Container loading and unloading shore bridge with lifting type double-layer girder and three trolleys

A lifting type and container technology, which is applied in the direction of trolley cranes, transportation and packaging, load blocks, etc., can solve the problems of easy swing of the spreader, waste of time, long time for the spreader to descend and lift, etc., to improve loading and unloading efficiency, The effect of improving throughput and avoiding alignment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

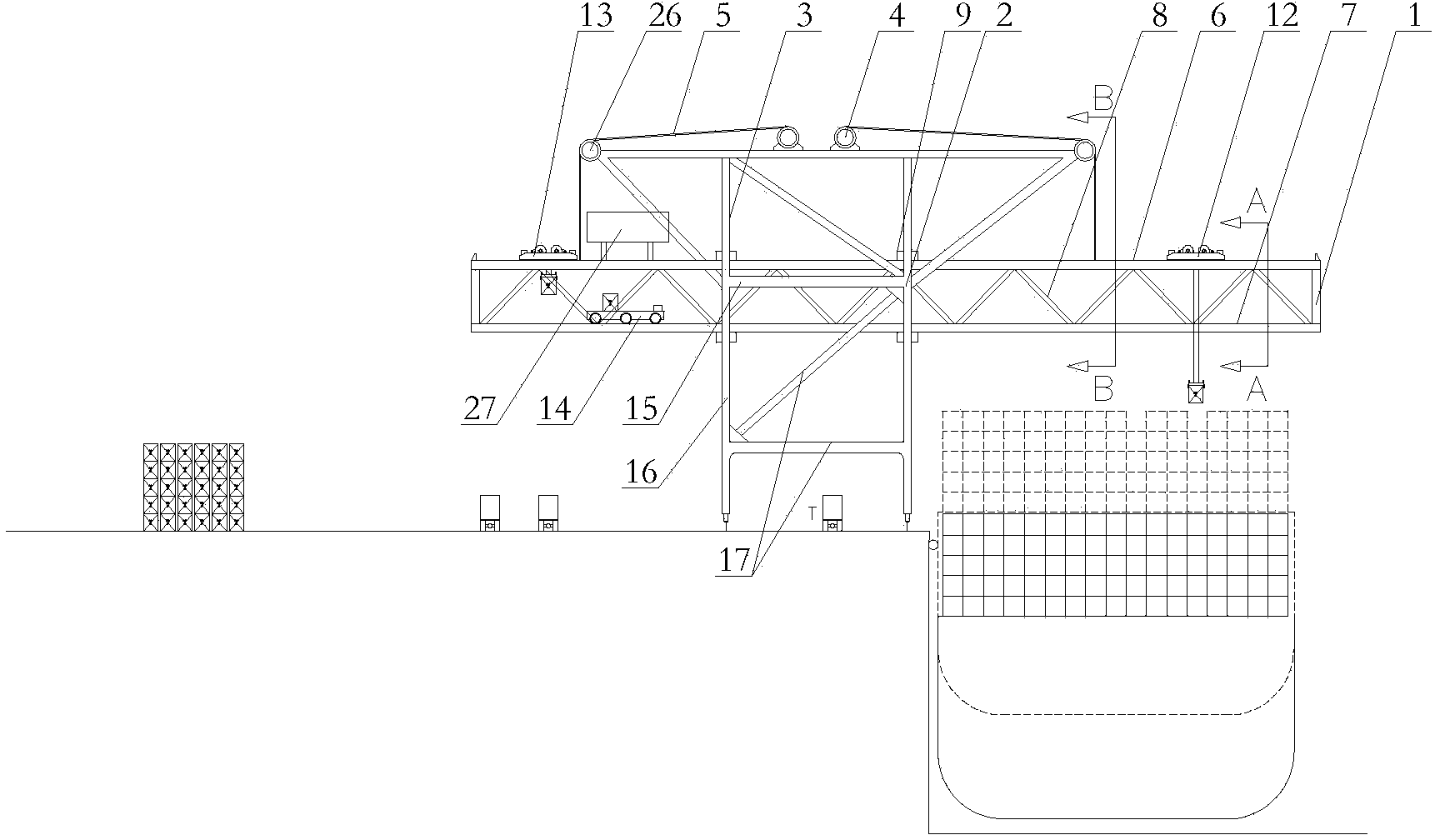

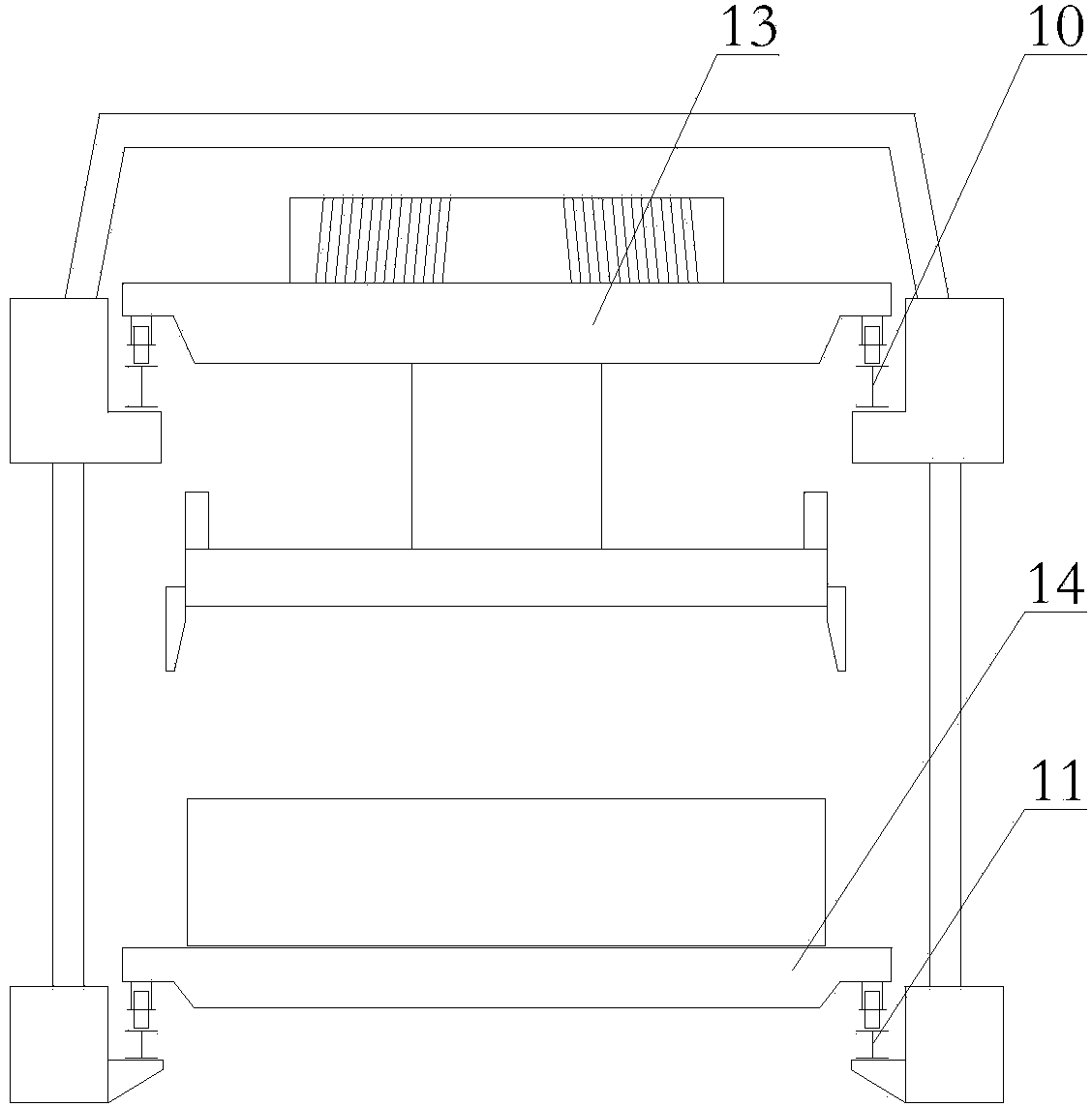

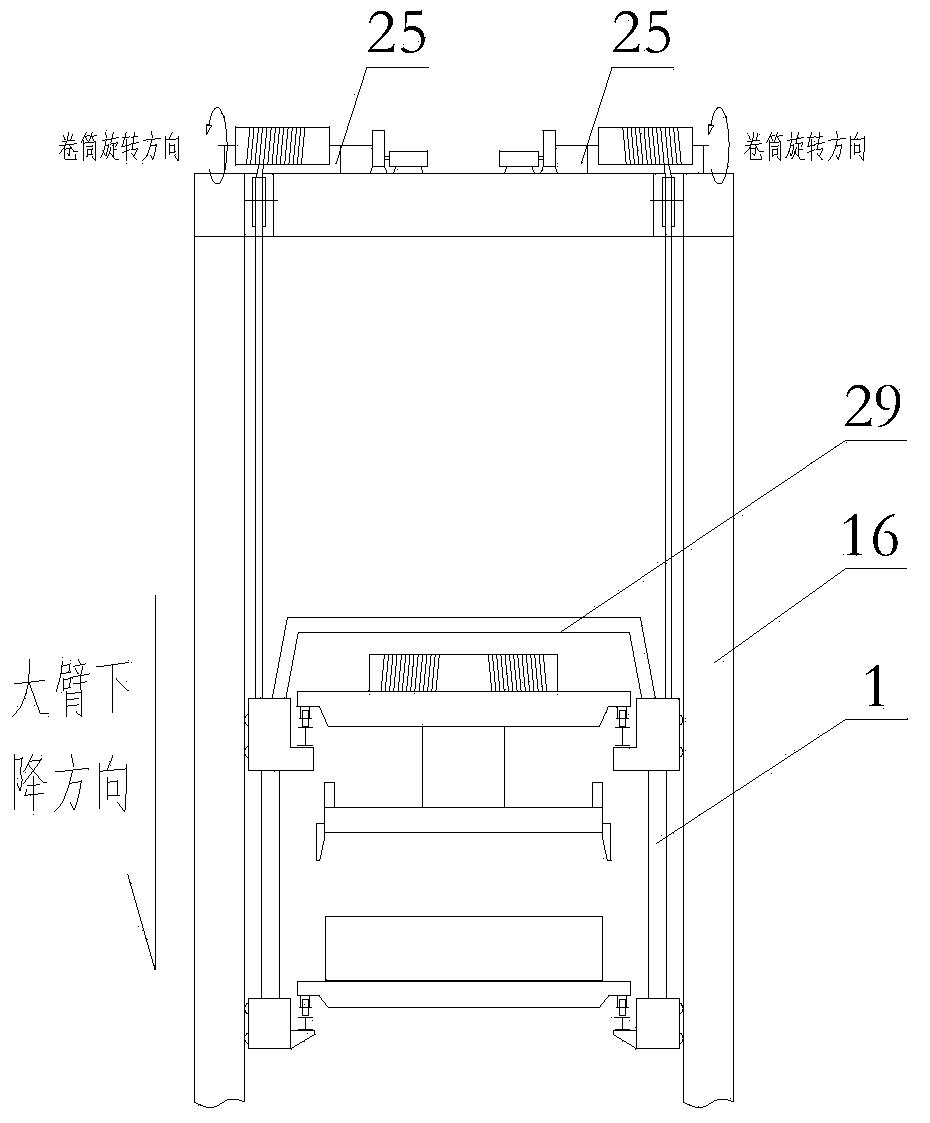

[0023] Embodiments of the present invention: as figure 1 A container loading and unloading quay bridge with lifting double-layer girders and three trolleys is shown, including an integral lifting girder 1 and a supporting frame 2, and the overall lifting girder 1 includes two upper load-bearing beams 6 and two lower load-bearing beams 7, two The upper load beam 6 is arranged above the two lower load beams 7, and the upper load beam 6 and the lower load beam 7 on the same side are connected by a connecting beam a8, as figure 2 As shown, the inner sides of the upper bearing beam 6 and the lower bearing beam 7 are respectively provided with a track a10 and a track b11, the lifting trolley A12 and the lifting trolley B13 are respectively arranged on the track a10 at both ends of the upper bearing beam 6, and a transfer trolley 14 is arranged on the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com