Patents

Literature

5495results about "Water/sewage treatment by substance addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treating produced waters

InactiveUS20070102359A1Complicate purificationIncrease ratingsUltrafiltrationTreatment involving filtrationEmulsionUnit operation

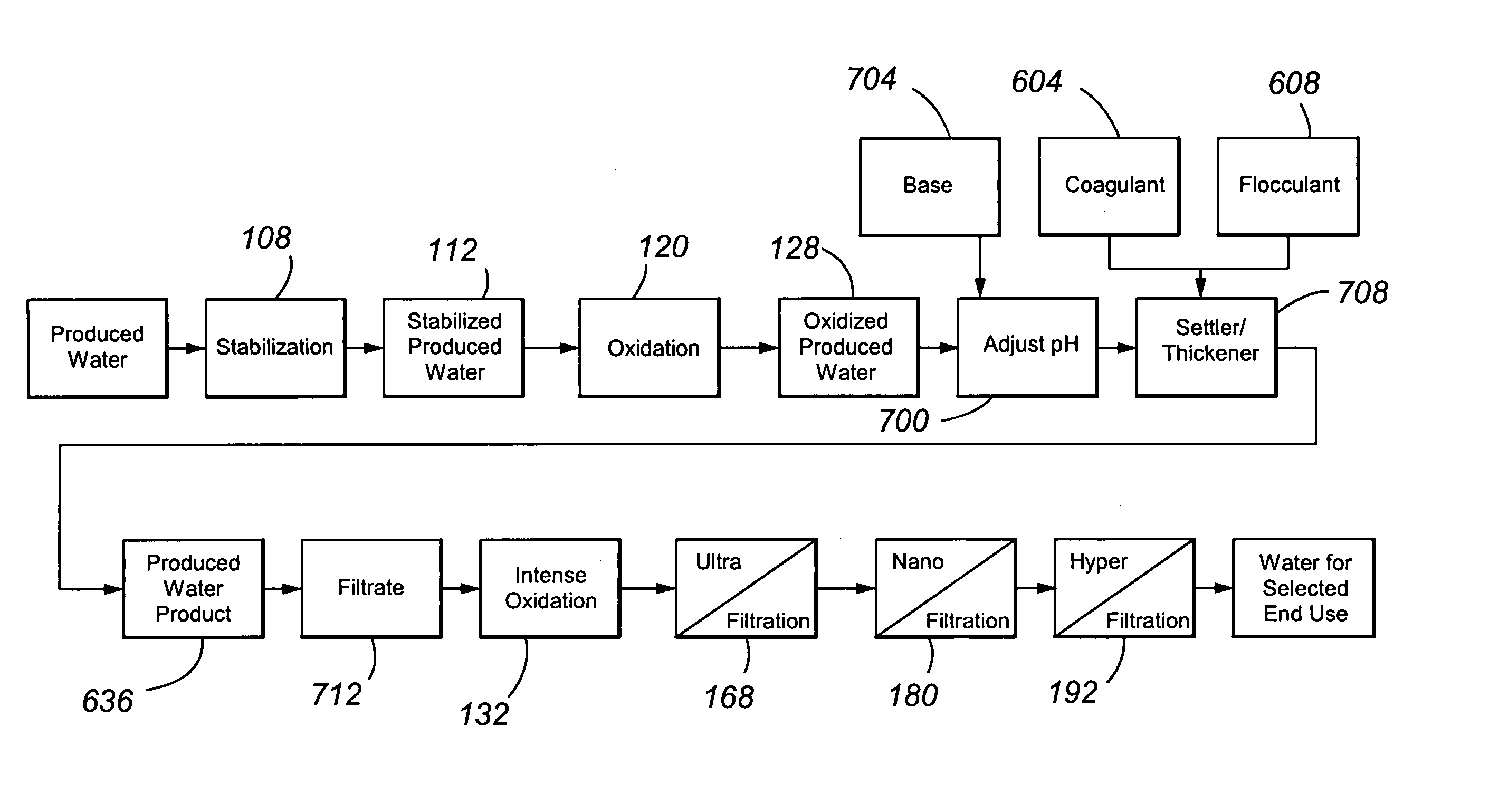

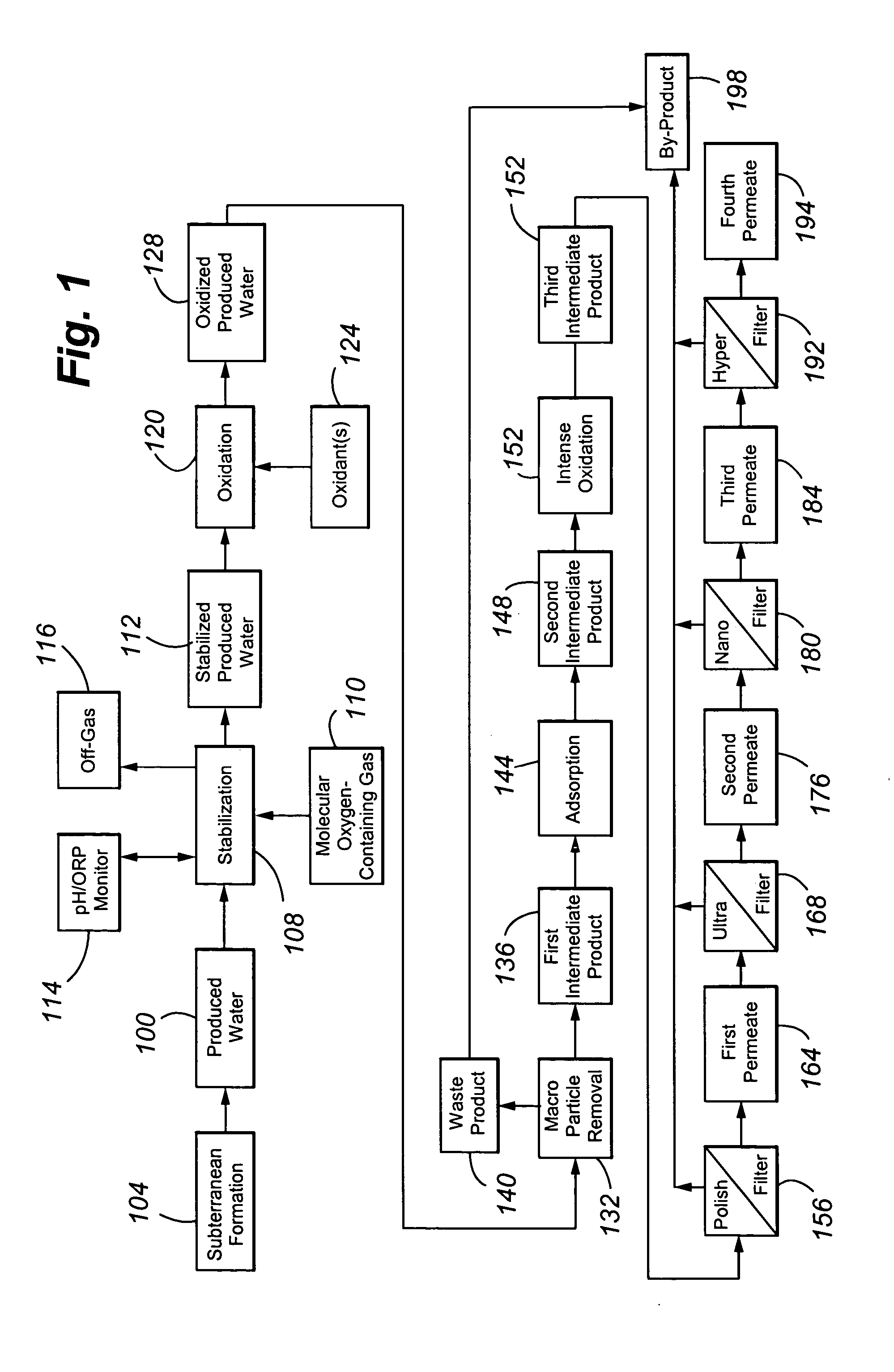

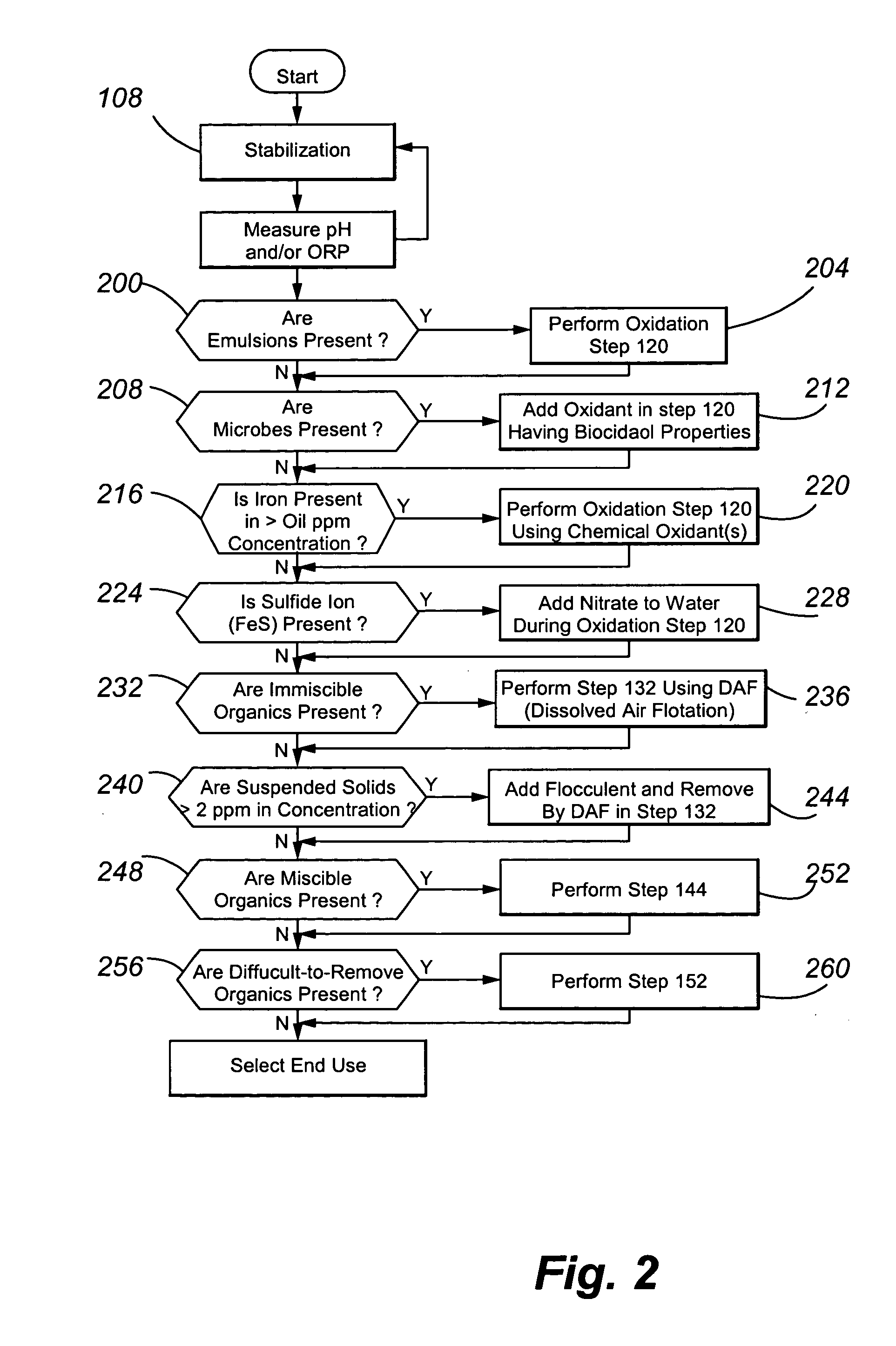

The present invention is directed to various sets of unit operations for treating aqueous effluents and logic for designing and effecting the treatment. The unit operations include stabilization of subterranean waters, sequential oxidation steps to alter selected target materials, oxidation to break up emulsions prior to removal of the emulsion components, and intense oxidation to break up difficult-to-remove organic target materials.

Owner:HW PROCESS TECH

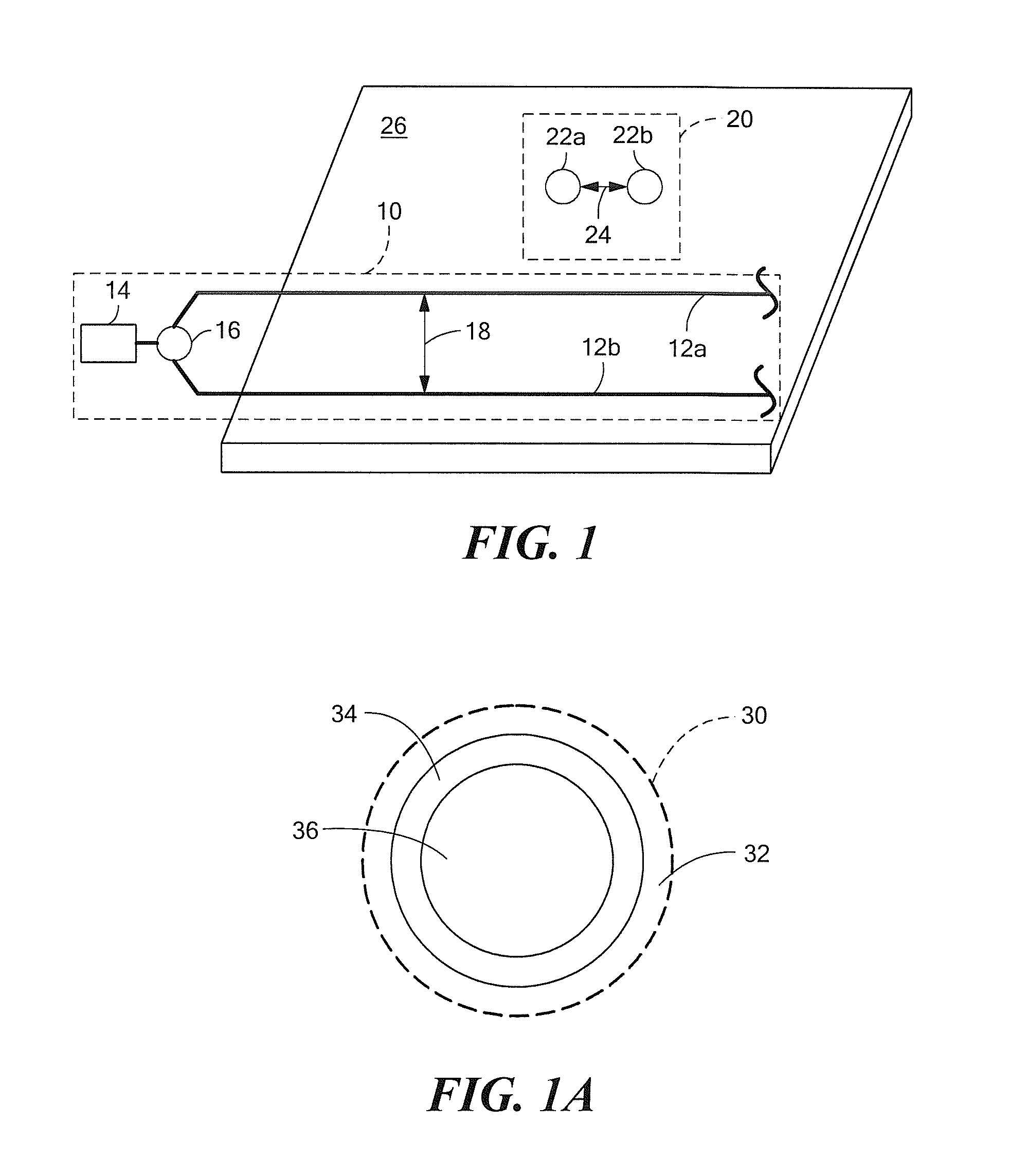

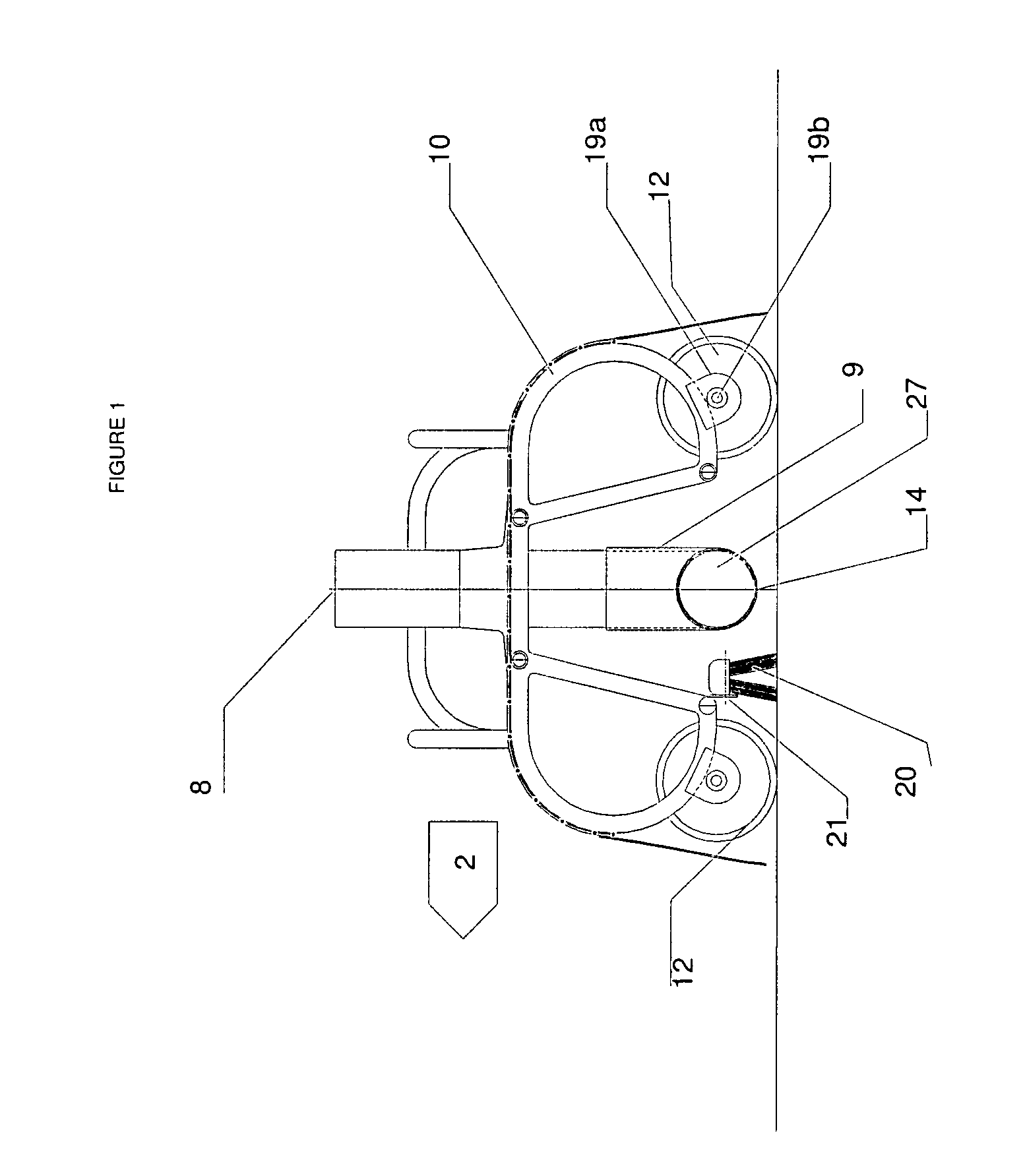

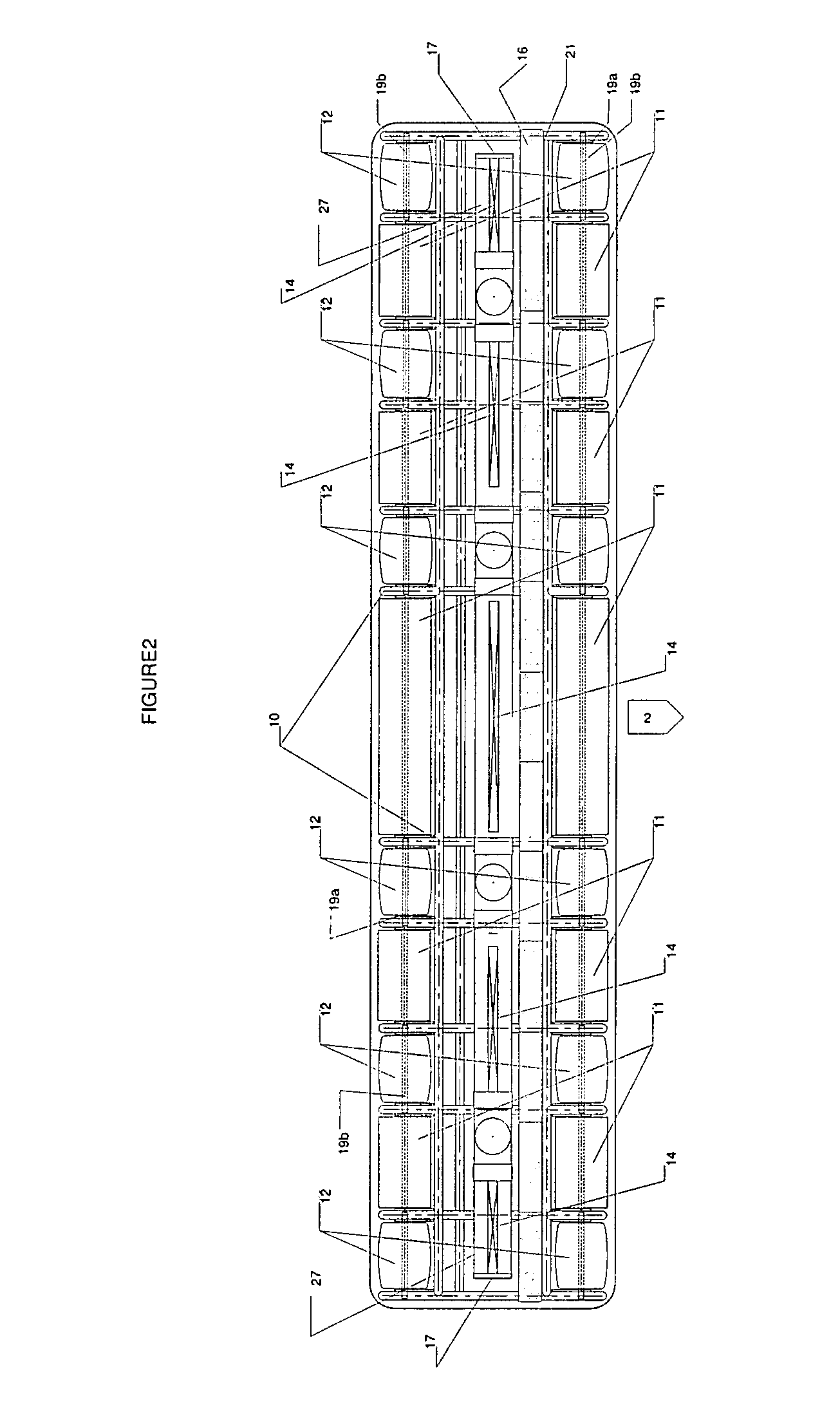

Method and apparatus for Anti-biofouling of a protected surface in liquid environments

ActiveUS20130048877A1Avoid biological contaminationReduce and eliminate needWater/sewage treatment by substance additionDeodrantsBiofoulingOptoelectronics

A system includes a UV light source and an optical medium coupled to receive UV light from the UV light source. The optical medium is configured to emit UV light proximate to a surface to be protected from biofouling. A method corresponds to the system.

Owner:RAYTHEON CO

Slurry dewatering and conversion of biosolids to a renewable fuel

ActiveUS20060096163A1Readily removed mechanicallyLow oxygenBio-organic fraction processingBiofuelsEmission standardSlurry

In the processes for treating municipal sewage and storm water containing biosolids to discharge standards, biosolids, even after dewatering, contain typically about 80% water bound in the dead cells of the biosolids, which gives biosolids a negative heating value. It can be incinerated only at the expense of purchased fuel. Biosolids are heated to a temperature at which their cell structure is destroyed and, preferably, at which carbon dioxide is split off to lower the oxygen content of the biosolids. The resulting char is not hydrophilic, and it can be efficiently dewatered and / or dried and is a viable renewable fuel. This renewable fuel can be supplemented by also charging conventional biomass (yard and crop waste, etc.) in the same or in parallel facilities. Similarly, non-renewable hydrophilic fuels can be so processed in conjunction with the processing of biosolids to further augment the energy supply.

Owner:SGC ADVISORS

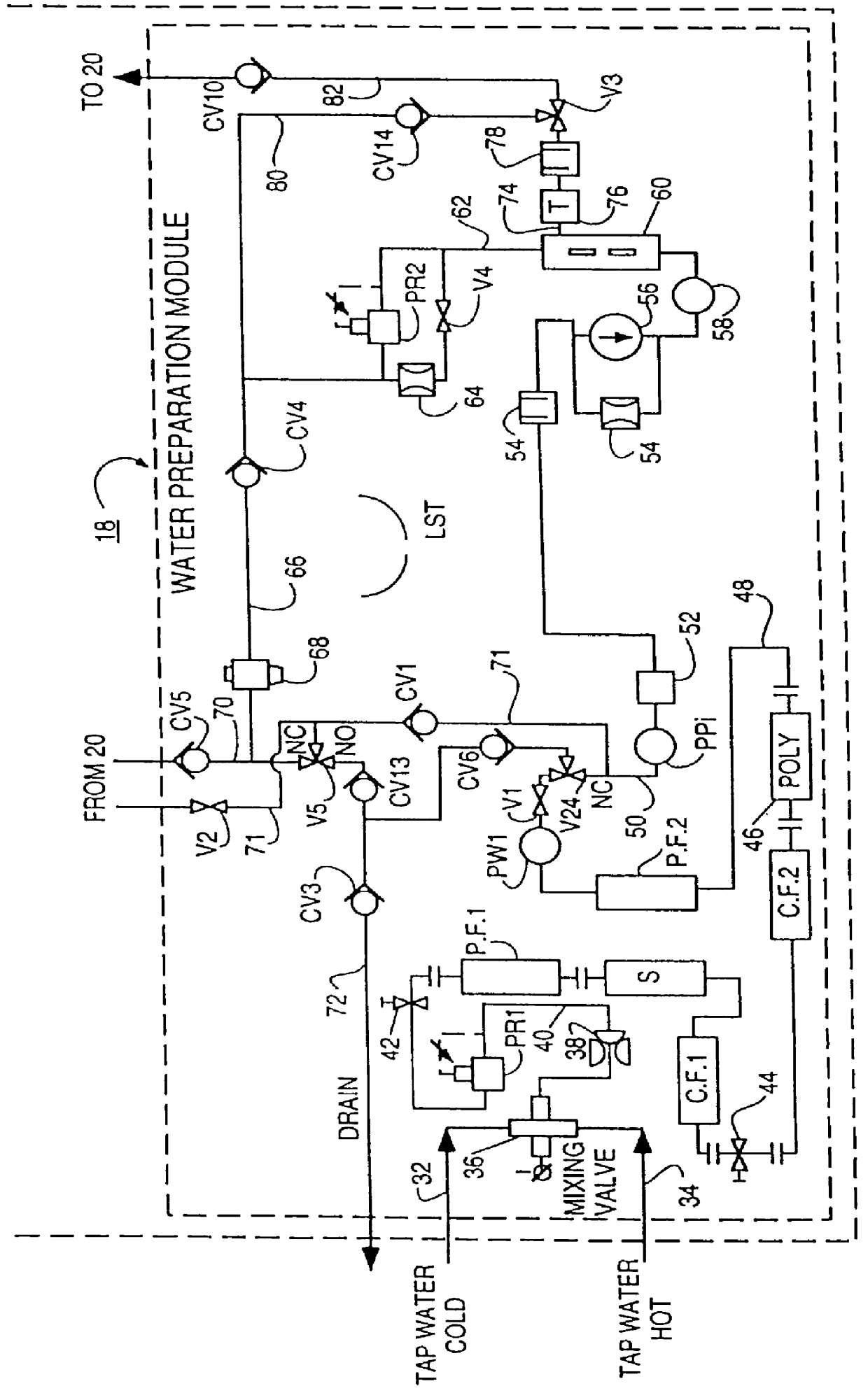

Point-of-use water purification system with a cascade ion exchange option

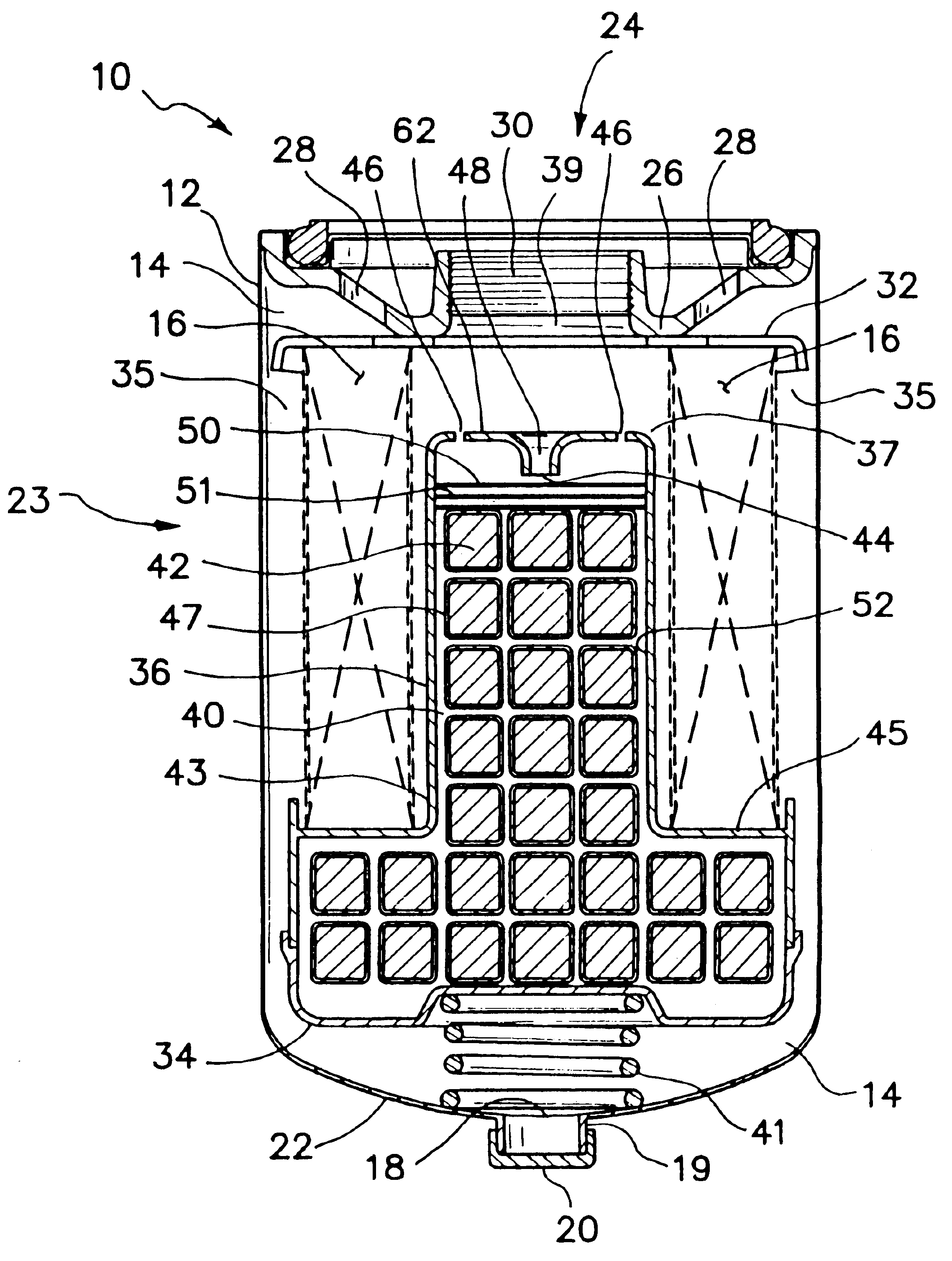

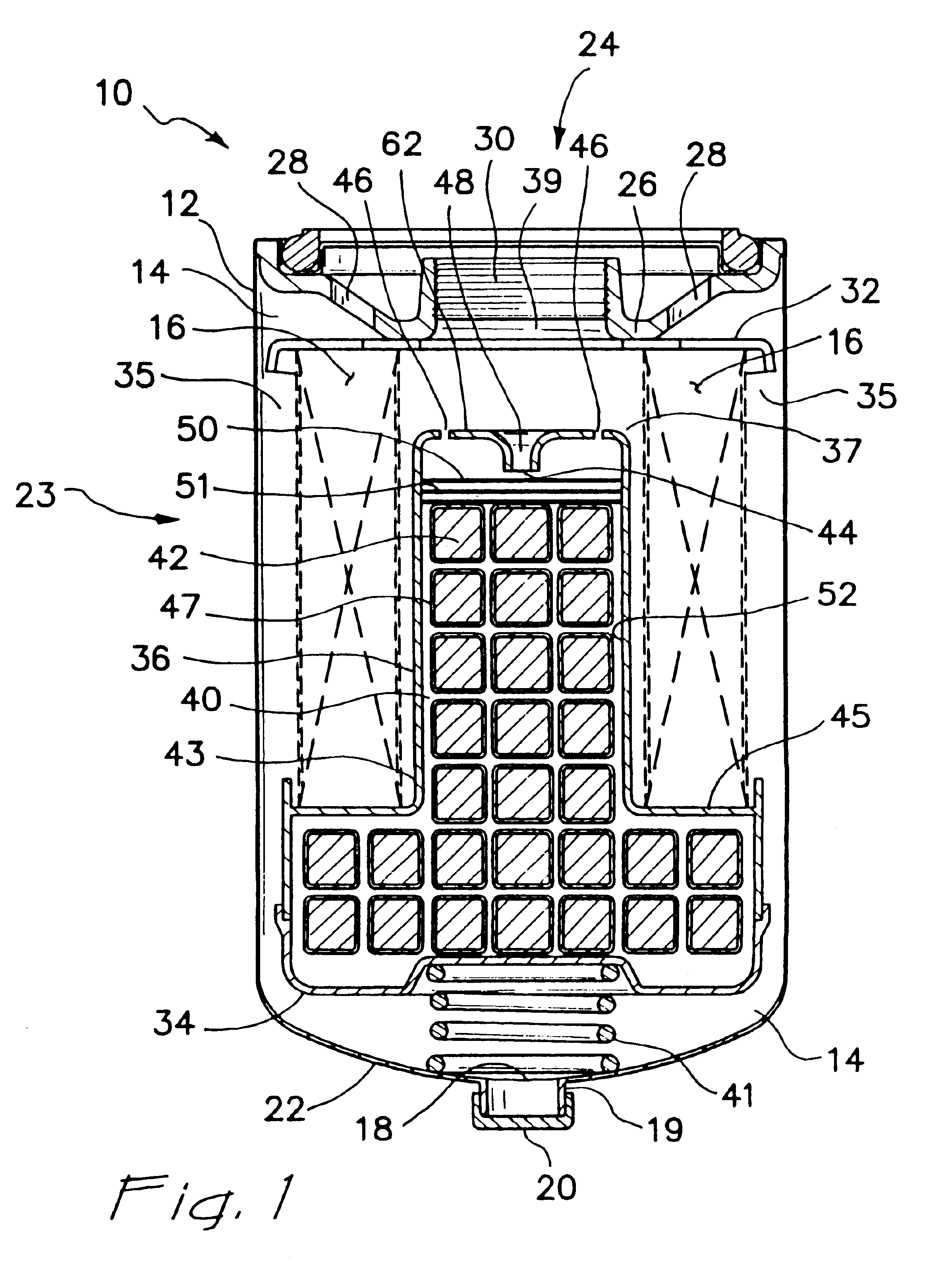

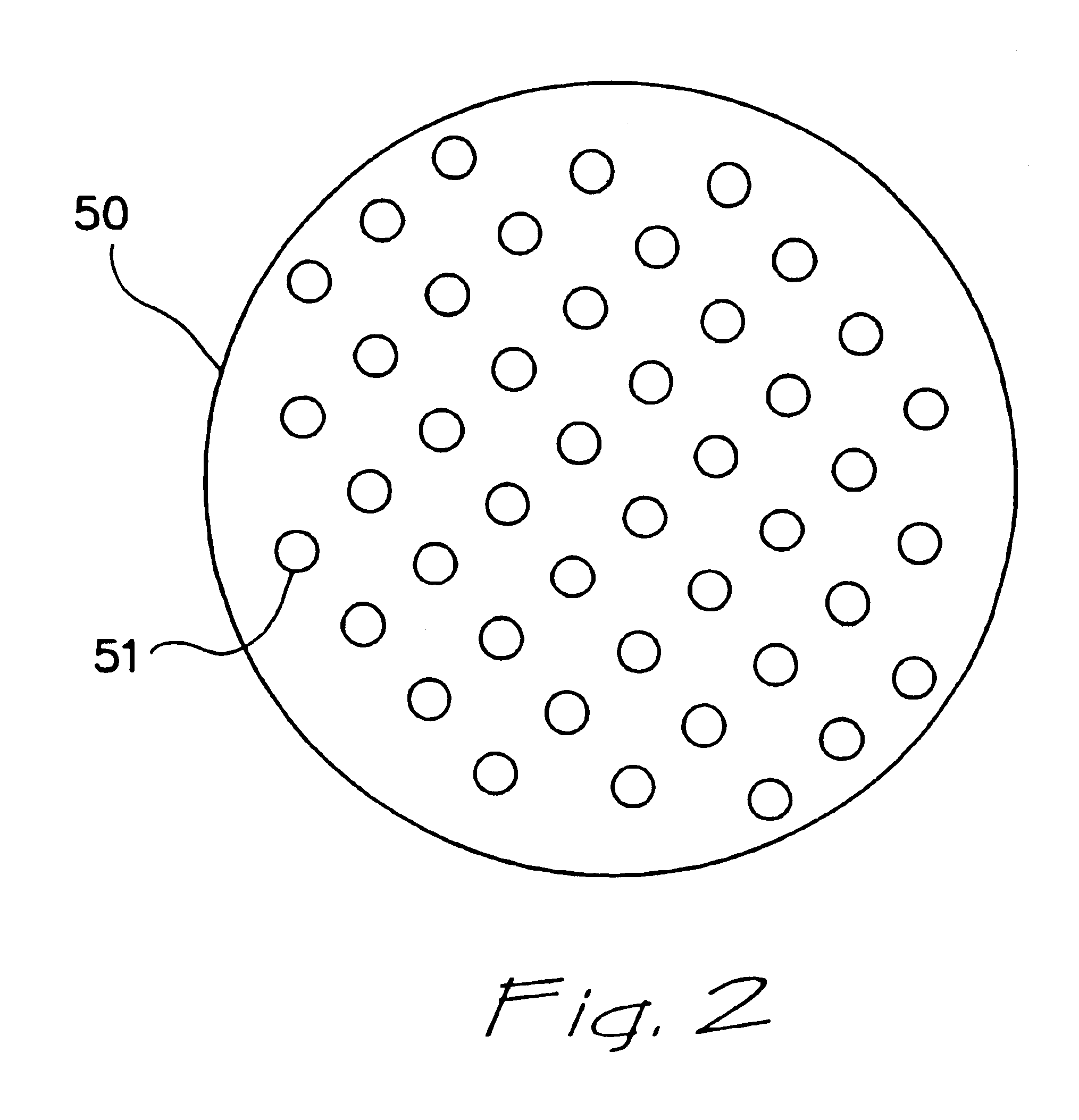

InactiveUS6080313AHigh purityEasy to install and replaceSolid sorbent liquid separationLoose filtering material filtersFiltrationIon exchange

A modular water treatment and purification system, suitable for home use, is connected to a water supply and contains a closed fluid treatment circuit extending to a water outlet. The closed fluid circuit flows through a plurality of replaceable water treatment modules each having a specific water treatment function, such as the removal of a particular material from the water by the use of filtration, carbon adsorption, ion exchange or the addition of a chemical to balance the desired water conditions. Preferably the circuit also includes traversing a radiation device, for example an ultra violet light, for the purpose of sanitizing the water.

