Patents

Literature

3868results about How to "Smooth feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

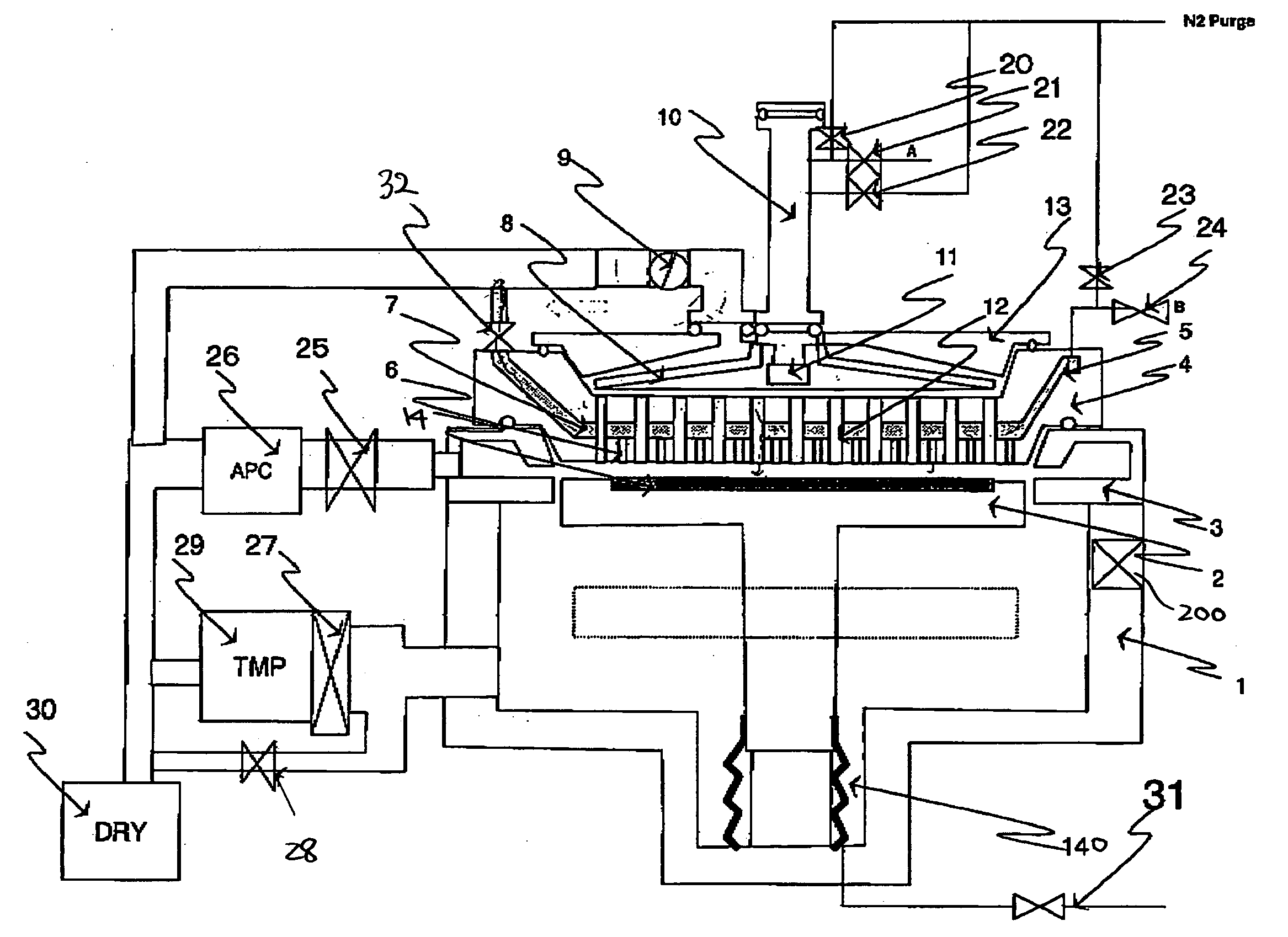

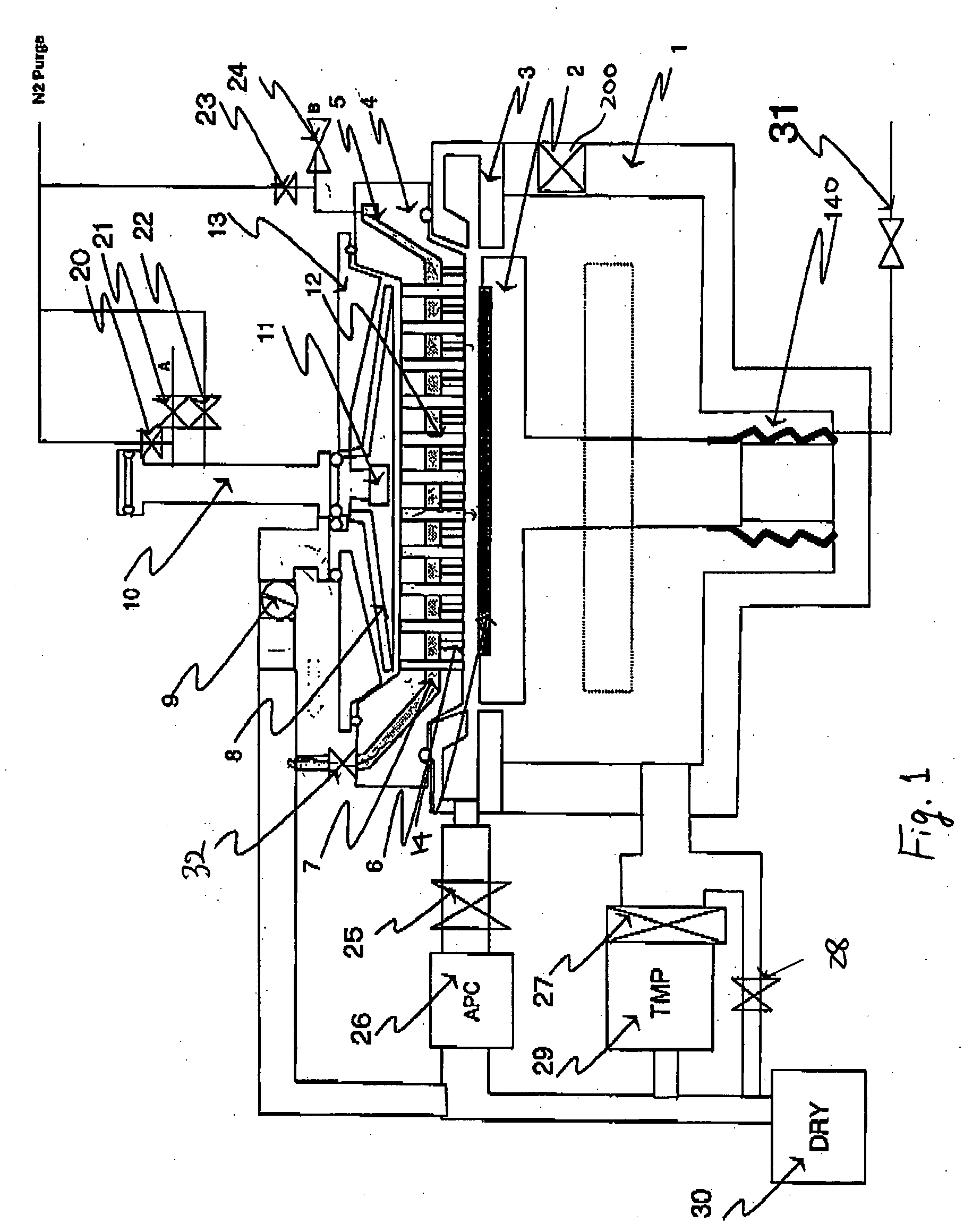

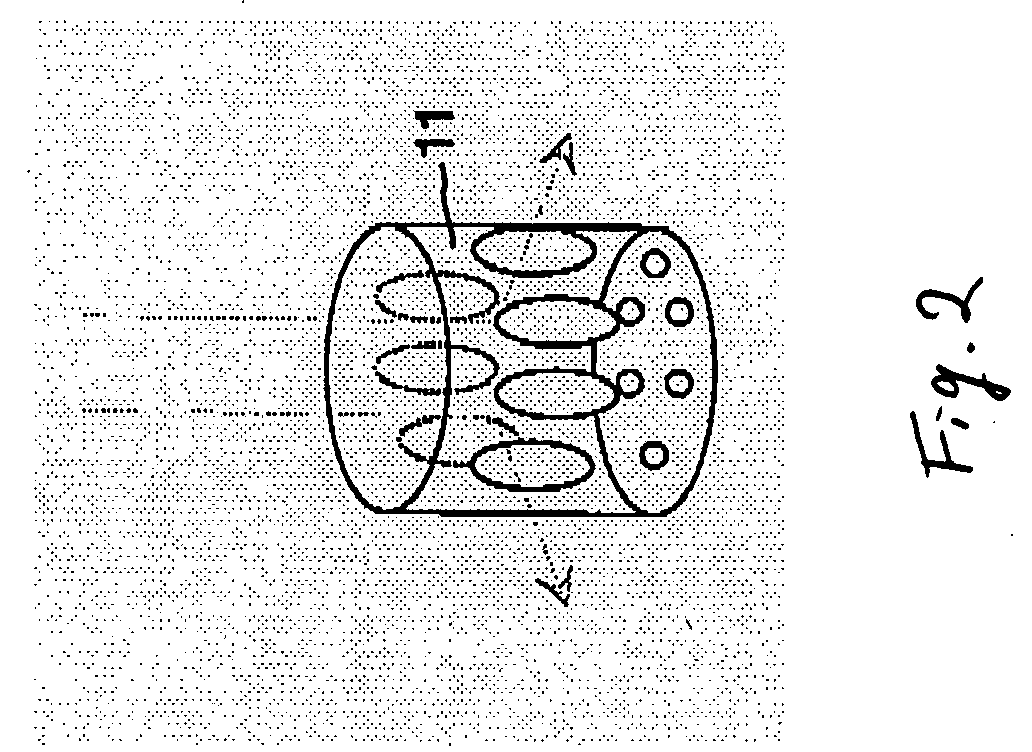

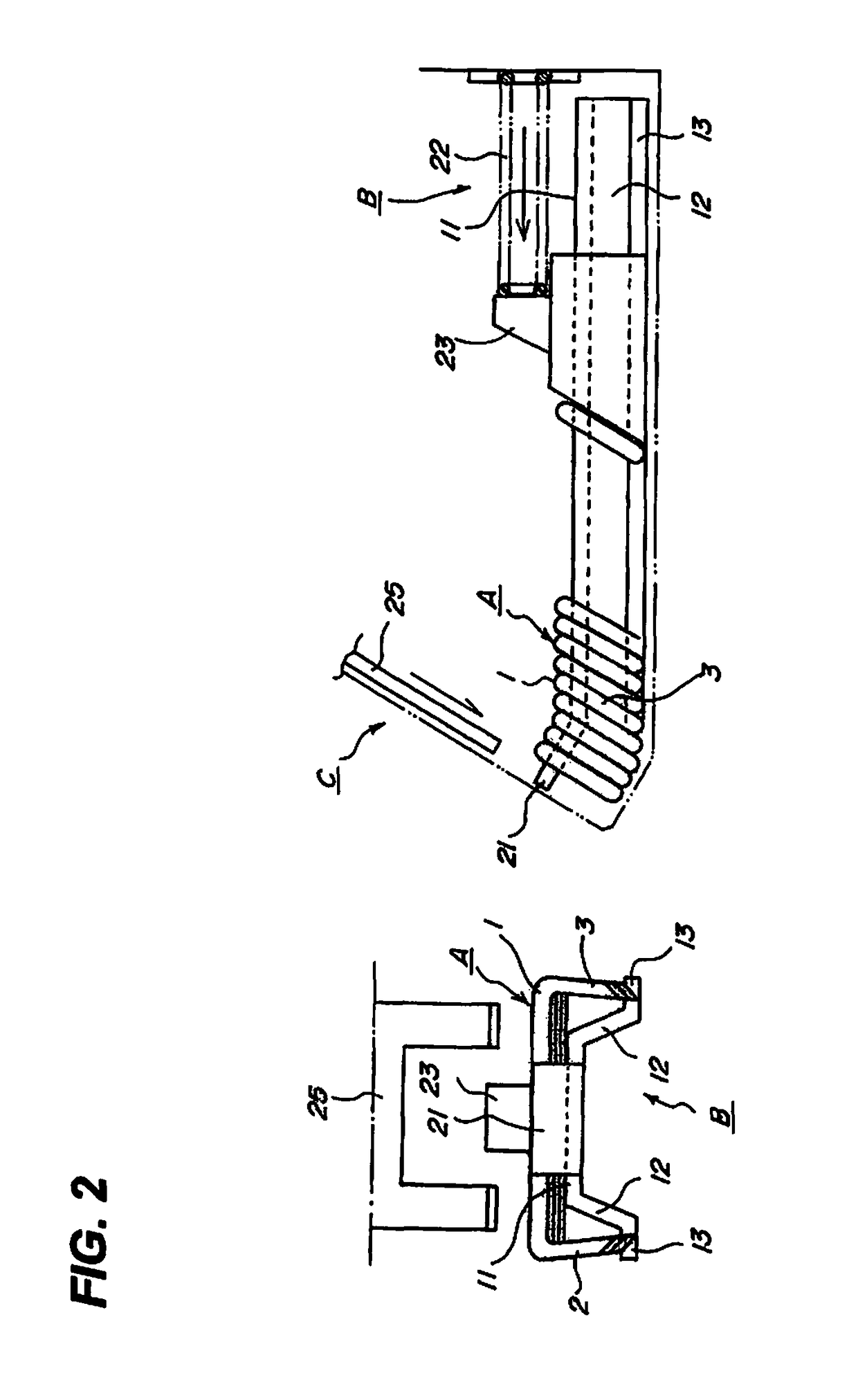

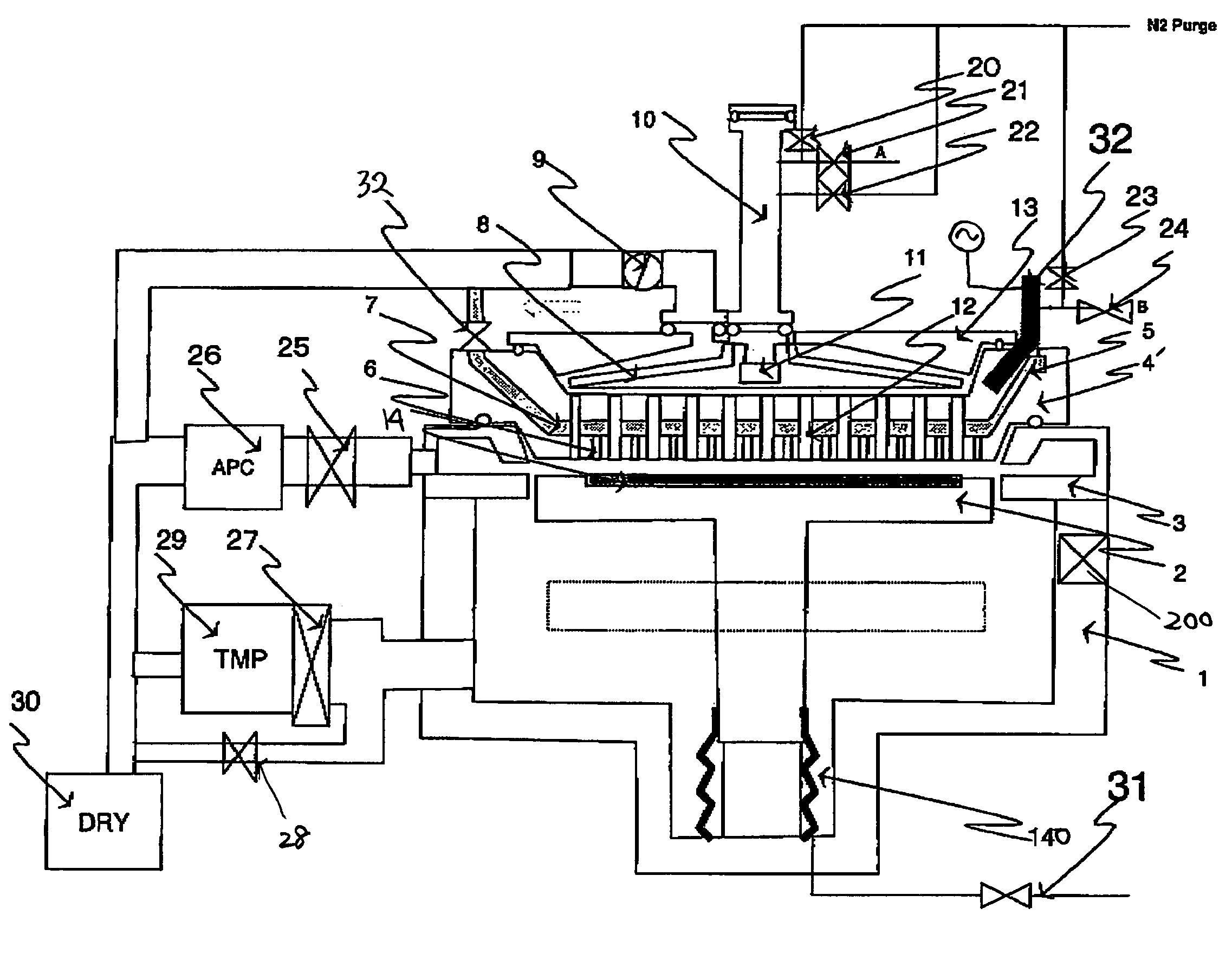

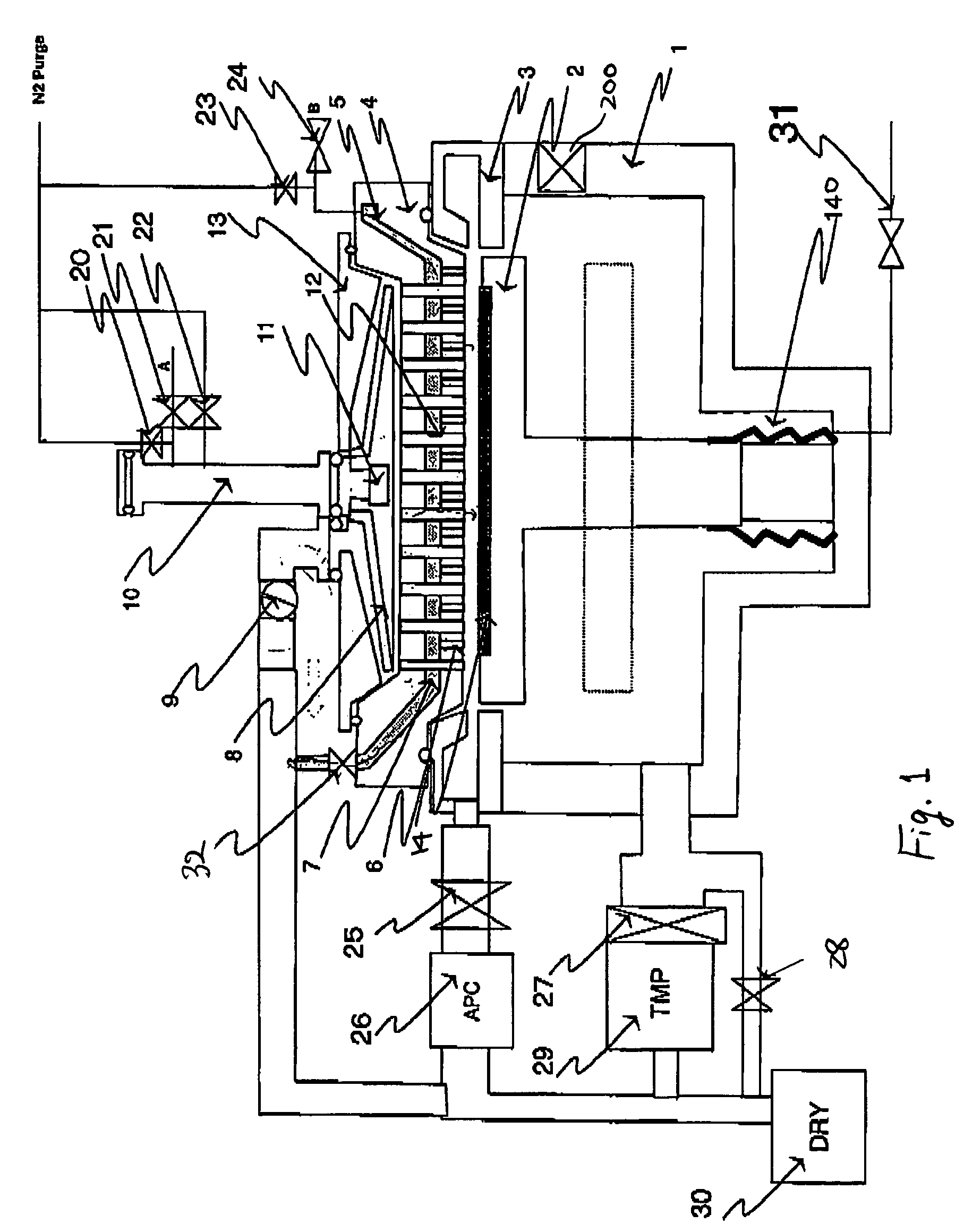

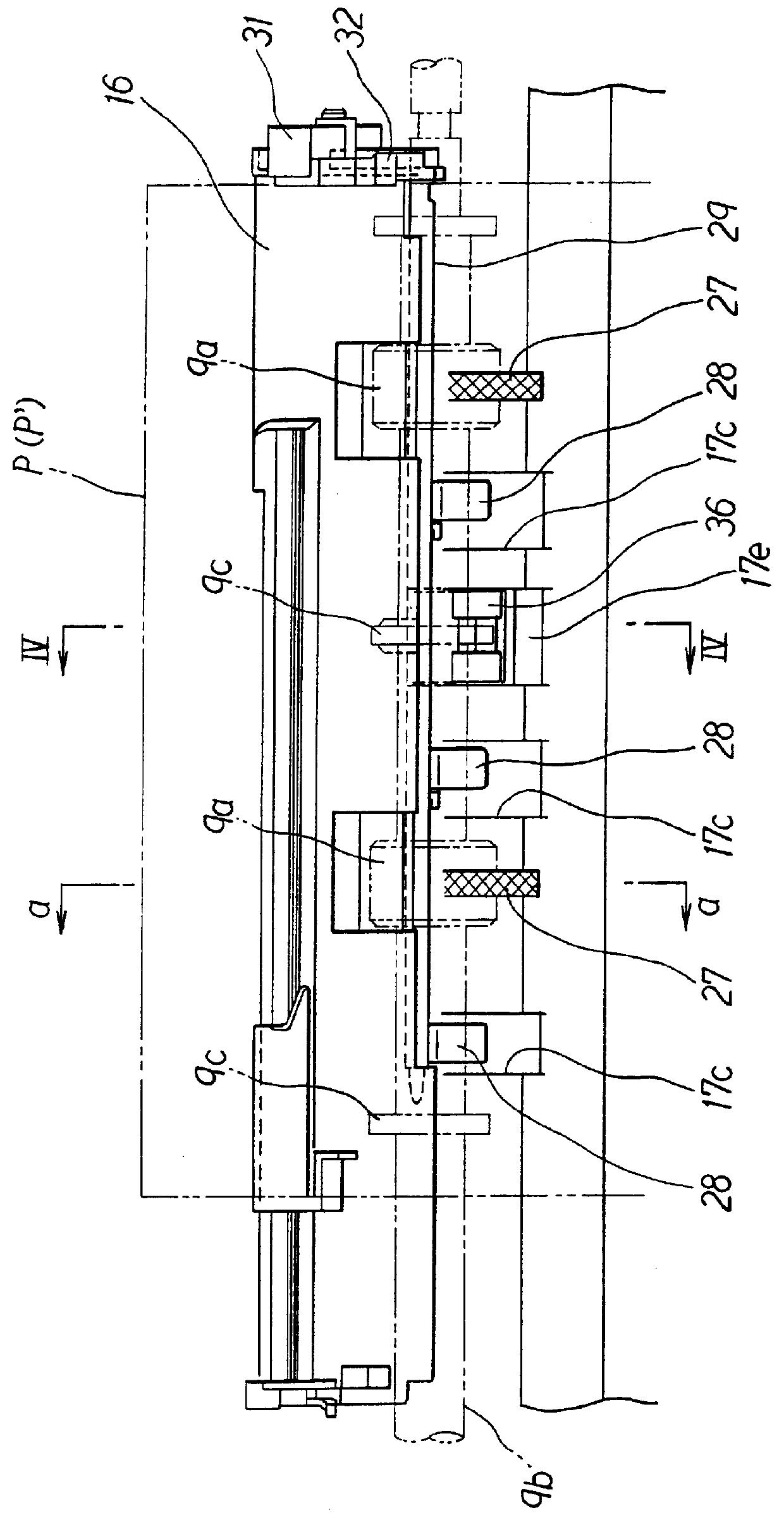

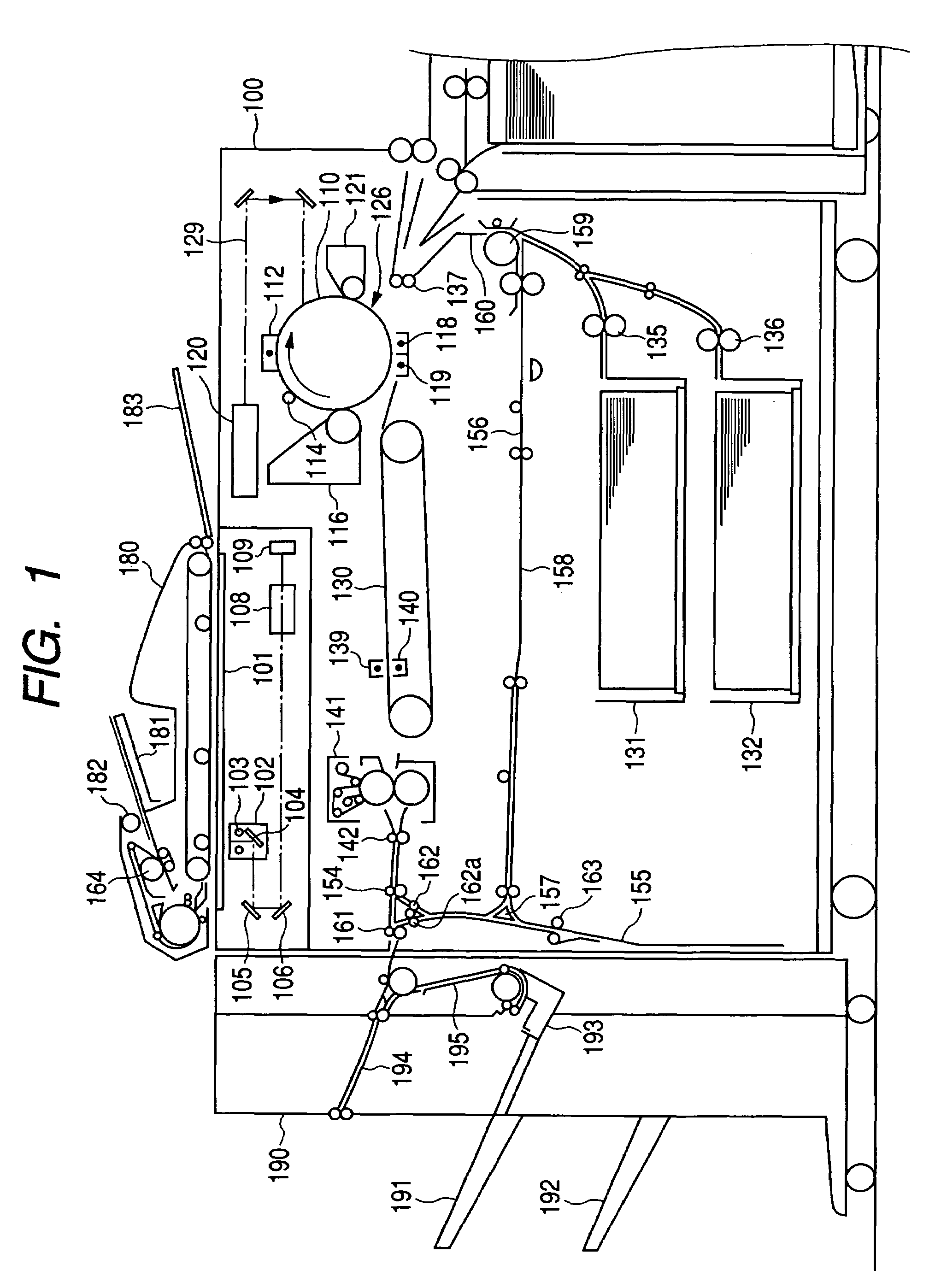

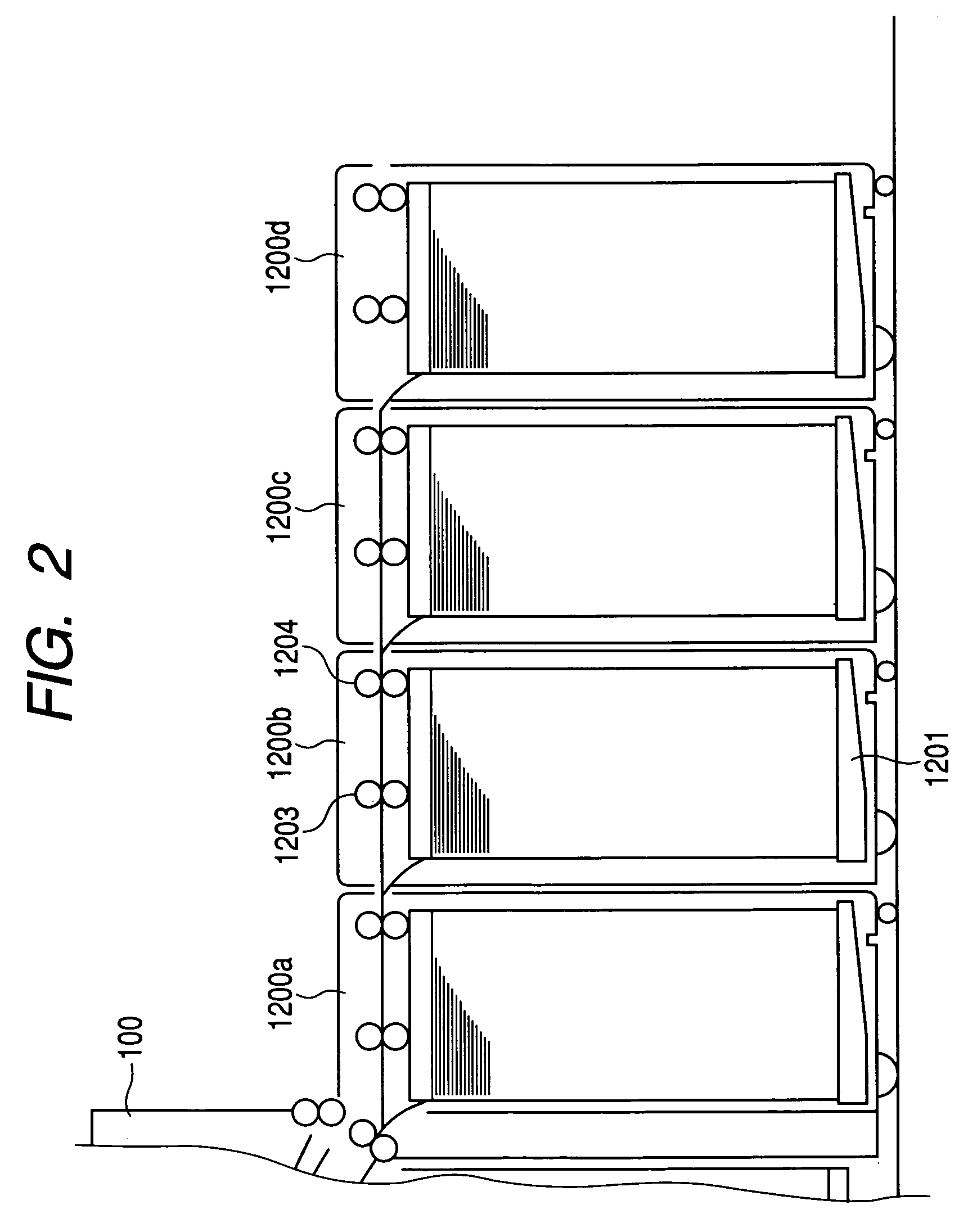

Thin-film deposition apparatus

ActiveUS20050229848A1Hinder reactionAvoid reactionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

A gas-feeding apparatus configured to be connected to an evacuatable reaction chamber includes a gas-distribution head for introducing gases into the chamber through a head surface. The gas-feeding head includes a first section for discharging a gas through the head surface toward a susceptor and a second section for discharging a gas through the head surface toward the susceptor. The first and the second sections are isolated from each other in the gas-distribution head, at least one of which section is coupled to an exhaust system for purging therefrom a gas present in the corresponding section without passing through the head surface.

