Patents

Literature

1722results about "Safety devices for heat exchange apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

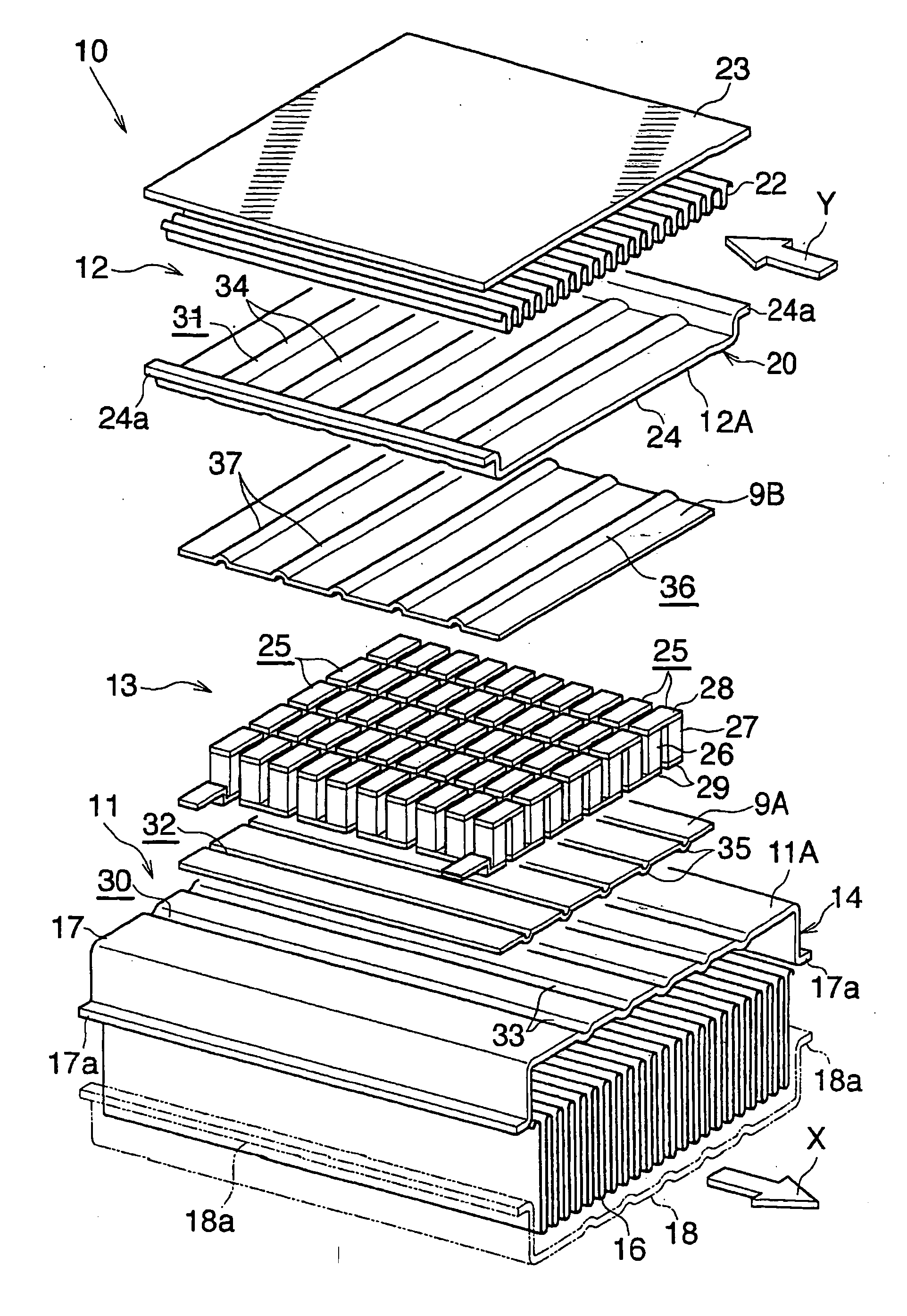

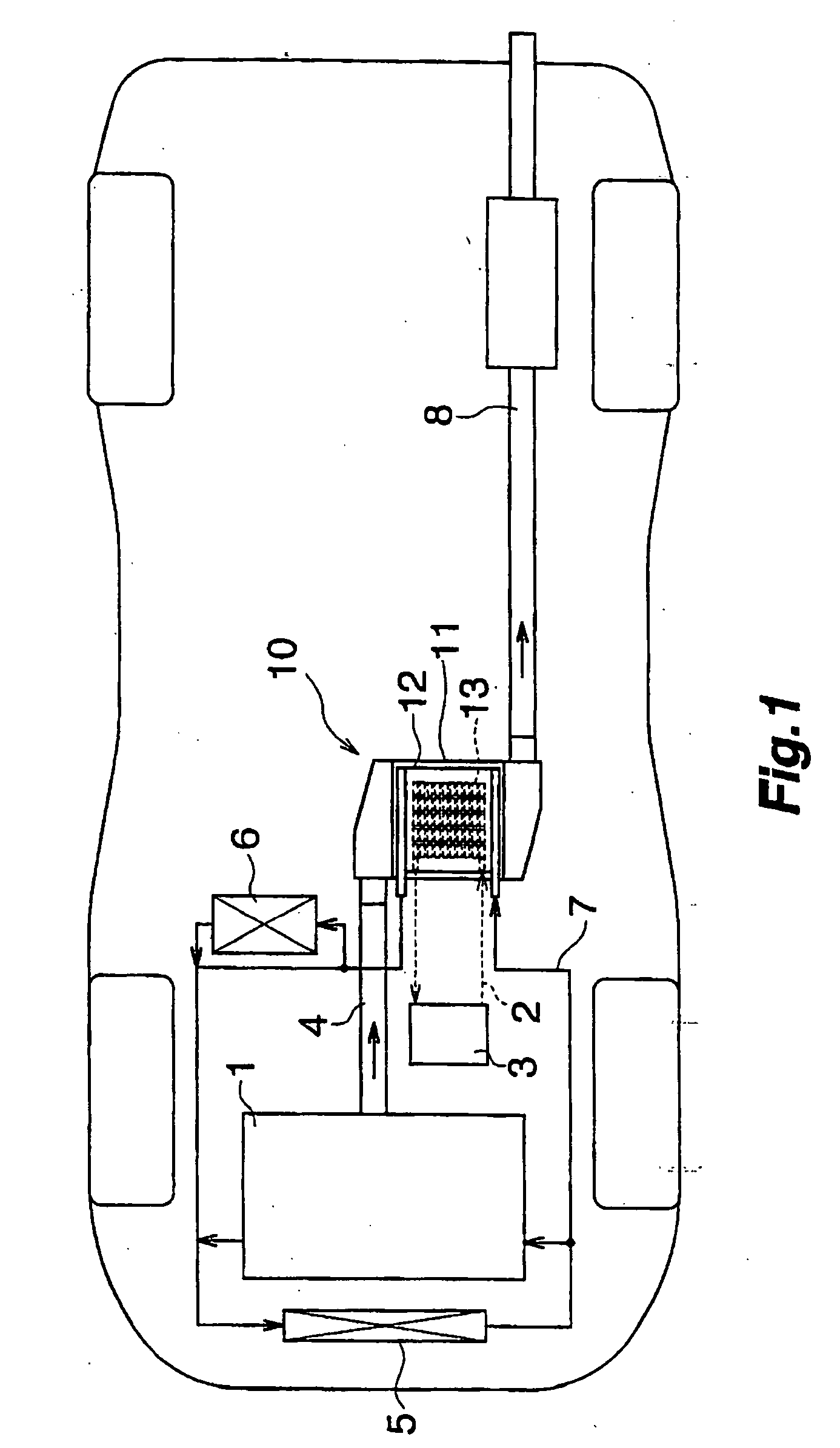

Waste heat recovery system and thermoelectric conversion system

InactiveUS20060157102A1Increase powerImprove efficiencyInternal combustion piston enginesThermoelectric device with peltier/seeback effectWaste heat recovery unitFuel cells

A waste heat recover system includes a mechanism for supplying power by use of a thermoelectric conversion unit, and a mechanism for utilizing heat released from the thermoelectric conversion unit. Heat released from the thermoelectric conversion unit is utilized for, for example, heating, defrosting, defogging, temperature keeping of fuel, temperature keeping of an internal combustion engine, and temperature keeping of a fuel cell. The waste heat recovery system is equipped in, for example, cars, incinerators, fuel cells, and industrial machinery.

Owner:SHOWA DENKO KK

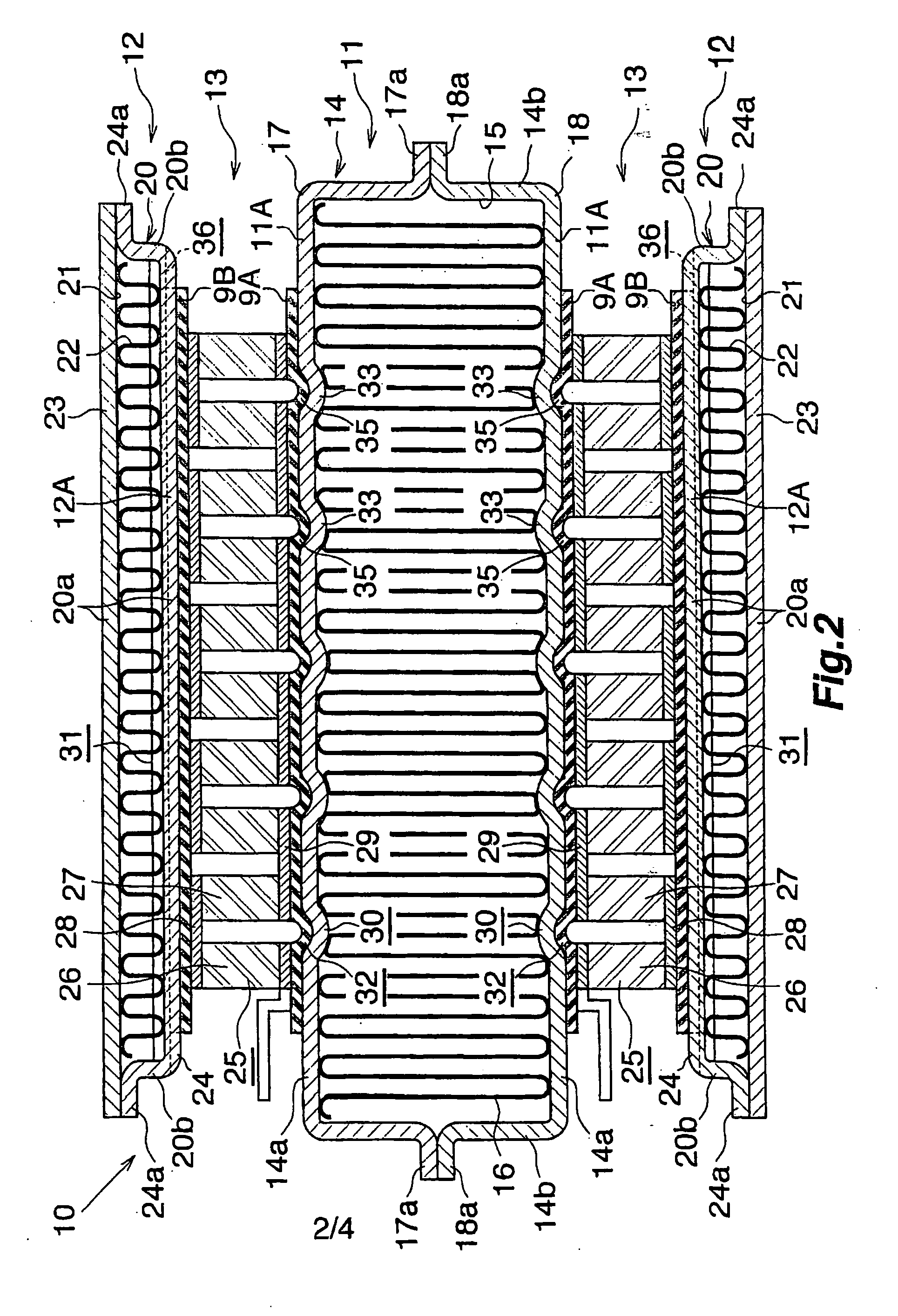

Heat exchanger with flat tubes

ActiveUS20050161206A1Reinforcing meansInternal combustion piston enginesElectrical and Electronics engineeringHeat exchanger

A heat exchanger with a plurality of stacked flat tubes and a collecting tank having a wall extending around the entire periphery of, and connected to, the end of the stacked flat tubes. A first medium may be distributed through the collecting tank and flat tubes. Internal inserts are in the flat tubes, with the inserts being bonded between the broad sides of the tubes and, in the region of connection of the tubes to the collecting tank, being configured to compensate for length changes in the stacking direction caused by temperature changes, as by recesses in connectors such as wave flanks or by corrugated wave flanks. The flat tubes with inserts such as described may be separately provided for use in manufacture of heat exchangers.

Owner:MODINE MFG CO

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS6840251B2Reduce Microbial ContaminationReduce removalDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

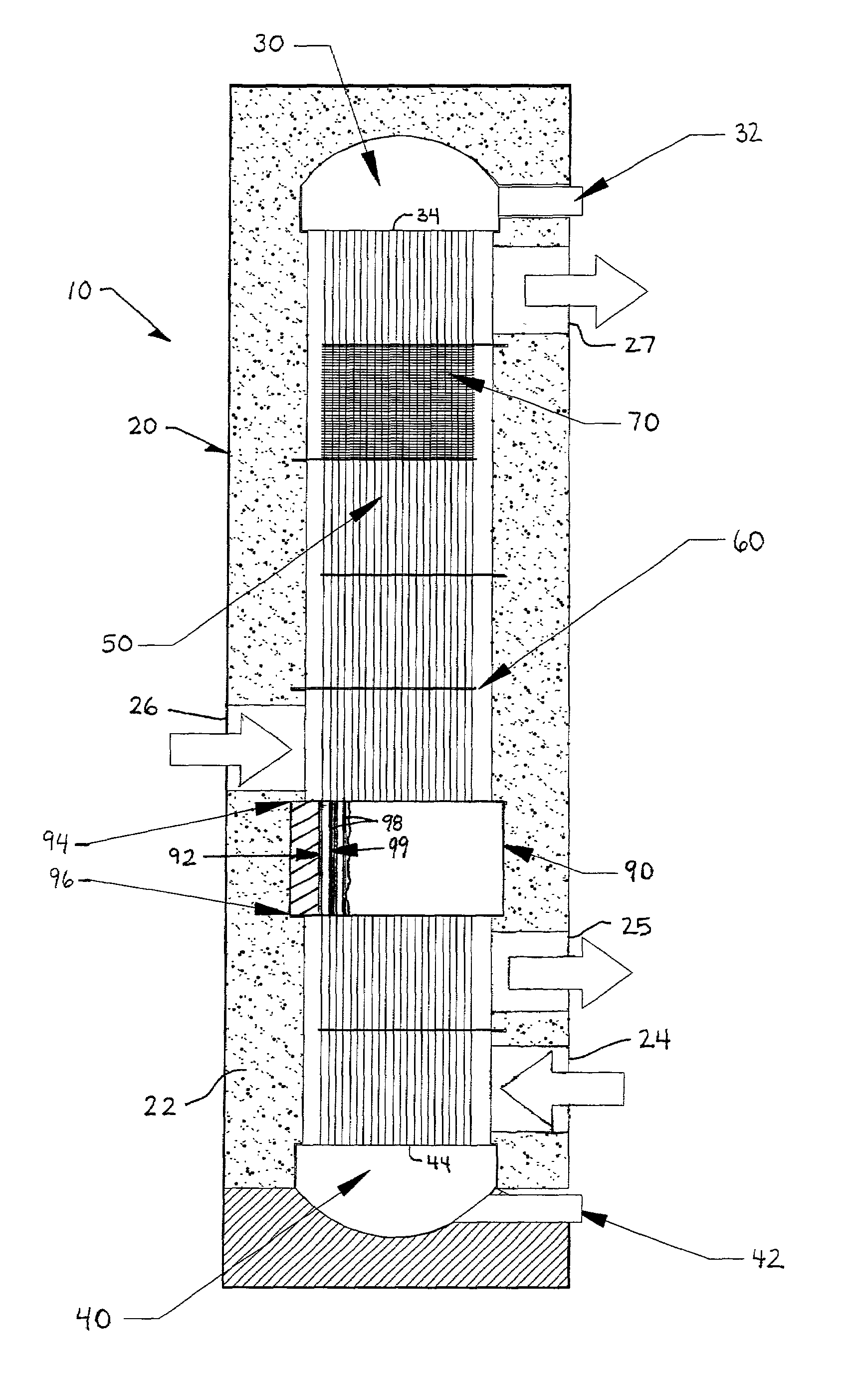

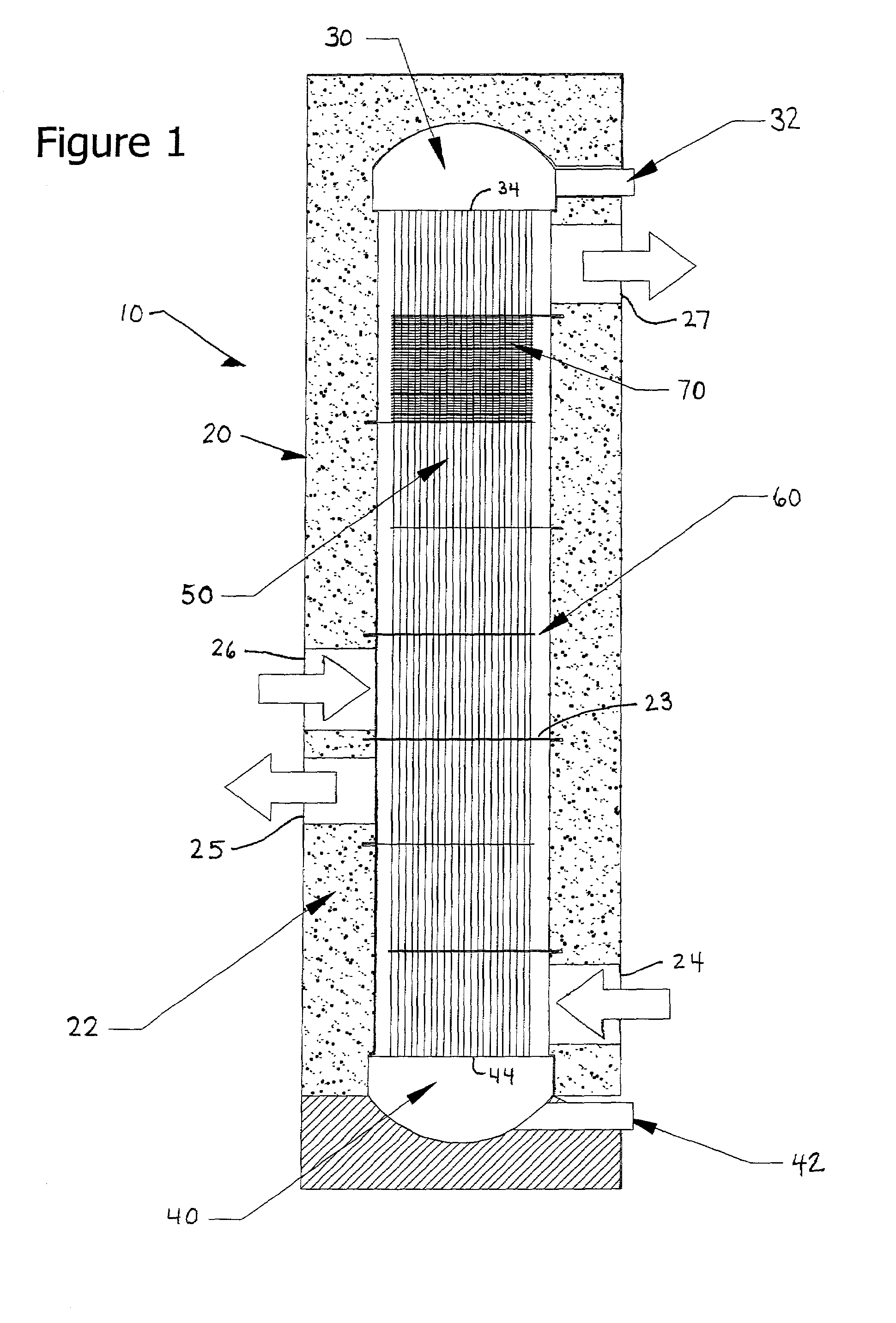

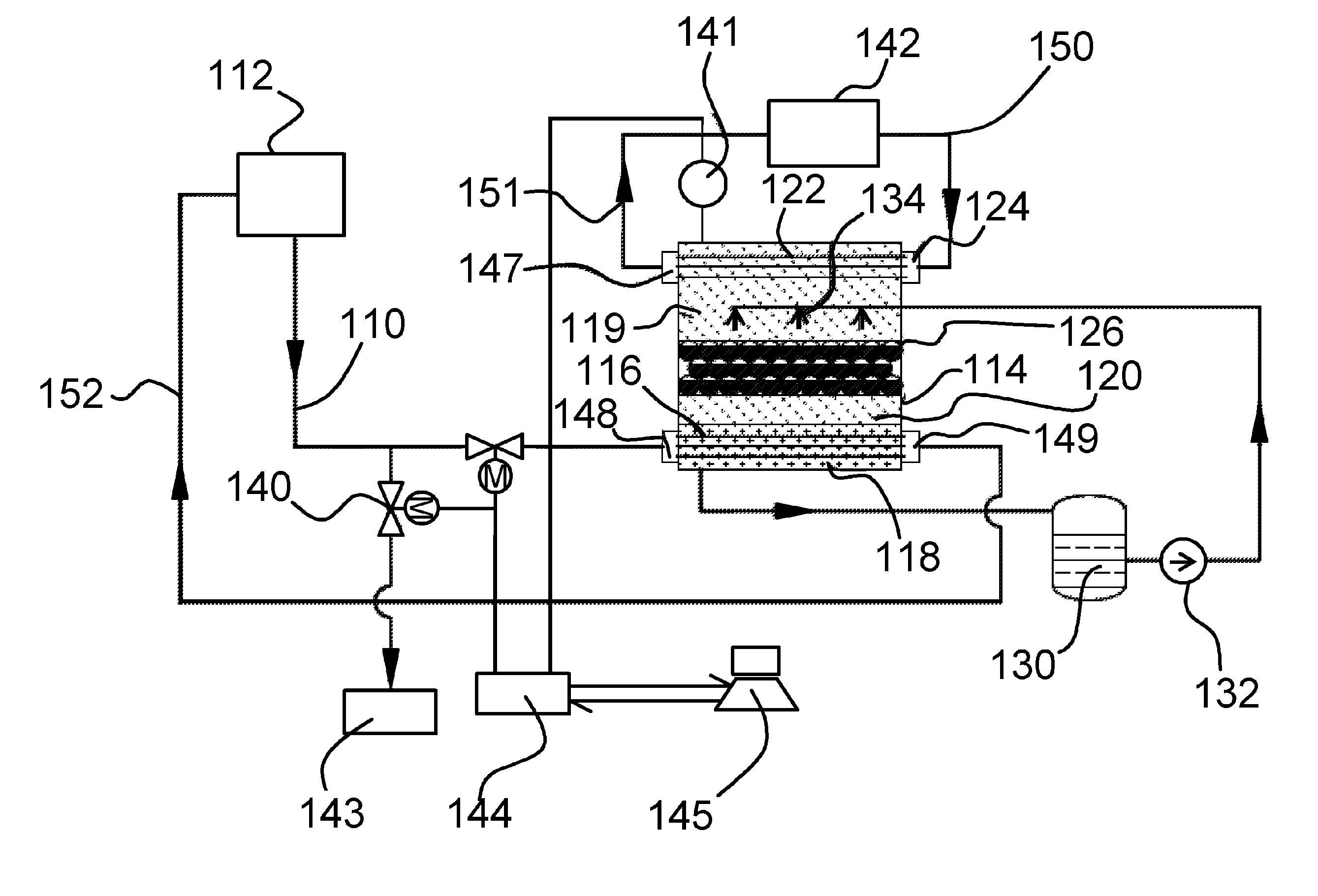

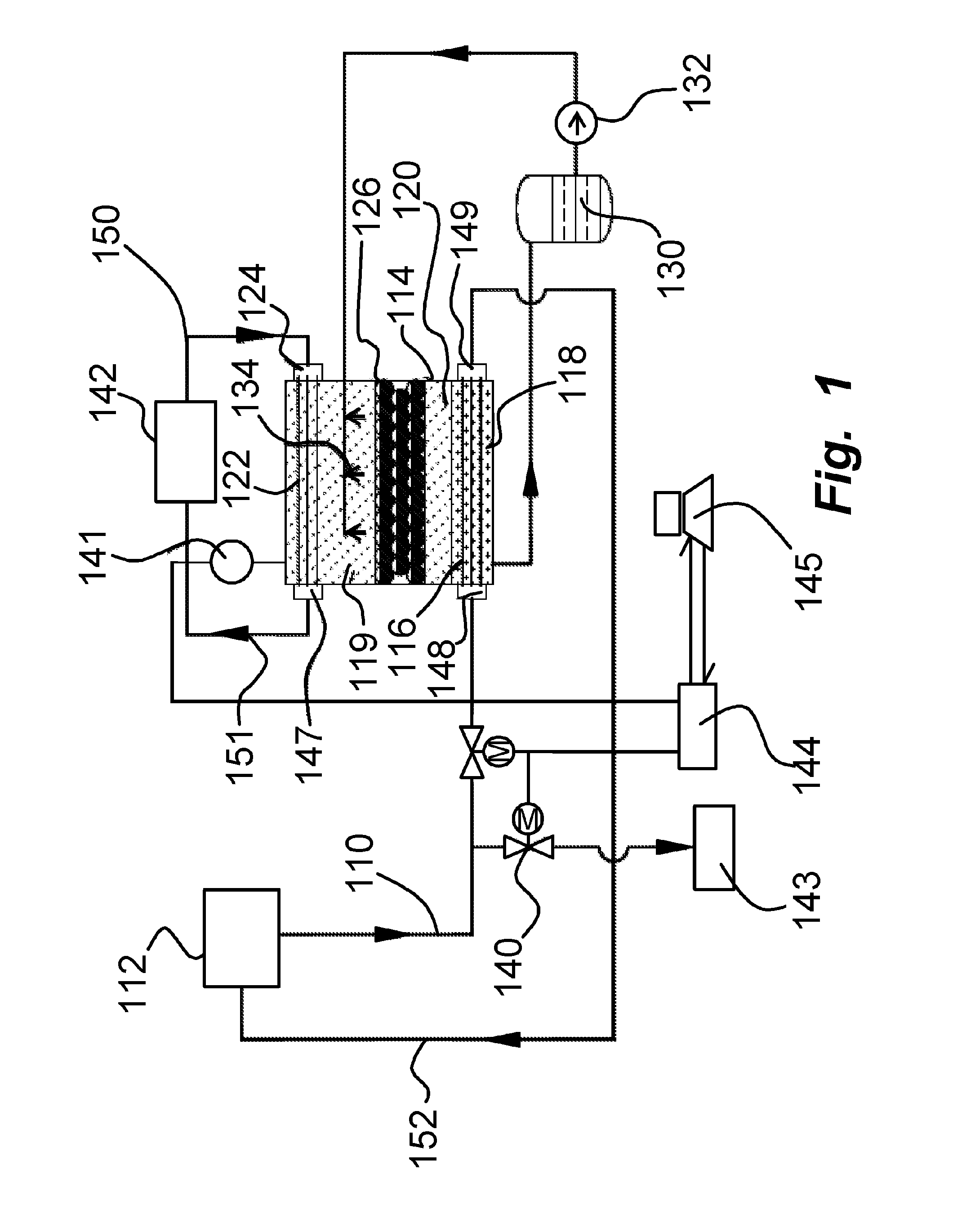

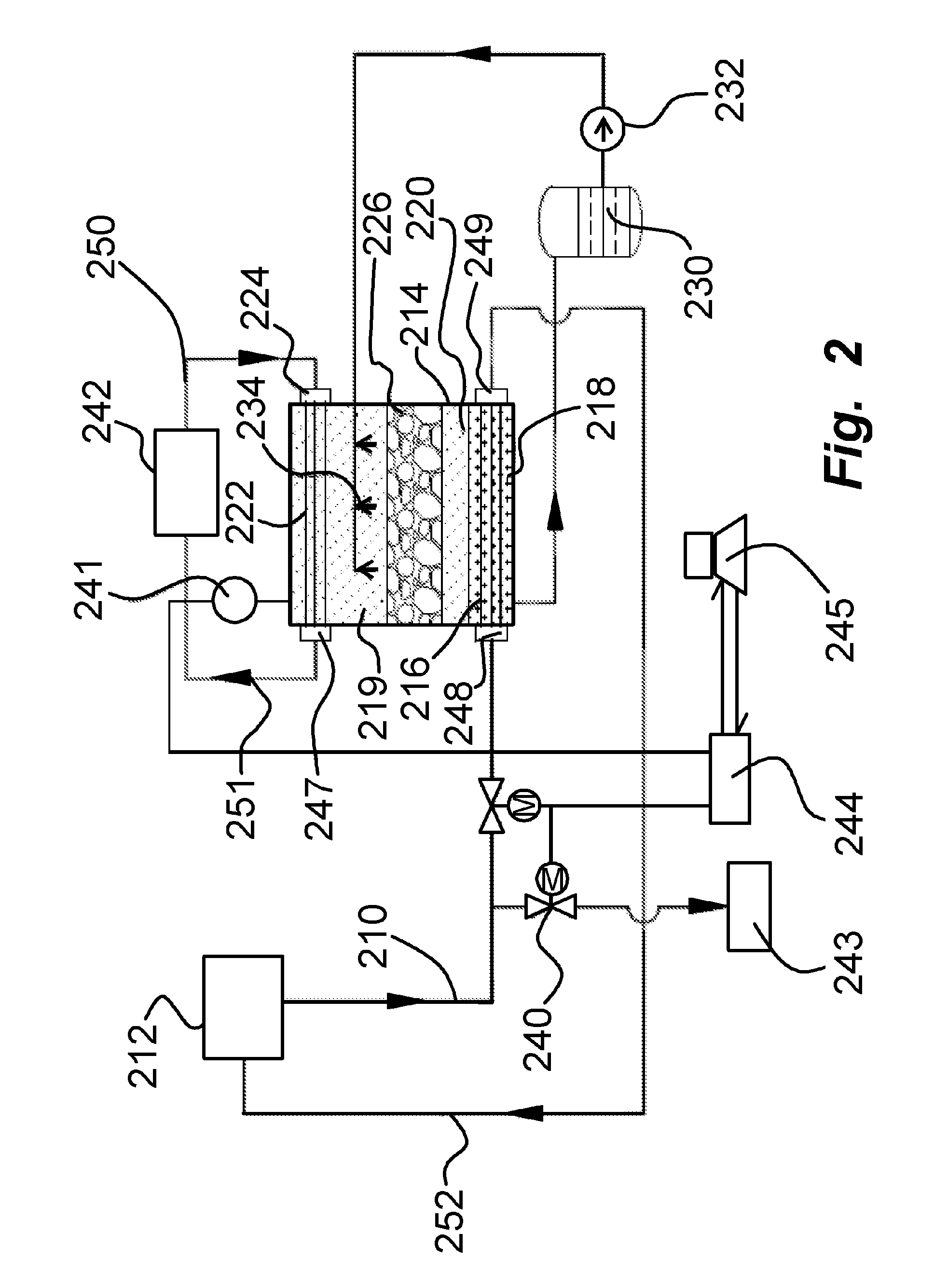

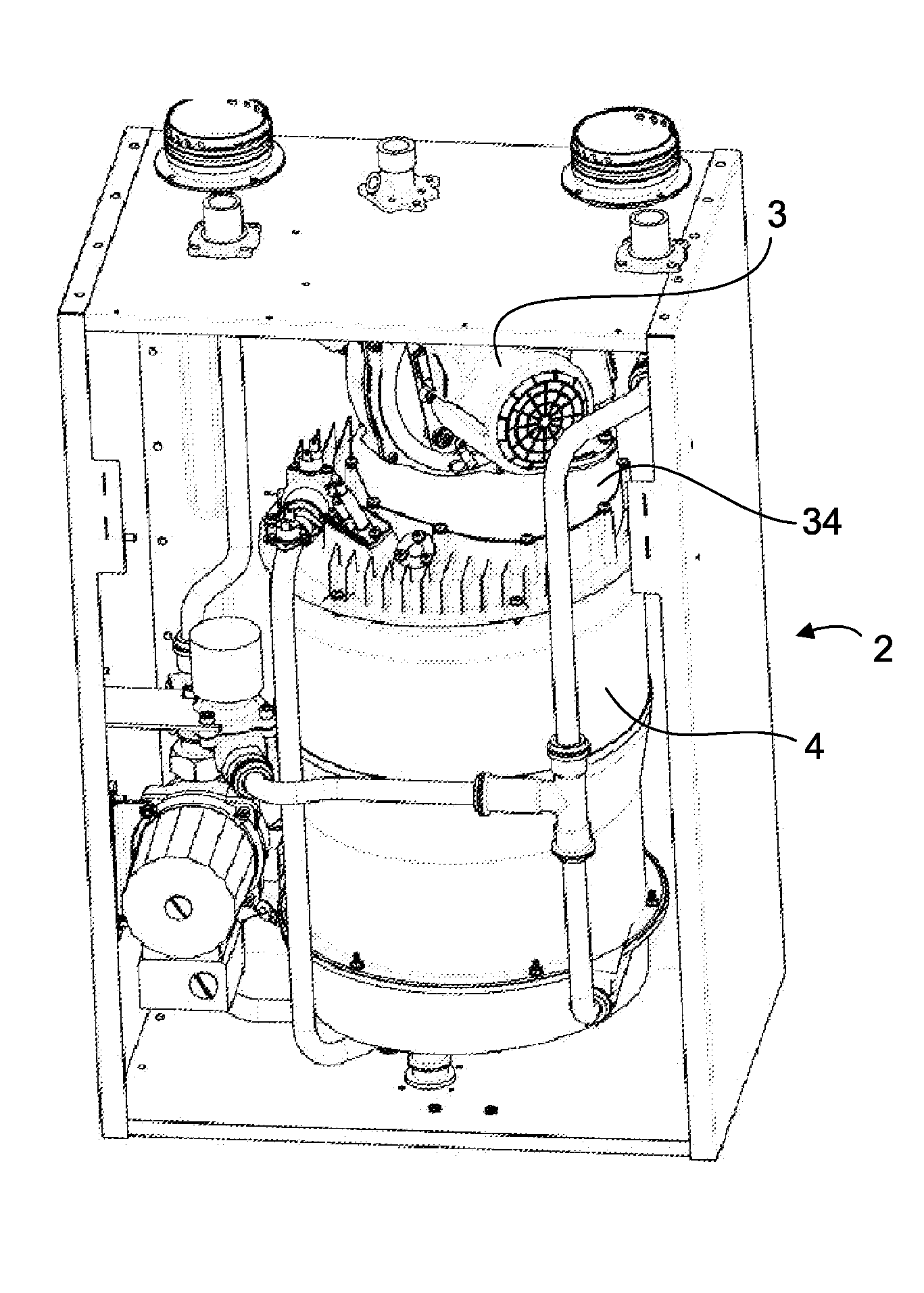

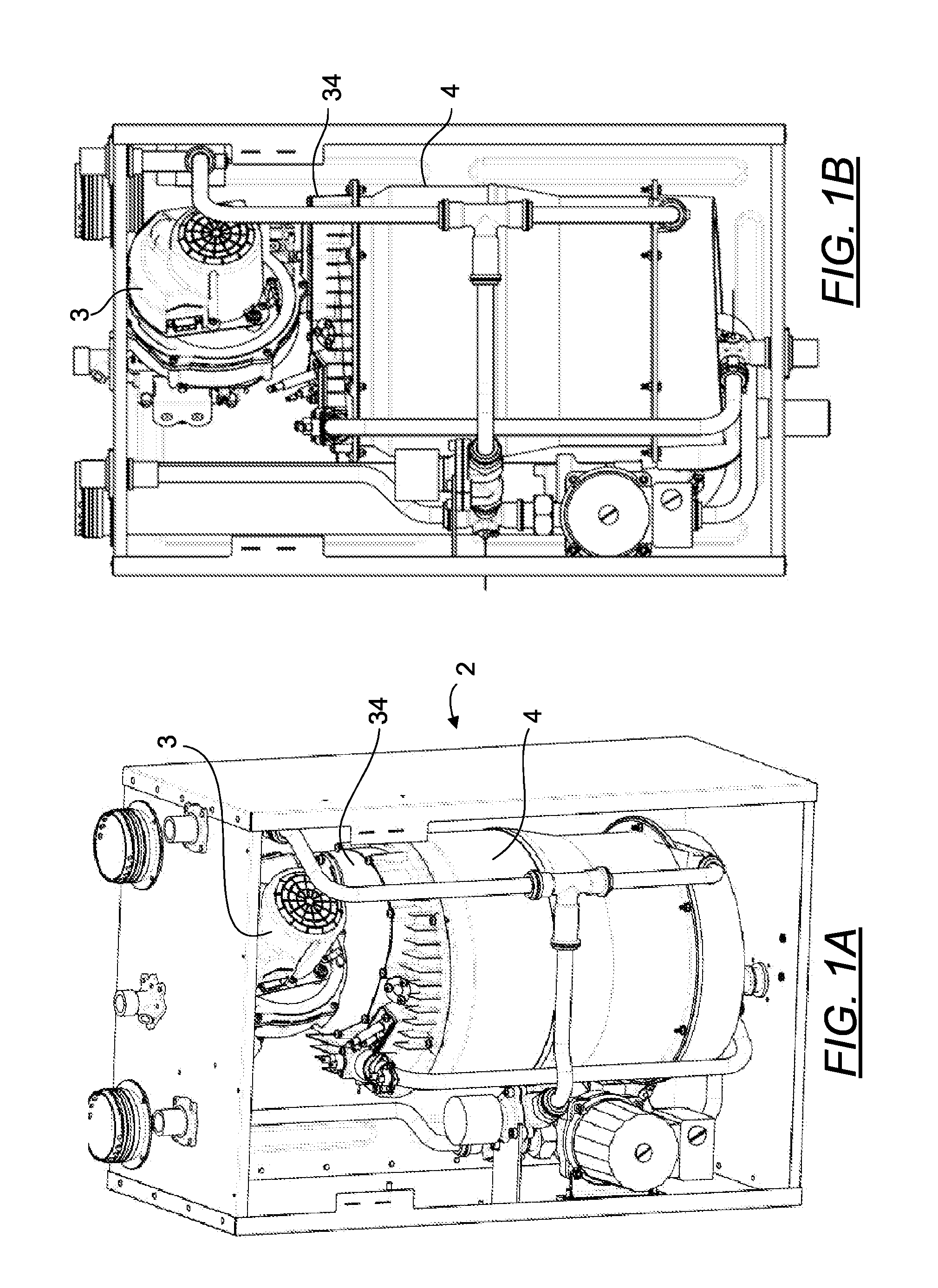

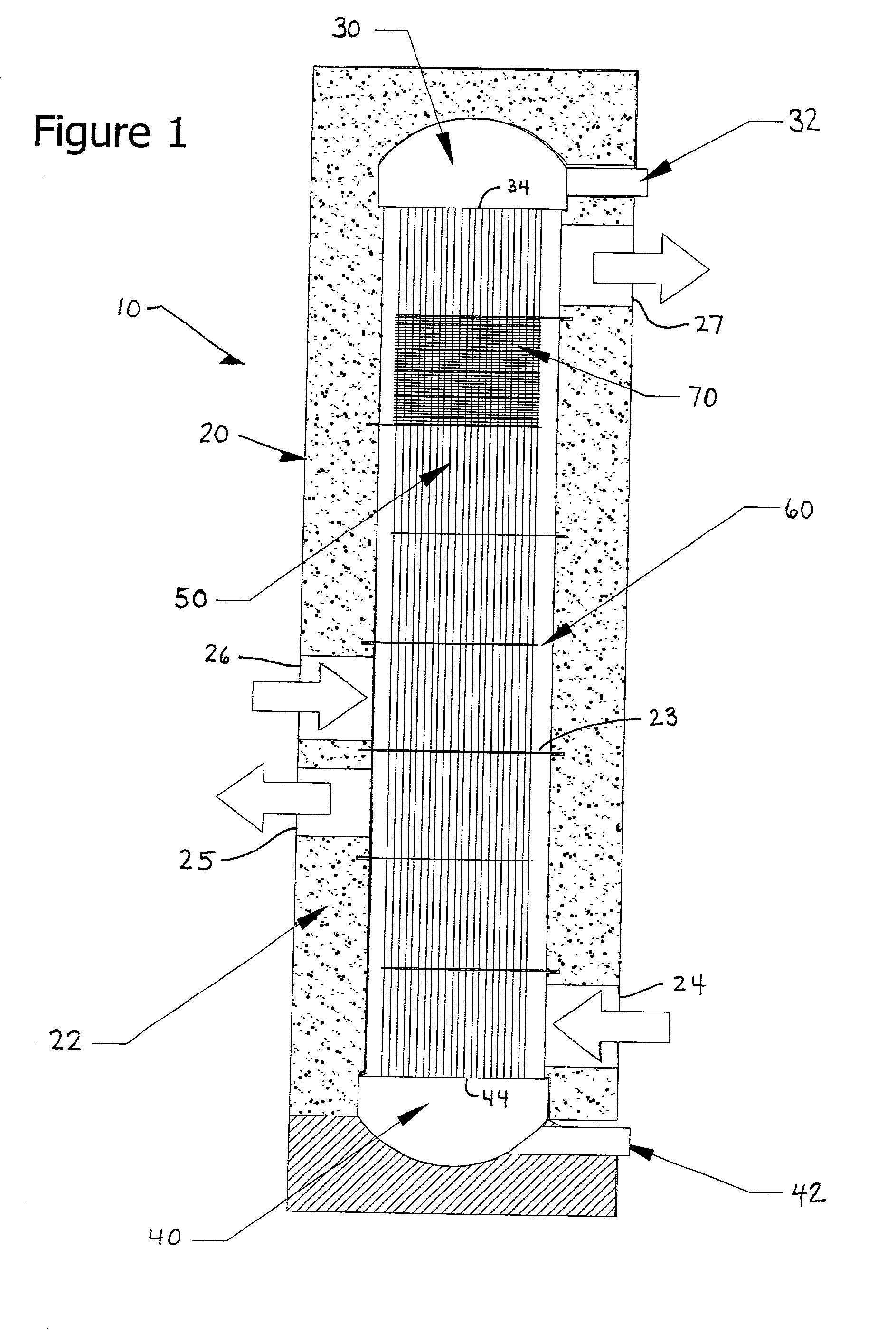

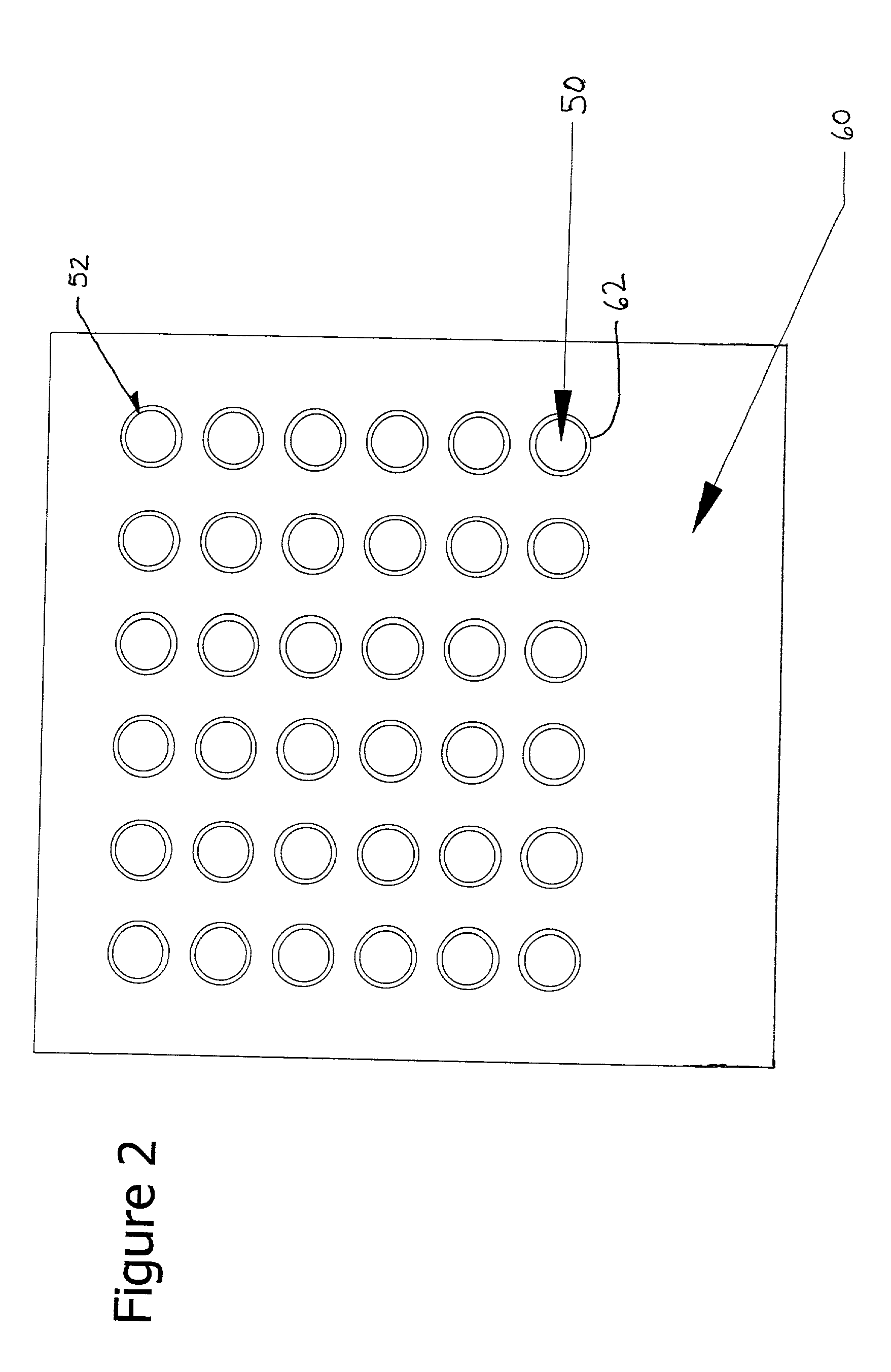

Systems and Methods of Thermal Transfer and/or Storage

ActiveUS20110162829A1System design difficultSolar heating energySolar heat devicesEngineeringInput device

Systems, methods, and computer-implemented embodiments consistent with the inventions herein are directed to storing and / or transferring heat. In one exemplary implementation, there is provided a system for transferring / storing heat comprised of a heat exchange / storage apparatus including a chamber, and a heat input device adapted to heat / provide a vapor into the chamber. Other exemplary implementations may include one or more features consistent with a heat output device through which a working medium / fluid passes, a thermal storage medium located within the chamber, and / or a heat exchange system that delivers a heat exchange medium / fluid to the thermal storage medium.

