Method and equipment for drilling micro-holes with variable parameter vibration drill

A technology of drilling equipment and variable parameters, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., to achieve the effect of simple and compact structure, stable feeding and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

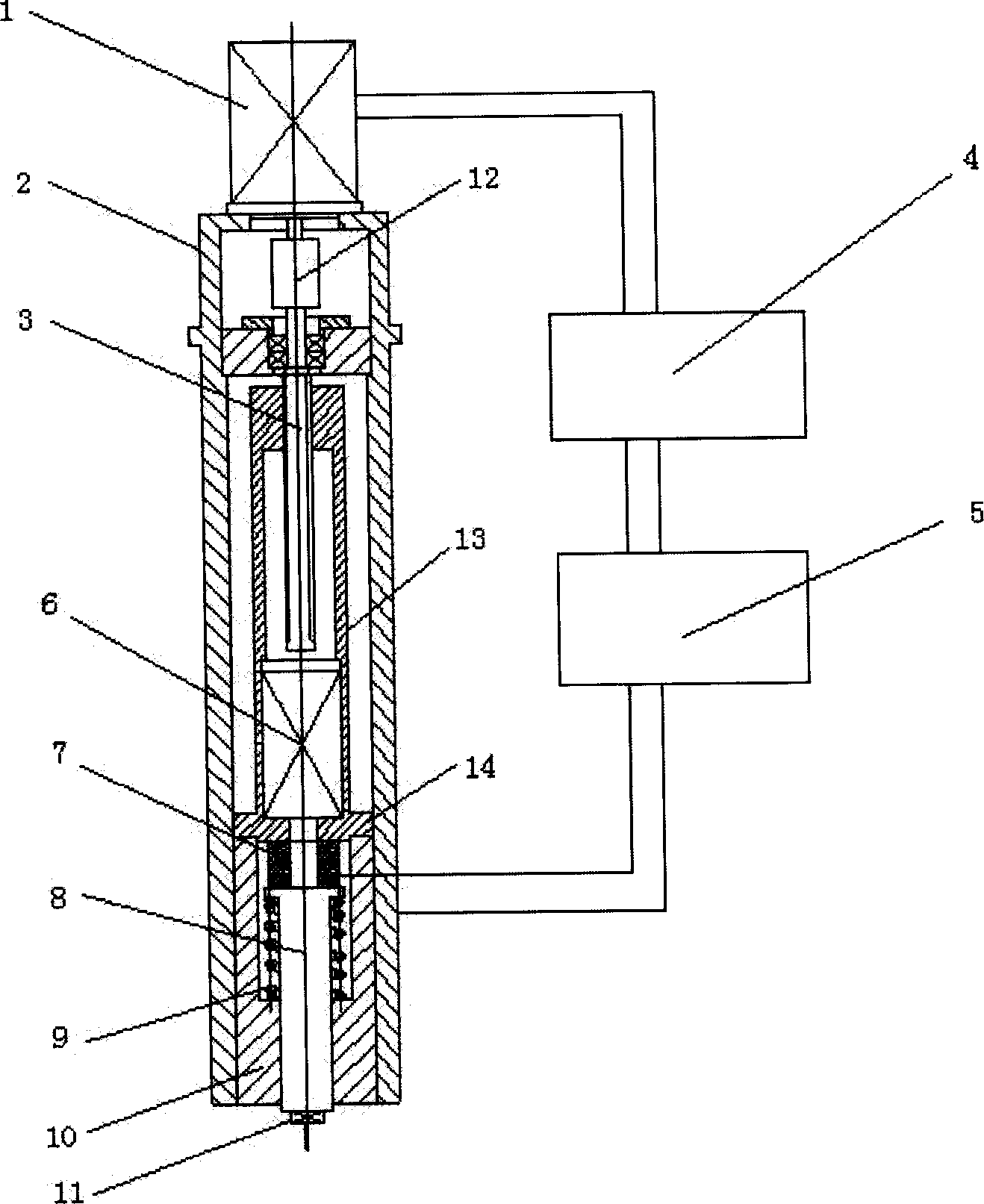

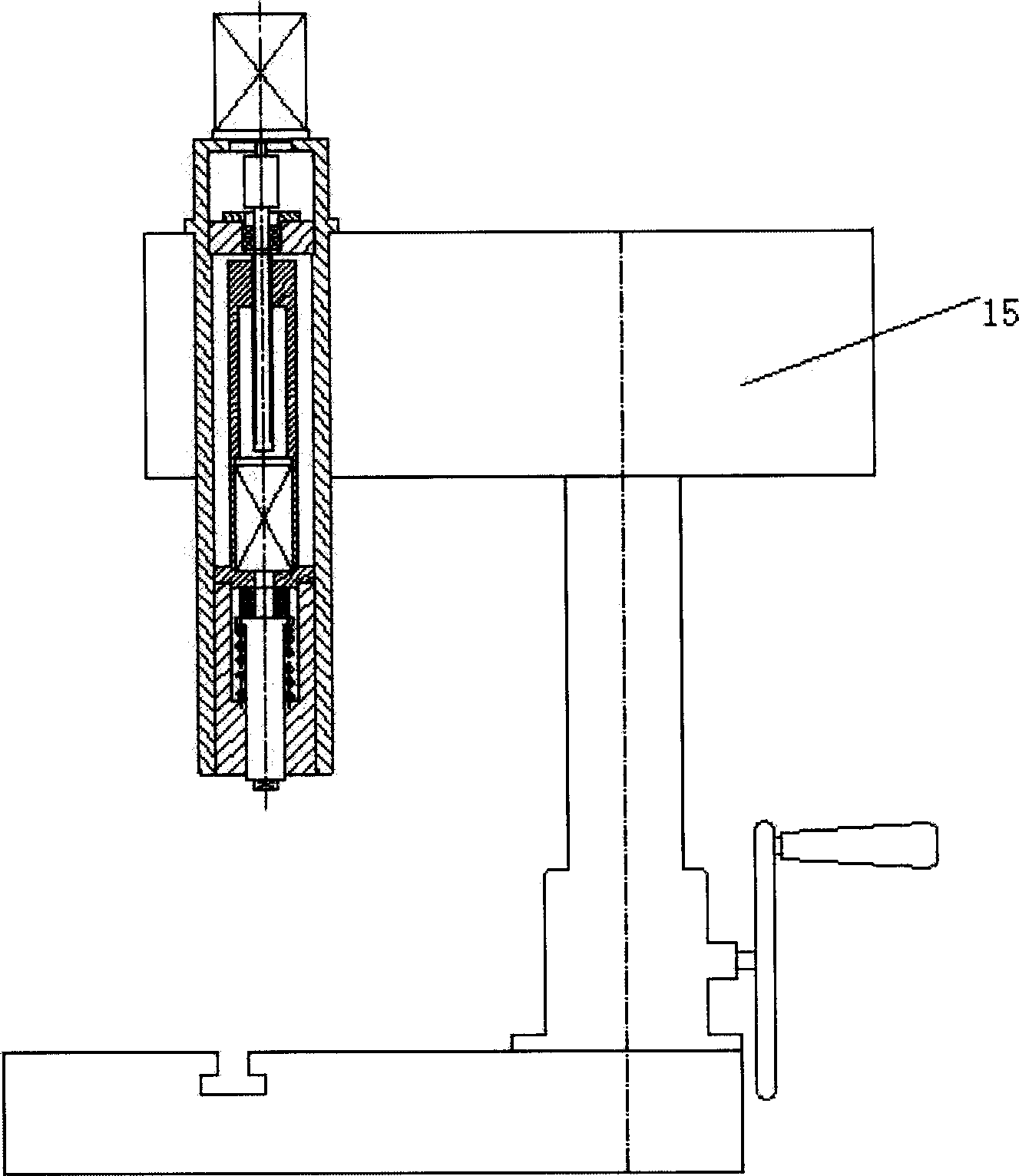

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

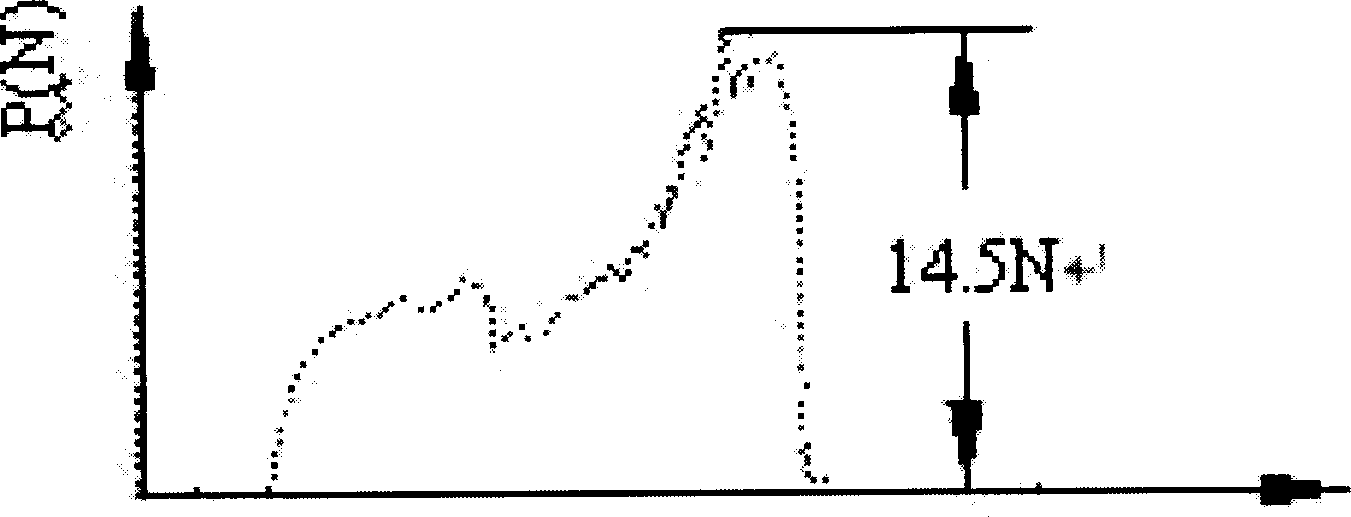

[0020] The variable-parameter vibration drilling method for micro-holes of the present invention selects different processing parameters according to different stages of the drilling processing. The drilling processing includes three stages: the drilling stage, the drilling stage, and the drilling stage. In the drilling stage, it is required to ensure that the drill has a high center of rotation and smoothly enter the drill; the drilling stage must ensure smooth chip breaking and chip removal, and the cooling fluid can better cool and lubricate the drill to improve the life of the drill; in the drilling stage The outlet burr is required to be small, and the drilling force will not increase suddenly and cause the drill bit to break. For this reason, different processing parameters must be selected in these three stages. The processing parameters include: spindle speed, feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com