Load-adjustable step feeding type entrained flow bed gasifier

A technology of gasification device and entrained bed, which is applied in the field of load-adjustable segmented feeding type entrained bed gasification device, can solve the problems of increasing specific oxygen consumption and specific coal consumption, reducing cold gas efficiency, etc., achieving long residence time, Wide range of load adjustment, the effect of increasing the output of a single furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand this solution, the following is a detailed description through specific implementation cases and in conjunction with the accompanying drawings:

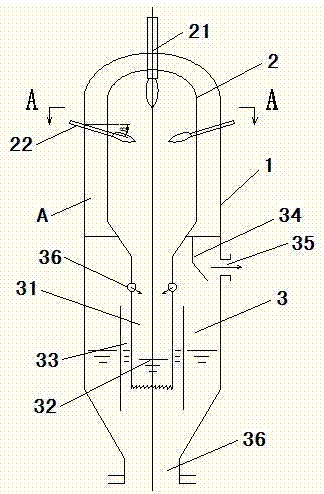

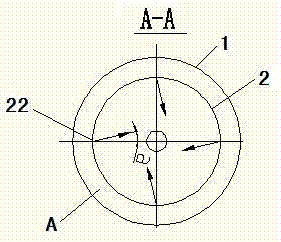

[0024] see Figure 1 to Figure 2 , the present invention is a load-adjustable segmented feeding type entrained bed gasification device, comprising: a pressure shell 1 and a reaction chamber 2 and a cooling chamber 3 in a cooling and dedusting water bath arranged inside the pressure shell. The cooling and dedusting water bath chilling chamber 3 is coaxially arranged at the lower part of the reaction chamber 2 . An annular space A is left between the pressure shell 1 and the water-cooled wall of the reaction chamber 2, which is convenient for installation and maintenance.

[0025] The reaction chamber 2 is composed of a membrane wall, and its fire-facing surface is a membrane water-cooled wall structure, and a layer of refractory lining can also be applied on the water-cooled wall. The reaction ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com