Owner:ASM JAPAN

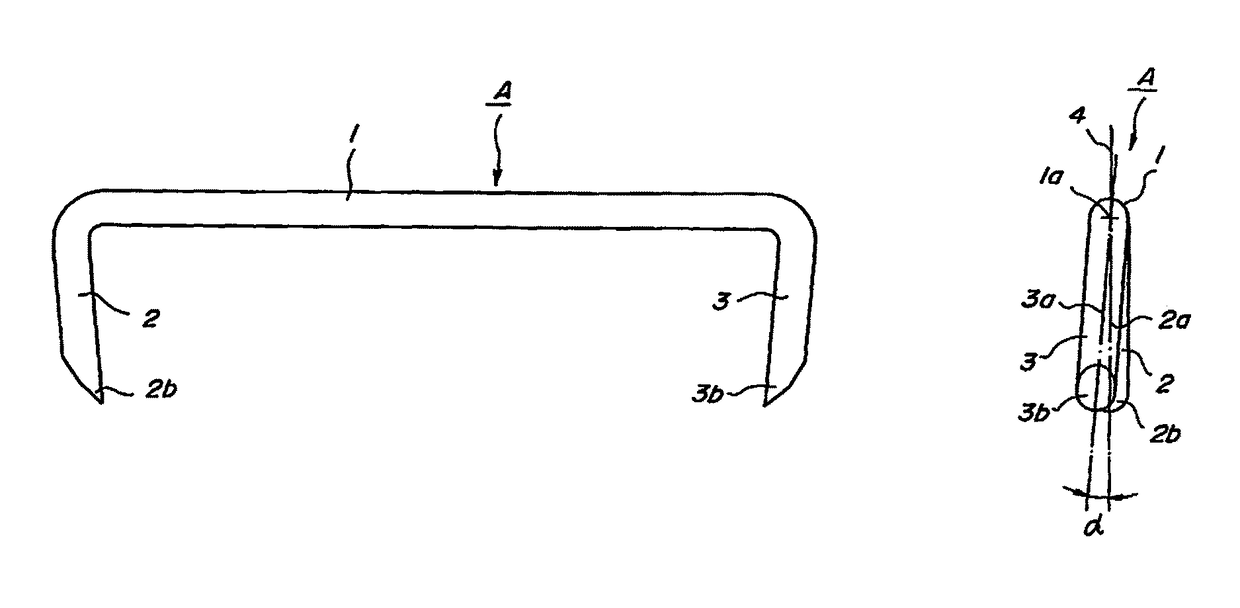

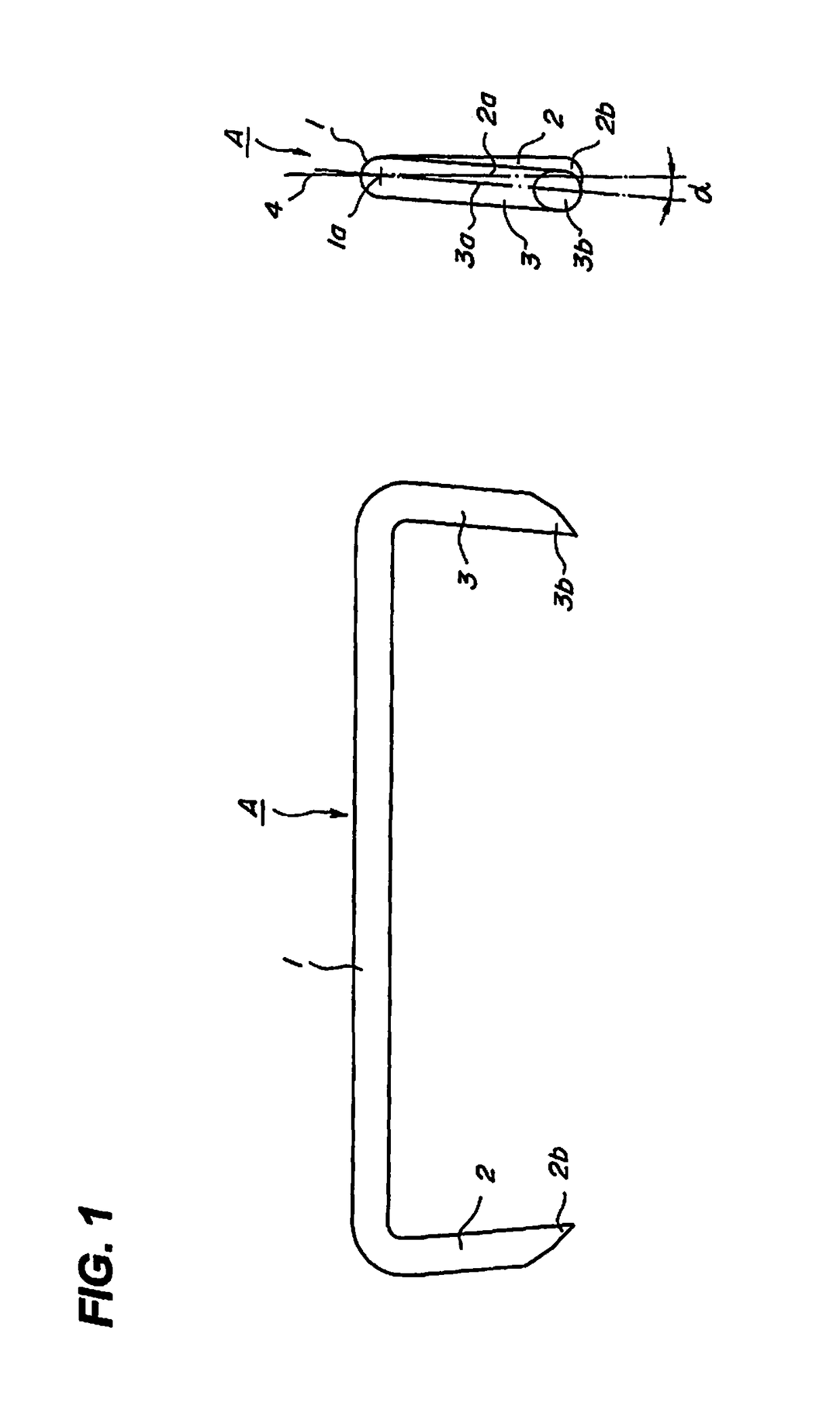

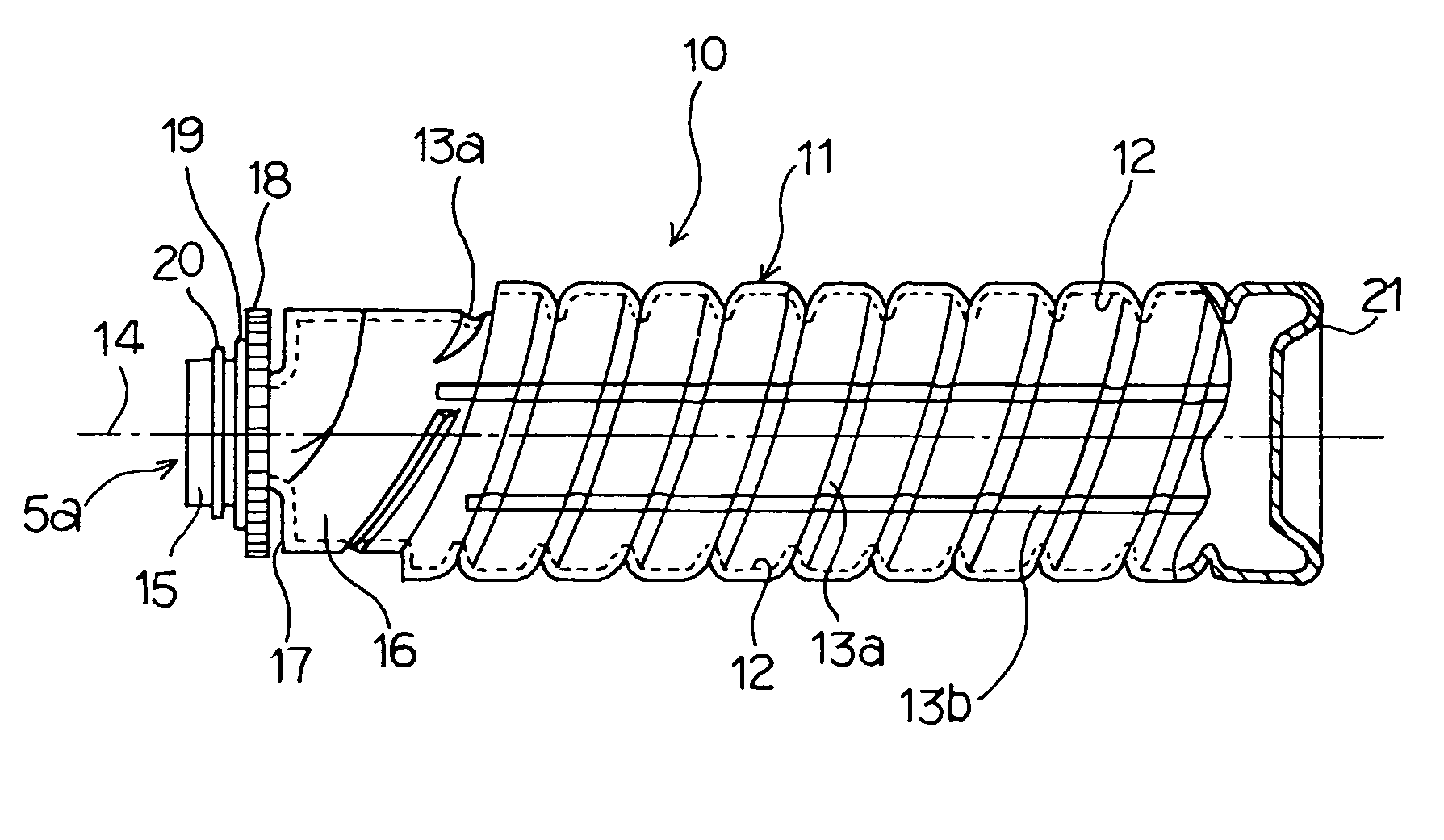

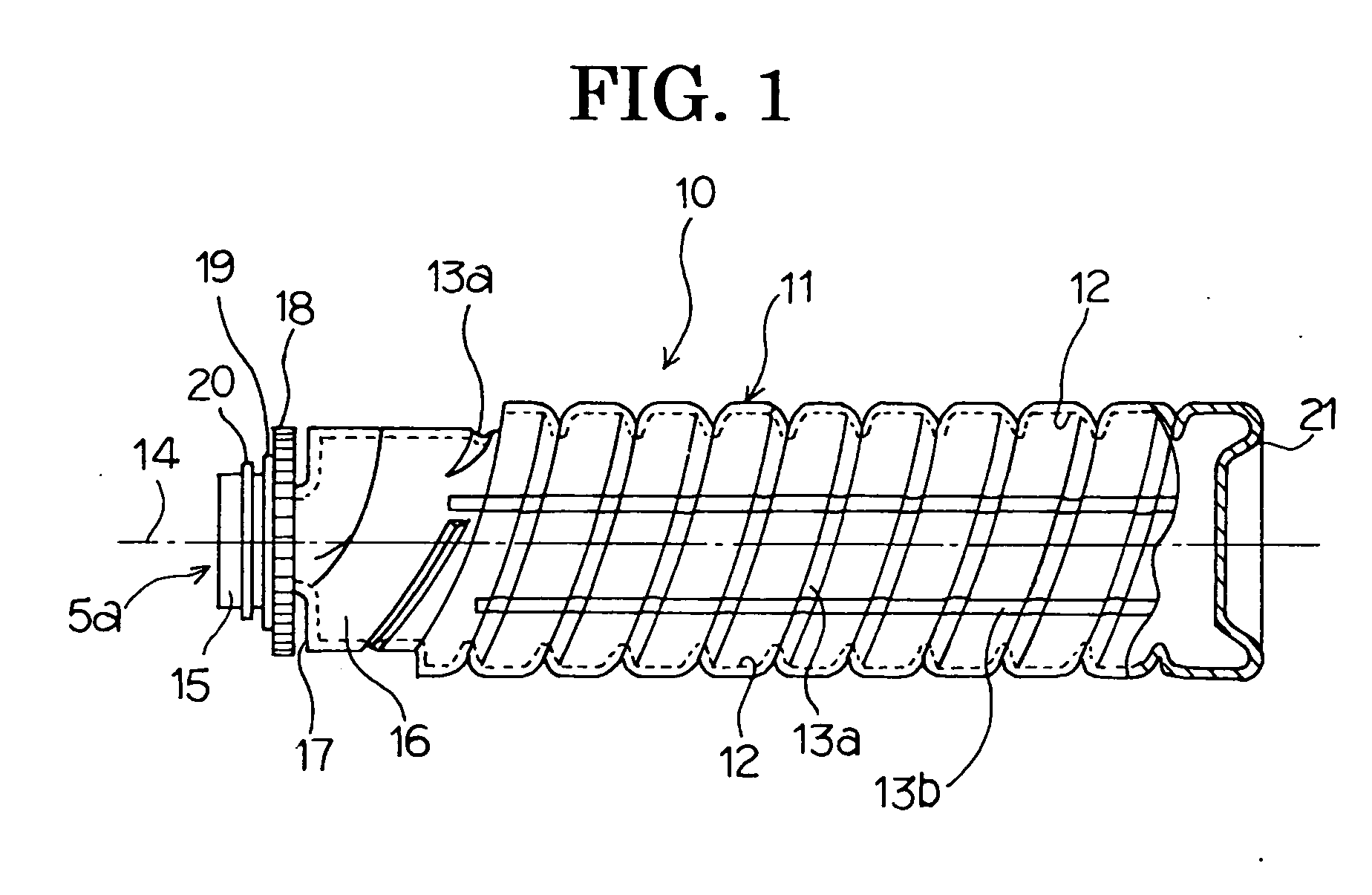

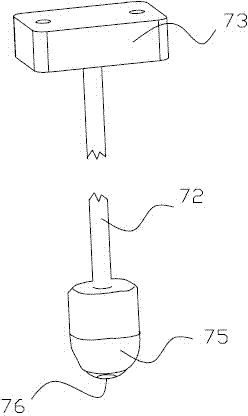

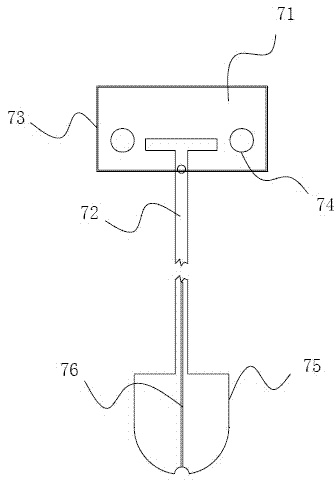

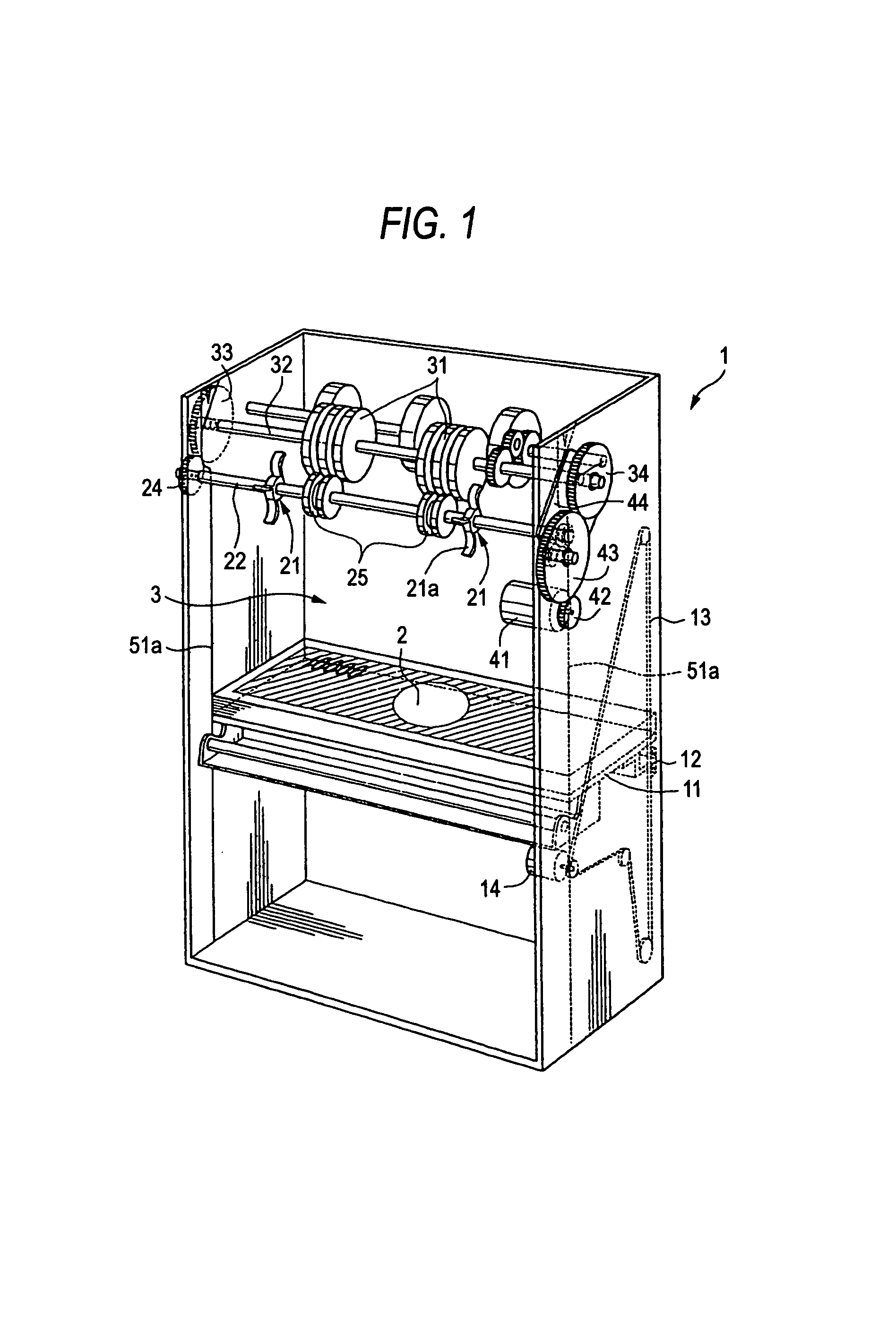

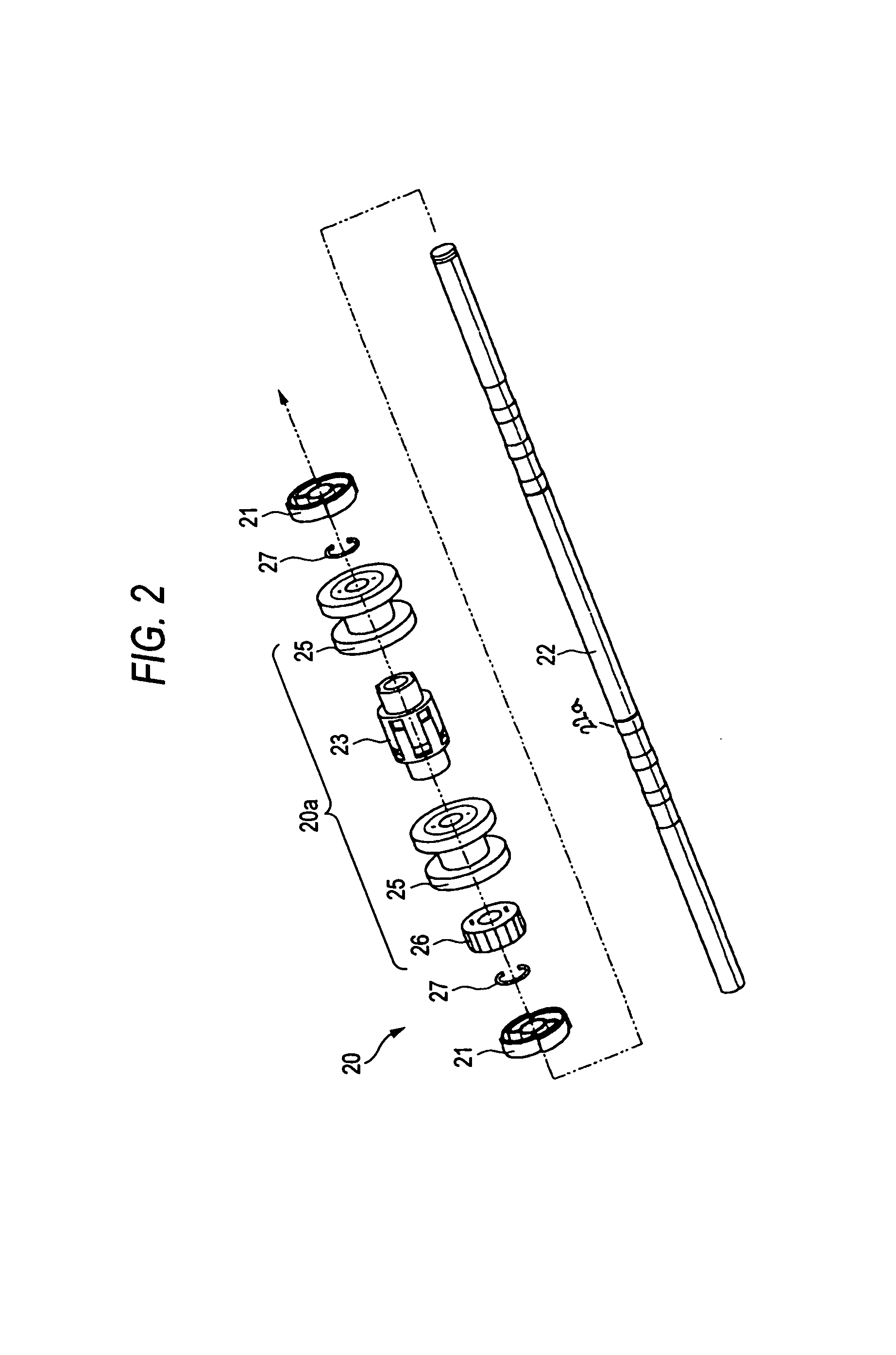

Medical staple and magazine

ActiveUS9610079B2Easy to useSmooth feedingSuture equipmentsStapling toolsEngineeringMechanical engineering

There are provided a medical staple realizing smooth feeding when loaded in a magazine and a magazine which can realize stable feeding by using the medical staple. Where the medical staple includes a body portion; and a pair of legs formed at both ends of the body portion, wherein the legs are tilted at an angle in which the legs become closer to each other and either one leg is twisted with respect to a plane including the body portion and the other leg in the out-of-plane direction. The magazine includes a body guiding portion which has a size substantially equal to or slightly smaller than the length of the body portions of the staples and carries and guides the body portions thereon; wherein the plurality of staples are loaded in a state where the legs are tilted to the downstream side in the discharge direction and the body portions to the upstream side in the discharge direction.

Owner:MATSUTANI SEISAKUSHO CO LTD

Thin-film deposition apparatus

ActiveUS7273526B2Avoid reactionPurge very quicklySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEngineering

Owner:ASM JAPAN

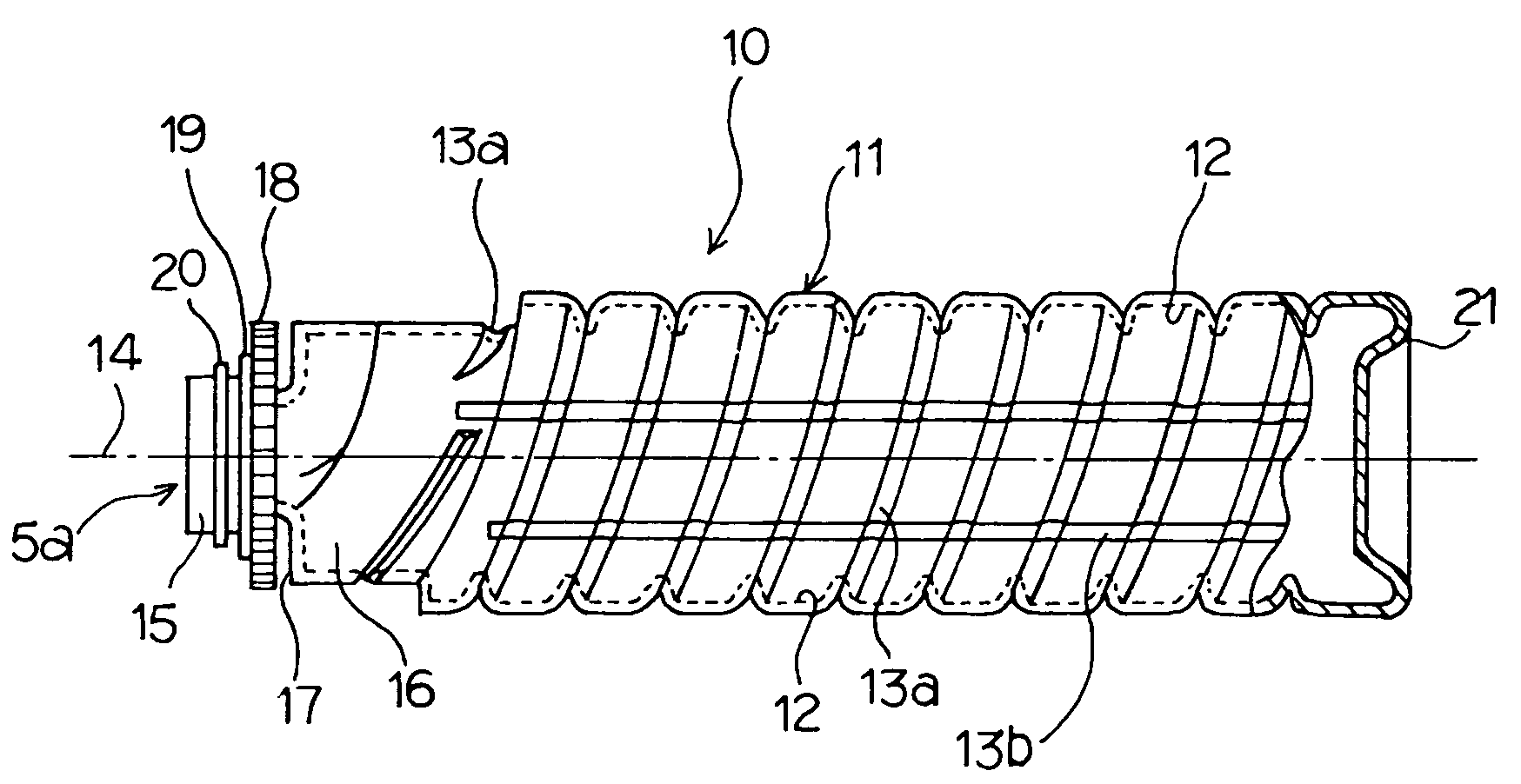

Toner bottle, process for producing the same, toner container, and toner cartridge, and, image forming apparatus and image forming process

ActiveUS20070077100A1Small possibilityImprove accuracyPowdered material dispensingElectrographic process apparatusGear wheelEngineering

The object of the present invention is to provide toner bottles and the like in which the possibility to damage the ring gear, in particular the teeth of the ring gear, is remarkably suppressed at processing the toner bottle such as handling, packaging, and transporting, thus packaging and transporting are principally possible without cushioning materials. Accordingly, provided is a toner bottle comprising a cylindrical bottle having a bottom, a cylindrical aperture for supplying a toner, and a ring gear, wherein a helical concave is formed on the side wall of the cylindrical bottle along the axis of the cylindrical bottle, the cylindrical aperture is disposed at one end of the cylindrical bottle, the cylindrical aperture is concentric with the cylindrical bottle, and the outside diameter of the cylindrical aperture is smaller than the outside diameter of the cylindrical bottle, the ring gear is disposed on the cylindrical aperture, the ring gear is concentric with the cylindrical aperture, and the tip circle diameter of the ring gear is smaller than the outside diameter of the cylindrical bottle.

Owner:RICOH KK

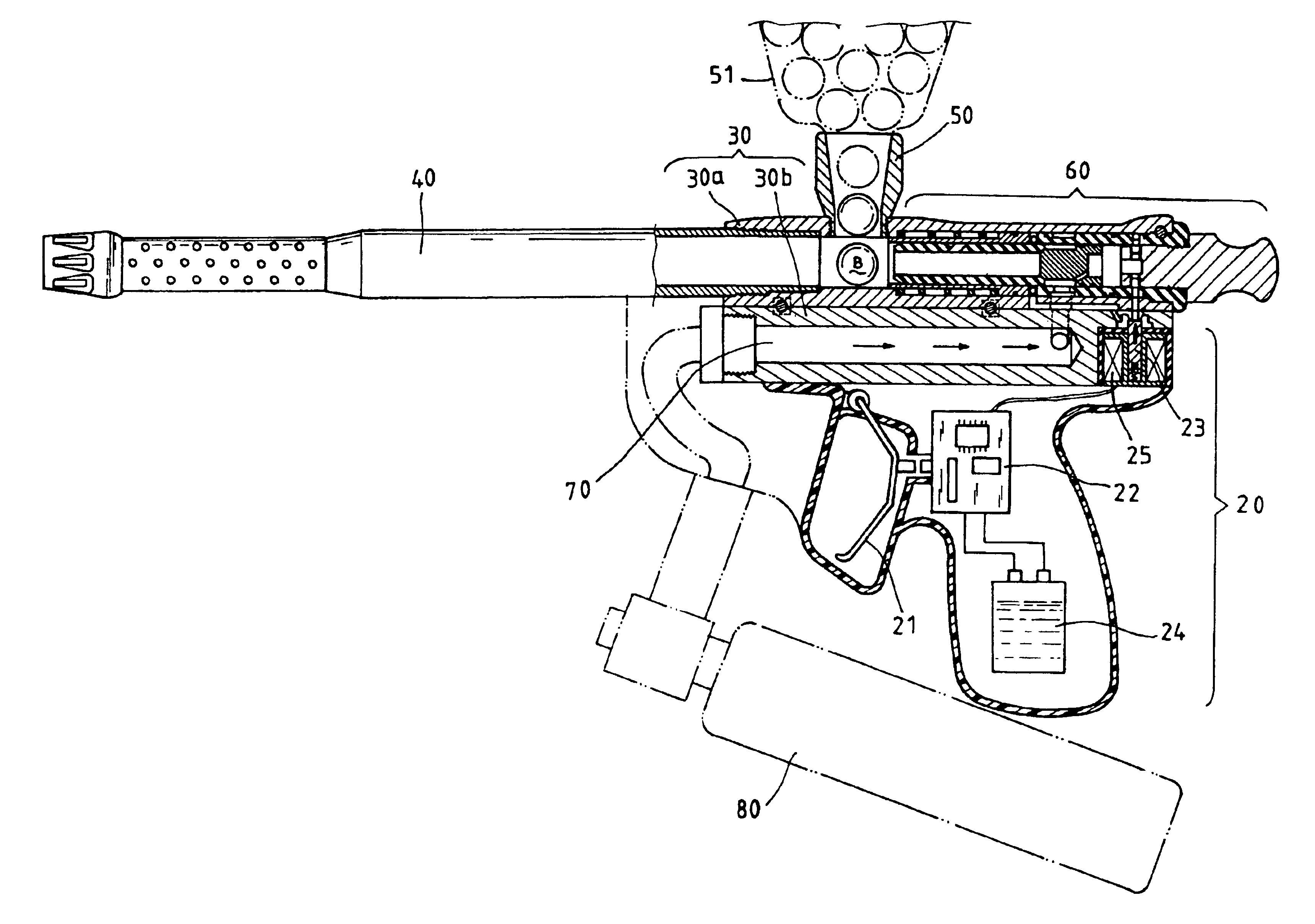

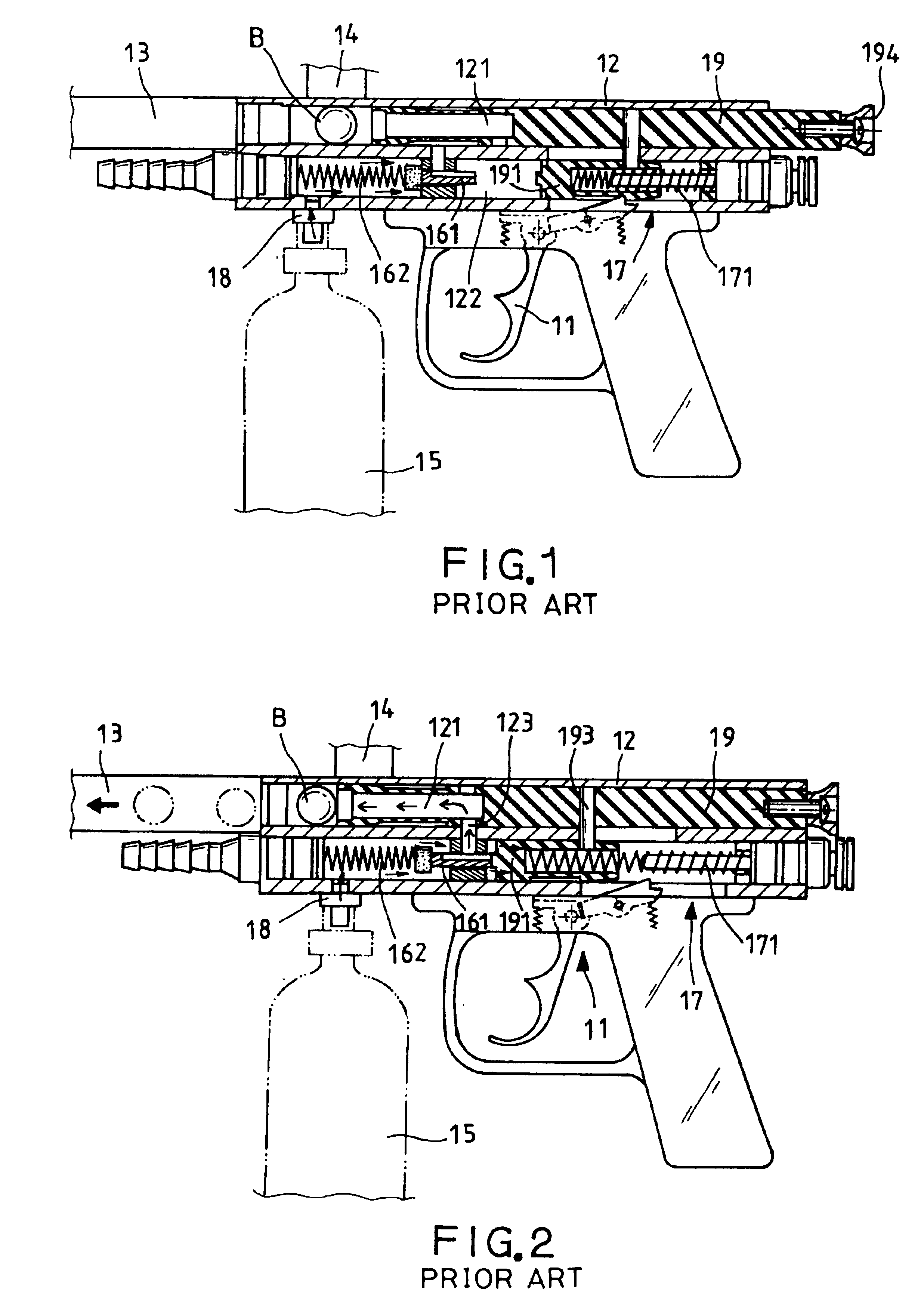

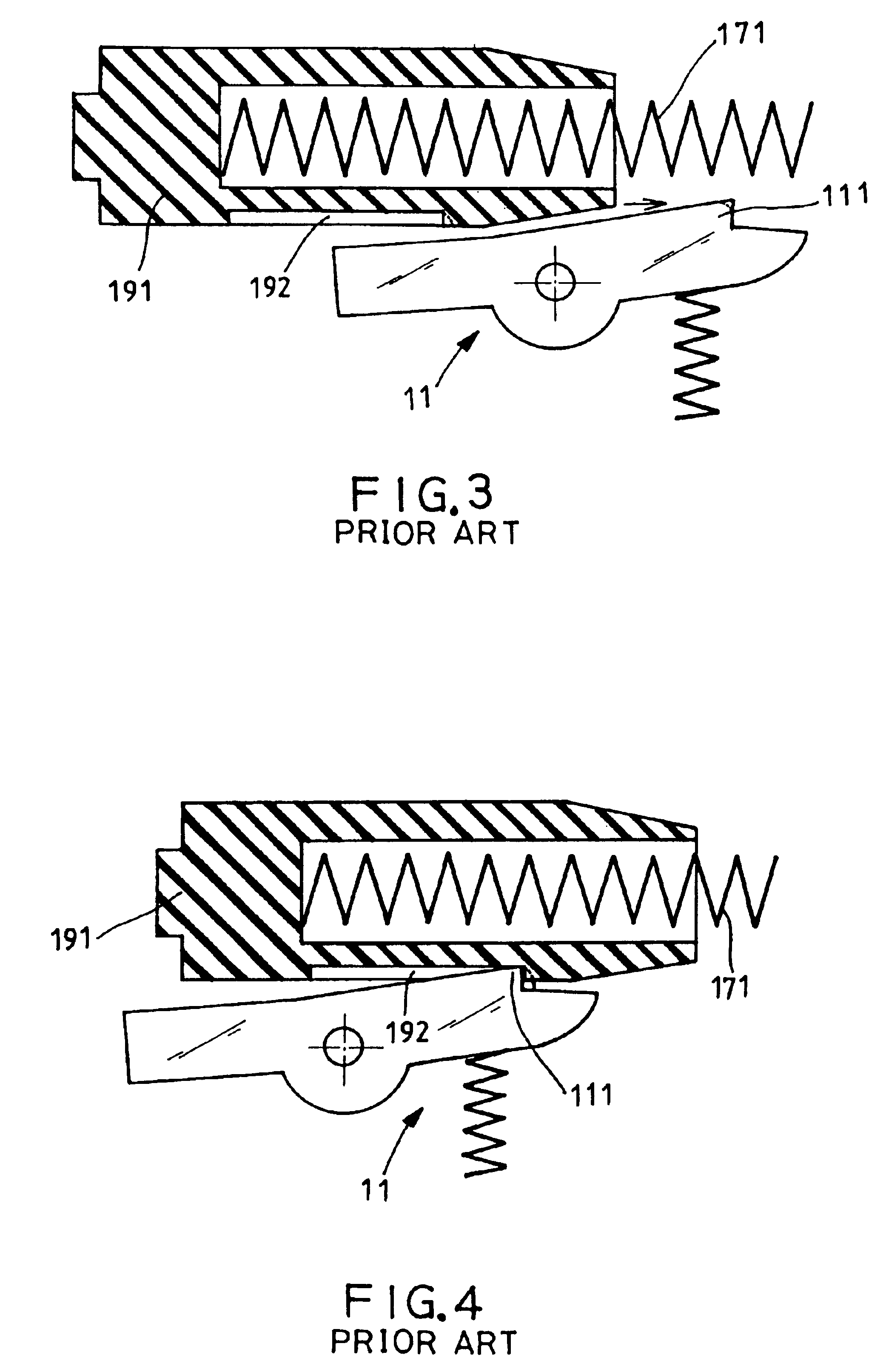

Paintgun with pneumatic feeding and discharging process

InactiveUS6925997B2More securityReduce failureWatering devicesFire rescuePressure differenceAir channel

Owner:SHENG CHIH SHENG

Toner container and image forming apparatus

ActiveUS7313349B2Small possibilitySmooth feedingPowdered material dispensingElectrographic process apparatusGear wheelEngineering

The object of the present invention is to provide toner bottles and the like in which the possibility to damage the ring gear, in particular the teeth of the ring gear, is remarkably suppressed at processing the toner bottle such as handling, packaging, and transporting, thus packaging and transporting are principally possible without cushioning materials. Accordingly, provided is a toner bottle comprising a cylindrical bottle having a bottom, a cylindrical aperture for supplying a toner, and a ring gear, wherein a helical concave is formed on the side wall of the cylindrical bottle along the axis of the cylindrical bottle, the cylindrical aperture is disposed at one end of the cylindrical bottle, the cylindrical aperture is concentric with the cylindrical bottle, and the outside diameter of the cylindrical aperture is smaller than the outside diameter of the cylindrical bottle, the ring gear is disposed on the cylindrical aperture, the ring gear is concentric with the cylindrical aperture, and the tip circle diameter of the ring gear is smaller than the outside diameter of the cylindrical bottle.

