Patents

Literature

2778results about "Trolleys" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

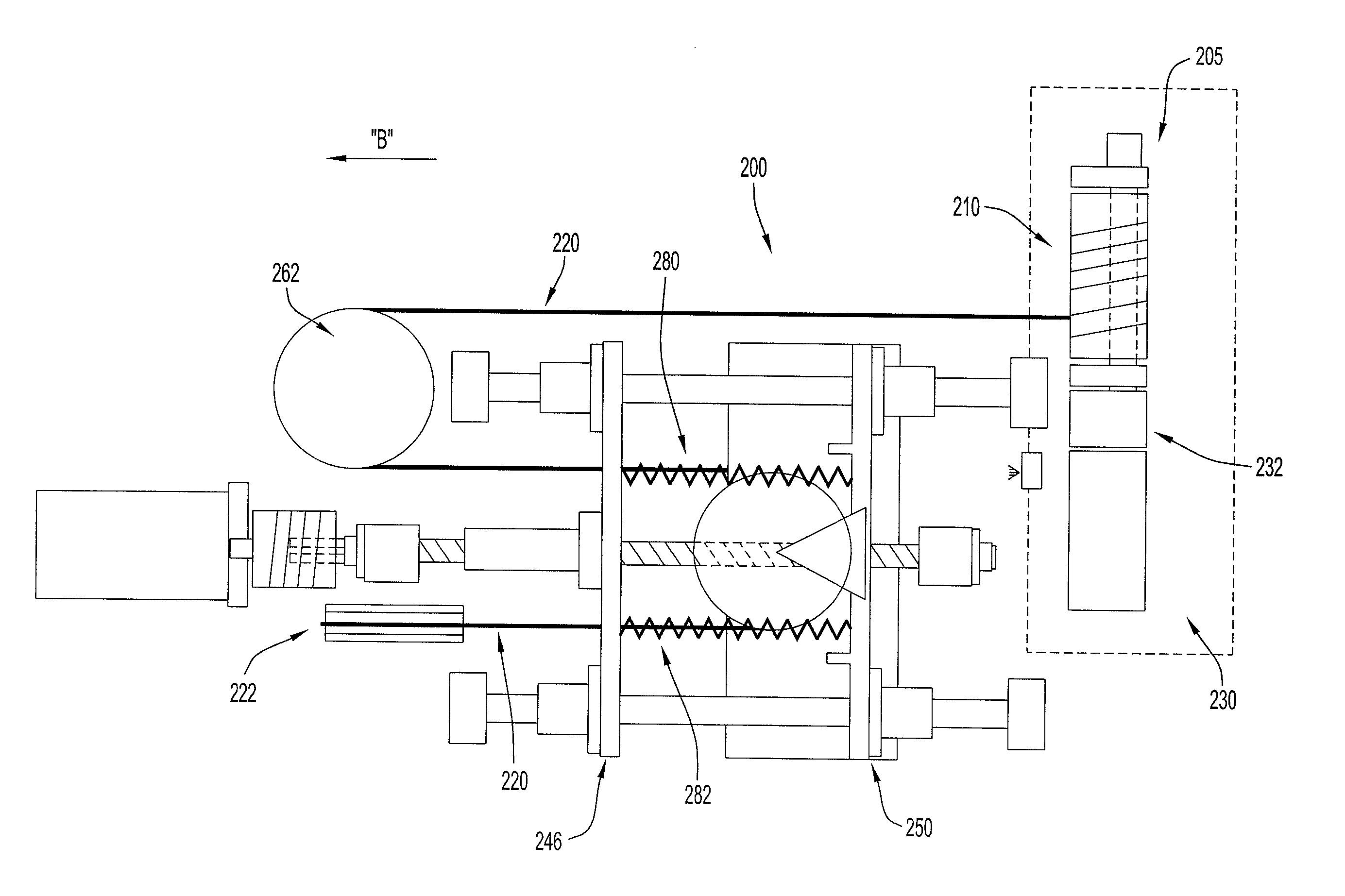

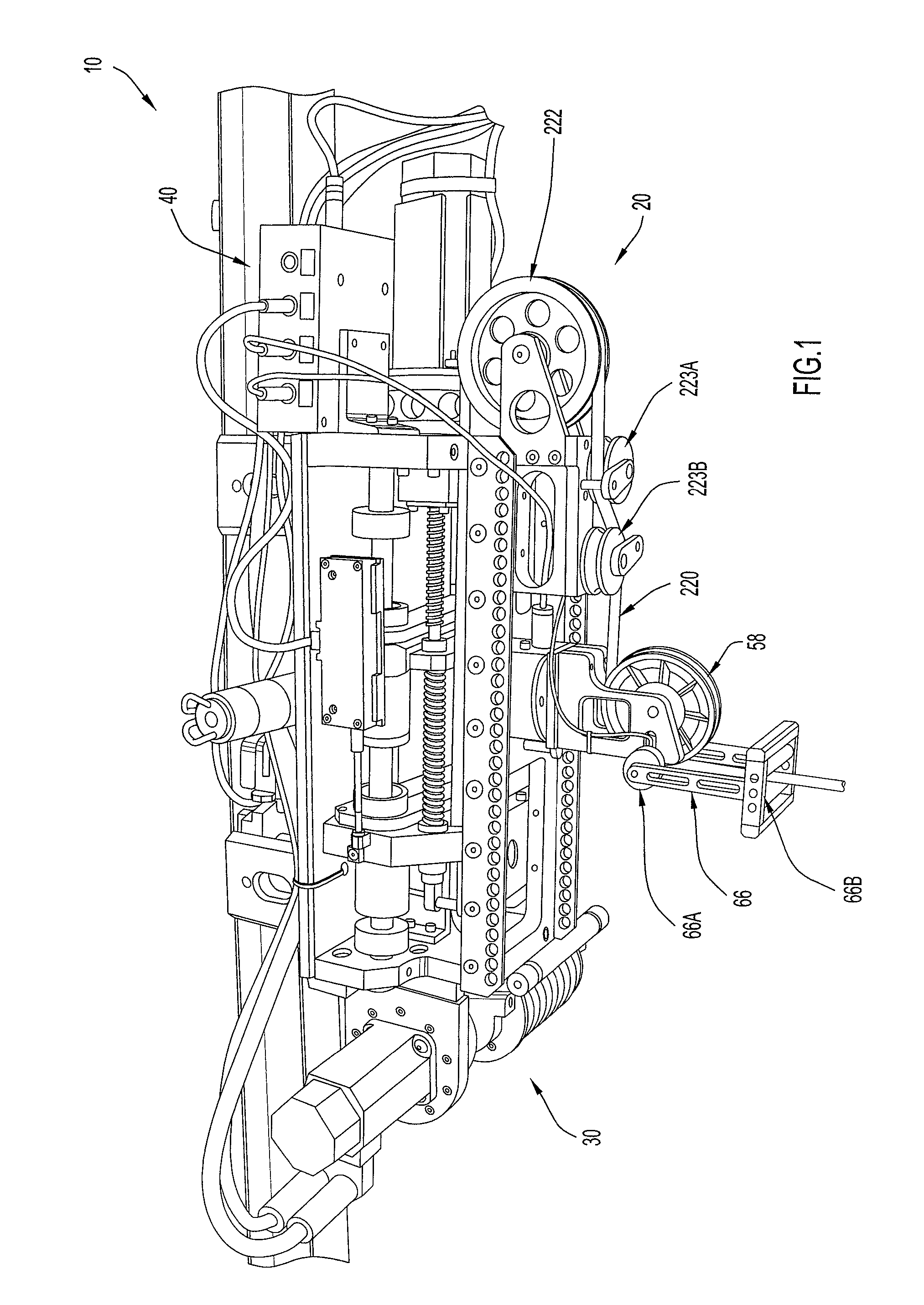

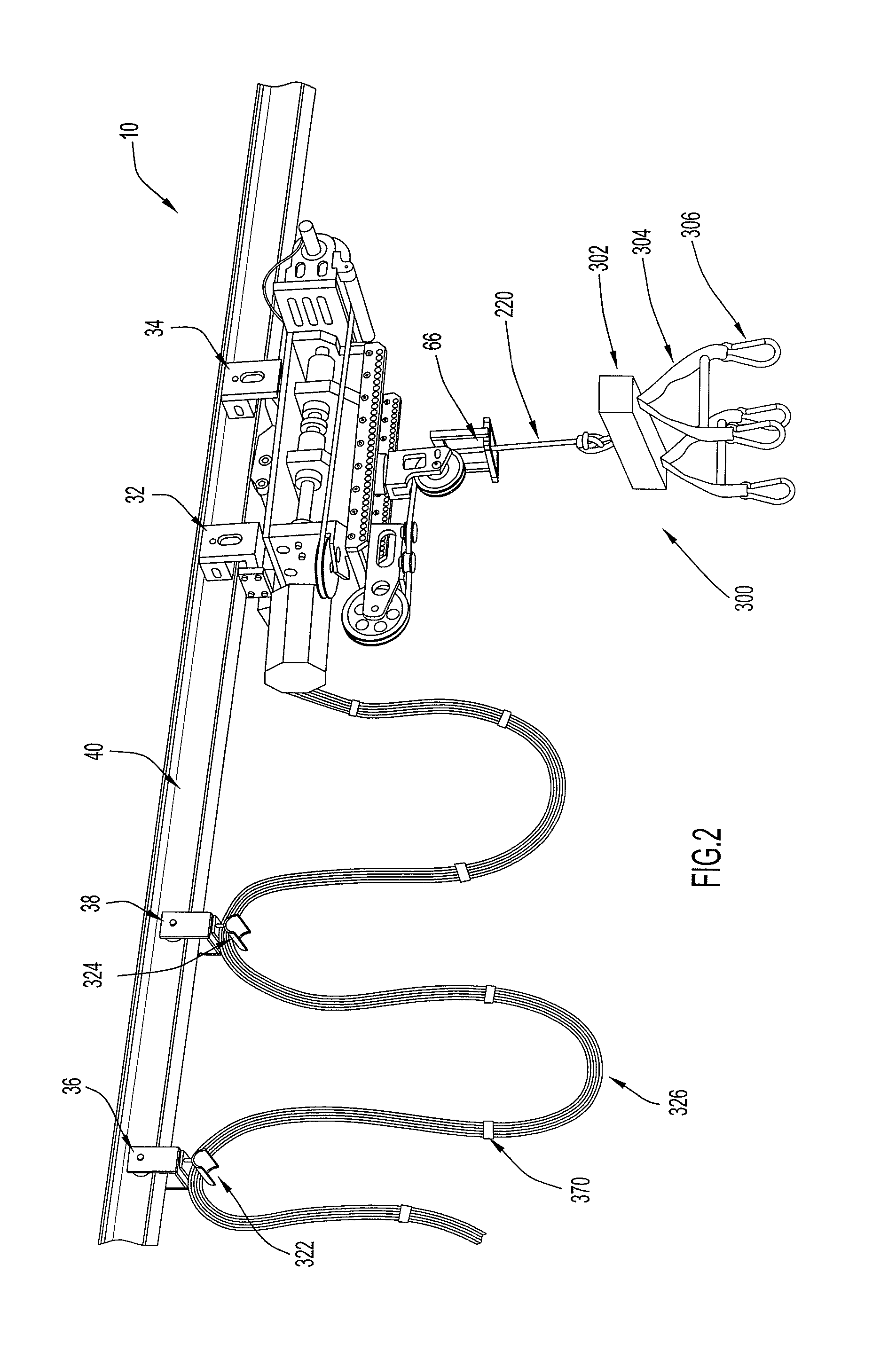

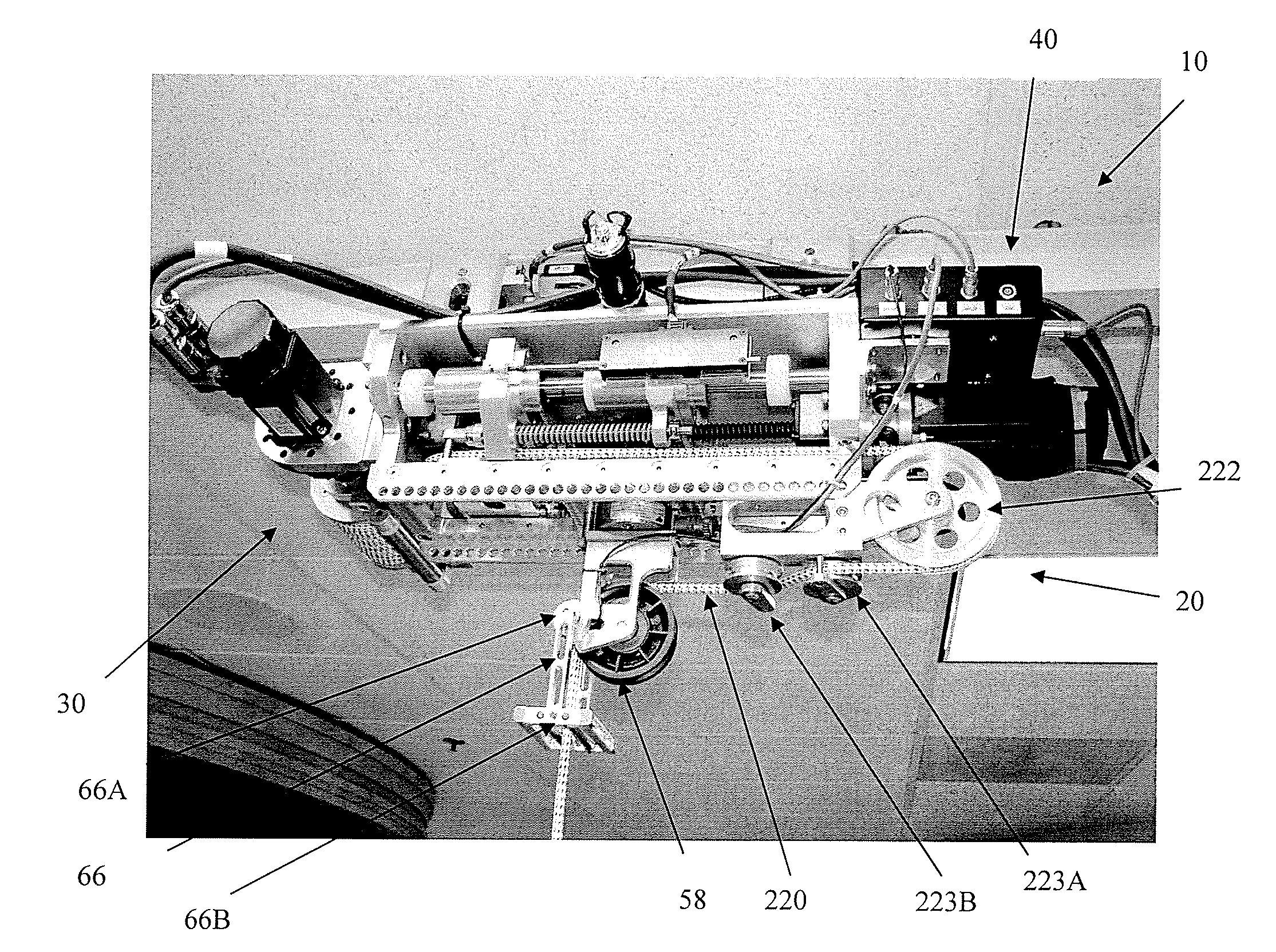

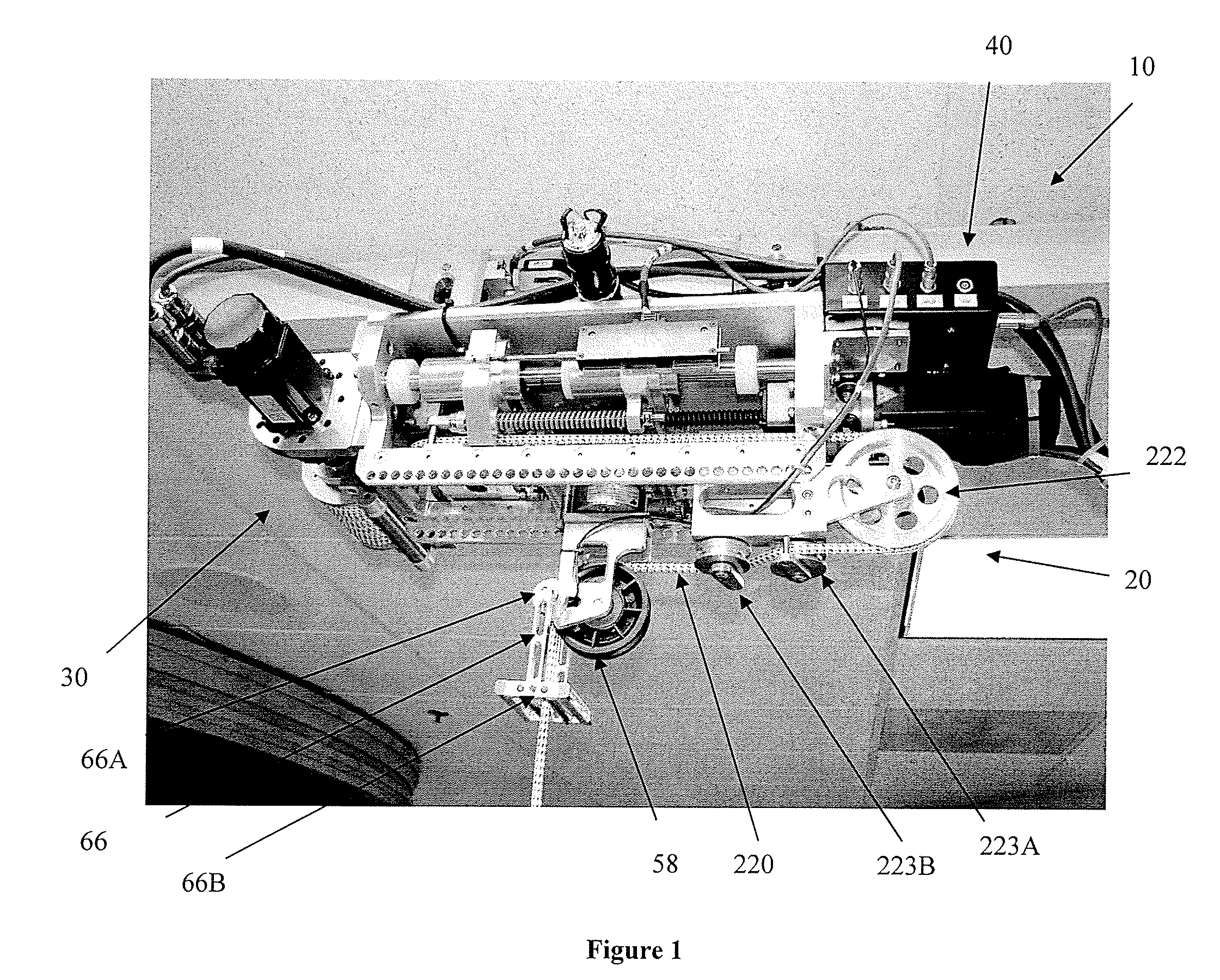

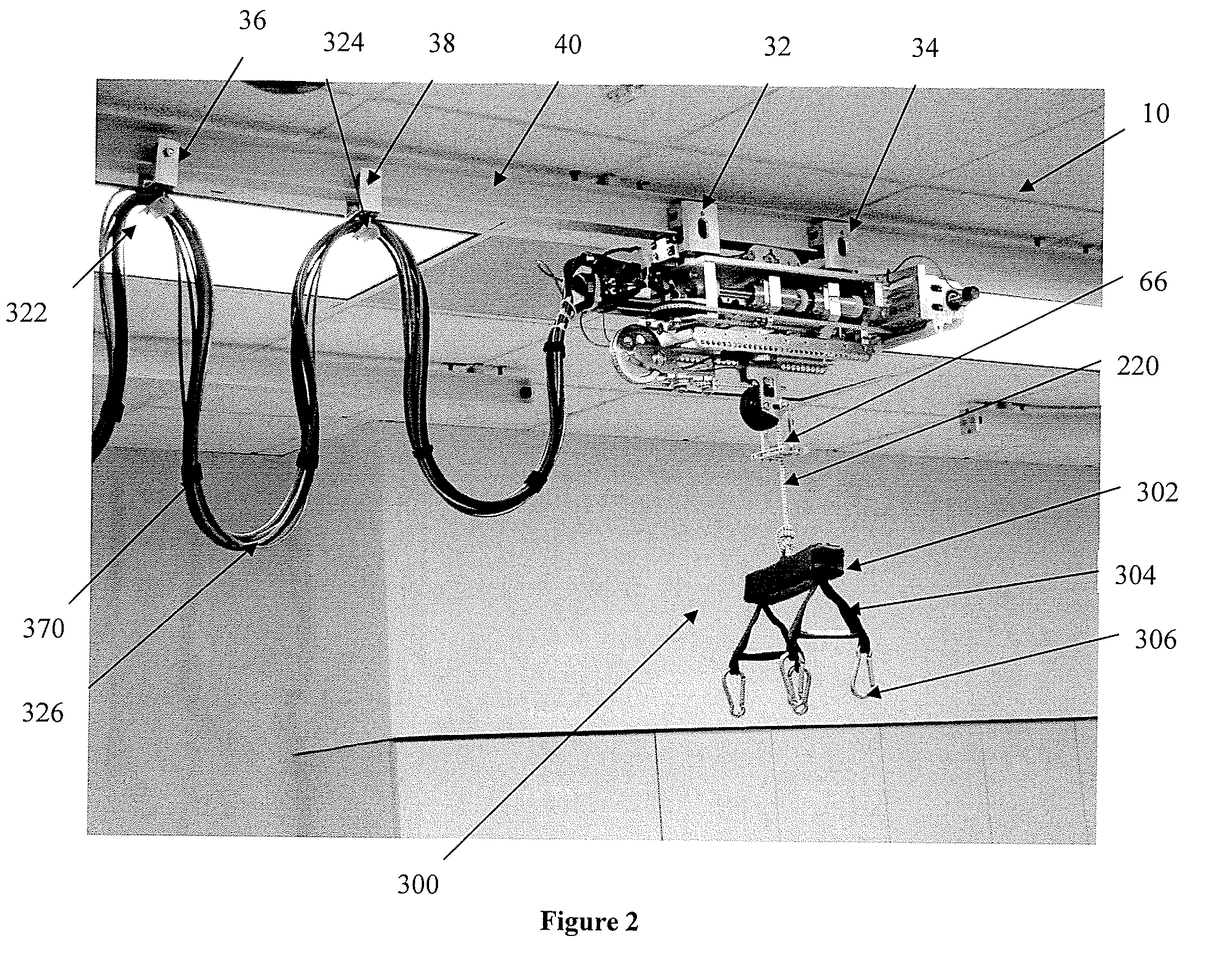

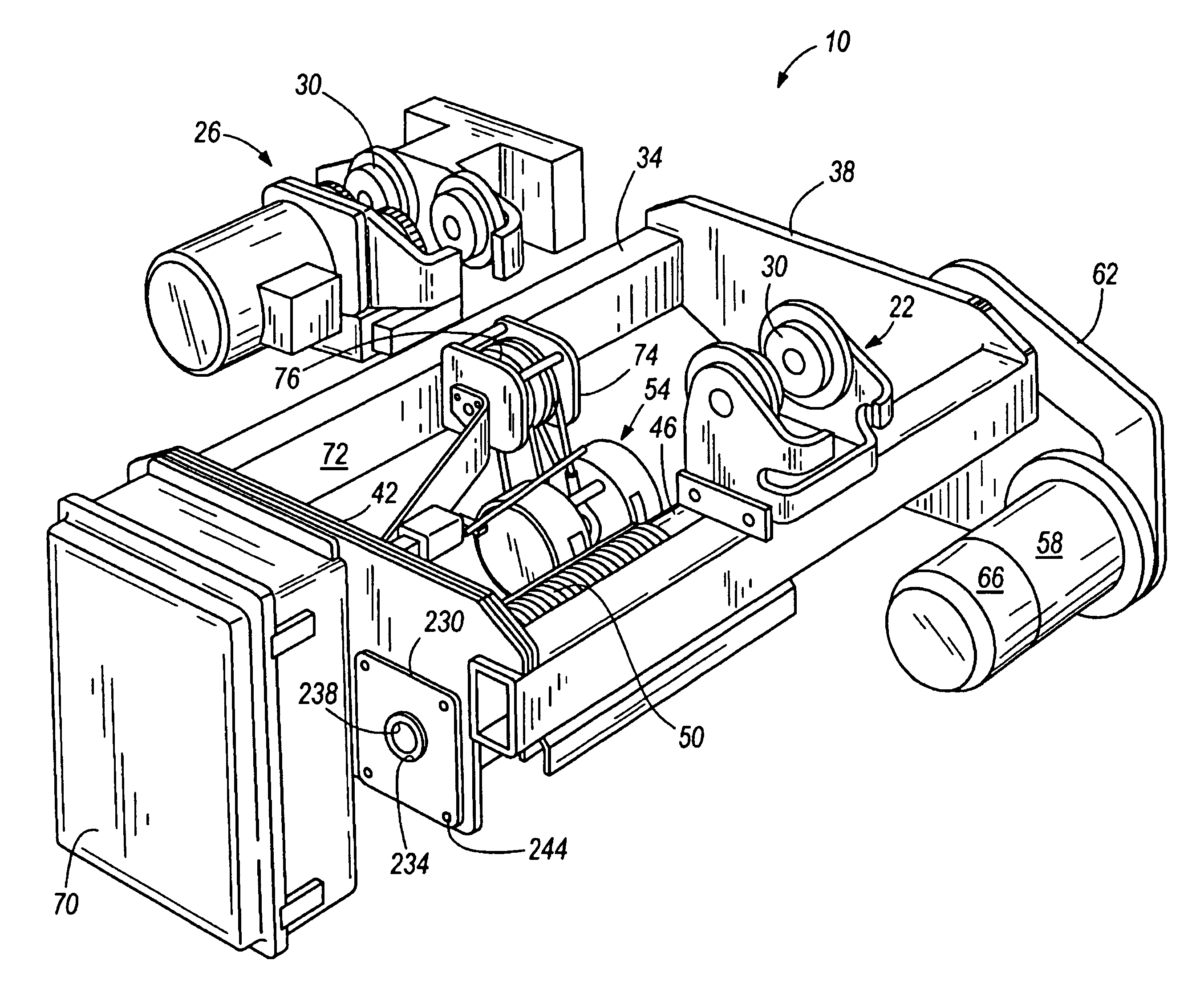

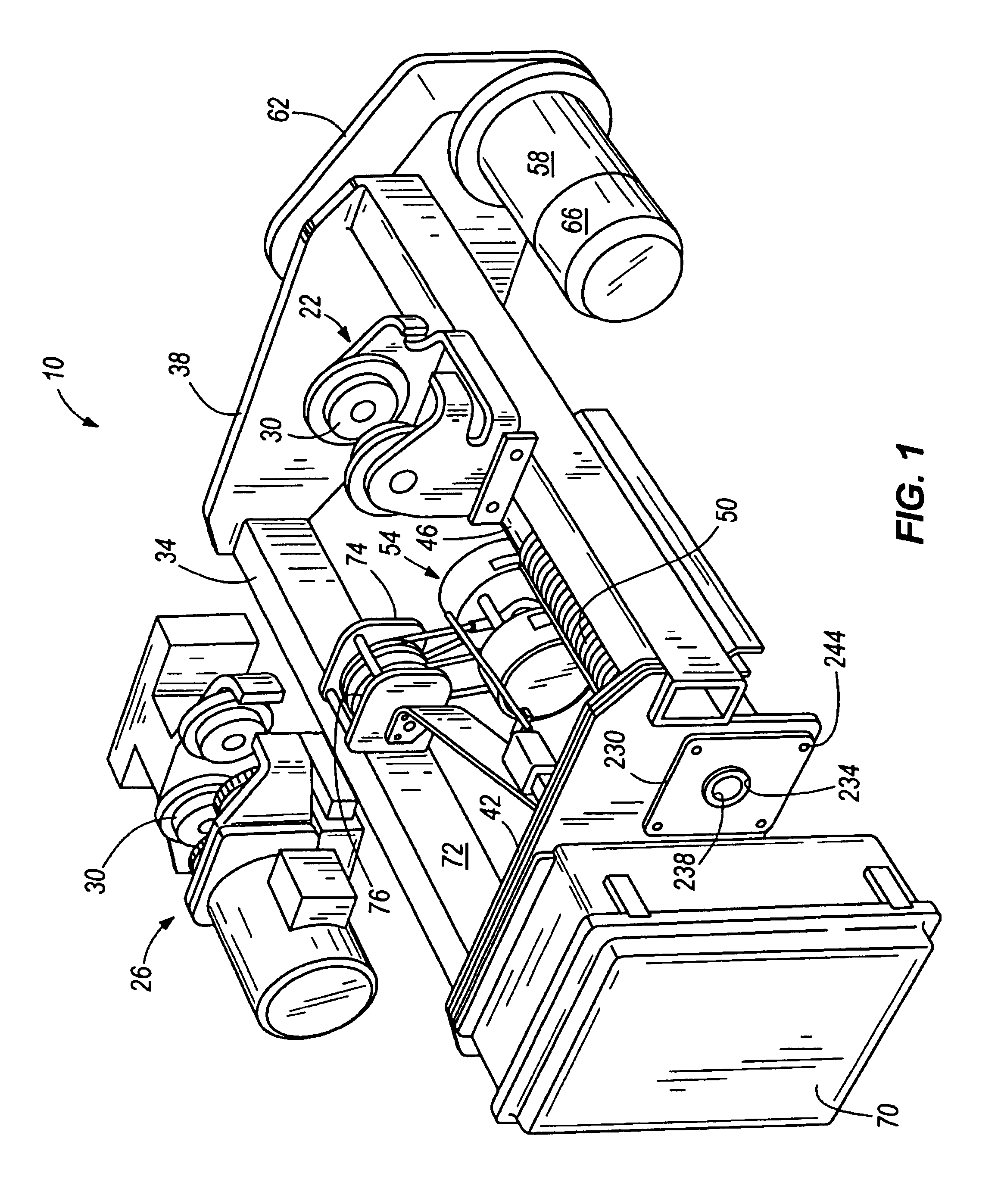

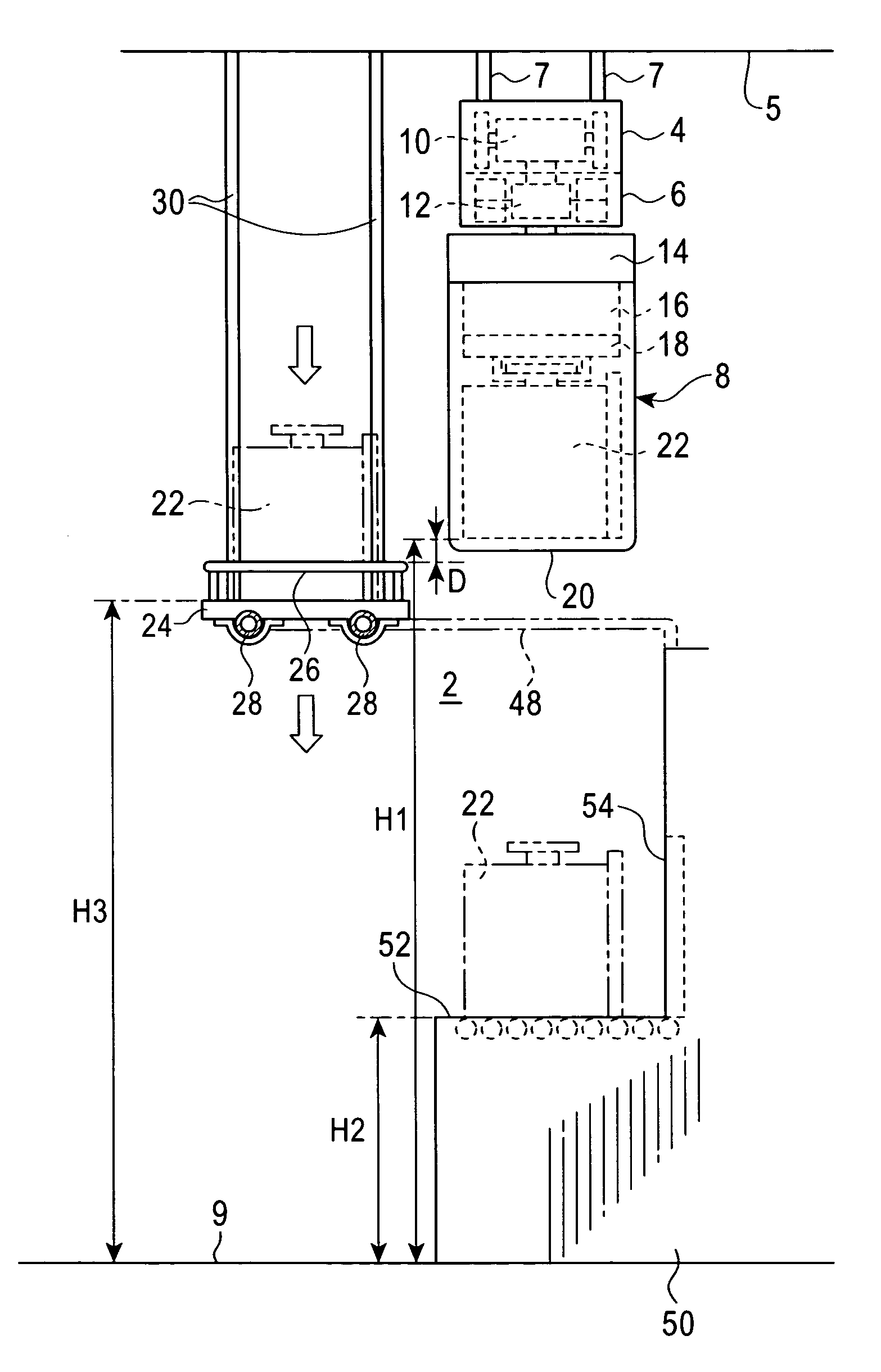

Body weight support system and method of using the same

A body-weight support system that allows individuals with severe gait impairments to practice over-ground walking in a safe, controlled manner is disclosed. The system includes a body-weight support system that rides along a driven trolley and can be controlled in response to the movement of the subject using the system.

Owner:HIDLER JOSEPH

Body Weight Support System and Method of Using the Same

ActiveUS20080287268A1Practical limitationChiropractic devicesWalking aidsSupporting systemControl manner

A body-weight support system that allows individuals with severe gait impairments to practice over-ground walking in a safe, controlled manner is disclosed. The system includes a body-weight support system that rides along a driven trolley and can be controlled in response to the movement of the subject using the system.

Owner:HIDLER JOSEPH

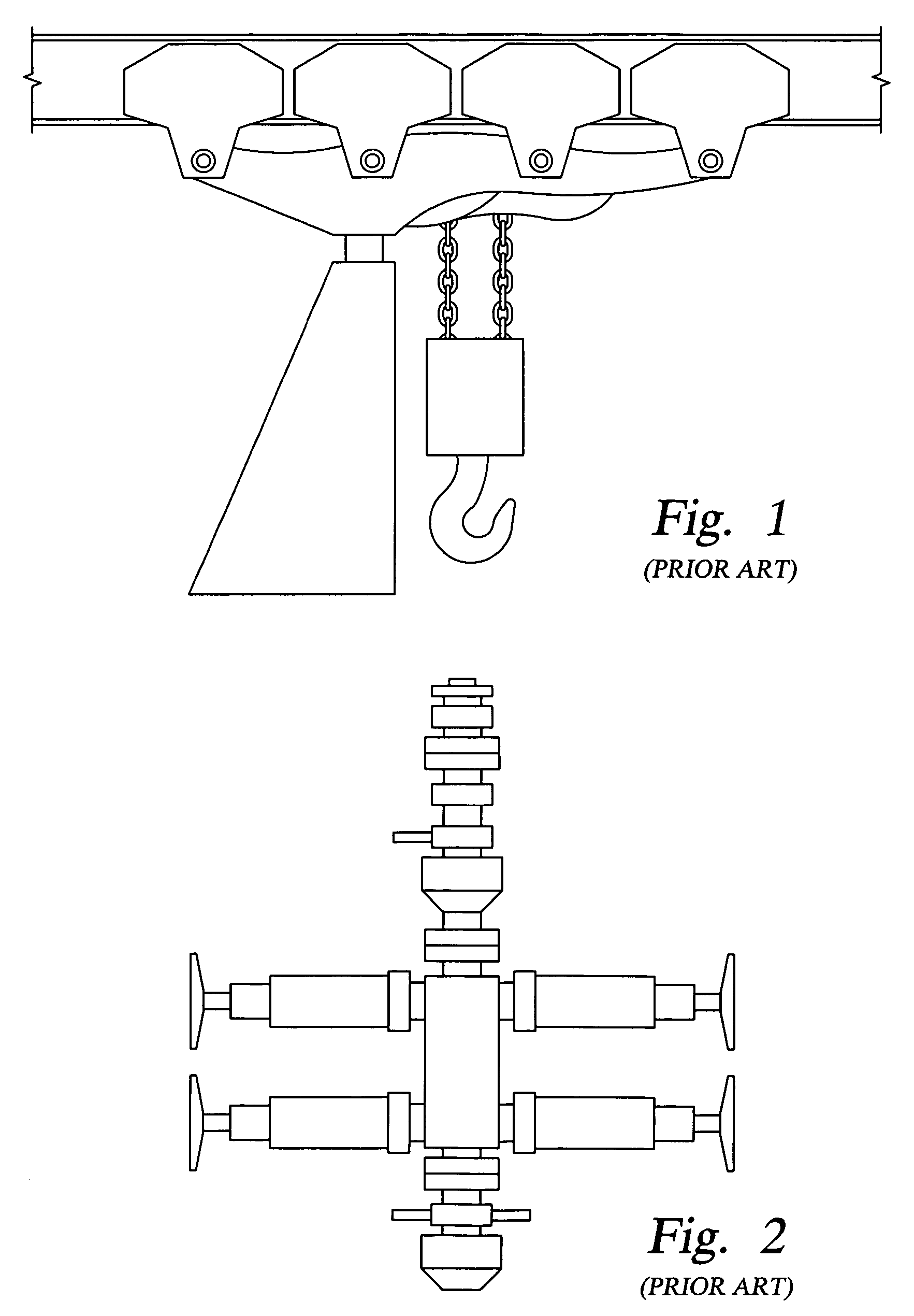

Hoist apparatus

The invention relates to a hoist apparatus including at least one of a three-part double reeved bottom block that has the same height profile as a two-part bottom block and the same lifting capacity as a three-part bottom block that includes an integral equalizer sheave nest, a device for limiting the rotation of a hoist drum beyond a desired position, a hybrid gear box adapted for use on two different categories and / or types of hoist apparatuses through the use of an adapter plate that permits coupling of the gearbox to the hoist drum of the hoist apparatus in a plurality of configurations and an external ring gear that results in a second output torque and speed of the gearbox, a self-lubricating load braking assembly having lubrication inlet holes and lubrication outlet holes for pumping lubrication into and out of the load brake assembly, a gearbox for use on the hoist apparatus including a two-stage high gear ratio gear set and a load brake assembly, a controller configured to acquire operational data representative of the hoist apparatus and generate an output indicative of a remaining useful life of the hoist apparatus, and an inverter controller configured to control verify load integrity and prevent possible load loss without the use of a load brake assembly and / or an encoder or similar feedback device.

