Patents

Literature

373results about How to "Realize automatic assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

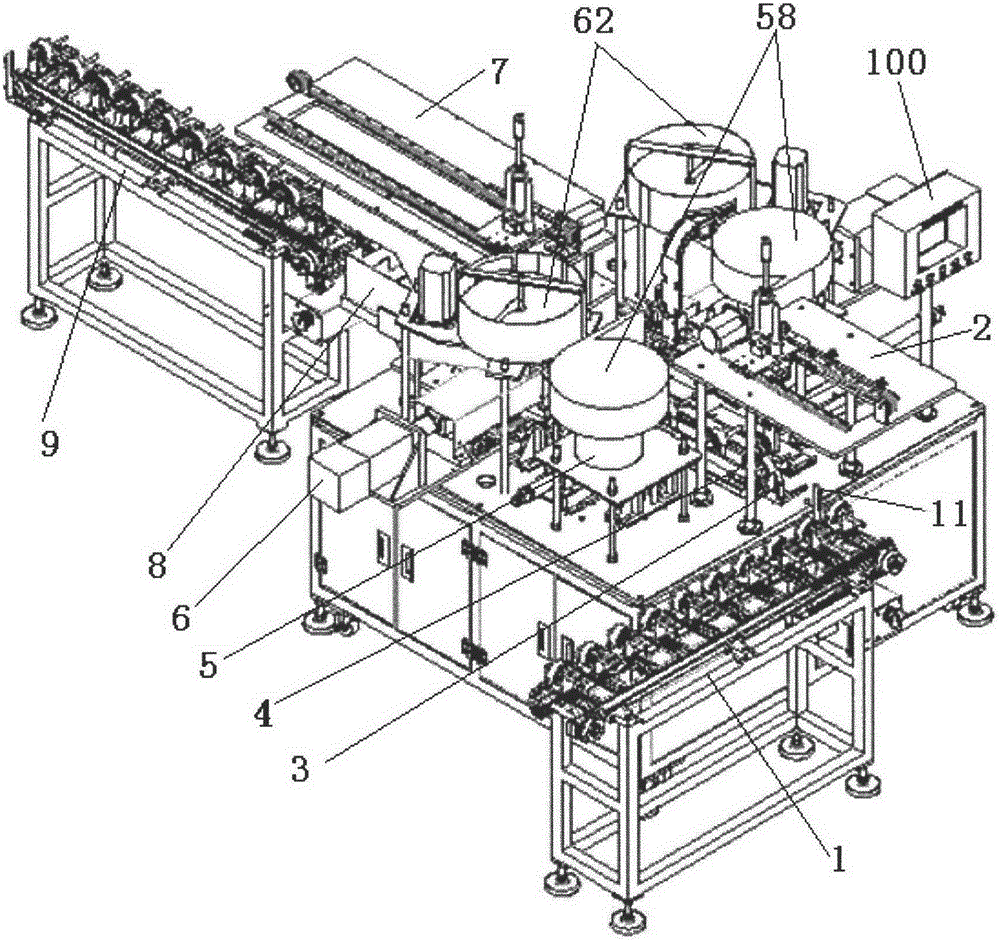

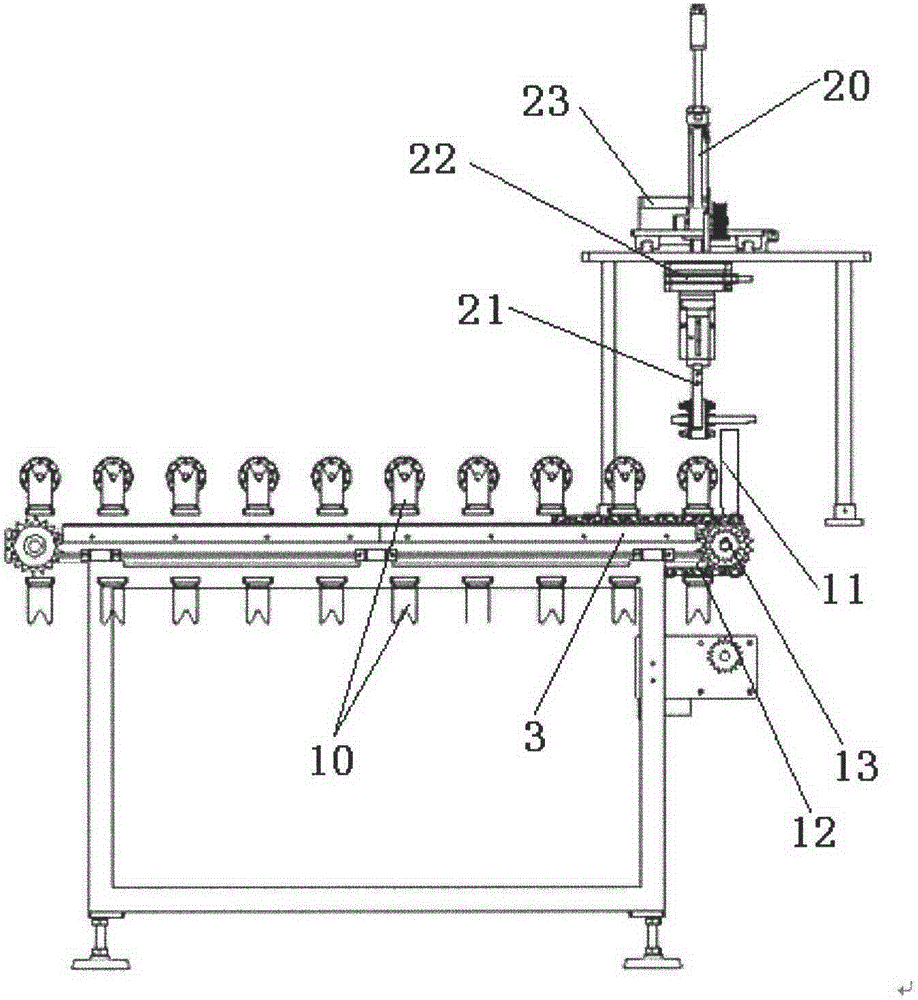

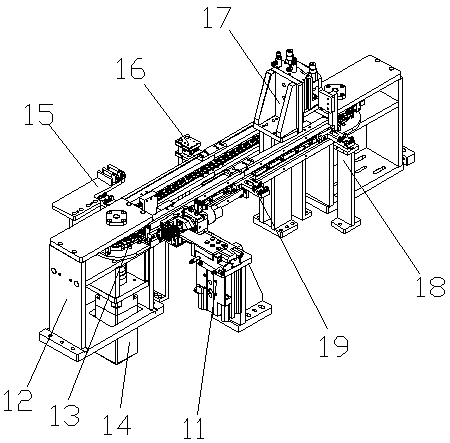

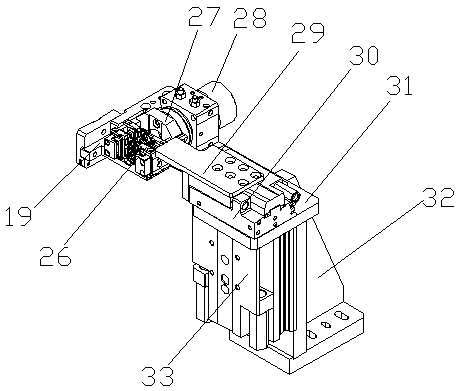

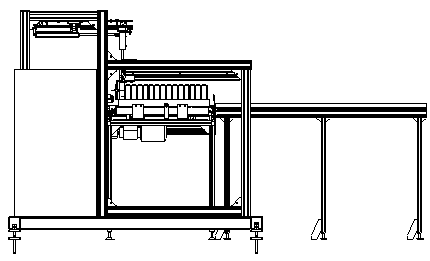

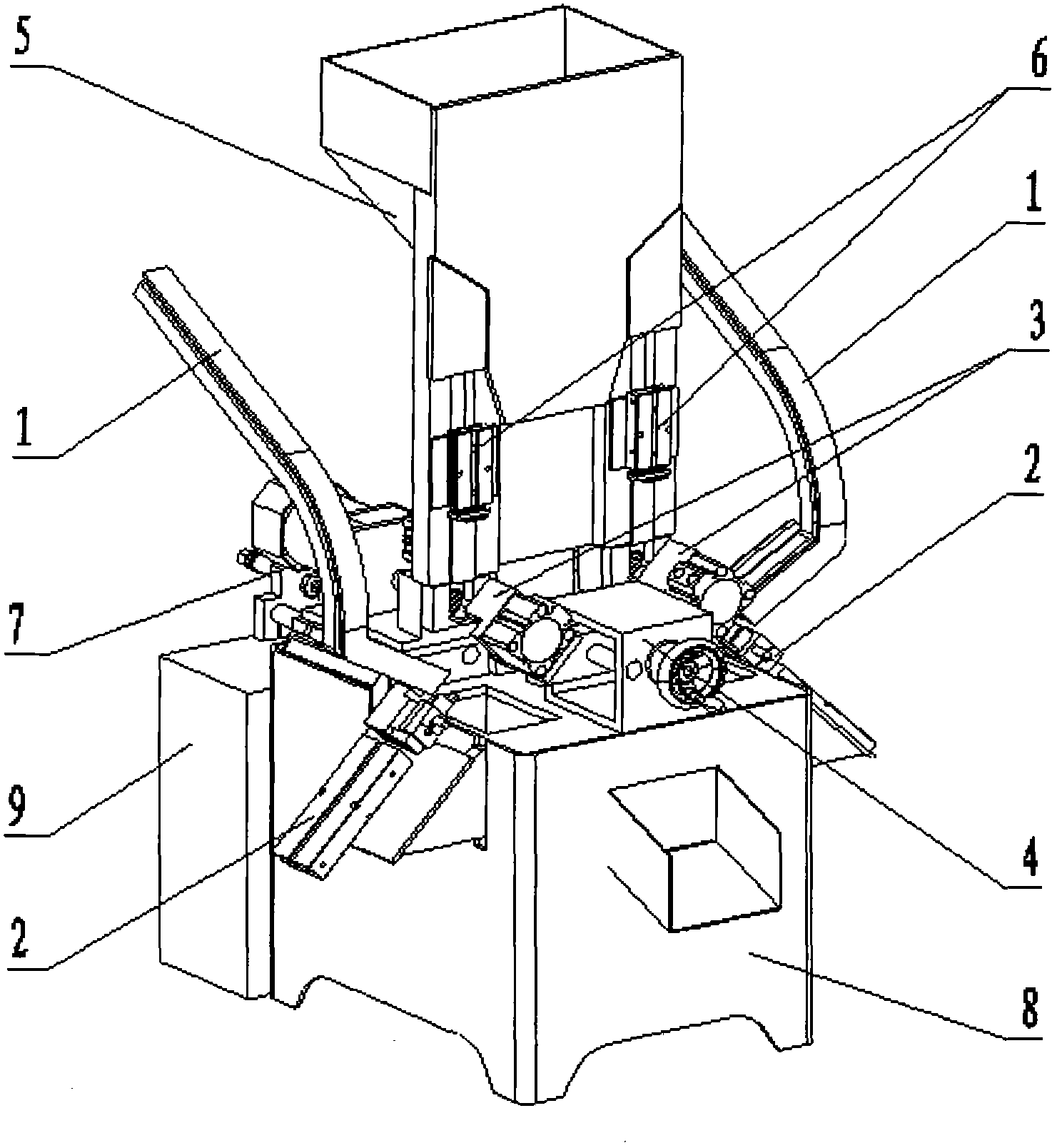

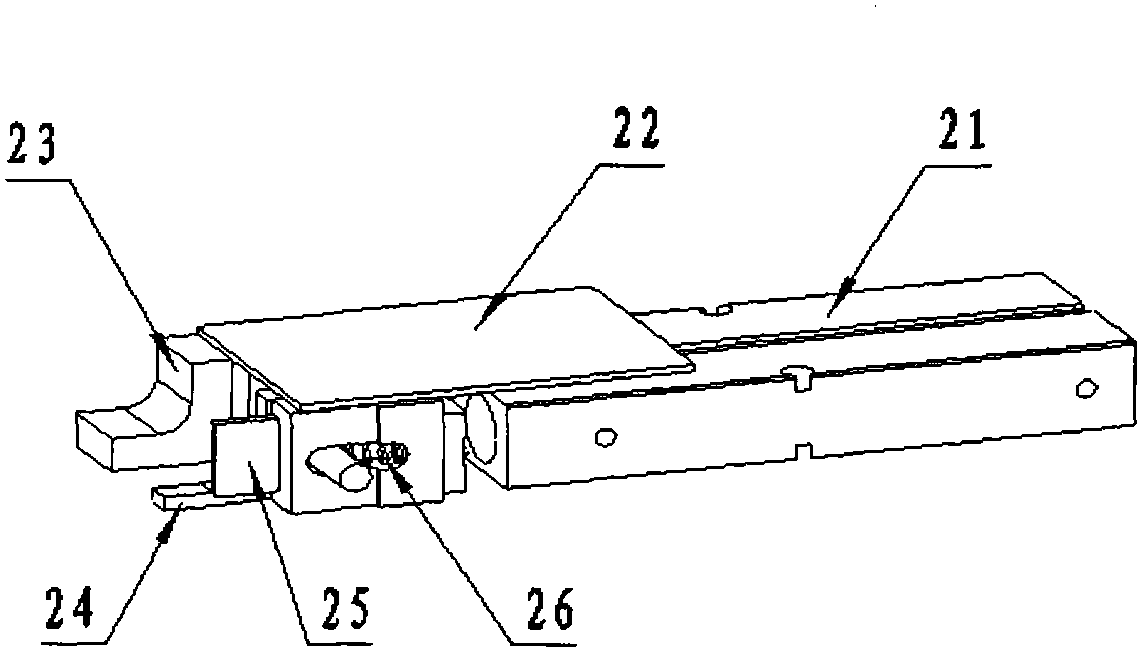

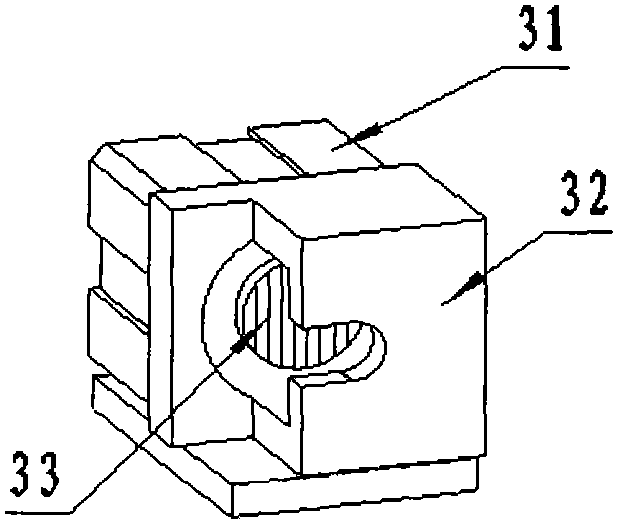

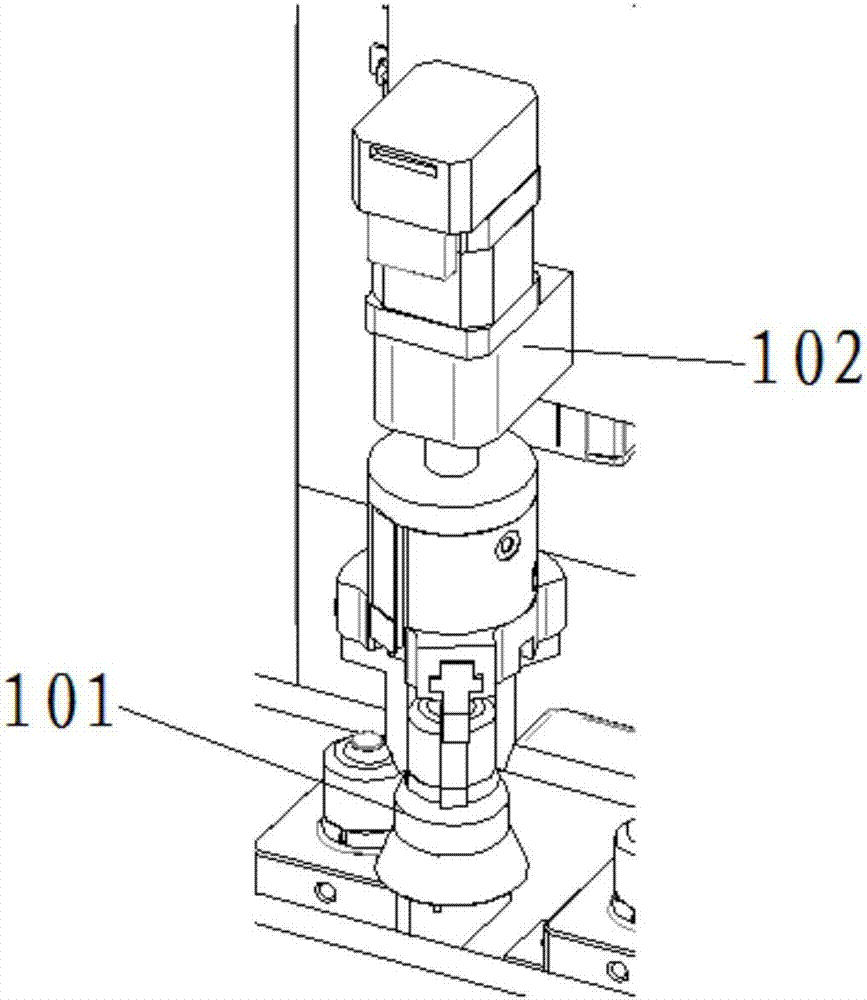

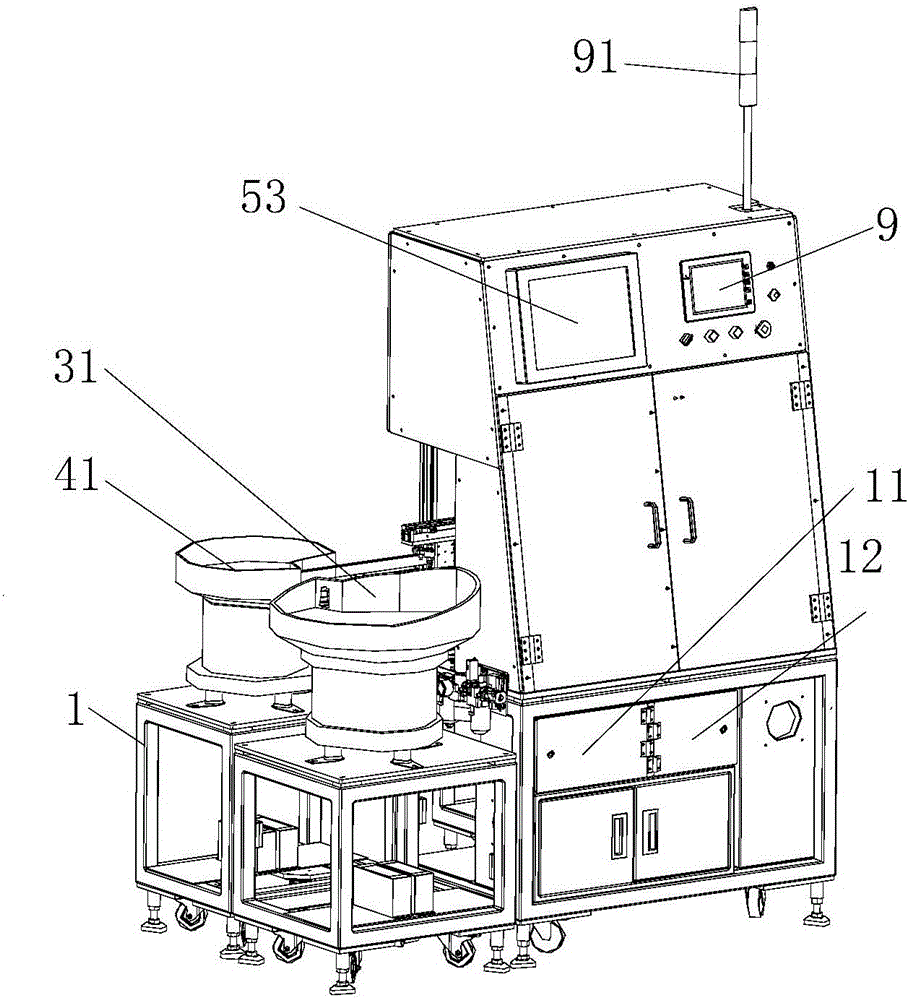

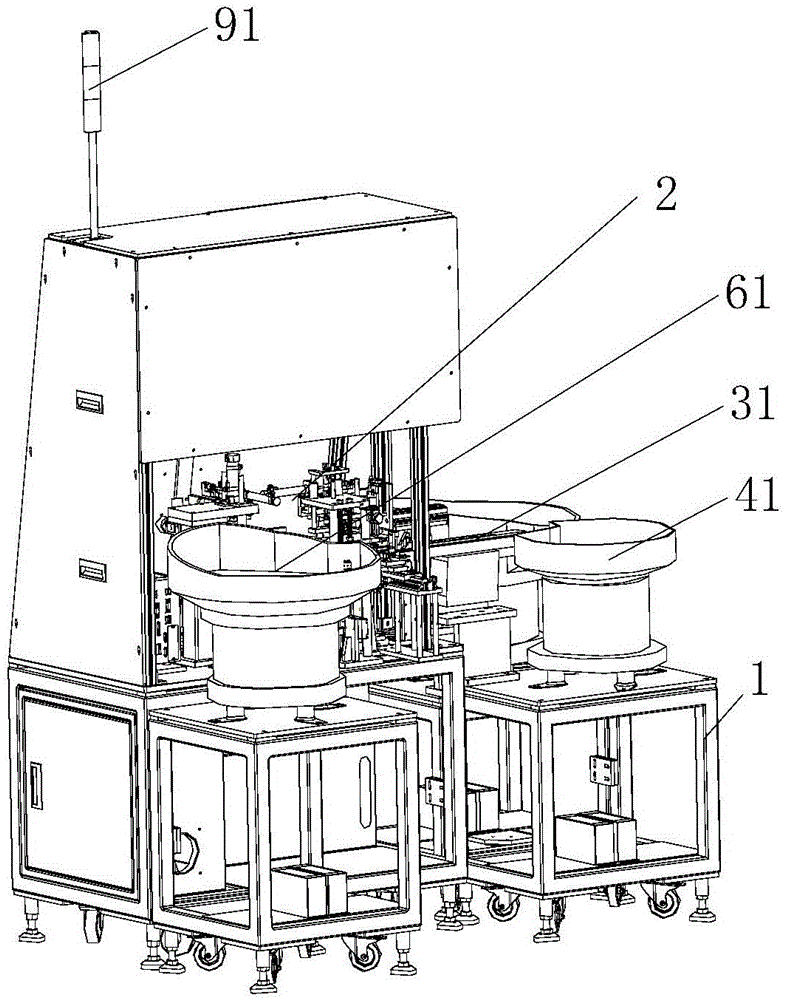

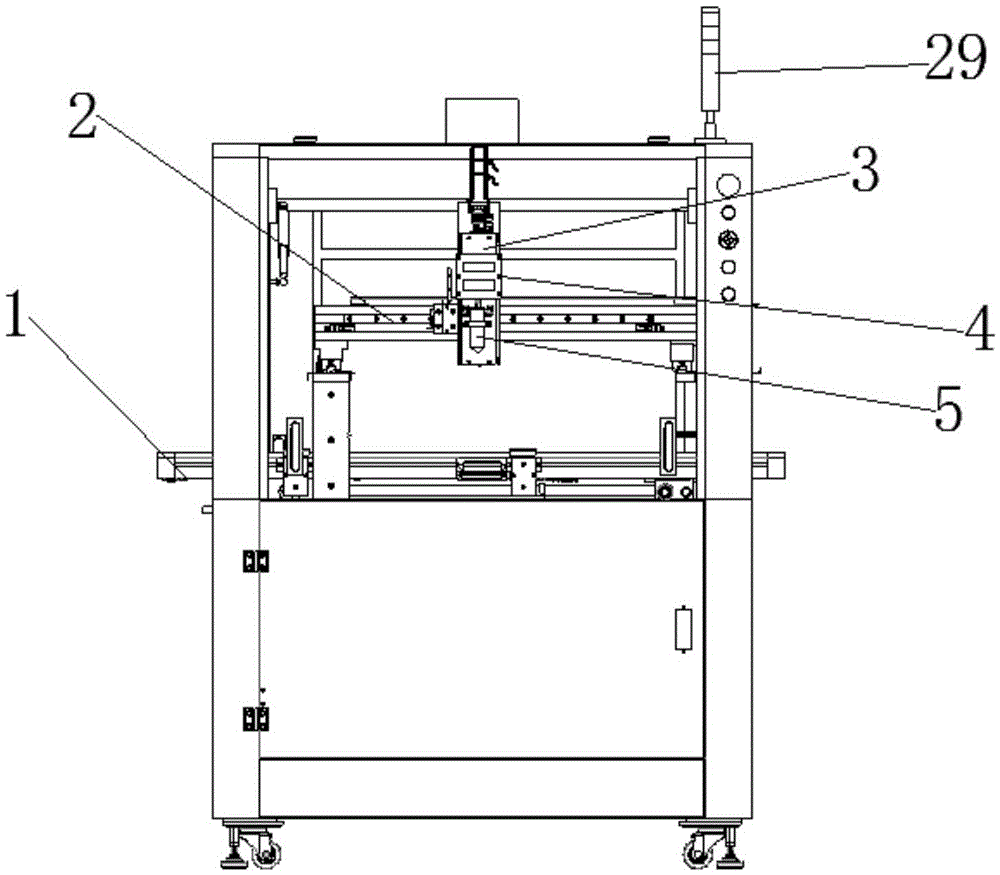

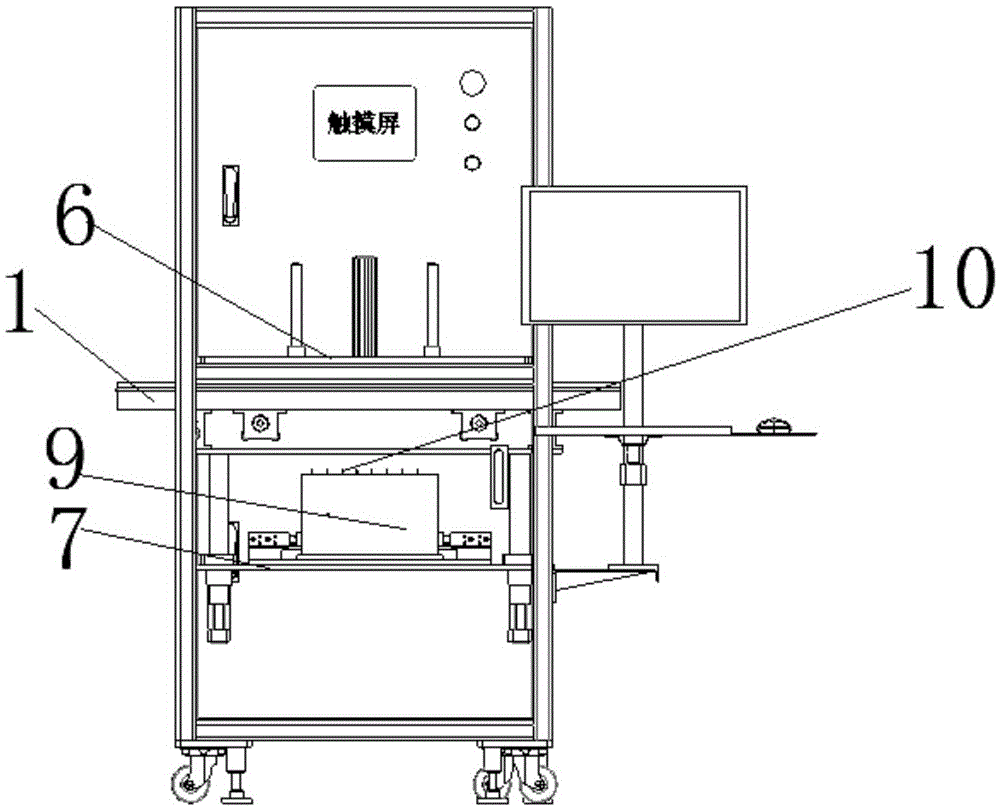

