Patents

Literature

1241results about How to "Prevent flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

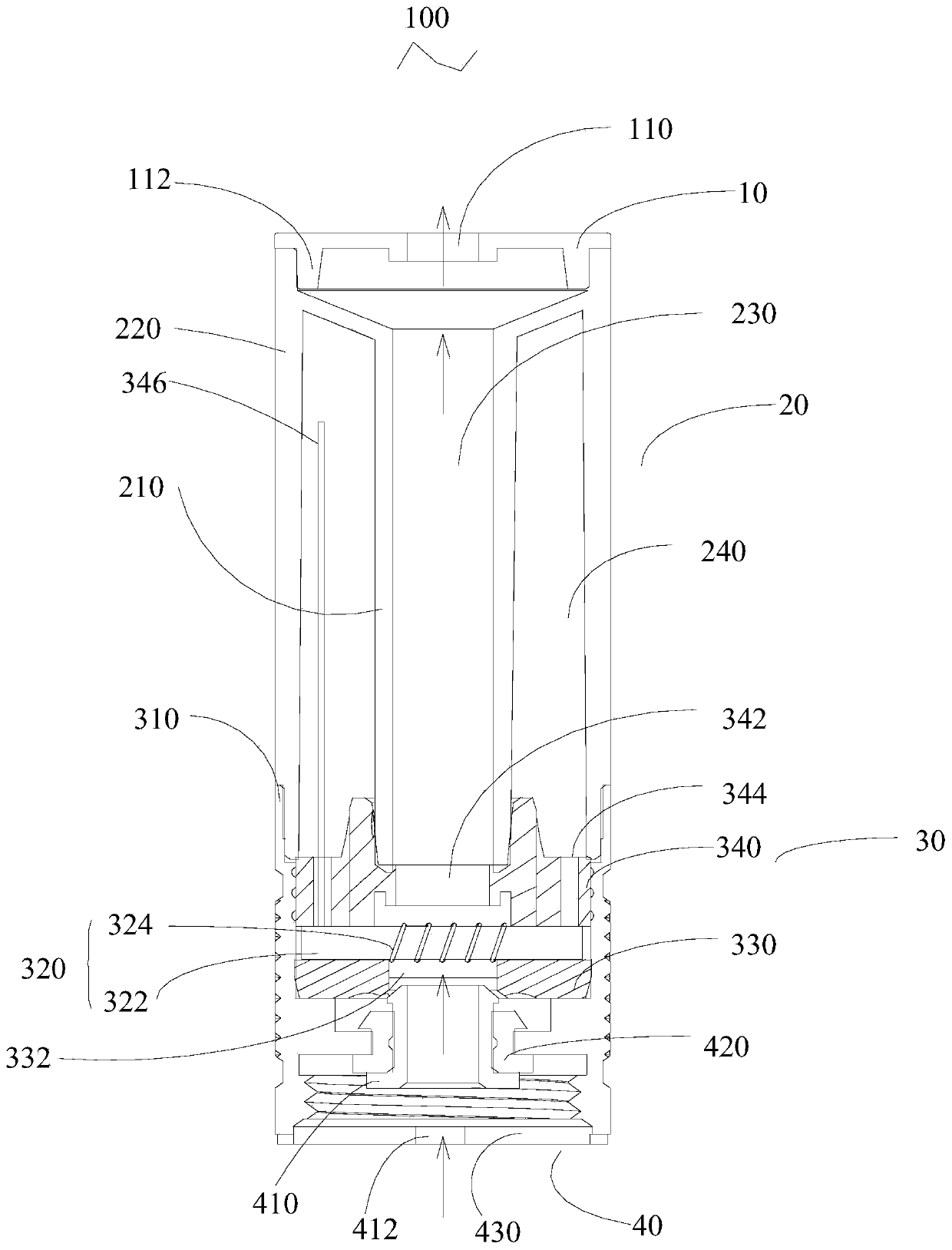

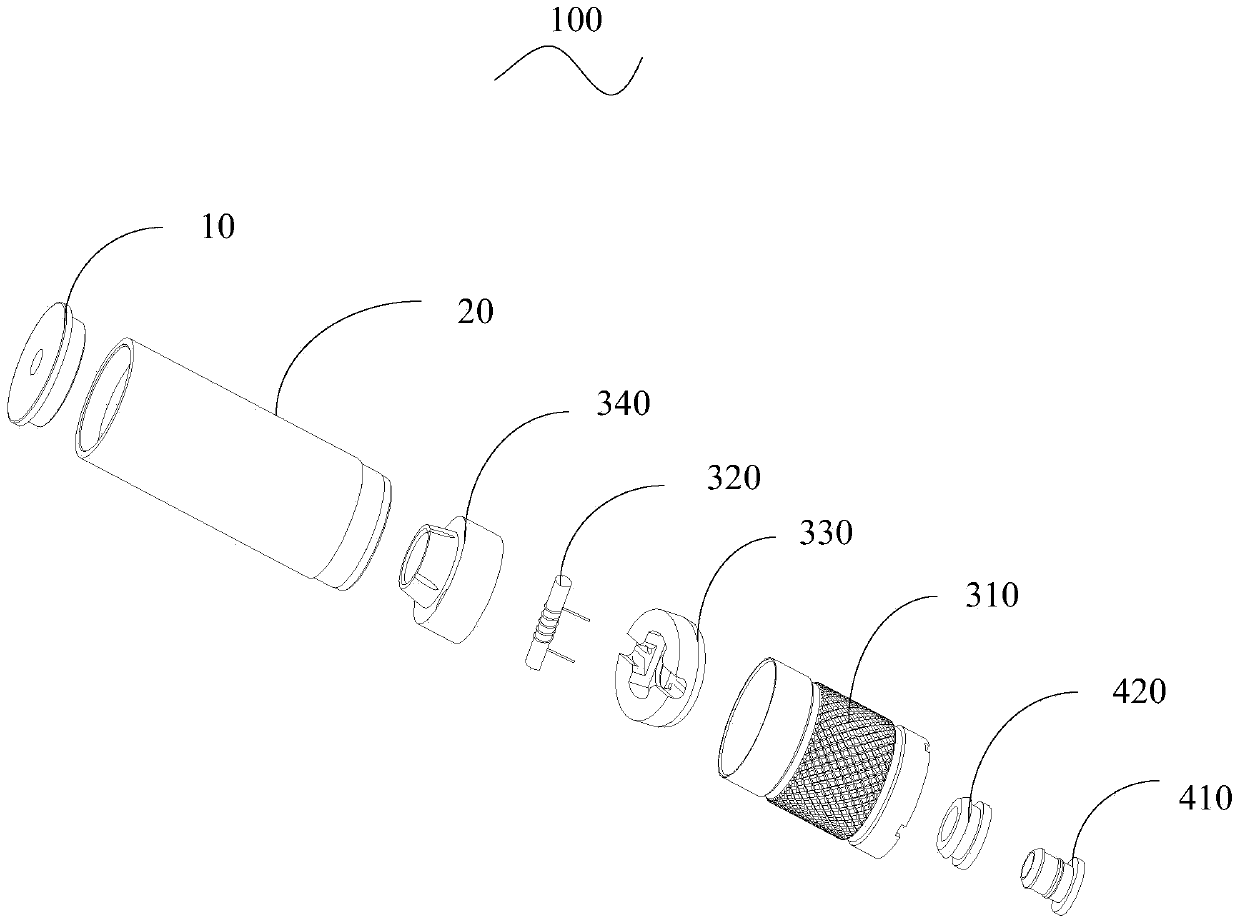

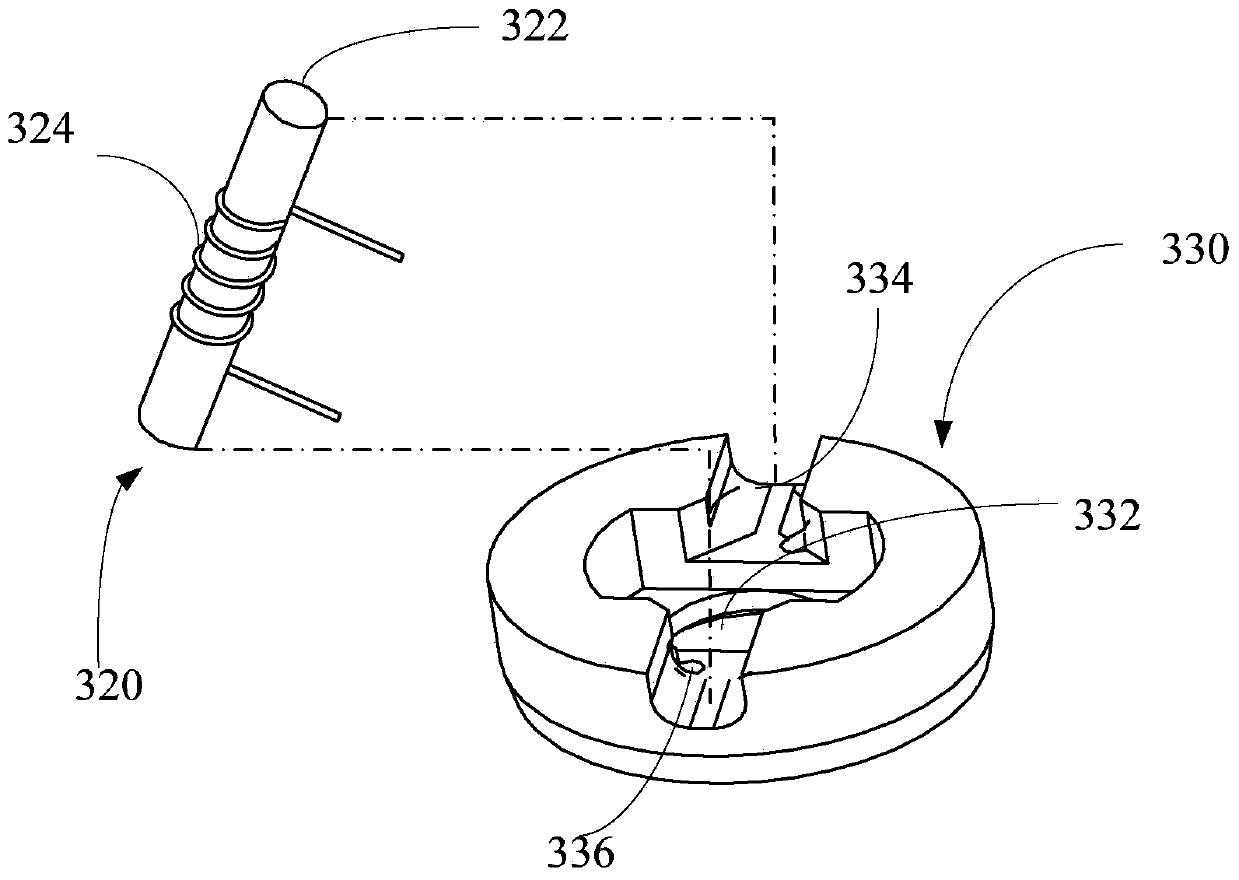

Electronic cigarette

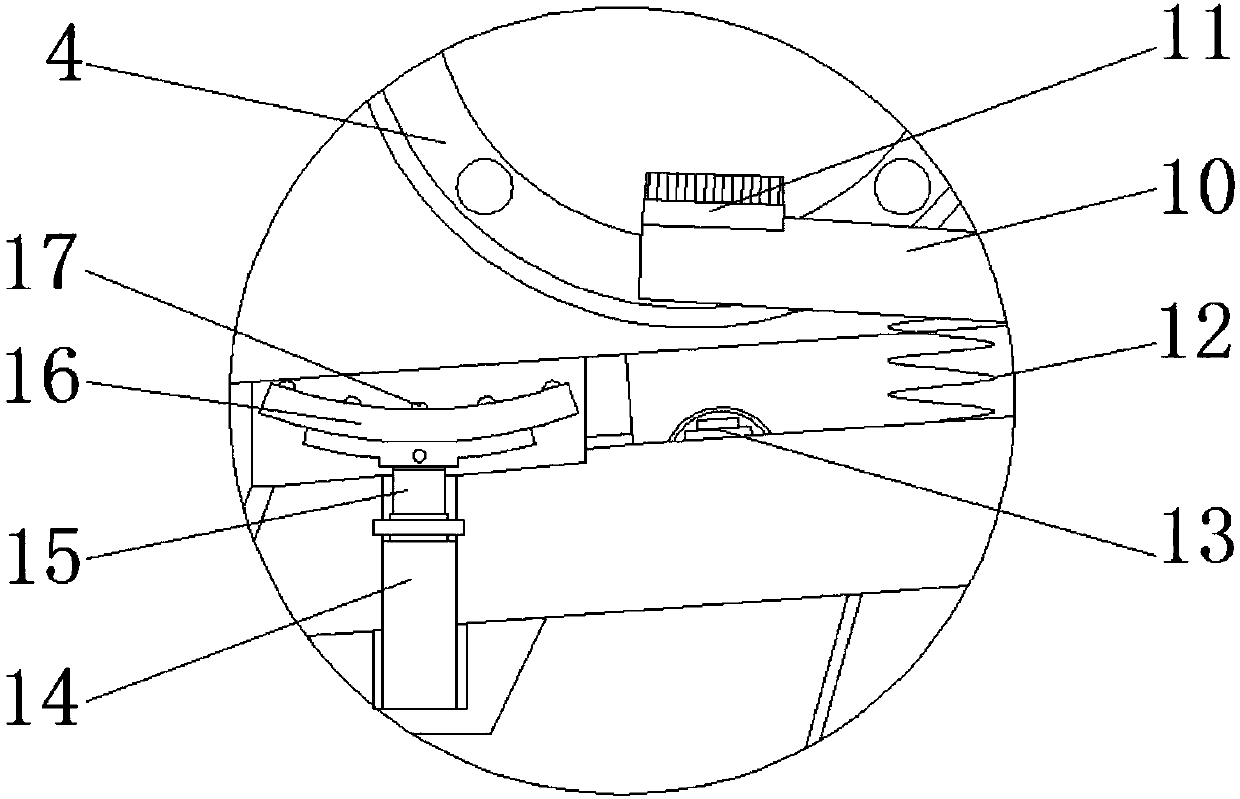

The invention relates to an electronic cigarette which comprises a cigarette cartridge provided with a liquid storage cavity and a flue, and an atomizing component. The atomizing component comprises an atomizer sleeve, a liquid guide device plugging at a cavity port of the liquid storage cavity, a base axially abutted against the tail end of the liquid guide device, and a heating element positioned between the base and the liquid guide device, the liquid guide device, the heating element and the base are contained in the atomizer sleeve, an air passage communicated with the flue is arranged in the atomizer sleeve, an end face groove is arranged on the front end face of the base and communicated with the air passage, the heating element comprises a linear liquid absorbing rope and a heating wire wound on a part of line section of the liquid absorbing rope, the liquid absorbing rope which is not wound by the heating wire is contained in the end face groove, the liquid absorbing rope which is wound by the heating wire and the heating wire are positioned in the air passage and are not directly connected with an outlet of a liquid outgoing hole, and the liquid outgoing hole capable of supplying liquid to the liquid absorbing rope positioned in the end face groove is arranged on the liquid guide device. The electronic cigarette is simple in structure and high in stability.

Owner:SHENZHEN SMOORE TECH LTD

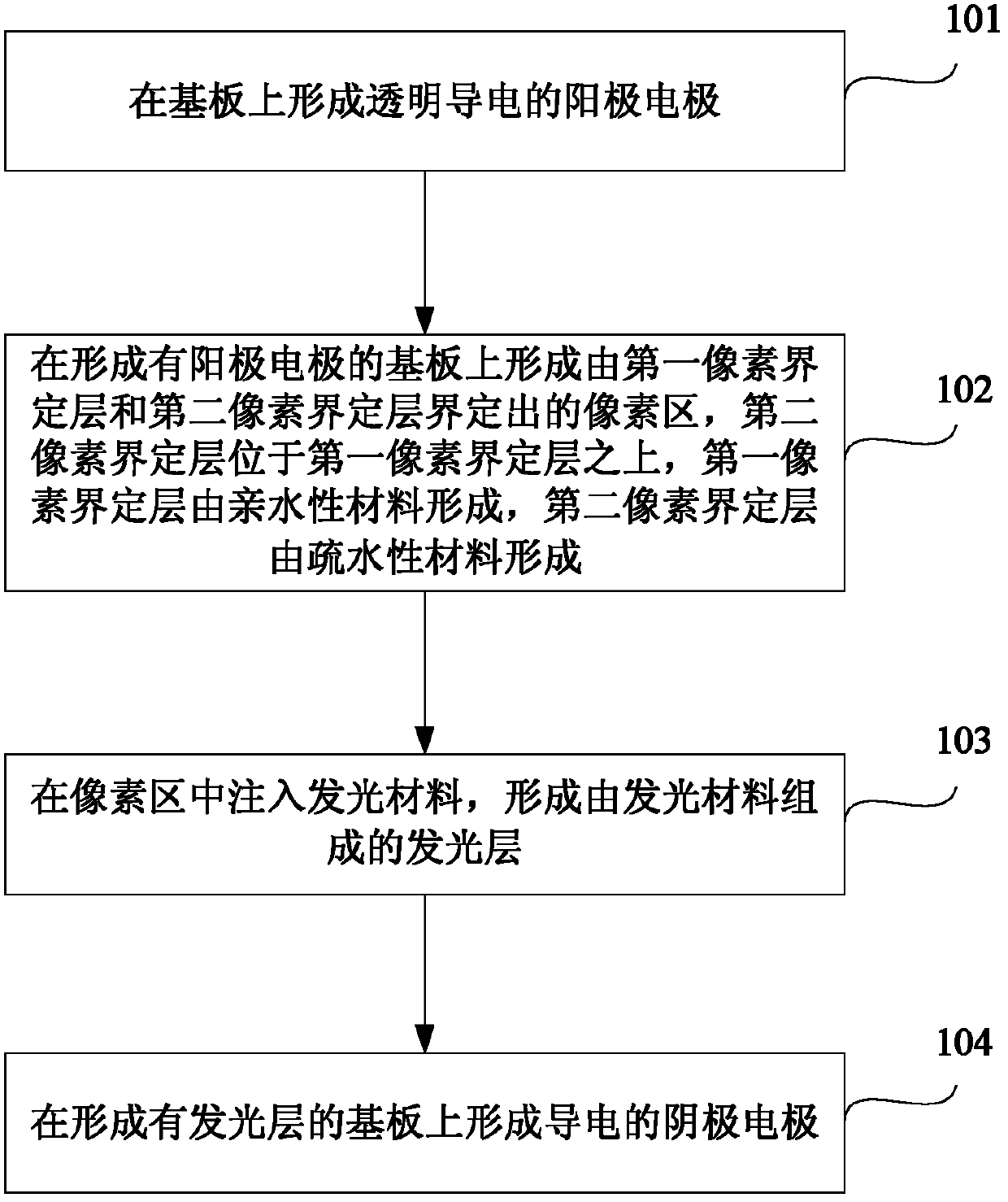

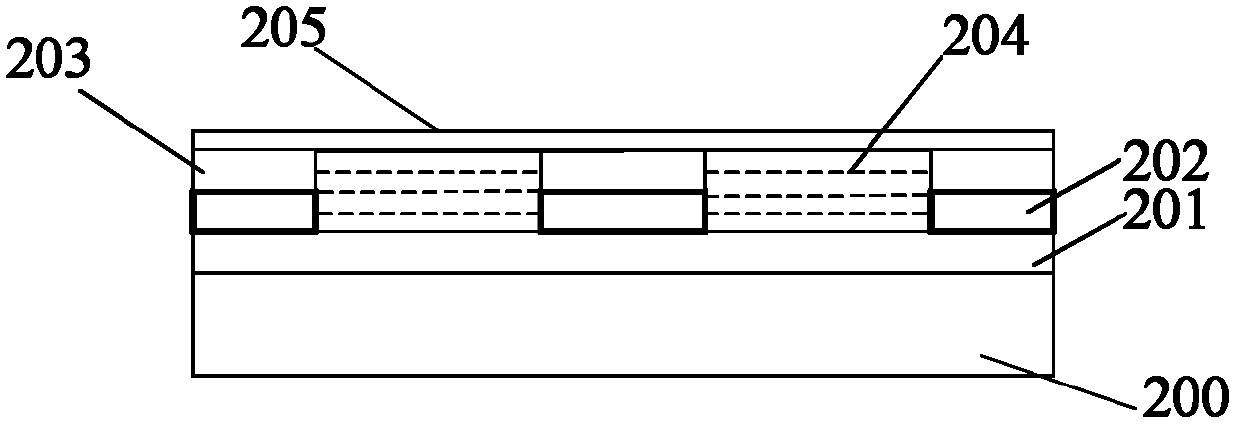

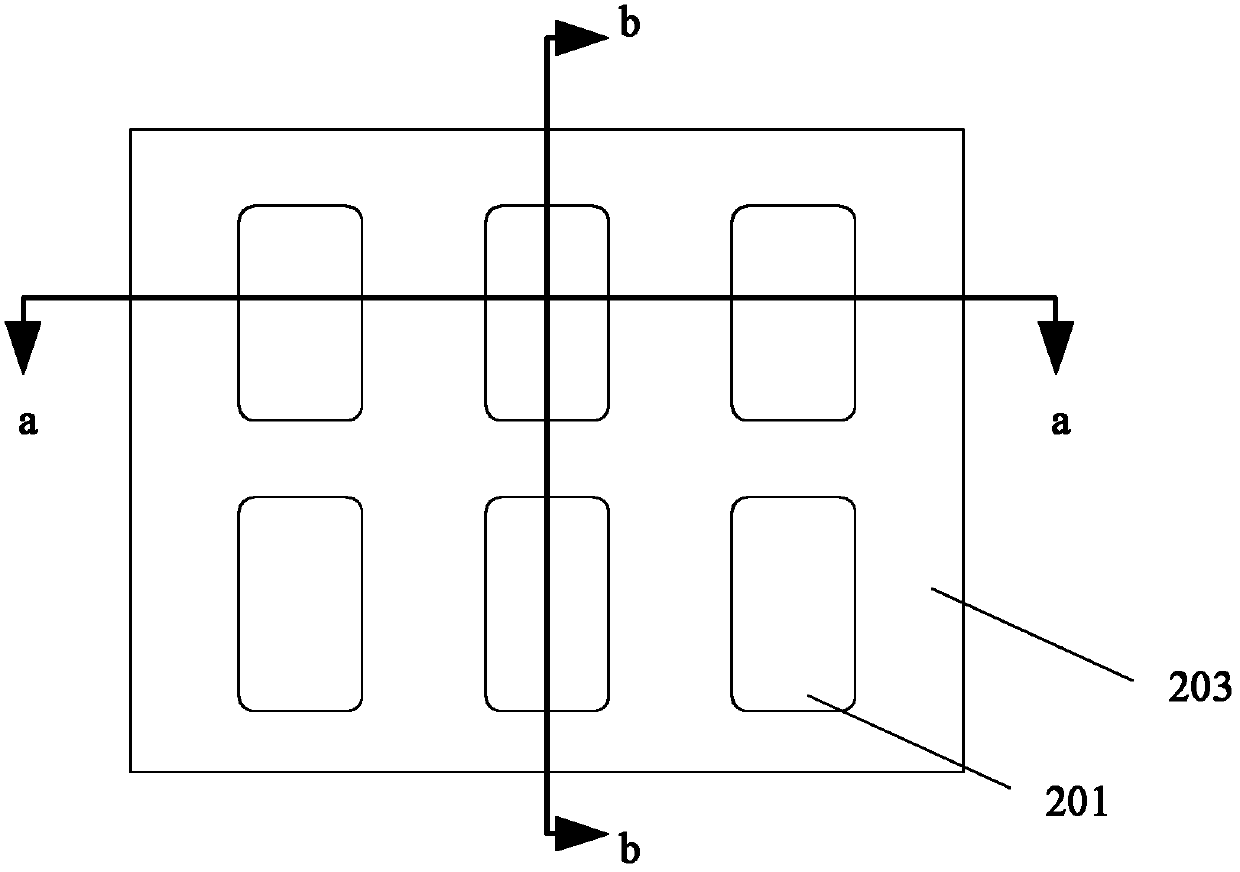

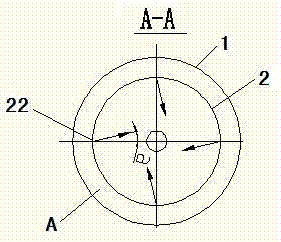

Light-emitting diode display back plate, manufacturing method and display device for light-emitting diode display back plate

ActiveCN102705790AImprove lighting qualityChange wetting propertiesPoint-like light sourceLighting support devicesDisplay deviceEngineering

The invention provides a light-emitting diode display back plate, a manufacturing method and a display device for the light-emitting diode display back plate and belongs to the field of displaying. The manufacturing method for the light-emitting diode display back plate includes steps: forming a transparent and conductive anode on a substrate; forming a pixel area defined by a first pixel defining layer and a second pixel defining layer on the substrate where the anode is formed; injecting light-emitting materials into the pixel area, and forming an light-emitting layer comprising the light-emitting materials; and forming a conductive cathode on the substrate where the light-emitting layer is formed. The second pixel defining layer made of hydrophobic materials is located above the first pixel defining layer made of hydrophilic materials. By the aid of the light-emitting diode display back plate, the manufacturing method and the display device for the light-emitting diode display back plate in the technical scheme, the light-emitting materials can be flatly laid on the light-emitting diode display back plate, and light-emitting quality of the light-emitting diode display back plate is improved.