Owner:U S BANK NAT ASSOC

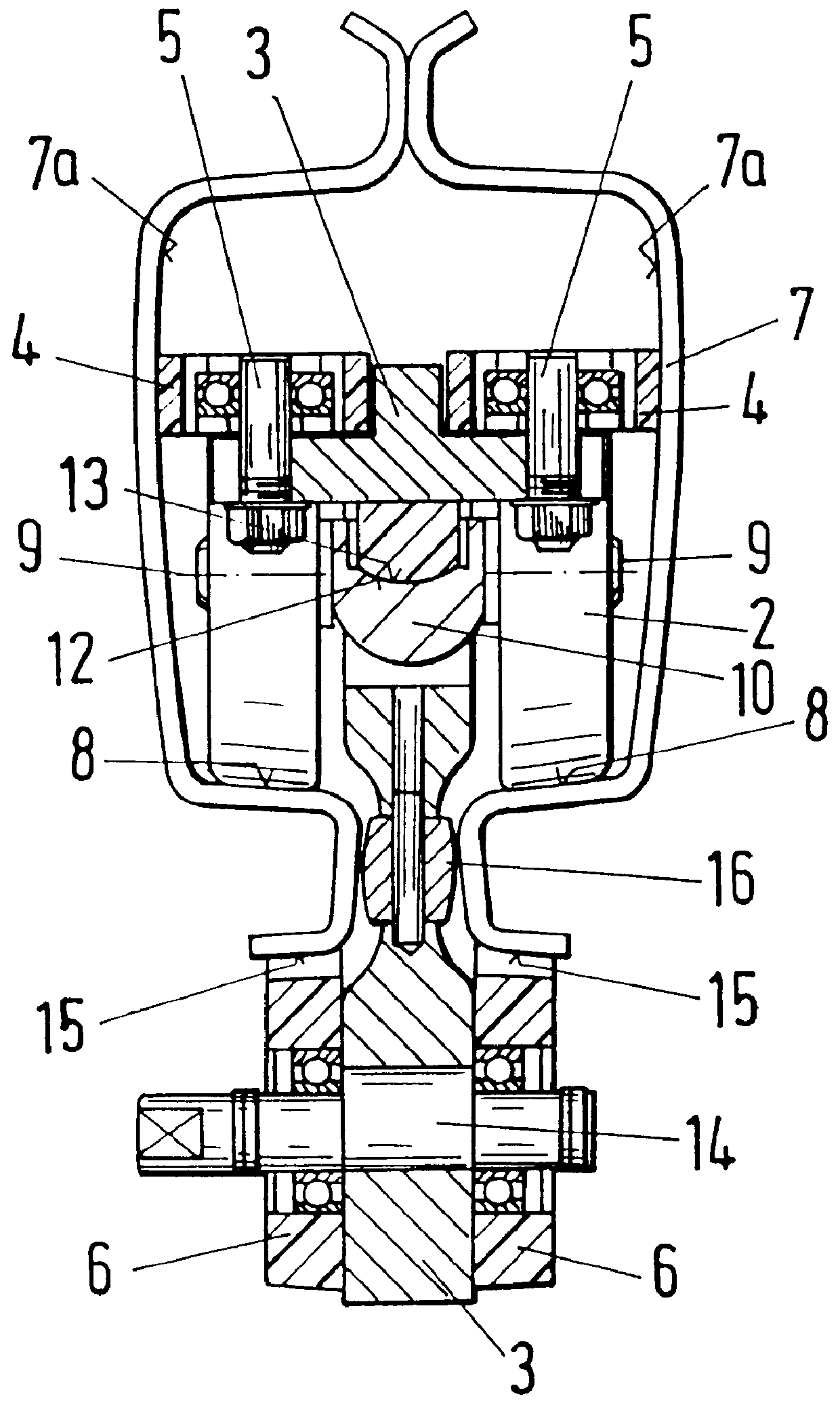

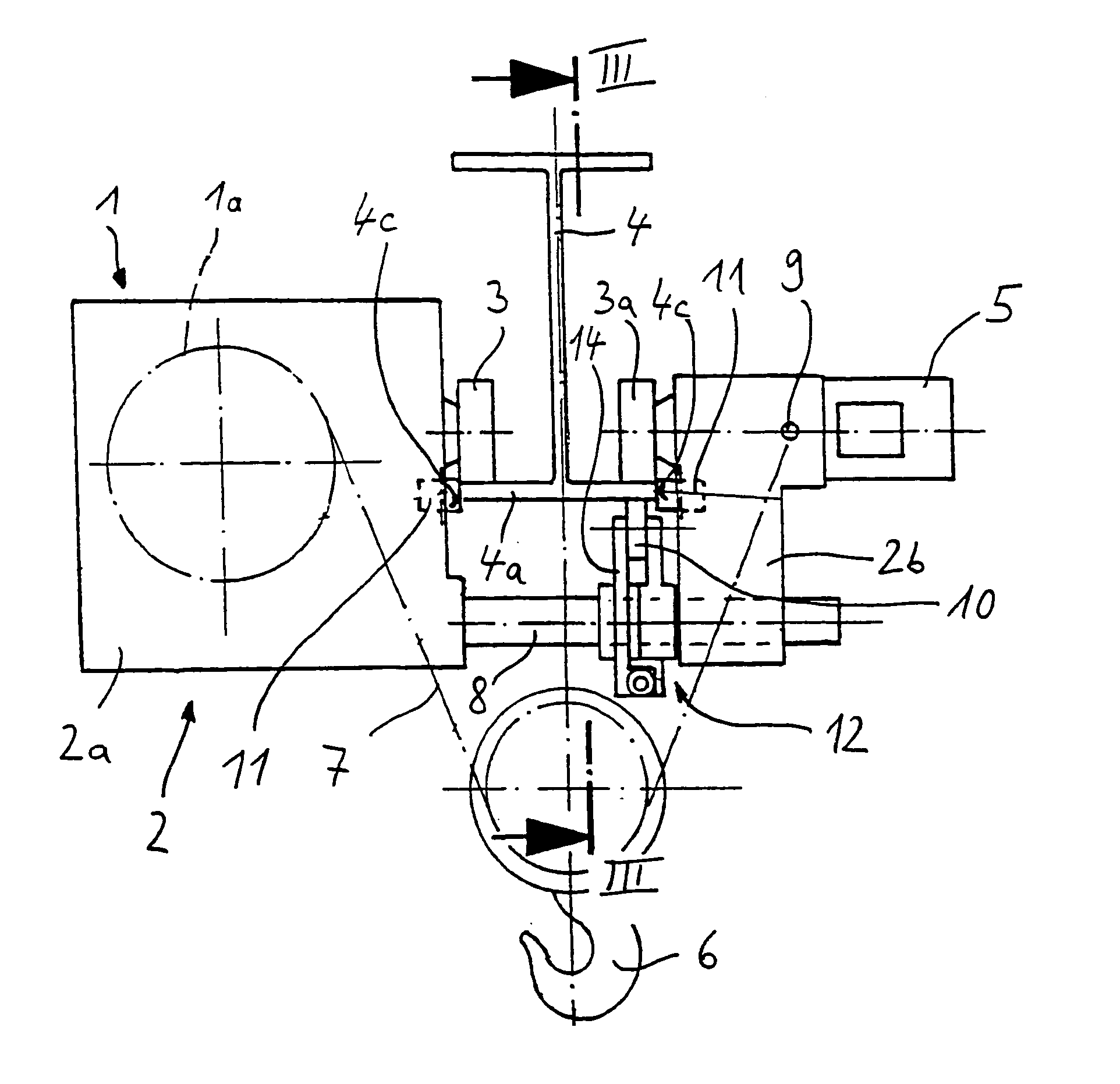

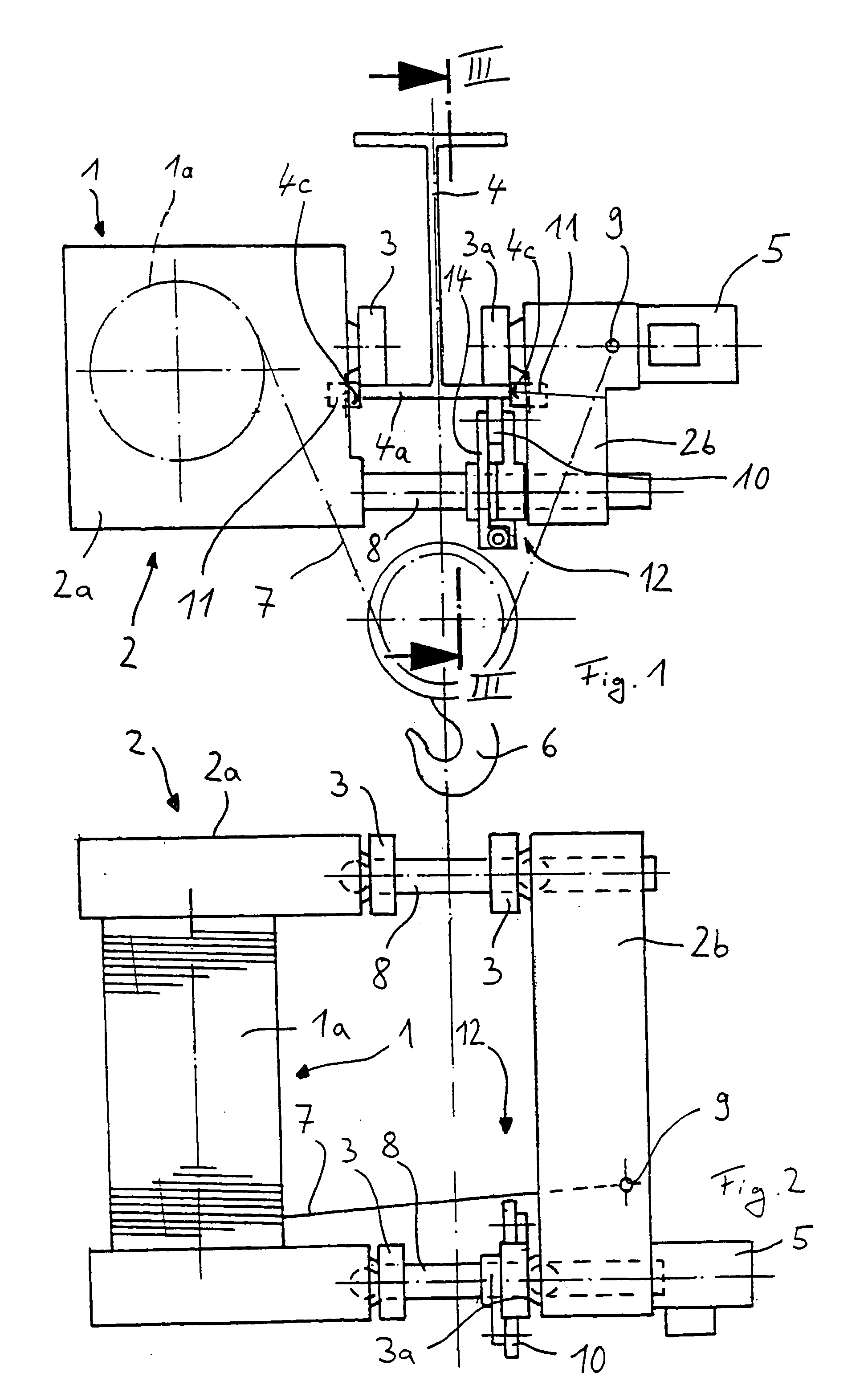

Traveling mechanism in a lifting arrangement which is moveable on rails

InactiveUS6058849AGuaranteed uptimeAvoid destructionMonorailsRailway componentsHorizontal forceFree rotation

A traveling mechanism for a lifting device, especially for a lifting device having a laterally cantilevering boom, is movable on rails with at least two running wheels. A connection element for attaching a load to said traveling mechanism is supported in the rail by the running wheels which are arranged on both sides of the connection element. The connection element has, at the region projecting down out of the rail, at least one running roller which is freely rotatable about a horizontal axis and rolls on a horizontal outer running surface of the rail. To effectively divert horizontal forces and uniformly distribute the vertical forces to the running wheels, running wheel axles are rigidly connected with a running wheel carrier, and the running wheel carrier and connection element are swivelably connected by a universal type joint. In addition, at least one support roller is rotatably mounted at the connection element in the interior of the rail. The support roller freely rotates about a vertical axis and rolls along at least one of the side surfaces to transmit horizontal forces to the rail.

Owner:TEREX MHPS

Powered auxiliary hoist mechanism for a gantry crane

ActiveUS7546929B2Reduce hoist capacityProtection overloadTrolley cranesTrolleysLifting capacityEngineering

Owner:MARINE TRAVEELEVATOR

Transport system

InactiveUS6851913B2Avoid enteringEffective avoidanceSemiconductor/solid-state device manufacturingThin material handlingTransport systemEngineering

A transport system for transporting transport containers storing articles in a sealed condition is disclosed. Each transport container has a support portion formed on an upper portion thereof. When the transport container is moved with the support portion suspended, a receiving device supports the bottom of the transport container to lessen the load applied to the support portion. As a result, deformation of the transport container is restrained to maintained the sealed condition.

Owner:DAIFUKU CO LTD

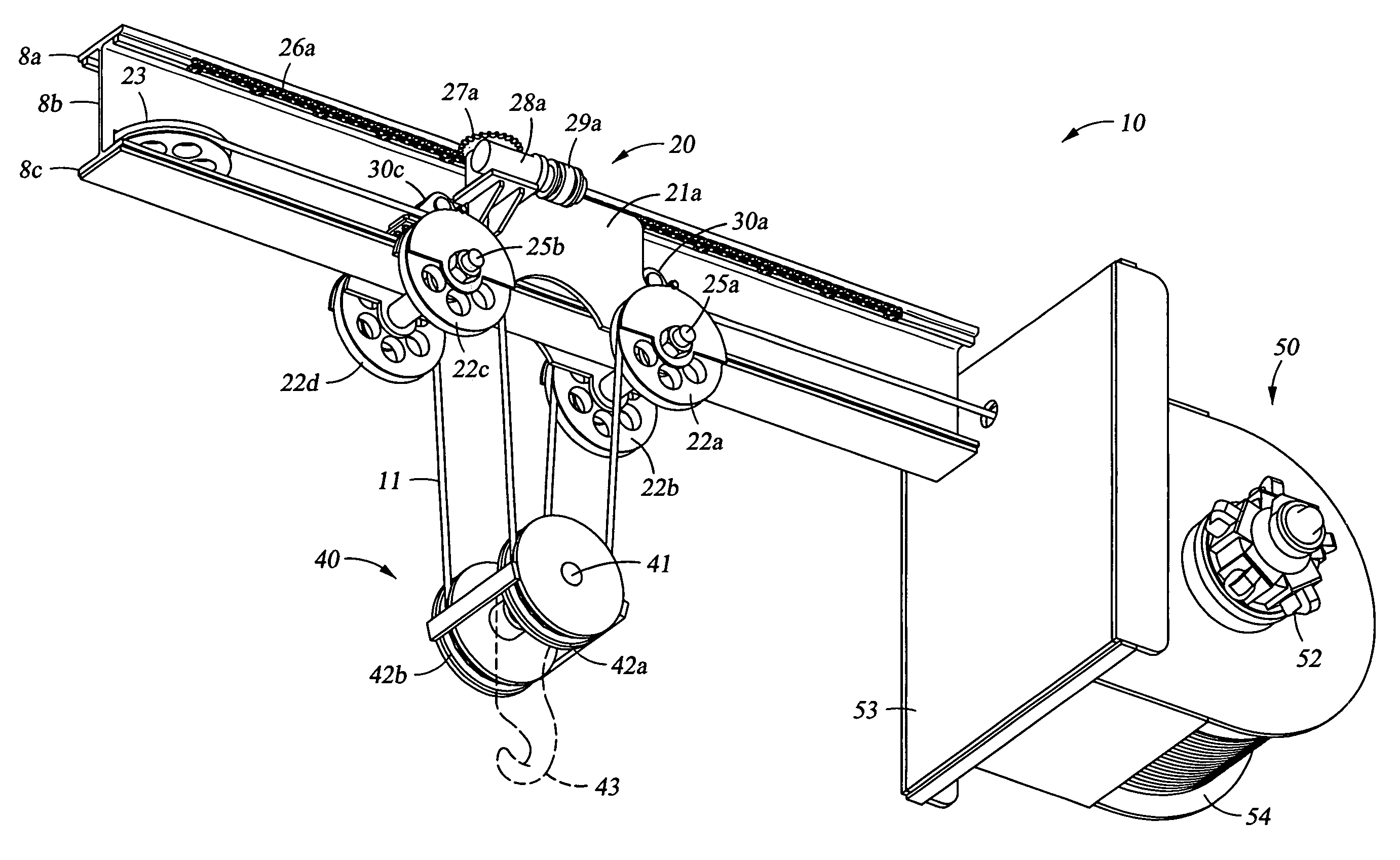

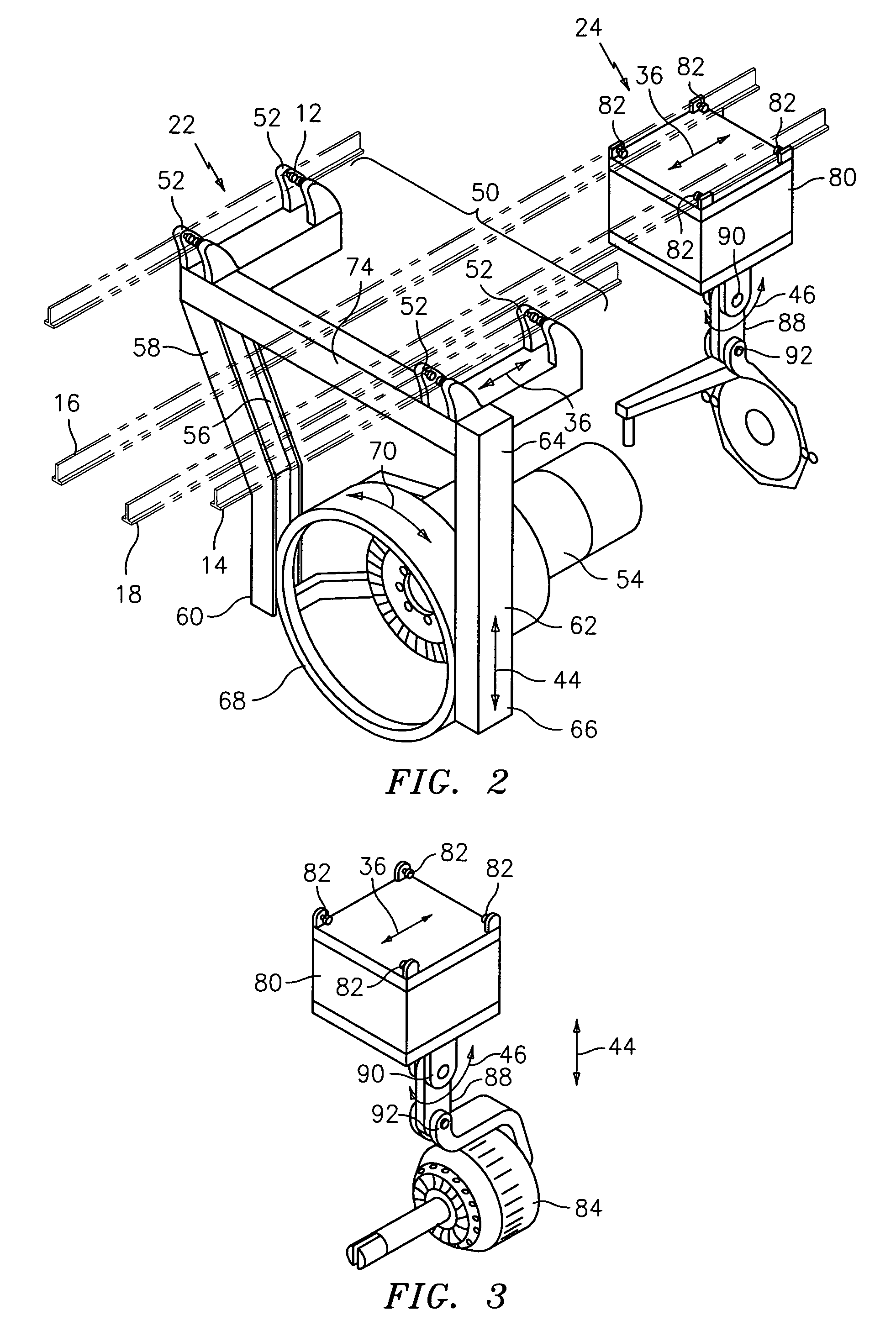

Compact hoist for drilling or workover rig

InactiveUS20060180564A1Expands vertical and horizontal rangeExpanding the range of operation increases usable rig storage spaceTrolley cranesTravelling gearLifting capacityWell drilling

The present invention provides a compact hoist system for use on a drilling or workover rig. The present invention eliminates problems related to chain failures in hoist systems by incorporating wire rope in a vertically and horizontally compacted arrangement to provide maximum vertical lift capacity and improved versatility. Caterpillar bearings, wire rope tension equalizing sheaves and a winch coupled to a axially movable spiral-grooved drum are combined to provide a system that enables cantilever jack-up rigs to handle blow-out preventer stacks of increased height and size.

Owner:KEPPEL JAMES R

Gantry crane with elevating operator cab

InactiveUS7070060B1Avoid vertical movementReduce stepsTrolley cranesTrolleysHydraulic cylinderMechanical engineering

A gantry crane has first and second side support frames spaced by a pair of trolley beams. A load lifting mechanism is connected to the trolley beams and includes a lift frame for engaging a load to be lifted. An operator cab is mounted on the first side support frame and is vertically moveable between a lowermost position and an uppermost position in an operational plane defined by the first side support frame. A cab lift cable has a length and a first end fixed to the operator cab and a second end fixed to the side support frame. A hydraulic cylinder urges the cable between its fixed first and second ends in a direction transverse to a portion of its length. In another embodiment of the invention, an operator cab is adapted to be horizontally moveable. The elevating operator cab of the present invention can be configured to move horizontally. The elevating operator cab is lifted by a carriage beam vertically moveable along vertical legs of the first side support frame. The operator cab is moveable horizontally along the carriage beam.

