Patents

Literature

1460results about "Sludge treatment by oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

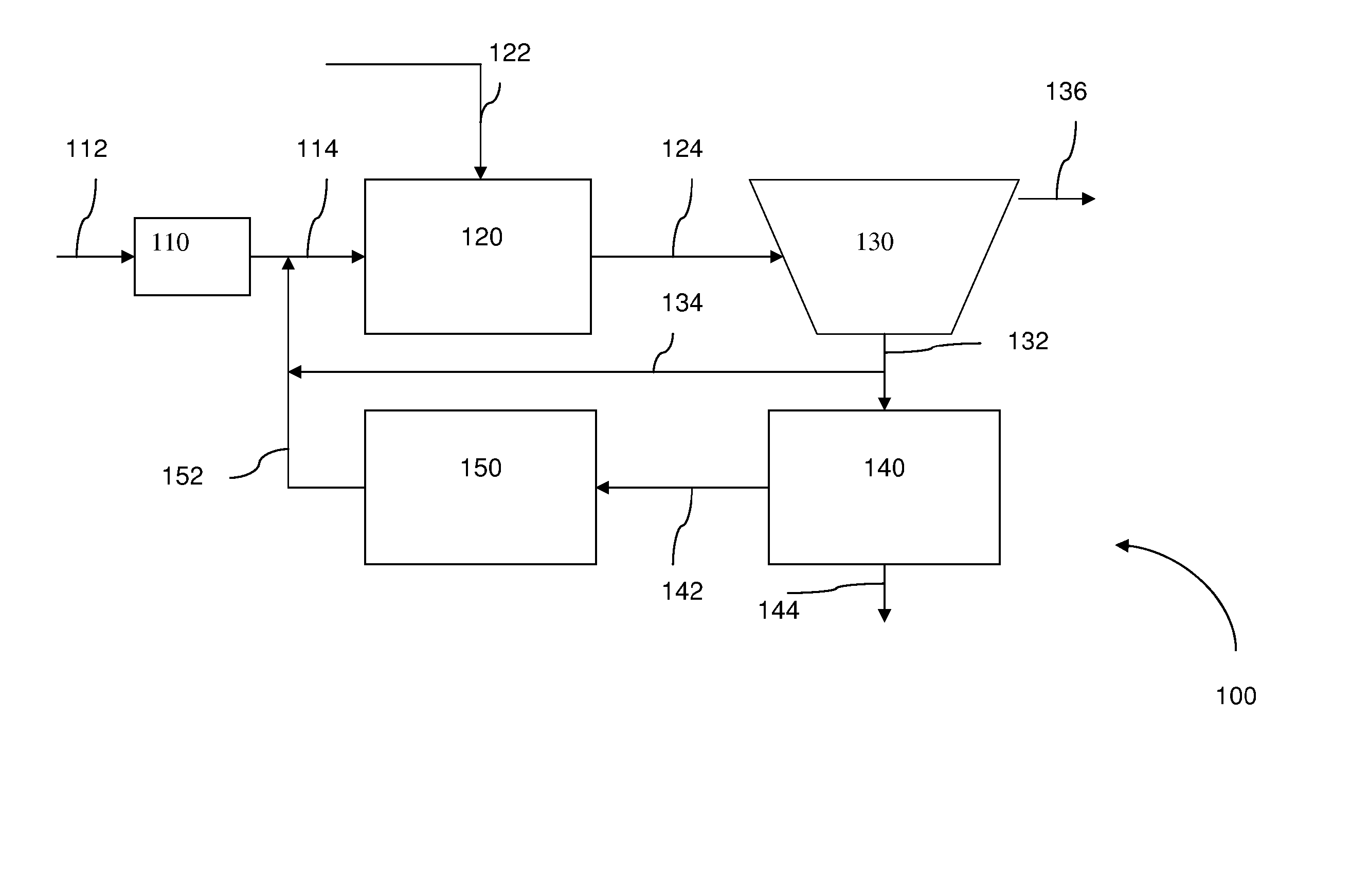

Method for processing lignocellulosic material

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

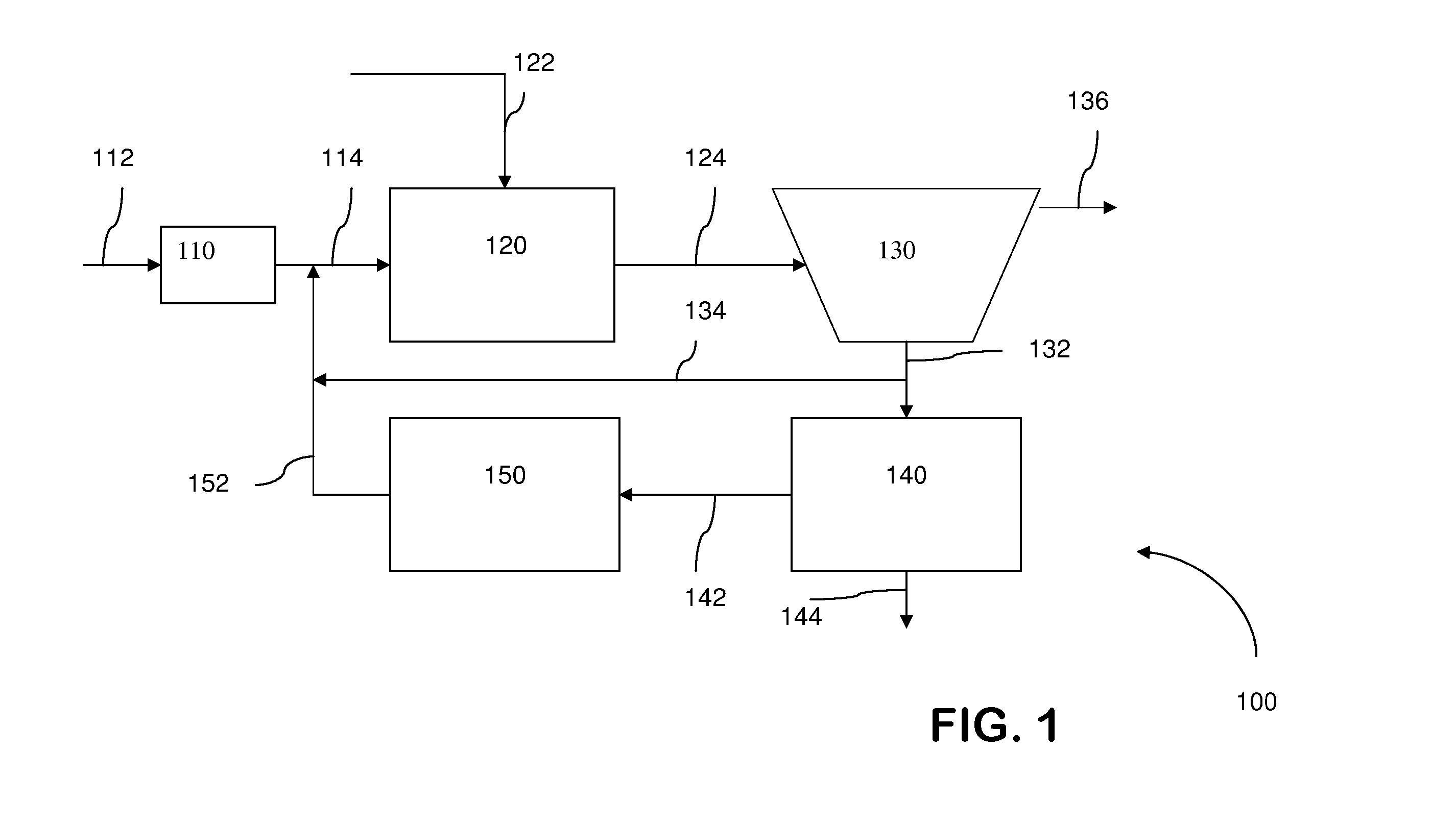

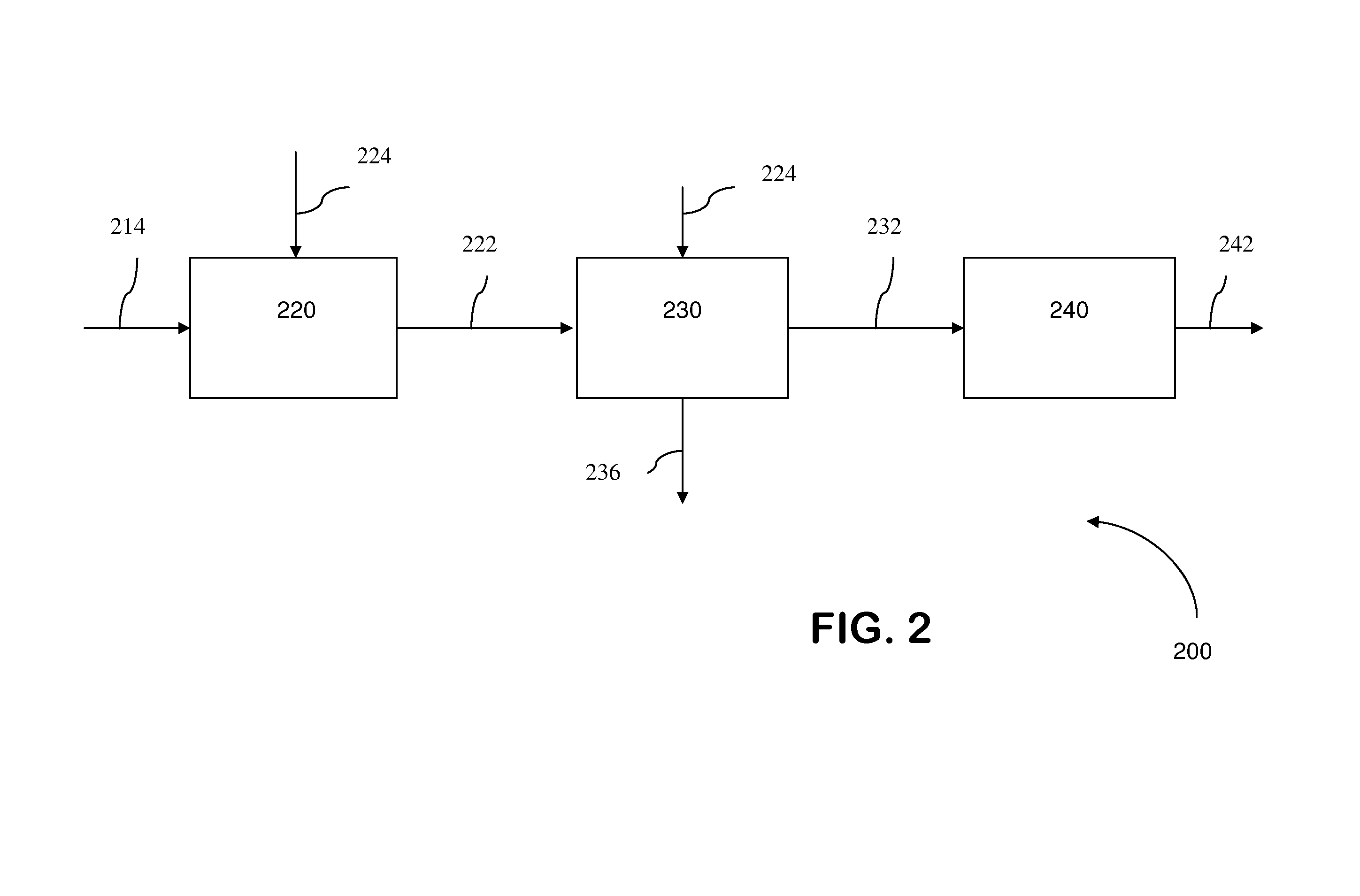

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

Wastewater treatment system and method

ActiveUS20070209999A1Treatment using aerobic processesTreatment involving filtrationActivated carbonWater treatment system

The invention is directed to a method and apparatus for treating wastewater. The wastewater treatment system includes a bioreactor including activated carbon and a first biological population. The wastewater treatment system may also include a membrane bioreactor and / or a wet oxidation unit.

Owner:SIEMENS ENERGY INC

Method for processing lignocellulosic material

InactiveUS20020192774A1High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseEnvironmental engineering

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process. involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

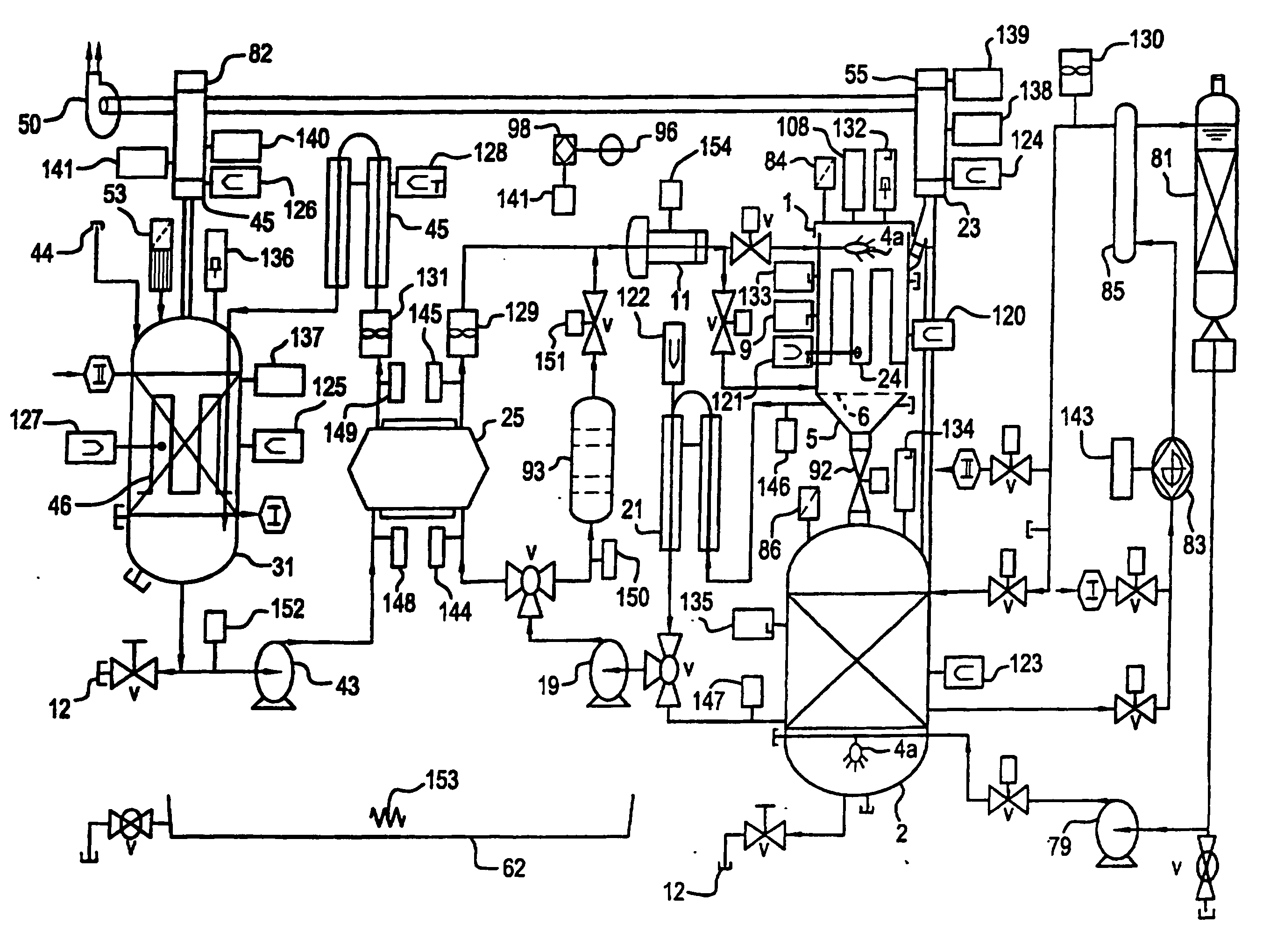

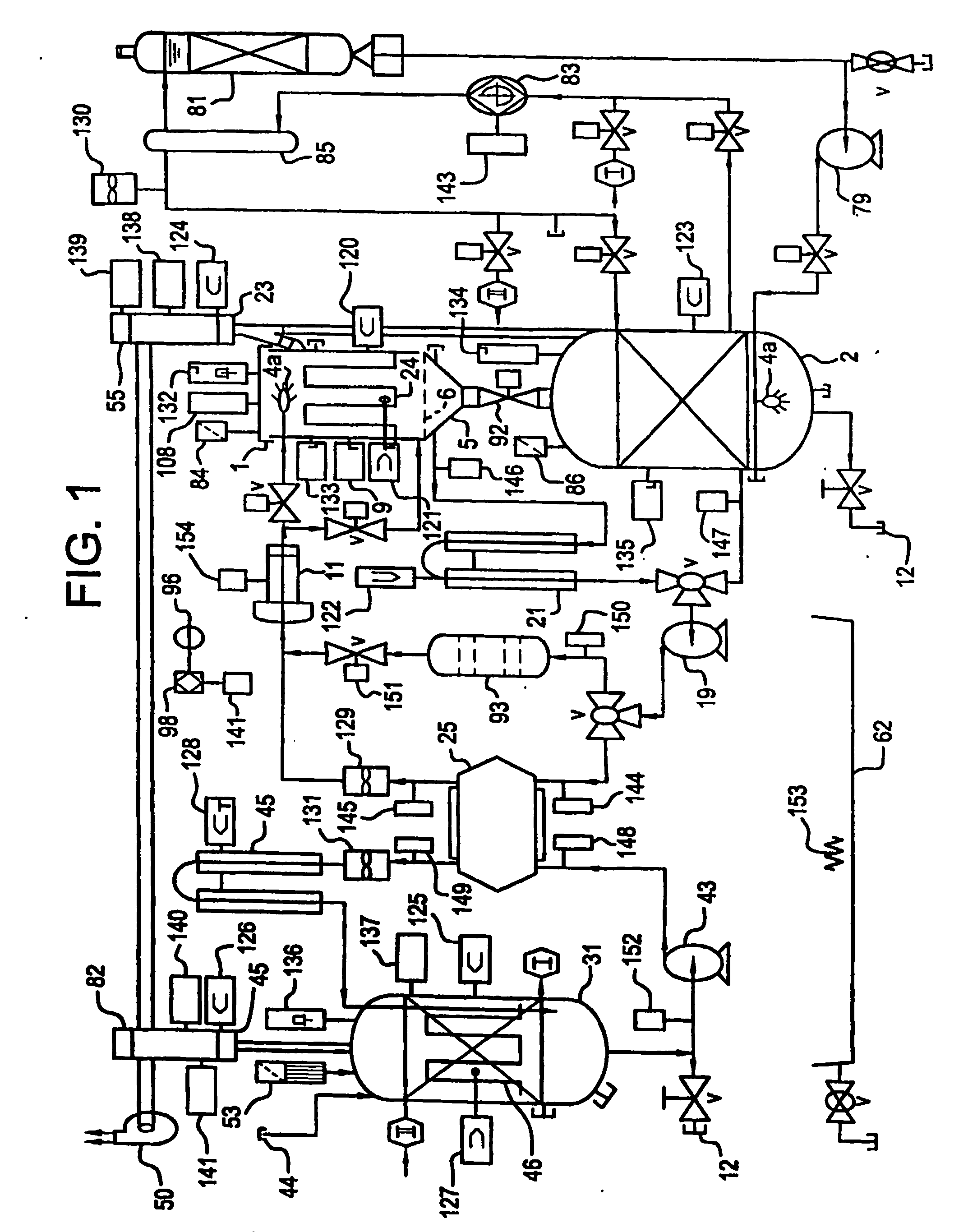

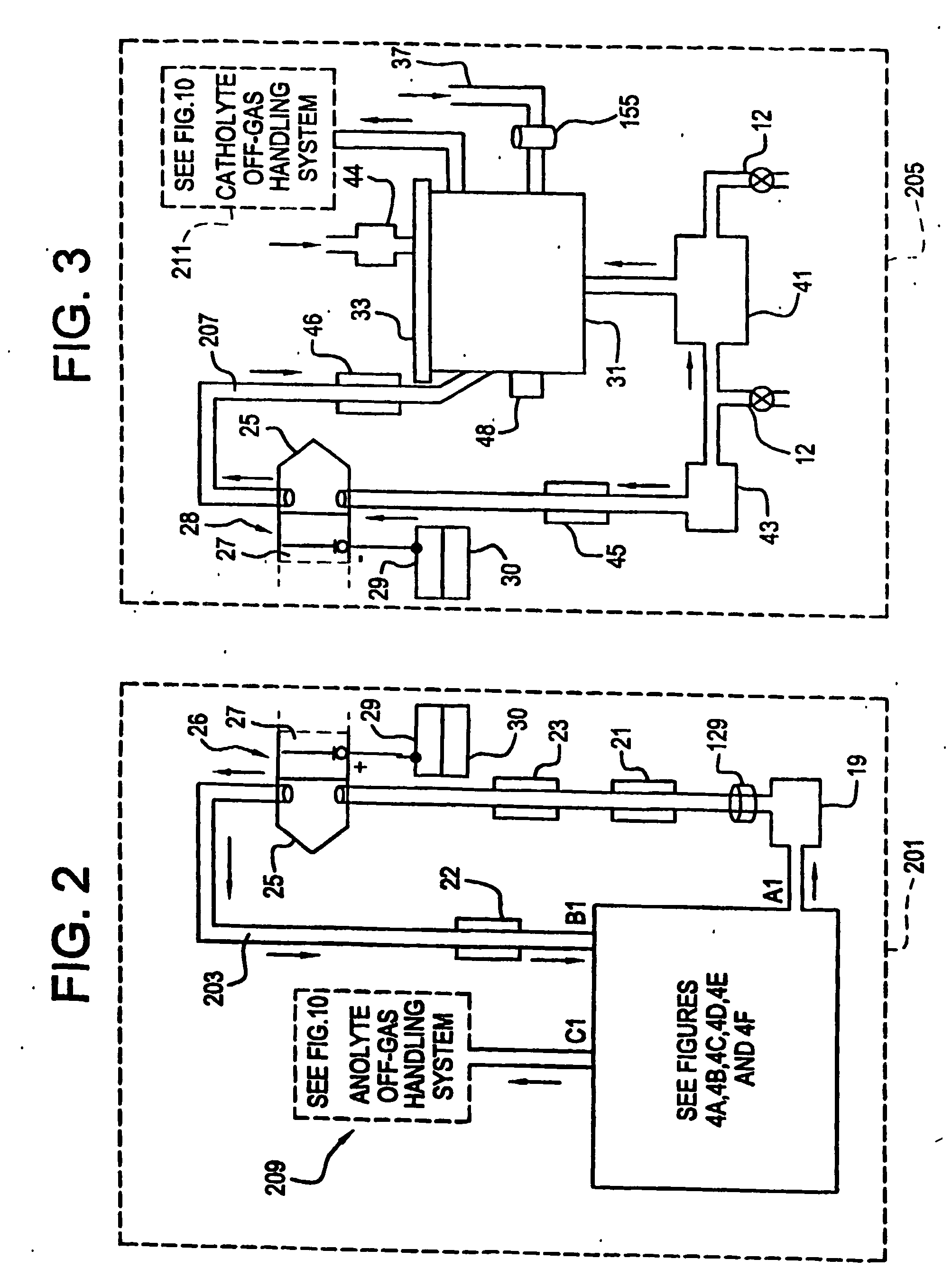

Apparatus and process for mediated electrochemical oxidation of materials

A unique apparatus unique apparatus and process that uses mediated electrochemical oxidation (MEO) for: (1) Destruction of: a) nearly all organic solid, liquid, and gases materials, except fluorinated hydrocarbons; b) all biological solid, liquid, and gases materials; c) and / or dissolution and decontamination (such as cleaning equipment and containers, etc.) of nearly all inorganic solid, liquid, or gas where higher oxidation states exist which includes, but is not limited to, halogenated inorganic compounds (except fluorinated), inorganic pesticides and herbicides, inorganic fertilizers, carbon residues, inorganic carbon compounds, mineral formations, mining tailings, inorganic salts, metals and metal compounds, etc.); and d) combined materials (e.g. a mixture of any of the foregoing with each other); henceforth collectively referred to as materials. (2) Sterilization / disinfection of equipment, glassware, etc., by destroying all existing infectious materials. (3) Dissolution of transuranic / actinide materials and / or destruction of the oxidizable components in the hazardous waste portion of mixed waste. (4) Generation of hydrogen and oxygen from MEO of materials. (5) Alteration of organic, biological, and inorganic materials by MEO to produce other compounds from these materials. The materials are introduced into an apparatus for contacting the materials with an electrolyte containing the oxidized form of one or more reversible redox couples, at least one of which is produced electrochemically by anodic oxidation at the anode of an electrochemical cell. The oxidized forms of any other redox couples present are produced either by similar anodic oxidation or reaction with the oxidized form of other redox couples present and capable of affecting the required redox reaction. The oxidized species of the redox couples oxidize the materials molecules and are themselves converted to their reduced form, whereupon they are reoxidized by either of the aforementioned mechanisms and the redox cycle continues until all oxidizable material species, including intermediate reaction products, have undergone the desired degree of oxidation. The entire process takes place at temperatures between ambient and approximately 100° C. The oxidation process may be enhanced by the addition of reaction enhancements, such as: ultrasonic energy and / or ultraviolet radiation.