Owner:KELADA MAHER I

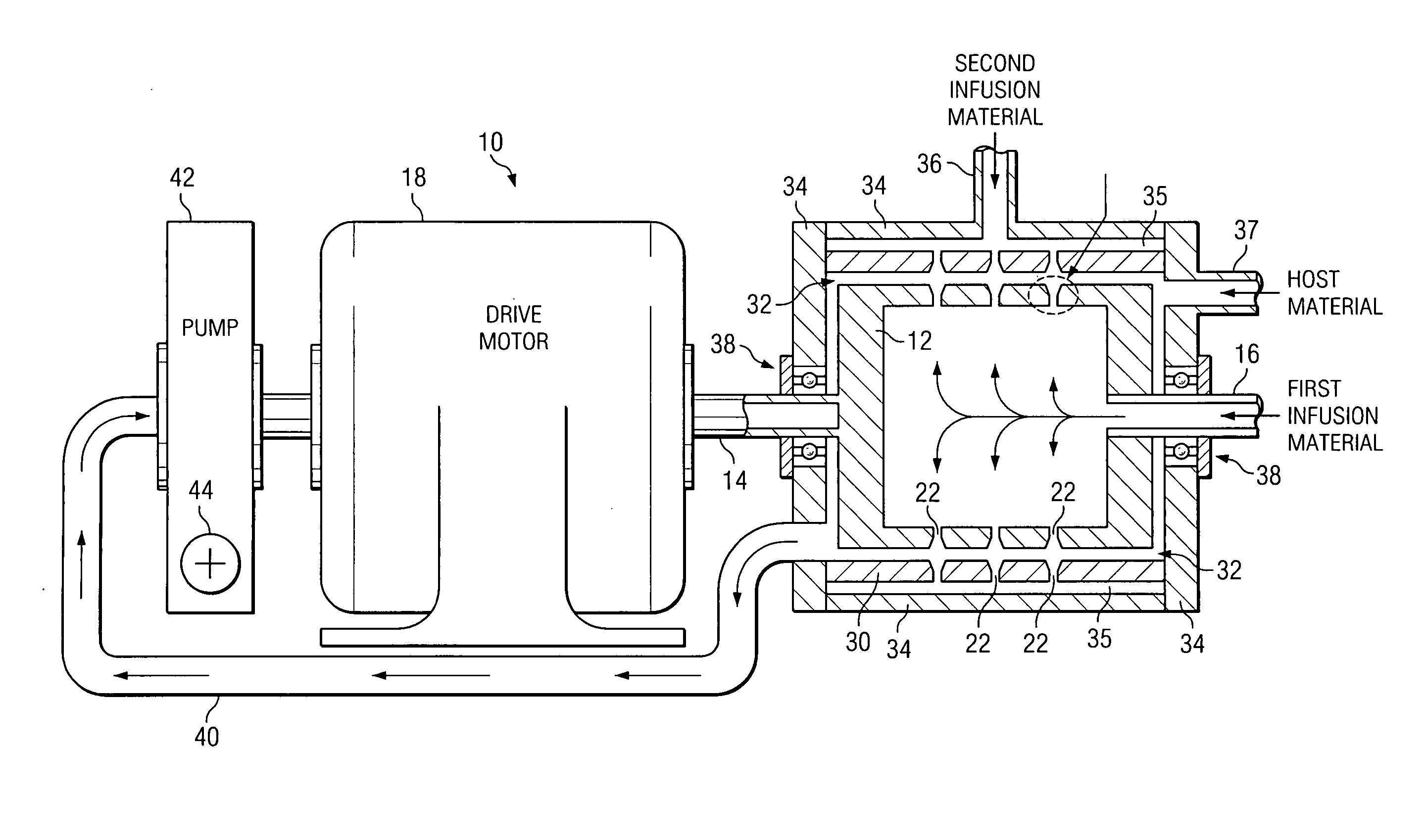

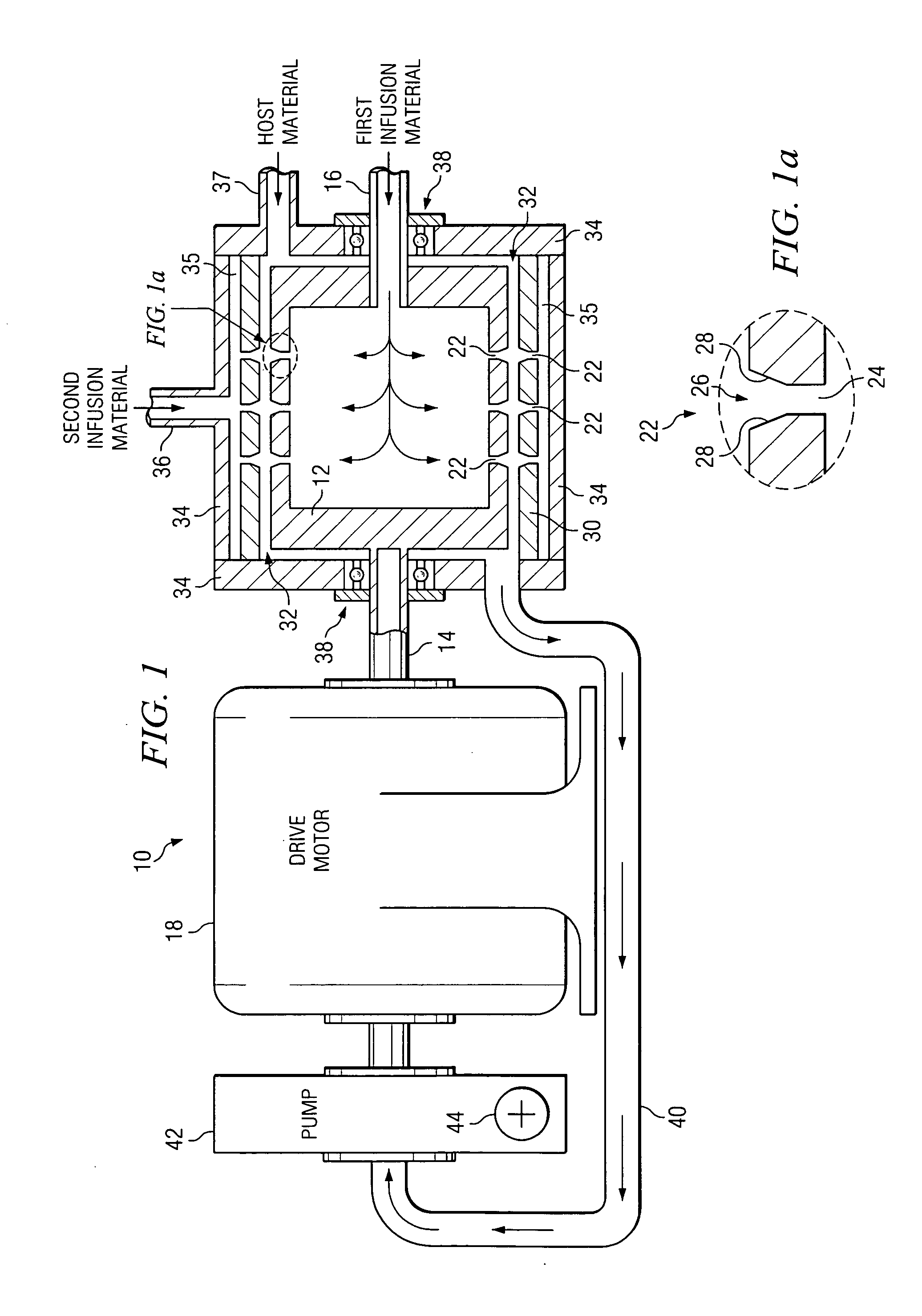

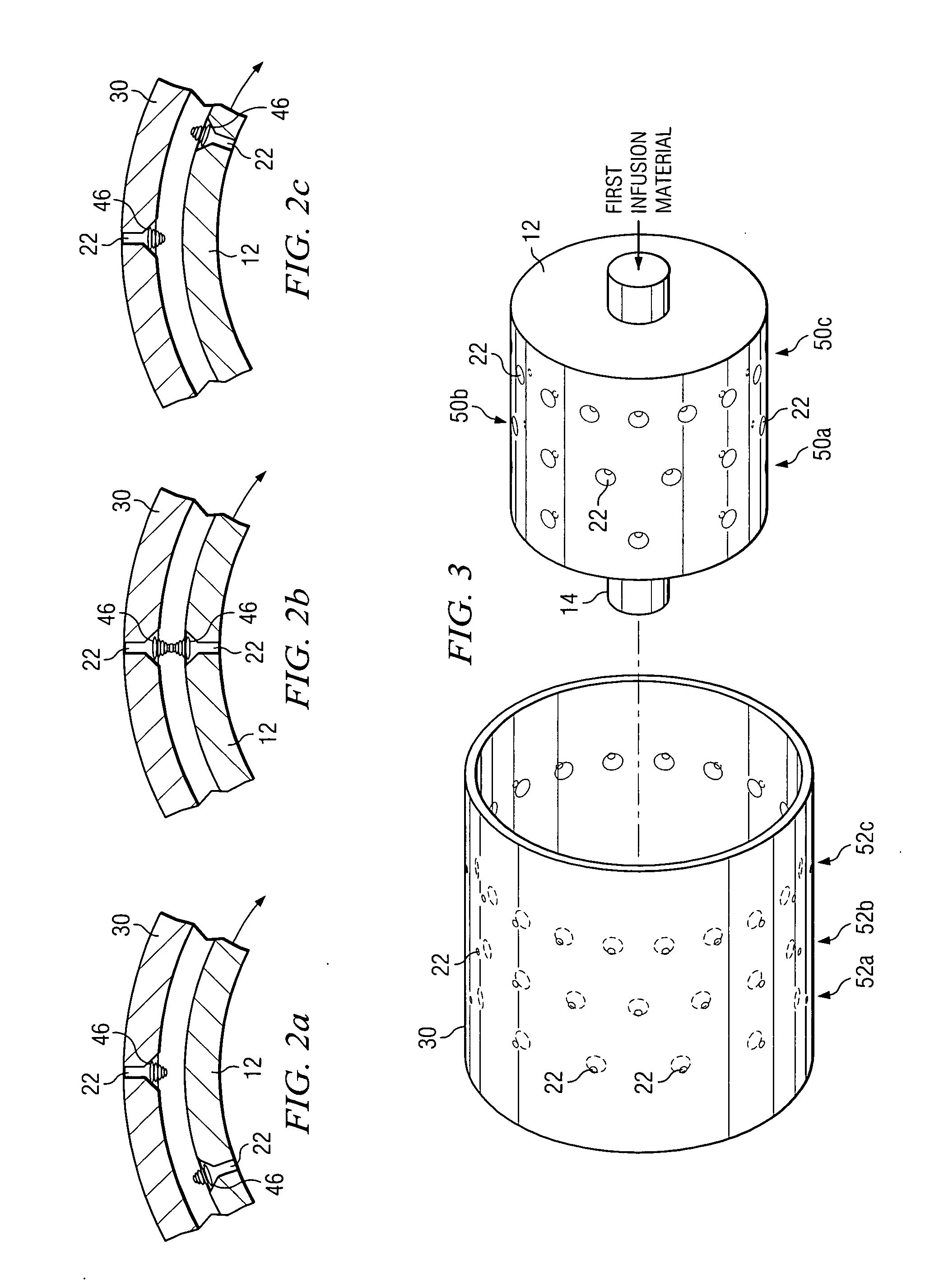

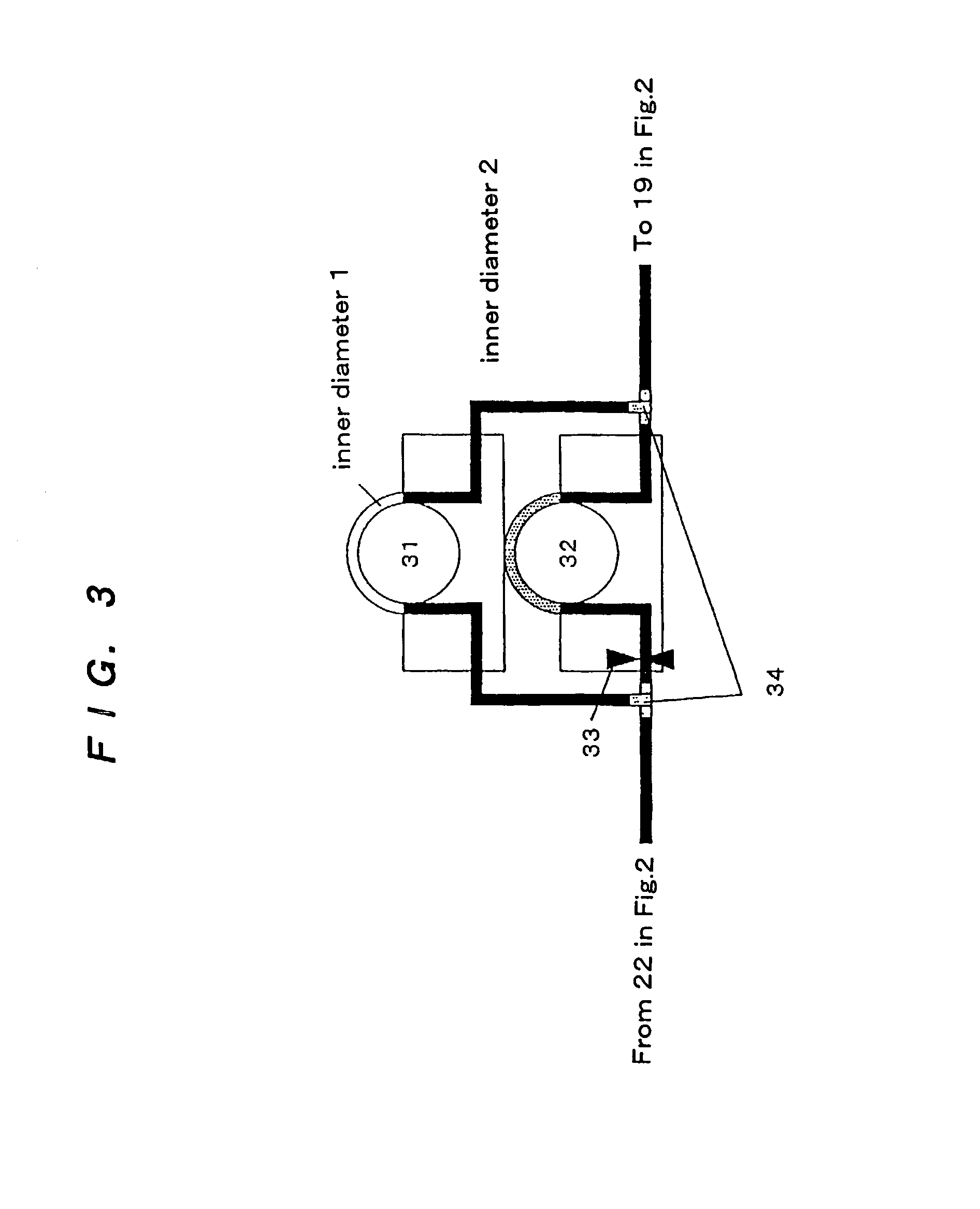

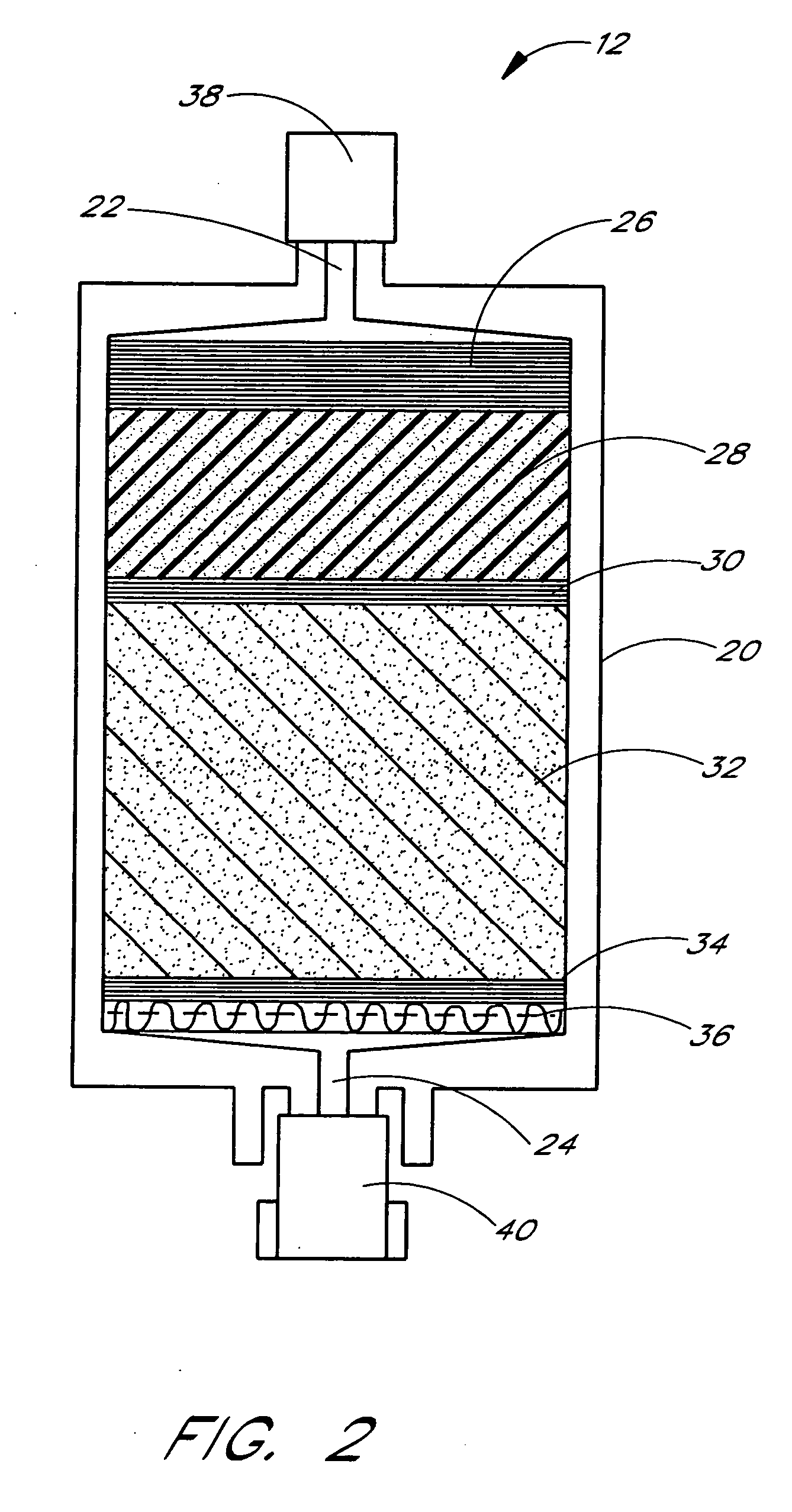

System and method for therapeutic application of dissolved oxygen

InactiveUS20050047270A1Rotary stirring mixersUsing liquid separation agentCavitationAqueous solution

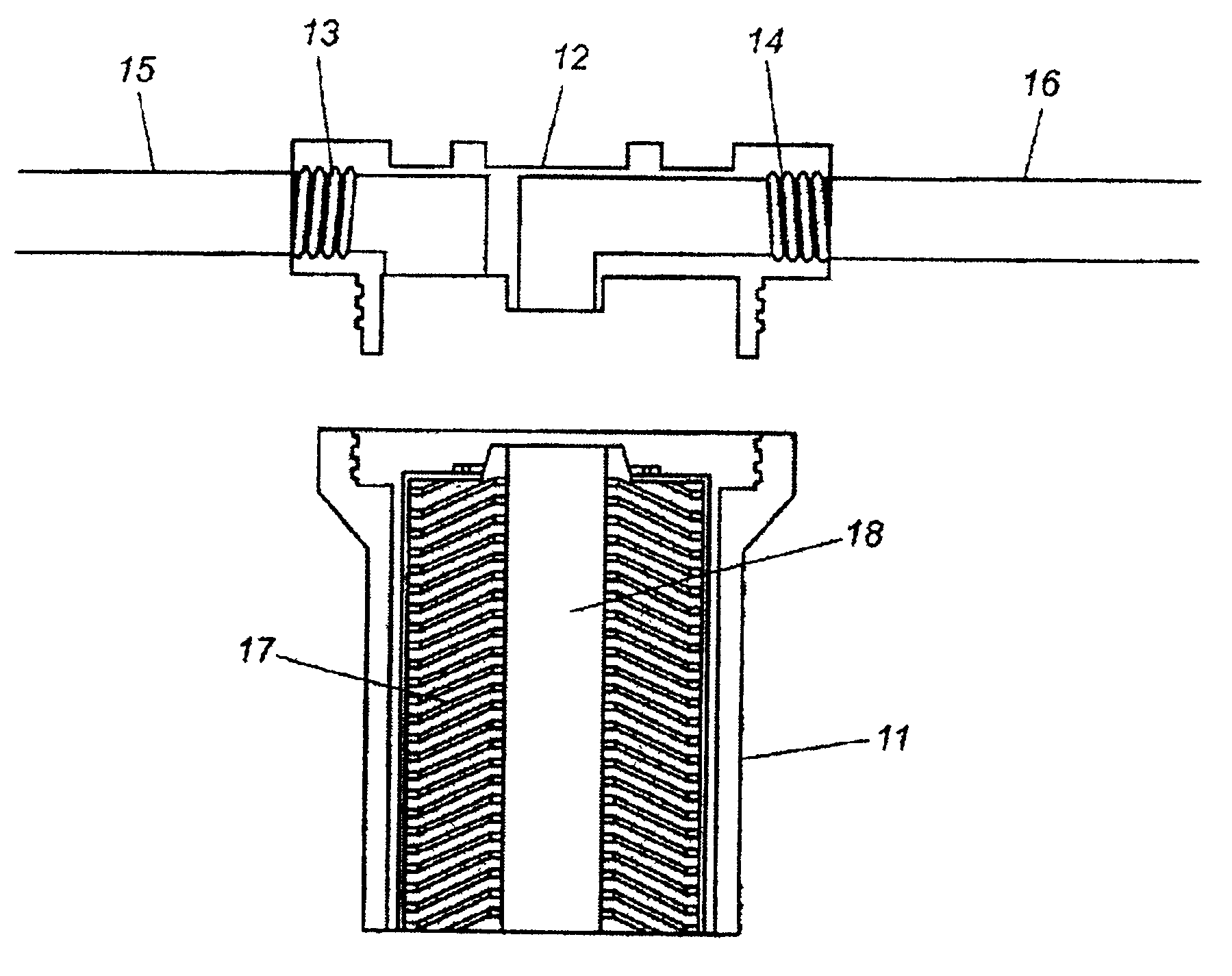

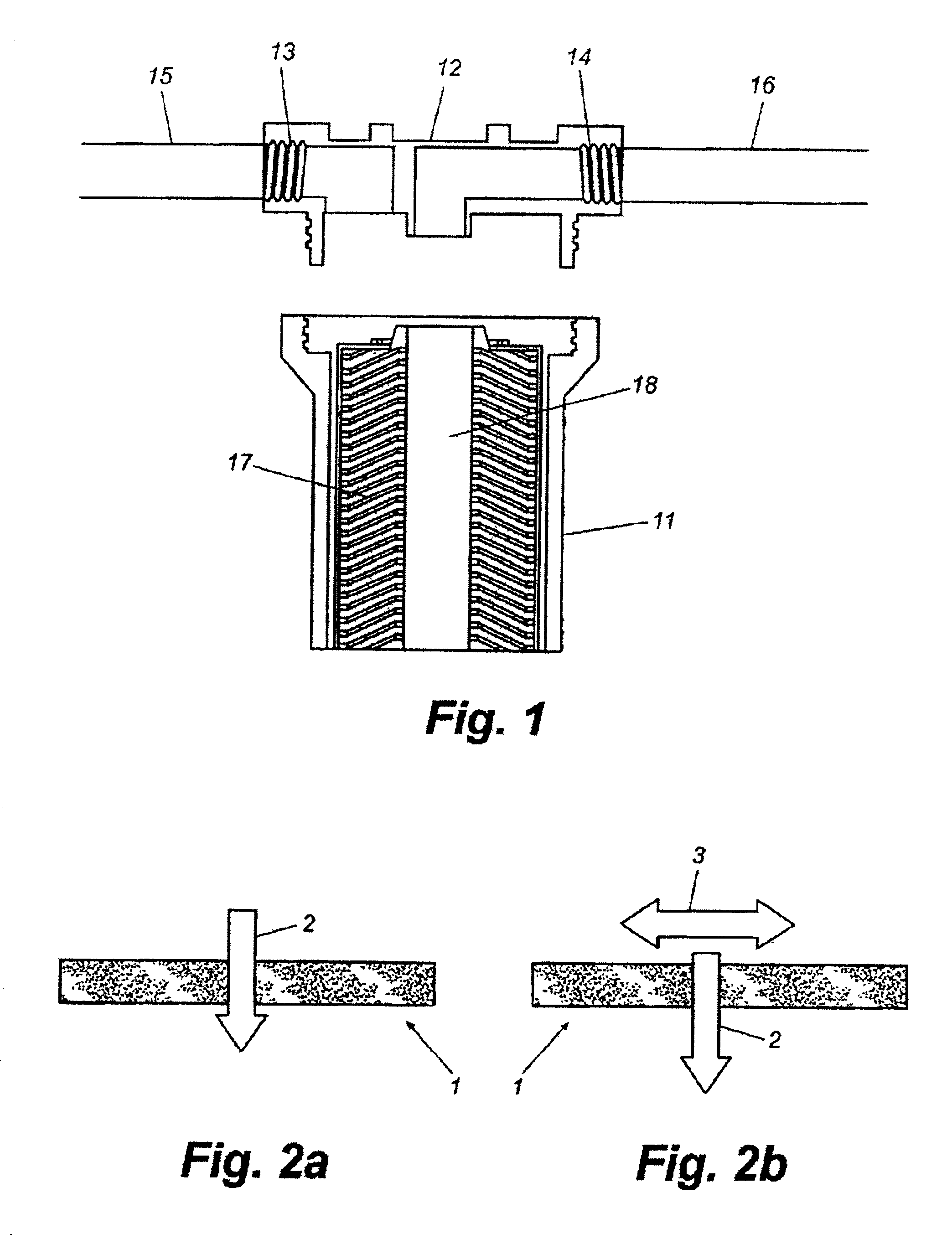

A system and method for generating an oxygen enriched aqueous solution for therapeutic application includes a diffuser comprising a first diffusing member having a surface incorporating surface disturbances, and a second diffusing member positioned relative to the first diffusing member to form a channel through which an aqueous solution and oxygen gas may flow. A reservoir containing the aqueous solution is connected to a pump that draws the aqueous solution from the reservoir and inputs the aqueous solution into the diffuser. The aqueous solution is moved through the channel relative to the surface disturbances to create cavitation in the aqueous solution to diffuse the oxygen gas into the aqueous solution to produce an oxygen enriched aqueous solution.

