Patents

Literature

274results about How to "Uniform magnetic field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

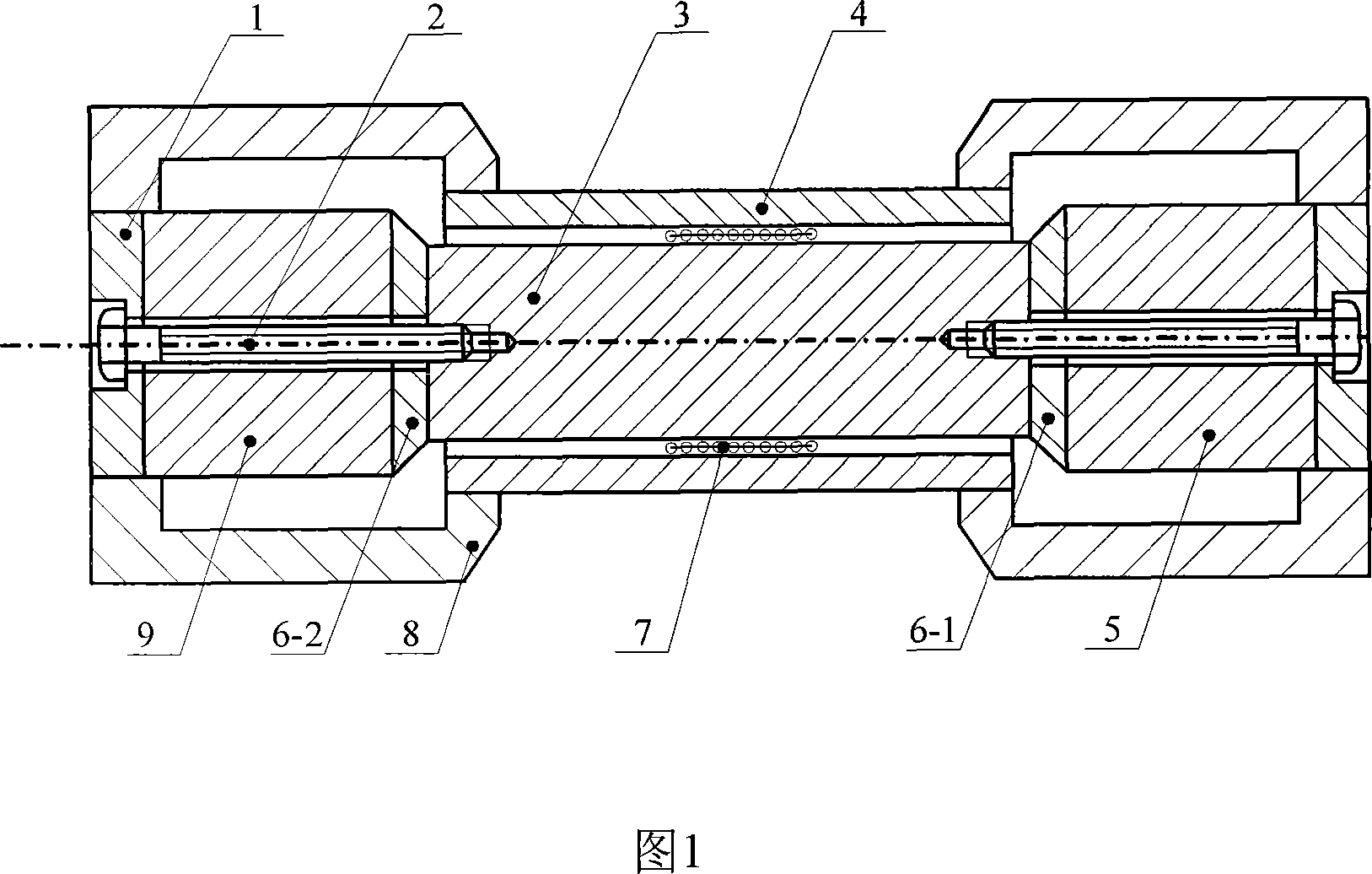

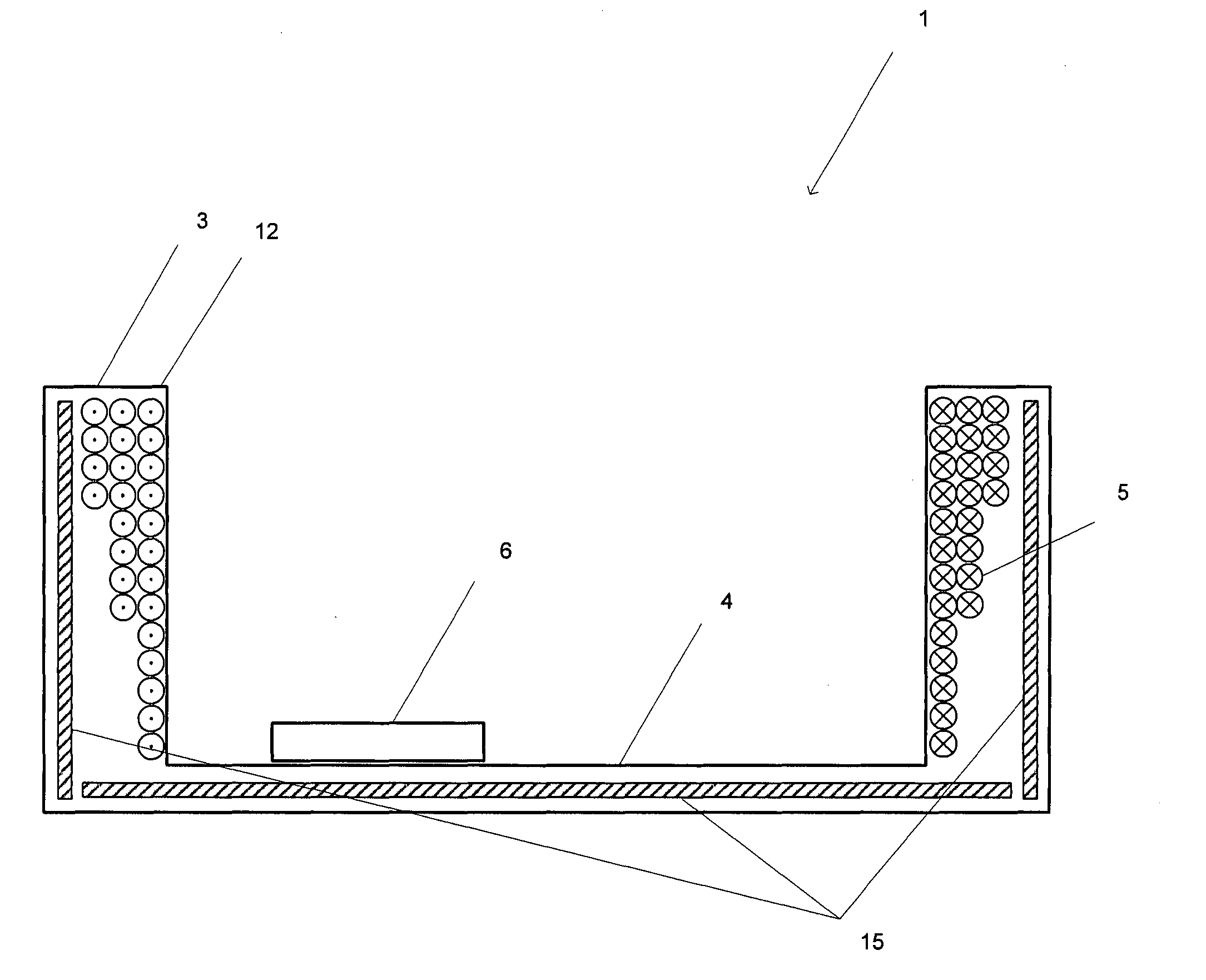

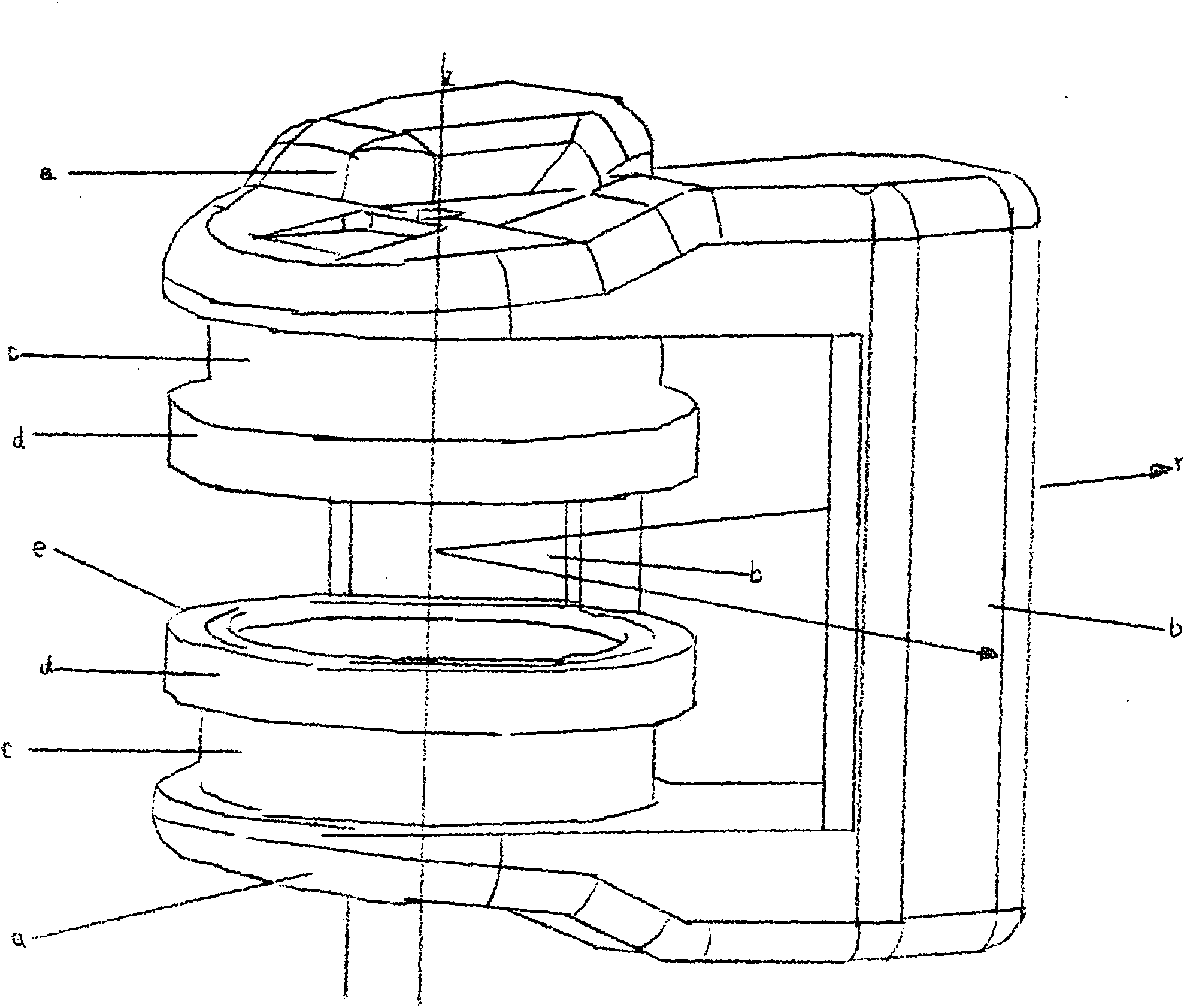

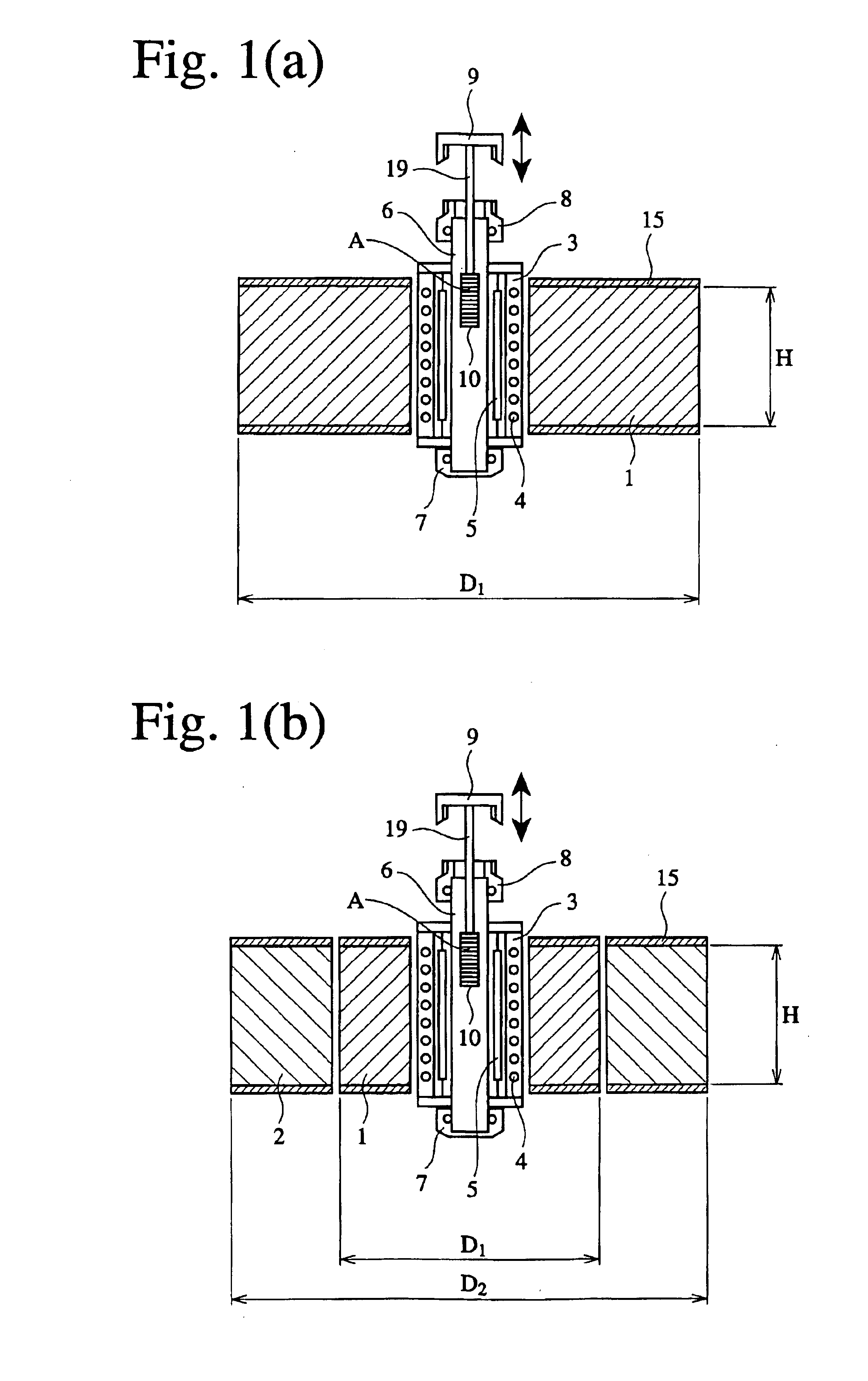

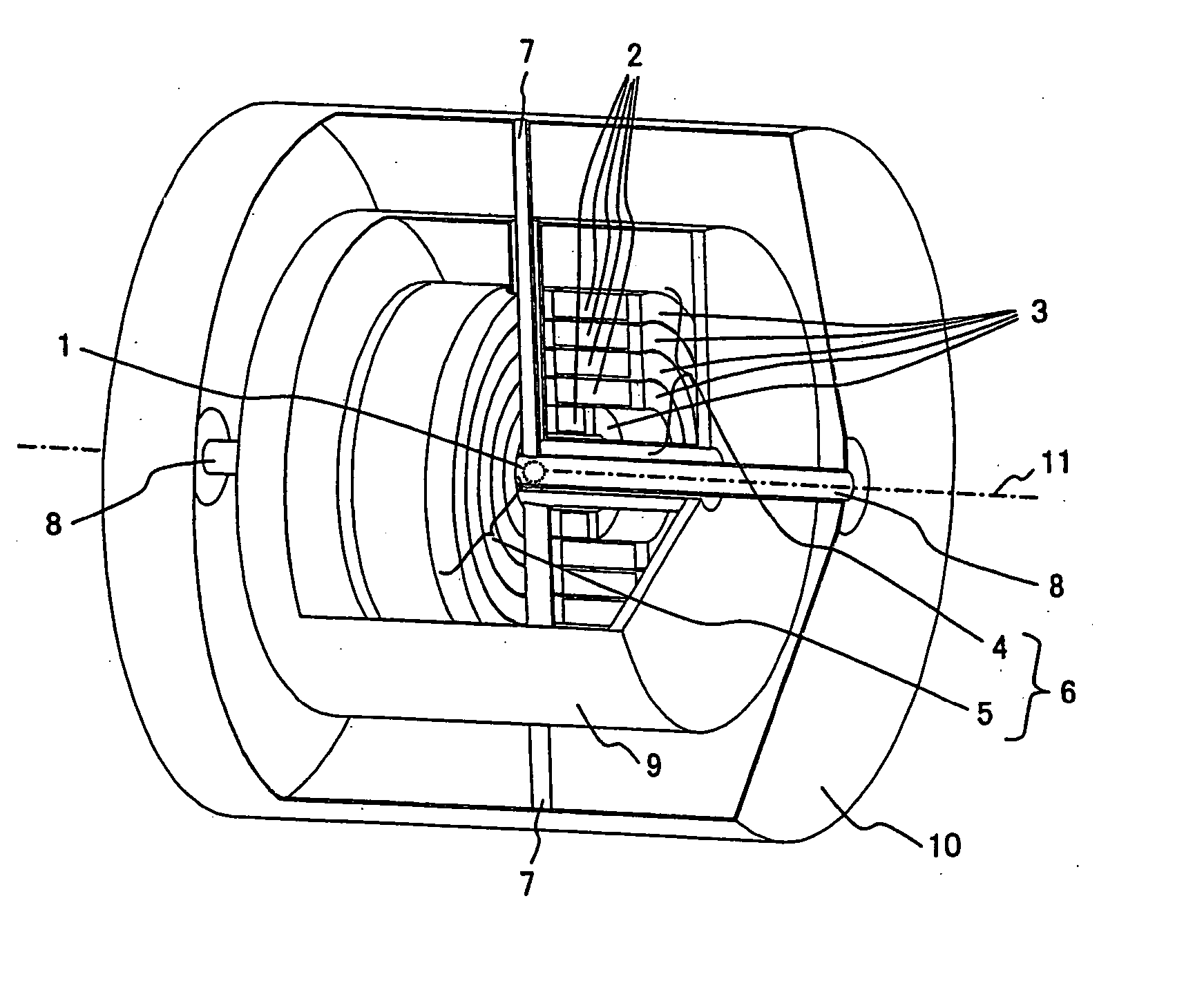

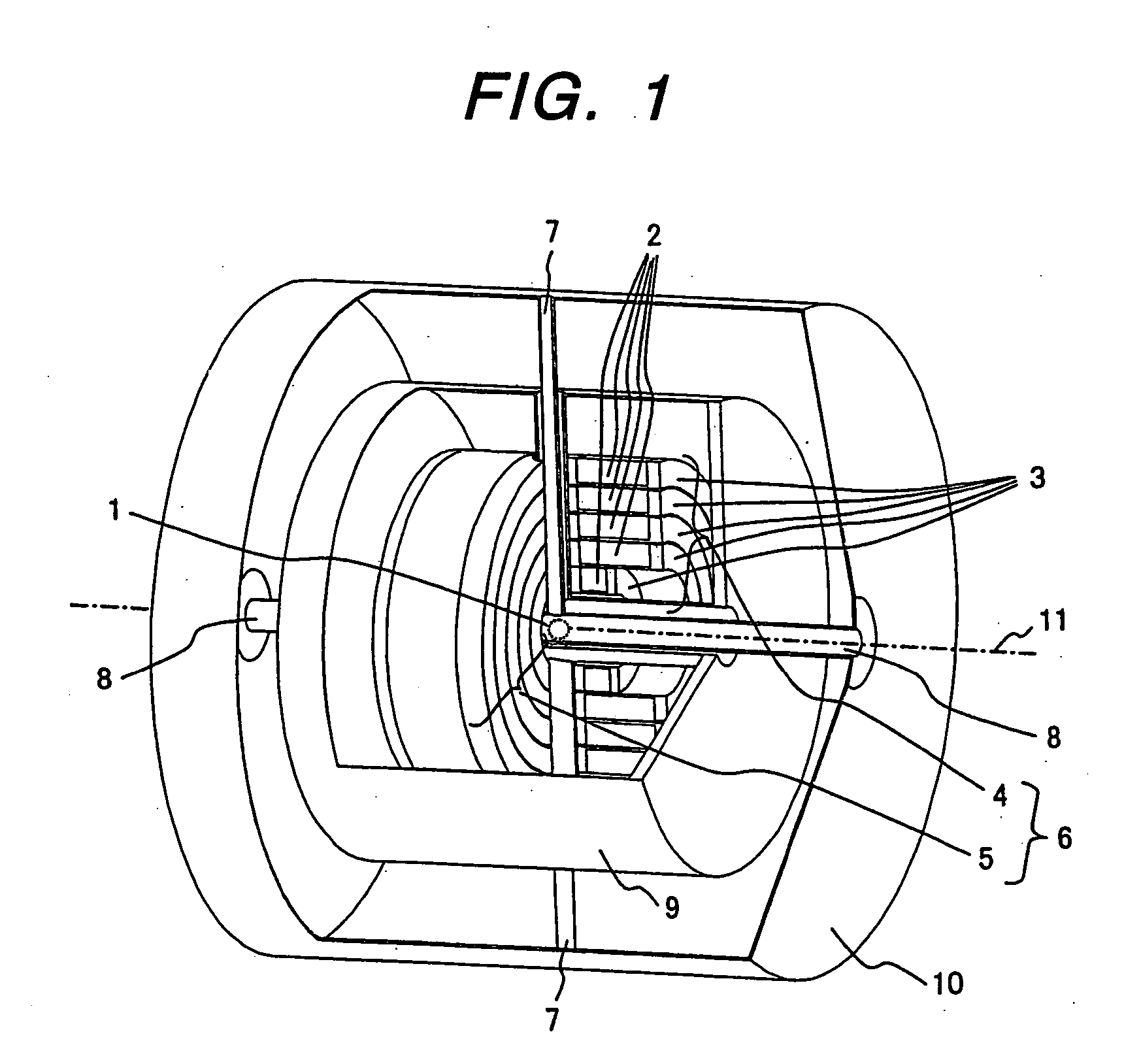

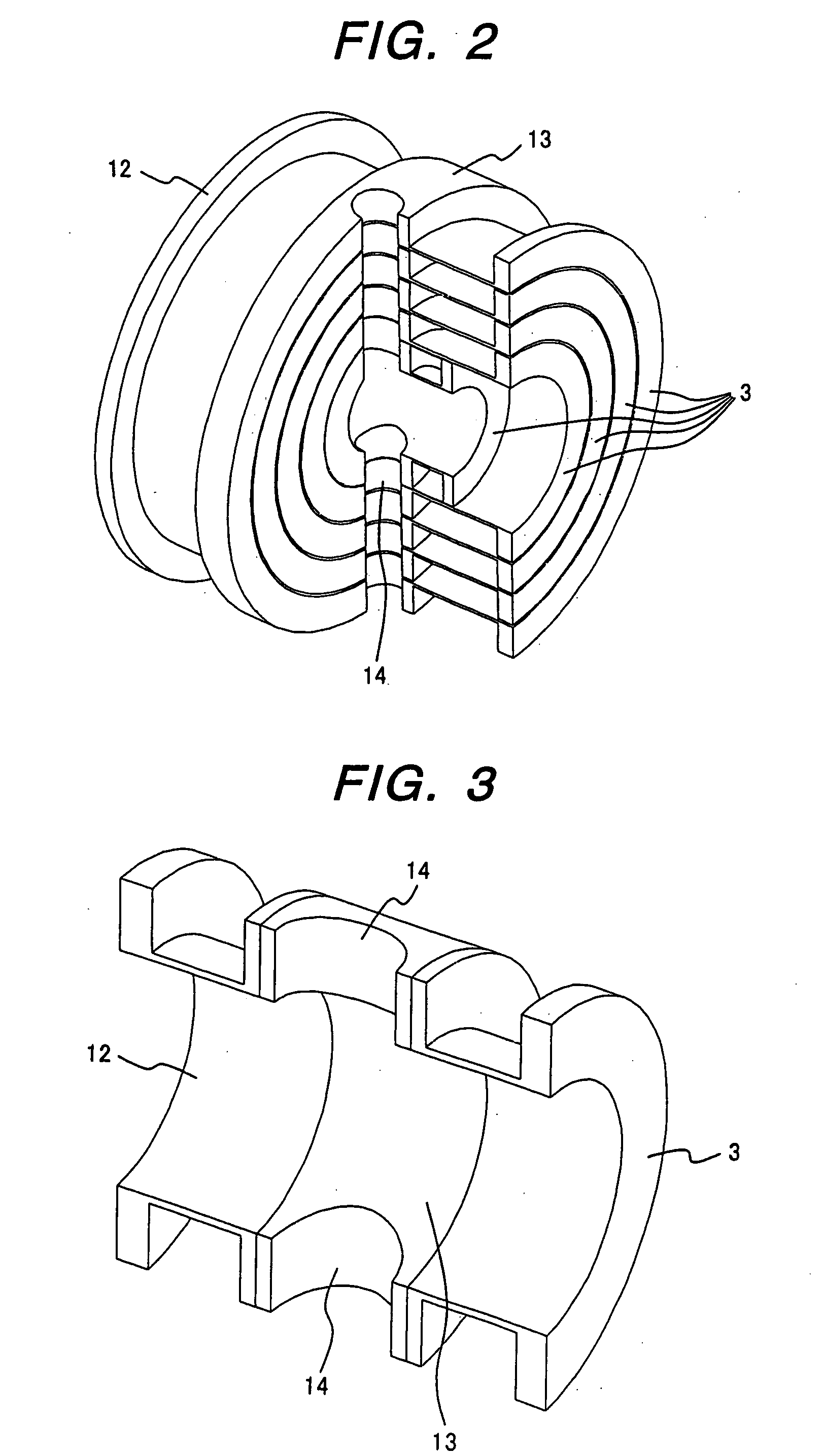

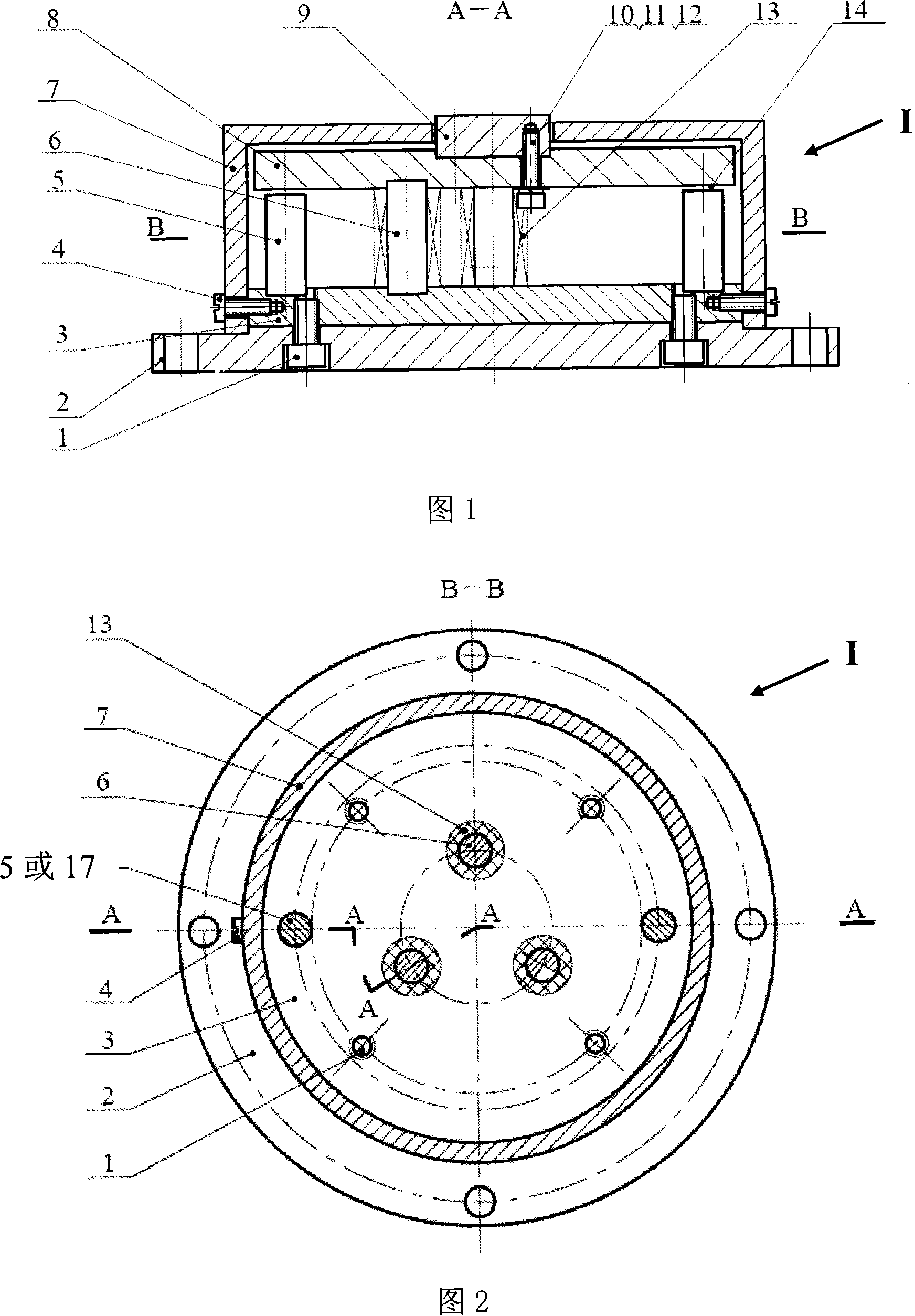

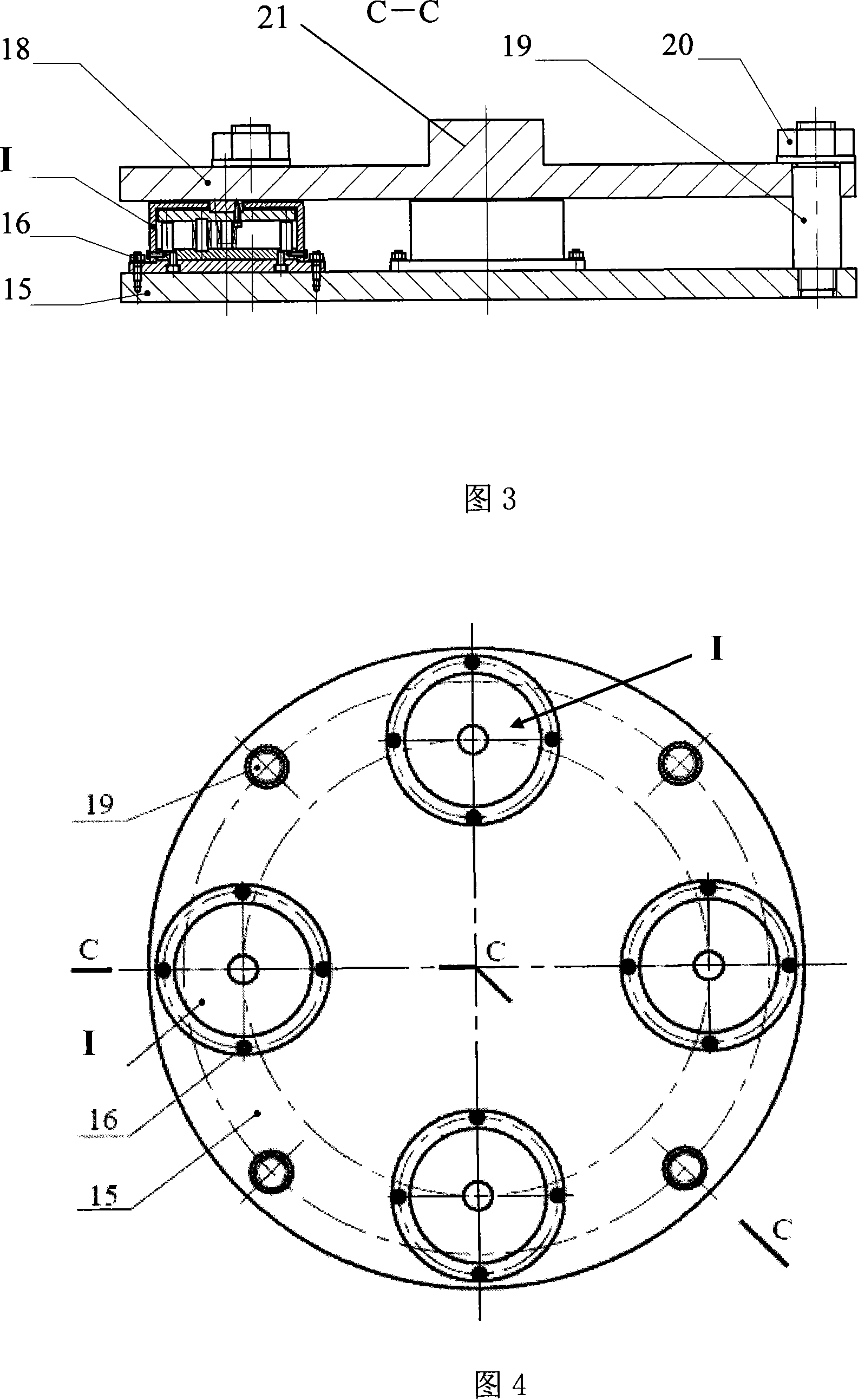

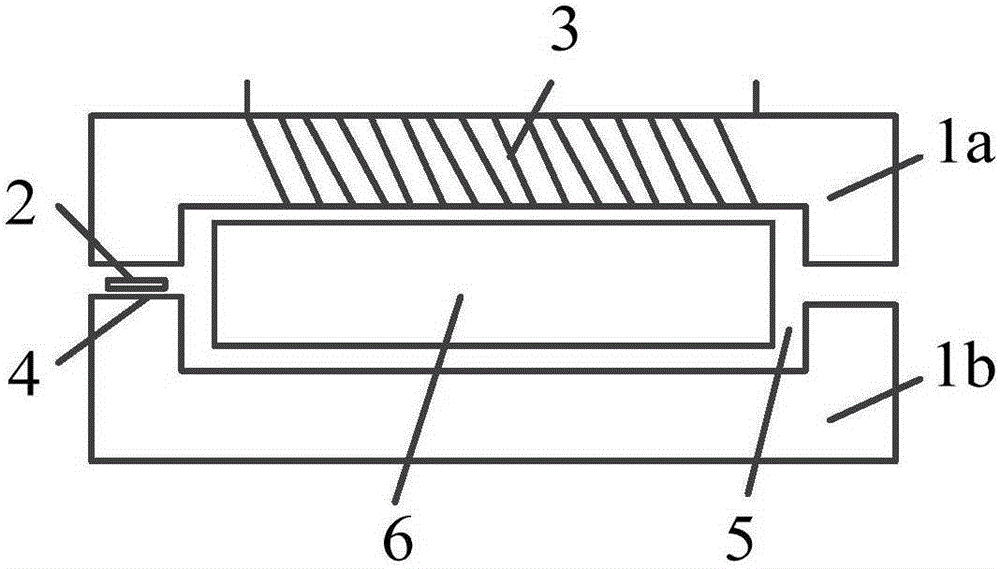

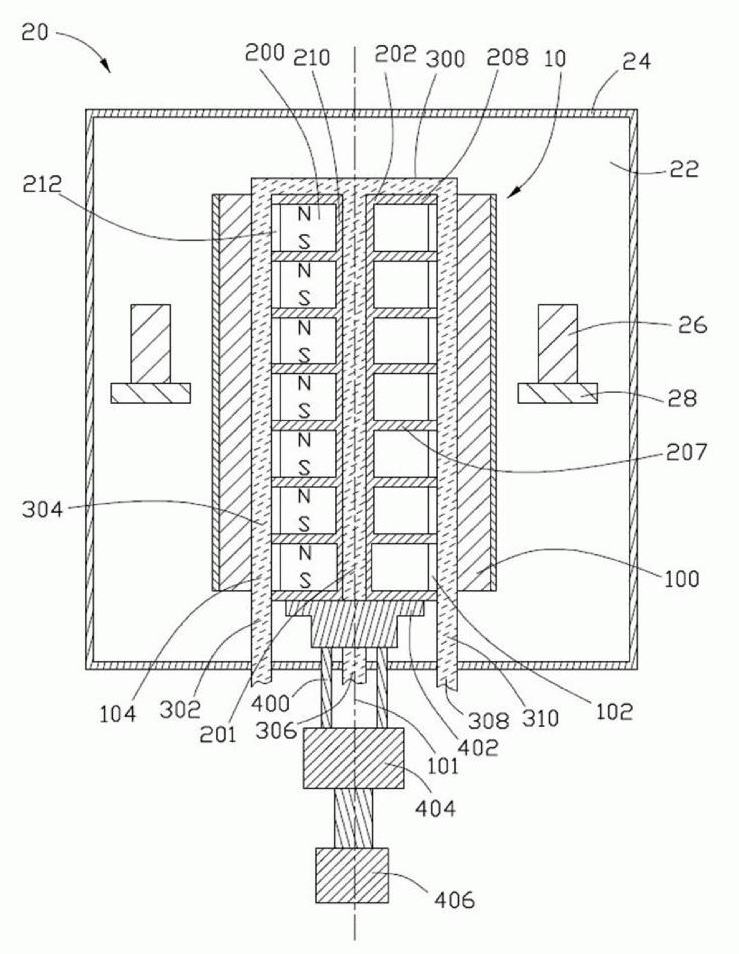

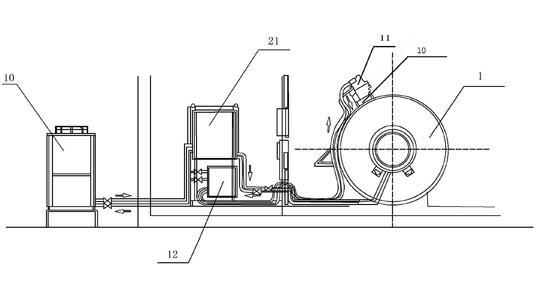

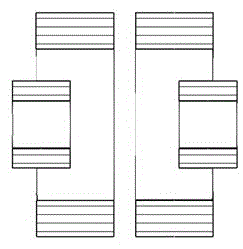

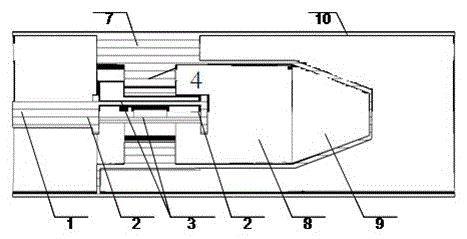

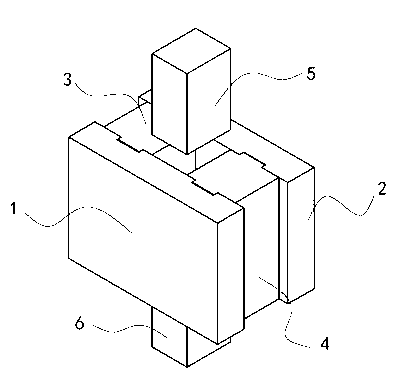

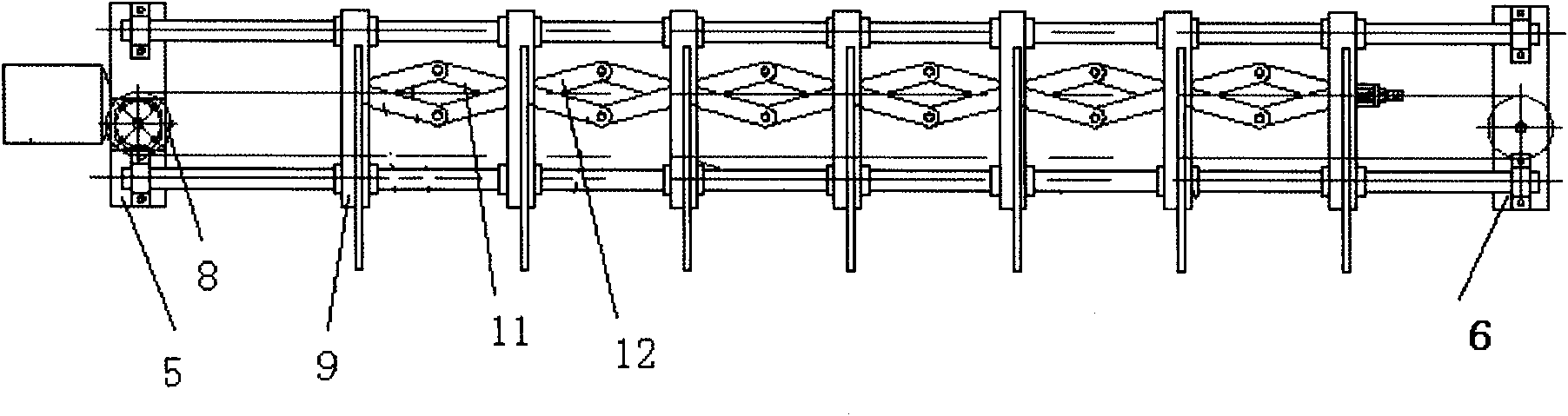

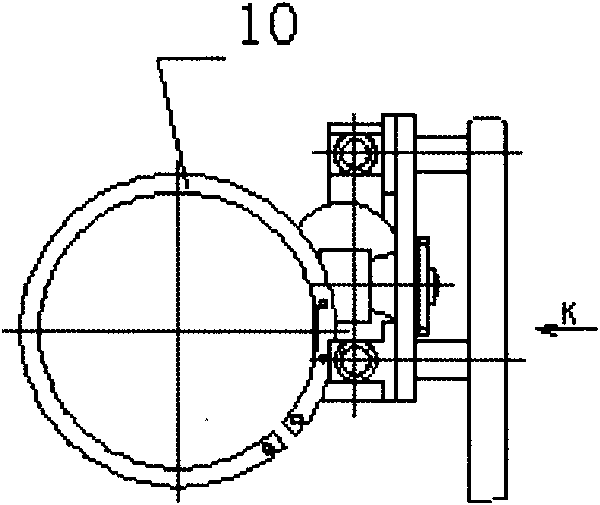

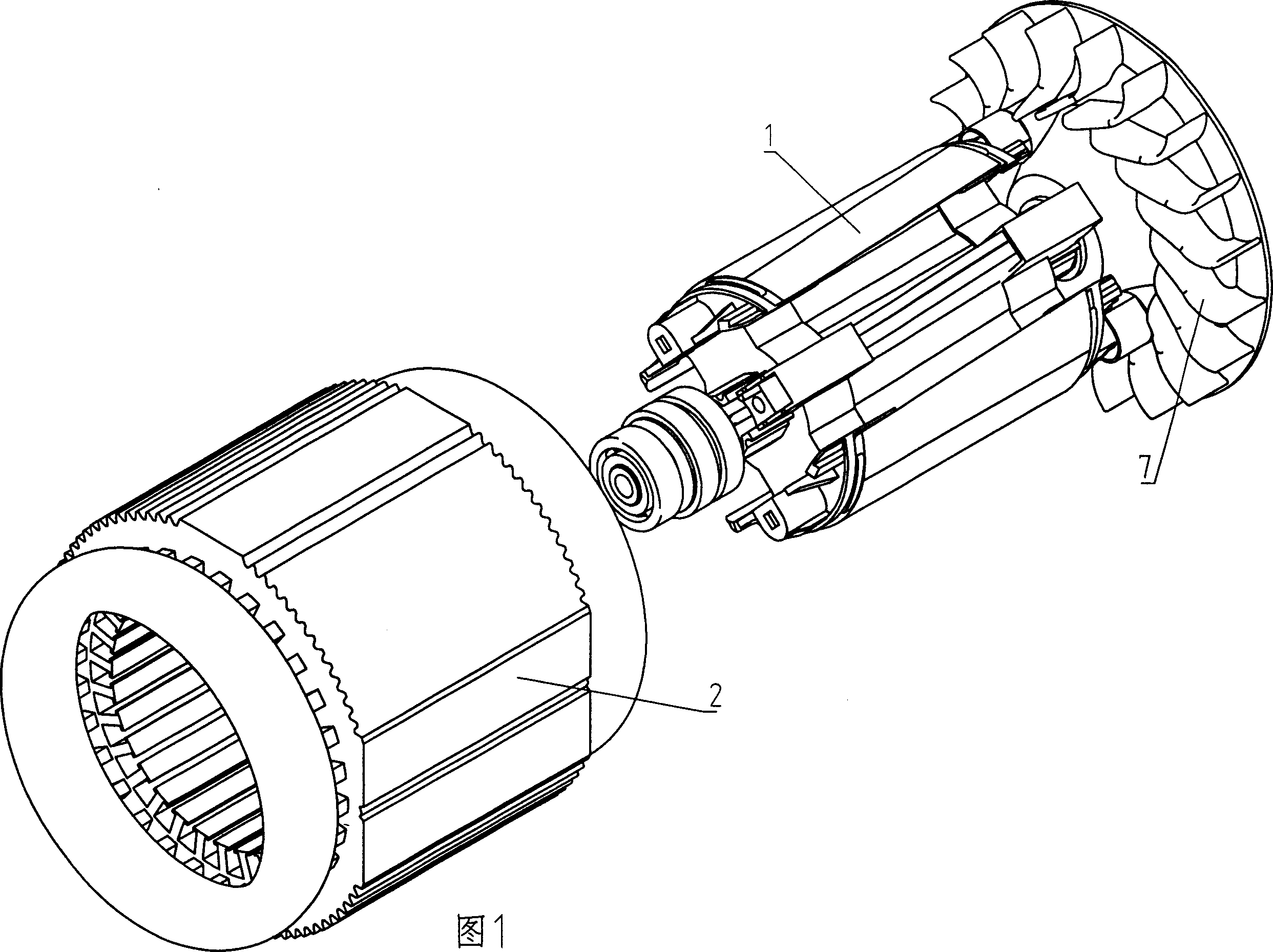

Two magnetic route structure of large-stroke electromagnetic vibration

ActiveCN101069884AUniform magnetic fieldReduce Flux LeakageMechanical vibrations separationCoaxial lineNuclear magnetic resonance

The present invention relates to a double magnetic path structure of large-stroke electromagnetic vibration table. Said double magnetic path structure includes coaxially successively-connected first magnetic body, first central magnetic ring, central magnetic pole, second central magnetic ring and second magnetic body. Said first magnetic body and second magnetic body are respectively fixed in the outer shell interior, a cylindrical coil and an outer magnetic pole are coaxially cover-mounted on the exterior of central magnetic pole, and two ends of said outer magnetic pole are fastened with outer shell end port. Said invention also provides the working principle said double magnetic path structure and its concrete operation method.

Owner:ZHEJIANG UNIV

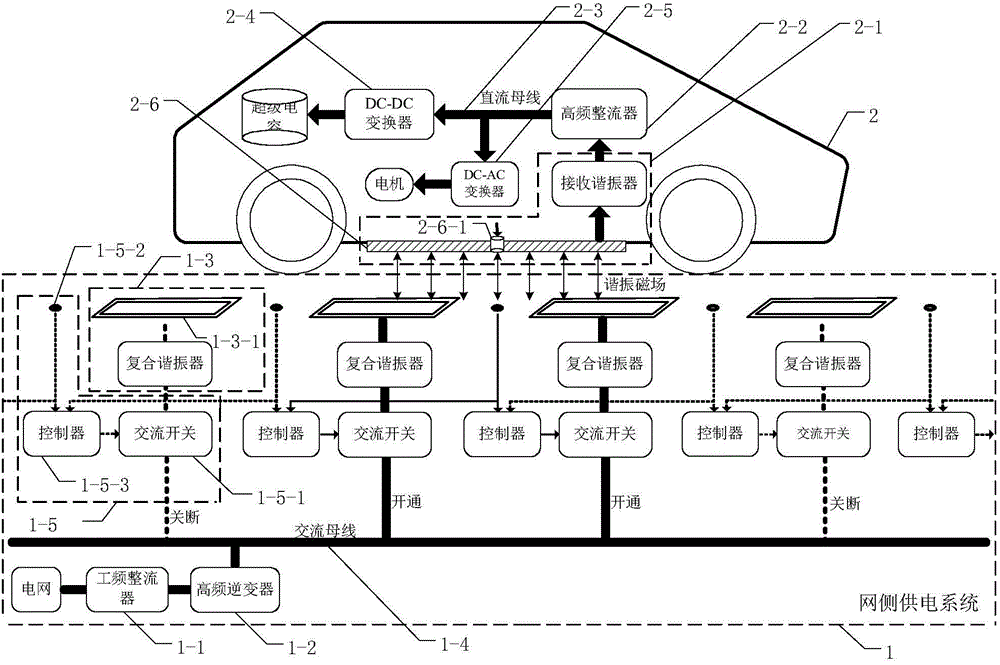

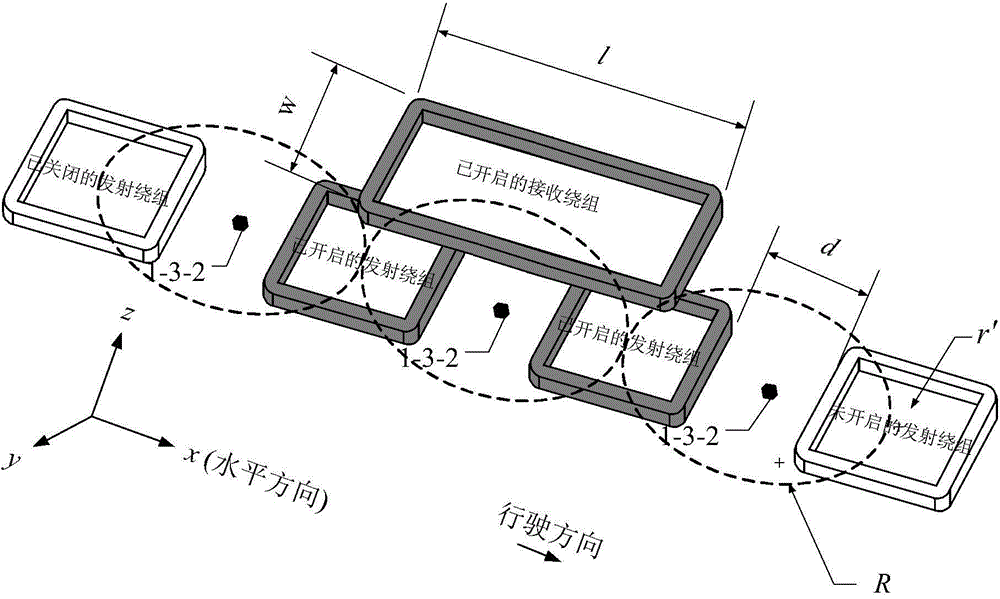

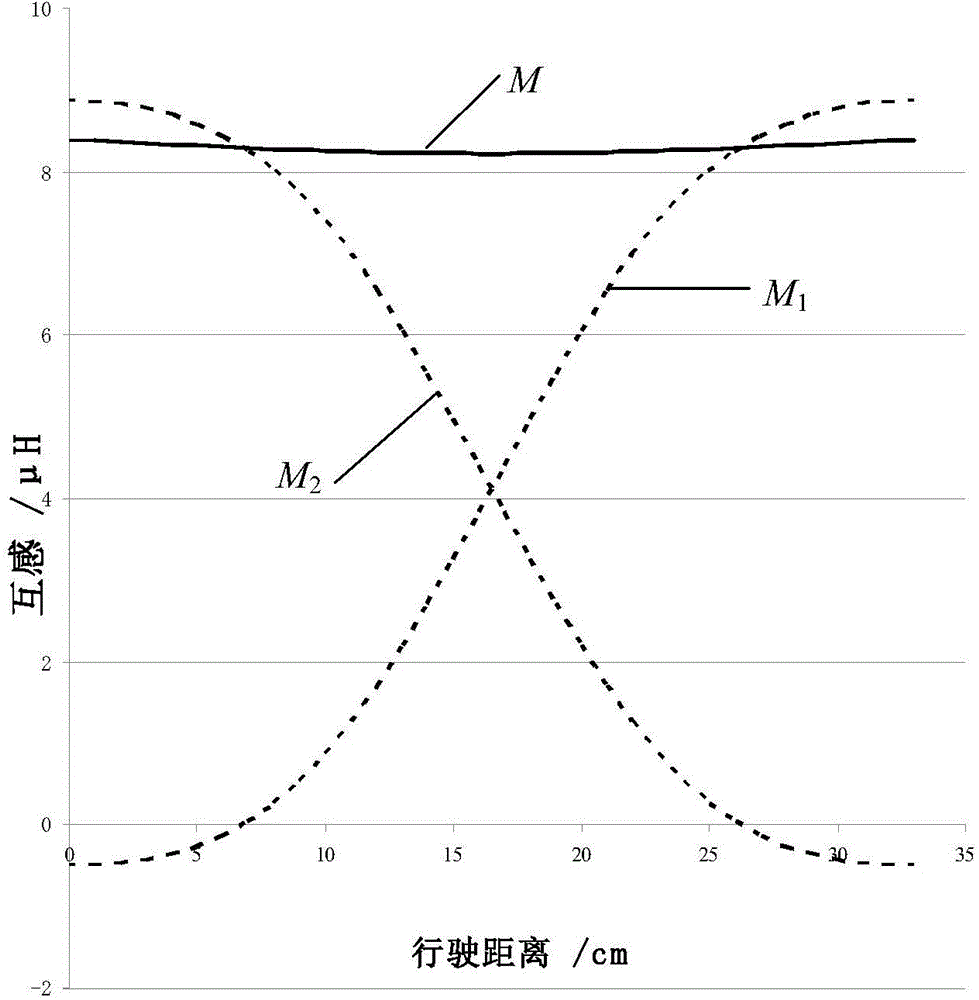

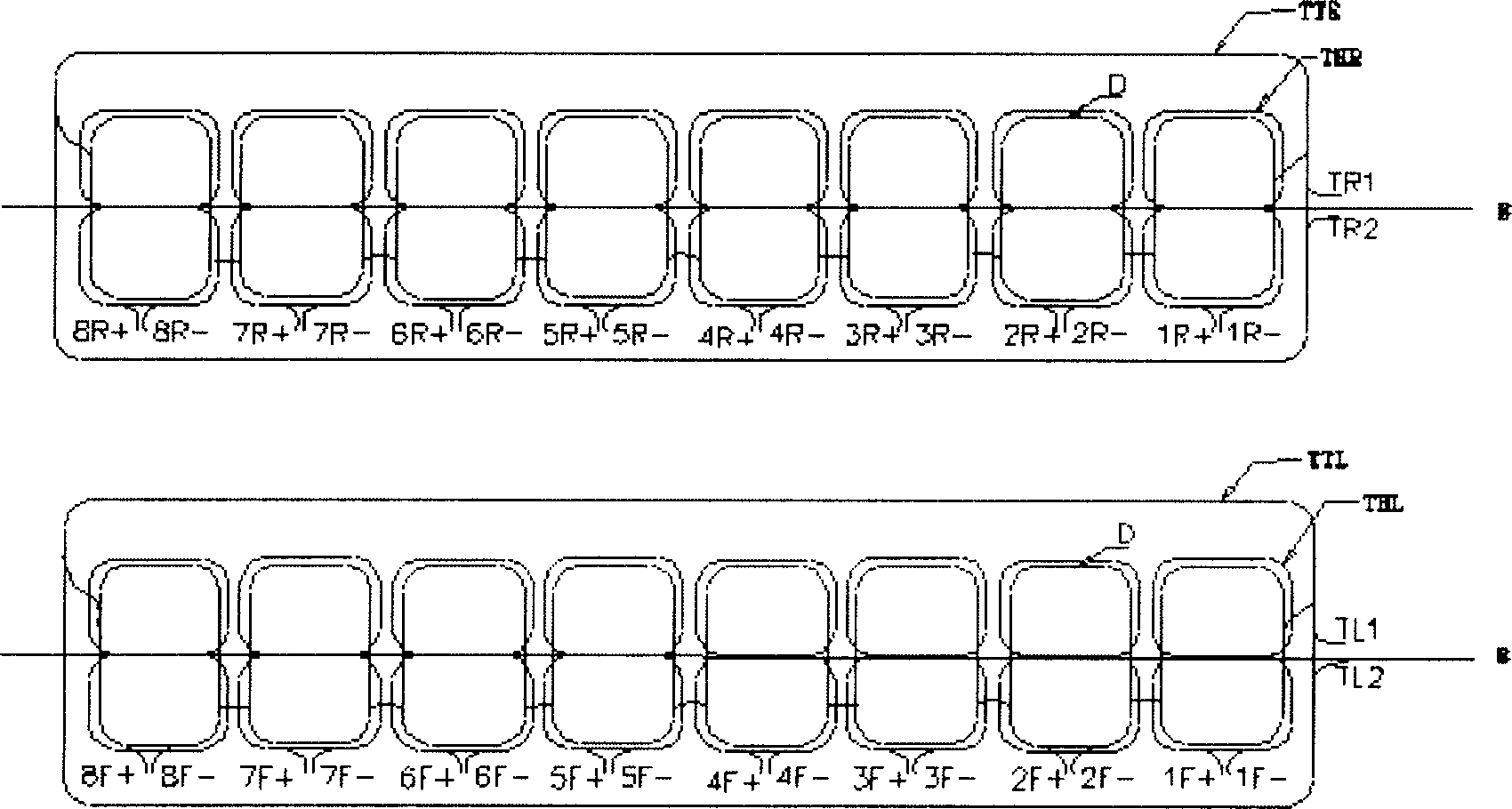

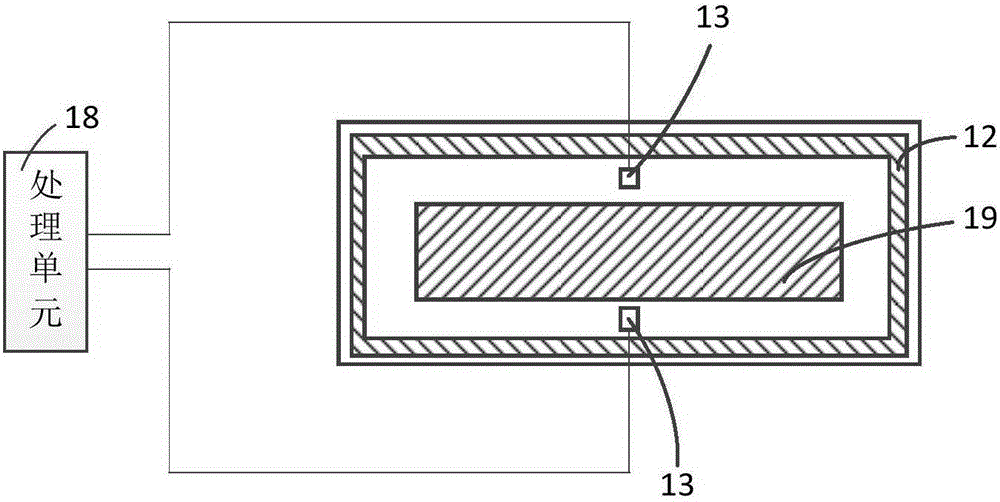