Owner:BOE TECH GRP CO LTD

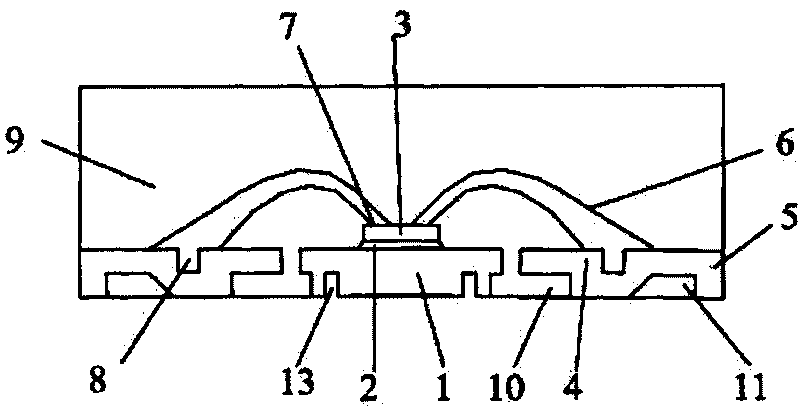

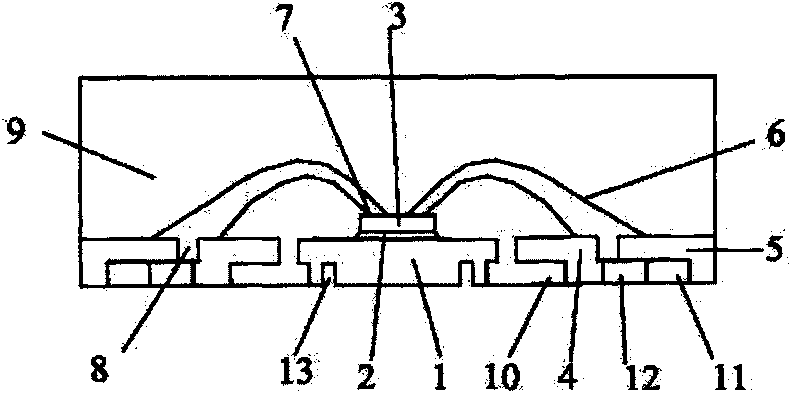

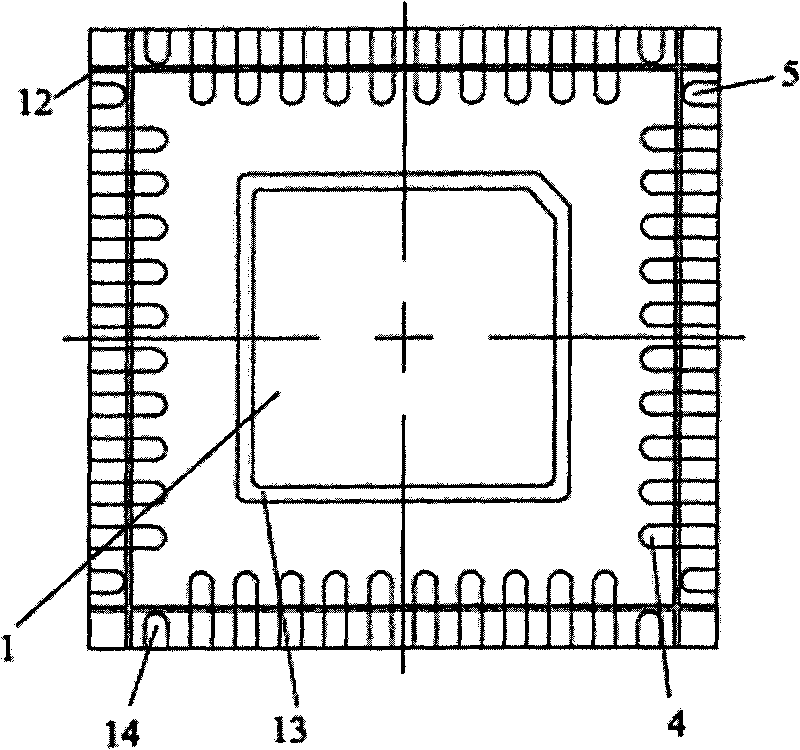

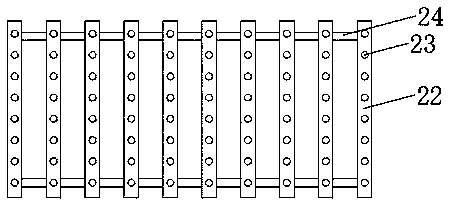

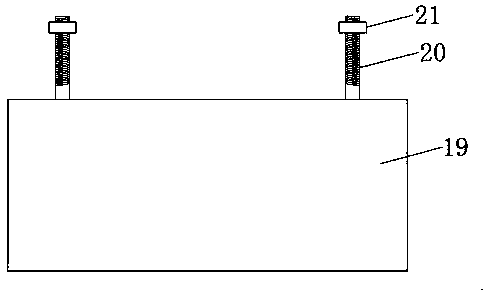

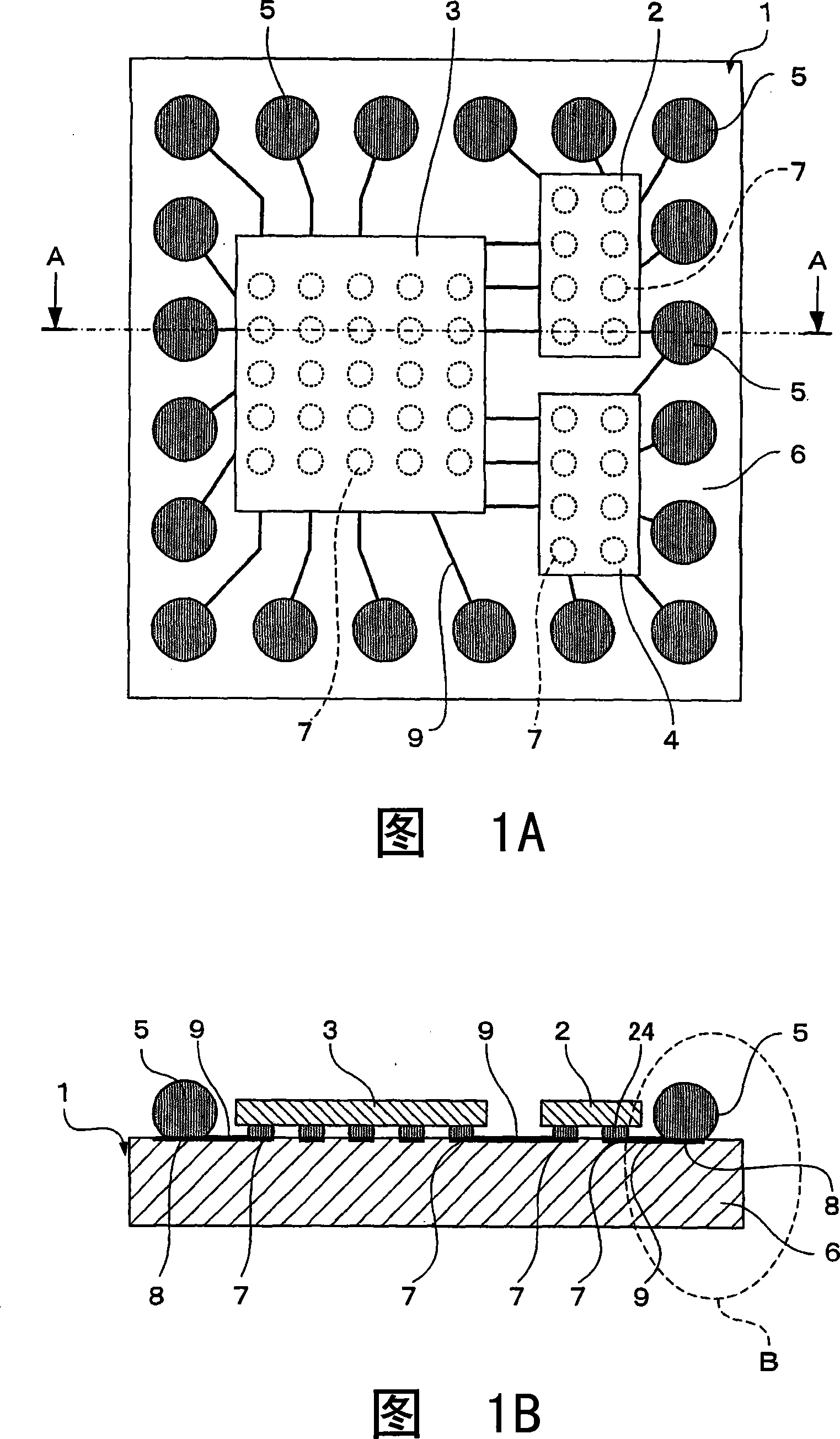

Packaging part with double-row pins and four flat and pin-free surfaces and production method thereof

ActiveCN101694837AShort wirePrevent flowSemiconductor/solid-state device detailsSolid-state devicesHigh density packagingBond line

The invention relates to a packaging part with double-row pins and four flat and pin-free surfaces and a production method thereof. The packaging part comprises a lead frame carrier, an IC chip, a bonding pad, inner lead pins, bonding lines and a plastic packaging body and is characterized in that the inner lead pins are arranged into two rows, i.e. the inner lead pin (4) and the inner lead pin (5), each pair of lead pins are connected together, a groove is arranged in the middle of the connected pins, the bonding pads are respectively connected with the inner lead pin (4) and the inner lead pin (5) through the bonding lines, an anti-spilling groove is arranged at the bottom of the carrier, and grooves are arranged at the bottoms of the inner lead pins. The packaging part is processed and produced through the processes of reduction, scribing, chip installation, press welding, plastic packaging, electroplating, cutting and the like. The carrier is diminished, the inner lead pins are inwards extended and designed into double rows, and the packaged I / O number is increased, thereby not only markedly saving the cost of plastic packaging materials, but also realizing the thin and miniaturized packaging of portable products, being suitable for multi-pin high-density packaging, and improving the packaging density.

Owner:TIANSHUI HUATIAN TECH

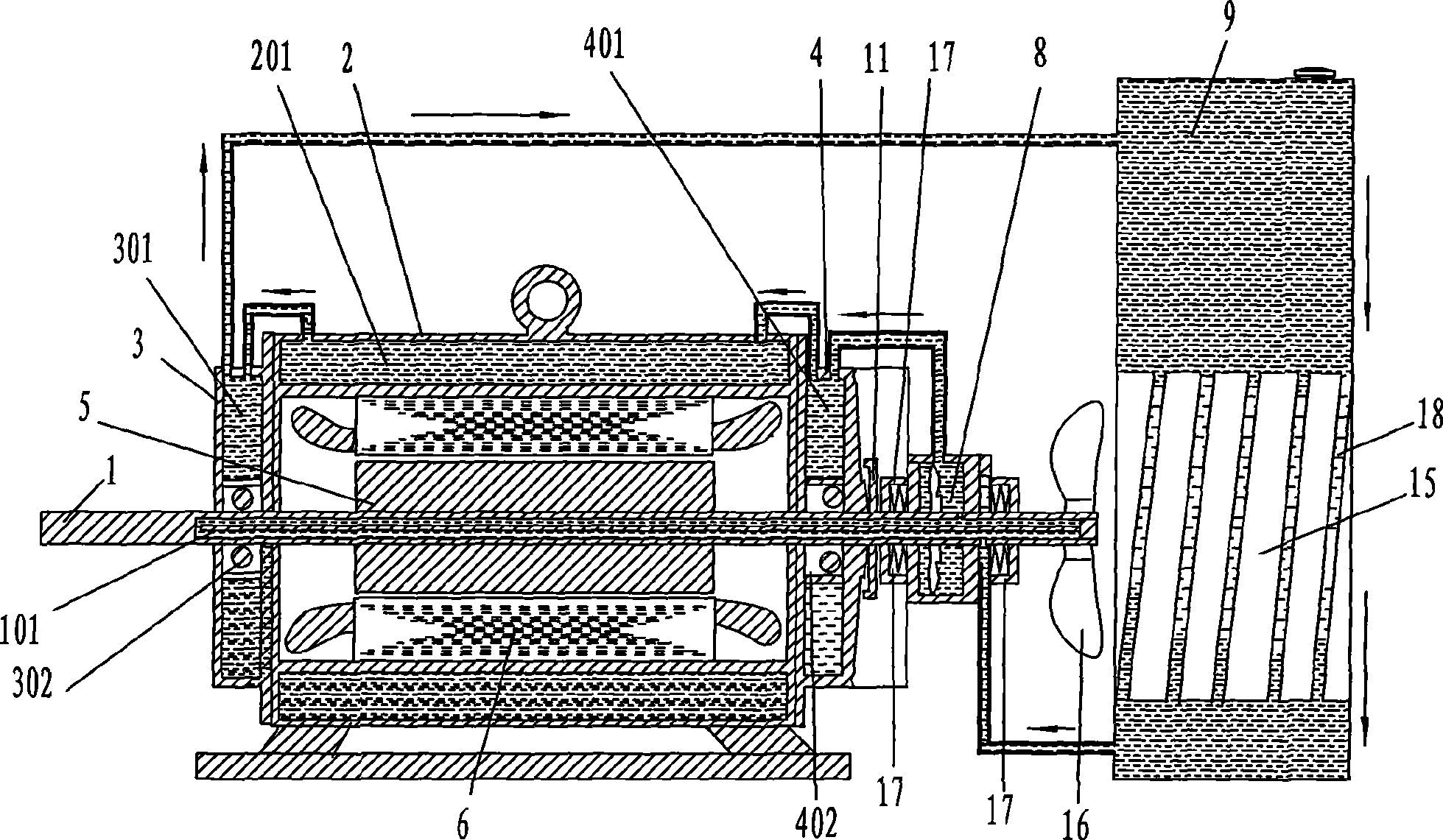

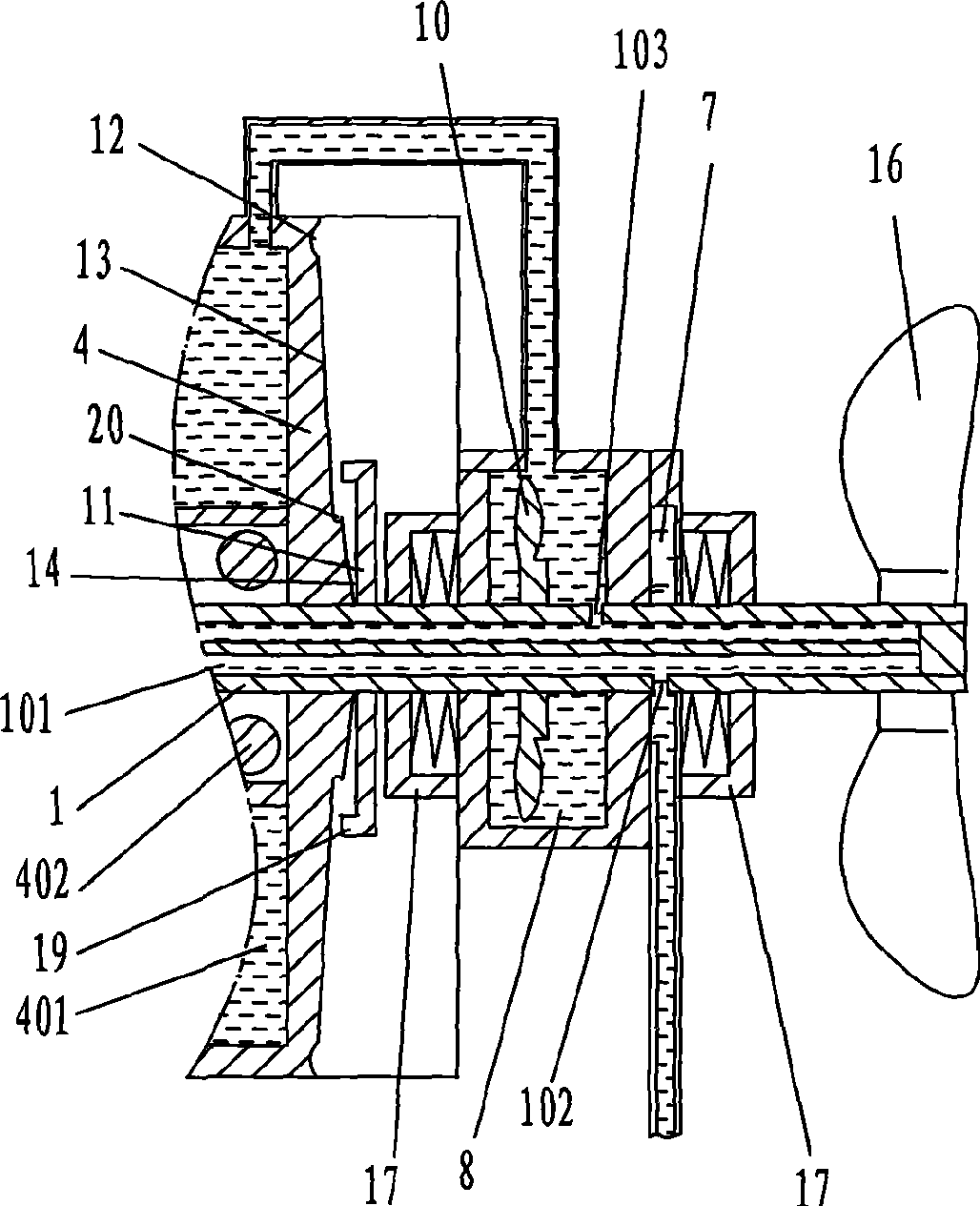

Liquid cooling motor

InactiveCN101499697AWill not affect workWill not flowCooling/ventillation arrangementSupports/enclosures/casingsEngineeringCooling fluid

The invention relates to a liquid cooling motor, comprising a rotor (5), a rotation shaft (1), a shell (2), a front cover (3) and a rear cover (4); the rotor (5) is arranged in the shell (2); the front cover (3) and the rear cover (4) are respectively arranged at two ends of the shell (2); the front end of the rotation shaft (1) passes through the front cover (3); the rotation shaft (1) is internally provided with a circular cooling liquid passage (101); and the rotation shaft (1) is provided with a liquid inlet (102) and a liquid outlet (103) which are communicated with the circular cooling liquid passage (101). Compared with the prior art, the rotation shaft is internally provided with the circular cooling liquid passage, therefore, heat of the rotor of the motor can be directly dissipated by cooling the rotation shaft in a liquid cooling way.

Owner:武汉唯特特种电机有限公司

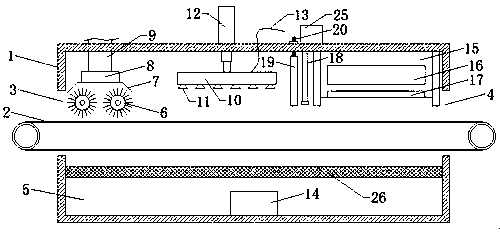

Paint-spraying device with desusting and drying integrated structure

InactiveCN109261416AGuaranteed long-term useSolving Recycling ProblemsPretreated surfacesLiquid spraying apparatusSprayerEngineering

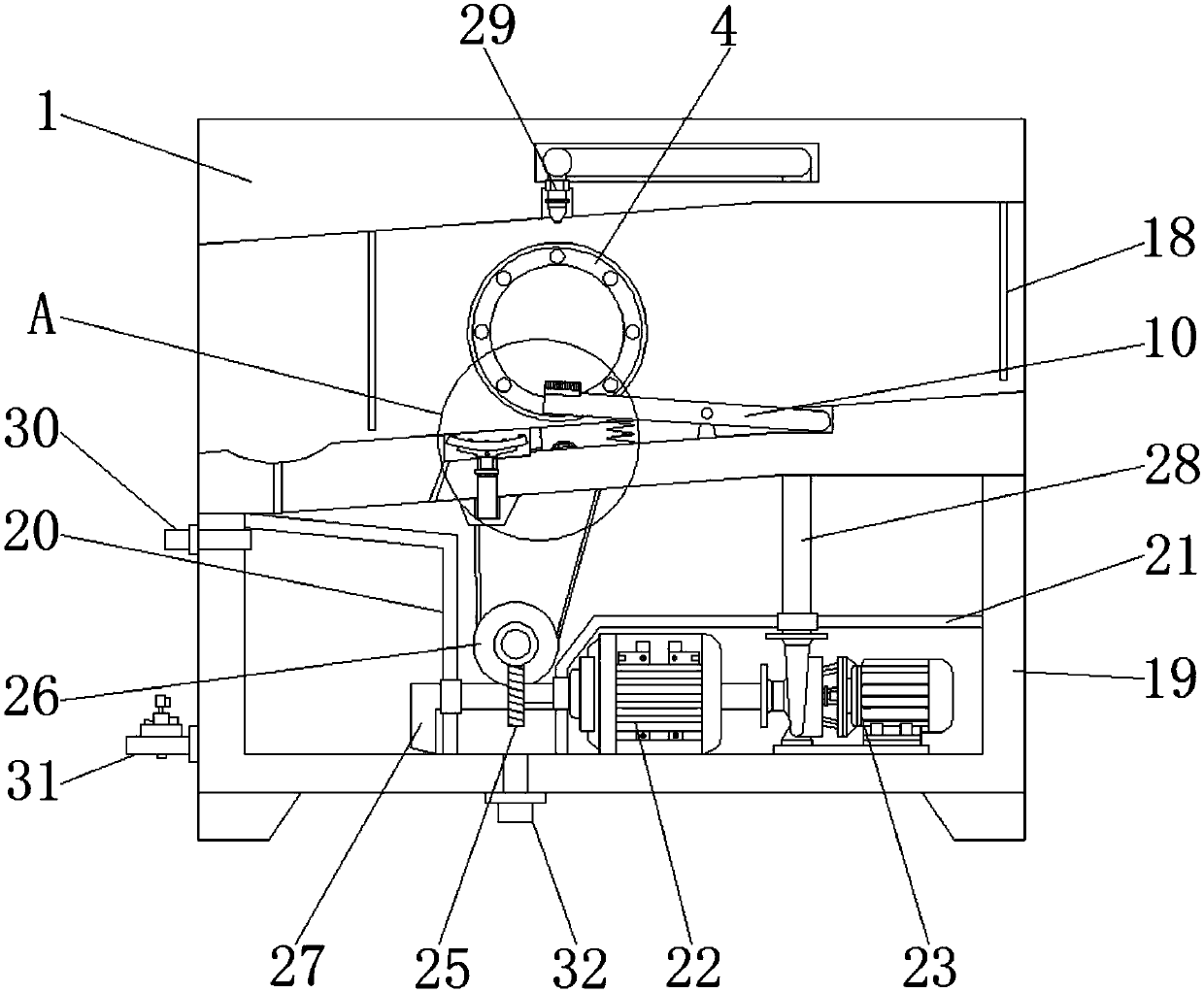

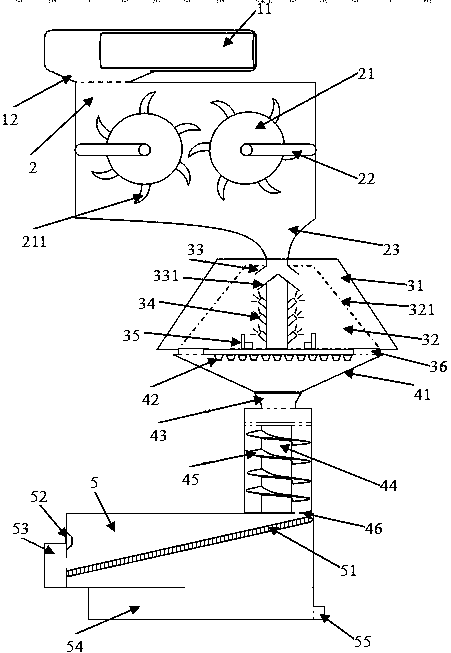

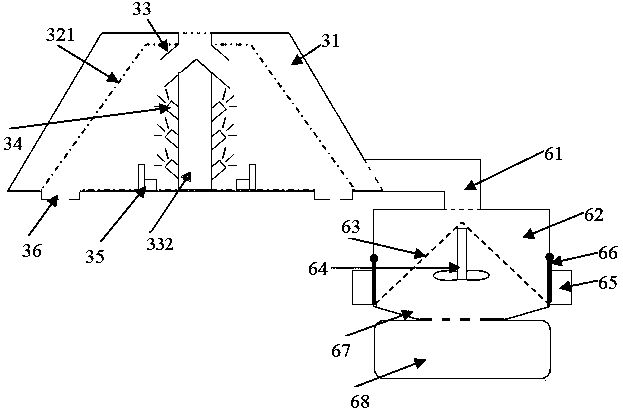

The invention relates to the field of paint spraying, and particularly discloses a paint-spraying device with a desusting and drying integrated structure. The paint-spraying device comprises a shell,a conveying belt, a feeding inlet, a discharging outlet and a paint collection tank, wherein a dust suction hood, an installation support and a drying cavity are arranged / formed above the conveying belt from left to right in sequence; a plurality of brush rollers are arranged below the dust suction hood, the dust suction hood is communicated with a dust suction blower, and the installation supportis fixedly connected with an electrical telescoping rod which stretches and retracts in the vertical direction; a vertical hot air suction pipe is arranged on the outer portion on the left side of the drying cavity, and a wind deflector with adjustable height is arranged on the left side of the hot air suction pipe. By means of the drying cavity, the paint on the surface of wood can be quickly dried, meanwhile, hot air overflows outwards can be recycled, the hot air is prevented from flowing to the position of a paint sprayer, the paint is prevented from being dried in the sprayer, it is ensured that the paint sprayer is used for a long time, and the service life is prolonged.

Owner:湖南匡沐环保科技有限公司

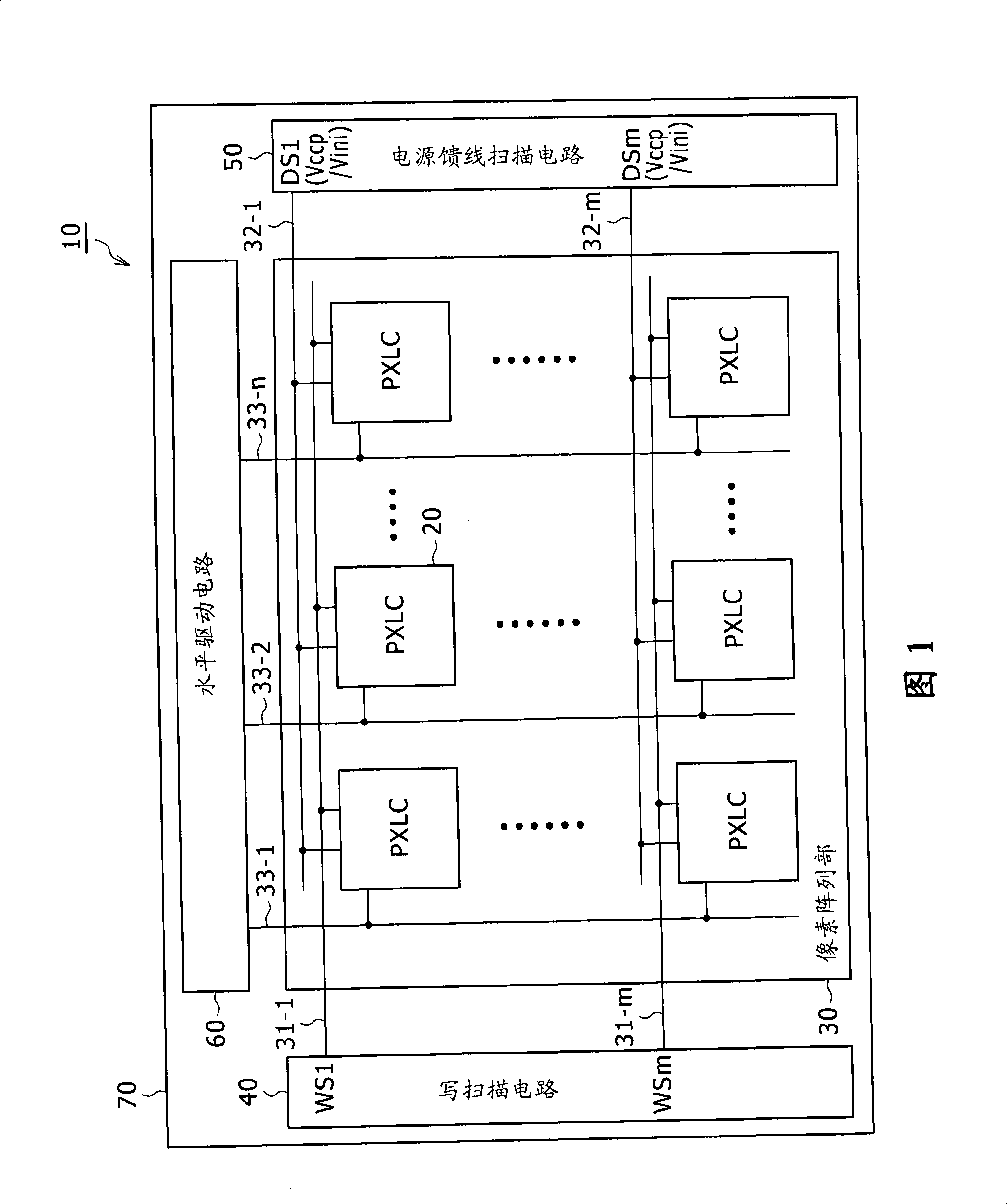

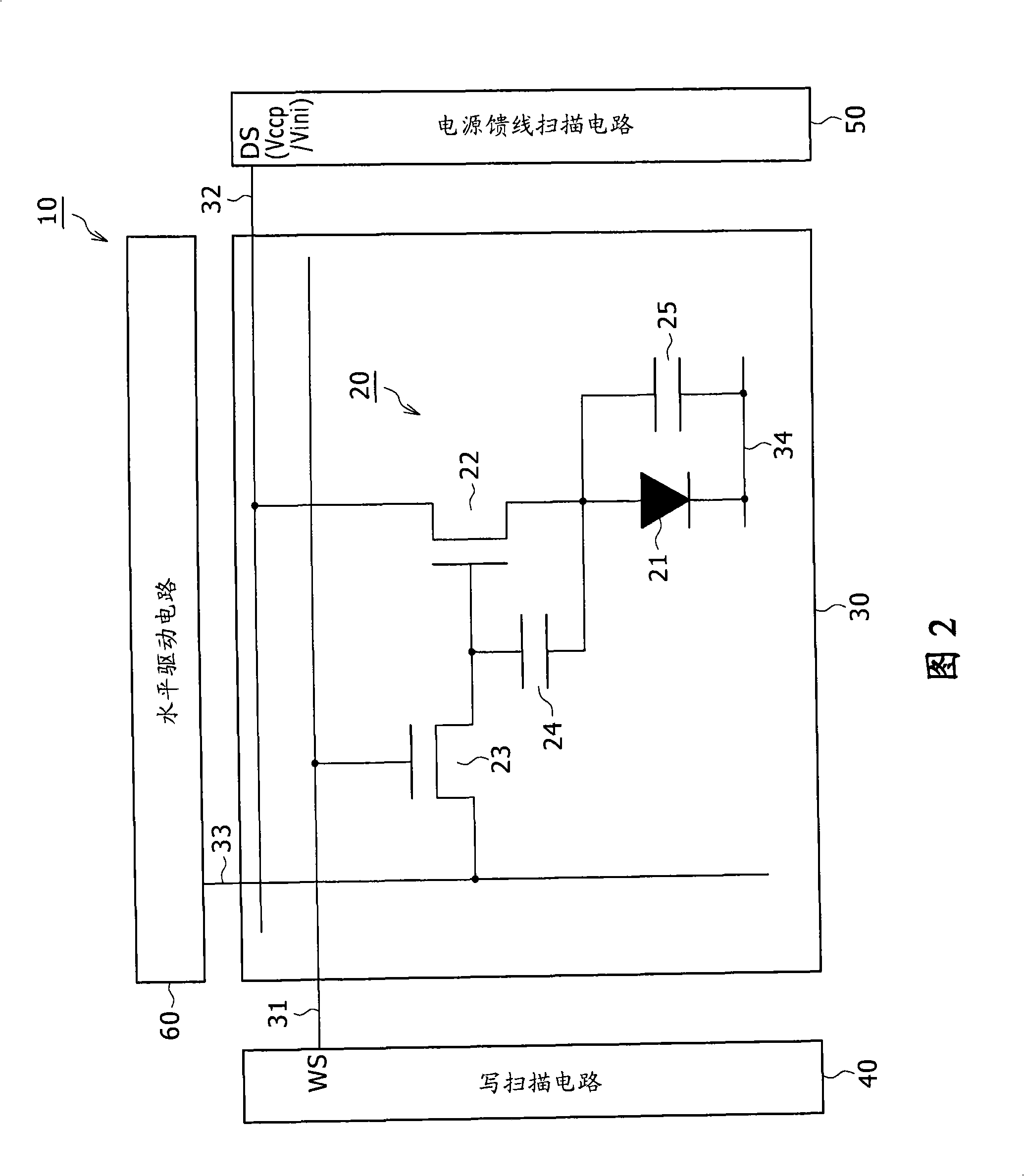

Display apparatus, display apparatus driving method and electronic equipment

InactiveCN101266754APrevent flowQuality improvementStatic indicating devicesElectroluminescent light sourcesEngineeringOpto electronic

In the present invention, there is provided a display apparatus including: a pixel array section including pixel circuits each having an electro-optical device, a write transistor configured to carry out a voltage storing process, a holding capacitor configured to hold the sampled video signal, and a driving transistor configured to drive the electro-optical device; first scan means for carrying out a selective scan operation in row units and driving each of the write transistors; second scan means for selectively supplying either a first or second electric potential synchronously with the selective scan operation for feeding a current to each of the driving transistors; and control means for sustaining a power-supply feed line in a floating state during a period ending at a time not earlier than the start of the voltage storing process after a voltage corresponding to the threshold voltage of the driving transistor has been held in the holding capacitor.