Owner:REVALESIO CORP

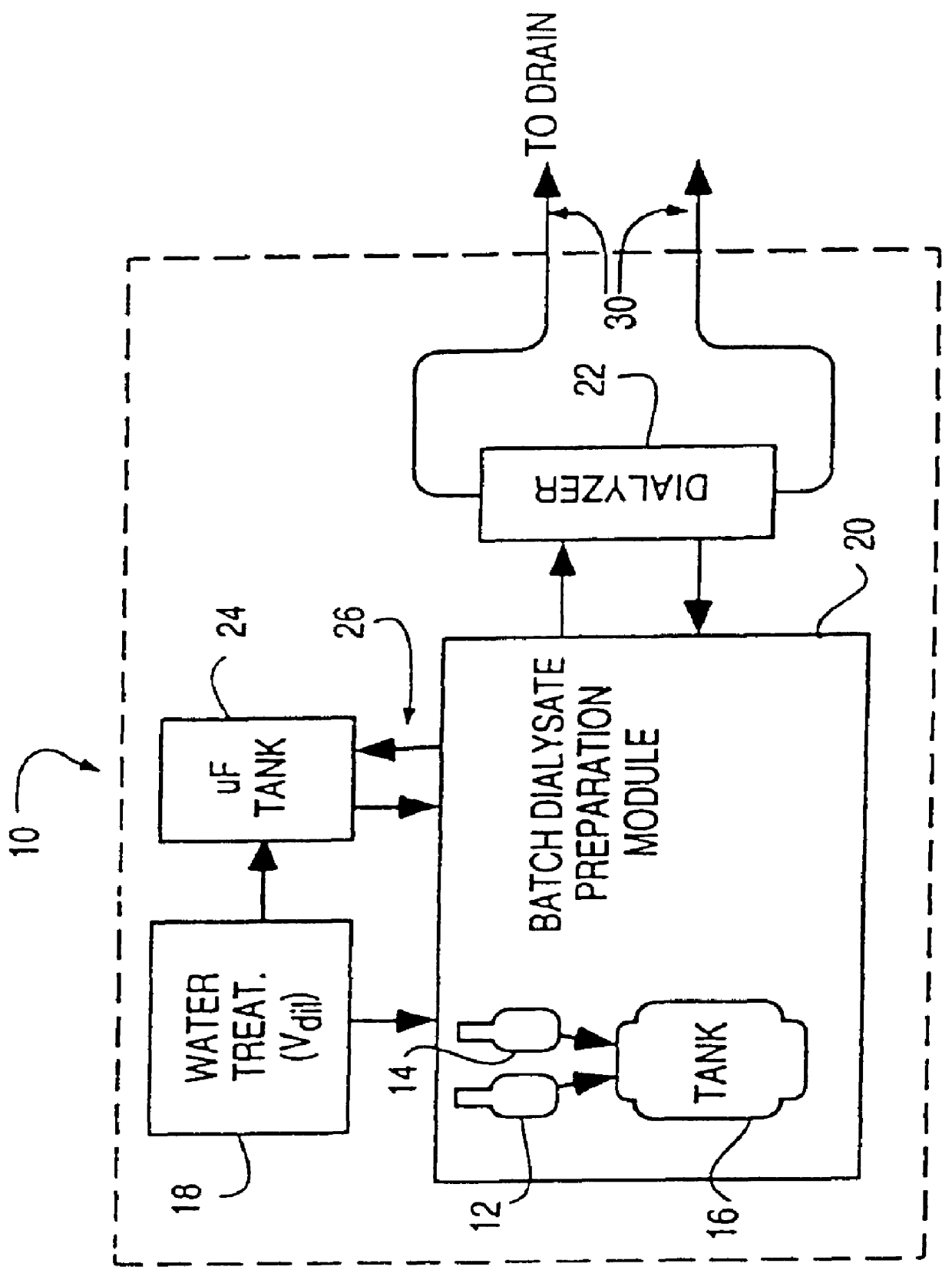

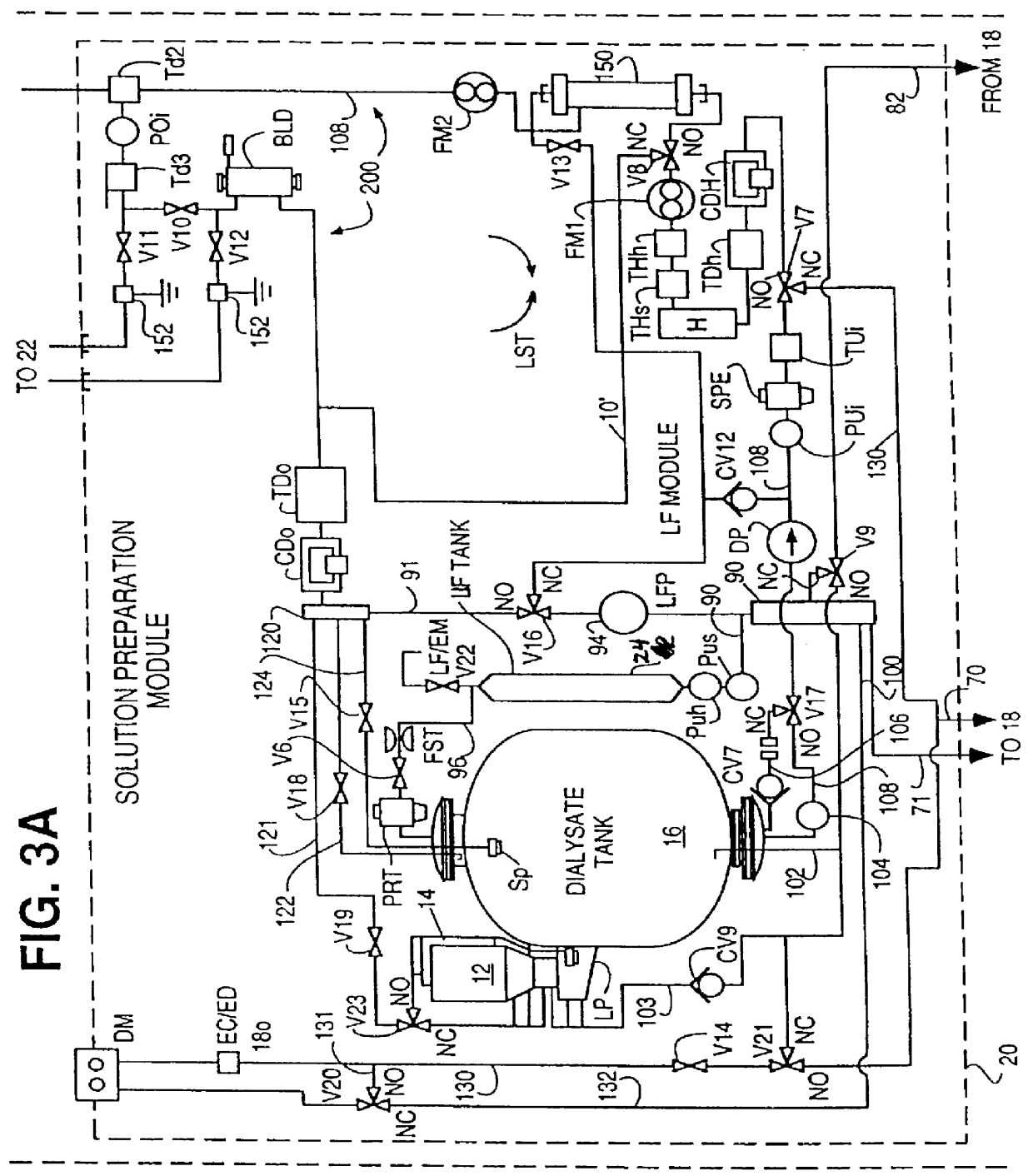

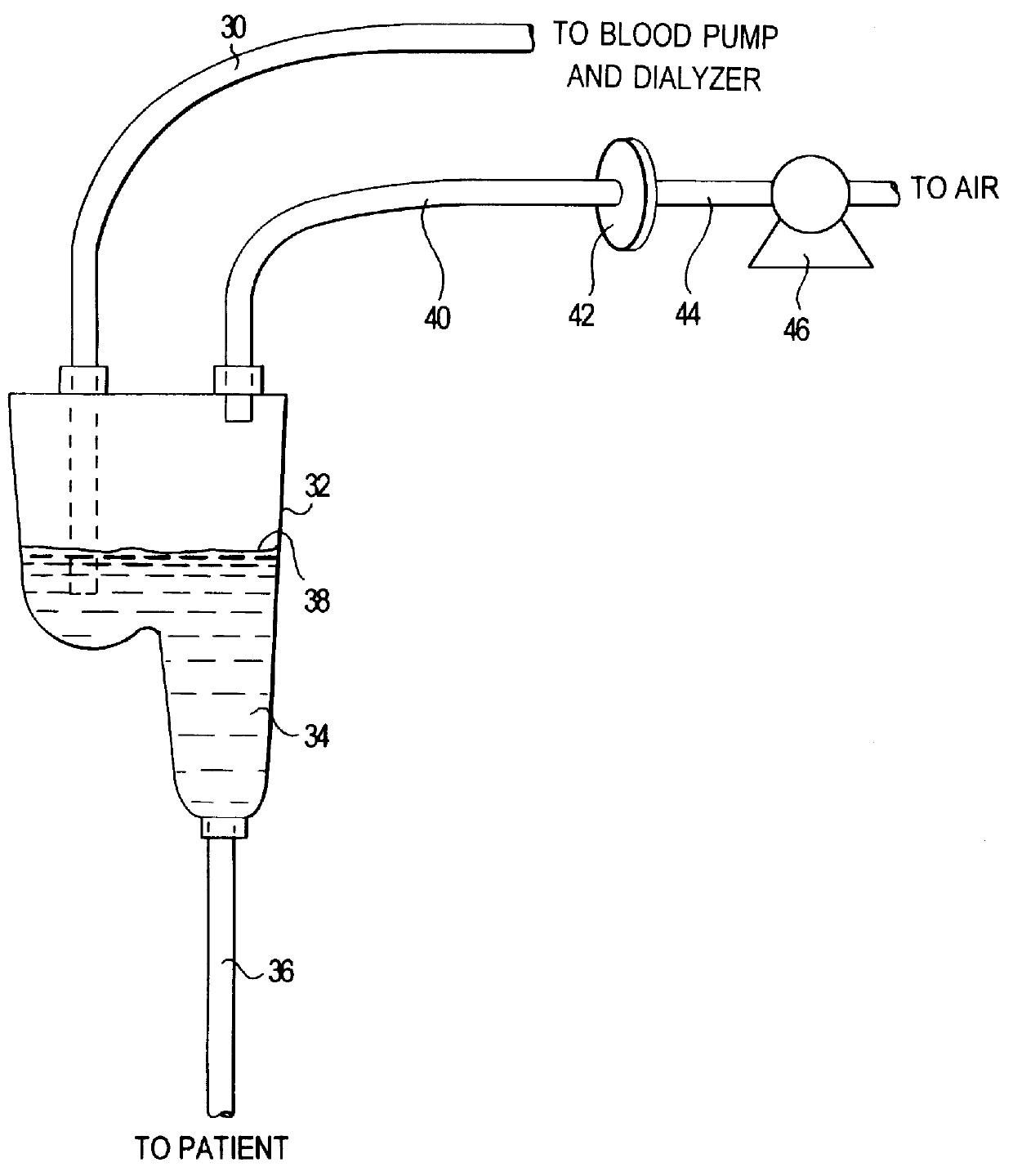

Method of preparation of batch of physiologic solution

A batch of dialysate solution is made from a mixture of bicarbonate formulation and a liquid acid formulation. The liquid acid formulation is introduced into a dialysate tank and then removed from the tank and stored elsewhere, such as in an ultrafiltration tank, where it is diluted with a few litres of water. The dialysate tank is then filled with water and the bicarbonate formulation is added to the dialysate tank. The bicarbonate formulation is mixed and dissolved by circulation in a closed loop, with the liquid acid formulation kept separate. When the bicarbonate solution has been prepared, the liquid acid solution and the bicarbonate solution are mixed together and stored in the dialysate preparation tank. An additional quantity of dilution water is introduced into the dialysate system to bring the final conductivity down to the desired range. The excess dialysate solution can be used for several purposes, such as an endotoxin flush of the blood tubing set or a dialyzer clearance test.

Owner:HHD LLC A DELAWARE LLC +2

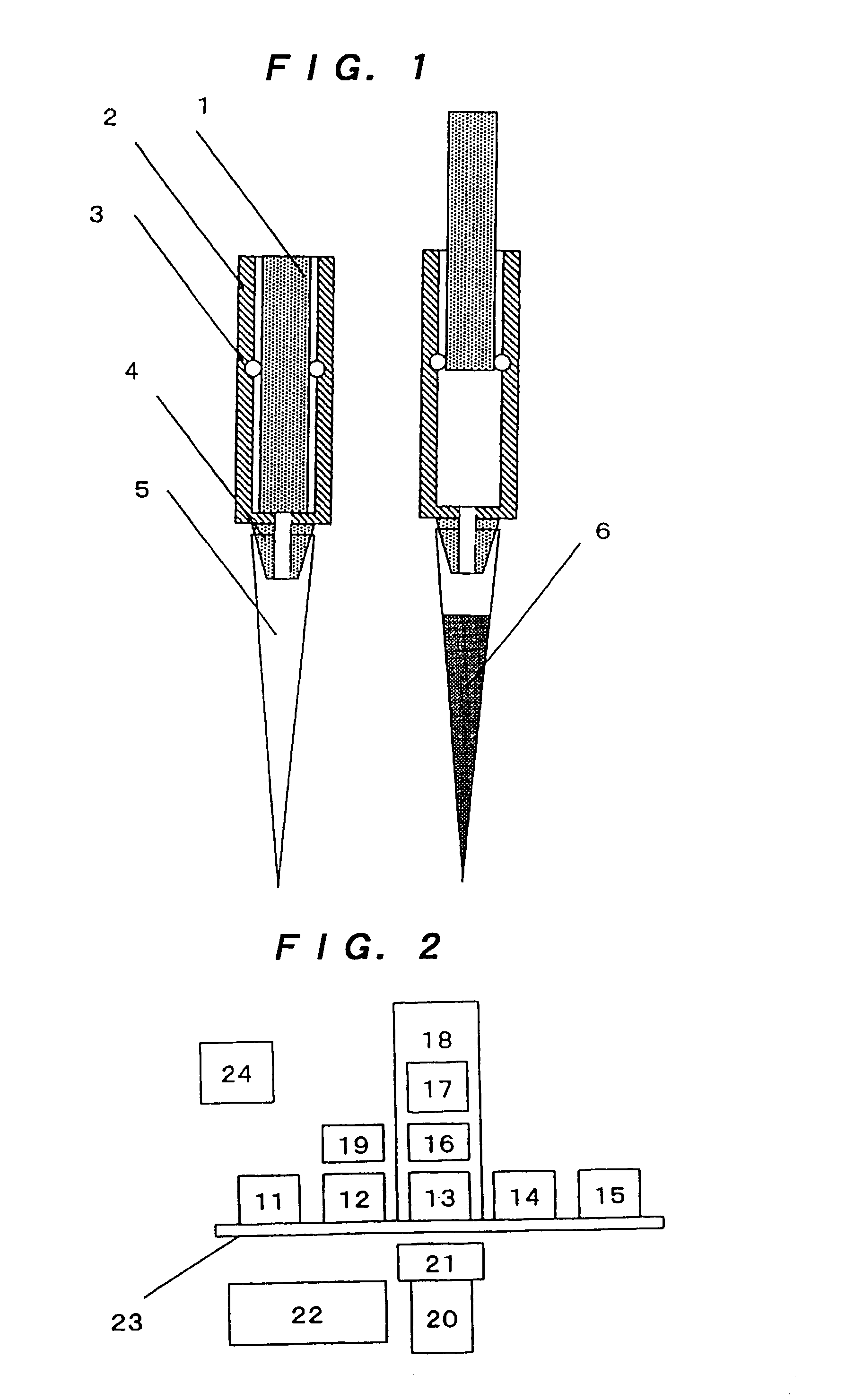

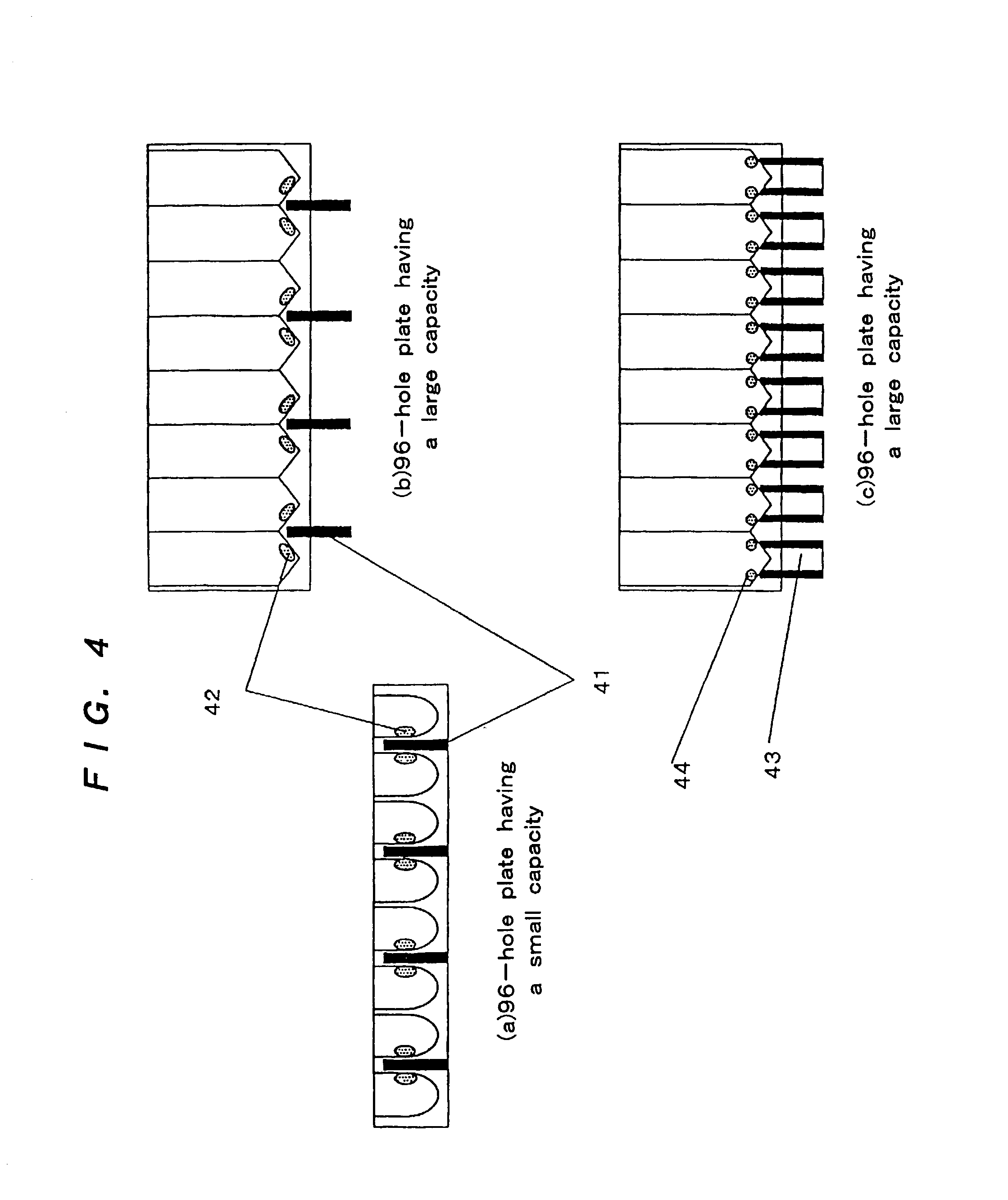

Apparatus for purifying nucleic acids and proteins

InactiveUS20030006193A1Facilitating resuspensionReduce the precipitation rateAnalysis by subjecting material to chemical reactionWater/sewage treatment by substance additionHigh rateBiology

The present invention provides an apparatus for purifying nucleic acids such as DNA and RNA or proteins such as enzymes and antibodies from microorganisms such as viruses and bacteria or animal and plant tissues, the apparatus being capable of fast processing of a plurality of samples. More specifically, the present invention provides an apparatus for purifying nucleic acids or proteins using magnetically attractable particles, the apparatus comprising a plurality of piston pumps; a plurality of nozzles capable of having a plurality of disposable tips which are automatically attachable / detachable; and a mechanism which is capable of dispensing a desired amount of a reagent to be used subsequently in the next step into the same number of sections as that of the samples with high accuracy and at a high rate, while a mixture of a sample and a reagent are being mixed (stirred) by the pumps and nozzles, the apparatus being capable of rapidly processing a plurality of samples, wherein a series of steps from mixing (stirring) of the magnetically attractable particles and concentration of the sample to purification is automated with reduced wastes.

Owner:TOYO TOYOBO CO LTD

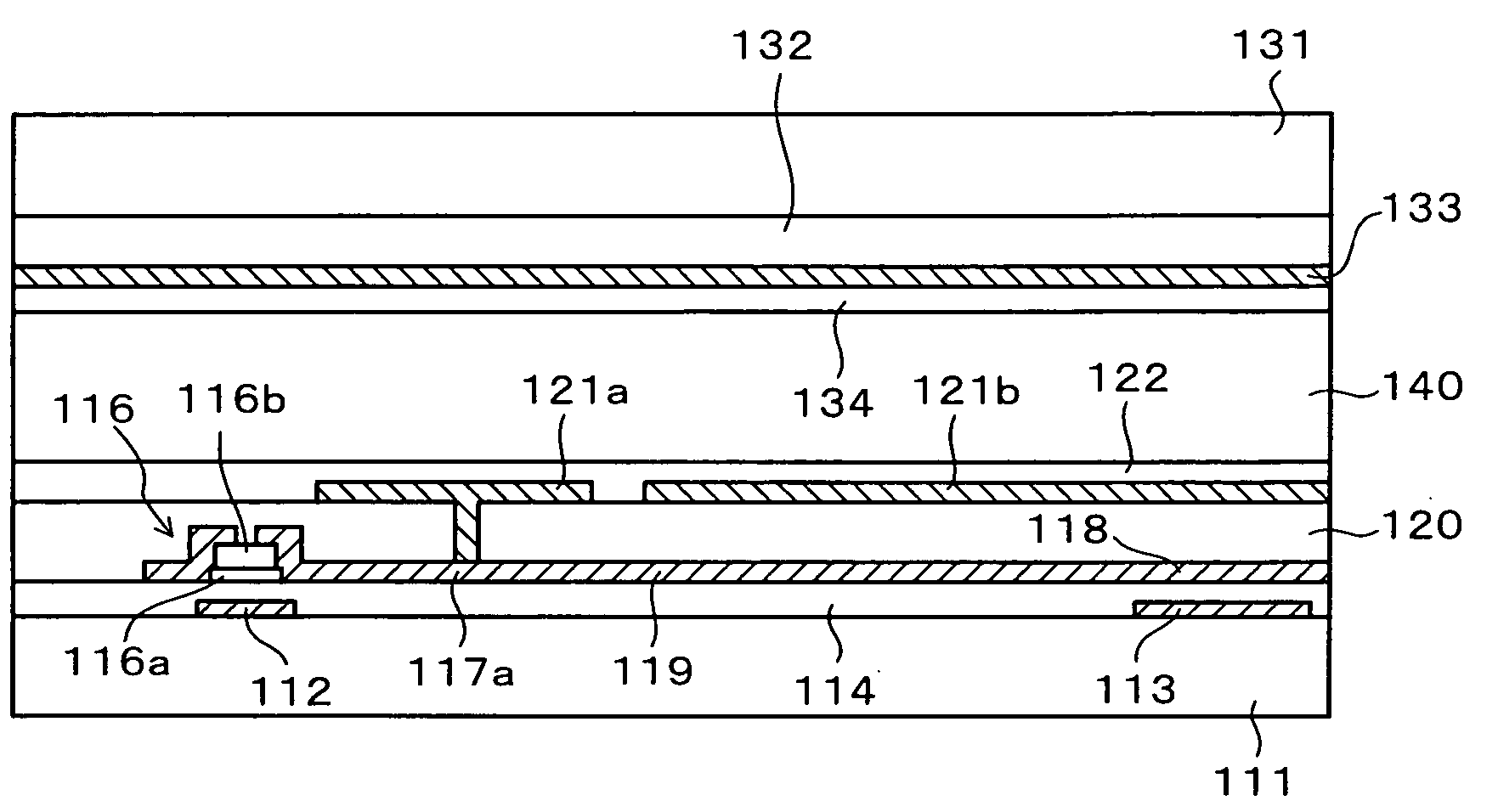

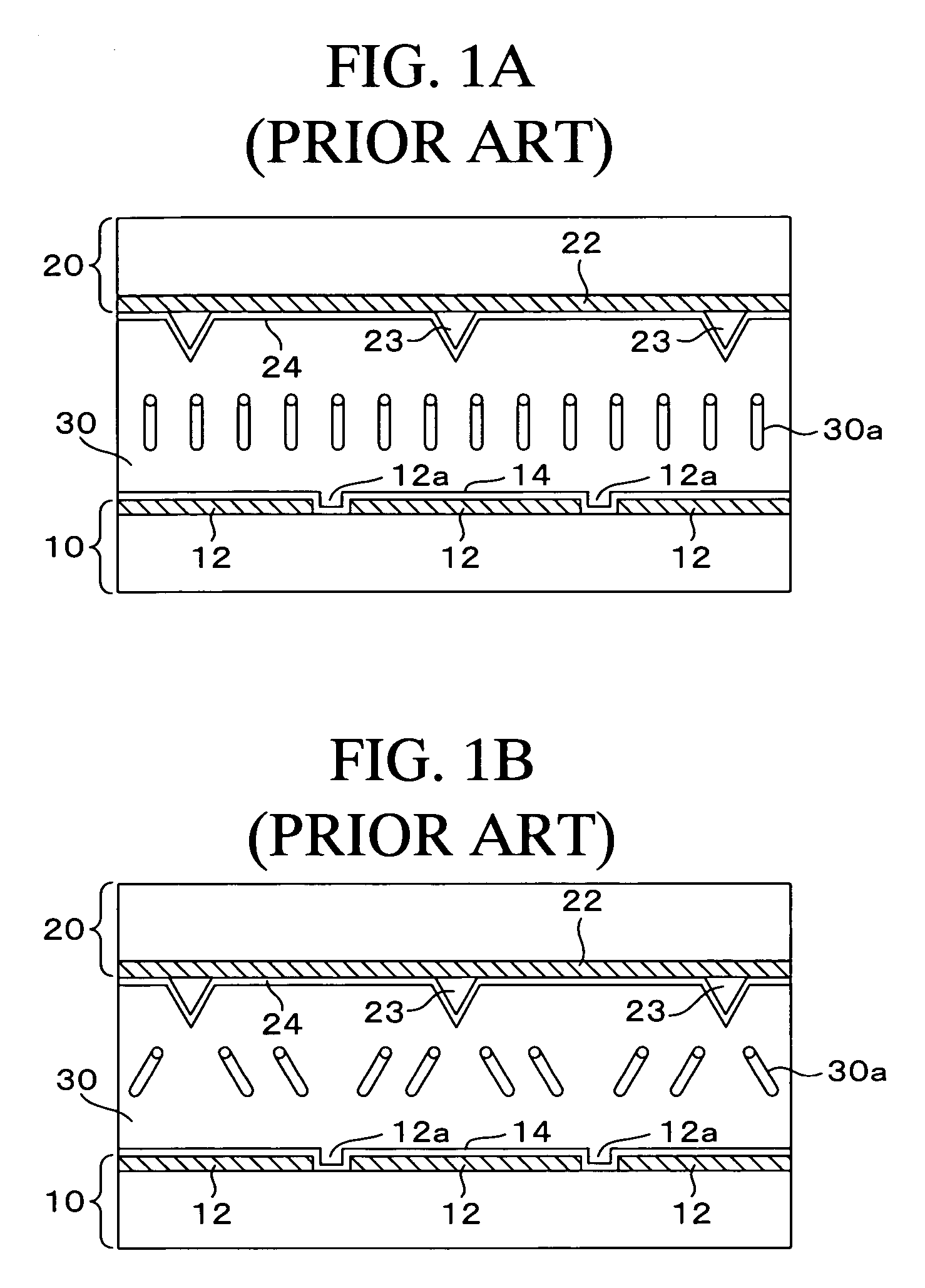

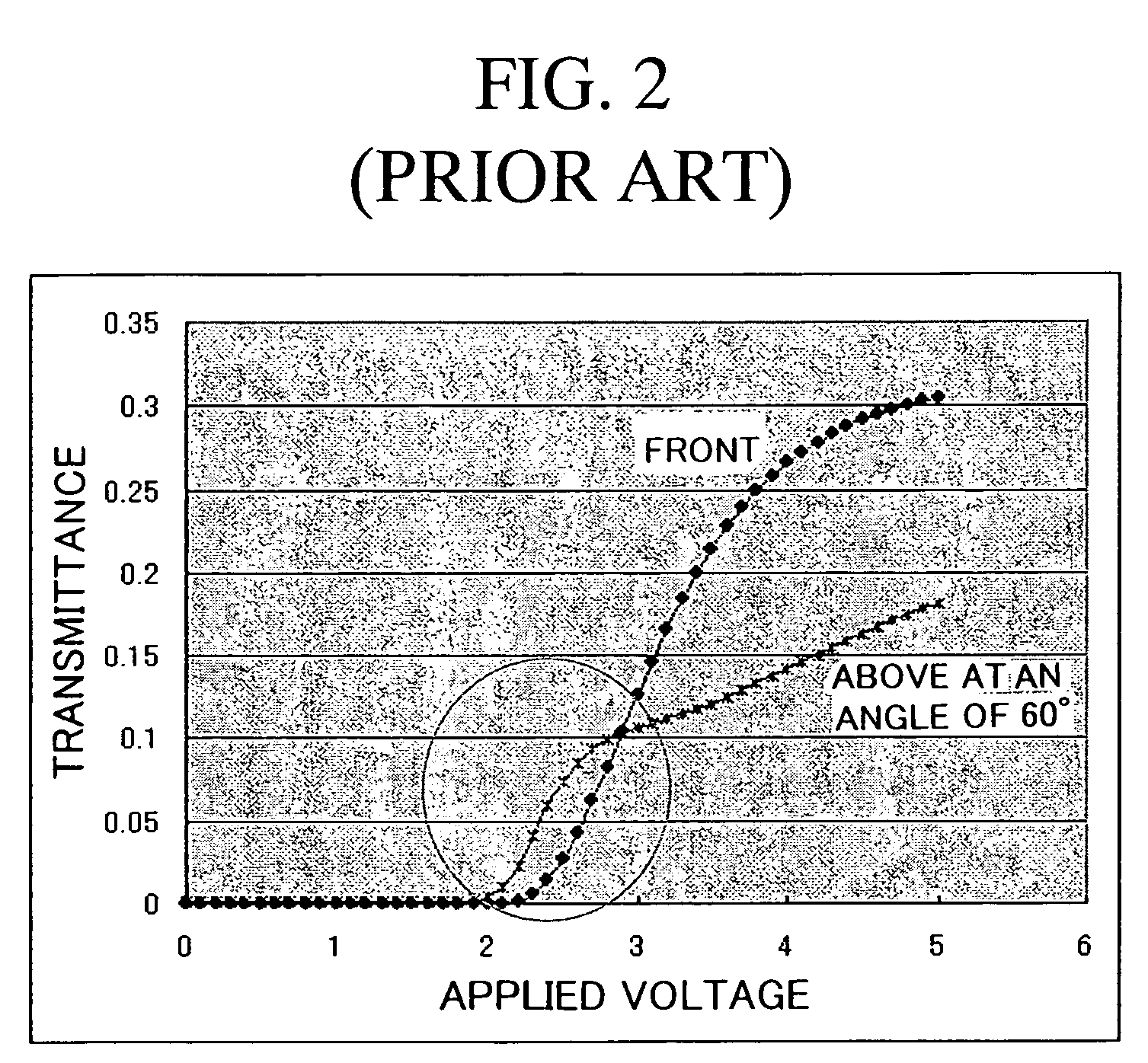

Liquid crystal display device and method of preventing image sticking thereon

ActiveUS20060023137A1Avoid it happening againSuppressing washIon-exchange process apparatusWater/sewage treatment by magnetic/electric fieldsCapacitanceElectricity

A sub picture element electrode directly connected to a thin film transistor is disposed between a floating sub picture element electrode capacitively coupled to a control electrode and a gate bus line in order to prevent injection of electric charges from the gate bus line to the floating sub picture element electrode. Moreover, a shield pattern electrically connected to an auxiliary capacitance bus line is formed between the floating sub picture element electrode and a data bus line. This shield pattern avoids injection of electric charges from the data bus line to the floating sub picture element electrode.

Owner:AU OPTRONICS CORP

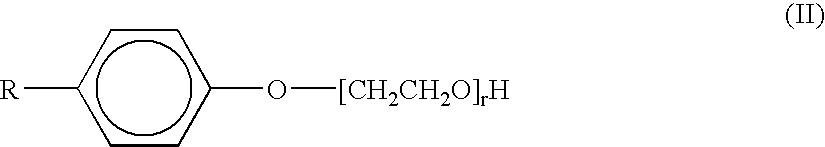

Removal of fluorinated surfactants from waste water

The present invention provides a method of removing a fluorinated surfactant from waste water comprising fluoropolymer particles. The method comprises (i) adding a non-fluorinated surfactant to the waste water (ii) contacting the thus obtained waste water with adsorbent particles to adsorb at least a portion of the fluorinated surfactant to the adsorbent particles and (iii) separating the waste water and the adsorbent particles.