Owner:BLUELAGOON TECH

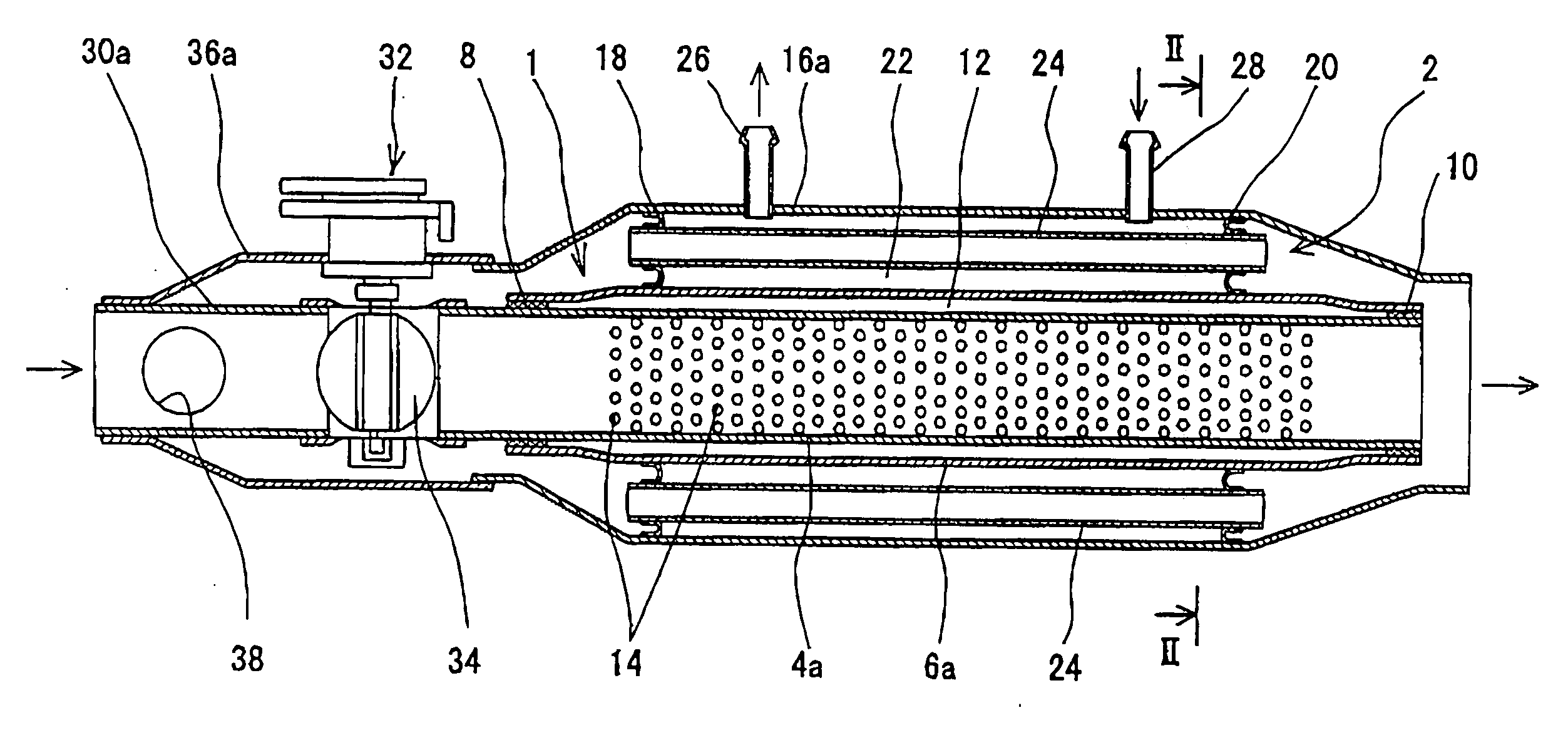

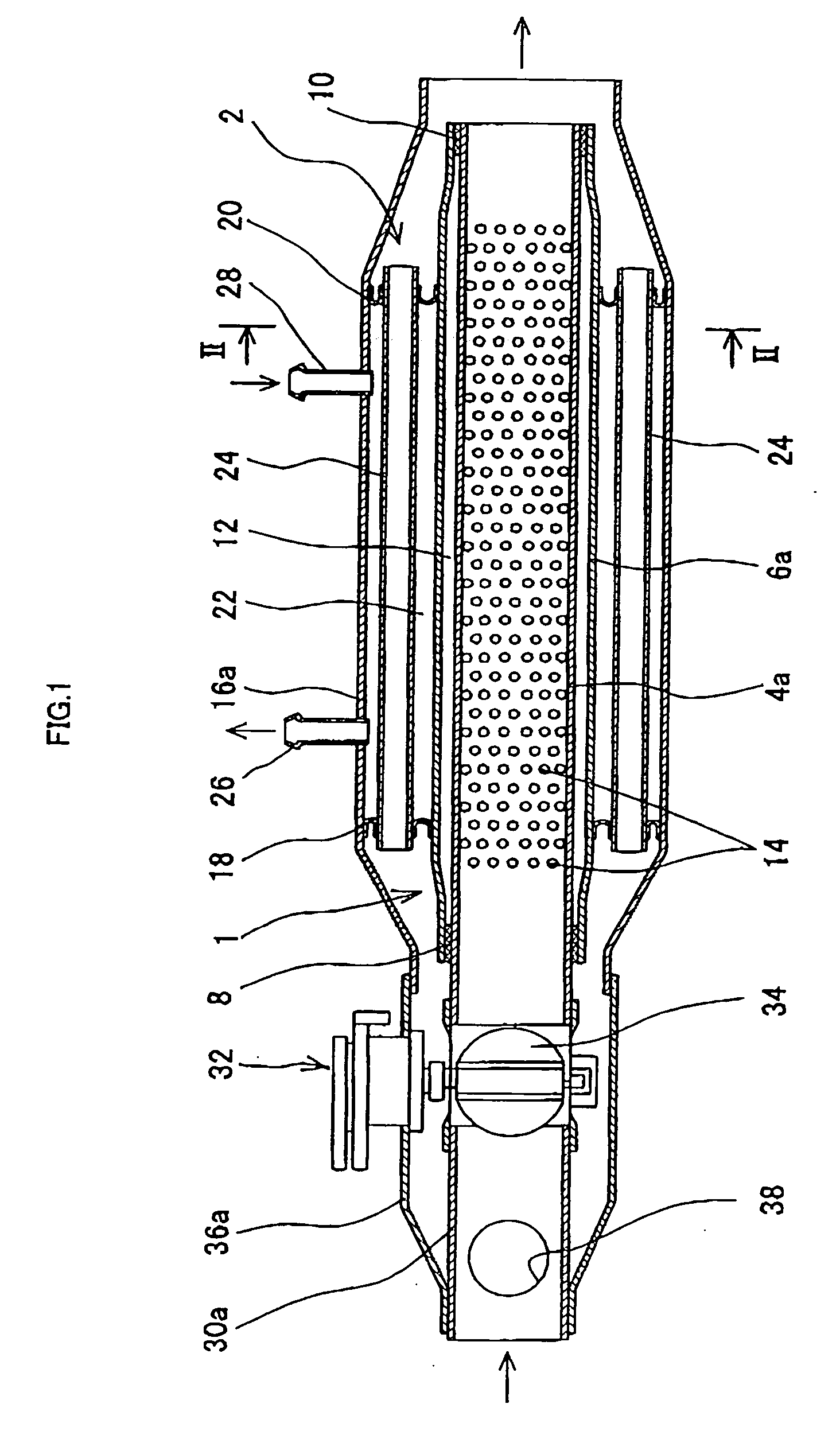

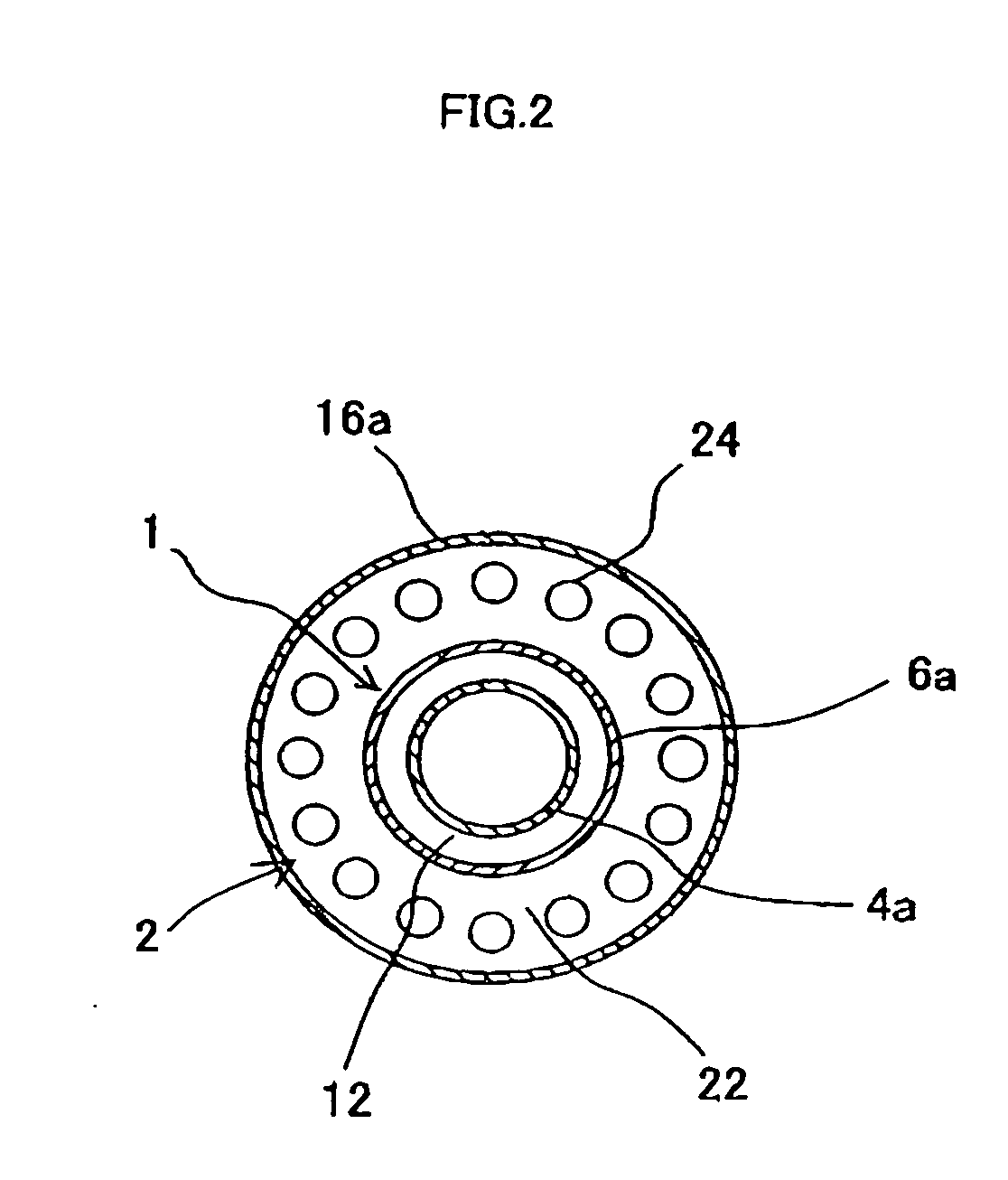

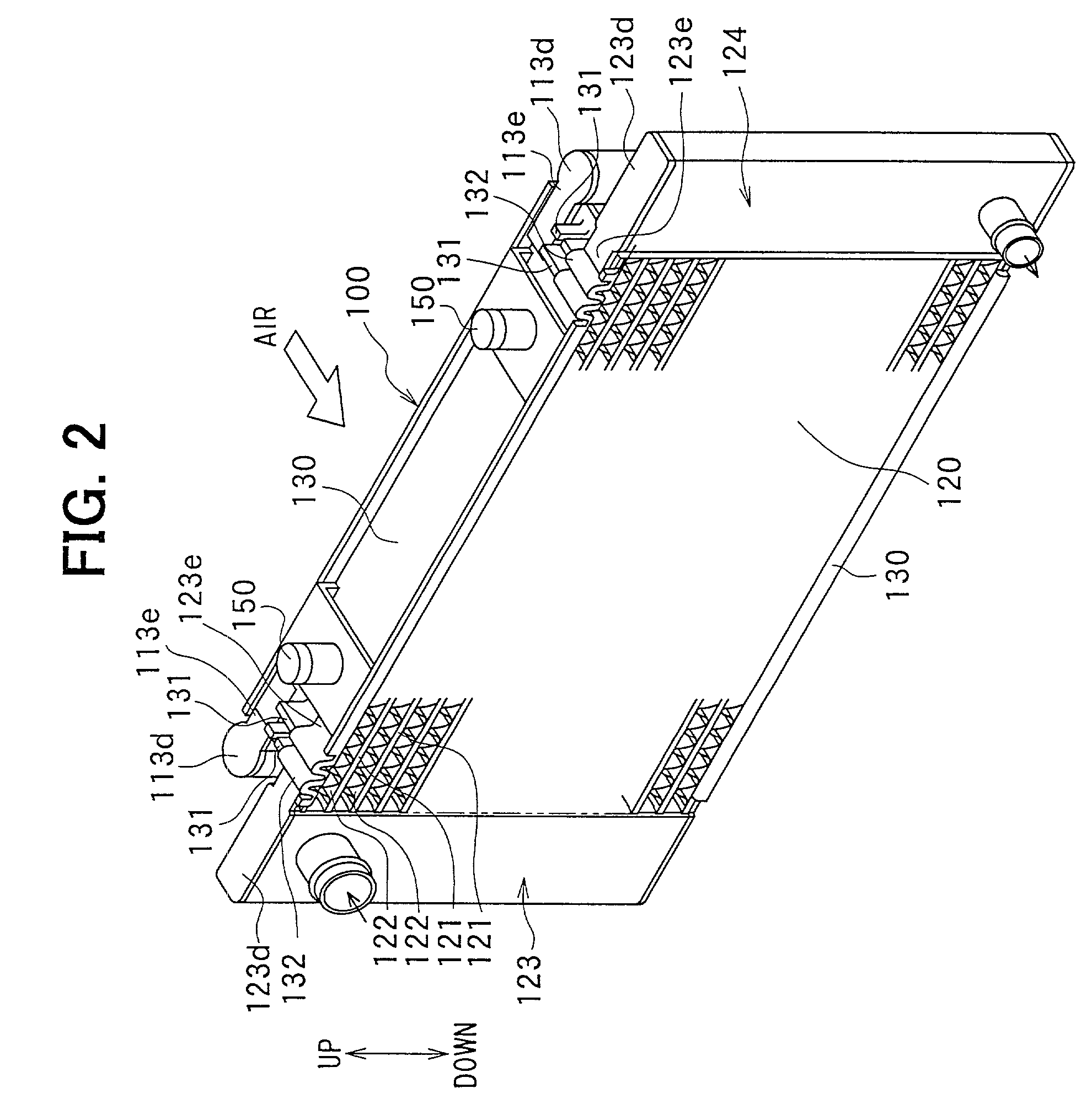

Exhaust heat recovery muffler

InactiveUS20060054381A1Easy to manufactureIncrease the cross-sectional areaInternal combustion piston enginesRecuperative heat exchangersWaste heat recovery unitEngineering

The exhaust heat recovery muffler includes a muffler unit having the outer surface thereof covered, an exhaust heat recovery unit disposed integrally with the muffler unit, and a switching valve that switches the flow of exhaust gas into the muffler unit and into the exhaust heat recovery unit. An outer pipe of the muffler unit and a cylindrical shell of the exhaust heat recovery unit, covering the outer circumference of the outer pipe, are coaxially disposed. The exhaust heat recovery unit includes a heat exchange chamber, formed by a pair of partitions provided between the inner circumference of the shell and the outer circumference of the outer pipe, and small-diameter pipes penetrating through the pair of partitions and extending through the heat exchange chamber. A heat exchange medium flows inside of the heat exchange chamber.