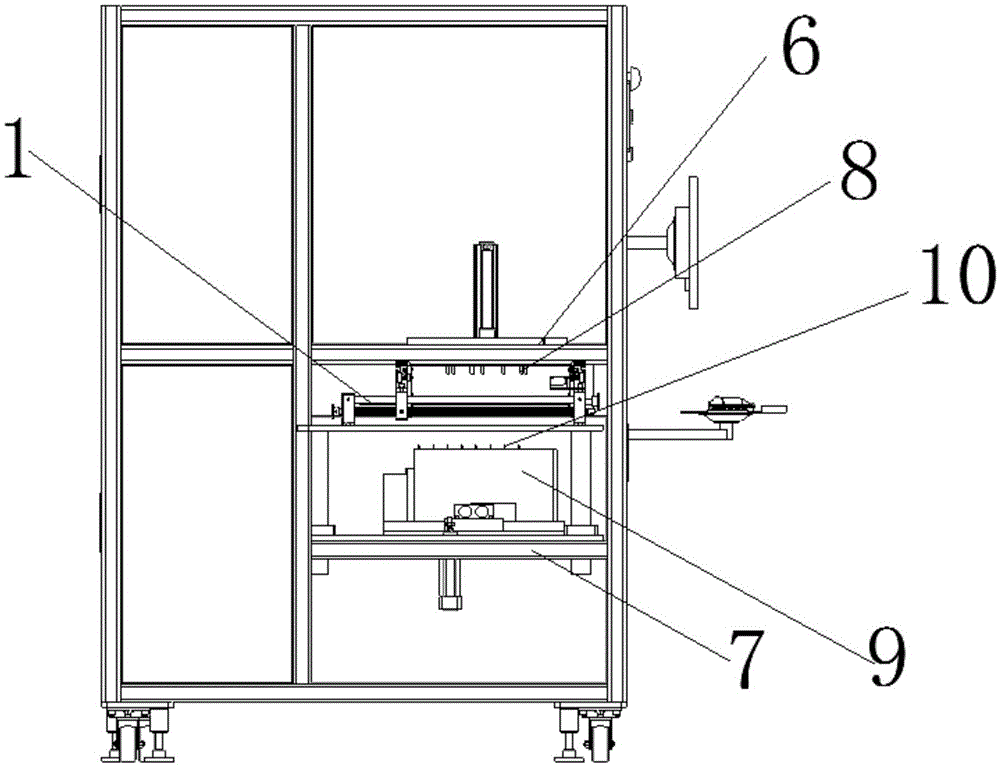

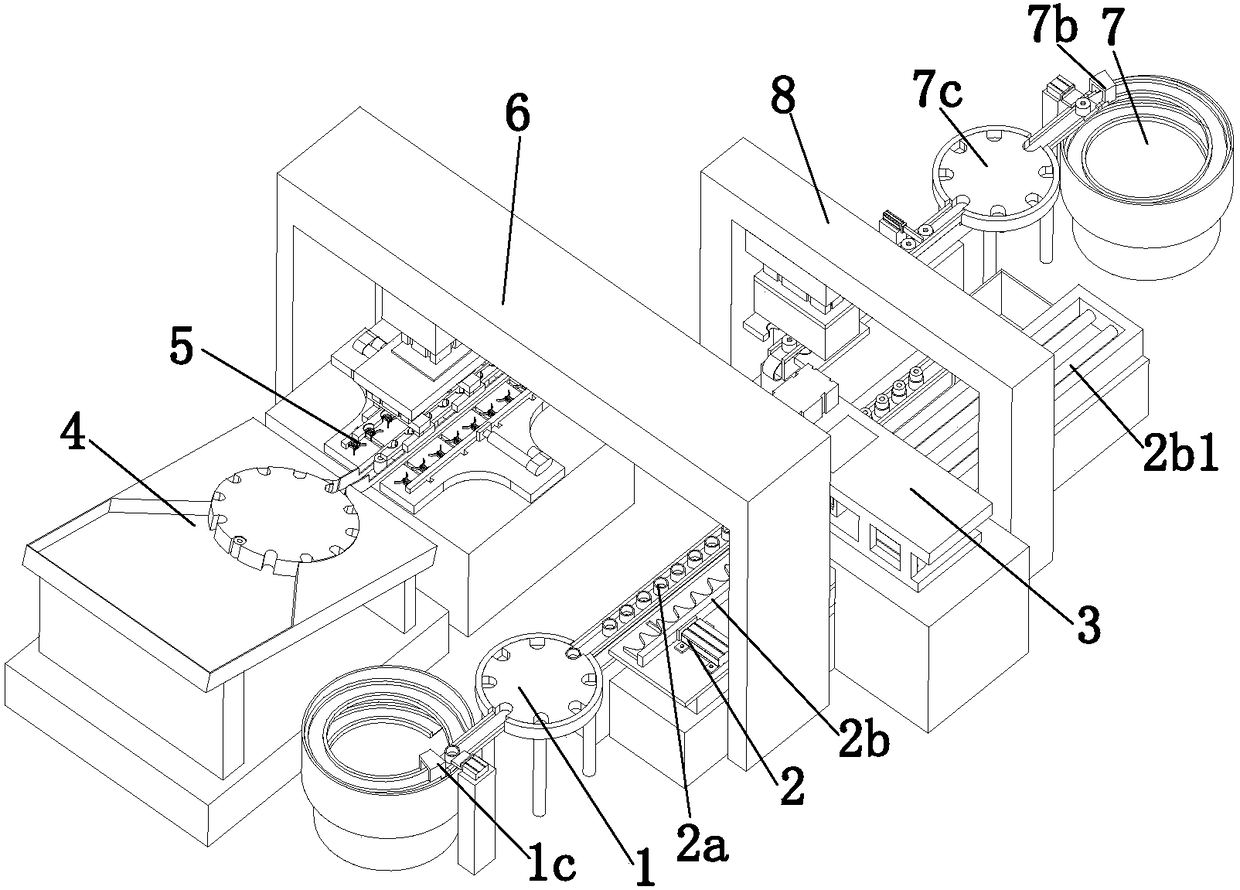

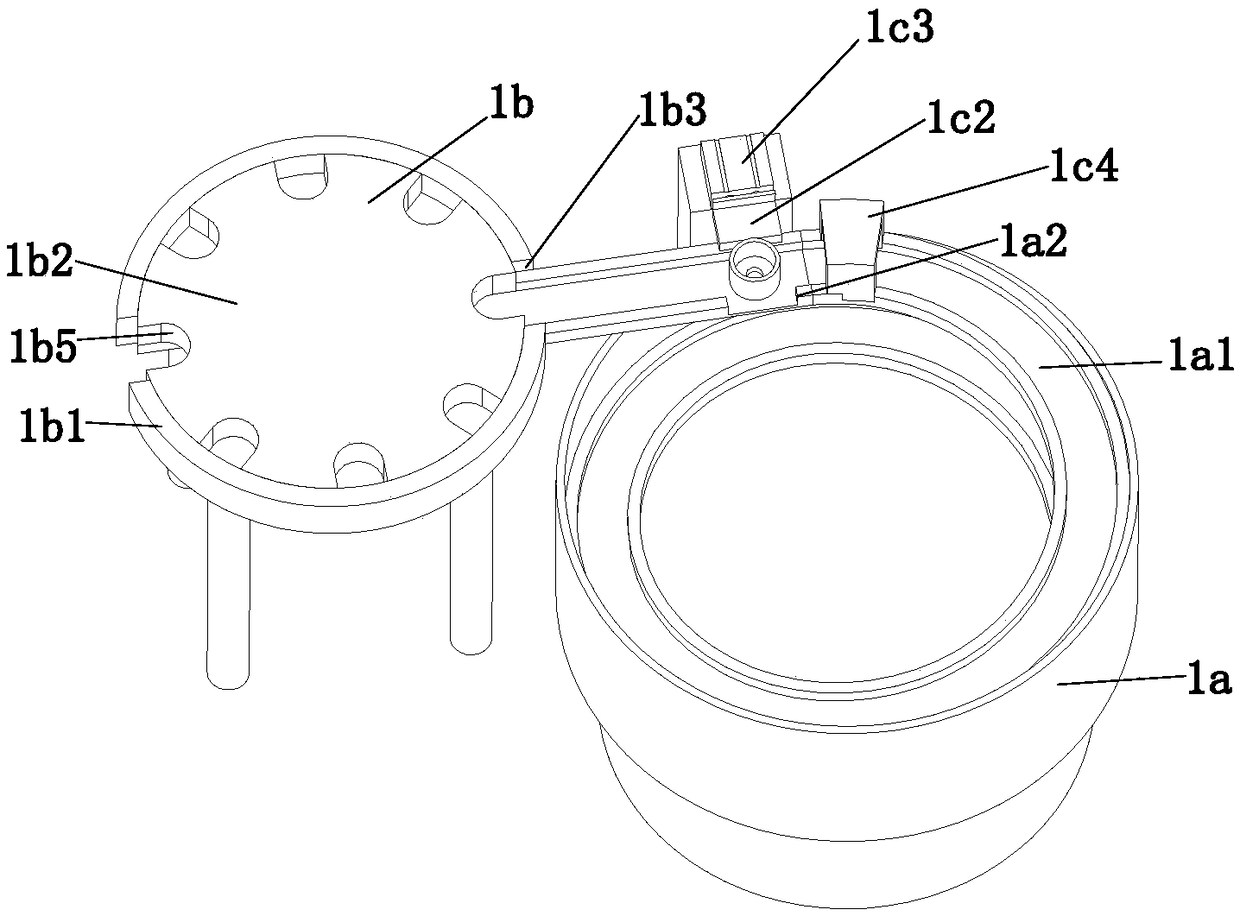

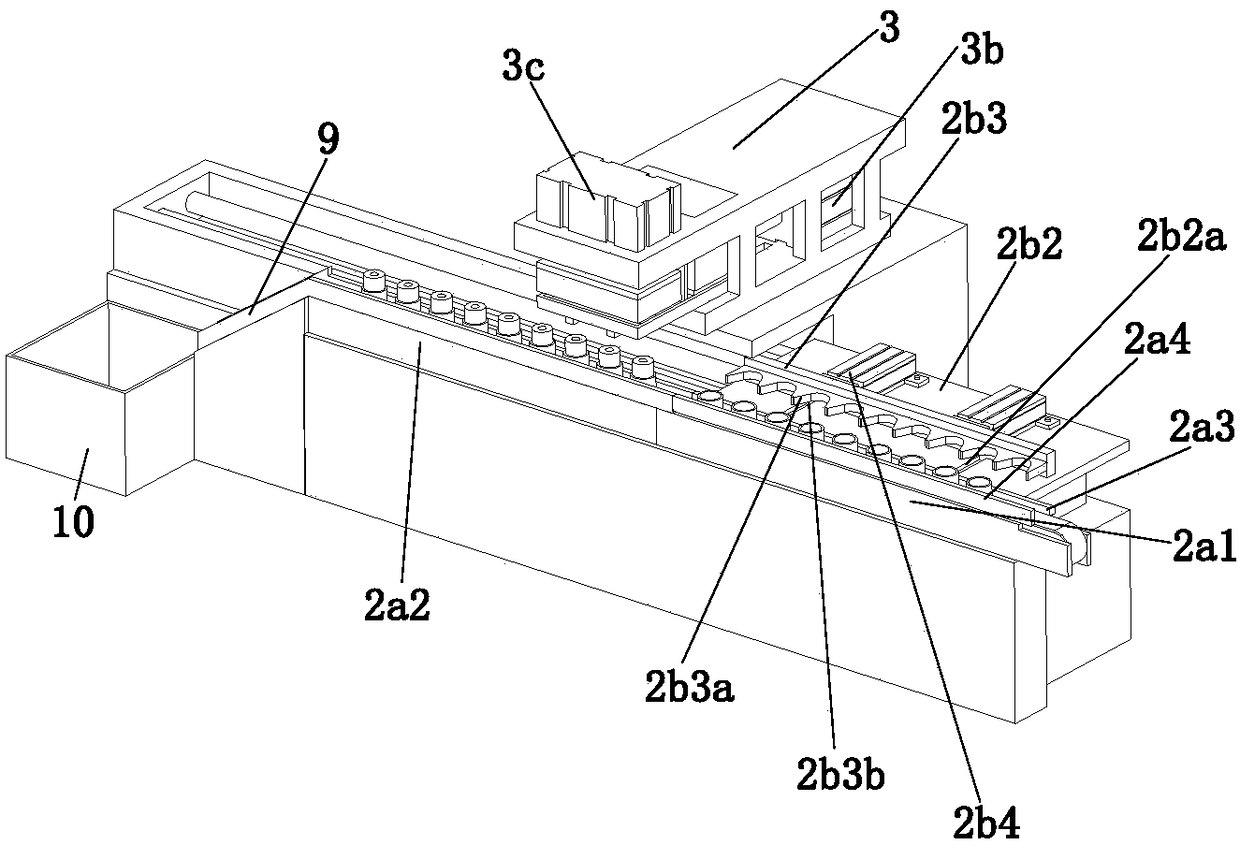

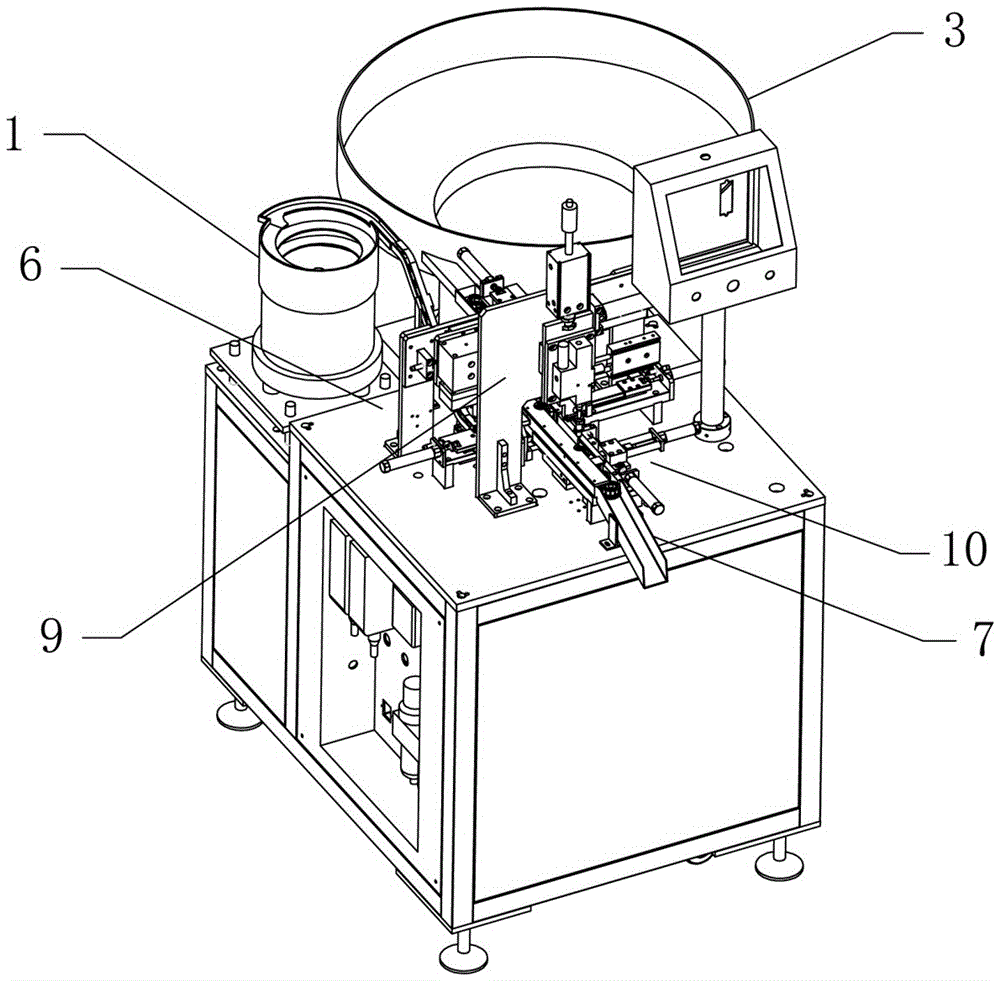

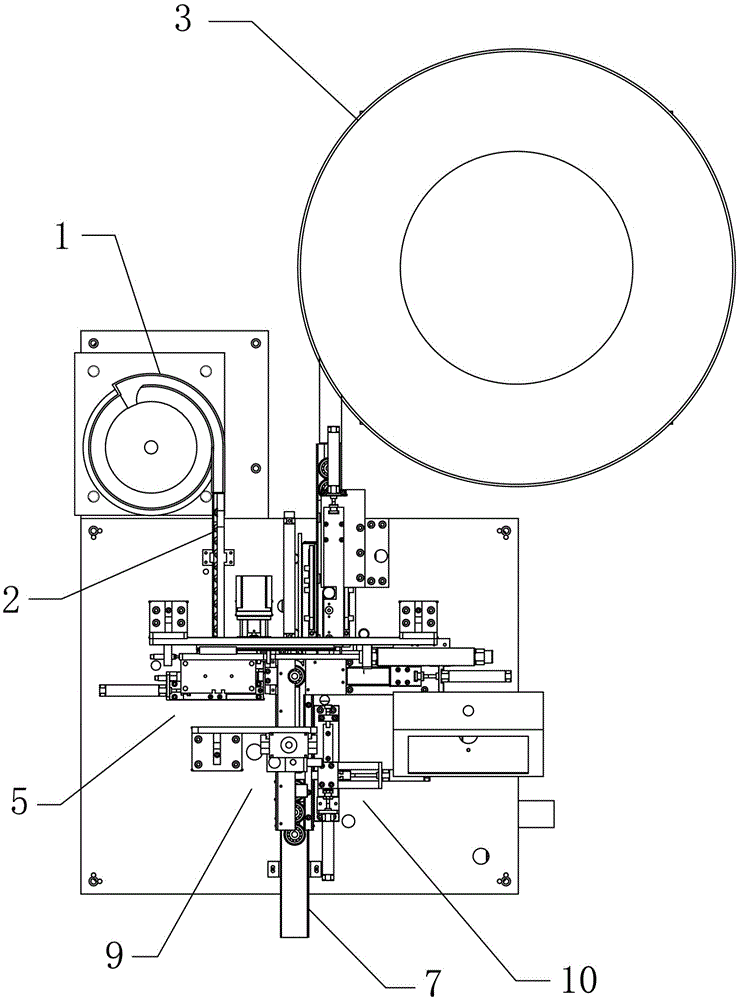

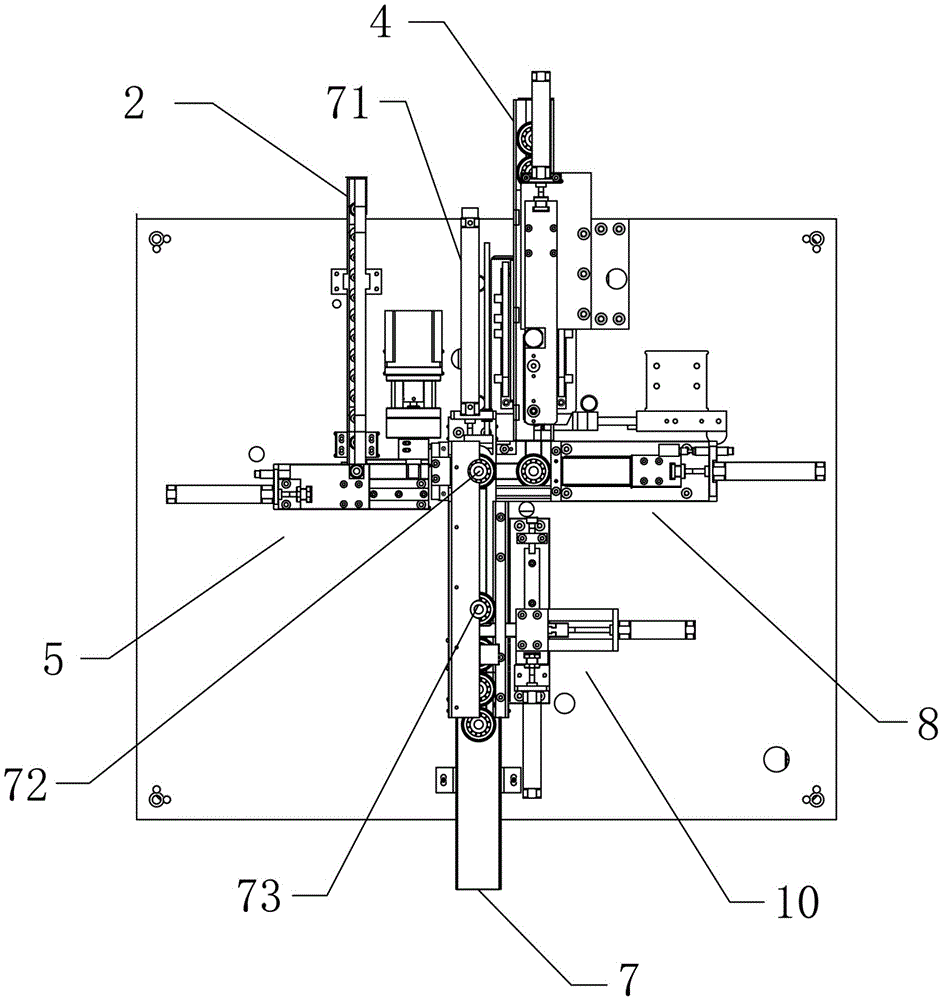

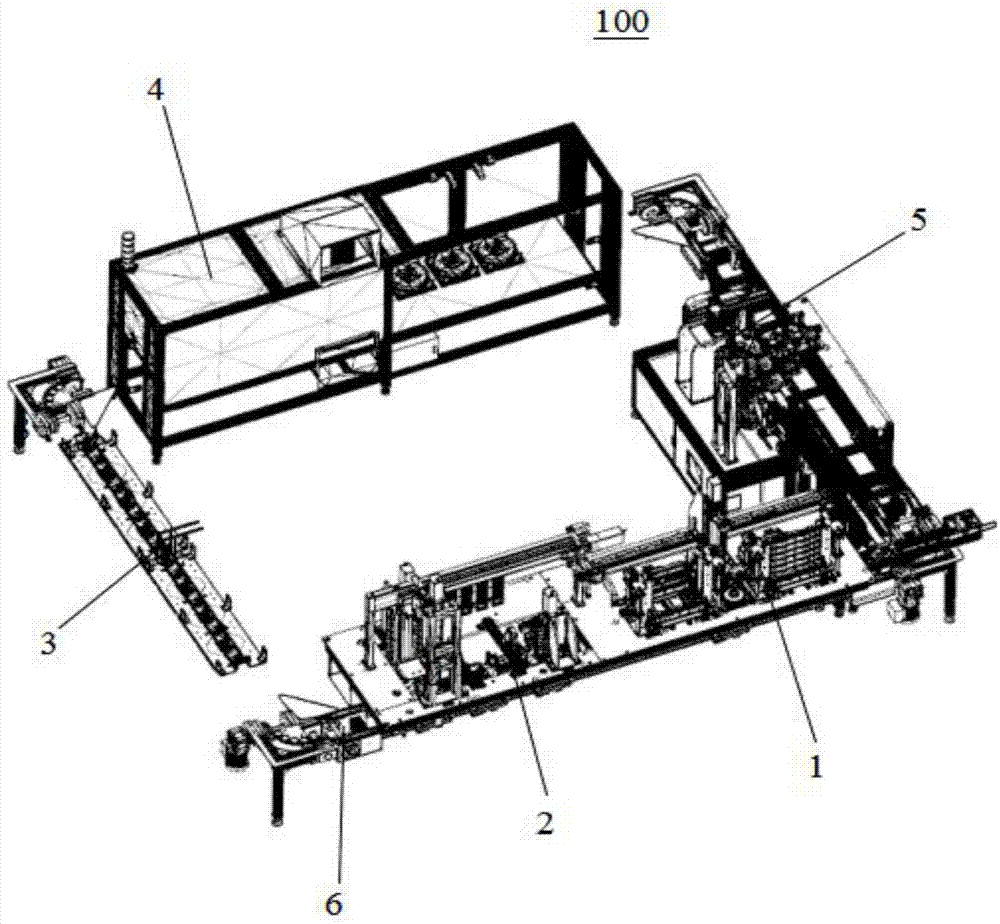

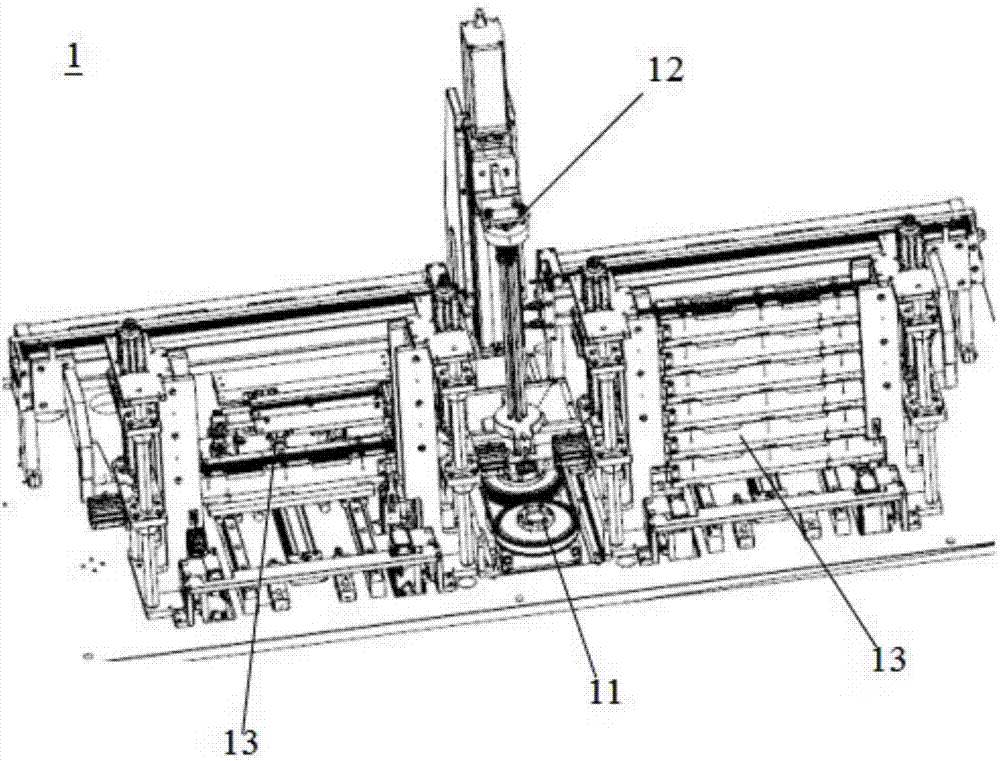

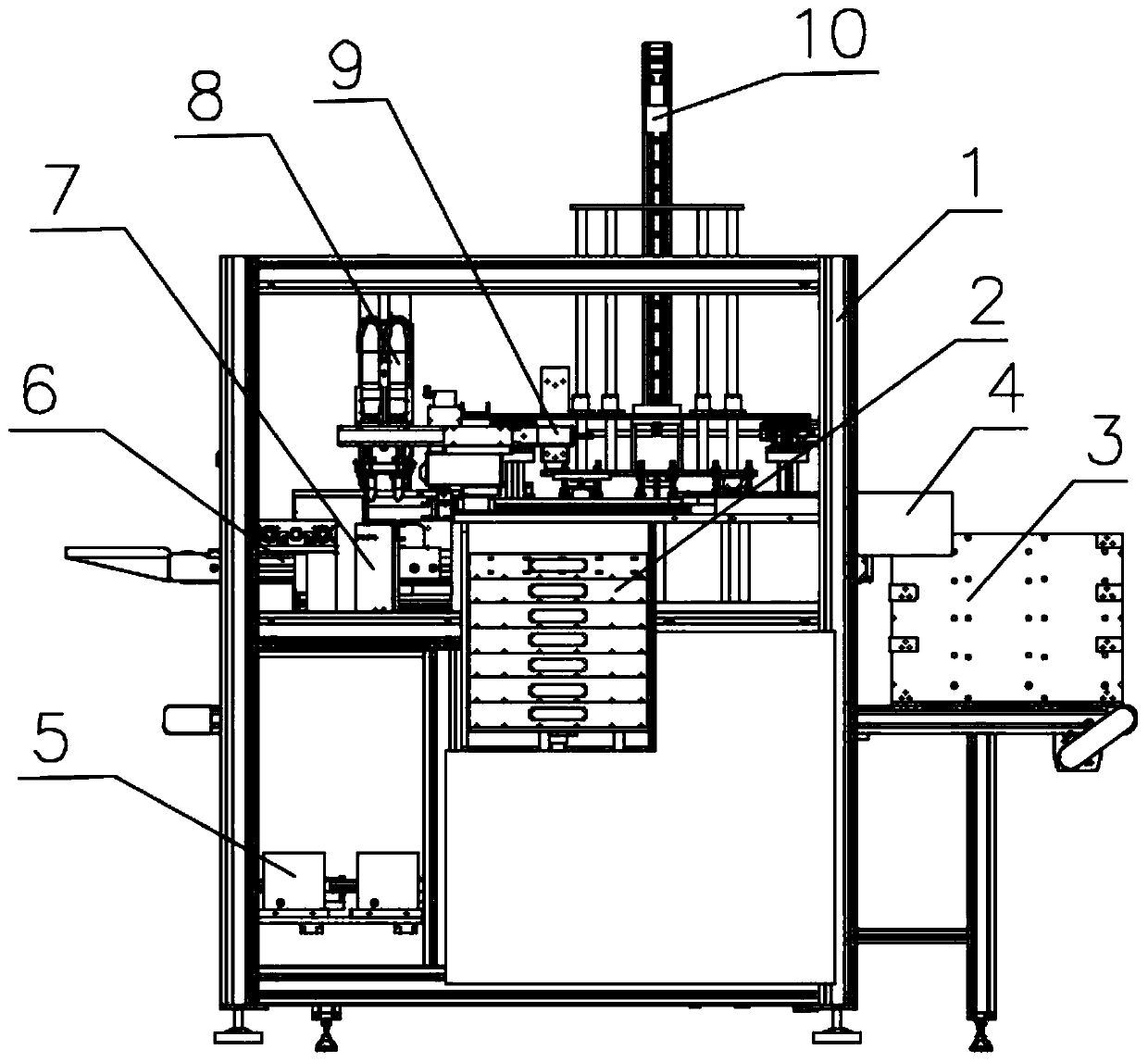

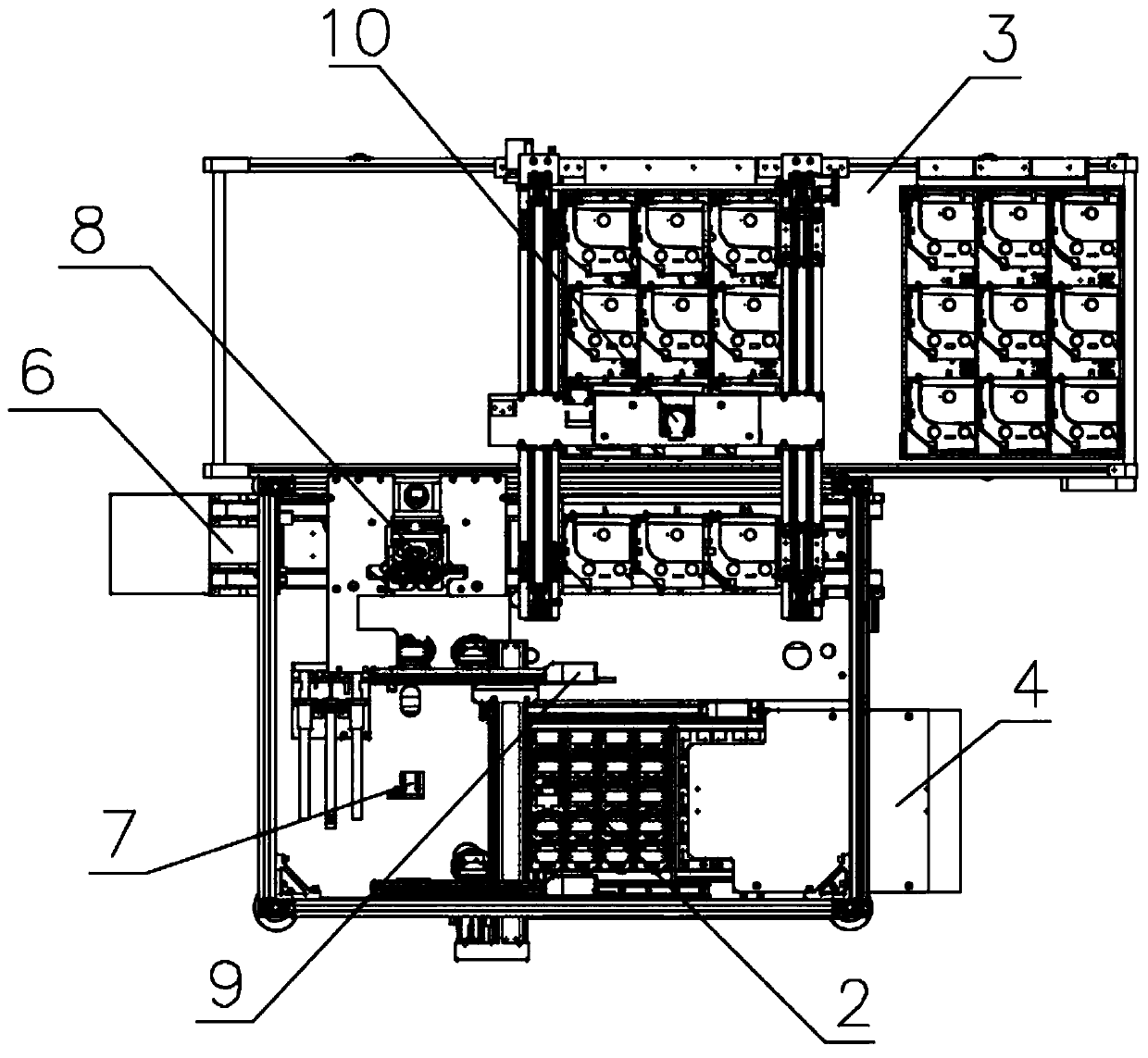

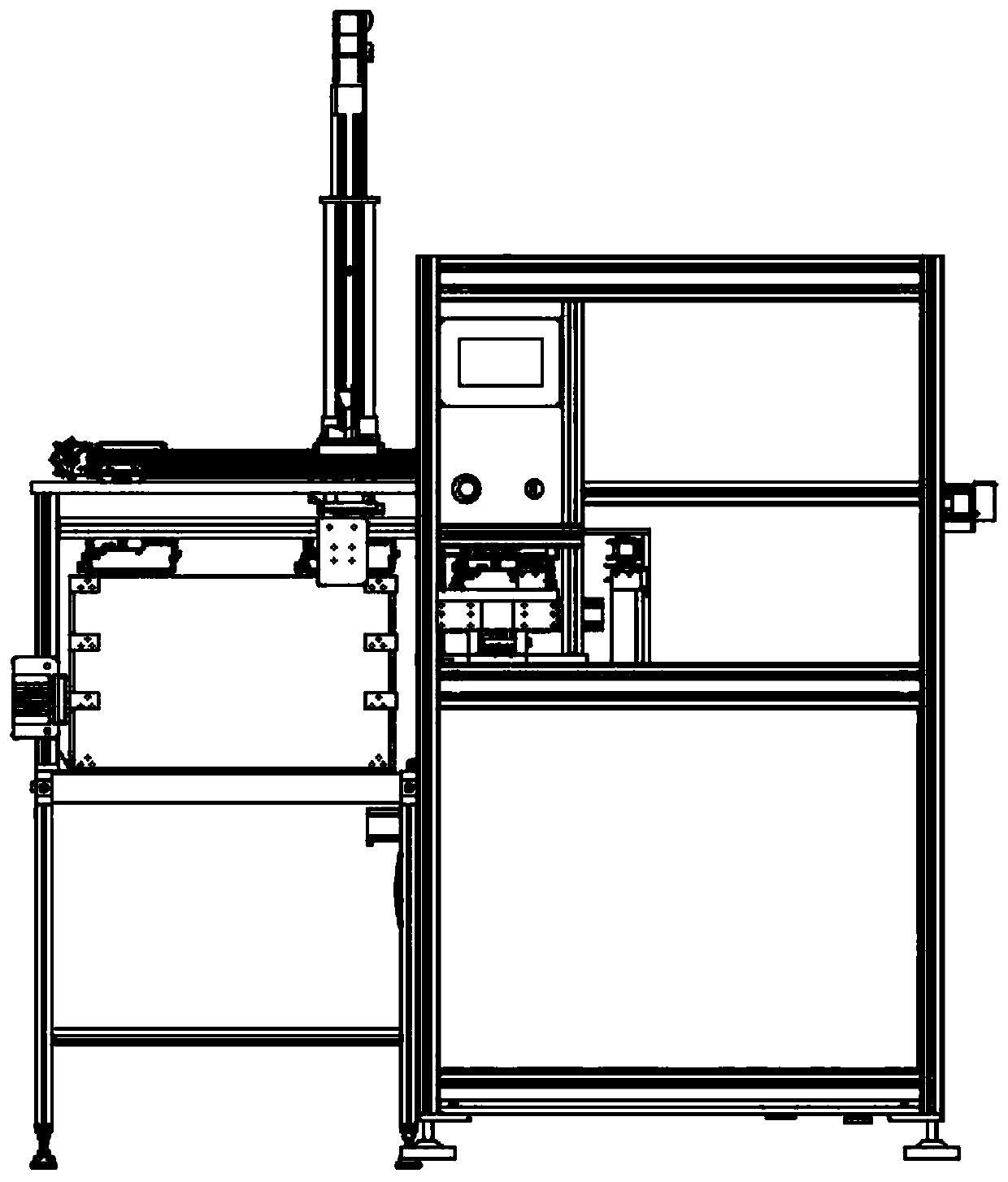

Full-automatic integrated device for bearing pressing and liner installation

InactiveCN102744601ARealize automatic assemblyImprove securityAssembly machinesProduction chainEngineering

