Patents

Literature

1005 results about "Primary treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

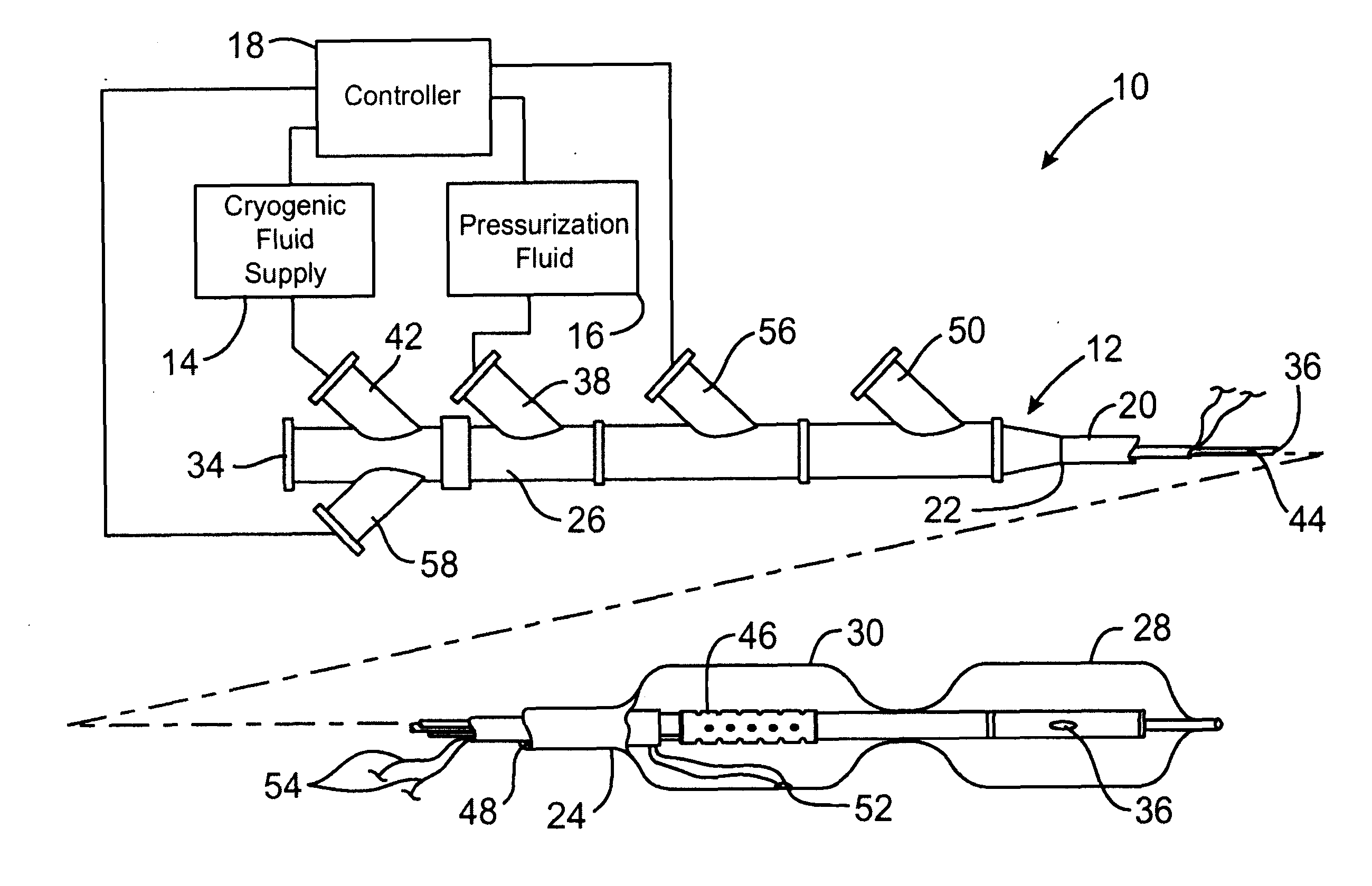

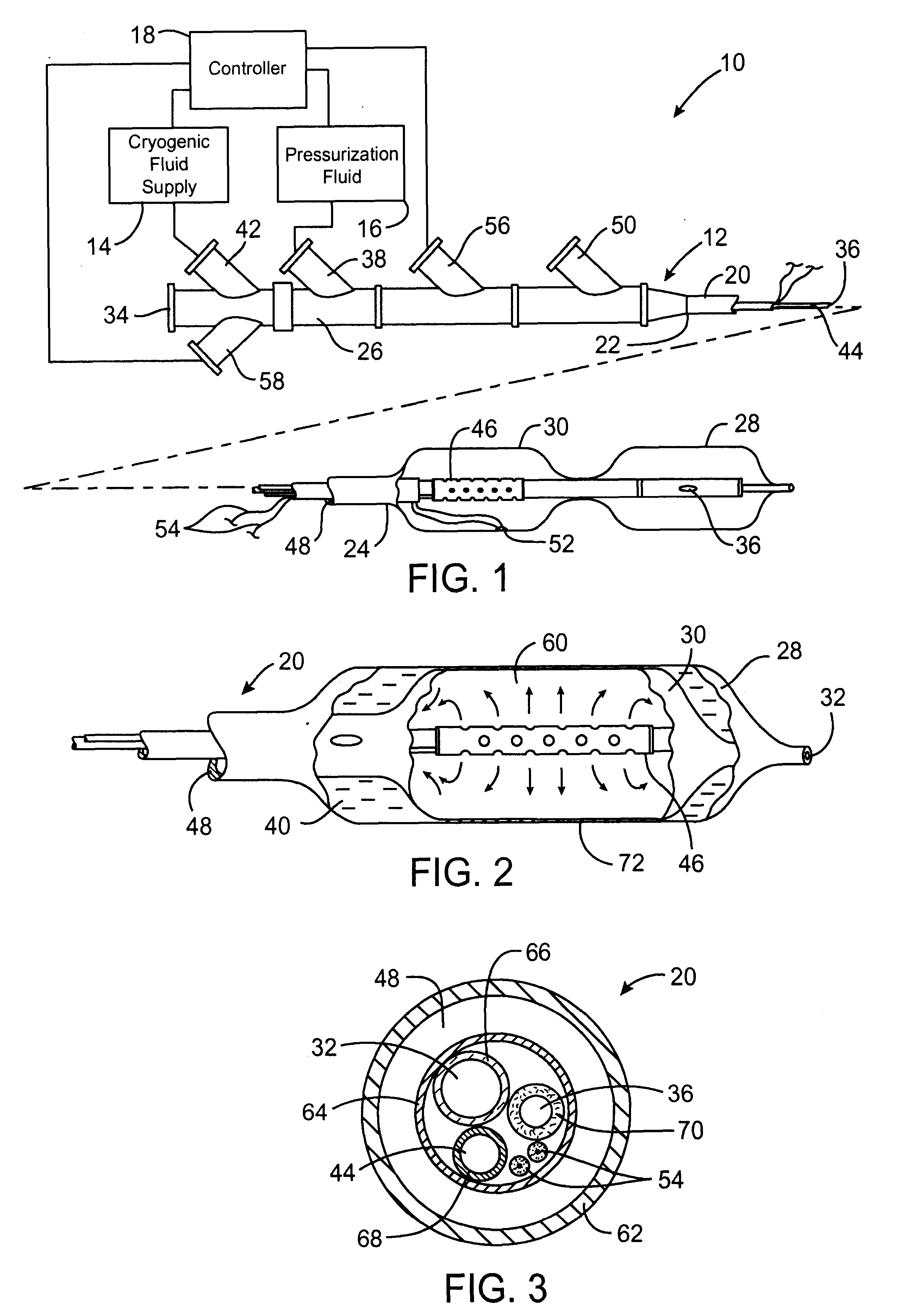

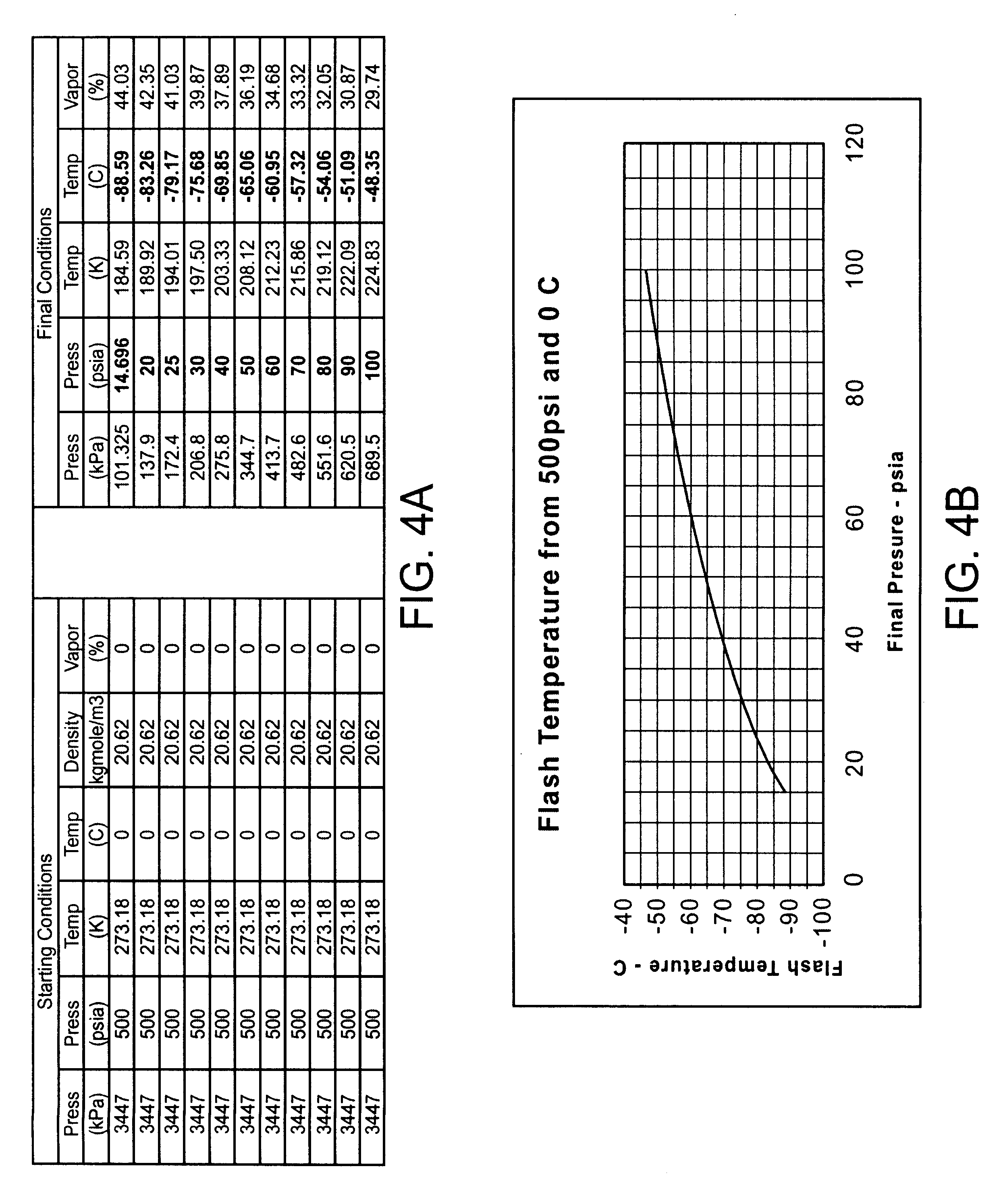