Owner:RICOH KK

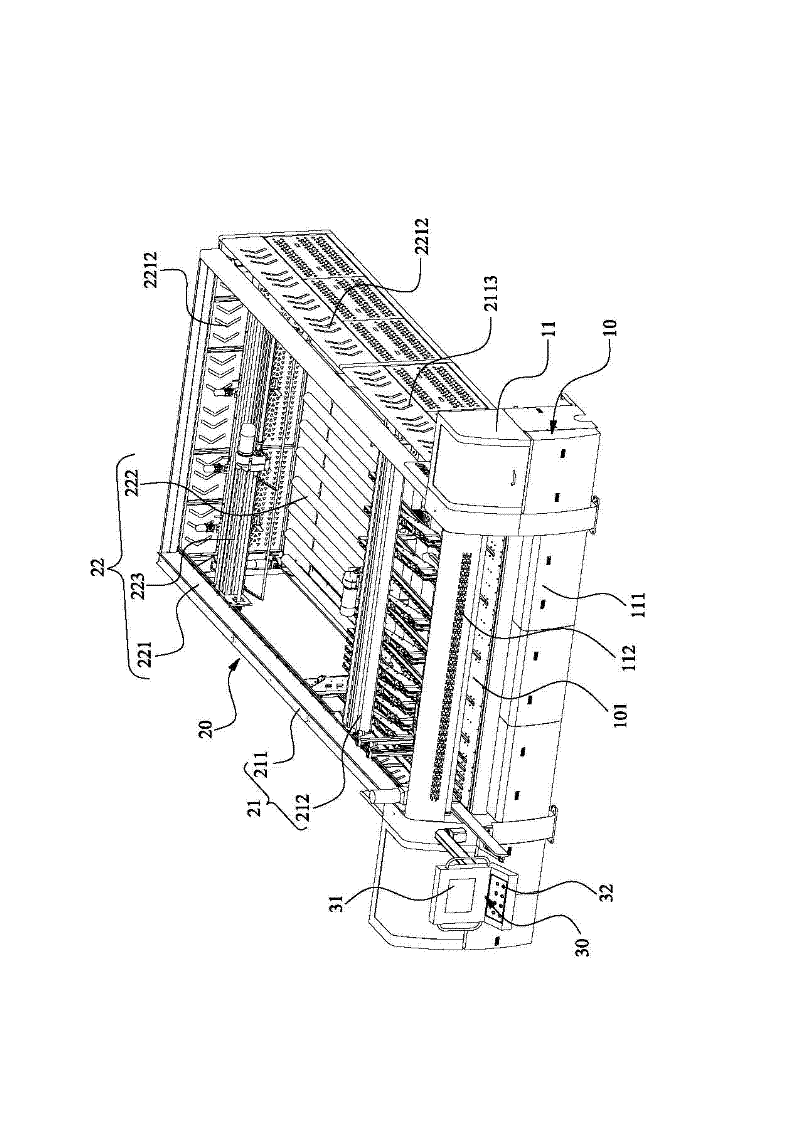

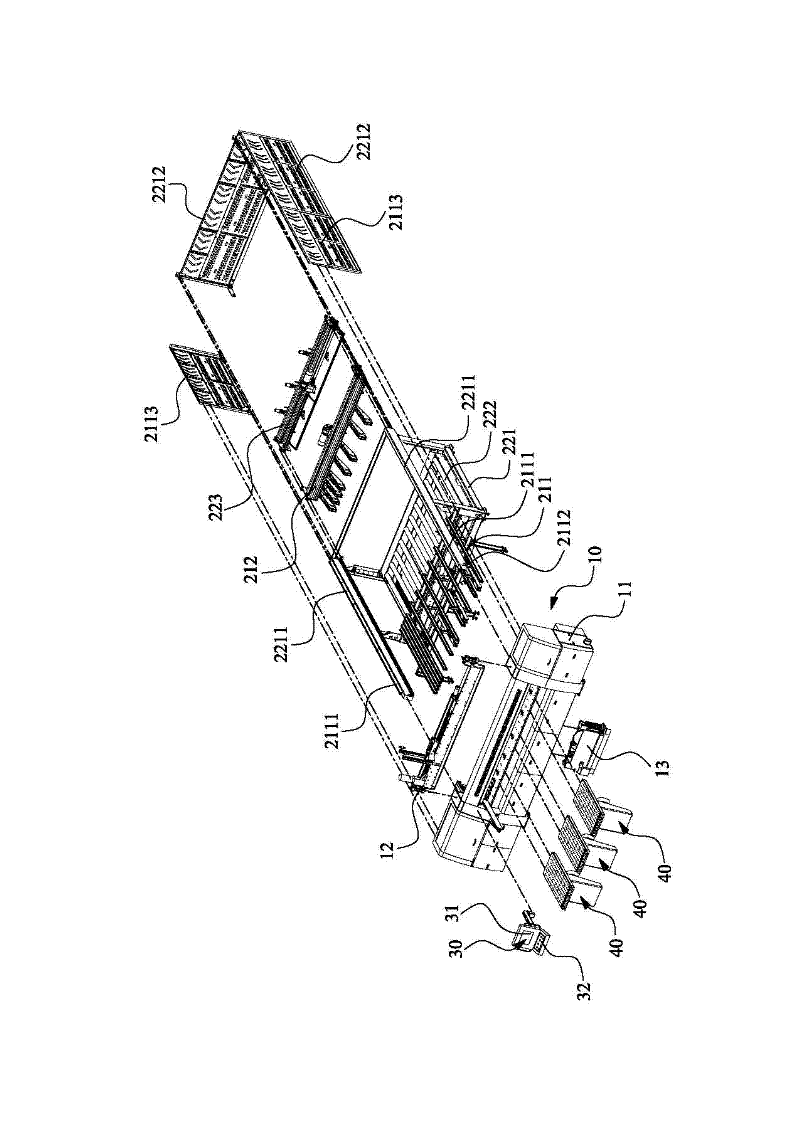

Back loading high-speed computer panel saw

ActiveCN102390063AGuaranteed cutting accuracyConducive to survivalFeeding devicesCircular sawsComputer control systemEngineering

The invention discloses a back loading high-speed computer panel saw comprising a machine station main body, a material feeding unit and a computer control system, wherein the machine station main body comprises a worktable, a material pressing device and a cutting device; the material pressing device and the cutting device are both arranged on the worktable; the material feeding unit is arranged at the back side of the machine station main body; the material feeding unit comprises a material feeding device and a material loading device; the material feeding device is arranged between the machine station main body and the material loading device; the material feeding device comprises a material feeding bracket and a first propulsion mechanism; the material loading device comprises a material loading bracket, a lifting table and a second propulsion mechanism; the computer control system controls the work of the material pressing device, the cutting device, the material feeding device and the material loading device, thereby realizing automation operation in the overall process of panel cutting, being favorable for ensuring the cutting precision of panel material, improving the work efficiency effectively, reducing the number of operation personnel and reducing the work strength for workers, thus reducing the production cost for an enterprise and being beneficial to the survival of the enterprise.

Owner:NANXING MACHINERY CO LTD

Wood plastic composite foaming material and forming process and equipment thereof

The invention relates to a wood plastic composite foaming material and a forming process and forming equipment thereof. The diameters of foam holes of the wood plastic composite foaming material are 0.01 to 5 millimeters; and the main component of the material is a mixture of thermoplastic plastic and plant fiber powder, or a mixture of thermoplastic plastic, starch and plant fiber powder, or a mixture of thermoplastic plastic, rubber powder and plant fiber powder. The invention also relates to the forming process and the forming equipment for the wood plastic composite foaming material. The wood plastic composite foaming material has the advantages of low density, high strength and low production cost, is suitable to be used as a packing material for various commodities, a buffering member for various devices, an elastic member of a product such as a sofa, a mattress, a sole and the like and a structural component of a household electric appliance, and is used for replacing wood for manufacturing floors, handrails, doors and windows, resting chairs used in gardens and the like.

Owner:佛山市科昌塑料制品有限公司

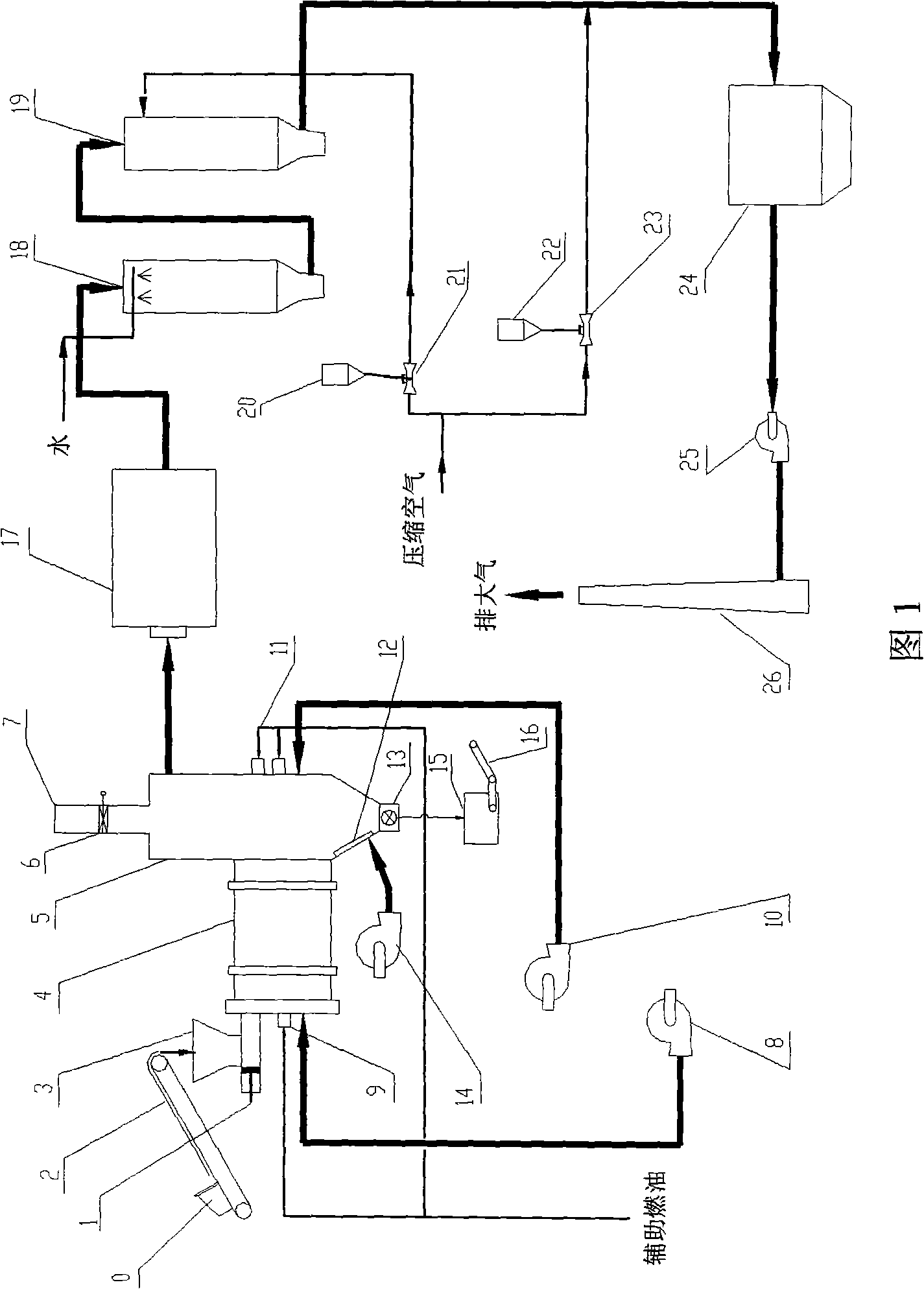

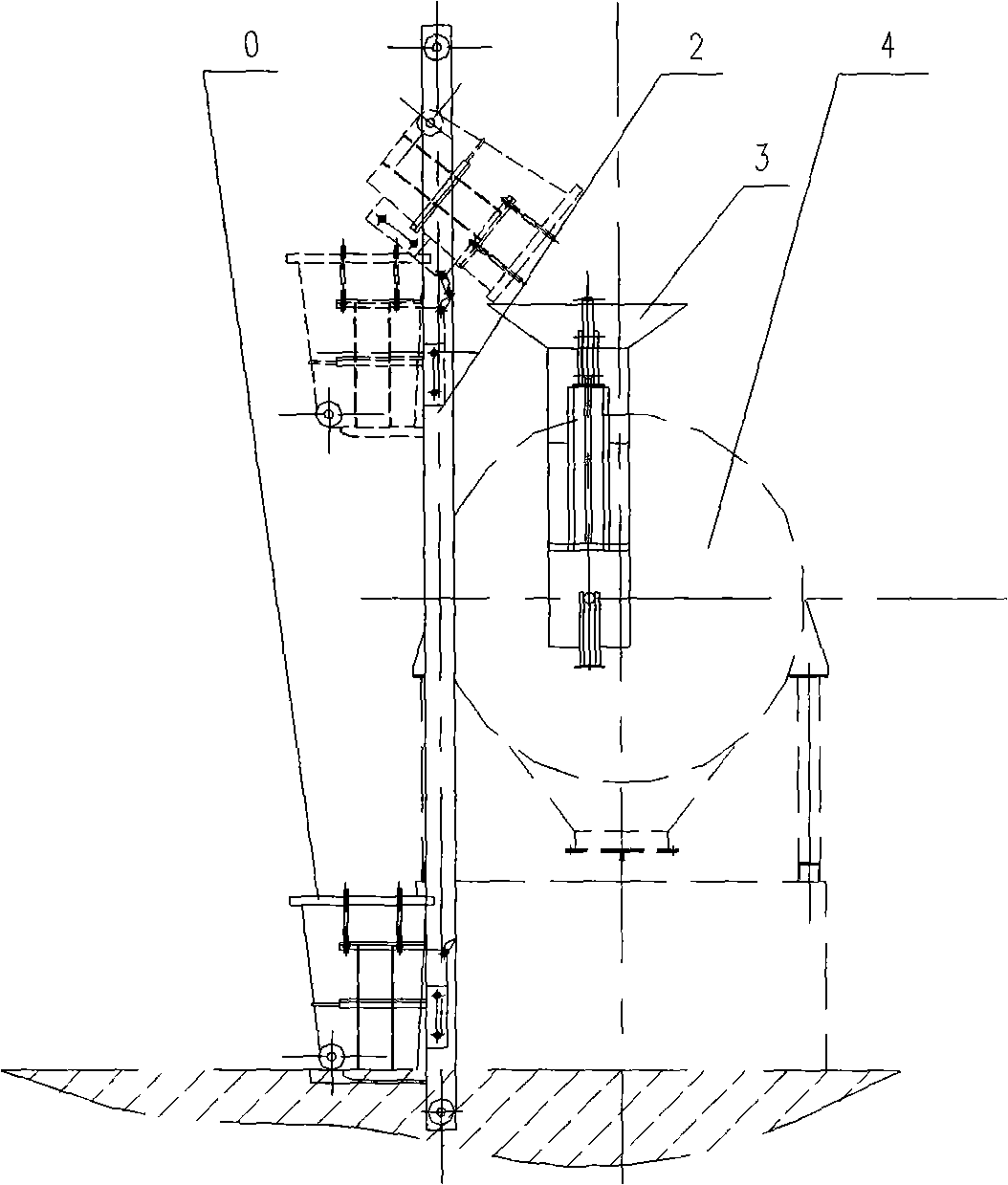

Pneumatic medical waste burning process for rotary kiln and device therefor

InactiveCN101285577AAvoid destructionAchieve turbulent combustionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberAtmospheric air

The invention discloses a process and a device for incinerating rotary kiln gas-controlled medical waste, relating to the environmental protection technical field. The process of the invention comprises the following steps of: collecting the whole packet of medical waste refuse bag and feeding into a feeding hopper, then feeding into a rotary kiln initial combustion chamber by a feeding mechanism which is closed by chain, and completing the processes of drying, pyrolyzing and air controlled anoxycausis of the medical waste. Waste gas generated by the rotary kiln initial combustion chamber enters to a secondary combustion chamber to undergo the process of air controlled oxygen-enriched complete combustion, wherein bottom ash with a little redial carbon is flamed at an inclined fire grate which is arranged in an ash well at the lower part of the secondary combustion chamber. The smoke gas at an outlet of the secondary combustion chamber is exhausted into the atmosphere by a draft fan through a chimney after surplus heat utilization of a surplus heat boiler, smoke gas sharp quenching of a quench tower, a dry-type deacidification and cloth-bag dust removal of a bag-type duster. Compared with the prior art, the process and the device for incinerating rotary kiln gas-controlled medical waste have the advantages of good operating economical efficiency, automatic safety continuous feeding, fluent slag tapping system and low index of pollution emission.

