Patents

Literature

613 results about "Supercritical water oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

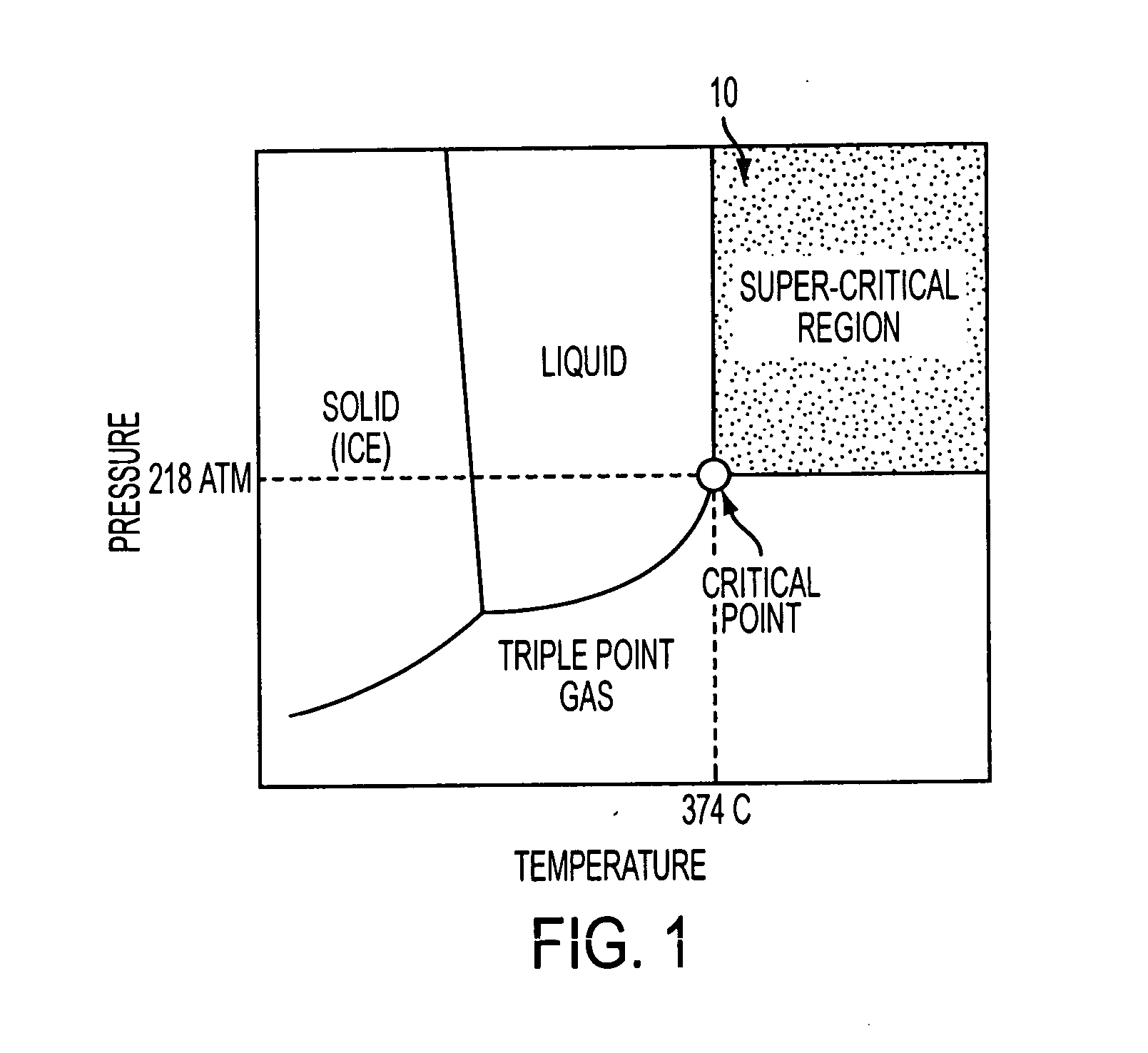

Supercritical water oxidation or SCWO is a process that occurs in water at temperatures and pressures above a mixture's thermodynamic critical point. Under these conditions water becomes a fluid with unique properties that can be used to advantage in the destruction of hazardous wastes such as PCBs. The fluid has a density between that of water vapor and liquid at standard conditions, and exhibits high gas-like diffusion rates along with high liquid-like collision rates. In addition, the behavior of water as a solvent is altered (in comparison to that of subcritical liquid water) - it behaves much less like a polar solvent. As a result, the solubility behavior is "reversed" so that chlorinated hydrocarbons become soluble in the water, allowing single-phase reaction of aqueous waste with a dissolved oxidizer. The reversed solubility also causes salts to precipitate out of solution, meaning they can be treated using conventional methods for solid-waste residuals. Efficient oxidation reactions occur at low temperature (400-650 °C) with reduced NOx production.

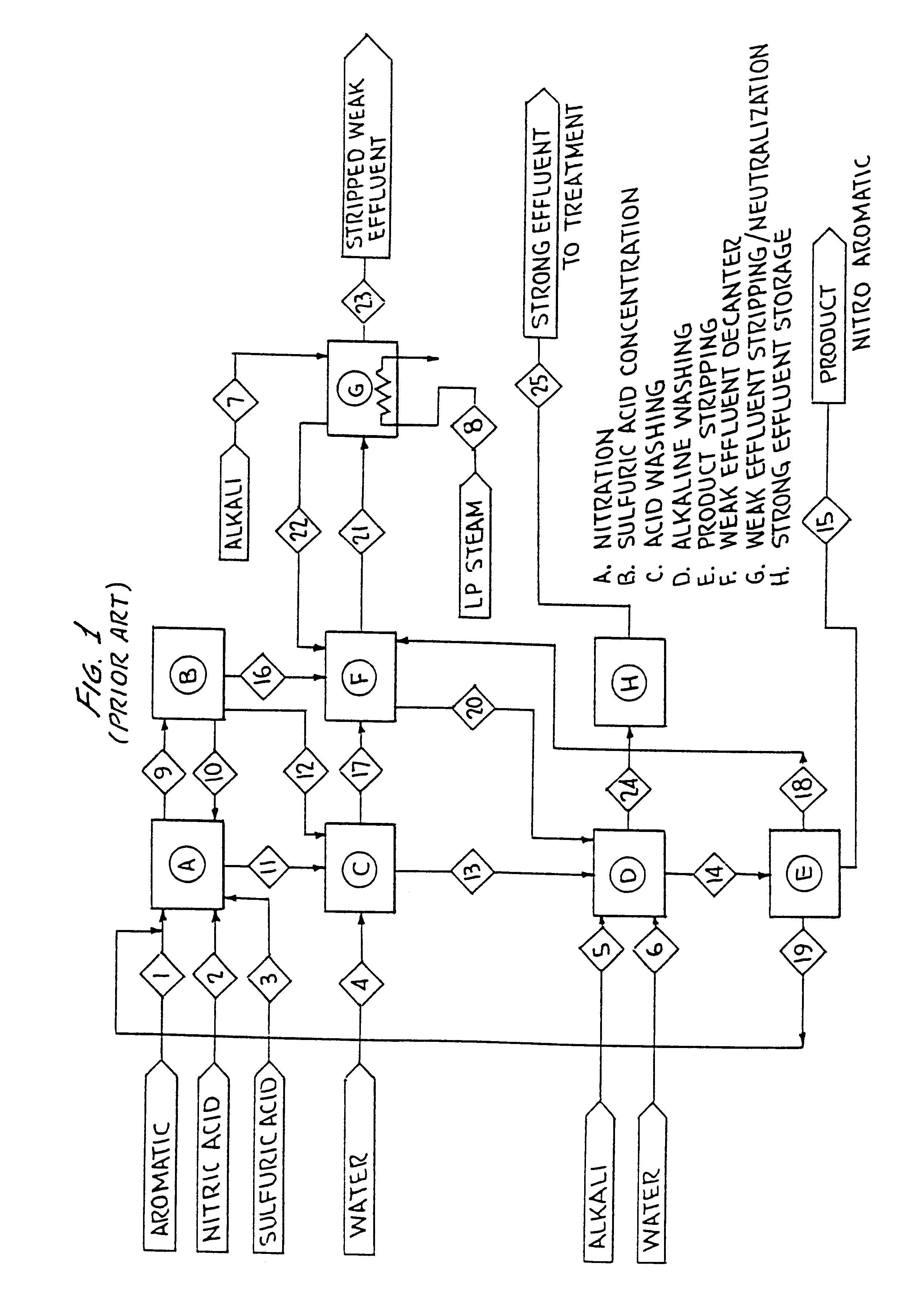

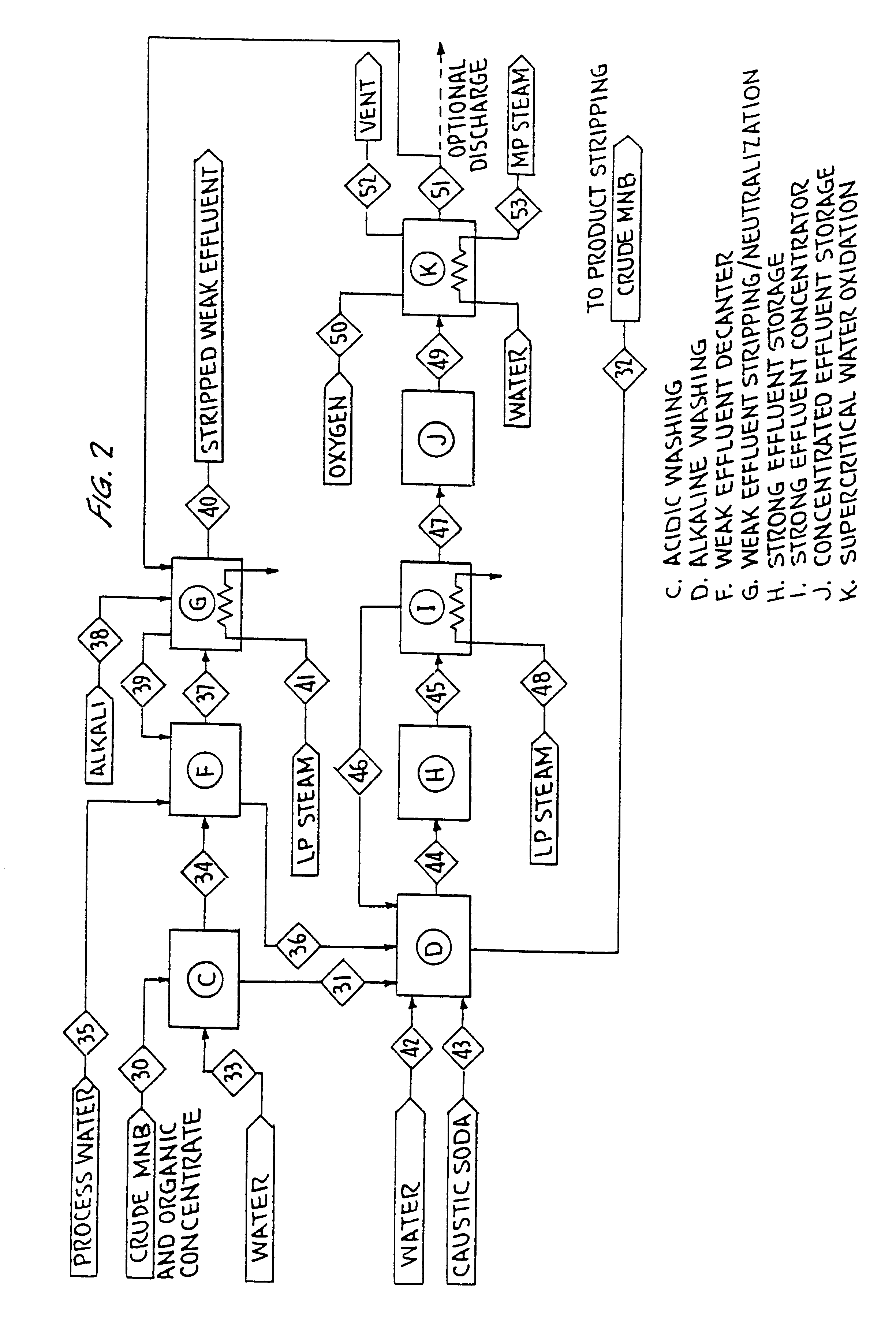

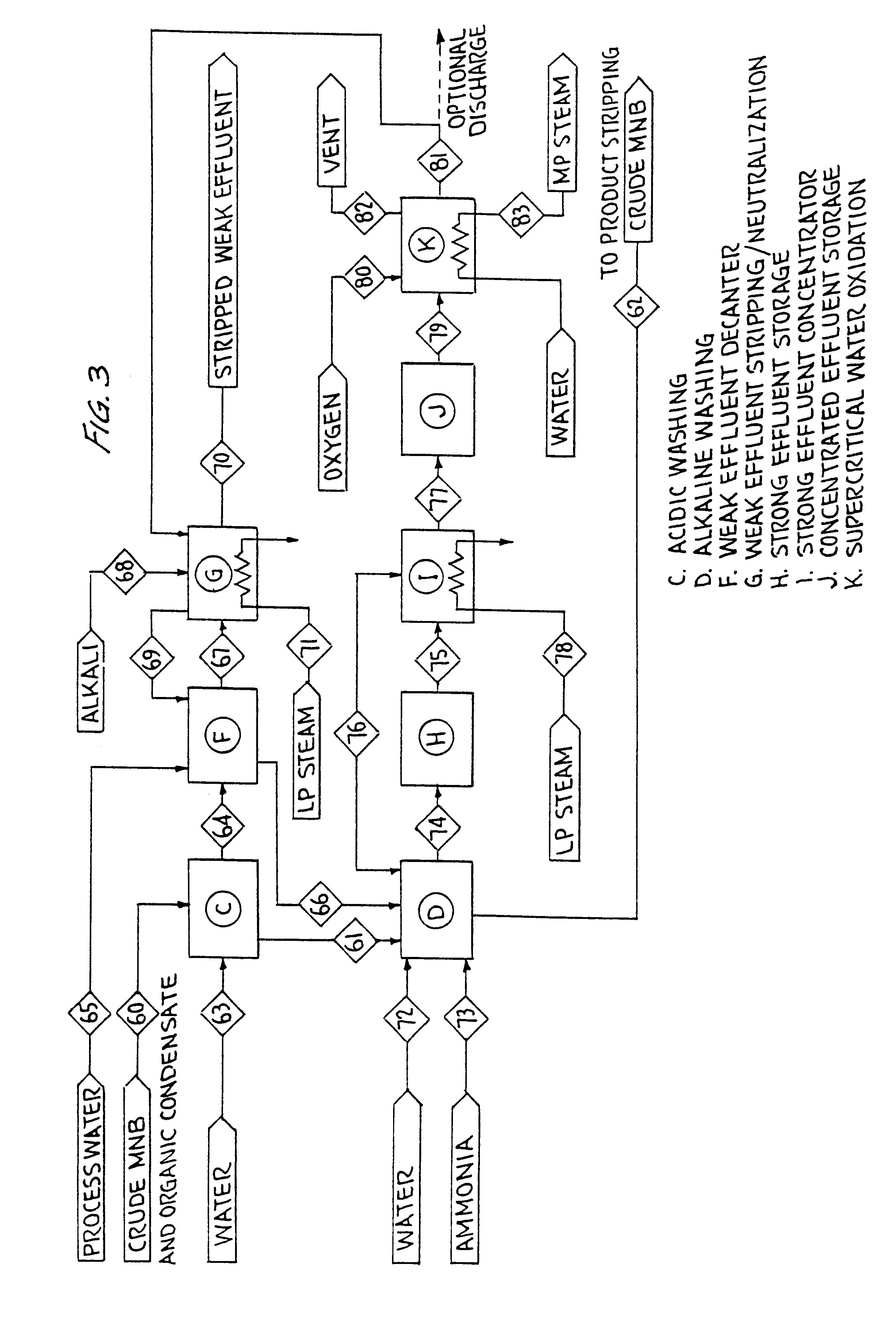

Integrated effluent treatment process for nitroaromatic manufacture

InactiveUS6288289B1Highly destructiveReduce consumptionOrganic chemistrySludge treatment by oxidationWash waterSupercritical water oxidation

An integrated process for treating alkaline wash water effluent from nitroaromatic manufacture, principally containing nitro-hydroxy-aromatic compounds is described. The integrated process concentrates the alkaline wash water to recover chemicals and water prior to treating the concentrate through supercritical water oxidation. The supercritical water oxidation step consists of treating the concentrate in the presence of an oxygen source at conditions, which are supercritical for water to cause a substantial portion of the organic component of the concentrate to oxidize. The product effluent includes a gaseous component and a clean water component, and in the event that insoluble ash is formed, an ash component. The new integrated process results in reduced chemical and water consumption compared to existing processes. In addition, the treated wash water effluent can be recycled to process or directly discharged.