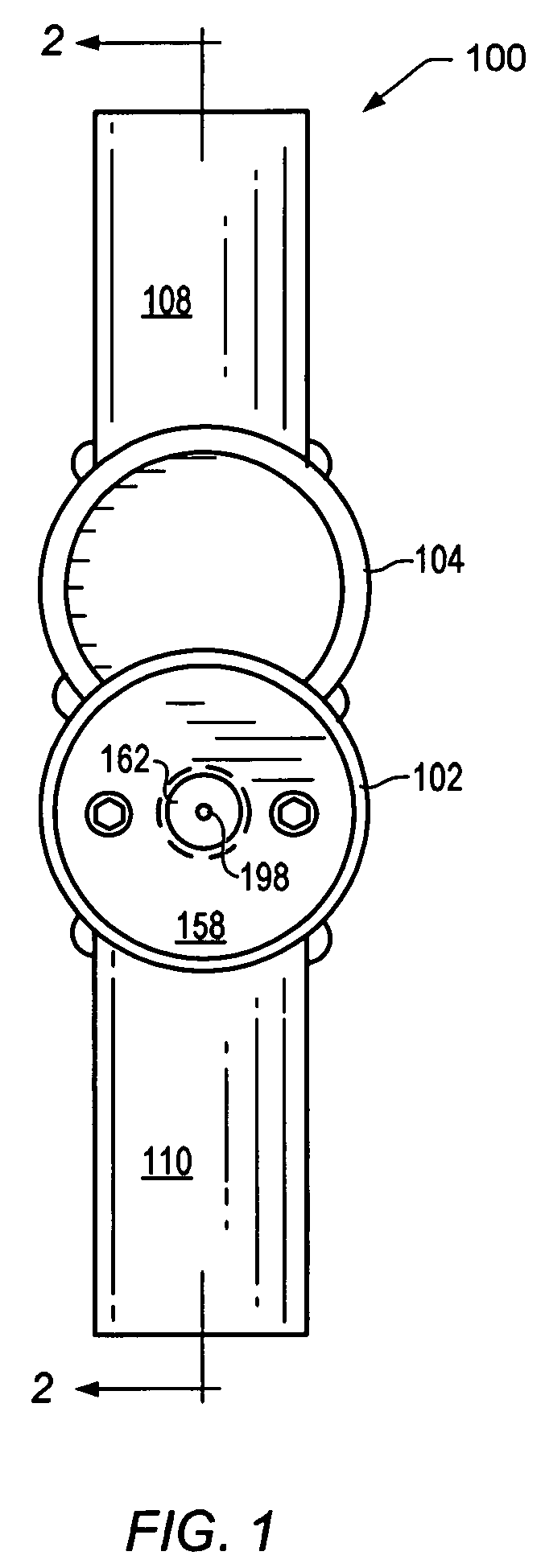

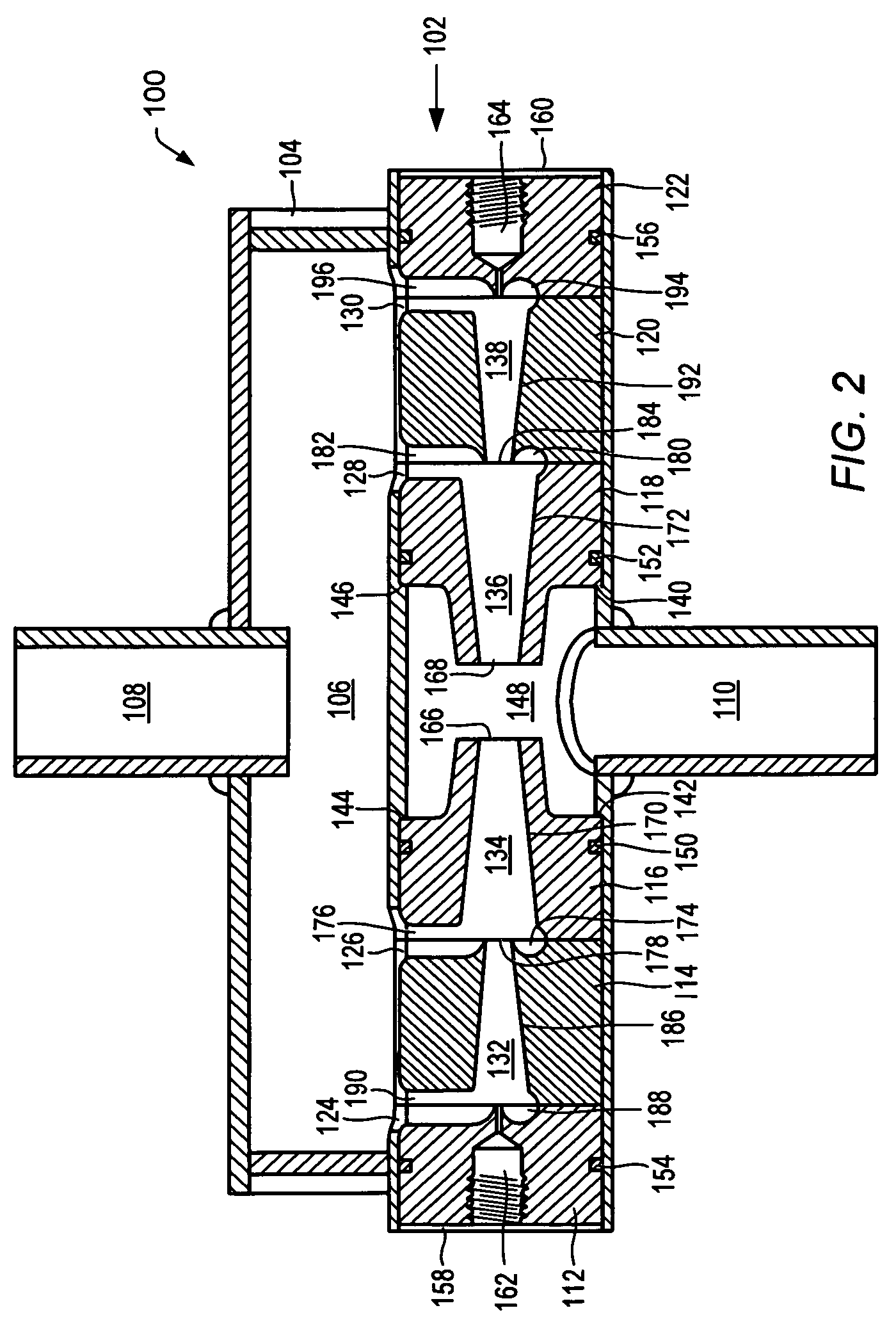

Cryogenically enhanced intravascular interventions

InactiveUS6468297B1Less stenosisLowering indexCatheterSurgical instruments for coolingPercent Diameter StenosisPercutaneous angioplasty

