Supercritical water oxidation treatment system and technology for dyeing sludge

A technology for supercritical water oxidation, printing and dyeing sludge, applied in water/sludge/sewage treatment, sludge treatment, sludge oxidation treatment, etc. The effect of avoiding blockage of pipes, maximizing energy utilization and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

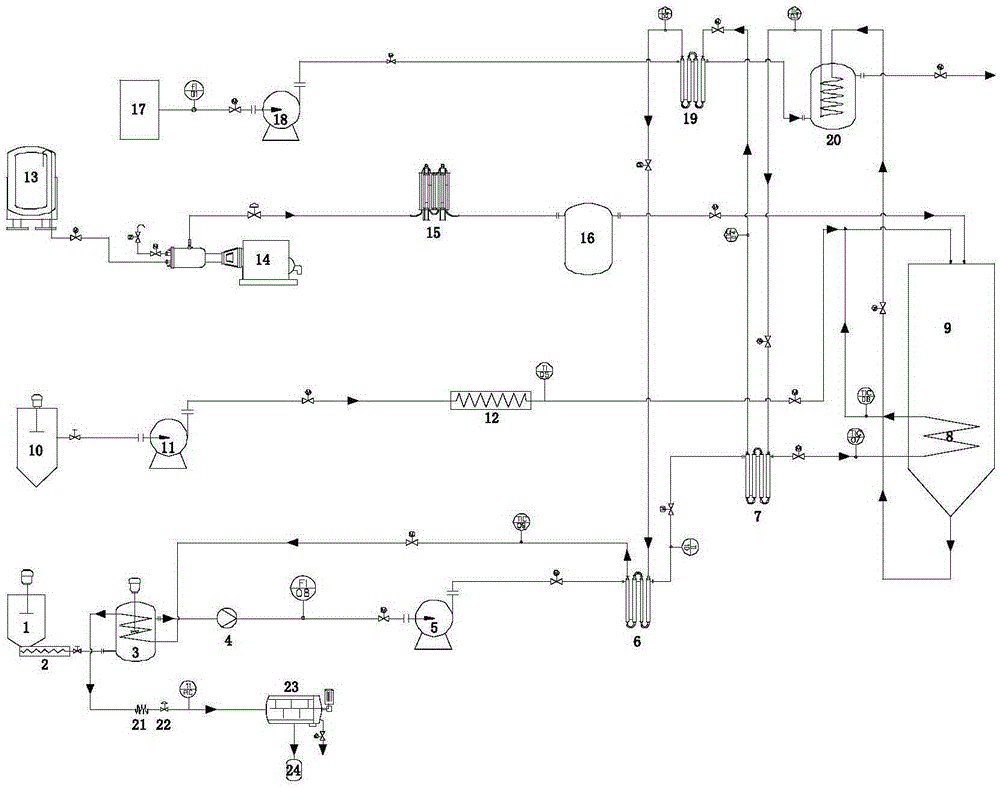

[0030] Such as figure 1 As shown, a supercritical water oxidation treatment system for printing and dyeing sludge of the present invention includes a sludge pretreatment part, a material preheating part, a mixed reaction part, a heat recovery part and a pressure reduction part. The connection mode of the equipment in the system is as follows:

[0031] The sludge pretreatment part includes a sludge storage tank 1, the outlet of the sludge storage tank 1 is connected to the inlet of the screw pump 2, the outlet of the screw pump 2 is connected to the inlet of the shell side of the sludge heater 3, and the outlet of the shell side of the sludge heater 3 is connected The homogeneous emulsification pump 4 inlet, the homogeneous emulsification pump 4 outlet communicates with the high-pressure sludge diaphragm pump 5 inlet.

[0032] The material preheating part includes a methanol starting electric heater 12 and a sludge preheater III 8. The inlet of the methanol starting electric he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com