Owner:MI JACK PRODS

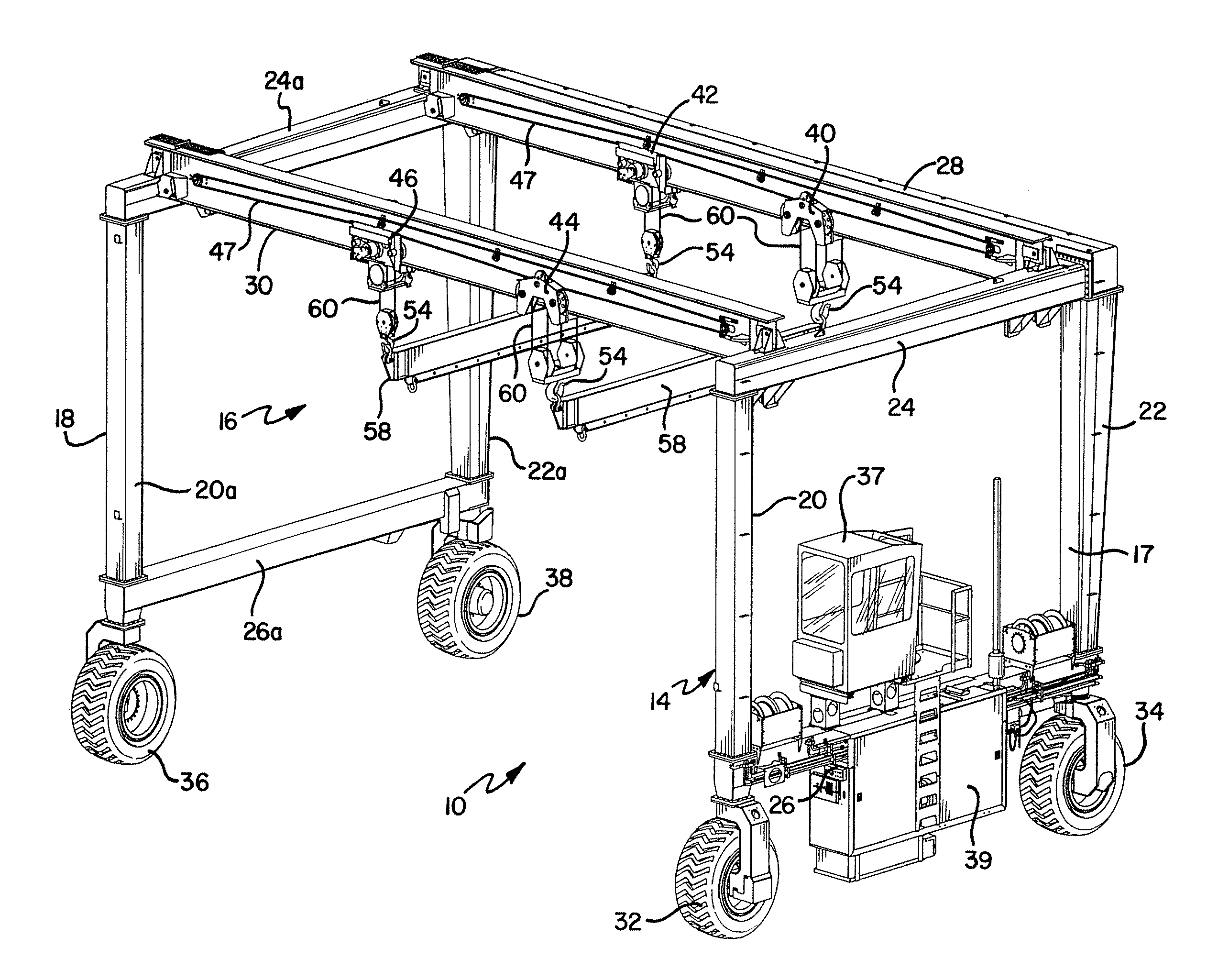

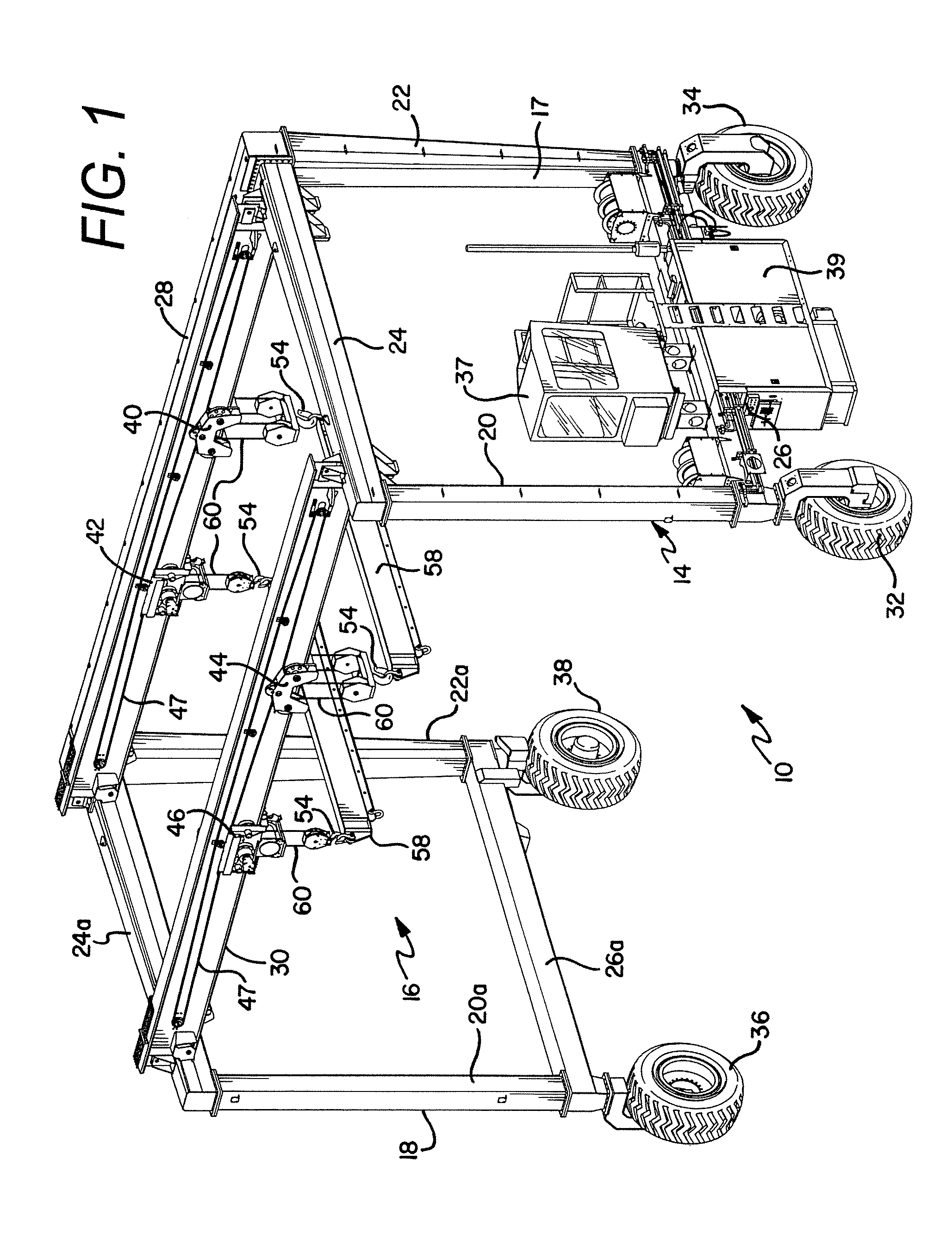

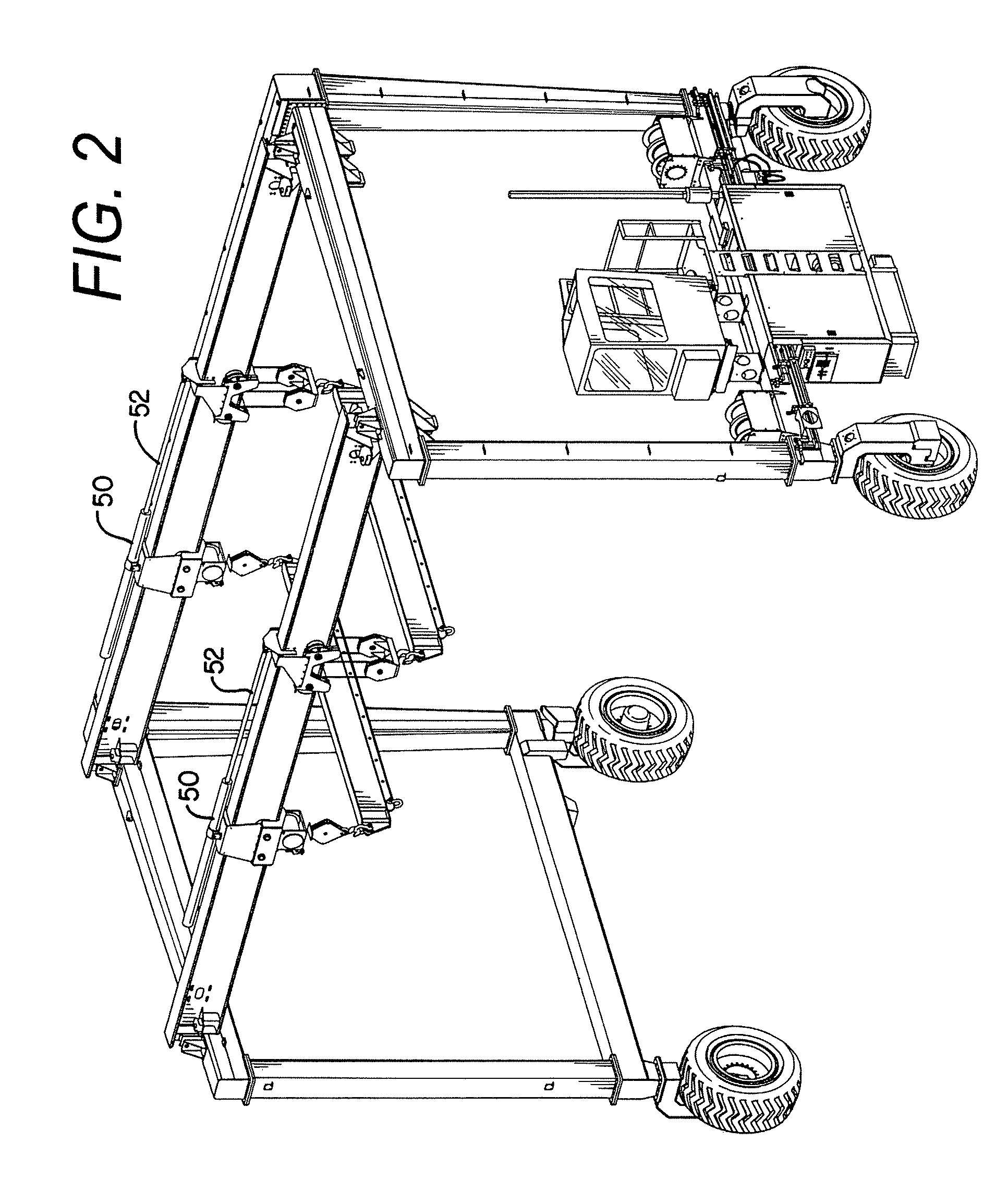

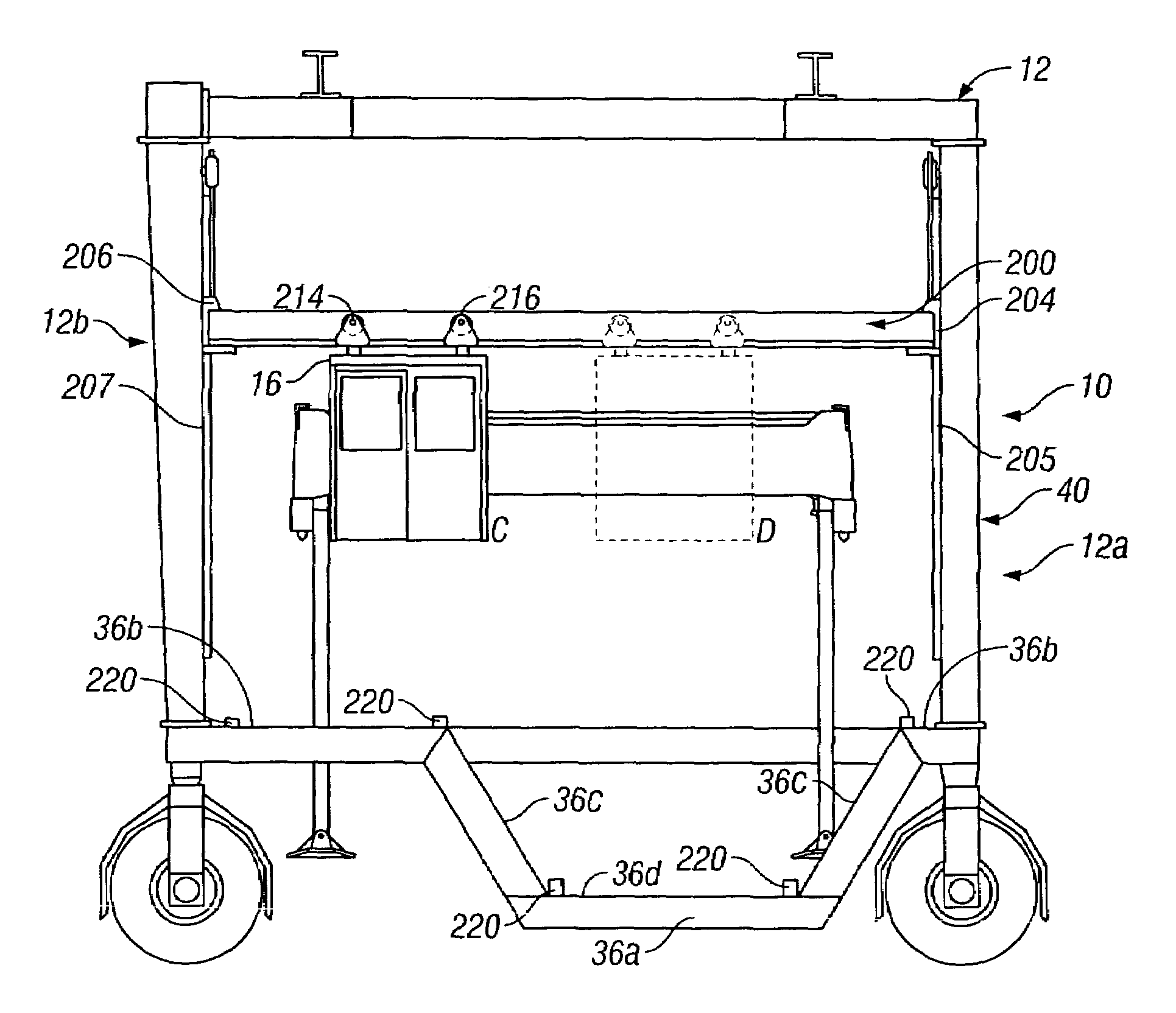

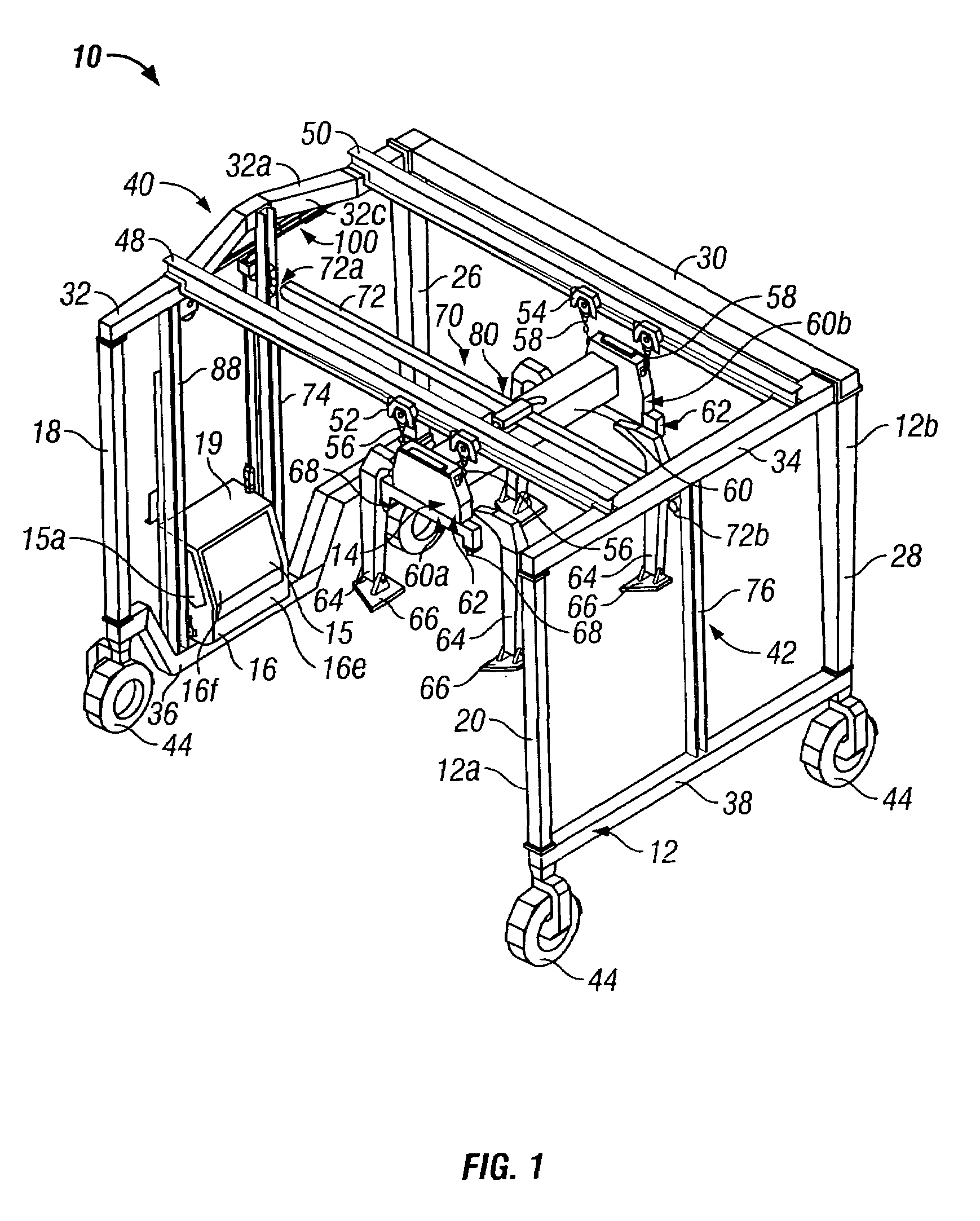

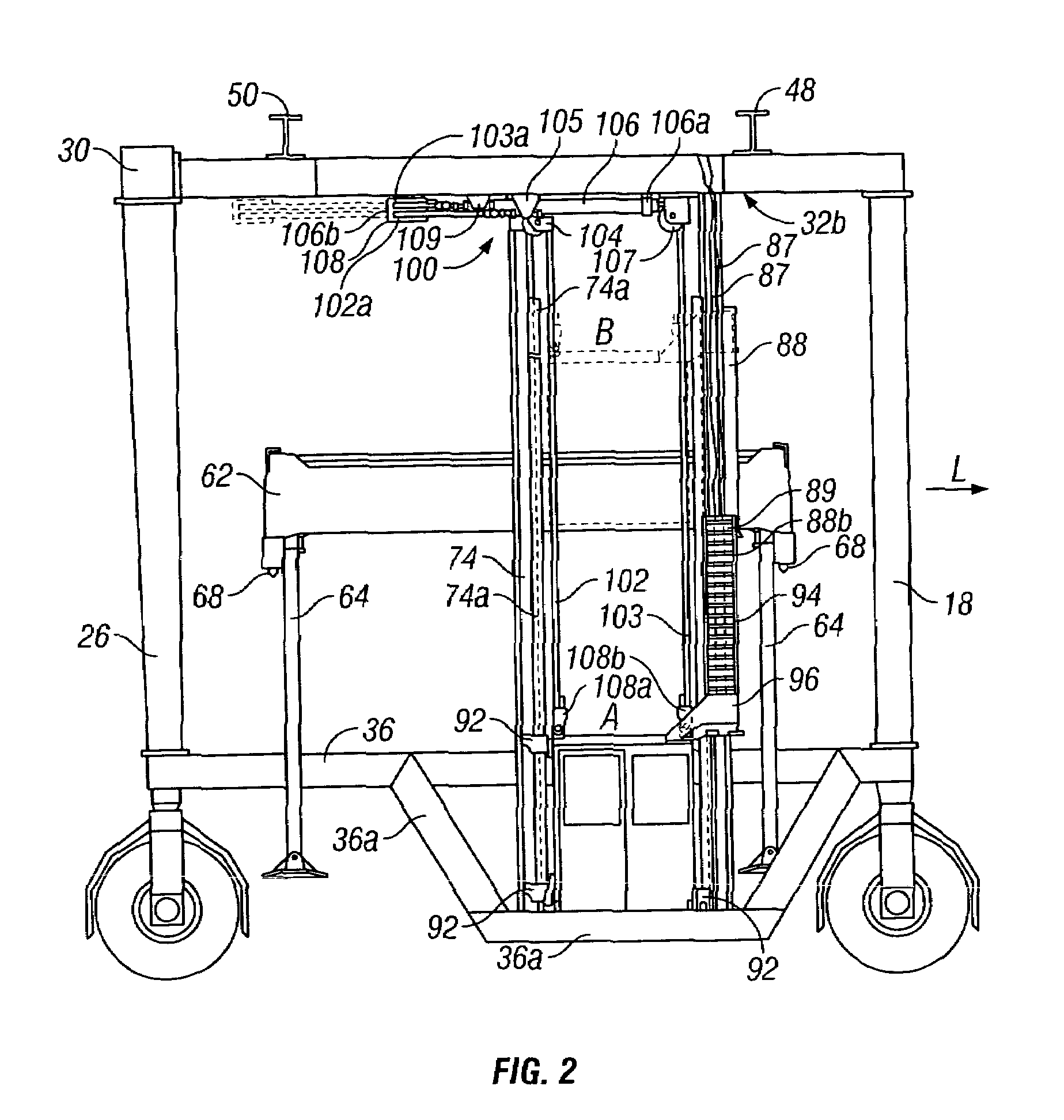

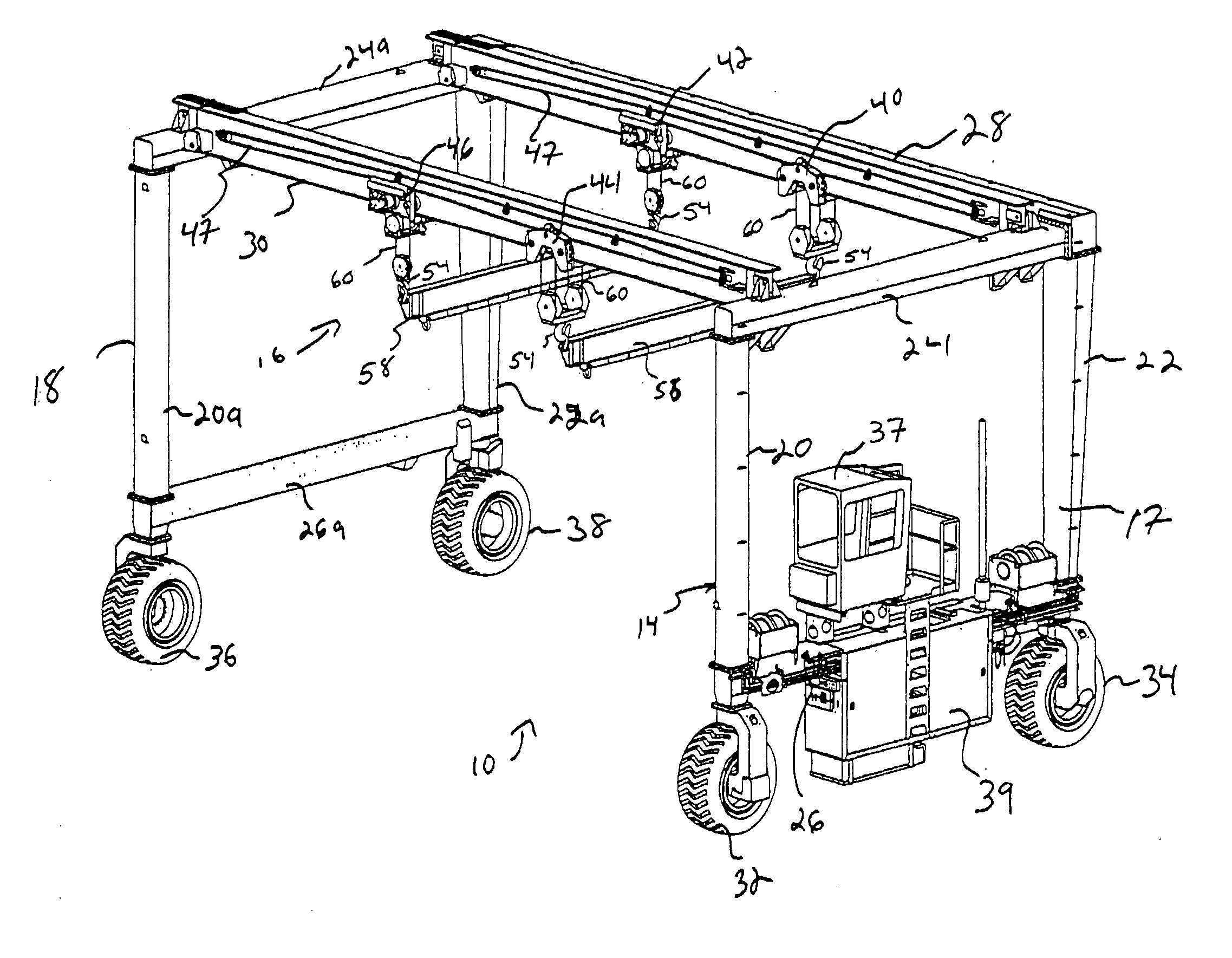

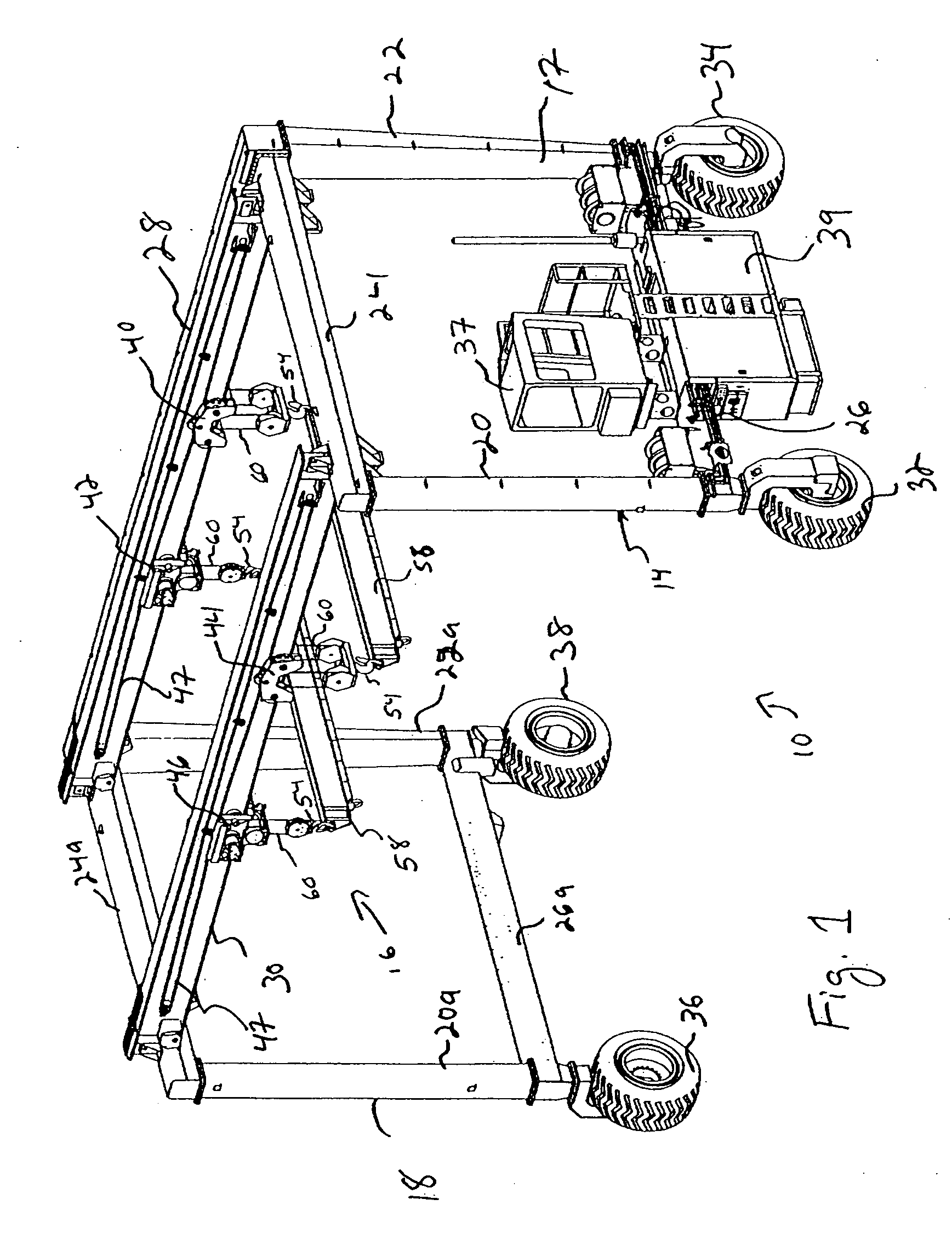

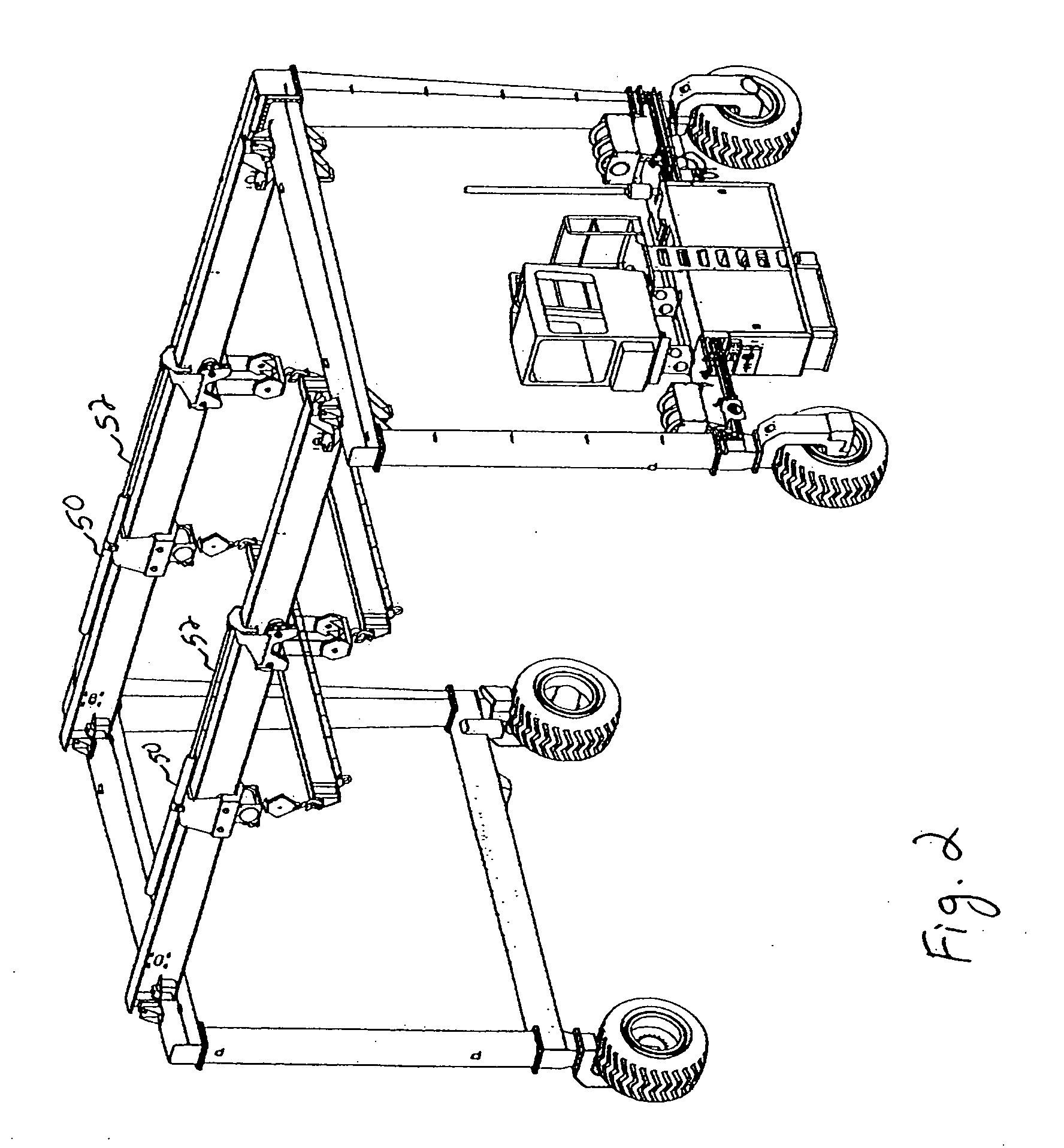

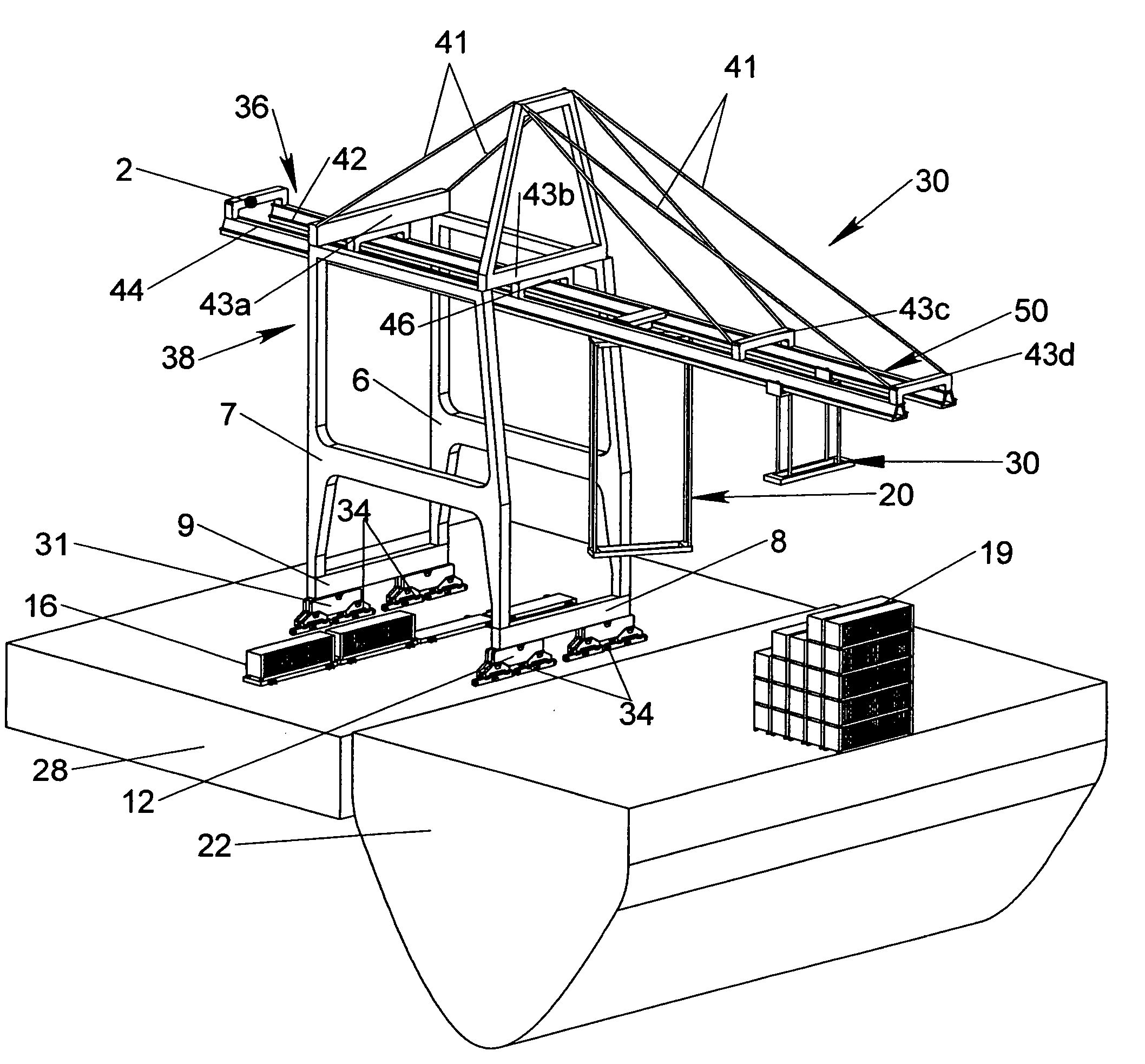

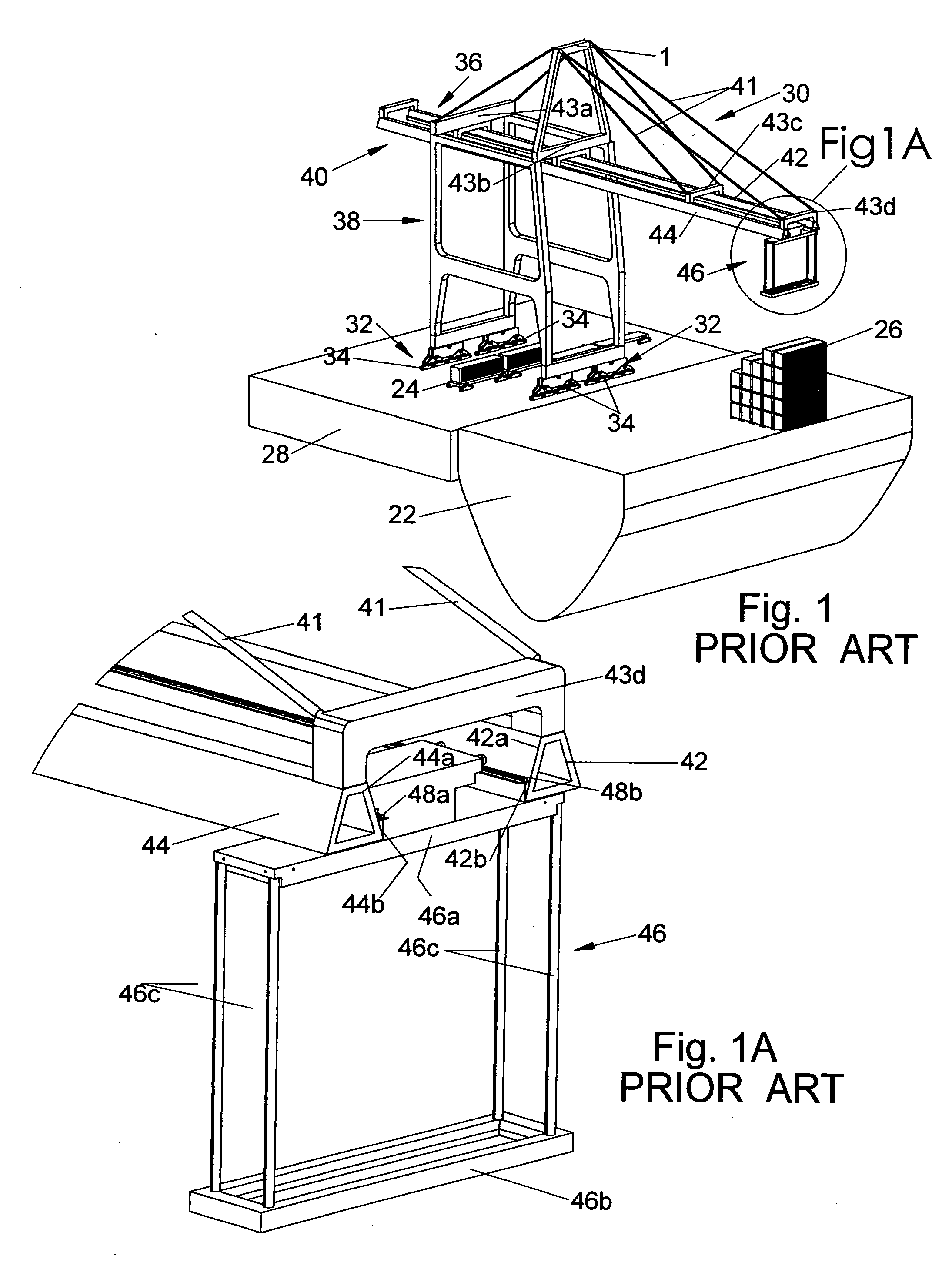

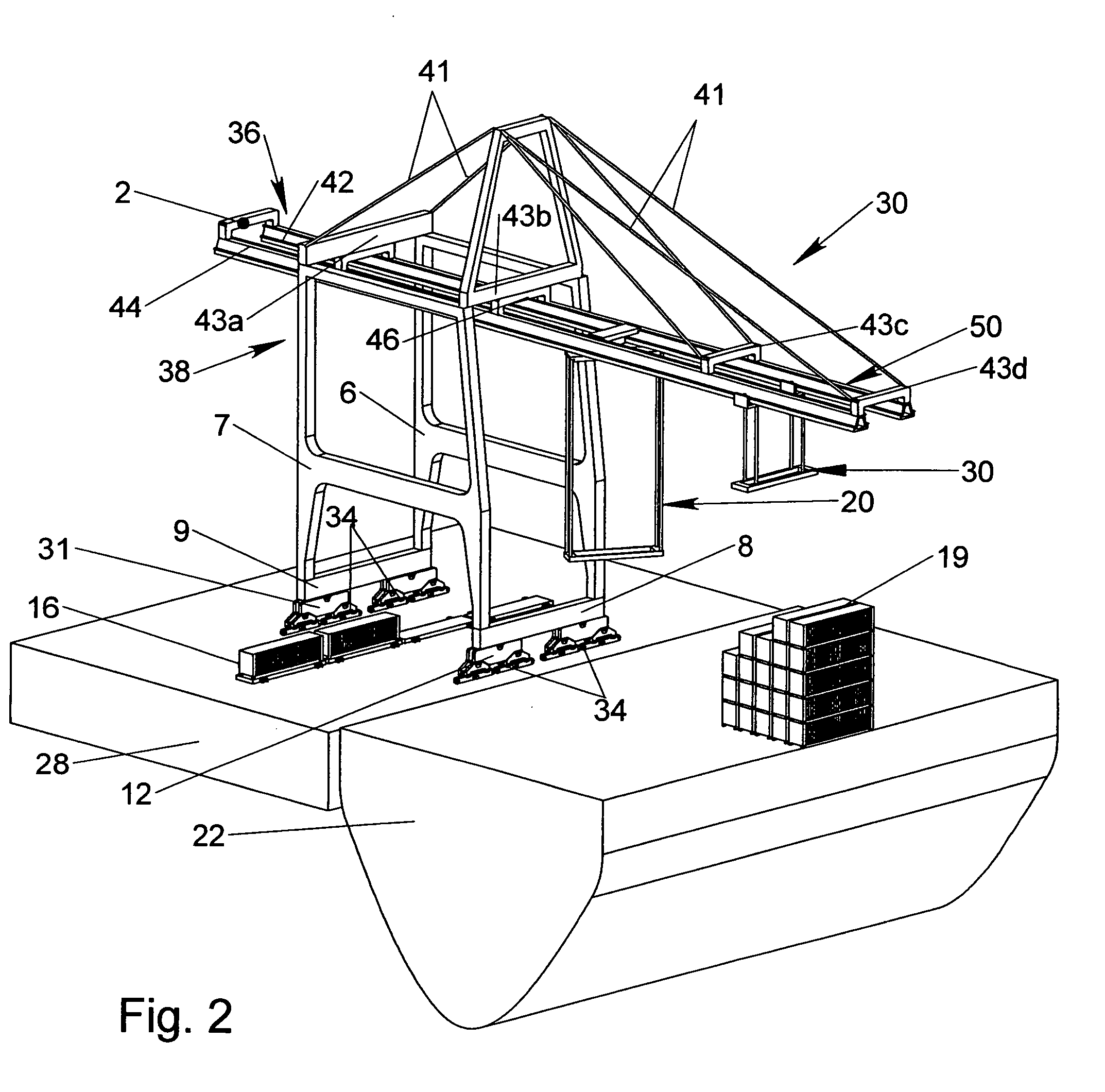

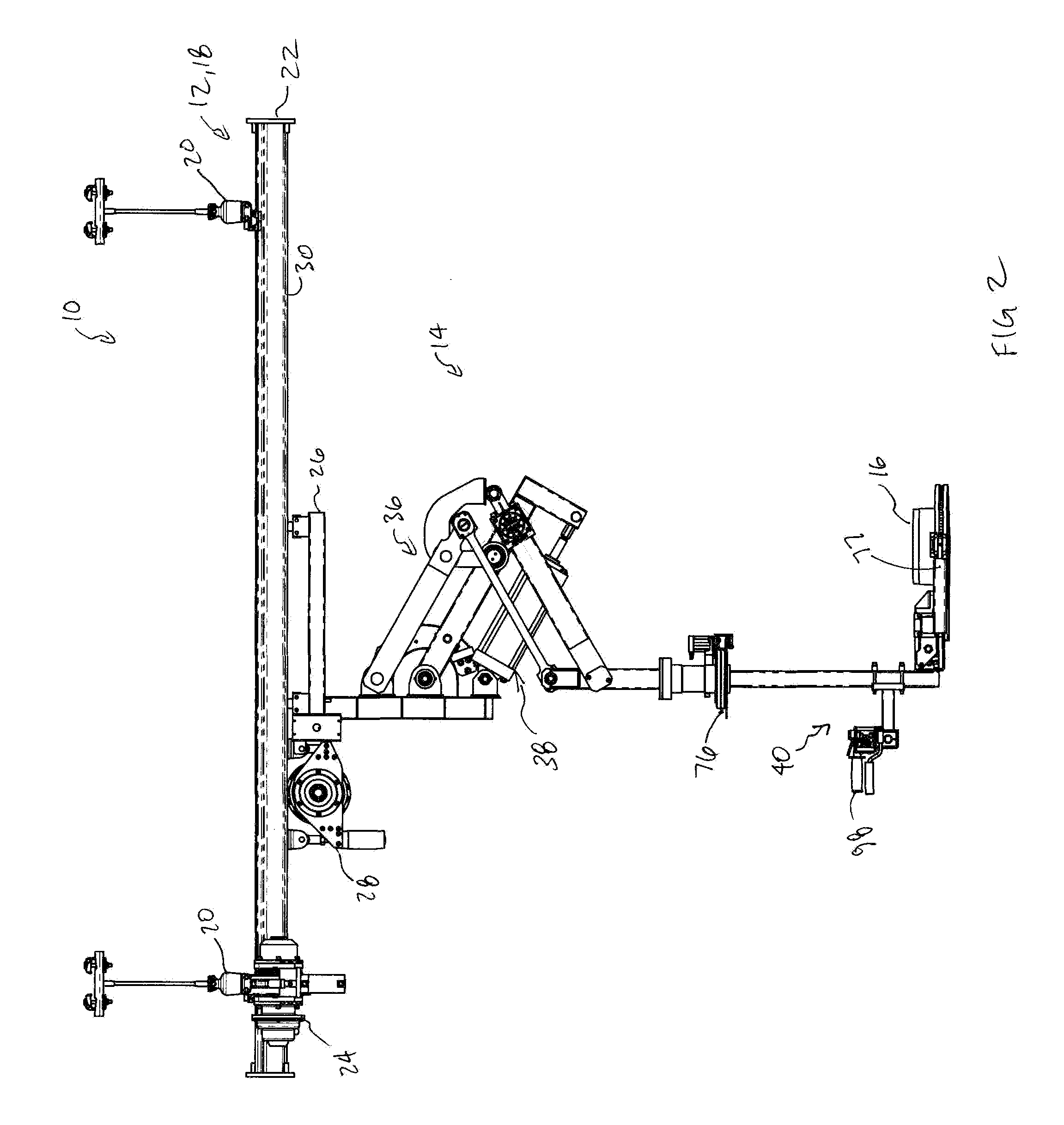

Powered auxiliary hoist mechanism for a gantry crane

ActiveUS20070095777A1Reduce hoist capacityProtection overloadTrolley cranesTrolleysLifting capacityEngineering

A gantry crane (10) is configured in a panel turner application. The gantry crane (10) generally includes a gantry crane structure (14) having a first cross-beam (28) and a second cross-beam (30). A first main hoist mechanism (40) and a first auxiliary hoist mechanism (42) are coupled to the first cross-beam (28), and a second main hoist mechanism (44) and a second auxiliary hoist mechanism (46) are coupled to the second cross-beam (30). The crane (10) includes a hydraulic system configured to reduce the lift capacity of the first and / or second main hoist mechanism (40, 44), and to equalize the hoist capacity between the first and second main hoist mechanisms (40, 44) or the first and second auxiliary hoist mechanisms (42, 46) in certain applications. The auxiliary hoist mechanism (42, 46) are configured for powered movement along the respective cross-beams (28, 30).

Owner:MARINE TRAVEELEVATOR

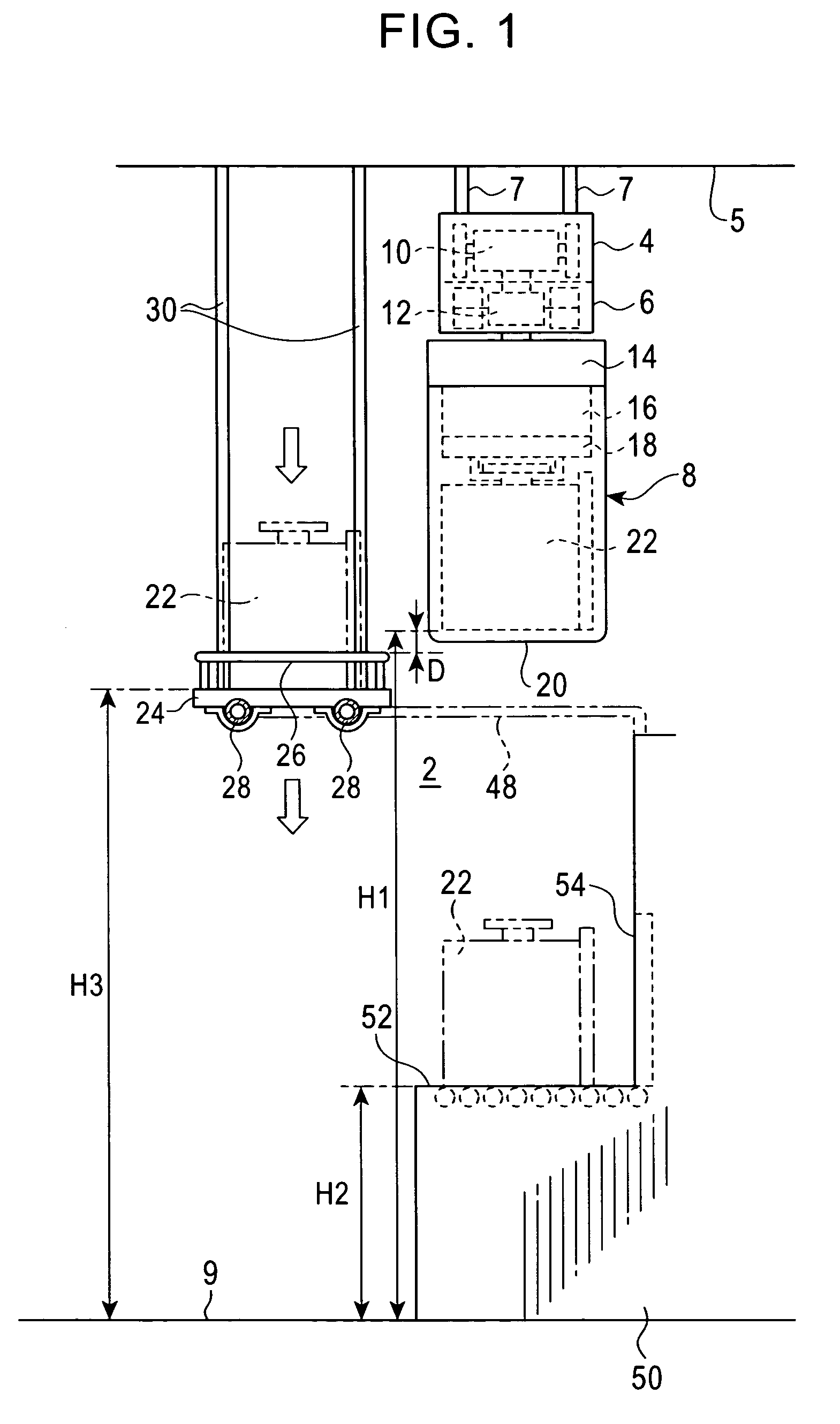

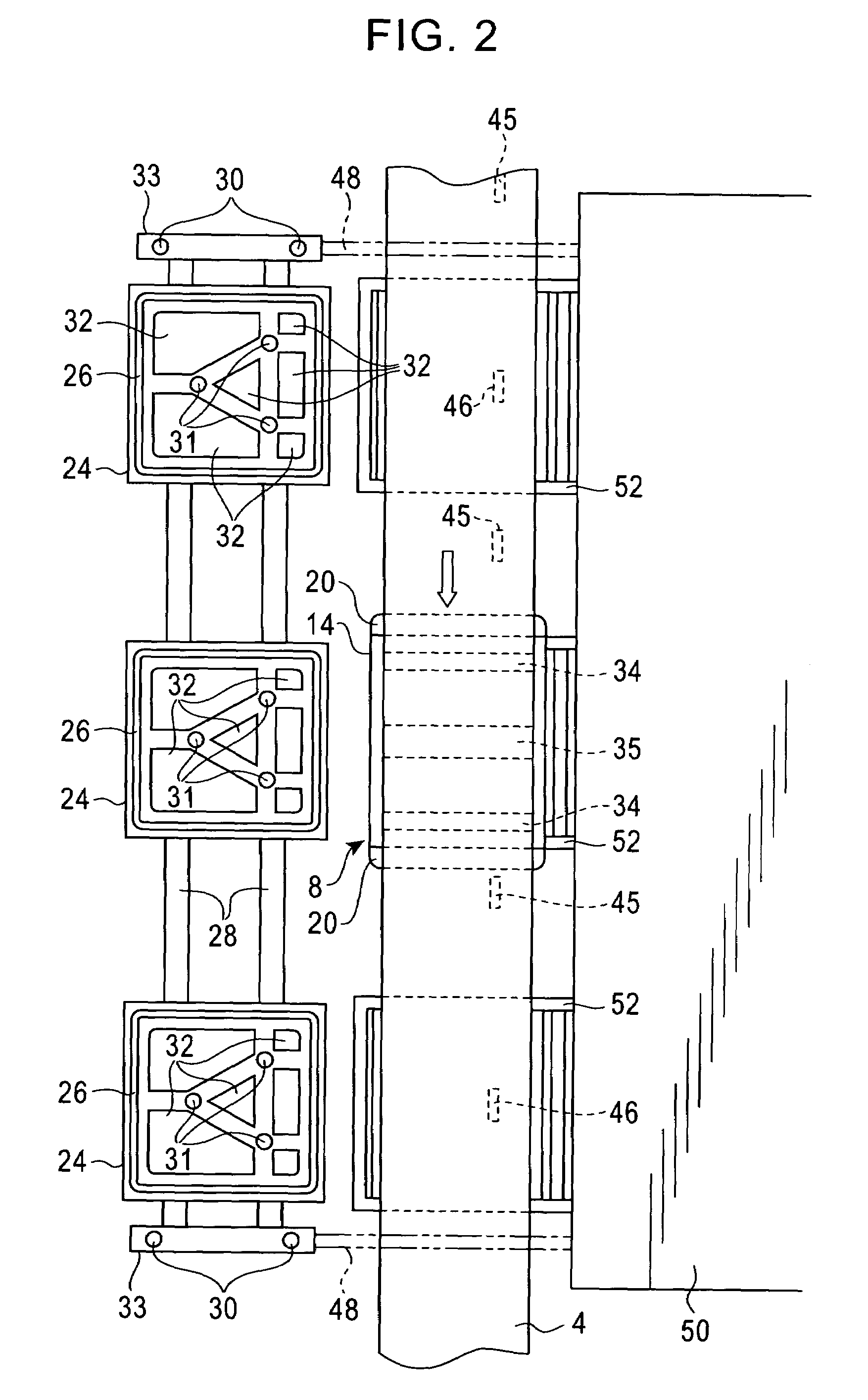

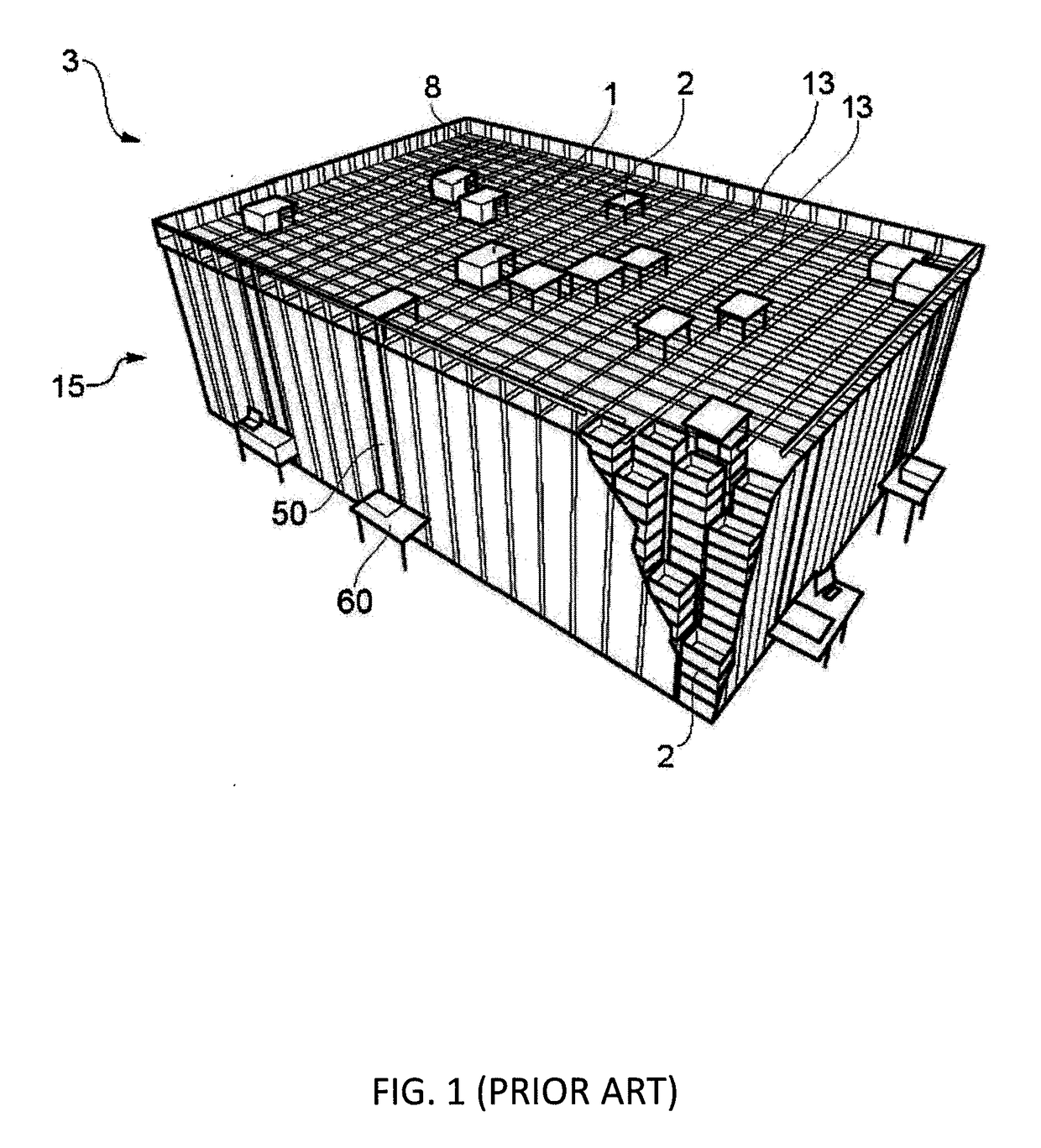

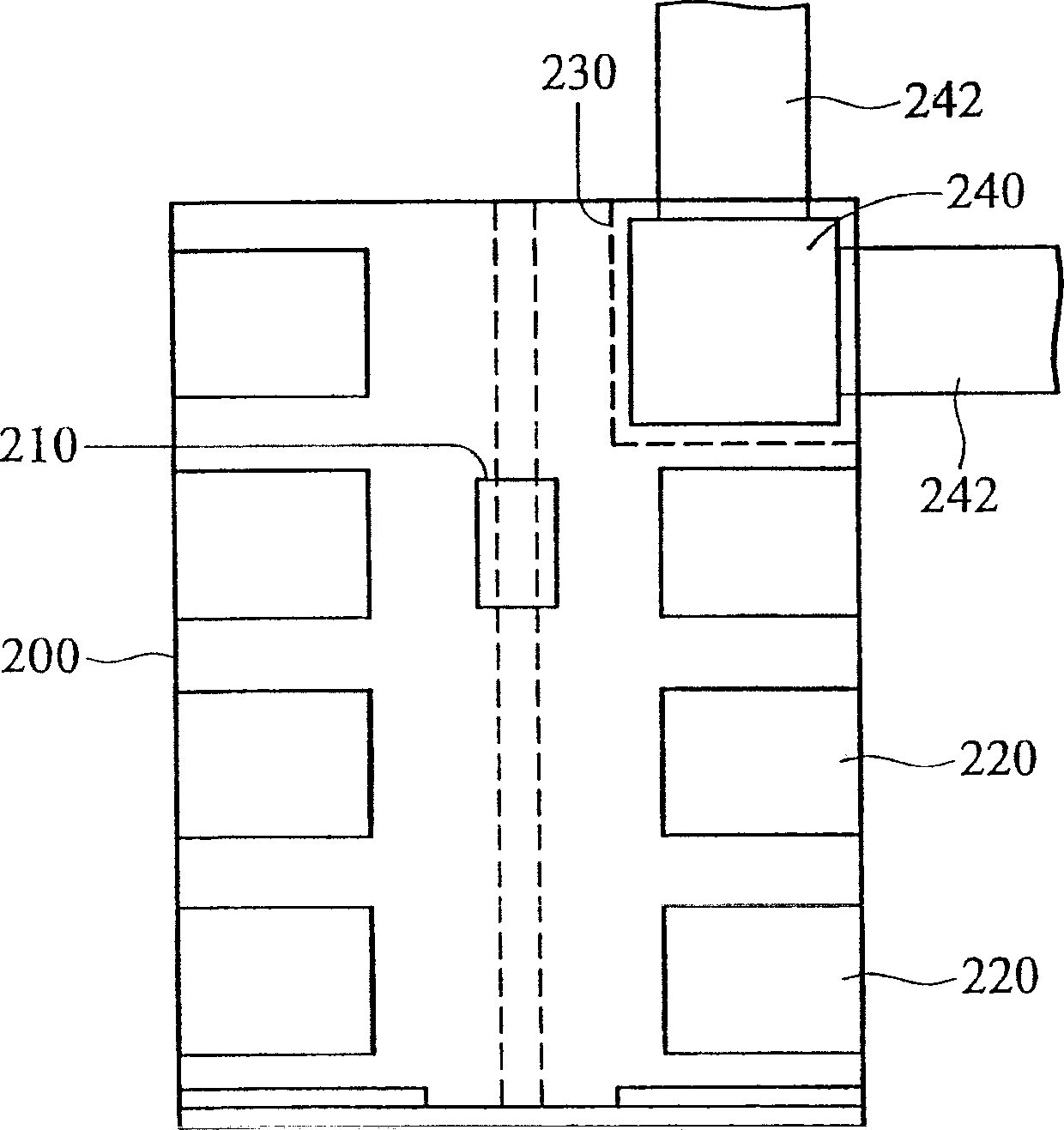

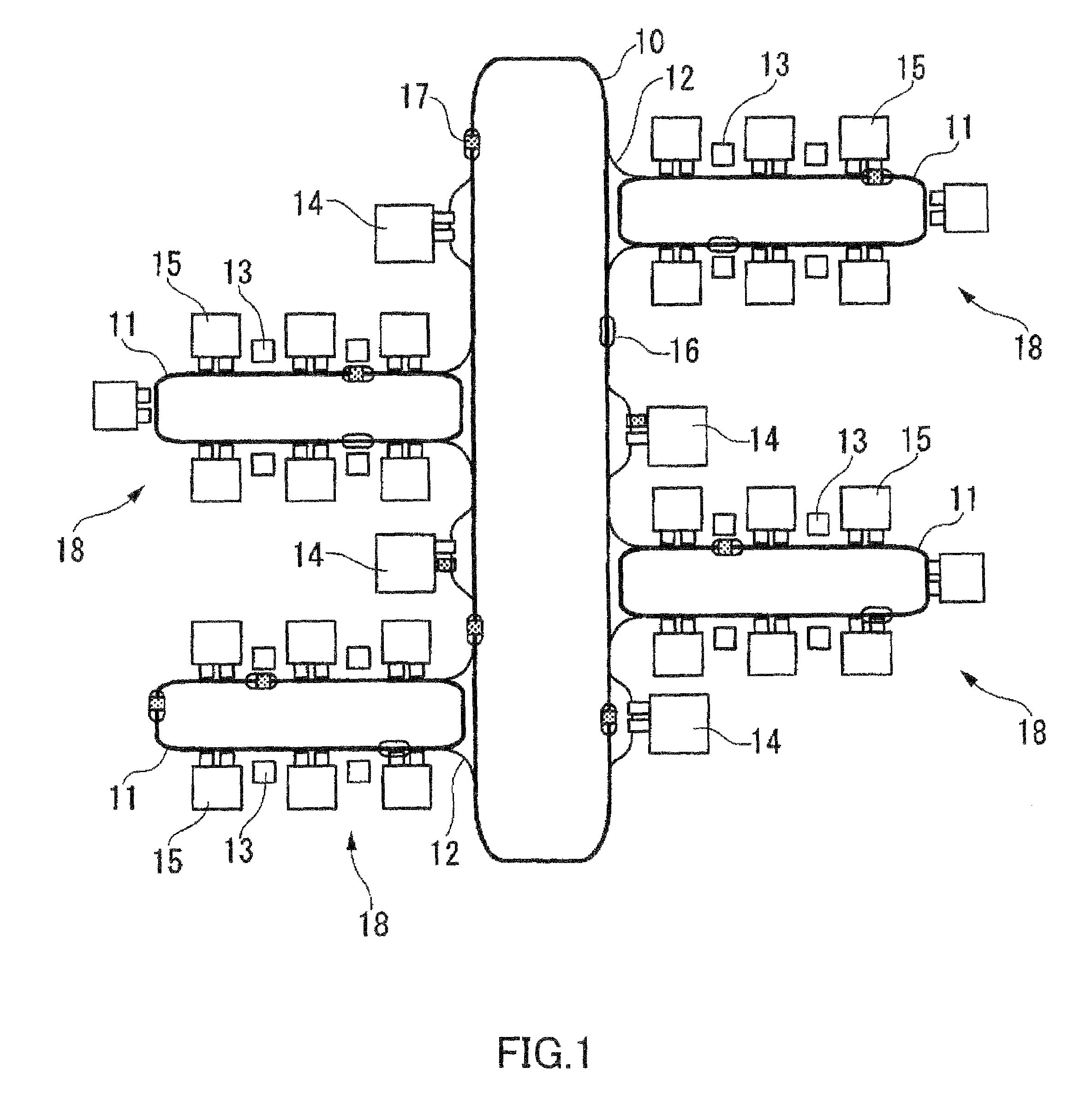

Overhead travelling carriage system

ActiveUS7441999B2Easy transferEffectively utilize a space located below the overhead bufferRailway heating/coolingSemiconductor/solid-state device manufacturingTrackwayEngineering

An overhead buffer 24 is provided on a side of a running rail 4 for an overhead travelling carriage 8. The height level of an article on the overhead buffer 24 is slightly lower than that on the running overhead travelling carriage 8. This height is at least such that the overhead buffer 24 does not interfere with an operator. According to the present invention, the overhead buffer can be installed even if load ports are consecutively provided.