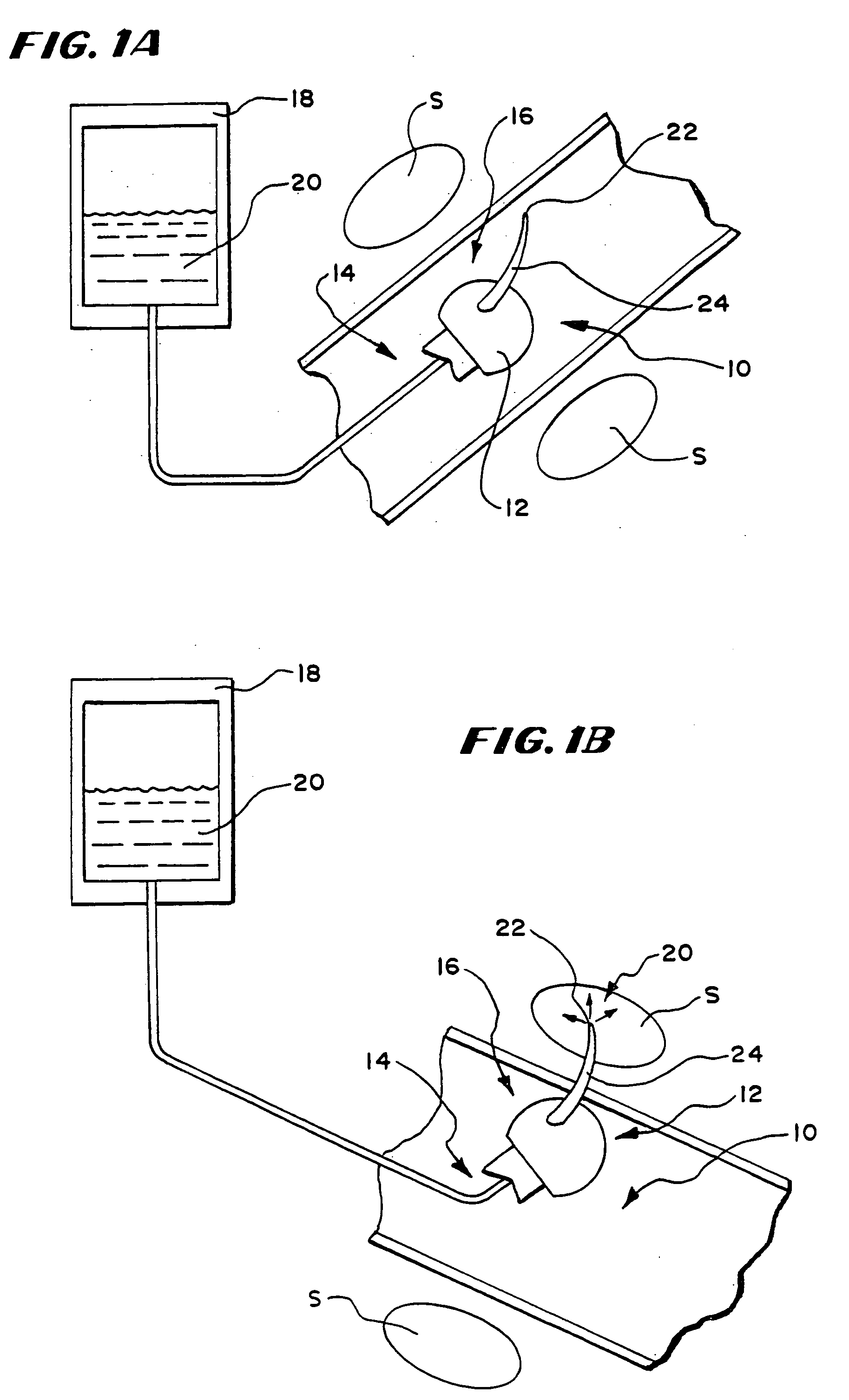

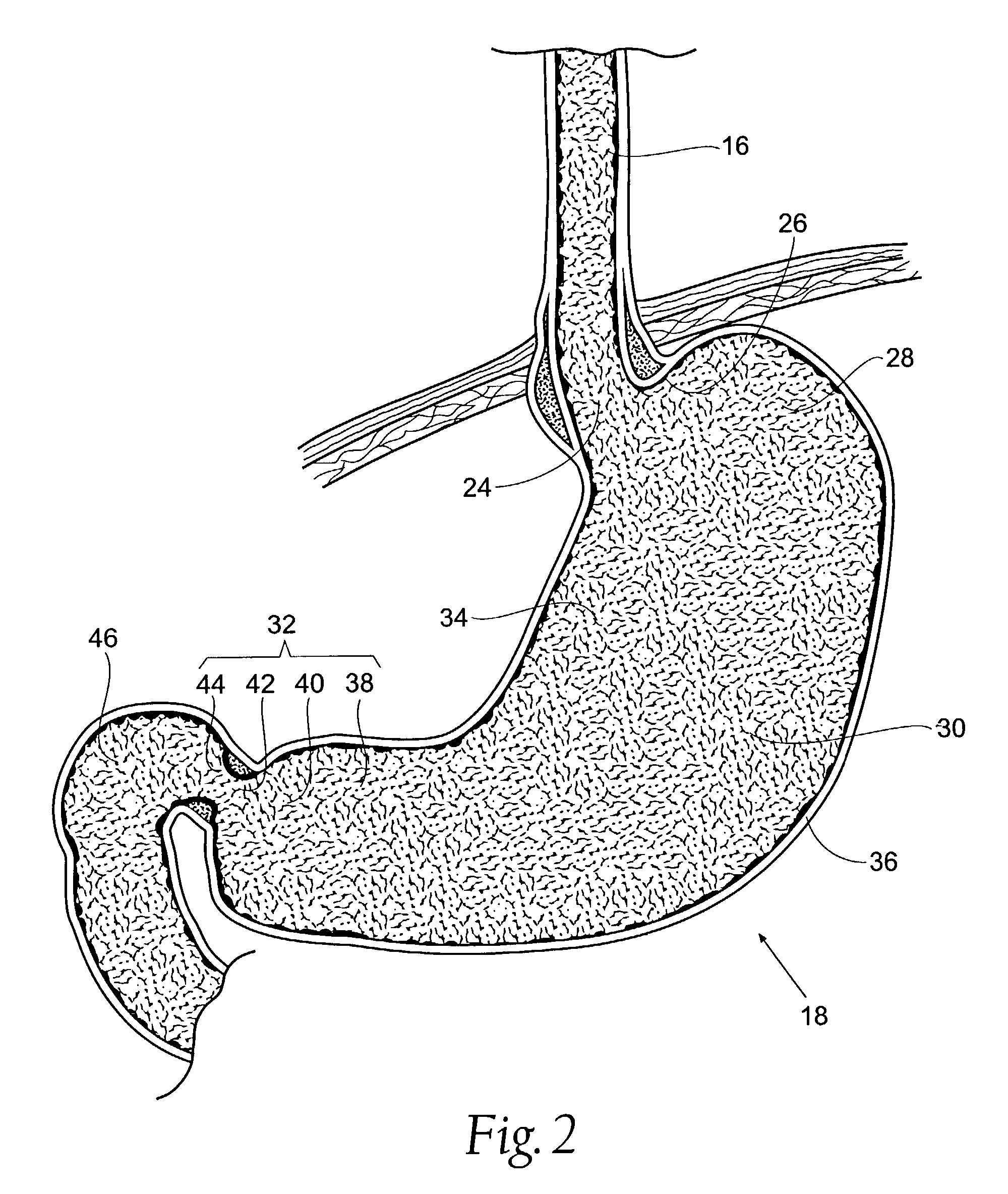

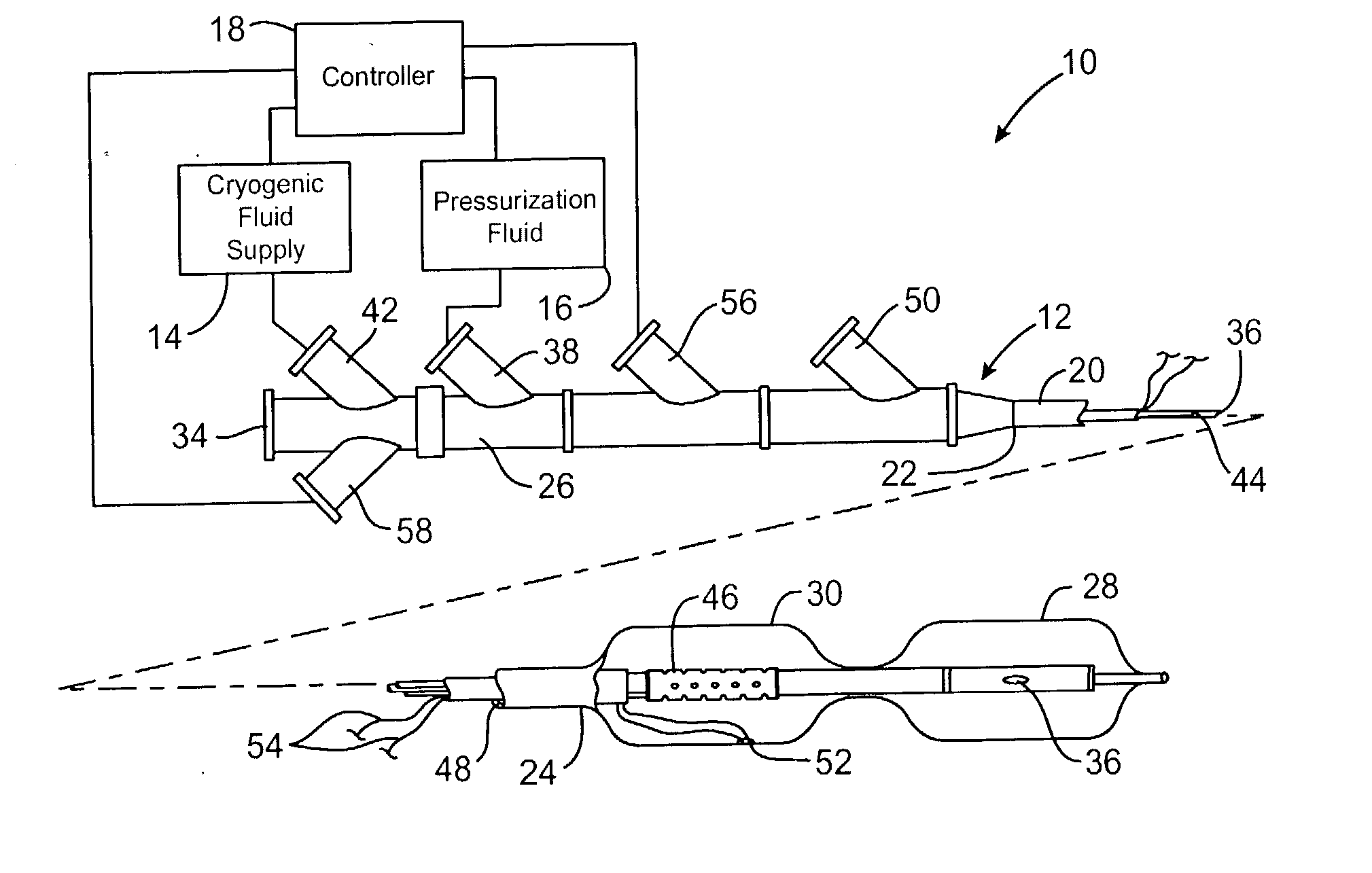

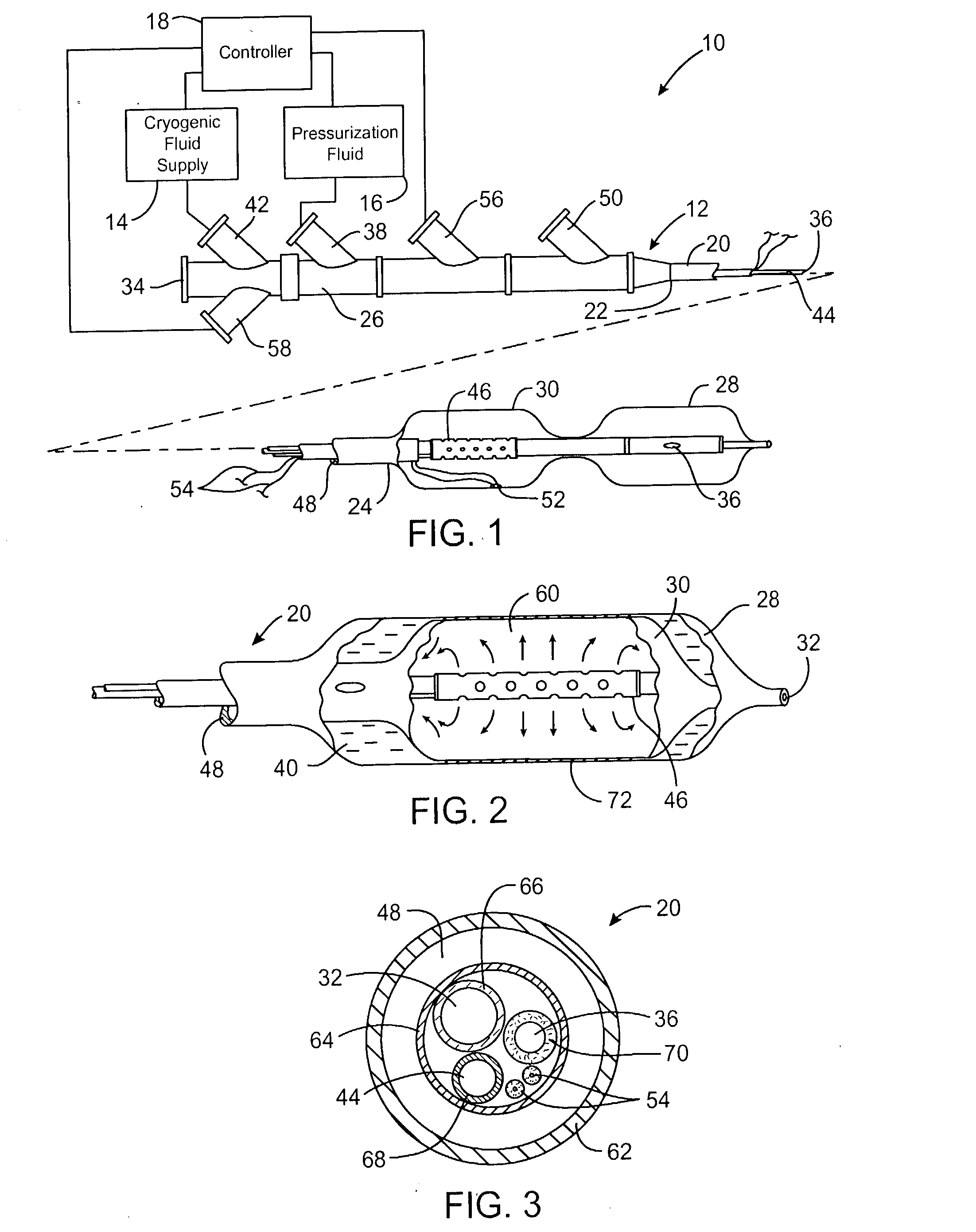

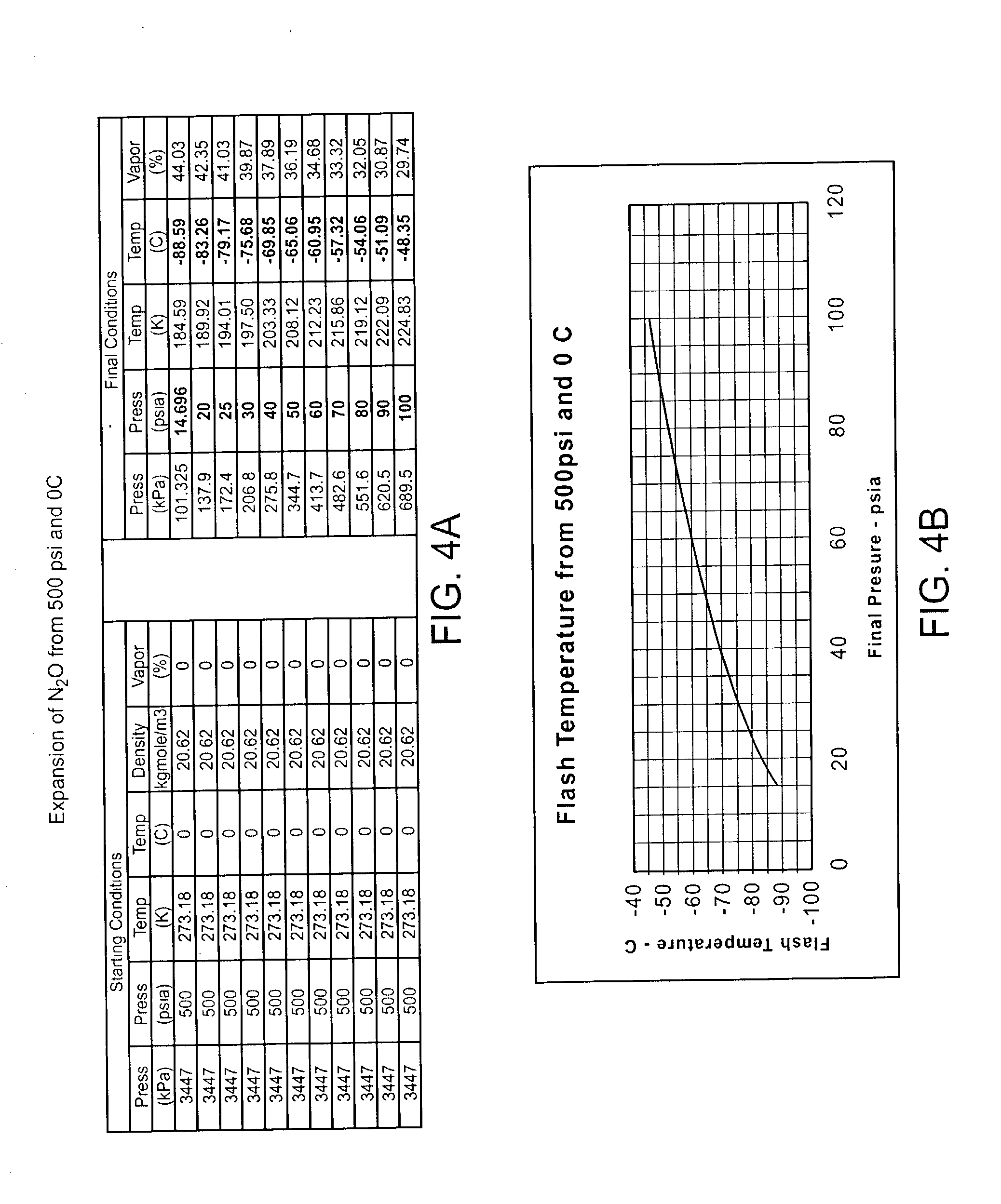

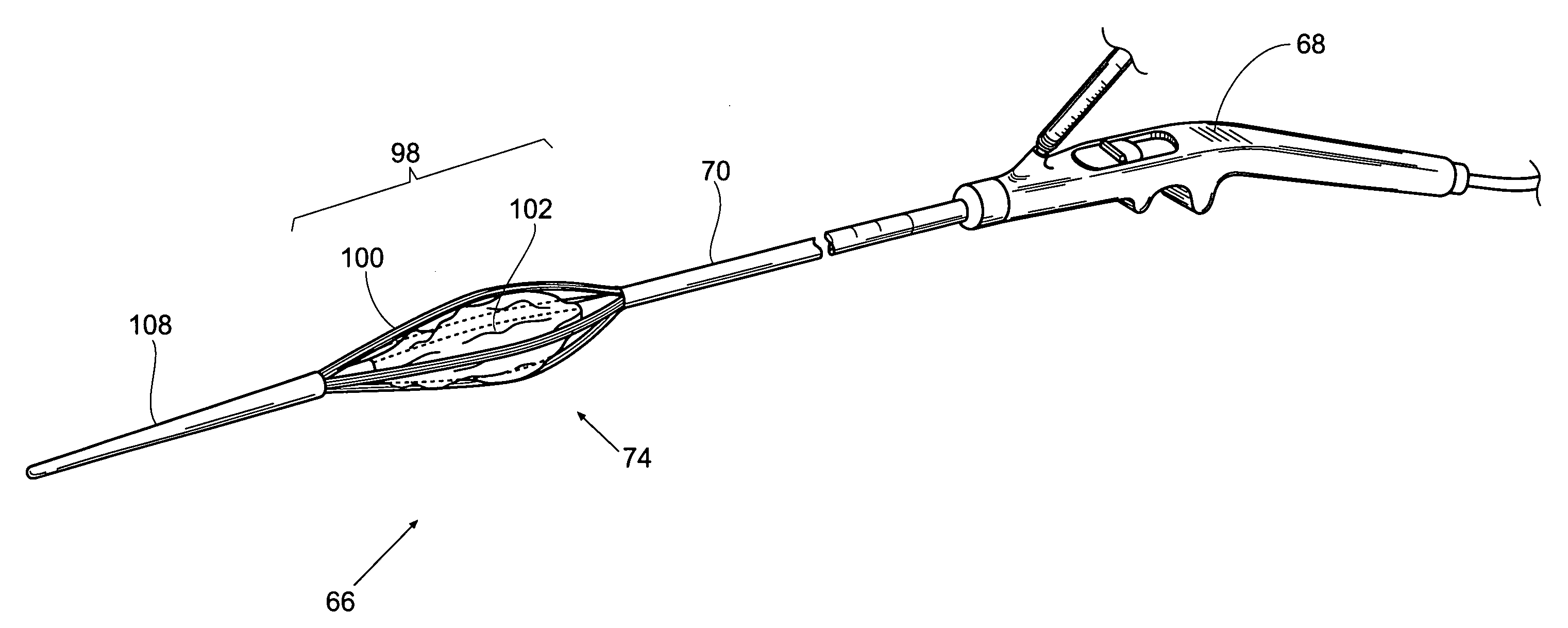

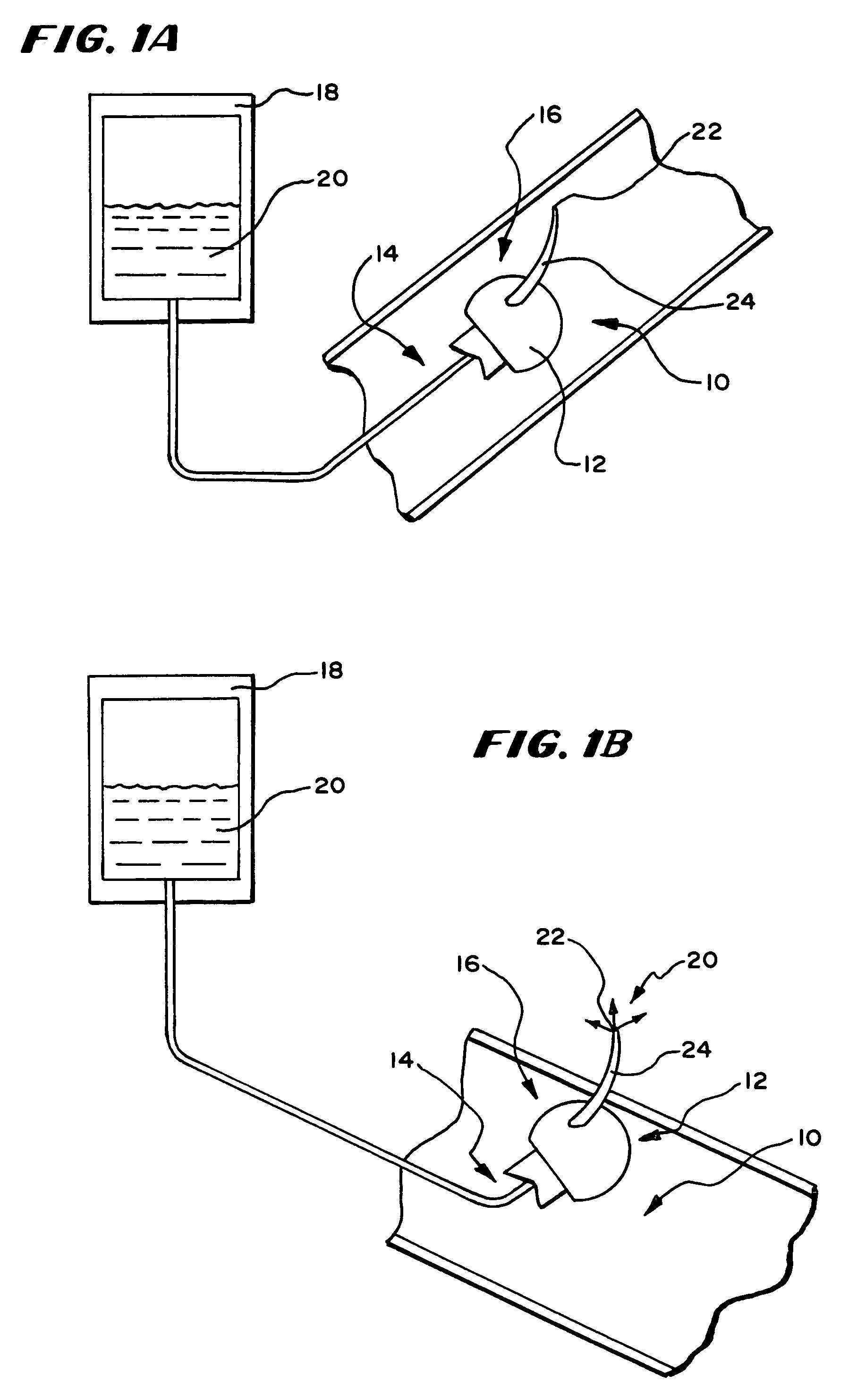

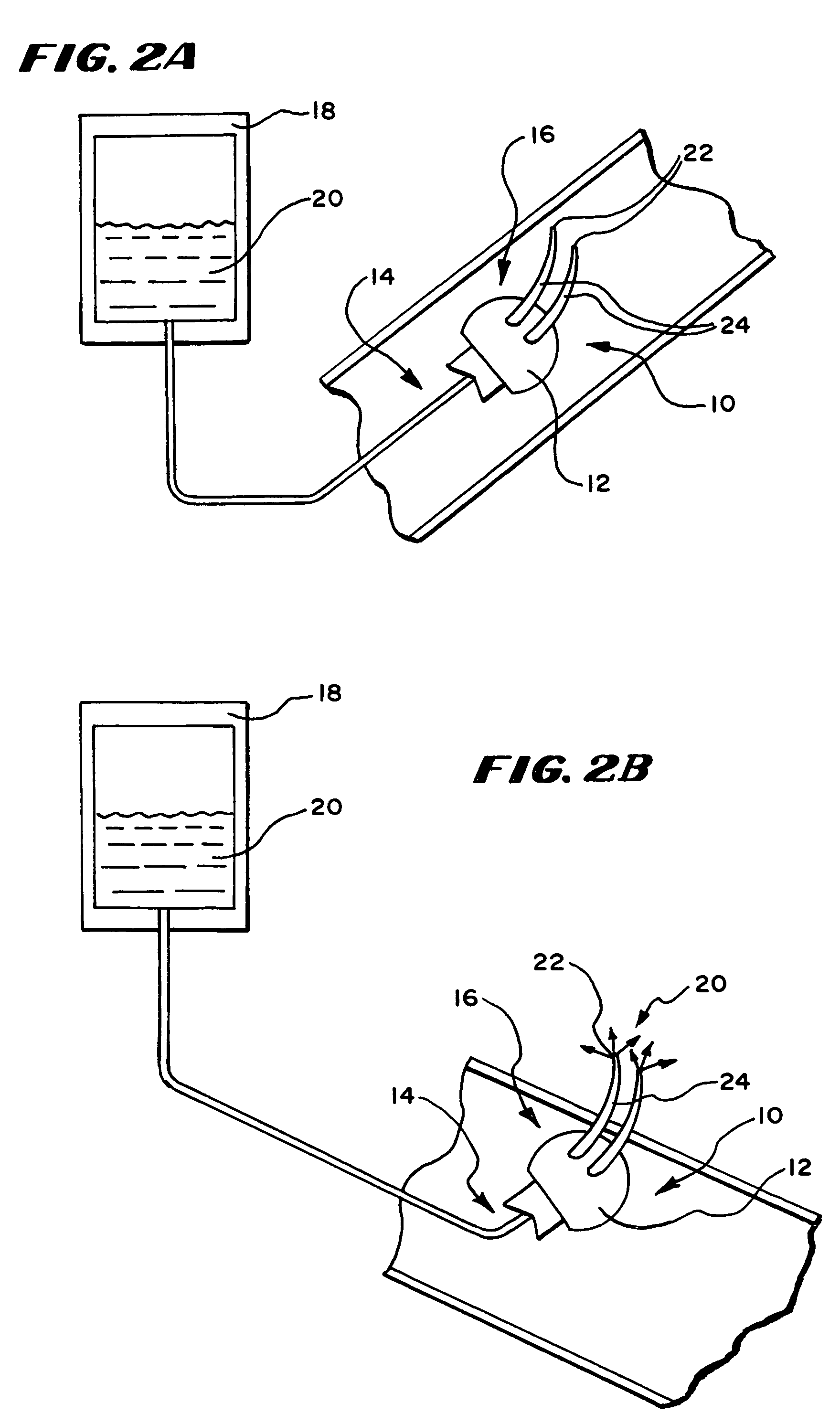

Techniques and devices for treating atherosclerotic disease use controlled cryogenic cooling, often in combination with angioplasty and / or stenting. A combination cryogenic / angioplasty catheter may cool the diseased blood vessel before, during, and / or after dilation. Controlled cooling of the vessel wall reduces actual / observed hyperplasia as compared to conventional uncooled angioplasty. Similar reductions in restenosis may be provided for other primary treatments of the blood vessel, including directional arthrectomy, rotational arthrectomy, laser angioplasty, stenting, and the like. Cooling of vessel wall tissues will often be performed through plaque, and the cooling process will preferably take the thermodynamic effects of the plaque into account.

Owner:BOSTON SCI SCIMED INC

Systems methods for applying a selected treatment agent into contact with tissue to treat sphincter dysfunction

InactiveUS20050010162A1Reduction in tissue complianceReduction in tighteningElectrotherapySurgical needlesDiseaseFecal incontinence