Owner:TSINGHUA UNIV +1

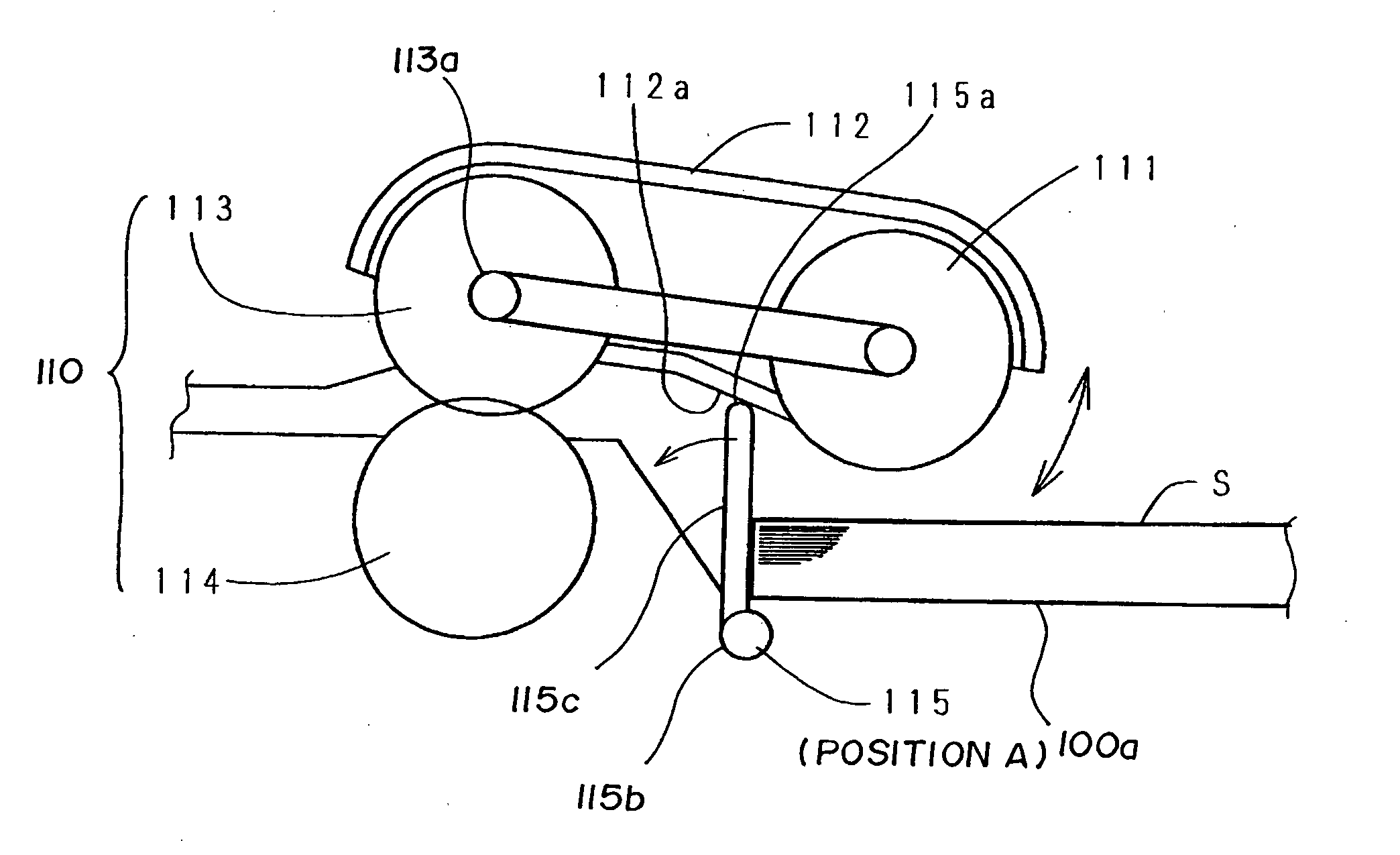

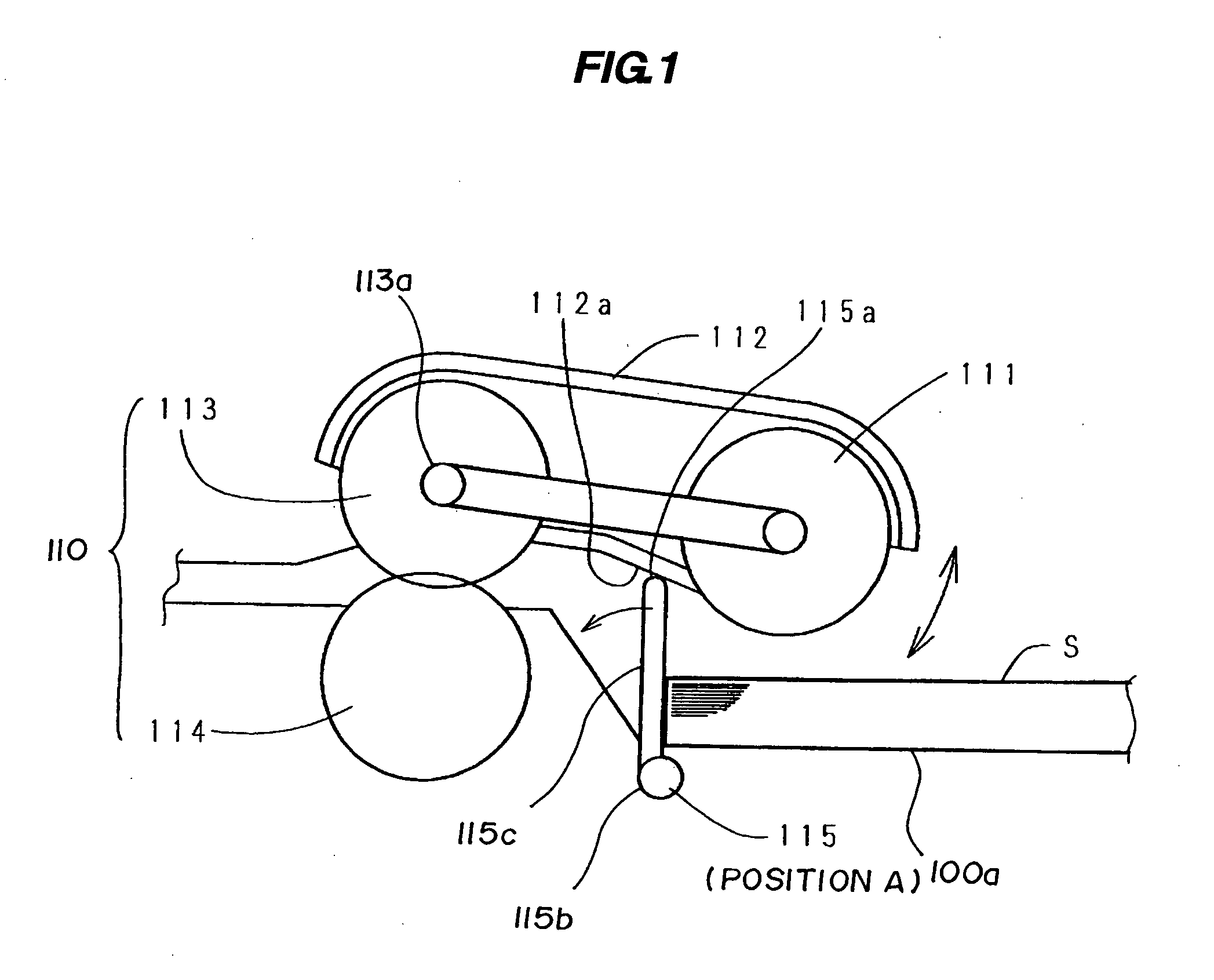

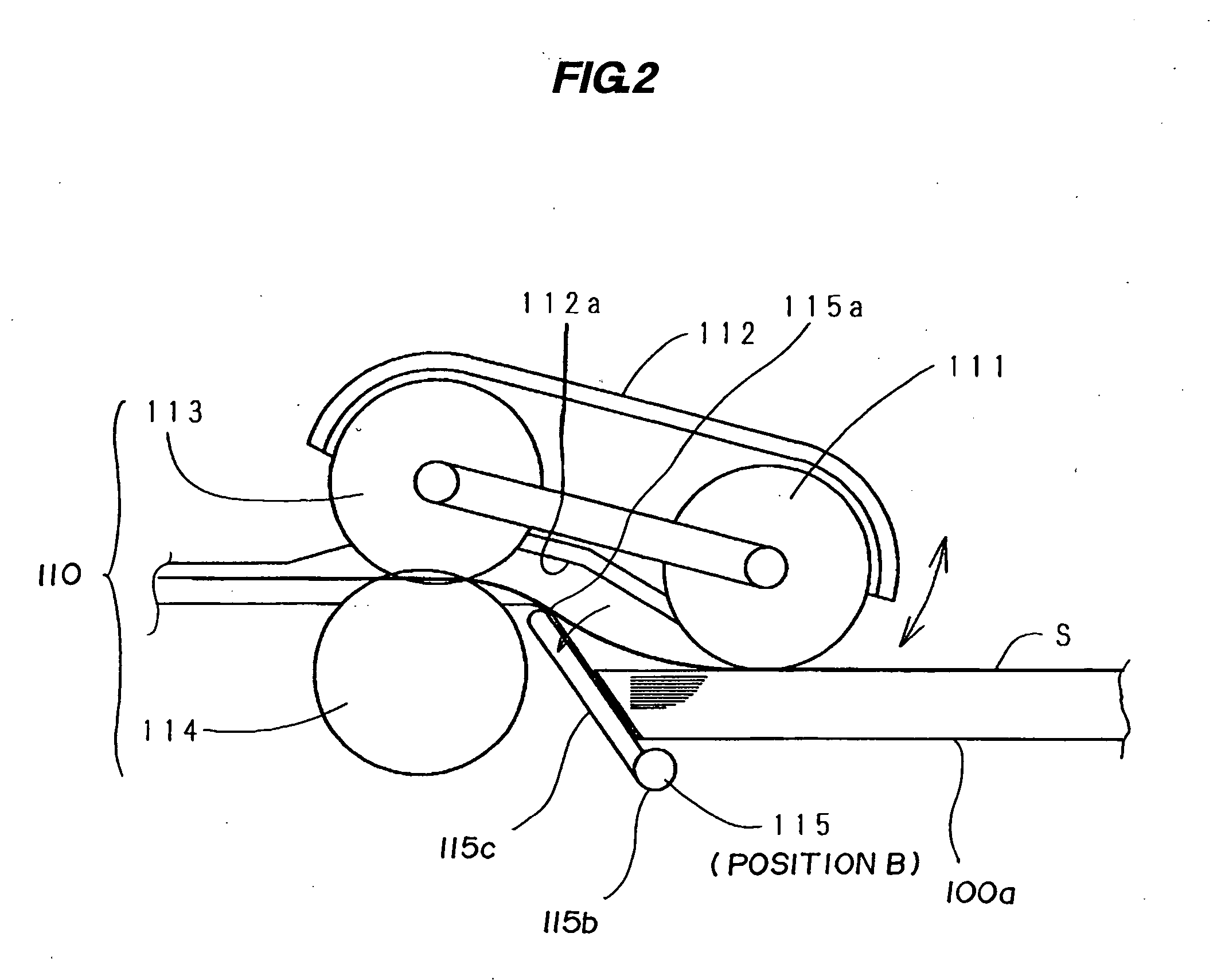

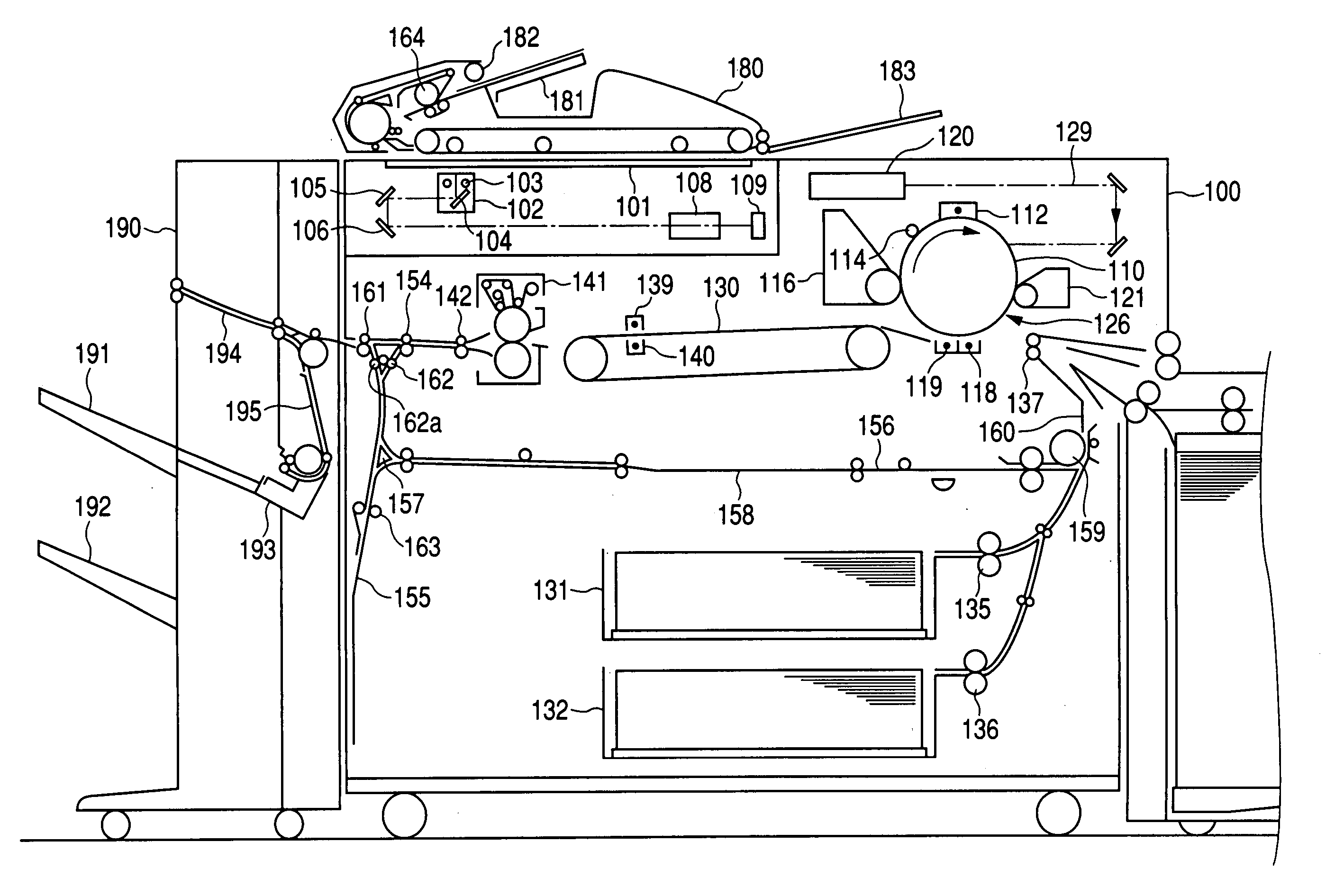

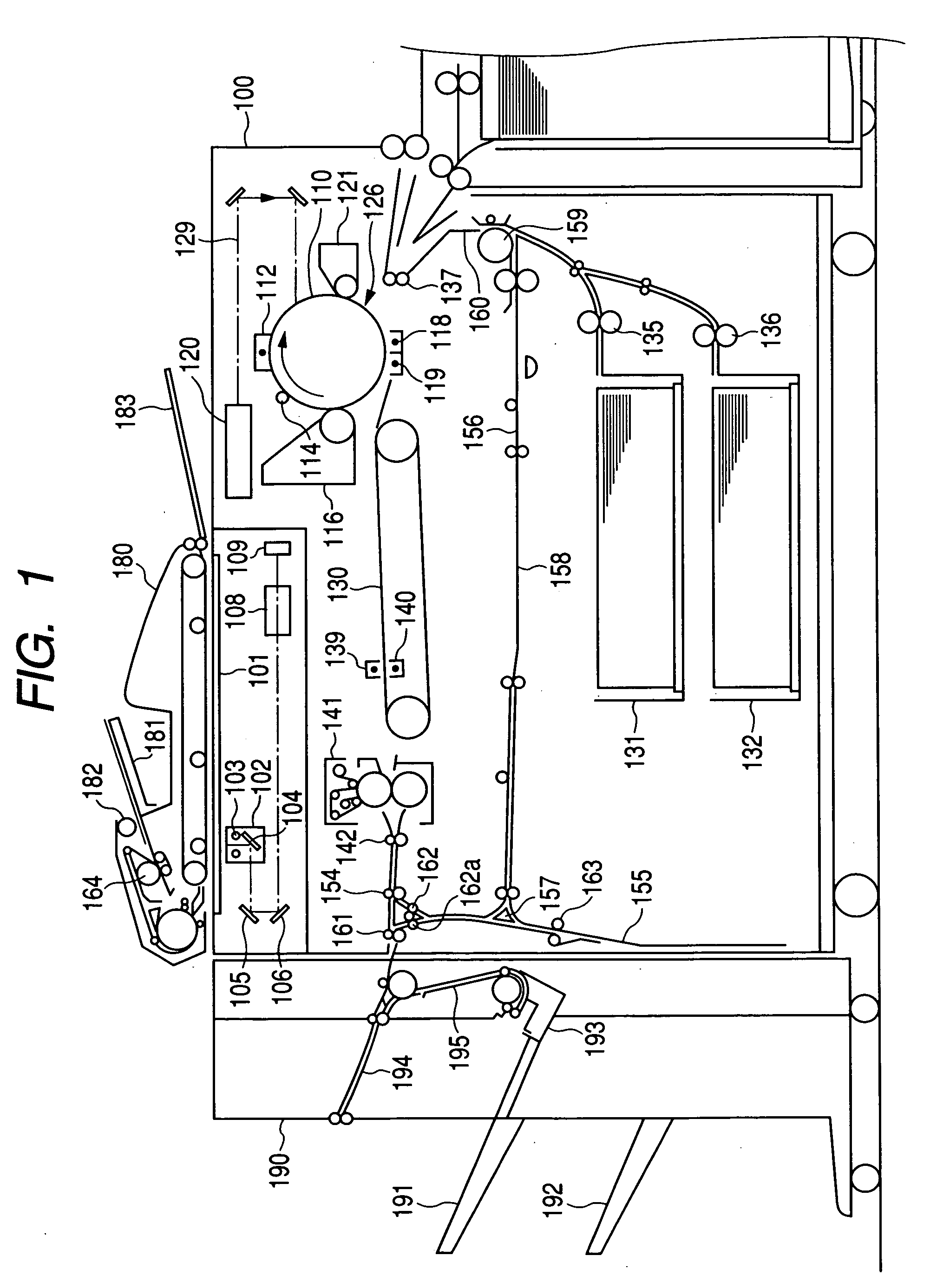

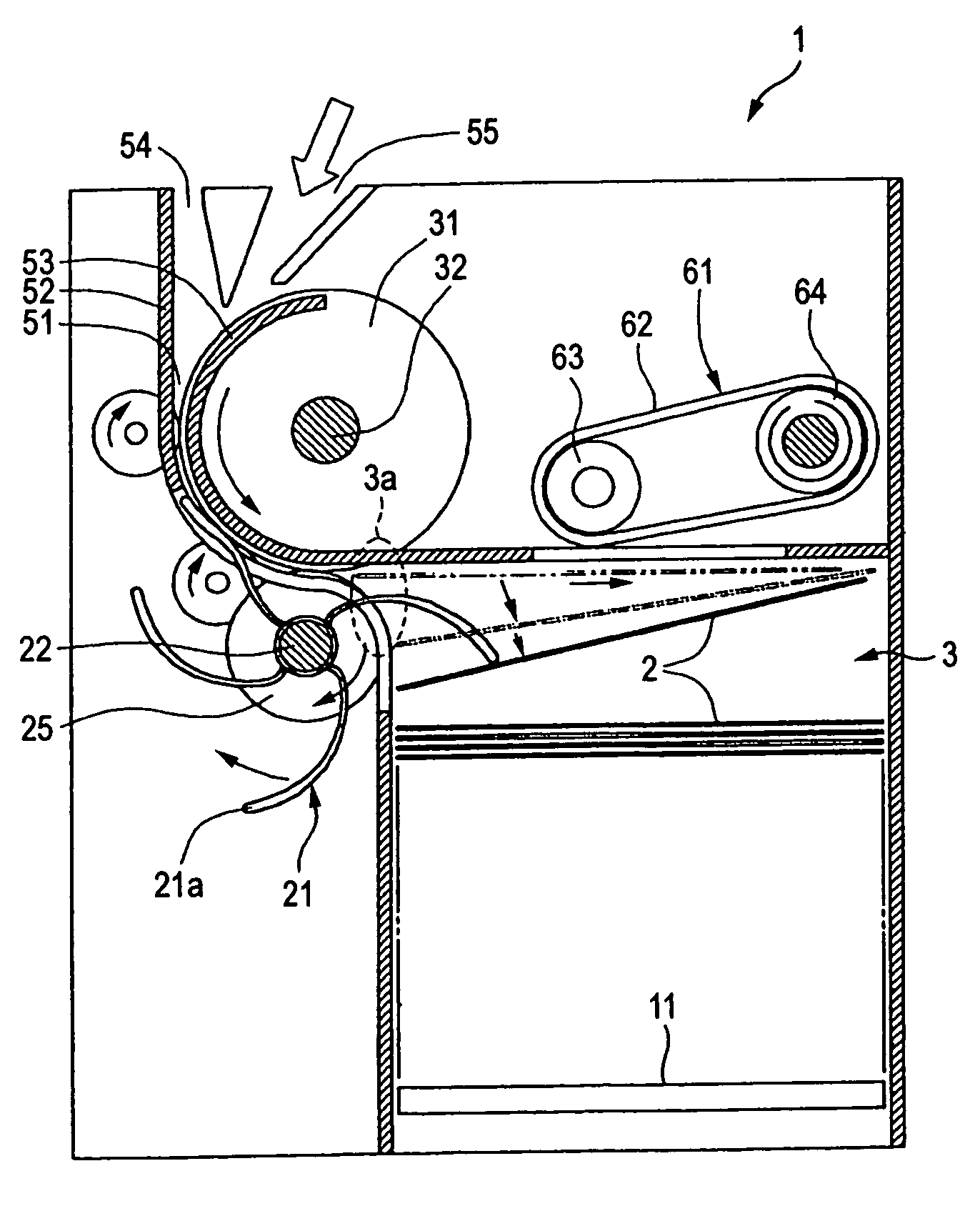

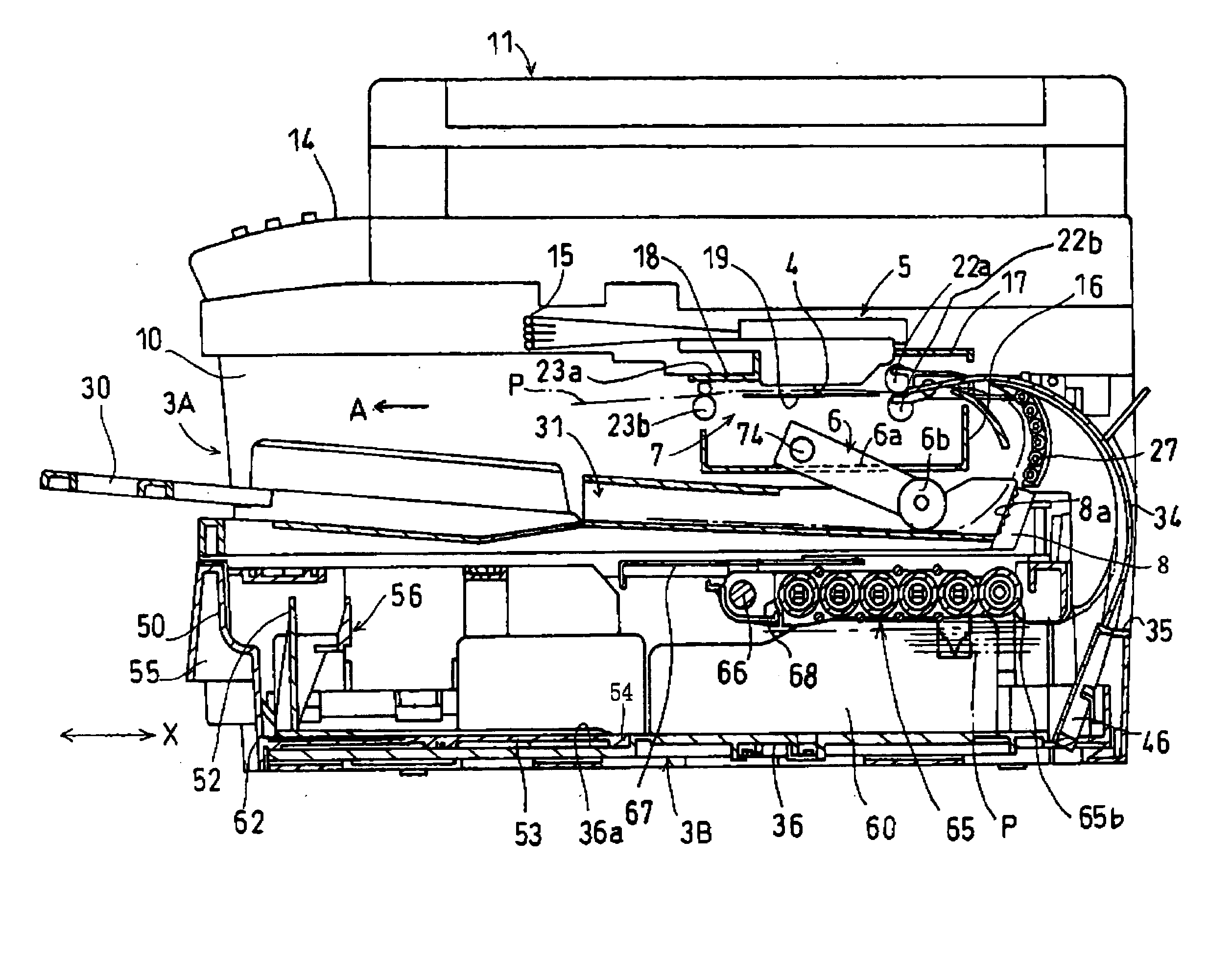

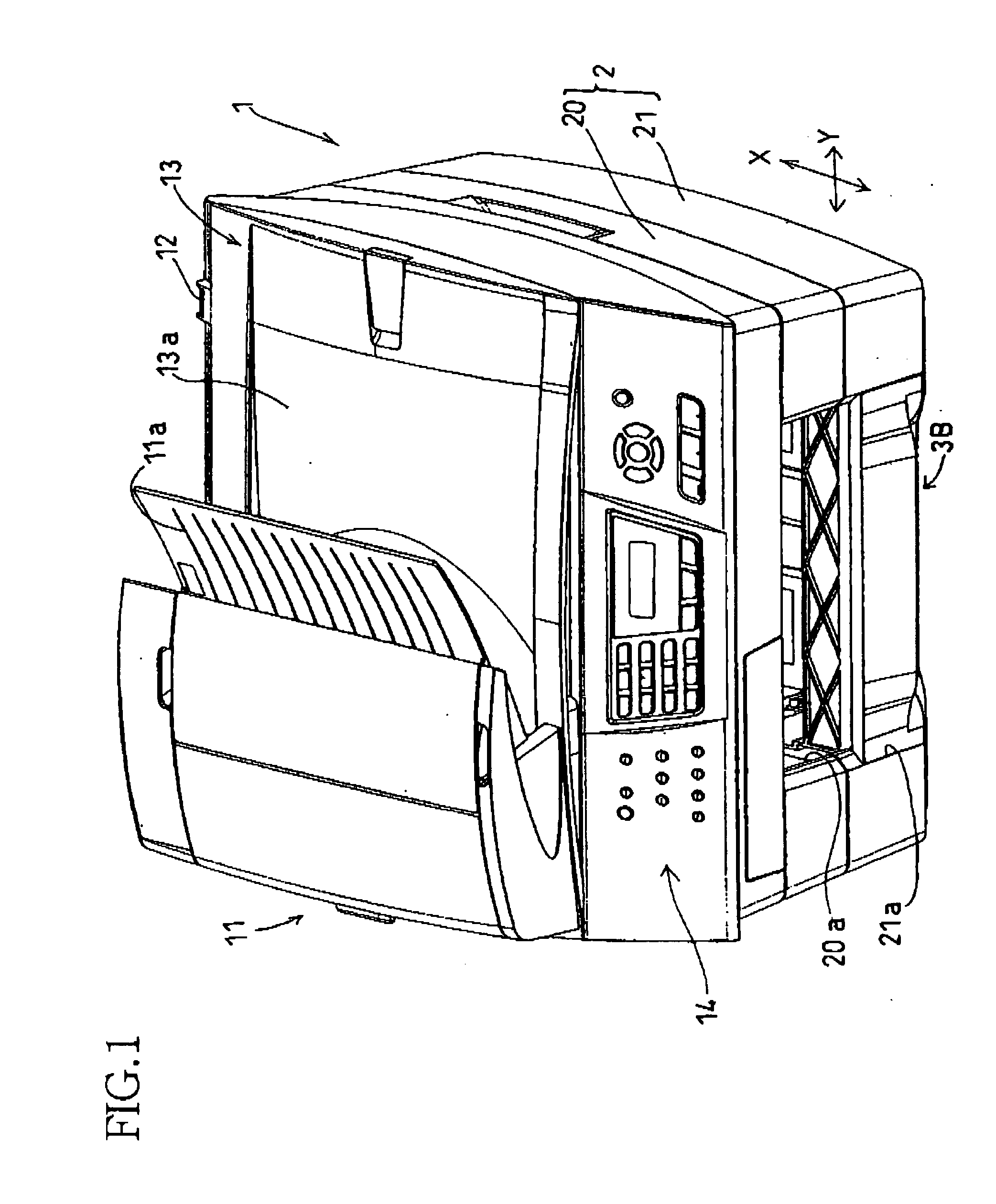

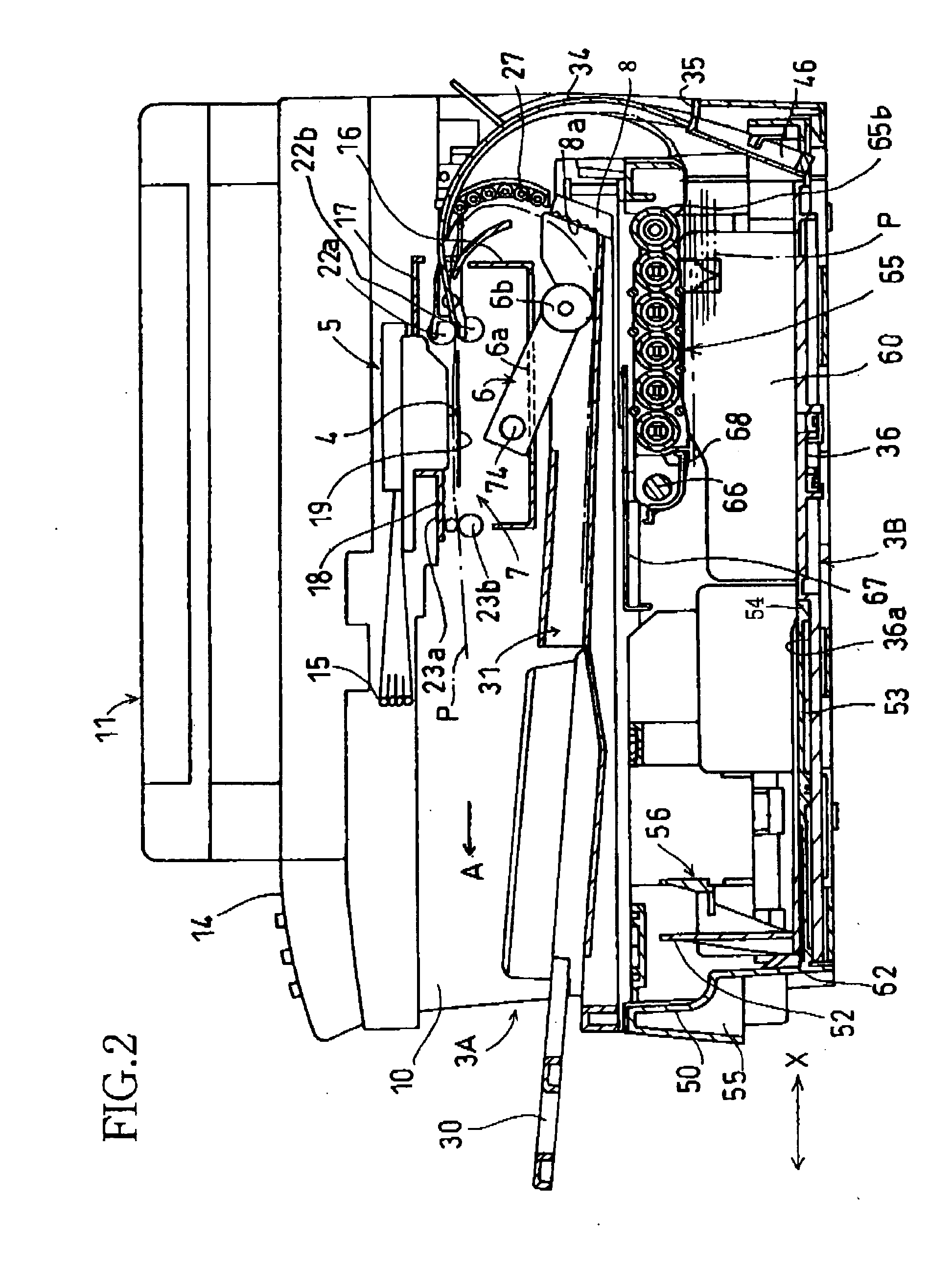

Sheet feeding apparatus and image processing apparatus

ActiveUS20060038339A1Small sizeLow costRegistering devicesArticle separationImaging processingEngineering

The invention relates to a sheet feeding apparatus, including a feeding unit for feeding sheets stacked up in a sheet stock unit, and a leading end regulating member for regulating the leading ends in feeding direction of sheets stacked up in the sheet stock unit, in which the feeding unit is free to contact with or depart from the sheets, the leading end regulating member is movable in the sheet feeding route from a regulating position for regulating the leading ends of sheets, and a retreat position for releasing from regulation of leading end of sheets by moving away from the sheet feeding route, and the leading end regulating member holds the feeding unit at a position apart from the sheets at the regulating position, and brings the feeding unit into contact with the sheets at the retreat position.

Owner:CANON DENSHI KK

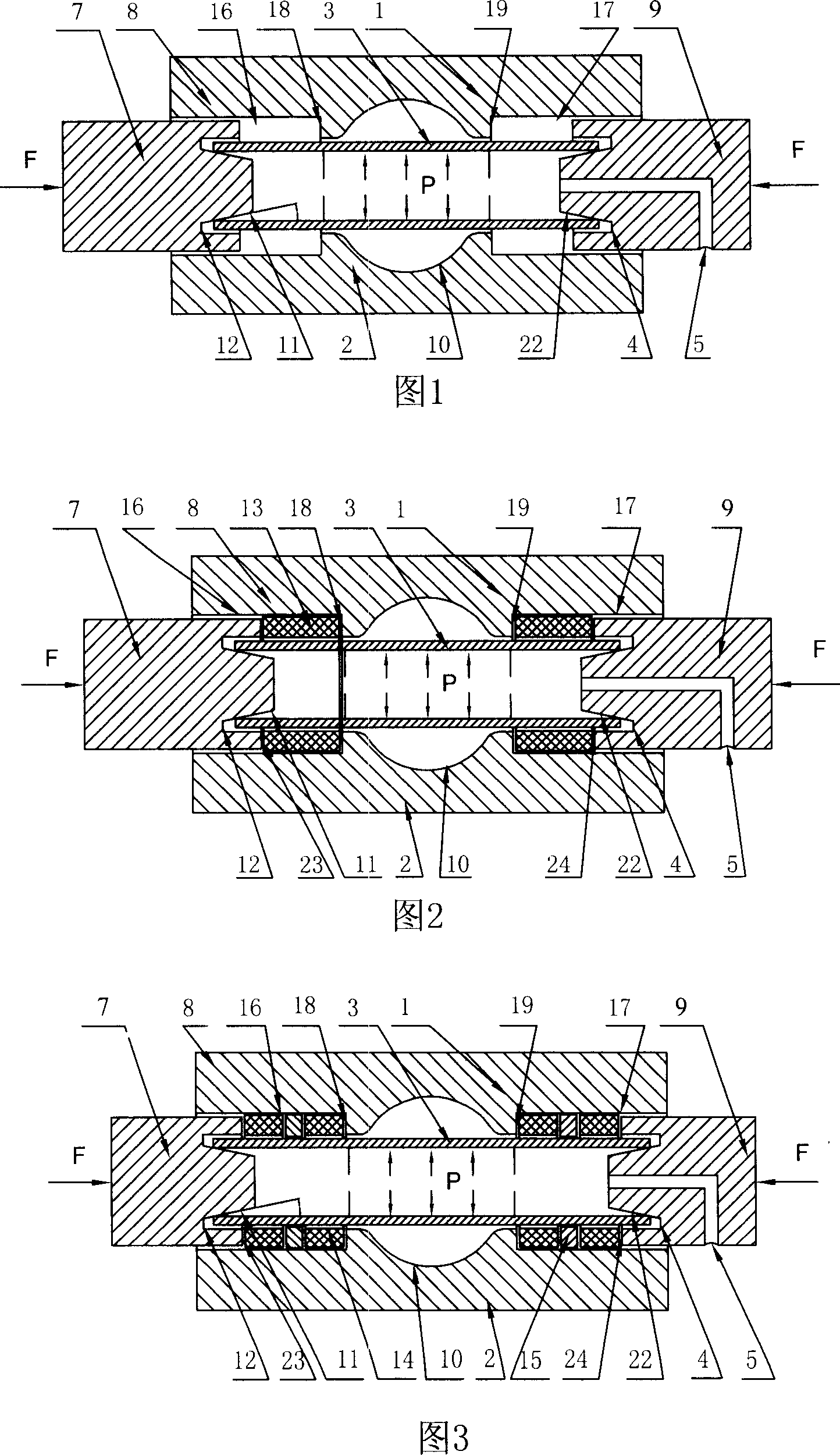

Device for reducing friction of guided region when forming high pressure in pipe

InactiveCN101011715ASolve the sealing problemEliminate high pressure contact areasShaping toolsEngineeringHigh pressure

The invention relates to a device for reducing guiding zone friction in high pressure formation of tubular material. It comprises dies, left punch head, right punch head, right round body on the right end face of the left punch head with right guiding ring slot, so does the right punch head, with gaps between the die, left punch head and the right punch head. It can eliminate the high touch pressure zone of the tubular end and the die guiding zone inner wall, reducing the friction resistance to improve production efficiency and die durability, and lowered requirement for tonnage.

Owner:严格集团股份有限公司

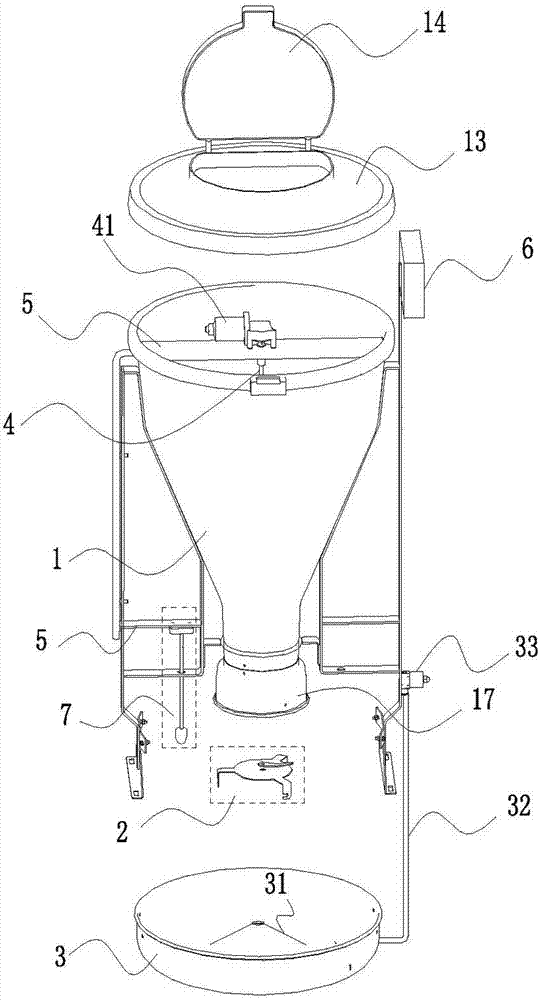

Intelligent food feeder and program control method for intelligent food feeder

ActiveCN104488748AEasy to operateSmall footprintAnimal watering devicesAnimal feeding devicesAutomatic controlElectric machinery

The invention relates to an intelligent food feeder and a program control method for the intelligent food feeder. A push device is arranged at a first discharge hole of a food bucket; the bottom end of a rotating shaft is connected with the push device; the top end of the rotating shaft is linked with the output shaft of a motor; a water pipe is provided with a water valve; the water valve and the motor are connected with the control device; a support is fixedly provided with a touch device; the touch device comprises a discharge switching device and a level detection device; the top end of an oscillating bar of the discharge switching device is provided with a travel switch; the bottom end of the oscillating bar is provided with a gravity touch end; the discharge switching device is connected with the control device; a probe of the level detection device is arranged in the gravity touch end and is used for detecting food amount on a manger and sending a detection signal to the control device. The signal is transmitted to the control device through a sensor, so that an automatic control function is realized; the intelligent food feeder is simple in structure, space-saving, convenience to use and convenient to install and detach.

Owner:GUANGDONG PROVINCE MODERN AGRI EQUIP RES INST +1

Sheet feeder for feeding sheets of different rigidity

InactiveUS6158733AIncrease frictional resistanceReduce frictional resistanceFunction indicatorsOther printing apparatusEngineeringFrictional resistance

A sheet feeder includes a support plate inclined backward and a feed roller for feeding one by one the sheets of paper stacked on the plate. A first support surface and a second support surface are formed at or near the bottom of the plate to support the front ends of the sheets. The second surface is lower in frictional resistance than the first surface. The second surface can be moved by an operating lever between a first position, where it is protruded from the first surface toward the sheets, and a second position, where it is retracted from the first surface away from the sheets. If the sheets are relatively rigid, their front ends are supported by the second surface in the first position, and they can therefore be fed smoothly.

Owner:BROTHER KOGYO KK

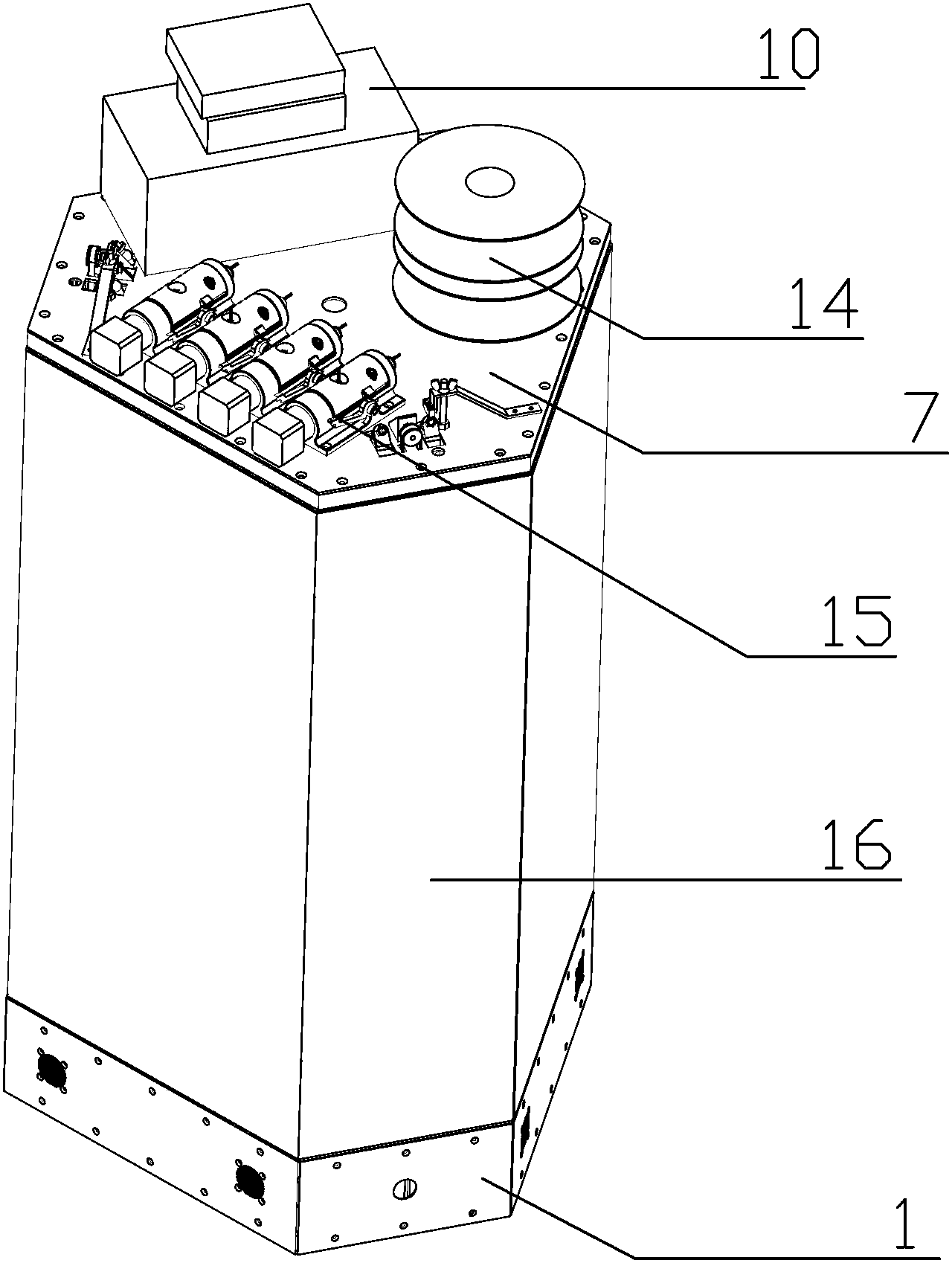

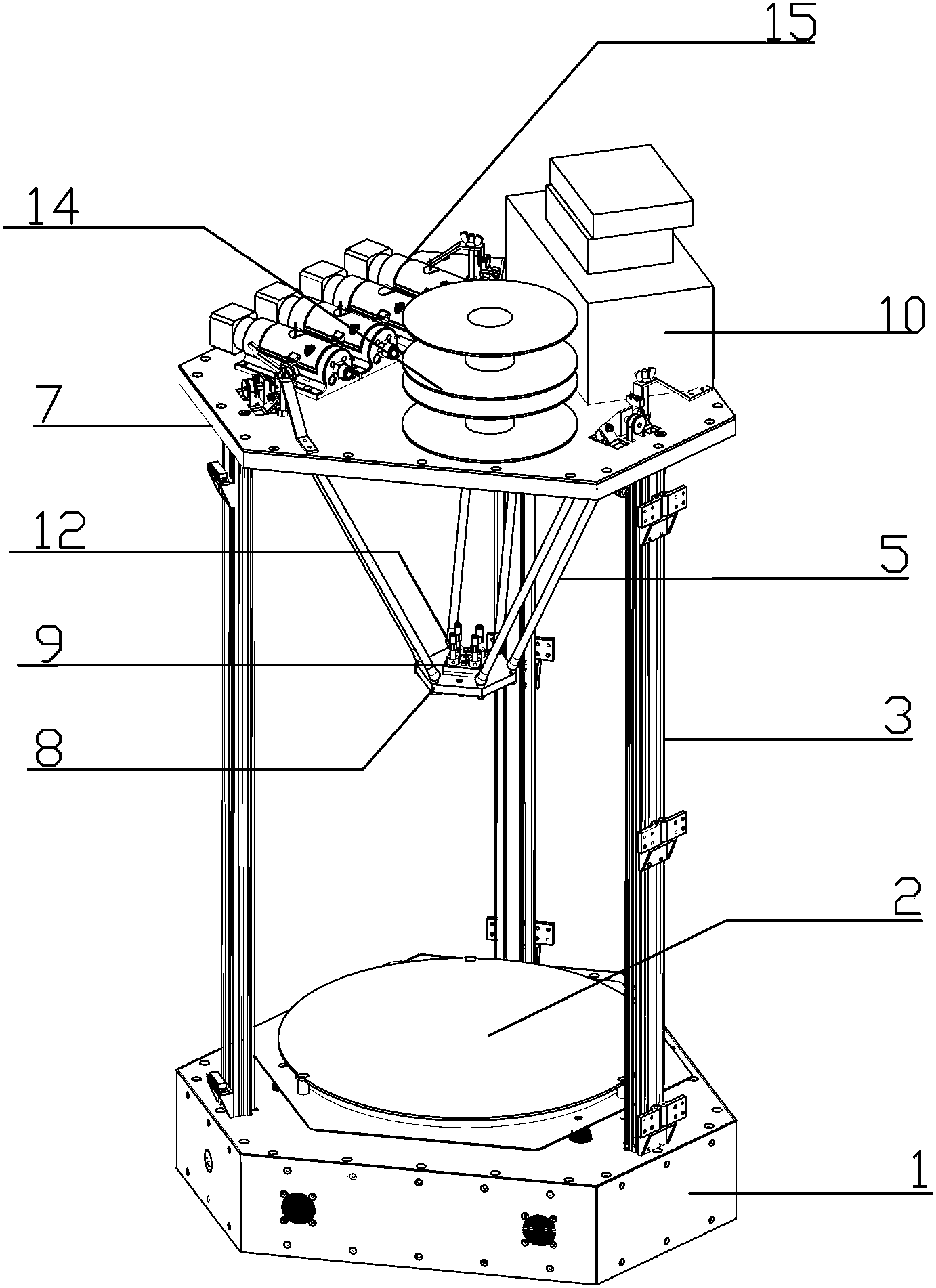

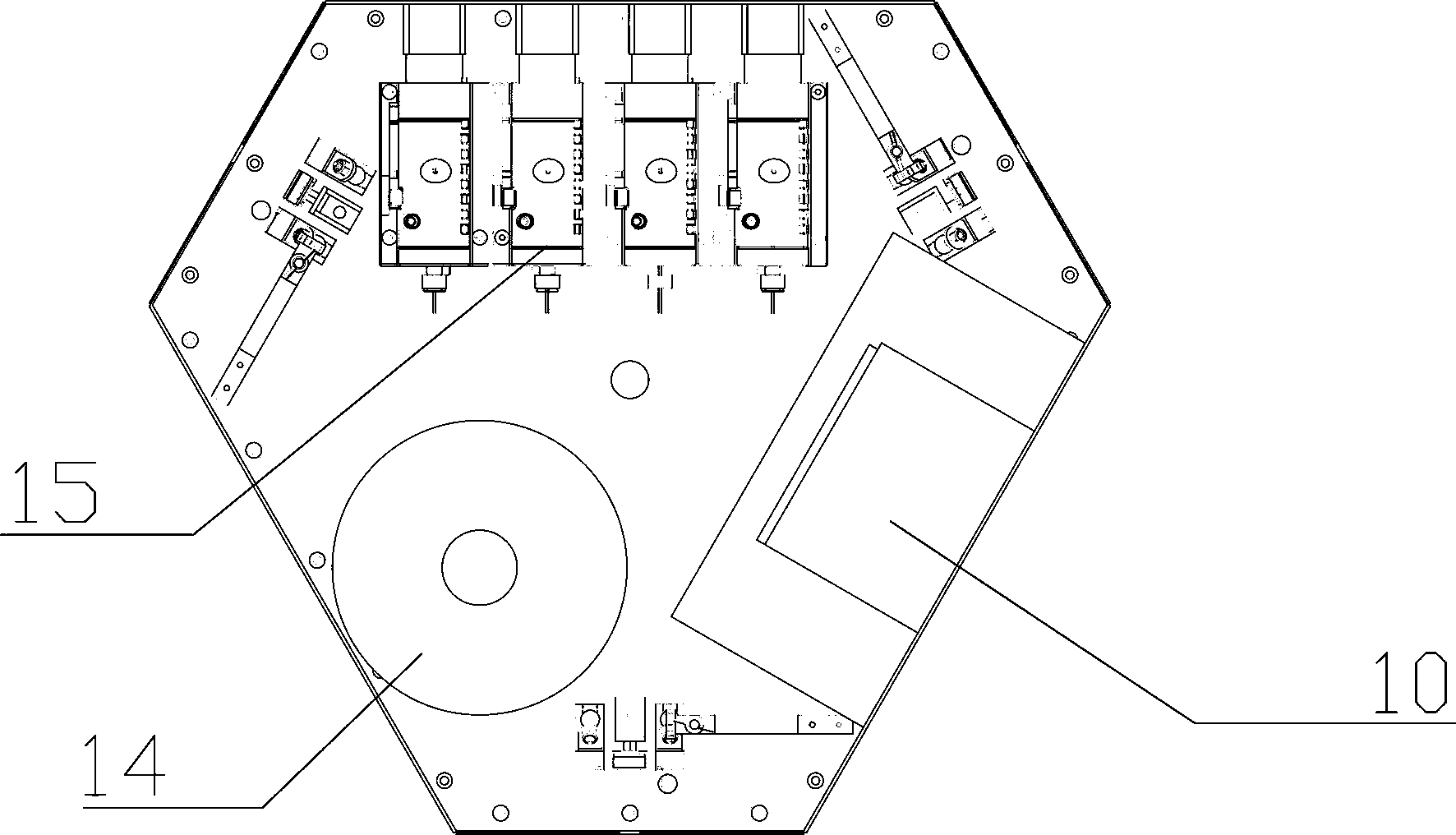

Three-dimensional printer extrusion head capable of feeding in switching mode

ActiveCN102922745AAvoid Mechanical Positioning ErrorsConstant feed frictionDrive motorElectrical and Electronics engineering

The invention discloses a three-dimensional printer extrusion head capable of feeding in a switching mode. The three-dimensional printer extrusion head comprises a base, a feeding switching assembly, a printing filament heating fusing channel, a filament driving motor, a driving feeding wheel and a linkage swinging mechanism, wherein the feeding switching assembly is rotatably connected with the base through a first rotating shaft, driven feeding pressing wheels are arranged on two sides of the driving feeding wheel respectively, one end of the printing filament heating fusing channel is connected with printing filaments respectively, the other end of the printing filament heating fusing channel is connected with printing filament extrusion nozzles respectively, the filament driving motor is installed on the base, the driving feeding wheel is directly connected with the filament driving motor, the linkage swinging mechanism has the bistable state characteristic, and positions of the printing filament heating fusing channel and printing filament extrusion nozzles are not changed respectively during the switching printing of two kinds of printing materials. Only one feeding driving motor is used, the alternate switching feeding of two kinds of filaments can be achieved through changing of the rotation direction of the motor and positions of corresponding driven feeding pressing wheels, mechanical positioning errors caused by switching moving of the extrusion head or nozzles are avoided, the feeding friction force of the driving feeding wheel is constant, and the stable feeding during printing can be achieved.