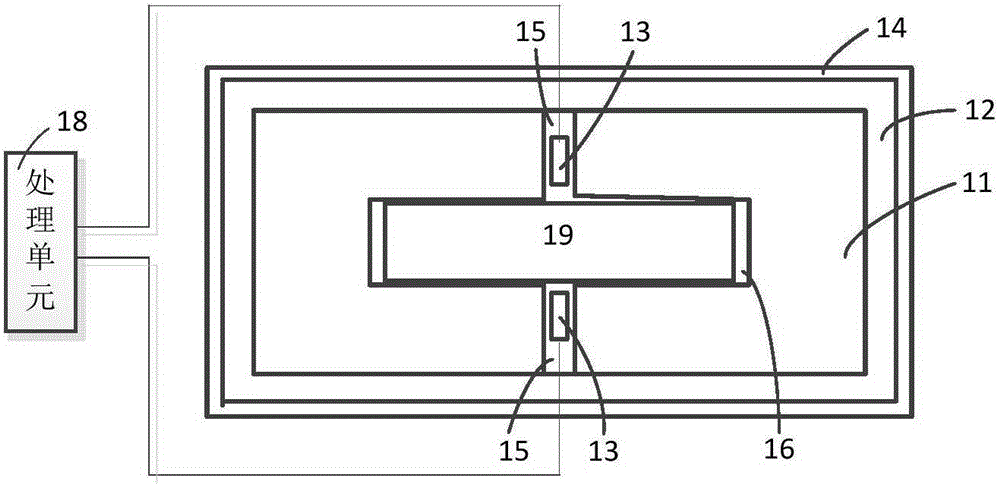

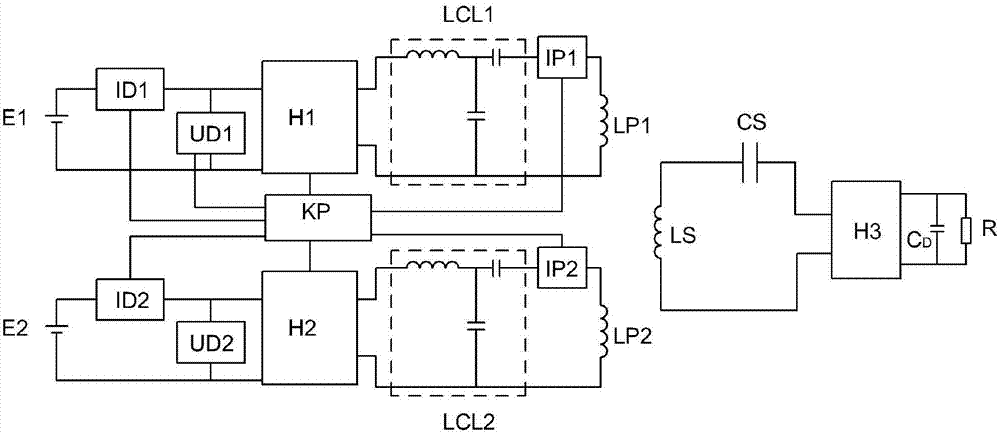

Dynamic wireless power supply system used for electric vehicle and based on parallel multistage composite resonant structures and power supply method realized by adopting system

ActiveCN104682580AReduce construction costsRealize wireless power supplyBatteries circuit arrangementsElectromagnetic wave systemElectric power transmissionEngineering

The invention discloses a dynamic wireless power supply system used for an electric vehicle and based on parallel multistage composite resonant structures and a power supply method realized by adopting the system, belongs to the field of wireless power transmission, and solves problems of mutual inductance non-uniform of long-distance power supply coupling mechanisms and electromagnetic radiation generated for pedestrians in an existing road-type dynamic wireless power supply technology for electric vehicles. The dynamic wireless power supply system comprises a network-side power supply system and an electric vehicle-side power receiving system, wherein the network-side power supply system is used for wirelessly supplying power to the electric vehicle-side power receiving system; electric energy output by an electric network is transmitted to a high-frequency inverter through a power-frequency rectifier, and n stages of composite resonant circuits are connected in parallel with an alternating-current bus of output of the high-frequency inverter; an alternating-current switch is arranged on a branch of each stage of composite resonant circuit, a magnetic sensor is arranged in the center of two adjacent emitting windings or the geometric center of each emitting winding, a receiving winding is arranged on a receiving resonant circuit, and a magnetic nail is arranged on the receiving winding and mounted in the geometric center of the receiving winding. The dynamic wireless power supply system is mainly used for performing wireless power transmission on the electric vehicle.