Owner:MURATA MASCH LTD

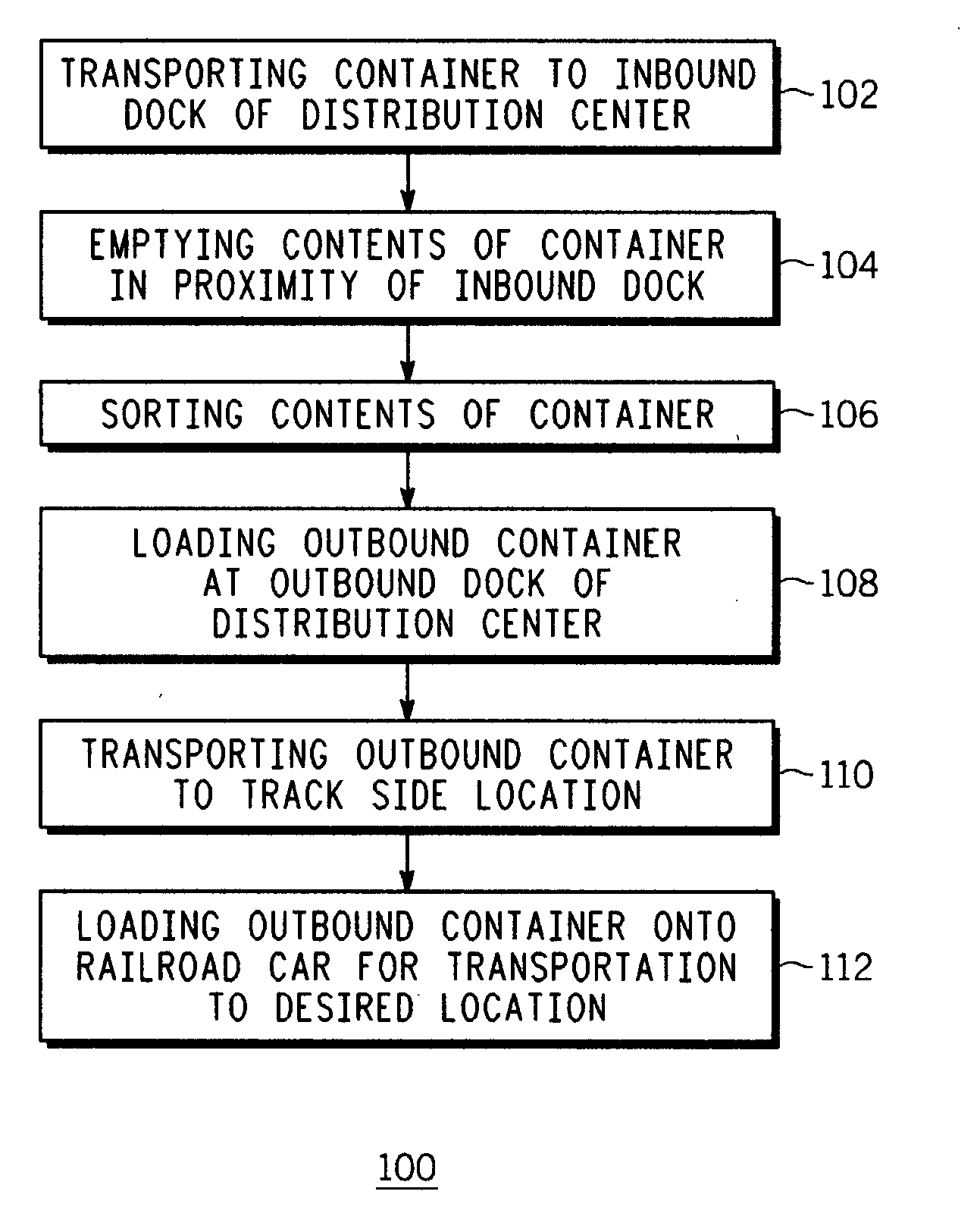

Hub and distribution system

ActiveUS20090003985A1Improve productivityTruck, buffer and crane utilization and efficiencyDigital data processing detailsLifting devicesDistribution systemMechanical engineering

A hub and distribution system (600) is disclosed. It comprises the steps of: delivering (602) a container via rail to a terminal; assigning (604) a corridor as to where to deliver the container, the corridor including a block of pathways in proximity to a track side location; picking (606) the container from a rail car and placing (608) it in one of the pathways in the corridor; and transporting (610) the container to a desired remote destination. The system provides an efficient, effective and semi-automated post-blocking method, such that each post-blocked group of containers has a similar desired remote destination, so that the containers can be easily located, loaded, handed-off and transported to a desired location.

Owner:MI JACK PRODS

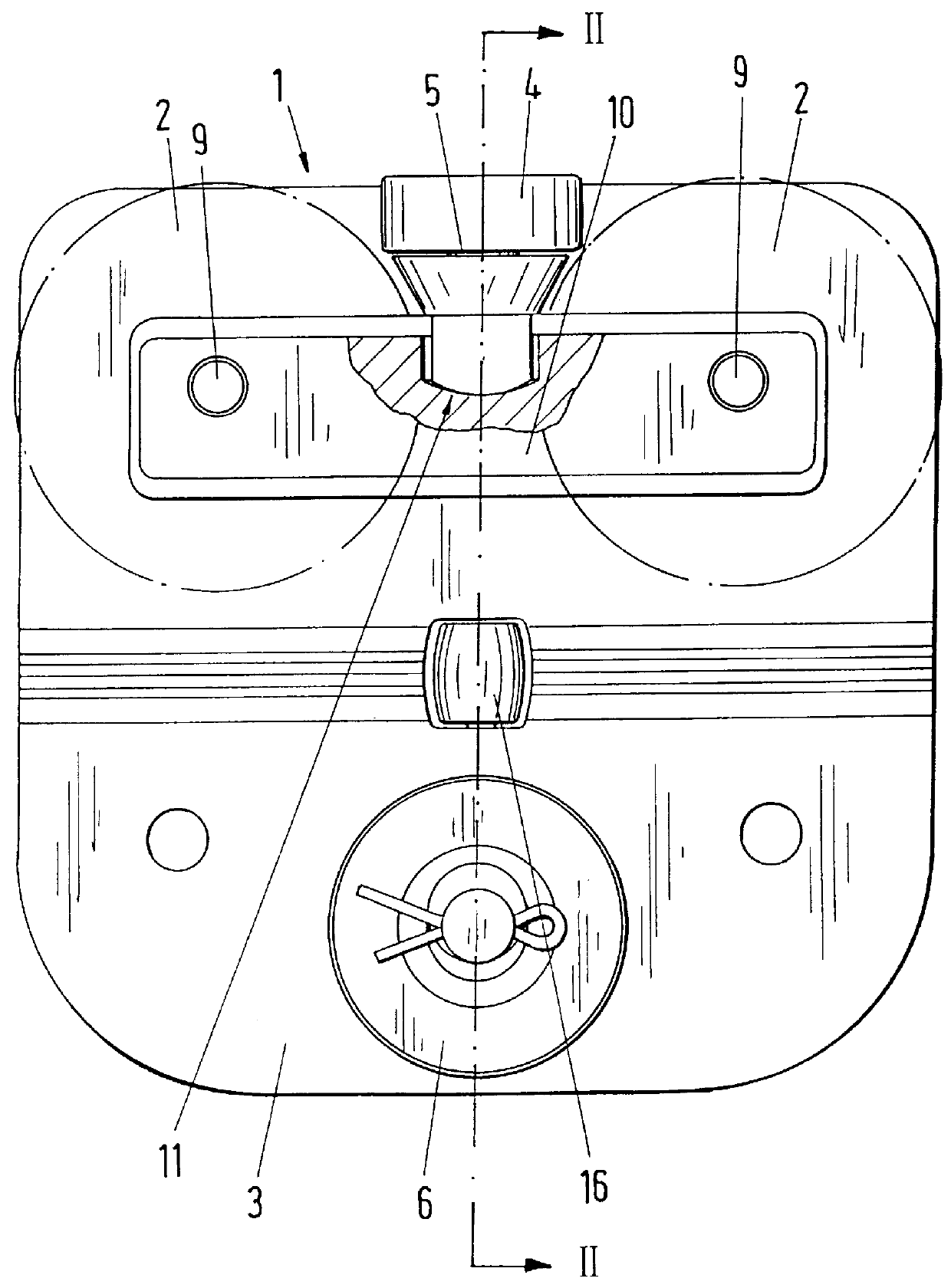

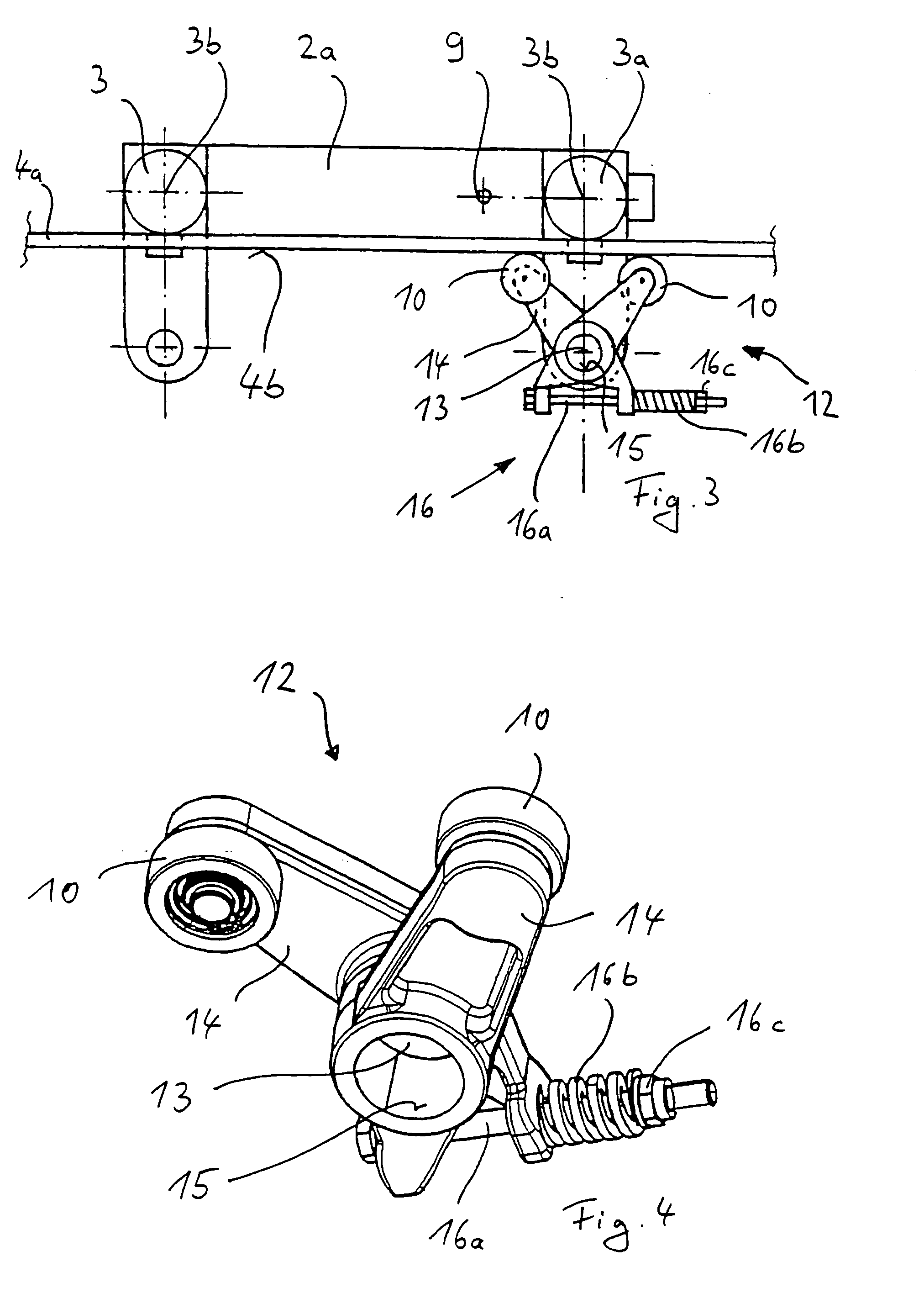

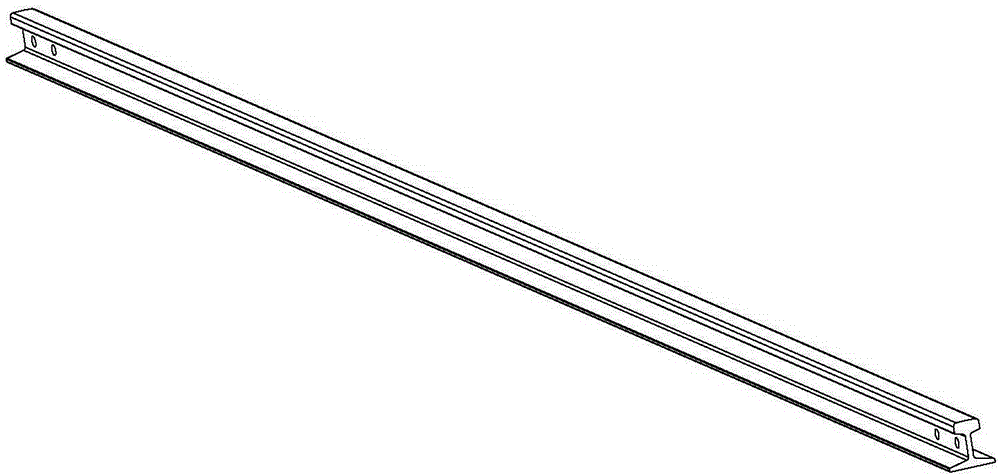

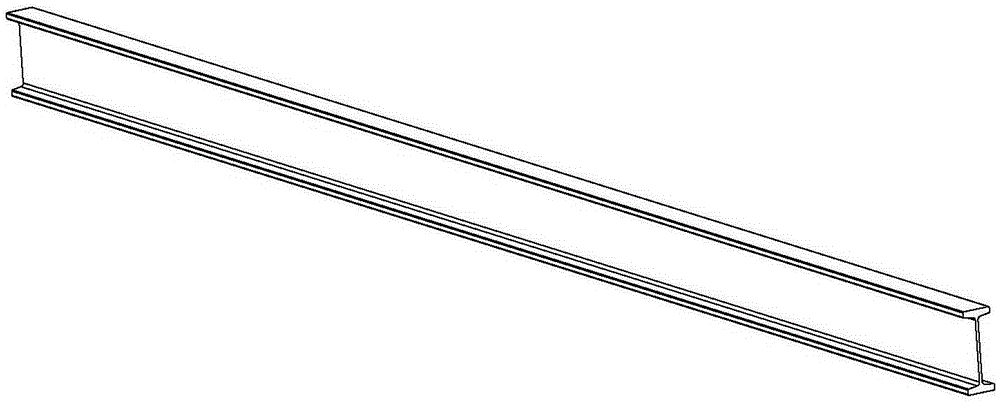

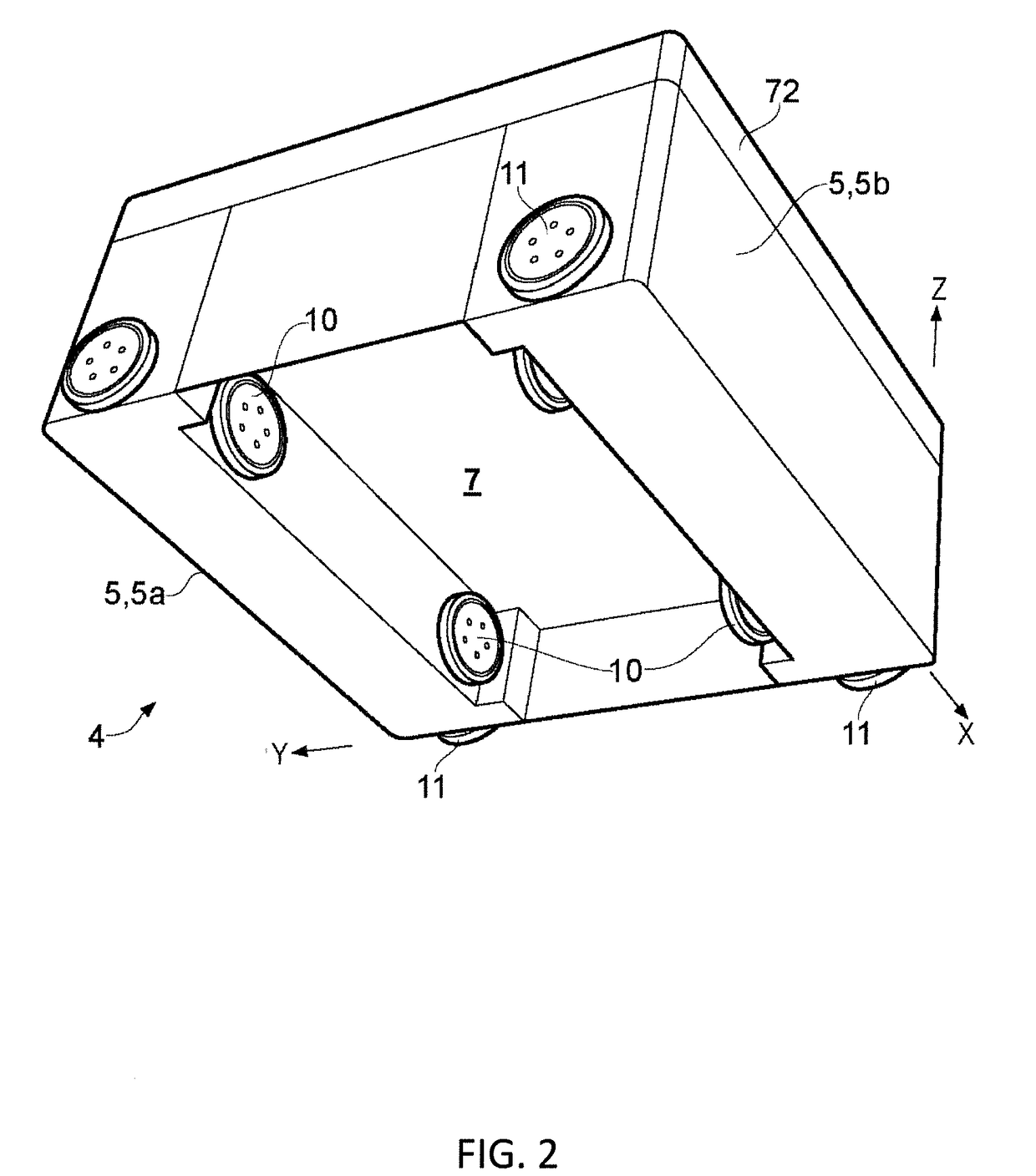

Crane trolley with low overall height

A crane trolley, especially a single-rail trolley with a short overall height, with a traveling mechanism frame (2) having a hoisting mechanism (1), which can travel by running wheels (3, 3a) on a rail, especially a lower flange (4a) of an essentially horizontal beam (4), wherein at least one running wheel (3a) can be driven, and a friction roller (10) interacting with the driven running wheel (3a) is arranged on the underside (4b) of the rail. In order to create a crane trolley that guarantees a reliable reduction in the slippage of the driven running wheel (3a) with a simple design, a pair of friction rollers (10) is provided, which may be positioned against the underside (4b) of the rail by adjusting the spacing from each other via a common pressing mechanism.

