Patents

Literature

964 results about "It equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Information technology (IT) equipment positioning system

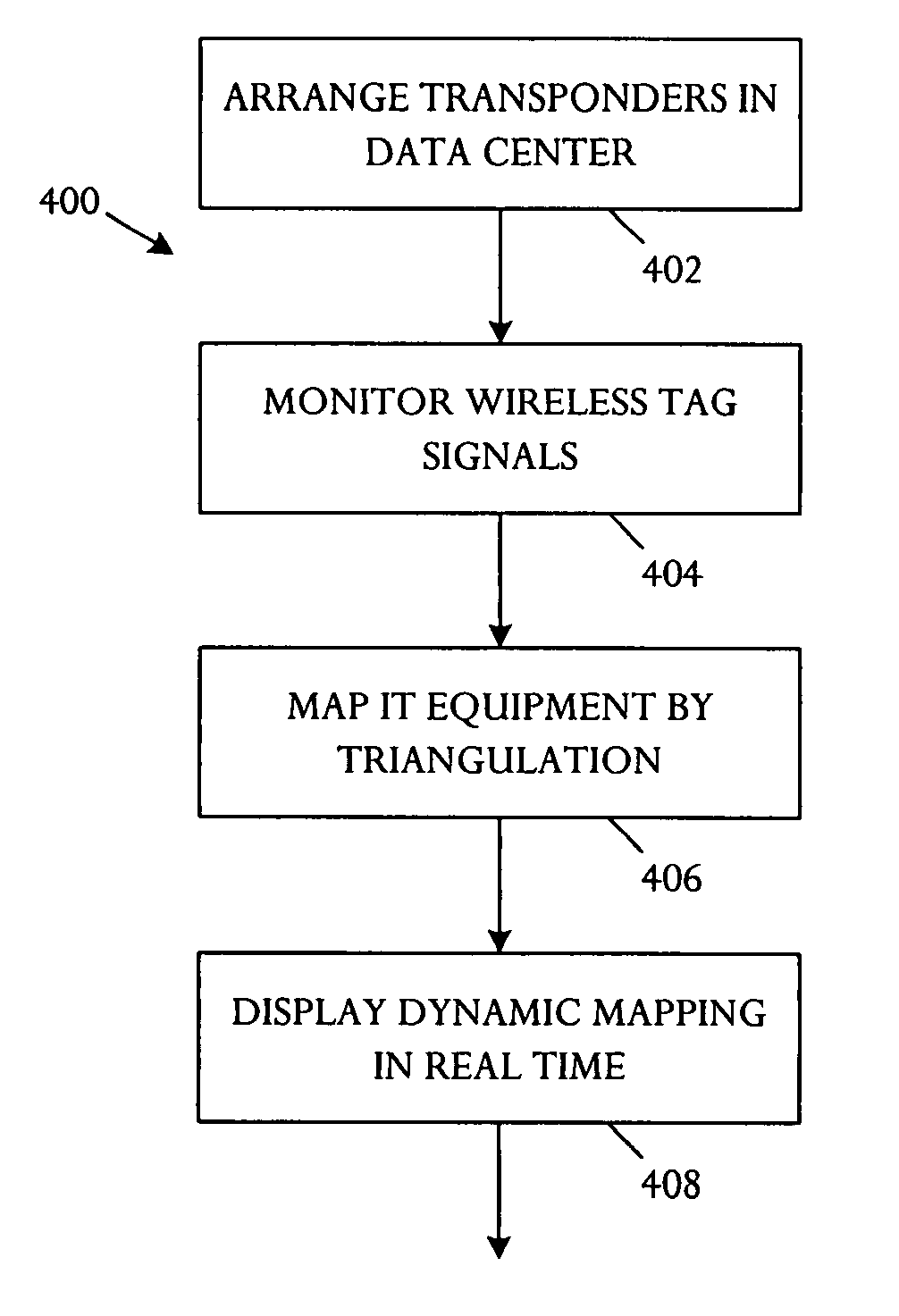

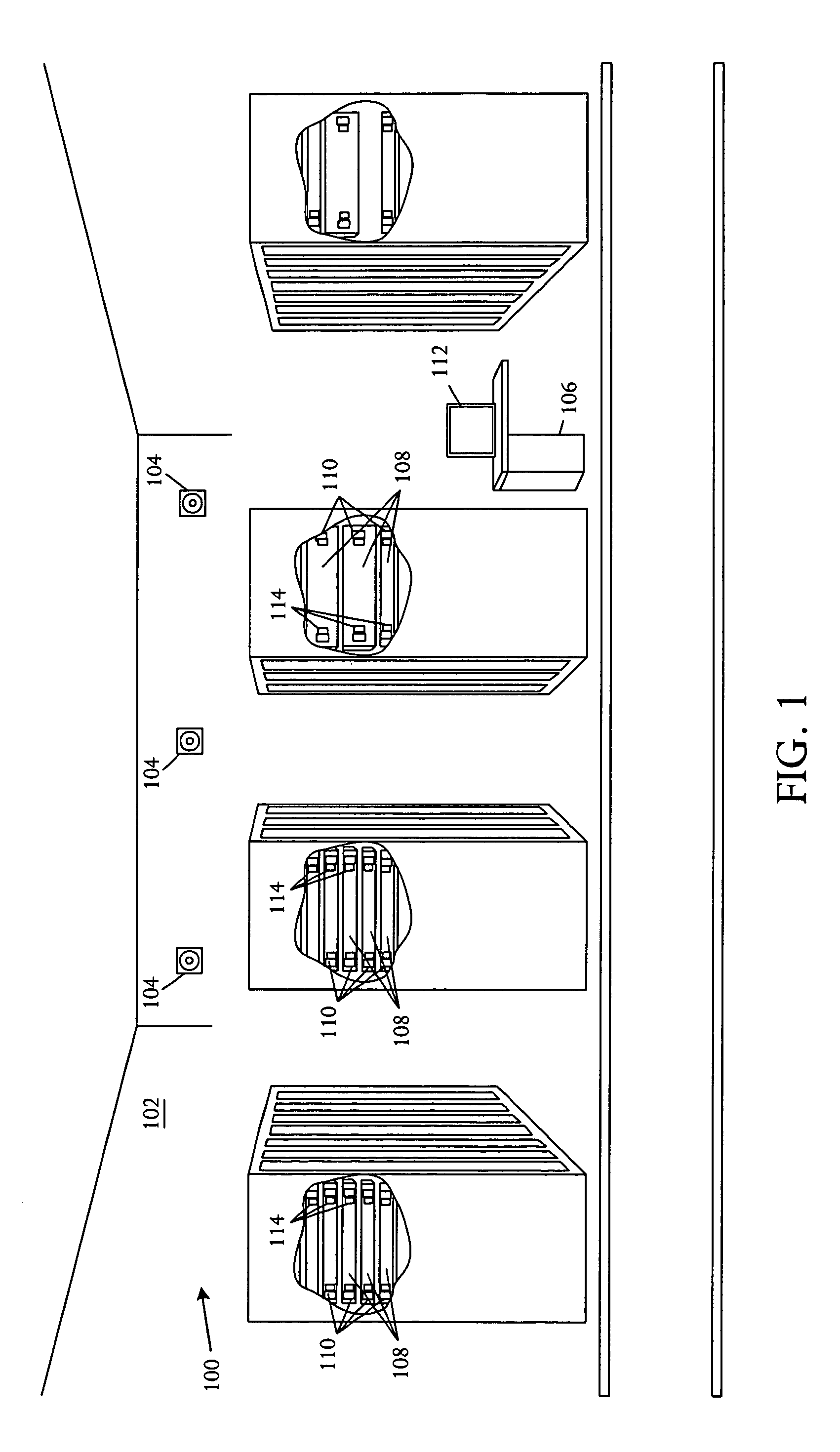

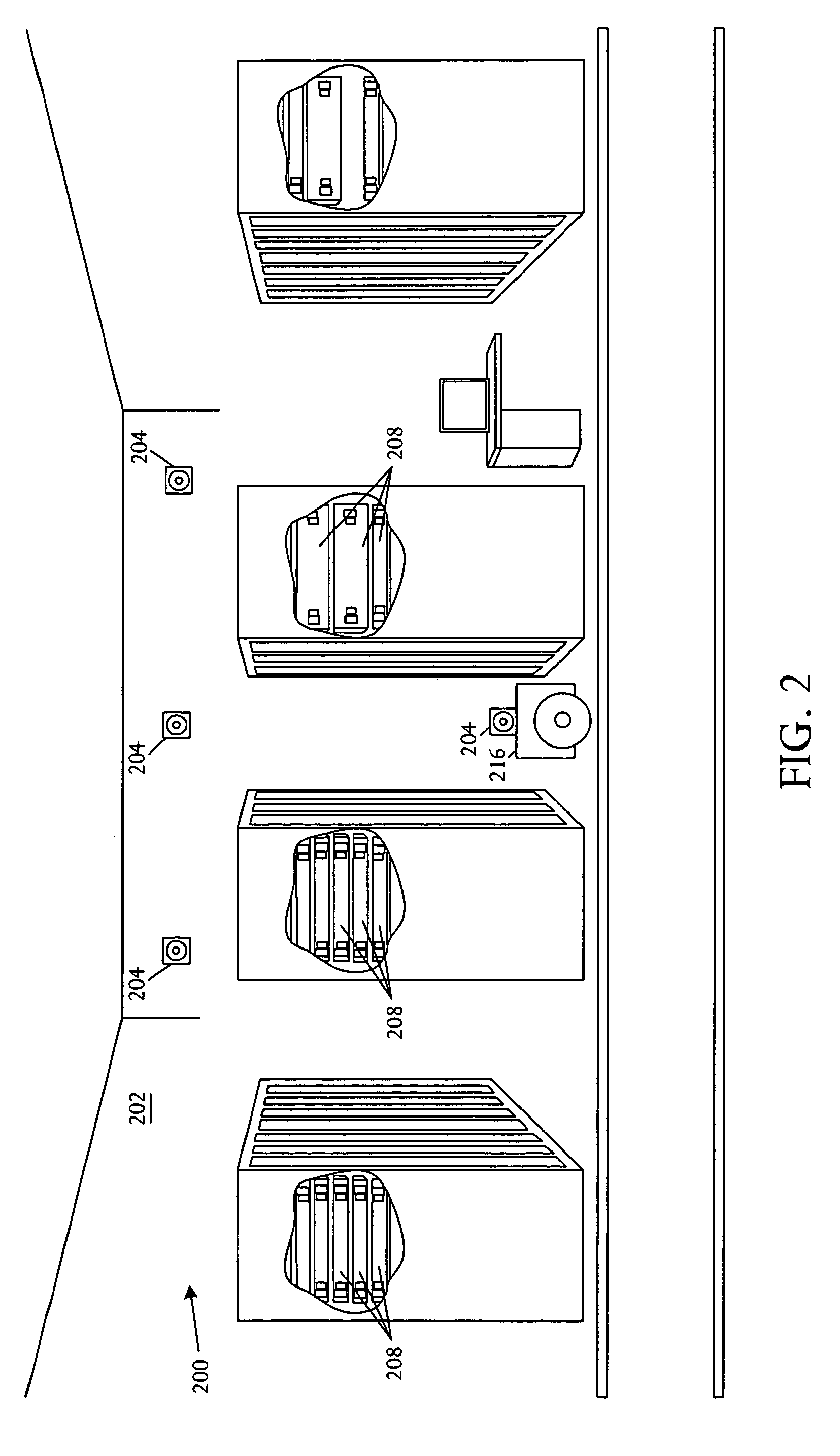

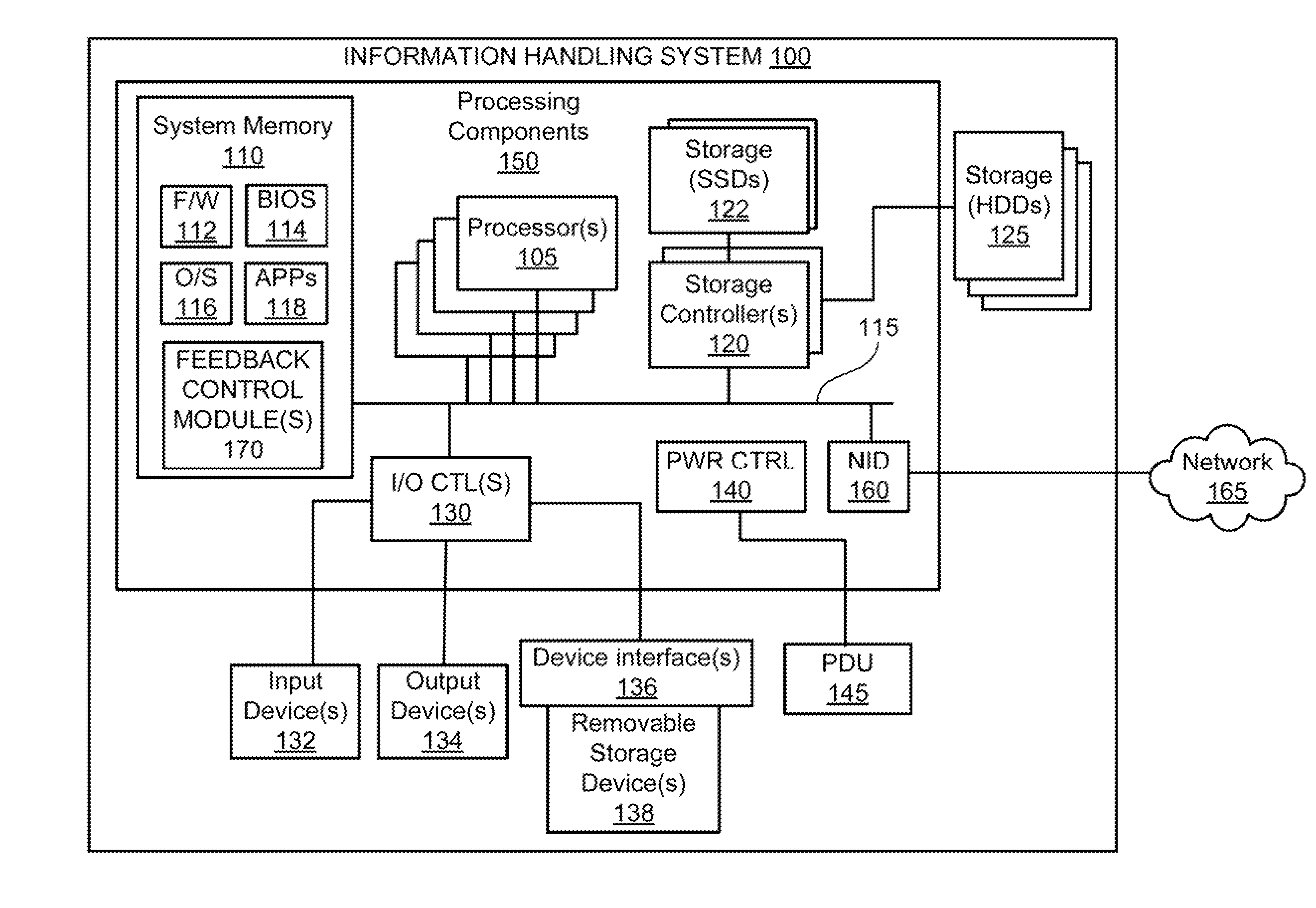

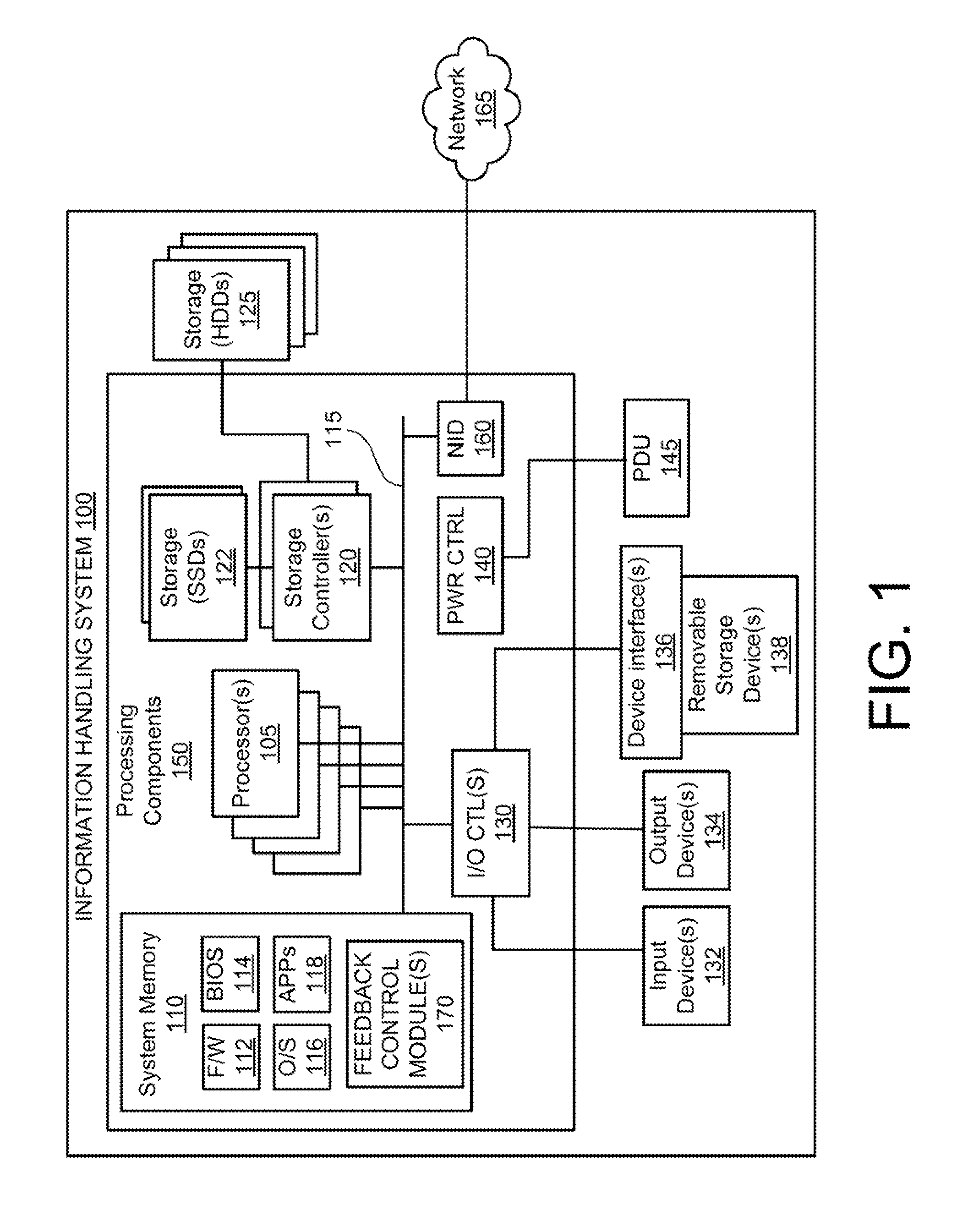

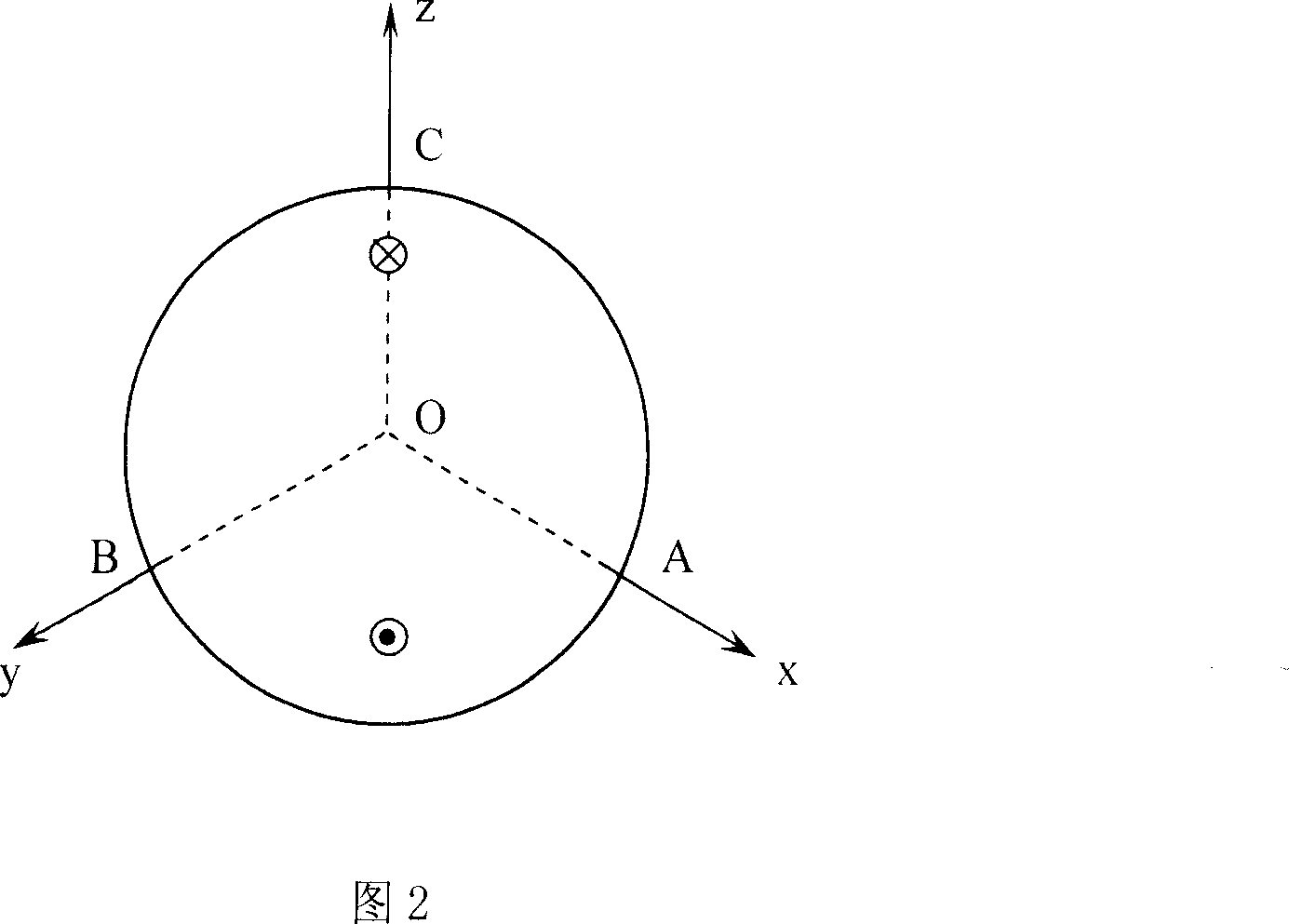

An information technology (IT) equipment positioning system comprises a plurality of wireless transponders distributed in multiple locations in the data center and a controller. The controller is adapted to operate the transponders using triangulation to identify and detect positioning according to three-dimensional coordinates for wireless-tagged IT equipment located in the data center.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

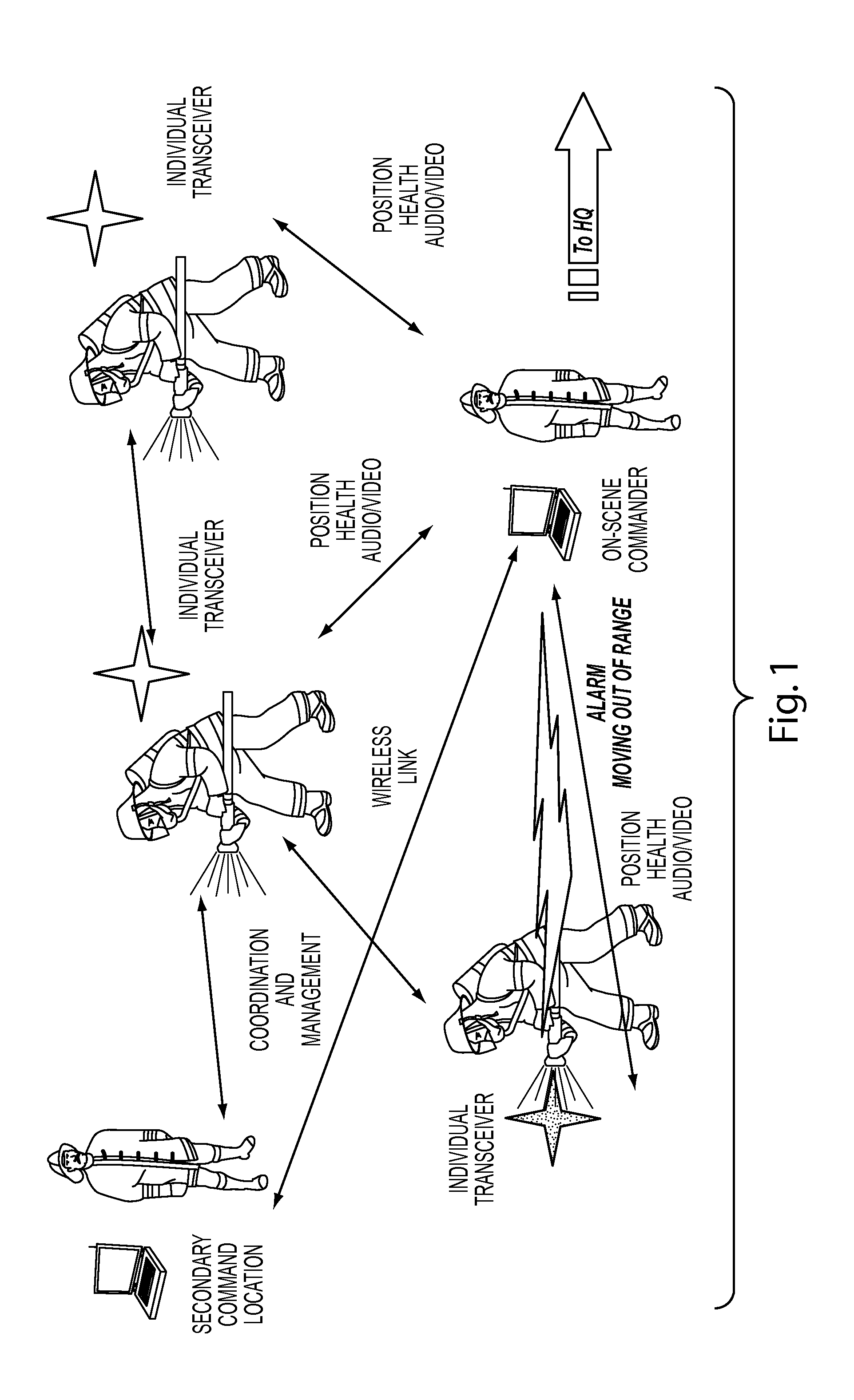

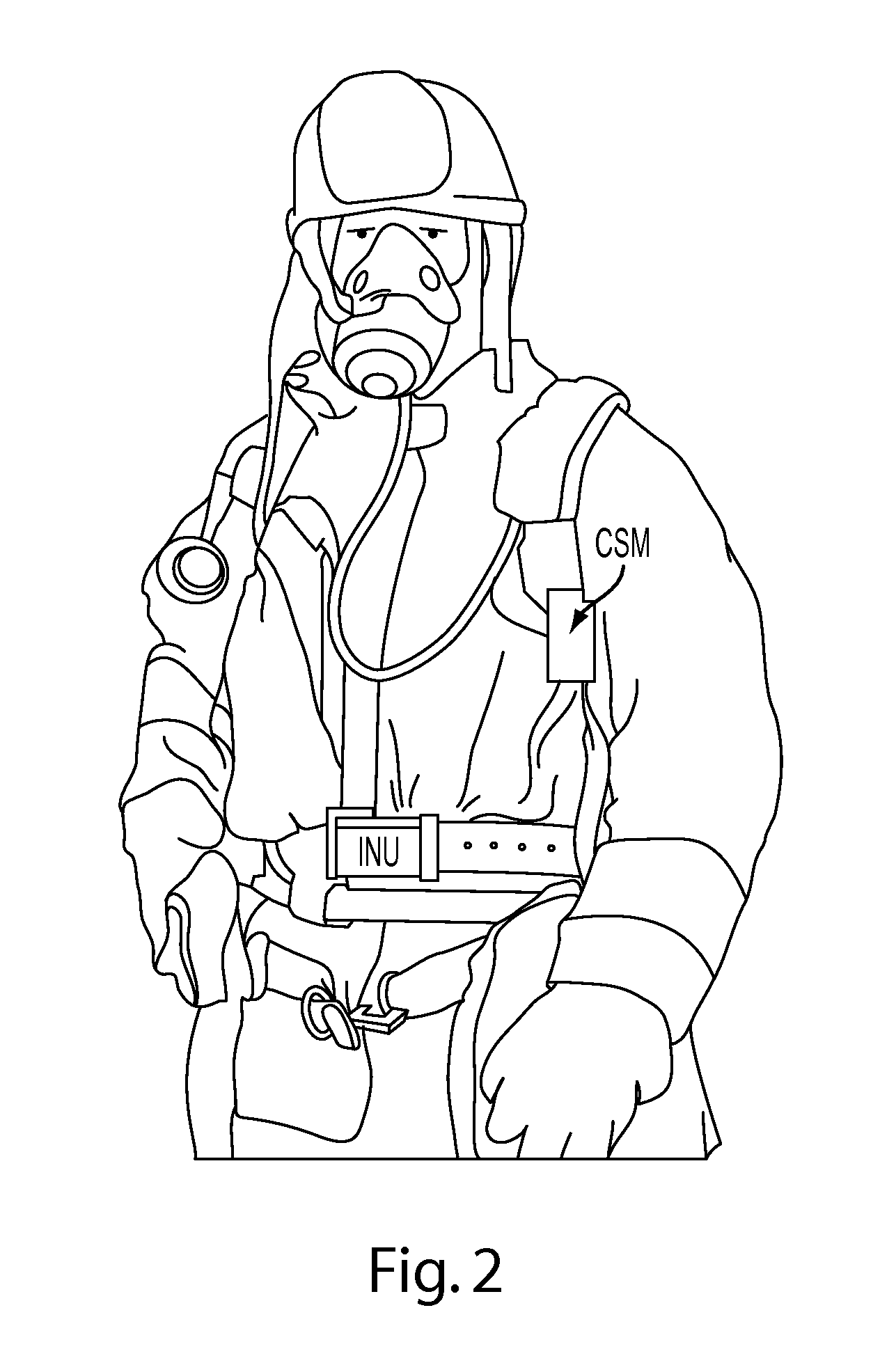

Method and system for locating and monitoring first responders

ActiveUS20130166198A1Minimize tracking errorInstruments for road network navigationRoad vehicles traffic controlService personnelIt equipment

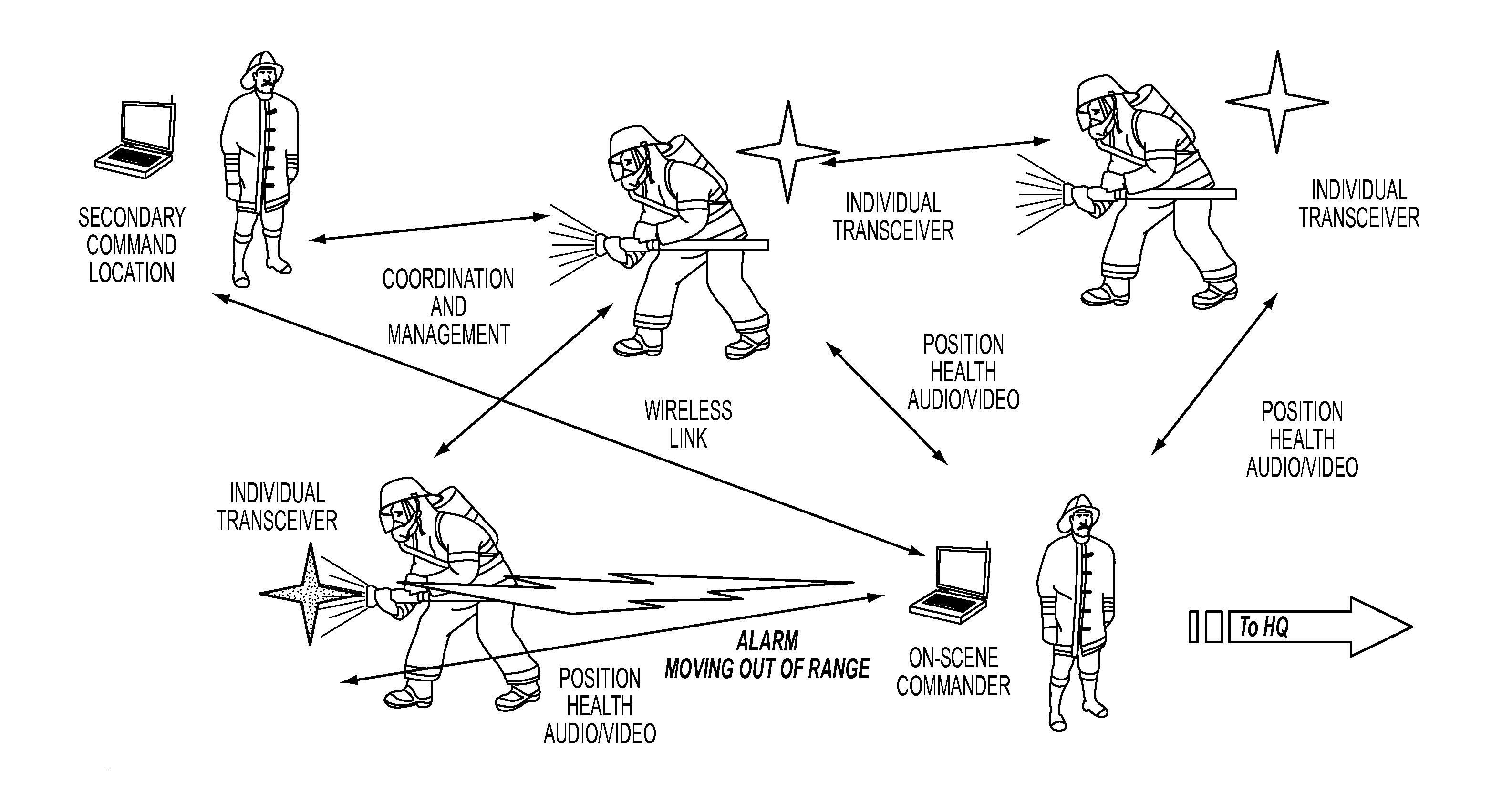

The invention is directed to methods and systems for locating and monitoring the status of people and moveable assets, such as first responders, including firefighters and other public service personnel, and their equipment both indoors and out. The invention provides for locating and monitoring the status of people and assets in environments where GPS systems do not operate, or where operation is impaired or otherwise limited. The system and method uses inertial navigation to determine the location, motion and orientation of the personnel or assets and communicates with an external monitoring station to receive requests for location, motion orientation and status information and to transmit the location, motion orientation and status information to the monitoring station.