Owner:HARBIN INST OF TECH

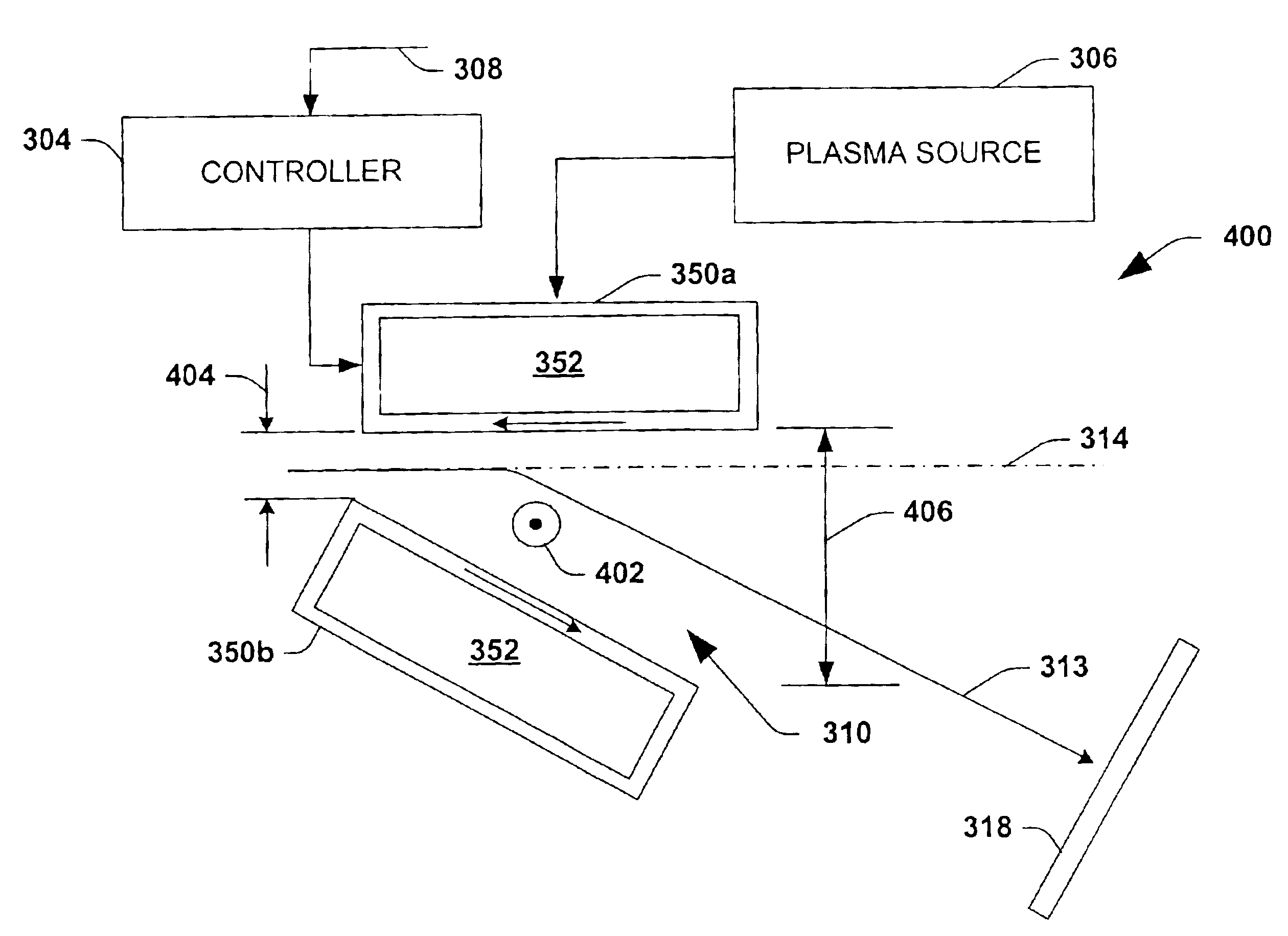

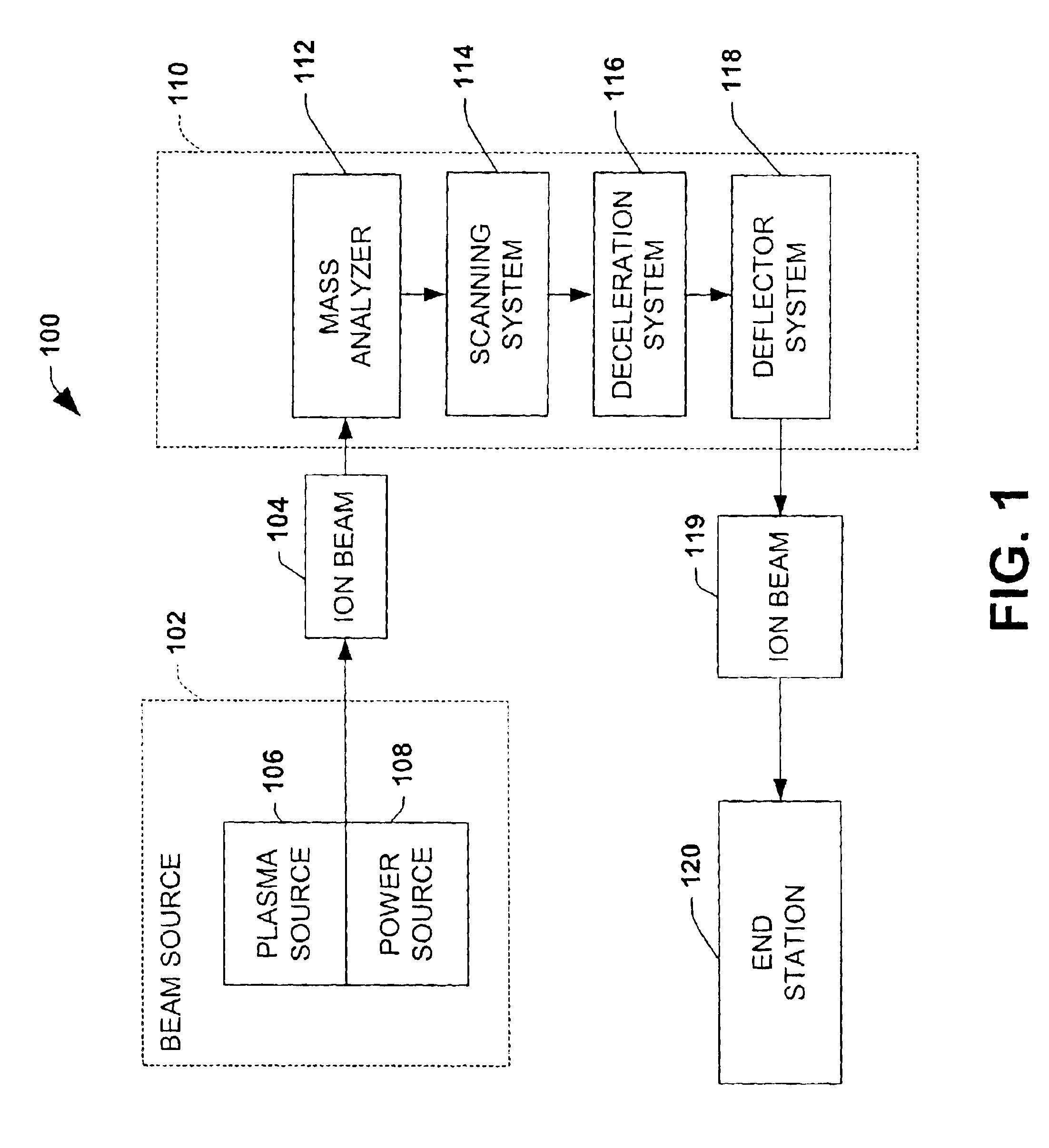

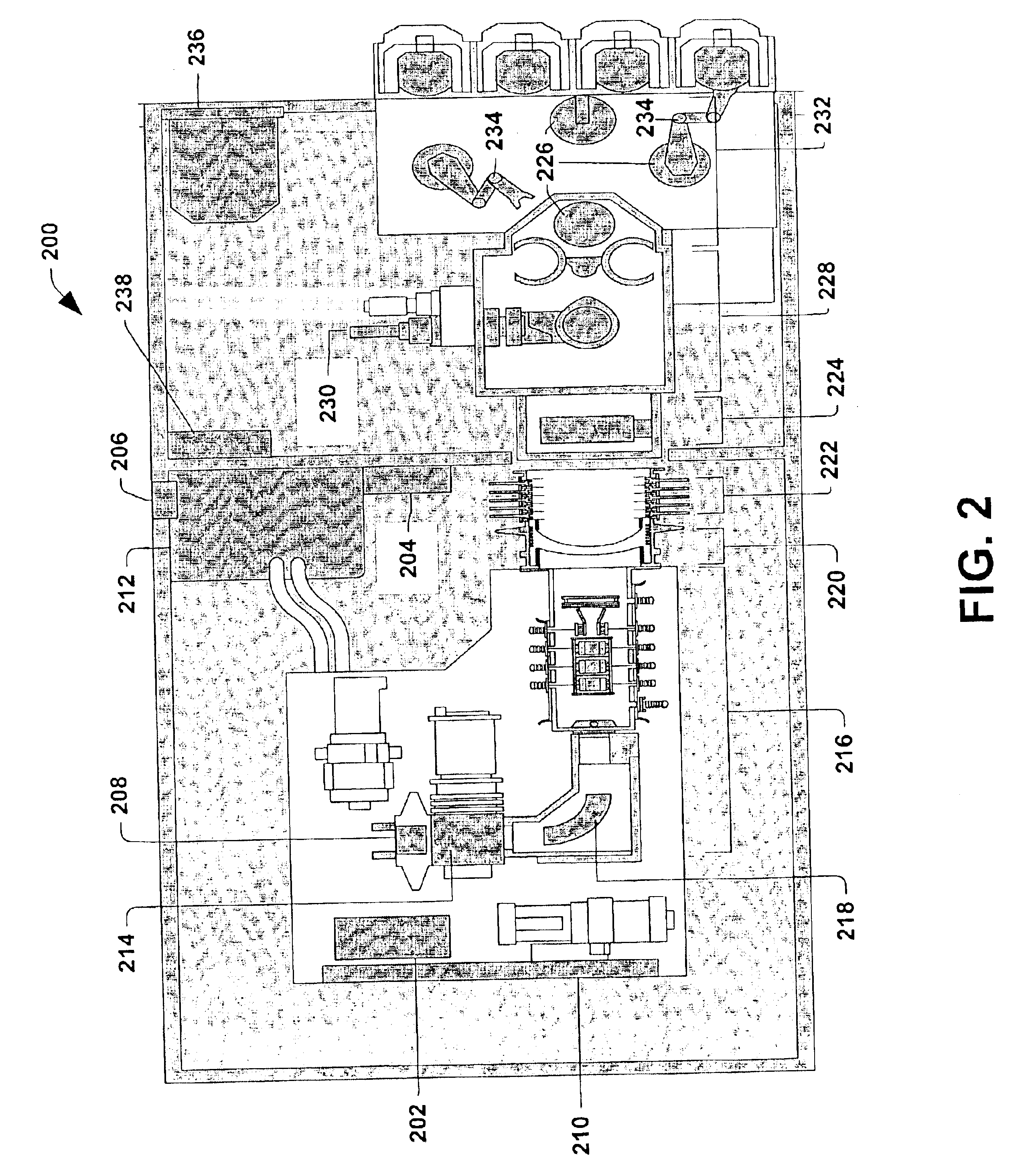

Hybrid magnetic/electrostatic deflector for ion implantation systems

ActiveUS6881966B2Uniform magnetic fieldEasy to neutralizeThermometer detailsStability-of-path spectrometersIon beamLight beam

A magnetic deflector for an ion beam is disclosed and comprises first and second coils. The coils are positioned above and below the beam, respectively, and extend along a width of the beam. Current passes through the coils to generate a magnetic field therebetween that is generally perpendicular to a direction of travel of the beam along substantially the entire width thereof. In another aspect of the invention, a method of deflecting a beam prior to implantation into a workpiece is disclosed. The method includes determining one or more properties associated with the beam and selectively activating one of a magnetic deflection module and an electrostatic deflection module based on the determination.

Owner:AXCELIS TECHNOLOGIES

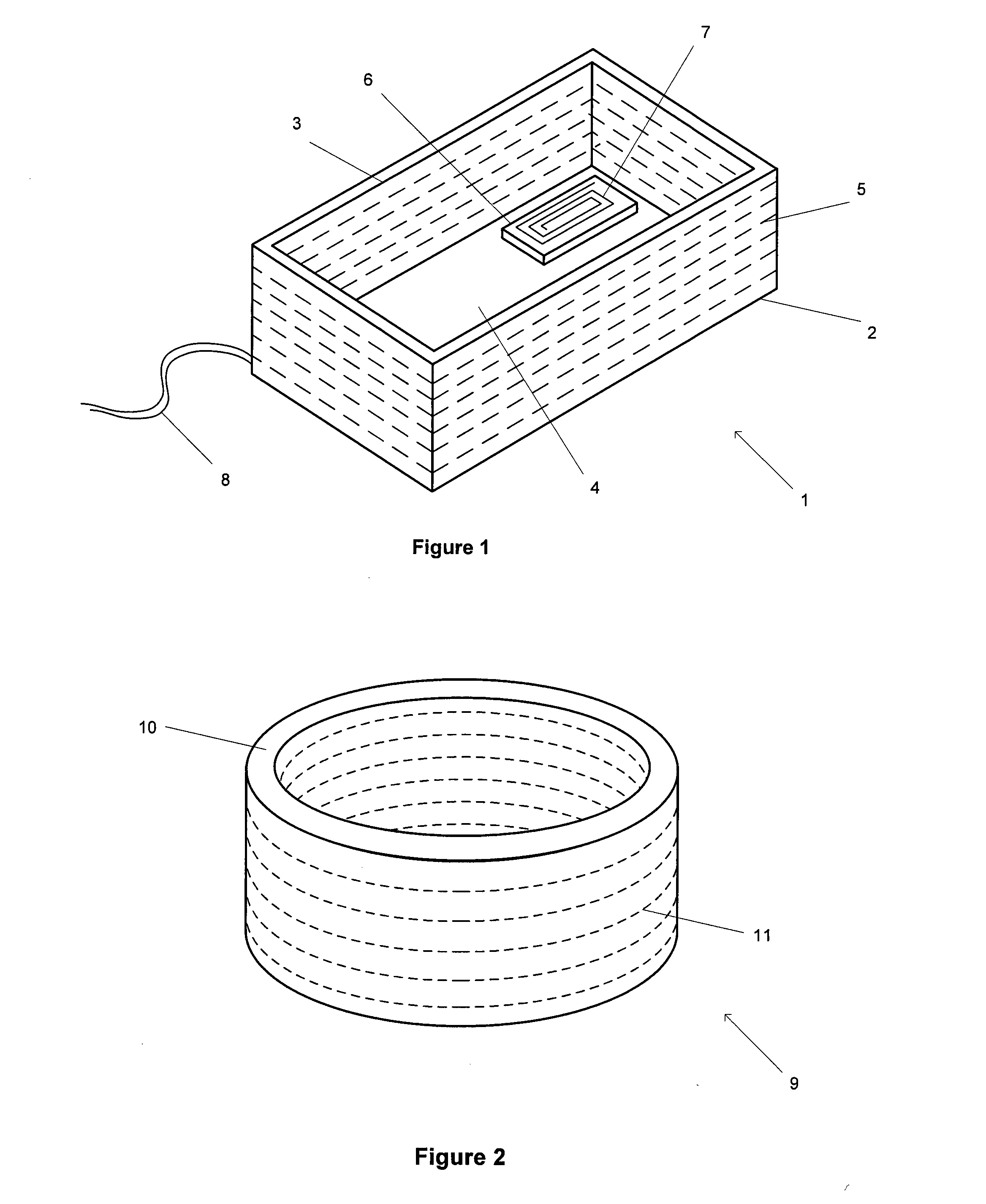

Transmitter for an inductive power transfer

InactiveUS20150295416A1Avoid missing transfersSpeed up the flowBatteries circuit arrangementsTransformersElectric energyEngineering

An inductive power transfer transmitter that includes an enclosure for accommodating devices to be energised. The enclosure has one or more side walls and one or more coils for generating an alternating magnetic field within the enclosure. The density of the one or more coils varies with distance from an end of the one or more sidewalls. There is also disclosed an inductive power transmitter that includes one or more magnetically permeable layers wherein the combined thickness or the permeability of the one or more magnetically permeable layers varies.

Owner:APPLE INC

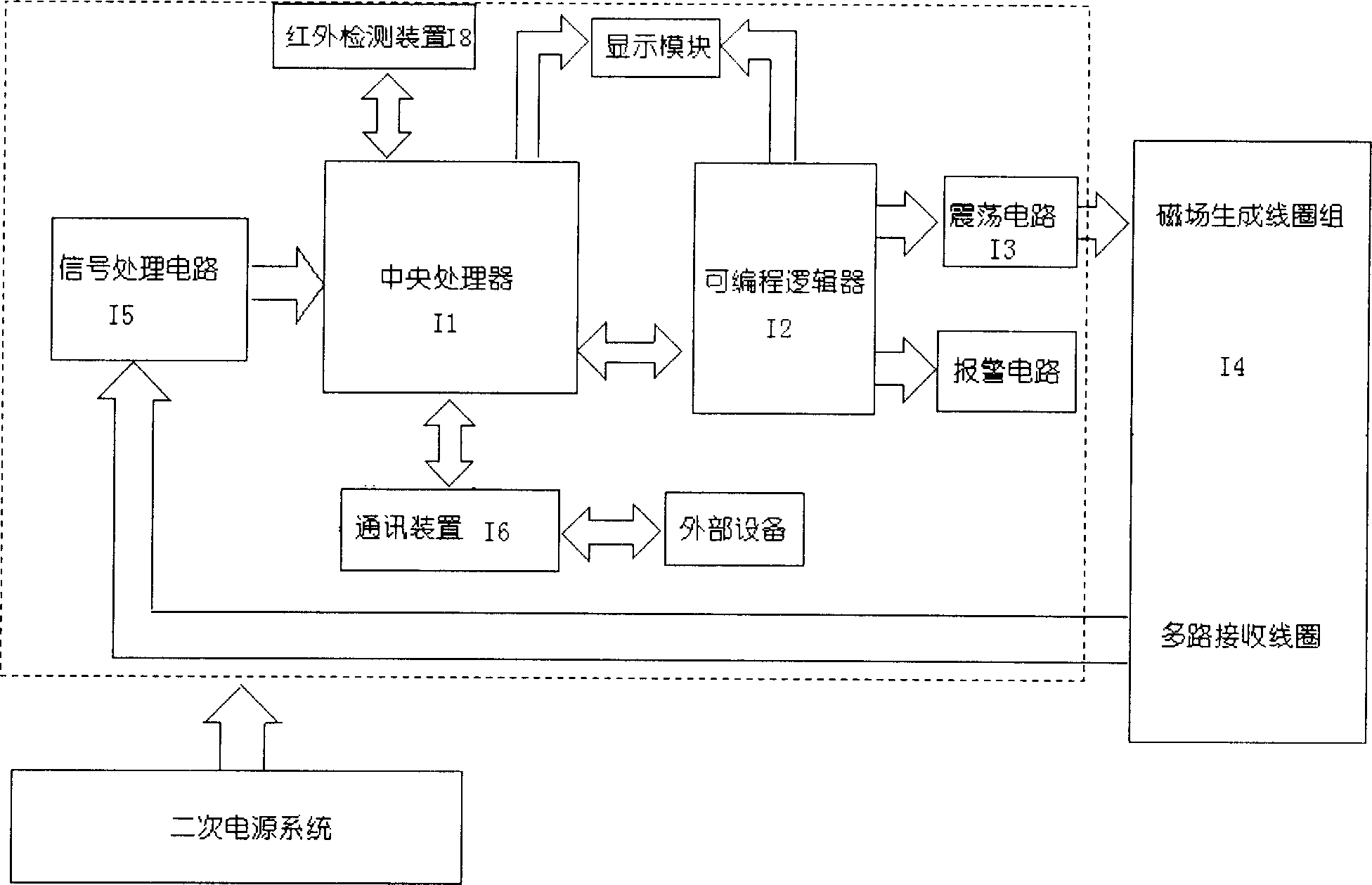

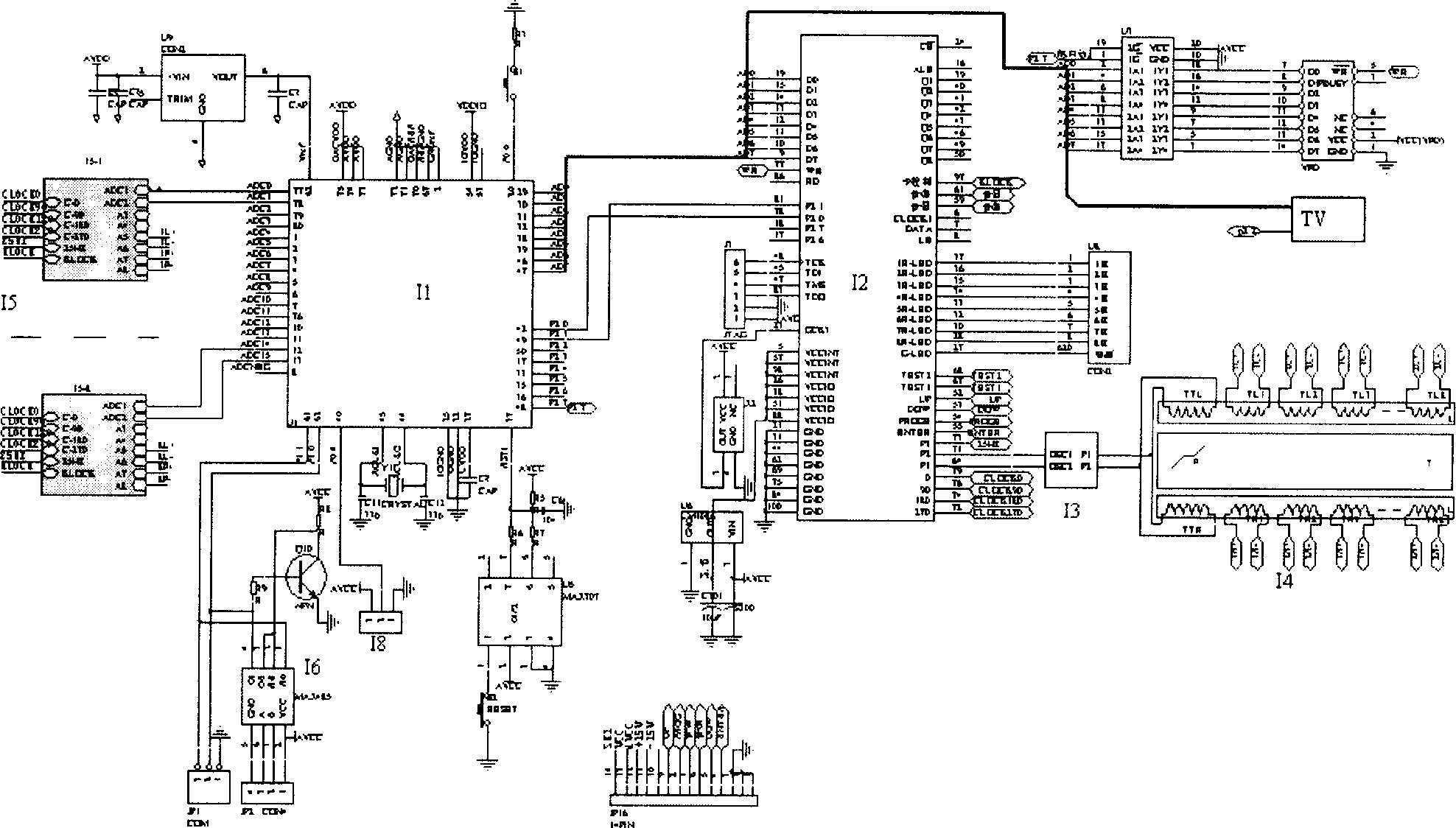

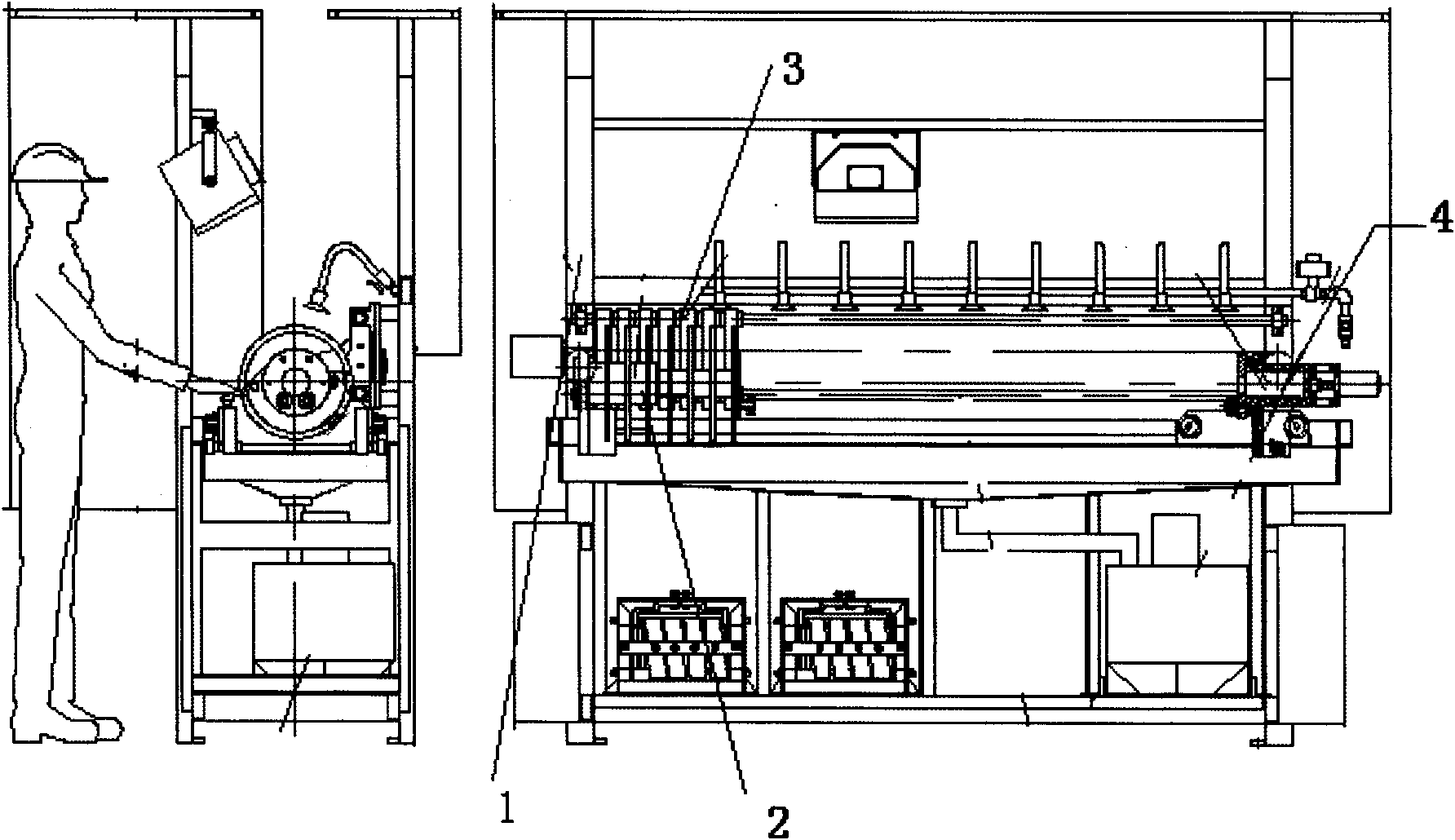

Through type metal detecting system

InactiveCN1834690AAccurate identificationUniform magnetic fieldElectric/magnetic detectionAcoustic wave reradiationSignal processing circuitsElectromagnetic interference

The invention relates to a passing through type metal probe system that includes signal process circuit, CPU, oscillating circuit and coil assembly that includes emitting coil and receiving coil. The invention could equally probe magnetic field and has good anti electromagnetic interference ability. It could determine the approximate location of the metal object.

Owner:郭有军

High-field-intensity focusing nuclear magnetic resonance magnetic field and preparation method thereof

InactiveCN101825692AHigh mechanical strengthImprove permeabilityMeasurements using magnetic resonanceDual columnRare earth

The invention relates to a nuclear magnetic resonance magnetic field and a preparation method thereof, which belong to the field of rare earth permanent magnetic materials and nuclear magnetic resonance imaging. The invention particularly relates to a high-field-intensity focusing nuclear magnetic resonance magnetic field and a preparation method thereof. The high-field-intensity focusing nuclear magnetic resonance magnetic field adopts a dual-column C-shaped open structure; a C-shaped machine frame adopts 45# steel with high mechanical strength and magnetic conductivity and a composite polar plate, and is designed with a magnetic gathering ring; and simultaneously the distance between the polar plate and a vertical supporting yoke is increased, and a passive artificial shimming and an active computer-assisted shimming are adopted. The preparation method can prepare a high-field-intensity focusing magnet, has an easily controlled technological process and is suitable for batch production.

