Patents

Literature

282results about How to "Save handling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

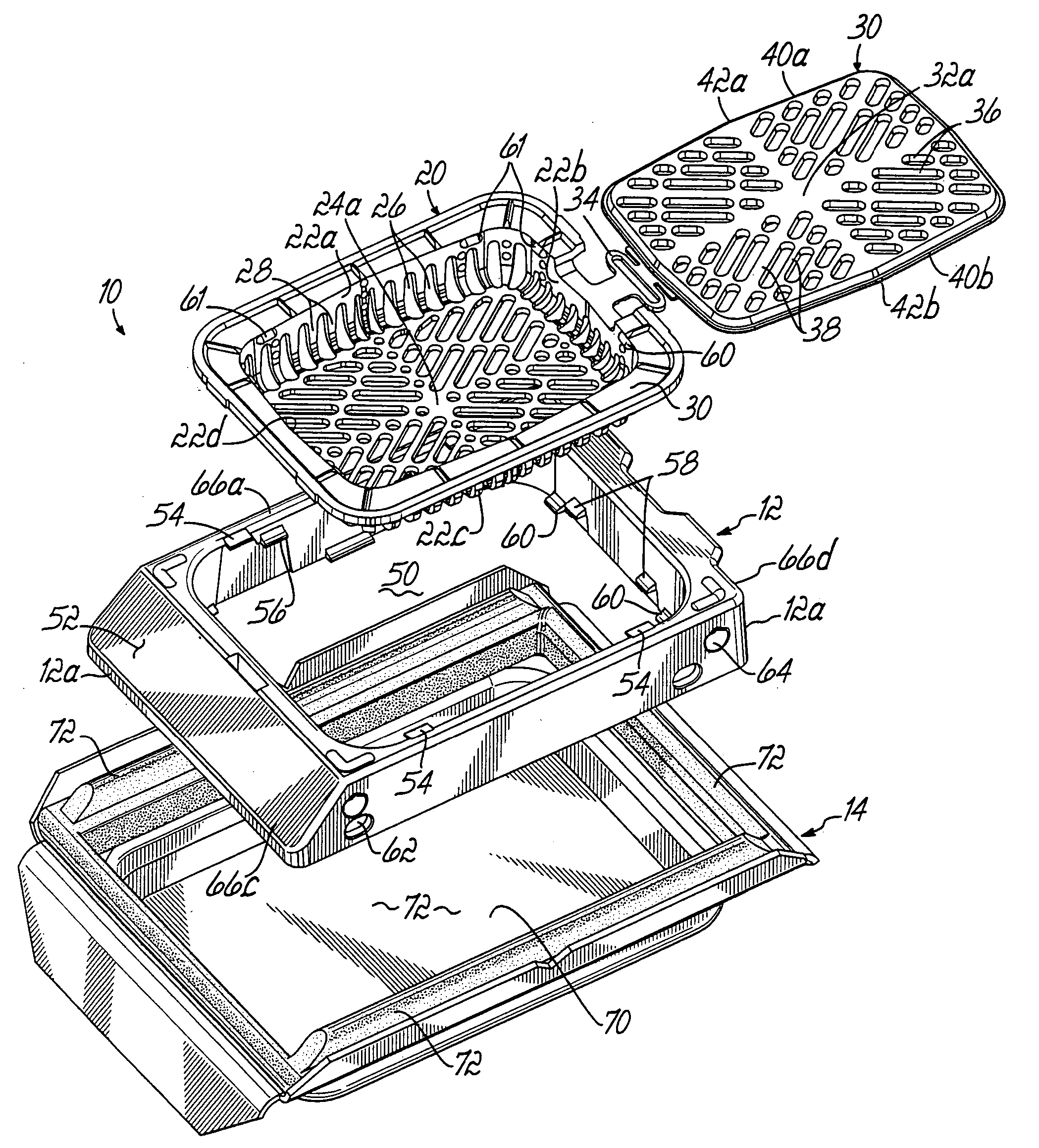

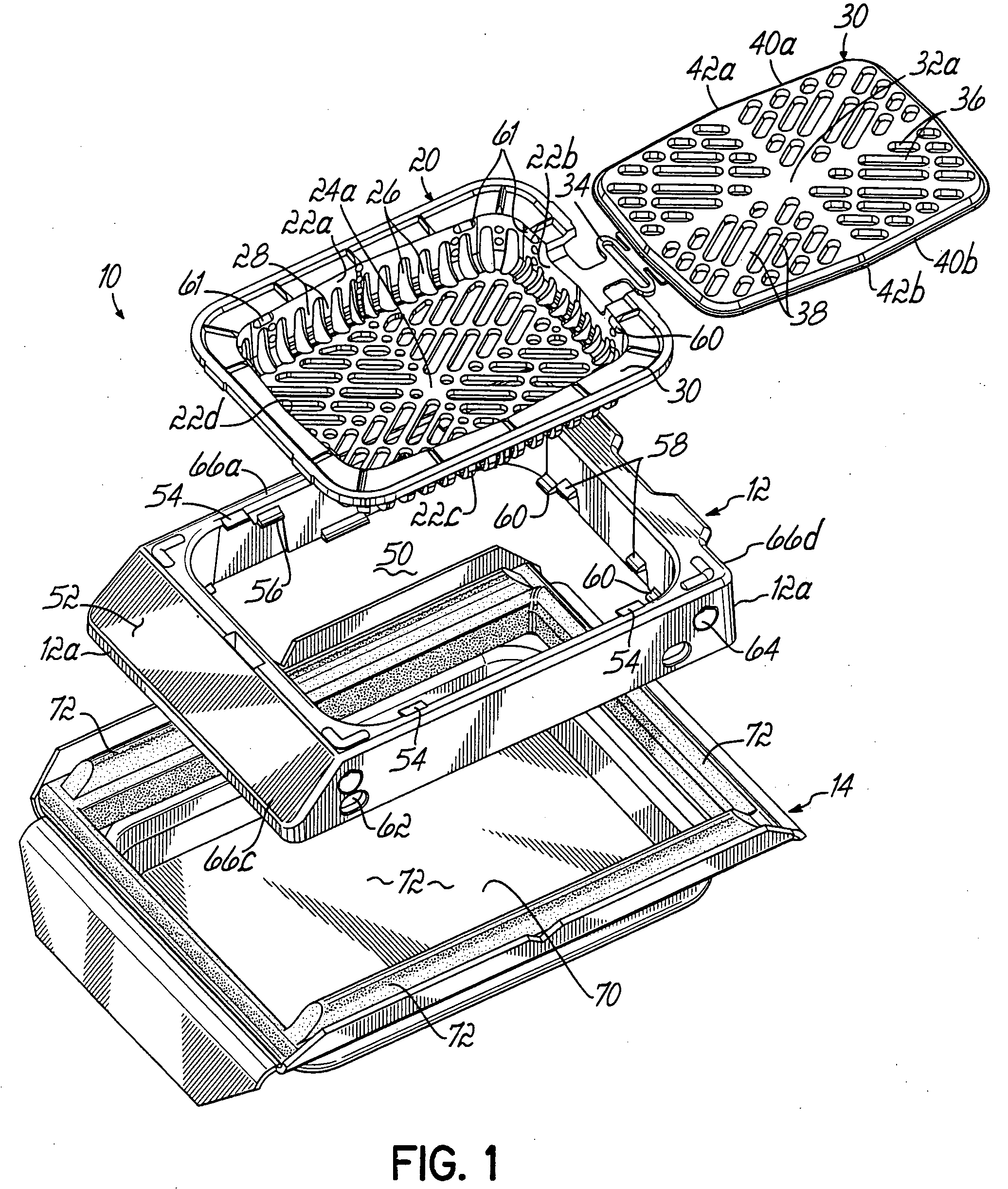

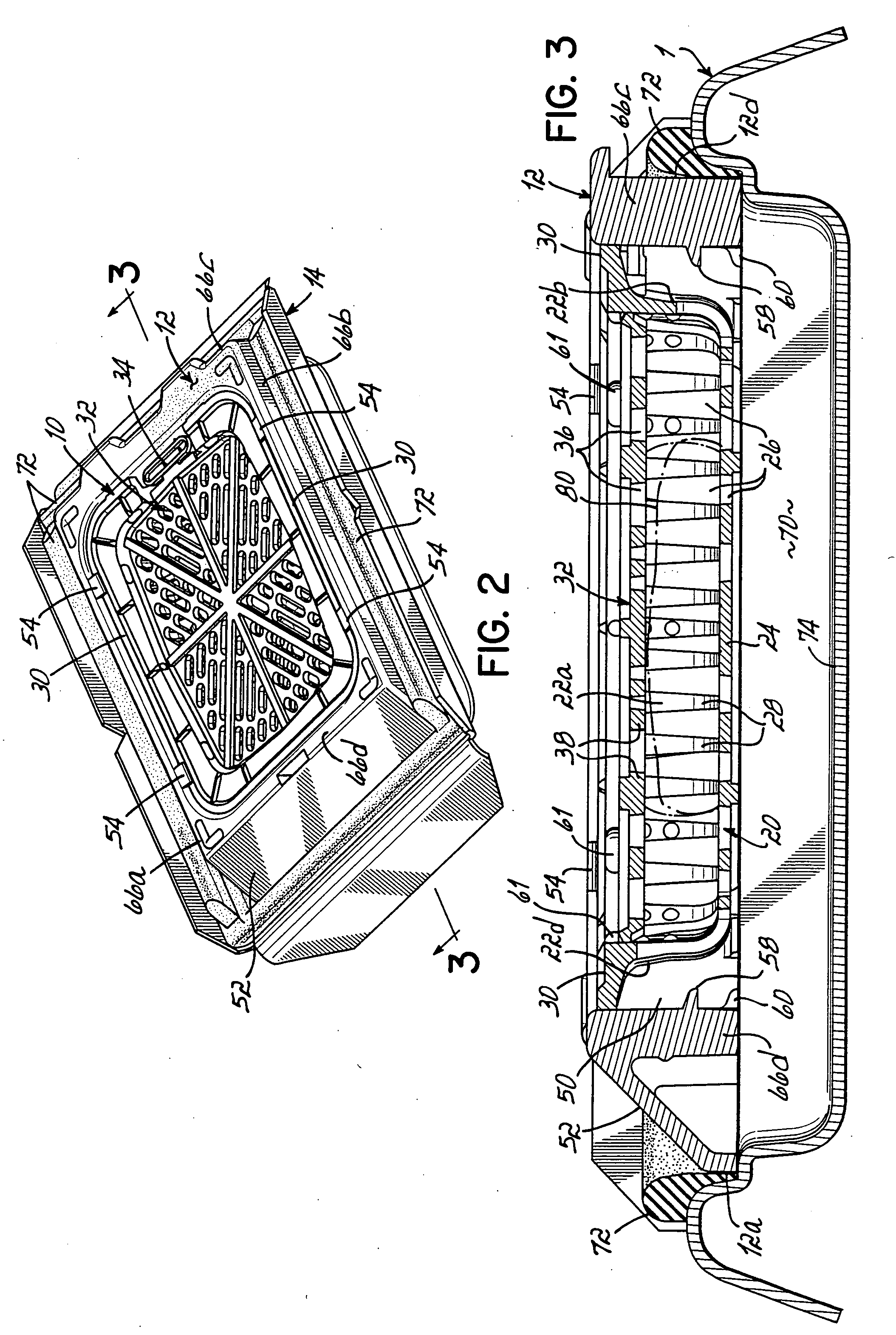

Cassette and embedding assembly for handling and holding tissue samples during processing, embedding and microtome procedures, staging devices therefore, and methods therefor

ActiveUS20050147538A1Reduce processing stepsSave amountBioreactor/fermenter combinationsBiological substance pretreatmentsDetentTissue sample

The disclosure relates to a cassette, frame and mold for holding a tissue sample during an embedding and mircotoming process, and related methods. The cassette is sectionable in a microtome and includes a body with a bottom wall and a plurality of side walls. First and second side walls are generally V-shaped to present an apex of the “V” to the microtome blade. A lid of the cassette is stiffer than the bottom wall of the cassette to assist with positioning the tissue sample. The side walls of the cassette are perforated so as to significantly reduce the amount of cassette material that must be cut by the microtome blade. In one embodiment, to additionally reduce blade wear the ribs on one side wall are offset lengthwise relative to the ribs on an opposite side wall. An upper flange of the cassette includes depressions configured to register with detents in the frame.

Owner:BIOPATH AUTOMATION

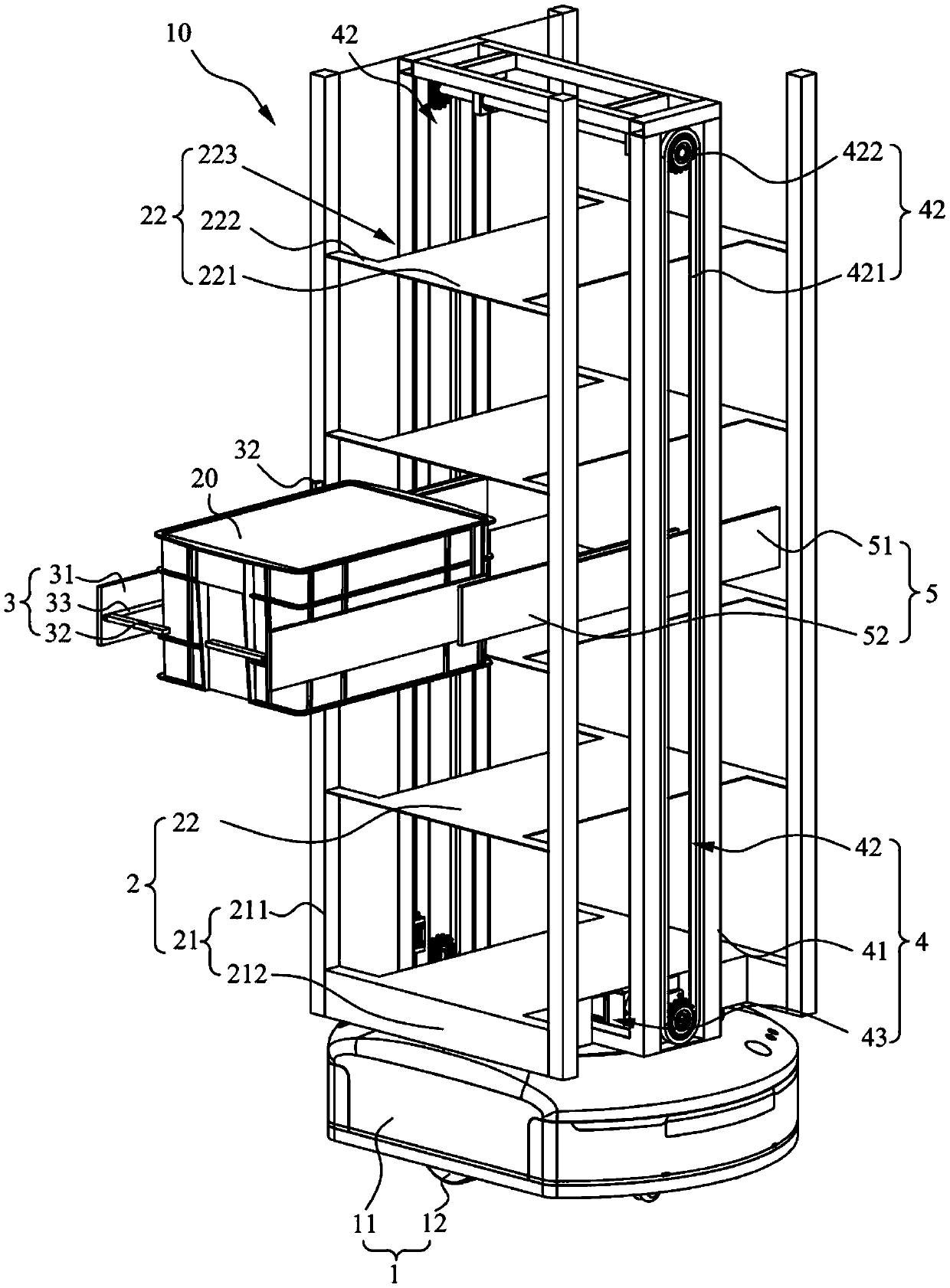

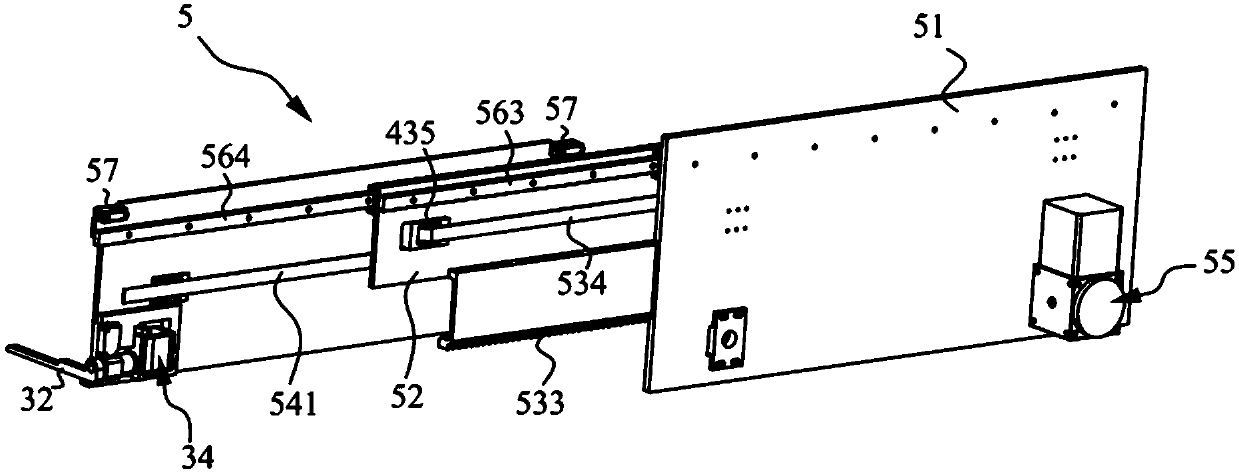

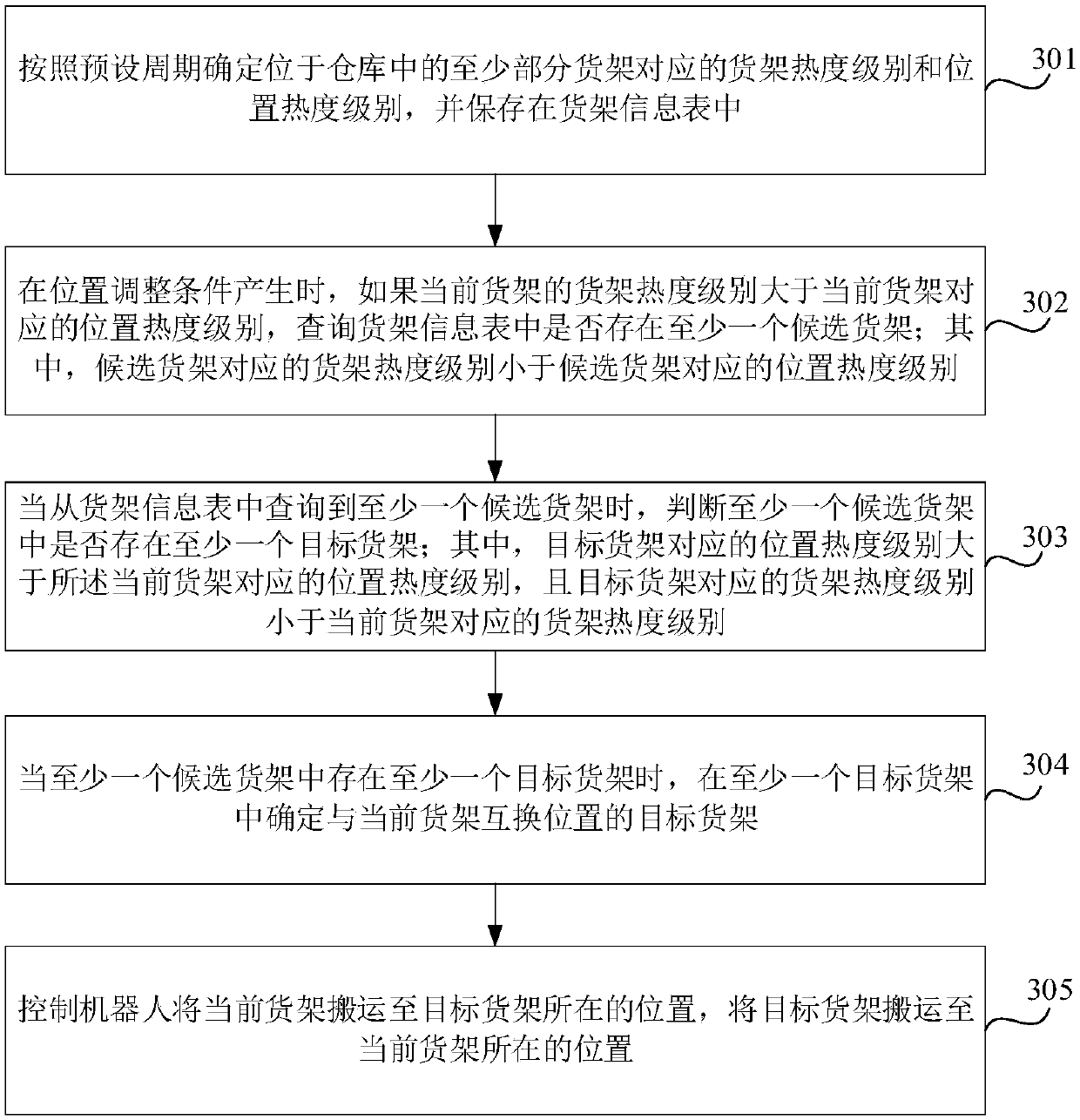

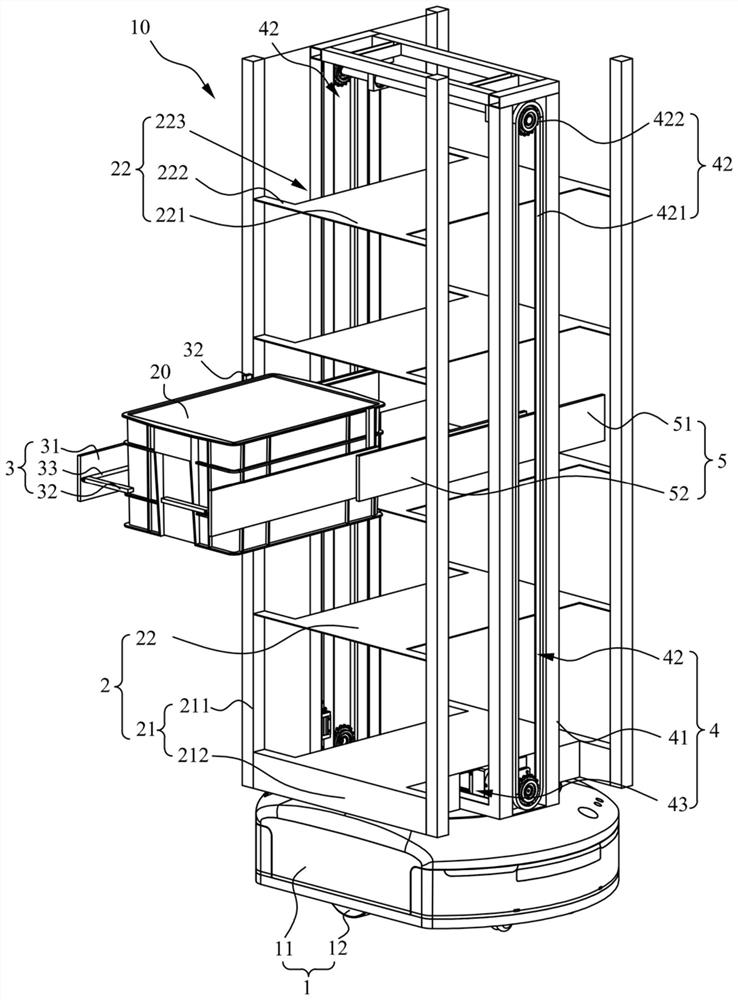

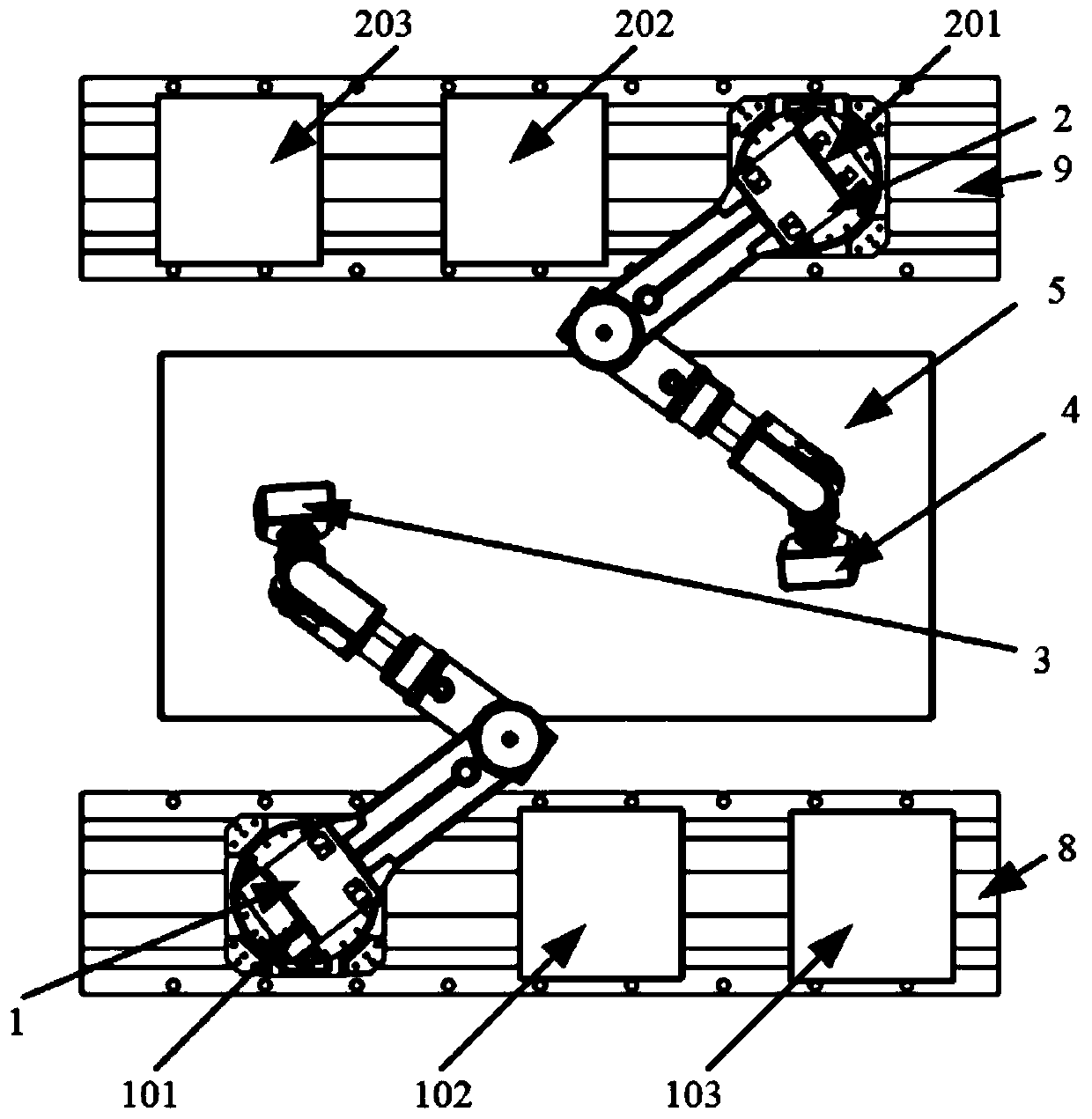

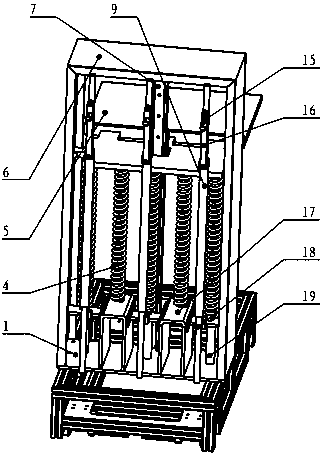

Handling robot, warehouse logistics system and packing box handling method

PendingCN109573449ALess room for movementIncrease profitStorage devicesLogistics managementMechanical engineering

The invention belongs to the technical field of warehousing logistics, and particularly discloses a handling robot, a warehouse logistics system and a packing box handling method. The handling robot comprises a movable base plate which can move along a channel between adjacent inventory containers, temporary storage racks which are arranged on the movable base plate and used for temporarily storing a target packing box, and box taking assemblies which are arranged on the movable base plate, wherein the box taking assemblies can horizontally stretch relative to the movable base plate so as to pick and place the target packing box between the inventory containers and the temporary storage racks, and the horizontal stretching direction of the box taking assemblies is perpendicular to the moving direction of the handling robot. The warehouse logistics system comprises the handling robot, and the packing box handling method adopts the handling robot to convey the target packing box. According to the handling robot, the warehouse logistics system and the packing box handling method, the occupied space of the handling robot on warehouse channels can be reduced, the utilization rate of thewarehouse can be improved, and meanwhile the handling efficiency of the packing box can be improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