Owner:3M INNOVATIVE PROPERTIES CO

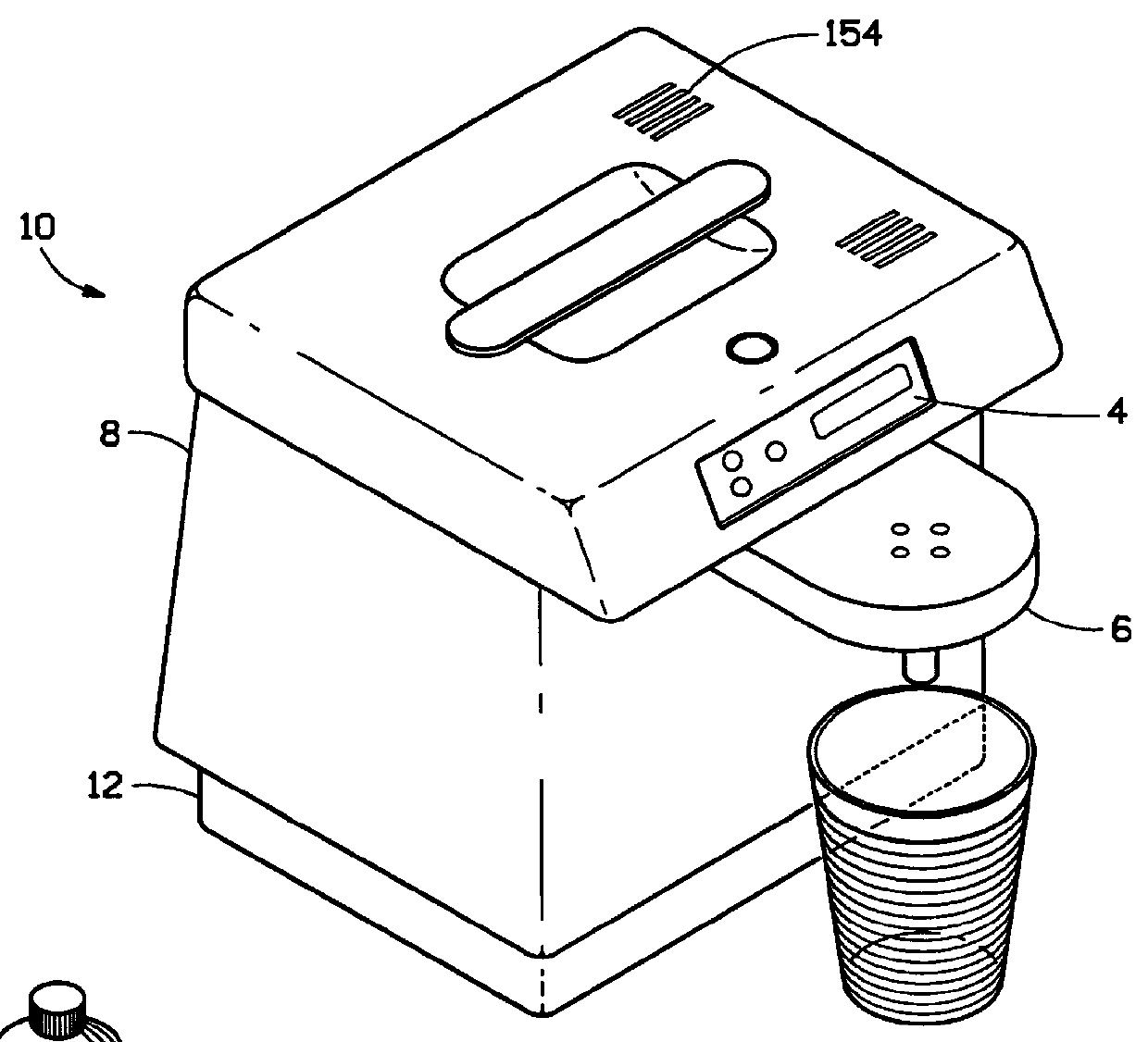

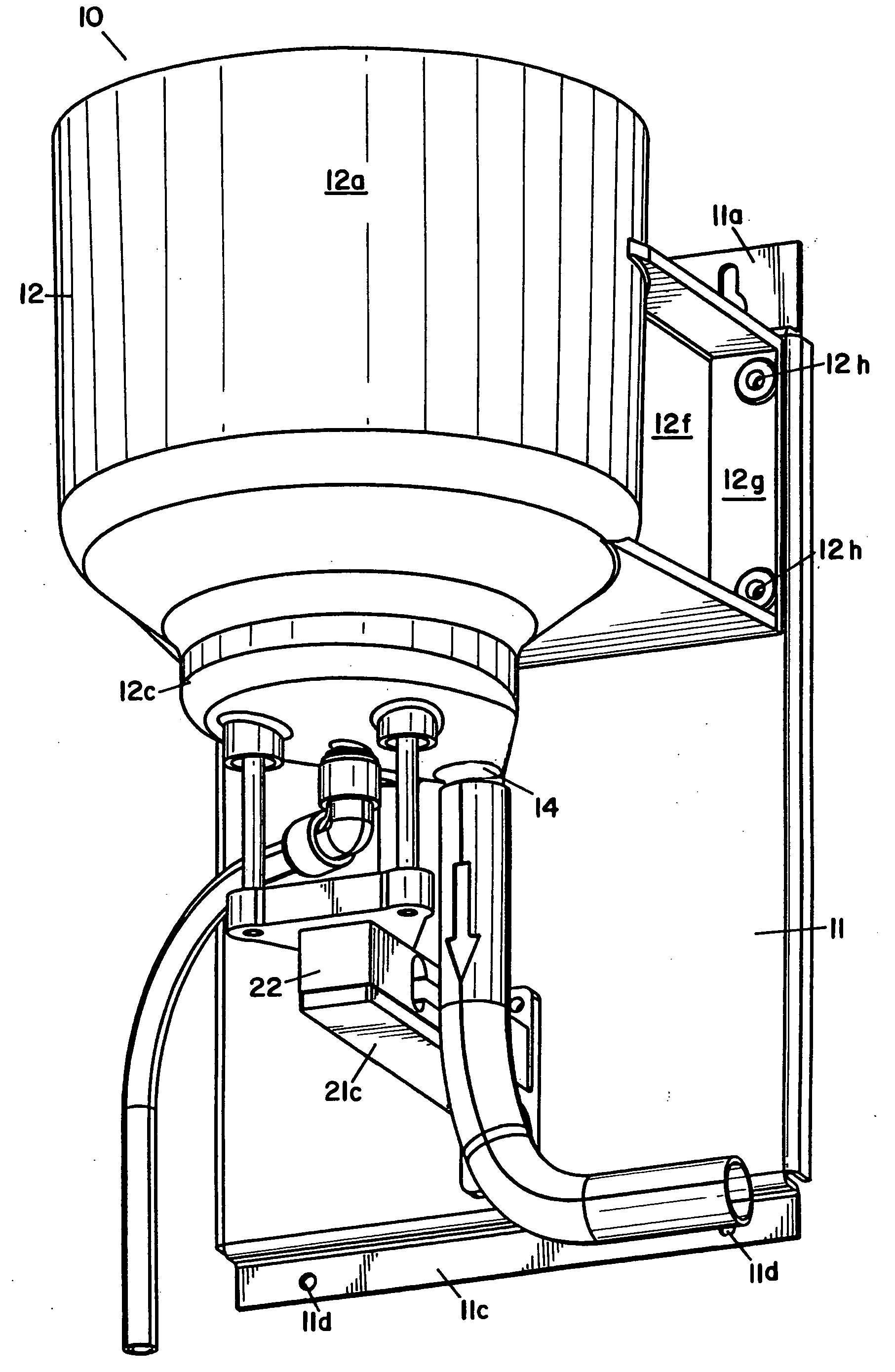

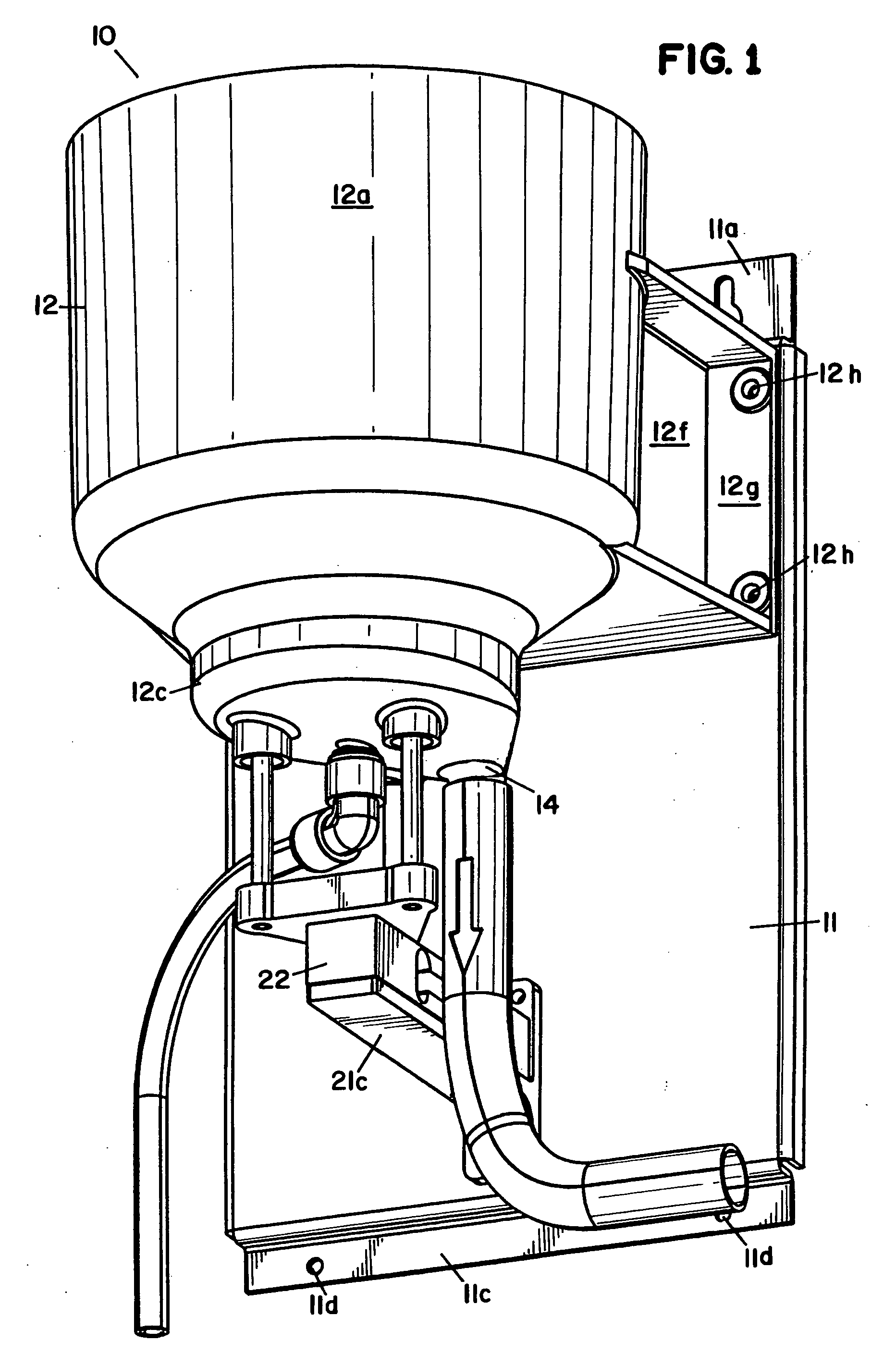

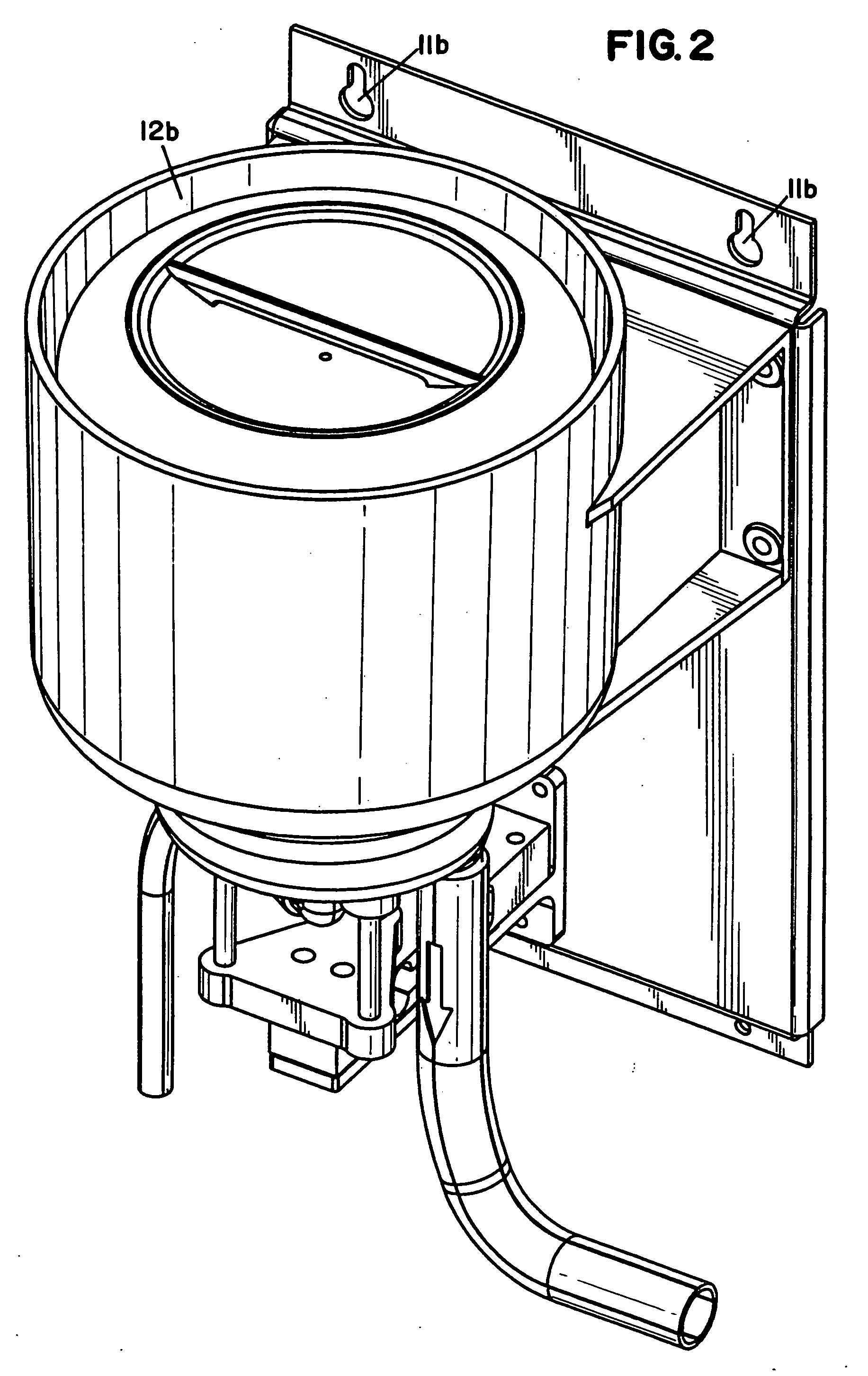

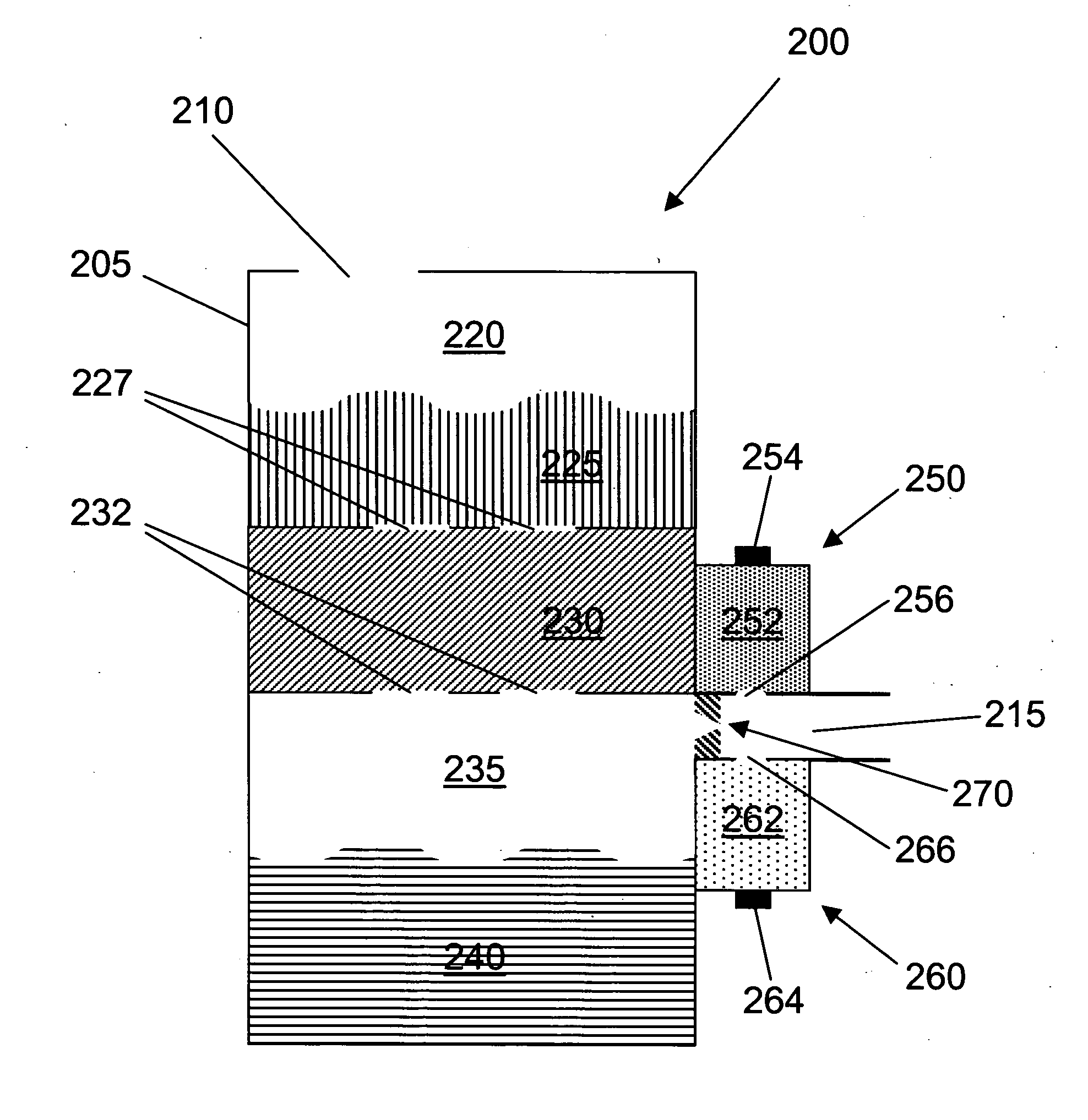

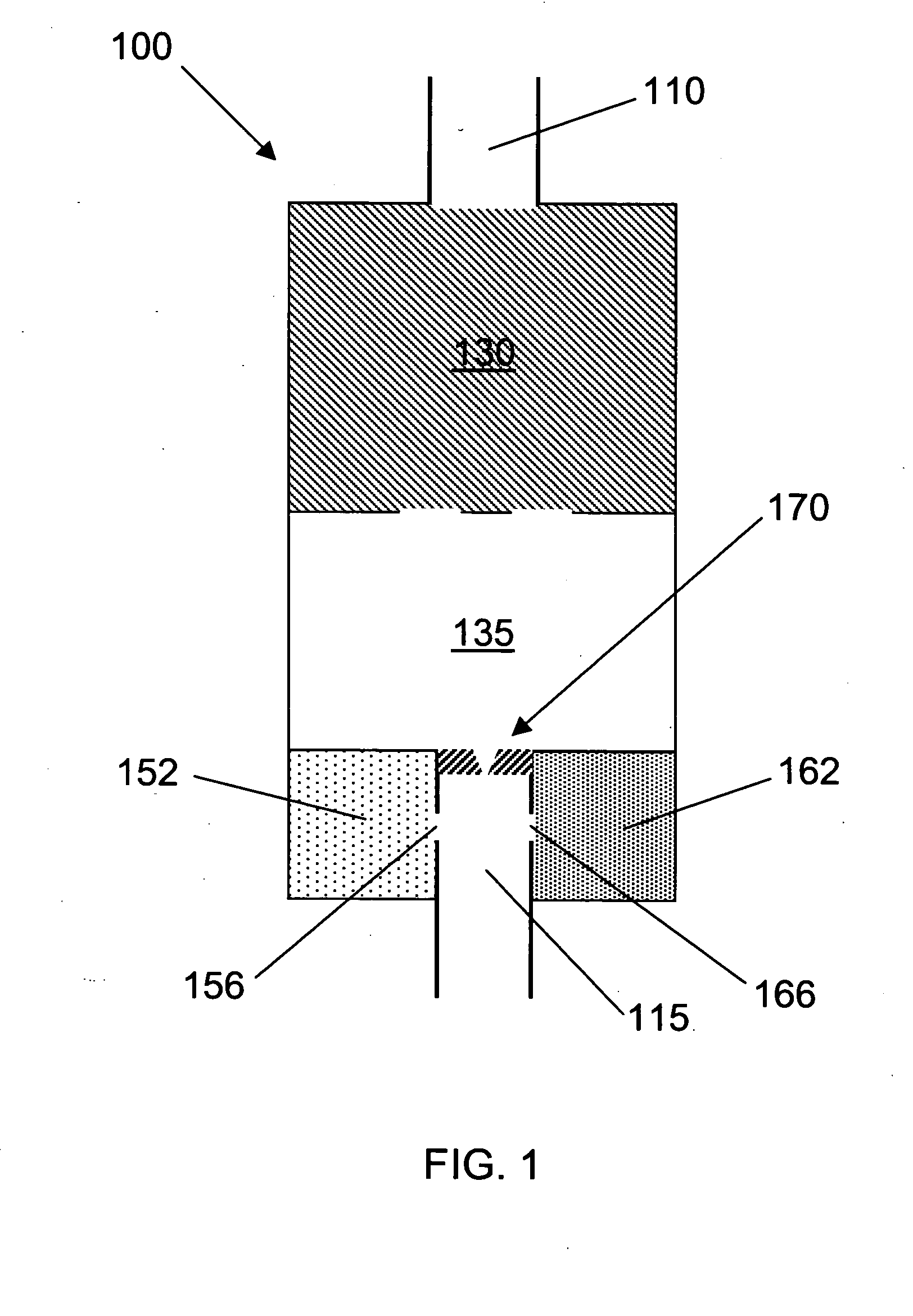

Method and apparatus for mass based dispensing

ActiveUS20040245284A1Excessive shock to the scale is prevented during loadingTableware washing/rinsing machine detailsTransportation and packagingDiluentEngineering

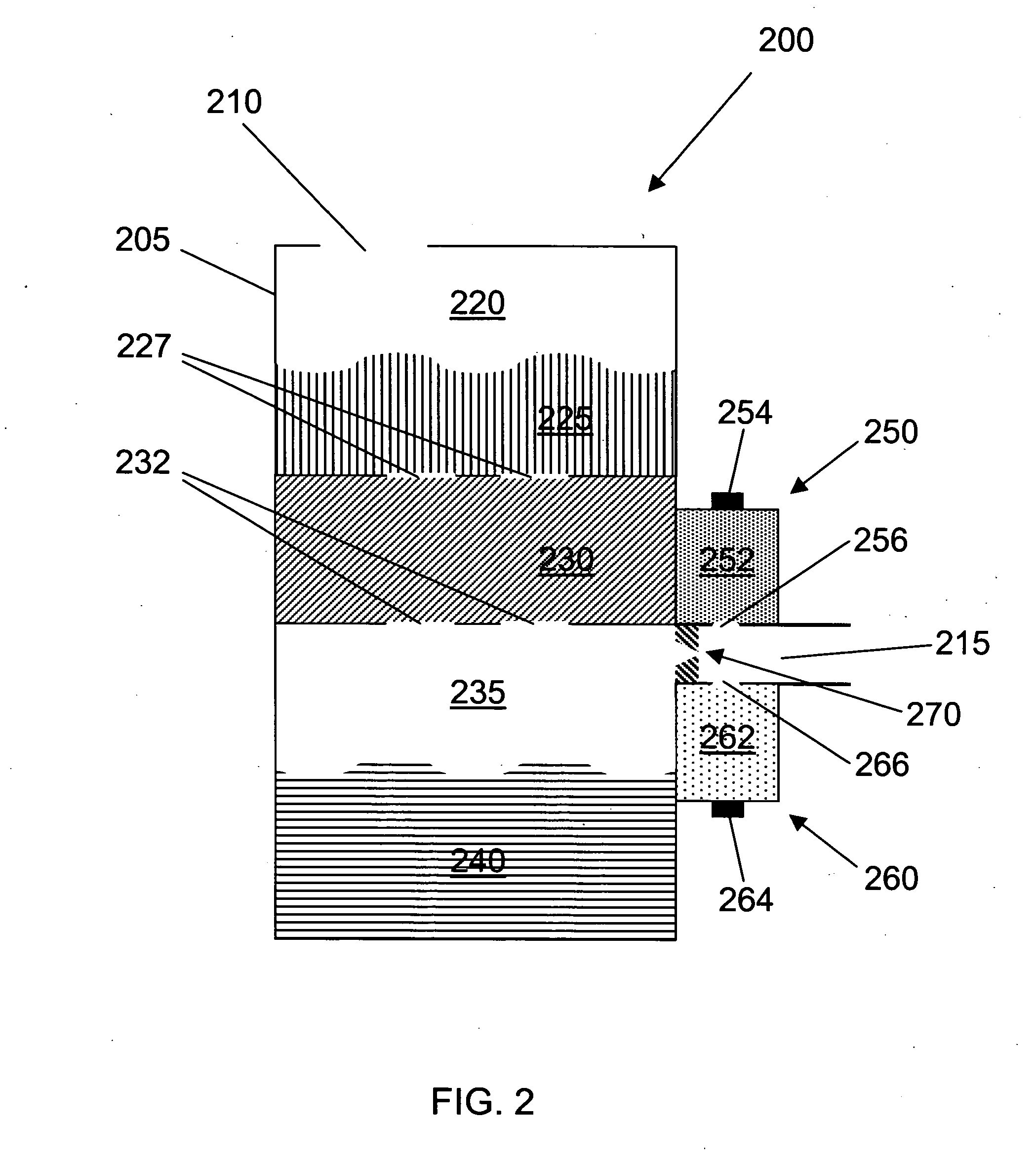

A dispenser (200) dispenses an amount of concentrate in a container (204) using a diluent to form a use solution. A dispenser includes a housing (201). A product holder (210) is positioned to support the container (204) with the concentrate in the cavity of the housing. The product holder (210) carried by a scale (240), wherein weight of the concentrate is concerned. A moveable container holder (215) is moveable between a first position and a second position. The container holder is positioned between the housing (201) and the container (204). A cover (216) is operatively connected to the container holder (215) at a connection. A cam surface is adjacent the housing (201). The cover (216) has a cam (216d) for contacting the cam surface (201a), wherein when the cover (216) is moved from a closed position to an open position, the connection moves upward, thereby carrying the container holder (215) and the container (204) which are moved upward lifting the container (204) off of the product holder (210).

Owner:ECOLAB USA INC

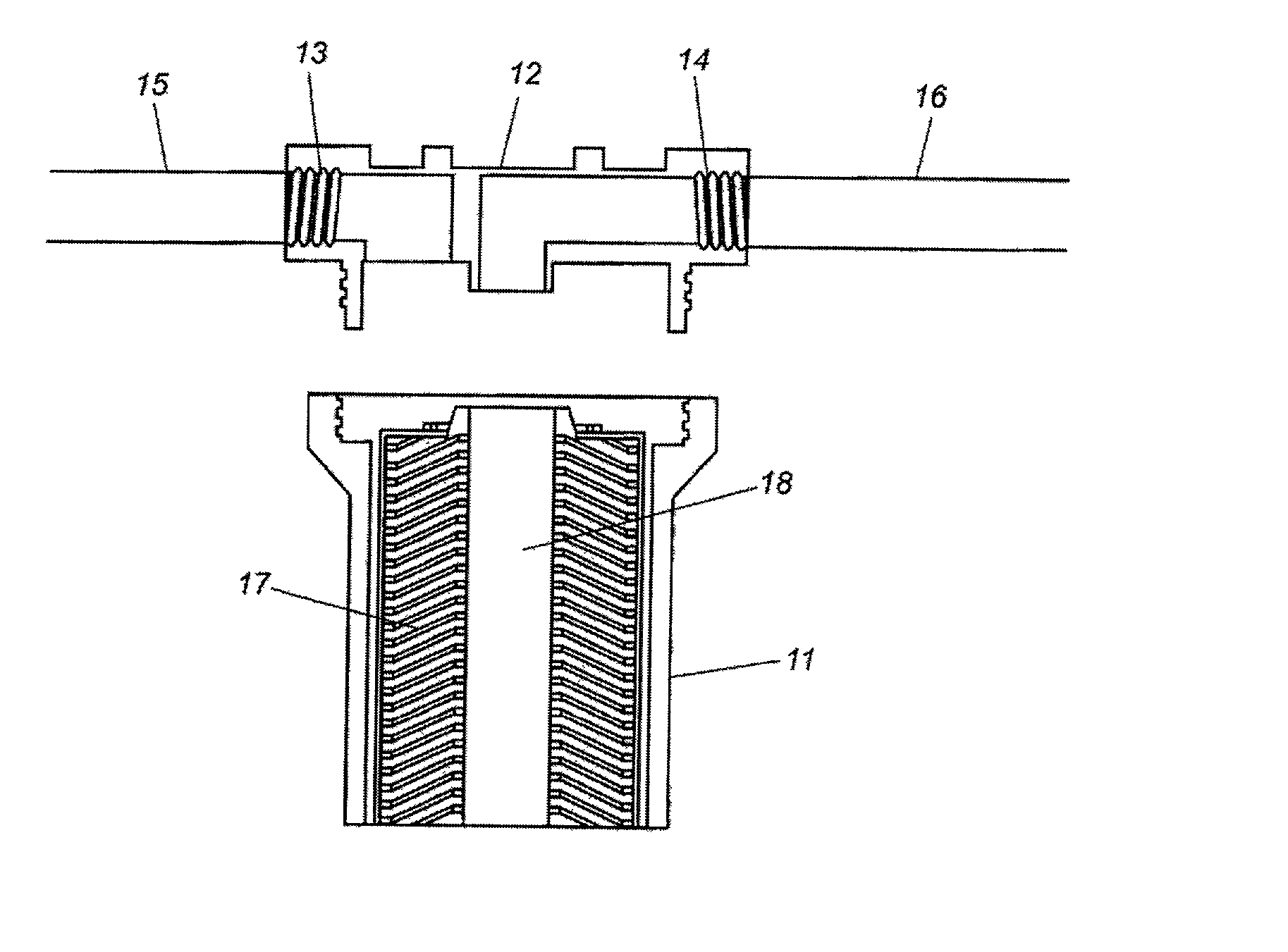

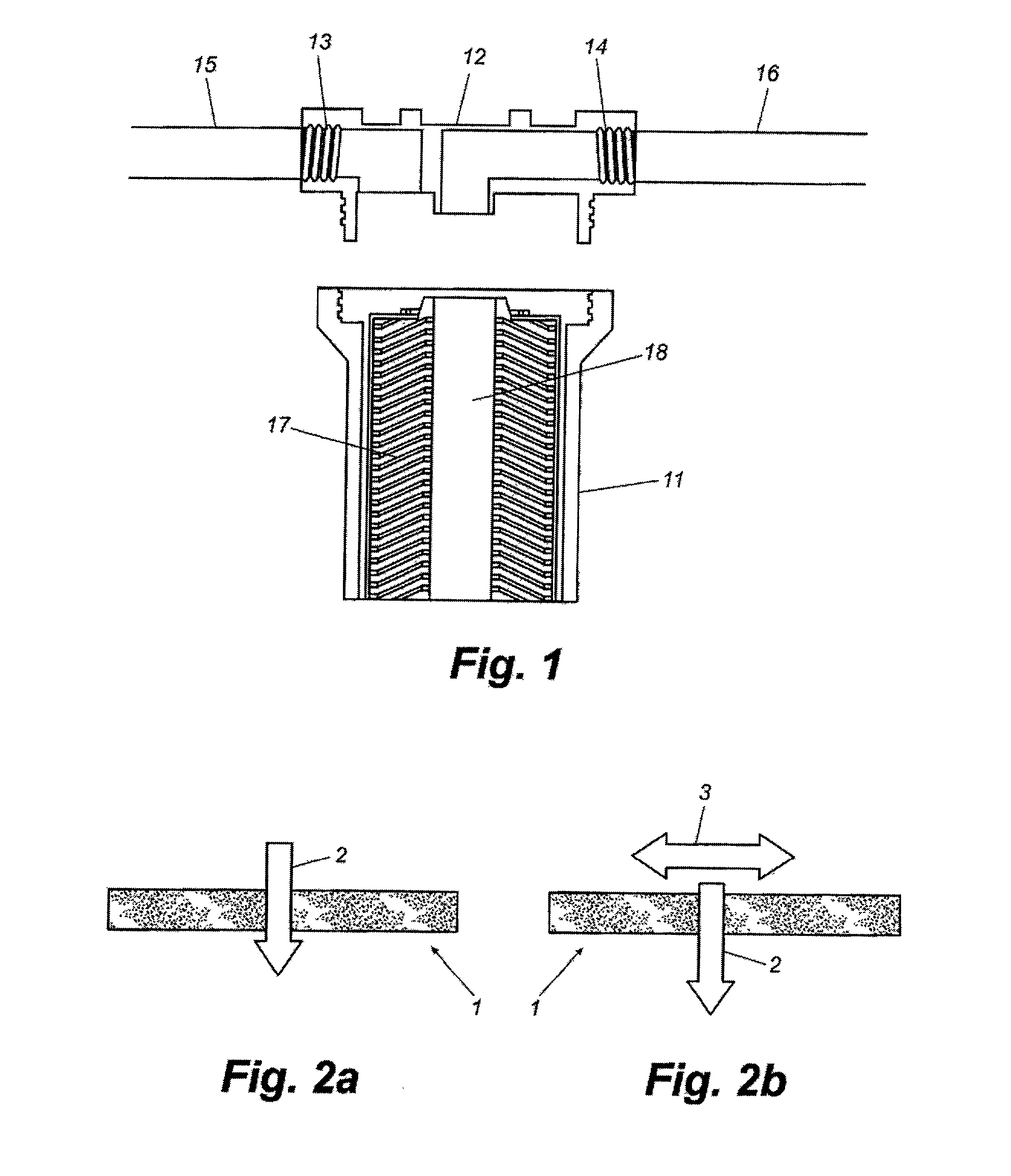

Fuel filter including slow release additive

This invention relates to a fuel filter for use with internal combustion engines. The fuel filter includes a fuel additive that can be released into fuel. The rate of release for the fuel can be controlled. In one form the fuel additive can be mixed with a matrix material and released at a substantially constant rate to maintain a uniform level of fuel additive in the fuel. Use of the present invention provides a fuel filter having an extended life span that is longer than fuel filters typically used with combustion engines.

Owner:DOBER CHEMICAL CORPORATION +1

Dual layer tablet, method of making and use thereof

InactiveUS6863830B1Easy to optimizeComprehensive treatmentOrganic chemistryOther chemical processesPotassium persulfateLithium hypochlorite

A method for treating a recirculating water system which comprises introducing into said water system a multifunctional, multilayer tablet, wherein the multilayer tablet comprises a fast dissolving layer and a slow dissolving layer, wherein said fast dissolving layer releases a combination of active ingredients including a member selected from the group consisting of lithium hypochlorite, calcium hypochlorite, trichloroisocyanuric acid (TCCA), anhydrous sodium dichloroisocyanurate, sodium persulfate, potassium persulfate, potassium monopersulfate, sodium monopersulfate, and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent, fragrance, or surfactant and, wherein said slow dissolving layer includes a member selected from the group consisting of trichloroisocyanuric acid (TCCA), calcium hypochlorite, 1,3-dichloro-5,5-dimethylhydantoin (DCDMH), 1,3-dibromo-5,5-dimethylhydantoin (DBDMH), 1-bromo-3-chloro-5,5-dimethylhydantoin (BCDMH), 1,3-dichloro-5-ethyl-5-methylhydantoin (DCEMH), 1,3-dibromo-5-ethyl-5-methylhydantoin (DBEMH), 1-bromo-3-chloro-5-methyl-5-ethylhydantoin (BCEMH), and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent or surfactant.