Owner:MIANYANG WESTMAG MAGNETISM & ELECTRICITY CO LTD

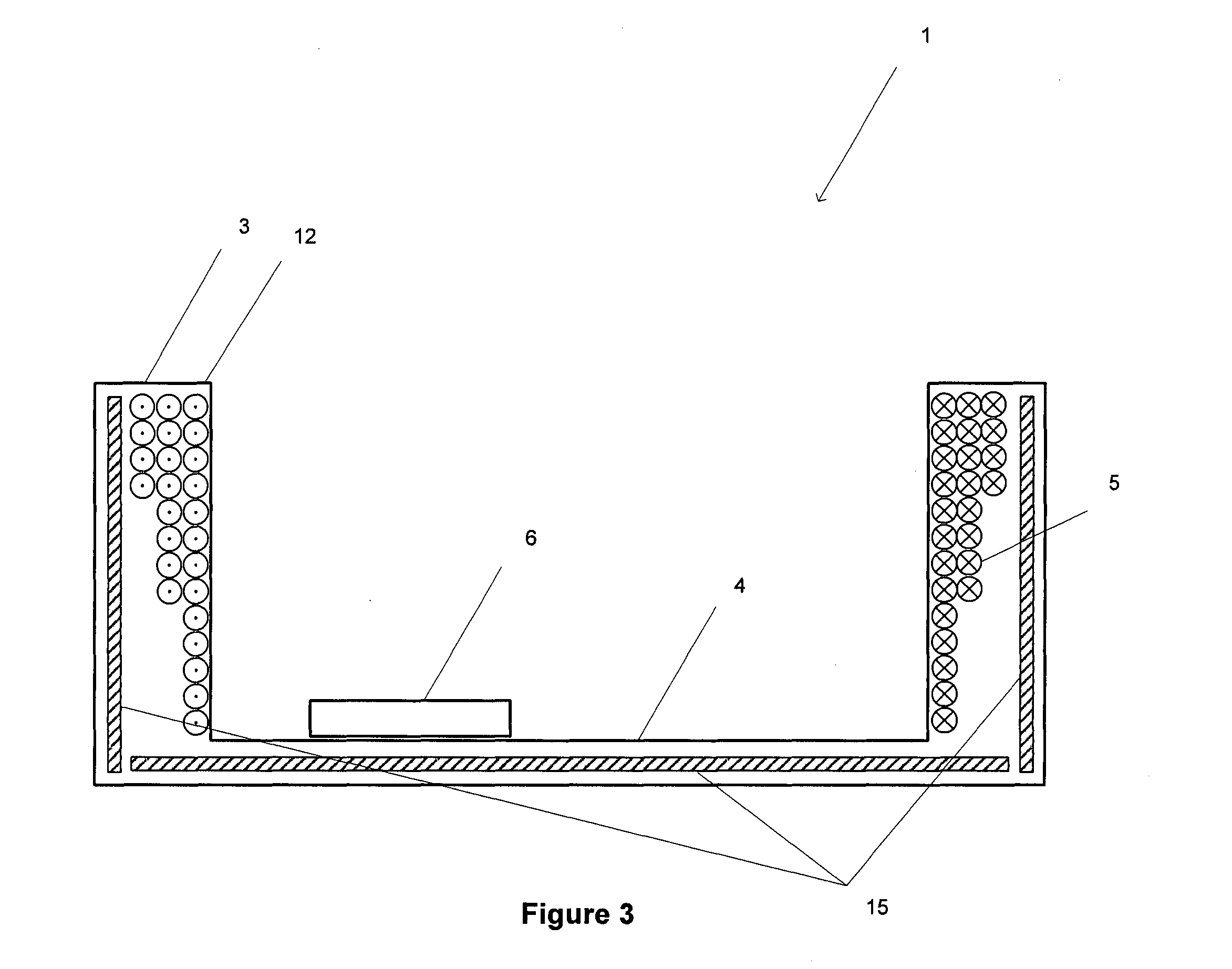

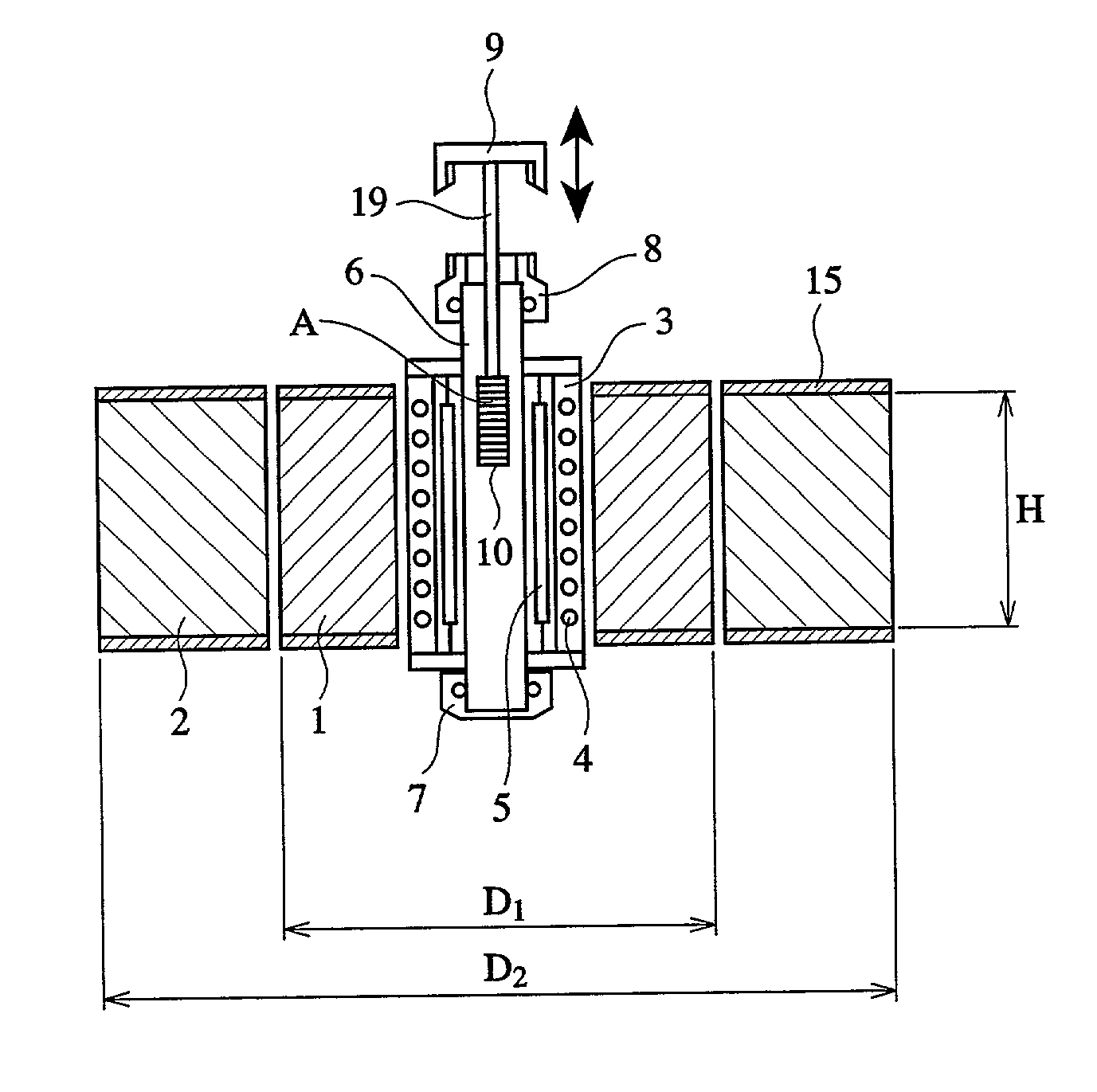

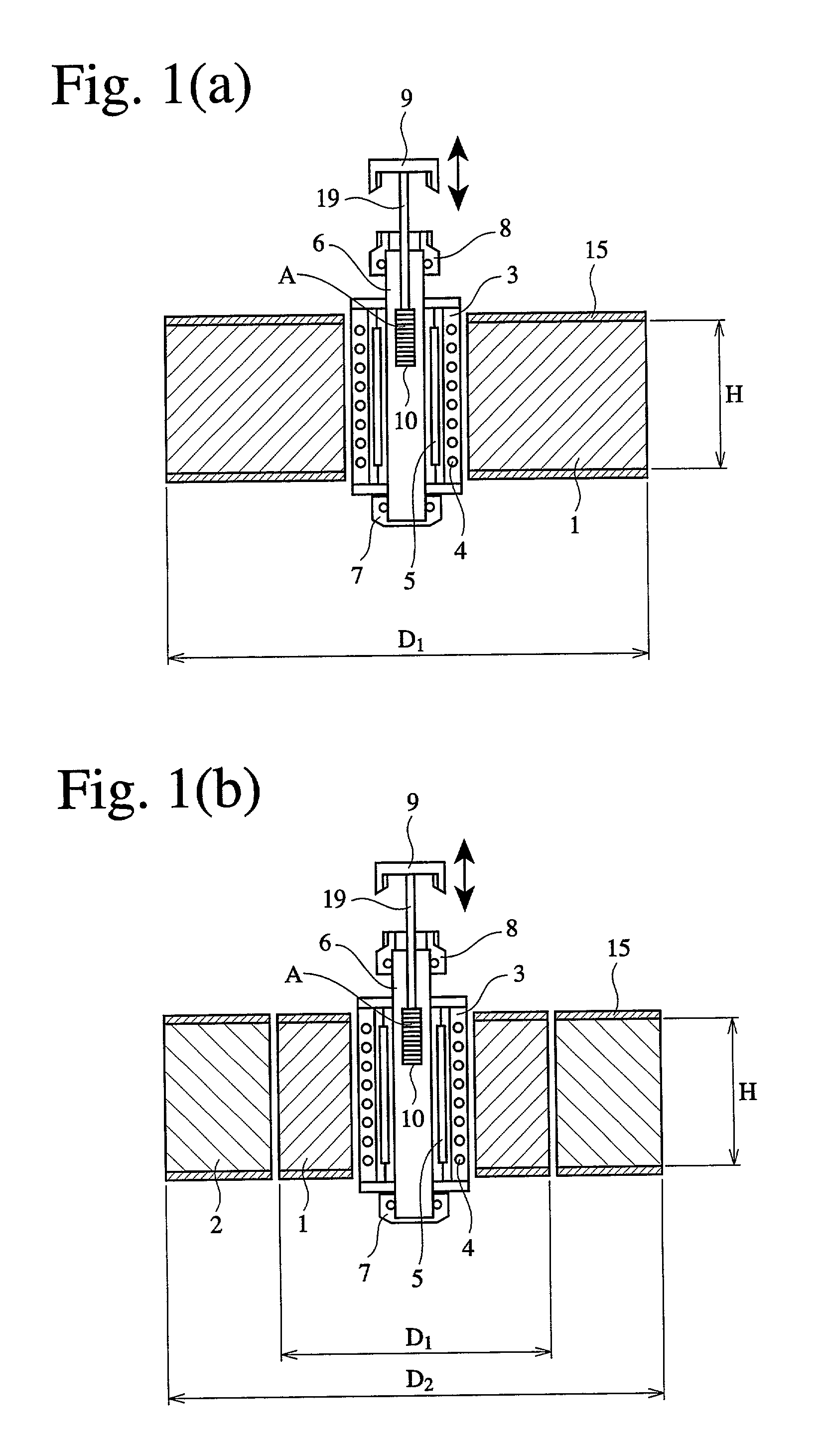

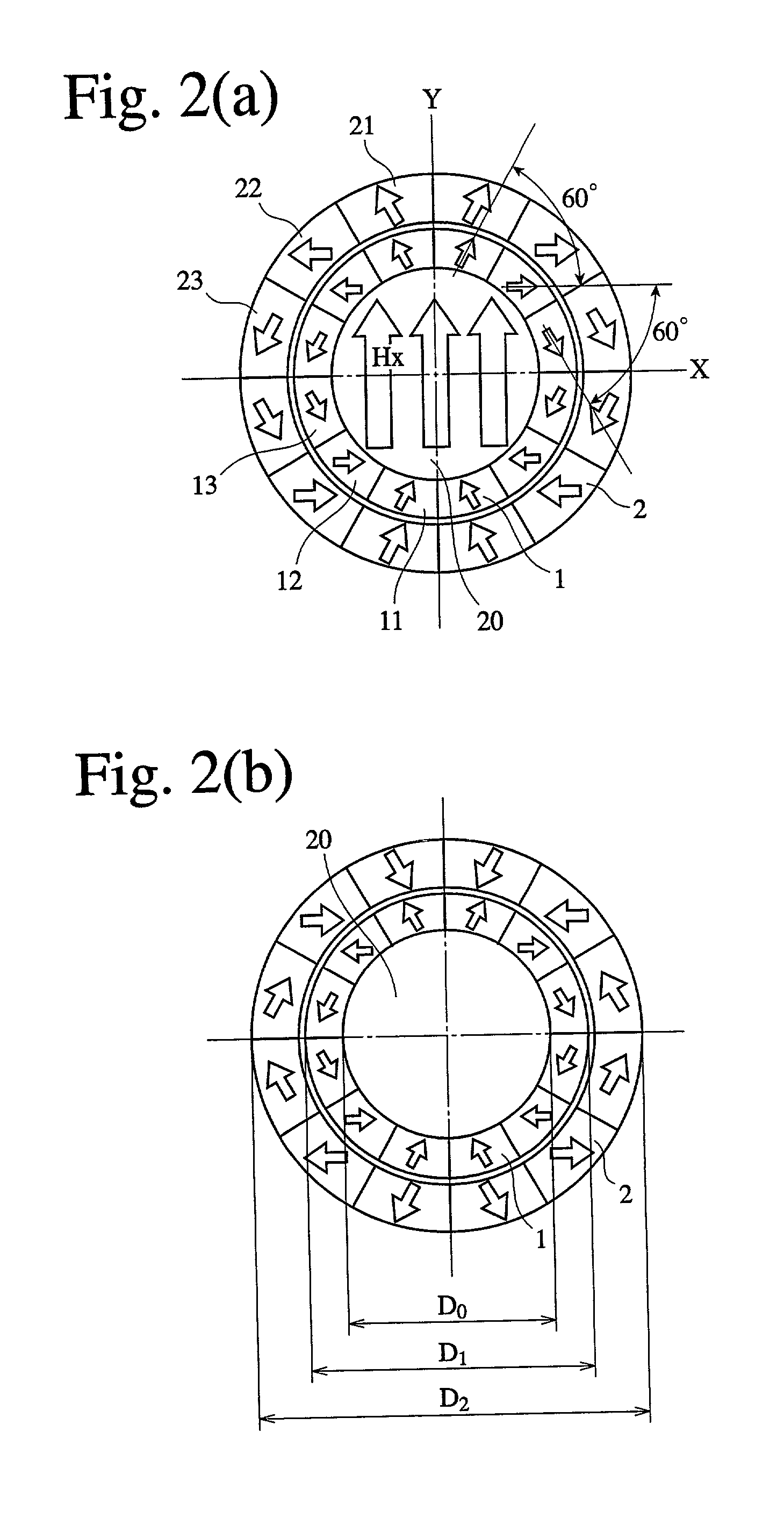

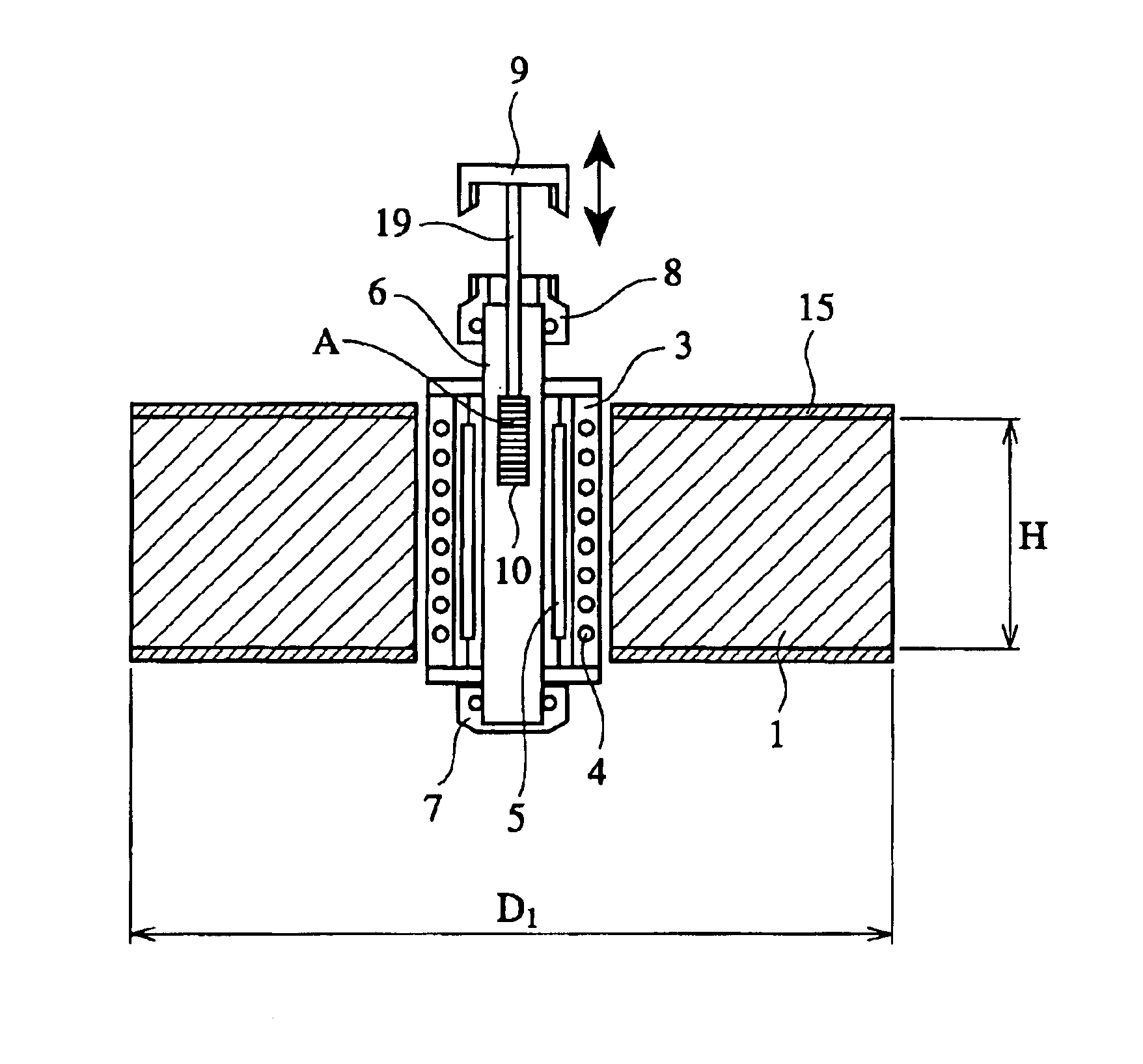

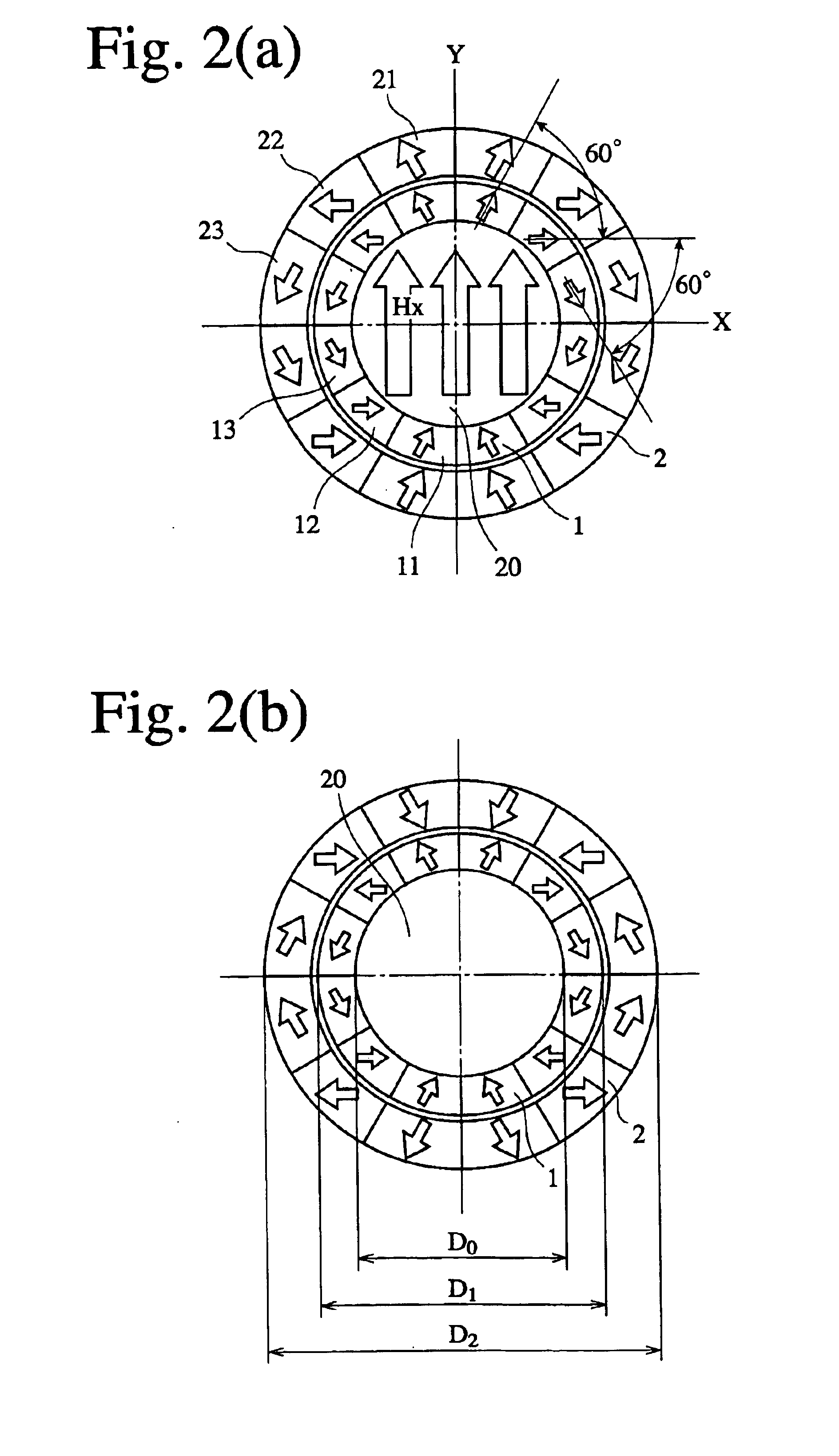

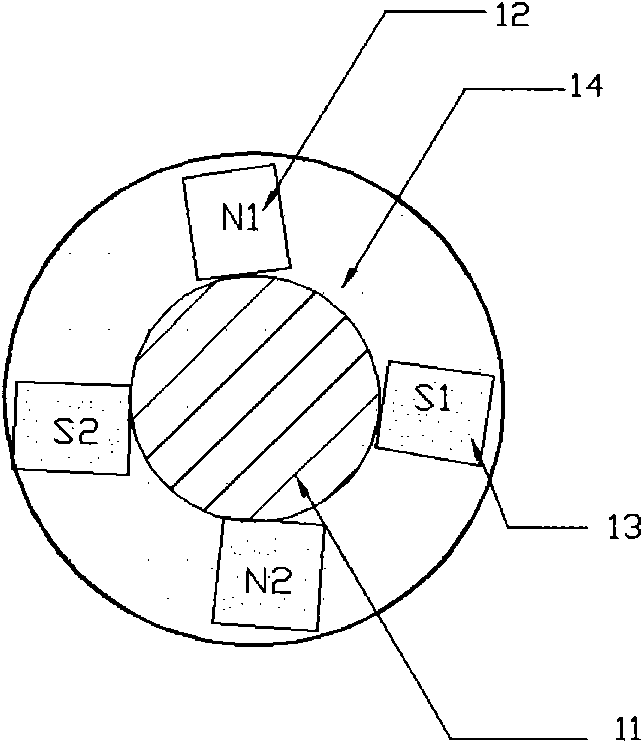

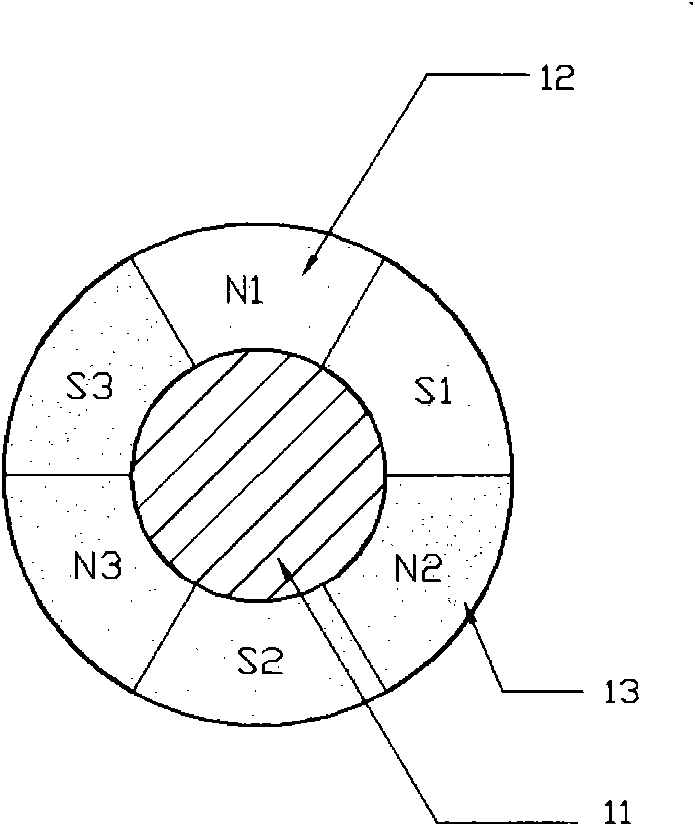

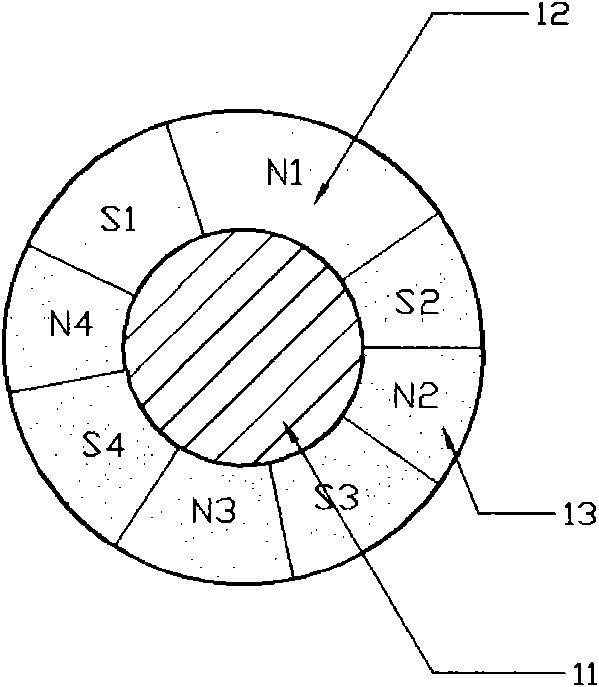

Heat-treating furnace with magnetic field and heat treatment method using same

InactiveUS20020182557A1Reduce magnetic field leakageUniform magnetic fieldFurnaces without endless coreBaking ovenMagnetizationMagnetic flux

A heat-treating furnace with a magnetic field comprising (a) a magnetic field-generating means constituted by an outer, ring-shaped, permanent magnet assembly comprising a plurality of permanent magnet segments combined with their magnetization directions oriented such that a magnetic flux flows in a diameter direction, and an inner, ring-shaped, permanent magnet assembly disposed inside the outer, ring-shaped, permanent magnet assembly and comprising a plurality of permanent magnet segments combined with their magnetization directions oriented such that a magnetic flux flows in a diameter direction; and (b) a heat treatment means disposed in a center hole of the inner, ring-shaped, permanent magnet assembly and comprising a cooling means, a heating means, and a heat-treating container containing heat-treating holder for holding a plurality of articles to be heat-treated in this order from outside, wherein an axial center of a magnetic field generated by the inner and outer ring-shaped, permanent magnet assemblies is substantially identical with an axial center of an article assembly in the heat-treating container.

Owner:HITACHI METALS LTD

Heat-treating furnace with magnetic field and heat treatment method using same

InactiveUS6833107B2Reduce magnetic field leakageUniform magnetic fieldFurnaces without endless coreBaking ovenMagnetizationMagnetic flux

A heat-treating furnace with a magnetic field comprising (a) a magnetic field-generating means constituted by an outer, ring-shaped, permanent magnet assembly comprising a plurality of permanent magnet segments combined with their magnetization directions oriented such that a magnetic flux flows in a diameter direction, and an inner, ring-shaped, permanent magnet assembly disposed inside the outer, ring-shaped, permanent magnet assembly and comprising a plurality of permanent magnet segments combined with their magnetization directions oriented such that a magnetic flux flows in a diameter direction; and (b) a heat treatment means disposed in a center hole of the inner, ring-shaped, permanent magnet assembly and comprising a cooling means, a heating means, and a heat-treating container containing heat-treating holder for holding a plurality of articles to be heat-treated in this order from outside, wherein an axial center of a magnetic field generated by the inner and outer ring-shaped, permanent magnet assemblies is substantially identical with an axial center of an article assembly in the heat-treating container.

Owner:HITACHI METALS LTD

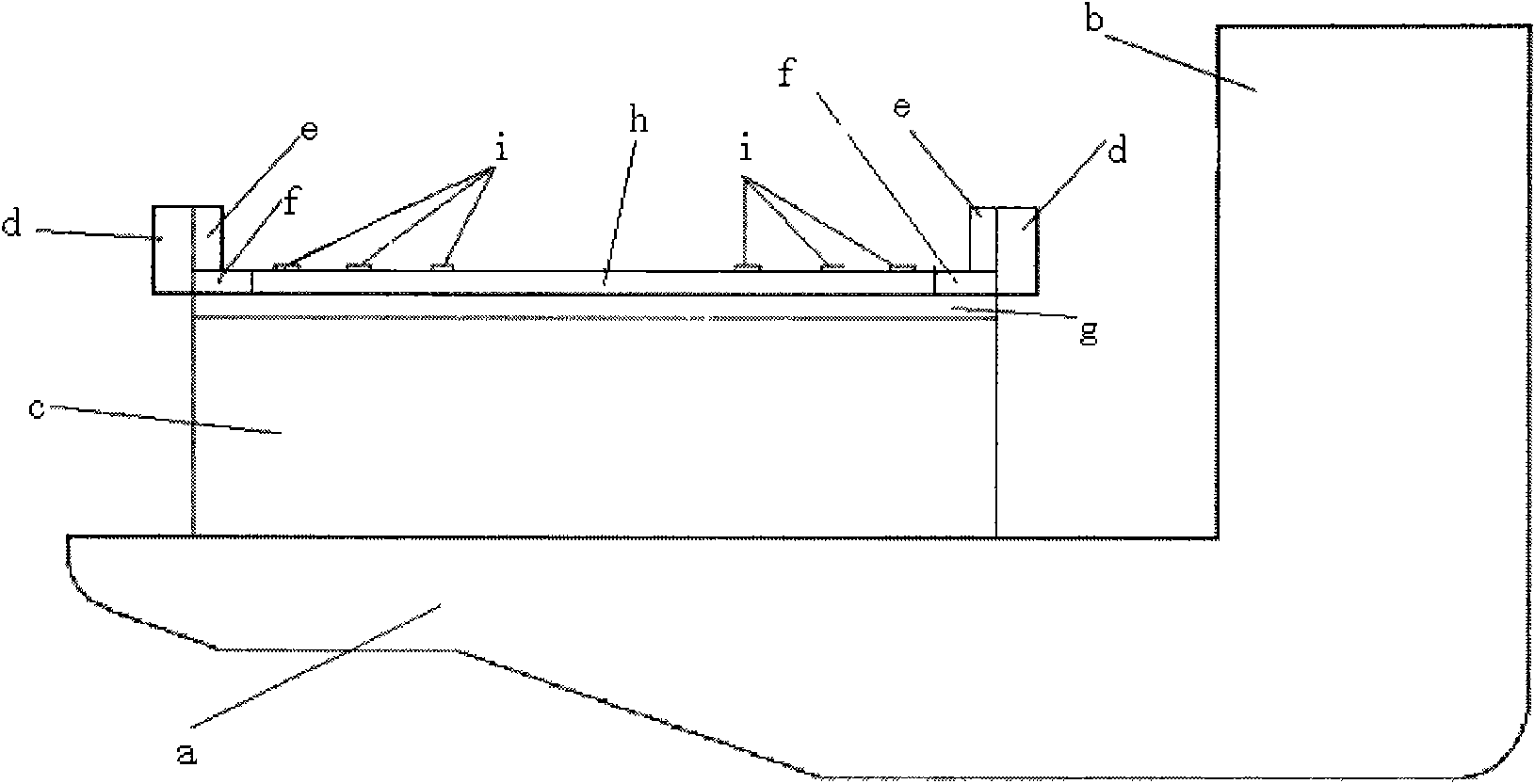

Electromagnetic wave welding method and device for solar cells

InactiveCN101797661AAccurate distanceSimple structureFinal product manufactureHigh frequency current welding apparatusHigh frequency powerEngineering

The invention discloses an electromagnetic valve welding method and an electromagnetic valve welding for solar cells. The method comprises the following steps of: superposing the solar cells and welding strips on a non-magnetic workbench and allowing the welding strips to contact bus bars of the solar cells; pressing the welding strips and the cells together by using an elastic pressing device; supplying power to a copper pipe induction coil, which is arranged below the workbench surface, by using a high-frequency power supply, wherein the copper pipe induction coil is 'u'-shaped; allowing a cooling medium which flows in the inner part of the copper pipe induction coil to cool the copper pipe induction coil; uniformly heating the welding strips and the bus bars of the panels with high-frequency oscillation electromagnetic waves generated by the copper pipe induction coil; and welding the welding strips and the bus bars of the panels together. The device comprises the workbench, the elastic pressing device and the high-frequency power supply, wherein the elastic pressing device is arranged above the workbench; the high-frequency power supply is connected with the copper pipe induction coil; and the copper pipe induction ring is 'u'-shaped and fixed below the workbench surface. The electromagnetic valve welding method and the electromagnetic valve welding for the solar cells have the advantages of high heating speed, high production efficiency, simple structure, uniform magnetic field and high welding quality.

Owner:SUZHOU SUOLIWANG NEW ENERGY TECH CO LTD

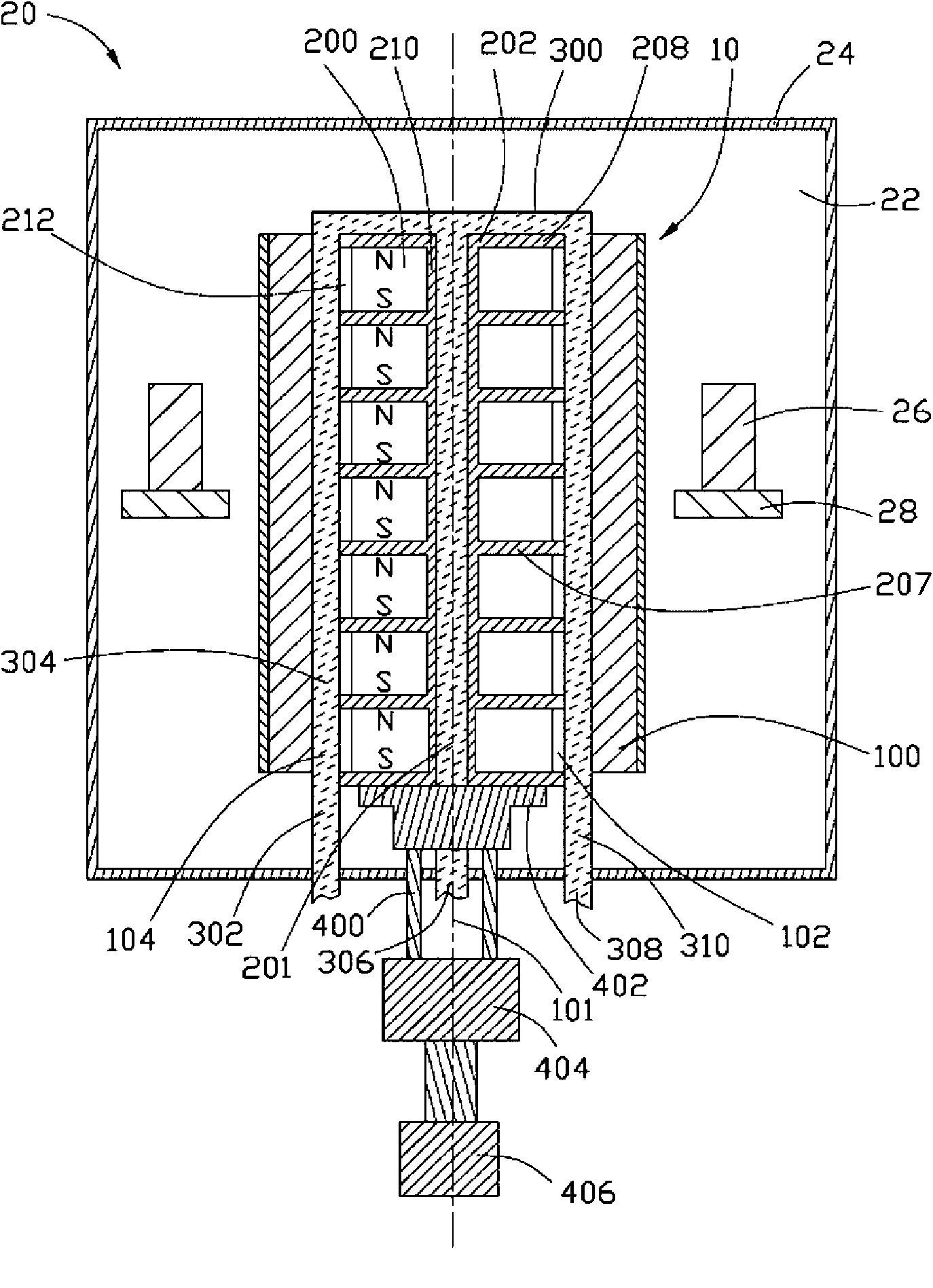

Superconductivity magnet apparatus

InactiveUS20050134414A1Uniform magnetic fieldErroneous generation can be suppressedMagnetic measurementsMagnetsSuperconducting magnetBobbin

The present invention provides a superconductivity magnet apparatus for generating a uniform magnetic field suitable for NMR applications. The superconductivity magnet apparatus has an access port for allowing an access to the center of the magnetic field from an external position separated away from the center in a direction other than the axial direction of a split-type superconductivity electromagnet employed in the magnet apparatus. In the superconductivity magnet apparatus, a gap exists between first and second superconductivity coil blocks facing each other to form the split-type superconductivity electromagnet. To put it in detail, the access port allows an access to a measurement space at the center of the magnet by way of the gap. A configuration element of the magnet such as a coil bobbin is cut out for providing the access port. An area including a deficiency portion caused by the cutout portion or the like is filled up with a material having a relative magnetic permeability in the range 1.000 to 1.002 as an axis-symmetrical area. By using the material with a relative magnetic permeability in the range 1.000 to 1.002, the strength of an erroneously generated magnetic field can be reduced so that a magnet producing a uniform magnetic field can be provided.