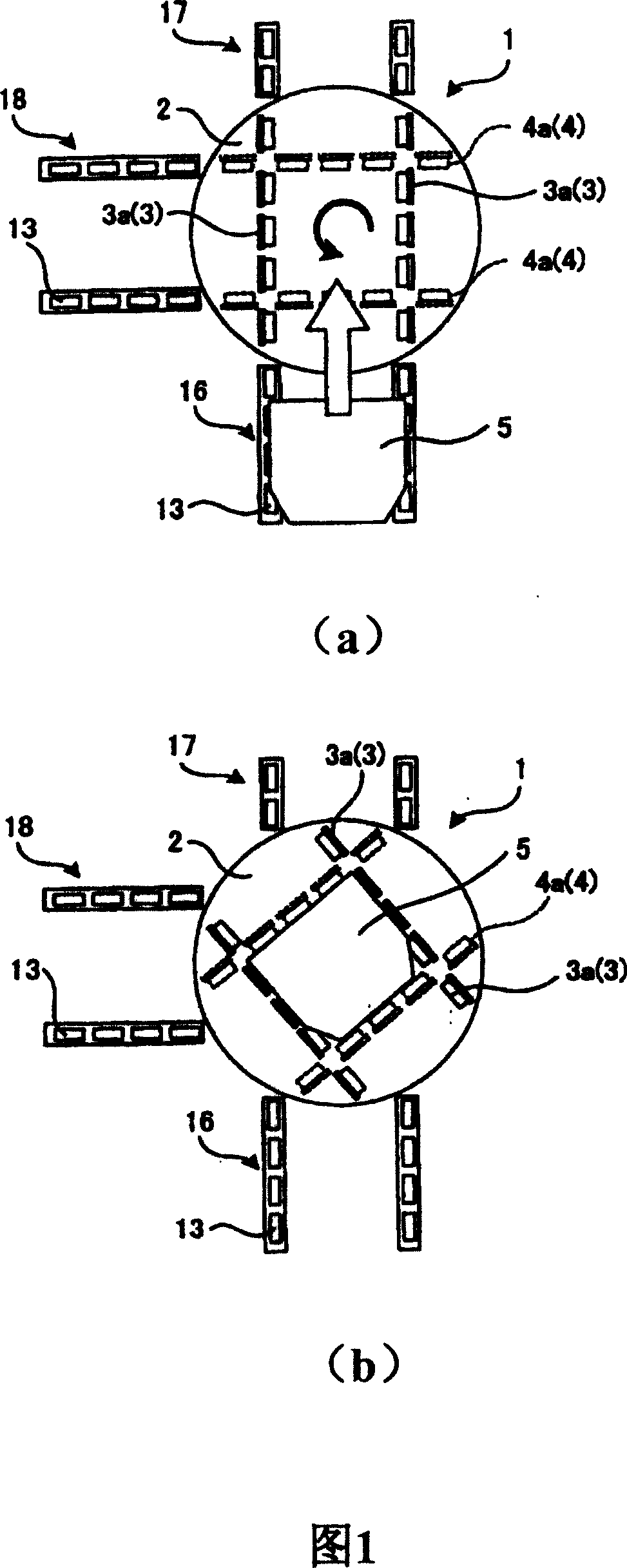

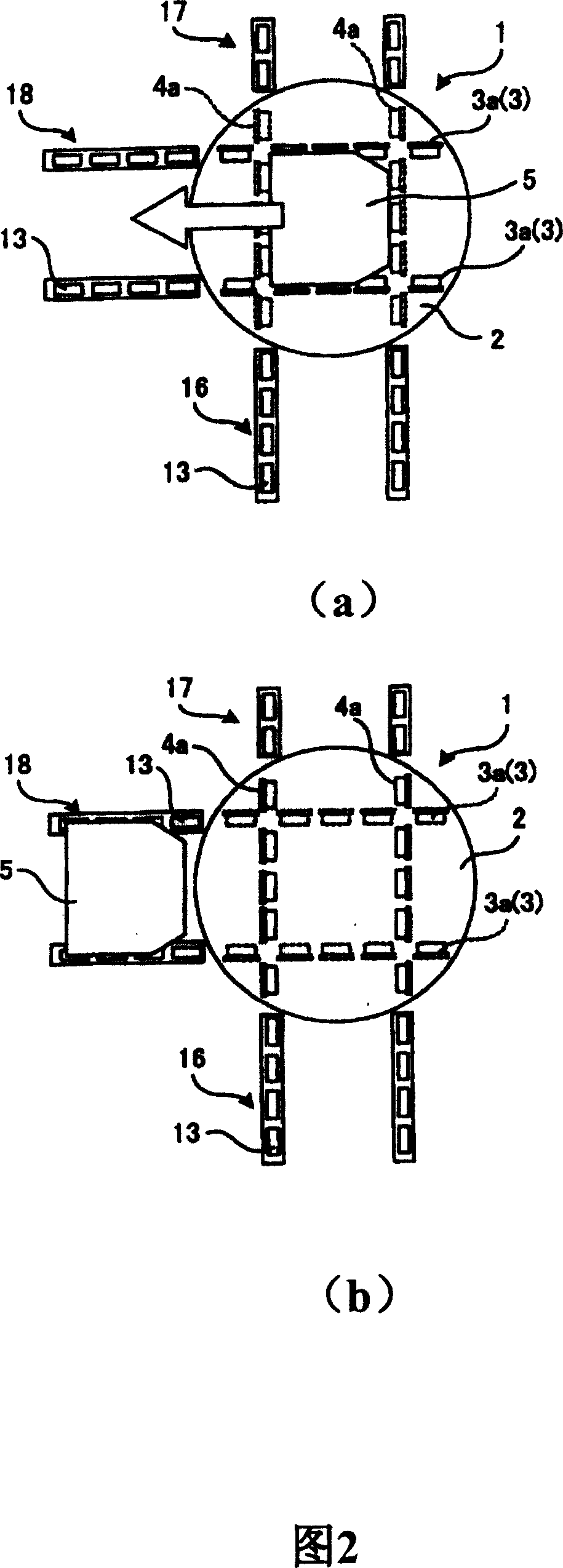

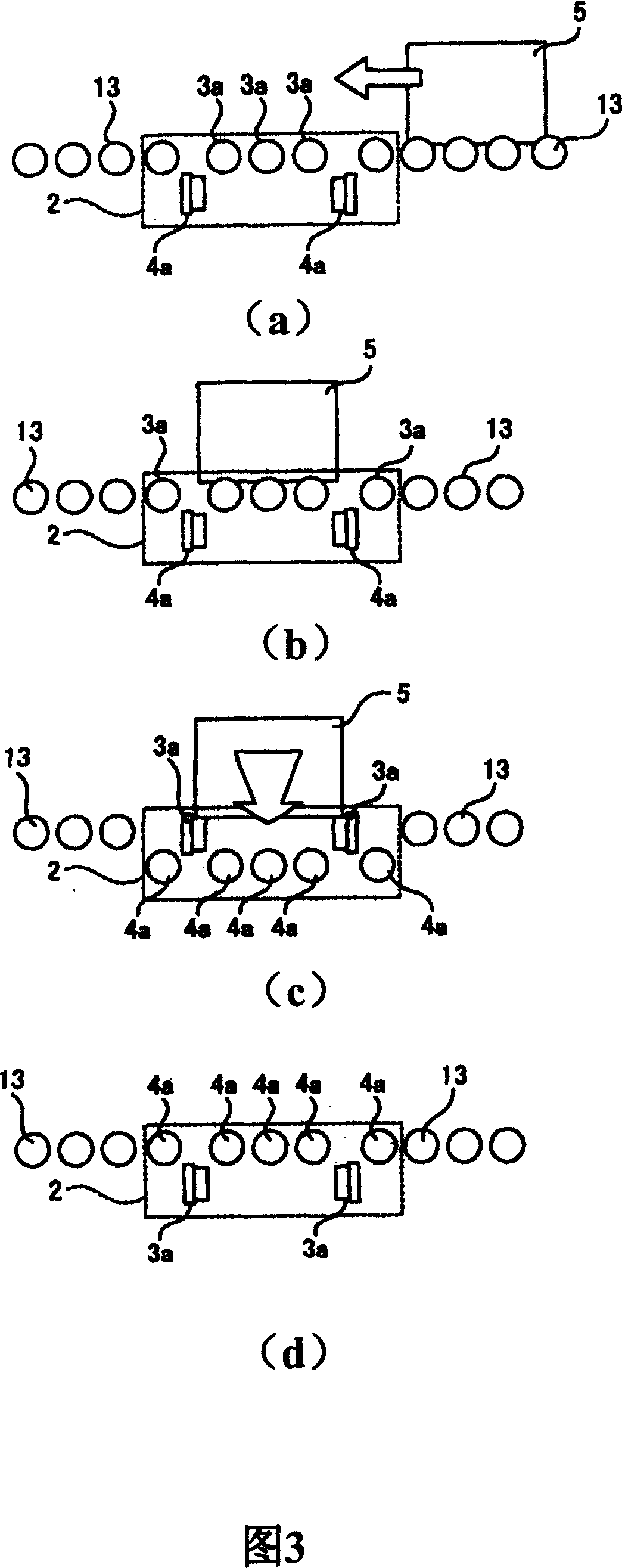

Direction change device

InactiveCN101020537ASave handling timeSemiconductor/solid-state device manufacturingControl devices for conveyorsTransport timeTransport engineering

The present invention provides a direction change device which can reduce the transport time, including first and second transport passage 3, 4, in which one of the transport passages is disposed at the same vertical position as that of the first transport rail 16, the other is disposed below the one, a rotating unit 22 rotating the transport passages 3, 4 about their central points, a lift unit 23 lifting the transport passages 3, 4 in a vertical direction and a control unit 21. The control unit 21 controls such that when the FOUP 5 is carried out from the transport rail 16 to the transport passage disposed at the same vertical position as that of the transport rail 16, rotating the transport passages 3, 4 by about 90 DEG, carrying out the FOUP 5 from one of the transport passages, and exchanging the respective vertical positions of the first and second transport passages 3, 4.

Owner:ASYST SHINKO INC

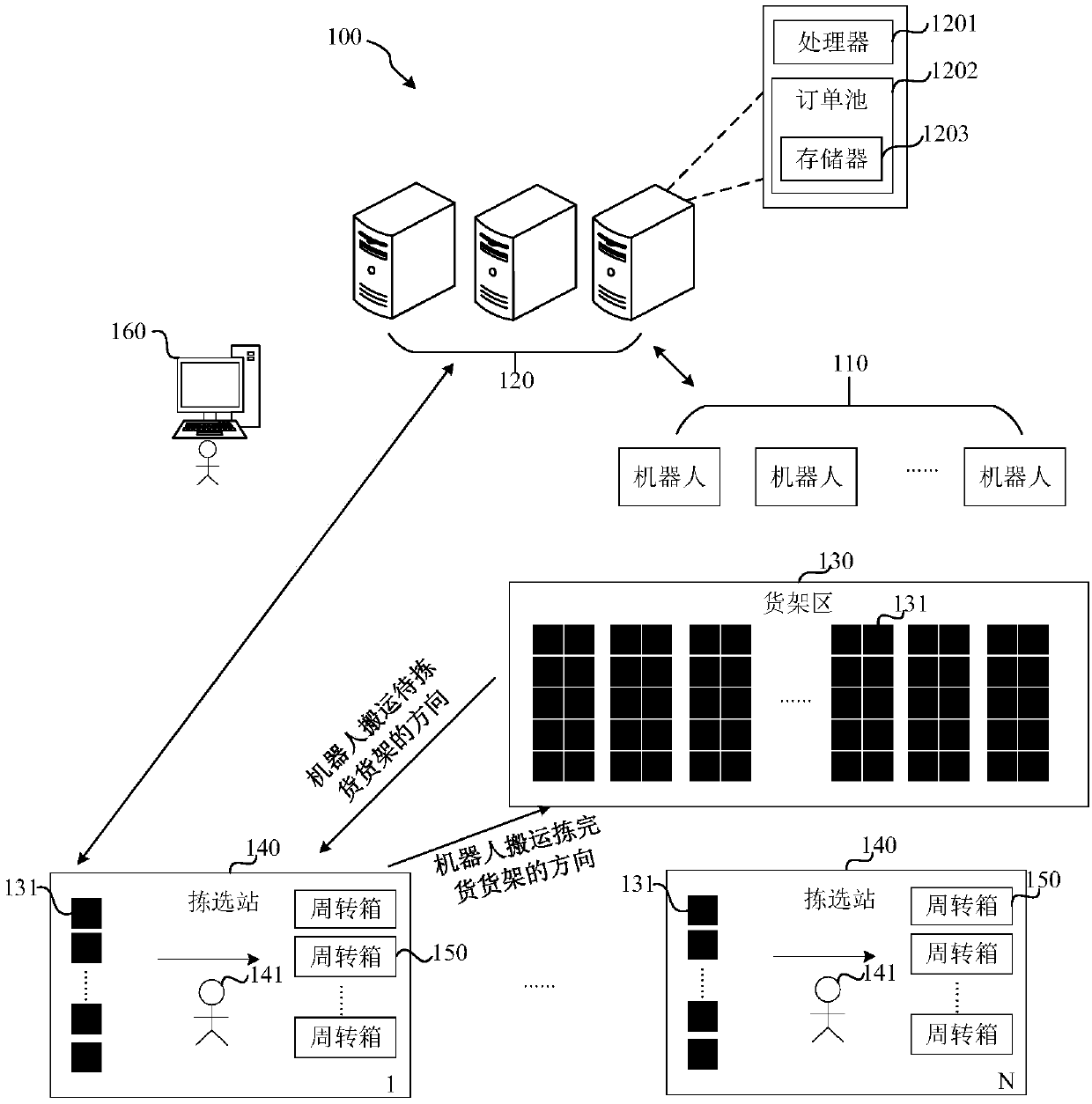

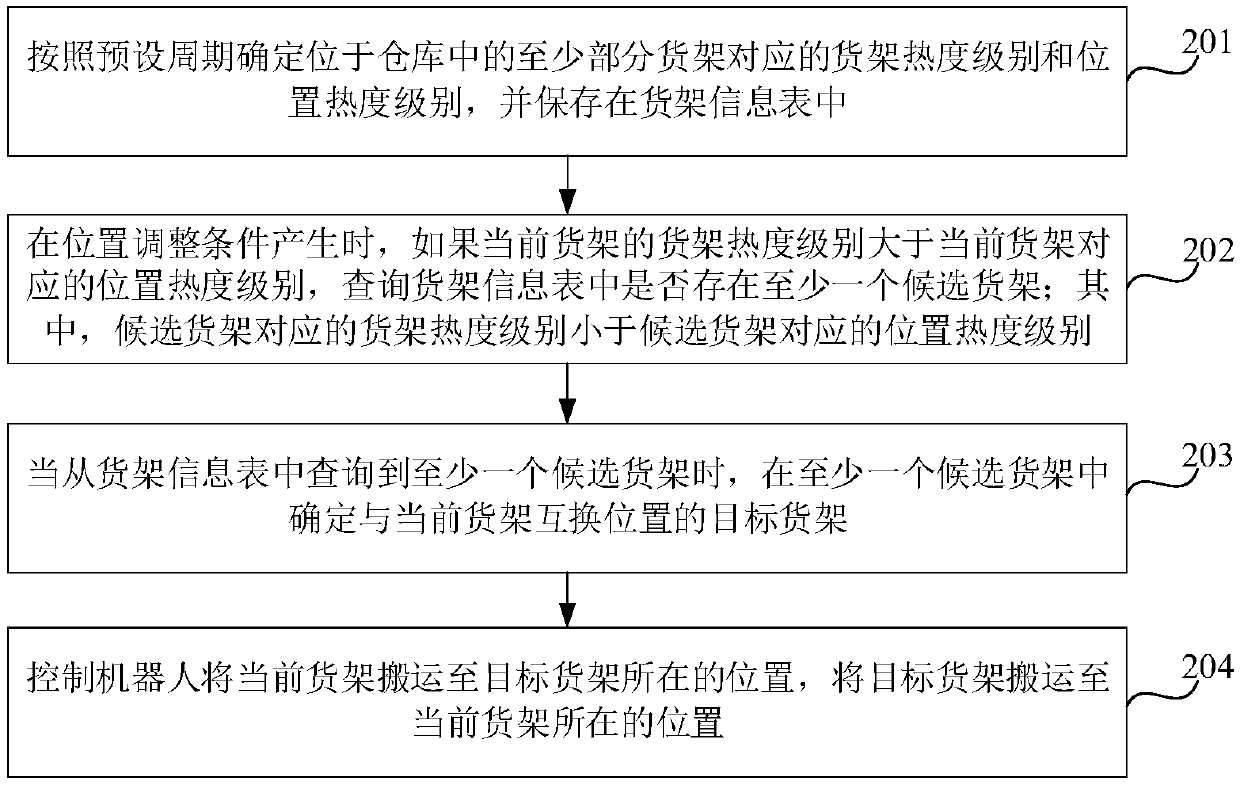

Shelf position adjusting method, device, computer device and storage medium

ActiveCN109086921AReduce the number of handlingShorten exercise distanceForecastingLogisticsComputer engineeringComputer device

The embodiments of the present invention disclose a shelf position adjusting method, a device, a computer device and a storage medium, The method comprises: determining a shelf heat level and a position heat level corresponding to at least a portion of shelves located in the warehouse according to a preset period, and stored in the shelf information table, as the position adjustment condition occur, if the shelf heat level of the current shelf is greater than the corresponding position heat level of the current shelf, querying whether at least one candidate shelf exists in the shelf information table, wherein the shelf heat level corresponding to the candidate shelf is smaller than the position heat level corresponding to the candidate shelf, and when the at least one candidate shelf is queried from the shelf information table, determining a target shelf in the at least one candidate shelf that is interchangeable with the current shelf; controlling the robot to move the current shelf to the location of the target shelf. The embodiment of the invention can reduce the moving distance of the shelf conveying robot, reduce the shelf conveying times, shorten the conveying time, and improve the picking efficiency.

Owner:BEIJING JIZHIJIA TECH CO LTD

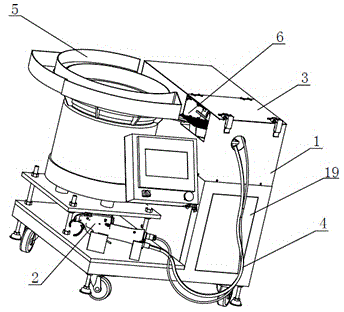

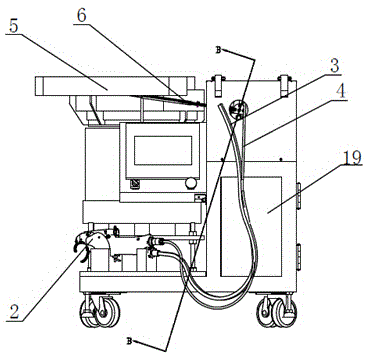

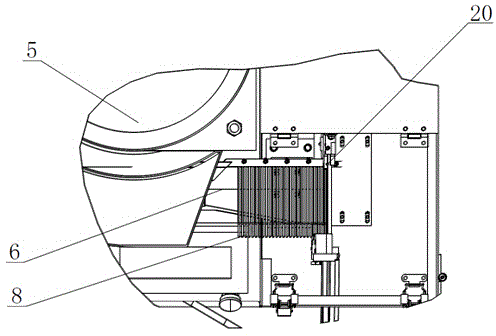

Hand-held automatic binding tool

ActiveCN104150006AImprove the efficiency of strapping operationsUniform tensionBinding material applicationBundling machine detailsHand heldEngineering

The invention provides a hand-held automatic binding tool which comprises a main machine, a gun head, a feeding pipe and a data line. The main machine is connected with the gun head through the feeding pipe and the data line. The hand-held automatic binding tool further comprises a vibrating plate and straight vibrator. The vibrating plate is located on the left side of the main machine. The straight vibrator is connected to the right side of the vibrating plate. The straight vibrator is connected with a pushing chamber. The vibrating plate screens and sorts bulk binding bands. When an optical fiber sensor detects that the front-most binding band is in position, an air cylinder pushes the front-most binding band into the feeding pipe, a trigger is pulled to allow compressed air to feed the binding band into the gun head, and the gun head completes winding, perforating, tightening and cutting off. The hand-held automatic binding tool has the advantages that binding efficiency is increased greatly, binding can be completed while hands are not in contact with the binding bands, labor intensity of workers is relieved greatly, the gun head is small in size and lightweight, and the gun head is connected with main machine through the flexible pipeline.

Owner:SHENZHEN SWIFT AUTOMATION TECH CO LTD

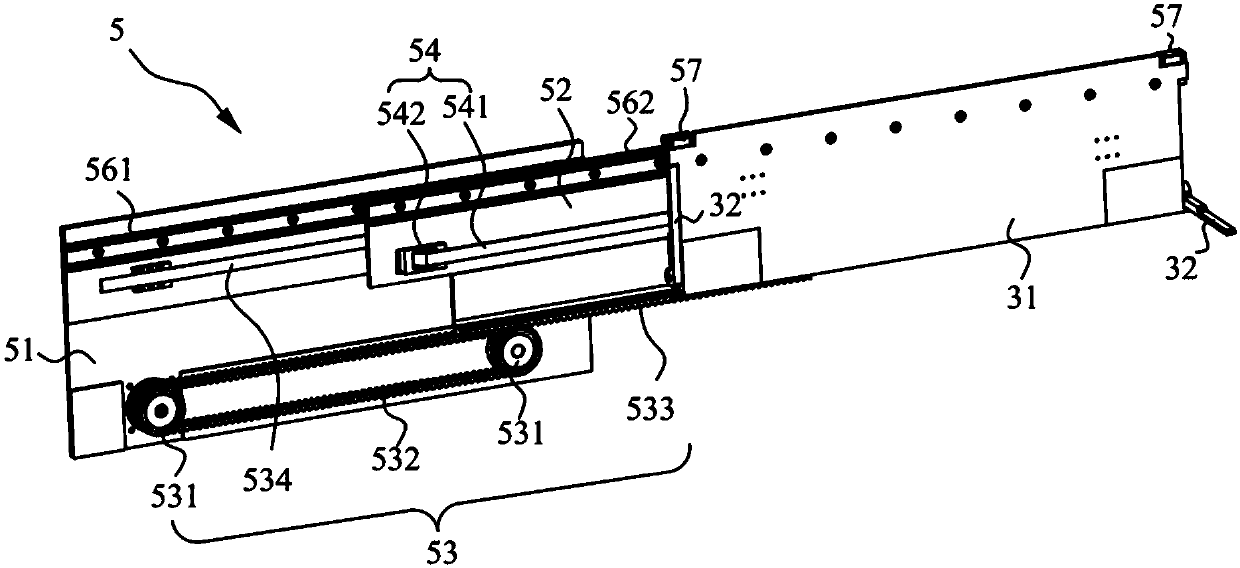

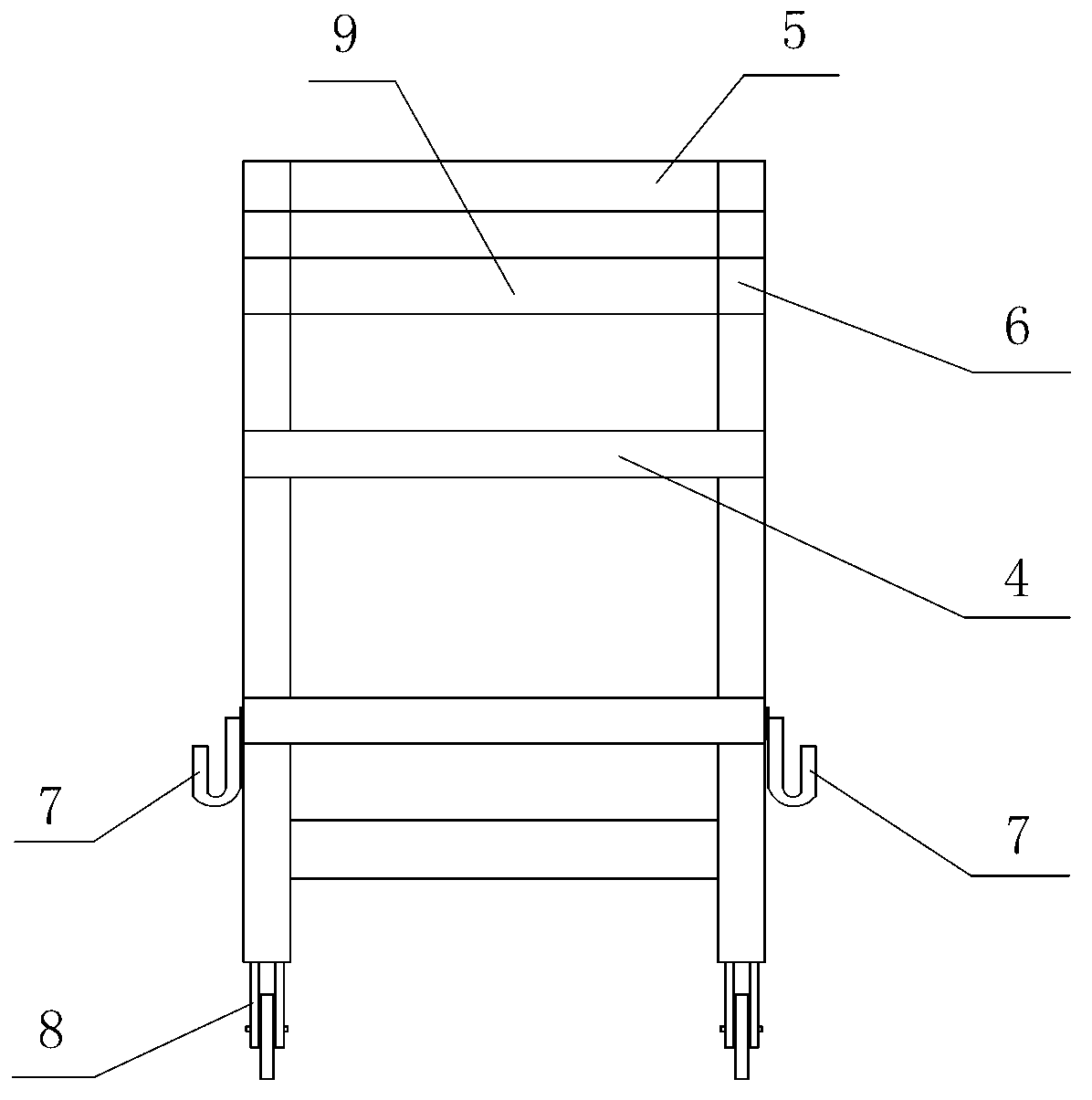

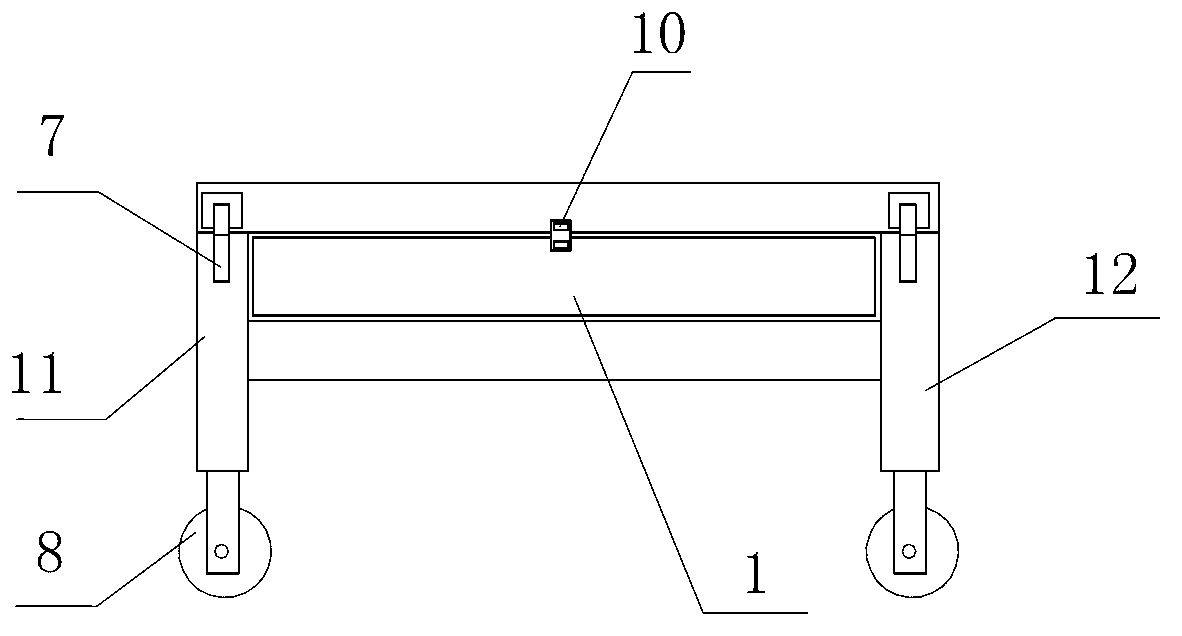

Carrying robot, container taking method and container placing method

ActiveCN111620024ALess room for movementIncrease profitStorage devicesLogistics managementIndustrial engineering

The invention belongs to the technical field of storage logistics, and particularly discloses a carrying robot, a storage logistics system and a container carrying method. The carrying robot comprisesa movable chassis, a temporary storage frame and a container taking assembly, wherein the movable chassis can move along a channel between adjacent inventory containers, the temporary storage frame is arranged on the movable chassis and used for temporarily storage target containers, the container taking assembly is arranged on the movable chassis, the container taking assembly can stretch and retract horizontally relative to the movable chassis so as to take and place target containers between the inventory containers and the temporary storage frame, and the horizontal stretching direction of the container taking assembly is perpendicular to the motion direction. The storage logistics system comprises the carrying robot. The container carrying method adopts the carrying robot for carrying target containers. According to the carrying robot, the storage logistics system and the container carrying method, the occupied space of the carrying robot in a warehouse channel can be reduced, the warehouse utilization rate is increased, and meanwhile the target container carrying efficiency can be improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