Owner:NORAM INT

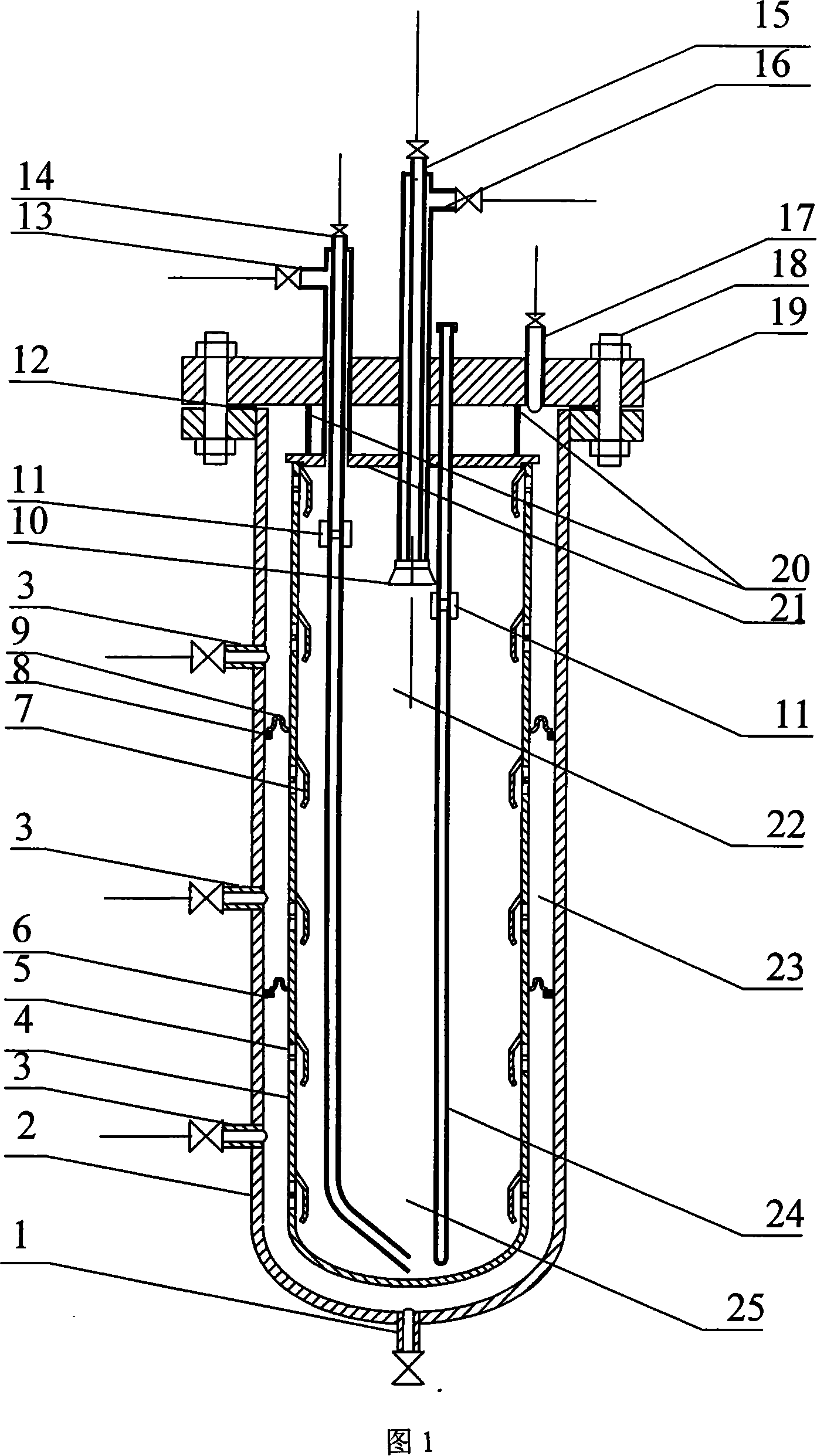

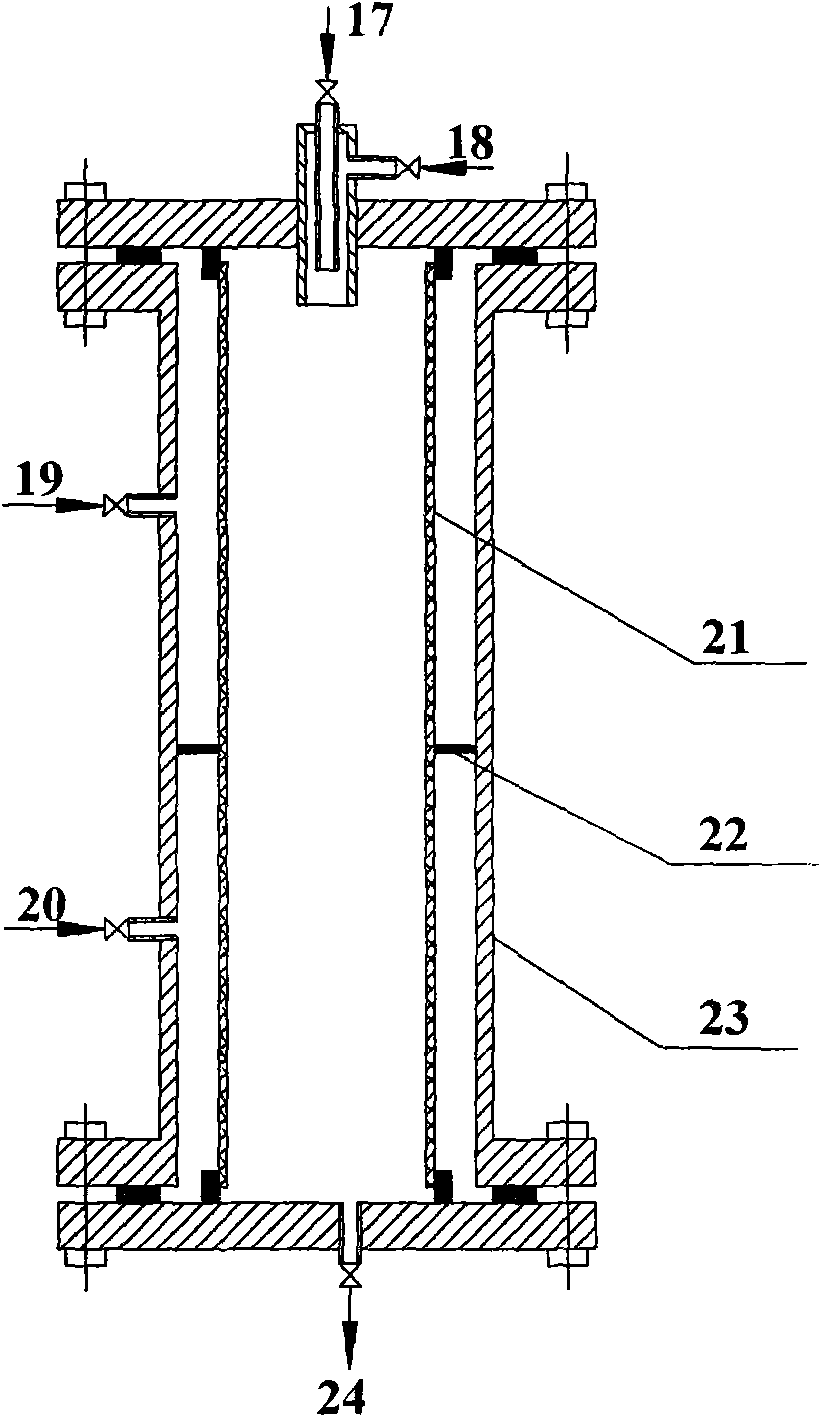

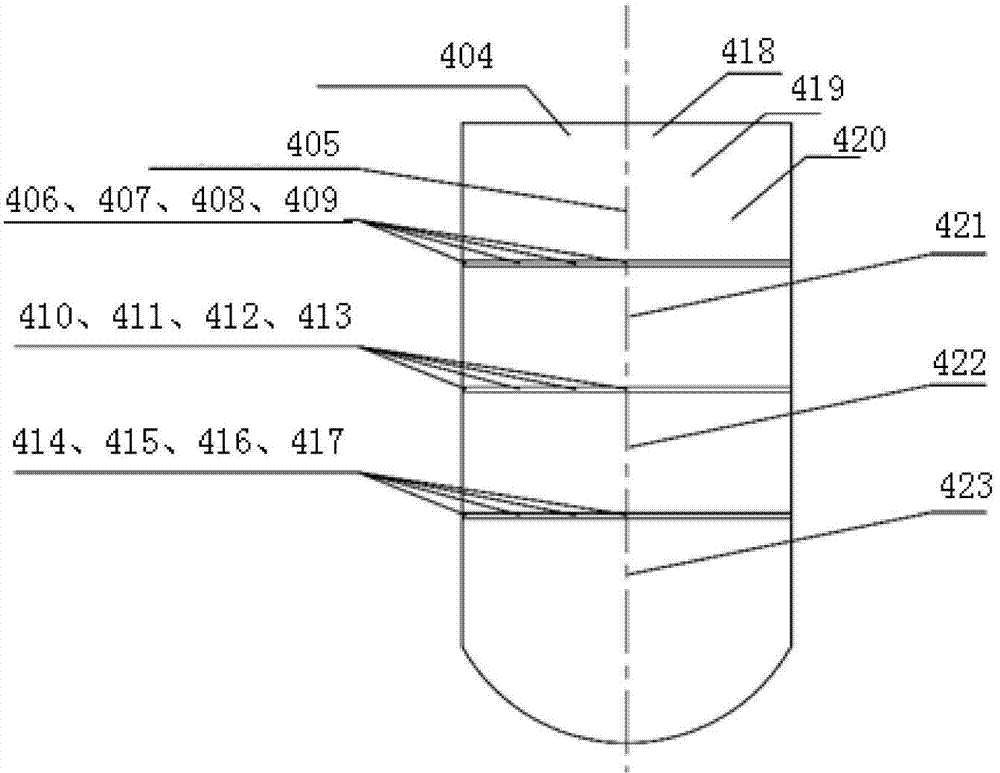

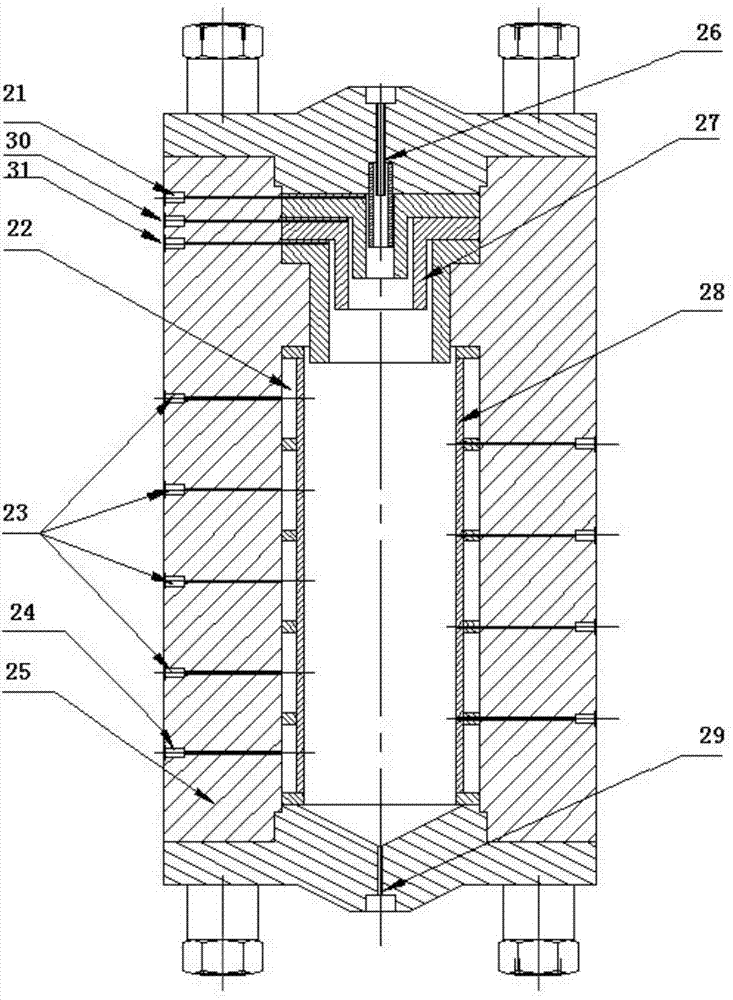

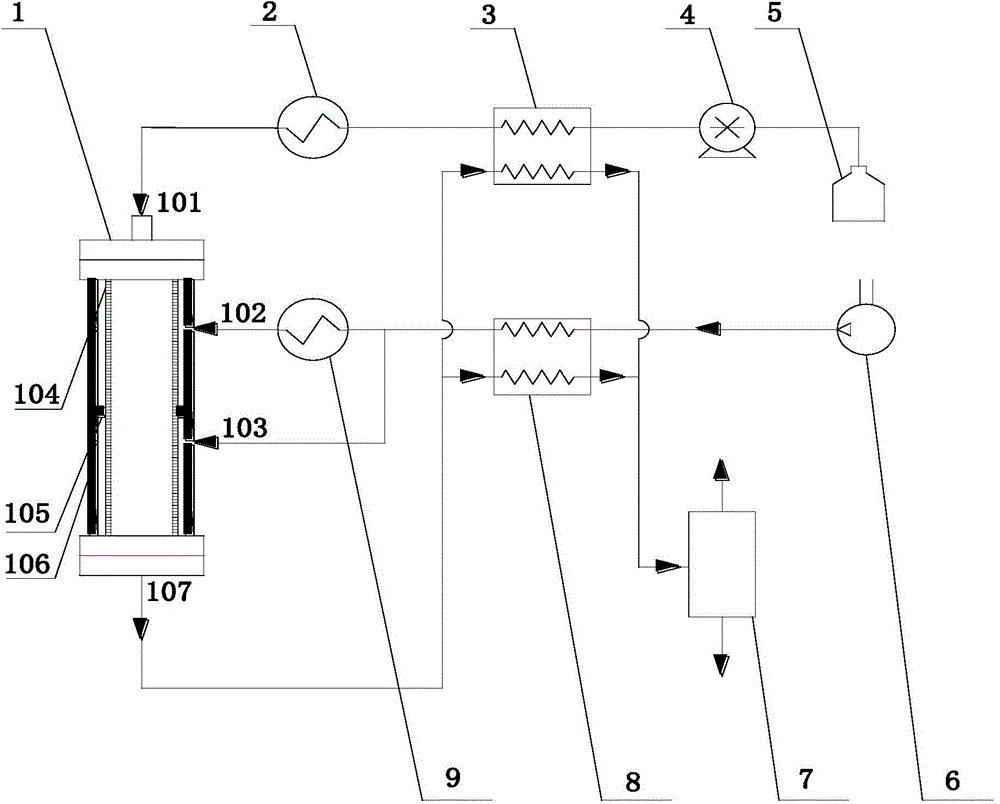

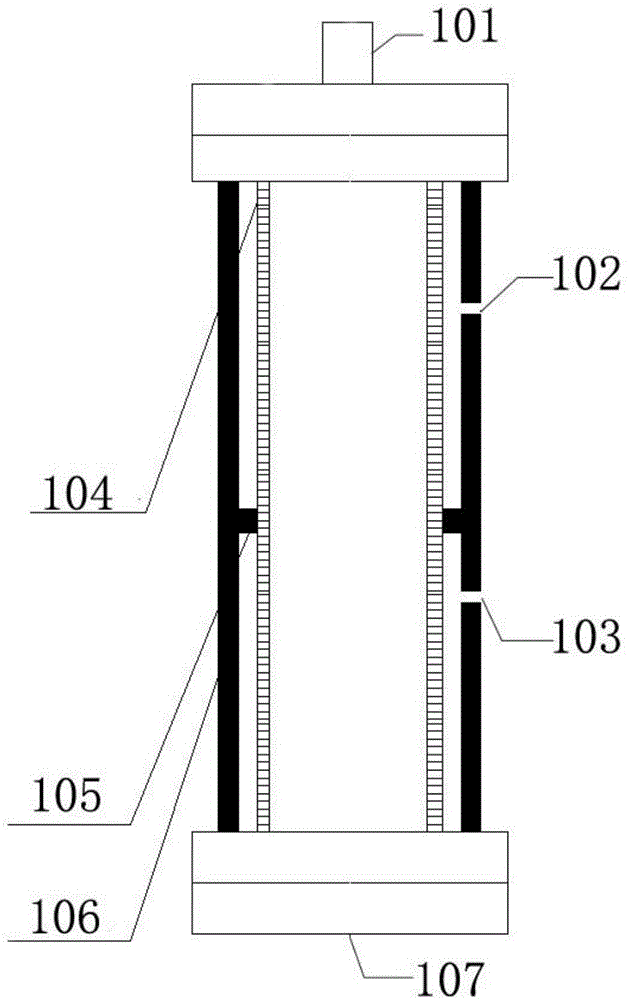

Corrosion-resisting clogging-proof overcritical water oxidization reactor

InactiveCN101164912ALarge choiceAvoid corrosionWater/sewage treatment by oxidationCentral line placementOxygen

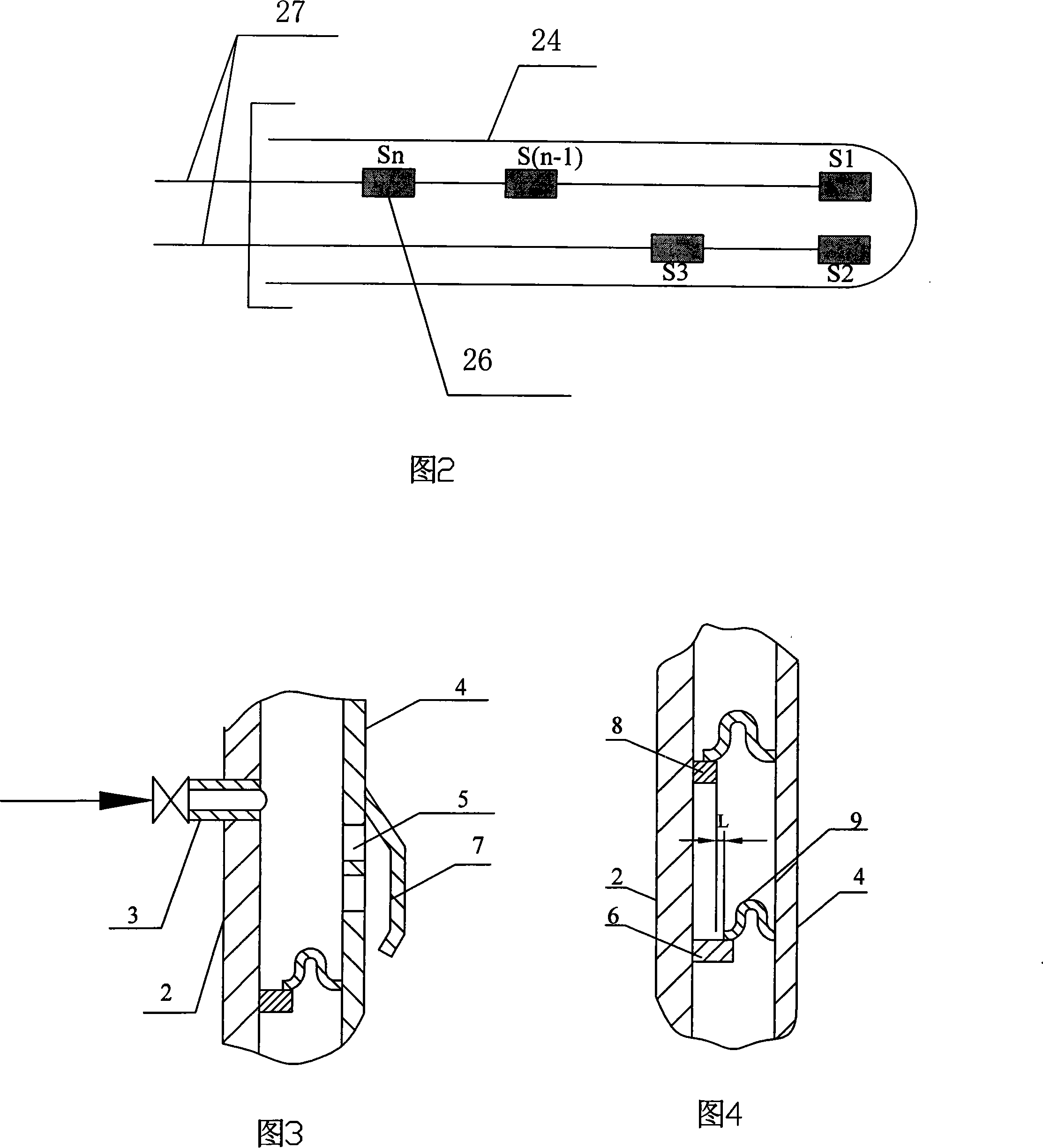

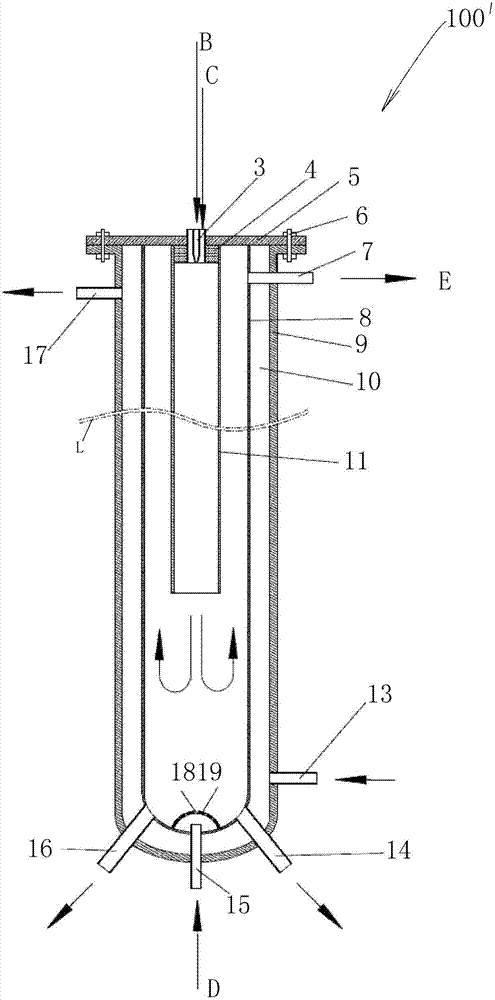

This invention relates to a corrosion-resistance and blocking-resistance supercritical water oxidation reactor. It is composed of: a casing, a water inlet, a jacketed supporting ring and a spring ring, an annular water entrance and a water dash plate, inner cylinder of the reactor, raw material feeder, nozzle, an outlet of reactant and multi-point optical fiber online thermo-detector. In said reactor, there are a process water jacket area, supercritical water oxidation area, a sub-critical water area for dissolving inorganic salts on the bottom of the inner cylinder of the reactor. The process water jacket area is divided into two or more than two layer area by the supporting ring and the spring ring. The water, after removing oxygen and removing salts, passes through porous-wall structure enters the reaction area and forming a protective water membrance over the inner wall of the reactor. The temperature sensor and optical fiber are placed in a sleeve which is placed near the central line of the reactor. Advantages are: easy to be maintained, safety operation.

Owner:SHANDONG UNIV

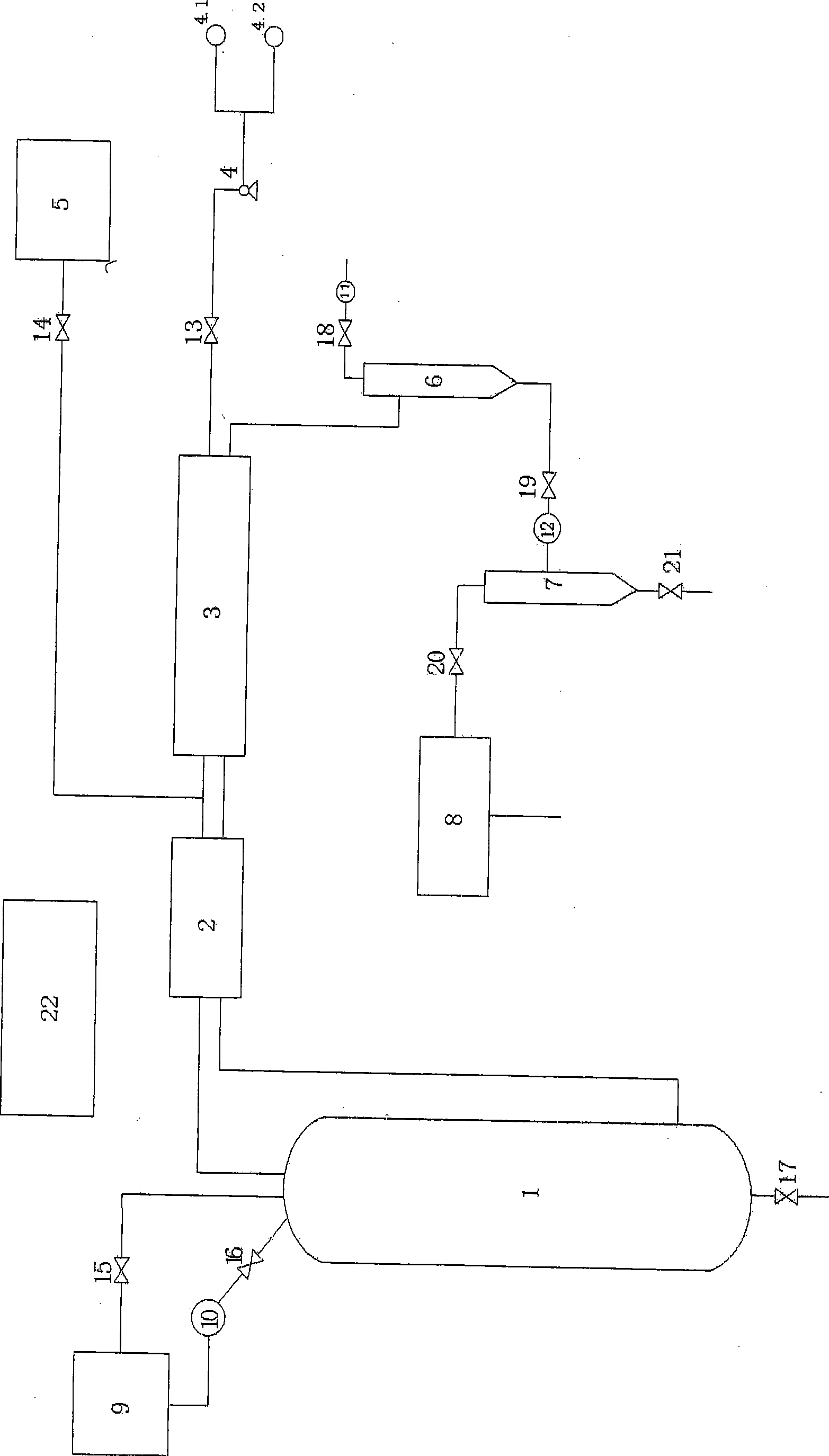

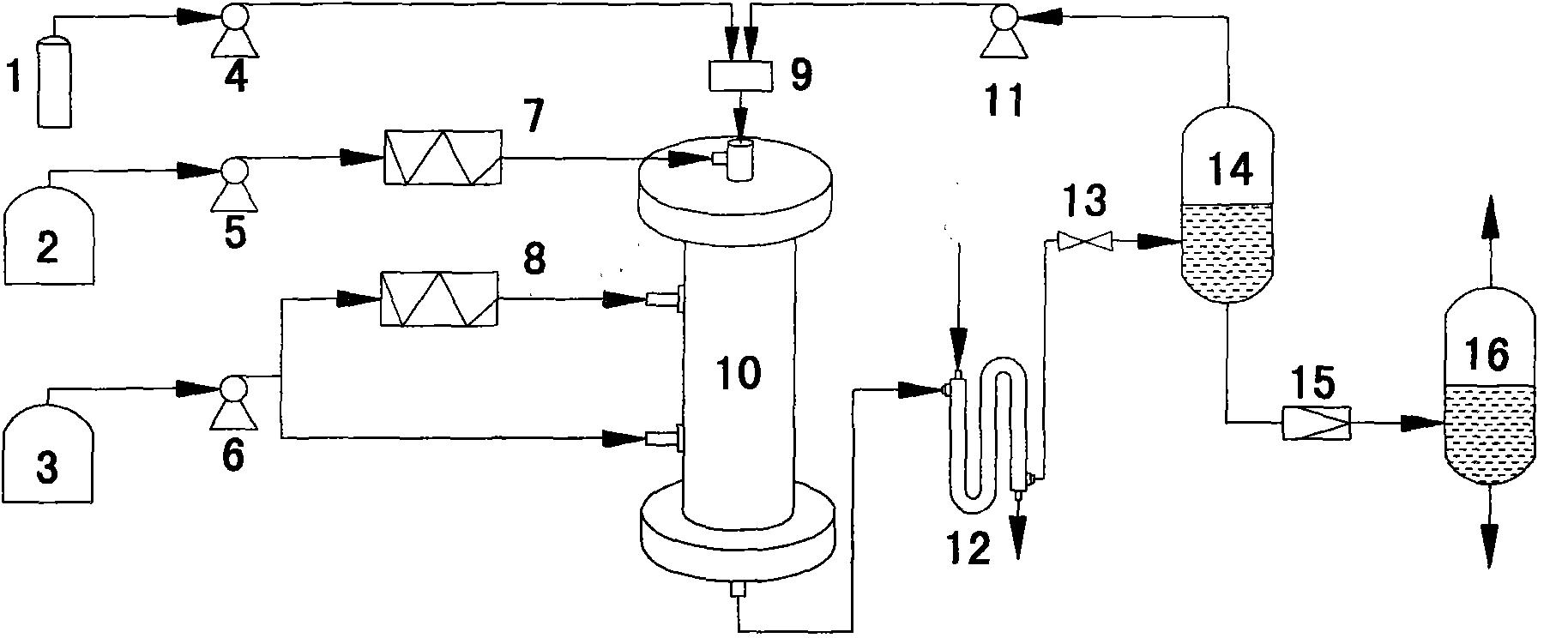

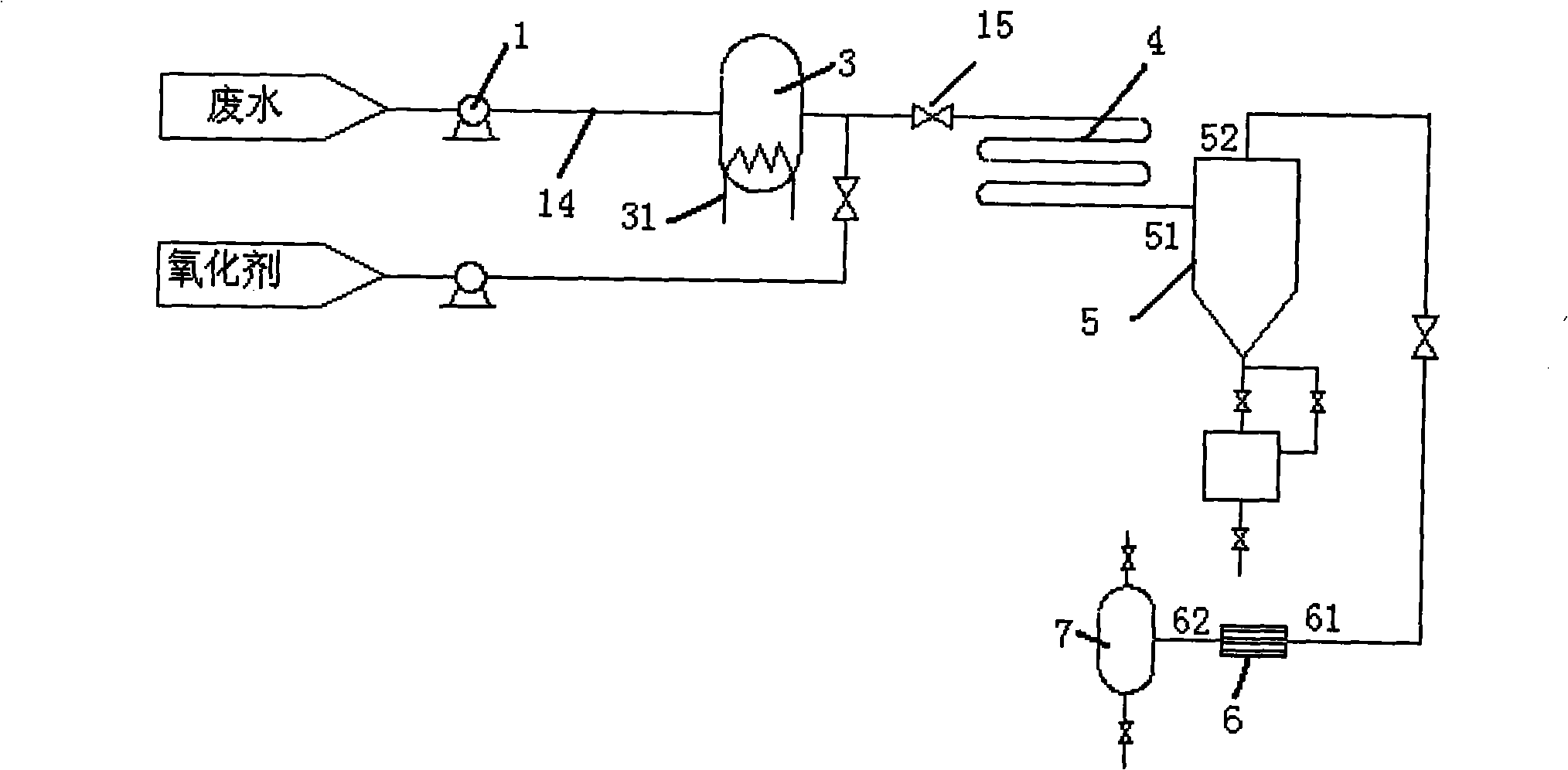

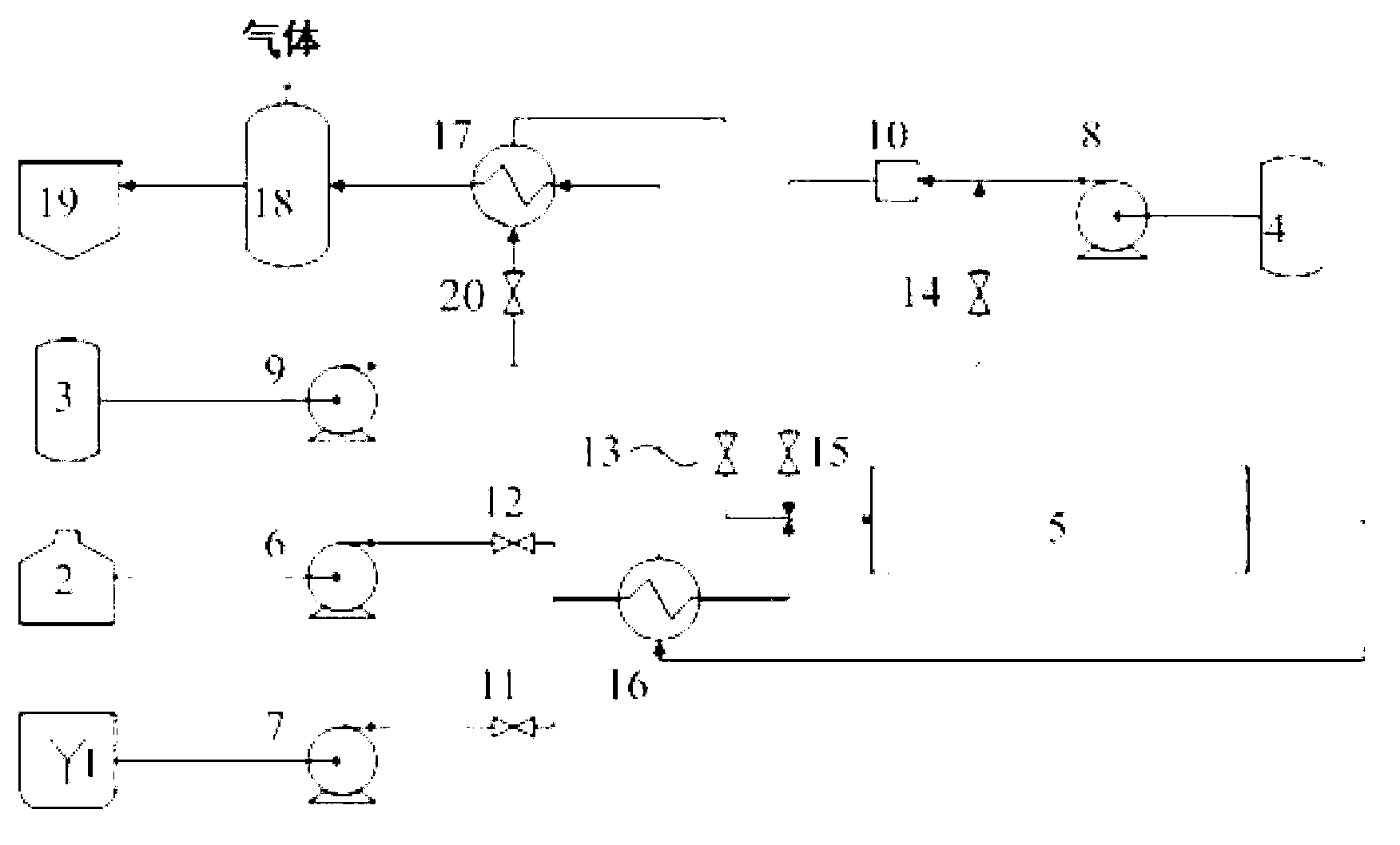

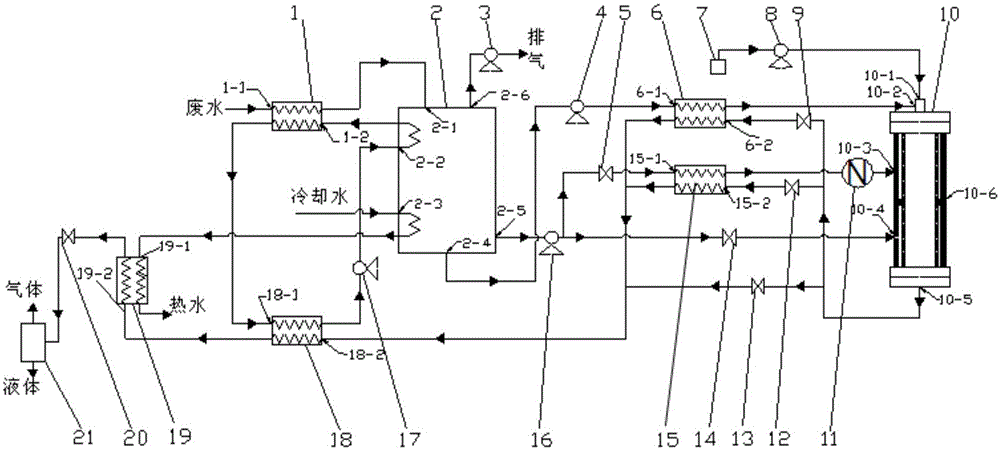

Method and device for oxidizing and treating sewage or sludge containing organic substances by supercritical water