Owner:TRX SYST

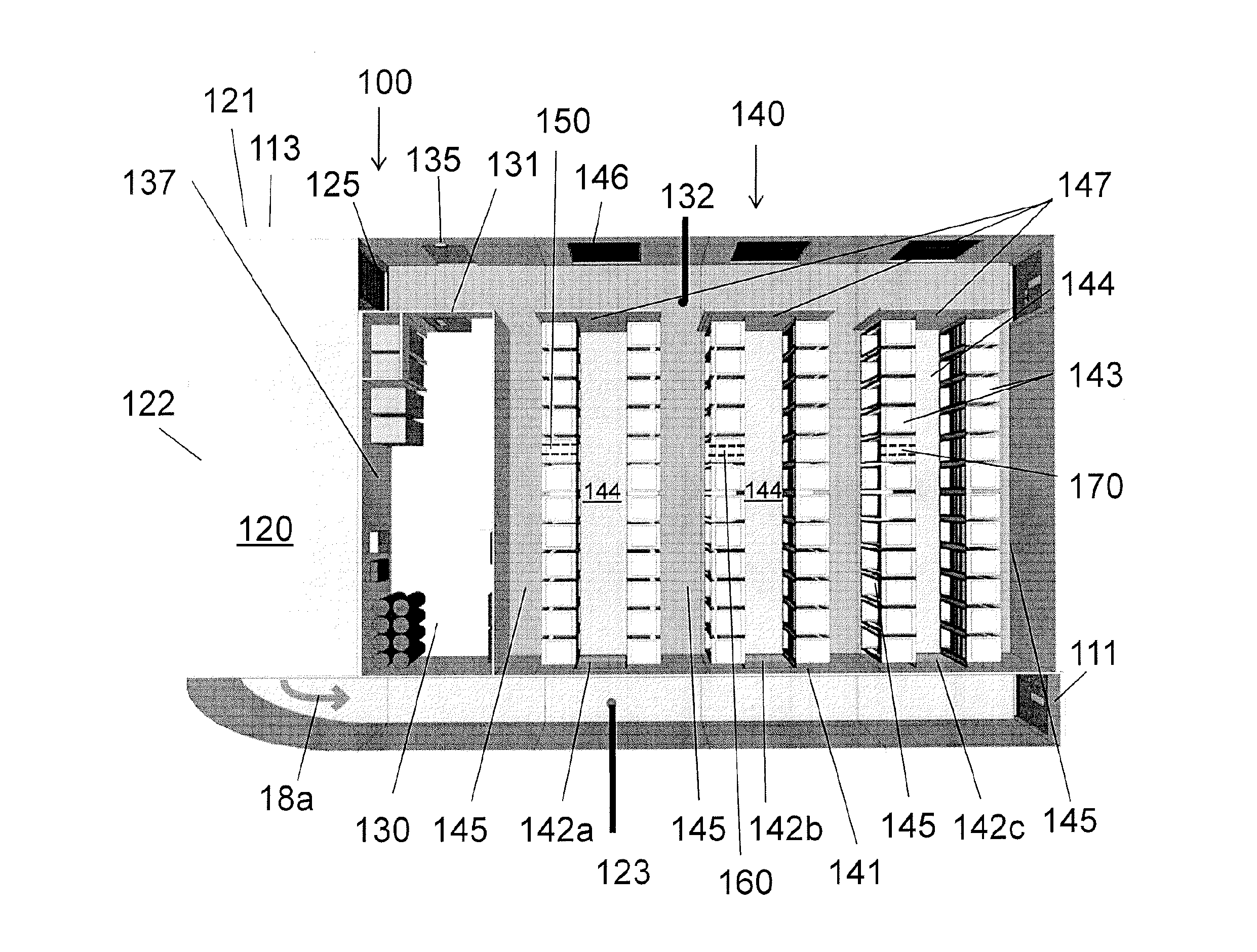

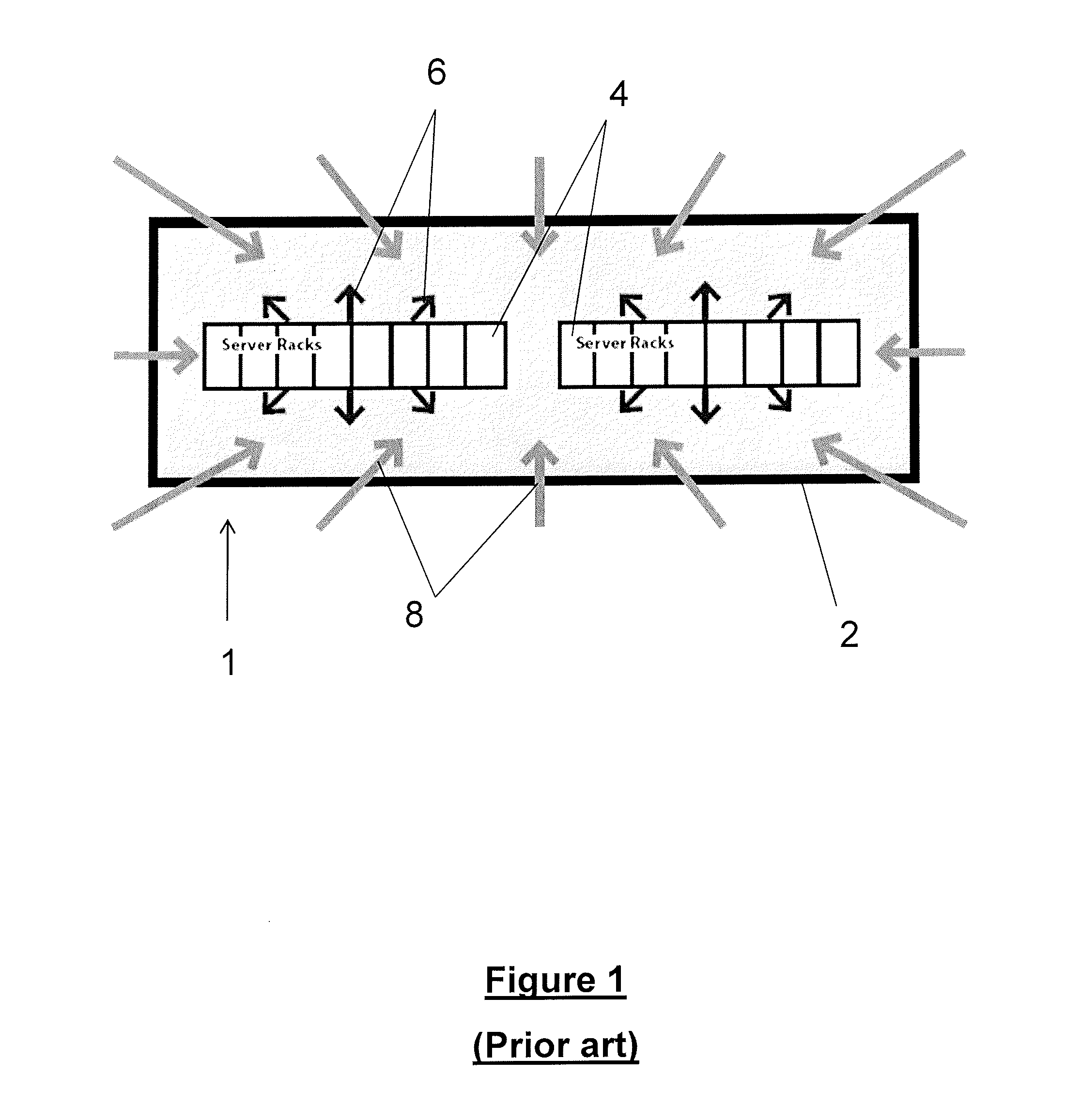

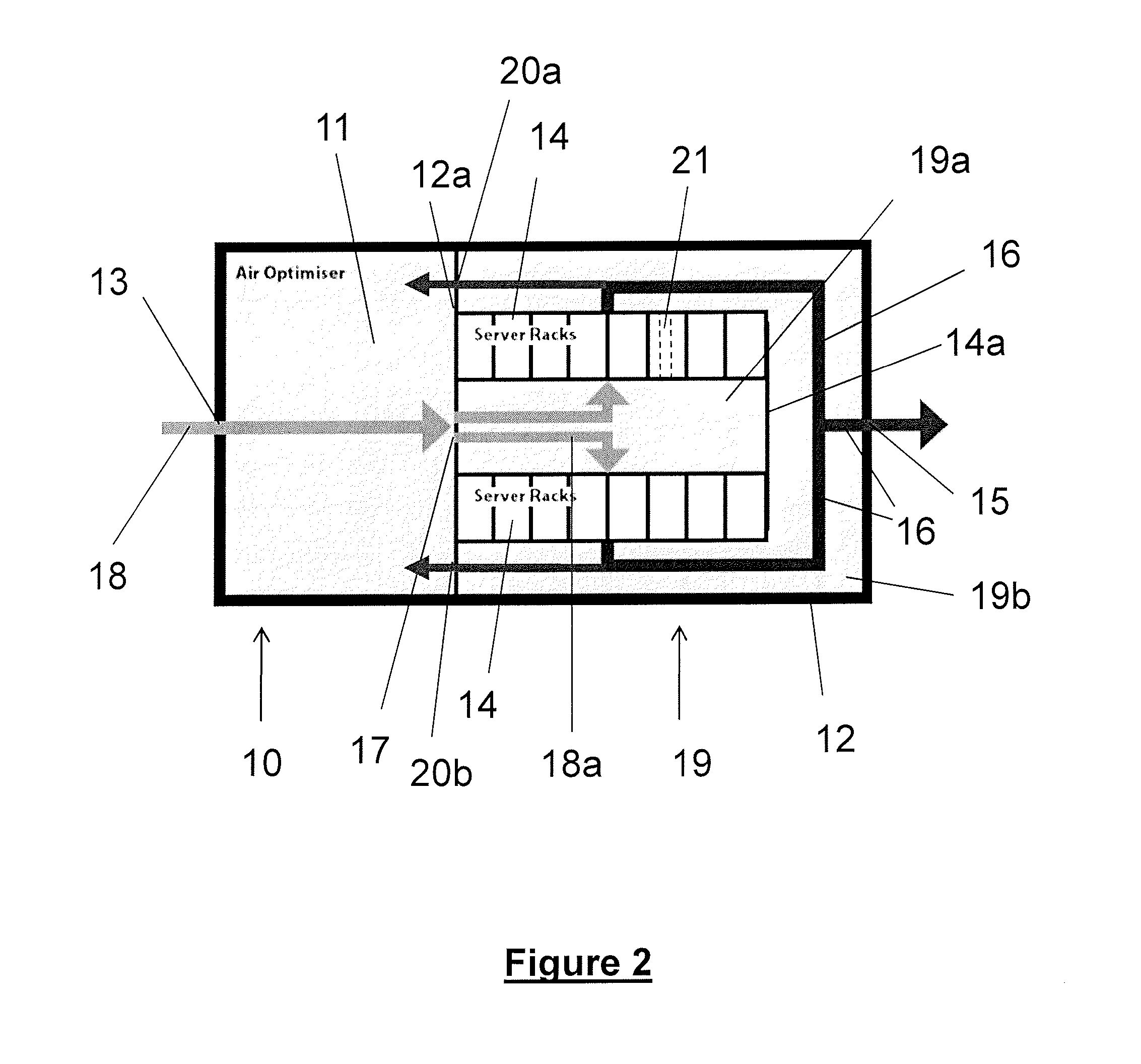

Data Centre Cooling Systems

ActiveUS20130062047A1Energy efficiencyIncreased riskSpace heating and ventilation safety systemsLighting and heating apparatusOne-hotData center

A method of cooling a data centre having at least one hot aisle (145) and at least one cold aisle (144), including the steps of producing cooling air having controlled to have temperature and relative humidity within certain pre-defined limits; supplying the cooling air to a plurality of items of IT equipment (143) located in the data centre between the cold aisle and the hot aisle; measuring the velocity of air flowing from the hot aisle to the cold aisle through an opening (150) between the hot aisle and the cold aisle; and controlling the rate of supply of cooling air to the items of IT equipment in dependence on the velocity of air so measured.

Owner:BRIPCO

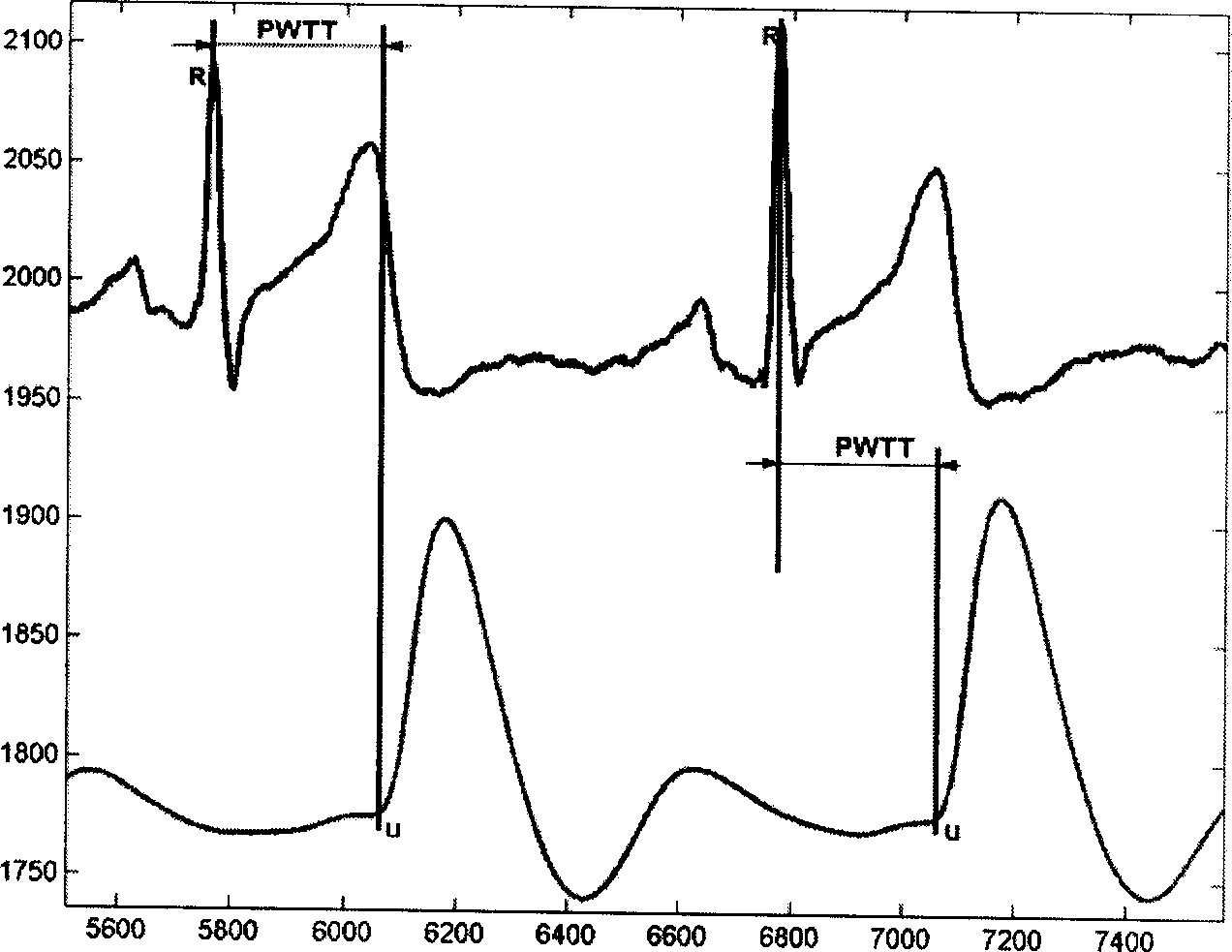

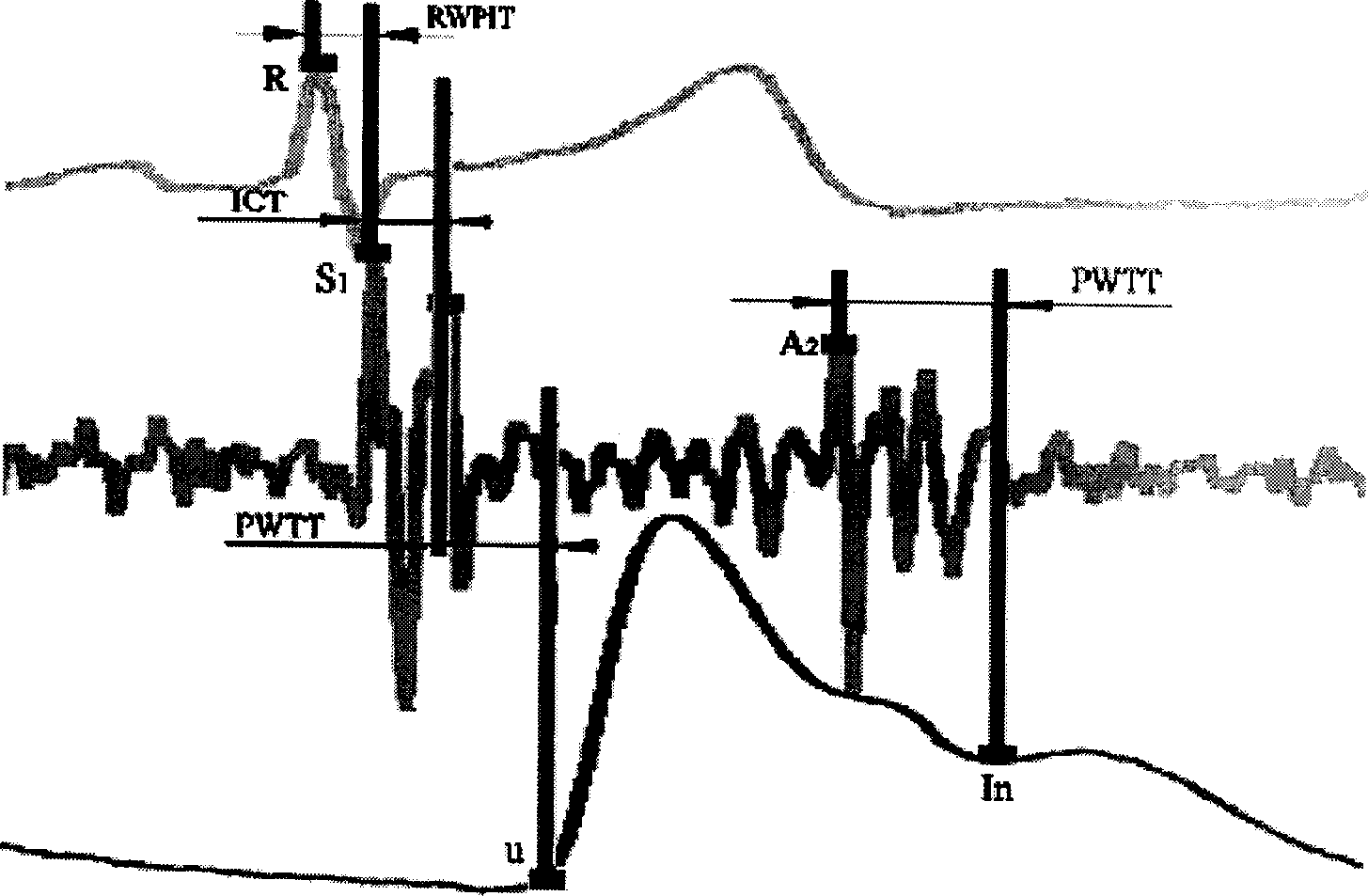

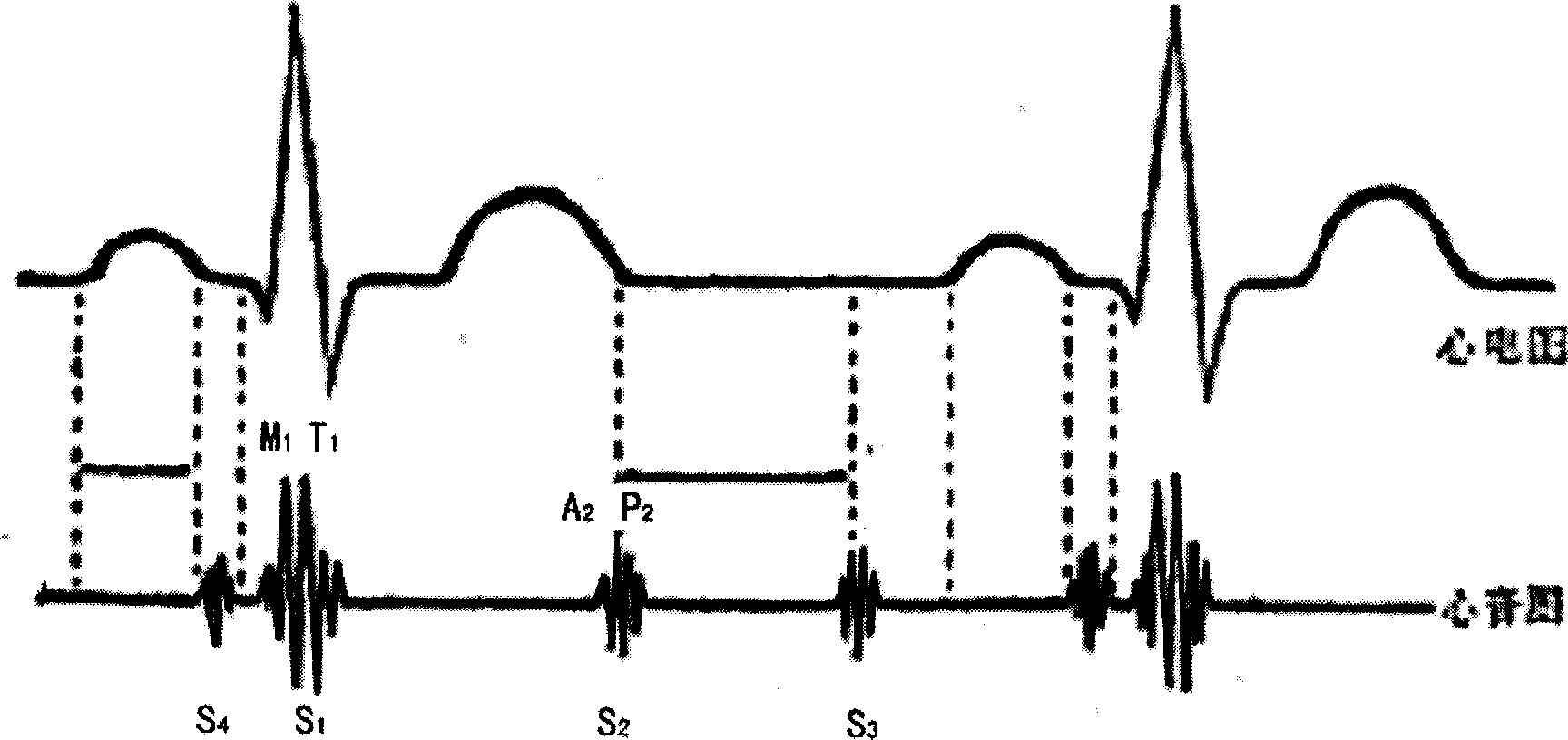

Method and apparatus for continuously measuring blood pressure

InactiveCN1849998AExclude positiveEliminate distractionsEvaluation of blood vesselsSensorsPersonalizationCardiac cycle

The present invention relates to a method for continuously measuring blood pressure and its equipment. Said method is characterized by that it creates a regression equation between pulse wave conduction time and arterial pressure: BP=a+b*PWTT for measurand person; and utilizes personalization correction technique to define intercept and regression coefficient b of measurand person. Besides, said invention also provides a method for continuously obtaining pulse wave conduction time PWTT by using pulse wave of human body, electrocardiogram signal and phonocardiogram signal and its concrete steps. Said method can raise accuracy for continuously measuring blood pressure, and can be used for measuring head blood pressure.

Owner:AVIATION MEDICINE INST AIR FORCE PLA +1

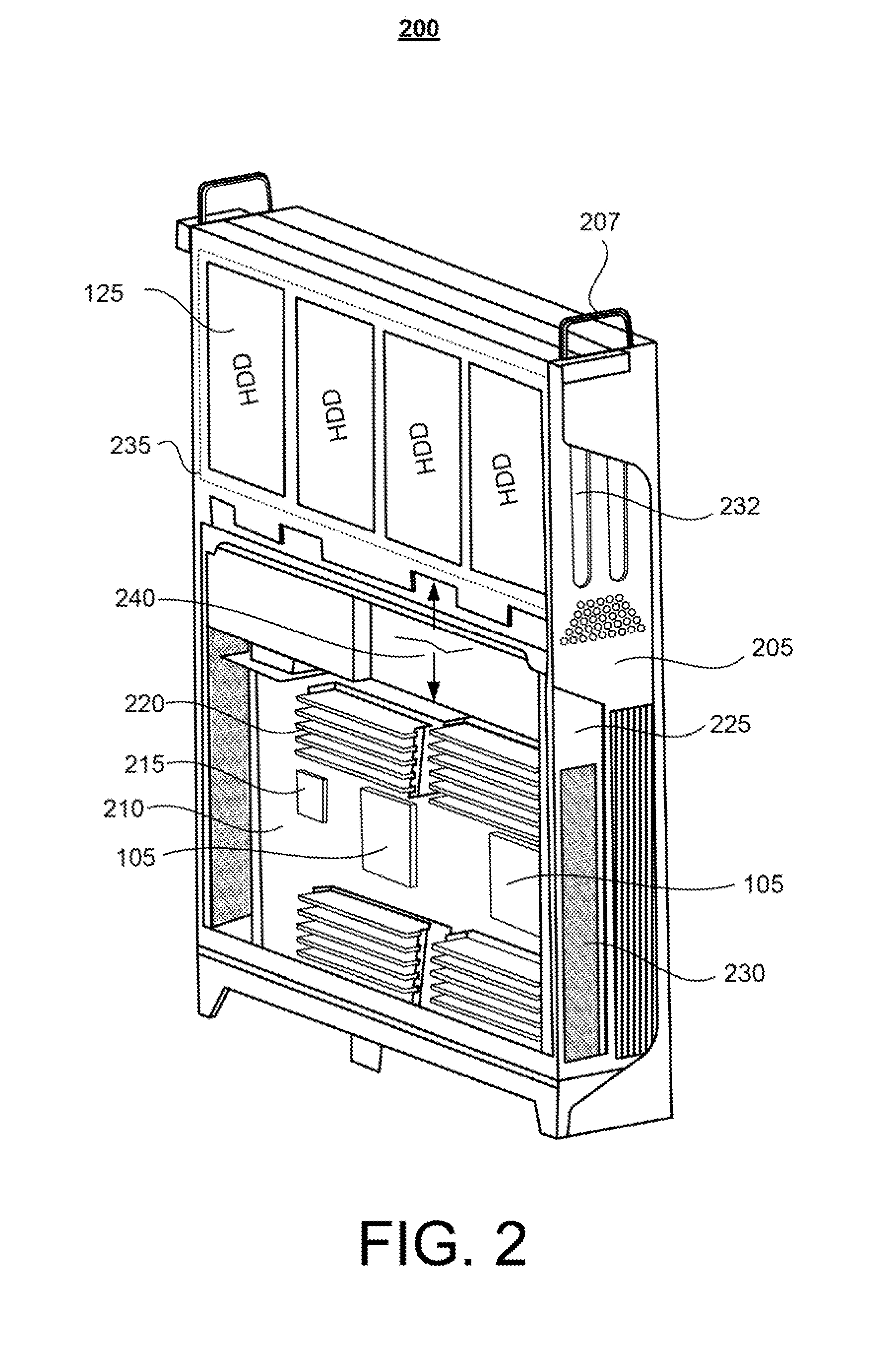

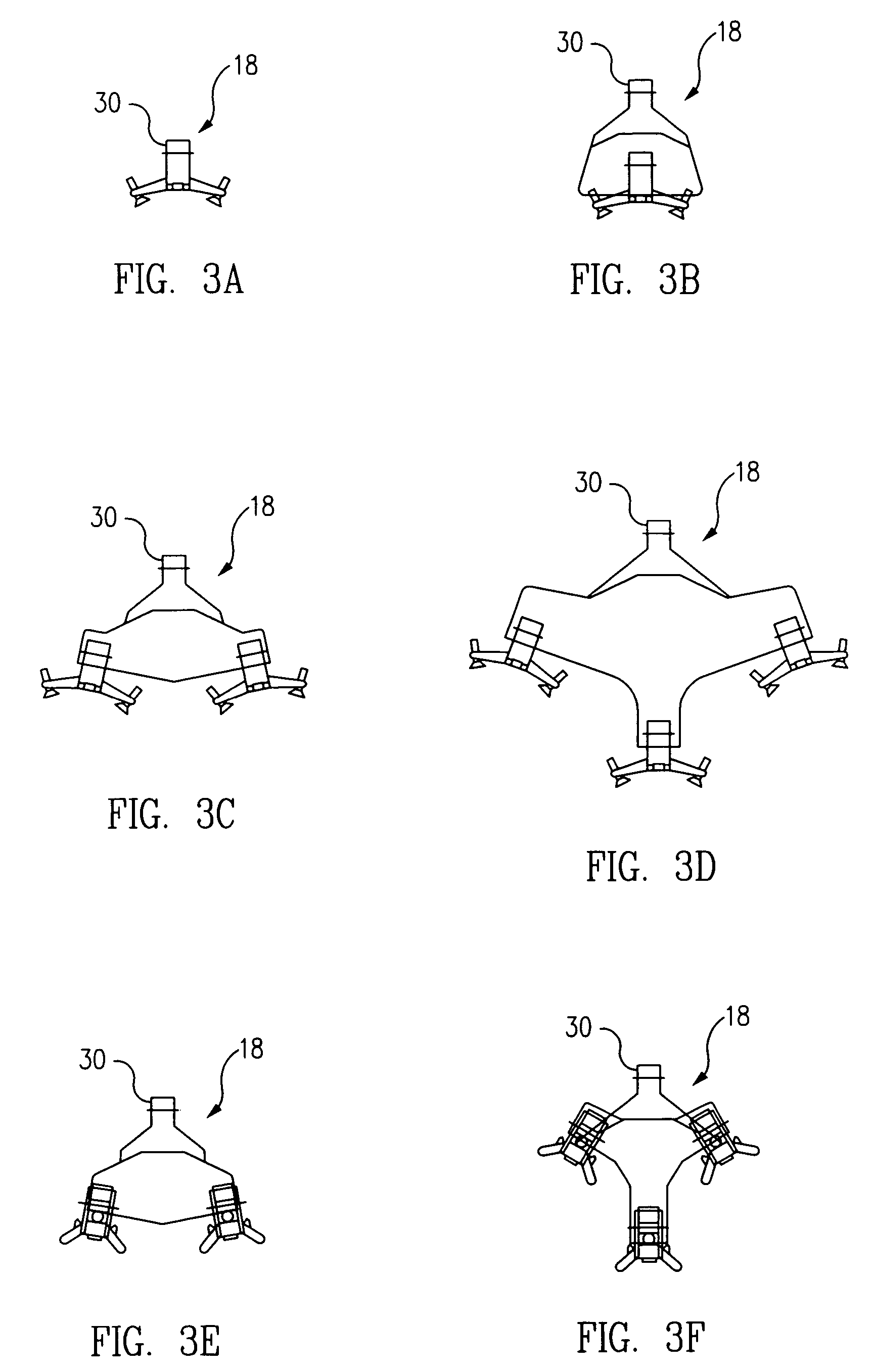

Partitioned, Rotating Condenser Units to Enable Servicing of Submerged IT Equipment Positioned Beneath a Vapor Condenser Without Interrupting a Vaporization-Condensation Cycling of the Remaining Immersion Cooling System

ActiveUS20140216686A1Safety devices for heat exchange apparatusDigital data processing detailsIt equipmentBoiling point

An immersion cooling tank includes: a tank comprised of a base wall, and perimeter walls, and having a lower tank volume in which a liquid can be maintained and heated to a boiling point to generate a rising plume of vapor; a rack structure within the tank volume that supports insertion of multiple, heat dissipating electronic devices in a side-by-side vertical configuration; and a condenser configured as a plurality of individually rotatable condenser sub-units, with each condenser sub-unit located above a vertical space that extends vertically from the lower tank volume and within which an electronic device can be inserted. Each individual condenser sub-unit can be opened independent of the other sub-units and each other condenser sub-unit can remain in a closed position while a first condenser sub-unit is opened to allow access to a first vertical space and any existing electrical device contained therein below the first condenser sub-unit.