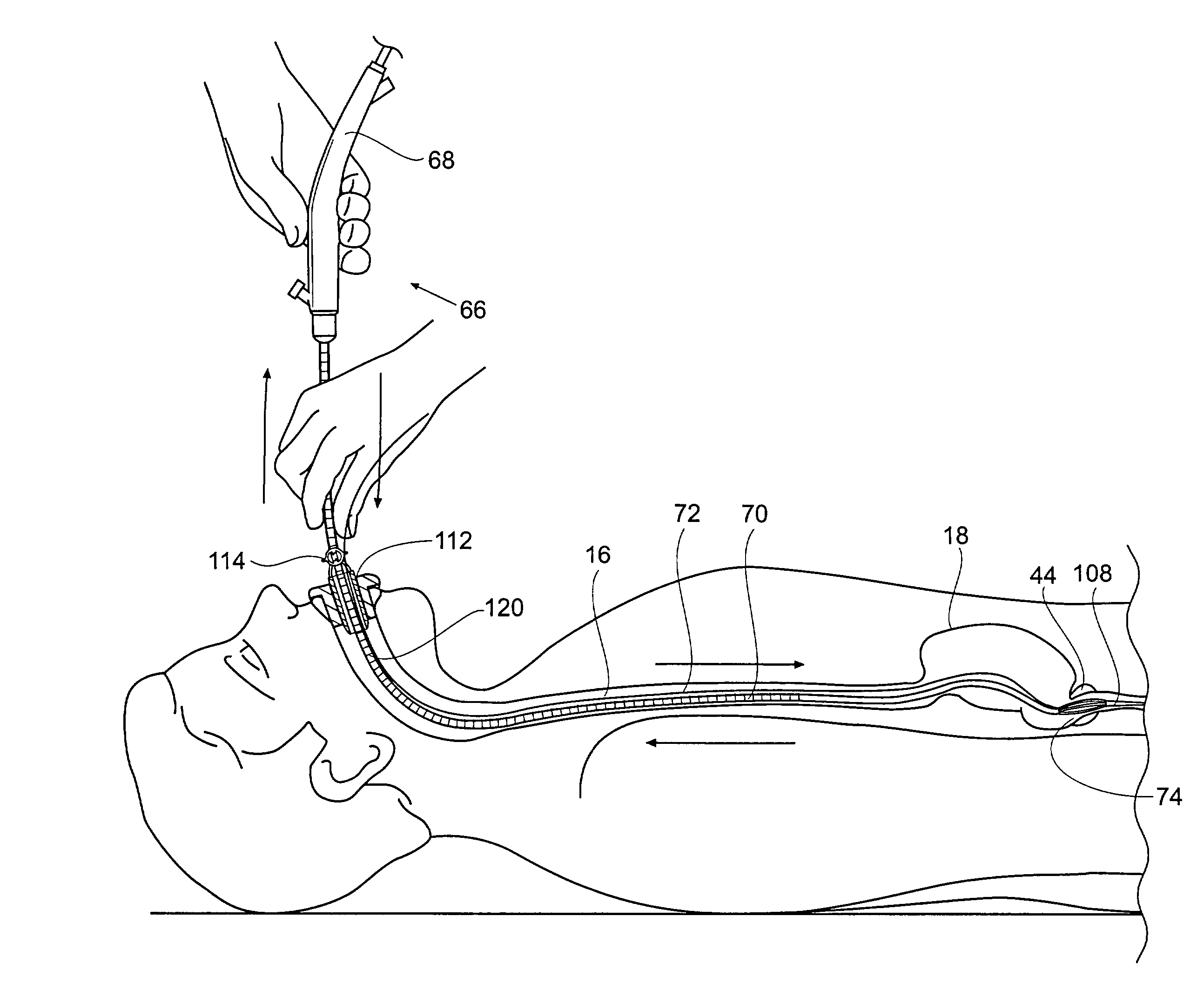

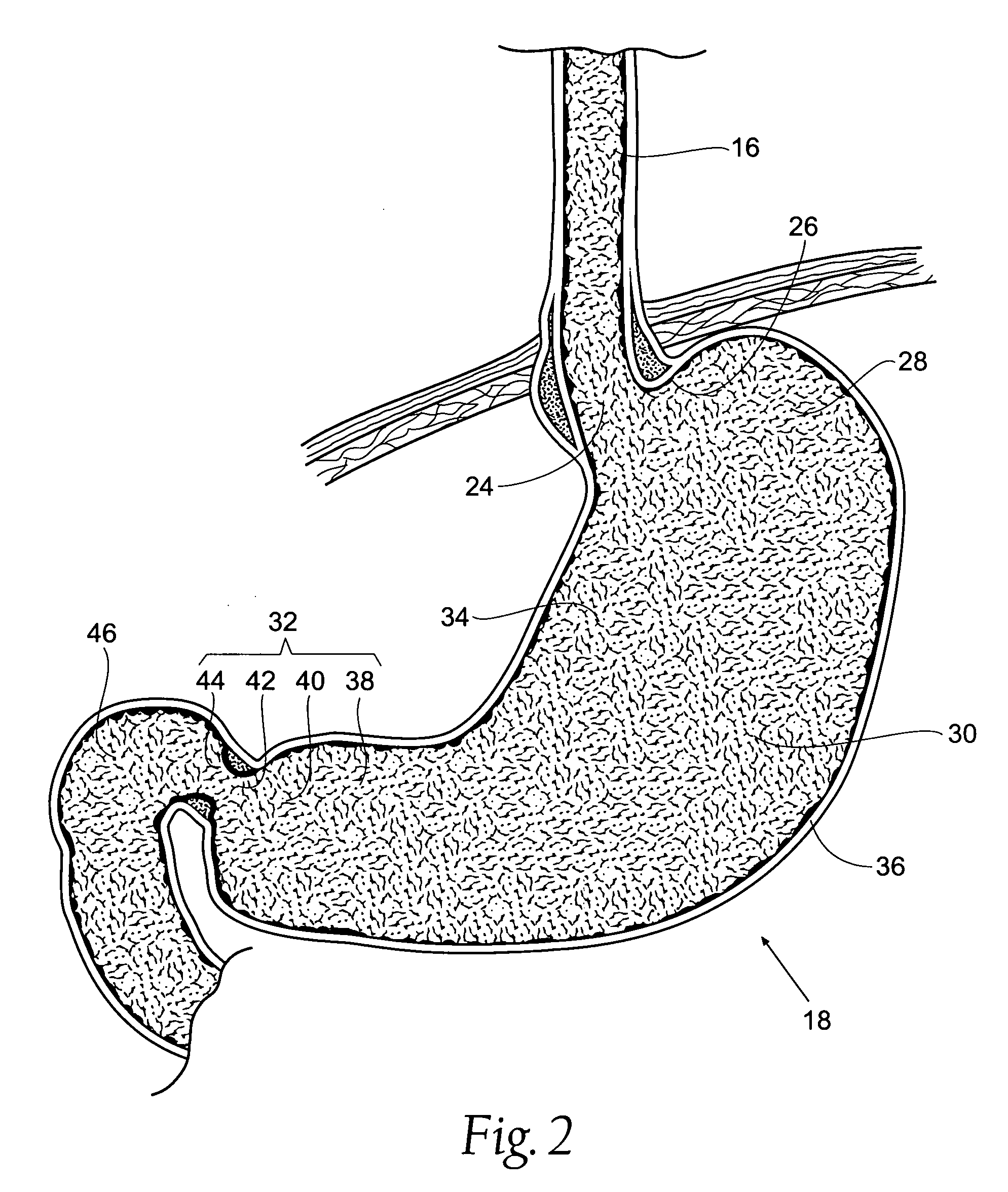

Systems and methods apply a selected treatment agent or agents into contact with tissue at or in the region of a dysfunctional sphincter (in the case of GERD, fecal incontinence, or other dysfunctional sphincter disorders) to affect improved sphincter barrier function and / or to disrupt abnormal nerve pathways. The treatment agent can include at least one cytokine and / or at least one tissue bulking agent and / or at least one vanilloid compound to evoke a desired tissue response. The systems and methods can be used a primary treatment modality, or applied as a supplementary treatment before, during or after a primary intervention.

Owner:MEDERI RF LLC

Systems and methods for treating obesity and other gastrointestinal conditions

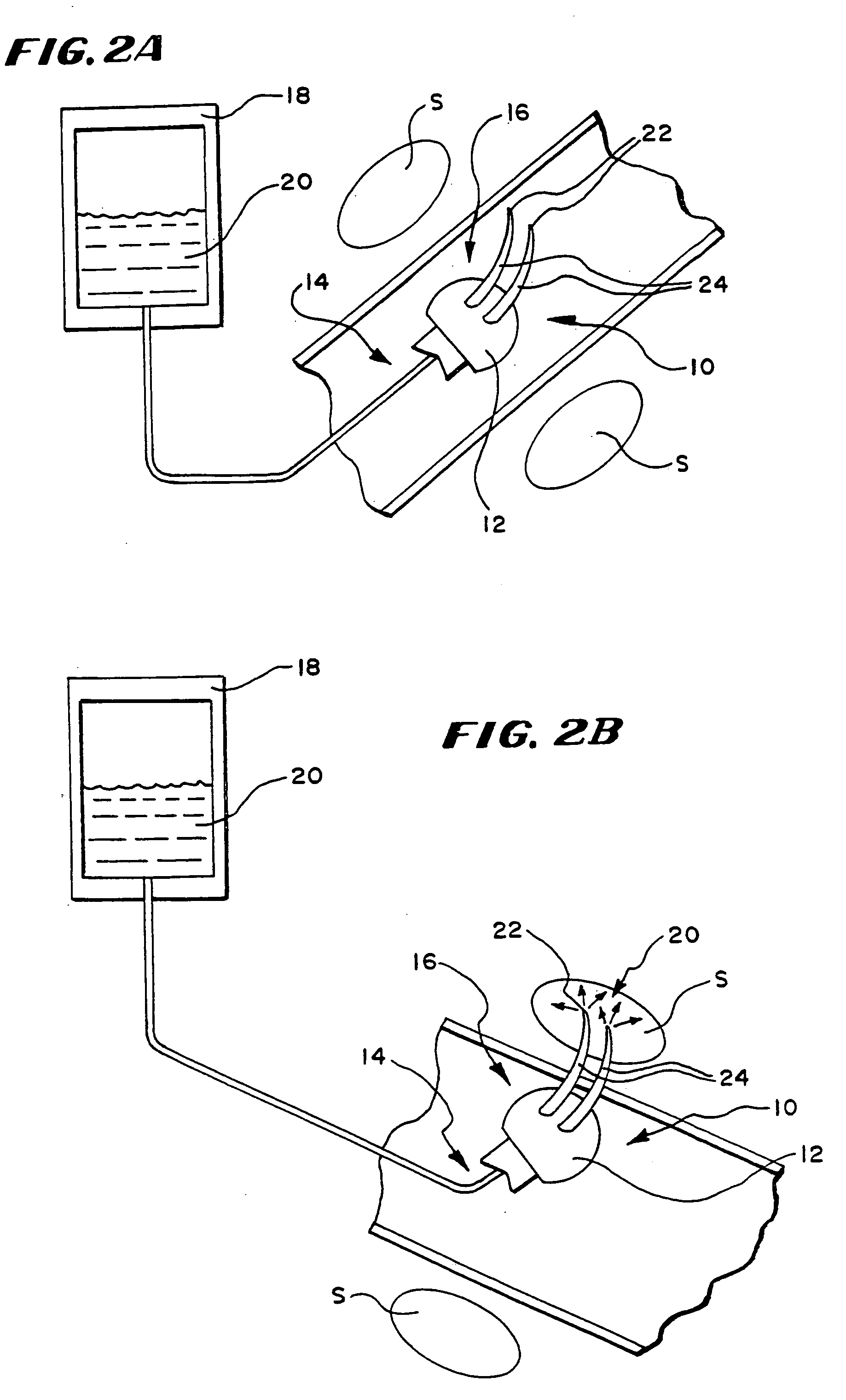

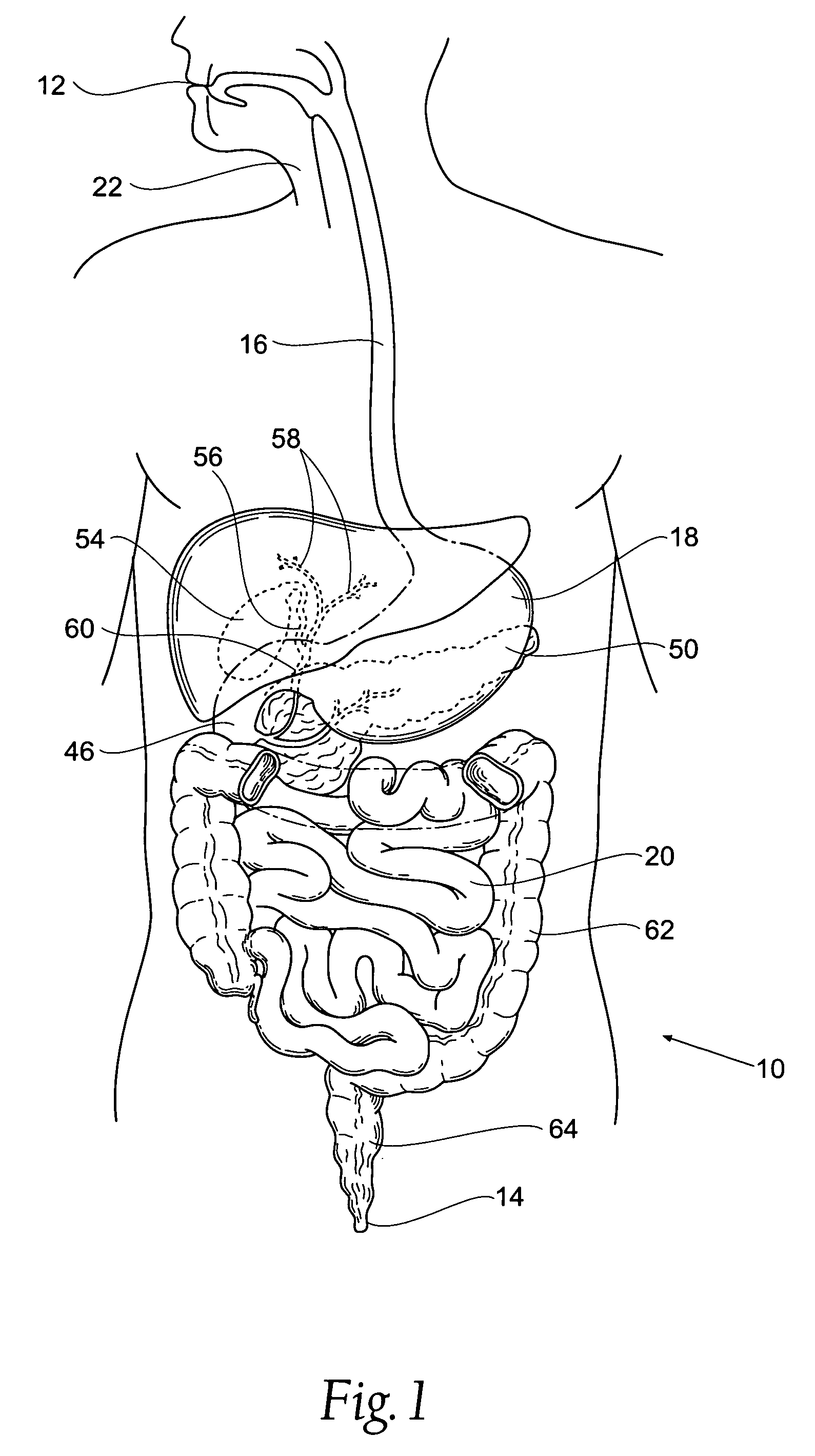

InactiveUS7468060B2Increase satietyReduce and moderate incidenceElectrotherapyMetabolism disorderReflexOesophageal tube

Systems and methods affect tightening of the pyloric sphincter and / or serve to mediate or moderate receptive relaxation of muscles in the stomach, to treat or mitigate various physiologic conditions, such as obesity, biliary reflex, GERD, and / or Barrett's esophagus. The systems and methods may be used as either a primary treatment modality, or applied as a supplementary treatment before, during or after a primary intervention.