Owner:HITACHI LTD

Magnet apparatus and mri apparatus

InactiveUS6853281B1Increase production costSignificant valueMagnetsMagnetic materialsPhysicsMagnet device

A magnet device includes two sets of static magnetic field generation sources spaced from each other in the vertical direction such that the uniform magnetic field region (patient space) is between then. Each set has concentric current carrying coils to generate a uniform magnetic field in a first direction (the vertical direction). Several such coils are used in each set, disposed such that when a first axis which is parallel to the first (vertical) direction and passes substantially through the centers of the current carrying coils crosses, at a first point, a second axis which is orthogonal to the first axis and is at substantially equal distance from the respective static magnetic field generation sources, the current carrying coils are disposed in such a manner that when geometrical centers of cross sections of the current carrying coils are projected on a first straight line that is in a first plane containing the first axis, the second axis and the first point and passing through the first point, the directions of the currents of the carrying coils at the respective corresponding projections align alternatively in positive and negative directions on the first straight line.

Owner:HITACHI MEDICAL CORP +1

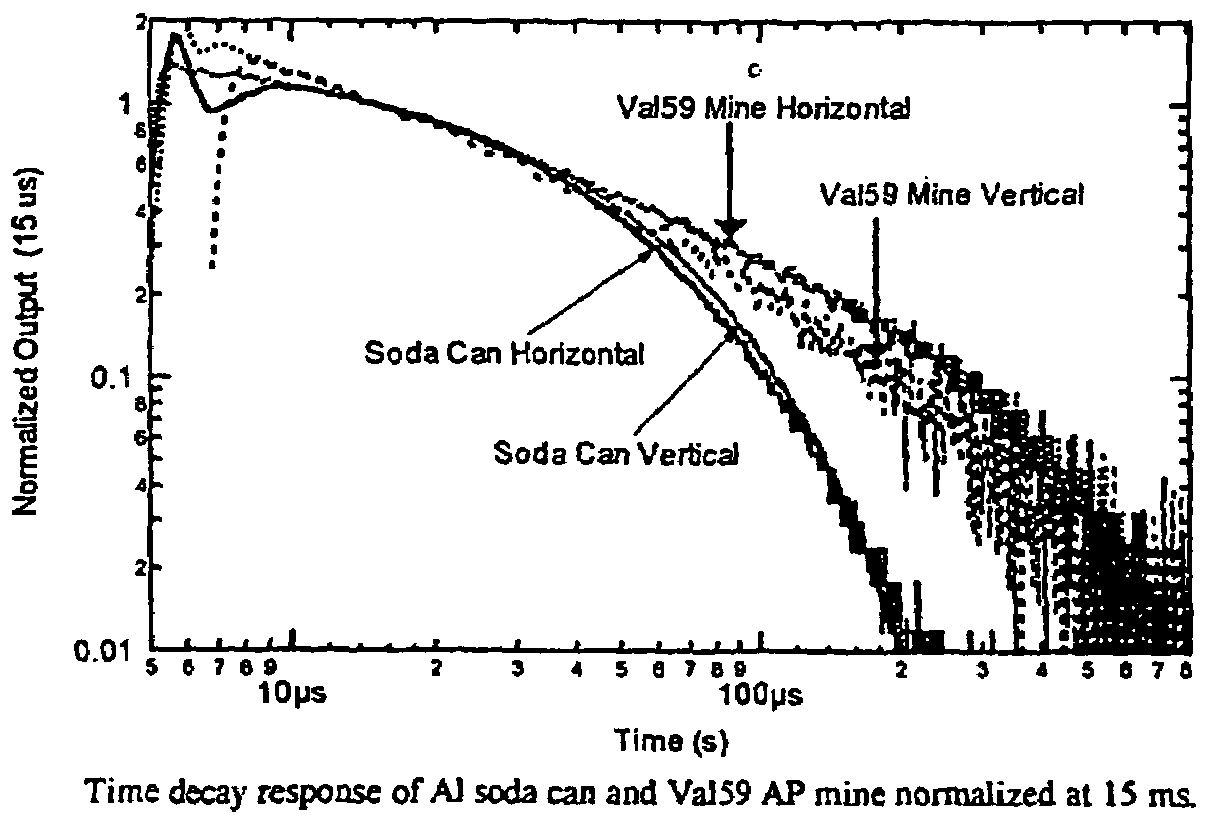

Method for metal object identification using a three-dimensional steerable magnetic field antenna

InactiveUS7106194B2Efficient identificationUniform magnetic fieldBurglar alarm by hand-portable articles removalElectric/magnetic detectionSearch algorithmTensor

A method for identifying a buried metal object using a three-dimensional steerable magnetic field (3DSMF) system. The method comprises generating a magnetic field vector (MFV) at a first MFV position above the buried metal object; measuring a time decay response at the first MFV position; generating a MFV at a next MFV position above the buried metal object; measuring a time decay response at the next MFV position; repeating the above steps until a complete 360-degree measurement of time decay responses of the buried metal object is completed; processing all measured time decay responses with a target search algorithm to determine a magnetic polarizability tensor of the buried metal object; and identifying the buried metal object by matching the magnetic polarizability tensor of the buried metal object to a known magnetic polarizability tensor of an object.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

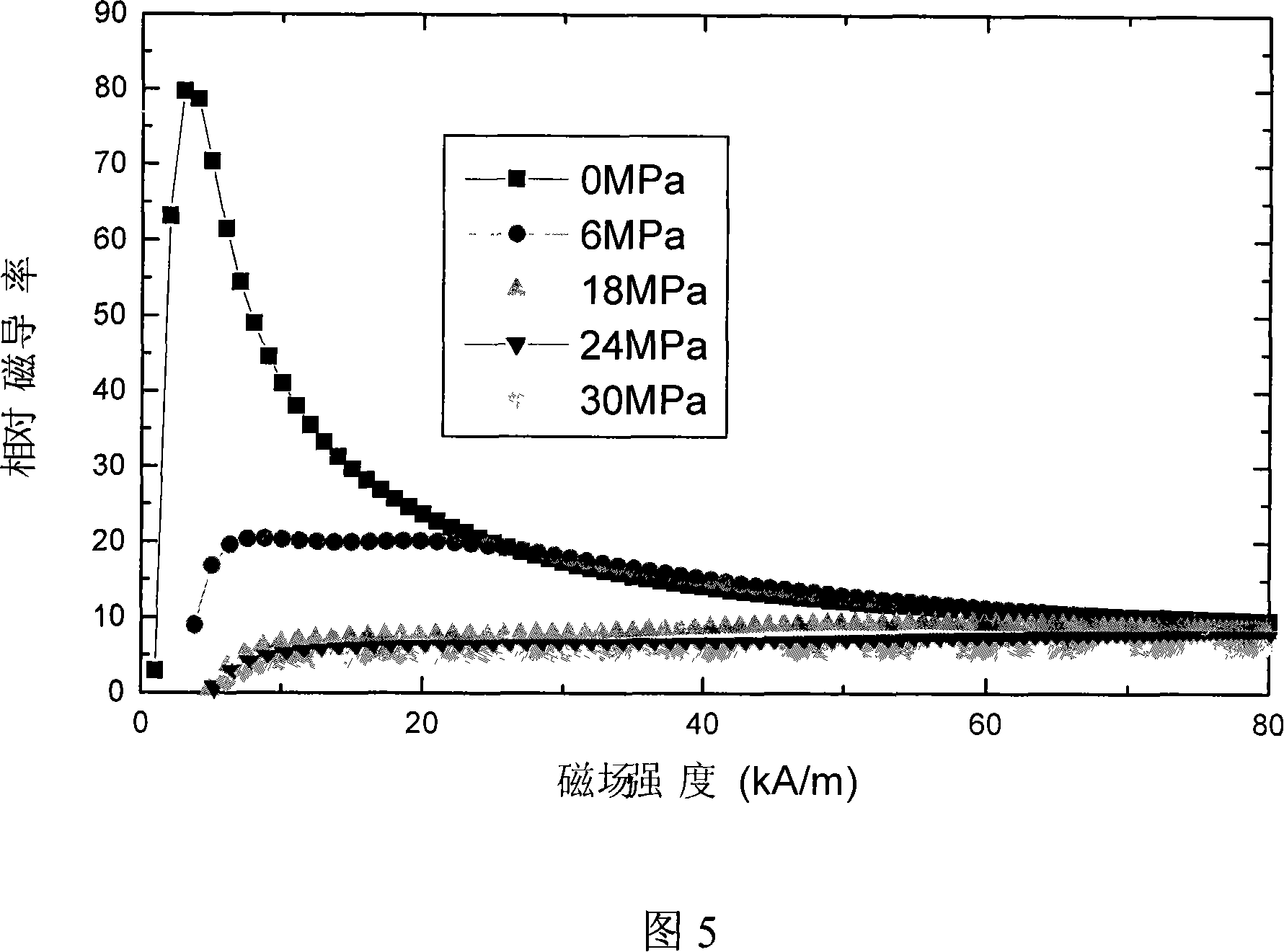

Magnetostrictive stress sensor

InactiveCN101153824AHigh sensitivityHigh precisionForce measurement by measuring magnetic property varationFluid pressure measurement by electric/magnetic elementsEngineeringNon magnetic

The invention relates to a giant magnctostrictivc material pressure sensor, which is characterized in that three giant magnctostrictivc material rods are vertically and evenly arranged on an inner circle of a sensor base and two permanent magnetic rods or two excitation windings are arranged vertically and systemically on three giant magnctostrictivc material rods; upper and lower disk magnetic inductive plates are respectively arranged on the above and at the bottom of the three giant magnctostrictivc material rods and the radiuses are a little bit bigger than the mounting radiuses of the permanent magnetic rods or the excitation windings; the magnetizing directions of the two permanent magnetic rods are axial and are the same; the two excitation windings have the same coiling direction and also the same current direction; the length of the permanent magnetic rods or the excitation windings is a little bit shorter than the length of the giant magnctostrictivc material rods to enable a gap between the top of permanent magnetic rods or the excitation windings and the bottom of the upper disk magnetic inductive plat; non-magnetic inductive glue is filled in the gaps to glue Hall units; inductive windings are coiled on the giant magnctostrictivc material rods; the upper disk magnetic inductive plate are arranged on a bearing block, the lower disk magnetic inductive plates are arranged on the base, an outer cover is arranged on the lower disk magnetic inductive plates, and encloses all parts on the base as a whole but the bearing block protrudes out of the upper surface of the outer cover.

Owner:HEBEI UNIV OF TECH +1

Isotropic bonded NdFeB magnet and magnetic roller consisting of same

ActiveCN101673606AHigh energy productImprove remanencePermanent magnetsInorganic material magnetismMetallurgyRare earth

The invention relates to a magnetic roller used in a laser printer and a copier. An isotropic bonded NdFeB magnet used by the magnetic roller contains rare earth permanent magnetic powder and adhesive resin, wherein the rare earth permanent magnetic powder is a mixture of NdFeB magnetic powder and ferrit magnetic powder, and the formed magnet has the length of between 210 and 910mm. When the isotropic bonded NdFeB magnet is used to replace one or more ferrit permanent magnet poles in the magnetic roller, because the bonded NdFeB magnet has stronger magnetic performance than ferrit magnets, a strong magnetic filed can be formed on an outer surface taking the bonded NdFeB magnet as a pole so as to provide stronger magnetic filed adsorptive power, contribute to the size distribution of multiple kinds of color matching powder, and reduce the grey back of copying and printing to contribute to clear imaging.

Owner:上海三环磁性材料有限公司 +1

Current sensor and measuring apparatus including current sensor

InactiveCN106556730AImprove accuracy and anti-interference abilityEliminates deviations in the magnetic fieldCurrent/voltage measurementPhysicsMeasurement device

The invention provides a current sensor and a measuring apparatus. The current sensor includes a magnetic induction unit and a processing unit provided on the outside of the wire to be measured, the magnetic induction unit is used for sensing a magnetic field generated by a current flowing through the wire to be measured and obtaining an induced signal corresponding to magnetic field intensity; the input end of the processing unit is electrically connected with the output end of the magnetic induction unit to process the induced signal, and at least one pair of magnetic induction units are arranged on the outside of the wire to be measured, the processing unit obtains the value of the current flowing through the measured wire through differential operation based on the paired induced signals. The current sensor is high in measurement accuracy, high in anti-interference capability, and low in installation requirement.

Owner:BEIJING JIAYUE TONGLEJI ELECTRONICS

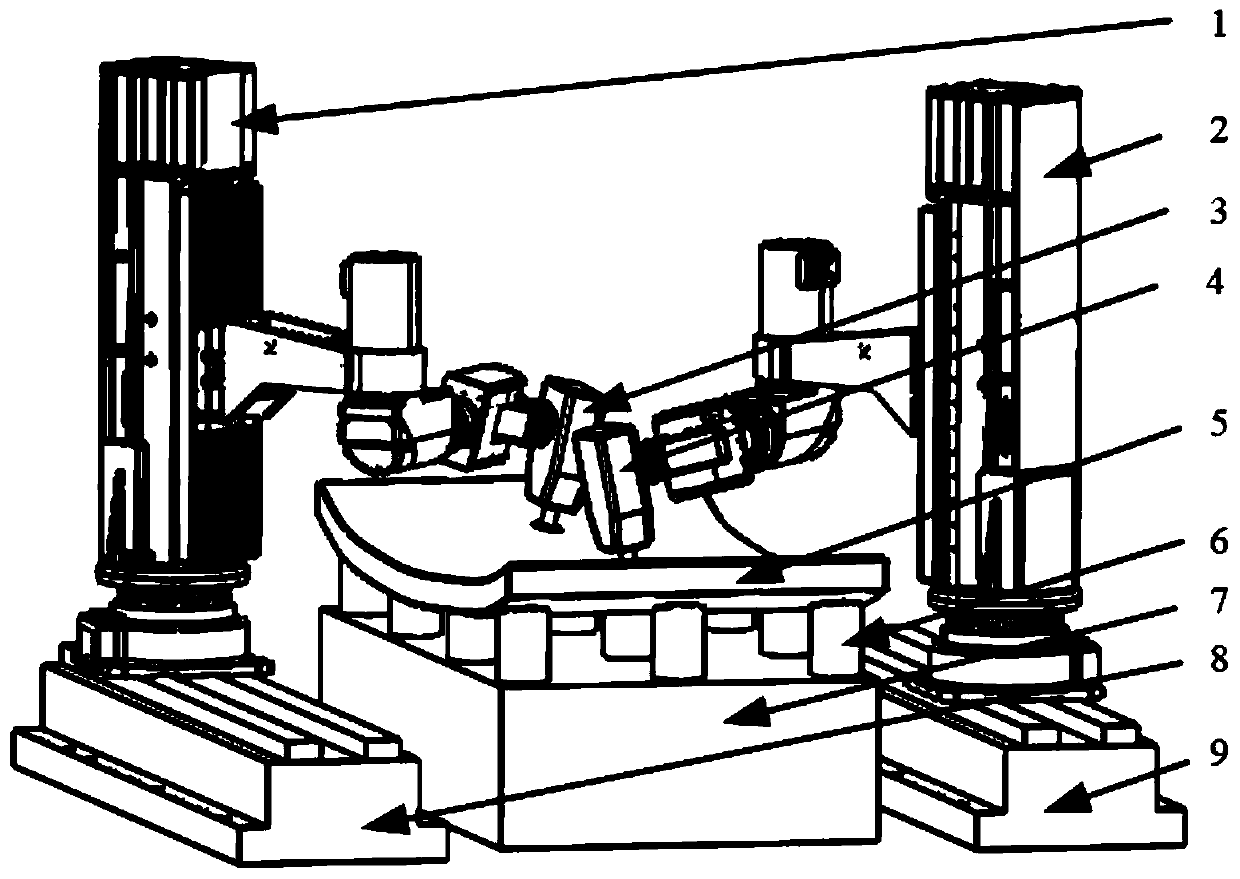

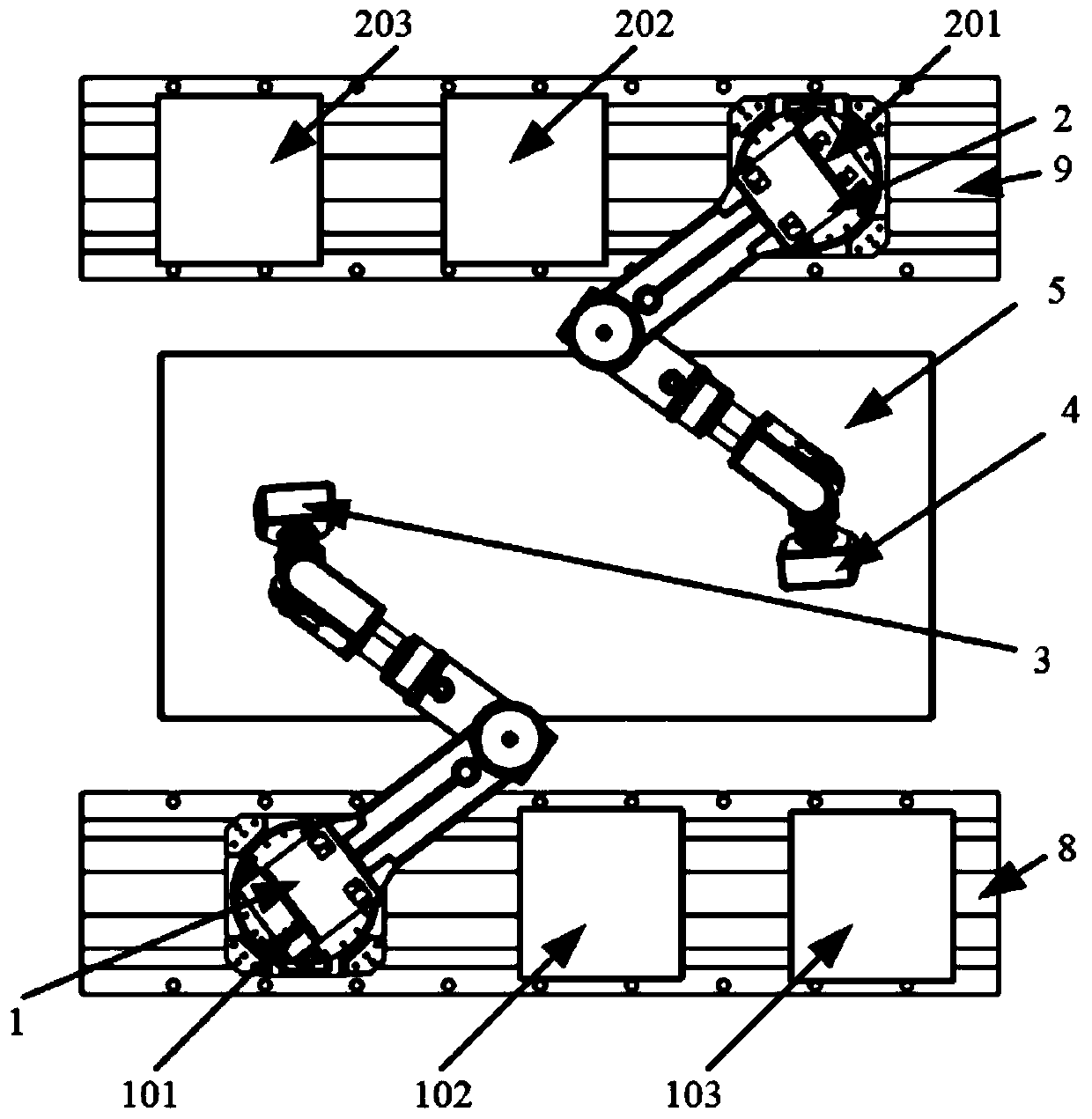

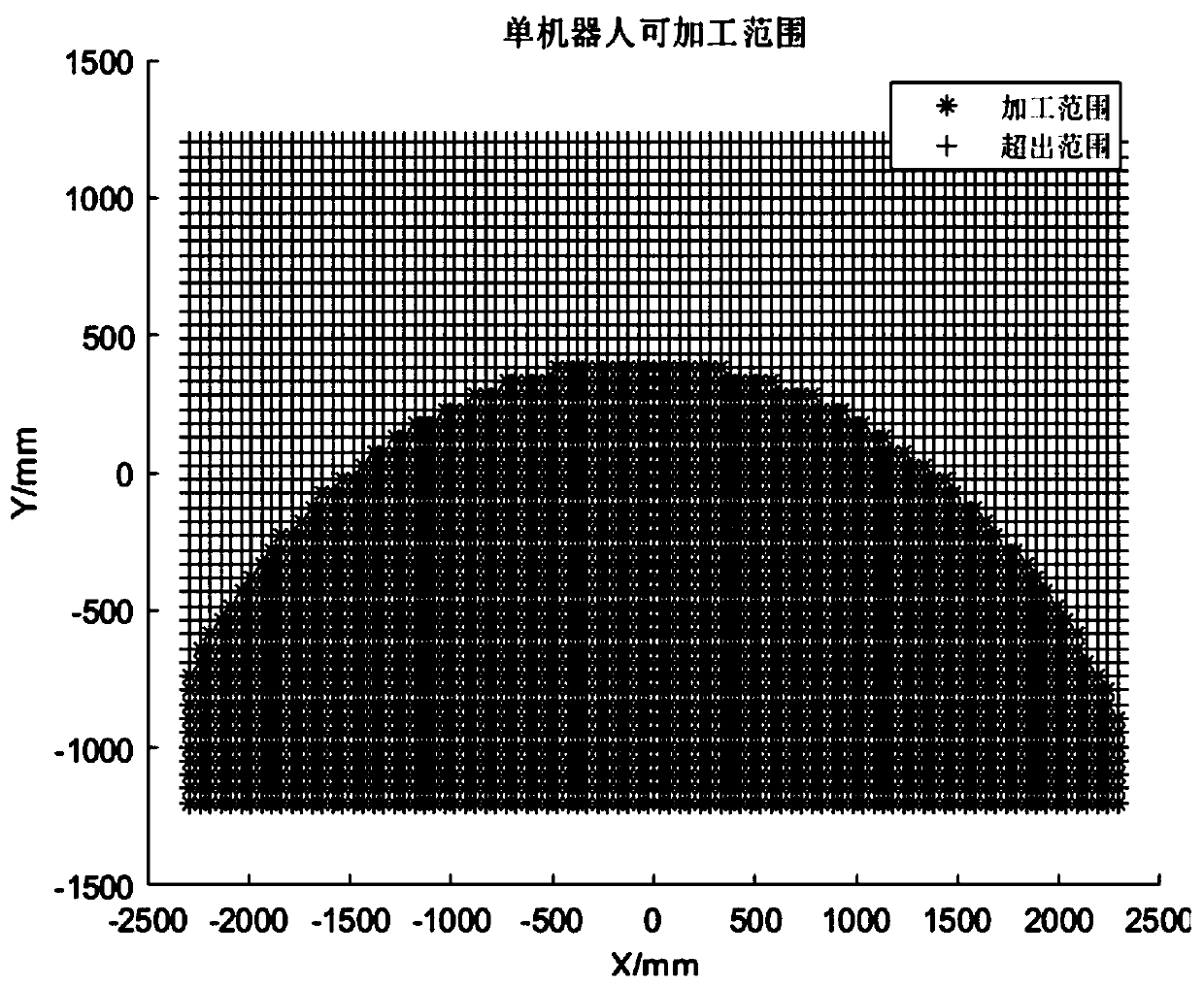

Multi-robot precision machining system and method for large-aperture integral optical element

ActiveCN110732932AShorten the production cycleSave handling timeOptical surface grinding machinesLapping machinesOptical processingRobot machining

The invention discloses a multi-robot precision machining system and a method for a large-aperture integral optical element. The multi-robot precision machining system comprises a robot machining system part and a modular machining tool, the modular machining tool comprises a grinding disk machining module, a polishing fluid supply recycling tool head module and a magnetorheological polishing toolhead module. The multi-robot precision machining system and method adopts a flexible intelligent robot with the low cost for machining, by means of multi-robot collaborative machining, machining of large-aperture integrated optical elements with various curvature is realized, meanwhile, the manufacturing efficiency of the optical elements is greatly improved, and a highly integrated modular chemical tool head enables the machining system to be able to conduct grinding modification, polishing modification and precision polishing modification on the large-aperture integral optical elements. Thesystem completes the whole optical machining process, the manufacturing cost of the large-aperture optical elements is greatly saved, and the cycle of the large-aperture optical elements is greatly shortened.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

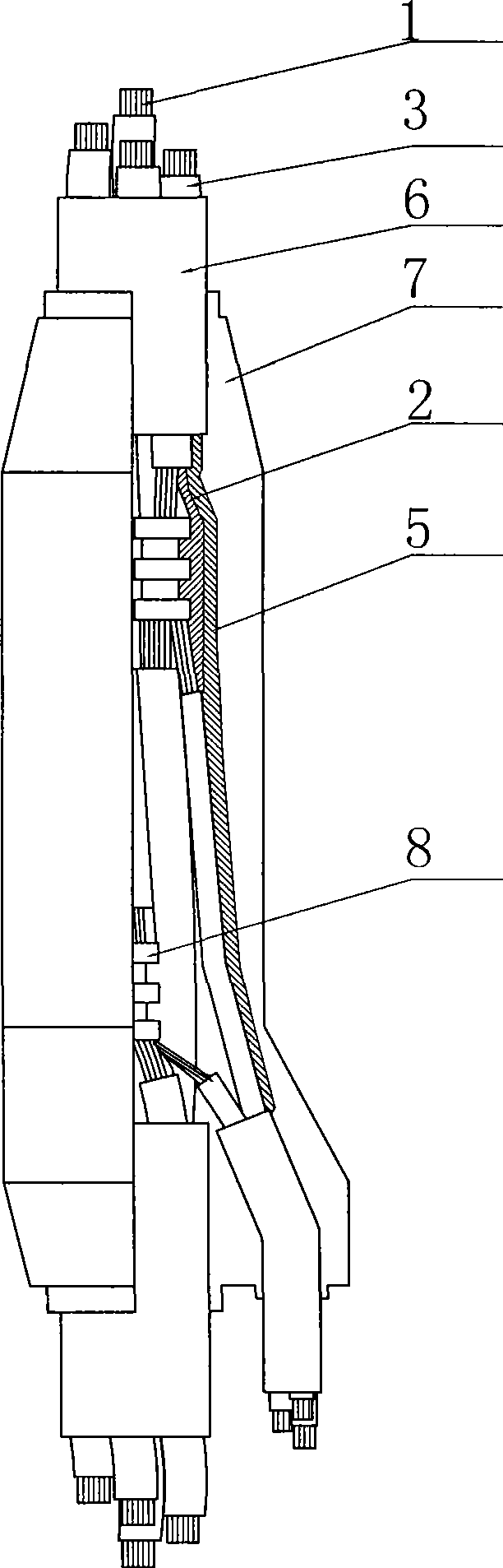

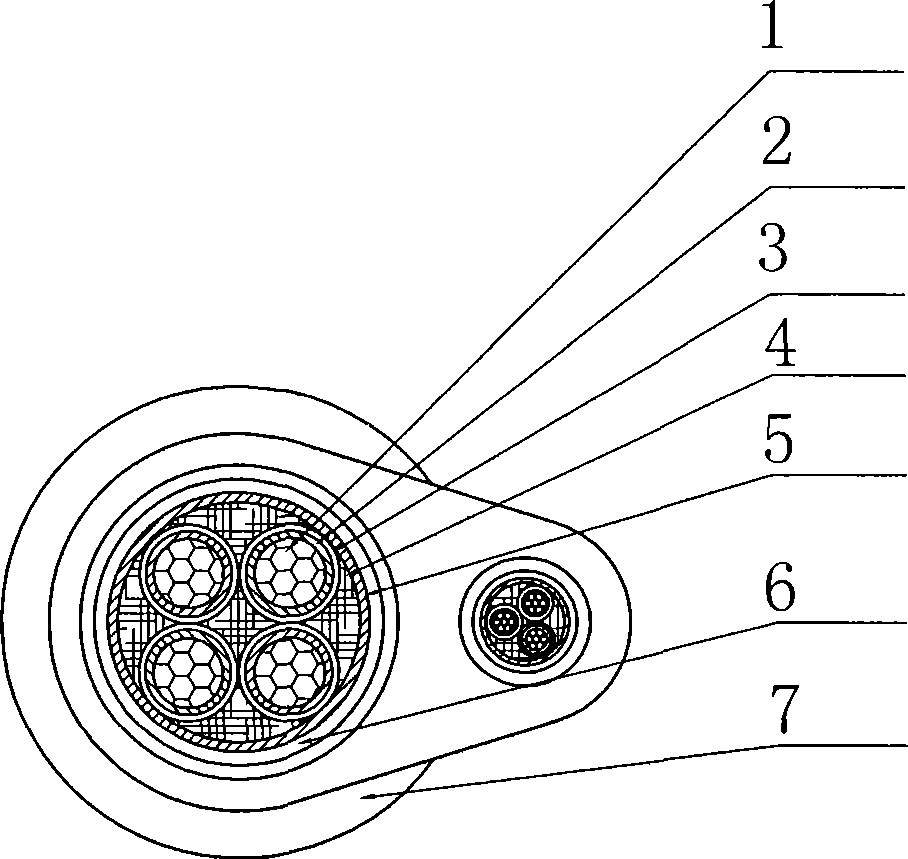

Multi-core integrated branch cable and production method thereof

InactiveCN101521052AUniform electric fieldUniform magnetic fieldRubber insulatorsPlastic/resin/waxes insulatorsCross-linkCopper conductor

The invention relates to a multi-core integrated branch cable and a production method thereof. The multi-core integrated branch cable comprises a main cable, branch cables, connecting fixtures and the like, wherein the main cable or each branch cable is formed by twisting 2 to 5 insulated conductors into a core wire, winding, coating and binding the core wire by bags into a cable core, and coating a layer of plastic outer sheath on the cable core through extrusion; the main cable is provided with phase conductor openings connected with terminations of the branch cables; the phase conductor openings are staggered at equal intervals in turn; copper conductors of the terminations of the branch cables with the same phase are in crimp connection with copper conductors at the phase conductor openings of the main cable into a branch connecting body through the connecting fixtures and a compression mould; the crimp connection part is coated with an ethylene propylene rubber self-adhesive tape which is coated with a cross-linked polythene insulation layer; and a sheath of the branch connecting body is moulded on the insulation layer. The multi-core integrated branch cable has a reasonable and compact structure, realizes that a single cable replaces four or five single core cables for use, and has simple laying and small occupied space.