Owner:BIO LAB

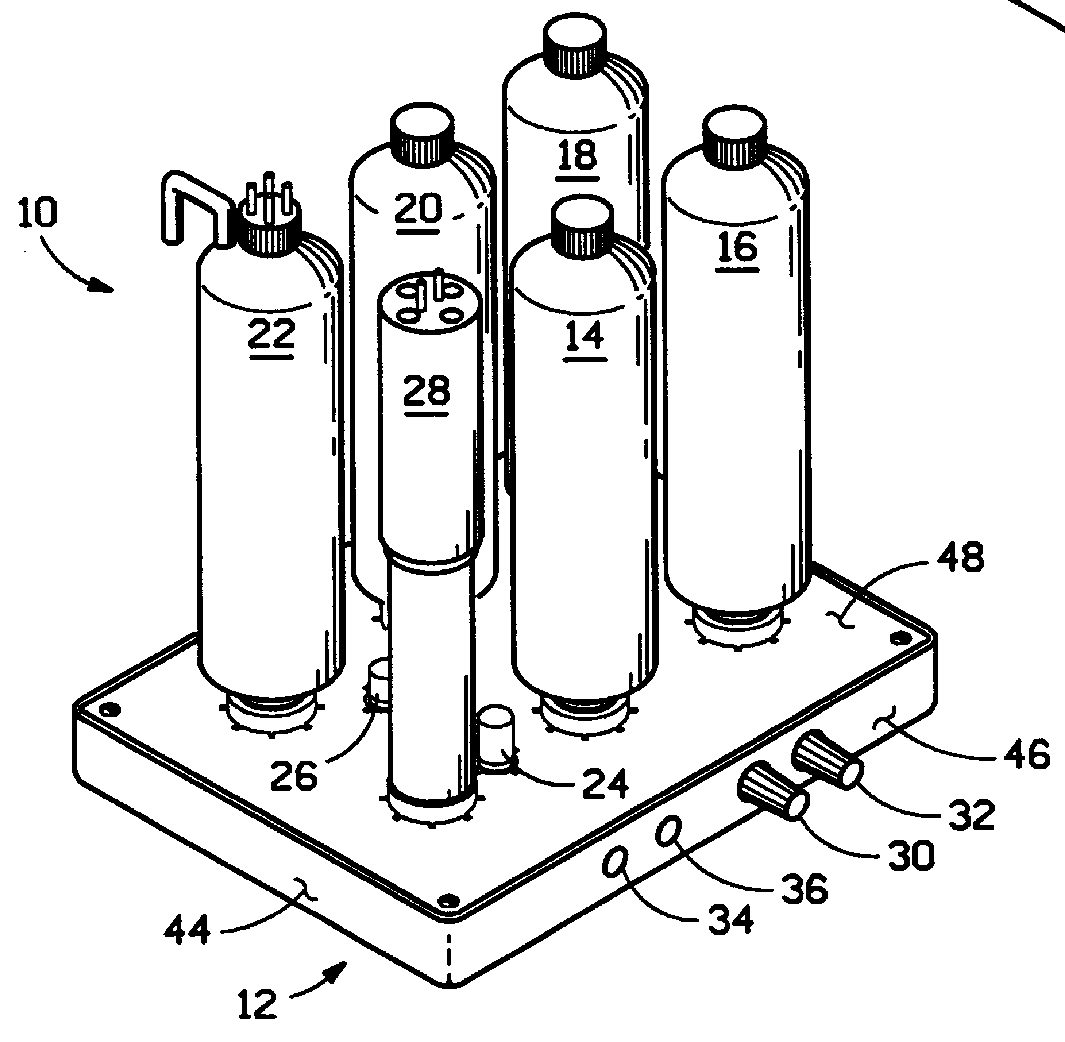

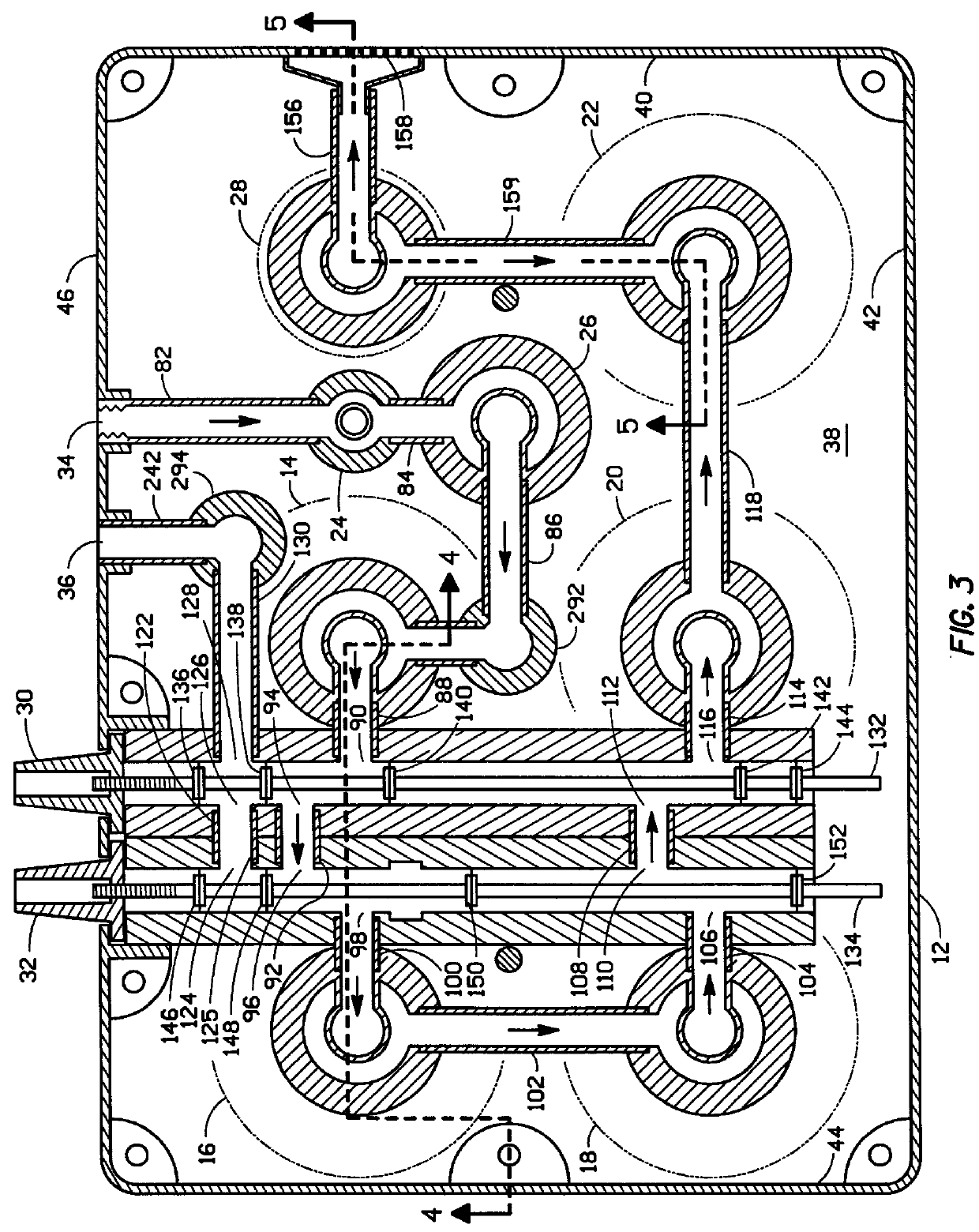

Apparatus for the purification of water and method therefor

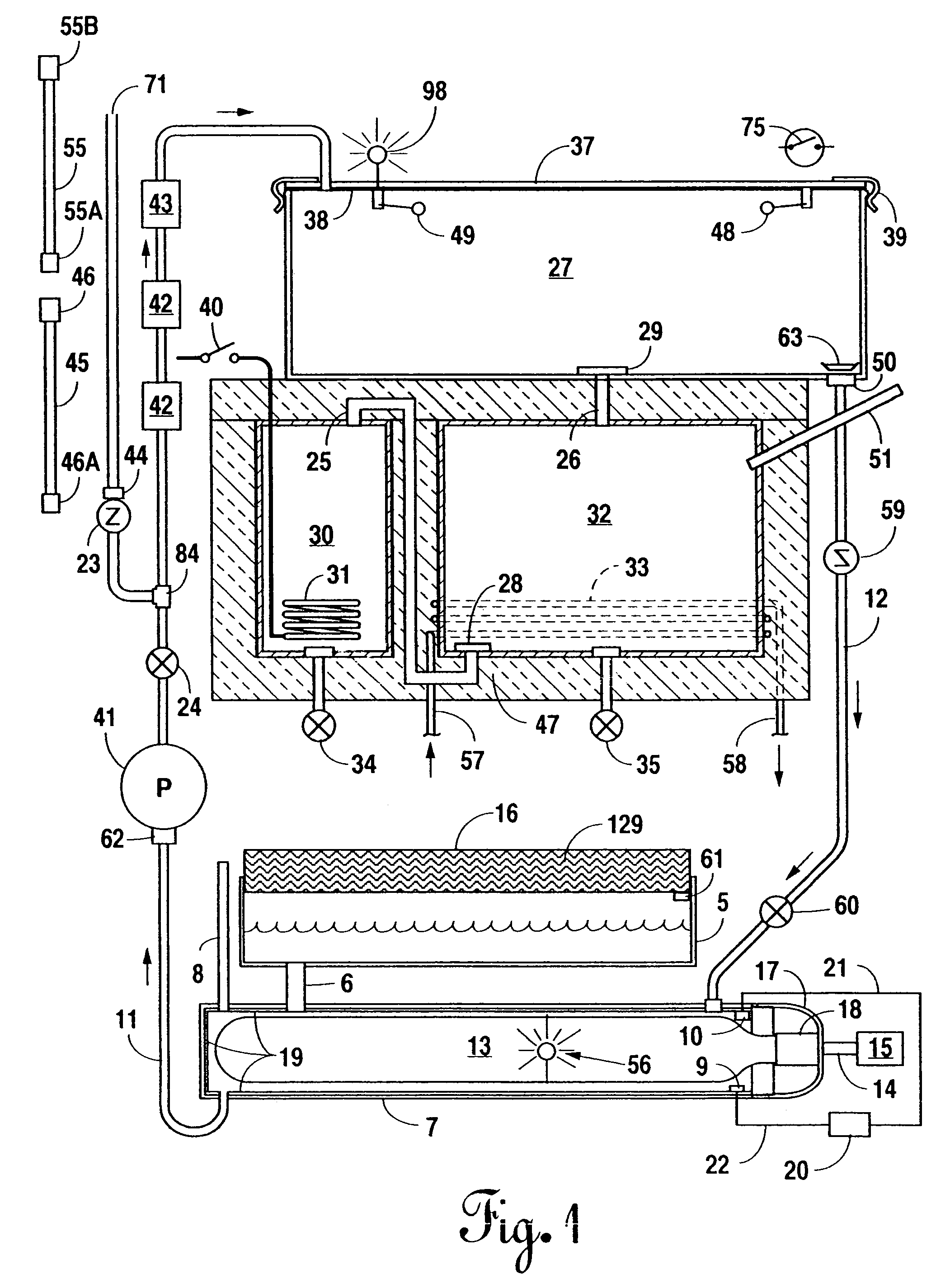

InactiveUS6090294AComprehensive understandingSignificant utilityOther chemical processesIon-exchanger regenerationSolubilityGas phase

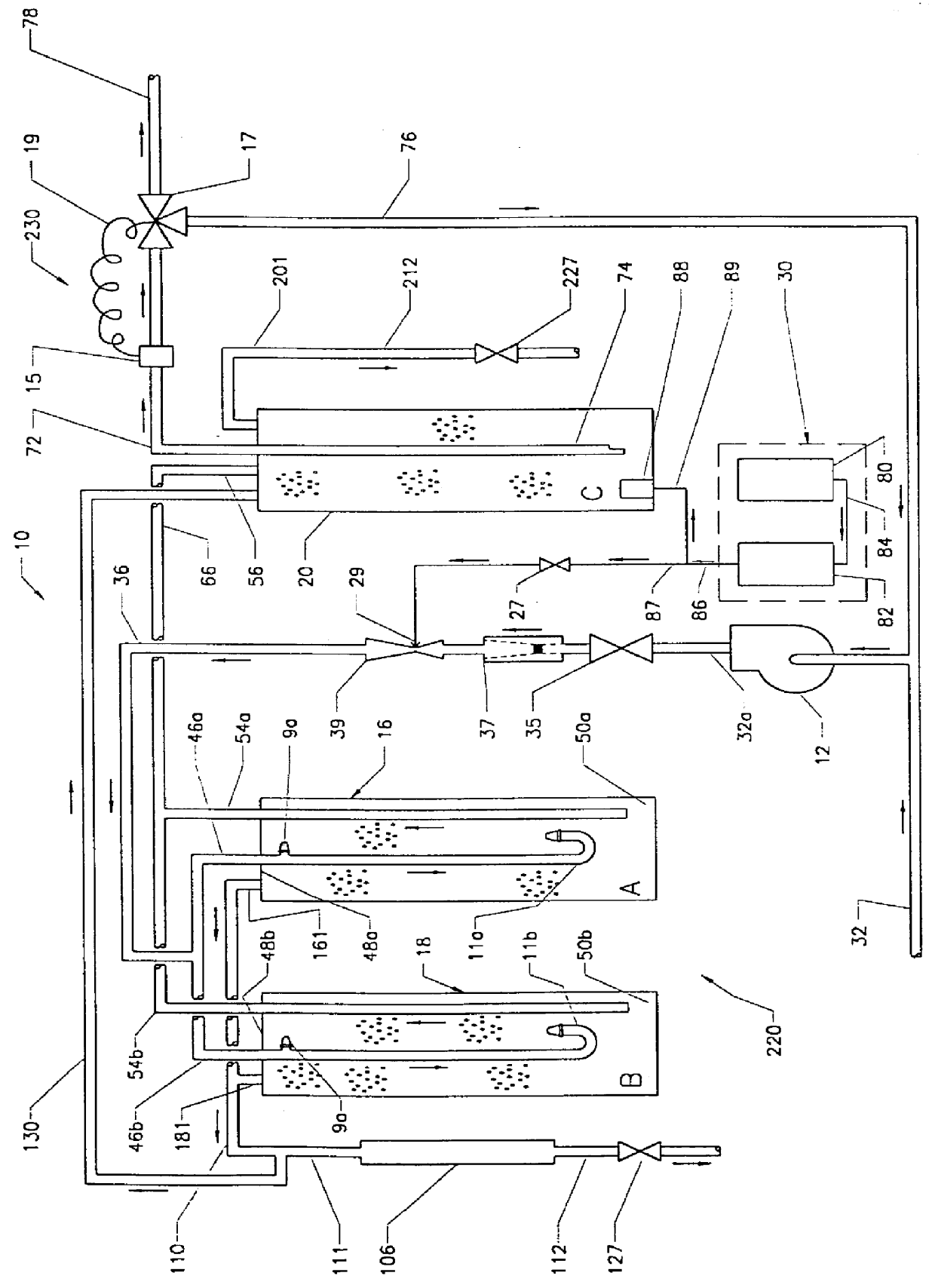

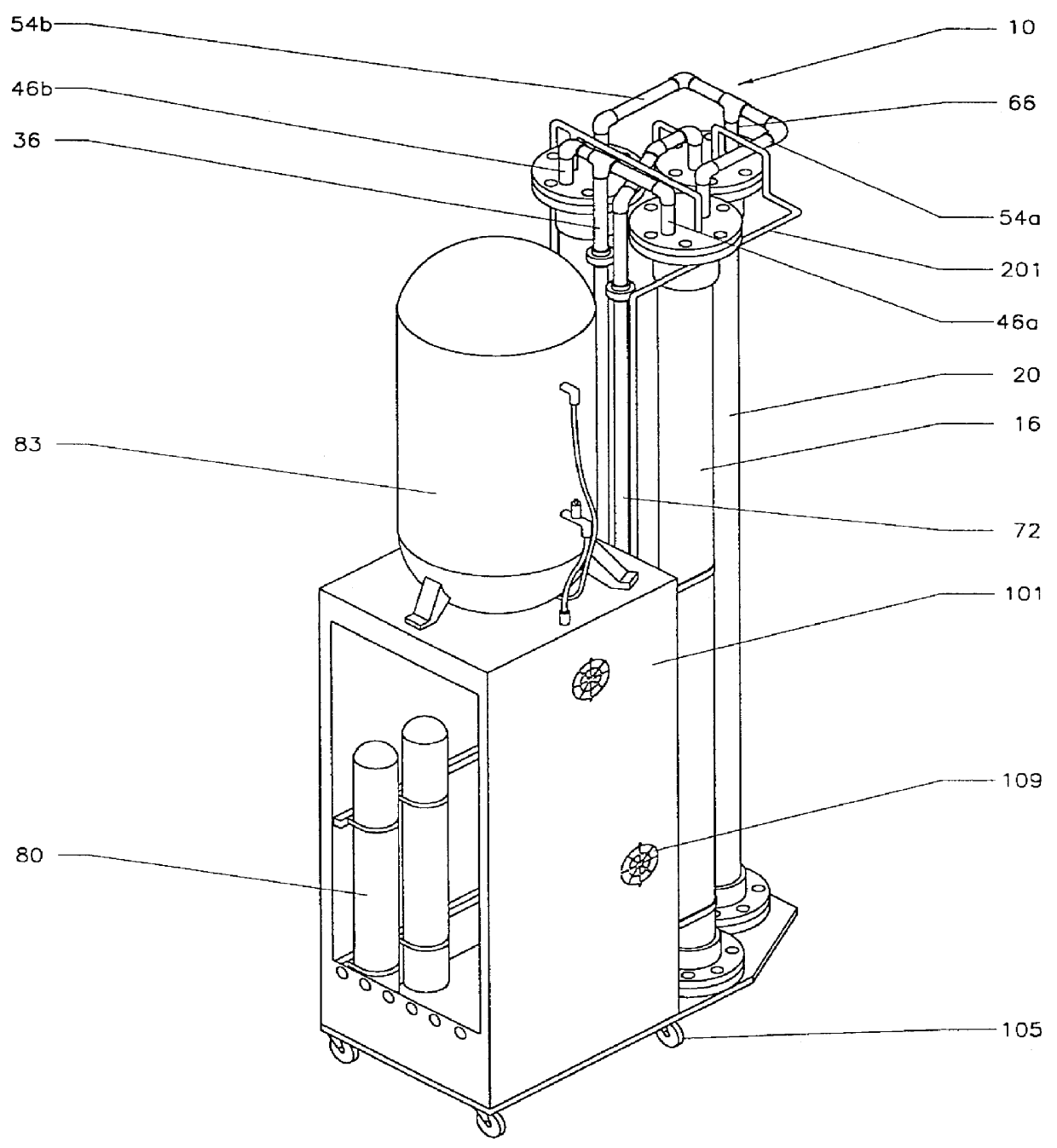

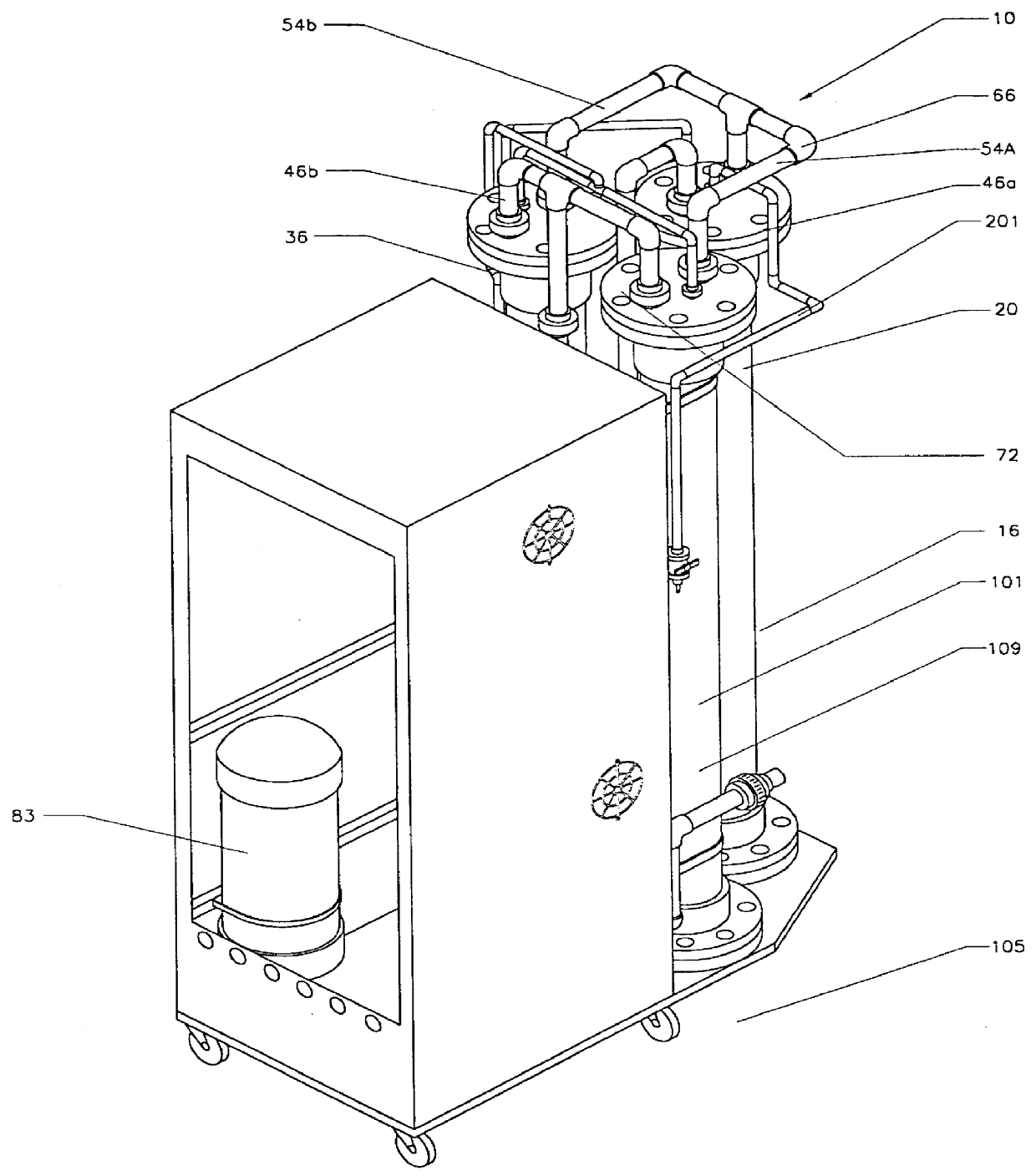

An apparatus and method for the purification of contaminated water whereby the contamination level of the wastewater is automatically monitored and treatment self-adjusted and continued until the desired level of purification is reached. Specifically, if upon treatment a pre-set purification level is not obtained a water recycle control means completely precludes the uptake of additional contaminated water and recycles wastewater within the apparatus until the desired level of purification is obtained. The present invention more particularly pertains to an efficient, turn key, economical, movable, automatic and compact apparatus and method for treating a fluid with ozone comprising multiple pressurized contact columns which are arranged in a hybrid parallel and series column configuration, which utilizes a unique water recycle control system and piping arrangement to improve the efficiency of the mass transfer of ozone into the water and increase its solubility by increasing the contact time between the water phase and the gas phase. The apparatus and method of the present invention has the further advantage that it requires minimal installation and may be used to fulfill the clean and safe water needs of any hotel, resort, restaurant, hospital, light industry, commercial business, apartment complex or small city.

Owner:AGRIMOND USA CORP

Reactive compositions for fluid treatment

InactiveUS6861002B2Easy to disassembleImprove efficiencyPerfluorocarbons/hydrofluorocarbons captureLoose filtering material filtersCystFiltration

A method and device for the chemical conversion, filtration and / or purification of fluids water or other solutions containing microbiological and chemical contaminants, such as fluids containing arsenic, chlorine, bacteria, viruses, and cysts, where the fluid is passed through a purification material composed of fluid treatment carbon, metal phosphates, metal oxides, reduced metals, metal silicates, metal sulfates, metal carbonates, metal hydroxides, or combinations thereof. The material may be included in a fixed binder matrix.

Owner:WATERVISIONS INT

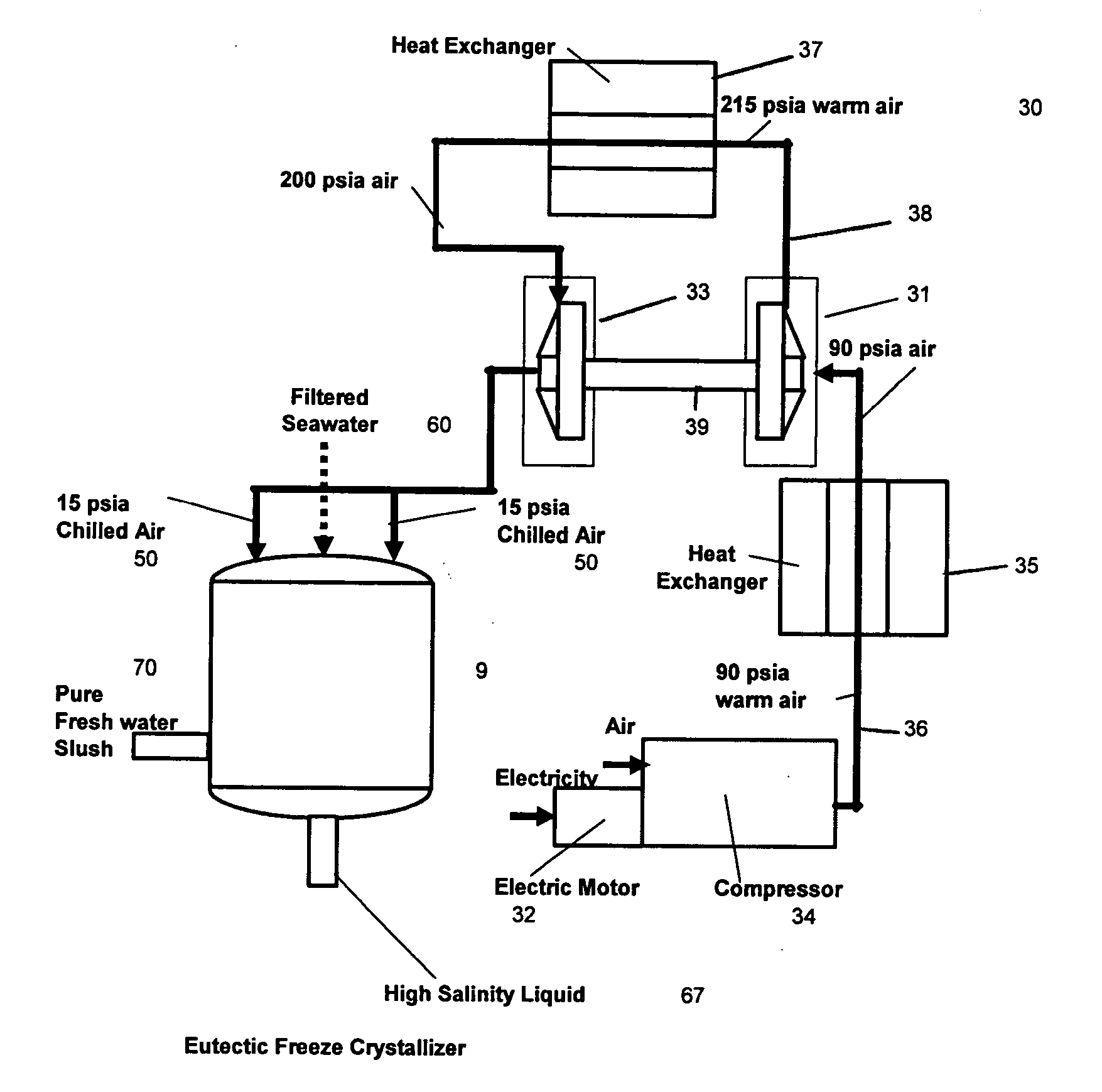

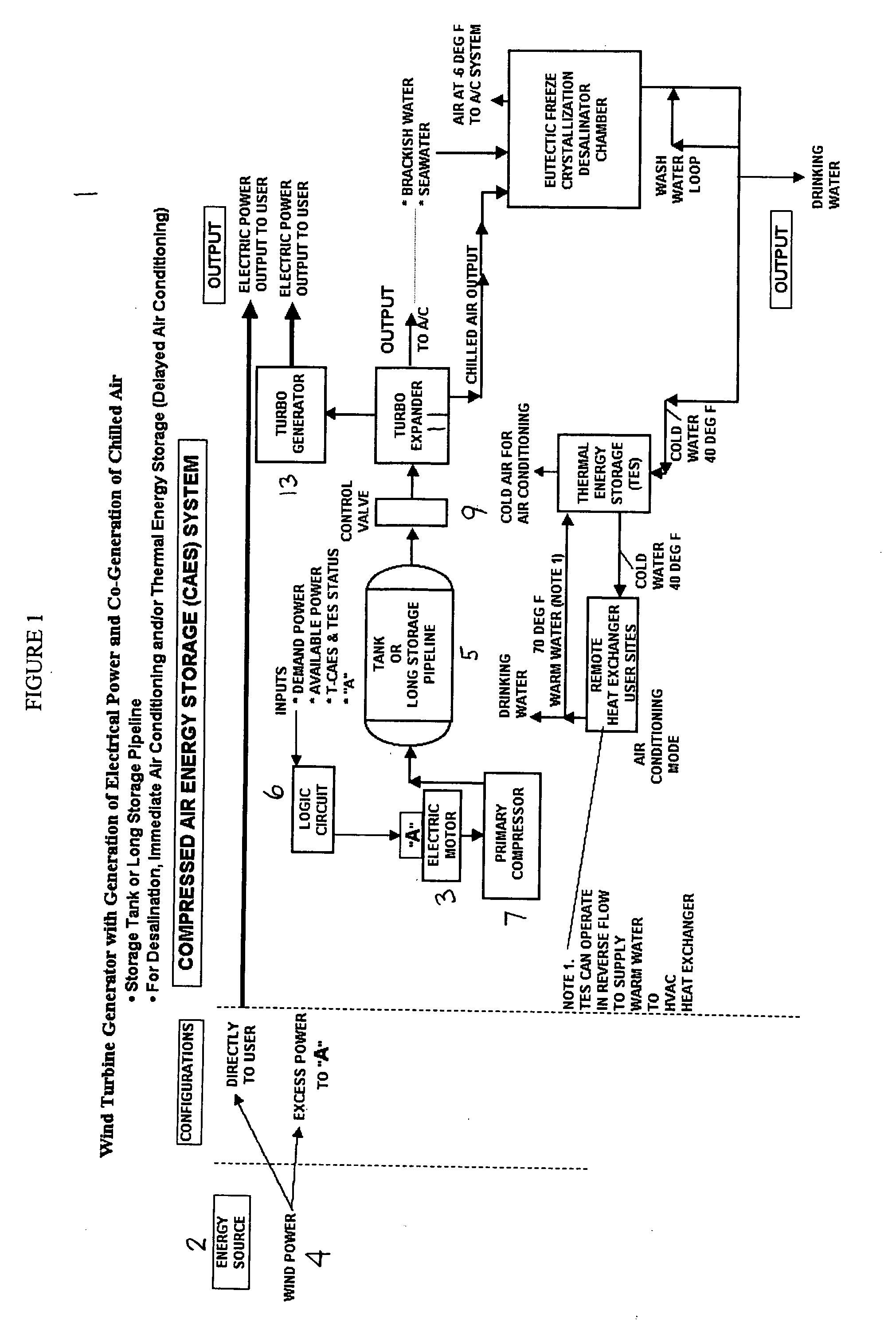

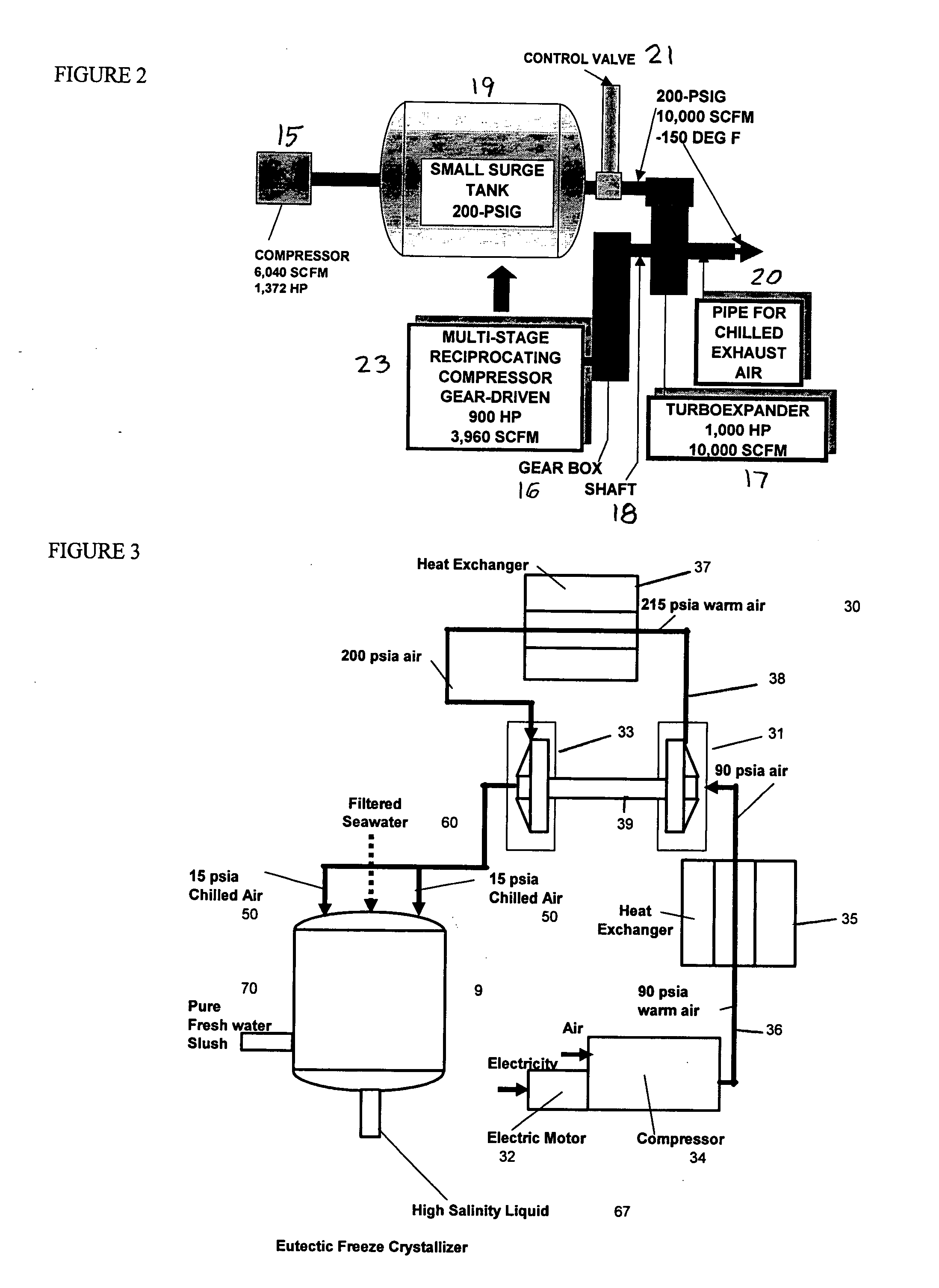

Desalination method and system using compressed air energy systems

InactiveUS20070295673A1Promote meltingFacilitate runoffWater treatment parameter controlWater cleaningSaline waterDesalination

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a crystallization chamber. Also injected into the chamber is a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, and which is then circulated and exposed to the chilled air in the chamber. The sizes of the droplets can vary, but are preferably predetermined, along with the relative temperatures, flows and speeds of the spray and chilled air, such that when the droplets are circulated within the chilled air, and settle at the bottom of the chamber, they are deposited at slightly above the eutectic temperature. This way, the ice / snow mass that forms at the bottom of the chamber will consist of frozen ice crystals, and a residue of salt water brine, which can runoff from the mass, either from the sides, or through any voids or channels that may form within the mass.

Owner:ENIS BEN M +1

Process to obtain water bodies larger than 15,000 m3 for recreational use with color, transparency and cleanness characteristics similar to swimming pools or tropical seas at low cost

The invention discloses a process to implement and maintain water bodies larger than 15,000 m3 for recreational use, such as lakes or artificial lagoons, with excellent color, transparency and cleanness properties at low cost, which comprises the following steps:a.—providing a structure able to contain a large water body larger than 15,000 m3;b.—feeding the structure of step (a) with inlet water having iron and manganese levels lower than 1.5 ppm and turbidity lower than 5 NTU;c.—measuring water pH, ideally it should be within a range lower than 7.8;d.—adding an oxidizing agent to the water contained in the structure of step (a), with which a 600 mV minimal ORP is controlled in water for a minimal period of 4 hours and in maximal cycles of 48 hours;e.—adding a flocculating agent in concentrations within 0.02 and 1 ppm with maximal frequencies of 6 days and cleaning the bottom of the structure of step (a) with a suction device to remove precipitated impurities from the bottom of said structure, together with the additional flocculants and;f.—generating a displacement of surface water containing impurities and surface oils by means of the injection of inlet water according to step (b), which generates said displacement in such a way to remove said surface water by means of a system for impurities and surface oils removal arranged in the structure of step (a), which together with step (e) replaces traditional filtering.The present invention also discloses a structure to contain large water bodies comprising a system for the removal of impurities and surface oils by means of skimmers and the suction device to clean said structure.