Owner:JOLED INC

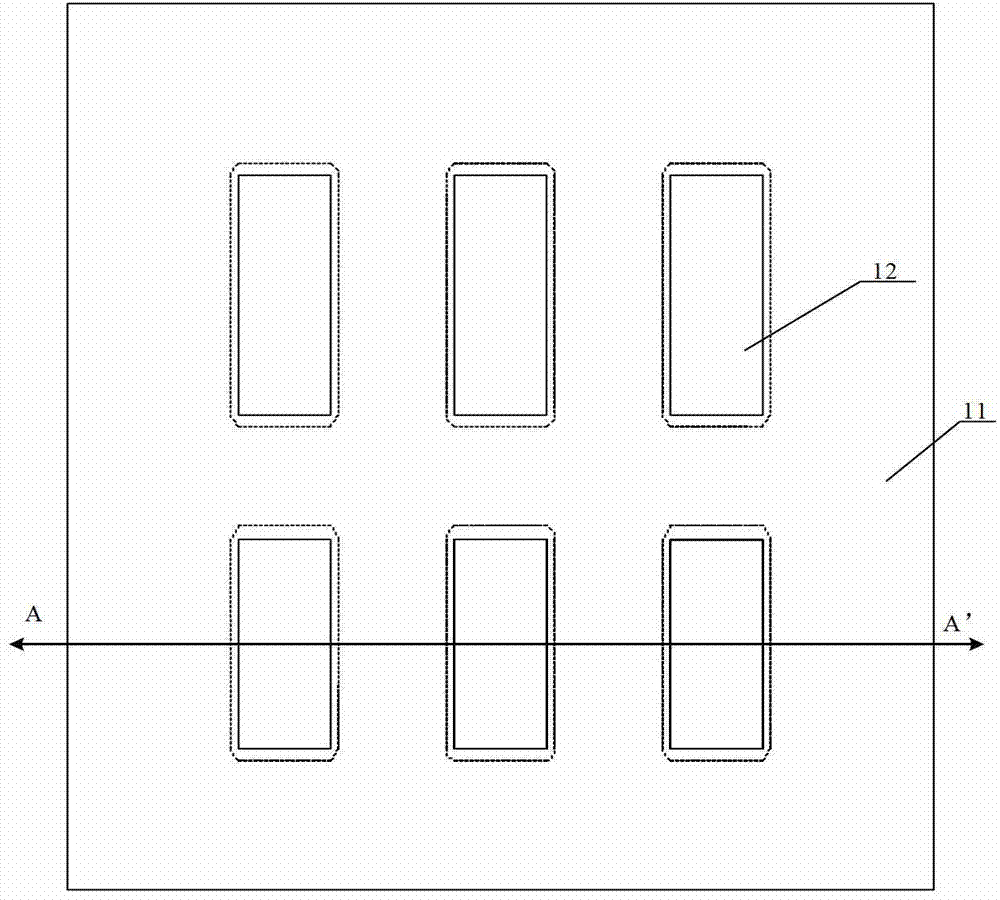

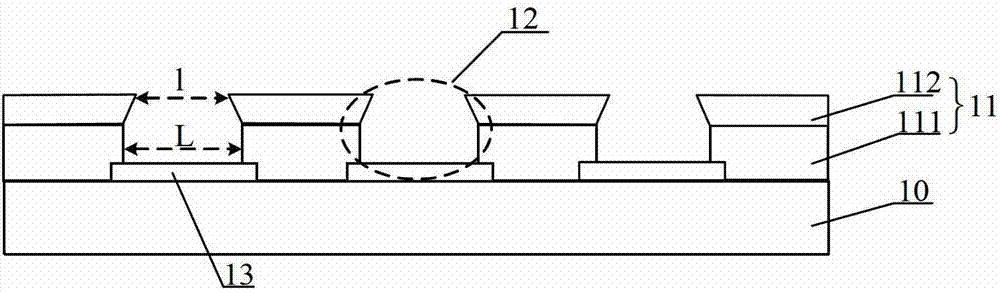

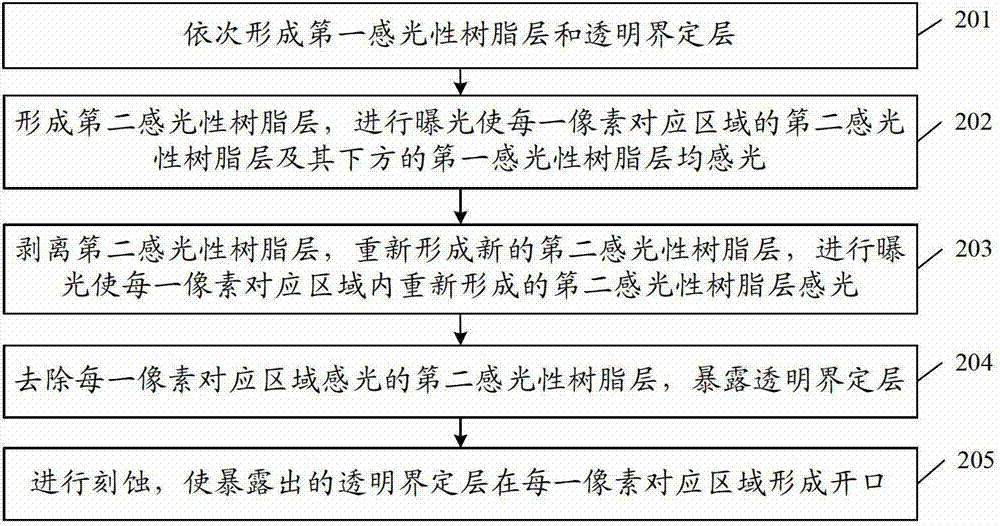

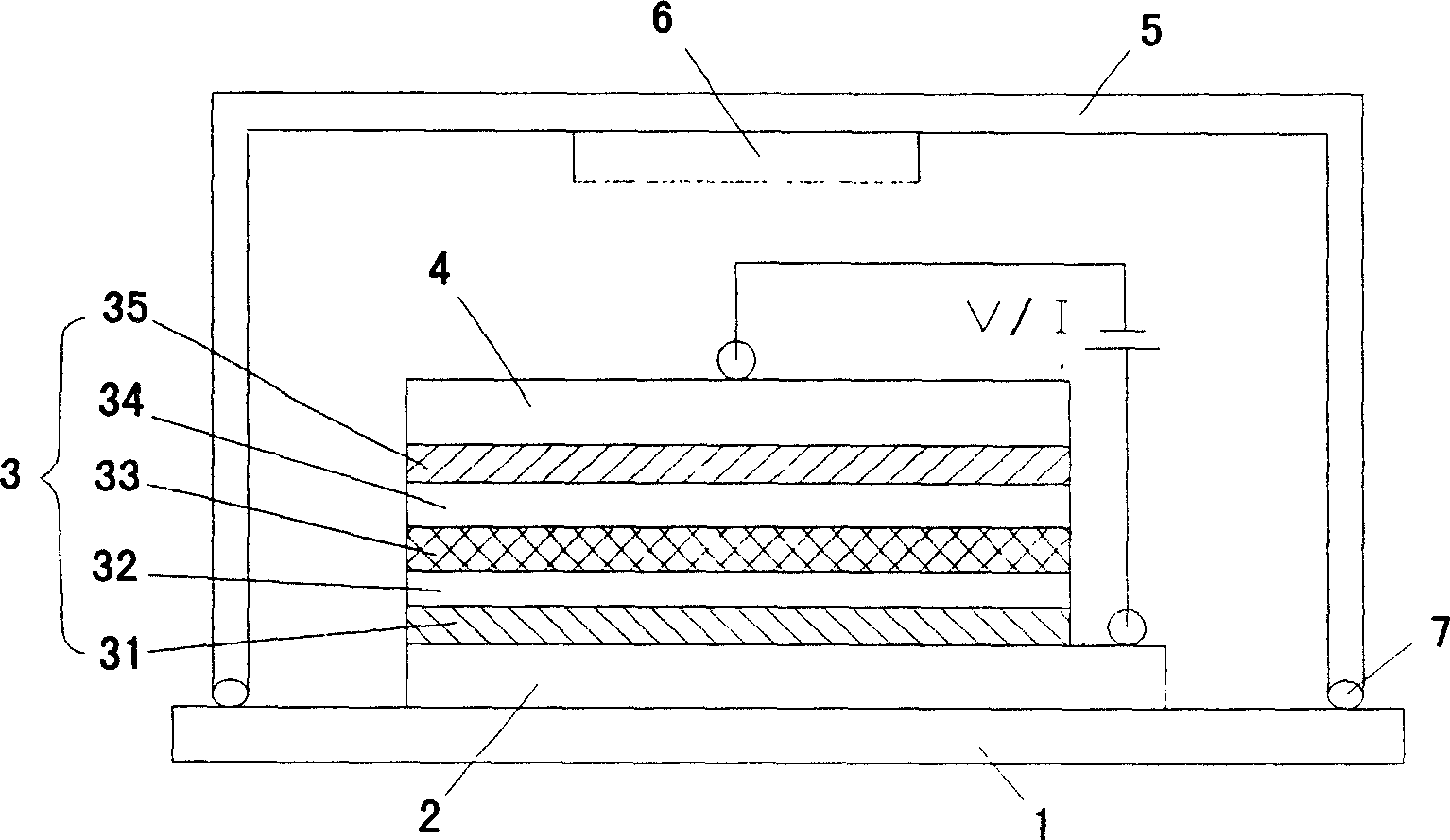

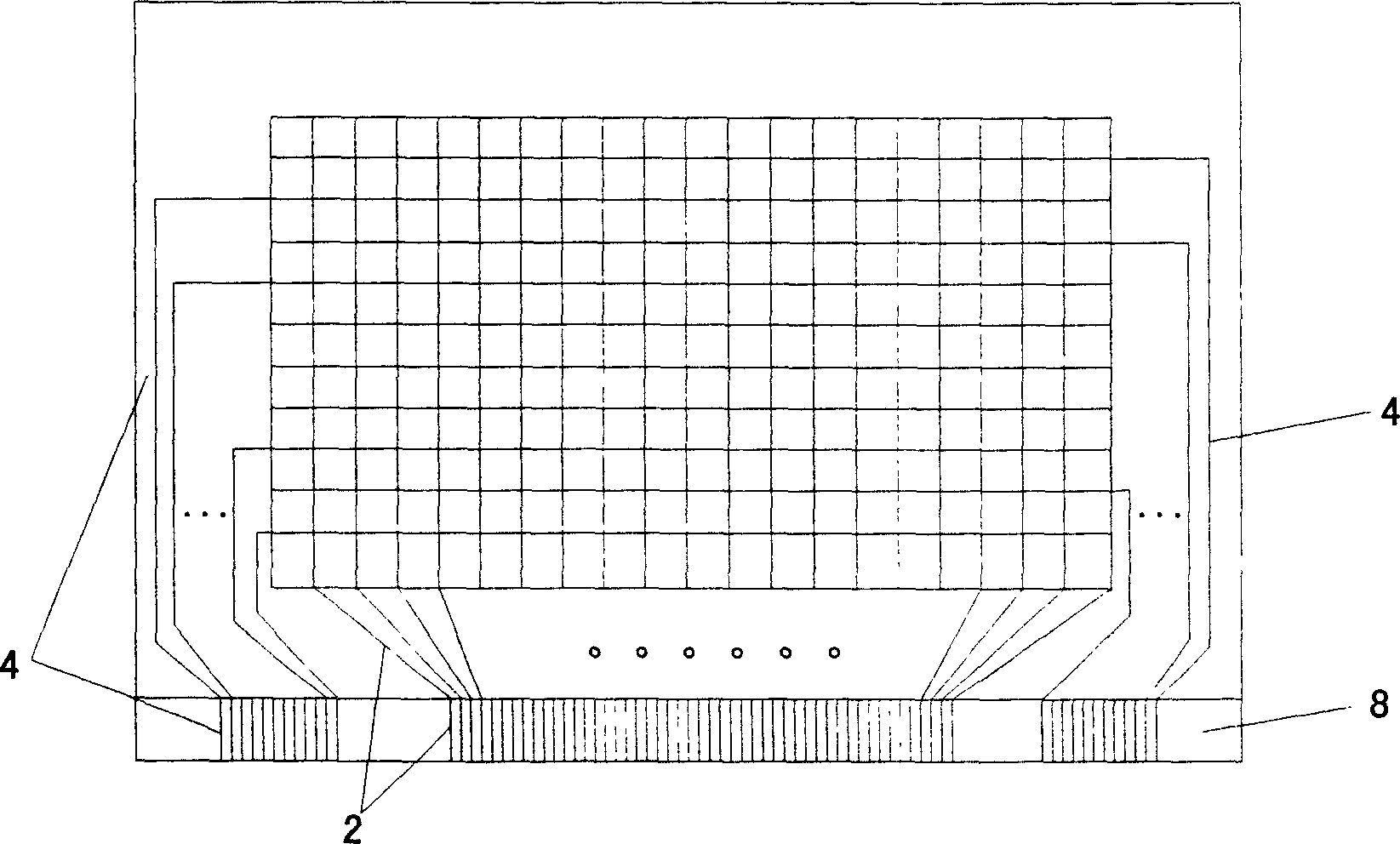

Luminous display back plane, method for preparing pixel definition layer thereof and display device

InactiveCN102969333APrevent flowReduce usageElectroluminescent light sourcesSolid-state devicesDisplay deviceComputer science

The invention discloses a luminous display back plane, a method for preparing a pixel definition layer thereof and a display device and relates to the field of display. The luminous material drops formed in printing can be laid in a pixel area of the pixel definition layer and cannot flow to the adjacent pixel area. The luminous display back plane comprises a substrate and the pixel definition layer arranged on the substrate, the pixel definition layer comprises a phototonus resin layer and a transparent definition layer, the phototonus resin layer and the transparent definition layer are arranged from bottom to top, openings are arranged on the corresponding area of every pixel of the phototonus resin layer and the transparent definition layer, the opening of the transparent definition layer is less than that of the phototonus resin layer, and a luminous material filling region which is narrow on the upper portion and wide on the lower portion is formed.

Owner:BOE TECH GRP CO LTD

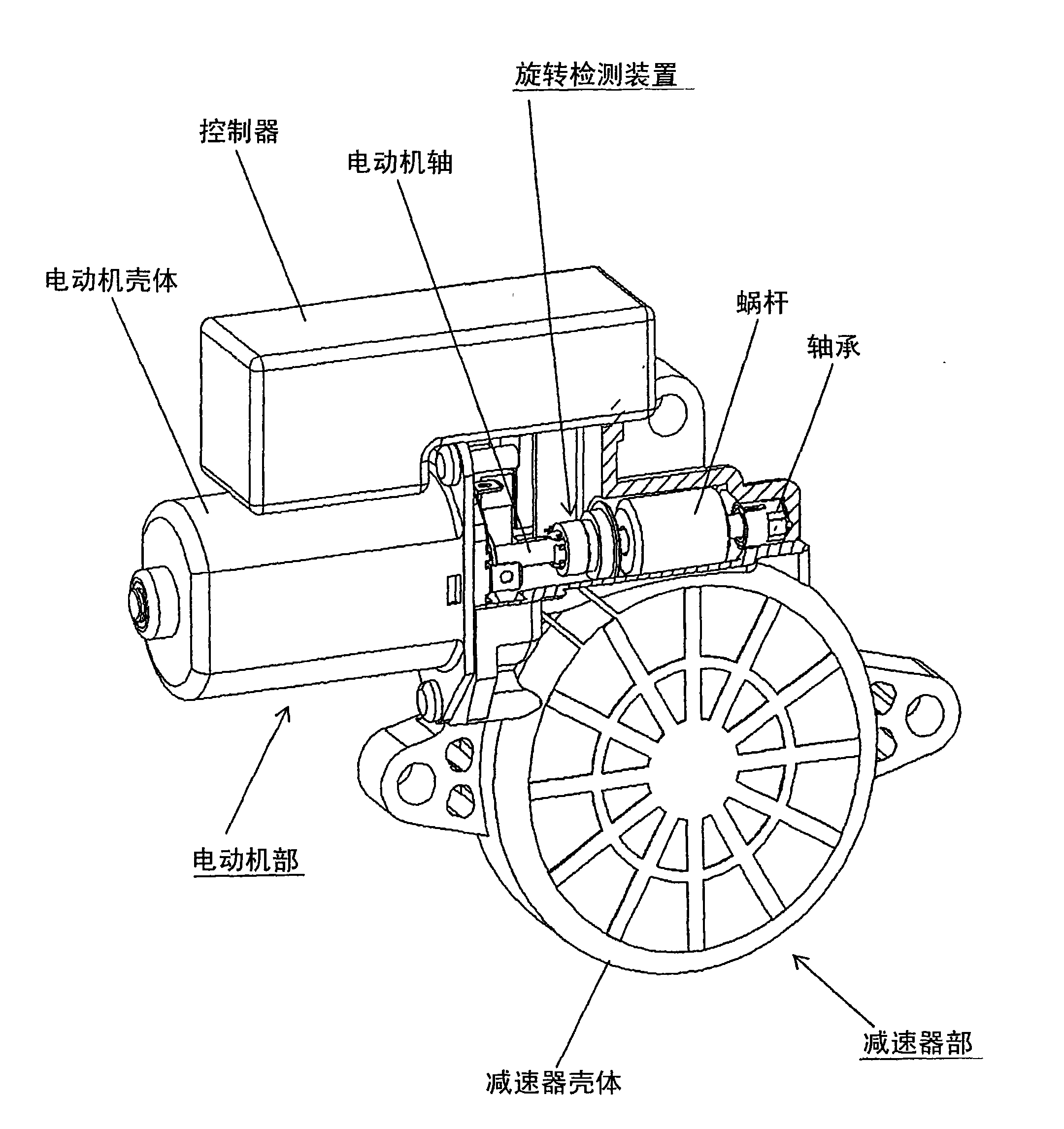

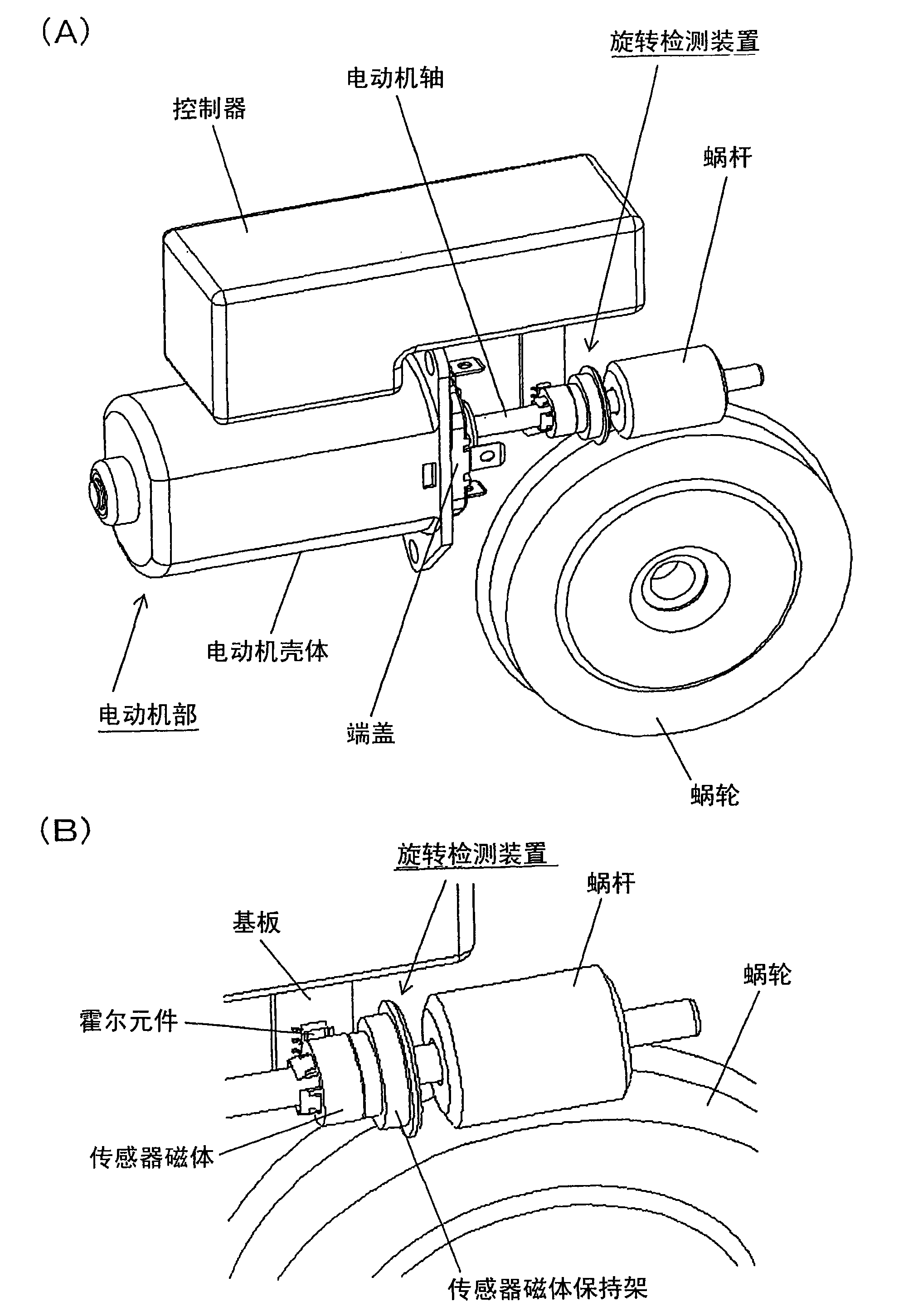

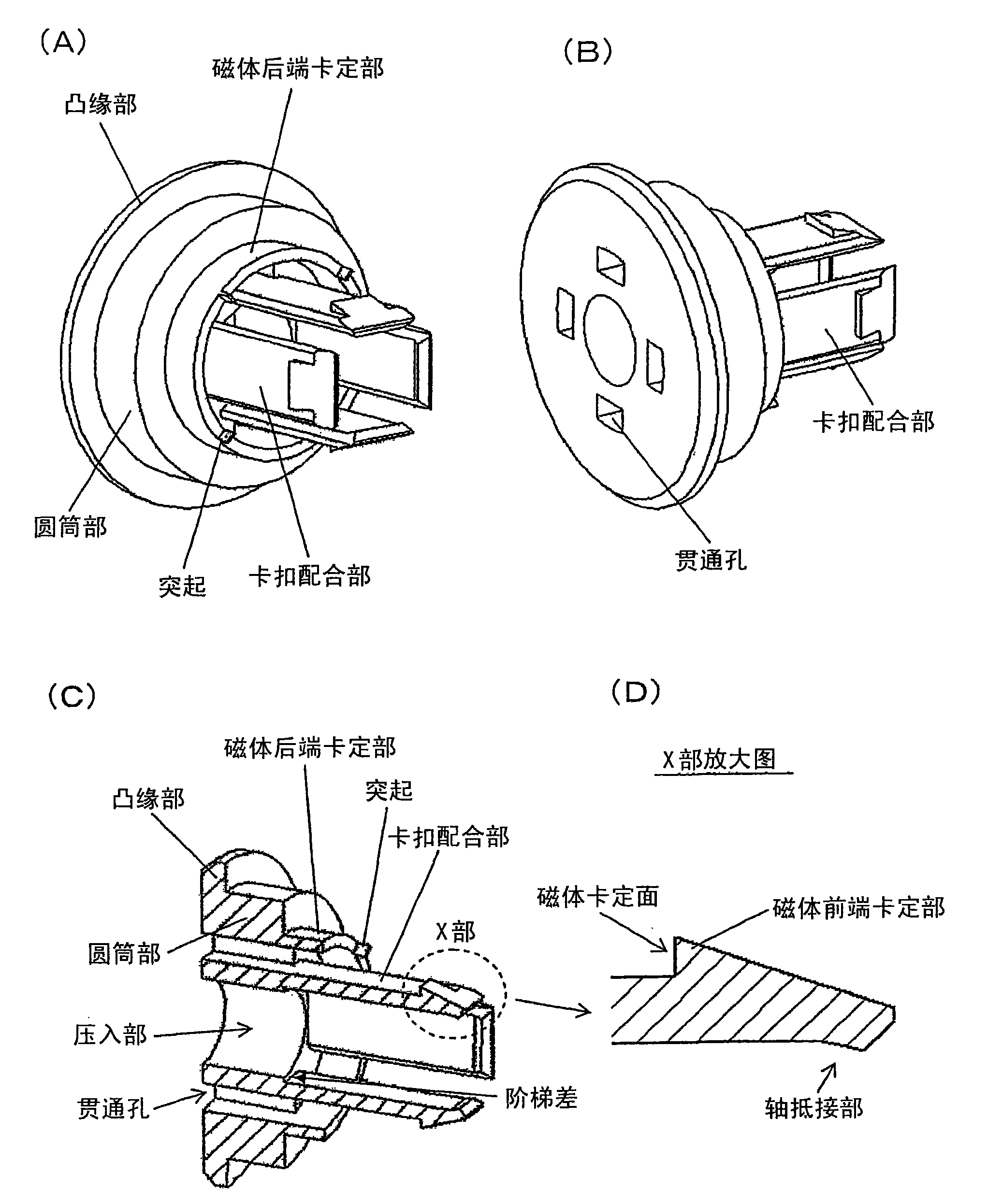

Sensor magnet holder, motor having the holder incorporated therein, and method of manufacturing the motor

ActiveCN101630888AAvoid crackingImprove resistance to movementManufacturing dynamo-electric machinesDC commutatorEngineeringMotor shaft

A sensor magnet holder is formed such that a cylindrical portion, a flange portion formed by increasing the diameter of one end part of the cylindrical portion, a magnet rear-end engagement portion formed at the other end part of the cylindrical portion, and four plate-like snap fit tongues are formed integral with one another. The cylindrical portion including the flange portion has, on its inner diametral side, a press fit portion to be press-fitted to a motor shaft. The four plate-like snap fit tongues have respective magnet front-end engagement portions formed on an outer diametral side of their tip portions. The four snap fit tongues are brought into contact with respective flat inner surfaces of the sensor magnet having four flat inner surfaces, by utilizing elasticity of the snap fit tongues. The sensor magnet is retained between the magnet rear-end engagement portion and the magnet front-end engagement portions.