Owner:GUANGZHOU ELECTRONICS TECH

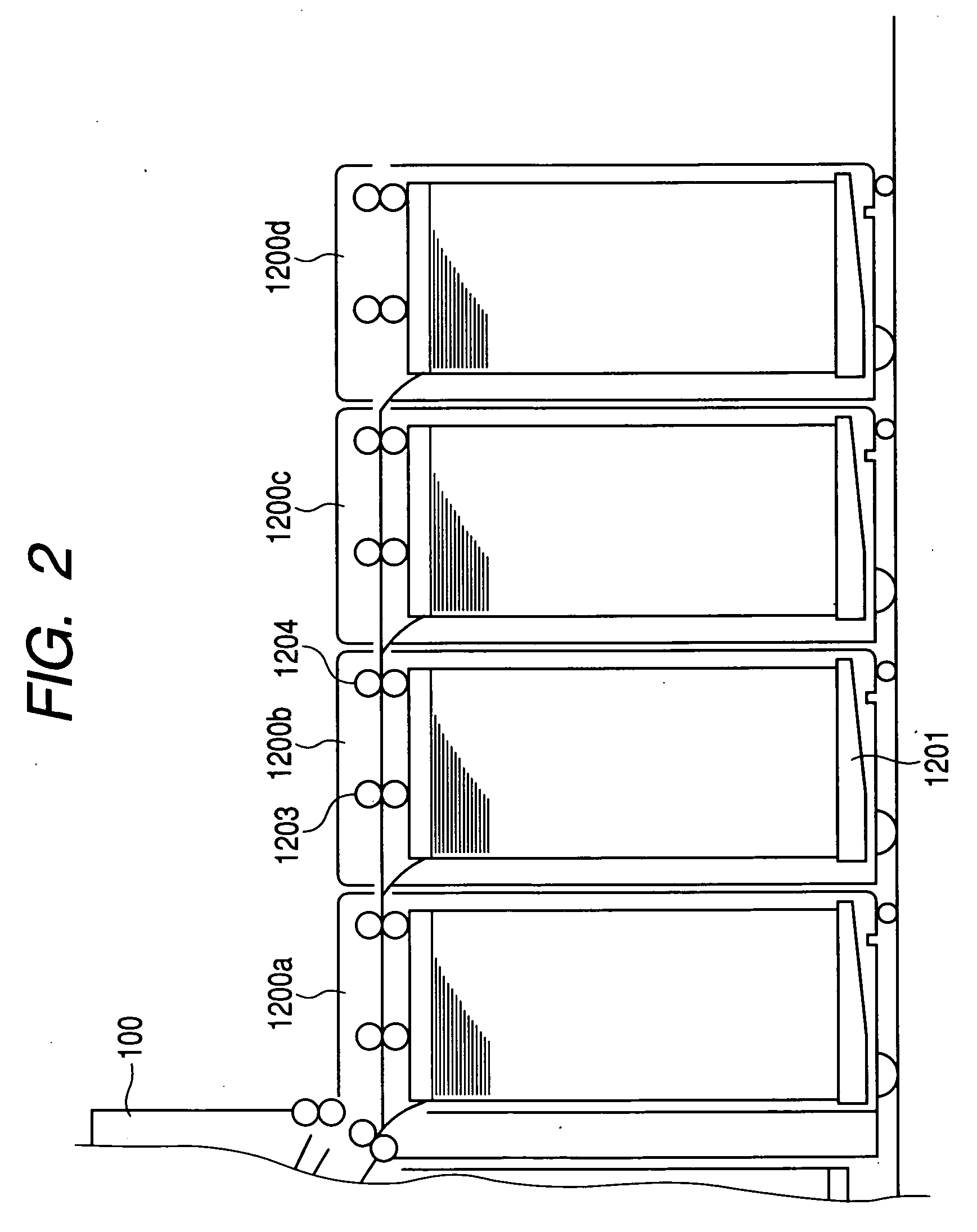

Sheet feeding apparatus, sheet feeding method and control program

ActiveUS20050206068A1Improve performanceLow costFunction indicatorsPile receiversEngineeringPaper sheet

Owner:CANON KK

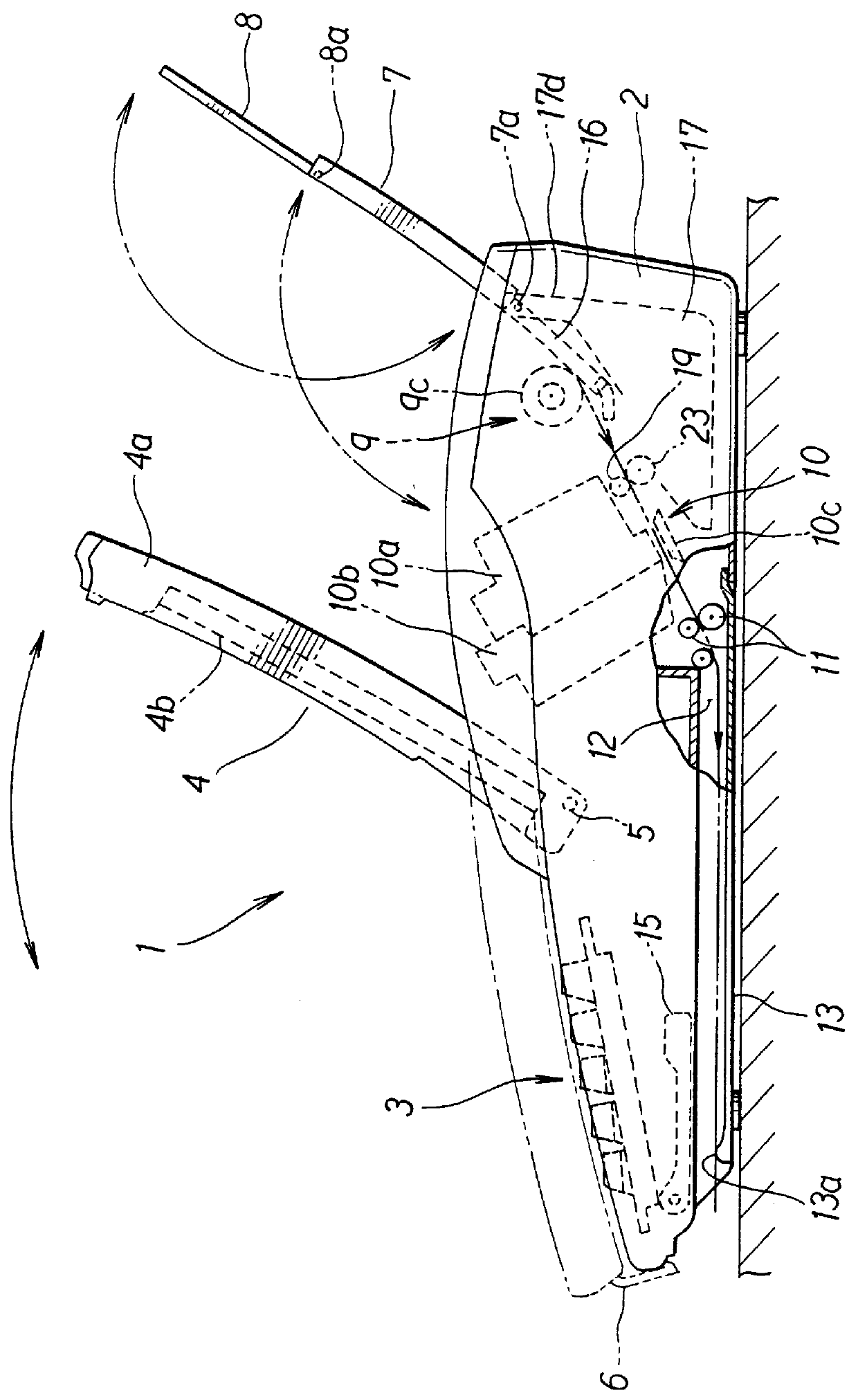

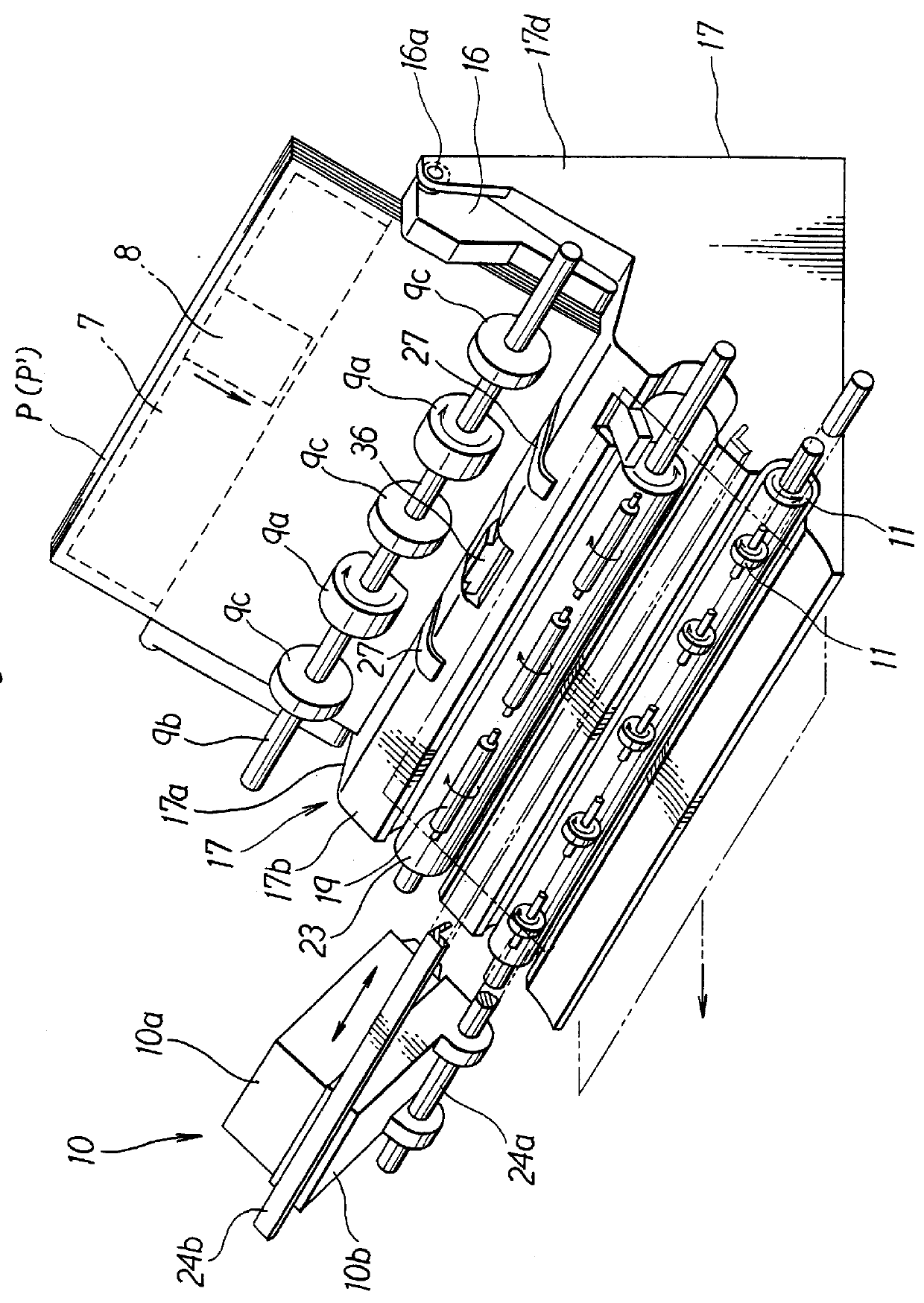

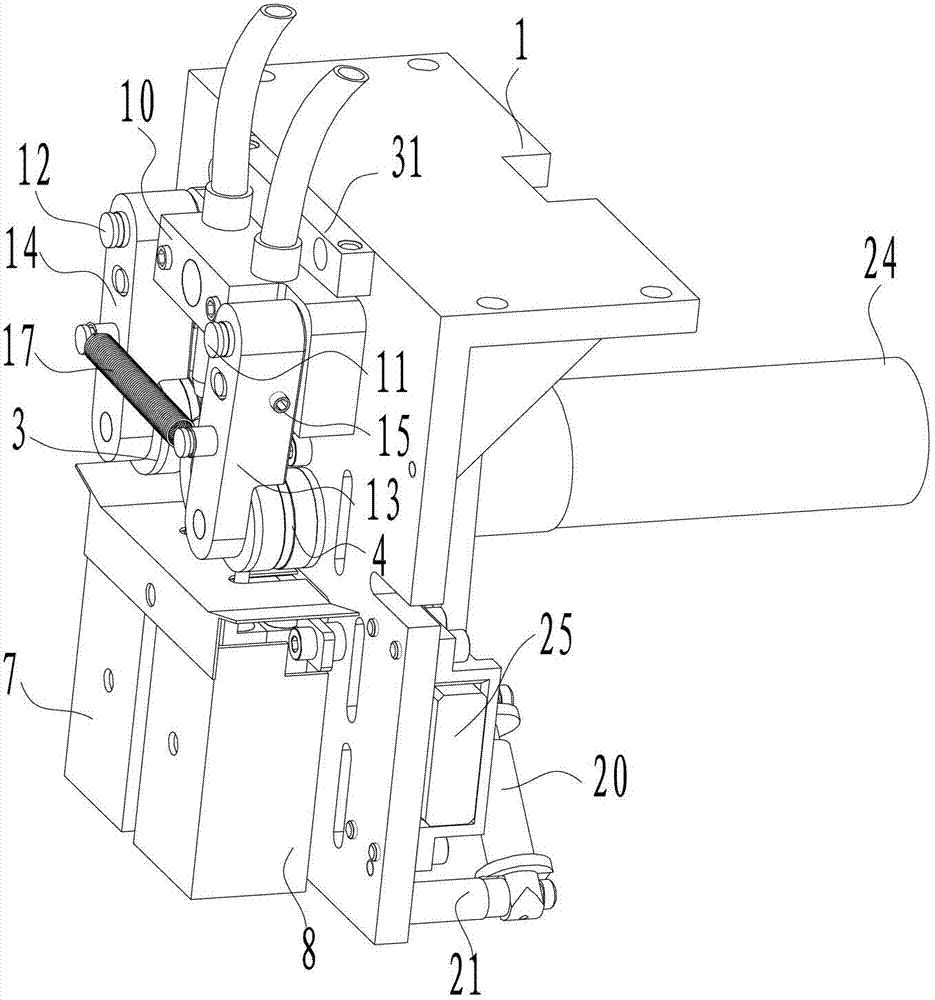

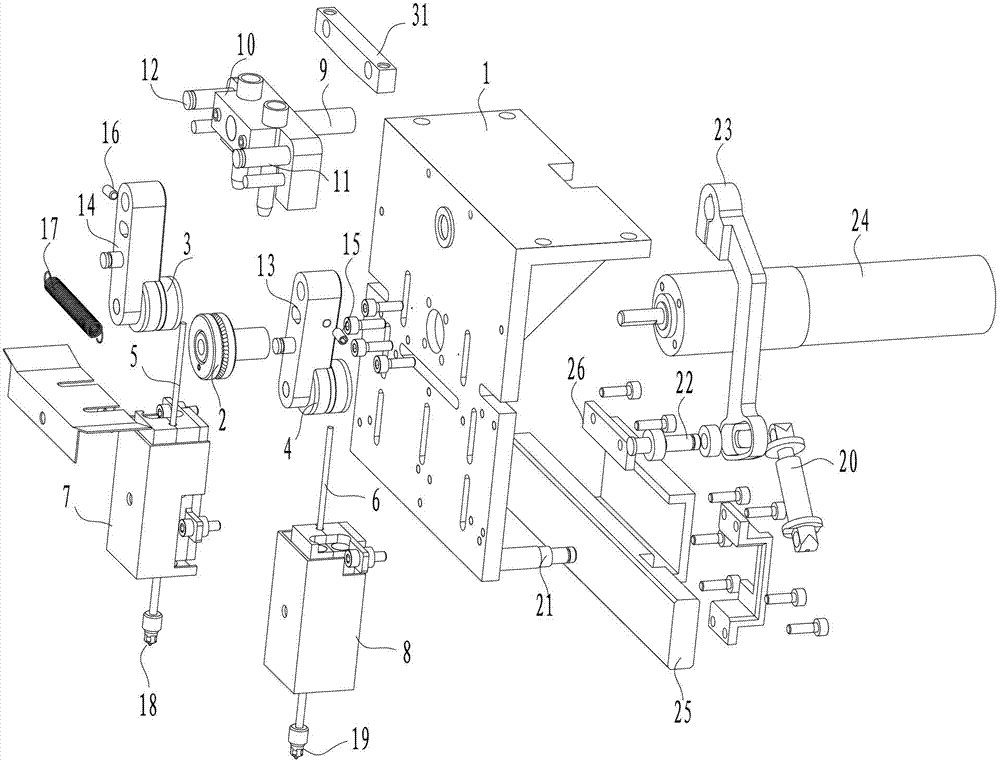

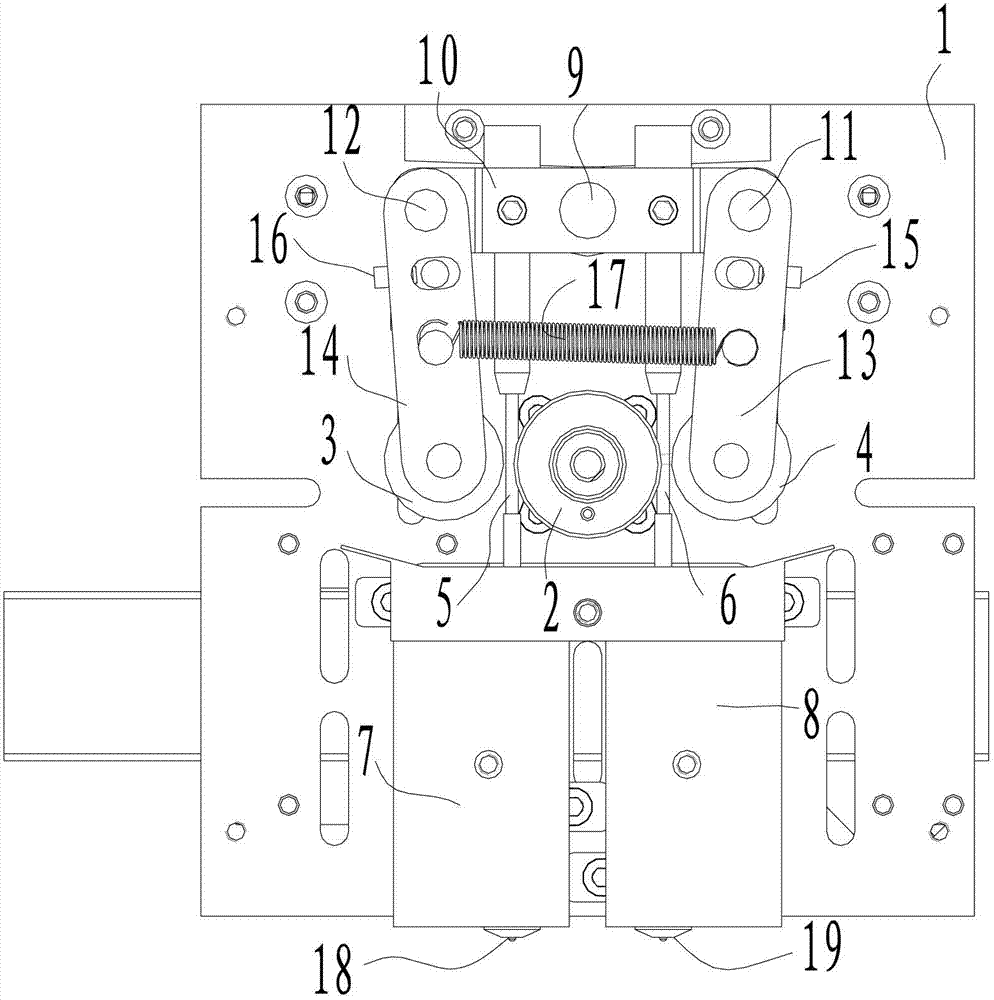

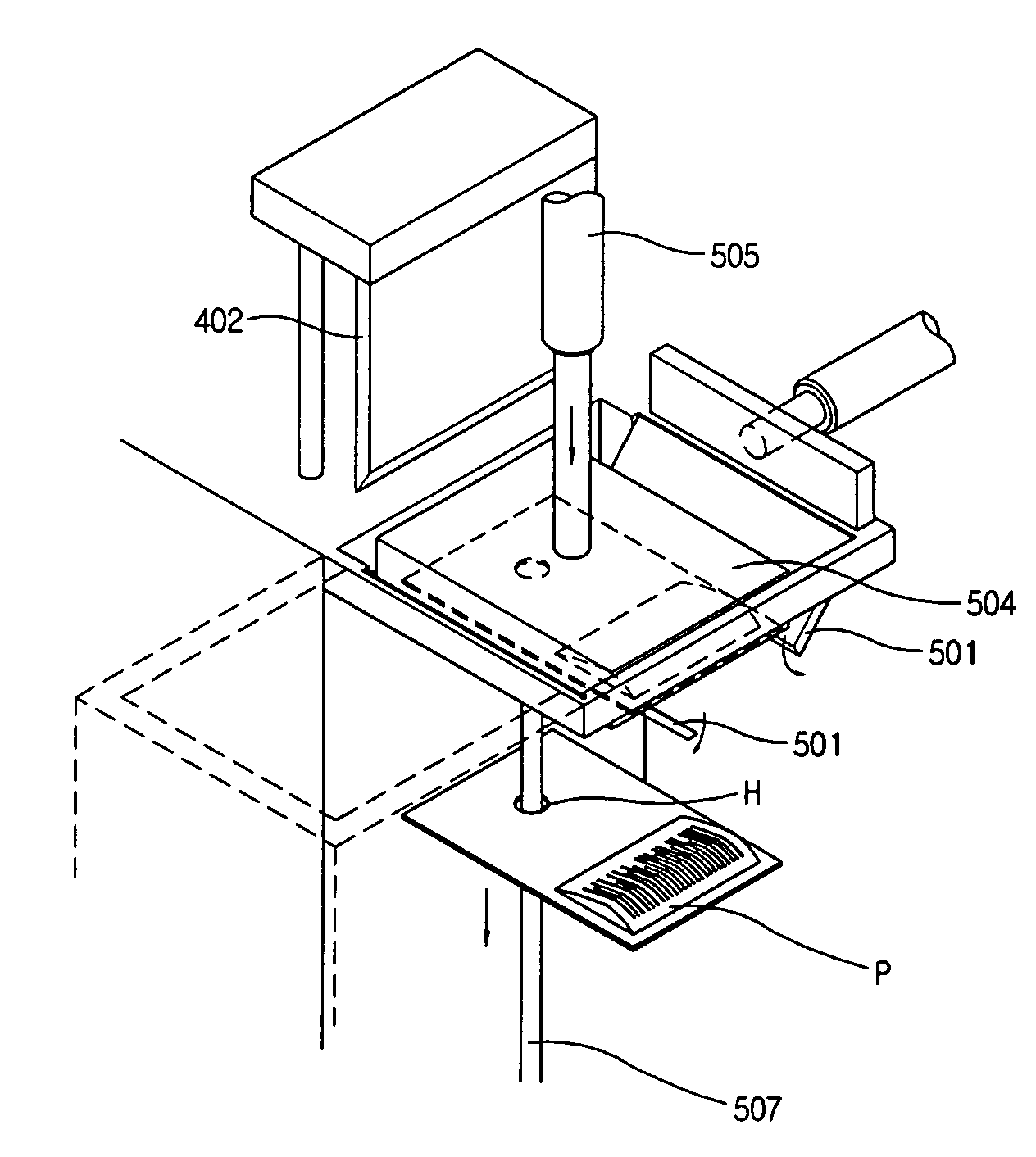

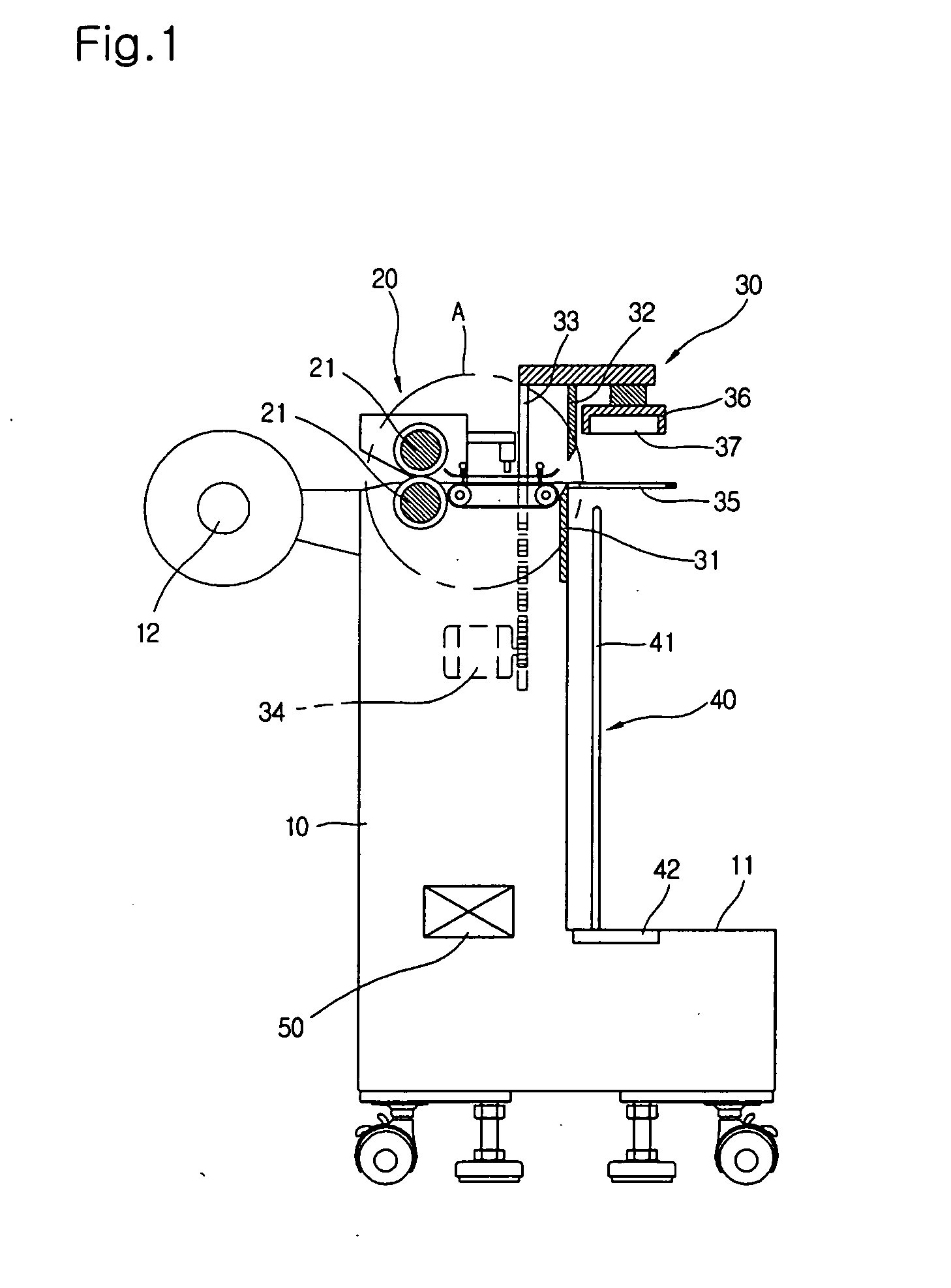

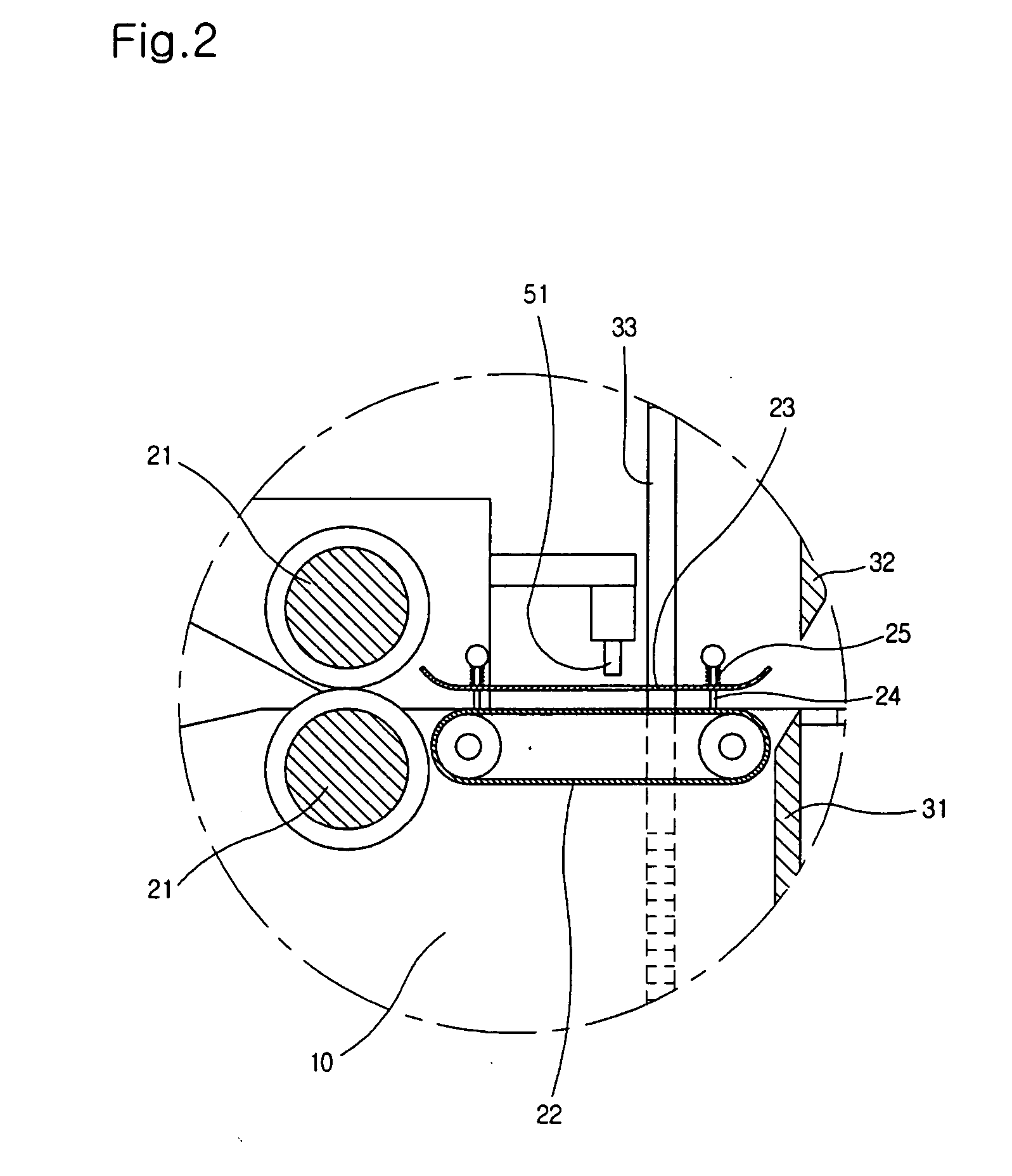

Apparatus for cutting series of medicine packets

InactiveUS20060266188A1Smooth feedingSimple structurePackagingMetal working apparatusIndividual dosePosition sensor

An apparatus for cutting a series of medicine packets discharged from an automatic medicine packaging machine into individual doses to automatically load the cut medicine packets on a loading device is disclosed. The apparatus includes a feeding device for feeding the series of medicine packets from the upper side of a main body to a stepped part at the other side of the main body, a cutting device for cutting the series of medicine packets by one medicine packet at the stepped part, a loading device for loading the medicine packets, cut by the cutting device and dropped to the stepped part, by a predetermined number, and a controller including a position sensor for detecting a position of the hole in the medicine packet and controlling the feeding device and the cutting device based on the position information of the hole of the medicine packets inputted from the position sensor.

Owner:JVM CO LTD

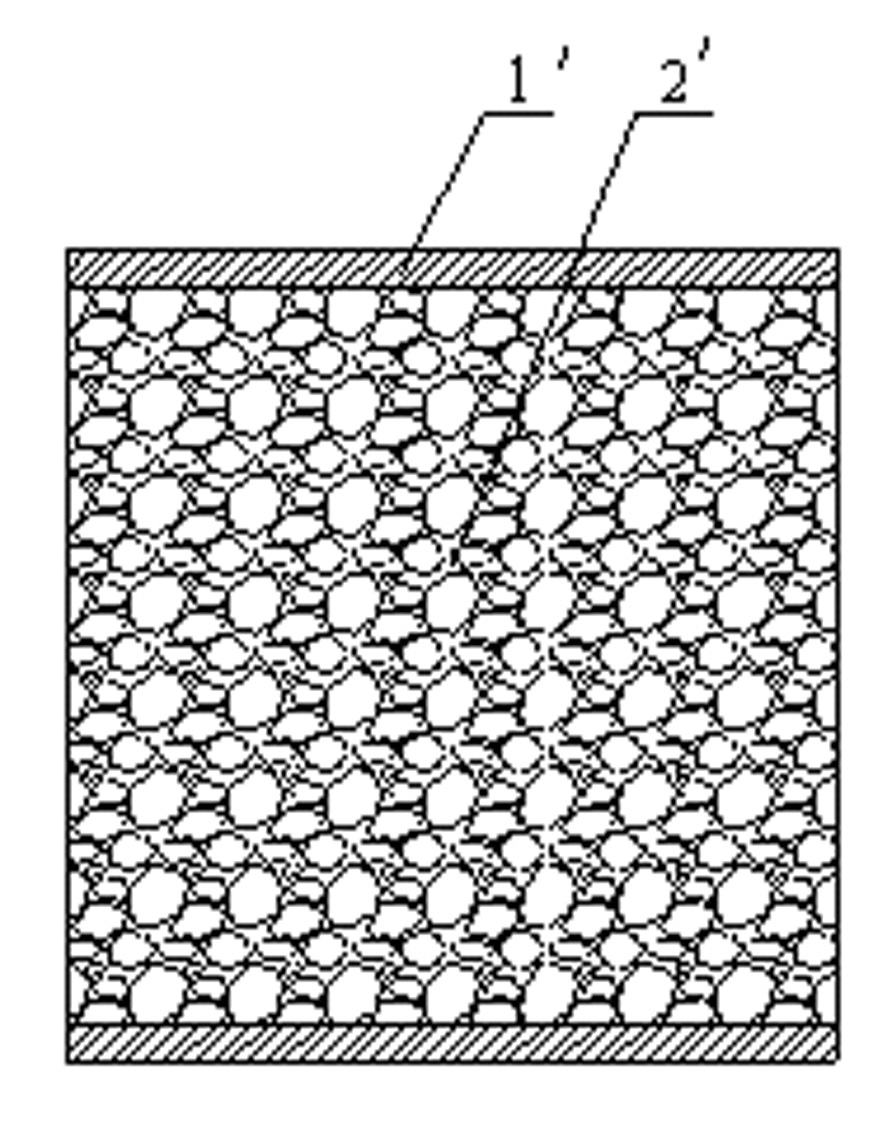

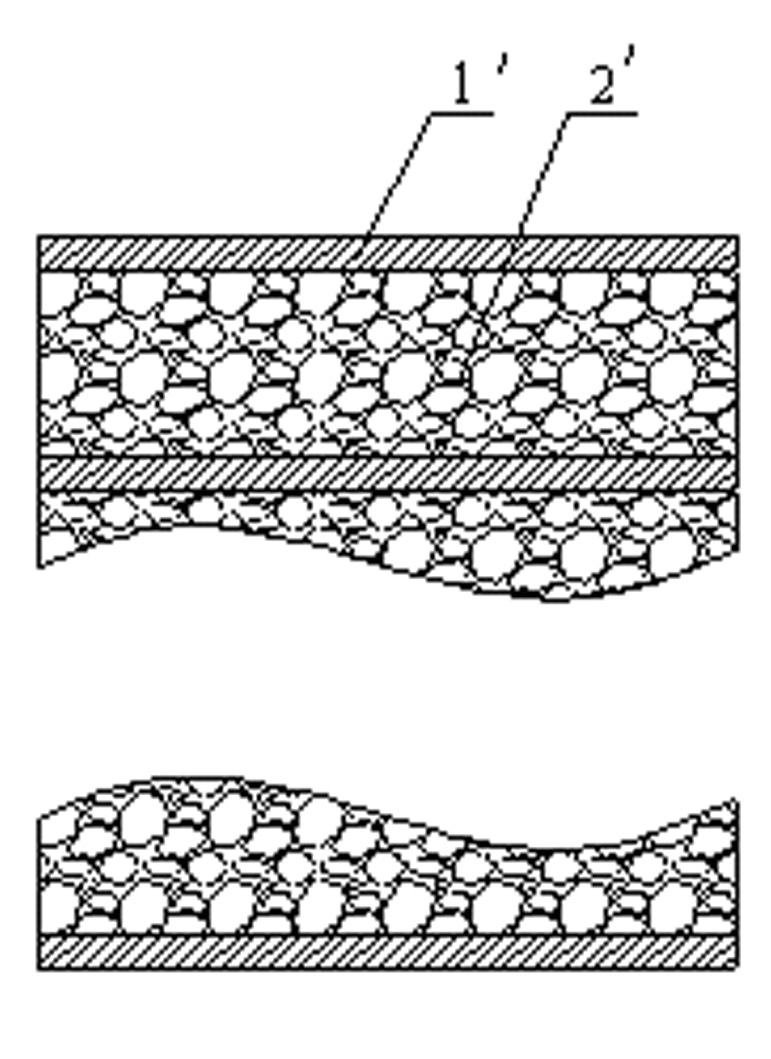

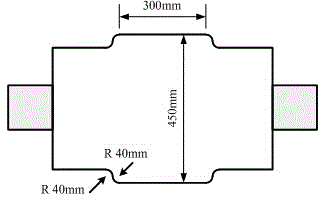

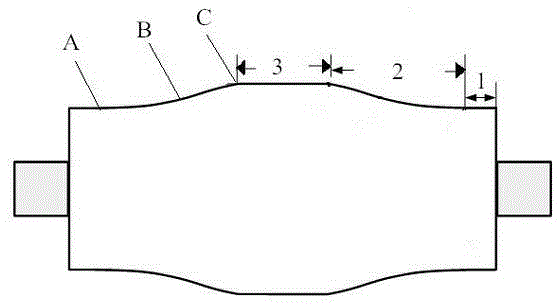

Gradient curvature raised roller of tension leveler for cogged ingot continuous casting and use method

ActiveCN104399924AIncrease the amount of deformationRealize the process purpose of extrusionStress concentrationMetallurgy

The invention belongs to the field of cogged ingot continuous casting production and especially relates to a gradient curvature raised roller of a tension leveler for cogged ingot continuous casting and a use method. The gradient curvature raised roller of the tension leveler provided by the invention is composed of a roller shaft and a roller body, wherein the roller body is composed of an edge area, a gradient curvature area and a flat roller area; the gradient curvature area is composed of an arcing area and an arc-varying area; the arc curvature between an arcing point and an arc-varying point of the arcing area is gradually increased; the arc curvature between the arc-varying point and an arc-ending point of the arc-varying area is gradually reduced; the flat roller area is raised relative to the edge area. At least four tension levelers with the gradient curvature raised rollers are used for pressing a cogged ingot continuous casting slab; during the pressing process, the average temperature of the surface of the continuous casting slab is controlled at above or equal to 800 DEG C and the temperature difference of surface center and corner is at below or equal to 150 DEG C; lastly, the continuous casting slab with improved central segregation and loosening is acquired. The smooth transition between the flat roller area and the raised roller area is realized by the gradient curvature raised roller provided by the invention and the crack defect caused by the stress concentration of the transition area is effectively avoided.