InactiveCN101544419AGuaranteed uptimeReduce construction costsSludge treatment by oxidationByproduct vaporizationCombustionSludge

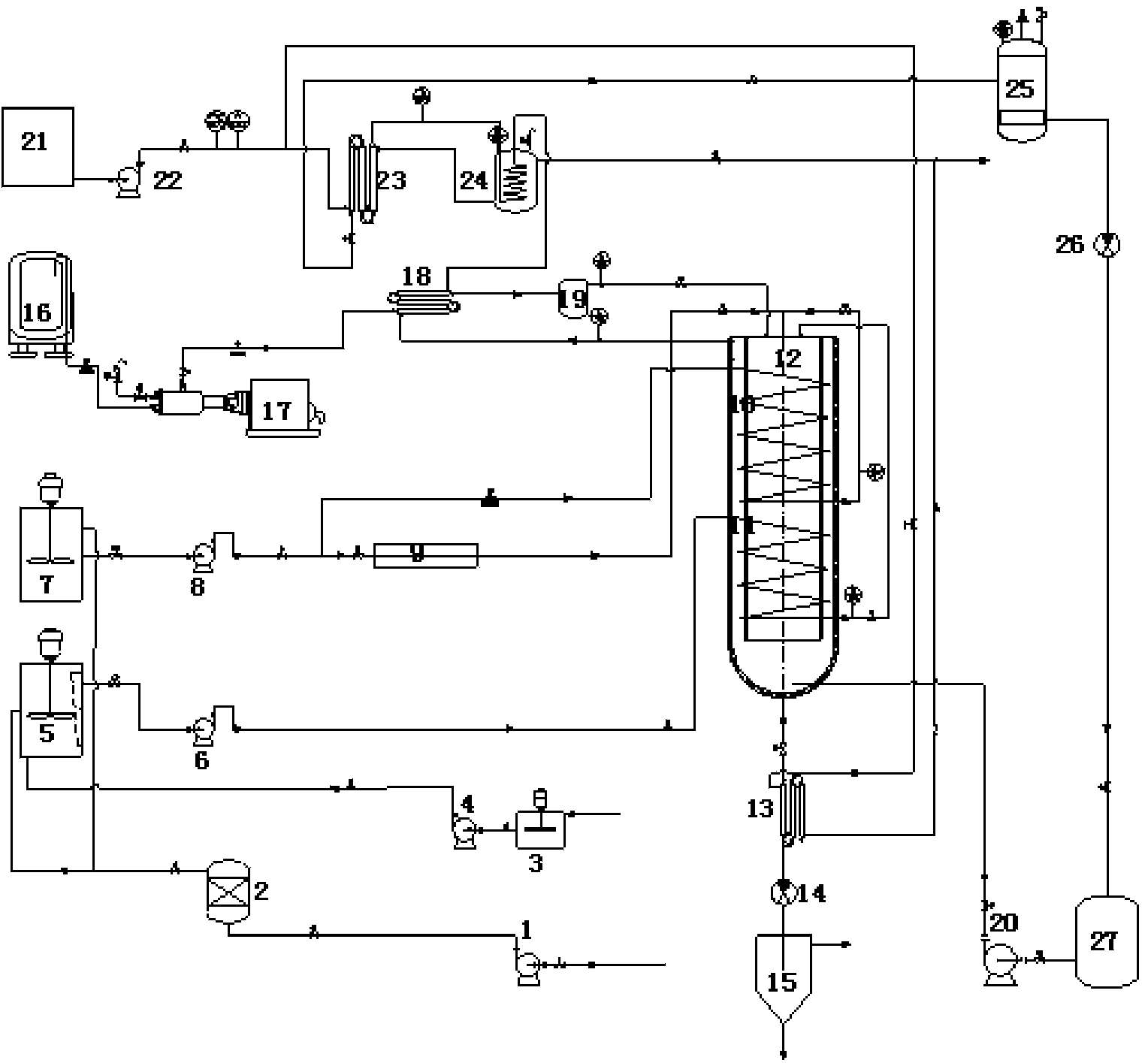

The invention relates to a method and a device for oxidizing and treating sewage or sludge containing organic substances by supercritical water. The method adopts a combustion reaction furnace, and is characterized in that substance flow of the sewage or the sludge containing the organic substances and oxidant (such as oxygen or hydrogen peroxide and the like) are preheated by a heat exchange device respectively and then enter the combustion reaction furnace, the sewage or the sludge containing the organic substances is oxidized and treated under a supercritical state, the treated substance flow is cooled by the heat exchange device again, then residual gas in the substance flow is separated by adopting a gas-liquid separator, and the lower part of the combustion reaction furnace discharges salt slag through a slag discharging hole and a valve. The method has the advantages of reasonable and practical process, energy conservation and low operation cost.

Owner:楼龙春

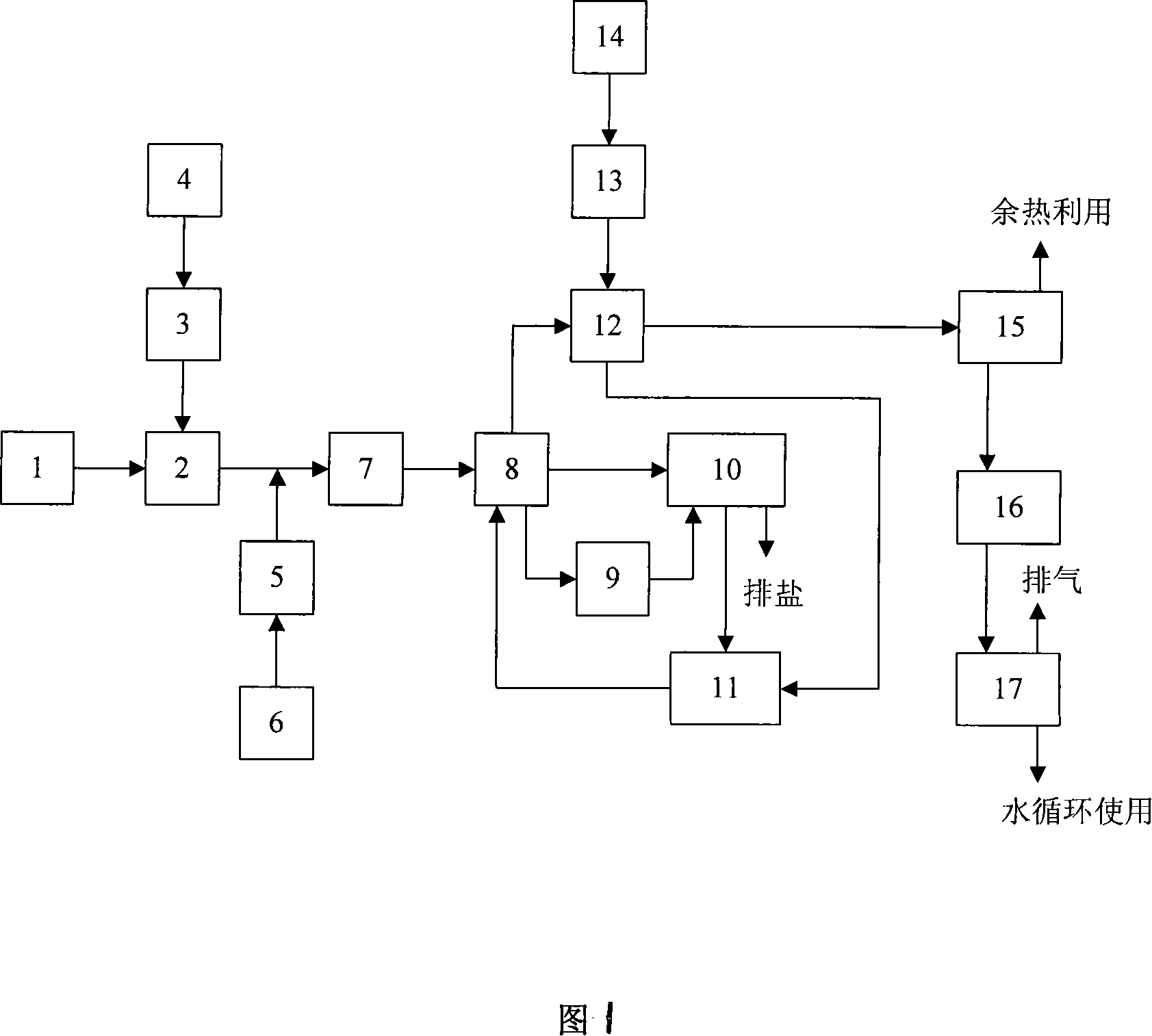

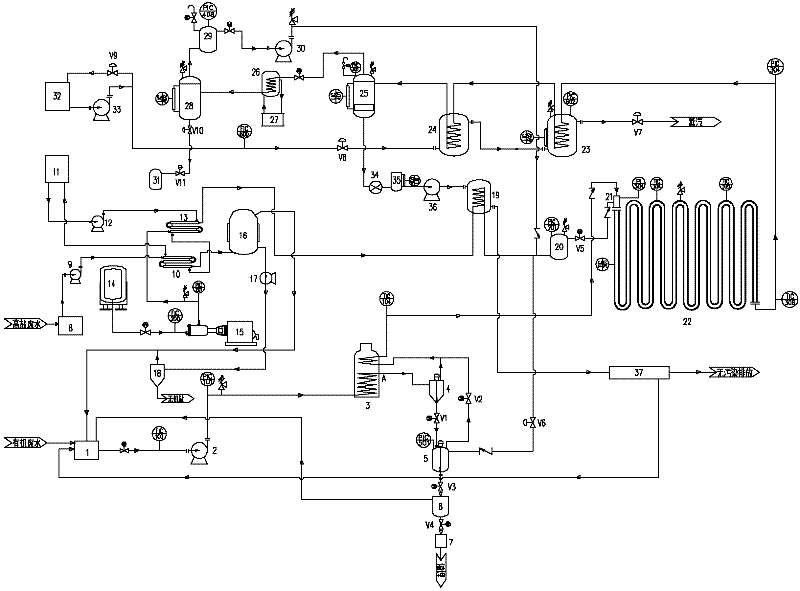

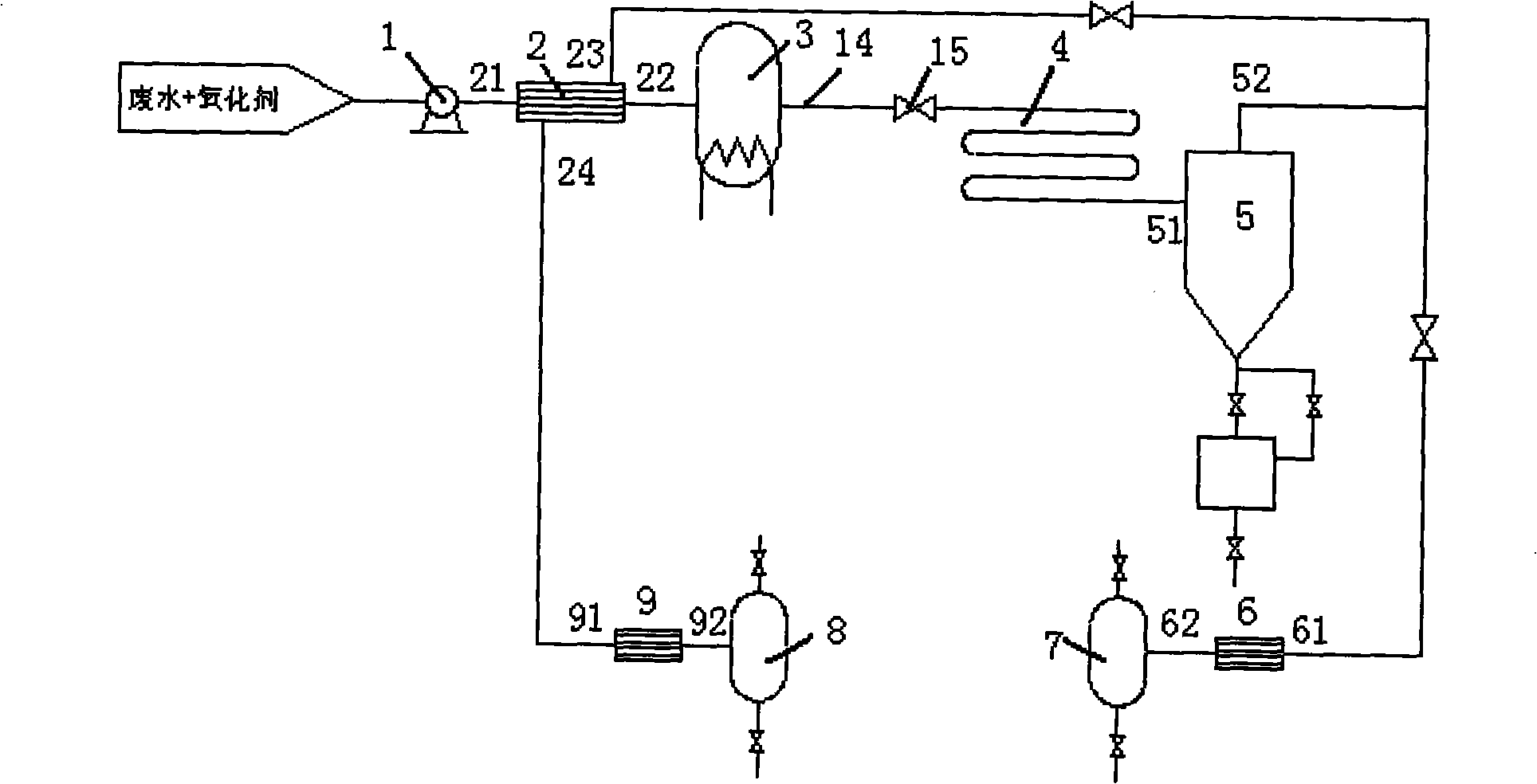

Technique for processing coking wastewater or organic wastewater by supercritical water oxidization technique

InactiveCN101209883AEmission reductionEfficient removalScale removal and water softeningMultistage water/sewage treatmentWater cyclingSolid particle

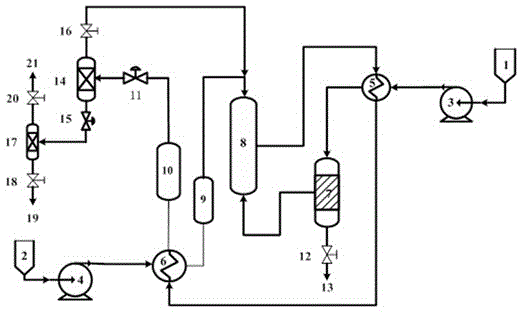

The invention relates to a process by adopting supercritical water oxidation technology to treat coking wastewater or organic wastewater. The invention is that: coking wastewater or organic wastewater is pretreated to obtain wastewater without solid granules; the wastewater is heated to 380-450 DEG C with a first interchanger and / or a supercritical boiler, and then enters demineralizing equipment to remove the salt in the wastewater by taking advantage of the property that supercritical inorganic matter is indissoluble; the wastewater after desalting is put in a reaction kettle to generate autothermal reaction with an heated and pressurized oxidant to obtain high-temperature gas-liquid mixture with higher temperature; the high-temperature gas-liquid mixture enters the first interchanger and acts as thermal medium to exchange heat with new coming coking wastewater or organic wastewater and then goes through a secondary interchanger to enter a cooler and is cooled to normal temperature, after pressure thereof is adjusted by a pressure regulation device, the high-temperature gas-liquid mixture enters a gas-liquid separator for separation, and then the air is discharged, while the liquid, namely the treated water is recycled. The organic contamination and oxidant are all dissolved in the wastewater; oxidation reaction is generated in homogeneous phase, in short reaction time, oxygenolysis of organic contamination is carried out quickly.

Owner:北京能泰高科环保技术有限公司

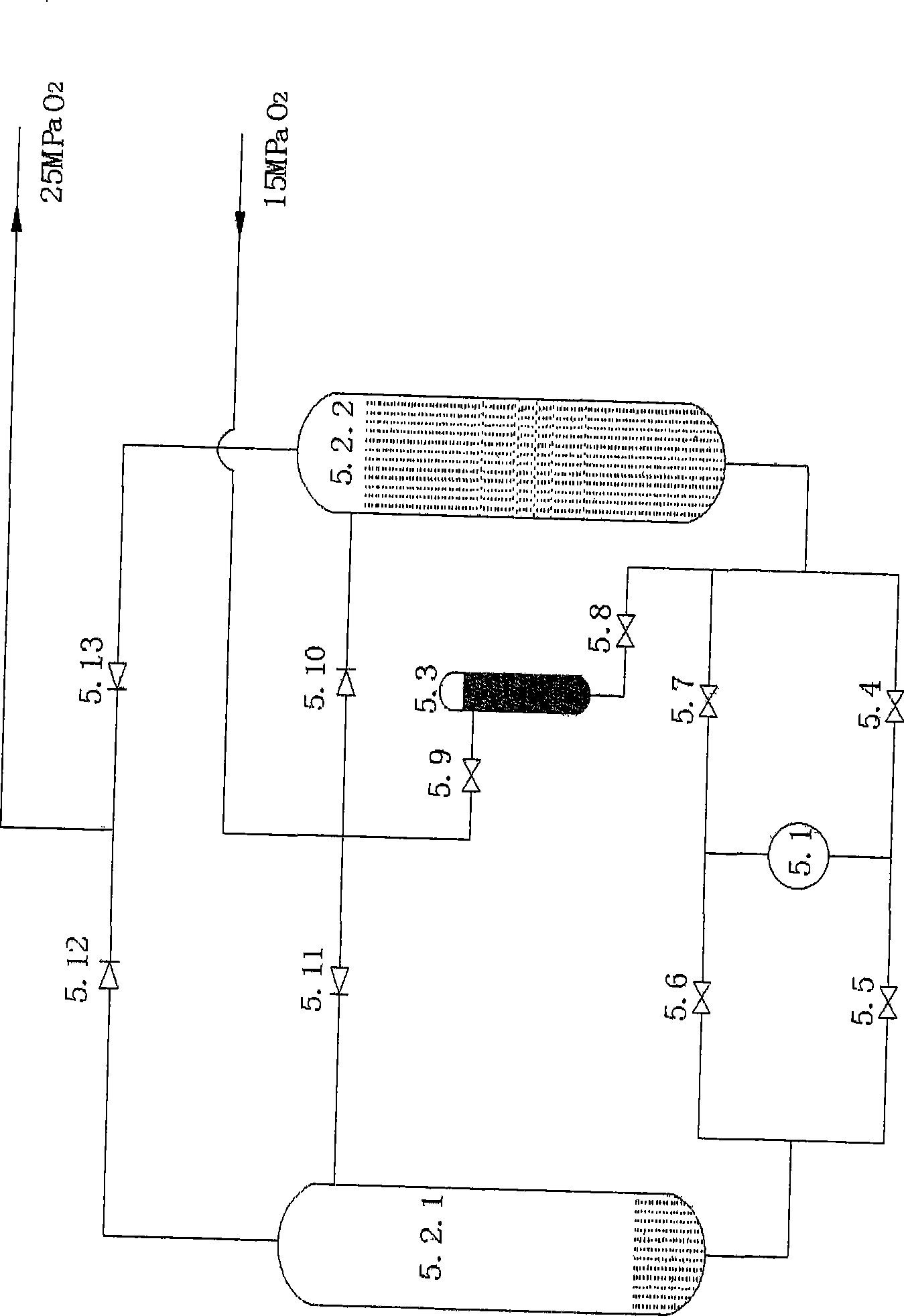

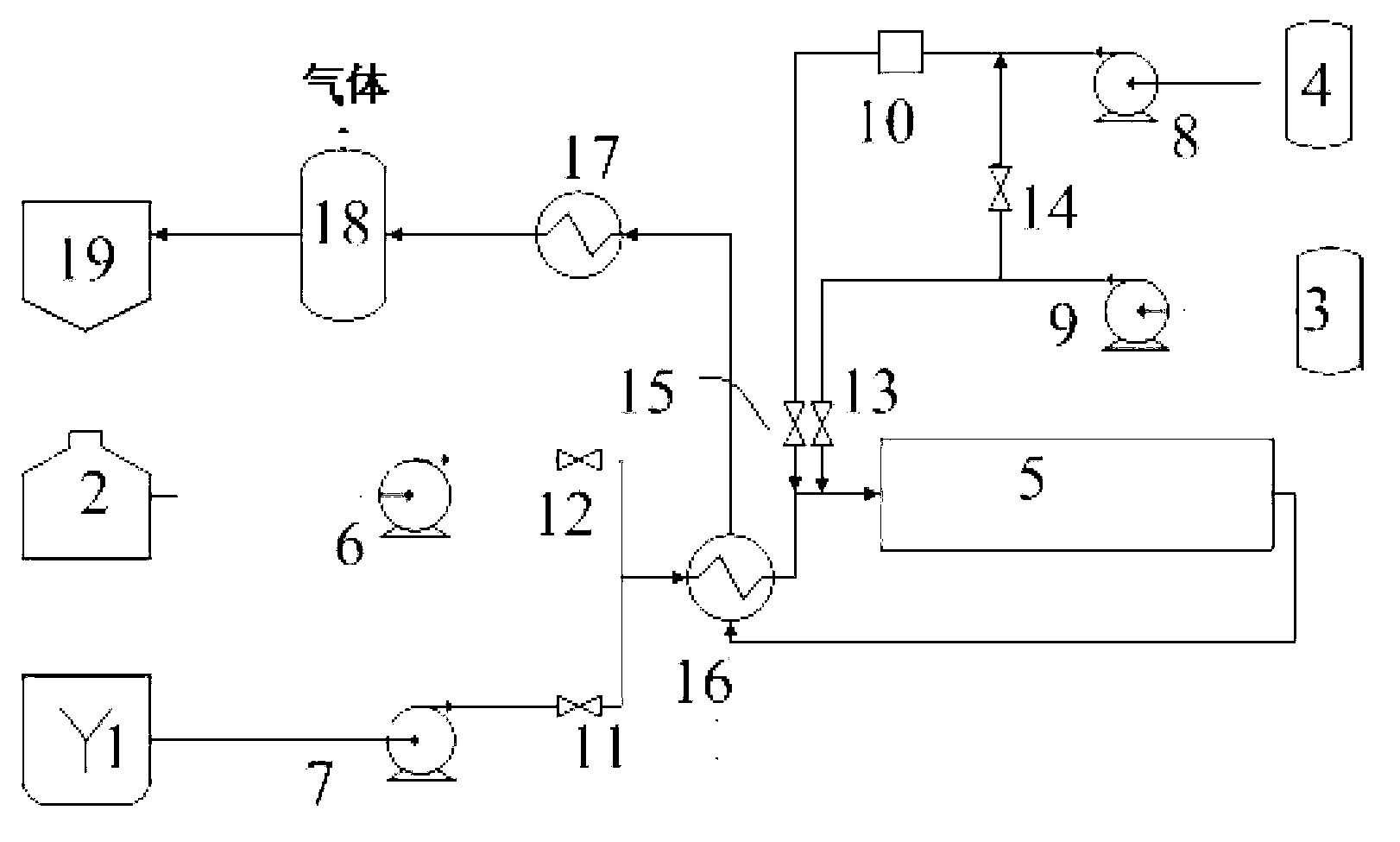

Supercritical water oxidation reaction system for obtaining heat supplemented by auxiliary fuel

ActiveCN102190362ARapid coolingPrevent salt depositsSludge treatmentWater contaminantsSolubilityWastewater

The invention discloses a supercritical water oxidation reaction system for obtaining the heat supplemented by auxiliary fuel. The supercritical water oxidation reaction system comprises a reactor, a material device, an oxidant device, a desalting device, a fuel supplementing device and a cooling water device, wherein the material device is communicated with a material inlet on a reactor end cover; the oxidant device is communicated with an oxidant inlet on the reactor end cover; and the desalting device is communicated with a solid salt outlet at the bottom of the reactor. The energy is supplemented to the system by the auxiliary fuel, thereby reducing higher equipment input and operation cost brought by arranging an electric heater; by adopting the single-pass heat return, on the premise of ensuring the effective heat of a recovering system, the complexity of the system is reduced and further the equipment input is reduced and the operating and running stability of the system is improved; and a reasonable desalting scheme is provided for simultaneously desorbing solid salts and soluble salts generated in the reaction process. The supercritical water oxidation reaction system canbe widely applied to the innocent treatment process of high-condensation pollutants, such as organic wastewater / landfill leachate, and the like which are difficult to biochemically degrade.

