Patents

Literature

96 results about "Increased height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surgical staple

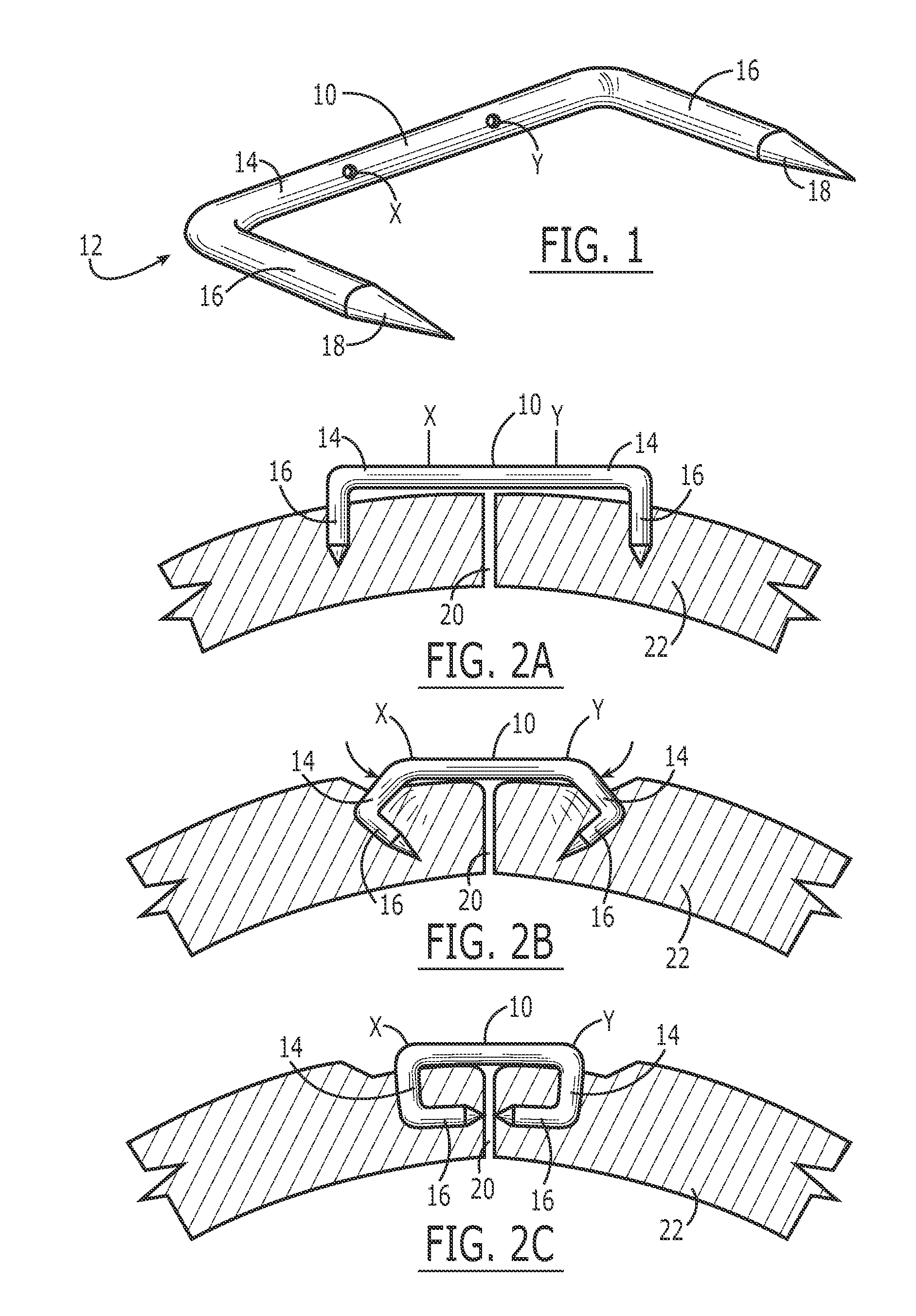

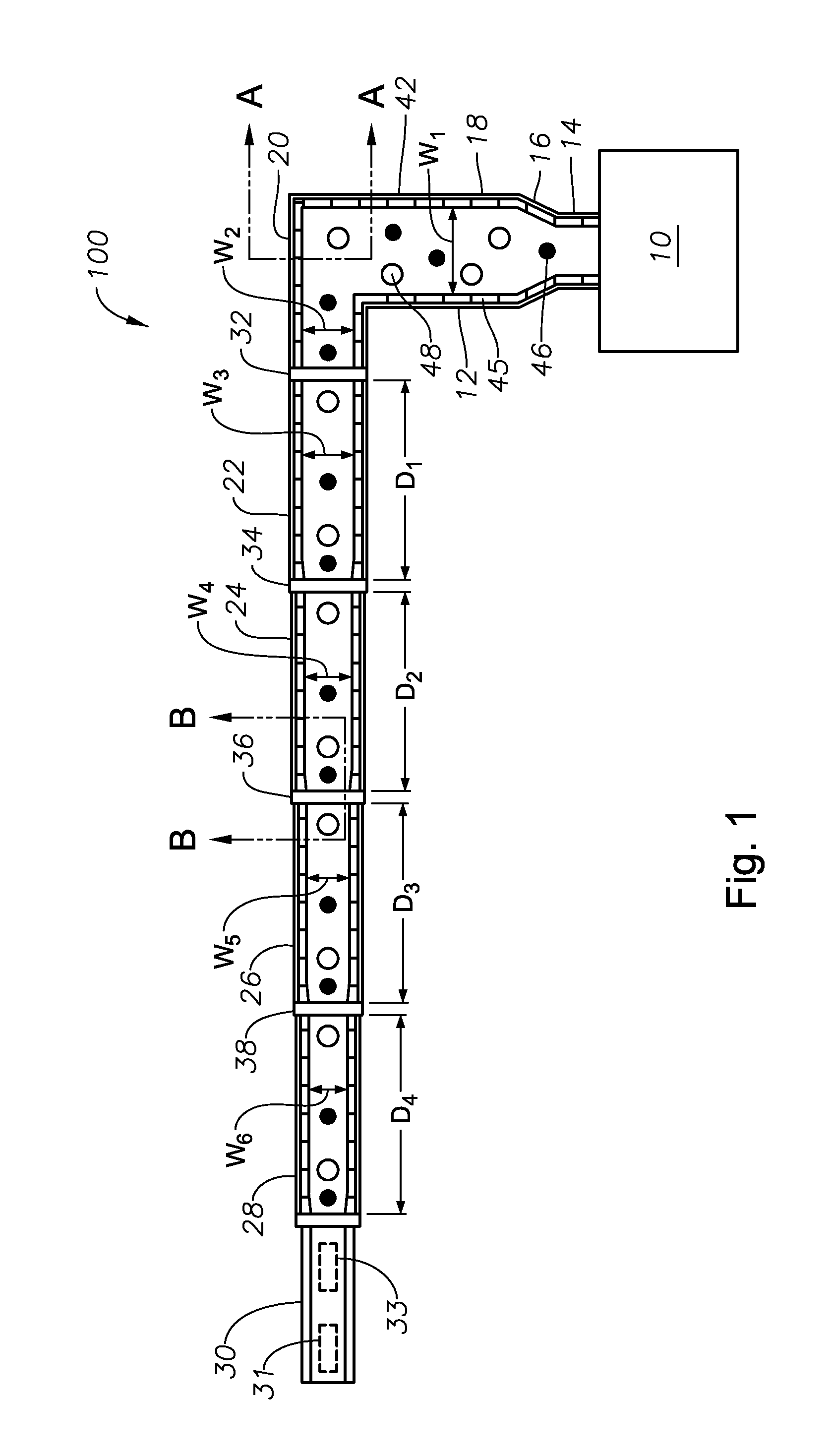

InactiveUS20050267530A1Increased area of compressionIncrease the areaStaplesNailsSurgical stapleEngineering

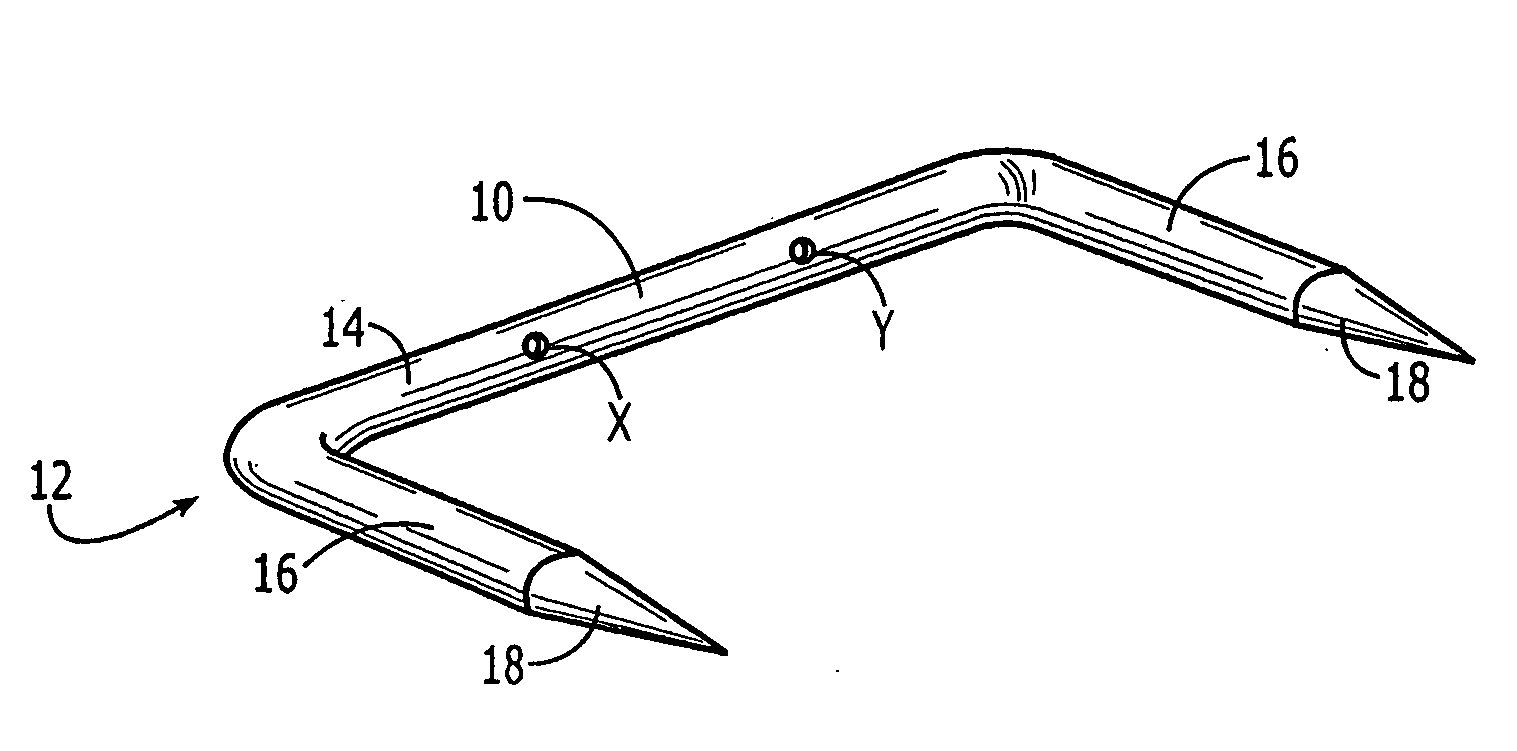

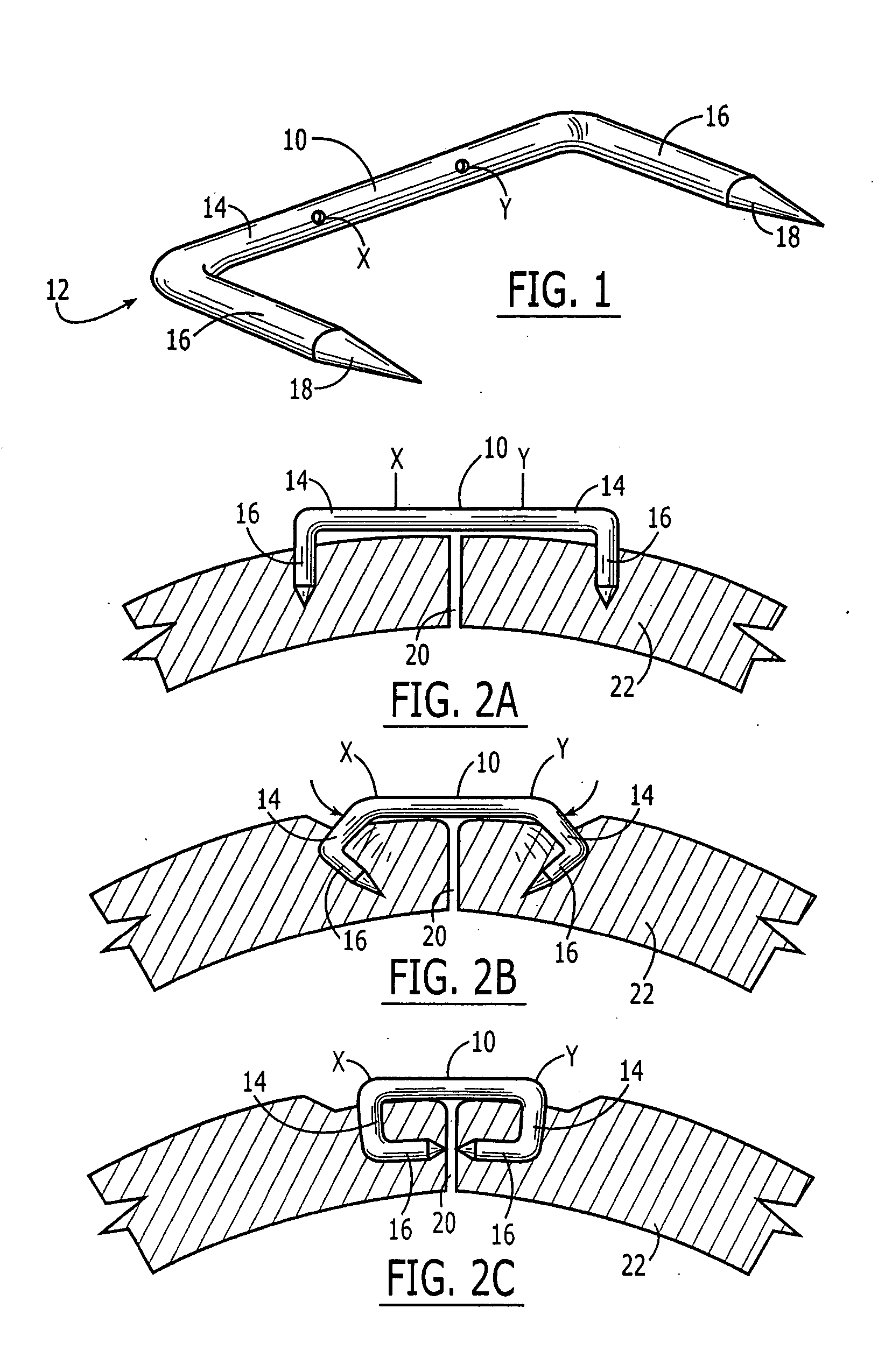

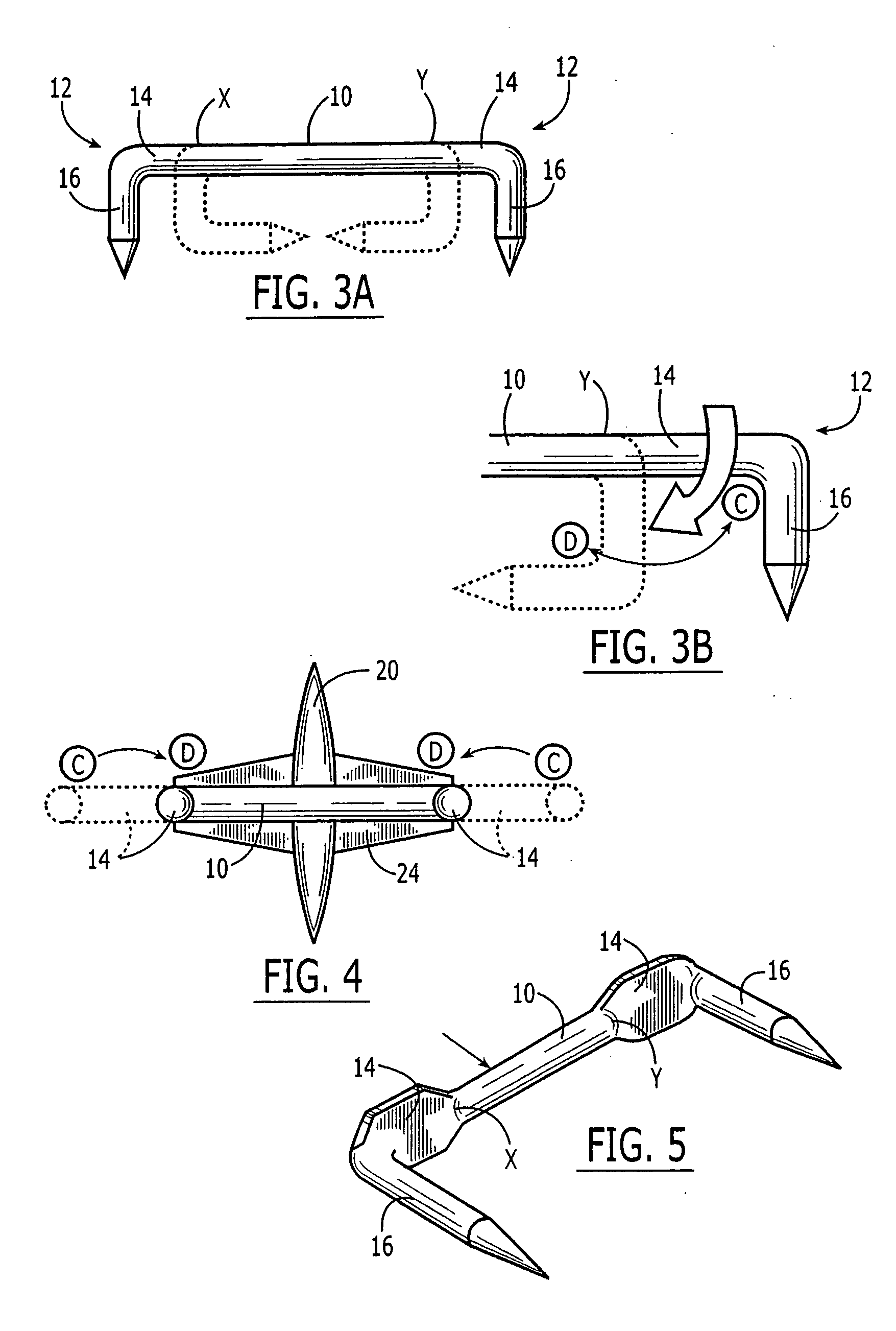

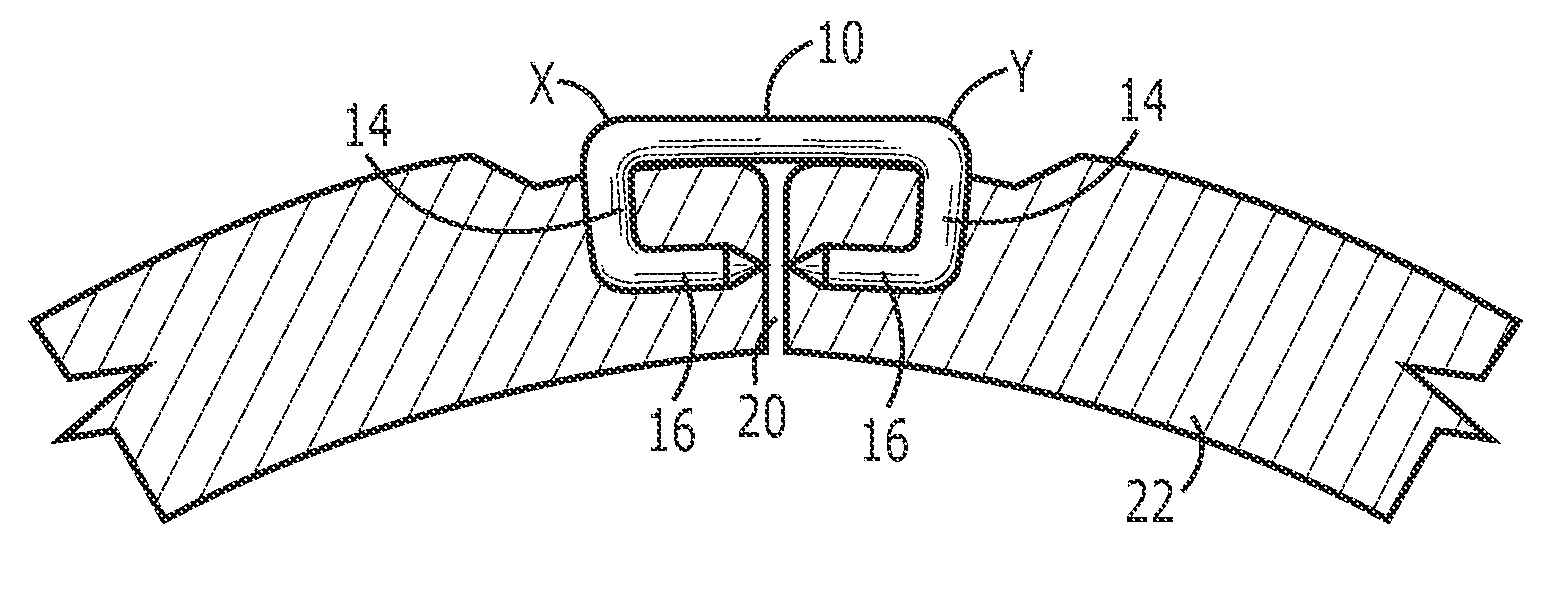

In certain exemplary embodiments, a generally U-shaped surgical staple is provided having a base and a pair of legs extending substantially perpendicularly from opposite ends of the base respectively. The legs in use of the staple are bent through approximately 90° relative to the base. To effect a greater compression of the stapled tissue, the legs can include a penetrative portion adjacent the tip and a compressive structure which, due to its increased height relative to that of the penetrative portion, spreads the compressive forces of the staple further along the length of the incision being closed. The compressive portion also provides a depth stop to avoid the tip penetrating too deeply into the tissue in which it is deployed.

Owner:INTECH DIRECT

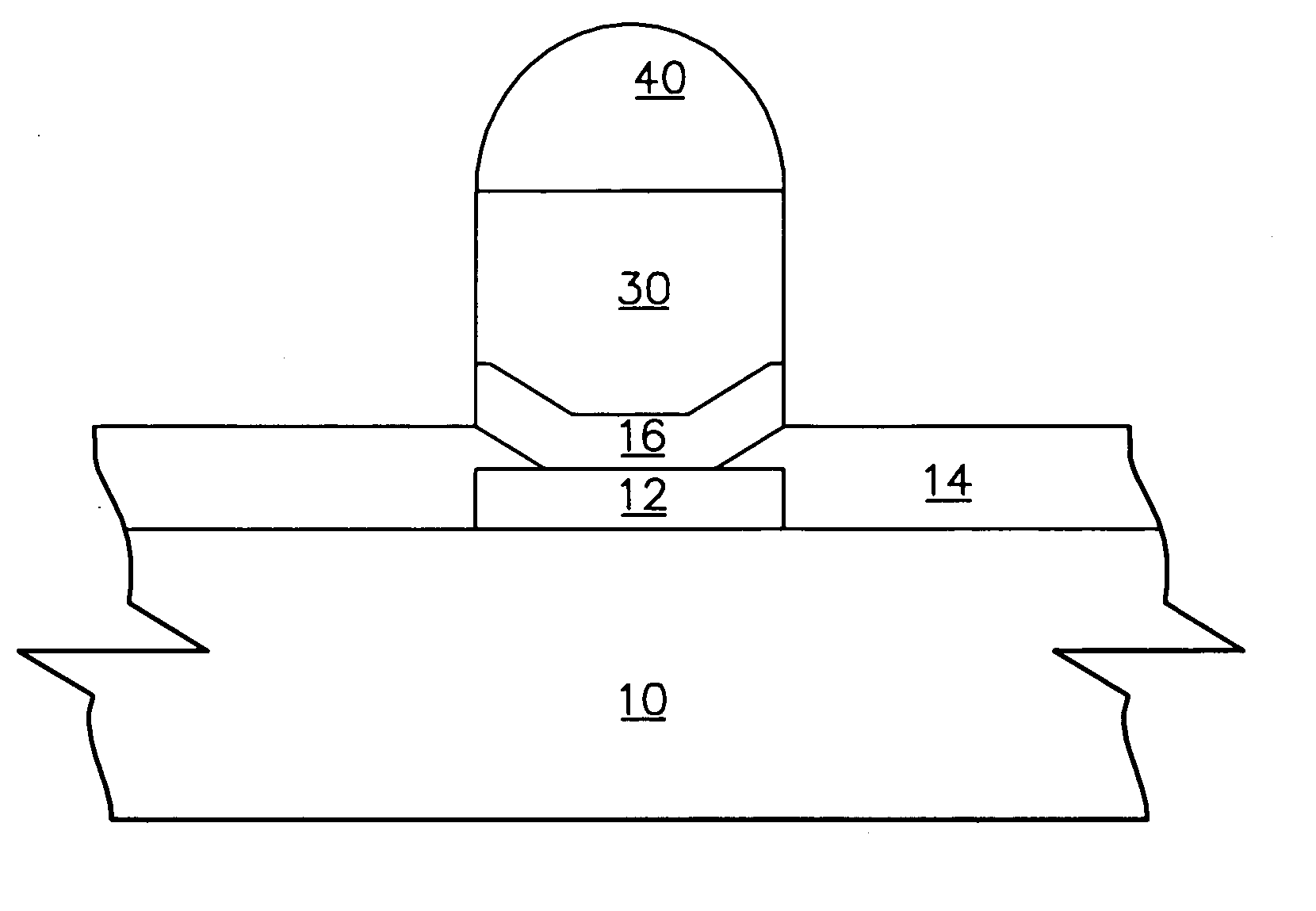

Surgical Staple

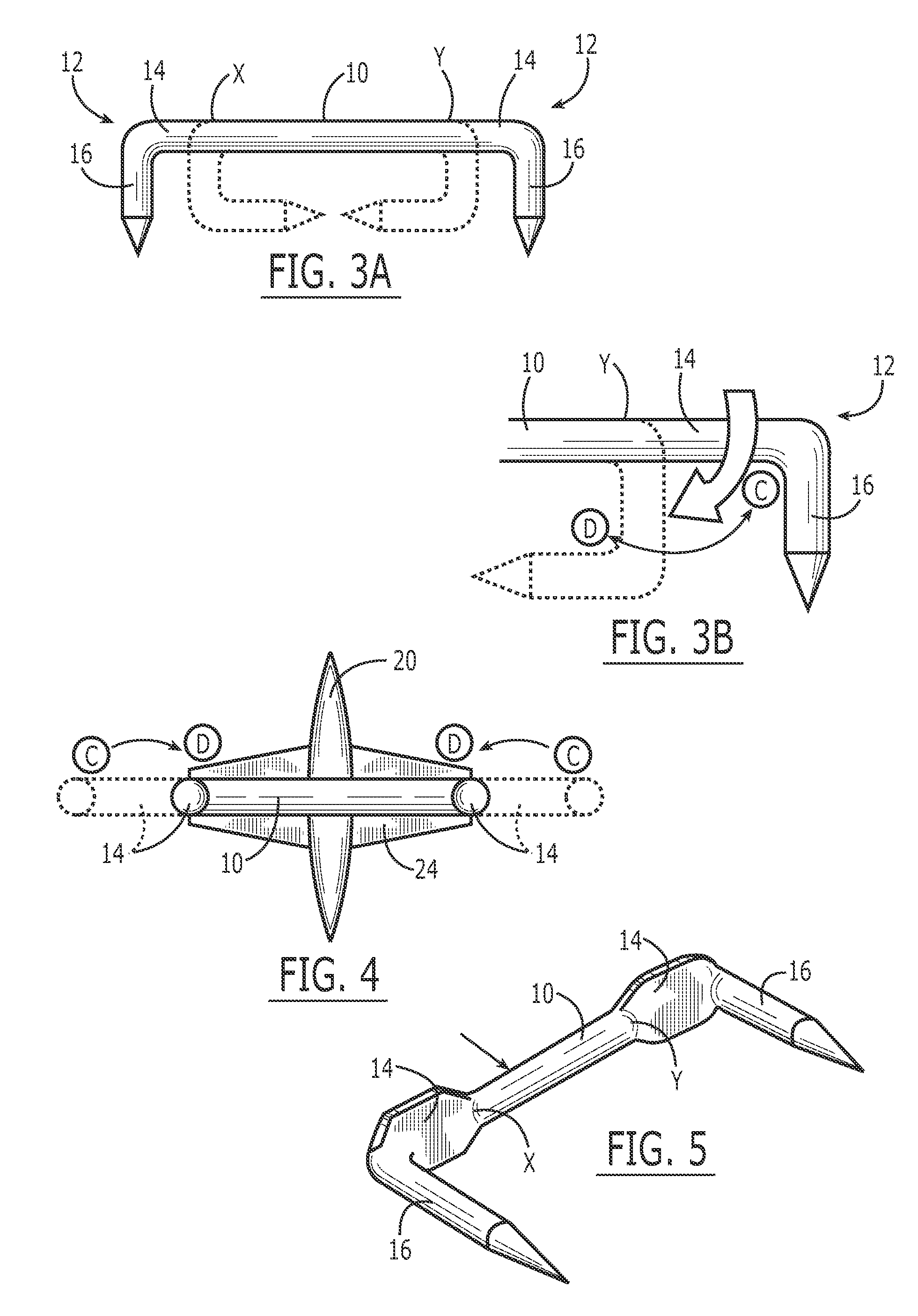

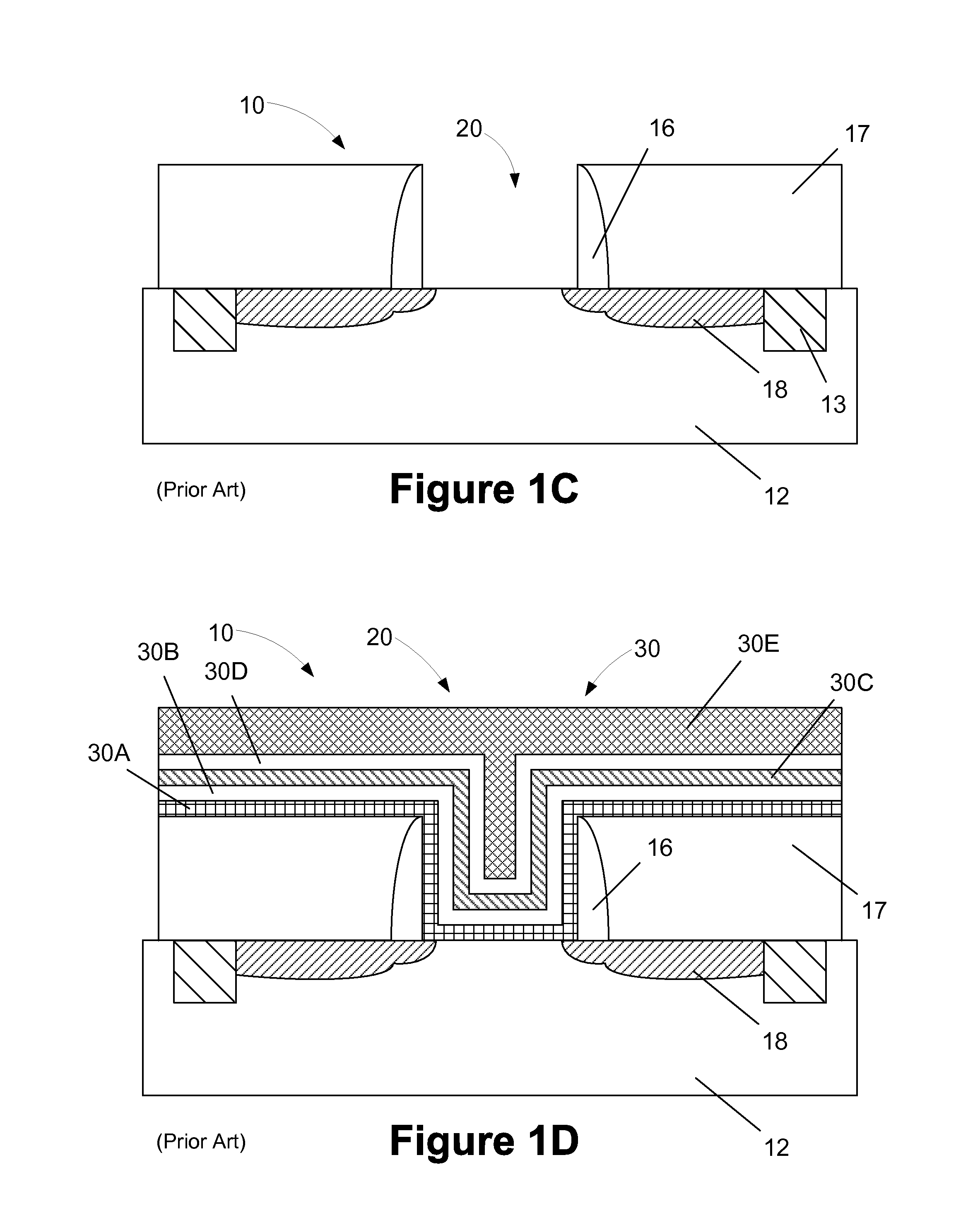

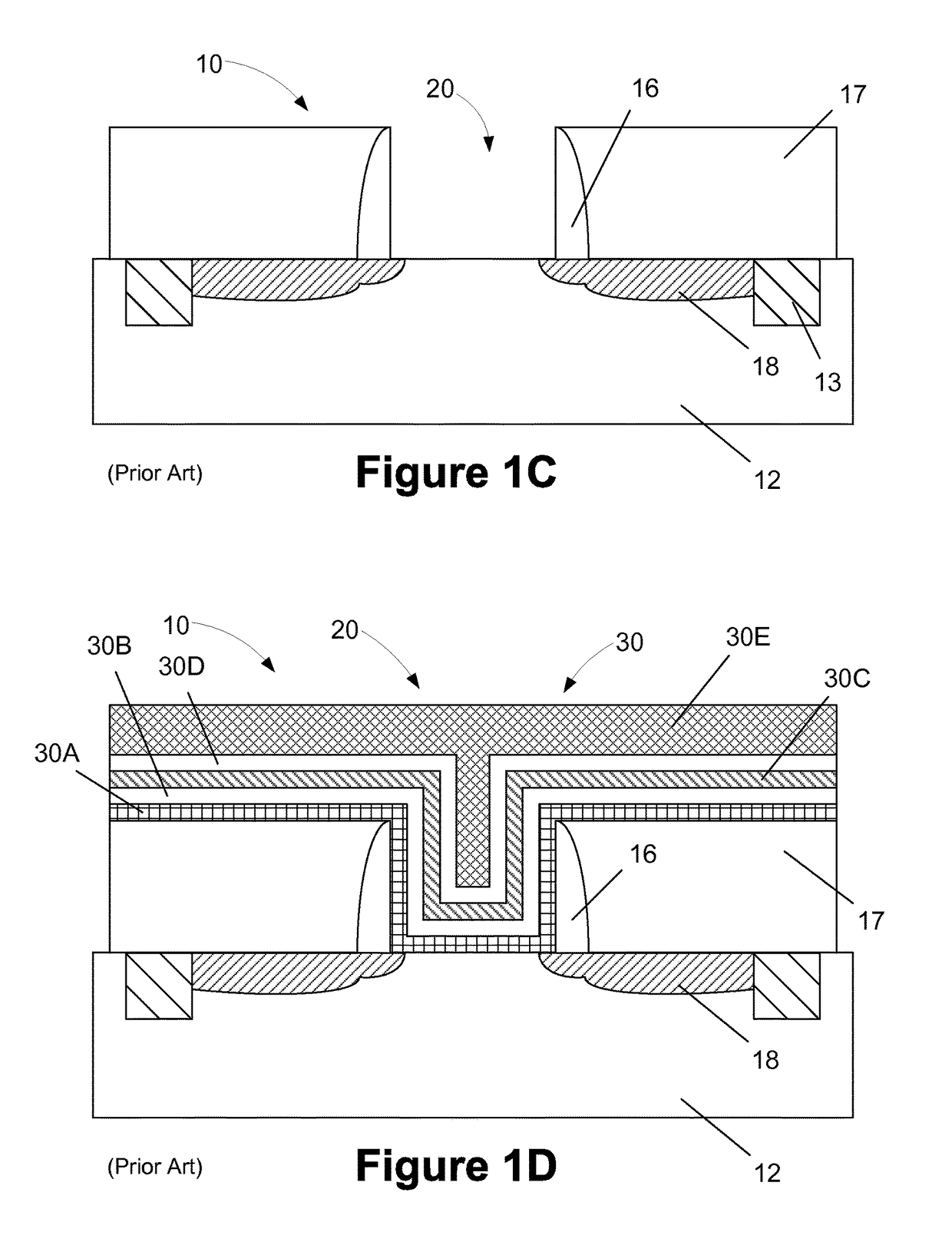

InactiveUS20070010854A1Increased area of compressionIncrease the areaStaplesNailsSurgical stapleEngineering

A generally U-shaped surgical staple comprises a base 10 and a pair of generally “L”-shaped legs 12 extending substantially perpendicularly from opposite ends of the base respectively. The legs 12 in use of the staple are bent through approximately 90° relative to the base. To effect a greater compression of the stapled tissue the legs include a penetrative portion 16 adjacent the tip and a compressive structure 30 which, due to its increased height relative to that of the penetrative portion, spreads the compressive forces of the staple further along the length of the incision being closed. The compressive portion also provides a depth stop to avoid the tip penetrating too deeply into the tissue in which it is deployed.

