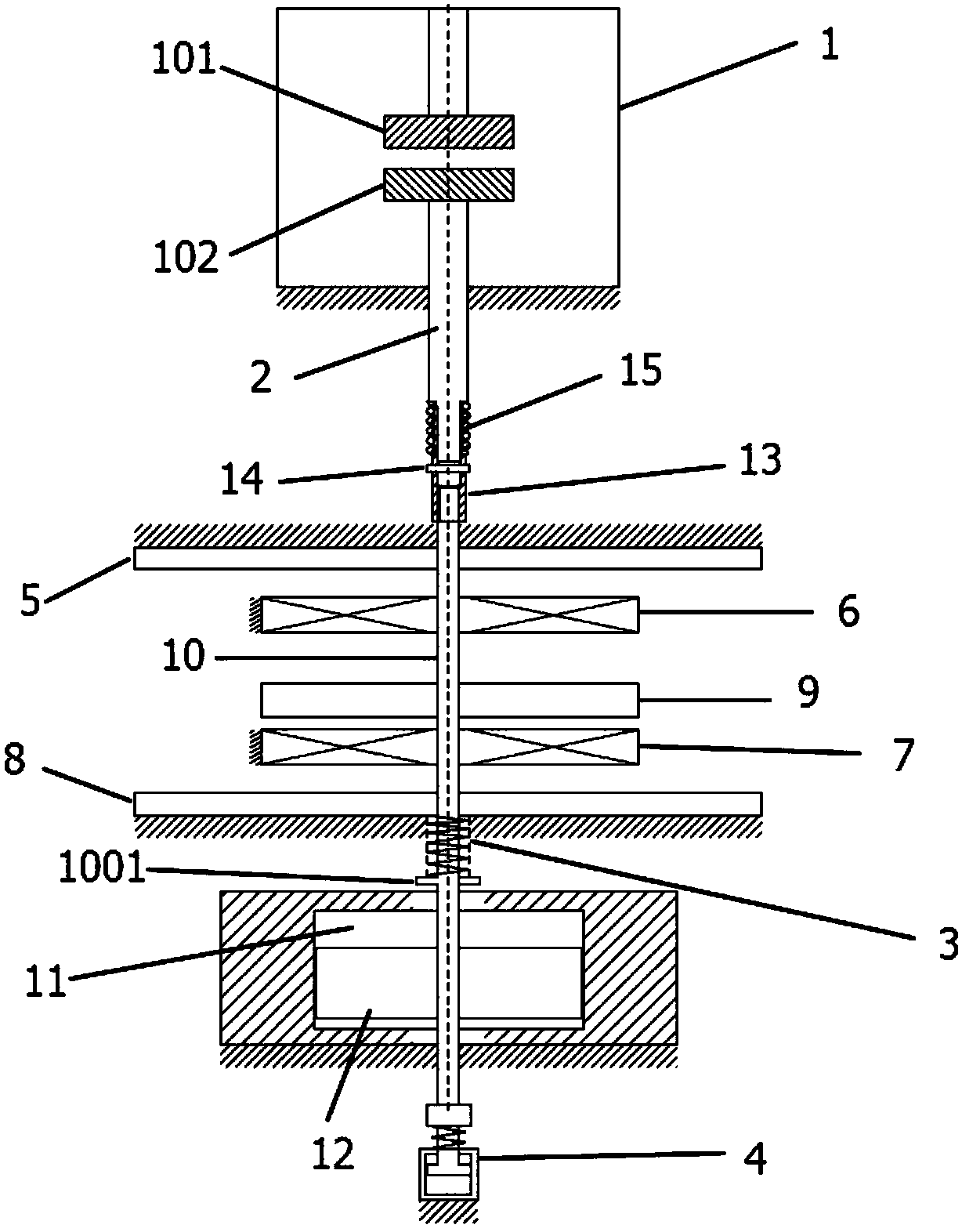

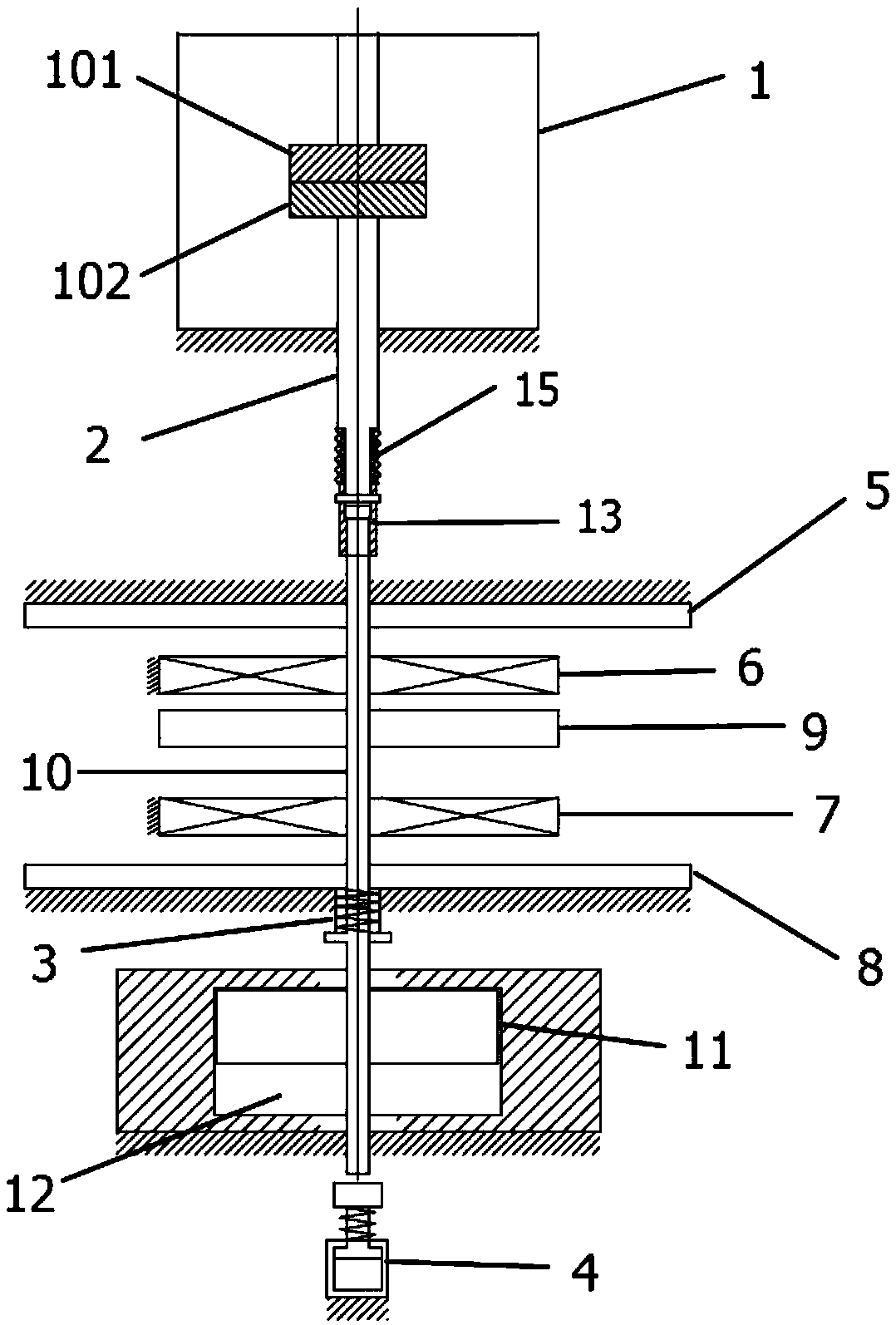

DC breaker based on dual-coil monostable permanent magnet mechanism

ActiveCN108400056ASlow down the speed of the upward movementReduce bouncingHigh-tension/heavy-dress switchesAir-break switchesContact pressureDual coil

The invention relates to the technical field of the high-voltage device, and discloses a DC breaker based on a dual-coil monostable permanent magnet mechanism. The DC breaker comprises a vacuum arc-extinguishing chamber; a static contact and a movable contact are arranged in the vacuum arc-extinguishing chamber from top to bottom, the bottom surface of the movable contact is connected with a movable conducting rod; the movable conducting rod is connected with a dual-coil repulsion mechanism through a spring steering mechanism, the dual-coil repulsion mechanism is connected with a permanent magnet mechanism through a switch-off maintaining spring, and a switch-off buffer is arranged below the permanent magnet mechanism; the switch-off maintaining spring is used for providing the switch-offmaintaining force, the permanent magnet mechanism is used for providing a switch-on maintaining force, the spring steering mechanism is used for providing the switch-on assisting force in the switch-on, thereby increasing the contact pressure of the movable contact and the static contact; the dual-coil repulsion mechanism is used for providing the starting acting force of the switch-off and the starting acting force of the switch-on through the electromagnetic induction; and the switch-off buffer is used for absorbing excessive kinetic energy in the switch-off process. The DC breaker disclosedby the invention is simple and reliable, convenient for application, and has good in market promotional value.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +2