Owner:XI AN JIAOTONG UNIV

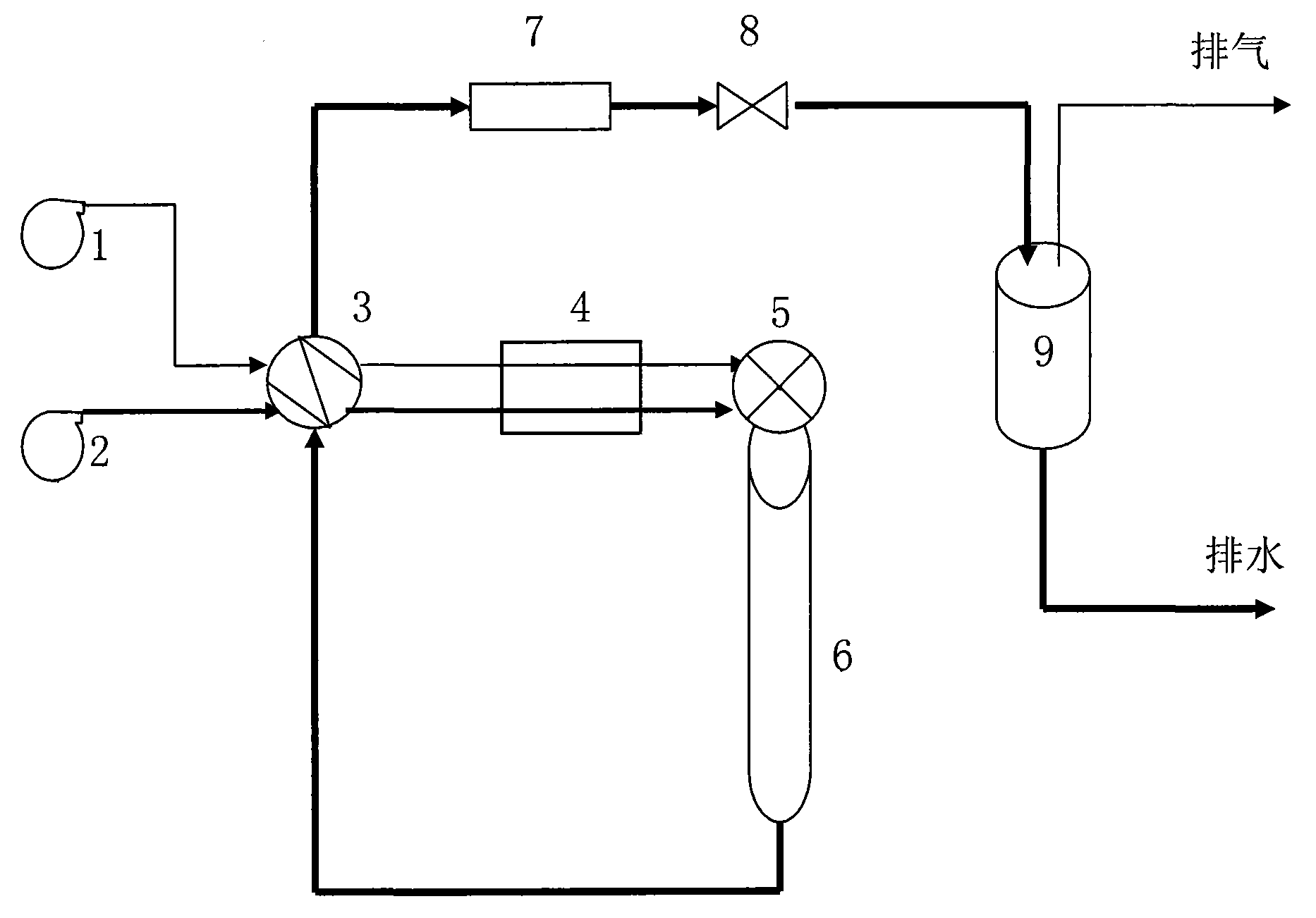

Method for improving oxygen utilization rate of supercritical water oxidation system

InactiveCN101830554AHigh oxygen utilizationLower oxygen peroxide coefficientWater/sewage treatment by oxidationRunning economyOxygen utilization rate

The invention relates to a method for improving oxygen utilization rate of a supercritical water oxidation system. The method comprises the following steps of: injecting excessive oxygen and preheated organic waste liquid from the upper part of an evaporation wall reactor, mixing the oxygen and the organic waste liquid, performing supercritical water oxidation reaction on the mixture, and injecting evaporation water from the lateral surface of the evaporation wall reactor so as to form a supercritical temperature reaction area on the upper part and a sub-critical temperature salt dissolution area on the lower part in the reactor. When the reacted rest oxygen downwards flows to the sub-critical temperature salt dissolution area from the supercritical temperature reaction area, a part of oxygen is separated out and circulated to the supercritical temperature area on the upper part of the reactor to form internal circulation utilization of the oxygen; and the reacted fluid enters a high-pressure gas-liquid separator through condensation and pressure reduction, is dissolved into sub-critical water and carries the oxygen flowing out of the reactor, is separated by the high-pressure gas-liquid separator and then is re-injected to the reactor to form external circulation utilization. The method remarkably reduces the excessive oxygen amount coefficient by improving the utilization rate of the oxygen, and improves the running economy of the supercritical water oxidation system.

Owner:SHANDONG UNIV

Supercritical water oxidation reaction apparatus and method

ActiveCN103708599ALower requirementReduce manufacturing difficultyWater/sewage treatment by oxidationEngineeringHigh pressure

The invention relates to a supercritical water oxidation reaction apparatus, which comprises a case body produced by an overpressure-resistant material; an inner case body produced by a heatproof material, wherein the inner case body is supported in the outer case body, an interval zone is provided between the inner case body and the outer case body, and the interval zone is isolated with cavity fluid; an end cap arranged at the open end of the inner case body and the outer case body in a sealing mode; a reactant nozzle arranged on the end cap and used for injecting an oxidizing agent and a reaction raw material into the inner case body, so that the oxidizing agent and the reaction raw material are subjected to an oxidation reaction near the reactant nozzle to form a reaction zone and generate the reaction products; and a products outlet arranged on the inner case body and extended to the outside part of the outer case body to discharge the reaction products outwardly. A cooling medium is provided in the interval zone. The invention also provides a supercritical water oxidation reaction method. The effective separation is carried out through a high-temperature region and a high-pressure area supported by the wall of a reactor by using the inner case body and the outer case body; the material selection difficulty and manufacture difficulty of the supercritical water oxidation reaction apparatus can be reduced, and the cost is effectively reduced.

Owner:ENN SCI & TECH DEV

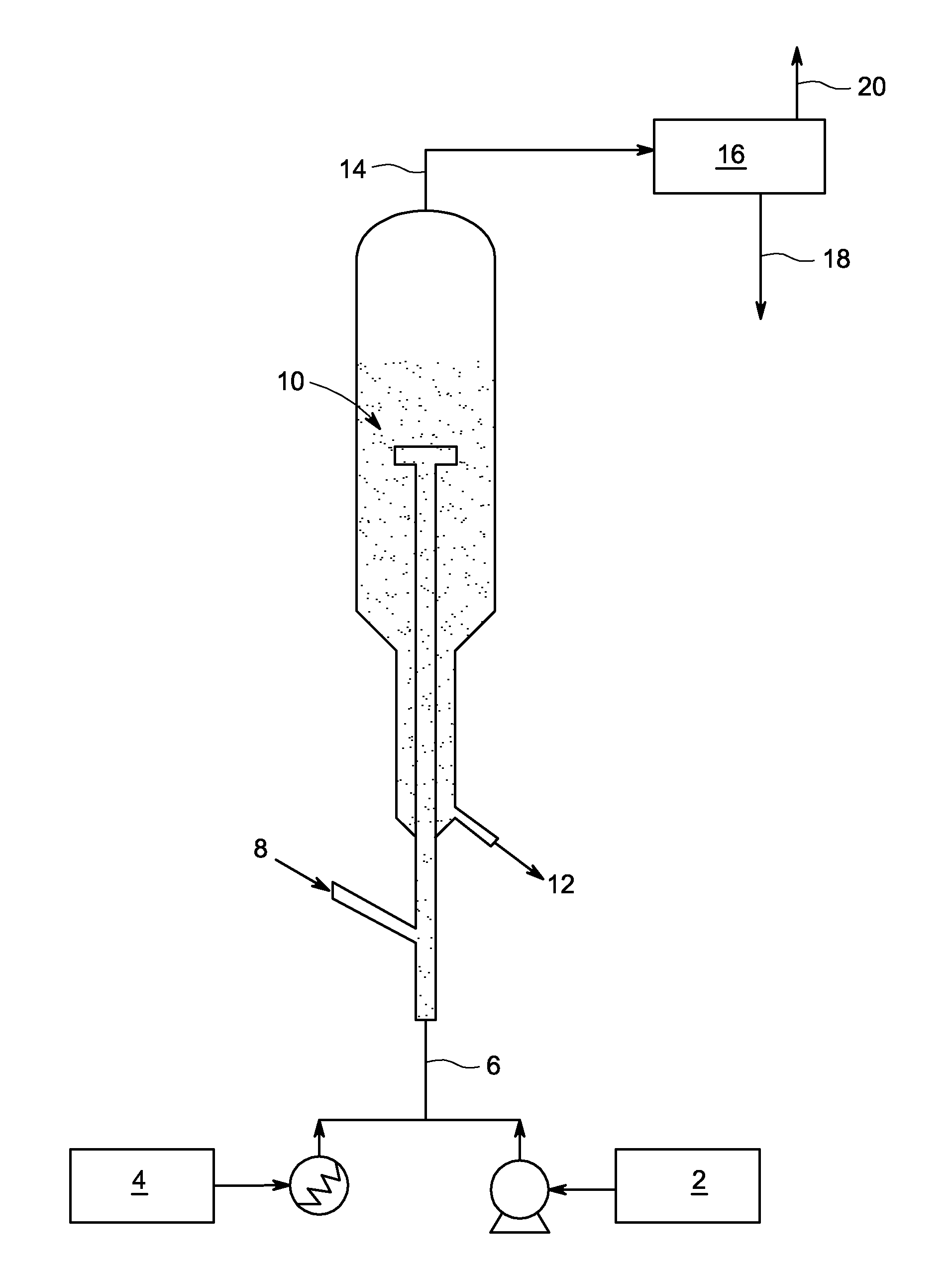

Supercritical water oxidation treatment system for printing and dyeing wastewater and sludge

InactiveCN104030427AReduce volumeReduce secondary pollutionSludge treatment by oxidationWaste water treatment from textile industryLiquid wasteHigh concentration

The invention discloses a supercritical water oxidation treatment system for printing and dyeing wastewater and sludge. The system comprises a concentration pretreatment device, a supercritical water oxidation device, an oxidizing agent supply device and a wastewater recycling system, wherein the concentration pretreatment device comprises a waste liquid storage tank, a nanofiltration membrane concentration module and a printing and dyeing sludge storage pool, the oxidizing agent supply device comprises a liquid oxygen storage tank, a liquid oxygen gasifier and a buffer tank, and the supercritical water oxidization device comprises an auxiliary heating supercritical water oxidization reactor, a methyl alcohol starting preheater, a methyl alcohol preheater and a waste liquid preheater. The system can be used for realizing efficient, clean and harmless treatment of high-concentration printing and dyeing wastewater and sludge at low cost.

Owner:山川丽(苏州)环保科技有限公司

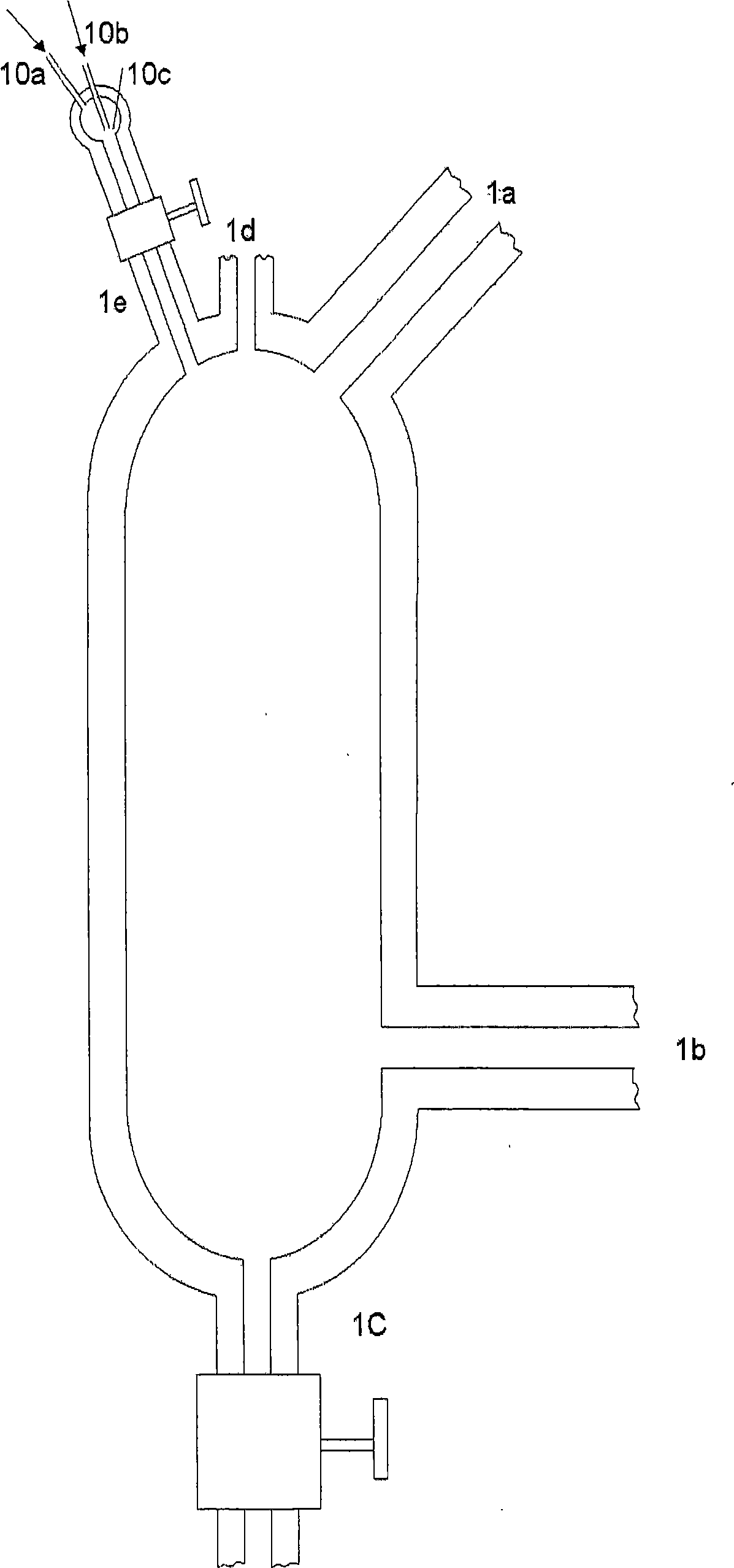

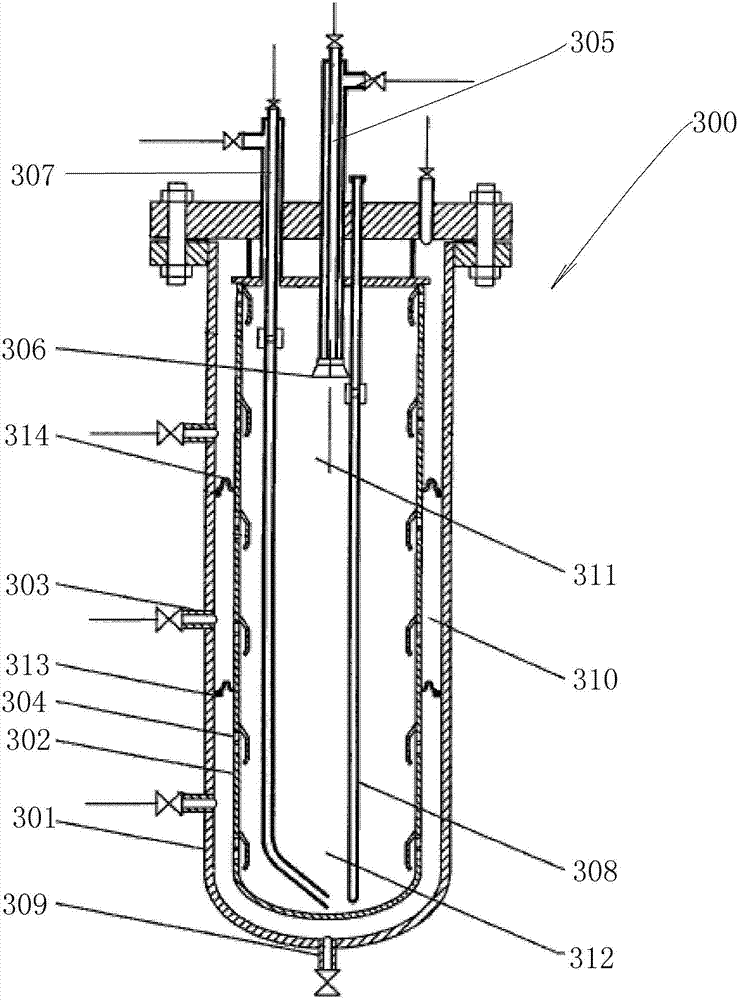

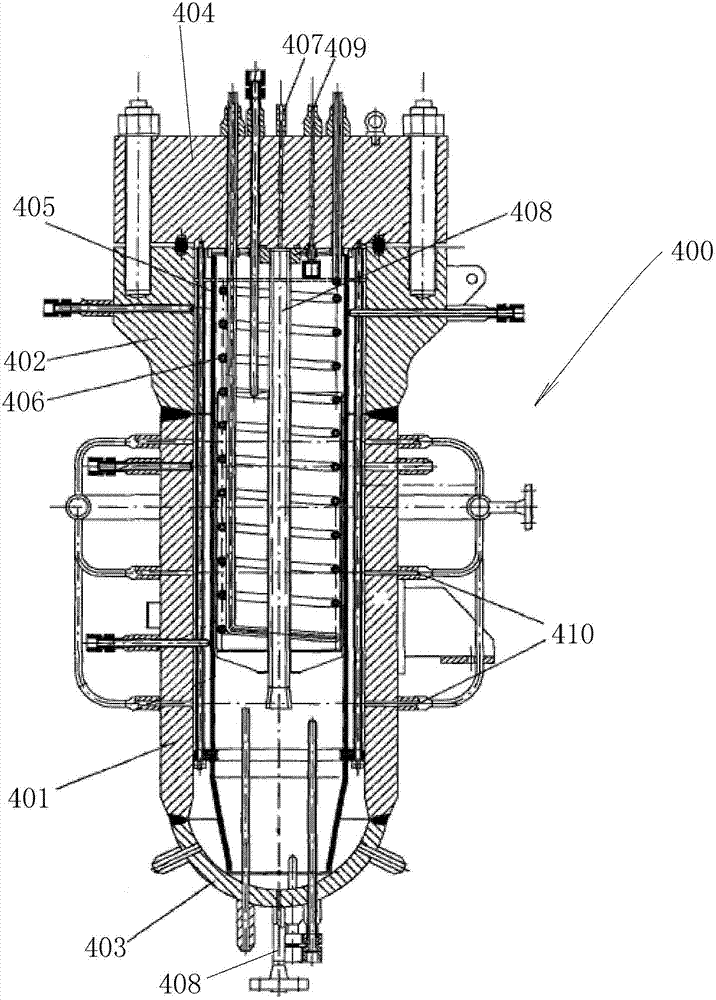

Supercritical water oxidation reactor by using auxiliary fuel for supplying heat

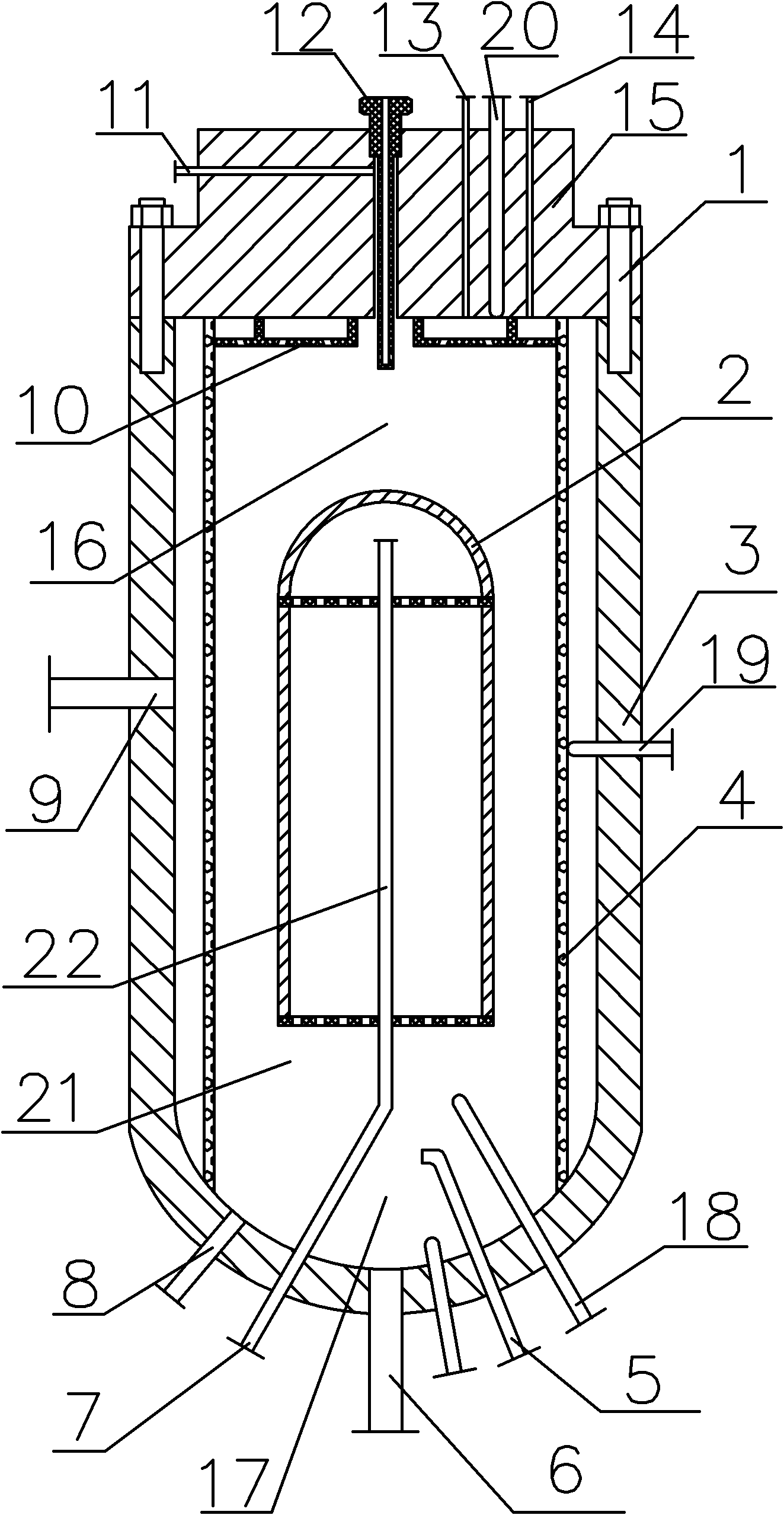

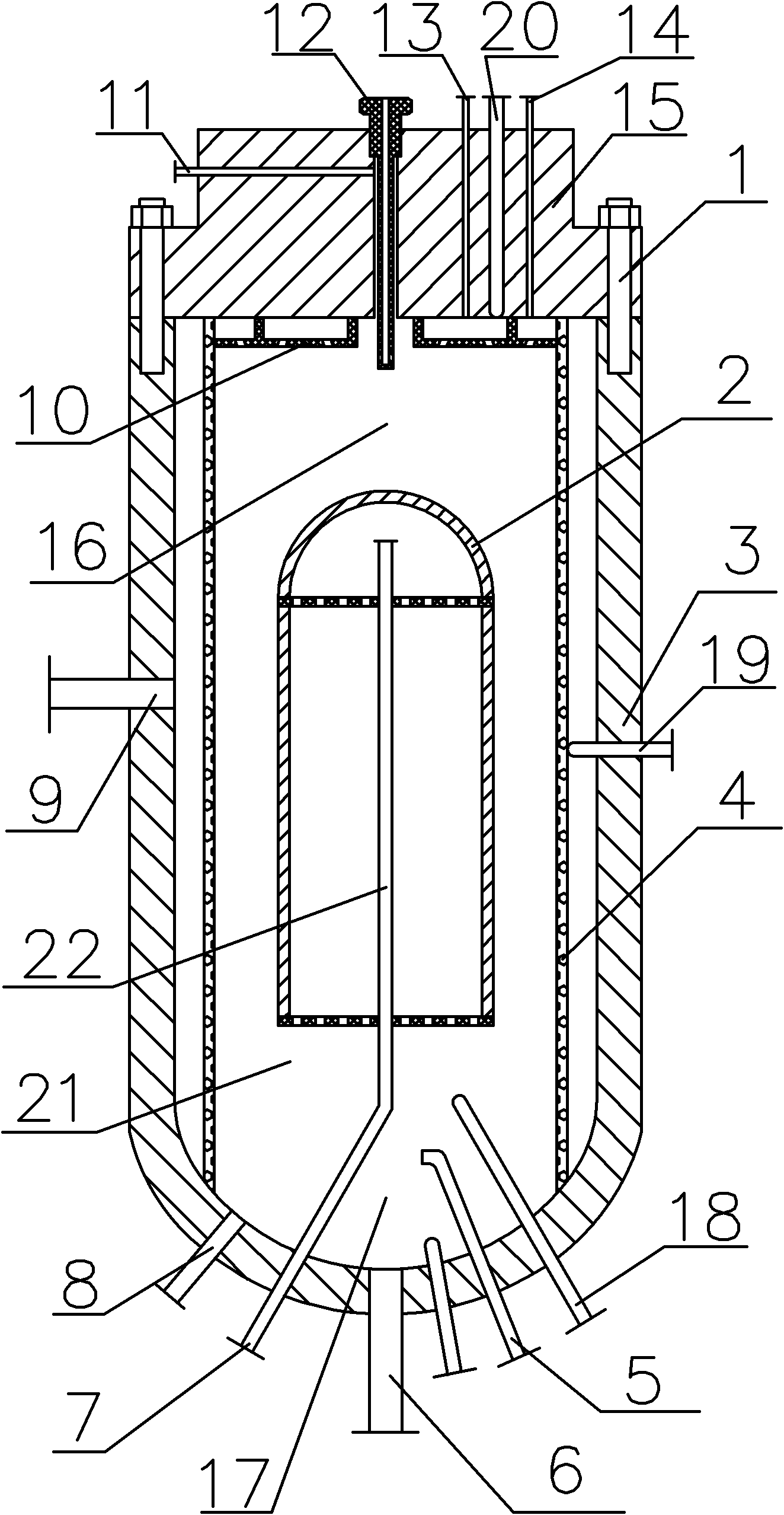

ActiveCN102190363AEfficient mixingEfficient combustionSludge treatmentWater/sewage treatment by oxidationNuclear engineeringOrganic fluid

The invention discloses a supercritical water oxidation reactor by using an auxiliary fuel for supplying heat, the heat required for a reaction can be supplied by using the auxiliary fuel, Material, fuel and an oxidizing agent (air or oxygen) are mixed with a high efficiency through the different directional jets for raising oxidation efficiency. According to the invention, the reactor employs a combination structure of evaporation wall and pot type backflow, the reaction vessel volume is effectively used and the reaction time is increased, the blockage problem generated by salt deposition can be also prevented, the corrosion problem of the reactor is effectively reduced. The temperature of the reactor bottom can be preciously controlled through a cooling water pipeline at the reactor bottom, thereby the safe operation of equipment is guaranteed. The reactor effectively solves the economic problem of a supercritical water reaction system by using the auxiliary fuel for supplying, the invention has the advantage of easy industrial amplification, and is widely applied to organic liquid such as high density and difficult biodegradation organic waste water / garbage leachate and the like for a harmlessness processing.