Owner:ABBOTT CARDIOVASCULAR

Apparatus, systems and methods for conditioning molten glass

Owner:JOHNS MANVILLE CORP

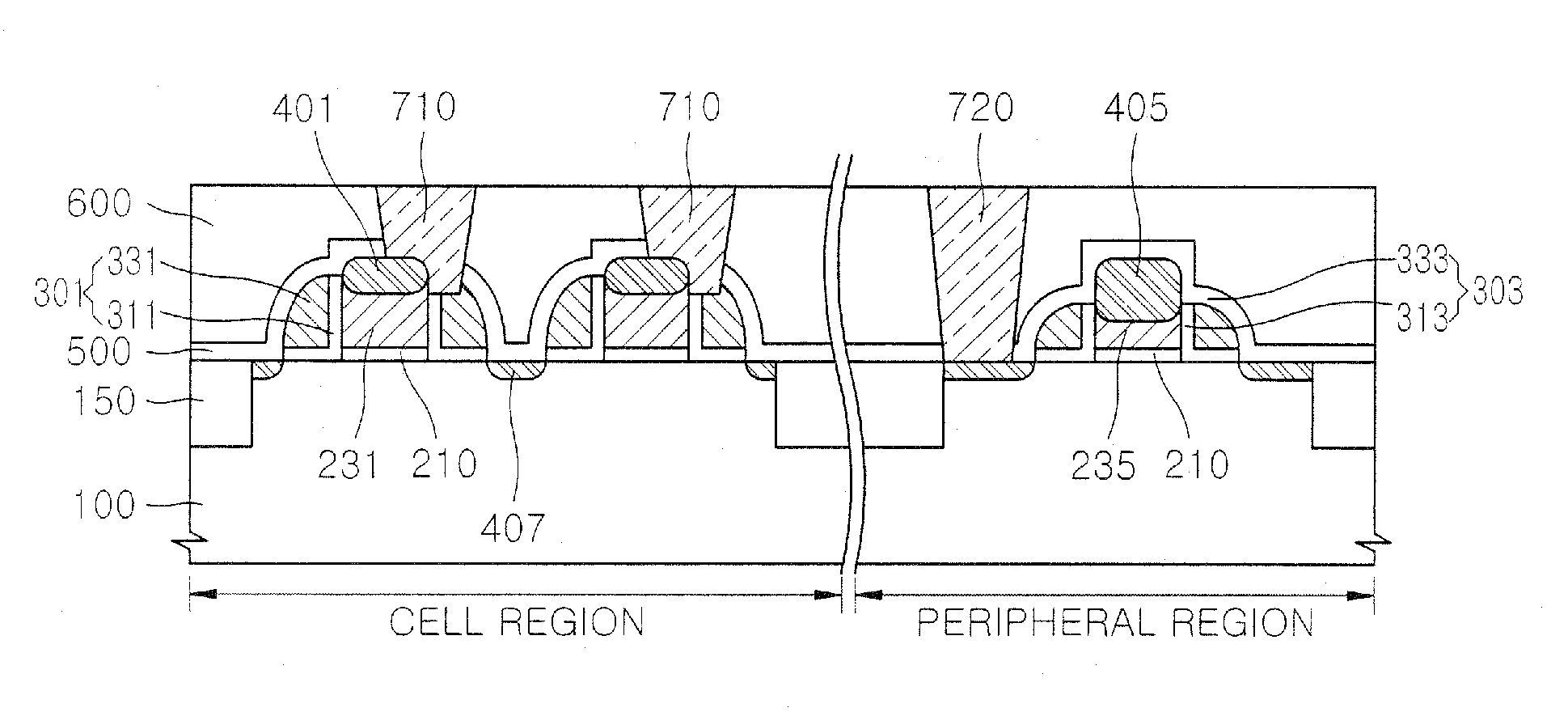

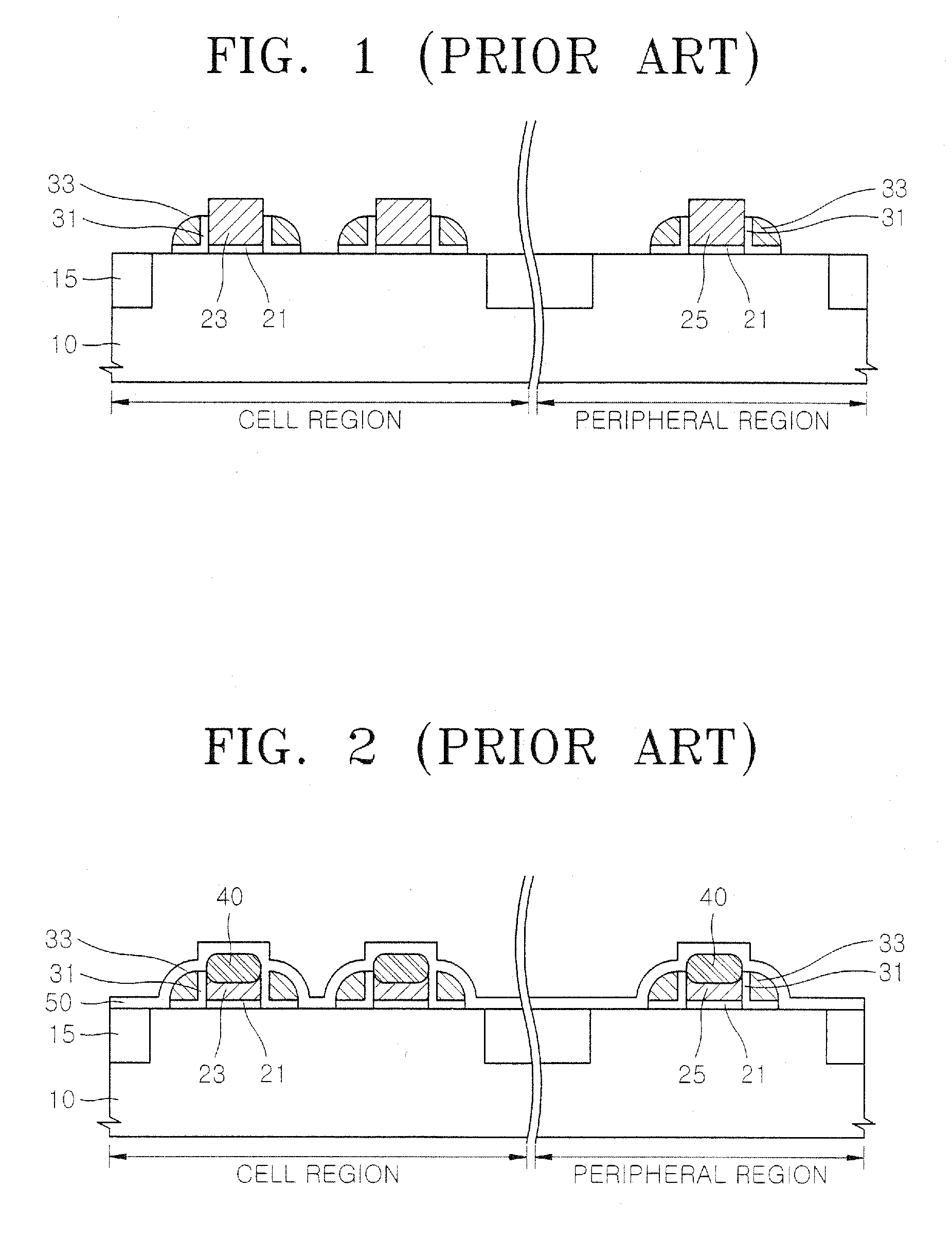

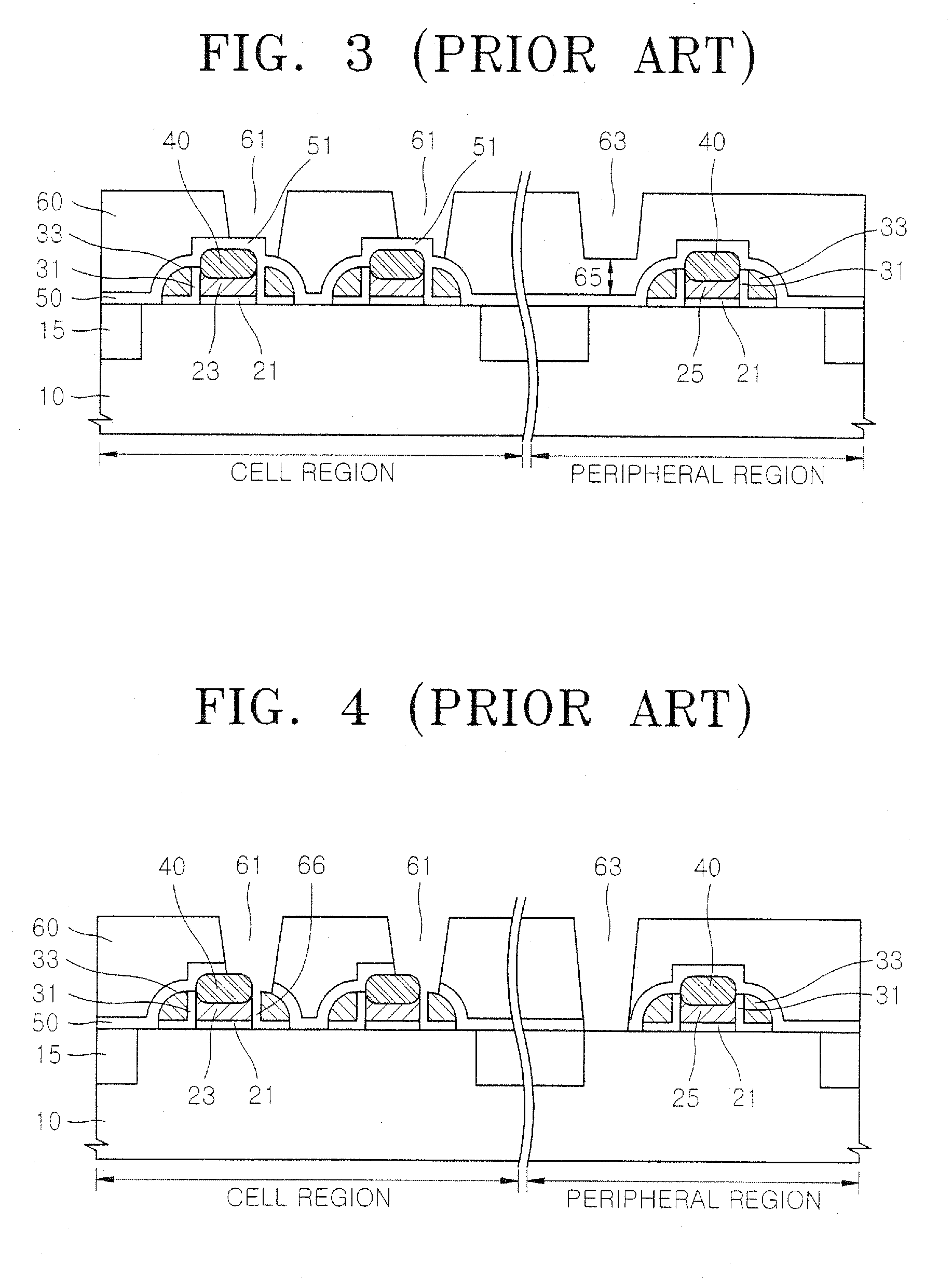

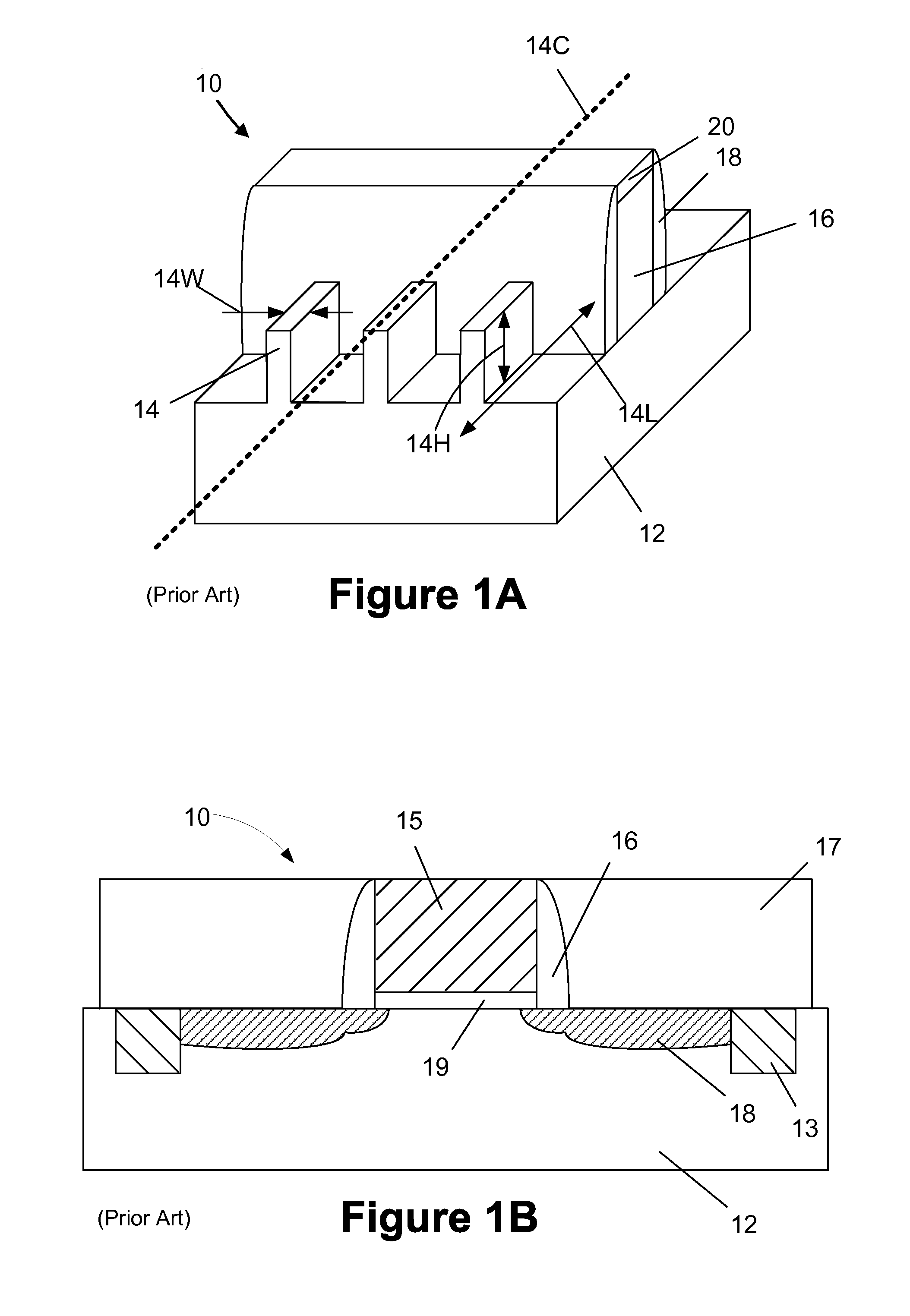

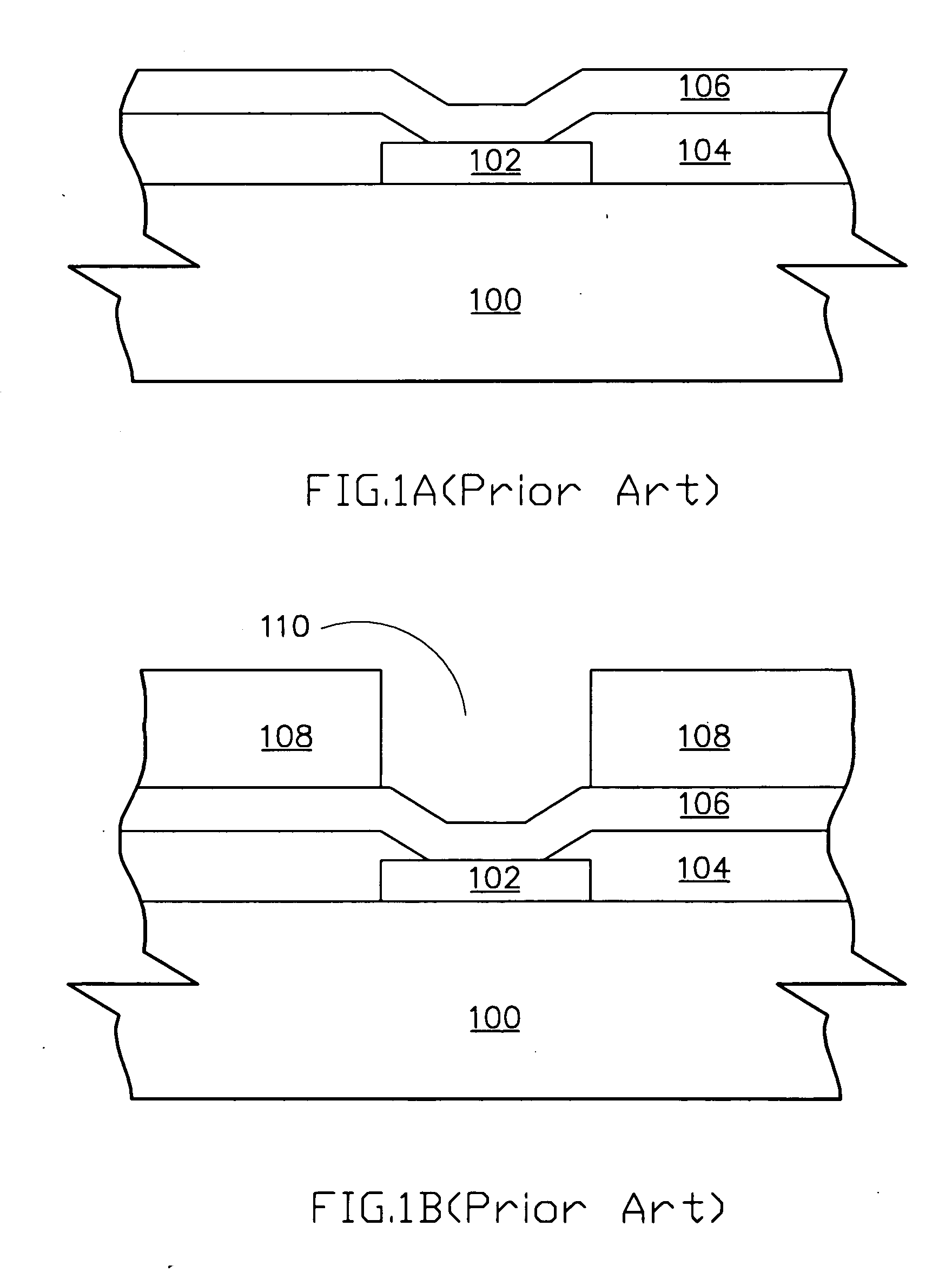

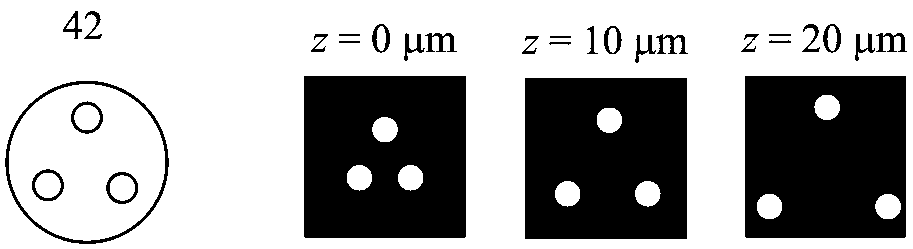

Semiconductor device with improved gate resistance and method of its manufacture

A semiconductor device is formed with a normal, non-recessed, spacer structure in a cell region and a recessed spacer structure in a peripheral region. The recessed spacer structure is formed as by etch masking those in the cell region and exposing those in the peripheral region, then performing an etch process. The increased height of the cell region spacers is adapted to further prevent over-etching during gate interconnect formation which would otherwise result in etching through the spacer to the substrate and subsequent short circuit. Therefore, it is also possible to prevent bridge defects due to over-etching, which occurs because the barrier metal layer for a subsequent interconnection contact is accidentally connected to the underlying substrate. Also, since the recessed spacer structure is provided in the peripheral region, it is possible to remarkably enhance a resistance distribution of a cobalt silicide layer occurring in a gate line width of 100 nm or less.

Owner:SAMSUNG ELECTRONICS CO LTD

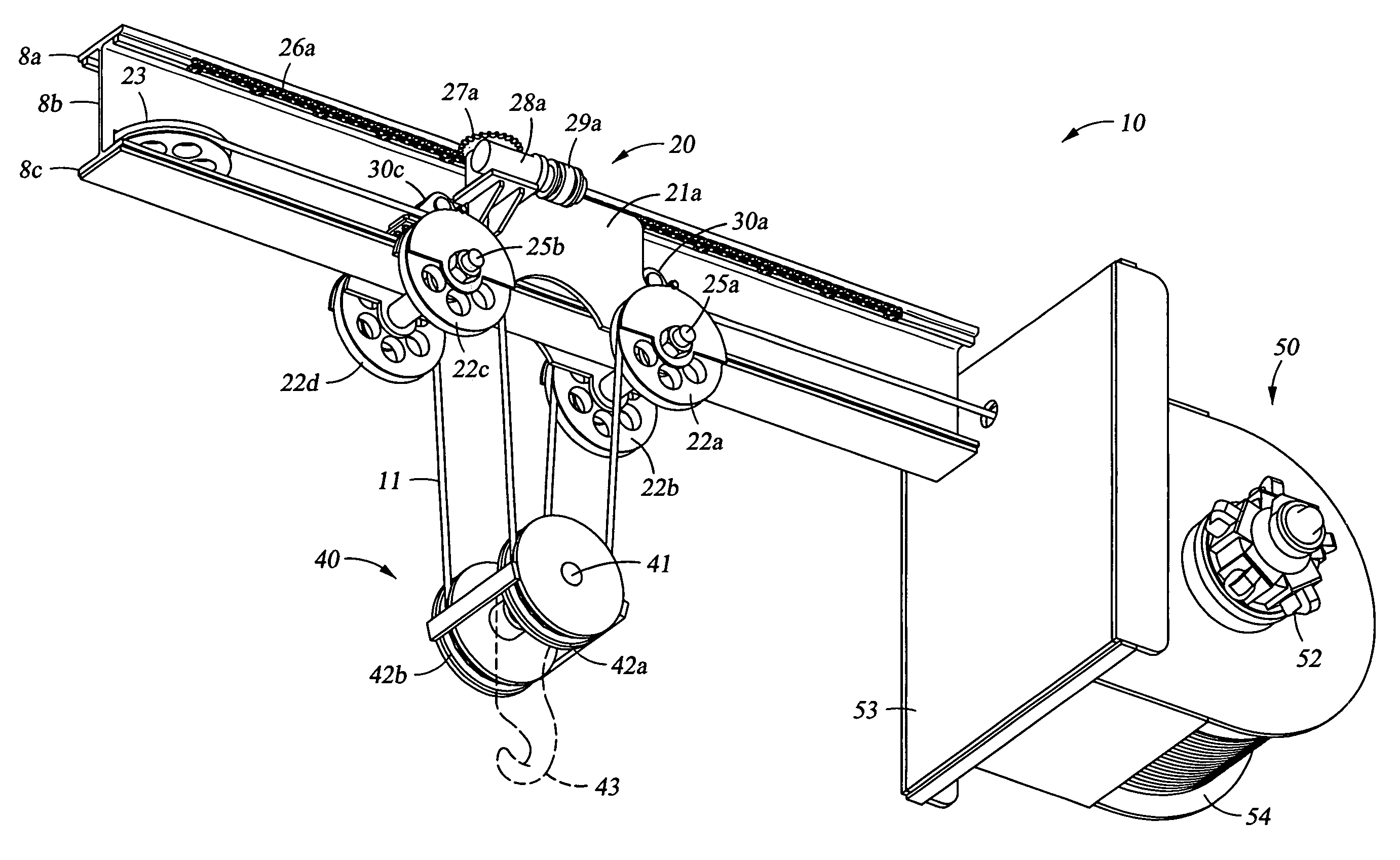

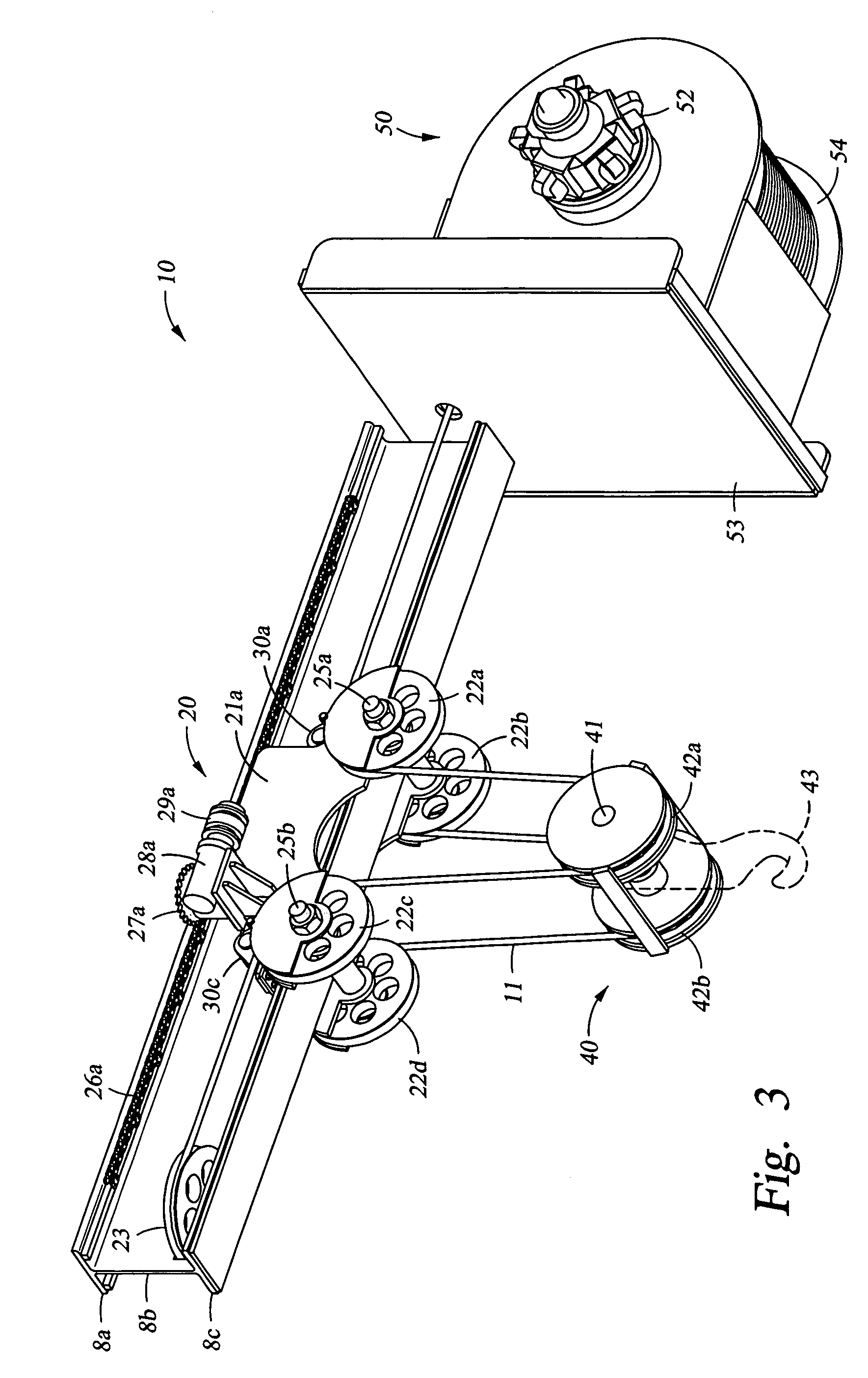

Compact hoist for drilling or workover rig

InactiveUS20060180564A1Expands vertical and horizontal rangeExpanding the range of operation increases usable rig storage spaceTrolley cranesTravelling gearLifting capacityWell drilling

The present invention provides a compact hoist system for use on a drilling or workover rig. The present invention eliminates problems related to chain failures in hoist systems by incorporating wire rope in a vertically and horizontally compacted arrangement to provide maximum vertical lift capacity and improved versatility. Caterpillar bearings, wire rope tension equalizing sheaves and a winch coupled to a axially movable spiral-grooved drum are combined to provide a system that enables cantilever jack-up rigs to handle blow-out preventer stacks of increased height and size.

Owner:KEPPEL JAMES R

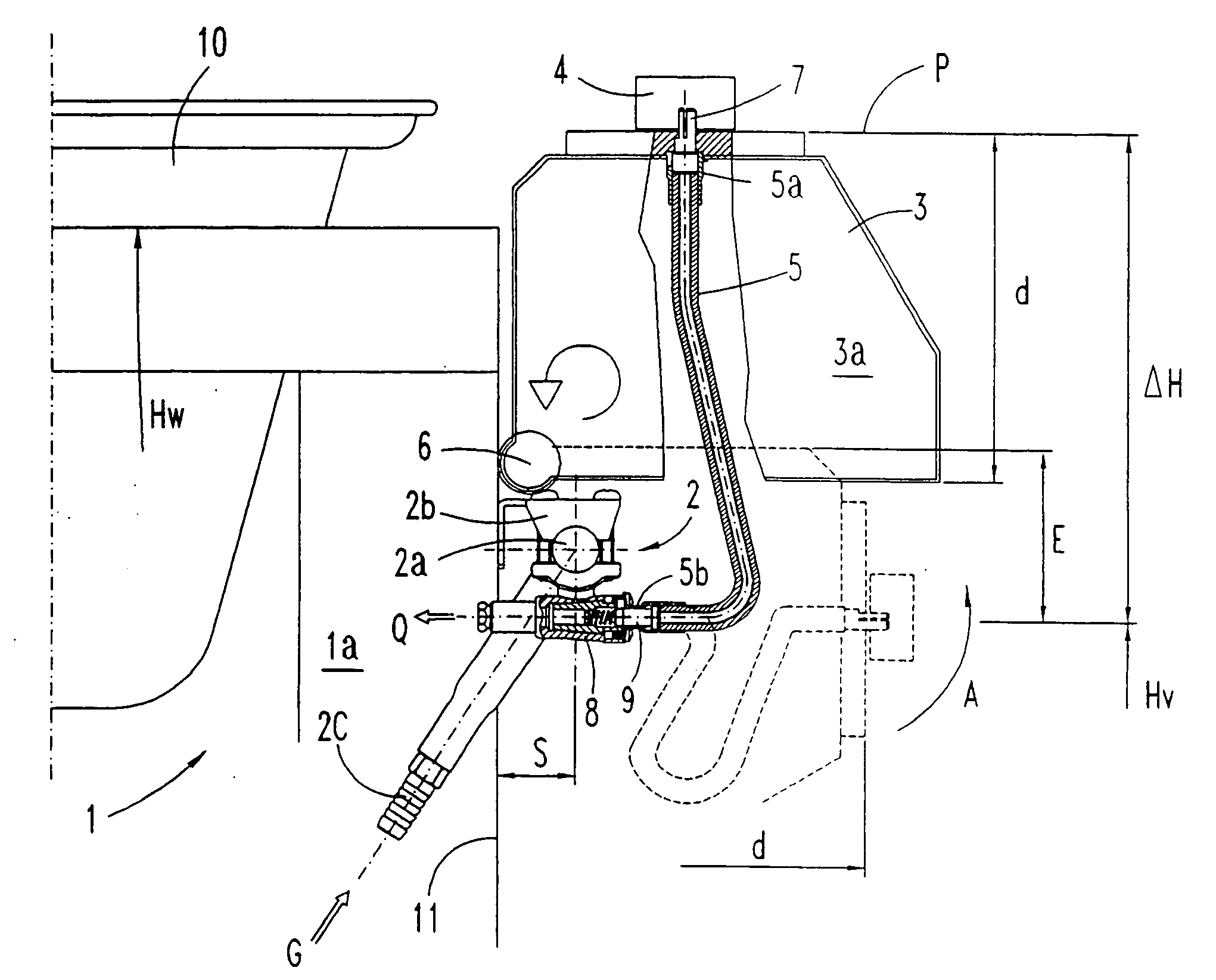

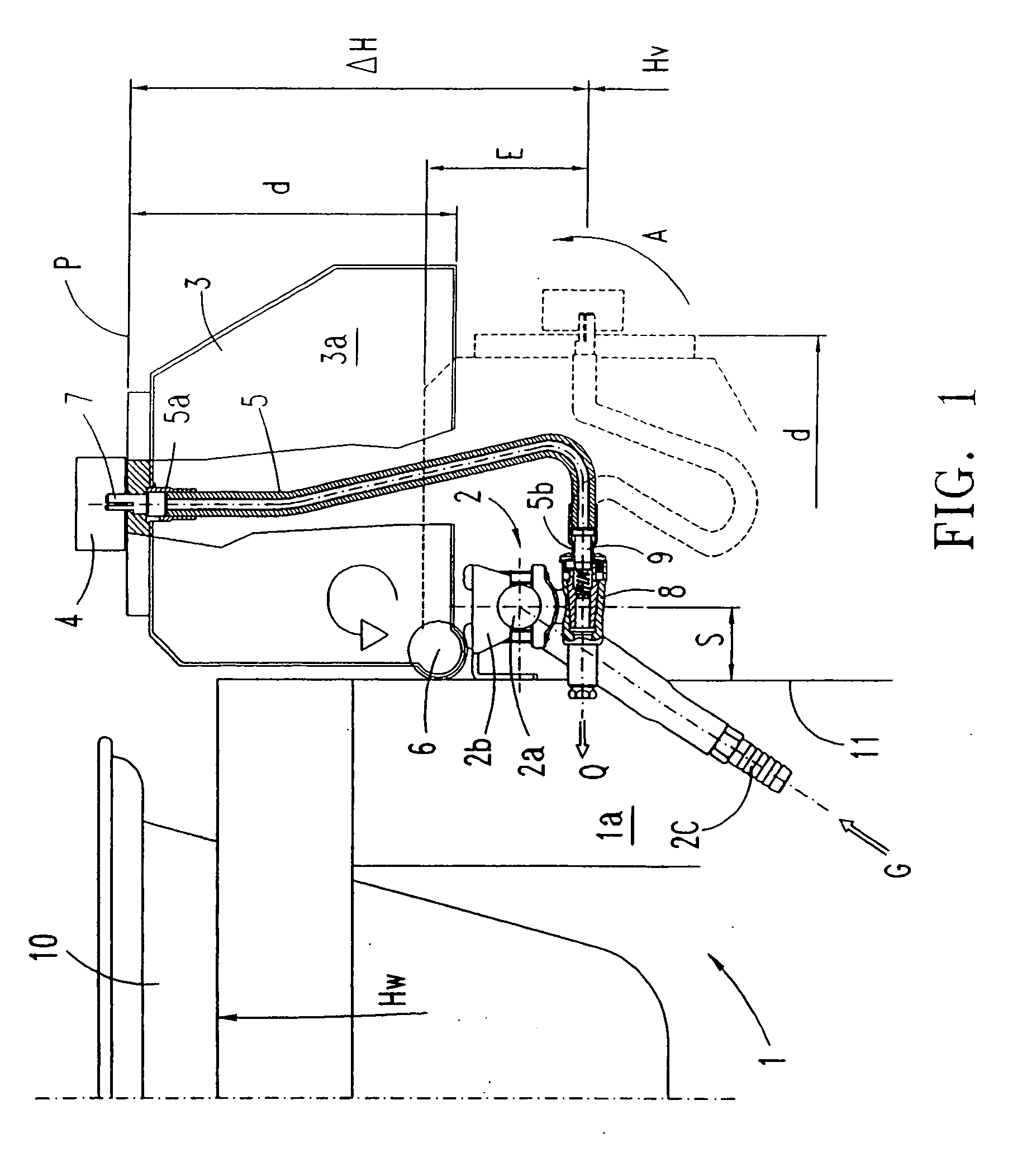

Gas cooker appliance with an orientable control panel

InactiveUS20070210069A1Convenient heightDomestic stoves or rangesLighting and heating apparatusRest positionEngineering

The cooker appliance (1) has a horizontal cooking surface (10) of a given height (Hw), a gas “G” manifold assembly (2) with a plurality of taps (8) provided with a rotary shaft (9) for regulating the gas flow (Q), supported in a fixed position apart from one another on a front support wall (11) and at a given height (Hv) of the appliance. The control panel (3) provided with each of the rotary tap control knobs (4) is orientable up to as much as a right angle (A) by means of a pivoting axle (6), whereby the control knobs (4) are positioned either downwards in a rest position or else upwards at the level of the cooking plane (10) for the regulating manoeuvre, on a horizontal plane (P) at an increased height “Hv+Hv”. The control knob shafts (7) are coupled to the taps (8) by means of a flexible shaft (5) for transmitting the respective rotation, extended within a cavity (3a) for housing the taps (8) which is formed by the control panel.