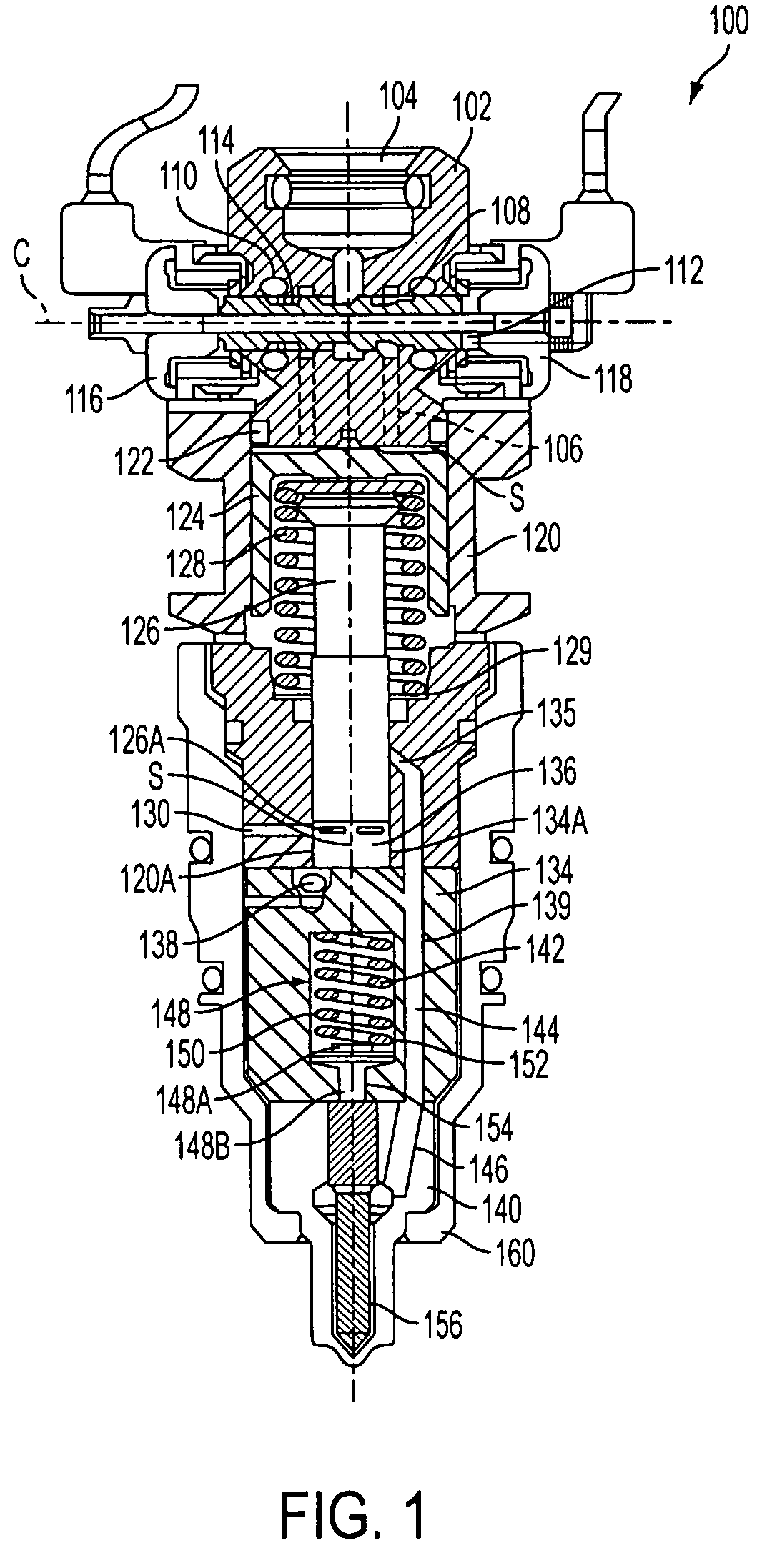

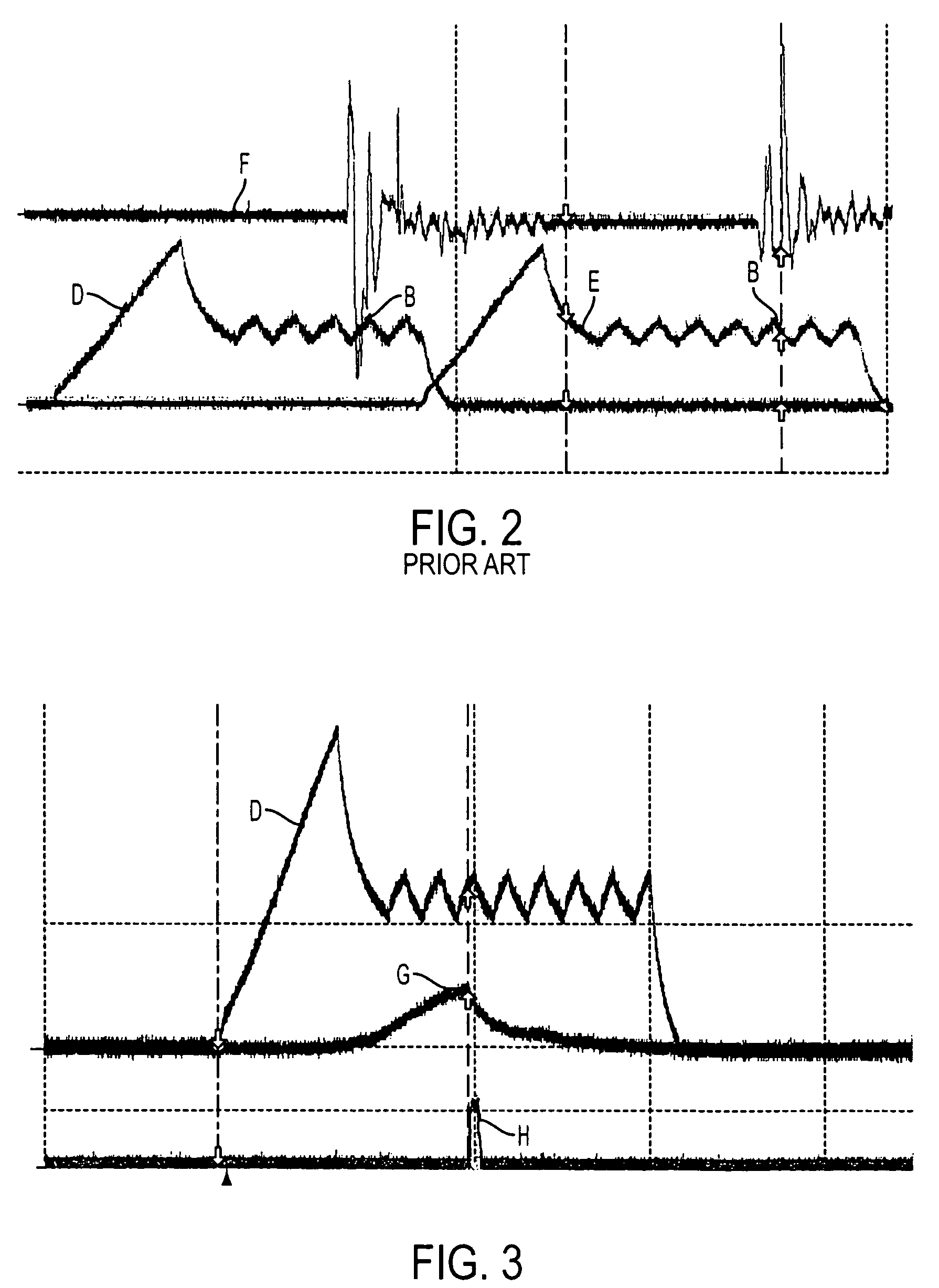

Control method for closed loop operation with adaptive wave form of an engine fuel injector oil or fuel control valve

ActiveUS7984706B2Reduce bouncingElectrical controlOperating means/releasing devices for valvesWave formClosed loop

A method and system controls motion of an armature 112 of a fuel injector 100. The armature moves between an open coil 118 and a close coil 116 of the injector. Acceleration current of a certain polarity is applied to the open coil 118 with the armature disposed at the close coil 116. De-latching current of a polarity opposite of the certain polarity is applied to the close coil 116 to release magnetic latch on the armature thereby accelerating movement of the armature towards the open coil 118. Deceleration current is applied the close coil 116 thereby decelerating the armature prior to reaching the open coil. Latching current of the certain polarity is applied to the open coil 118 prior to or just after impact of the armature 112 with the open coil 118 to magnetically latch the armature to the open coil 118 thereby reducing bounce of the armature at impact.

Owner:VITESCO TECH USA LLC

Surface treatment method of rivet electric contact, grinding material and grinding material preparation method

InactiveCN107378741AReduce contact resistanceRp decreasesEdge grinding machinesPolishing machinesEpoxyElectricity

The invention discloses a surface treatment method of a rivet electric contact, a grinding material and a grinding material preparation method. The surface treatment method comprises the following steps that mixed powder and epoxy resin are mixed according to the ratio and then placed in a stirring machine; gel is taken out after stirring is conducted for a period of time and then squeezed to obtain a blank; after being subjected to cold storage for a period of time, the blank is taken out, and then the cylindrical grinding material is obtained; and through the grinding material, rammer-making burrs and ring marks of the rivet electric contact can be rapidly removed, and the contact resistance can be decreased. According to the grinding material and the grinding material preparation method, the rammer-making burrs and ring marks of the rivet electric contact can be simultaneously removed, and the contact resistance is decreased; and meanwhile the grinding time is shortened, the testing cost is saved, and technological support is provided for development of the low-voltage electrical apparatus industry.