Owner:XI AN JIAOTONG UNIV

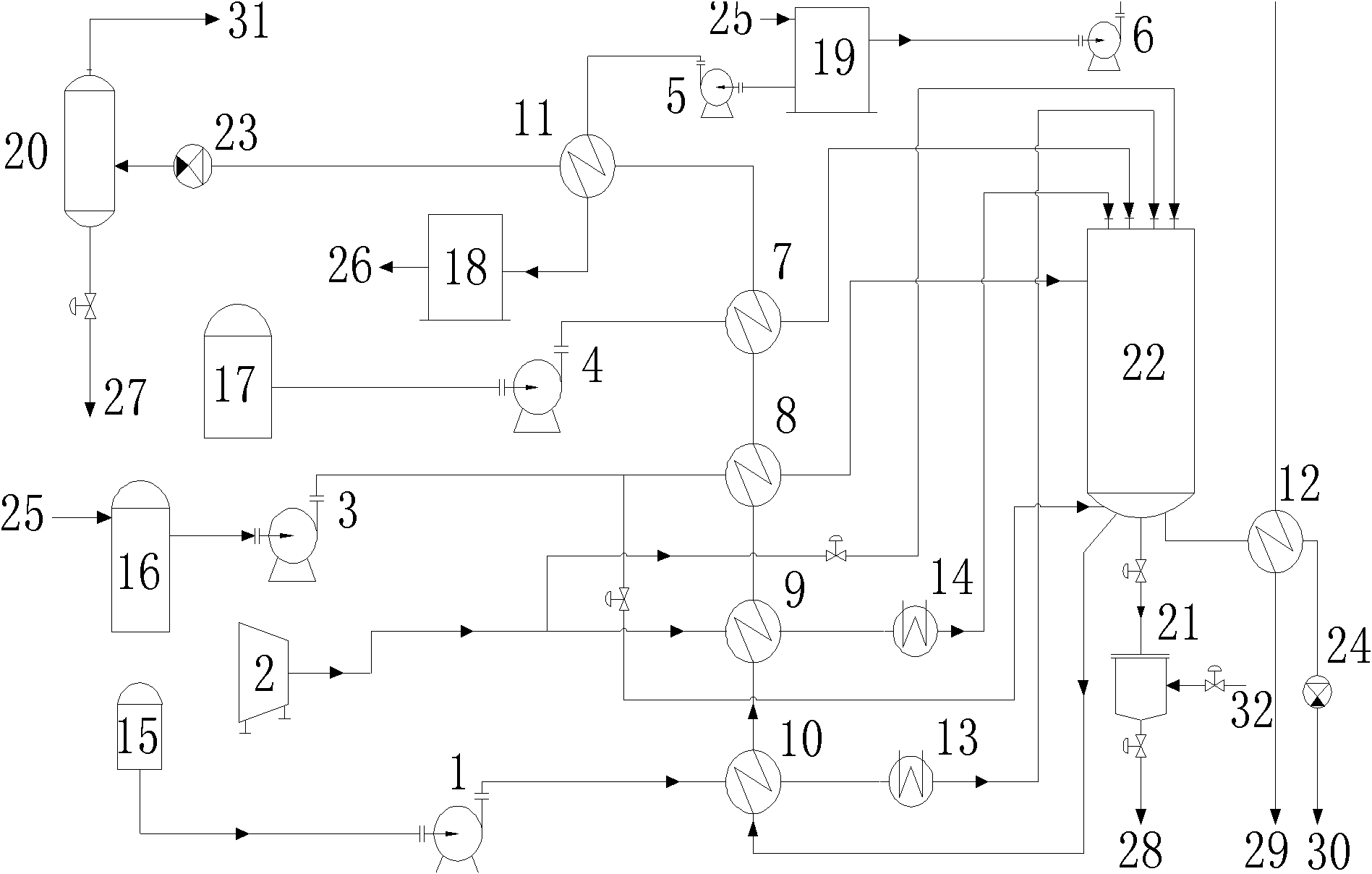

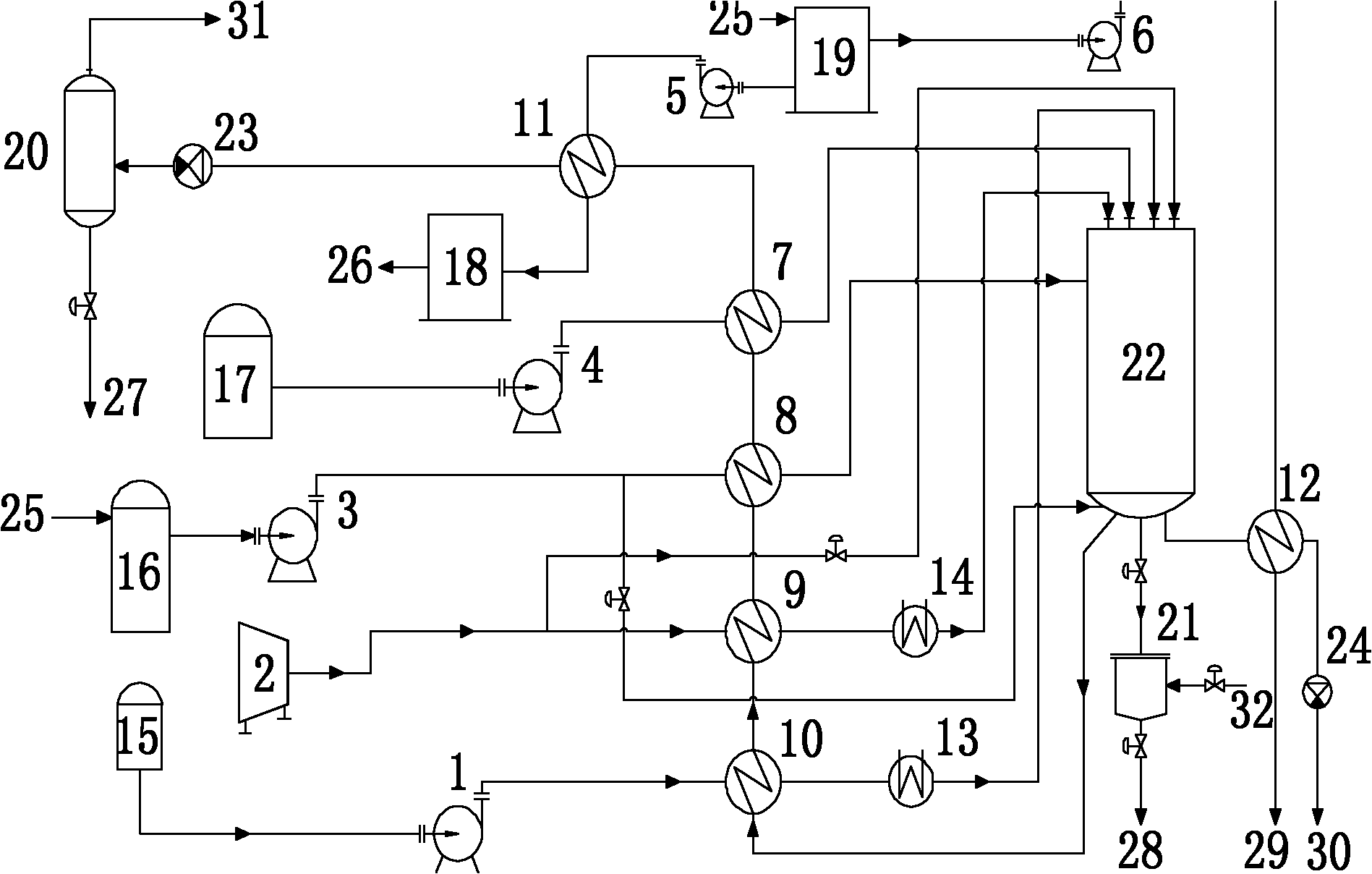

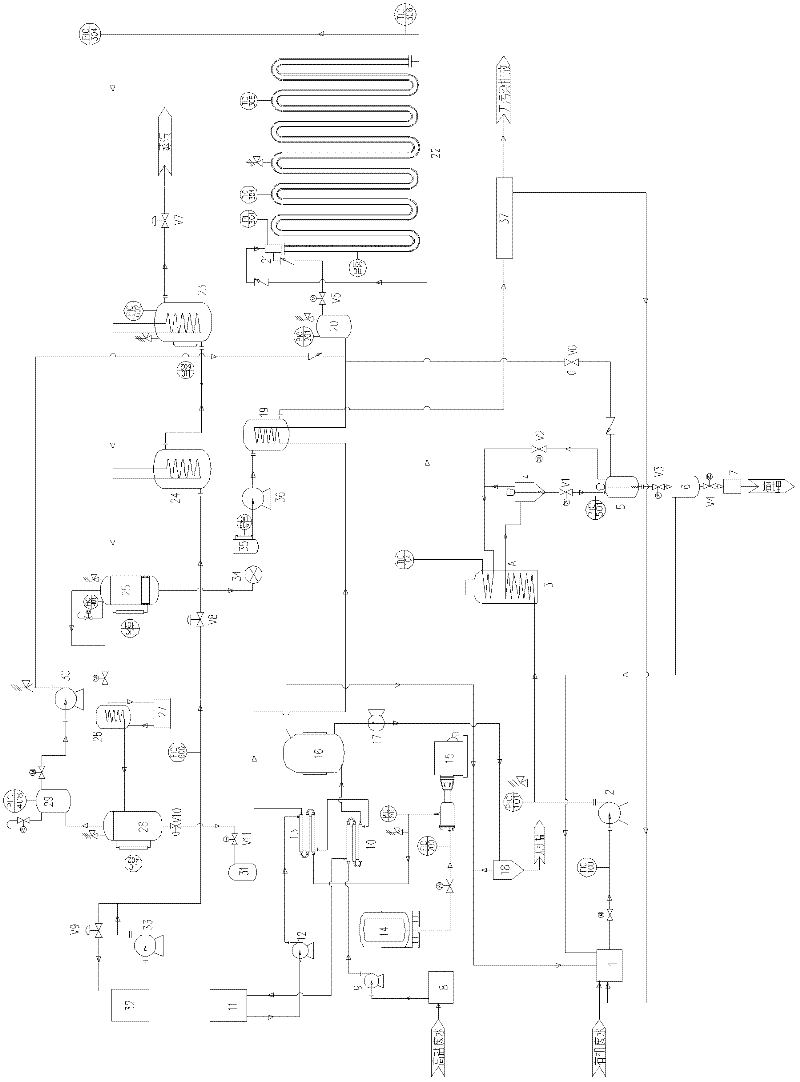

Supercritical water oxidization treatment system for high-salinity organic waste water

InactiveCN102642947AGuaranteed heat transfer coefficientAvoid cloggingSolidificationLiquefactionCycloneReaction temperature

The invention discloses a supercritical water oxidization treatment system for high-salinity organic waste water. The high-salinity waste water is subjected to cooling crystallization through cold energy of liquid oxygen to reduce mass concentration of inorganic salt in the waste water; a large amount of solid salt grains separated out from the waste water are removed by using a hydraulic cyclone device under a supercritical water condition to effectively prevent a subsequent pipeline and a reactor of the hydraulic cyclone device from plugging; and a desalting device is arranged at the lower part of the hydraulic cyclone device to continuously remove the inorganic salt from the system. In addition, excessive oxygen and CO2 product gas are recovered through a separation recovery part; the reaction time and the reaction temperature of supercritical water oxidization are reduced through arranging a simple subsequent treatment unit; and the system recovers heat energy of the reacted high-temperature fluid in a steam mode through the arrangement of a water softening device, so that the operation cost of the system is reduced. The system can be widely applied to the innocent treatment process of the high-salinity organic waste water.

Owner:XI AN JIAOTONG UNIV +1

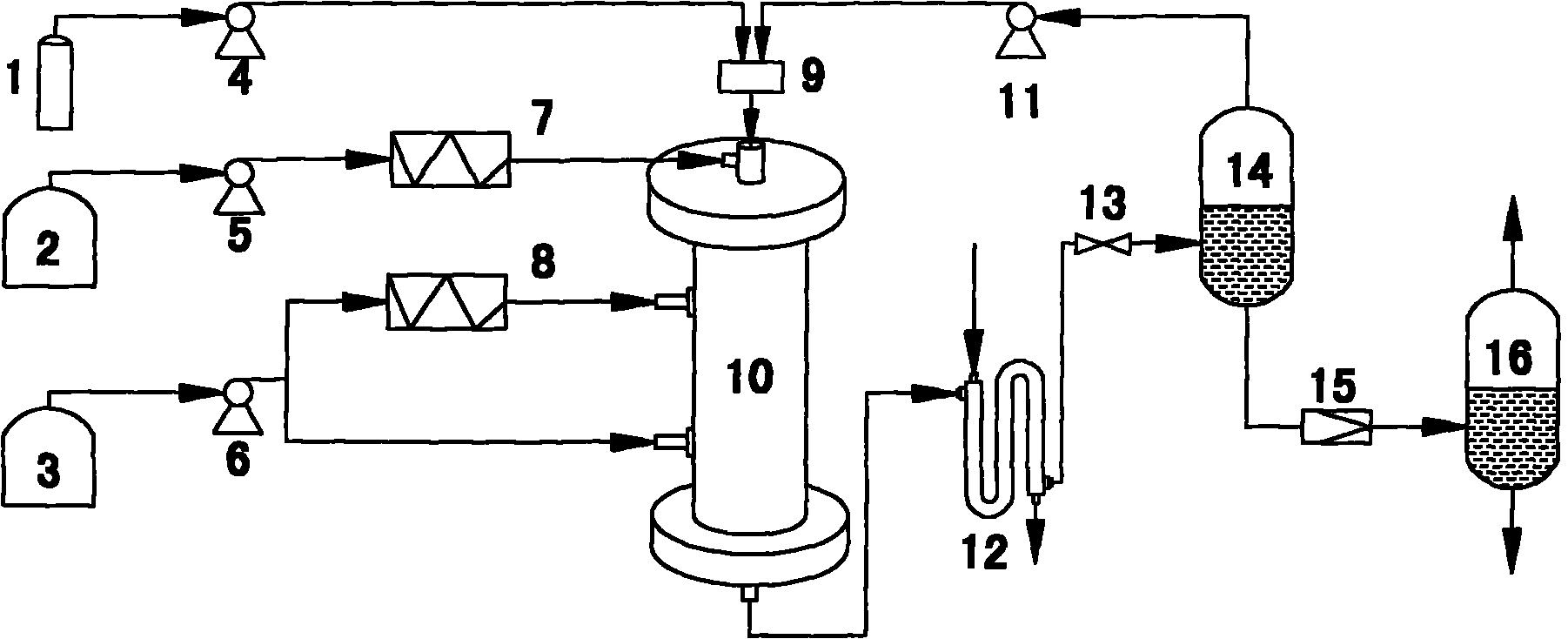

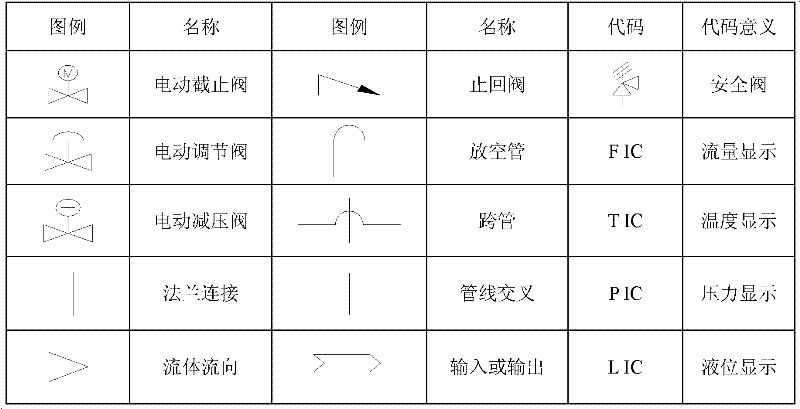

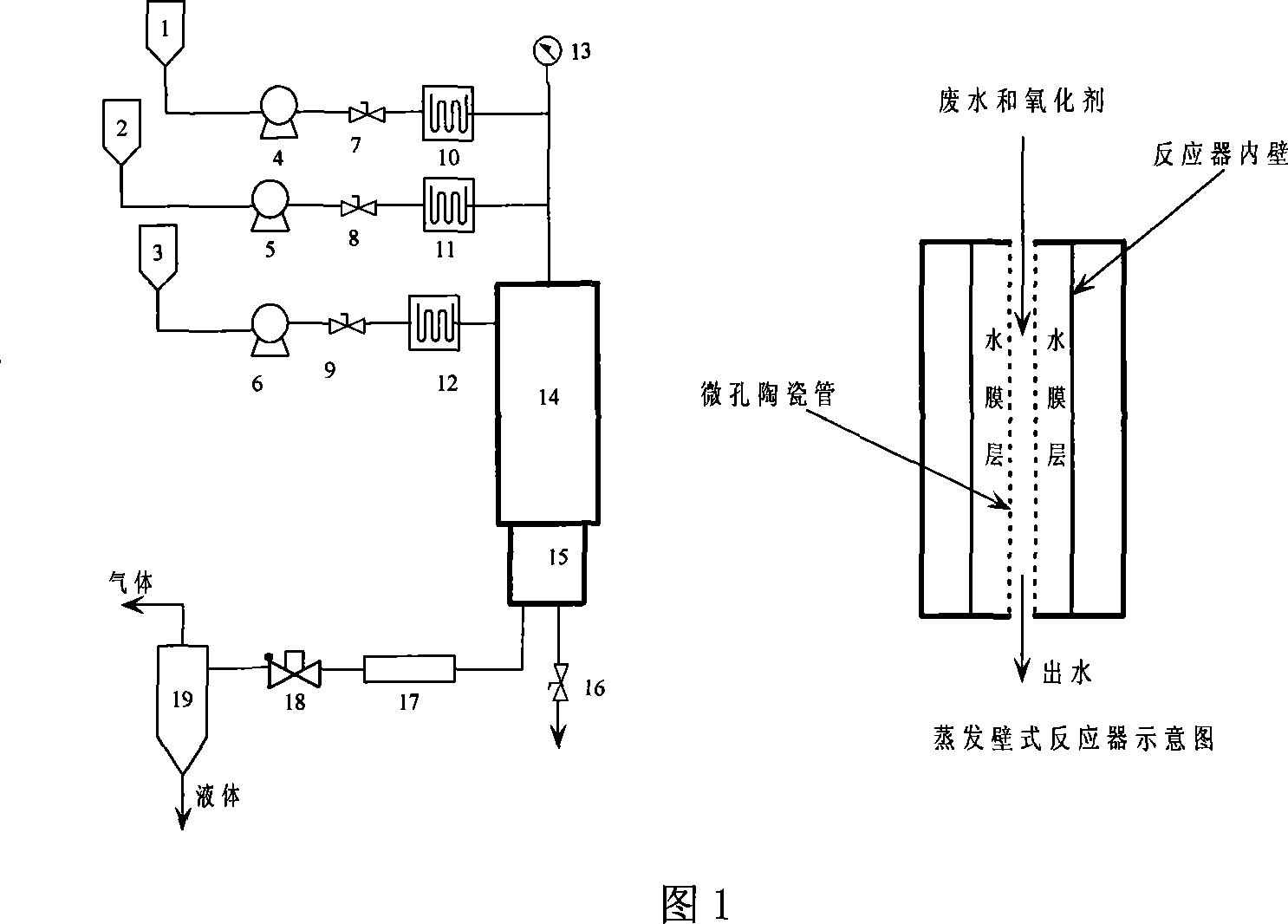

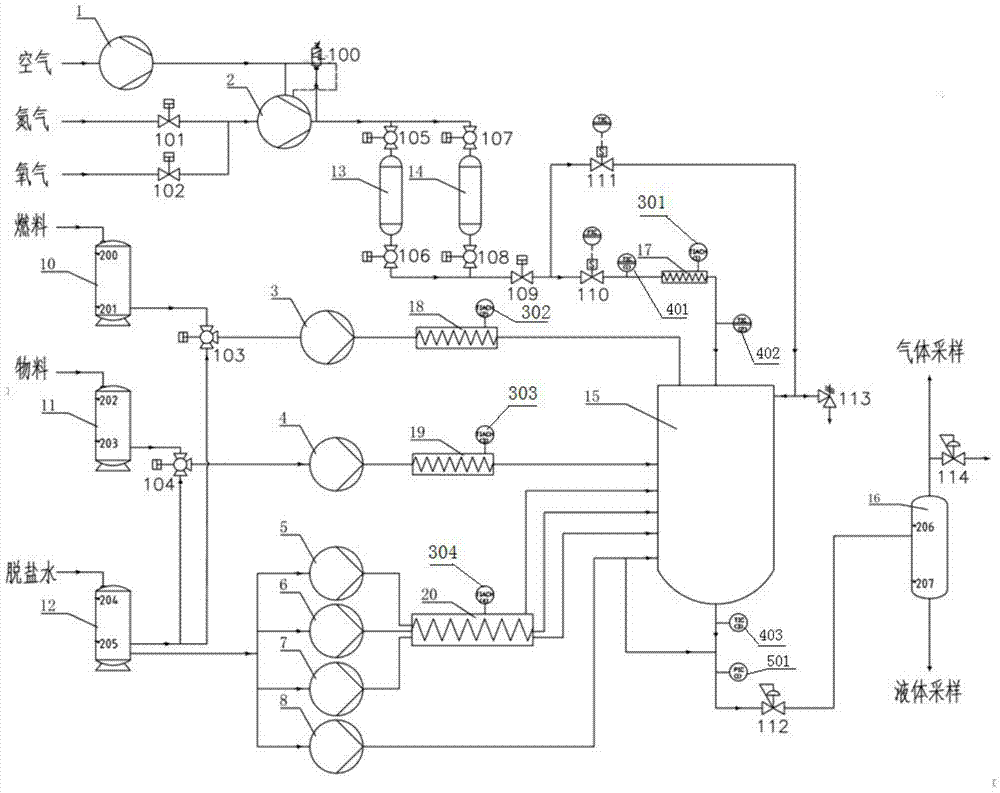

Method for treating high-concentration organic waste water in acroleic acid production

InactiveCN101182065ASolve corrosiveSolve the problem of pipeline blockageNature of treatment waterWater/sewage treatment by oxidationHigh concentrationHigh pressure