Owner:MABUCHI MOTOR

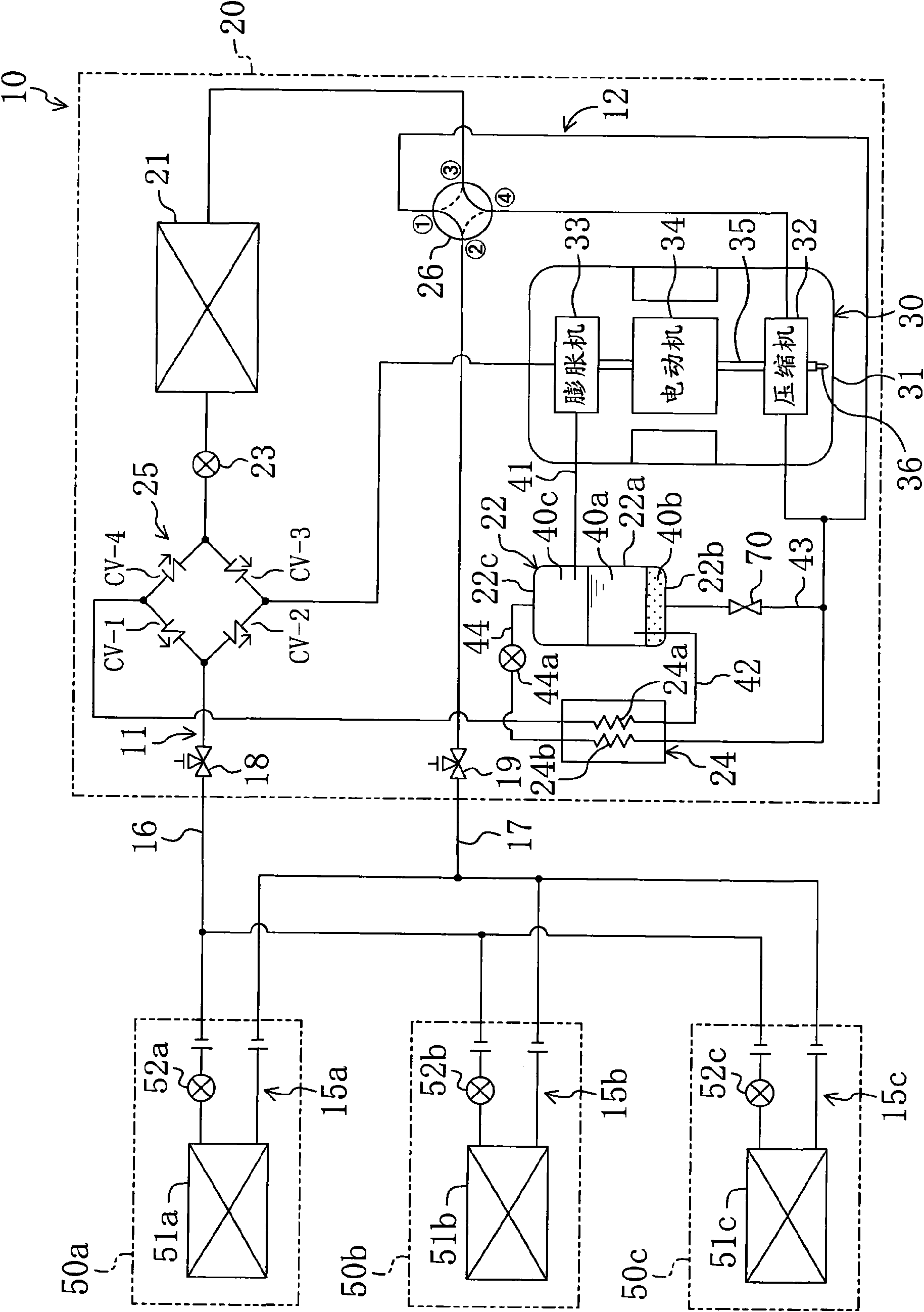

Refrigerating device

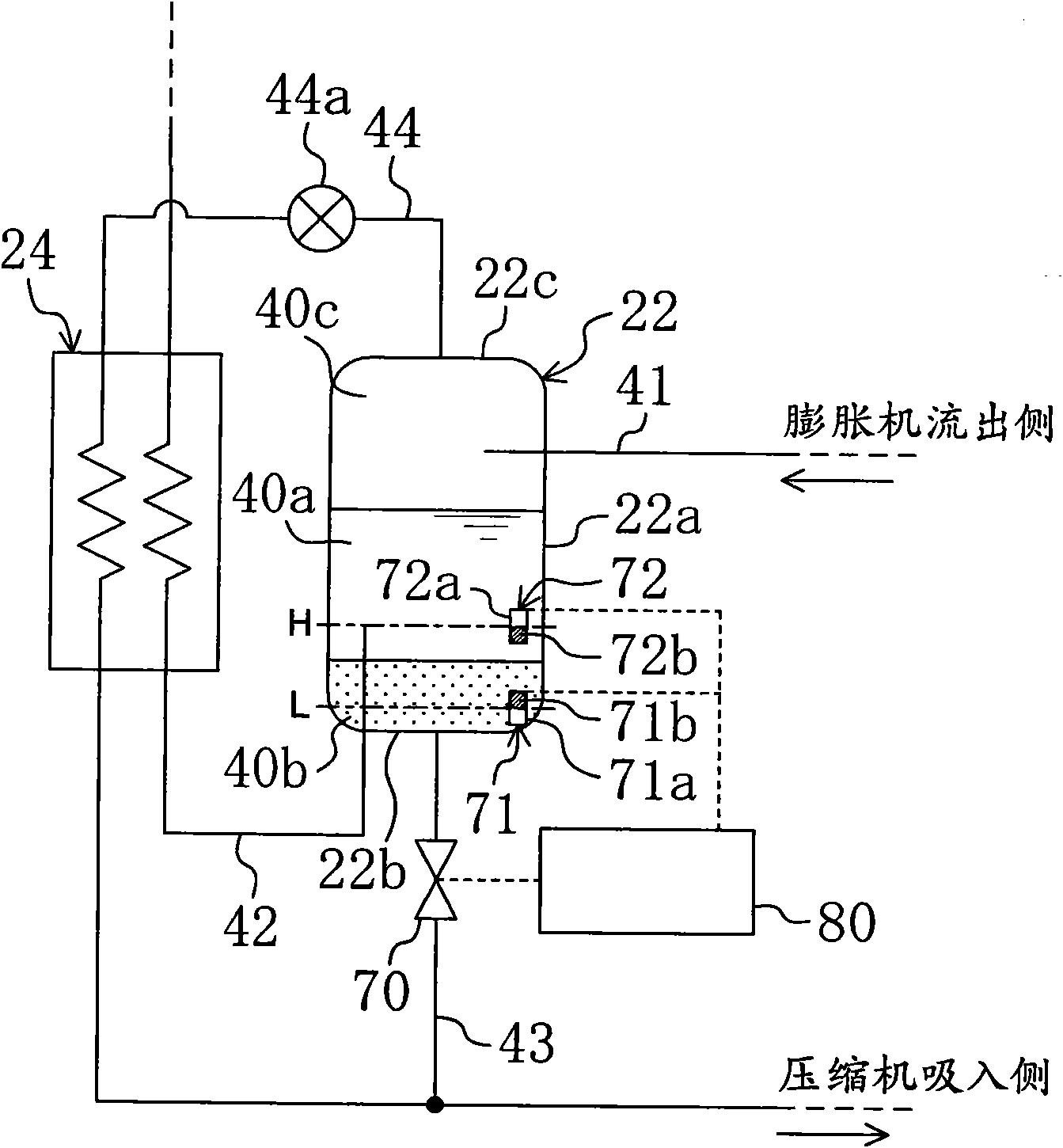

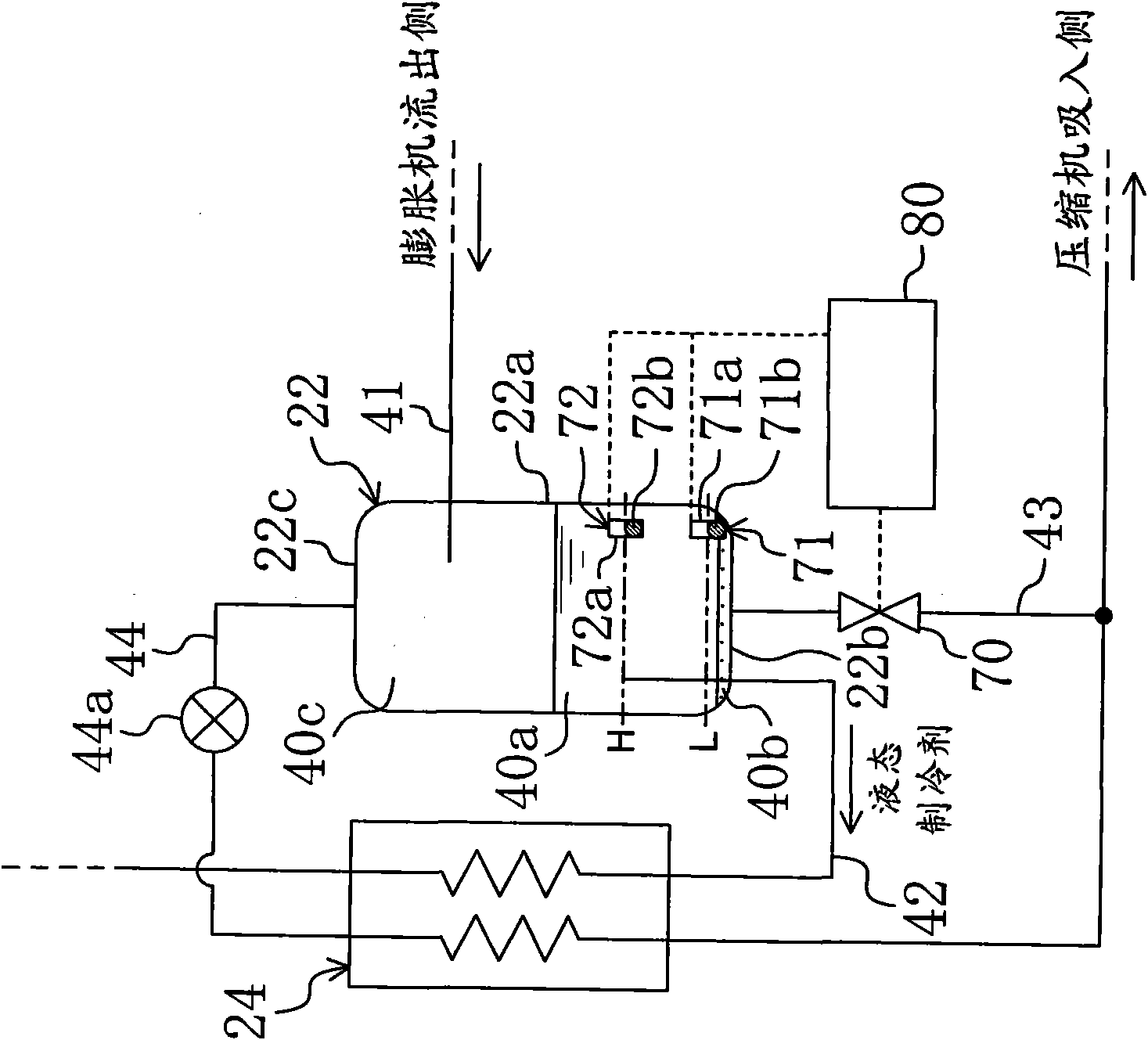

ActiveCN101646908AAvoid inhalationPrevent suction sideCompressorCompression machines with non-reversible cycleRefrigerantMechanical engineering

An opening / closing valve (70) is provided in an oil feed pipe (43). When a liquid refrigerant enters from an oil separator (22) into the oil feed pipe (43), the temperature of the liquid refrigerant depressurized by the opening / closing valve (70) is suddenly lowered. When the lowering amount of the temperature detected by a temperature sensor (73) exceeds a prescribed value, it is judged that theliquid refrigerant enters into the oil feed pipe (43), and the valve (70) is closed.

Owner:DAIKIN IND LTD

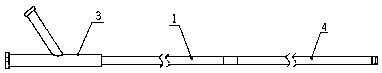

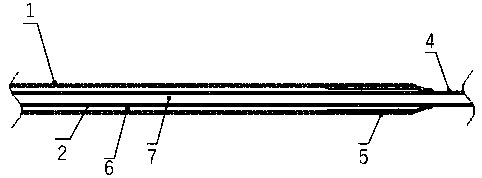

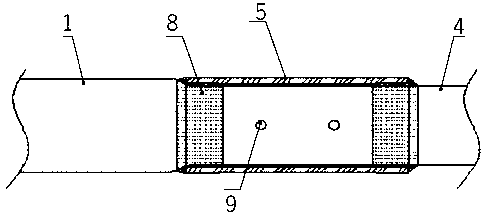

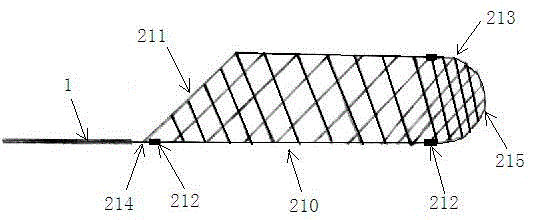

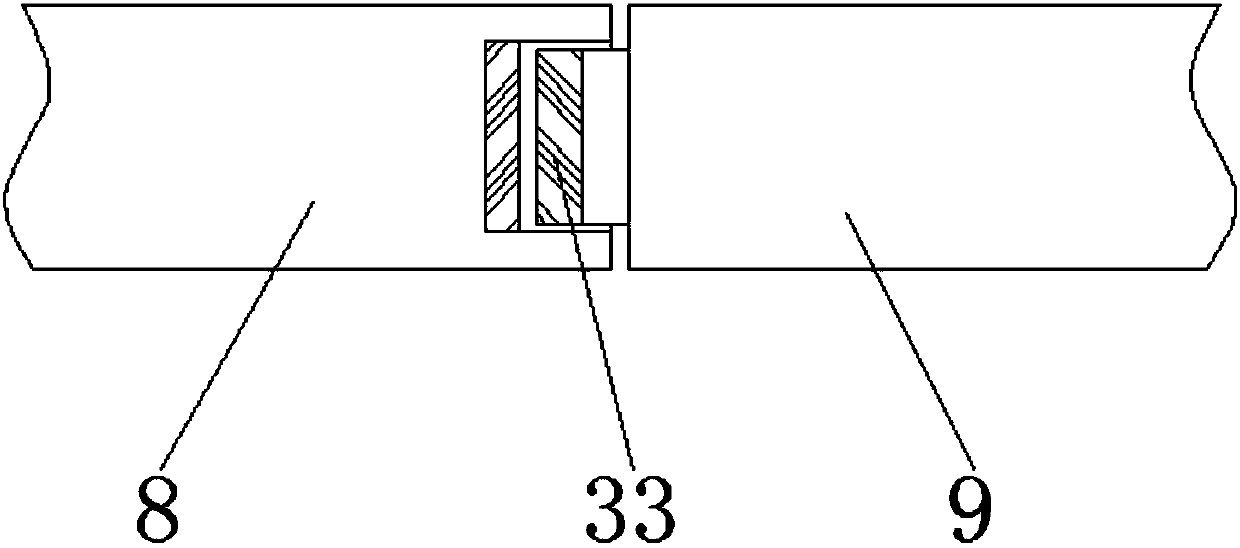

Balloon guide catheter

The invention provides a balloon guide catheter, and in particular relates to the technical field of medical apparatus and instruments. The catheter is a composite pipe composed of an outer tube, an inner tube, and a suction tube positioned at the far end of the catheter which are coaxial, and a flexible balloon capable of realizing the full or contraction state is connected to the outer layer ofthe far end of the outer tube; an annular cavity between the inner tube and the outer tube forms a balloon filling cavity; the far end of the inner tube is welded to the near end of the suction tube;an inner cavity of the inner tube is connected with the inner cavity of the suction tube in series to form a guide cavity of the catheter, namely, a thrombus suction cavity; a main inner hole of a Y-shaped joint communicates with the inner cavity of the inner tube to form a wire guide cavity and the thrombus suction cavity; and the axis of side holes of the Y-shaped joint and the axis of the maininner hole of the Y-shaped joint have intersection at the near end direction of the catheter to form an acute angle, and the side holes of the Y-shaped joint and a gap between the outer wall of the inner tube and the inner wall of the outer tube communicate to form the balloon filling cavity. For the balloon guide catheter, during the interventional treatment process, blood flow can be blocked, sothat small broken thrombus is prevented from blocking the far end, and meanwhile, large thrombus blocks at the near end can be sucked, so that the surgery effect is greatly improved.

Owner:南京普微森医疗科技有限公司

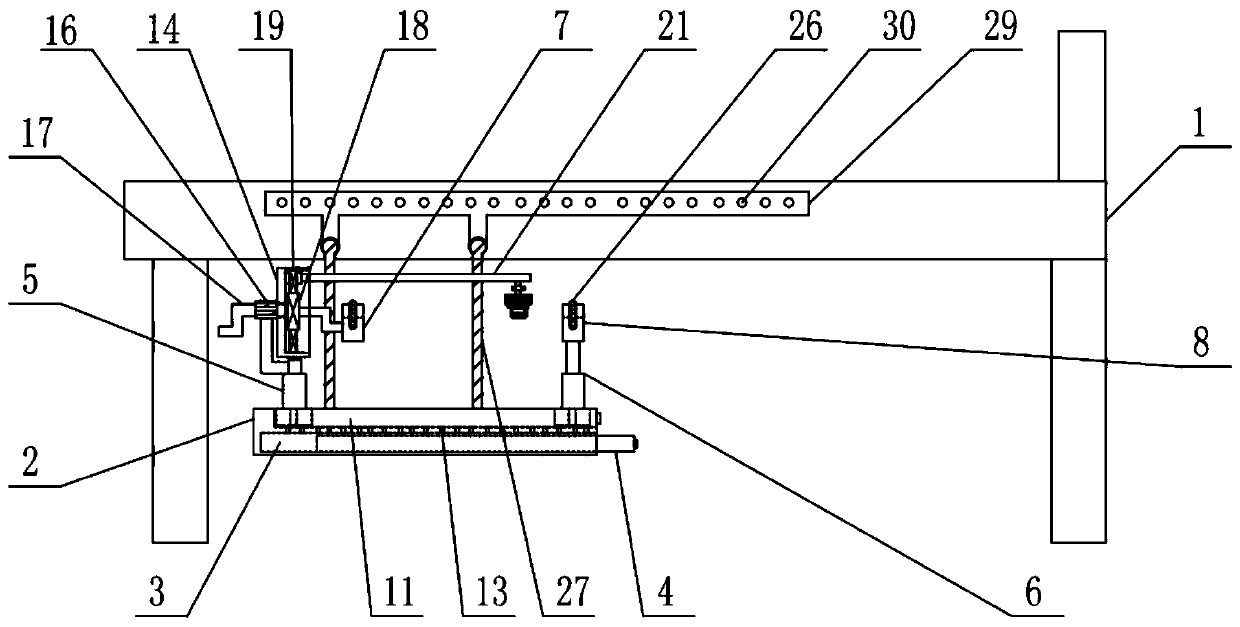

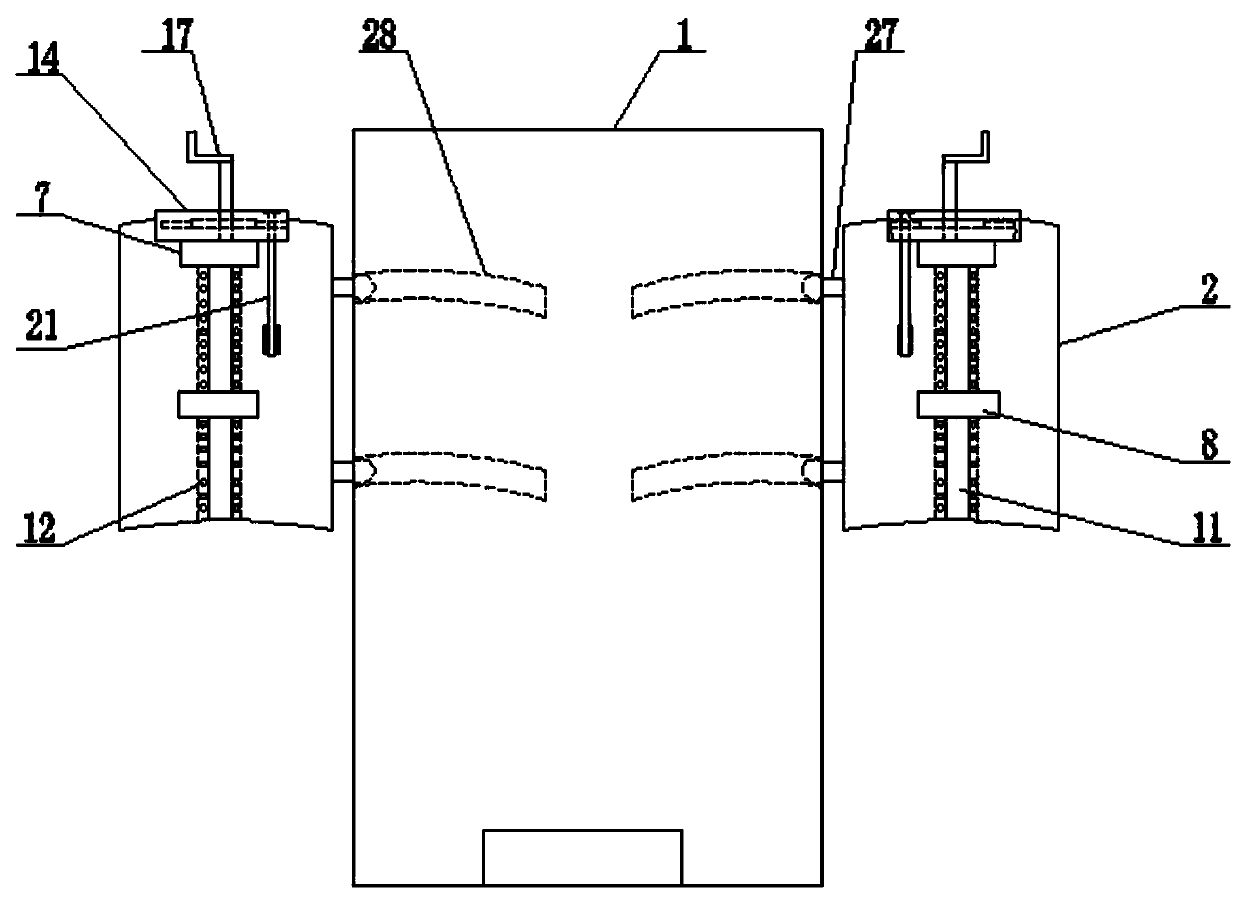

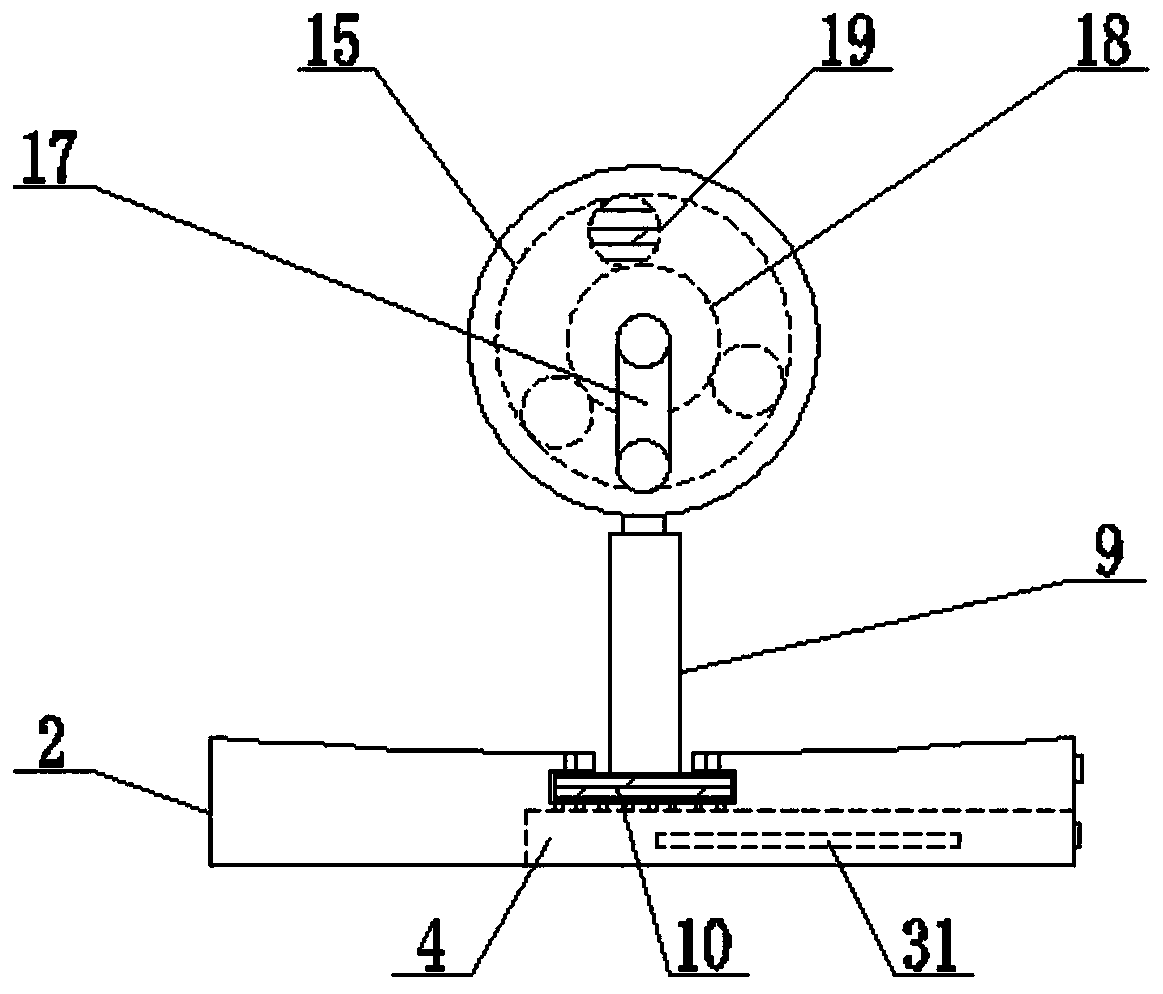

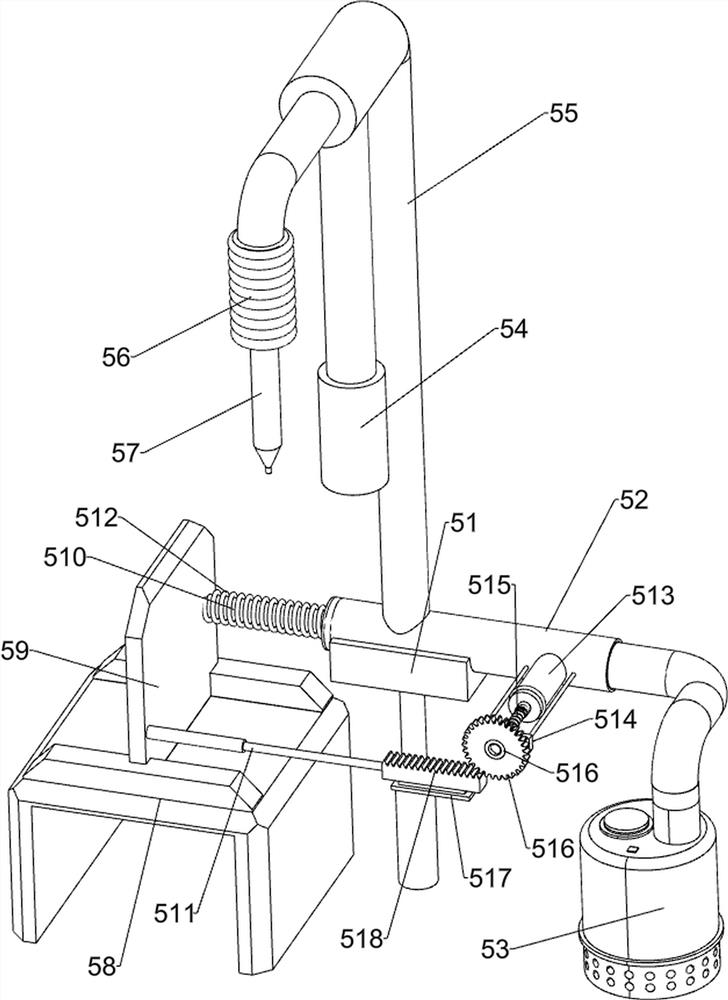

Automatic spiral-dressing type dressing changing device

ActiveCN109966100ARelieve painEasy to take medicineOperating tablesBandagesCircular discWound dressing

The invention discloses an automatic spiral-dressing type dressing changing device. The automatic spiral-dressing type dressing changing device comprises a sickbed body, and wound dressing devices symmetrically arranged on two sides of the sickbed body. Each wound dressing device comprises a support plate, a lifting mechanism slidably connected with the support plate, and a transmission mechanismarranged on the lifting mechanism. Each transmission mechanism comprises a rotating disc and a bandage winding device. Each bandage winding device comprises a screw, a casing sleeving the screw, and atraveling gear in meshed connection with the screw. A central shaft of each traveling gear extends to the outside of a limiting slot to be connected with a 'T'-shaped connecting rod. An elastic bandage fixing clip is connected to the bottom end of each connecting rod through a rotating mechanism. The automatic spiral-dressing type dressing changing device has the advantages that a spirally-reverse folding method is realized through the wound dressing devices to prevent deflection of bandages during dressing, uniformity and firmness in dressing are achieved, and the dressing efficiency is improved; the tensioning degree of the bandages can be automatically adjusted during dressing to avoid loosening of the bandages; the wound dressing devices are pushed below the sickbed body, and accordingly, the occupying space of the wound dressing devices is saved.