Owner:FUDA ALLOY MATERIALS

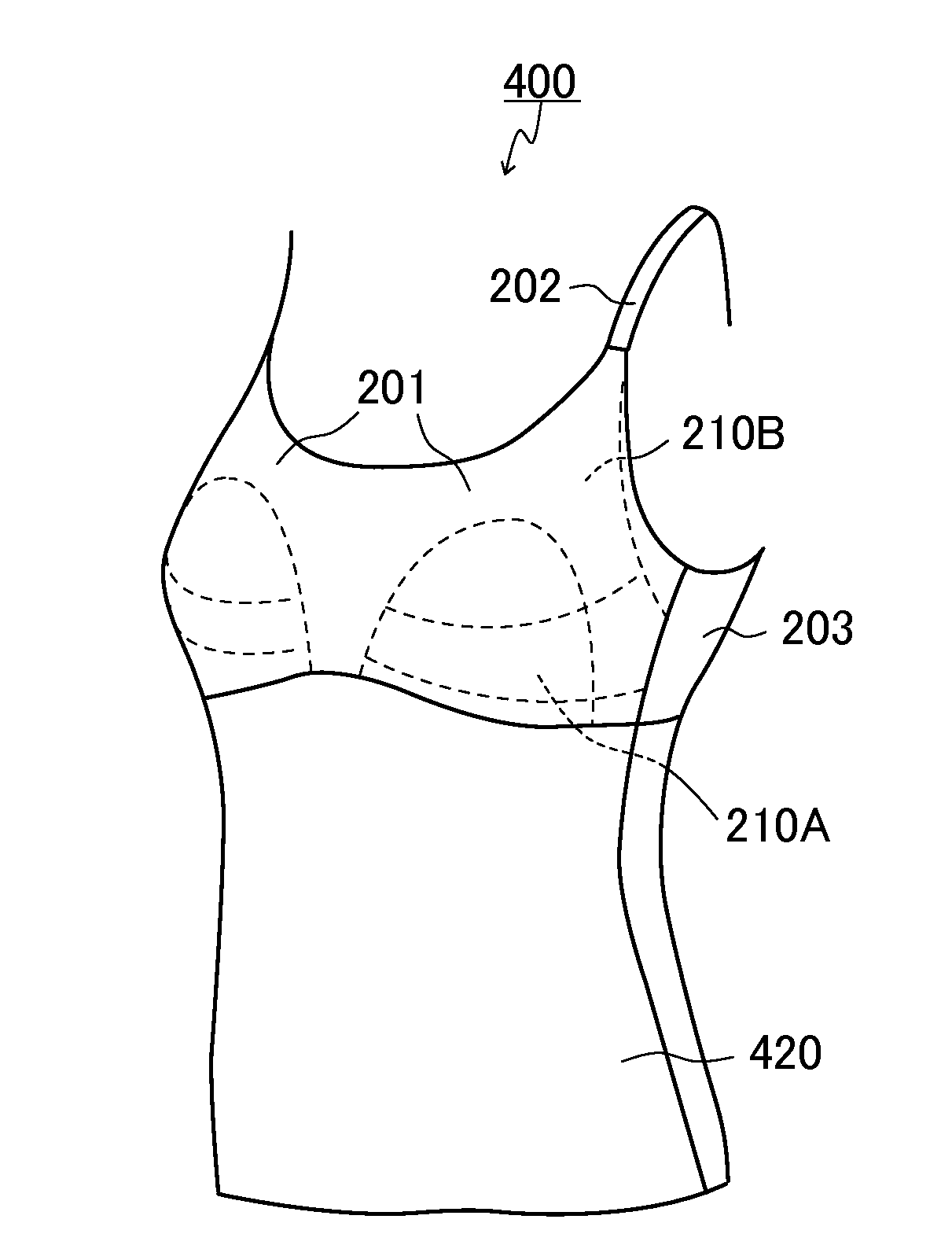

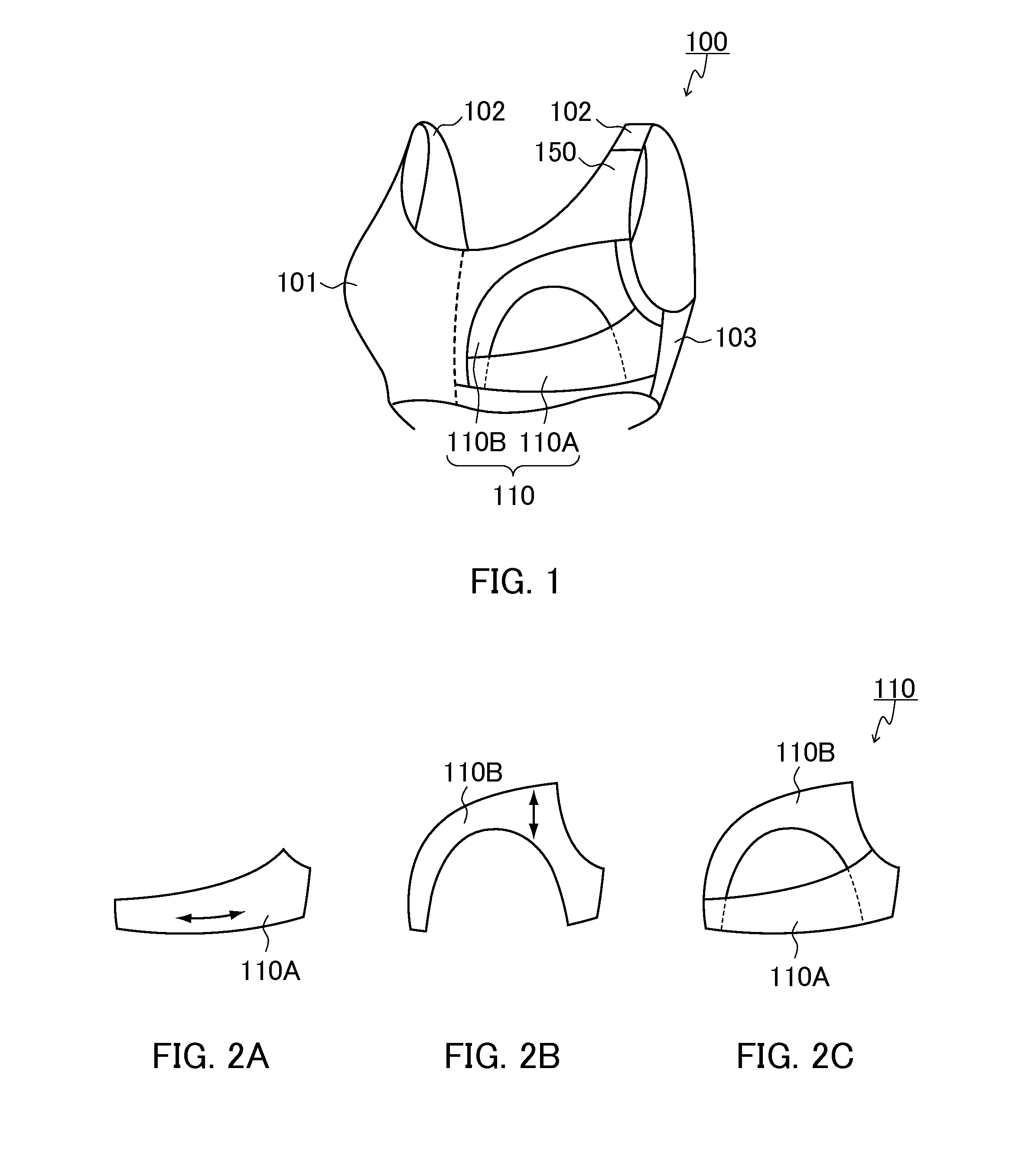

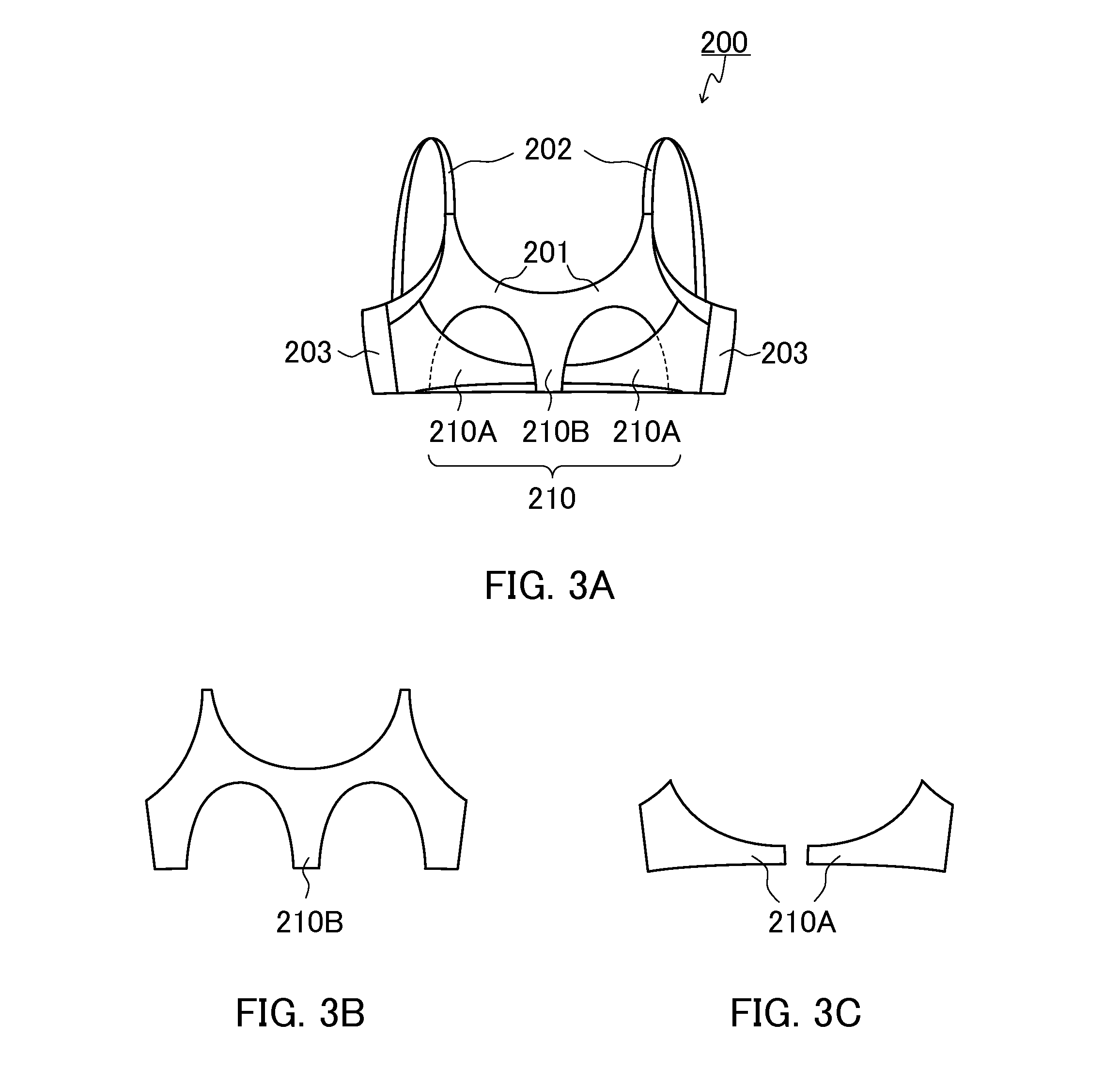

Garment with Cup Portions

InactiveUS20140017977A1Reduce bouncingFine bust silhouetteBrassieresEngineeringMechanical engineering

Owner:WACOAL

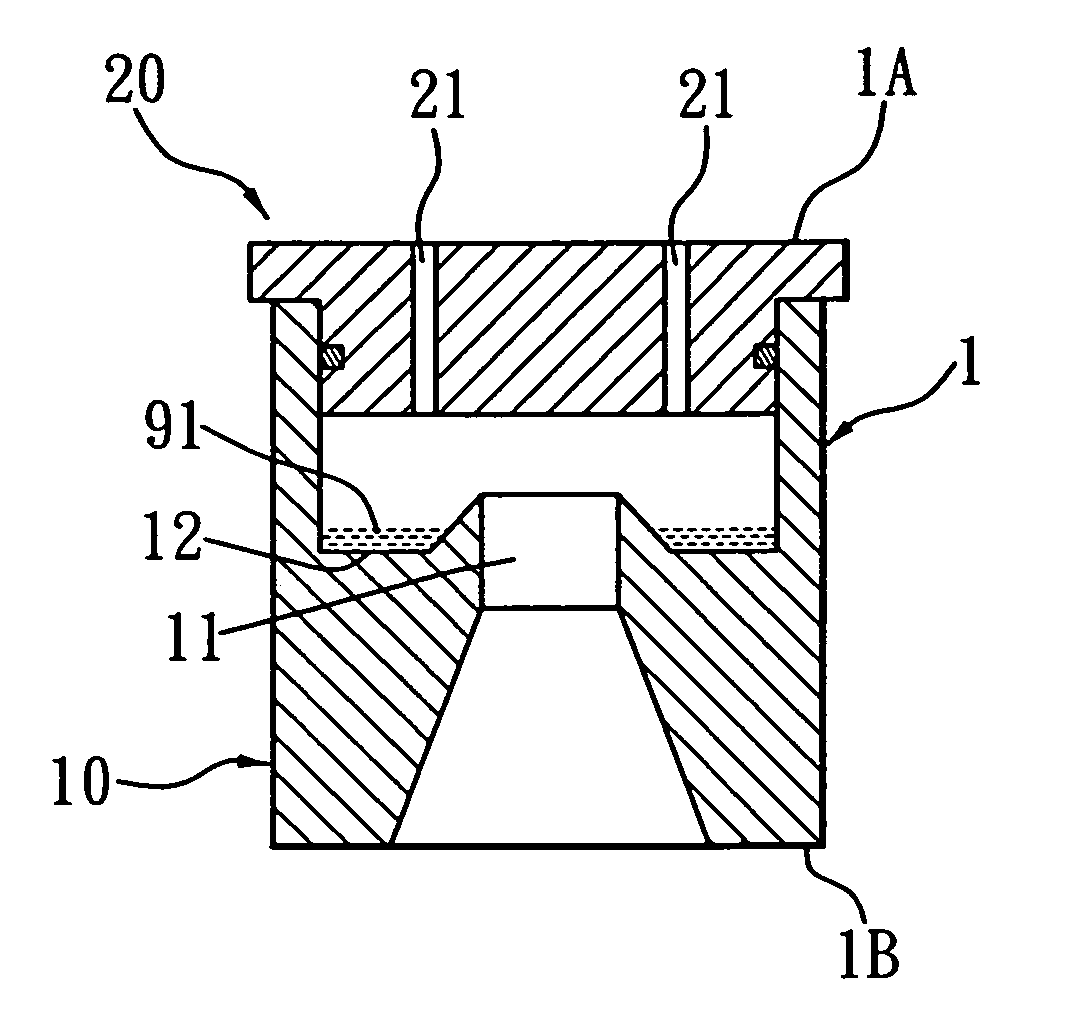

Aerosol size-selective impactor for reducing particle bounce

InactiveUS20070056389A1Reduce bouncingImprove accuracyWithdrawing sample devicesDispersed particle separationSize selectiveDehydration

An aerosol size-selective impactor for reducing particle bounce includes a main structure, a buffering layer, and a dehydration preventing layer. This main structure with an inlet and an outlet has a central channel and a receiving cavity. There are many nozzles in the inlet. The buffering layer is filled in the receiving cavity. The dehydration preventing layer is coated on the buffering layer for reducing the dehydration of water contained in the buffering layer. So, this invention utilizes the design of the receiving cavity to receive both layers. Its accuracy is high. Its sampling time lasts longer. It can endure vibrations. This invention can yield the particle bounce effect with lower cost. And, its application scope is wide.

Owner:CHUNG SHAN MEDICAL UNIVERSITY

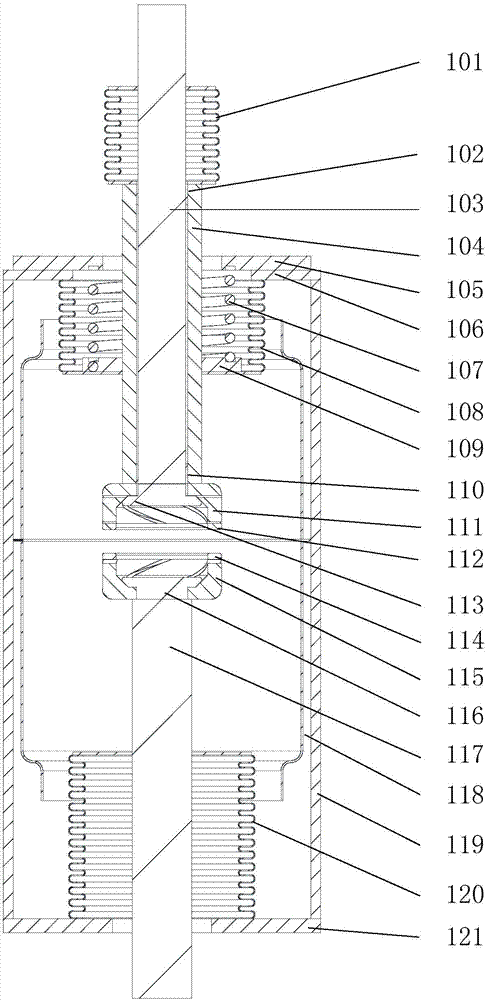

Vibration reducer and switching device

The invention discloses a vibration reducer and a switching device. The vibration reducer comprises a cylinder, a piston, a piston rod and a pressure relieving device, wherein one end of the piston rod penetrates through a first end cover, and extends into the cylinder to be fixed with the piston in the cylinder; a cavity of the cylinder is divided into a first cavity and a second cavity at the sides of the first end cover by the piston; the pressure relieving device is assembled on the cylinder, and a valve core rod part of a pressure relieving valve rod in the pressure relieving device extends into the first cavity; an extension rod is positioned in the pressure relieving valve core for adjusting a pressure relieving trigger travel; a first limiting mechanism is arranged between the extension rod and the pressure relieving valve core; and the pressure relieving device and the second cavity are communicated through a channel provided with an adjusting valve. The switching device comprises a single-pole switch; the single-pole switch is axially connected with the vibration reducer; when the switch is switched on, the damping is relieved at the tail section of the moving contact travel, so that the switching-on bounce of a moving contact of the switching device accelerated by the damping force is prevented, and the switching-on time is shortened; the damping releasing strength is adjusted; and the vibration reducer and the switching device are in synergistic effect to optimize the switching-on performance.