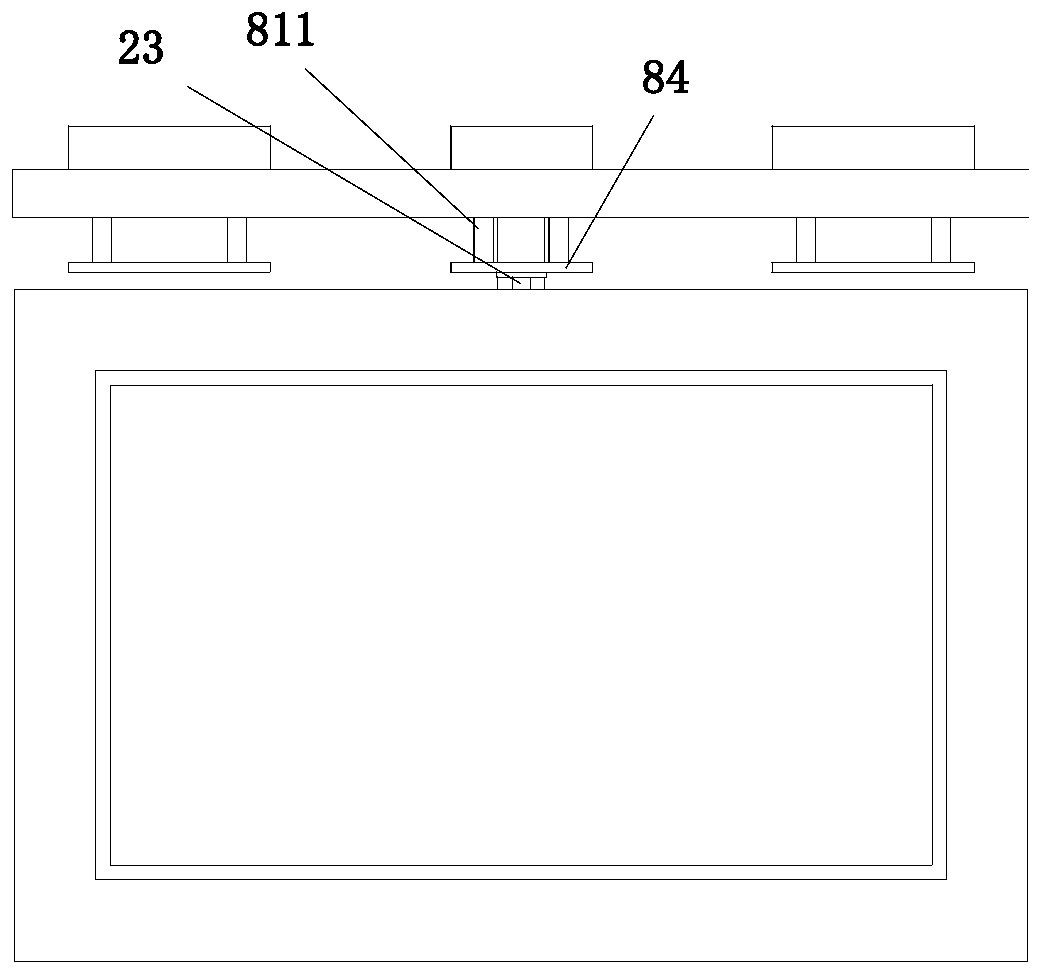

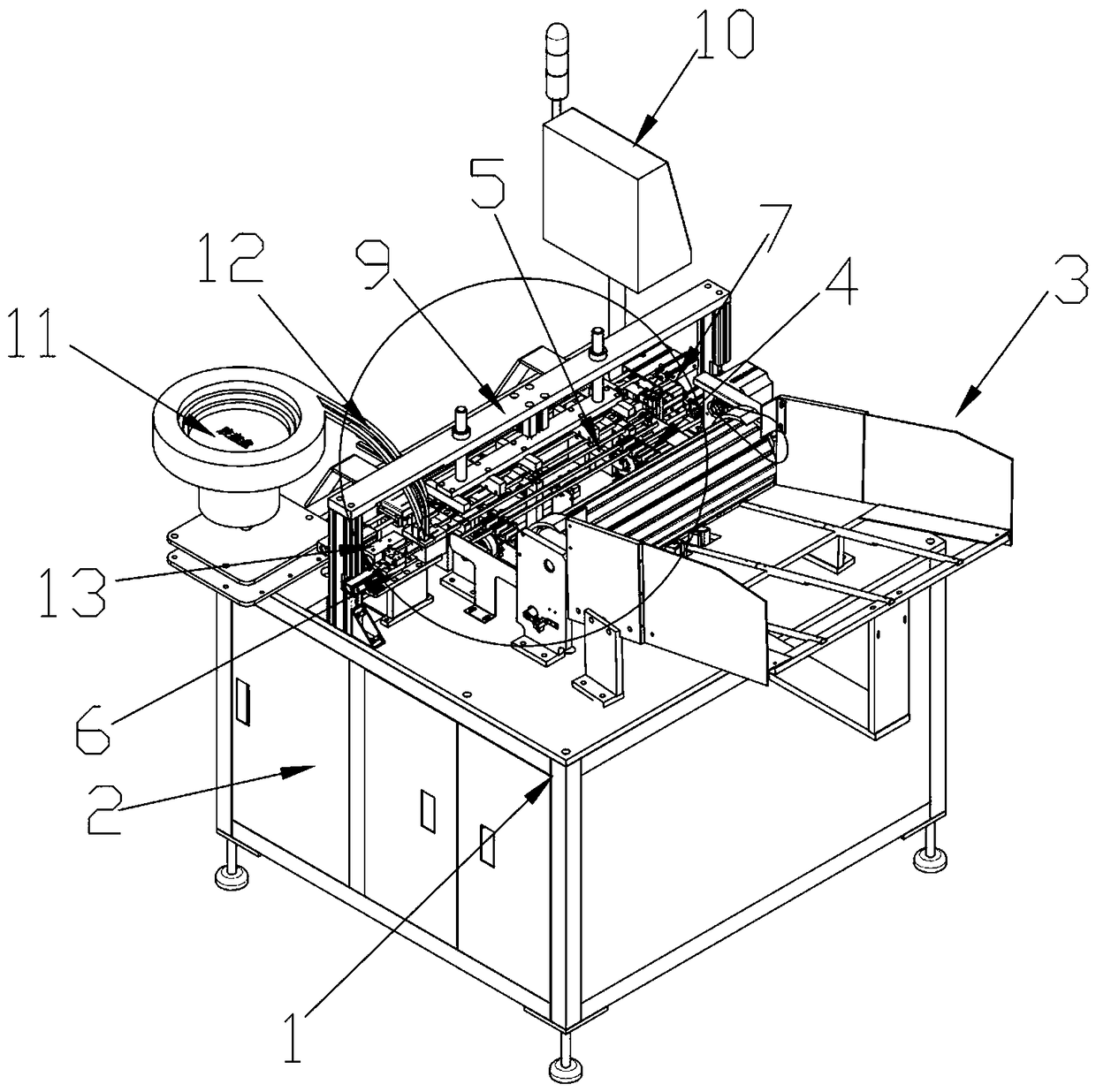

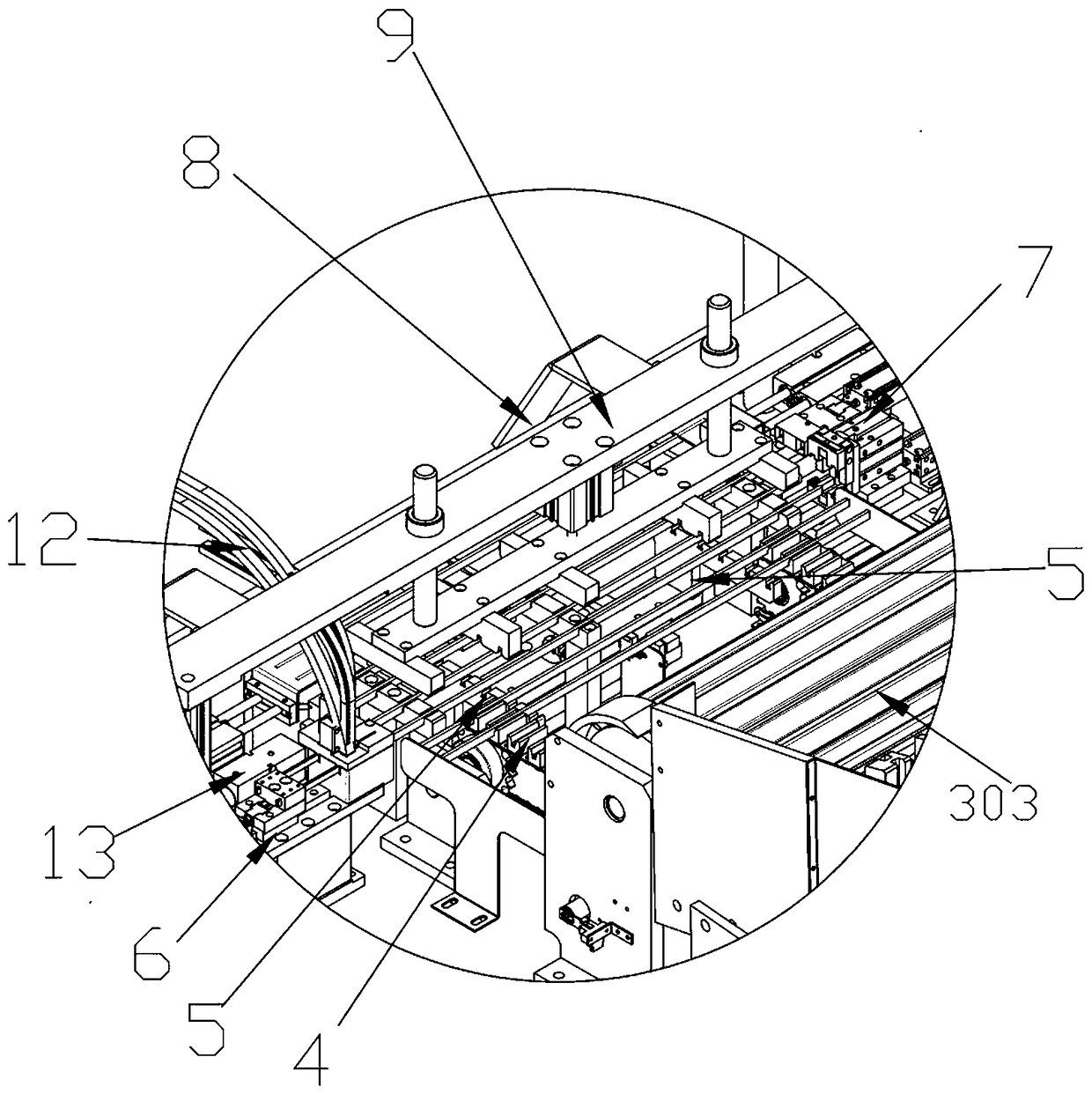

The invention discloses a full-automatic integrated device for bearing pressing and liner installation, comprising an automatic feeding production chain for conveying products, a material takeout mechanism, a positioning mechanism, a lifting transportation mechanism, a liner installation mechanism, a bearing pressing mechanism, a discharging mechanism, an NG material platform, and a finished product production chain; the automatic feeding production chain is arranged below the material takeout mechanism; the positioning mechanism is used for positioning the products on the automatic feeding production chain; the lifting transportation mechanism conveys the products on the automatic feeding production chain to the liner installation mechanism and the bearing pressing mechanism; the discharging mechanism and the NG material platform are arranged at the back end of the bearing pressing mechanism; the finished product production chain is arranged at the back end of the discharging mechanism; the bearing pressing mechanism is provided with a bearing feeding tray; and the liner installation mechanism is provided with a liner vibrating tray. With the mode, the full-automatic integrated device for bearing pressing and liner installation saves manpower, is simple to operate, has high assembly accuracy and strong common property, and is safe and reliable.

Owner:吴江市昊睿精密机械设备有限公司

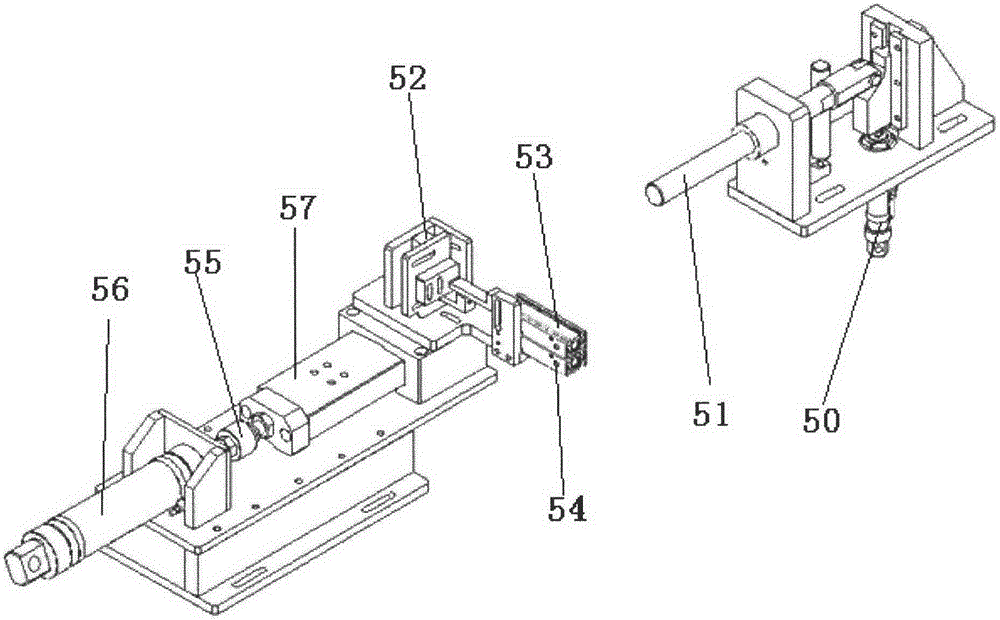

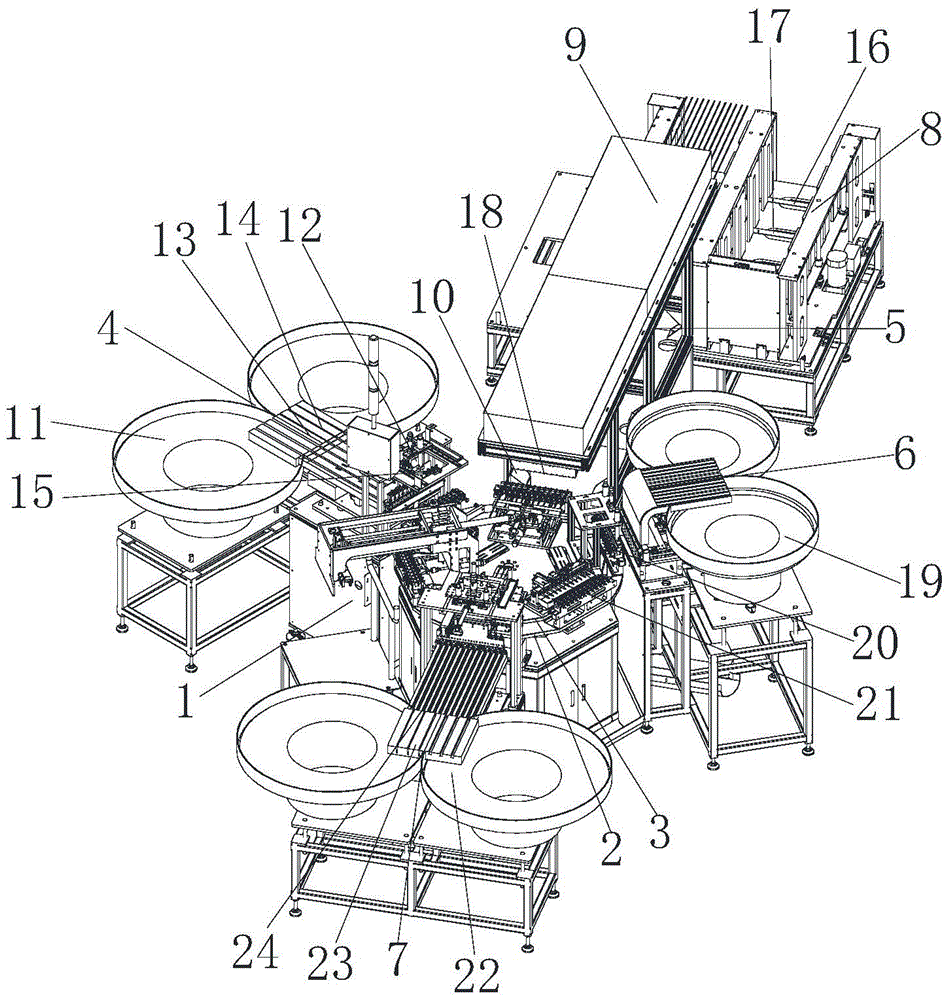

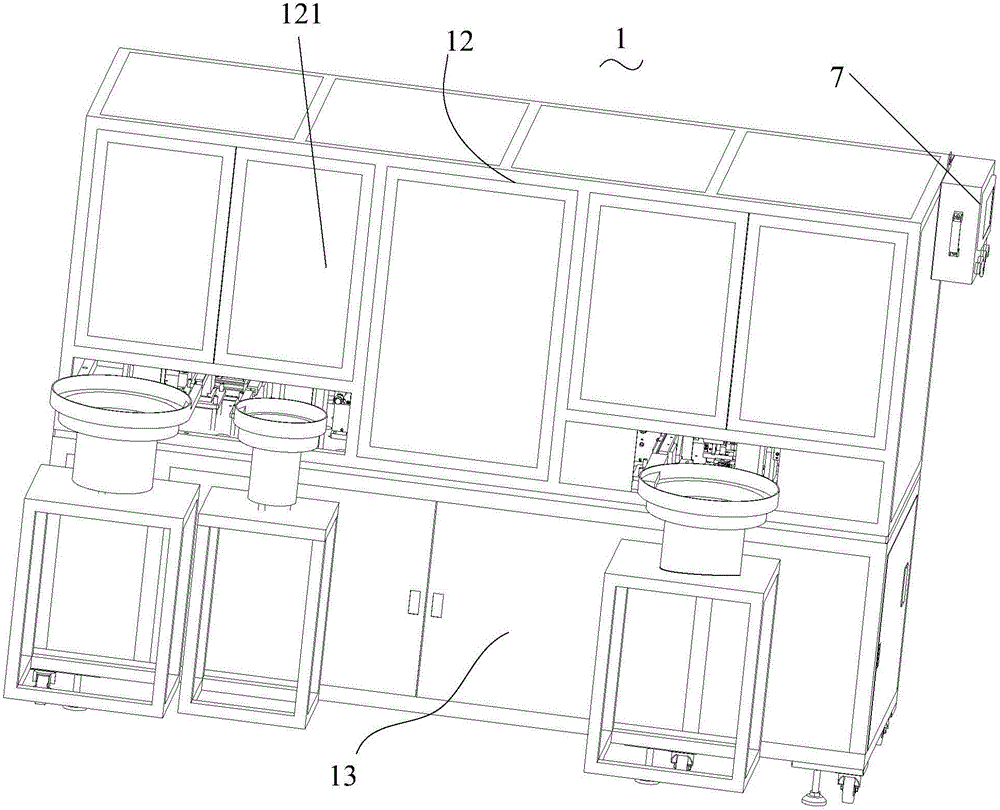

Fully automatic assembling machine for spring fasteners

InactiveCN108390236AQuick and automatic assemblyHigh efficiency of one-time assemblyContact member assembly/disassemblyAssembly machinesDistribution controlMaterial distribution

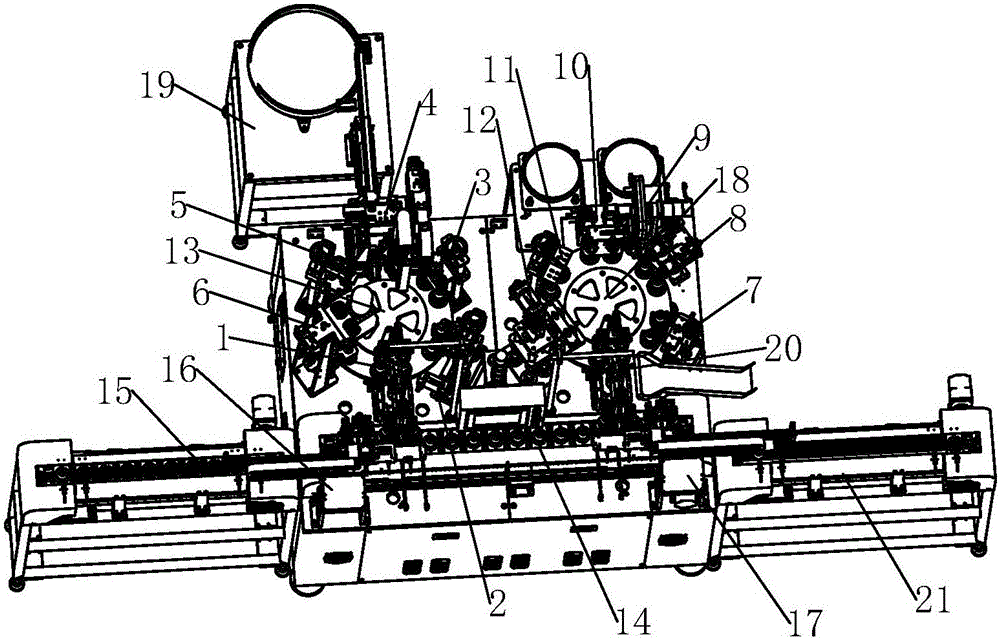

The invention relates to a fully automatic assembling machine for spring fasteners. The fully automatic assembling machine comprises a rack and a power distribution control box. The rack is provided with a circulation conveying device, a rubber shell feeding device, a fastener feeding device and a spring feeding device, wherein the rubber shell feeding device, the fastener feeding device and the spring feeding device are sequentially arranged on the periphery of the circulation conveying device. The rubber shell feeding device comprises a rubber shell feeding vibration disc disposed on the left front side of the circulation conveying device, and the rubber shell feeding vibration disc is communicated with a rubber shell material distribution block through a rubber shell conveying track; arubber shell conveying manipulator matched with the rubber shell material distribution block is disposed above the circulation conveying device, a rubber shell clamping device is arranged on the portion, below the rubber shell conveying manipulator, of the right front side of the circulation conveying device, and a fastener pushing-in device matched with the circulation conveying device is arranged under the rubber shell clamping device. The circulation conveying device is adopted for feeding and conveying materials, and the fasteners are pushed into insertion holes in a rubber shell from bottom to up through the fastener pushing-in device. The one-time assembling efficiency is high, the operation is convenient, fast and automatic assembly of the spring fasteners is achieved, and the production efficiency is improved.