Owner:SCIMIST LNC

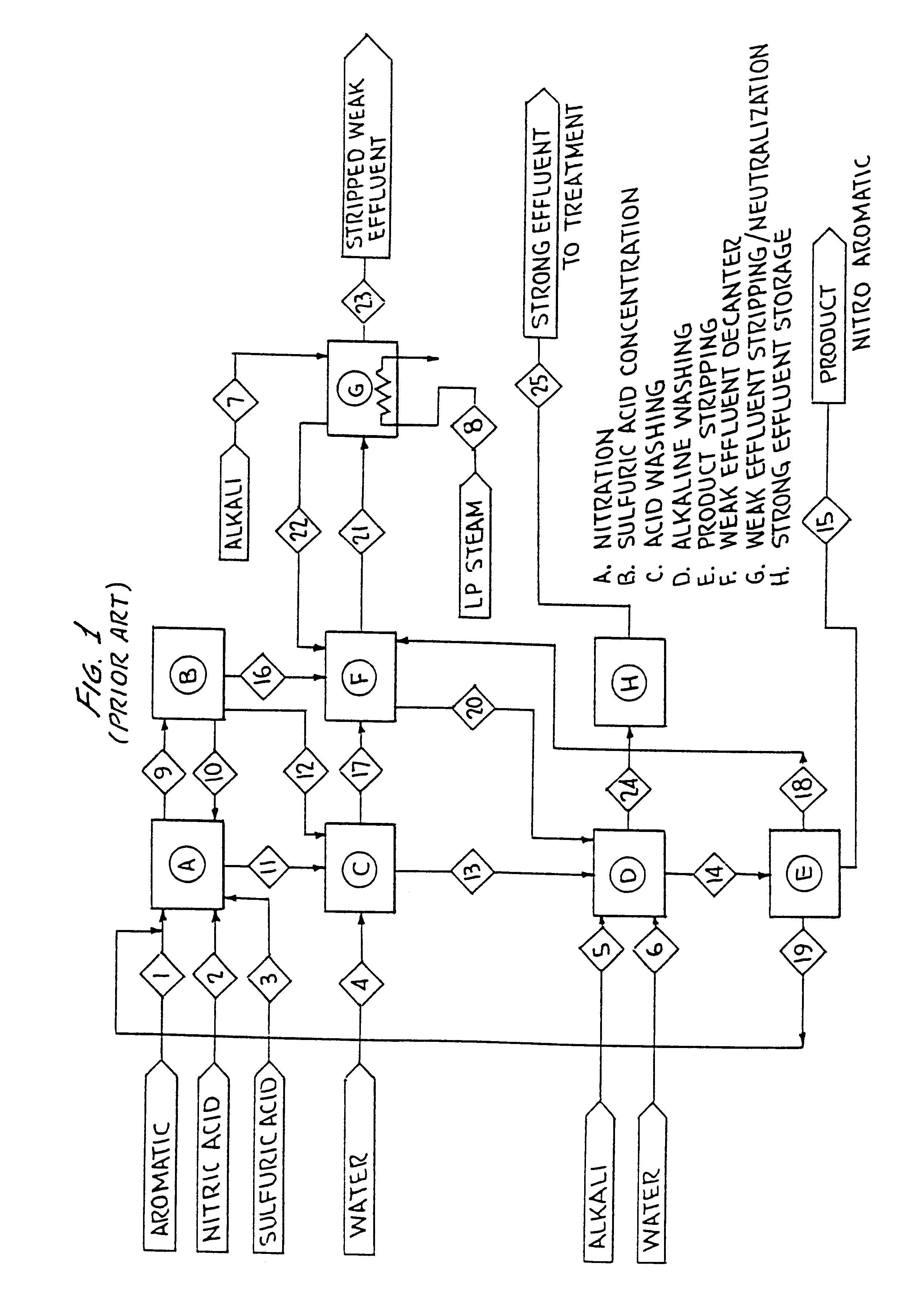

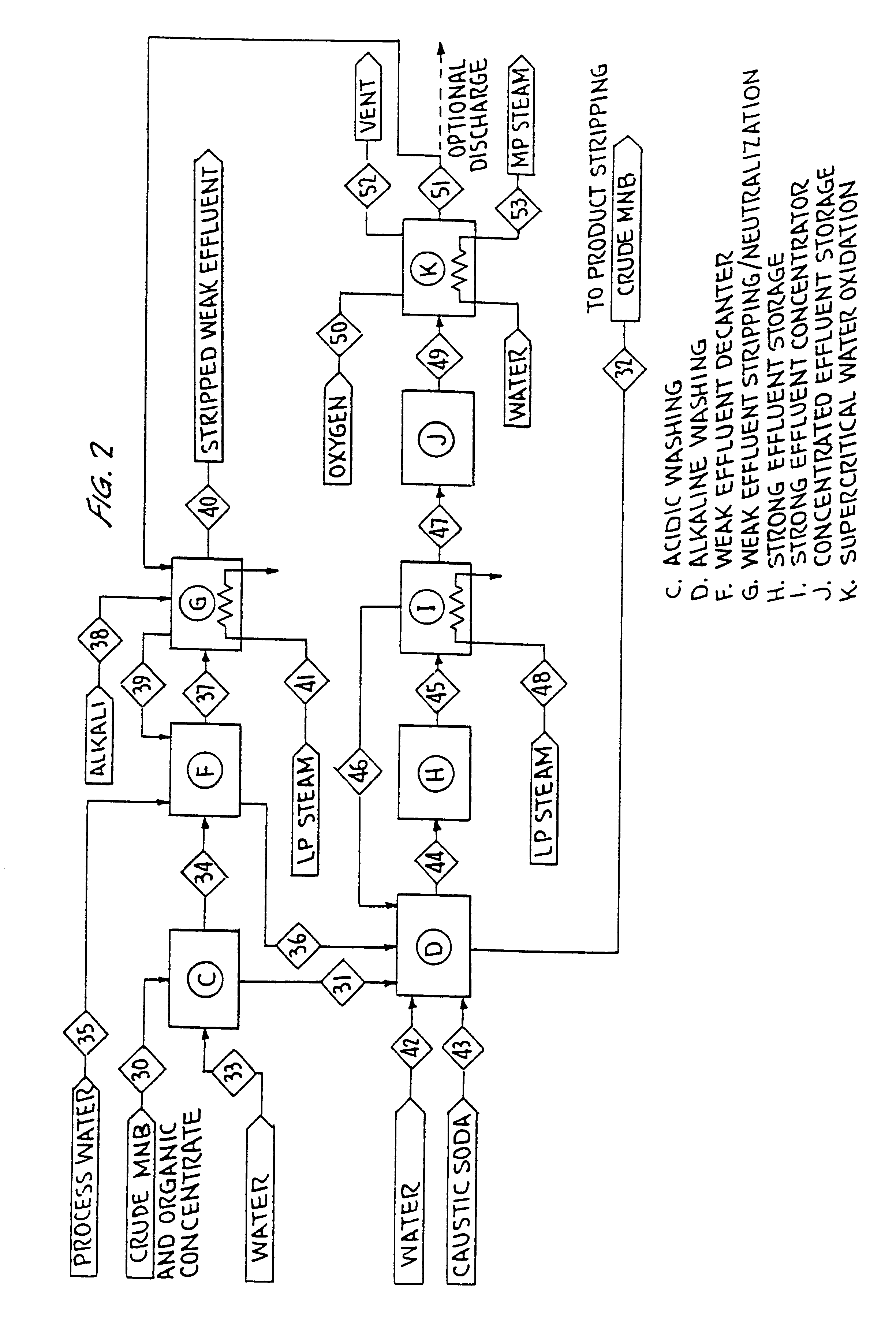

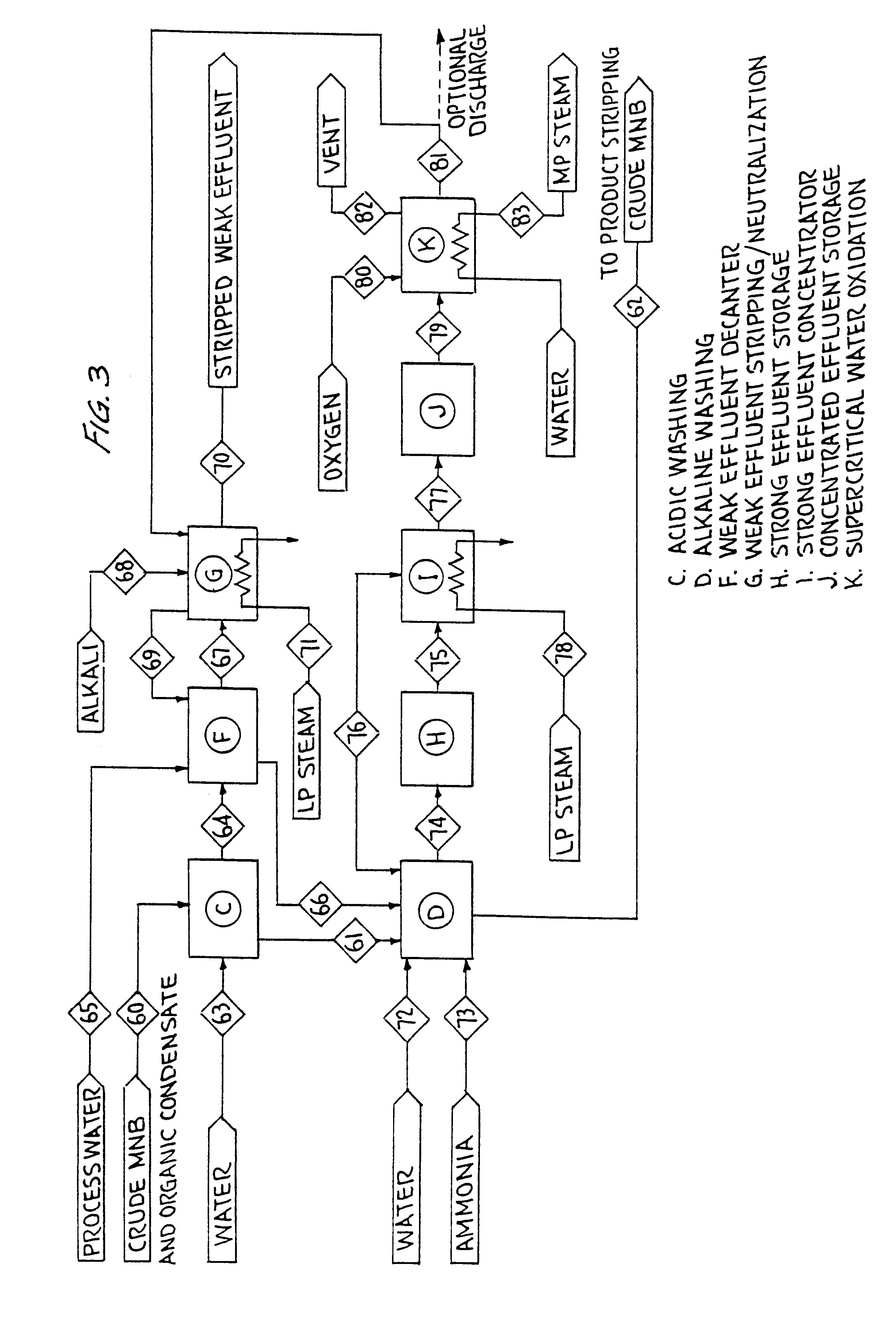

Integrated effluent treatment process for nitroaromatic manufacture

InactiveUS6288289B1Highly destructiveReduce consumptionOrganic chemistrySludge treatment by oxidationWash waterSupercritical water oxidation

An integrated process for treating alkaline wash water effluent from nitroaromatic manufacture, principally containing nitro-hydroxy-aromatic compounds is described. The integrated process concentrates the alkaline wash water to recover chemicals and water prior to treating the concentrate through supercritical water oxidation. The supercritical water oxidation step consists of treating the concentrate in the presence of an oxygen source at conditions, which are supercritical for water to cause a substantial portion of the organic component of the concentrate to oxidize. The product effluent includes a gaseous component and a clean water component, and in the event that insoluble ash is formed, an ash component. The new integrated process results in reduced chemical and water consumption compared to existing processes. In addition, the treated wash water effluent can be recycled to process or directly discharged.