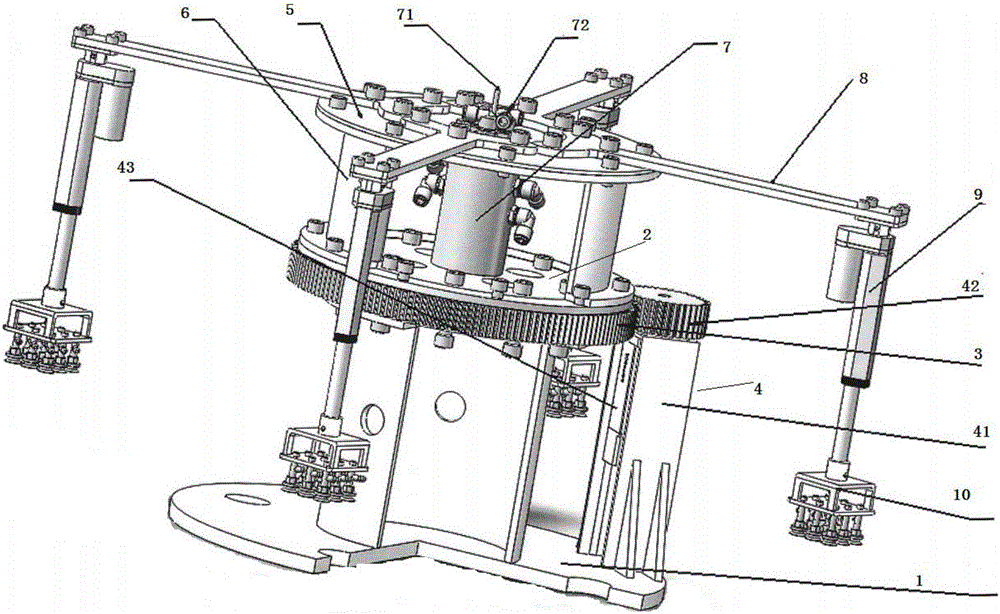

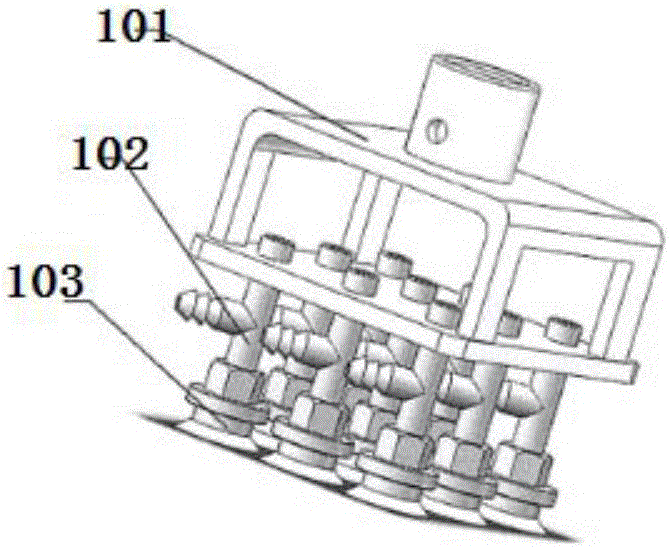

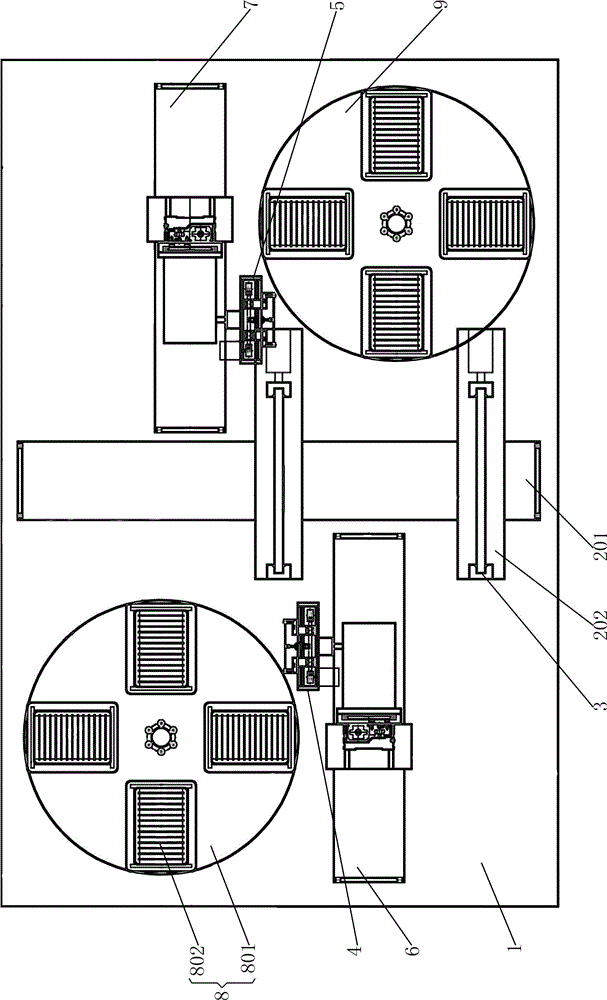

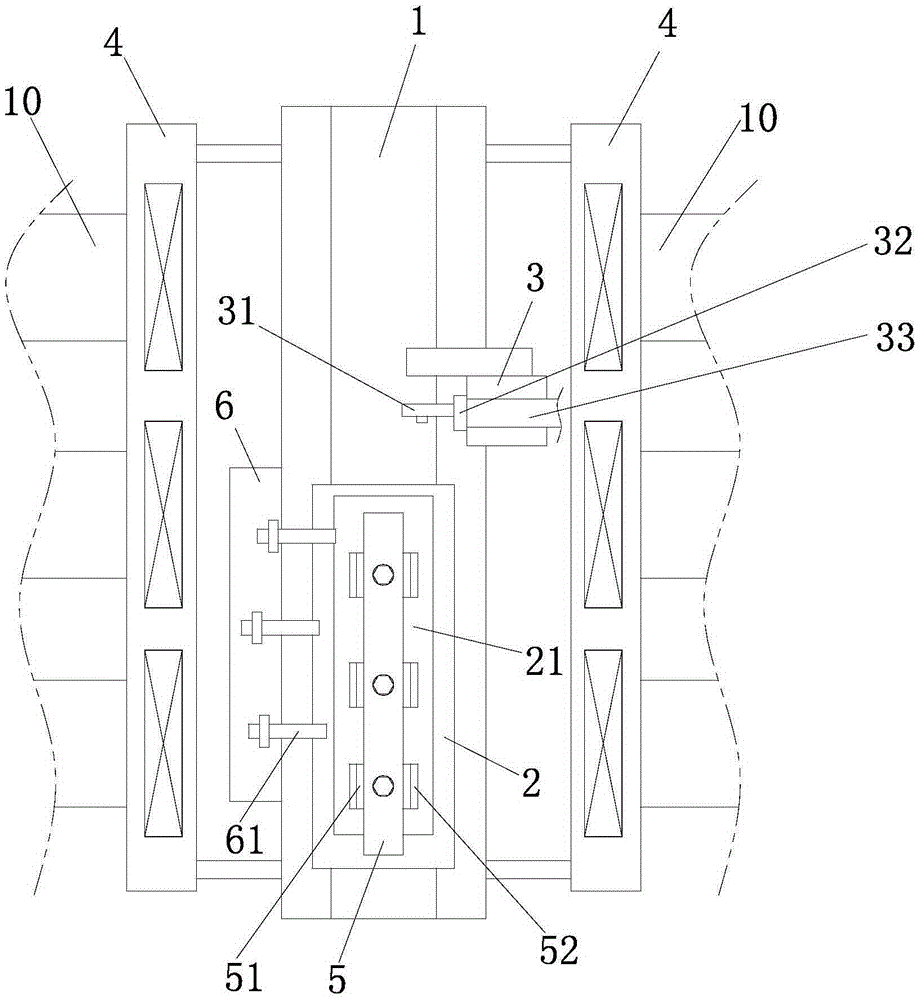

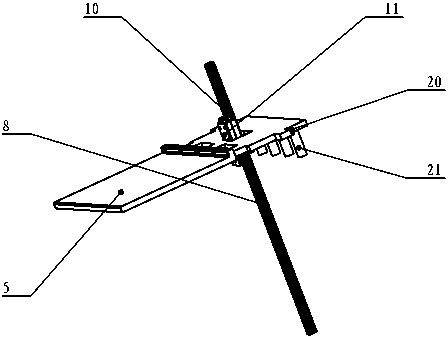

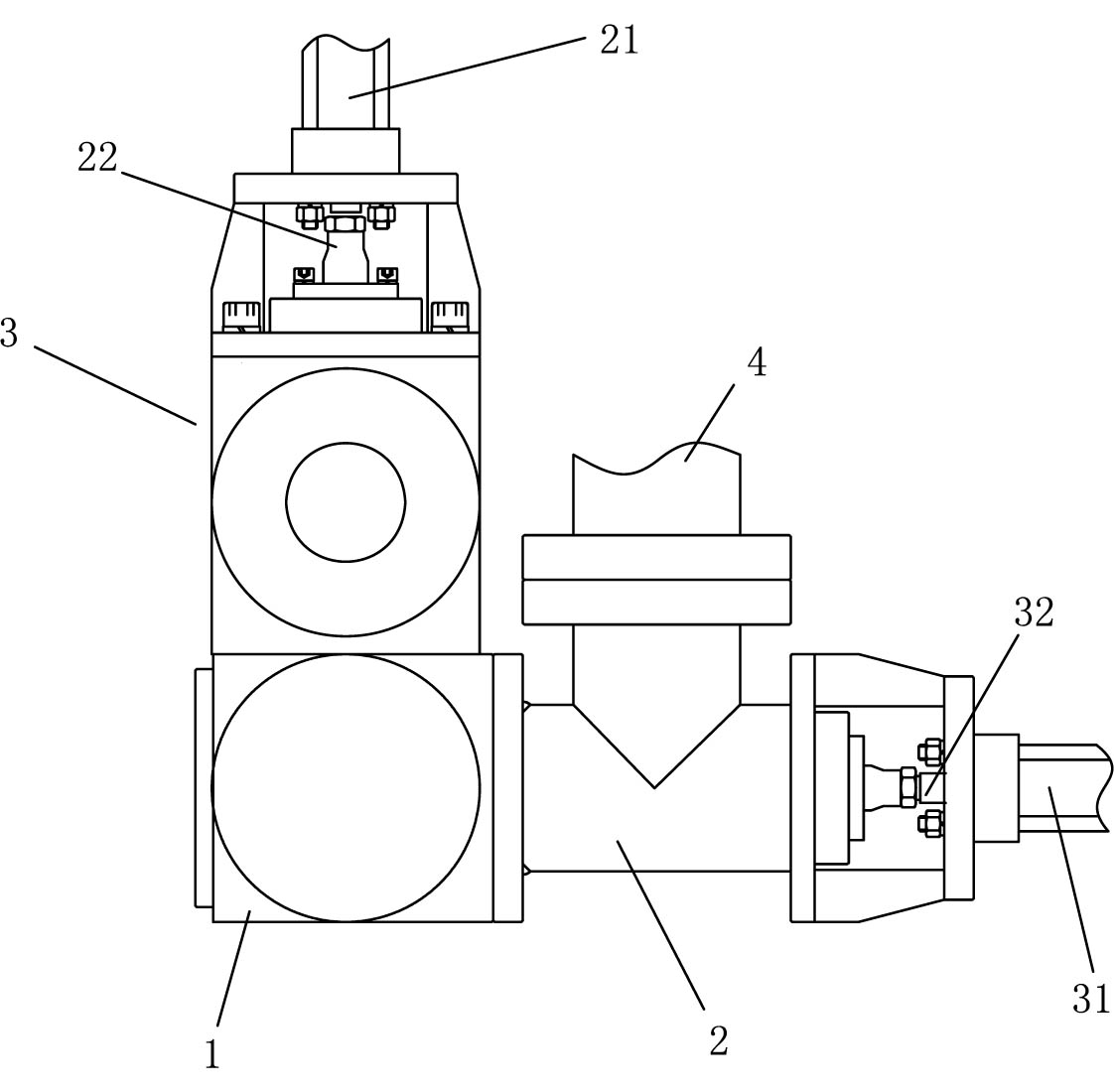

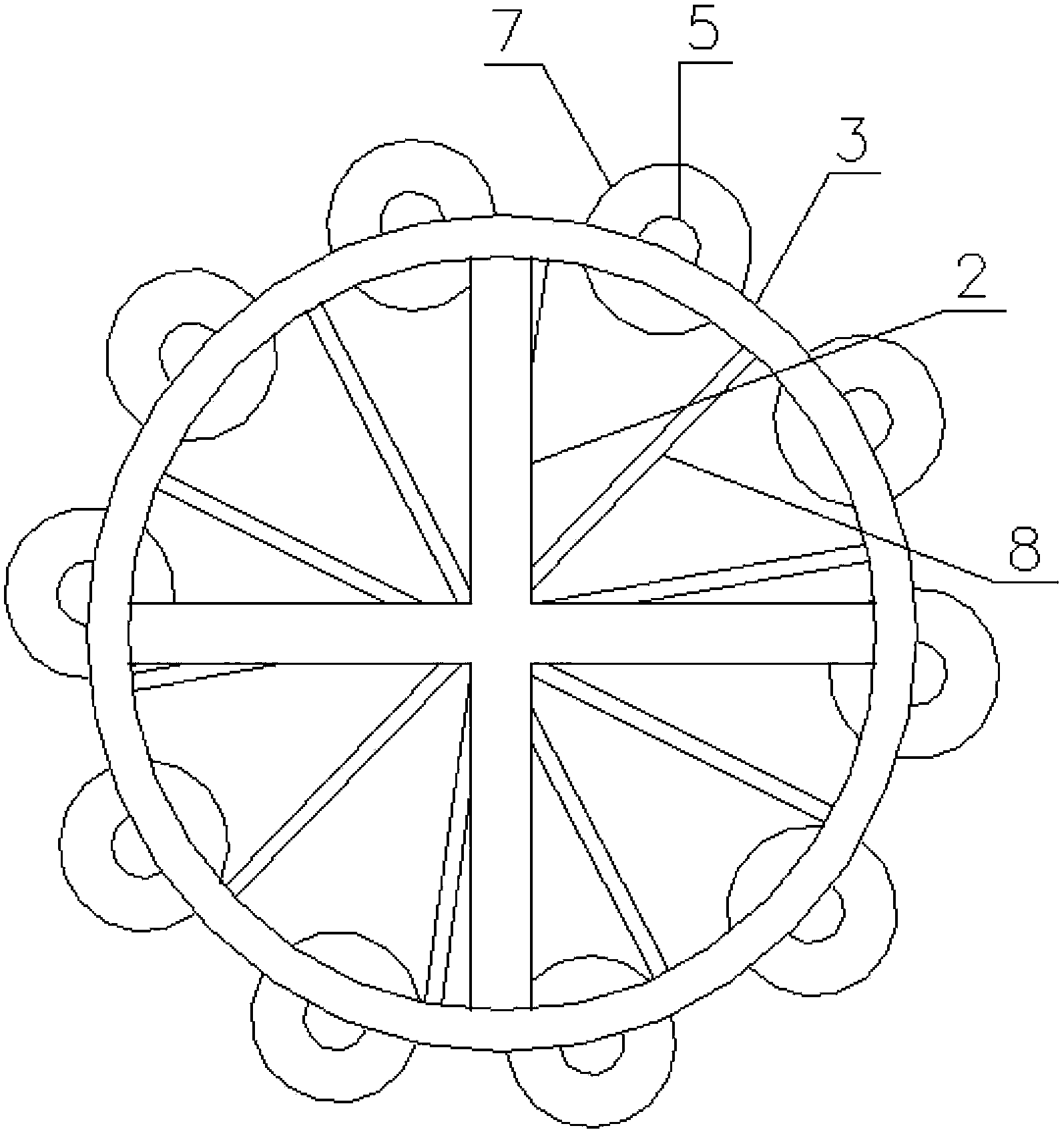

Rotary carrying manipulator

InactiveCN106629036ASave handling timeIncrease productivityProgramme-controlled manipulatorConveyor partsDrive motorManipulator

The invention provides a rotary carrying manipulator. The rotary carrying manipulator comprises a base and an annular rotary support connected with the base, wherein the rotary support comprises a rotary support inner ring and a rotary support outer ring, and the rotary support outer ring is of a dentate structure; a drive device is arranged on one side of the base and comprises a motor bracket arranged at the upper end of the base, a drive motor is arranged in the motor bracket, and the output shaft end of the drive motor is connected with a drive gear meshed with the rotary support outer ring; and an upper cover plate is arranged at the upper end of the rotary support outer ring and connected with the rotary support outer ring through an upper support column, a through hole is formed in the middle part of the upper cover plate, a pneumatic / electric rotating joint is mounted at the lower end of the through hole, four support arms are evenly distributed on the 360-degree circumference of the upper cover plate, one end of each support arm is fastened to the upper end of the upper cover plate through a bolt, an electric push rod is mounted below the other end of each support arm, and a vacuum cup array is mounted at an extending end of each electric push rod.

Owner:SHANGHAI DIANJI UNIV

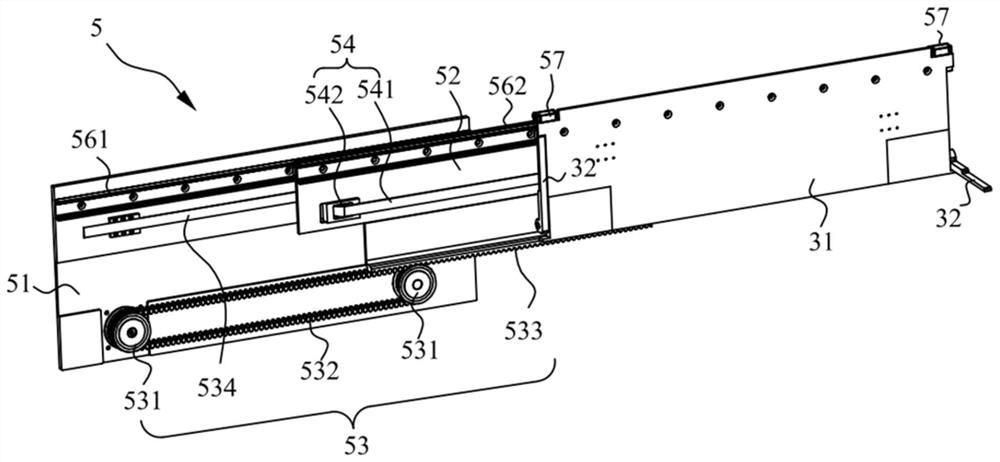

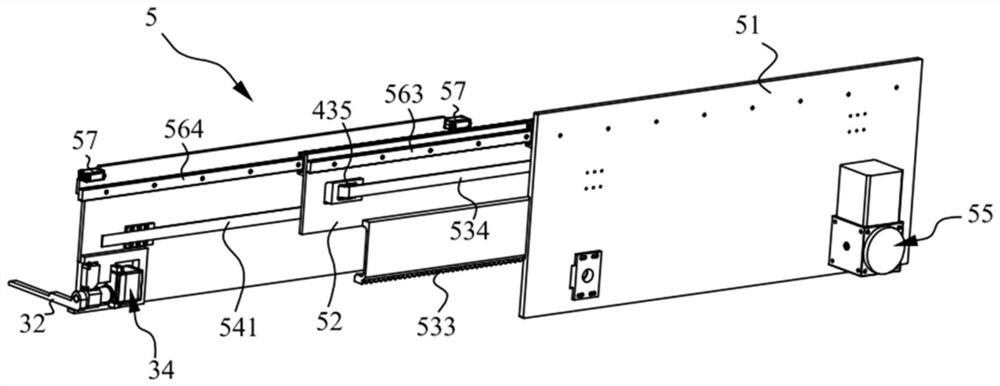

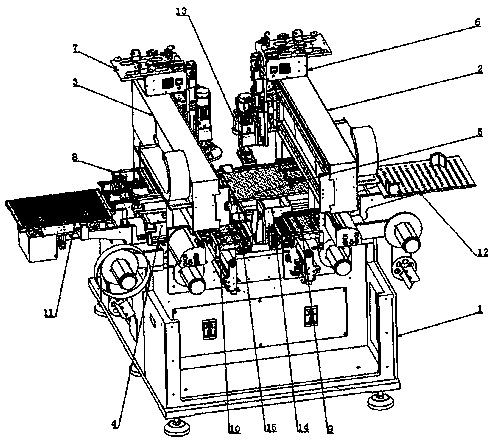

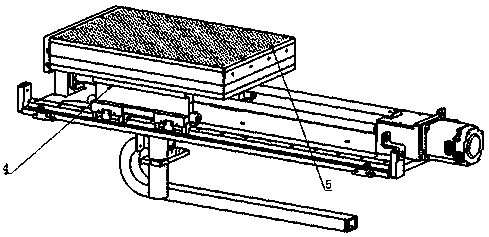

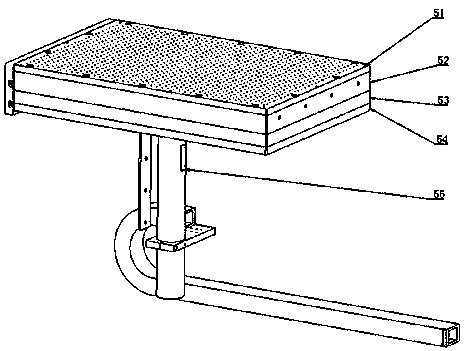

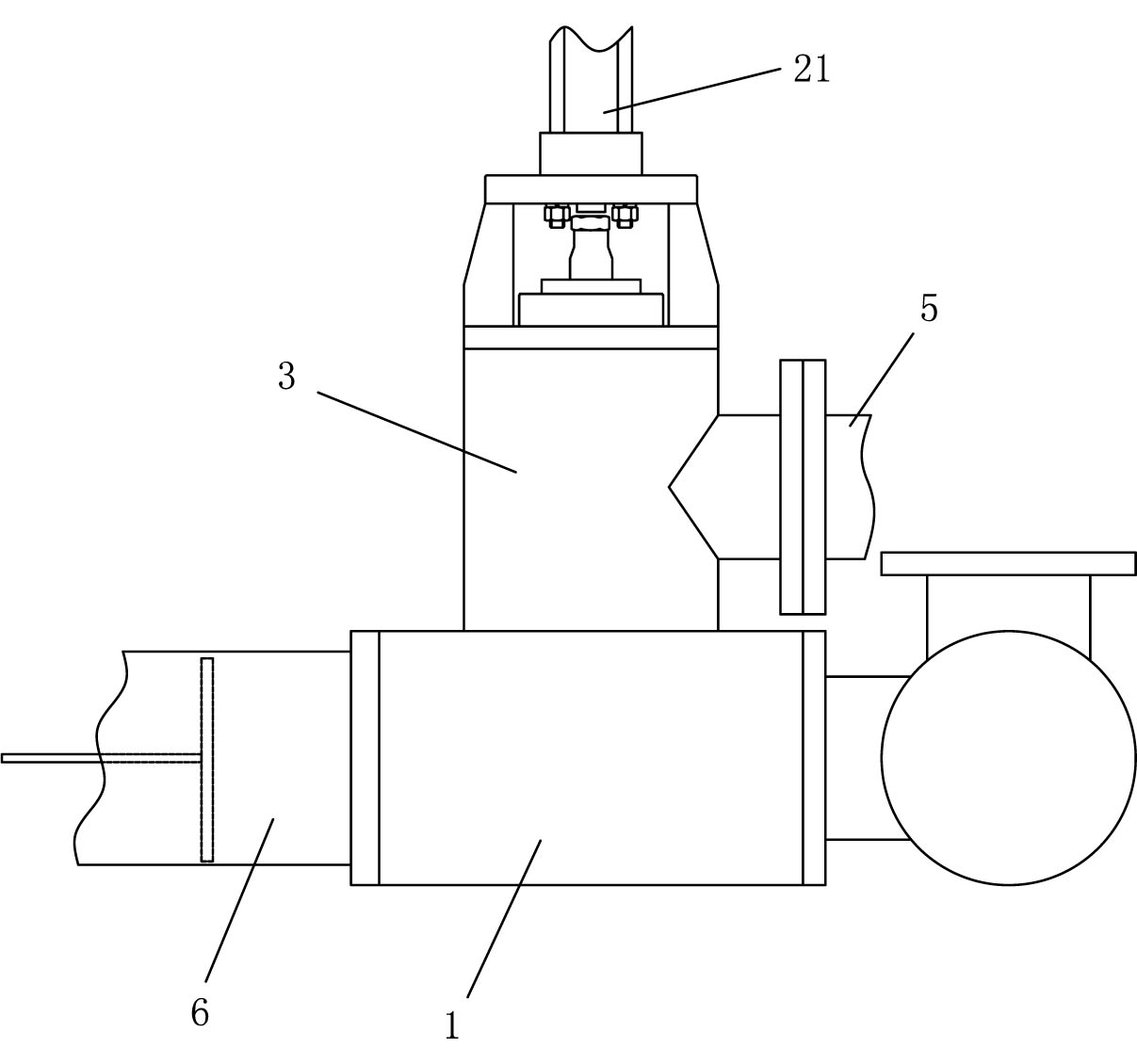

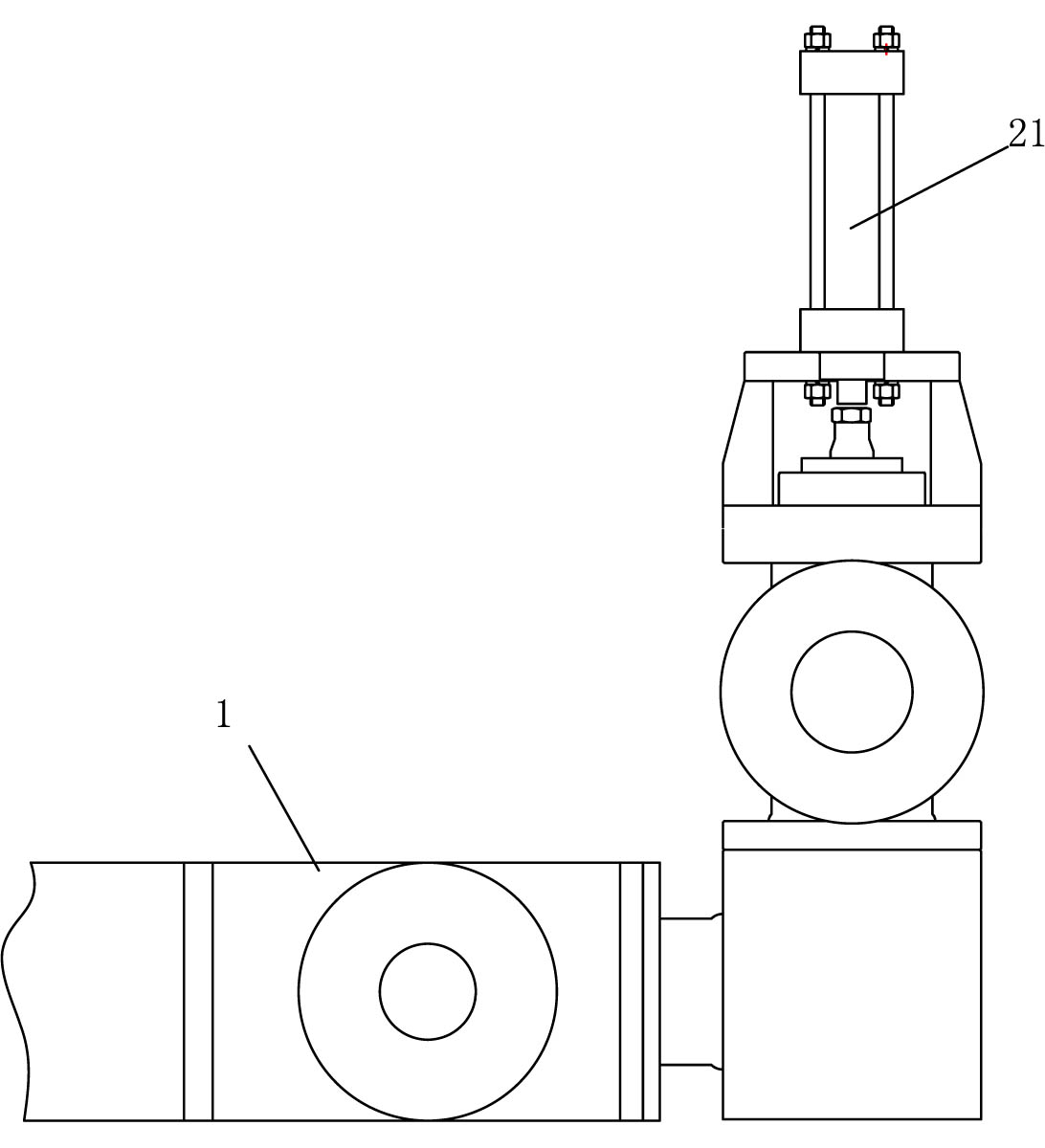

Bifacial feeding/discharging machine

ActiveCN105129413ASave handling timeIncrease productivityCharge manipulationConveyor partsMechanical engineeringEngineering

The invention relates to a bifacial feeding / discharging machine. The bifacial feeding / discharging machine is provided with a jig shifting shaft, a jig worktable, a jig and a jig driving mechanism, and thus, can be used for delivering a workpiece between the current feeding / discharging position and the next feeding / discharging position in a reciprocating mode; the feeding / discharging position and processing position are staggered, both sides of the jig shifting shaft are respectively provided with a clamping jaw driving mechanism and a receiving device, and the two clamping jaw driving mechanisms respectively drive clamping jaws; and simultaneous feeding or simultaneous discharging, or one-side feeding and one-side discharging can be set according to the practical production condition. The two clamping jaw driving mechanisms independently operate without interference, the jig can move on the jig workbench according to the positions of the clamping jaws, and the workpiece can be transported from the receiving device to the jig and delivered to the next processing position for processing, or transported from the jig to the receiving device after the processing is finished, thereby greatly shortening the transportation time of the workpiece between the receiving device and jig, and further enhancing the production efficiency.