Owner:MEDERI THERAPEUTICS

Cryogenically enhanced intravascular interventions

InactiveUS20030109912A1Reduce stenosisPrevent restenosisCatheterSurgical instruments for coolingPercent Diameter StenosisPercutaneous angioplasty

Techniques and devices for treating atherosclerotic disease use controlled cryogenic cooling, often in combination with angioplasty and / or stenting. A combination cryogenic / angioplasty catheter may cool the diseased blood vessel before, during, and / or after dilation. Controlled cooling of the vessel wall reduces actual / observed hyperplasia as compared to conventional uncooled angioplasty. Similar reductions in restenosis may be provided for other primary treatments of the blood vessel, including directional arthrectomy, rotational arthrectomy, laser angioplasty, stenting, and the like. Cooling of vessel wall tissues will often be performed through plaque, and the cooling process will preferably take the thermodynamic effects of the plaque into account.

Owner:BOSTON SCI SCIMED INC

Apparatus to establish and optimize sedimentation and methane fermentation in primary wastewater ponds

InactiveUS6923906B2Raise the pHIncreases the rate of die-away of pathogenic bacteriaLiquid degasificationMixing methodsSludgeIncrease ph

Owner:GREEN FRANKLIN BAILEY +2

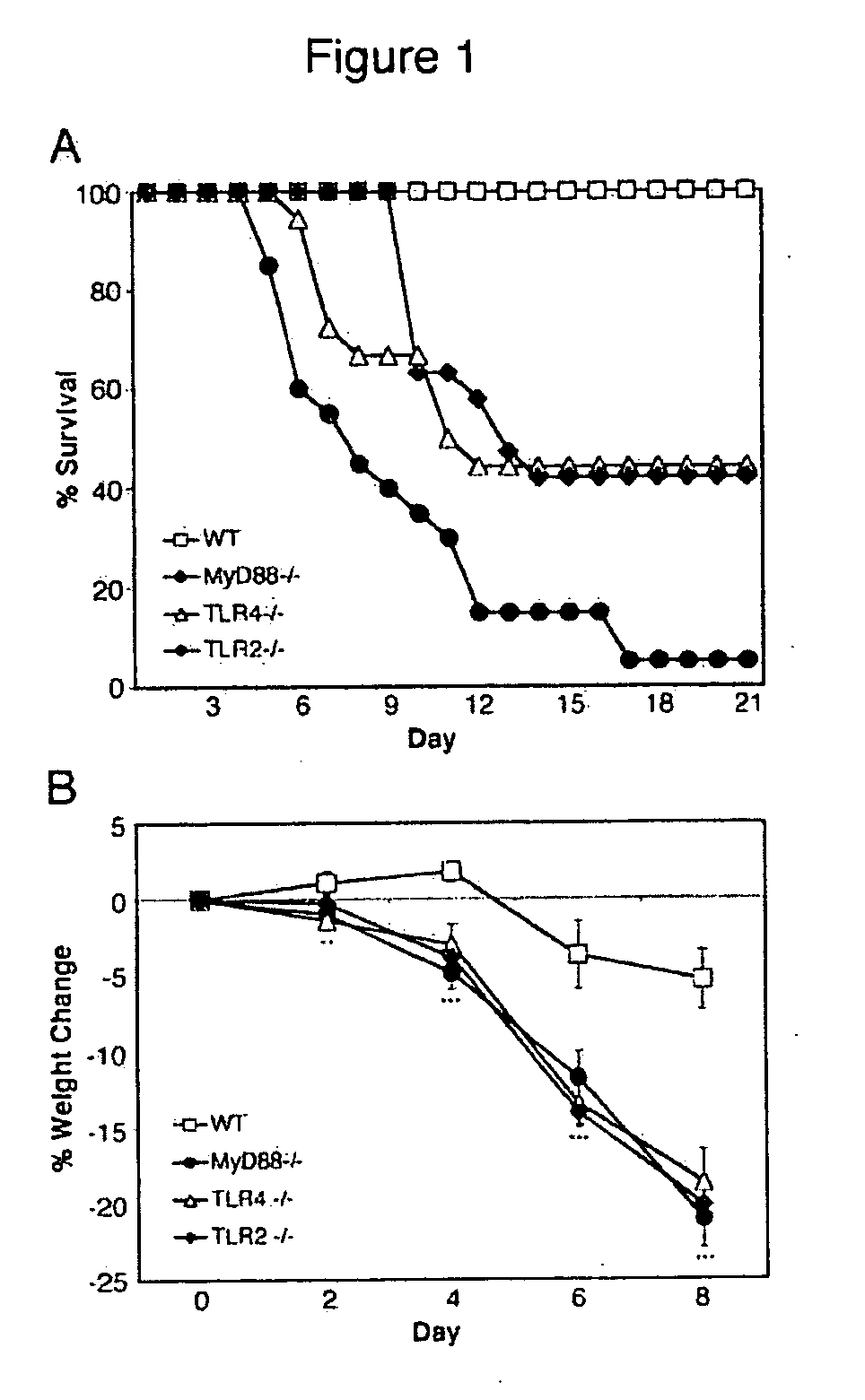

Treatment with agonists of toll-like receptors

InactiveUS20050163764A1Avoid damageMinimize complicationsBiocideOrganic active ingredientsToll-like receptorAgonist