Owner:NORAM INT

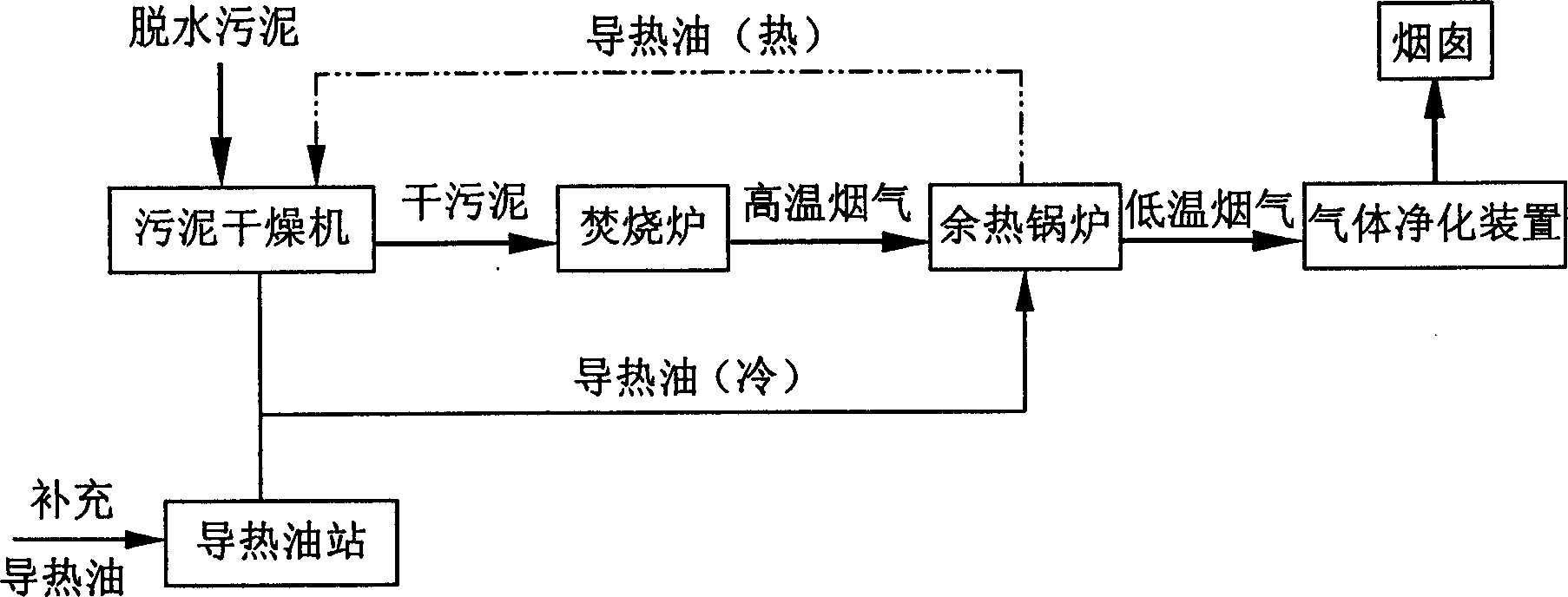

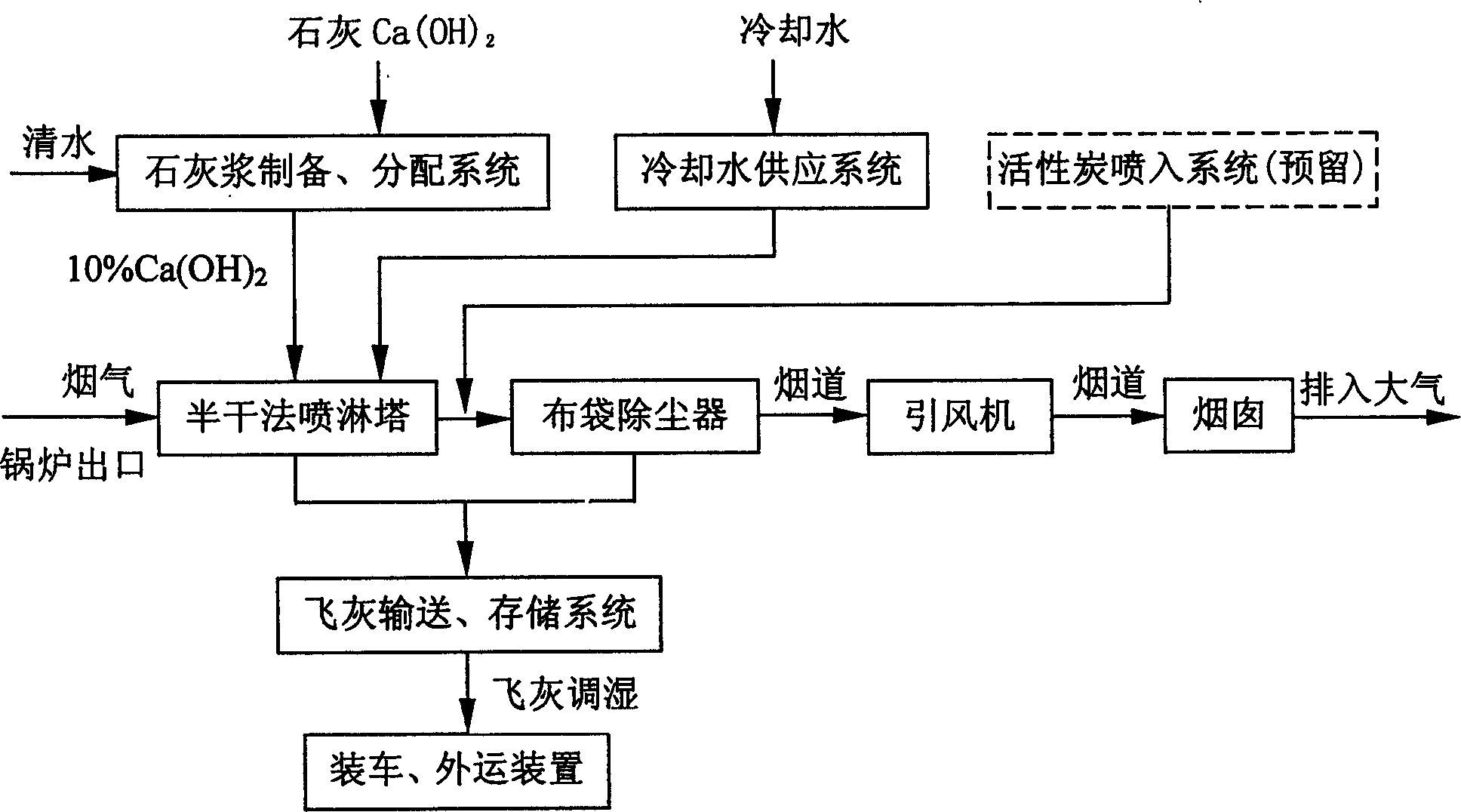

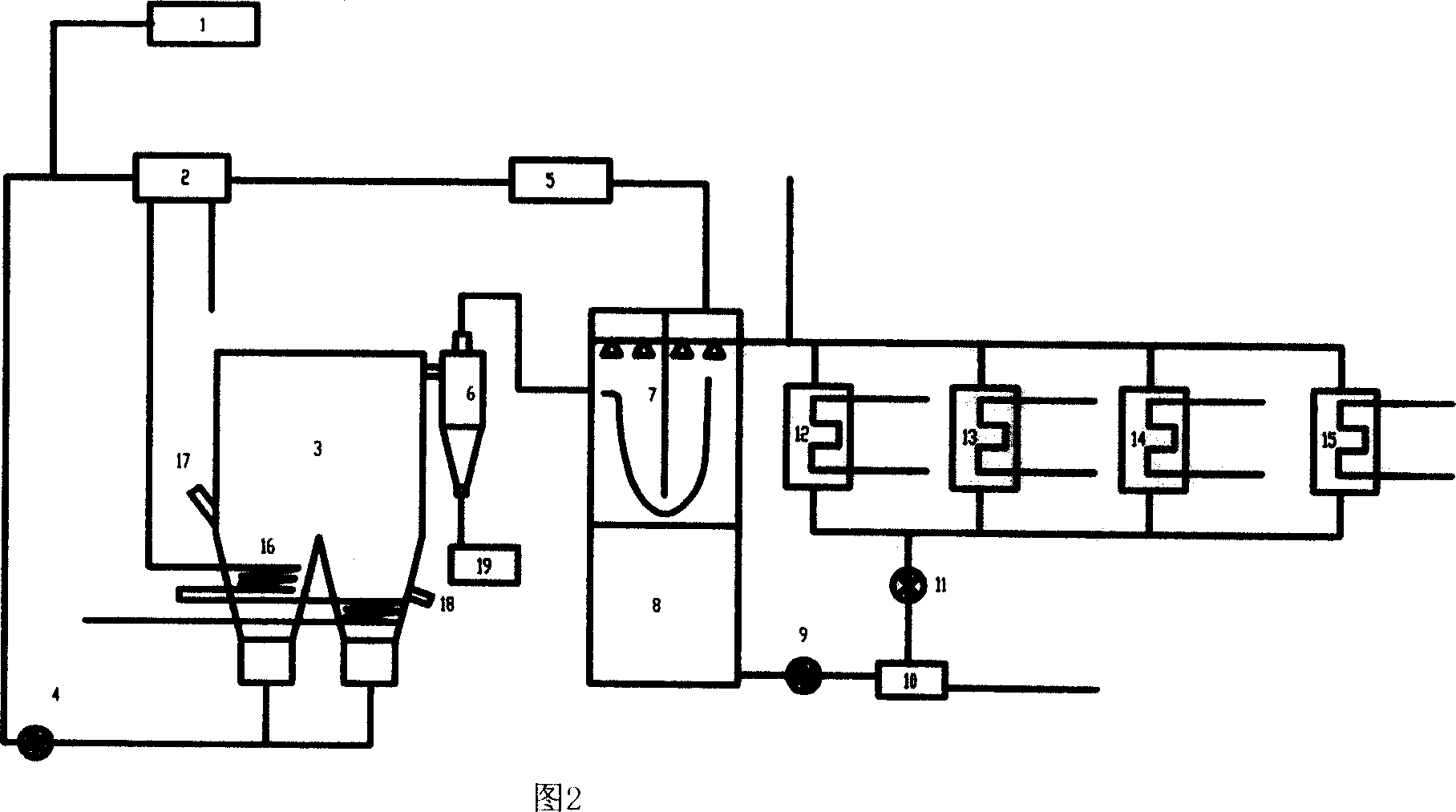

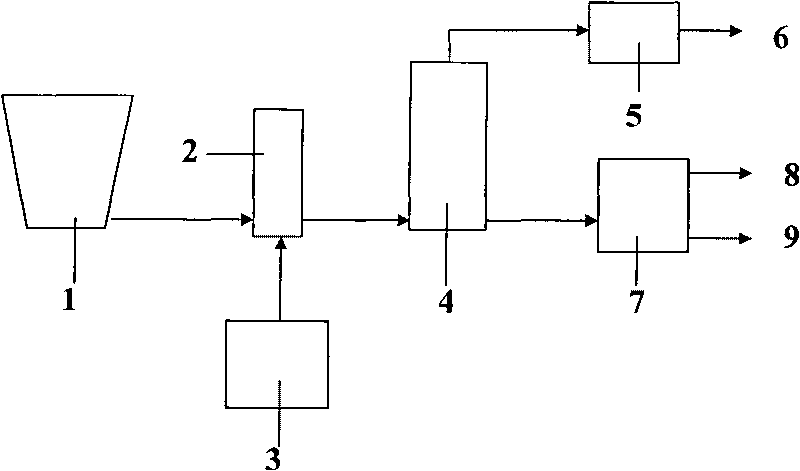

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

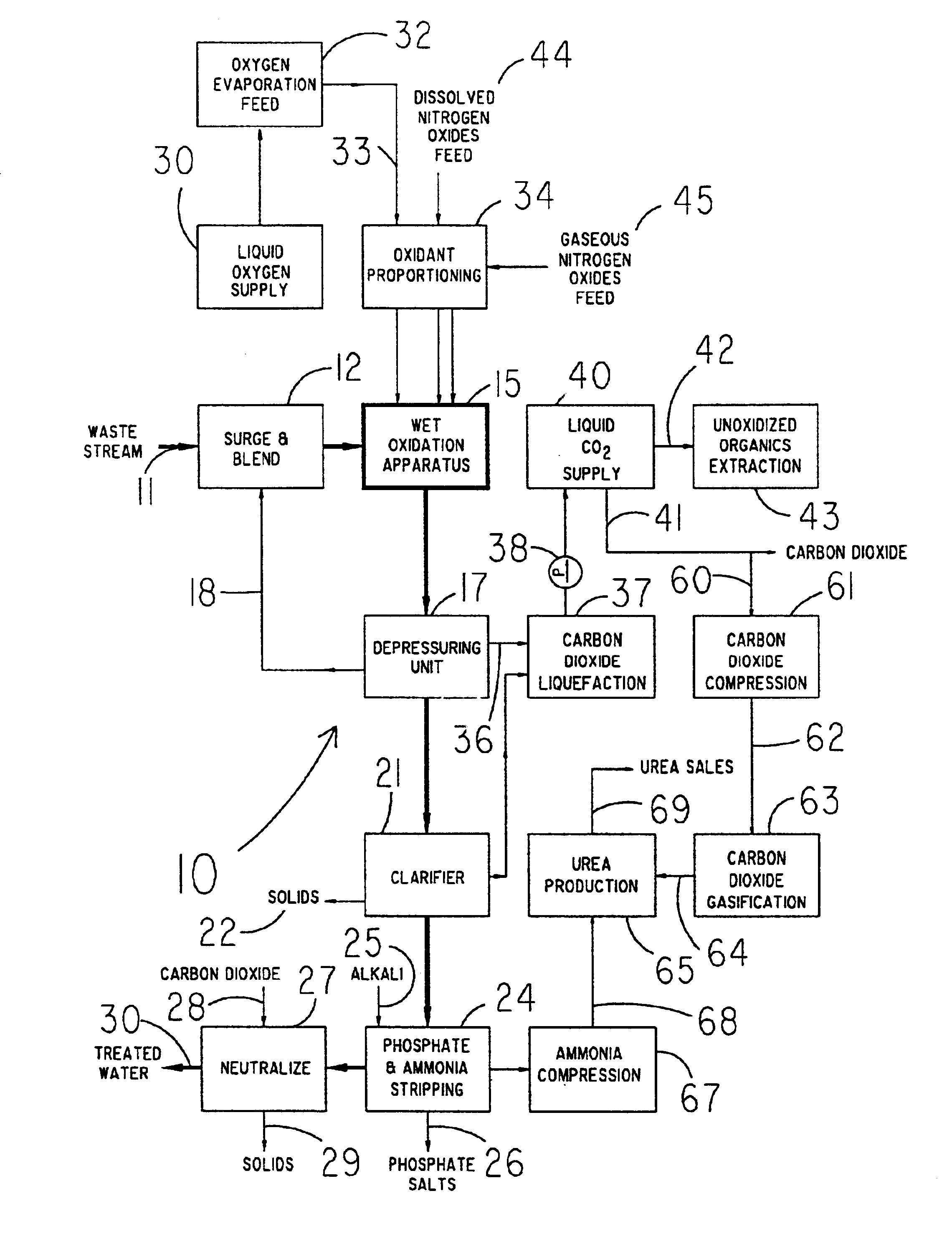

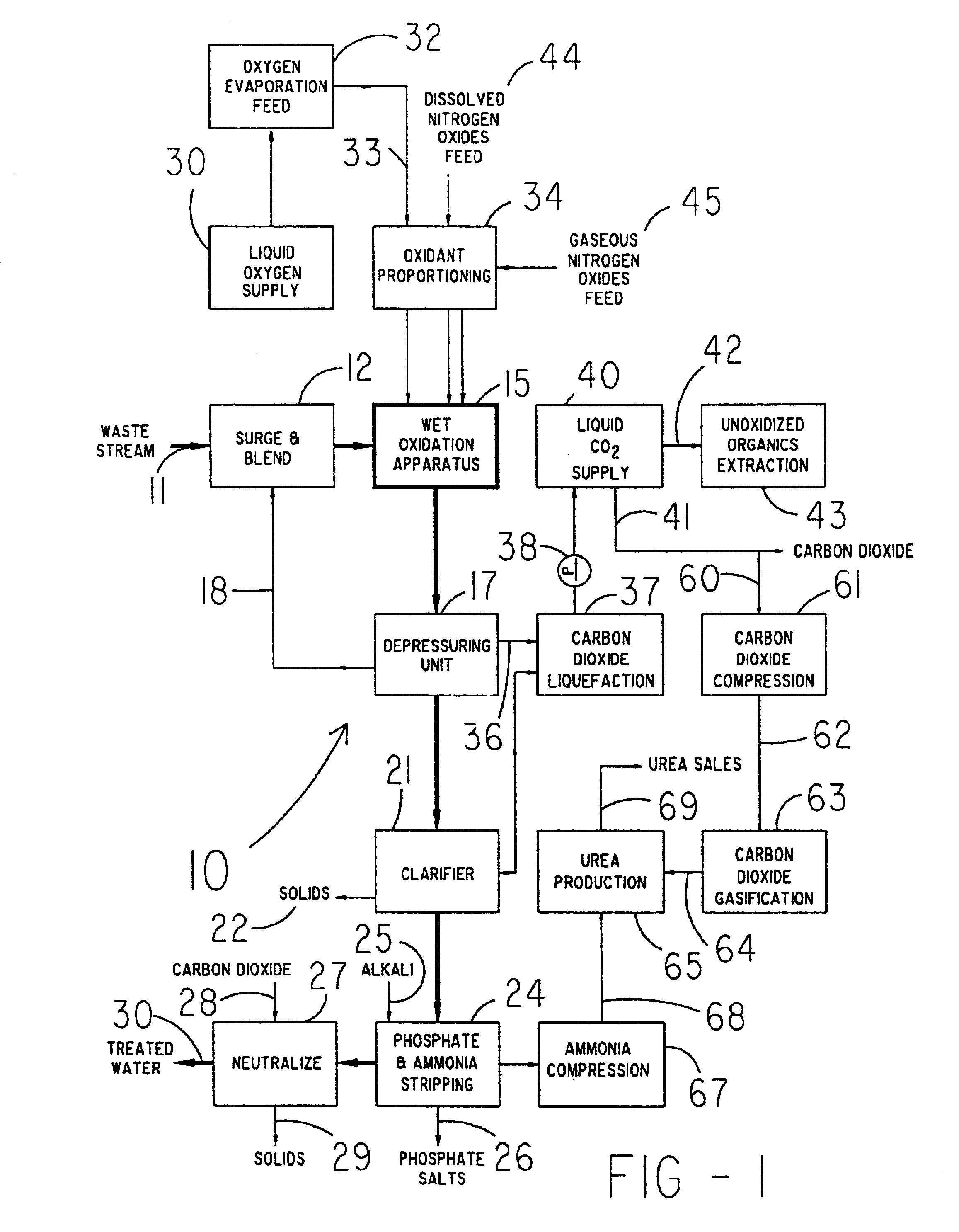

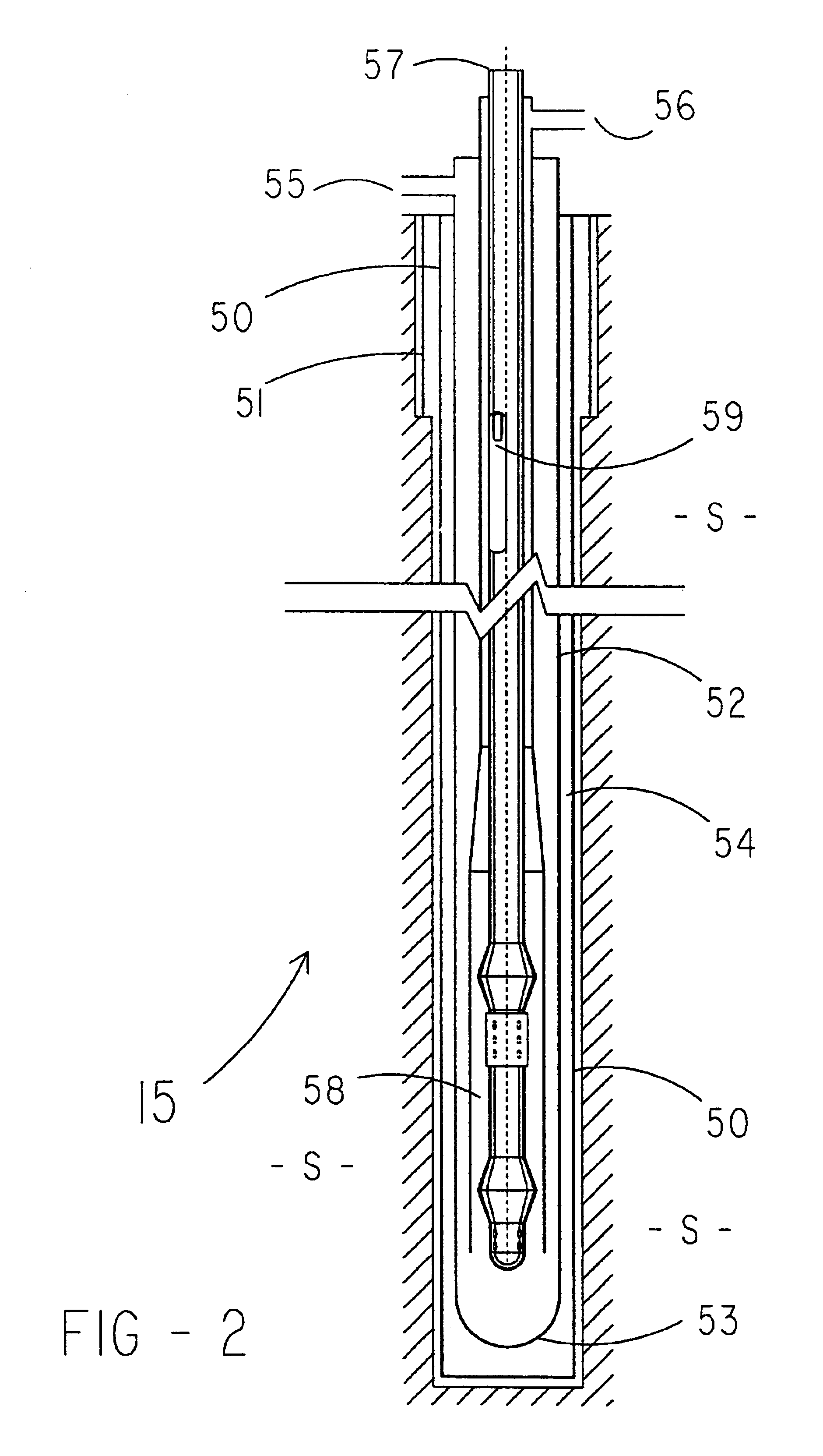

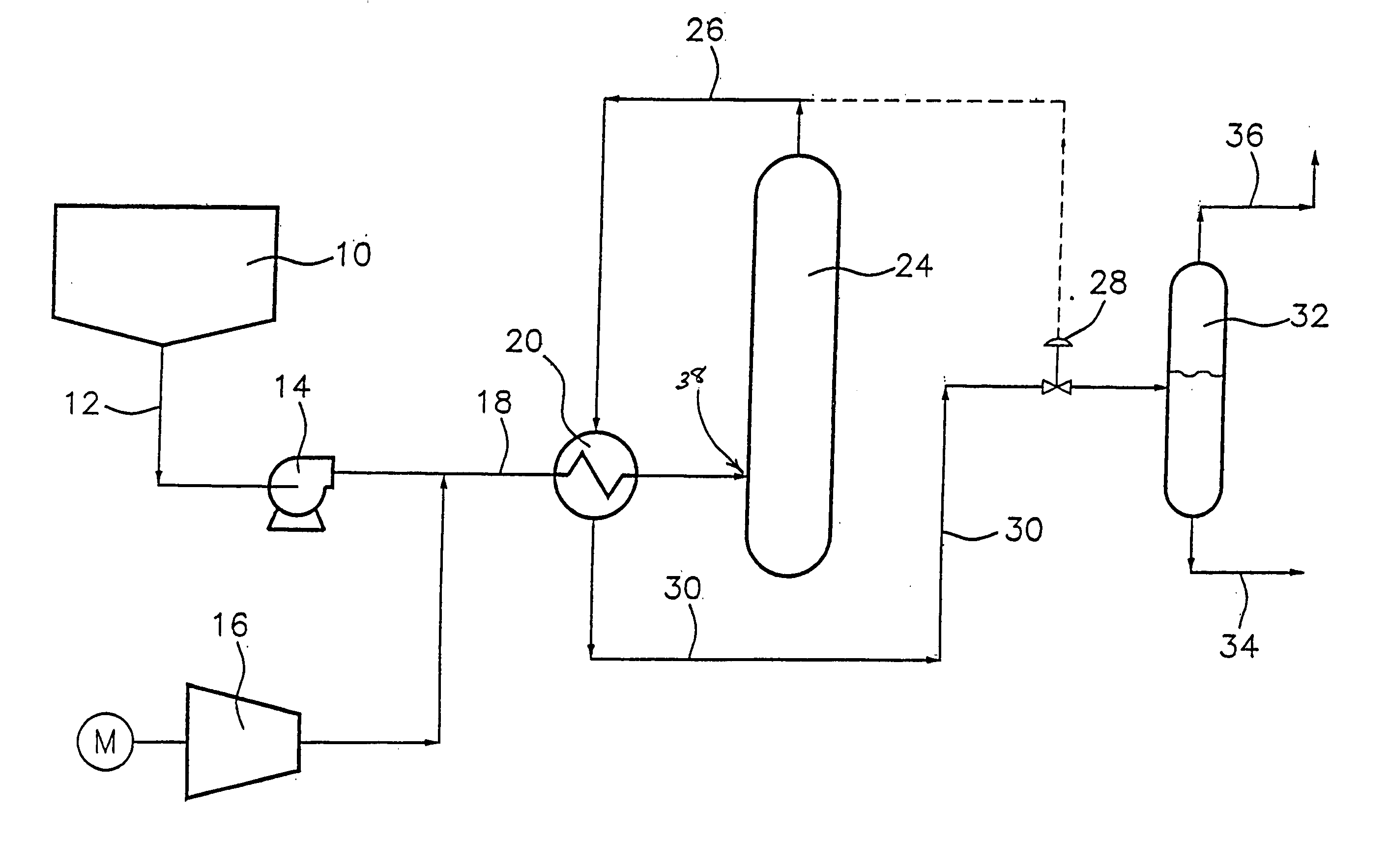

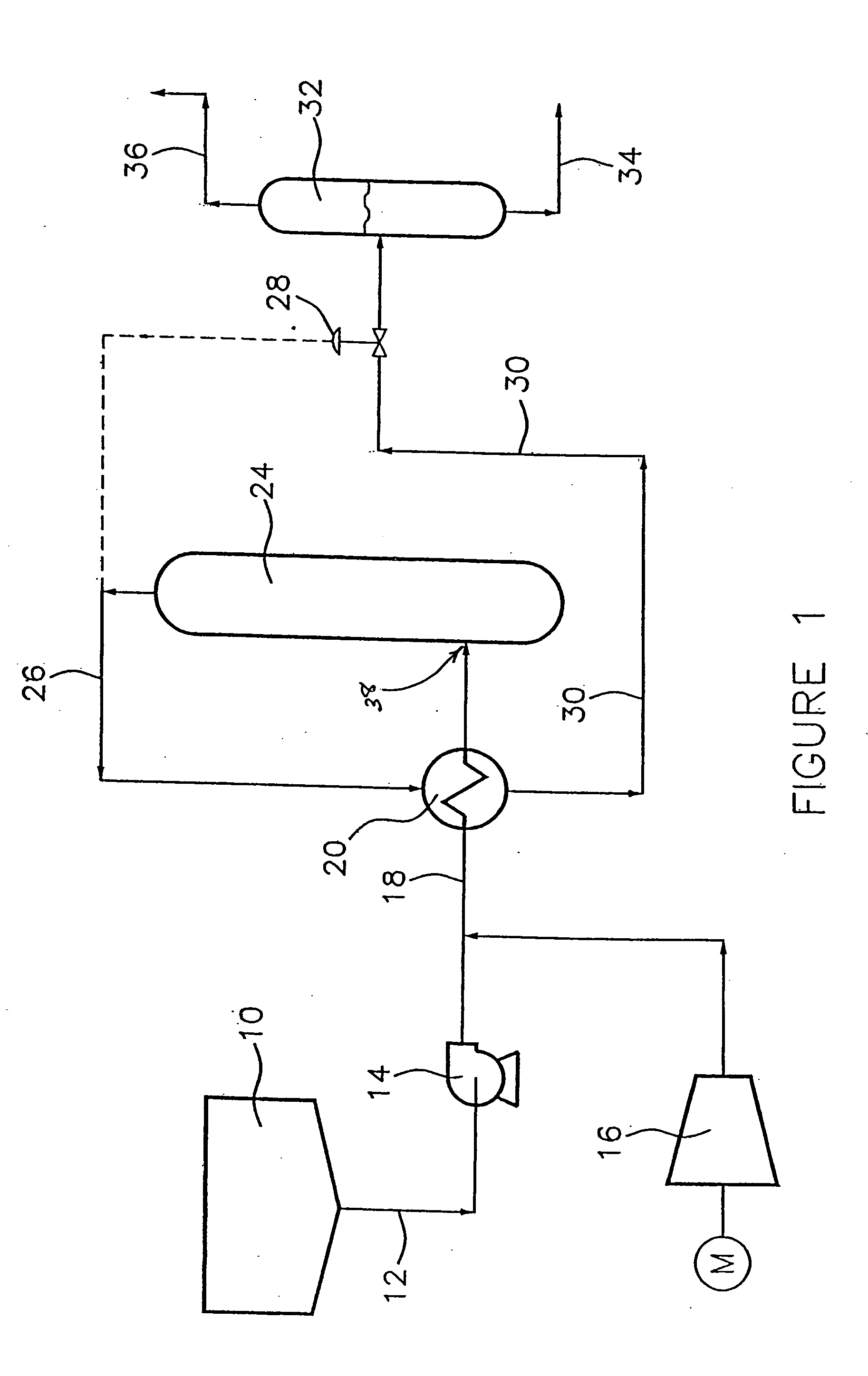

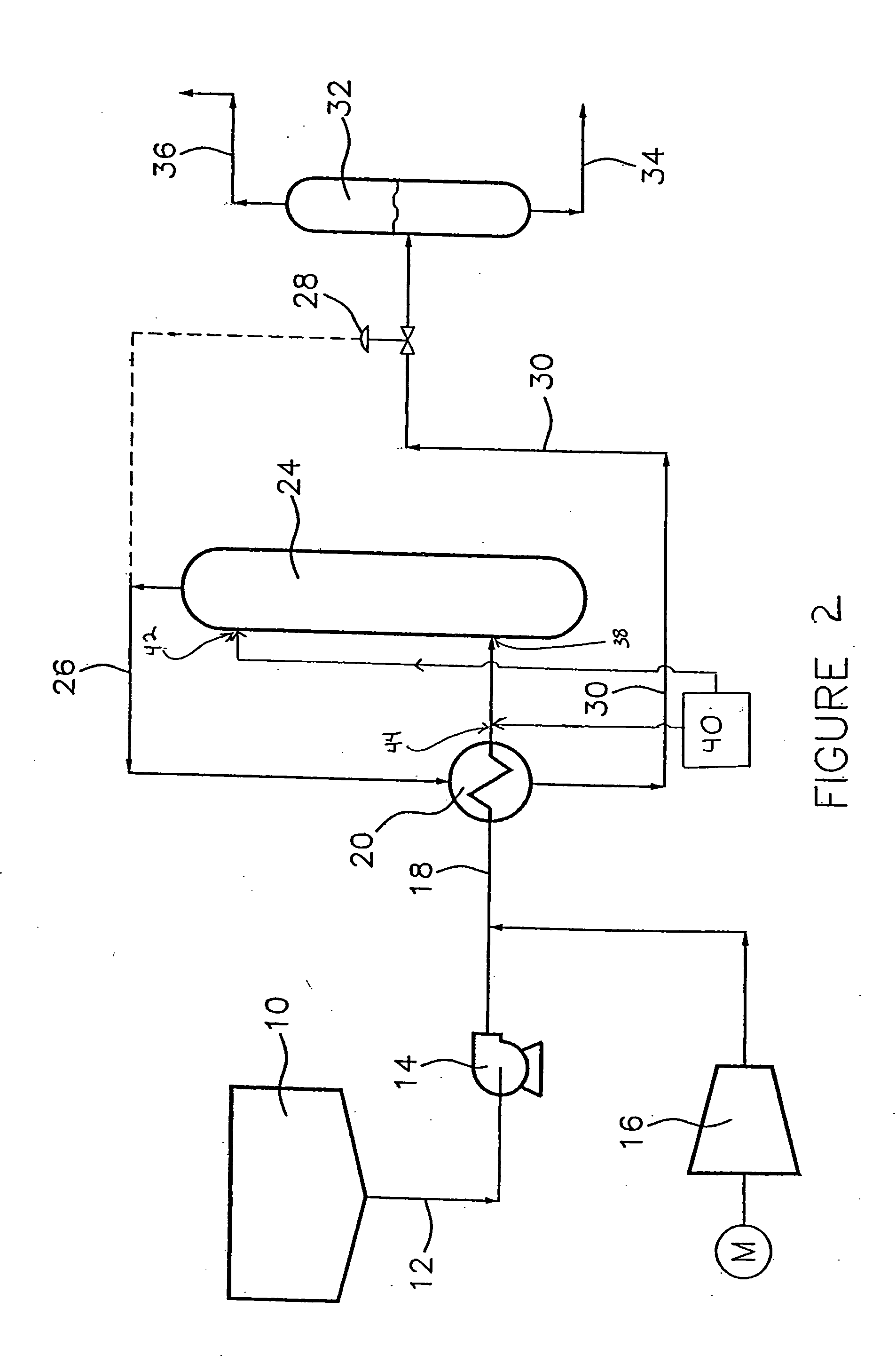

Method and apparatus for treating waste streams

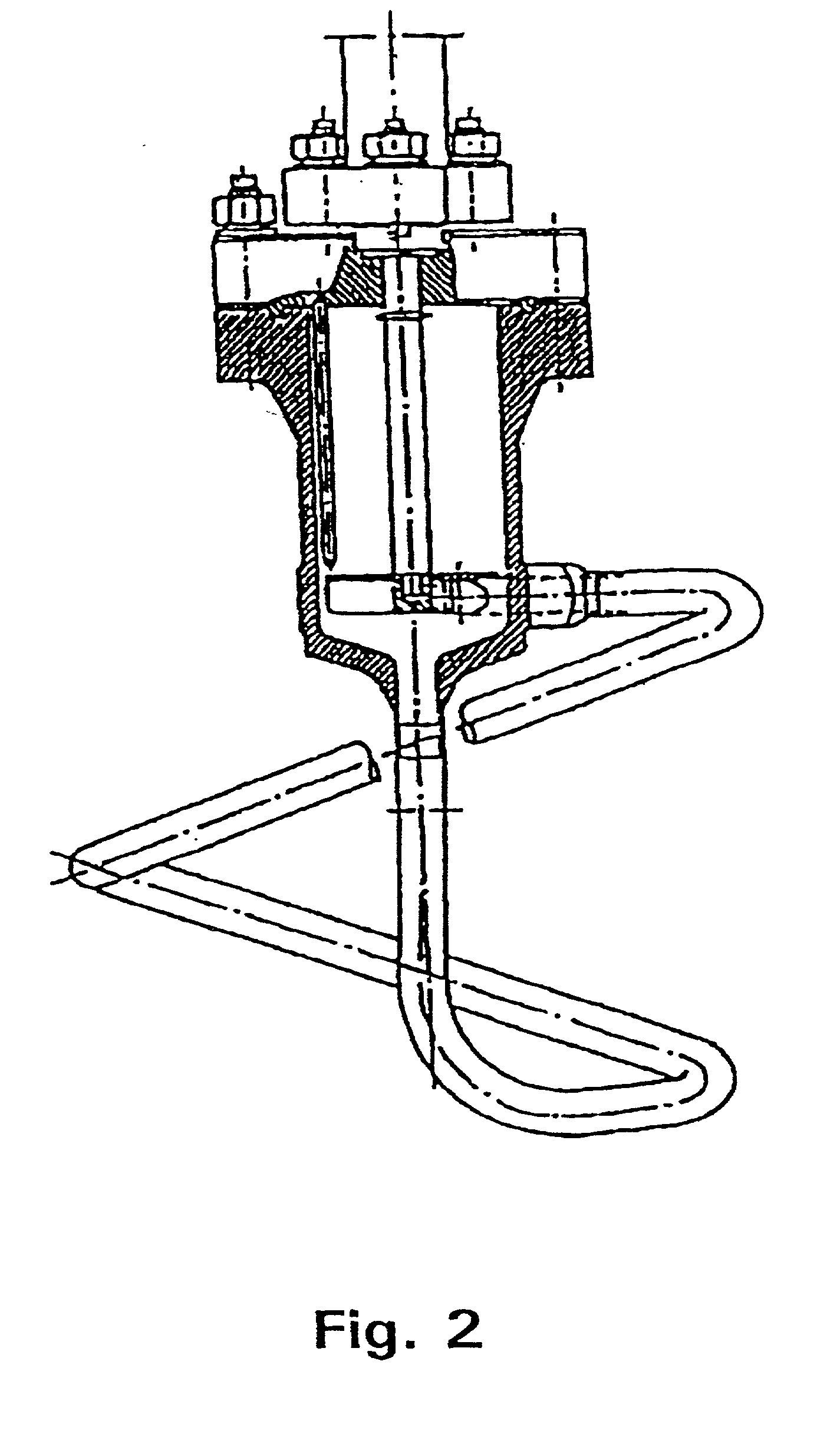

InactiveUS6716360B2Overcome problemsUrea derivatives preparationSludge treatment by oxidationSufficient timeWaste stream

A method for treating a waste stream, the method including the steps of providing a waste stream that includes waste solids suspended in water, feeding the waste stream to the top of a hydraulic downdraft column, conducting the waste stream to the bottom of the hydraulic downdraft column, conducting the waste steam to a first reaction zone, introducing nitrogen-containing oxides into the first reaction zone so that the waste stream is contacted with the nitrogen-containing oxides, conducting the waste stream up a hydraulic updraft column into a second reaction zone, where the second reaction zone is configured to provide sufficient time so that a reaction between the nitrogen-containing oxides and waste solids can take place and substantially consume the nitrogen-containing oxides, introducing oxygen gas into the waste steam after the nitrogen-containing oxides are substantially consumed, thereby providing a second reactant that reacts with waste solids suspended within the stream, conducting the stream to the top of the hydraulic updraft column.

Owner:EAU VIRON

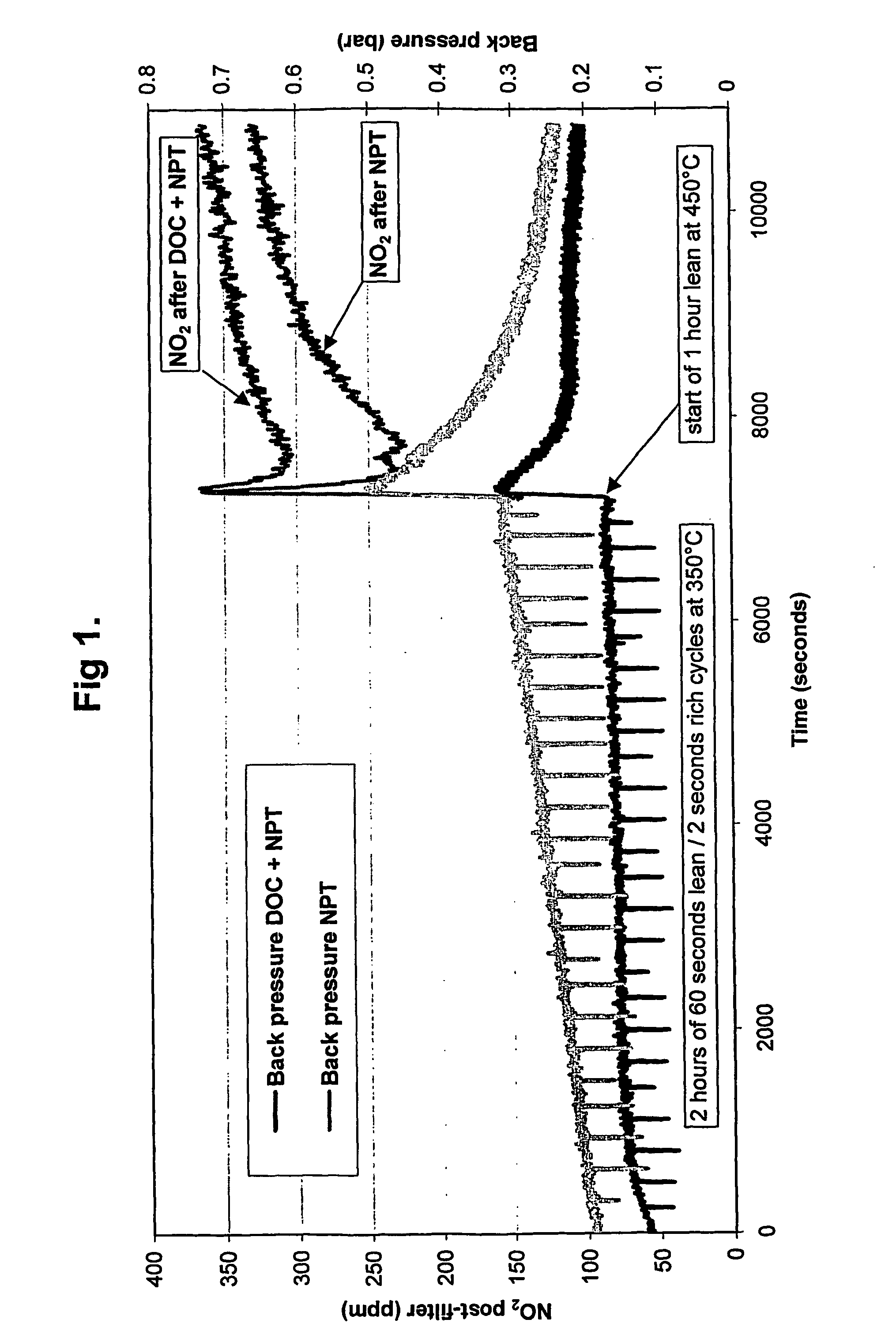

Exhaust system for a lean burn internal combustion engine

An exhaust system for an internal combustion engine has a catalysed ceramic wall flow particulate filter coated with a washcoat composition. The washcoat composition includes an oxidation catalyst of at least one platinum group metal and a NOx absorbent. The washcoat composition has a D50 of less than or equal to 8 μm. The NOx absorbent absorbs NOx contained in an exhaust gas when the composition of the exhaust gas is lambda >1, and releases the NOx absorbed in the NOx absorbent when the exhaust gas composition is 1≦lambda. The exhaust system has a platinum group metal catalyst upstream of the filter for oxidising NO to NO2 at least when the composition of the exhaust gas is lambda >1. The uncoated portions of the ceramic wall flow particulate filter have a porosity of >40% and a mean pore size of 8-25 μm.