Owner:DELL PROD LP

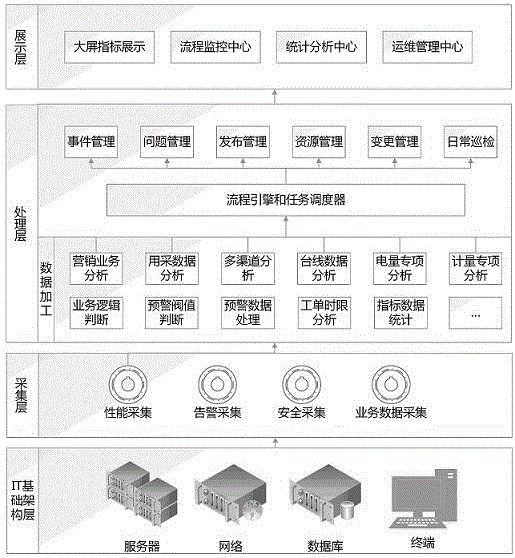

Operation and maintenance monitoring platform based on big power marketing data

InactiveCN105871605AEasy to useFlexible displayData processing applicationsData switching networksIt equipmentClosed loop

The invention relates to an operation and maintenance monitoring platform based on big power marketing data. The operation and maintenance monitoring platform comprises a data acquisition layer, a data processing layer and a data use layer. The platform monitors operation conditions of all kinds of computer equipment, network equipment, safety products, application systems and IT equipment and all kinds of network behaviours, performs comprehensive, centralized and unified management of all kinds of equipment, finds all kinds of abnormal conditions in time, rapidly locates all kinds of event failures, automatically forms a work order, and dispatches the work order to a related department to process, such that the closed loop of a flow is finally formed; and thus, monitoring integration, service coverage generalization, monitoring intellectualization and display visualization can be realized. By means of the operation and maintenance monitoring platform disclosed by the invention, a decision-making level of the provincial power company can know whole conditions of various basic units more transparently; a management level can supervise and control works of various basic units more powerfully; therefore, various branch companies can find out weak links more rapidly and accurately; the business and service work quality supervision is improved; and power marketing staffs are technologically helped to comprehensively supervise and manage whole marketing services.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

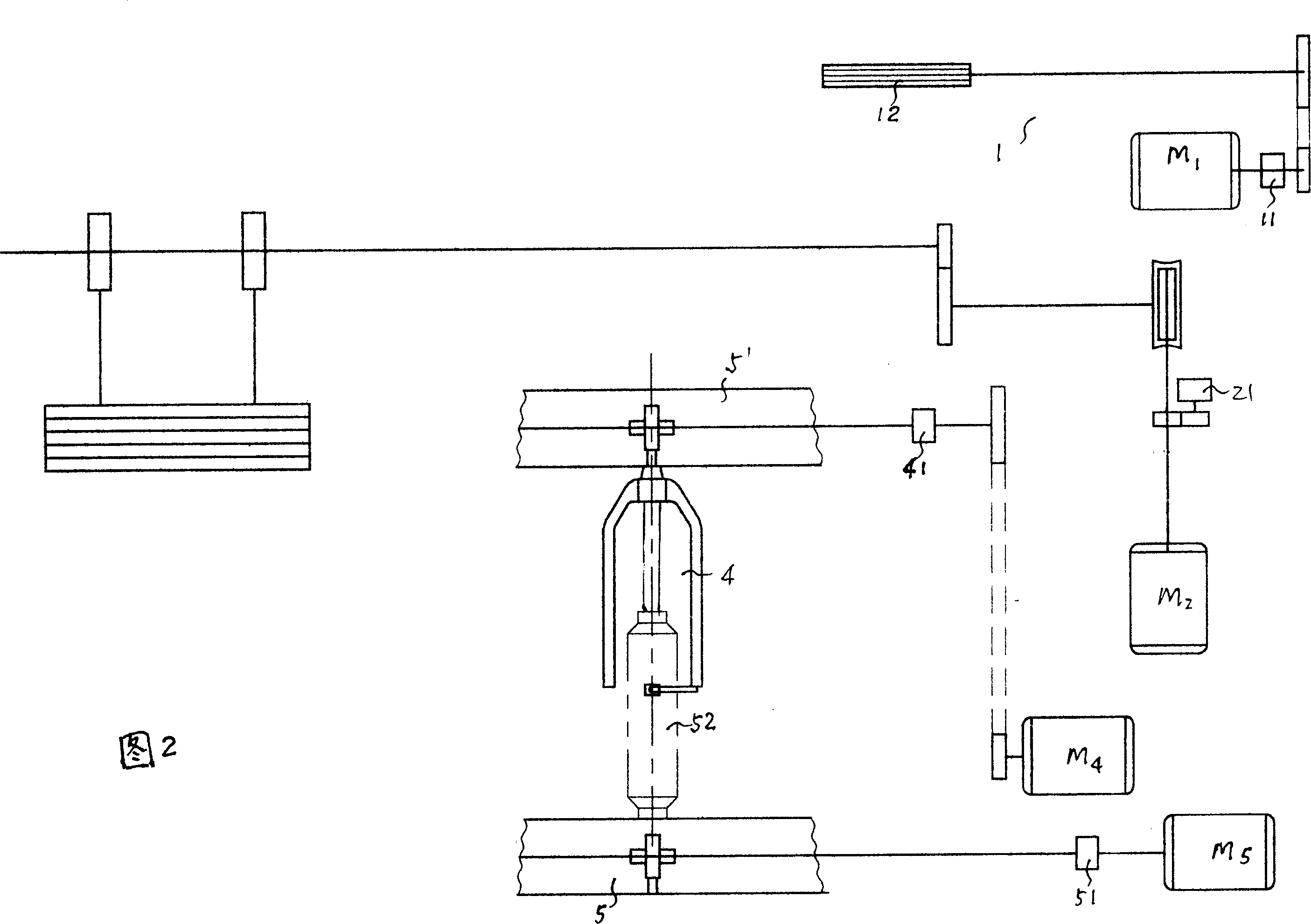

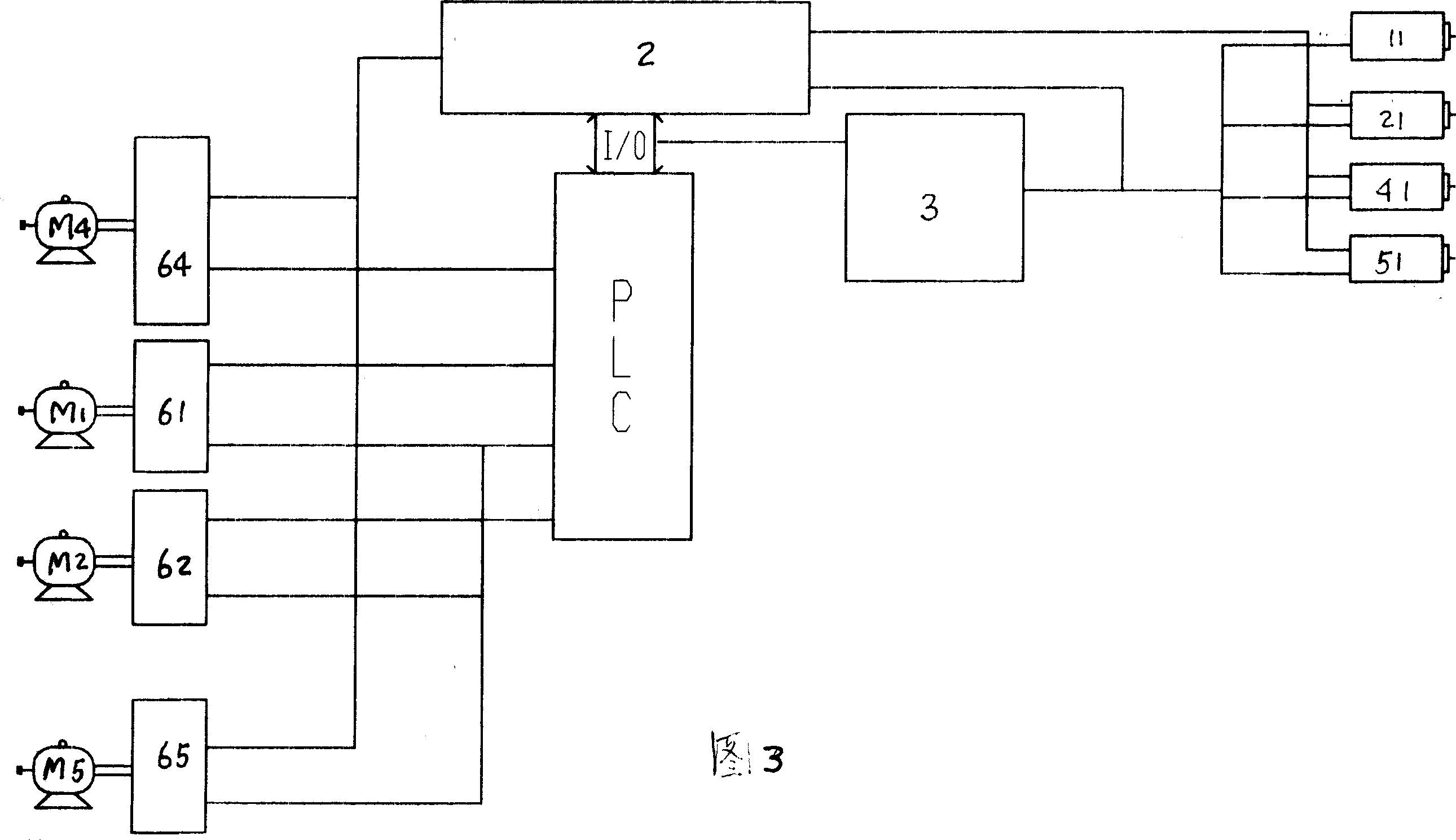

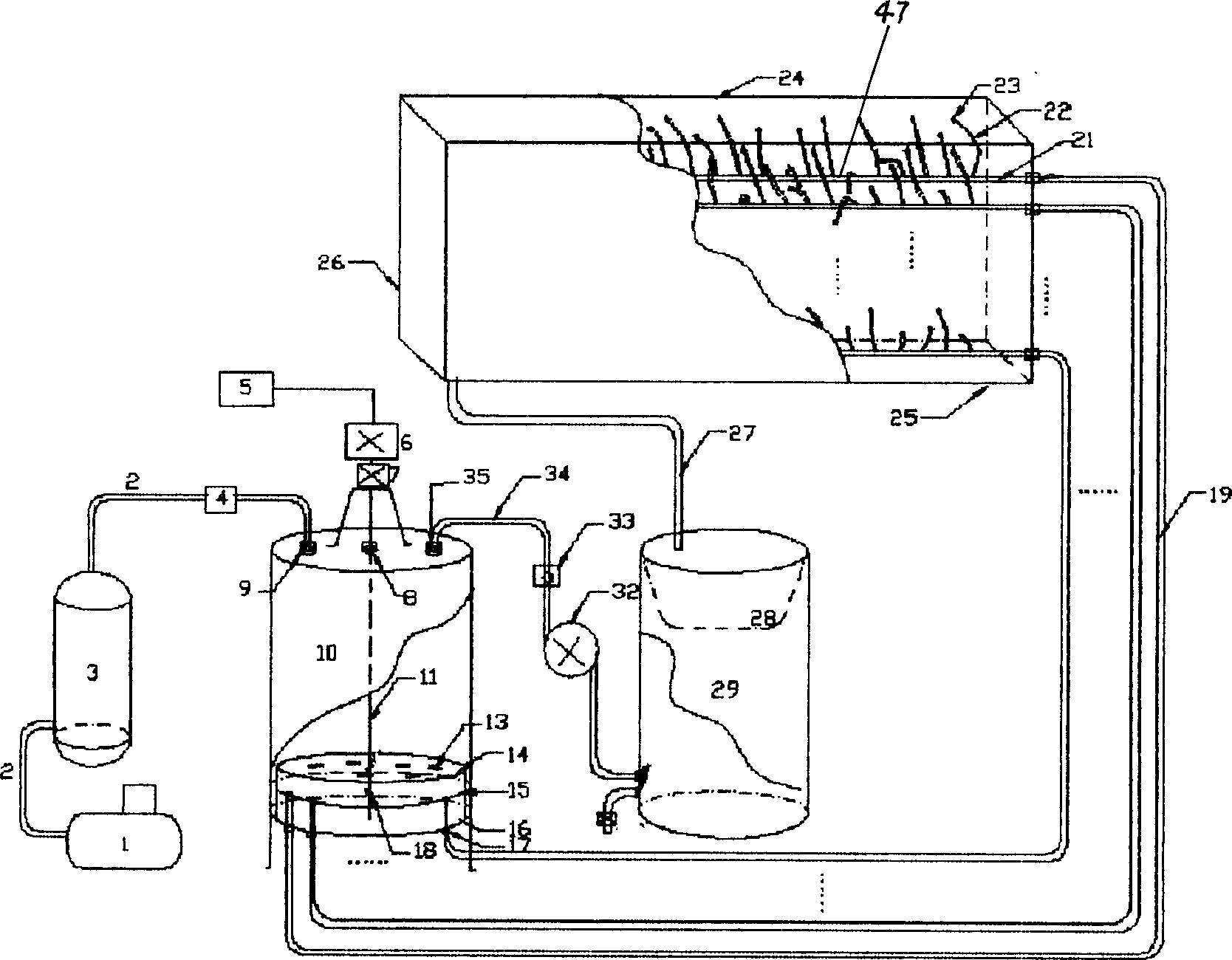

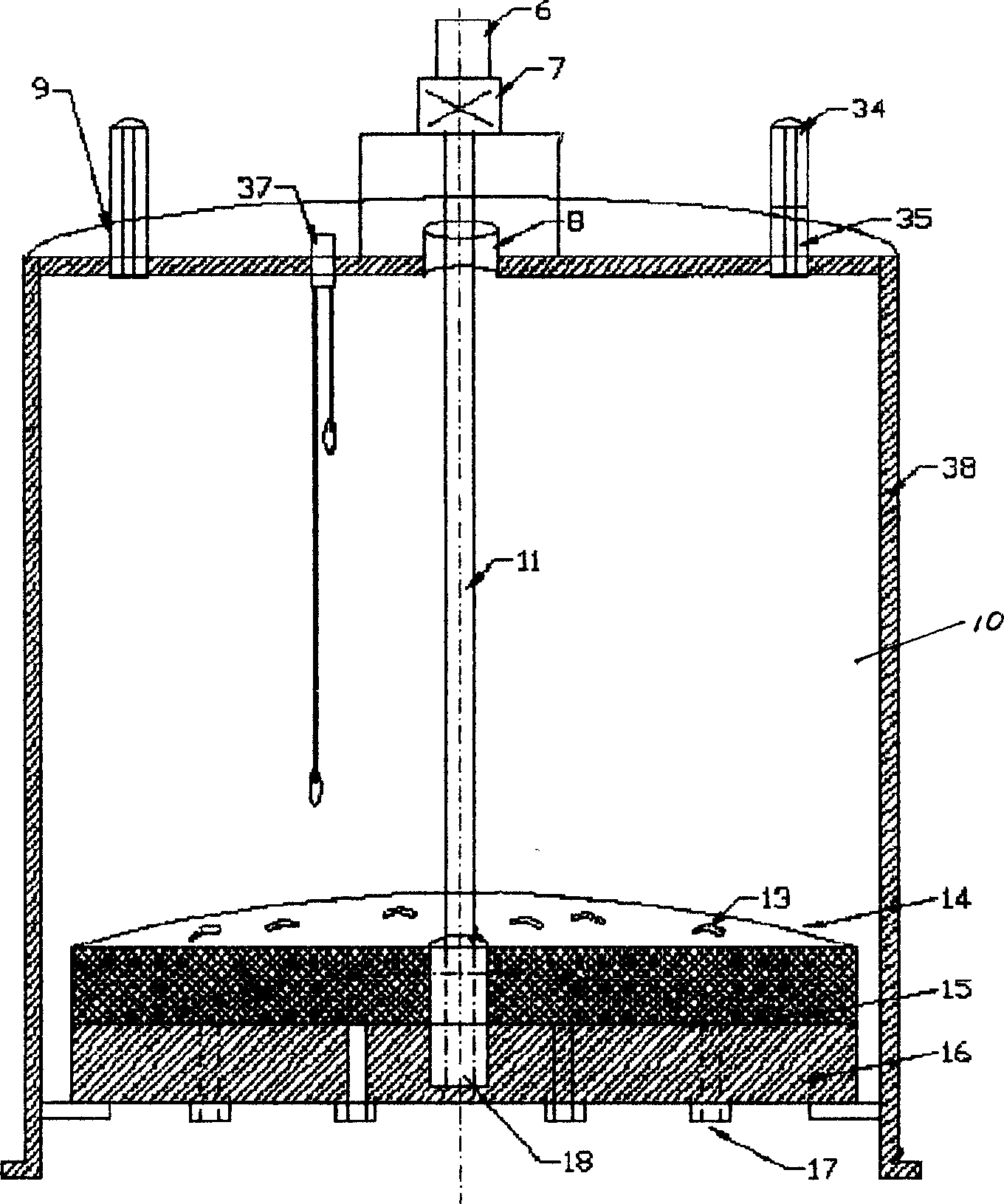

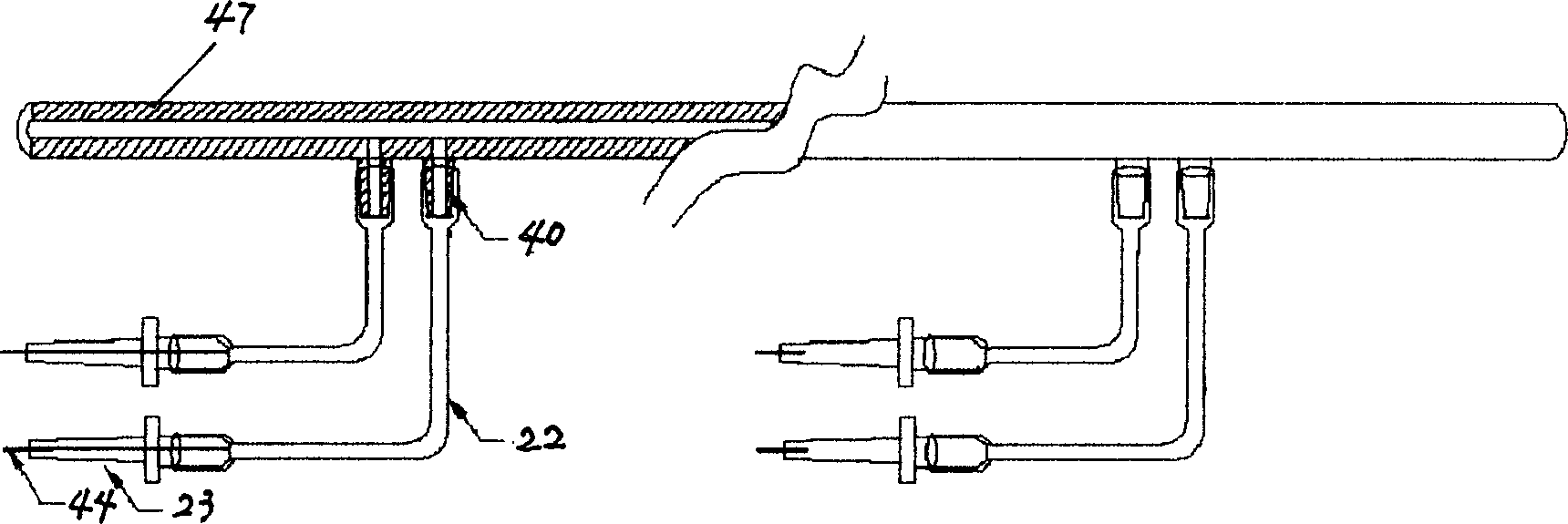

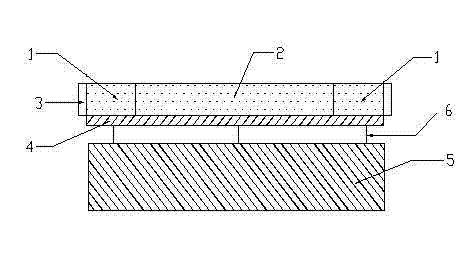

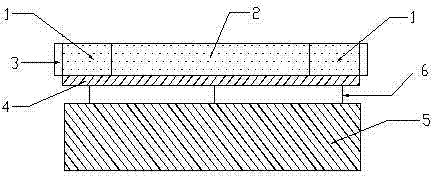

Dewatering technology of mud and its device

InactiveCN1948192ADehydration fastReduce moisture contentSludge treatment by de-watering/drying/thickeningIt equipmentBiomedical engineering

The present invention relates to a sludge dehydration process and its equipment. Said equipment includes a mechanical filter pressing device, an ultrasonic quality-improving device, a pressure synergistic electroosmosis dehydration device and an adsorption dehydration material device. The cathode of the pressure synergistic electroosmosis dehydration device is placed at one side of sludge dehydration device, and its anode is placed at another side of sludge. Said ultrasonic quality-improving device is mainly composed of three portions of ultrasonic generator, ultrasonic convertor and ultrasonic contact. Besides, said invention also provides its working principle and concrete operation method and steps.

Owner:TIANJIN UNIV

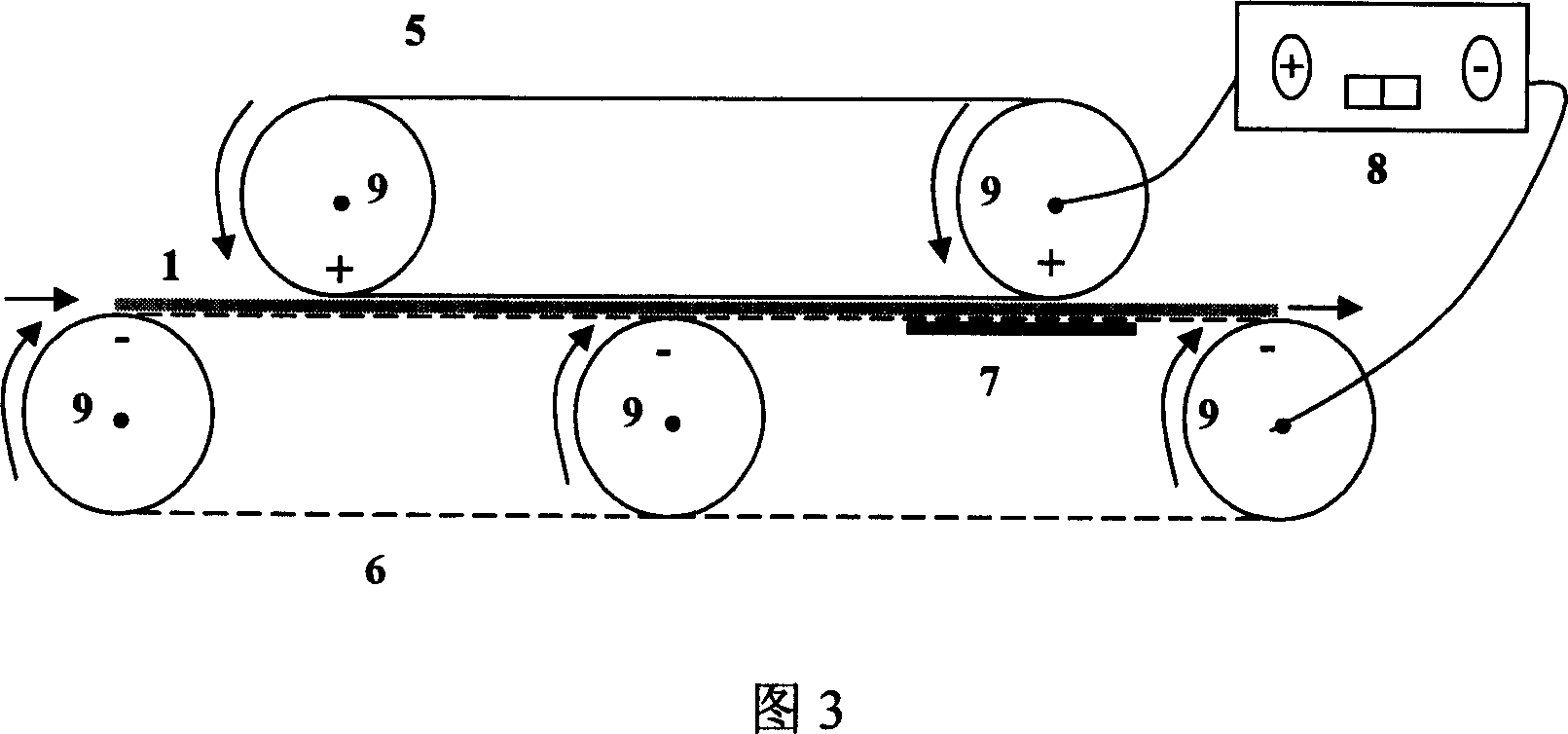

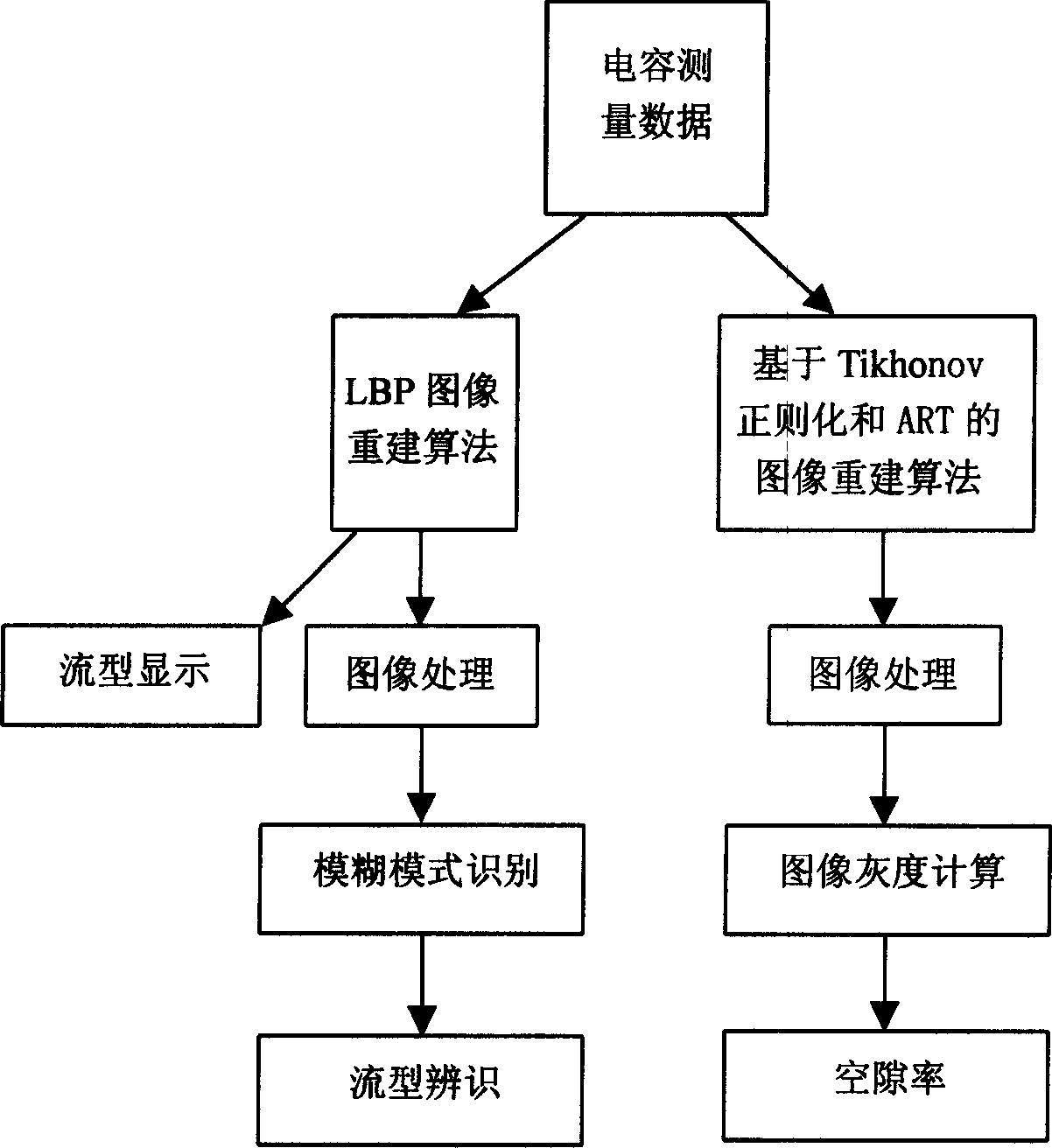

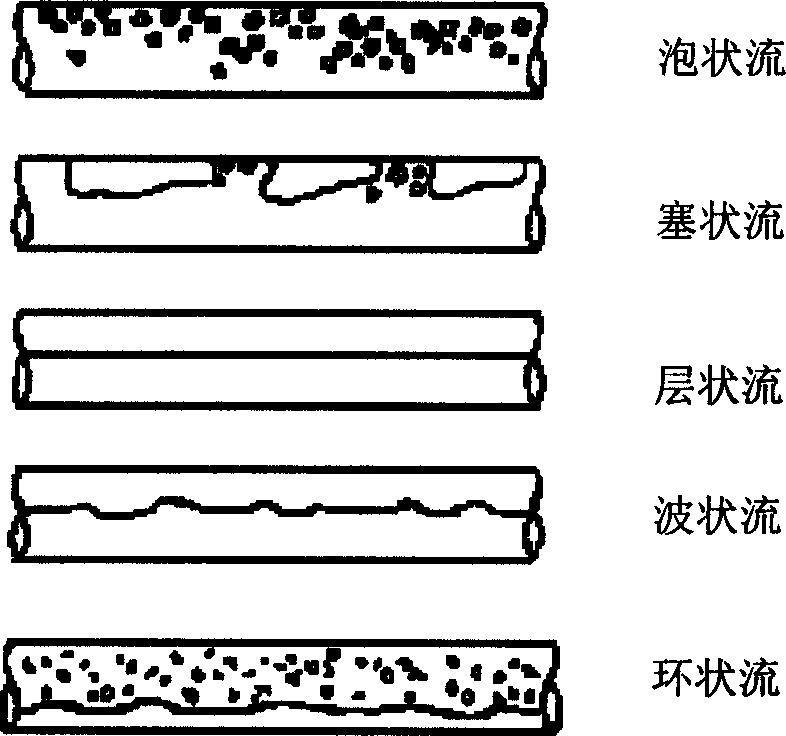

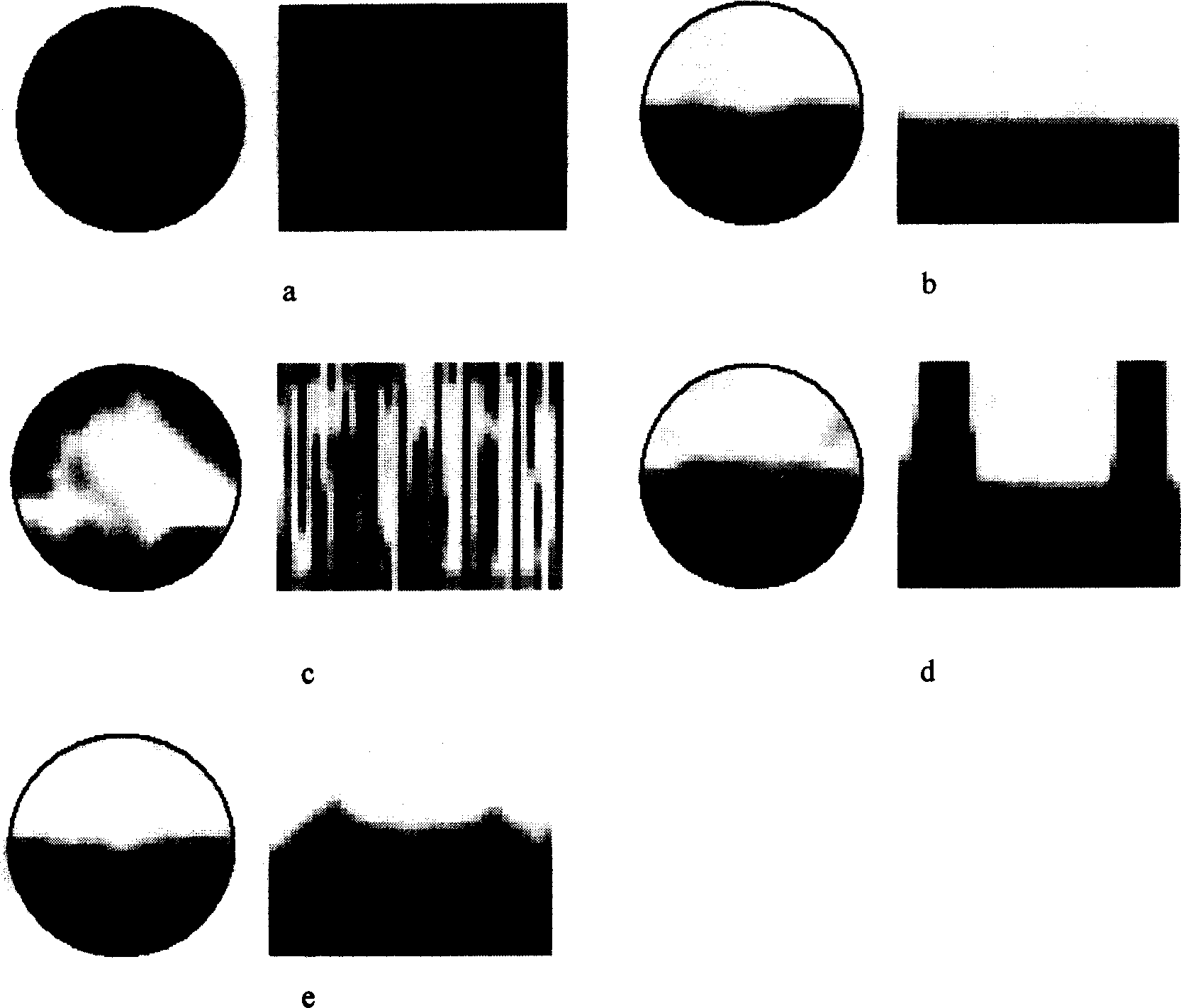

Oil-gas two-phase flow measuring method based on copacitance chromatorgraphy imaging system and its device

InactiveCN1538168AReal-time displayRealize online automatic identificationMaterial capacitancePorosityIt equipment

A method based on capacitance chromatographic imaging system for measuring the two-phase oil-gas stream features that a reverse projection algorithm is used to reconfigure the oil-gas stream's medium distribution image to real-time show the stream type in pipeline, a fuzzy pattern recognization is used for in-line automatic recognization of stream type, a combined image rebuilding algorithm is used to rebuild the image for showing oil and gas distribution, and the image is processed to obtain the porosity of the oil-gas stream. Its equipment is composed of array-type capacitance sensor, data acquisition unit and computer. Its advantages are high speed and high precision.

