Liquid crystal display panel and manufacturing method thereof

A technology for liquid crystal display panels and manufacturing methods, applied in nonlinear optics, instruments, optics, etc., which can solve the problems of ITO electrodes not being able to conduct normally, ITO not being able to conduct, and screens not being displayed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

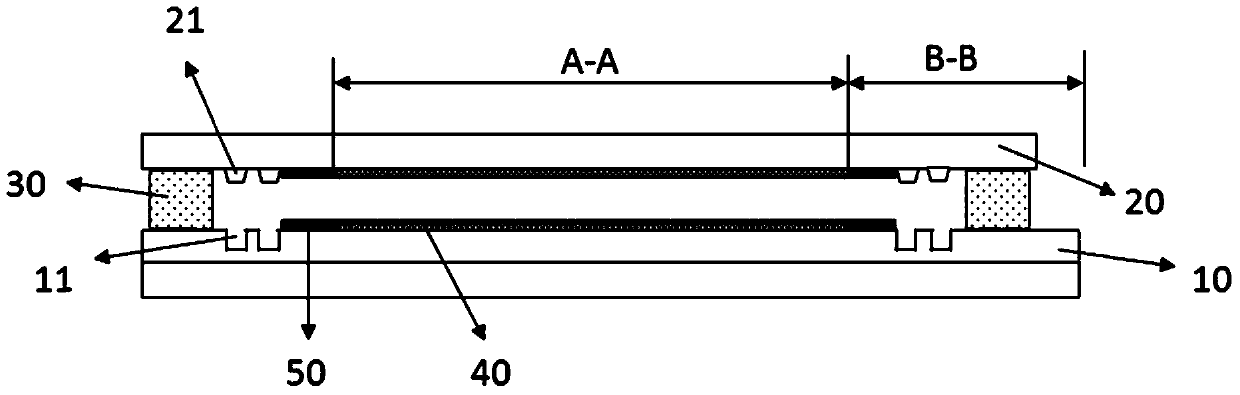

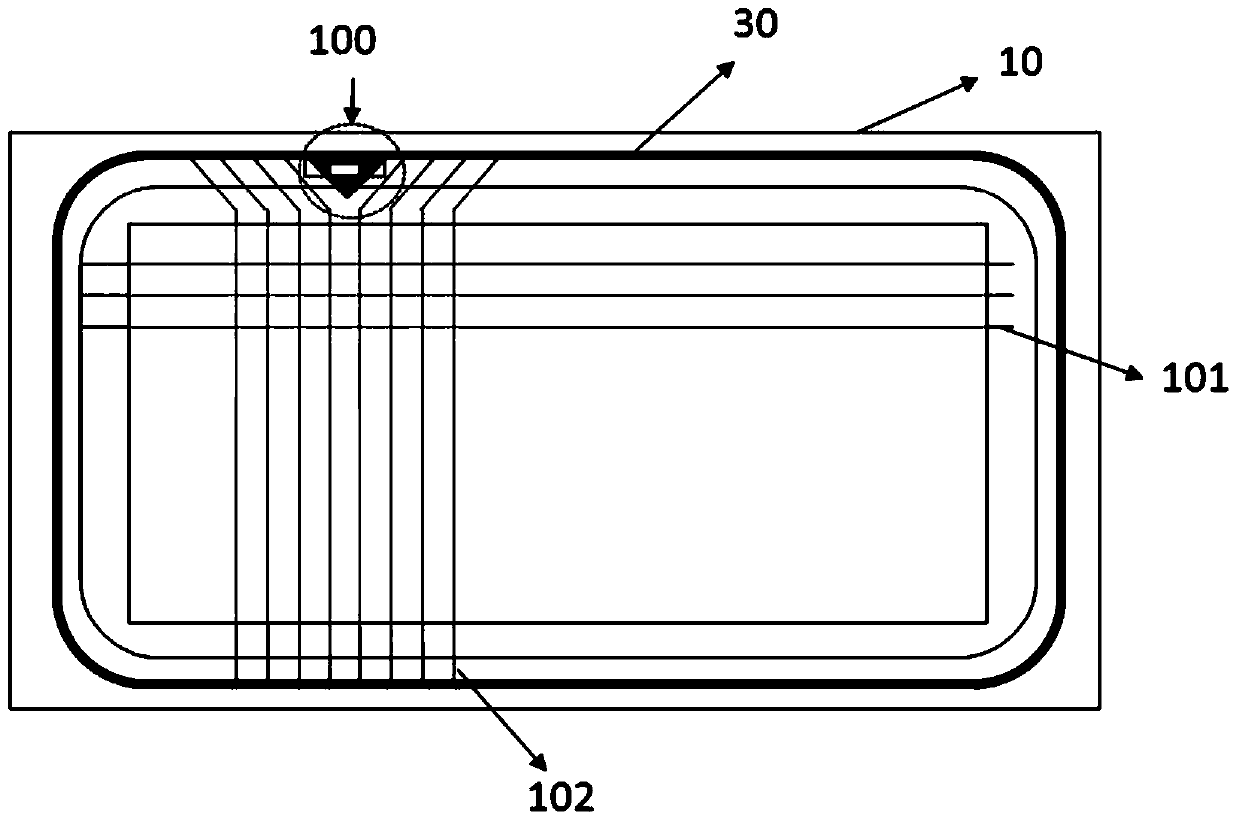

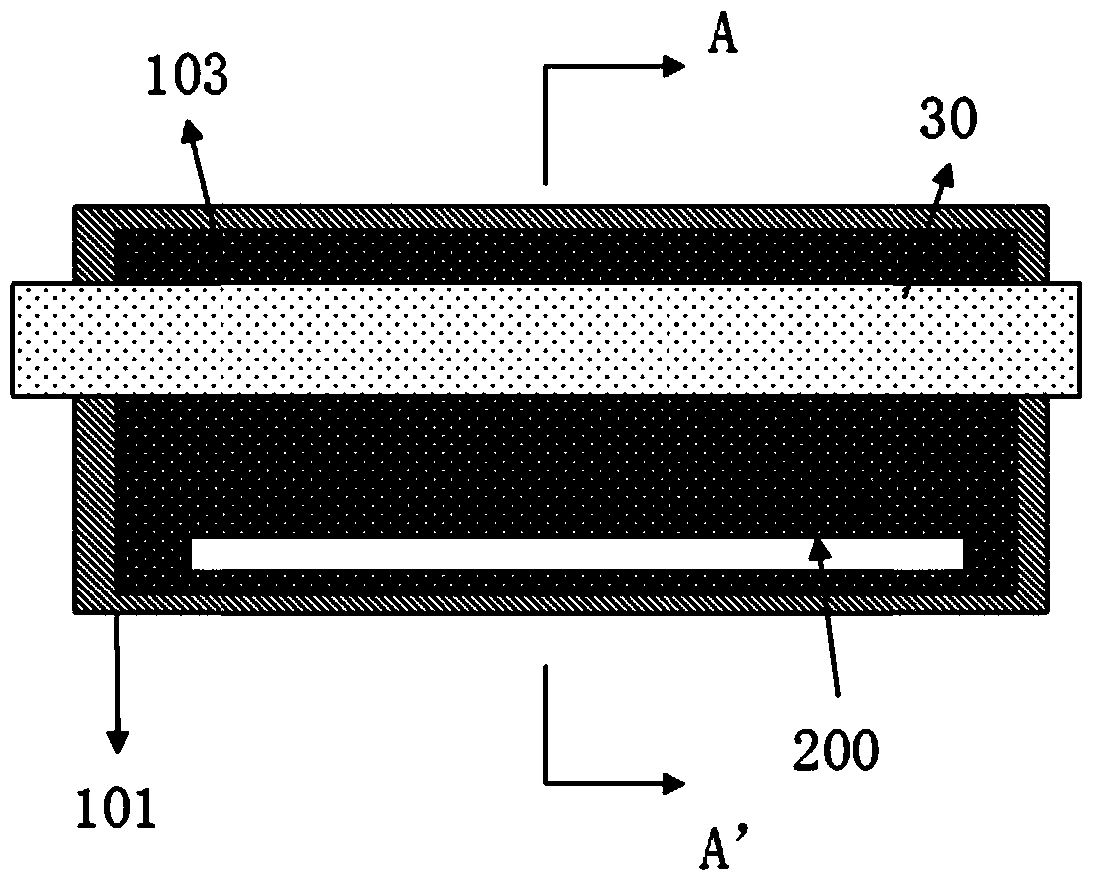

[0049] In order to make the technical problems, technical solutions, and advantages to be solved by the embodiments of the present invention clearer, a detailed description will be given below with reference to the drawings and specific embodiments.

[0050] The present invention is based on the improvement where the existing alignment film flows under the sealant area, which causes the color film substrate and the ITO electrode on the array substrate to fail to conduct normally. The present invention uses the contact position of the array substrate and the color film substrate to specifically At the position of the sealant matching the array substrate and the color filter substrate, a semiconductor layer is provided under the ITO of the array substrate, and a color layer is provided under the black matrix layer of the corresponding color filter substrate, so that the opposite ITO forms an island pattern. It is an amorphous silicon, polysilicon or metal oxide layer with a thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com