Owner:CHANGZHOU NO 2 PEOPLES HOSPITAL

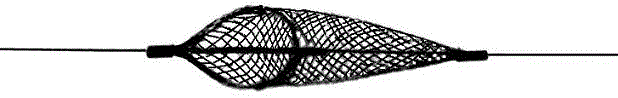

Micro-invision intervened thrombus taking system

The invention discloses a micro-invision intervened thrombus taking system, which comprises a conveyor guide wire, a thrombus catching device, a microcatheter and a guide catheter; the thrombus catching device is a net-shaped bracket formed by knitting one or more wires, a remote end of the bracket is closed or necked, a near end thereof is opened and in the shape of cone. The net-shaped bracket can sleeve relatively big main thrombus and also catch stripped small thrombus, so as to prevent small thrombus flowing to the blood vessel at remoter end and largely reduce the possibility of secondary stroke. The head end of the guide catheter is soft and can be expanded by the thrombus to obtain larger thrombus. The fracture resistance and the flexibility of the remote end of the guide catheter are largely improved, therefore, the guide catheter can be conveyed to the blood vessel at remoter end. The net-shaped bracket is also used as a bracket and reserved in a narrow-section blood vessel to expand the blood vessel and dredge the blood flow, therefore, the additional function of the disease is eased. By using the system, the operation time can be saved to win the treatment time for patients with acute cerebral apoplexy stoke, thus the success rate of the revascularization of the patients is improved.

Owner:吕文峰

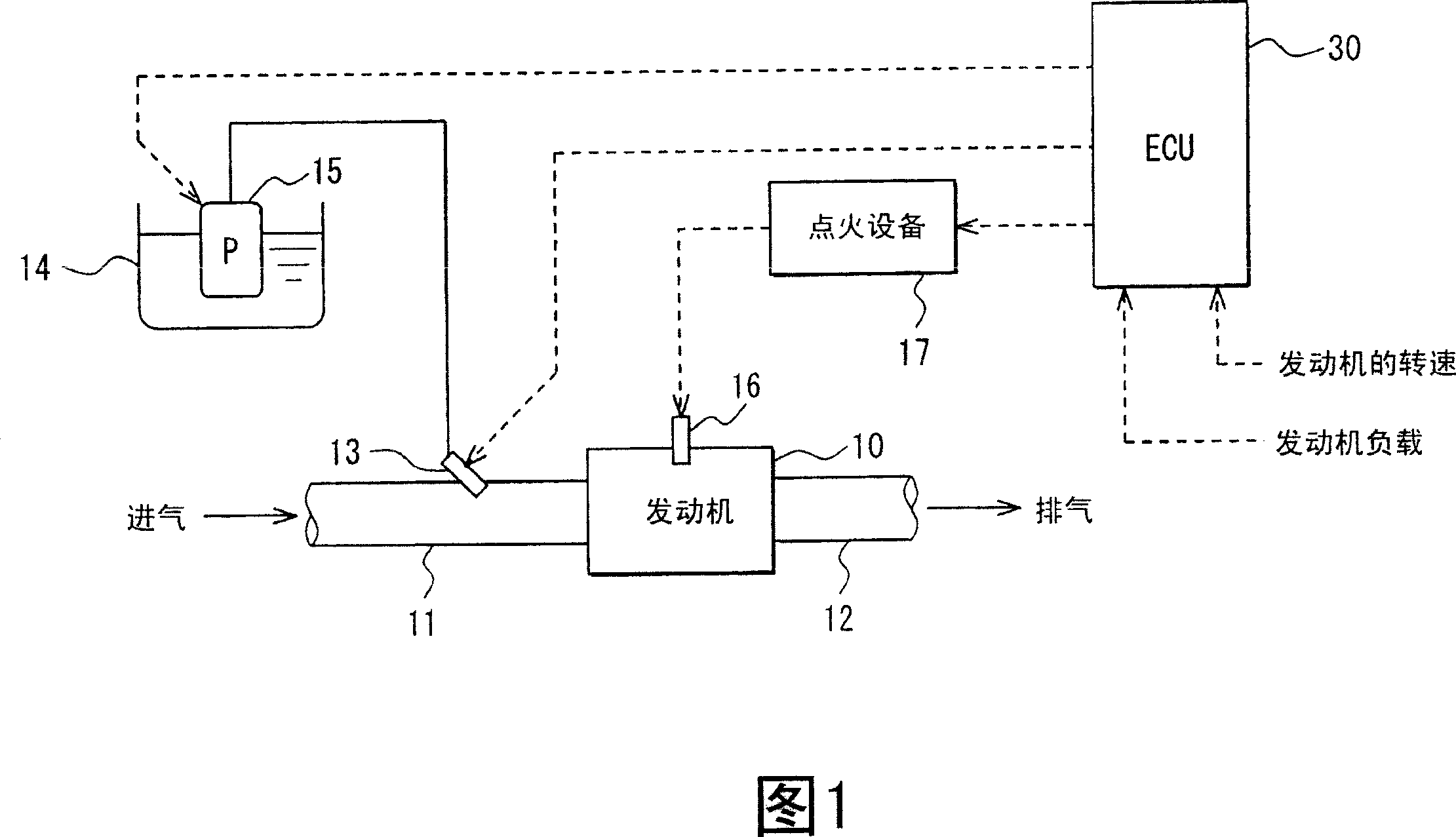

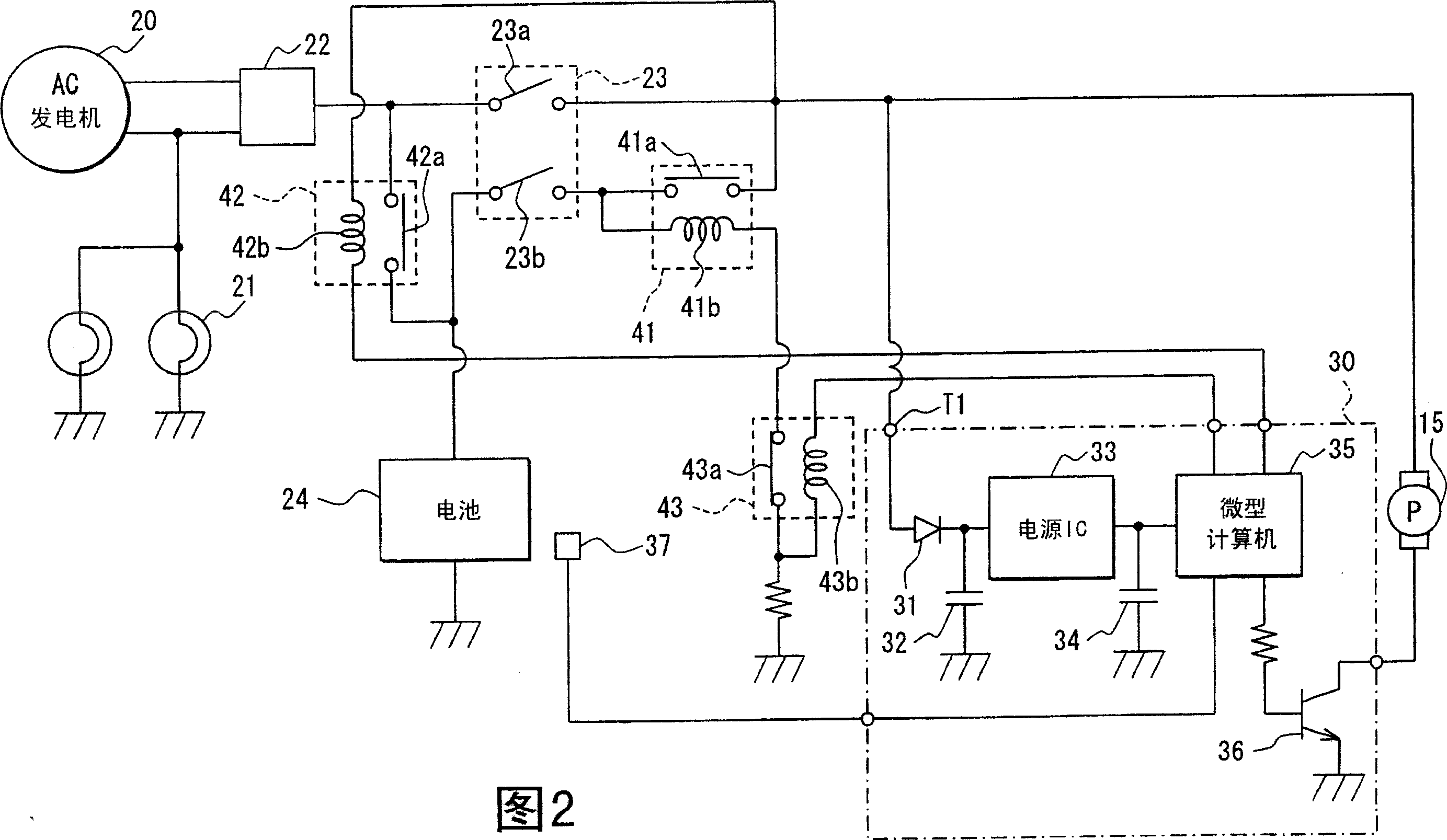

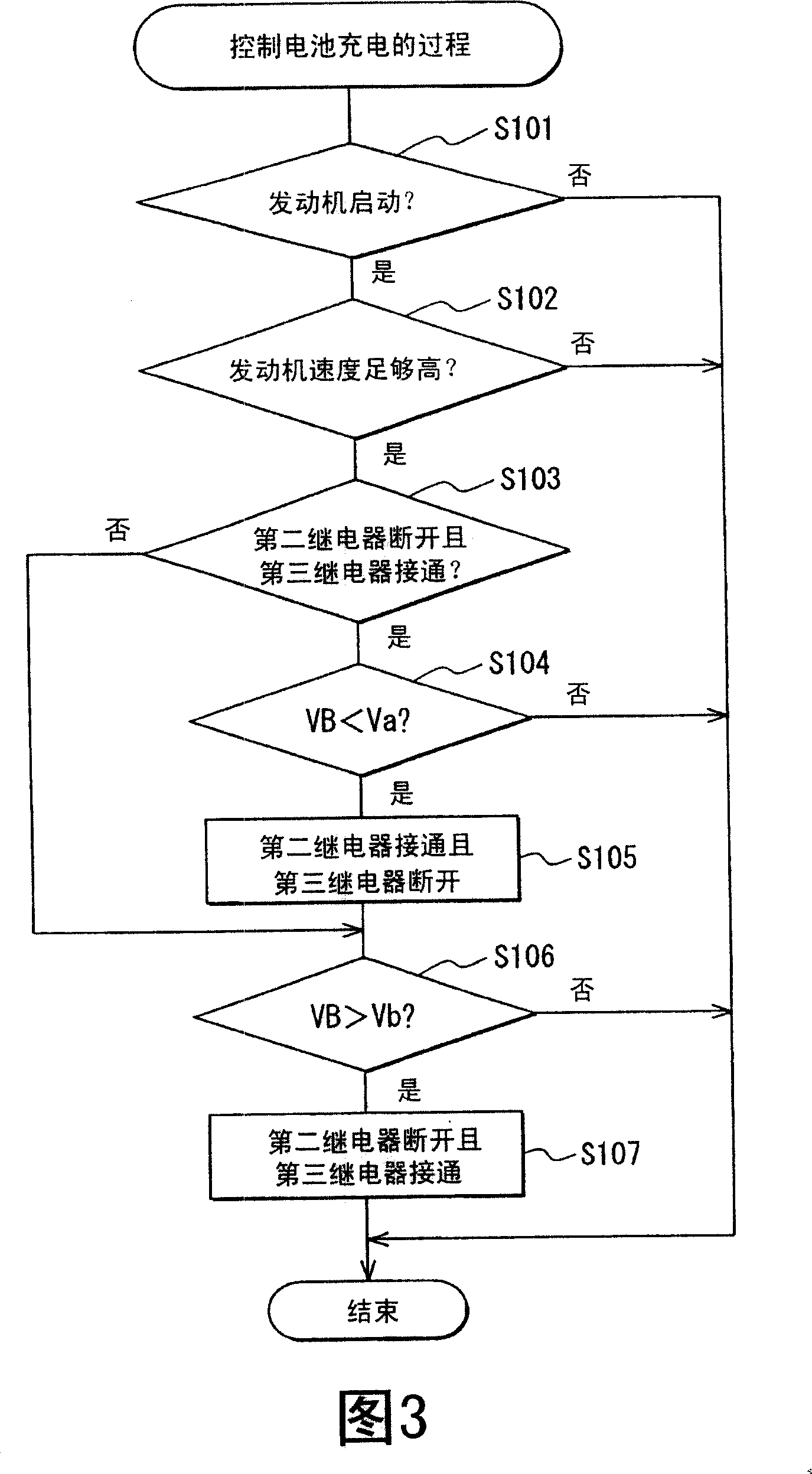

Power supply system for automobile

ActiveCN101007523AGuaranteed normal startupPrevent flowBatteries circuit arrangementsElectric machinesElectricityMobile vehicle

An electricity supply system is mounted on vehicle such as motorbicycle. The electricity supply system includes an electric generator 20 drived by a motor 10, onboard battery 24, and electric load, such as spark plug 16 and fuel injector 13. In order to start the motor 10, checking battery voltage, opening charged circuit for the battery 24 when the voltage is lower than preset level. Through initial rotation of the motor 10, generating electric power in the electric generator 20 for providing exculsively to the electric load to start successfully the motor 10. After the electric power generated in the electric generator 20 gets to enough high level, the battery 24 is charged by the electric power generated in the electric generator 20.

Owner:DENSO CORP

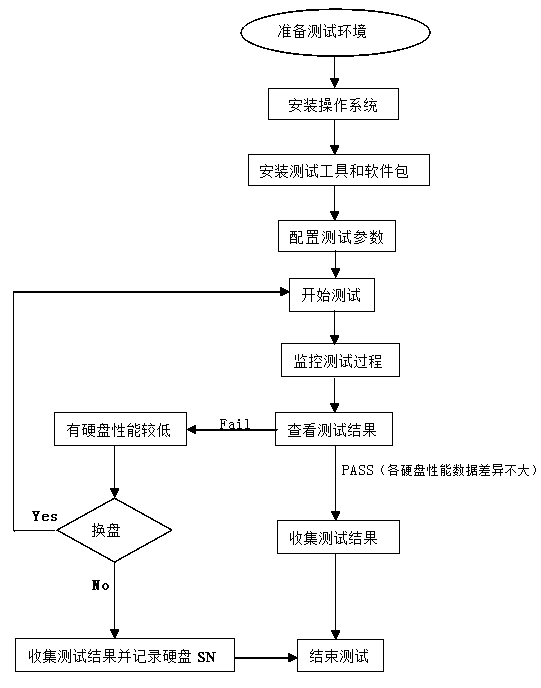

Method for automatically testing hard disk performance fluctuation

InactiveCN104317693AEasy to operateHigh degree of automationFunctional testingOperating systemSoftware engineering

The invention discloses a method for automatically testing hard disk performance fluctuation, and belongs to the technical field of hard disk performance fluctuation testing. The method includes the following steps: (1), setting up a tester, and preparing a testing environment; (2), installing a Linux operating system or a CentOS (community enterprise operating system), and copying a hard disk performance test tool into the tester; (3), installing an rpm software package as need by testing; (4), configuring test parameters, and correcting a hard disk number corresponding to the hard disk performance test tool according to a hard disk number in actual configuration; (5), starting testing on the hard disk performance fluctuation; (6), checking and monitoring the test process by an iostat command; (7), checking a test result; (8), collecting the test result; (9), completing testing. By the method, the system can automatically test and compare hard disk performance and can output the test result.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

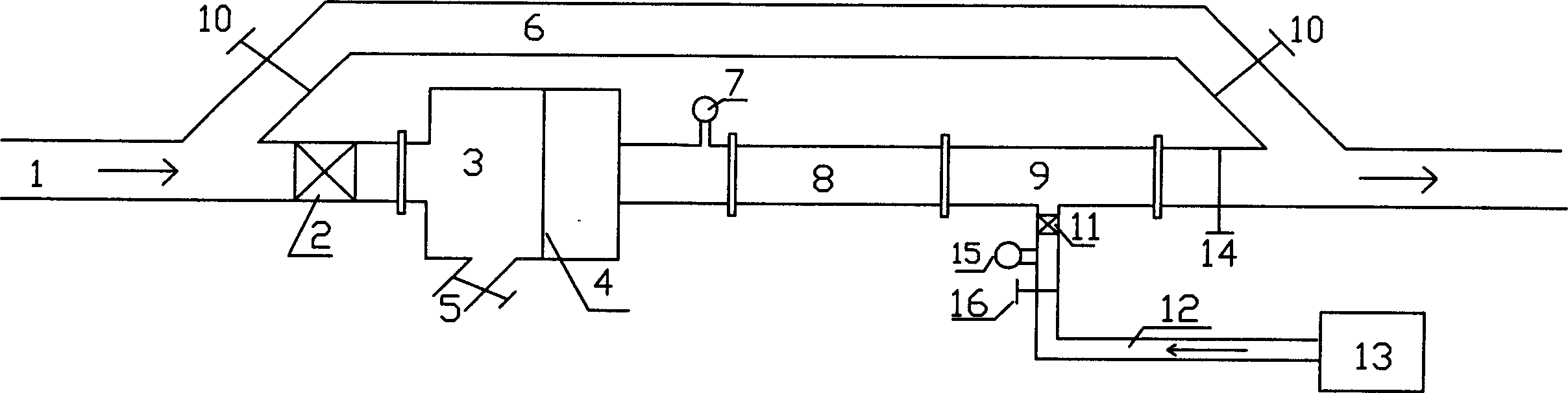

Three-phase foam preparing system for preventing coal self-ignition

InactiveCN1776195APrevention and Control of Spontaneous FiresEfficient removalDust removalFire preventionCoal spontaneous combustionGas phase

A three-phase foam preparing system for preventing coal spontaneous combustion consists of agitator, foam generator, filter connected with agitator and foam generator, air inlet in wall of foam generator, nitrogen injection device, air compressor, bypass pipe on slurry injection pipe. The prepared slurry is filtered then pressed into air or nitrogen, foaming to form air-liquid-solid three-phase foam. Said invention has high foaming efficiency.

Owner:CHINA UNIV OF MINING & TECH

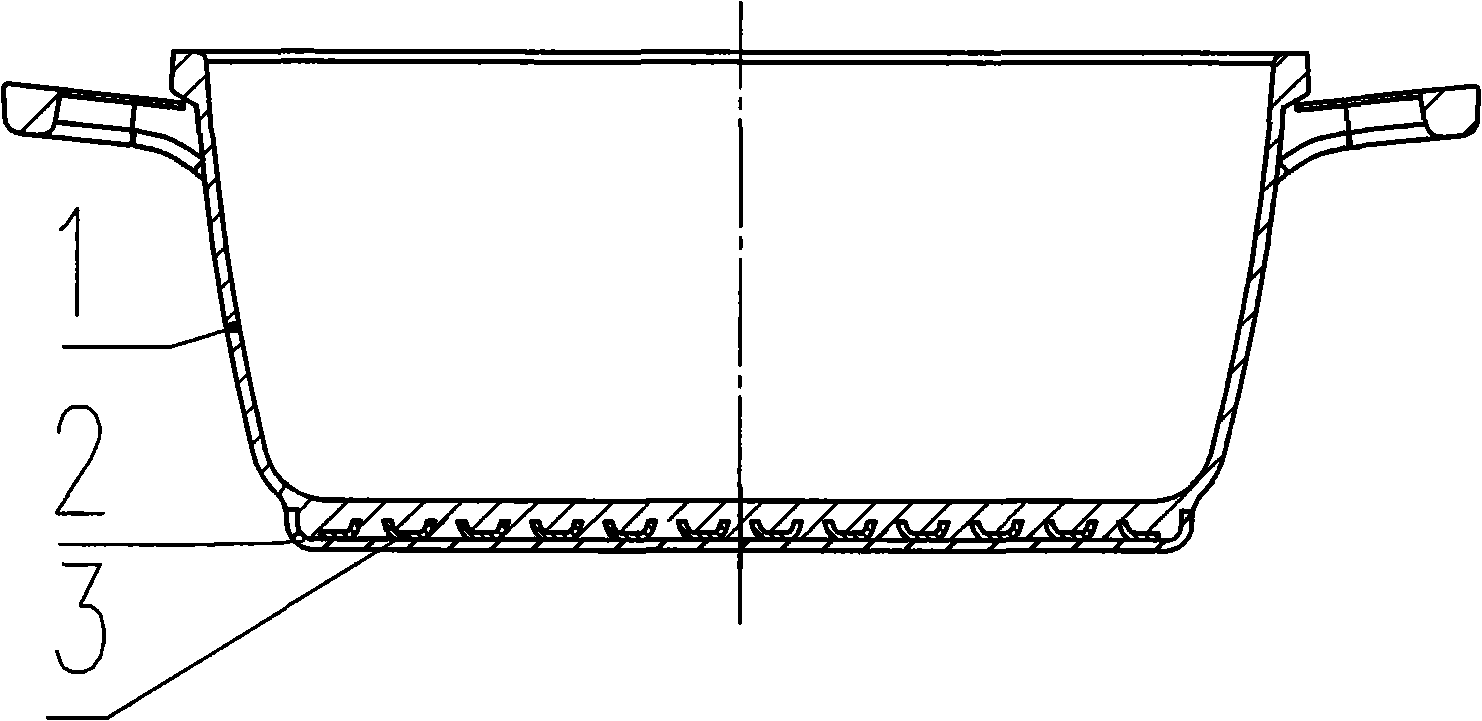

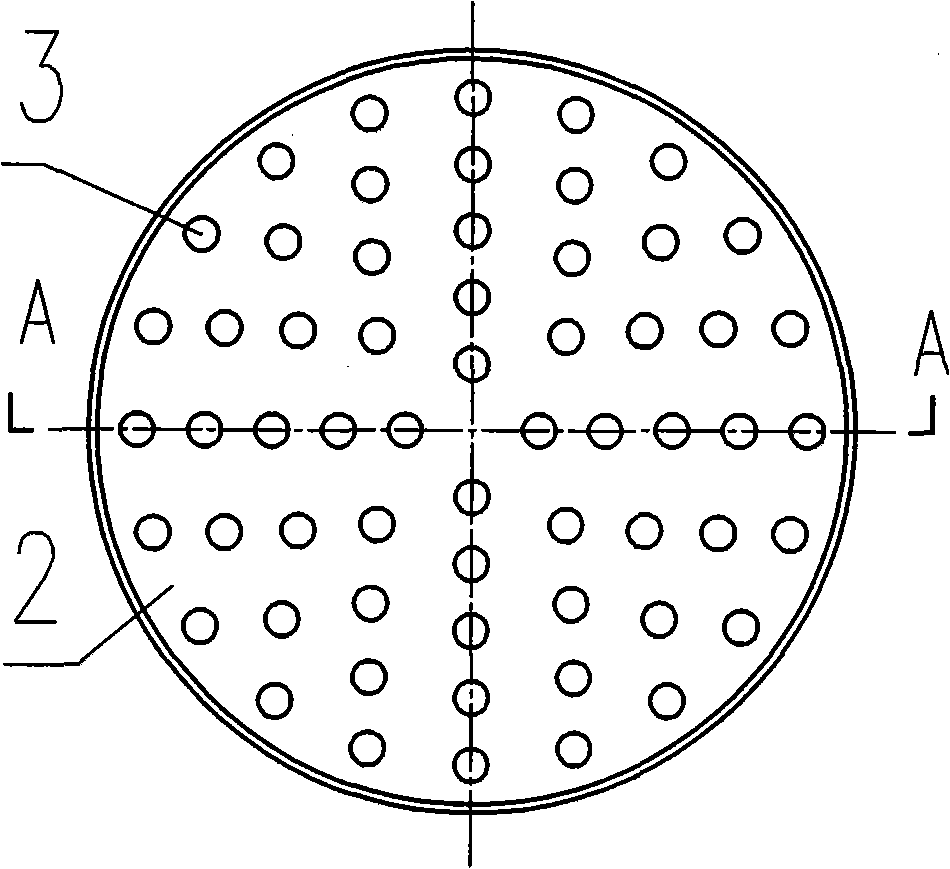

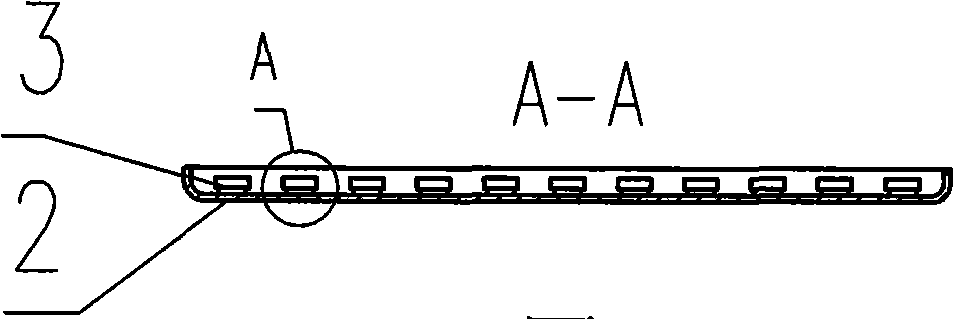

Press-casting multi-bottom pan and press-casting forming manufacturing process

ActiveCN101278801AHigh thermal fatigue stabilityHigh thermal efficiencyCooking-vessel materialsMolten stateInjection pressure

The invention relates to a die-casting composite bottom pan, including an aluminum alloy pan body and a stainless iron composite bottom sheet. The invention is mainly characterized in that the stainless iron composite bottom sheet is provided with a plurality of clip pieces; the edge of the stainless iron composite bottom sheet is provided with a flange coating the lower peripheral of the pan body; the lower part of the aluminum alloy pan body and the stainless iron composite bottom sheet are cast into a whole body by a die-cast machine. The invention also relates to a die-cast manufacturing technique of the die-casting composite bottom pan. The manufacturing technique includes the following procedures: (1) the composite bottom sheet is manufactured: the stainless iron composite bottom sheet is stamped for forming and the clip piece is welded on the stainless iron composite bottom sheet; (2) the stainless iron composite bottom sheet is placed: the stainless iron composite bottom sheet is placed into a die mold setting cavity; (3) die casting: after matching the die, the die-cast machine fills the liquid aluminum alloy in the melting state with 600 to 700 DEG C temperature and 20 to 80MPa injection pressure ratio into the setting cavity at the injection speed of 20 to 60m / s, the filling time is 0.02 to 0.07s, and after the setting cavity is full of the aluminum liquid, the pan body and the stainless iron composite bottom sheet are cast into a whole body by the die-cast machine; (4) surface treatment: after the die-casting pan is cooled, flash edges of the pan body are removed, and then the pan body is sandblast and sprayed, thus manufacturing the die-casting composite bottom pan. The invention is a cook applicable to electromagnetic stove with the advantages of stable connection with the composite bottom sheet, high heat efficiency, good heat and fatigue resistance, simple manufacturing technique and high rate of finished products, etc.