Owner:COPRECITEC

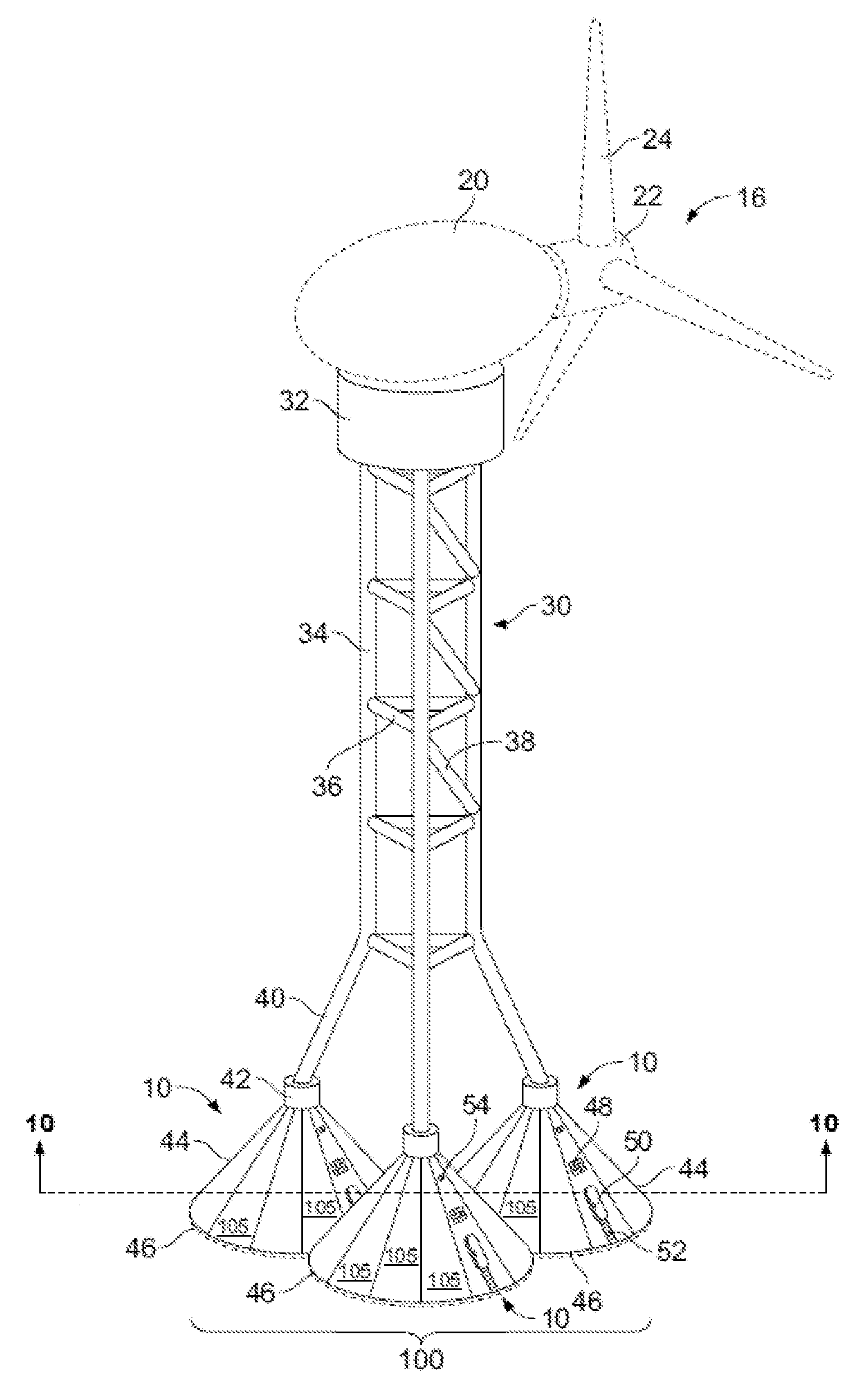

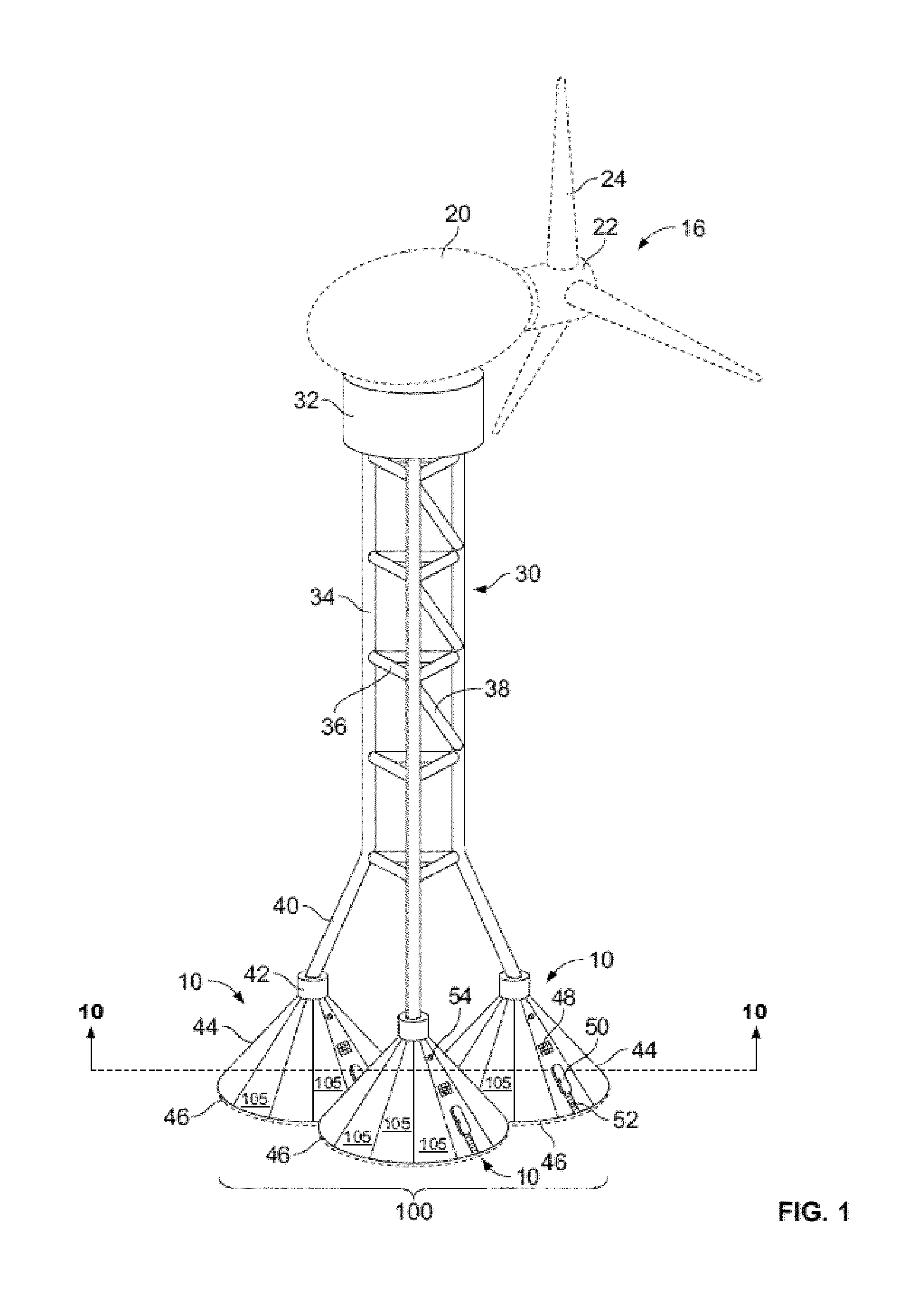

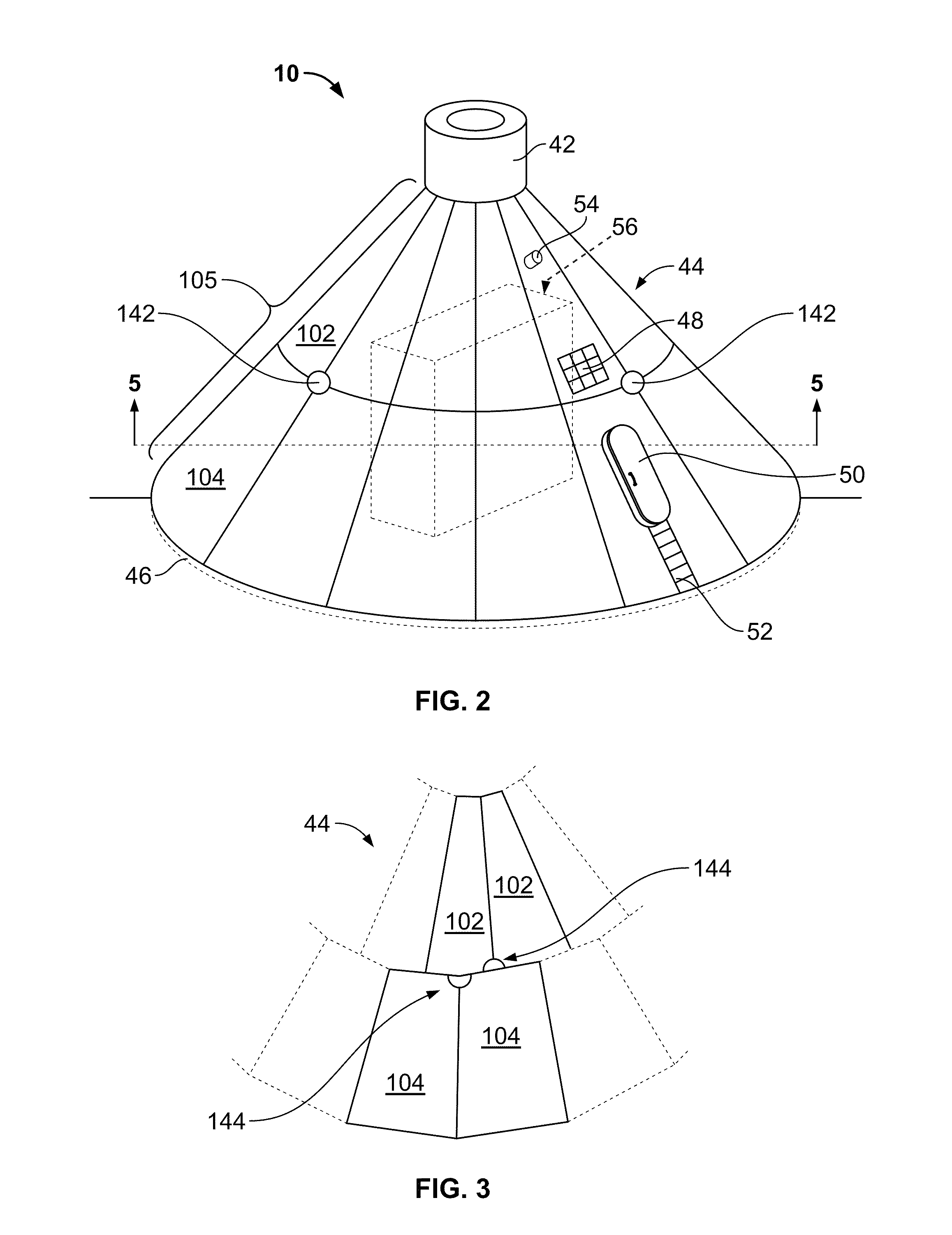

Modular surface foundation for wind turbine space frame towers

InactiveUS20100132270A1Reduce excavation costsLess material to installTransformer housesWind motor assemblyInterior spaceTower

A modular surface foundation for wind turbine space frame towers, an apparatus to form panels of housing members of modular surface foundation, and method of forming the modular surface foundation for wind turbine space frame towers is provided. The modular surface foundation comprises a plurality of footing members, and a housing member disposed on each of the footing members, the housing members extending from the footing members and attaching to one or more structural members forming a portion of a wind turbine tower, wherein the housing member provides support and increased height for the space frame tower and includes an interior space.

Owner:GENERAL ELECTRIC CO

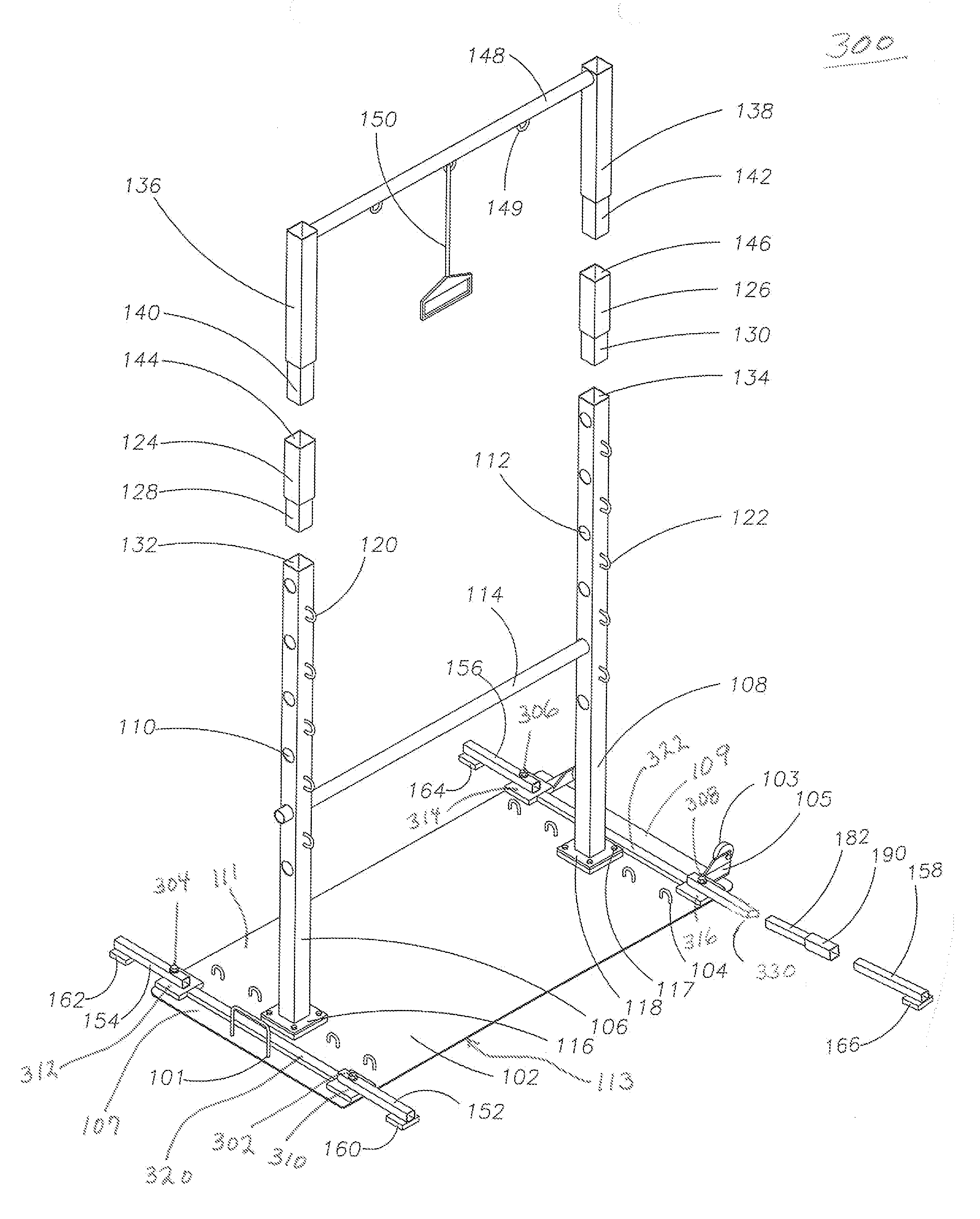

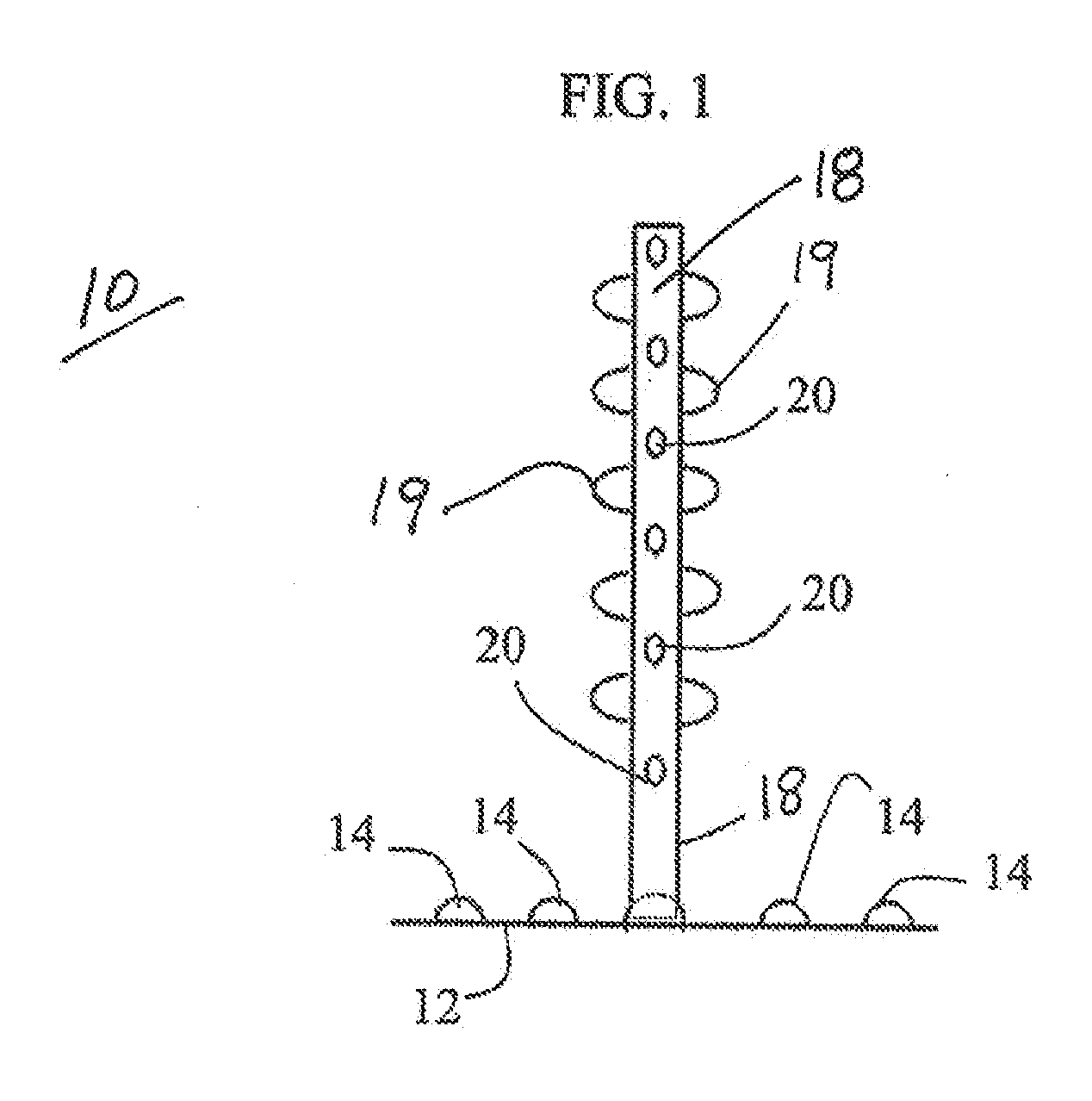

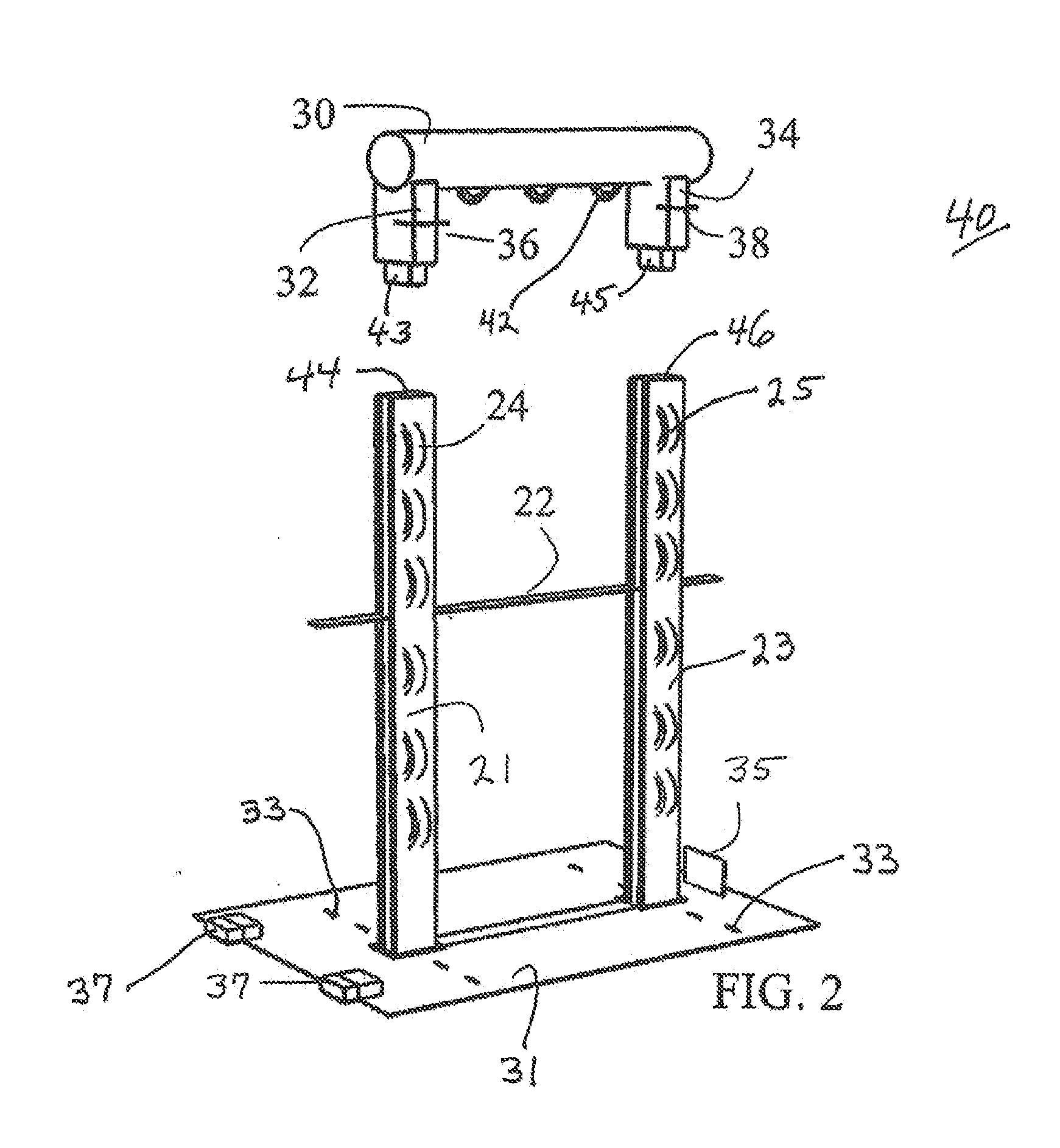

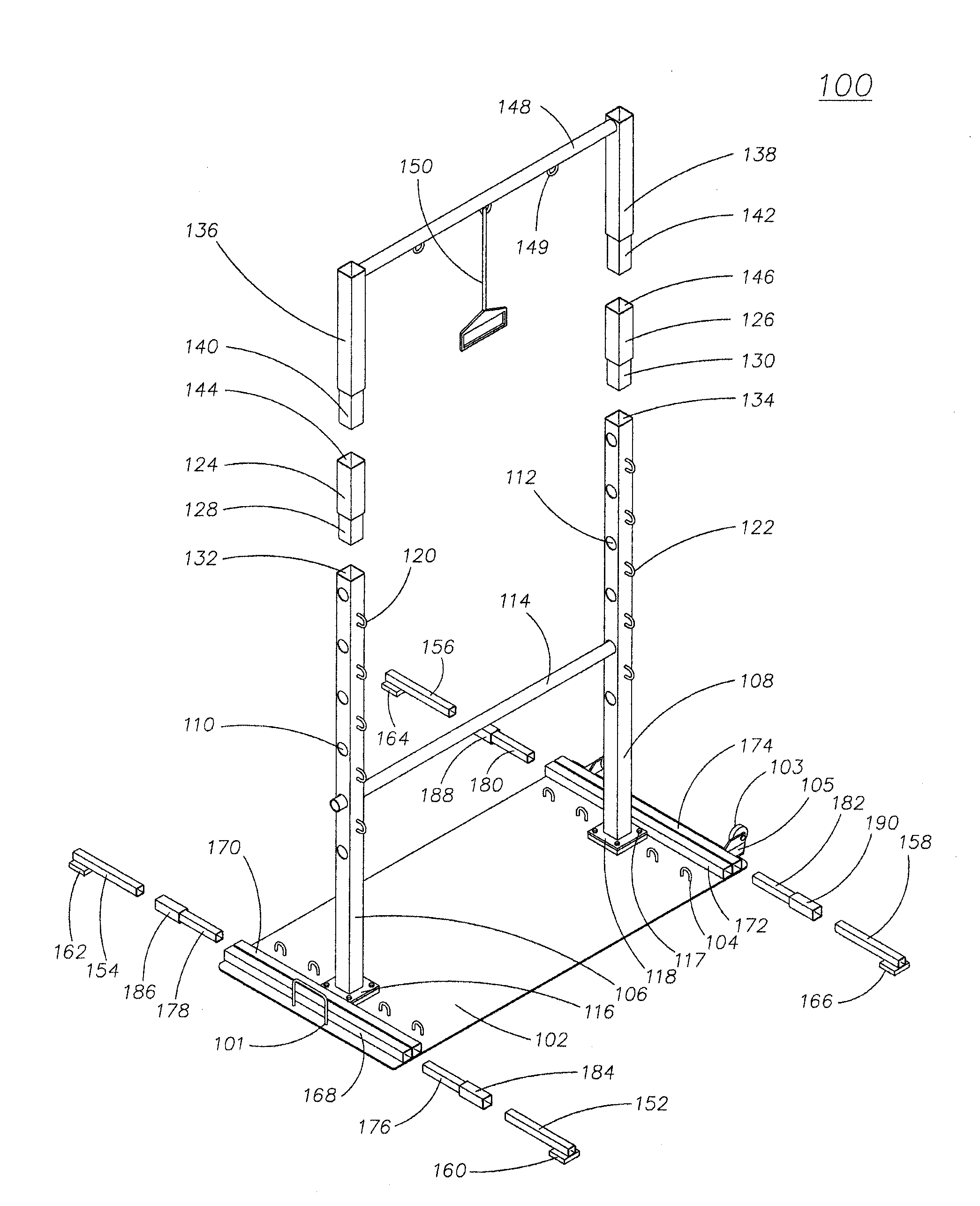

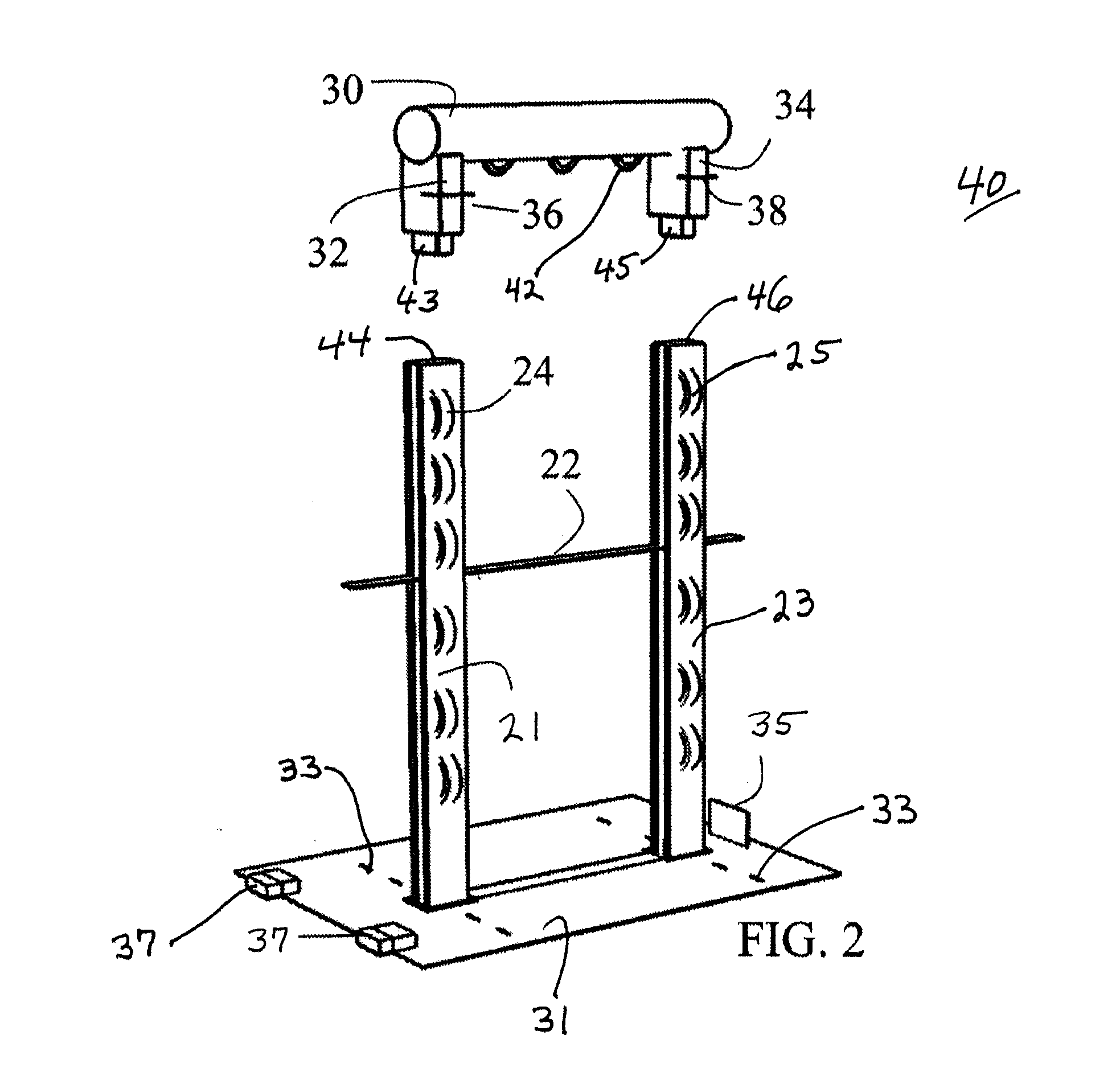

Apparatus for Performing Body Exercises Having Pivotally Mounted Stabilizers

Exercise apparatus having vertical towers rigidly attached to a base plate, including tower extensions that slide inside the tops of the vertical towers to increase their height, and further including base stabilizer leg extensions connected to the base plate to further stabilize the apparatus due to increased height. Base stabilizer mounts are secured to the top of the base plate for receiving base stabilizer legs that extend from the base plate to provide additional stability to the exercise apparatus during operation. Base stabilizer leg extensions can be included to extend the length of the base stabilizer legs. Each of the base stabilizer mounts are aligned along different geometric lines, and do not share any common geometric lines. Stabilizer arms also can be pivotally mounted to the corners of the base plate to provide additional directional stability for the exercise apparatus.

Owner:ROCHFORD TIMOTHY S

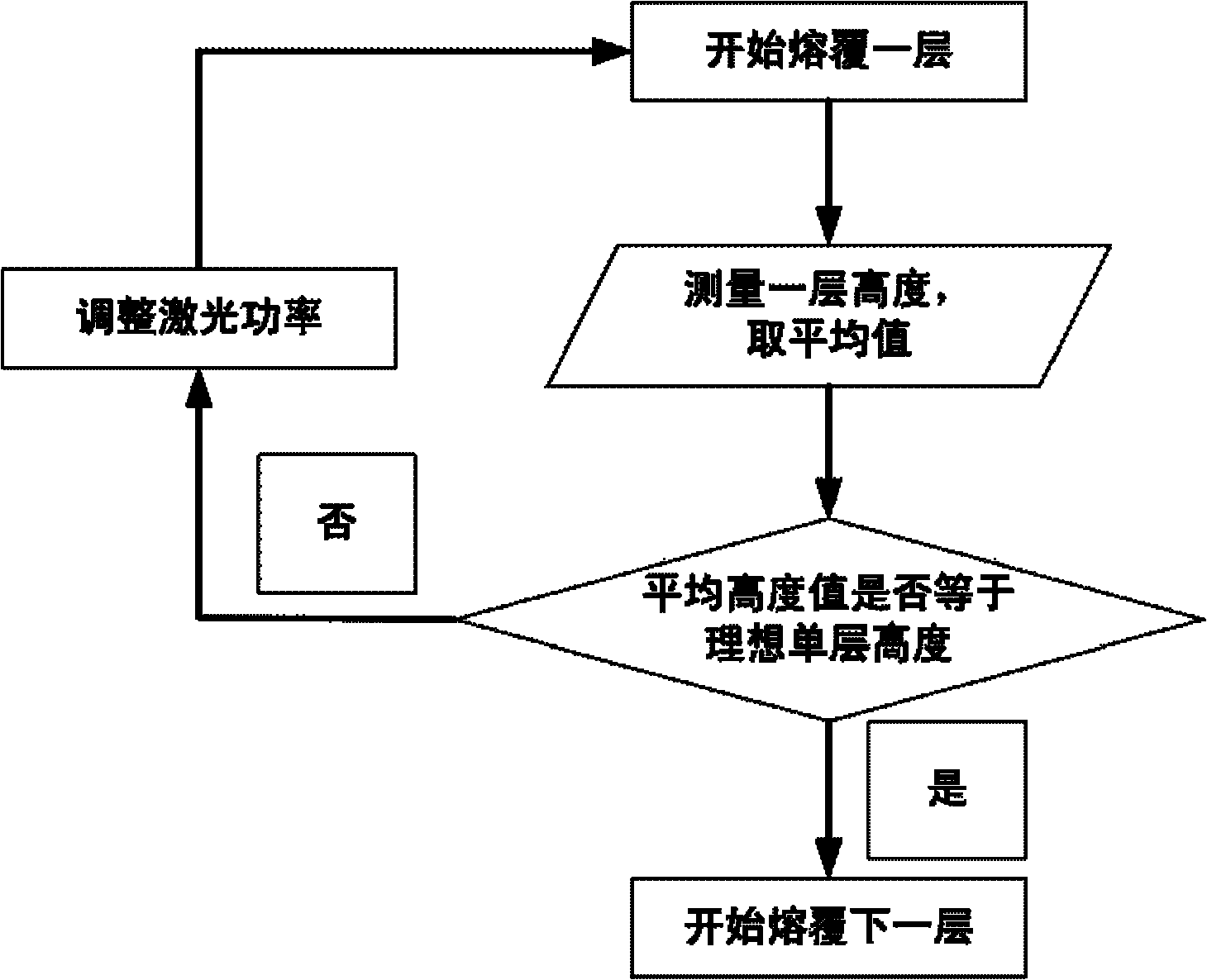

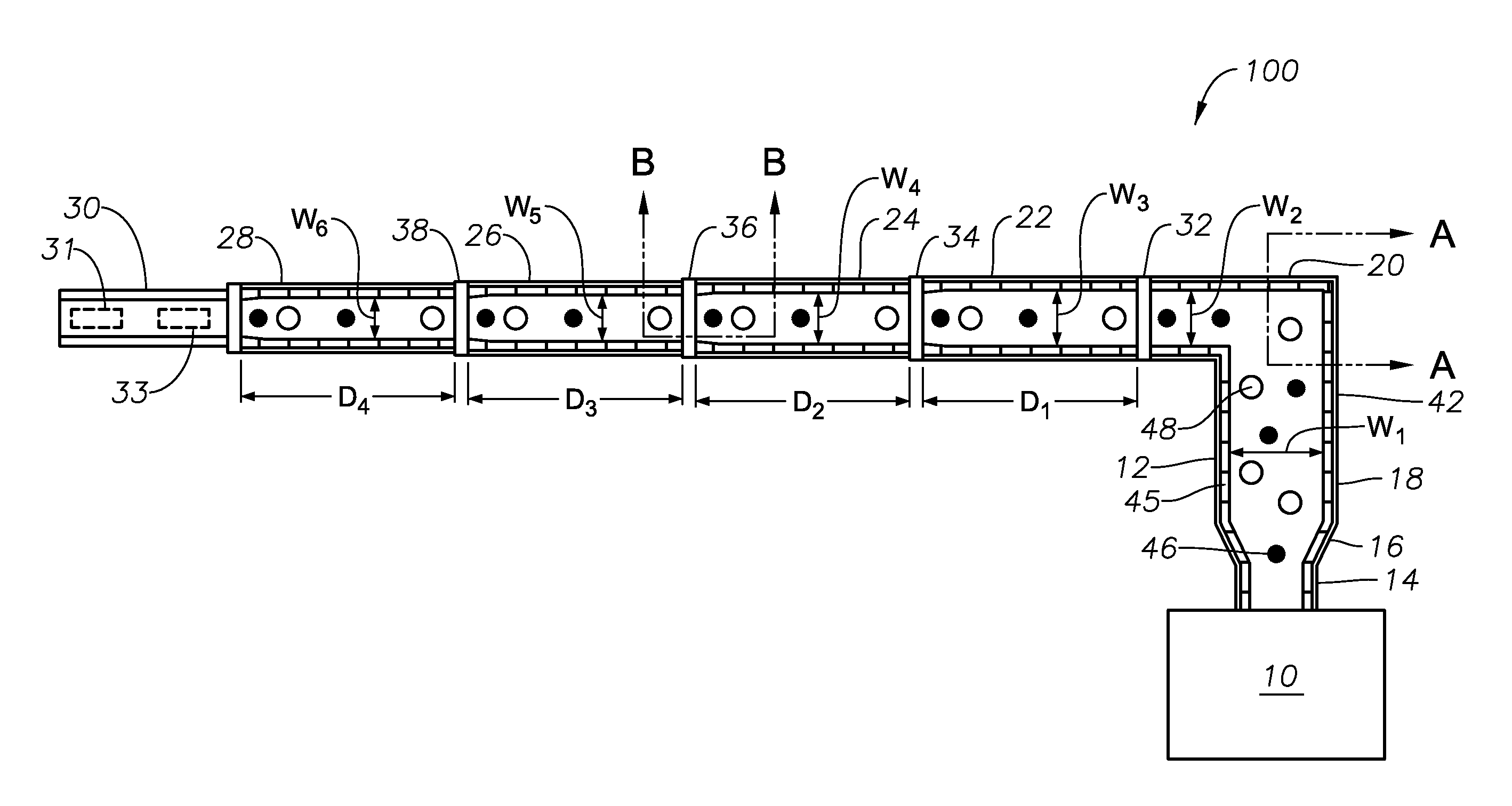

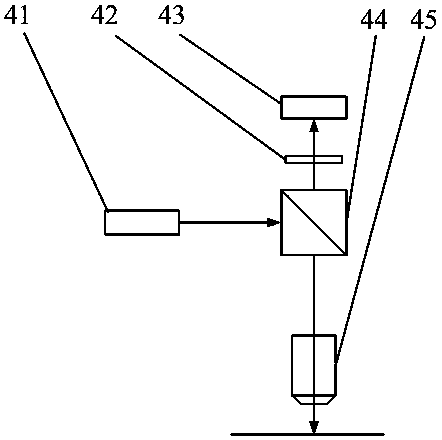

Method for detecting and controlling laser metal forming height on line

InactiveCN101893426AHeight uniform growthLaser formed surface smoothingUsing optical meansMetallic material coating processesMetal formingSpray nozzle