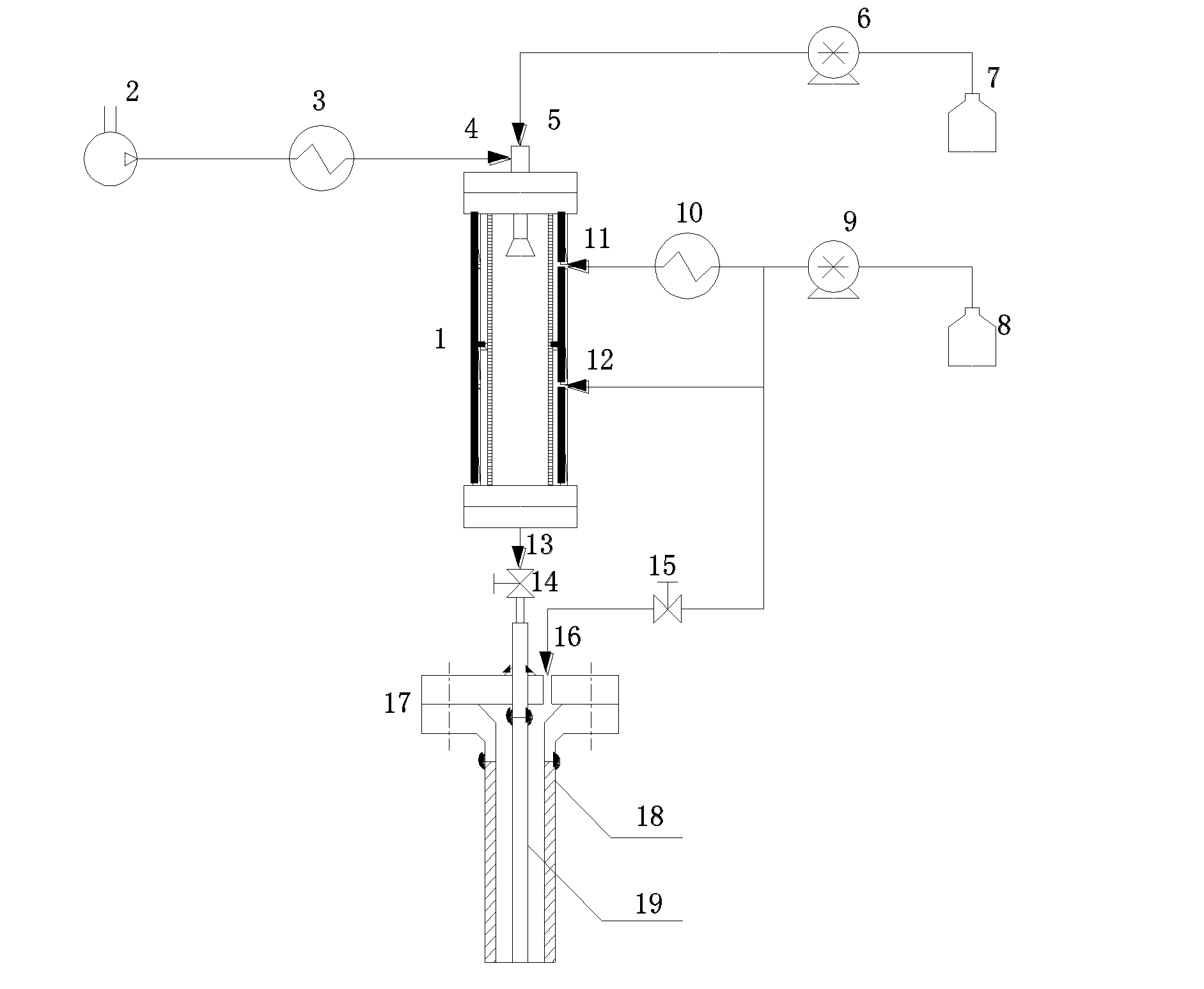

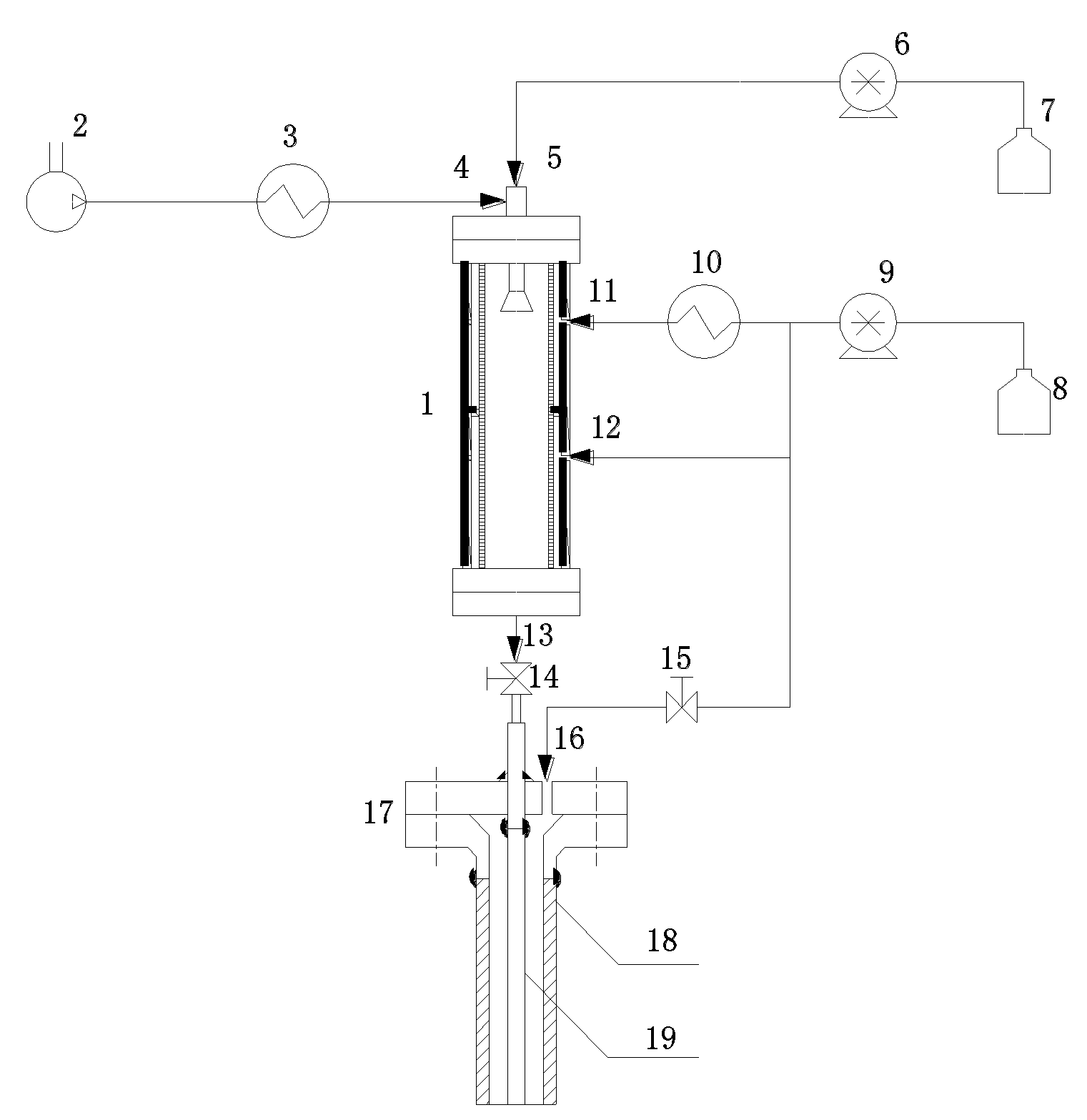

The invention relates to a high concentrated organic compound wastewater treating method in the acrylic acid production, including that firstly oxidant and deionized water are mixed for preparing oxidant solution and is put in an oxidant tank. Secondly, wastewater and clear water for the acrylic acid production are respectively arranged in a wastewater tank and a clear water tank and catalysts are added in the wastewater. Thirdly, a pre-heater is heated to be at the temperature of 300-400 degree Celsius and a reactor is heated to be at the temperature of 400-600 degree Celsius. Fourthly, a high pressure plunger pump is opened, in which a sampler is put. The wastewater and the oxidant solution enter a microporous ceramic tube of the reactor after being preheated and pressurized respectively. The supercritical water oxidation under the pressure of 22-28MPa and the temperature of 374-600 degree Celsius is implemented. The clear water infiltrates into the microporous ceramic tube through an exine of a ceramic film. Fifthly, the treated effluent is qualified to be discharged through the cooling and the gas-liquid separation. The invention solves problems of the reactor inner wall corrosion and the tube blockage of a traditional supercritical water oxidation technology. The organic removal rate reaches to 99.99 percent above. And no secondary pollution can be made. The invention is friendly to the environment.

Owner:DONGHUA UNIV

Method for treating refractory wastewater by virtue of supercritical water oxidation technology

InactiveCN103601282AImprove processing efficiencyEasy to recycleWater/sewage treatment by oxidationVapor–liquid separatorDesalination

The invention provides a method for treating refractory wastewater by virtue of a supercritical water oxidation technology. The method comprises the following steps of: feeding the preheated wastewater into a salt separator for supercritical desalination, heating an oxidant which is preheated previously through a heat exchanger to a desired temperature, feeding the heated oxidant and the desalinated wastewater into a supercritical water oxidation reactor from the two ends of the reactor, respectively, controlling the system pressure by a back pressure valve, and carrying out a supercritical water oxidation reaction to degrade pollutants in the wastewater into non-toxic matters such as CO2, N2 and H2O; feeding the clean high-temperature and high-pressure fluid obtained after the reaction into the heat exchanger to exchange heat with the wastewater and the oxidant, respectively, and then cooling and separating, returning the excessive oxidant to the supercritical water oxidation reactor and causing the liquid into a normal-pressure gas-liquid separator, discharging the gases such as CO2 and N2 through the top of the normal-pressure gas-liquid separator, and discharging the treated clean water from the bottom of the normal-pressure gas-liquid separator. The method for treating the refractory wastewater by virtue of the supercritical water oxidation technology has the advantages of being high in wastewater treatment efficiency without secondary pollution, and suitable for treating the refractory wastewater different in concentration.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Injection production process of fluids produced by supercritical water oxidation

The invention relates to an injection production process of fluids produced by supercritical water oxidation fluids. The fuel is injected from the top of an evaporation wall reactor after being boosted to 22.1-30 MPa; the air is injected from the top of the reactor after being boosted to the same pressure and pre-heated to reach 300-500 DEG C. Evaporable water is injected from the side surface of the evaporation wall reactor in two branches after being boosted to the same pressure as the fuel; the initial temperature of the evaporable water in the upper branch after being pre-heated is 400-600 DEG C; the evaporable water in the lower branch is at normal temperature. After the supercritical water oxidation in the reactor starts, the evaporable water in the upper branch declines to 250-370 DEG C. The fluid in the reactor flows out from the outlet of the reactor and then is injected to the oil well through an injection pipe after being regulated to 5-30 MPa by a pressure regulating valve; and the evaporable water with the same pressure is injected to the annular space between the injection pipe and a shaft. According to the injection production process, the multiple hot fluids produced when the fuel is processed by the supercritical water oxidation are injected to the oil well, so that the viscosity of the thickened oil is reduced, the oil productivity is increased and the application prospect is wide.

Owner:SHANDONG UNIV

Supercritical water oxidation treatment method for high-concentration organic wastewater

ActiveCN101928080AReduce processing equipment material requirementsReduce difficultyMultistage water/sewage treatmentWater/sewage treatment by degassingHigh concentrationWastewater

The invention provides a supercritical water oxidation treatment method for high-concentration organic wastewater, which comprises the following steps of: pressurizing, preheating, performing supercritical water oxidation reaction and the like. By limiting the content of chloride ions and the content of salt in the wastewater, equipment corrosion and pipeline blockage are controlled in a tolerable range; by controlling the COD concentration of the wastewater, the oxidation reaction is autothermal reaction; and by adopting a multi-tube reactor, the requirement on treatment equipment materials and the equipment processing difficulty are reduced. The method makes the TOC removal rate of over 99 percent, and has the characteristics of small reactor volume, short reaction time, high treatment efficiency, low energy consumption of running, continuous and stable running of the treatment system and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing system and method for printing and dyeing wastewater

InactiveCN101279803AMultistage water/sewage treatmentWaste water treatment from textile industryHigh concentrationVapor–liquid separator

The invention relates to a treatment system and a method for dyeing wastewater, which aims to solve the problem of difficult high concentration refractory dyeing and desizing wastewater treatment, and provides the system and the method for treating volumes of high concentration dyeing and desizing waste water by adopting the supercritical water oxidation technique. The treatment system has the technical proposals for realizing the invention that: the dyeing wastewater treatment system comprises a high pressure plunger pump, a feeding pipeline, a reactor and a first gas-liquid separator, the high pressure plunger pump, the reactor and the first gas-liquid separator are connected with one another sequentially through the feeding pipeline, and the system is characterized in that the treatment system is also provided with a high pressure storage tank, the high pressure storage tank is connected between the high pressure plunger pump and the reactor through the feeding pipeline, a valve is arranged on the pipeline between the high pressure storage tank and the reactor, and the high pressure storage tank is also equipped with a heater.

Owner:NANJING UNIV OF TECH

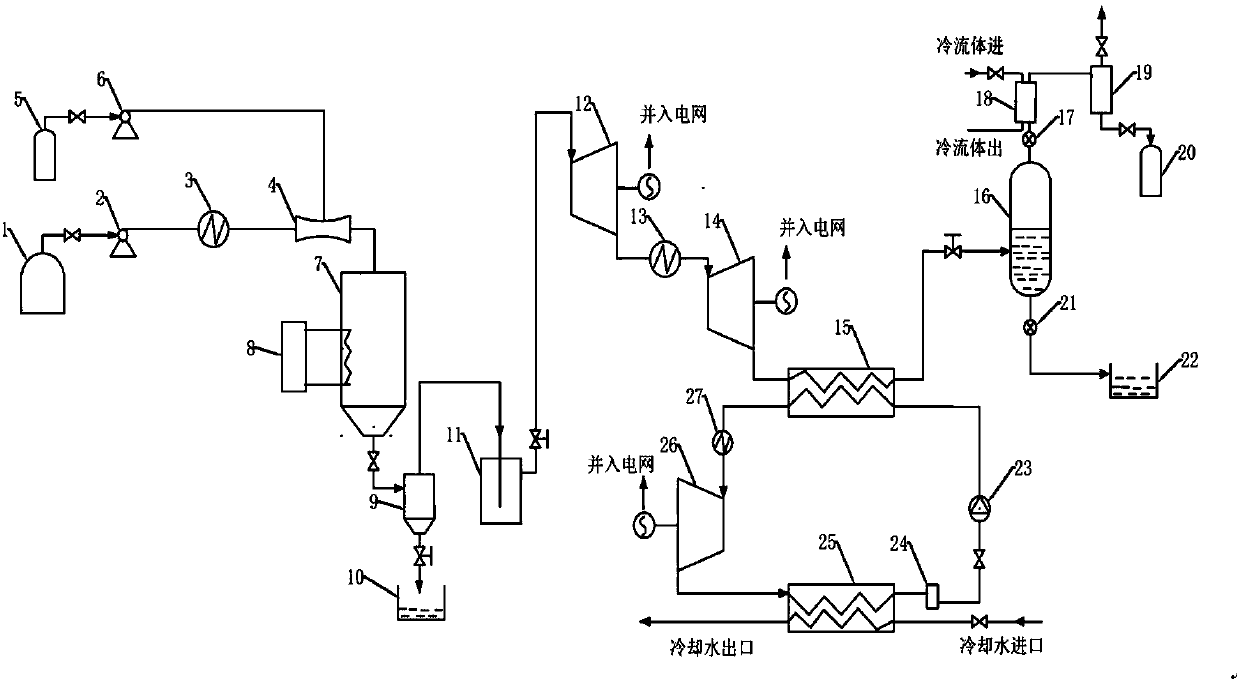

Supercritical-water-oxidation energy recovery system

PendingCN107935287AEmission reductionReduce energy inputWater/sewage treatment by centrifugal separationWater treatment parameter controlInorganic saltsSewage outfall

The invention discloses a supercritical-water-oxidation energy recovery system. The supercritical-water-oxidation energy recovery system disclosed by the invention has the beneficial effects that theoutlet end of a supercritical water oxidation reactor is connected with a high-pressure hydrocyclone, inorganic salts in reaction products in the supercritical water oxidation reactor are discharged from a sewage discharging port, high-pressure and high-pressure gas generated is exhausted into a buffering tank to carry out flat-pressing treatment, then the flatly-pressed gas passes through a high-pressure turboexpander and a low-pressure turboexpander in sequence to carry out residual-heat utilization for generating power, an outlet of the low-pressure turboexpander is connected with an evaporator, a Rankine circulation system is connected on the evaporator and is utilized for further utilizing residual heat of fluid passing through the evaporator, so that the energy input of the Rankine circulation system is reduced; the supercritical water oxidation system and a residual-heat and residual-pressure recovery system are fully combined, and heat energy and pressure energy of supercritical water oxidation products are fully utilized, so that the energy recovery and utilization rate of the supercritical water oxidation system is increased; carbon dioxide in the products is separated and recovered by utilizing a gas-liquid separator and a rectifying tower, so that the emission of greenhouse gas is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

