Clamp assembling machine

A clamp group and clamp technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency, wrong direction, increase of labor force and production cost, etc., so as to improve work efficiency and reduce production cost , to avoid the wrong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

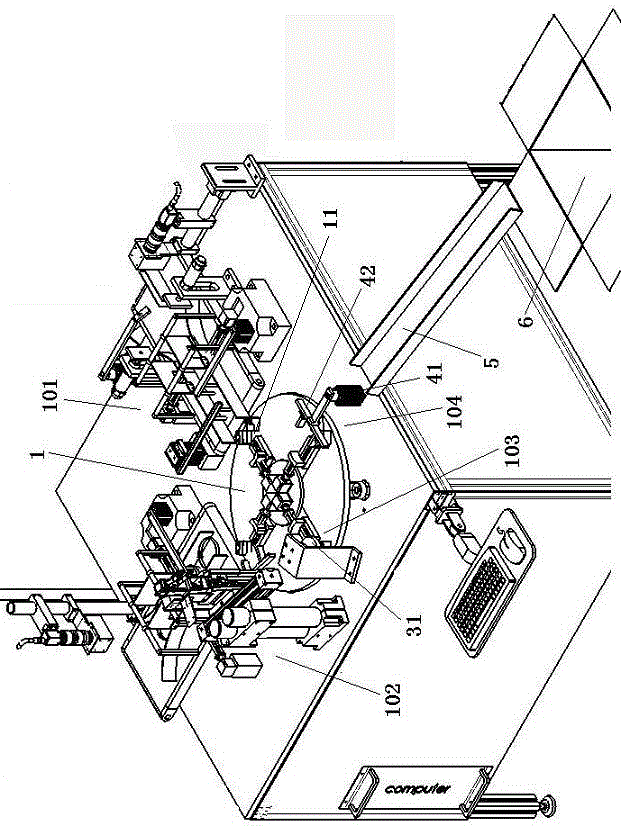

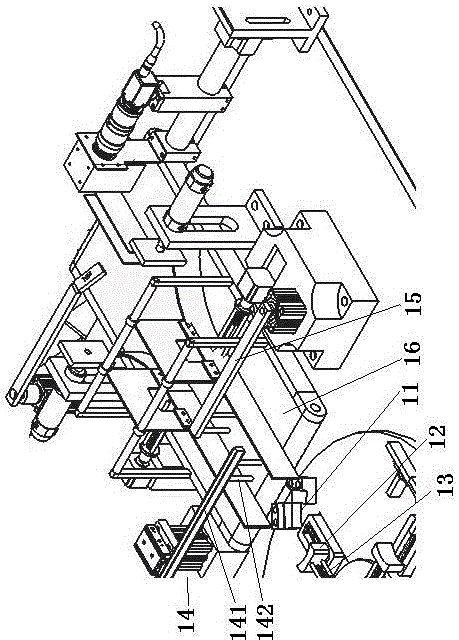

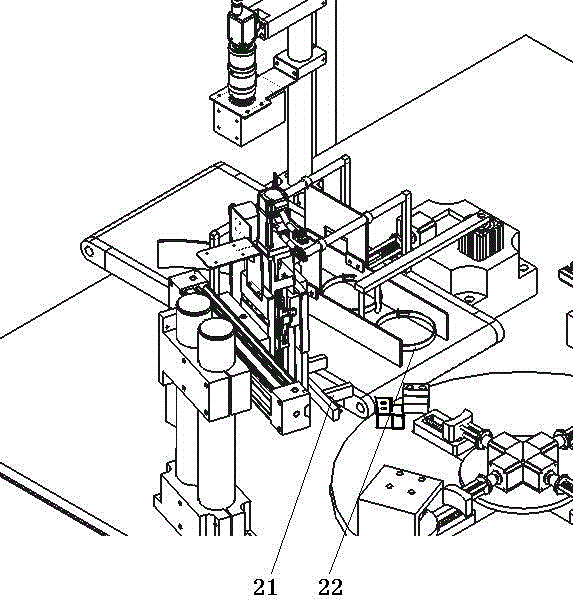

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0022] like figure 1 , figure 2 and image 3 As shown, the hoop assembling machine of the present invention includes a turntable 1 with four stations. The turntable is driven by a driving mechanism and rotates 90 degrees each time, so that each station rotates to the next station in turn. Two vibrating plates can be arranged outside the turntable 1, one of which is adjusted to output the flat outer hoop sequentially through vibration adjustment, and the other vibrating plate is output to the vertical inner hoop sequentially through vibration adjustment.

[0023] At the first station 101, after judging the direction of the screw head on the outer hoop according to the image of the outer hoop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com