Owner:FUTABA IND CO LTD

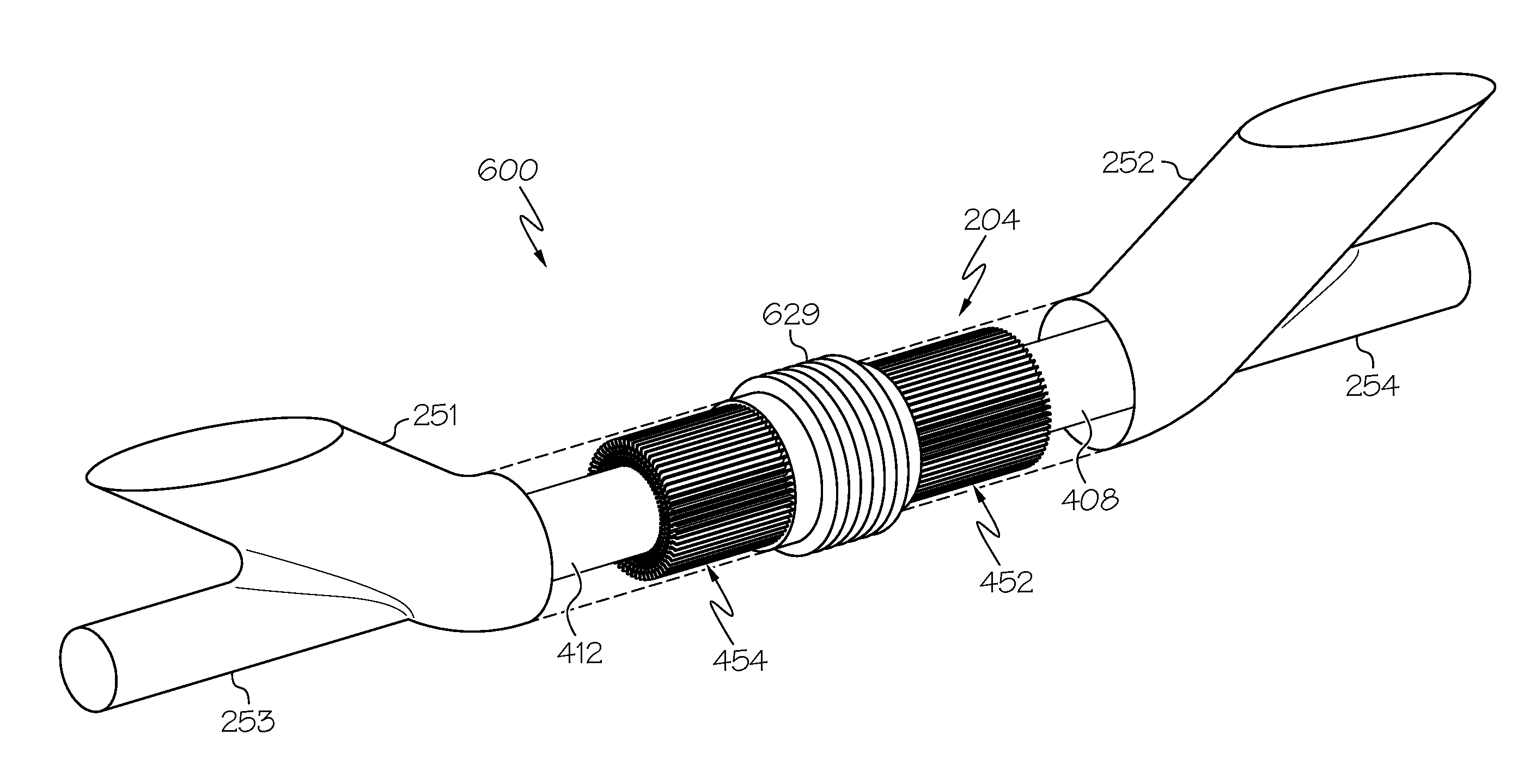

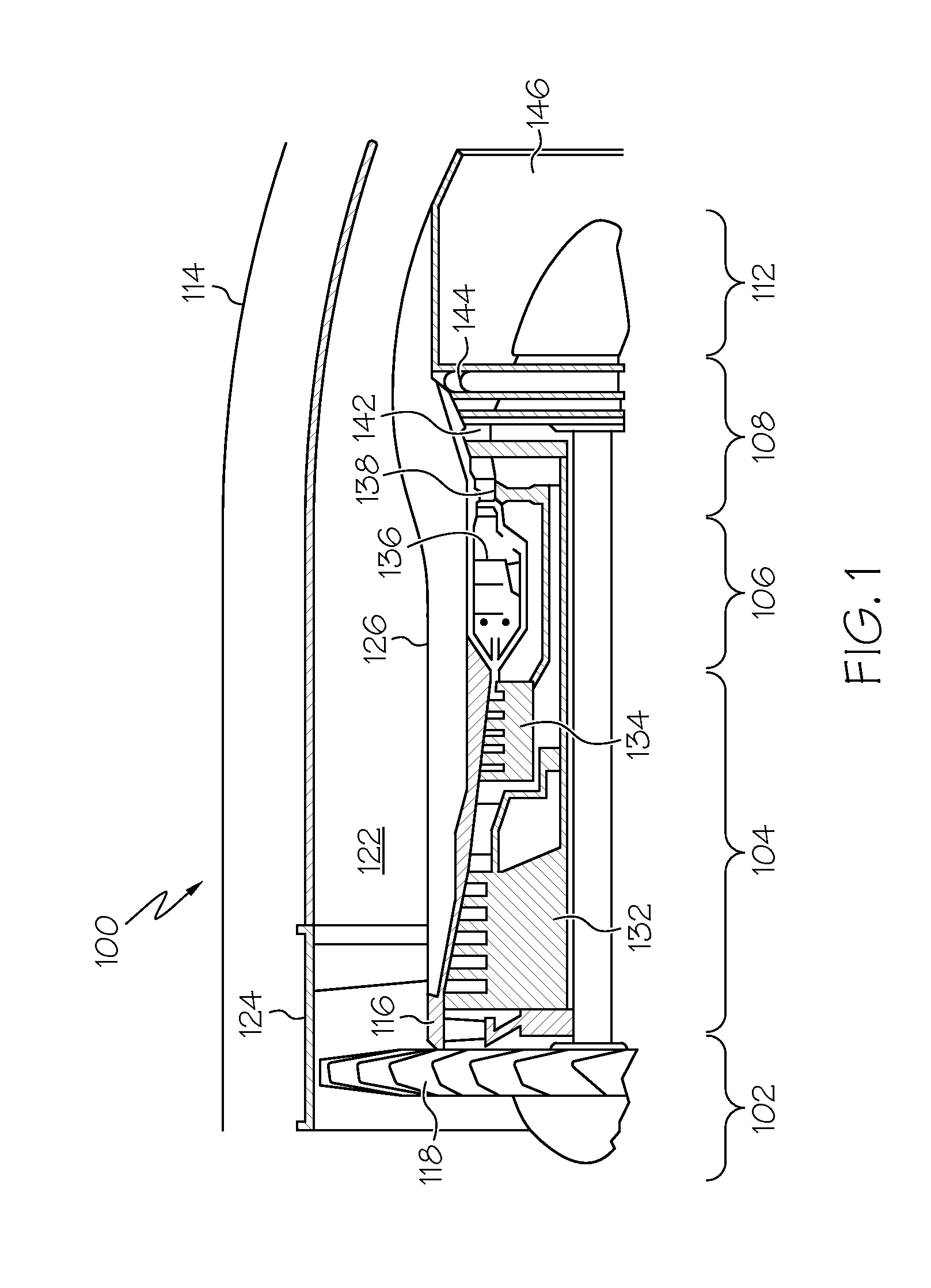

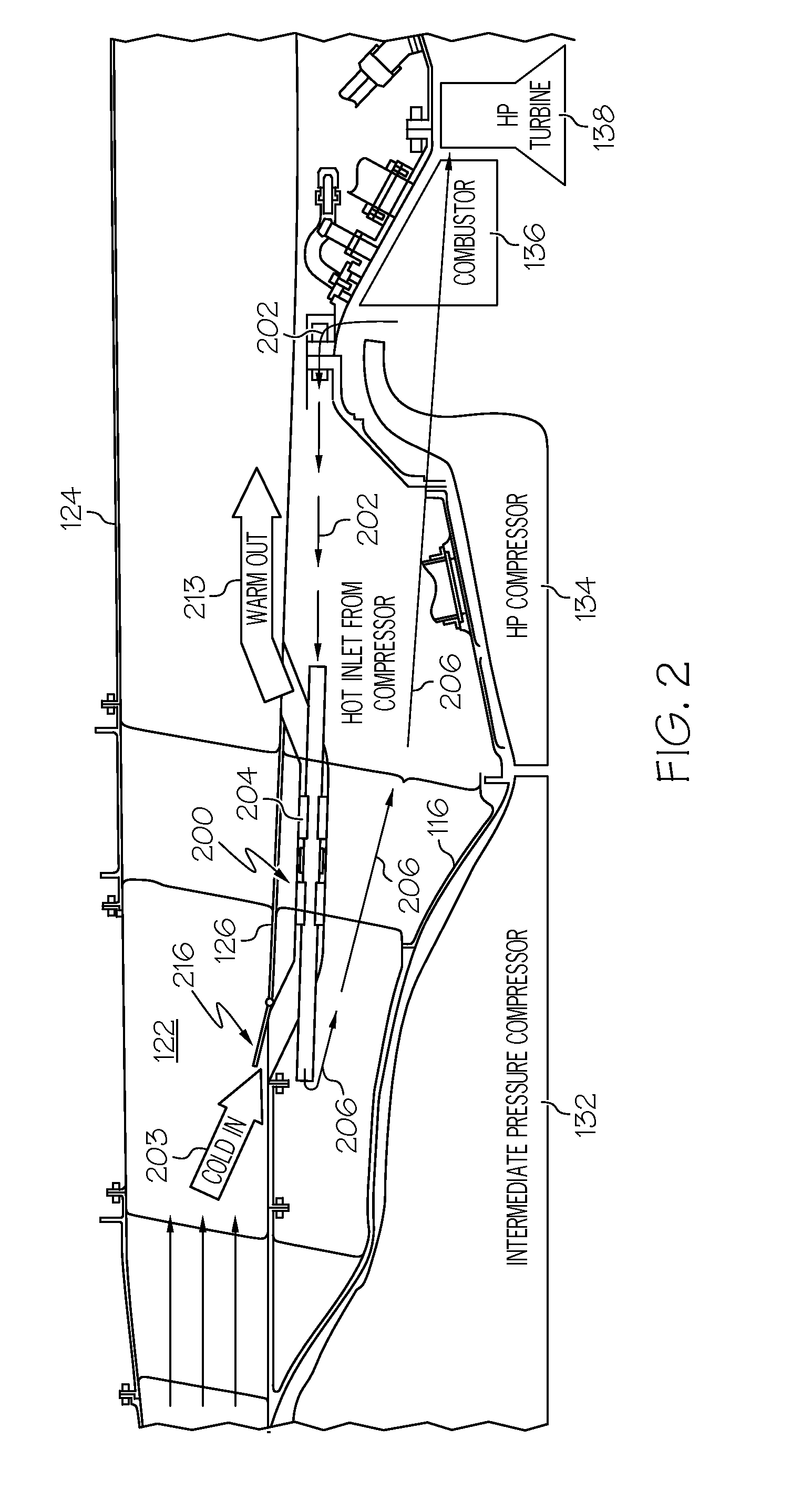

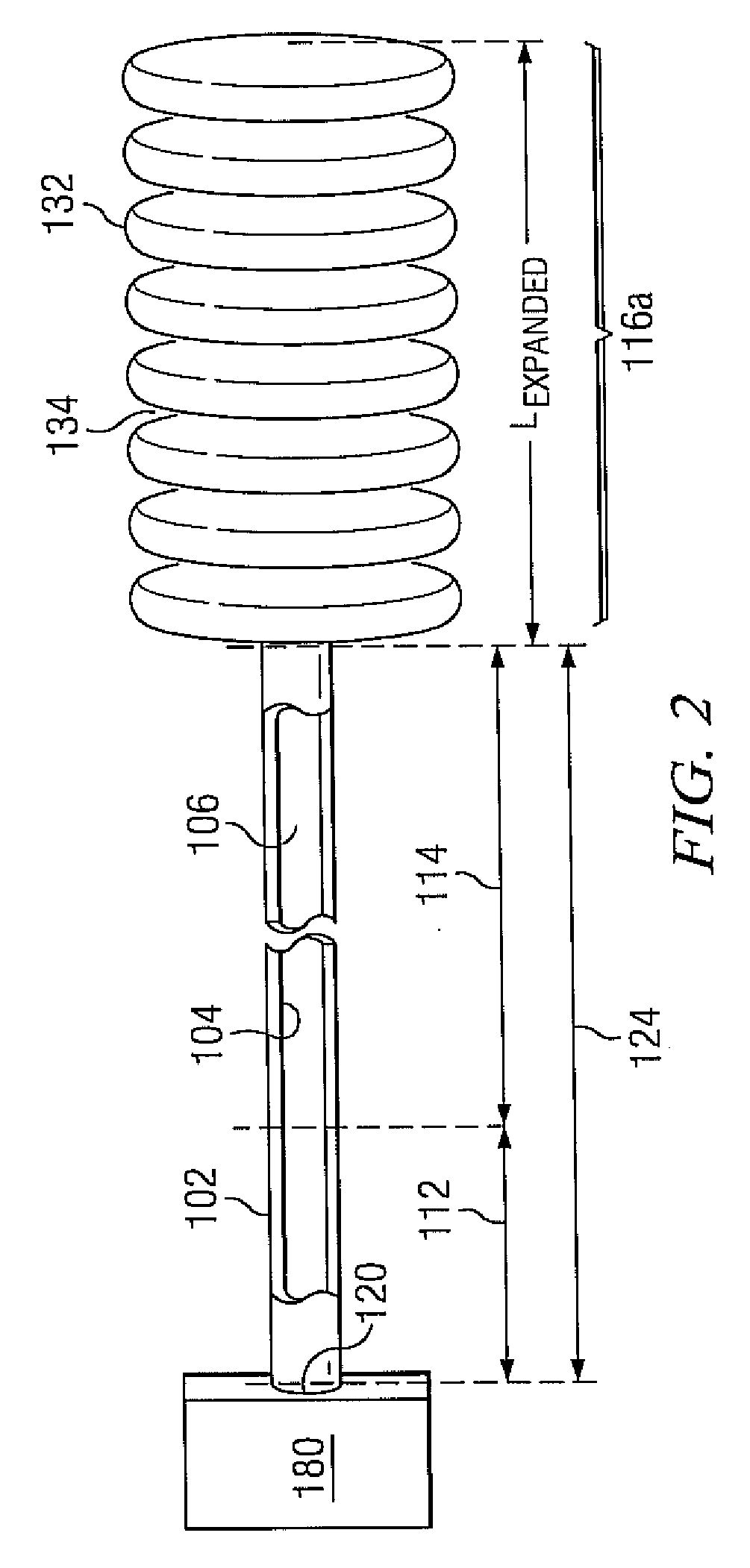

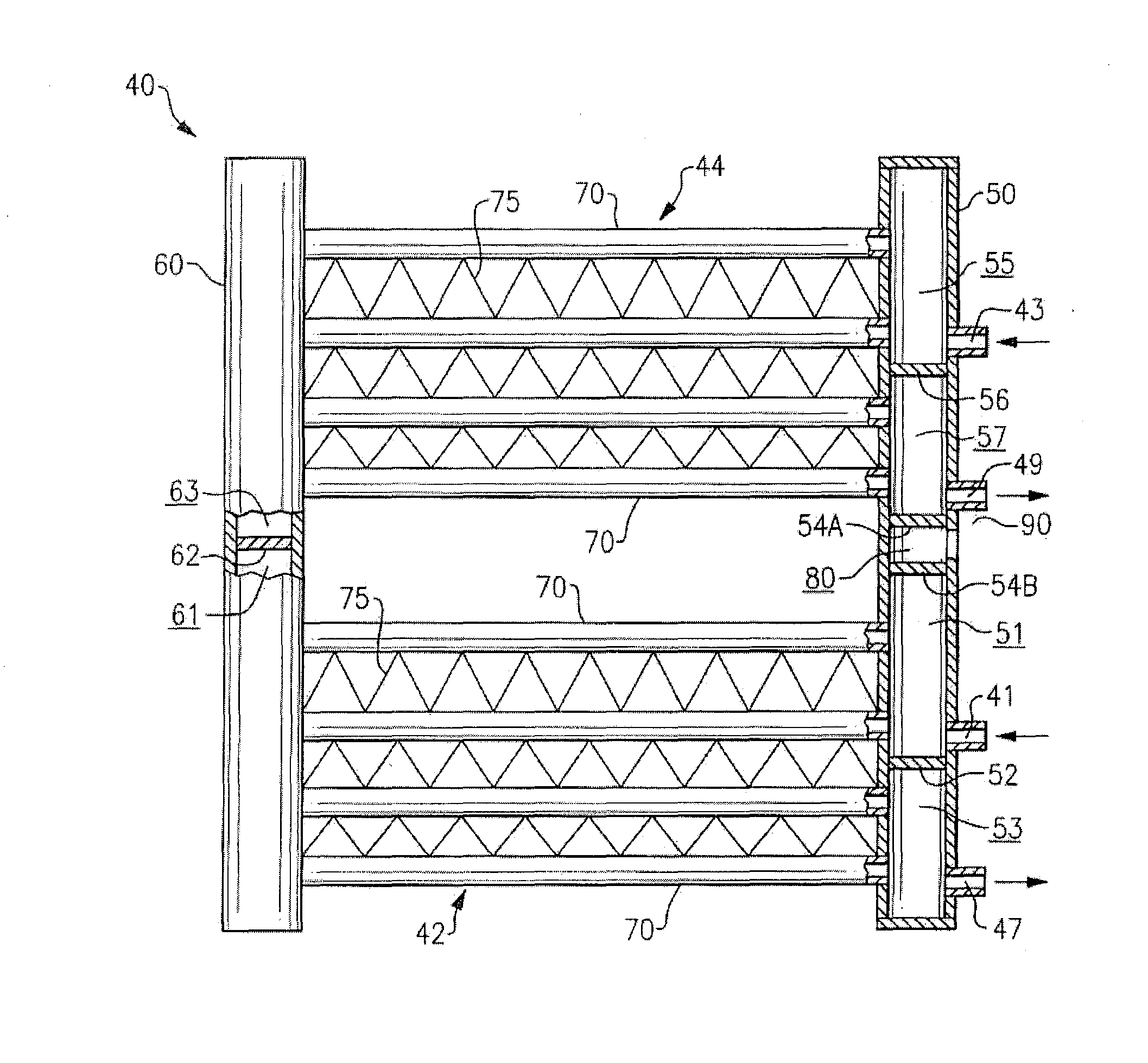

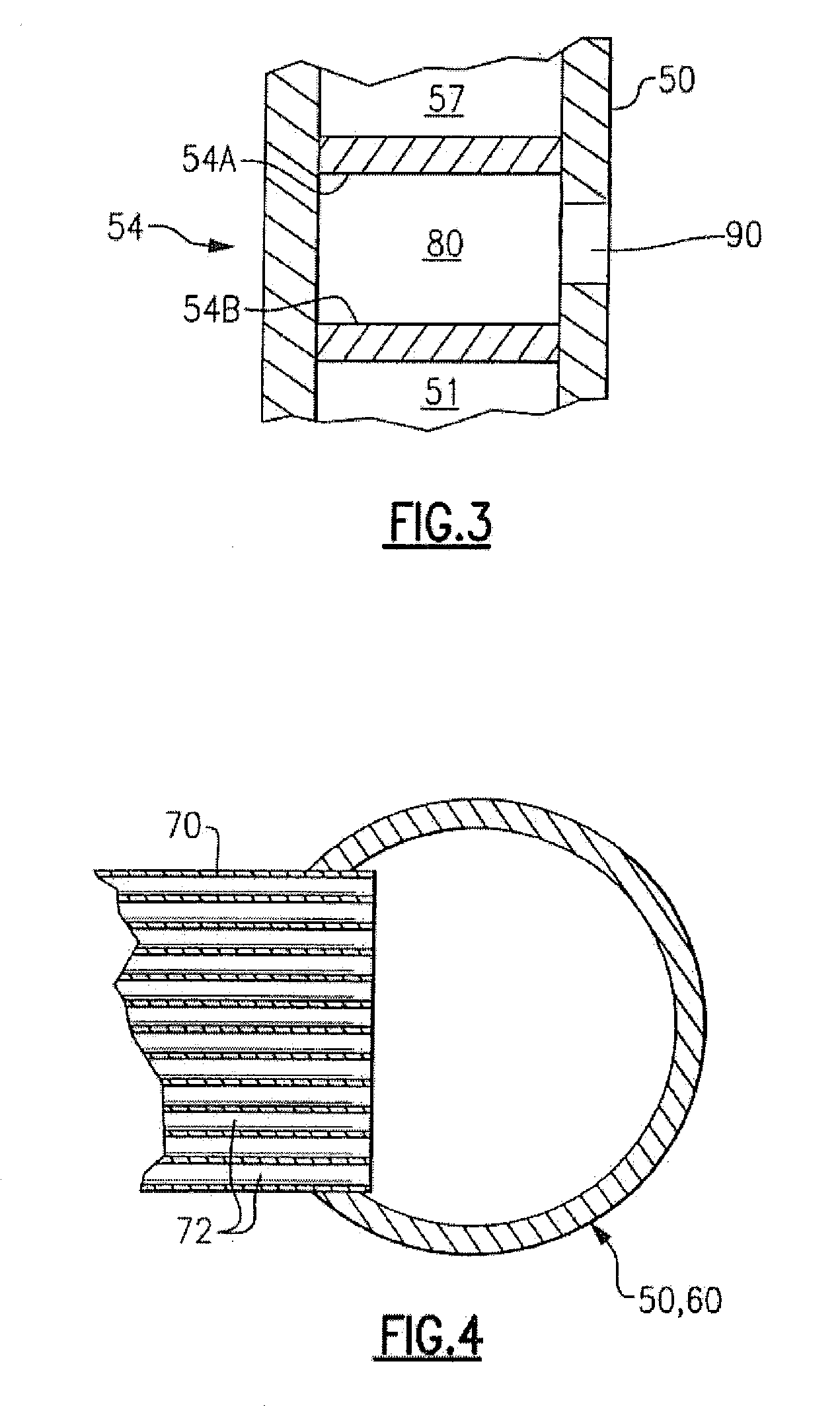

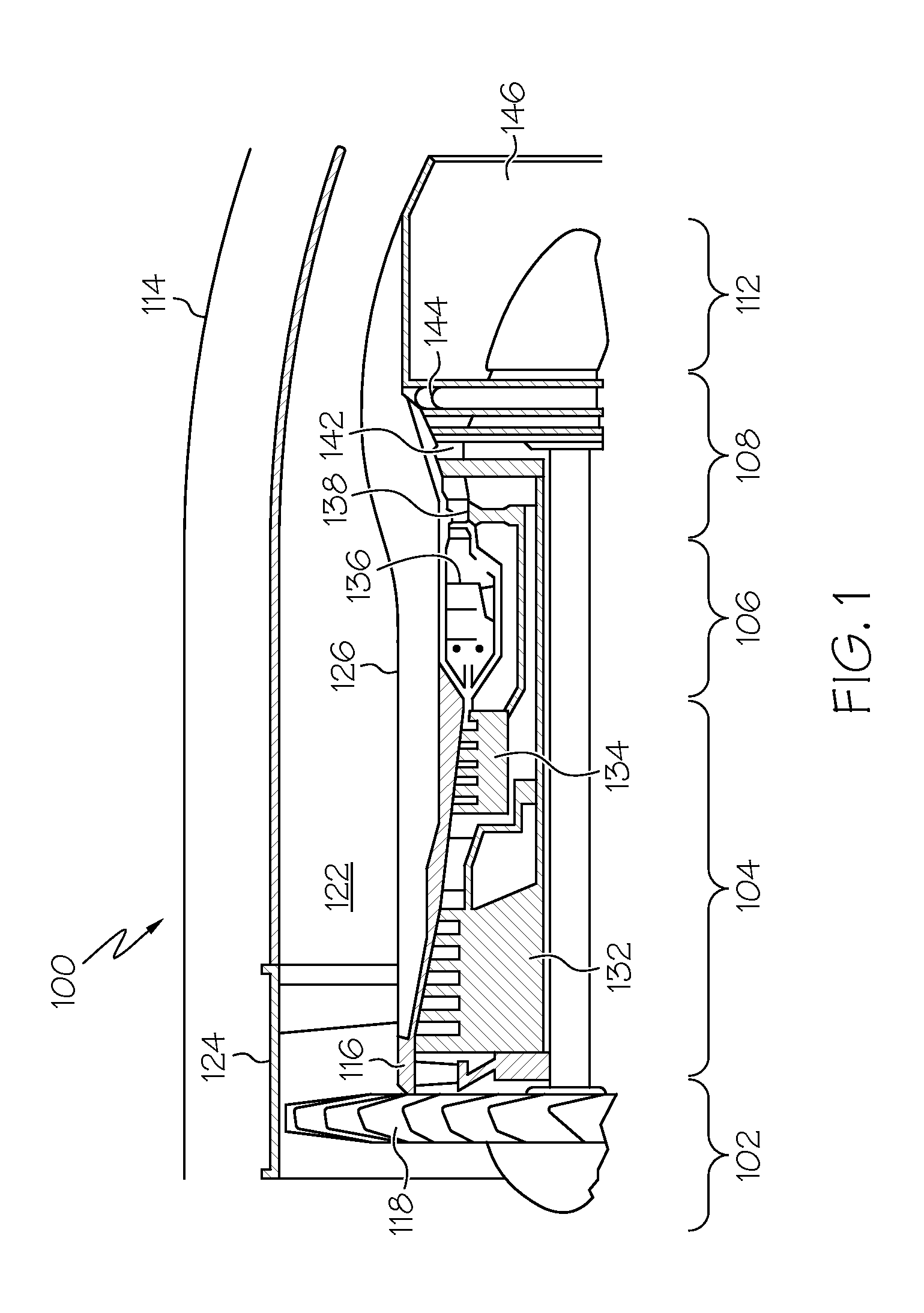

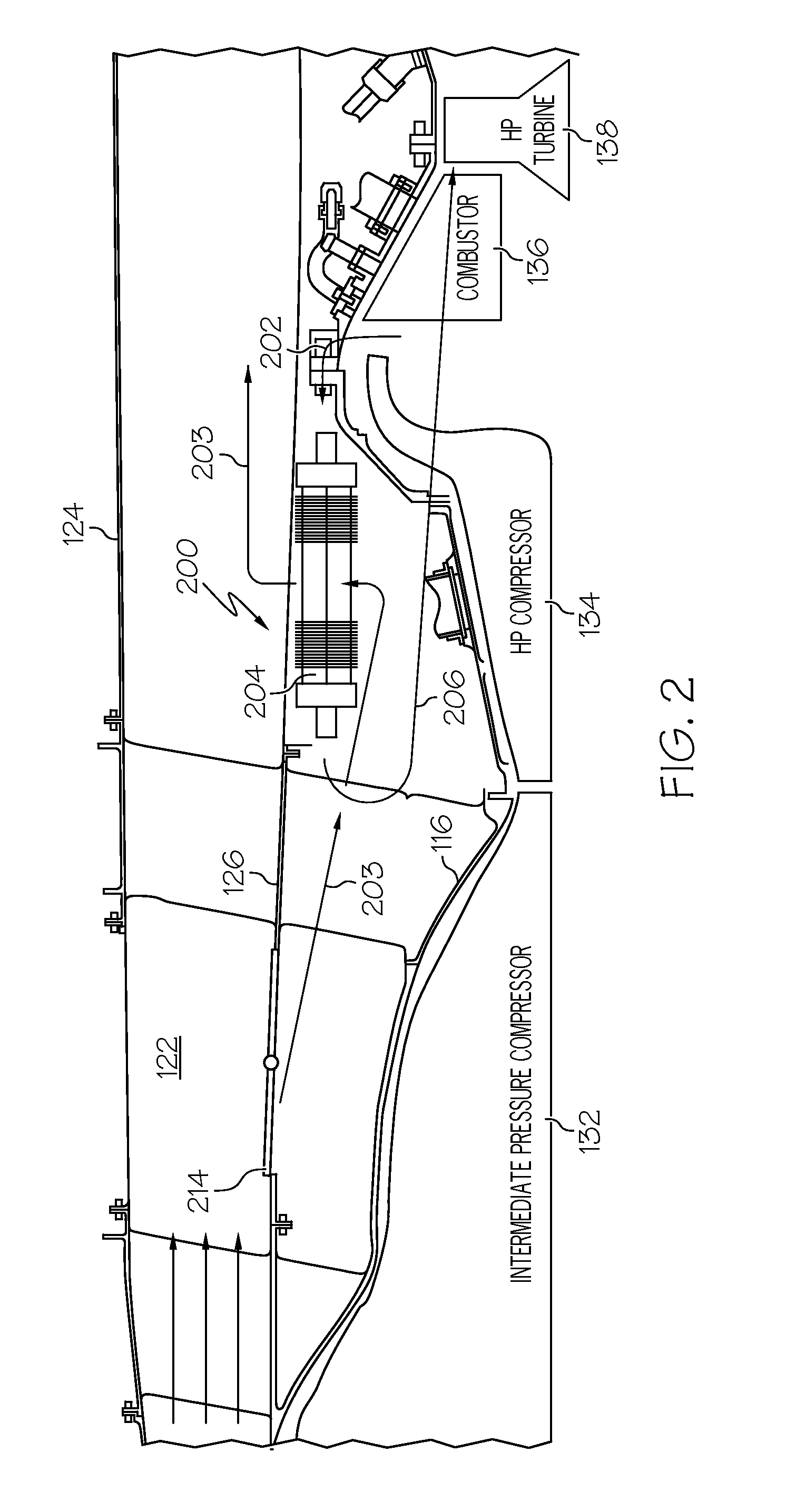

Counter-flow heat exchange systems

ActiveUS20150114611A1Safety devices for heat exchange apparatusTurbine/propulsion engine coolingCounter flowEngineering

A heat exchange system includes a tubular fan air inlet portion and a tubular cooled air outlet portion connected to a first end of a tubular mid portion. The heat exchange system further includes a tubular hot air inlet portion and a tubular recycled fan air outlet portion connected a second end of the mid portion. Still further, the heat exchange system includes an integrally-formed, compliant heat exchanger tube extending between the hot air inlet portion and the cooled air outlet portion within the mid portion to define a heat exchanger first flow passage within the heat exchanger tube and a second flow passage outside of the heat exchanger tube but within the tubular mid portion. Methods for fabricating such heat exchange systems are also provided.

Owner:HONEYWELL INT INC

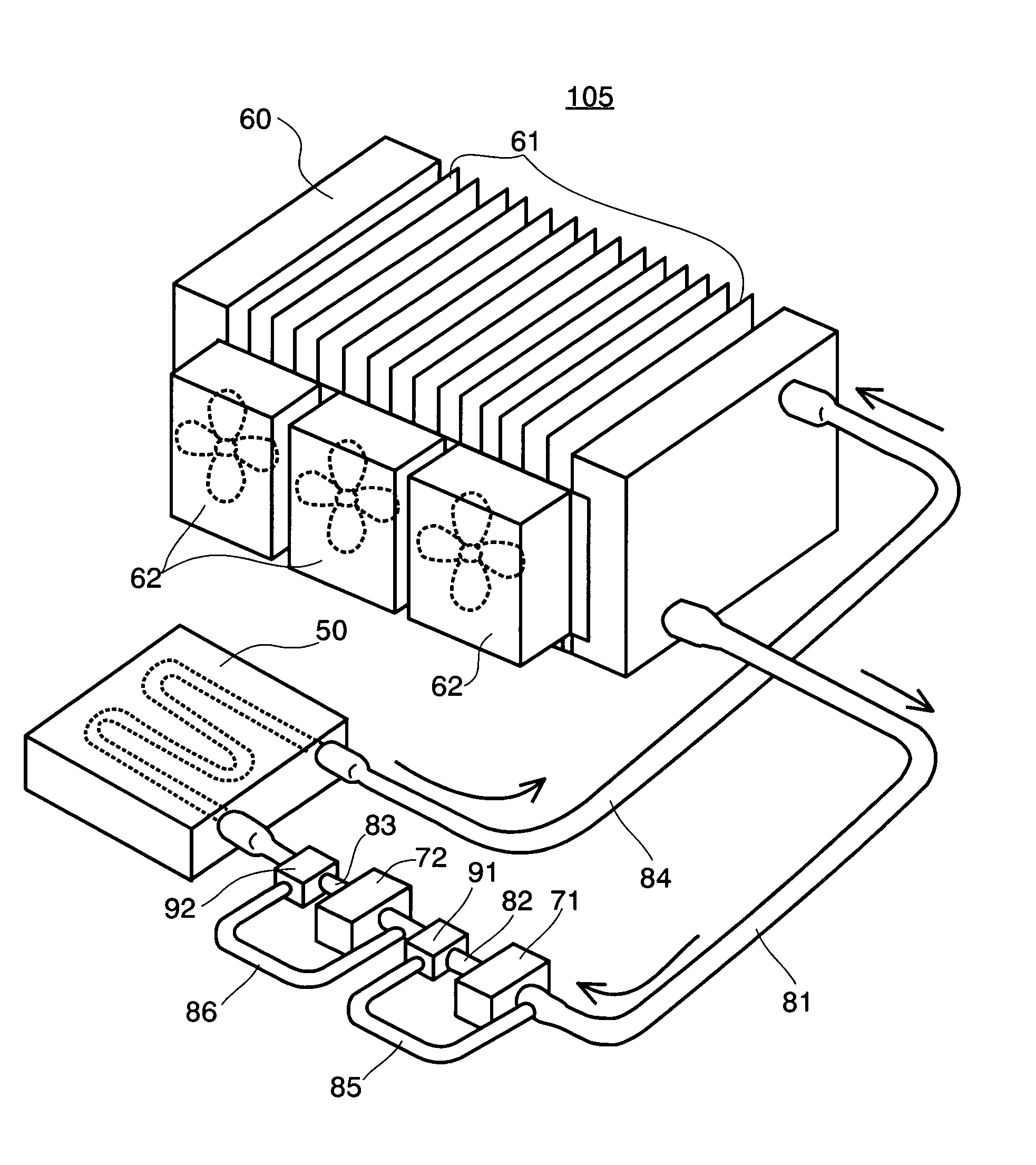

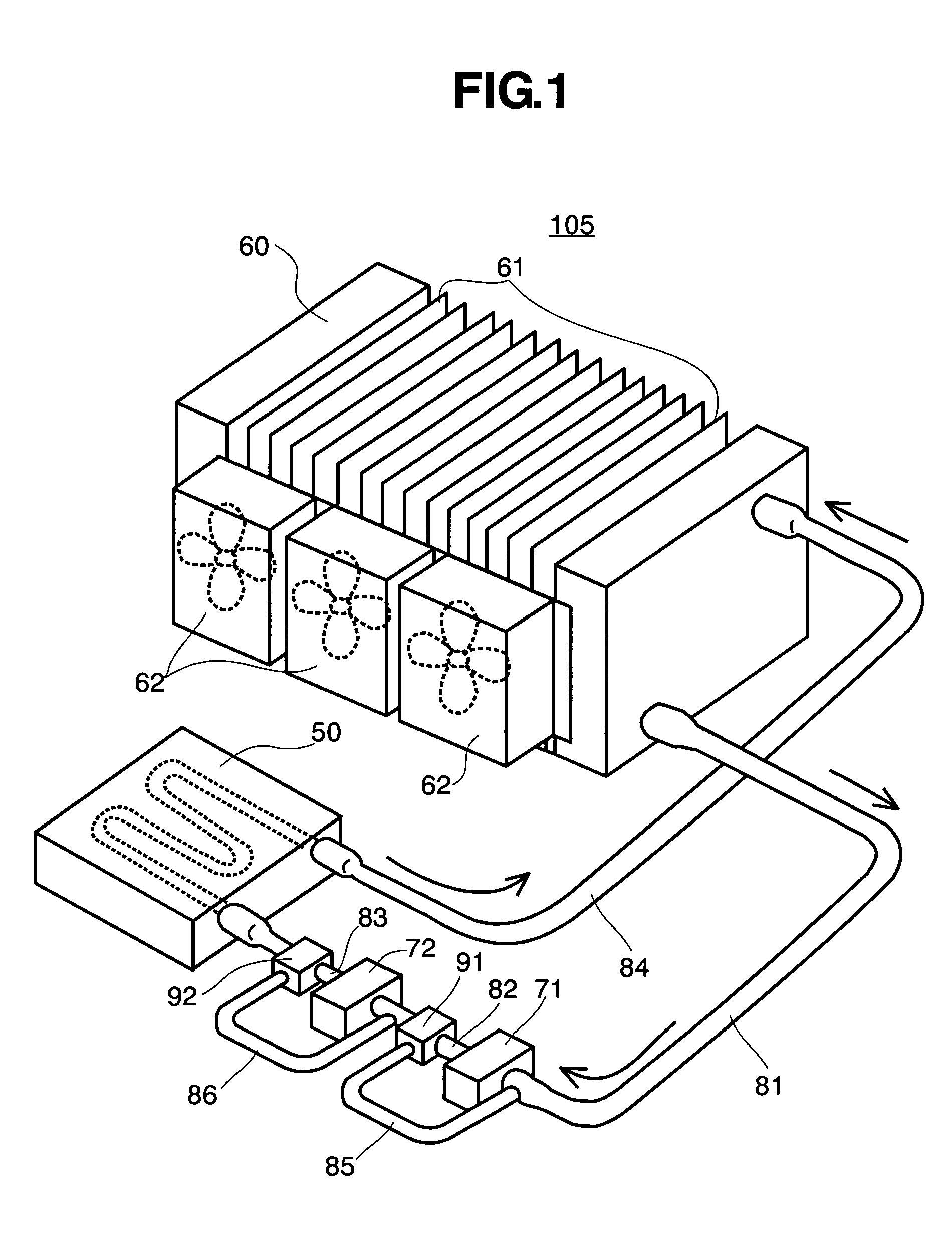

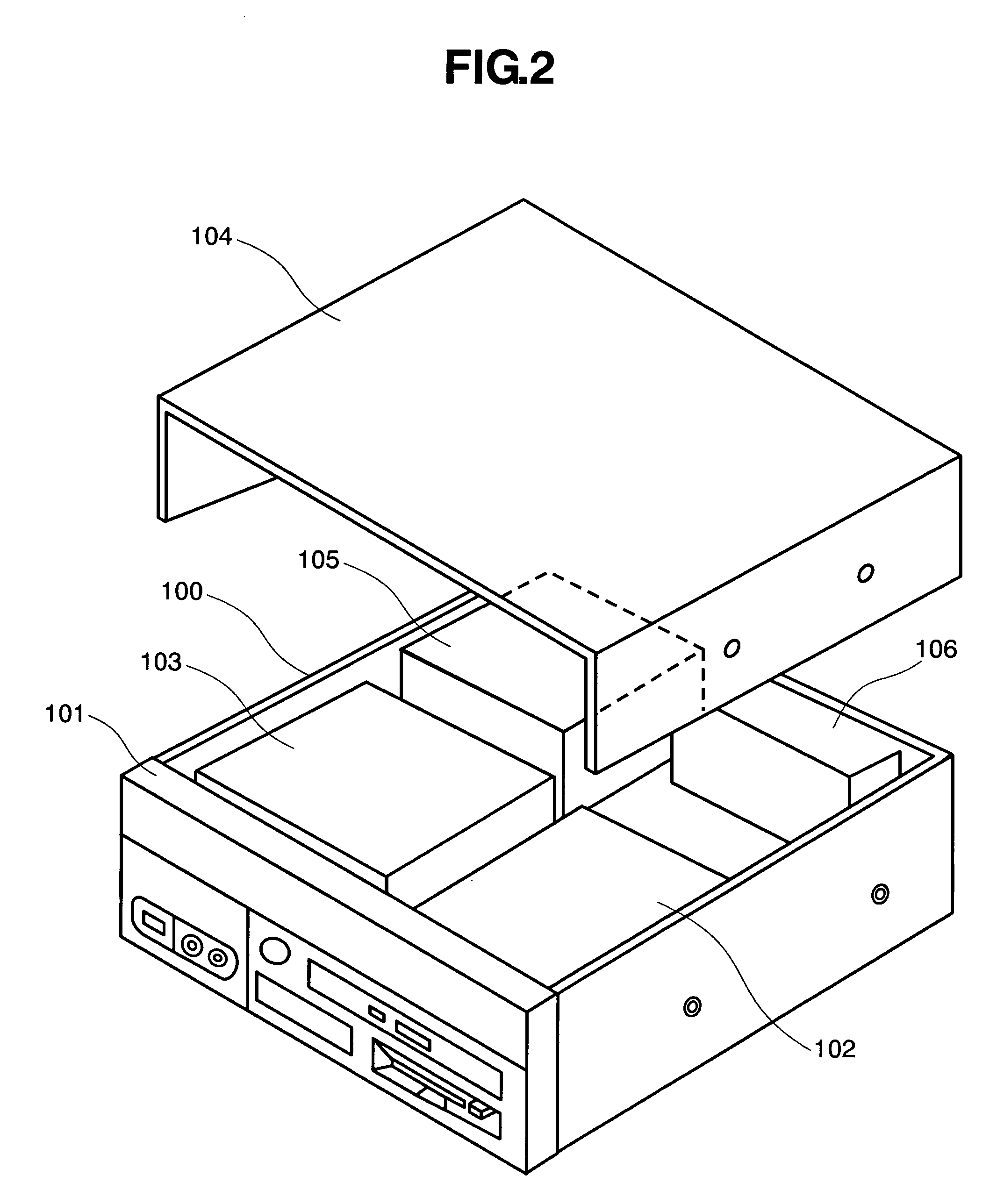

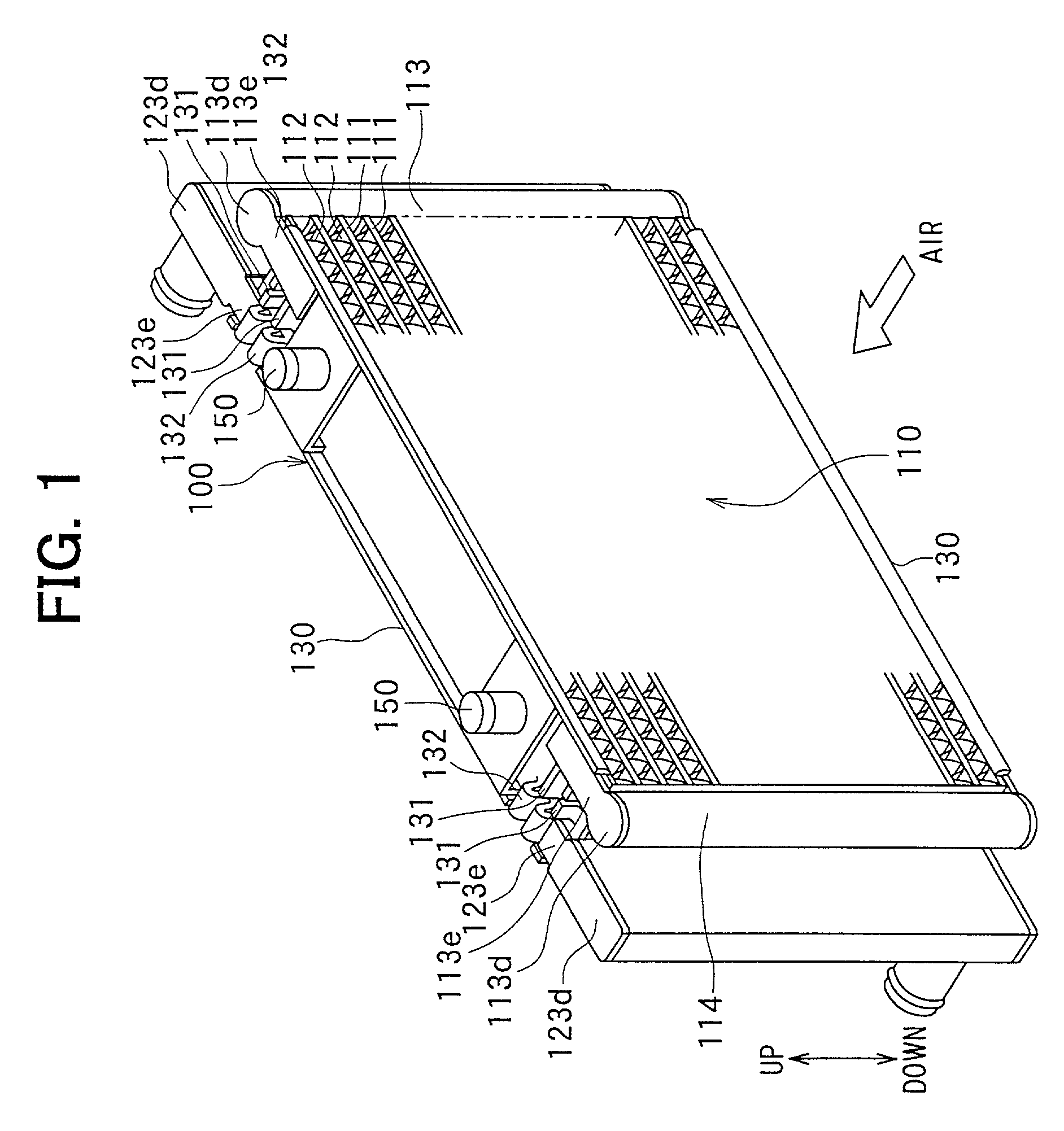

Redundant liquid cooling system and electronic apparatus having the same therein

ActiveUS7149084B2Improve cooling efficiencySuitable for useDomestic cooling apparatusDigital data processing detailsNuclear engineeringLiquid cooling system

Owner:MAXELL HLDG LTD

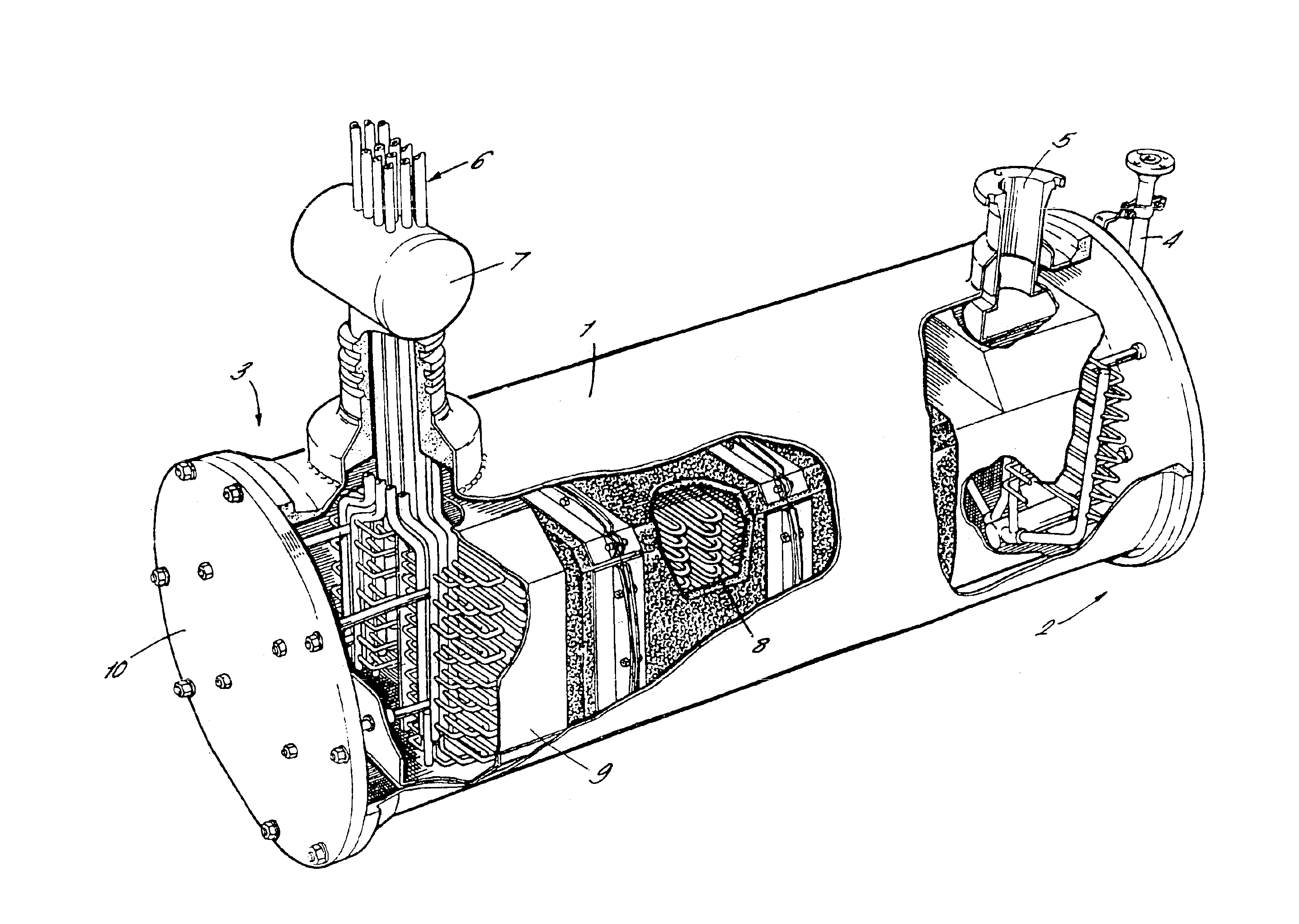

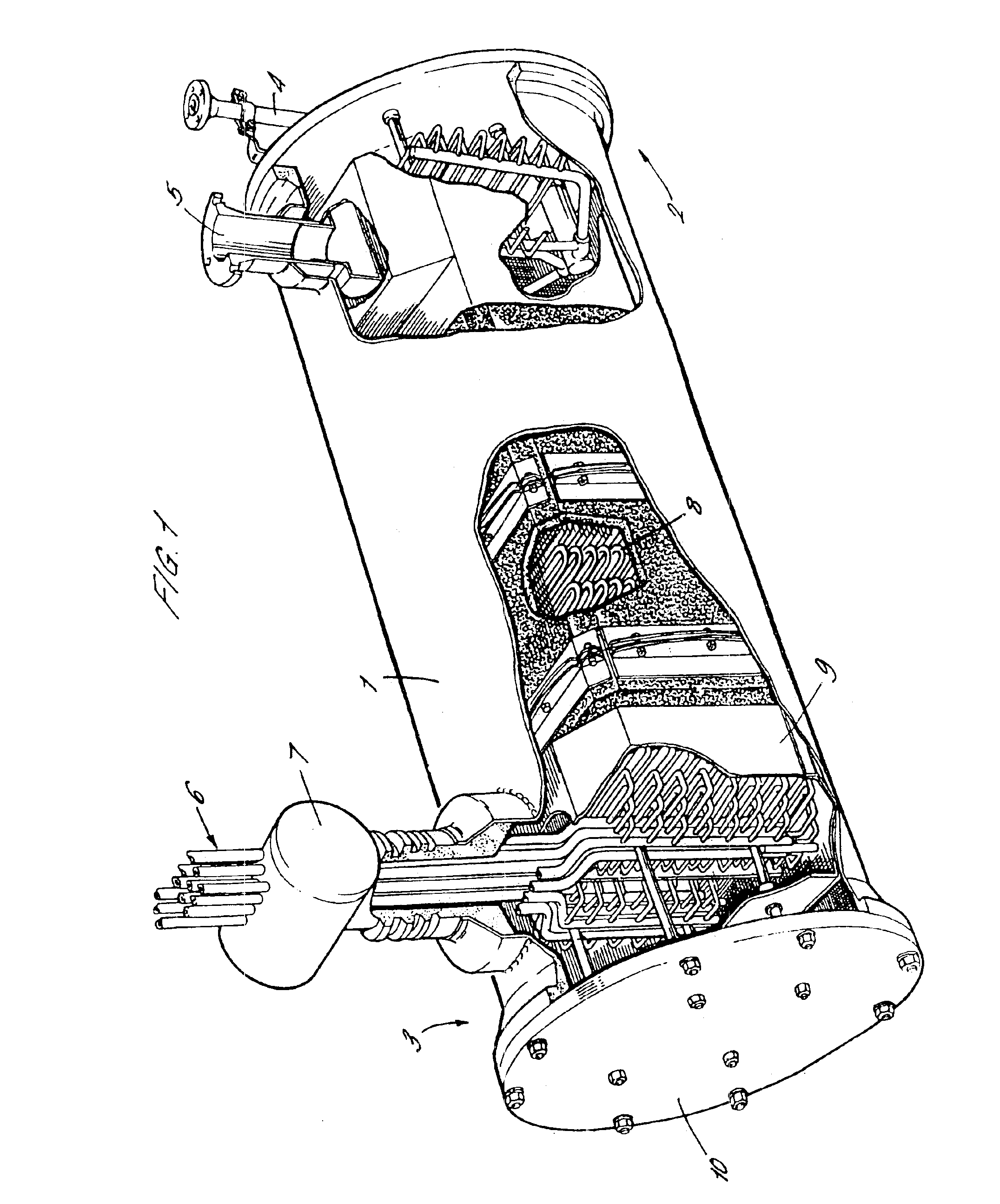

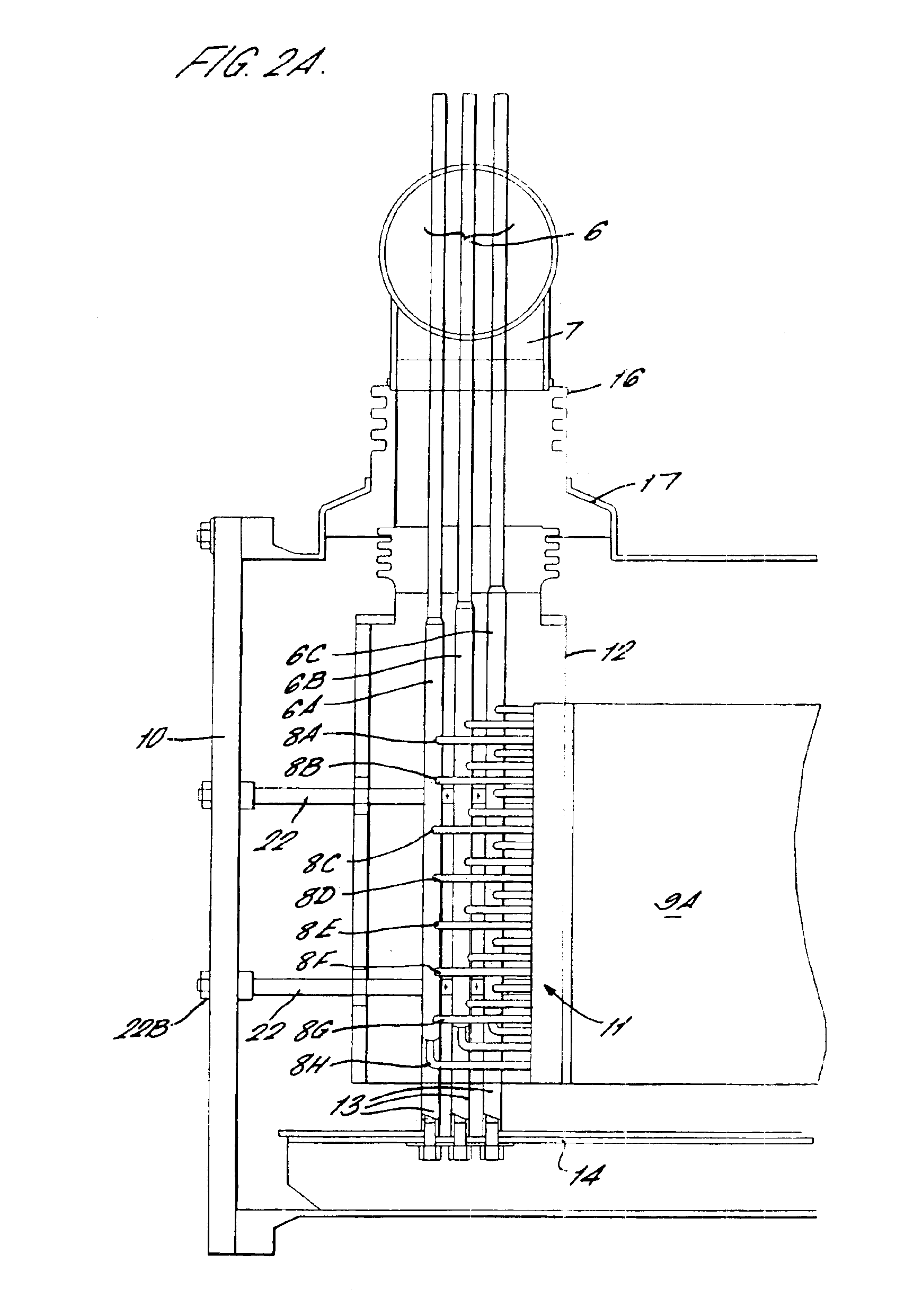

Heat exchanger

InactiveUS6840309B2Increase temperatureEasy to disassembleThermal insulationExhaust apparatusThermal insulationEngineering

A heat exchanger comprising a pressure vessel (1). A plurality of serpentines (8) convey a fluid to be heated through the pressure vessel (1) in one direction. A duct (9) surrounding the serpentines (8) conveys a second fluid in the opposite direction to give up its heat to the first fluid. The duct (9) is spaced from the pressure vessel (1) and is surrounded with thermal insulation (23). An opening in the duct (9) equalizes the pressure between the inside and the outside of the duct (9) which is also supported against expansion caused by the pressure inside the duct (9) exceeding the pressure outside the duct (9).

Owner:INNOGY

Modified heat pipe for phase change cooling of electronic devices

InactiveUS20100300654A1Improve cooling effectIncrease volumeSafety devices for heat exchange apparatusSemiconductor/solid-state device detailsEngineeringPhase change

Exemplary embodiments provide a heat pipe including a flexible chamber that is capable of expanding, compressing and / or restoring. In one embodiment, the heat pipe can include a hollow metal casing including a pipe structure connected to an expandable chamber at one end of the pipe structure. The other end of the pipe structure can include an evaporating section for receiving heat and the expandable chamber can include a condensing section for releasing the heat. The expandable chamber can be configured to change in volume to control one or both of a temperature and a pressure in the hollow metal casing. The heat pipe can also include a capillary system arranged at an inner surface of the hollow metal casing that includes the pipe structure and the expandable chamber.

Owner:TEXAS INSTR INC

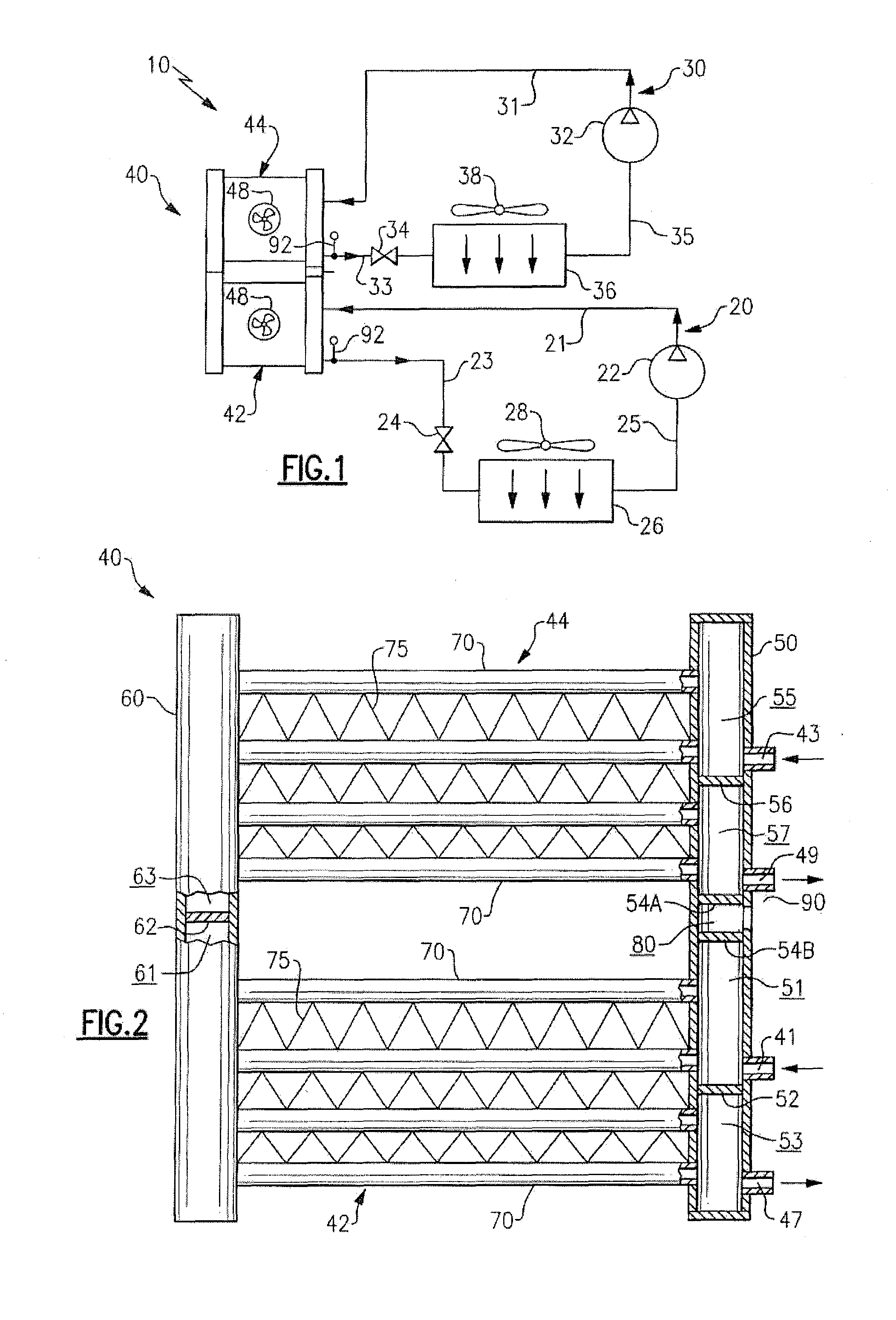

Multi-circuit heat exchanger

InactiveUS20120011867A1Preventing fluid cross-contaminationSafety devices for heat exchange apparatusCompression machines with non-reversible cycleEngineeringMechanical engineering

A baffle assembly is disposed within a manifold of a multi-circuit heat exchanger for dividing the interior volume of that manifold into a first chamber associated with one circuit and a second chamber associated with another circuit. The baffle assembly includes a pair of baffle members that extend generally transversely across the interior volume of the manifold are disposed in spaced apart relationship thereby forming a void space therebetween. The void space is in fluid communication with a region exterior of that manifold whereby any fluid leaking from either of the first or second chamber into the void space will be vented therefrom.