Owner:陈鸽

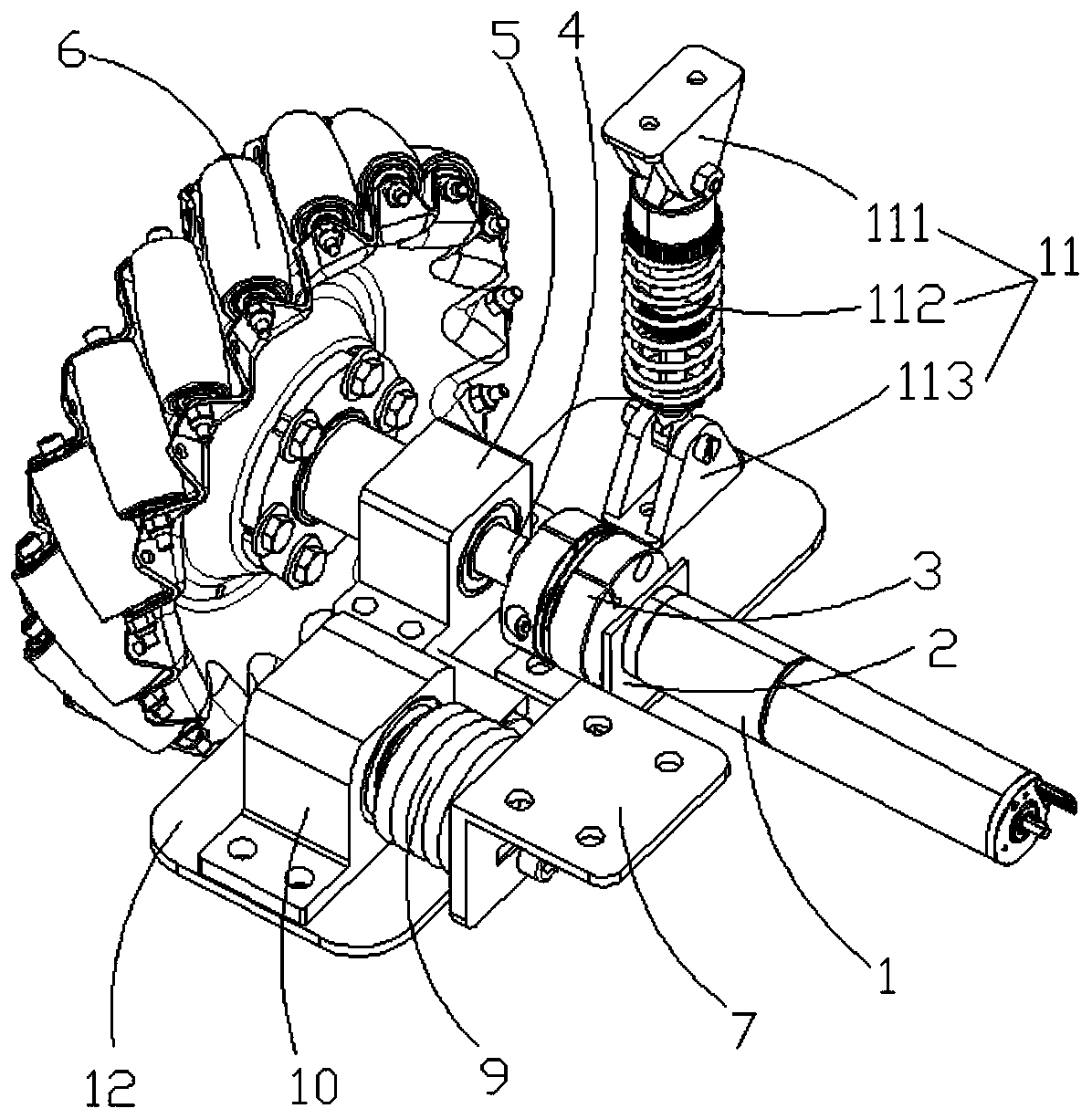

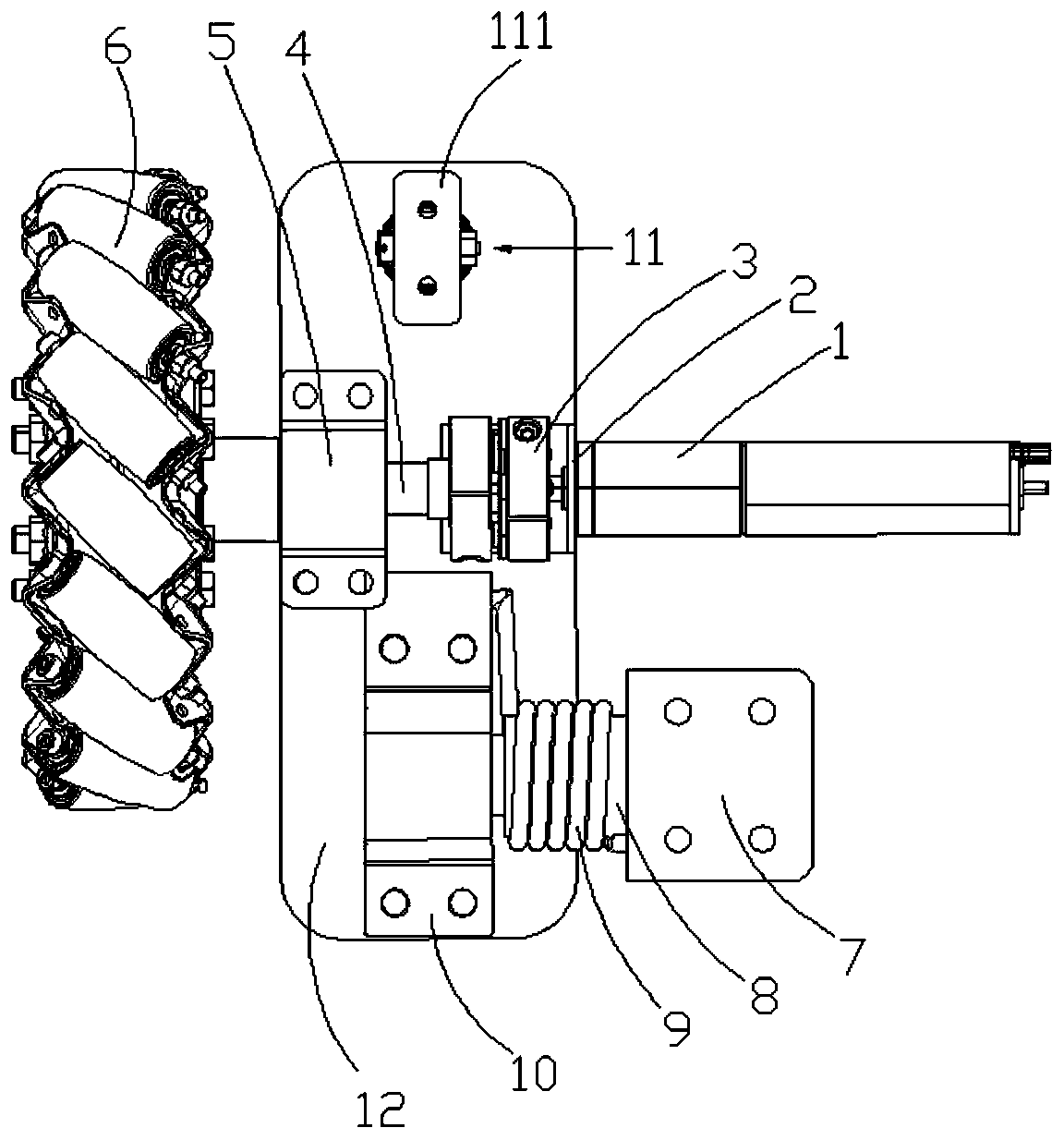

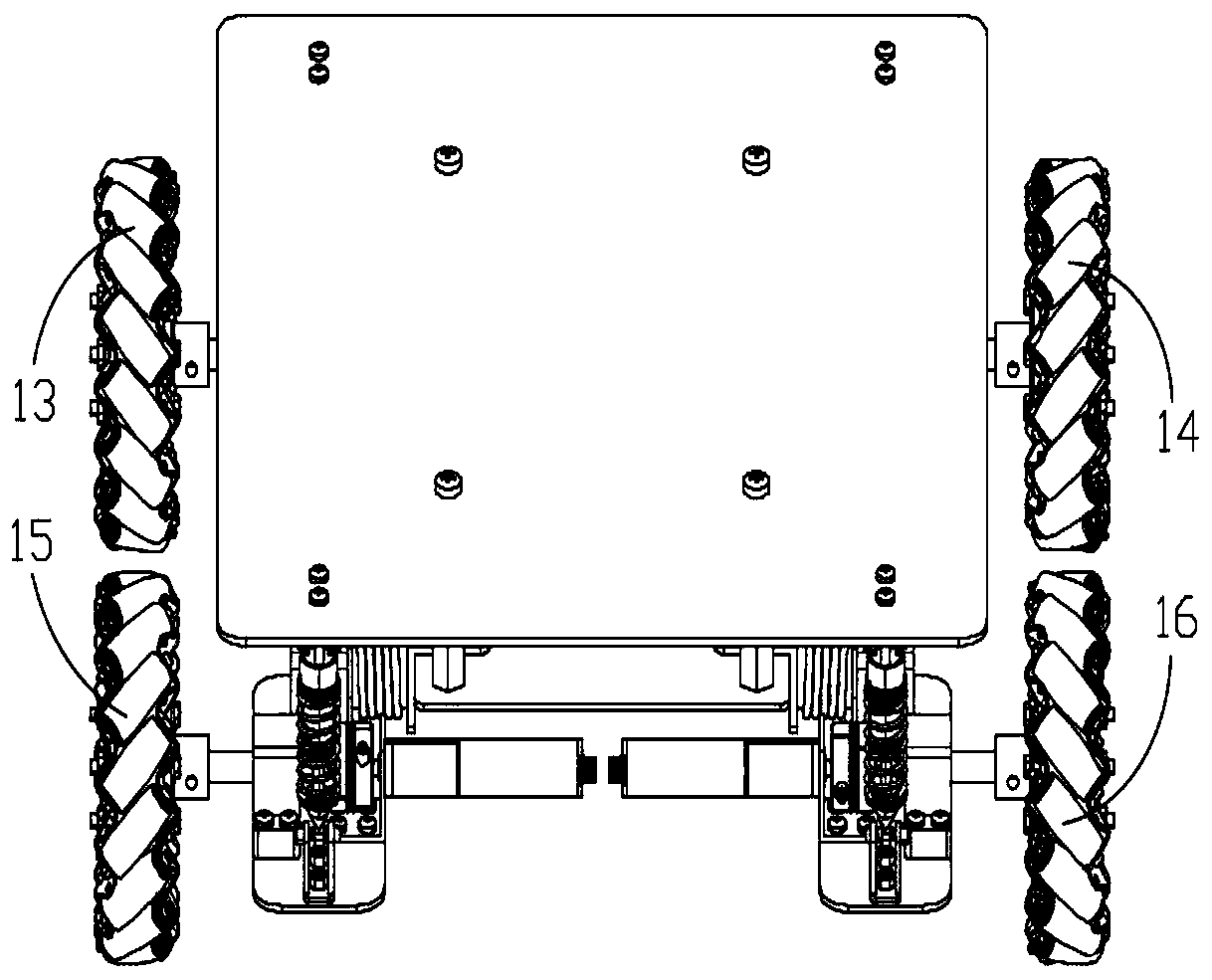

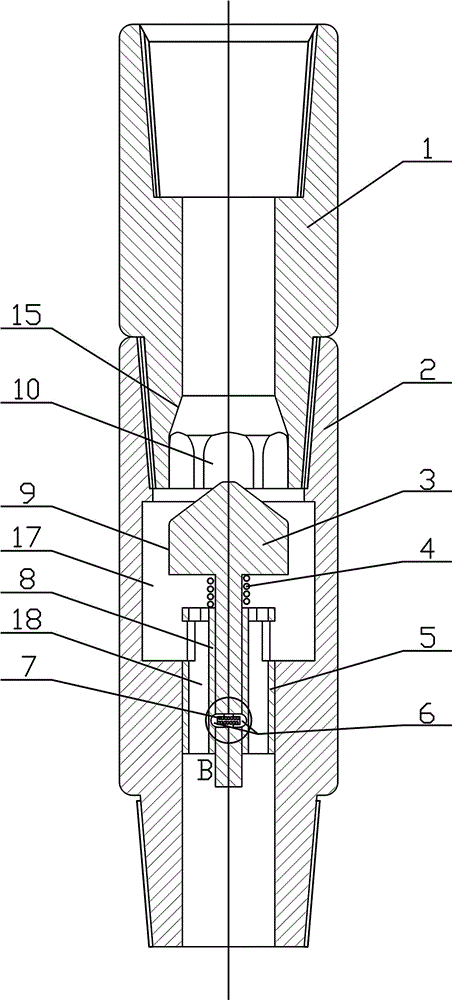

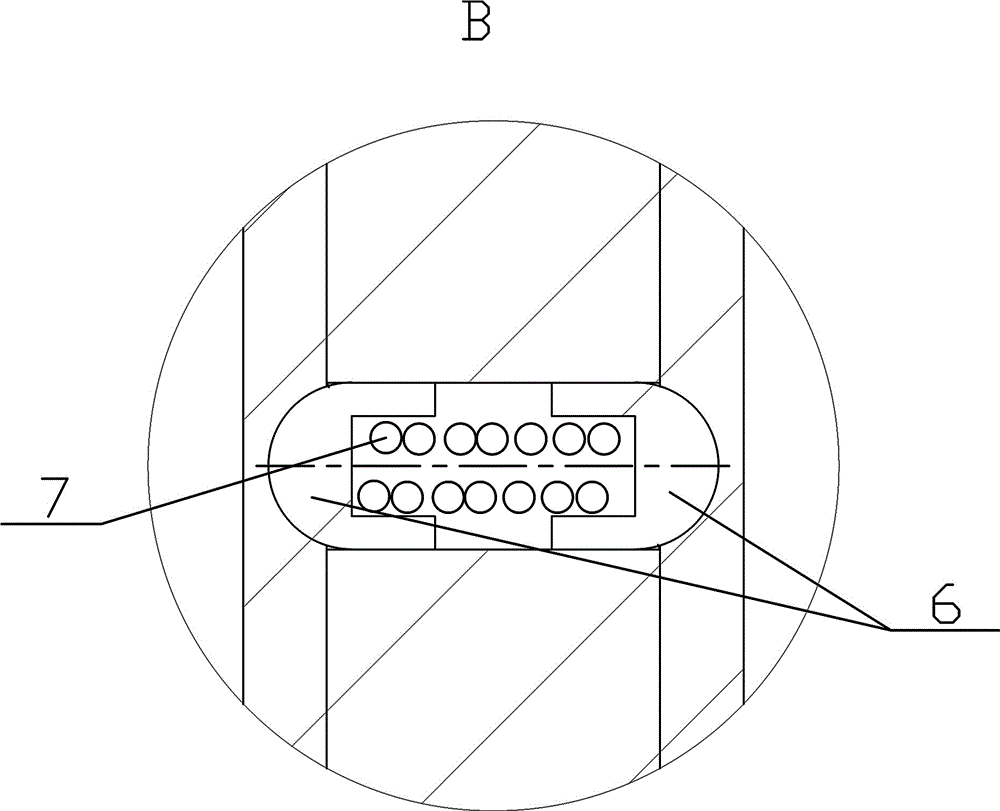

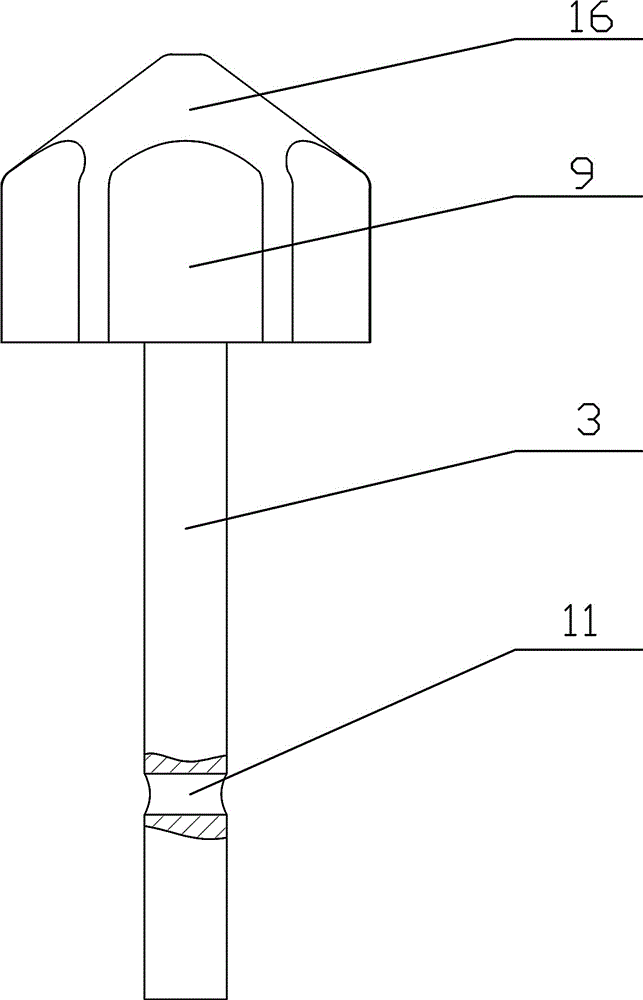

Independent suspension structure of Mecanum wheel omni-directional mobile robot

PendingCN110077184ASmooth motionReduce bouncingResilient suspensionsVehicle springsMotor speedReduction drive

The invention provides an independent suspension structure of a Mecanum wheel omni-directional mobile robot. The independent suspension structure of the Mecanum wheel omni-directional mobile robot comprises a suspension bottom plate; a motor speed reducer, an L-shaped support, a shaft coupling, an output shaft, an axle bearing seat and a shock absorbing device are mounted on the suspension bottomplate in a matched manner; the motor speed reducer is connected with one end of the output shaft through the shaft coupling; the other end of the output shaft is fixedly connected with a Mecanum wheel; the independent suspension structure of the Mecanum wheel omni-directional mobile robot further comprises a torsion spring, a torsion spring shaft, an L-shaped connecting piece and a torsion springshaft bearing seat; a torsion spring shaft bearing is mounted in the torsion spring shaft bearing seat; the axis of the torsion spring shaft bearing is parallel to the axis of an axle bearing; one endof the torsion spring shaft is fixed on a vehicle body through the L-shaped connecting piece; the other end of the torsion spring shaft is inserted into an internal ring of the torsion spring shaft bearing; the torsion spring is arranged on the torsion spring shaft in a sleeving manner; one end of the torsion spring is fixed on the L-shaped connecting piece; and the other end of the torsion