Owner:KONECRANES GLOBAL

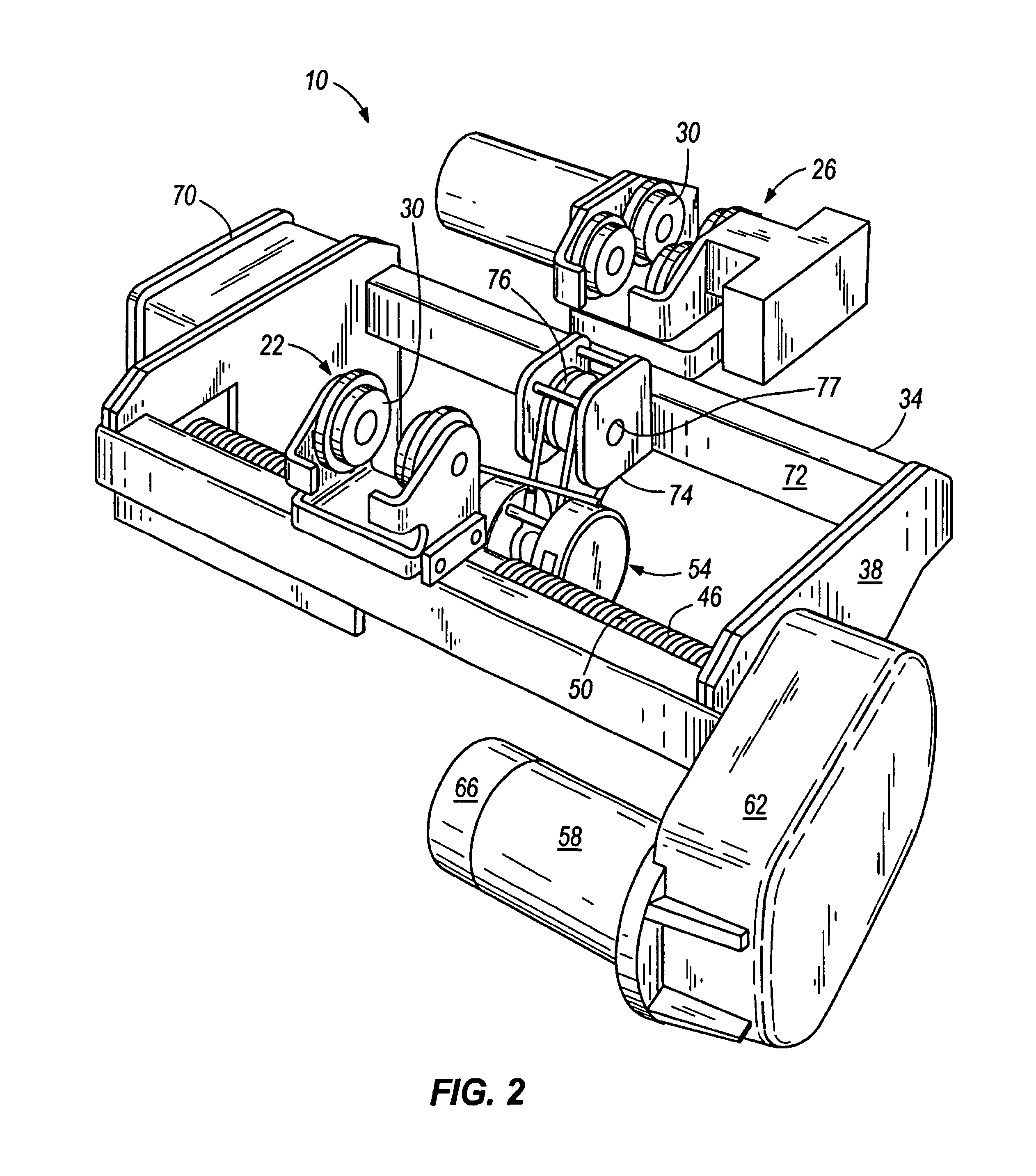

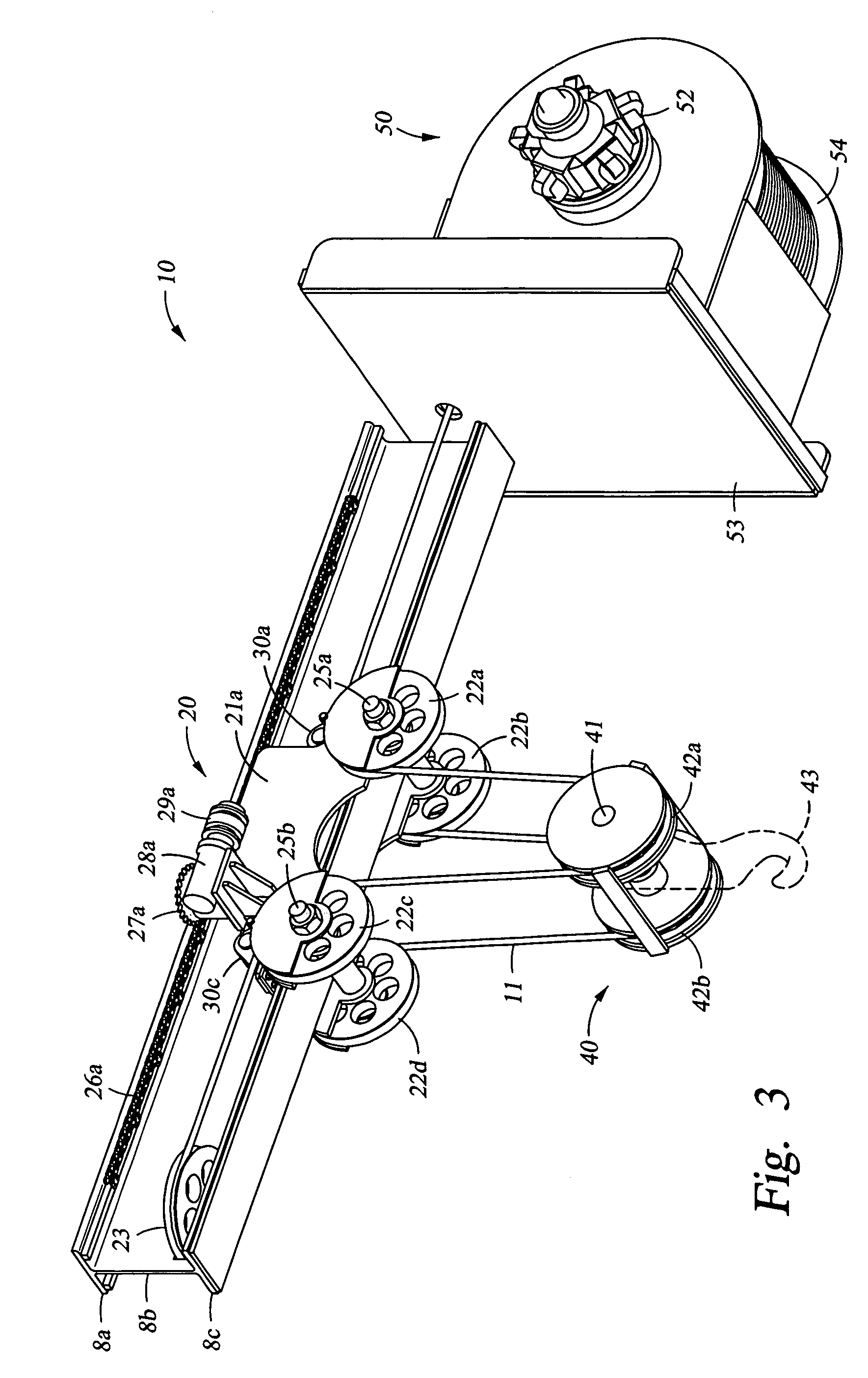

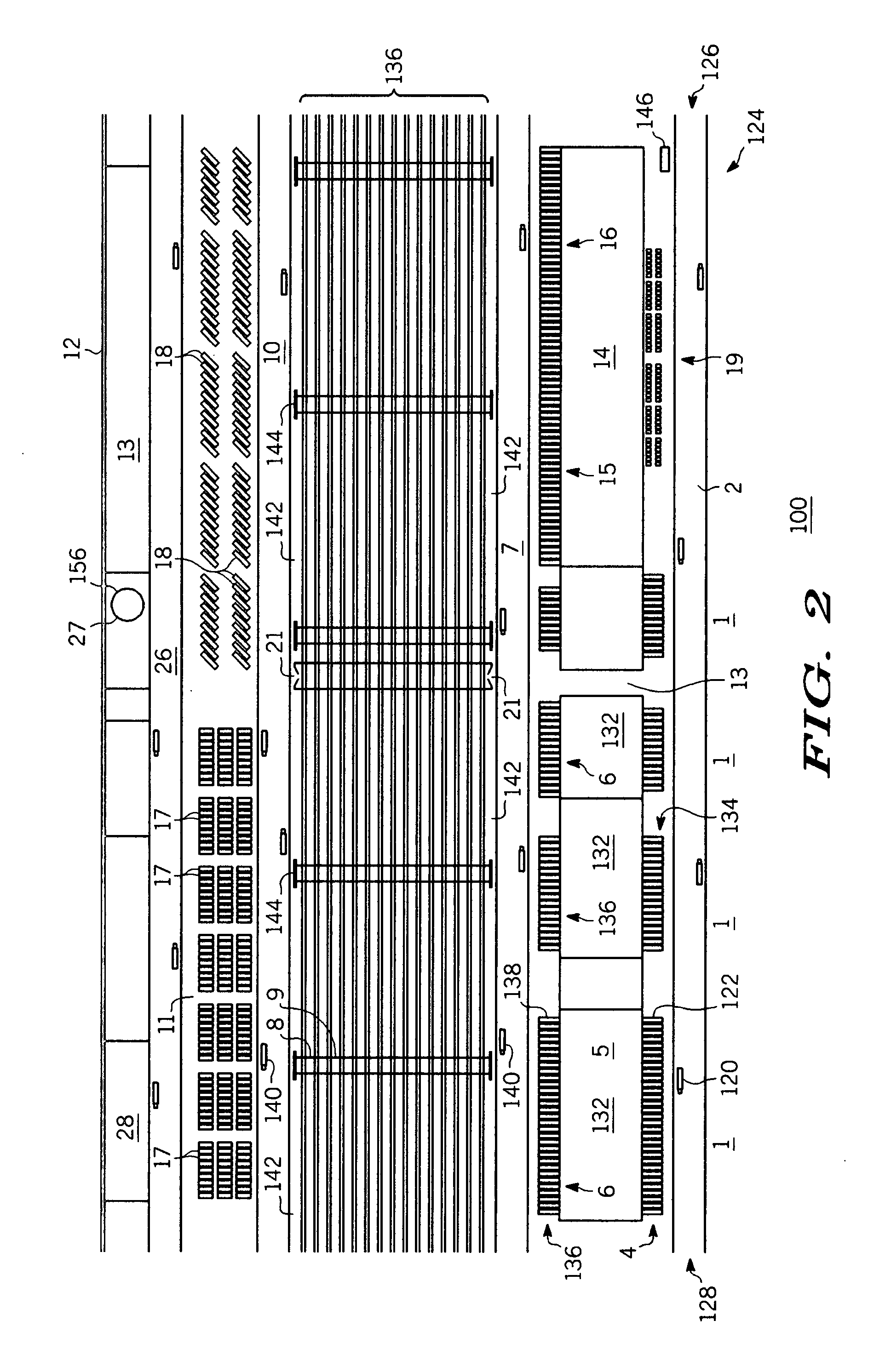

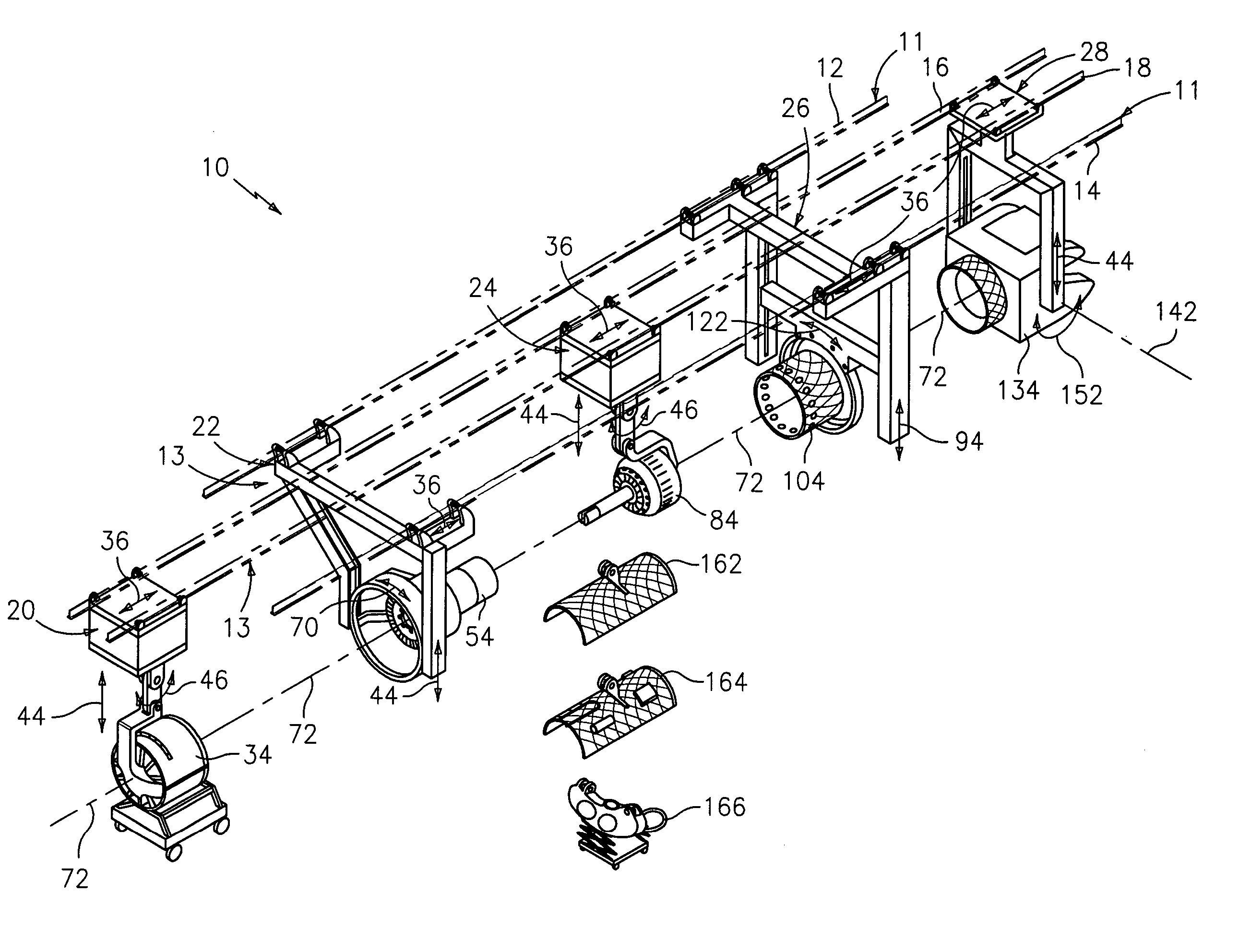

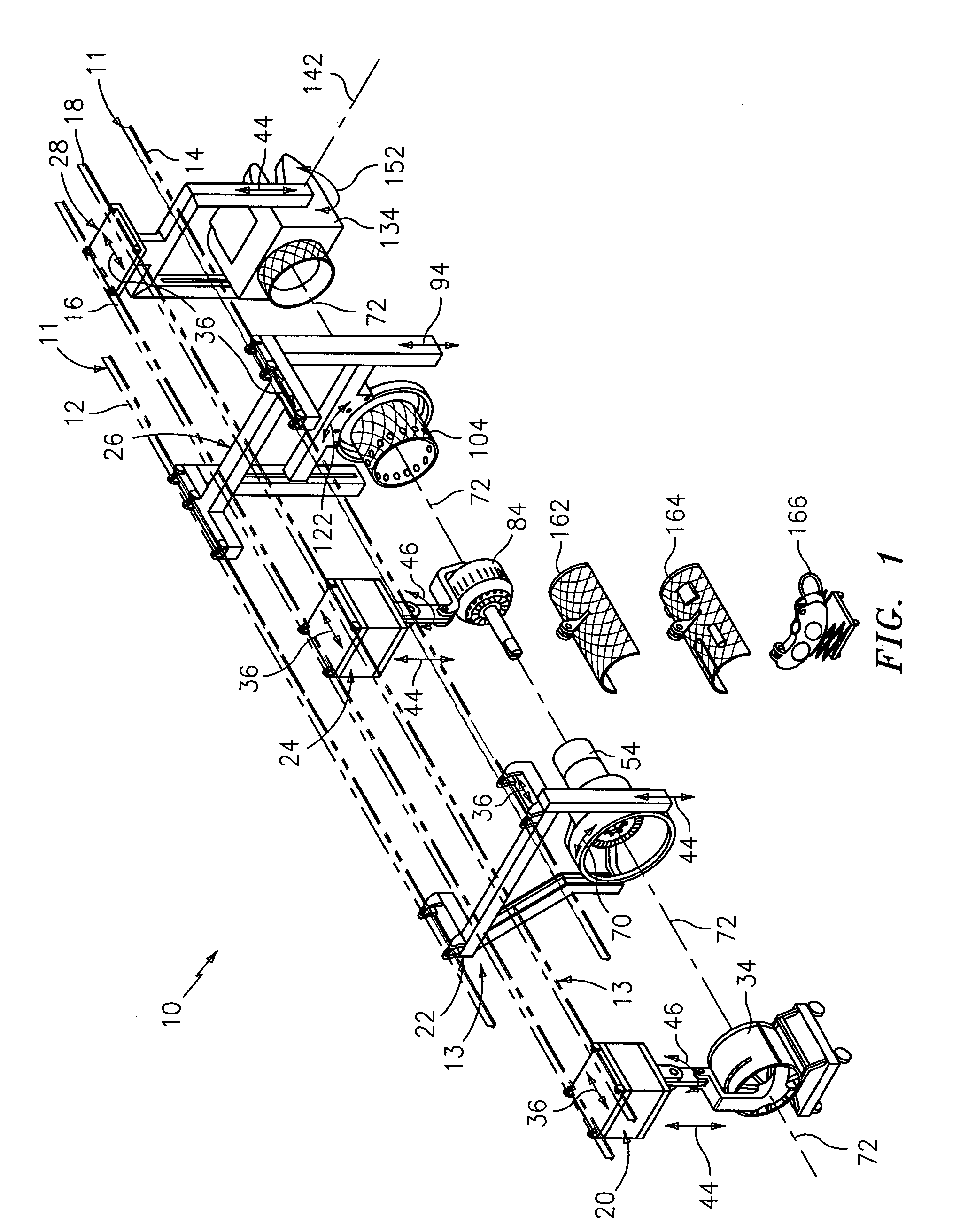

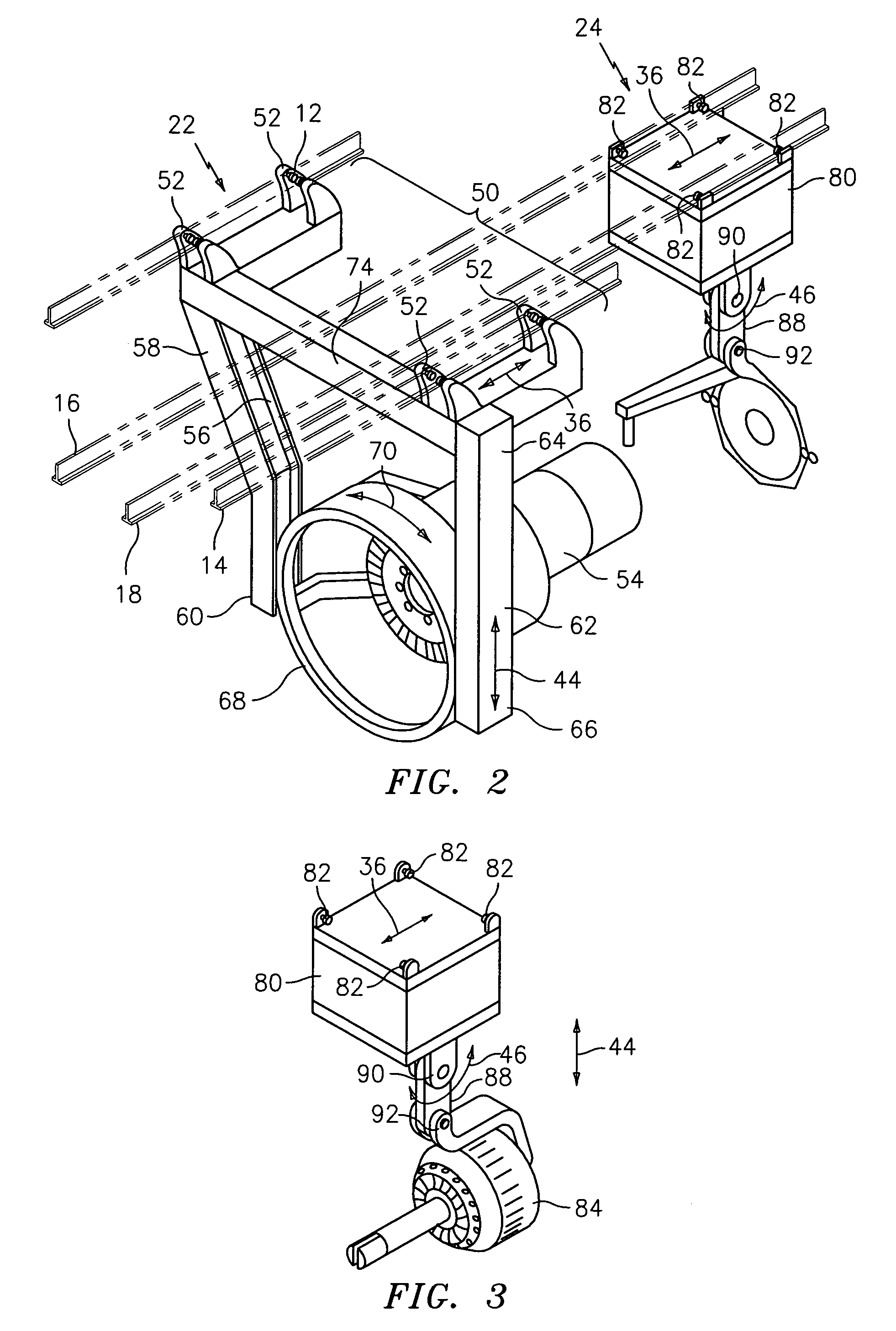

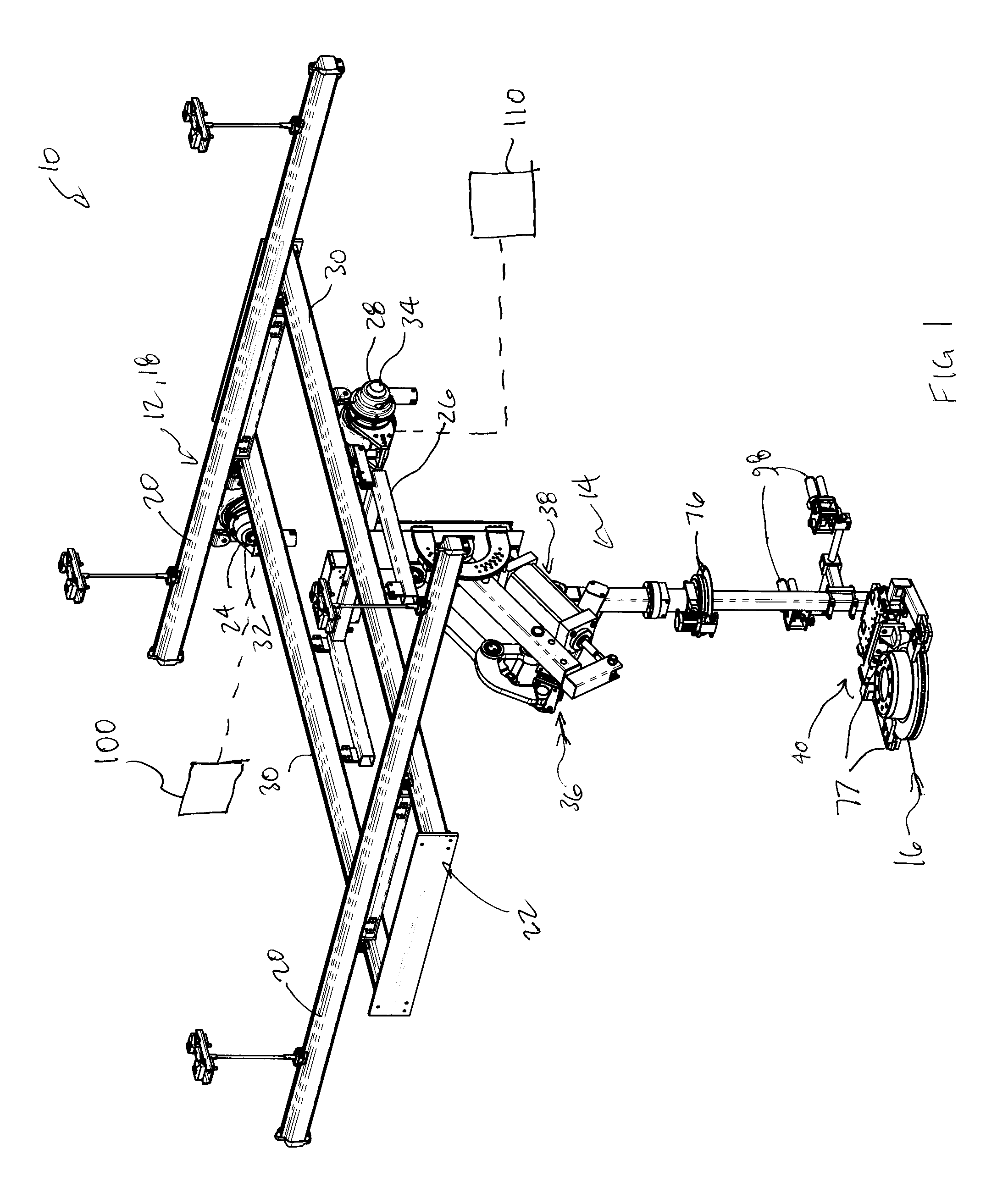

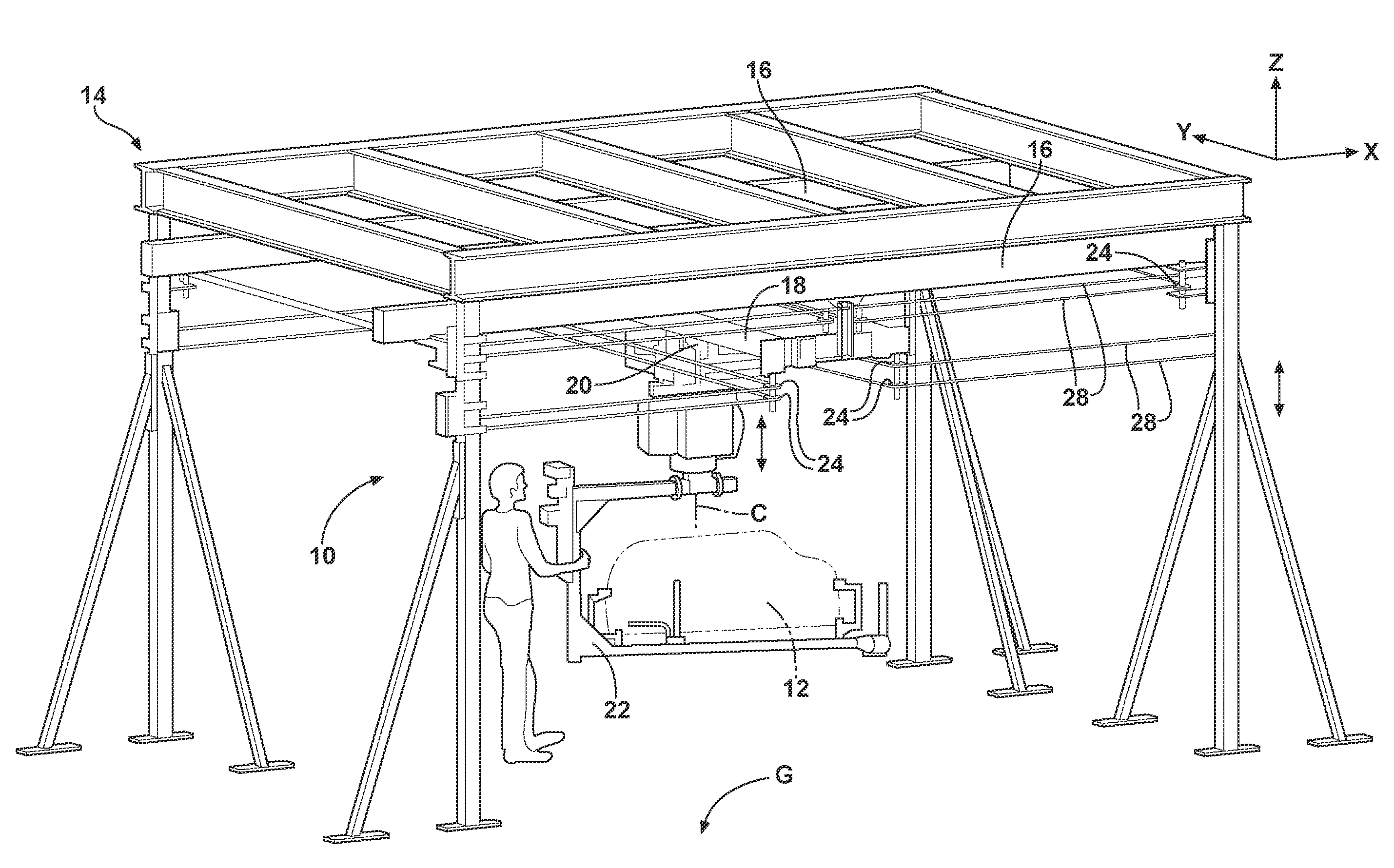

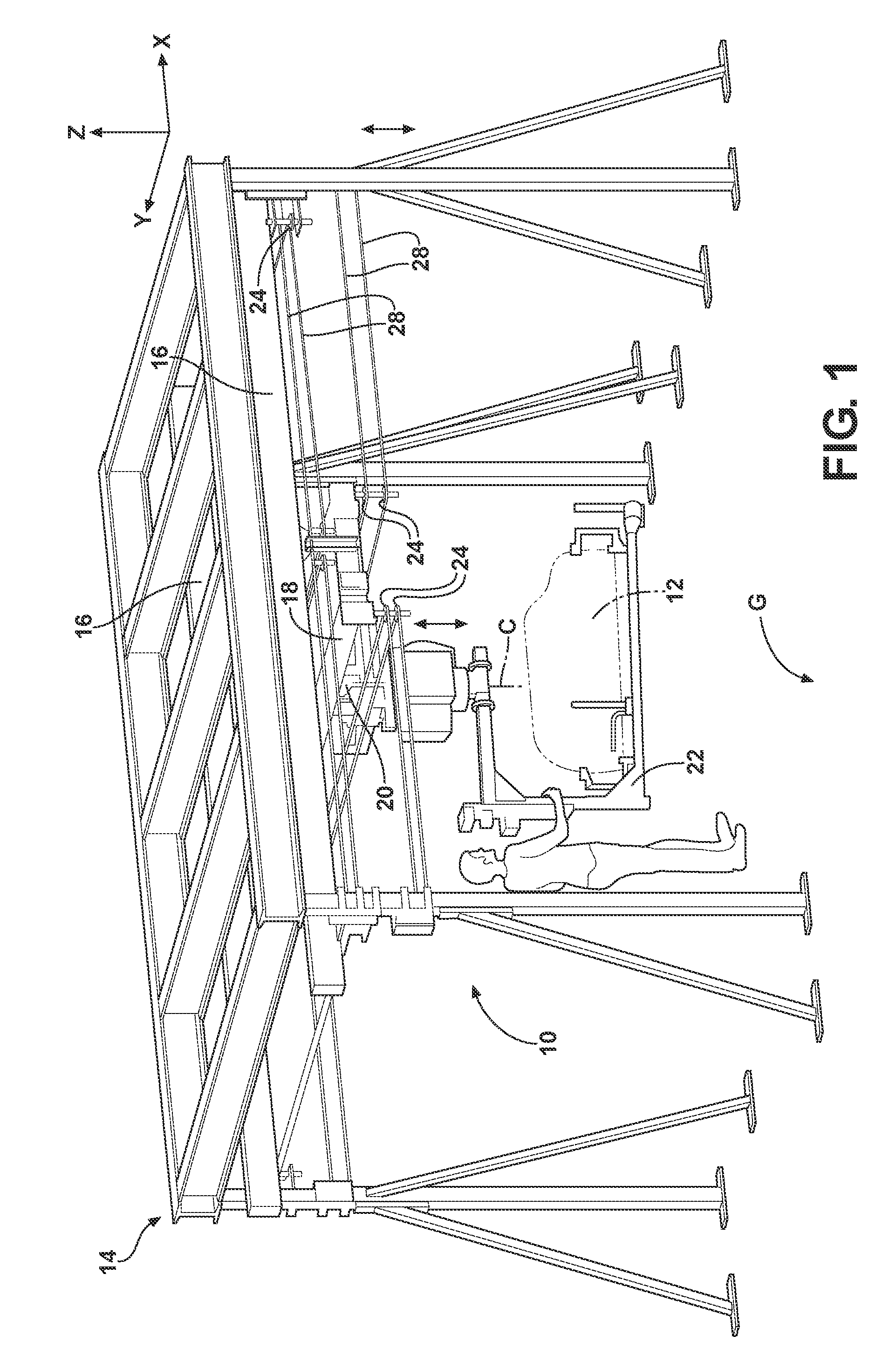

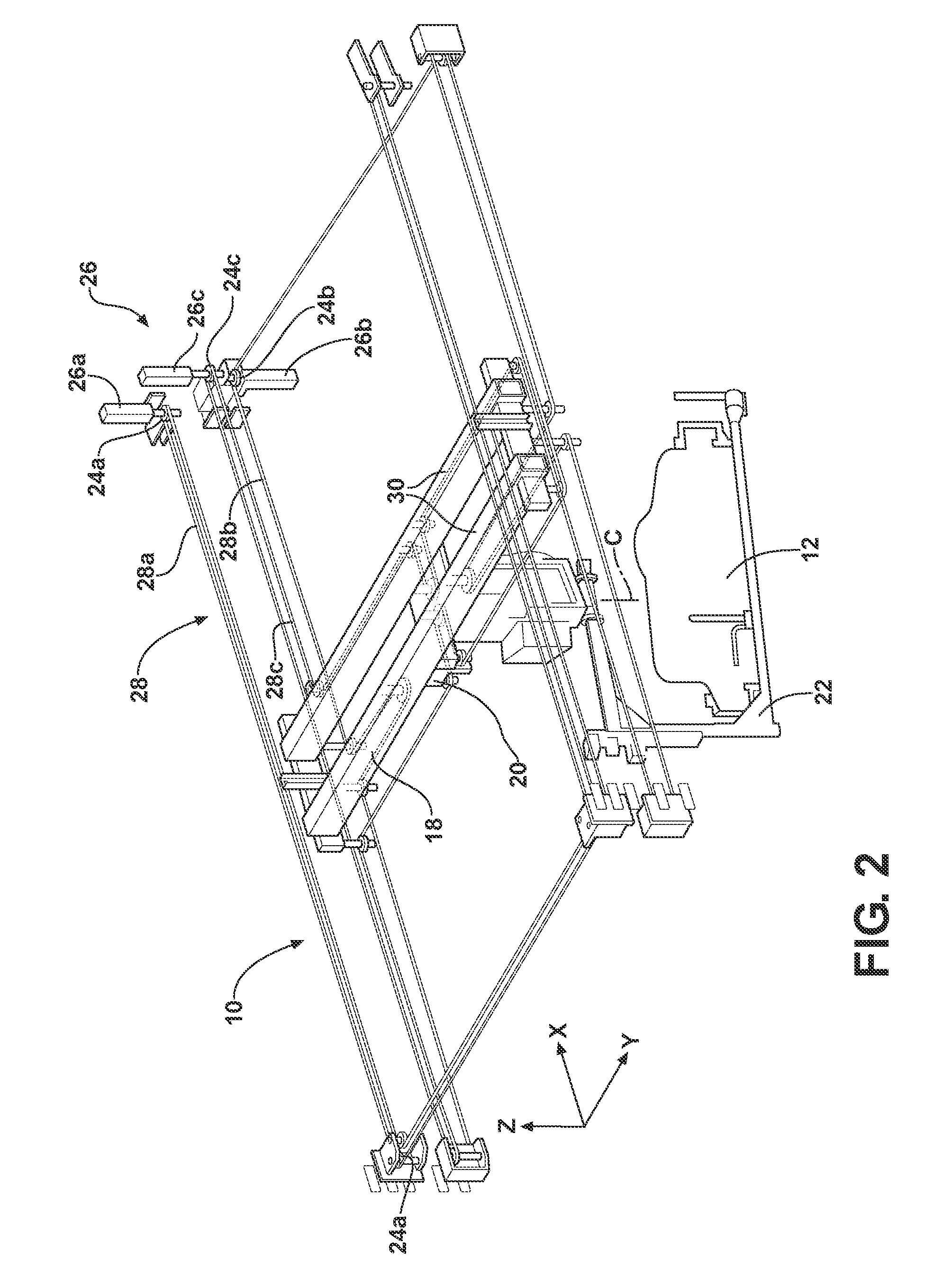

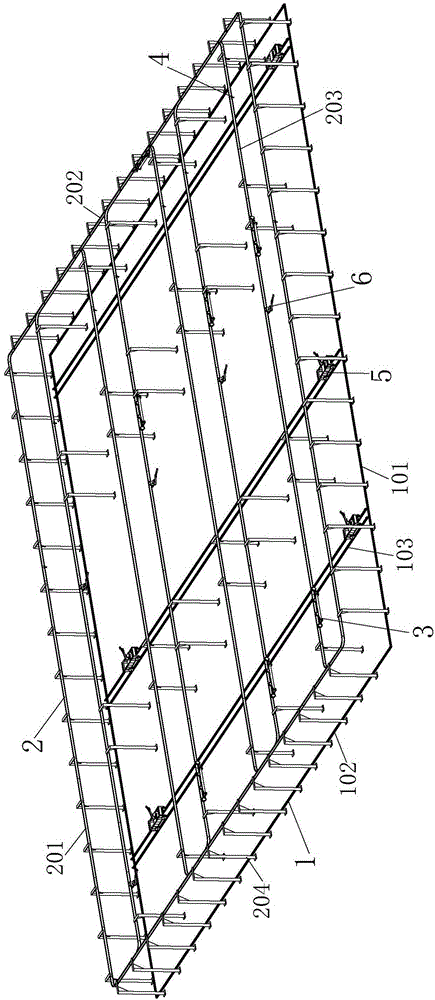

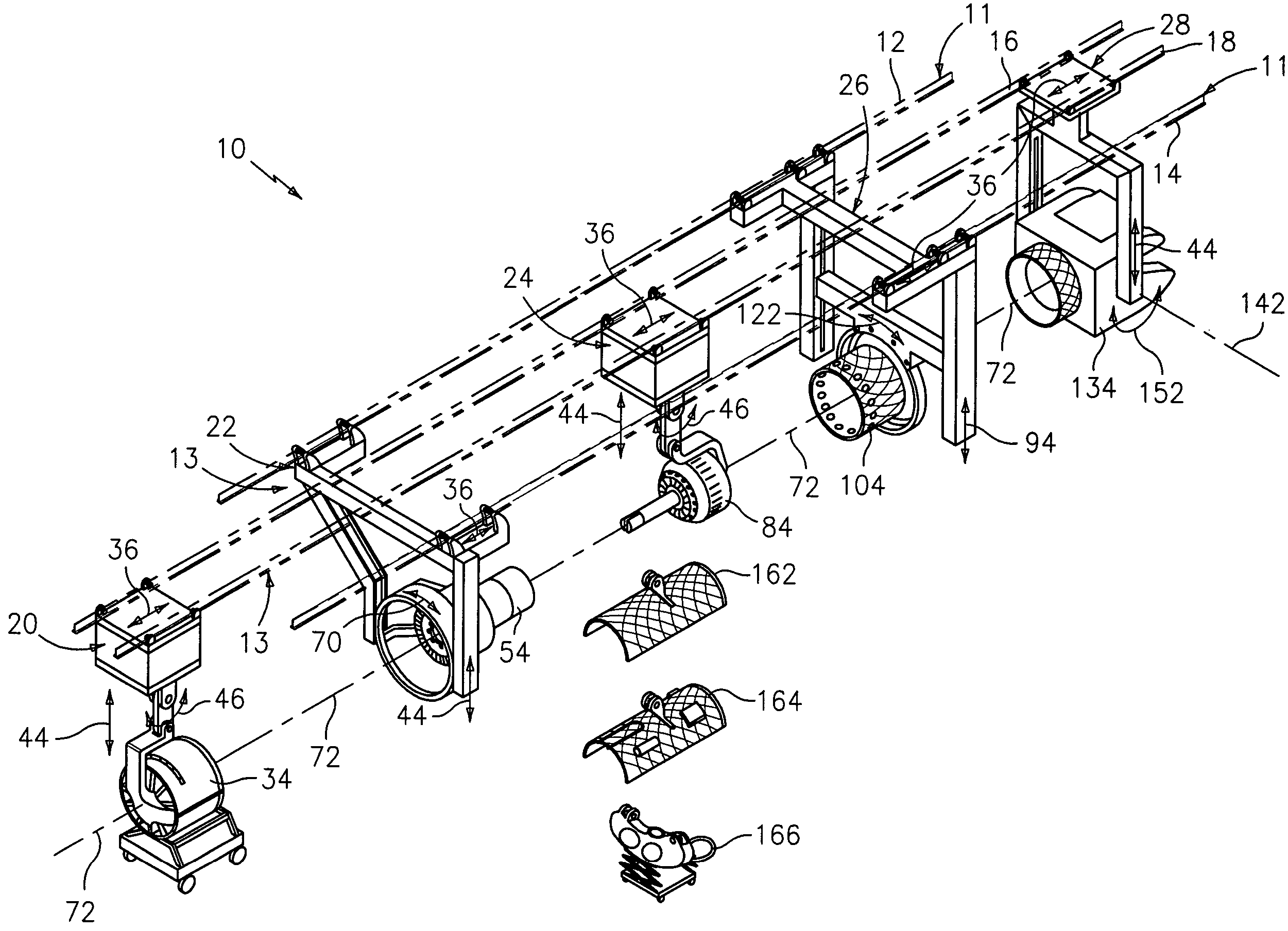

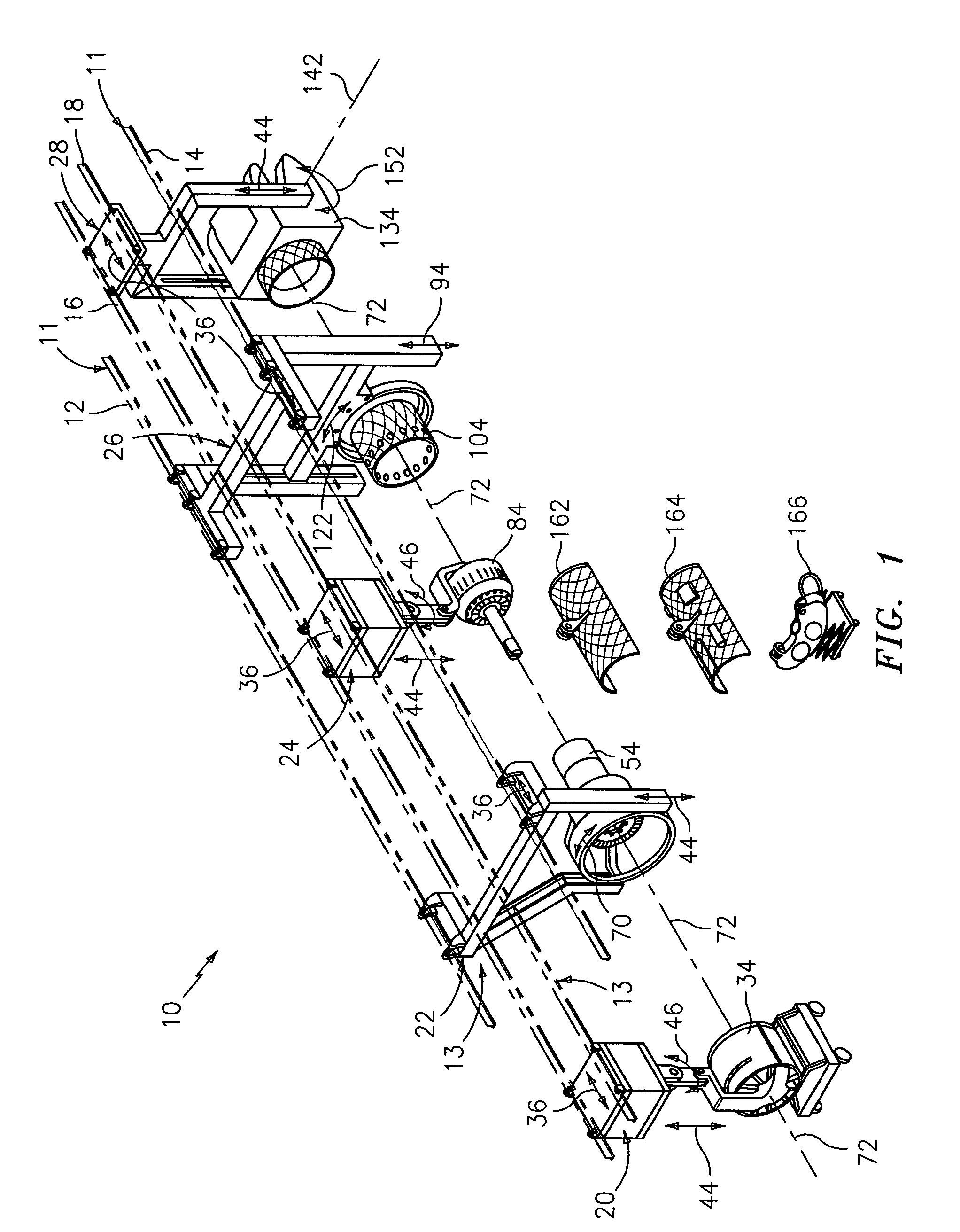

Apparatus and method for quadrail ergonomic assembly

ActiveUS20070033795A1Permit some movementEfficient propulsion technologiesMachines/enginesEngineeringWorkload

A quadrail ergonomic apparatus includes two or more pathways designed to permit movement in two or more directions mounted to a static object above a surface. One or more carriages designed to move in two or more directions are disposed within the pathways. Each carriage is suspended above the surface from the pathways and capable of maintaining a workload in place and permitting movement of the workload in at least four directions.

Owner:RTX CORP

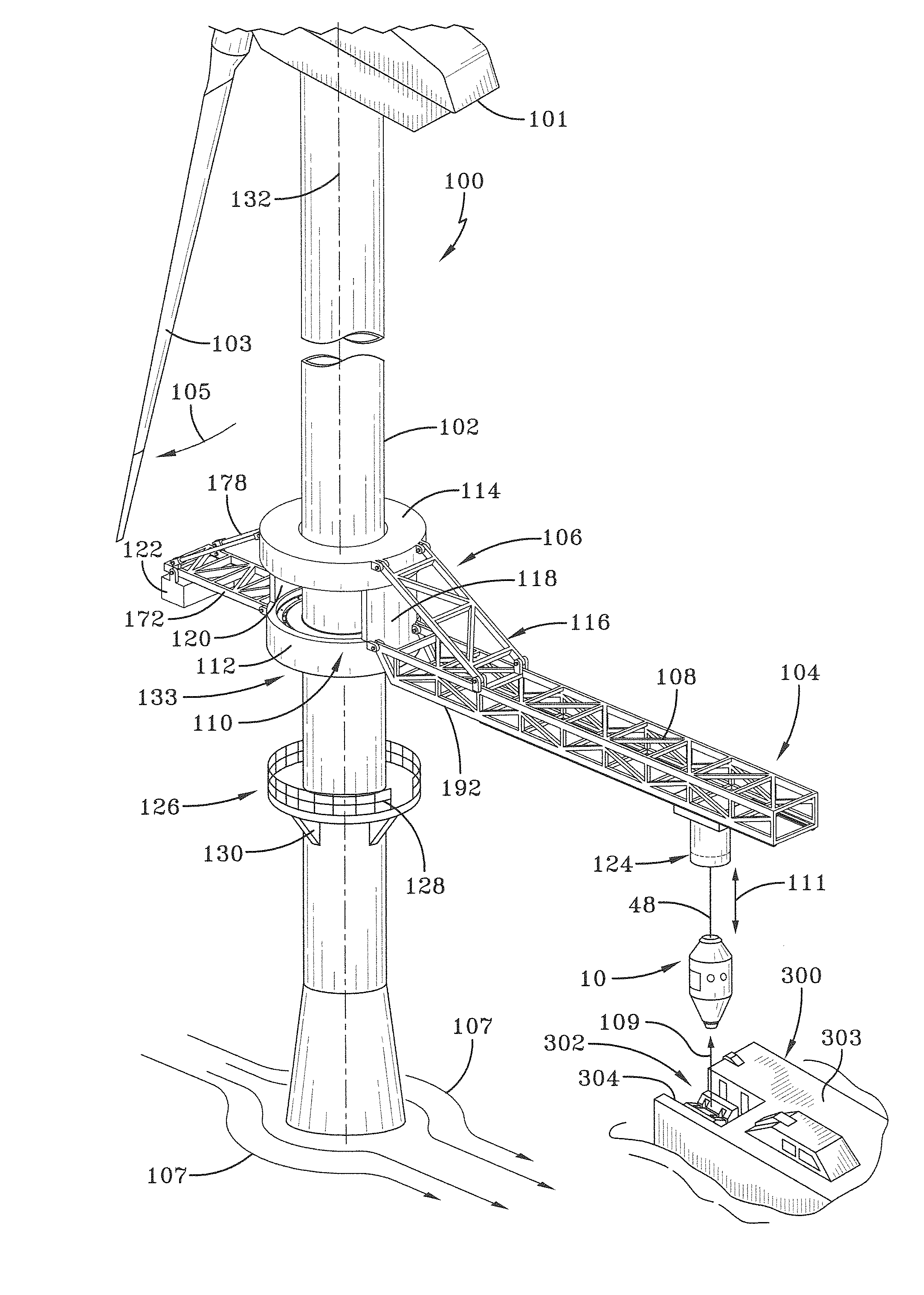

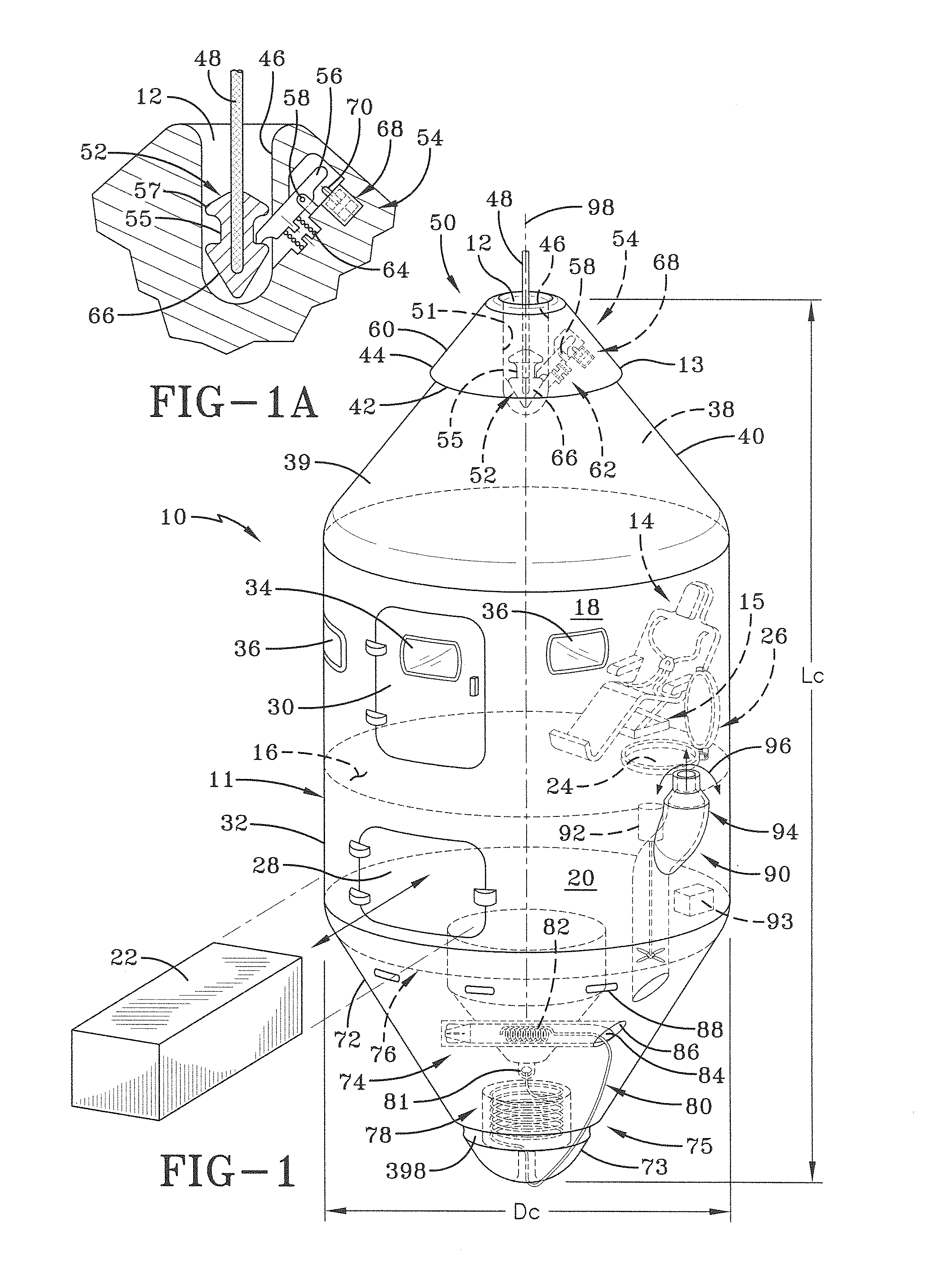

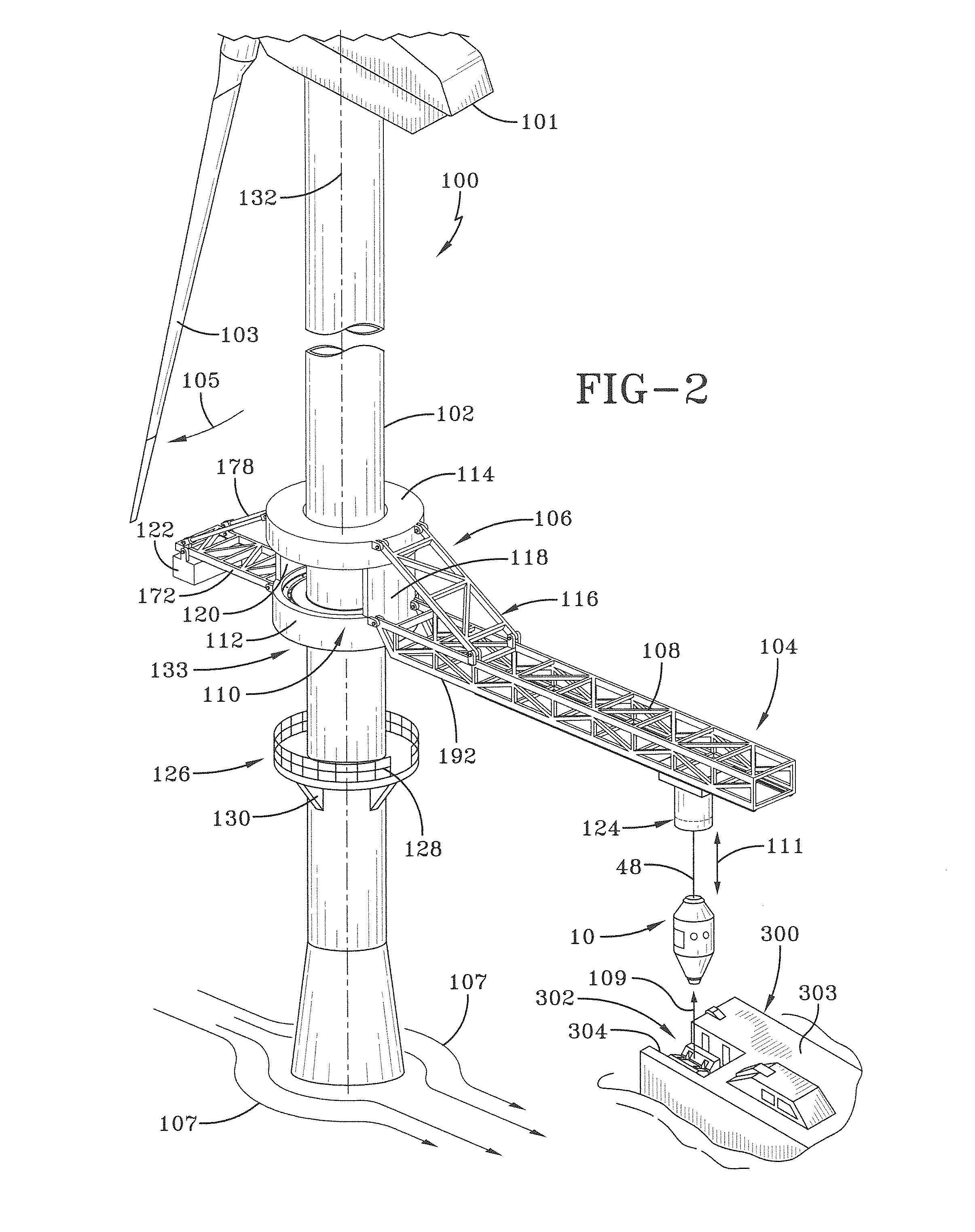

Weather maintenance system for an offshore wind turbine maintenance program

ActiveUS20160068373A1Effective maintenanceFast transferWind motor supports/mountsMachines/enginesOn boardTower

An all-weather maintenance system for an offshore wind turbine maintenance program includes a maintenance capsule for transporting tools, parts and maintenance personnel to and from respective wind turbine towers, a maintenance vessel with a capsule support apparatus for transporting capsules supported on board by the capsule support apparatus to and from respective wind turbine towers, and a crane assembly with a trolley for transporting capsules between the respective wind turbine towers and the maintenance vessel.