Owner:CARRIER CORP

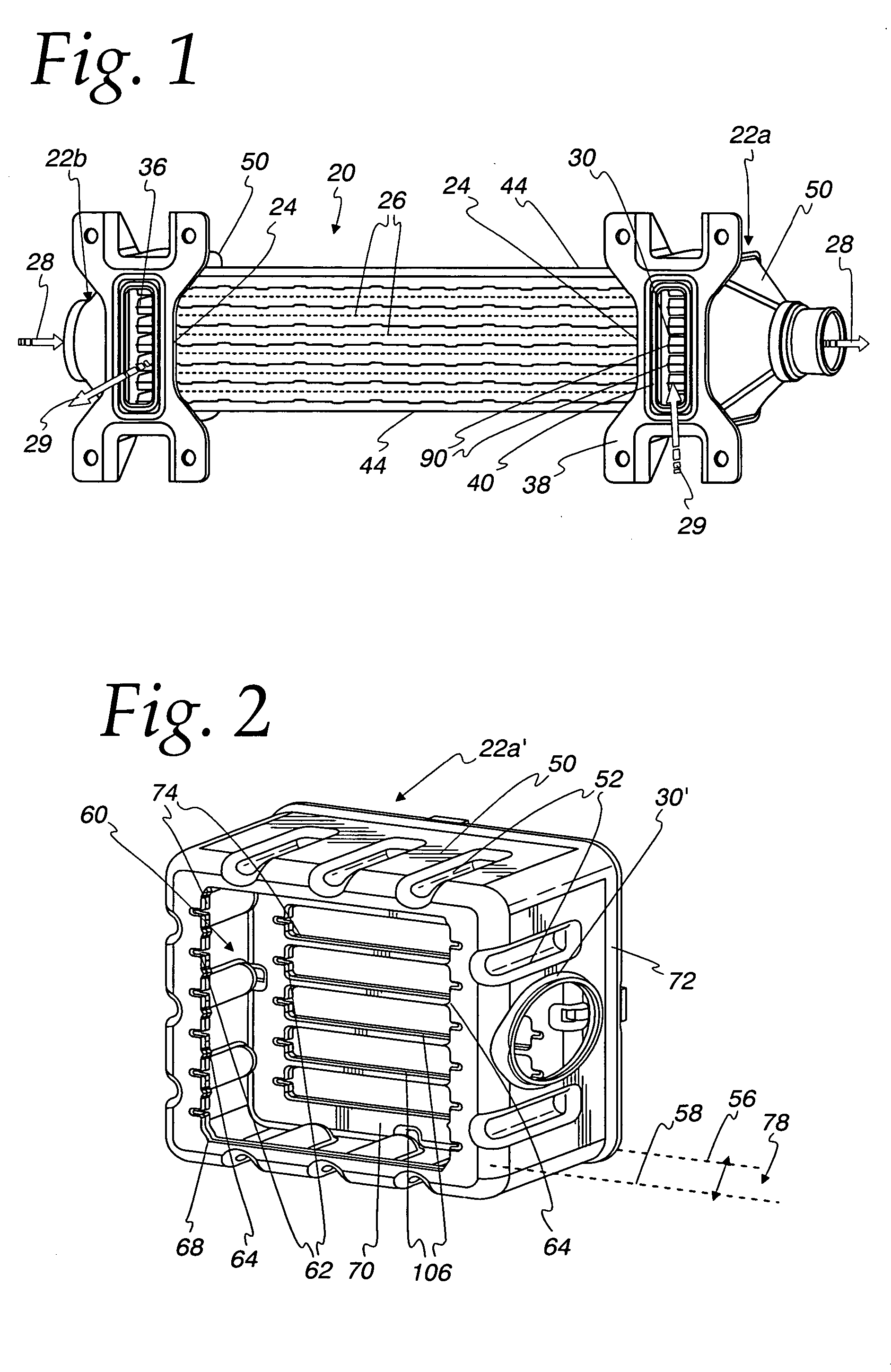

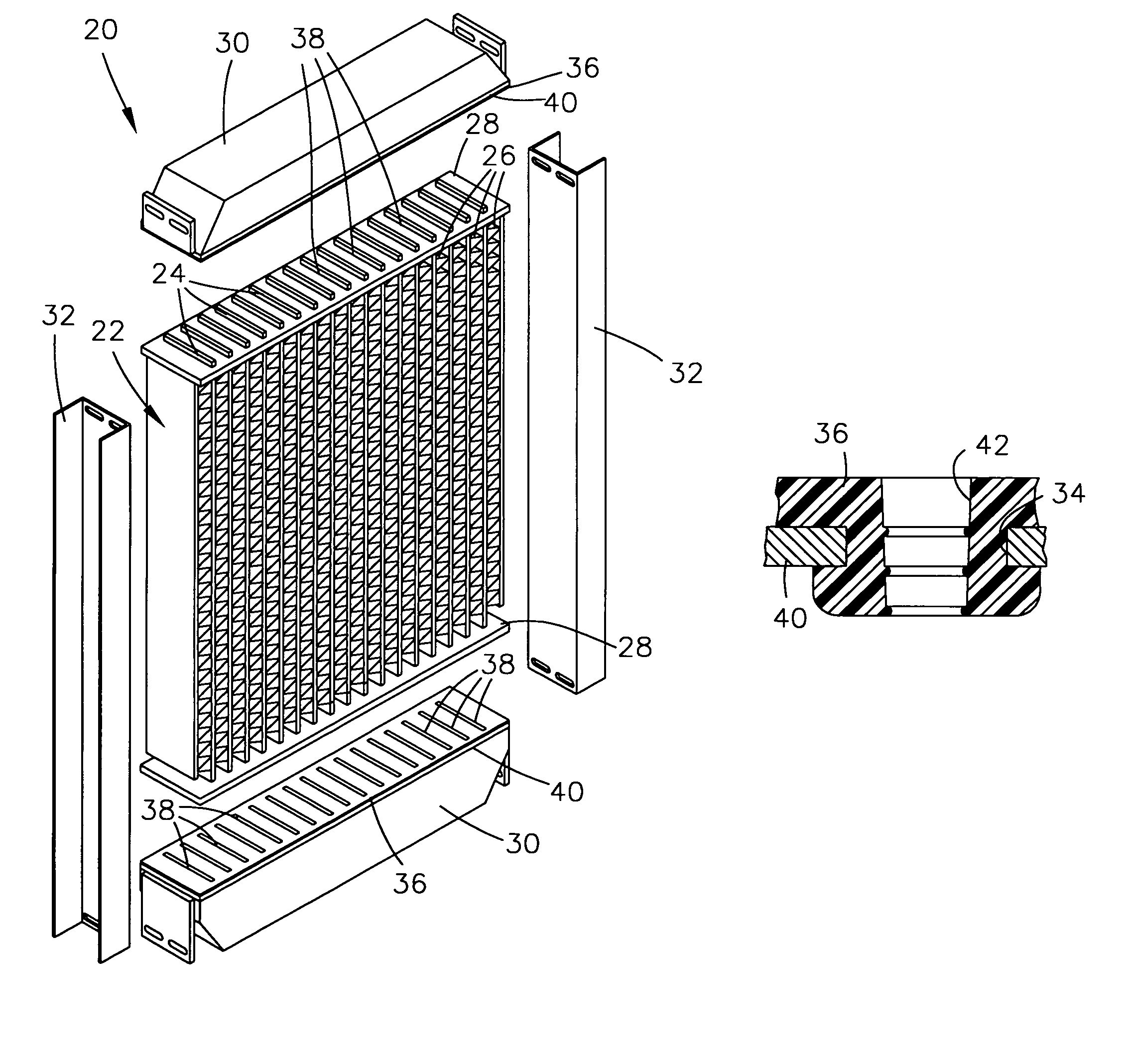

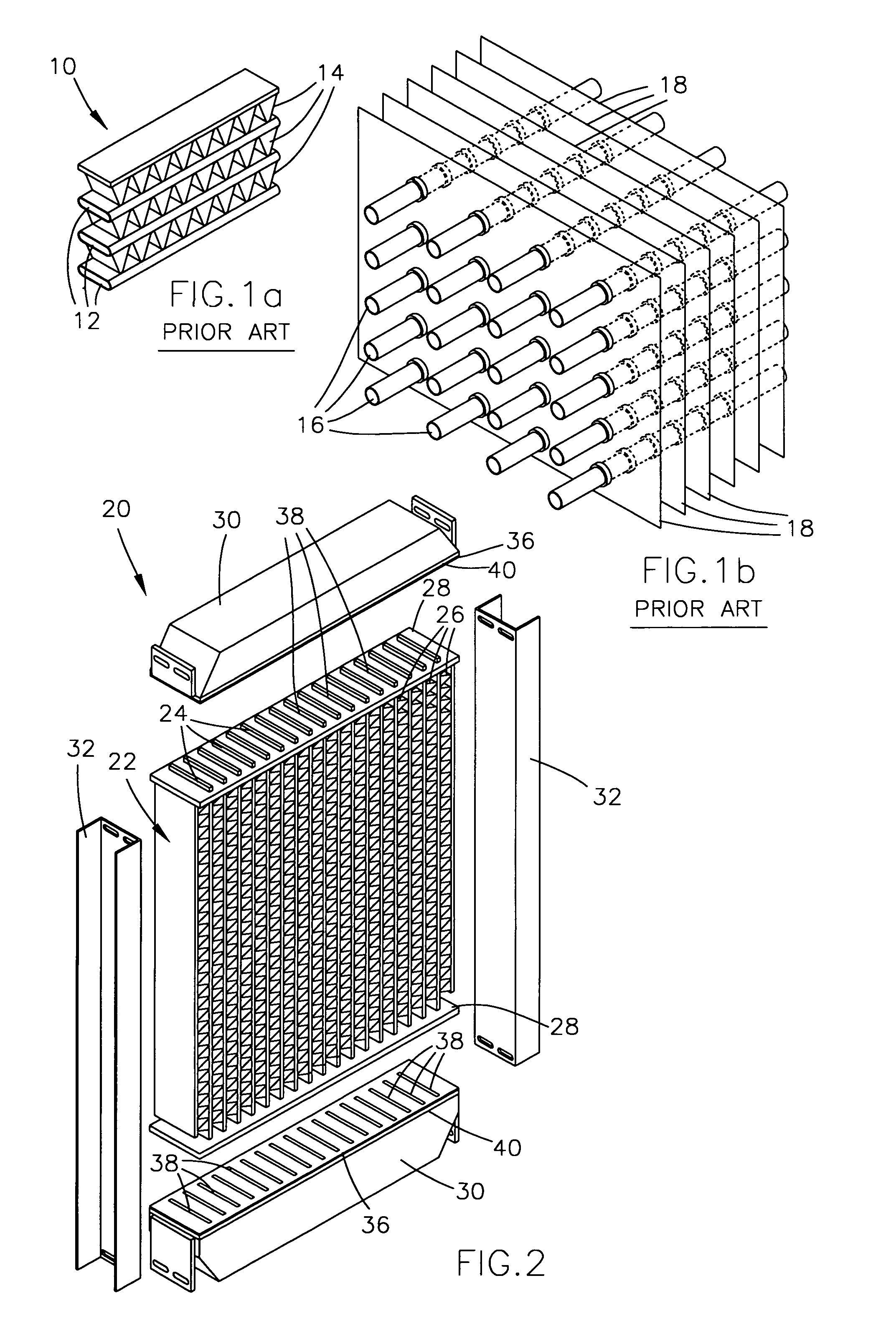

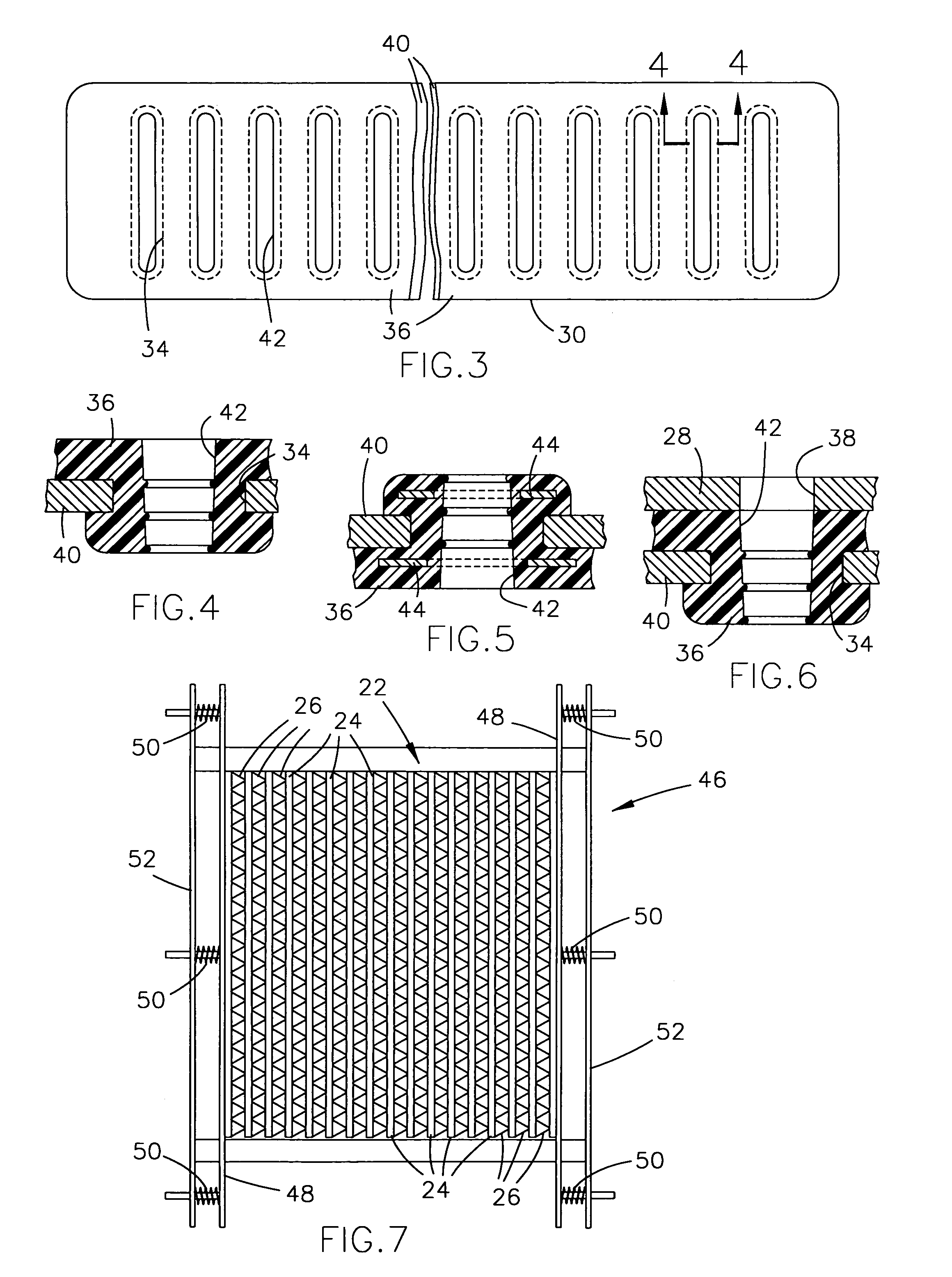

Modular heat exchanger having a brazed core and method for forming

InactiveUS7234511B1Improve heat transfer efficiencyReadily dismantled and rebuiltReinforcing meansSafety devices for heat exchange apparatusPosition toleranceNuclear engineering

An improved modular heat exchanger suitable for automotive applications, and particularly radiators for heavy duty equipment, and methods for forming the modular heat exchanger. The modular heat exchanger construction incorporates a brazed core assembly composed of flat-type cooling tubes and sinusoidal centers. The ability to use a brazed core assembly within a modular heat exchanger construction promotes enhanced heat transfer efficiencies associated with the use of flat tubes and sinusoidal centers, as compared to mechanically-joined round tubes and fins. The required positional tolerances of the tubes for mating with the remainder of the heat exchanger are maintained within the brazed core assembly by eliminating core shrinkage attributable to the use of clad aluminum alloy components to construct the core assembly. In two embodiments, core shrinkage is physical suppressed through the use of an expandable brazing fixture or the inclusion of sub-headers in the brazed core assembly. In a third embodiment, a clad slurry containing a braze alloy is deposited prior to brazing on a core assembly composed of unclad tubes and centers.

Owner:LESAGE PHILIP GEORGE

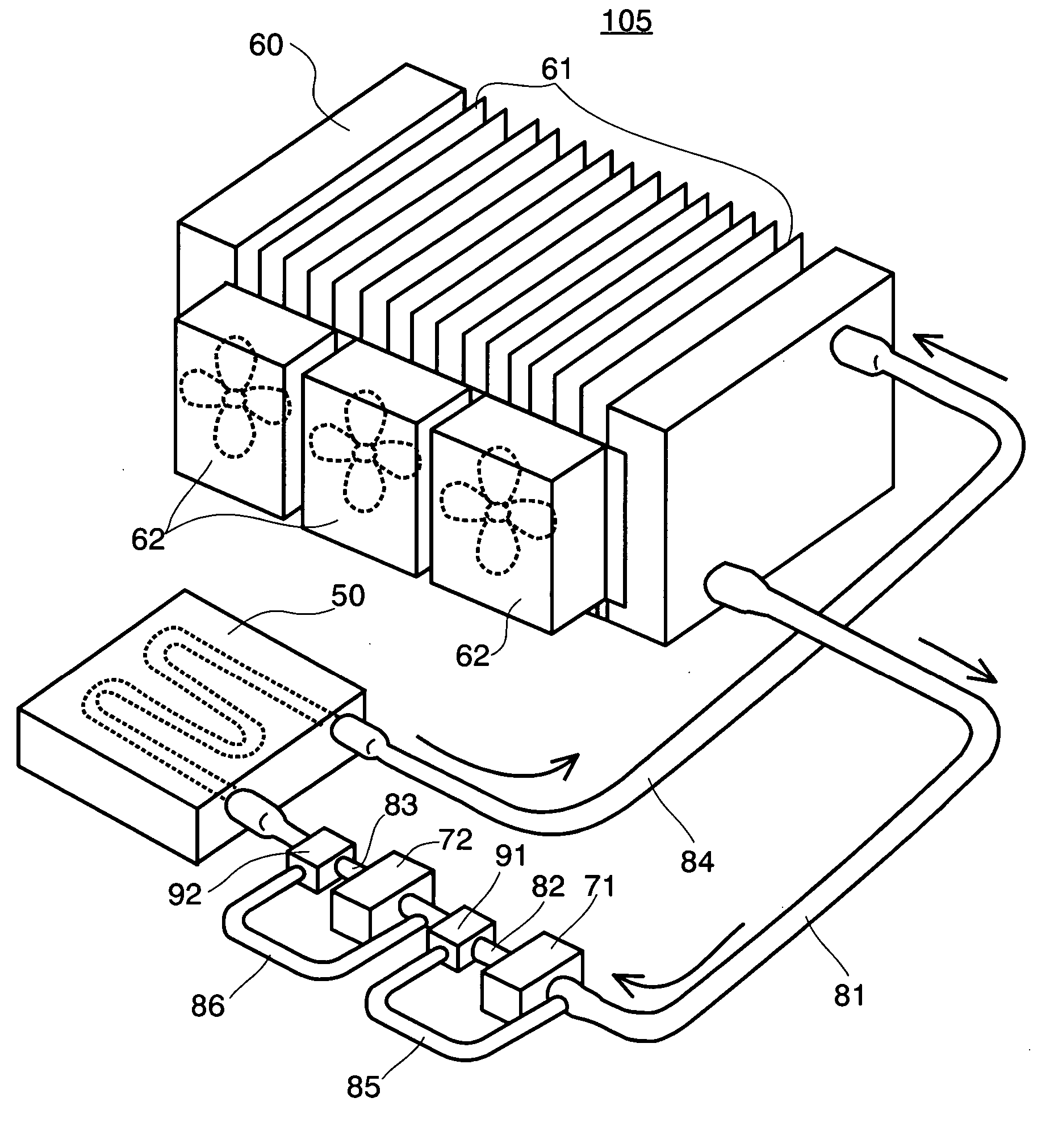

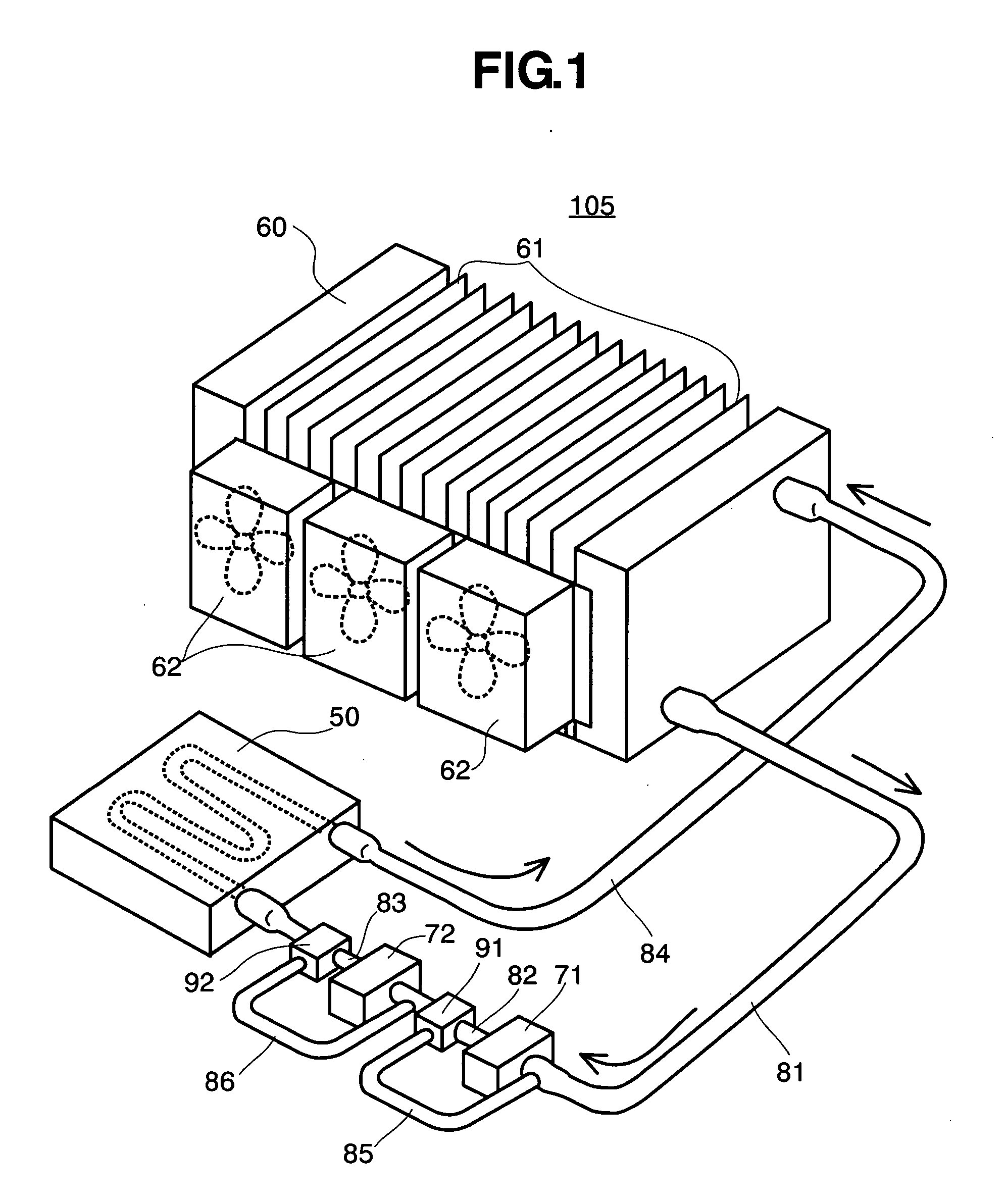

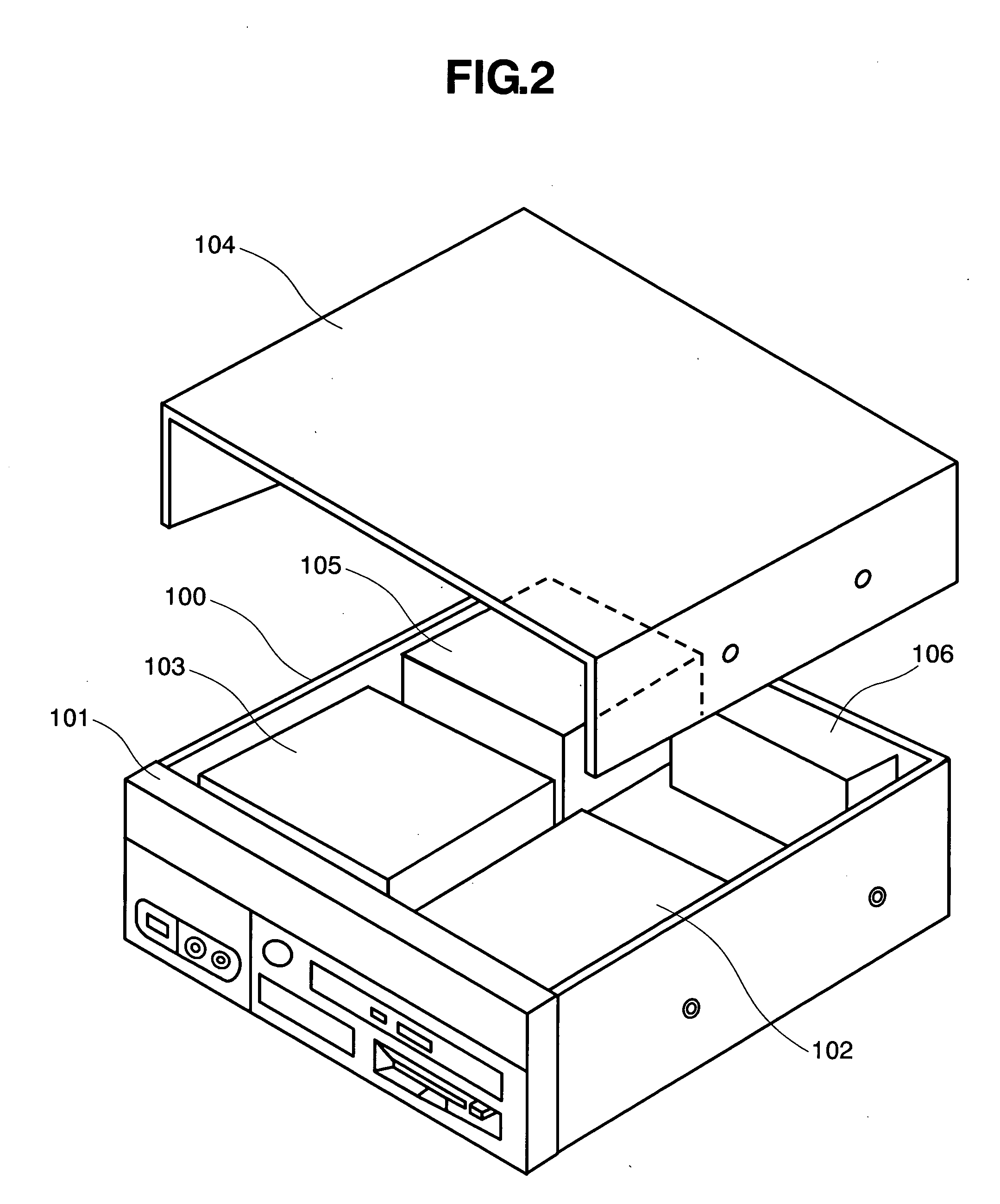

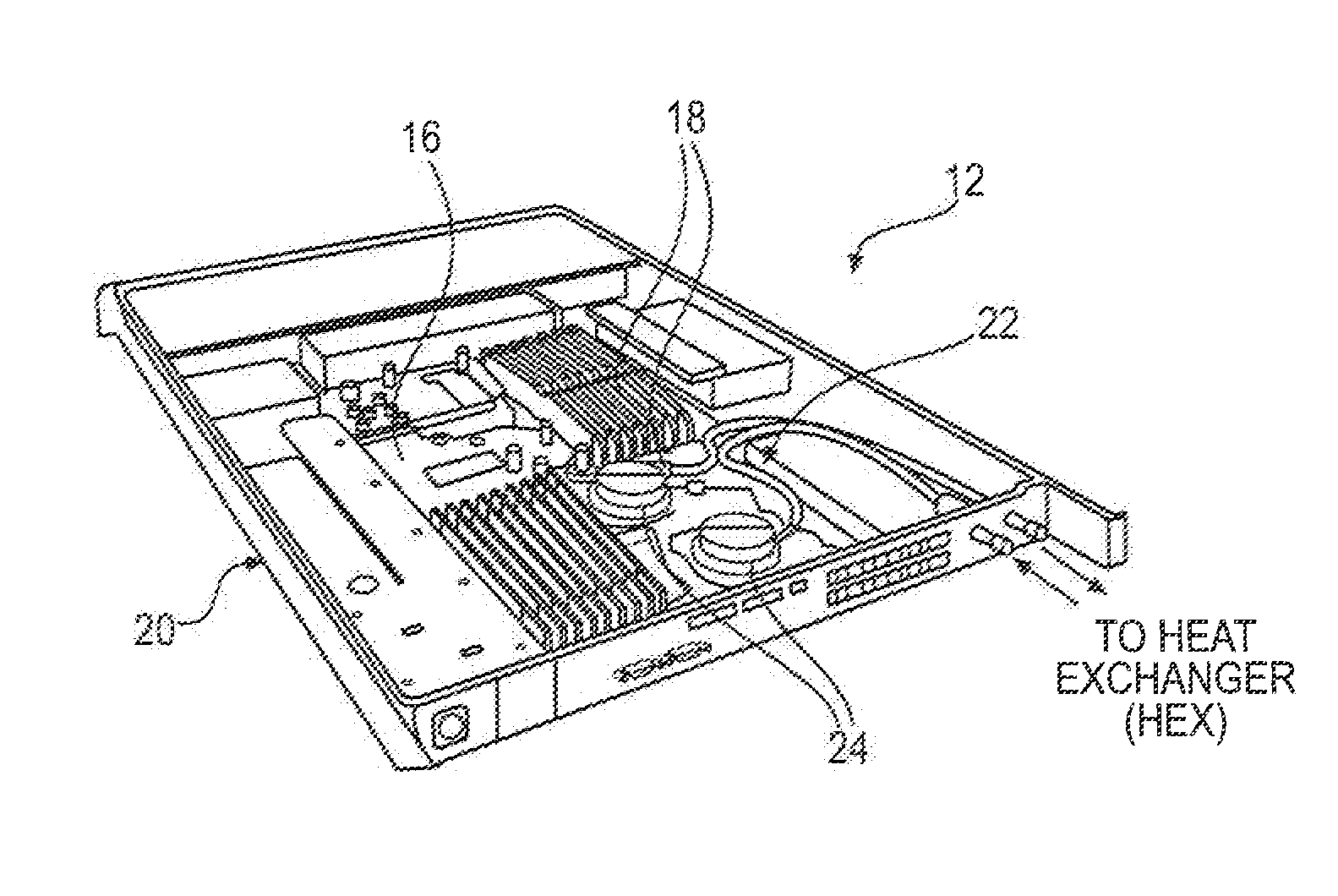

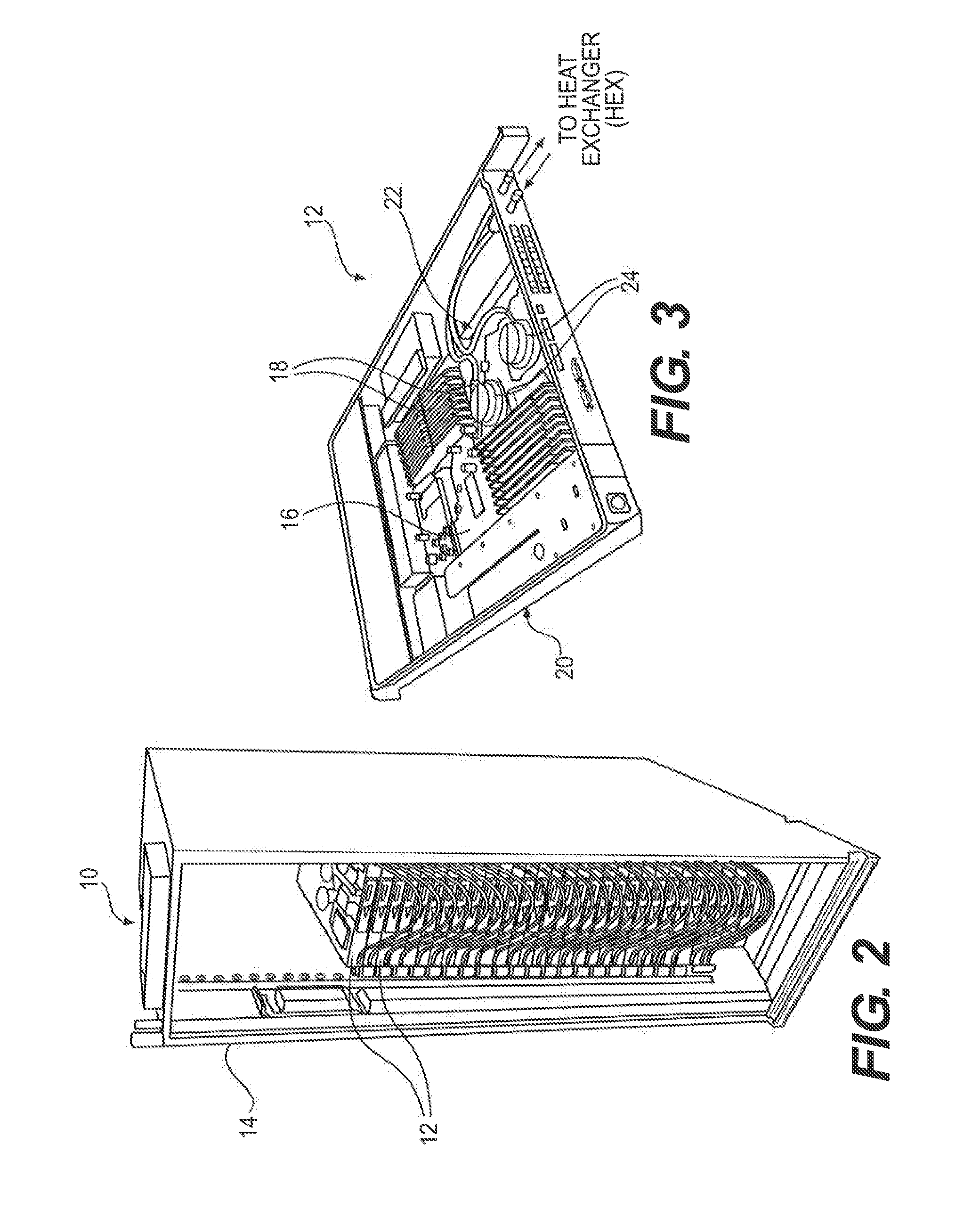

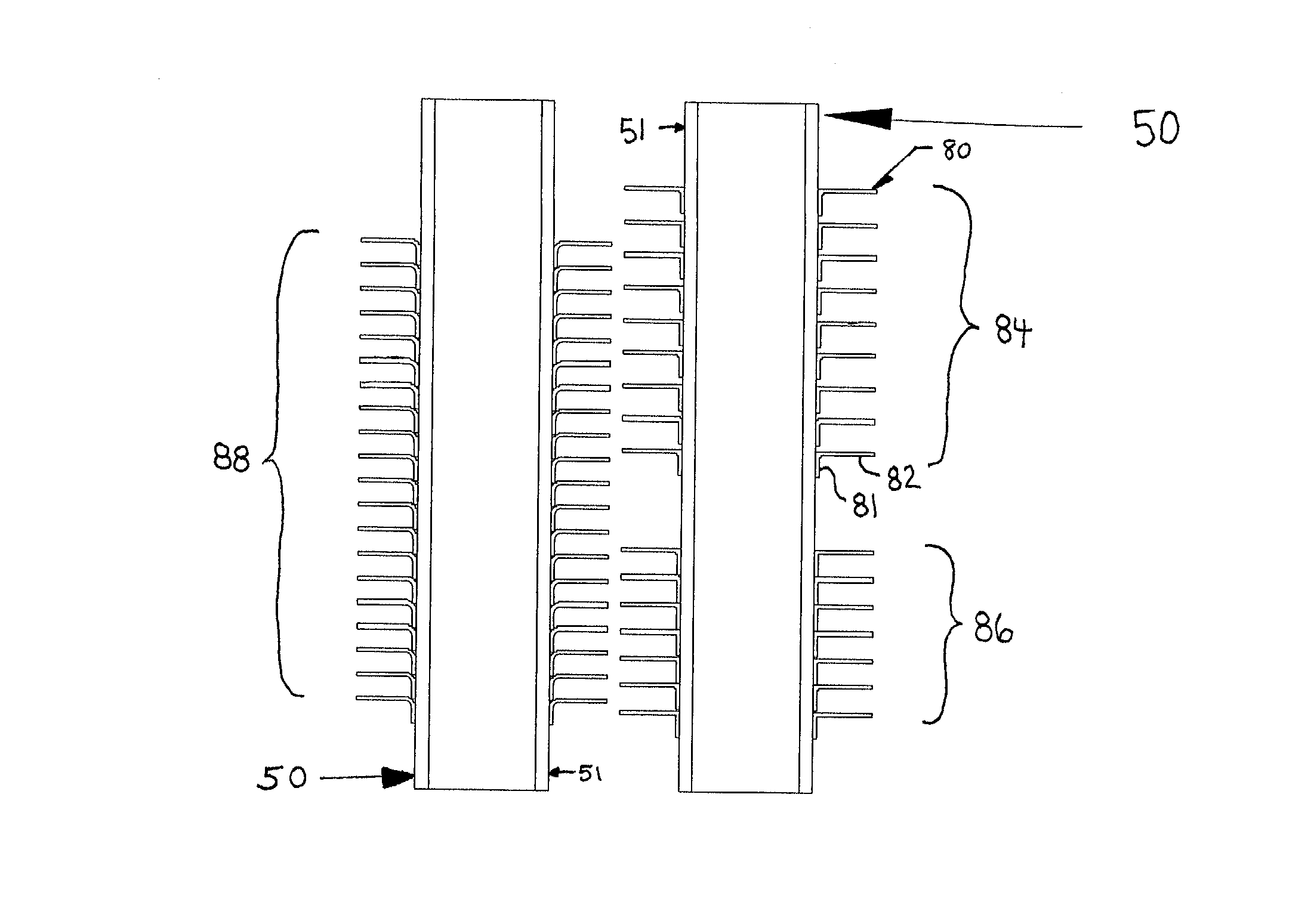

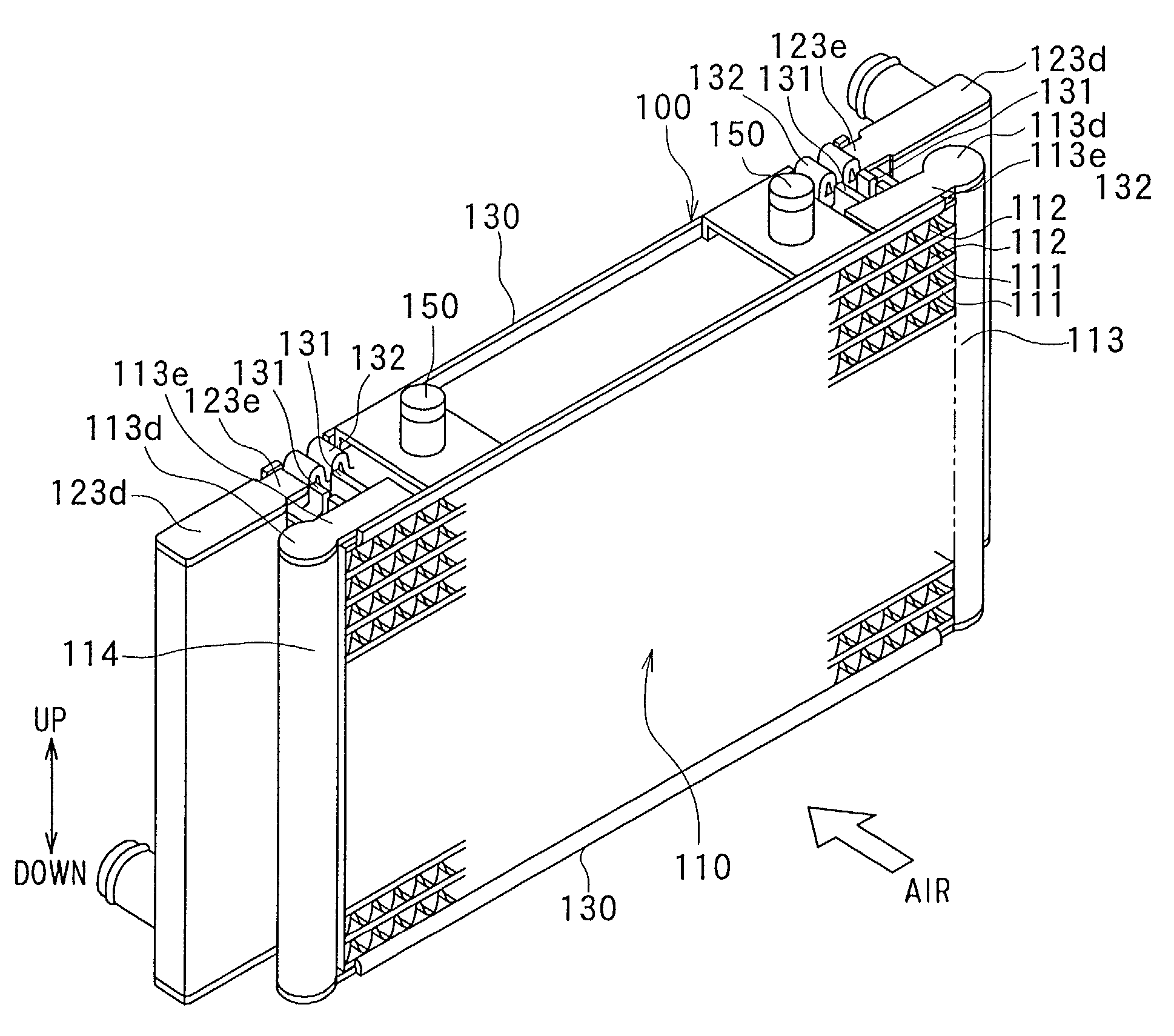

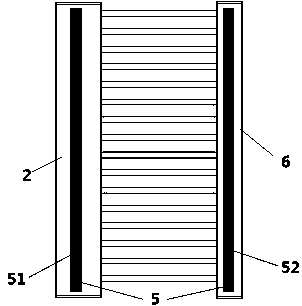

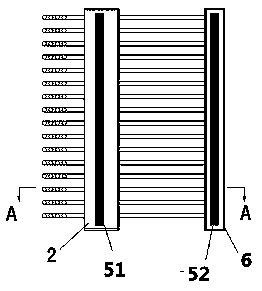

Redundant liquid cooling system and electronic apparatus having the same therein

ActiveUS20050180105A1Improve cooling efficiencySuitable for useDomestic cooling apparatusDigital data processing detailsNuclear engineeringLiquid cooling system

In an electronic apparatus, including personal computers, being called by a desktop type and a notebook type, as well as a server, etc., comprising a redundant cooling system, mounting a CPU 200 necessitating cooling in a housing 100, wherein a liquid cooling system for cooling the CPU comprises: a cooling jacket 50; a radiator 60; and two (2) sets of circulation pumps, and there are further provided check valves 91 and 92 and conduits 81, 82 . . . , so as to maintain circulation of the liquid coolant even when one of the two (2) sets of circulation pumps stops the function thereof, through the other circulation pump, thereby built up a redundant liquid cooling system.