Owner:NORTHEASTERN UNIV

3D printer

The invention relates to a 3D printer based on a fusion accumulation rapid-forming process. The 3D printer is characterized by comprising a transmission mechanism, a worktable, a feeding mechanism and an isolating device. By utilizing a specific driving wheel and driven wheel and line transmission fit manner, the friction coefficient is increased, the problem that a belt wheel slips in a belt transmission process is solved, and transmission motion is accurate and reliable.

Owner:朱兴建

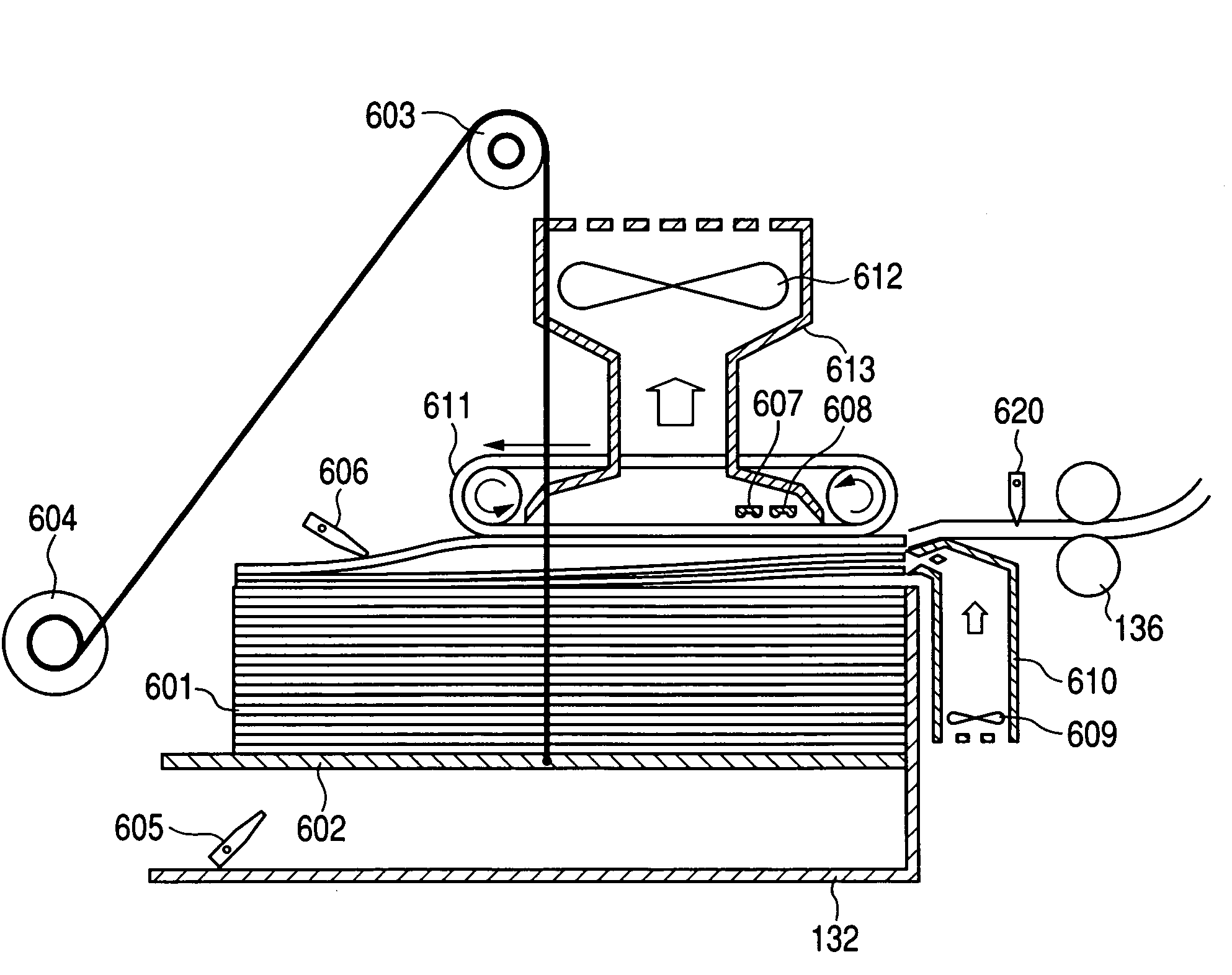

Paper gathering and feeding method and device therefor, and rotation member

Owner:HITACHI CHANNEL SOLUTIONS CORP

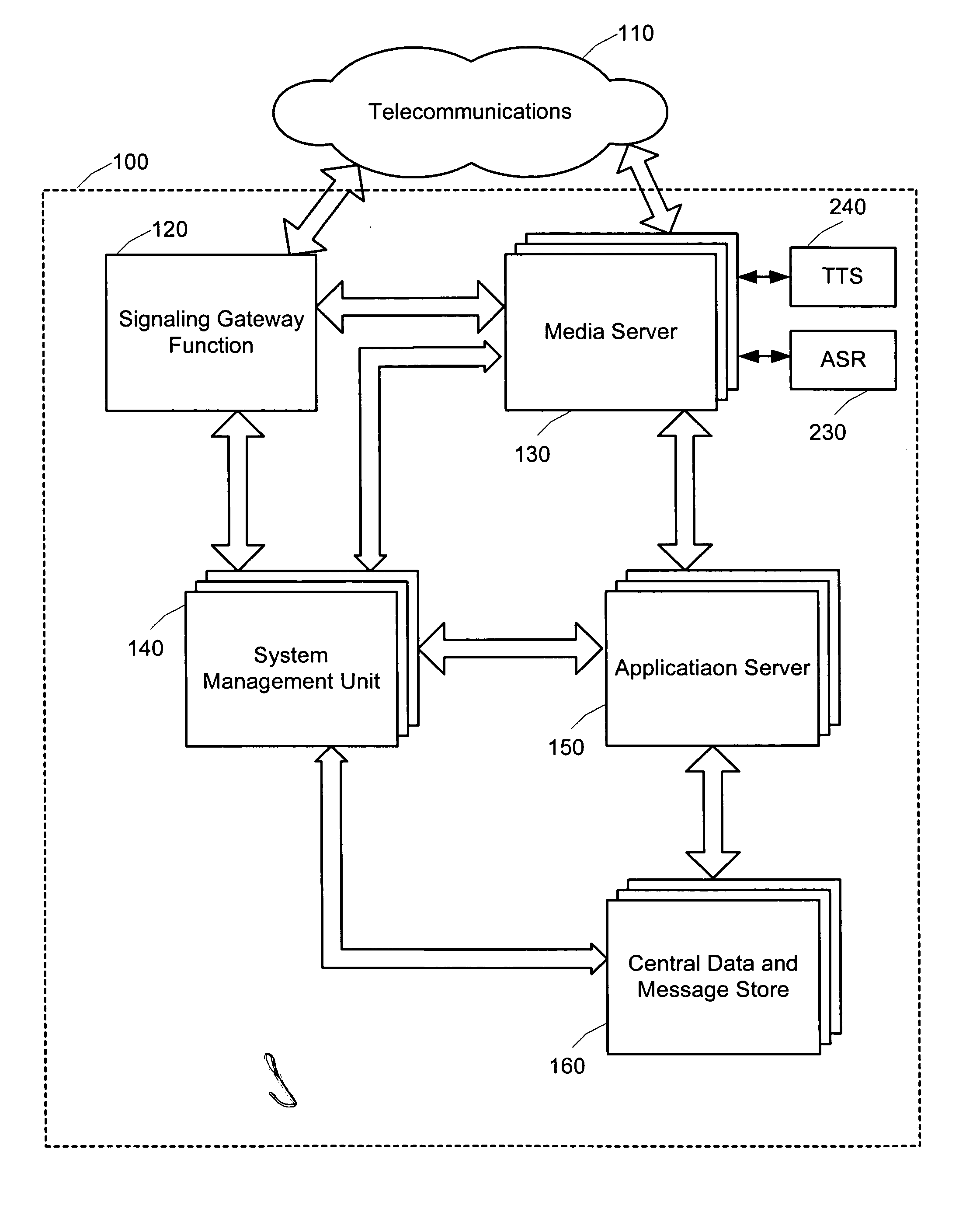

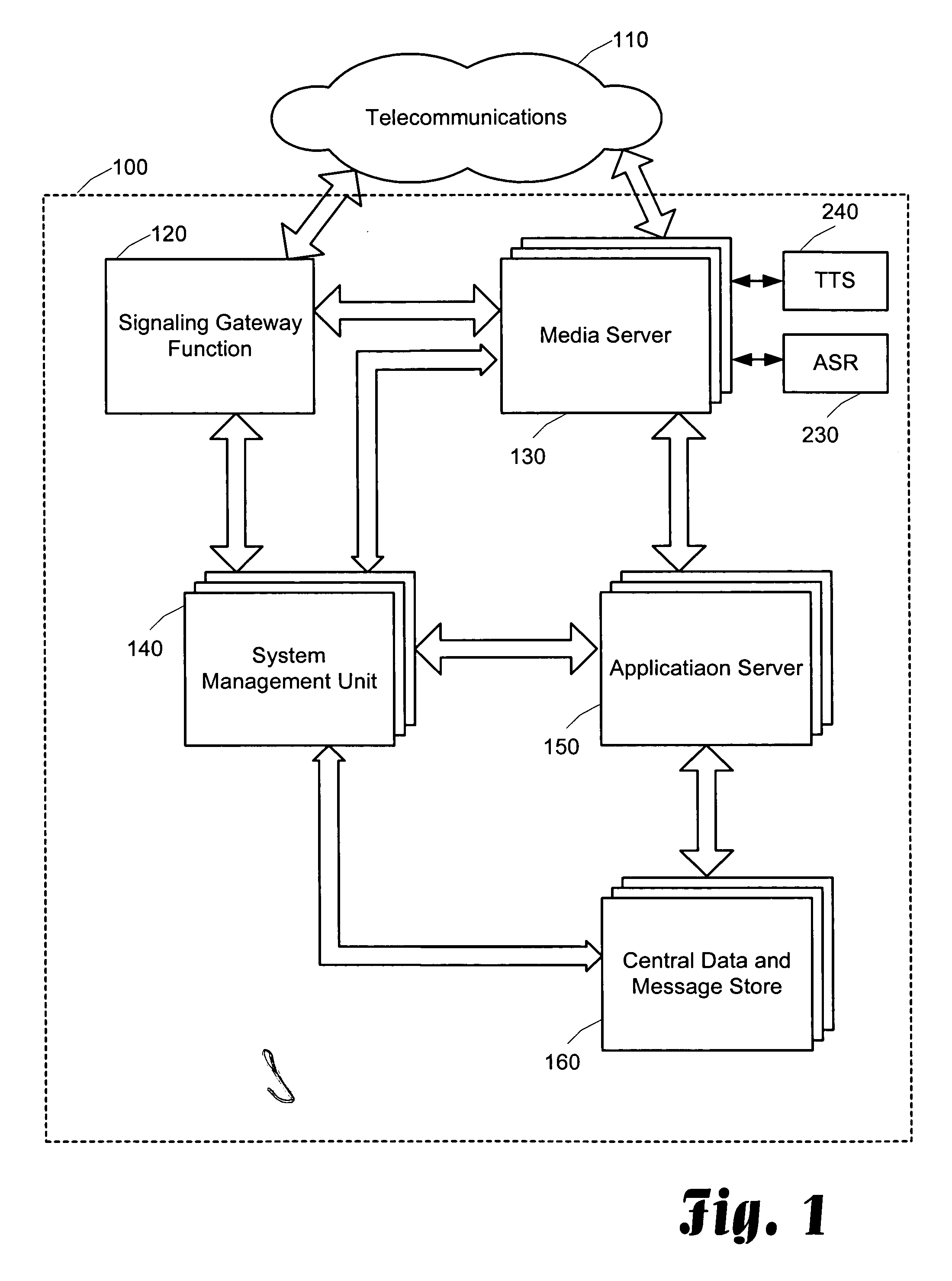

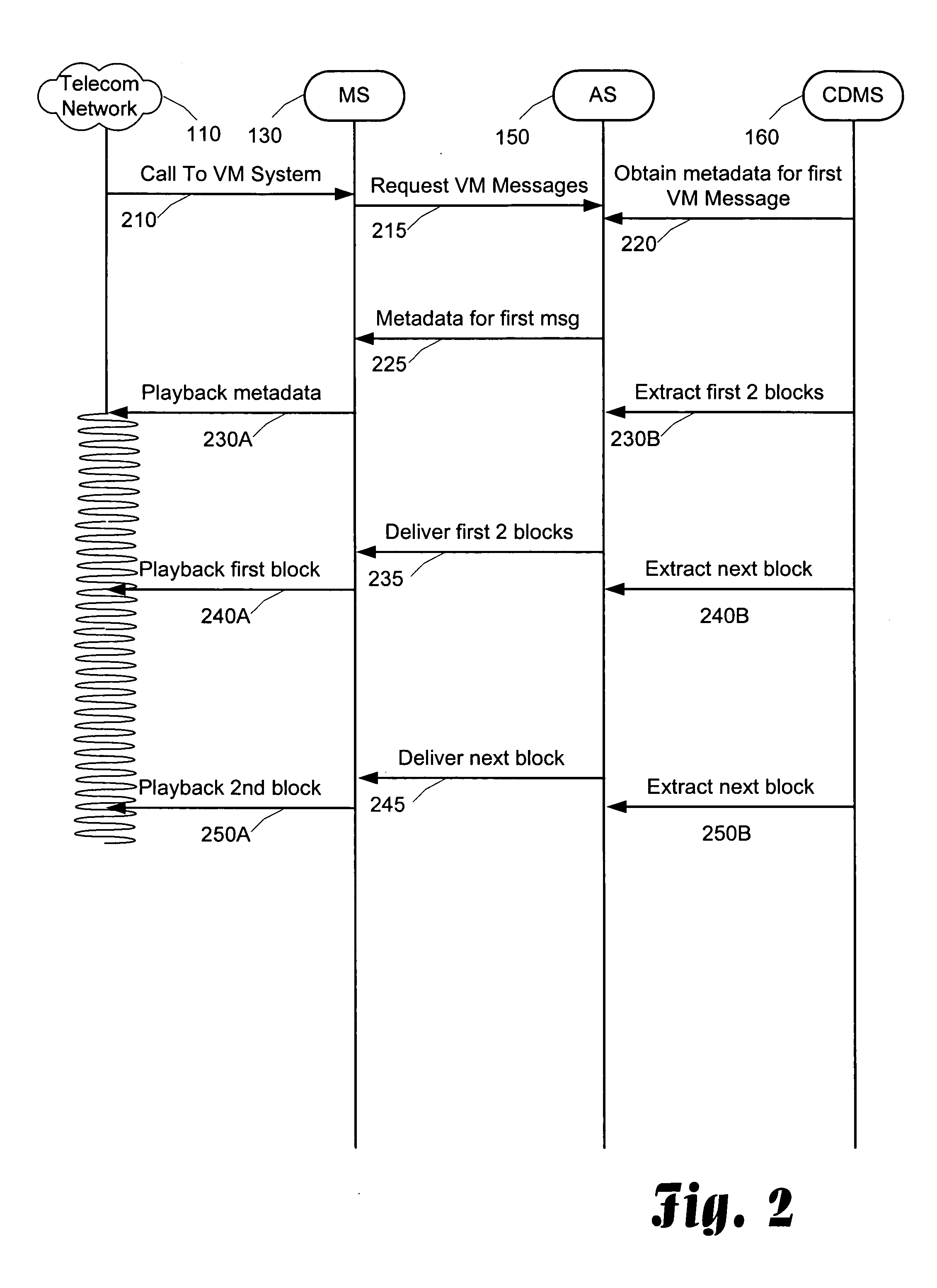

Audio chunking

InactiveUS20060002523A1Minimum delayEasy accessAutomatic call-answering/message-recording/conversation-recordingSpeech analysisComputer hardwareSpeech sound

A voice mail system that allows for the delivery of voice messages by chunks, thereby optimizing the delivery of the information. When a subscriber attempts to listen to his or her voice mail message, the header information for the first voice mail message is down loaded and played back to the subscriber. While the subscriber listens to the header information, the next two blocks of data of the voice message are downloaded. Upon the completion of the playback of the header information, the first two blocks of the voice mail message are available for playback and the first block is immediately available for playback. As the subscriber listens to the voice mail message subsequent blocks of the first voice mail message, and optionally header information and blocks of subsequent voice mail messages are simultaneously down loaded. Thus, the subscriber is able to seamlessly listen to the voice mail messages without a delay in the retrieval of the voice mail messages regardless of the order the subscriber listens to the messages.

Owner:GLENAYRE ELECTRONICS INC

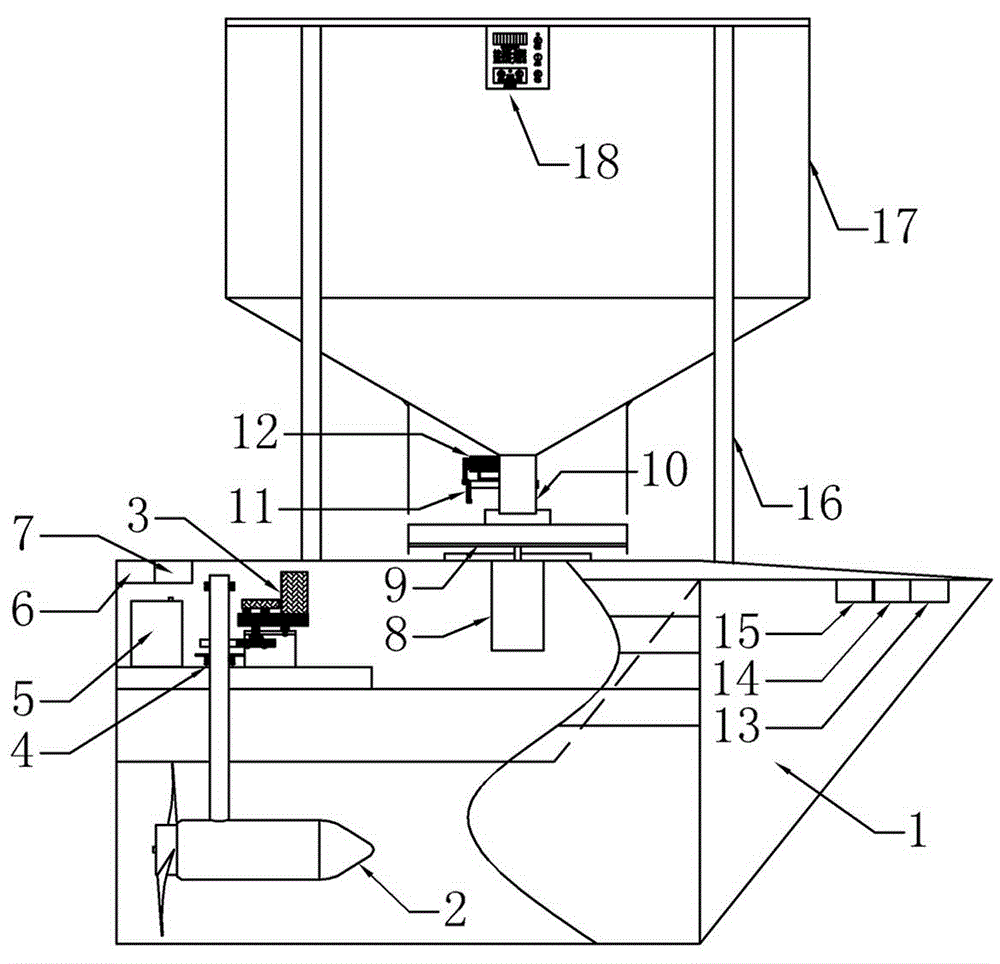

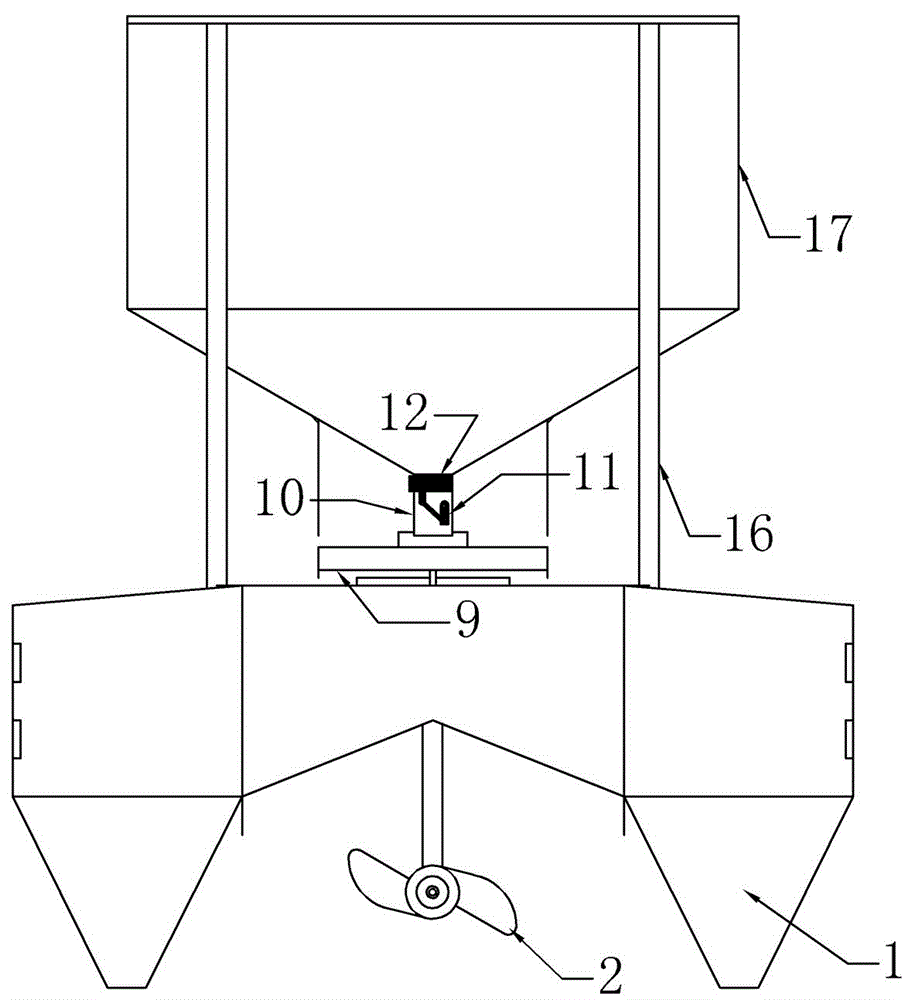

Aquaculture robot

InactiveCN103329824ASmooth feedingAvoid wastingClimate change adaptationPisciculture and aquariaAquaculture industryRemote control

An intelligent unmanned aquaculture robot comprises a ground station, remote control equipment, a hull part, a sailing controller, a feeding execution part, a bait casting controller, a data acquisition module, a data and image transmission module. The sailing controller receives instructions from the ground station, the remote controller or a shipborne panel, and is divided into a remote control mode and an automatic mode; the automatic mode completes scheduled sailing independently in an unmanned manner according to a preset route and a GPS (Global Position System) via real-time dynamic course control and velocity control, so that the fixed route is ensured; and the feeding velocity controlled dynamically in real time according to parameters such as real-time voyage, velocity and material quantity, so that uniform bait casting is ensured. The data and image transmission part transmits data collected by the data acquisition part and operating parameters related to a system to the ground station in real time. The robot can complete tasks such as the bait casting, fertilizing, spraying, seeding, mowing, oxygenating, pool patrolling, bird expelling, monitoring and the like independently. With the adoption of the robot, fixed quality, fixed points, fixed time and fixed quantity of large-scale aquaculture are realized, and the excess dependence of the aquiculture on the labor force is reduced.

Owner:周长宾

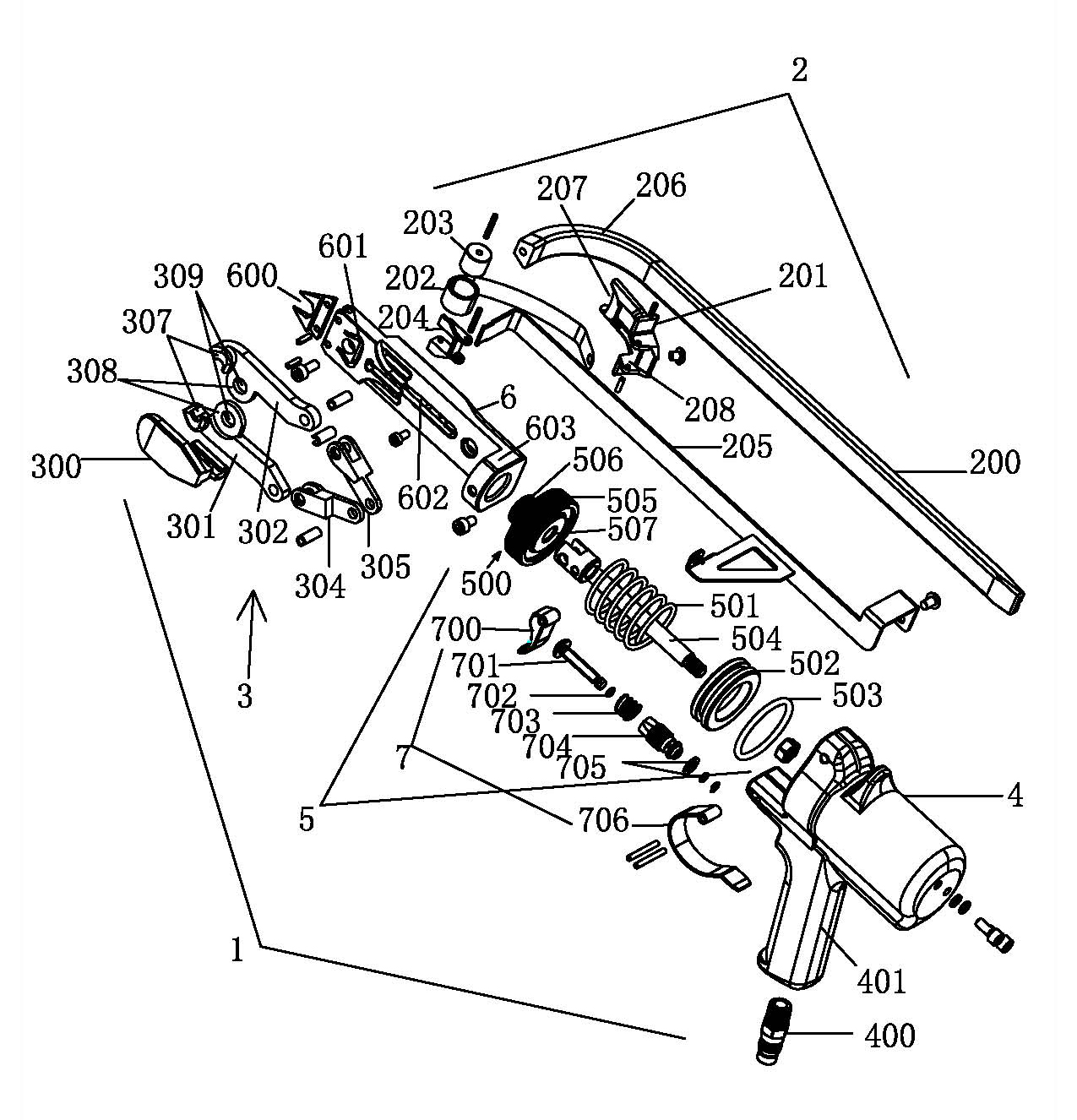

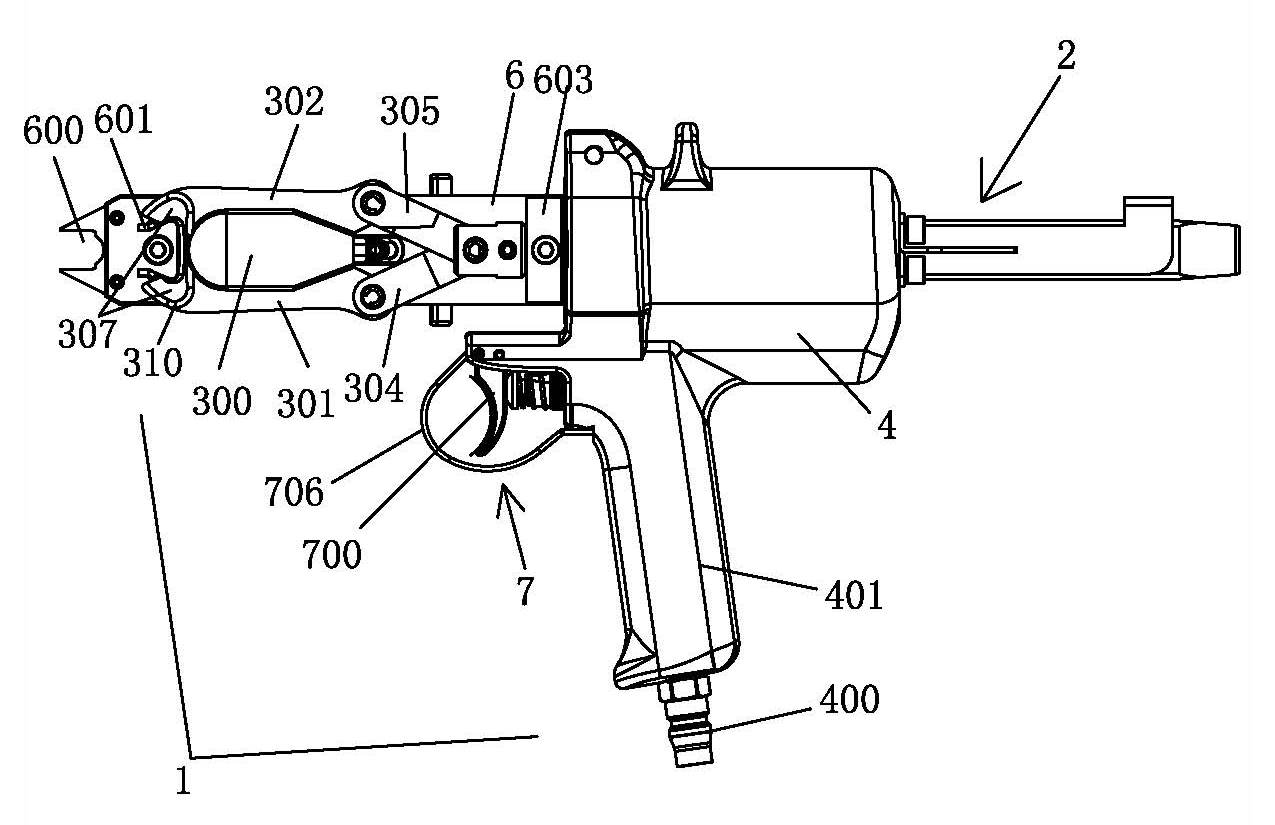

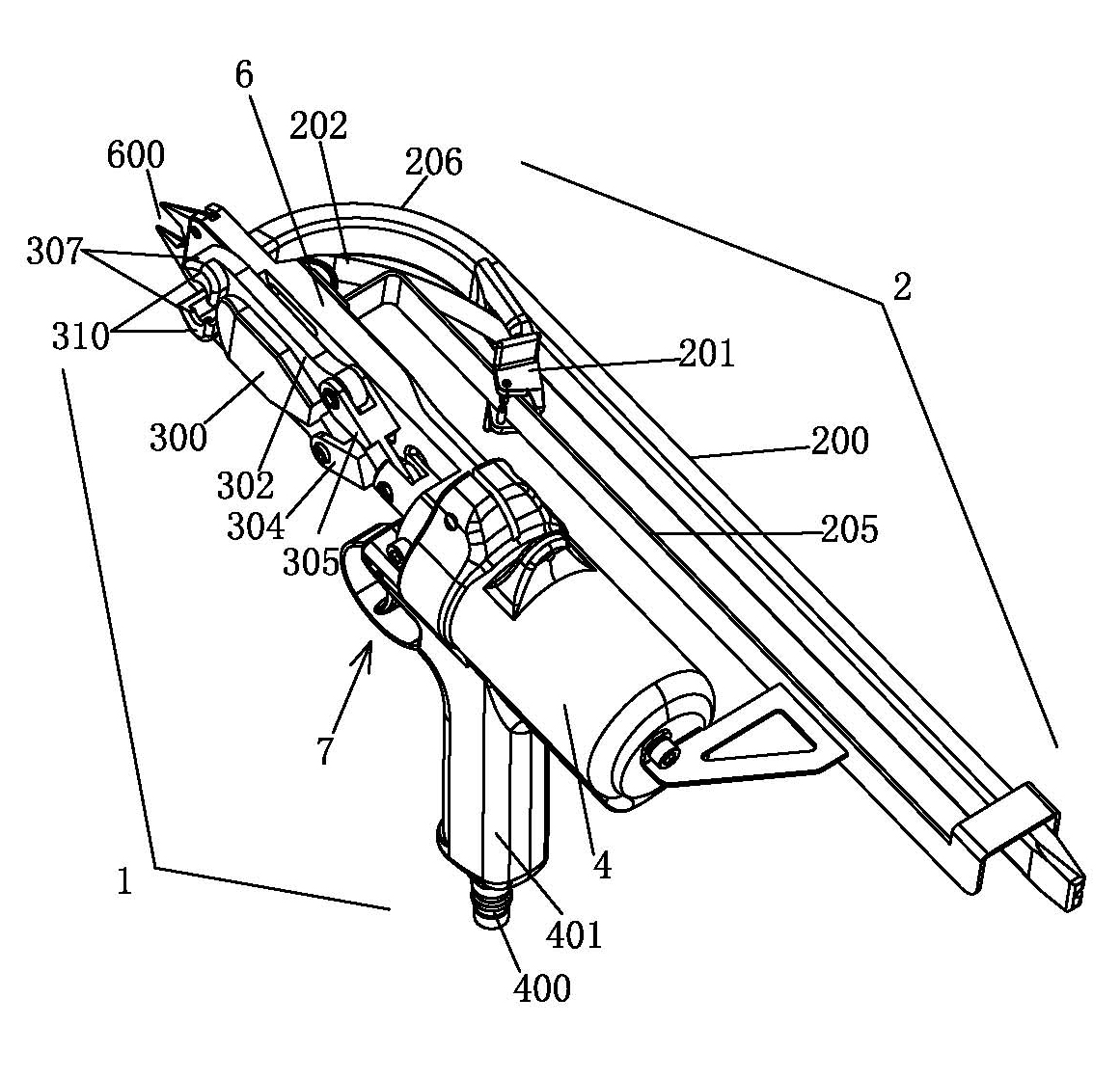

Pneumatic steel wire gauze gun

ActiveCN102350472ASmooth feedingNot easy to get stuckWire networkPortable power-driven toolsWire gauzeMechanical engineering

The invention relates to a pneumatic steel wire gauze gun. The pneumatic steel wire gauze gun provided by the invention comprises a pincers gun and a nail box, wherein the coiled spring of the nail box pulls back a nail feeder by installing the nail box at one side of a gun rack, so that a metal clamping slice nail is automatically delivered into a pincers mouth of the pneumatic steel wire gauze gun; a piston rod of a cylinder simultaneously pushes the rear ends of left and right connecting rods, and forces are transmitted to left and right clamping jaws at the front ends of the left and right connecting rods so as to drive a sliding block to slide forwards along a guide slot of the gun rack; when the front end of the sliding block abuts against the front end of the guide slot, the sliding block stops sliding; the rear ends of the left and right clamping jaws are pushed by the forces to stretch by taking the hinge pin of the sliding block as the fulcrum, so that pincers mouths of the left and right clamping jaws are closed, and the metal clamping slice nails arranged in the pincers mouths are pressed to be rolled. The pneumatic steel wire gauze gun provided by the invention has the advantages of automatic nail delivery, convenience in operation, time and labor conservation and high safety.