Owner:CHIN +1

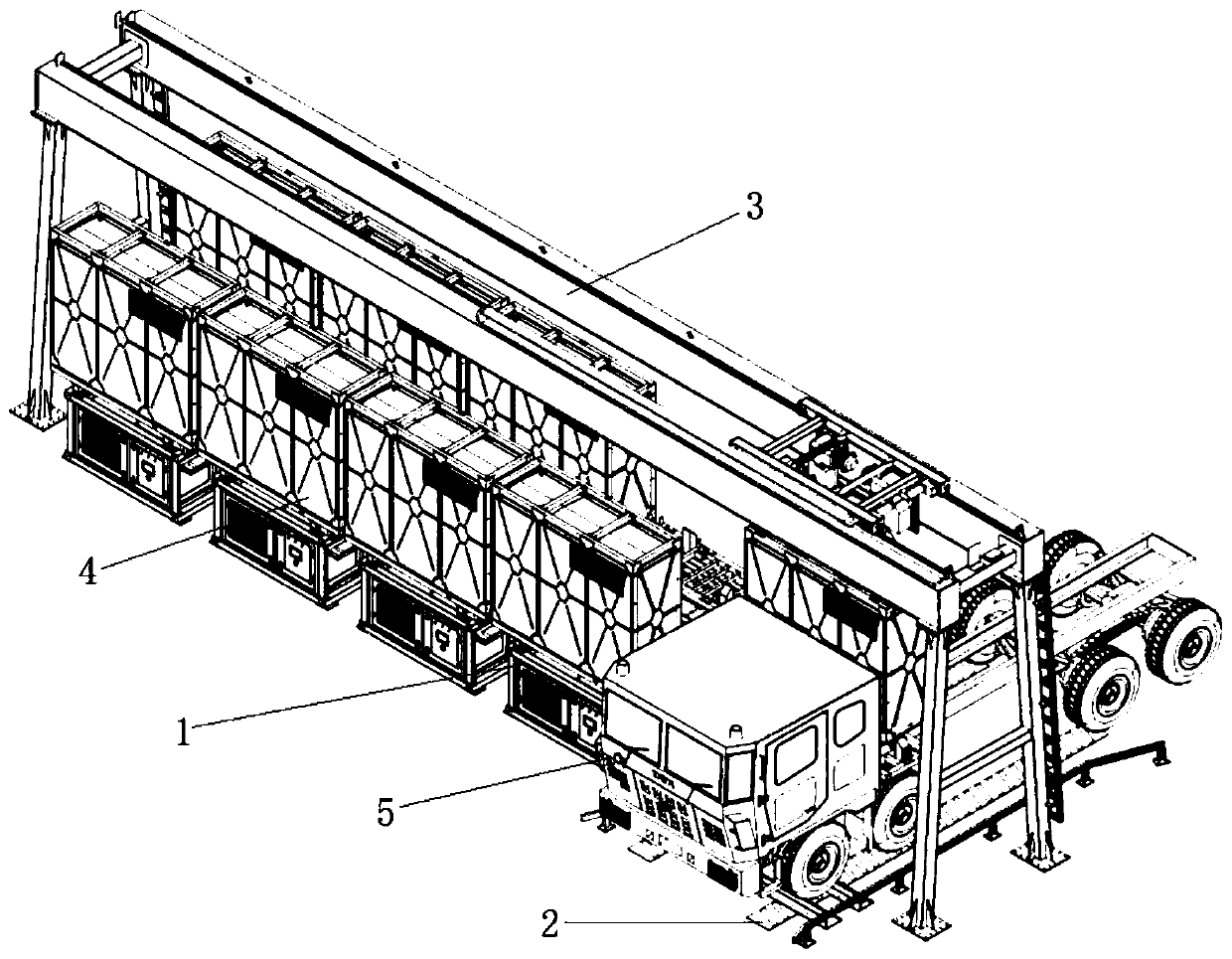

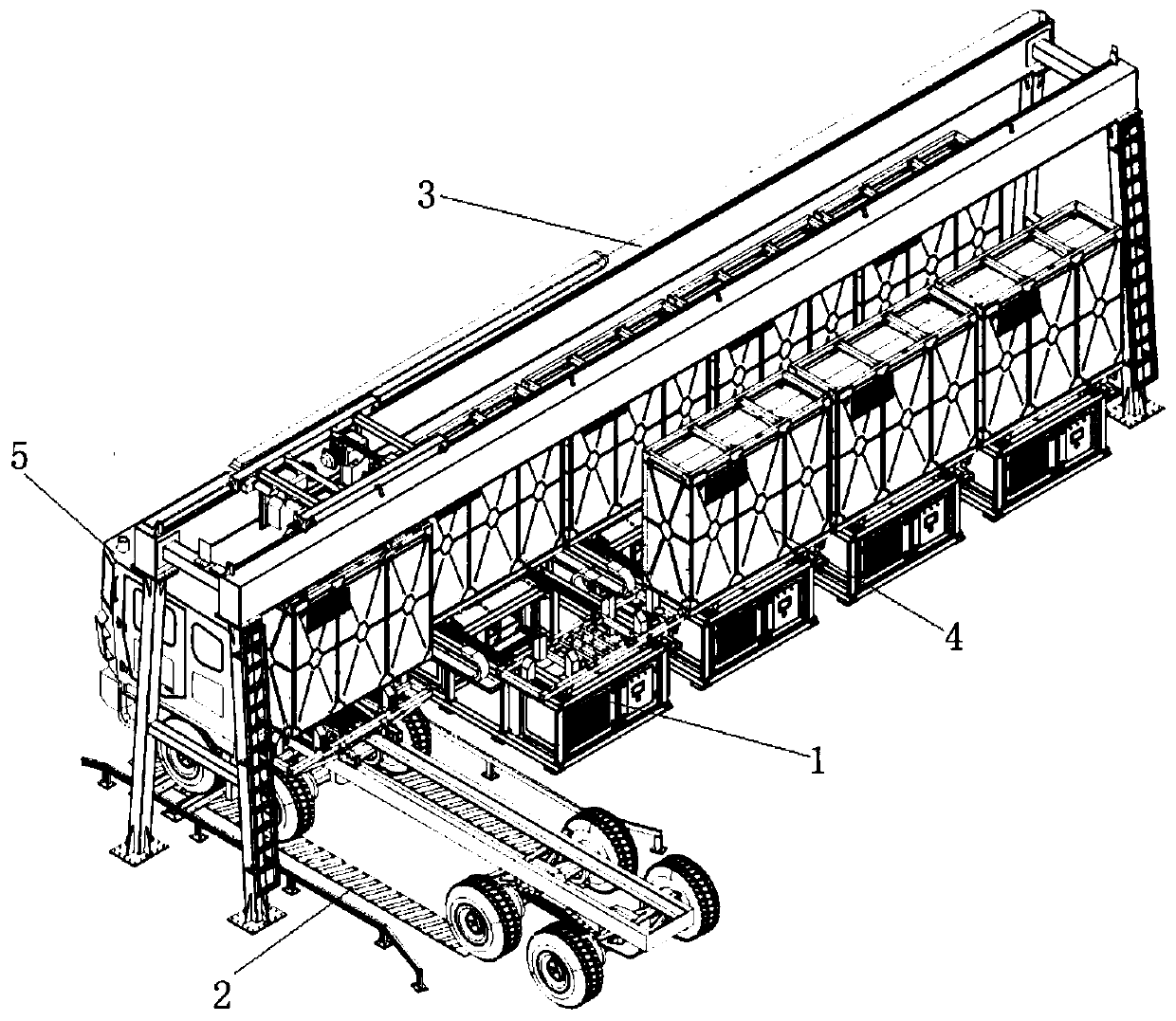

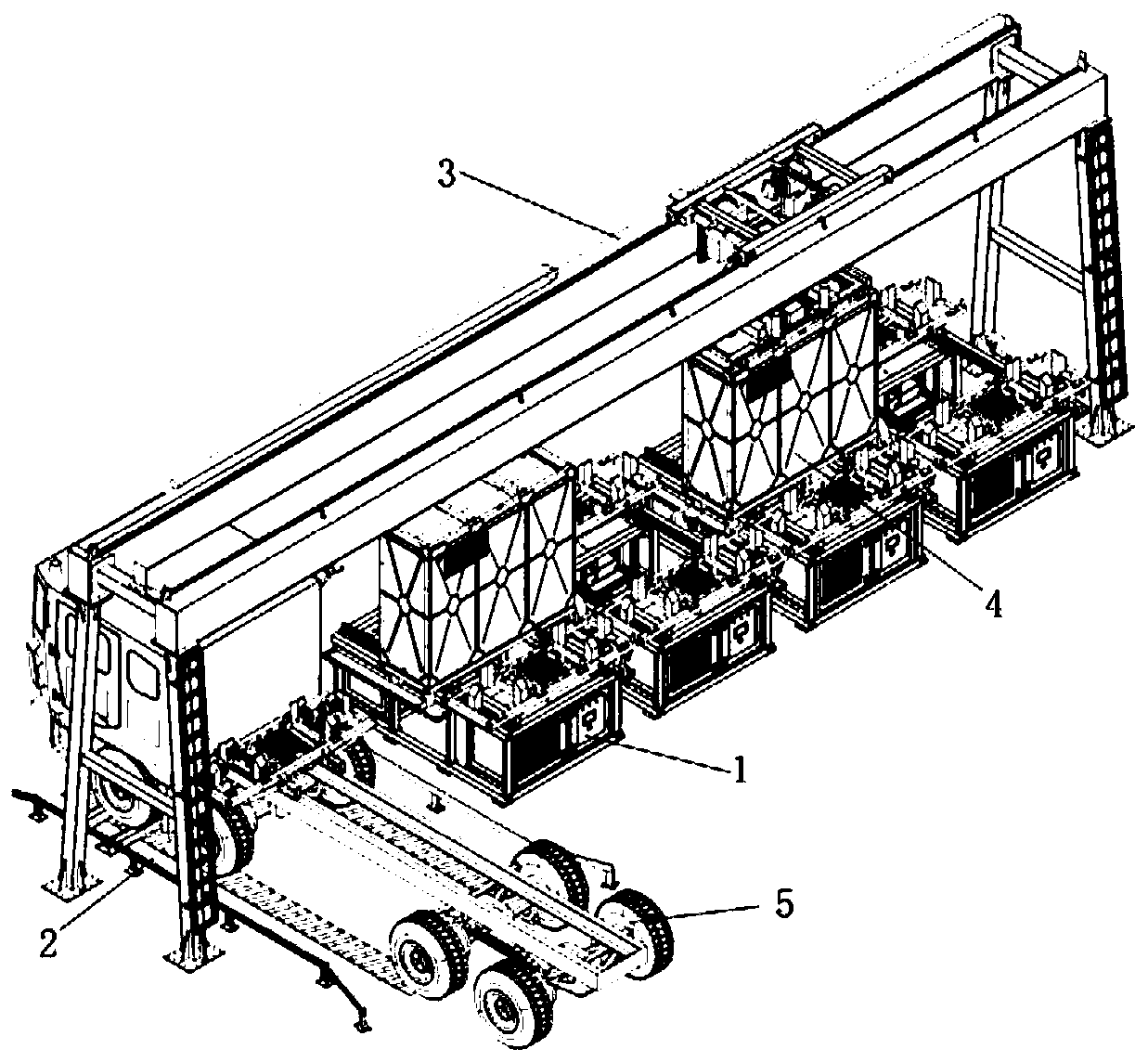

Electric heavy truck battery charging and replacing system

PendingCN110862008AReduce loadImprove interchangeabilityBase supporting structuresElectric propulsion mountingParking areaBattery charge

The invention provides an electric heavy truck battery charging and replacing system. The system comprises a battery box storage platform, a battery to-be-replaced vehicle parking area and a hoistingmechanism, wherein the platform comprises a circulating channel located between the middle and storage areas located on the two sides, the circulating channel is used for transferring a battery box, and providing transfer space; the storage areas are used for storing the battery box, and / or charging the battery box, movable devices are arranged between the storage areas on the two sides and the circulating channel, so that the battery box can move between the circulating channel and the storage areas on the two sides; and the battery to-be-replaced vehicle parking area is used for parking to-be-replaced vehicles, the hoisting mechanism is located above the movable battery box platform and the battery to-be-replaced vehicle parking area and used for lifting the battery box between to-be-replaced battery vehicles and the middle channel to realize the replacement of the battery box of the battery to-be-replaced vehicles. According to the system, the system structure is simplified, the battery replacement time can be controlled to 3 minutes, and the system has the advantages of being small in size, low in cost and the like.

Owner:SHANGHAI ENNEAGON ENERGY TECH CO LTD

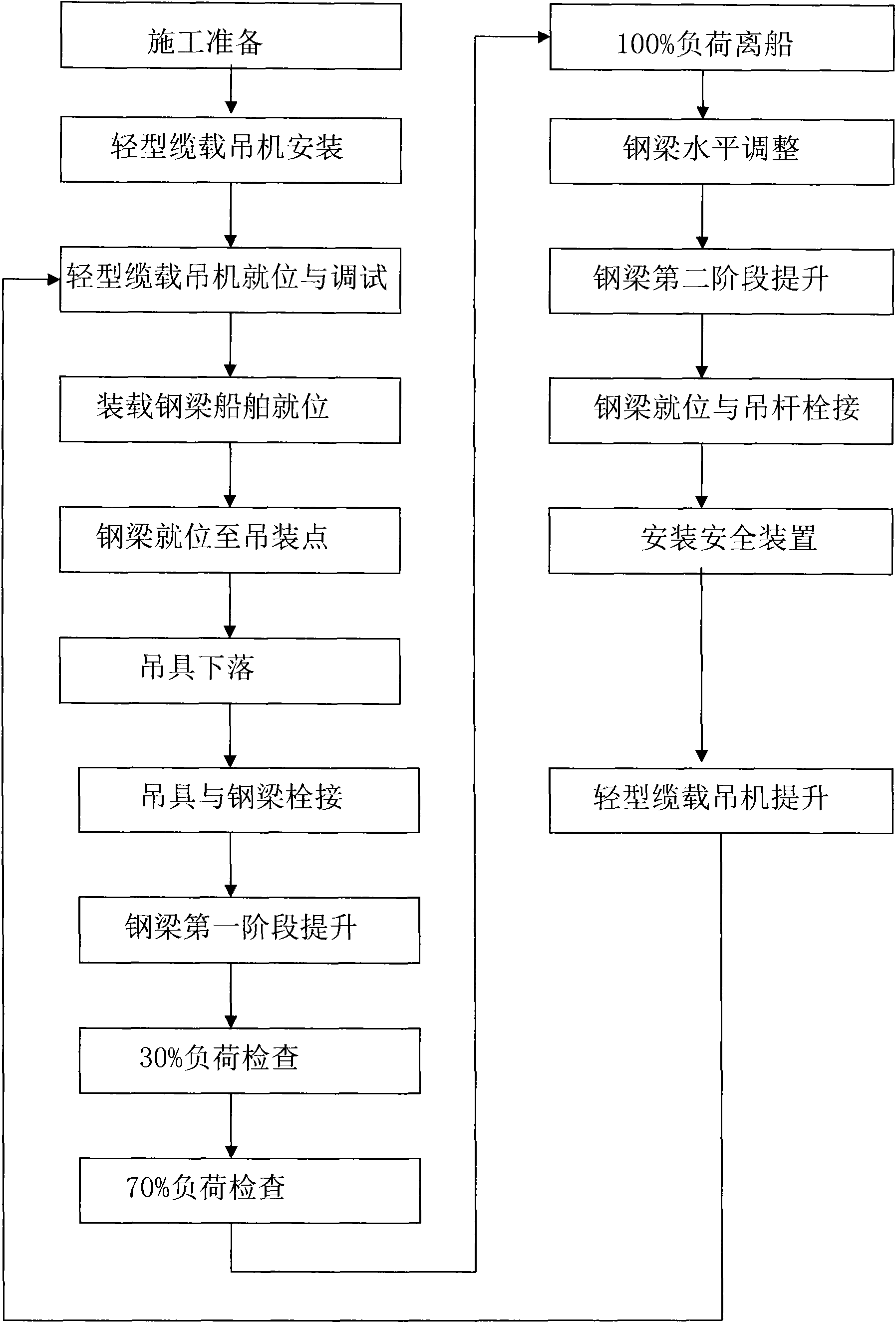

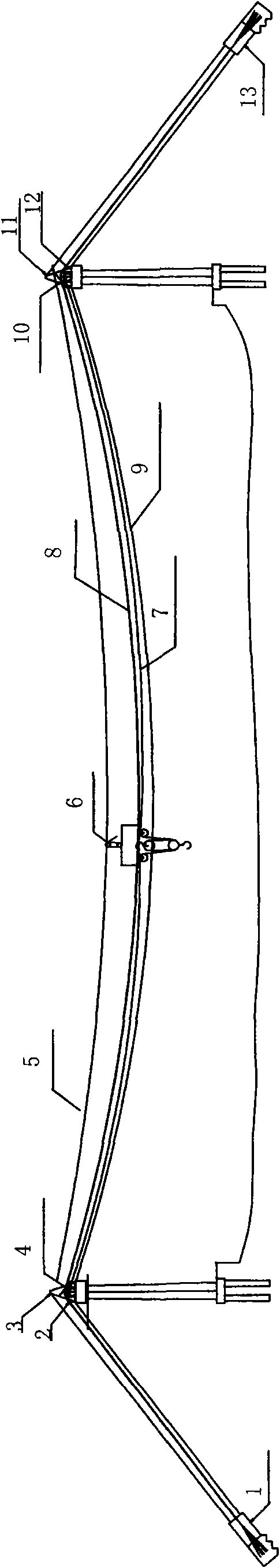

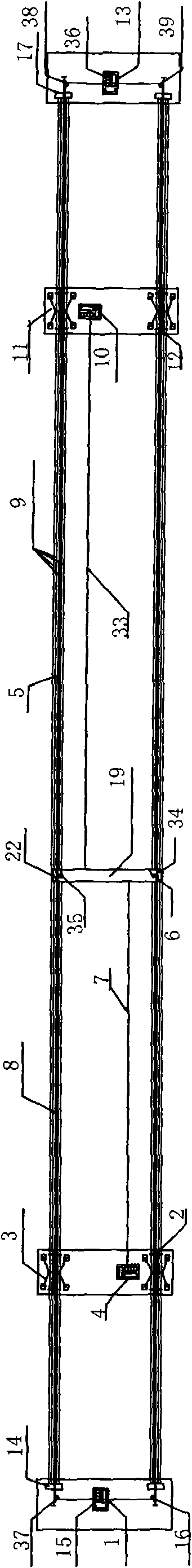

Process method for construction of steel-structured suspension bridge and light type cable carrying crane specially used in same

InactiveCN101684639AReduce weightSimple structureSuspension bridgeBridge erection/assemblyStructural engineeringLightering

The invention provides a process method for the construction of a steel-structured suspension bridge and a light type cable carrying crane specially used in the same, wherein the process flow comprises the steps of construction preparation, assembly of the light type cable carrying crane, the positioning and debugging of the light type cable carrying crane, the positioning of a ship carrying steelbeams, the lifting of the steel beams up to the hoisting point, the descent of a lifting device, the bolting connection of the lifting device and the steel beams, the first stage lifting of the steelbeams, the 30-percent load detection, the 70-percent load detection, the 100-percent load detection, the horizontal adjustment of the steel beams, the second stage lifting of the steel beams, the positioning of the steel beams and boiling connection of a lifting rod, the assembly of a security device, the lifting of the light type cable carrying crane, the movement positioning of the light type cable carrying crane; and the special light type cable carrying crane consists of a load-bearing mechanism, a load-lifting mechanism, a traveling mechanism, an anchoring mechanism and a weight-balancing beam. The process method and the special light type cable carrying crane have the advantages of light weight, simple structure, easy processing, convenient assembly and disassembly, no waterway occupation, big free space brought to transport barges and waterway traffic, high flexibility and maneuverability, high lifting speed, low construction cost, low labor intensity of workers and the suitability for the construction of the suspension bridge.

Owner:CHINA FIRST METALLURGICAL GROUP

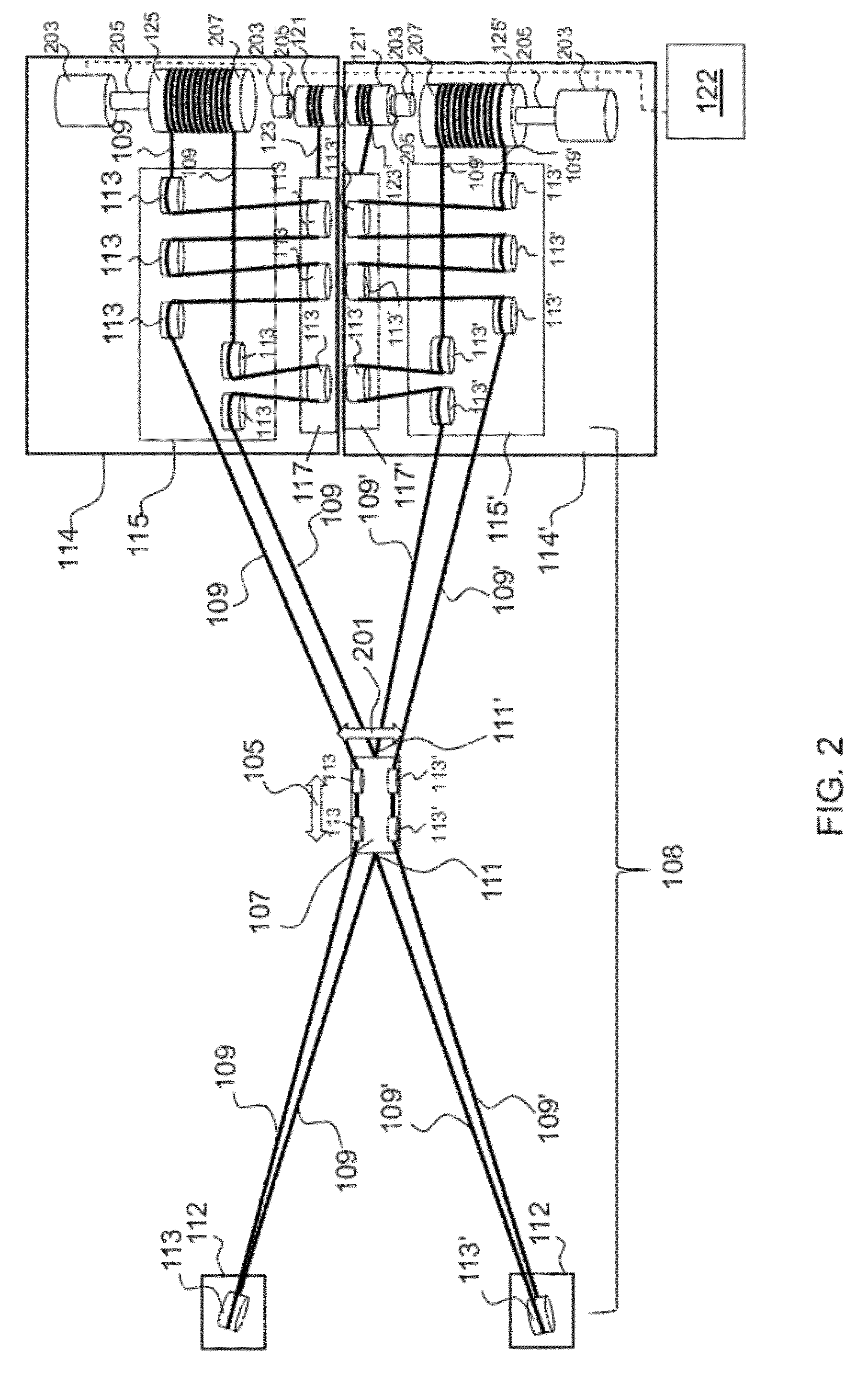

Dual trolley, single boom crane system

InactiveUS20080264889A1Valid conversionMinimum amount of downtimeBase supporting structuresBraking devices for hoisting equipmentsEngineeringMechanical engineering

A dual trolley, single boom crane system for loading and unloading containers from ships moored at a dock that effectively doubles the rate of container loading and unloading of conventional prior art single boom crane systems. The present invention also concerns a novel method for retrofitting conventional prior art single boom crane systems to convert them to dual trolley systems, while at the same time retaining the basic geometry of the prior art system so that the same number of multiple cranes may be positioned over the dock side.

Owner:LARSEN STUART

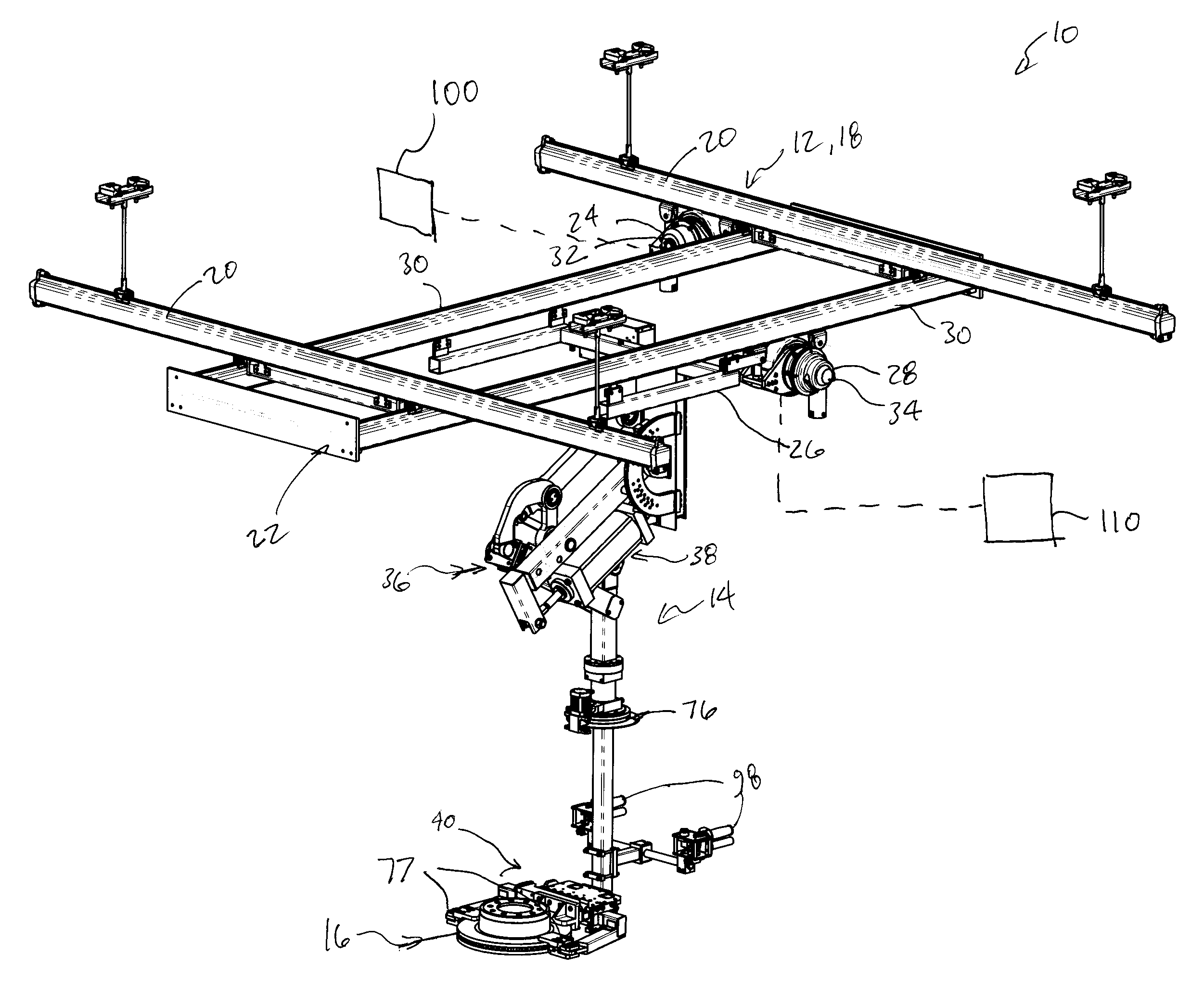

Compound-arm manipulator

ActiveUS20090283490A1Large range of motionReduced footprintProgramme-controlled manipulatorCurtain suspension devicesTransport systemRange of motion

In a first aspect, the invention is directed to a manipulator that is relatively compact and has a relatively large range of motion. The manipulator includes a linkage that folds back on itself, which reduces the footprint of the linkage. In a particular embodiment, the manipulator includes a linkage and a load balancing device. The linkage includes a first link, a second link, a third link and a fourth link. The first link and second links are rotatably connected to a base about first and second connection axes. The third and fourth links are connected to the first and second links respectively about third and fourth connection axes respectively. The third and fourth links are rotatably connected to a lift arm about fifth and sixth connection axes respectively, wherein the fifth and sixth connection axes are horizontally displaced from the third and fourth connection axes in the direction of the first and second connection axes. The load balancing device is configured to support the linkage in a selected position against a load and configured to permit the load to be moved upwards or downwards with a selected amount of force on the lift arm. The manipulator may be provided as part of a load maneuvering system that further includes a transport system that may be similar to that used on an overhead crane.

Owner:GIVENS RAY

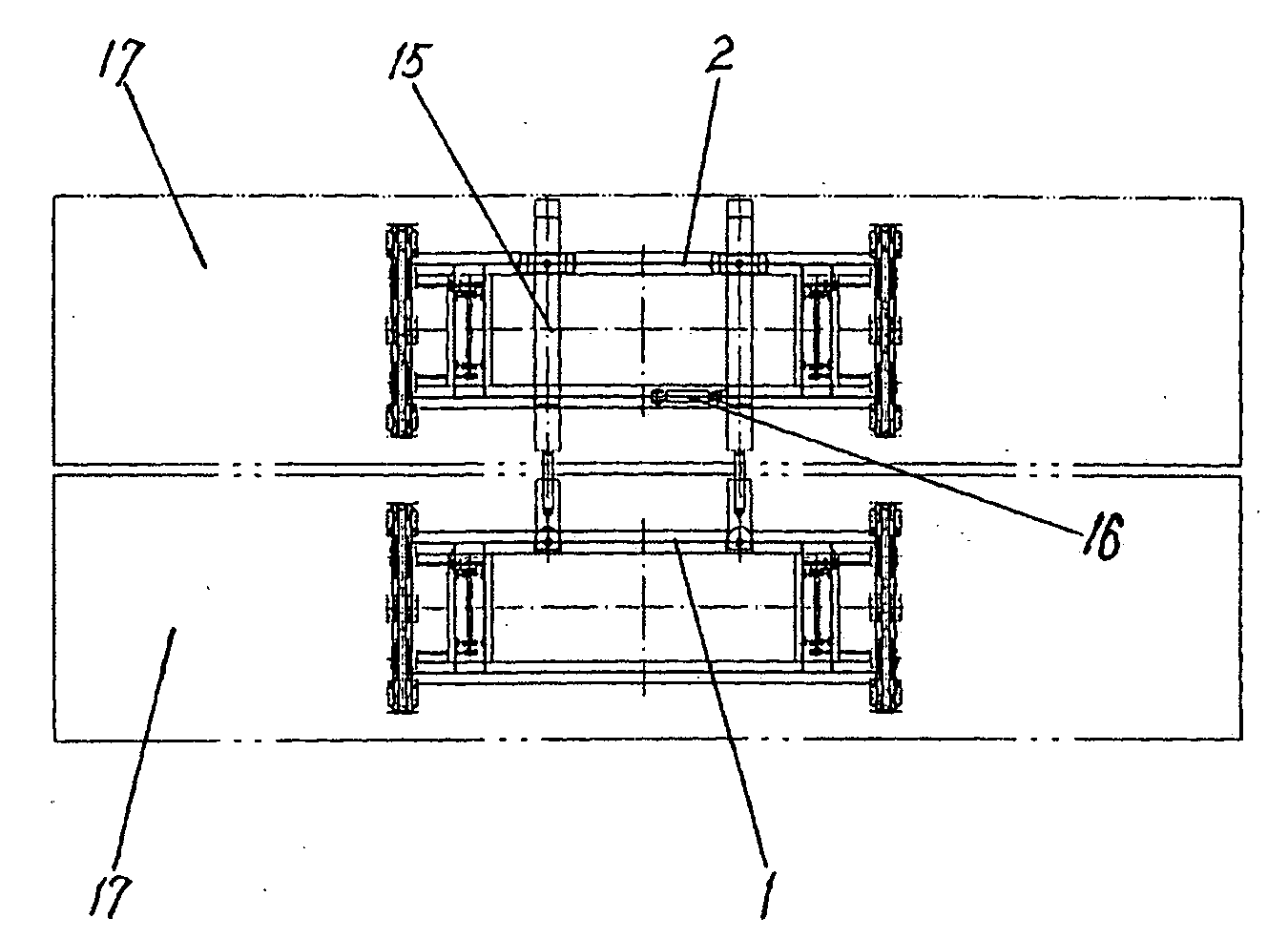

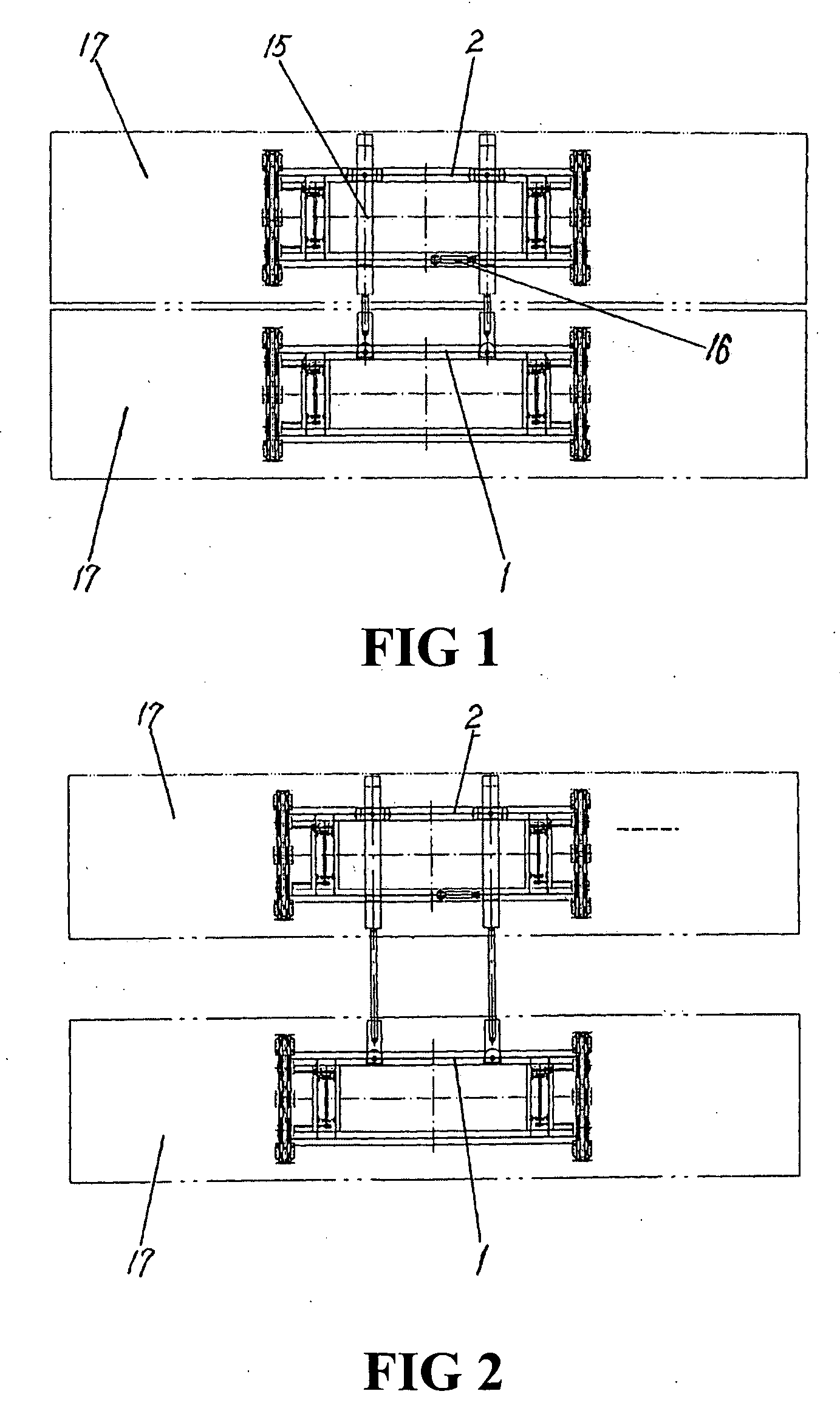

Container lifter being able to lift two 40 feet containers

The invention is related to a type of the container lifter which is able to lift two 4 feet containers at a time, it includes two sets of the crane main lifting mechanisms and the wire rope winding systems being separate, two cranes and drive cylinders, the pulleys arranged at the crane upper frame and the two lifting pulley groups arranged on the carrier. The first crane lifting mechanism and the second crane lifting mechanism are equipped with the barrel, the crane lifting mechanism motor, the brake and the crane lifting redection gear box respectively, the two sets of the crane lifting mechanism are synchronously operated, the approach and separation are achieved by the first crane and the second crane using the connection cylinder. The invention uses the two separate cranes, the functions of separation, differential in height, displacement, included angle and releasing of the two cranes are achieved by the cylinders, two 40 feet containers can be lifted, also the cylinders can be separated so that the separate operations of the two cranes can be obtained. By using the container lifter of the invention, the efficiency of the load and unload is increased, high repayment is obtained with less increasing the equipment cost, the larger beneficial result is occurred, also it has the wider applicable prospect.

Owner:SHANGHAI ZHENHUA HEAVY IND

Actuation system configured for moving a payload

An actuation system includes a bridge crane, a trolley, and an end effector and is configured for moving a payload. A first actuator is operatively connected to the bridge crane. The bridge crane is configured for moving along an X axis in response to the first actuator being actuated. The trolley extends from the bridge crane. A second actuator is operatively connected to the trolley. The trolley is configured for moving along a Y axis in response to the second actuator being actuated. The end effector extends from the trolley and is configured for supporting a payload. A third actuator is operatively connected to the end effector. The end effector is configured for rotating about the Z axis in response to the third actuator being actuated to rotate the end effector. Each actuator is disposed in spaced relationship to the bridge crane, the trolley, and the end effector.

Owner:UNIV LAVAL +1

Intelligent agricultural production system based on rail transportation and use method

InactiveCN105174055AImprove the efficiency of lifting objectsAutomate transportationRailway componentsMechanical conveyorsRemote controlAgricultural engineering

The invention discloses an intelligent agricultural production system based on rail transportation and a use method. The intelligent agricultural production system based on rail transportation comprises a ground rail system, an air rail system, an air rail lifting transportation device, a photographing detecting and online trading system, a harvesting and fertilizing controlling system and a picking and sprinkling irrigation control system. According to the intelligent agricultural production system based on rail transportation and the use method, a unified transportation and working platform is provided for various agricultural machines, and therefore automatic transportation, photographing monitoring, fertilizing, picking, sprinkling irrigation and other work of agricultural products can be achieved, and remote control can be conducted through a mobile control terminal. Meanwhile, real-time online sharing and online trading of agricultural product information between a farmer and a purchaser can be achieved. The intelligent agricultural production system based on rail transportation and the use method are suitable for large farms in China, automatic management and intelligent production of the large farms can be achieved, and the prospect in the future is wide.

Owner:ANHUI UNIV OF SCI & TECH

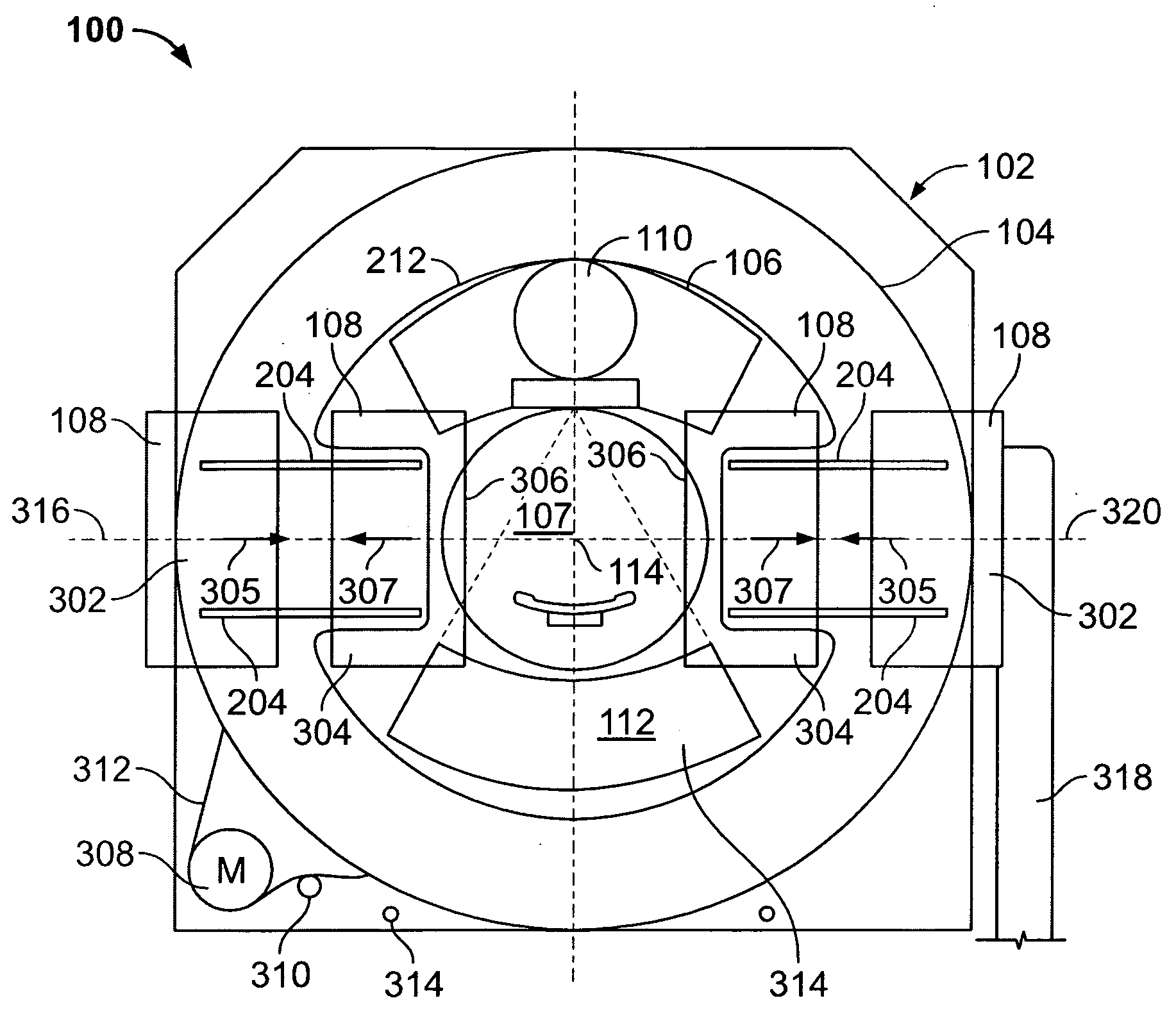

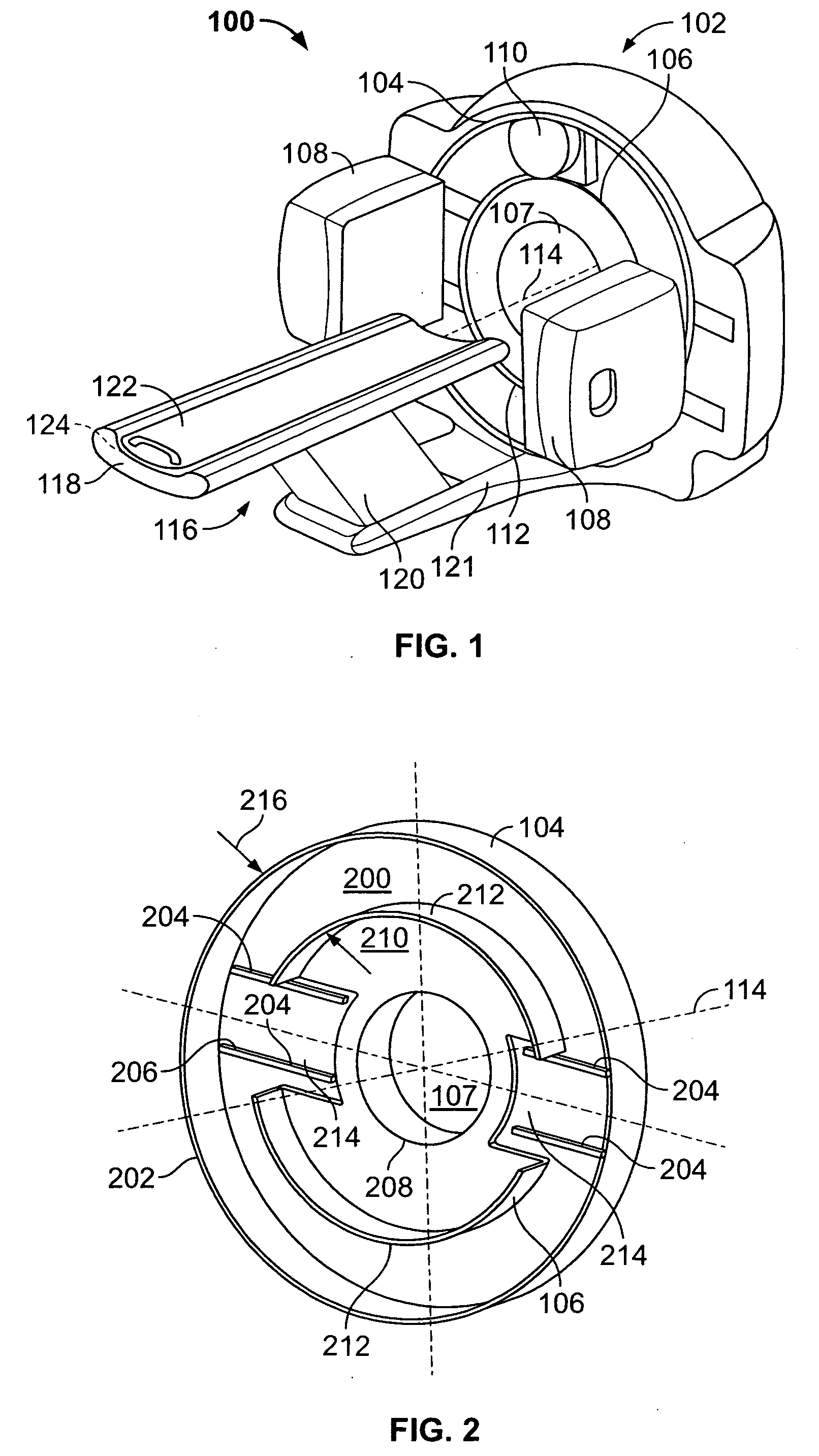

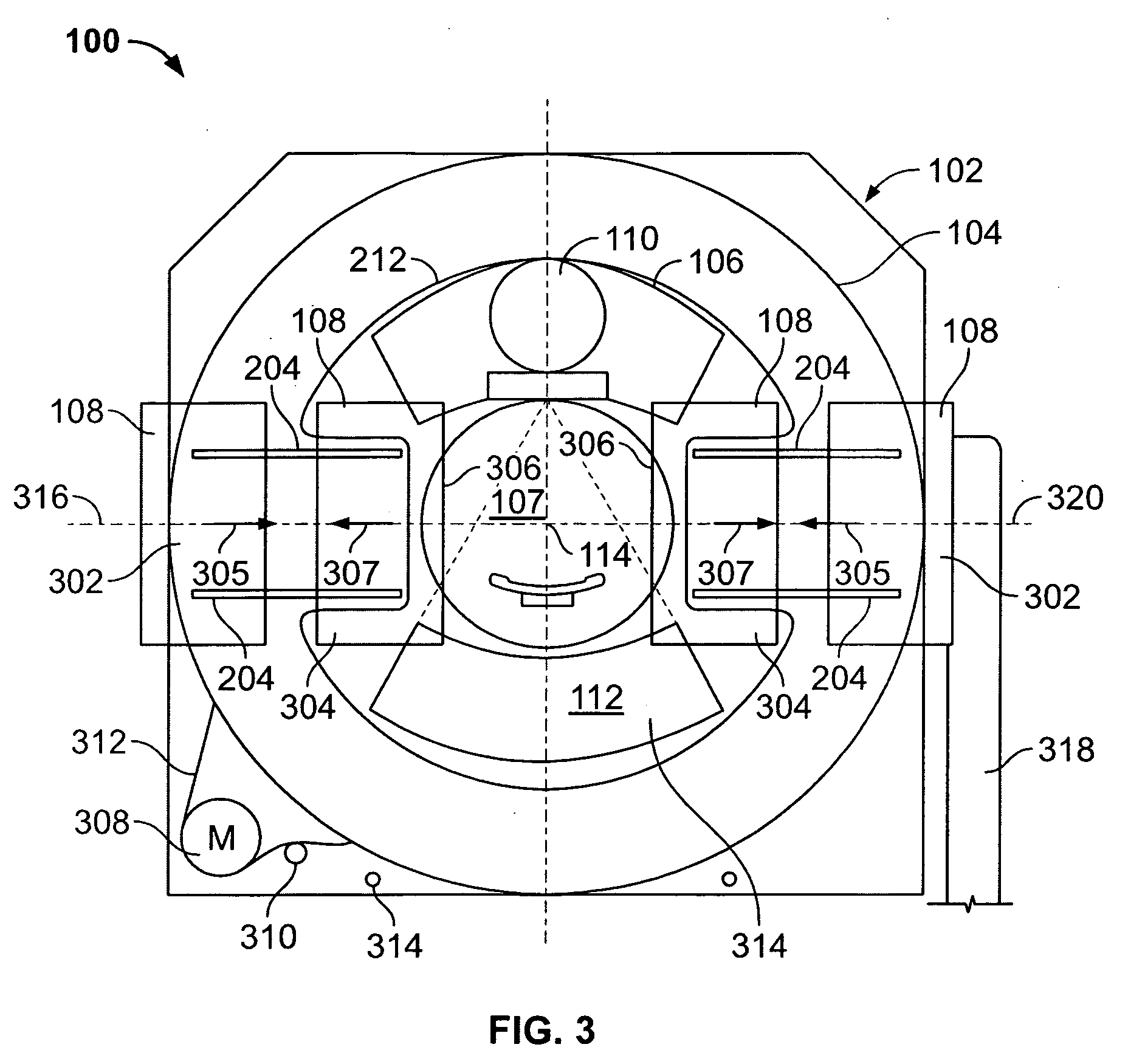

Methods and systems for medical imaging

Methods and systems for medical imaging are provided. The system includes a gantry assembly having a stator, a first rotor rotatably coupled to the stator, the first rotor configured to rotate about an examination axis at a first rotational speed, and a second rotor rotatably coupled to at least one of the stator and the first rotor, the second rotor configured to rotate about the examination axis at the first and a second rotational speed, the second rotational speed being greater than the first rotational speed, the first and second rotors configured to be locked in position with respect to each other during rotation at the first rotational speed, the first rotor configured to be locked in position with respect to the stator during rotation of the second rotor at the second rotational speed.