Owner:MAXELL HLDG LTD

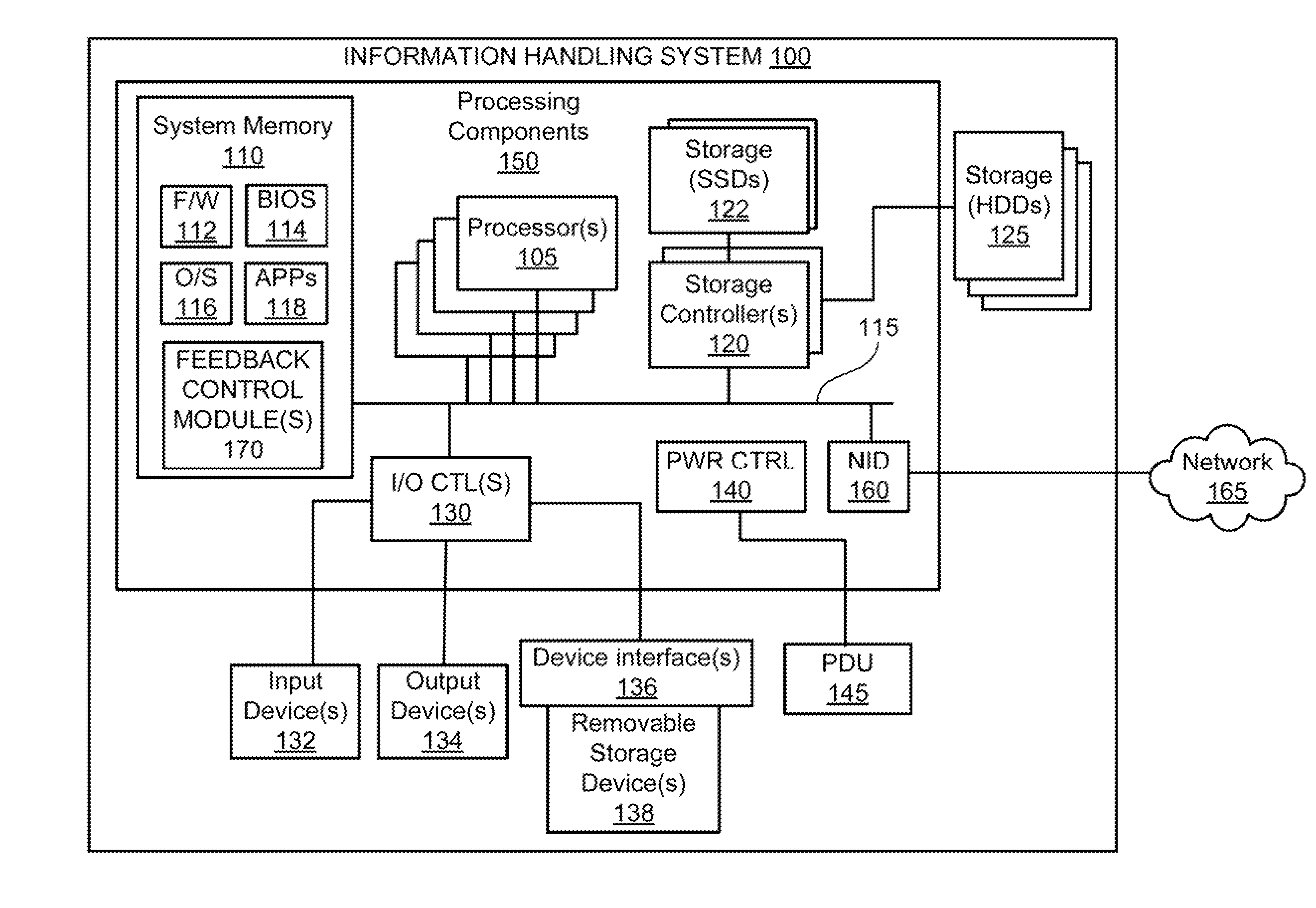

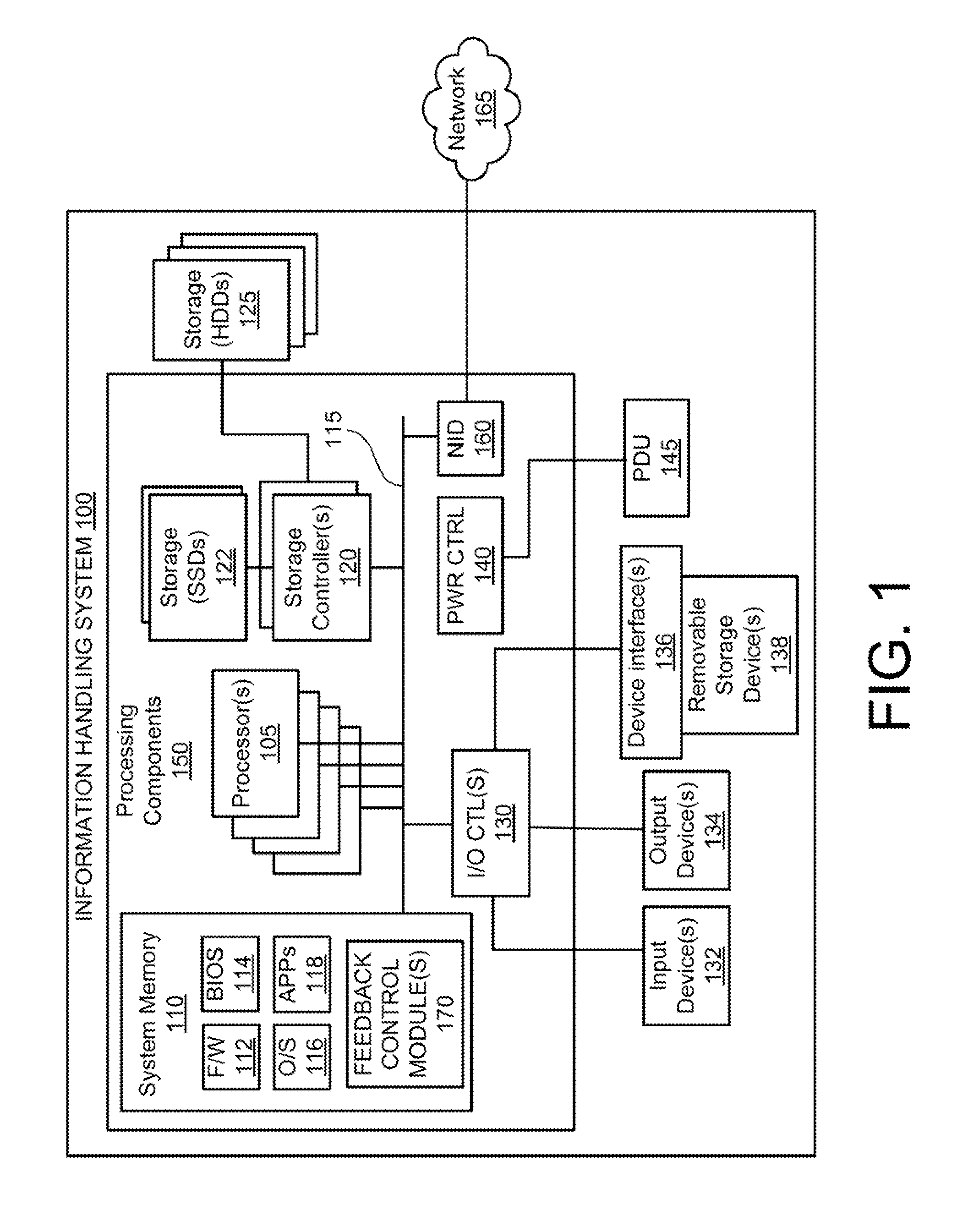

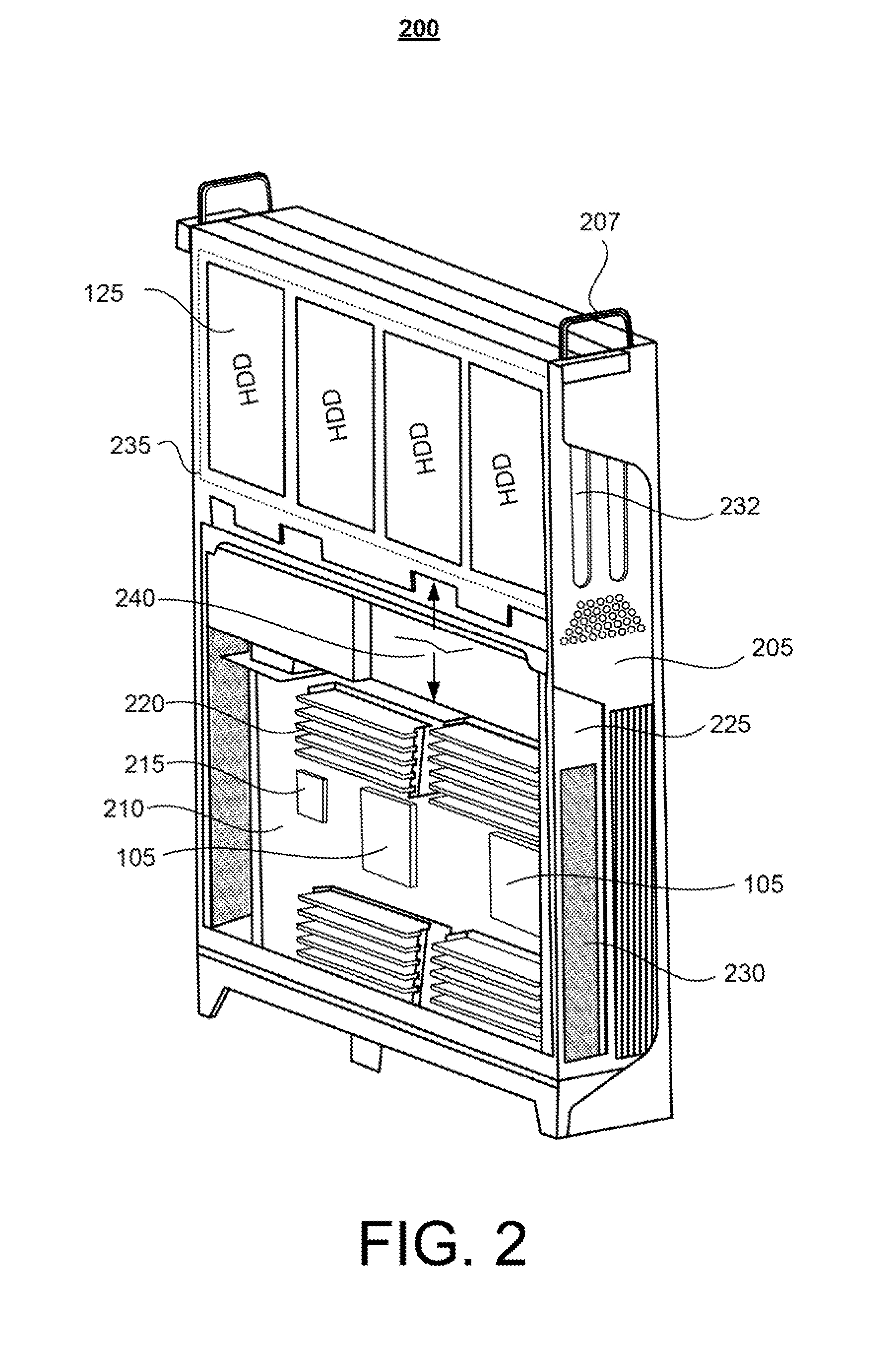

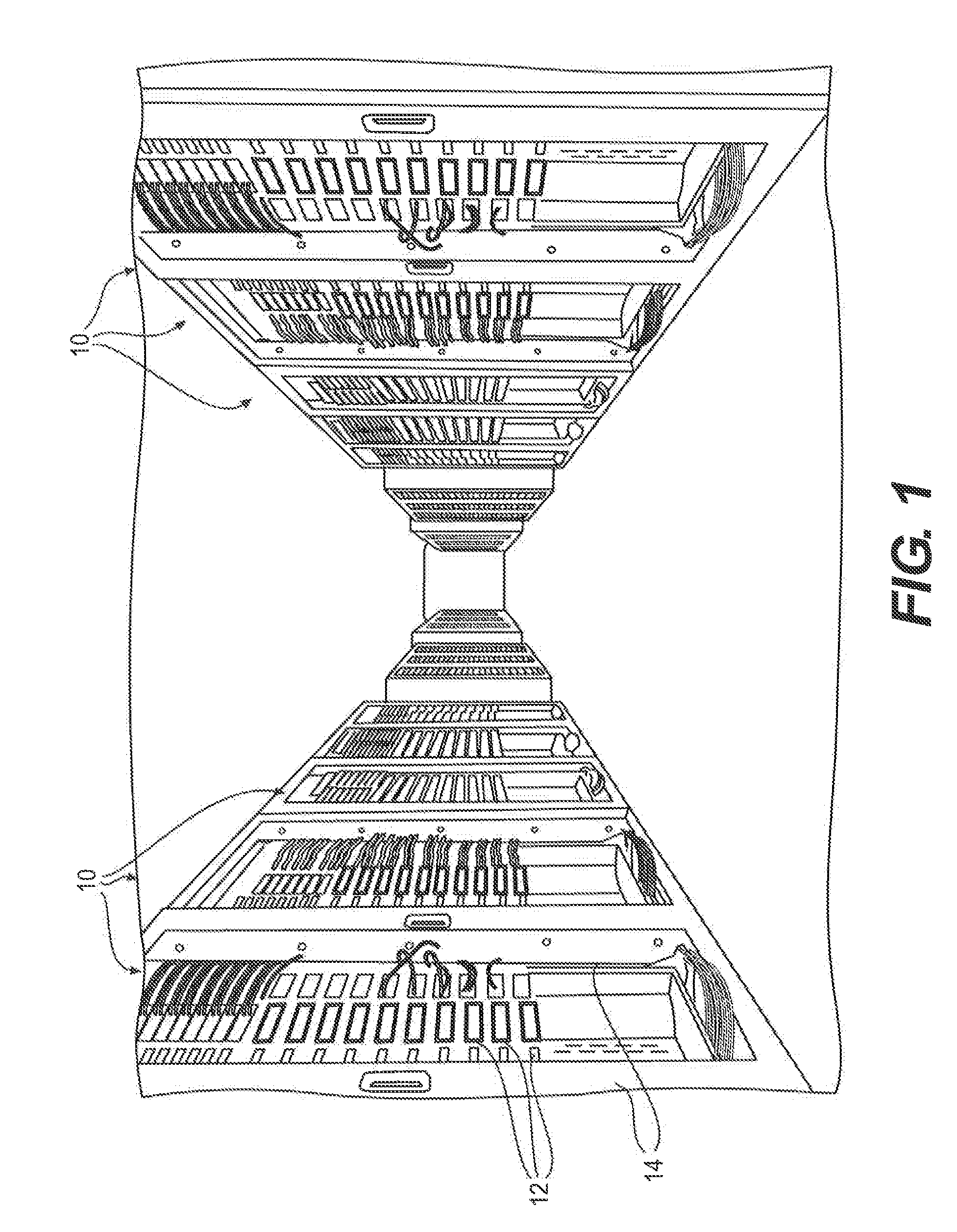

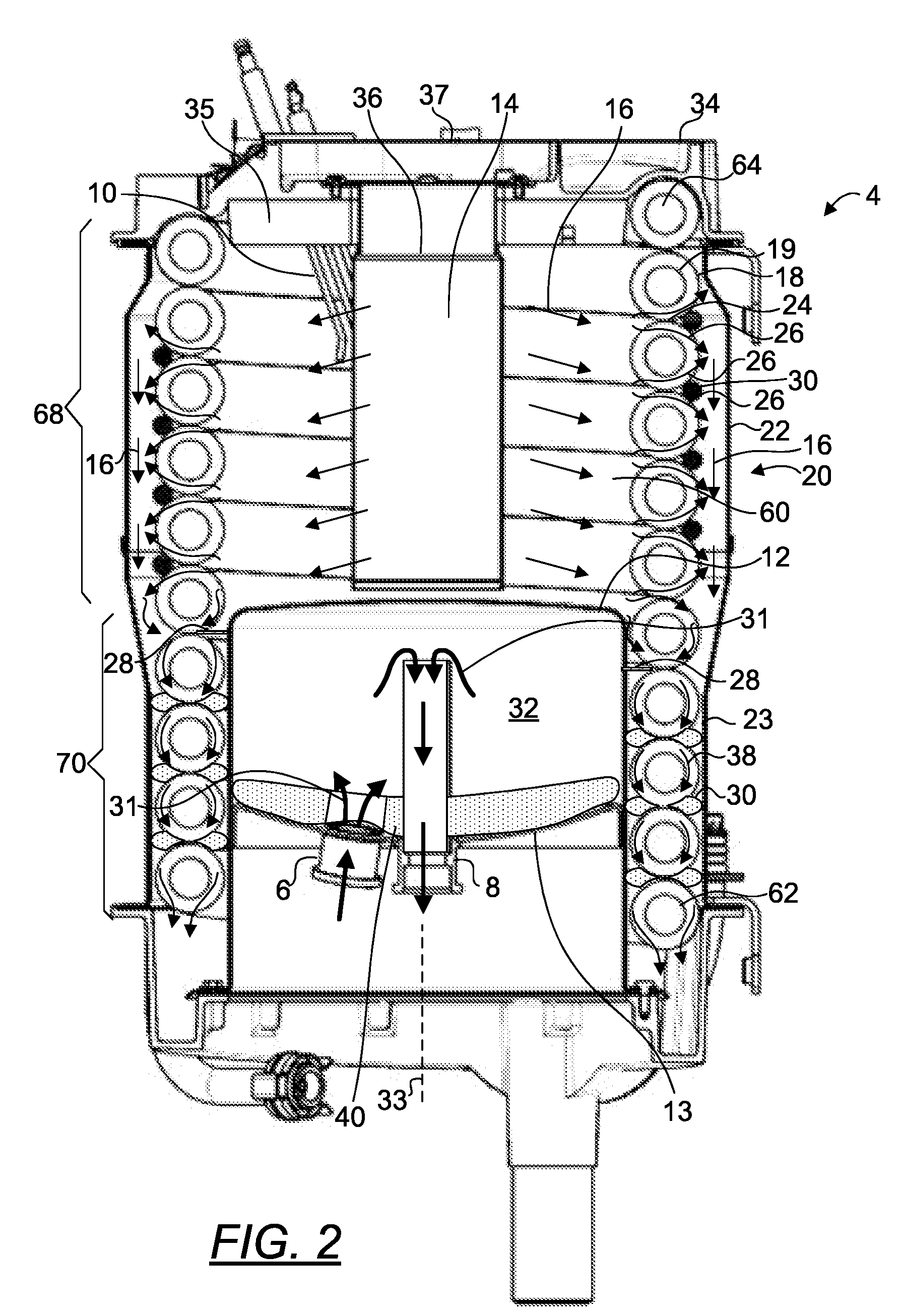

Partitioned, Rotating Condenser Units to Enable Servicing of Submerged IT Equipment Positioned Beneath a Vapor Condenser Without Interrupting a Vaporization-Condensation Cycling of the Remaining Immersion Cooling System

ActiveUS20140216686A1Safety devices for heat exchange apparatusDigital data processing detailsIt equipmentBoiling point

An immersion cooling tank includes: a tank comprised of a base wall, and perimeter walls, and having a lower tank volume in which a liquid can be maintained and heated to a boiling point to generate a rising plume of vapor; a rack structure within the tank volume that supports insertion of multiple, heat dissipating electronic devices in a side-by-side vertical configuration; and a condenser configured as a plurality of individually rotatable condenser sub-units, with each condenser sub-unit located above a vertical space that extends vertically from the lower tank volume and within which an electronic device can be inserted. Each individual condenser sub-unit can be opened independent of the other sub-units and each other condenser sub-unit can remain in a closed position while a first condenser sub-unit is opened to allow access to a first vertical space and any existing electrical device contained therein below the first condenser sub-unit.

Owner:DELL PROD LP

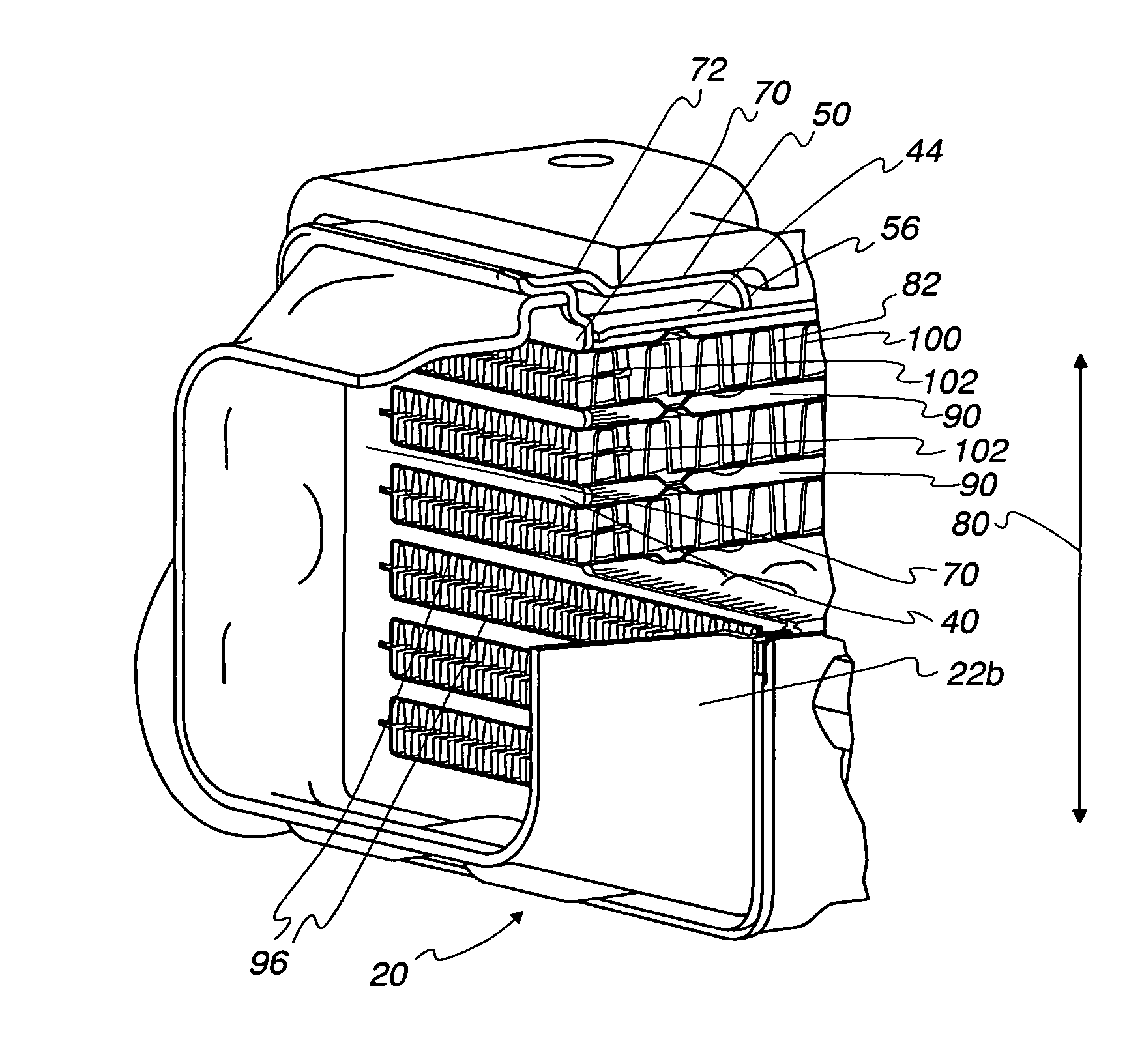

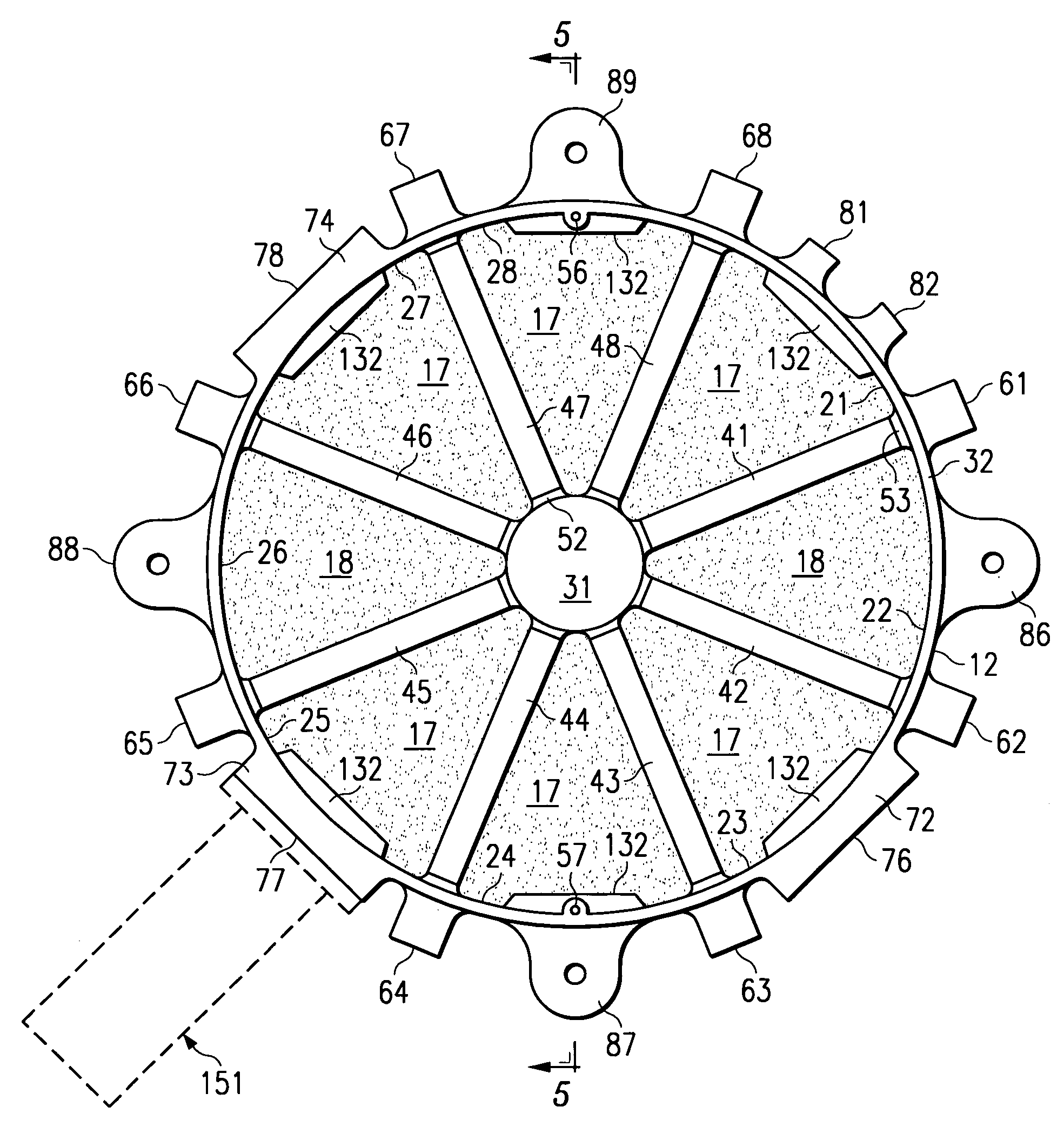

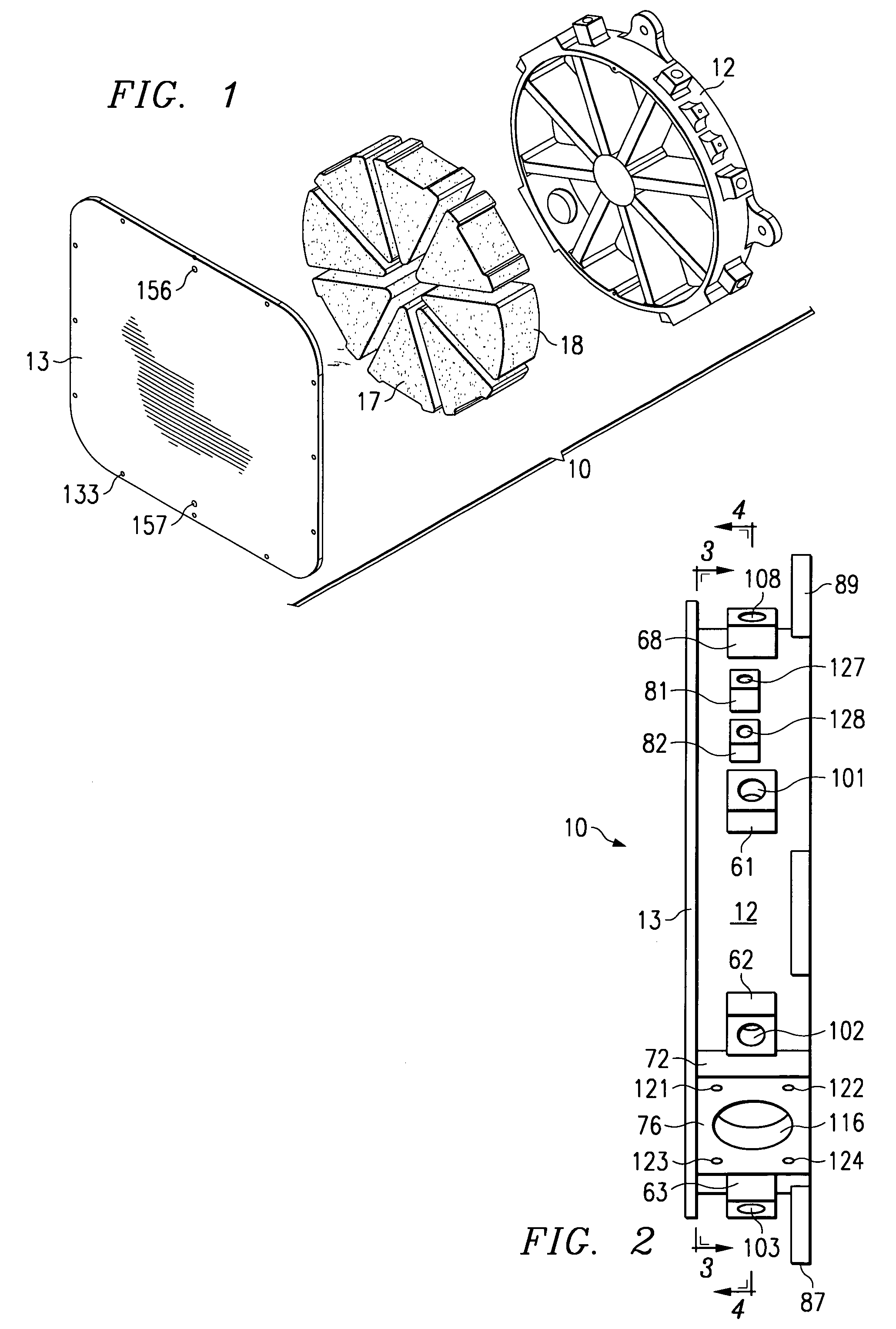

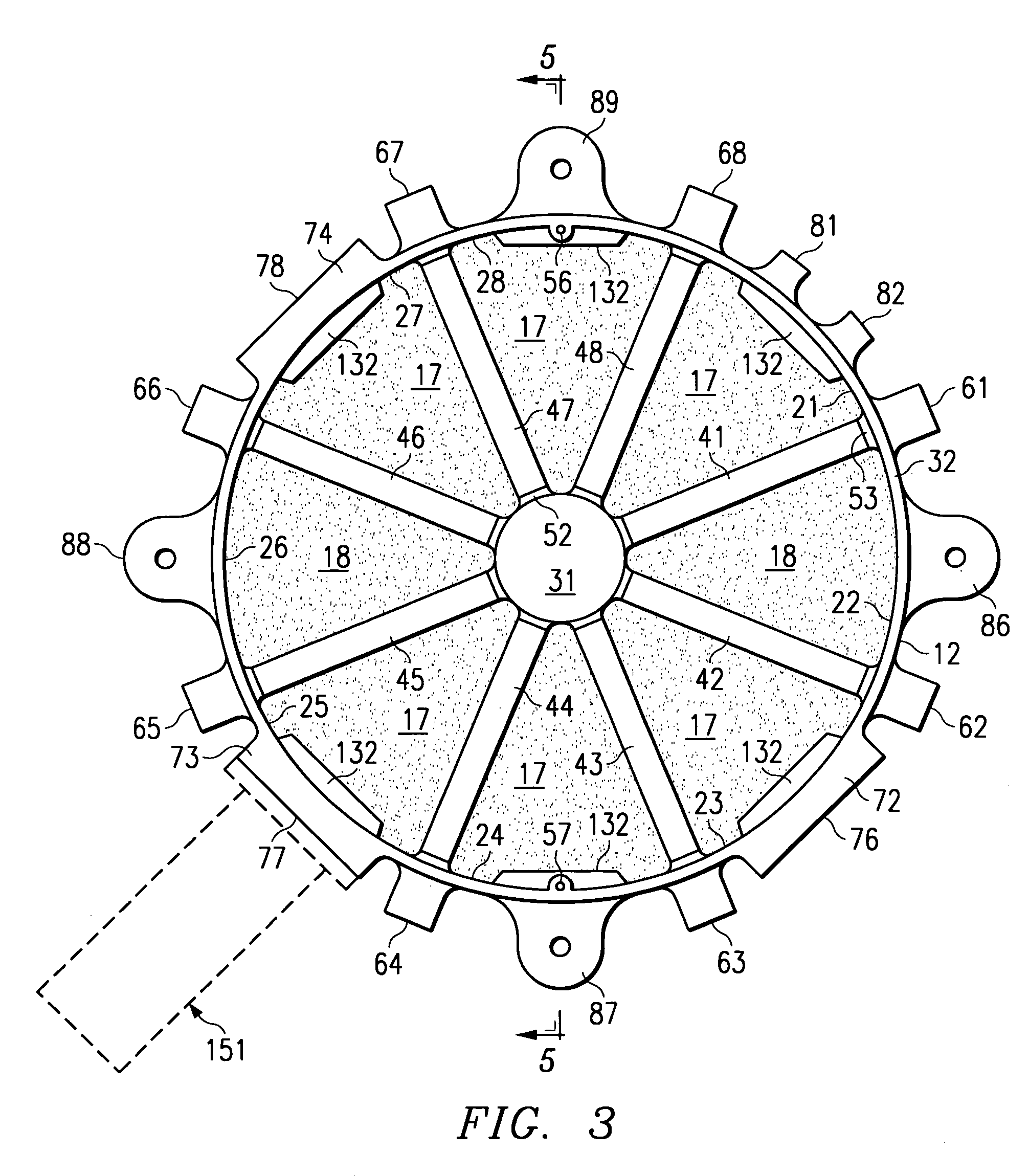

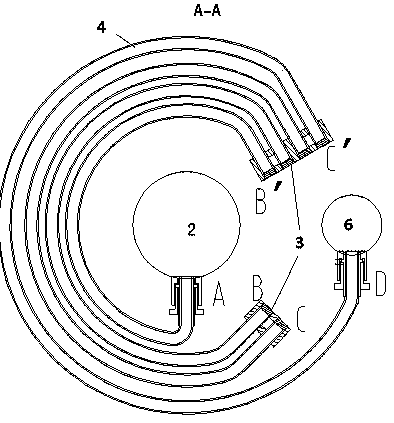

Method and apparatus for cooling with a phase change material and heat pipes

A cooling apparatus (10) includes a housing defined by two aluminum parts (12, 13) which are brazed to each other. A plurality of sector-shaped recesses (21–28) are provided within the housing, and collectively define a chamber having a plurality of ribs (41–48) extending therethrough. Each recess contains a sector-shaped piece of porous material (17, 18), which is brazed to surfaces of the housing parts. The remaining space within the chamber is filled with a phase change material. Each of the ribs has therein a respective radially extending opening (101–108) which contains a heat pipe (141). Expansion accumulators (151) are mounted on the housing, and communicate with the chamber therein, in order to accommodate expansion of the phase change material within the chamber as the phase change material is heated.