Owner:ZHEJIANG CHUNZHOU ALUMINUM IND

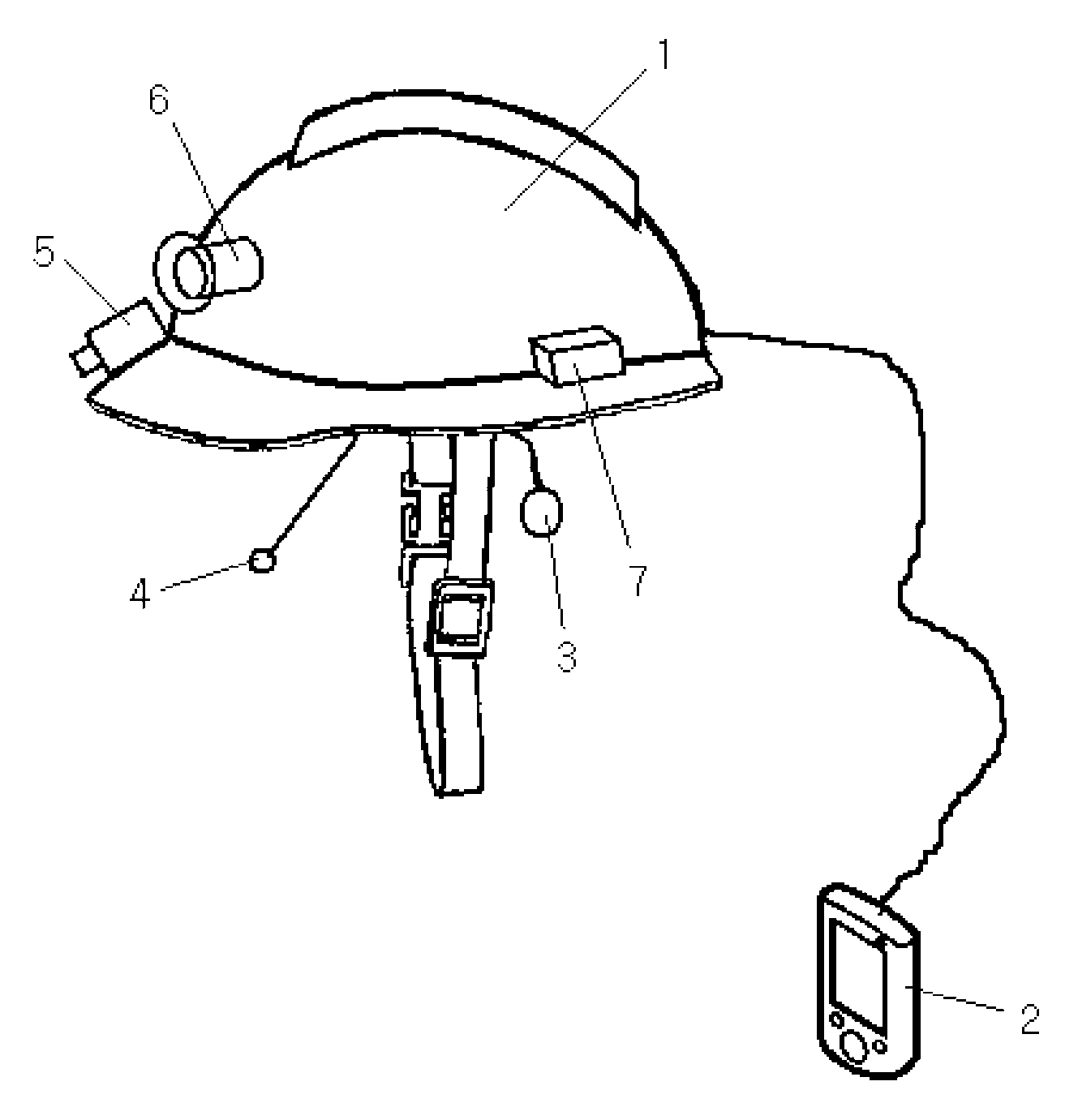

Mobile electric power monitoring device

InactiveCN103054255APrevent flowReduce labor costsClosed circuit television systemsHelmetsEngineeringComputer terminal

The invention discloses a mobile electric power monitoring device, relates to the technical field of electric power construction, and solves the technical problem for effectively managing and controlling electric working process. The mobile electric power monitoring device comprises an insulating safety helmet and a mobile terminal, a helmet-carried earphone, a helmet-carried microphone, a helmet-carried camera, a headlamp and an electric shock preventing alarming module are arranged on the safety helmet, the mobile terminal is provided with an audio output port, an audio input port and a video input port and is embedded with a wireless communication module, the audio output port of the mobile terminal is connected with the helmet-carried earphone on the safety helmet, the audio input port of the mobile terminal is connected with the helmet-carried microphone on the safety helmet, and the video input port is connected with the helmet-mounted camera on the safety helmet. By the aid of the mobile electric power monitoring device, human cost can be reduced, electric working process can be standardized, and electric working power, working standardization and working safety can be improved.

Owner:SHANGHAI CHUANGPING INFORMATION TECH

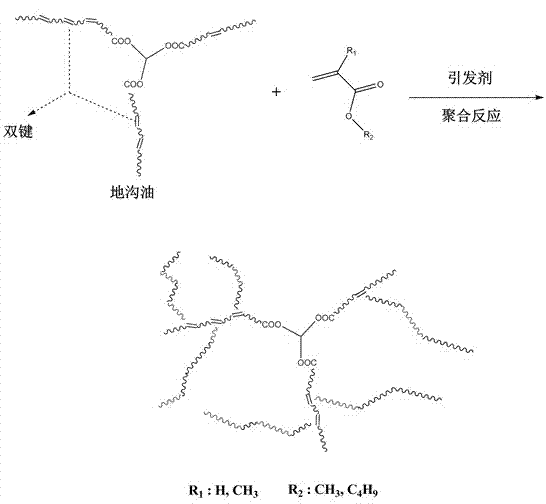

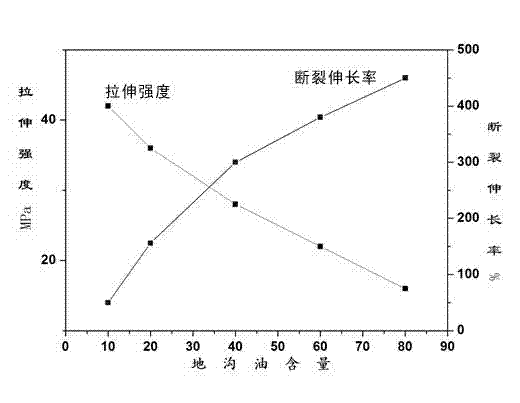

Preparation method of macromolecule plasticizer based on recycled cooking oil

The invention discloses a preparation method of macromolecule plasticizer based on recycled cooking oil, which is characterized in that the purified recycled cooking oil is copolymerized with monomers with polyvinyl chloride (PVC) and similar solubility parameters in a radical grafting way, the glass-transition temperature of a material is adjusted through the molecular design, so that the non-transference macromolecule plasticizer which is applicable to the PVC is obtained. Compared with the traditional plasticizer such as dioctyl phthalate (DOP), the macromolecule plasticizer has the advantages of no volatilization, no transference, low cost, durability and stability of plasticizing property and the like. The macromolecule plasticizer based on the recycled cooking oil can be widely used in the field of semi-hard or soft PVC composite materials such as an oil-resisting and heat-resisting PVC cable, a gasket, artificial leather and the like.

Owner:宁波市江北成达色母粒有限公司

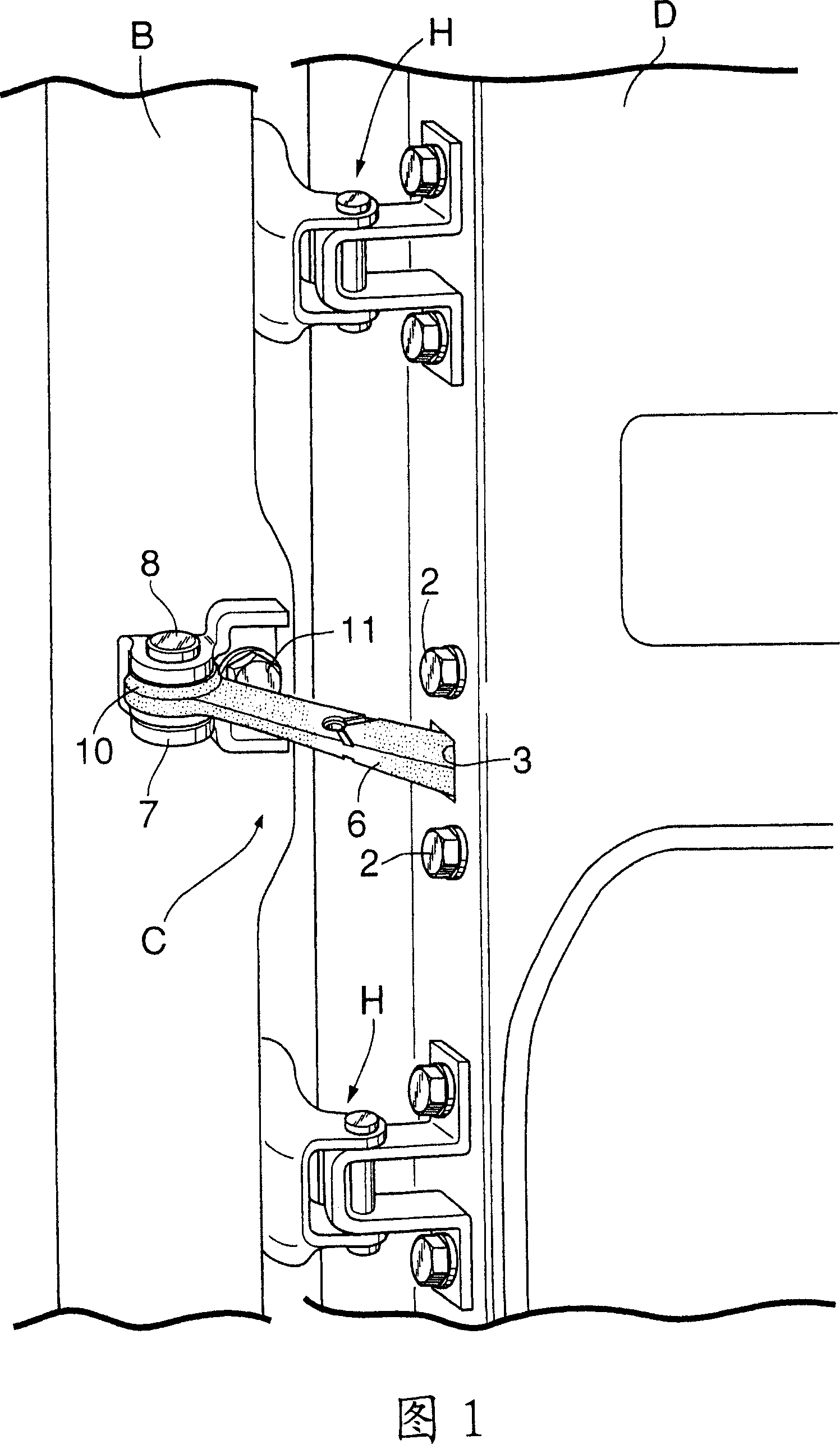

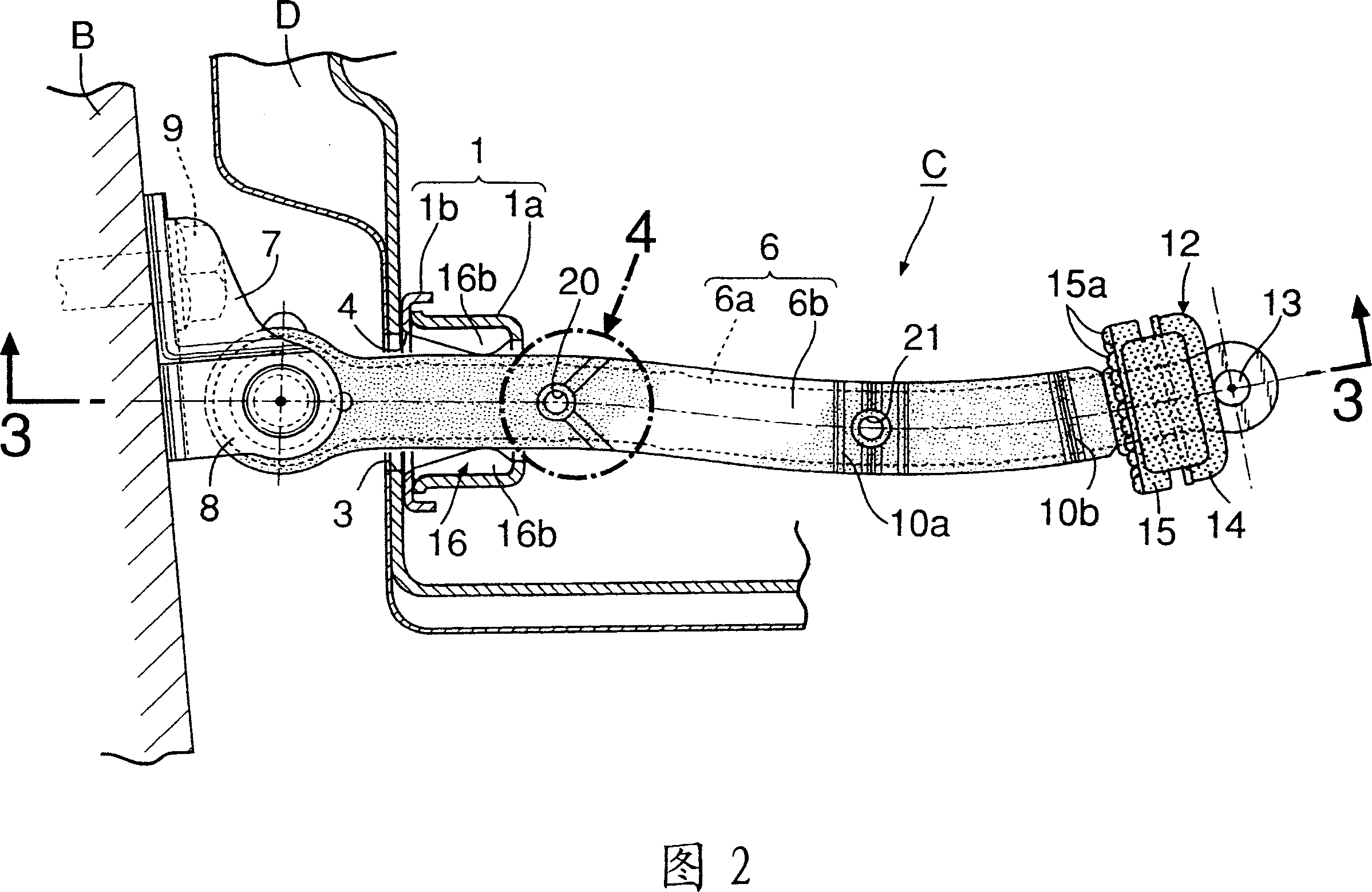

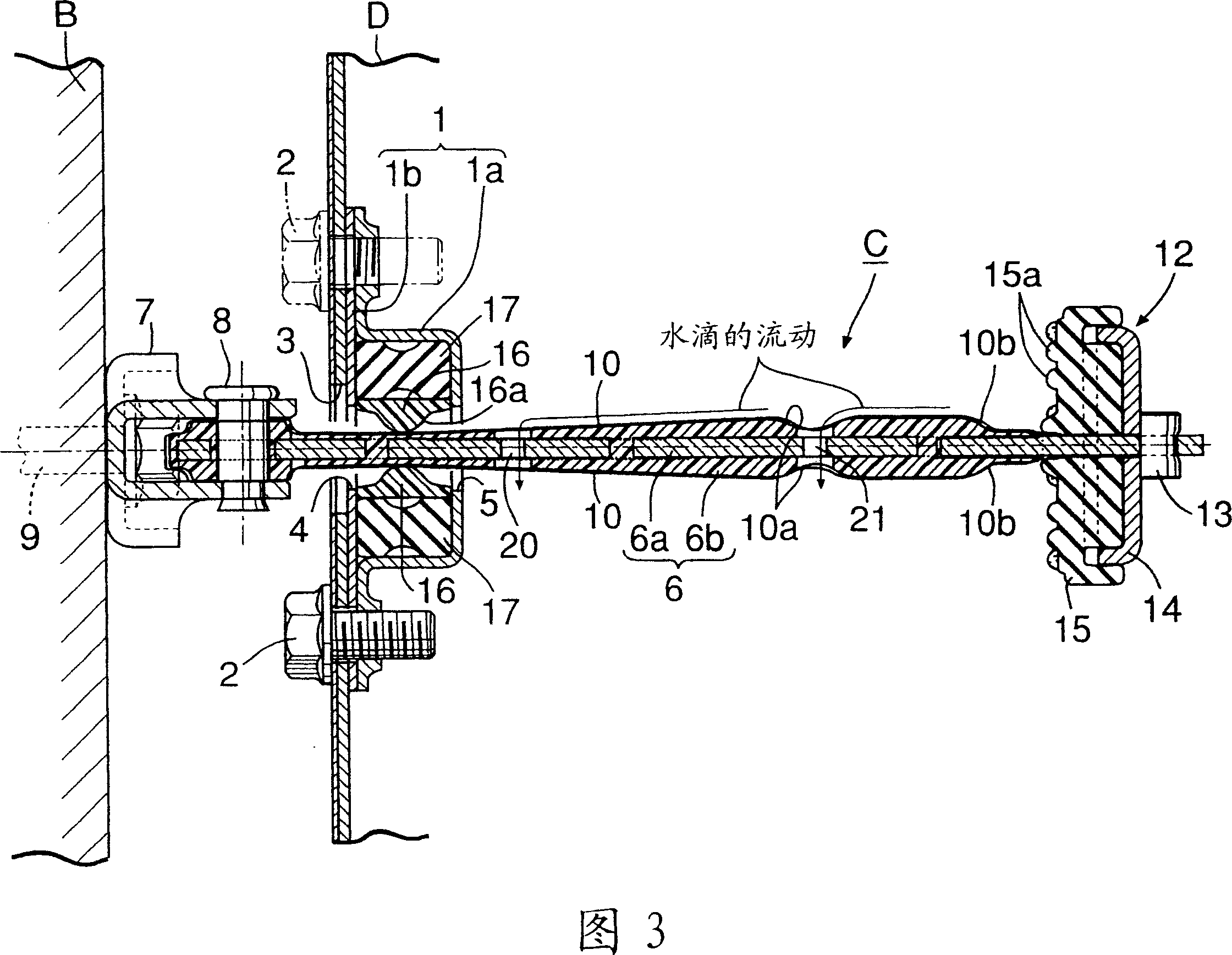

Door checker for automobile

InactiveCN1920233AAvoid enteringPrevent bad situationsBuilding locksWing fastenersEngineeringCar door

A door checker for an automobile, includes: a case 1 fixed to a door D; a check plate 6 which movably penetrates the case 1 and is turnably connected to a body B; a pair of upper and lower detent members 16 slidably held in the case 1 to hold the door D at a predetermined opening position in cooperation with a pair of upper and lower detent surfaces 10 of the check plate 6 ; and an elastic member 17 which is made of an elastic material for generating a detent force between the detent member 16 and the detent surface 10 . In this door checker, a drain hole 20 is provided in the check plate 6 in a portion projecting into the door D from the case 1 and at least at a position close to the case 1 as to penetrate the upper and lower detent surfaces 10 when the door is fully closed. Thus, even if rainwater and the like go into the door D and drop onto the upper surface of the check plate 6 , it is drained quickly from the check plate 6 and are prevented from flowing into the case 1.

Owner:RIKEN KAKI KOGYO CO LTD

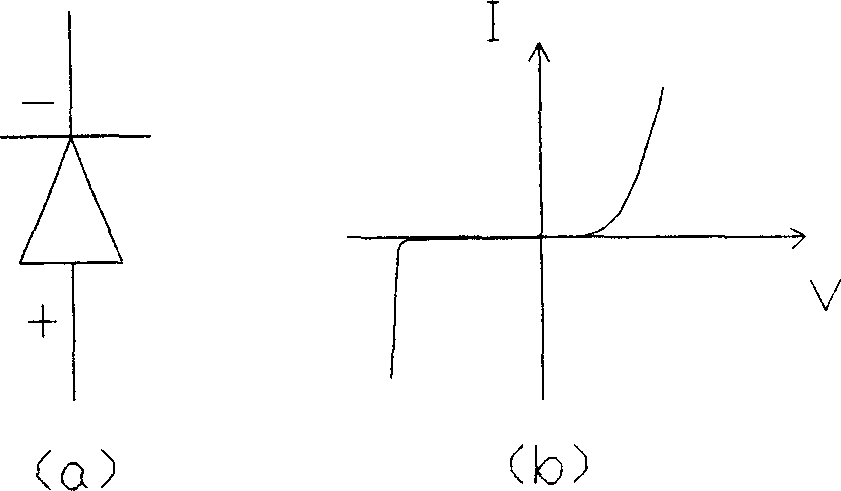

Organic electroluminescence display and its producing method

ActiveCN1822737AAvoid wastingImprove yield rateElectrical apparatusElectronic circuit testingOrganic electroluminescenceBurning out

Said invention discloses organic electroluminescent display and manufacture method. It contains applying forward voltage (current pulse), reverse voltage pulse or both of them between anode and cathode of display device before packaging organic electroluminescent display device or in aging, partial short circuit fault instant burning-out or partial diode characteristic broken down instead of presenting short circuit phenomena and to make unstabilized short circuit fault speeding up representation for taking out as unqualified product. Said invented method can effectively inspect even eliminate short circuit fault before bonding electroluminescent display device and integrated circuit driving chip, raising non-defective rate and greatly reducing production costs.

Owner:TRULY SEMICON

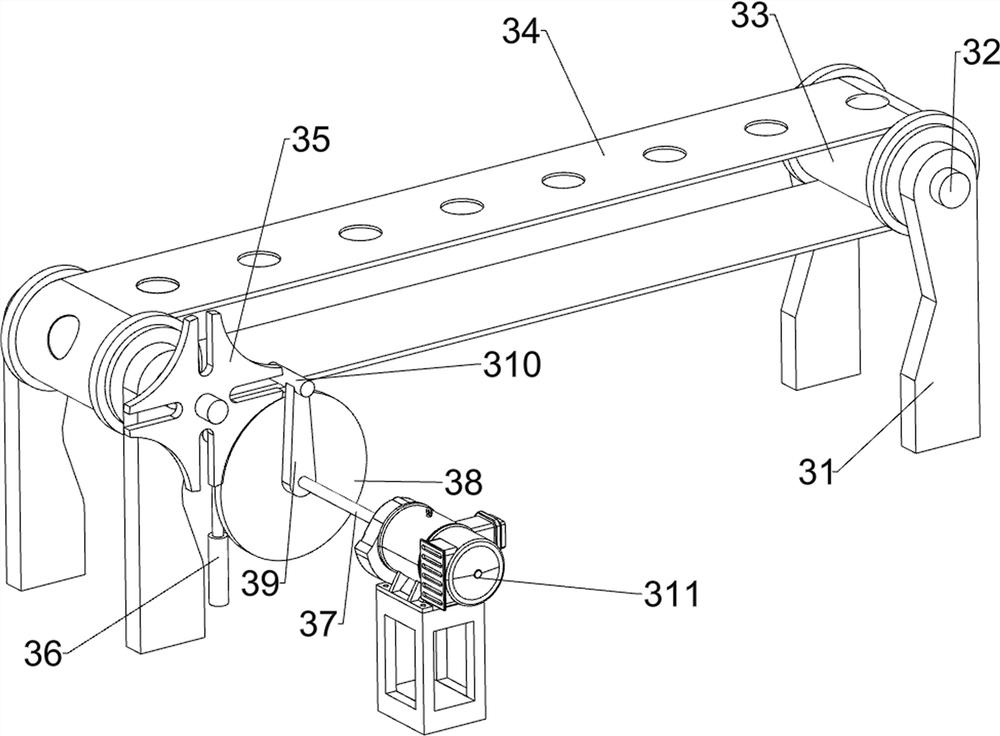

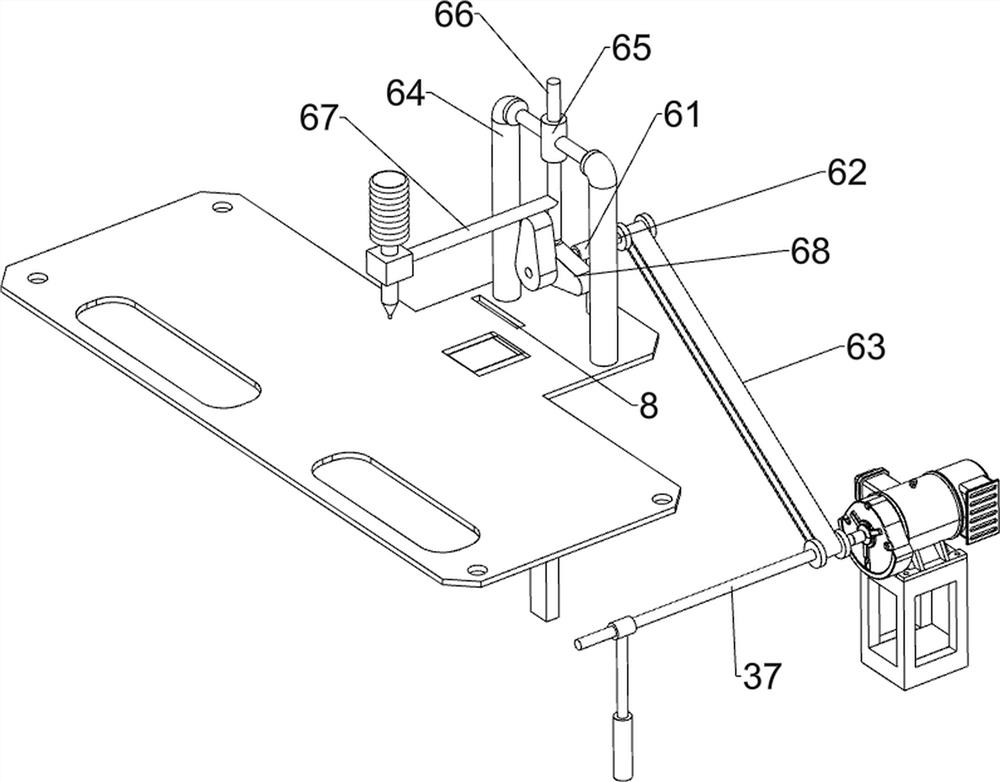

Automatic beverage filling equipment

The invention relates to filling equipment, particularly relates to automatic beverage filling equipment and provides automatic beverage filling equipment capable of enabling bottles to be not prone to displacement and automatically filling beverages. The automatic beverage filling equipment comprises a base, a feeding device, a filling box, an opening and closing device and a lifting device, wherein a workbench is arranged at the top of the base; the feeding device is arranged at the top of the base; the filling box is arranged at the top of the base; a square groove is formed in the fillingbox; the opening and closing device is arranged at the top of the base; and the lifting device is arranged on the workbench. According to the automatic beverage filling equipment, the feeding device is capable of achieving intermittent leftward movement of the bottles; then the opening and closing device and the lifting device cooperate to intermittently fill the beverages into the bottles; a second connecting rod can drive a discharging pipe to move up and down; the lower part of the discharging pipe moves into bottles, so that the beverages can be better filled into the bottles; meanwhile, the automatic beverage filling equipment is also capable of preventing the beverages from flowing out of the bottles during infusion, so that the waste is avoided.