Owner:DONGGUAN UNIV OF TECH

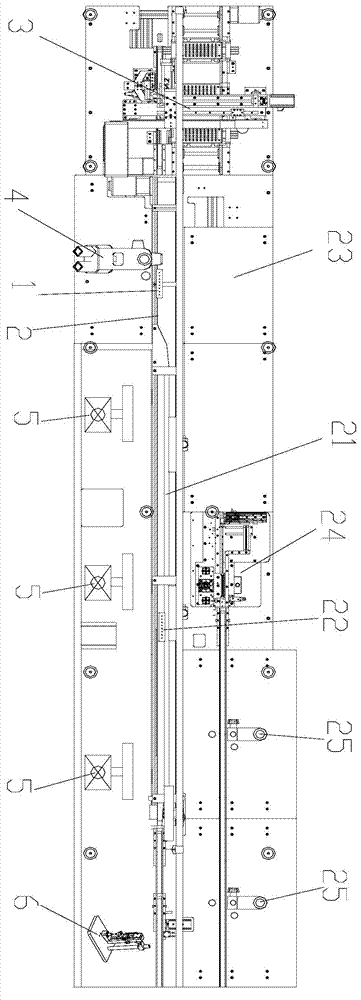

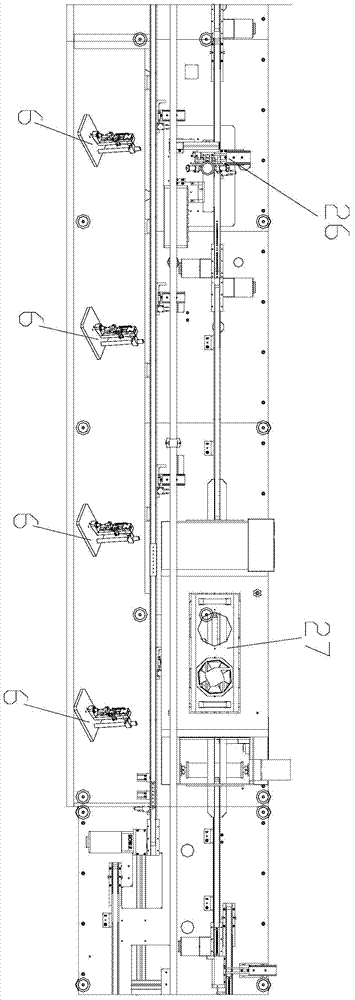

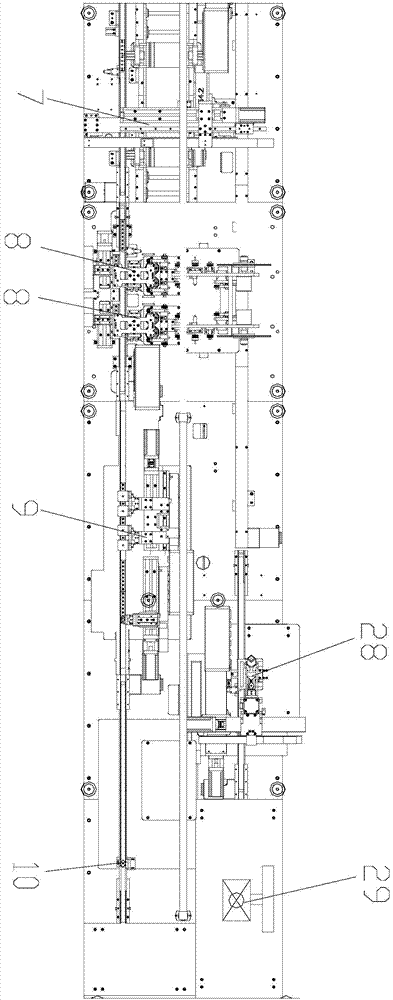

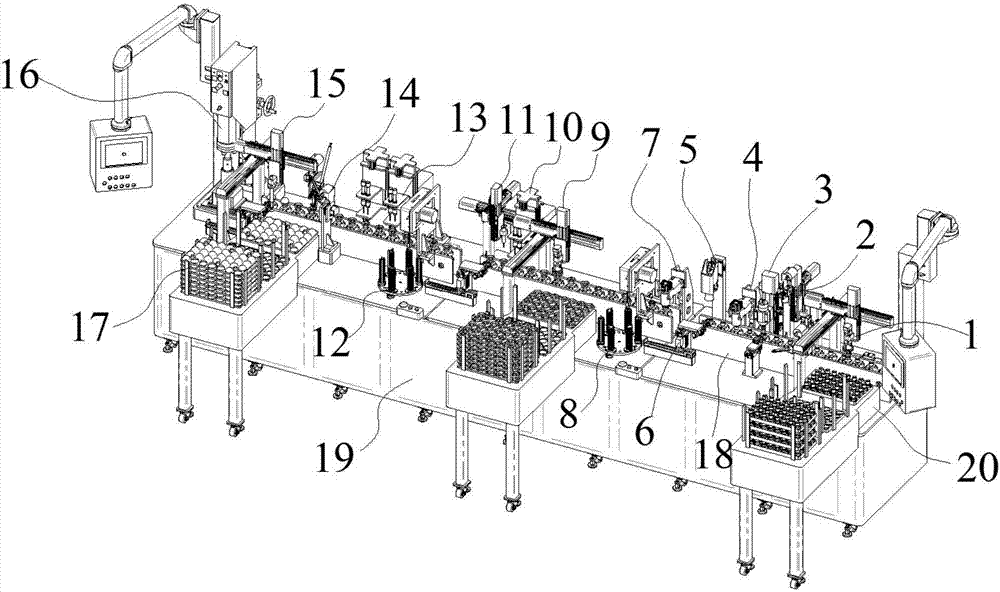

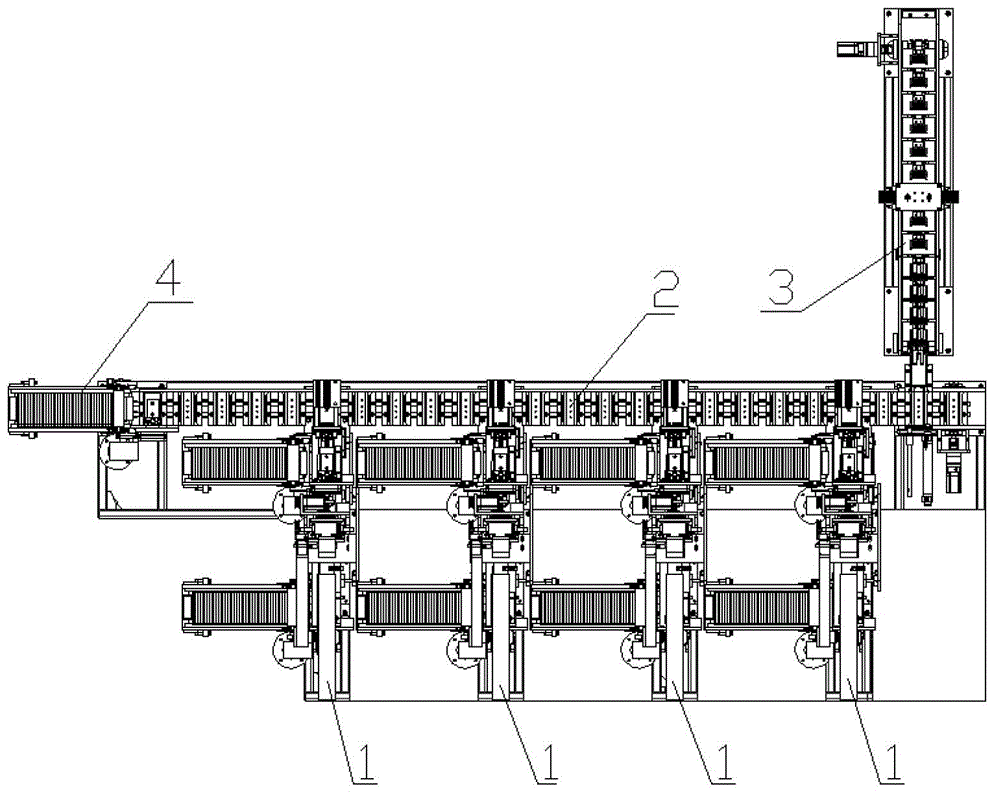

New energy power module assembling line

ActiveCN107819134ARealize the assemblyRealize automatic assemblyPrimary cell manufactureAssembling battery machinesNew energyBattery cell

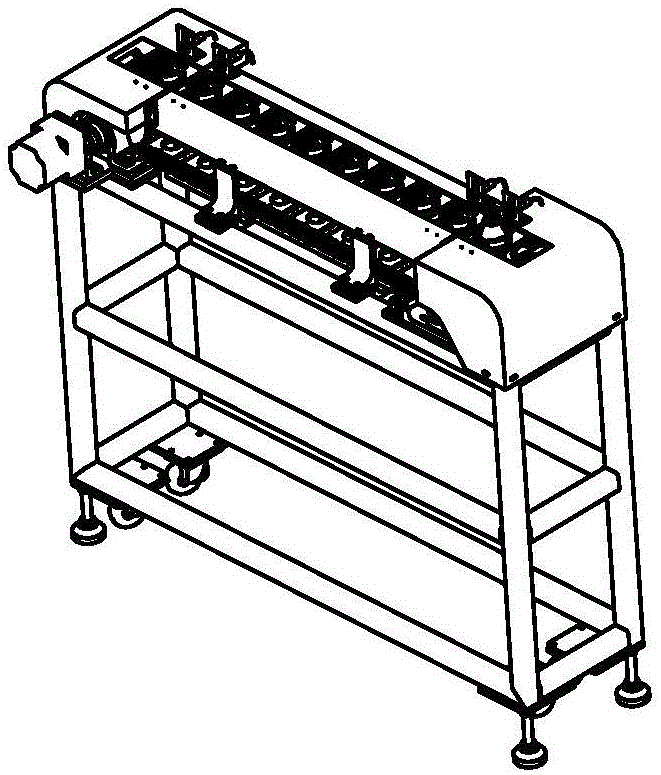

The invention discloses a new energy power module assembling line relating to the technical field of tools for battery modules. A battery cell detection station is arranged on one side of a battery cell loading assembly, a automatic battery cell frame mounting station is arranged on one side of the battery cell detection station, a battery cell splicing station is arranged on one side of the automatic battery cell frame mounting station, a side loading line of the battery cell splicing station is arranged on one side of the battery cell splicing station, a battery cell module transplanter is arranged on one side of the side loading line of the battery cell splicing station, and a riveting machine is mounted on the battery cell module transplanter. The new energy power module assembling line can achieve assembly of a new energy battery module and can achieve automatic assembling, so that the labor and the time are saved and the efficiency is high.

Owner:丁琛琦

Bolt and nut automated assembly machine

The invention relates to a bolt and nut automated assembly machine which comprises a bolt steering slide channel, a bolt conveying device, a bolt clamping device, an adjusting device, a nut loading device, a nut propulsion device, a nut screwing working head device, a rack and an electrical control system, wherein directed bolts are sent to the bolt conveying device through the bolt steering slide channel and are sent one by one to the bolt clamping device through the bolt conveying device, the bolts are positioned and clamped in the bolt clamping device, and the nuts are directed through the nut loading device, then sent to the nut propulsion device through the slide channel, sent out through the nut propulsion device, and pushed into the nut screwing working head device. The nut screwing working head device enables the nuts to rotate and pushes the nuts to the positioned clamped bolts. The nuts and the bolts are screwed together, and then automated assembly is completed. The bolt and nut automated assembly machine has the advantages of being high in reliability, low in cost, simple in structure, and capable of achieving bolt and nut automated assembly and overcoming the problems that production efficiency is poor, the labor intensity of workers is high, assembly is not in place, the surfaces of the bolts and nuts are collided and the like in manual assembly.

Owner:STATE GRID CORP OF CHINA +1

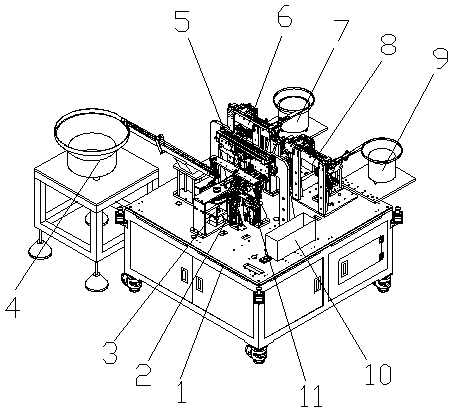

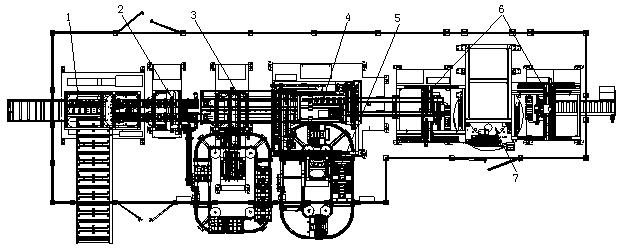

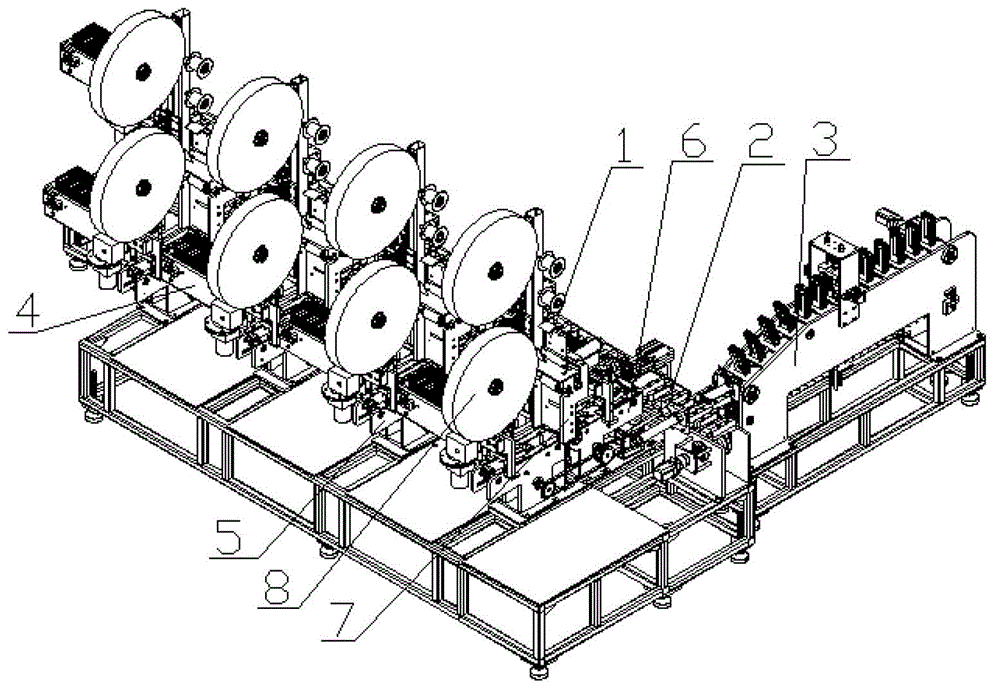

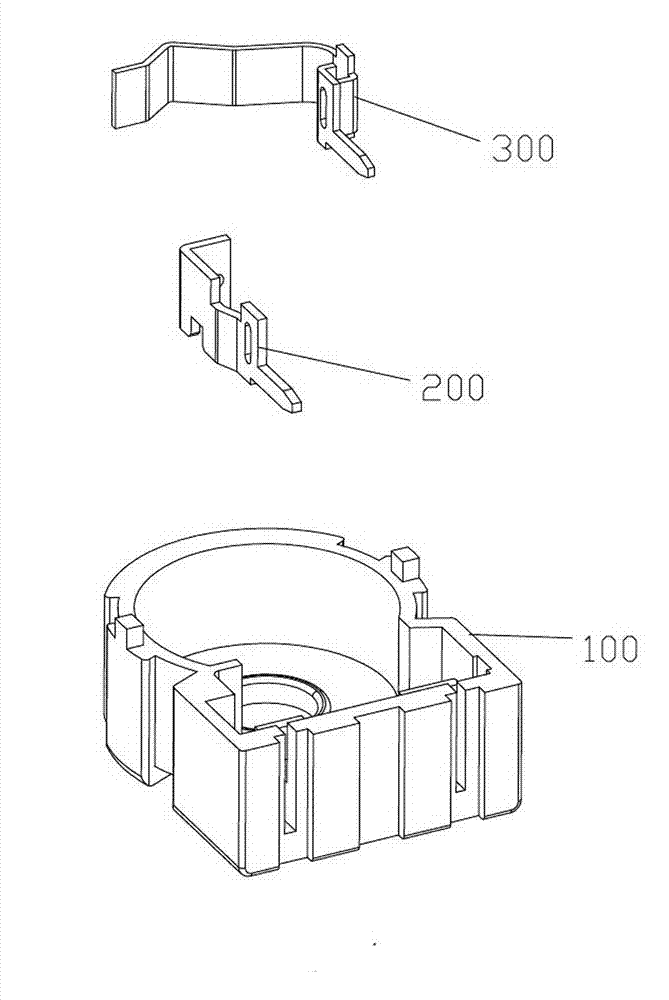

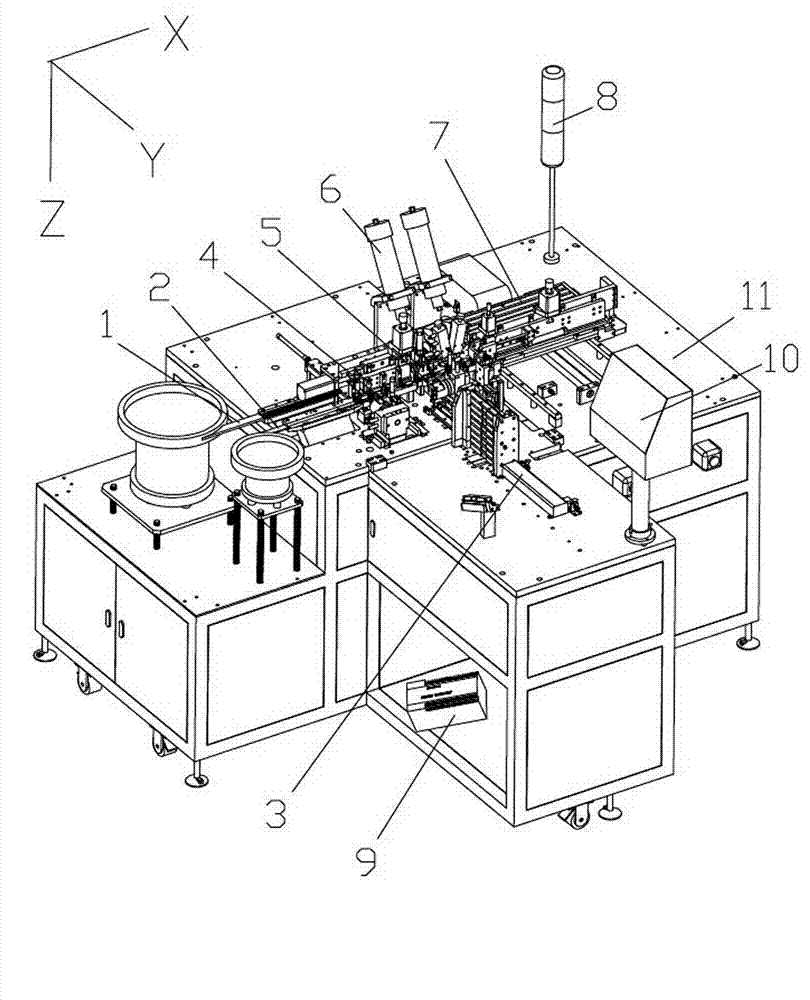

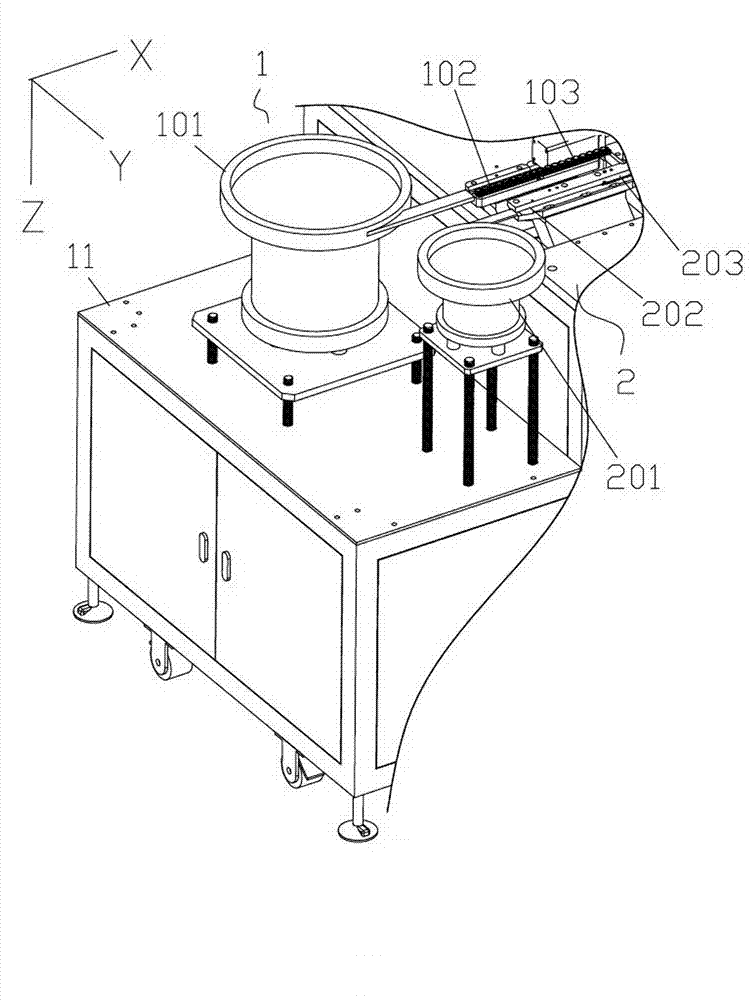

Mobile phone motor automatic assembly production line

ActiveCN103501085ARealize automatic assemblySave human effortManufacturing dynamo-electric machinesMobile phoneManufacturing line

The invention discloses a mobile phone motor automatic assembly production line which comprises a rotor assembly production line, an end cover assembly production line and a motor assembly production line which are arranged on one production line. The rotor assembly production line and the end cover assembly production line are arranged side by side; and the motor assembly production line is arranged at the tail ends of the rotor assembly production line and the end cover assembly production line. According to the mobile phone motor automatic assembly production line disclosed by the invention, the rotor assembly production line and the end cover assembly production line are arranged side by side, a stator housing assembly is combined at the position where assembly of a rotor assembly and an end cover assembly is completed, two production lines which are arranged side by side are converged into one motor assembly production line and all production processes are completed on the same production line, and thus, automatic assembly of the rotor assembly, the end cover assembly and a motor assembly can be implemented, labor can be saved, turnaround time is reduced and production efficiency is improved.

Owner:CHONGQING LINGLONG AUTOMATION EQUIP CO LTD

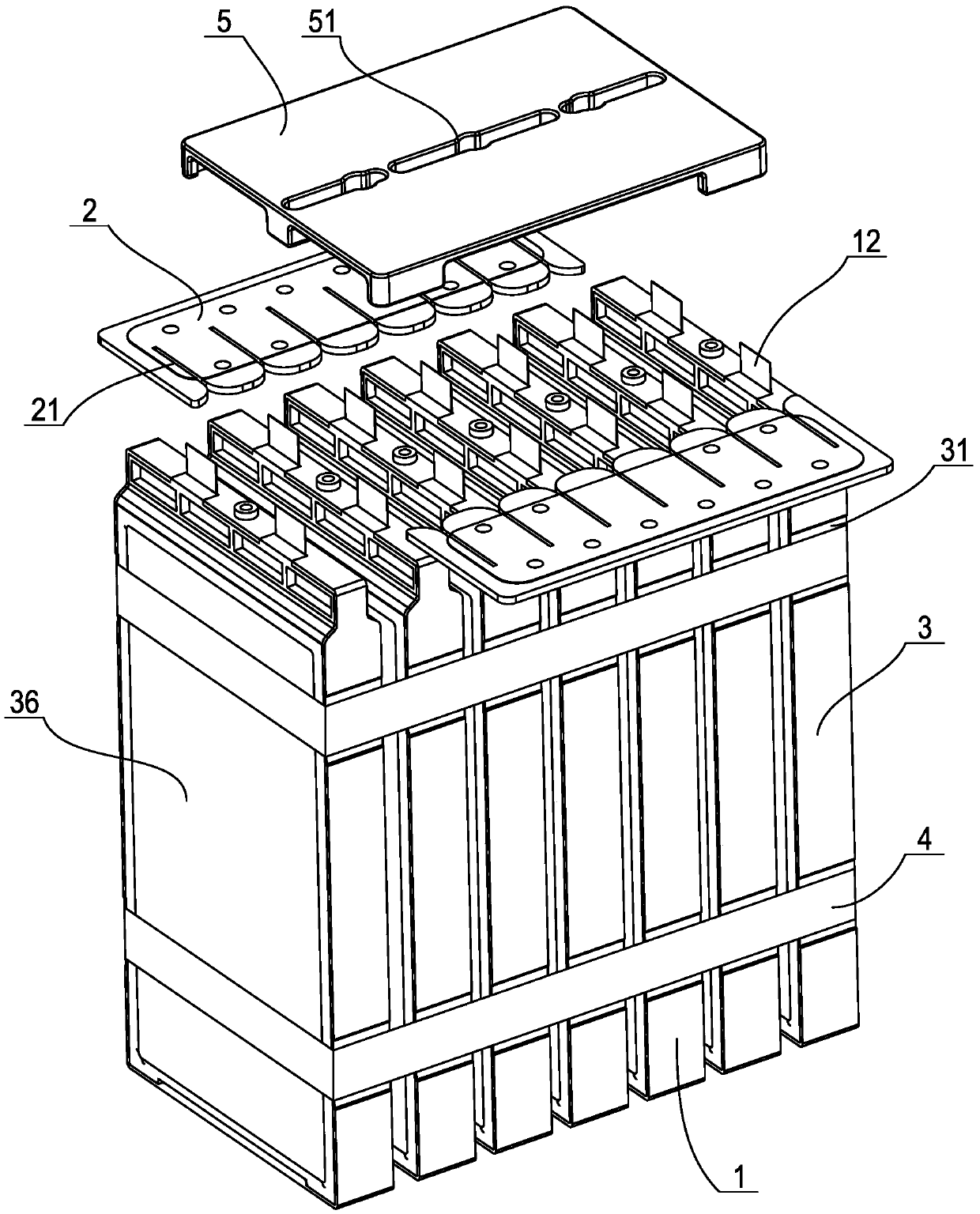

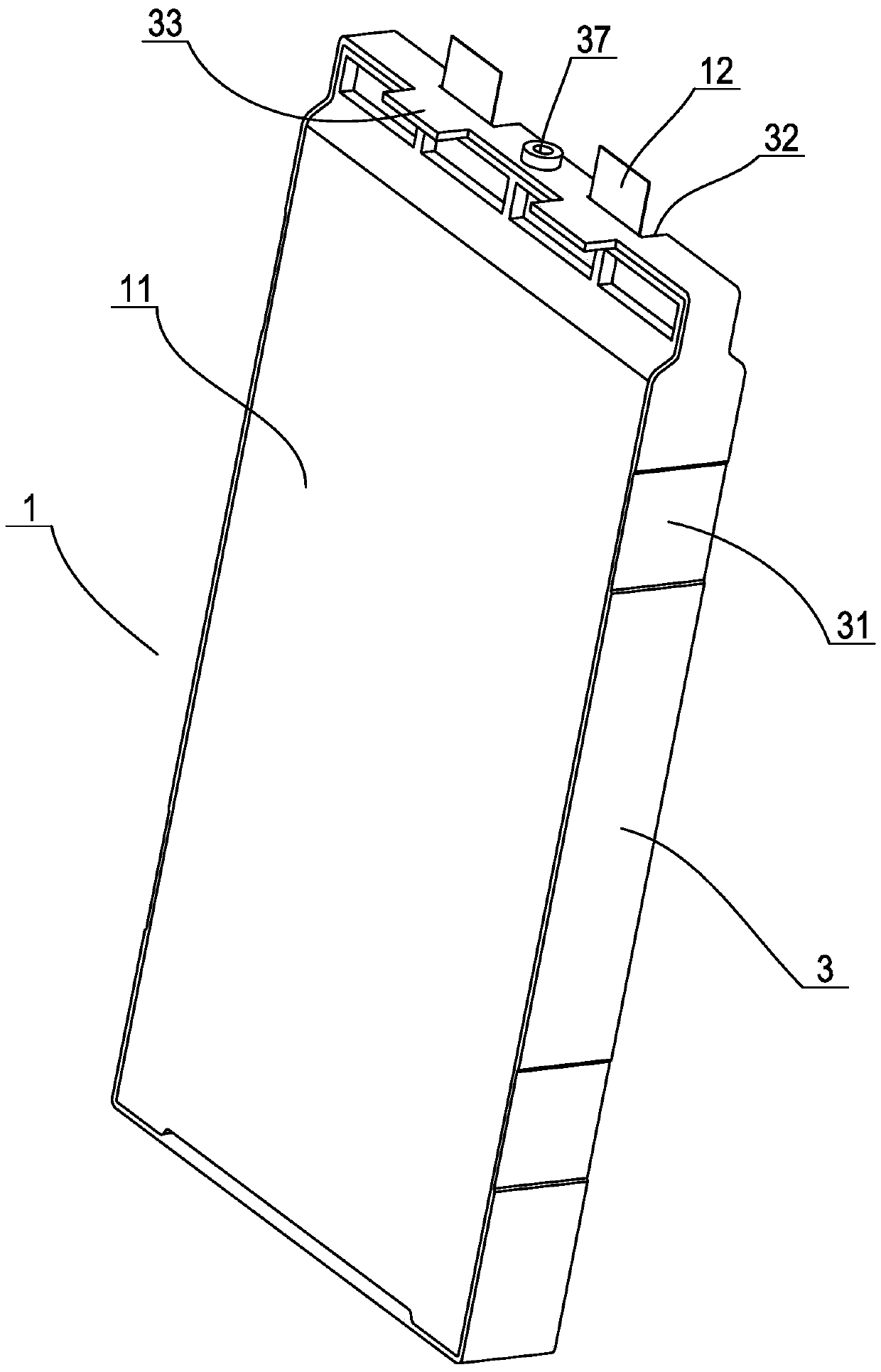

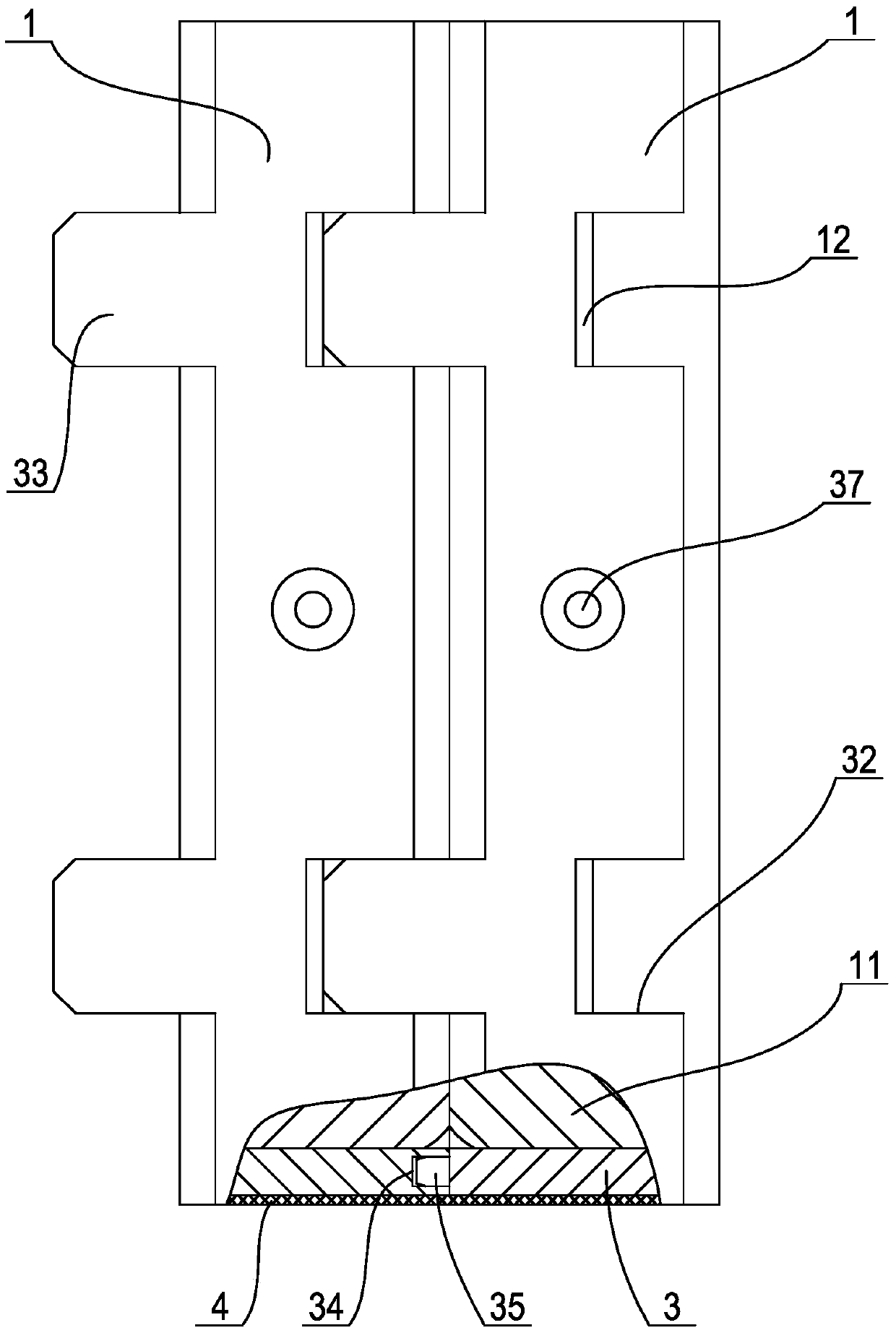

Convenient-to-assemble automatically power battery module and electric motor car

ActiveCN105514498AHigh strengthImprove protectionFinal product manufactureCell component detailsPower batteryElectrical battery

The invention discloses a convenient-to-assemble automatically power battery module and an electric motor car. The electric motor car adopts the power battery module; the power battery module comprises a plurality of soft pack battery cells; positive electrode lugs of each soft pack battery cell are connected via a bus bar, correspondingly, negative electrode lugs of the soft pack battery cell are connected via another bus bar; the two bus bars are arranged oppositely side by side; electrode lug grooves are formed in edges on the opposite sides of the two bus bars at intervals respectively; bell mouths, which are larger and larger gradually, are formed in corners at the opening of the electrode lug grooves; the electrode lugs of the soft pack battery cells are clamped in the corresponding electrode lug grooves of the bus bars on two sides sequentially, extend out of the upper ends of the bus bars, and then bend to cling to and be connected to the upper surfaces of the bus bars. The convenient-to-assemble automatically power battery module is simple in integral structure, the soft pack battery cells can be connected with the bus bars conveniently, automatic assembly can be realized, the assembly efficiency is high, the outline after packing is regular, and the soft pack battery cells are low in damage possibility.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