Owner:GENERAL ELECTRIC CO

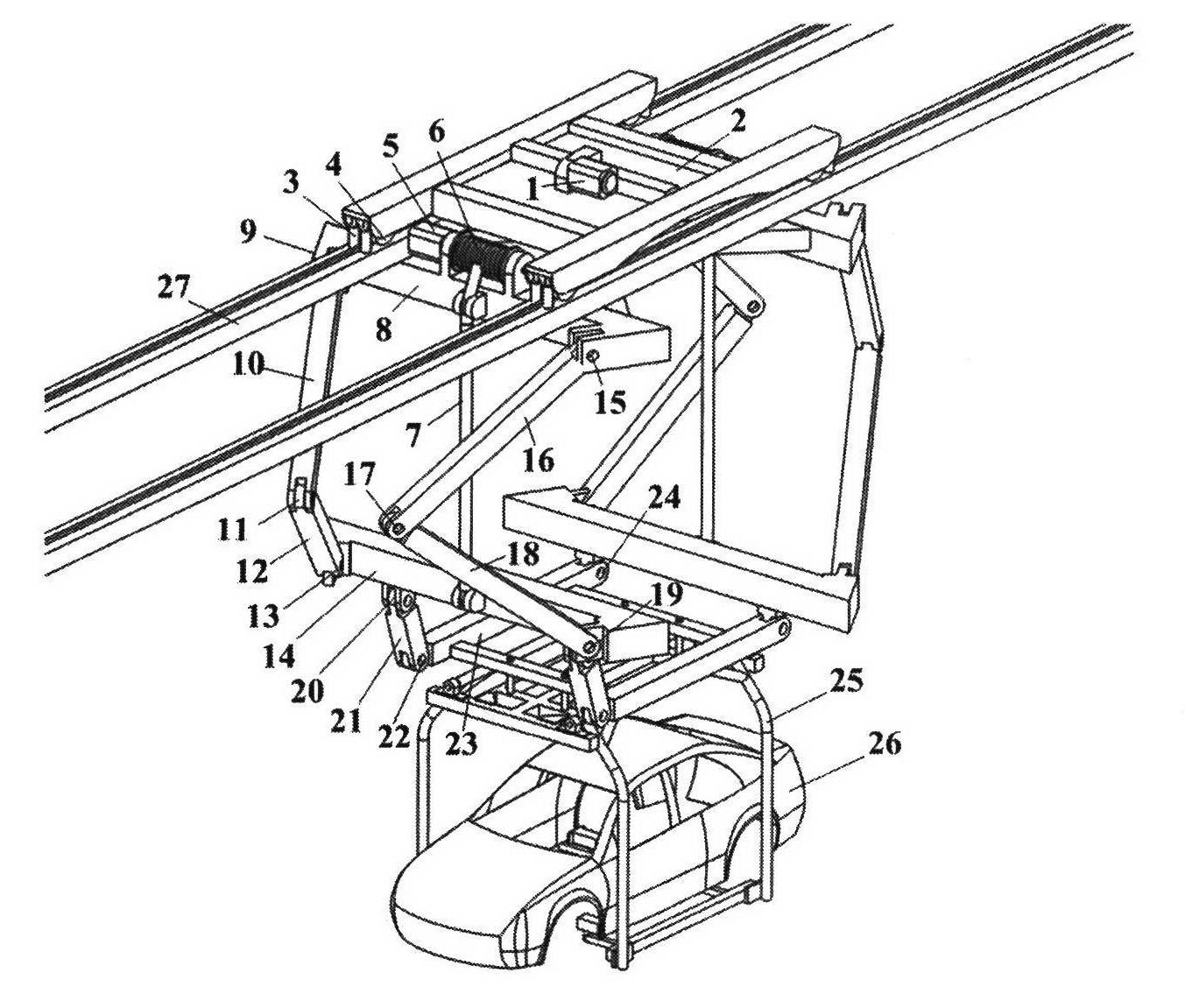

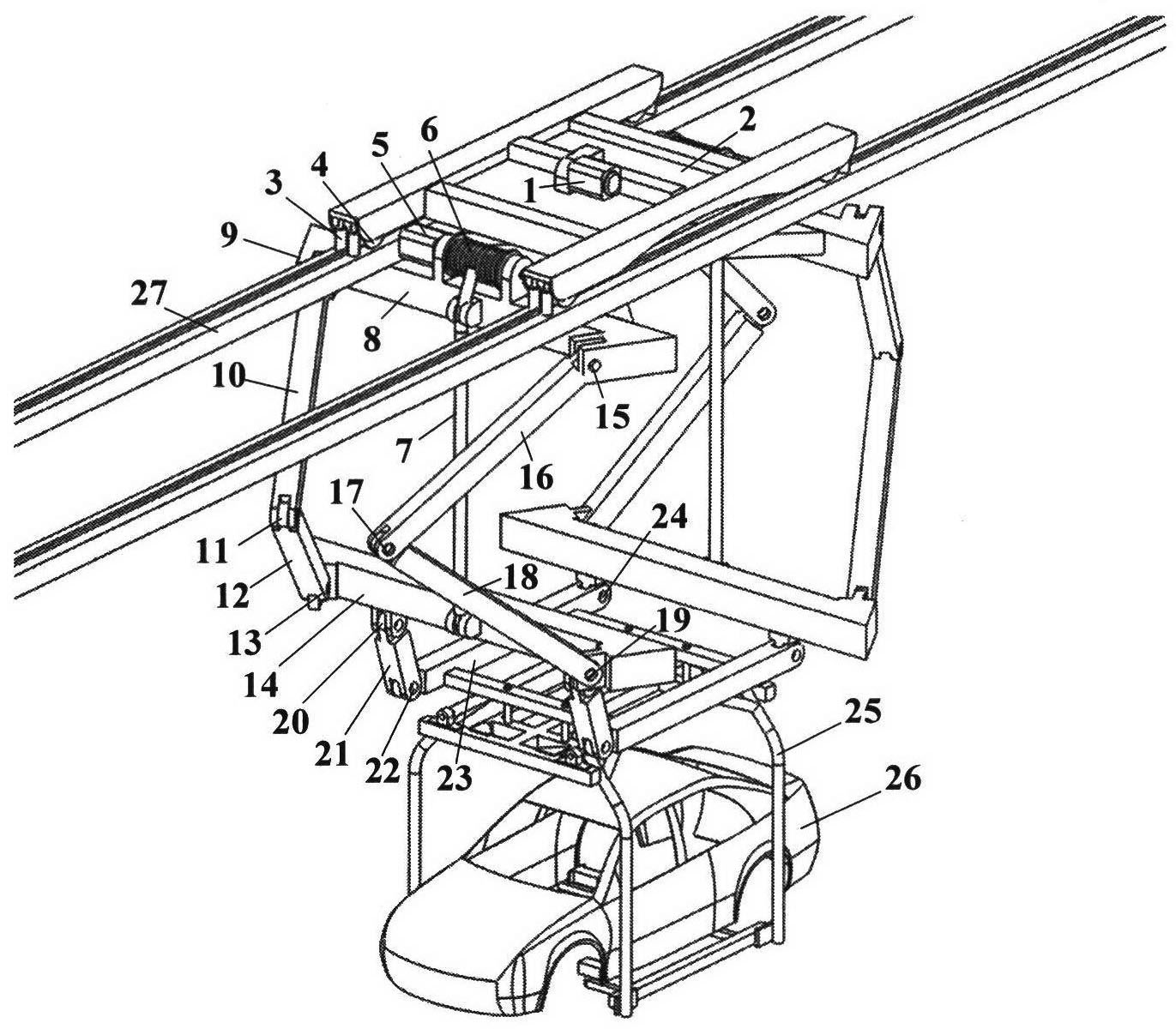

Cable traction automobile coating conveyor

InactiveCN102616668AIncrease stiffnessImprove stabilityElectrophoretic coatingsTrolley cranesEngineeringTraction drive

The present invention relates to a cable traction automobile coating conveyor. The conveyor comprises two functional parts of a walking mechanism and a hoisting and flipping mechanism, wherein the walking mechanism is provided for completion of walking and conveying of the conveyor, and the hoisting and flipping mechanism comprises two linear guide mechanisms and a hoisting connection rod. According to the present invention, the cable traction drives the hoisting and flipping mechanism to complete the hoisting and / or flipping movement of the conveyed object; the movement of the walking mechanism is combined with the movement of the hoisting and flipping mechanism to drive the automobile to perform forward and backward movement, hoisting and tilting movement, flipping movement or the composition of the above movements; the whole weight of the conveyor is reduced, and the space utilization efficiency in the vertical direction is improved; and the dual guide rail and the linear guide mechanism are adopted so as to increase the stiffness and the stability of the conveyor.

Owner:TSINGHUA UNIV

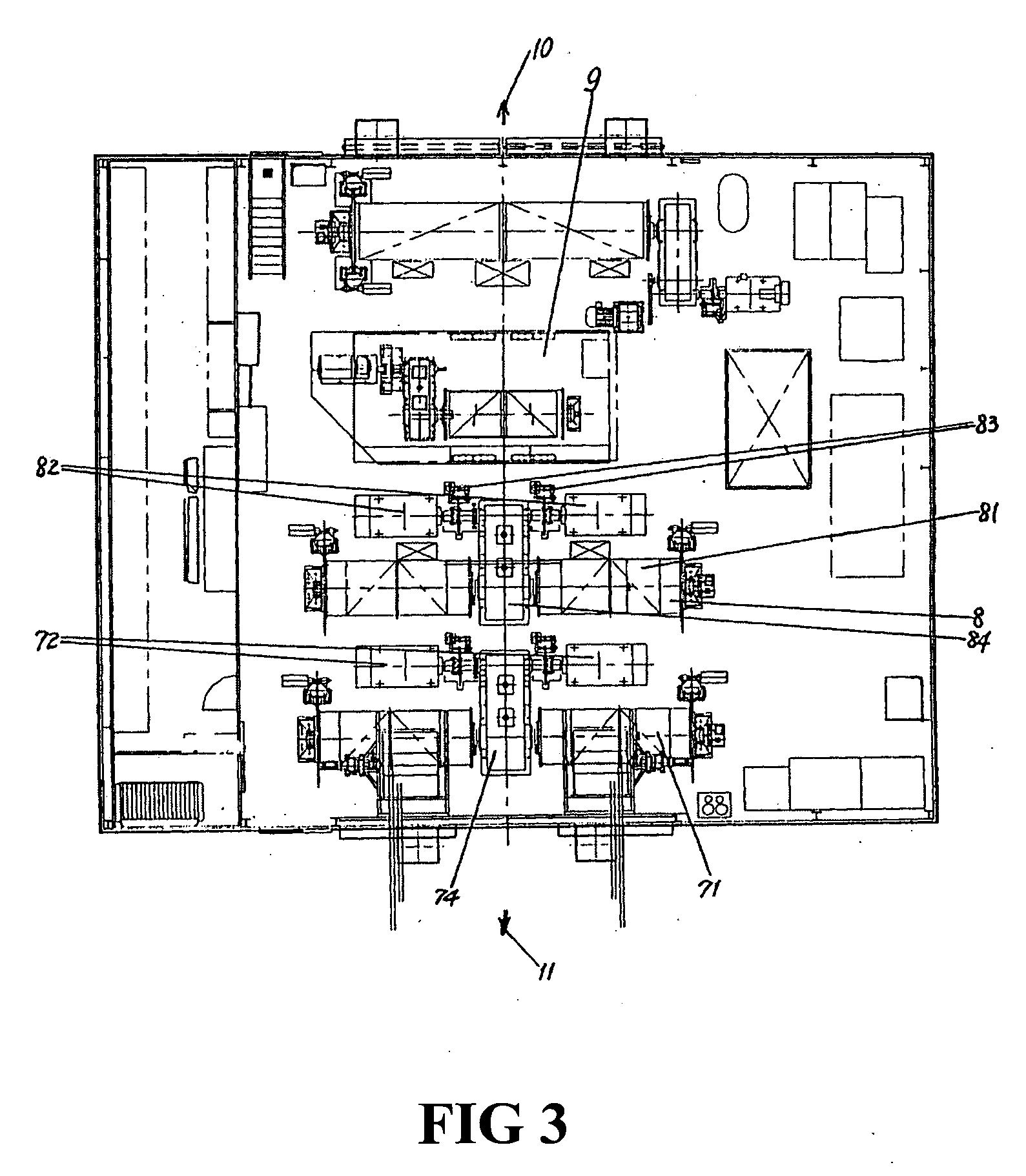

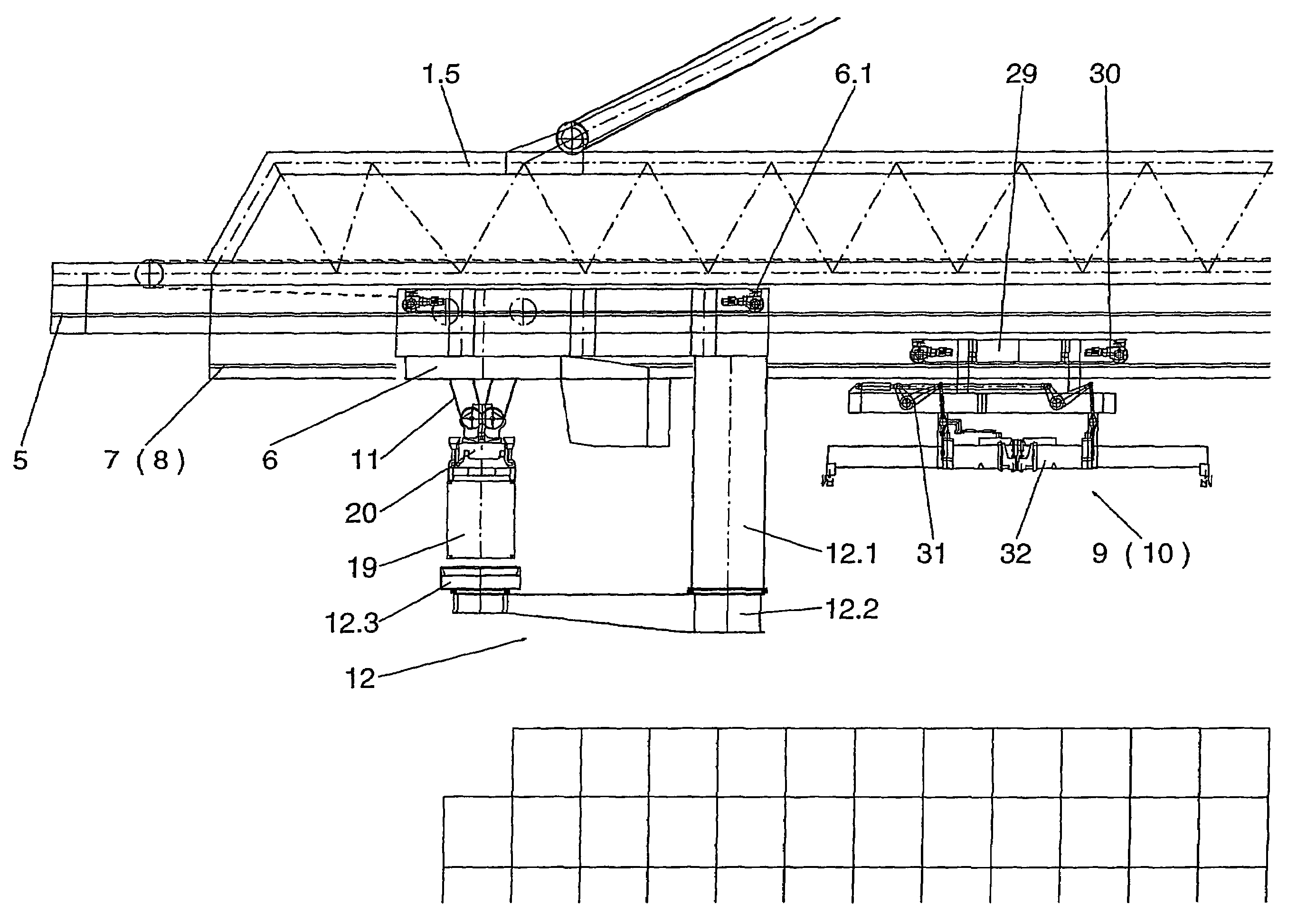

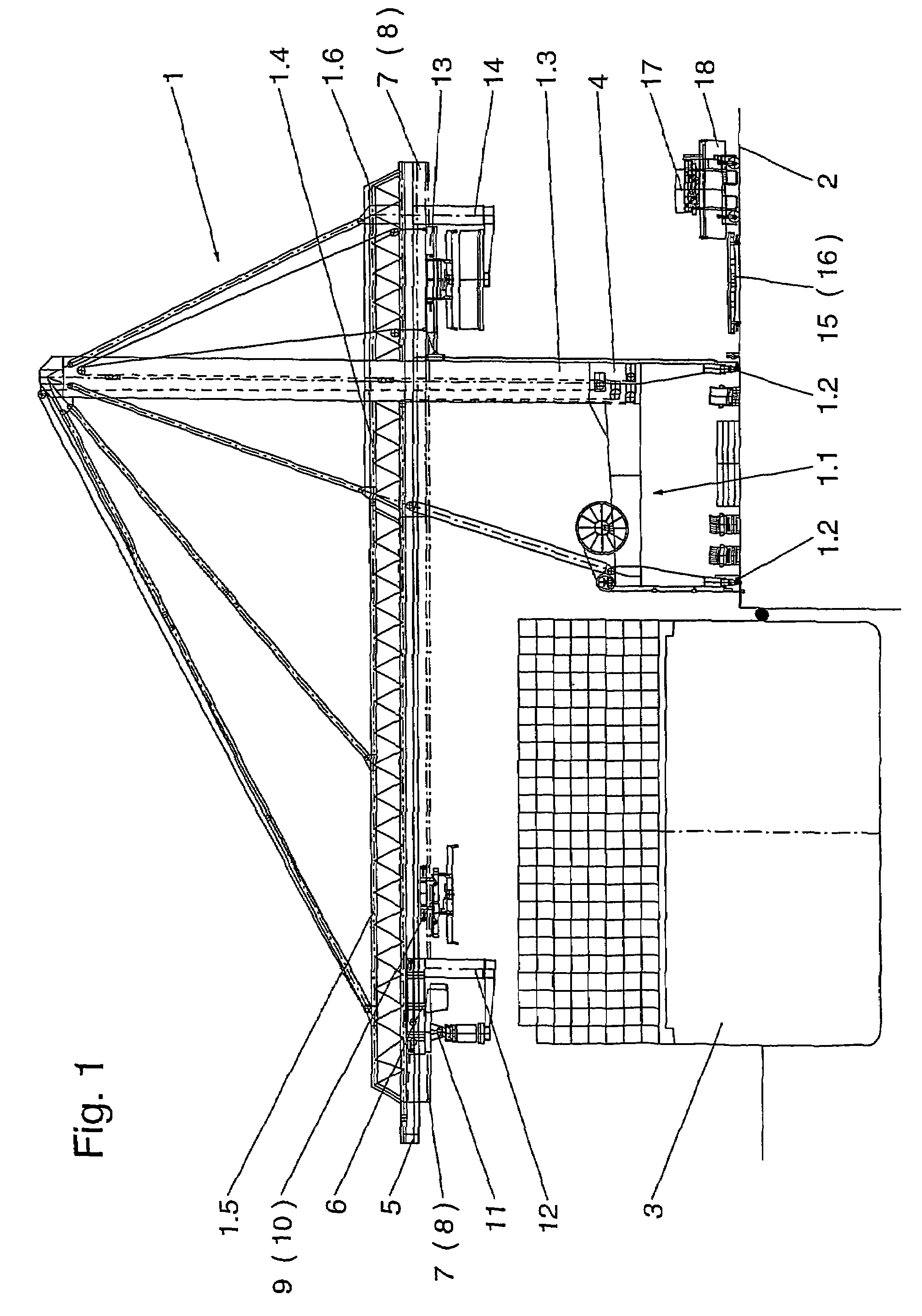

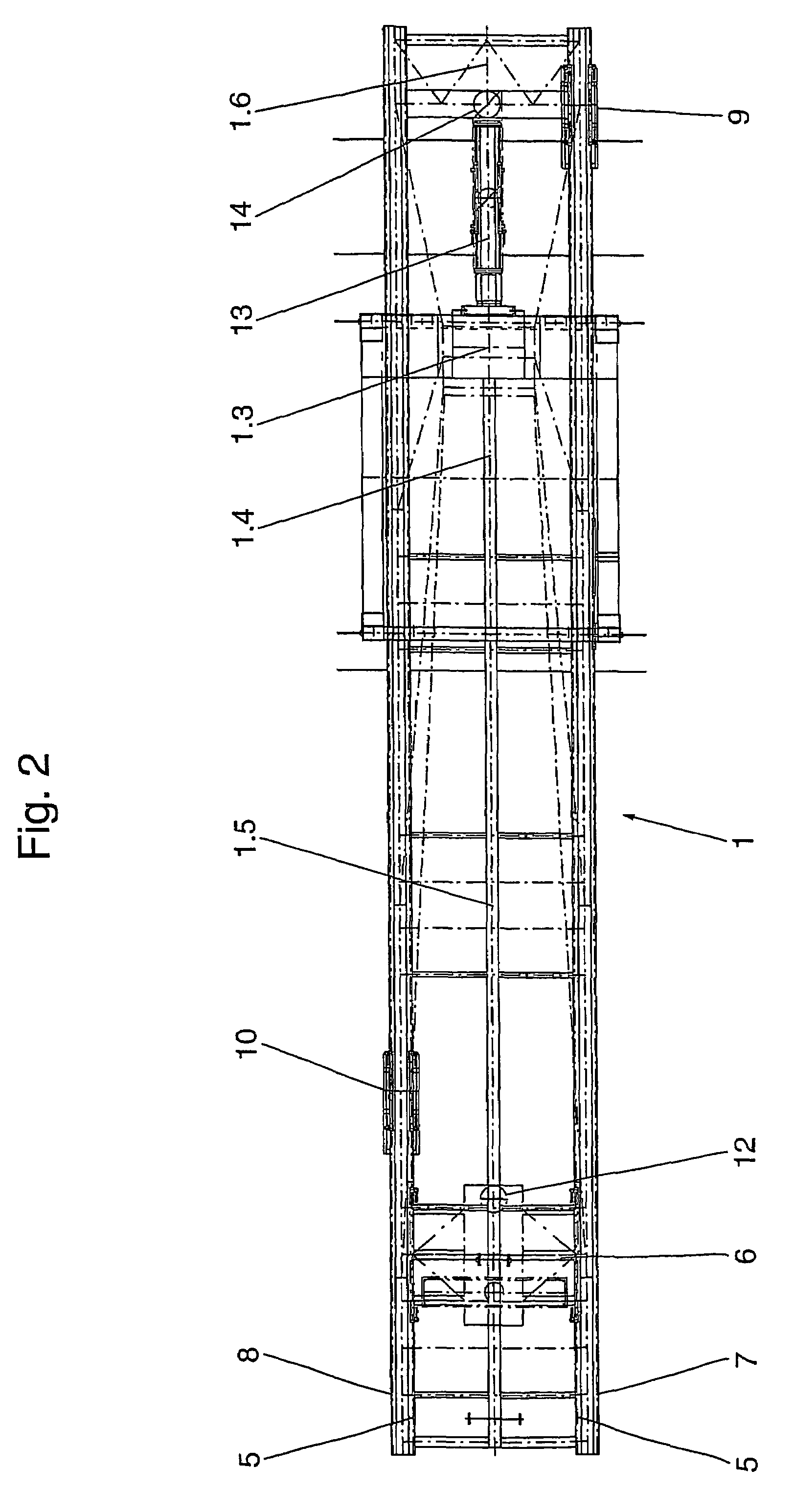

Transfer plant and method for loading and unloading containers from container ships

InactiveUS7410339B2Improve handlingShorten the timeCargo handling apparatusBase supporting structuresEngineeringRe engineering

The invention relates to a transfer plant, especially for loading and unloading ISO containers from container ships at seaports, comprising a vertical support which is propped up on the land side and on which a horizontal extension arm is braced. Said horizontal extension arm, along which a horizontal conveying device can be displaced, protrudes across the ship that is to be unloaded on the sea side. The horizontal conveying device cooperates with hoisting and lowering devices which pick up and put down the containers. The aim of the invention is to create a redesigned transfer plant and a method for loading and unloading containers, preferably ISO containers, from container ships in seaports, which allow the transfer rate to be significantly increased and consequently the lay times of the container ships at the pier to be substantially reduced. Said aim is achieved by disposing at least two horizontal conveying devices (9, 10) on the horizontal extension arm (1.4, 1.5, 1.6), which can be displaced independently of each other along said horizontal extension arm (1.4, 1.5, 1.6) between the hoisting and lowering devices (11, 13) that are located on the land side and the sea side. In addition, intermediate storage devices (12, 14), into which the containers can be placed and from which said containers can be picked up by the hoisting and lowering devices (11, 13) that are located on the land side and the sea side and the horizontal conveying devices (9, 10), are disposed on the horizontal extension arm in the area of the hoisting and lowering devices (11, 13) that are located on the land side and the sea side.

Owner:GOTTWALD PORT TECH

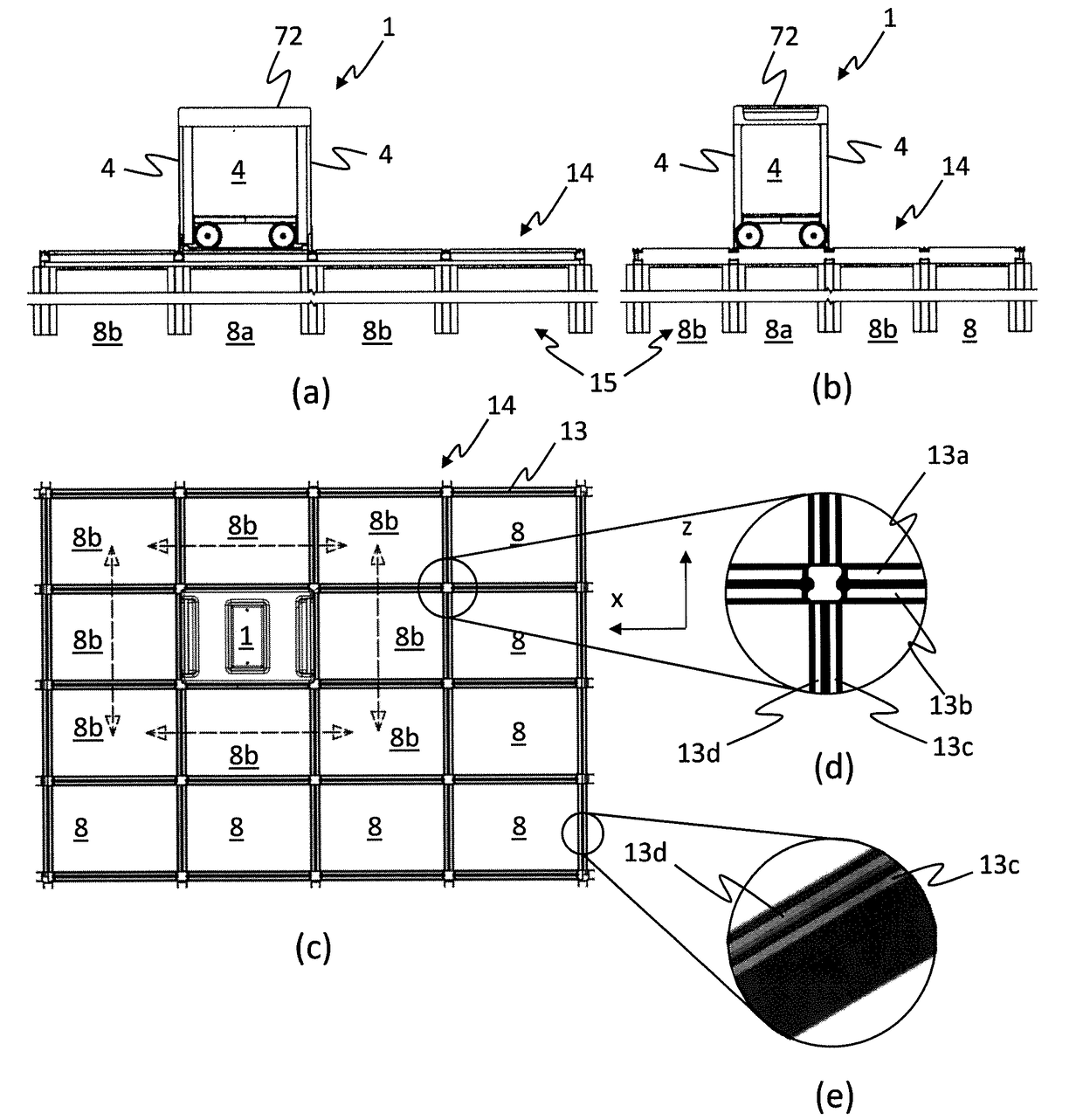

Robot for transporting storage bins

ActiveUS20170129702A1Stable pressureIncrease contactProgramme-controlled manipulatorStorage devicesRemotely operated vehicleRobot

A remotely-operated vehicle assembly for picking up storage bins from a storage system and a method for changing vehicle direction includes a body displaying a cavity, a lifting device connected to the body for lifting the bin into the cavity, a displacement arrangement including a displacement motor which provides power to displace one or both of first and second sets of vehicle rolling means between a displaced state where the relevant rolling means is displaced away from the underlying system during use, and a non-displaced state where the relevant rolling means is in contact with the underlying system during use, and driving means coupled to the displacement arrangement. The driving means further includes first and second sets of rolling means connected to the body allowing movement of the vehicle along first and second directions, respectively, within the system. The first and second directions are perpendicular.

Owner:AUTOSTORE TECH AS

Apparatus and method for quadrail ergonomic assembly

Owner:RTX CORP

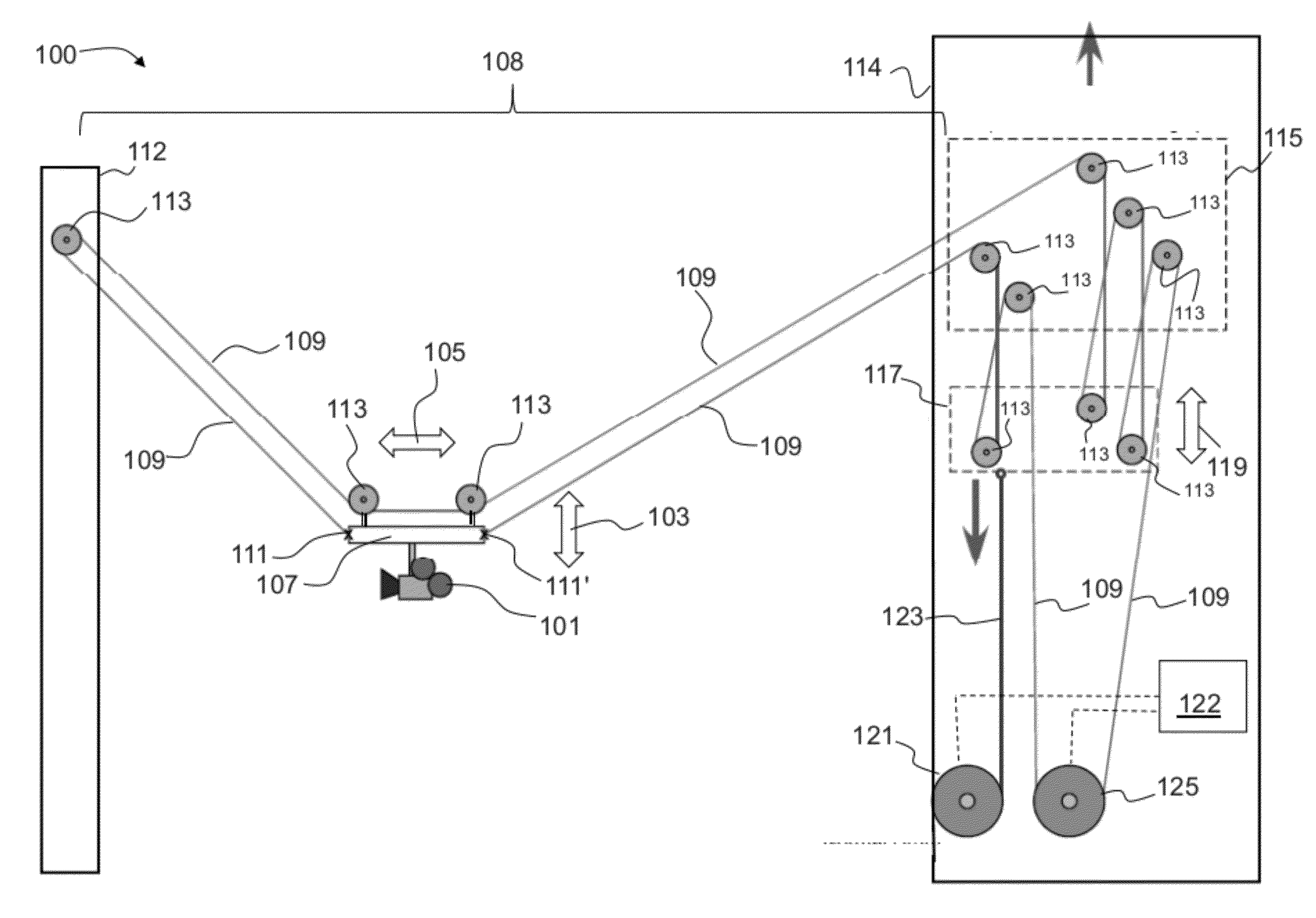

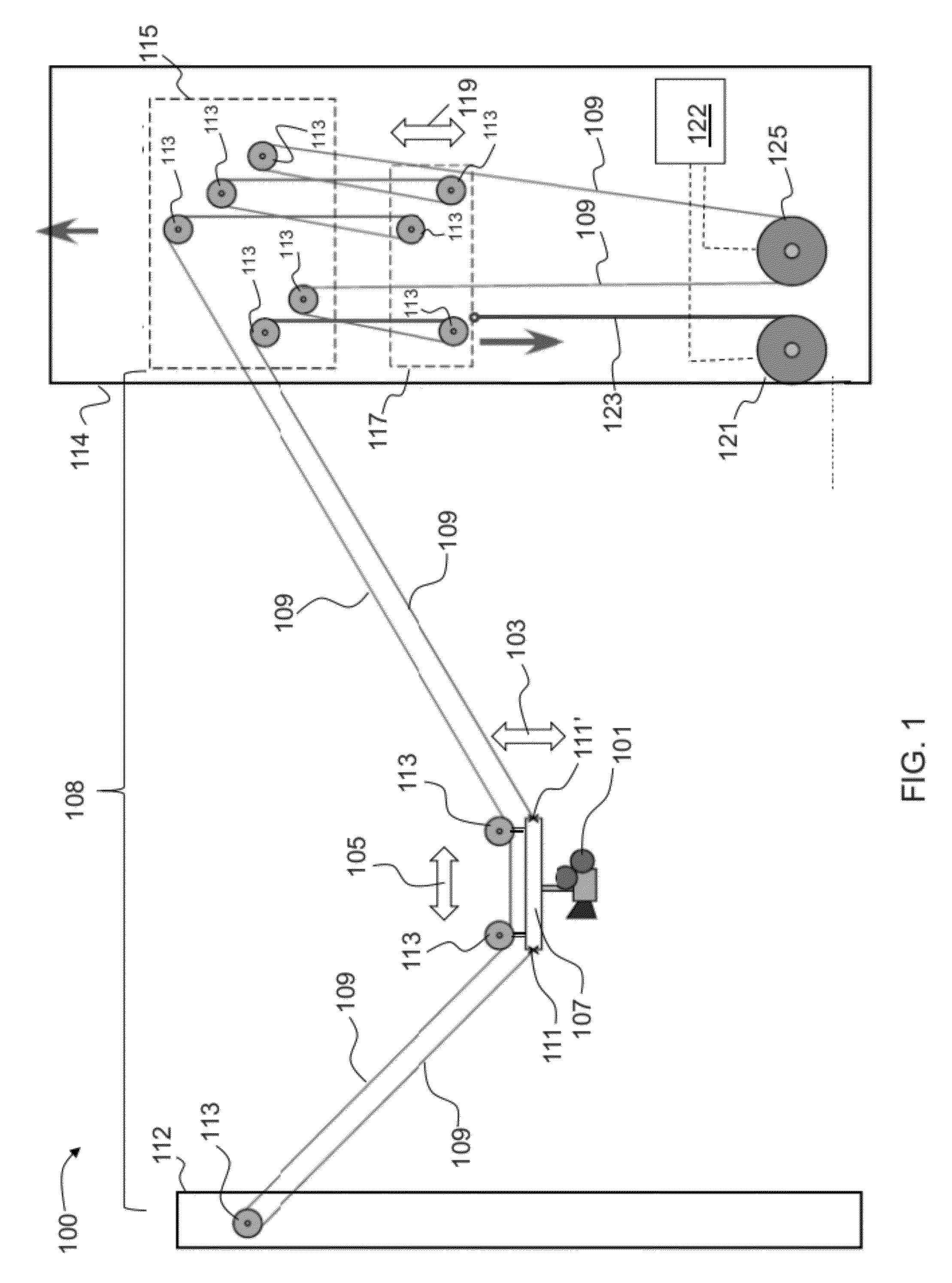

Multidimensional positioning system and method

A multidimensional positioning system including a first block assembly including a fixed first block portion and a moveable second block portion. A first travel cable is arranged on pulleys operatively connected to the first block portion, the second block portion and a predetermined location. The first travel cable is affixed to a base supporting a load. A first travel drive is operatively connected to the first travel cable to facilitate movement of the base in a second travel direction. A first lift drive is arranged and disposed to provide movement of the second block portion relative to the first block portion to selectively alter the length of the first travel cable in a working space and selectively move the base in a first travel direction.