Owner:LINGDI EQUIP

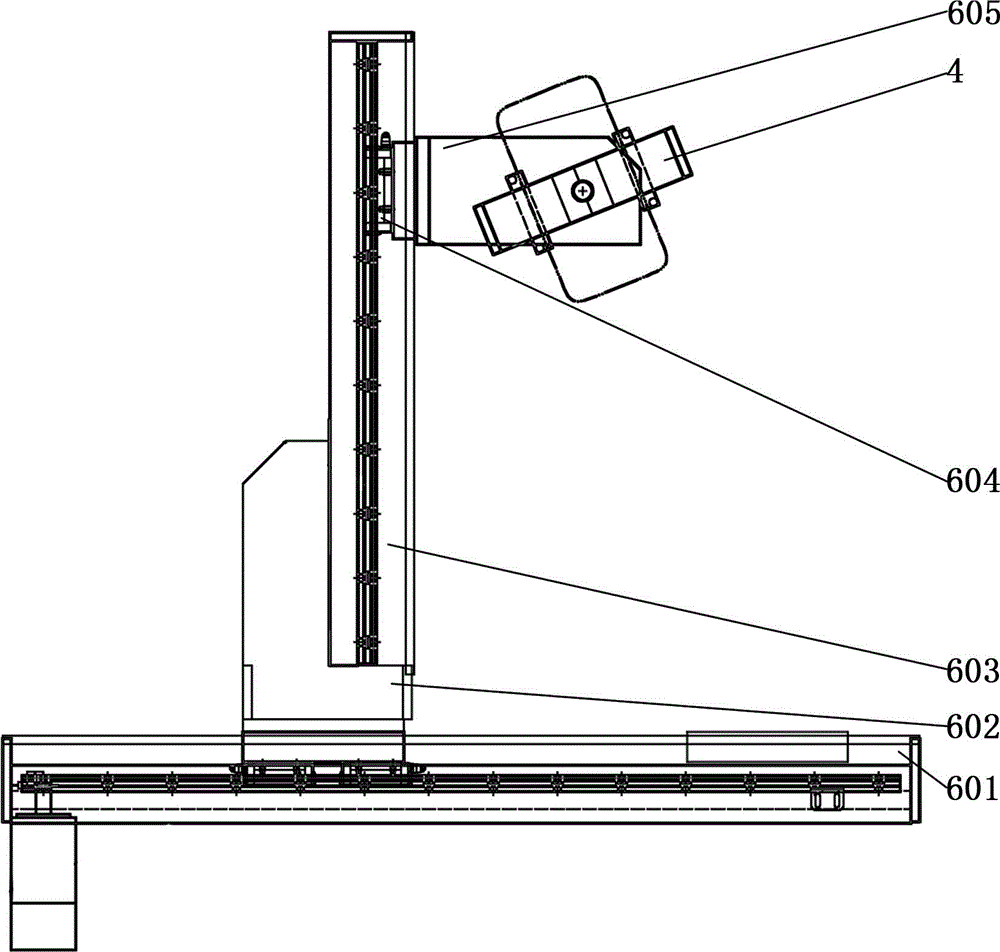

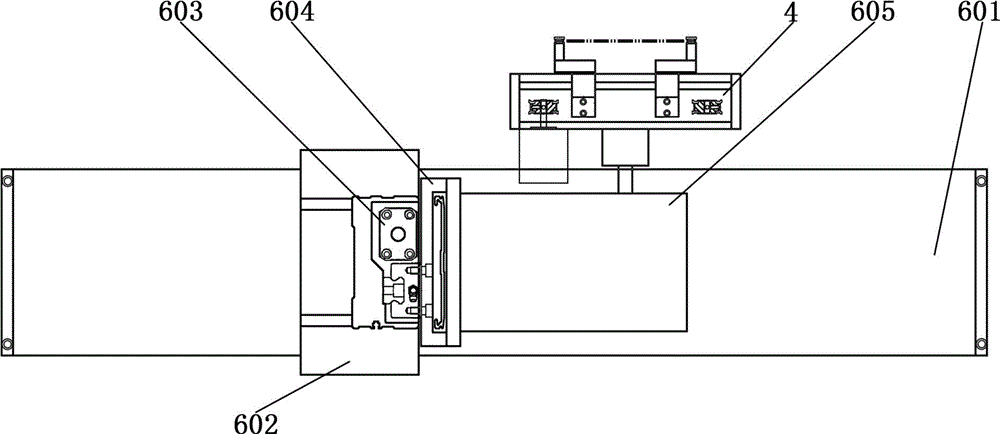

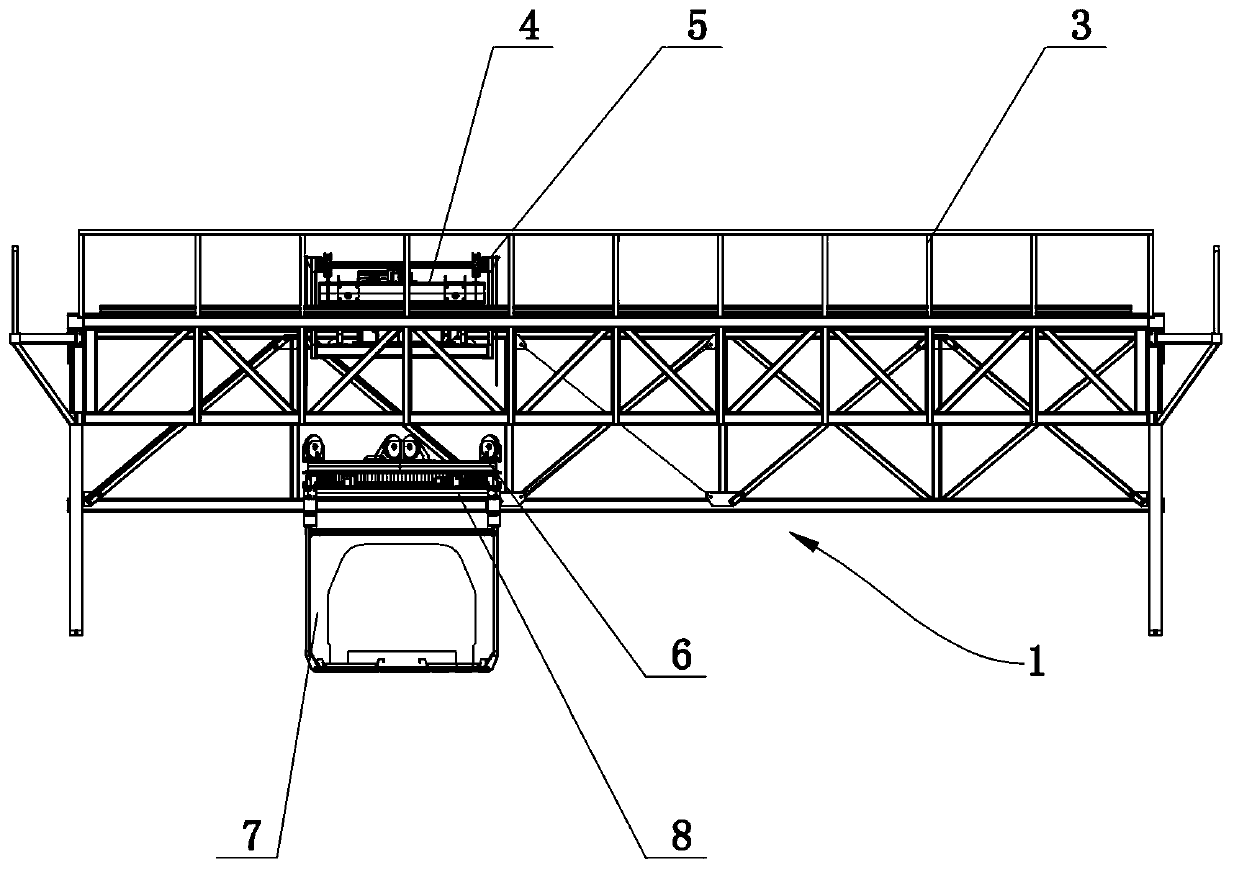

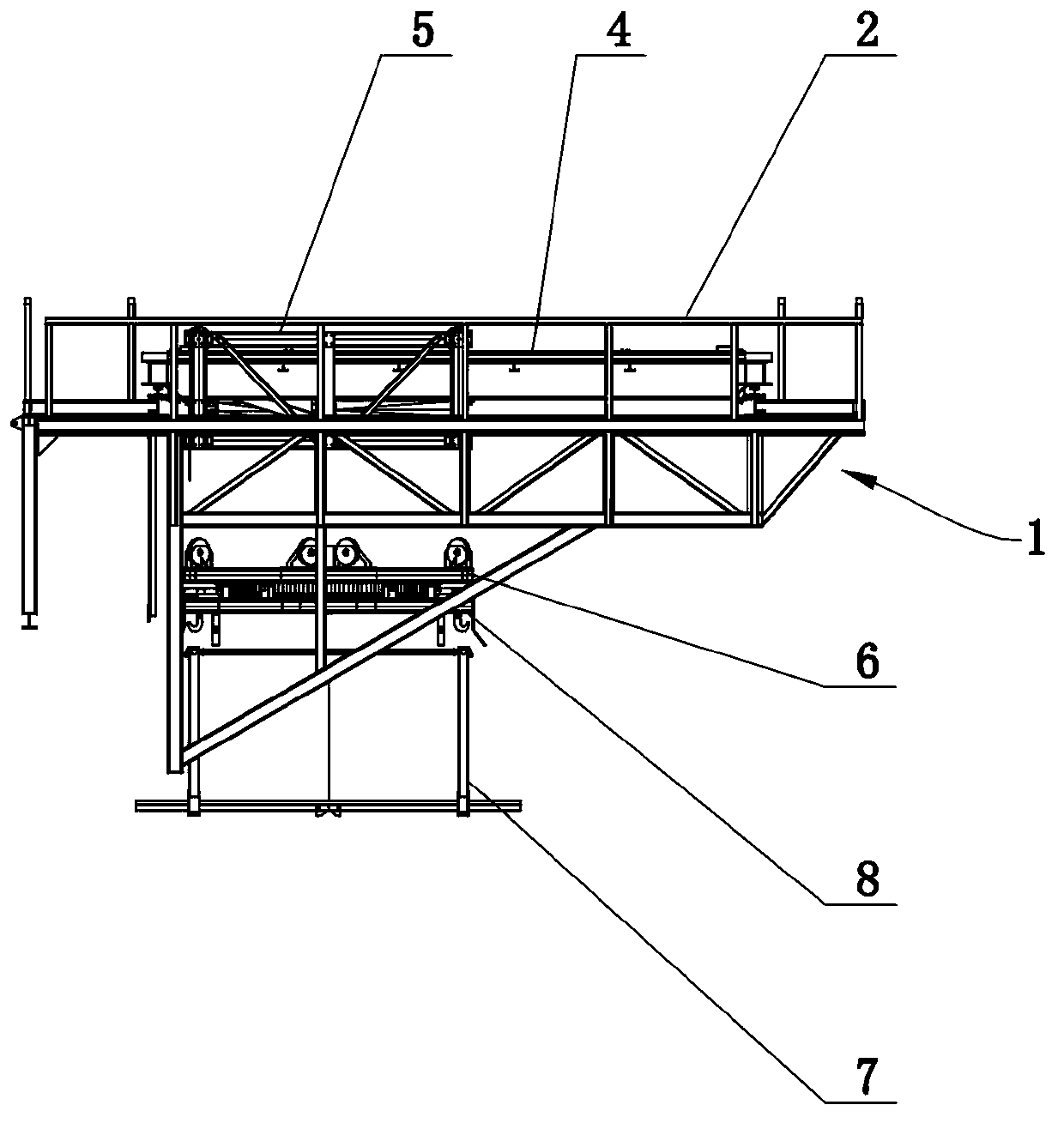

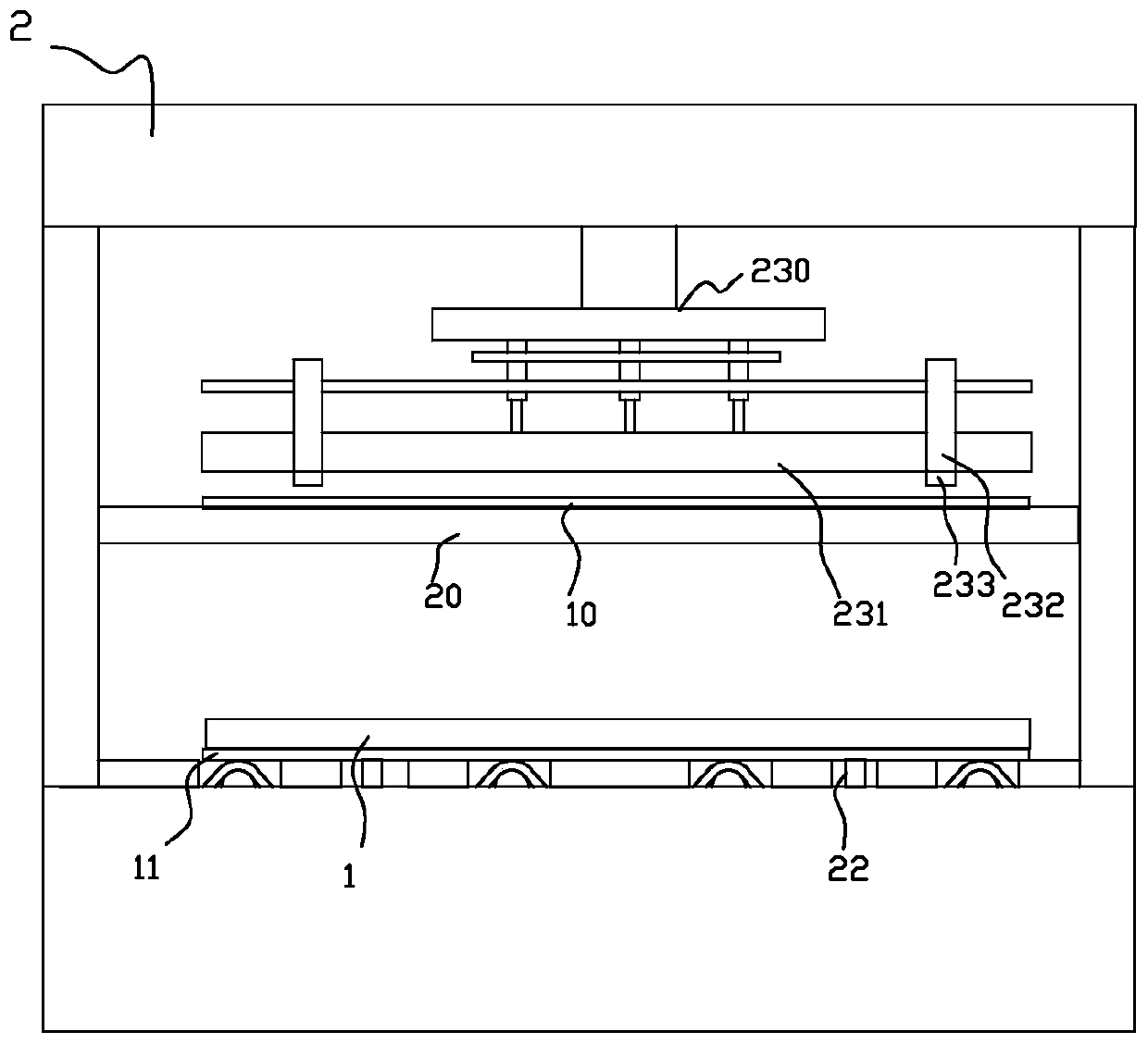

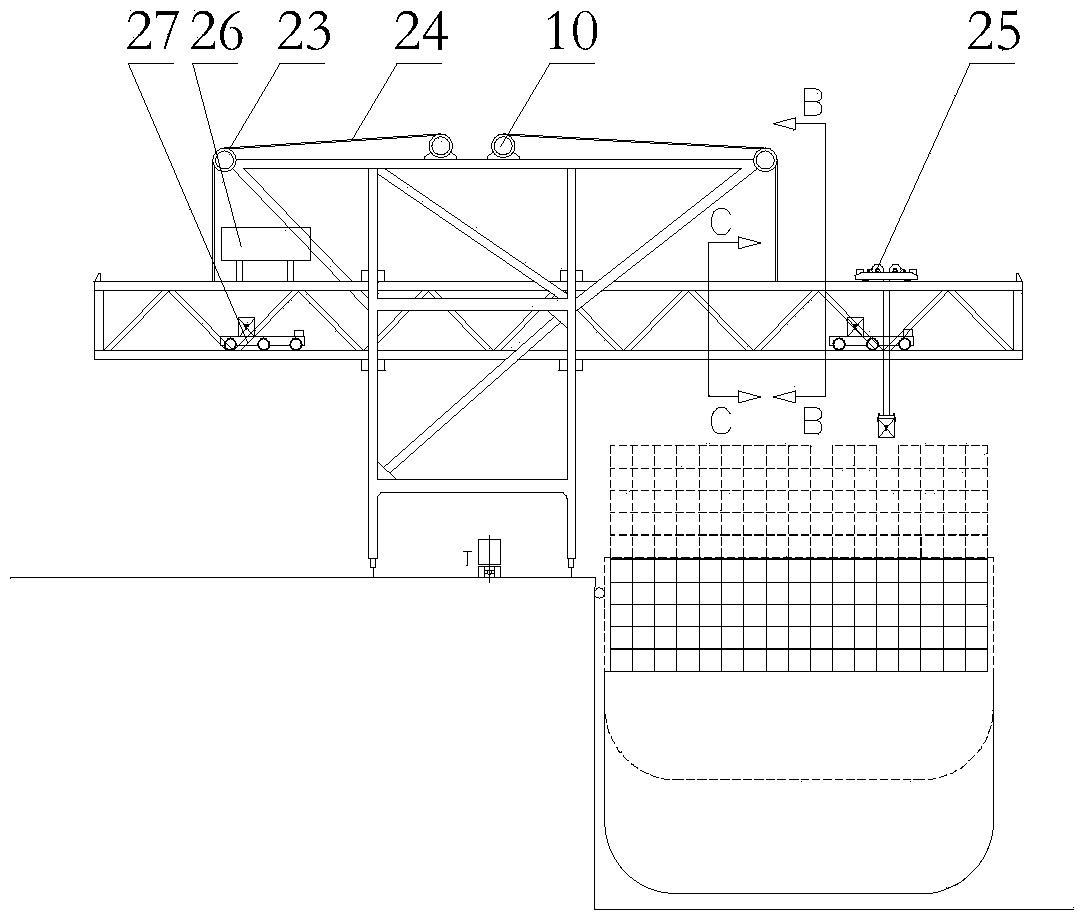

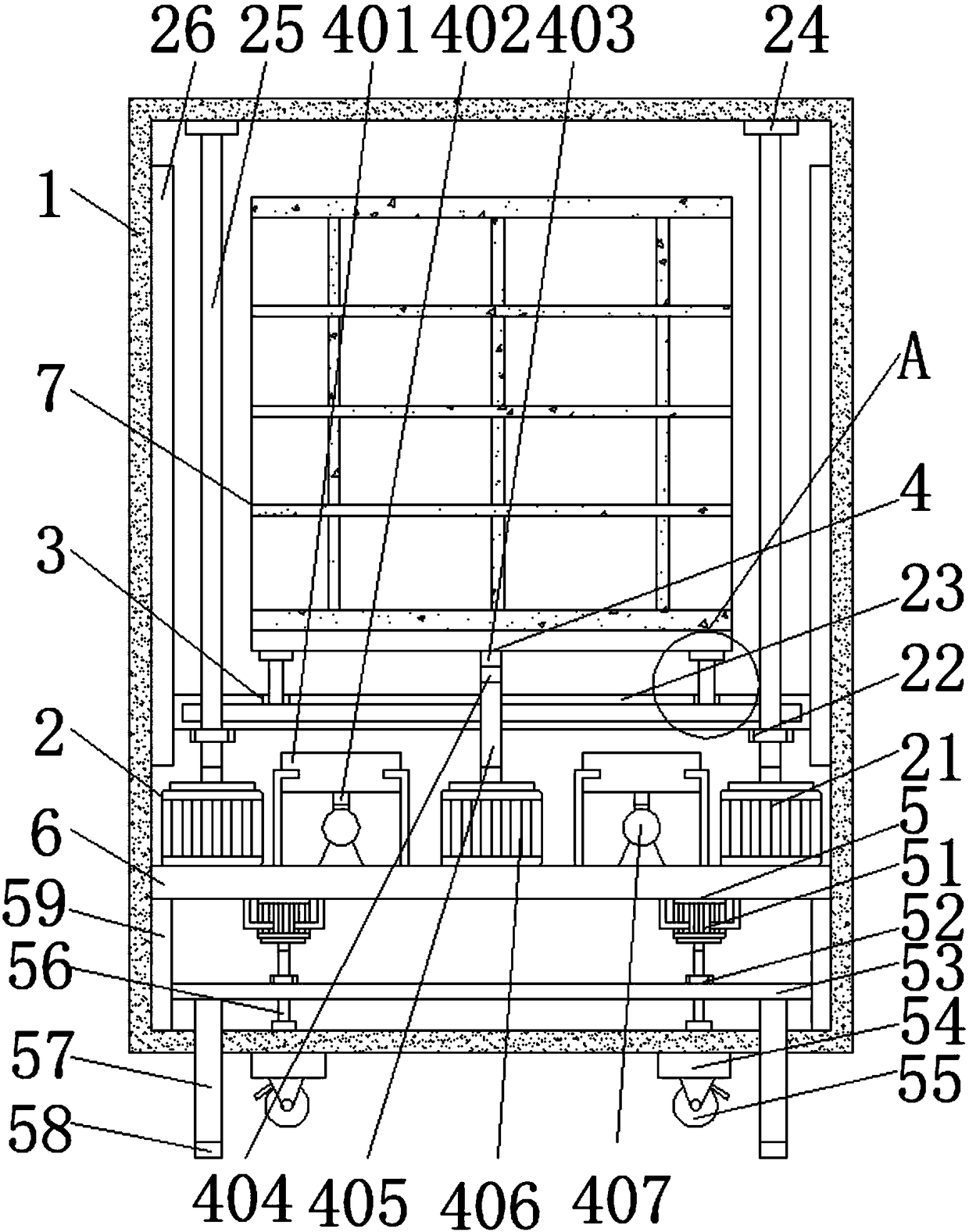

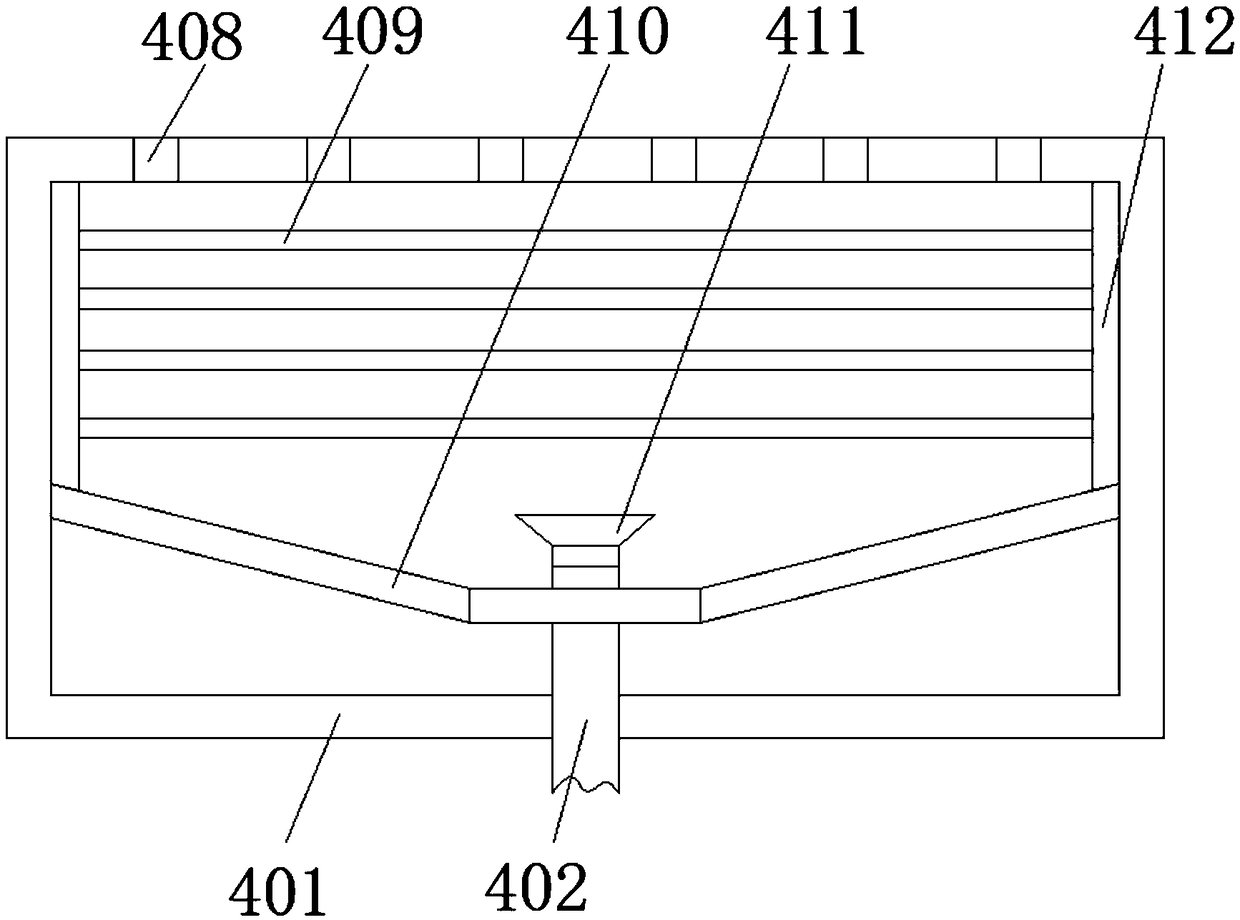

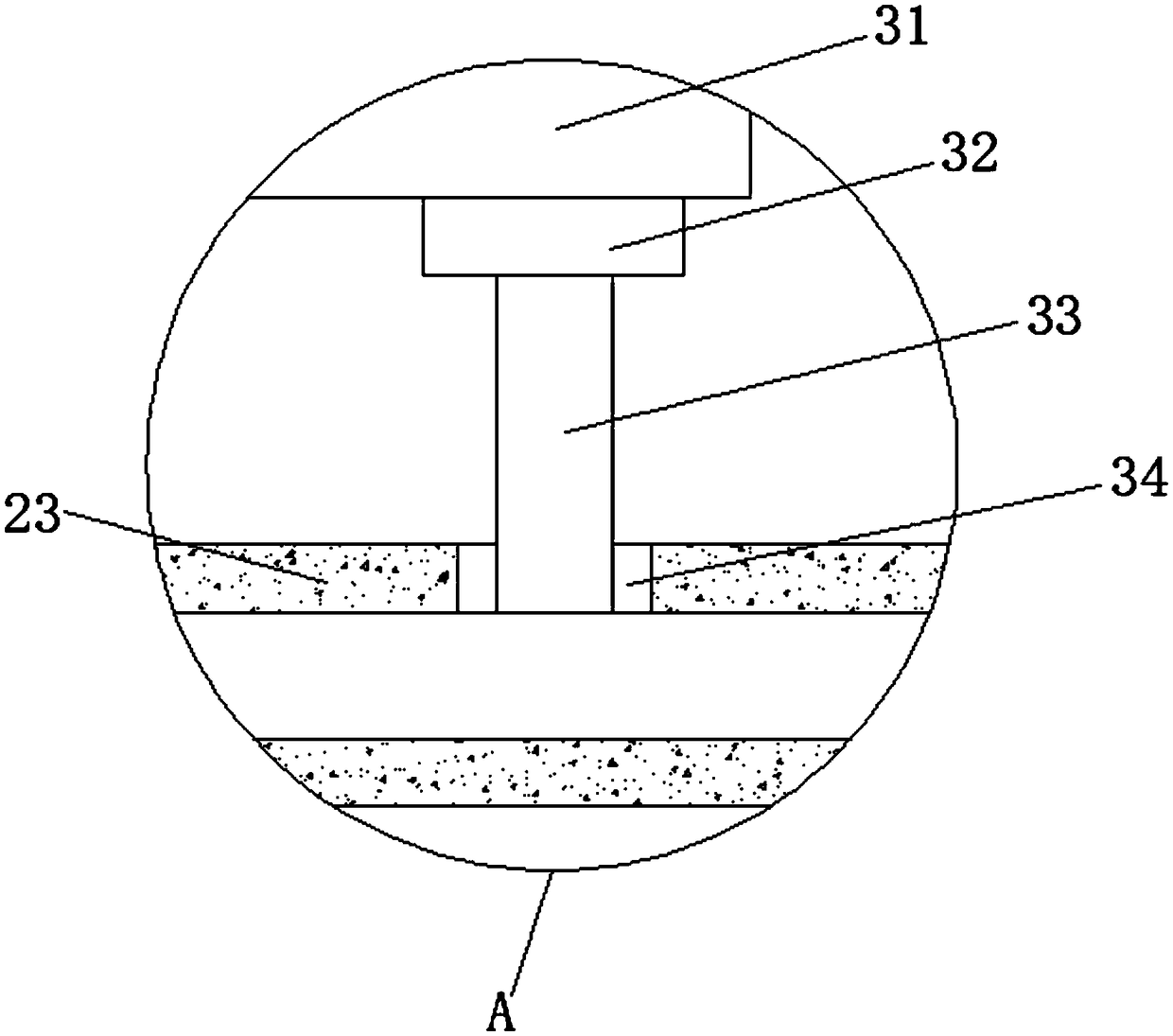

Four-freedom-degree vehicle carrier for three-dimensional parking equipment

The invention discloses a four-freedom-degree vehicle carrier for three-dimensional parking equipment and belongs to the technical filed of mechanical parking devices. The four-freedom-degree vehicle carrier comprises a cantilever support above a top-layer parking space, the cantilever support comprises two oppositely-arranged cantilever longitudinal beams and two oppositely-arranged cantilever cross beams, and the cantilever longitudinal beams and the cantilever cross beams are arranged in a rectangular mode. A transversely-moving mechanism driven by a first power plant is arranged on the cantilever support in a transversely-moving mode, and a longitudinally-moving mechanism driven by a second power plant is arranged on the transversely-moving mechanism in a longitudinally-moving mode. The longitudinally-moving mechanism is provided with a lifting transmission mechanism which is driven by a third power plant and capable of lifting in the vertical direction, and the lifting transmission mechanism is connected with a grabbing rotary mechanism which is driven by a fourth power plant and capable of rotating around a vertical axial line and used for grabbing lifting vehicle platforms. The four-freedom-degree vehicle carrier does not occupy ground space and enables arrangement of garage entrances and exits to be flexible; in the process of parking and taking vehicles, transverse moving, longitudinal moving, lifting and rotating of the vehicles and the lifting vehicle platforms can be finished at the same time, and working efficiency of parking and taking the vehicles is improved.