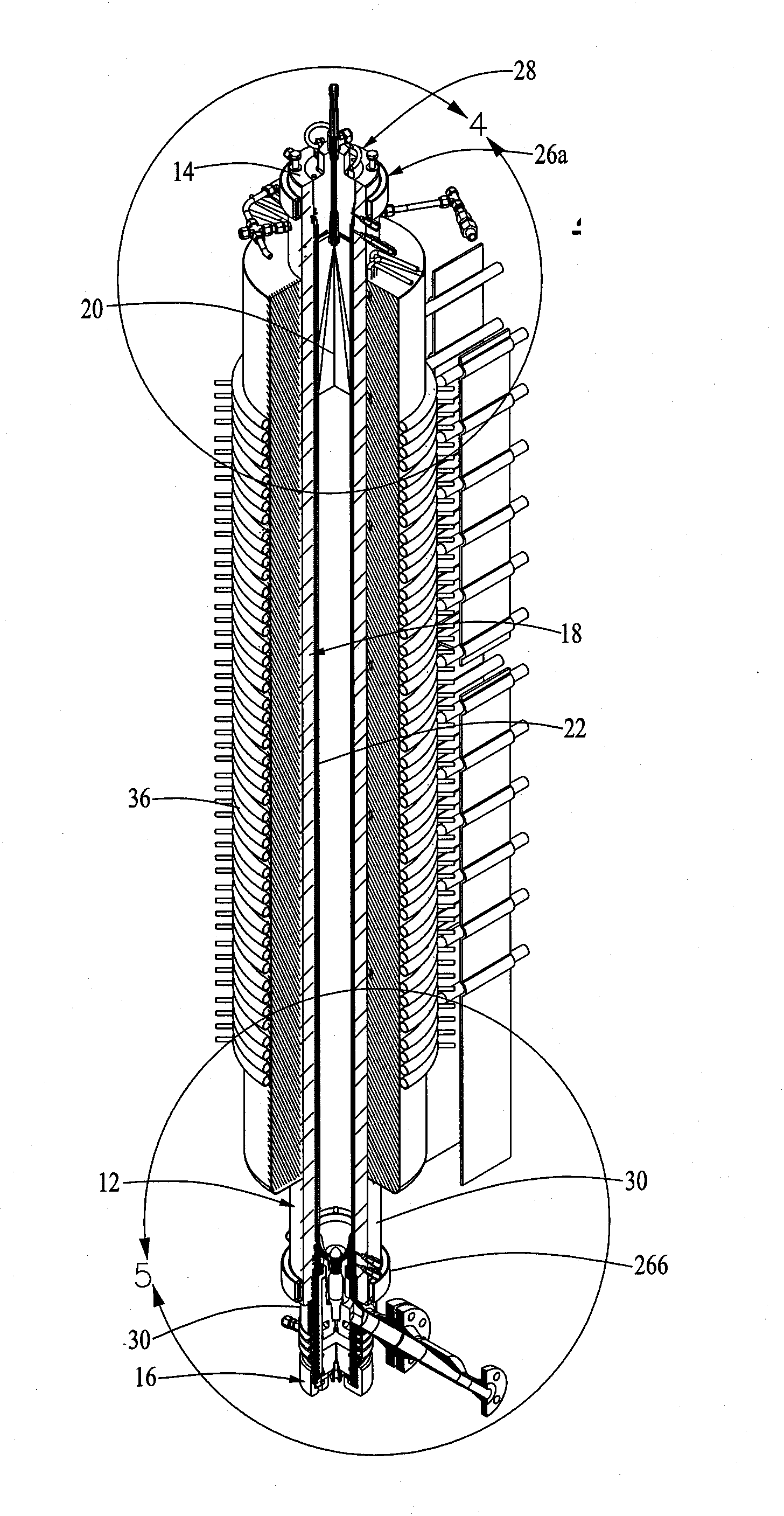

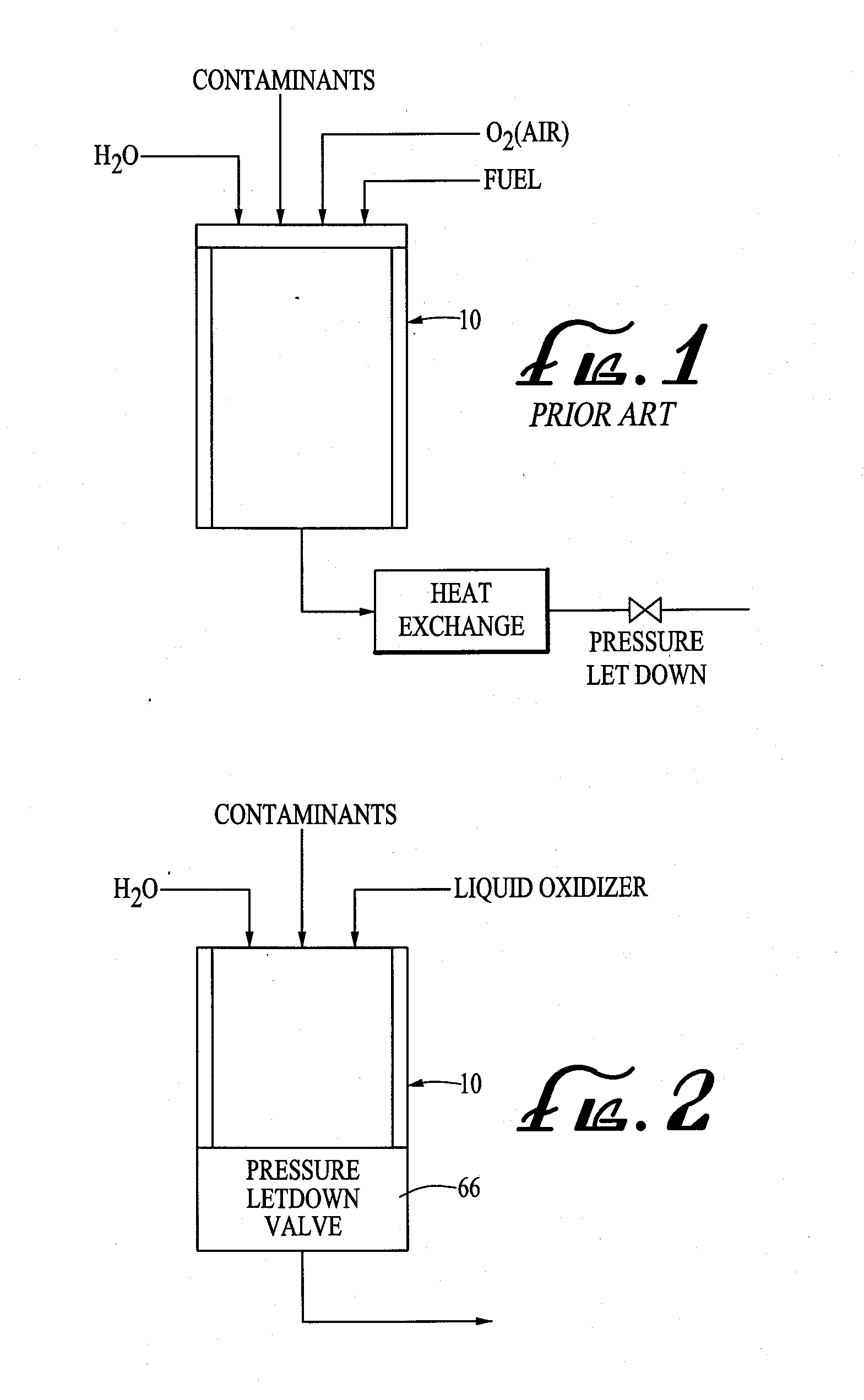

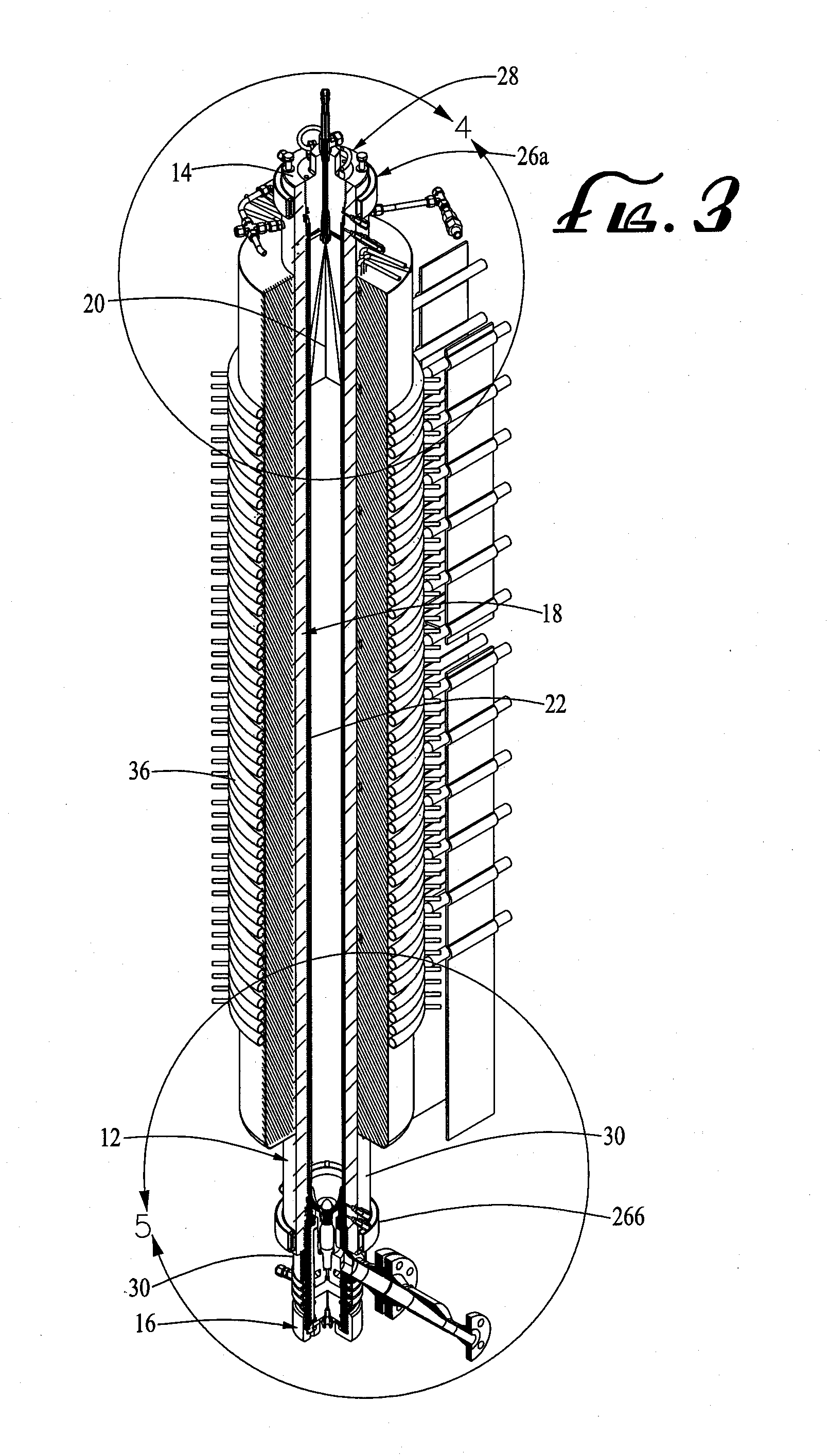

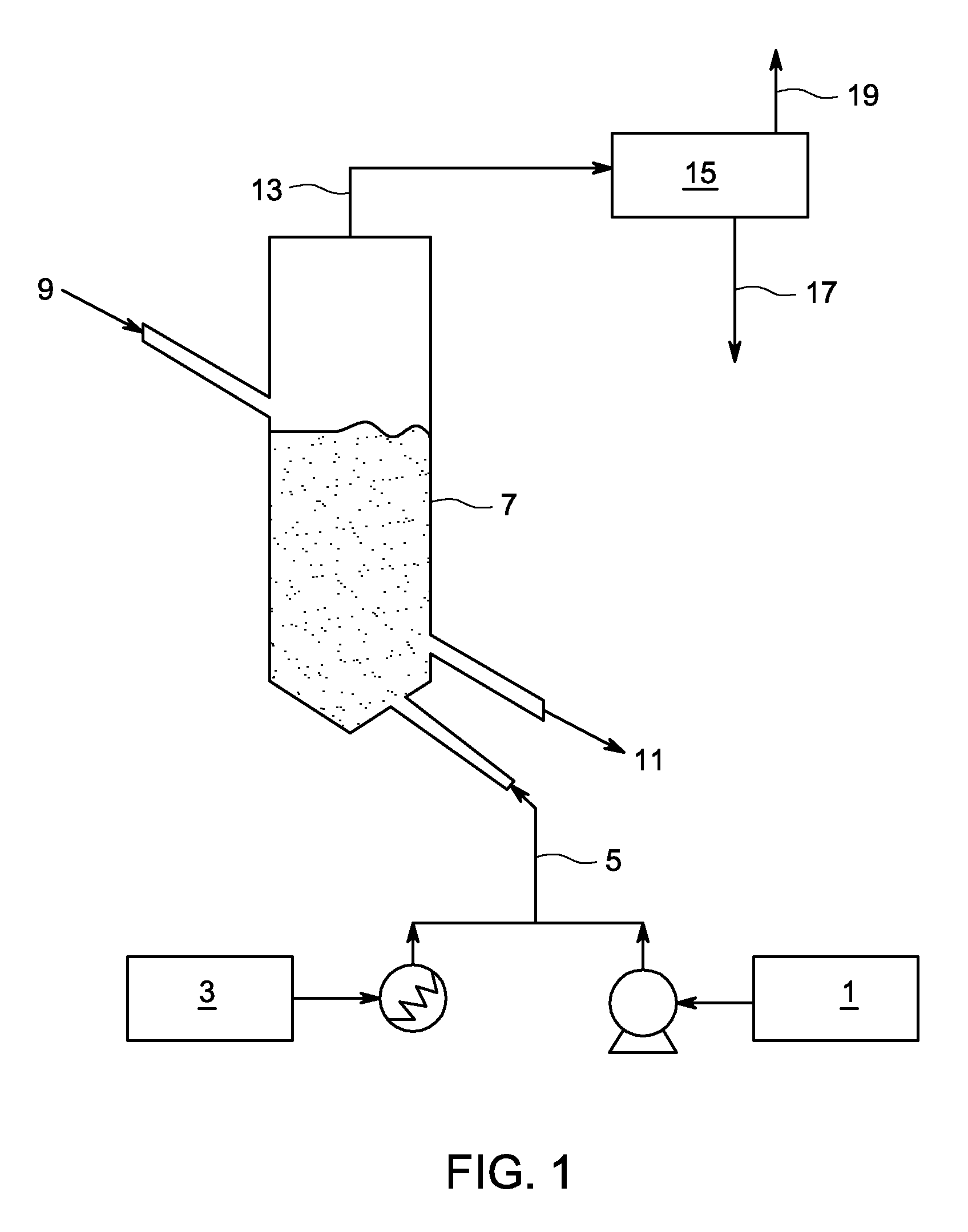

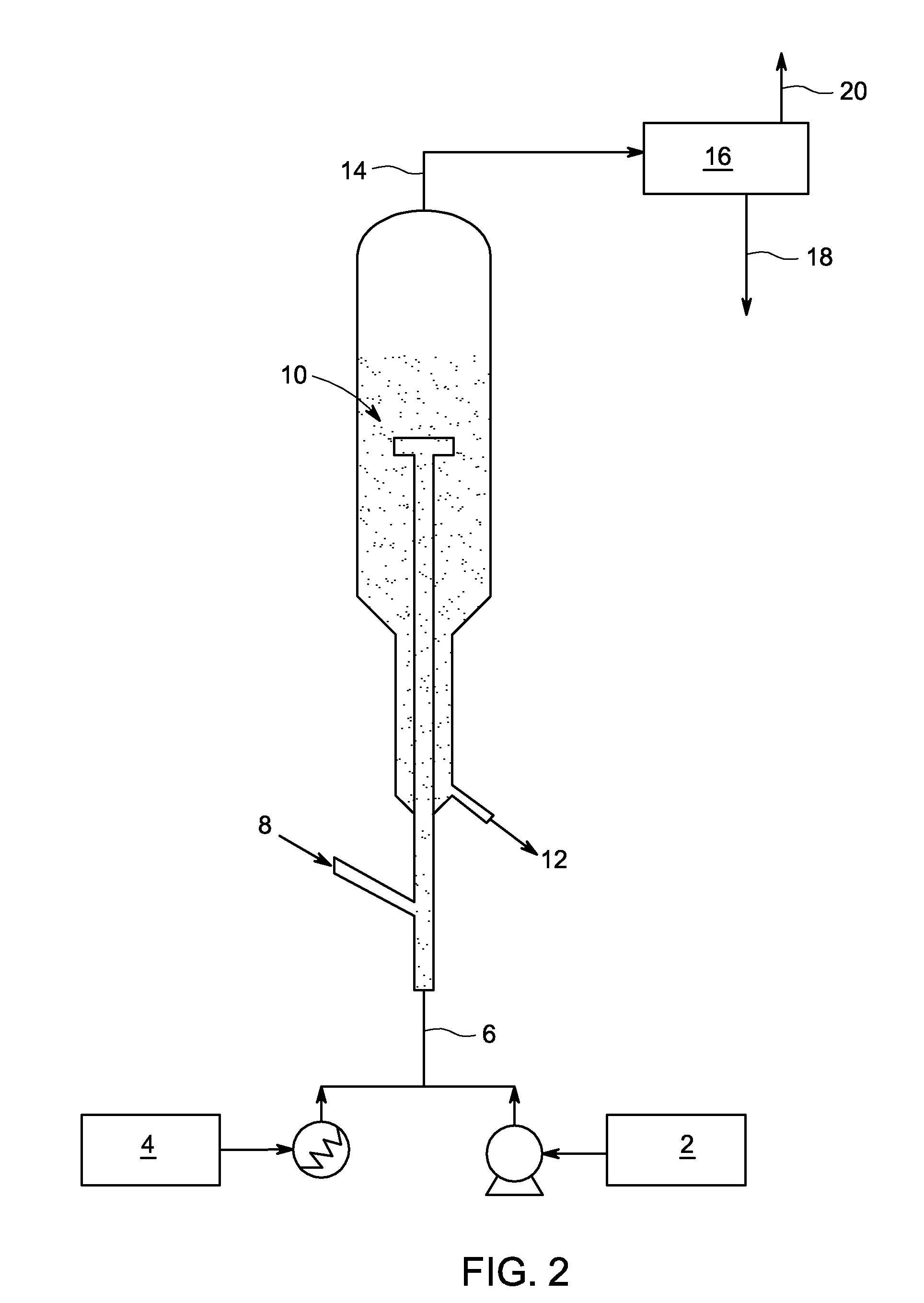

Supercritical water oxidation apparatus and process

ActiveUS20080283472A1Pressurized chemical processSludge treatmentContinuous flowSupercritical water oxidation

A method for oxidizing an organic material includes the steps of (a) forming a preoxidation mixture comprising the organic material and water, and (b) causing the preoxidation mixture to react with a liquid oxidizer in a continuous flow reactor supercritical conditions for water, including a pressure of at least 3206 psia and a temperature of at least 705° F., to form a post-oxidation mixture containing condensible material and non-condensible material, wherein substantially all of the organic material has been oxidized.

Owner:PARSONS CORPROATION

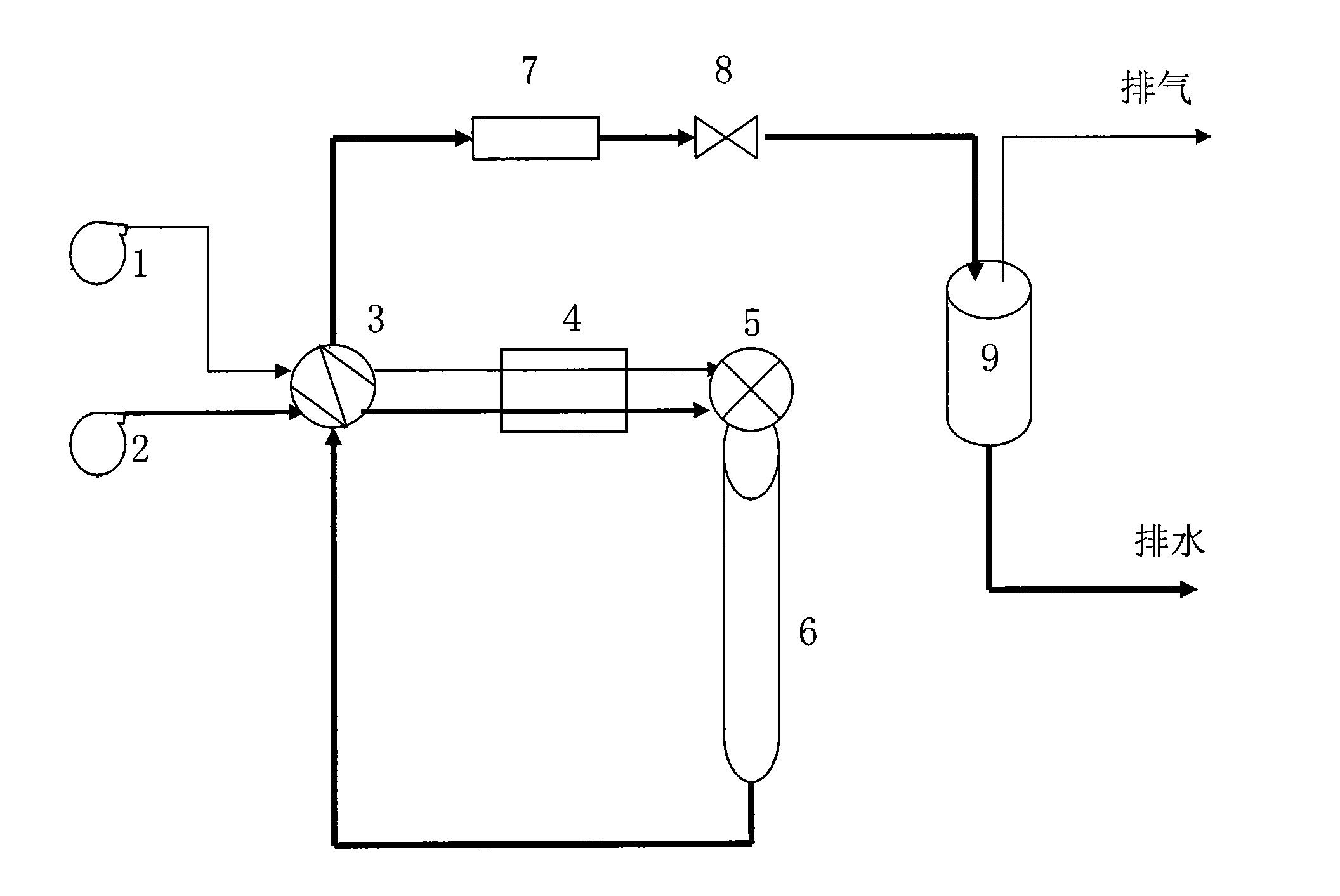

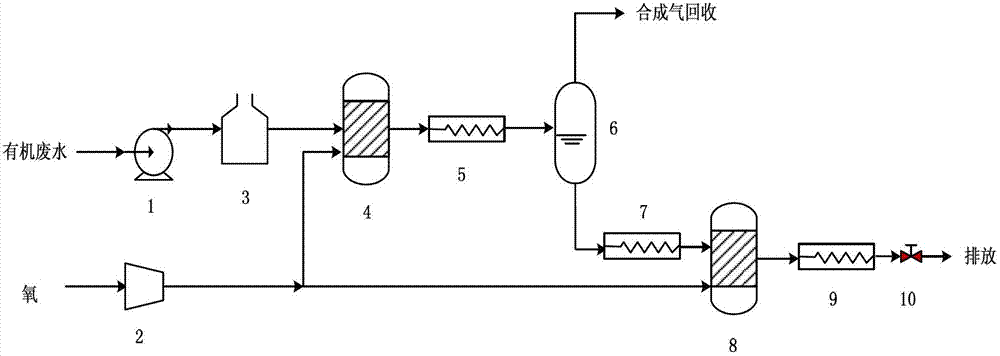

Supercritical water gasification-oxidation method for treating organic wastewater and recycling synthesis gas

ActiveCN102874916AImplement resourcesAchieving processing powerHydrogenBulk chemical productionHigh concentrationHigh pressure

The invention discloses a supercritical water gasification-oxidation method for treating organic wastewater and recycling synthesis gas. The supercritical water gasification-oxidation method comprises the following steps that: (1) the organic wastewater enters a preheater and a supercritical water gasification device sequentially by a high-pressure pump, and oxygen is divided by a compressor, so that one part of oxygen enters the supercritical water gasification device; (2) fluid from an outlet of the supercritical water gasification device enters a high-pressure gas-liquid separator by a heat exchanger, the synthesis gas of H2, CO and CH4 on the upper part is recycled, the fluid at the bottom enters a heater and a supercritical water oxidation reactor sequentially, and the part of oxygen which is divided by the compressor enters the supercritical water oxidation reactor; and (3) the fluid passing through the supercritical water oxidation reactor passes through a cooler and a back pressure valve sequentially and is discharged under the condition of reaching the standard. The supercritical water gasification-oxidation method can be widely applied to the treatment of the high-concentration organic wastewater.

Owner:XI AN JIAOTONG UNIV +1

Method for treating carbon-containing organic matter by supercritical water oxidation

ActiveCN103073103AAchieve self-sufficiencyStart raw material without heatingWater/sewage treatment by oxidationDecompositionSupercritical water oxidation

The invention relates to a method for treating carbon-containing organic matter by supercritical water oxidation. The method comprises the step of obtaining oxidative decomposition product by oxidizing the carbon-containing organic matter in the supercritical state of water and under the effect of oxidant; heat released by the supercritical water oxidation treatment of the carbon-containing organic matter at least can satisfy the heat required by warming the carbon-containing organic matter to the supercritical state of the water, thereby energy is not required to be provided by the outside in the stable operation process, and the self-supply of reaction energy is completely achieved; and the cold start of the reaction is achieved by the cold start mode of low-temperature combustion catalysis.

Owner:ENN SCI & TECH DEV

Small-size supercritical water oxidation reaction system and control method thereof

InactiveCN104709998AExtended service lifeReduce energy consumptionWater/sewage treatment by oxidationVapor–liquid separatorWater storage tank

Owner:王冰

Plasma water treatment method

InactiveCN1367140AImprove degradation rateWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by oxidationCavitationPhosphate

In the water to be treated, a soluble phosphate and / or a photocatalyst of mixture formed from Pt, Ag, Pd, Au or Ru metal and sulfur compound as active component or sulfur compound in which the metal ions of Fe(3+), V(4+) or Ru (3+) is doped are added, the above-mentioned materials can raise the effects of high-temp. pyrolysis, photochemical oxidation, hydroelectric cavitation degradation and supercritical water oxidation produced in the discharge process so as to greatly raise the water treatment effect.

Owner:EAST CHINA UNIV OF SCI & TECH

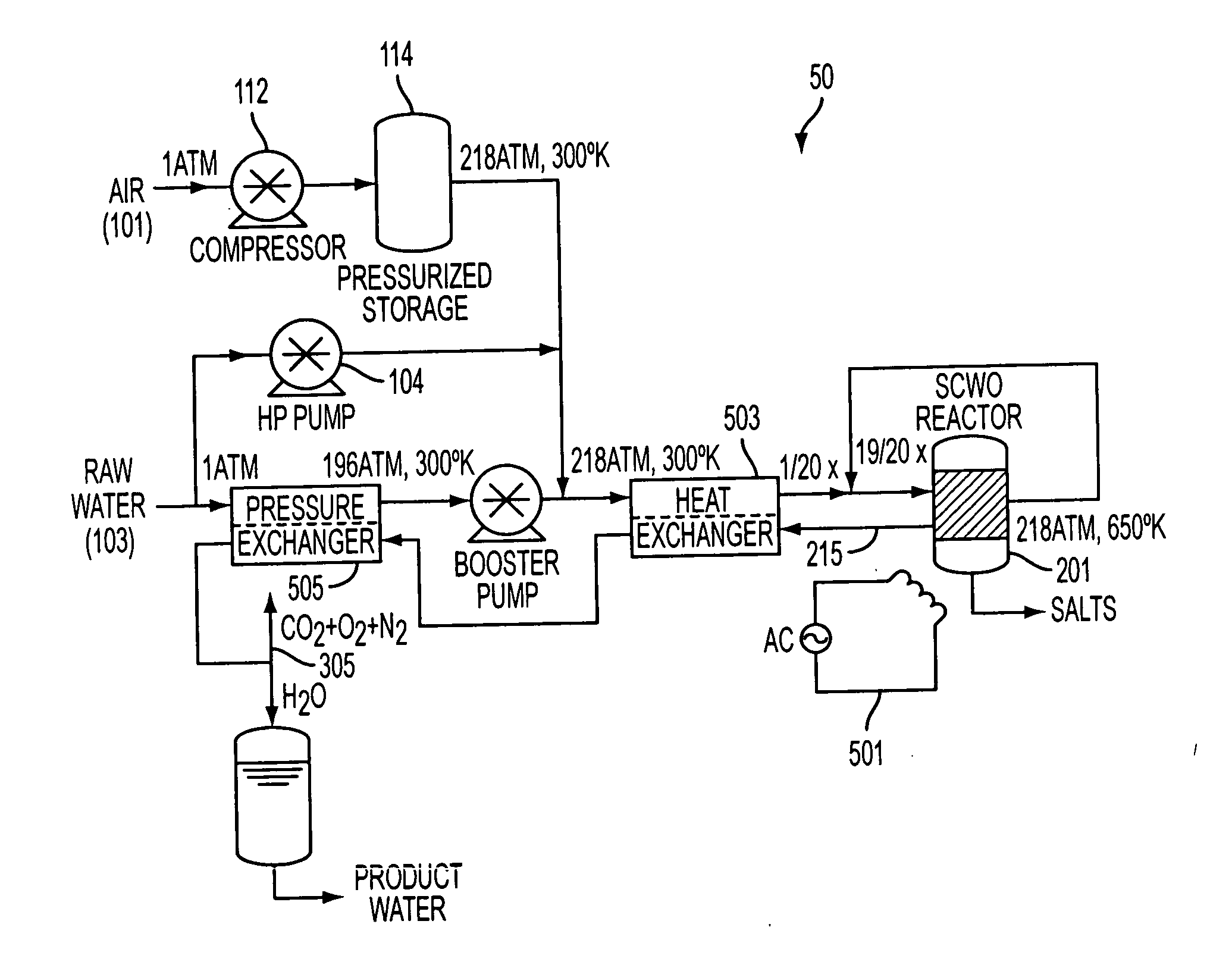

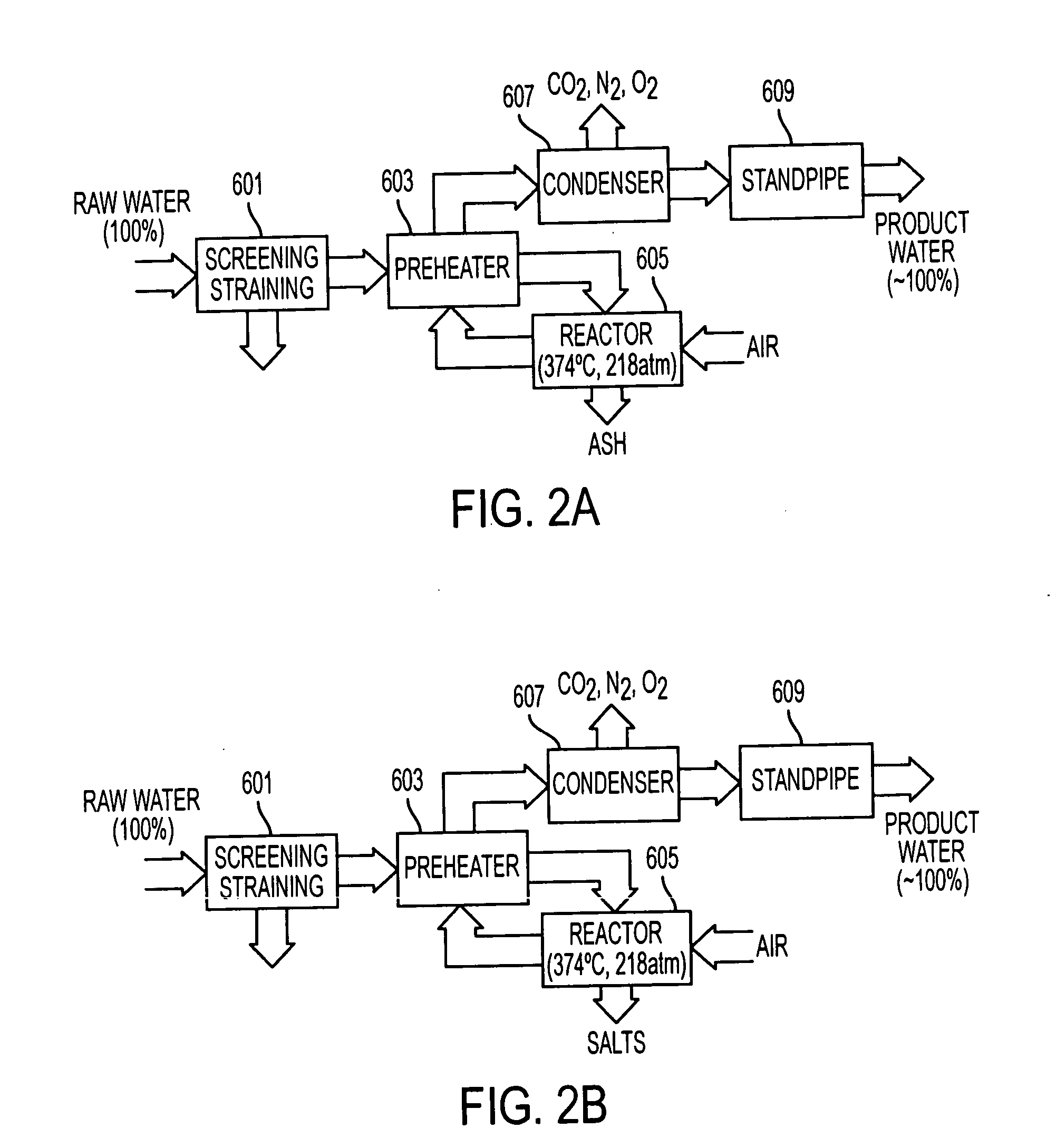

Systems and methods for water purification through supercritical oxidation

ActiveUS20050006317A1High speed purifyingReduced Power RequirementsSludge treatment by oxidationSeawater treatmentSupercritical water oxidationOxygen

Supercritical water (SCW) systems and methods using the properties of supercritical water to allow a raw water stream including water and a contaminant to be purified. A supercritical water oxidation (SCWO), water purifier may generally include water and oxidizer (such as oxygen in air) pumping and mixing apparatus, a supercritical water reactor, and a system for separating the resultant purified water from other relatively harmless outputs of the supercritical water reactor.

Owner:DRS SUSTAINMENT SYST

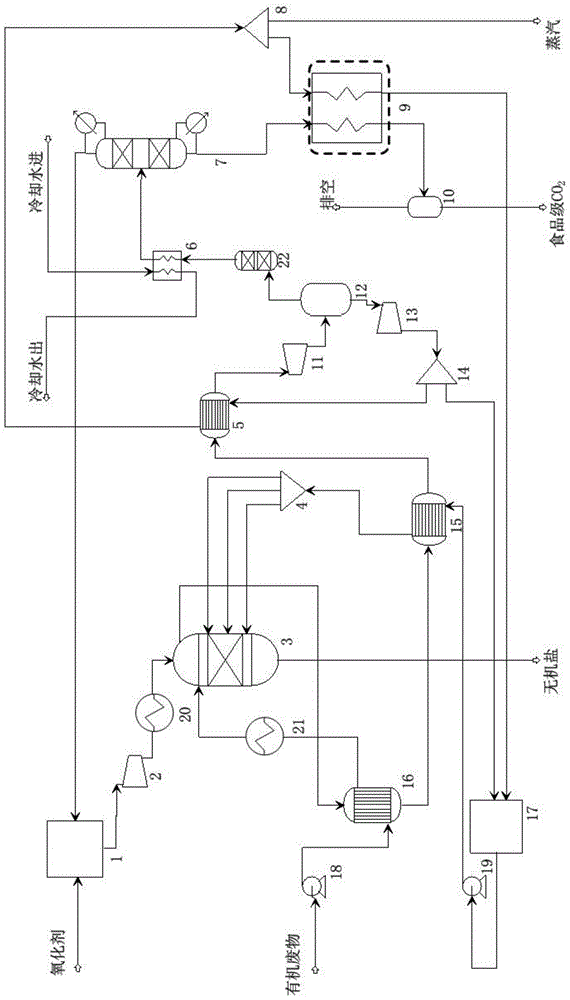

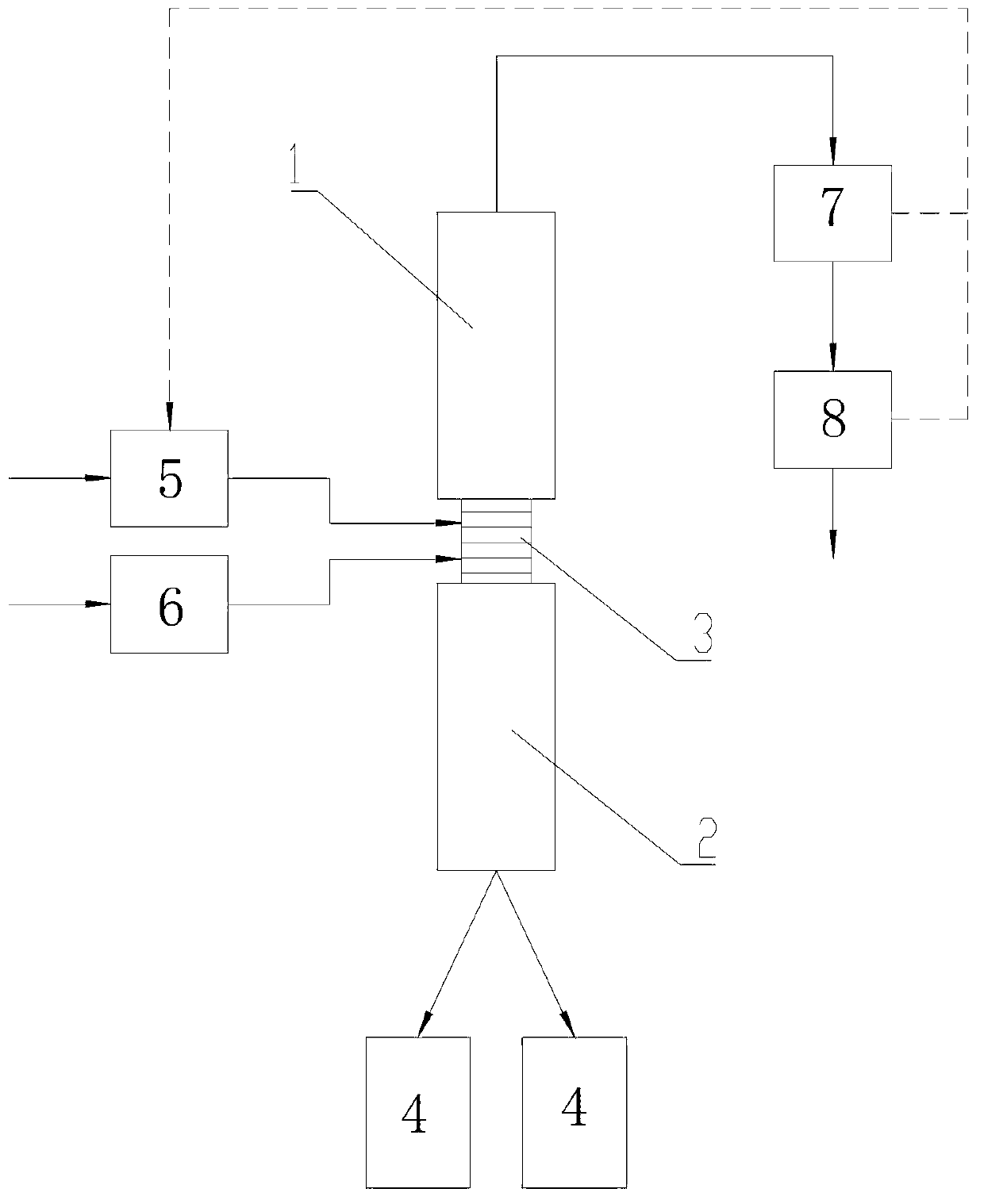

Novel supercritical water oxidation comprehensive treatment system and method

InactiveCN104445573ANo cloggingAvoid depositionWater/sewage treatment by oxidationEnergy recoverySupercritical water oxidation

The invention relates to a novel supercritical water oxidation comprehensive treatment system. The novel supercritical water oxidation comprehensive treatment system comprises the following units: an oxidant supplying unit (1), a raw material supplying unit (2), a supercritical water oxidation desalination unit (3), a pressure energy recovery unit (4), a waste heat recovery unit (5), a carbon dioxide generating unit (6) and an evaporative water generating unit (7). A novel supercritical water oxidation comprehensive treatment method comprises the following steps: (1) supplying the oxidant; (2) supplying the raw material; (3) carrying out supercritical water oxidation desalination; (4) recovering pressure energy; (5) recovering waste heat; (6) generating carbon dioxide; and (7) generating evaporative water. By the novel supercritical water oxidation comprehensive treatment system and method, the phenomenon of clogging of a pipeline due to the deposition of salts cannot be caused, the deposition of salt substances on the wall of the reactor is avoided and the corrosion is decreased; since the waste water and pressure are recycled and the oxygen-enriched tail gas is also reused, the running cost is decreased; and by selling byproducts, namely, food-grade carbon dioxide and saturated steam, profits can be enlarged.