Owner:TAIT TOWERS

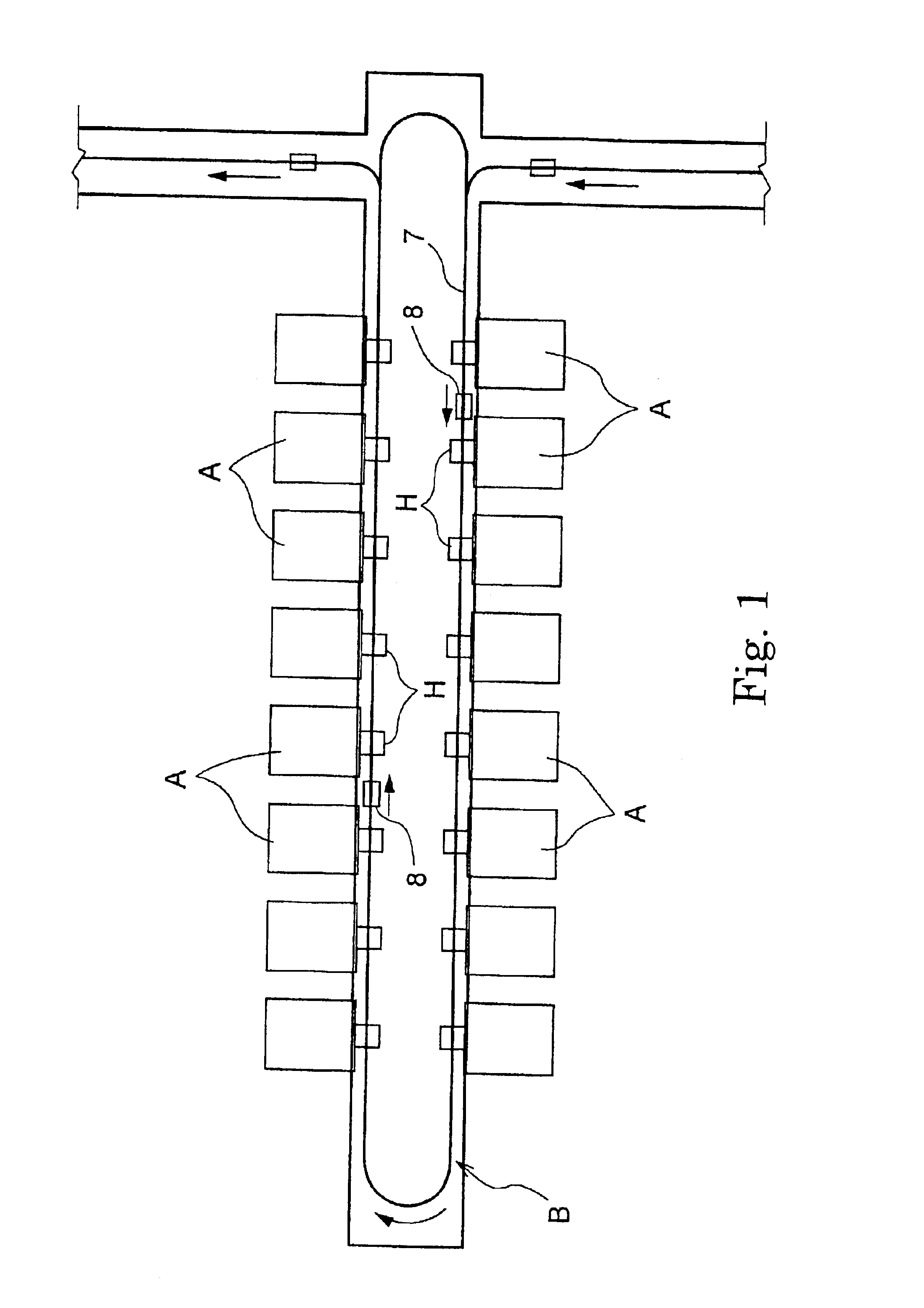

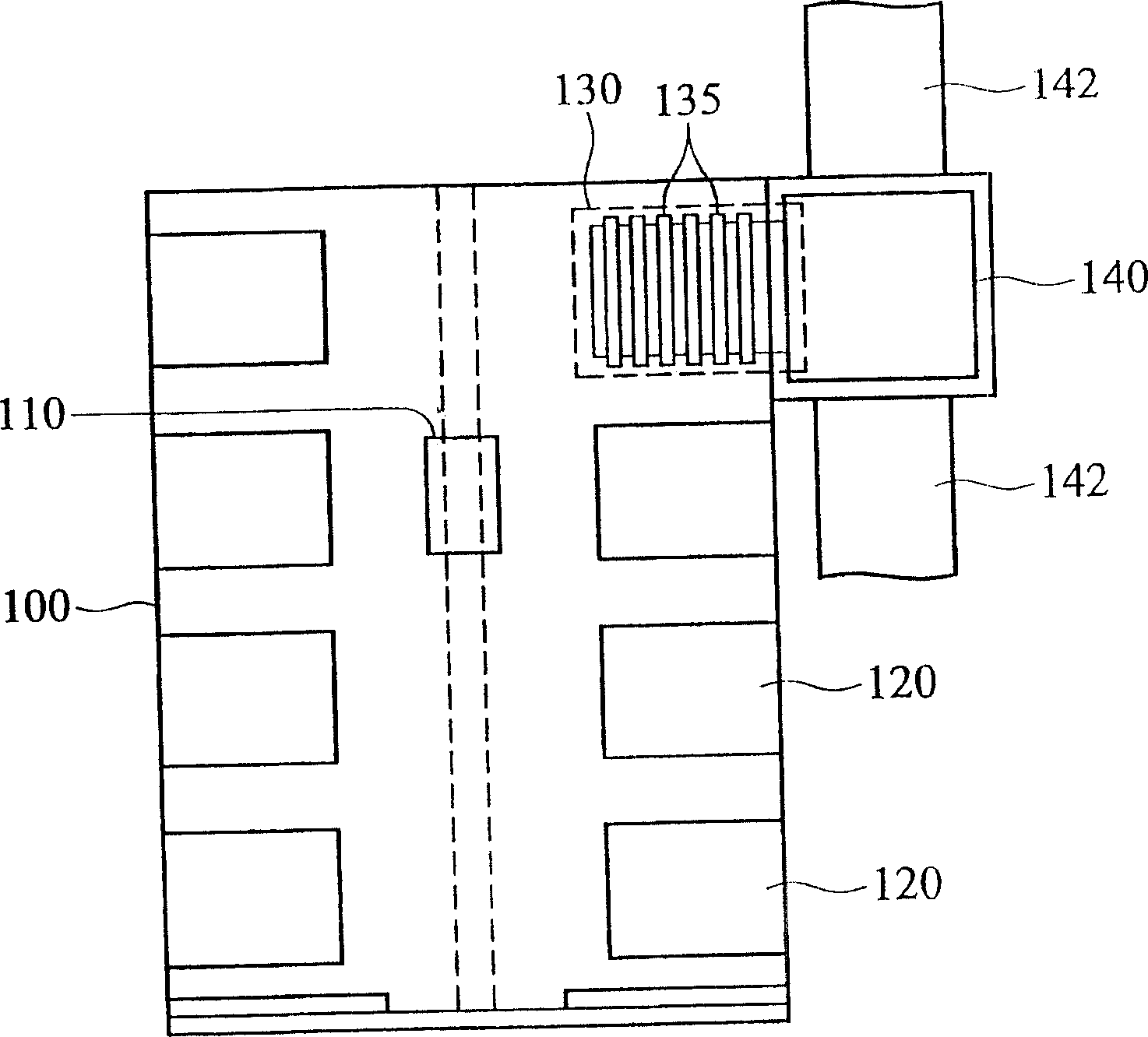

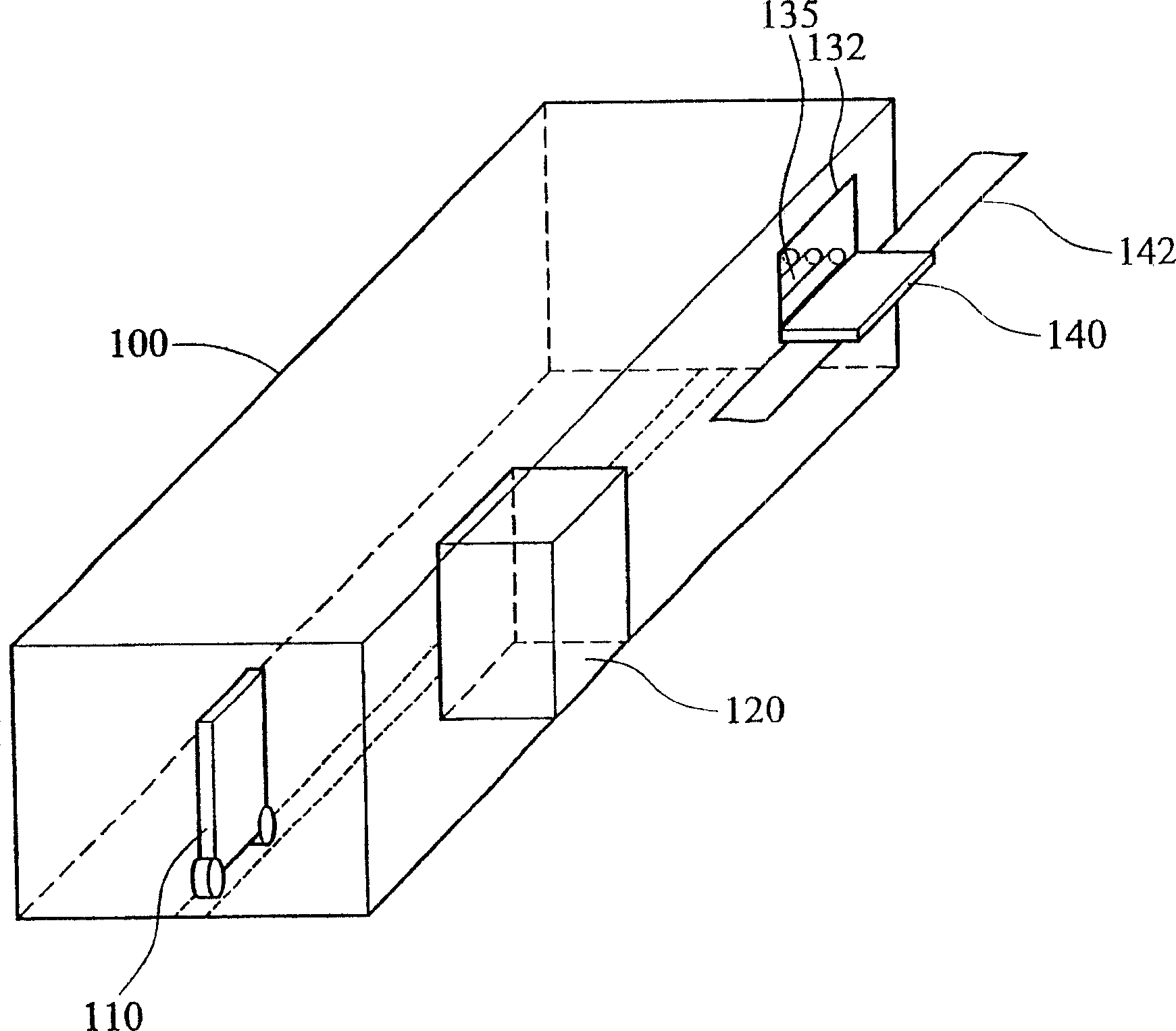

Automatized material conveying system and its storage cabinet

InactiveCN1579899ASimple designReduce waiting timeStorage devicesTrolleysEngineeringMechanical engineering

The invention discloses a automatic material lifting system, it includes a transporting trail(crown block trail), a transporting vehicle(crown block) and a storage. The transporting vehicle can move on the trail. The storage includes a taking and putting part, which is in the storage. The transporting trail enters into the storage, and overlaps with the taking and putting part, when the transporting vehicle is in the taking and putting part, the moving loading machine puttes the material into the transporting vehicle.

Owner:AU OPTRONICS CORP

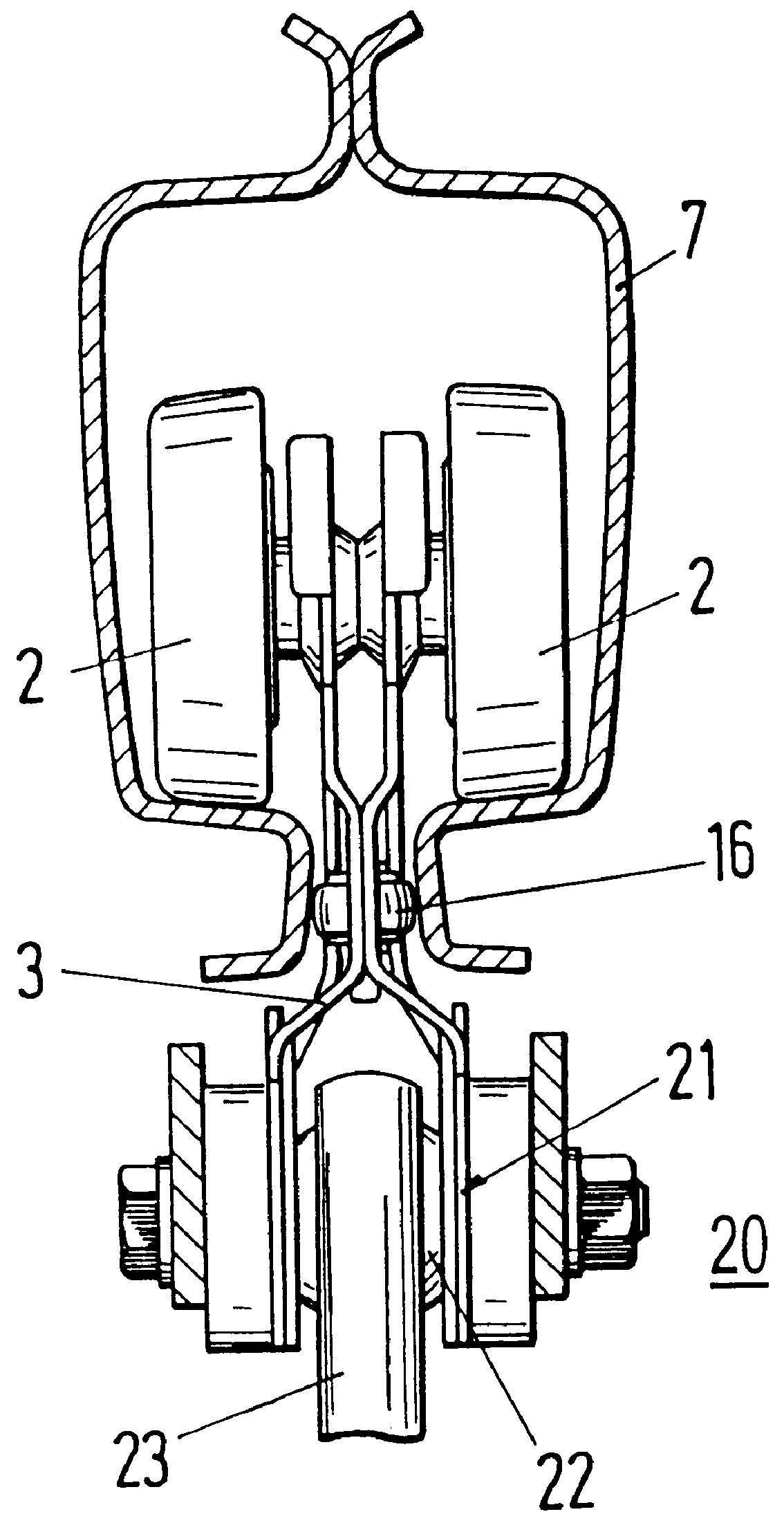

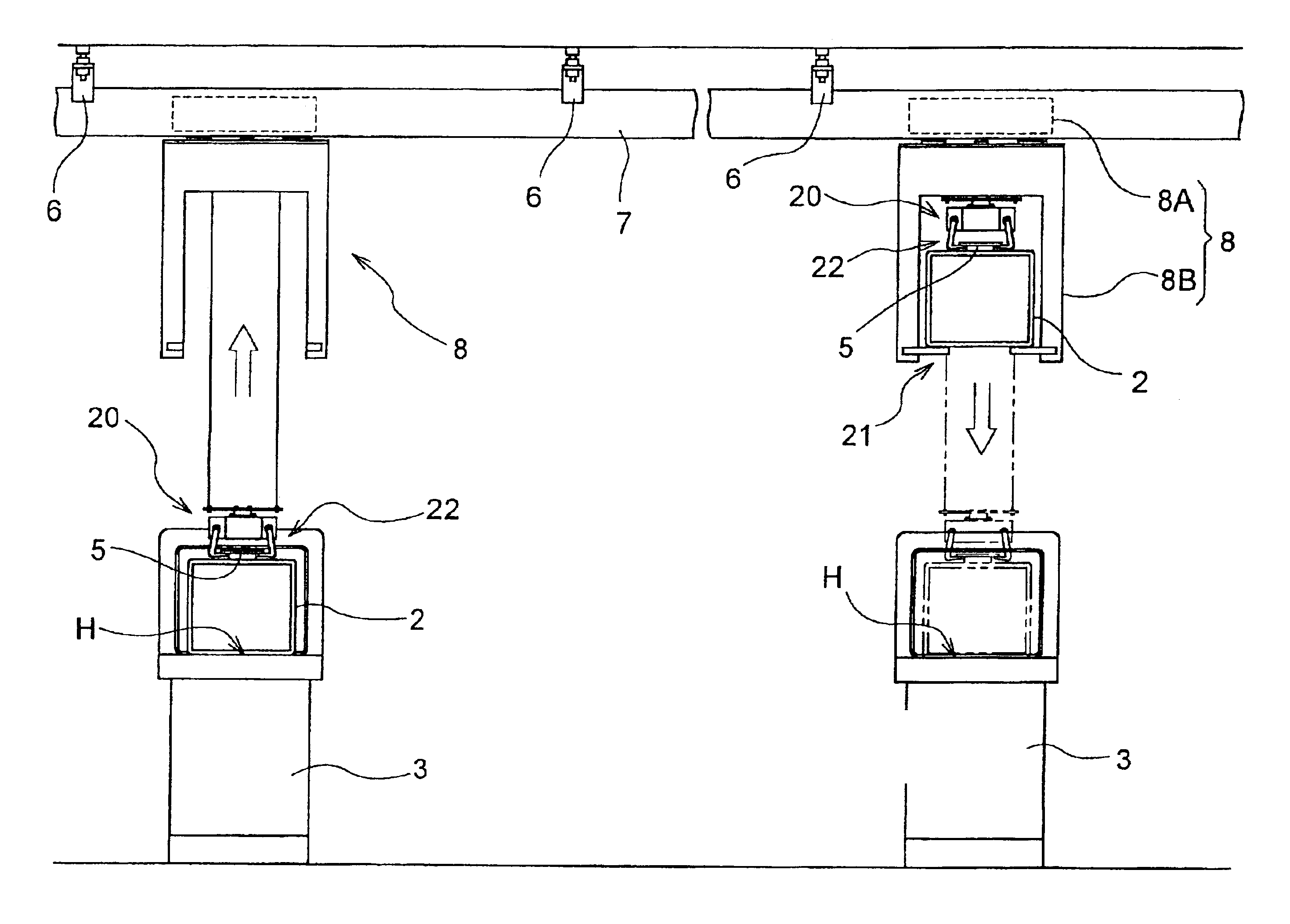

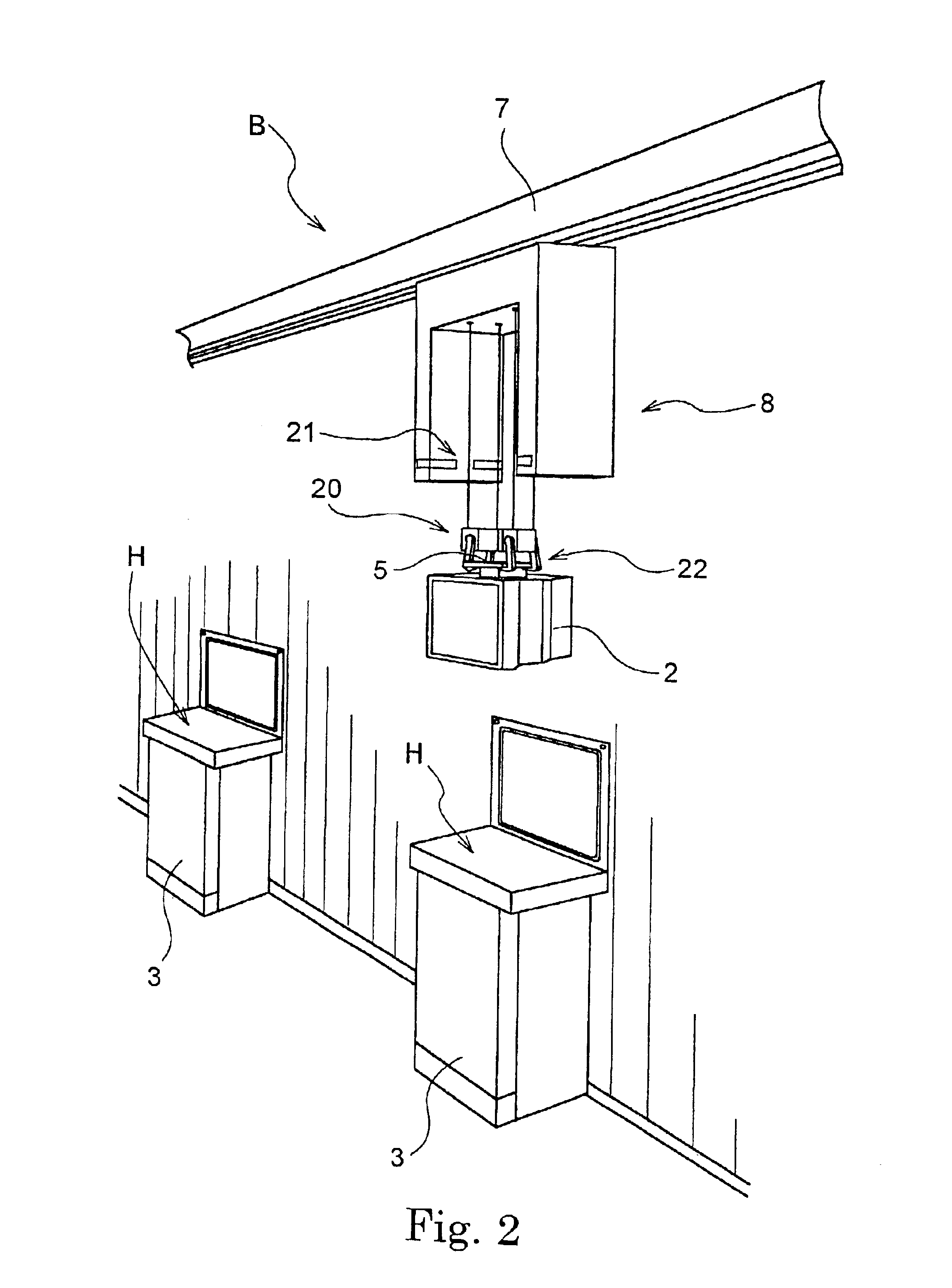

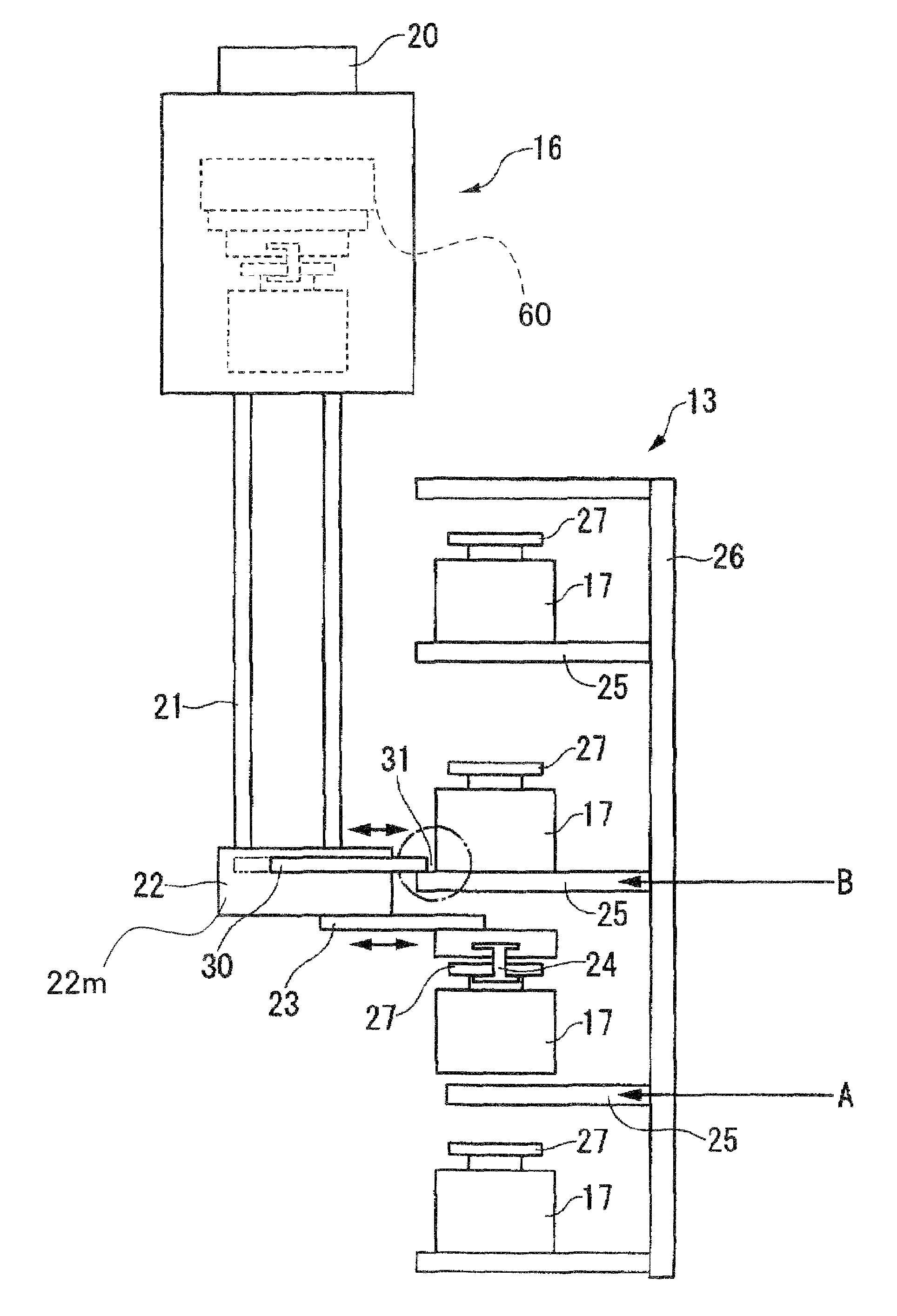

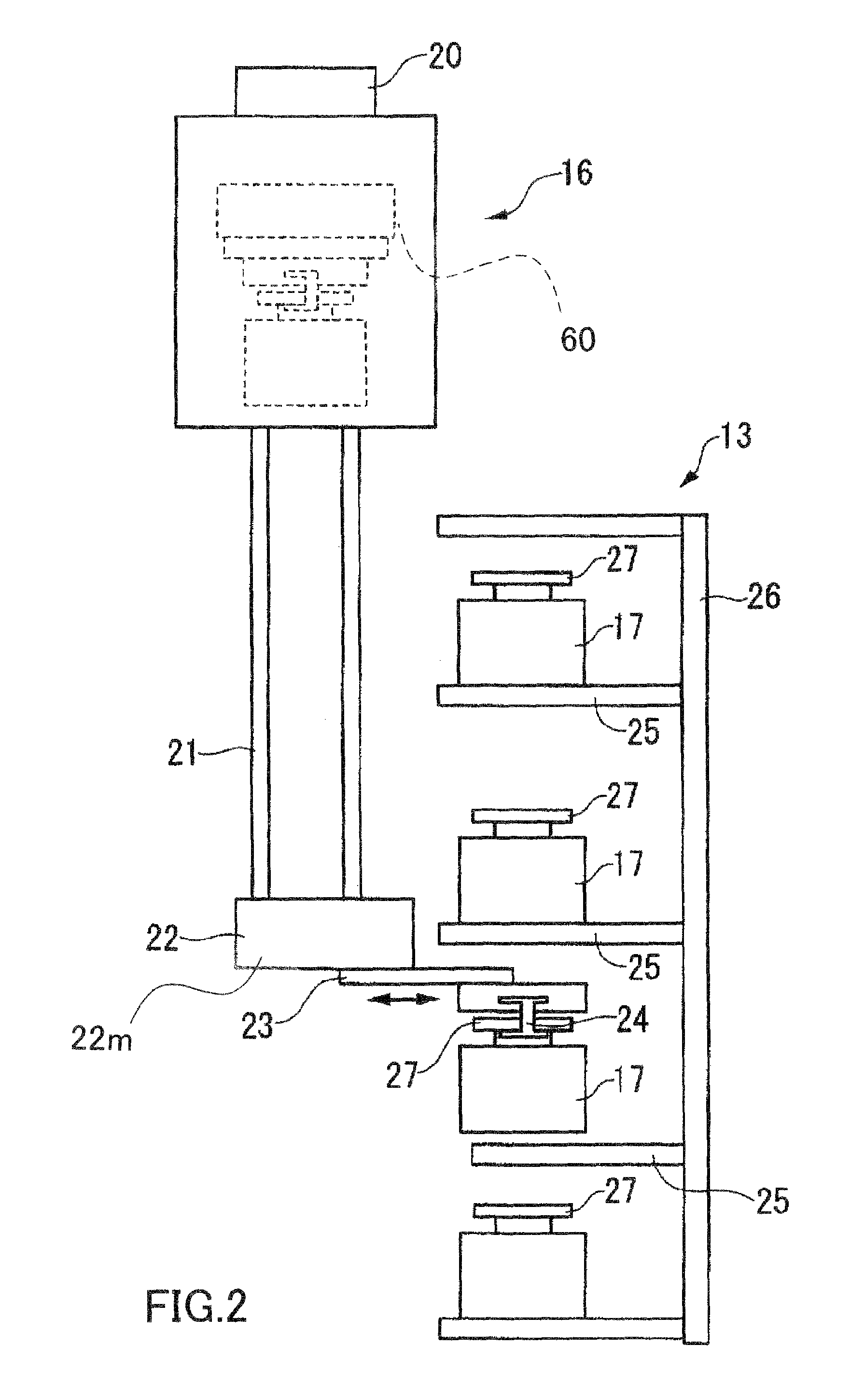

Suspended type transporting carriage and transporting system

InactiveUS7686176B2Low costImprove reliabilitySemiconductor/solid-state device manufacturingTrolley cranesEngineeringMechanical engineering

A suspended type transporting carriage (16) is provided with: a gripping mechanism (22) for gripping a transported object (17); a hoisting mechanism (21) for hoisting the gripping mechanism; and a traveling mechanism (60), on which the hoisting mechanism is mounted in a suspended condition, for traveling on a rail (20) installed on or near a ceiling. The gripping mechanism is provided with (i) an elongating and contracting device (23) capable of horizontally elongating and contracting and (ii) a gripping device (24) disposed at a tip portion of the elongating and contracting device for selectively gripping the transported object.

Owner:MURATA MASCH LTD

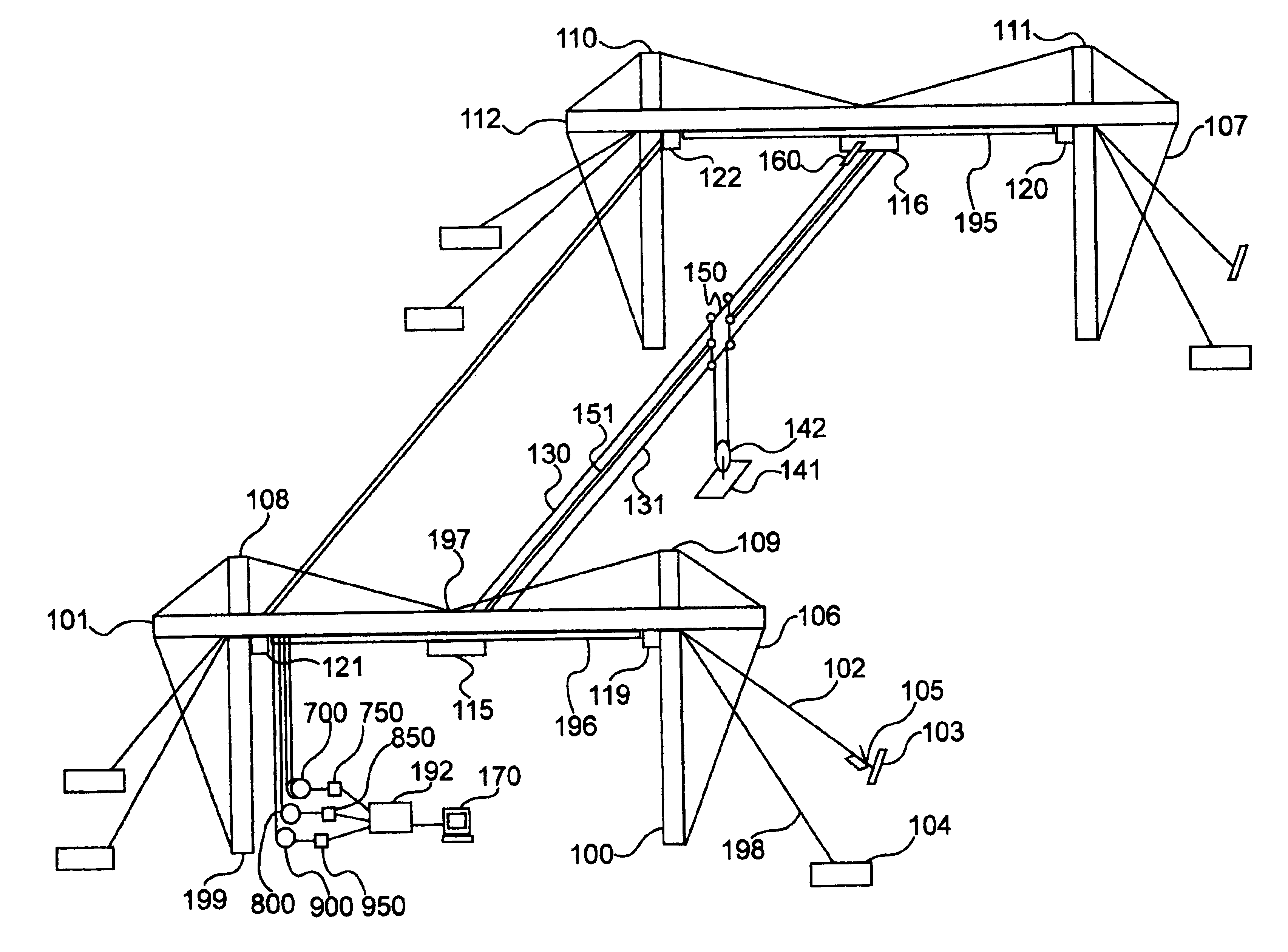

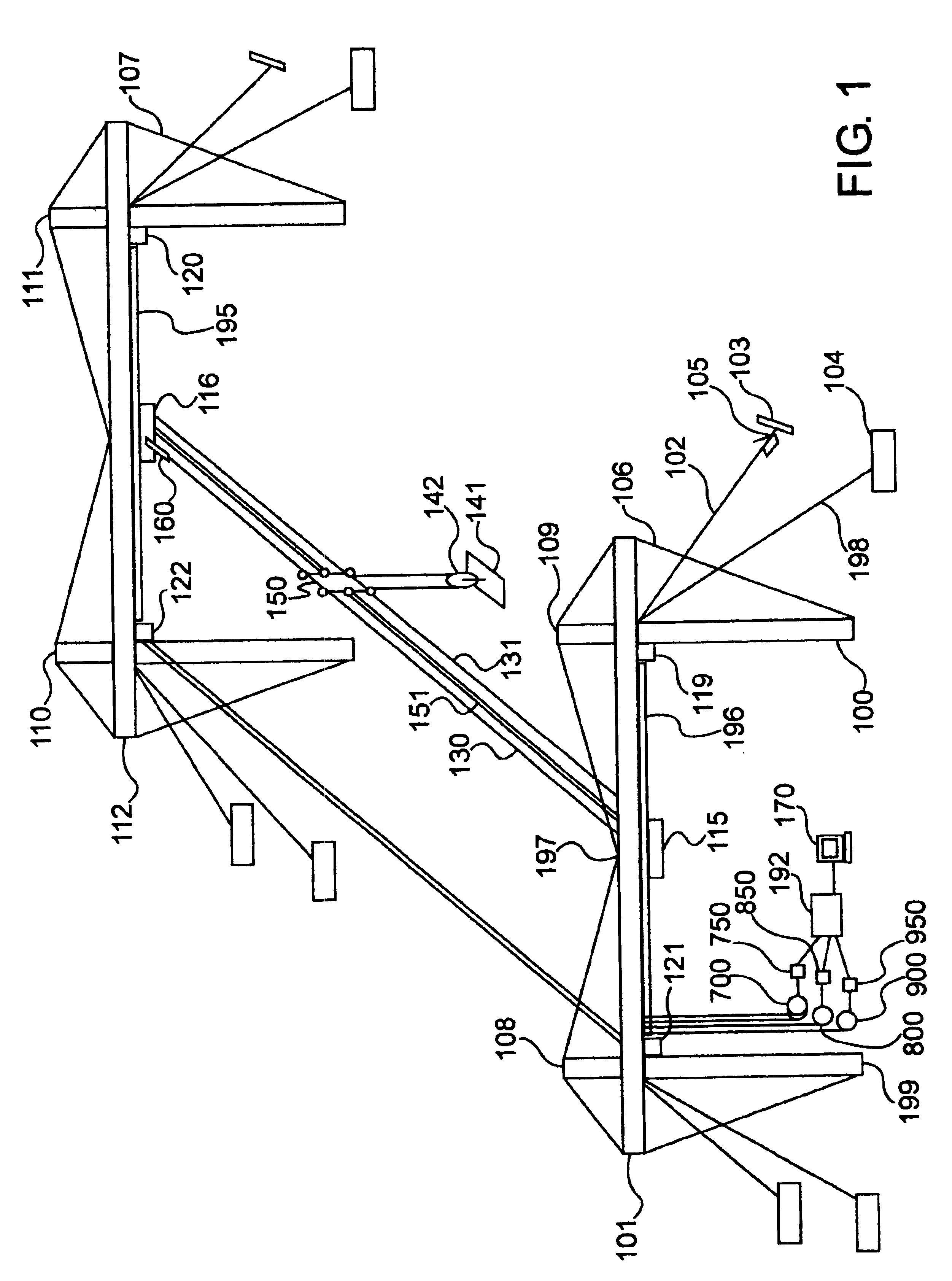

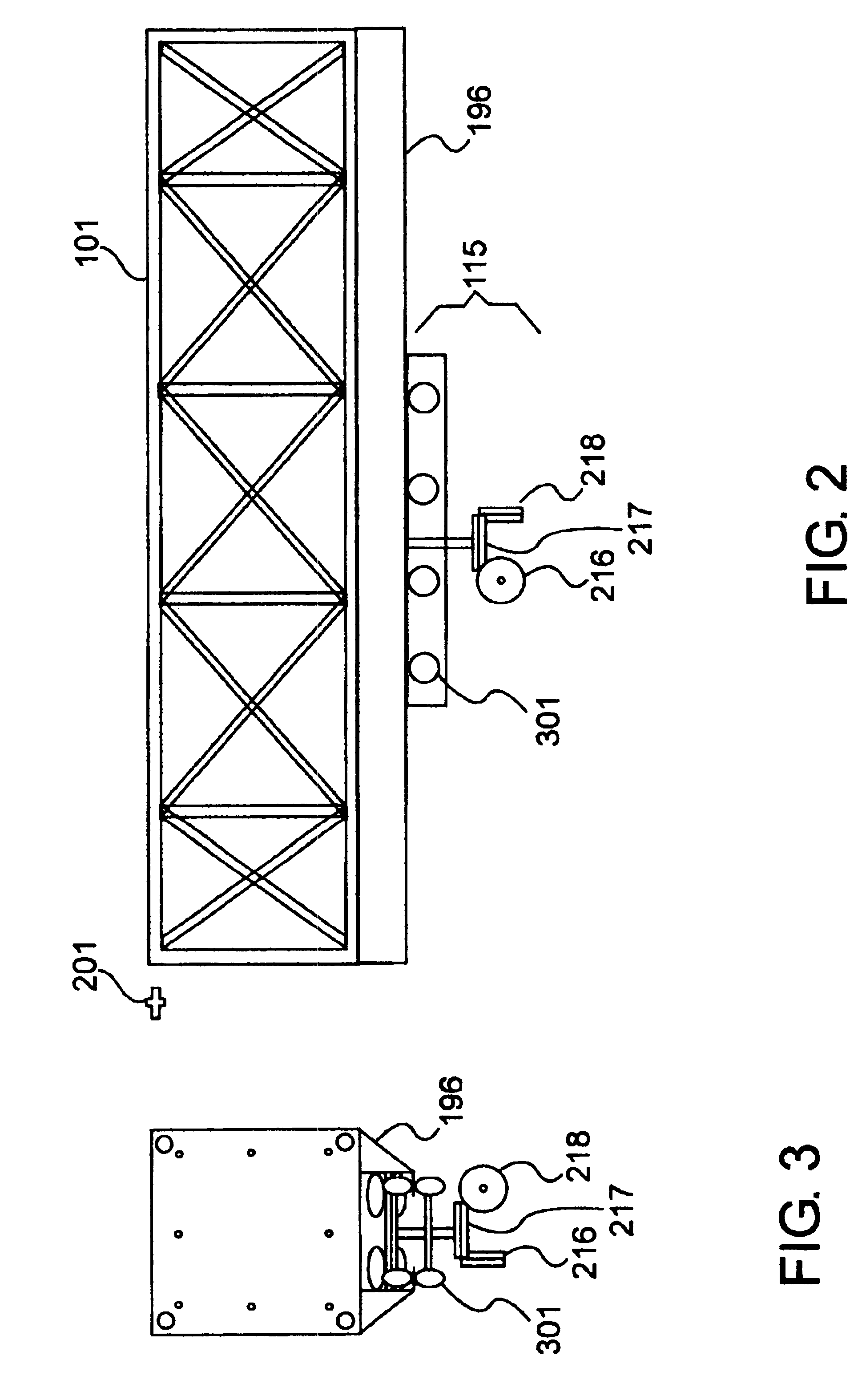

Traveling highline system

InactiveUS6886471B2Moving objectStable positionTramway railsRailway tracksAerial cableIndependent motion

A traveling highline aerial cable rail system for moving objects over large distances in three-dimensional space. A pair of track dollies mounted beneath substantially parallel and distantly separated support trusses allow the entire load bearing highline itself to traverse X-axis space. The highline defines the Y-axis of the system and supports a skate that moves along this axis. A platform suspended from the skate moves vertically in the Z-axis and can support extremely heavy loads depending on the gauge of the rope used in the system. A three motor pulley system with a multiplicity of sheaves allow independent movement of all three axes. The system can move objects weighing thousands of pounds stably at 60 miles per hour or more through three-dimensional space. The system can be modularly widened along the X-axis by adding truss sections, and the highline can be configured to up to 1000 feet or more, using rope that can support several tons or more. The Z-axis displacement can be multiplied via a pulley arrangement.

Owner:FORTRESS CREDIT CORP AS AGENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com