Owner:DAYANG PARKING CO LTD

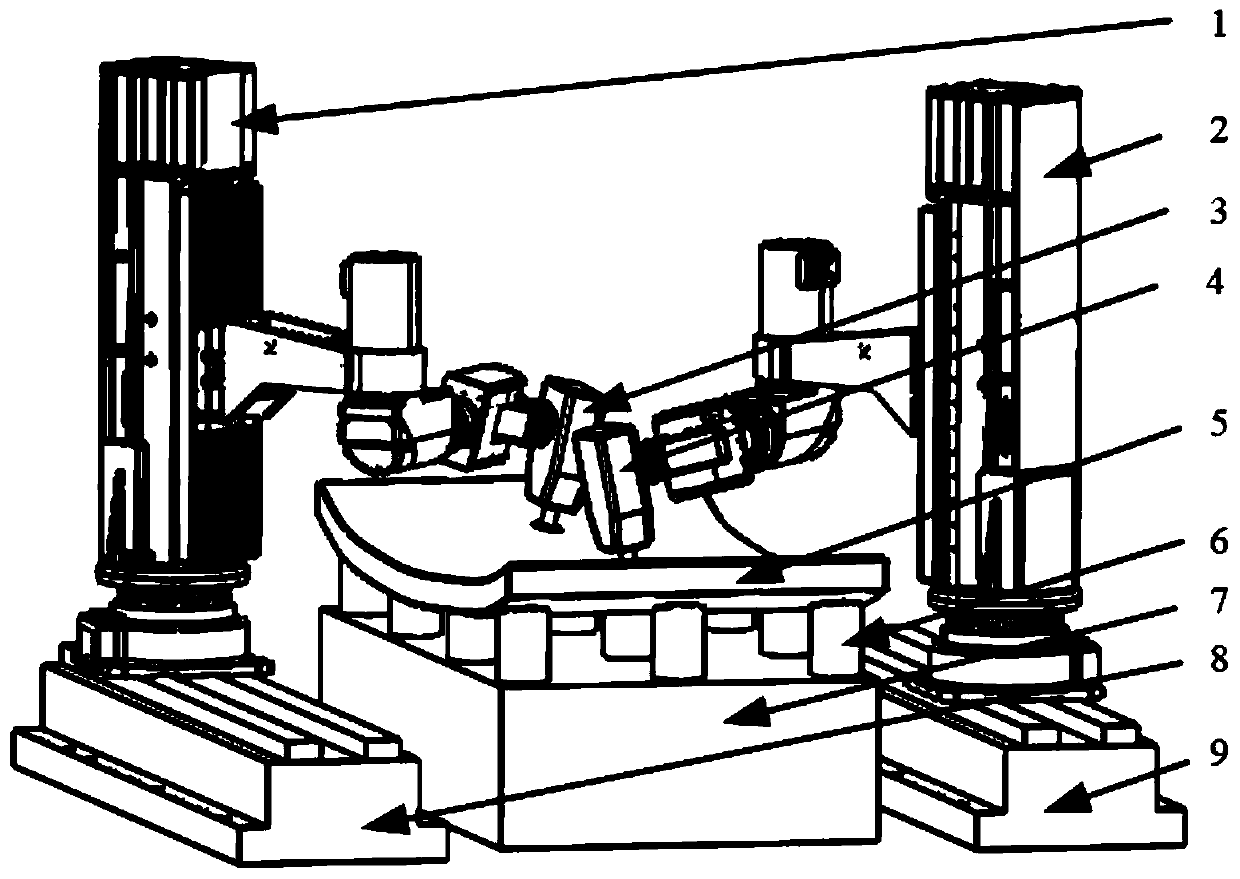

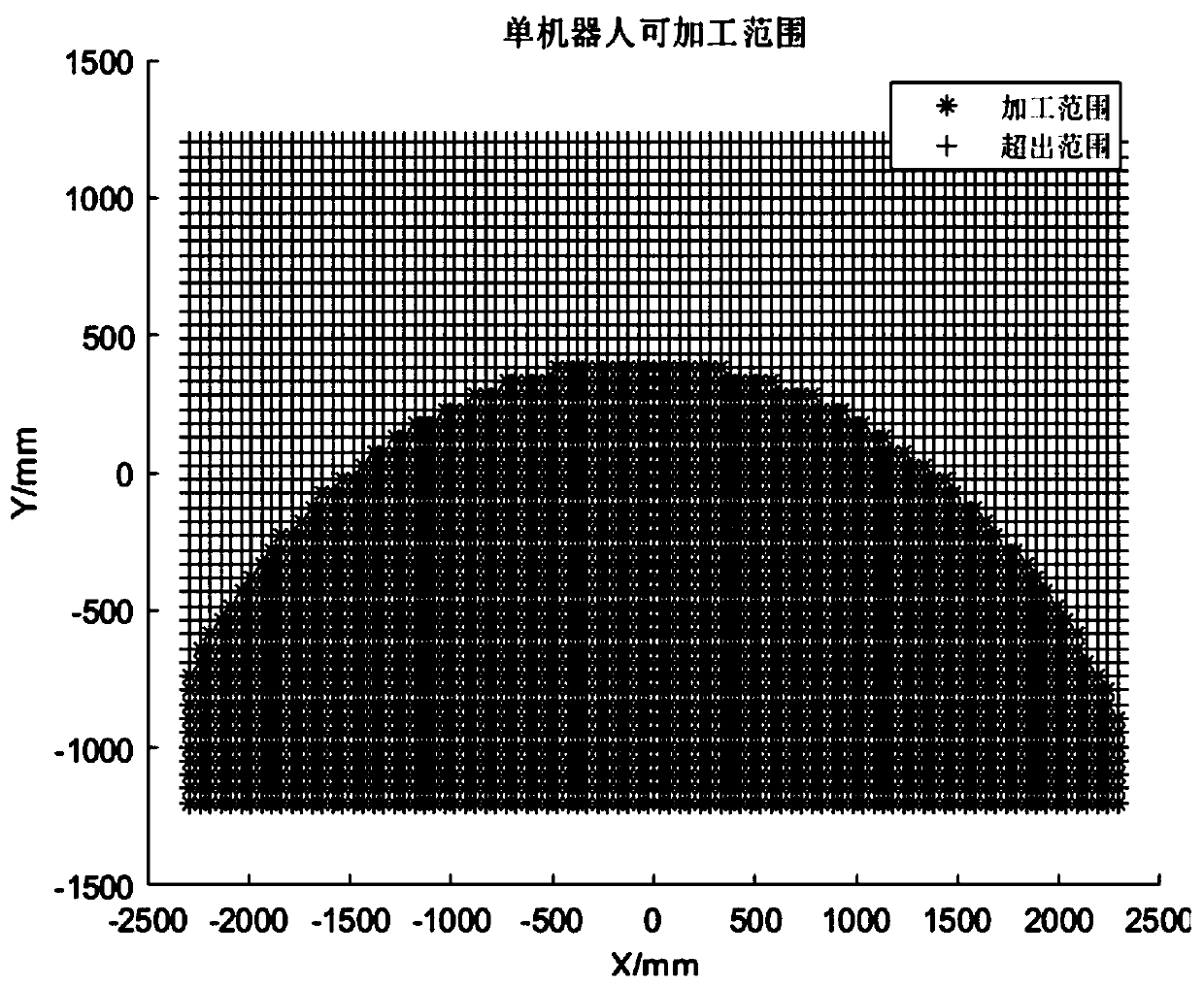

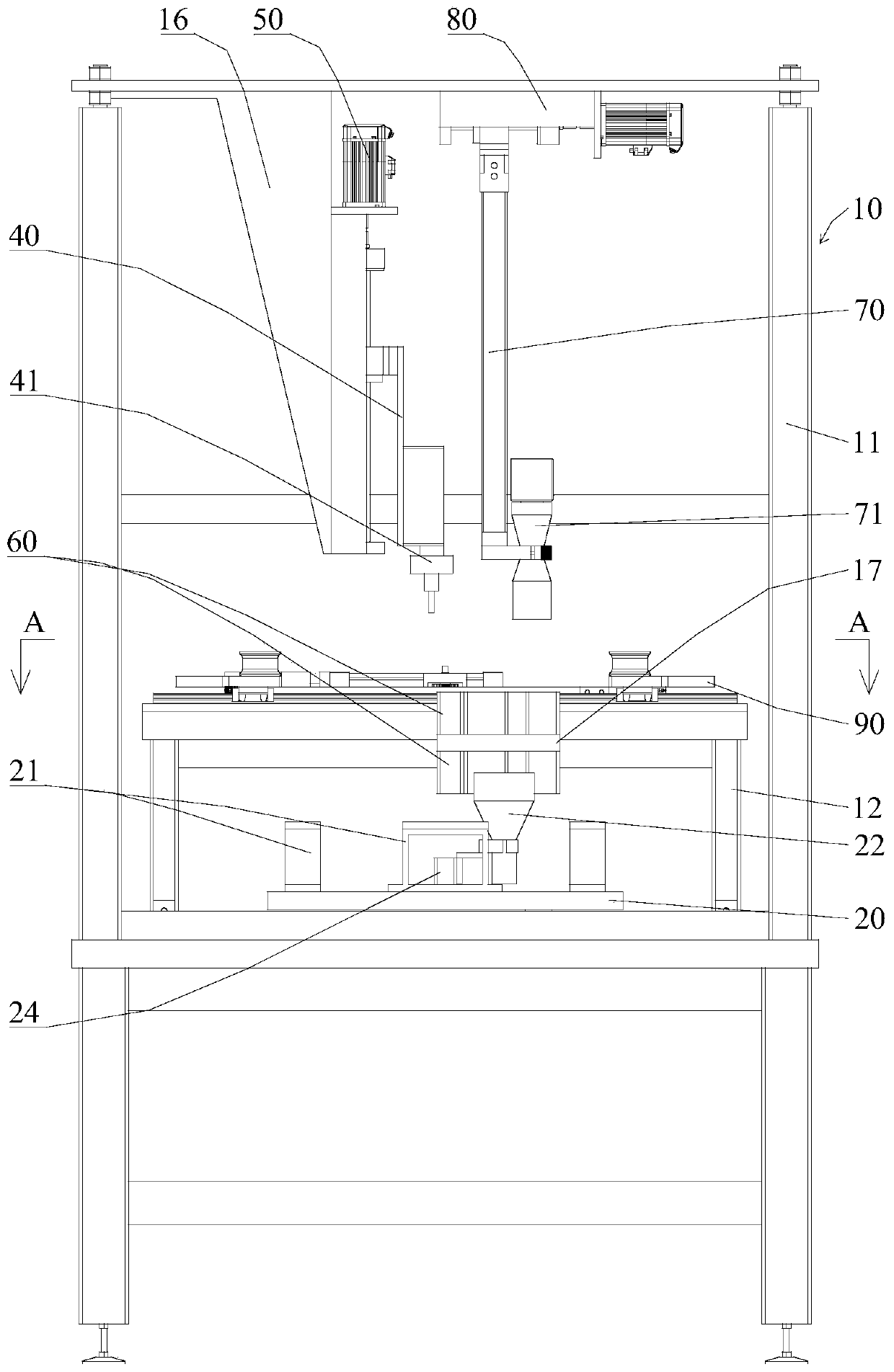

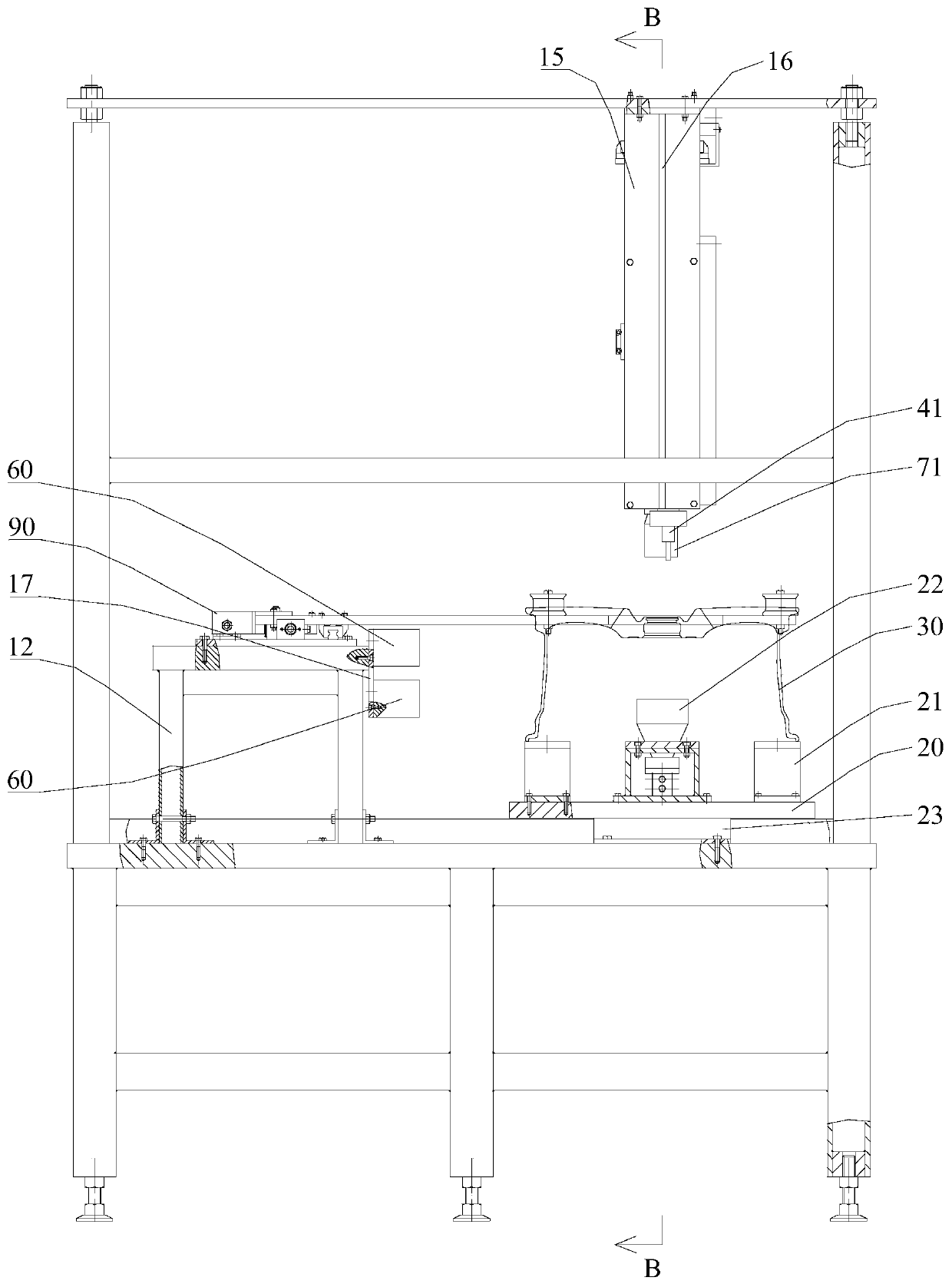

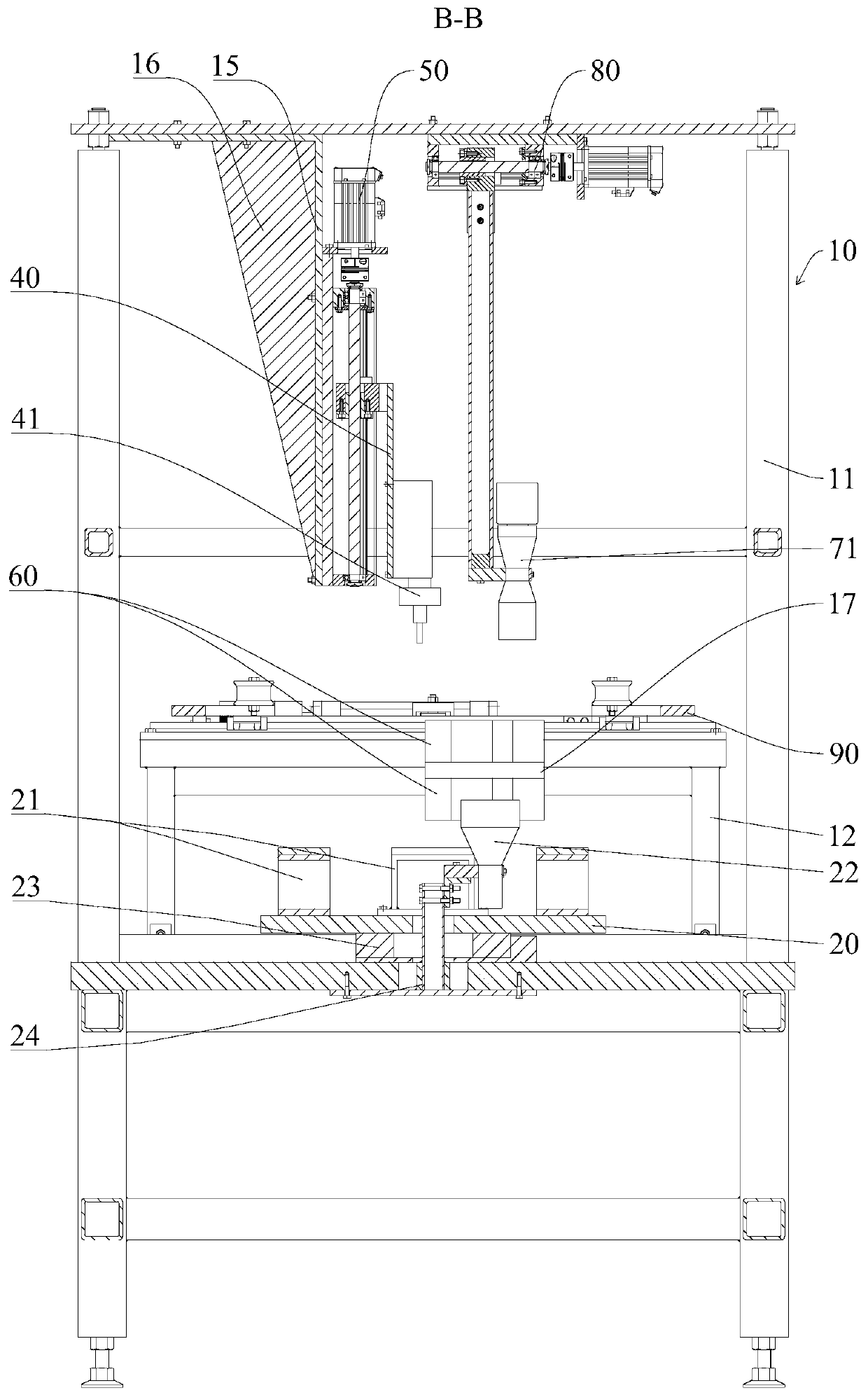

Multi-robot precision machining system and method for large-aperture integral optical element

ActiveCN110732932AShorten the production cycleSave handling timeOptical surface grinding machinesLapping machinesOptical processingRobot machining

The invention discloses a multi-robot precision machining system and a method for a large-aperture integral optical element. The multi-robot precision machining system comprises a robot machining system part and a modular machining tool, the modular machining tool comprises a grinding disk machining module, a polishing fluid supply recycling tool head module and a magnetorheological polishing toolhead module. The multi-robot precision machining system and method adopts a flexible intelligent robot with the low cost for machining, by means of multi-robot collaborative machining, machining of large-aperture integrated optical elements with various curvature is realized, meanwhile, the manufacturing efficiency of the optical elements is greatly improved, and a highly integrated modular chemical tool head enables the machining system to be able to conduct grinding modification, polishing modification and precision polishing modification on the large-aperture integral optical elements. Thesystem completes the whole optical machining process, the manufacturing cost of the large-aperture optical elements is greatly saved, and the cycle of the large-aperture optical elements is greatly shortened.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

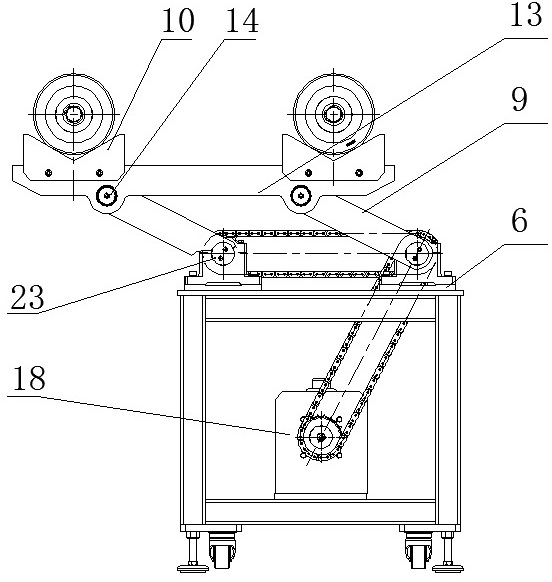

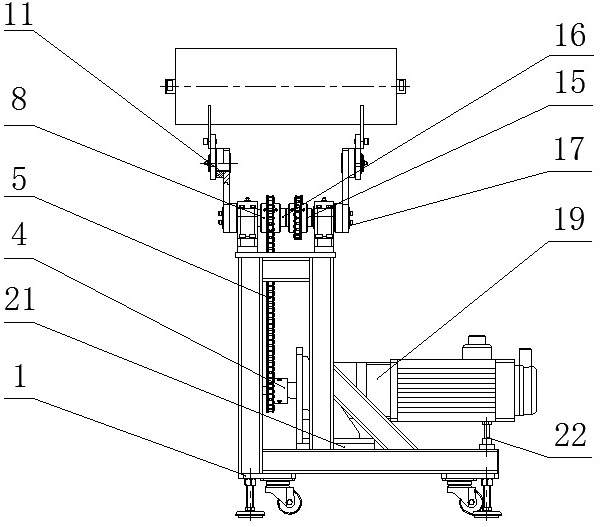

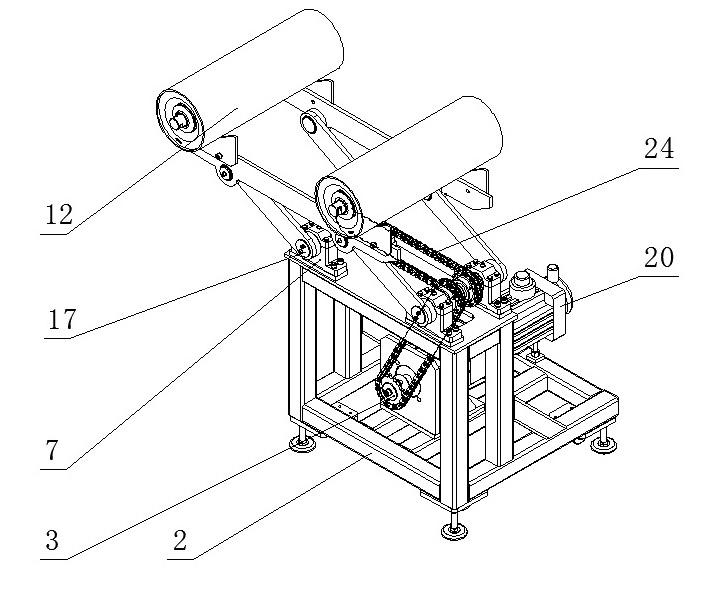

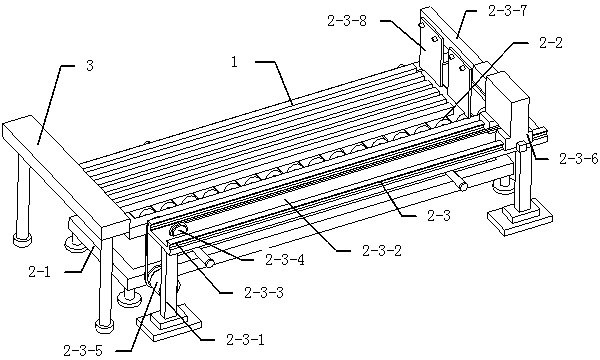

Feeding and discharging manipulator

A feeding and discharging manipulator comprises a feeding rack, two groups of parallel bearing seats are arranged on the feeding rack, two drive shafts are arranged between the two groups of bearing seats and respectively provided with a driven chain wheel II, the two driven chain wheels are meshed with the same chain, one drive shaft is further provided with a driven chain wheel I, two ends of the drive shafts are connected with a swing arm which is connected with brackets by a pin shaft, a pair of brackets are arranged on a supporting plate and are V-shaped, a motor seat is further arranged on the feeding rack and provided with a speed reducer which is connected with a motor, a drive chain wheel is arranged on the output shaft of the speed reducer and meshed with the driven chain wheel I on the same chain. The feeding and discharging manipulator can be used for feeding and discharging pipe and shaft workpieces in a belt conveyor DTII type carrier roll production equipment room.