Owner:GUANGDONG MINGHUI PNEUMATIC TECH CO LTD

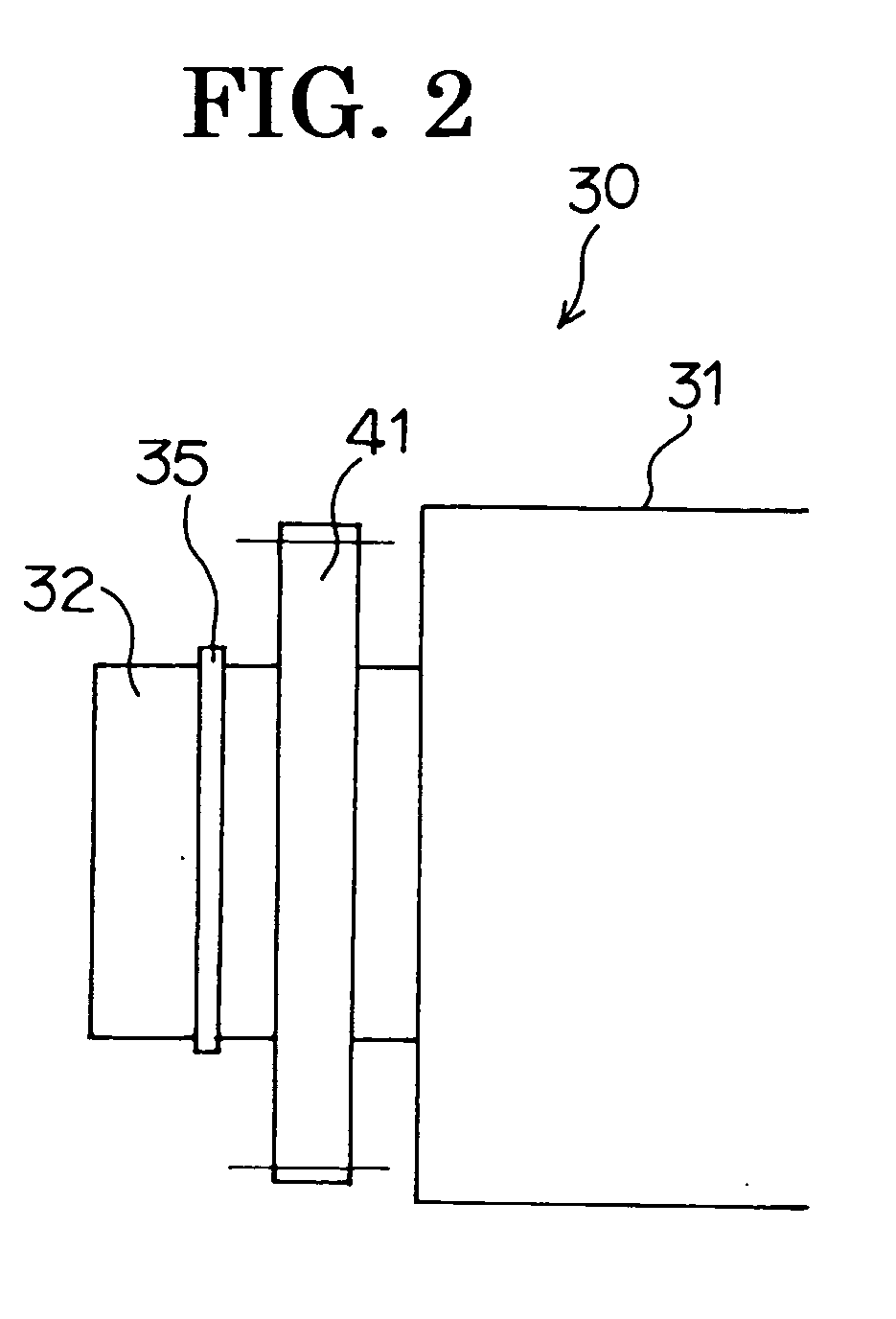

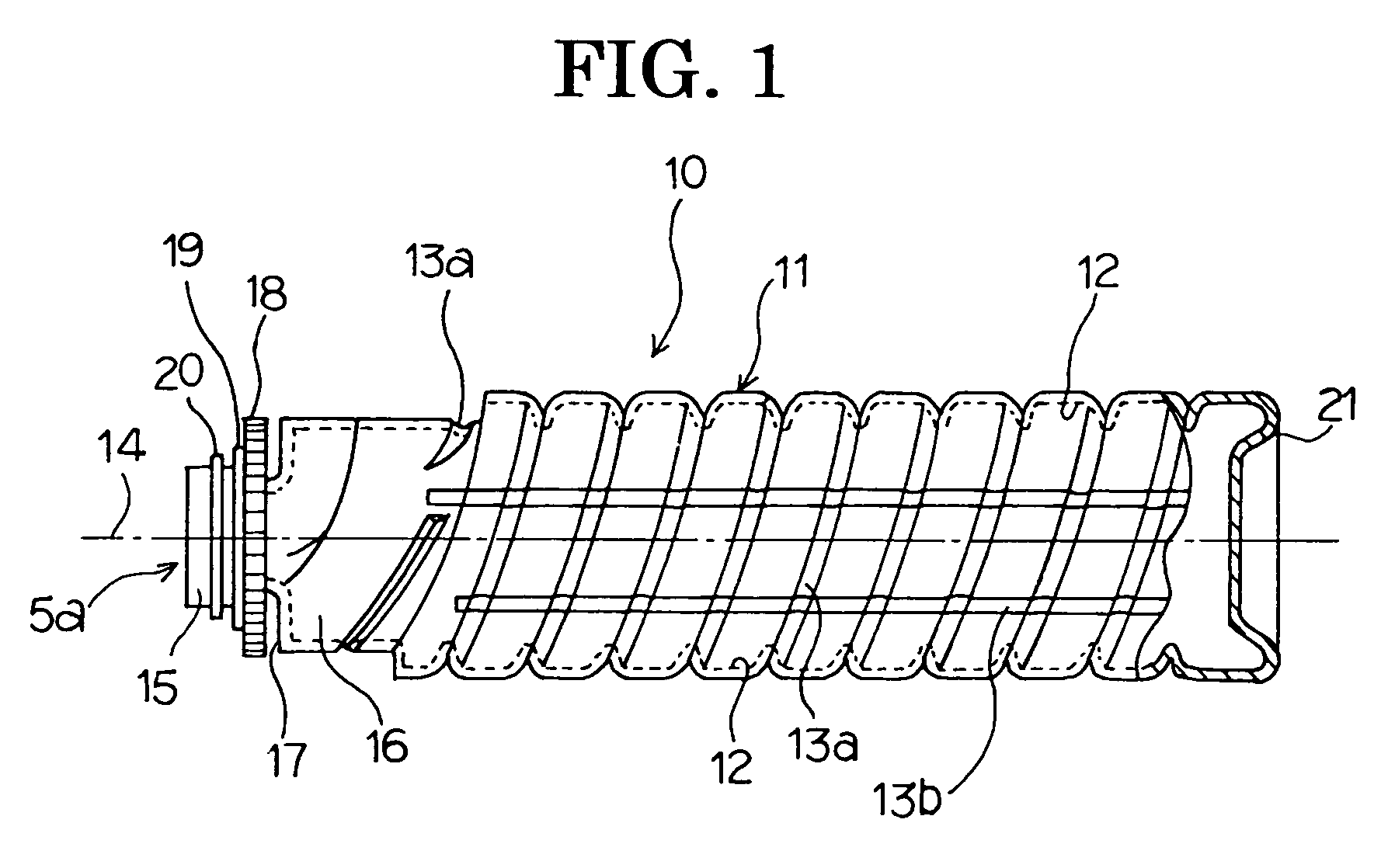

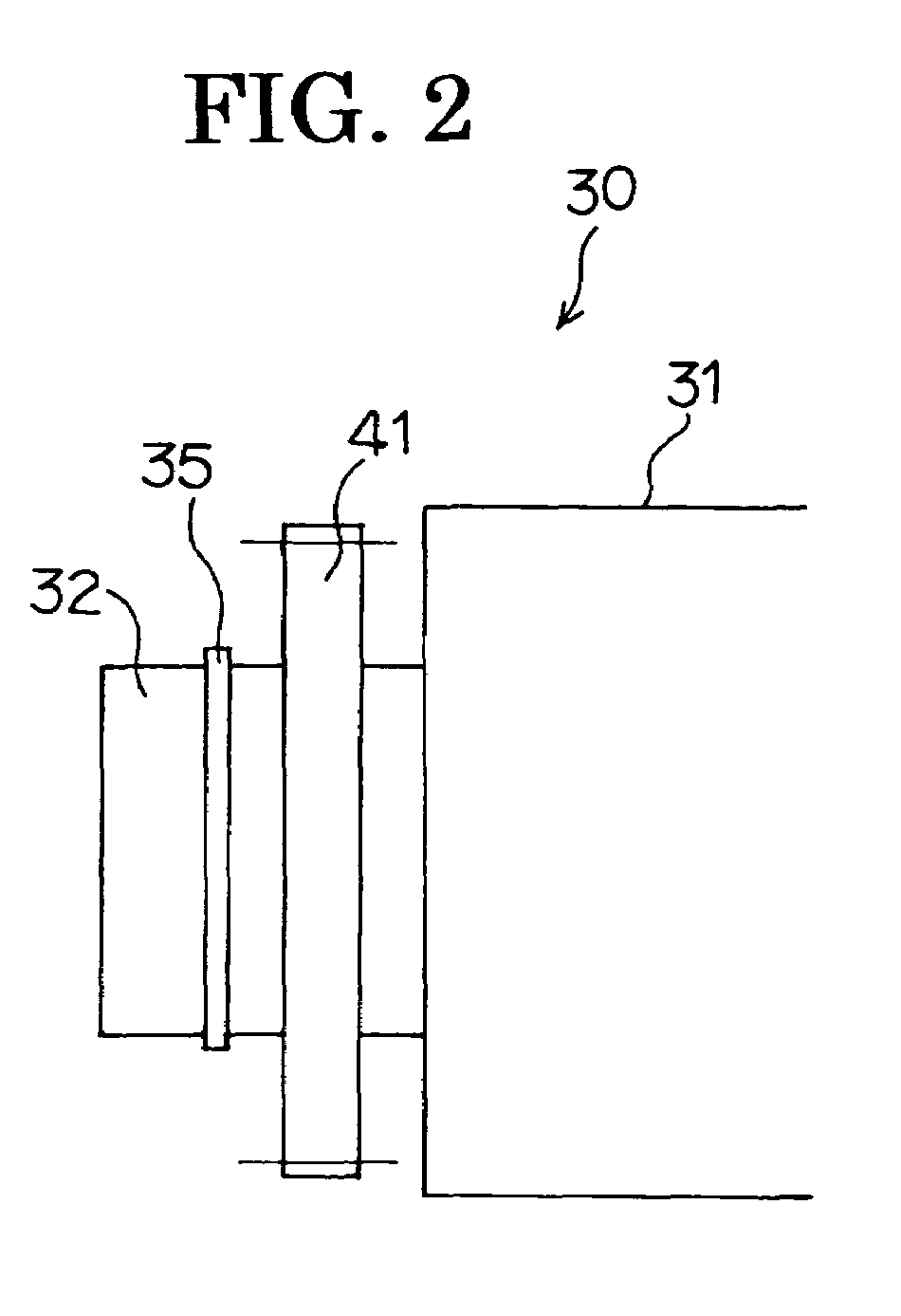

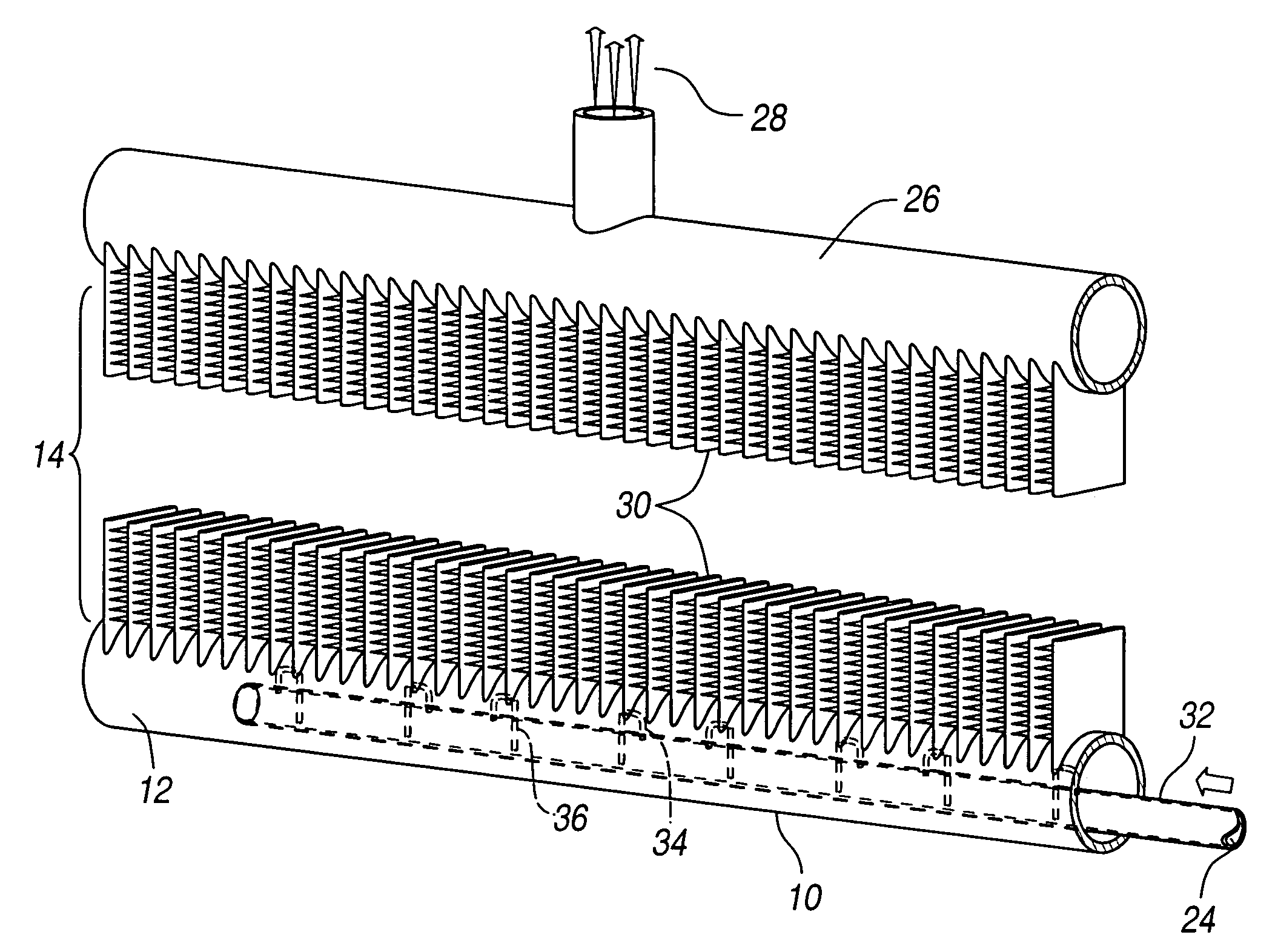

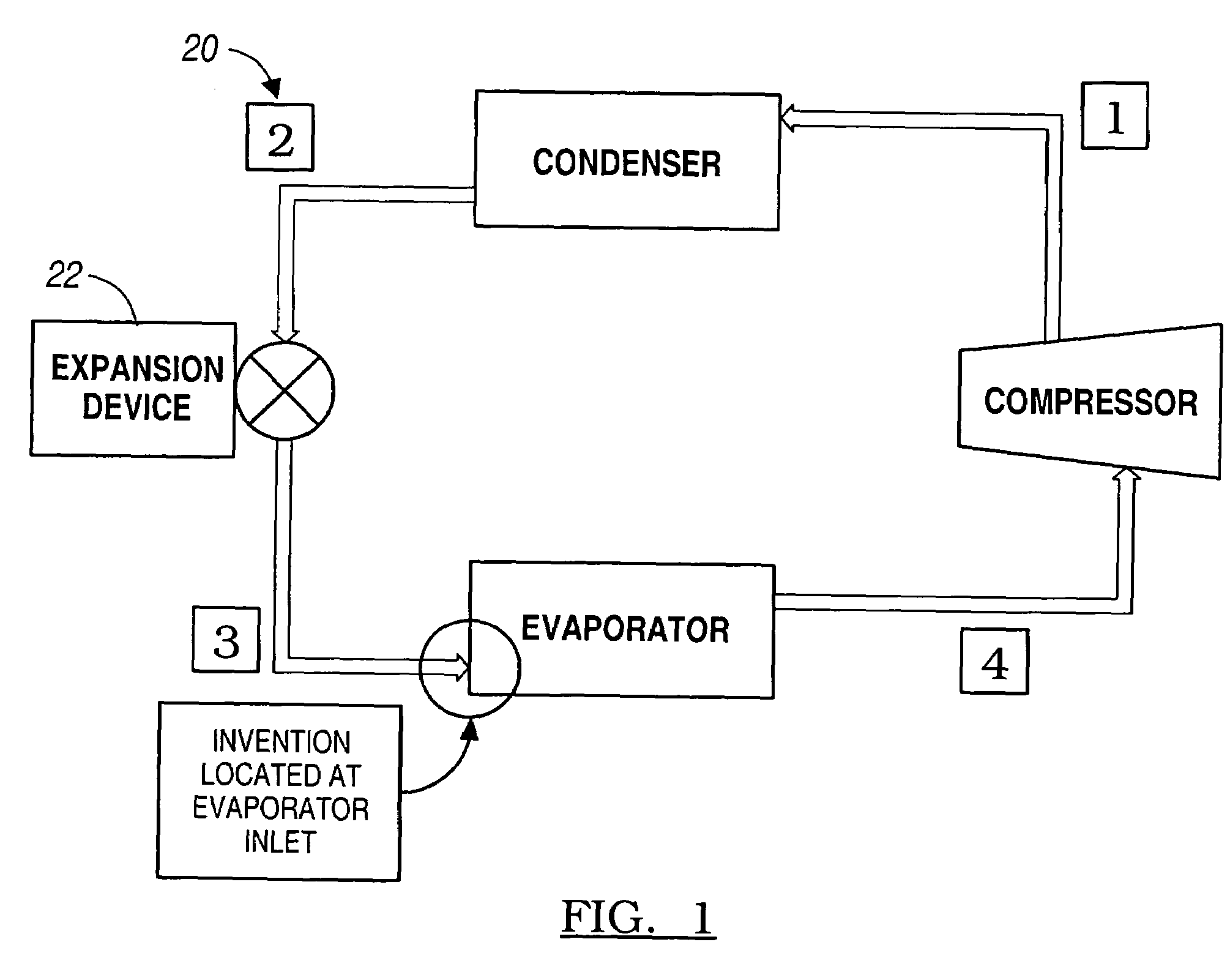

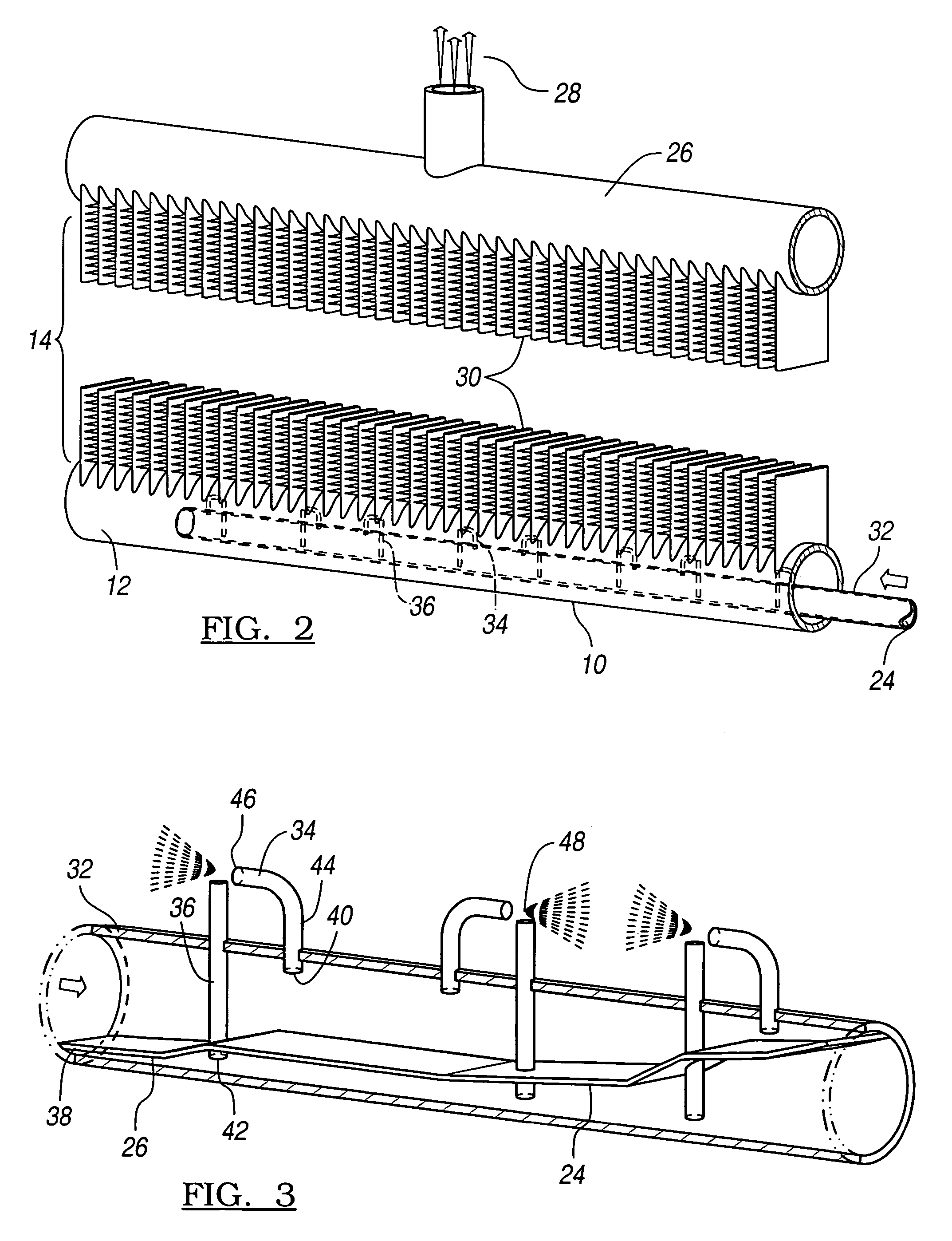

Refrigerant distribution device and method

ActiveUS7086249B2Smooth feedingUniform utilizationEvaporators/condensersHeat exchanger casingsRefrigerant distributionEngineering

A refrigerant distribution device 10 situated in an inlet header 12 of a multiple tube heat exchanger 14 of a refrigeration system 20. The device 10 includes an inlet passage 32 that is in communication with an expansion device. Small diameter nozzles 34 are disposed within the inlet header 12 and are in fluid communication with the inlet passage 32. Capillary liquid nozzles 36 also lie within the inlet header 12 and are in fluid communication with the inlet passage 32. A two-phase refrigerant fluid in the inlet passage 32 has a refrigerant liquid-vapor interface 38. The vapor nozzles 34 have vapor inlet ports 40 that lie above the refrigerant liquid-vapor interface 38. The capillary liquid nozzles 36 have liquid inlet ports 42 that lie below the refrigerant liquid-vapor interface 38. Vapor emerging from the vapor nozzles 34 blow onto and atomize liquid emerging from the liquid nozzle to create a homogeneous refrigerant that is uniformly delivered to the multiple tubes. The invention also includes a method for delivering a uniform distribution of a homogeneous liquid mixture of liquid and vaporous refrigerant through the heat exchanger tubes.

Owner:LENNOX INTERNATIONAL

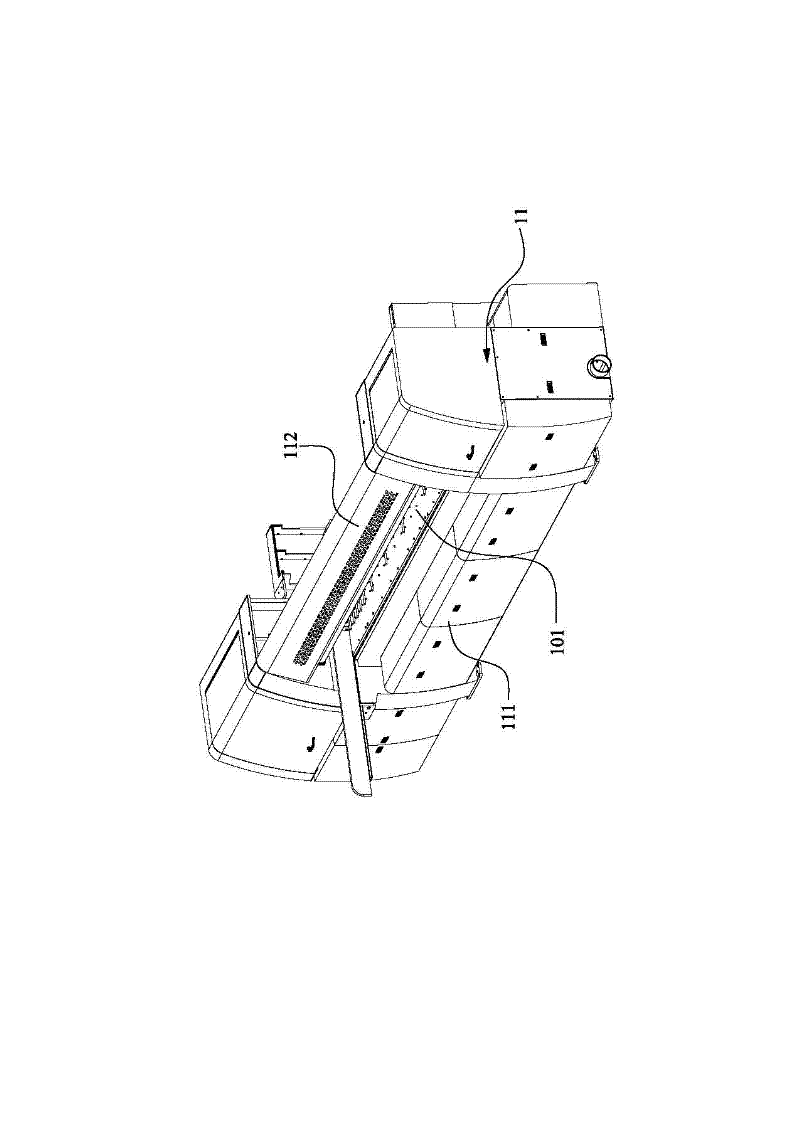

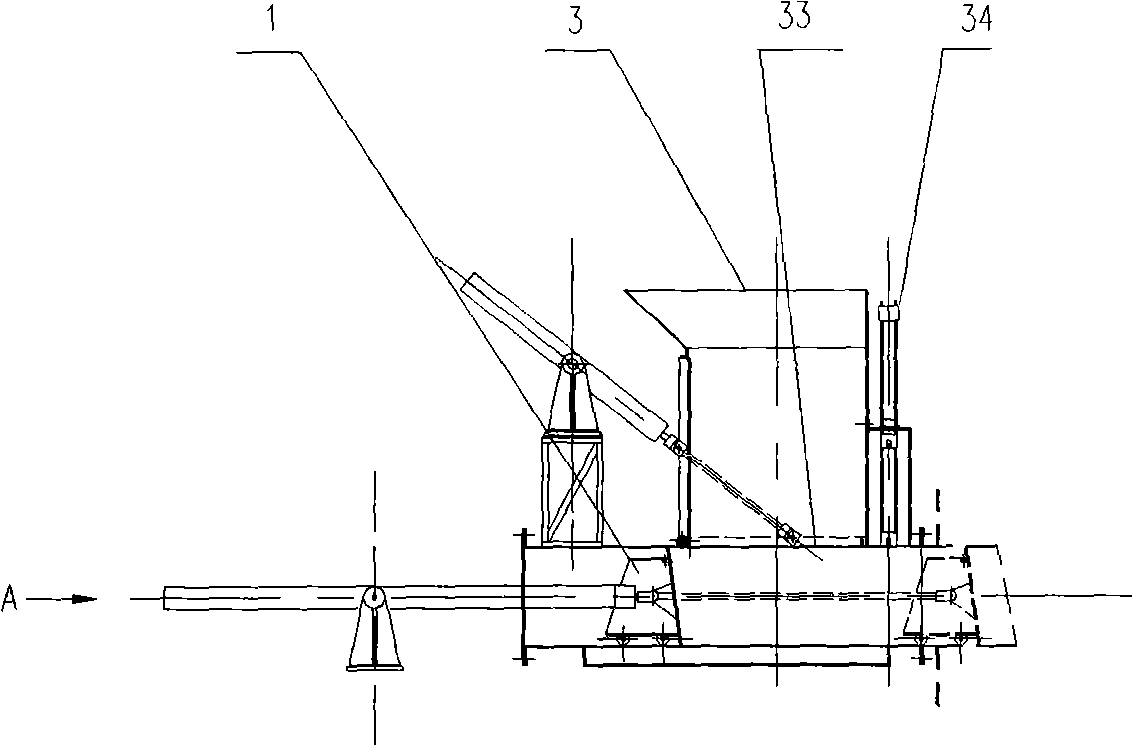

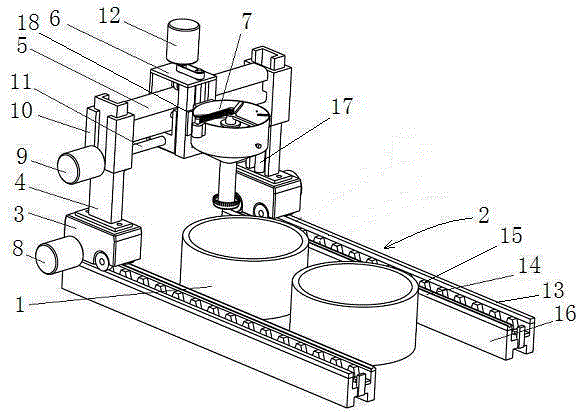

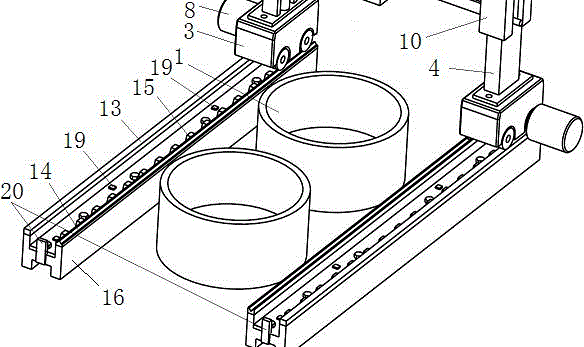

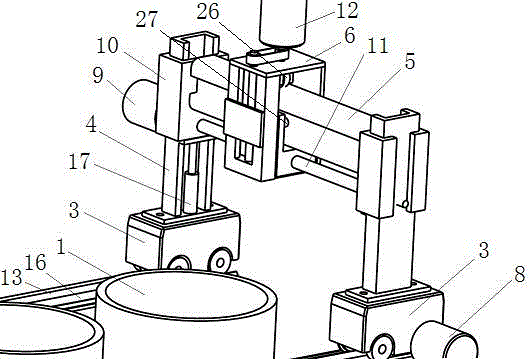

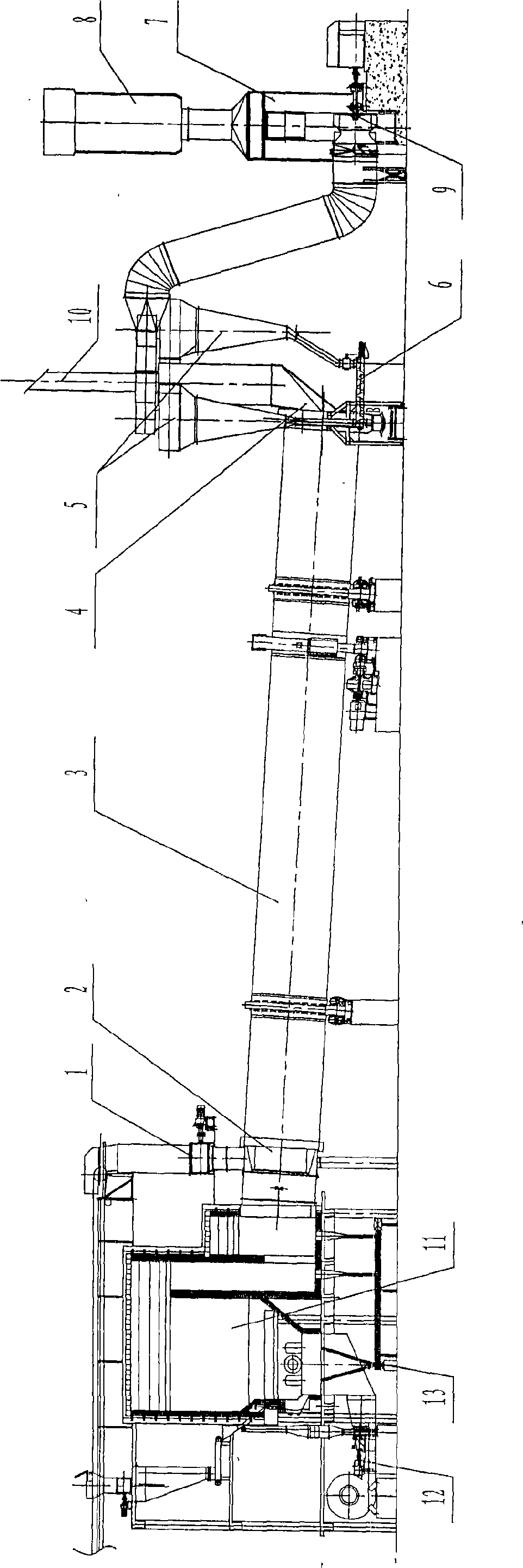

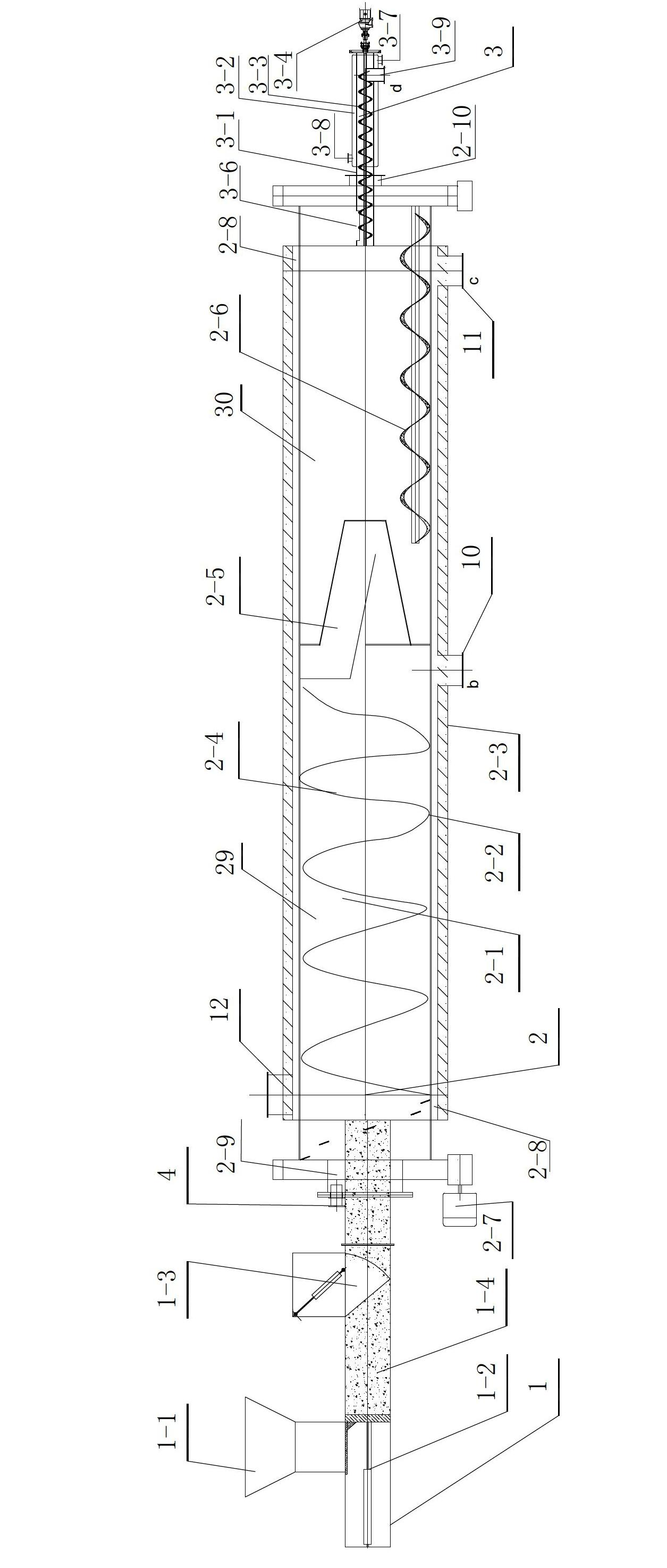

Gantry fermented grain automatic loading machine and loading method

InactiveCN104816954AIncrease loading capacityLower performance requirementsConveyorsAlcoholic beverage preparationSteam pressureControl system

The invention discloses a gantry fermented grain automatic loading machine. The gantry fermented grain automatic loading machine comprises a gantry fermented grain loading robot, a fermented grain loading execution mechanism, a binocular vision identifying system and a control system, wherein the gantry fermented grain loading robot consists of two horizontal guide rails, two stand columns, a cross beam and a ram; the fermented grain loading execution mechanism is mounted on the ram; and the binocular vision identifying system comprises a steam running identification thermal infrared imager and a height identification thermal infrared imager, whose output ends are connected to an input end of the control system. The gantry fermented grain loading robot is excellent in loading capacity, and the performance requirement of the robot can be reduced, so that the equipment cost investment is reduced; the guide rails consisting of a flat guide rail, a V-shaped guide rail and a rack composition are adopted to bear the position deviation caused by slight displacement generated in the fermented grain loading motion process, so that the material distributing and feeding accuracy is guaranteed, and the distilling effect is improved; and the binocular vision identifying system is adopted to obtain the material surface temperature distribution and height, so that fermented grains are uniform to prevent the air way blockage and the steam pressure, and the distillation effect is guaranteed.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

Image-recording apparatus, and recording-medium supply device

InactiveUS20060071389A1Improve stabilityReduce exerciseElectrographic process apparatusArticle feedersRotational axisDrive shaft

An image-recording apparatus including (a) a carriage carrying a recording head, (b) a maintenance unit disposed at a standby position located outside a recording area (L) of the recording head, (c) medium feeding devices to feed recording media from respective cassettes (d) first, second and third gears which are disposed outside the recording area and through which a drive force is selectively transmitted from a drive-force output gear to one of the medium feeding devices and the maintenance device, and (e) a power-transmission switching device having a shift gear which is moved for selective meshing engagement with the first, second and third gears according to a distance of movement of the carriage from the recording area toward the maintenance unit. In at least one of the medium feeding devices, a support arm pivotally supported at its proximal end portion by a drive shaft and rotatably supporting a rotary medium-supply member at its free end portion is biased by a biasing device pivotally about the axis of rotation of the drive shaft in a direction for moving the free end portion toward the stack of recording media, and in an axial direction of the drive shaft against a support frame which rotatably supports the drive shaft.