Owner:XI AN JIAOTONG UNIV +1

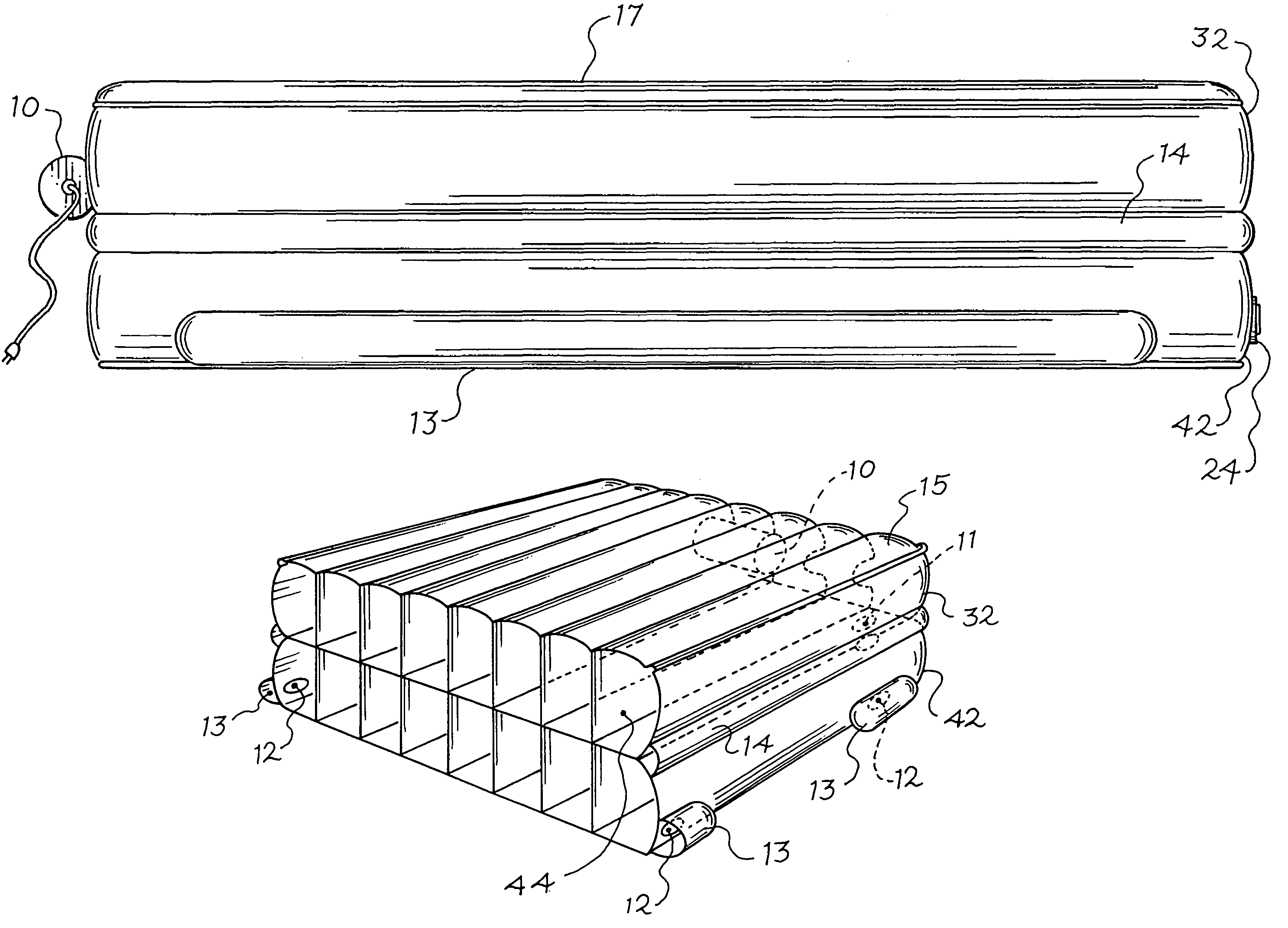

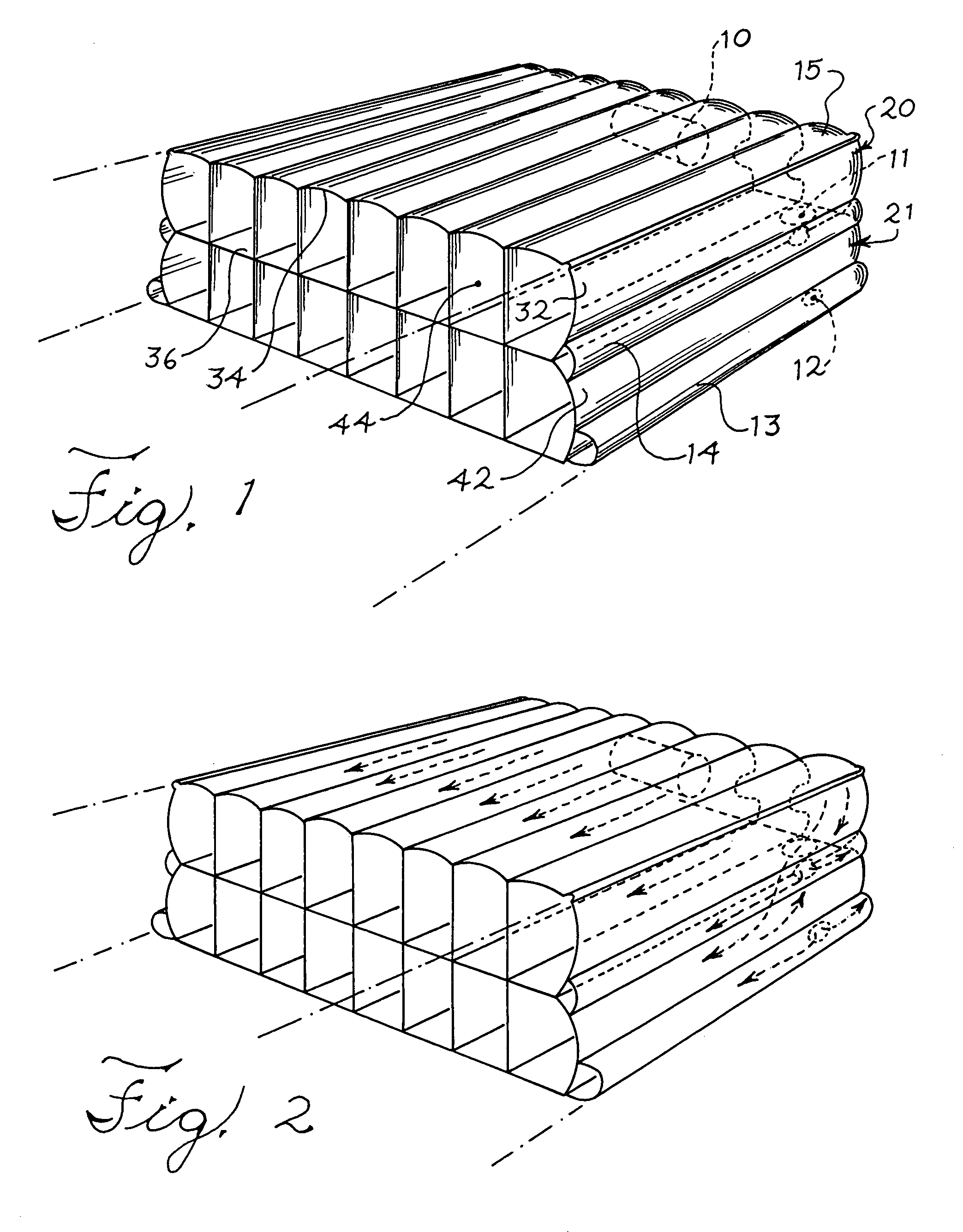

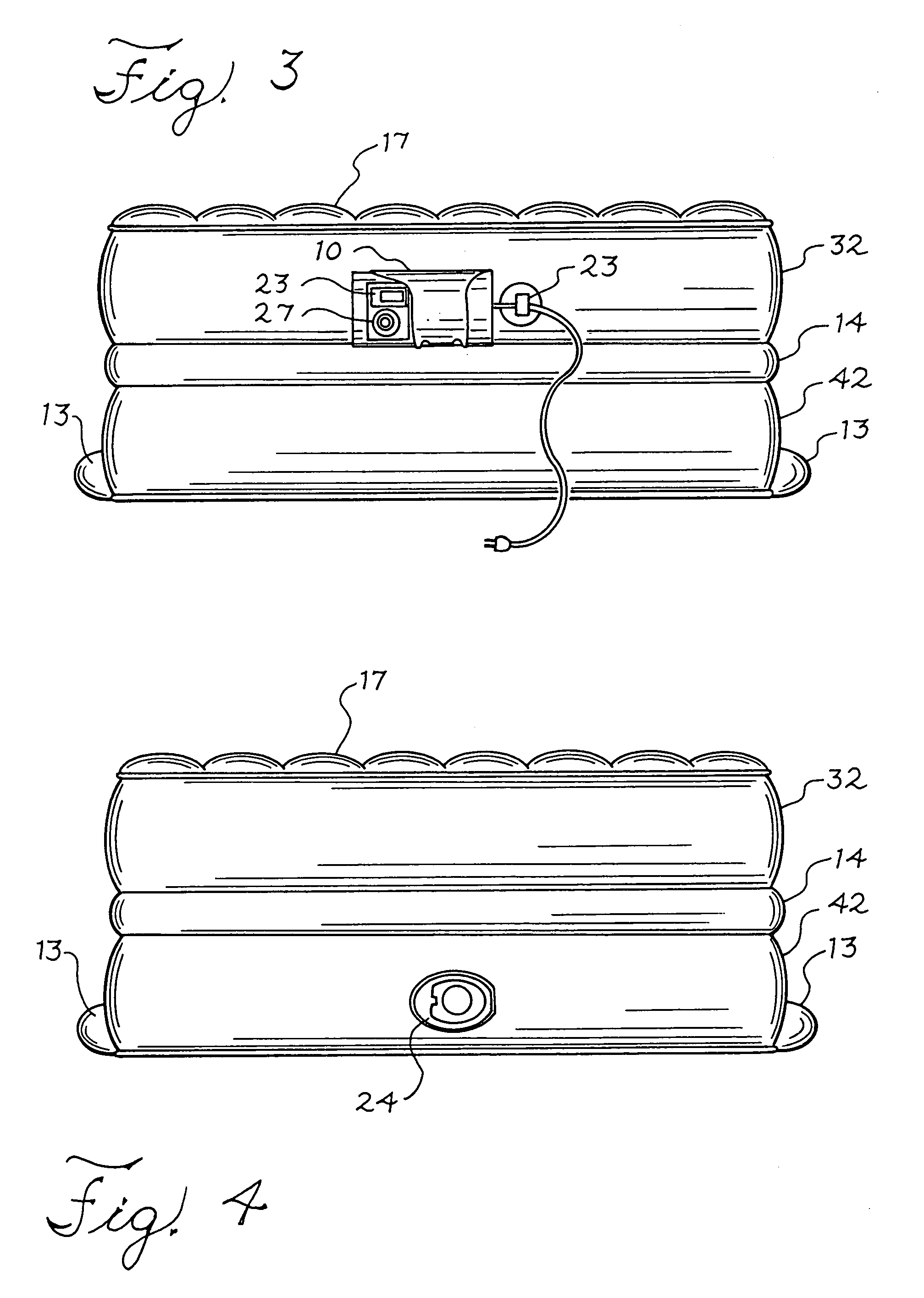

Increased height inflatable support system

InactiveUS6996867B2Increase surface areaDistribute weightStuffed mattressesSpring mattressesSupporting systemEngineering

An inflatable mattress is provided having an upper and a lower inflatable support chamber which are arranged in a substantially vertical manner. Each inflatable support chamber has a top layer, a bottom layer, and a side gusset. At least one inflatable stabilizing component is attached at the bottom layer of the lower inflatable support chamber and is of a height less than the height of the lower inflatable support chamber.

Owner:THE COLEMAN CO INC

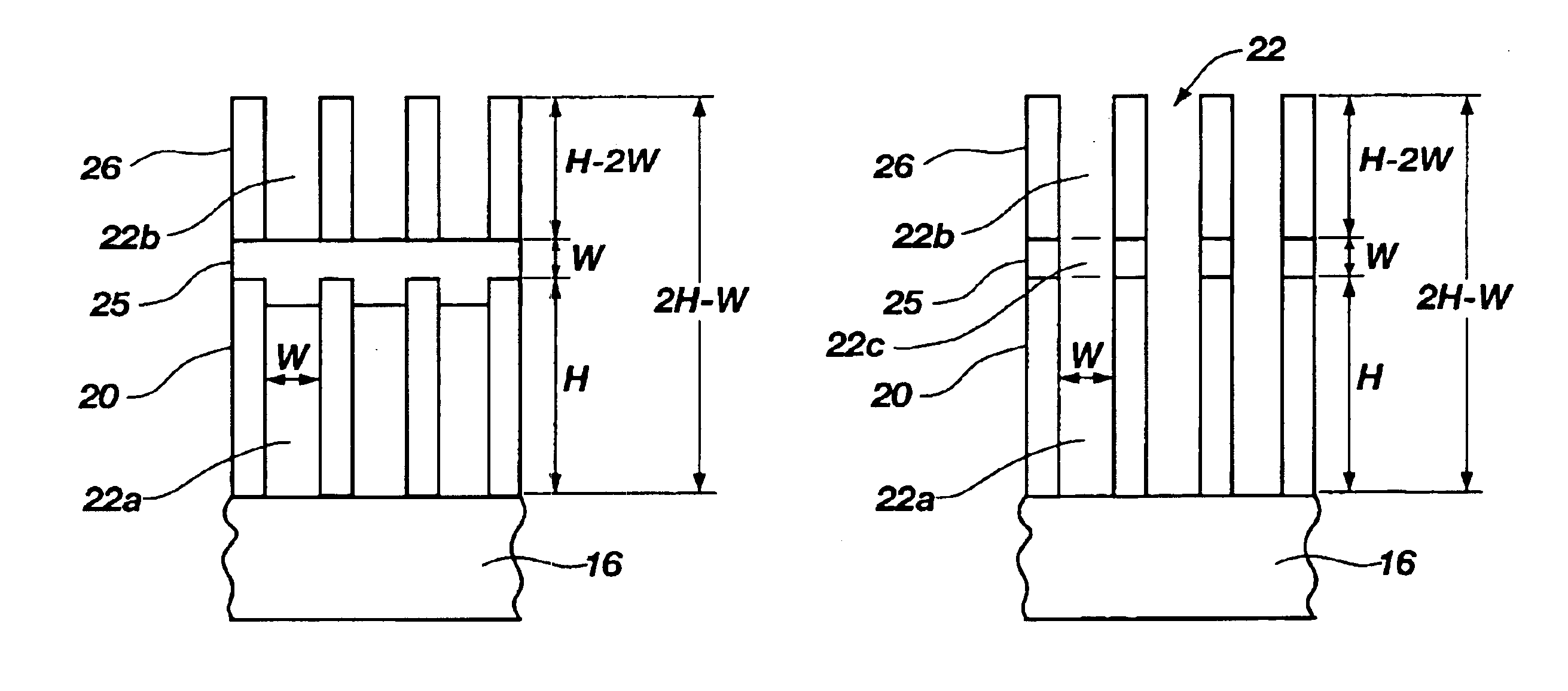

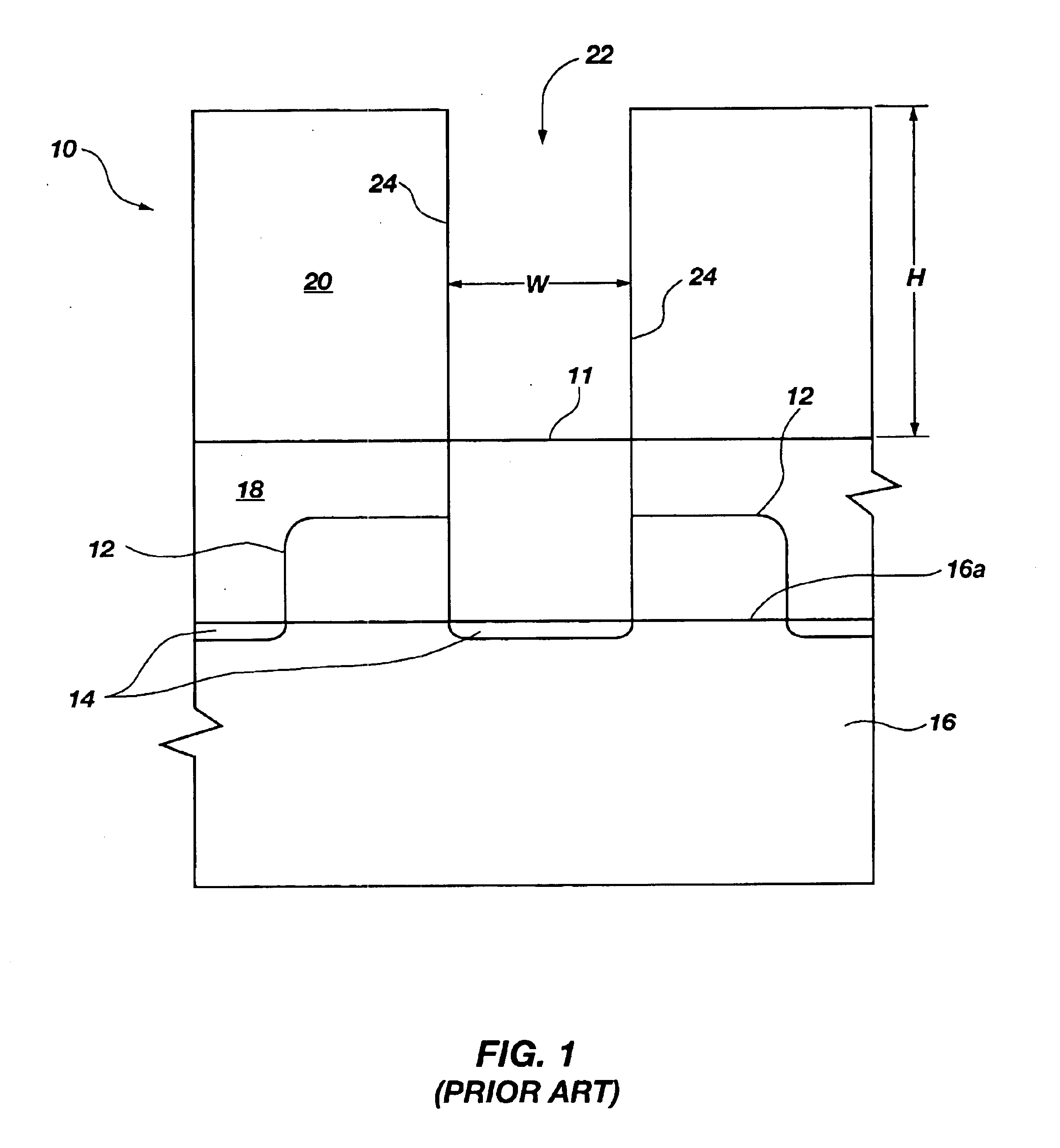

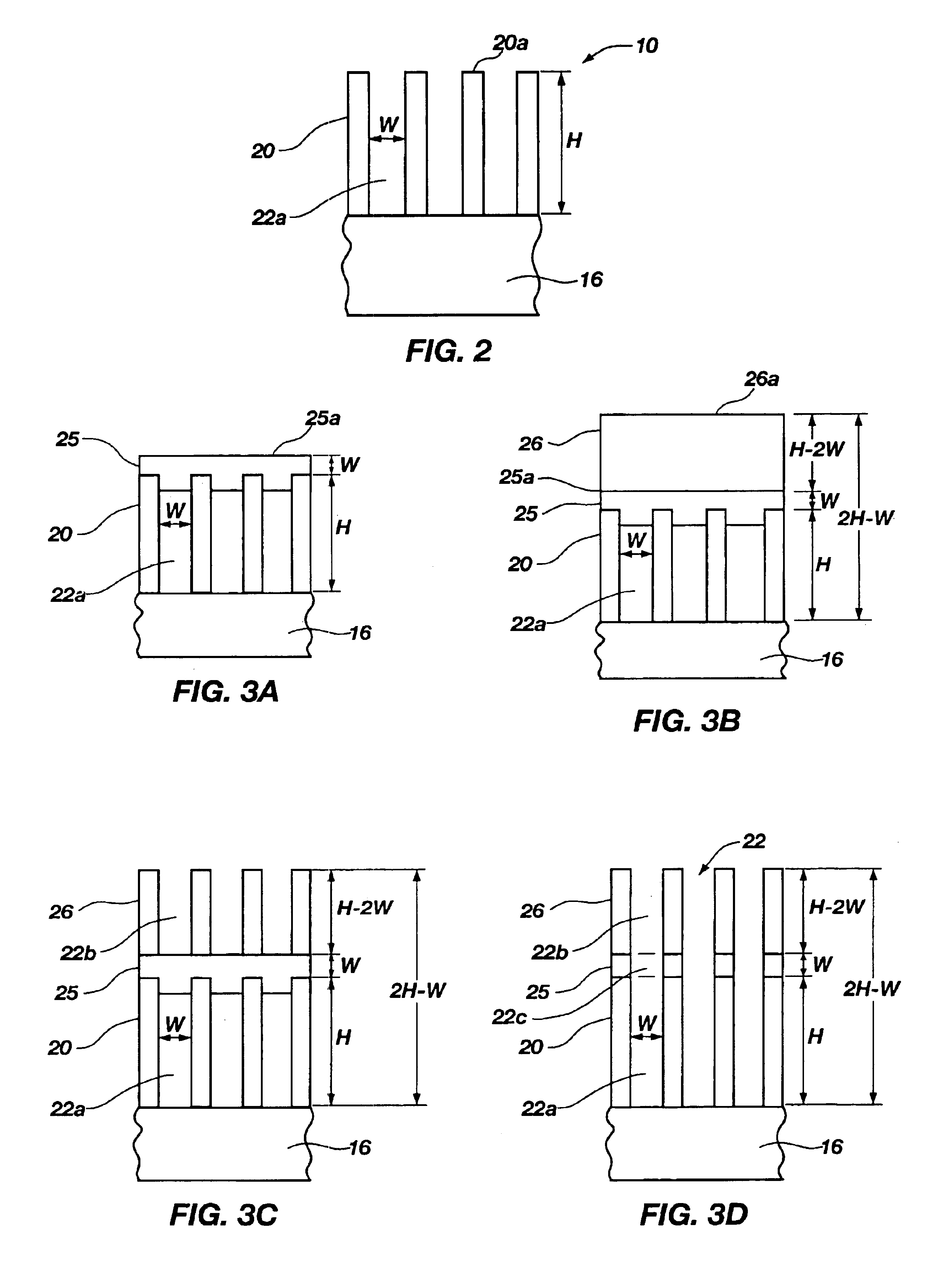

Methods for making semiconductor device structures with capacitor containers and contact apertures having increased aspect ratios

InactiveUS6927170B2Increase heightHigh aspect ratioTransistorSolid-state devicesInterconnectionEngineering

Semiconductor device structures and methods of making such structures that include one or more etched openings (e.g., capacitor containers and / or contact apertures) therein with increased height-to-width ratios are provided. The structures of the present invention are formed by successive layer deposition wherein conventional patterning techniques may be utilized in a stepwise fashion as the height of the structure is increased. Further provided is a self-aligning interconnection structure which may be used to substantially vertically align openings formed in successively deposited, vertically placed structural layers of a semiconductor device. The interconnection structure utilizes a cap-and-funnel model that self-aligns to the center plane of an opening in a first structural layer and also substantially prevents subsequently deposited material from entering the opening.

Owner:MICRON TECH INC

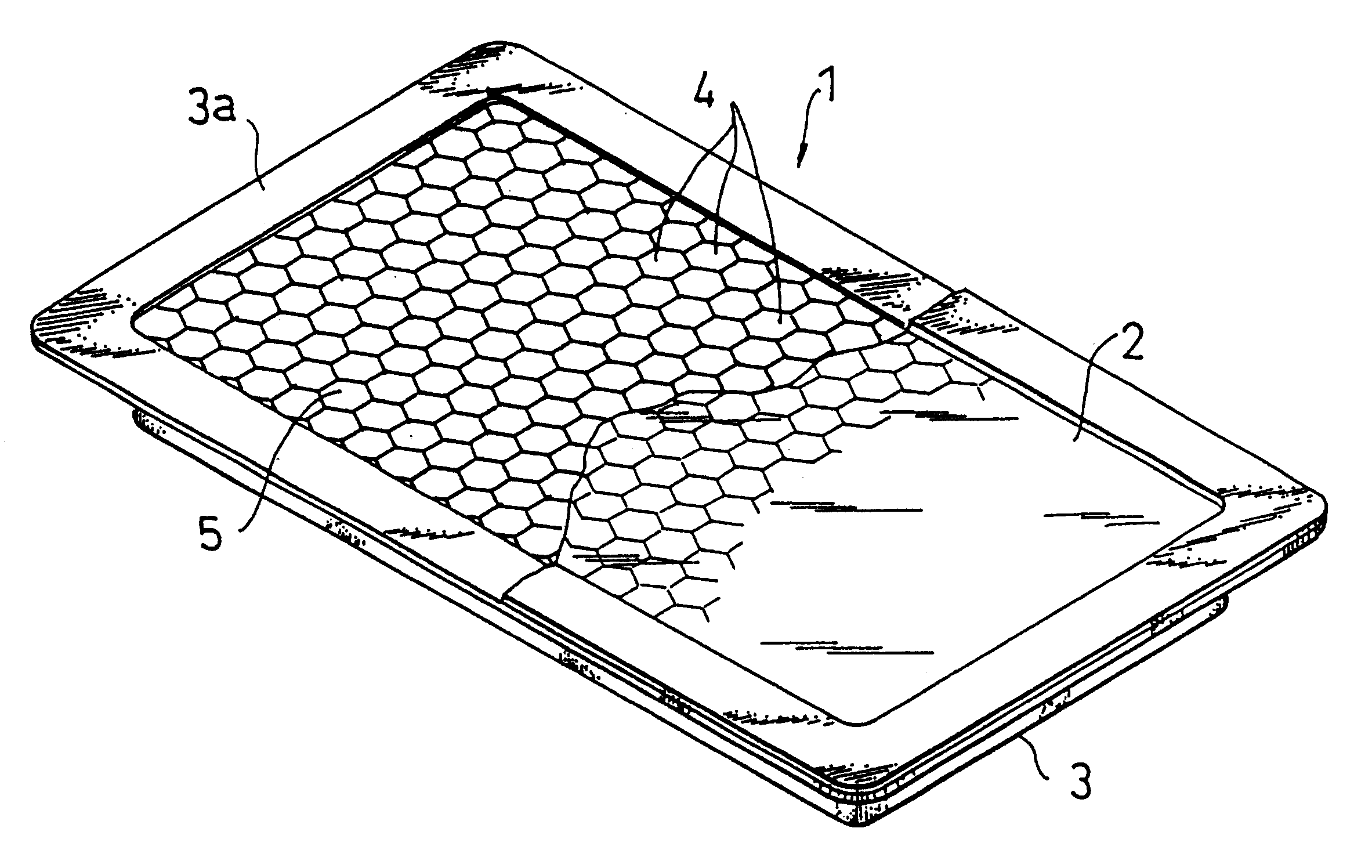

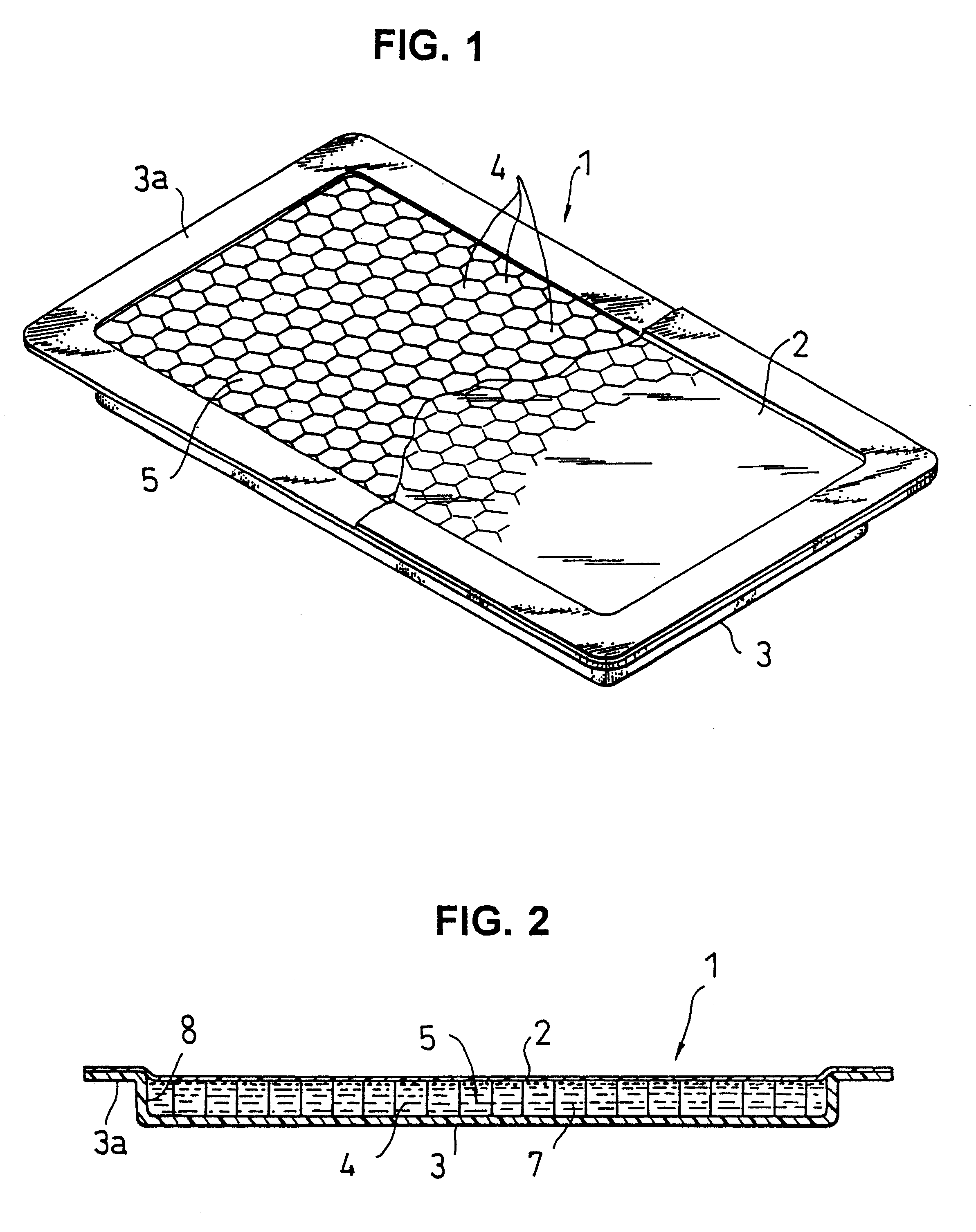

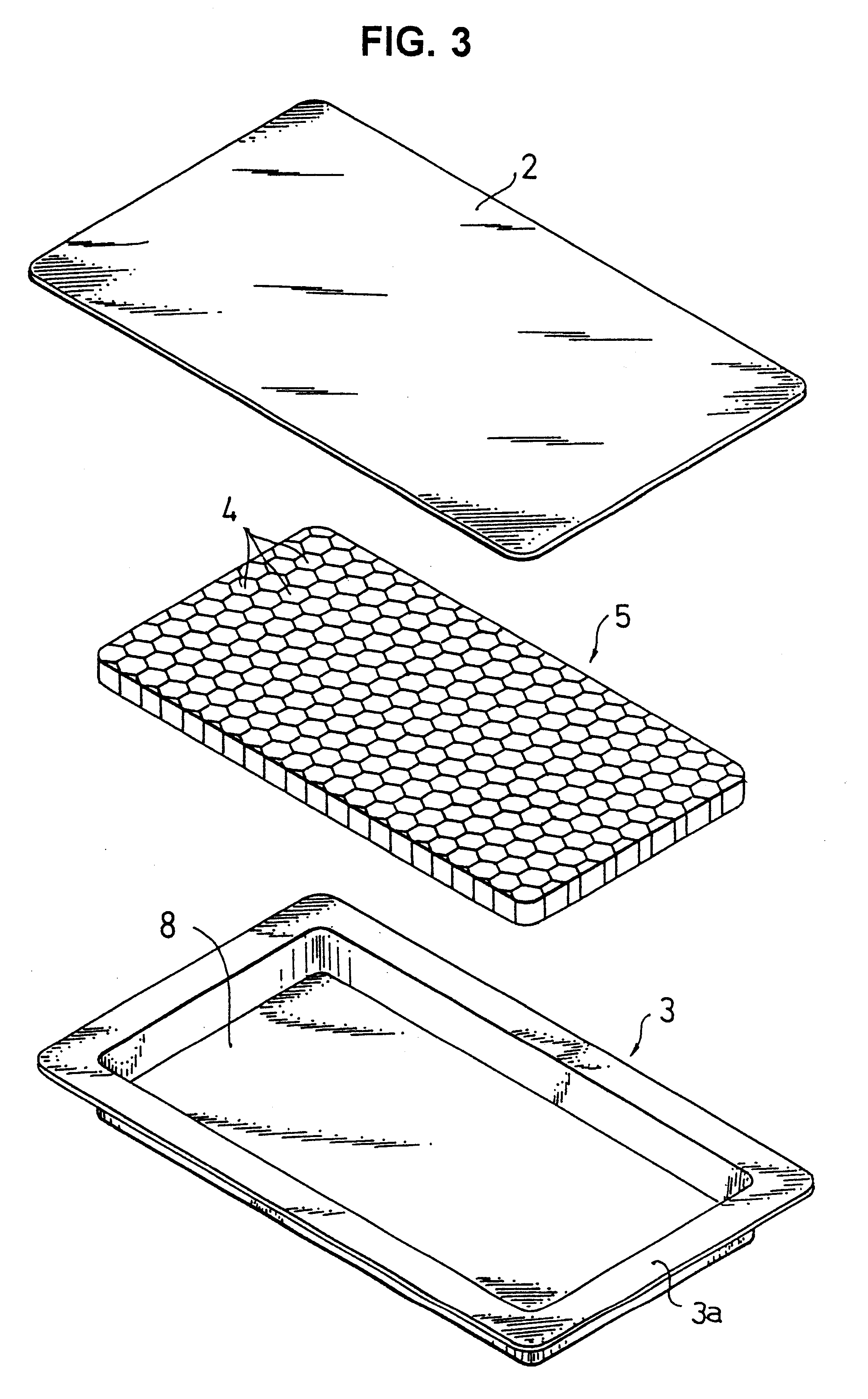

Magnetic display panel and method for producing the same

InactiveUS6629847B1Minimize damageAvoid breakingWriting boardsIdentification meansAdhesiveEngineering

A magnetic display panel capable of ensuring safety to the body of an infant, permitting drawing of clear lines and ensuring safe disposal thereof. A magnetic display panel (1) includes a core housing (3) which has a peripheral edge (3a) formed to have an increased height and is formed therein with a recess (8), a plate-like face member (2) arranged so as to cover the recess (8), and a core block (5) provided with a number of cells (4) in which a plastic dispersion liquid (7) containing magnetic particles is encapsulated and sealedly joined between the core block (5) and the plate-like face member (2) by an adhesive. The core housing (3) and plate-like face member (2) are each made of olefin synthetic resin. One of the core housing (3) and plate-like face member (2) constitutes a drawing faceplate which is formed to be transparent or semi-transparent. The core block (5) is formed of pulp made paper.