Owner:SHENZHEN CEMCN

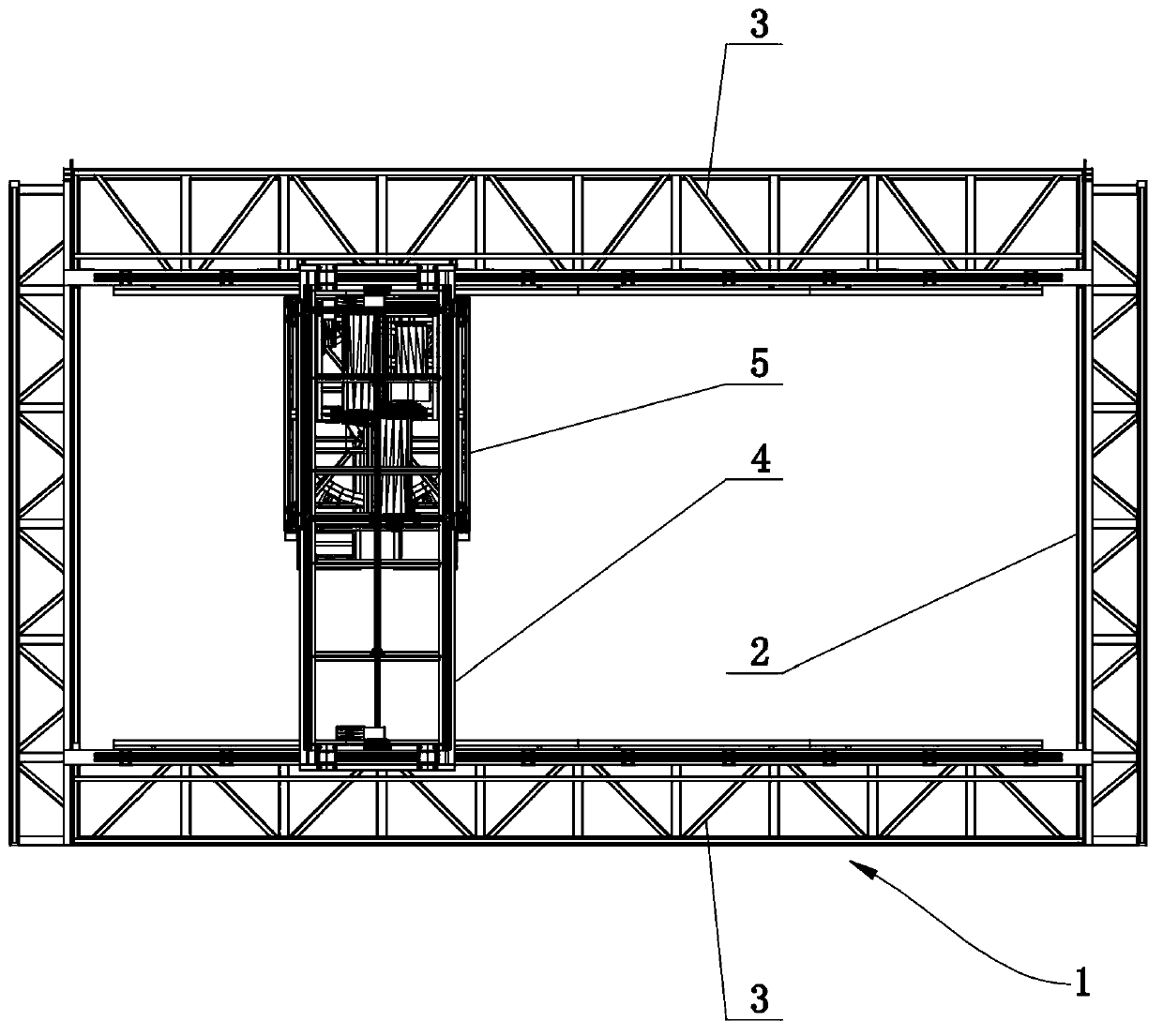

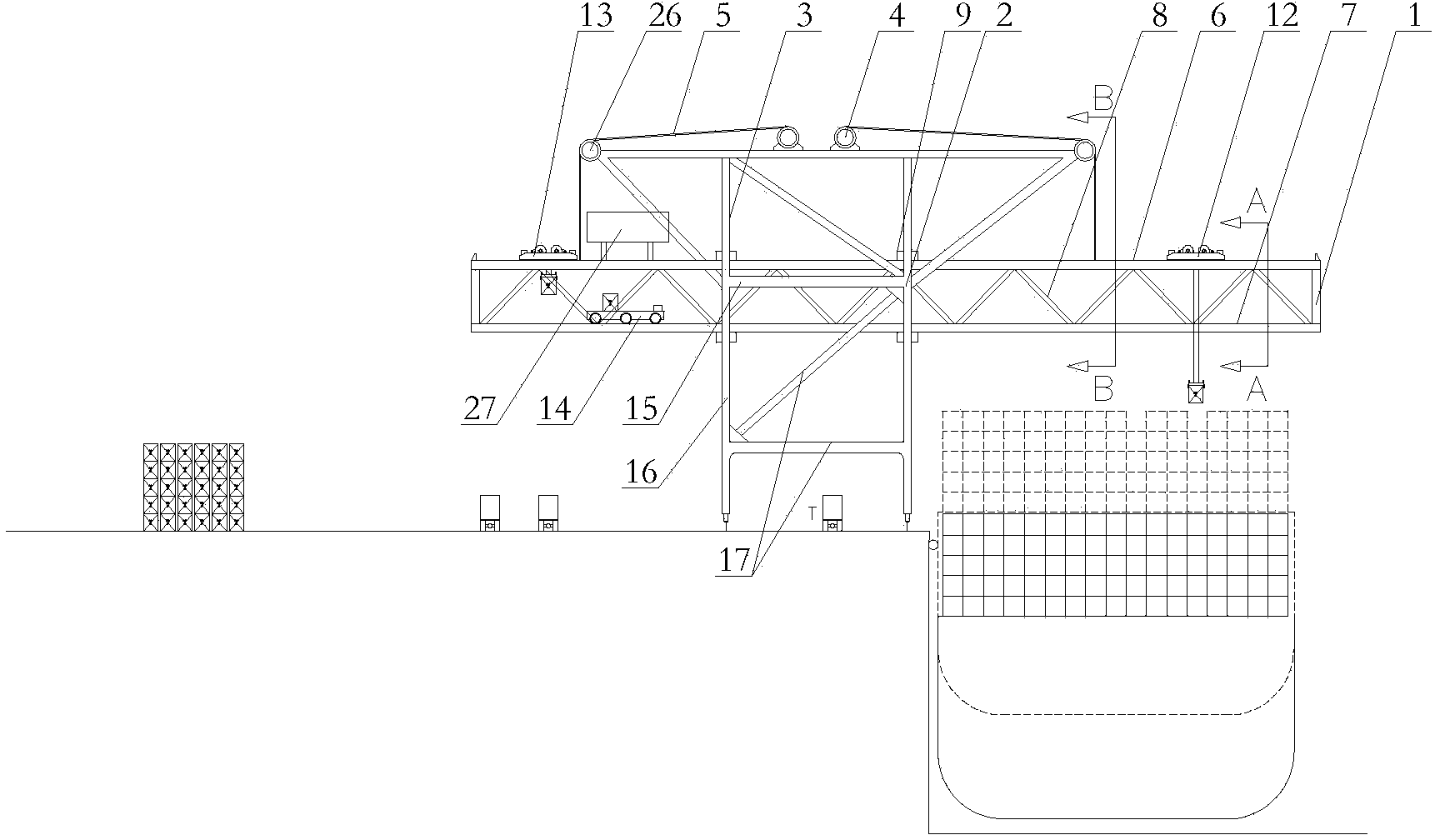

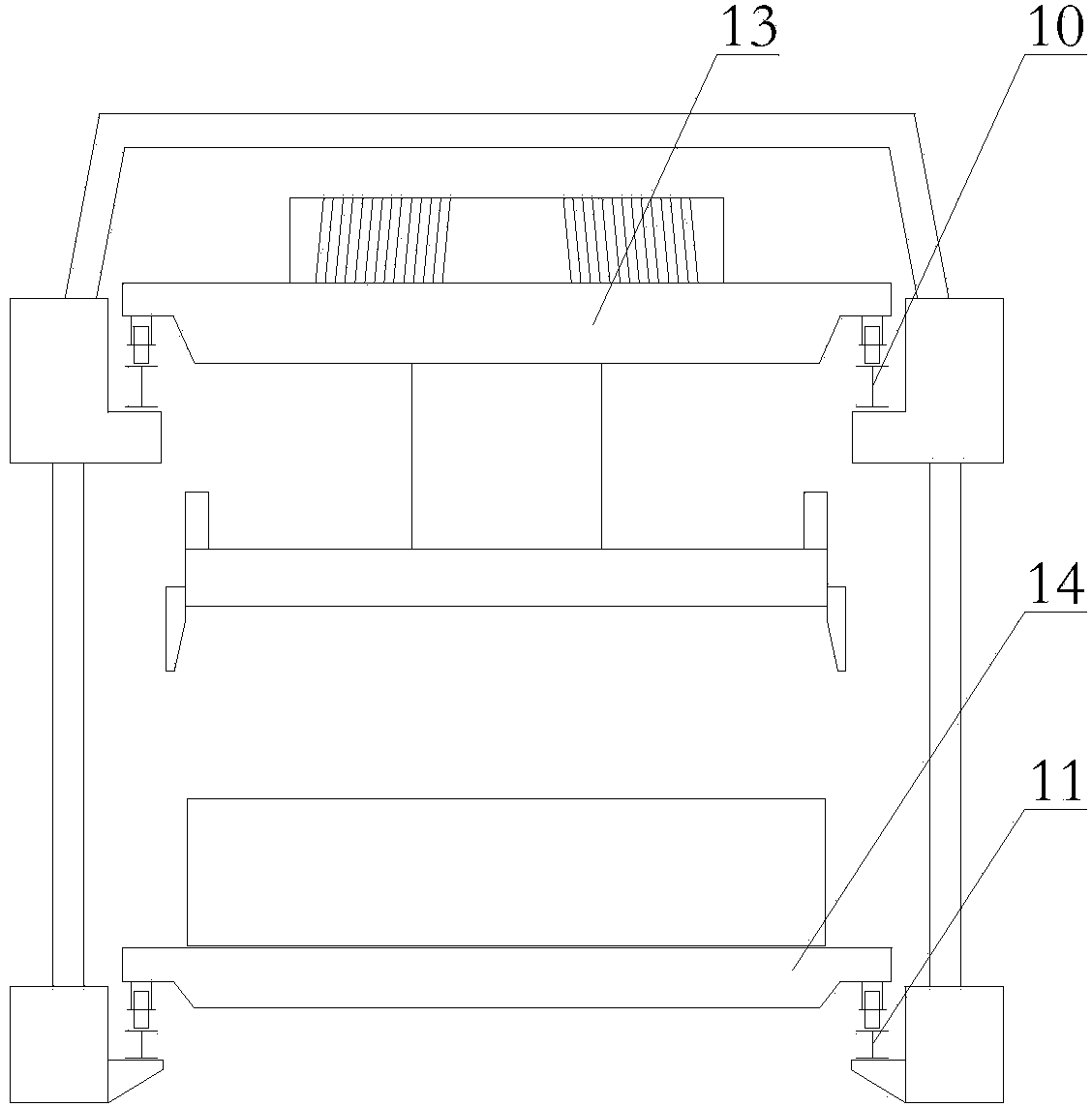

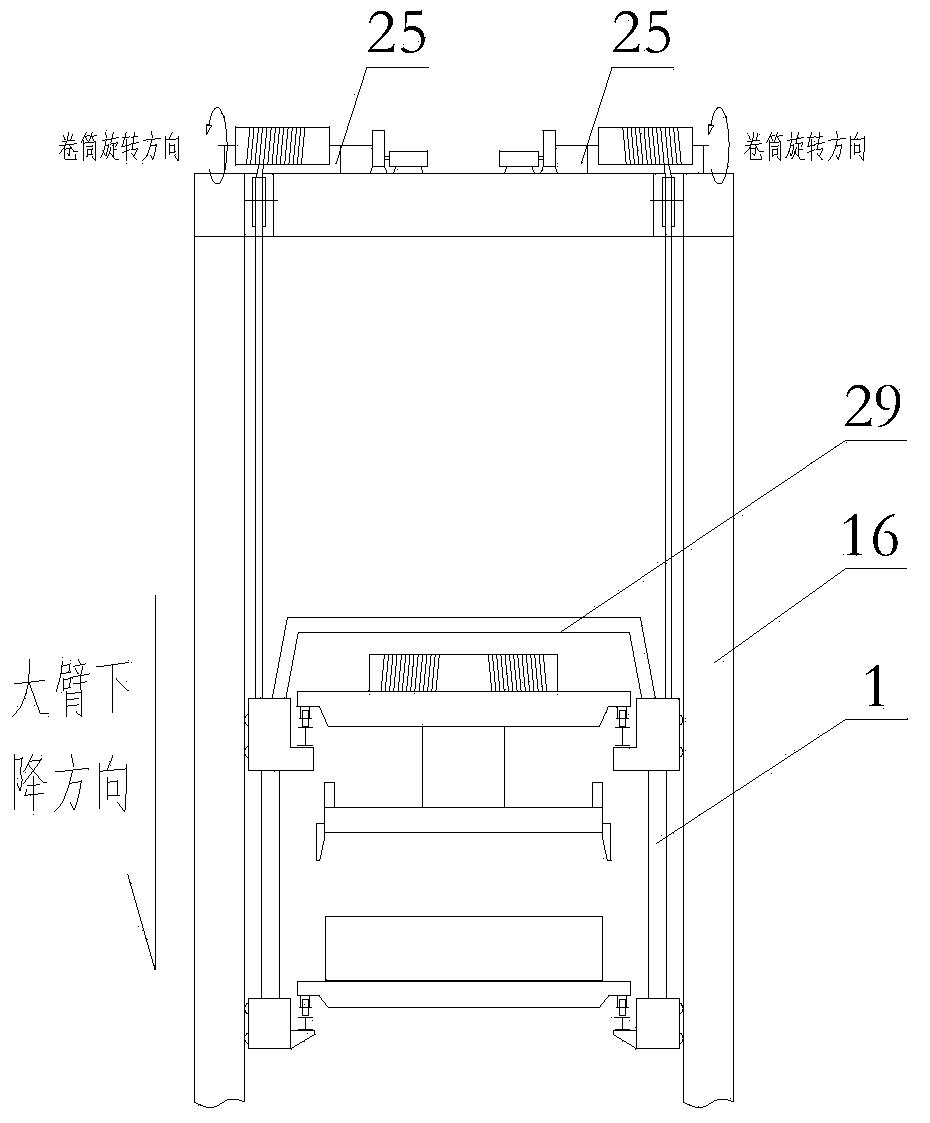

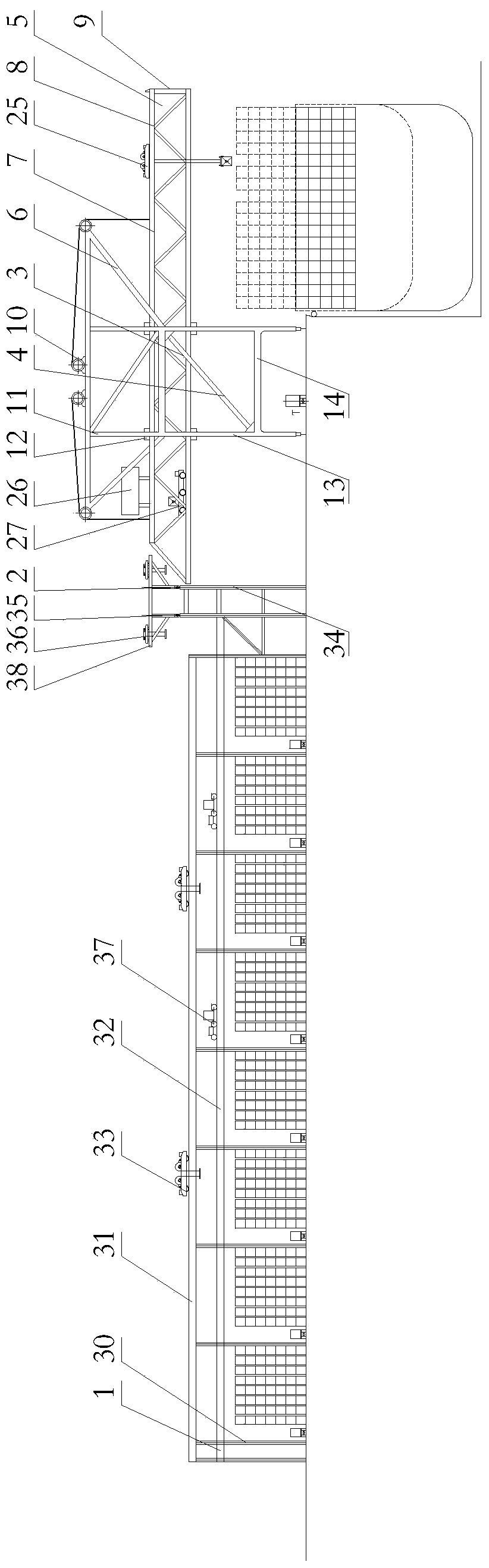

Container loading and unloading shore bridge with lifting type double-layer girder and three trolleys

InactiveCN103523680ASave handling timeImprove handling efficiencyTrolley cranesRunwaysBraced frameEngineering

The invention discloses a container loading and unloading shore bridge with a lifting type double-layer girder and three trolleys. The container loading and unloading shore bridge comprises a whole lifting girder and a supporting frame, wherein the whole lifting girder comprises upper bearing beams and lower bearing beams; a hoisting trolley A and a hoisting trolley B are respectively arranged on the upper bearing beams; a transporting trolley is arranged on the lower bearing beams; the two sides of the whole lifting girder are provided with more than 8 girder locking devices; and a lifting mechanism is arranged above the supporting frame and is connected with the whole lifting girder by a hoisting steel rope. Compared with the traditional technology, the container loading and unloading shore bridge disclosed by the invention has the advantages that the whole lifting girder can move up and down on the supporting frame and can be locked at a proper position by the girder locking devices, and the height of the whole lifting girder can be adjusted timely in the loading and unloading process, so that the carrying time of containers is effectively shortened; the two hoisting trolleys and one transporting trolley are adopted for carrying the containers, so that the alignment problem of one trolley for transporting the containers is avoided and the container loading and unloading efficiency is improved.

Owner:HUADIAN HEAVY IND CO LTD

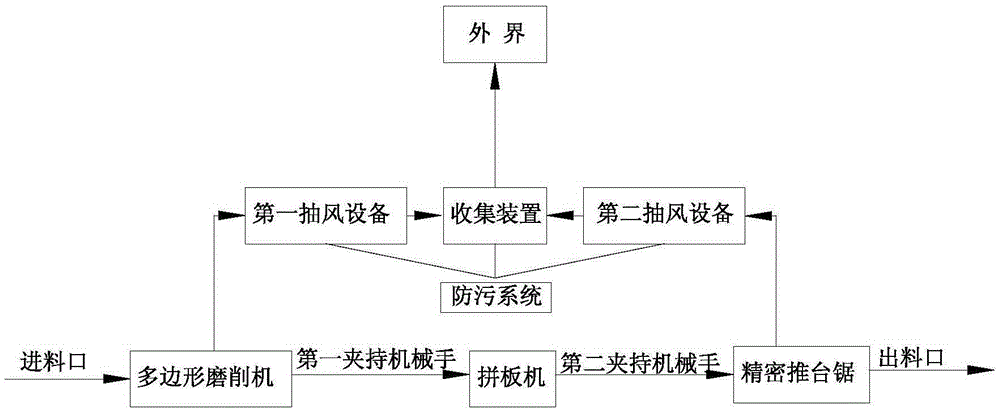

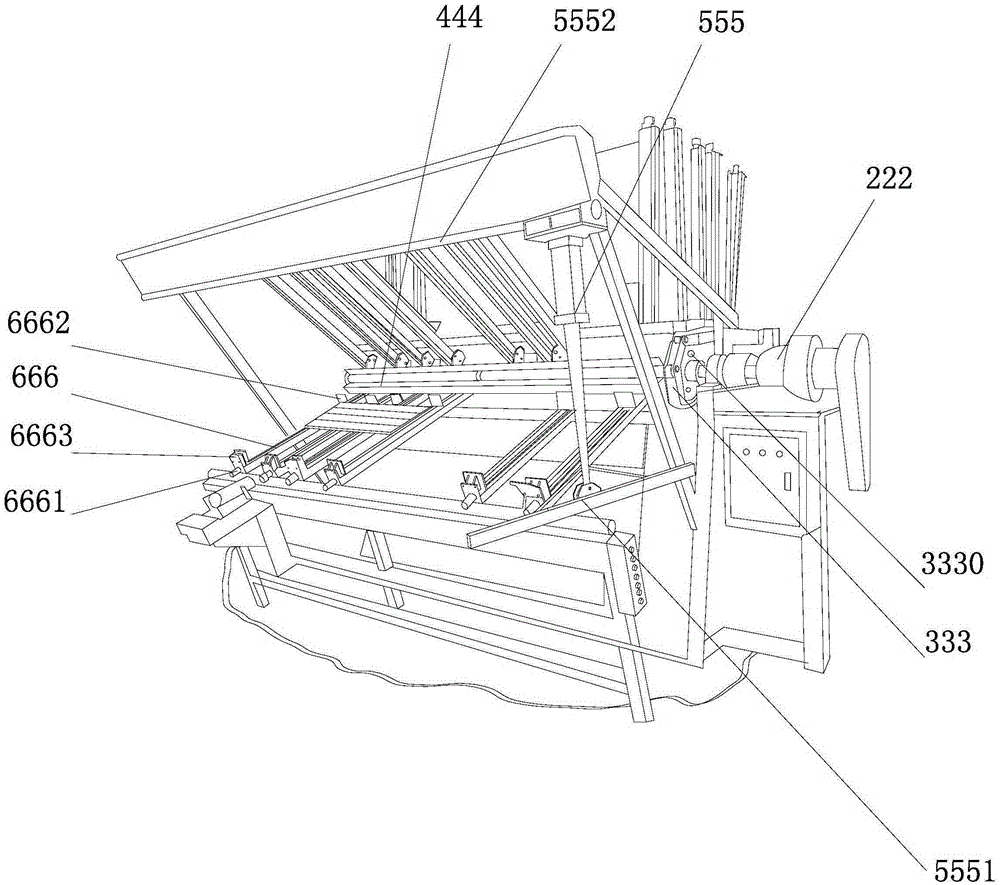

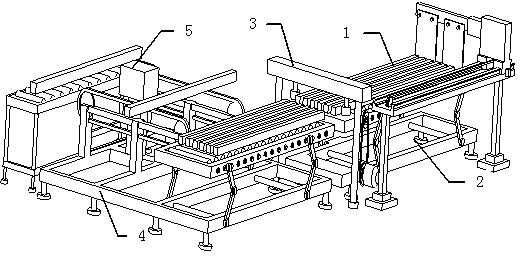

Combined production line for furniture wood processing

InactiveCN105415460ASave handling timeImprove the level of large-scale productionWood veneer joiningGrinding machinesProduction lineWood machining

The invention discloses a combined production line for furniture wood processing. The combined production line for furniture wood processing comprises a polygon grinding machine, a board splicing machine, a precise sliding table saw and an antifouling system, wherein the polygon grinding machine is used for grinding wood into a plurality of polygonal battens; the board splicing machine is used for splicing the polygonal battens into a wood board; the precise sliding table saw is used for cutting the wood board into semi-finished products of specified dimensions; the antifouling system comprises first exhaust equipment, second exhaust equipment and a collection device; the first exhaust equipment is used for sucking flying chips generated during machining of the polygon grinding machine; the second exhaust equipment is used for sucking flying chips generated during machining of the precise sliding table saw; the collection device is connected with the output end of the first exhaust equipment and the output end of the second exhaust equipment. The wood conveyed from a feed inlet is ground by the polygon grinding machine for formation and conveyed to the board splicing machine in a clamped mode through a first clamping manipulator, and the wood board formed through splicing is conveyed to the precise sliding table saw in a clamped mode through a second clamping manipulator and discharged from a discharge outlet after being cut. According to the combined production line for furniture wood processing, an assembly line type production mode is adopted, the manufacturing cost of products is reduced by improving the scale production level, and a good production environment in a workshop is guaranteed.

Owner:JIANGMEN XINYUANSEN FURNITURE CO LTD

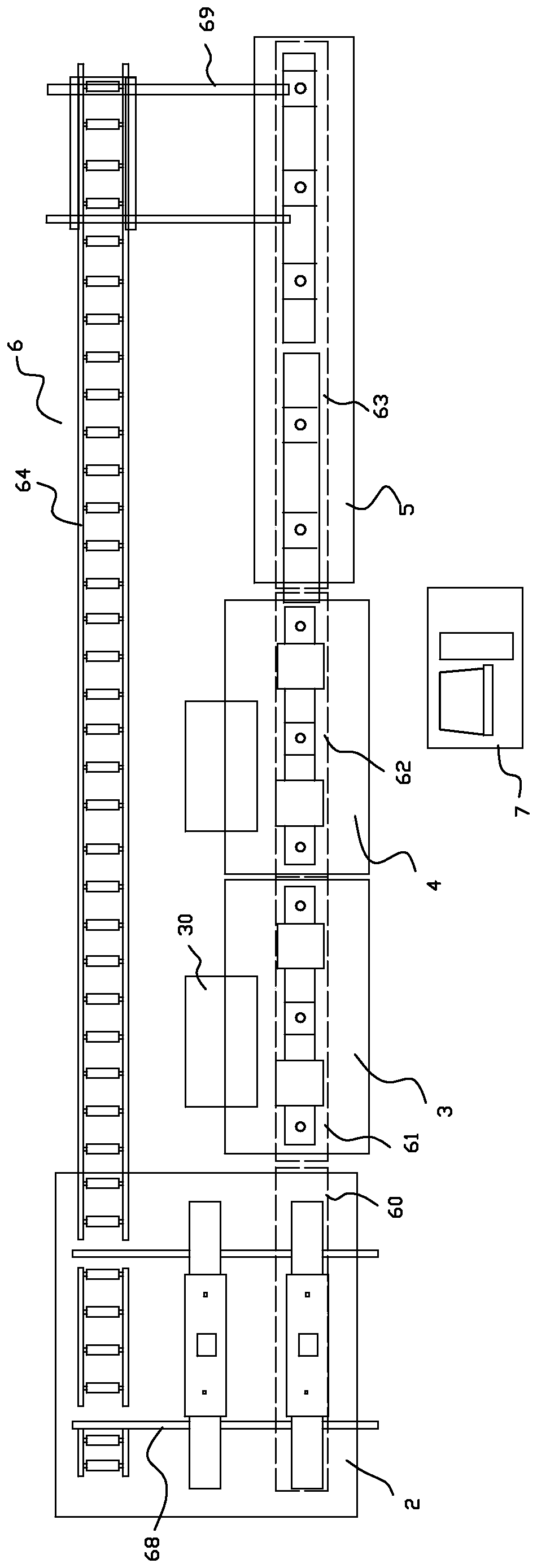

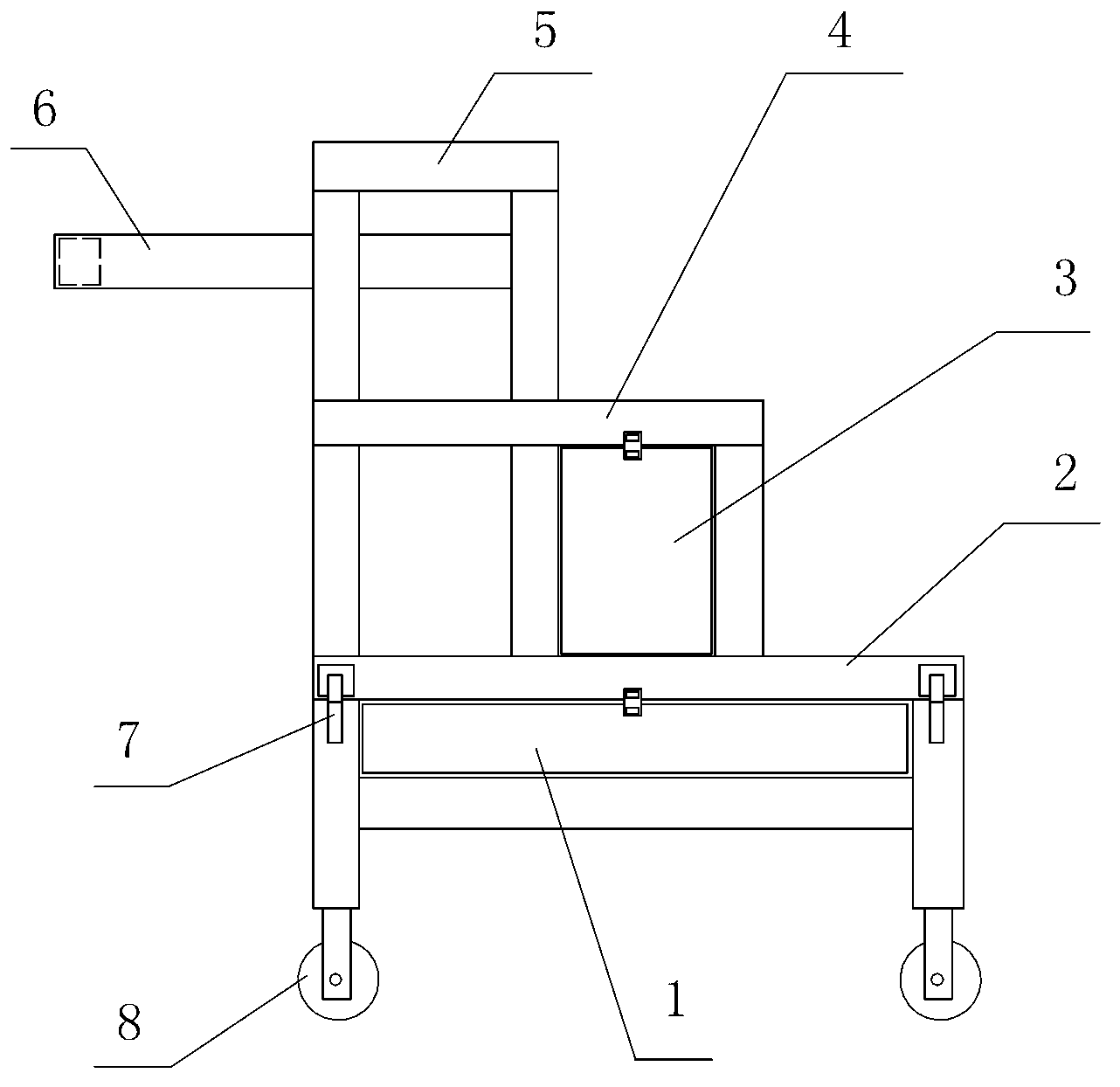

High-frequency compacted wood combined production line

PendingCN109808013ASave handling timeImprove the level of large-scale productionWood compressionWood treatment detailsProduction linePunching

The invention provides a high-frequency compacted wood combined production line. Operation equipment and an auxiliary panel are included. The auxiliary panel comprises an upper steel plate and a lowersteel plate which are used for clamping wood. The operation equipment comprises a throwing-in and taking-out part, an auxiliary high-frequency softening part, a main high-frequency punching part, a cooling part, a moving device and an operation device, wherein the throwing-in and taking-out part is arranged to be used for placing the upper steel plate and the lower steel plate to a conveying chain station and taking out the upper steel plate and the lower steel plate after the wood is machined; the auxiliary high-frequency softening part is provided with a high-frequency heating part for heating softening of a machining assembly; the main high-frequency punching part is provided with a high-frequency heating device and a press for continuously heating and compressing the wood obtained after softening treatment; the cooling part is provided with a water cooling device and / or an air cooling device to cool the compressed machining assembly; the moving device is arranged to be a conveyingchain which contains the machining assembly, sequentially penetrates through various parts and circularly conveys the wood; and the operation device is connected with various electromechanical control systems. According to the production line, the wood carrying time is greatly shortened, and the large-scale production level is improved.

Owner:王凯

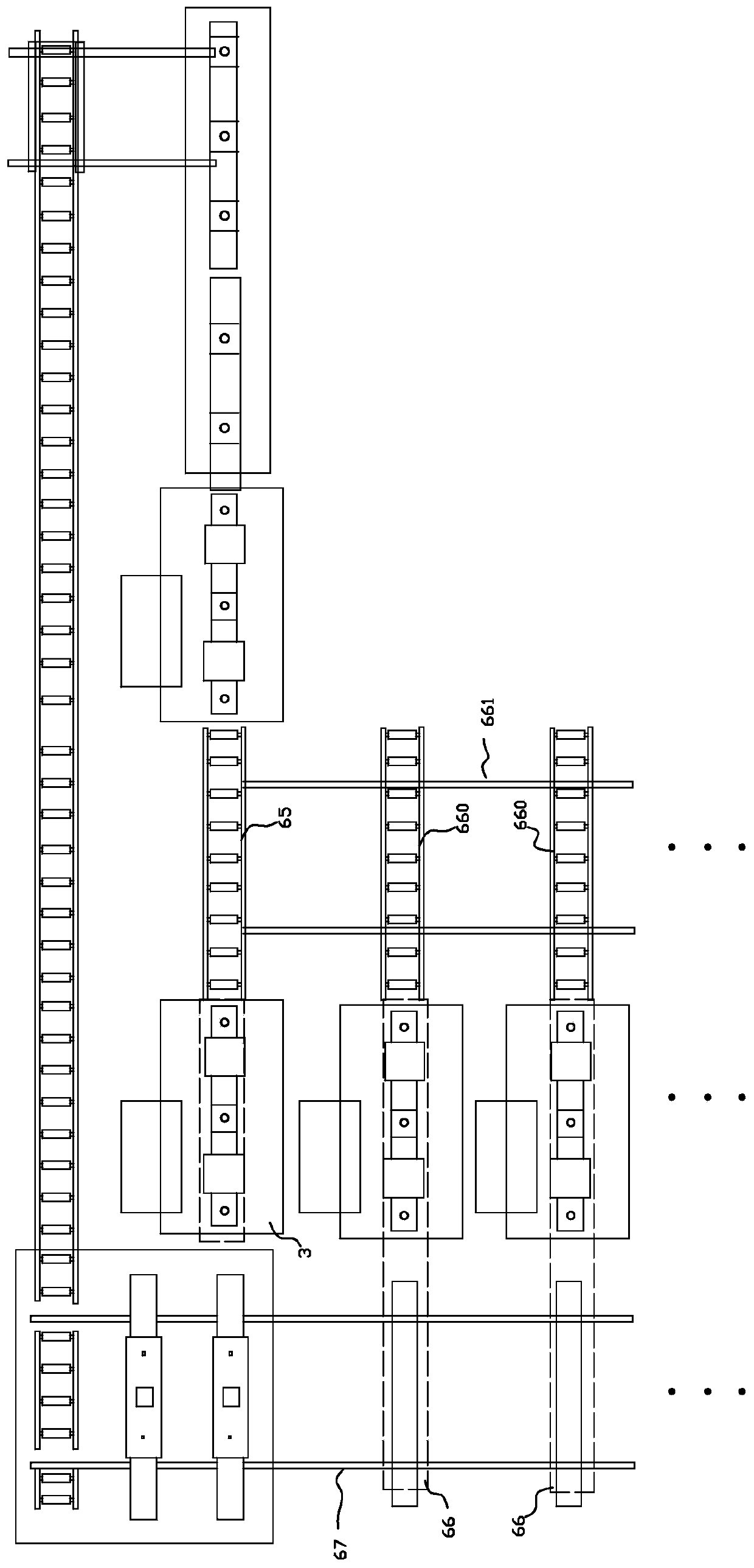

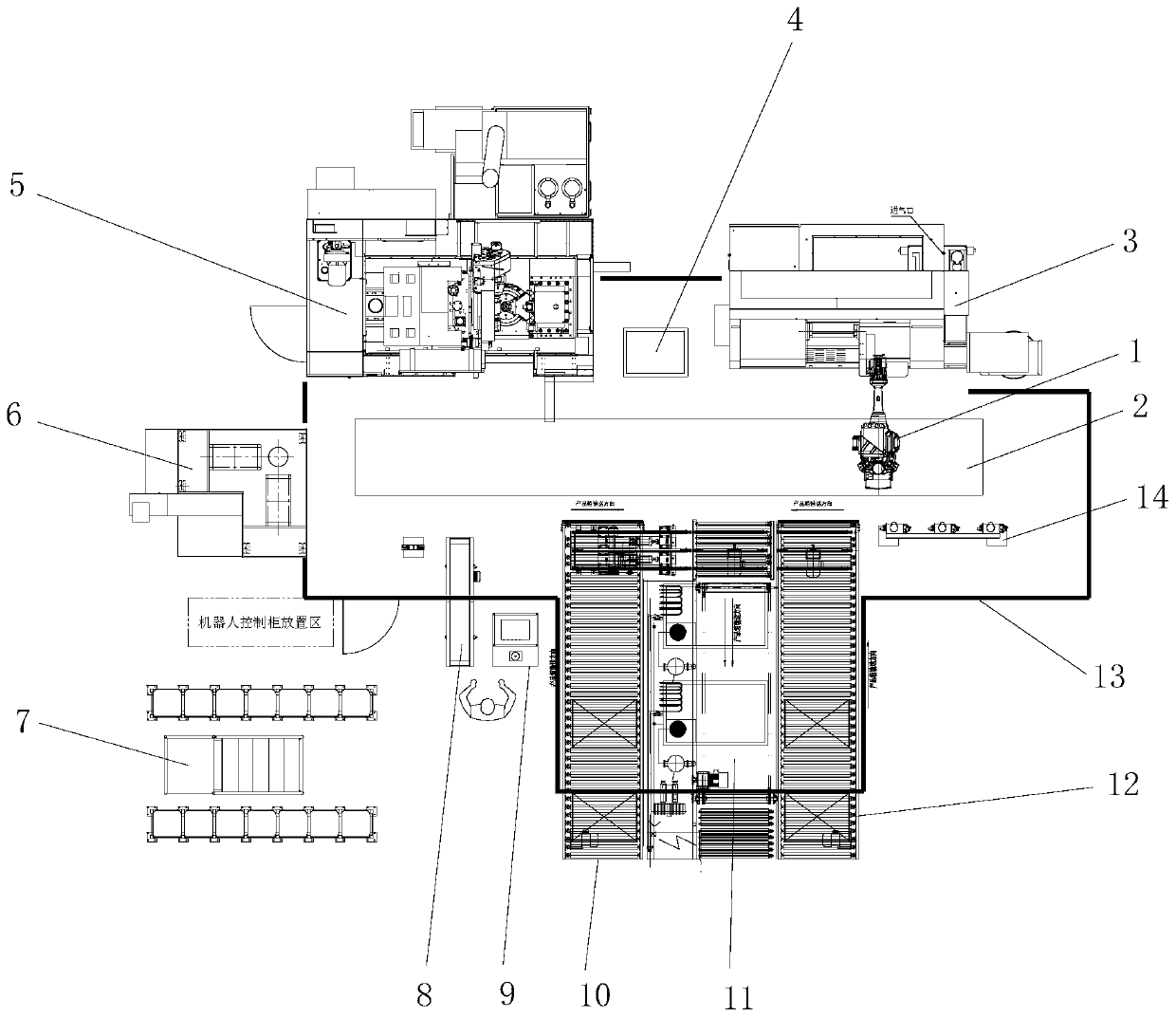

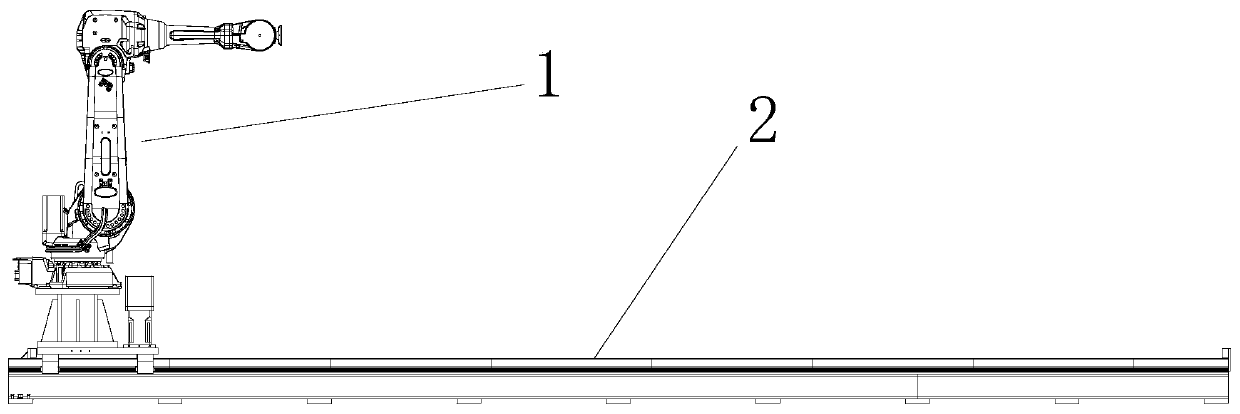

Automatic production line of planetary gears and method

InactiveCN110757171AGuaranteed machining accuracyGuarantee processing qualityOther manufacturing equipments/toolsMetal working apparatusNumerical controlProduction line