Owner:RAYTHEON CO

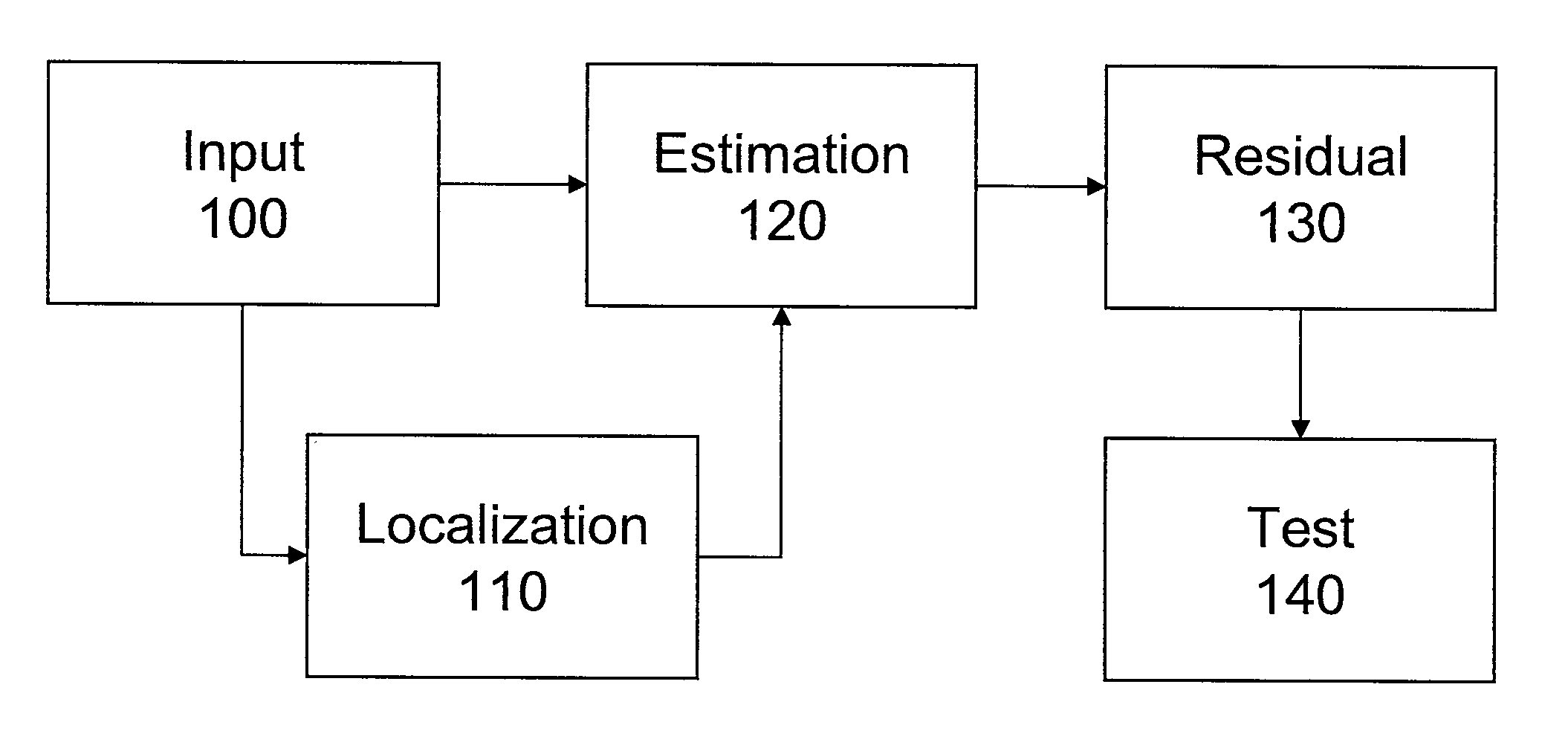

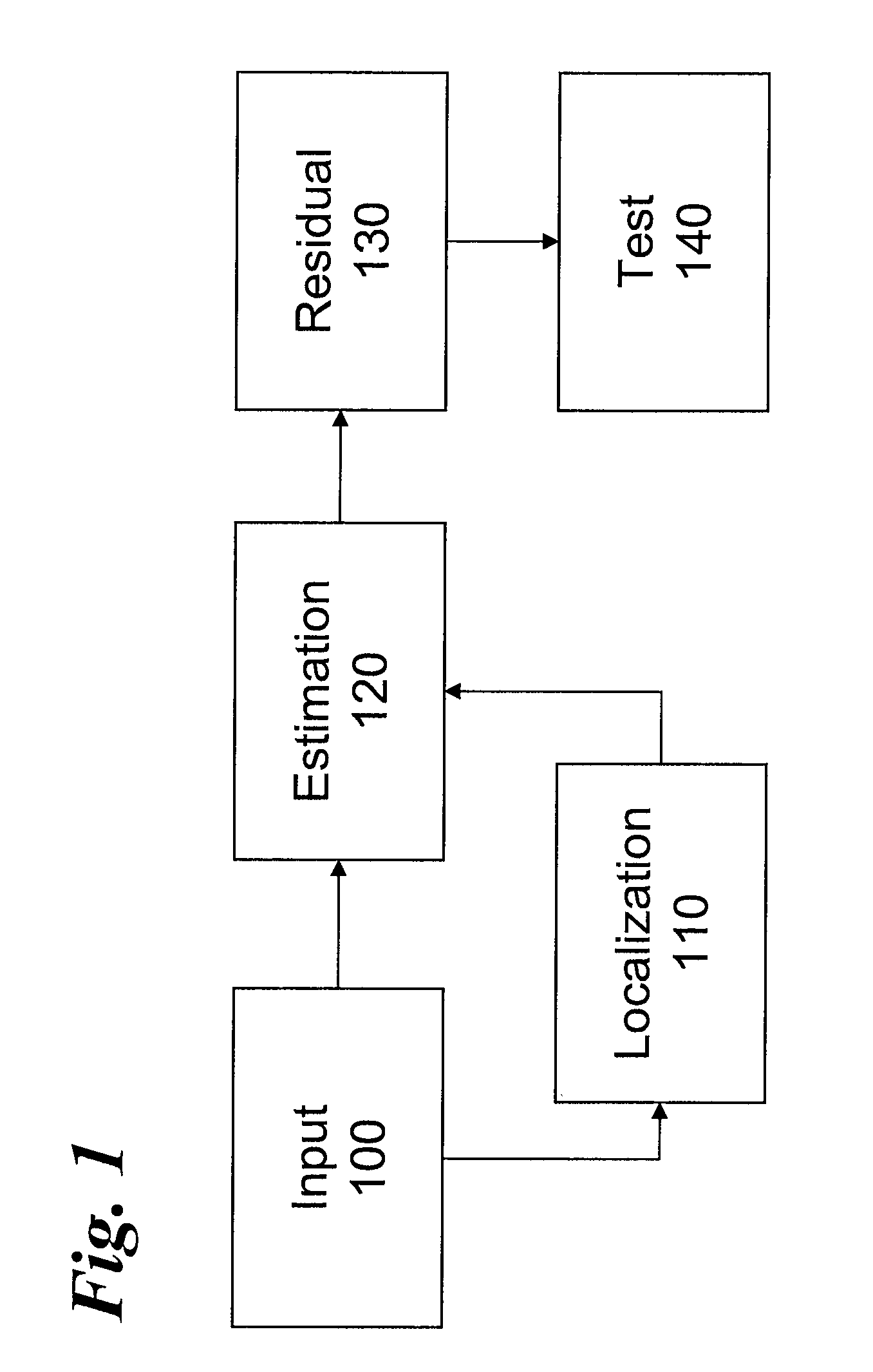

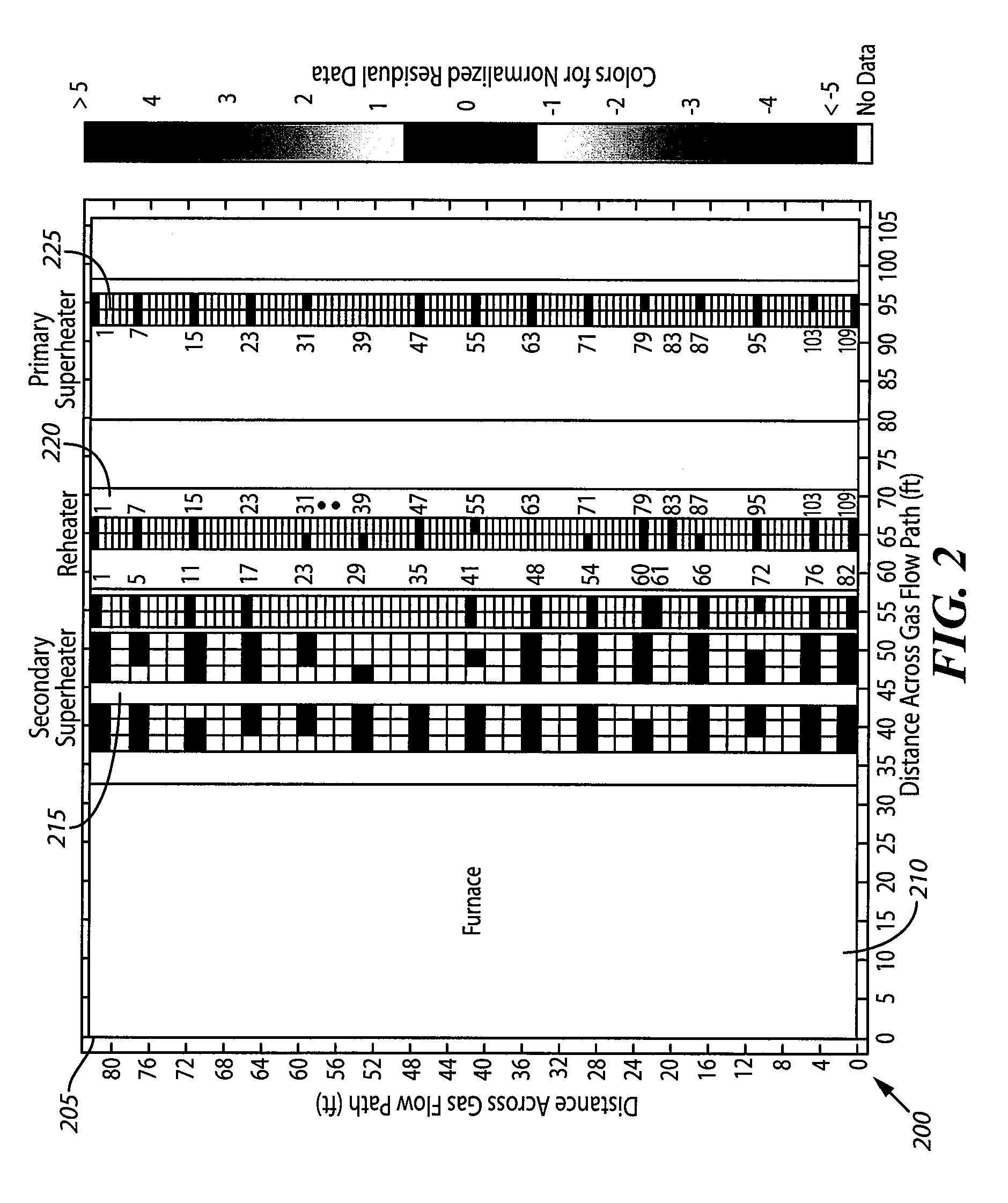

Kernel-based method for detecting boiler tube leaks

ActiveUS8275577B2Accurate accountingBoiler water tubesSafety devices for heat exchange apparatusMonitoring systemData source

Owner:SMARTSIGNAL CORP

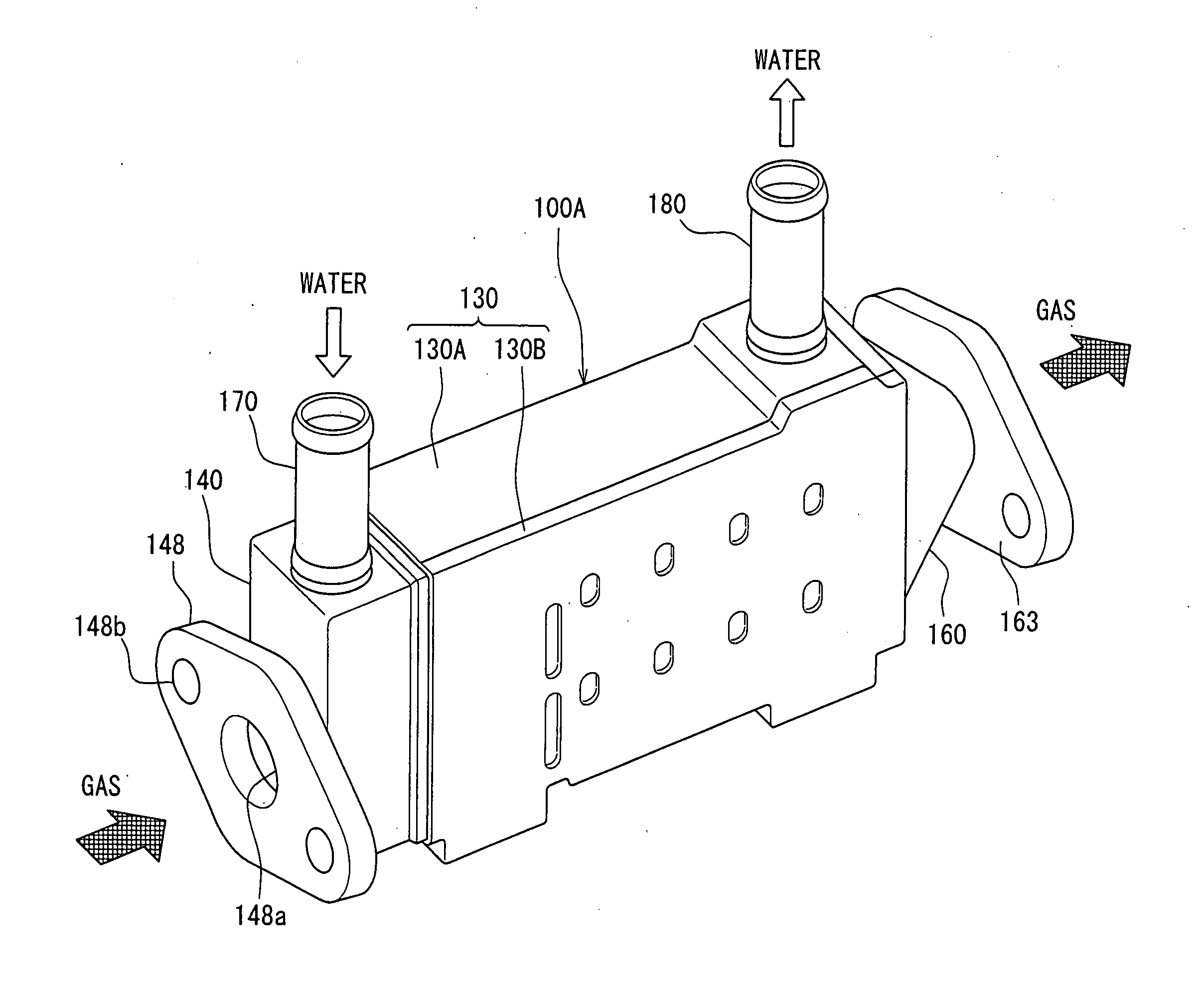

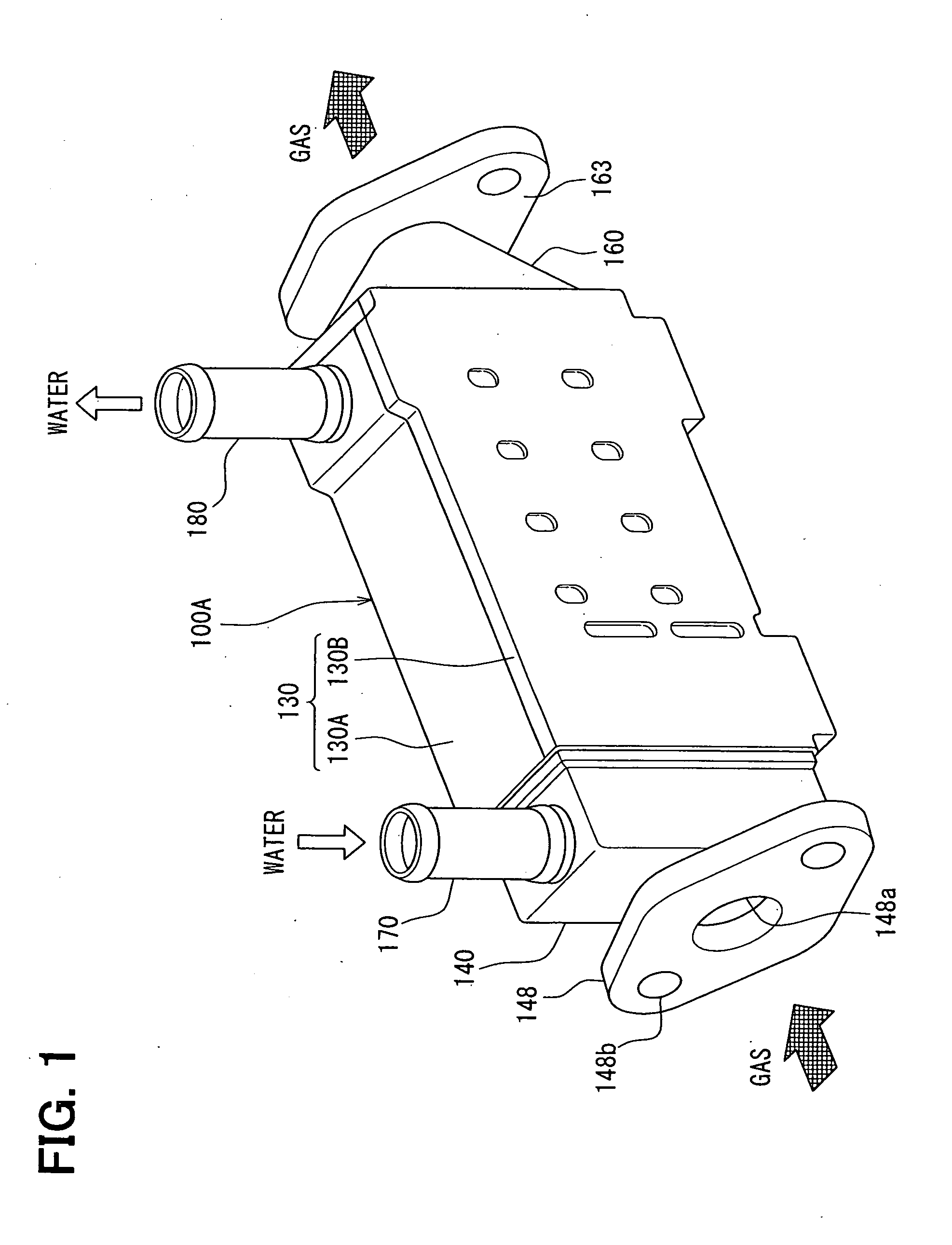

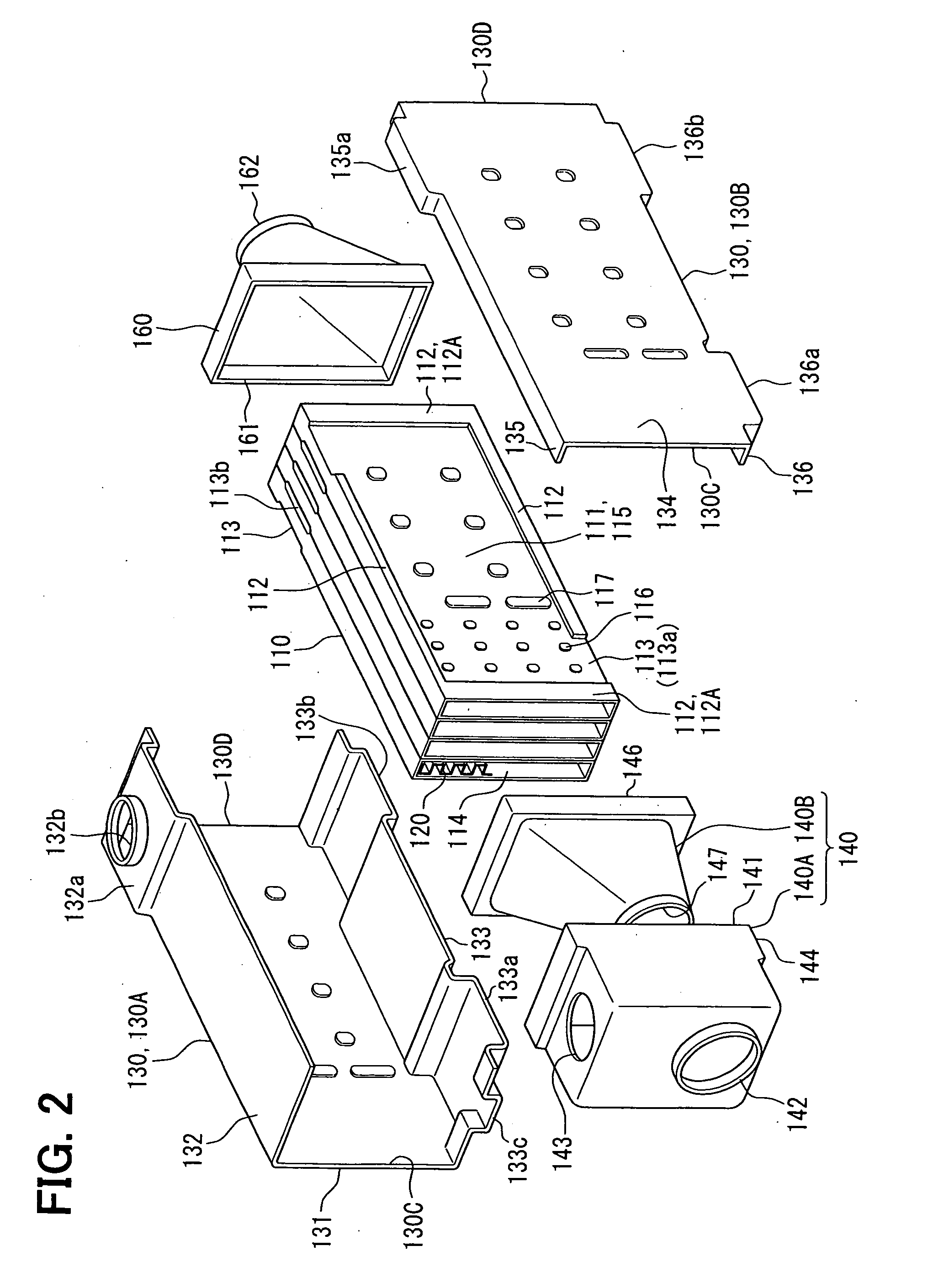

Exhaust heat exchanger

InactiveUS20110247318A1Non-fuel substance addition to fuelInternal combustion piston enginesNuclear engineeringWater tanks

An exhaust heat exchanger includes a water tank accommodating tubes and having an outside space defined outside of the tubes, a gas tank having an exhaust passage and an outside space defined outside of the exhaust passage, a dividing portion to separate the outside space of the water tank from the exhaust passage of the gas tank, and a communication portion. The outside space of the gas tank and the outside space of the water tank communicate with each other through the communication portion.

Owner:DENSO CORP

Plastic heat exchanger

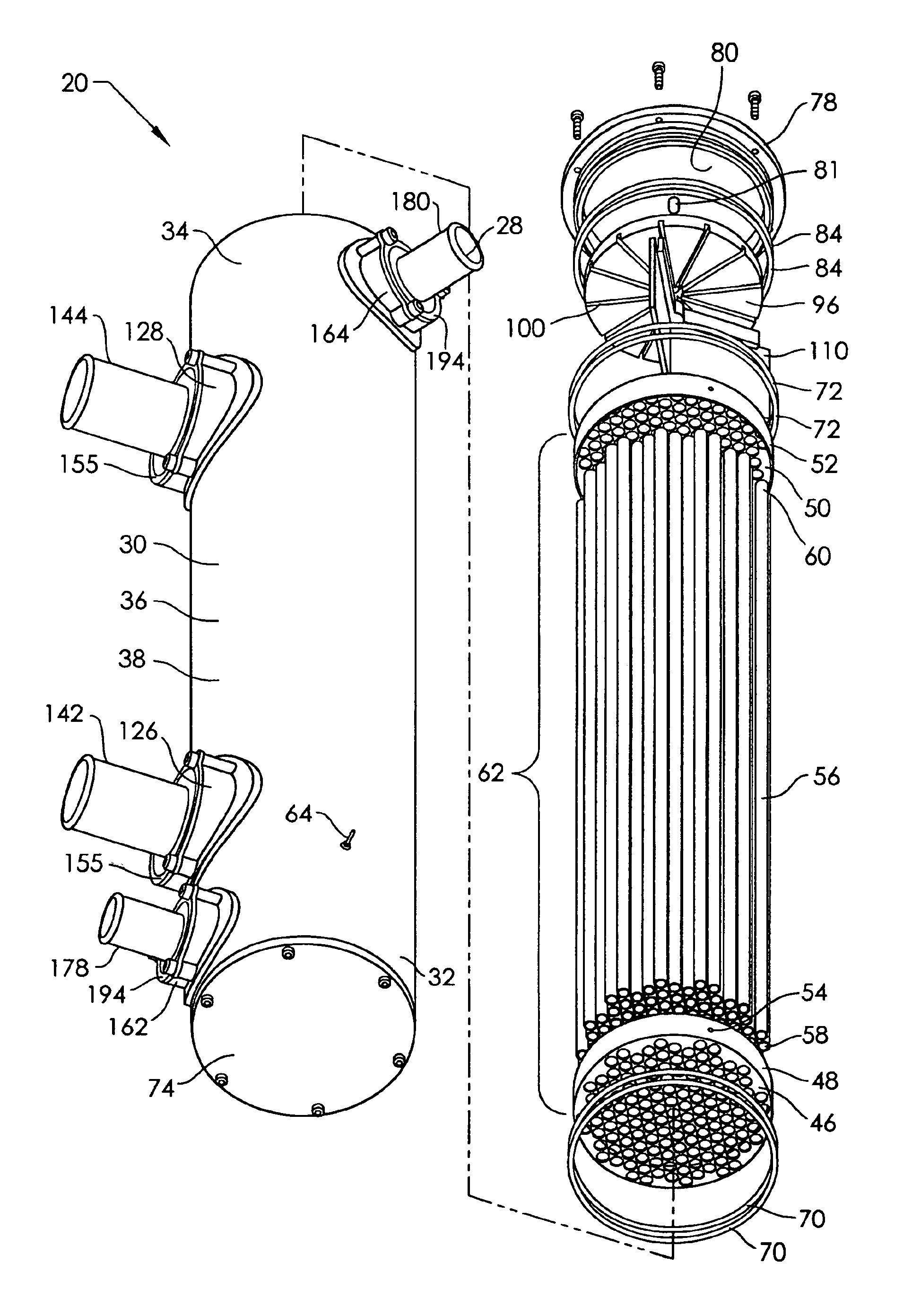

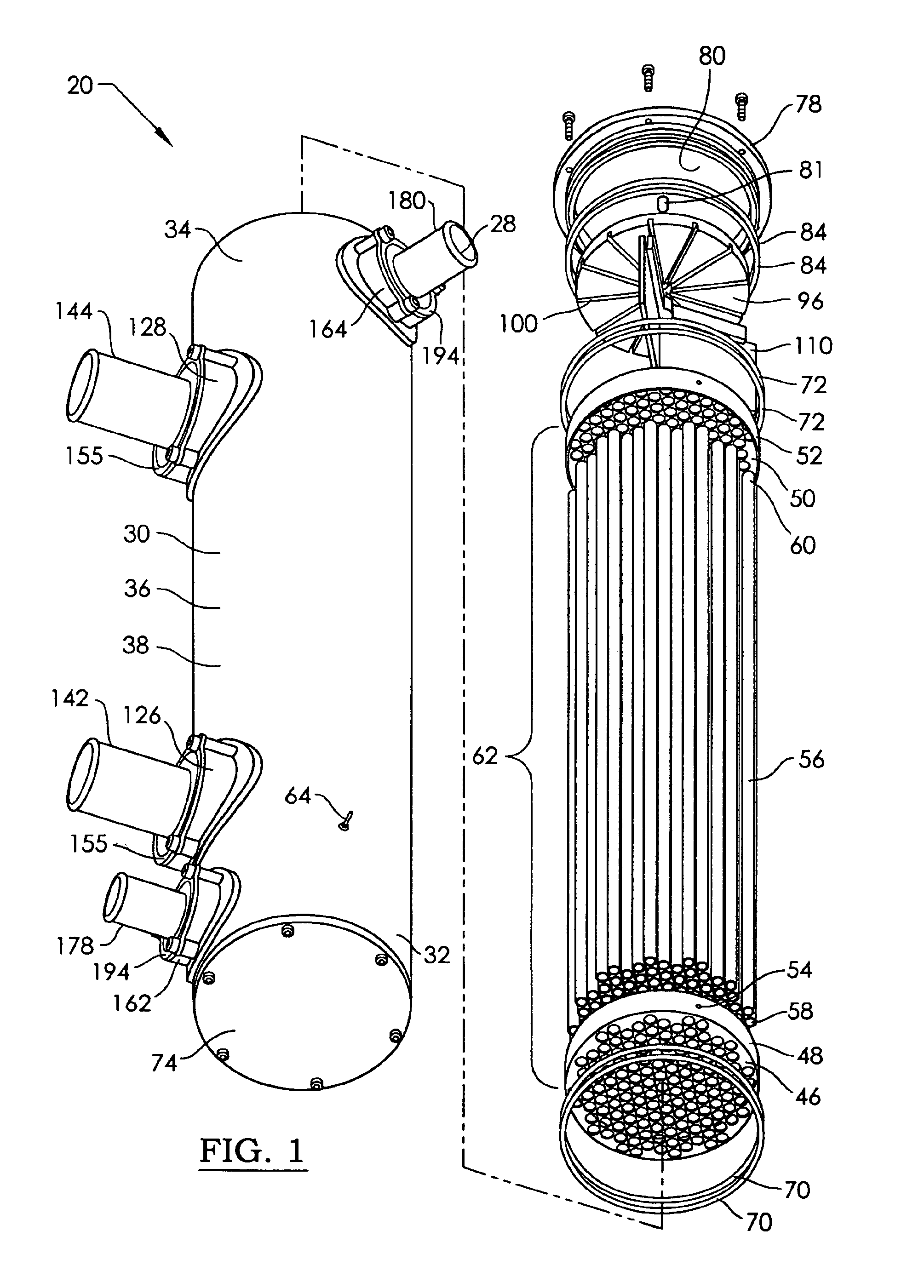

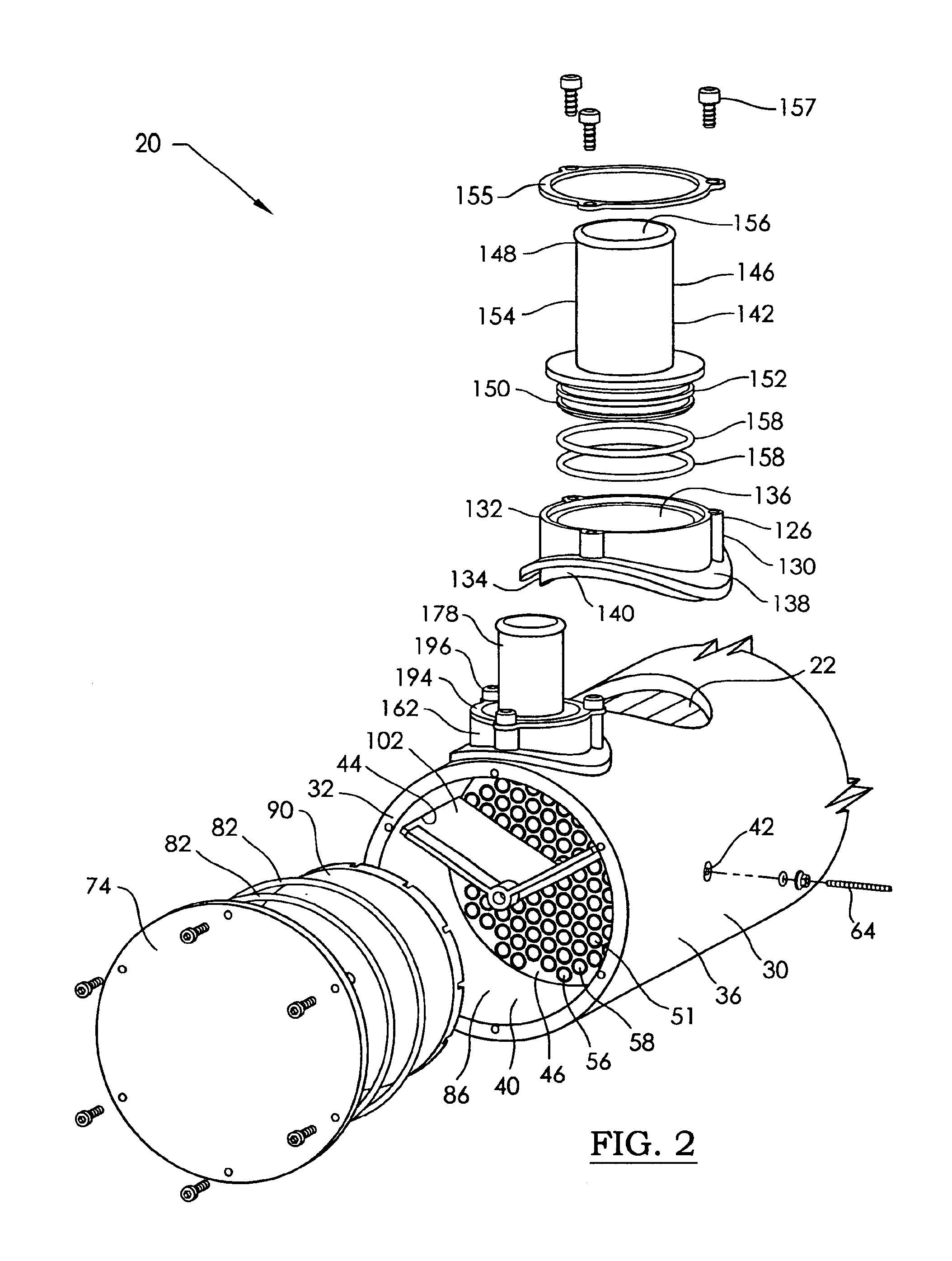

ActiveUS6899169B1Safety devices for heat exchange apparatusHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

A shell and tube heat exchanger has two shell coolant and two tube coolant passageways communicating with a cavity in a shell. Removably received in the shell cavity is a tube bundle with tube headers. A locating screw extends through the shell to engage a locating recess in one tube header. The screw locates the tube bundle angularly about the central axis and longitudinally along the central axis, and is also used to electrically ground the tube bundle. An end cover, a flow separator, and resilient disc to take up thermal expansion are installed in each end of the shell to direct coolant through the tube bundle in multiple passes. Receivers with rotatable connectors are bonded to each shell coolant and tube coolant passageway. Angled connector nozzles can be connected to external conduits in any orientation.

Owner:R&D ENTERPRISES

Leak detection system for a liquid cooling system

InactiveUS20140251583A1Safety devices for heat exchange apparatusDigital data processing detailsControl systemRemedial action

A liquid cooling system for a computer may include a cold plate configured to be positioned on a heat generating electronic device of the computer and adapted to pass a coolant therethrough. The cooling system may also include a leak detection system configured to detect a coolant leak in the computer, and a control system coupled to the leak detection system. The control system may be configured to take remedial action when the coolant leak is detected by the leak detection system.

Owner:ASETEK DANMARK

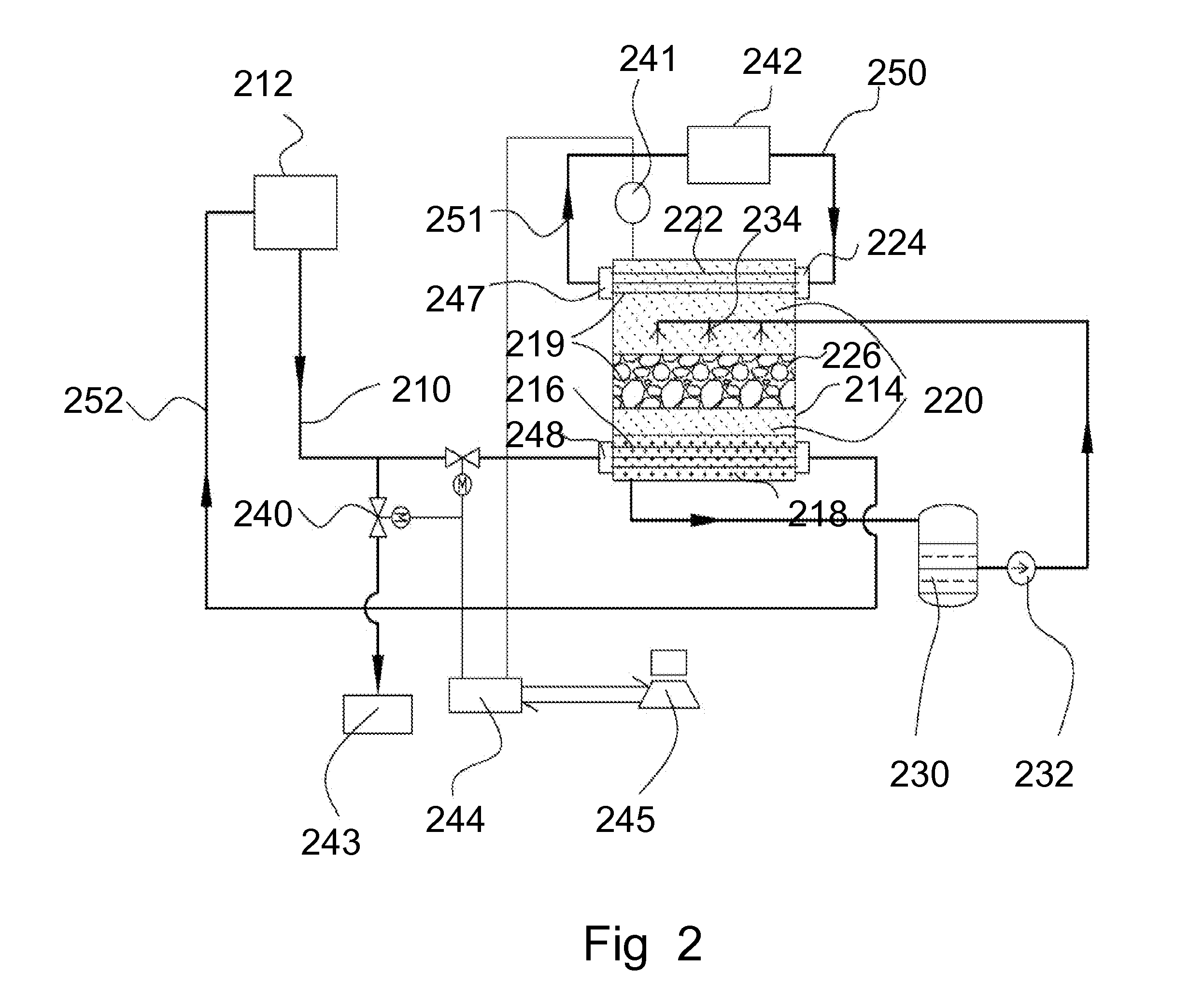

Cartridge-based thermoelectric systems

InactiveUS20130104953A1Internal combustion piston enginesThermoelectric device with peltier/seeback effectElectricityEngineering

Cartridge-based thermoelectric assemblies and systems are provided which include at least one shunt configured to extend around a conduit, a plurality of thermoelectric elements in thermal communication and in electrical communication with the at least one shunt with at least a portion of the at least one shunt sandwiched between the at least one first thermoelectric element and the at least one second thermoelectric element. The thermoelectric elements are electrically isolated from the conduit. The thermoelectric assemblies and systems further include at least one heat exchanger in thermal communication with the at least one shunt and configured to be in thermal communication with a second fluid.