Owner:JOHNSON MATTHEY PLC

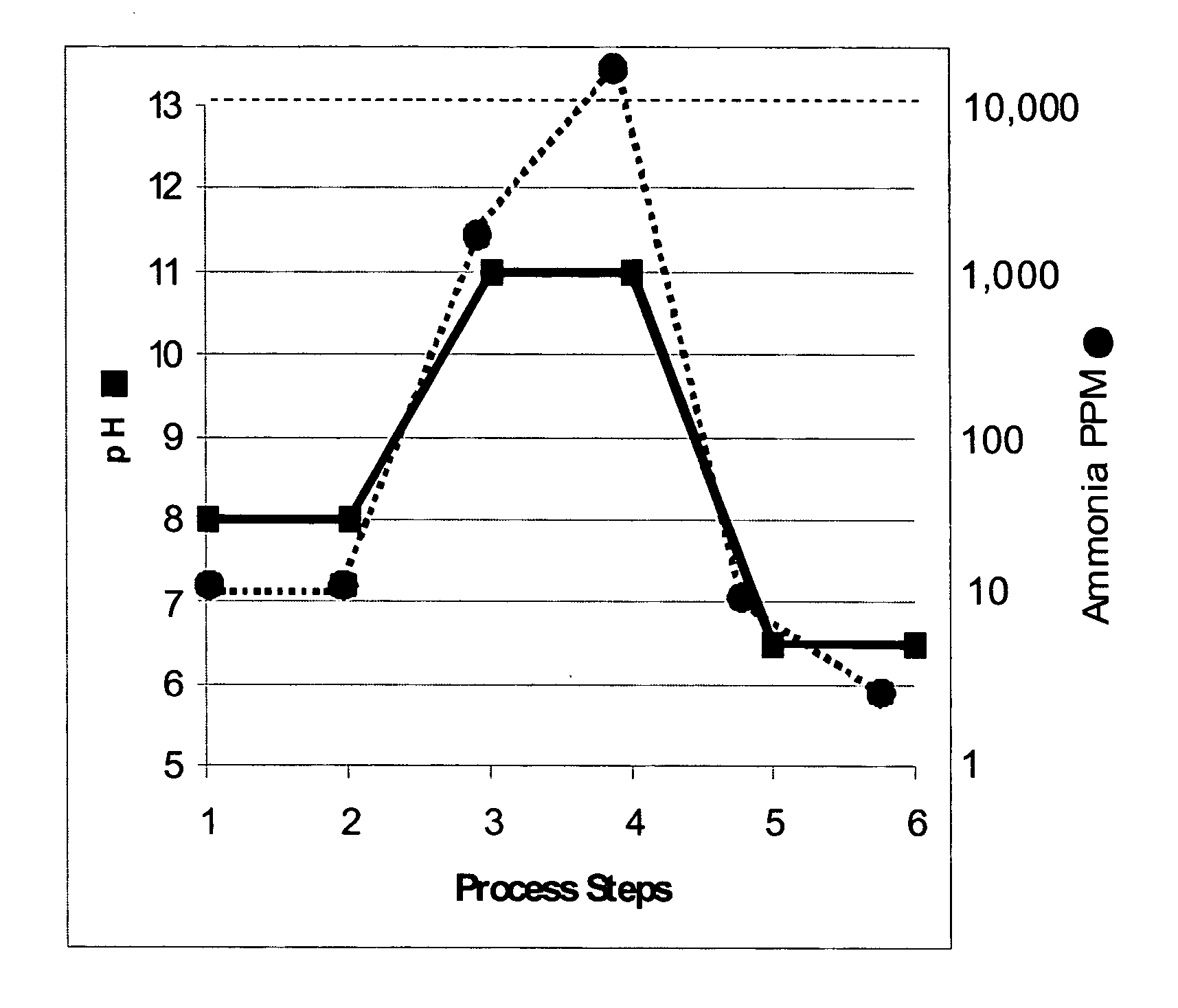

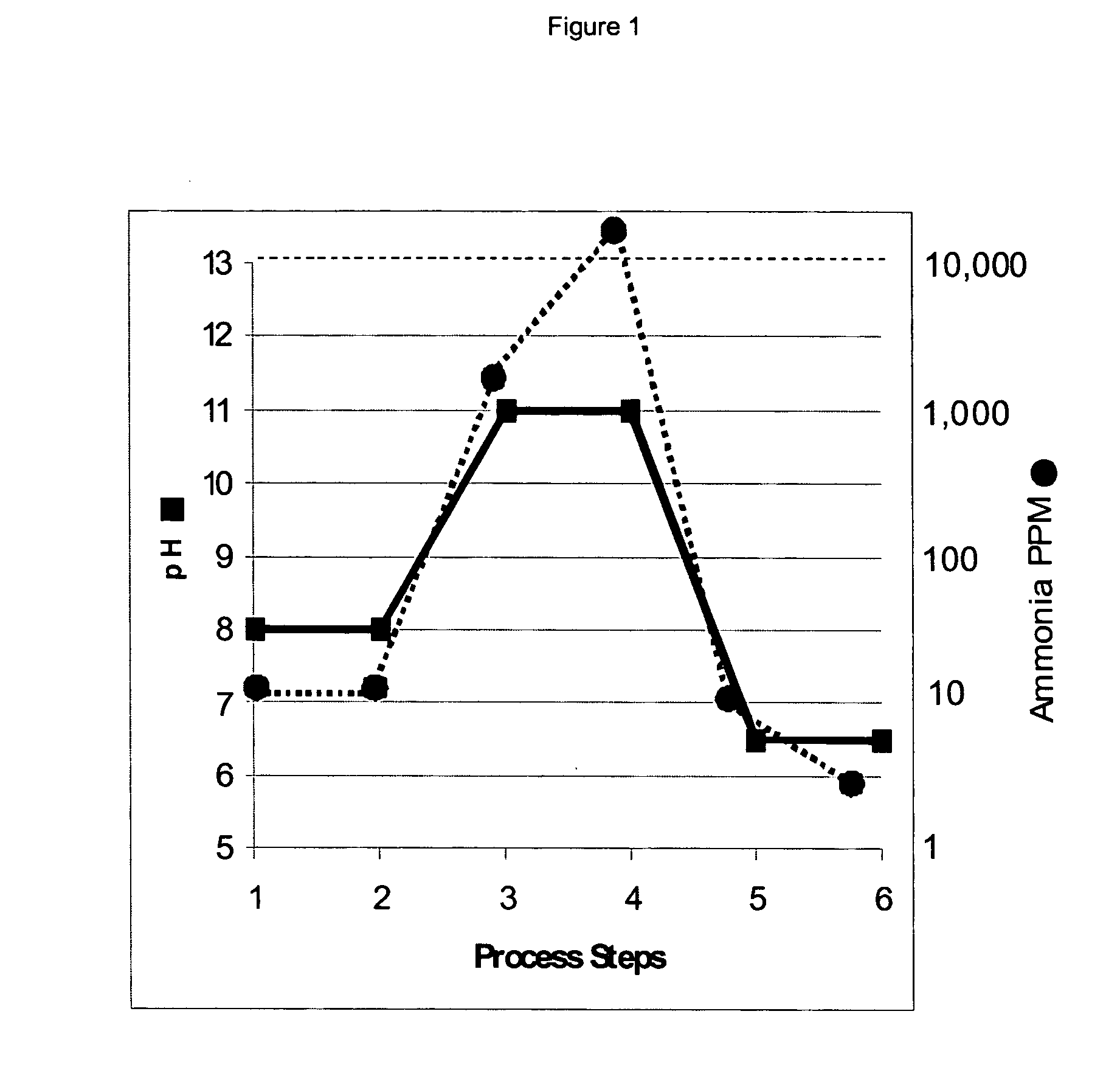

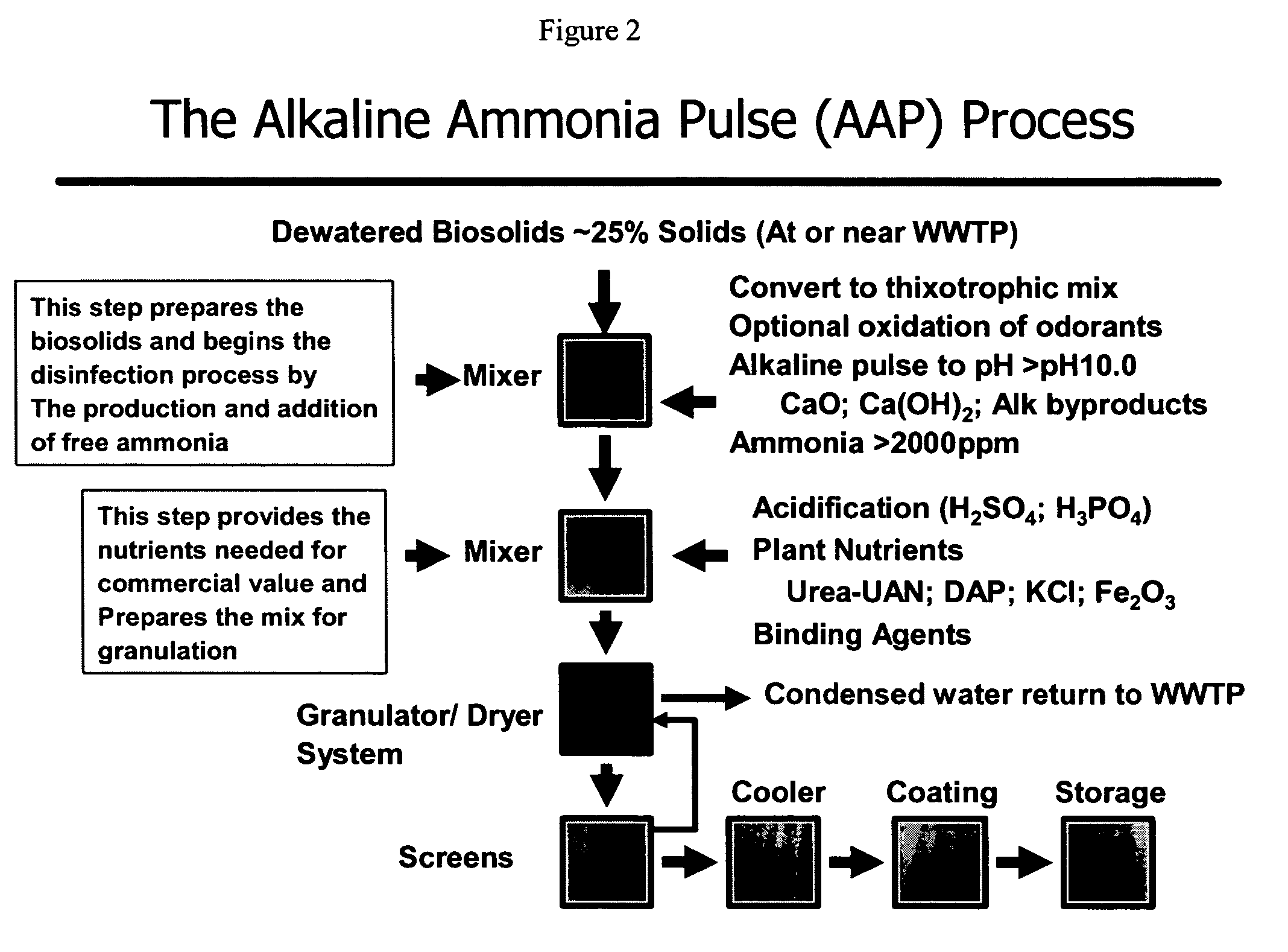

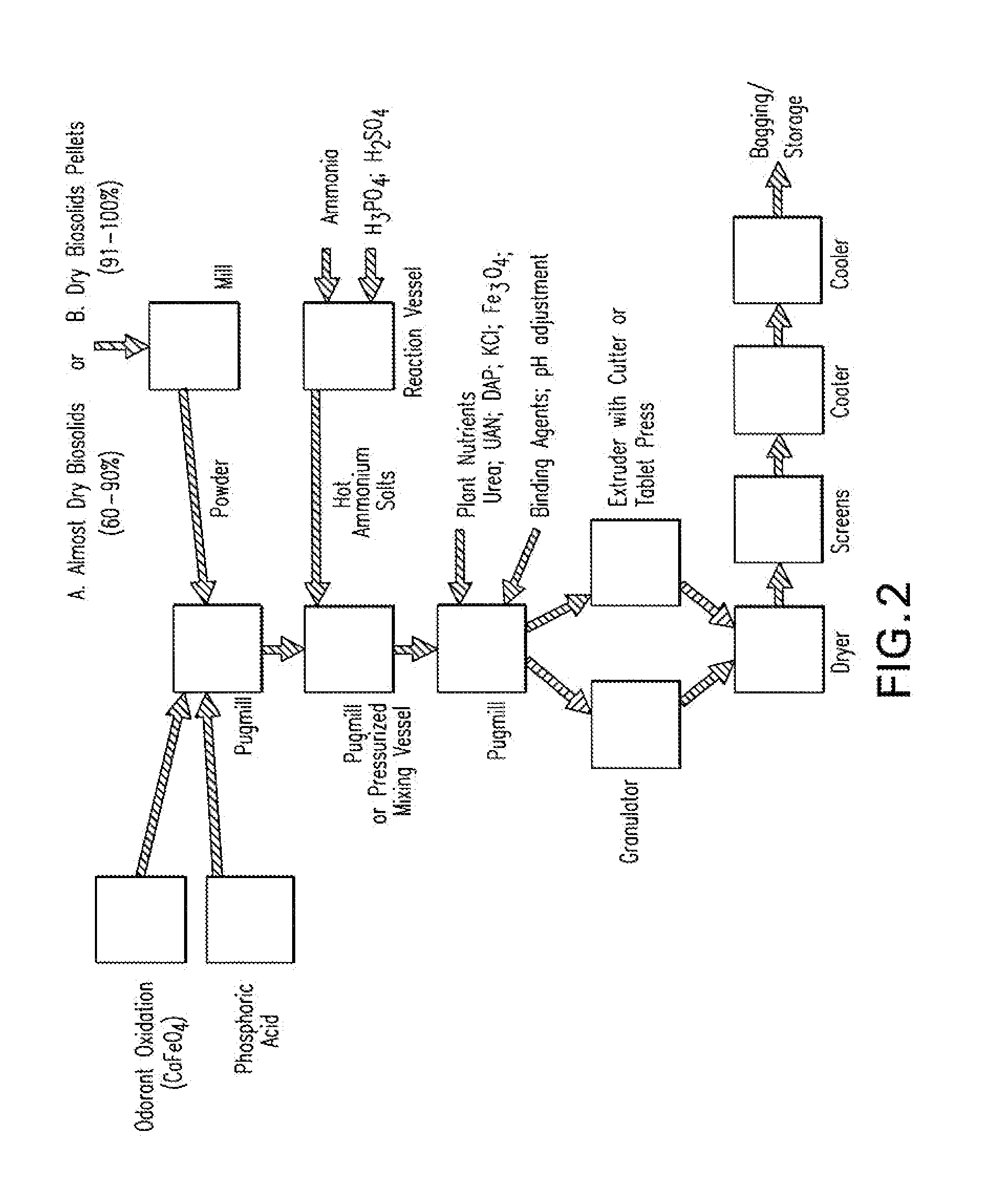

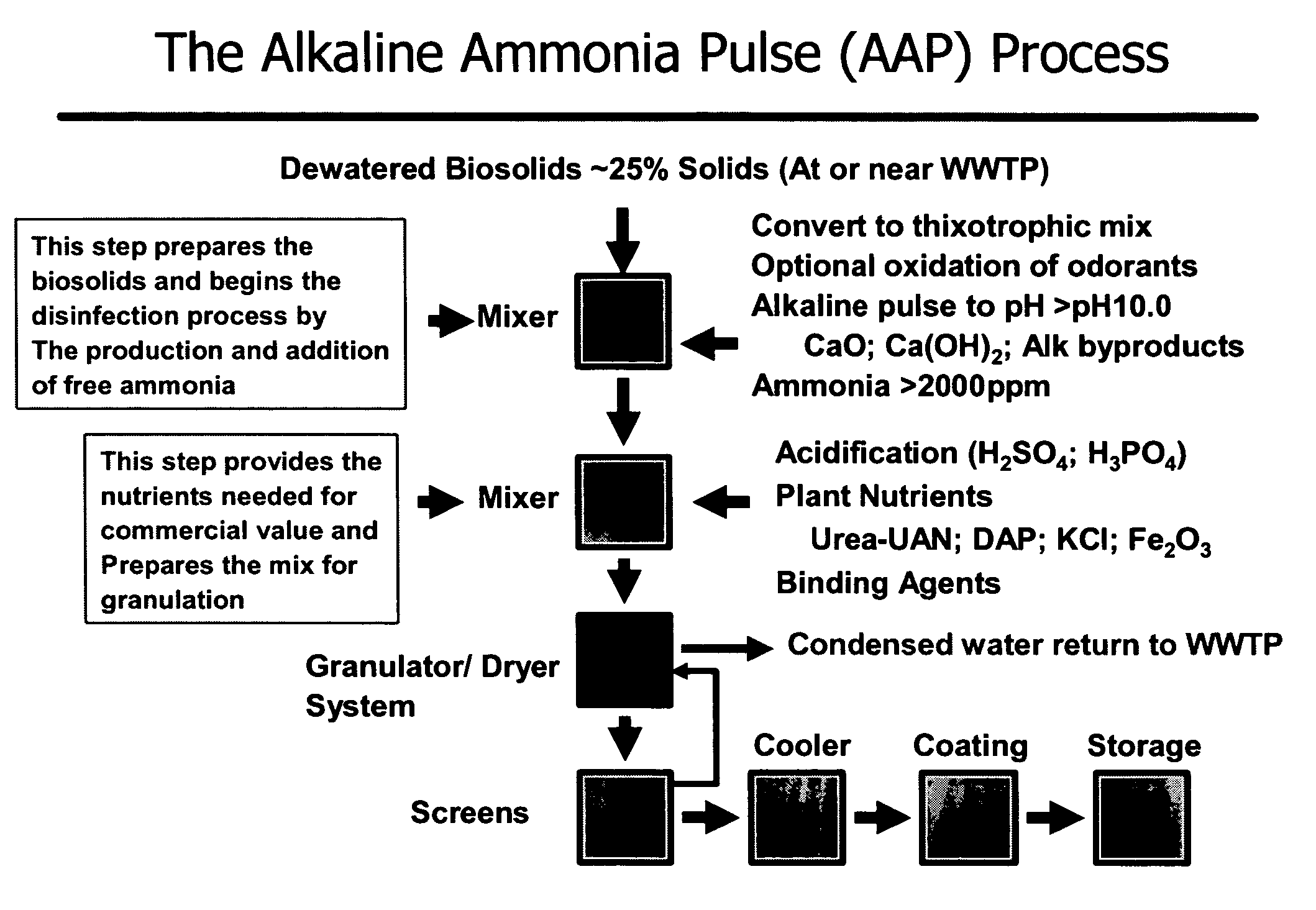

Organic containing sludge to fertilizer alkaline conversion process

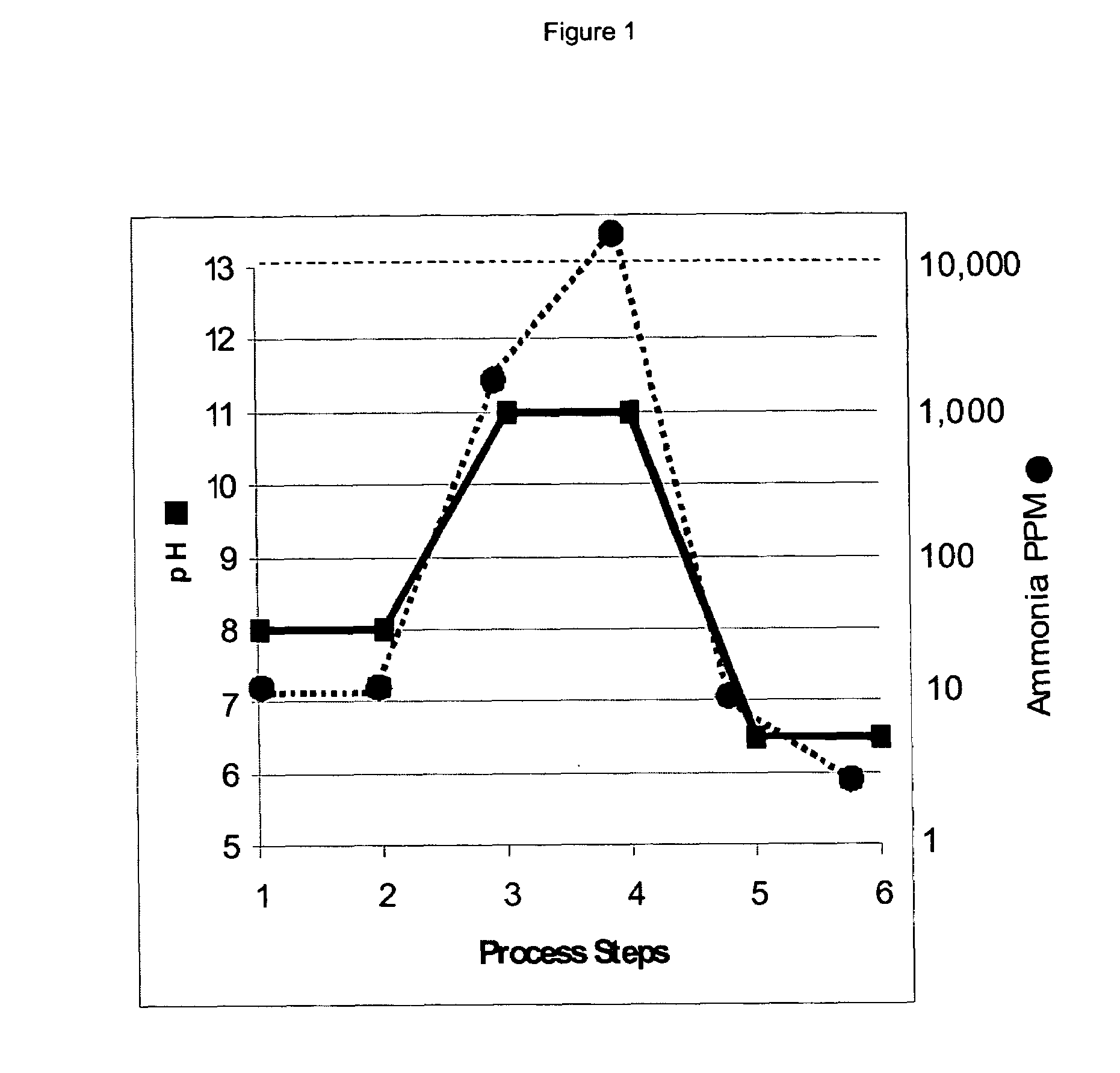

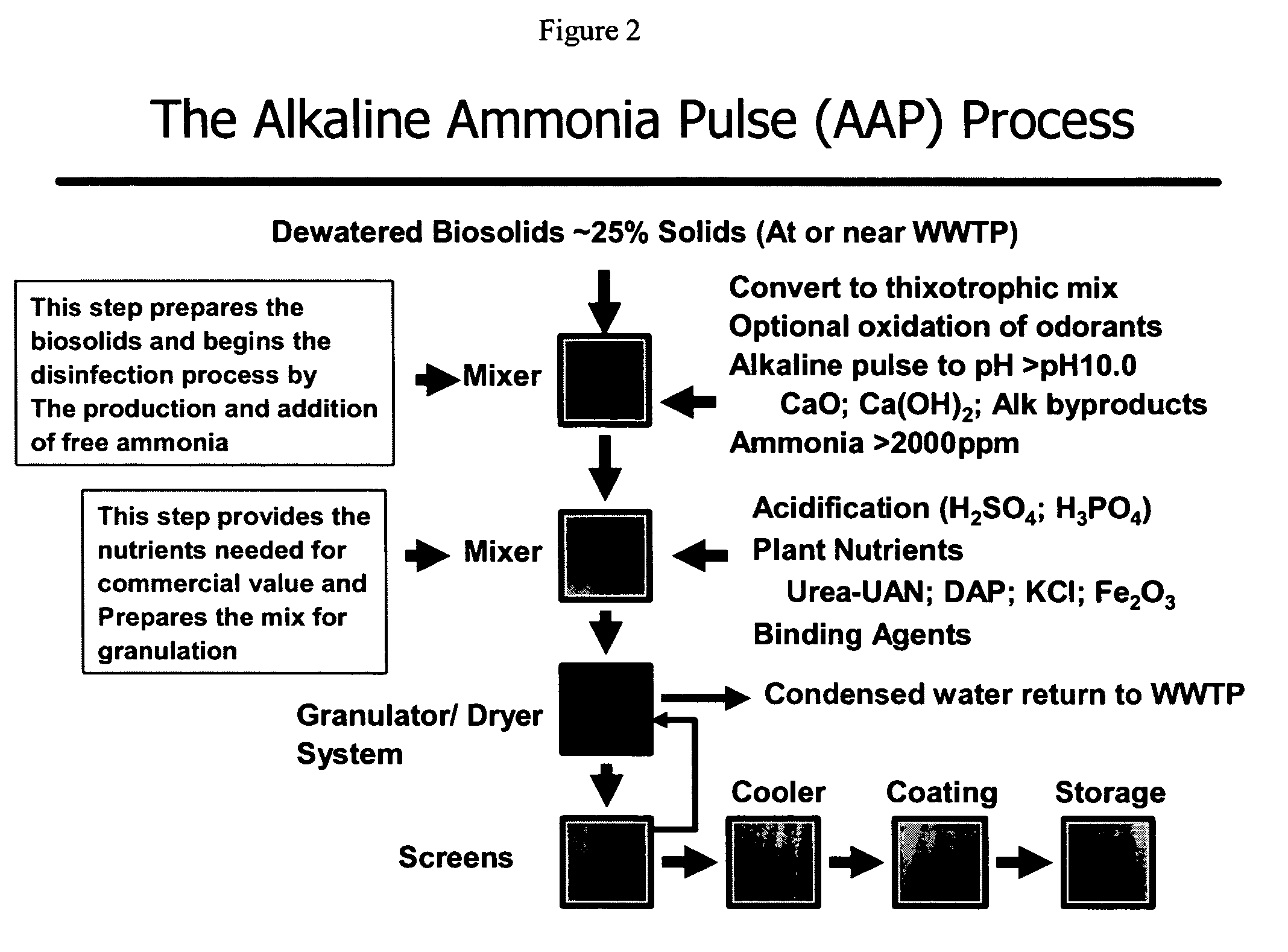

InactiveUS20070062233A1Increases plant nutrient contentReduce odorCalcareous fertilisersBio-organic fraction processingSludgeOrganic manure

This invention is directed to systems, devices and methods for treating organic-containing sludges and converting such sludges to high value fertilizers containing both inorganic and organic fertilizer components, which creates an inorganically-augmented bioorganic fertilizer. The invention describes methods to create a thixotrophic or paste-like material via the application of mixing energy to the organic sludge followed by an alkaline treatment and a subsequent ammoniation. The invention further describes a method to increase the plant nutrient content in the organic containing product to a level which permits the finished granular fertilizer product to compete in the commercial agricultural fertilizer marketplace. Further, the invention reduces odors associated with said organic-containing sludges.

Owner:GENERATE LENDING LLC

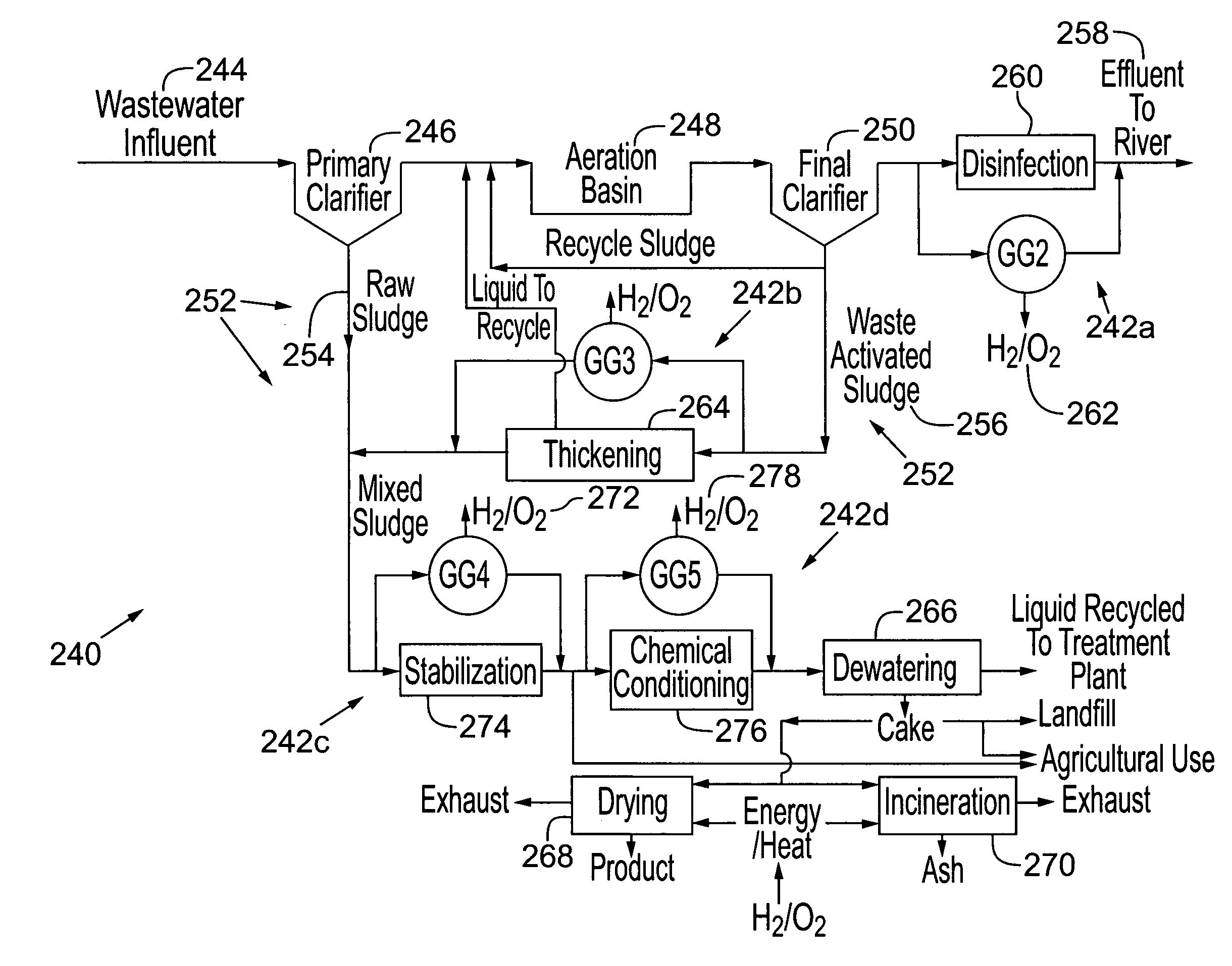

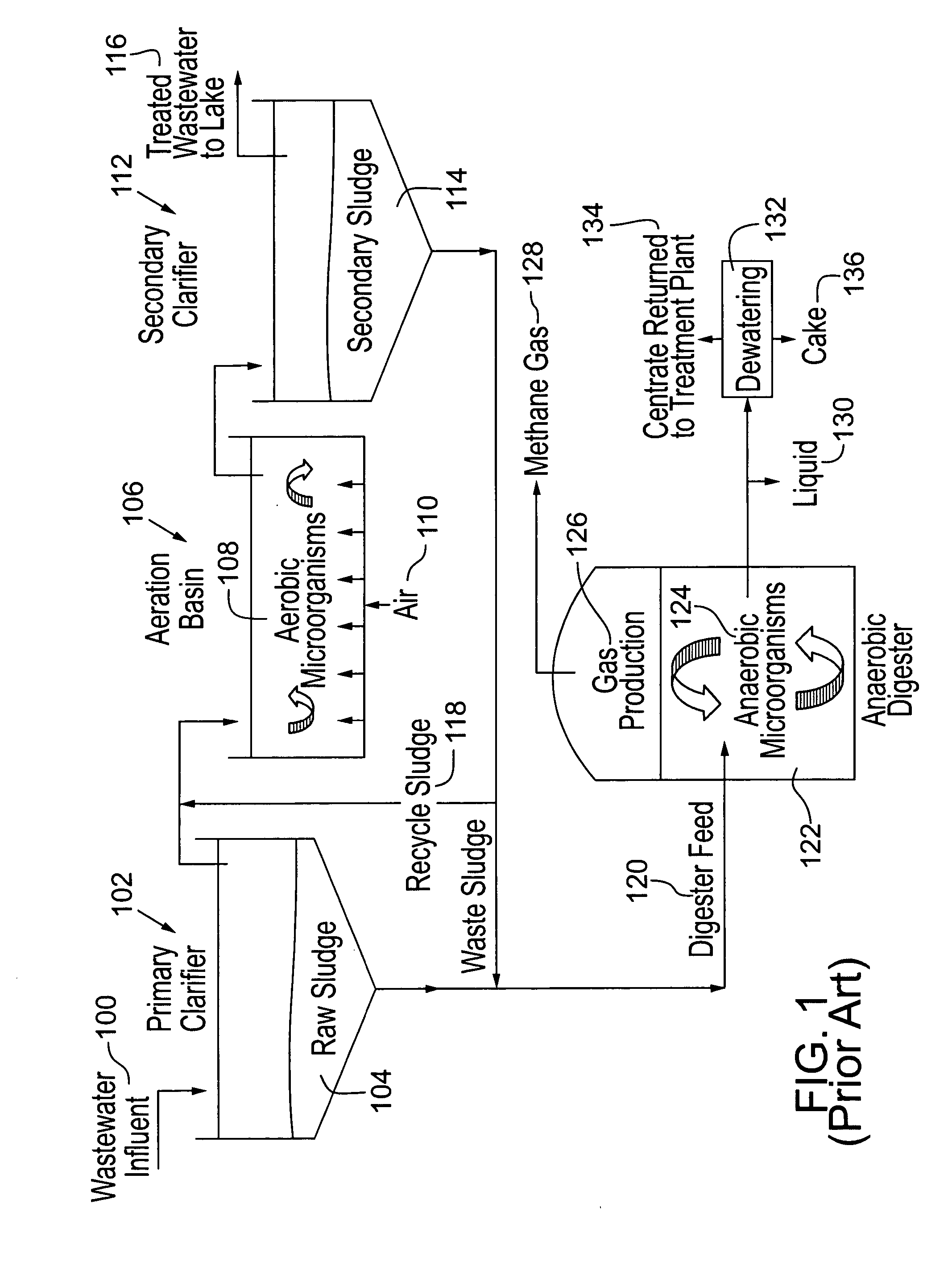

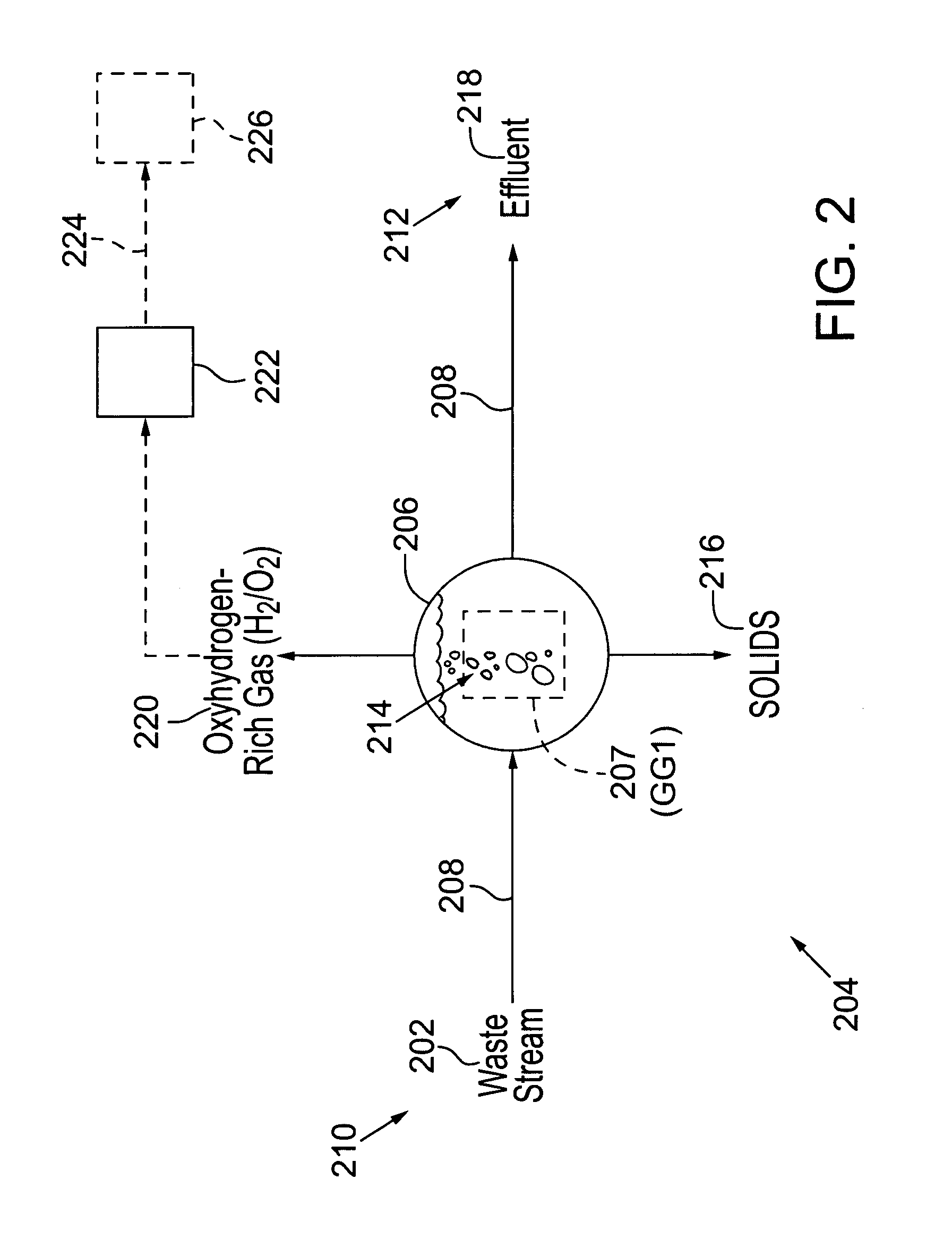

Treatment of a waste stream through production and utilization of oxyhydrogen gas

Methods and systems for treating a waste stream in a waste treatment system involve performing a unit process of the waste treatment system by contacting the waste stream with oxyhydrogen-rich gas generated on-site by an oxyhydrogen gas generator that implements water dissociation technology. In a preferred embodiment, the oxyhydrogen gas generator involves applying a pulsed electrical signal to a series of closely-spaced electrodes that are submerged in the waste stream to produce oxyhydrogen-rich gas from a water component of the waste stream. Operation of the oxyhydrogen gas generator in the waste stream may accomplish one or more unit processes for waste treatment, such as conditioning, stabilization, thickening, and dewatering, among others. At least a portion of the oxyhydrogen-rich gas can be conveyed for a second use in the waste treatment system, such as a source of combustible fuel for incineration or power generation, for example.