Owner:CRYSTAL LAGOONS TECH INC

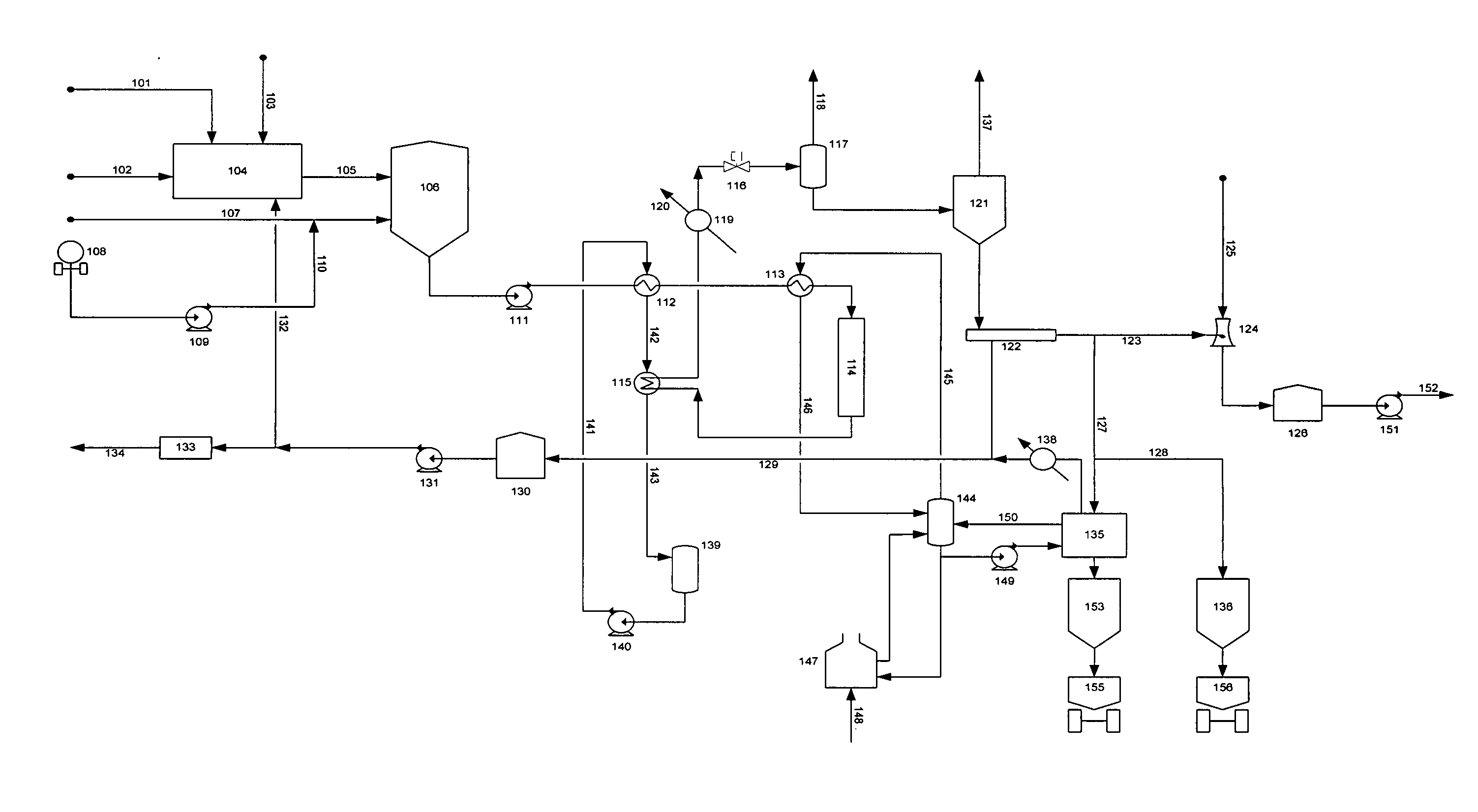

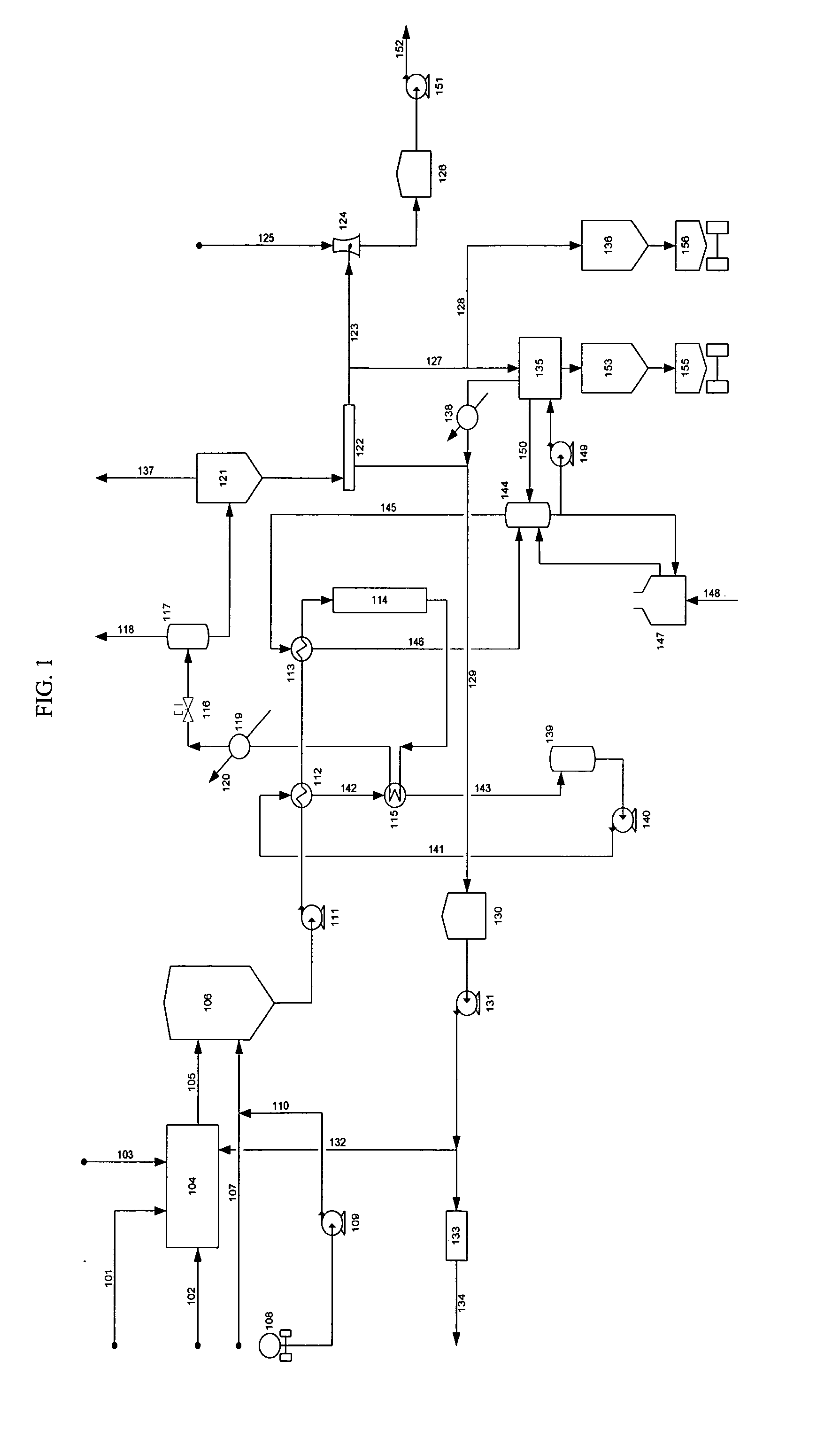

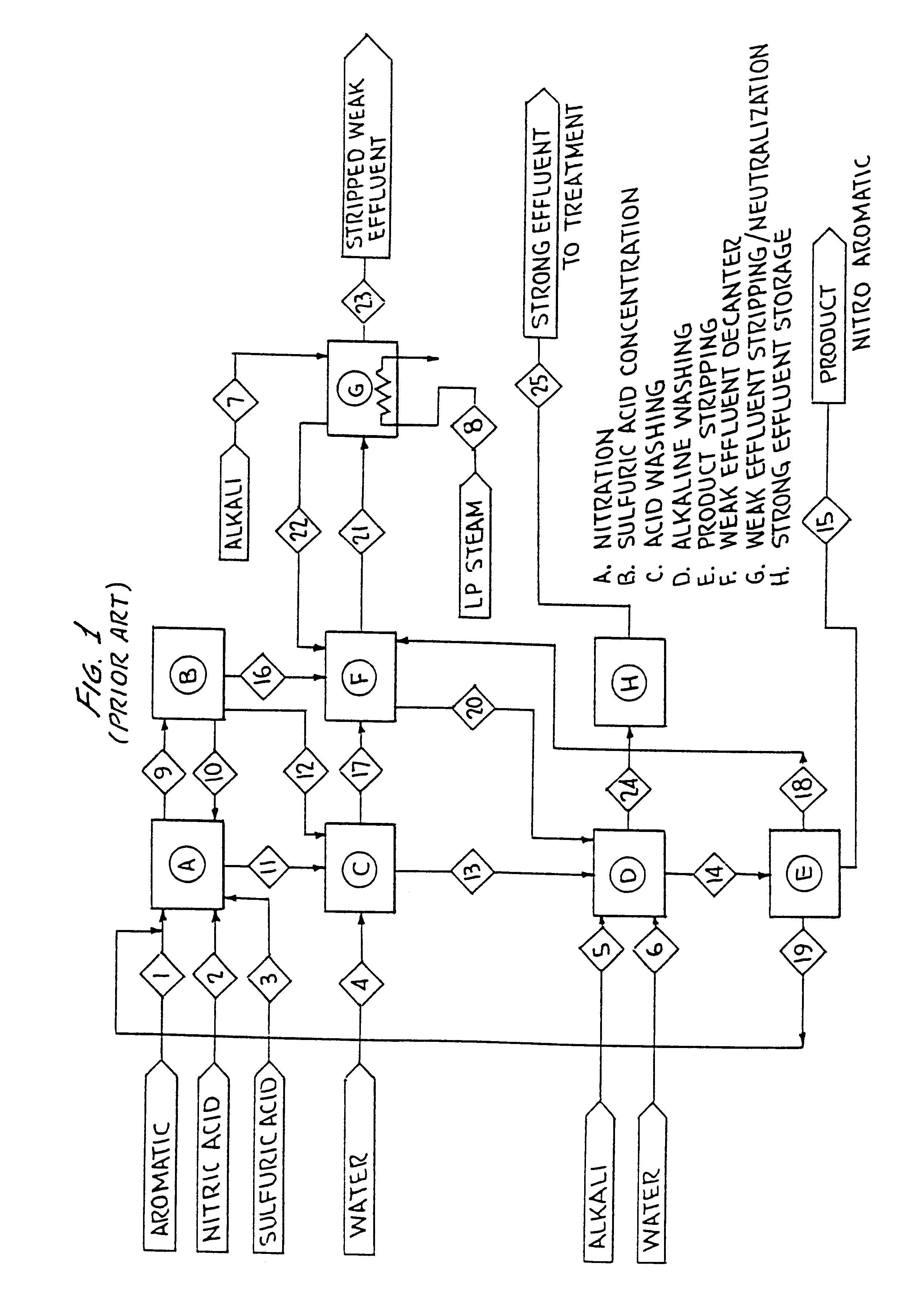

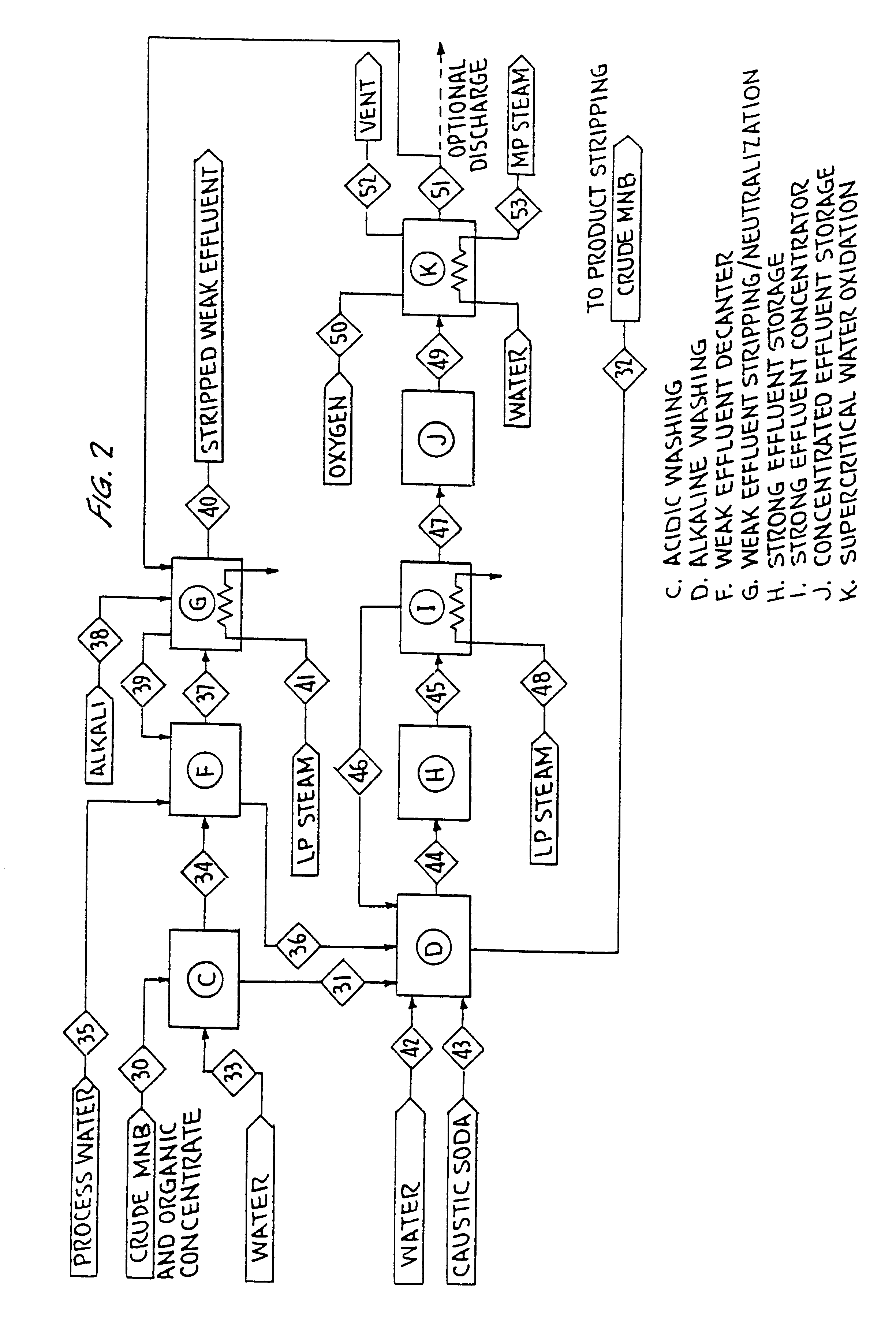

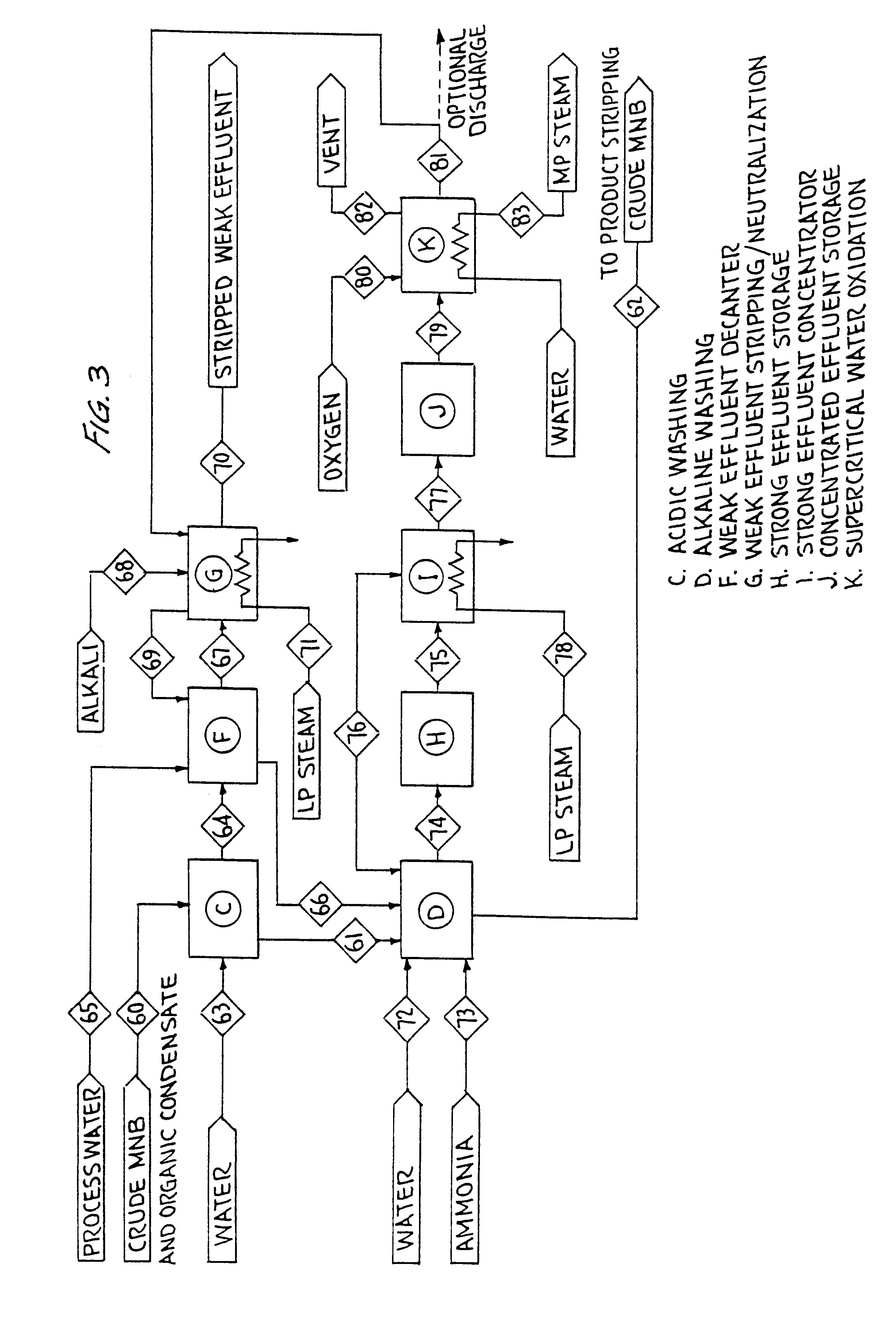

Integrated effluent treatment process for nitroaromatic manufacture

InactiveUS6288289B1Highly destructiveReduce consumptionOrganic chemistrySludge treatment by oxidationWash waterSupercritical water oxidation

An integrated process for treating alkaline wash water effluent from nitroaromatic manufacture, principally containing nitro-hydroxy-aromatic compounds is described. The integrated process concentrates the alkaline wash water to recover chemicals and water prior to treating the concentrate through supercritical water oxidation. The supercritical water oxidation step consists of treating the concentrate in the presence of an oxygen source at conditions, which are supercritical for water to cause a substantial portion of the organic component of the concentrate to oxidize. The product effluent includes a gaseous component and a clean water component, and in the event that insoluble ash is formed, an ash component. The new integrated process results in reduced chemical and water consumption compared to existing processes. In addition, the treated wash water effluent can be recycled to process or directly discharged.

Owner:NORAM INT

Reactive compositions for fluid treatment

InactiveUS20030196966A1Perfluorocarbons/hydrofluorocarbons captureLoose filtering material filtersFiltrationPhosphate

A method and device for the chemical conversion, filtration and / or purification of fluids water or other solutions containing microbiological and chemical contaminants, such as fluids containing arsenic, chlorine, bacteria, viruses, and cysts, where the fluid is passed through a purification material composed of fluid treatment carbon, metal phosphates, metal oxides, reduced metals, metal silicates, metal sulfates, metal carbonates, metal hydroxides, or combinations thereof. The material may be included in a fixed binder matrix.

Owner:WATERVISIONS INT

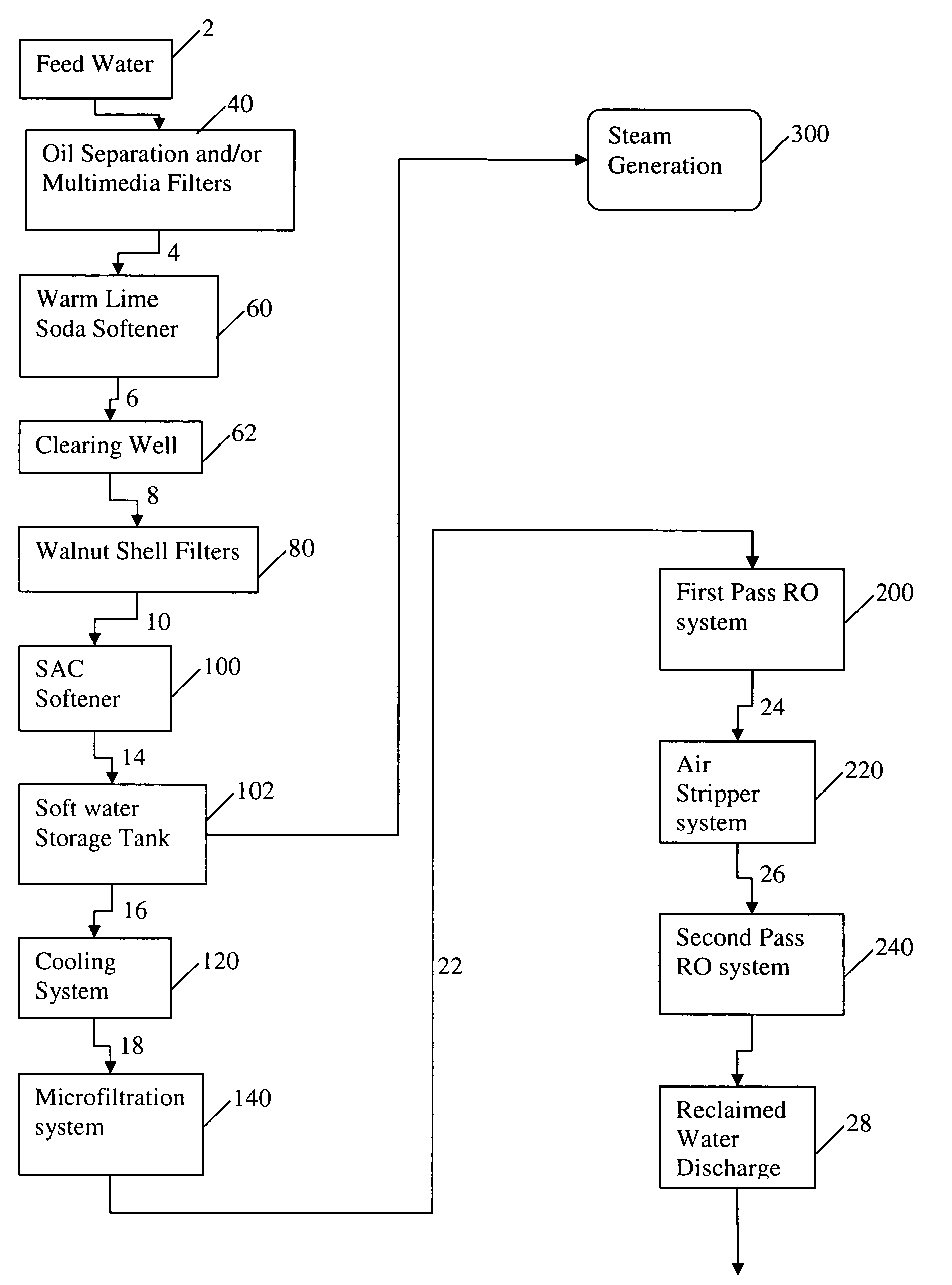

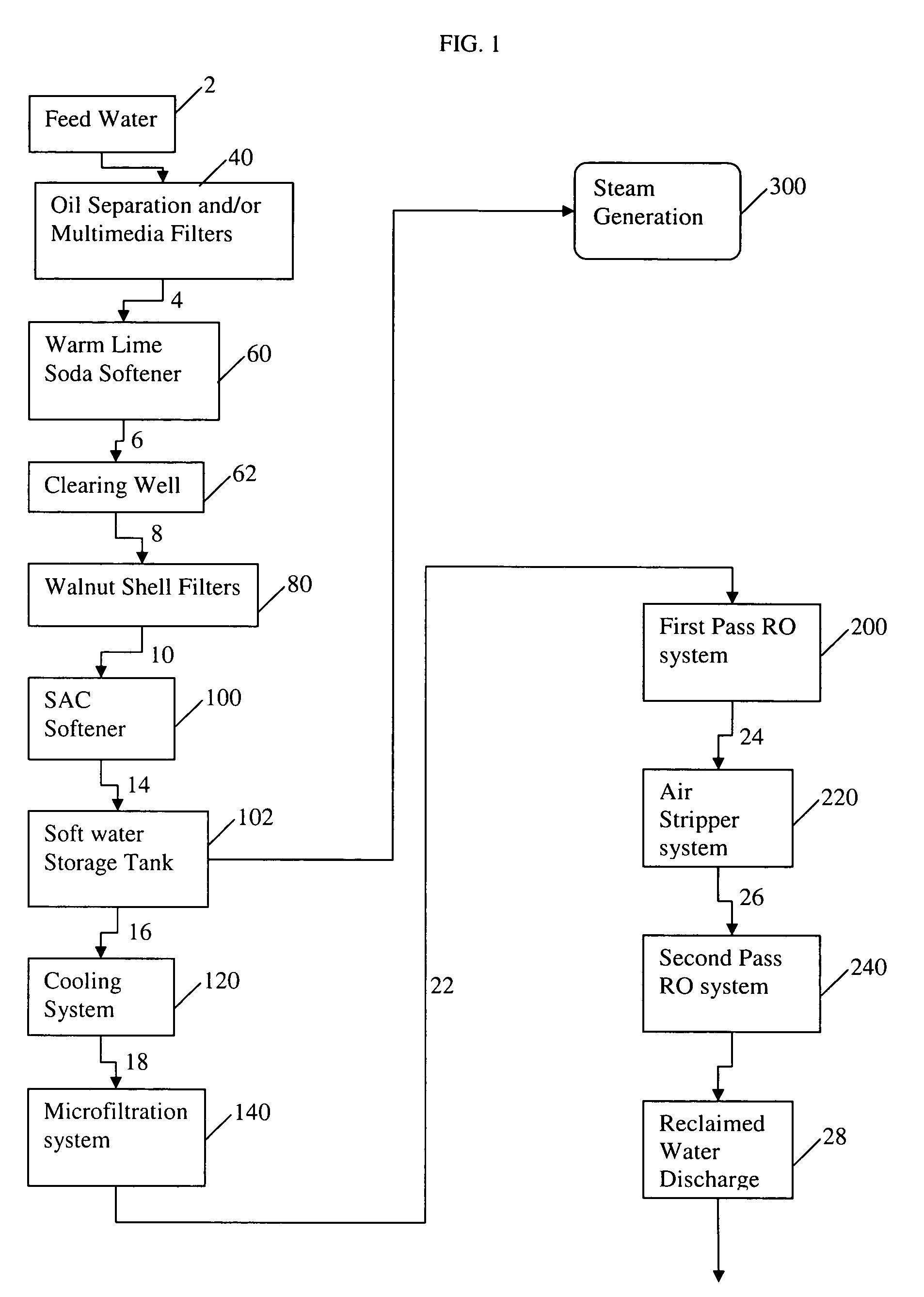

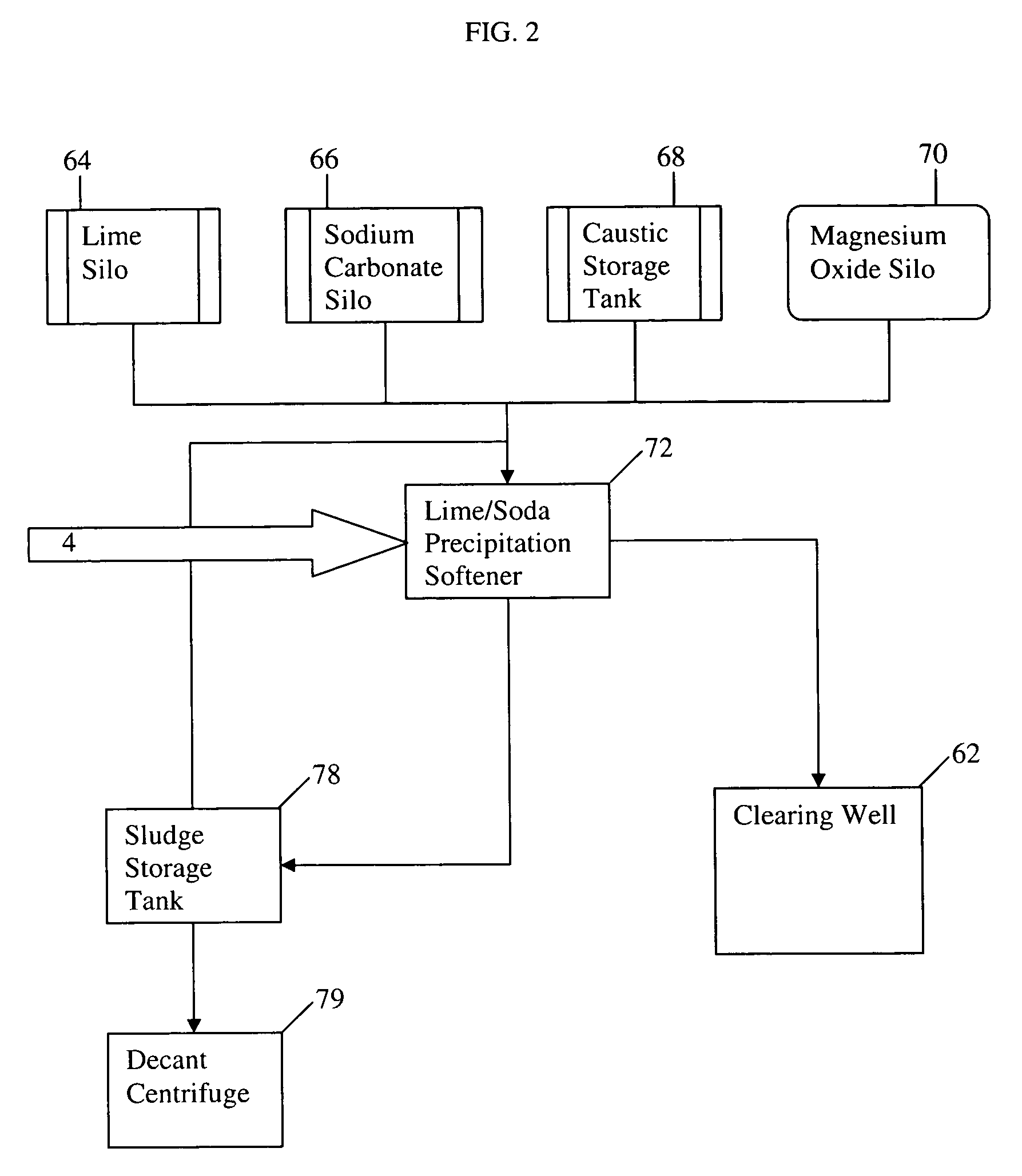

Water treatment process for oilfield produced water

ActiveUS7520993B1Minimize continued precipitationLiquid separation auxillary apparatusUsing liquid separation agentSludgeTreatments water

The invention relates to a method and system for treating an aqueous liquid containing dissolved minerals and dissolved hydrocarbons. Method steps and apparatus for treating a waste water feed stream are disclosed which utilize a warm lime softening system in fluid communication with the waste water feed stream, wherein sludge from the warm lime softening system is recycled to improve lime utilization and enhance silica and boron removal without the addition of an external source of magnesium. In addition, a microfiltration system and / or an air stripper system may be used in fluid communication with at least one reverse osmosis system to produce a treatment water that meets state and federal guidelines for surface discharge.

Owner:WATER & POWER TECH

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS6840251B2Reduce Microbial ContaminationReduce removalDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

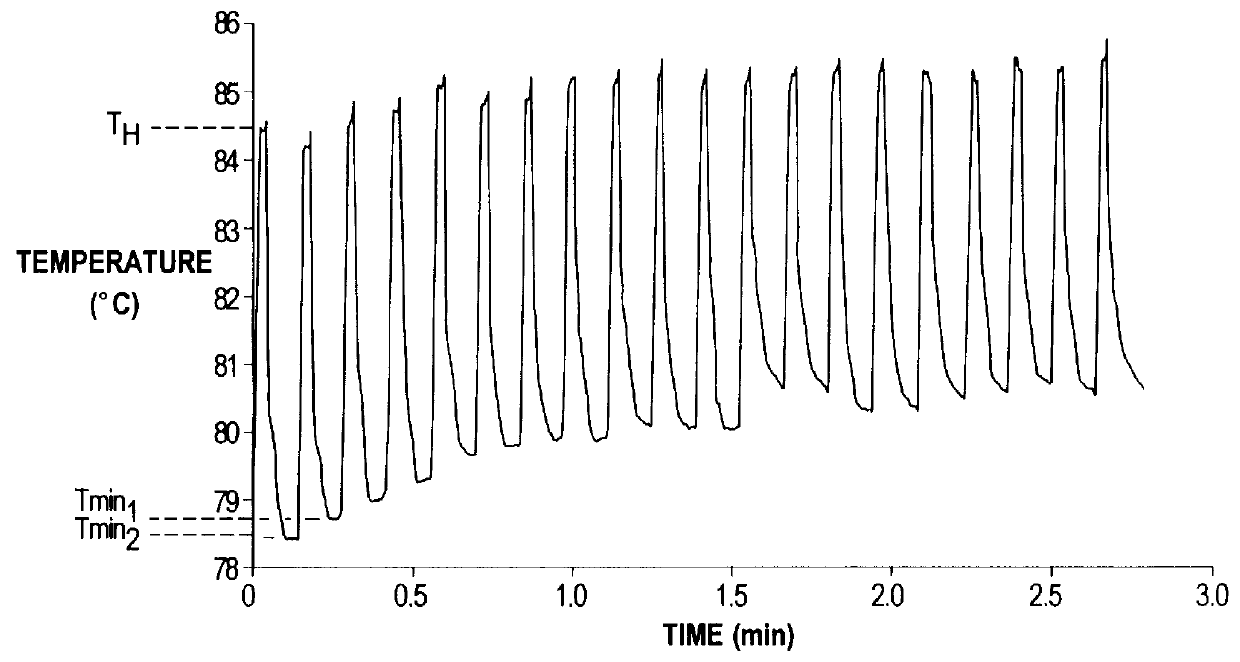

Disinfection of dead-ended lines in medical instruments

A method of disinfection of a dead-ended fluid line in a medical instrument such as a dialysis machine is described. The method comprises introducing a heated fluid into the fluid line, allowing the fluid to remain in the line for an experimentally determined optimal dwell period, removing the fluid from the fluid line, and then repeating the cycle for a time period sufficient to achieve a disinfection of the fluid line. The optimum dwell period and frequency for exchanging the heated fluid is determined so that the heated fluid is left resident in the line to exert a cidal effect but not so long that the it cools to the point of being ineffective, nor changed so frequently that that the time spent with no hot water resident in the line begins to detract (e.g., unduly prolong) the disinfection process. A representative cycle is introducing water at a temperature of about 85 degrees C, allowing it to reside in the fluid line for about 10 seconds, withdrawing the water, and then reintroducing water at 85 degrees C. The process continues for 1-2 hours. Variation from the representative cycle will be expected based on parameters such as the degree to which disinfection is to be achieved, the length and diameter of the fluid line, the temperature of the fluid, the ambient temperature, the presence of elements in the fluid line that contribute to heat loss, the material used for fluid line tubing, and whether the fluid comprises water or a disinfection solution such as a dilute citric acid solution. The optimum dwell period and frequency of the cycles can be determined experimentally from the teachings described herein.