Owner:GENTHERM INC

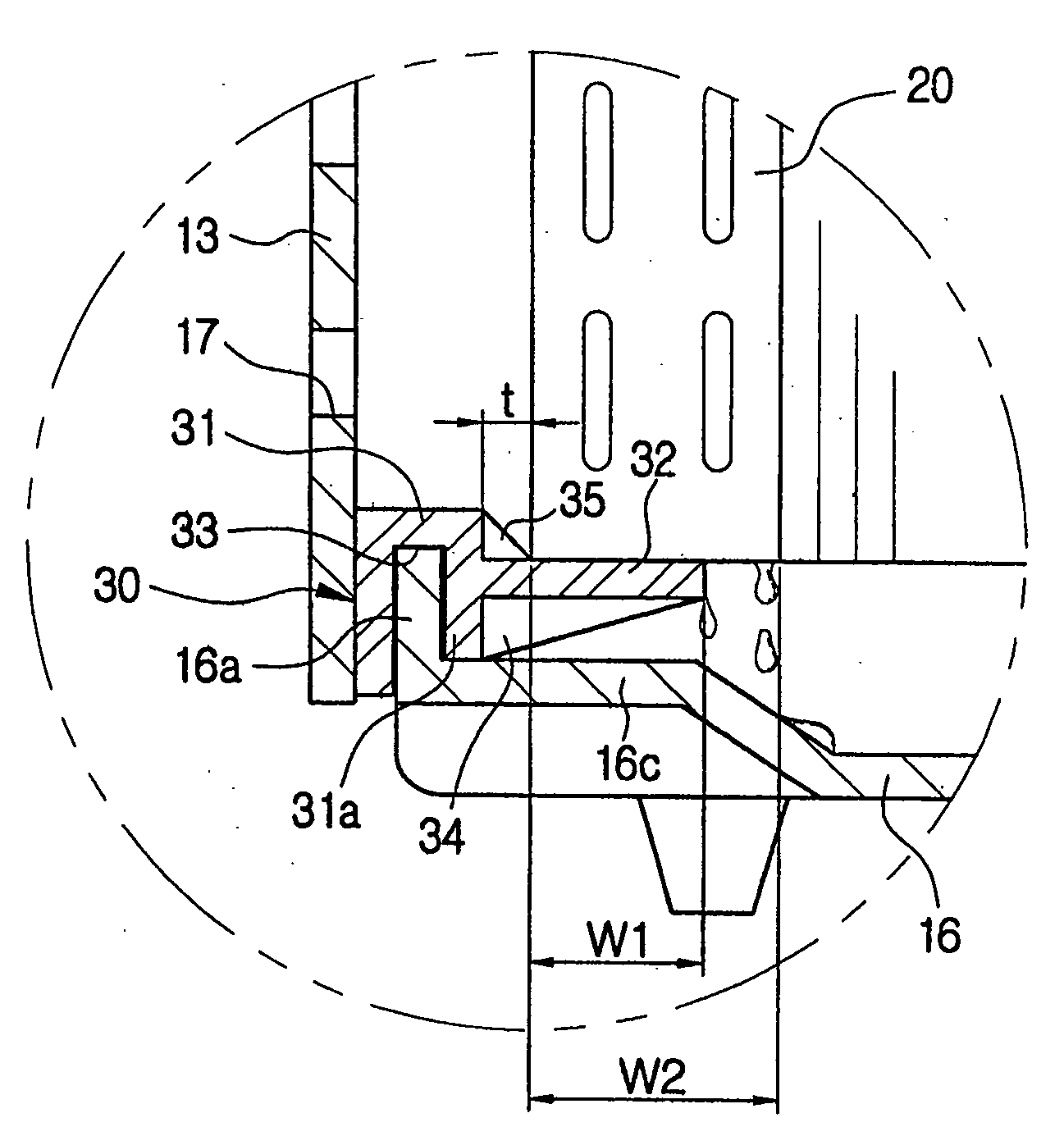

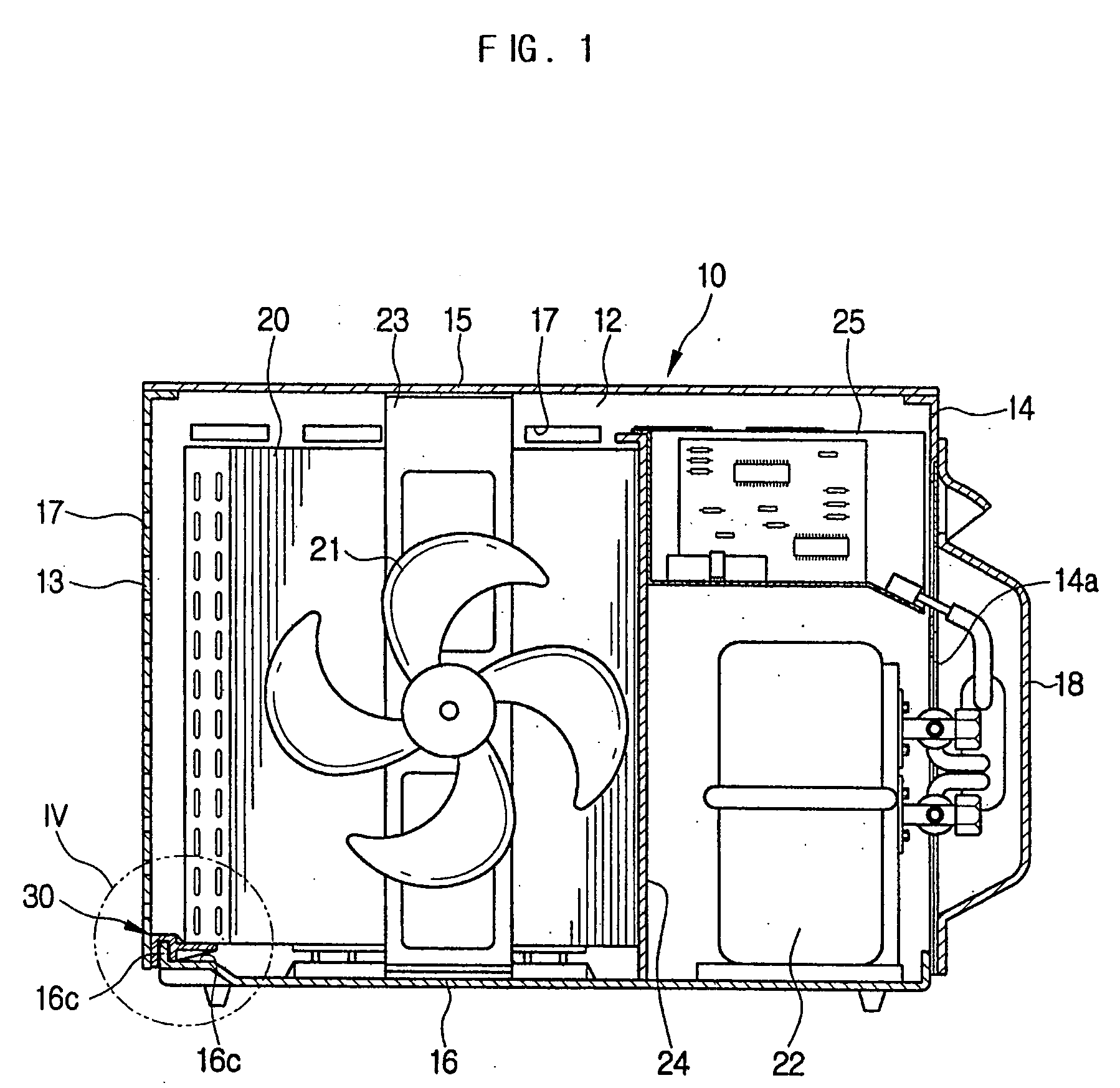

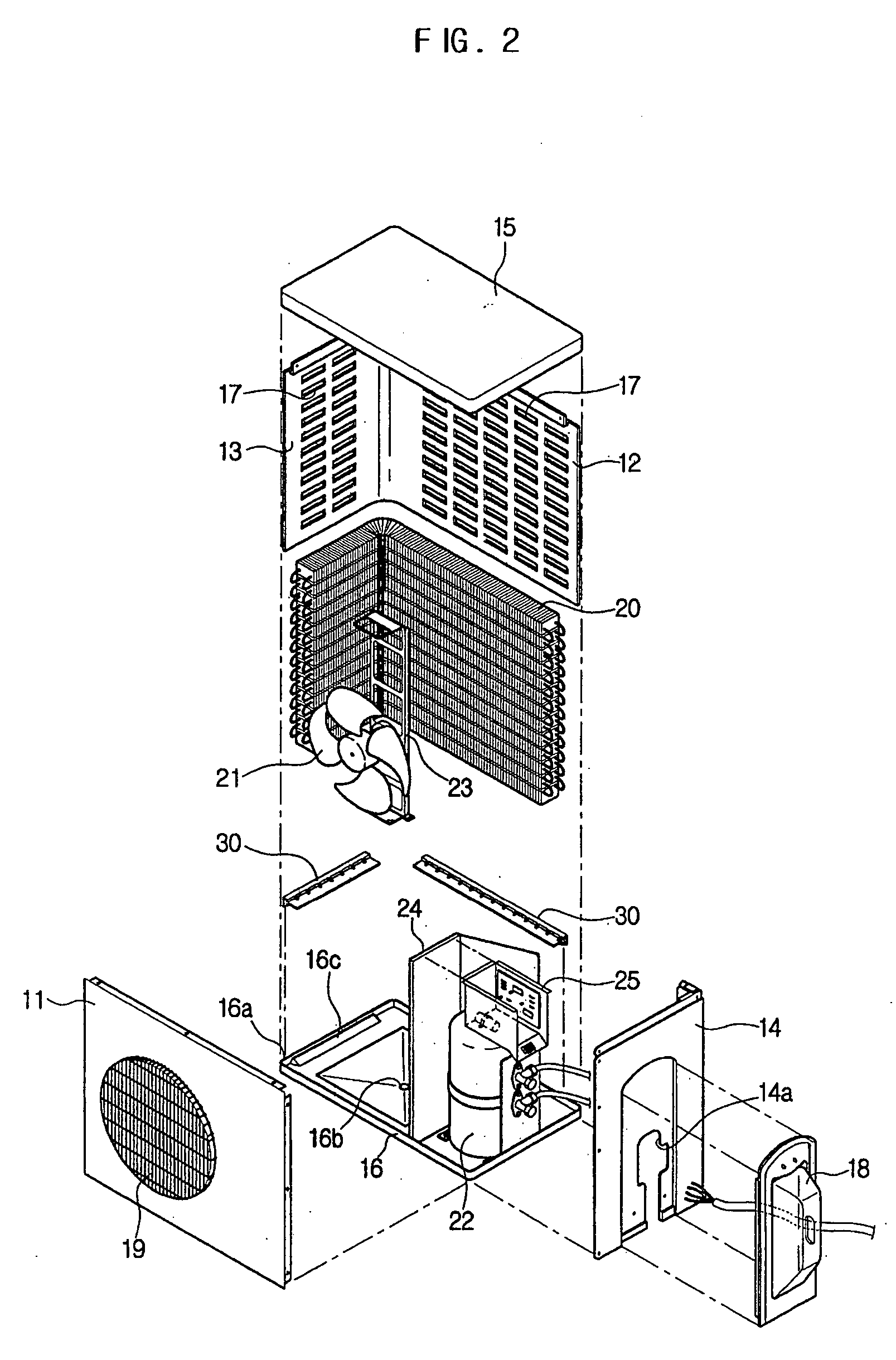

Outdoor unit for air conditioner

InactiveUS20050034471A1Easy dischargePreventing the condensed water from freezingThermal insulationCondensate preventionMechanical engineeringWaste management

An outdoor unit for an air conditioner allows condensed water generated from an outdoor heat exchanger to be easily discharged, and prevents coldness from the outdoor heat exchanger from being transmitted to a bottom of the outdoor unit, thus preventing freezing of the condensed water on the bottom. The outdoor unit includes a cabinet having a bottom panel, an outdoor heat exchanger installed in the cabinet, and a support member made of heat insulating material supporting the outdoor heat exchanger with a spacing between a lower end of the outdoor heat exchanger and the bottom panel of the cabinet, to prevent condensed water generated from the outdoor heat exchanger from freezing.

Owner:SAMSUNG ELECTRONICS CO LTD

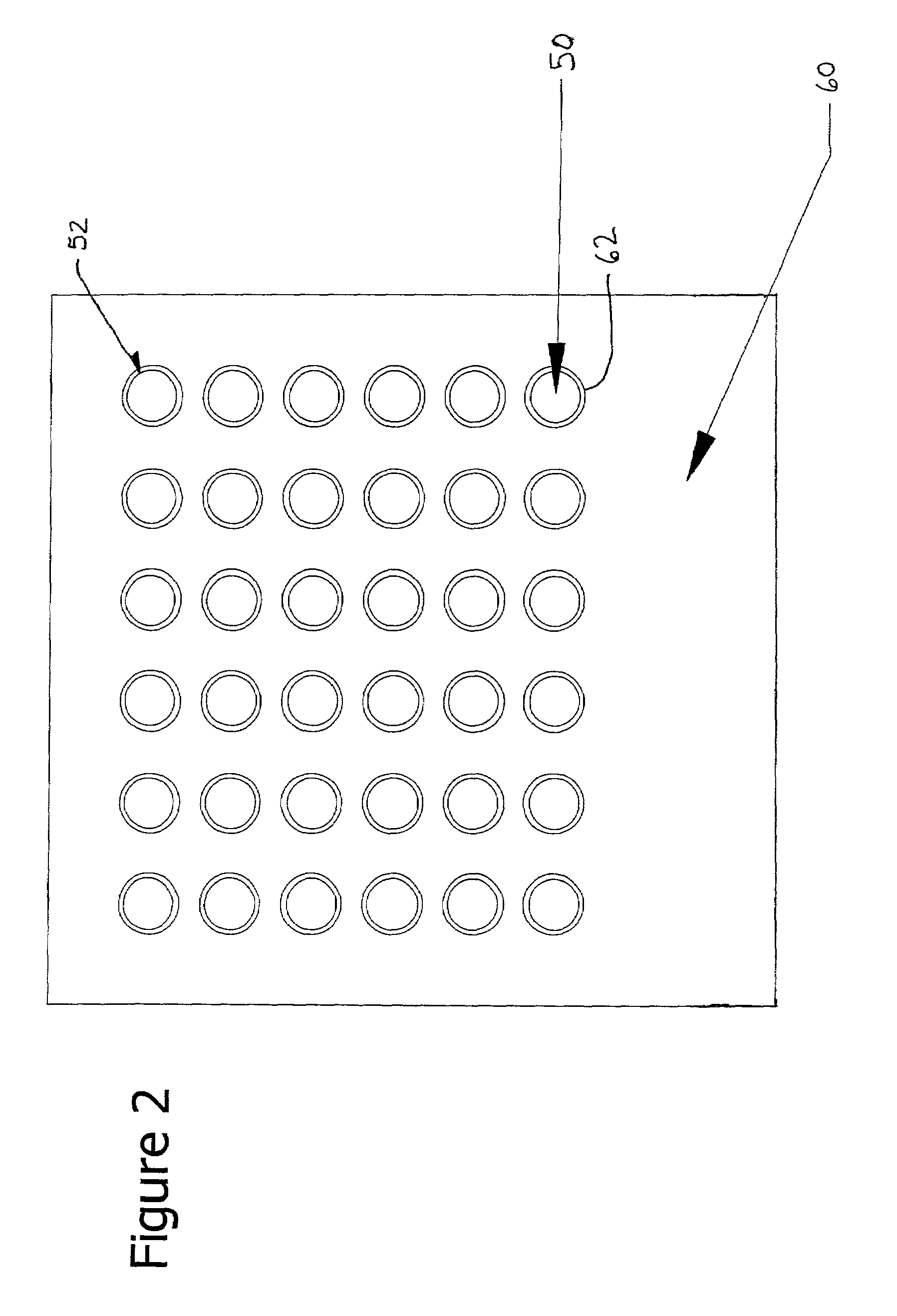

Method and apparatus for minimizing adverse effects of thermal expansion in a heat exchange reactor

InactiveUS7117934B2Improve corrosion resistanceHigh strengthChemical/physical/physico-chemical reactor detailsHydrogen/synthetic gas productionThermal expansionEngineering

A heat exchange reactor including a housing, a plurality of tubes mounted in the housing and configured to carry a first fluid, and a baffle having a plurality of holes receiving the tubes. The baffle is configured to guide a second fluid provided within the housing to flow in a direction generally perpendicular to the tubes. The reactor includes various configurations for minimizing adverse effects of thermal expansion of the baffle and the tubes. The reactor is configured to minimize mechanical interference between the baffle and the tubes in both an operational state and a non-operational state, for example, by shaping the holes in the baffle to take into account thermal expansion. The reactor also includes a thermal insulator along a length of the tubes at a large temperature gradient zone within the reactor. The reactor further includes a heat transfer fin in contact with only one of the tubes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

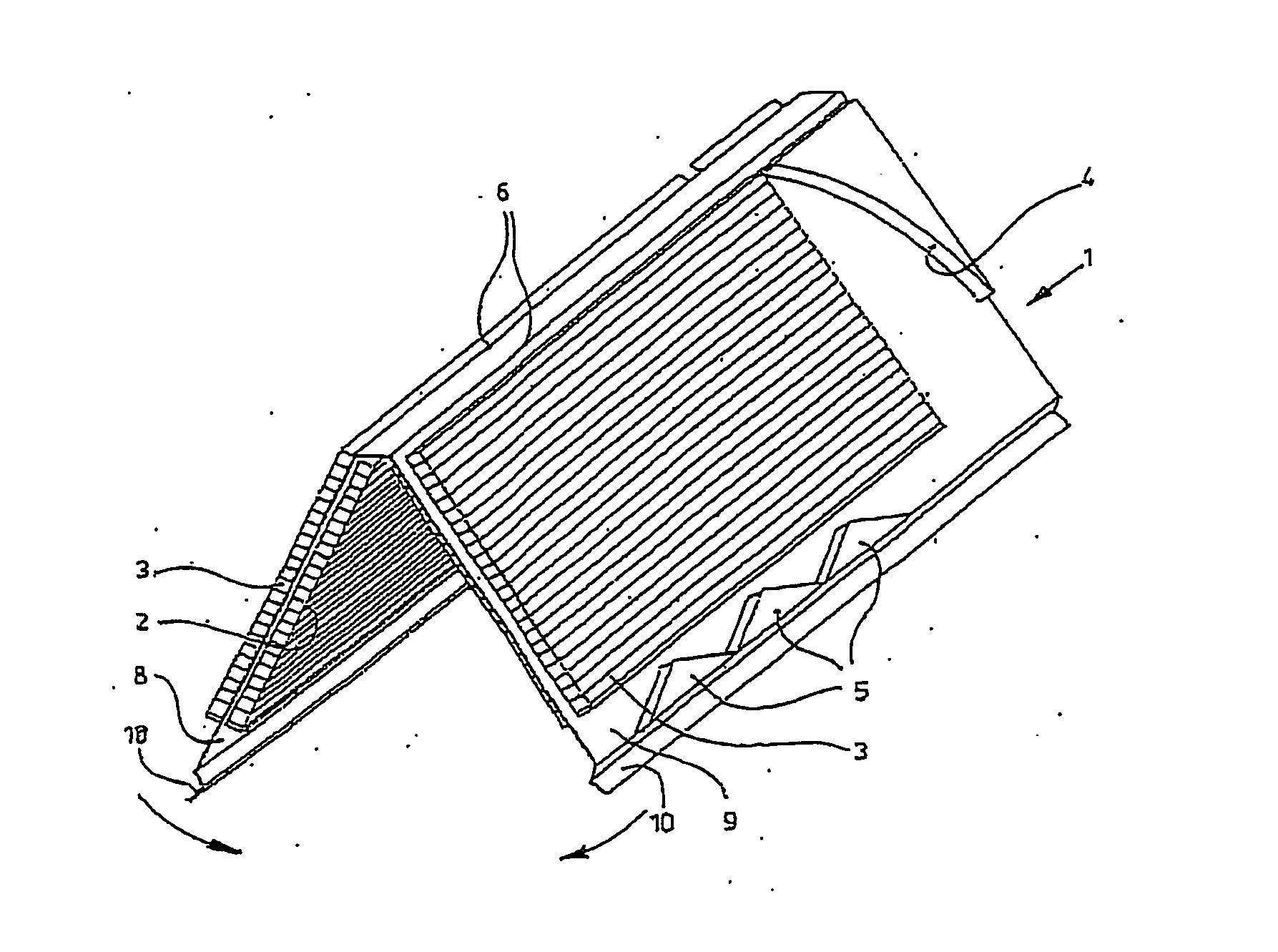

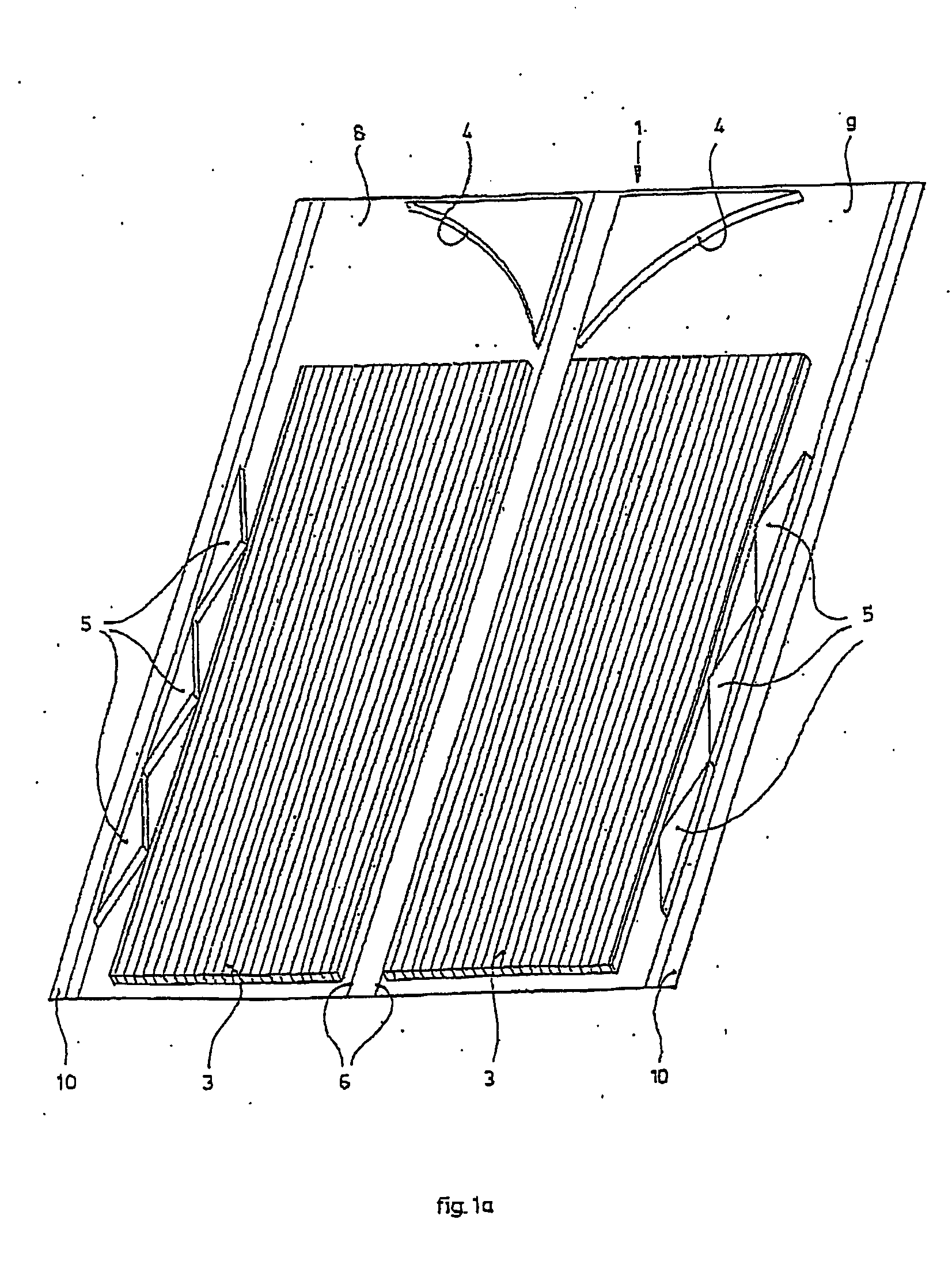

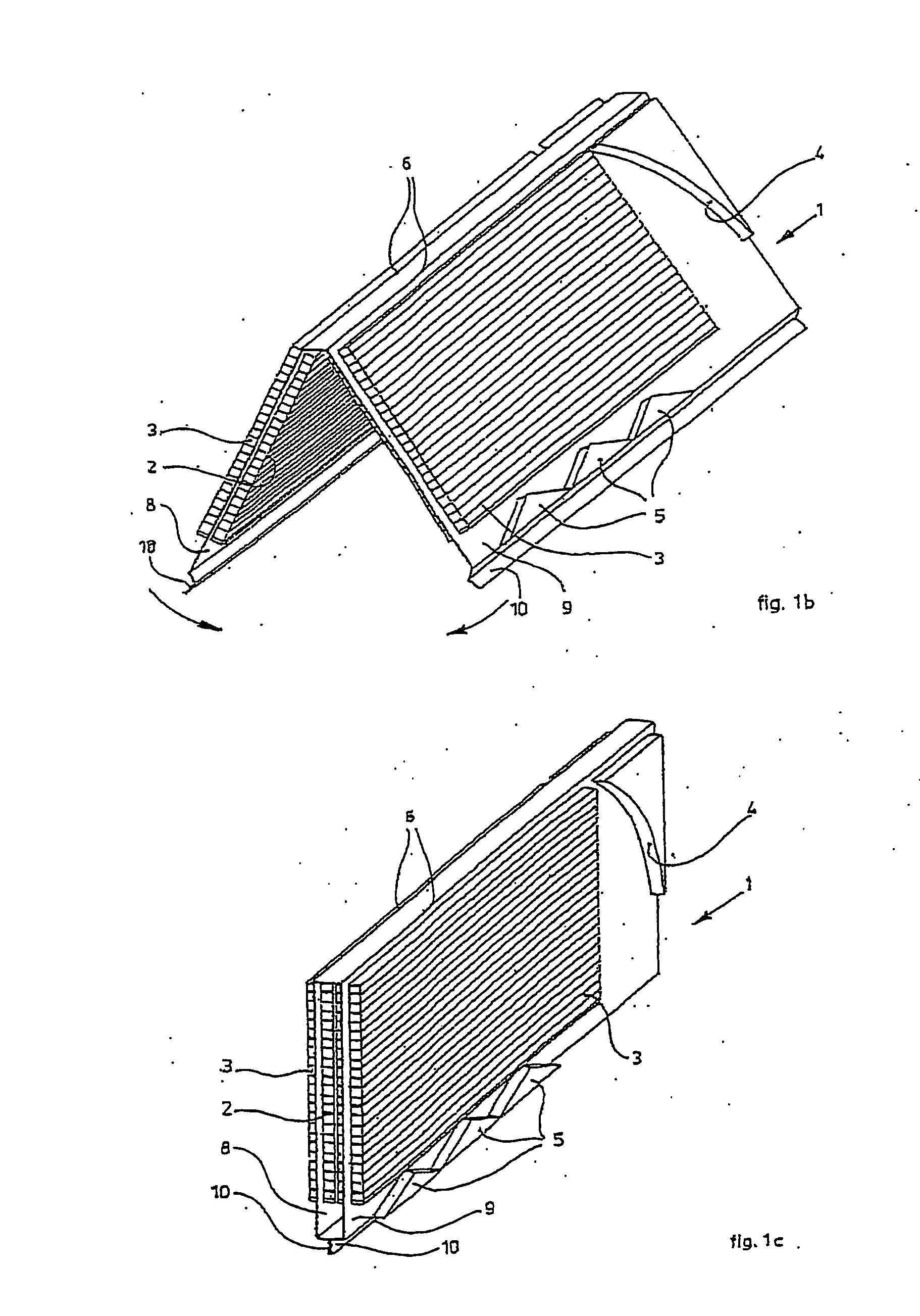

Heat exchanger and method of manufacture thereof

InactiveUS20060124287A1Improve heat transfer performanceEasy to produceSafety devices for heat exchange apparatusFree-cooling systemsEngineeringMetal

Method of manufacturing a heat exchanger from a formable laminate (1, 11, 105) of a metal layer and a heat-seal layer whereby the laminate is sealed under heat and pressure to itself or to another similar laminate to form a flow channel for a heat exchange medium. Preferably the heat exchanger includes a series of fins (3, 106, 107) formed on the laminate (1, 11, 105) to increase heat transfer and may also include a water retaining layer (204).

Owner:OXYCOM BEHEER BV

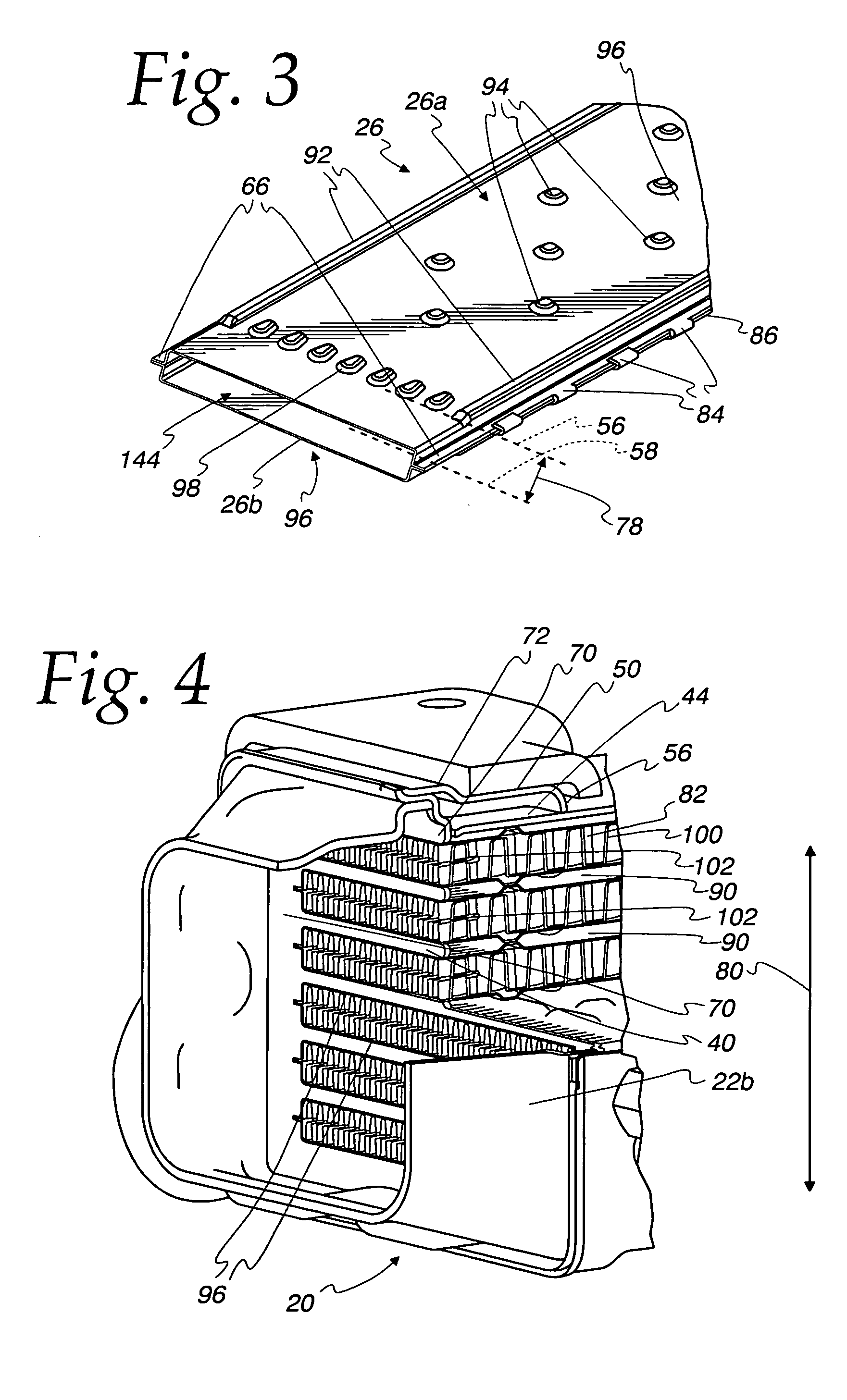

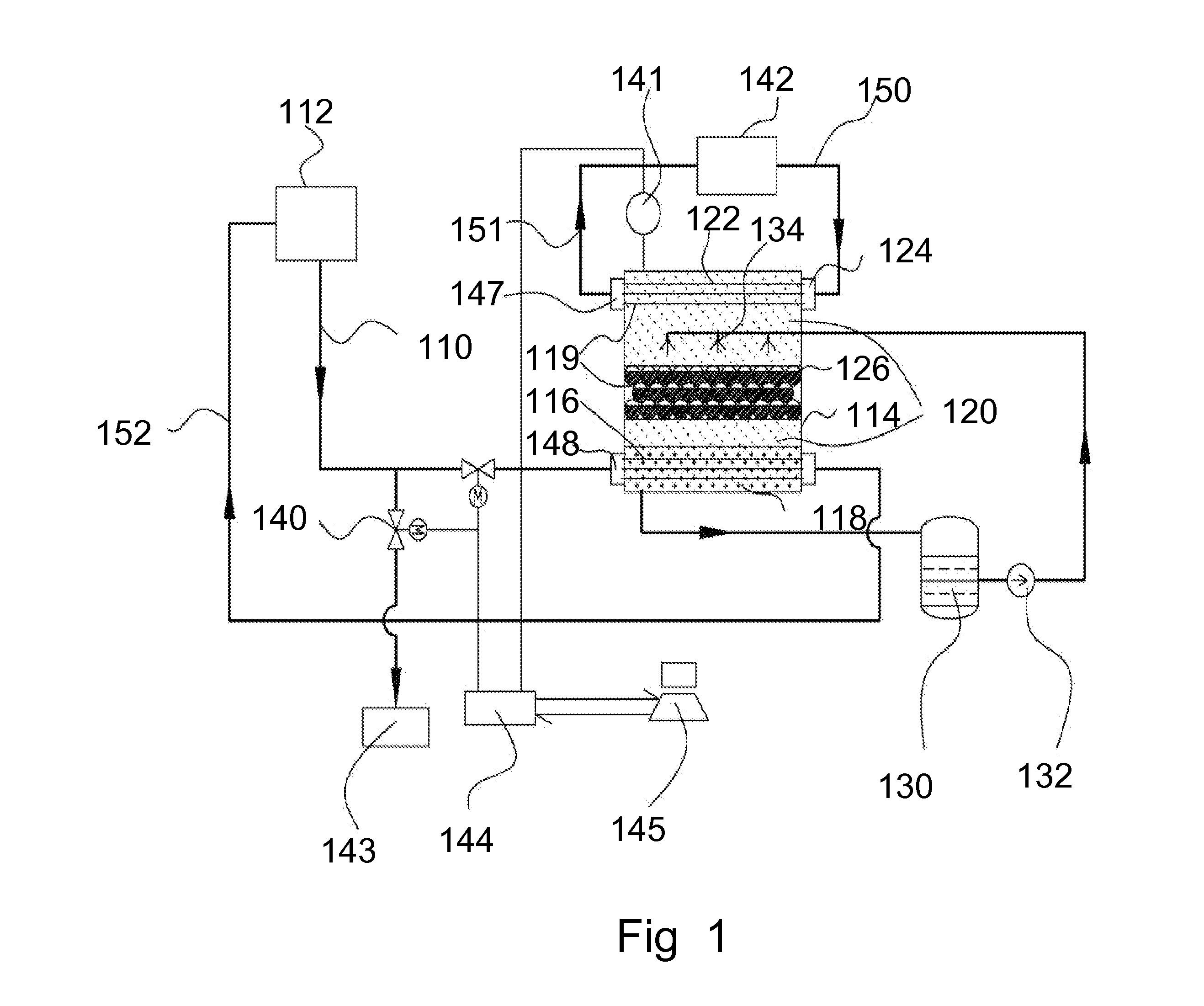

Systems and methods of thermal transfer and/or storage

ActiveUS20110120673A1Heat storage plantsSafety devices for heat exchange apparatusEngineeringInput device

Systems, methods, and computer-implemented embodiments consistent with the inventions herein are directed to storing and / or transferring heat. In one exemplary implementation, there is provided a system for transferring / storing heat comprised of a heat exchange / storage apparatus including a chamber, and a heat input device adapted to heat / provide a vapor into the chamber. Other exemplary implementations may include one or more features consistent with a heat output device through which a working medium / fluid passes, a thermal storage medium located within the chamber, and / or a heat exchange system that delivers a heat exchange medium / fluid to the thermal storage medium.

Owner:BLUELAGOON TECH

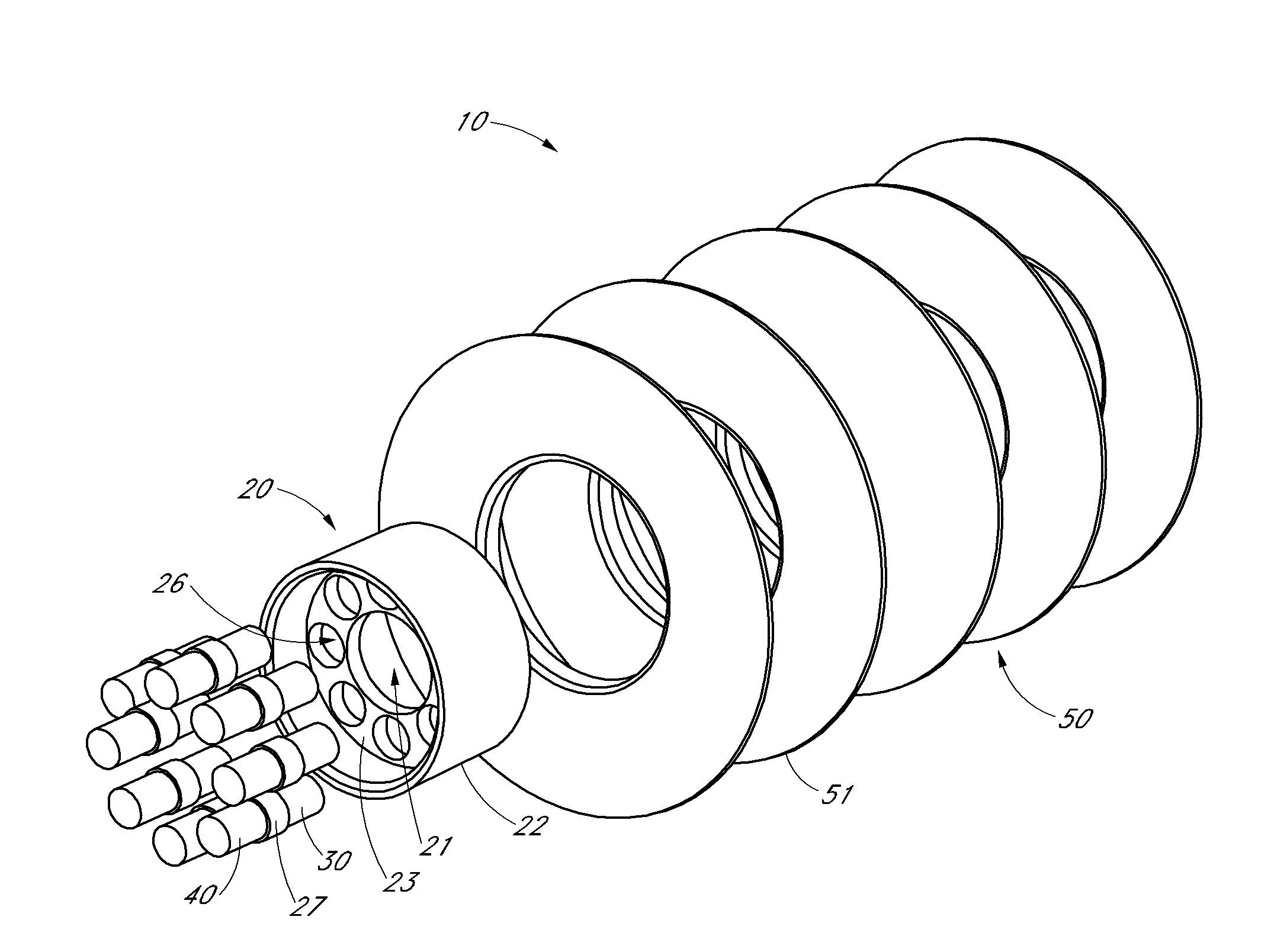

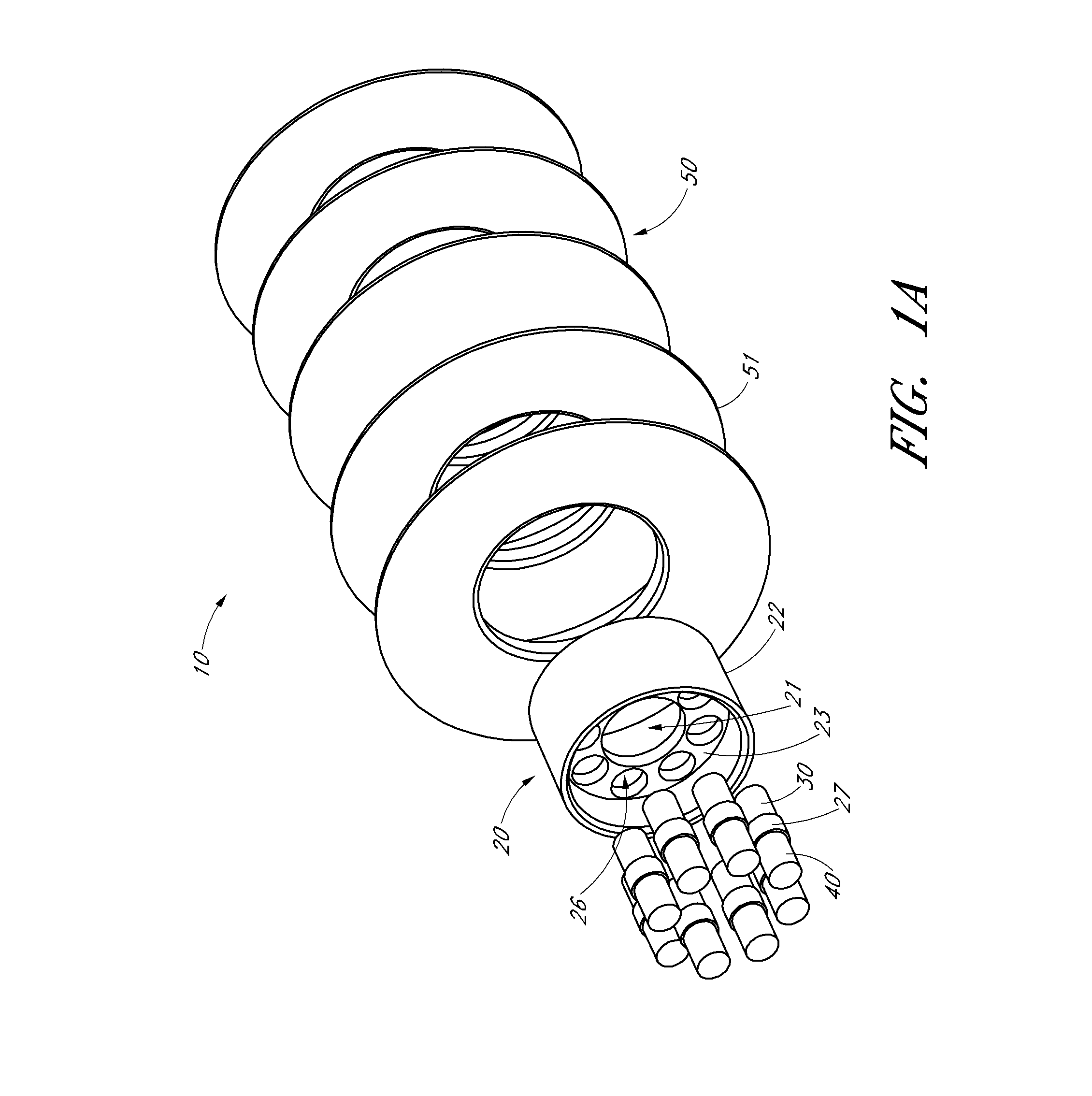

Coil tube heat exchanger for a tankless hot water system

A novel water heat exchanger with a helix coil incorporated into a stainless steel elongated variable diameter cylindrical housing. A buffer tank is incorporated within the lumen of the helix coil. In one embodiment, the heat exchanger utilizes a radial direct-firing burner and a blower-driven hot flue gas to heat water for domestic and commercial use. In one embodiment, at least a rope seal is disposed between adjacent coil loops of a portion of the helix coil for enhancing heat transfer to the helix coil. In one embodiment, solar and electric heating systems are combined with the helix coil heat exchanger and disposed within the buffer tank to provide supplemental heating. In another embodiment, the heat exchanger further comprises a Stirling engine comprised of a free piston having hot and cold ends that is disposed within the cavity taken up the buffer tank, wherein the hot end receives heat from the burner and the cold end is cooled by the incoming cold water line to form an electric power generator.