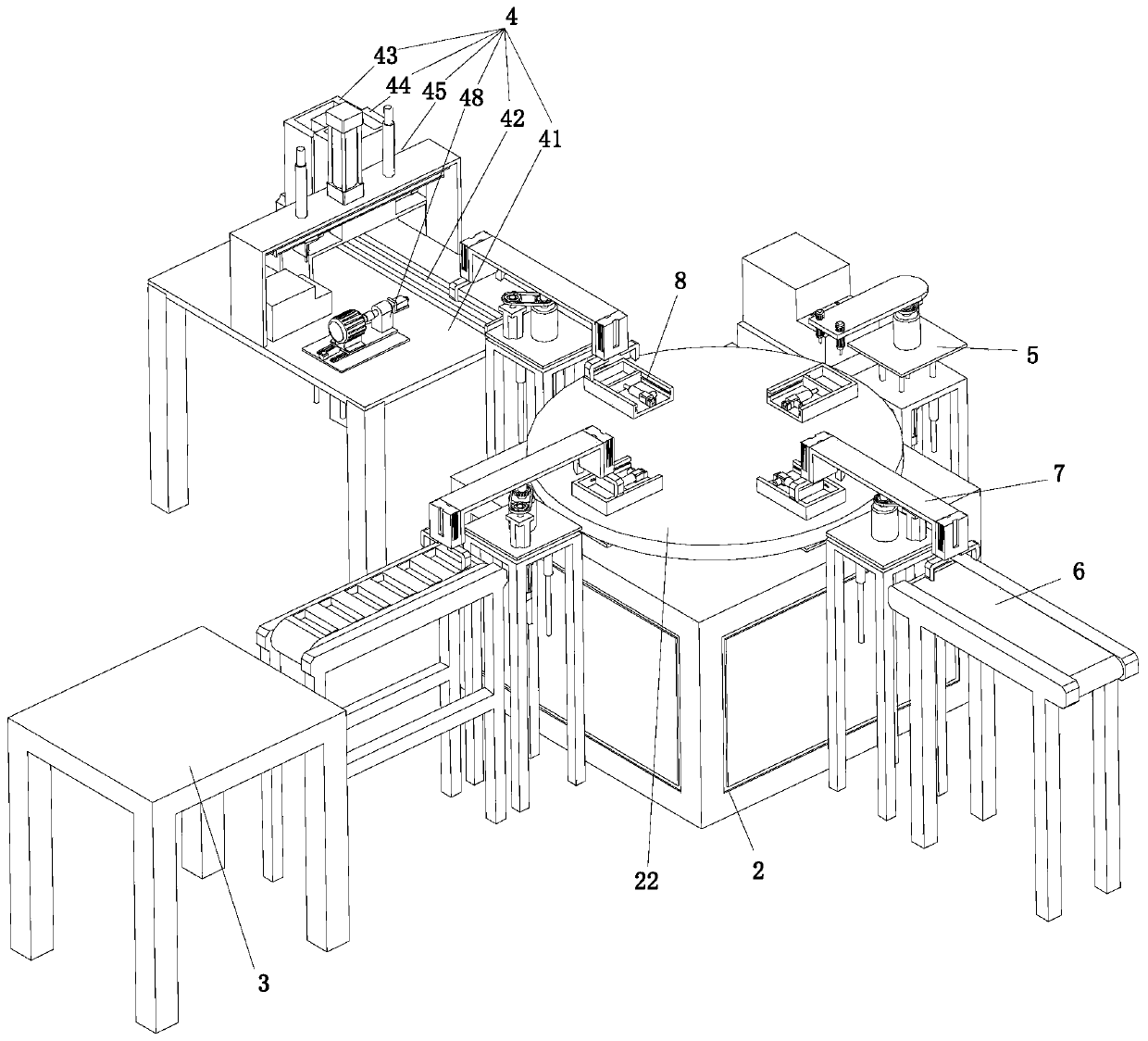

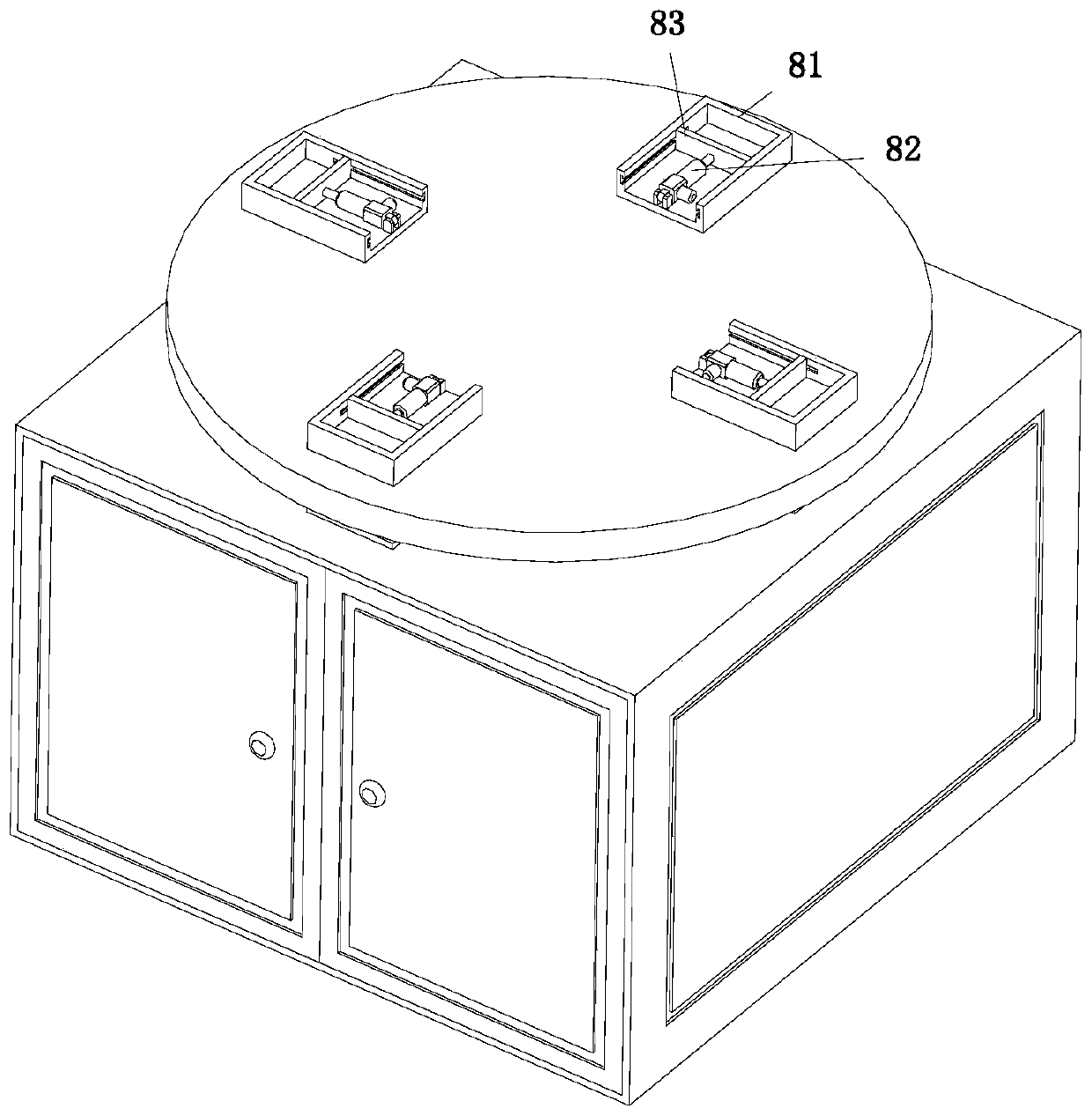

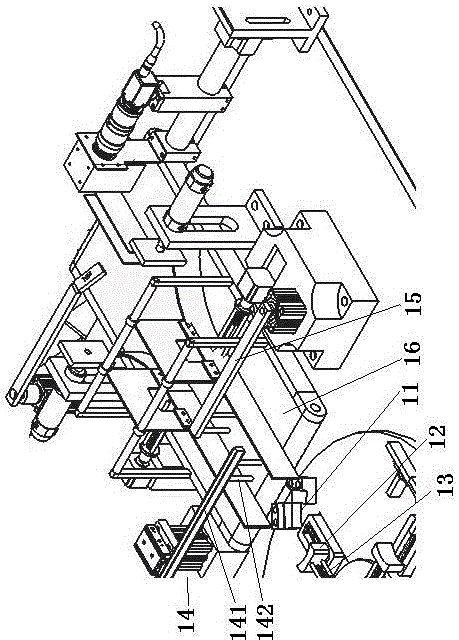

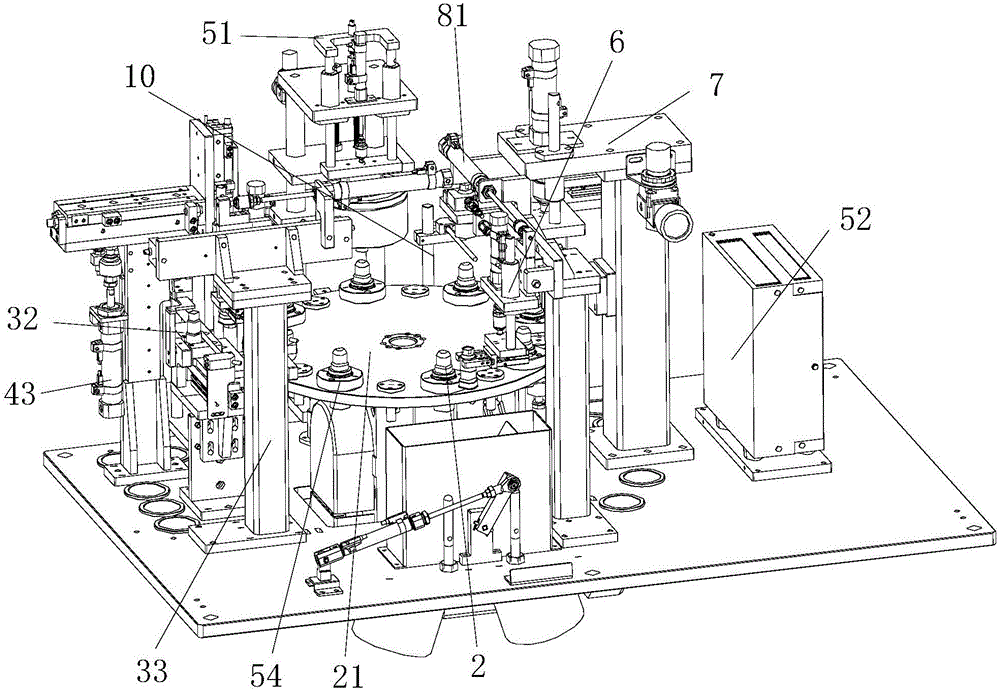

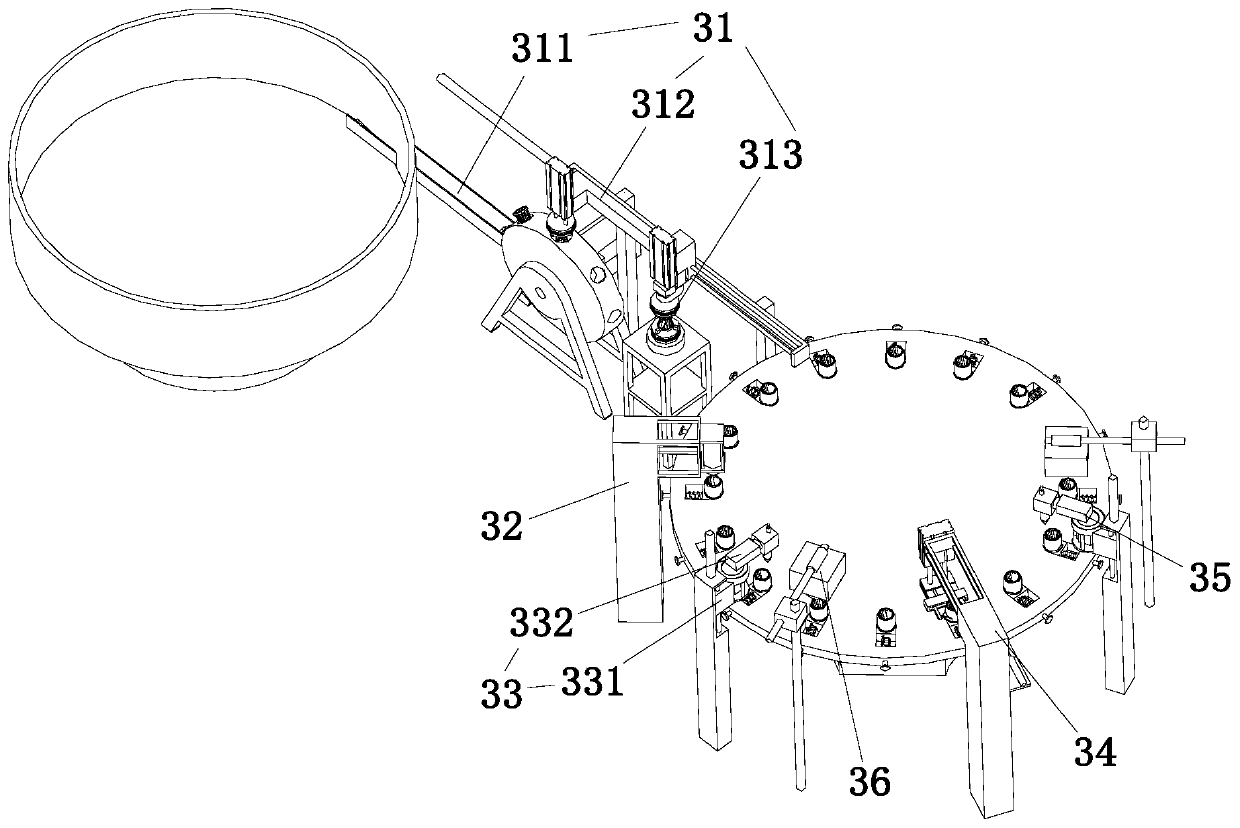

Surge protective device and assembly equipment thereof

PendingCN110227921ARealize semi-automatic assemblyImprove assembly efficiencyMetal working apparatusEmergency protective arrangements for limiting excess voltage/currentSurge protectorSemi automation

The invention relates to the technical field of surge protective devices, in particular to a surge protective device and assembly equipment thereof. The surge protective device comprises a protectivedevice body, a working table, a first assembly device, a second assembly device, a tightening device and a feeding conveyor belt; the first assembly, the second assembly device, the tightening deviceand the feeding conveyor belt are uniformly distributed around the working table; transfer devices are arranged on the sides of the first assembly, the second assembly device and the feeding conveyorbelt; the working table is internally provided with a stepping motor of which the output end is provided with a rotating disk, and the rotating disk is provided with four locating fixtures; the working table is internally provided with a lifting cylinder, and the second assembly device comprises a support frame, a screw sliding table, a first feeding component, a second feeding component, a tightening component and a turnover component; the screw sliding table is installed on the top of the support frame; and a sliding table of the screw sliding table is provided with a limiting frame. According to the surge protective device, semiautomatic assembly of the power surge protective device is achieved, so that the assembly efficiency is improved, and the labor demands are reduced.

Owner:上海优泰欧申智能科技有限公司

Lamp holder assembly equipment

Lamp holder assembly equipment comprises a feeding manipulator, a first rotary feeding mechanism and a second rotary feeding mechanism. The feeding manipulator is used for grasping and moving a workpiece which is arranged on a first connection conveying chain mechanism onto a conveying chain transmission mechanism. The first rotary feeding mechanism is used for moving the workpiece onto a first rotary table mechanism from the conveying chain transmission mechanism. A live line correcting mechanism, a lamp holder correcting mechanism, a screw base assembly mechanism, a screw base pressing and correcting mechanism and a screw base screwing mechanism which are used for processing the workpiece are arranged on the rotary path of the first rotary table mechanism in order. The first rotary feeding mechanism moves the workpiece which is subjected to the processing of the screw base screwing mechanism to the conveying chain transmission mechanism. The second rotary feeding mechanism is used for moving the workpiece which is arranged on the conveying chain transmission mechanism and is subjected to the processing of the screw base screwing mechanism to a second rotary table mechanism. A lightening testing mechanism, a live line cutting mechanism, a rivet feeding mechanism, a rivet pressing mechanism and a screw base riveting mechanism are arranged on the rotary path of the second rotary table mechanism. The lamp holder assembly equipment has the characteristics of being simple in structure, low in cost and high in efficiency.

Owner:SHENZHEN XUANSHUO INTELLIGENT MANUFACTURING TECHNOLOGY CO LTD

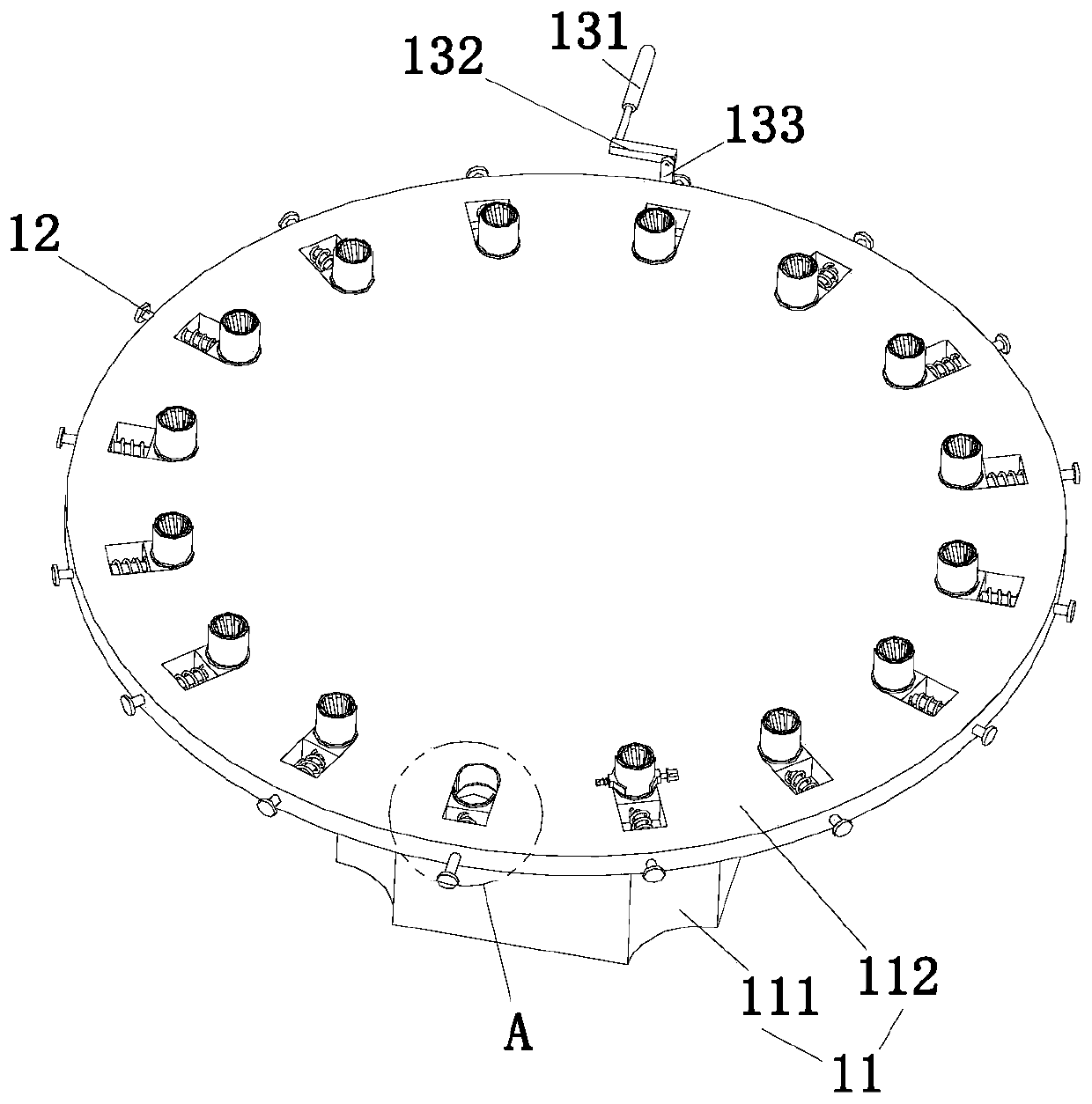

Assembly machine for connecting wires of lower ends of infusion apparatuses

ActiveCN104958806AReasonable designSimple structureInfusion devicesAssembly machinesButt jointCatheter

The invention discloses an assembly machine for connecting wires of lower ends of infusion apparatuses. The assembly machine comprises a machine frame, on which a lower rotating disc is arranged. The lower rotating disc is connected with an upper rotating disc by means of a splitter. An adjusting box feeding mechanism, a guide pipe feeding mechanism, an adjusting wheel feeding mechanism and a filter dispensing feeding mechanism, located above the upper rotating disc, are fixedly connected to the lower rotating disc. A guide pipe material-storage mechanism is arranged on the machine frame. A guide pipe carrying mechanism capable of conveying guide pipes in the guide pipe material-storage mechanism to the guide pipe feeding mechanism is arranged above the guide pipe material-storage mechanism. Working stations, in butt joint with the adjusting box feeding mechanism, the guide pipe feeding mechanism, the adjusting wheel feeding mechanism and the filter dispensing feeding mechanism, are arranged on the upper rotating disc. The assembly machine for connecting wires of lower ends of infusion apparatuses is reasonable in design, simple in structure and high in degree of automation.

Owner:ZHEJIANG SANCHUANG BIOTECH

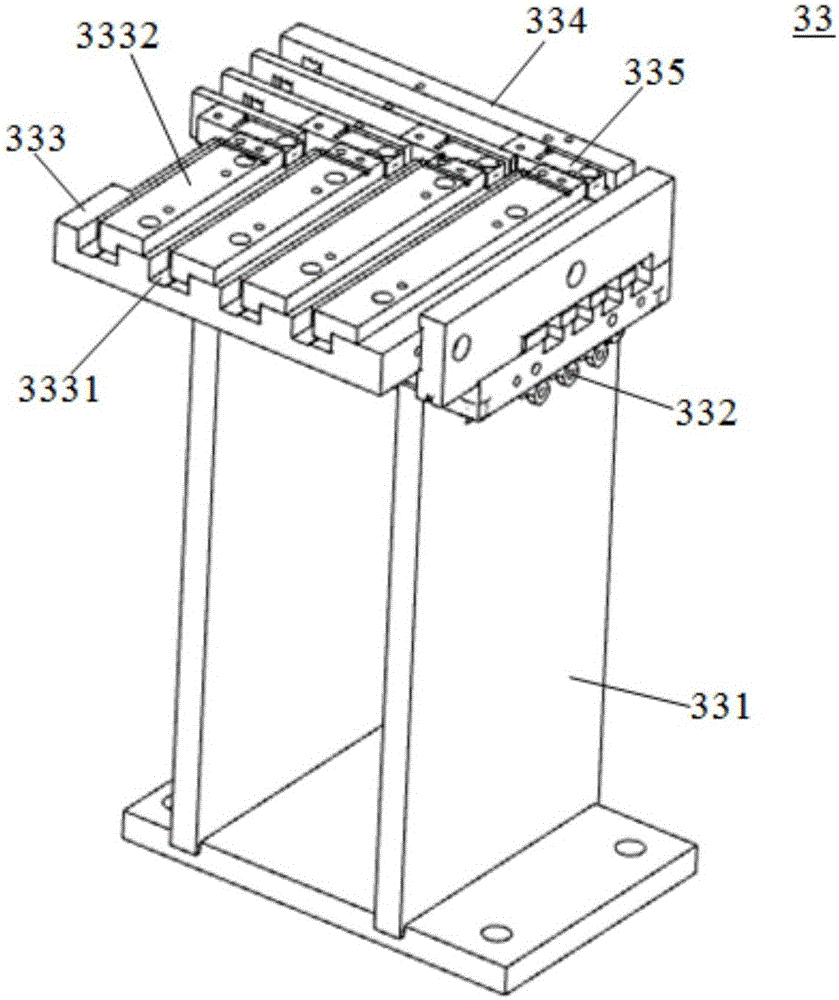

Clamp assembling machine

ActiveCN105033605ARealize automatic assemblyImprove work efficiencyMetal working apparatusManipulator

The invention discloses a clamp assembling machine. The clamp assembling machine comprises a rotary table provided with four stations. At the first station, a standing inner clamp body provided with movable overlapping lap joint openings is pushed down, then conveyed into a clamping base on the rotary table in a flat lying mode and compressed through a movable side pressing block so that the diameter of the inner clamp body can be smaller than that of an outer clamp body; at the second station, the outer clamp body lying flat is clamped by a manipulator to be placed on the inner clamp body in the clamping base, and the outer clamp body is partially arranged outside the inner clamp body in a sleeving mode; at the third station, a pressing plate is arranged to exert vertically downward pressure on the outer clamp body so that the outer clamp body half arranged outside the inner clamp body in the sleeving mode can be completely pressed outside the inner clamp body, and the assembled clamp is formed; at the fourth station, a discharging manipulator is arranged, and the assembled clamp is clamped out of the clamping base through the discharging manipulator. According to the clamp assembling machine, automatic assembling of the inner clamp body and the outer clamp body are achieved; the multiple stations work at the same time, and accordingly working efficiency is improved, and production cost is reduced; it can be guaranteed that the lap joint openings of the assembled inner clamp body face the same direction, and mistakes caused by manual operation are avoided.

Owner:JIANGSU BVM INTELLIGENT TECH

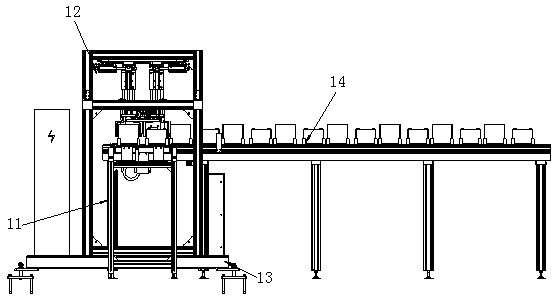

LED bulb lamp assembling system

PendingCN107263098ARealize automatic assemblyImprove assembly efficiencyAssembly machinesSemiconductor devices for light sourcesEngineeringAssembly line

The invention provides an LED bulb lamp assembling system. The LED bulb lamp assembling system comprises an automatic feeding station, a screw welding station, a mouth metal fixing station, a grinding station, a checking station, an overturning and carrying station, a re-positioning station, a heating plate assembling station, a lower lampshade assembling station, a first screw assembling station, a glue injection station, a lamp panel assembling station, a second screw assembling station, a wire tidying welding station, an upper lampshade assembling station, a lampshade fusion point lamp station and a discharging station. The above stations are sequentially arranged along a conveying assembly line of the LED bulb lamp assembling system. The stations and the conveying assembly line are integrated on a machine table of the LED bulb lamp assembling system. The LED bulb lamp assembling system achieves automatic LED bulb lamp assembling and is high in assembling efficiency and good in precision, the problems existing in the prior art are solved, and the modern industry production requirement is sufficiently met.

Owner:苏州凯良拓自动化科技有限公司

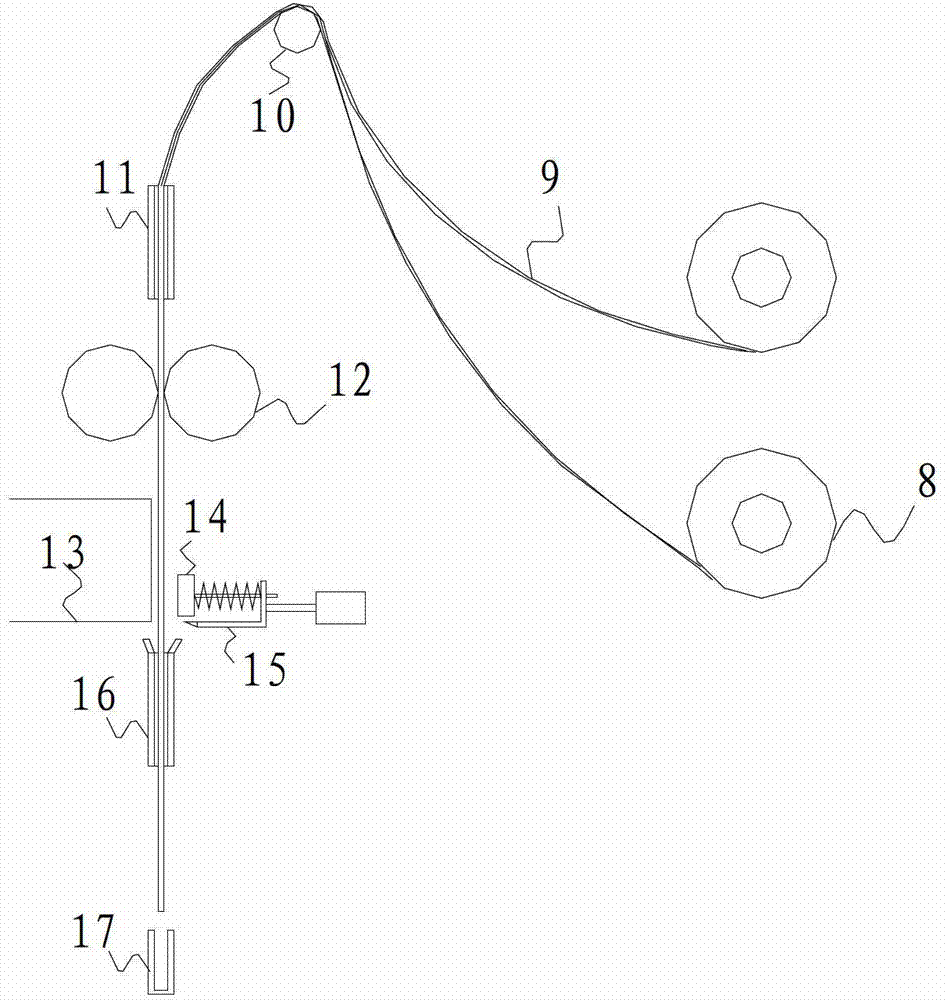

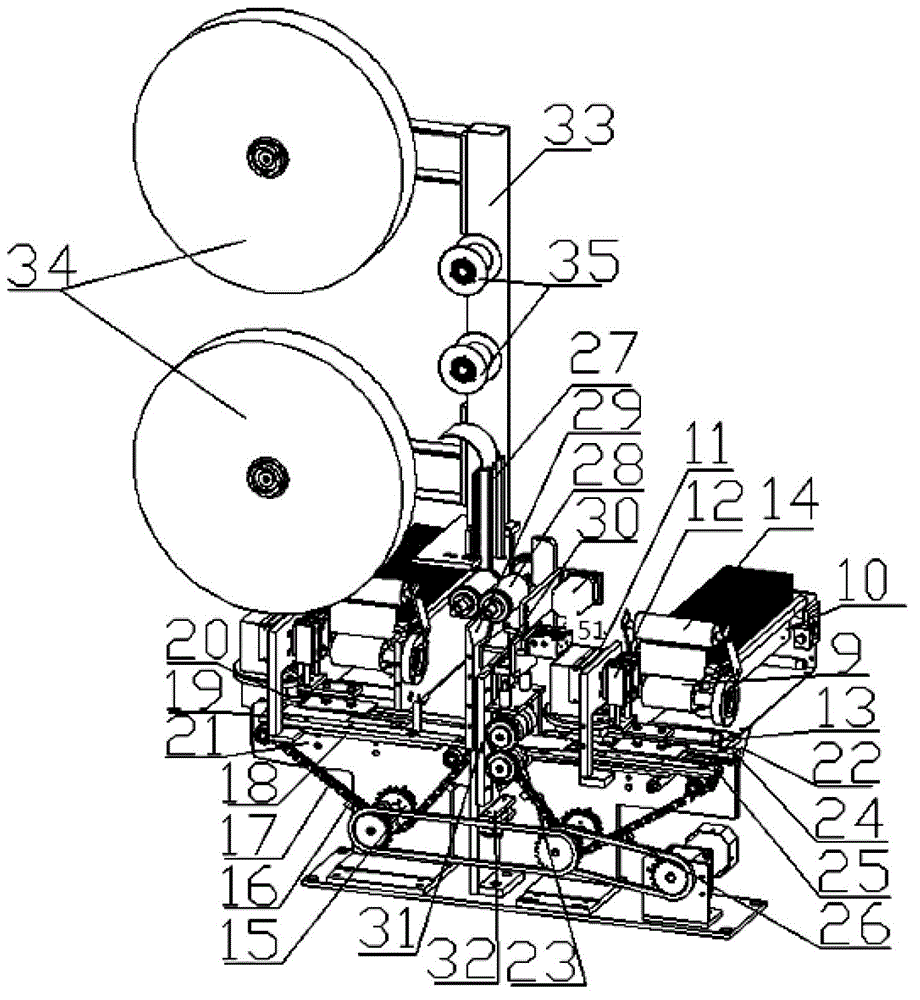

Automatic stacking machine for pole plates

ActiveCN103401027ARealize automatic assemblyAchieve transshipmentFinal product manufactureSecondary cells manufactureStack machineEngineering

The invention discloses an automatic stacking machine for pole plates. The automatic stacking machine comprises a pole plate supplying mechanism, a division plate supplying mechanism and a pole plate stacking mechanism, wherein the pole plate supplying mechanism comprises two pole plate conveying belts, two pole plate storage frames and pole plate top rods arranged under the corresponding pole plate storage frames; the division plate supplying mechanism comprises two raw material rolls, a first guide cylinder used for bearing division plates, a pair of division plate pull rolls, a division plate cutting-off mechanism, a second guide cylinder used for bearing the division plates and a division plate bracket, and a gap through which the pole plates can pass is formed between the division plate bracket and an outlet of the second guide cylinder; the pole plate stacking mechanism comprises two guide rails, two transferring arms, a conveying chain, a plurality of pole plate transferring boxes and a pole plate push hook; a channel through which the division plate can pass is formed in the guide rail positioned at the lower part; the pole plate transferring boxes are fixedly arranged on the conveying chain; the pole plate push hook is used for transferring the pole plates from the two guide rails onto the pole plate transferring boxes. The automatic stacking machine for the pole plates realizes the automatic supply of the positive and negative pole plates and the division plates, the automatic stacking of the positive and negative pole plates and the automatic assembly and transfer of pole groups.

