Method for promoting sludge to be reduced by ozone

A technology of sludge and ozone, applied in the direction of oxidation treatment of sludge, biological sludge treatment, waste fuel, etc., can solve the problems of slow rate of hydrolysis, low gas production, long residence time of sludge anaerobic digestion, etc., to achieve saving Subsequent treatment costs, increased gas production, and good resource utilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

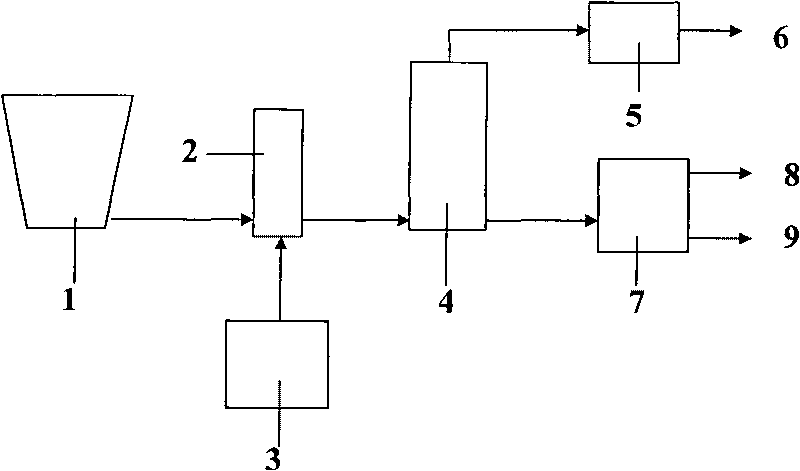

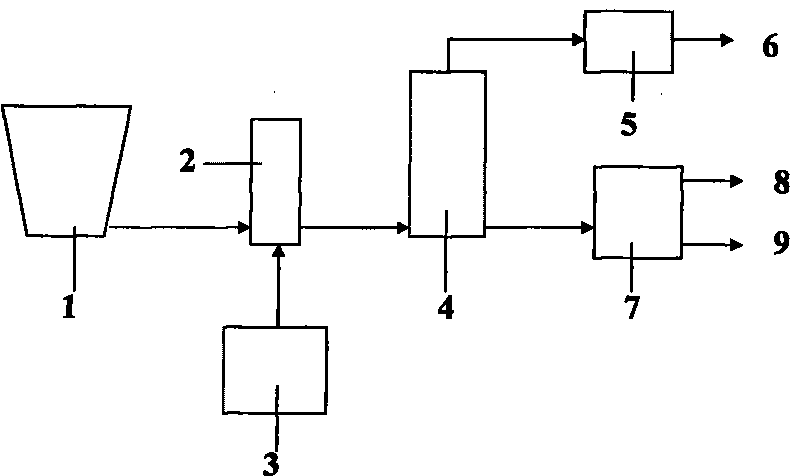

[0023] The remaining sludge of a certain urban sewage treatment plant, after being concentrated in the sludge concentration tank 1, has the following properties: the water content is 98.8%, the sludge SS is 12.01g / L, the VSS is 9.272g / L, and the soluble COD is 100.6mg / L. Adjust the pH to 9.03, take 1.2L of sludge and put it into the 2.5L sludge pretreatment reactor 2, the ozone generated by the ozone generator 3 enters the sludge pretreatment reactor 2 from the bottom, and the tail gas is emptied after being treated. The dosage of ozone is 0.3g / gTSS, the soluble COD in the sludge after treatment becomes 4899.5mg / L, the soluble COD increases 49 times, and the sludge SS reduction rate is 41.06%. After ozone pretreatment, the sludge enters the anaerobic digestion reactor 4, and the gas produced by digestion is removed by the gas purification device 5 2 After waiting for impurities, methane gas 6 can be obtained; the anaerobic digestion temperature is 35±1°C, and the inoculum slud...

Embodiment 2

[0025] The remaining sludge of a certain urban sewage treatment plant, after being concentrated in the sludge concentration tank 1, has the following properties: the water content is 98.2%, the sludge SS is 18.53g / L, the VSS is 14.48g / L, and the soluble COD is 110.5mg / L. Adjust the pH to 7.0, take 1.2L of sludge and put it into the 2.5L sludge pretreatment reactor 2, the ozone generated by the ozone generator 3 enters the sludge pretreatment reactor 2 from the bottom, and the tail gas is emptied after being treated. The dosage of ozone is 0.05g / gTSS, the soluble COD in the sludge after treatment becomes 3049.1mg / L, the soluble COD increases 28 times, and the sludge SS reduction rate is 16.1%. After ozone pretreatment, the sludge enters the anaerobic digestion reactor 4, and the gas produced by digestion is removed by the gas purification device 5 2 After waiting for impurities, methane gas 6 can be obtained. The temperature of anaerobic digestion is 25±1°C. The inoculum sludge...

Embodiment 3

[0027] The remaining sludge of a petrochemical sewage treatment plant, after being concentrated in the sludge concentration tank 1, has the following properties: the water content is 99.2%, the sludge SS is 8.218g / L, the VSS is 5.811g / L, and the soluble COD is 49.0mg / L. Adjust the pH to 10.0, take 1.2L of sludge and put it into the 2.5L sludge pretreatment reactor 2, the ozone generated by the ozone generator 3 enters the sludge pretreatment reactor 2 from the bottom, and the tail gas is emptied after being treated. The dosage of ozone is 0.02g / gTSS, the soluble COD in the sludge after treatment becomes 733.1mg / L, the soluble COD increases 15 times, and the sludge SS reduction rate is 8.65%. After ozone pretreatment, the sludge enters the anaerobic digestion reactor 4, and the gas produced by digestion is removed by the gas purification device 5 2 After waiting for impurities, methane gas 6 can be obtained. The anaerobic digestion temperature is 55±1°C. The inoculum sludge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com