Owner:ZHEJIANG UNIV

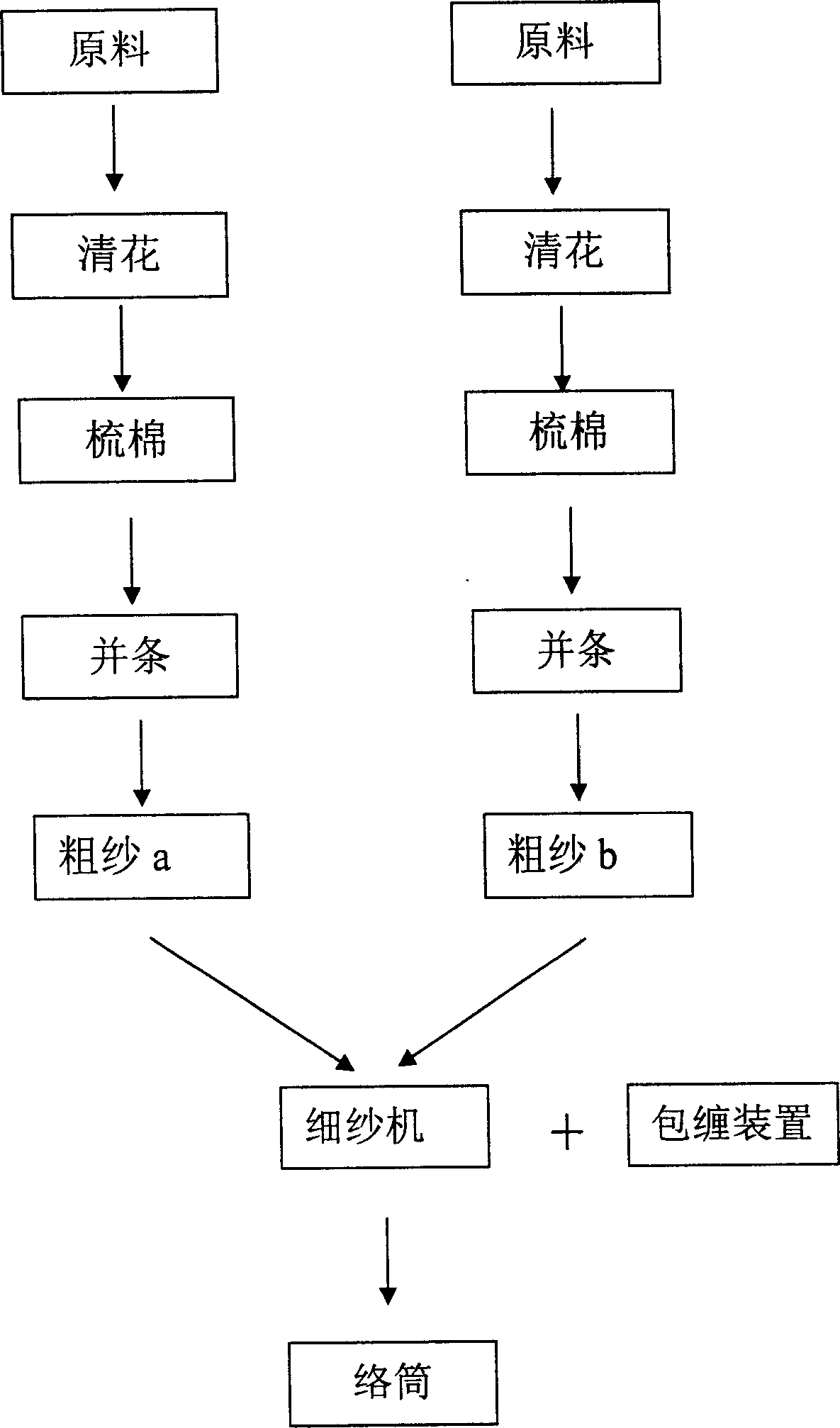

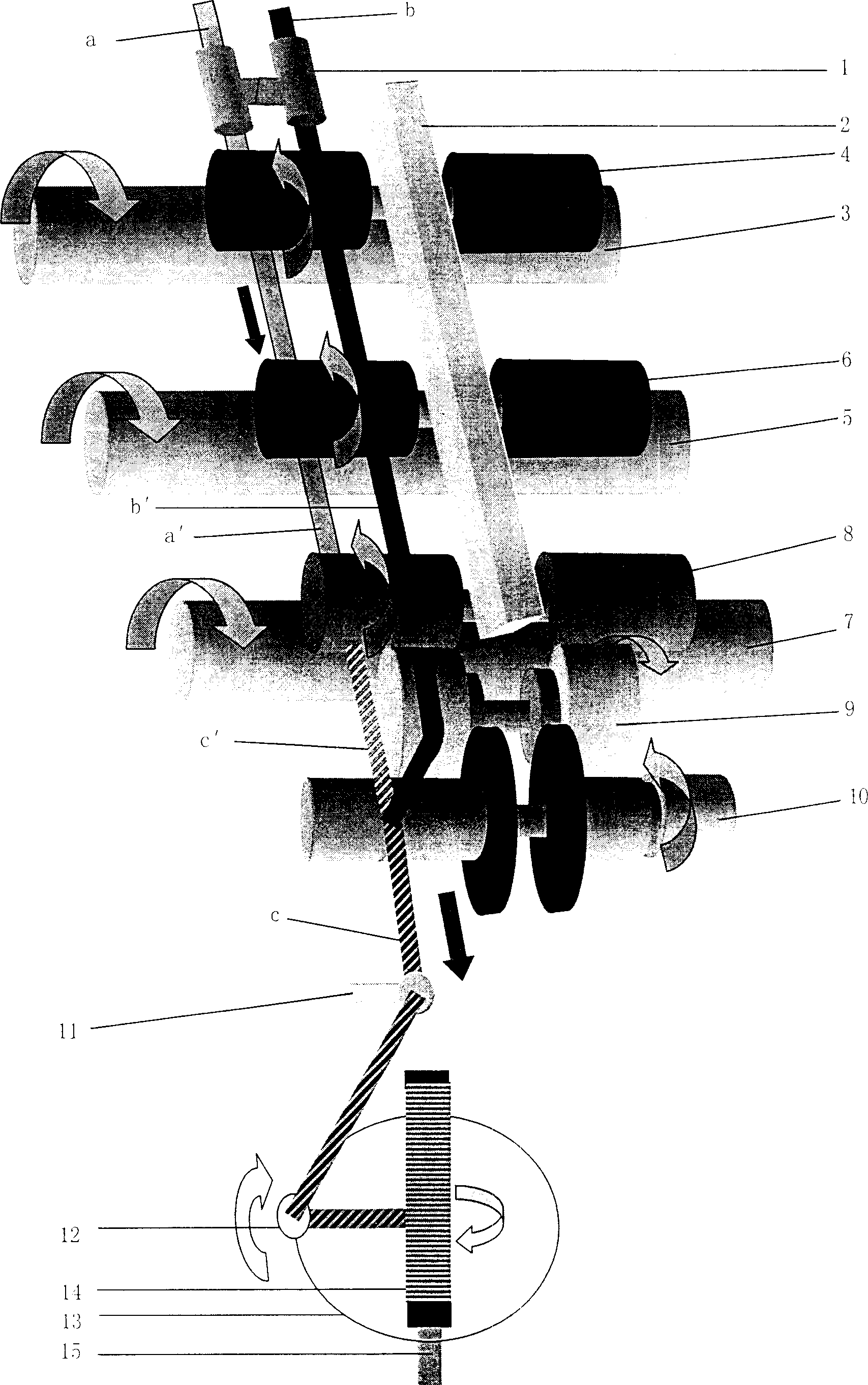

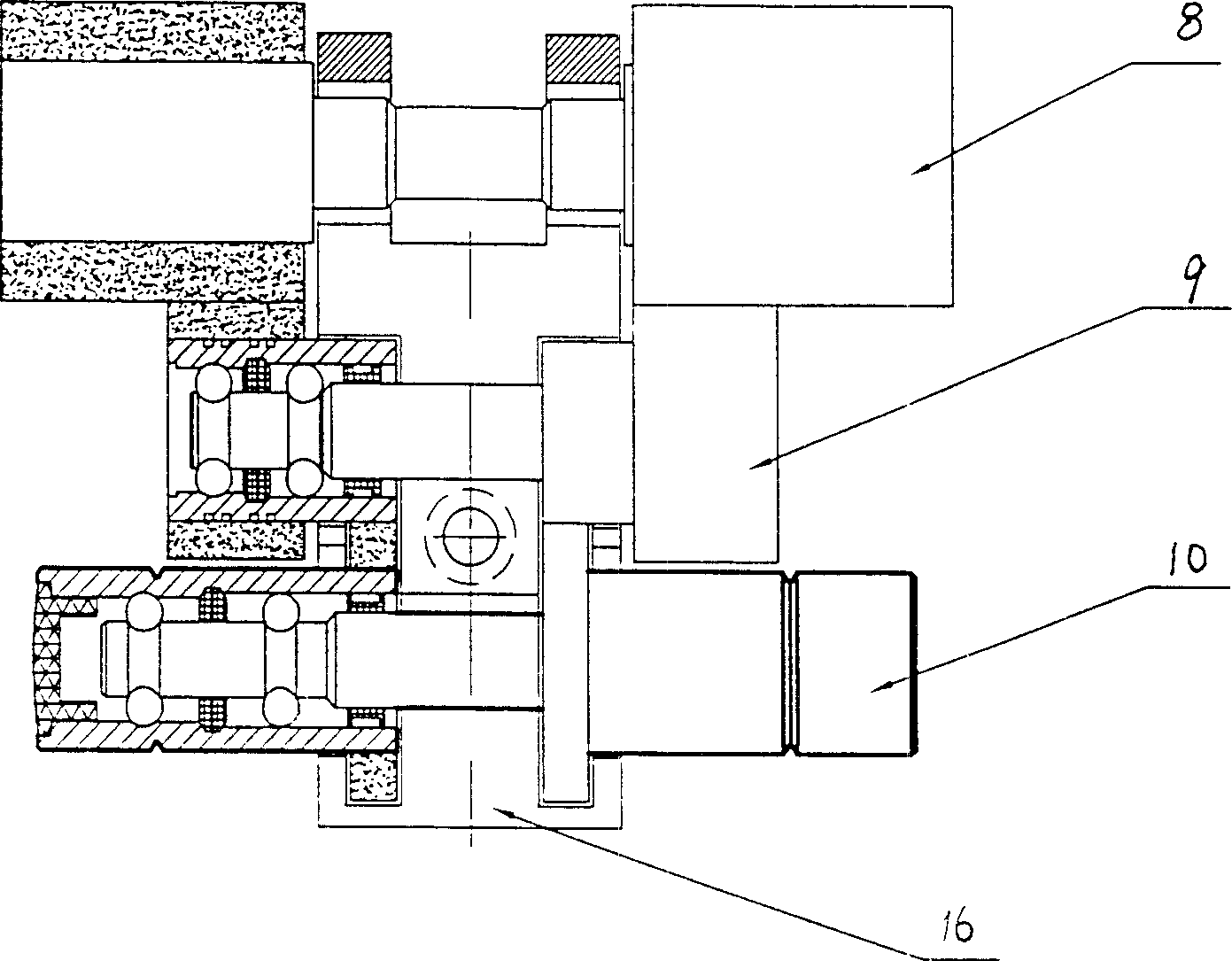

Production method of short staple enveloped composite yarn and its device

The present invention discloses a production method of short fibre wrapped composite yarn and its equipment. Said invention is implemented by using spinning frame and wrapping device, and its production method includes the following steps: raw material, scotching, carding, drawing, roving, spinning and doffing.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

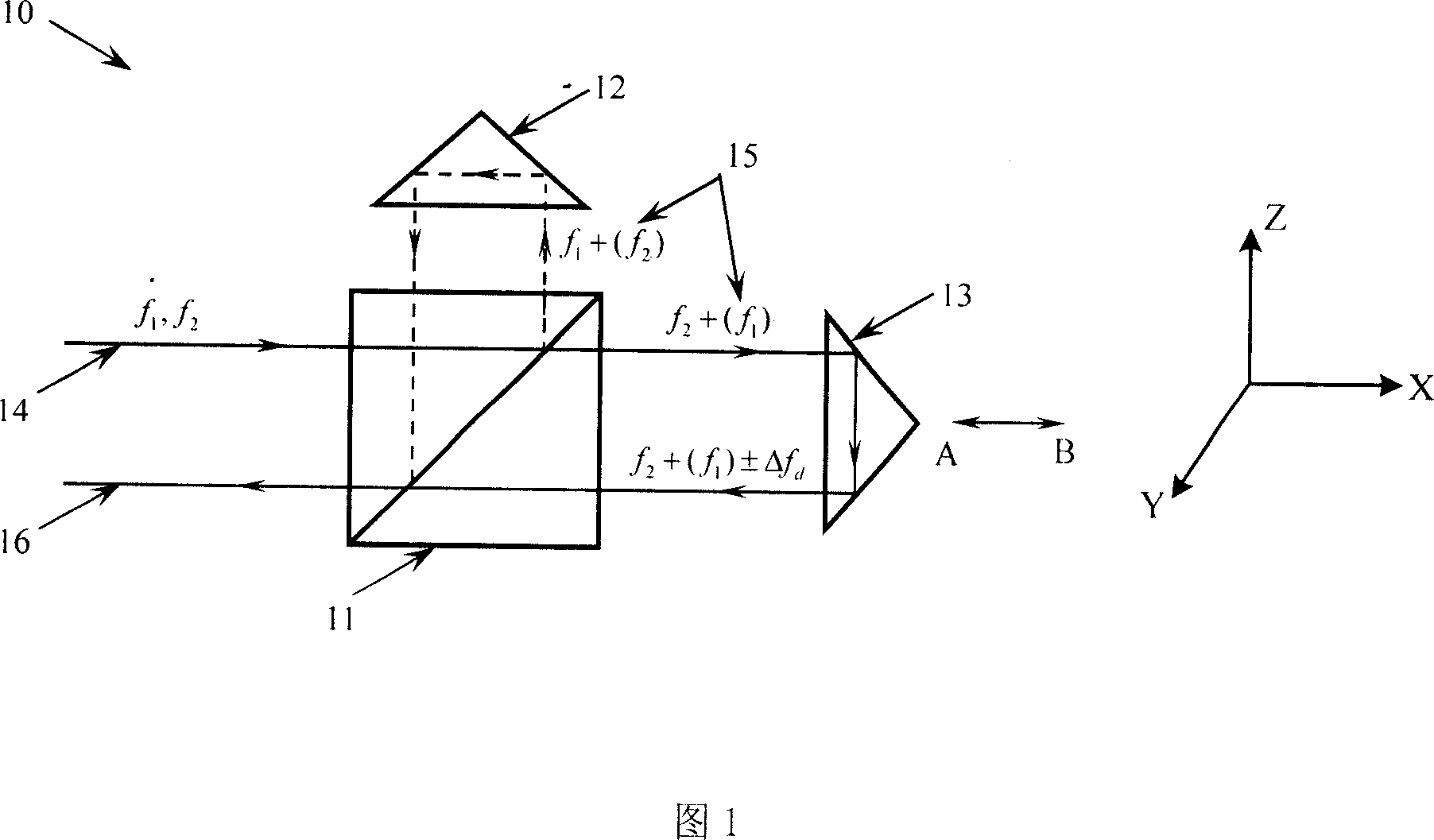

Method and apparatus for reducing heterodyne interference nonlinear error first harmonic component

InactiveCN101067546AReducing Nonlinear Errors of Laser Heterodyne InterferometrySimple methodUsing optical meansRotary stagePrism

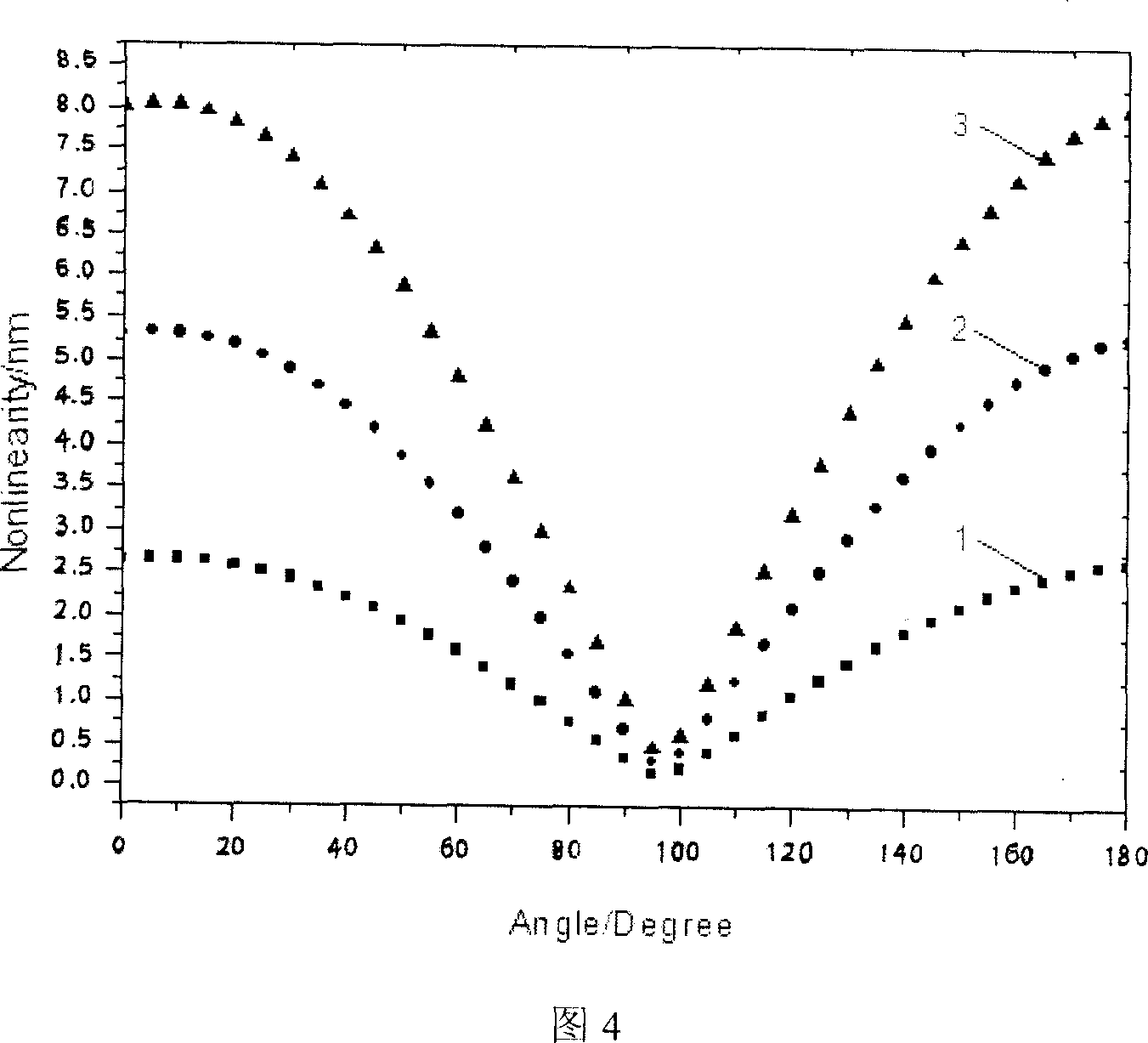

The invention relates to a method of reducing the heterodyne interference non-linear error first harmonic component and its equipment, the existing kinds of system and the method are all very complex. The invention includes: the light beams which contains two frequencies, two polarization directions and sends out by the double frequency laser; this light beam divides into two bunches of light after the spectroscope, the reflected light forms the reference signal after the analyzer by the photo detector receive; the transmitted light enters the polarization spectroscope to divide into two bunches of light which includes the reflected light of polarization direction vertical paper surface and parallel paper surface transmitted light, the reflected light reflects to the polarization spectroscope after the reference pyramid prism, the transmitted light after survey pyramid prism installed on the swivel table also reflects the polarization spectroscope; above two bunches of light converge in the polarization spectroscope place, and formed the survey signal by the reflector reflection after the analyzer by the photo detector; swivel table axial revolves the survey pyramid prism along the survey pyramid prism heading, swivel table anti-clockwise or clockwise axial revolves 97 degree. The invention uses to increase the heterodyne interference measuring accuracy.

Owner:HARBIN INST OF TECH

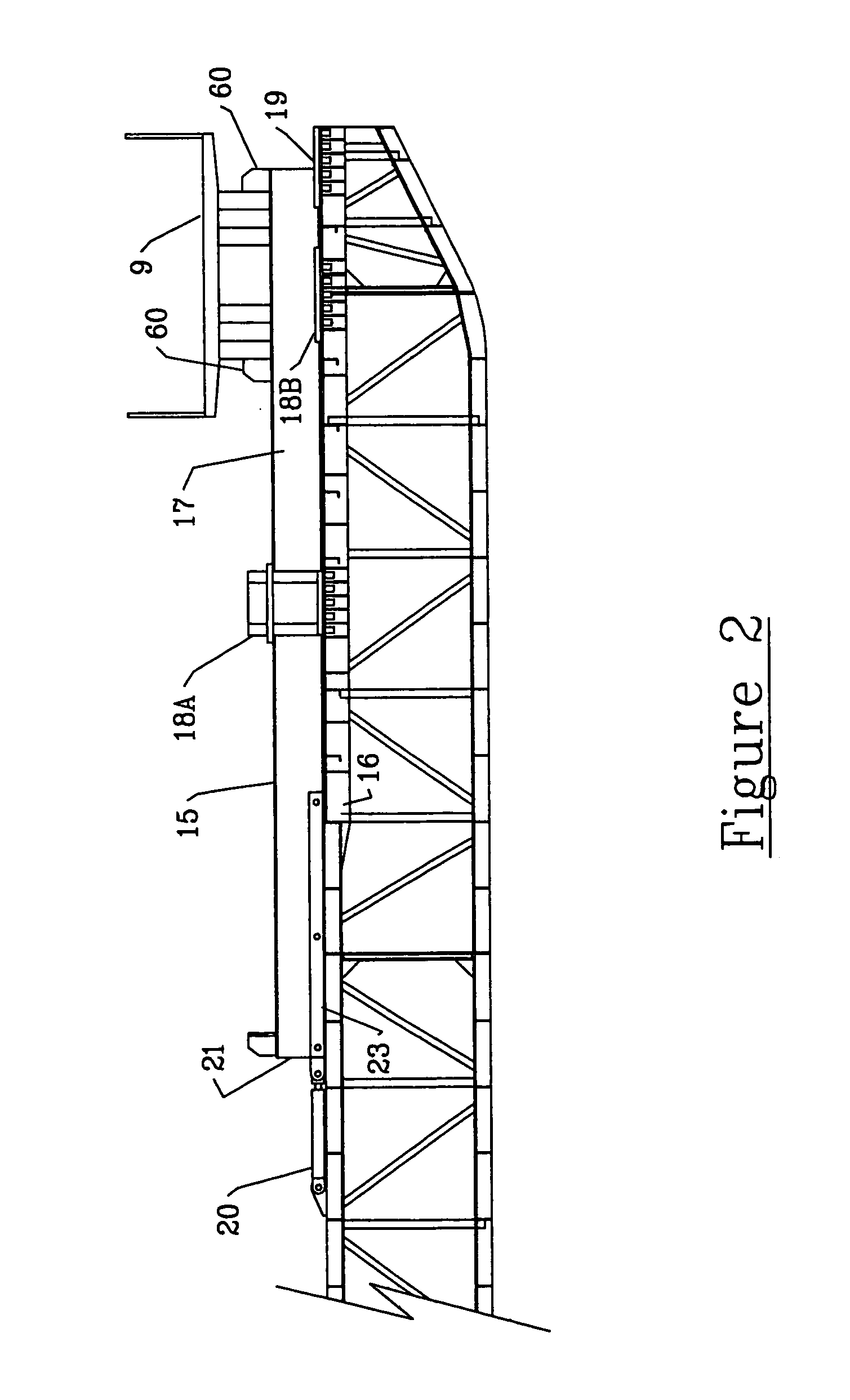

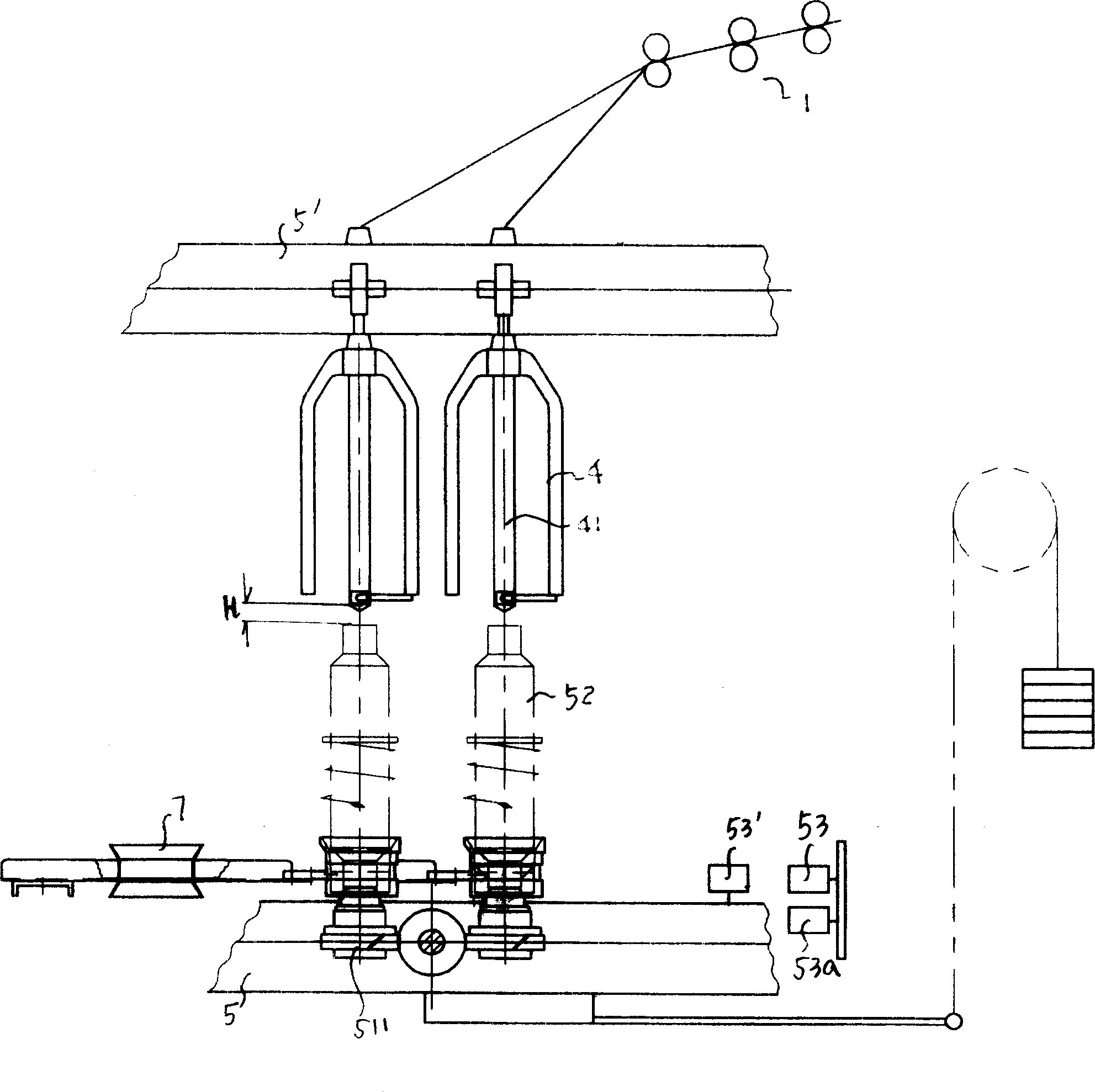

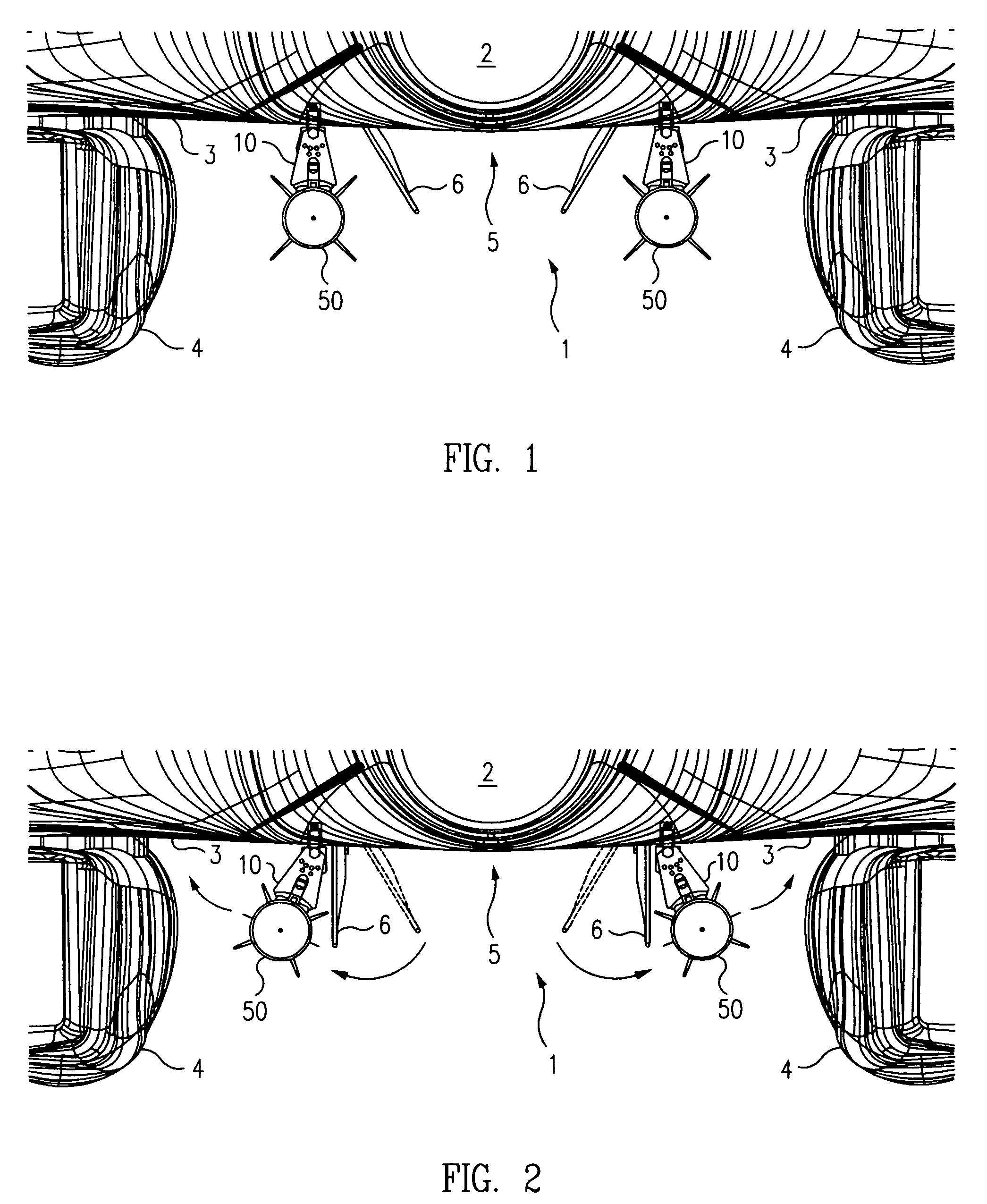

Jack up workover rig with removable workover floor unit

InactiveUS6926097B1Low costEasy to installArtificial islandsDerricks/mastsIt equipmentMarine engineering