Owner:山东美果来食品有限公司

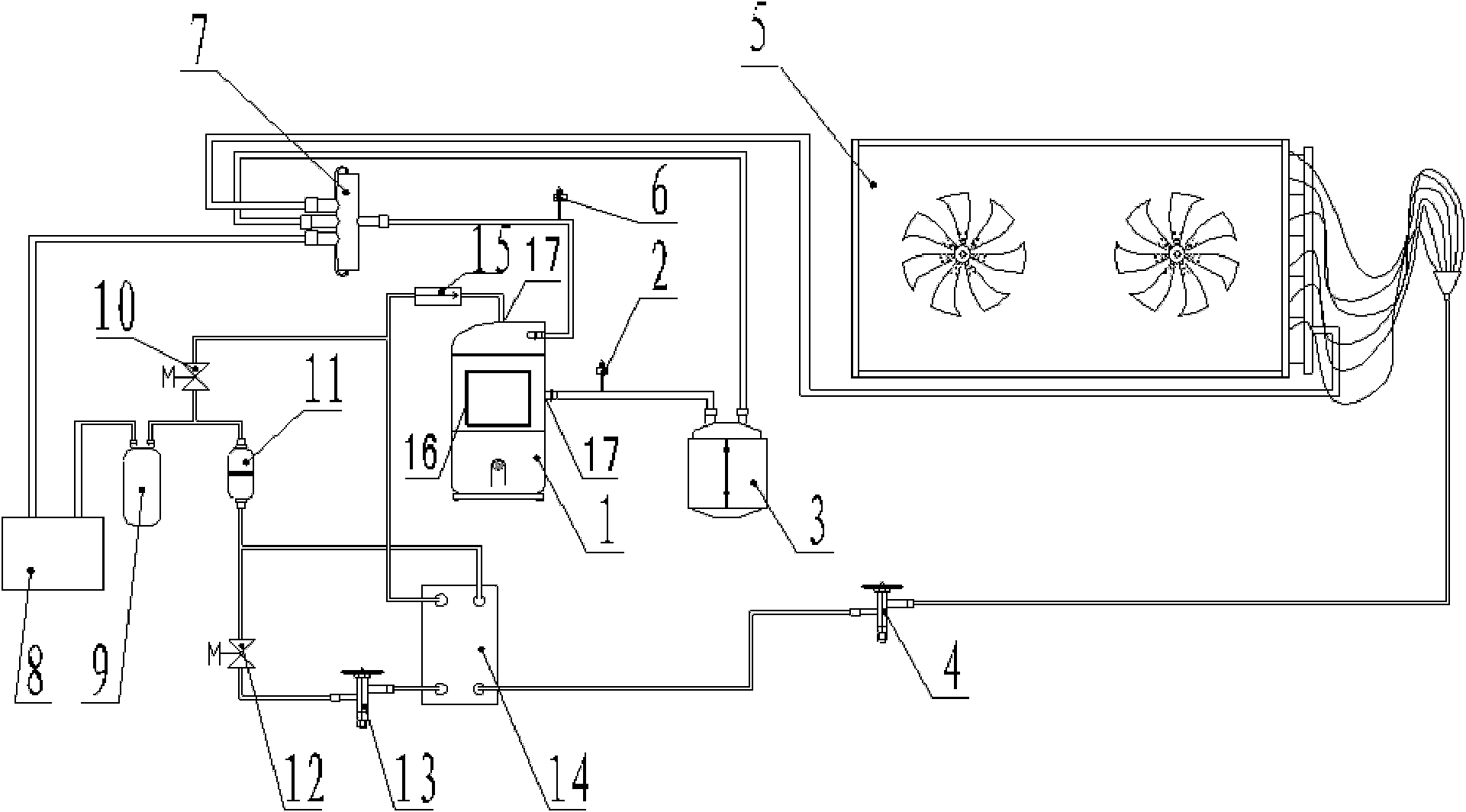

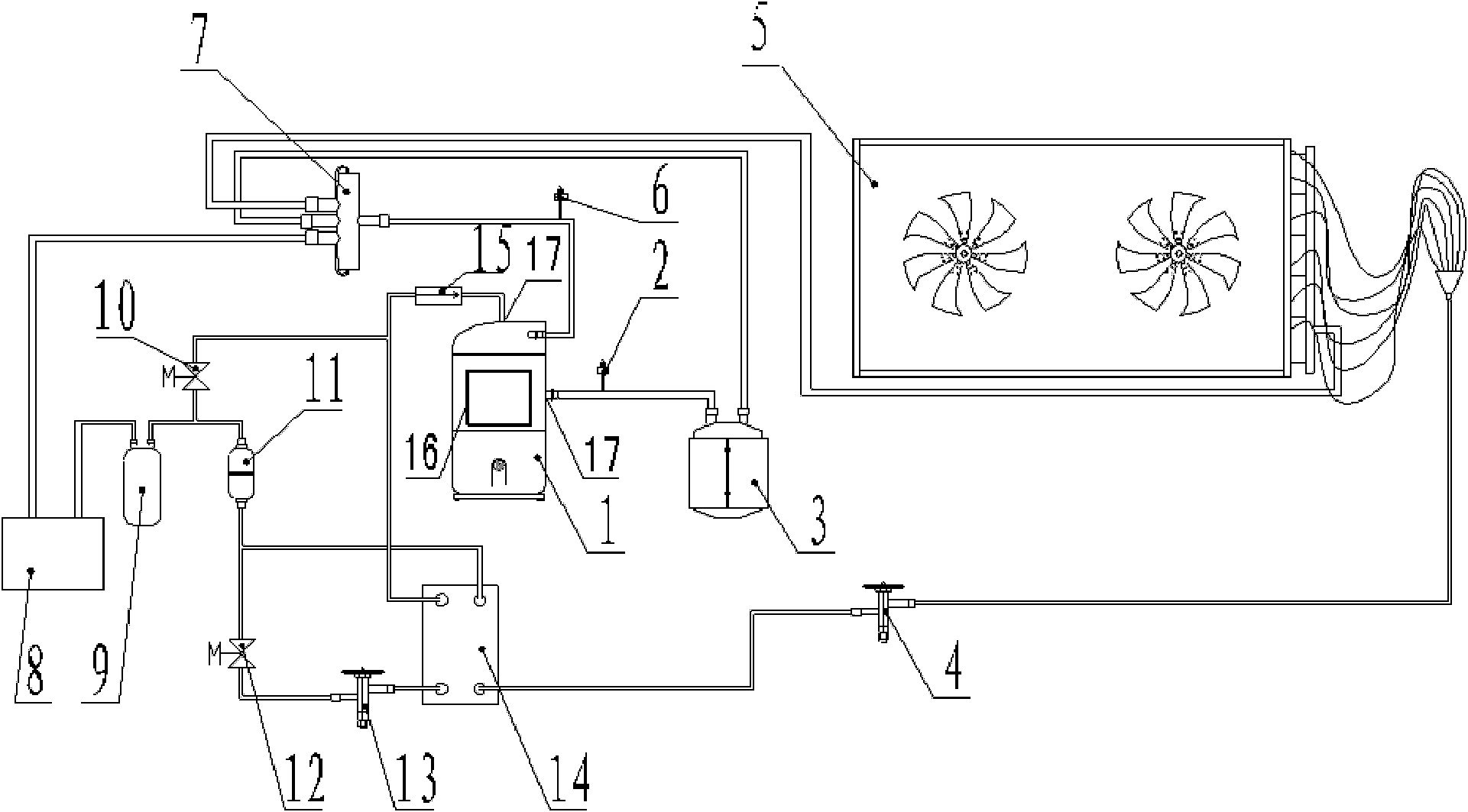

Ultralow temperature air source heat pump hot-water machine

InactiveCN101957060AReduce exhaust temperatureIncrease heat transferFluid heatersFluid circulation arrangementBusiness efficiencyThermal energy

The invention relates to a ultralow temperature air source heat pump hot-water machine, which comprises a compression engine(1),a air-side heat exchanger (5) and a hot-water-side heat exchanger(8) which are connected by pipeline; the compression engine(1) is internally provided with a cavity(16), one side of the compression engine(1) is provided with an air-supplement port. The heat pump hot-water machine further comprises an air-supply return circuit, a refrigerating circuit and an auxiliary air-supply return circuit. The heat pump hot-water machine can work in the ultralow temperature work environment, and has low delivery temperature, improves the conversion of thermal energy effect and the system energy efficiency ratio, and is favor of energy saving and environmental protection.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

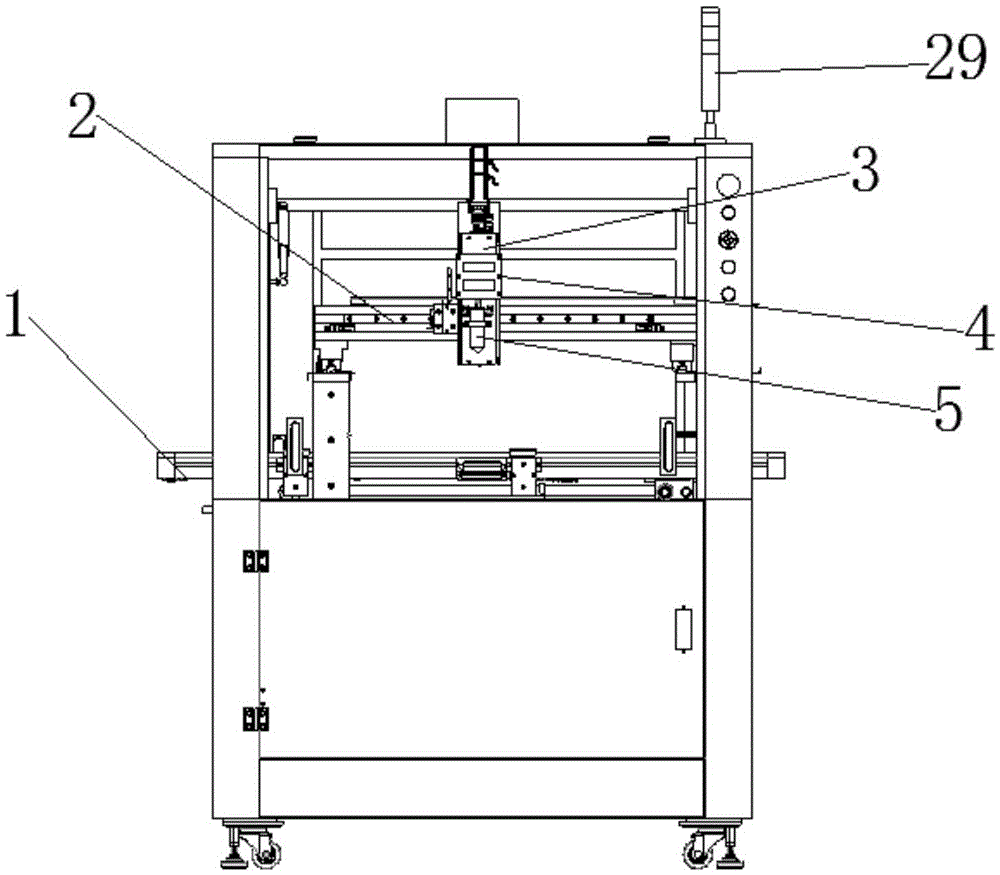

Circuit board assembly detection system

InactiveCN105486996ARealize automatic assemblyEasy to detectPrinted circuit assemblingElectronic circuit testingTest efficiencyCooking & baking

The invention discloses a circuit board assembly detection system. The circuit board assembly detection system mainly comprises a conveying device as well as code spraying equipment, ICT test equipment, nixie tube plugging equipment, FCT test equipment, CCD scanning equipment and oil spraying equipment which are sequentially arranged along the conveying direction of the conveying device. According to the circuit board assembly detection system, the code spraying machine can perform automatic code spraying on circuit boards; the ICT test equipment can automatically perform ICT tests on the circuit boards; the nixie tube plugging equipment can automatically plug nixie tubes into the circuit boards, so that the speed and efficiency of the plugging of the nixie tubes can be improved; the FCT test equipment can automatically perform FCT tests on circuit boards to be detected, and therefore, test efficiency and test accuracy can be both improved; the CCD scanning equipment can perform automatic detection on the nixie tubes on the circuit boards; and the oil spraying equipment can perform automatic oil spraying processing on circuit boards which have been subjected to assembly detection, and the oil spraying equipment is connected with a baking box, and therefore, ink drying time can be shortened, and the production cycle of the circuit boards can be shortened.

Owner:SUZHOU JINGSHUO AUTOMATION EQUIP CO LTD

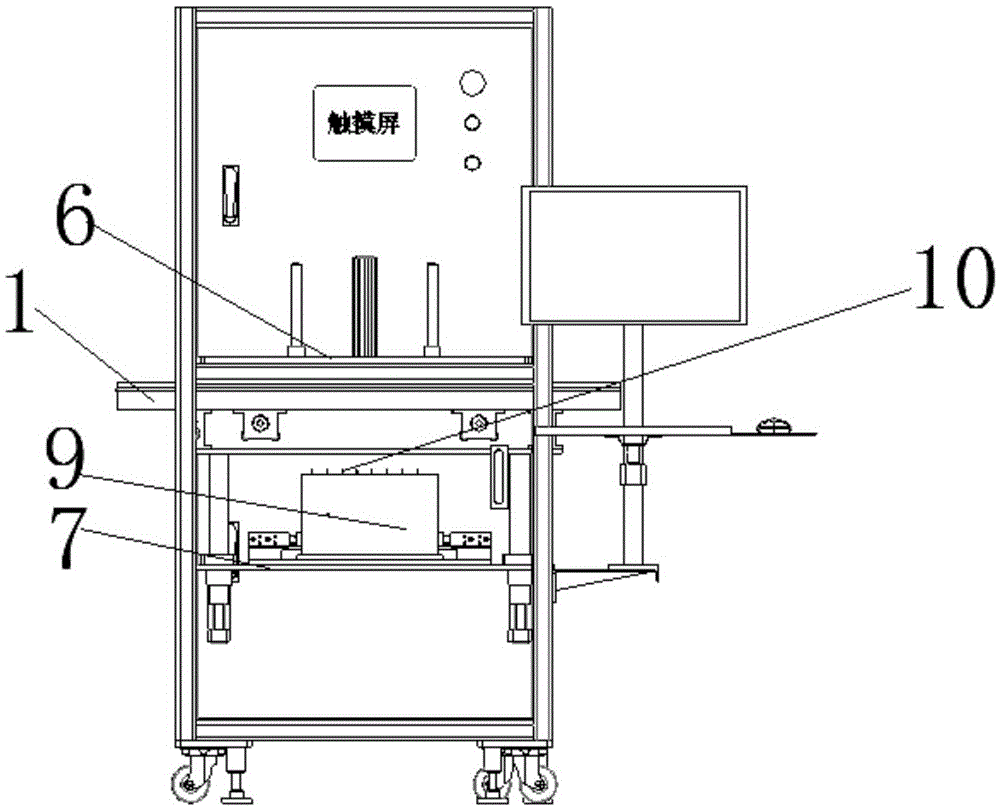

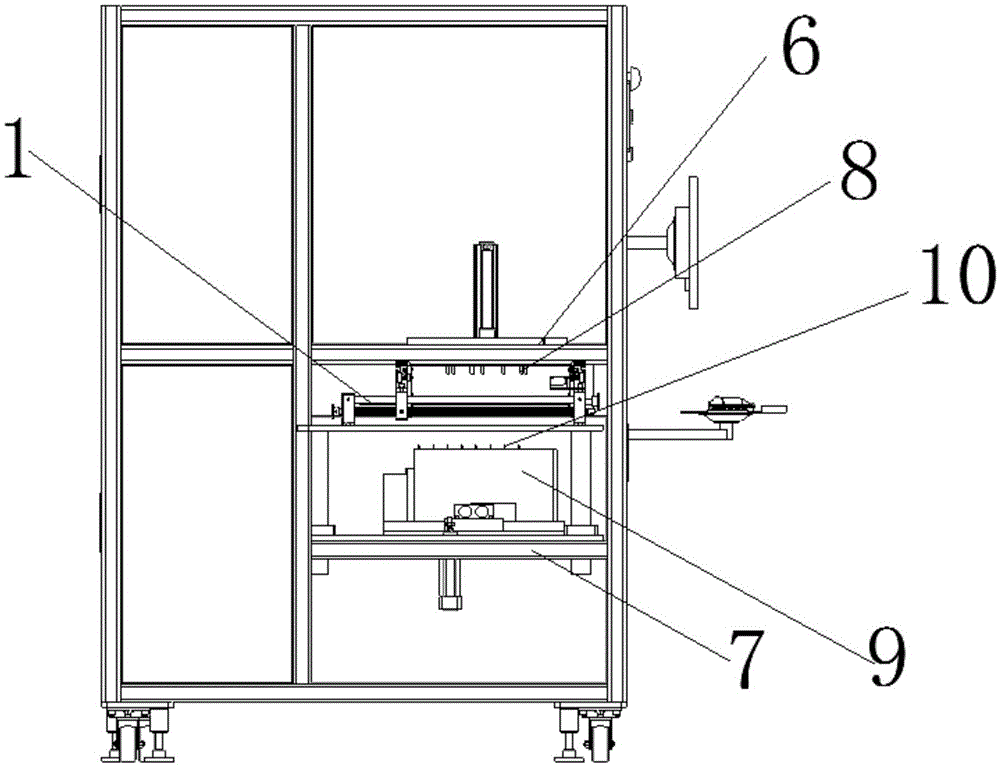

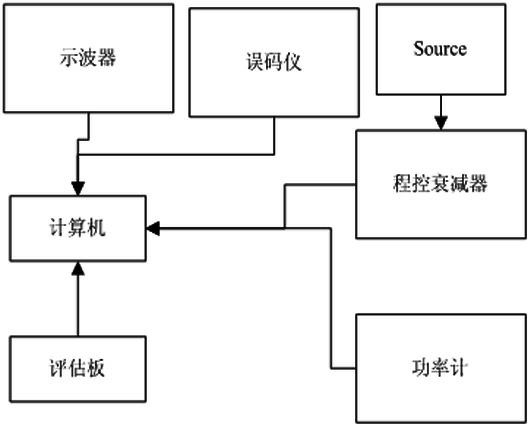

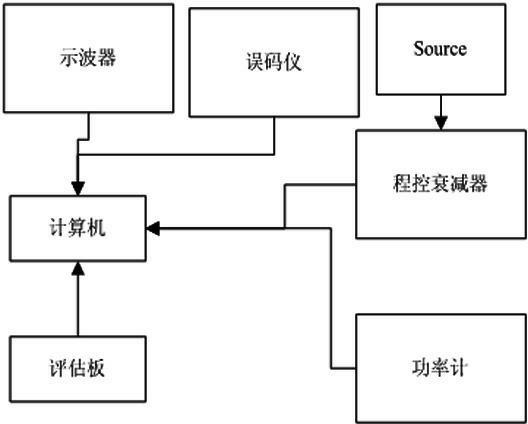

On-line automatic testing system in production of optical module

ActiveCN102252820AHigh precisionEasy data traceabilityTesting optical propertiesLight sourceData processing

The invention relates to an on-line automatic testing system in production of an optical module. The on-line automatic testing system is suitable for a testing platform for an automatic production line of the optical module; a control computer operates multiple kinds of testing instruments which comprise an oscilloscope, a light source, an optical attenuator, an error code tester, an optical power meter, a spectroanalysis instrument, a pattern generator and the like; and the automatic testing system modularizes all details, and divides instrument and equipment control, debugging, measurement,calibration, insertion removal judgment, data storage and data processing into independent modules, and a data exchange mechanism in each module is refined and packaged. All modules are spliced and combined in a mode of a frame structure to ensure that all the modules have high flexibility and generality, and the system can become a new automatic testing system by only changing one of the modules. The system integrates a plurality of processes of debugging, testing, calibration and the like, and the phenomenon that a rejected product enters the next process due to personal factors is avoided as much as possible; and the system is easy to operate, improves the production efficiency and test accuracy, and makes data tracing possible.

Owner:SICHUAN XINYISHENG COMM TECH CO LTD

Air filter core cleaning device

InactiveCN107754456AClean to avoid impactNo manual operationGas treatmentDispersed particle filtrationAir filtrationAir filter

The invention discloses an air filter core cleaning device. The air filter core cleaning device comprises a cleaning box, front and rear sides in the cleaning box are provided with transfer bins, theinner walls of the transfer bins are rotatably connected to a first pulley, a clamping cylinder is slidingly connected to the interior of the first pulley, one end of the clamping cylinder is slidingly connected to a first electric telescopic rod through a chute, one end of the first electric telescopic rod far away from the clamping cylinder is fixedly connected to the inner wall of the transferbin, and the inner walls of the two transfer bins are fixedly provided with motors. The air filter core cleaning device utilizes a pressing plate to start a touch switch. After an air filter core presses down the left end of the pressing plate, the right end of the pressing plate can block a later air filter core so that cleaning of the previous air filter core is not influenced. A brush at the top of the pressing plate can brush the outer side of the air filter core. The air filter core cleaning device can be automatically started without manual operation and is easy to use.

Owner:HAINING WEITAI BIOTECH CO LTD

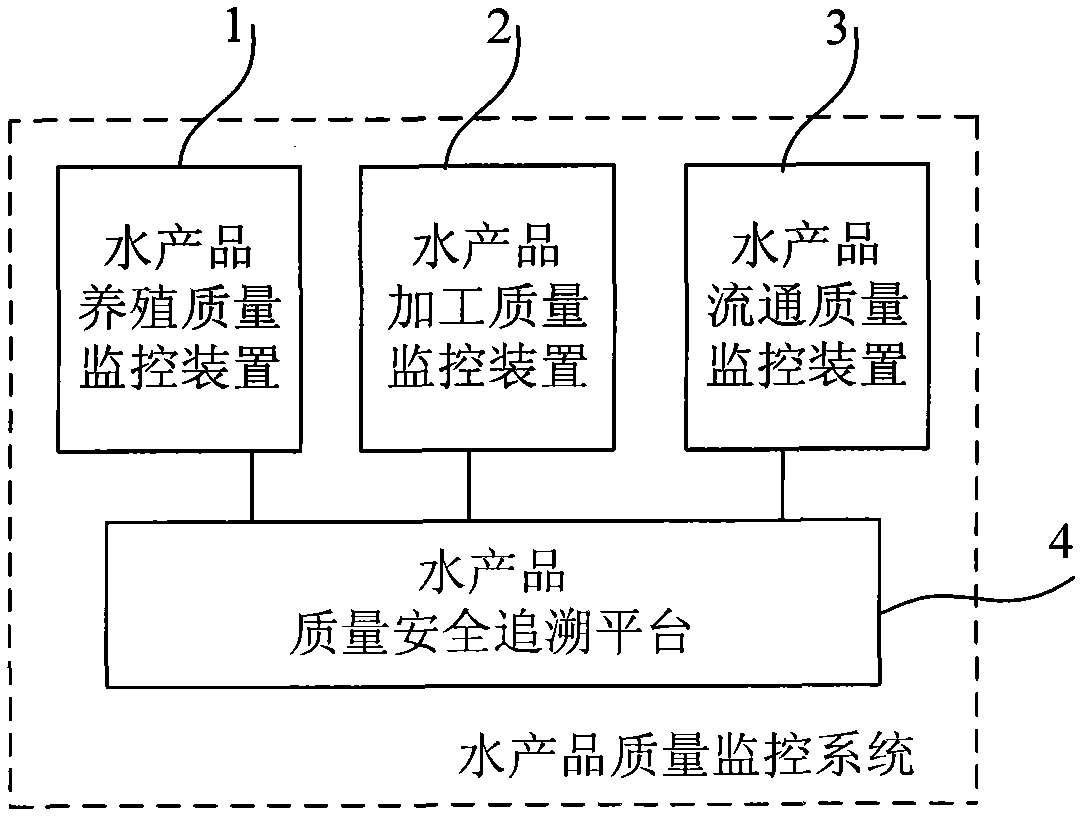

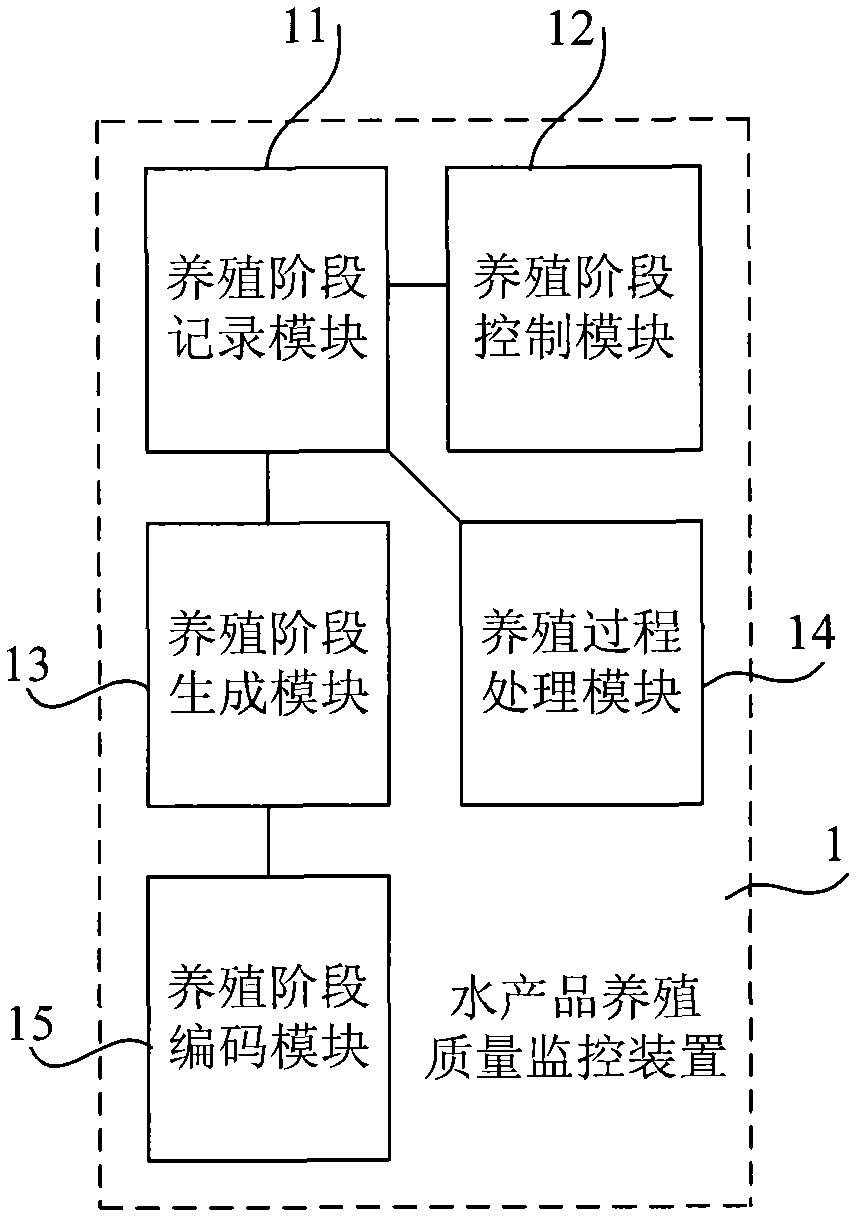

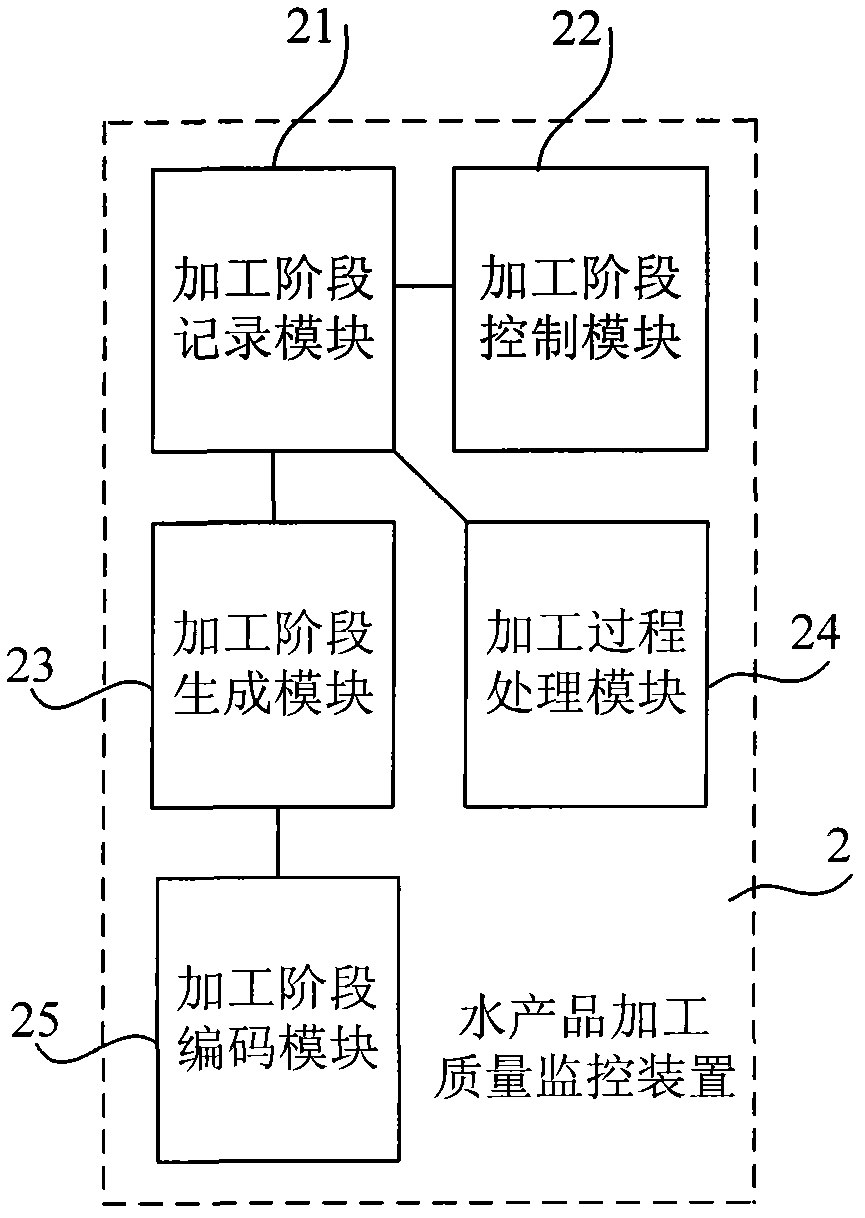

Quality control method of aquatic product and system thereof

InactiveCN101930567ABuy with confidenceEat with confidenceCommerceRecord carriers used with machinesAquatic productQuality control