Owner:BAOSHENG SCI & TECH INNOVATION

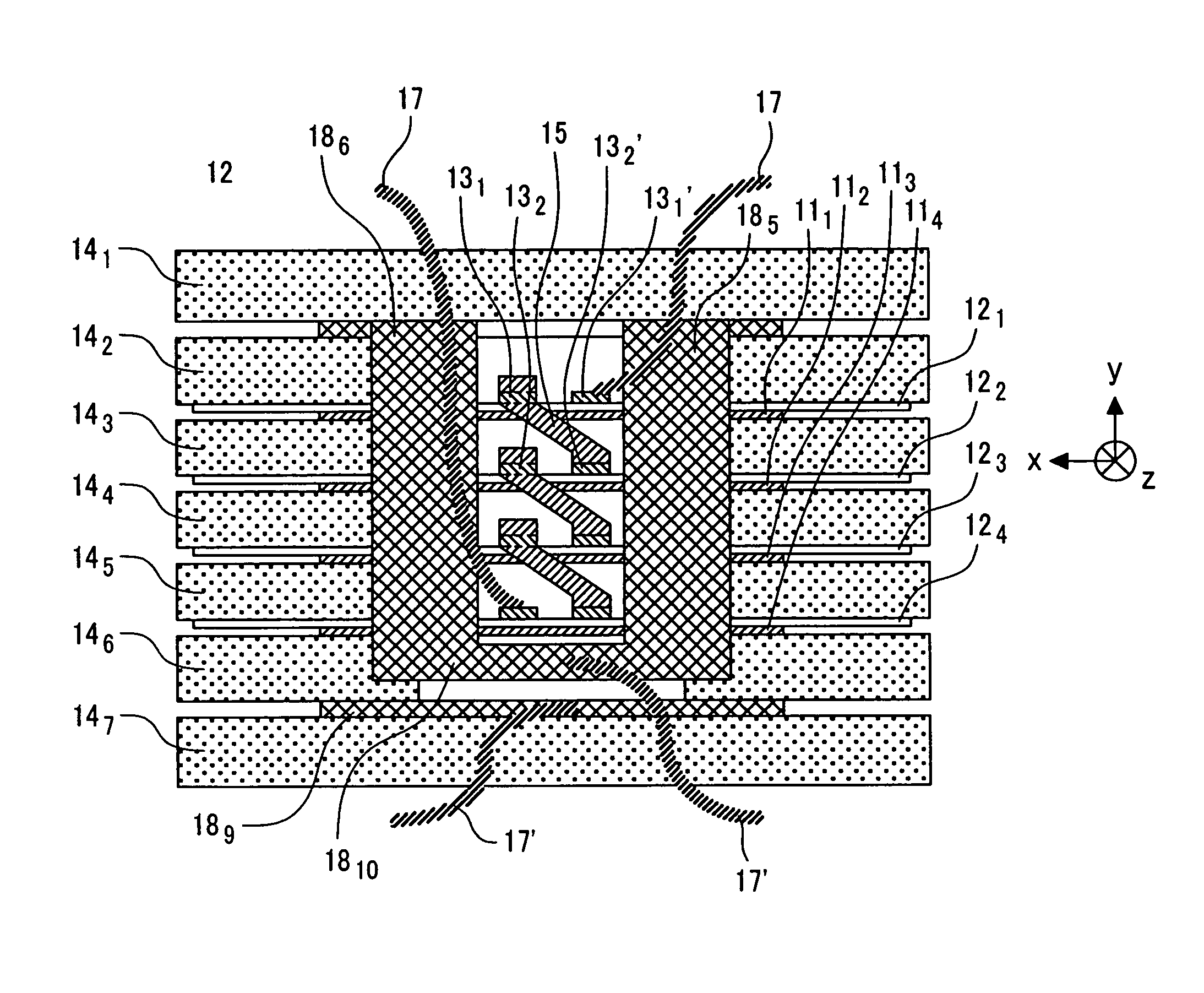

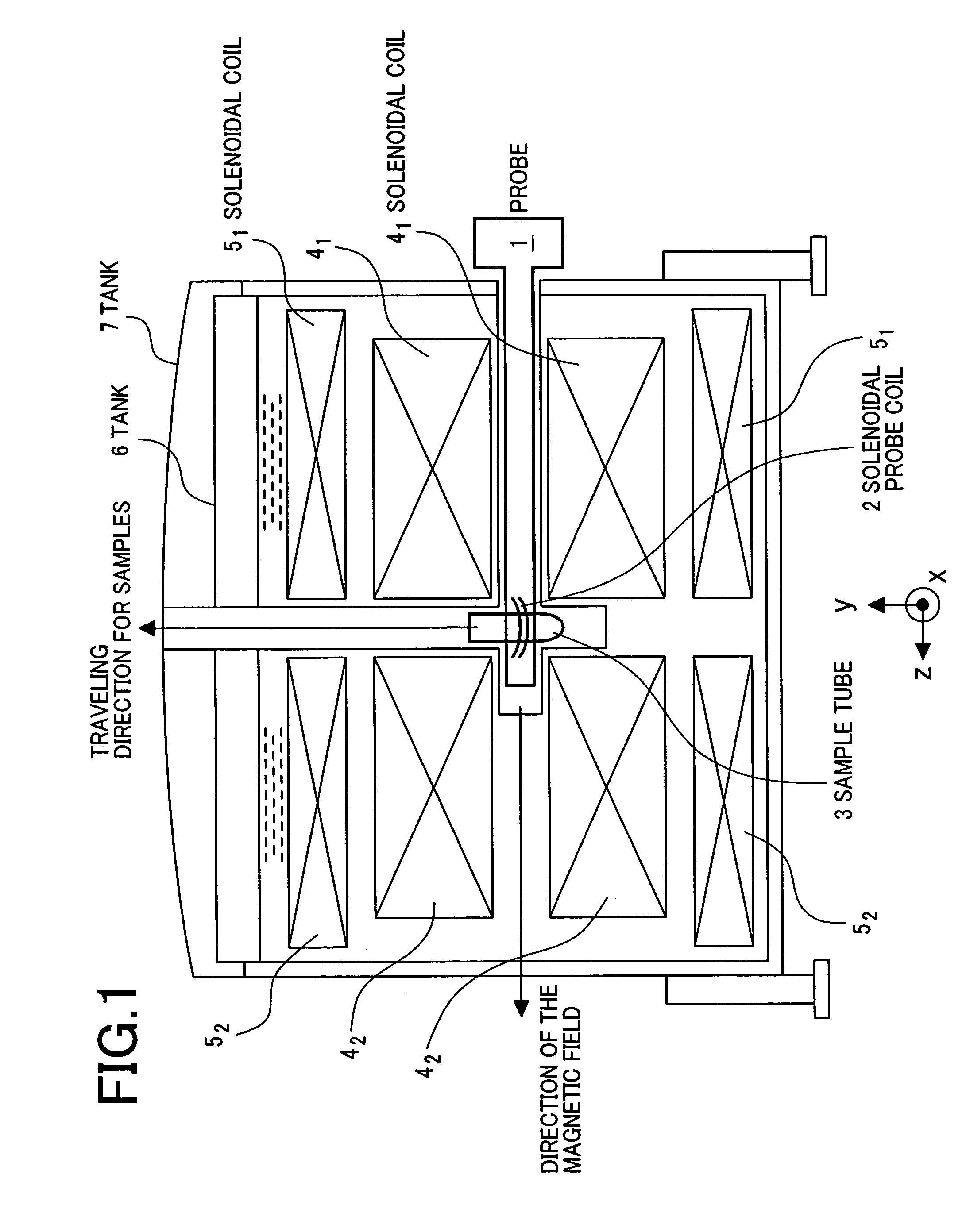

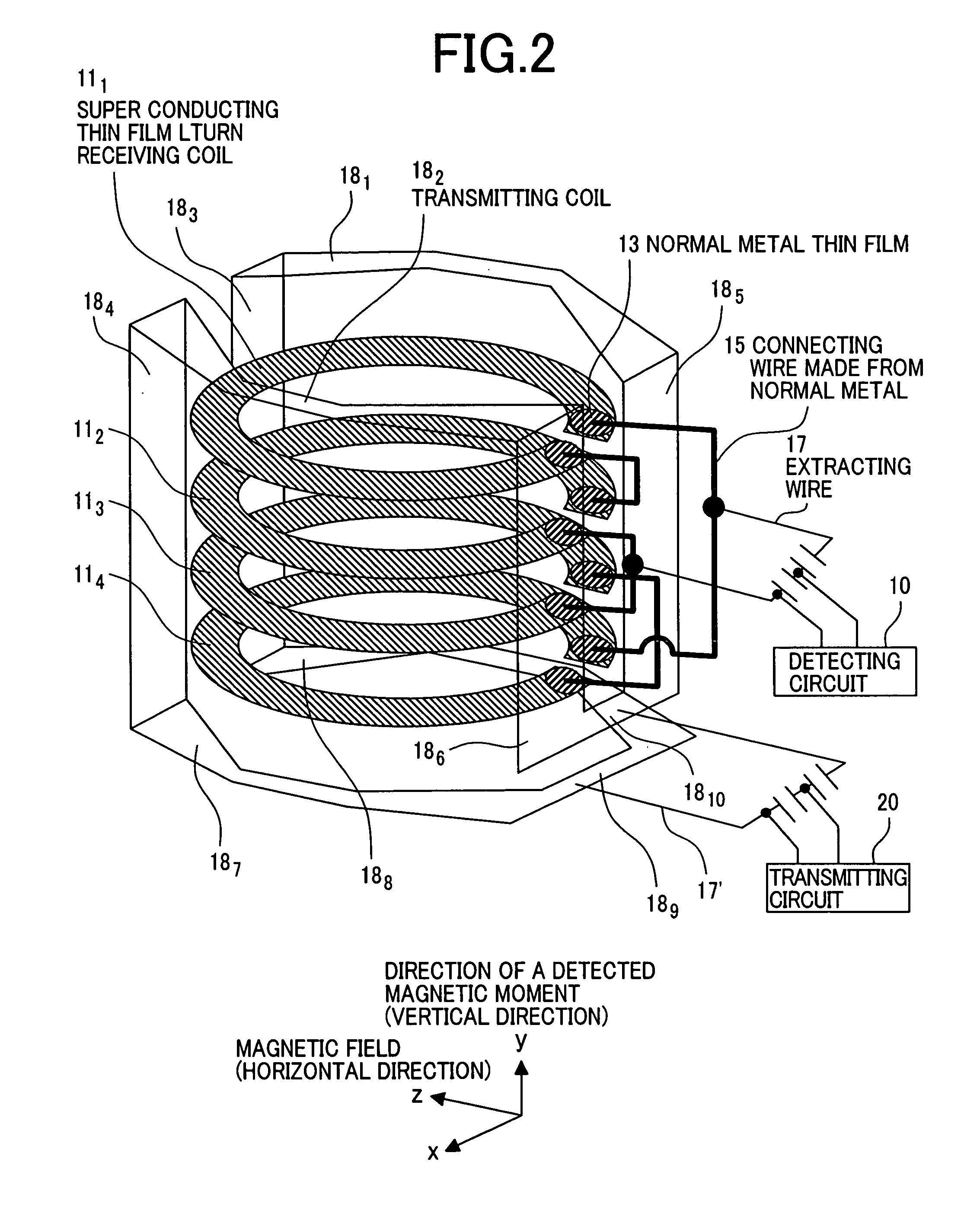

Nuclear magnetic resonance probe coil

InactiveUS7164269B2High quality factorUniform magnetic fieldMagnetic measurementsElectric/magnetic detectionElectrical resistance and conductanceCapacitance

A solenoid-type probe coil wherein superconductive thin film is used, whose quality factor is high, and which is put in an uniform magnetic field and occupies a small space is provided. For that purpose, the coil is made by piling up, in generally parallel, two or more substrates on which superconductive film is formed and connecting superconductors and normal-metal thin films through capacitance or low contact resistance.

Owner:HITACHI LTD

Magnetron sputtering device

InactiveCN101994093AEven consumptionIncrease profitElectric discharge tubesVacuum evaporation coatingSputteringReciprocating motion

The invention provides a magnetron sputtering device, which comprises a shell for defining a sputtering space and a target source positioned in the shell. The target source comprises a cylindrical target with a central axis, a plurality of magnetic elements and an actuator. The plurality of magnetic elements are arranged in the target along the central axis. The actuator is arranged along the central axis and used for driving the plurality of magnetic elements to rotate around the central axis and move to and fro along the central axis direction. By reciprocating motion of the magnetic elements along the axial direction, the magnetic fields applied on the surface of the target become uniform. The frequency bombarded on the surface of the target becomes equal, and then the surface of the target is uniformly consumed, so the utilization rate of the target is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

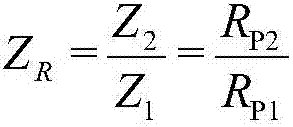

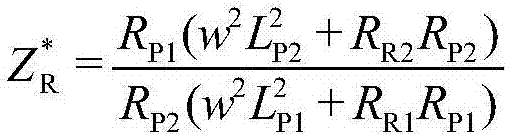

Dynamic wireless power supply system for tramcar and efficiency optimization control method of system

ActiveCN107512176AEliminate the zero magnetic field pointStable outputCharging stationsCircuit arrangementsOffset distancePower flow

Disclosed are a dynamic wireless power supply system for a tramcar and an efficiency optimization control method of the system. The system device comprises a first transmitting terminal circuit and a second transmitting terminal circuit on the ground, and a receiving terminal circuit mounted on the tramcar. First and second transmitting coils and a receiving coil of the system adopt a winding mode of 8-shaped coil rows, and two sub-coils of each 8-shaped coil have opposite winding directions. The first transmitting coil (LPl) and the second transmitting coil (LP2) are completely overlapped in the width direction, and overlapped in an offset manner in the length direction, and the offset distance is one quarter of the length of one single 8-shaped transmitting coil. According to the invention, the ratio of the effective values of currents of the two transmitting coils can be adjusted in real time, and the ratio of the effective values of the currents of the transmitting coils is the ratio of the system at optimum efficiency, so as to improve the efficiency of the system. By applying the method, the transmission efficiency of the dynamic wireless power supply system for the tramcar provided with the 8-shaped coil rows can be effectively improved through simple and convenient control, the power supply capacity of the system is reduced, reliability is high, and control is easy.

Owner:SOUTHWEST JIAOTONG UNIV

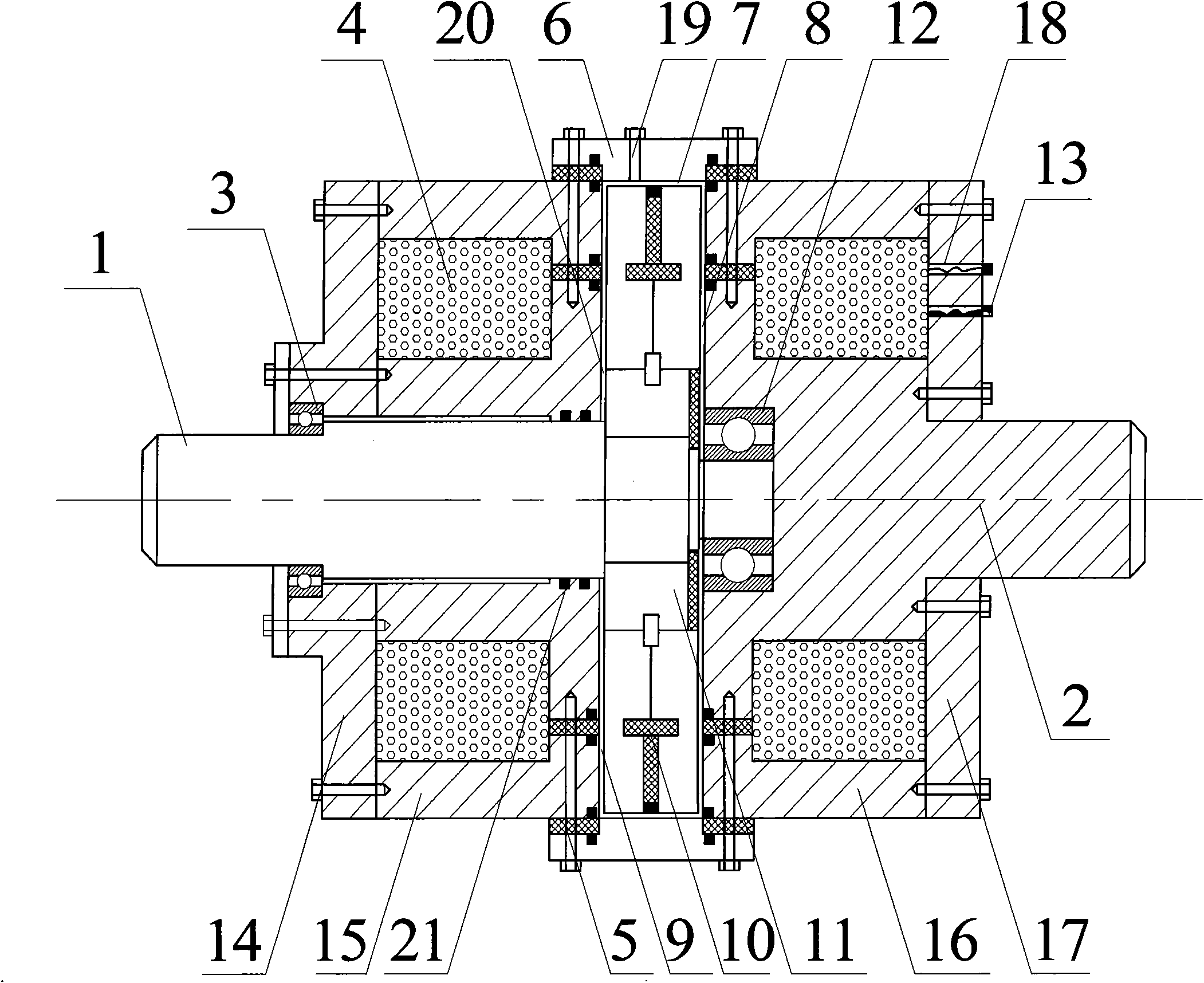

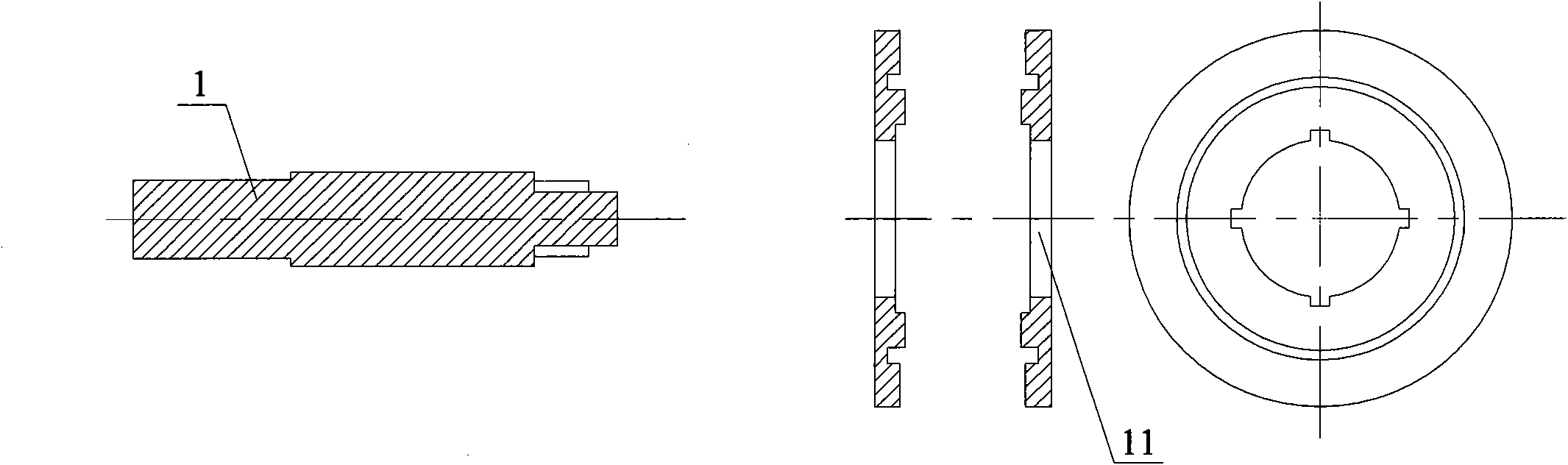

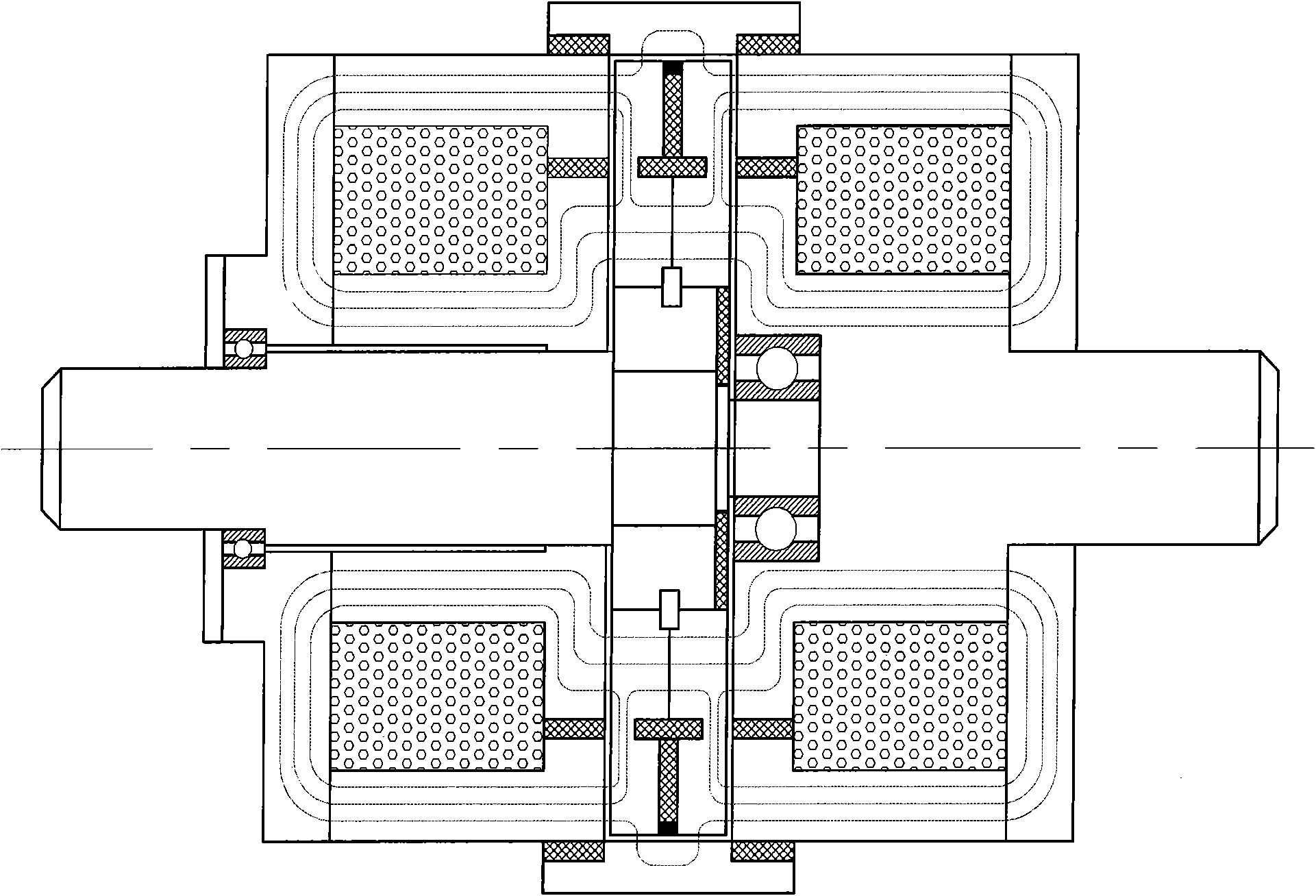

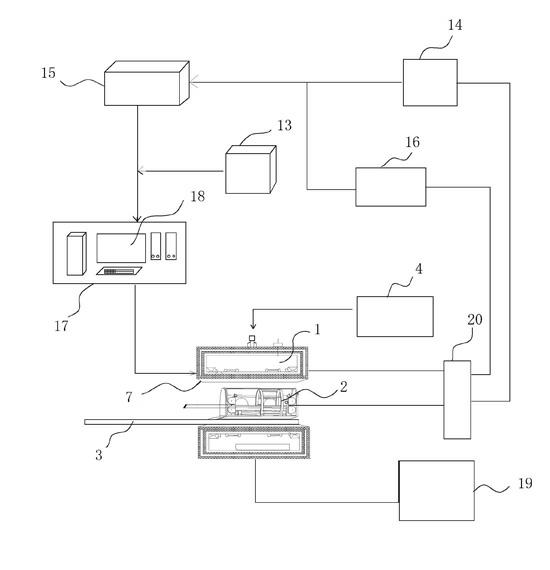

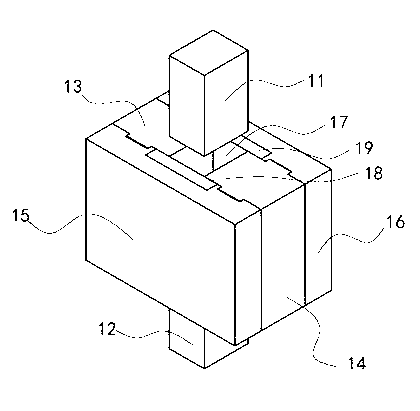

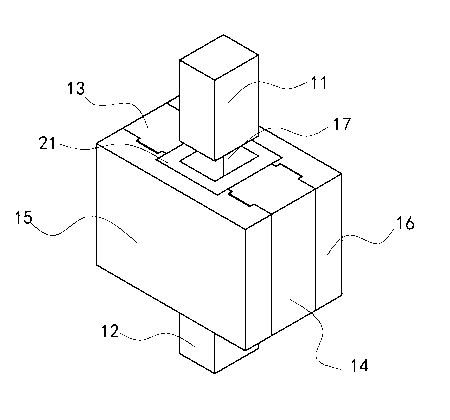

Uniwafer three-disk magnetic rheological clutch

The invention discloses a uniwafer three-disk magnetic rheological clutch which comprises a drive shaft (1), a driven shaft (2), a drive disk (11), a magnet exciting coil (4), a magneto rheological left disk channel (9), a magneto rheological right disk channel (8), a magneto rheological circular channel (7), a left shell (14), a left driven member (15), a right shell (17), a right driven member (16), a drive disk magnetism-isolating copper ring (10), a driven member magnetism-isolating copper ring (5), an angle contact ball bearing (3), a thrust ball bearing (12), a magneto rheological liquid (20) and a sealing device, wherein the drive disk (11) is positioned in a cavity surrounded by the left driven member (15), the right driven member (16) and a driven connecting member (6), and the magneto rheological liquid is filled in the cavity; and magnetic fields vertical to three disk surfaces of the drive disk (11) pass through the same, which can more effectively develop magneto rheological effect. The invention overcomes the defects of slow response, easy abrasion, large noise, more heat generation, unstable control and the like of the traditional clutch, and has the advantages of smaller volume, bigger drive torque, simpler structural design and less power consumption compared with the traditional magneto rheological clutch.

Owner:HOHAI UNIV

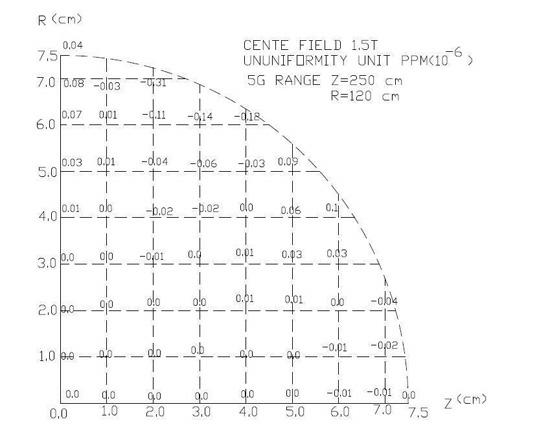

Special magnetic resonance imaging device for baby

ActiveCN102579047ASmall sizeUniform magnetic fieldDiagnostic recording/measuringSensorsSupporting systemSoftware system

The invention discloses a special magnetic resonance imaging device for a baby. The special magnetic resonance imaging device comprises a magnetic resonance imager, a filter board (20), a control device, a software system and a display system. The magnetic resonance imager consists of a superconducting magnet (1), a radio frequency system (2), a gradient system (7) and a patient supporting system (3). The superconducting magnet (1) comprises a superconducting magnetic field coil (5), a driving and driven shimming system (6) and a refrigerating system (4). The diameters of the inner walls of the superconducting magnetic field coil (5), the driving and driven shimming system (6) and the gradient system (7) are sequentially arranged in descending order. The refrigerating system is a classified refrigeration cycle system. By the adoption of the structure, the magnetic field is uniform; and the temperature variation is smooth and the environment is stable by the space positioning of a magnetic resonance imaging system signal and the two-stage refrigeration cycle system.