spring is fixed on the suspension bottom plate. According to the independent suspension structure of the Mecanum wheel omni-directional mobile robot, a spring damping shock absorber and the torsion springare utilized to perform double shock absorption so that the shock absorbing effect is better and the robot motion is more stable.

Owner:HEBEI UNIV OF TECH

Arrow-shaped check valve

ActiveCN105888610AExtended service lifePrevent jumpingWell/borehole valve arrangementsSealing/packingHigh pressureCheck valve

The invention provides an arrow-shaped check valve. The arrow-shaped check valve comprises an upper valve body and a lower valve body which are connected with each other. A through hole is formed in the upper valve body, and a conical surface and a first spline surface are arranged at the bottom of the through hole in sequence. An arrow-shaped valve element sliding in the axial direction of the lower valve body is arranged in the lower valve body, and a frustum in sealing fit with the conical surface and a second spline surface in sealing fit with the first spline surface are correspondingly arranged at the top of the arrow-shaped valve element. According to the arrow-shaped check valve, by the adoption of the spline surface structure, the open area is increased and exceeds the original open area by 1.5-2 times on the premise of not increasing the stroke or the outer diameter; by the adoption of the combination scheme of conical surface and spline surface fit, the sealing effect is improved; especially, by the adoption of the scheme, it is unnecessary to arrange additional sealing elements such as sealing rings, sealing cylinders and other structures made of rubber, so that it is avoided that sealing elements are rapidly abraded by high-pressure mud, and the service life of the arrow-shaped check valve is prolonged.