Owner:BAXTER INT INC +2

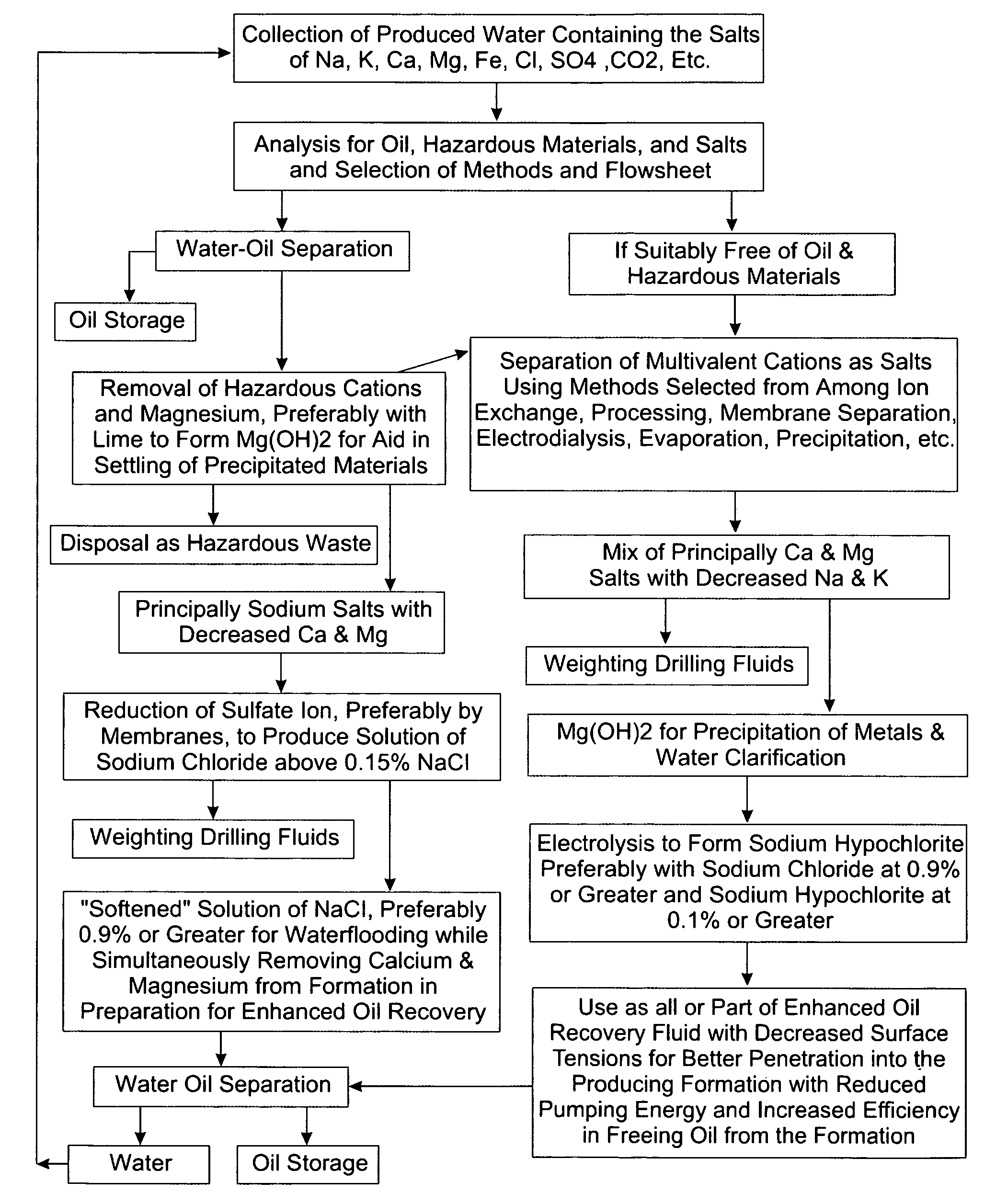

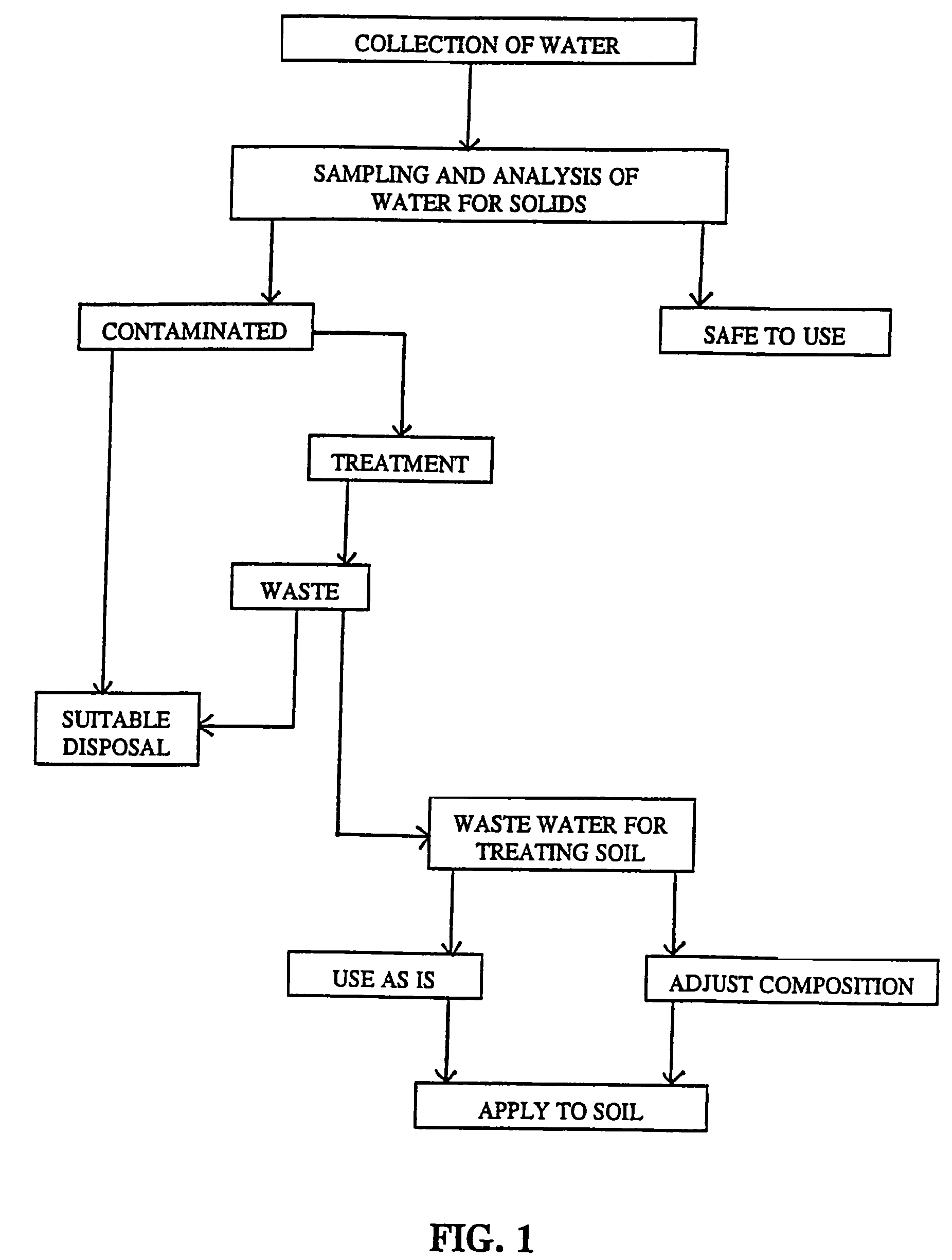

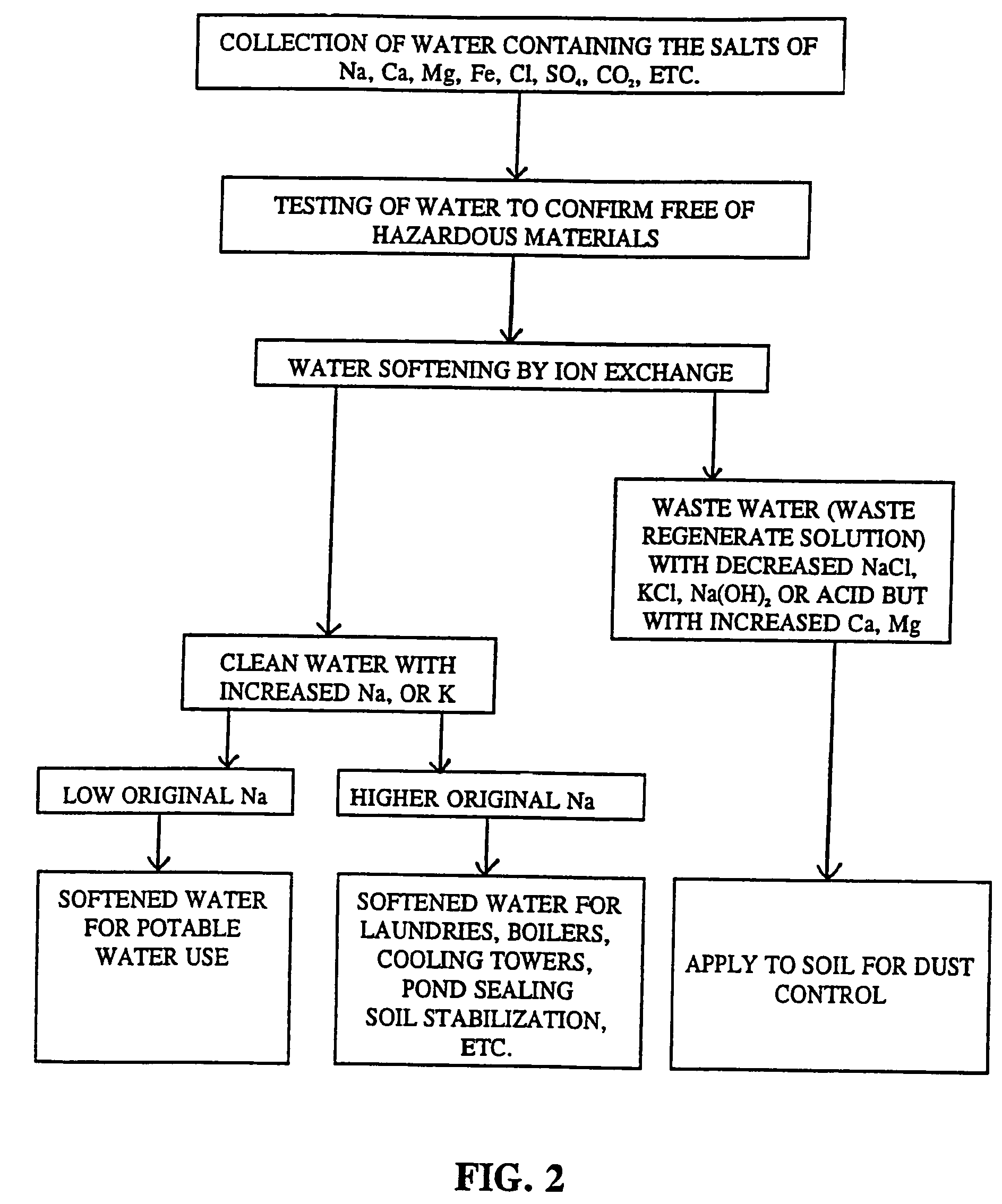

Methods of improving oil or gas production with recycled, increased sodium water

InactiveUS7717173B2Reduction tendencySpecific water treatment objectivesScale removal and water softeningLiquid productEnvironmental engineering

A method of improving oil or gas well production has the steps of (a) collecting contaminated water having 0.15% or more by weight of the salts of Na, Ca, Mg, K, Cl, SO4 or CO3 or combinations thereof (b) separation processing the contaminated water to produce i.) a first separated liquid product having increased sodium chloride and decreased magnesium chloride and calcium chloride or combinations thereof than the collected water, and ii) a second solid or liquid product having decreased sodium chloride and increased magnesium chloride and calcium chloride or combinations thereof than the collected water, and (c) injecting the first liquid product into an oil or gas well formation to improve production.

Owner:ECYCLING

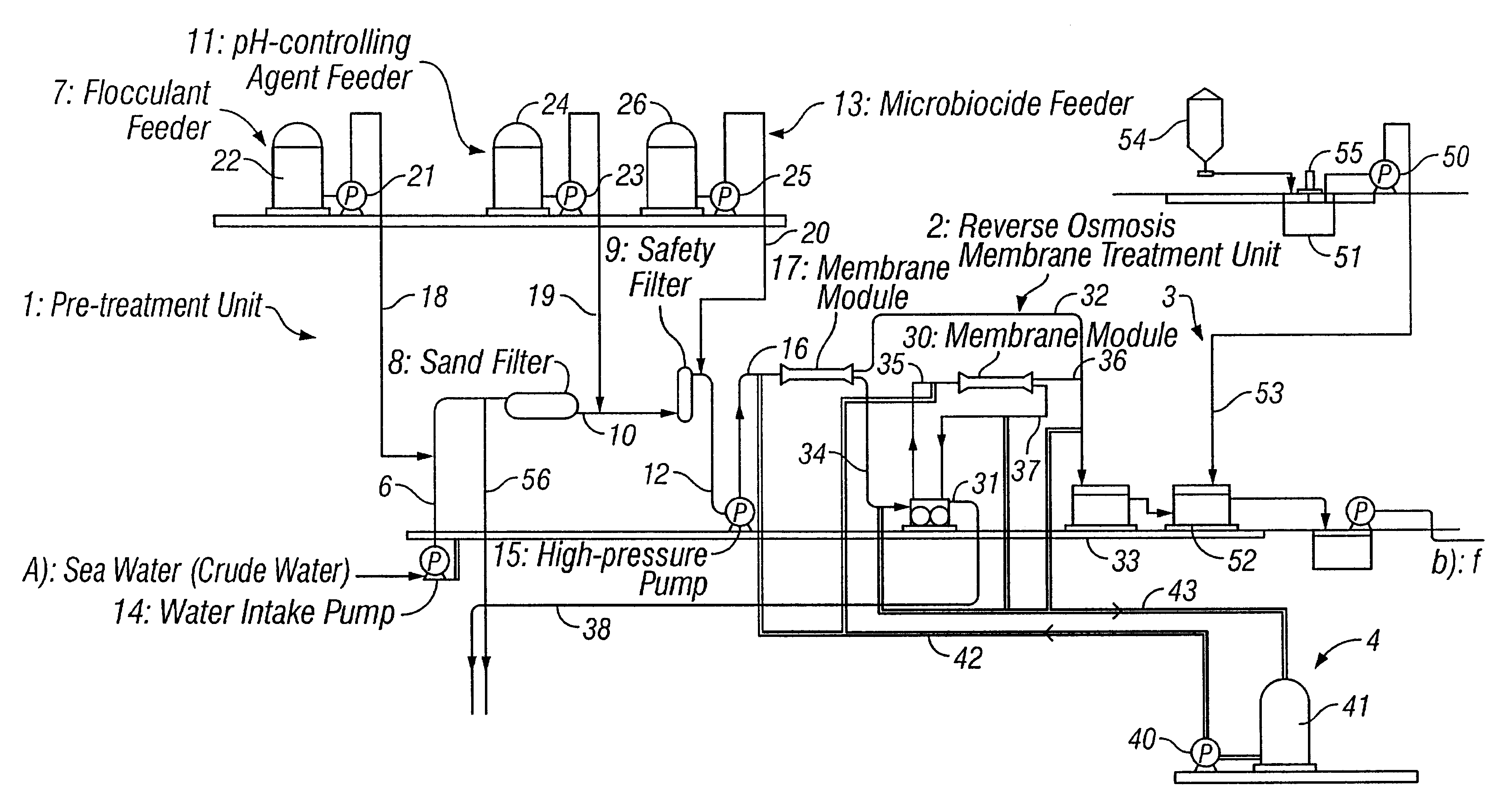

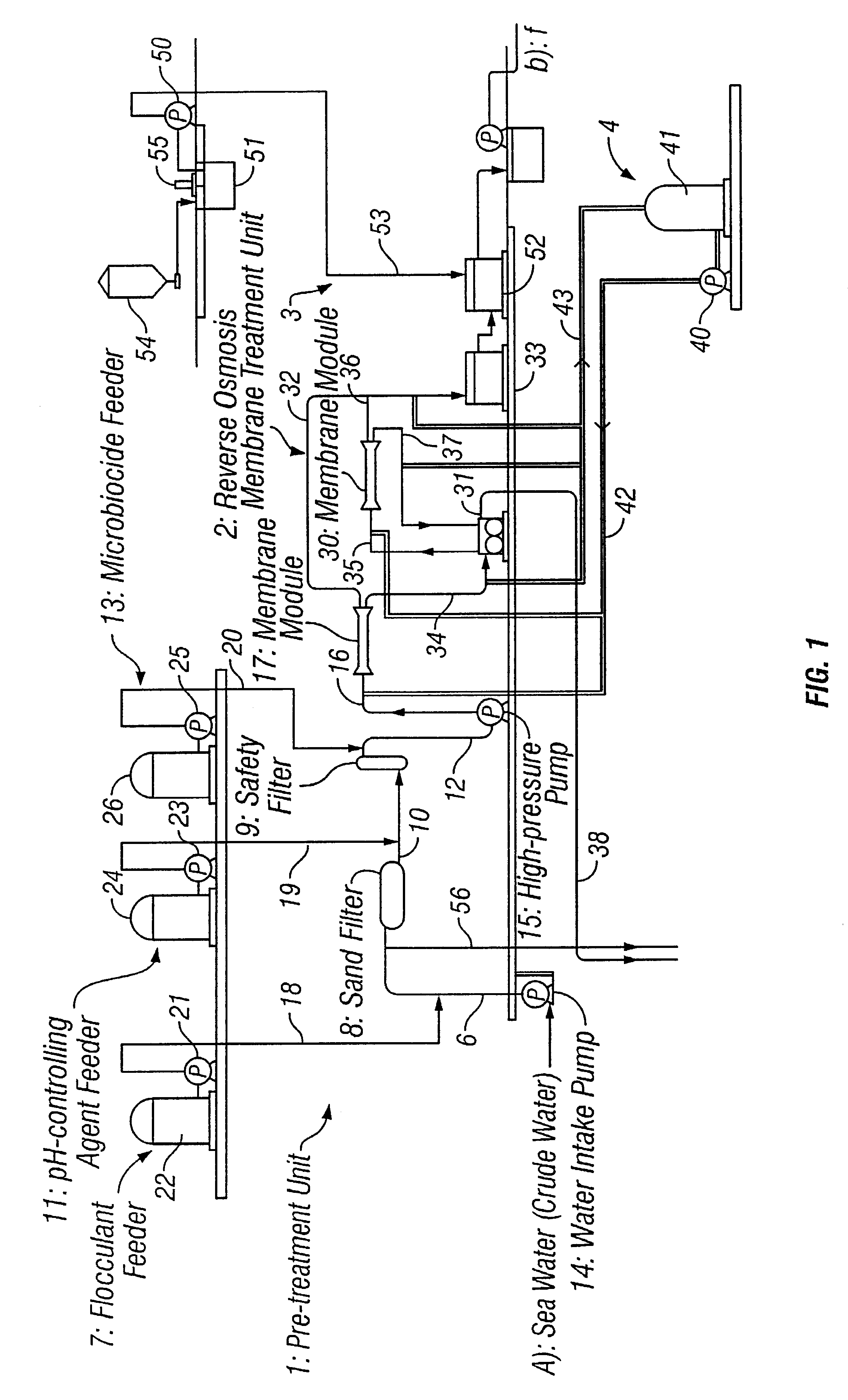

Method for inhibiting growth of bacteria or sterilizing around separating membrane

InactiveUS6468430B1Conserve costReduce the impactMembranesSolid sorbent liquid separationPre treatmentPermselective membrane

In the invention, the pipe lines around permselective membranes and the surfaces of permselective membranes are intermittently disinfected by adding an inexpensive acid such as sulfuric acid or the like to pre-treated crude water so as to make the water have a pH of 4 or lower. Accordingly, the invention provides a method of surely disinfecting the permselective membranes in membrane separation systems.

Owner:TORAY IND INC

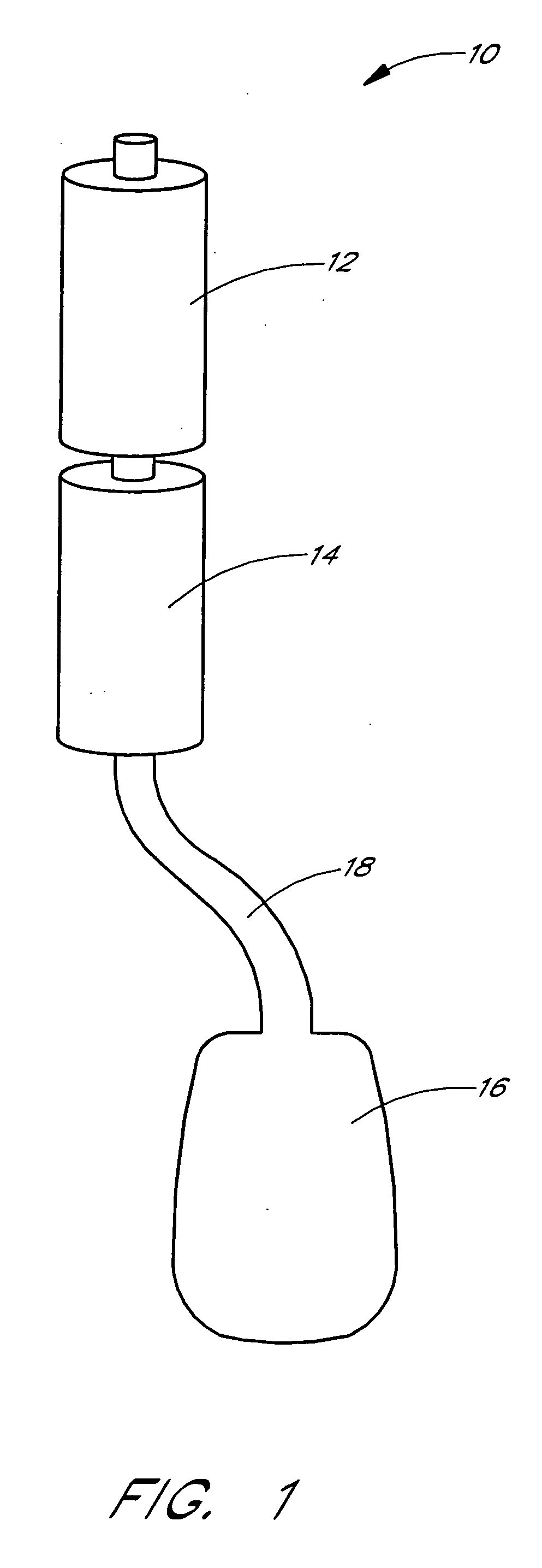

Water purification pack

InactiveUS20050113796A1General water supply conservationTransportation and packagingHuman bodyQuality level

An apparatus and methods are disclosed for purifying fluid, such as potable water, to quality levels suitable for medical application, particularly to applications involving injection of the fluid into a human body. The apparatus comprises a portable purification pack constructed for a single use. The pack houses depth filtration, activated carbon, mixed bed ion exchange resins and terminal filtration stages in series. The terminal filter comprises a fine (microfiltration or ultrafiltration), permeable membrane, treated with an endotoxin-binding chemistry. In contrast with semi-permeable osmotic membranes, the permeable membrane produces high flow rates at relatively low pressures, while still safely purifying fluid to injection quality.

Owner:TAYLOR MICHAEL A

Aqueous composition containing H2O2, acids and Ag, preparation method therefor and use thereof for disinfection, hygiene and/or pollution control

The present invention relates to an aqueous decontaminating composition comprising(A) an amount of H2O2 less than or equal to 60% by weight, based on the total weight of said composition;(B) an RCO3H / RCO2H mixture, where R is methyl or ethyl, as indicated above, said mixture being present in an amount such that the weight ratio of said mixture to the hydrogen peroxide is between 0.15 / 1 and 0.85 / 1;(C) a silver component as a source of Ag ions, selected from the group consisting of silver salts and complexes, said silver component being present in an amount such that the weight ratio of said silver component to the hydrogen peroxide is between 0.0005 / 1 and 0.015 / 1;(D) a stabilizer present in an amount such that the weight ratio of said stabilizer to the hydrogen peroxide is between 0.0005 / 1 and 0.025 / 1; andwater to make up to 100% by weight. It further relates to the method of preparation and to the use of said composition.