The invention discloses an automatic production line of planetary gears and a method. The automatic production line comprises a numerically-controlled lathe, a gear hobbing machine, a chamfering machine, a temporary storage platform, a cleaning machine and a robot. The robot is arranged on one guide rail and can move along the arranged guide rail; one side of the robot is provided with the numerically-controlled lathe, the temporary storage platform and the gear hobbing machine; the numerically-controlled lathe conducts rough turning and finish turning on blanks; the temporary storage platformis used for putting the blanks machined by the numerically-controlled lathe, and the gear hobbing machine conducts gear hobbing on the blanks to obtain semi-finished products; the end of the robot isprovided with the chamfering machine, and the chamfering machine conducts chamfering on the semi-finished products; the other side of the robot is provided with a detection platform, a cleaning device and a first feeding line; the detection platform is used for detecting the quality of finished products, the cleaning device cleans the qualified planetary gears, and the first feeding line is usedfor conveying the blanks.

Owner:青岛默森智能科技有限公司

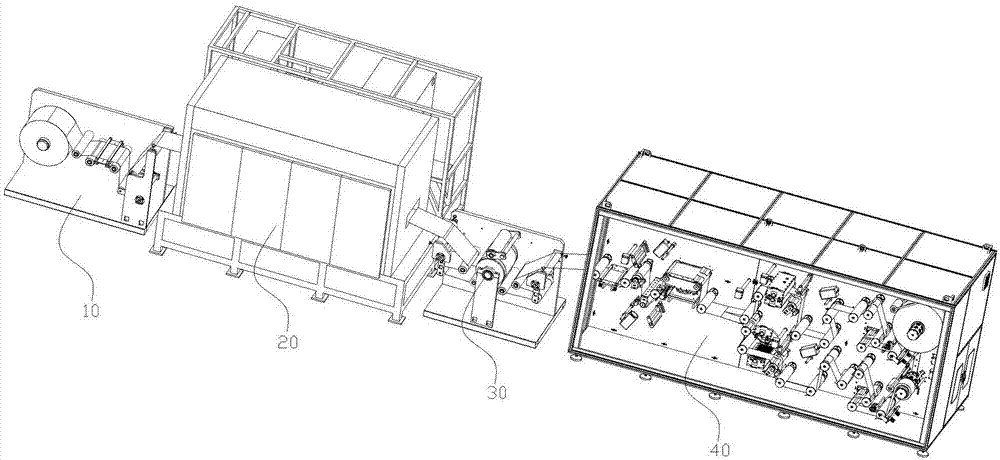

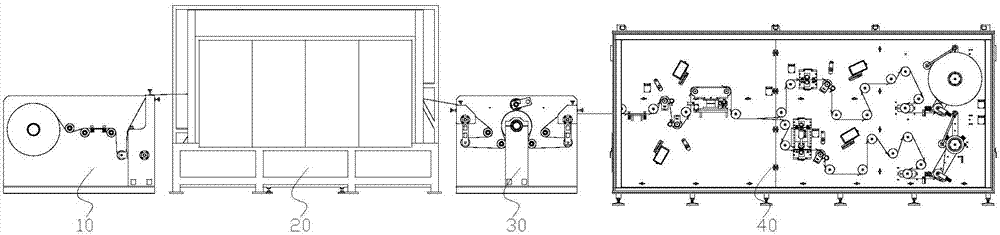

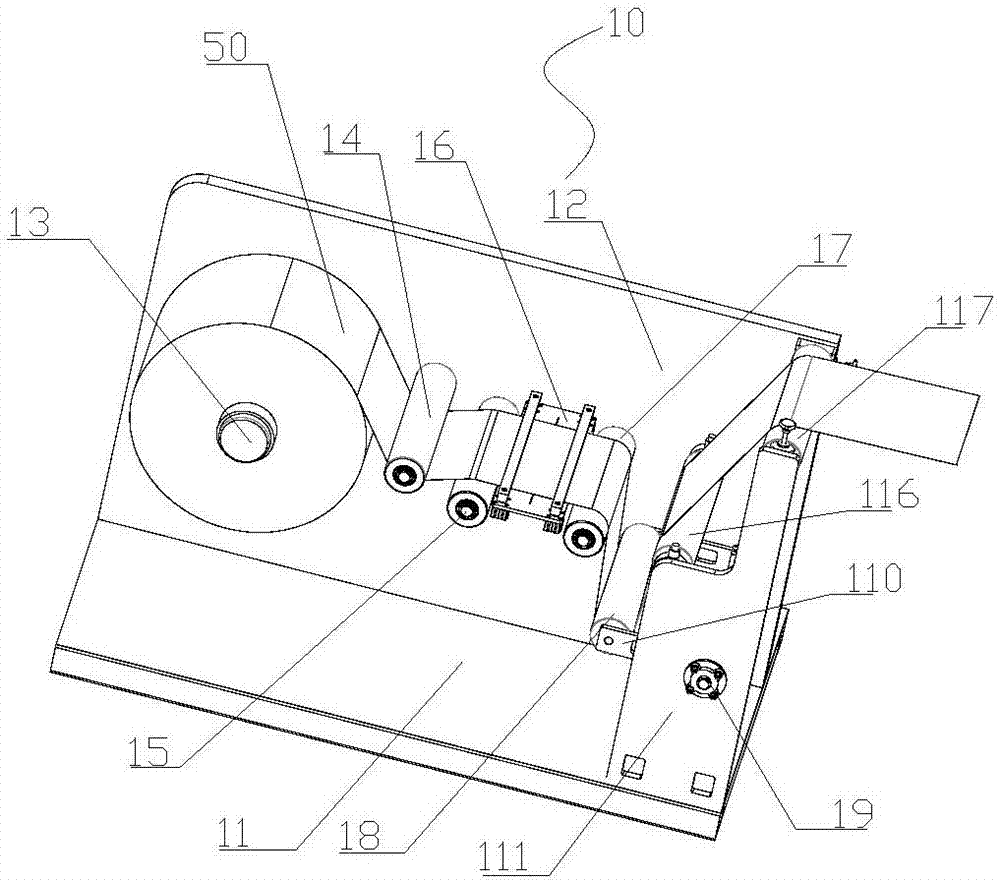

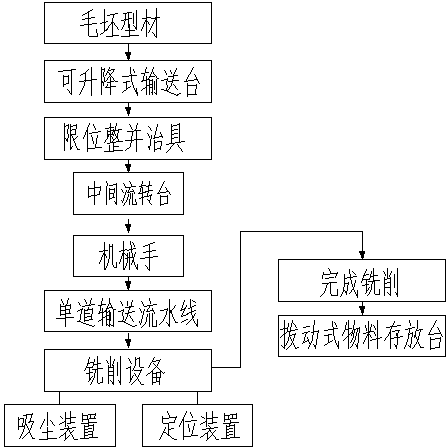

Drying and slitting all-in-one machine for lithium battery pole pieces

PendingCN107398408ASimple production processShorten the lengthPretreated surfacesCoatingsPole pieceMechanical engineering

The invention discloses a drying and slitting all-in-one machine for lithium battery pole pieces. The drying and slitting all-in-one machine comprises an unreeling module, a drying module, a cooling module and a slitting reeling module, wherein a pole piece baseband is arranged on an unreeling air-expanding assembly of the unreeling module, enters the drying module to dry, and enters the slitting reeling module after being cooled by a cooling roller of the cooling module; the slitting reeling module comprises a slitting knife group and two reeling rollers; the pole piece baseband is slit by the slitting knife group to form two pile piece bands; and each of the two pile piece bands is separately equipped with a reeling roller for reeling. According to the drying and slitting all-in-one machine disclosed by the invention, the slitting reeling module is arranged behind the cooling module, and the cooled pole piece baseband is directly slit, the cooled pole piece baseband does not need to reel, and is unreeled onto the slitting reeling module again, so that a production process of the lithium battery pole piece baseband is optimized, production cost is reduced, and production efficiency is improved.

Owner:深圳市新伟创实业有限公司

Automatic aluminum-plastic section milling process and automatic aluminum-plastic section milling equipment

InactiveCN104275621AEasy to manageSave handling timeMilling machinesMilling equipment detailsProduction lineMilling cutter

The invention provides an automatic aluminum-plastic section milling process and automatic aluminum-plastic section milling equipment. According to the process, blank sections, a liftable conveying table, a merging limit fixture, a middle conveying table, a manipulator, a single-track conveying production line and milling equipment are adopted for milling. The process is implemented by virtue of the following processing steps: feeding the blank sections by virtue of the liftable conveying table; merging and conveying the whole row of aluminum-plastic blank sections to the middle conveying table by virtue of the merging limiting fixture; arranging the clamping manipulator at the edge of the middle conveying table; arranging one end of the single-track production line at a feed opening of the milling equipment which is provided with a locating device; milling four sides of each aluminum-plastic blank section by use of upper, lower, left and right milling cutters which are provided with dust collection devices; feeding the milled sections into a pull-type material storage table. A production line control technology is adopted for a process from feeding to discharging, so that the working efficiency is improved, and shop management is convenient; each working procedure is performed on the production line, so that the workpiece carrying time can be reduced and a lot of manpower and material resources can be saved.

Owner:JIANGSU JULONG NEW MATERIALS

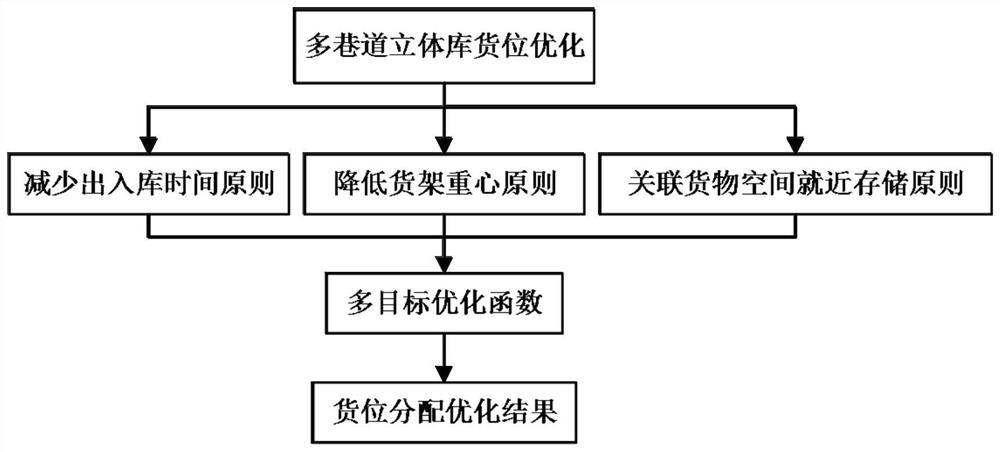

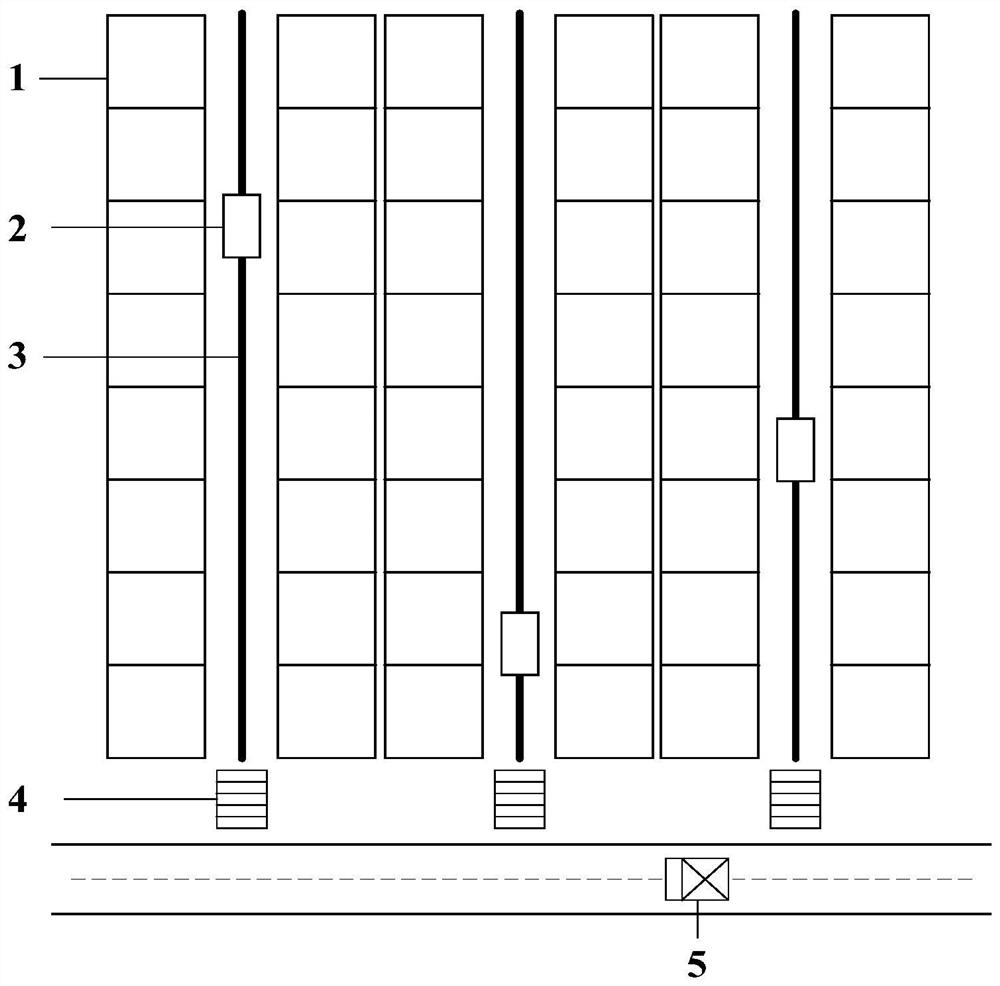

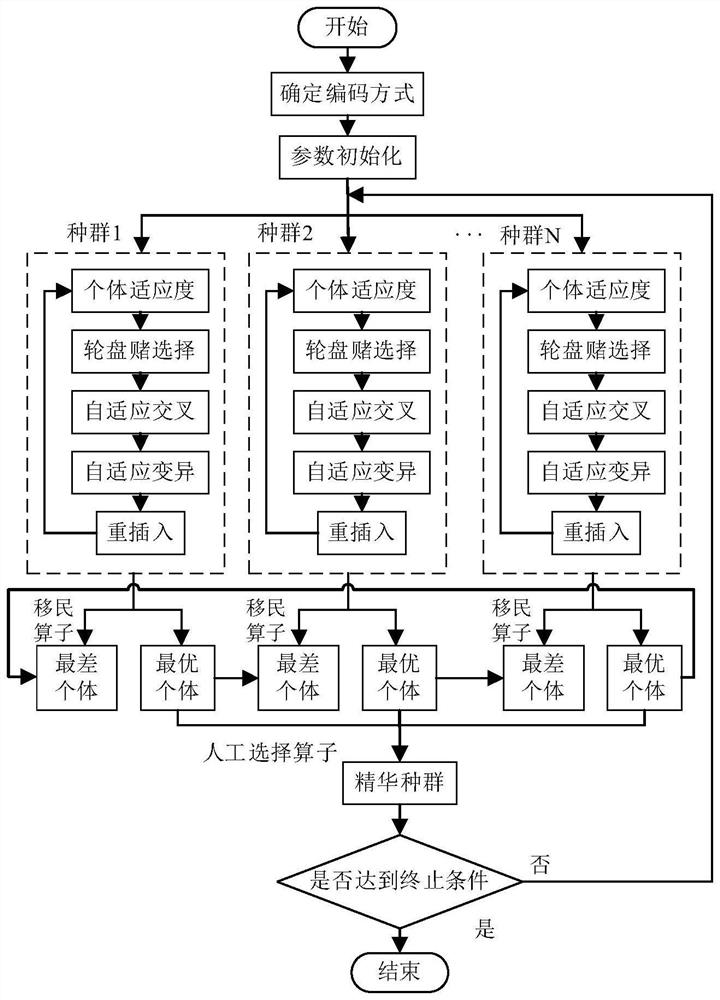

Genetic algorithm-based automatic stereoscopic warehouse goods allocation optimization method

ActiveCN114417696ALower center of gravitySave handling timeInternal combustion piston enginesCharacter and pattern recognitionDecision makerAlgorithm

The invention relates to the technical field of automatic stereoscopic warehouse storage, in particular to an automatic stereoscopic warehouse goods allocation optimization method based on a genetic algorithm. The method comprises the following steps: firstly, obtaining warehouse-in and warehouse-out frequency of goods according to historical order information of parts, and establishing a mathematical model for reducing warehouse-in and warehouse-out carrying time; counting the mass of the parts, and establishing a calculation formula for lowering the gravity center of the goods shelf; on the basis, clustering is carried out based on the correlation degree, and a mathematical model is established with the aim of improving the spatial aggregation degree of related products. The operation time, the shelf stability and the product correlation degree are comprehensively considered, a multi-target goods allocation optimization model is constructed, and the method is more comprehensive and reasonable than a single optimization target. According to the method, the comprehensive mathematical model is optimized and solved through the improved genetic algorithm, the obtained optimal solution is the current optimal goods allocation scheme, goods allocation distribution of parts can be effectively optimized, and decision makers are helped to formulate a reasonable scheme.

Owner:CHANGCHUN UNIV OF TECH

Container loading and unloading method and elevation type double-layer girder shore crane container loading and unloading system

The invention discloses a container loading and unloading method and an elevation type double-layer girder shore crane container loading and unloading system. The loading and unloading system comprises a yarn crane, a ferry crane and a shore crane, the yarn crane is connected with the shore crane through the ferry crane, the shore crane comprises a framework a, an integrated elevation girder and a framework b, and the framework b is arranged above the framework a. The integrated elevation girder comprises an upper-portion beam, a lower-portion beam and a girder locking device. The framework b comprises an elevation mechanism and a gantry, and the elevation mechanism is arranged on the gantry. Compared with the prior art, the integrated elevation girder can move up and down on the frameworks; due to the fact that the integrated elevation girder is provided with the girder locking device, the integrated elevation girder can be locked at a proper position through the girder locking device; the height of the integrated elevation girder is changed to adjust the hoisting height of a container, the distance between the integrated elevation girder and the container is kept unchanged, the time for carrying the container is effectively shortened, the efficiency of carrying the container is greatly improved in a large degree, and the handling capacity of a port is improved.

Owner:HUADIAN HEAVY IND CO LTD

Multifunctional operational tool vehicle for switching operation

The invention belongs to the field of electrical equipment, and particularly relates to a multifunctional operational tool vehicle for switching operation. The multifunctional operational tool vehicle for the switching operation is characterized by comprising a first step rack, a second step rack, a third step rack, wheels and a handle rack. The second step rack is fixed onto the left of the upper end of the first step rack, the third step rack is fixed onto the left of the upper end of the second step rack, the upper portion of the first step rack is provided with a first storage box, the lower four corners of the first step rack are all provided with the wheels, the right portion of the second step rack is provided with the second storage box, and the left end of the third step rack is fixedly provided with the handle rack. The left end and the right end of the front side surface of the first step rack are both provided with hooks, and the left end and the right end of the rear side surface of the first step rack are both fixedly provided with hooks. The multifunctional operational tool vehicle for the switching operation can achieve multifunction and shorten the moving time of tools during the switching operation.

Owner:STATE GRID CORP OF CHINA +1

Hub detection device

ActiveCN110230988AImprove accuracyNo damageUsing optical meansMechanical measuring arrangementsLaser rangingEngineering

The invention provides a hub detection device, and belongs to the technical field of the hub detection equipment. The device comprises a rack; a rotary worktable arranged on the rack, and used for supporting a to-be-detected hub and driving the hub to rotate in relative to the rack; and a center hole size detection device located above the rotary worktable, wherein a one-dimensional laser rangingsensor for detecting the diameter of a hub center hole is arranged at the bottom; the center hole size detection device is connected with a first driving device arranged on the rack; the first drivingdevice is used for riving the center hole size detection device to axially move along a rotating shaft of the rotary worktable, and the one-dimensional laser ranging sensor can move into the center hole of the hub under the driving of the first driving device; and the hub detection device further comprises a hub pedal contour detection device and a hub size detection device. The hub detection device provided by the invention can simultaneously detect the pedal contour, the center hole size and the bolt hole size of the hub, and the detection precision is high.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

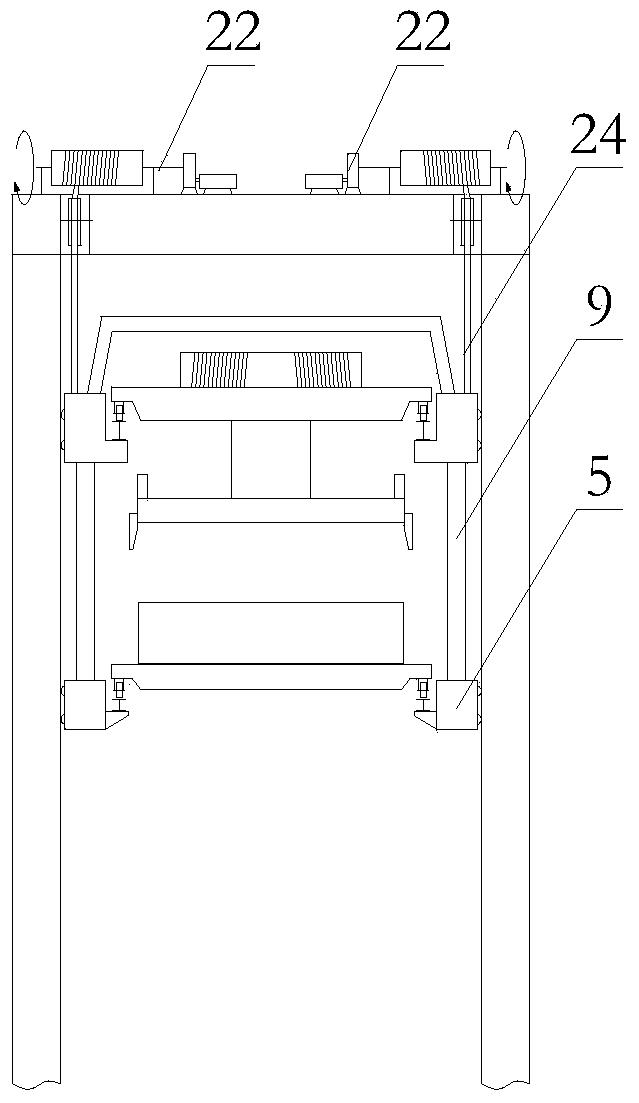

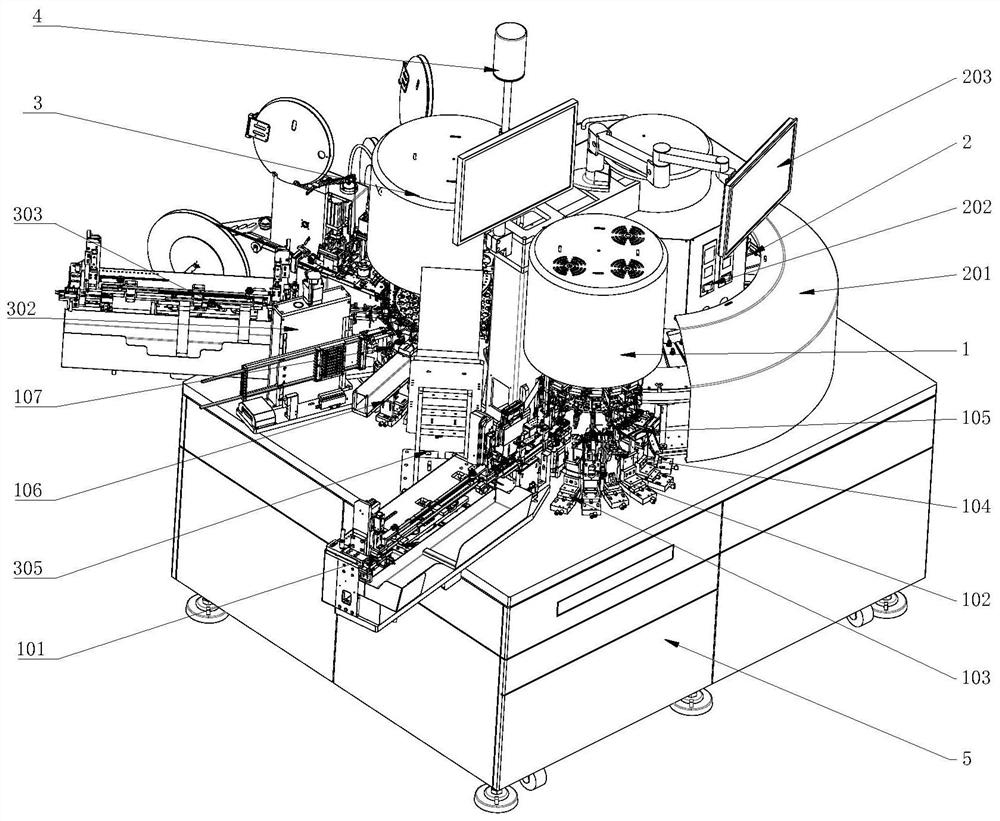

Full-automatic multifunctional laminating machine

InactiveCN110505765ASave handling timeRealize continuous laminating productionCircuit bendability/stretchabilityPrinted circuit secondary treatmentLinear motionEngineering

The invention provides a full-automatic multifunctional laminating machine comprising a machine frame, a first X axis linear motion module group, a second X axis linear motion module group, a Y axis straight line motion module group, a laminating platform, two laminating heads, double carrying feeding discharging arms, two feeding devices, a feeding box, and a discharging box. The laminating machine is provided with the double carrying feeding discharging arms, and then the feeding and the discharging can be carried out at the same time, and therefore FPC board conveying time can be saved. A plurality of laminating machines can be assembled in a cooperated manner, and by adopting a way of sharing the feeding box and the discharging box, the continuous laminating production of the FPC boards can be realized, and reinforced sheets of various specifications can be laminated continuously. The two laminating heads and the corresponding feeding devices are used to absorb the reinforced sheets alternately and repeatedly, and are attached to predetermined positions to be provided with the FPC in an attached way, and therefore laminating efficiency is greatly improved. Meanwhile, an image processor is provided in a matched manner, and the laminating precision is improved. The laminating heads are provided with springs, and by controlling the amount of compression of the springs, the pressing strength of the laminating heads applied to the FPC boards during the laminating can be controlled, and the FPC boards can be prevented from being damaged.