Owner:MUDANJIANG XINBEIFANG PETROLEUM DRILLING TOOL +1

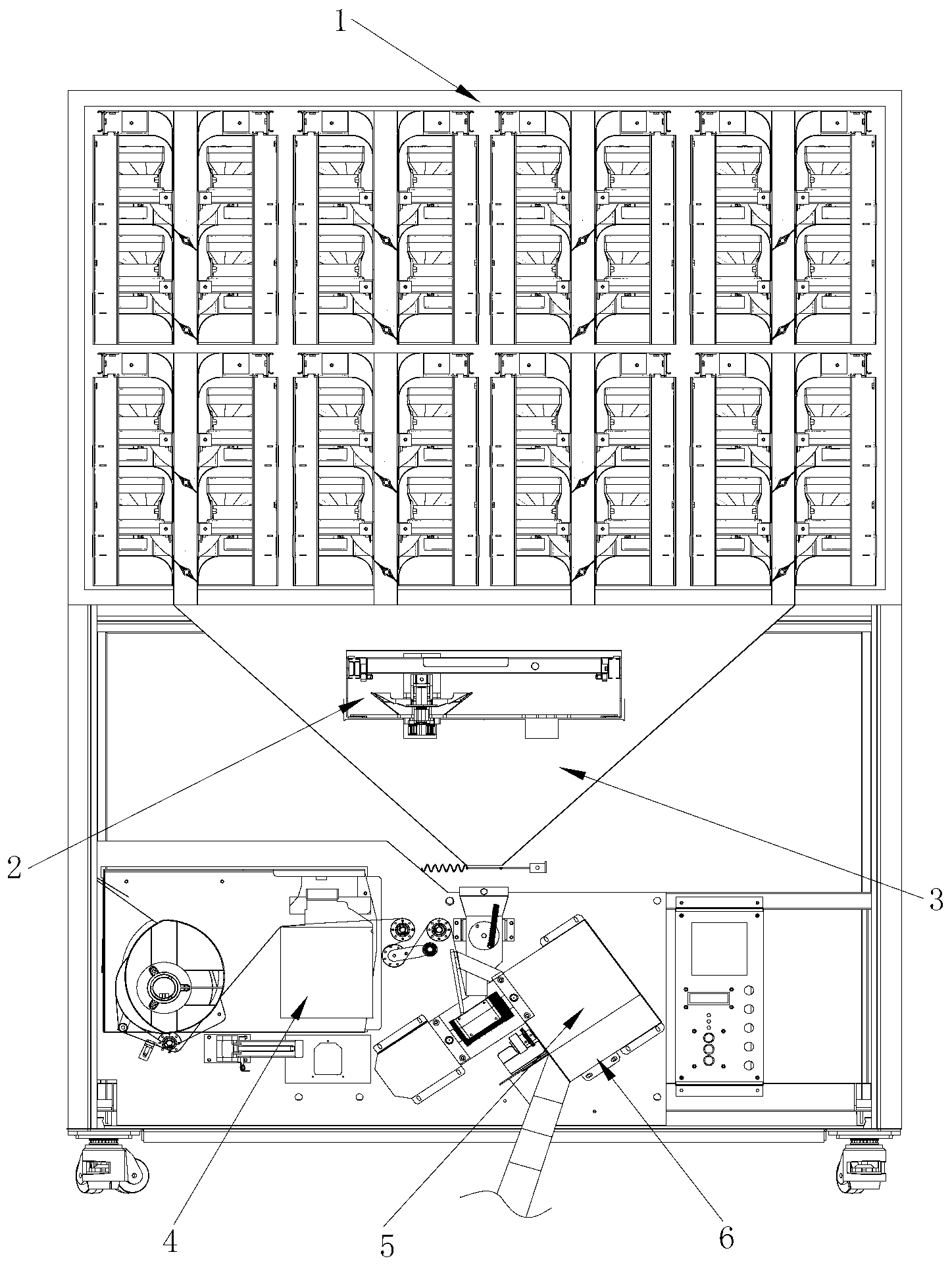

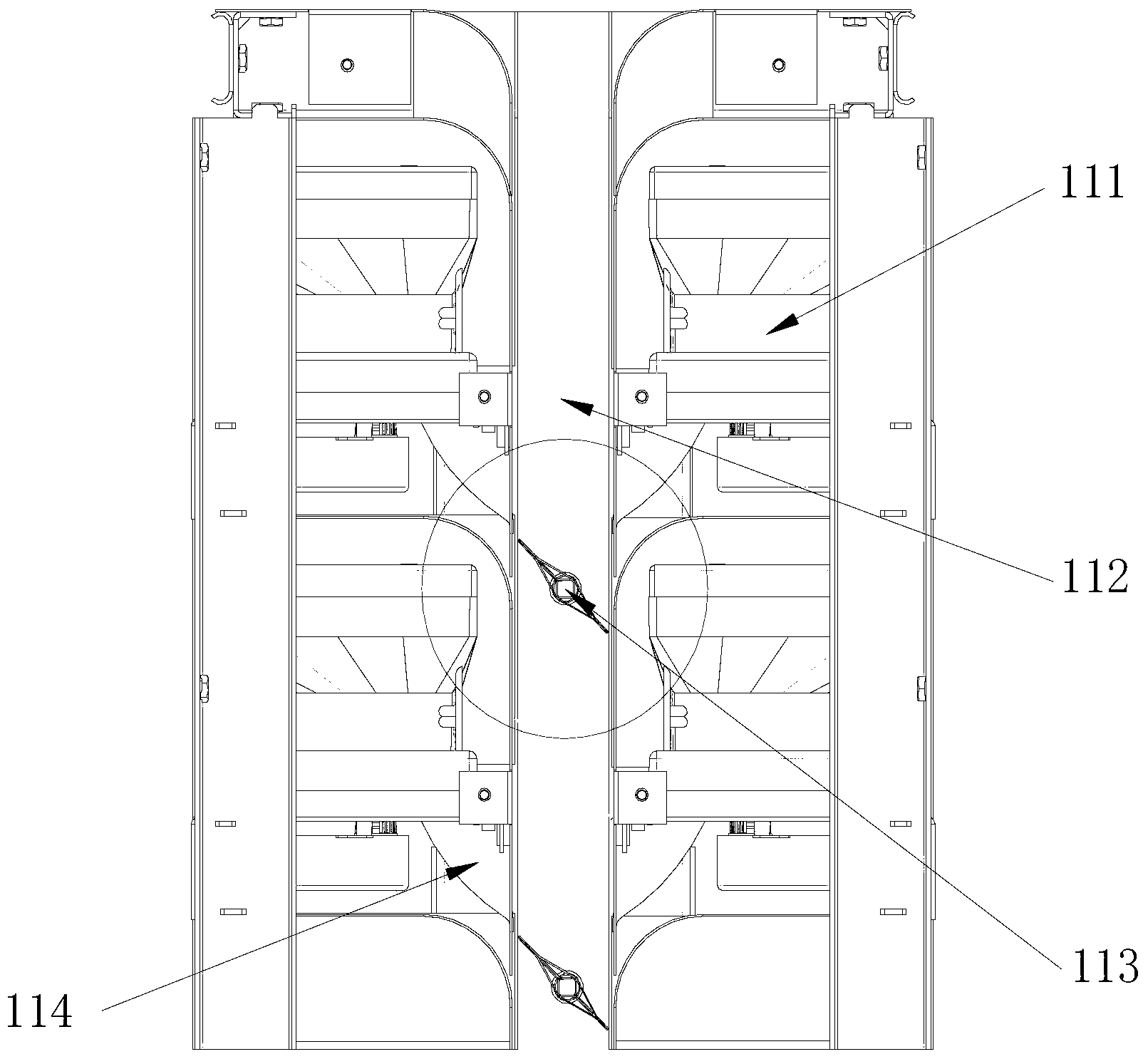

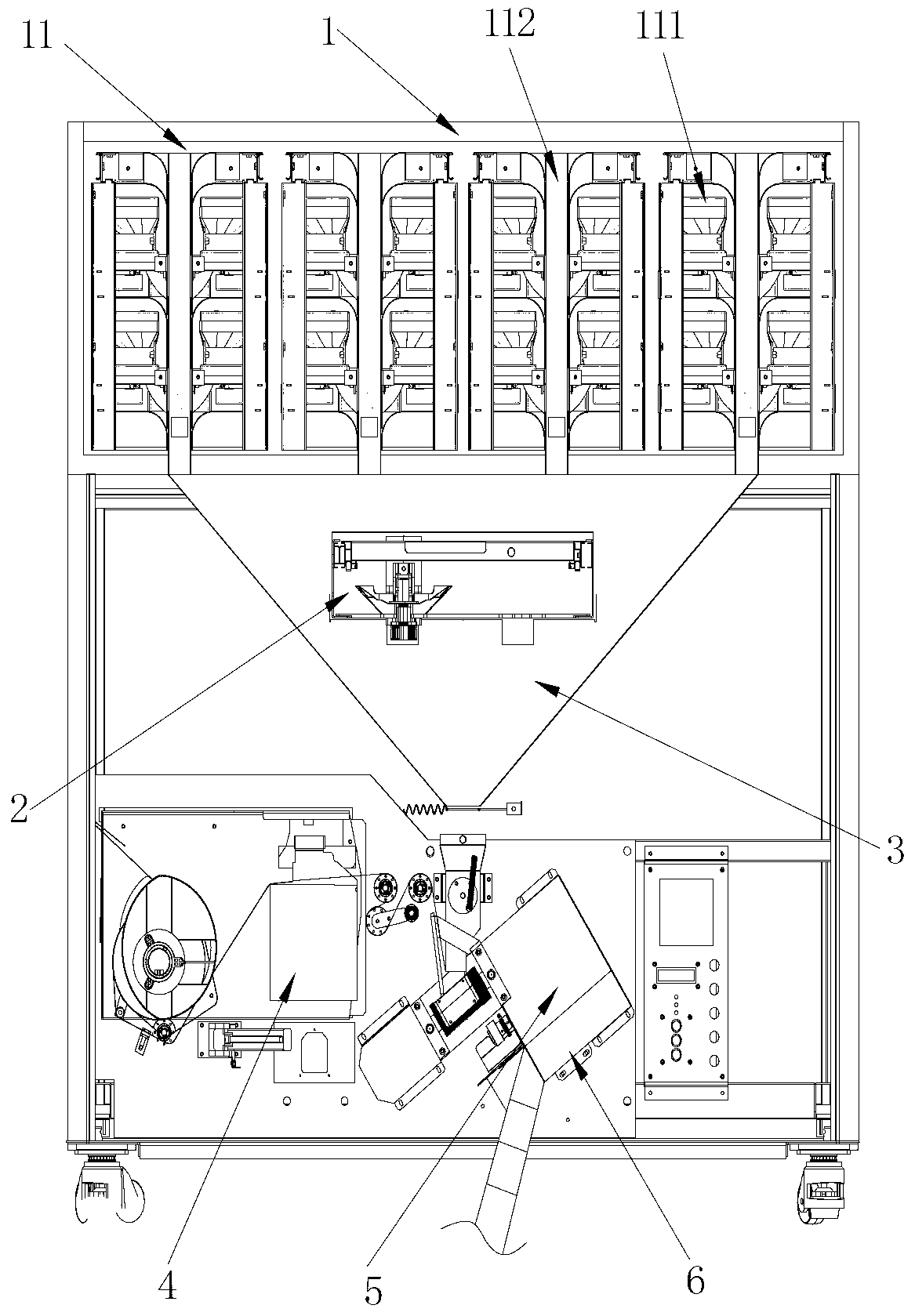

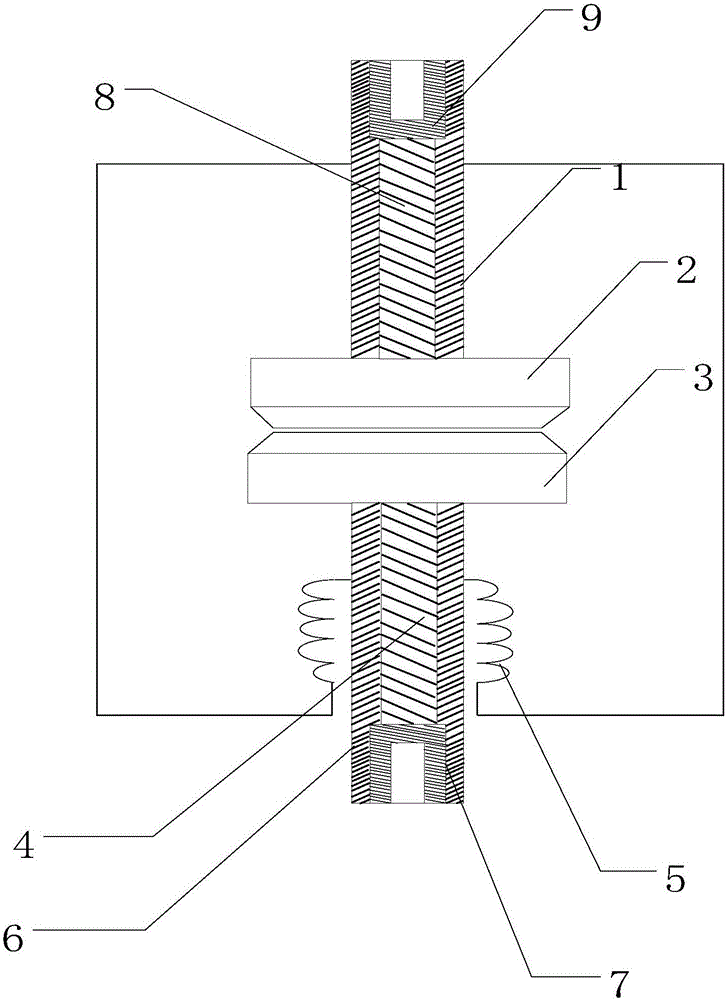

Fast full-automatic medicine packaging device

ActiveCN103318591AReduce travel timeReduce kinetic energySolid materialStorage devicesBiomedical engineeringComputer case

The invention discloses a fast full-automatic medicine packaging device which comprises a medicine storage cabinet and a case. A collection mechanism 3 is arranged in the case, a printing mechanism 4 is arranged on the lower surface of the collection mechanism 3 and is connected with a packaging mechanism 5, and the packaging mechanism 5 is communicated with a bag discharge mechanism 6. At least one medicine supply combination unit 11 is arrayed in the medicine storage cabinet 1. The fast full-automatic medicine packaging device disrupts the intrinsic flow process of medicine packaging in the prior art, many medicine bags can discharge medicines simultaneously without affecting each other through the at least one medicine supply combination unit, a medicine collection channel sharing structure, an interception device multi-collection structure and the like, and the medicine packaging speed of the whole packaging device is manifold improved.

Owner:TIANJIN SENYA MEDICAL EQUIP TECH CO LTD

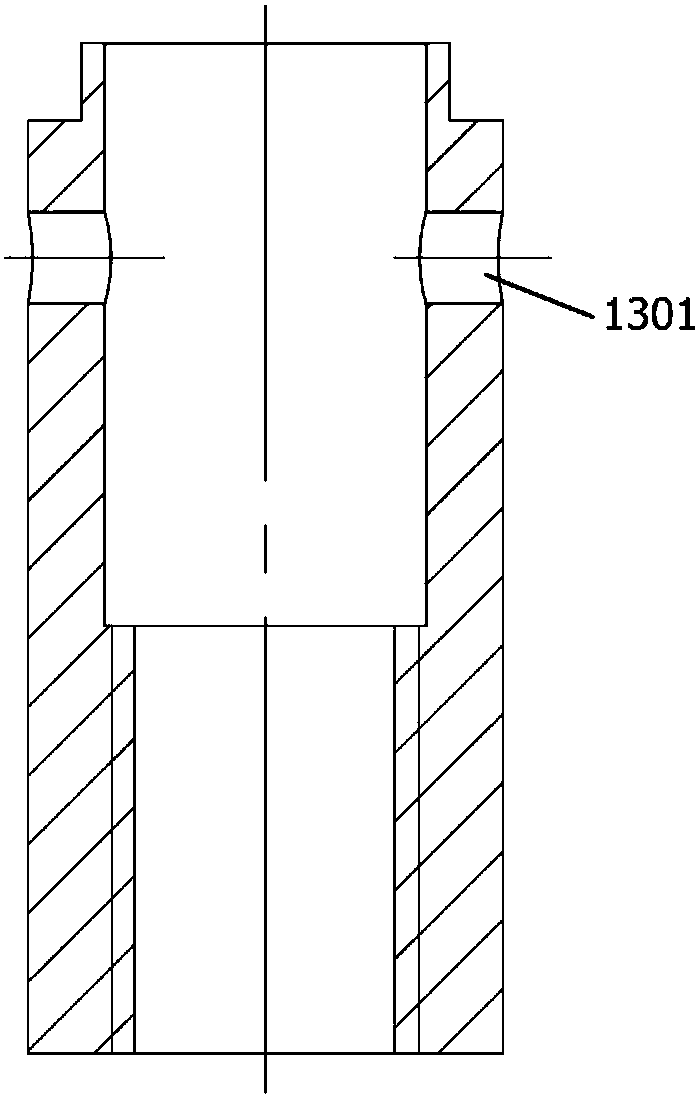

Conductive rod structure for vacuum arc-extinguishing chamber

InactiveCN106128853AHigh mechanical strengthLight in massHigh-tension/heavy-dress switchesAir-break switchesMechanical impactElectrical performance

A conductive rod structure for a vacuum interrupter belongs to the technical field of electrical switches. The dynamic and static conductive rods are equipped with dynamic and static conductive rod cores. The dynamic and static conductive rod cores are located at the center of the dynamic and static conductive rods. One end of the dynamic and static conductive rods is connected with a dynamic and static contact. The moving contact is in flush contact, and the lower end of the steel core of the static conductive rod is in flush contact with the static contact. The mechanism of the invention is simple, by assembling the structure of the dynamic and static conductive rod cores in the center of the dynamic and static conductive rods, the mechanical strength of the dynamic conductive rod is effectively improved, and the conductive rod structure of the fast mechanical switch is prevented under the same extrusion stress Roughly deformed due to mechanical impact, good mechanical properties and low processing cost. The density of the core material of the dynamic and static conductive rods is lower than that of copper, which reduces the mass of the dynamic conductive rod, thereby reducing the closing bounce and ensuring electrical performance.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com