Owner:ZHEJIANG TIANNENG POWER ENERGY

Full-automatic assembling apparatus for connector protective jackets

InactiveCN105048236ARealize automatic assemblyPrevent inflowLine/current collector detailsCircular discEngineering

The invention discloses a full-automatic assembling apparatus for connector protective jackets. The full-automatic assembling apparatus comprises a frame and an assembling apparatus assembly arranged on the frame; the assembling apparatus assembly comprises a turnplate mechanism; the turnplate mechanism comprises a disc and a disc driving mechanism for driving the disc to rotate; at least six fixtures for holding materials are arranged on the disc in the circumferential direction; the assembling apparatus assembly further comprises a lower shell loading mechanism, a protective jacket loading and assembling mechanism, an upper shell loading and assembling mechanism, an upper shell press-fitting mechanism and a discharge mechanism, all of which are connected with a controller arranged on the frame, respectively; a product receiving box is further arranged under the turnplate mechanism; automatic assembling of the connector protective jackets is realized; the assembling is more accurate; the labor is saved and the production efficiency is improved.

Owner:SUZHOU HYH AUTOMATION EQUIP CO LTD

Parallel connection plate wrapping mechanism of storage battery pole plate

InactiveCN102945984ARealize automatic feedingRealize automatic assemblyFinal product manufactureLead-acid accumulators constructionEngineeringMechanical engineering

The invention provides a parallel connection plate wrapping mechanism of a storage battery pole plate. The parallel connection plate wrapping mechanism comprises a pole plate feed mechanism for providing a first pole plate, an independent conveying mechanism, a lamination mechanism and an erecting mechanism, the first pole plate and a second pole plate which are subjected to plate wrapping are stacked at intervals to form a plate wrapping group by the independent conveying mechanism, the clustering is achieved by the lamination mechanism, and the erecting mechanism erects and arranges a cluster. The parallel connection plate wrapping mechanism of the storage battery pole plate has the advantages that the structure is compact and reasonable, the operation is convenient, pole plate automatic feeding, automatic plate wrapping, pole plate automatic assembly after plate wrapping and cluster erecting and arranging are achieved, the production efficiency is greatly improved, the labor intensity of workers is reduced, and harm of lead dust is reduced.

Owner:SHANGHAI RUNTECH ELECTRONICS TECH

Switch automated assembling device

InactiveCN103198949AStandard stepSimple and efficient operationElectric switchesProgrammable logic controllerHuman–machine interface

The invention provides a switch automated assembling device and relates to the switch automated assembly technology. The switch automated assembling device comprises a body conveying device, a terminal conveying device, a shrapnel conveying device, a body and terminal assembling unit, a shrapnel assembling unit, a glue filling unit, a programmable logic controller (PLC) die set and a human-computer interface, wherein the body conveying device, the terminal conveying device, the shrapnel conveying device, the body and terminal assembling unit, the shrapnel assembling unit, the glue filling unit, the PLC die set and the human-computer interface are all arranged on a machine. The switch automated assembling device is characterized in that firstly, terminals are assembled into a body through the body and terminal assembling unit, then shrapnel is assembled on the body assembled with the terminals through the shrapnel assembling unit, and then an assembled switch is obtained, and lastly, glue is filled into the terminals and the shrapnel of the assembled switch through the glue filling unit. Therefore, the problem of automated assembling a switch body, the terminals and the shrapnel into a switch product is solved, automated assembling of the switch body, the terminals and the shrapnel on an assembling device is achieved, uniformity and reliability of the switch product are improved, assembling efficiency is high, and assembling cost is low. Meanwhile, labor capacity of a worker is small, labor intensity is less, and physical health is benefited.

Owner:SOUNDWELL ELECTRONICS PROD GUANGDONG

Circuit board assembly detection system

InactiveCN105486996ARealize automatic assemblyEasy to detectPrinted circuit assemblingElectronic circuit testingTest efficiencyCooking & baking

The invention discloses a circuit board assembly detection system. The circuit board assembly detection system mainly comprises a conveying device as well as code spraying equipment, ICT test equipment, nixie tube plugging equipment, FCT test equipment, CCD scanning equipment and oil spraying equipment which are sequentially arranged along the conveying direction of the conveying device. According to the circuit board assembly detection system, the code spraying machine can perform automatic code spraying on circuit boards; the ICT test equipment can automatically perform ICT tests on the circuit boards; the nixie tube plugging equipment can automatically plug nixie tubes into the circuit boards, so that the speed and efficiency of the plugging of the nixie tubes can be improved; the FCT test equipment can automatically perform FCT tests on circuit boards to be detected, and therefore, test efficiency and test accuracy can be both improved; the CCD scanning equipment can perform automatic detection on the nixie tubes on the circuit boards; and the oil spraying equipment can perform automatic oil spraying processing on circuit boards which have been subjected to assembly detection, and the oil spraying equipment is connected with a baking box, and therefore, ink drying time can be shortened, and the production cycle of the circuit boards can be shortened.

Owner:SUZHOU JINGSHUO AUTOMATION EQUIP CO LTD

Assembly equipment for electromagnet core

InactiveCN108091476AReduce manual laborReduce the cost of the provincial capitalManufacturing stator/rotor bodiesMagnetic core manufactureMechanical equipmentElectromagnet

The invention relates to the field of mechanical equipment, in particular to assembly equipment for an electromagnet core. The assembly equipment comprises a lower cover feeding device, a lower coverpositioning device, a dispensing device, a core feeding device, core positioning devices, a core conveying device, an upper cover feeding device and an upper cover conveying device, wherein the lowercover positioning device and the dispensing device are sequentially arranged at the side of the lower cover feeding device; the core positioning devices are arranged at two sides of the core feeding device and the core positioning devices both are located at the side of the lower cover feeding device; the core conveying device is located above the core positioning devices and the lower cover feeding device; the upper cover feeding device is located at the side of the lower cover positioning device; the upper cover conveying device is located above the upper cover feeding device and the lower cover positioning device; the dispensing device comprises a mounting rack, a gluing component and a dispensing component; a mounting plate is arranged at the upper part of the mounting rack; and a plurality of connection posts are arranged between the mounting plate and the mounting rack. According to the assembly equipment for the electromagnet core, automatic assembly of the electromagnet core isachieved, so that the production efficiency is improved.

Owner:ZHEJIANG UNIV OF TECH FENGHUA SMART ECONOMY RES INST

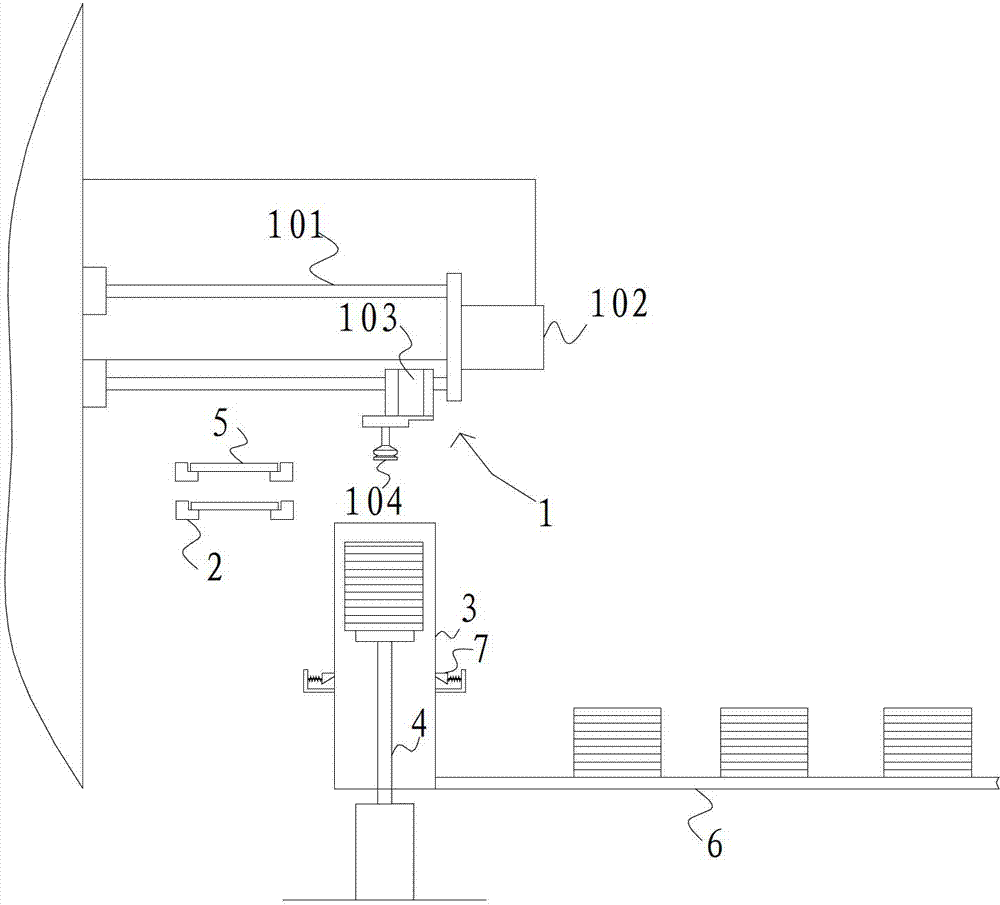

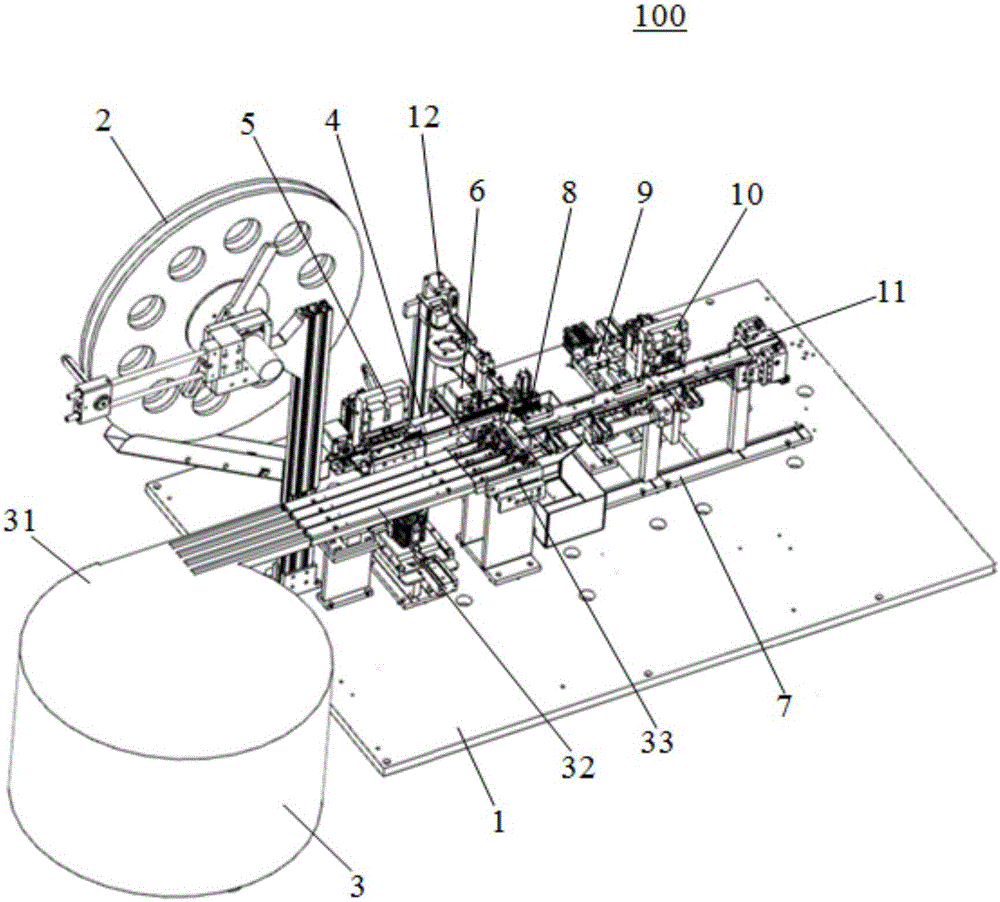

Numerical control automated assembly equipment for ceramic bearing

ActiveCN105540202ARealize automatic assemblyHigh degree of automationConveyorsControl devices for conveyorsNumerical controlEngineering

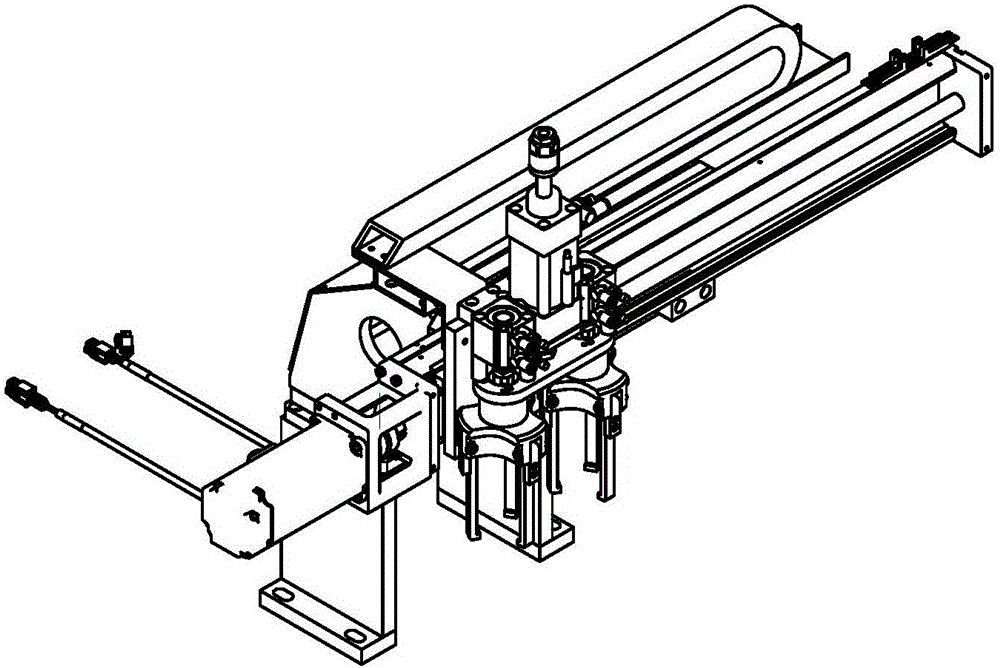

The invention discloses numerical control automated assembly equipment for a ceramic bearing. The equipment comprises a bearing feeding device for inputting the bearing, bearing conveying guide rails for guiding the bearing, a shaft sleeve feeding device for inputting a shaft sleeve, shaft sleeve conveying guide rails for guiding the shaft sleeve, a bearing turnover mechanism for turning the bearing to the front side, an assembly mechanism for sleeving the bearing with the shaft sleeve to form an assembly as well as assembly conveying guide rails for guiding the assembly.

Owner:佛山市东丽塑胶有限公司

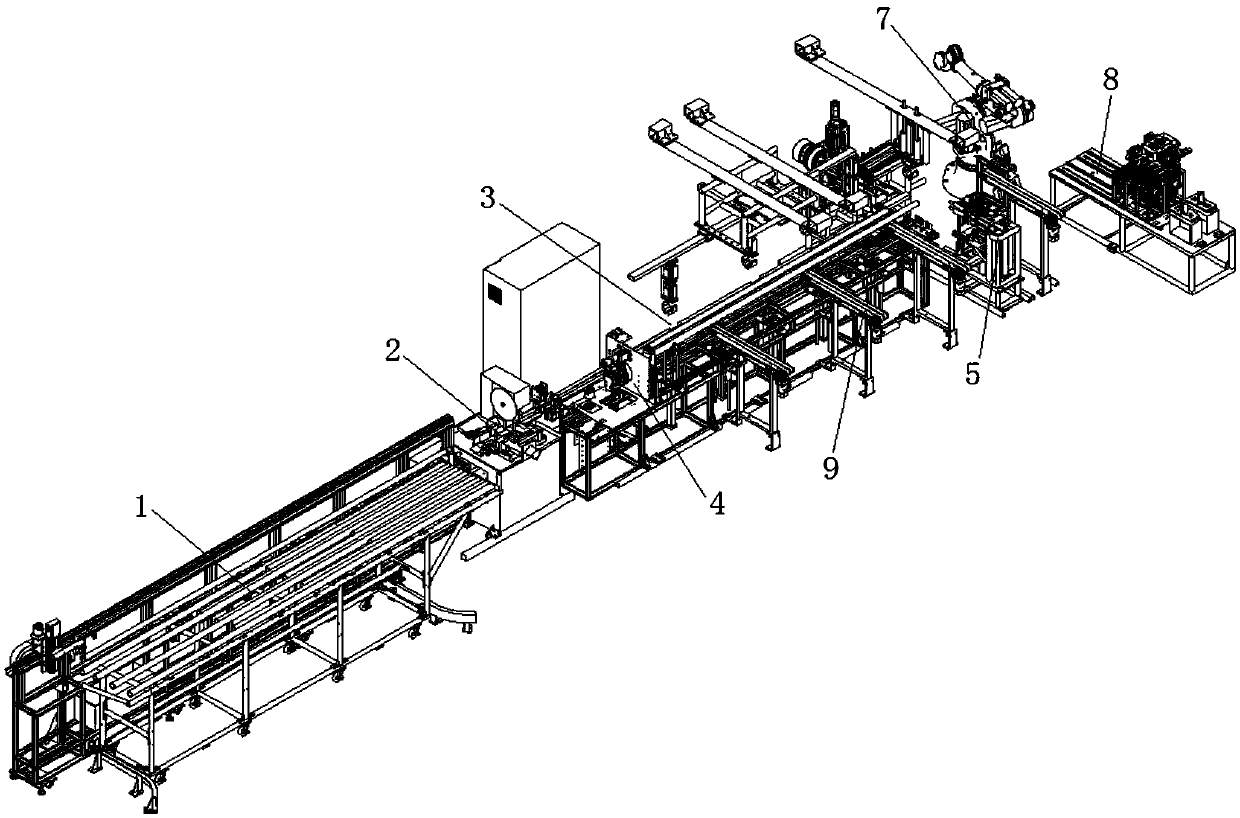

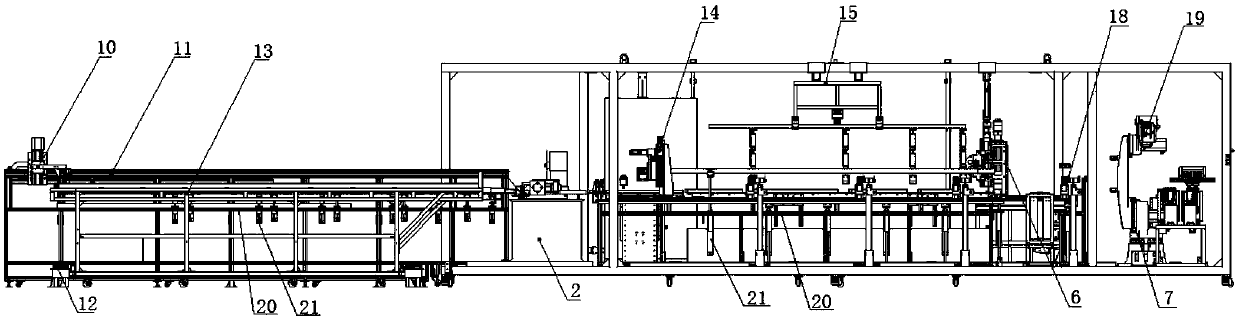

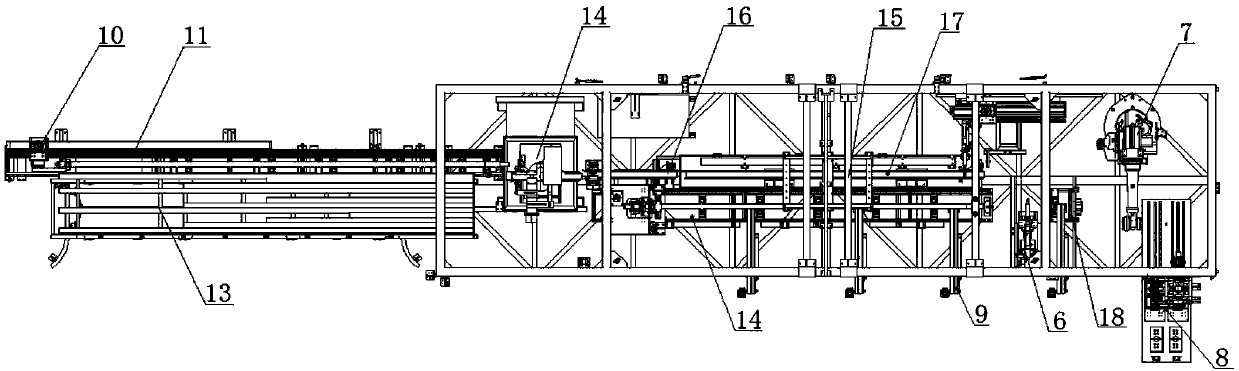

Pipe material assembling platform production line

ActiveCN109648343ARealize continuous automatic feedingImprove continuityOther manufacturing equipments/toolsTube shearing machinesProduction lineContact network

The invention discloses a pipe material assembling platform production line. The pipe material assembling platform production line comprises a feeding conveying part, a cutting machine, a carrying part, a hole finding part and a robot, wherein an output end of the feeding conveying part is in butt joint with an input end of the cutting machine, an output end of the cutting machine is in butt jointwith an input end of the carrying part, the hole finding part is arranged on one side of the carrying part, and the robot is arranged on one side of the hole finding part. continuous automatic feeding, length fixing, cutting and hole finding of a pre-assembled contact network cantilever pipe material and automatic assembling of a workpiece and the pipe material can be realized, field operators can be reduced, the labor intensity can be reduced, and the working efficiency can be improved.

Owner:武汉中安佳通装备技术有限公司

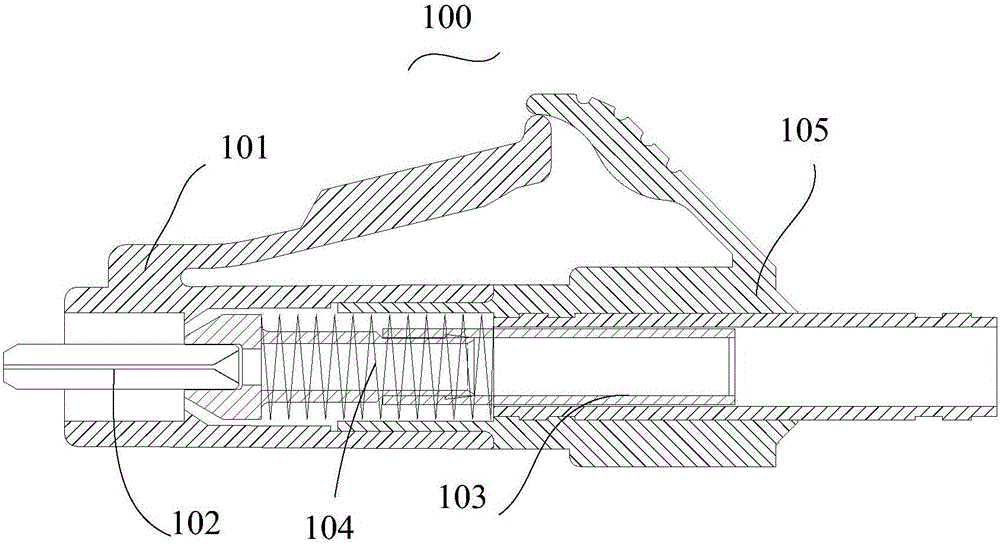

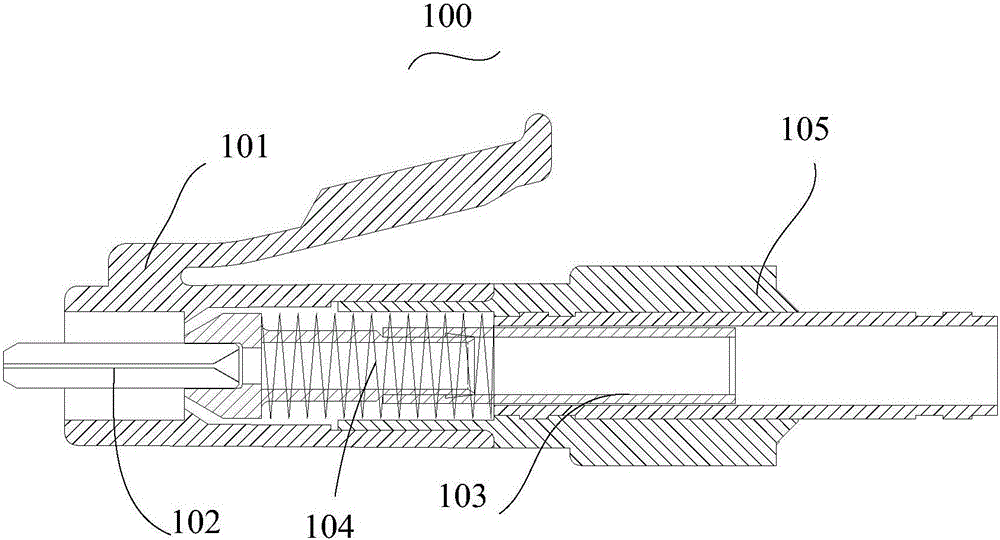

Automatic assembling machine for optical fiber connectors

InactiveCN105750905AImprove installation efficiencyReduce installation costsAssembly machinesCoupling light guidesEngineeringOptical fiber connector

The invention discloses an automatic assembling machine for optical fiber connectors. Each optical fiber connector comprises a front frame sleeve, a handle insertion core, a transparent tube, a spring and a plug; the automatic assembling machine for the optical fiber connectors comprises a base and a mounting guide rail, sliding blocks, a manipulator assembly, a feeding device and a driving device which are all mounted on the base; the driving device drives the sliding blocks to slide to a destination end from a starting end of the mounting guide rail; in the sliding process of the sliding blocks, the manipulator assembly splices the front frame sleeves, the handle insertion cores, the transparent tubes, the springs and the plugs which are sequentially provided by the feeding device onto the sliding blocks one by one. According to the invention, the mounting efficiency of the optical fiber connectors is improved, a great amount of labor is not required to mount the optical fiber connectors, and mounting cost of the optical fiber connectors is reduced.

Owner:SHENZHEN LONGSHENG PHOTOELECTRIC

Automatic assembly and detection equipment for magnetic shoe products

ActiveCN107965505ARealize automatic pre-installation positioningRealize automatic assemblyLiquid surface applicatorsMaterial gluingCooling chamberStructural engineering

The invention discloses automatic assembly and detection equipment for magnetic shoe products. The automatic assembly and detection equipment comprises a magnetic shoe pre-assembly locating mechanism,a magnetic shoe dispensing assembly mechanism, a baking chamber, a cooling chamber, a detection and discharge mechanism, an automatic conveying device penetrating all the above mechanisms and a toolmoving on the automatic conveying device. The magnetic shoe pre-assembly locating mechanism comprises a magnetic shoe loading unit for loading multiple magnetic shoes at equal angles, a magnetic shoepress-in unit pressing the magnetic shoes down to the tool from the magnetic shoe loading unit, and magnetic shoe supply and feed units symmetrically arranged on the two sides of the magnetic shoe loading unit. The magnetic shoe dispensing assembly mechanism comprises a dispensing unit for gluing the circumferences of the magnetic shoes, an additive layer forming unit for forming adhesive reinforcement layers on the surfaces of the inner walls of shells, a shell feed mechanism and a shell grabbing assembly mechanism. The automatic assembly and detection equipment is high in assembly precision,good in shell and magnetic shoe adhesion performance and high in production efficiency, and the production cost is greatly reduced.