Owner:SODIFRA

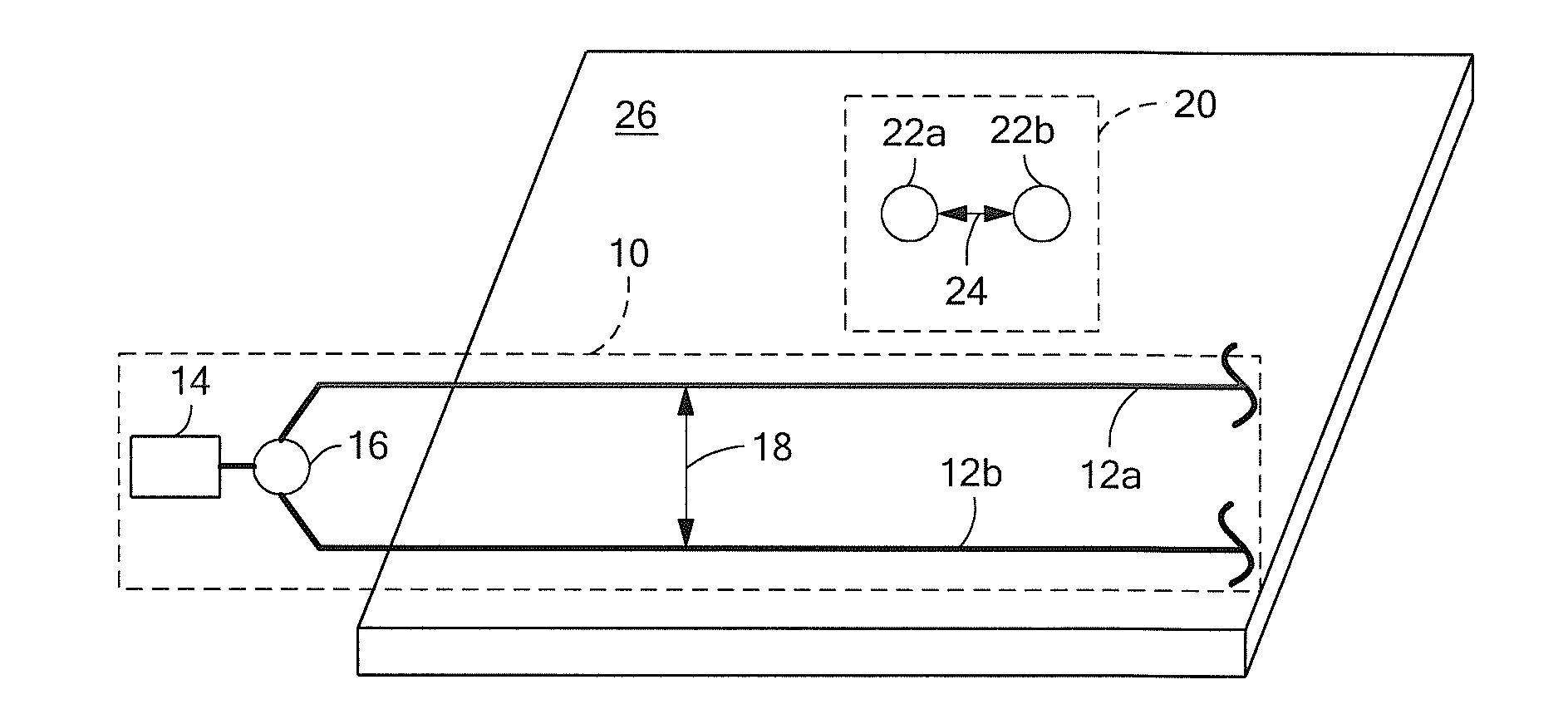

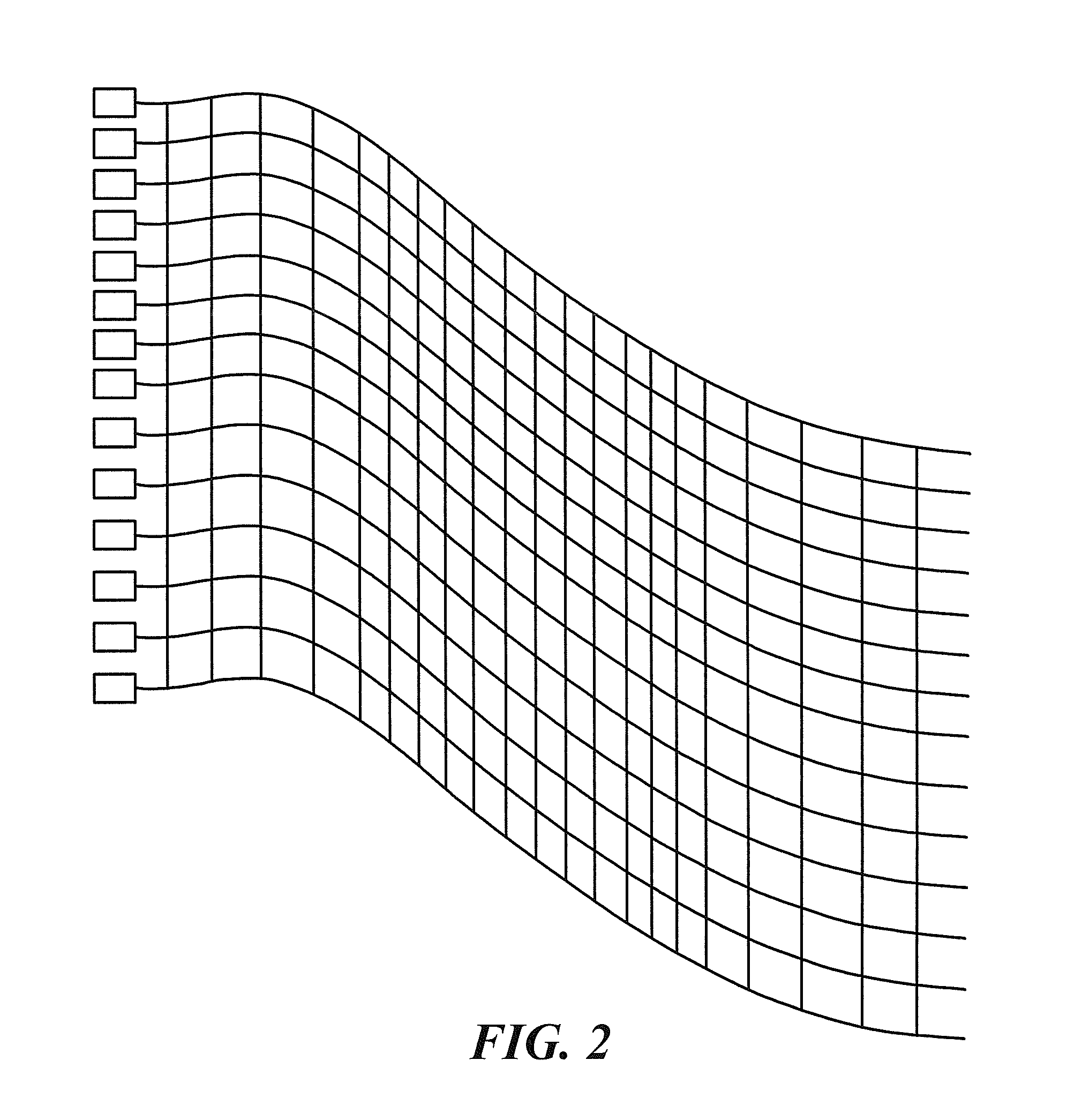

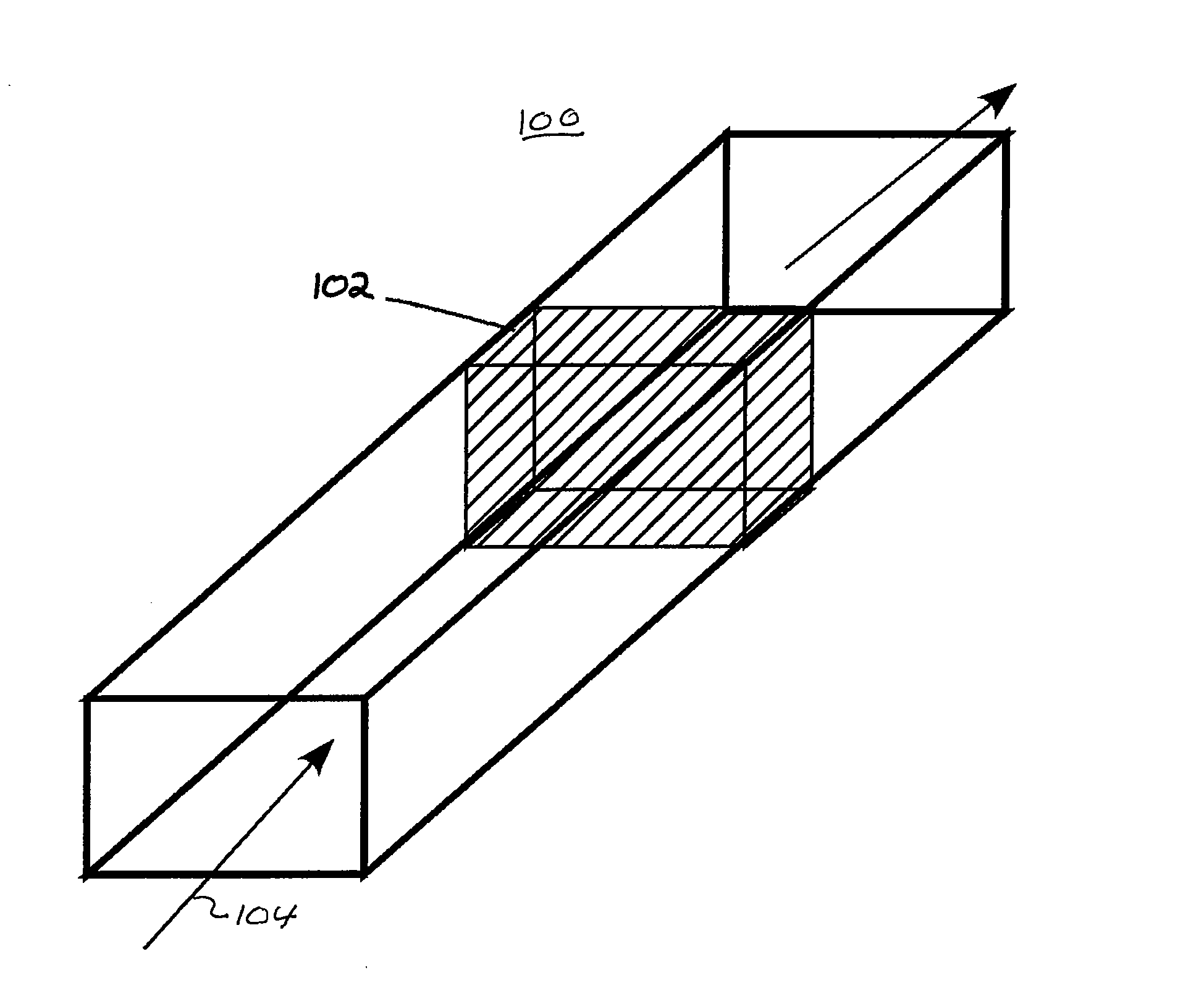

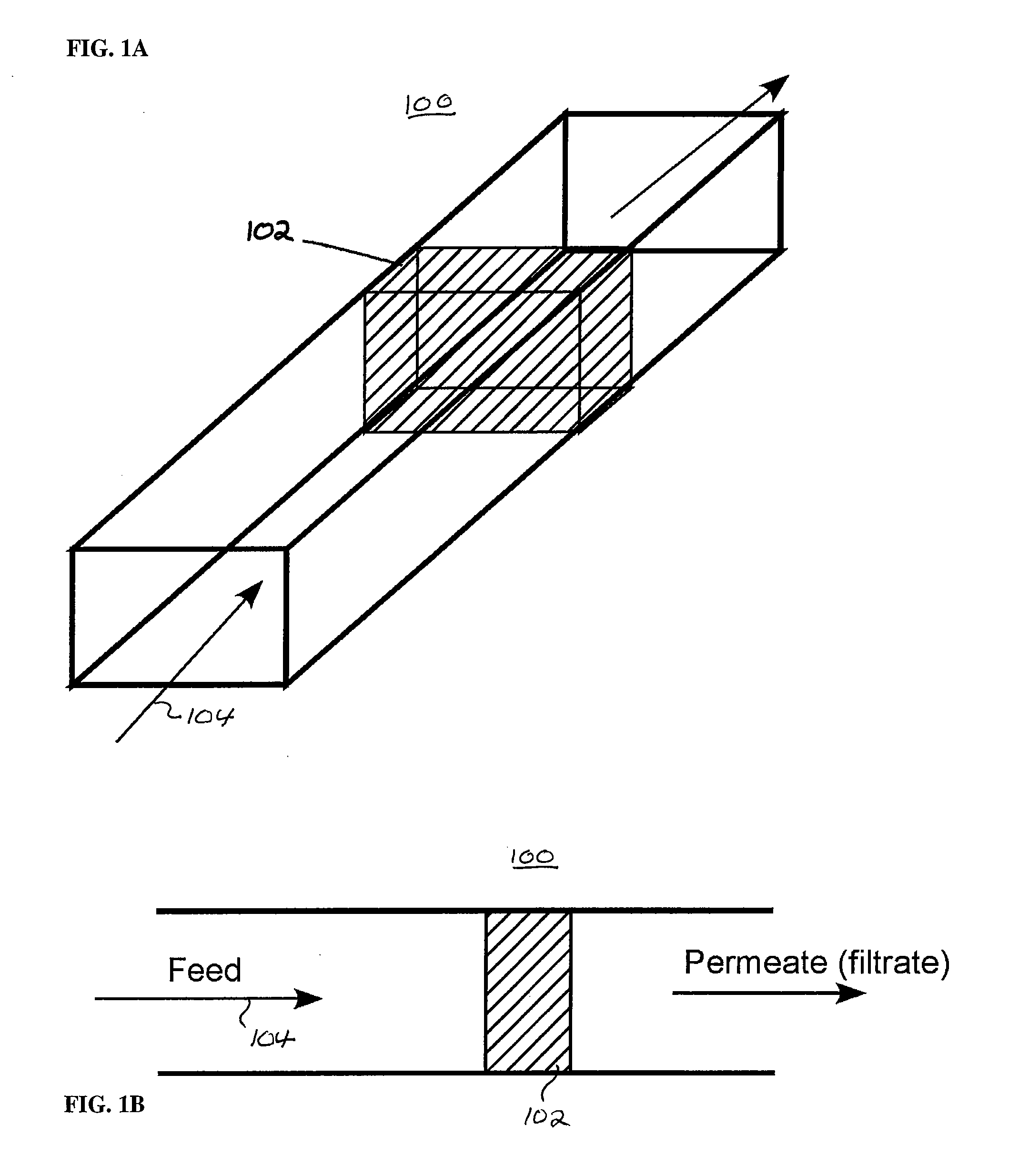

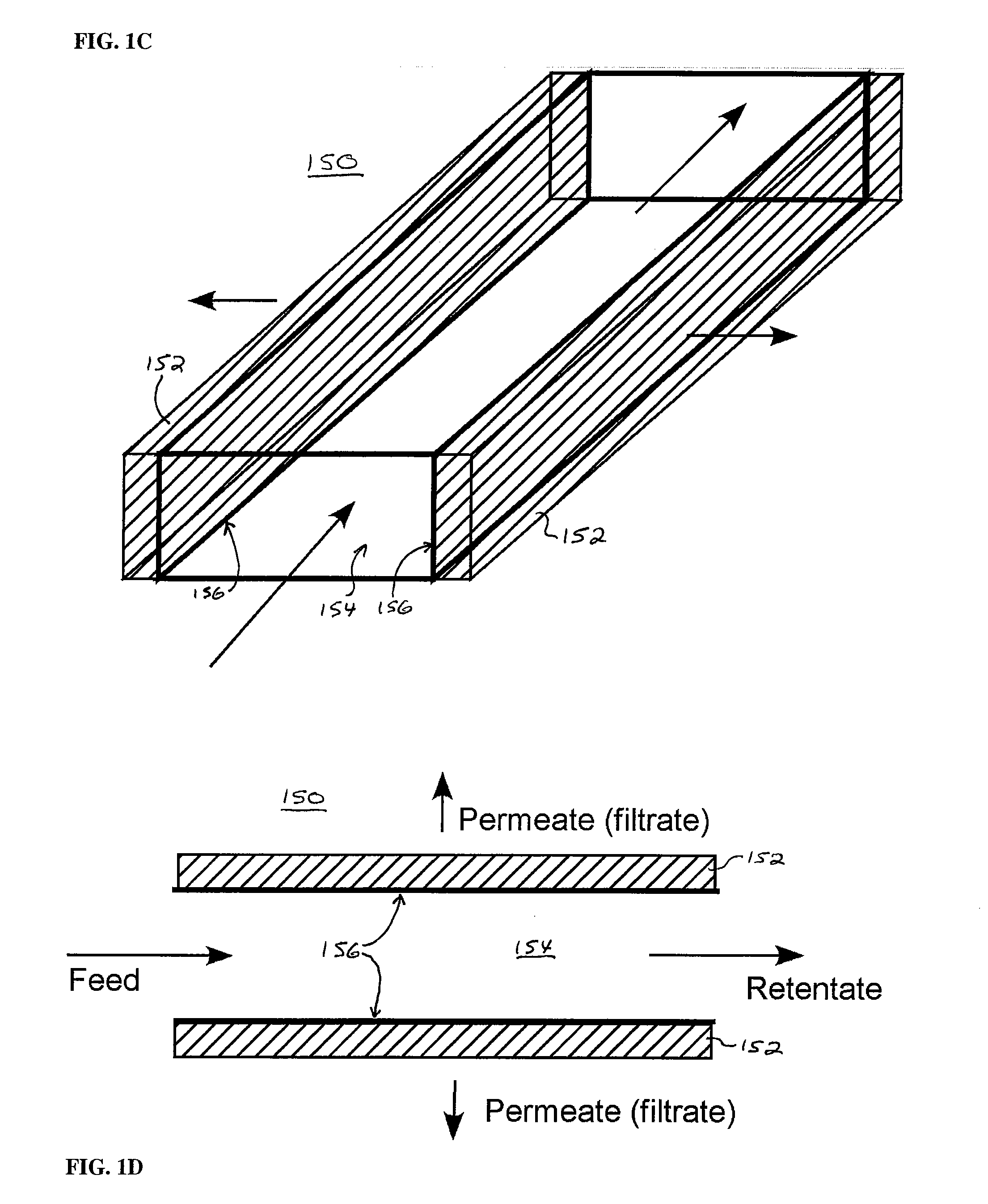

Biochip for High-Throughput Screening of Circulating Tumor Cells

ActiveUS20080318324A1Reduce direct impactShorten speedLiquid separation auxillary apparatusLaboratory glasswaresRe entryHigh-Throughput Screening Methods

Embodiments in accordance with the present invention relate to the use of effusive filtration to segregate tumor cells from a sample of bodily fluid. In one embodiment, fluid containing a cell is flowed down a channel having a filtration medium present along at least one side wall. The tumor cell is captured when the fluid passes through the filtration medium. Accumulated pressure on the captured tumor cell is reduced by allowing the fluid that has passed through the filtration medium to re-enter the channel. In a particular embodiment, the filtration medium may comprise side wall apertures having a width smaller than that of the cell, with downstream apertures allowing re-entry of the fluid into the channel.

Owner:UNIV OF WASHINGTON

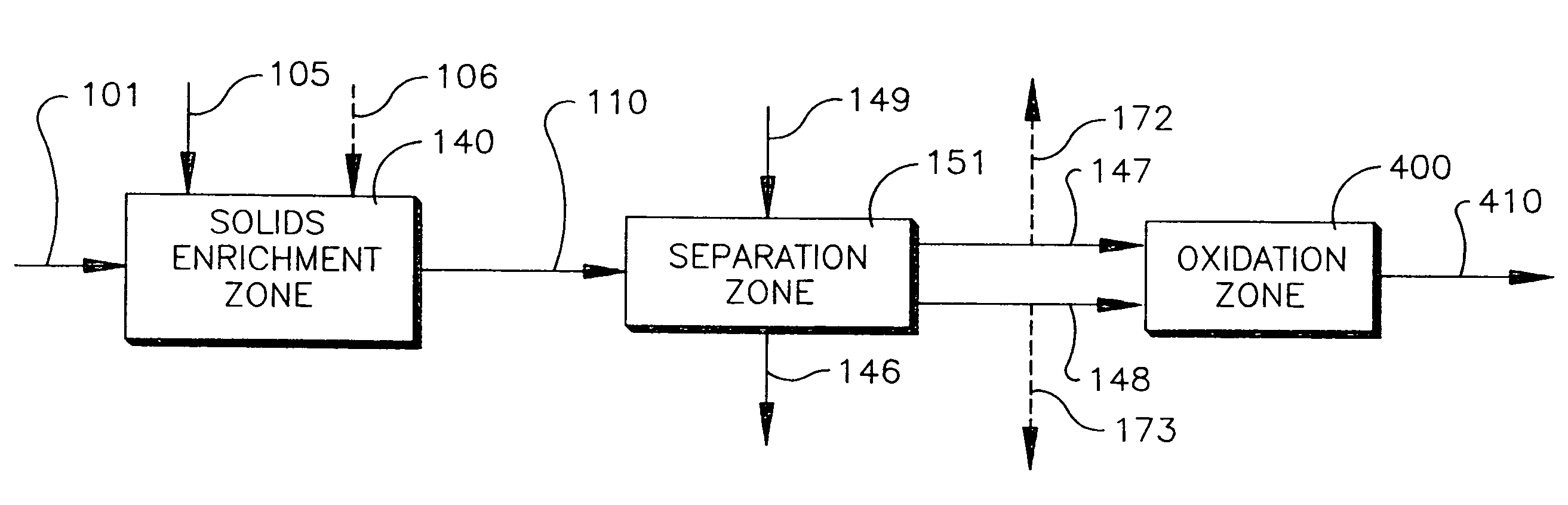

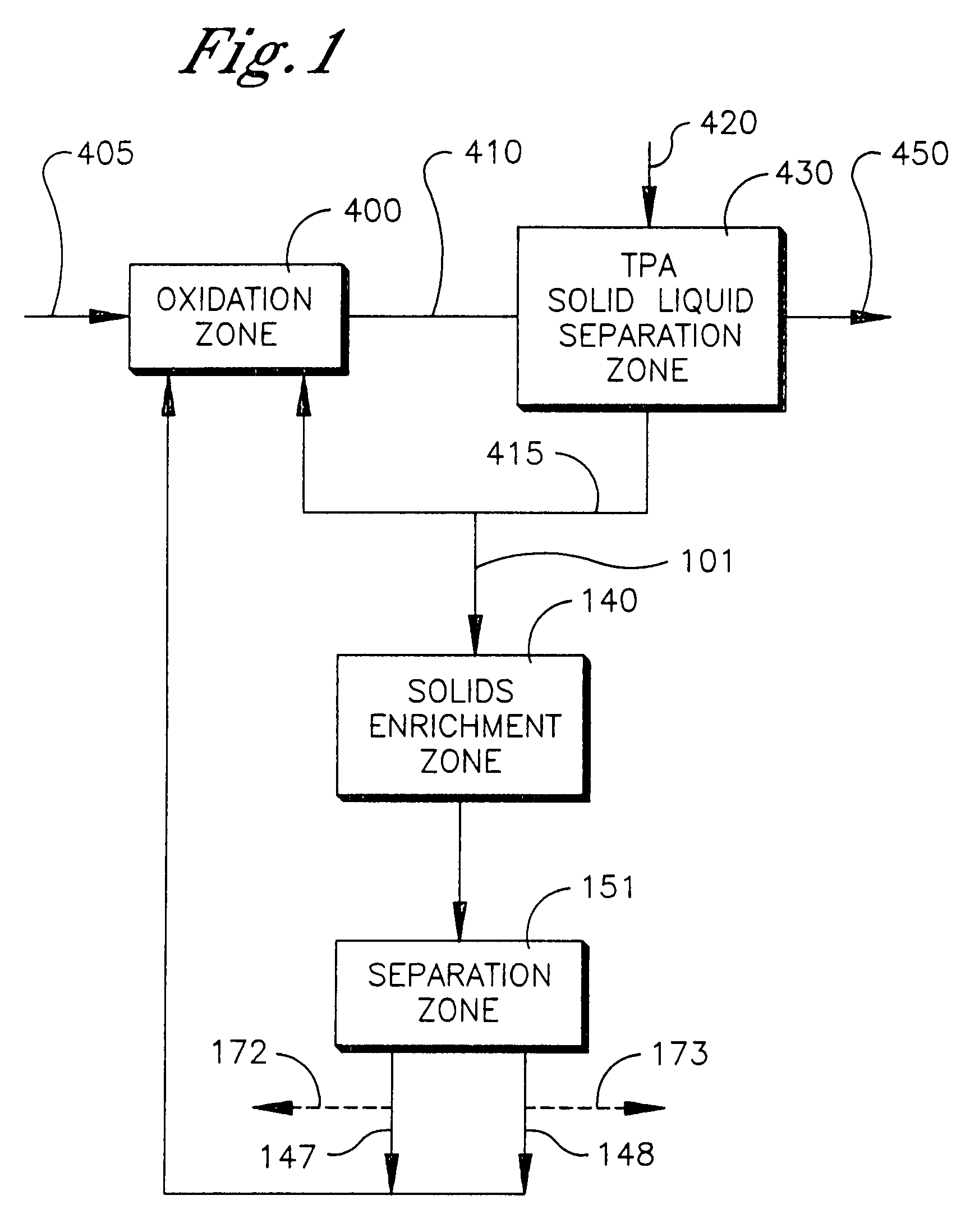

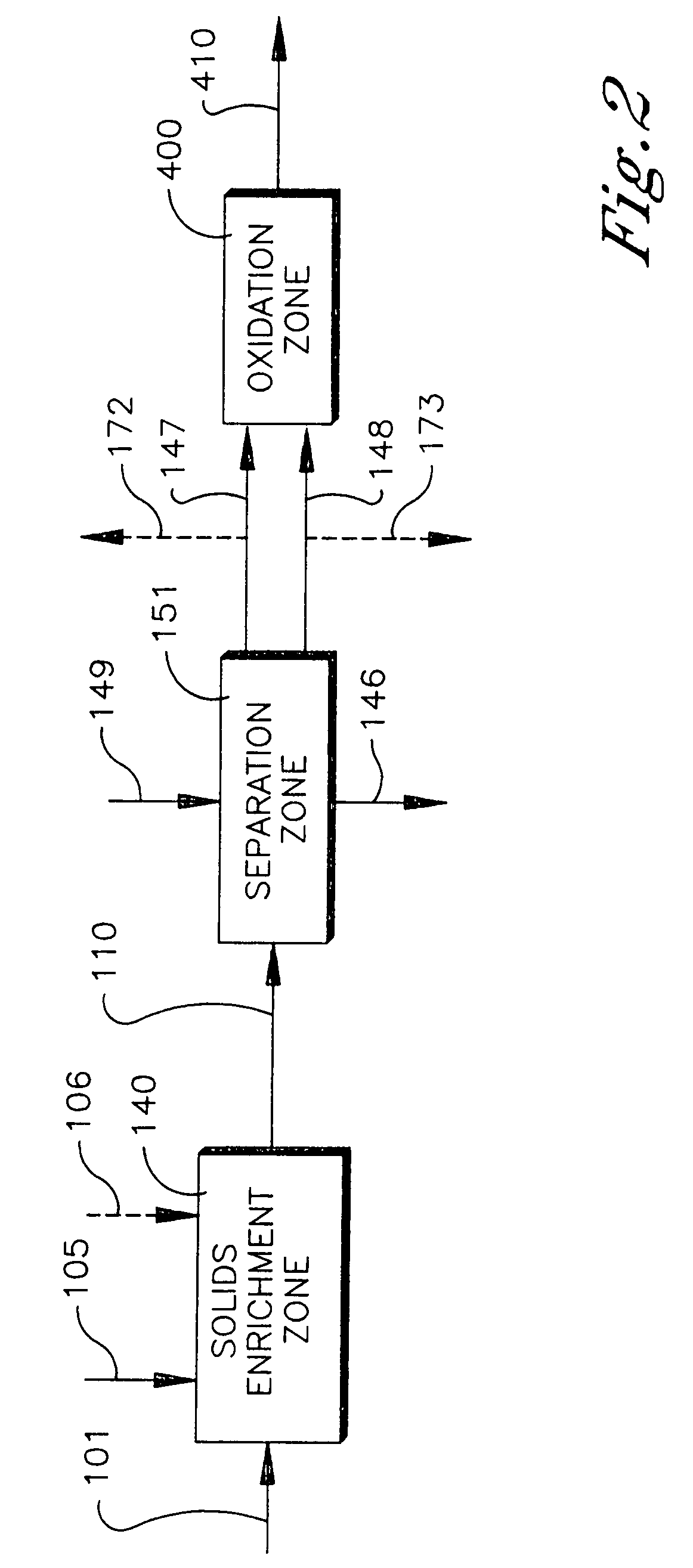

Process for removal of impurities from an oxidizer purge stream

A process is disclosed that relates to the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic. More particularly, the process involves the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream and then routing the mother liquor and or wash filtrate to an oxidation zone.

Owner:ALPEK POLYESTER SA DE CV

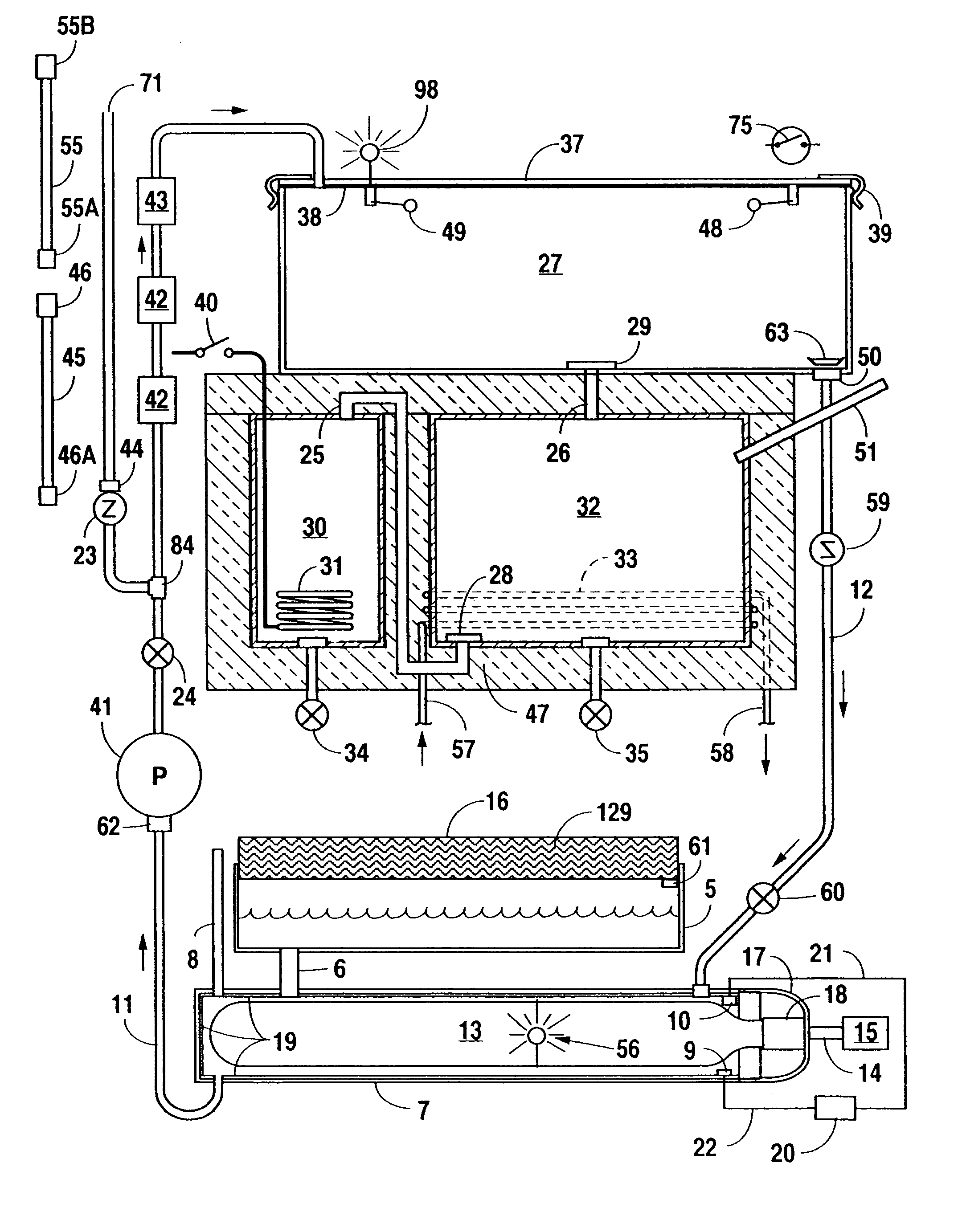

Portable, potable water recovery and dispensing apparatus

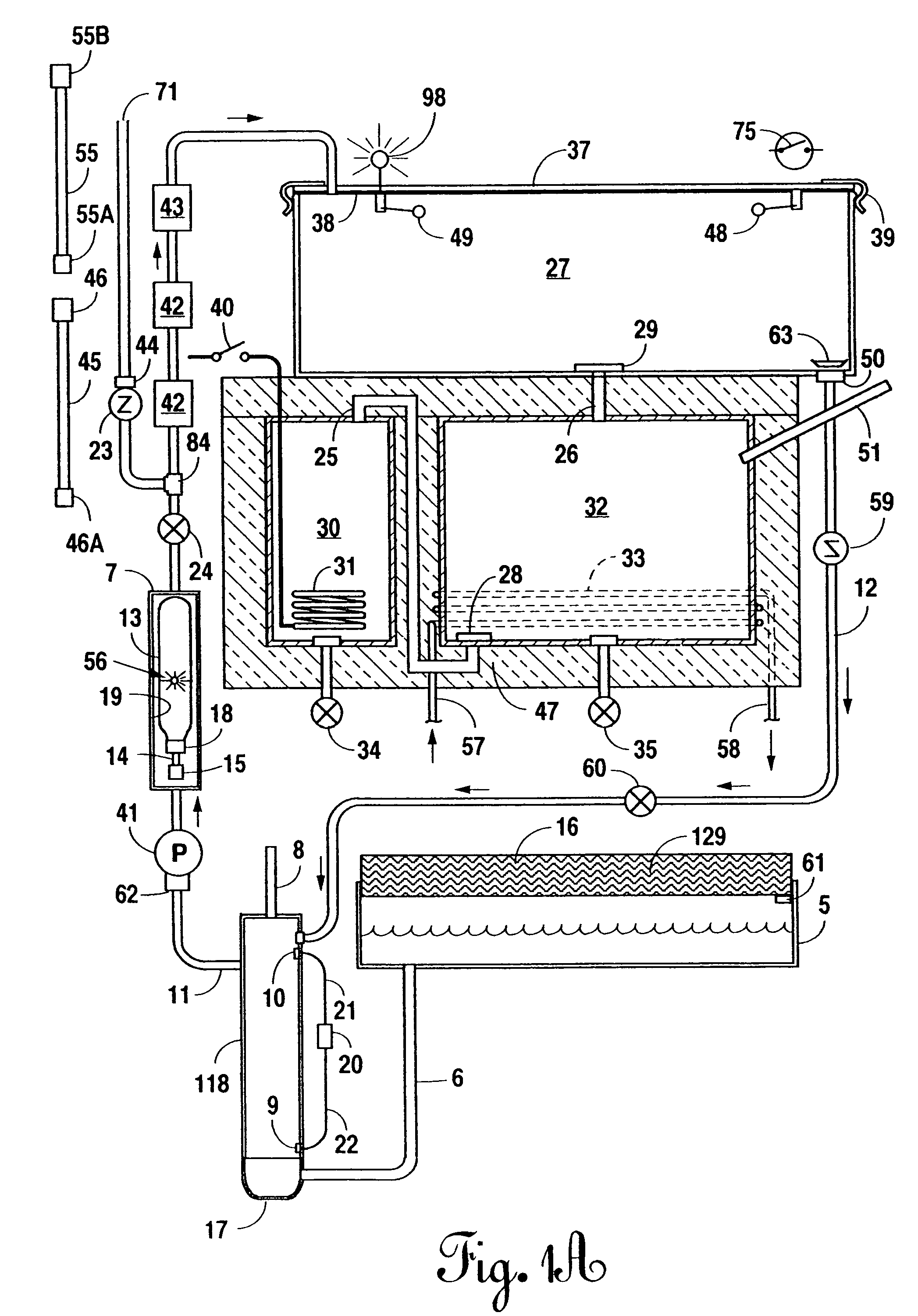

InactiveUS7089763B2Maximum efficiencyMaximum productionLiquefactionSpace heating and ventilationParticulatesBiological body

A portable, potable-water generator for producing high-purity liquid water by condensation of water vapor from ambient air. The generator (125) employs an air filter (119) to remove particulates and aerosols from the incoming air. An enclosed heat absorber cools the filtered air to its dew point and collects droplets of condensate into a condensate collector (5). Before discharge, the collected dew is treated in a bacteriostat loop to destroy adventitious living organisms and to filter out undesirable and dangerous contaminants. A recirculation loop provides the ability to recirculate stored condensate, including during periods of inactivity. Further, quick disconnect fittings (55b) and variable length flexible tubing allows use of the invention to serve remote dispensers and / or appliances and allow use of municipal water treated through the apparatus in low condensate situations.

Owner:WORLDWIDE WATER INC

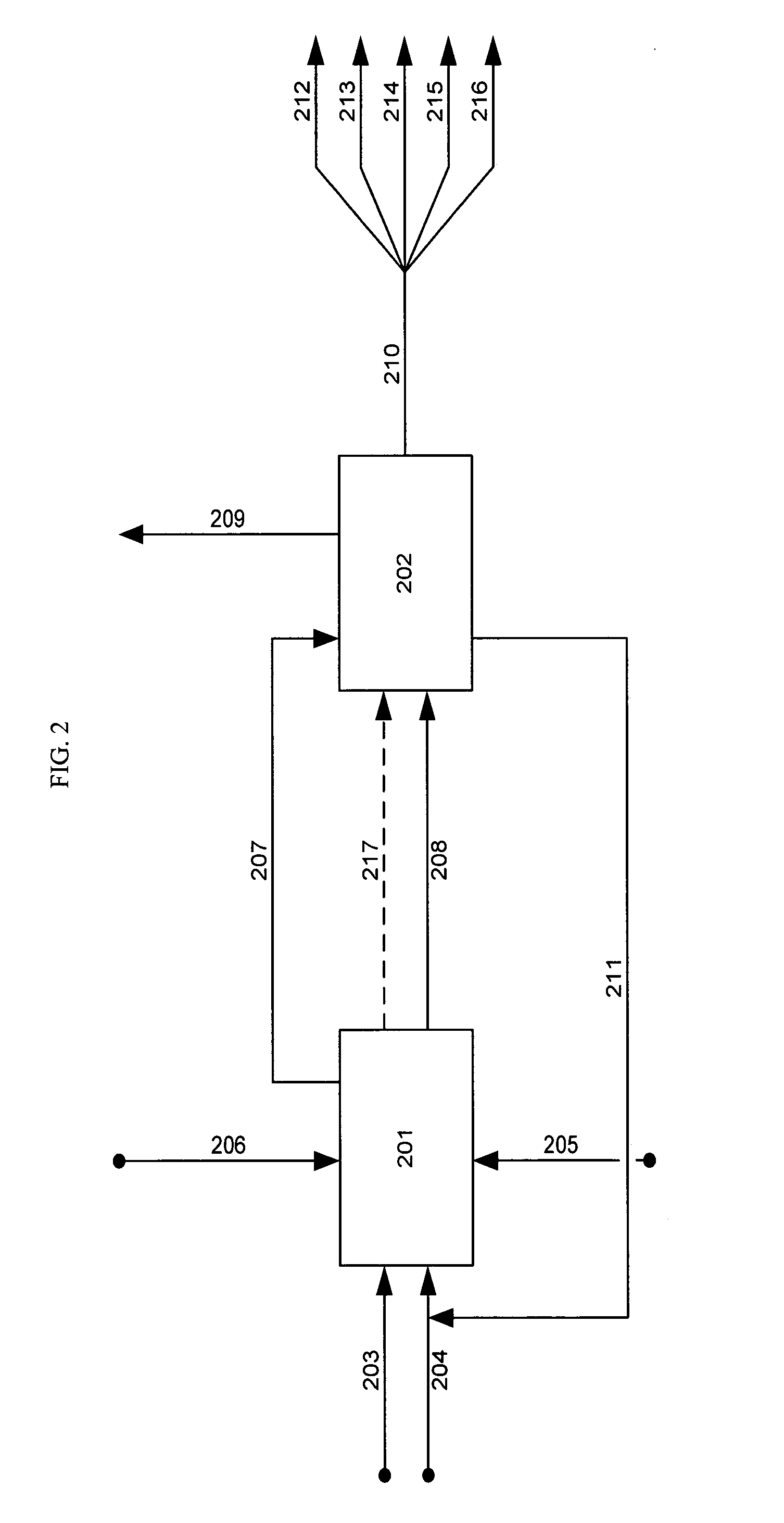

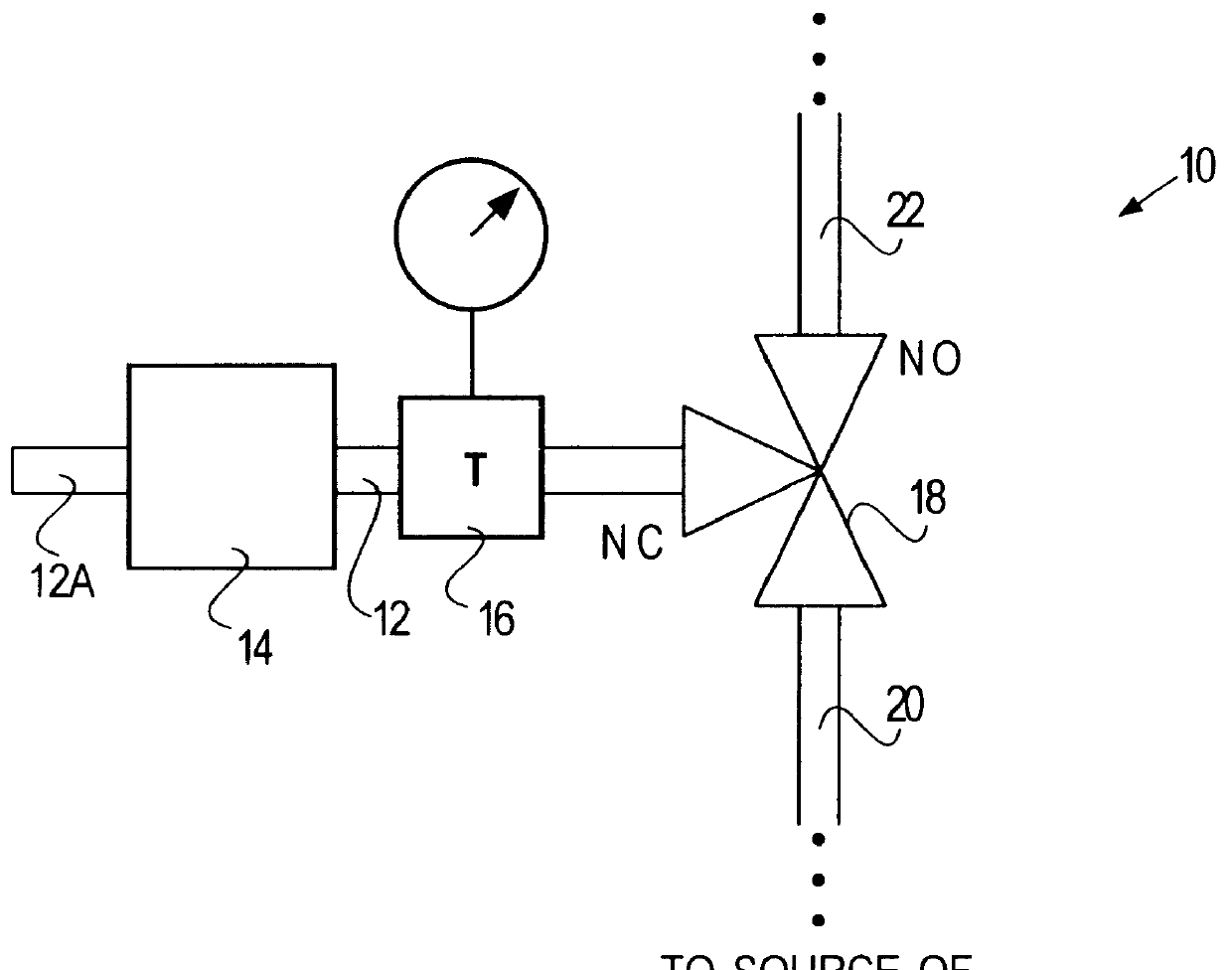

Control scheme for enhanced filtered water systems

ActiveUS20050133420A1Liquid separation auxillary apparatusPower operated devicesControl systemEnvironmental engineering

An enhancement control system that can be used as part of an enhanced water system to produce enhanced filtered water is described. The enhancement control system includes at least one enhancement delivery element that can dispense an enhancement(s) into filtered water in response to an enhancement delivery instruction(s). The enhancement control system can also include an input element that can enable transmittal of the enhancement delivery instruction(s) from a user to the enhancement delivery element(s). The control system can also include a memory element that can store information about the user and the user's preferences and information about the enhanced water system. The control system can also include a communication element that can provide information from the enhanced water system to the user. The control system can also include a monitor element that can gather data from outside the enhanced water system, such as user health information or environmental information, and provide the data to the enhanced water system. In some embodiments, a control logic element can be used to coordinate and control operation of the elements of the enhanced water system.

Owner:THE CLOROX CO

Popular searches

Reverse osmosis Liquid separation Water/sewage treatment by flocculation/precipitation Contaminated groundwater/leachate treatment Water/sewage treatment by oxidation Fatty/oily/floating substances removal devices Water/sewage treatment by irradiation Water treatment compounds Water/sewage treatment by ion-exchange Water/sewage treatment bu osmosis/dialysis

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com