Owner:TOMY CO LTD

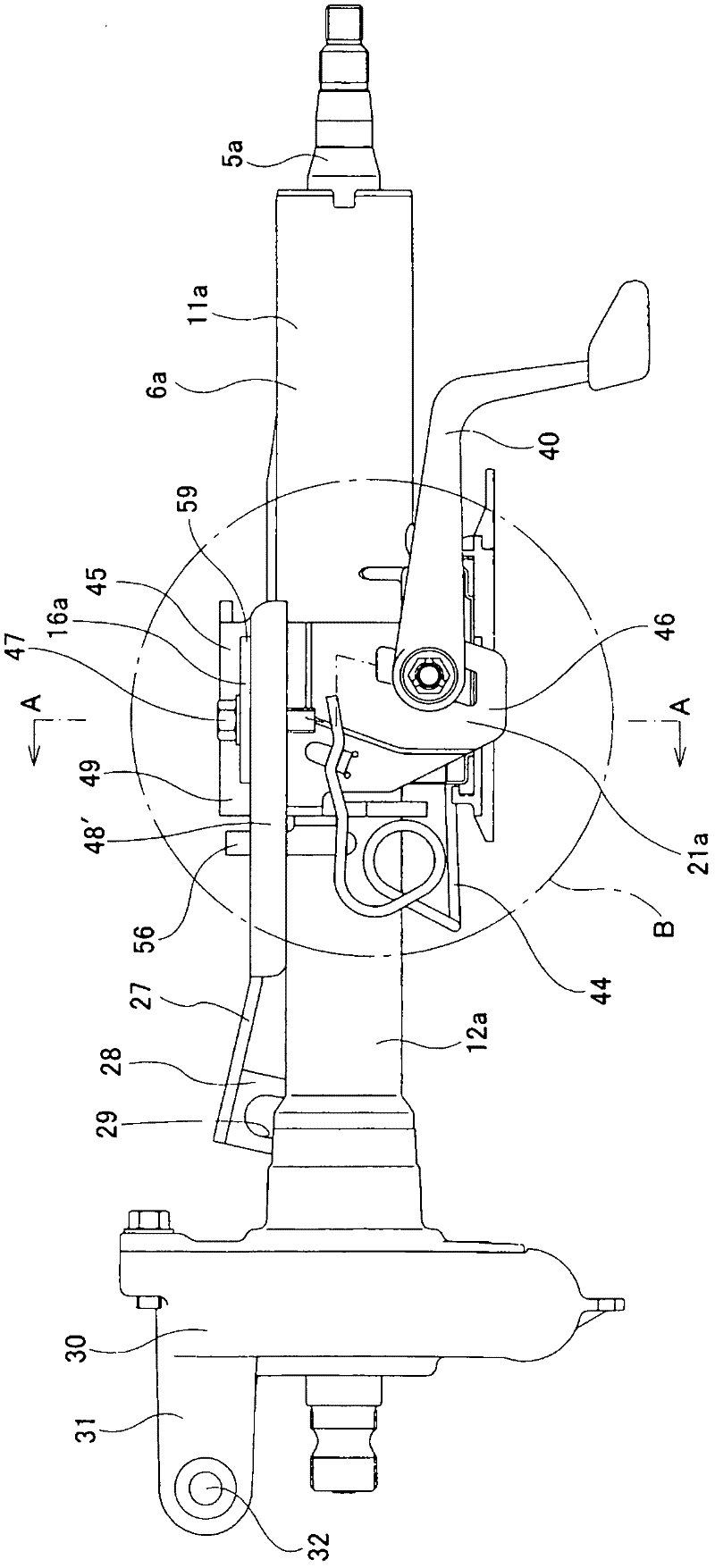

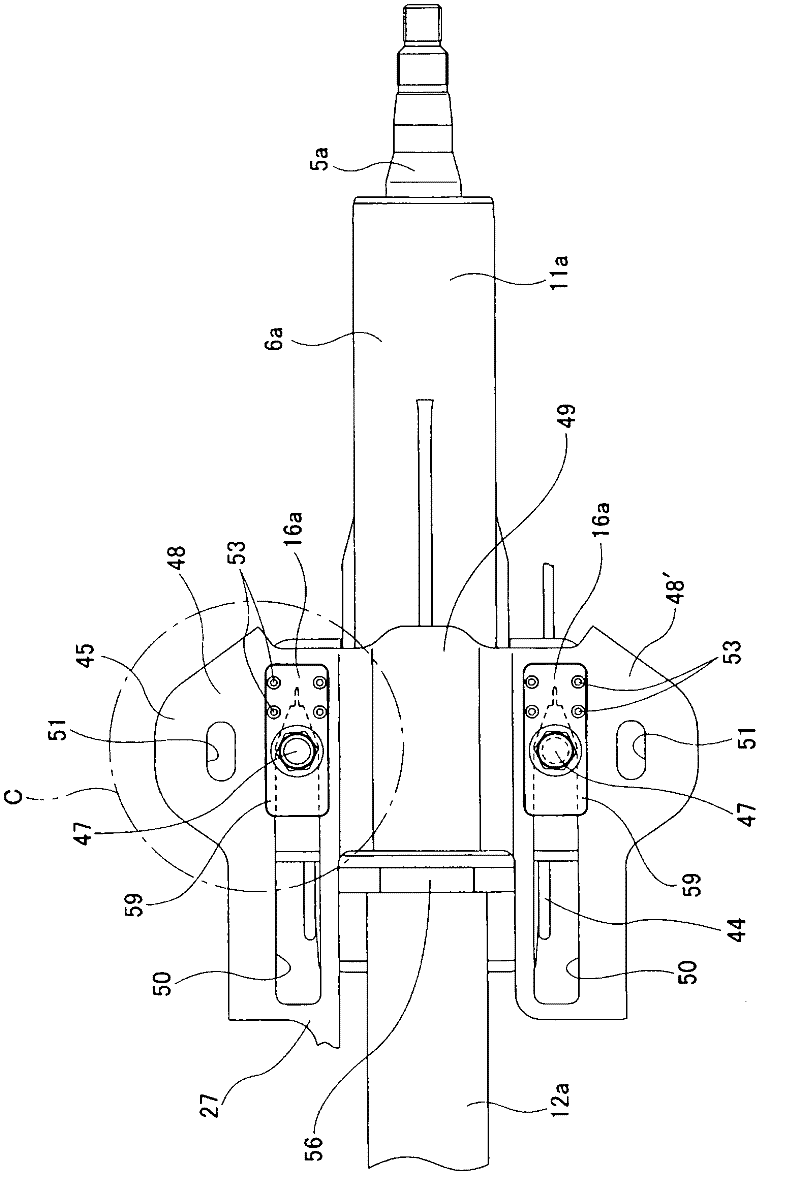

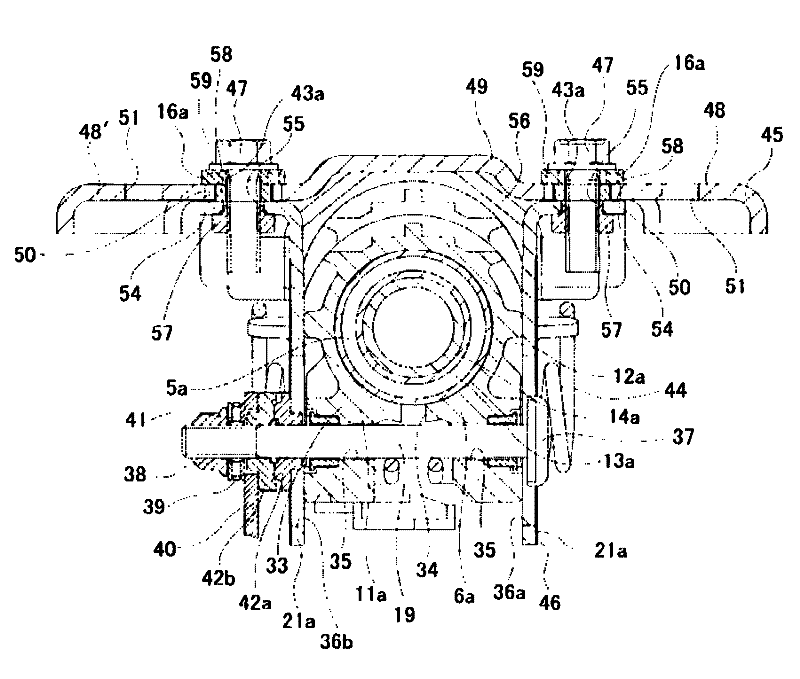

Steering column support device

ActiveCN102481945APrevent fallingSuppress height dimension increasePedestrian/occupant safety arrangementSteering columnsSteering columnEngineering

Disclosed is a structure which does not lead to increased height, which prevents a steering column (6a) from falling even if during second impact the steering column (6a) is displaced in the forward direction, and which, notwithstanding, ensures the function which allows smooth displacement of the steering column (6a) in the forward direction during second impact. The disclosed steering column support device is provided with a non-falling side bracket (45) fixed to the vehicle body, and a pair of bolts (47), a pair of support capsules (16a), and a falling side bracket (46) supported by the steering column (6a). During second impact, the supporting force of the support capsules (16a) against the non-falling side bracket (45) is lost, and the steering column (6a) is displaced in the forward direction along with the bolts (47) and support capsules (16a) and the falling side bracket (46), but the steering column (6a) does not fall off the non-falling side bracket (45).

Owner:NSK LTD

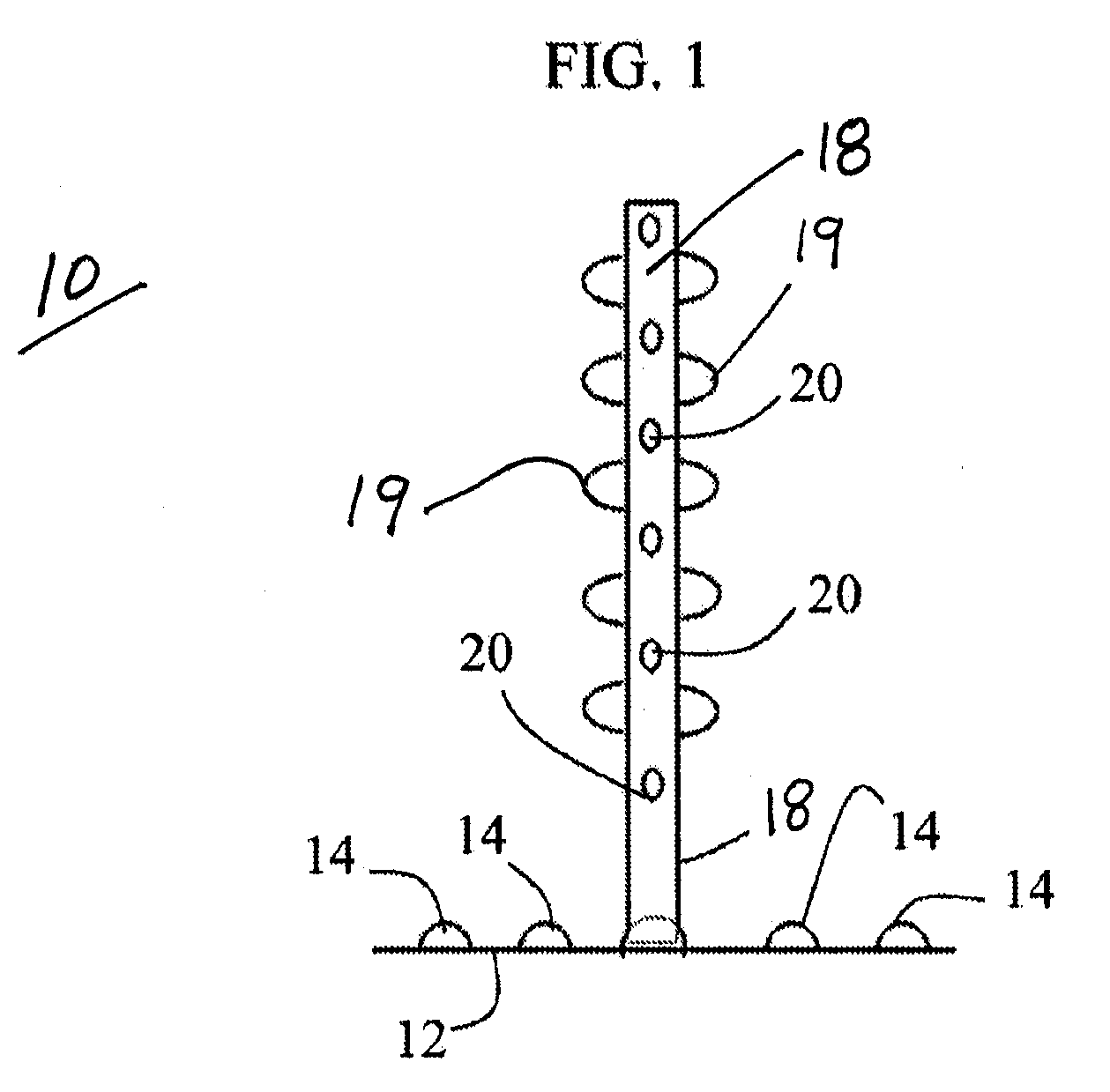

Apparatus for Performing Body Exercises

InactiveUS20110152046A1Improve stabilityIncrease the lengthHorizontal barsMuscle exercising devicesEngineeringIncreased height

Exercise apparatus having vertical towers rigidly attached to a base plate, including tower extensions that slide inside the tops of the vertical towers to increase their height, and further including base stabilizer leg extensions connected to the base plate to further stabilize the apparatus due to increased height.

Owner:ROCHFORD TIMOTHY S

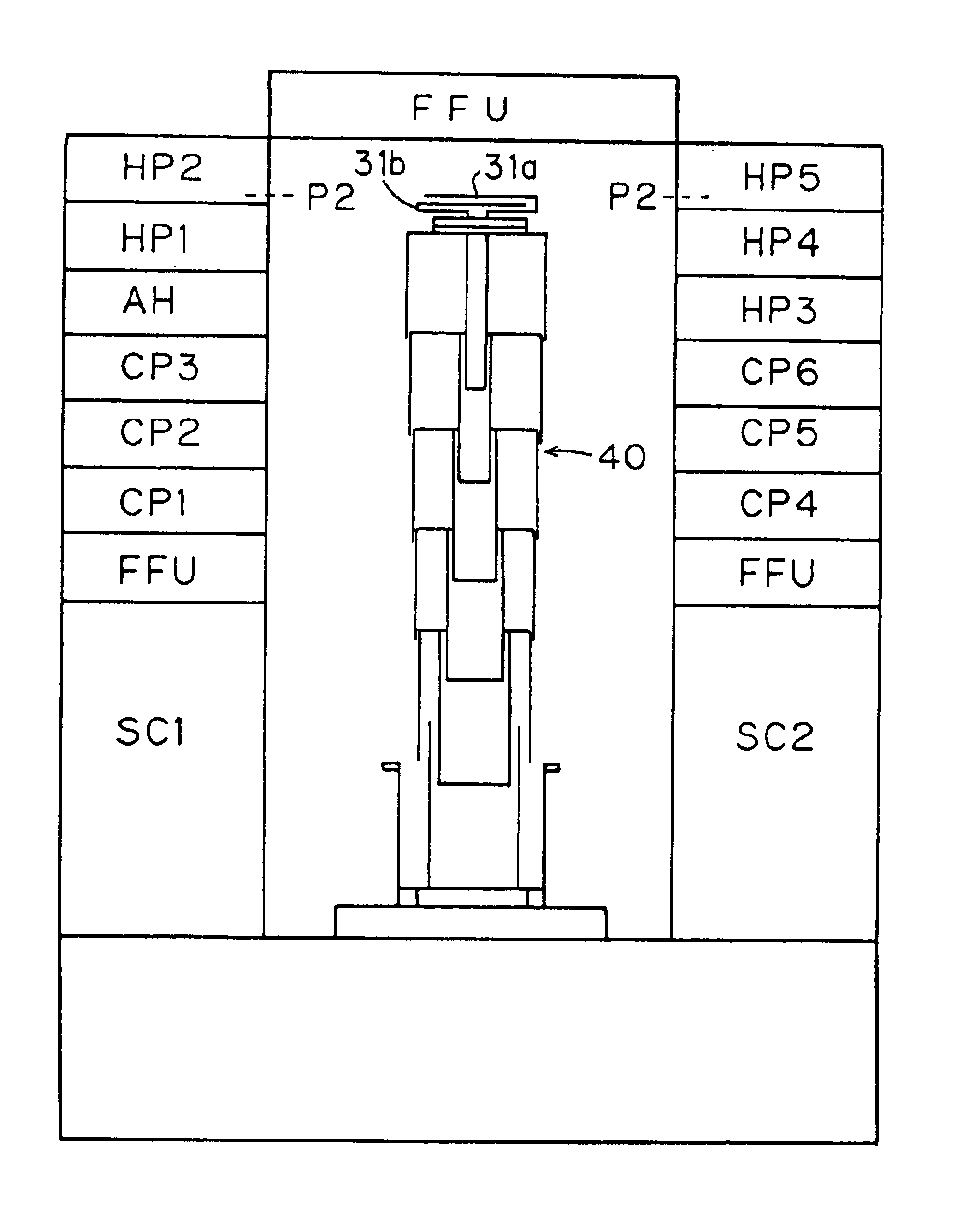

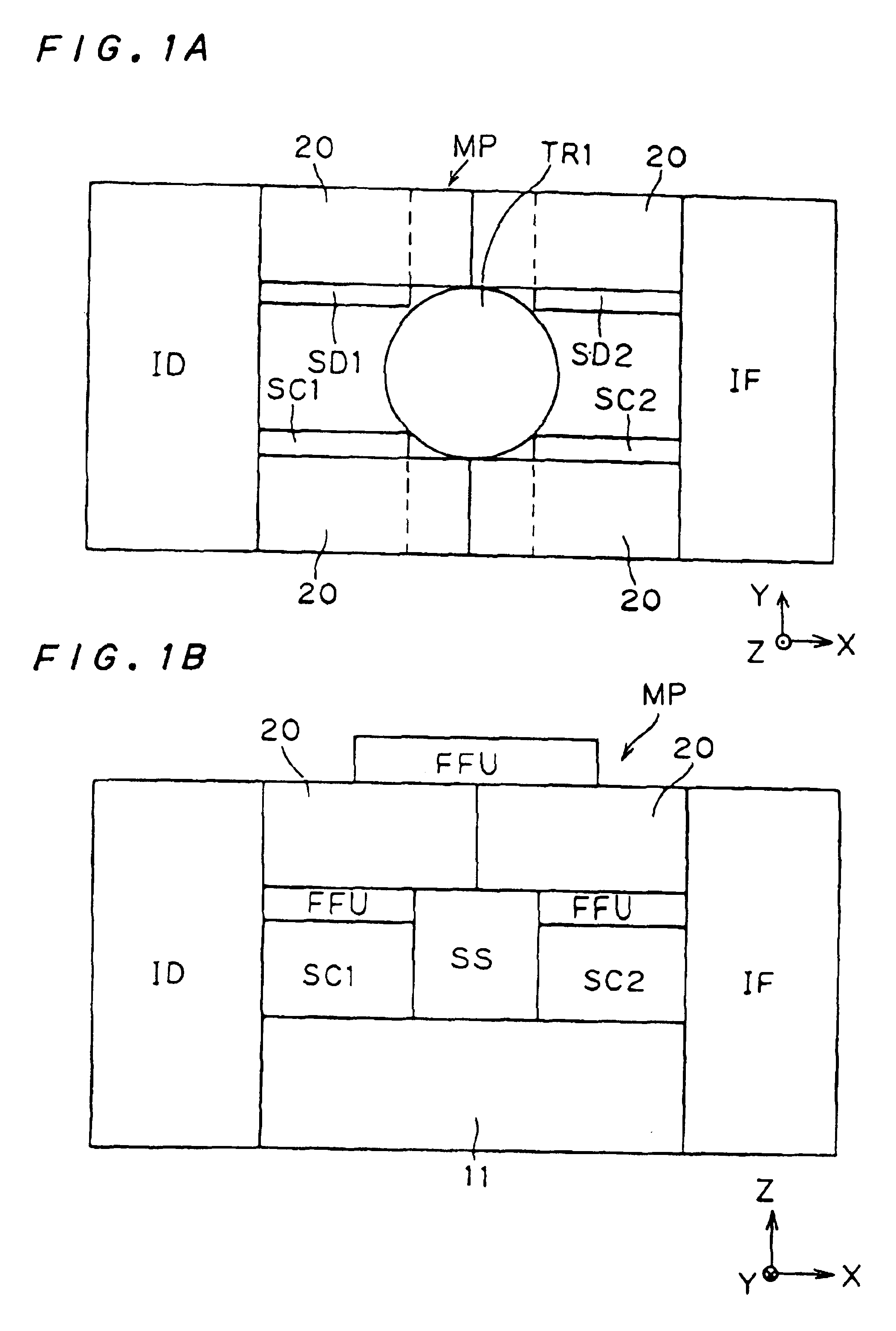

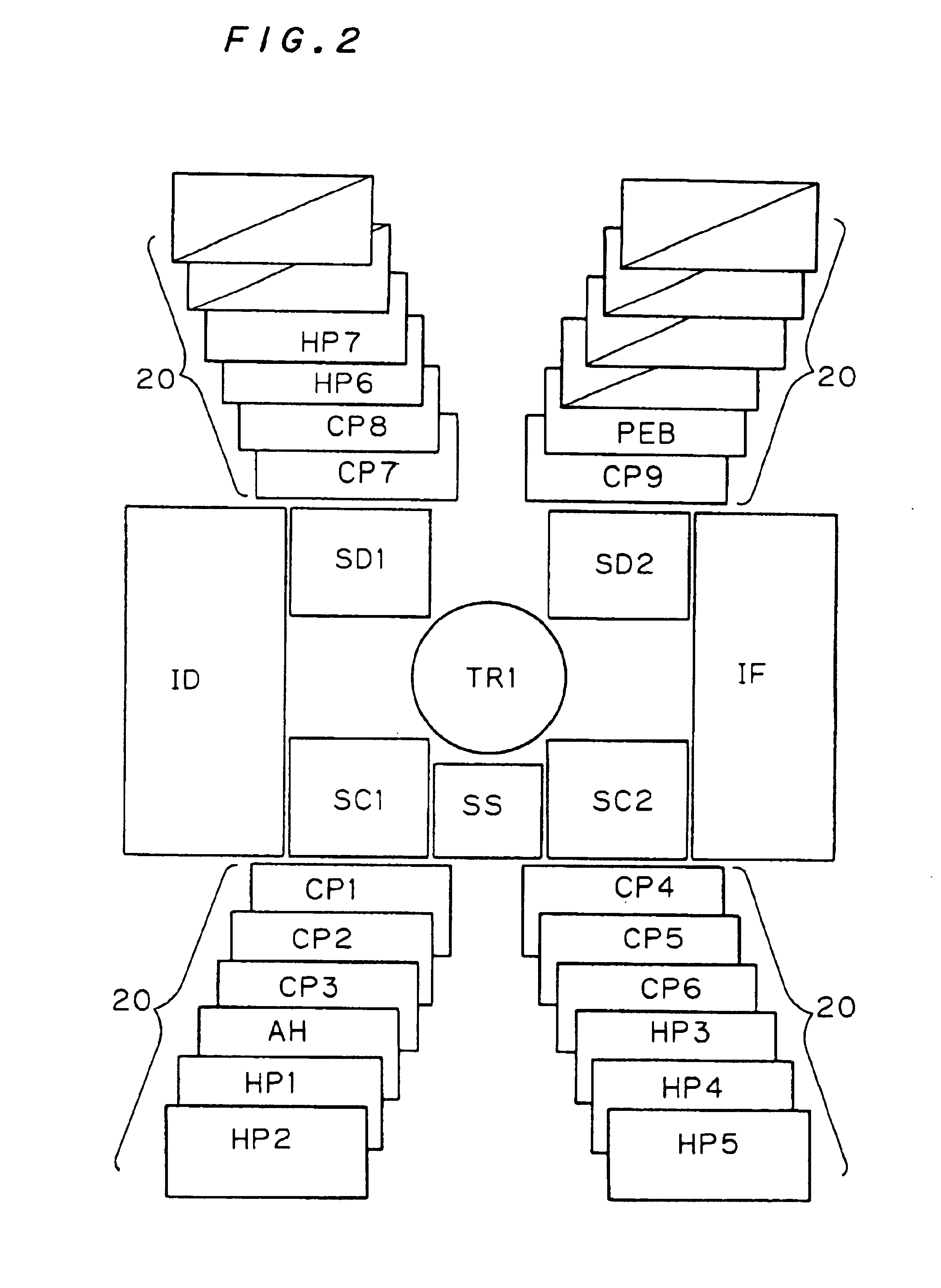

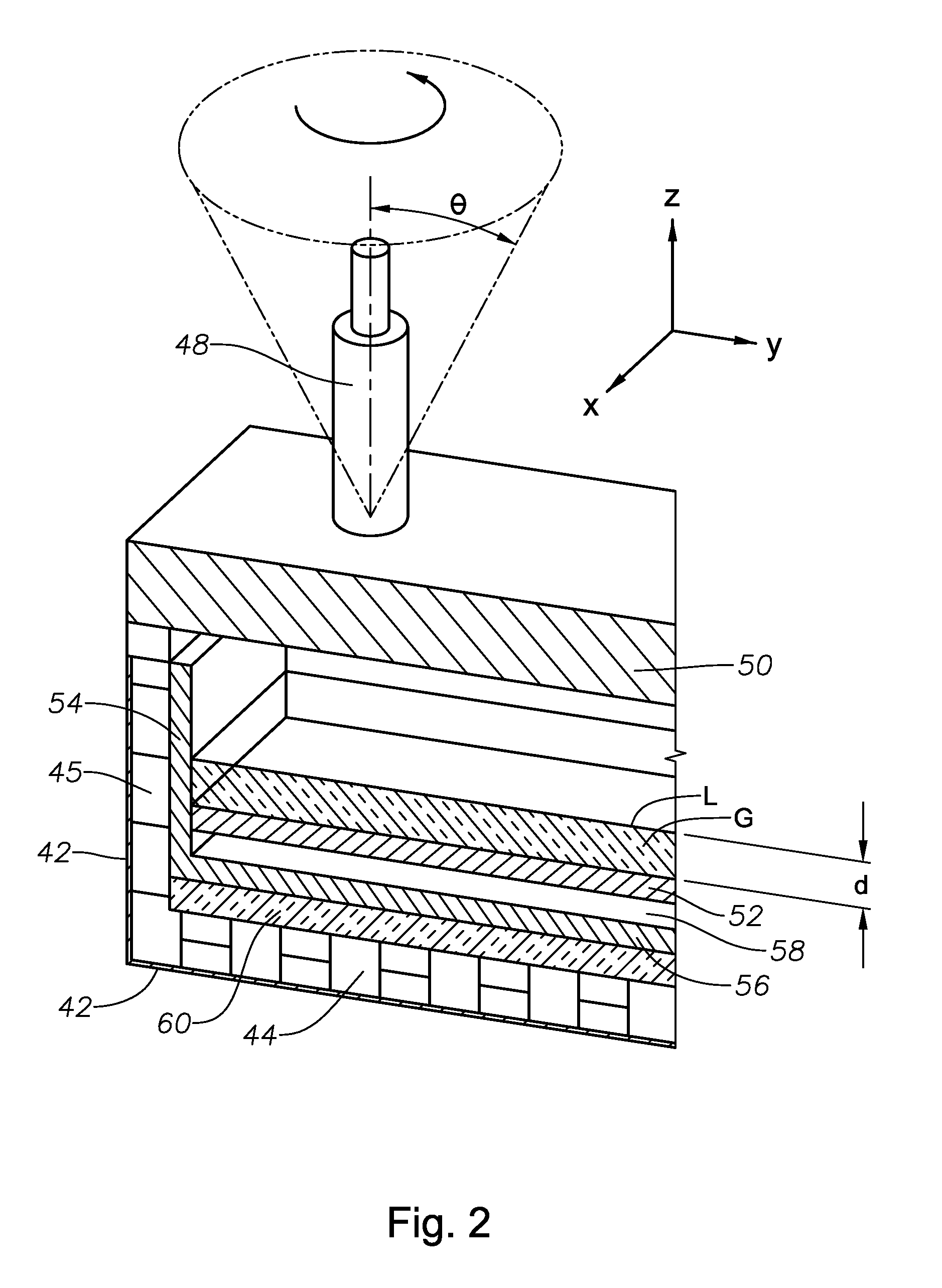

Substrate processing apparatus

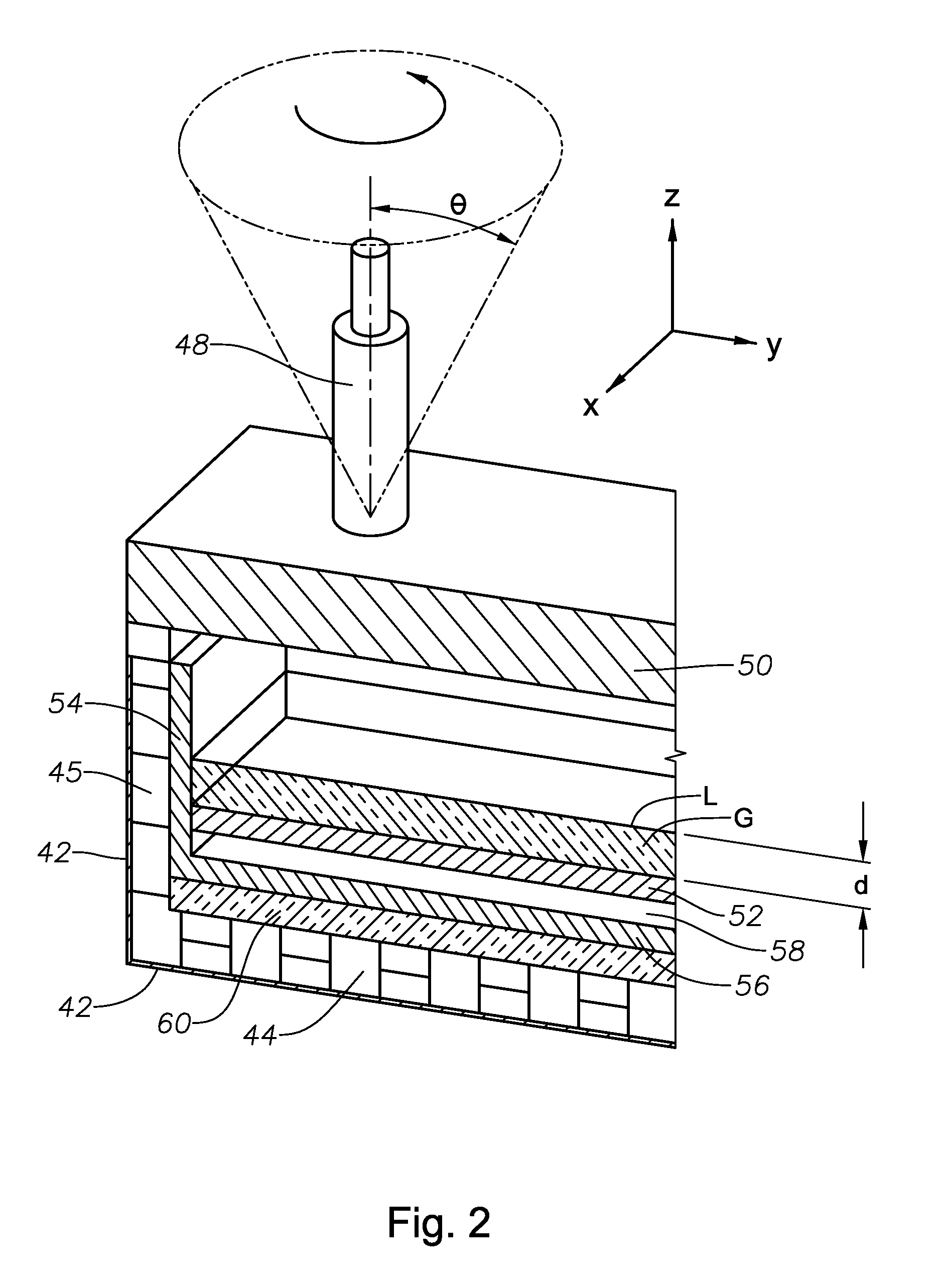

InactiveUS6896466B2Reduce vibrationReduce air turbulenceSemiconductor/solid-state device manufacturingCharge manipulationIncreased heightTransport engineering

A substrate processing apparatus includes a transport robot (TR1) formed with a telescopic vertical movement mechanism of a so-called telescopially nestable multi-tier construction. A drive mechanism (D1) is initially driven to move a support member (48) upwardly to simultaneously elevate a vertical movement member (42d). As the vertical movement member (42d) rises, a pulley (47c) simultaneously moves upwardly. As the pulley (47c) moves upwardly, a vertical movement member (42c) is lifted upwardly by a belt (L1). Similar actions elevate a pair of transport arms (31a, 31b) provided on the top of a vertical movement member (42a). The increase in the number of tiers of the nestable multi-tier structure precludes the increase in height of the transport robot (TR1) in its retracted position. The substrate processing apparatus, if having an increased height, is capable of transporting a substrate to and from processing portions and eliminates the need to reassemble and adjust the transport robot (TR1) for transportation of the apparatus.