Owner:苏州美尔科自动化设备有限公司

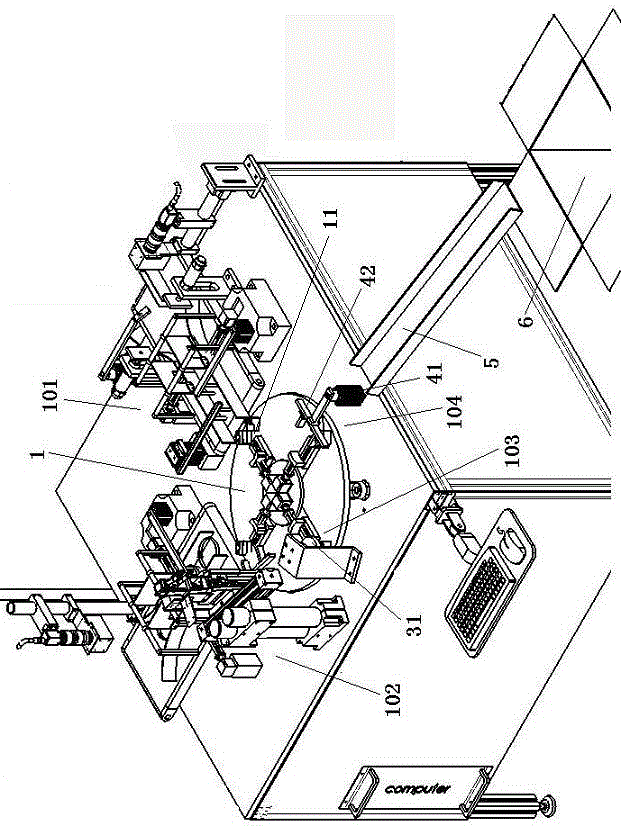

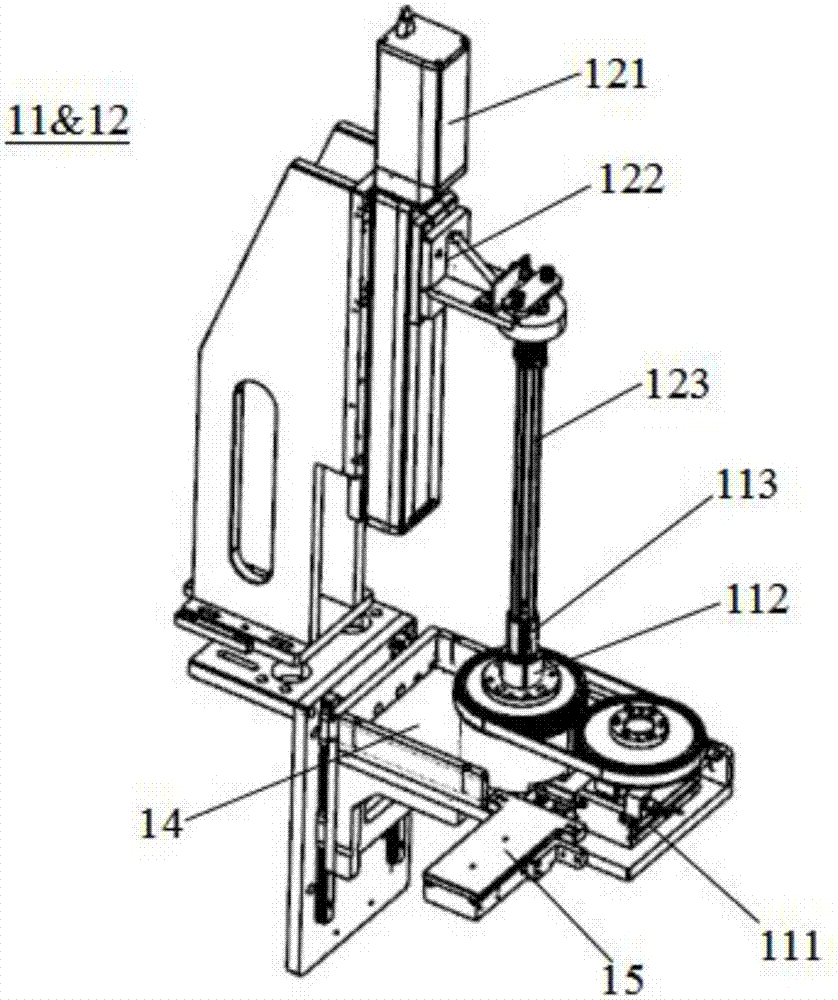

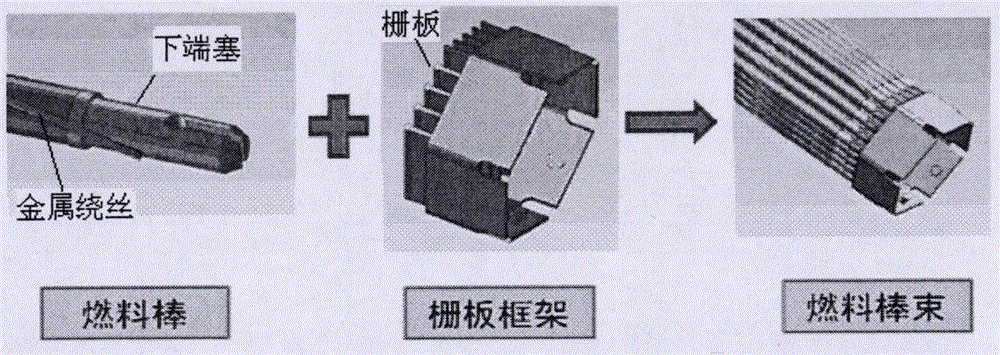

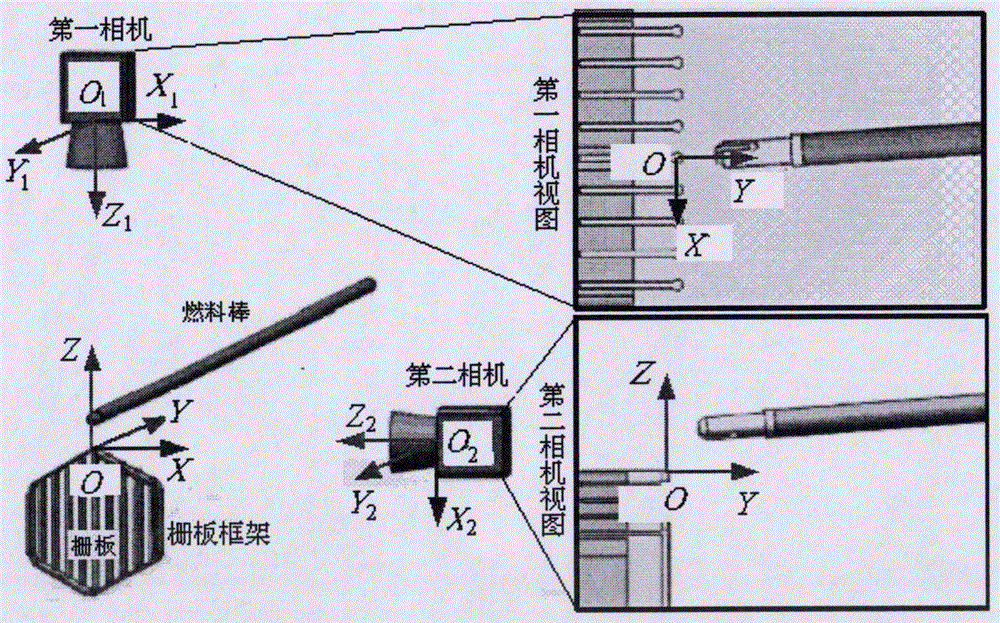

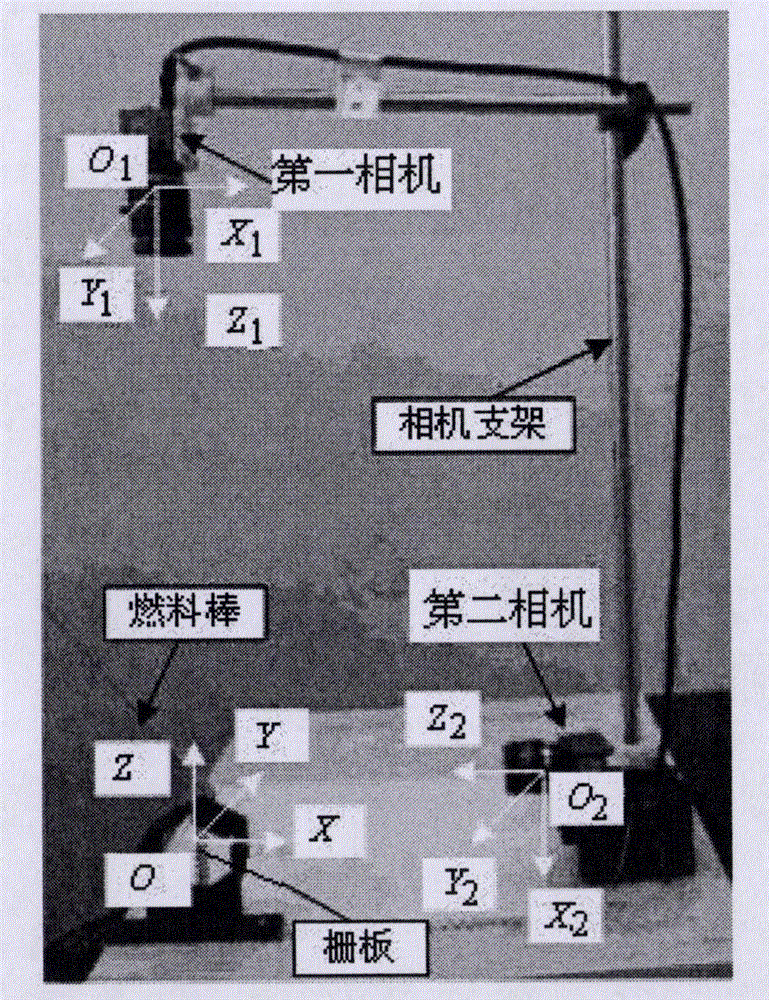

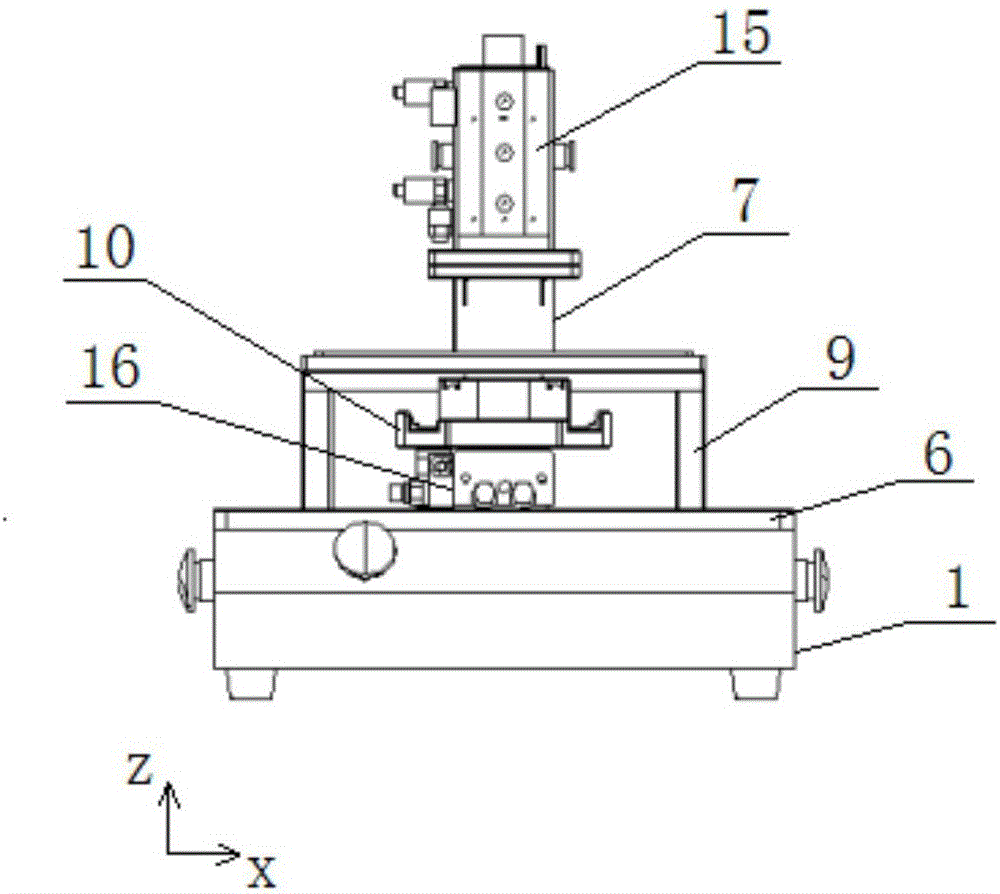

Nuclear rod pose automatic identification device and method

ActiveCN106123772AImprove securityImprove the level of intelligenceUsing optical meansShape changeMachine vision

The invention provides a nuclear rod pose automatic identification device and method and belongs to the technical field of machine vision and nuclear power equipment manufacturing automation. The device comprises a first camera and a second camera which are orthogonally arranged. The optical axis of the first camera is parallel to a Z axis, and horizontal and vertical coordinates of an image are parallel to an X axis and a Y axis respectively. The optical axis of the second camera is parallel to the X axis, and horizontal and vertical coordinates of an image are parallel to the Y axis and the Z axis respectively. The method comprises steps that firstly, image features of a lower plug of a nuclear rod are extracted, then space pose information of the lower plug of the nuclear rod is calculated, and finally the nuclear rod is assembled according to the space pose information. The automatic identification device and method can monitor shape change and pose change of the nuclear rod, provide a device basis and a theoretical basis for automatic assembly of the nuclear rod and a grid plate, and is beneficial for achieving automatic assembly of nuclear rod clusters. The safety of nuclear power equipment manufacturing is improved, and the intelligent level of nuclear power equipment manufacturing is greatly improved.

Owner:HARBIN INST OF TECH

Automatic assembling and lock pin equipment of air conditioner transformer

PendingCN111128540ARealize automatic transmissionRealize automatic assemblyInductances/transformers/magnets manufactureTransformerControl engineering

The invention discloses automatic assembling and lock pin equipment of an air conditioner transformer. The equipment comprises a frame, an automatic transformer body feeding mechanism, an automatic shell conveying mechanism, a transformer wire heat blowing mechanism, an automatic screw blowing mechanism, an automatic finished product output mechanism, a transformer wire stripping mechanism, an automatic nailing mechanism, an automatic transformer body grabbing mechanism, an automatic shell grabbing mechanism and a PLC control box, wherein the automatic transformer body feeding mechanism, the automatic shell conveying mechanism, the transformer wire heat blowing mechanism, the automatic screw blowing mechanism, the automatic finished product output mechanism, the transformer wire strippingmechanism, the automatic nailing mechanism, the automatic transformer body grabbing mechanism and the automatic shell grabbing mechanism are installed on the frame according to designated positions. And the PLC control box is electrically connected with automatic operation parts of all the mechanisms, and automatic operation is achieved through program control. The automatic assembling and lock pin equipment is compact in structure and reasonable in layout; automatic conveying, grabbing and assembling of a transformer shell and a transformer body, automatic supply and nailing operation of screws and automatic output of finished products are achieved; and automatic operation is completely adopted, labor is greatly saved, working efficiency is improved, labor intensity is reduced, and operation safety is greatly improved.

Owner:QINHUANGDAO FENGTAI AUTOMATION EQUIP MFG

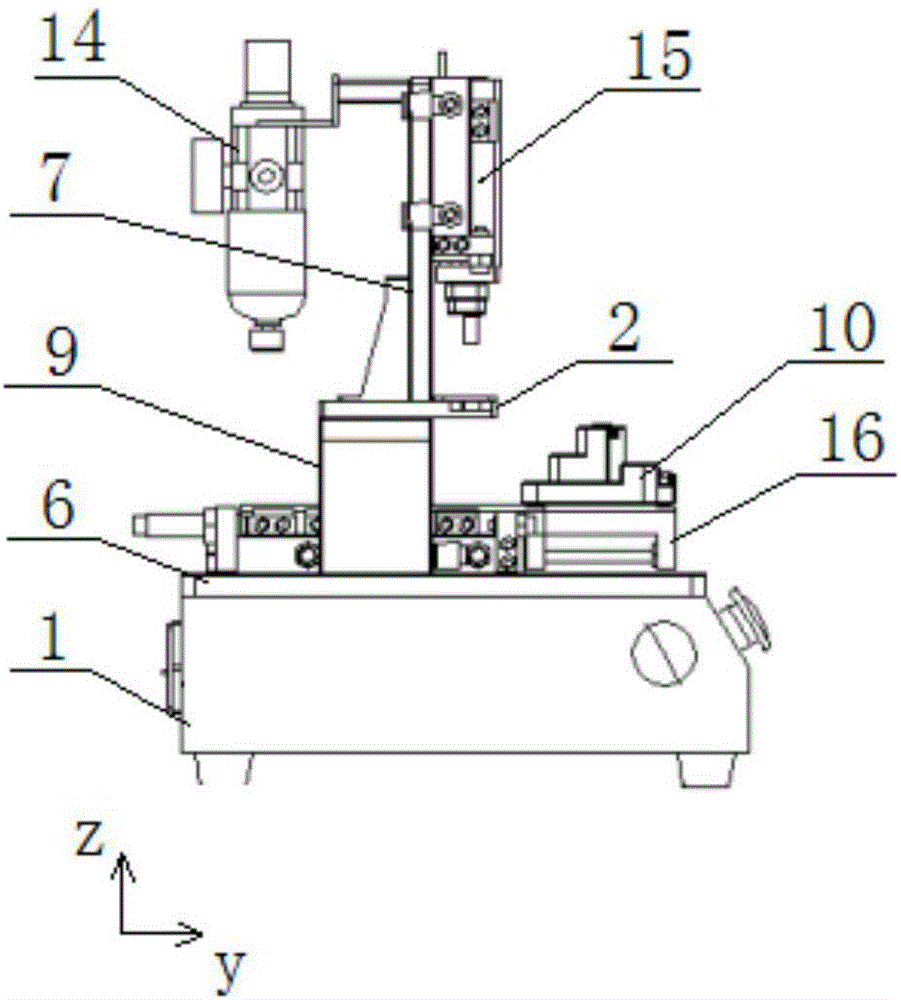

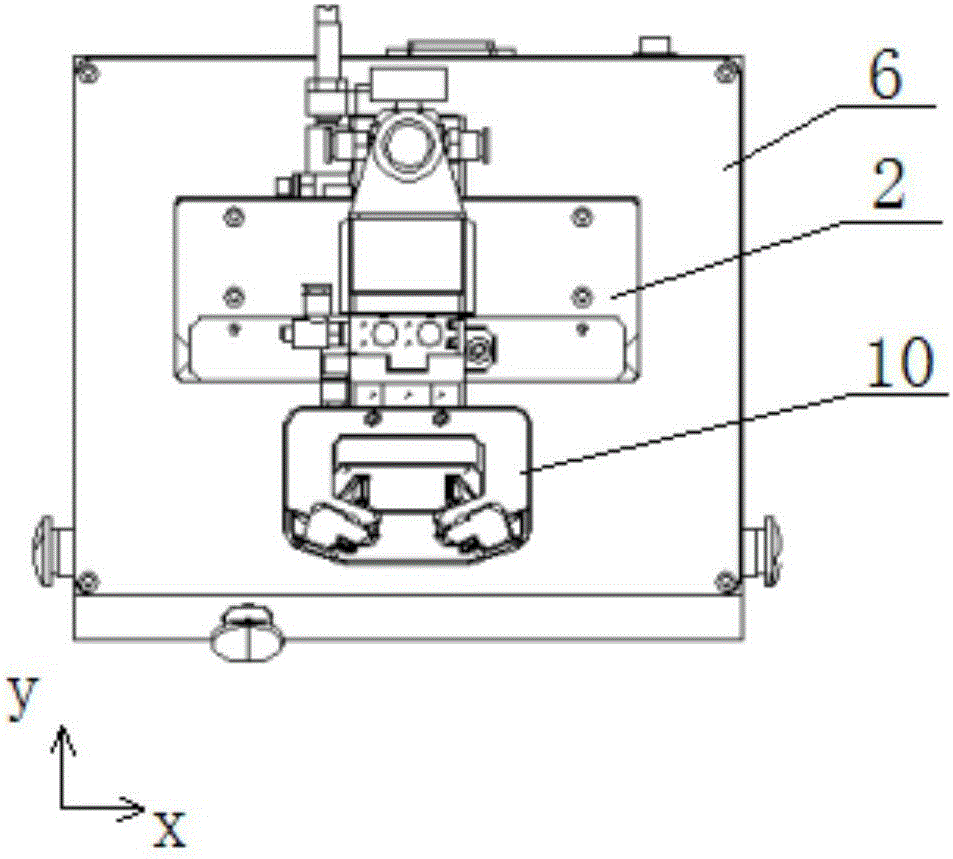

Semi-automatic magnet assembly tool

ActiveCN106695298ARealize automatic assemblySolve the problem of reverse installationMetal working apparatusSemi automaticEngineering

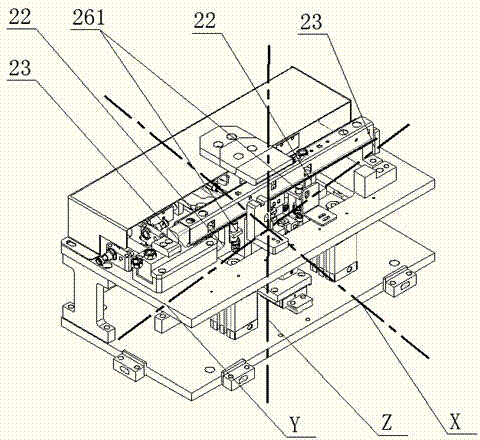

The invention belongs to the technical field of assembly of magnet products, in particular to a semi-automatic magnet assembly tool. The semi-automatic magnet assembly tool comprises an electric appliance control box, a magnet assembly baseplate, a magnet placing base, a fixed magnet, a support vertical plate, a slide table mounting vertical plate, a magnet pressing head, a Z-direction pneumatic slide table, a Y-direction pneumatic slide table and a positioning base, wherein the magnet placing base is arranged on the magnet assembly baseplate through the support vertical plate; a trough and a fixed groove are formed in the magnet placing base in an X direction; the fixed groove is positioned on the inner side of the trough; a guide groove is formed in the bottom end of the inner side of the trough; the fixed magnet is accommodated in the fixed groove; the Z-direction pneumatic slide table is arranged on the magnet placing base through the slide table mounting vertical plate; the Y-direction pneumatic slide table is arranged on the magnet assembly baseplate, and is positioned below the magnet placing base; the positioning base is arranged on the Y-direction pneumatic slide table; the magnet pressing head is arranged at the lower end of the Z-direction pneumatic slide table; and the Z-direction pneumatic slide table and the Y-direction pneumatic slide table are both connected with the electric appliance control box. The semi-automatic magnet assembly tool accelerates the operation speed, and is simple in structure and low in machining cost.

Owner:GEER TECH CO LTD

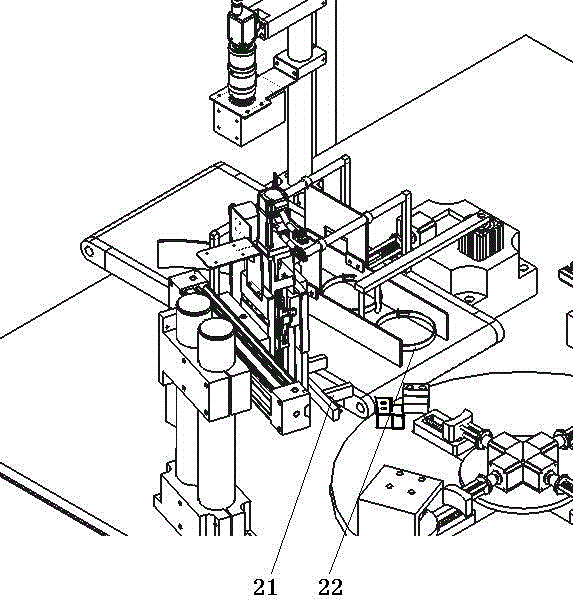

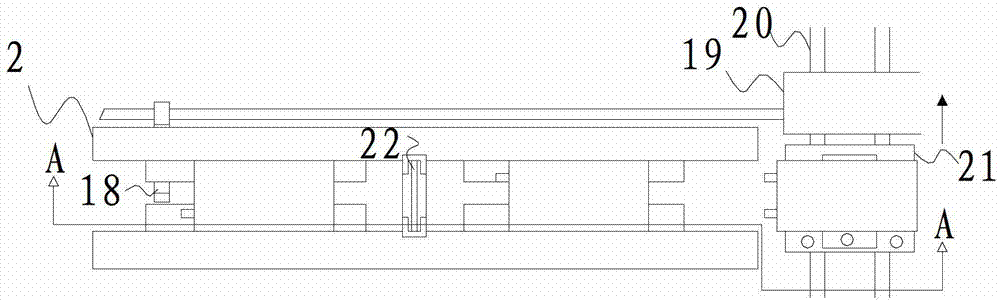

Slider lock assembly and automatic upper rail and lower rail assembly device and assembly method thereof

ActiveCN104772624AEffective automatic installationImplement automatic installationAssembly machinesEngineeringMechanical engineering

The invention discloses a slider lock assembly and automatic upper rail and lower rail assembly device and an assembly method thereof. The slider lock assembly and automatic upper rail and lower rail assembly device comprises a base, and also comprises a slider lock assembly mechanism, a feeding mechanism and an upper rail and lower rail assembly mechanism which are arranged on the base, the feeding mechanism is arranged on the base, the slider lock assembly mechanism is arranged on the feeding mechanism, and the upper rail and lower rail assembly mechanism is arranged at the upper end of the feeding mechanism in a clearance fit manner, and is matched with the slider lock assembly mechanism. By utilizing the inherent structural characteristics and mutual matching relation of an upper rail and a slider lock, by means of an ingenious upward pushing and downward placement structure, the slider lock assembly and automatic upper rail and lower rail assembly device can effectively fasten the slider lock onto the upper rail, thus realizing the automatic mounting of the slider lock; moreover, by sufficiently utilizing the matching between the upper rail structure and a lower rail structure and arranging a plurality of moving structures, the slider lock assembly and automatic upper rail and lower rail assembly device can effectively carry out the automatic assembly of the upper rail and the lower rail, realizes fully automated production, and greatly increases the efficiency of production; furthermore, manpower cost is reduced, and the degree of dependence on workers is decreased greatly.

Owner:苏州泰克诺机电有限公司

Electronic element rubber pipe and rubber plug assembly machine

The invention relates to an electronic element rubber pipe and rubber plug assembly machine in the field of automatic equipment. The machine comprises a frame, and an automatic assembly platform arranged at the top of the frame; the automatic assembly platform comprises a rubber pipe unloading mechanism, a rubber pipe conveying mechanism, a rubber plug unloading mechanism, a rubber pipe back end positioning mechanism, a shifting mechanism and a discharge mechanism; the shifting mechanism can be directly adopted to synchronously realize receiving, shifting and discharge actions, so that more shifting structures can be saved, and the overall structure is simple; compared with traditional manual assembly, an automatic production line is used for operating to realize automatic feeding, automatic assembly and automatic discharge, so that the working efficiency is high, the rejection rate is lower, and a lot of labor costs can be saved; the whole assembly process is precise in positioning; packing pipes are positioned from all directions; real-time detection can be realized after assembly; and precise assembly and precise detection can be realized through automatic machinery.

Owner:广州市速波光电科技有限公司

Automatic assembly mechanism for battery cover plate

PendingCN110212231ARealize automatic assemblyRealize automatic feeding processAssembling battery machinesFinal product manufactureRivetRotating disc

The invention discloses an automatic assembly mechanism for a battery cover plate. The automatic assembly mechanism comprises a rotating disc for carrying out a rotational motion, a plurality of bearing jigs arranged on the rotating disc at equal angle, and a positive and negative electrode rivet material loading unit, a lower insulation pad material loading assembly unit, an aluminum cover platematerial loading assembly unit, a negative electrode insulation pad and pressure plate material loading assembly unit, a positive insulation pad and pressure plate material loading assembly unit, a rivet riveting unit and a product material discharging unit which are arranged around the rotating disc annularly. According to the automatic assembly mechanism, automatic assembly of the battery coverplate can be realized, so that the production assembly efficiency and assembly quality are improved greatly.

Owner:S Z JUHONG COMP TELECOMM TECH CO LTD

Automatic production line for connectors and production technology of automatic production line

ActiveCN111230460ARealize automatic assemblyIncrease production capacityMetal working apparatusLaser beam welding apparatusProduction lineElectrical connection

The invention discloses an automatic production line for connectors, and relates to the technical field of production of the connectors. The automatic production line comprises a rotating transportation mechanism, a feeding mechanism, an assembling mechanism and a discharging mechanism; the feeding mechanism, the assembling mechanism and the discharging mechanism are circumferentially distributedon the side of the rotating transportation mechanism; the rotating transportation mechanism comprises a rotating component, a plurality of fixing components and a push-and-pull component matched withthe fixing components; the plurality of fixing components are circumferentially distributed at the upper end of the rotating component; the feeding mechanism comprises a sleeve feeding component and asleeve moving component; the sleeve feeding component is arranged on the side of the rotating component; and the sleeve moving component is arranged between the sleeve feeding component and the rotating component. According to the automatic production line, automatic assembling and welding production of the grid electrical connectors is realized, step-by-step processing by the aid of multiple devices is not required, manual product moving steps and positioning steps are reduced, and thus the production efficiency of the grid electrical connectors is improved effectively.

Owner:广州贝兴电子科技有限公司

Automatic assembling mechanism of connector assembly

ActiveCN105773147ARealize automatic assemblyImprove assembly accuracyAssembly machinesMechanical engineering

The invention discloses an automatic assembling mechanism of a connector assembly. The automatic assembling mechanism comprises a base, a first feeding device fixed to the base, a second feeding device positioned near the first feeding device, a conveying rail butted with the first feeding device, a first and a second cutting device sequentially arranged on the two sides of the conveying rail, a collecting guide rail device butted with the second feeding device, a plugging cutting device, a secondary hold-down device, a third cutting device, a turnover device and a detection device, wherein the plugging cutting device, the secondary hold-down device, the third cutting device and the turnover device are sequentially arranged on the two sides of the collecting guide rail device, and the detection device is arranged between the first and second cutting devices. The automatic assembling mechanism realizes automatic precise conveying action, automatic assembling action and automatic turnover action on the connector assembly, and is high in production efficiency, high in qualified rate and low in cost.