Owner:SHENZHEN BANGZHENG PRECISION MACHINERY CO LTD

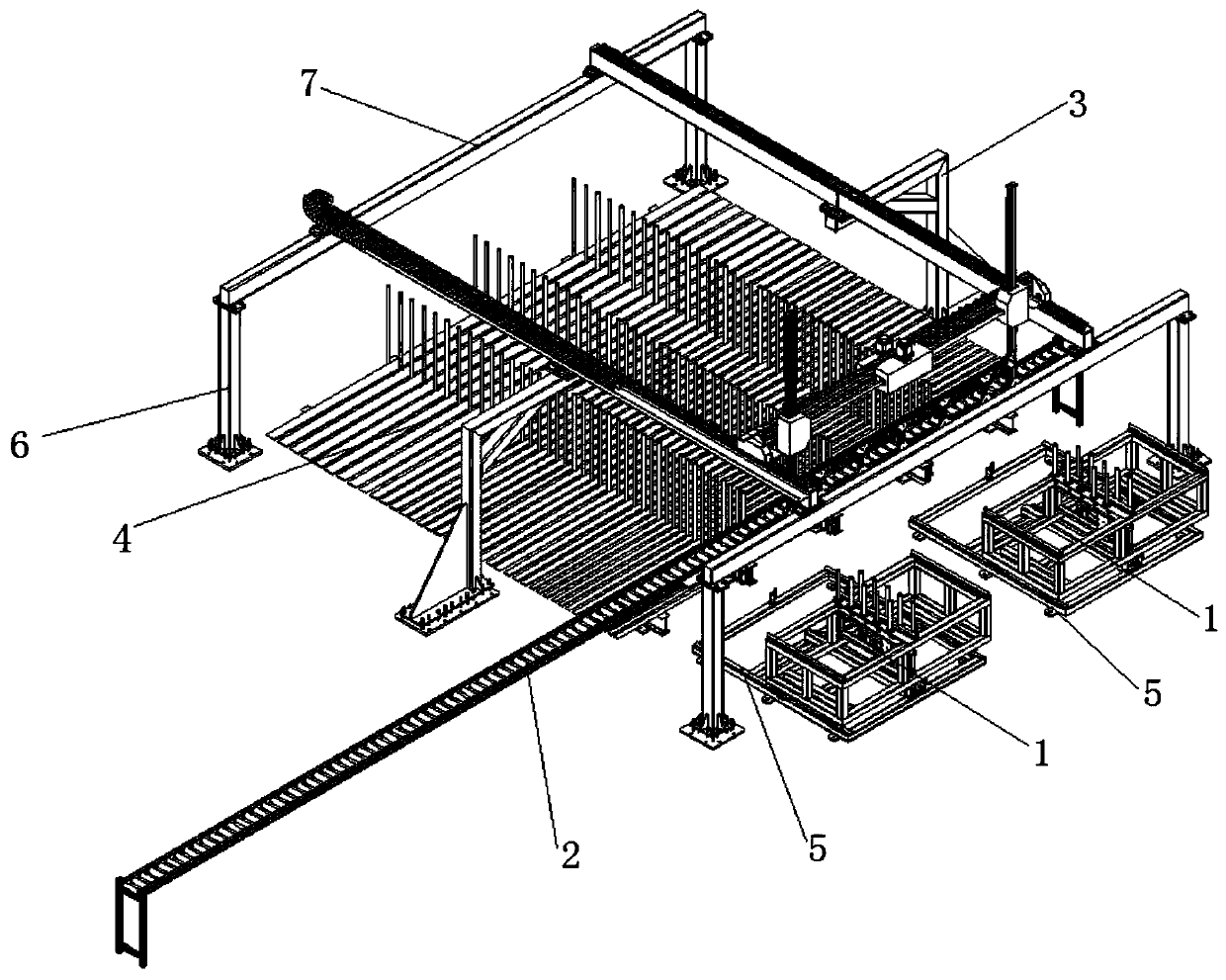

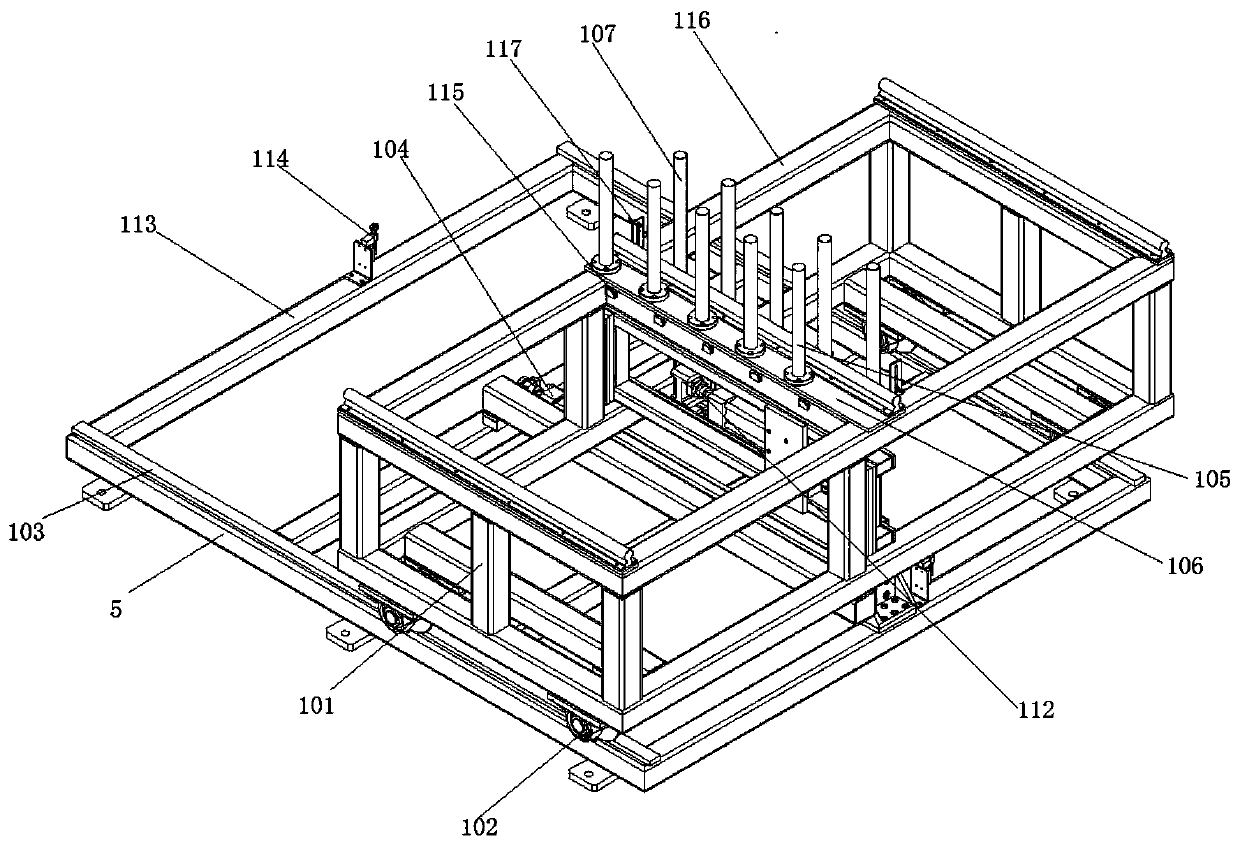

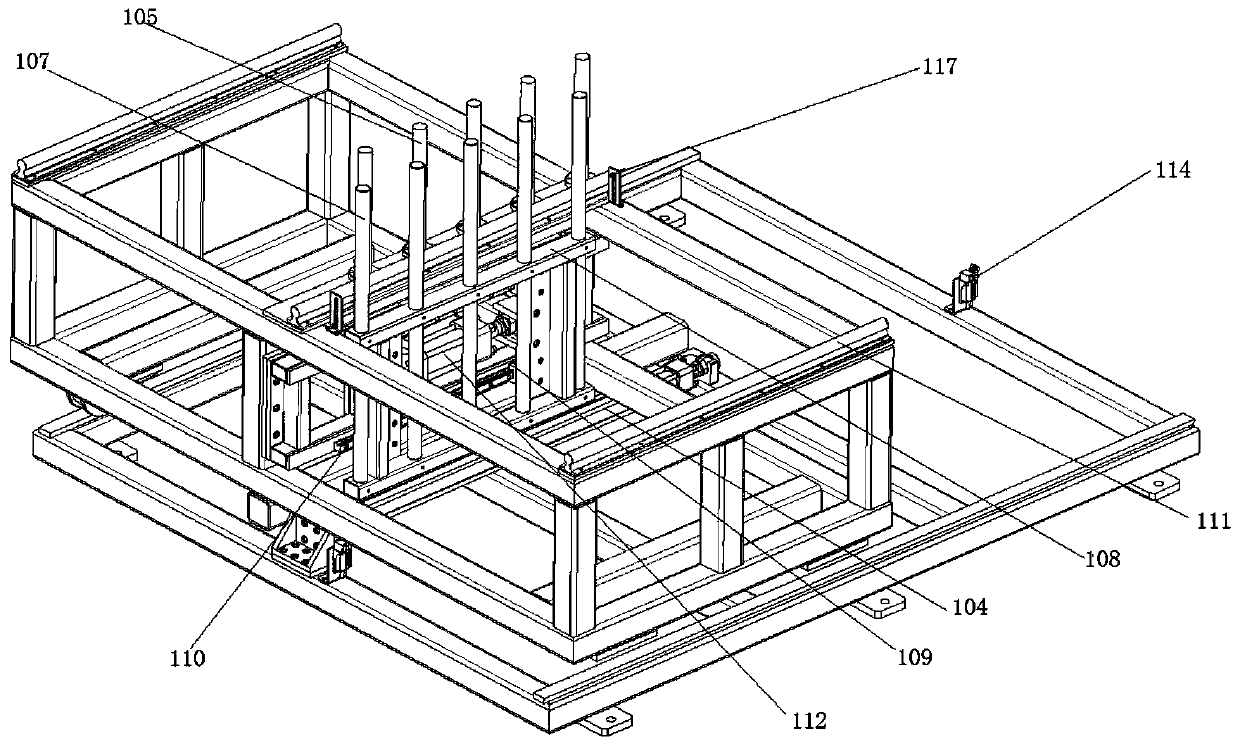

Automatic copper bar transplanting warehouse

The invention relates to an automatic copper bar transplanting warehouse which is used for carrying out warehouse-in and warehouse-out treatment on copper bar workpieces. The transplanting warehouse comprises a feeding and pushing platform, a roller conveying line, a truss manipulator and a copper bar storage location. The feeding and pushing platform is located at a feeding end of the truss manipulator. A bottom rack of the feeding and pushing platform is connected and fixed to the ground through an expansion bolt. The roller conveying line is located at the feeding end of the truss manipulator so as to carry out positioning operation on the copper bar workpieces. The truss manipulator comprises a steel structure transverse shaft supported by a stand column, a grabbing mechanism and a moving mechanism, wherein the grabbing mechanism and the moving mechanism are located on the transverse shaft. And the truss manipulator is used for completing warehouse-in and warehouse-out operation ofthe workpieces, and the copper bar storage location is located right below the truss manipulator and is used for storing the copper bar workpieces. The automatic transplanting warehouse can grab thecopper bars with different specifications, is excellent in compatibility, and can carry out classified warehouse-in and warehouse-out operation according to products with different specifications.

Owner:杭州研卓智能科技有限公司

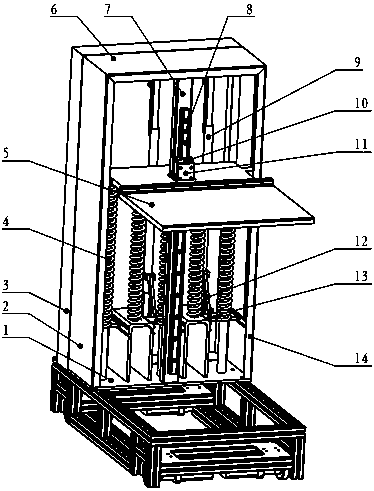

Carrying trolley capable of automatically adjusting height of objective table

The invention discloses a carrying trolley capable of automatically adjusting the height of an objective table. The carrying trolley capable of automatically adjusting the height of the objective table is characterized by comprising a machine frame, the objective table and an adjusting mechanism, the machine frame comprises a portal frame and a guide rail vertically mounted in the portal frame, and the machine frame is mounted on a trolley basis; the objective table is arranged on the guide rail through a sliding block and can move up and down along the guide rail; and a plurality of compression springs I are arranged between the objective table and a machine frame bottom plate, a plurality of compression springs II are arranged at the bottom of the objective table, the adjusting mechanismis connected to the lower ends of the compression springs II, and the adjusting mechanism can adjust the rigidity of the compression springs II. According to the carrying trolley capable of automatically adjusting the height of the objective table, automatic adjustment of the height of the objective table is realized, the labor strength of workers is reduced, the carrying efficiency is improved,carrying time is shortened, and the carrying trolley capable of automatically adjusting the height of the objective table further has the advantages of simple structure and convenient operation.

Owner:XIANGTAN UNIV

Powder slurry delivering device

The invention relates to a powder slurry delivering device comprising a slurry cavity. An inlet of the slurry cavity is provided with a feed interlock valve; an outlet of the slurry cavity is provided with a discharge interlock valve; the feed interlock valve is connected with a feed pipe; the discharge interlock valve is connected with a discharge pipe; and the slurry cavity is further connected with a delivering pump. During operation, the slurry from the feed pipe is sucked into the slurry cavity through the feed interlock valve under the action of the delivering pump and is then output to the discharge pipe through the discharge interlock valve, and materials are supplied for multiple slurry production devices. The device has the advantages of high automation degree, no pollution, no need of manual transportation during production of powder slurry and high working efficiency.

Owner:江门市正曦输送机械设备有限公司

One-step molding process of roller bar stock on lathe

The invention discloses a one-step molding process of a roller bar stock on a lathe. The process comprises the following steps of: leveling a right end surface by adopting an end surface cutter; after the end surface is leveled to an appointed size, digging a hole on the right side of a roller; cutting off by using a cut-off tool, and meanwhile, synchronously profiling the left chamfer from the outer diameter of the right chamfer; and after finishing slotting by a slotting tool which is a flat cutter and a 5-degree chamfering cutter, assisting a clamping head to clamp and twist off a roller. By adopting the method, the turning processing of all surfaces of the roller can be finished in one-step clamping, the processed roller is molded at one time and can be directly sent to a grinding procedure after being subjected to heat treatment. The one-step molding process of a roller bar stock on a lathe can be used for realizing the one-step turning and molding of the processed roller, saves the material handling time, combines the procedures, saves the labor power, avoids secondary clamping of the processed roller, improves the processing precision, improves the processing efficiency and saves the total processing time. After the process is applied to lathes, an operator can simultaneously operate 3-4 lathes, thus a large quantity of labor power is saved.

Owner:WAFANGDIAN BEARING GRP CO LTD +1

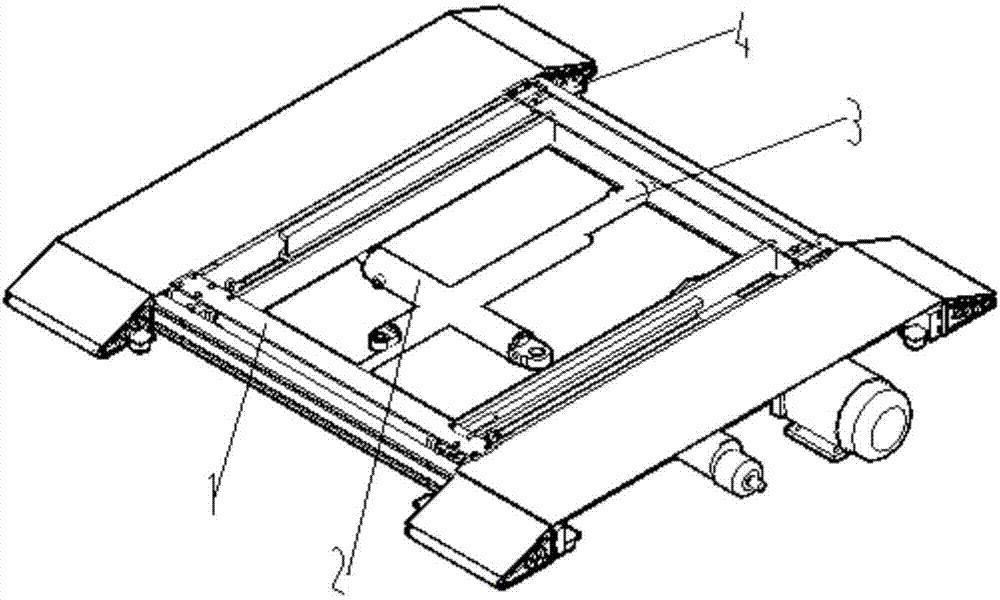

Automobile carrier for stereo garage automobile elevator

The invention discloses an automobile carrier for a stereo garage automobile elevator, and belongs to the technical field of mechanical type solid parking equipment. The automobile carrier comprises an underframe and a translation mechanism. The underframe is of a retractable type composite structure, the two parts of a front frame body and a rear frame body can be formed through longitudinal extension and contraction of the underframe, and the translation mechanism is connected to the position between the carrier underframe and the elevator; and the automobile carrier is connected with the horizontal face of an automobile elevator chassis in a relative moving mode, and the translation mechanism drives the carrier underframe to translate between the horizontal face of the elevator chassisand a corresponding parking space of a stereo garage to conduct automobile carrying. The automobile carrier can cooperate with automobile carrying work of a large roadway stacking type stereo garage,the automobile carrier is movably connected to the automobile elevator, a carrying route is clear, and the automobile parking and picking efficiency is high.

Owner:SHANDONG JIANZHU UNIV

Bookshelf with damp-proof function

InactiveCN108720344AImprove moisture resistanceWith moisture-proof functionBook cabinetsCarpet cleanersEngineeringMoisture

The invention provides a bookshelf with a damp-proof function, and relates to the field of bookshelves. The bookshelf with the damp-proof function comprises a protecting seat, wherein the cavity of the protecting seat is fixedly connected with a fixing plate; dustproof mechanisms are separately fixedly connected to two sides of the top of the fixing plate; each dustproof mechanism comprises a first rotation motor; first sliding tracks are fixedly connected to the two sides of the inner wall of the protecting seat separately and are positioned above the fixing plate; a first movable plate is slidably connected between the two first sliding tracks; and the bottom of the first movable plate is fixedly connected with a first threaded sleeve. According to the bookshelf with the damp-proof function, moisture in air can be removed by a heating wire, dryness of gas is maintained, by cooperation of an air outlet fan, an air outlet tube and an air outlet hole, the gas which has been dried is discharged from the air outlet hole, and flows to various places of the protecting seat through a through hole, dryness of the environment of the inner wall of the protecting seat is maintained, dampnessis prevented, and a damp-proof effect is achieved.

Owner:雷秀泗

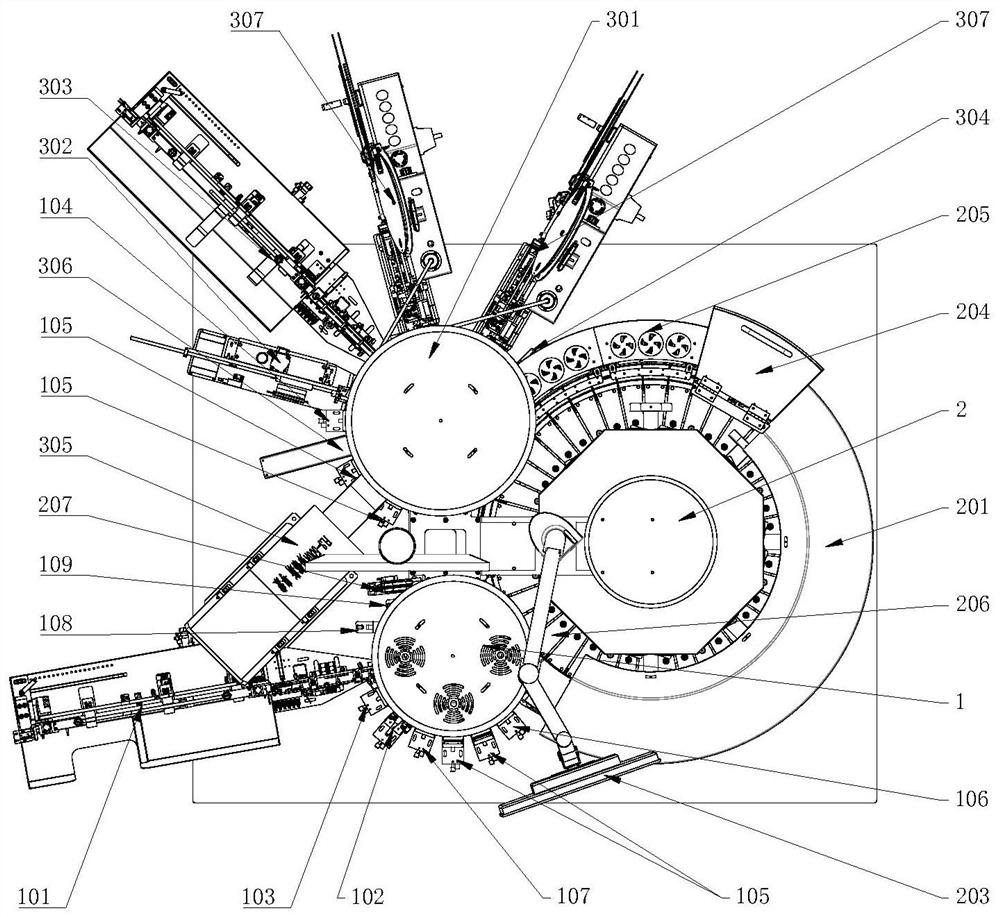

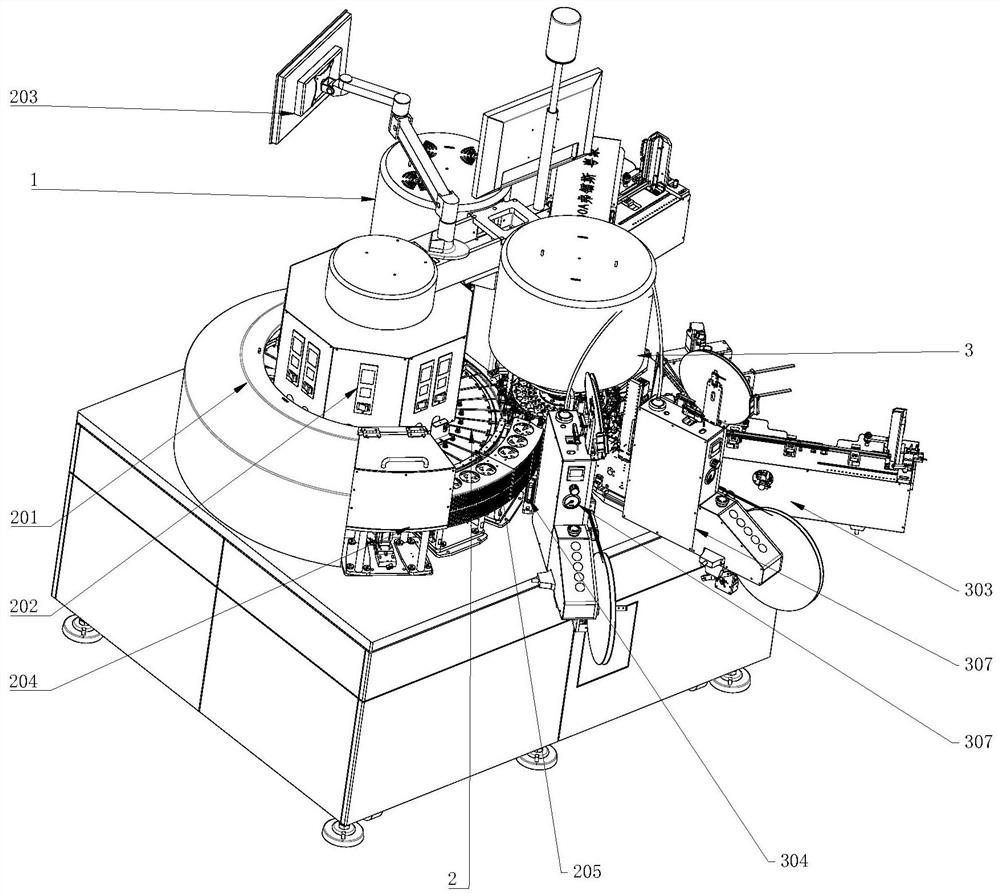

Chip constant-temperature and high-temperature testing and sorting all-in-one machine

The invention relates to the technical field of semiconductor processing, and discloses a chip constant-temperature and high-temperature testing and sorting all-in-one machine. The chip constant-temperature and high-temperature testing and sorting all-in-one machine comprises a feeding turret module, a high-temperature turret module, a discharging turret module, an equipment alarm system and an equipment power box mechanism, wherein the feeding turret module is fixedly connected with the left side of the upper surface of the equipment power box mechanism, the high-temperature turret module isarranged on the right side of the upper surface of the equipment power box mechanism, the discharging turret module is arranged at the upper end of the equipment power box mechanism, and the equipmentalarm system is fixedly connected with the upper end of the high-temperature turret module. According to the chip constant-temperature and high-temperature testing and sorting all-in-one machine, a plurality of independent normal-temperature and high-temperature testing and sorting equipment is completely integrated on one device, so that automobile electronic components can be sufficiently heated in a high-temperature tunnel, the electric performance testing in the high-temperature environment state is realized, the site space is saved, the product carrying time is shortened, and therefore the working efficiency is improved.

Owner:深圳市诺泰芯装备有限公司

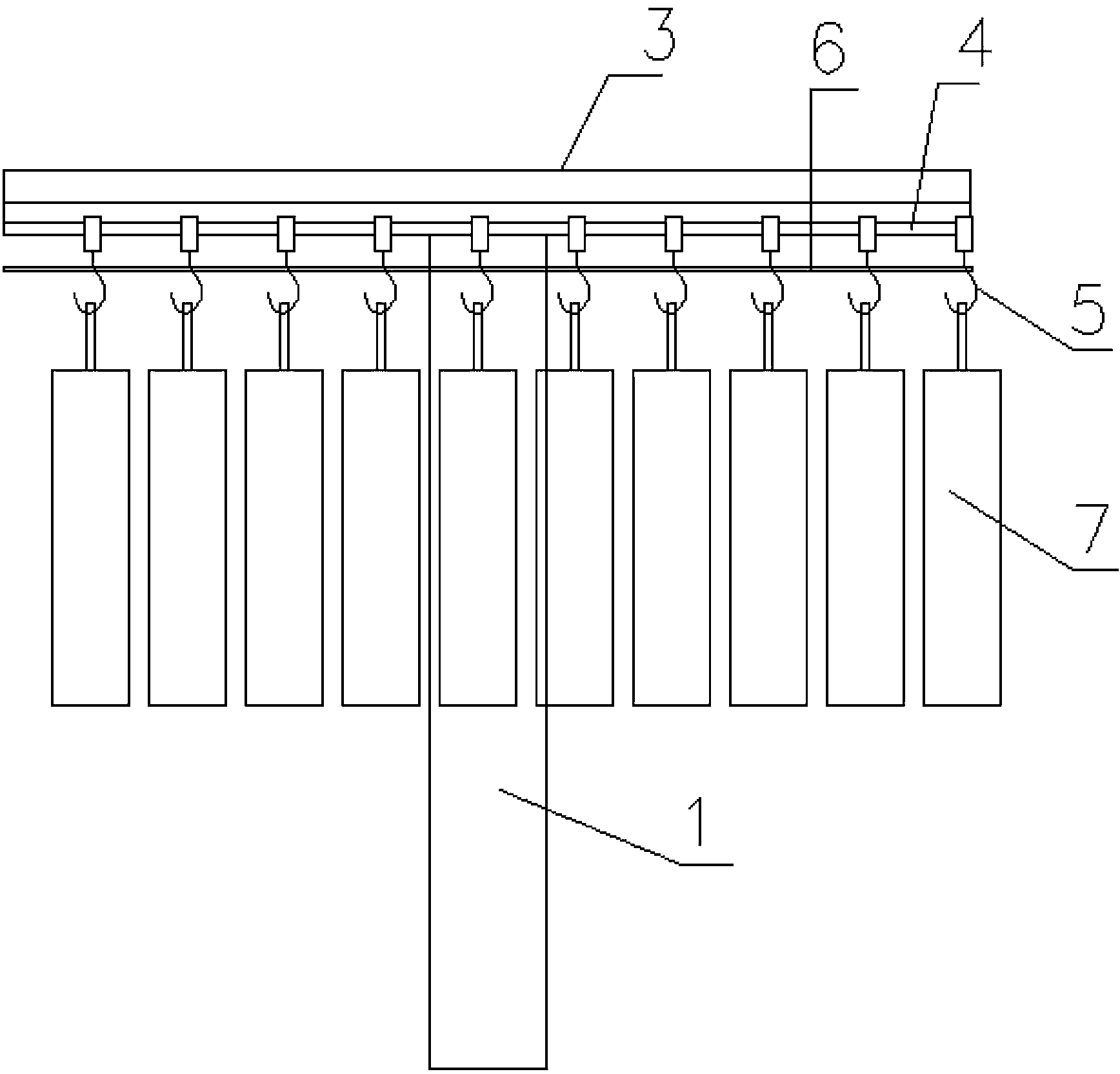

Receiver

InactiveCN103434785ASimple structureReasonable designLoading/unloadingManual conveyance devicesEngineering

A receiver, which relates to an auxiliary material device, comprises a support, horizontal fixed rods are arranged on the support, a ring frame is arranged on the horizontal fixed rods, a slide way is arranged in the ring frame, hooks are slidably arranged in the slide way, and are strung by a rope, the rope is knotted at both sides of each hook, and receiving hoppers are arranged on the lower ends of the hooks. The structure of the receiver is simple, the design is reasonable, the rope can be utilized to pull the hooks to slide to and fro on the ring to control the receiving hoppers to move, and the receiver is convenient and efficient, shortens the handling time, saves time and labor, and increases working efficiency.

Owner:戴启彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com