Owner:DAINIPPON SCREEN MTG CO LTD

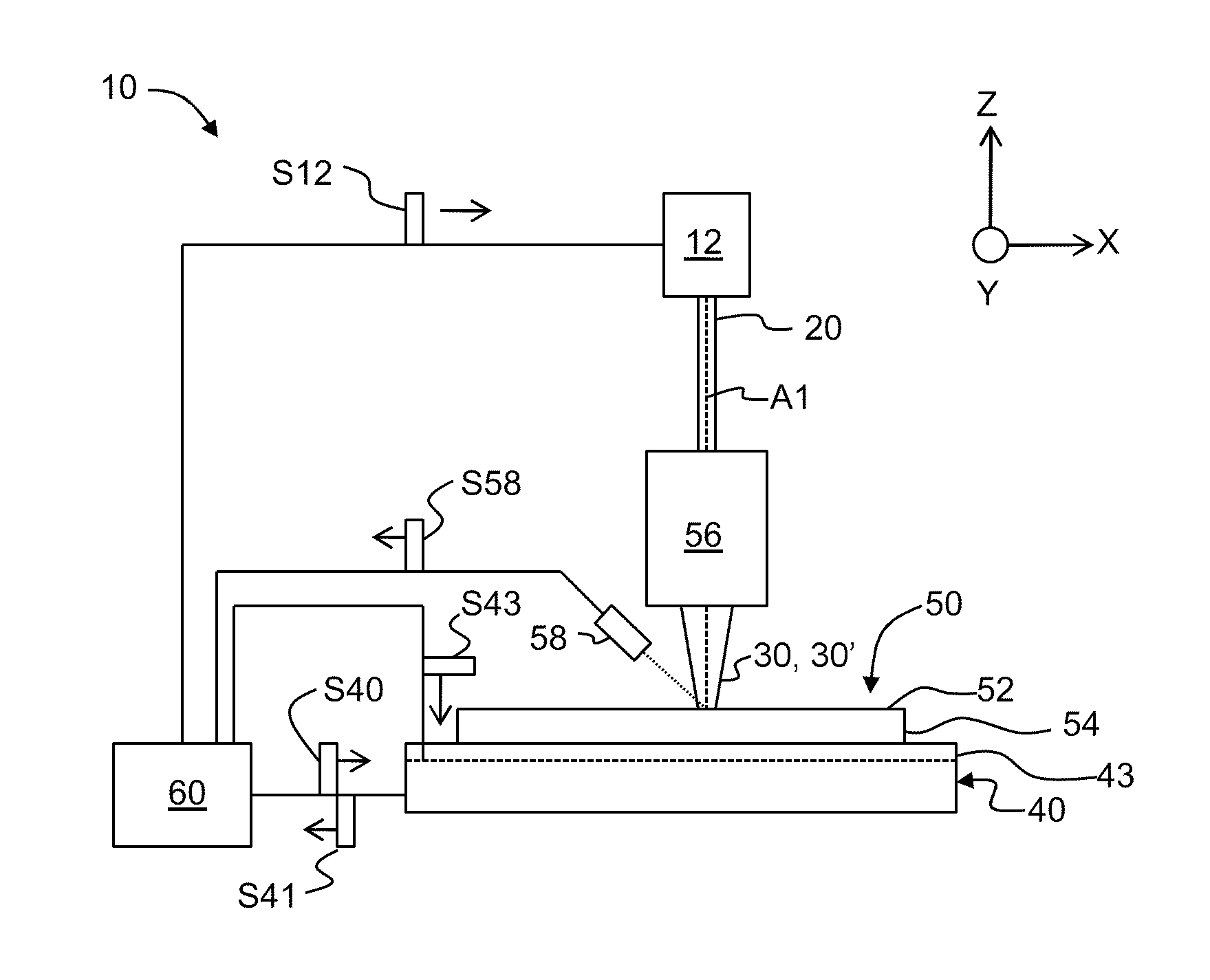

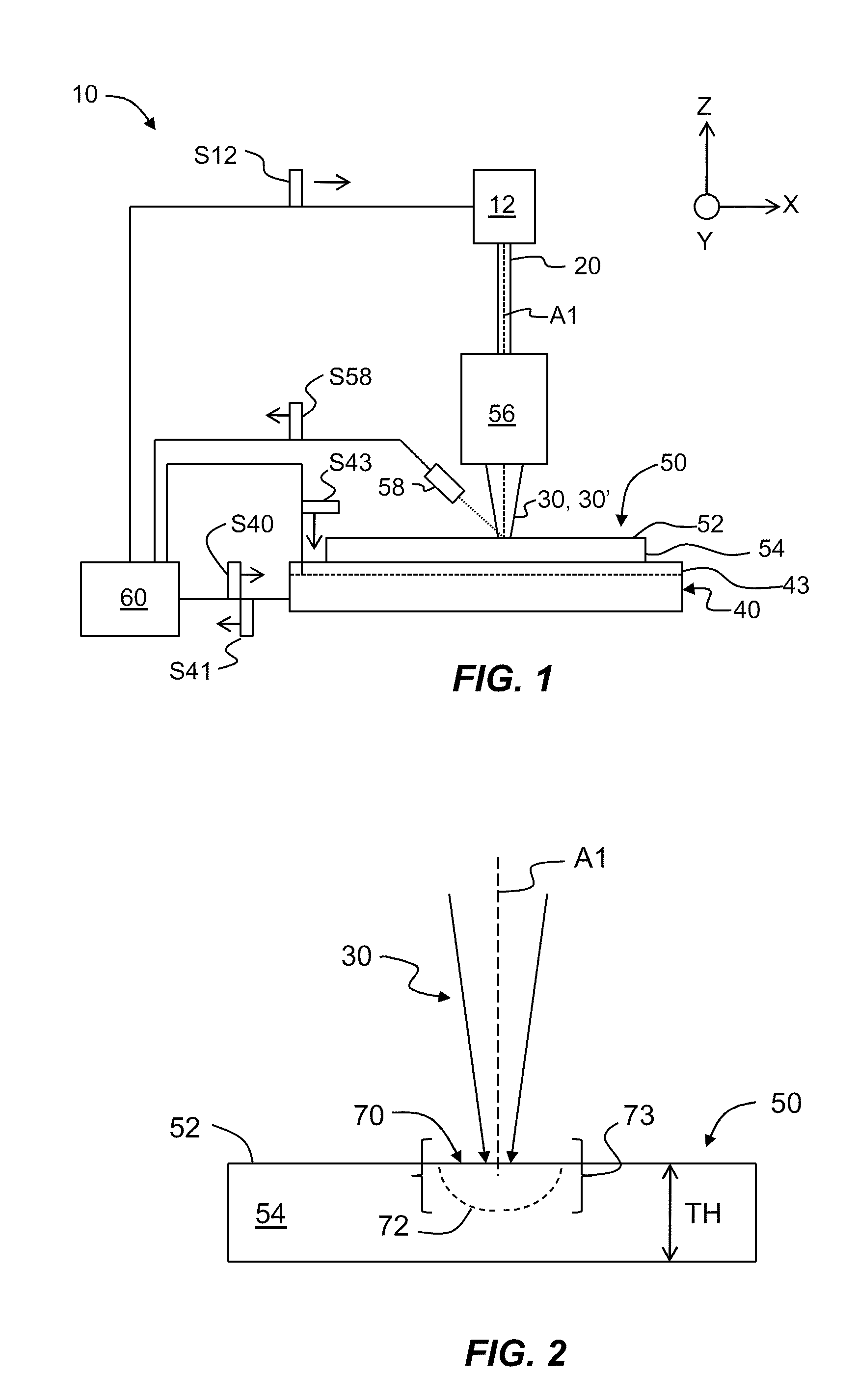

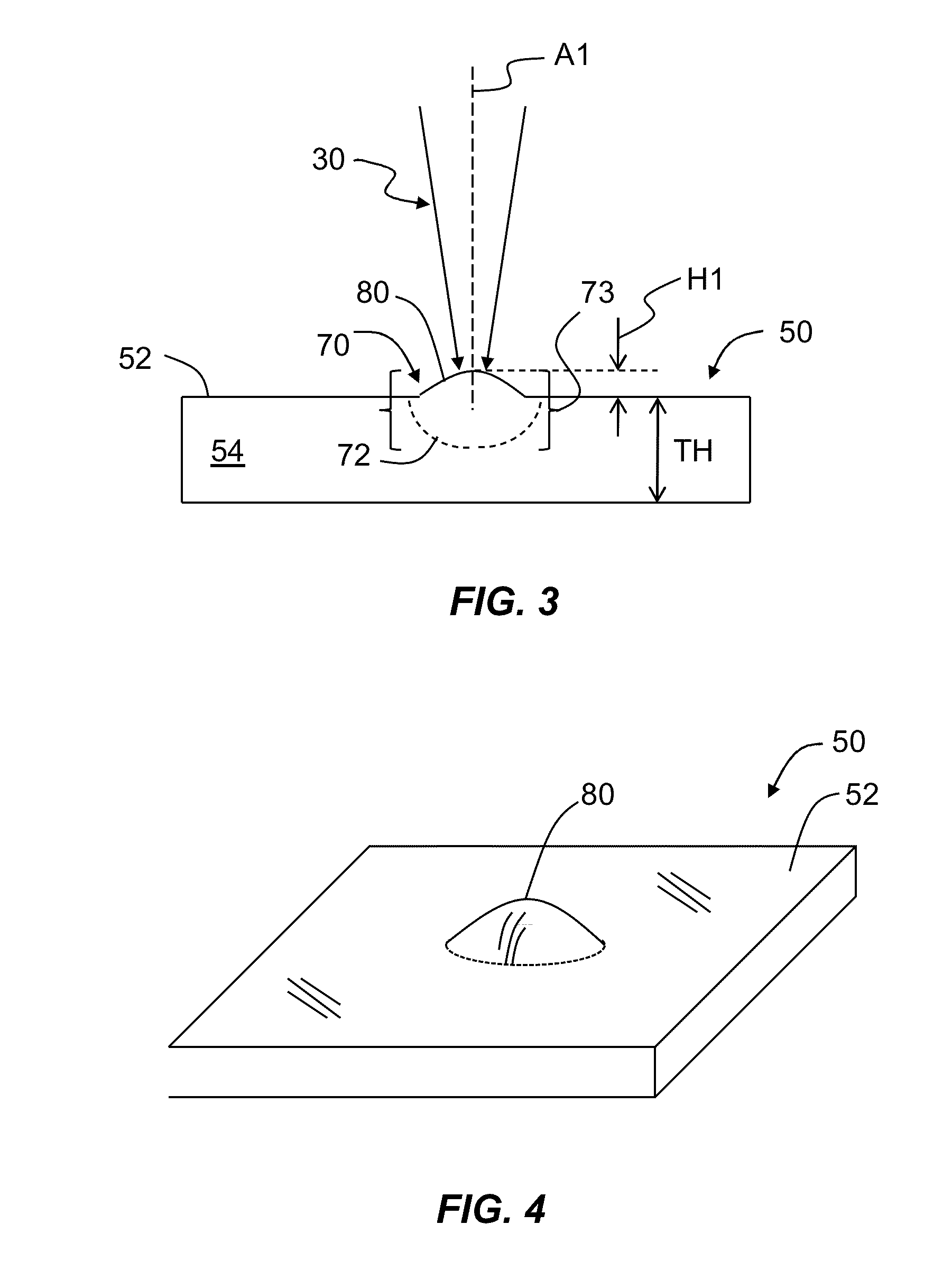

Formation of glass bumps with increased height using thermal annealing

InactiveUS20110100058A1Reduces and relieves laser-induced stressIncreasing bump heightDoors/windowsGlass reforming apparatusMetallurgyIncreased height

The disclosure teaches methods of forming at least one bump in a glass substrate having a surface and a body portion. The method includes performing a first irradiation of a portion of the glass substrate to form in the glass surface the at least one bump having bump height. The method also includes performing thermal annealing of at least a portion of the glass substrate that includes the first irradiated portion. The method then includes performing a second irradiation of the bump to increase the bump height.

Owner:CORNING INC

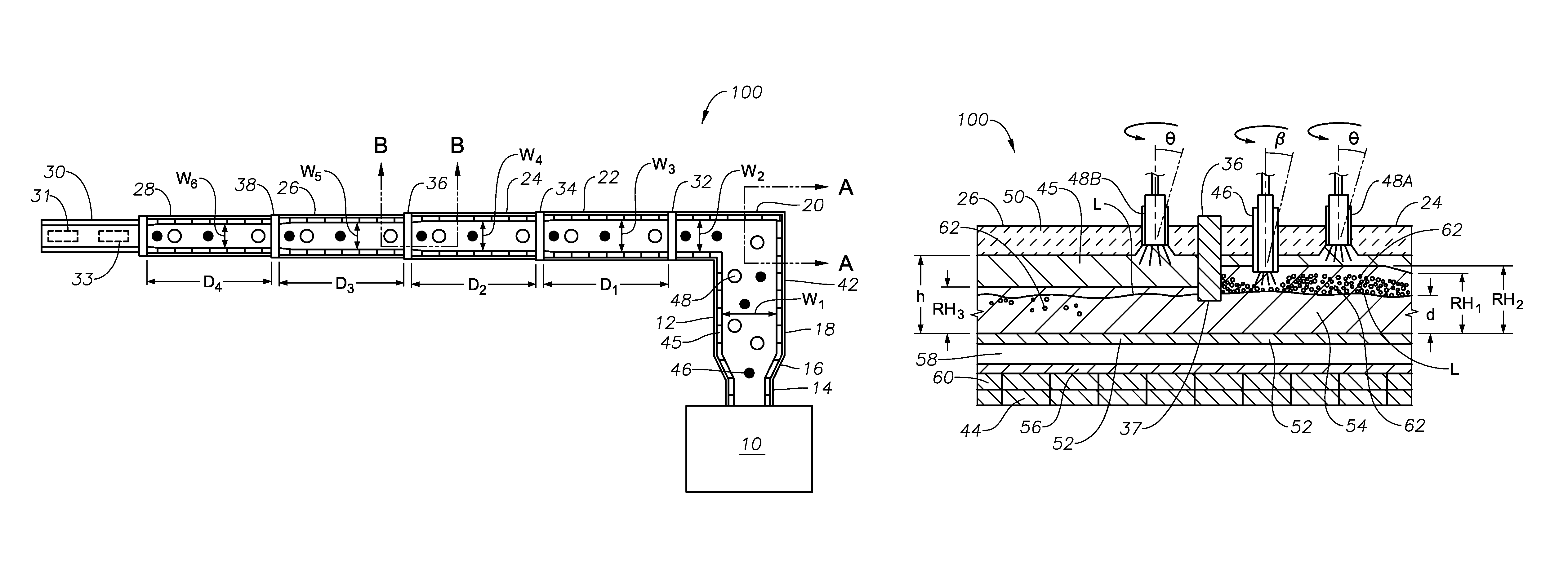

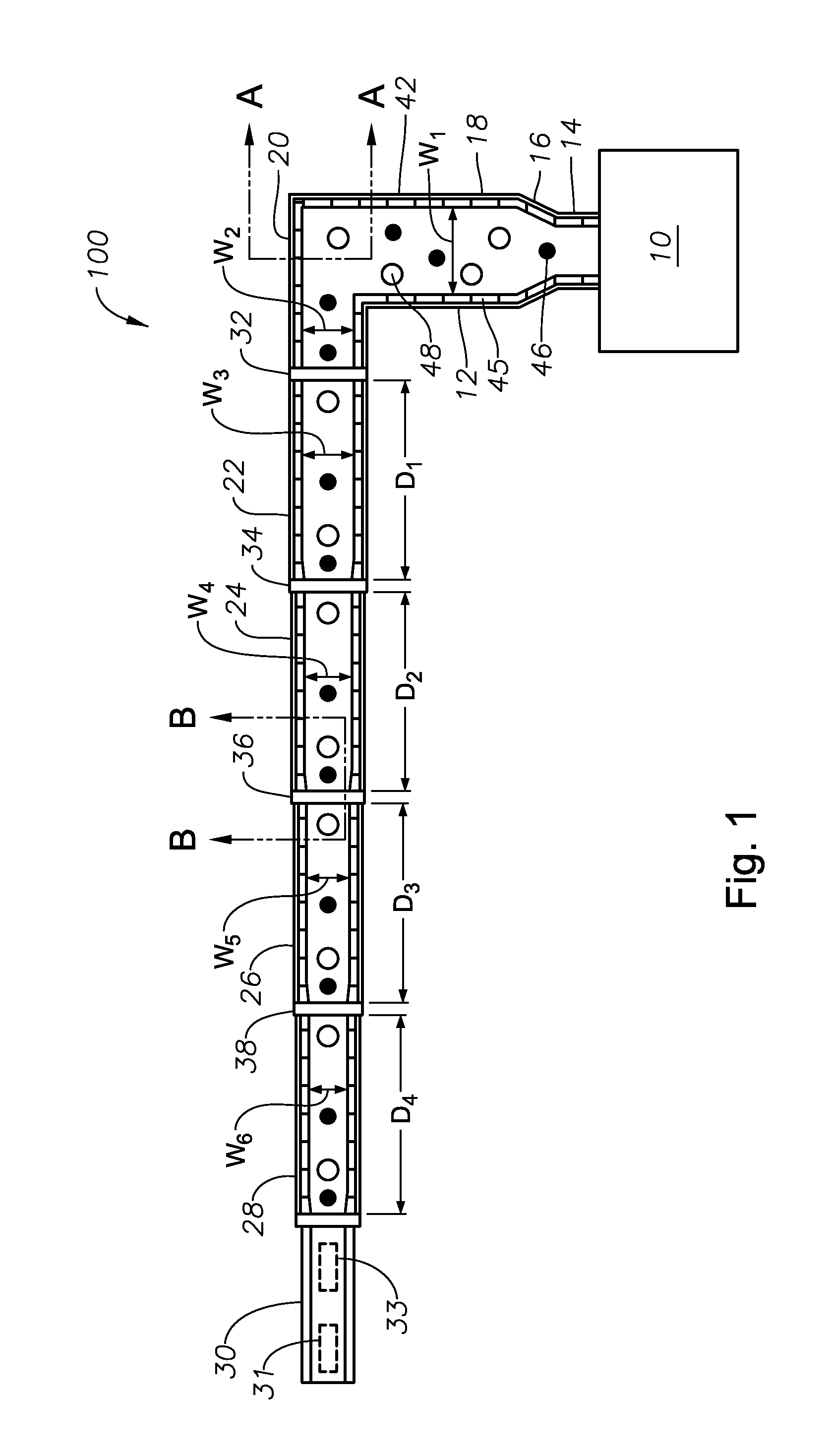

Apparatus, systems and methods for conditioning molten glass

Channel apparatus for use with submerged combustion systems and methods of use to produce glass. One channel apparatus includes a flow channel defined by a floor, a roof, and a wall structure connecting the floor and roof, the flow channel divided into sections by a series of skimmers. Channel apparatus include both high and low momentum combustion burners, with one or more high momentum combustion burners positioned immediately upstream of each skimmer in either the roof or sidewall structure, or both, and one or more low momentum combustion burners positioned immediately downstream of each skimmer in either the roof, the sidewall structure, or both, and positioned to transfer heat to the molten mass of glass without substantial interference from foamed material. Certain embodiments include increased height of glass-contact refractory, in particular immediately upstream of the skimmers.

Owner:JOHNS MANVILLE CORP

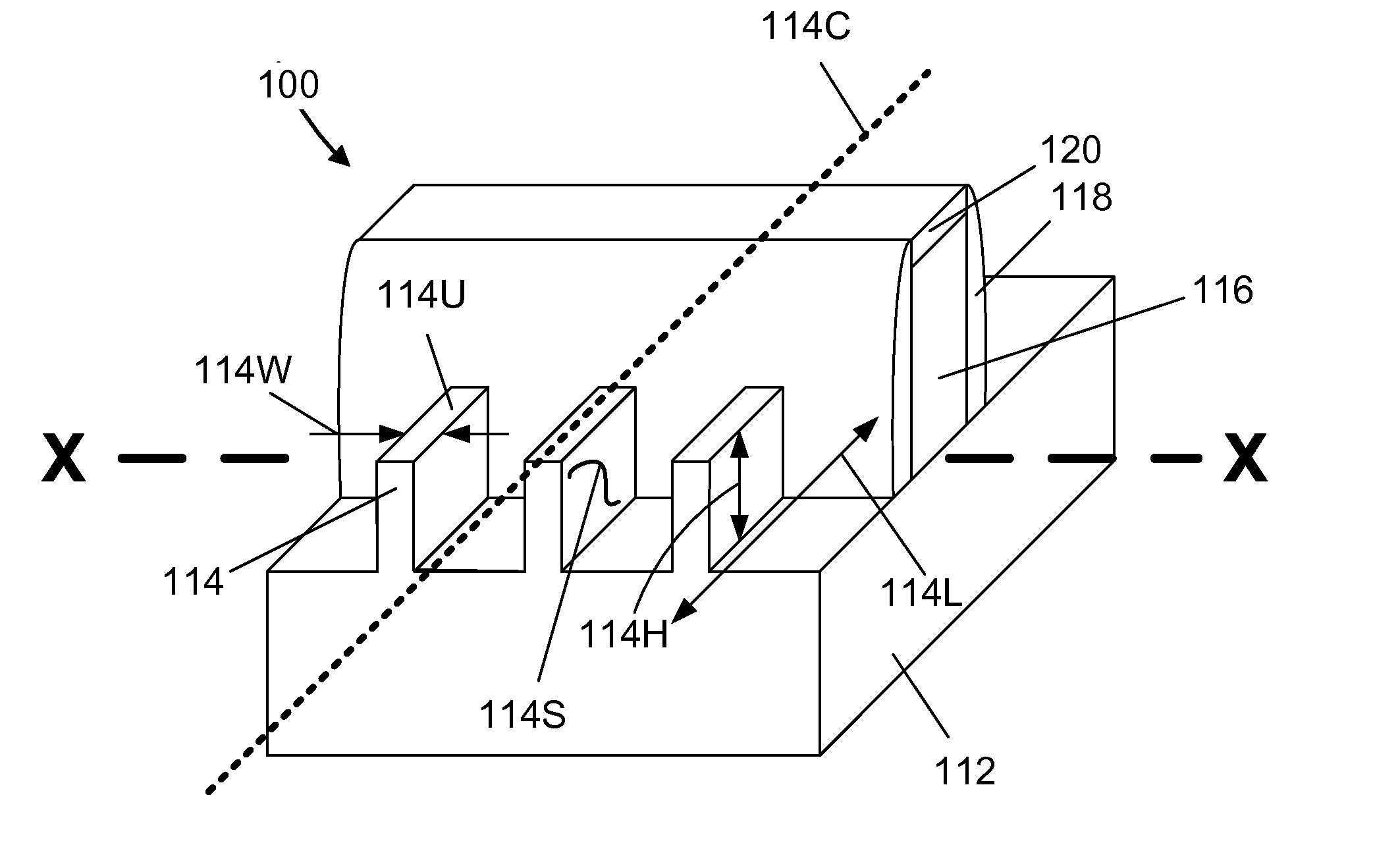

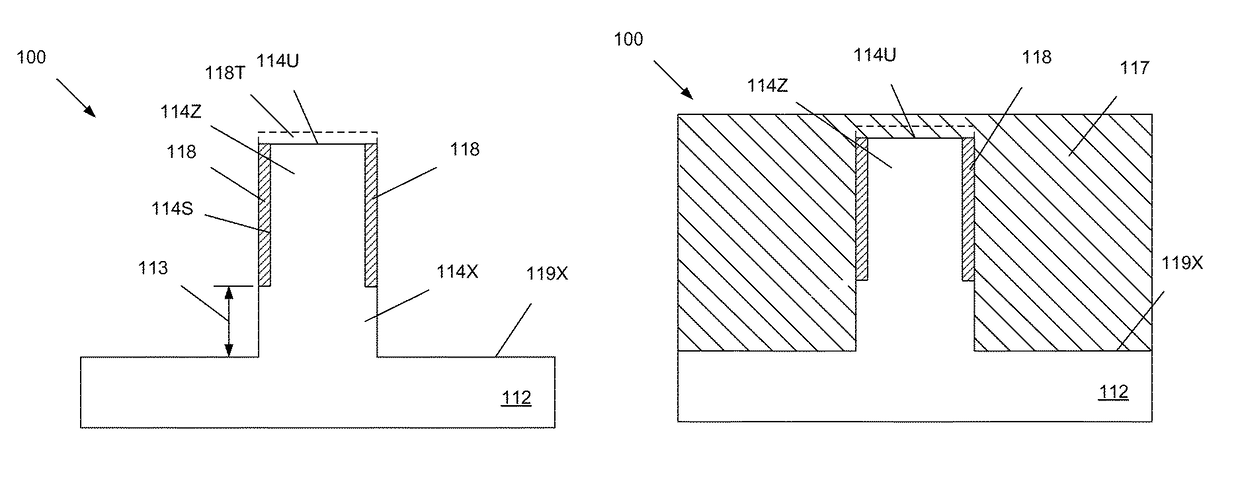

Methods of forming alternative channel materials on a non-planar semiconductor device and the resulting device

InactiveUS20150255295A1Well formedSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsEngineering

One illustrative method disclosed herein involves, among other things, forming trenches to form an initial fin structure having an initial exposed height and sidewalls, forming a protection layer on at least the sidewalls of the initial fin structure, extending the depth of the trenches to thereby define an increased-height fin structure, with a layer of insulating material over-filling the final trenches and with the protection layer in position, performing a fin oxidation thermal anneal process to convert at least a portion of the increased-height fin structure into an isolation material, removing the protection layer, and performing an epitaxial deposition process to form a layer of semiconductor material on at least portions of the initial fin structure.

Owner:IBM CORP +2

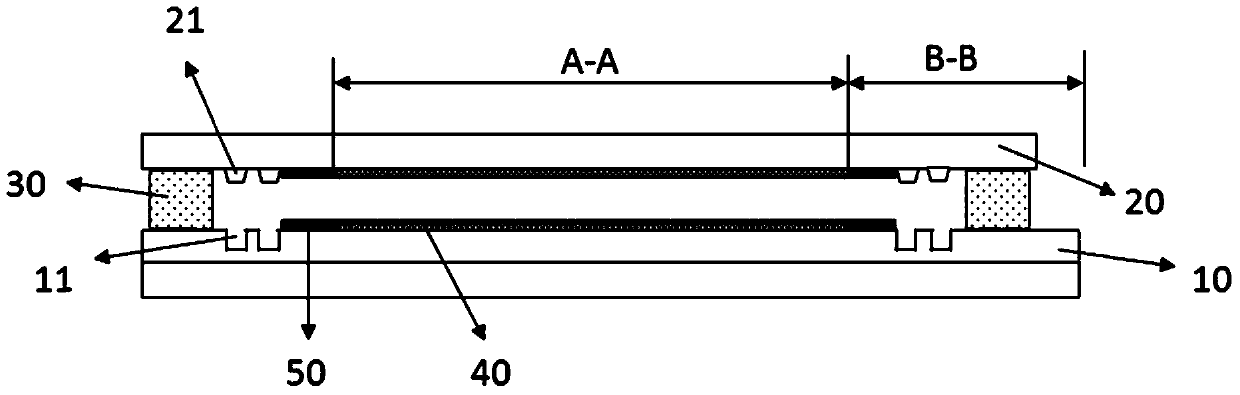

Liquid crystal display panel and manufacturing method thereof

ActiveCN104216189APrevent flowIncrease heightNon-linear opticsLiquid-crystal displayIndium tin oxide

The invention provides a liquid crystal display panel and a manufacturing method thereof. The liquid crystal display panel comprises an array substrate and a color film substrate which are oppositely arranged, wherein the array substrate and the color film substrate are adhered together through a sealant on the periphery; in an area corresponding to the sealant, a semiconductor layer is arranged below an ITO (Indium Tin Oxide) layer of the array substrate; a color layer is arranged in a black matrix layer of the color film substrate corresponding to the semiconductor layer. The semiconductor layer is arranged below the ITO on the array side of the peripheral area (contact position of the sealant), the color layer is arranged below BM on the side corresponding to the color film, and thus an island-shaped pattern is formed on the ITO, the thickness of an ordinary semiconductor layer is 2000 to 3000 Angstroms, the thickness of the color layer is 1.5 to 2 microns, and the increased height can effectively prevent PI from flowing to the upper part of the ITO.

Owner:NANJING CEC PANDA LCD TECH

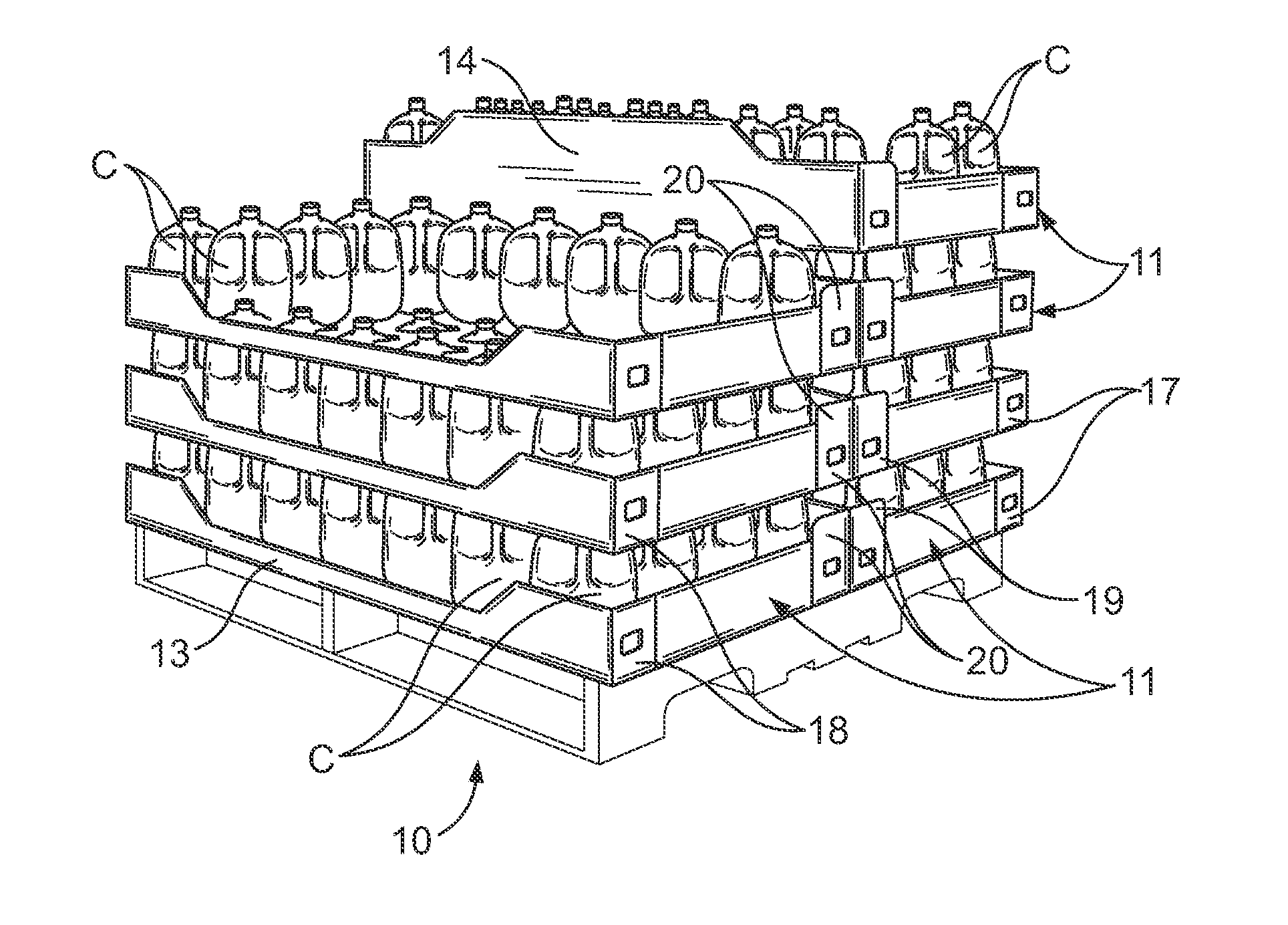

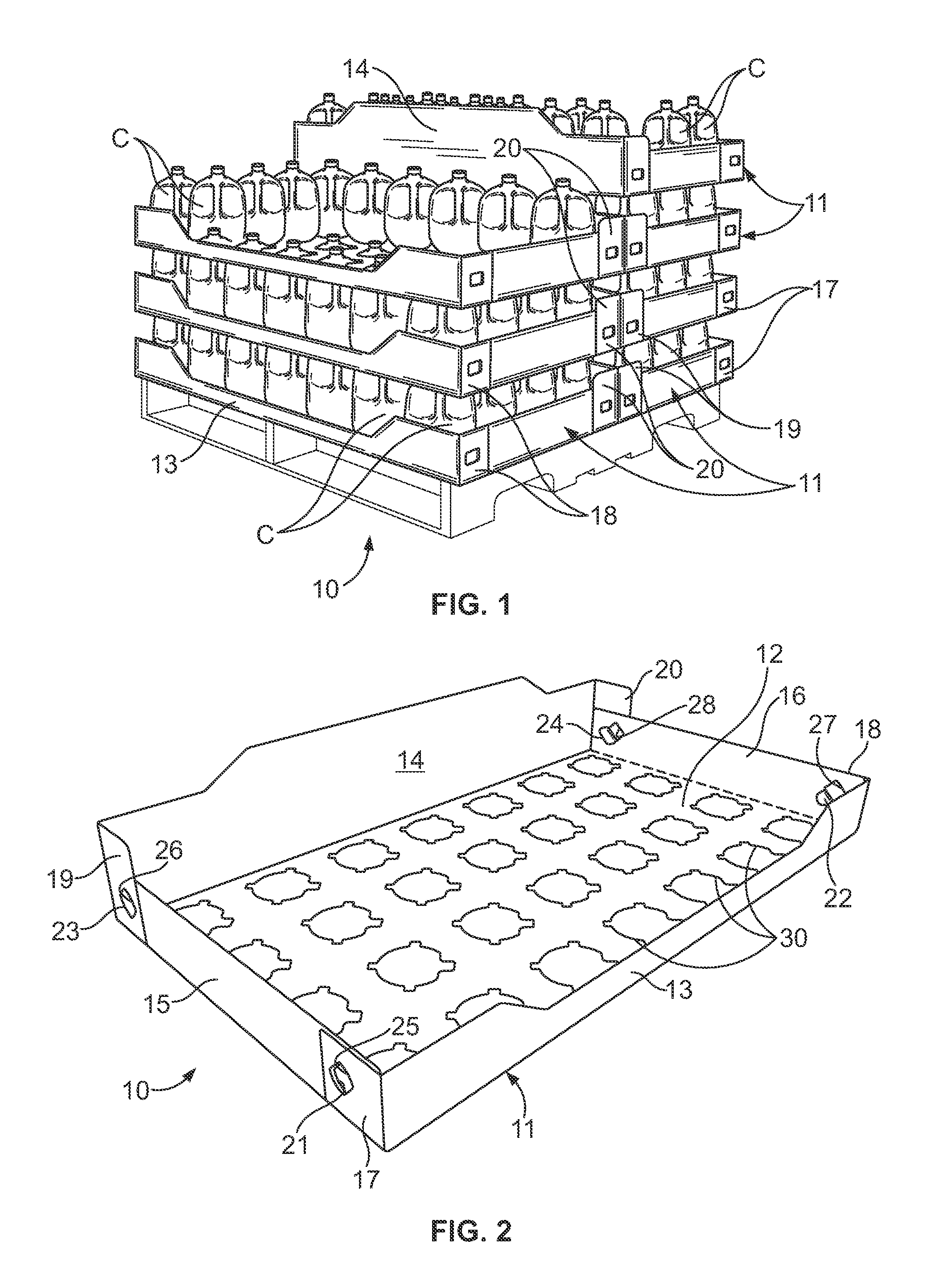

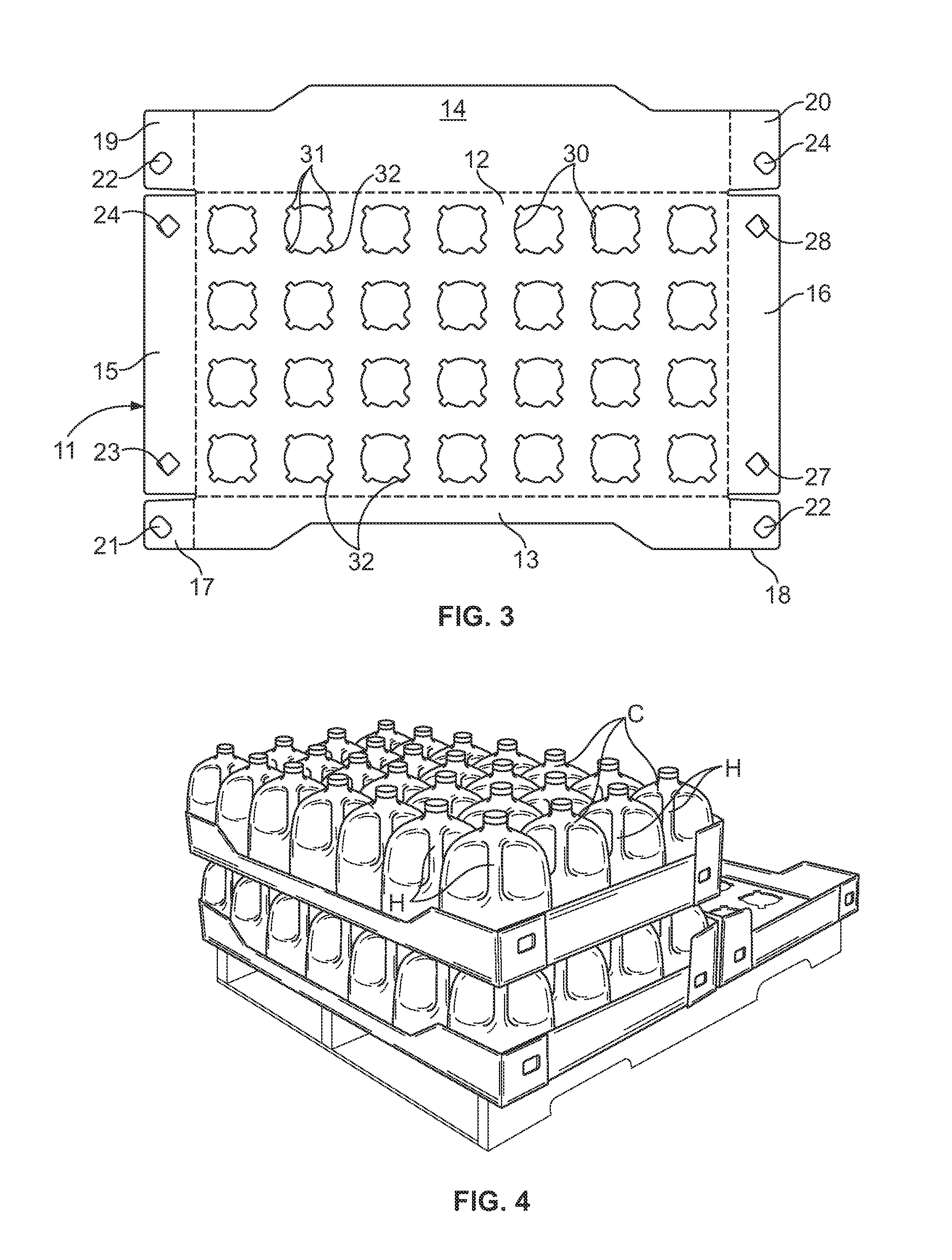

Stabilizing Tray For Shipping and Display Stacked Containers

InactiveUS20130087477A1Cheap to makeEconomical to useTray containersContainers with multiple articlesEngineeringIncreased height

A stabilizing tray for shipping and displaying stacked containers has a plurality of indexing openings through its bottom wall for receiving the necks of subjacent containers so that the necks of containers in a lower tray extend into recessed bottoms of containers in an upper tray. The bottom wall of the tray around the openings rests on shoulders of subjacent containers, and indexing notches around the edges of the indexing openings engage with protrusions on the containers to uniformly orient the containers. In one embodiment interlocking tabs and openings in adjacent walls hold the tray in erected configuration, and in another embodiment flaps on the ends of some of the walls are adhered to adjacent walls to hold the tray in erected configuration. The tray front wall has a reduced height and the back wall has an increased height to obscure date codes on the containers.