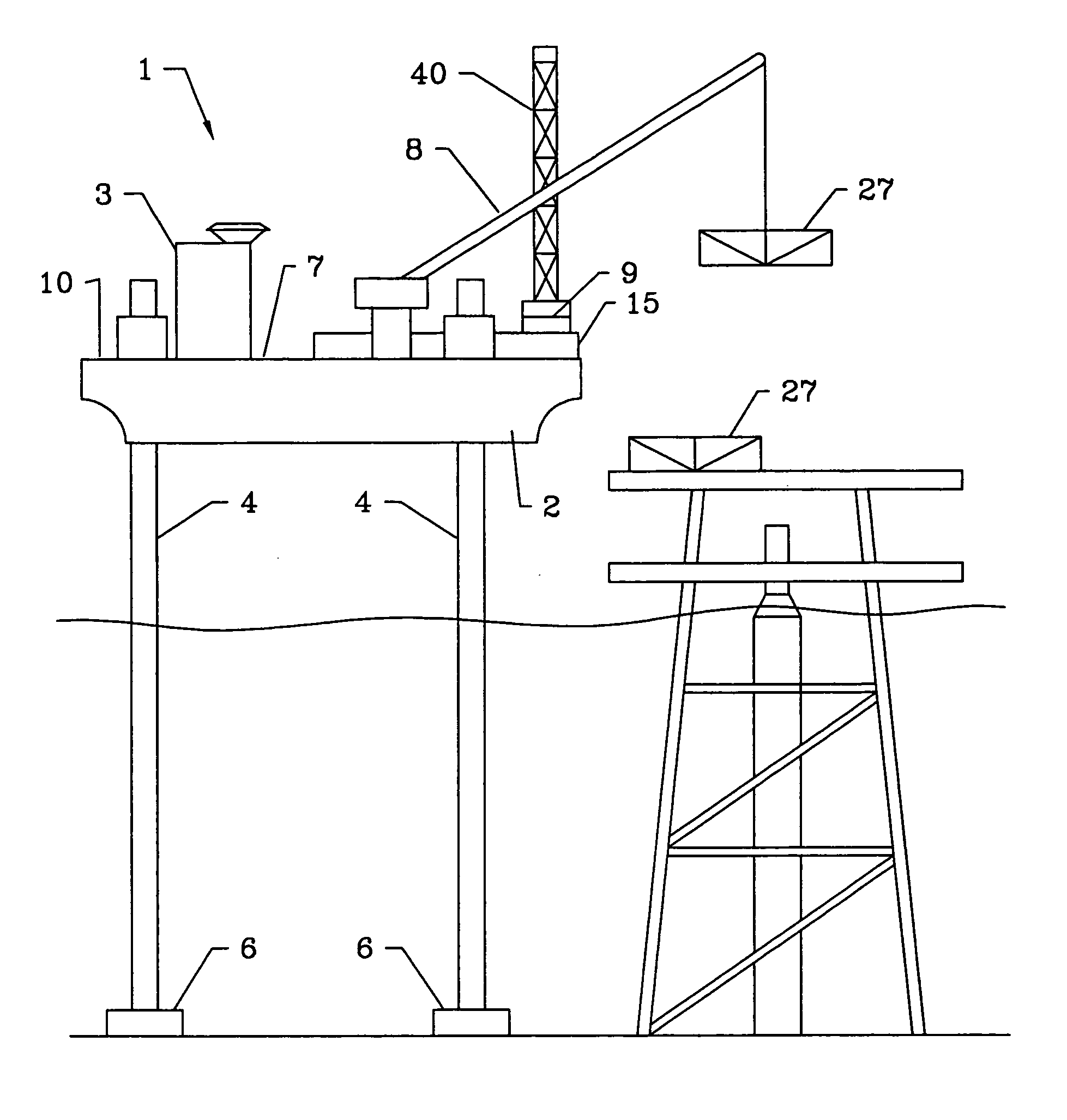

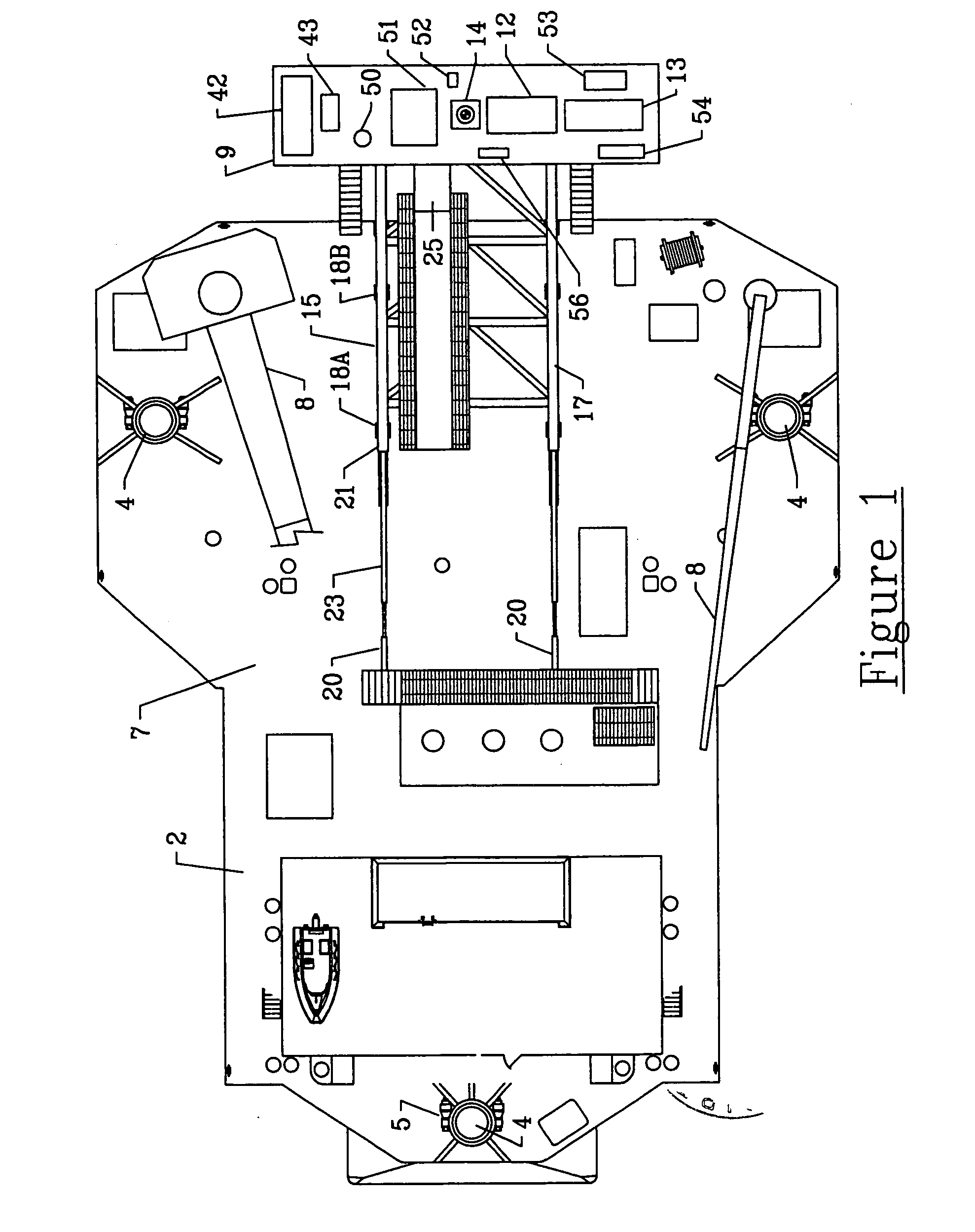

An offshore jack-up workover rig. The workover rig includes a vessel which may be self powered or powered by a tug. The vessel may be raised above the surface of a water body by extending the legs until they reach the water body bed and then continuing to extend the legs. The workover rig contains a workover floor unit which includes at least a drawworks, a drawworks motor, and a well aperture. The workover rig is detachably mounted on an extensible cantilevered frame. The frame may be extended to position the workover floor unit over an offshore platform to be serviced. The workover floor unit is also configured to mover laterally relative to the extensible frame. The vessel is also provided with a crane. The crane may be used to lift the detachable workover floor unit from the vessel and deposit it, including its equipment, on the platform.

Owner:BLAKE MICHAEL E

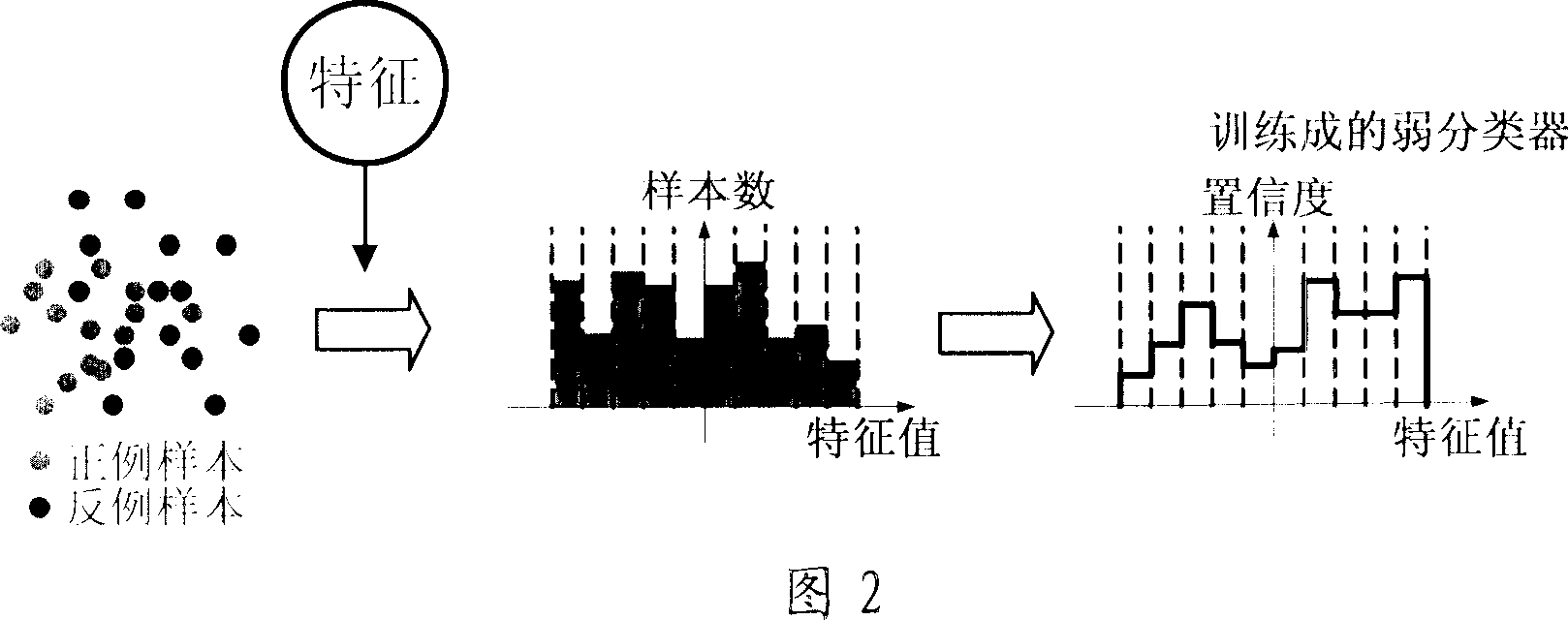

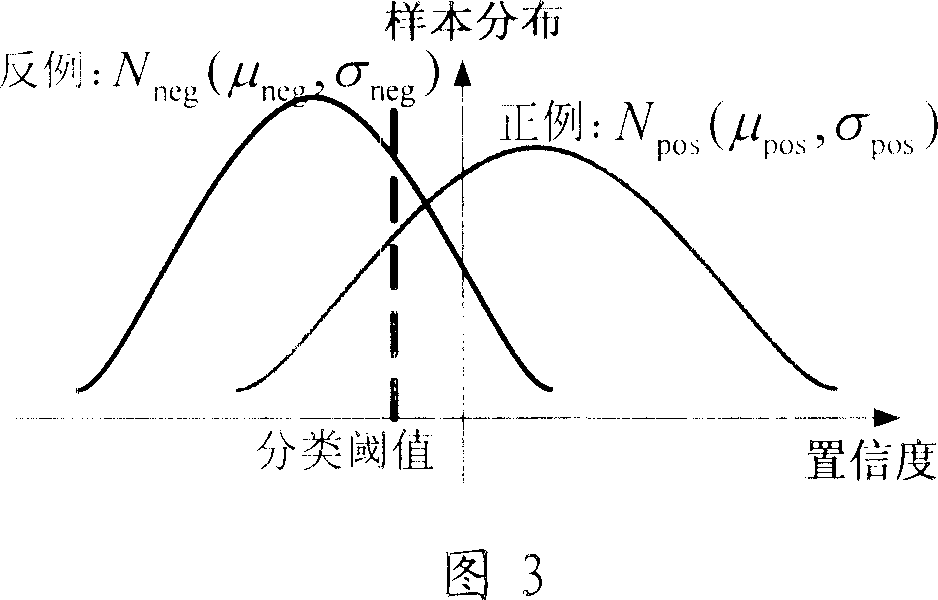

Tracking method and device for special shooted objects and tracking method and device for aspect parts

The present invention provides a specific shot body tracking method based on characteristic region detection and equipment, and characteristic region tracking method and its equipment. The specific shot body tracking method based on characteristic region detection is characterized by that it utilizes particle filter to divide multi-frame image of video sequence by means of sub window and make calculation treatment so as to define the position and size of shot body. The described characteristic region is one portion of specific shot body. The observation model of the described particle filter includes characteristic region observation model.

Owner:ORMON CORP +1

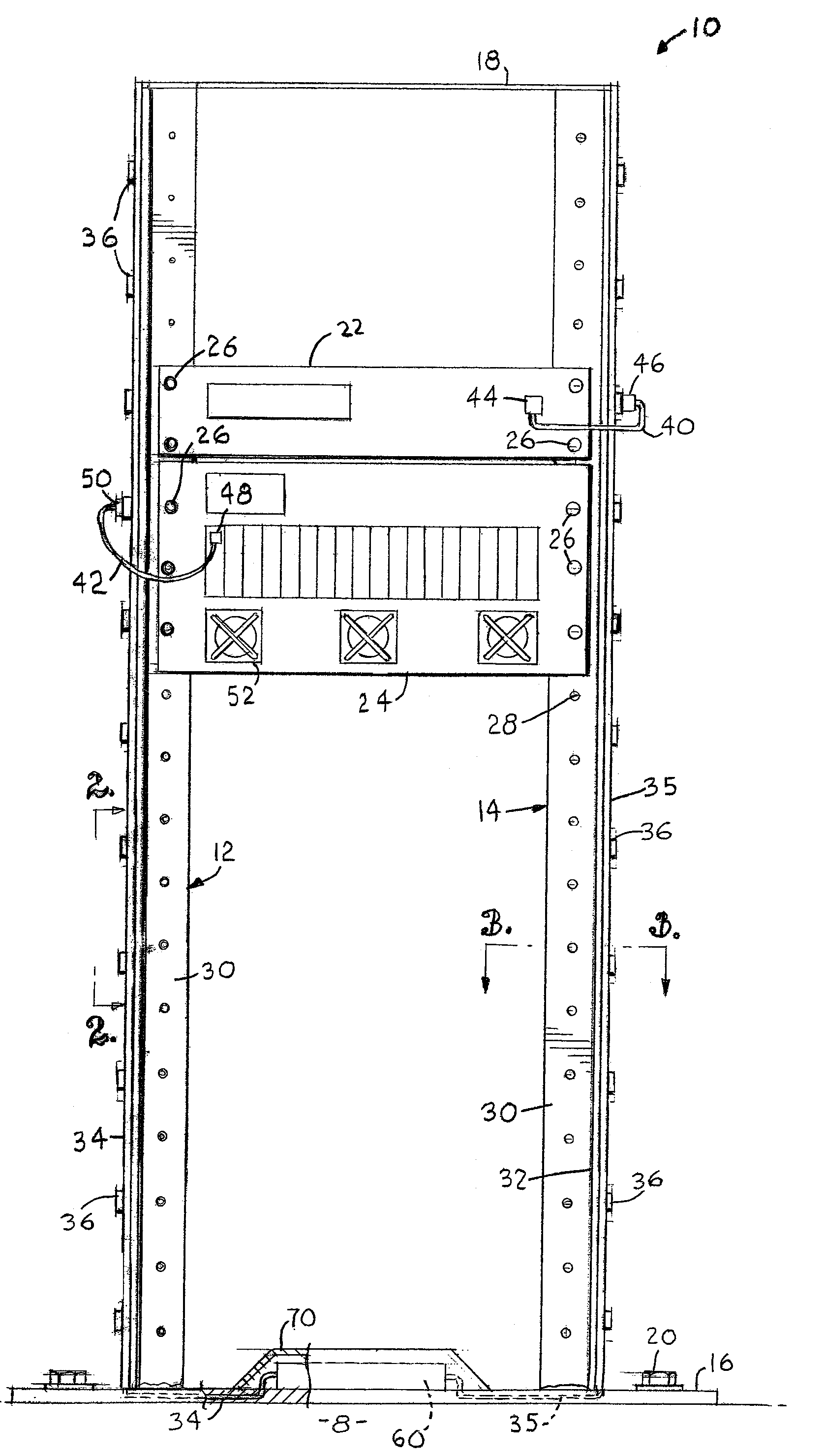

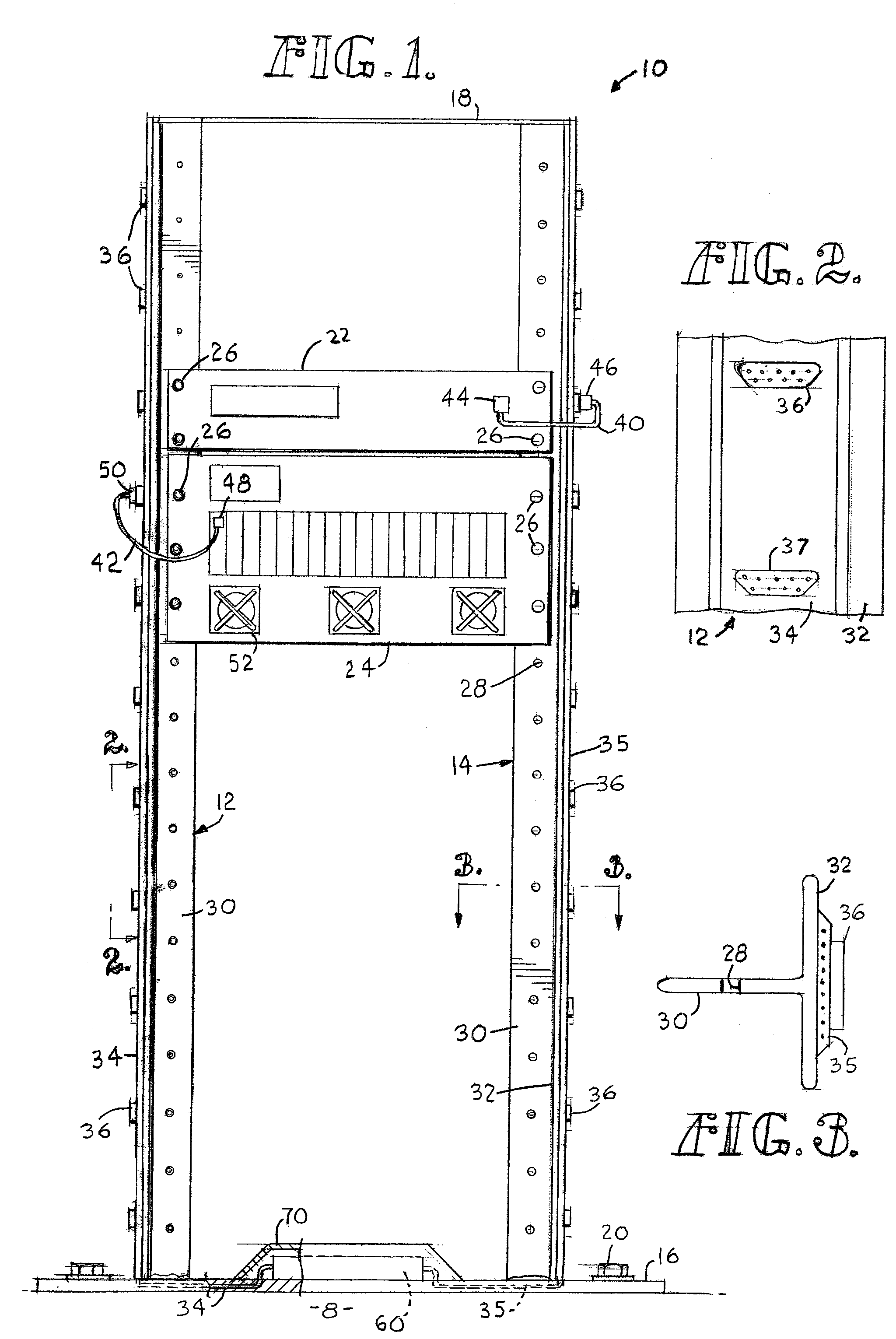

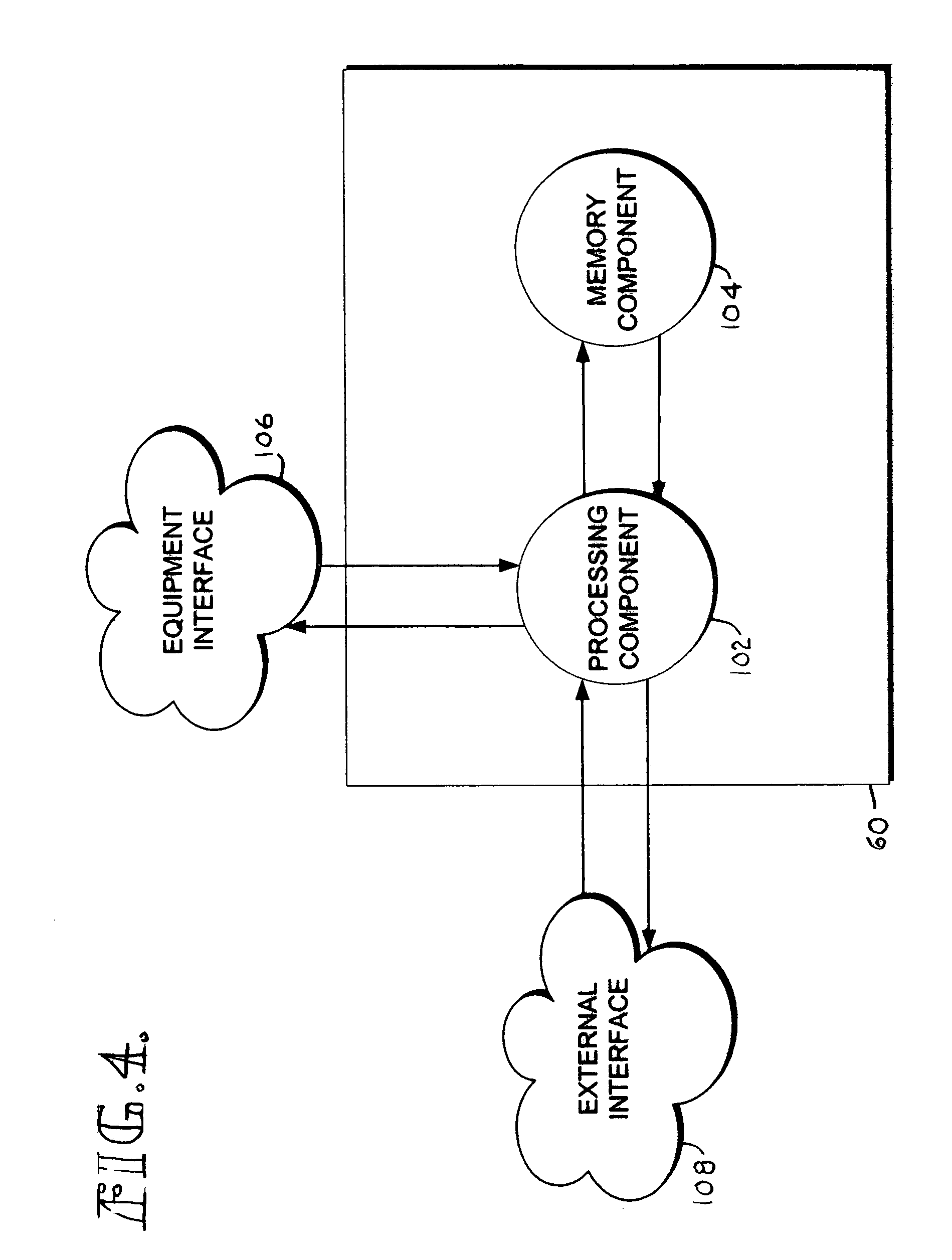

Equipment housing with interfacing computer

An equipment housing is provided upon which heavy computing equipment, such as servers, routers, switches, and others may be mounted. A computing device is attached to the housing. The computing device is interfaced with the equipment on the housing, and also with a system that is external thereto. The disclosed housing, and others like it, may be used by an organization along with a centralized computing system such that that organization will know the exact location and status of all of its equipment at the same time and may accurately and readily monitor all of its equipment-related-assets at any given time.

Owner:T MOBILE INNOVATIONS LLC

Method and device for automatic spinning repiece

InactiveCN1488798AOptimize structural configurationReduce twistPiercing arrangementsContinuous wound-up machinesYarnLow speed

The present invention relates to an automatic spinning new end forming method and its equipment. The roving machine utilizes the coder positioned at the drafting portion position to detect the full-yarn length when the bobbin can be fulled, and makes the roving machine spin to a certain length in low speed, after the roving is spun to a certain length, makes the roving machine operate in low speed, at the moment makes the spindle rail stop lifting movement and makes the yarn be in said height position, winds 2-3 turns of halching and makes the spindle rail be quickly lowered to form large thread pitch wind so as to make the roving do not take-off in its transportation process; changes the speed ratio of flywer and roller so as to reduce roving twist, and obtain undertwisted roving, and when the ultralowering of spindle rail is made to place, the yarn is stretch-broken to produce fuzzy fibre whose length can be suitable for secondary automatic spinning new end formation.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

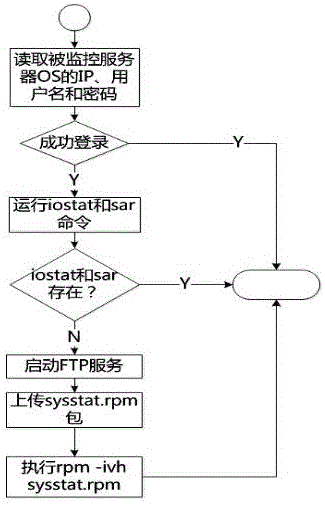

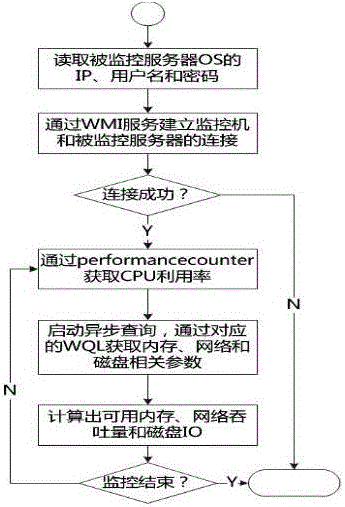

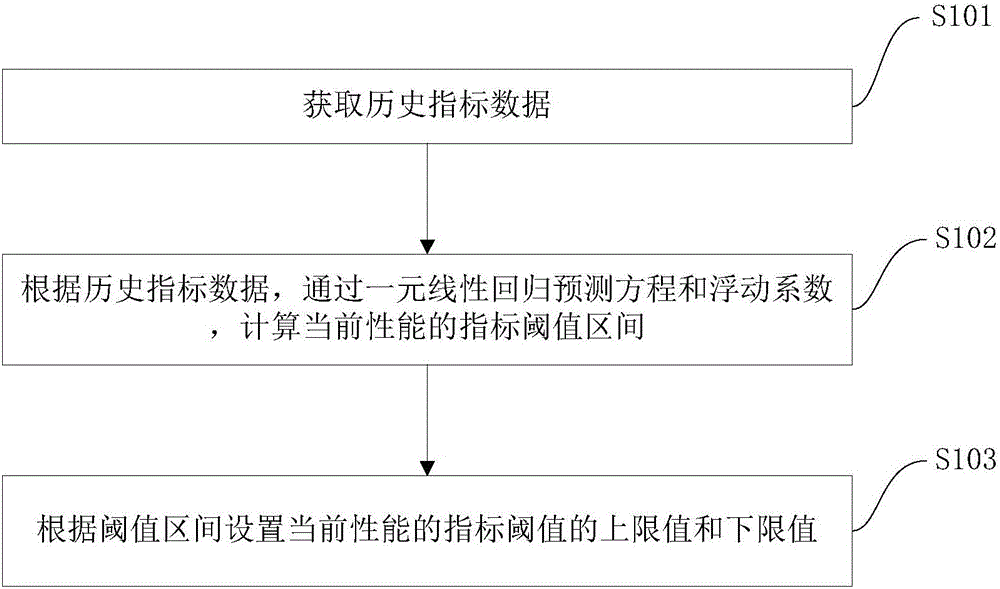

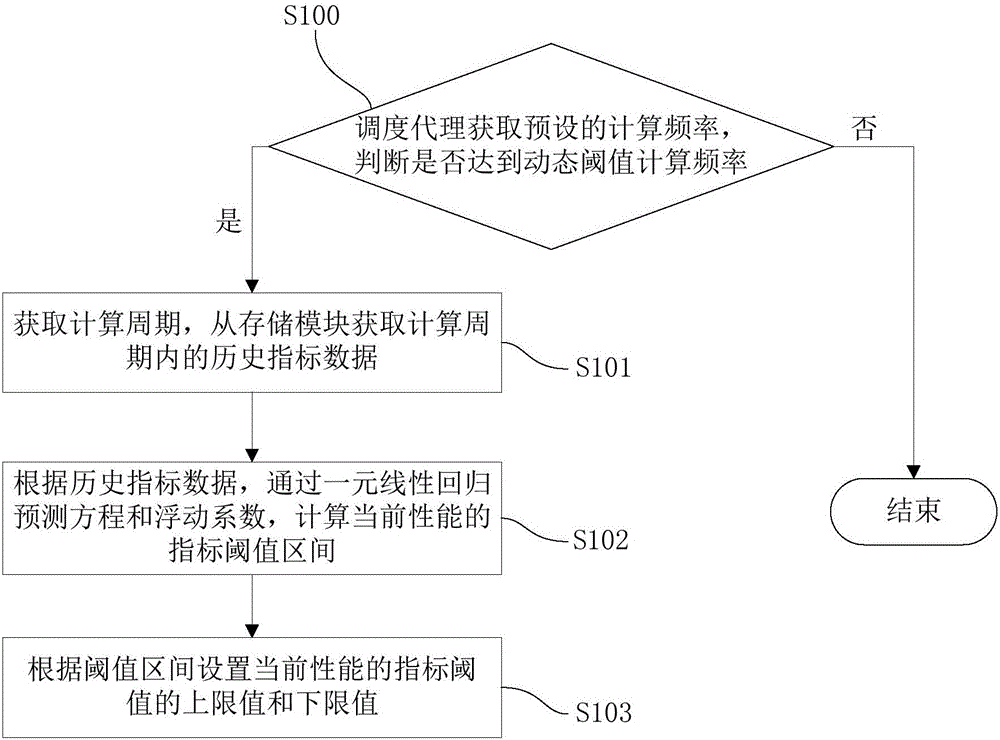

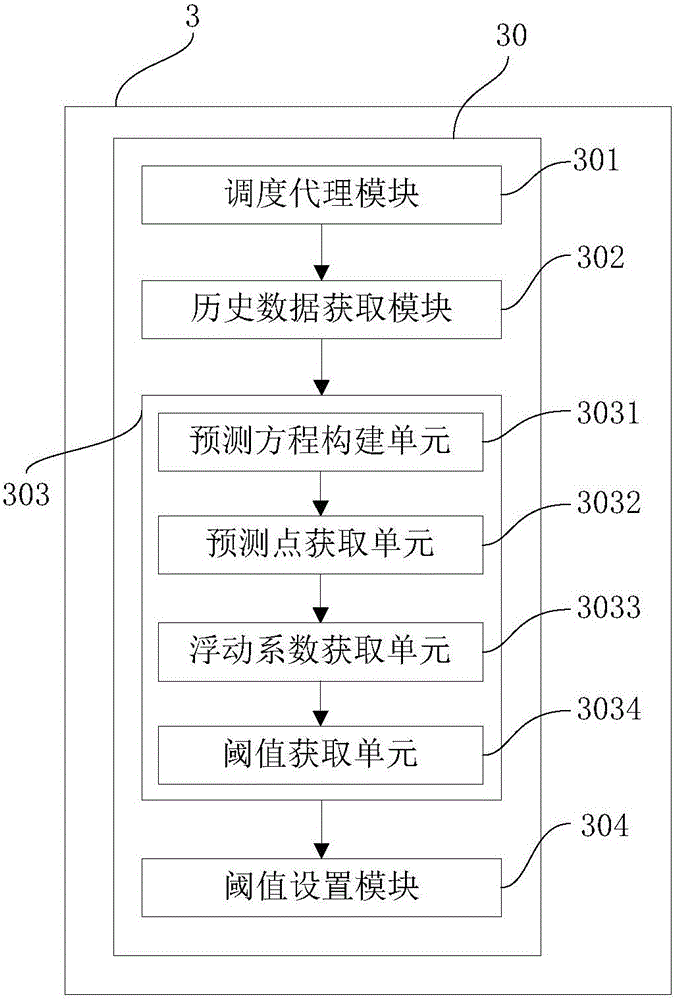

Method and system for dynamically setting performance index threshold of IT equipment

ActiveCN105956734AImprove accuracyIn line with actual operating conditionsResourcesLower limitIt equipment

The invention discloses a method and a system for dynamically setting a performance index threshold of IT equipment. The method is characterized by comprising the steps of acquiring historical index data of each performance of the IT equipment; according to the historical index data, calculating the index threshold interval of each performance through a unary linear regression equation and a floating coefficient; and setting the upper limit and the lower limit of the index threshold of each performance according to the threshold interval. The method and the system provided by the invention can dynamically calculate and set the performance index threshold of the equipment, thereby improving abnormity warning accuracy of monitoring equipment.

Owner:GUANGDONG XUANYUAN NETWORK & TECH

Method of high speed high pressure spraying decoration on textile paste yarn dyeing production line and its device

InactiveCN1718899ALow costEasy to produceDyeing processTextile treatment by spraying/projectingProduction lineYarn

The present invention relates to a production method for high-speed and high-pressure spraying pattern on textile size yarn-dyeing production line and its equipment. Said method includes the following steps: making yarn be uniformly advanced at a set speed, uniformly stirring fading agent or dyes and adjuvant, filtering and pressurizing, and utilizing multihole type spray head mounted on the pattern-spraying panel to high-frequency intermittently spray the above-mentioned liquid material on the several running yarns to make their local colour be changed so s to form pattern.