Owner:马启元

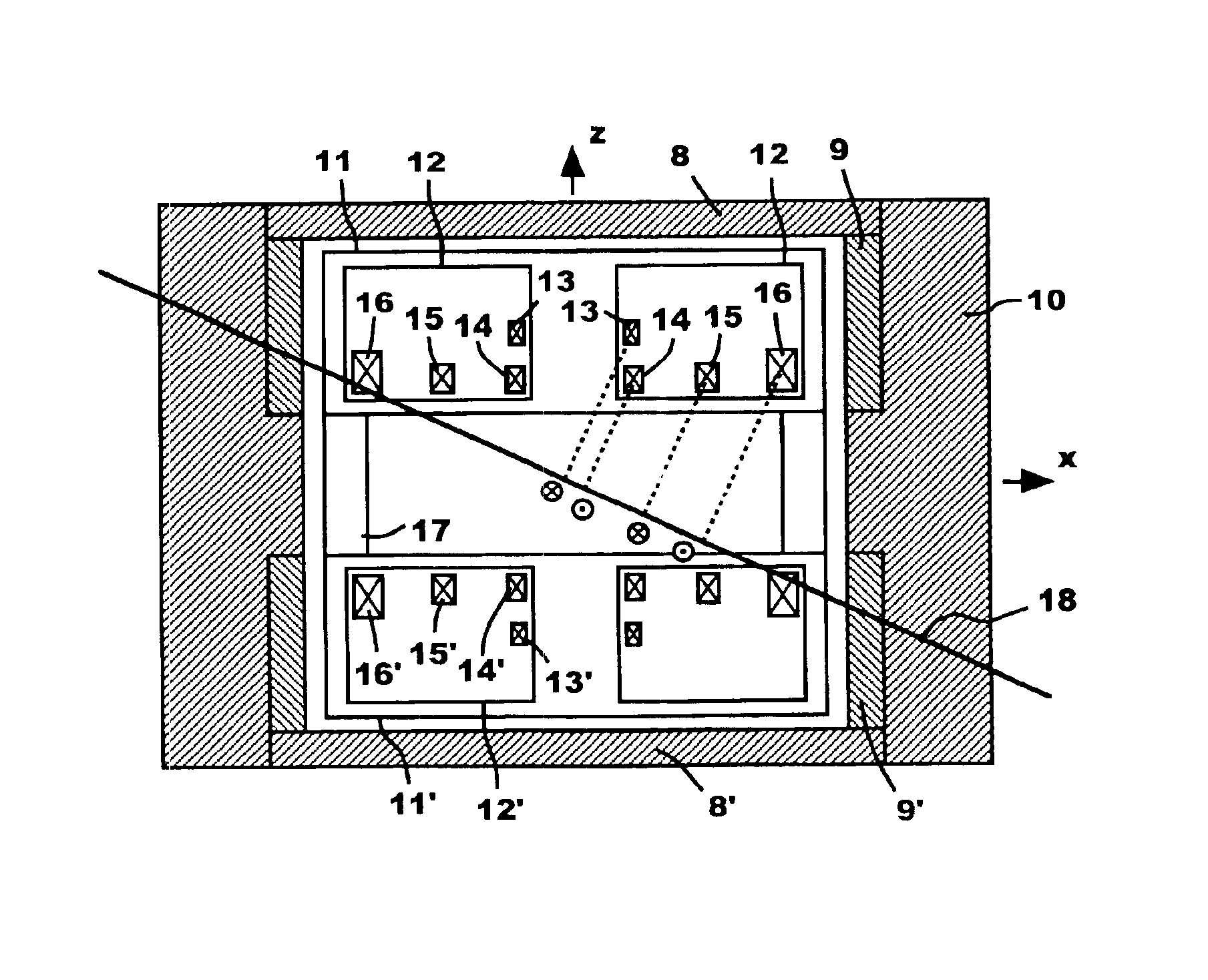

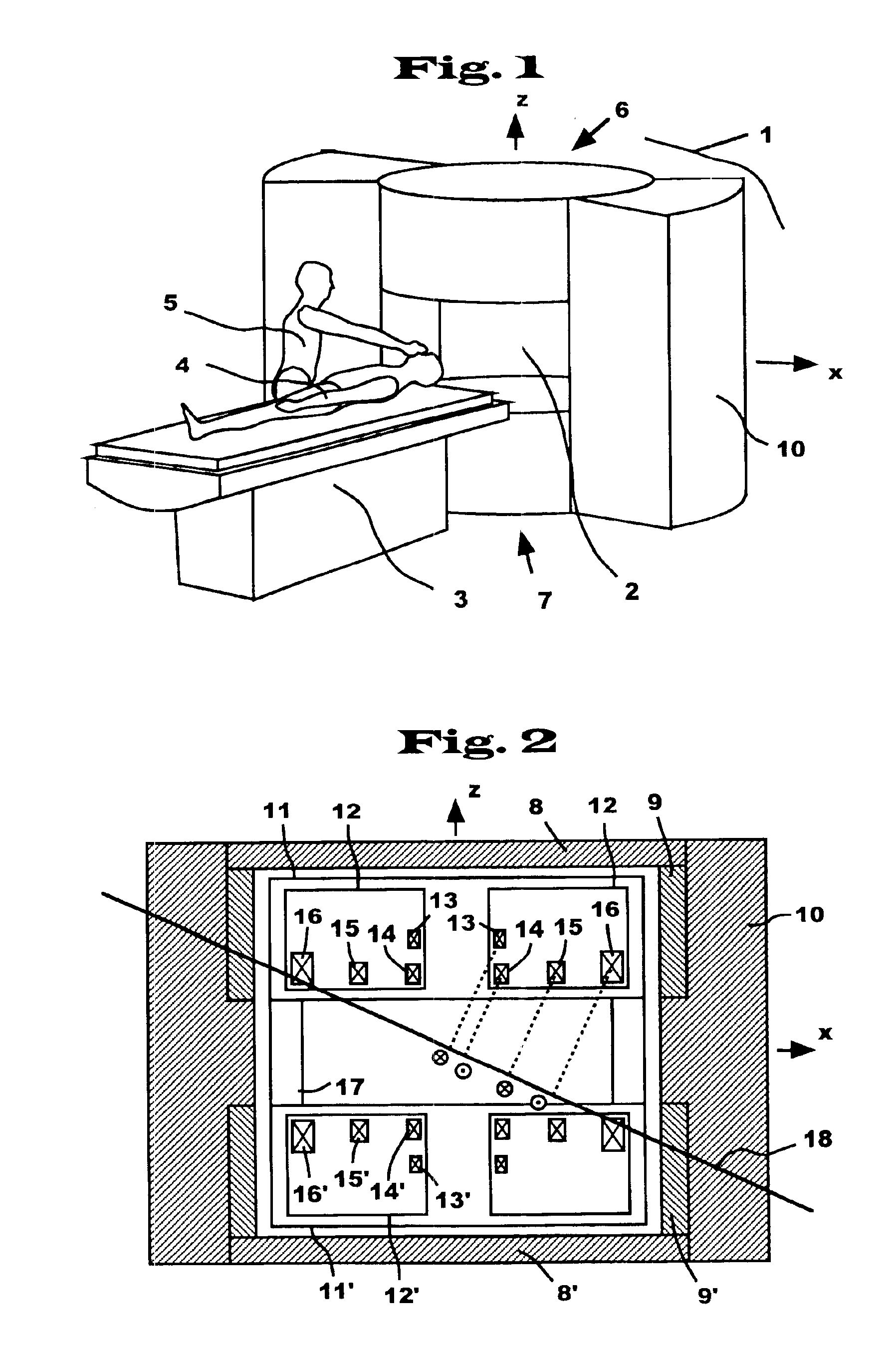

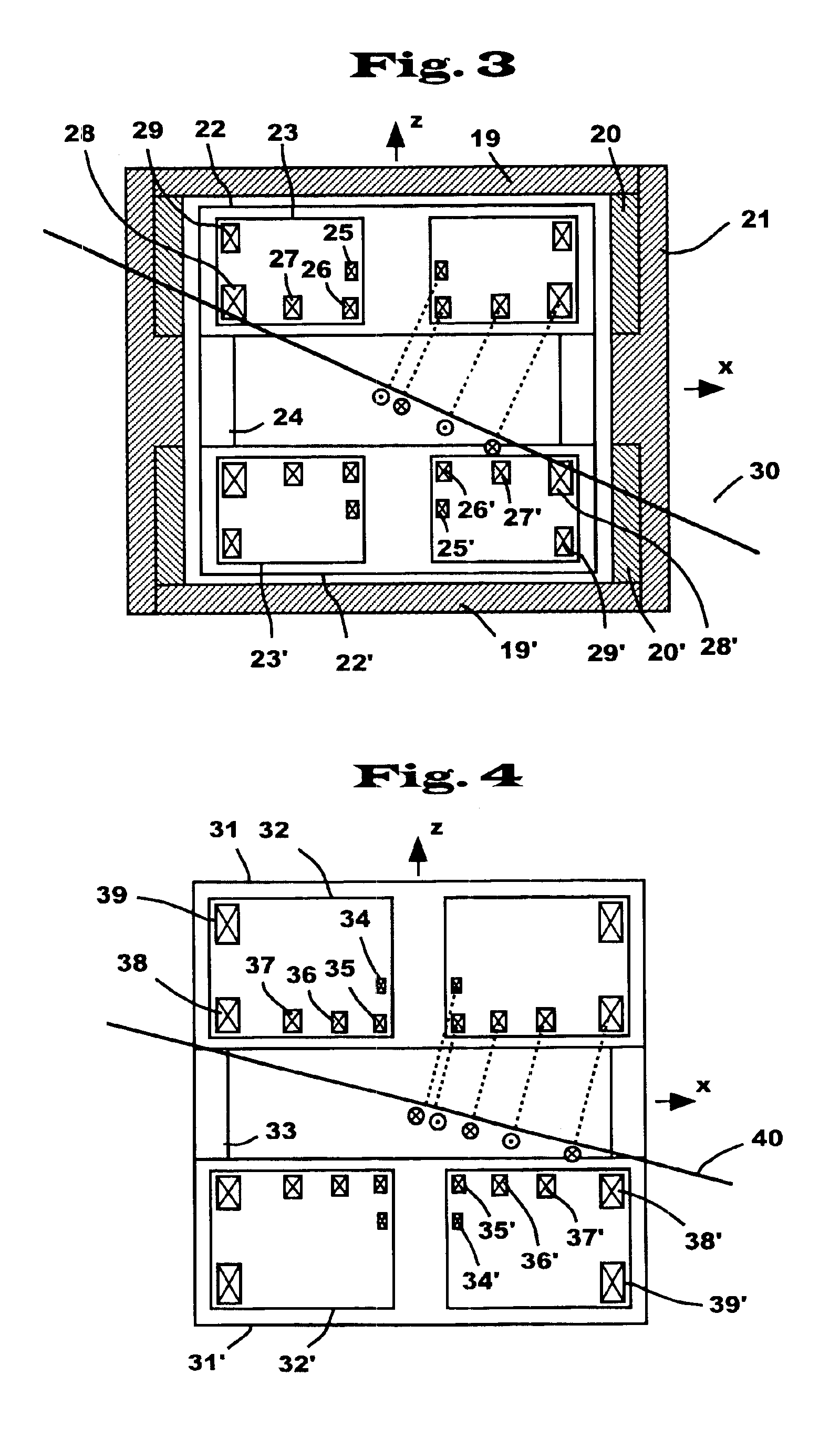

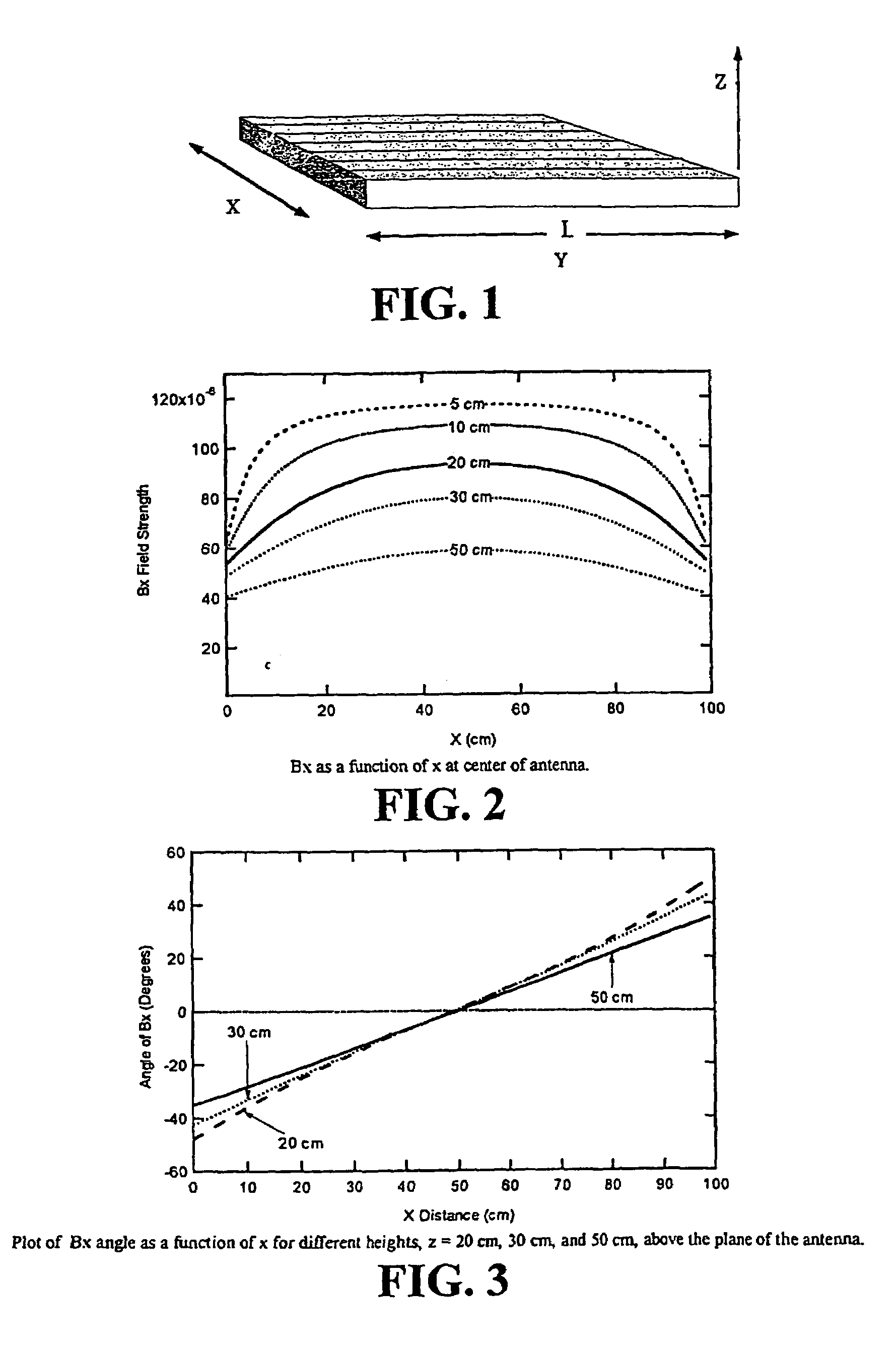

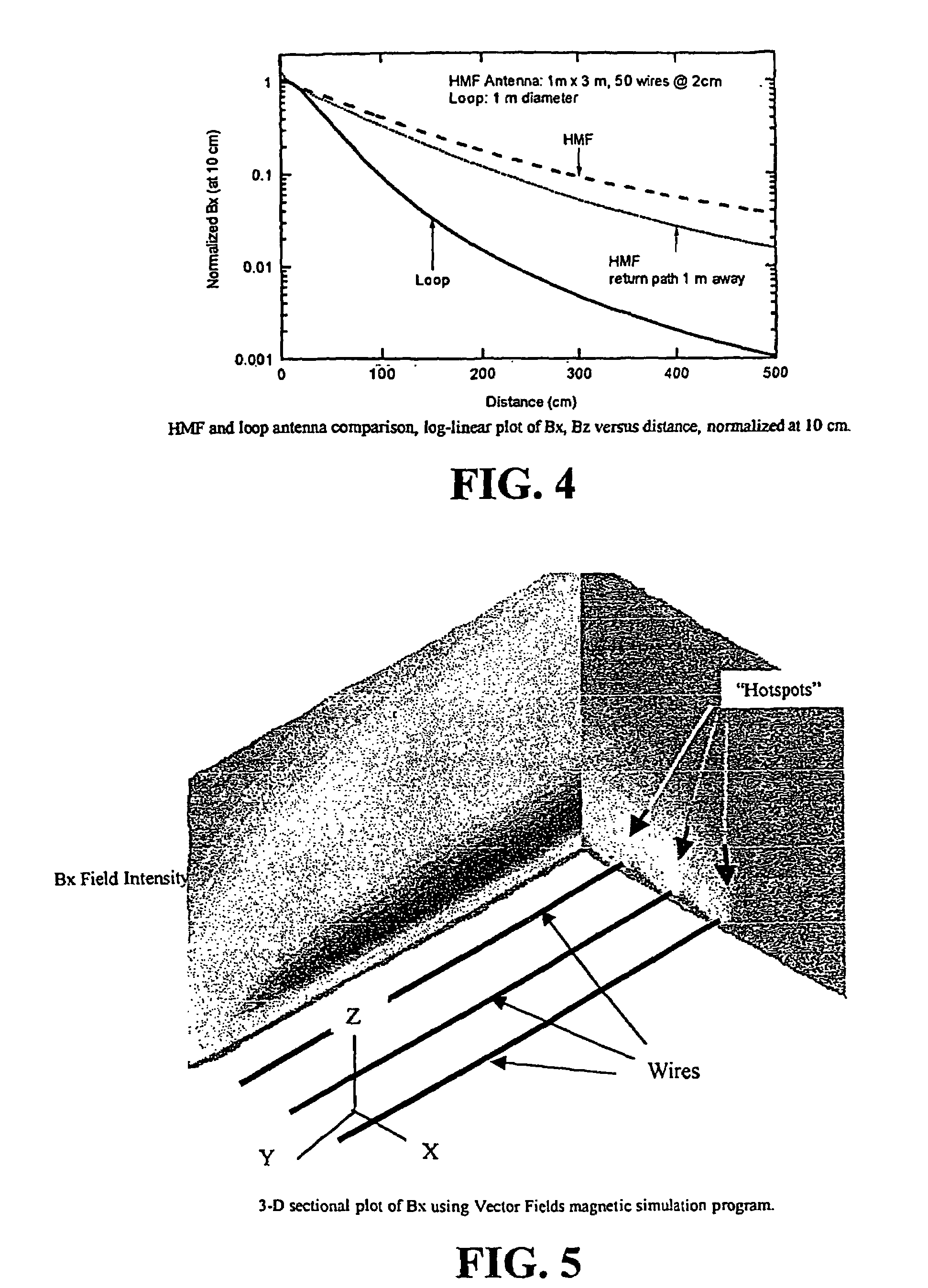

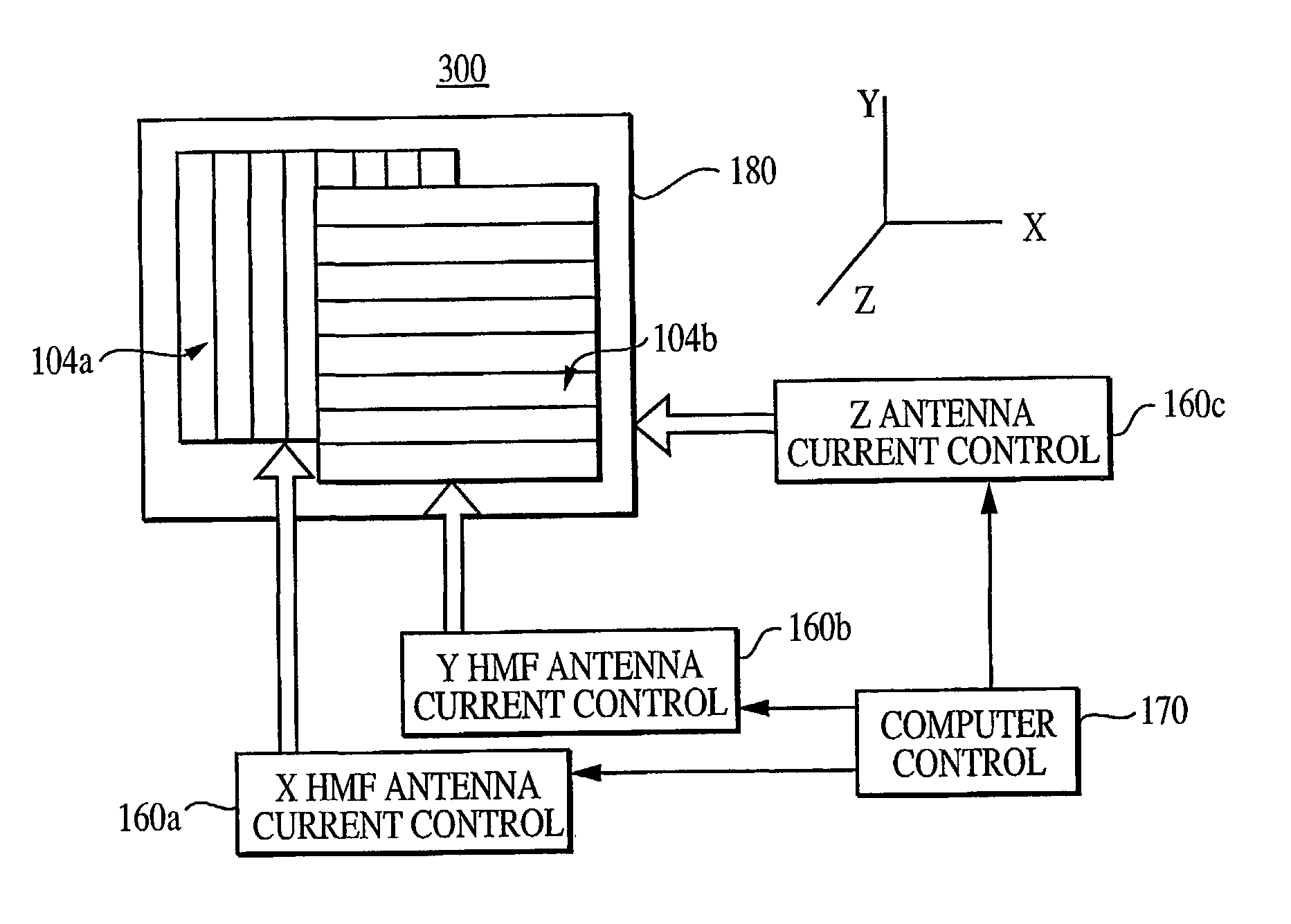

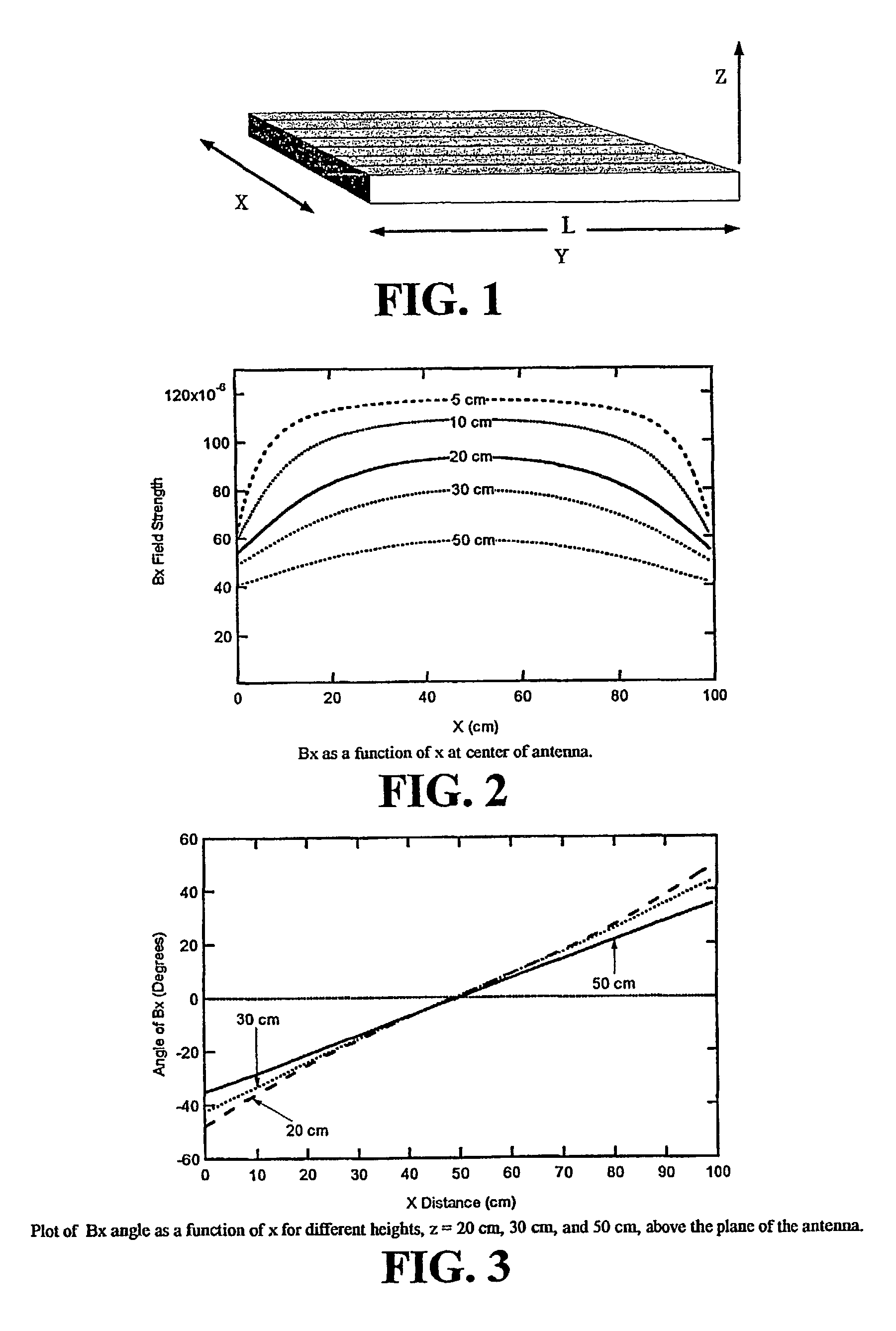

Steerable three-dimensional magnetic field sensor system for detection and classification of metal targets

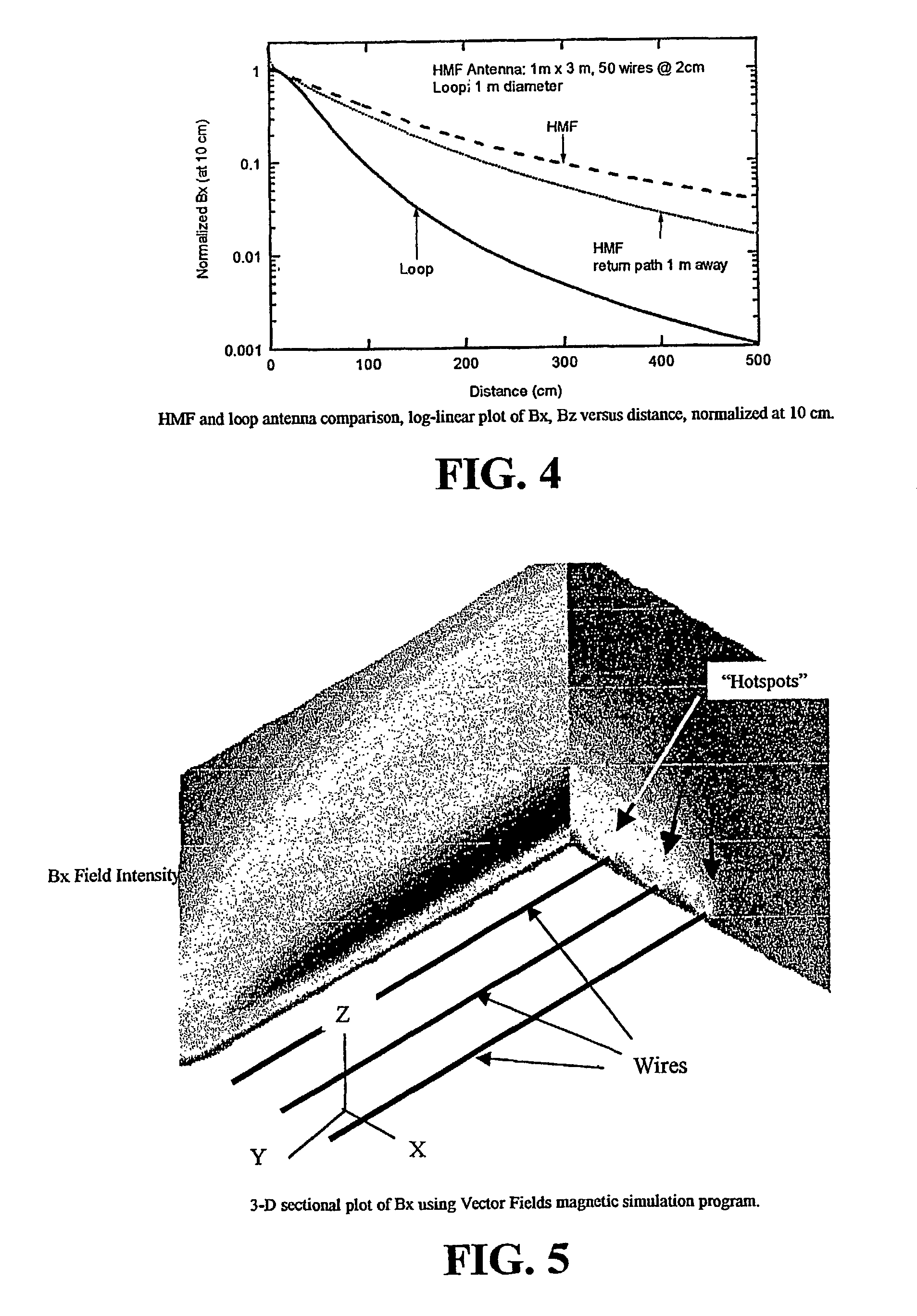

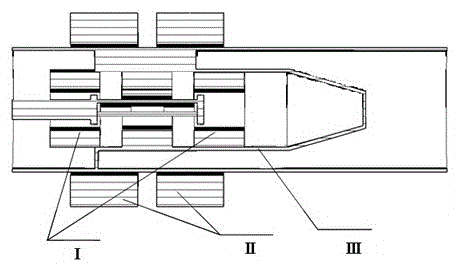

InactiveUS7030759B2Uniform magnetic fieldBurglar alarm by hand-portable articles removalBurglar alarm electric actuationPolarizability tensorPerpendicular magnetic field

A steerable electromagnetic induction (EMI) sensor system for measuring the magnetic polarizability tensor of a metal target. Instead of creating a vertical magnetic field from a horizontal loop transmitter configuration used by most prior art EMI metal detectors, the transmitter geometry of the sensor system's antenna is designed especially for creating multiple horizontal and vertical magnetic fields and for steering the same in all directions. The horizontal magnetic field (HMF) antenna has the potential advantage of a relatively uniform magnetic field over a large volume. A second potential advantage of the HMF antenna is that compared to a conventional loop antenna, the magnetic field intensity falls off slowly with distance from the plane of the antenna. Combining two HMF sensor systems creates a steerable two-dimensional magnetic field sensor. Combining the steerable HMF sensor with a vertical magnetic field antenna forms a three-dimensional steerable magnetic field sensor system.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Permanent-magnet packaging relativistic magnetron

The invention discloses a permanent-magnet packaging relativistic magnetron, which is of a whole-cavity extraction axial output structure composed of a cathode outer cylinder, an anode outer cylinder and an axial extraction structure. The permanent-magnet packaging relativistic magnetron comprises a plurality of annular permanent magnets, wherein a part of the permanent magnets sleeve the anode outer cylinder, the other part of the permanent magnets sleeve a cathode in the anode outer cylinder, and the permanent magnets and the magnetron are coaxially arranged. The permanent-magnet packaging relativistic magnetron adopts the internal embedding and external loading combined method for arranging the permanent magnets, enlarges size of the uniform region of the permanent magnets, a part of the permanent magnets are embedded in the interior of the magnetron, the internal space of the magnetron is fully utilized, so that the whole permanent-magnet packaging structure is compact. The permanent-magnet packaging structure can provide the required uniform magnetic field for the relativistic magnetron stably for a long time, so that the relativistic magnetron operates and generates gigawatt-level high-power microwave output, and can be well applied to compact-structured high-power microwave systems running at repeated frequency.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

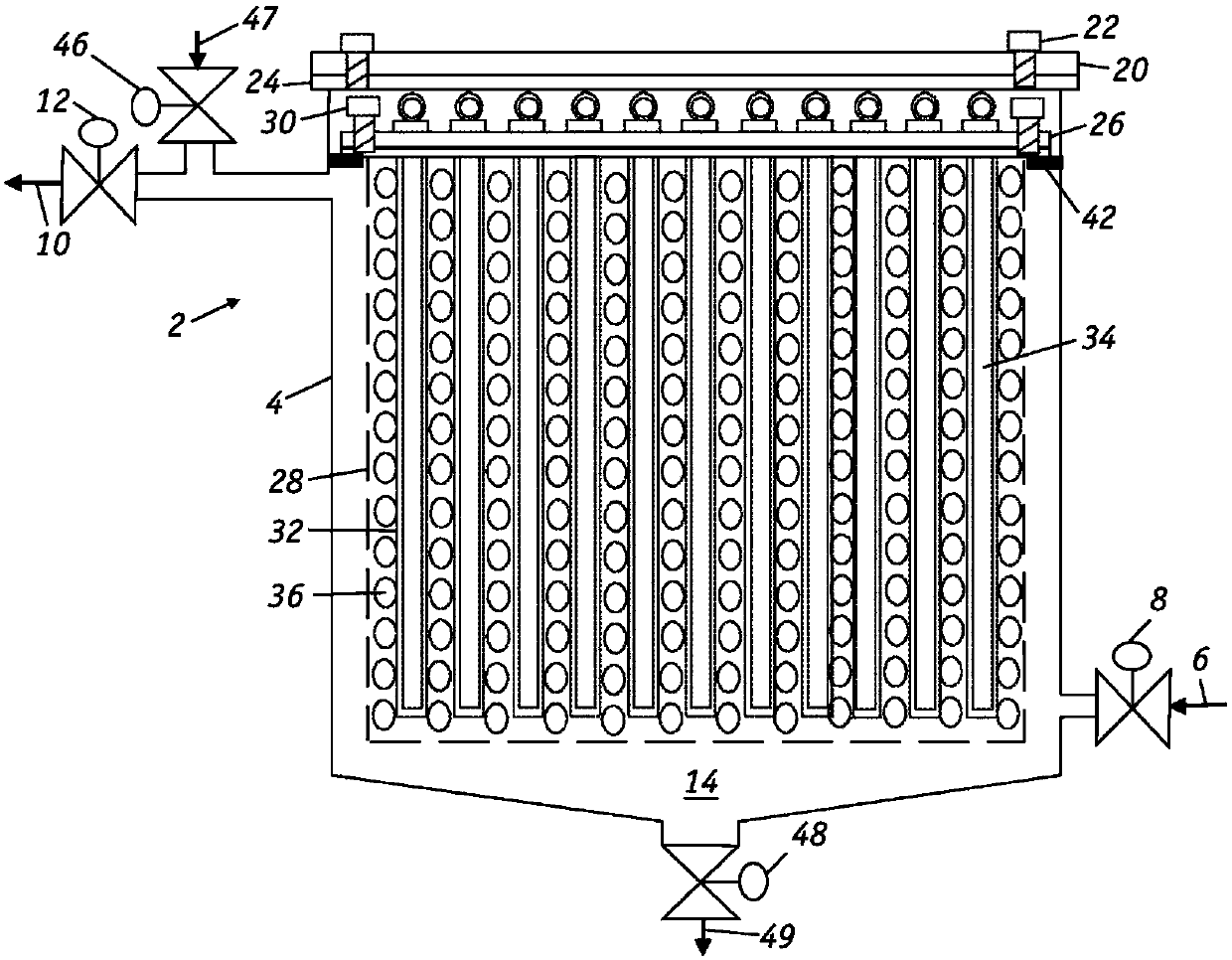

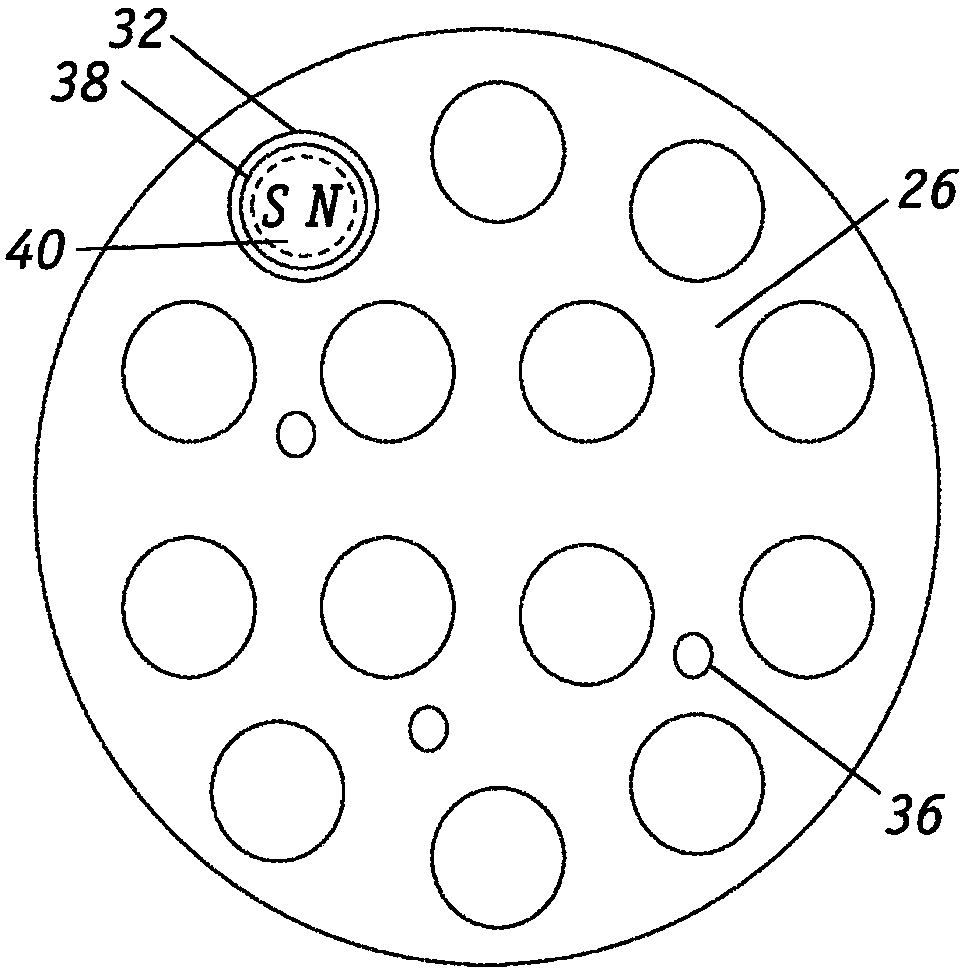

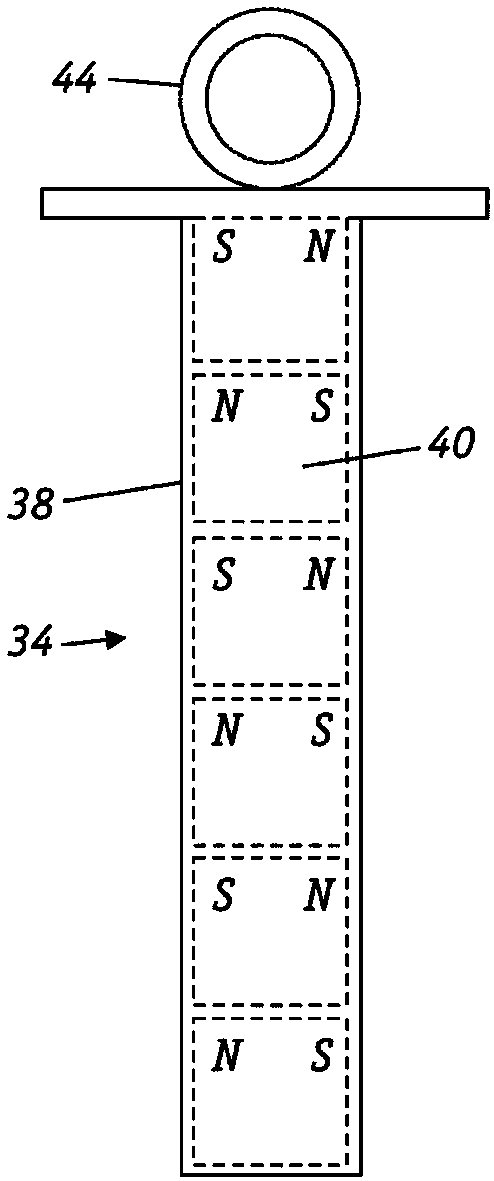

Filters for paramagnetic and diamagnetic substances

ActiveCN107921441AUniform magnetic fieldDispersed particle filtrationElectrostatic separationMagnetic sourceNon magnetic

A high capacity magnetic filter separates diamagnetic and / or paramagnetic substances from fluid streams. Diamagnetic solid substances are magnetized under an external magnetic field through coordinated interaction of diamagnetic solid substances with an inducement paramagnetic material (IPM). The magnetic filter serves as a separation zone created by the presence of IPM and magnets that are shielded from the IPM by non-magnetic sleeves or partitions. The IPM in the void volume between the magnets affords large surface area onto which diamagnetic and paramagnetic materials can contact and be attracted to. The relative position and distance of the magnetic source, such a magnetic bar or electromagnet, to the solid mixture of diamagnetic and IPM are adjusted to induce sufficiently strong magnetism in the diamagnetic solids which causes the diamagnetic solids to be attracted by the magnetic field as well. Both diamagnetic and paramagnetic substances can be removed from a liquid or gas.