Owner:XOGEN TECH

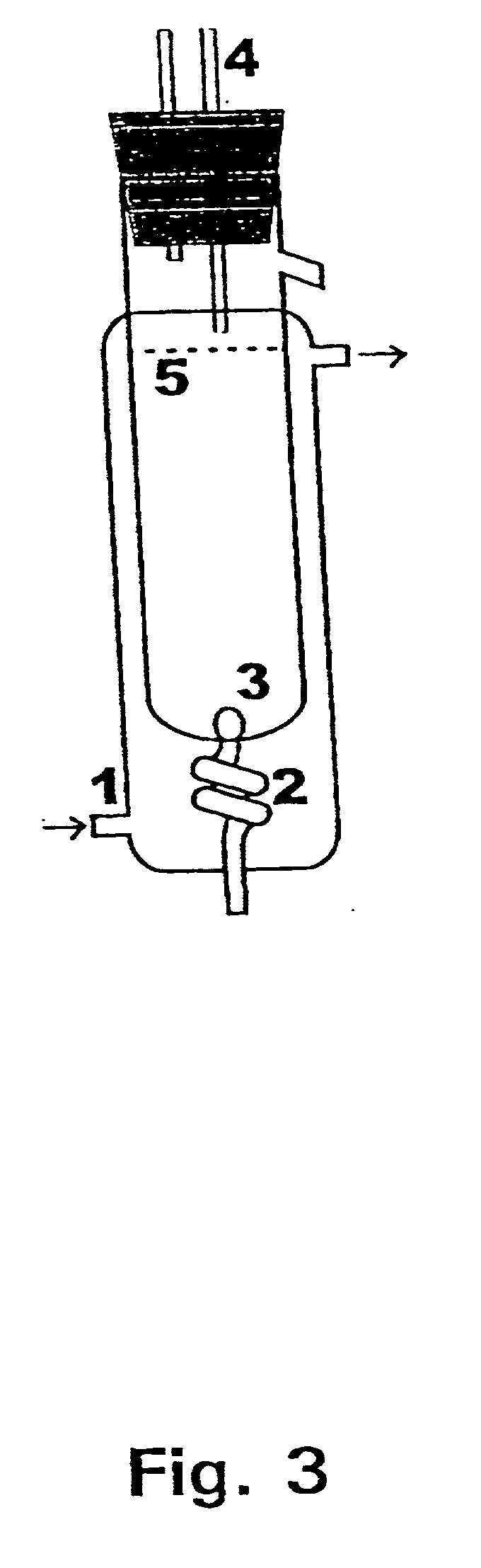

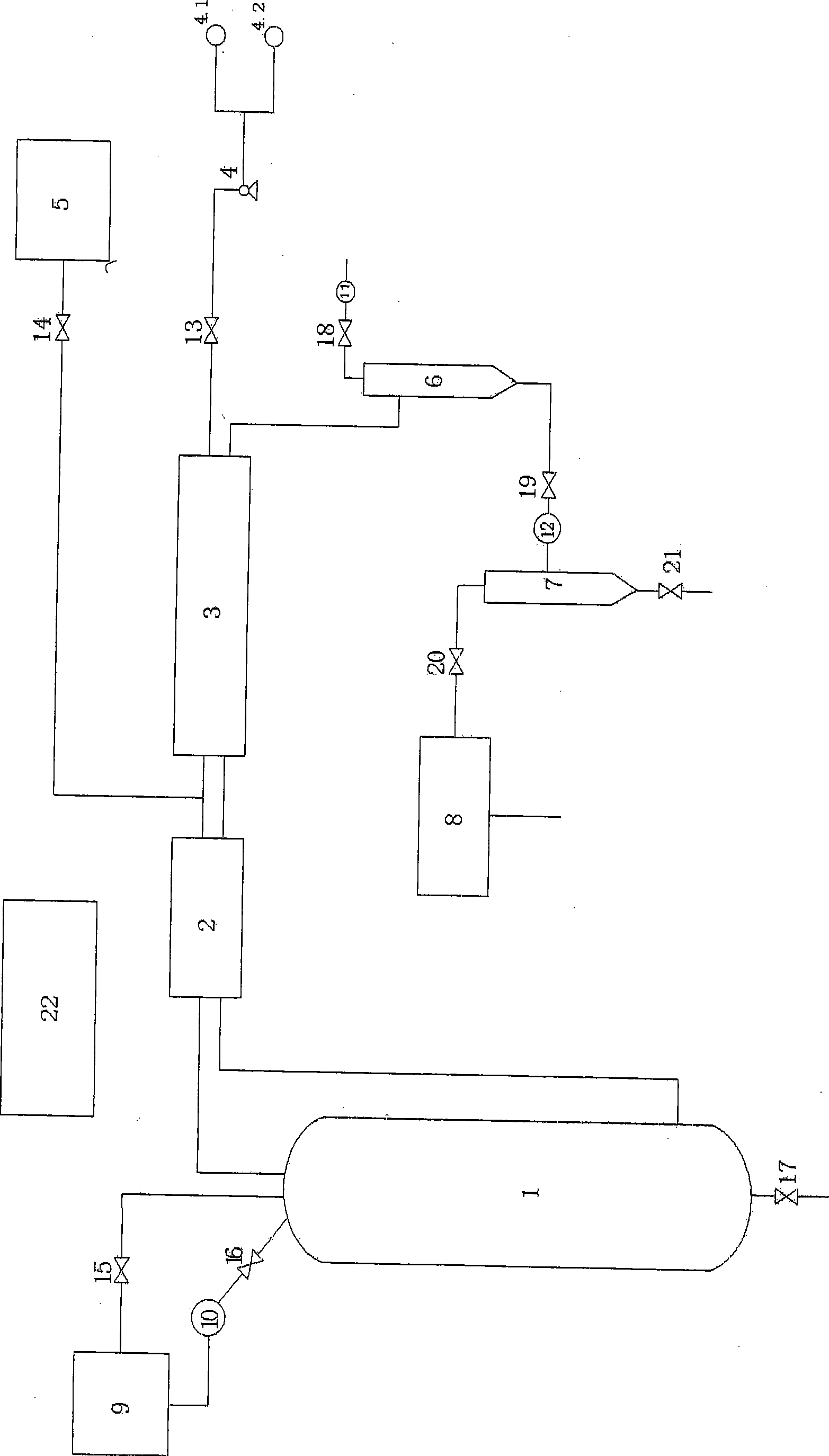

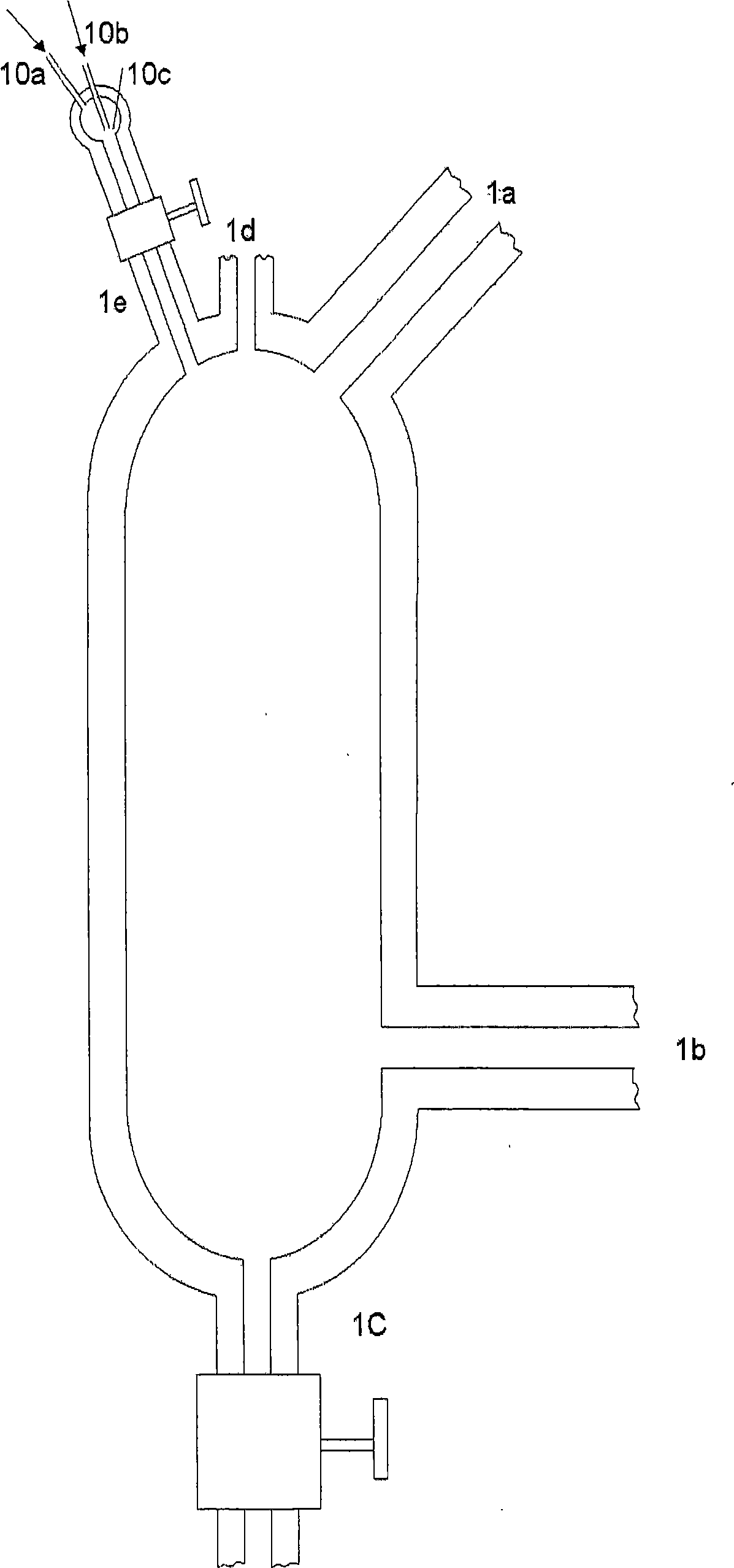

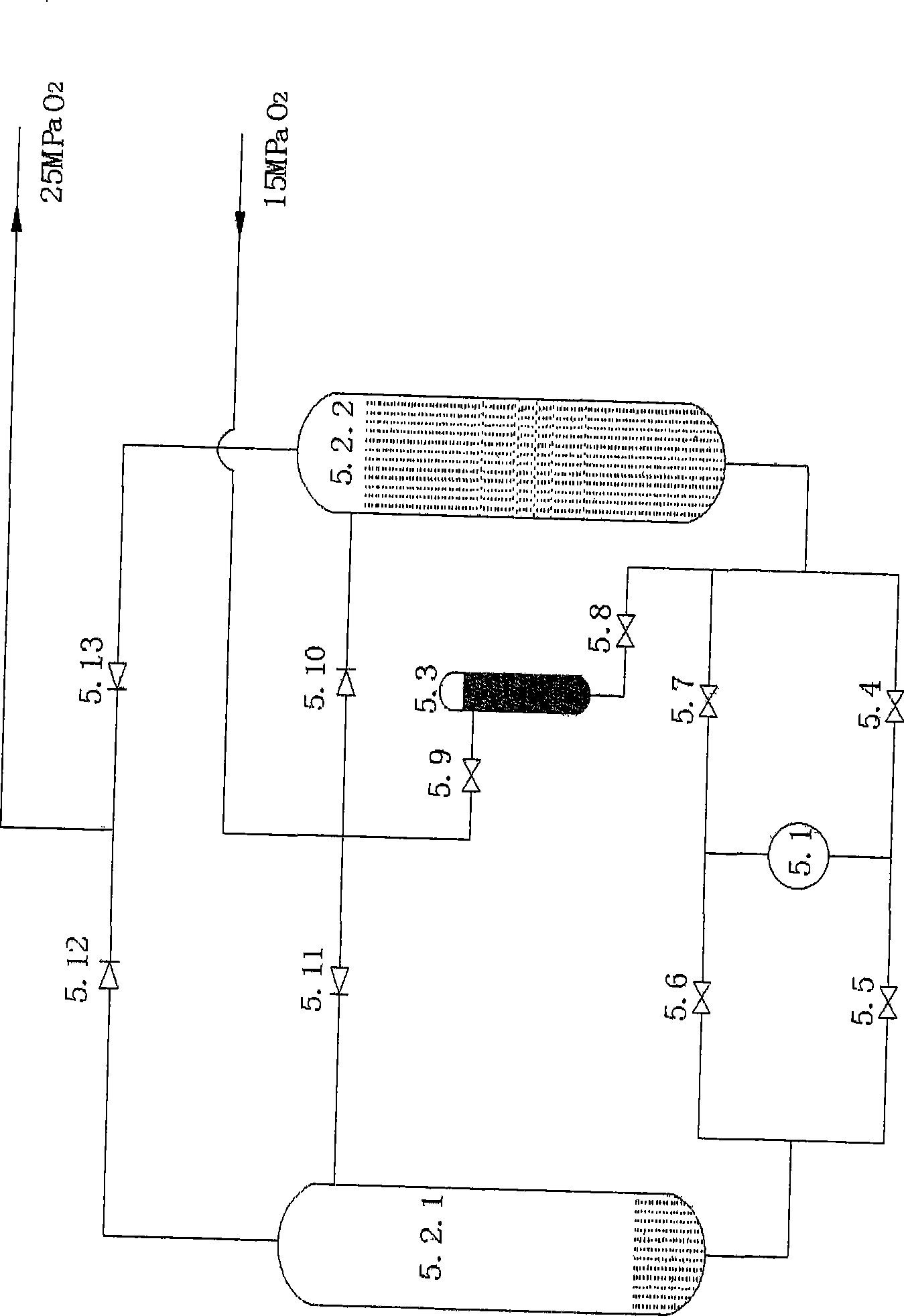

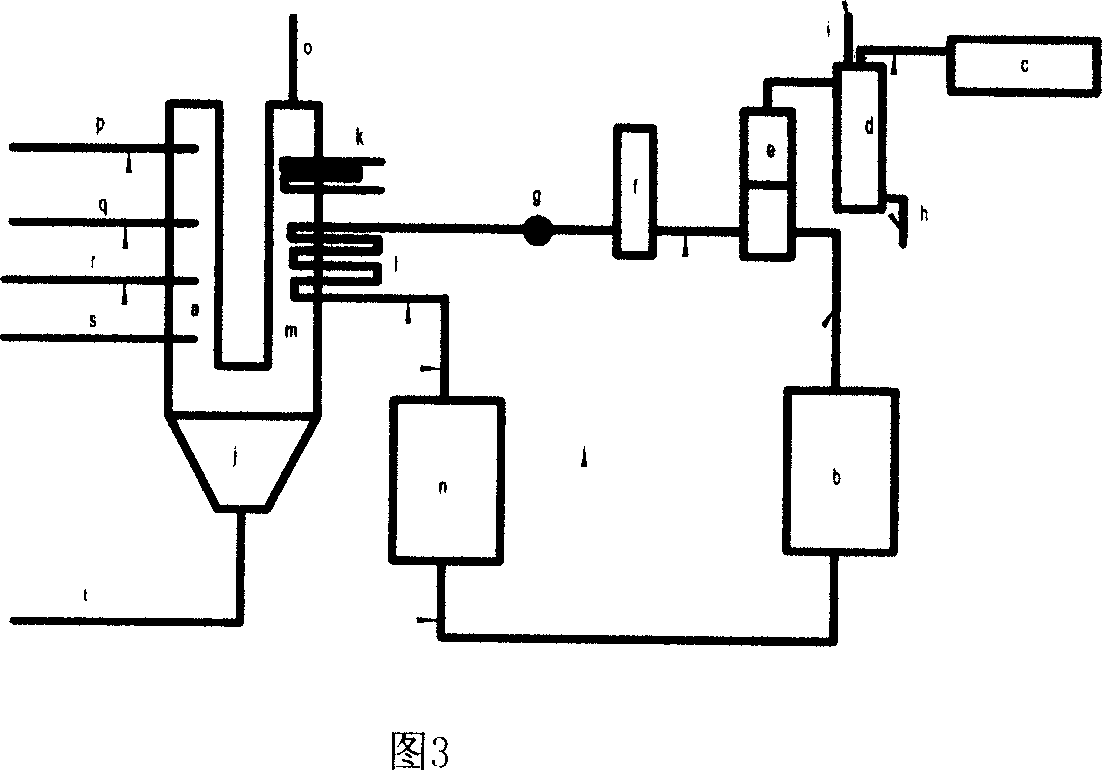

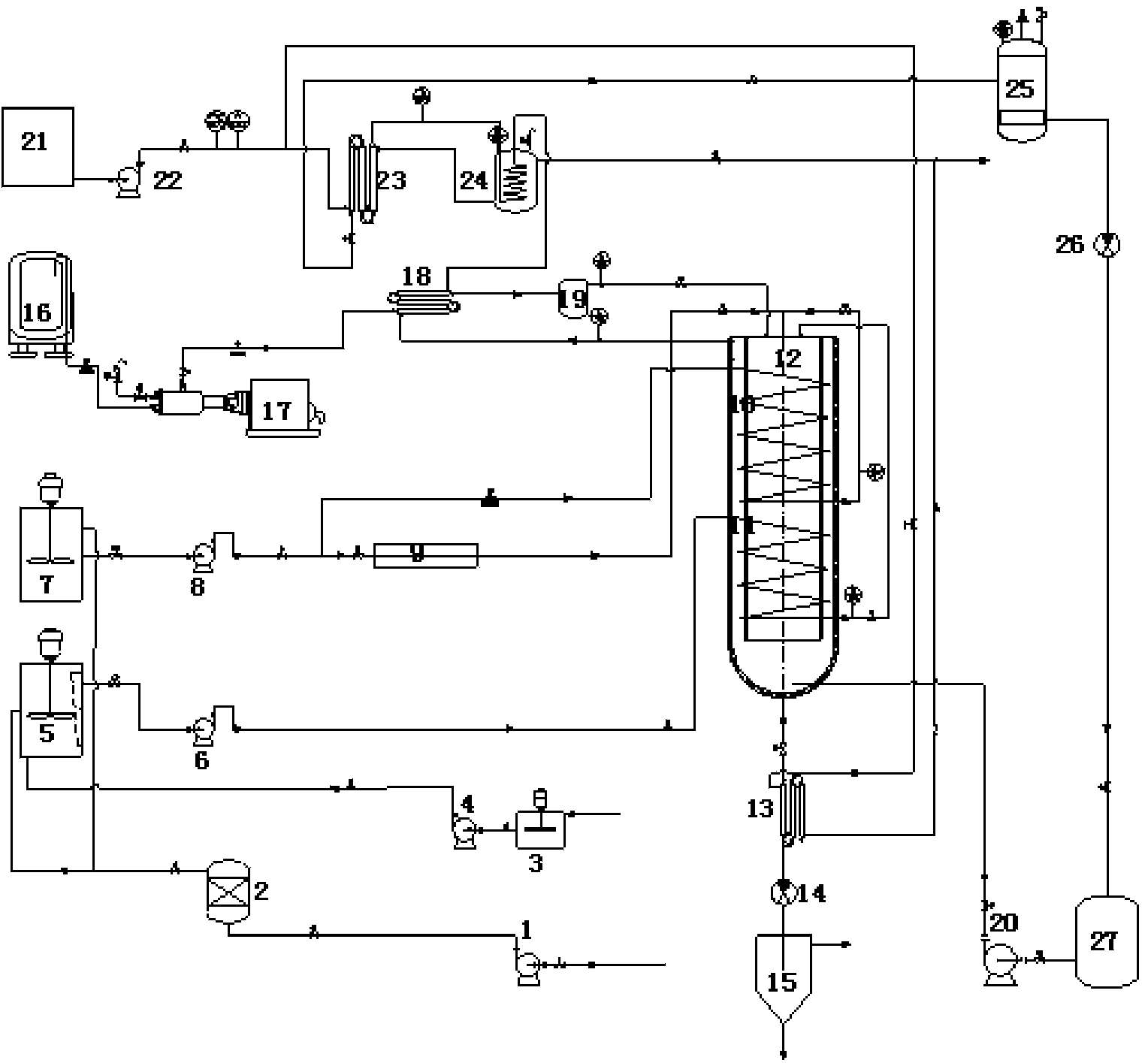

Method and device for oxidizing and treating sewage or sludge containing organic substances by supercritical water

InactiveCN101544419AGuaranteed uptimeReduce construction costsSludge treatment by oxidationByproduct vaporizationCombustionSludge

The invention relates to a method and a device for oxidizing and treating sewage or sludge containing organic substances by supercritical water. The method adopts a combustion reaction furnace, and is characterized in that substance flow of the sewage or the sludge containing the organic substances and oxidant (such as oxygen or hydrogen peroxide and the like) are preheated by a heat exchange device respectively and then enter the combustion reaction furnace, the sewage or the sludge containing the organic substances is oxidized and treated under a supercritical state, the treated substance flow is cooled by the heat exchange device again, then residual gas in the substance flow is separated by adopting a gas-liquid separator, and the lower part of the combustion reaction furnace discharges salt slag through a slag discharging hole and a valve. The method has the advantages of reasonable and practical process, energy conservation and low operation cost.

Owner:楼龙春

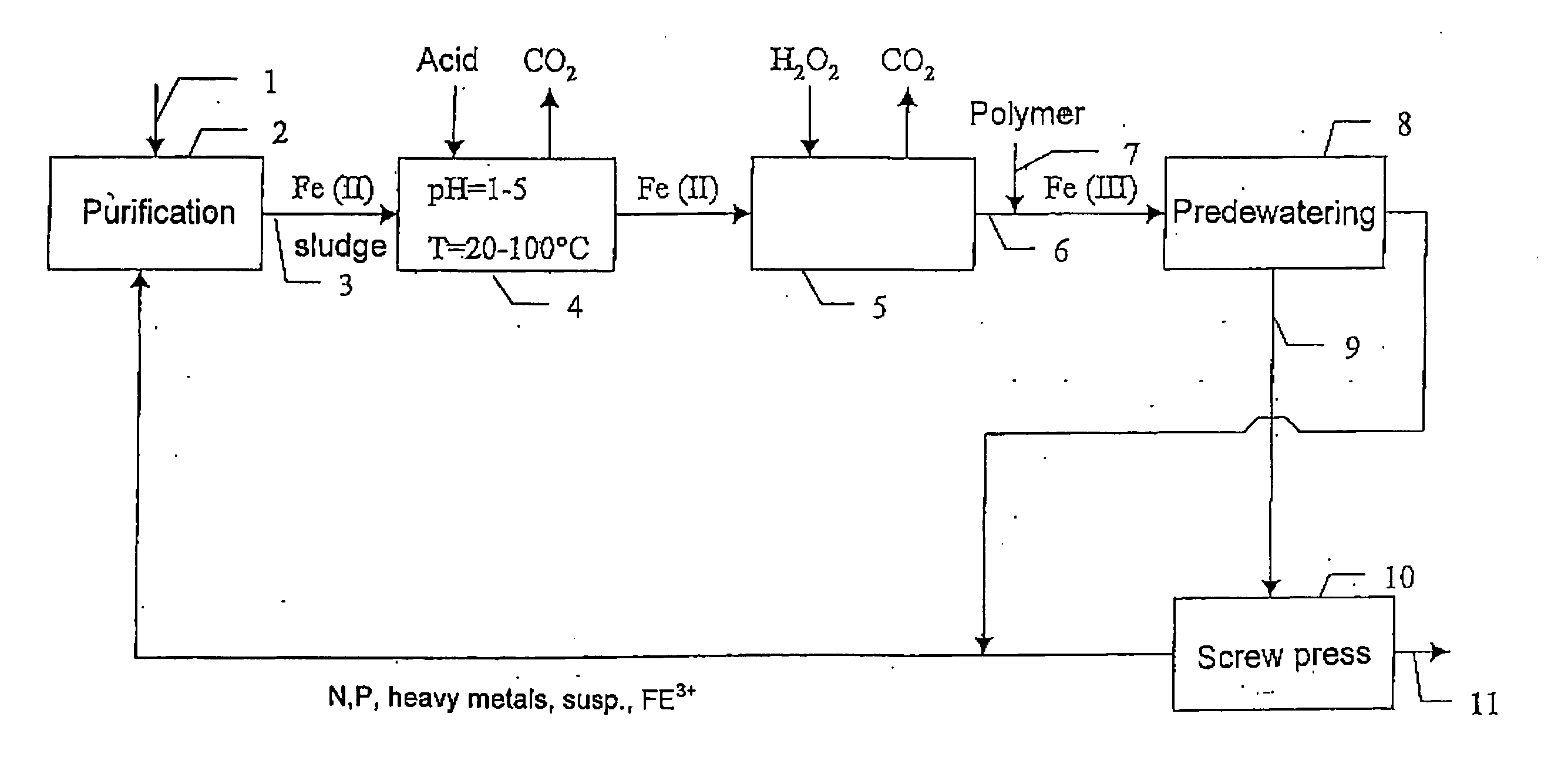

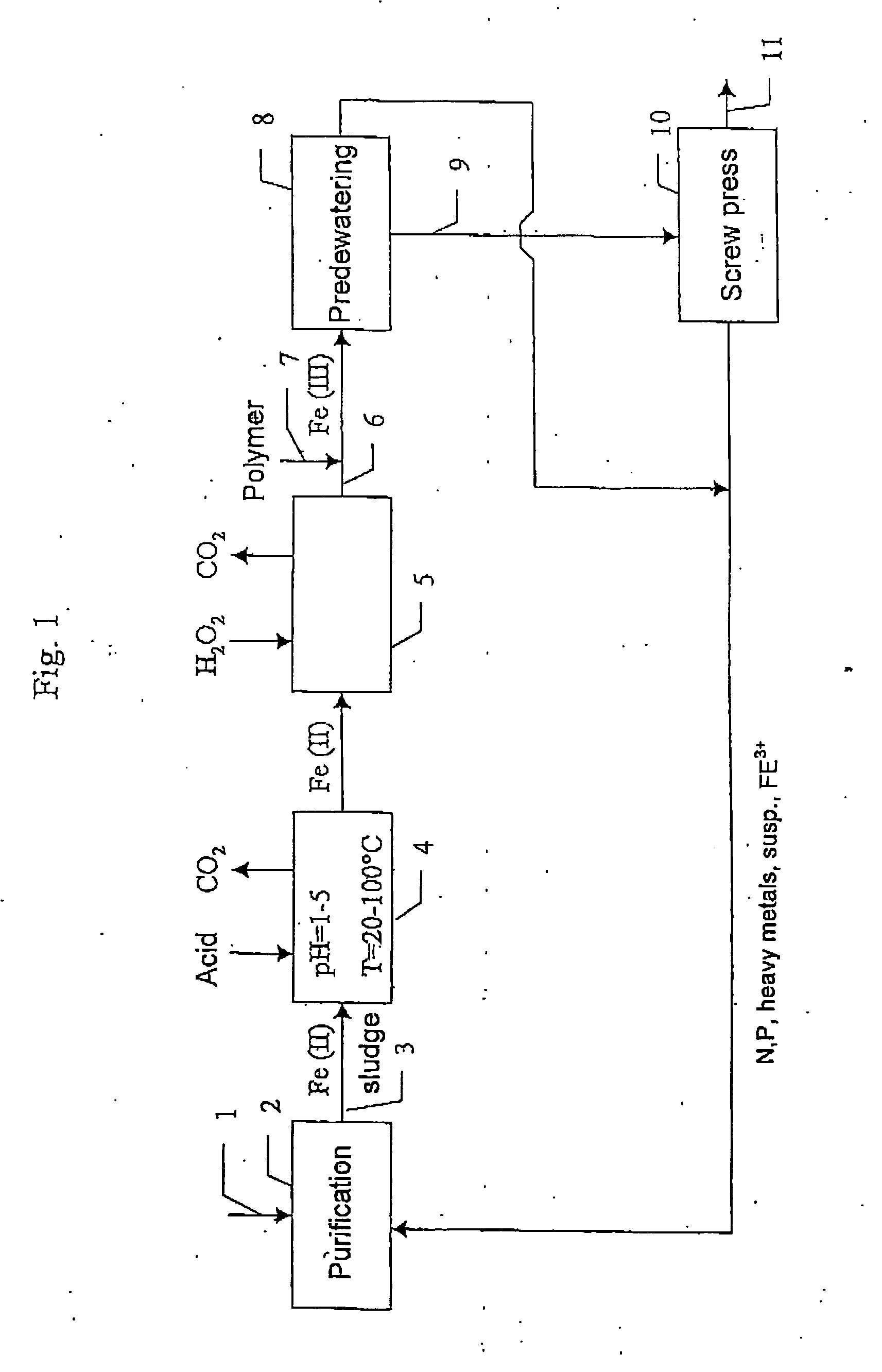

Method of treating digested sludge

InactiveUS20050000908A1Improve filtering effectKeep drySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeWastewater

A method of treating, in wastewater purification, sludge containing organic matter, divalent iron and phosphorus, in which the sludge that is treated is made to contain dissolved iron and phosphorus at a molar ratio Fe:P of above 1:1, the sludge is treated at 0-100° C. with an acid at a pH of 1-5 for dissolution of divalent iron and phosphorus from the sludge, the sludge is supplied with an oxidiser selected from hydrogen peroxide and percompounds, wherein divalent iron is oxidised by Fenton's reaction to trivalent iron, and (i) trivalent iron is precipitated as trivalent iron phosphate (ii) free radicals with a deodorisation and sanitation effect are formed by Fenton's reaction, the sludge is then dewatered at a pH of at most 7, and the aqueous solution obtained in dewatering is recirculated to the wastewater purification.

Owner:KEMIRA KEMI AB

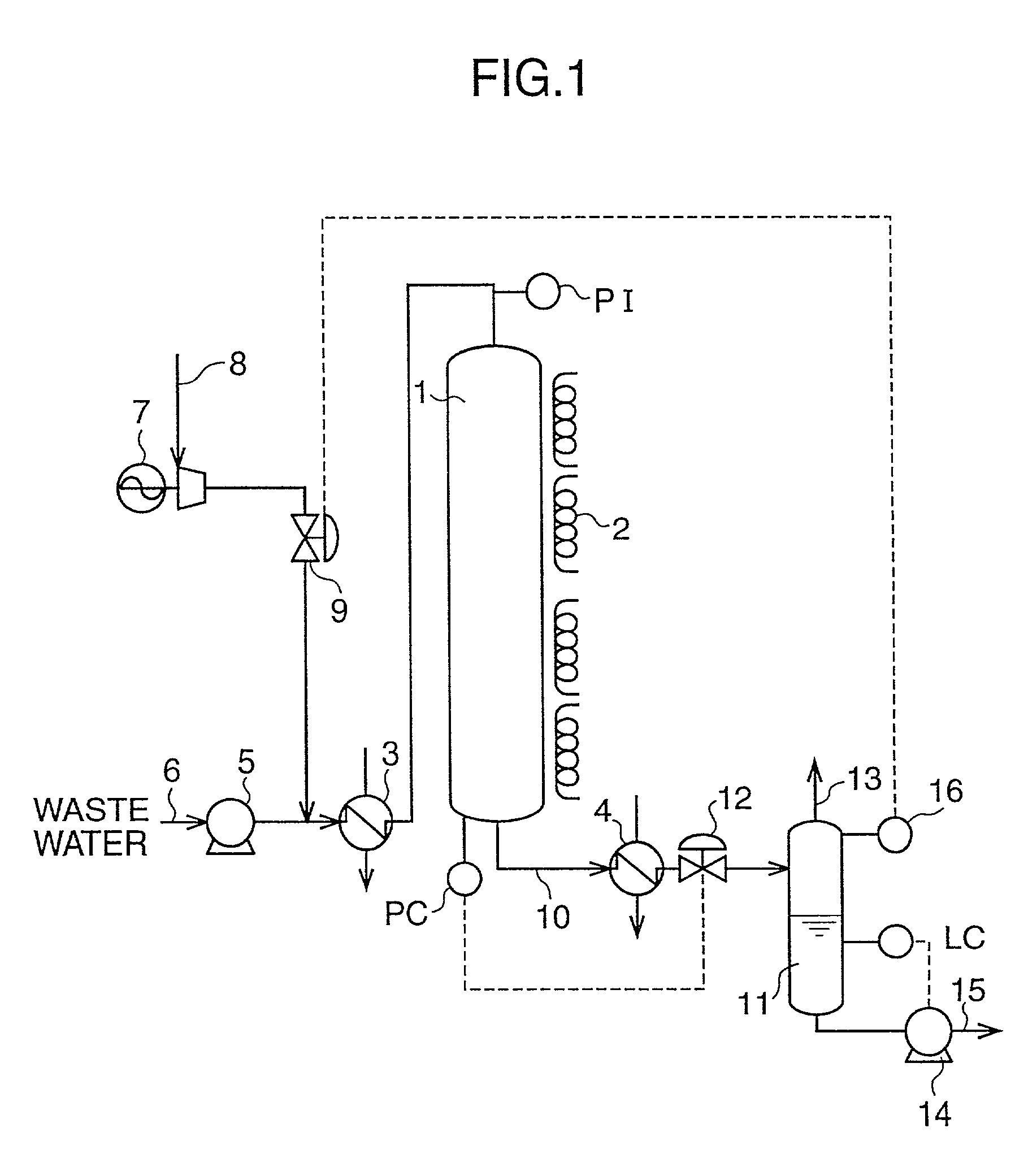

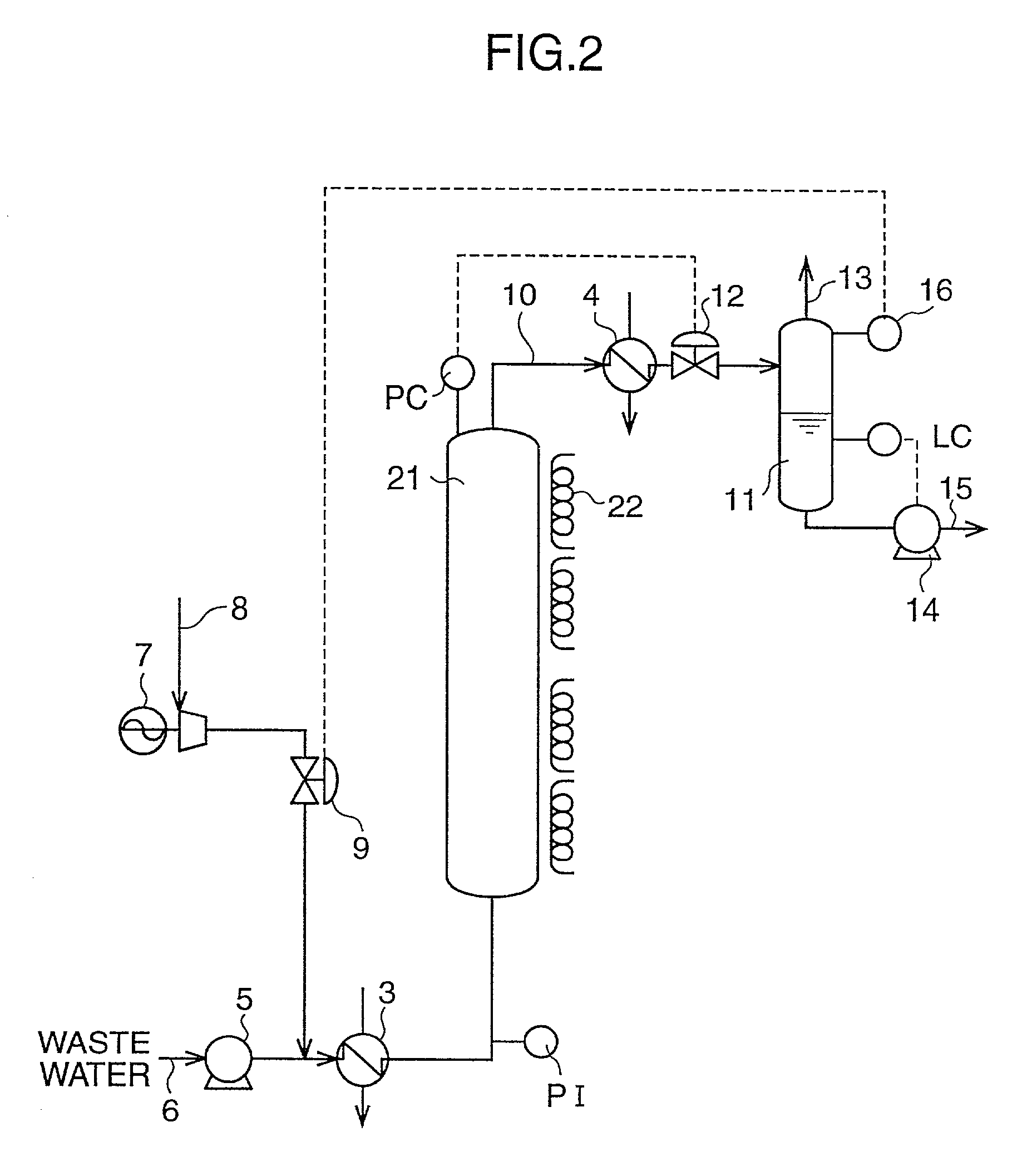

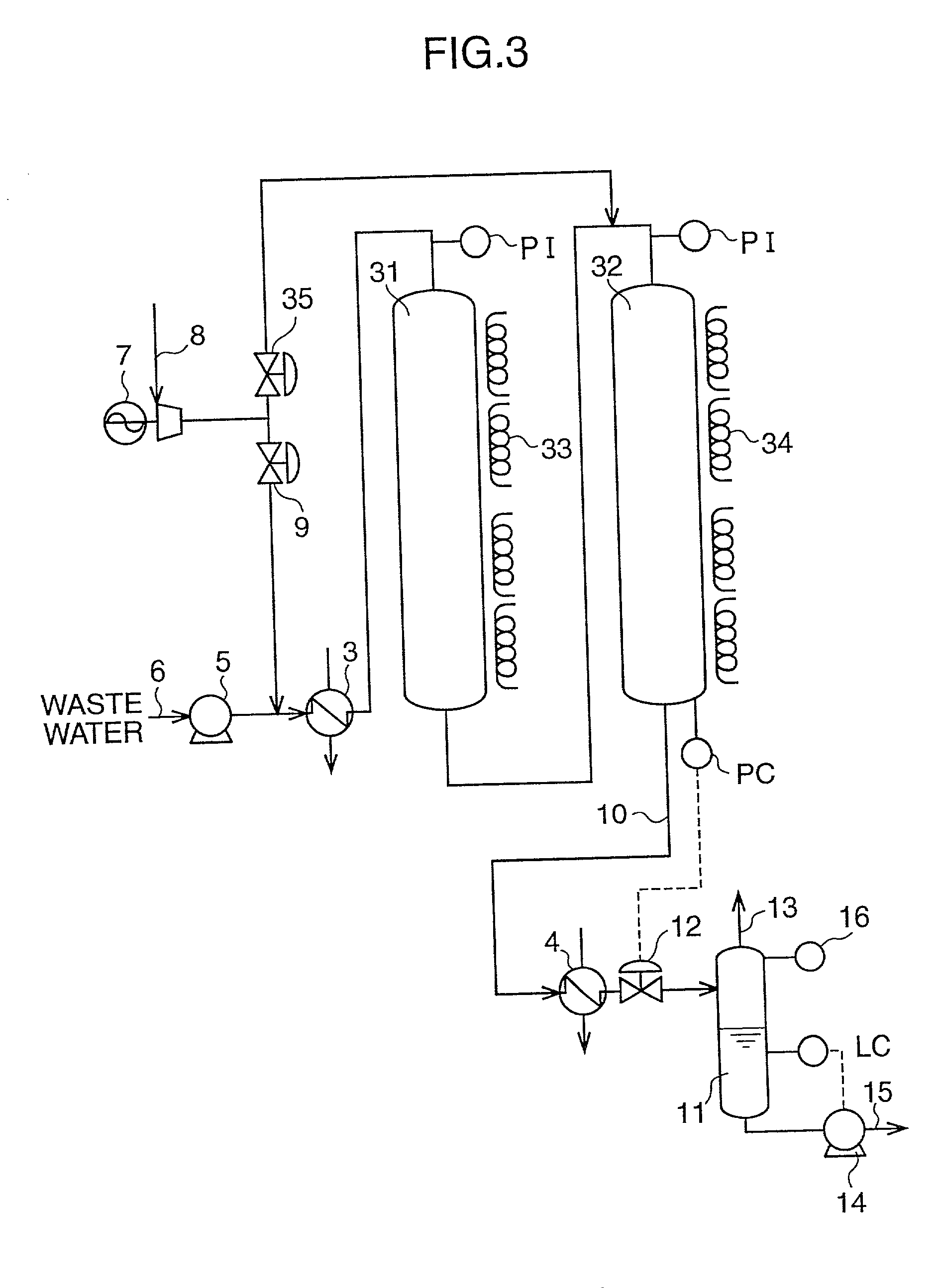

Catalyst for treating waste water, method for preparing the same and process for treating waste water