Owner:刘林泉

Production technology of preparing aminosal using hydrolysed residual active sludge by quick lime and its equipment

A process for preparing hydrolytic protein by using the calcium lime to hydrolyze the residual active sludge includes such steps as proportionally mixing residual active sludge, water and calcium line, stirring, hydrolyzing reaction, filtering, using hydrochloric acid to regulate pH=7.0-8.5, concentrating and drying. Its apparatus is also disclosed.

Owner:武汉市城市排水发展有限公司 +1

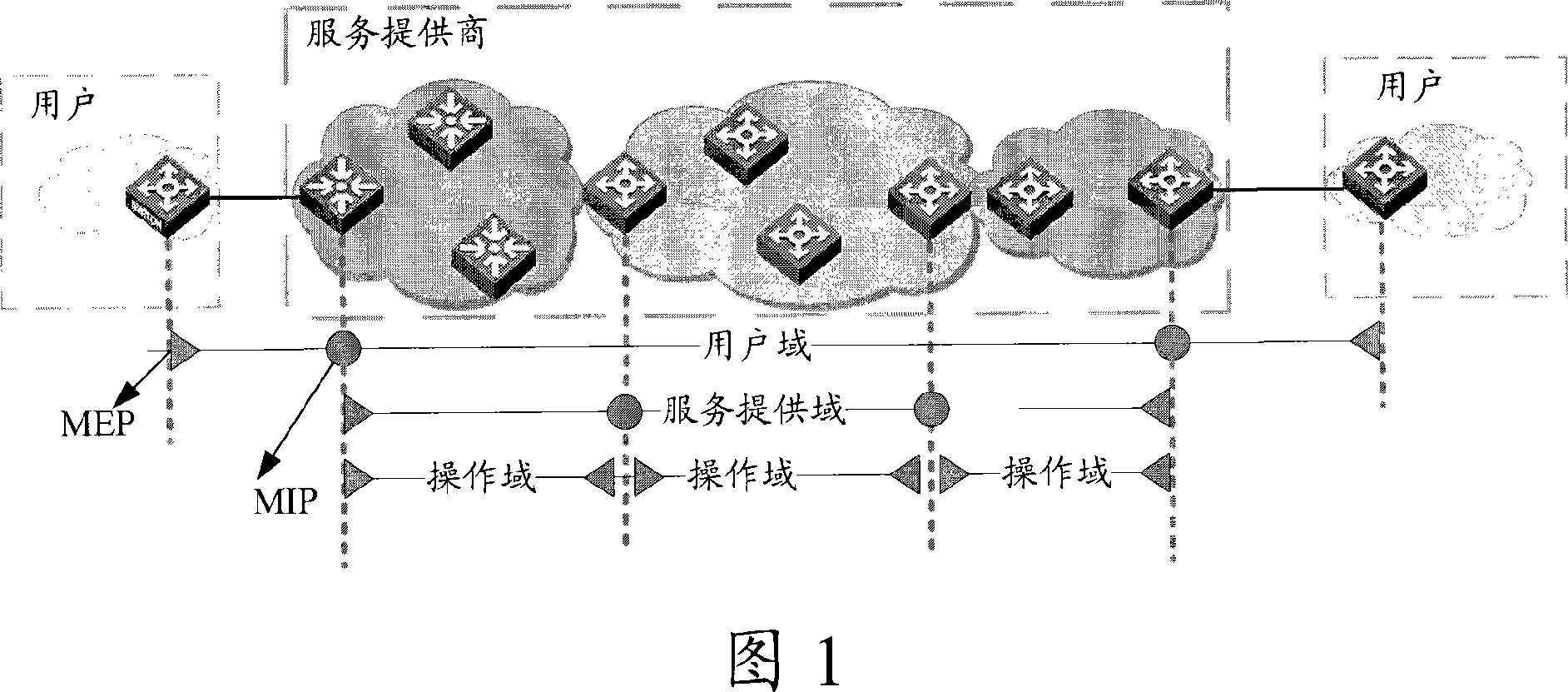

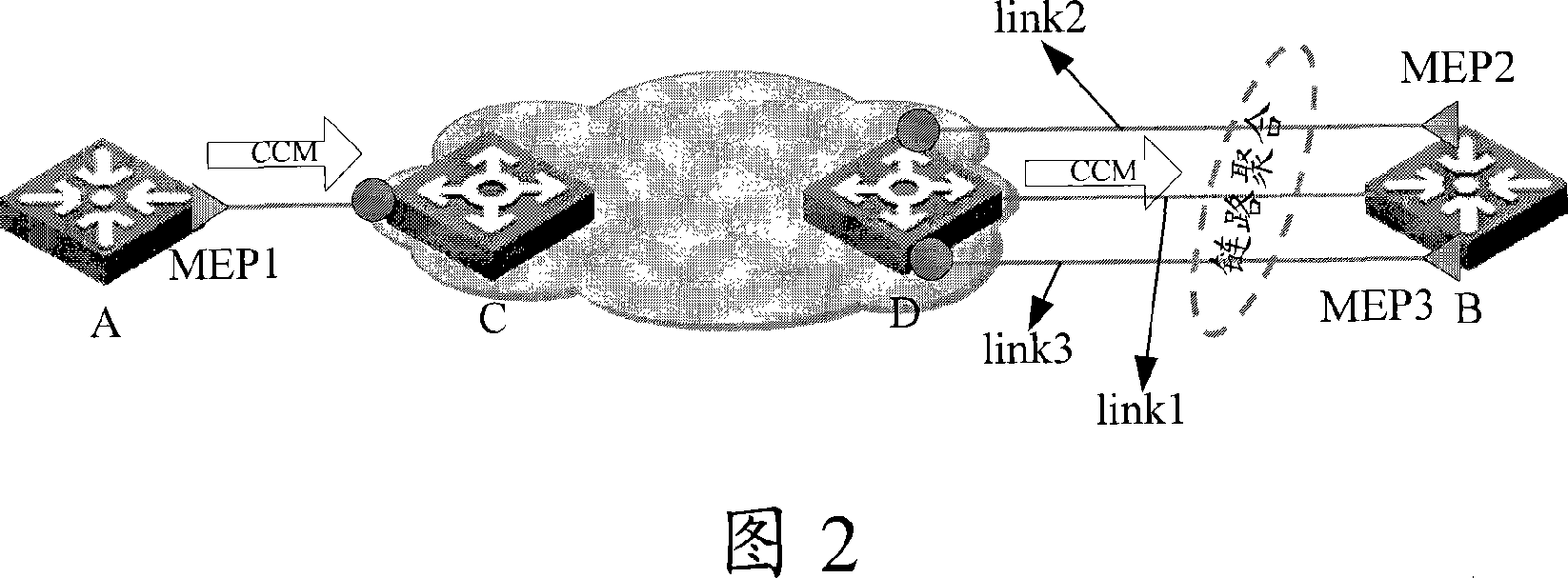

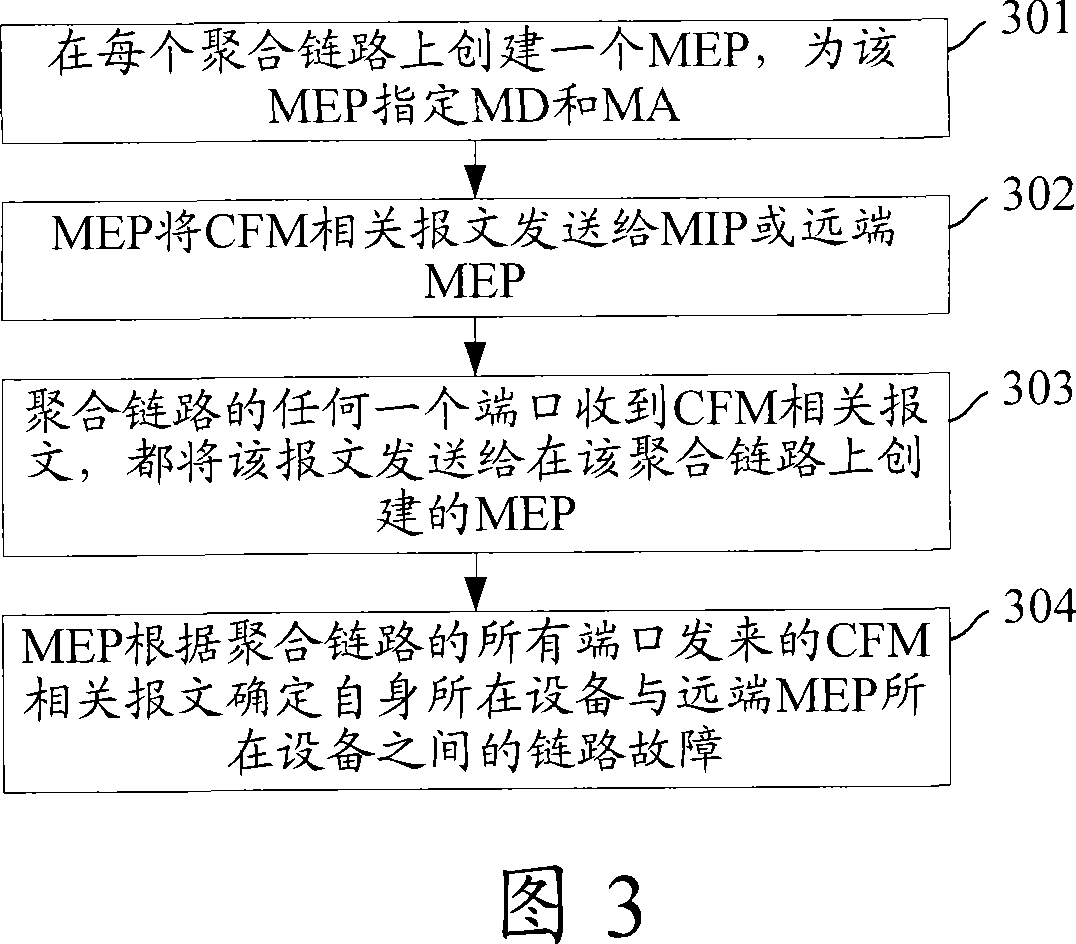

Link failure detection method and device

ActiveCN101056223AHigh precisionError preventionData switching by path configurationIt equipmentReal-time computing

Owner:NEW H3C TECH CO LTD

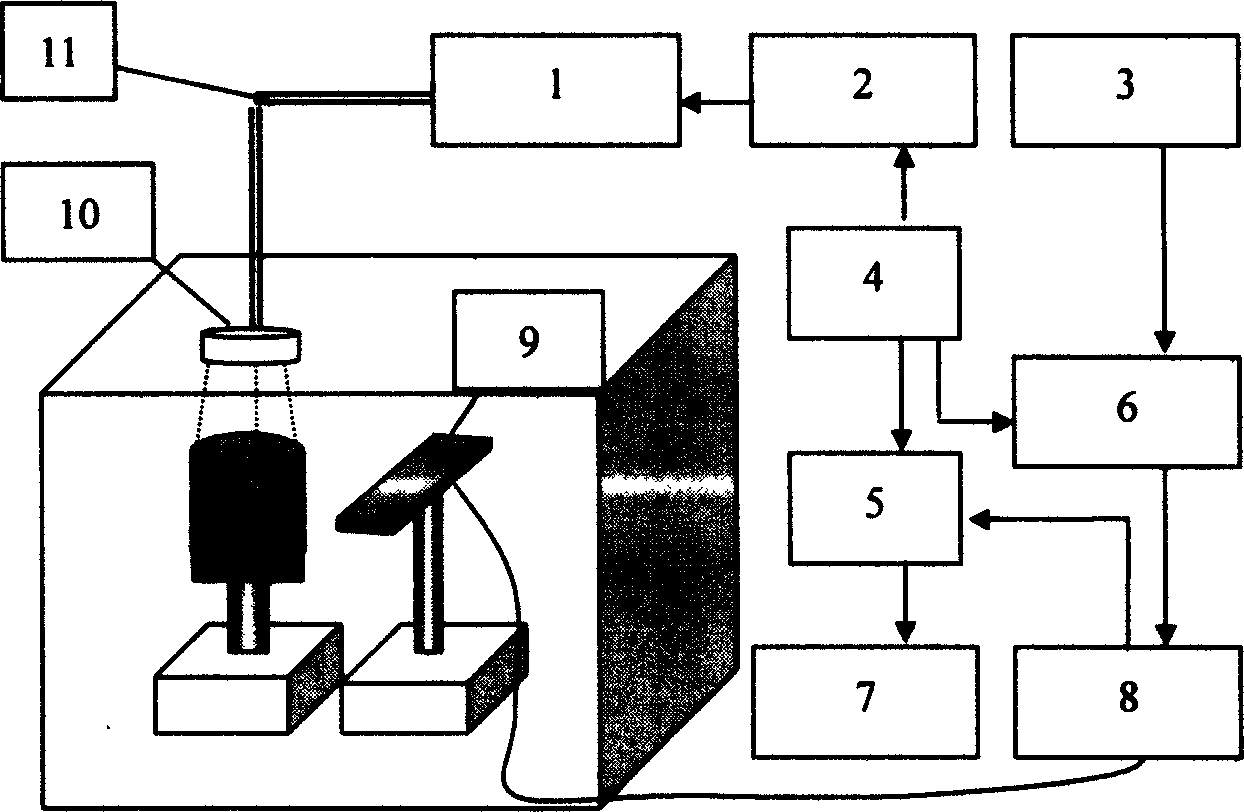

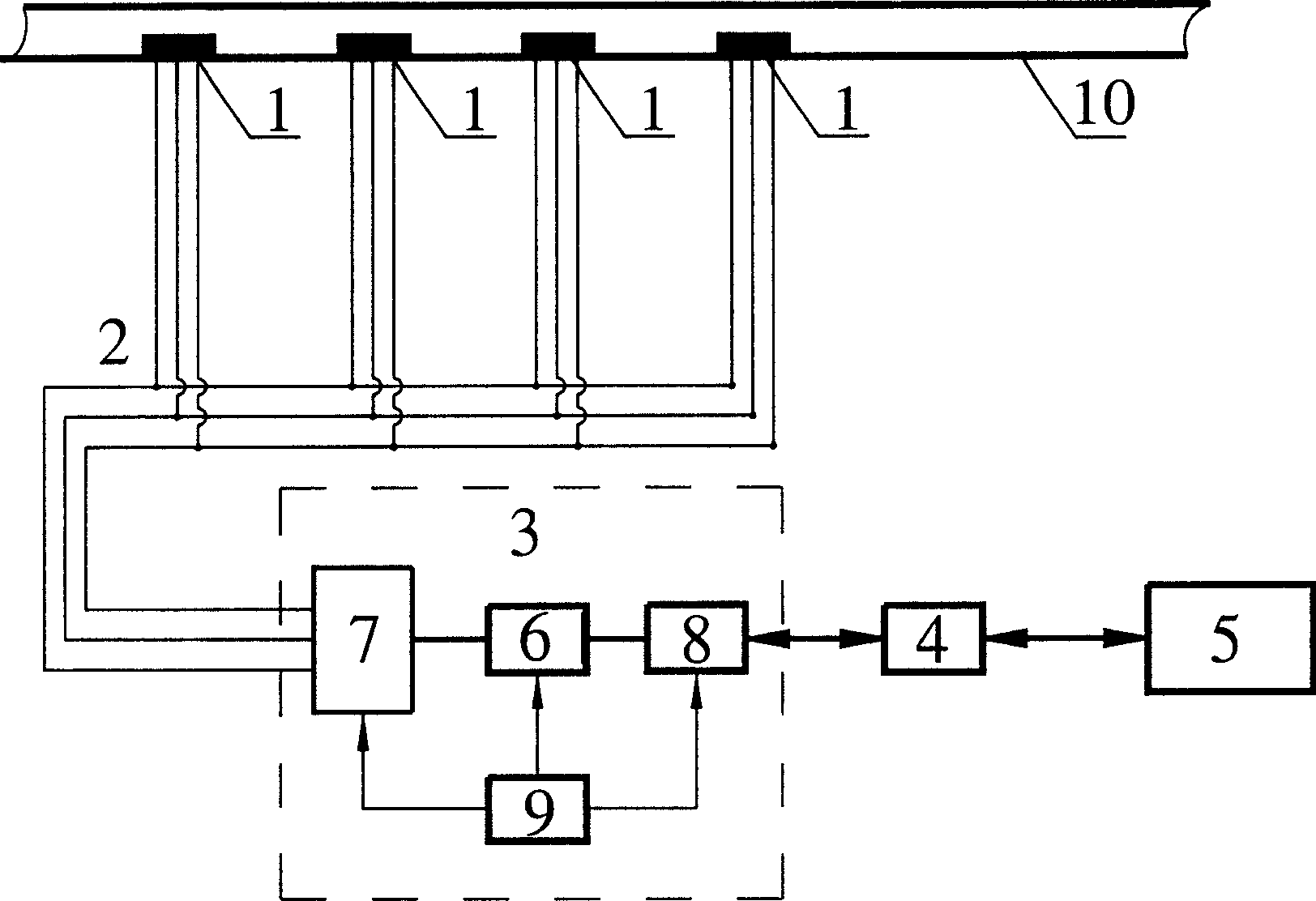

Method of biological tissue optical and ultrasonic collection and tomographic imaging and its device

InactiveCN1555764AImproving Imaging EfficiencySimple structureUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSonificationIt equipment

A method for optically and ultrasonically acquiring the information about biological tissue and chromatographic imaging includes ultrasonically scanning the biologic tissue to find out possible lesion position, emitting the laser pulses and ultasonic waves to the tissue at lesion position to obtain photoultrasonic and reflected ultrasonic signals, receiving the ultrasonic echo and photo-acoustical signals, data processing by computer, and straight projection for chromatographic imaging. Its equipment is composed of laser, multi-element ultrasonic array, externally triggered signal source, data acquisition card, delay circuit, and computer.

Owner:SOUTH CHINA NORMAL UNIVERSITY

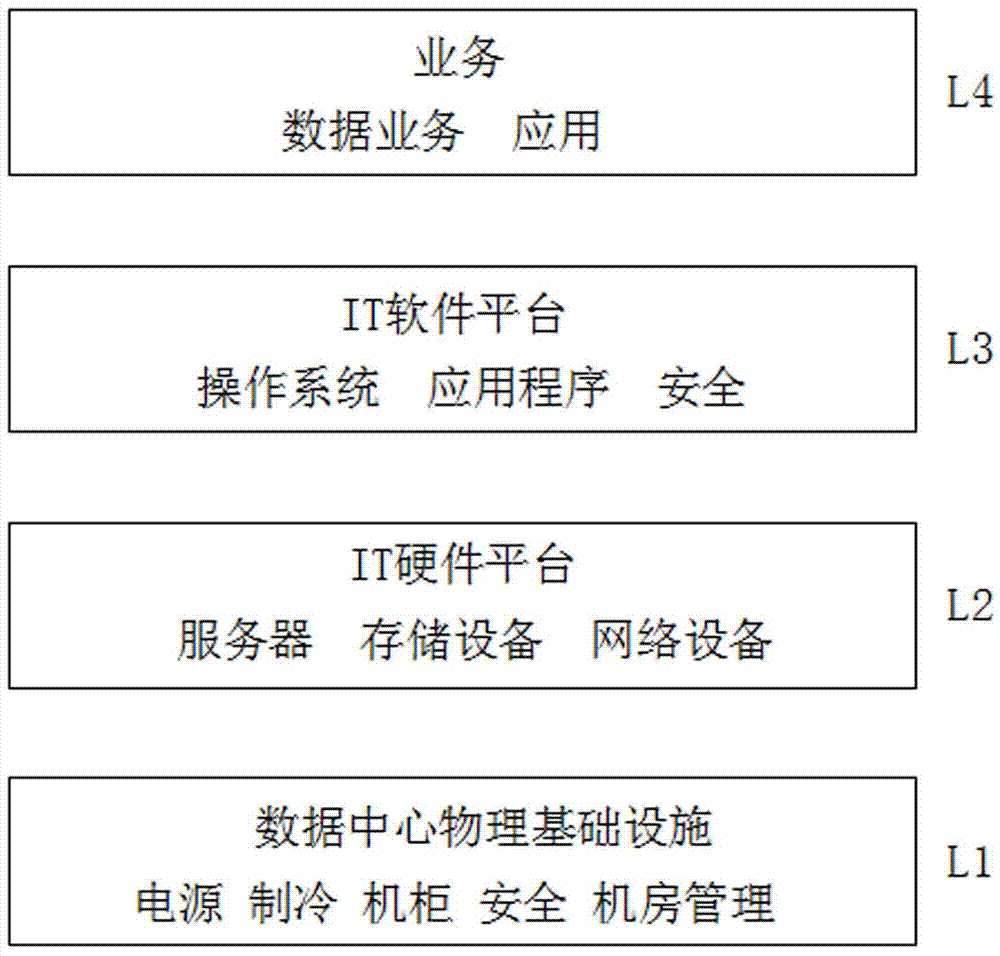

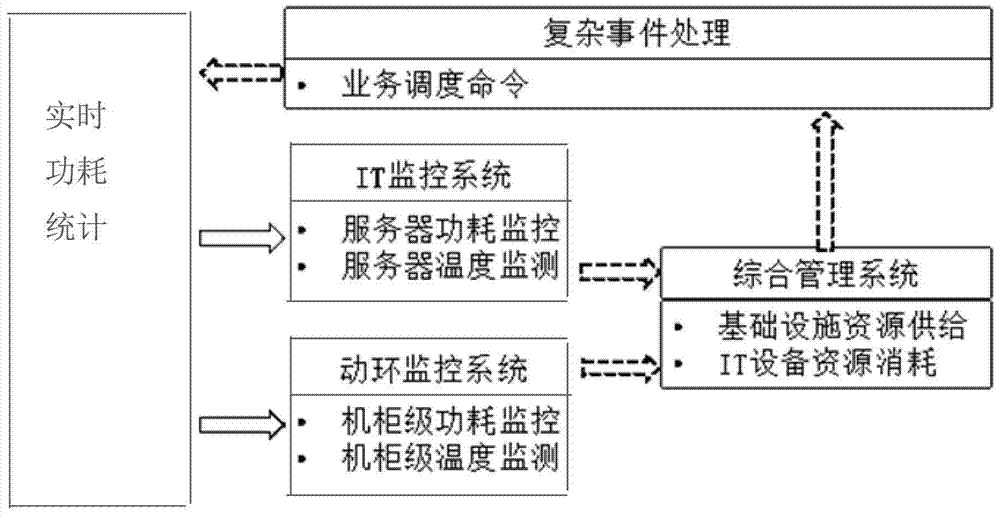

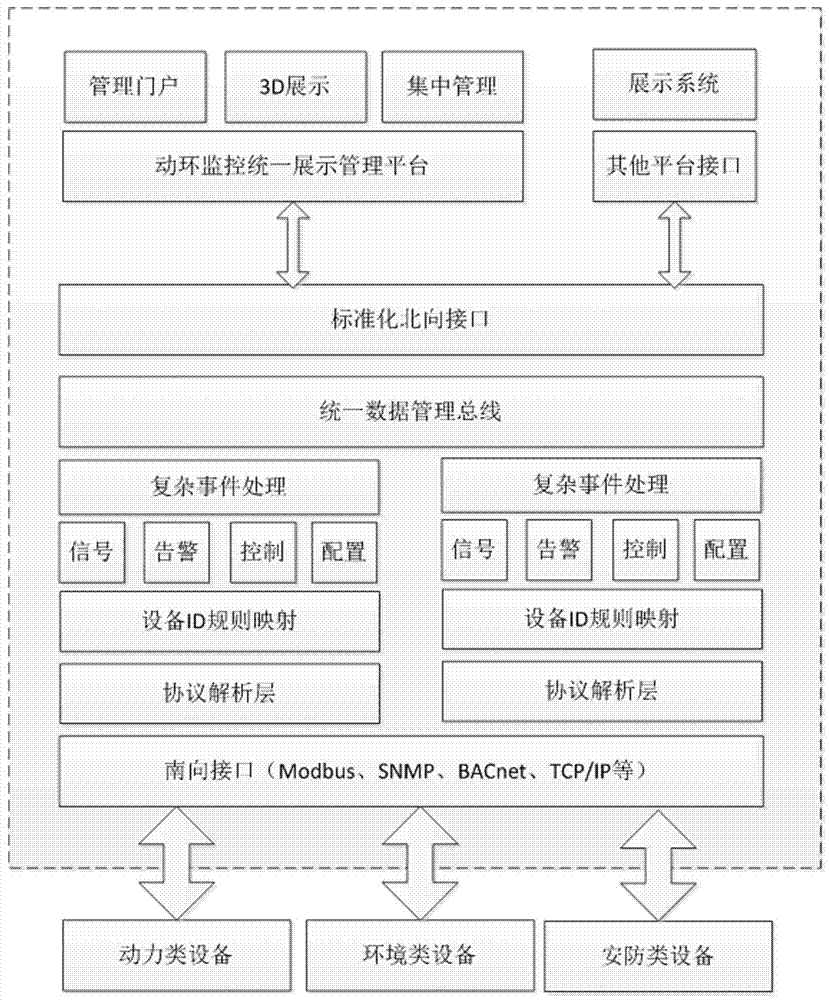

Integrated management method based on MDC

InactiveCN107070726AGuaranteed uptimeEasy to understandData switching networksInformation processingIntegrated monitoring

The invention discloses an integrated management method based on a MDC. Both hardware equipment and IT equipment are monitored at first; then, monitoring data is transmitted to an information processing module through a southbound interface; after encapsulating the monitoring data through a protocol, the information processing module sends the monitoring data to a MDC management platform through a northbound interface; and the information processing module is configured with a protocol analysis layer, an equipment ID rule and a complex event processing module. Compared with the prior art, the integrated management method based on the MDC disclosed by the invention can flexibly define the state of a business service index; therefore, users can observe the state of the index in real time, monitor the state of the index in time, and know the state of the business service index; the first-hand data of the business sate is obtained; and thus, normal operation of a business can be ensured.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

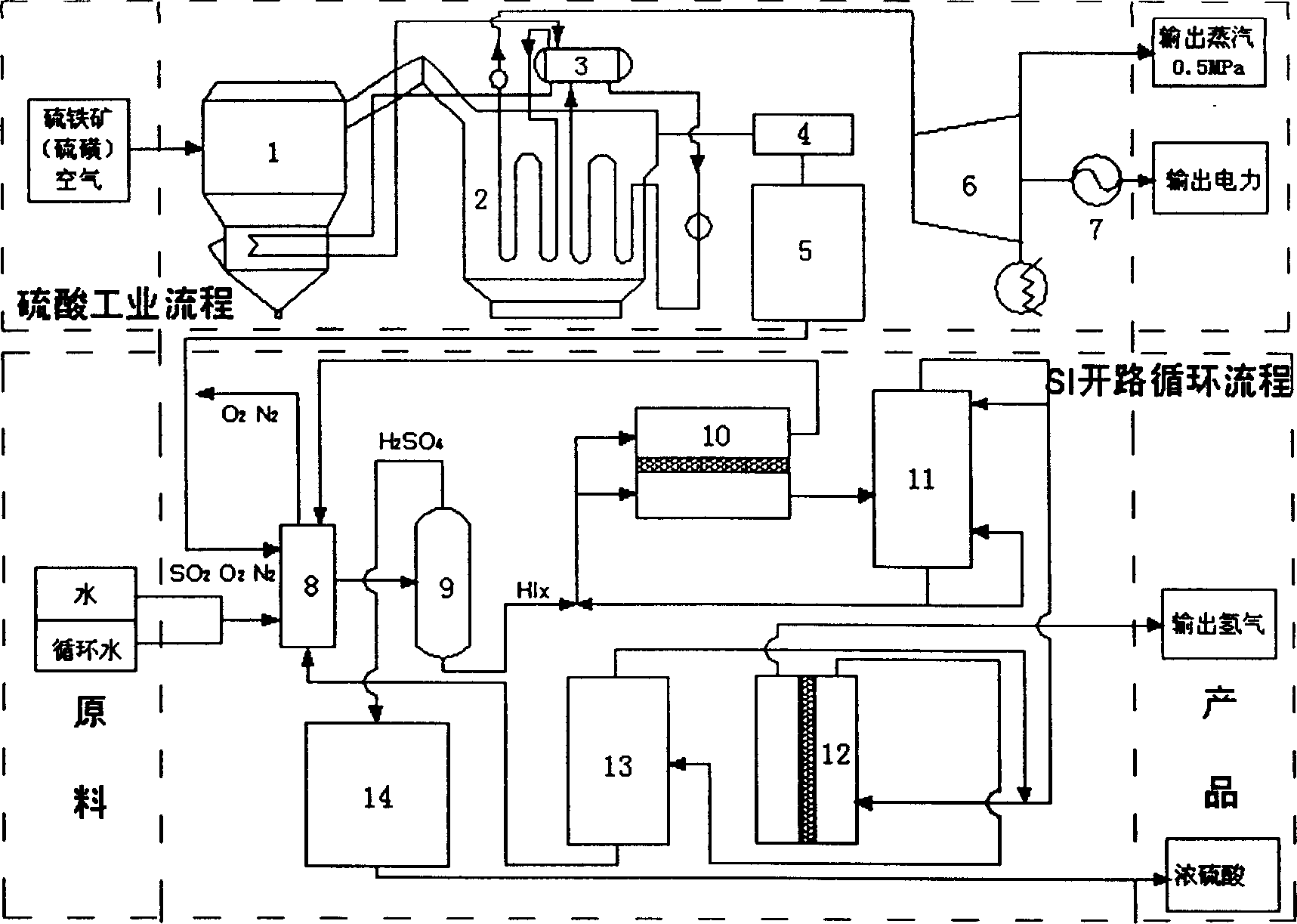

Technical method of sulfur iodine open circuit circulation hydrogen manufacture and its equipment

ActiveCN1785796AReduce the temperatureReduce energy consumptionIodine/hydrogen-iodideSulfur-trioxide/sulfuric-acidIt equipmentHydrogen

The present invention relates to a process for preparing hydrogen gas, and is aimed at providing a technological process capable of combining sulfur-iodine open-circuit circulation and sulfuric aid industry to simultaneously produce hydrogen gas and sulfuric acid and provide electric power and its equipment. Said method includes the following steps: roasting sulfur-bearing mineral, Bunsen reaction, separating HIx phase and H2SO4 phase solution, using electroosmose process to concentrate and purify HIx phase and utilizing HI membrane catalytic decomposition reactor to make decomposition to obtain I2 and find product H2.