Owner:INTELLIHOT

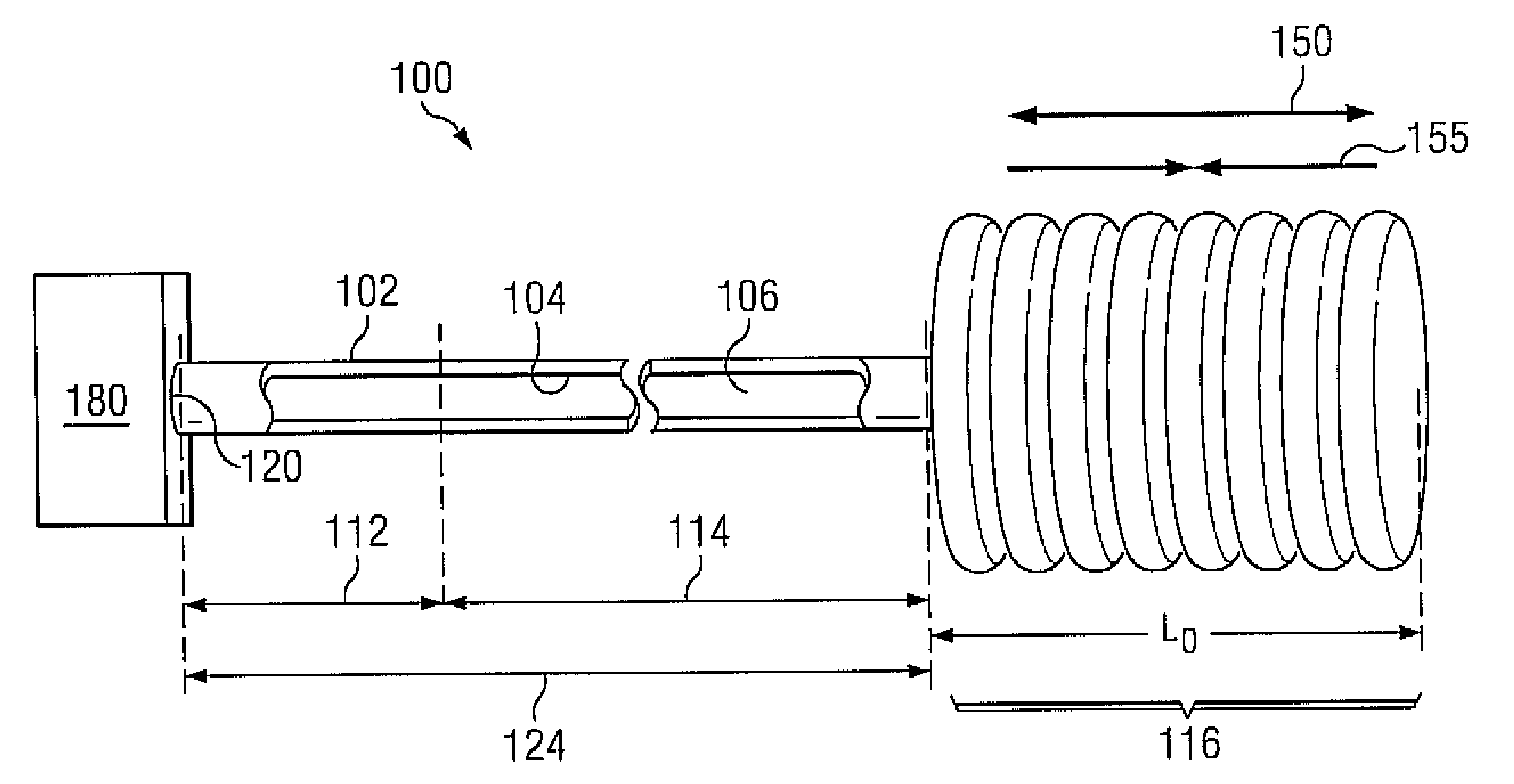

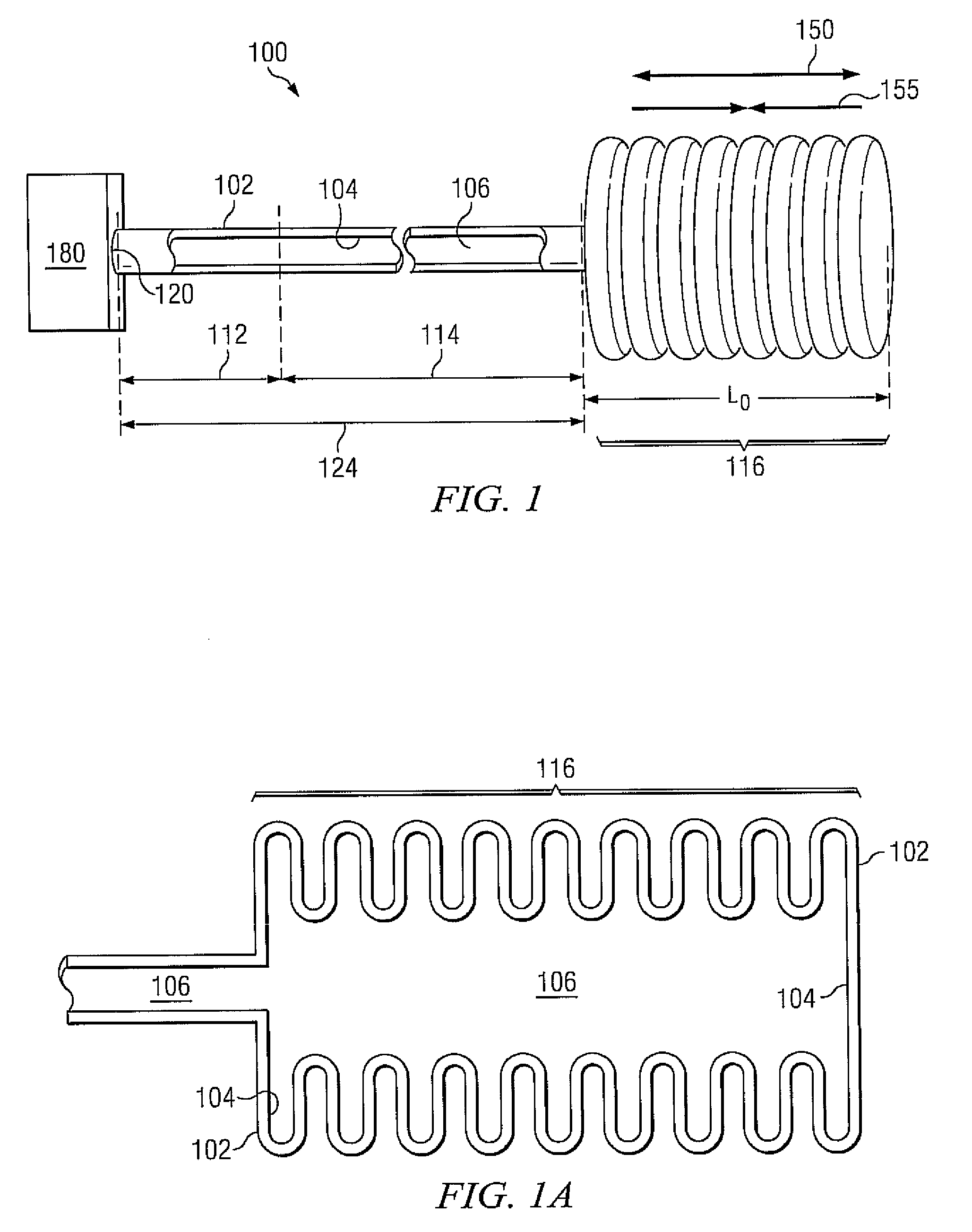

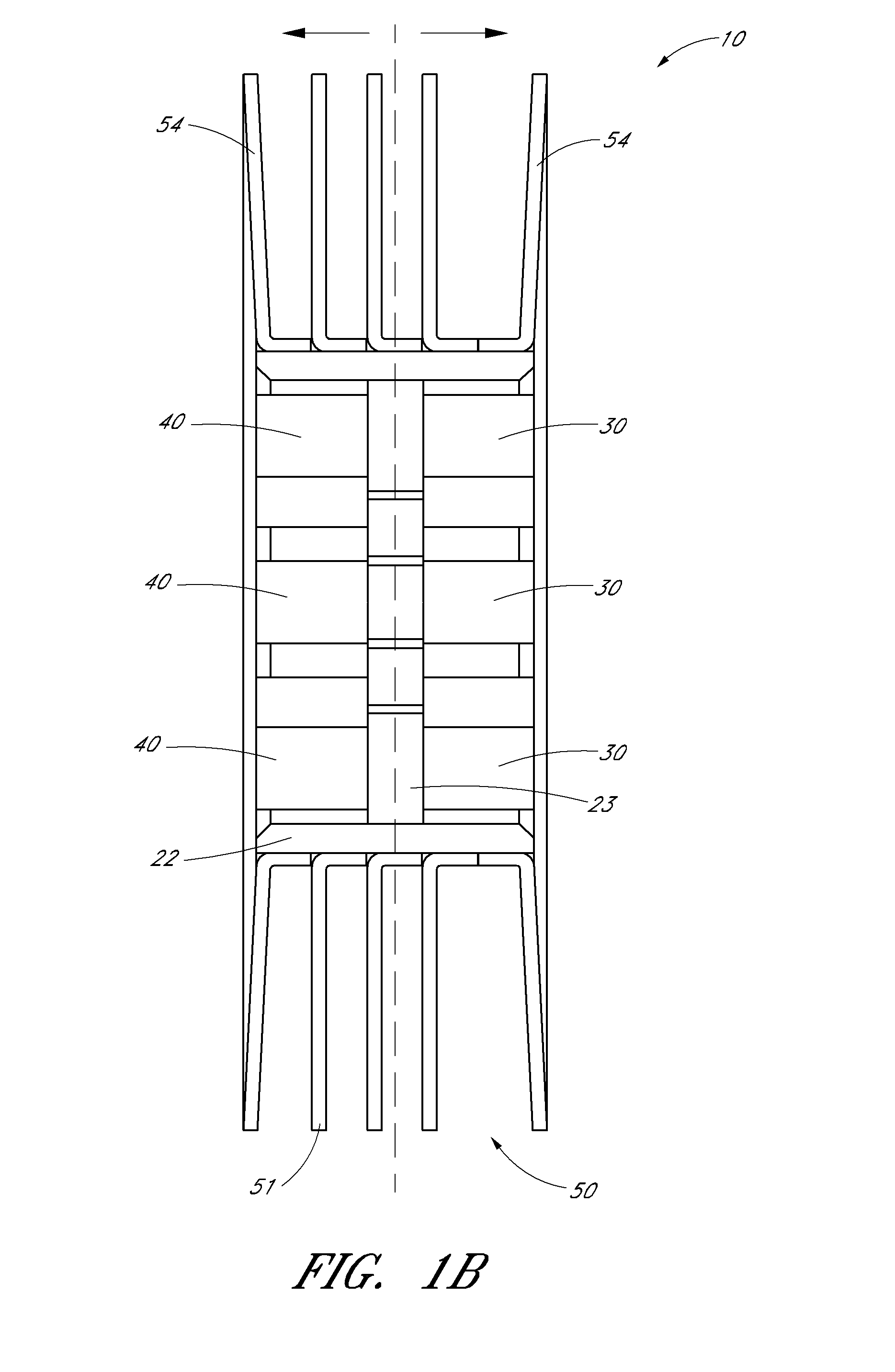

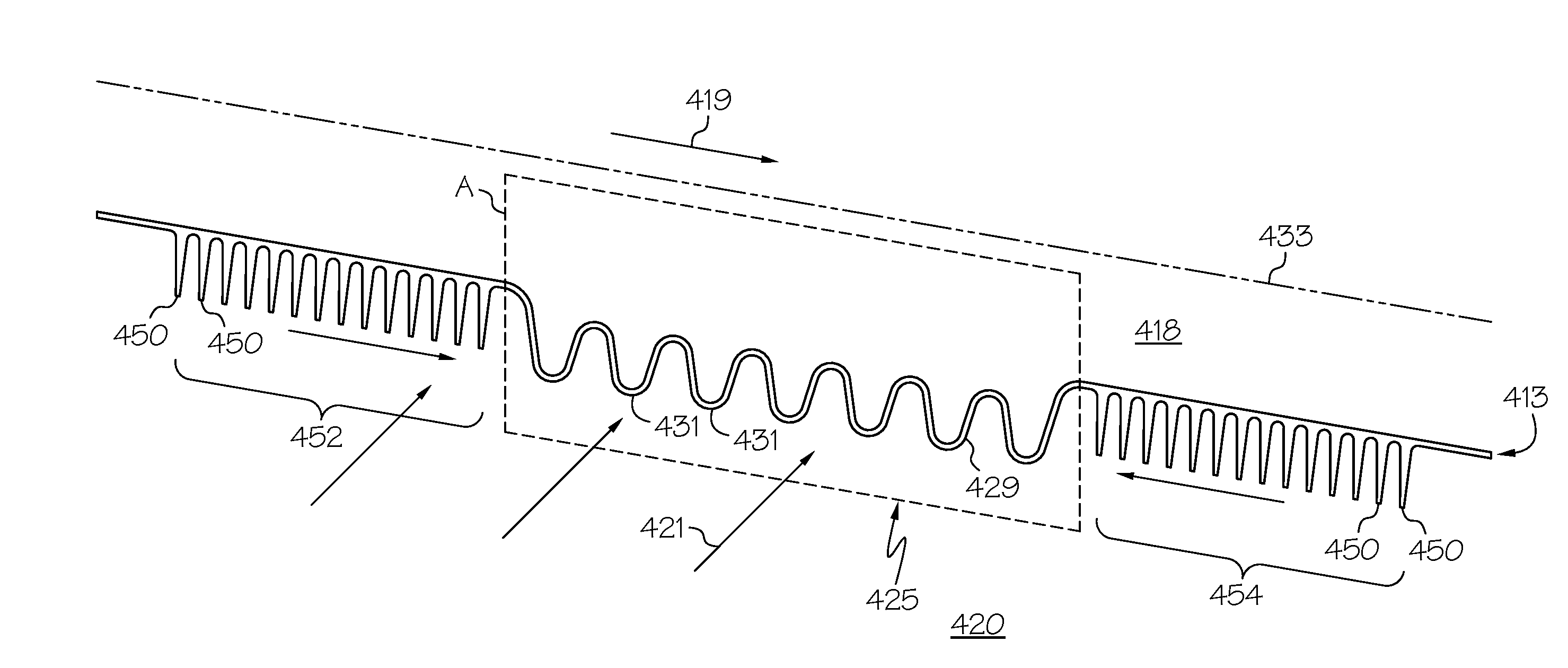

Unitary heat exchangers having integrally-formed compliant heat exchanger tubes and heat exchange systems including the same

ActiveUS20140360698A1Low costLow variabilityAdditive manufacturingSafety devices for heat exchange apparatusPlate heat exchangerEngineering

Unitary heat exchangers having integrally-formed compliant heat exchanger tubes and heat exchange systems including the same are provided. The unitary heat exchanger comprises an inlet plenum and an outlet plenum and a plurality of integrally-formed compliant heat exchanger tubes. The plurality of integrally-formed compliant heat exchanger tubes extend between and are integral with the inlet and outlet plenums to define a heat exchanger first flow passage. Each integrally-formed compliant heat exchanger tube comprises a tubular member and a plurality of integral heat transfer fins extend radially outwardly from at least one portion of the tubular member. The tubular member has a proximal tube end and a distal tube end and comprises a tubular wall having an outer wall surface and an inner wall surface.

Owner:HONEYWELL INT INC

Method and apparatus for minimizing adverse effects of thermal expansion in a heat exchange reactor

InactiveUS20030173062A1Minimize adverse effectsMinimize thermal expansion differencesChemical/physical/physico-chemical reactor detailsHydrogen/synthetic gas productionThermal expansionEngineering

A heat exchange reactor including a housing, a plurality of tubes mounted in the housing and configured to carry a first fluid, and a baffle having a plurality of holes receiving the tubes. The baffle is configured to guide a second fluid provided within the housing to flow in a direction generally perpendicular to the tubes. The reactor includes various configurations for minimizing adverse effects of thermal expansion of the baffle and the tubes. The reactor is configured to minimize mechanical interference between the baffle and the tubes in both an operational state and a non-operational state, for example, by shaping the holes in the baffle to take into account thermal expansion. The reactor also includes a thermal insulator along a length of the tubes at a large temperature gradient zone within the reactor. The reactor further includes a heat transfer fin in contact with only one of the tubes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Double heat exchanger with condenser and radiator

InactiveUS20020023735A1Reduce decreaseReduce heat stressSafety devices for heat exchange apparatusHeat exhanger finsWave shapeEngineering

In a double heat exchanger with a condenser and a radiator, a flexible portion formed into a wave shape to be flexible is provided in a side plate at least at one side of connection portions of the side plate, connected to condenser header tanks and radiator header tanks. Further, a slit is provided to be recessed from one longitudinal end of the side plate to the flexible portion. Accordingly, a heat stress generated in condenser tubes and radiator tubes can be absorbed by the flexible portion even when a length of the slit is made shorter.

Owner:DENSO CORP

Heat exchanger assembly capable of automatically controlling heating power of left tube box and right tube box

InactiveCN108800990AImprove heating efficiencySimple structureSafety devices for heat exchange apparatusStorage heatersAutomatic controlEngineering

The invention provides a heat exchanger assembly. The heat exchanger assembly comprises a left tube box, a right tube box and a heat exchange tube, wherein the heat exchange tube communicates with theleft tube box and the right tube box; electric heating devices are arranged in the left tube box and / or the right tube box; the left tube box, the right tube box and the heat exchange tube are filled with heating fluid to form a heating fluid closed cycle; the tube diameter of the left tube box is larger than that of the right tube box; and the tube diameter of the left tube box is 3-5 times ofthe tube diameter of the right tube box. Aiming at the deficiencies in the prior art, the immersed heat exchanger assembly is provided, the heating power is controlled to reach the best, and energy resources are saved.

Owner:ZHONGBEI UNIV

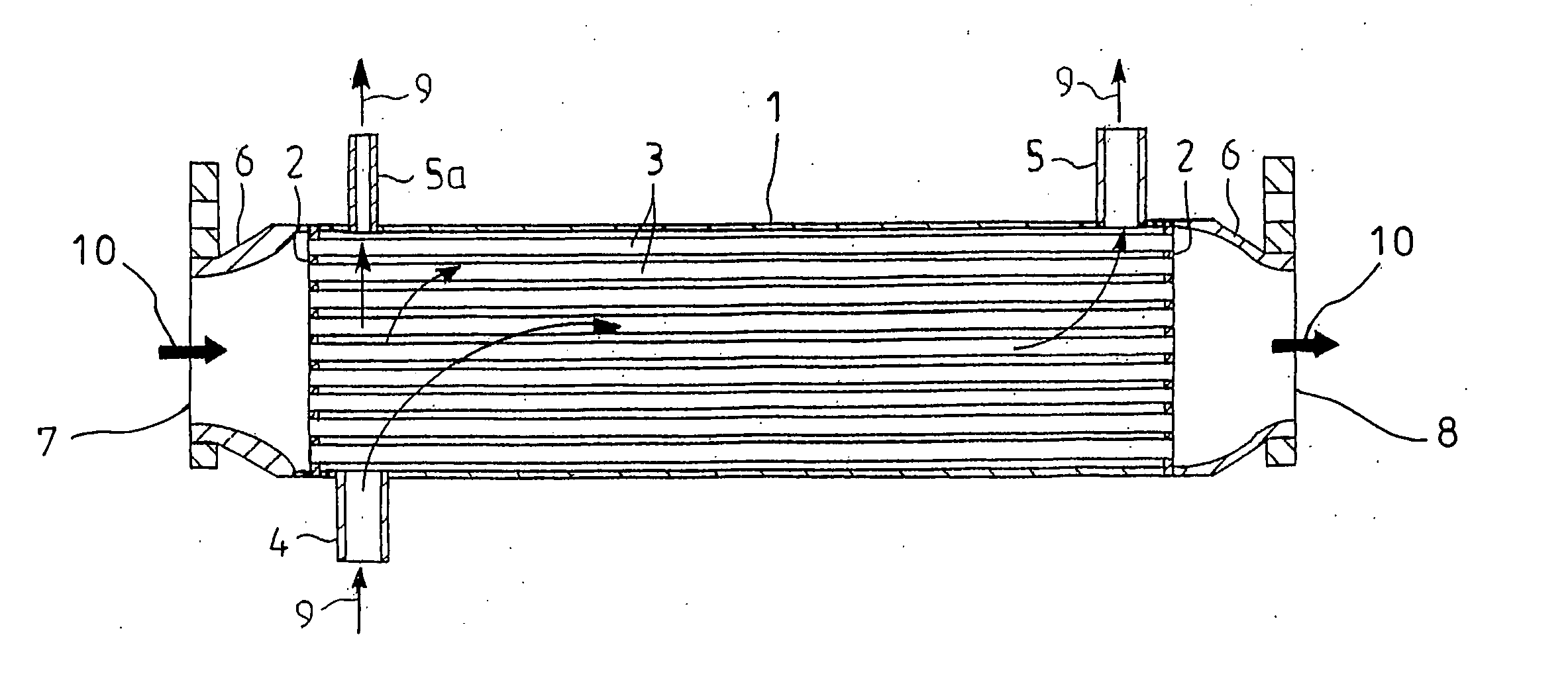

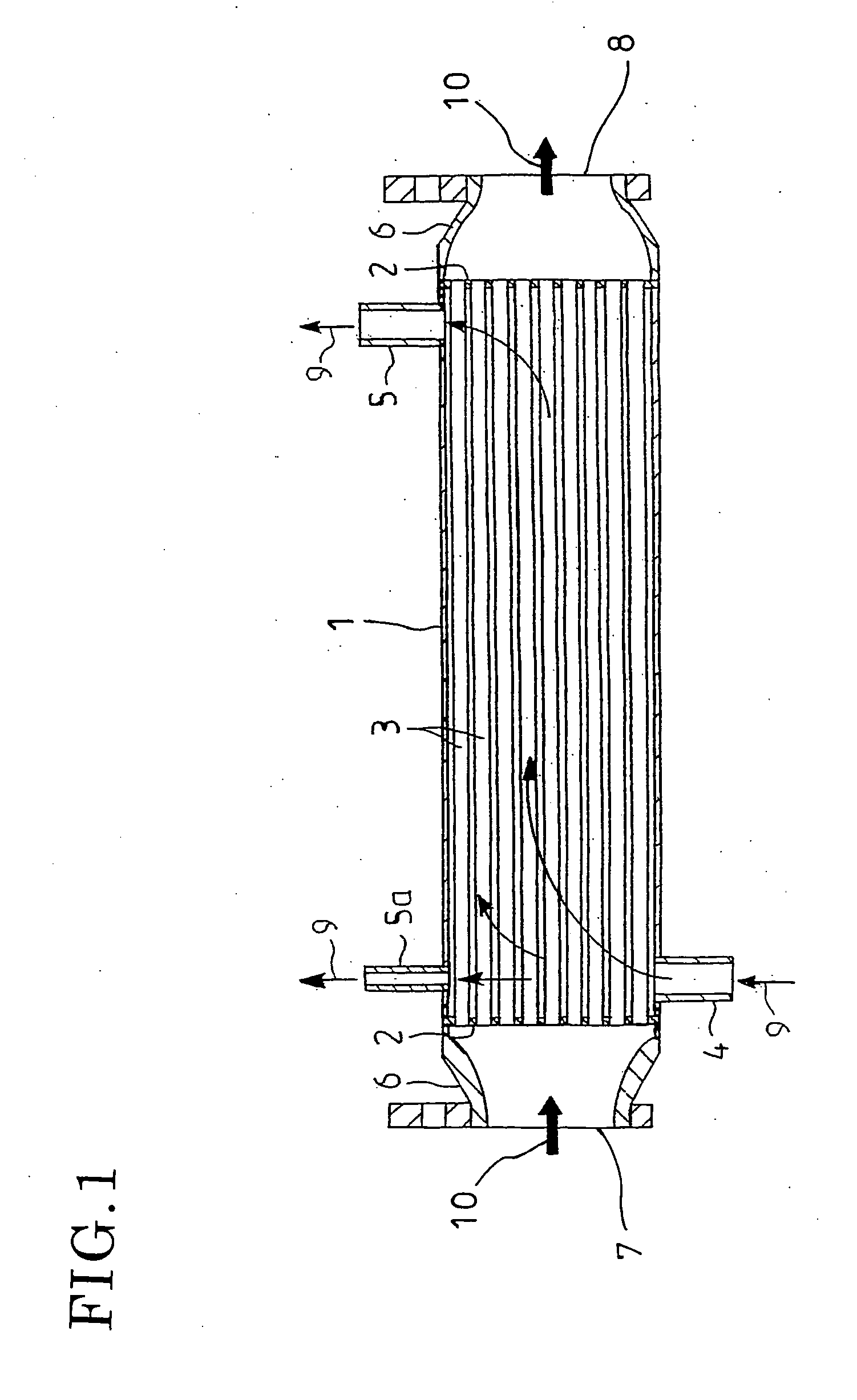

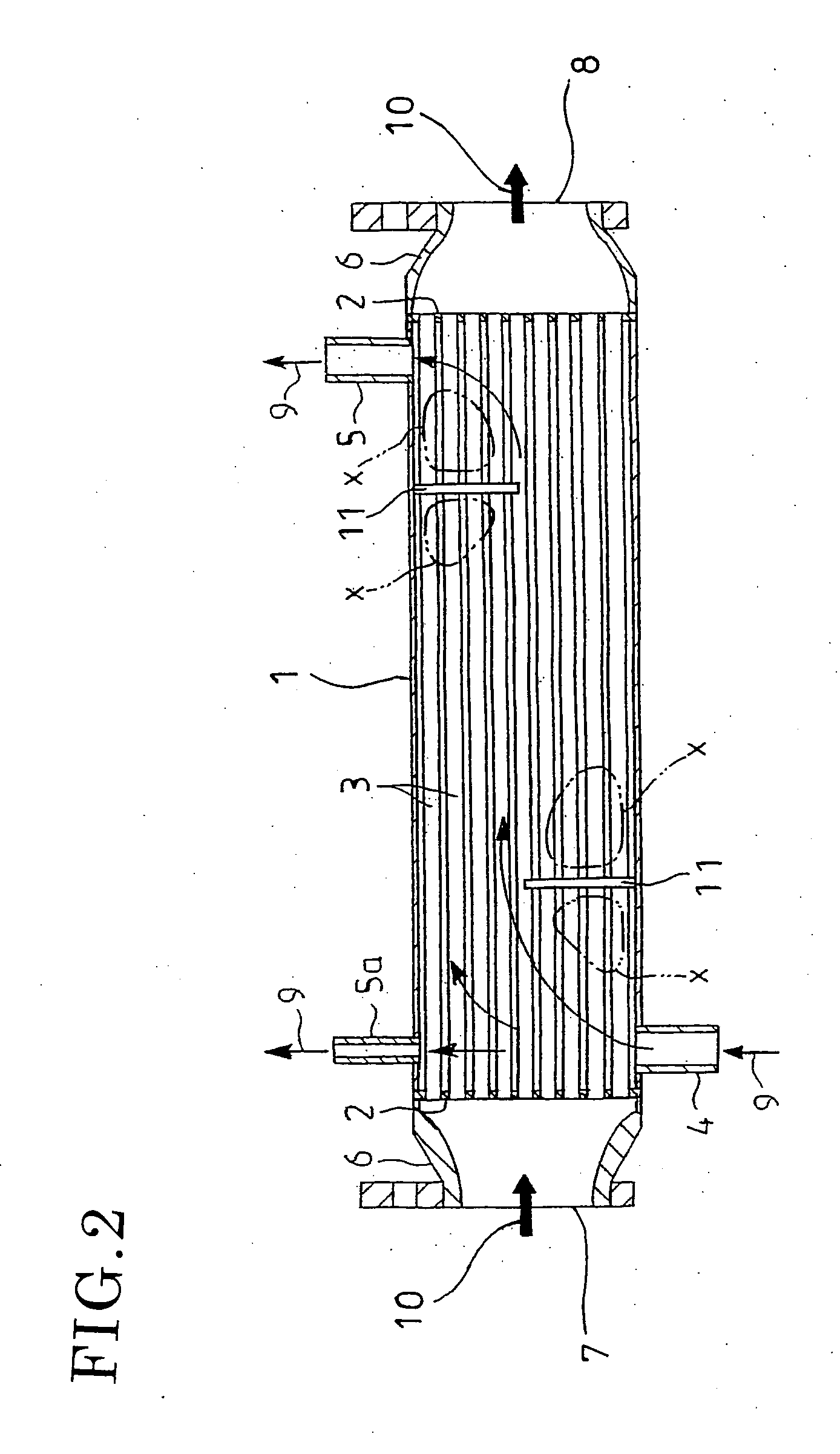

Egr cooler

InactiveUS20060231243A1Increased pressure lossImprove the exhaust effectNon-fuel substance addition to fuelInternal combustion piston enginesThermal deformationEngineering

Provided is an EGR cooler which can solve the problem of the vibrated tubes without causing thermal deformation due to stagnation of the coolant water, without complexity of piping in the coolant water system and without increase in pressure loss. The EGR cooler comprises tubes 3 and a shell surrounding the tubes 3, the coolant water being supplied and discharged to and from the shell 1 and being passed through the respective tubes 3 so as to make heat exchange of the exhaust gas with the coolant water. In the shell 1, an intermediate support plate 13 with a plurality of through-holes 14 is arranged and mutually adjacent ones of the tubes 3 are grouped for penetratingly fixture to the through-hole 14. A coolant water passage 15 is ensured between the tubes 3 grouped and penetratingly fixed to the same through-hole 14 of the intermediate support plate 13 for free communication between the tubes 3.

Owner:HINO MOTORS LTD +1

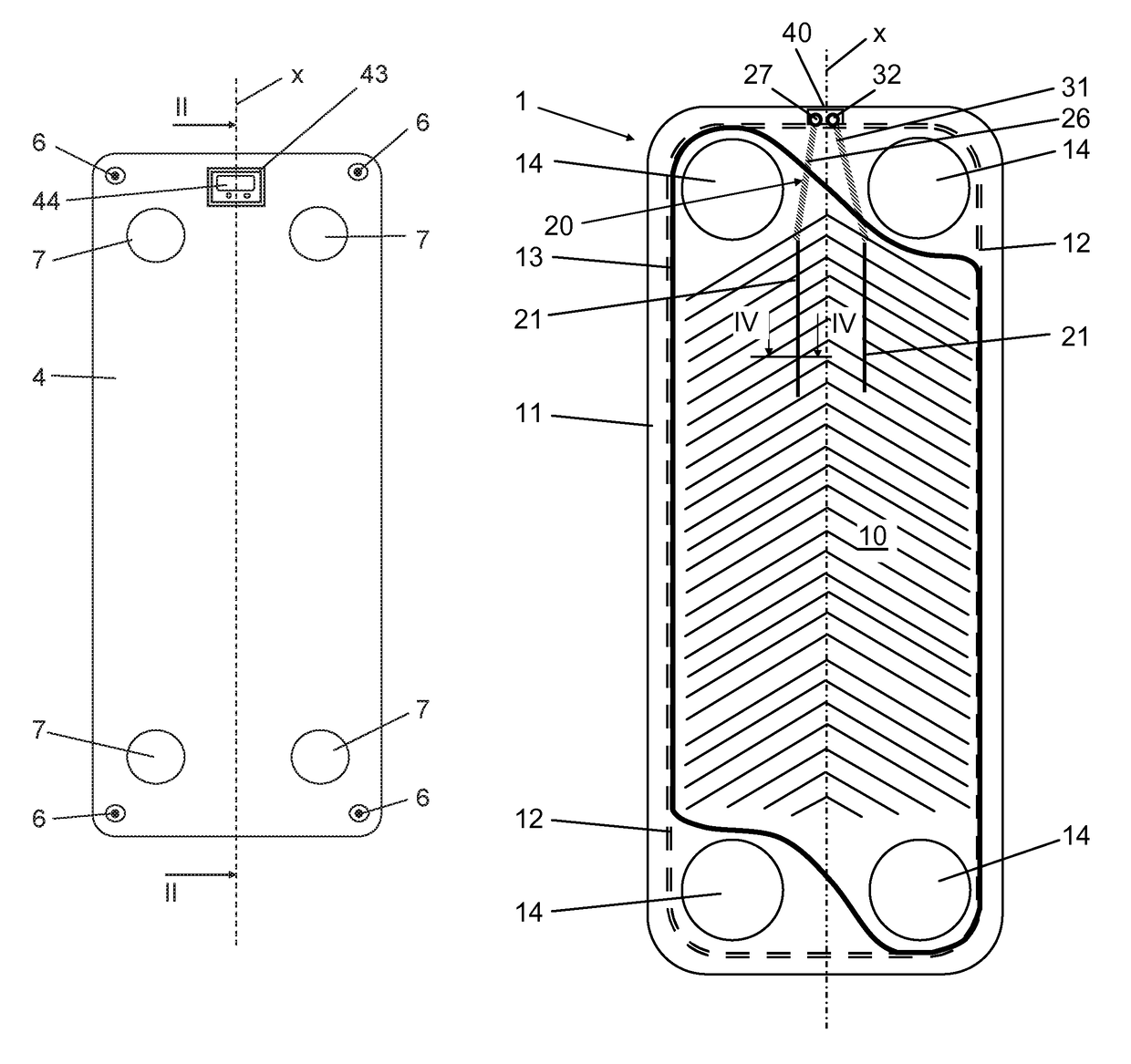

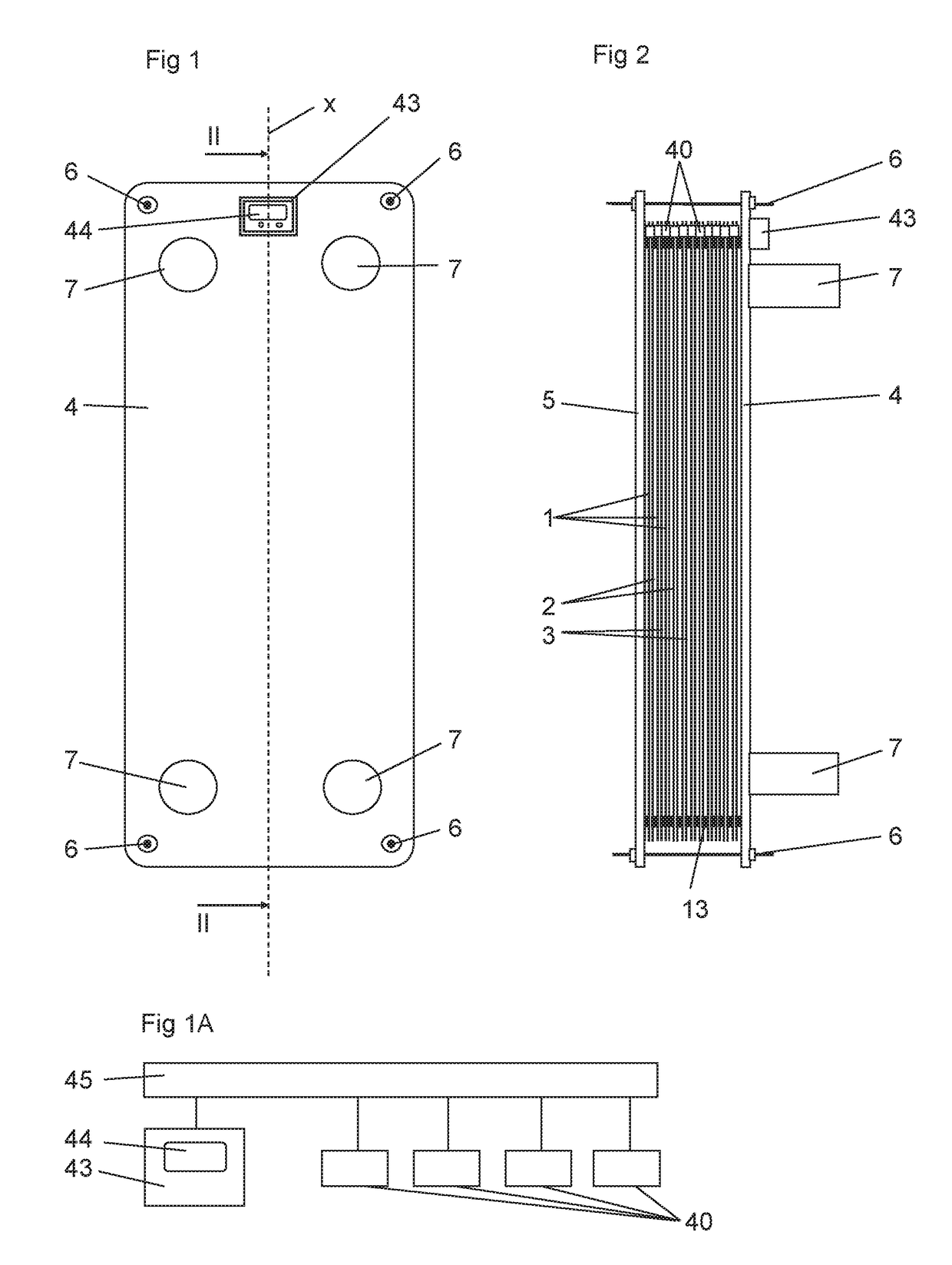

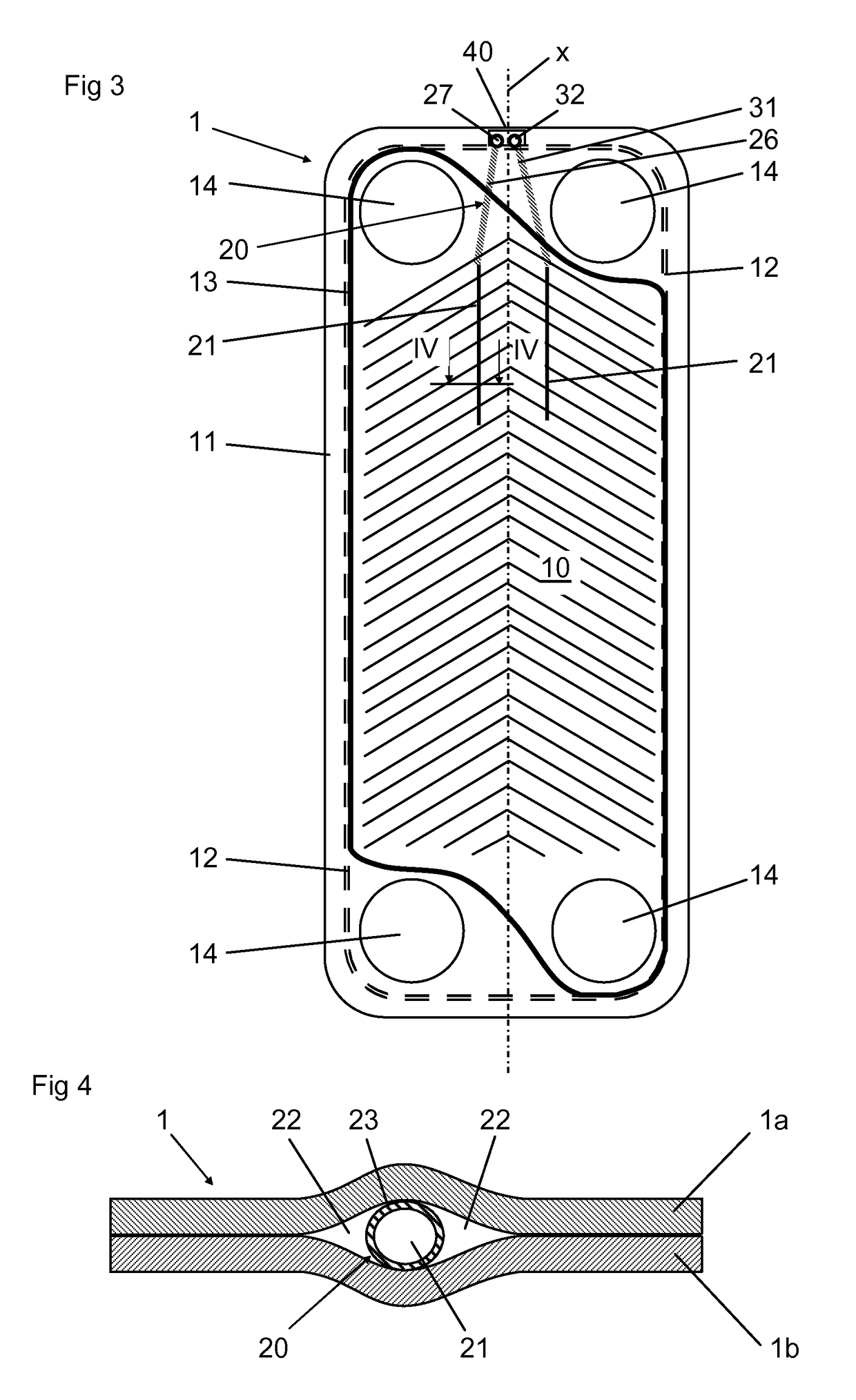

Heat exchanger plate and a plate heat exchanger with insulated sensor internal to heat exchange area

ActiveUS9739546B2Raise the possibilityDetection of leakageDetection of fluid at leakage pointAir-treating devicesDouble wallEngineering

A plate heat exchanger includes a heat exchanger plate having a heat transfer area and an edge area, extending around the heat transfer area. The heat exchanger plate is a double wall plate formed by two adjoining plates compressed to be in contact with each other. A sensor configured to sense at least one parameter and to produce a signal depending on the parameter includes a sensor probe that is provided between the adjoining plates.

Owner:ALFA LAVAL CORP AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com