InactiveUS20010022290A1Effective treatmentEffective recoverySludge treatment by oxidationCatalyst activation/preparationExhaust gasChemistry

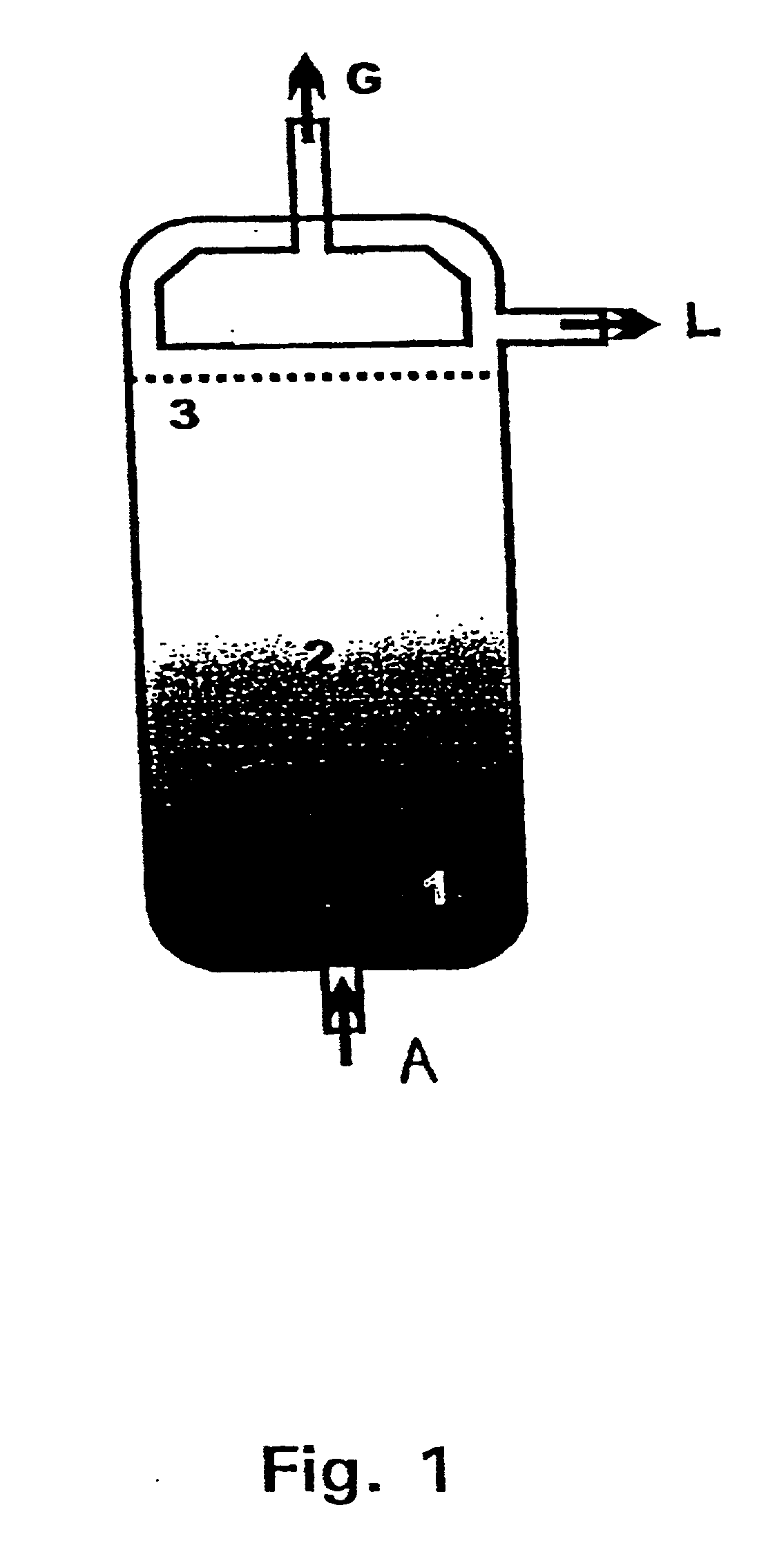

This invention discloses a method for oxidizing and / or decomposing organic and / or inorganic oxidizable substances in waste water by wet oxidation with a use of a catalyst, wherein the oxidizable substances are oxidized and / or decomposed with an oxygen containing gas in the presence of the catalyst under pressure such that said waste water retains the liquid phase thereof at temperature of 50 to less than 170° C.; the catalyst contains activated carbon; and controlling an oxygen concentration in an exhaust gas in the range from 0 to 5 vol %. The present inventive method is capable of treating waste water efficiently for a long period in a stable manner at the reduced temperatures and as compared with the substantially higher temperatures and pressures used in many of the prior art method.

Owner:NIPPON SHOKUBAI CO LTD

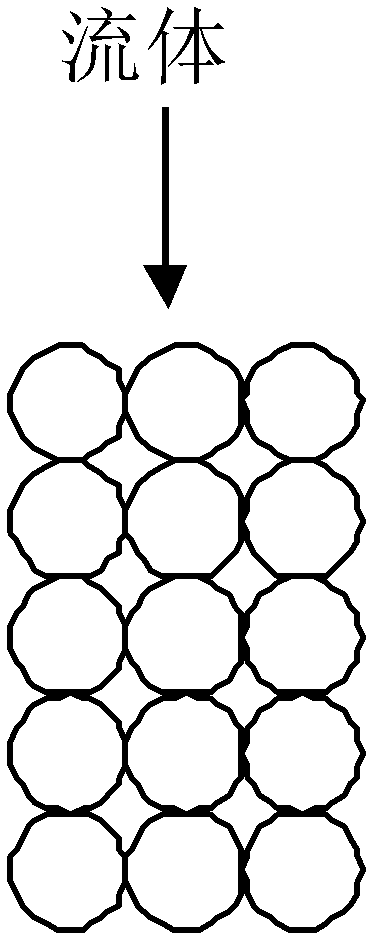

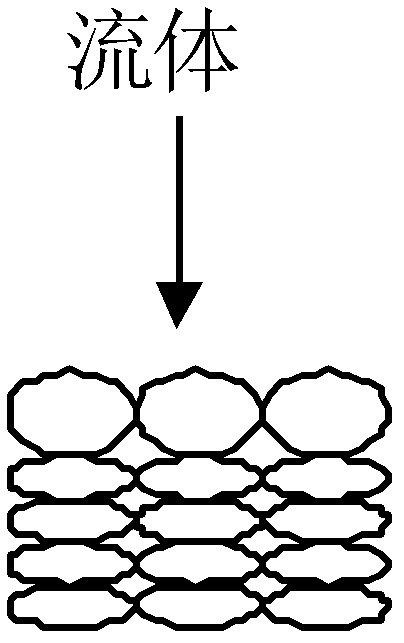

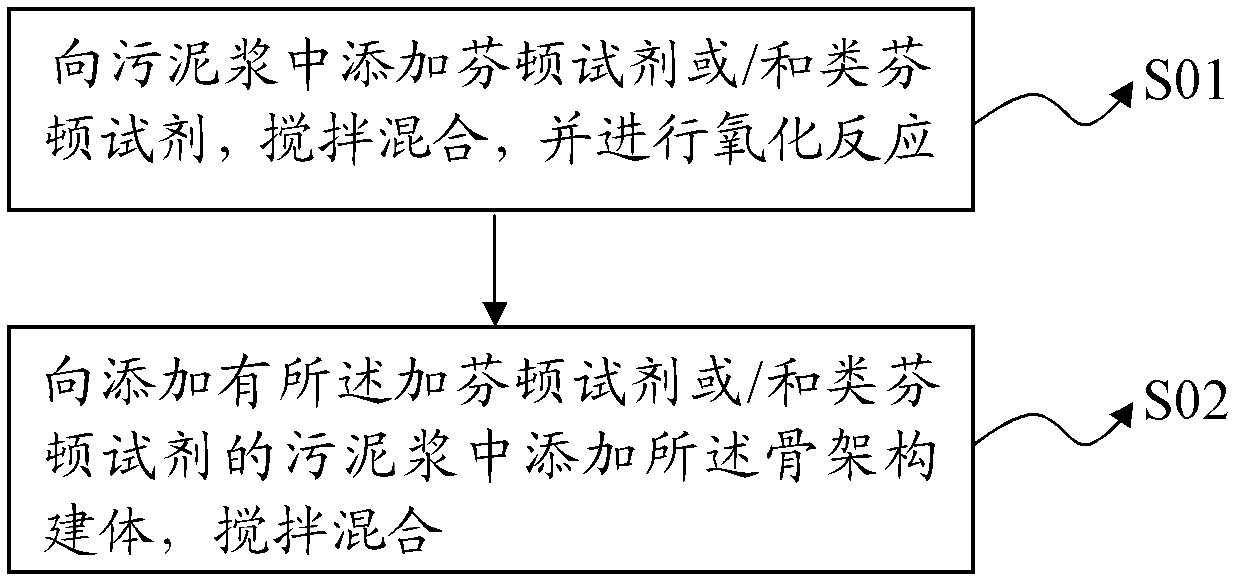

Sludge-dewatering compound conditioning agent and application method thereof

ActiveCN102381828AAchieve deep dehydrationShorten spin timeSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationPOLYMER SUBSTANCEFenton reagent

The invention provides a sludge-dewatering compound conditioning agent and an application method thereof. The sludge-dewatering compound conditioning agent comprises a Fenton reagent or / and similar Fenton reagent and a skeleton construct, and the weight ratio of the Fenton reagent or / and similar Fenton reagent and the skeleton construct is 1: (0.05-300); and the skeleton construct adopts a powder body. The application method comprises the following steps: adding the Fenton reagent or / and similar Fenton reagent into sludge slurry, and mixing for oxidation; and adding the skeleton construct into the sludge slurry with the Fenton reagent or / and similar Fenton reagent, and mixing. Due to synergy of the Fenton reagent or / and similar Fenton reagent and the powder type skeleton construct, extracellular polymeric substances in sludge can be destructed effectively, the compressibility of organic substances can be reduced, and the sludge dewatering performance of the sludge-dewatering compound conditioning agent can be improved greatly. The procedures of the application method are simple, the conditions can be controlled easily, the sludge dewatering time can be shortened, and the large-scale treatment of the sludge can be realized.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

Sludge drying and incinerating treatment process

InactiveCN1931753AAvoid pollutionAvoid harmSludge treatment by oxidationByproduct vaporizationChemical compositionSludge

The present invention relates to environmental protection engineering technology, and is especially sludge drying and incinerating treatment process. The present invention has effective utilization of heat energy, no exhaust of harmful gas and bad smell, no exhaust of dangerous clinker, simple structure and high burning efficiency of the sludge incinerating system, no need of auxiliary fuel and other advantages.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

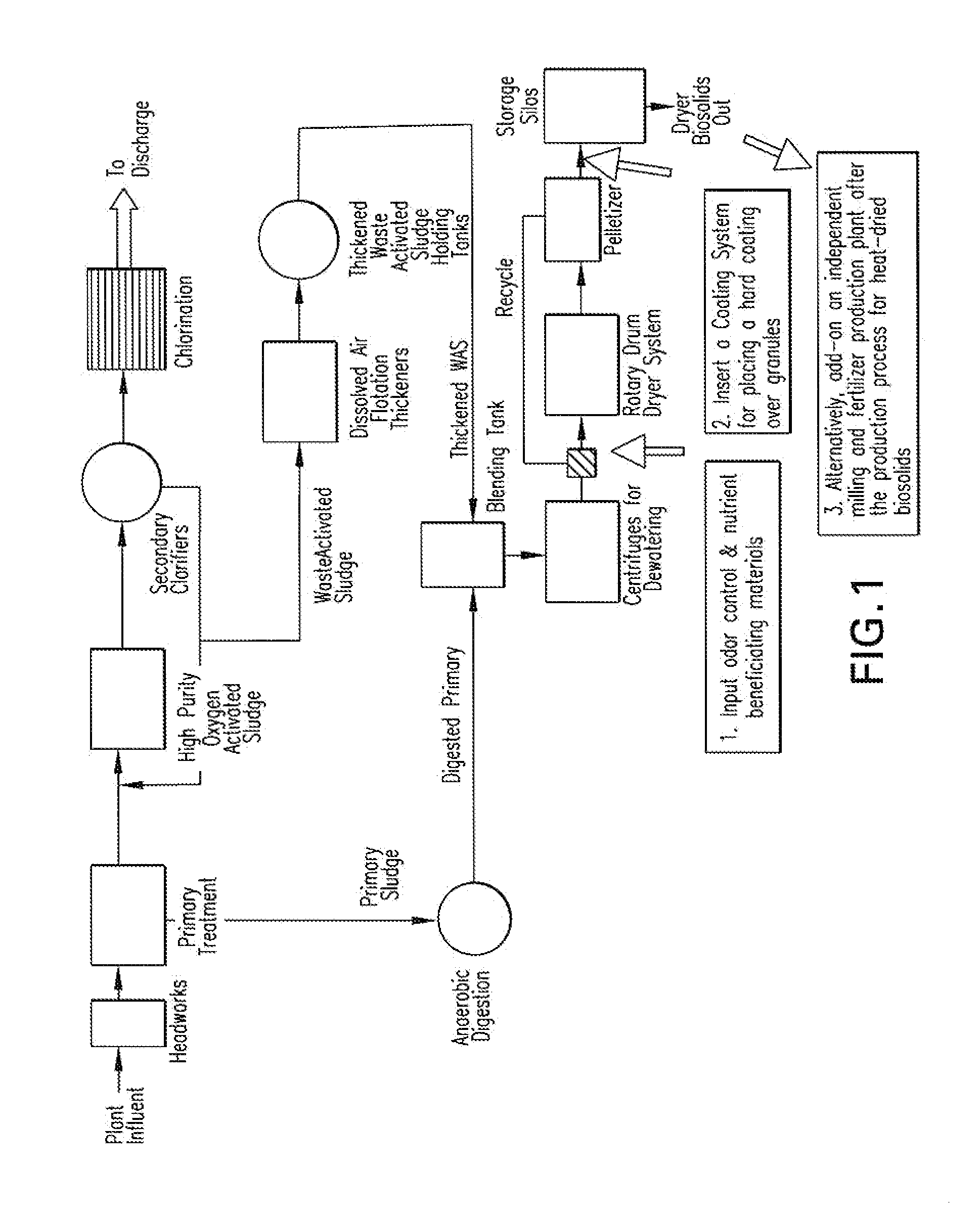

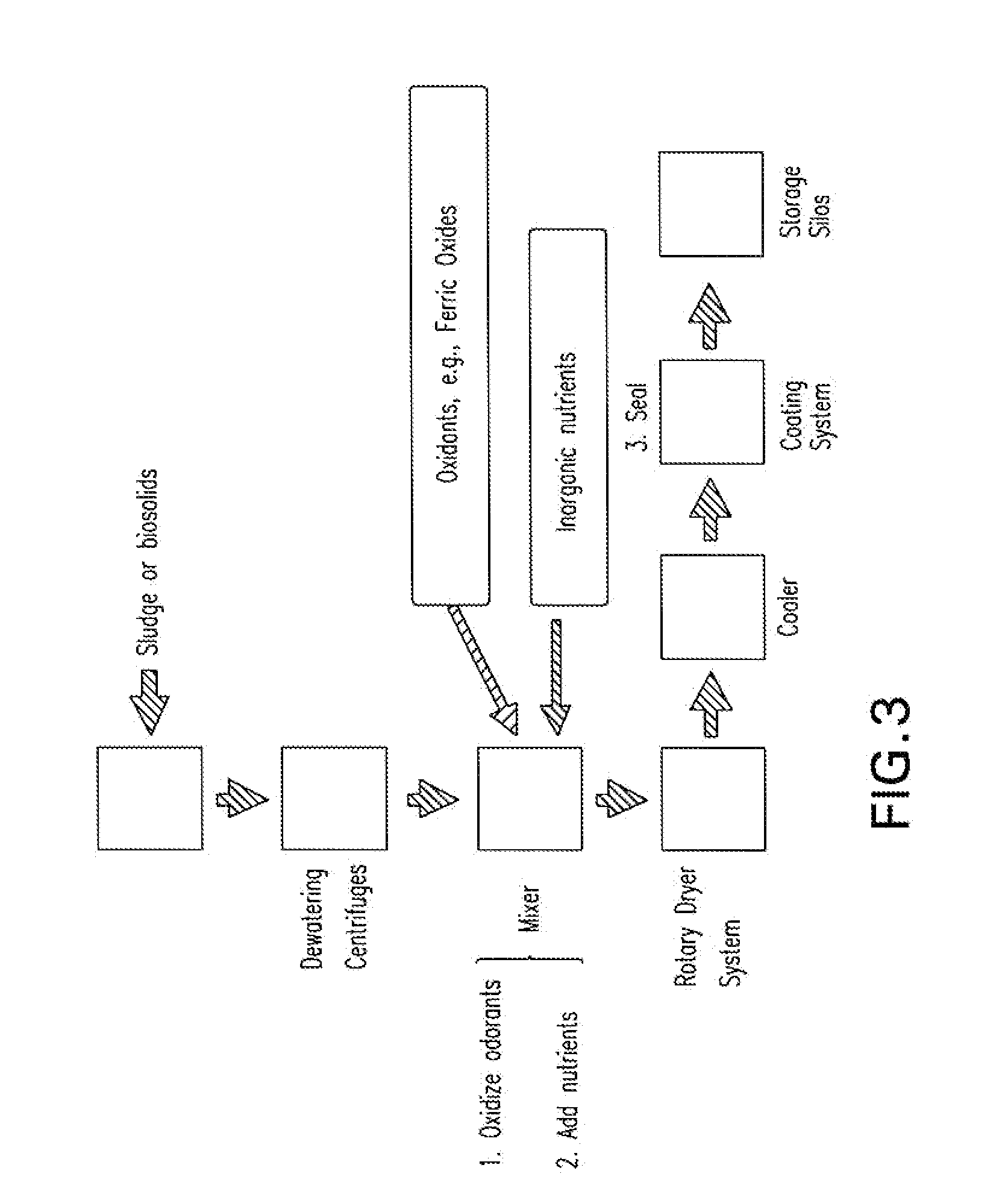

Beneficiated, heat-dried biosolid pellets

ActiveUS20100139346A1Calcareous fertilisersSludge treatment by de-watering/drying/thickeningDry heatSolid particle

This invention is directed to systems, devices and methods for modifying the process of producing dried biosolids pellets or granules into beneficiated inorganically-augmented bioorganic fertilizer. The present invention describes a method to beneficiate heat-dried biosolids or sludge pellets or granules as presently manufactured by municipalities or companies from a) dewatered municipal wastewater biosolids or sludges within the municipal wastewater treatment plant heat-dried biosolids production facility or from b) finished dry heat dried biosolids pellets or granules in a separate manufacturing facility from the municipal wastewater treatment plant to produce a fertilizer containing sufficient organic and inorganic plant nutrients to be valuable and saleable into the commercial agricultural industry. The present invention describes beneficiation methods to increase the plant nutrient content to a level which permits the finished beneficiated dried biosolids pellet or granule product to compete in the commercial agricultural fertilizer marketplace and also to reduce the odors associated with traditionally-produced heat dried biosolids.

Owner:PROFILE PRODS LLC +1

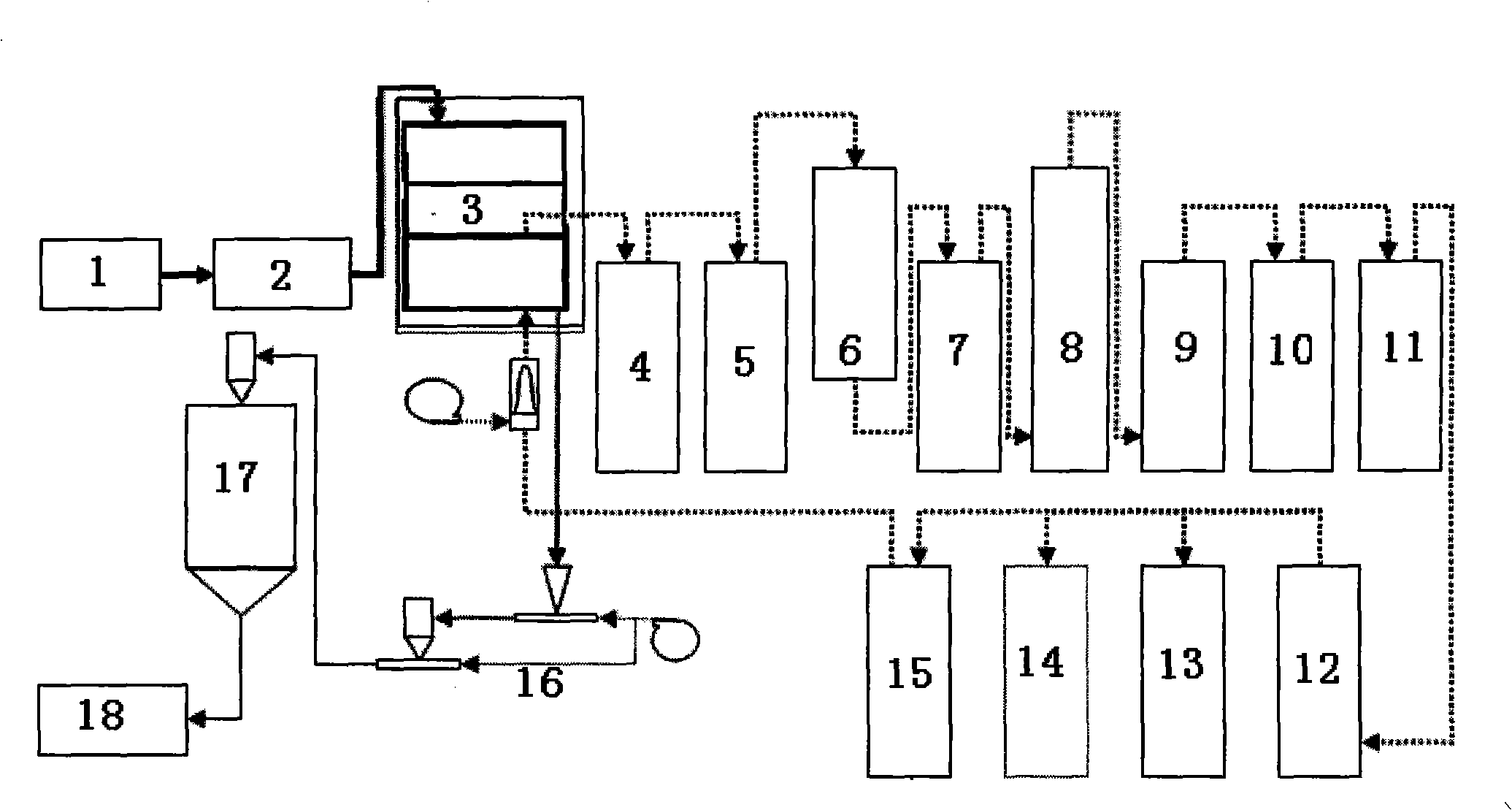

Method for promoting sludge to be reduced by ozone

InactiveCN101708937ASmall particle sizeLow mineralization rateSludge treatment by oxidationWaste based fuelBrickBiological filter

The invention relates to a method for promoting sludge to be reduced by ozone, in particular to a technology used for pretreating the sludge and accelerating anaerobic sludge digestion speed by utilizing ozone oxidation technique, which is widely applied to the sludge treatment technique of a sewage plant. The method comprises: the residual sludge of the sewage plant is concentrated and then treated by a sludge pretreatment reactor; due to the strong oxidizing property of ozone, the cell wall and the cell membrane of microorganism inside the sludge are broken, and a great deal of organic matter is released out of cells; after being treated by the ozone, the sludge enters into an anaerobic digestion reactor, and anaerobic digestion can be carried out in a closed anaerobic state; gas generated by digestion is treated by a gas purifying device, and methane can be obtained; after anaerobic digestion, the sludge is treated by flocculation and dehydration, and dewatering sludge can be obtained; then, final treatment can be carried out, for example, the sludge can be used for manufacturing agricultural fertilizer, bricks, porcelain granules or auxiliary fuel of fire coal; and anaerobic supernate is treated by biological filtering bed technique, so that the organic matter, ammonia and nitrogen in the solution can be removed.

Owner:NANJING UNIV OF TECH

Organic containing sludge to fertilizer alkaline conversion process

InactiveUS7662206B2Reduce odorHigh in nutrientsCalcareous fertilisersBio-organic fraction processingSludgeOrganic manure

This invention is directed to systems, devices and methods for treating organic-containing sludges and converting such sludges to high value fertilizers containing both inorganic and organic fertilizer components, which creates an inorganically-augmented bioorganic fertilizer. The invention describes methods to create a thixotrophic or paste-like material via the application of mixing energy to the organic sludge followed by an alkaline treatment and a subsequent ammoniation. The invention further describes a method to increase the plant nutrient content in the organic containing product to a level which permits the finished granular fertilizer product to compete in the commercial agricultural fertilizer marketplace. Further, the invention reduces odors associated with said organic-containing sludges.