Owner:王冰

Supercritical water oxidation system using air as protecting film and reaction process

ActiveCN104671388AAvoid corrosionAvoid salt depositsWater/sewage treatment by oxidationTectorial membraneWastewater

The invention provides a supercritical water oxidation system using air as a protecting film and a reaction process. The system comprises a double-housing reactor, an organic wastewater inputting pipeline, an air inputting pipeline and a reactant discharging pipeline, wherein the double-housing reactor comprises a porous wall arranged at the outer part, and a bearing wall arranged at the inner part; a separating ring is arranged between the porous wall and the bearing wall; a waste liquid inlet is formed in the top part of the double-housing reactor, and while a reactor outlet is formed in the bottom part of the double-housing reactor; an upper air inlet and a lower air inlet are formed in the bearing wall; the organic wastewater inputting pipe is connected with the waste liquid inlet; two branches of the air inputting pipeline are respectively connected with the upper air inlet and the lower air inlet; the reactant discharging pipeline is connected with the reactor outlet. The system achieves upercritical water oxidation reaction and porous wall protection, and can avoid concentrated release of reaction heat in the upper part of the double-housing reactor because that the concentrated release of the reaction heat leads to overheat of the upper part of the double-housing reactor and excessively large axial temperature gradient and damage to the porous wall; meanwhile, the corrosion and salt deposition of the double-housing reactor can be avoided.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

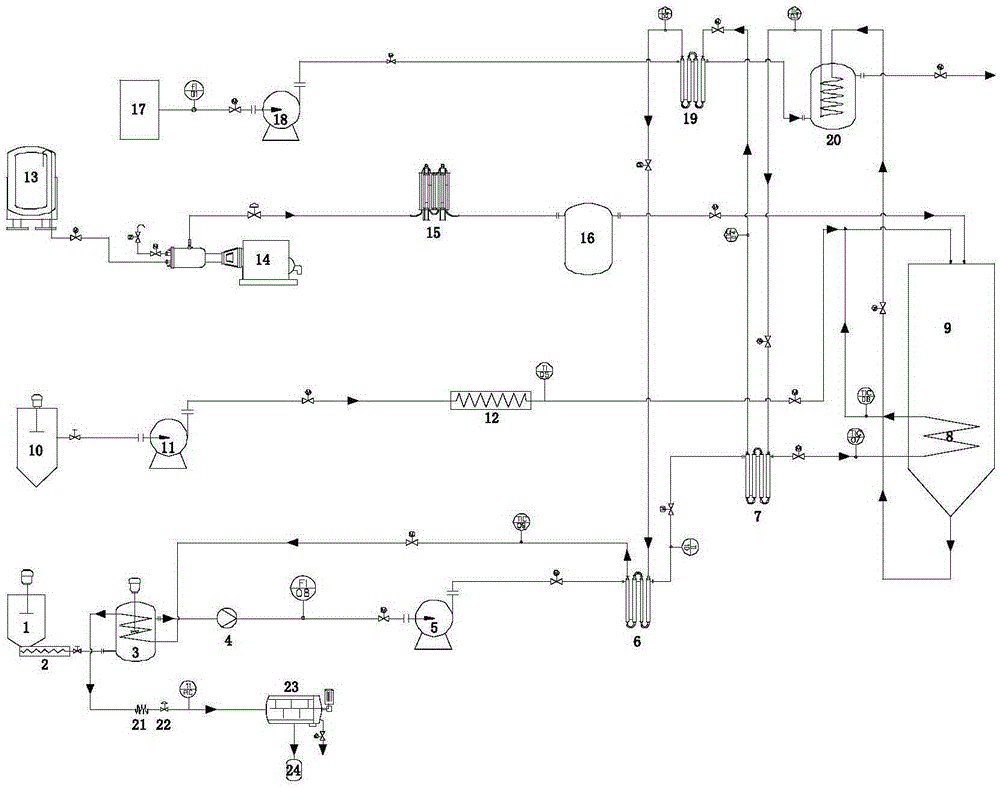

Supercritical water oxidation treatment system and technology for dyeing sludge

InactiveCN105254146APrevent coking and carbon depositionImprove heat transfer efficiencySludge treatment by oxidationByproduct vaporizationSludgeEngineering

The invention discloses a supercritical water oxidation treatment system and technology for dyeing sludge. A sludge heater is used for preheating the sludge to reduce the viscosity of the sludge, and thus the mobility of the sludge is improved; methyl alcohol is used for auxiliary heating to serve as a system preheating heat source in the starting stage, and the problem of pipeline coking congestion caused by direct heating of materials is solved; the flowing speed of fluid is controlled to prevent solid particles from settling and causing blockage in a system conveying pipeline, and the safe reliability of operation of the system is improved. The pressure of the system is reduced in the mode of combining capillary tubes with a regulating valve, corrosion or blockage of the solid particles on a depressurizing valve under a large pressure drop condition is avoided, and the pressure of the system can be accurately controlled. Oxidation released heat of organic matter is recycled in the mode of preheating the sludge and generating steam, energy is used in a gradient mode, the energy utilization rate is maximized, and the economy of the system is improved.

Owner:山川丽(苏州)环保科技有限公司

Methods for removing contaminants from water

InactiveUS20130126442A1Reduce level of contaminantSludge treatmentWater treatment compoundsFluidized bedSupercritical water oxidation

A method for reducing inorganic contaminant levels during supercritical water oxidation (SCWO) is provided. The method utilizes a fluidized bed reactor wherein inorganic contaminants in the water precipitate out onto the catalyst. The clean water is reclaimed after oxidation of organic contaminants and reduction of inorganic contaminant levels.

Owner:GENERAL ELECTRIC CO

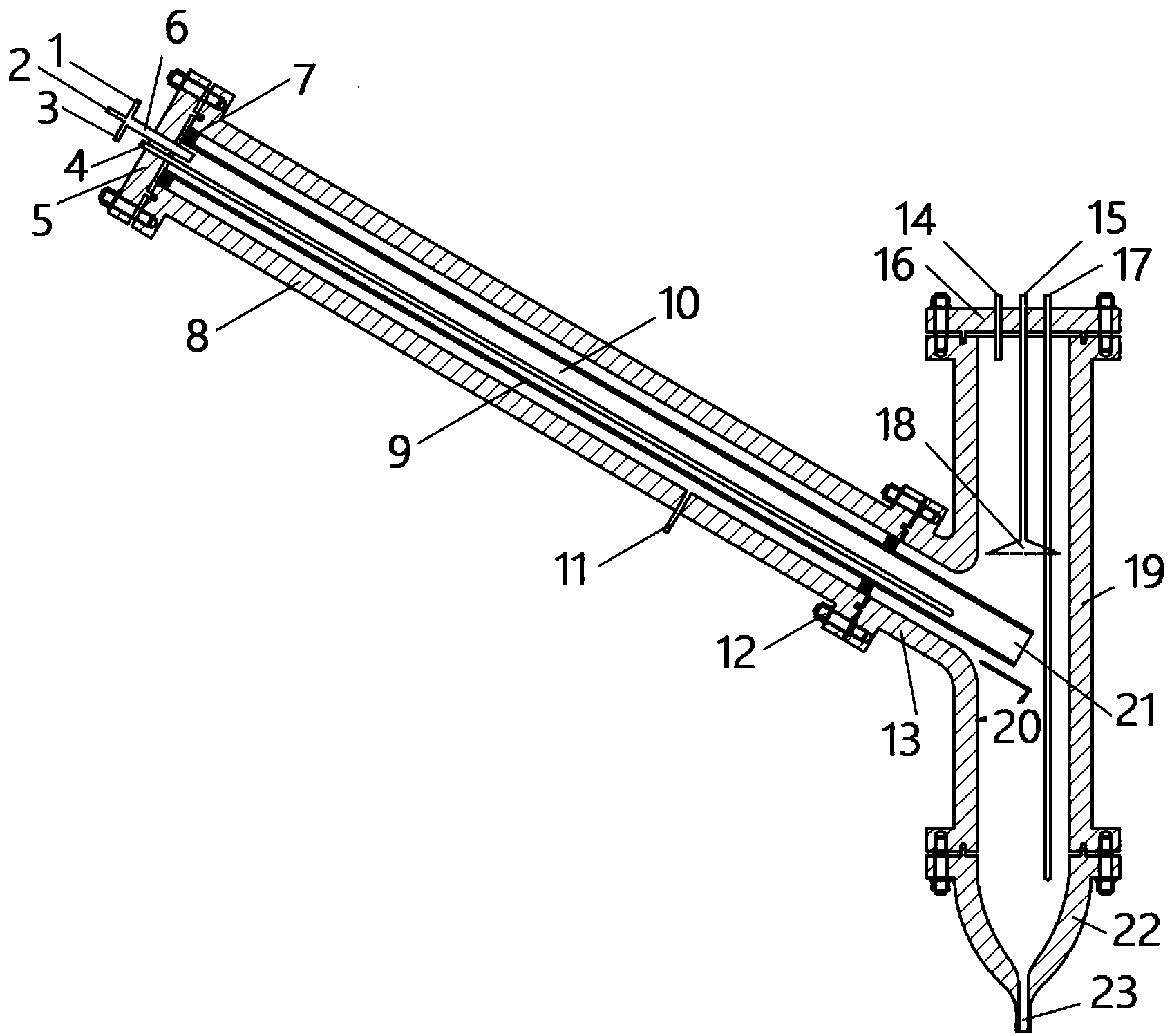

Supercritical water oxidizing device

ActiveCN104291546AAvoid depositionSafe Continuous Supercritical Water Oxidation TreatmentSludge treatment by oxidationSpecific water treatment objectivesEngineeringSupercritical water oxidation

The invention provides a supercritical water oxidizing device. The supercritical water oxidizing device comprises a reactor which is placed in an inclined manner, wherein the reactor comprises a reactor barrel body and an inner barrel body arranged in the reactor barrel body; a ring-shaped gap is formed between the reactor barrel body and the inner barrel body; an end enclosure is arranged at the upper end of the reactor; the inner barrel body is communicated with an oxidant inlet, a pollutant inlet and a supercritical water inlet by virtue of a channel arranged on the end enclosure; a plurality of through holes are formed in the inner barrel body; a boundary fluid inlet is formed in the reactor barrel body; the boundary fluid inlet is communicated with the inner part of the inner barrel body by virtue of the ring-shaped gap and the through holes; a vertically put separator comprises a separator barrel body and a cooling water distributor arranged in the separator barrel body, wherein a gas-liquid mixture discharging hole is formed in the upper end of the separator barrel body, a solid-liquid discharging hole is formed in the lower end of the separator barrel body; and the lower end of the reactor is connected to the circumferential side wall of the separator barrel body. According to the supercritical water oxidizing device disclosed by the invention, the reactor adopts an inclined type design, so that continuous treatment on pollutants with high solid content can be safely and stably realized.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

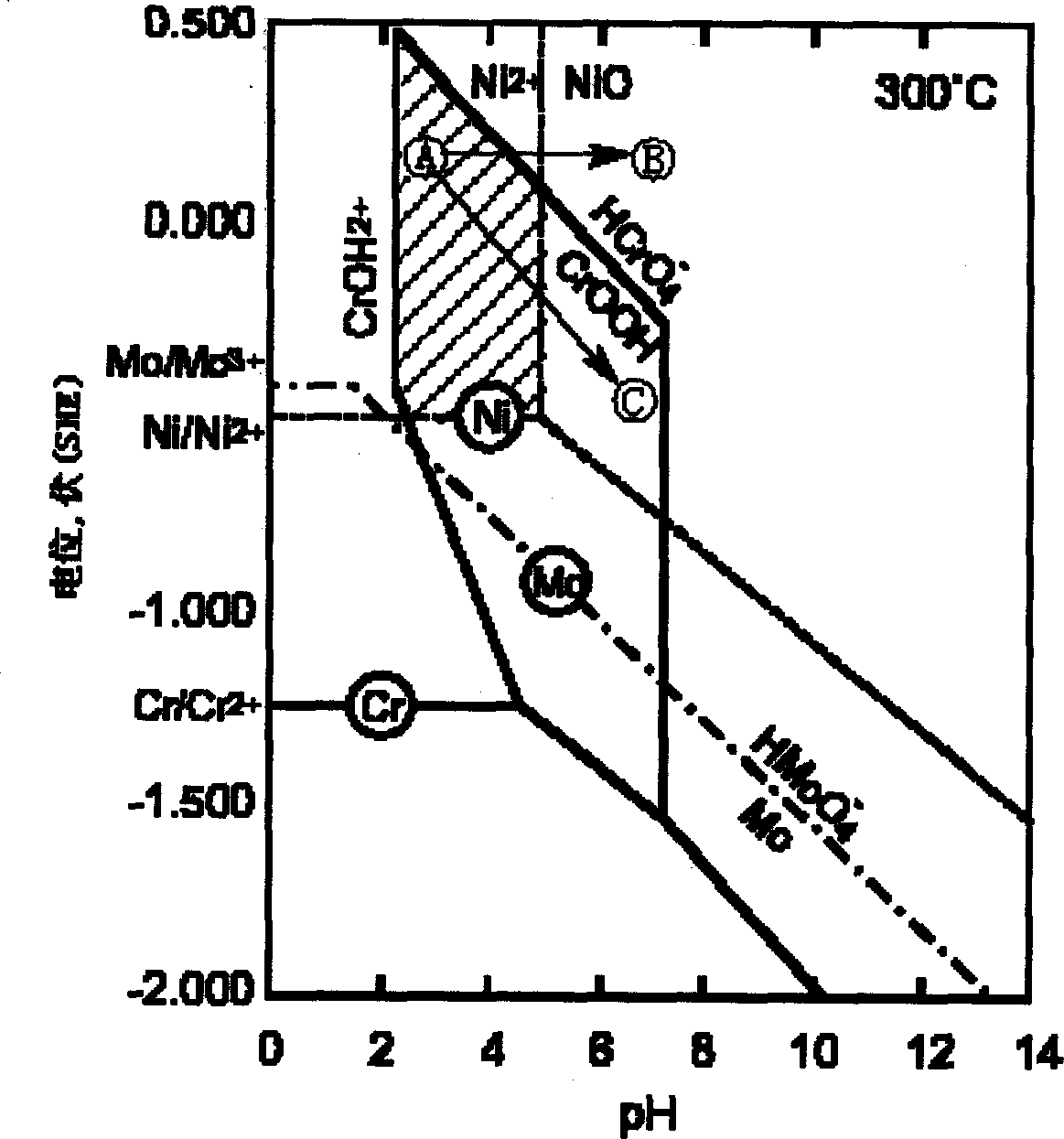

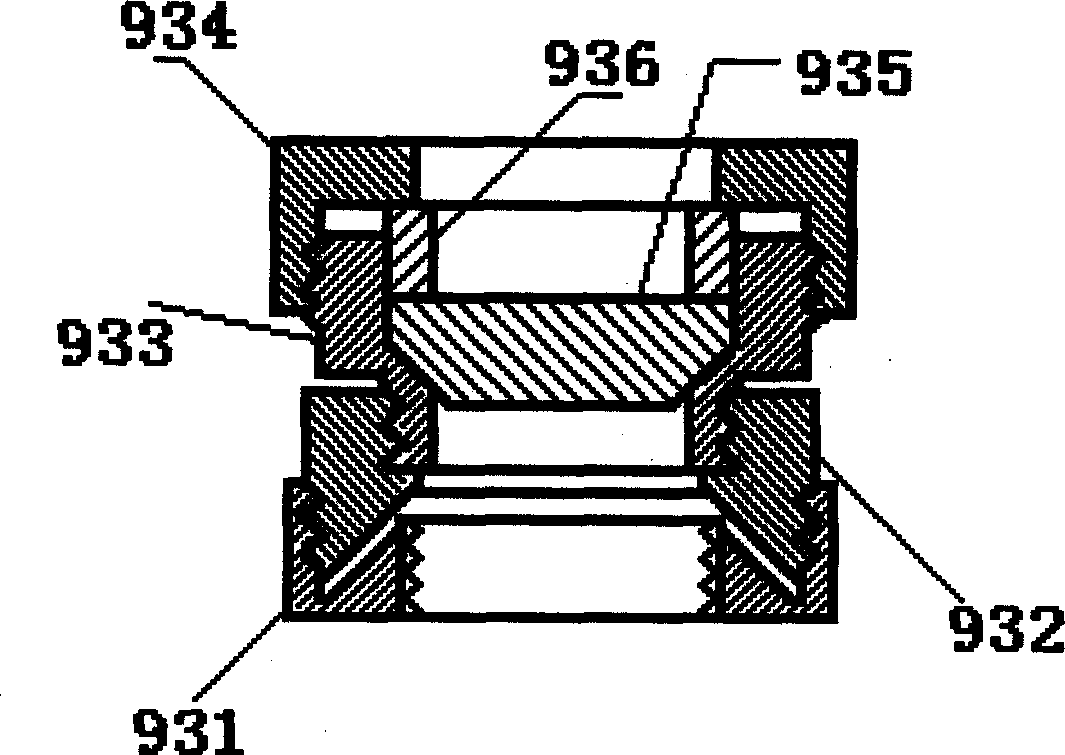

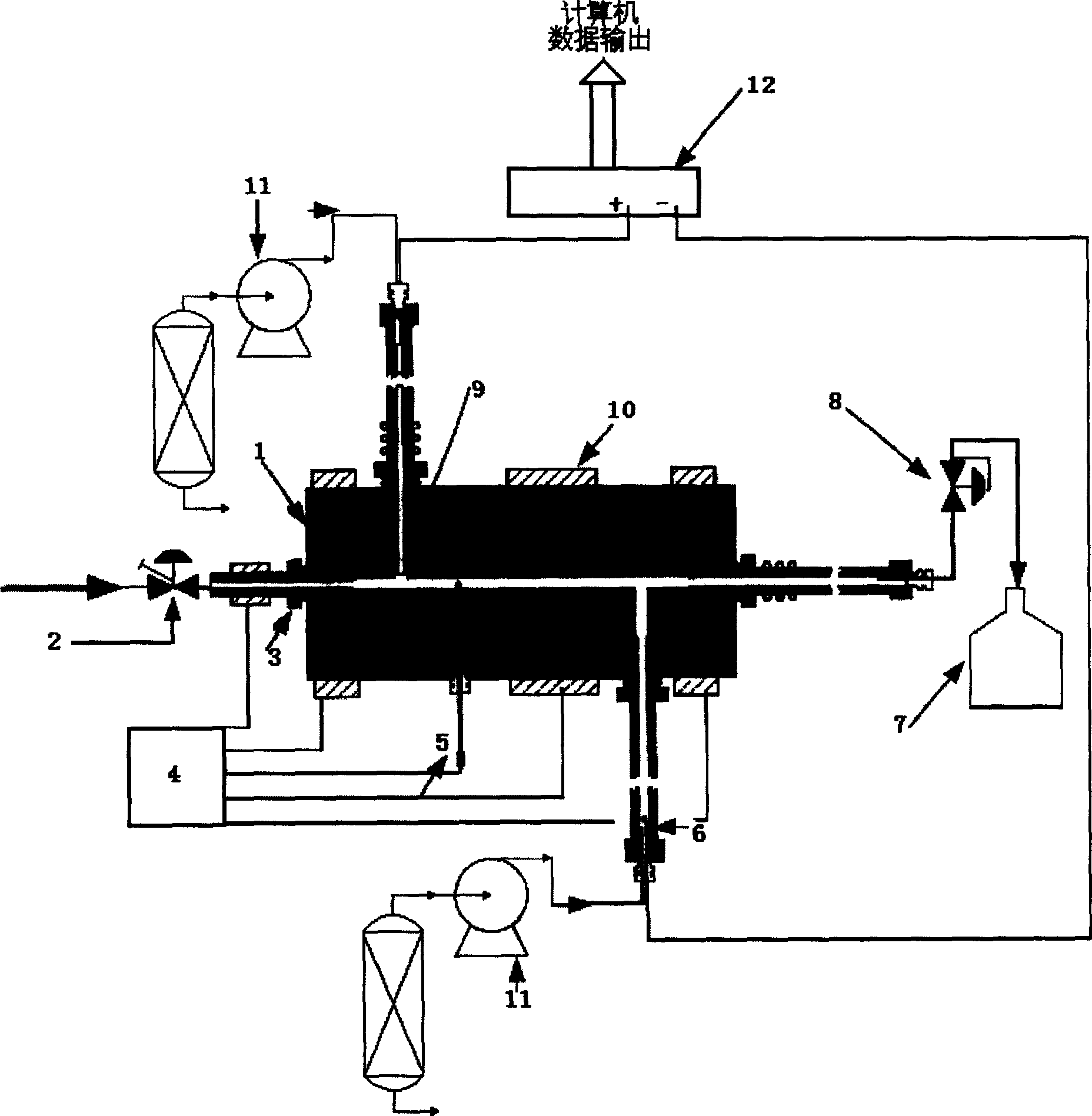

On-line testing method for PH value of bypass supercritical water oxidation environment and private apparatus thereof

InactiveCN1467495ALong-term online testStable jobMaterial electrochemical variablesElectrode potentialPhysical chemistry

The invention discloses a by-passage super critical water oxidation environment pH value online measuring method and dedicated apparatus thereof characterized by that, filling a standard solution into the electrochemical cell through a pH sensor, filling a reference solution into the electrochemical pool through a reference electrode, obtaining the electrode potential E1 of the pH value sensor in relative to the reference electrode, filling another standard solution into the electrochemical cell through the pH sensor, obtaining the electrode potential E2 of the pH value sensor in relative to the reference electrode in the same manner, stopping the filling of the standard solution, filling the test solution into the electrochemical cell, at the same time filling the reference solution into the reference electrode, obtaining the electrode potential test of the pH value sensor in the test solution environment in relative to the reference electrode, obtaining the pH-test value of the measured solution according to the high temperature calculating formula.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Corrosion-resistant anti-clogging organic pollutant supercritical water oxidation system

ActiveCN102989371ALow solid contentReduce heavy metal contentPressurized chemical processSludge treatment by oxidationSolubilityResource utilization

The invention discloses a corrosion-resistant anti-clogging organic pollutant supercritical water oxidation system which comprises a raw material preheating and feeding device, an oxidation degradation device and a material discharging and cooling device. The oxidation degradation device comprises a gas-solid separator communicated with an oxidation reactor. The system separates water insoluble solids and inorganic salt which are carried by pollutants and generated a degradation process during an oxidation degradation process by virtue of the characteristic of extremely low solubility of the inorganic salt in supercritical water, thereby avoiding heat / mass transfer efficiency reduction as well as pipeline clogging which are caused by the deposition and attachment of the water insoluble solids and the inorganic salt on the inner wall of the system; meanwhile, saline solution caused by alkaline liquid introduction and corrosion reduction can also be prevented, and thus the corrosion-resistant anti-clogging organic pollutant supercritical water oxidation system is more environment-friendly compared with the conventional equipment; and additionally, the system is provided with the equipment with high anti-corrosion capability, uses less process water, is low in energy consumption, can run in an industrialization scale easily, and can be widely applied to bio-safety disposal and resource utilization of organic waste water / liquid, urban sludge and volatile poisonous substances.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Heat energy recovery method for supercritical water oxidizing system

ActiveCN105152248AAchieve enrichmentRealized benefitsWater/sewage treatment by heatingWater heatersRecovery methodThermal energy

The invention relates to the technical field of energy and environments, in particular to a heat recovery method for a low-temperature multi-effect distillation united supercritical water oxidizing system. Supercritical water oxidizing reaction heat is recovered by three stages of heat recovery systems, wherein the heat of the first-stage recovery system is recovered to preheat condensed wastewater drained from a low-temperature multi-effect distiller and upper-branch evaporable water; the second-stage recovery system recovers the remaining heat recovered by the first-stage recovery system, and the heat is used for heating heat source water; the third-stage recovery system is used for recovering the remaining heat recovered by the second-stage recovery system and recovering heat generated at the bottom of the low-temperature multi-effect distiller, and the heat is used for heating cooling water. Through step-by-step heat recovery, the recovered heat is utilized stepwise, and the energy consumption of the system is greatly reduced.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com