Owner:KUSN 3E ELECTRONICS

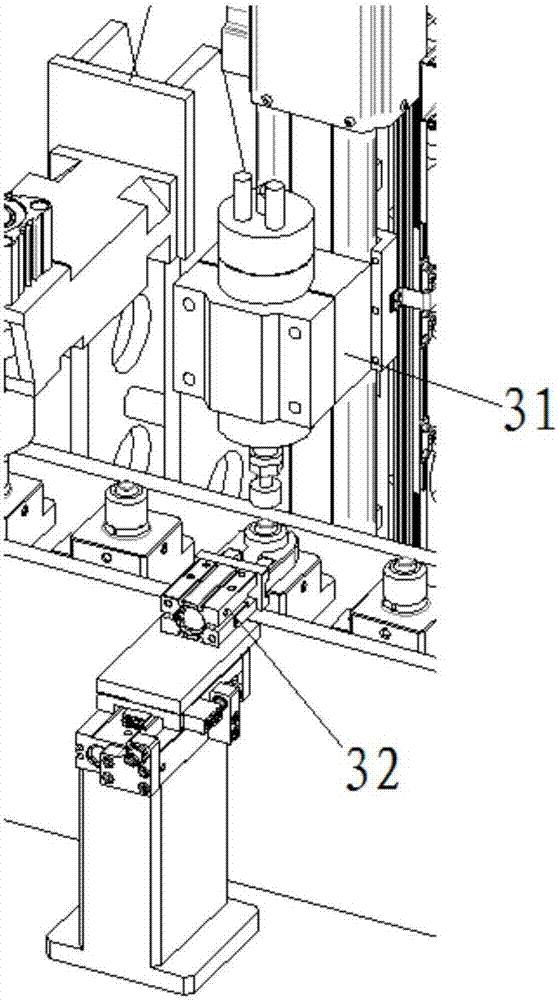

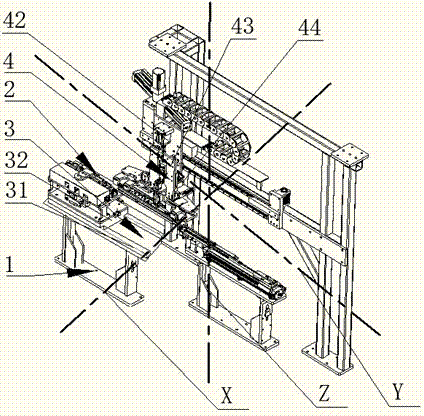

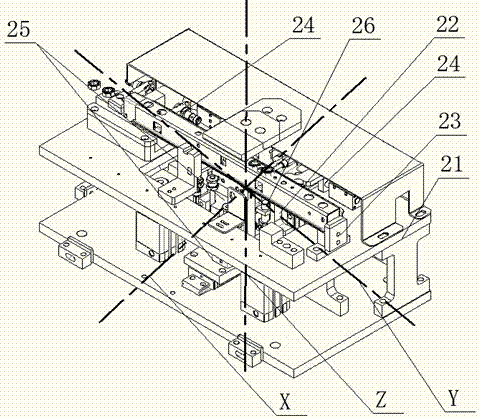

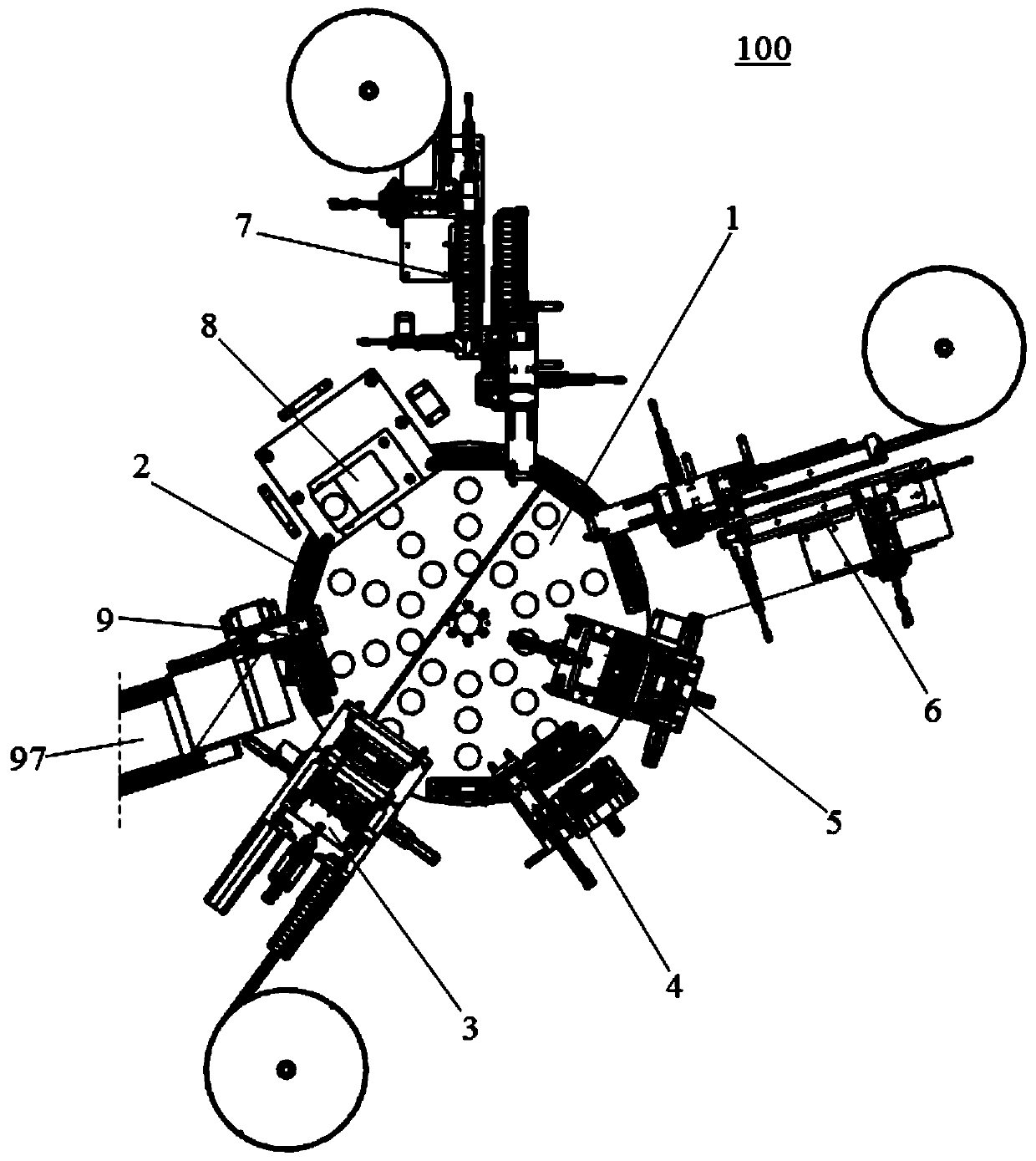

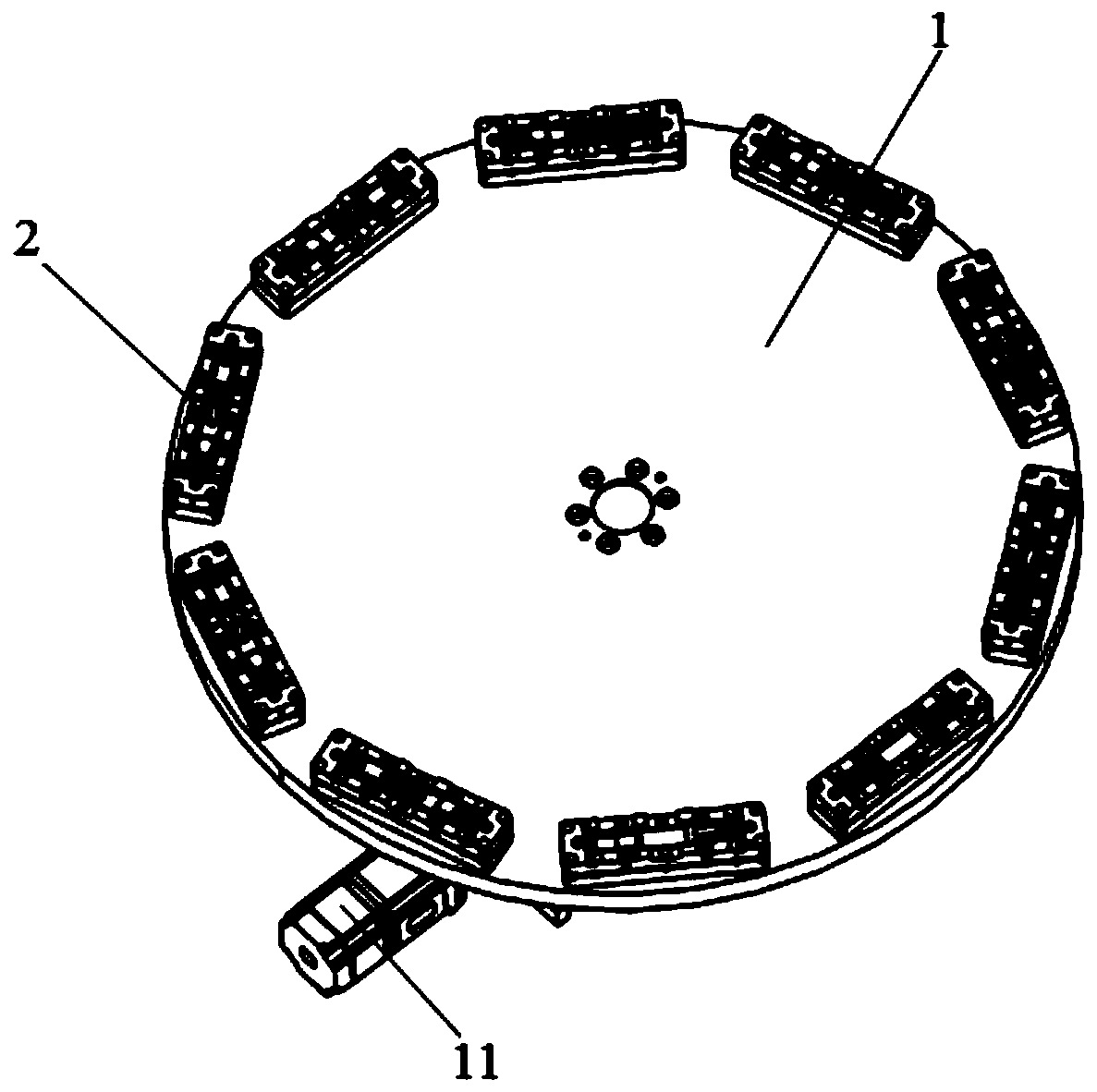

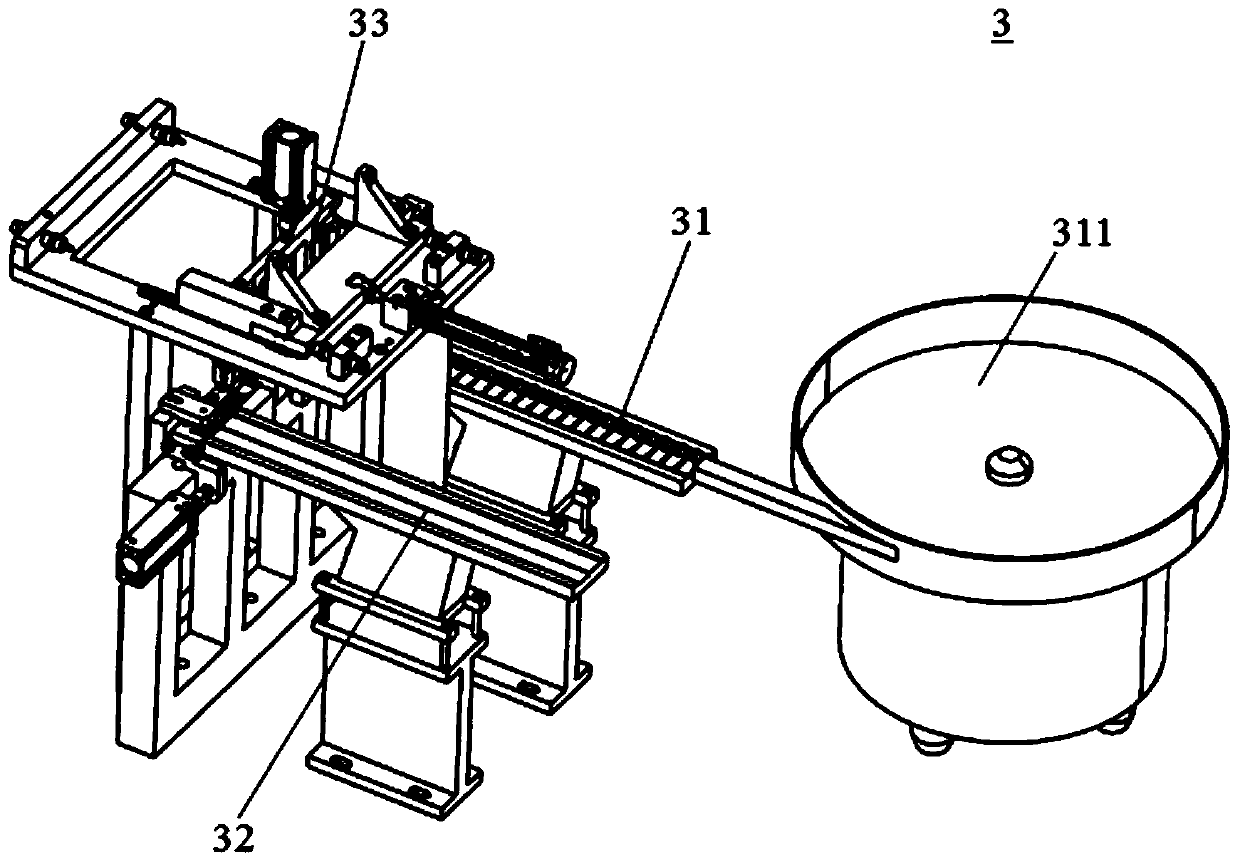

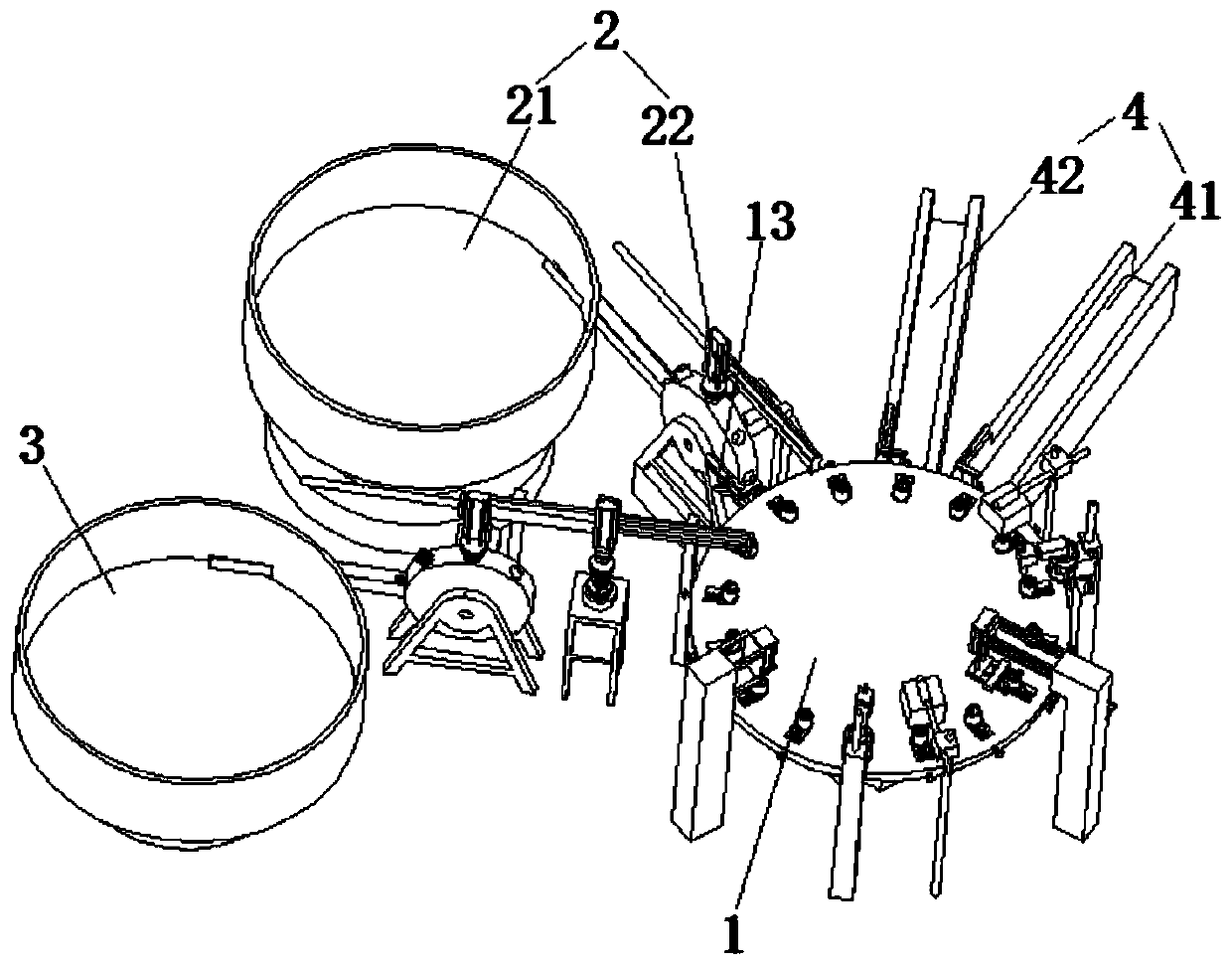

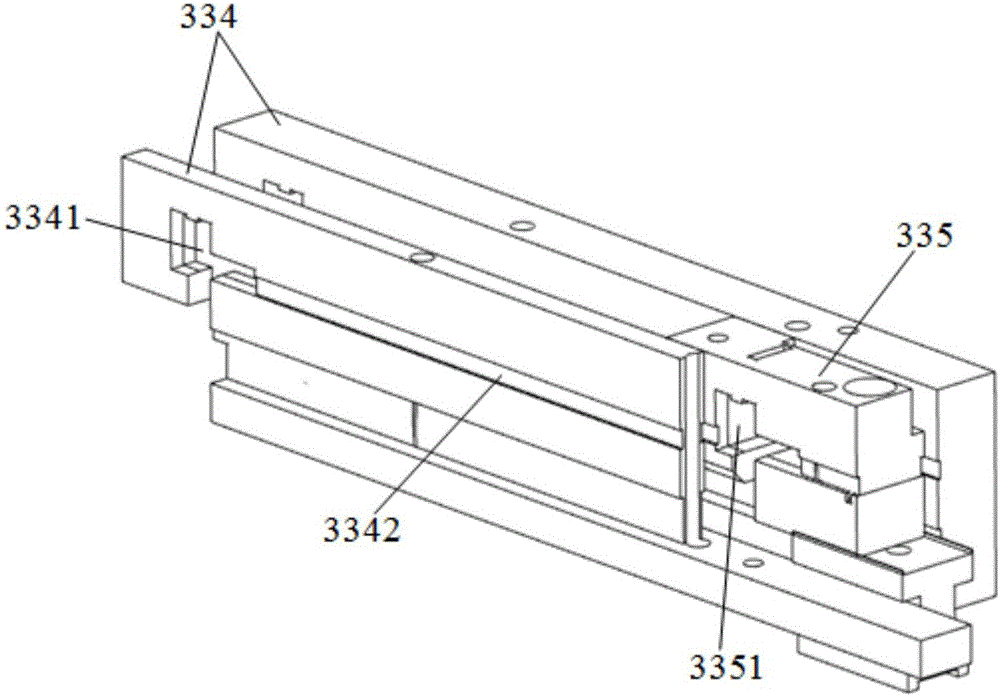

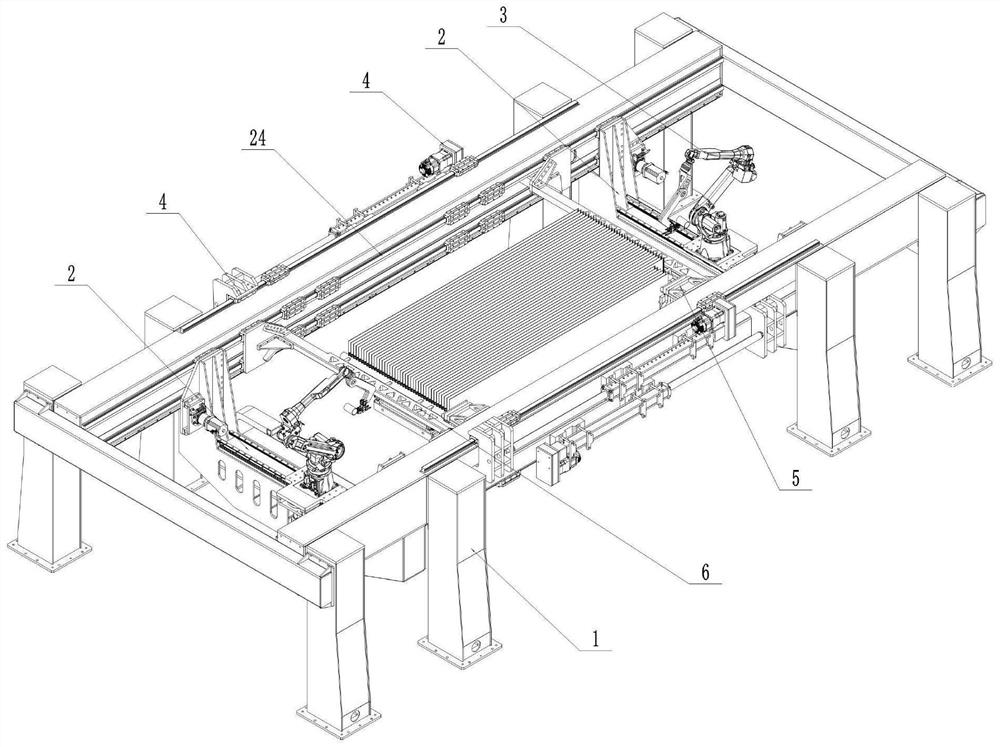

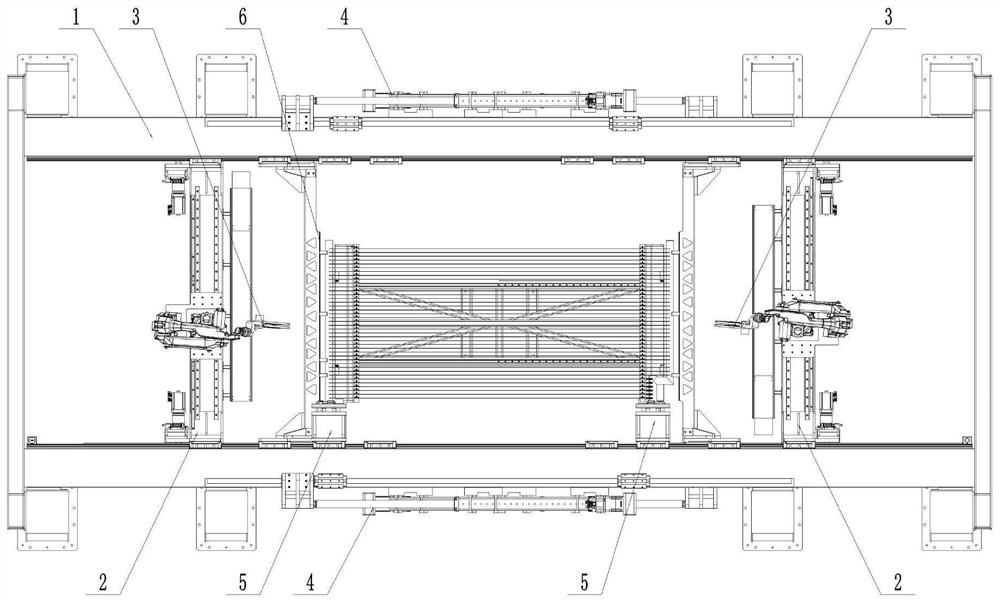

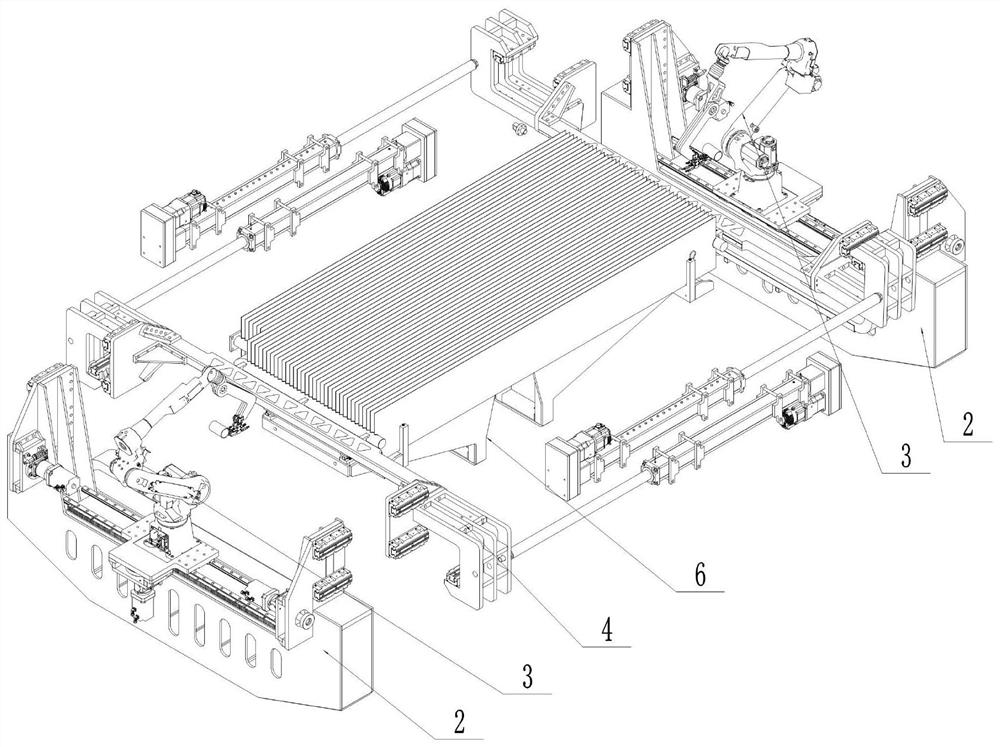

Flexible assembling and welding workstation for finned radiator for transformer and production method

PendingCN113182724ARealize automatic assemblyRealize automatic weldingProgramme-controlled manipulatorWelding/cutting auxillary devicesTransformerEngineering

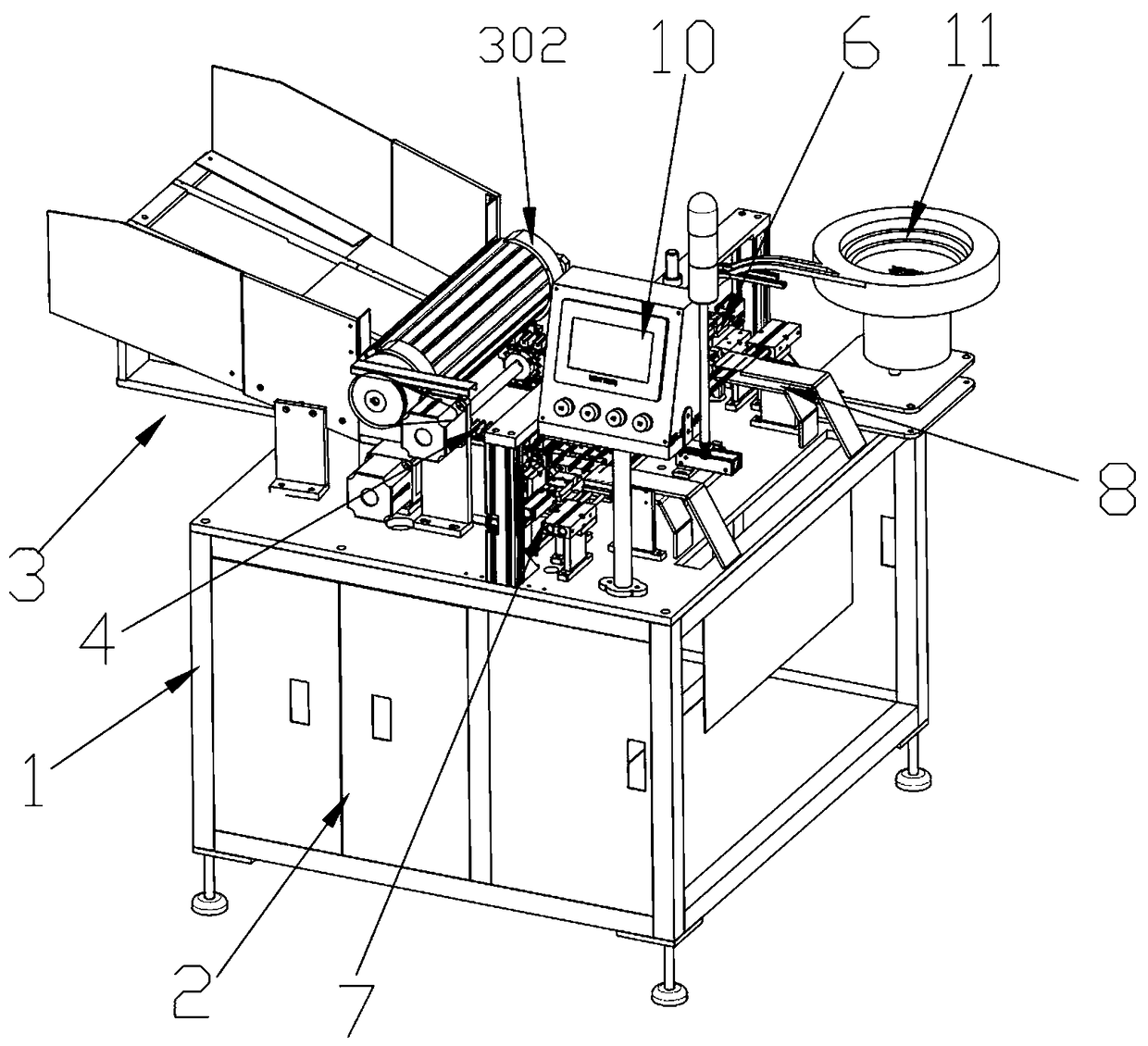

The invention discloses a flexible assembling and welding workstation for a finned radiator for a transformer and a production method, and relates to the technical field of finned radiators. The workstation comprises a supporting frame (1), a robot external shaft (2), a welding robot and welding gun (3), a centering sliding table (4), follow-up calipers (5) and a positioning comb plate (6), a flexible assembly welding production method is adopted, the robot external shaft (2), the centering sliding table (4) and the follow-up calipers (5) use the same track, the purpose of consistent foundation is achieved, and the positioning comb plate (6) can be compatible with conveying modes such as a conveying vehicle, a hoisting mode and a truss mode. According to the flexible assembling and welding workstation, according to the production mode and the process method of an existing finned radiator, the flexible assembly welding of finned radiator unit pieces and an oil collecting pipe is automatically upgraded, so that the problem of high manual labor intensity in a field production mode is solved, and the consistency of the welding quality of the unit pieces and the oil collecting pipe is also improved.

Owner:SHENYANG TIANTONG ELECTRICITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com