Owner:GENERATE LENDING LLC +1

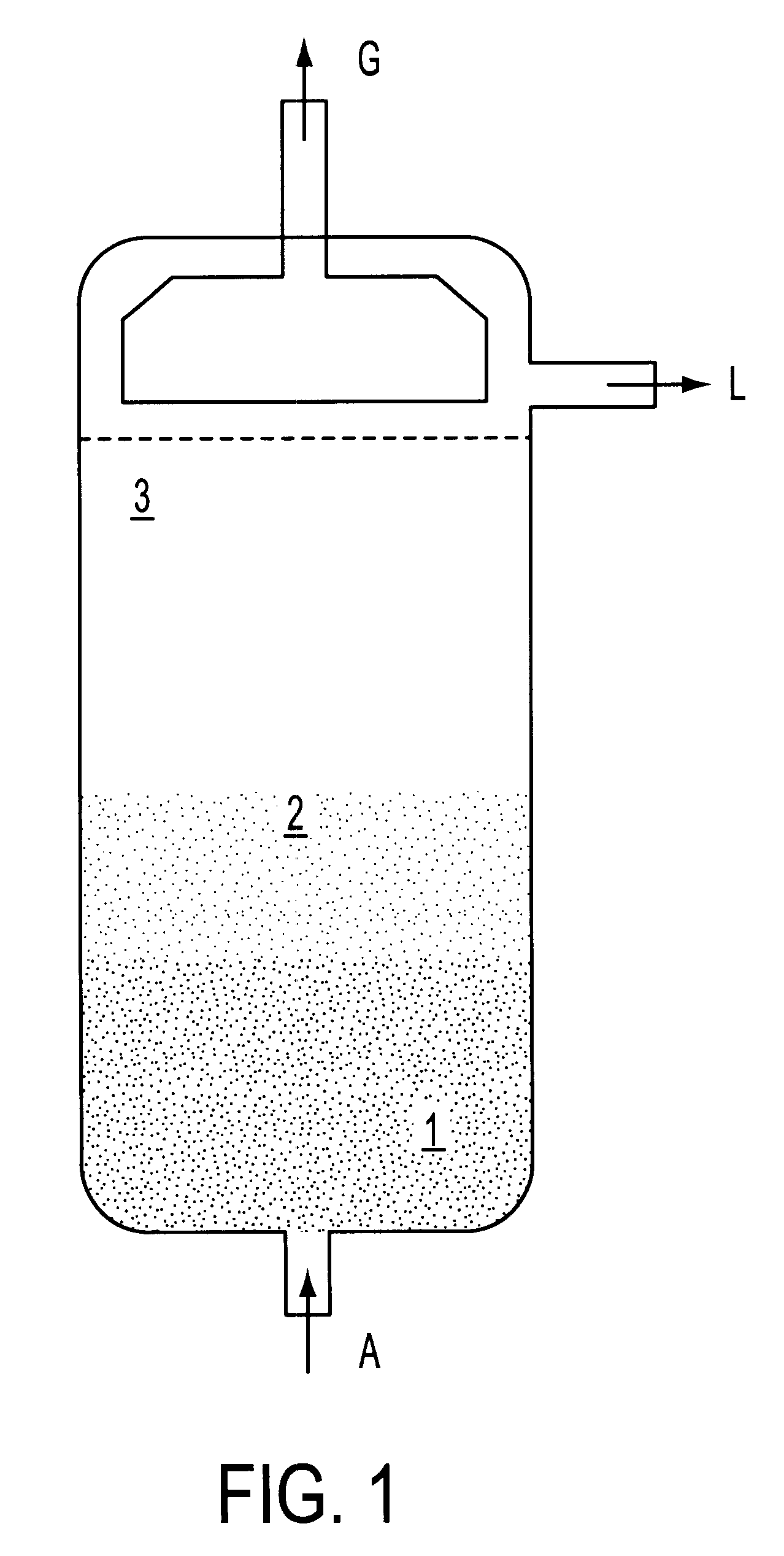

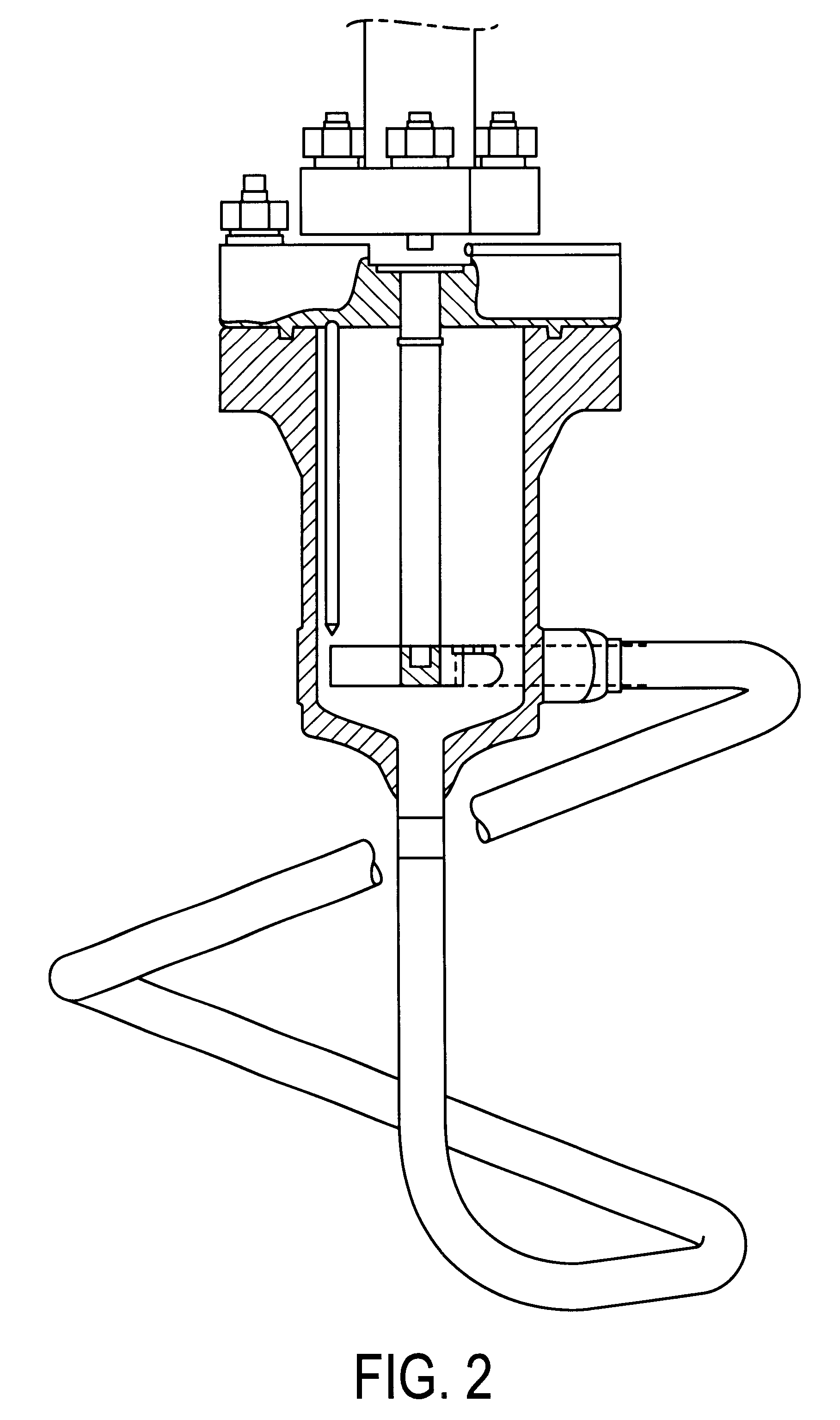

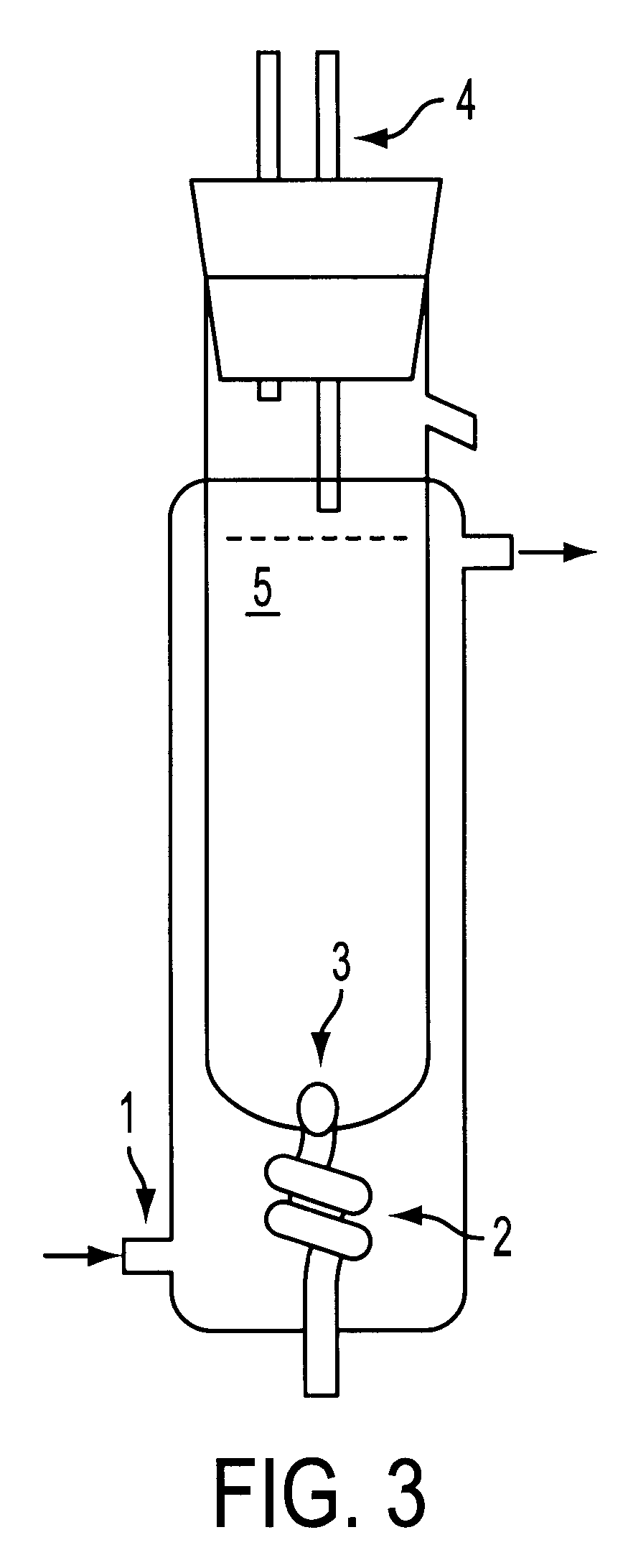

Wet oxidation process and system

InactiveUS20050171390A1Oxygen-containing compound preparationWater treatment parameter controlAdvanced oxidation processResidual carbon

A process and system for the destruction of compounds having a carbon-hetero atom bond. The process includes wet oxidation at elevated temperature and pressure of an aqueous mixture of at least one compound having a carbon-hetero atom bond to substantially destroy the carbon-hetero atom bond of the at least one compound. The resulting oxidized material may be further treated in an advanced oxidation process to destroy any residual carbon-hetero atom bonds remaining.

Owner:SIEMENS WATER TECH HLDG CORP

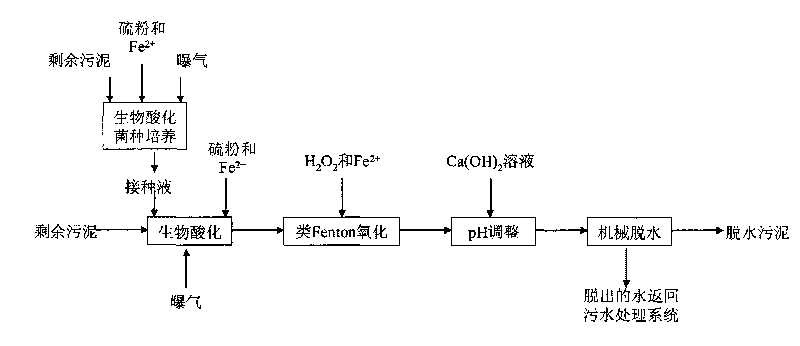

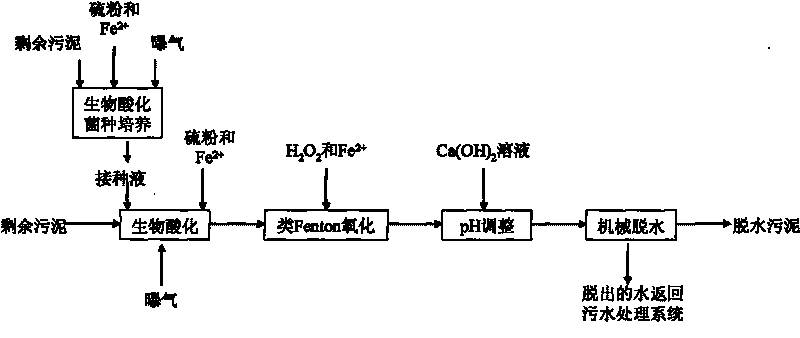

Method for improving dewatering performance of excess sludge by combining biological acidification and Fenton-like oxidation

InactiveCN101759337AImprove dehydration effectReduce volumeSludge treatment by oxidationBiological sludge treatmentFiltrationDewatered sludge

The invention relates to a method for improving dewatering performance of excess sludge by combining biological acidification and Fenton-like oxidation, which belongs to the technical field of sludge treatment. The method comprises that: under the condition of adding a sufficient quantity of substrates, indigenous acidification bacteria serving as inoculation liquid are cultured and acclimatized from sludge; the inoculation liquid is added to excess sludge in order to perform biological acidification on the sludge under an aerobic stirring condition in the presence of a sufficient quantity of substrates till the pH of the sludge is 2 to 3; under the catalytic action of Fe2+ and Fe3+, H2O2 produces strong oxidative free radicals and other Fenton-like oxidized sludge; Ca(OH)2 solution is added to the treated sludge to regulate the pH of the sludge to be between 6 and 7; and the treated sludge is dewatered by a plate-frame pressure filtration method or a centrifugal dewatering method in order to obtain dewatered sludge with water content between 65 and 75 percent. The combination of biological acidification and Fenton-like oxidation for improving the dewatering performance of excess sludge can improve reaction efficiency, shorten reaction time, increase treatment capacity and reduce cost for sludge treatment.

Owner:BEIJING FORESTRY UNIVERSITY

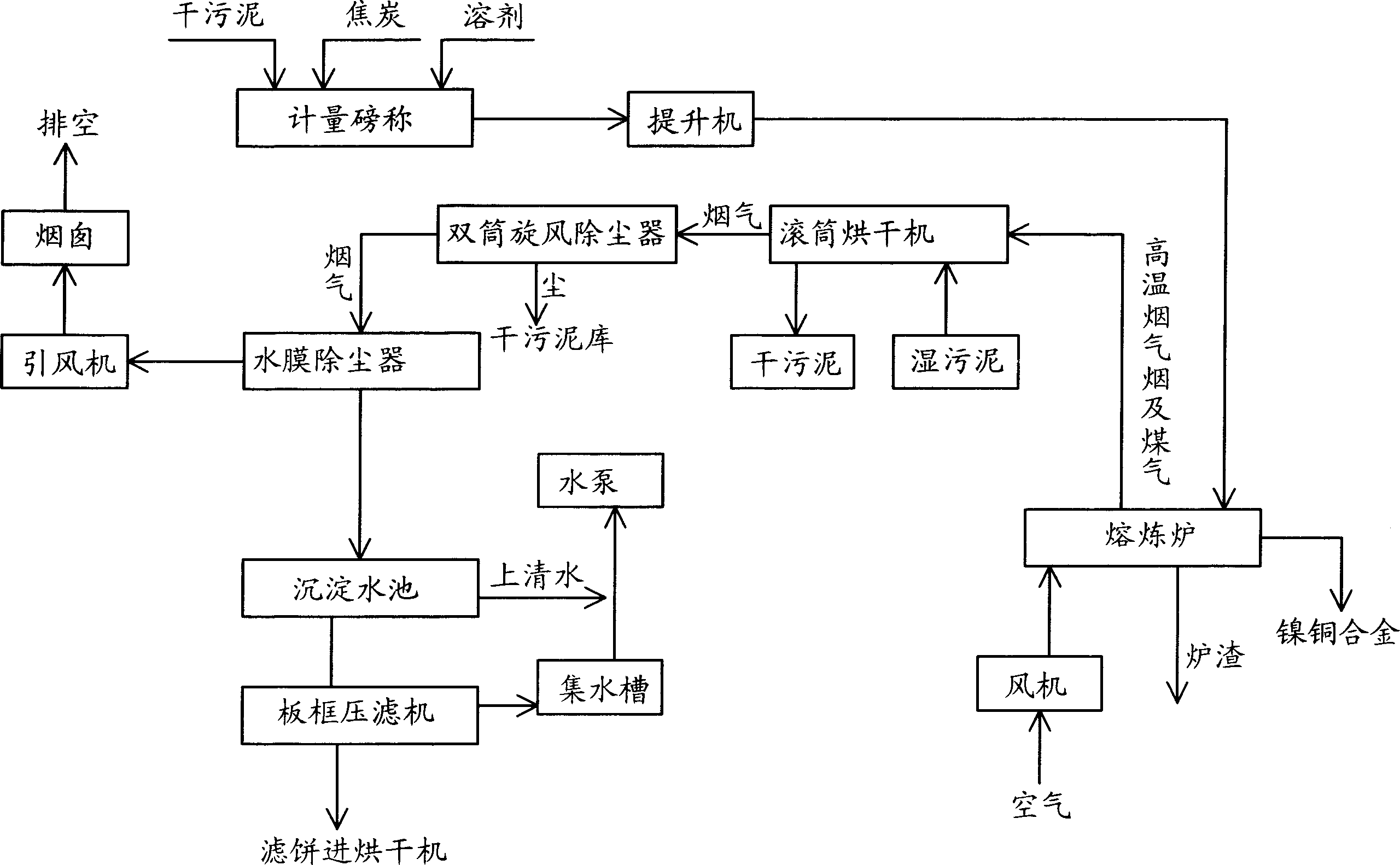

Resource recovery process of galvanizing sludge

InactiveCN1733628ASolve pollutionEfficient recyclingSludge treatment by oxidationSludgeHazardous substance

The invention relates to treatment technique for electroplated sludge, which comprises following steps: a. matching material by dried sludge, solvent and coke according to the weight proportion as 100:15~71:50~88; b. mixing the material evenly to put into melting furnace with temperature 1400~1600Deg for reducing melting, releasing the reduced nickel-copper alloy through ally output and liquid residue through slag hole; c. treating residue gas and discharging out. This method has well speed and high recovery ratio, and overcomes problems brought by slag.

Owner:台州盛世环境工程有限公司

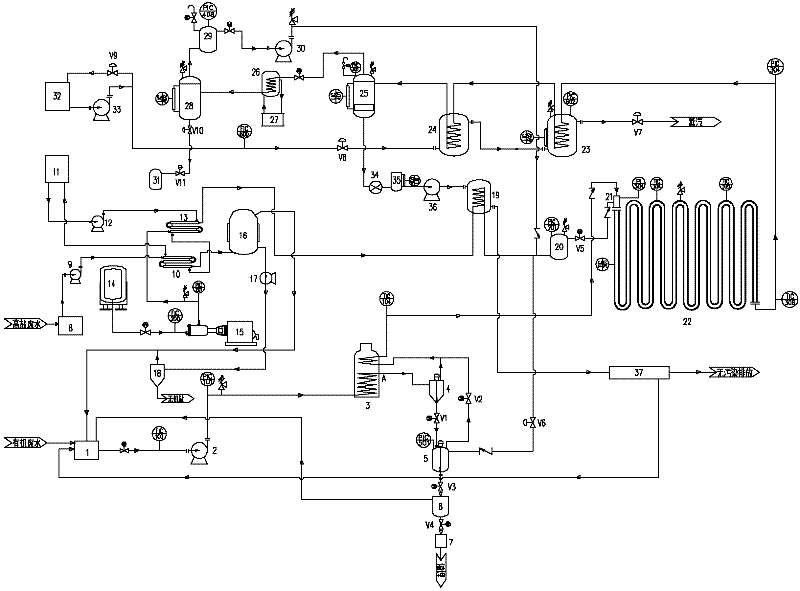

Supercritical water oxidation treatment system for printing and dyeing wastewater and sludge

InactiveCN104030427AReduce volumeReduce secondary pollutionSludge treatment by oxidationWaste water treatment from textile industryLiquid wasteHigh concentration

The invention discloses a supercritical water oxidation treatment system for printing and dyeing wastewater and sludge. The system comprises a concentration pretreatment device, a supercritical water oxidation device, an oxidizing agent supply device and a wastewater recycling system, wherein the concentration pretreatment device comprises a waste liquid storage tank, a nanofiltration membrane concentration module and a printing and dyeing sludge storage pool, the oxidizing agent supply device comprises a liquid oxygen storage tank, a liquid oxygen gasifier and a buffer tank, and the supercritical water oxidization device comprises an auxiliary heating supercritical water oxidization reactor, a methyl alcohol starting preheater, a methyl alcohol preheater and a waste liquid preheater. The system can be used for realizing efficient, clean and harmless treatment of high-concentration printing and dyeing wastewater and sludge at low cost.

Owner:山川丽(苏州)环保科技有限公司

A kind of separation method of oil sludge sand

ActiveCN102276127AEasy to desorbEfficient separationWaste water treatment from quariesSludge treatment by oxidationSludgeViscosity

The invention discloses a method for separating oily sludge and sands, which comprises the steps of: in the presence of water, carrying out a contact reaction on the oily sludge and sands and a catalyst and an oxidizing agent, and separating to obtain a water phase, a grease phase and sand, wherein the oxidizing agent is a matter capable of oxidizing grease in the oily sludge and sands and reducing the viscosity of the oily sludge and sands, and the catalyst is a matter capable of promoting the oxidizing agent to generate radicals with strong oxidability. According to the method for separating the oily sludge and sands, provided by the invention, the content of oil in oily sludge and sands can be remarkably reduced, therefore, grease, sand and water in oily sludge and sands can be effectively and efficiently separated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for Purification Treatment of Wastewater Containing Organic Substance

InactiveUS20070256972A1Pressurized chemical processTreatment involving filtrationFiltrationPrimary treatment

There is provided a process for purification treatment of wastewater containing an organic substance. There is provided a process for purification treatment of wastewater containing an organic substance by carrying out supercritical treatment or subcritical treatment, which comprises subjecting the wastewater to at least one solid-liquid separation pretreatment selected from separation treatment with a flocculant, sedimentation treatment, flotation treatment and filtration treatment; and then subjecting the wastewater to primary treatment as biological treatment; and subsequently purifying the wastewater by treatment including secondary treatment as supercritical treatment or subcritical treatment.

Owner:KANSAI PAINT CO LTD

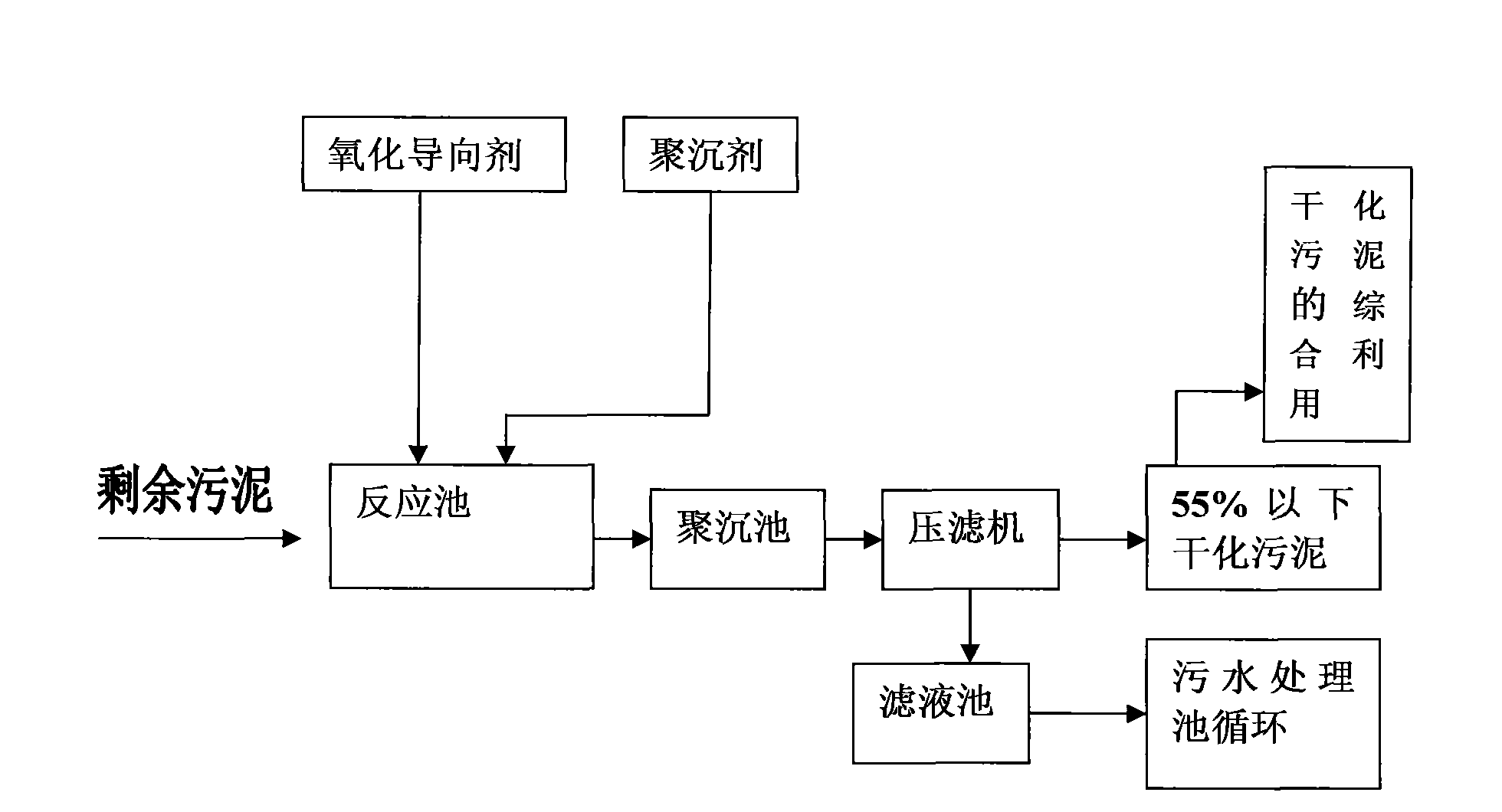

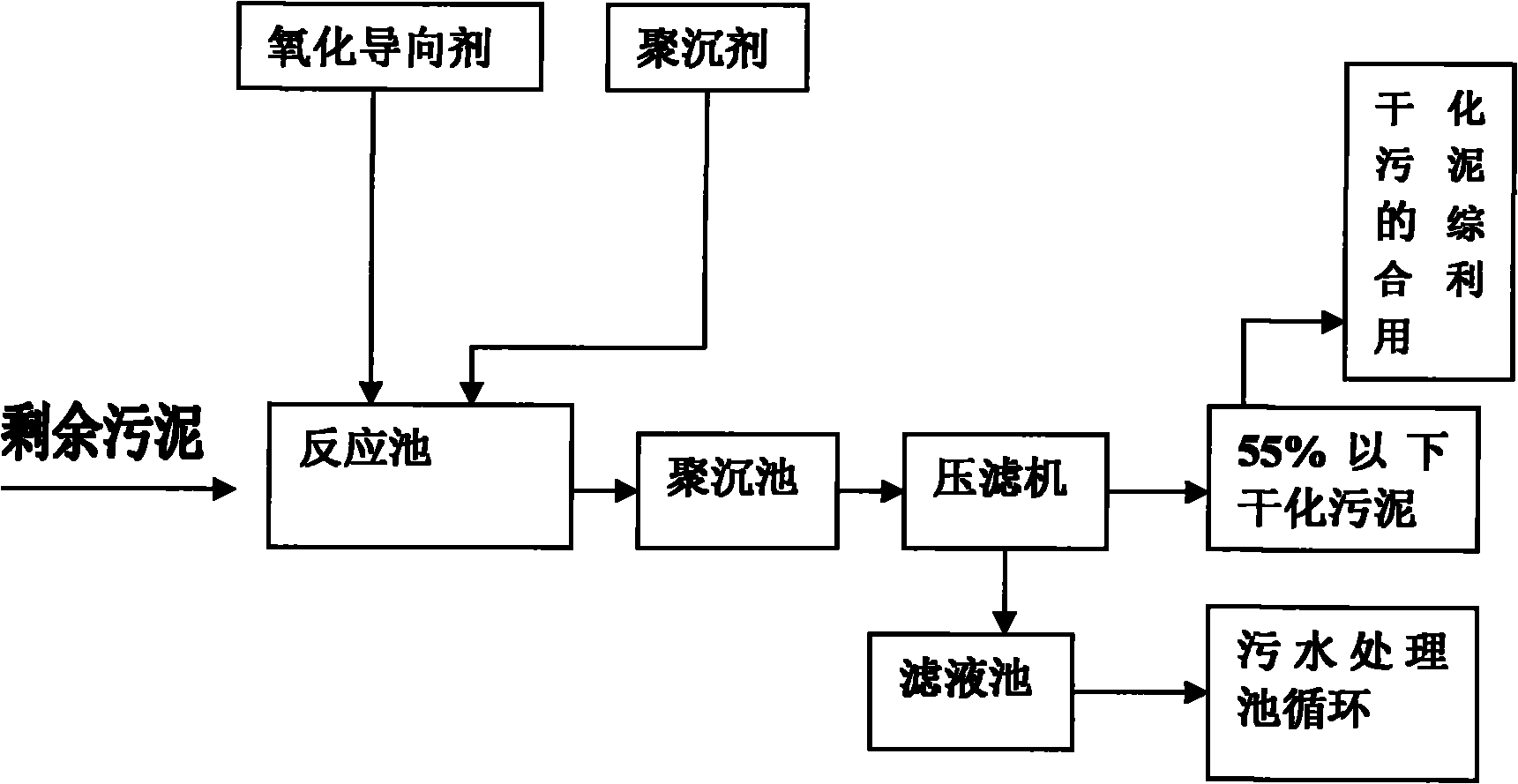

Method and equipment for treating sludge in normal state

InactiveCN102145974ALow bacterial indexStable structureSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationFiltrationReclaimed water

The invention relates to a method for treating sludge in municipal sewage, in particular to a method for separating water from sludge in the watery sludge. The method comprises the following steps of: (1) adding an oxidation directing agent and a regulator into the sludge, stirring the sludge and filling ozone into the sludge; and (2) after stirring to perform a reaction, adding a coagulant agent, and finally carrying out pressing filtration on the sludge to obtain the sludge with the moisture content of below 55 percent. By the method overcomes the technical bottleneck that in a normal temperature sludge treatment process, water adsorbed by the sludge containing organic matter cannot be removed, and achieves the aims that the cost is low, the effect is good and the processed sludge reaches the national standard.