Owner:ZHEJIANG UNIV

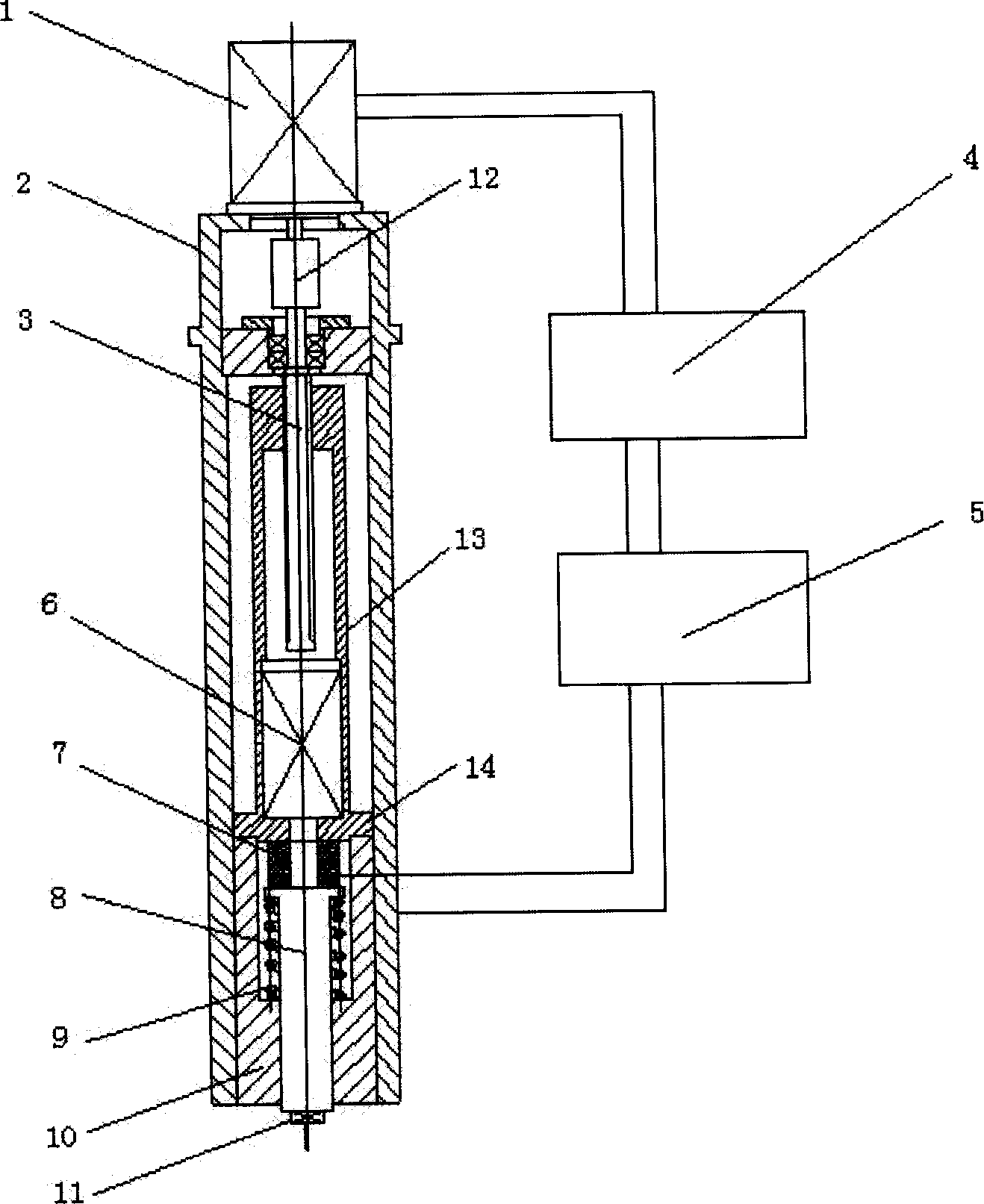

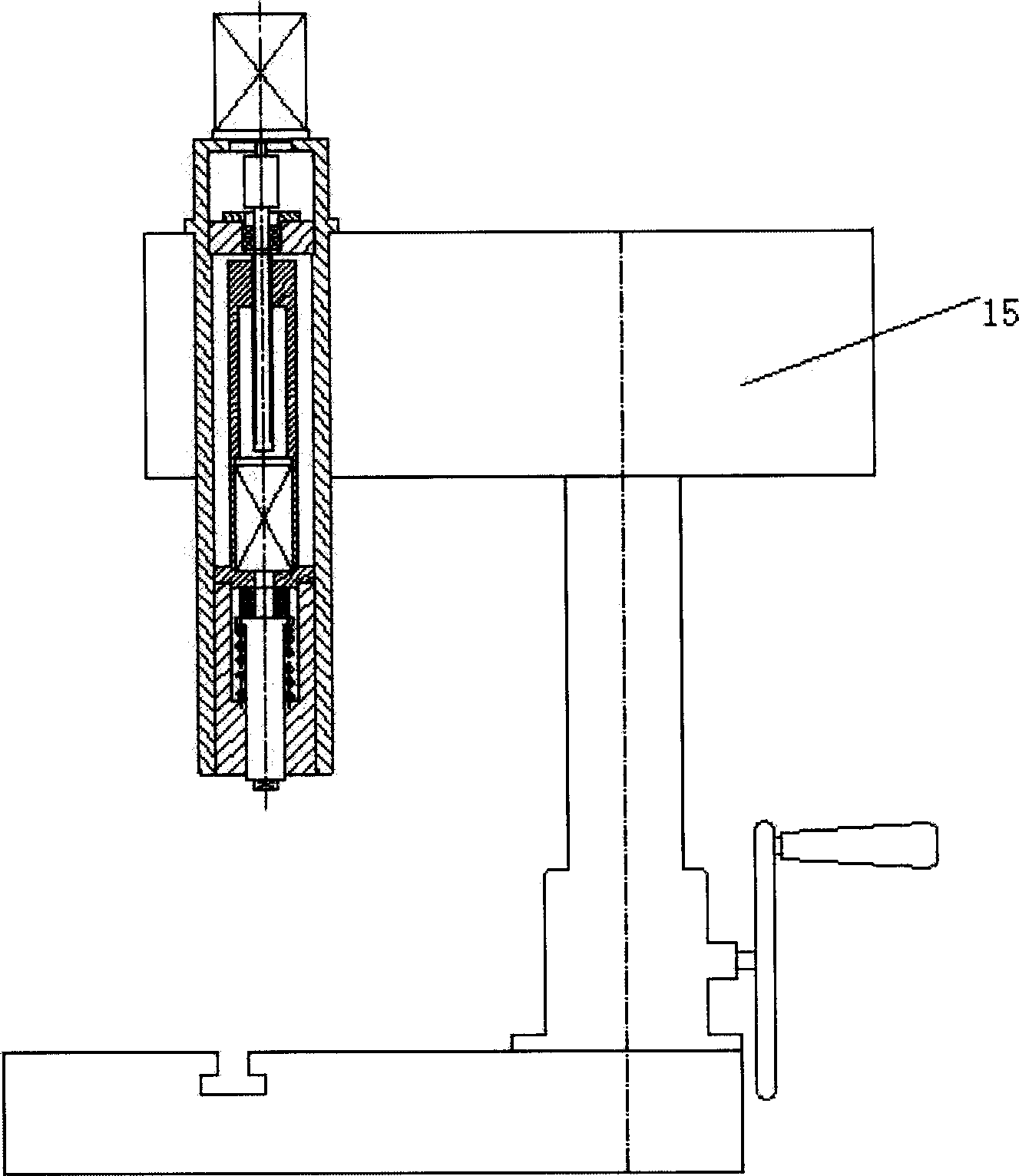

Method and equipment for drilling micro-holes with variable parameter vibration drill

InactiveCN1418747AReduce volumeCompact structureAutomatic control devicesFeeding apparatusIt equipmentCoupling

The present invention discloses a method for variable parameter vibration drilling microbore and its equipment. Said equipment consists of controller, power supply, stepper motor, precision spring holder and external sleeve, the interior of external sleeve is equipped with connecting coupler and lead-screw support of ballscrew, the output shaft of the motor is connected with coupler, another end of the coupler is connected with ballscrew, the ballscrew and D.C high-speed motor are cover-mounted in the main shaft motor support, and said main shaft motor support is integral connected with copper sleeve by pressure plate, the motor is fixed ont he pressure plate and connected with power supply, in the copper sleeve of lower end of the motor is connected with main shaft.

Owner:BEIHANG UNIV

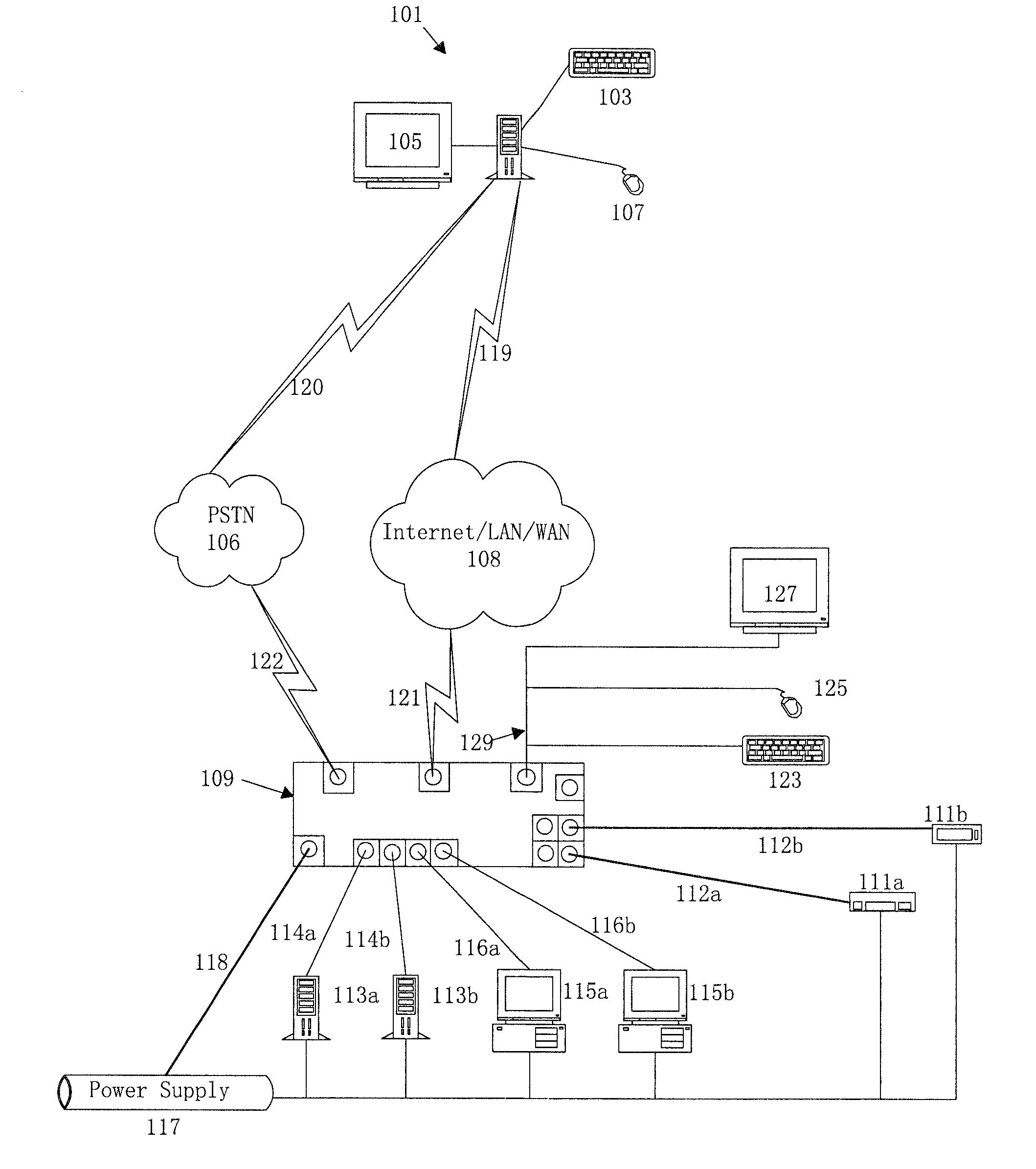

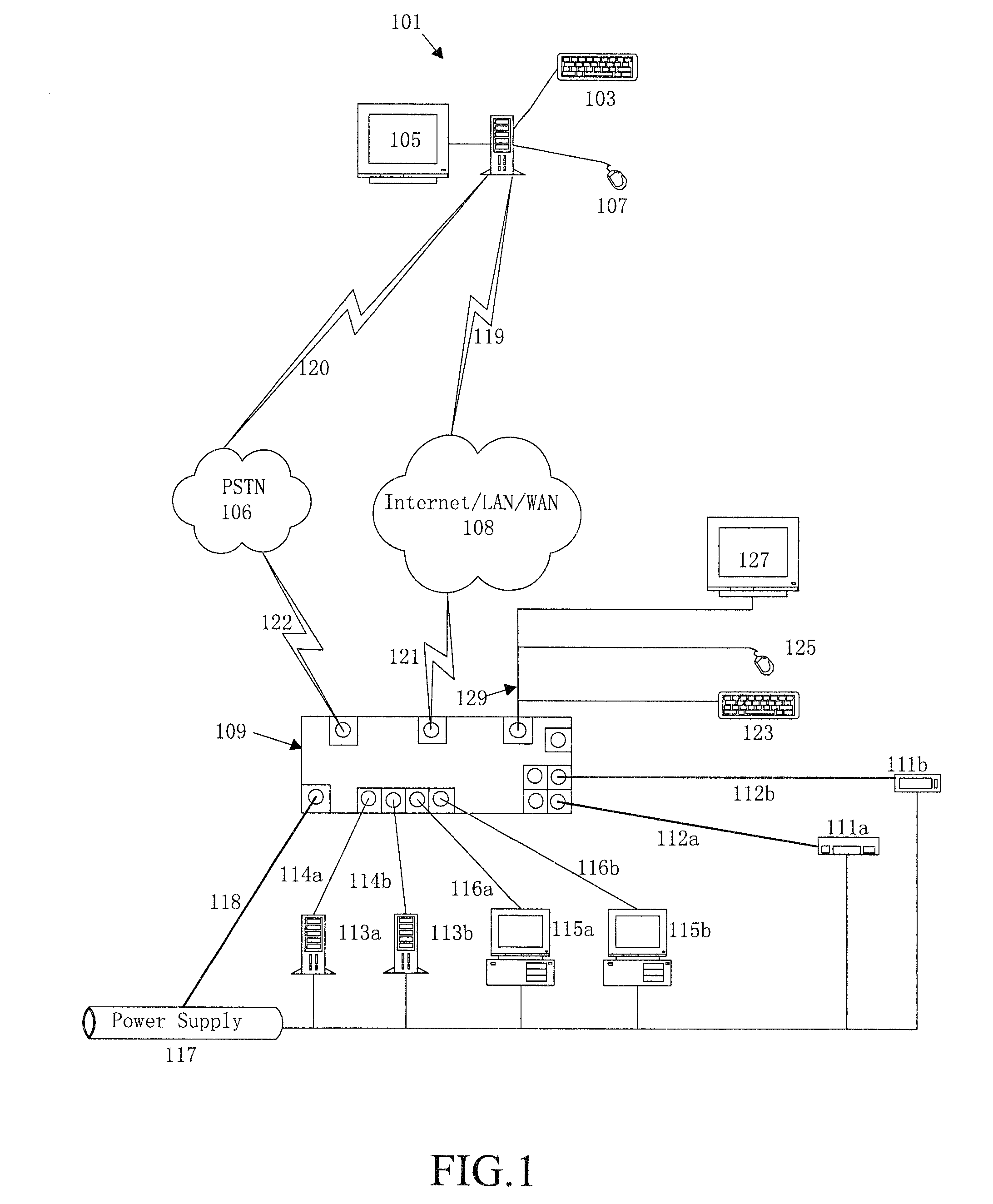

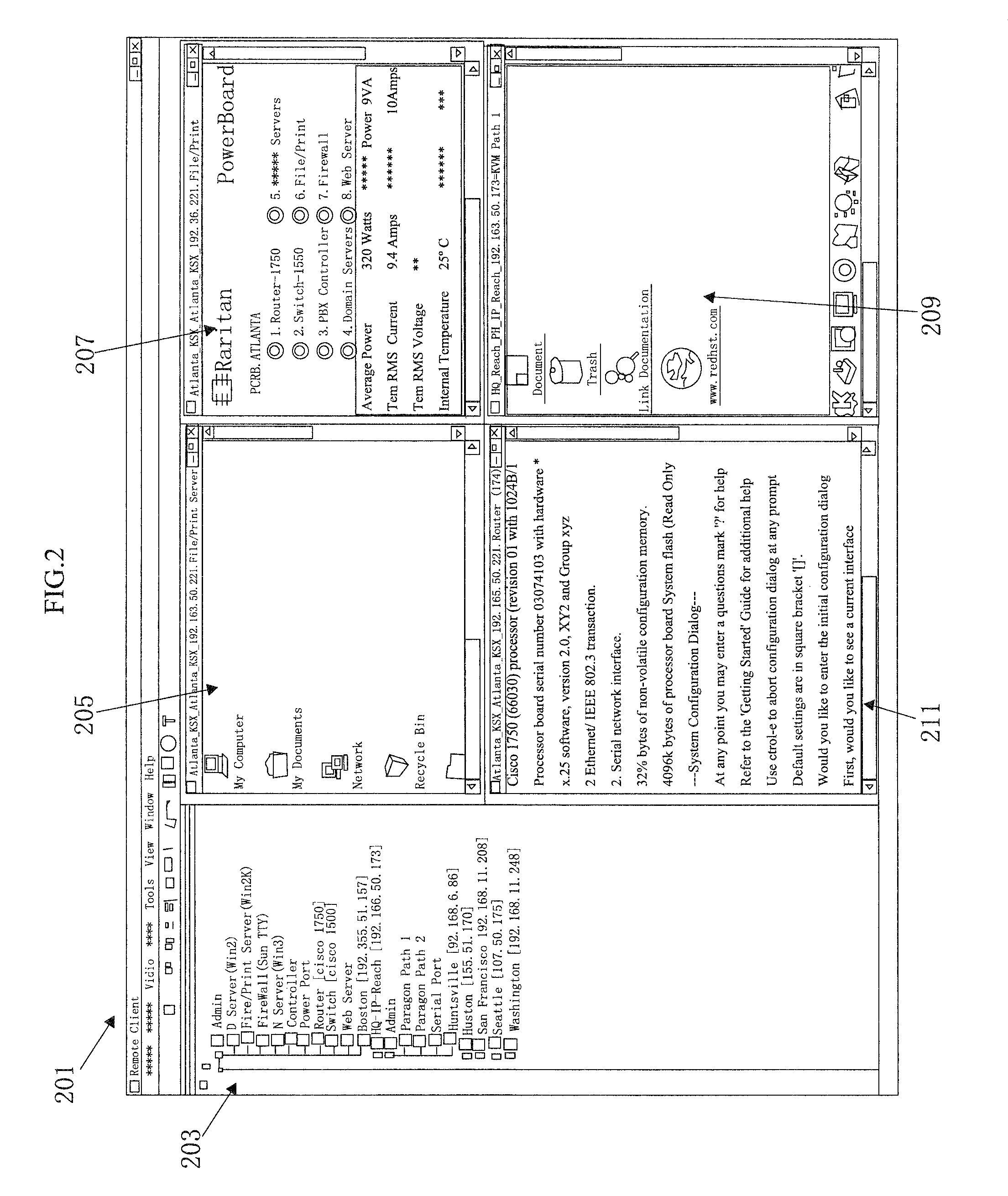

Remote network management system

ActiveUS8176155B2Easily transmittedReduce cable costsStatic indicating devicesPicture reproducers using cathode ray tubesApplication serverIt equipment

Disclosed is a remote network management system for coupling a series of remote domain servers, file / print servers, headless servers, network appliances, serial IT equipment, switches, routers, firewalls, security interfaces, application servers, load balancers, and environmental controls to one or more user workstations allowing for selective access of the remote devices. The remote devices are all connected to a remote management unit which interfaces each user workstation to the remote devices. The power supply of each remote device is similarly connected to the remote management unit through a controllable power supply. An option menu containing a list of all of the remote devices allows a user to select and operate any of the remote devices from the workstation. The option menu is also utilized to selectively control the power to the remote devices, servers, and computers.

Owner:RIIP

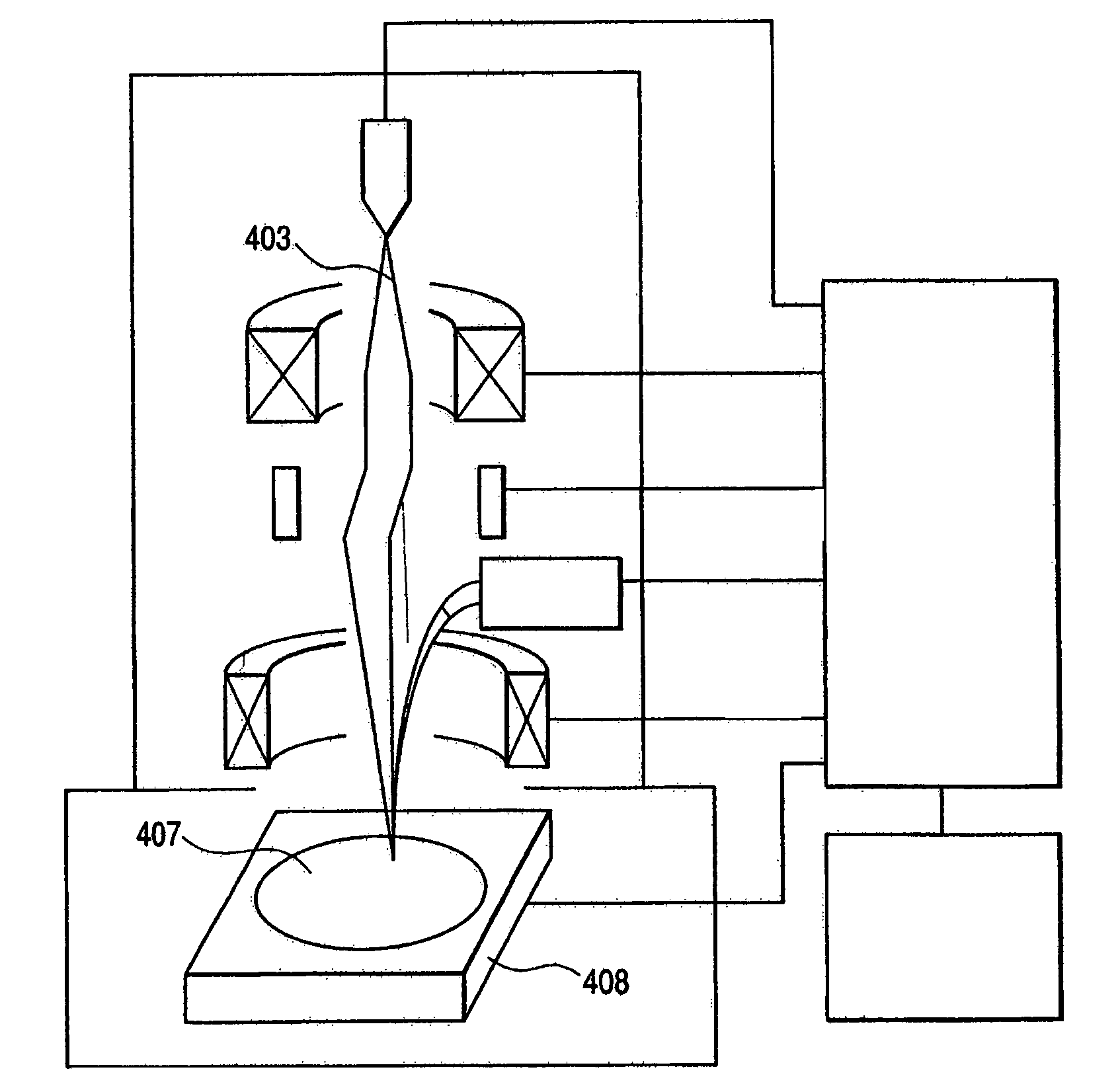

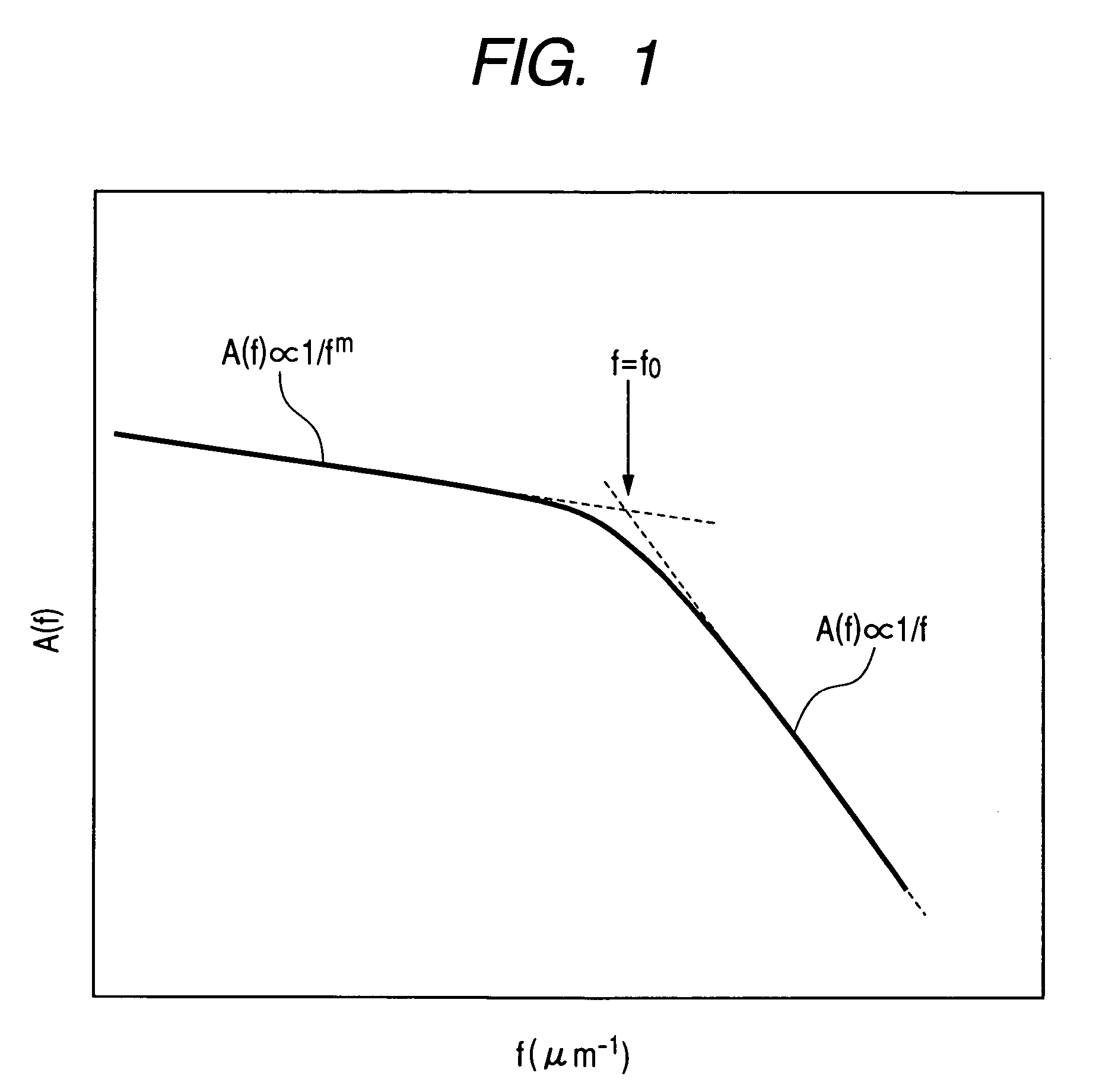

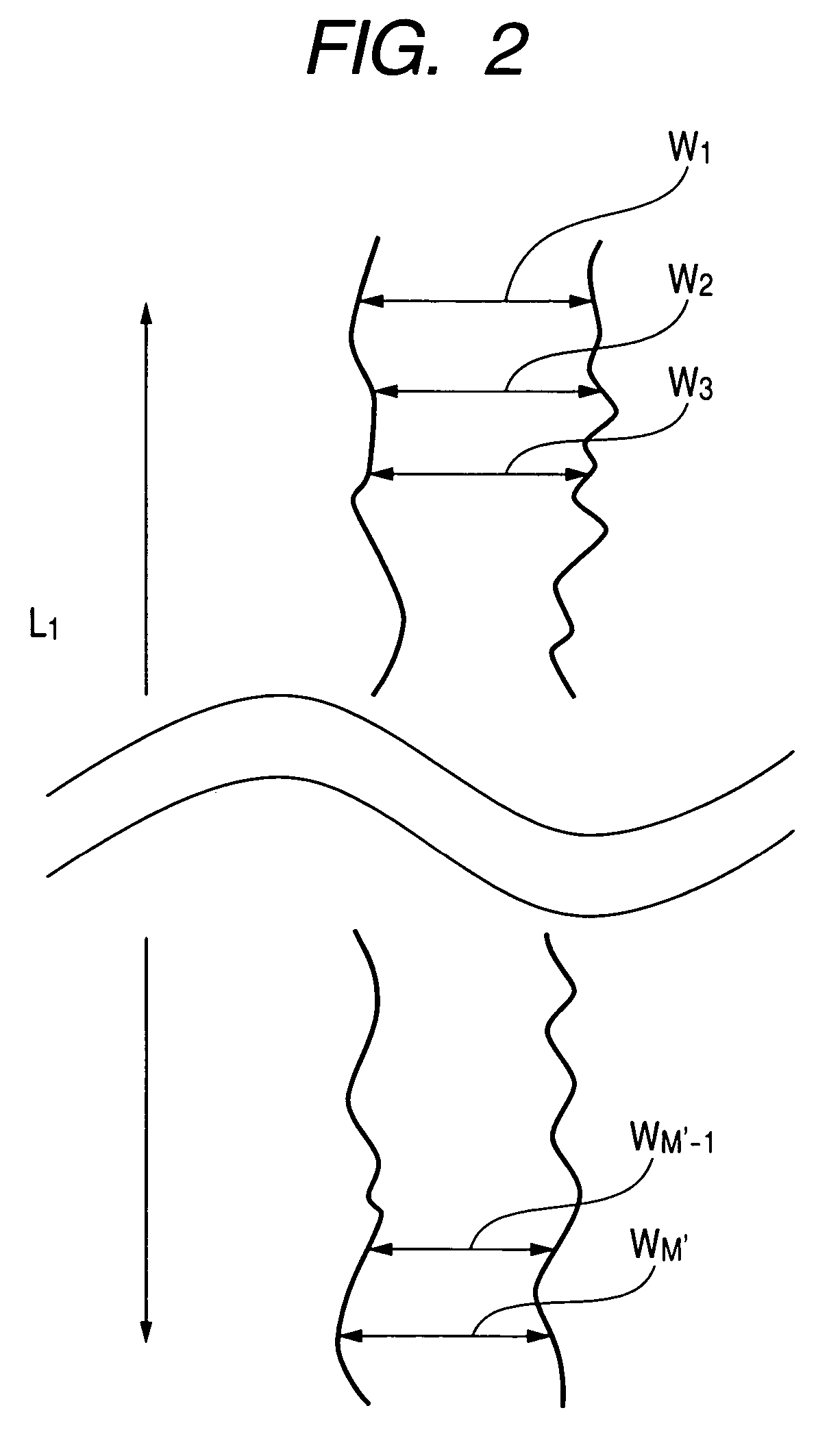

Evaluation method of fine pattern feature, its equipment, and method of semiconductor device fabrication

ActiveUS7366620B2Easy accessEasy to set upSpectral/fourier analysisSemiconductor/solid-state device testing/measurementFine lineIt equipment

Equipment extracts components of spatial frequency that need to be evaluated in manufacturing a device or in analyzing a material or process out of edge roughness on fine line patterns and displays them as indexes. The equipment acquires data of edge roughness over a sufficiently long area, integrates a components corresponding to a spatial frequency region being set on a power spectrum by the operator, and displays them on a length measuring SEM. Alternatively, the equipment divides the edge roughness data of the sufficiently long area, computes long-period roughness and short-period roughness that correspond to an arbitrary inspection area by performing statistical processing and fitting based on theoretical calculation, and displays them on the length measuring SEM.

Owner:HITACHI HIGH-TECH CORP

Large-sized digital machine room routing inspection method based on QR code and mobile technologies

InactiveCN106600741AImprove asset operation and maintenance management efficiencySave manual recordsChecking time patrolsCo-operative working arrangementsIt equipmentMaintenance management

The invention discloses a large-sized digital machine room routing inspection method based on QR code and mobile technologies. The QR code technology is adopted to generate unique identification codes which are associated with machine room equipment, and one-to-one mapping between the identification codes and ID information of the equipment is realized; changes of equipment information cannot actually affect the associativity except for the ID information of the equipment; and an inspector scans associated QR code labels on the machine room equipment with mobile equipment accessed into a local area network in a machine room to acquire the equipment information, fills fault conditions with App on a mobile terminal, and submits the fault conditions to a server, thus completing the fault declaration work for the machine room equipment. The large-sized digital machine room routing inspection method has the beneficial effects that operation and maintenance staff can hold an intelligent terminal in a hand to scan a QR code label on IT equipment and then submit defects and faults of the IT equipment, so that the processes of manual recording and filling with a PC terminal of the operation and maintenance staff are omitted. By the application of the QR code and mobile technologies, the operation and maintenance work can be carried out on the intelligent terminal, so that the operation and maintenance management modes and measures are enriched, and the operation and maintenance management efficiency of assets of the IT equipment is effectively improved.

Owner:云南电网有限责任公司信息中心

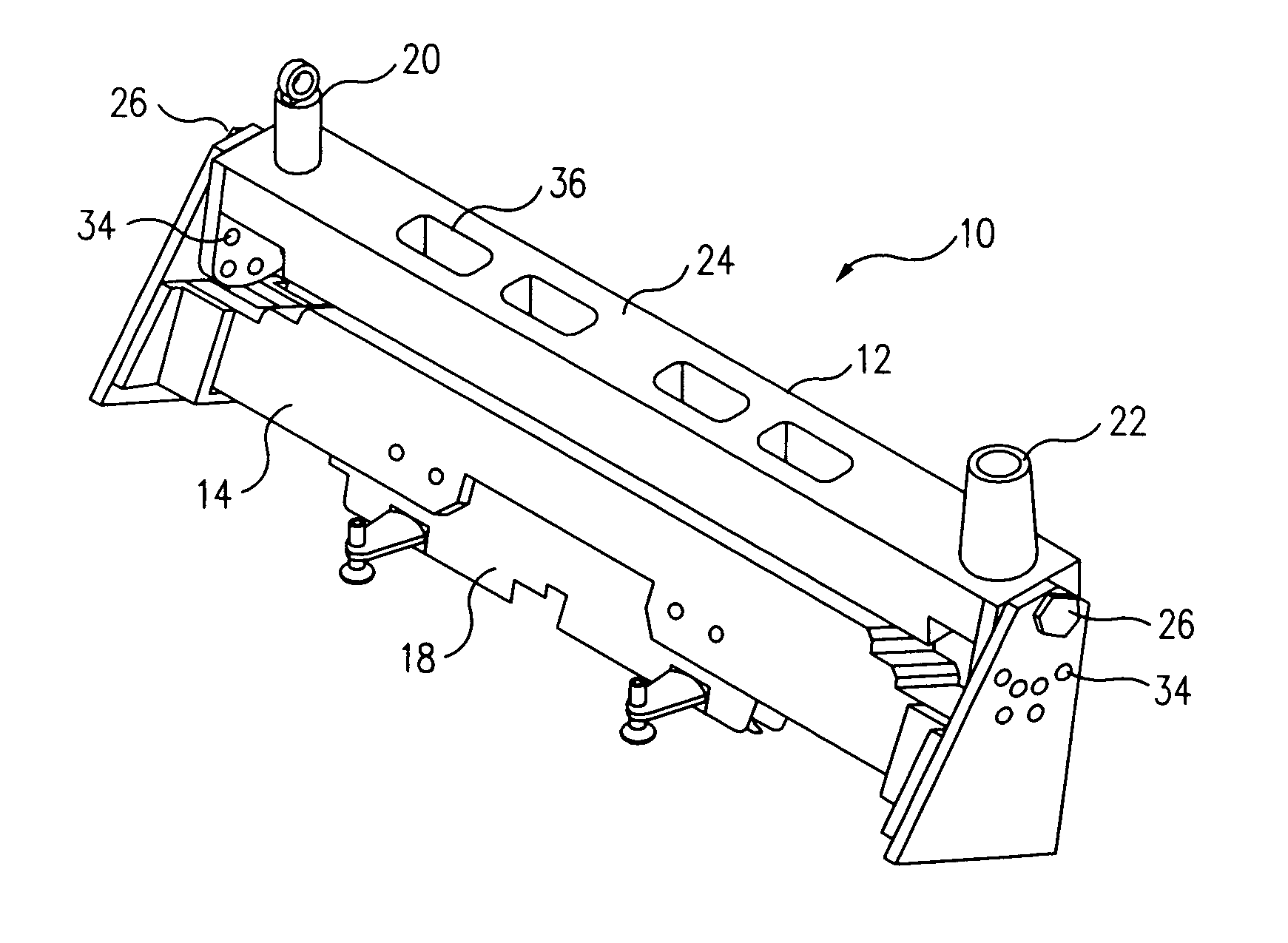

Pivotable pylon for external carriage of aircraft stores

ActiveUS7156347B2Limit its parasitic dragNecessary clearanceFreight handlingFuselagesIt equipmentLocking mechanism

A pivotable pylon for carrying stores, such as ordinance, sensors and pods external to an aircraft includes an elongated strongback coupled against an external surface of the aircraft and generally parallel to the longitudinal axis thereof. An elongated pivoting structure is pivotally coupled to the strongback for parallel pivotal movement relative thereto. A locking mechanism locks the pivoting structure in a selected one of a plurality of angular positions relative to the strongback. At least one stores rack is coupled to the pivoting structure for receiving and coupling at least one stores item to the pivoting structure. An aerodynamic fairing may be disposed on the pylon to decrease drag. The pylon can be mounted on either side of the aircraft and in any one of a plurality of longitudinal stations, and enables the aircraft to carry stores that are too large for its equipment bays, and to carry an optimal load of stores.