Owner:INT PAPER CO

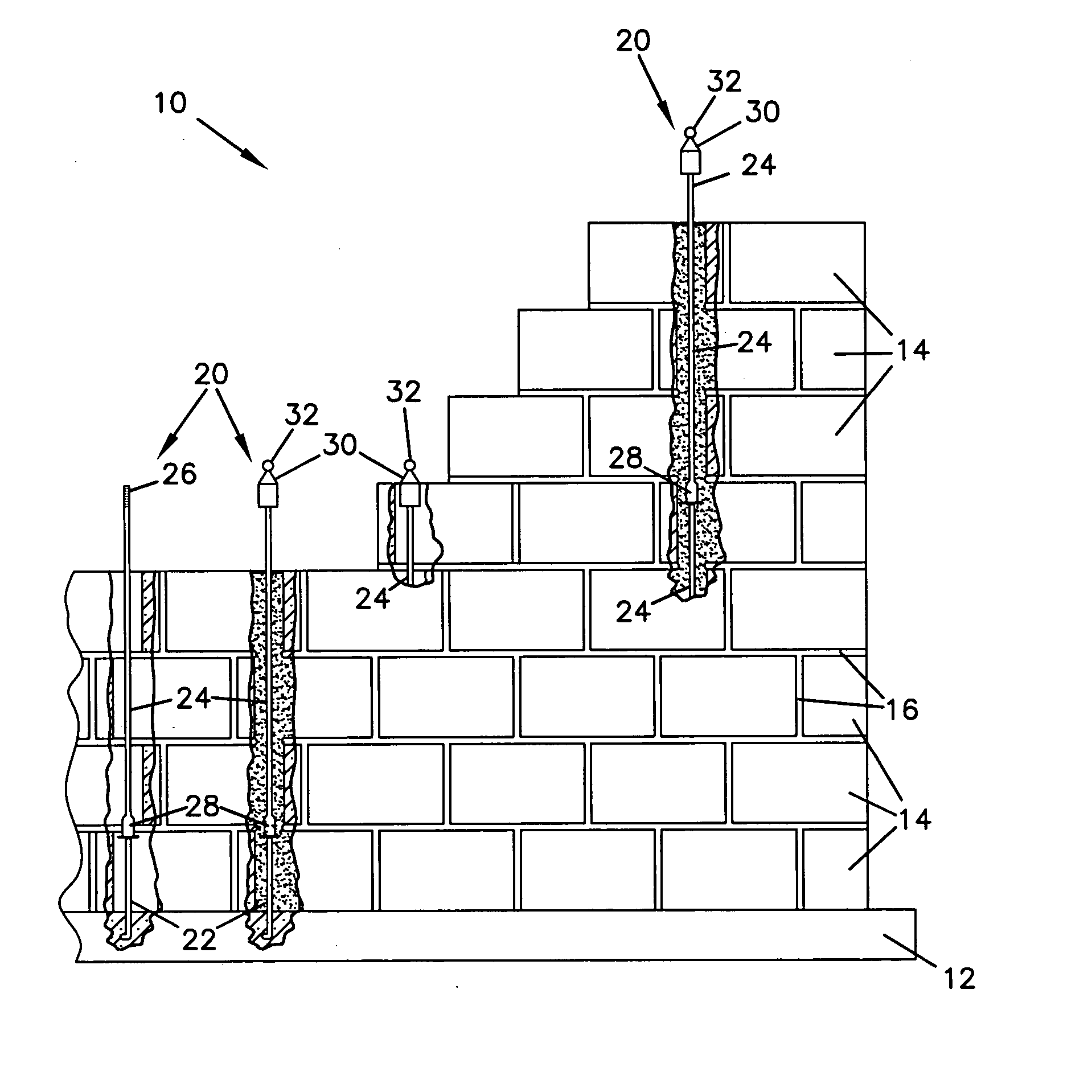

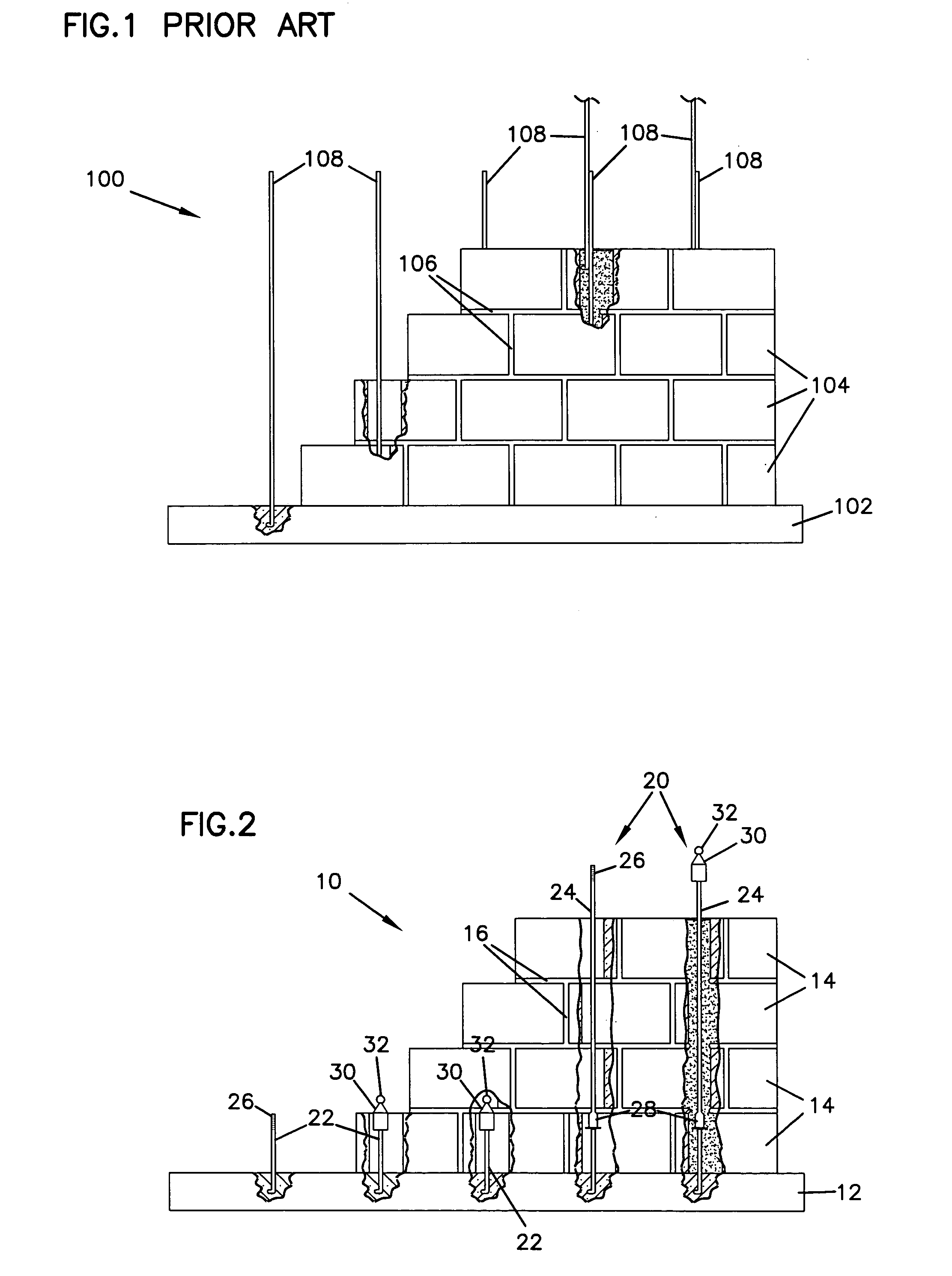

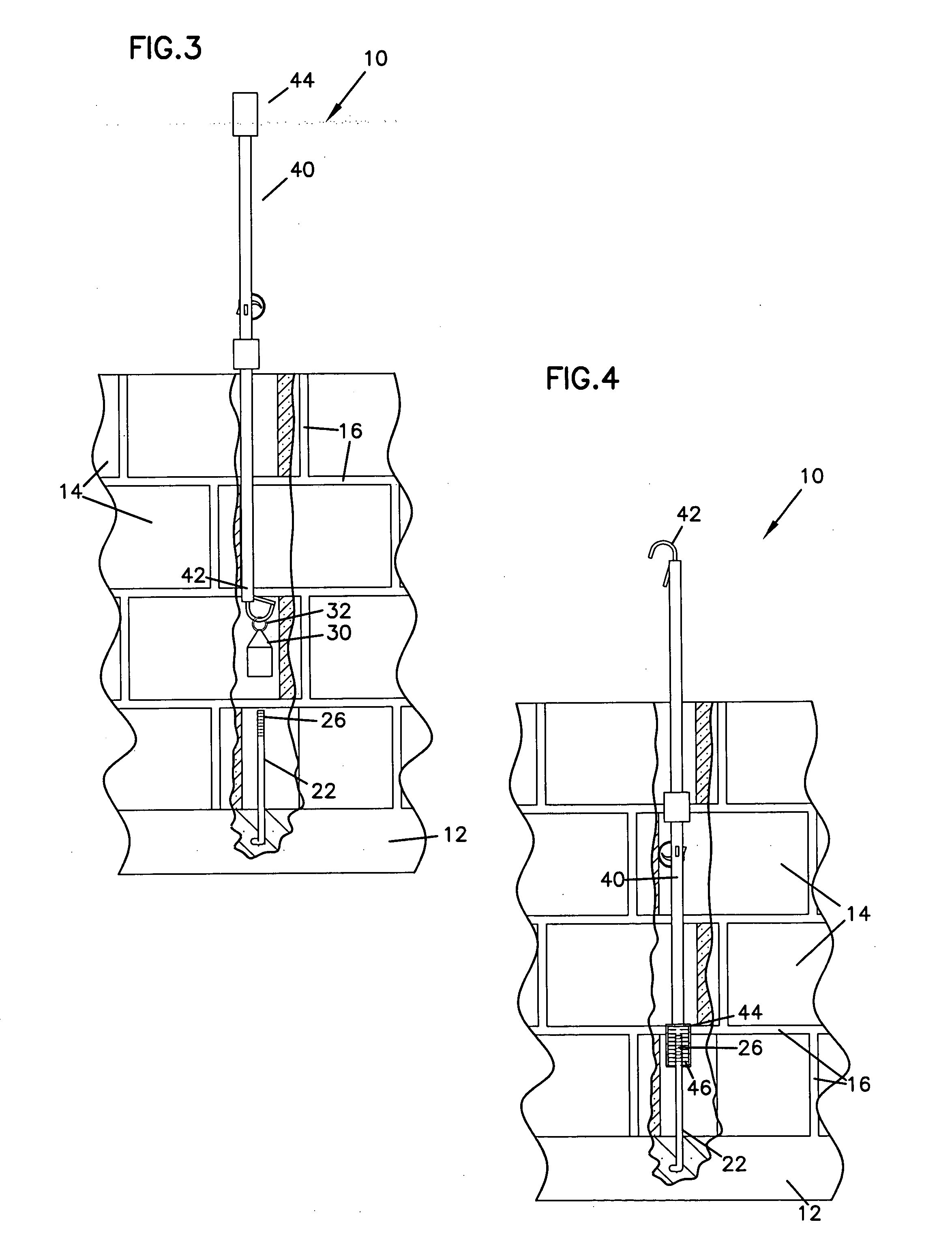

Rebar reinforced masonry wall system and method

A reinforced masonry wall system includes a foundation and layers of masonry block having aligned vertical openings formed therein. Base reinforcing members are set in the foundation and extend upright at a height approximately the same as the height of a masonry block. Covers are placed on the upper ends of the placed reinforcement members to protect the reinforcement members from falling mortar. The wall is built over the base reinforcement members. When additional vertical members are attached, the cover is removed and the ends of the reinforcing member are cleaned. An elongated reinforcing member is inserted through the aligned openings of the masonry blocks and connected to the previously attached reinforcing member. The process can be repeated to construct a wall of increased height with the reinforcing members connected in an end-to-end configuration. Tools are provided for removing the cover, cleaning the ends of the reinforcing member and tightening the newly placed reinforcing member while avoiding lifting blocks several feet over elevated vertically extending reinforcement members.

Owner:NORTHLAND CONCRETE & MASONRY

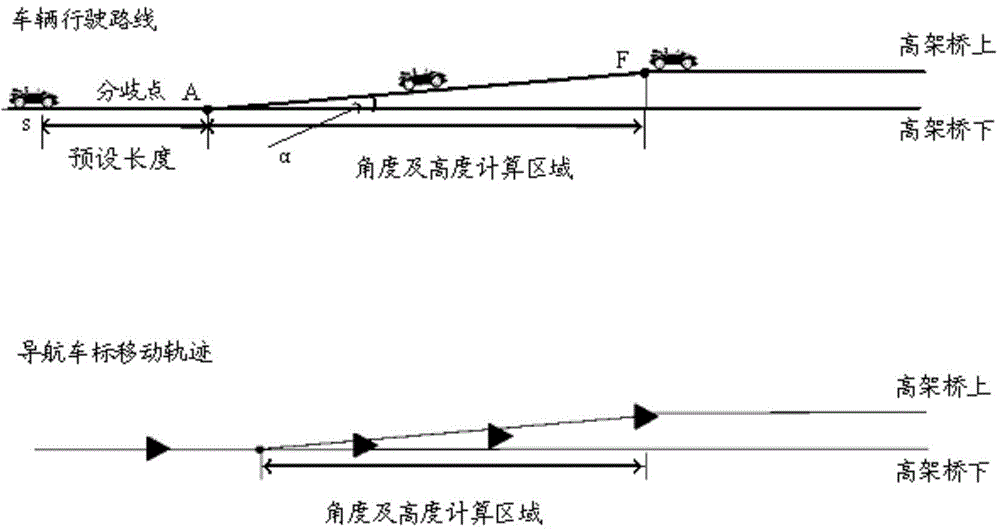

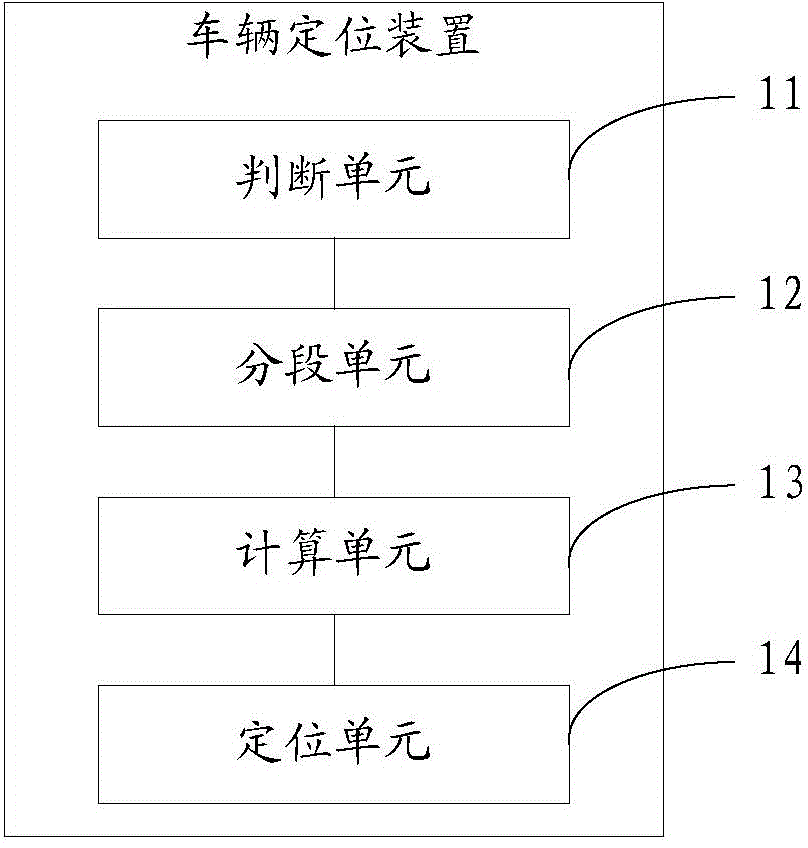

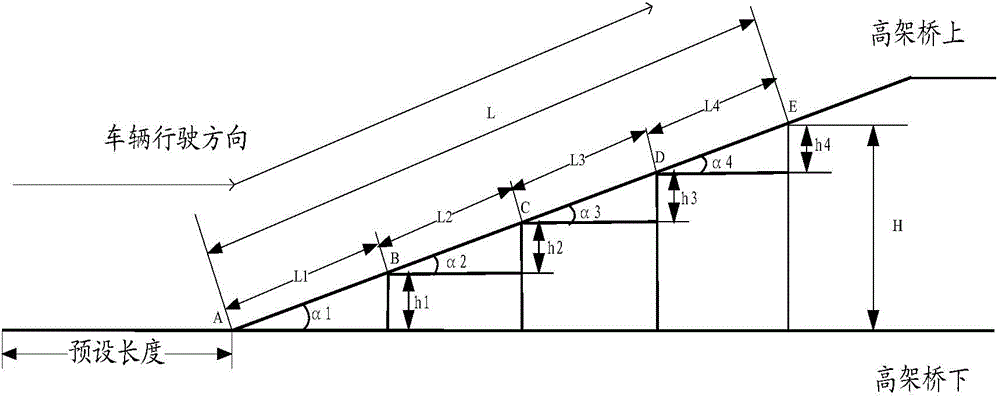

Vehicle positioning device

InactiveCN106032985AGuaranteed accuracyImprove reliabilityInstruments for road network navigationIncreased heightMarine navigation

The embodiment of the invention discloses a vehicle positioning device, and relates to the technical field of navigation, and aims to improve the reliability of vehicle positioning. The device includes the following parts: a judgment unit, which is used for detecting whether there is a bifurcation point ahead the vehicle according to the vehicle navigation information; a segmentation unit, which is used for segmenting a preset distance L, which is for the vehicle to pass by and has the bifurcation point as the starting point, if the judgment unit determines there is a bifurcation point ahead the vehicle; a calculation unit, which is used for calculating an increased height hi of the end point relative to the starting point of each distance divided by the segmentation unit, and summing up the height hi corresponding to each distance to obtain a height h corresponding to the preset distance; a positioning unit, which is used for comparing current height h of the vehicle with a road height H corresponding to the preset distance determined by the vehicle navigation information, and positioning the vehicle on or under a viaduct according to the comparison result. The invention is used for vehicle positioning.

Owner:FAURECIA CLARION ELECTRONICS (XIAMEN) CO LTD

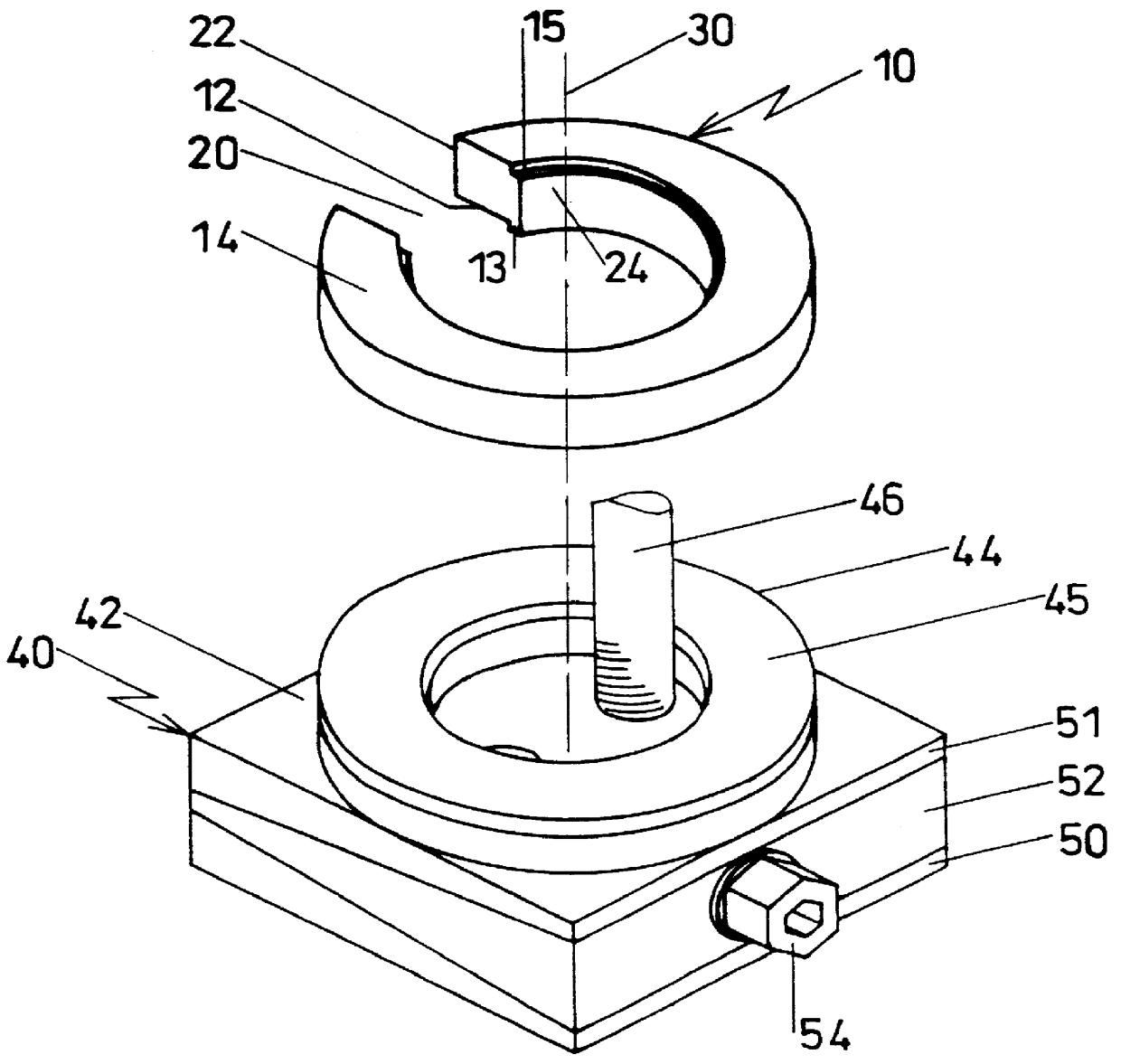

Device for increasing the height adjustment range with a levelling shoe provided therewith

InactiveUS6152409AExpand the adjustment rangePrevented from slipping and slidingPortable framesStands/trestlesEngineeringIncreased height

The height adjustment range of a levelling shoe with an annular support surface is increased by a device that includes a spacer ring having a first face and a second face. The first face has, at a radially inward location, an axially protruding annular projection. The second face has, at a radially inward location, a recess that is substantially complementary to the annular projection. There is also provided a slot that extends over the entire axial length of the spacer ring and projection and extends from an outside peripheral surface of the spacer ring to an inside peripheral surface of the projection. A levelling shoe includes a support ring, a levelling bolt and a spacer ring as described, where the outside diameter of the annular projection is smaller than the inside diameter of the support ring so that the projection engages the support ring to form a connection that is positively locking in the plane of the contacting surfaces and where the slot has a width that is greater than the diameter of the anchor bolt.

Owner:AIR LOC SCHREPFER

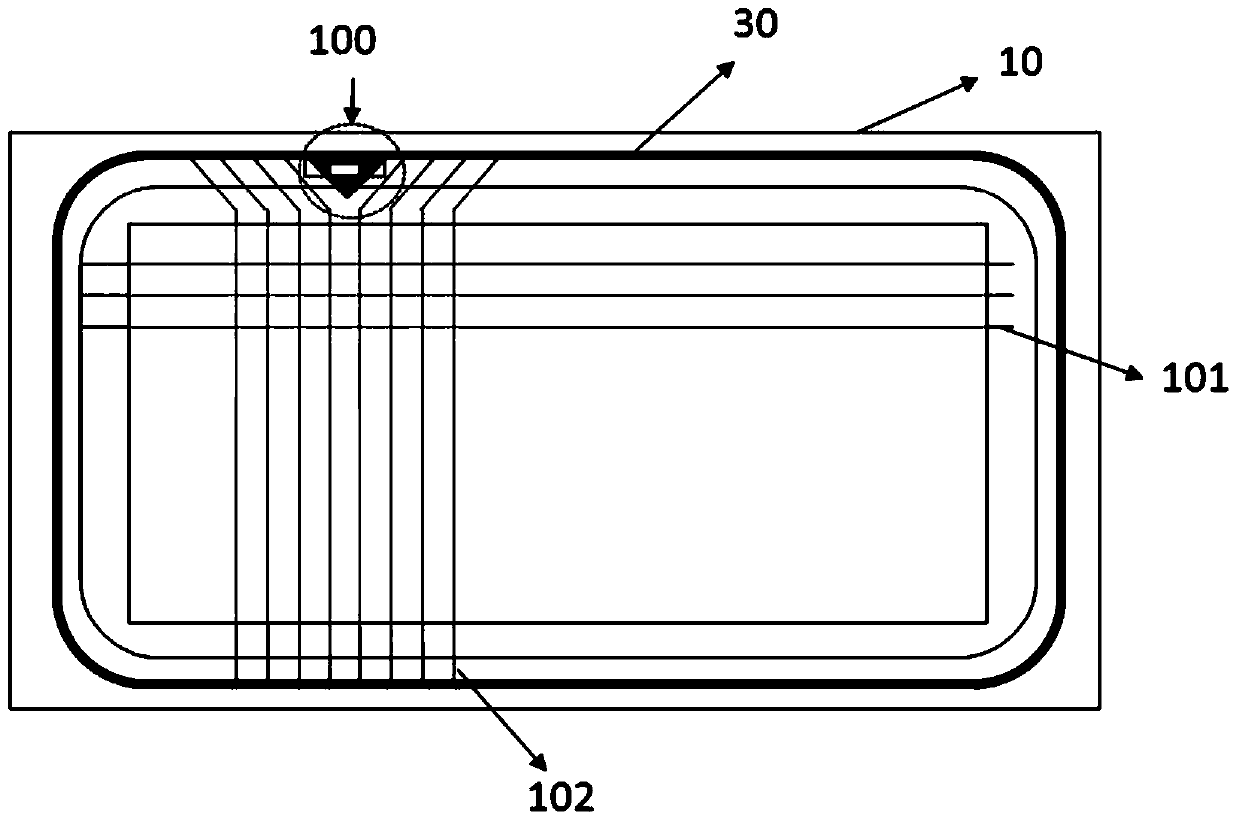

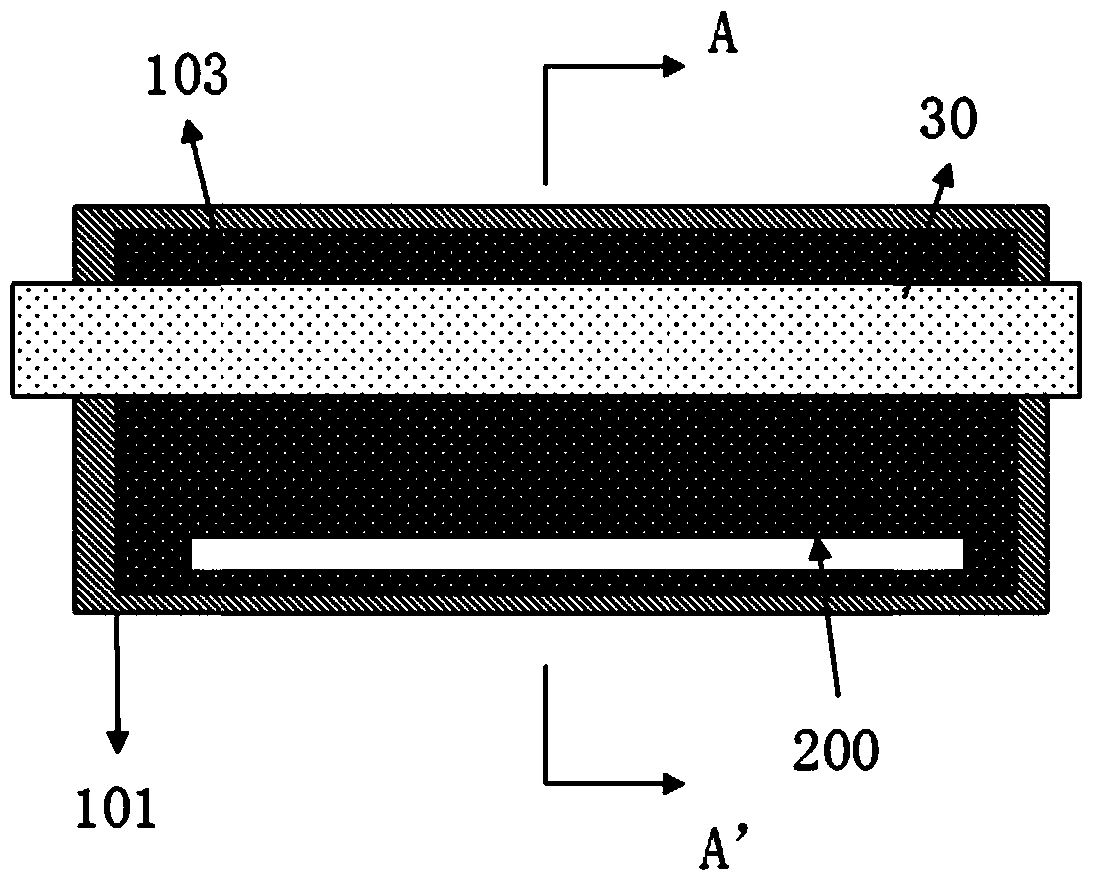

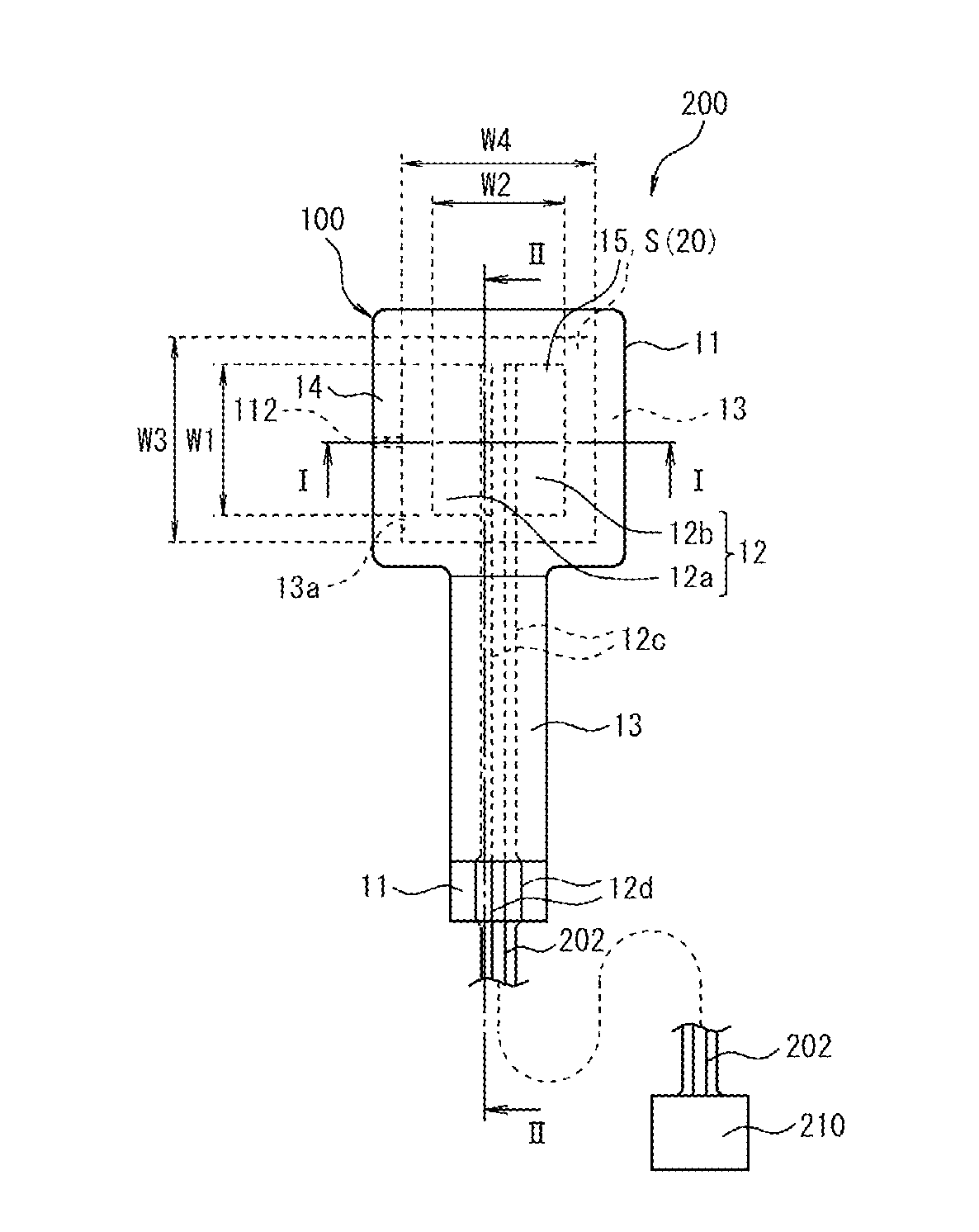

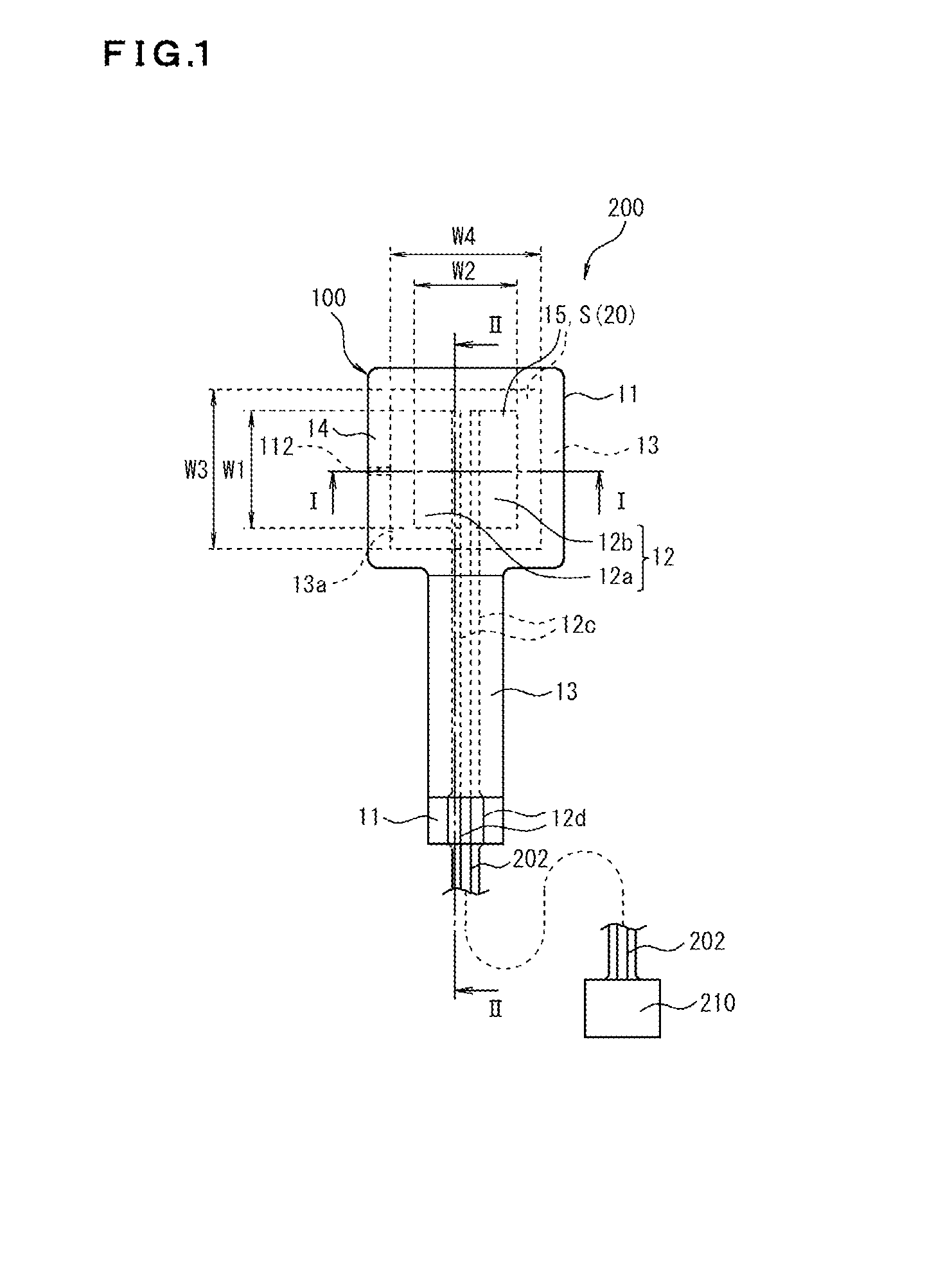

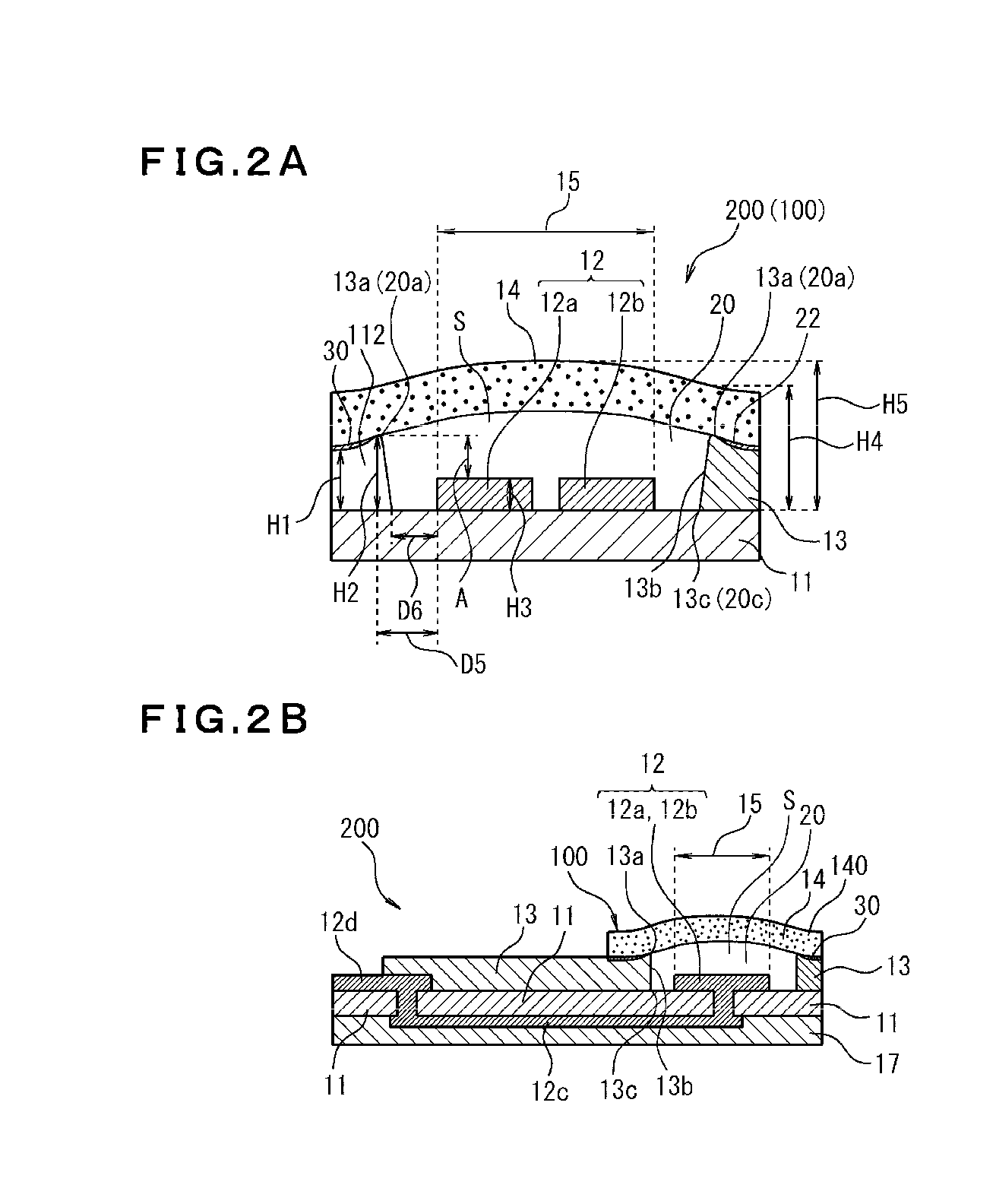

Pressure sensing element having an insulating layer with an increased height from the substrate towards the opening

ActiveUS20160363491A1Prevent short-circuitingHigh detection sensitivityForce measurementDiagnostic recording/measuringEngineeringIncreased height

A pressure sensing element (100) includes a support substrate (11); a sensor electrode (12) supported by the support substrate (11); a pressure sensing film (14) functionalized to be electro-conductive, at least in a portion thereof faced to the sensor electrode (12); and an insulating layer (13) which keeps the sensor electrode (12) and the pressure sensing film (14) apart from each other by a predetermined distance A, and has formed therein an opening (20) in which the sensor electrode (12) is exposed to the pressure sensing film (14), the insulating layer (13) having an aperture wall (13b) which partitions the opening (20), and an aperture end (top aperture end (13a)) faced to the pressure sensing film (14), and the insulating layer (13) being increased in height, measured from the support substrate (11), continuously towards the opening (20).