Owner:SHIN CHUANG TECH CO LTD

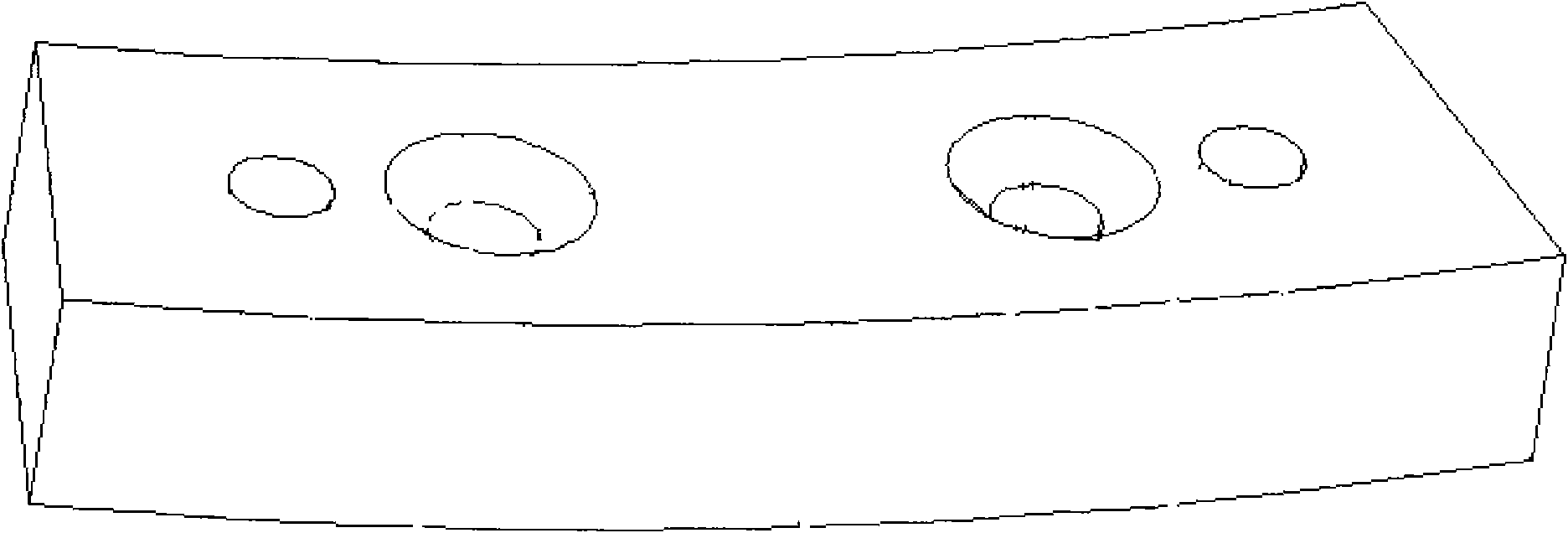

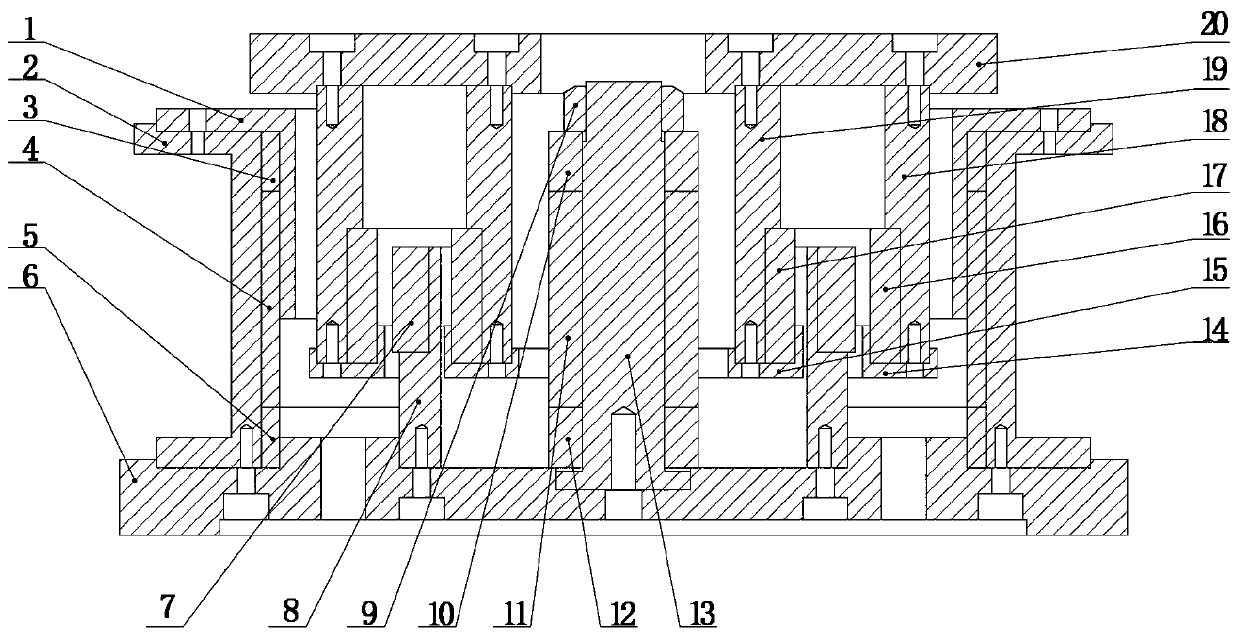

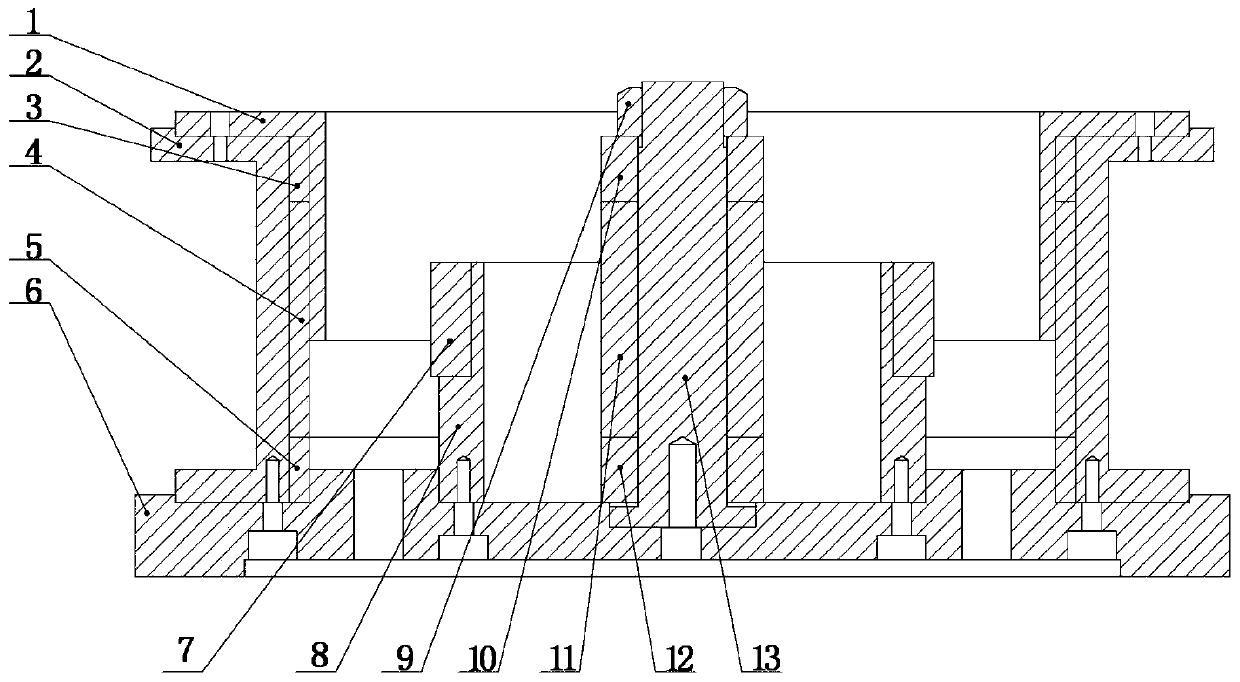

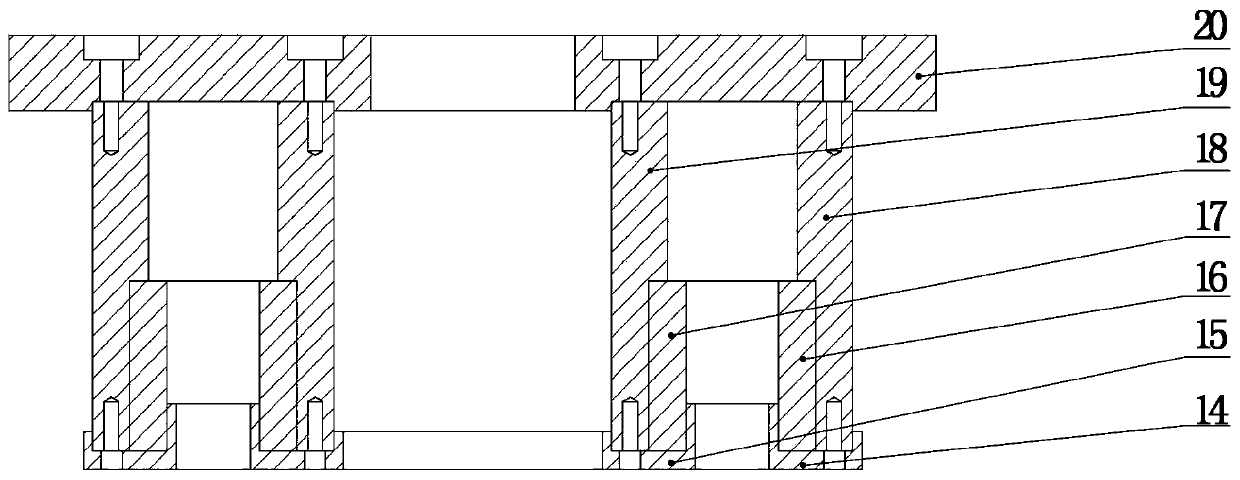

Magnetic material powder forming mold

ActiveCN102847938ADoes not affect suppressionUniform magnetic fieldShaping pressSaturation polarizationHomogeneous magnetic field

The invention discloses a magnetic material powder forming mold, which comprises a female die, wherein a female die cavity is arranged in the female die; and the saturation polarization strength of at least one side face of the female die cavity is consistent with the saturation polarization strength of magnetic material powder to be pressed. According to the magnetic material powder forming mold, the saturation polarization strength of the at least one side face of the female die cavity is consistent with the saturation polarization strength of the magnetic material powder, so that an edge distortion phenomenon of a magnetic field is transferred from the magnetic material powder to a side face of the female die cavity made of the material, the magnetic field of the magnetic material powder is guaranteed to be a uniform magnetic field, and the performance of a blank made through the mold is guaranteed. Because of an arrangement mode of an isolating plate, the material with the saturation polarization strength consistent with that of the magnetic material powder is arranged on different side faces according to different requirements, so that the application range is wide and the pressing of the magnetic powder is not affected.

Owner:JIANGXI JLMAG RARE EARTH

Crankshaft magnetic detector

ActiveCN101915802AUniform magnetic fieldSufficient magnetizationMaterial magnetic variablesFailure rateMagnetization

The invention provides a crankshaft magnetic detector comprising a main body and a control cabinet, wherein a head frame chunk and a tail frame chunk are arranged on a guide rail of a main body frame assembly to clamp an electrified circumferential magnetizing device, a left head-frame chunk base is fixed, the position of a right tail-frame chunk base can be moved and locked according to the length of a crankshaft, an air cylinder which is used for clamping the crankshaft is arranged behind the tail frame chunk, conducting plates which are electrified after clamping the crankshaft are respectively arranged on shafts of the head frame chunk and the tail frame chunk, and the left and right sides of the frame assembly are respectively provided with an electric case and a device pneumatic control case. The crankshaft magnetic detector is characterized in that a multiturn longitudinal magnetizing coil which can longitudinally extend is arranged between the head frame chunk and the tail frame chunk, and a workpiece rotating device is arranged on the chunk conducting plates. The crank magnetic detector can complete longitudinal magnetization or complex magnetization of the whole length of the crankshaft with a length between 800mm and 1500mm once, sufficiently and evenly magnetizes the parts of the crankshaft, is safe and reliable and has low failure rate.

Owner:SHANGHAI CHENGYOU INDAL GROUP +2

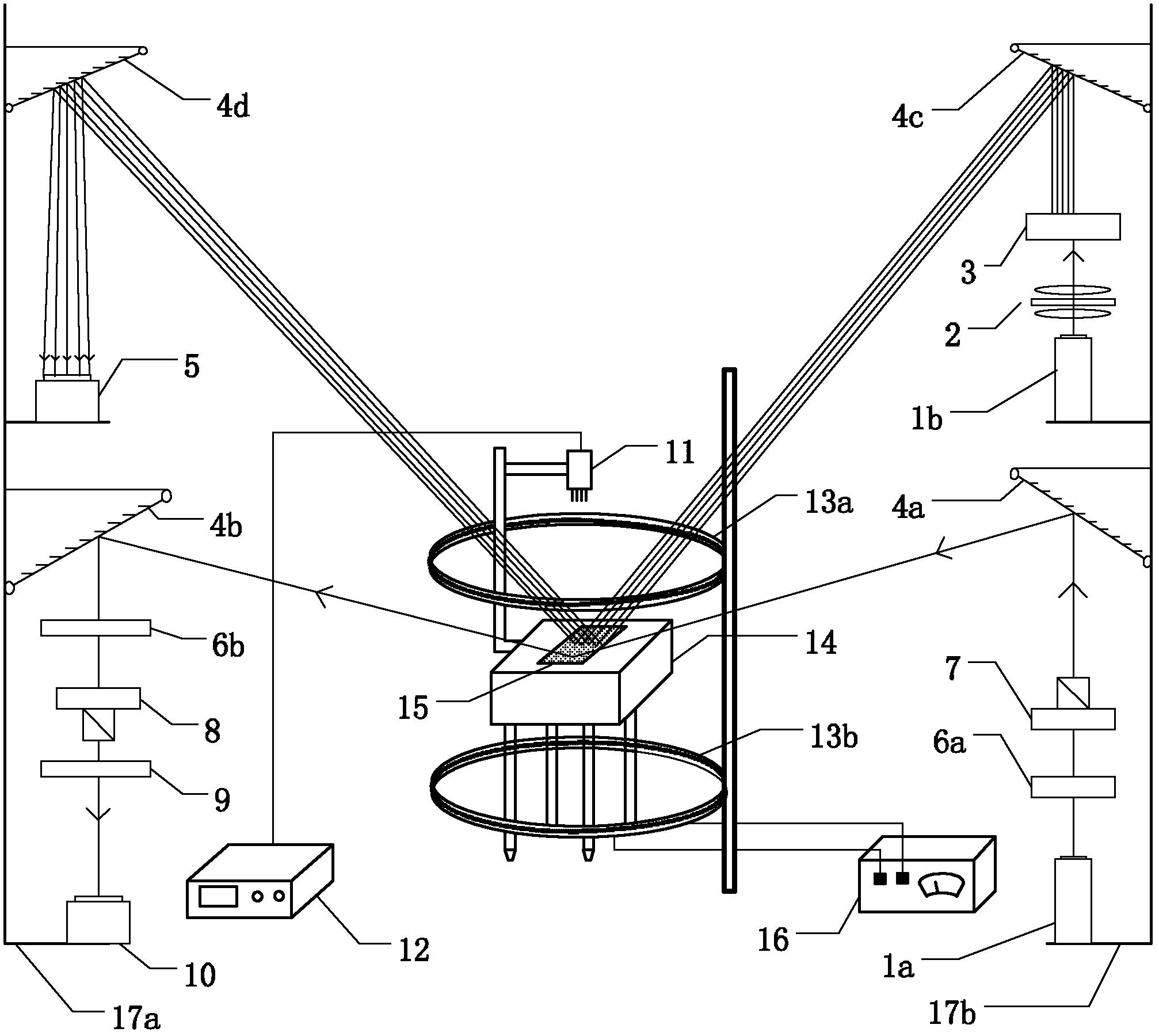

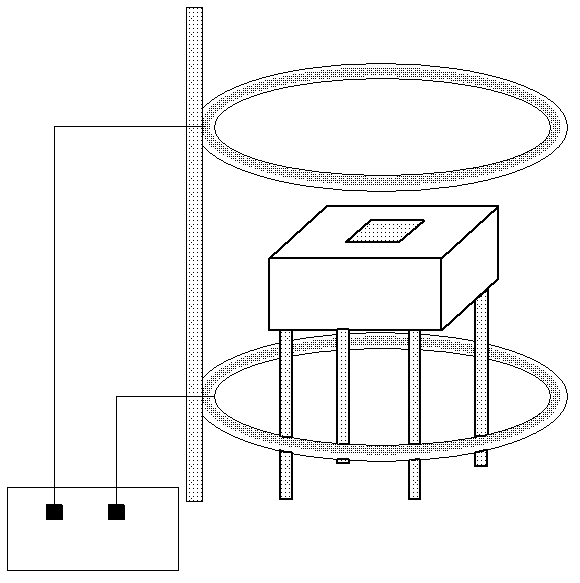

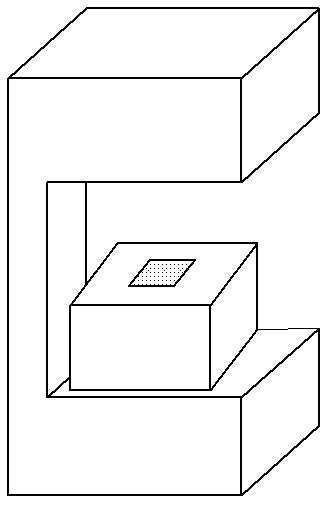

Device and method for detecting force electromagnetic coupling behavior of giant magneto resistive film

ActiveCN102508179ARealize online simultaneous measurementUniform magnetic fieldResistance/reactance/impedenceForce measurement by measuring optical property variationHysteresisFilm resistance

The invention discloses a device and a method for detecting the force electromagnetic coupling behavior of a giant magneto resistive film, and belongs to the technical field of engineering materials, structural deformation, mechanics experiment and electrical experiment. The device comprises a magnetic field generator, a giant magneto resistive film hysteresis loop measurement optical path, a film stress measurement optical path, and a film resistance probe tester. The giant magneto resistive film hysteresis loop measurement optical path comprises a laser, diaphragms, reflectors, a polarizer, an analyzer, a lens and a photoelectric detector; and the film stress measurement optical path comprises a laser, a spatial filter, a calibrator, reflectors, and a charge couple device (CCD) camera. A uniform magnetic field is provided by the magnetic field generator; the hysteresis loop is measured according to a magneto-optic Kerr effect; curvature of the surface of the film is measured by a multi-beam optical stress sensitivity technology; the stress of the film is obtained according to the relation expression of the curvature and the stress; the resistivity of a film material is measured by the film resistance probe tester; and coupling relational expressions of the resistance of the giant magneto resistive film and the magnetic induction density and stress of the film can be obtained finally.

Owner:TSINGHUA UNIV

Gravity compensator with low rigidity and large suspension force

ActiveCN111313763ALarge suspension forceUniform suspension forceMagnetic holding devicesEngineeringMagnetic field magnitude

The invention discloses a gravity compensator with low rigidity and large suspension force. A stator part comprises a stator inner ring permanent magnet, a coil and a stator outer ring permanent magnet; a mover part comprises a mover inner ring permanent magnet and a mover outer ring permanent magnet, the stator inner ring permanent magnet, the mover inner ring permanent magnet, the coil, the mover outer ring permanent magnet and the stator outer ring permanent magnet are sequentially arranged from inside to outside, gaps are formed between them, and the stator part and the mover part interactto generate suspension force. The inner ring and the outer ring of the stator respectively comprise three layers of permanent magnets in the axial direction such that the magnetic field intensity isincreased, and the suspension force generated by the gravity compensator is large; meanwhile, the magnetizing directions of an upper layer and a lower layer of the three layers of permanent magnets are opposite such that the magnetic field is more uniform, the suspension force is close to linearity, the suspension rigidity is reduced, the gravity of a load can be effectively compensated, the positioning of the bearing platform is realized, and the influence of internal and external disturbance sources on the load is reduced.

Owner:CHONGQING UNIV +1

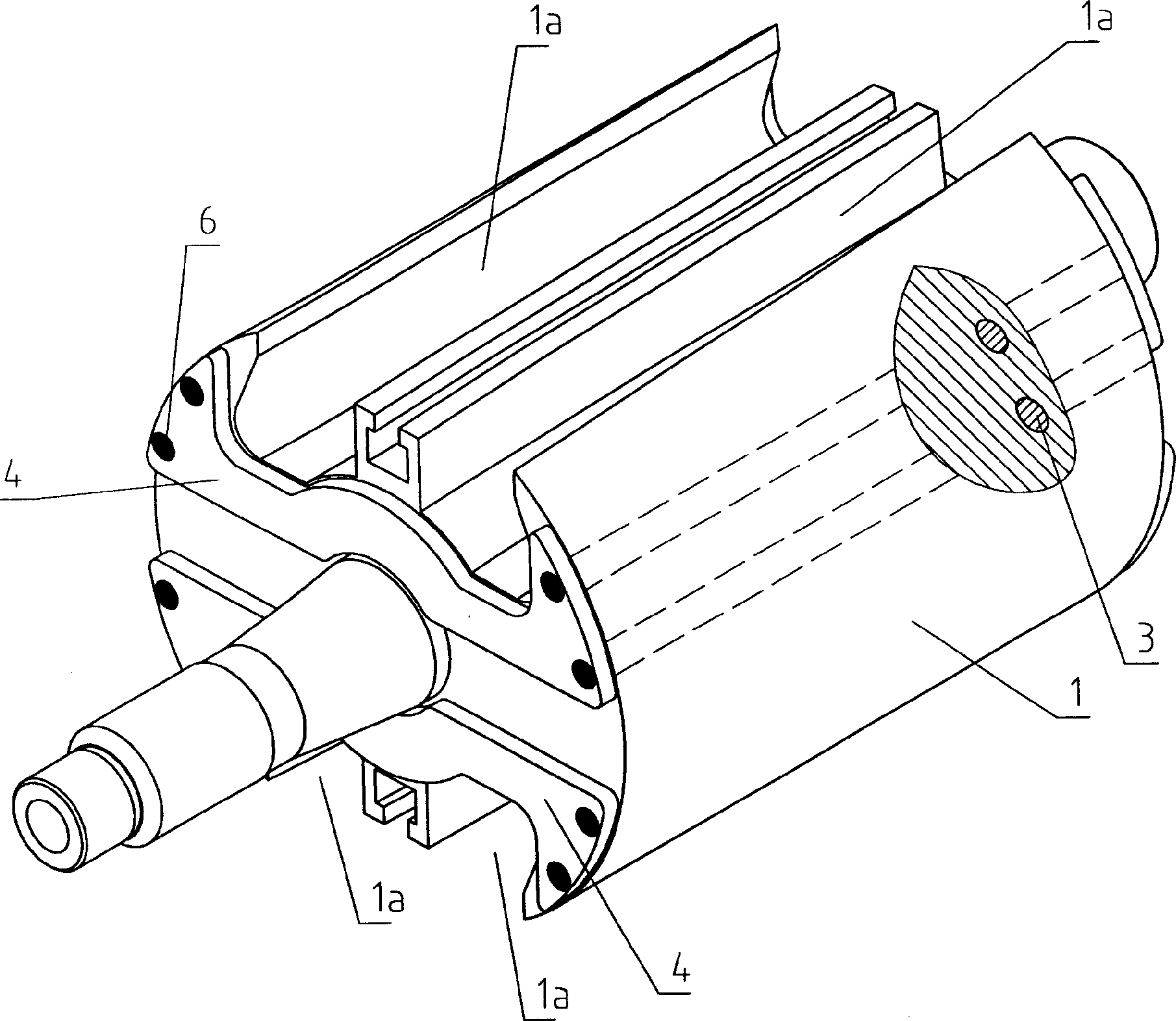

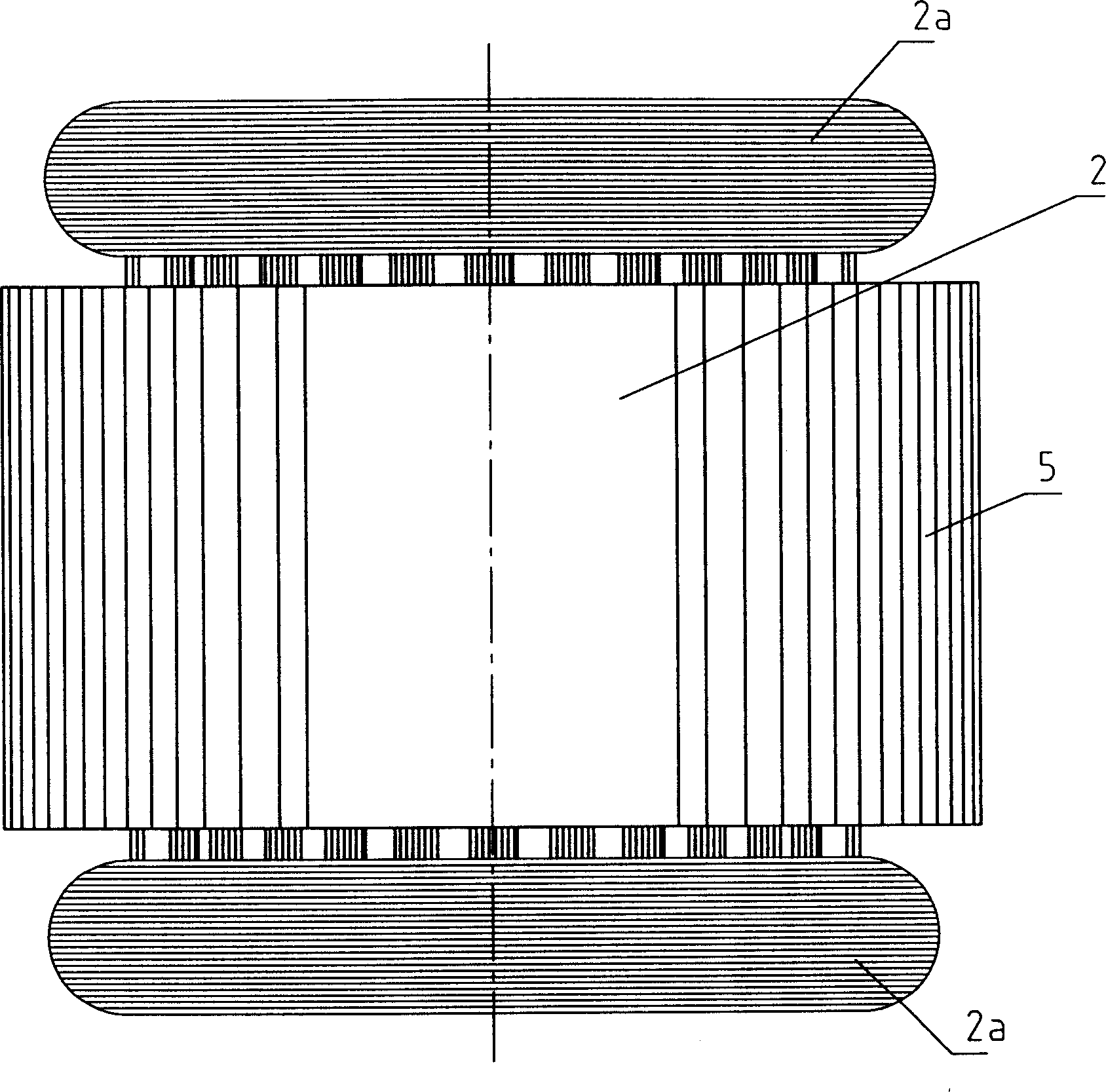

Small-sized dipolar single-phase generator

ActiveCN1665105AImprove distributionReduce lossSynchronous generatorsAsynchronous induction motorsSingle-phase generatorConductor Coil

The invention provides a small-scale bipolar single-phase generator, composed of a rotor and a stator, where the iron core of the rotor is provided with two damping windings, each composed of a damping bar and a damping plate, the damping plate arranged on two end faces of the iron core and the two ends of the damping bar axially passes through the iron core to be reliably connected with the damping plate; the stator winding coil is of a structure of equidistant bipolar winding. The winding slot on the rotor iron core makes an included angle of 3deg. - 5deg. with the wire embedding slot on the stator iron core. The outer surface of the stator iron core is distributed with axial grooves. The output voltage of the invention is stable and has good waveform, nearer to sine wave and having stronger adaptability to capacitance-type load, beneficial to prolonging the life of electric appliances and thus having a wide application range.

Owner:江苏神驰机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com