Owner:THE BOEING CO

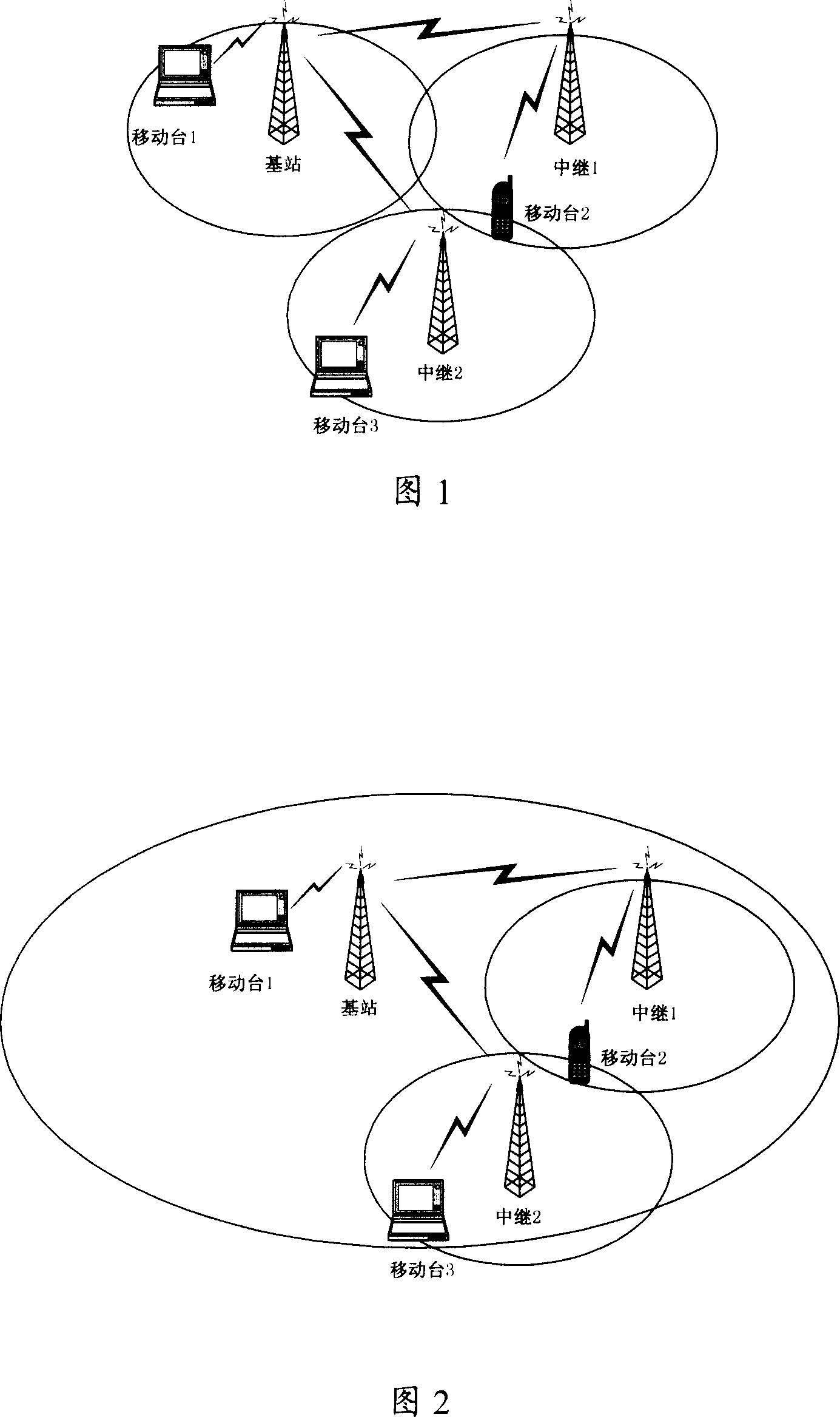

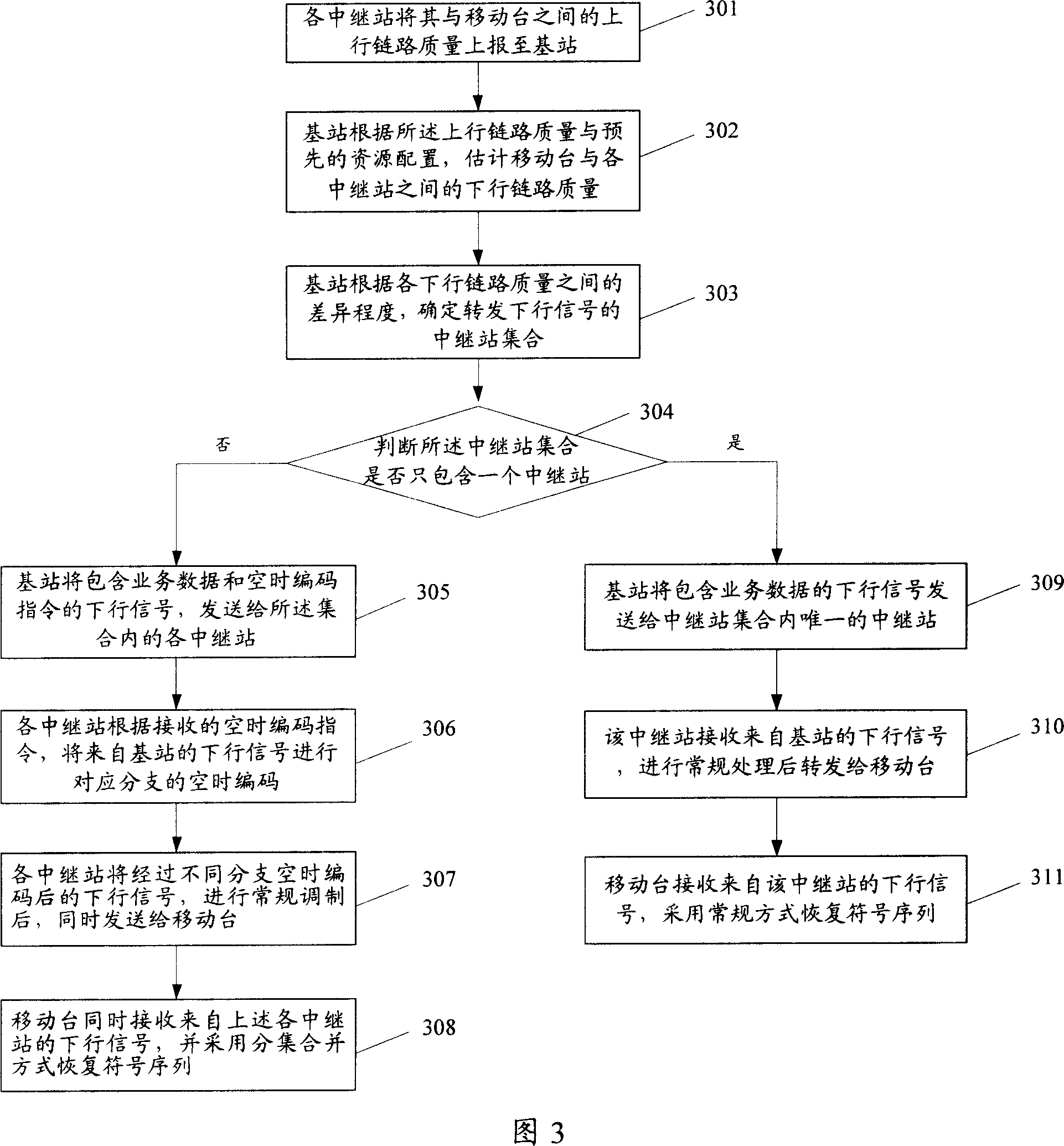

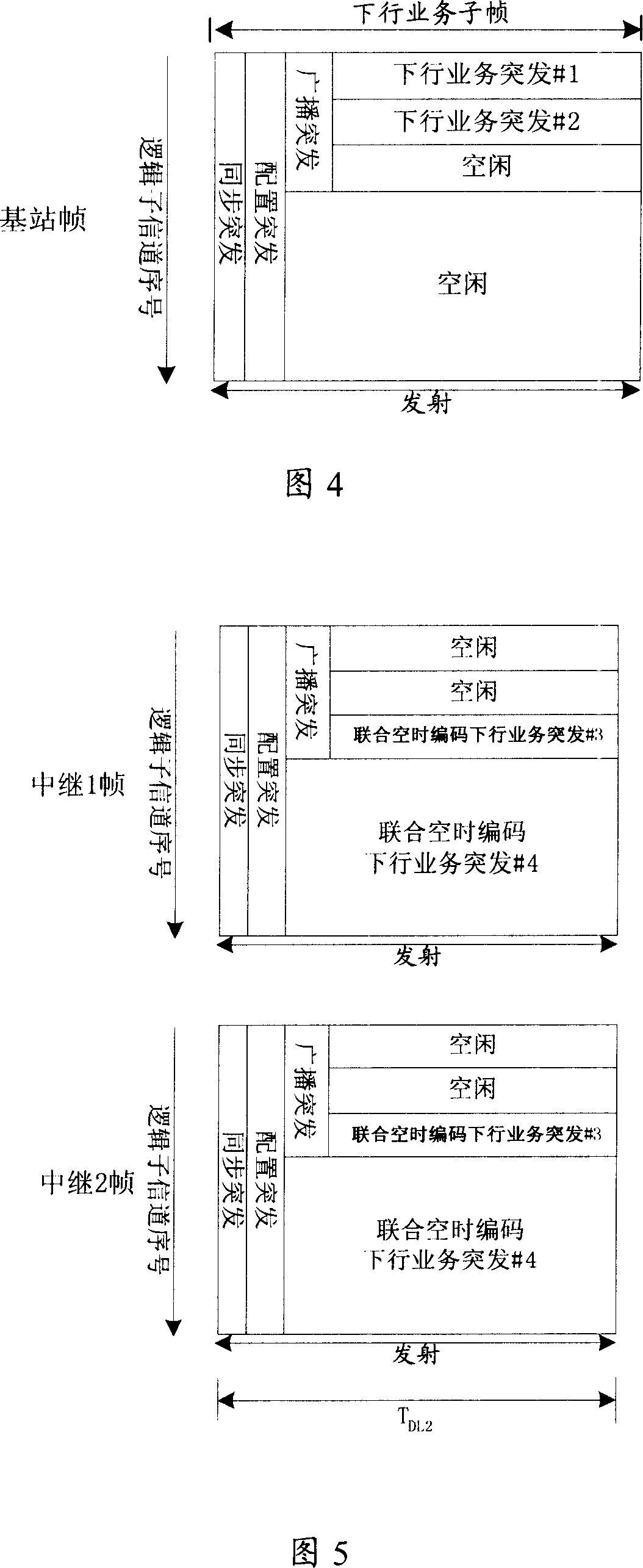

Method for converting downlink signal from repeater and its equipment

InactiveCN101001098AMeet service quality requirementsSatisfy the requirements of diversity mergeDiversity/multi-antenna systemsRadio/inductive link selection arrangementsIt equipmentMobile station

This invention discloses a method for transferring downlink signal by relay stations, which gets the down link quality between the mobile station and the relay stations to determine the relay set for transferring down signals based on the difference of the qualities, when the set includes multiple relay stations, it carries out empty time coding to the down signals by the relay stations in the set to be transferred to the mobile station. This invention also discloses a method for transferring down signal by relay stations including setting multiple relay stations for transferring down signals, getting the down link qualities between the mobile station and relay stations, determining relay station sets for transferring down signals according to the qualities of the relay stations and number of the relay stations, carrying out empty time coding by the stations in the set and transferring it to the mobile station.

Owner:HUAWEI TECH CO LTD

Explosive welding process for super-long and super-wide composite boards

InactiveCN102240845AImprove corrosion resistanceAchieve perfect unityWelding/soldering/cutting articlesNon-electric welding apparatusIt equipmentEngineering

The invention relates to an explosive welding process for super-long and super-wide composite boards, and provides a method which is convenient, economical and piratical, wherein an explosive is distributed in a three-section different-explosion-velocity manner and compacted at periphery; therefore, the explosive welding of super-long and super-wide TA2 / Q345R is realized, the problems that the side of the composite board is not composited or the bond strength of part of the composite board is too low in the explosive welding process of the super-long and super-wide TA2 / Q345R composite board are solved, and the requirement of our equipment manufacture industry on the super-long and super-wide TA2 / Q345R composite board is satisfied.

Owner:舞钢神州重工金属复合材料有限公司

Method for monitoring and evaluating safe operation of cable and device thereof

InactiveCN1687724AGuaranteed safe operationHigh sensitivityThermometer detailsElectric signal transmission systemsIt equipmentData acquisition

The invention is the monitoring and judging method of safe running of the cable and its equipment. The characteristics are: the said monitoring method through the pre-set fixing threshold and trend threshold sends the alarming information of the overheating situation of the cable core in time; the said judging method is according to the cable surface temperature, the ring temperature and the current value automatically stored to establish the cable surface temperature regression model and forecast the operation trend of the cable surface temperature and promote the judgment through the mathematical analysis of the difference between the forecasting value and the tested value. The invention also provides the device composed of the corresponding thermometric component, the data transmitting wires, the data collecting circuit assembly, the data converting circuit and the computer. The invention has fast storing performance, timely monitoring and stable judging.

Owner:TSINGHUA UNIV

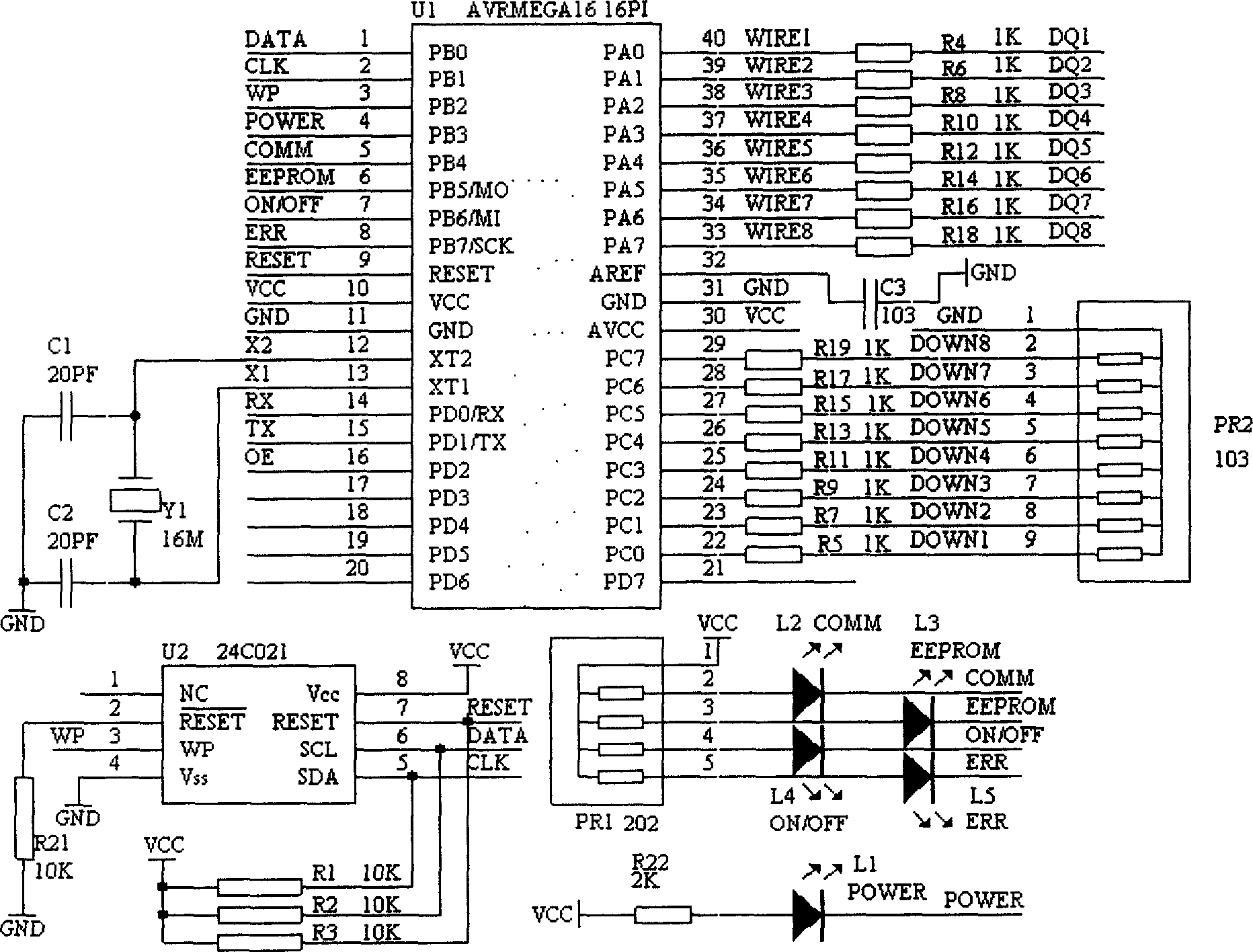

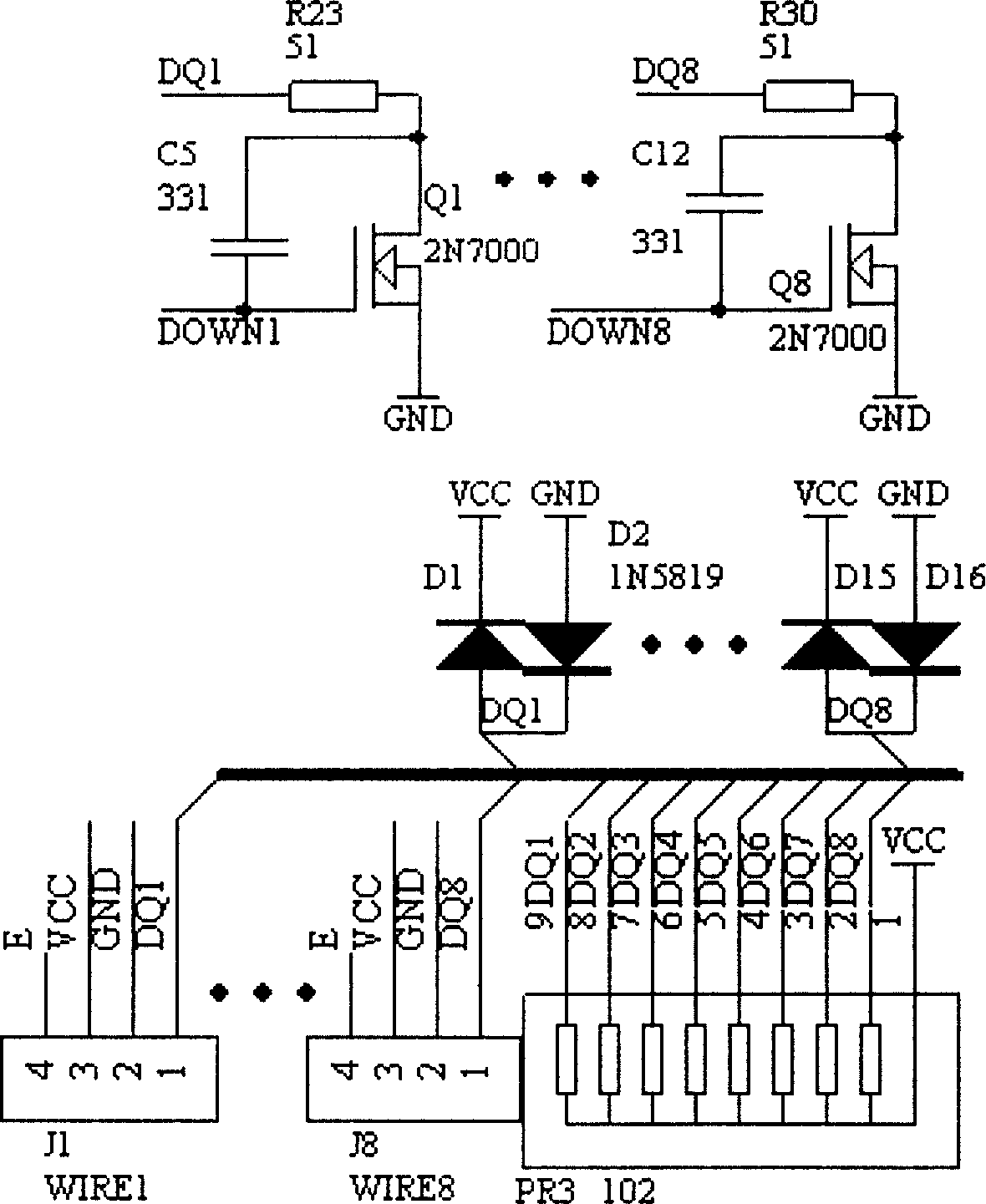

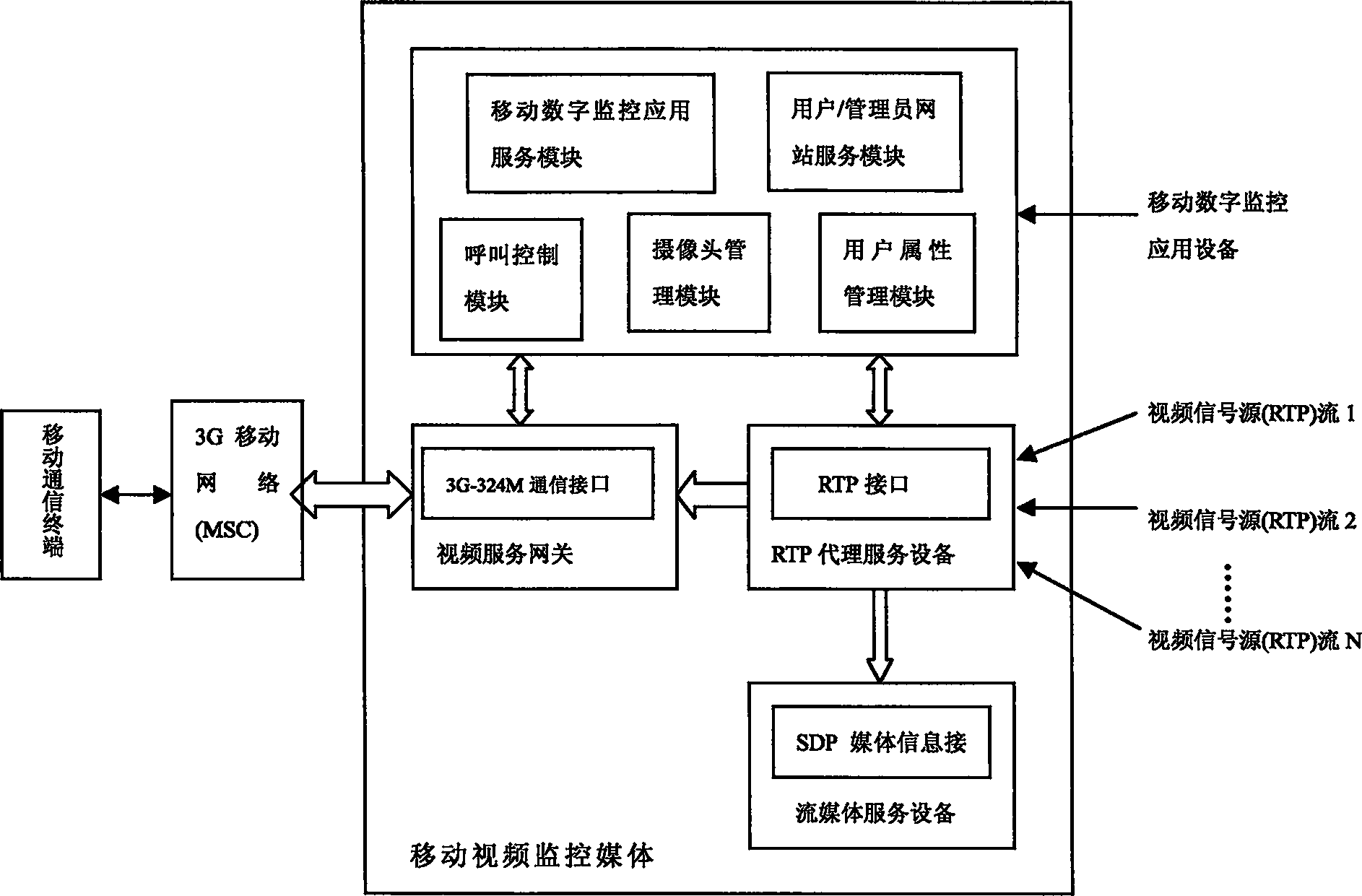

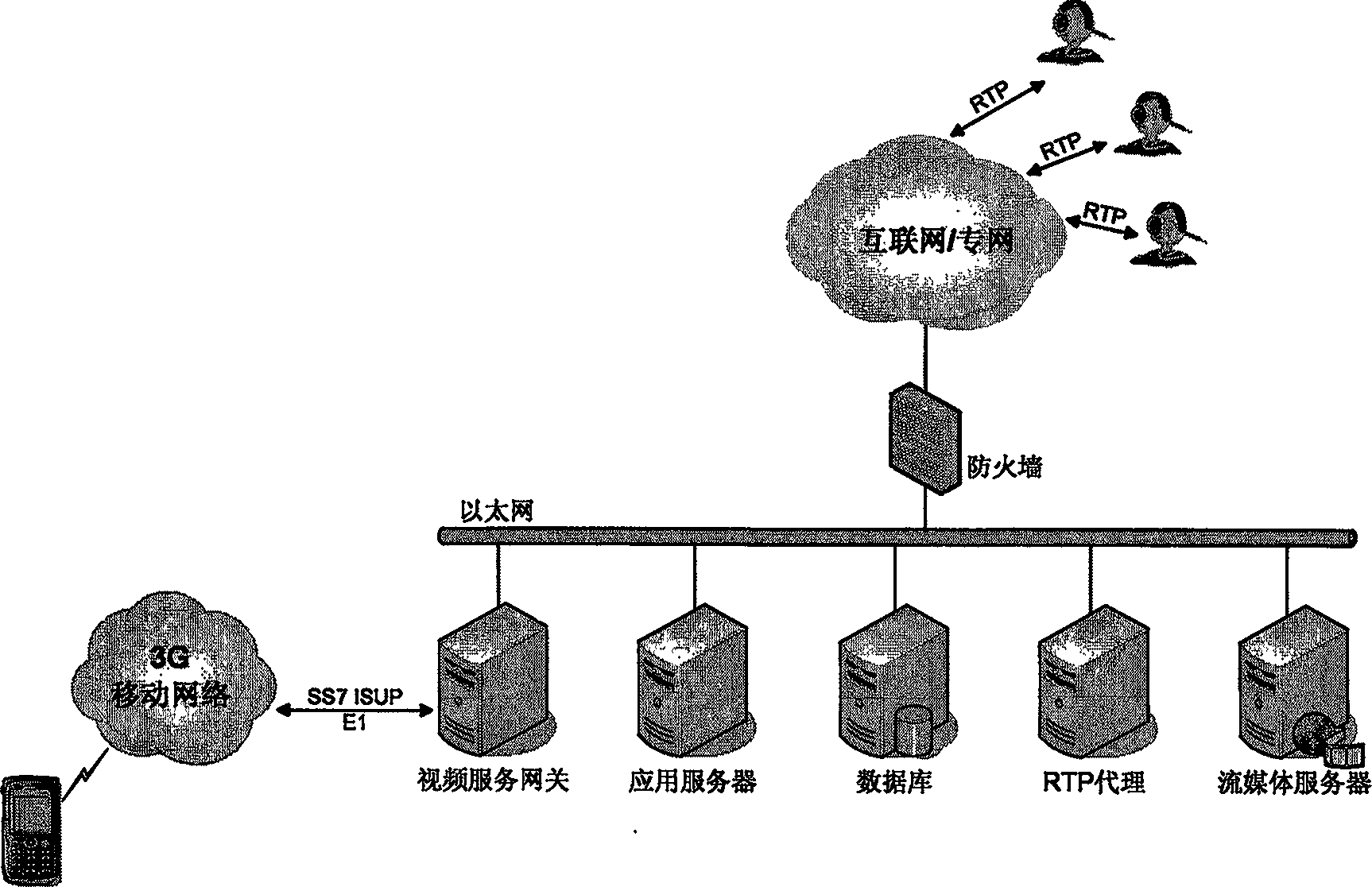

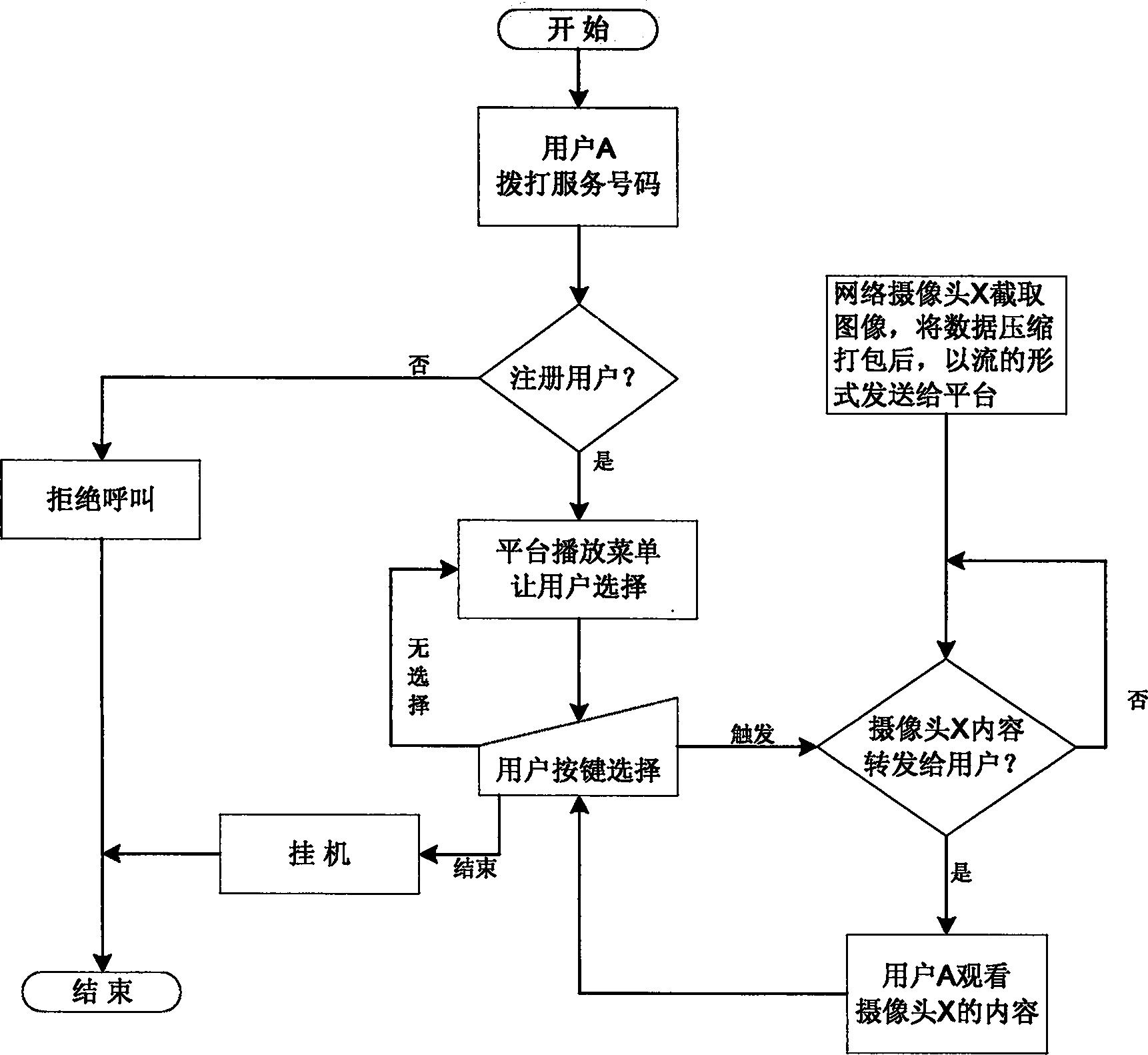

Video digital monitor and control system and method in use for 3G mobile communication

InactiveCN1874501AReduce difficultySave wireless resourcesClosed circuit television systemsDigital videoVideo monitoring

The invention comprises the following steps: connecting a 3G video call to a mobile video media monitoring platform; transmitting the 3G video call to an IP address and port appointed by the platform through RTP protocol and its equipment; when user makes a 3G video call, the system will display the sources of the video signal on an optional menu in term of the authority of the user in order to provide a selection for user; after user selects a source of video signals, the relevant video signals will can be played.

Owner:YIYUJINGCAI TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com