Owner:HUNAN XIANGNIU SLUDGE ADVANCED TREATMENT

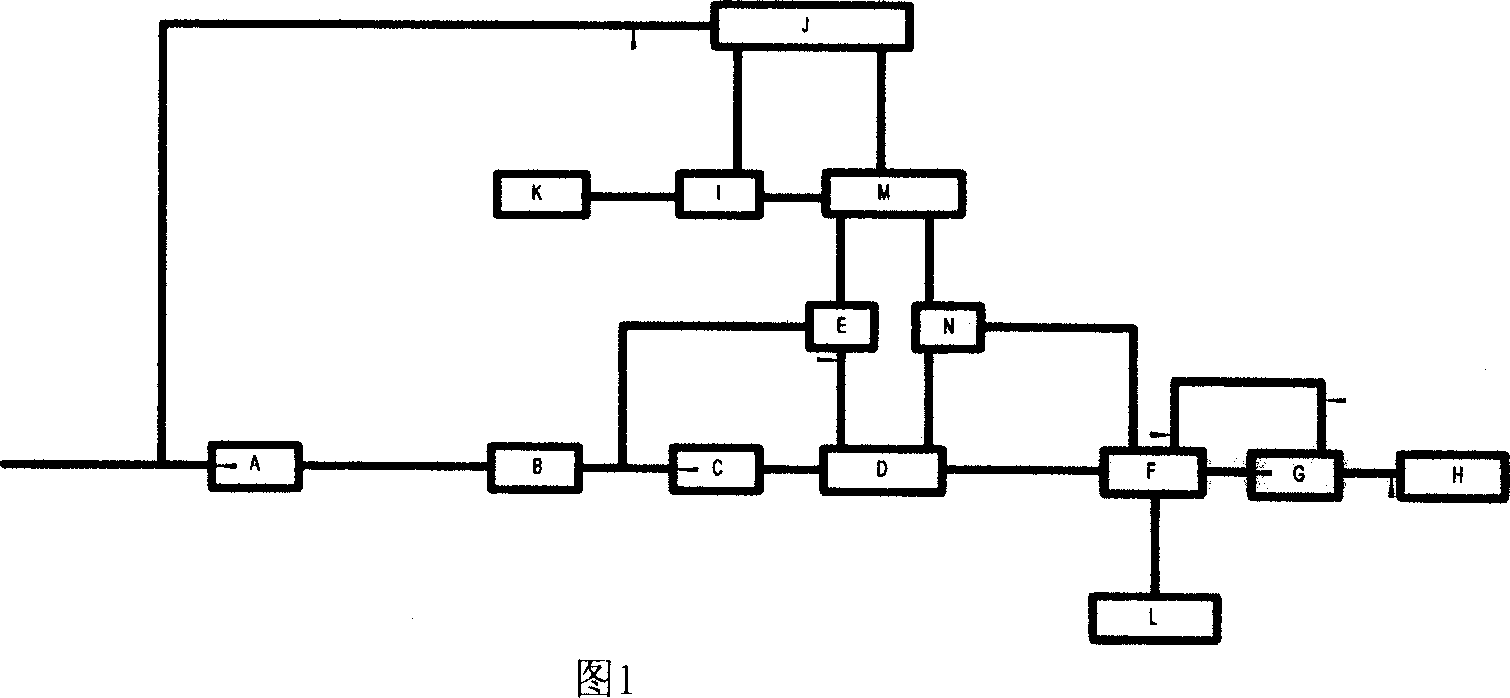

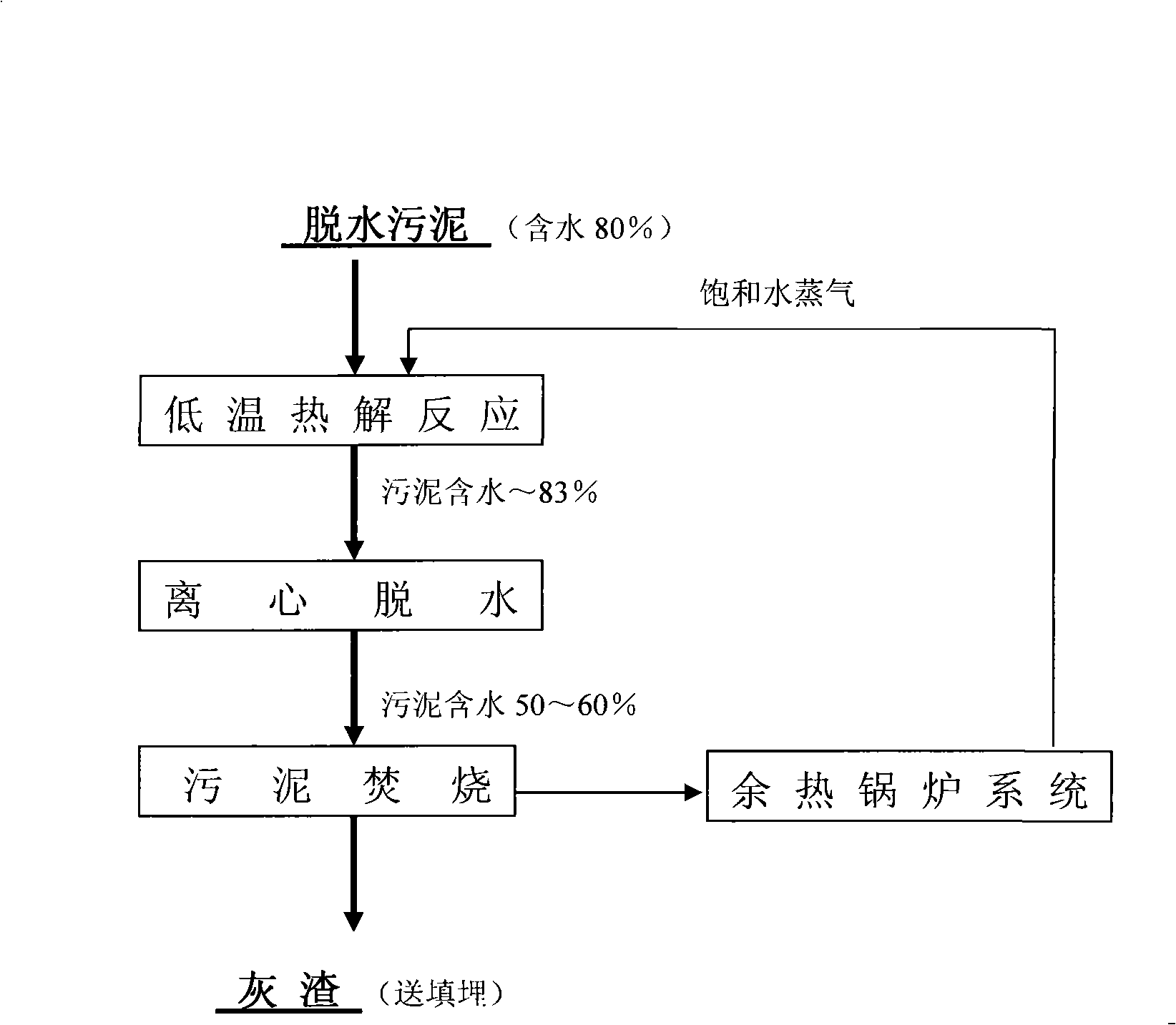

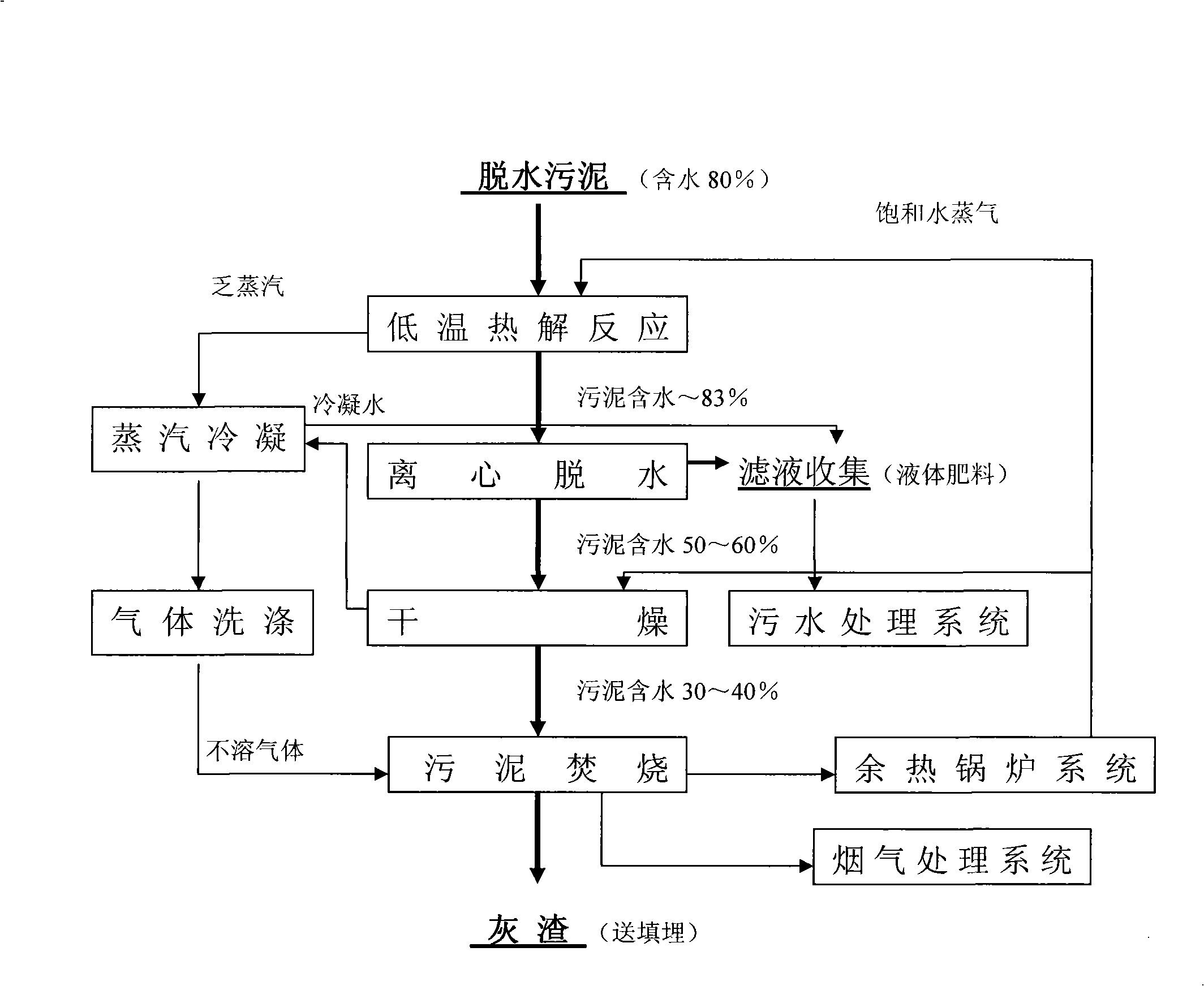

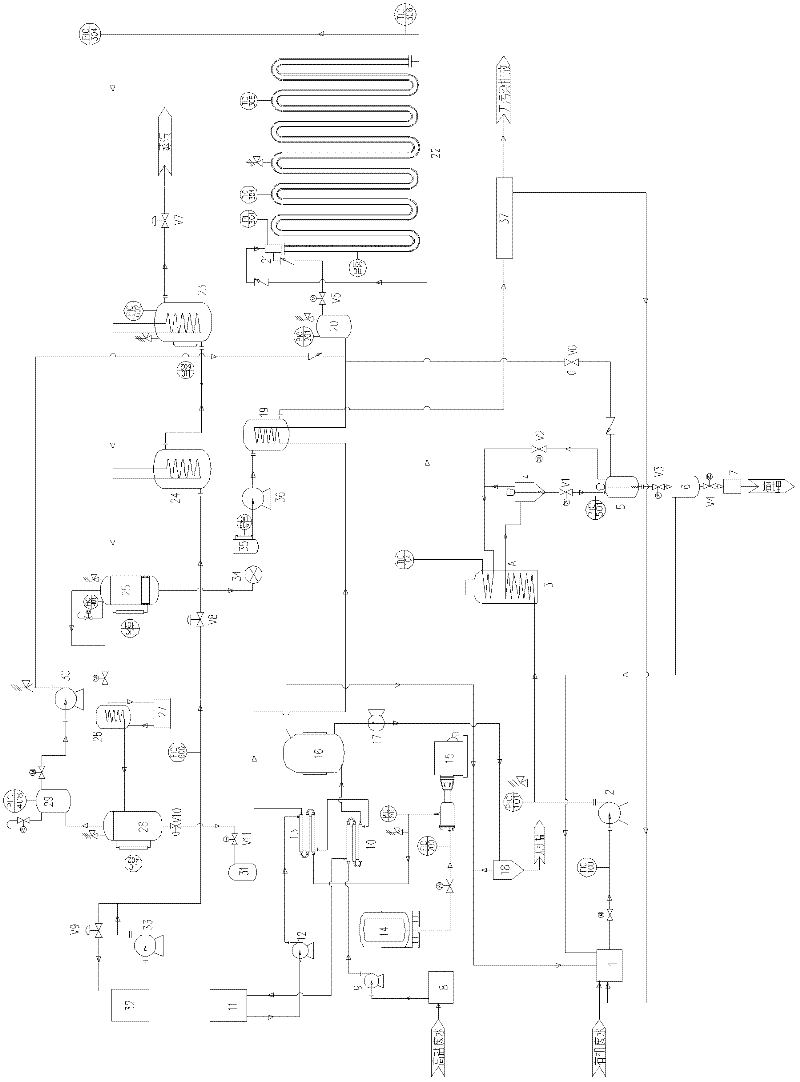

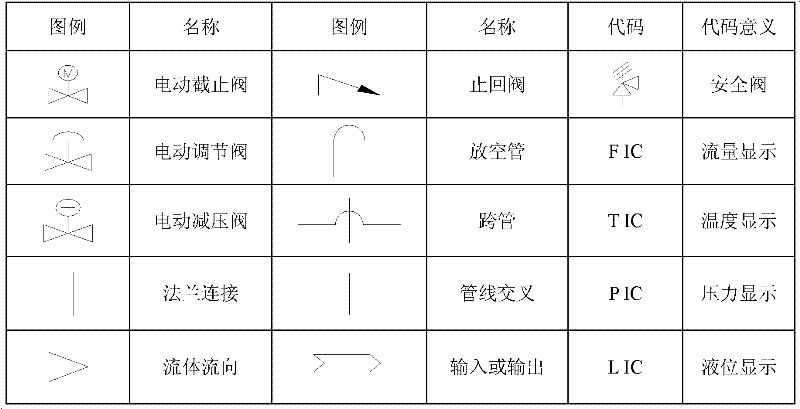

Wet sludge anhydration burning processing system and process

ActiveCN101290121AThoroughly deodorizedHarmlessDrying using combination processesSludge treatment by oxidationSteam condensationResource utilization

The invention relates to a wet sludge drying and incineration processing system. The system comprises a low-temperature pyrolytic reaction device, a centrifuging filtering device, a steam condensation device, a filtrate recovery device and a sludge incineration device; the low-temperature pyrolytic reaction device is used for carrying out low-temperature pyrolytic reaction between wet sludge and saturated steam in order to convert macromolecular organics in the wet sludge into low-molecular organics and destroy a sludge water-holding structure; the centrifuging device is used for carrying out centrifuging filtering to the wet sludge after pyrogenation; the steam condensation device is used for condensing and collecting bled steam converted from saturated steam in the low-temperature pyrolytic reaction device; the filtrate recovery device is used for collecting filtrate produced in the centrifuging device and for collecting condensed fluid from the steam condensation device; the sludge incineration device is used for incinerating semidry sludge after being dehydrated in the centrifuging device and insoluble gas remained in the steam condensation device as fuel. The system also relates to a process for carrying out the processing of wet sludge drying and incineration by adopting the processing system. The system and the process can solve the problem of sludge resource regeneration in a mode of environmental protection, energy conservation, high resource utilization rate and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

Supercritical water oxidization treatment system for high-salinity organic waste water

InactiveCN102642947AGuaranteed heat transfer coefficientAvoid cloggingSolidificationLiquefactionCycloneReaction temperature

The invention discloses a supercritical water oxidization treatment system for high-salinity organic waste water. The high-salinity waste water is subjected to cooling crystallization through cold energy of liquid oxygen to reduce mass concentration of inorganic salt in the waste water; a large amount of solid salt grains separated out from the waste water are removed by using a hydraulic cyclone device under a supercritical water condition to effectively prevent a subsequent pipeline and a reactor of the hydraulic cyclone device from plugging; and a desalting device is arranged at the lower part of the hydraulic cyclone device to continuously remove the inorganic salt from the system. In addition, excessive oxygen and CO2 product gas are recovered through a separation recovery part; the reaction time and the reaction temperature of supercritical water oxidization are reduced through arranging a simple subsequent treatment unit; and the system recovers heat energy of the reacted high-temperature fluid in a steam mode through the arrangement of a water softening device, so that the operation cost of the system is reduced. The system can be widely applied to the innocent treatment process of the high-salinity organic waste water.

Owner:XI AN JIAOTONG UNIV +1

Resource regeneration processing method and equipment for urban sewage sludge

InactiveCN101318759AReduce lossesAdaptableSludge treatment by oxidationByproduct vaporizationSludgeEnvironmental engineering

The invention discloses a resource treatment method for municipal sludge and equipment thereof. The method comprises the following steps that: the dried sludge is subject to carbonization treatment with a carbonization temperature range of between 450 and 650 DEG C and molded to produce a solid product; carbonization fractions in the carbonization treatment are reclaimed and a condensate is separated off; purified wood coal gas is comprehensively utilized; through a carbonization process adopting a biomass dynamic carbonization and pyrogenation comprehensive treatment technology, feeding, drying, carbonization, carbon generation, the dust removal of wood coal gas, condensation, washing and the separation of various byproducts can be continuously completed; carbonization equipment can realize automatic operation and can carry out resource treatment to biomass; the adopted process has strong adaptability to the variety and humidity of the biomass and has small loss of biomass and high treatment efficiency in the treatment process; as the process adopts a full-closed carbonization furnace, product yield is all products, wherein, the produced wood coal gas is used as fuel for drying, carbonization or power generation, thereby reducing production cost; and the whole system has perfect design and reasonable economical technology.

Owner:谢忠诚 +1

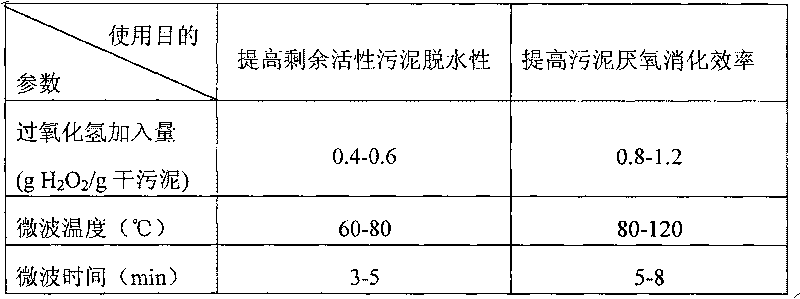

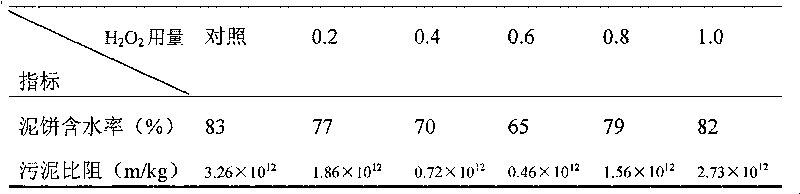

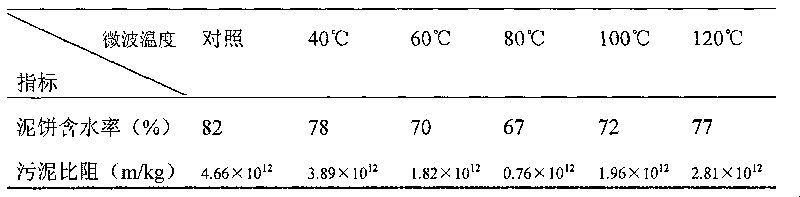

Silt pretreatment method for enhancing dehydration property and digestibility of silt

InactiveCN101698561AImprove decomposition abilityImprove dehydration effectSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationPretreatment methodSewage treatment

The invention relates to a silt pretreatment method for enhancing dehydration property and digestibility of silt and belongs to the field of sewage treatment. The invention is characterized in that when the method is used for enhancing the dehydration property of the remained silt, adding a peroxide solution to the silt (0.4-0.6 g H2HO / g dry silt), evenly stirring, and treating the silt by microwaves at 60-80 DEG C for 3-5 minutes; and when the method is used for enhancing the anaerobic digestion efficiency of the silt, adding a peroxide solution to the silt (0.8-1.2 g H2HO / g dry silt), evenly stirring, and treating the silt by microwaves at 80-120 DEG C for 5-8 minutes. The method enhances the dehydration property of the remained active silt and reduces the amount of the silt by utilizing the feature of high-speed high-efficiency heating and the strong oxidizing action of the free hydroxide radicals resulting from peroxide under microwave radiation. The method can also be used for enhancing the anaerobic digestion efficiency of the subsequent silt, thereby reducing the energy consumption and the amount of the silt. The method has the advantages of simple equipment, convenient operation and maintenance, does not produce any secondary pollution, and has wide application prospects in sewage treatment plants in large, medium-and-small-sized cities, and at sewage treatment stations in enterprises.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

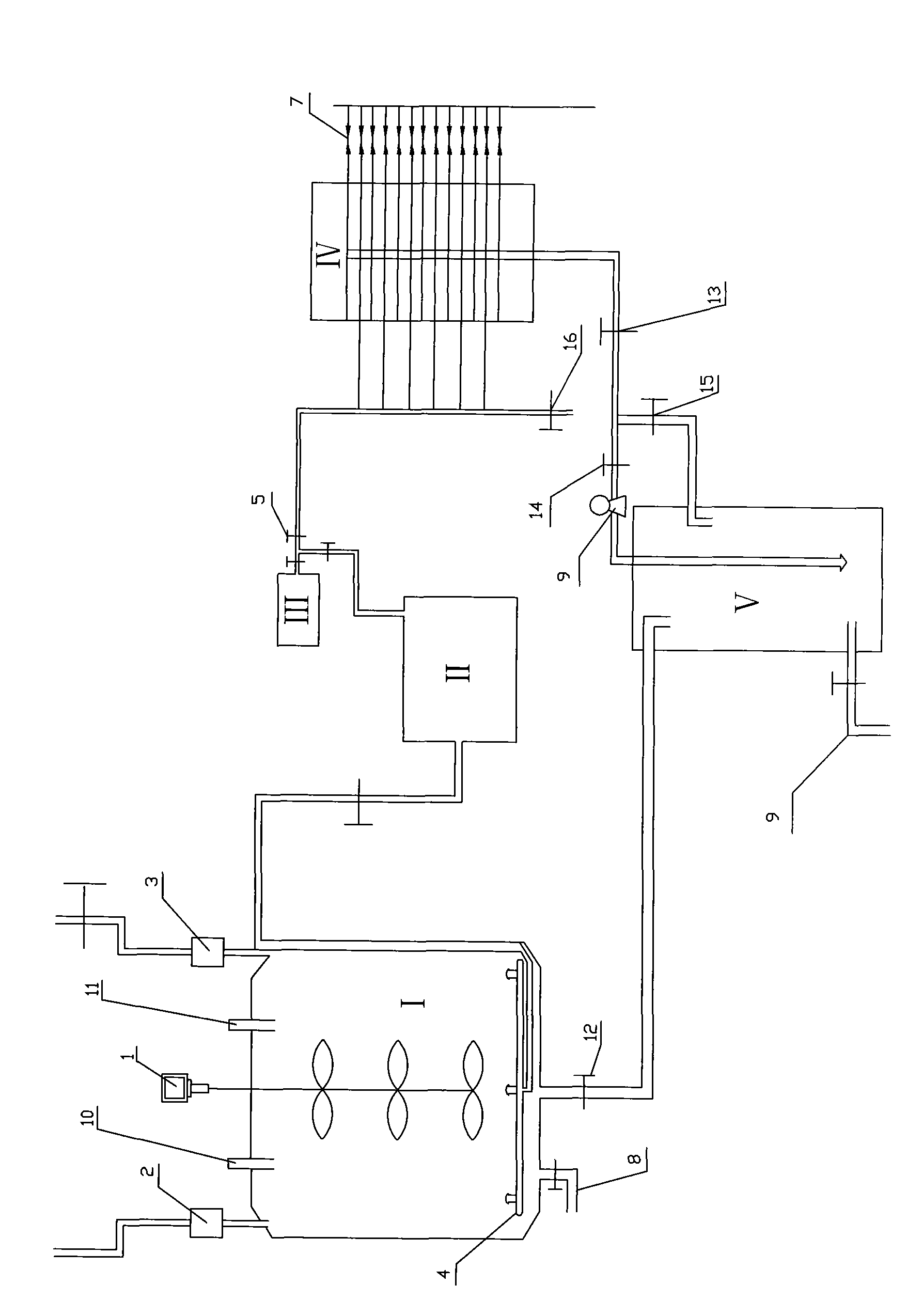

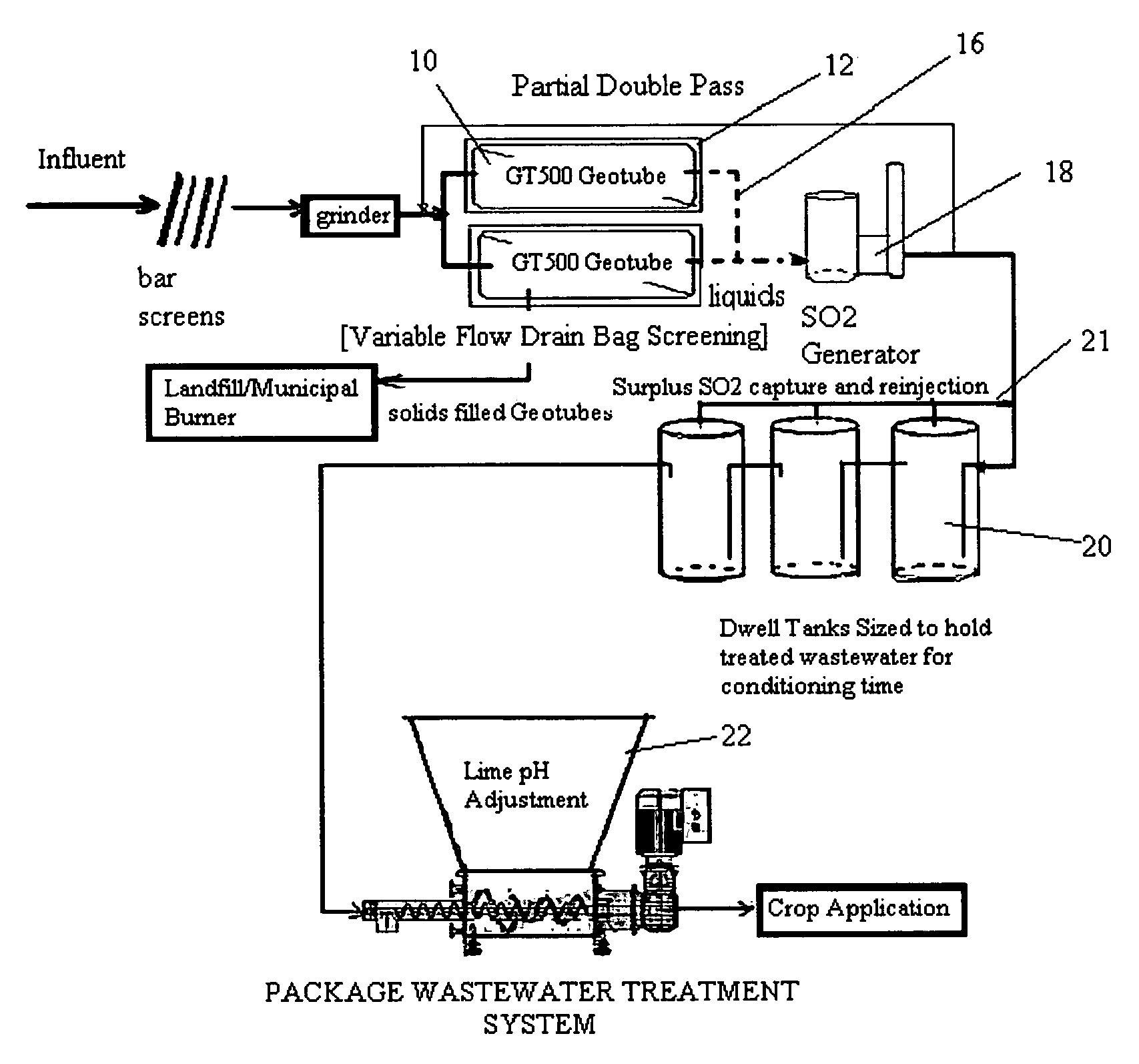

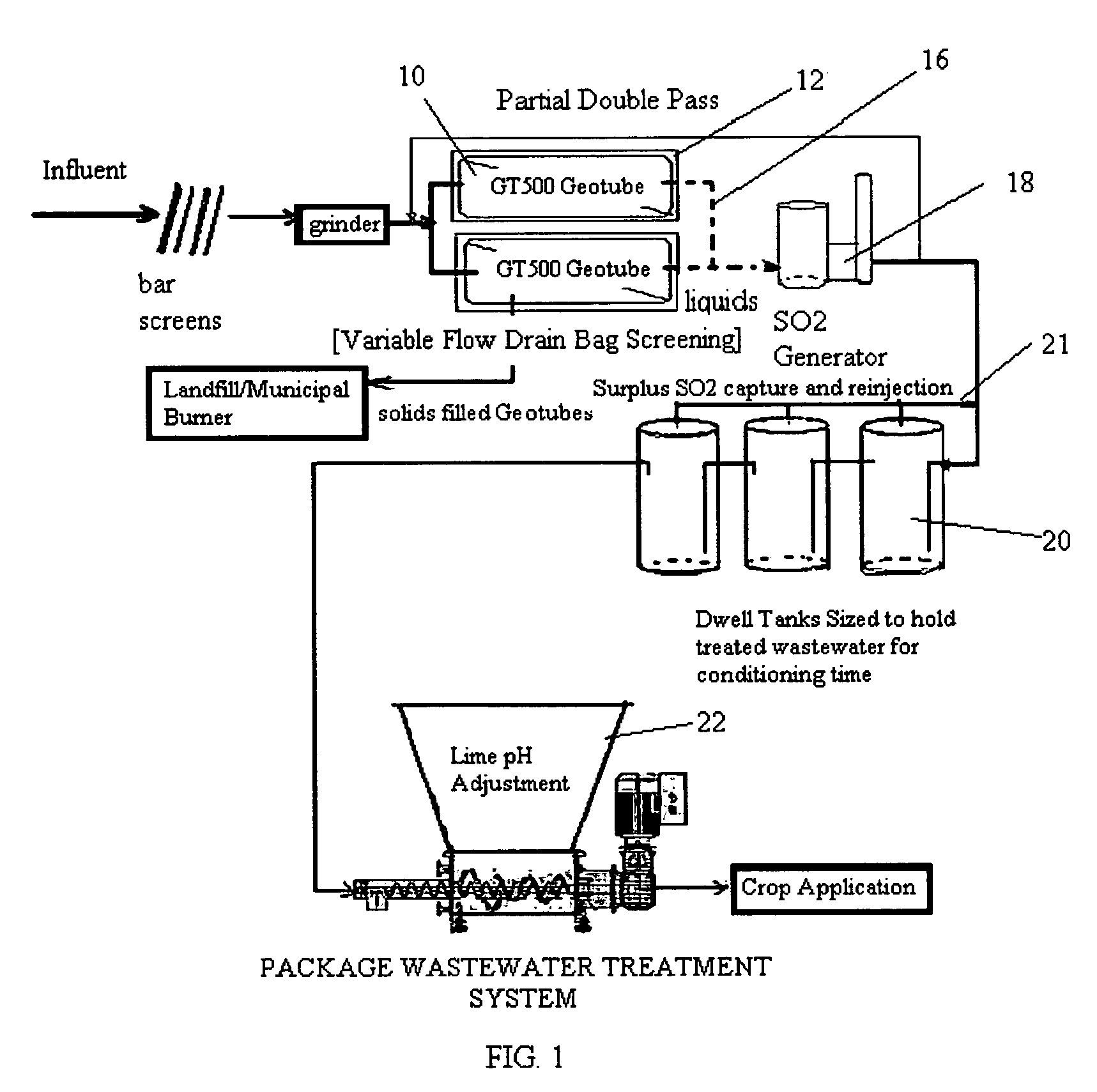

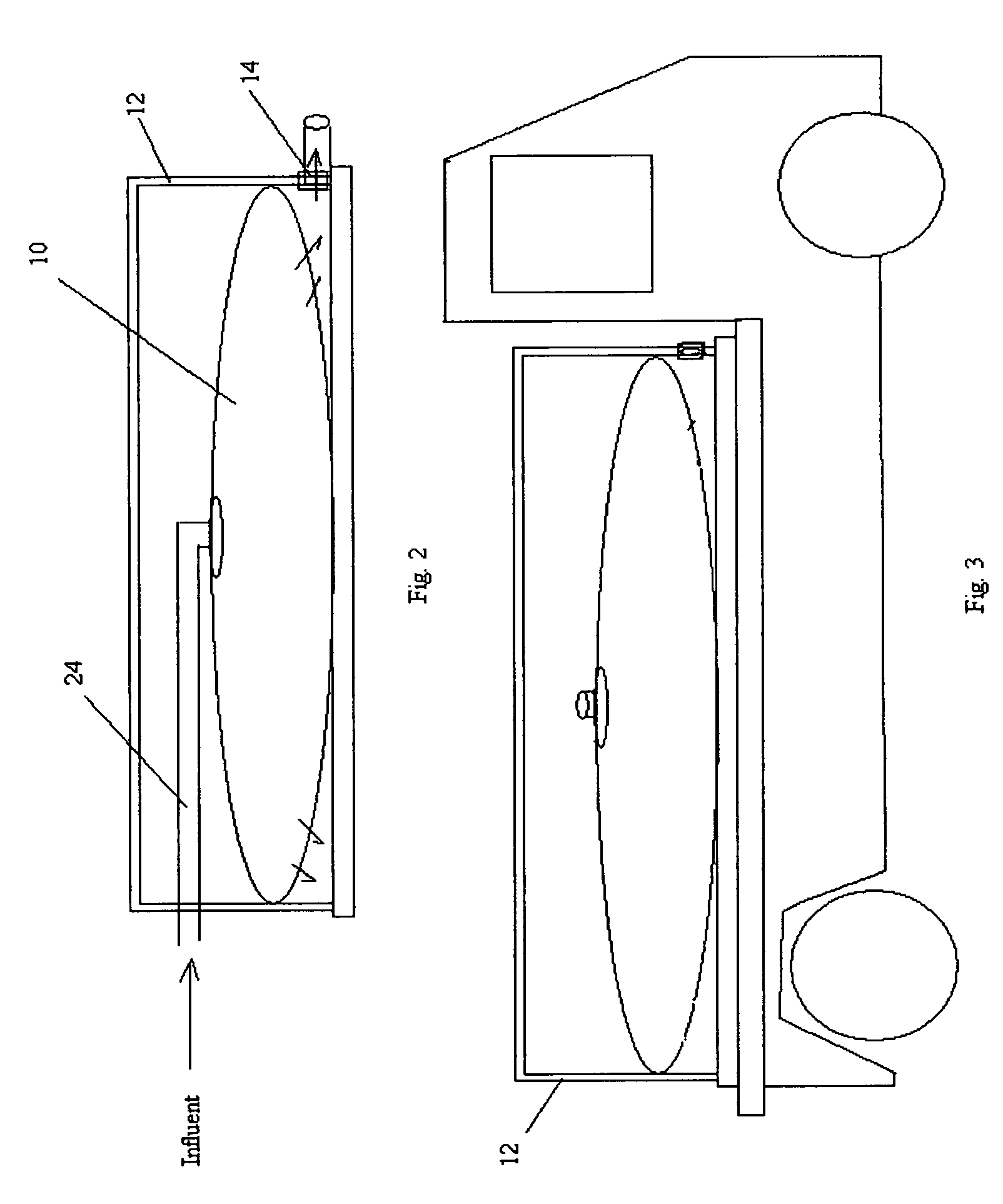

Package wastewater chemical/biological treatment method

ActiveUS7455773B1Preventing harmful operator exposureSaving additional treatment waterSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesSludgeCompound (substance)

A chemical / biological wastewater treatment plant method and apparatus employing rapid sludge chemical dewatering technology in conjunction with an environmental biological system for treating the separated treated wastewater by land applying it for plant consumption, and / or passing it through aqueous plant or microbial reduction of the dissolved solids and ammonia for BOD compliance to produce water of sufficient quality to meet open stream and ocean effluent discharge requirements; and disposing of the high BTU low moisture solids.

Owner:EARTH RENAISSANCE TECH

Popular searches

Treatment with anaerobic digestion processes Multistage water/sewage treatment Sustainable biological treatment Fermentation Treatment with aerobic and anaerobic processes Steroscopic systems Water/sewage treatment by centrifugal separation Specific water treatment objectives Electrical measurement instrument details Water contaminants

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com