The invention discloses a quality control method of an aquatic product and a system thereof. The method comprises the following steps: recording product quality information of the aquatic product during the cultivation and / or processing and / or circulation process; controlling the cultivation and / or processing and / or circulation process according to the product quality information during the cultivation and / or processing and / or circulation process; and generating a one-dimensional code and a two-dimensional code according to the product quality information during the cultivation and / or processing and / or circulation process, and printing the one-dimensional code and the two-dimensional code on a tracing tag. The invention provides a powerful guarantee for consumers to purchase safe and sanitary aquatic products, minimizes loss and guarantees legitimate rights and interests of the consumers, and motivates enterprises to positively guarantee quality safety, health and no drug residues of the aquatic product.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI +1

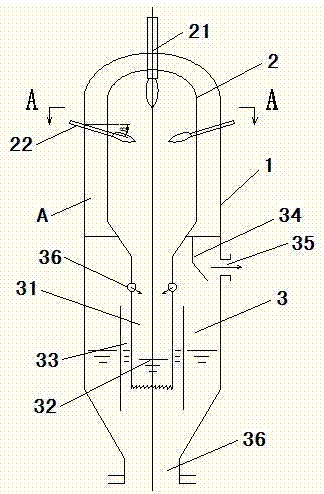

Load-adjustable step feeding type entrained flow bed gasifier

ActiveCN102827642AIncrease productionExtended stayGranular/pulverulent flues gasificationSyngasWater baths

The invention discloses a load-adjustable step feeding type entrained flow bed gasifier. The load-adjustable step feeding type entrained flow bed gasifier is characterized by comprising a pressure shell body, and a reaction chamber and a cooling / dust removal / water bath chilling chamber which are supported and hung in the pressure shell body, wherein the cooling / dust removal / water bath chilling chamber is coaxially arranged at the lower part of the reaction chamber; an annular gap space is arranged between the reaction chamber and the pressure shell body; and the reaction chamber is provided with a main nozzle and a plurality of load adjustment nozzles. The cooling / dust removal / water bath chilling chamber is coaxially arranged at the lower part of the reaction chamber, the main nozzle is arranged at the top part of the gasifier, the load adjustment nozzles are symmetrically arranged in the space at the upper part of the reaction chamber, and water is used to chill high-temperature synthetic gas and clinker discharged below the reaction chamber, so that the single-gasifier yield is effectively increased, the single-gasifier production load adjustment capability is realized, and the hearth reaction region is reasonably arranged, thereby ensuring that the synthetic gas in the hearth can produce a rotational flow, the retention time is long, the reaction is thorough and the load adjustment range is wide.

Owner:中国船舶集团有限公司第七一一研究所

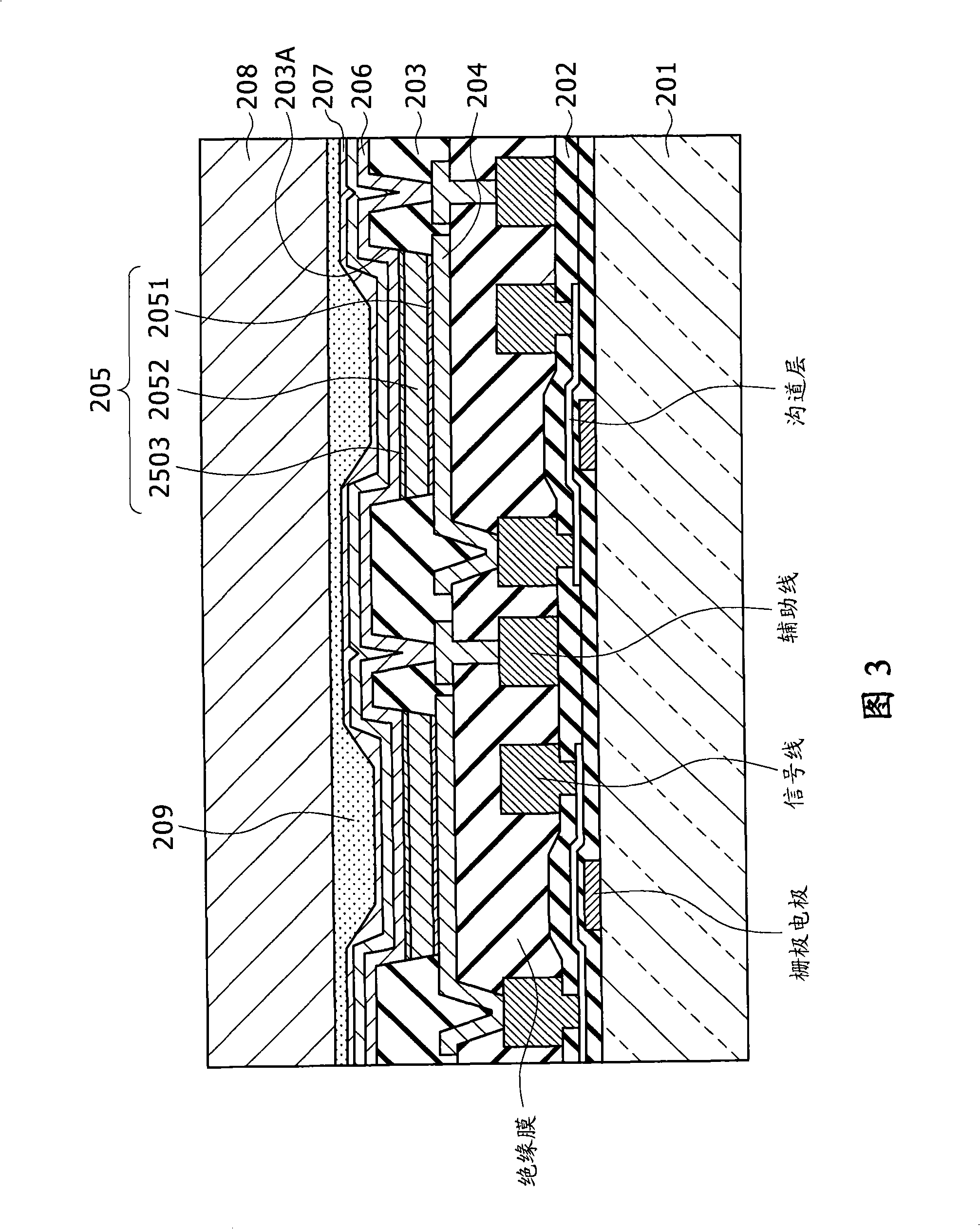

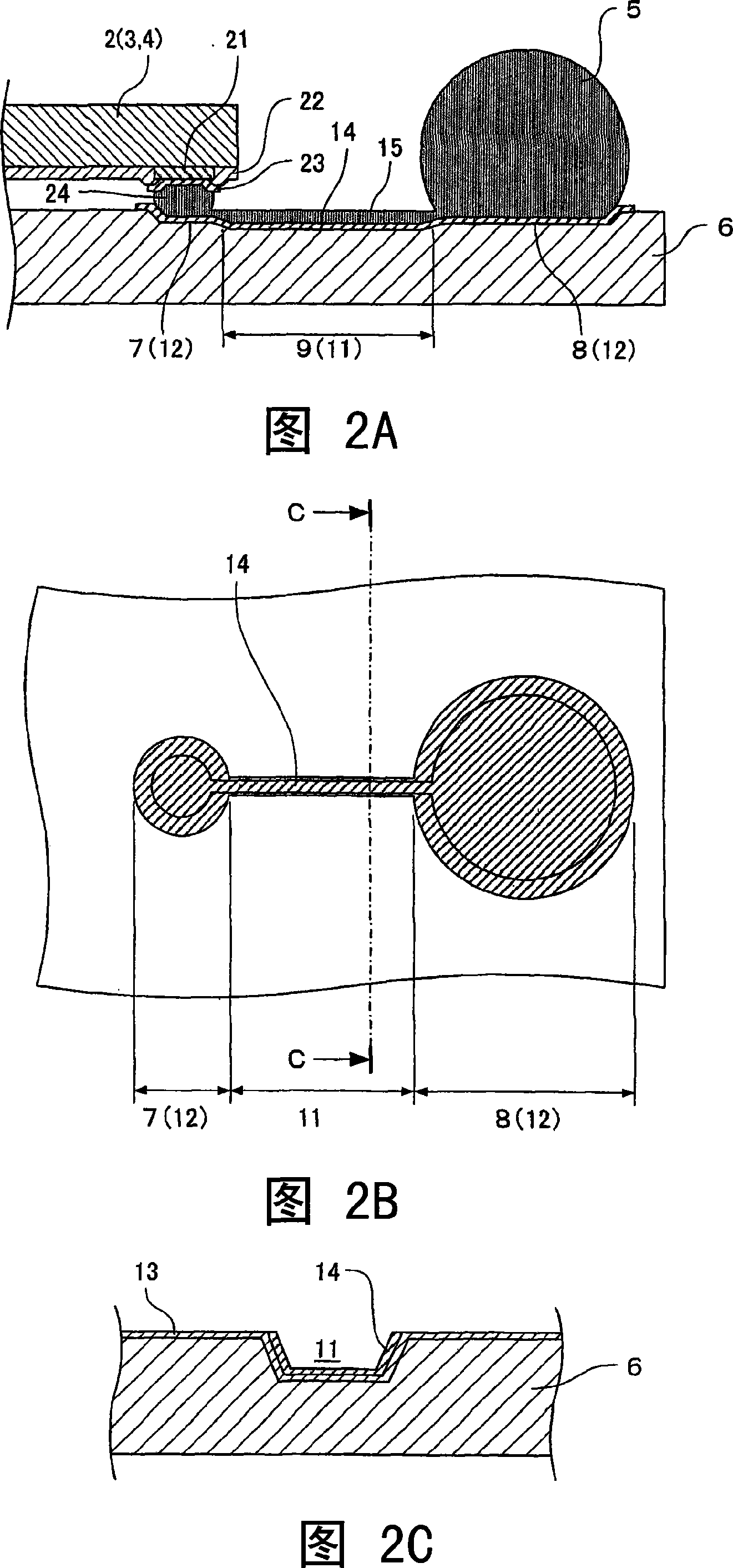

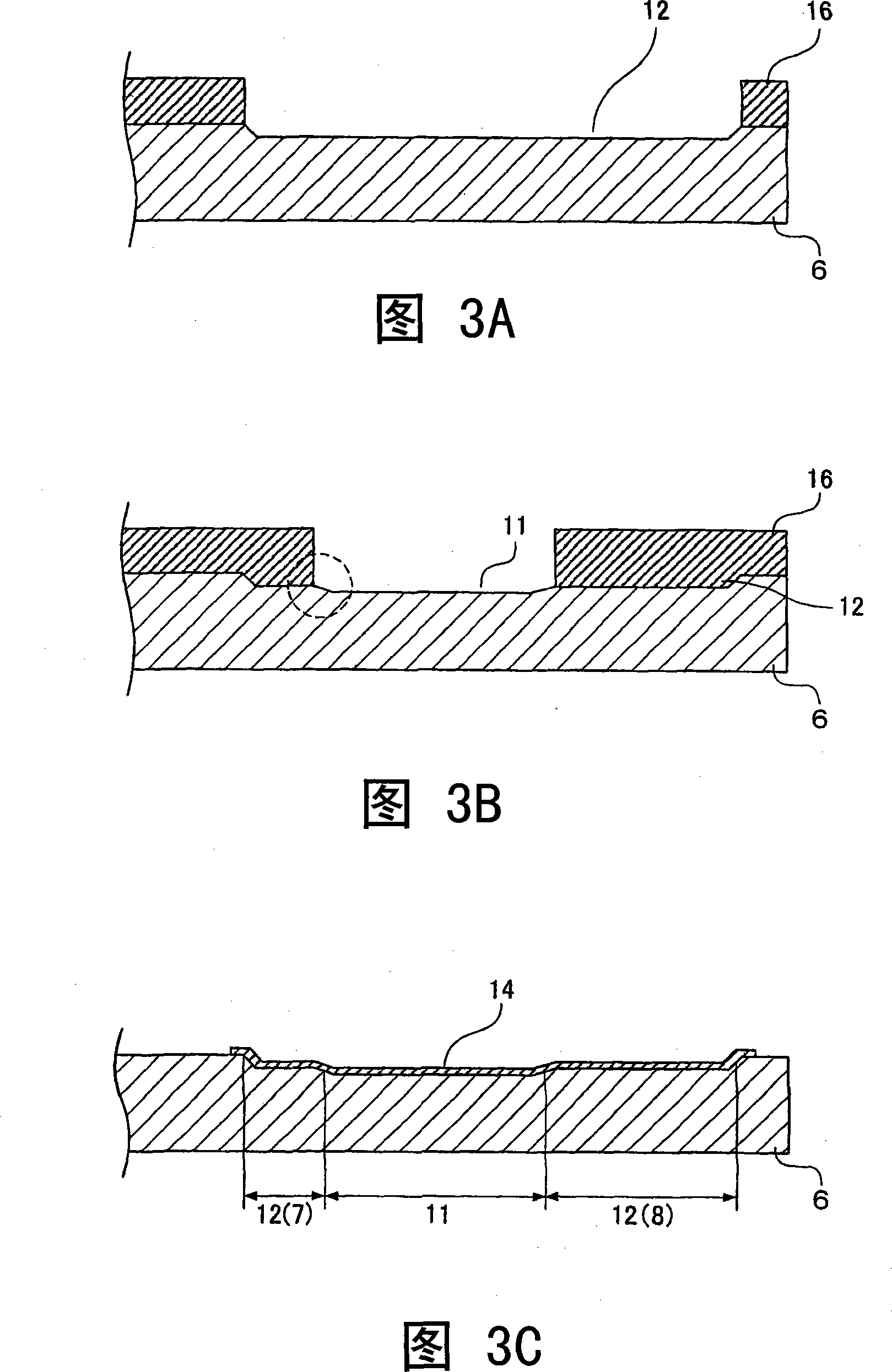

Semiconductor device and method for manufacturing same

InactiveCN101114630APrevent flowSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceElectrical conductor

Owner:PANASONIC CORP

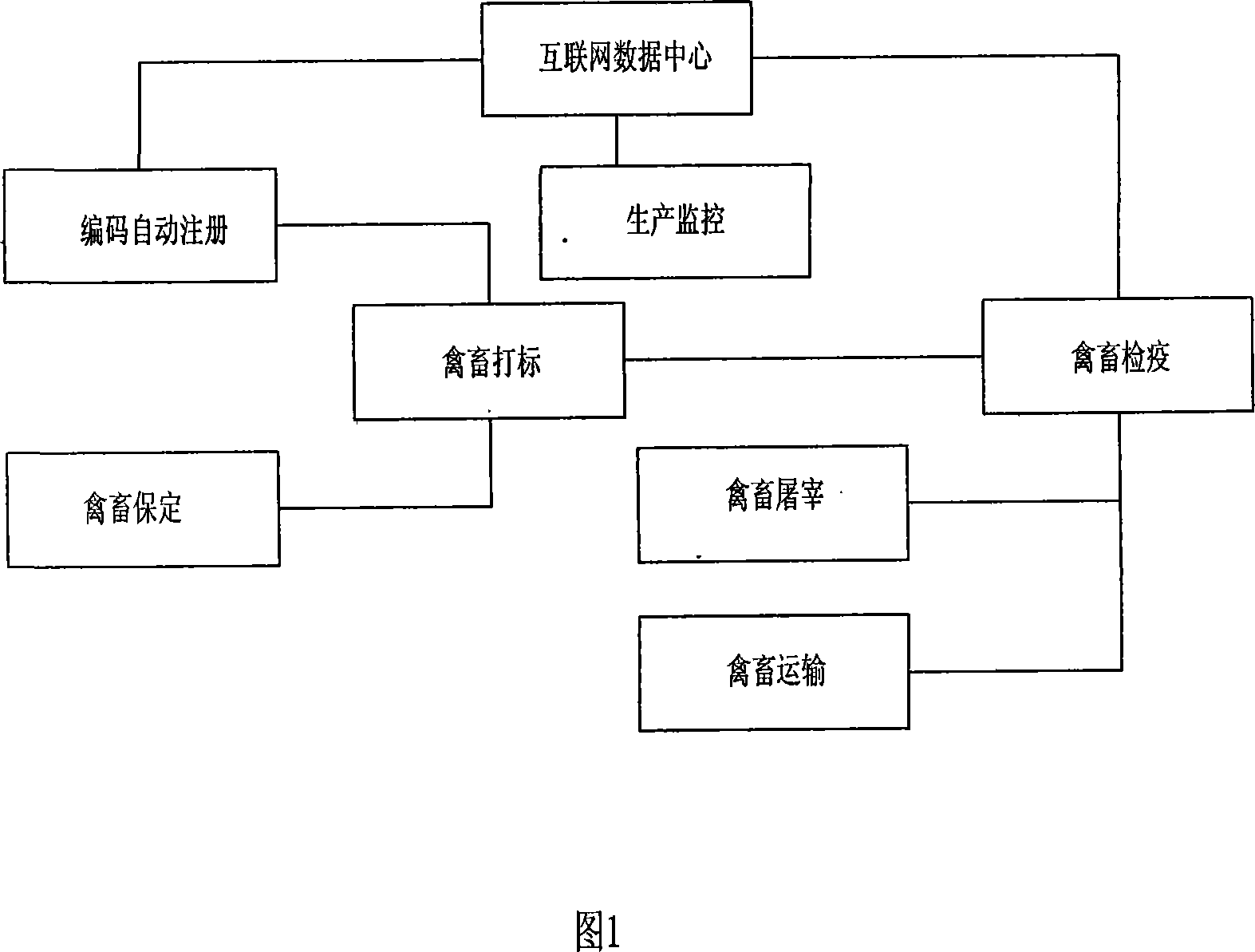

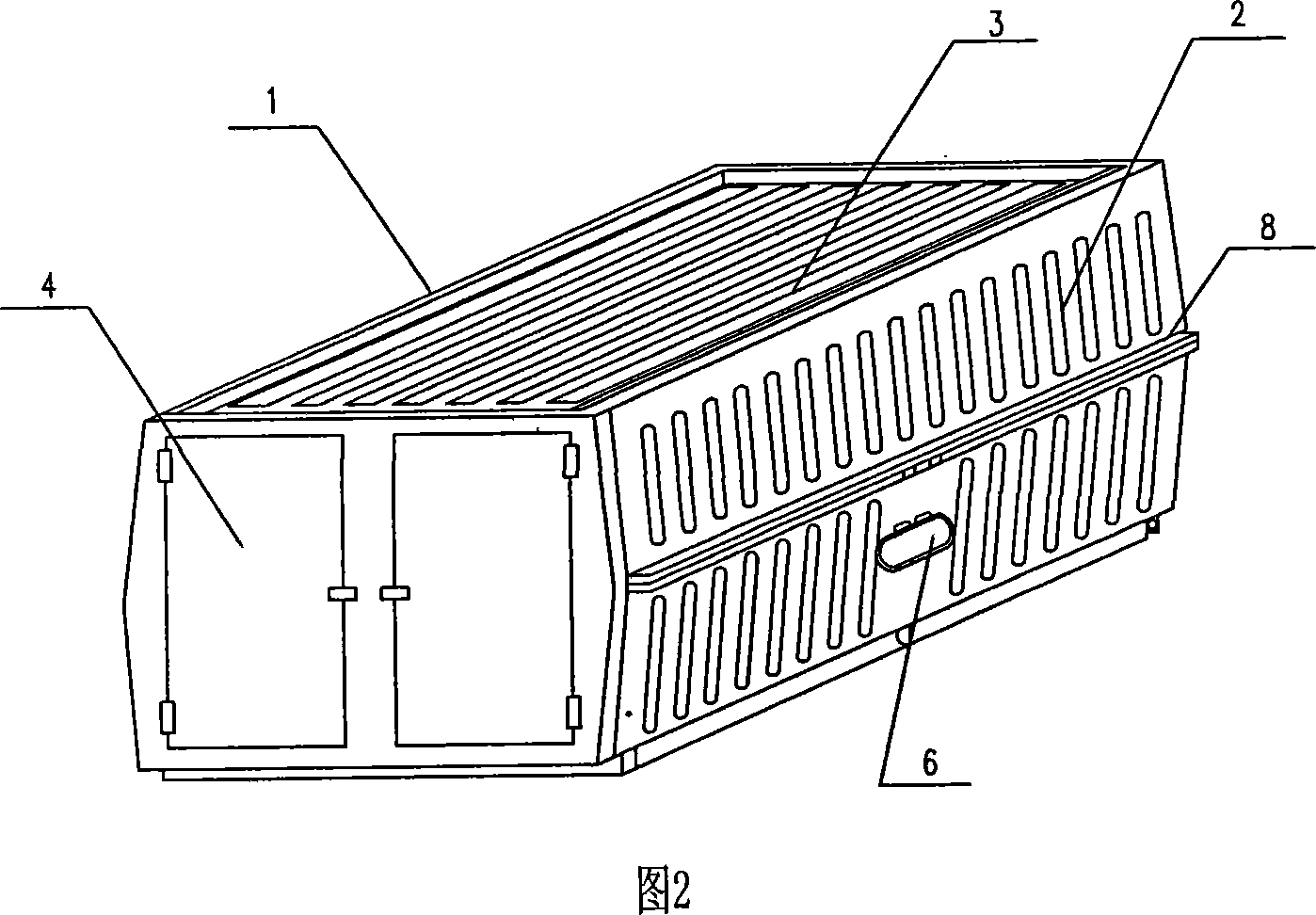

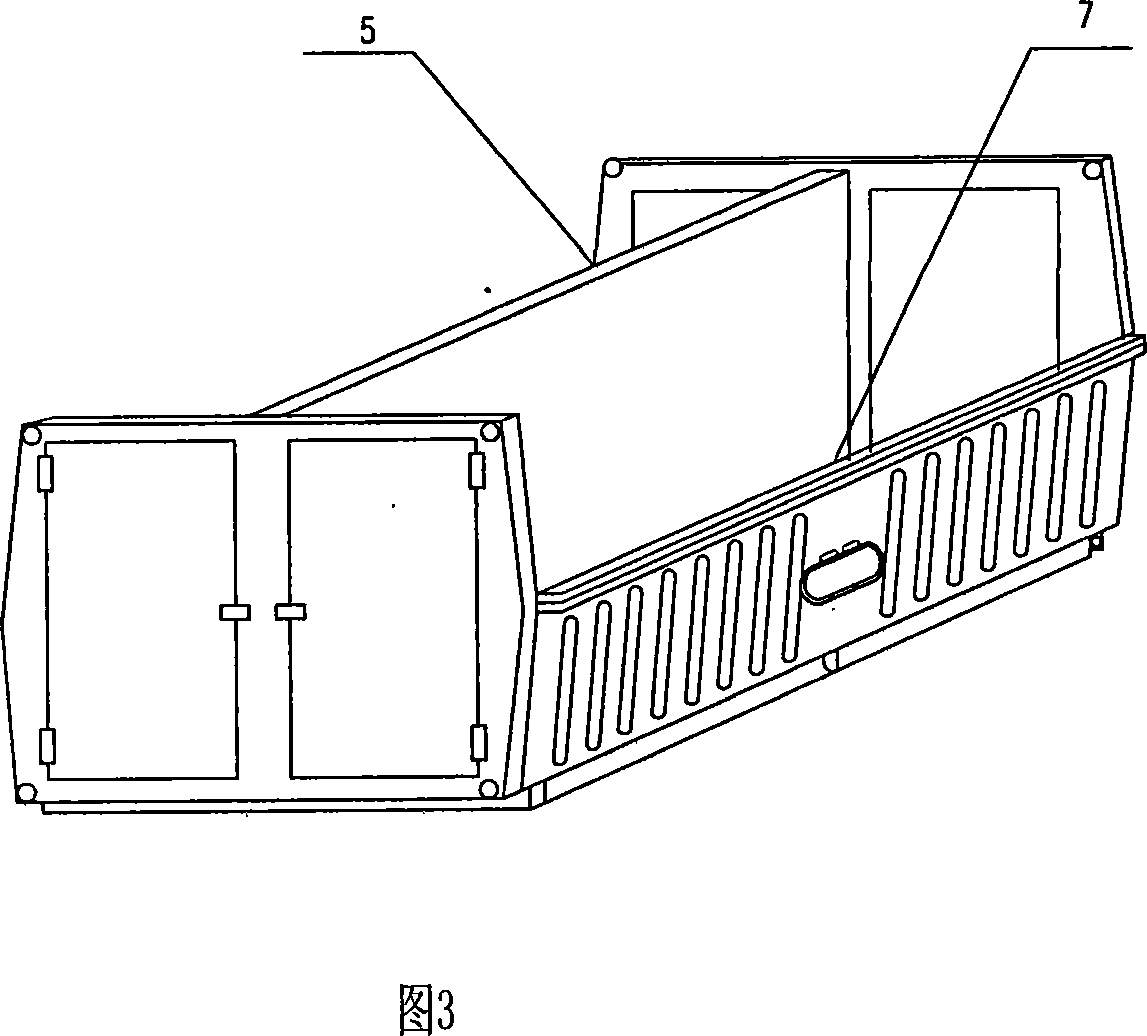

Automatic monitoring system and method for domestic animals safety production

InactiveCN101057561AEasy to monitor in real timePrevent disease in livestockLiving organism packagingPliersDomestic animalEngineering

The invention disclose an automatic monitoring system for livestock safe production, comprising livestock baoding instrument, animal marking device, animal transferring cage, livestock coding automatic registering software and livestock quarantining device equipped with automatic alarm for abnormal body temperature. It is characterized in that it also comprises automatic monitoring device which records every production process, and the monitoring device, livestock coding automatic registering software and livestock quarantining device are supported by internet. The invention is used for monitoring of livestock growth to look over every managing measurement, livestock immunity condition, drug utilization and plague record during livestock production course in real time, the utilization is convenient and spread value is good.

Owner:刘富来

Hydraulic engineering sludge separation device

ActiveCN107935347AAchieve friendlinessAvoid residueSludge treatment by de-watering/drying/thickeningTreatment involving filtrationSludgeSewage

The invention relates to a hydraulic engineering sludge separation device. The device comprises a sludge suction chamber, a crushing chamber, a separation chamber, a stirring and pushing chamber, a stone removal chamber and a sewage treatment chamber. The sludge separation device can realize the timely cleaning of the sludge during the construction of the hydraulic engineering. The cleaned sludgecan be transformed into valuables. The sludge, stones and sewage are treated so that sludge, stones and sewage can be reused. The hydraulic engineering sludge separation device is highly environmentally friendly.

Owner:湖南鑫丘建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com