Owner:BROTHER KOGYO KK

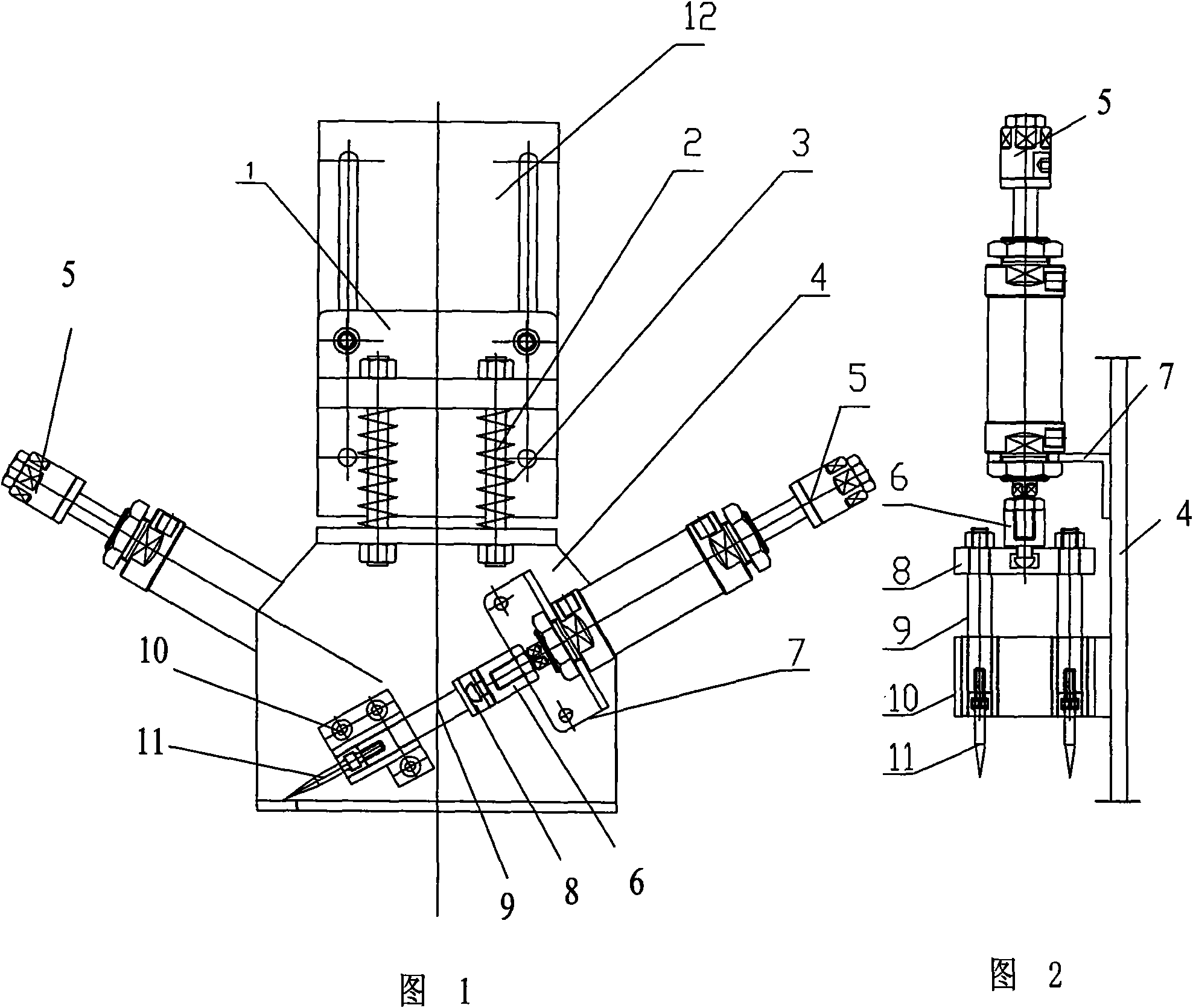

Automatic loading pricking device for automobile ceiling and carpet production line

InactiveCN101585186ASmooth feedingReduce labor intensityGripping headsConveyor partsProduction lineEngineering

The invention relates to an automobile ceiling production line, in particular to an automatic loading mechanism used for the production line, and belongs to the technical filed of mechanical structures. According to the technical proposal provided by the invention, the upper part of a framework is provided with a connecting plate on which a first guide post is arranged, the lower end of the first guide post is connected with the upper end of the framework, the first guide post is provided with a spring, the framework is provided with a cylinder bracket on which a stroke adjustable cylinder is arranged, a piston rod of the stroke adjustable cylinder is connected with a second guide post, and the end part of the second guide post is provided with a pinprick. The device has the characteristics of simple, compact and reasonable structure, high automatic degree, stable loading, improvement on the production efficiency, and reduction on labor intensity of workers.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

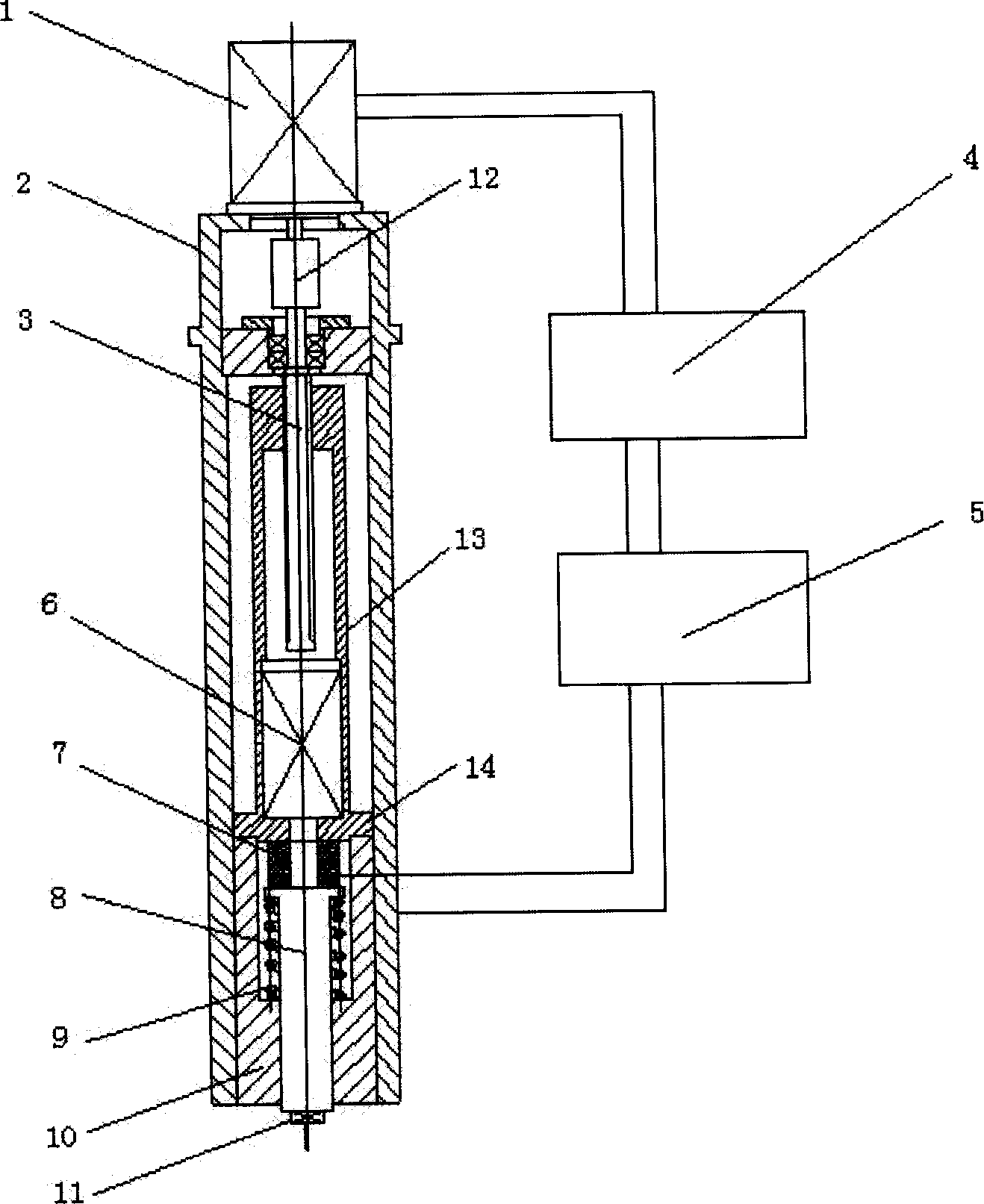

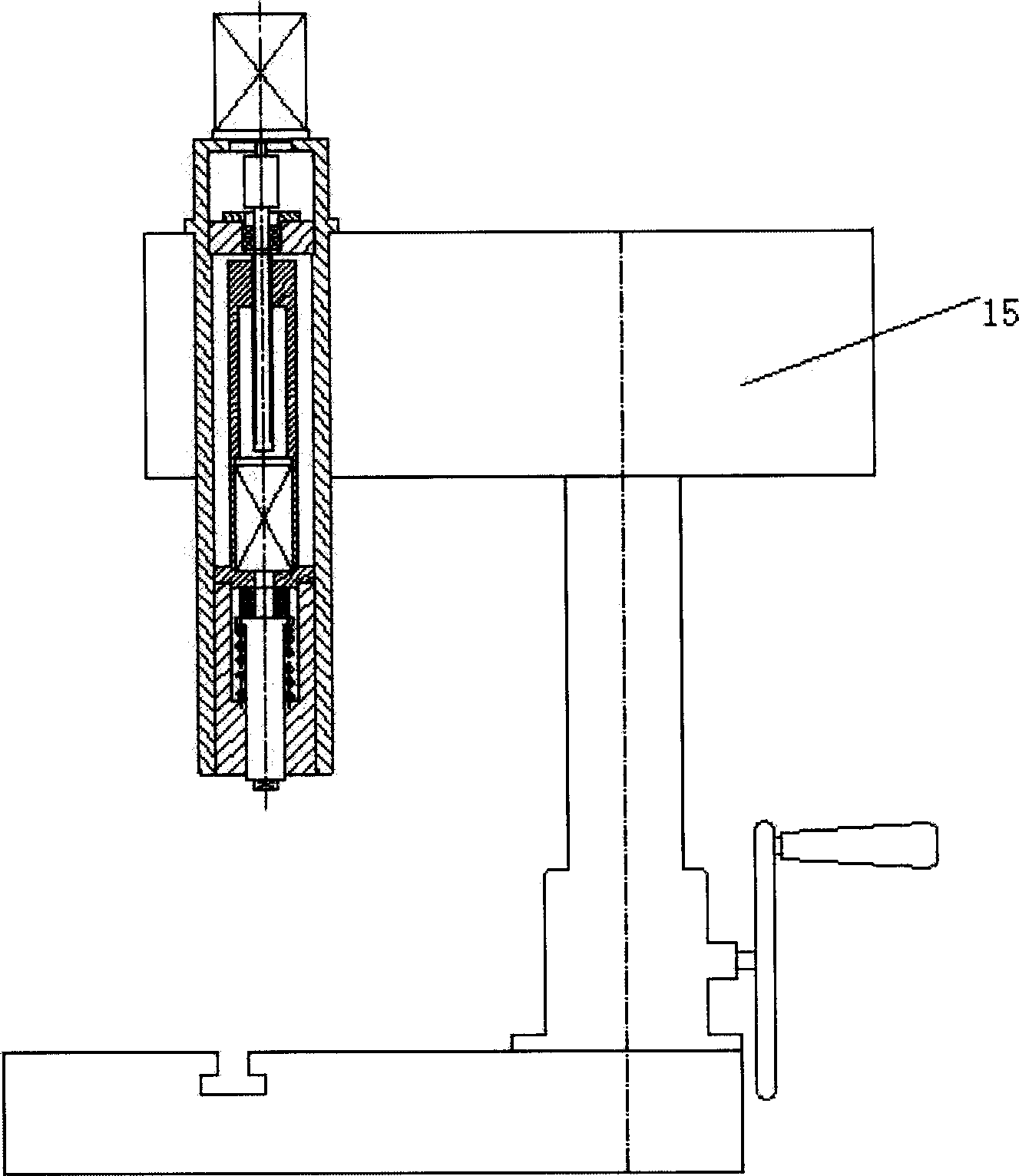

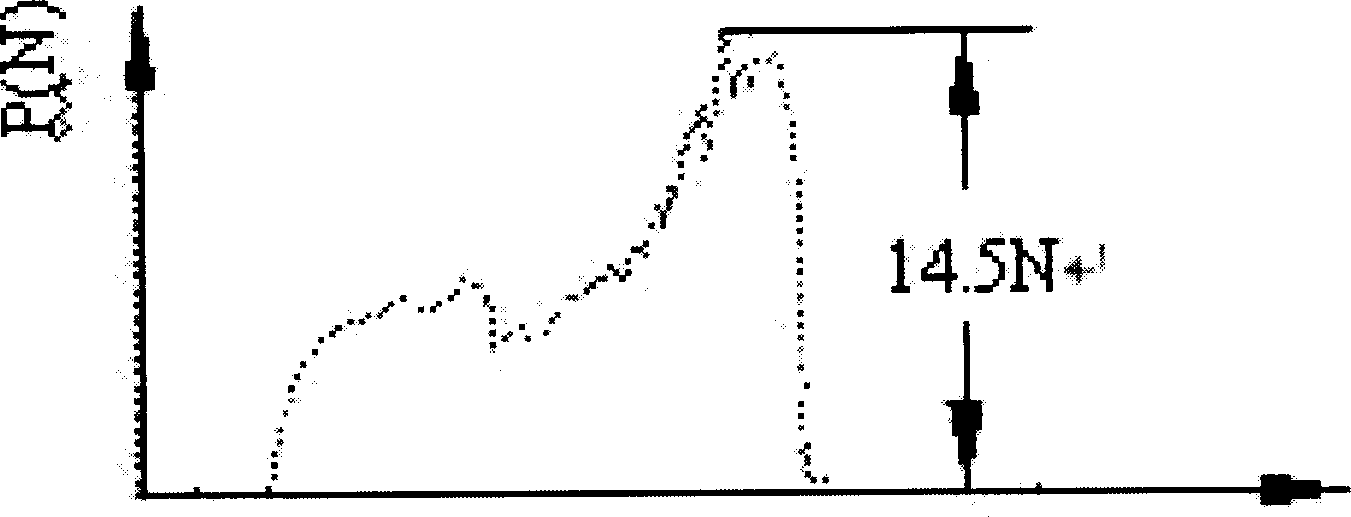

Method and equipment for drilling micro-holes with variable parameter vibration drill

InactiveCN1418747AReduce volumeCompact structureAutomatic control devicesFeeding apparatusIt equipmentCoupling

The present invention discloses a method for variable parameter vibration drilling microbore and its equipment. Said equipment consists of controller, power supply, stepper motor, precision spring holder and external sleeve, the interior of external sleeve is equipped with connecting coupler and lead-screw support of ballscrew, the output shaft of the motor is connected with coupler, another end of the coupler is connected with ballscrew, the ballscrew and D.C high-speed motor are cover-mounted in the main shaft motor support, and said main shaft motor support is integral connected with copper sleeve by pressure plate, the motor is fixed ont he pressure plate and connected with power supply, in the copper sleeve of lower end of the motor is connected with main shaft.

Owner:BEIHANG UNIV

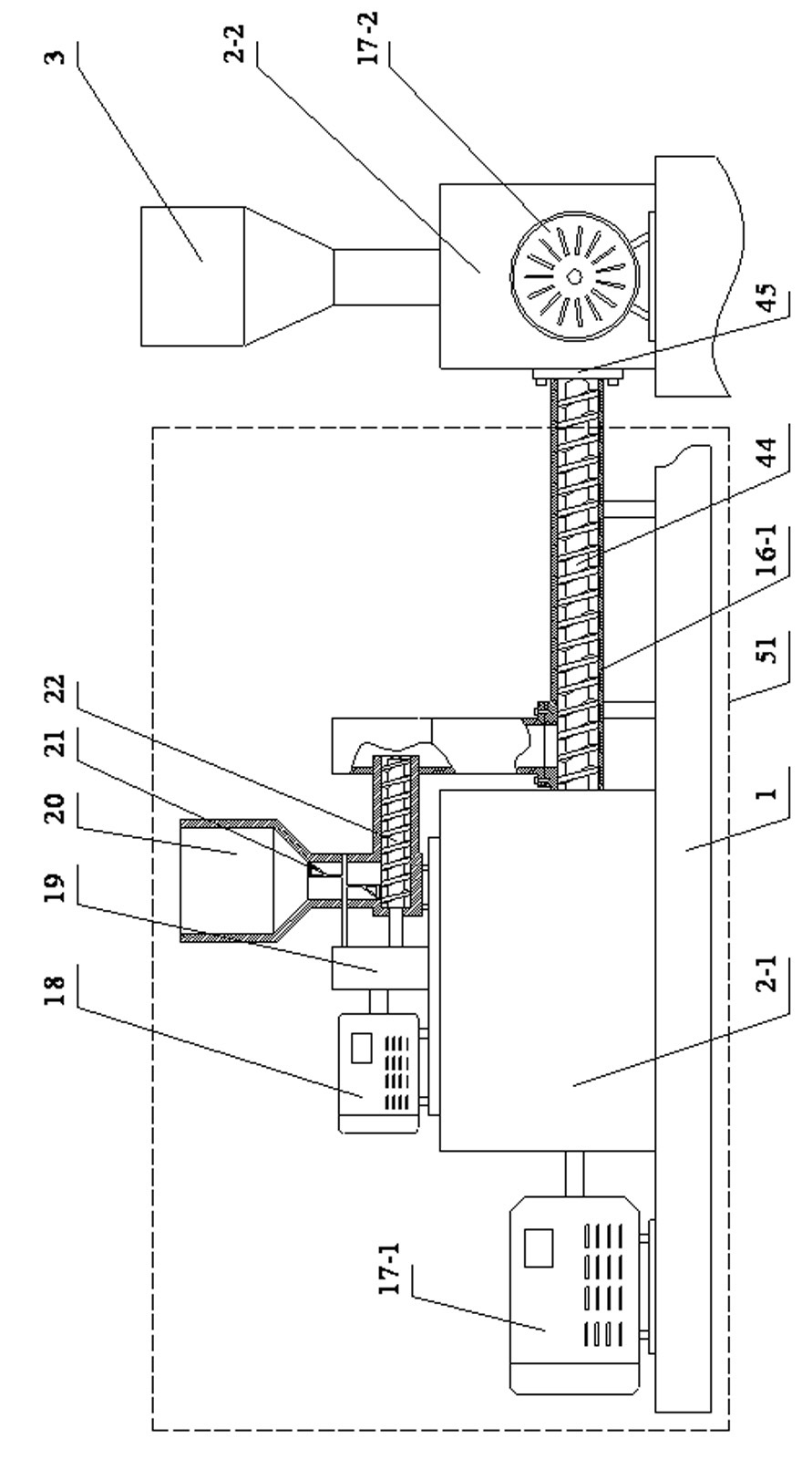

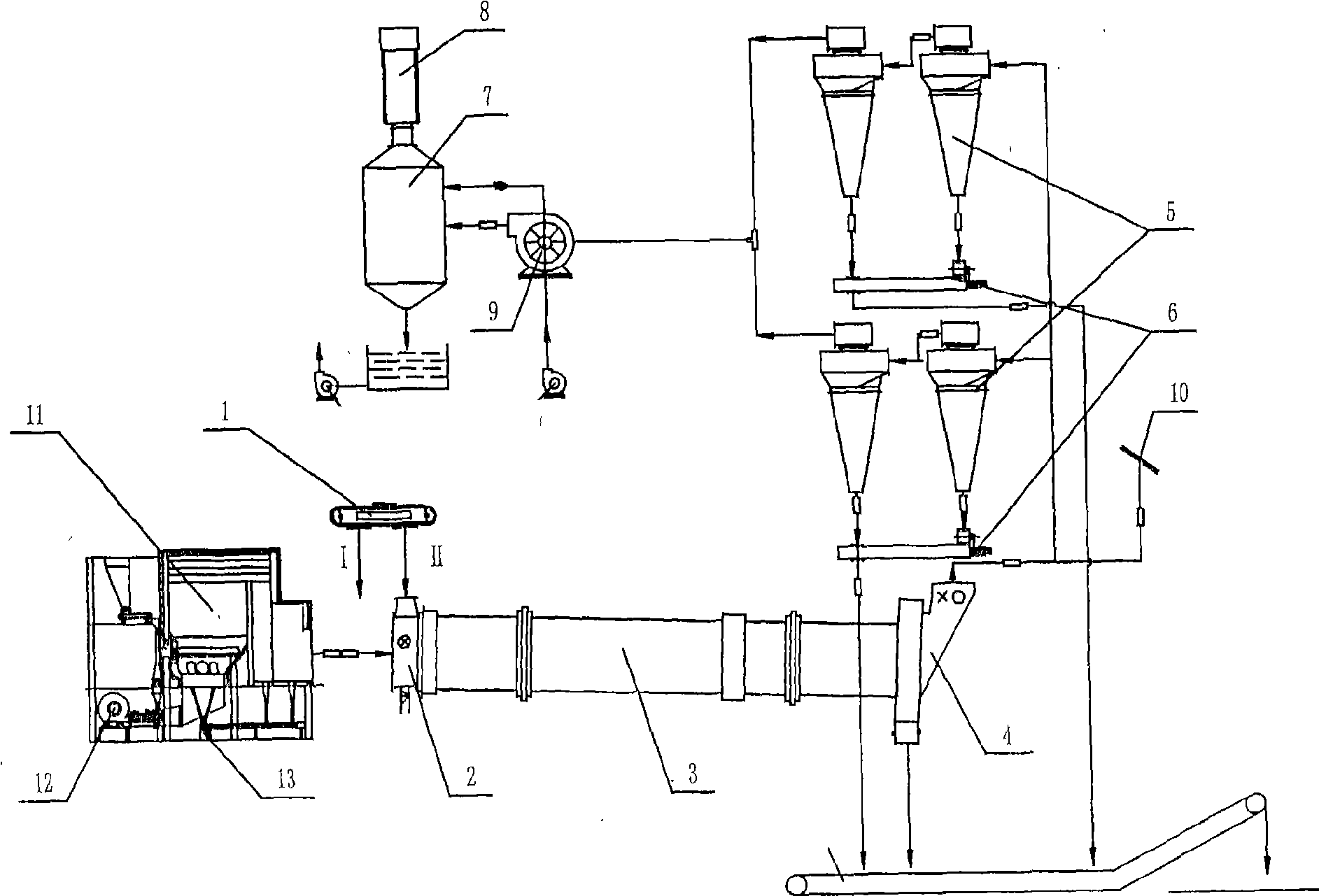

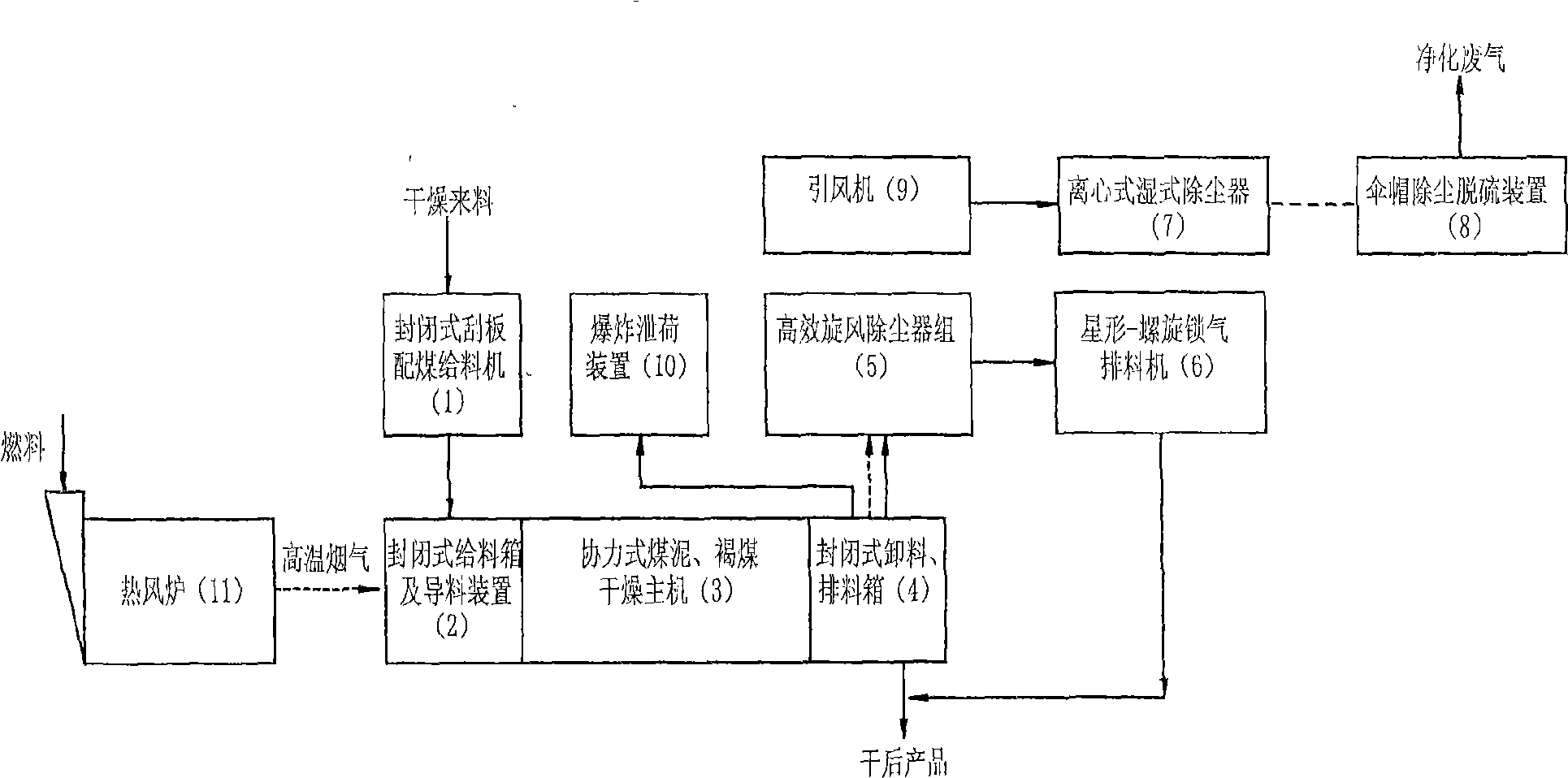

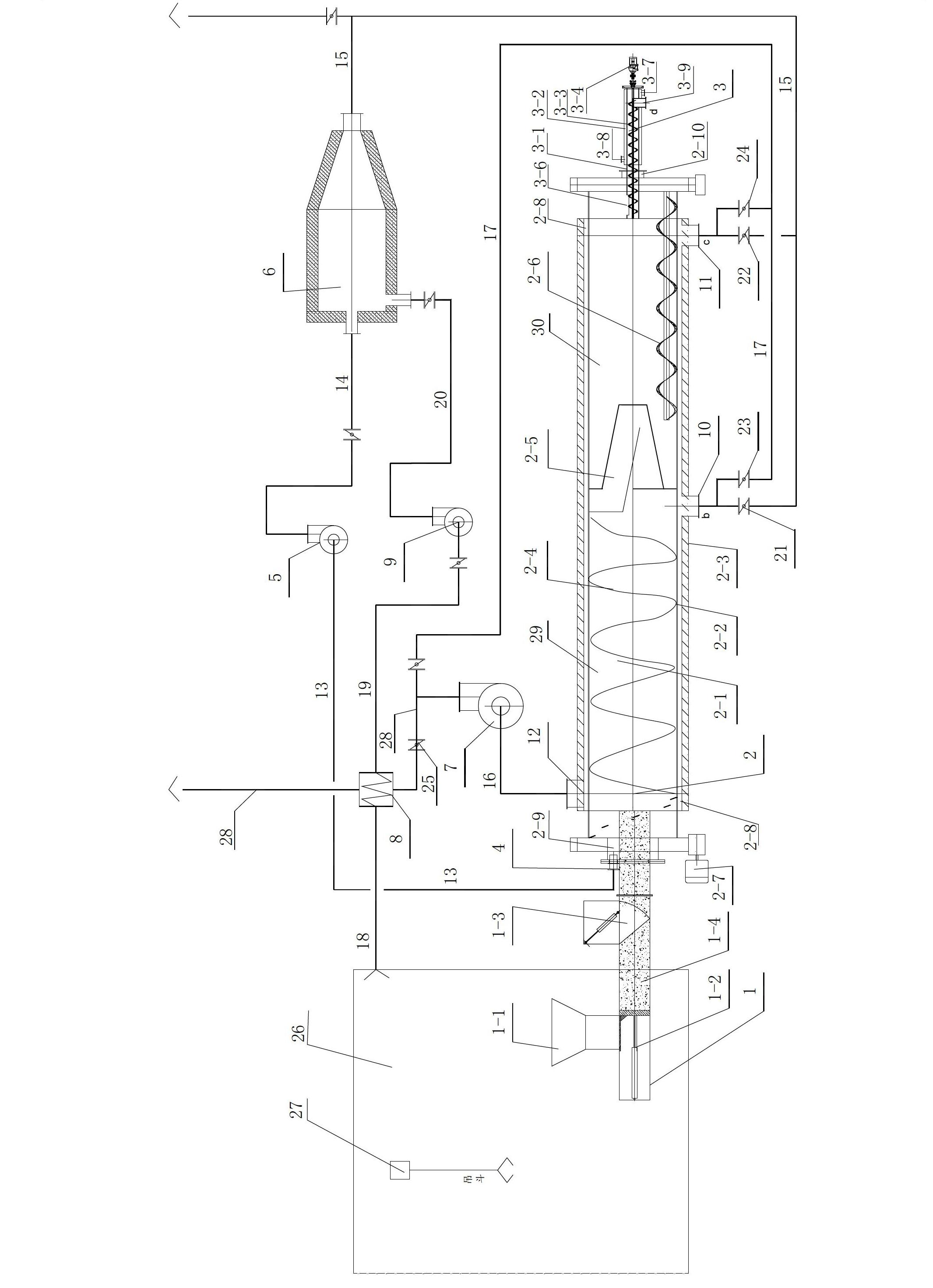

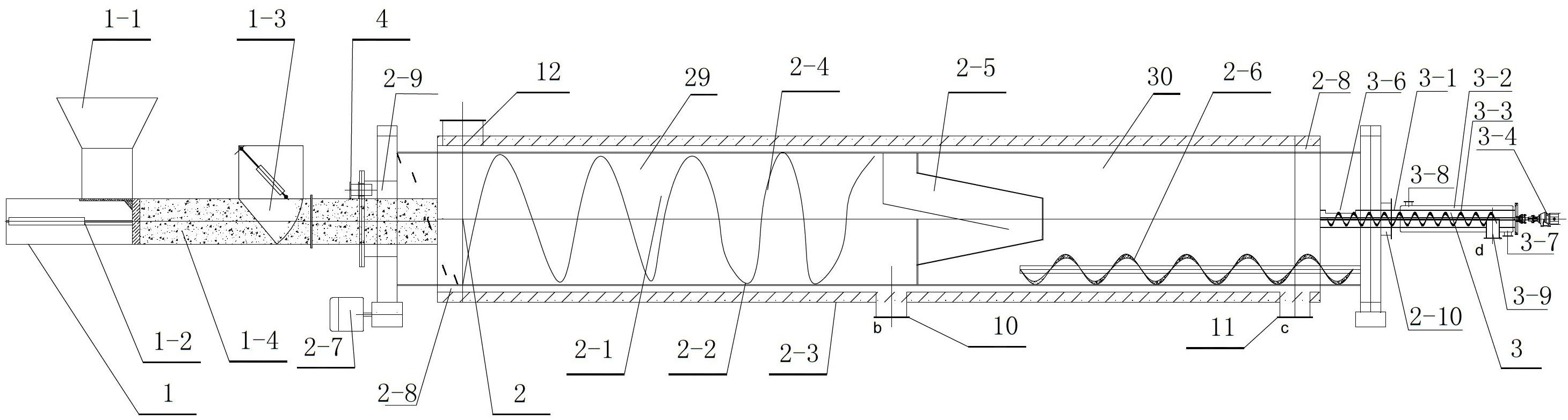

Process and equipment for improving the quality of coal slurry and lignite through drying same

InactiveCN101519617ASolve frequent blockagesSolve the burning problemSolid fuelsDrying peatEconomic benefitsProcess engineering

The invention relates to process and equipment for improving the quality of coal slurry and lignite through drying the same. The process comprises the following steps: (1) the coal slurry and the lignite are predried and then quantitatively fed to a drying system; (2) the coal slurry and the lignite are dried to be improved in quality by a material drying system; and (3) products are produced from the dried coal slurry and lignite of improved quality. The coal slurry and the lignite are dried and dewatered according to the physical and chemical properties of the same and the coal slurry and the lignite can not adhered to the wall of a cylinder of the equipment and can be cleaned automatically; the equipment is arranged integrally lineally on a plane so that the height of a factory building is lowered and the investment on the equipment is reduced by half compared with investment on the equipment arranged in a laminated mode; in addition, the equipment integrates feeing equipment, drying equipment and discharging equipment, has good sealing performance and high thermal efficiency which is increased to over 70 percent from the original 30-40 percent, saves energy to be consumed by one third, is environmentally friendly, can efficiently dewater the coal slurry and the lignite to improve the quality thereof and can be used safely and reliably so as to obtain obvious economic benefits.

Owner:张兆奇

Reflux rotating household garbage pyrolysis carbonization furnace system and garbage disposal process

InactiveCN102660306AEasy to handleAchieve reductionDirect heating destructive distillationSpecial form destructive distillationLitter decompositionCarbonization

The invention relates to a reflux rotating household garbage pyrolysis carbonization furnace system and a garbage disposal process. The system is composed of a feeding device, a pyrolysis carbonization furnace body and a spiral slag tapping device, all of which are arranged and connected in sequence together; and a gas / heat circulating device connected with the pyrolysis carbonization furnace body is combined for the completion of the system; and with control on the temperature of the pyrolysis carbonization furnace body and the garbage retention time, the disposal of the household garbage and organic solid wastes is realized. The reflux rotating household garbage pyrolysis carbonization furnace system is capable of effectively disposing the household garbage and the organic solid wastes, and has the advantages of noncoking, non-blockage, good heat transfer and mass transfer effects and high disposal efficiency; the garbage is decomposed into combustible gases and slags under the conditions of heating and no oxygen; and continuous operation including continuous feeding, continuous pyrolysis and continuous slag tapping can be realized.

Owner:李海明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com