Owner:NIPPON MEKTRON LTD

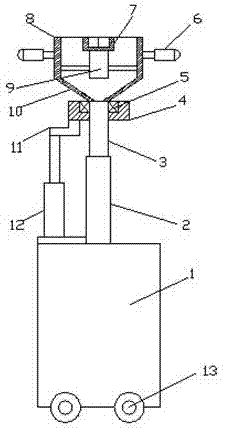

Automobile engine oil recovery device

InactiveCN107288705AEasy to recycleFlexible operationMachines/enginesLubricant filling/drainingPulp and paper industryIncreased height

The invention discloses an automobile engine oil recovery device which comprises a tank body, an extensile driving device, a cylinder and a funnel. A guiding tube is arranged at the top of the tank body, the funnel is arranged above the guiding tube, a floating tube extending into the guiding tube is arranged at the bottom of the funnel, the extensile driving device is arranged on the tank body, a supporting ring is arranged below the funnel, a bent plate connected with the supporting ring is arranged at the top of the extensile driving device, the cylinder is concentrically arranged at the top of the funnel, a supporting frame is arranged in the cylinder, and an upward extending nut is arranged on the supporting frame. In the mode, in the automobile engine oil recovery device, the height of the cylinder is changed through telescoping of the extensile driving device so adapt to the increased height of an automotive chassis, the nut is driven by the rotating cylinder to rotate, an oil draining bolt is screwed down, the operation is flexible, and engine oil recovery is convenient.

Owner:张家港光洲机械制造有限公司

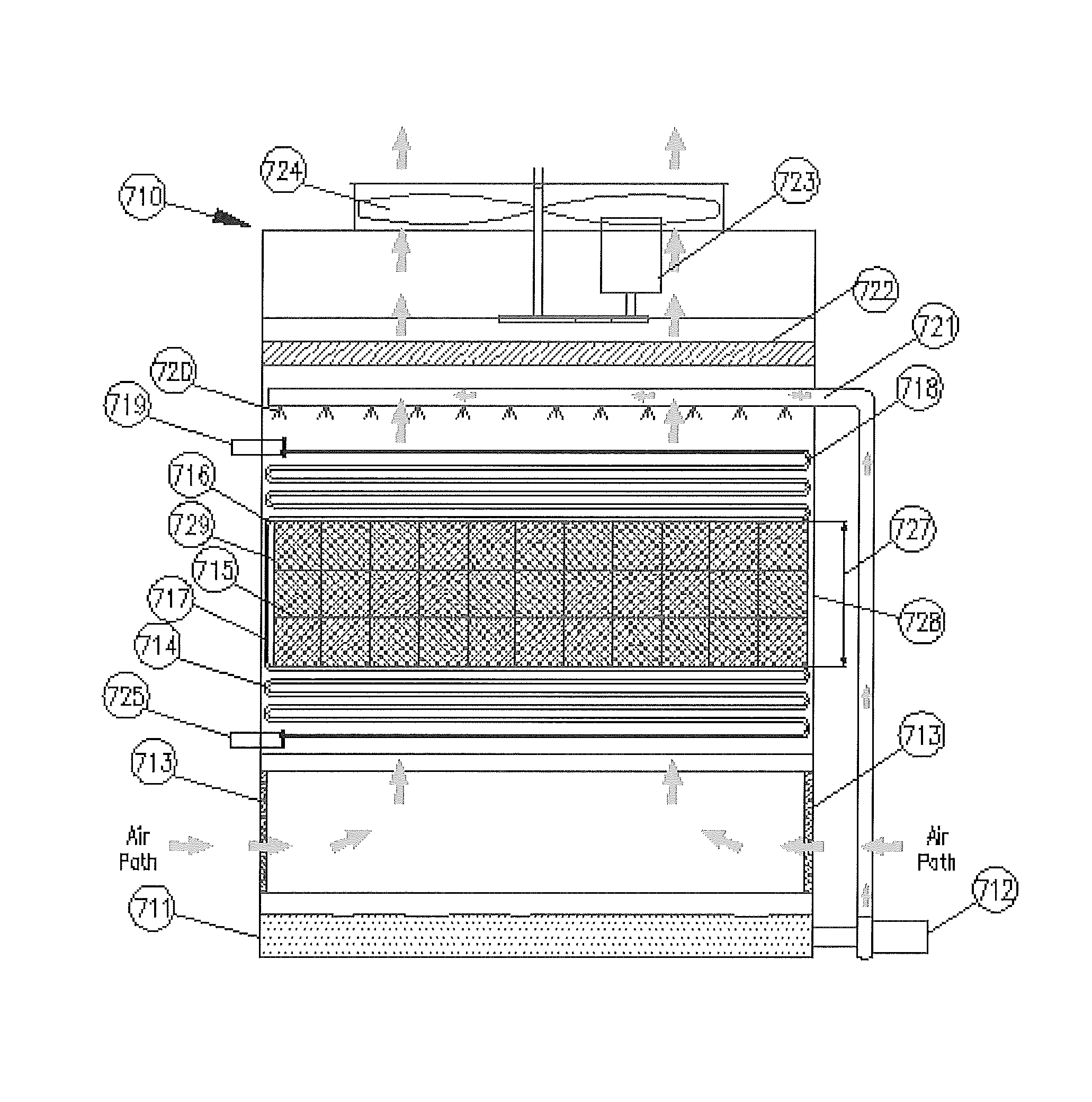

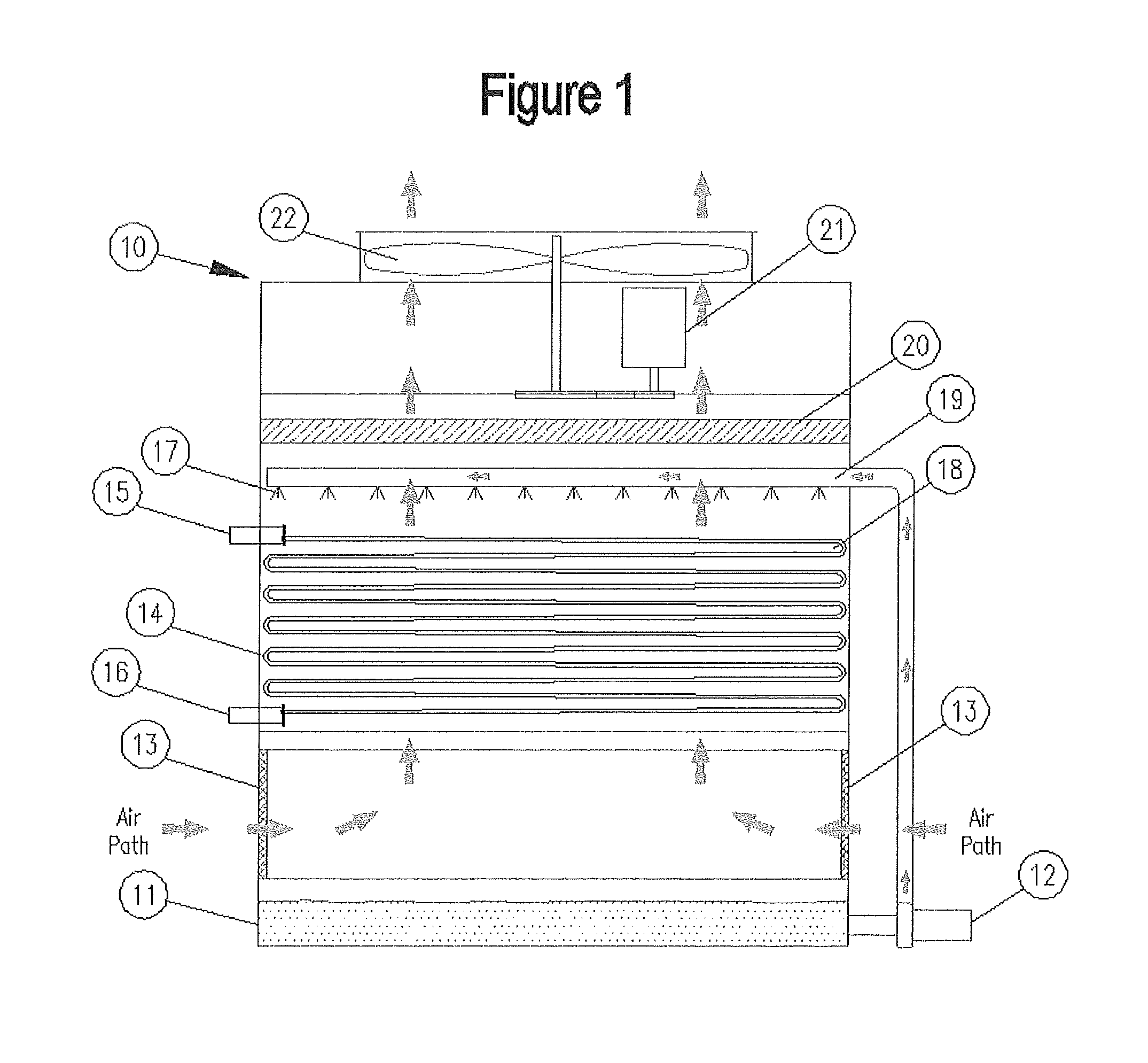

Cooling tower with indirect heat exchanger

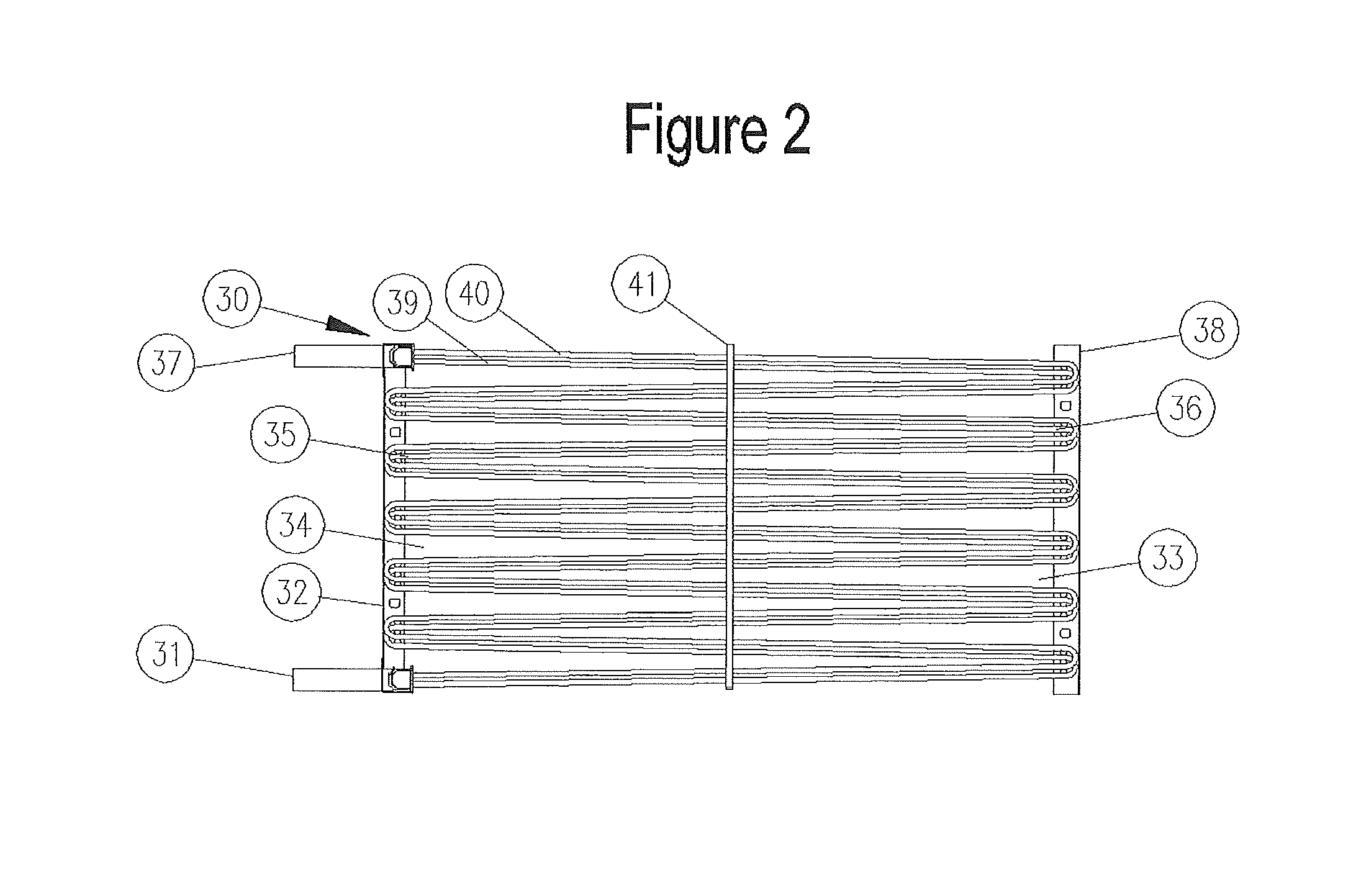

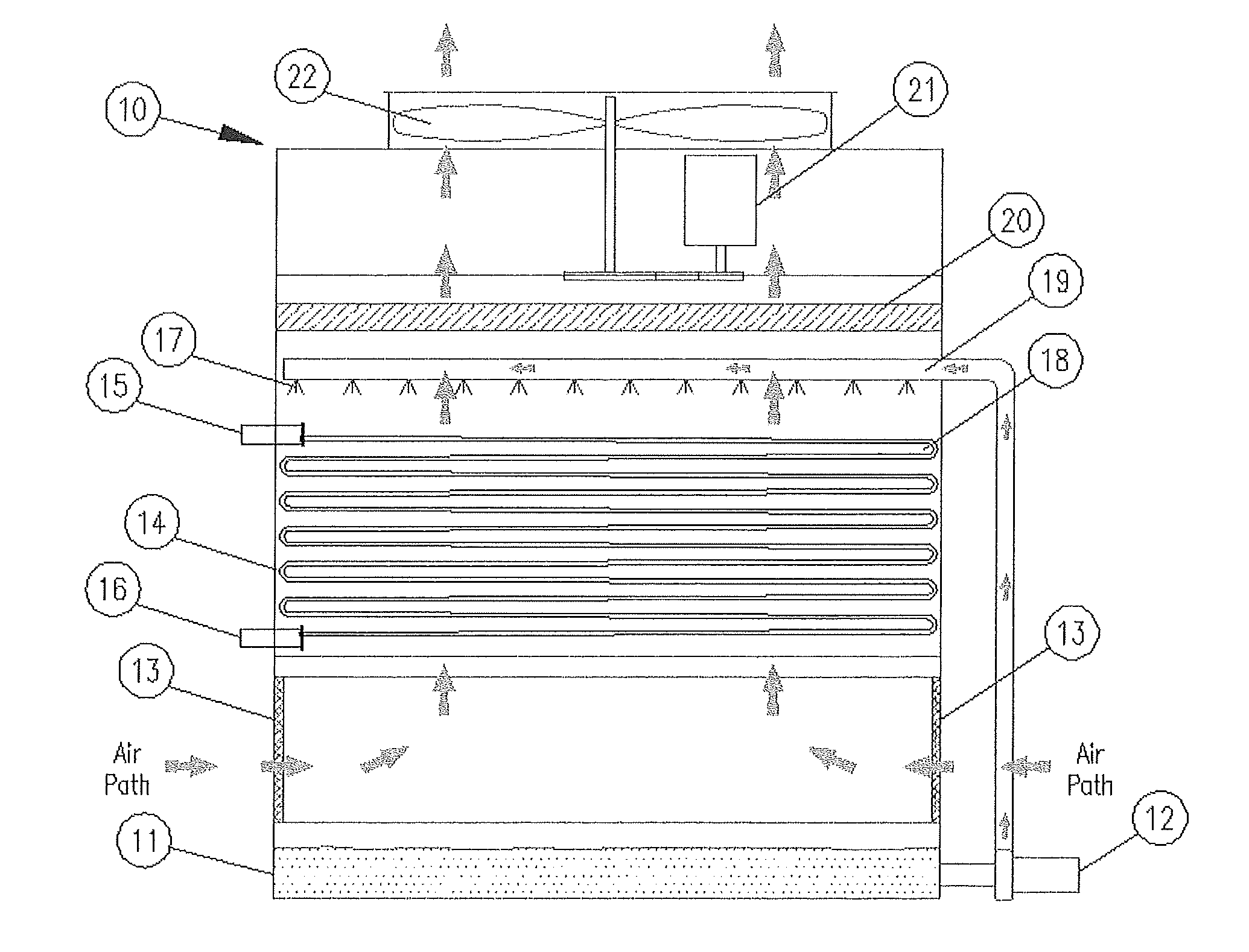

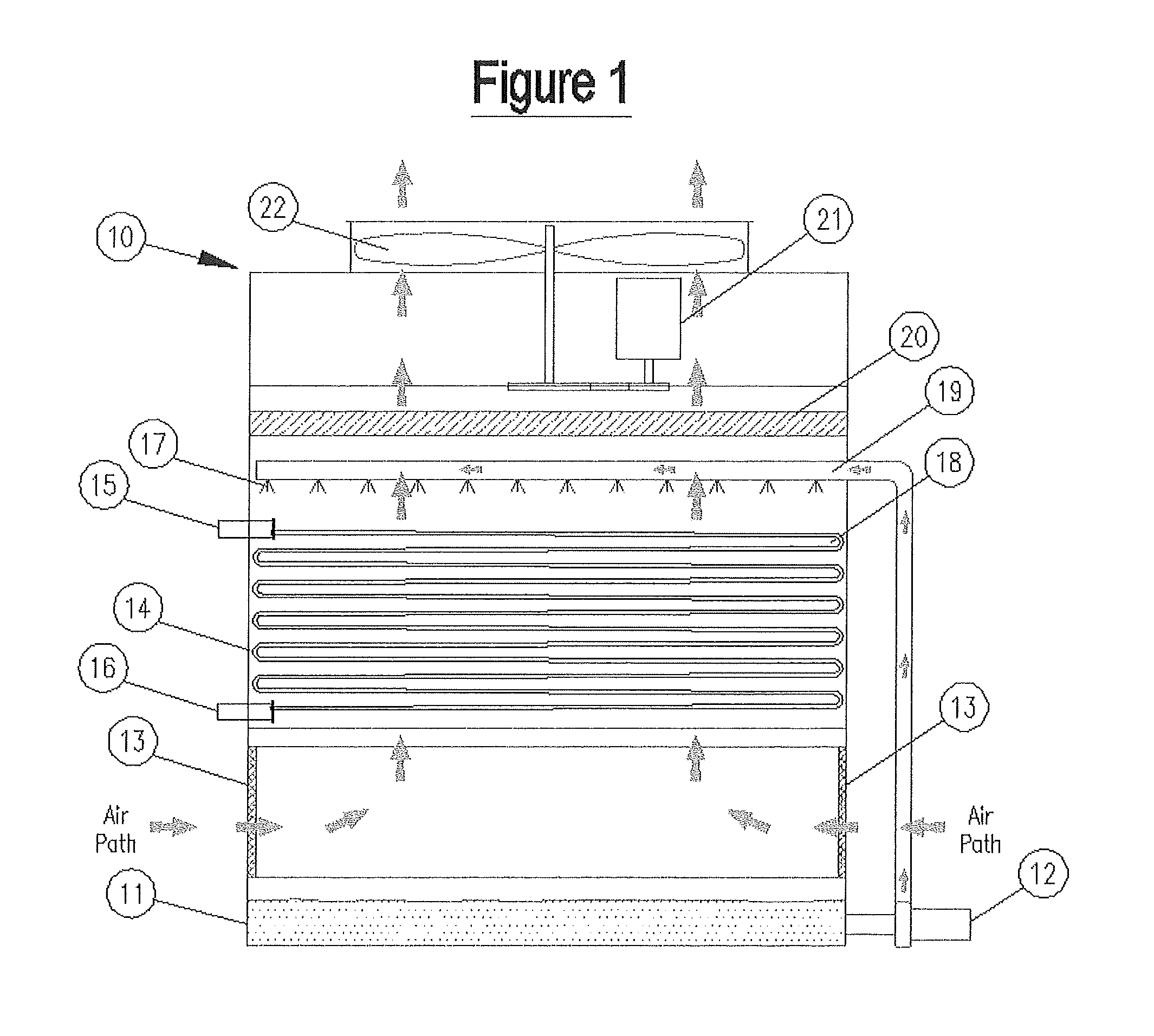

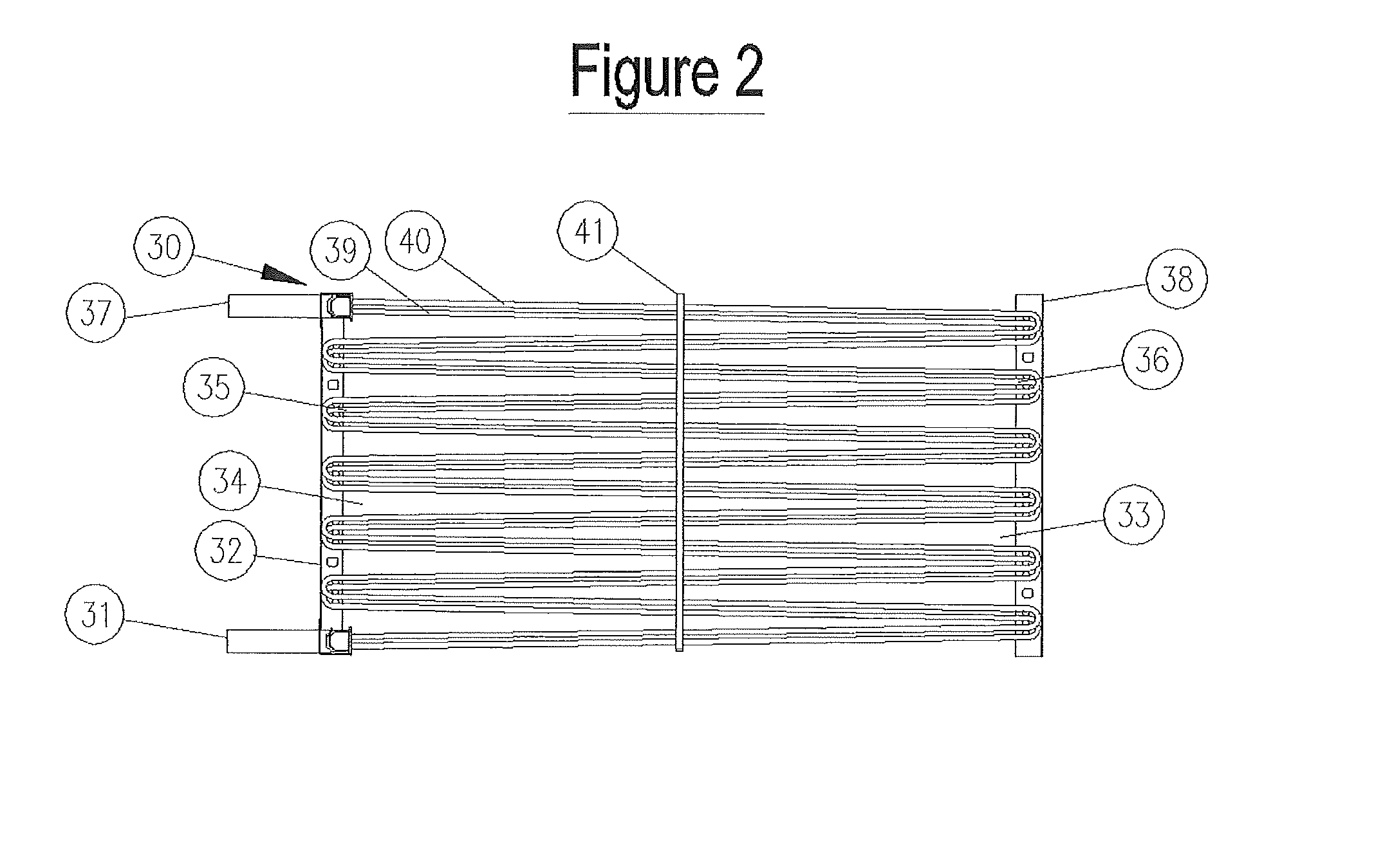

ActiveUS9587885B2Improve performanceIncrease distanceTransportation and packagingMixing methodsCooling towerEngineering

A heat exchange apparatus is provided with an indirect evaporative heat exchange section. The indirect evaporative heat exchange section is comprised of a series of serpentine tubes, and an evaporative liquid is passed downwardly onto the indirect heat exchange section. The evaporative liquid is collected in a sump and then pumped upwardly to be distributed again across the indirect heat exchange section. An improved heat exchange apparatus is provided with an indirect evaporative heat exchange section consisting of a series of serpentine tubes comprised of tube runs both of normal and increased height between tube runs. A direct heat exchange section may be provided in the increased vertical spacing between tube runs.

Owner:BALTIMORE AIRCOIL CO INC

Cooling tower with indirect heat exchanger

ActiveUS20160363376A1Improve performanceIncrease distanceTransportation and packagingEfficient regulation technologiesCooling towerEngineering

A heat exchange apparatus is provided with an indirect evaporative heat exchange section. The indirect evaporative heat exchange section is comprised of a series of serpentine tubes, and an evaporative liquid is passed downwardly onto the indirect heat exchange section. The evaporative liquid is collected in a sump and then pumped upwardly to be distributed again across the indirect heat exchange section. An improved heat exchange apparatus is provided with an indirect evaporative heat exchange section consisting of a series of serpentine tubes comprised of tube runs both of normal and increased height between tube runs. A direct heat exchange section may be provided in the increased vertical spacing between tube runs.

Owner:BALTIMORE AIRCOIL CO INC

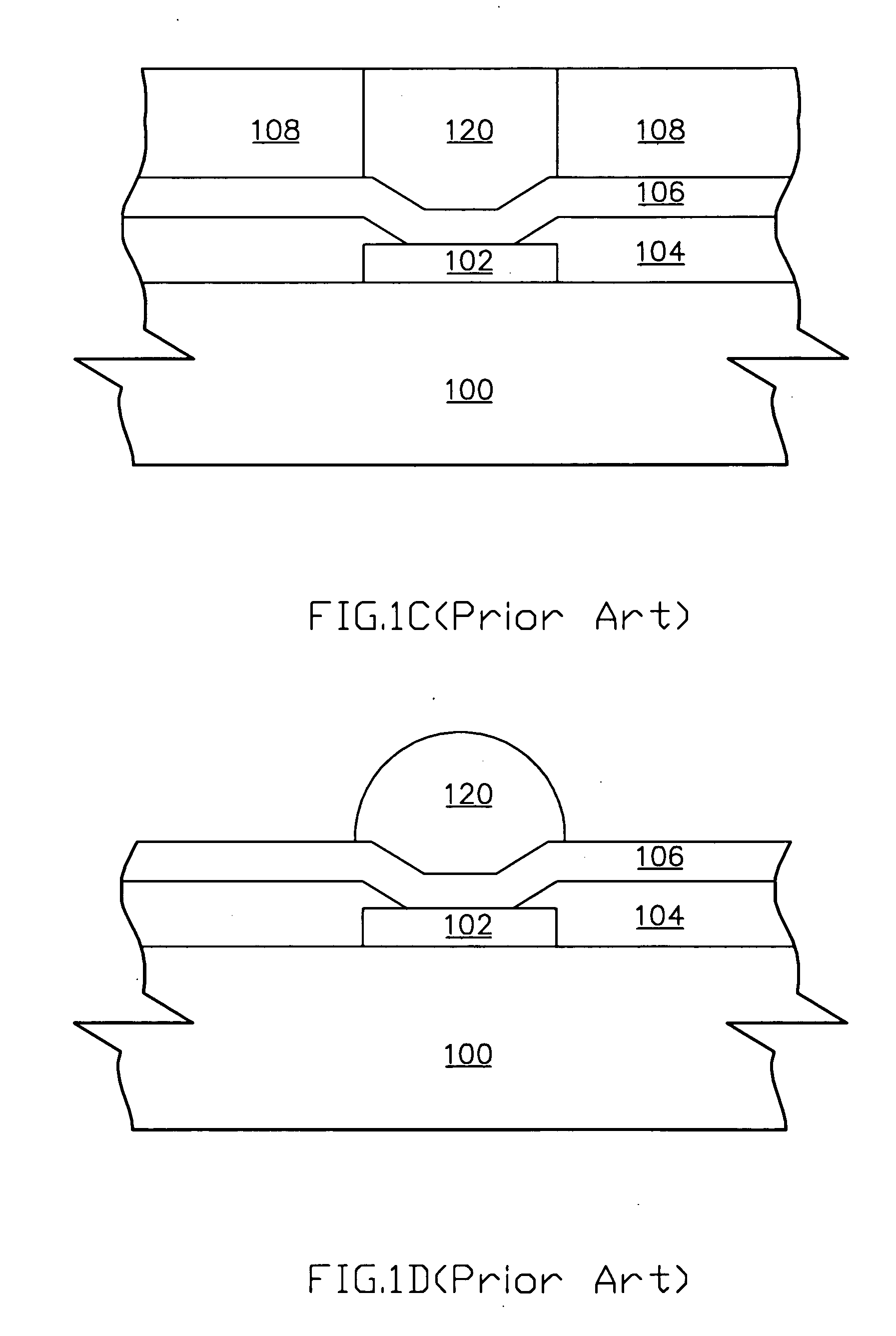

Method of forming a solder bump and the structure thereof

InactiveUS20050275097A1Improve reliabilityIncrease heightSemiconductor/solid-state device detailsSolid-state devicesConductive materialsOptoelectronics

A method of forming a solder bump and the associated structure is disclosed. A chip having a conductive pad is covered with a mask layer and exposing a potion of said conductive pad of said chip. Conductive material is then formed above the conductive pad not covered with said mask layer. After applying a flux material on the formed conductive material, a solder structure having a lower melting point than the conductive material is placed, and subsequently is reflowed at a temperature lower than the melting point of the conductive material. After removing the mask layer, the solder bump with increased height and reliability is thus attained.

Owner:ADVANCED SEMICON ENG INC

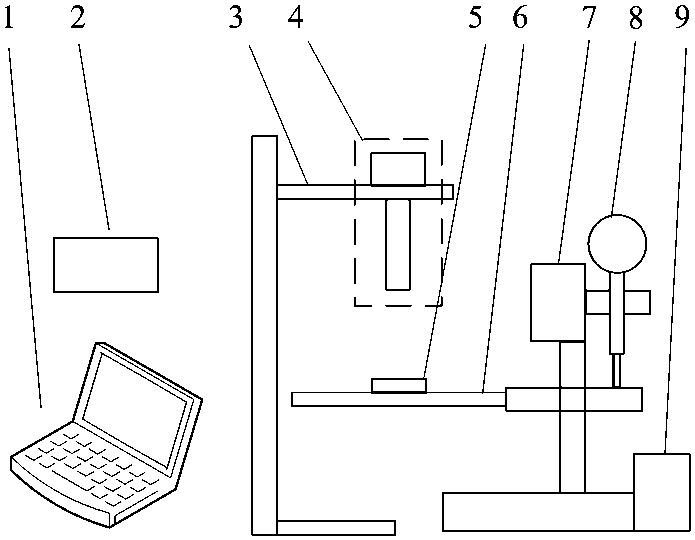

Non-contact optical component surface profile measuring device and method thereof

PendingCN109974583AAvoid damageOvercoming the problem of low efficiencyMechanical counters/curvatures measurementsMechanical thickness measurementsMeasurement deviceLight spot

The invention discloses a non-contact optical component surface profile measuring device and a method thereof. The device includes a host computer, an electronic control module, a probe supporting structure, an optical probe, a to-be-measured element, an element clamping device, a Z-axis electric translation stage, a dial indicator and an XY-axis electric translation stage; and the optical probe projects a focusing light spot on the surface of the to-be-measured element, and the light spot forms a three-hole bright spot through a three-hole diaphragm after being reflected back to an object lens. As the distance between the bright spots is related to the height position of the light spot, surface thicknesses can be obtained by collecting images in real time to calculate the distance betweenthe bright spots; in order to increase a height measuring range, the Z-axis electric translation stage can be used to move the to-be-measured element up and down, and the dial indicator can be used to measure the position of the element; and compared with traditional contact surface profile measuring systems, the device has the advantage of being non-contact, so that influences on the surface ofthe element can be avoided, and large measuring scope and high precision can be obtained.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Methods of forming alternative channel materials on a non-planar semiconductor device and the resulting device

InactiveUS9627245B2Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsEngineering

One illustrative method disclosed herein involves, among other things, forming trenches to form an initial fin structure having an initial exposed height and sidewalls, forming a protection layer on at least the sidewalls of the initial fin structure, extending the depth of the trenches to thereby define an increased-height fin structure, with a layer of insulating material over-filling the final trenches and with the protection layer in position, performing a fin oxidation thermal anneal process to convert at least a portion of the increased-height fin structure into an isolation material, removing the protection layer, and performing an epitaxial deposition process to form a layer of semiconductor material on at least portions of the initial fin structure.

Owner:IBM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com