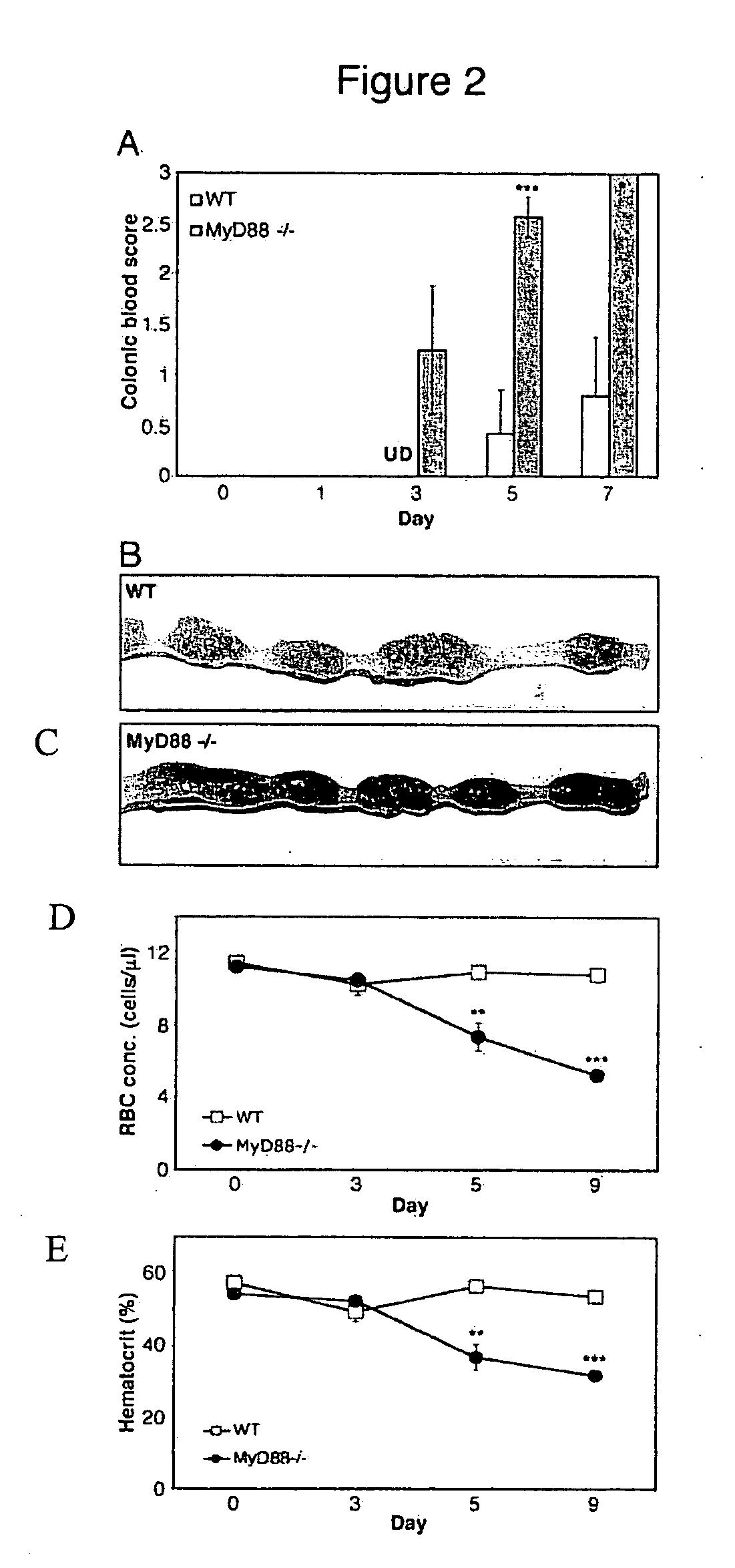

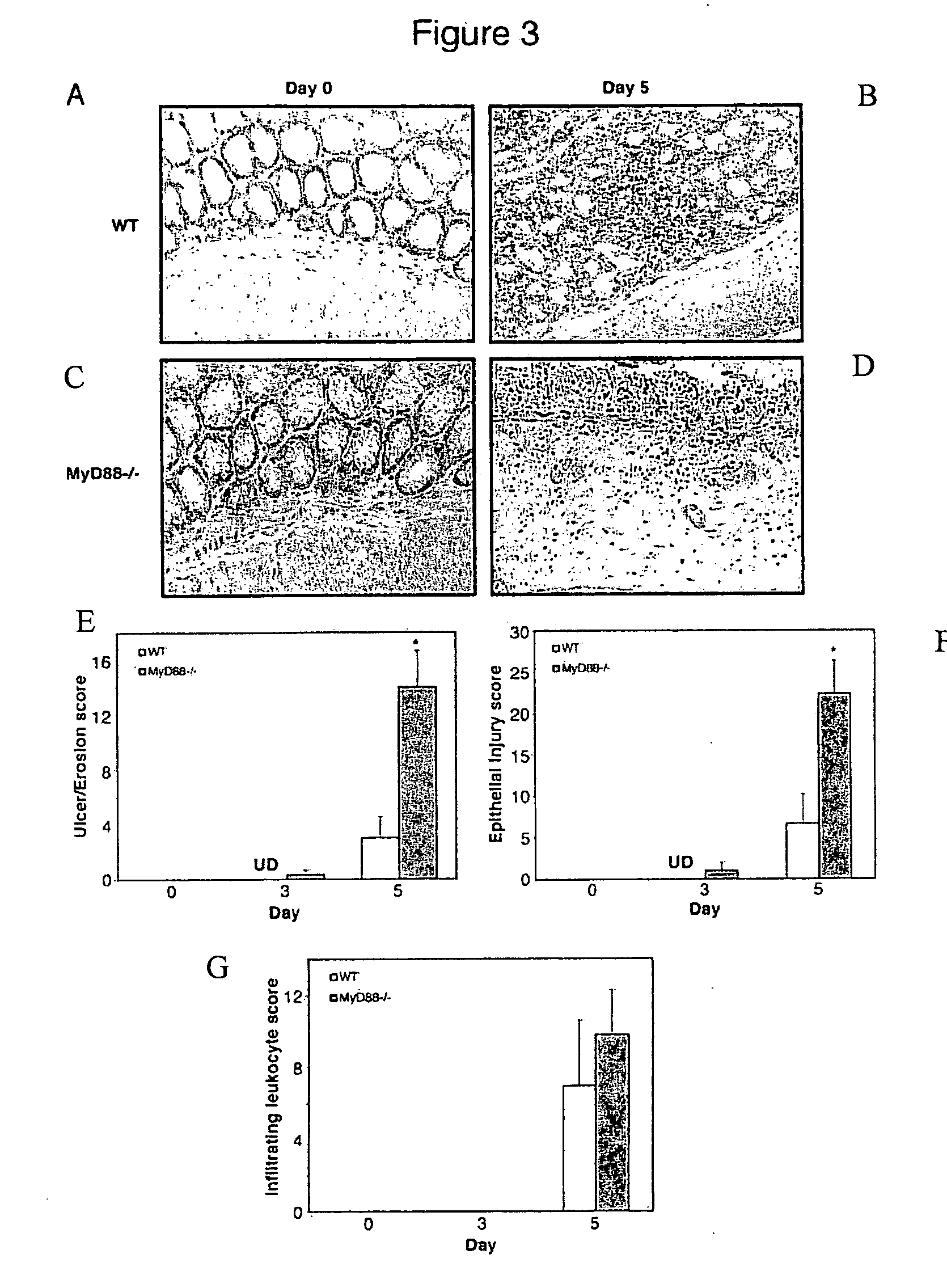

Mammals are treated with agonists of bacterially-activated TLRs. The agonist are administered orally or mucosally. In one embodiment, the mammal treated is subject to a gastro-intestinal injury. The agonist can be administered prior to infliction of the gastro-intestinal injury, subsequent to infliction of the gastro-intestinal injury and concurrently with infliction of the gastro-intestinal injury. In another embodiment, the mammal is subject to tissue damage. The agonist is administered prior to the primary treatment, following the primary treatment or concurrently with the primary treatment.

Owner:YALE UNIV

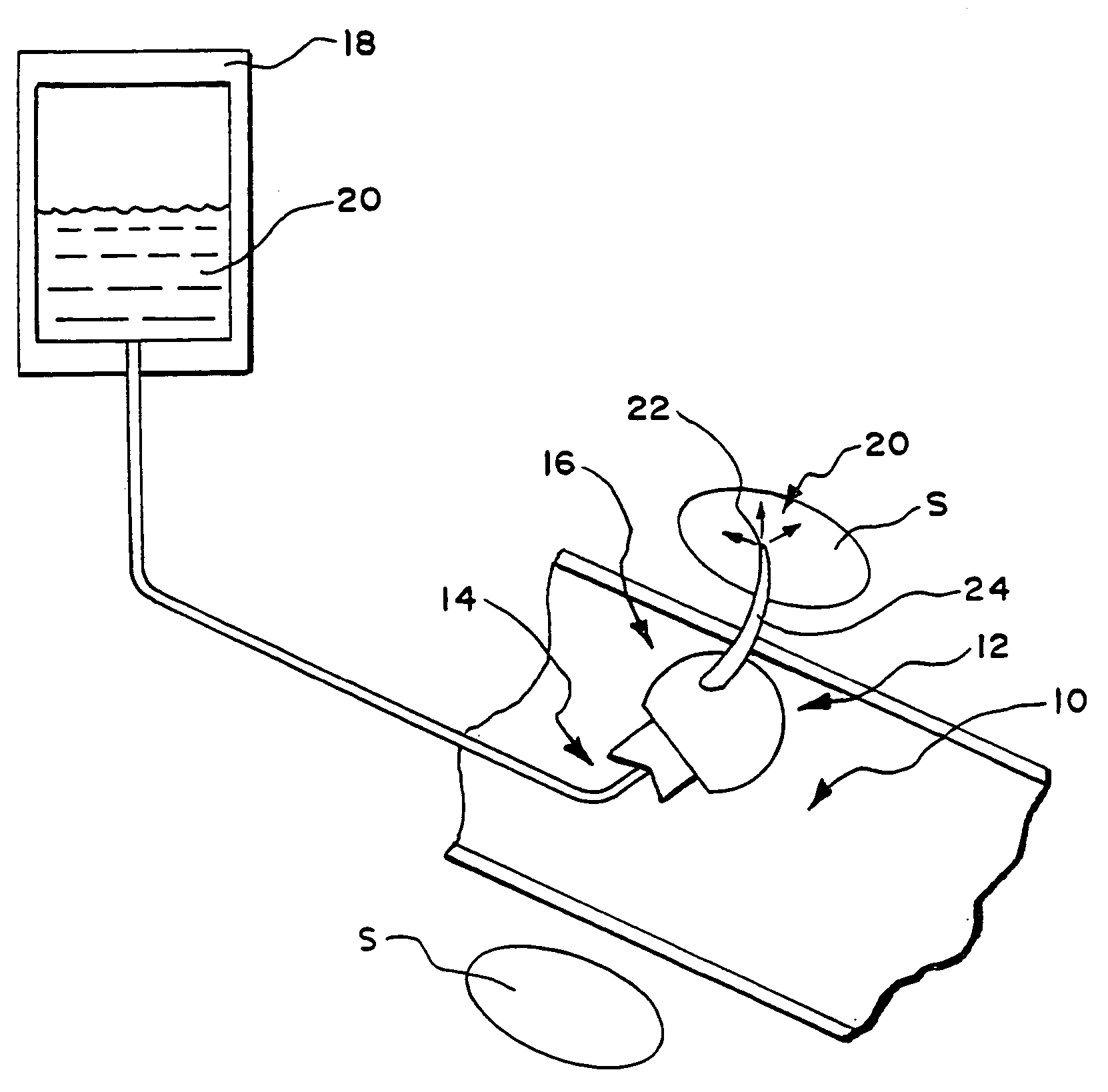

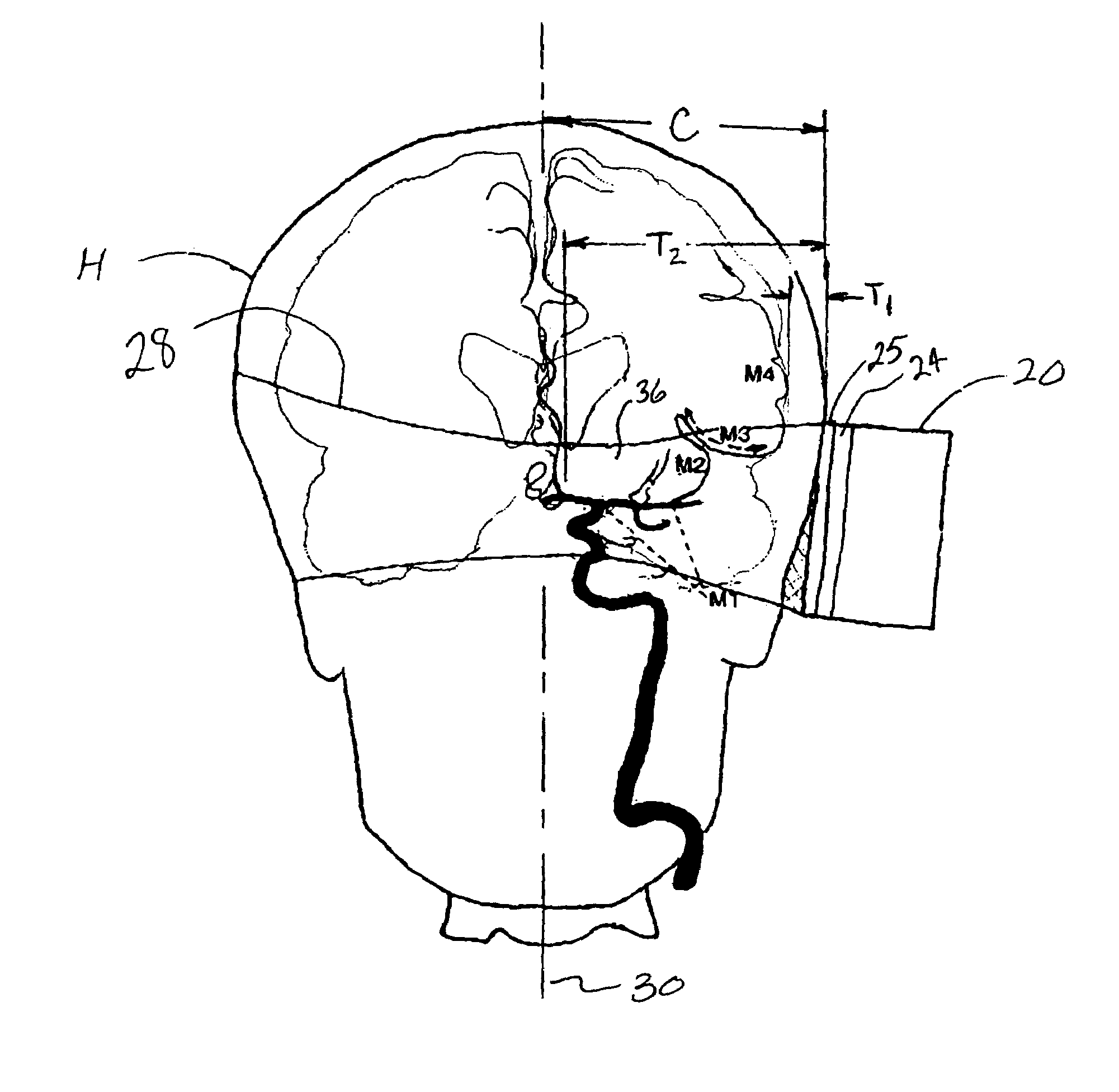

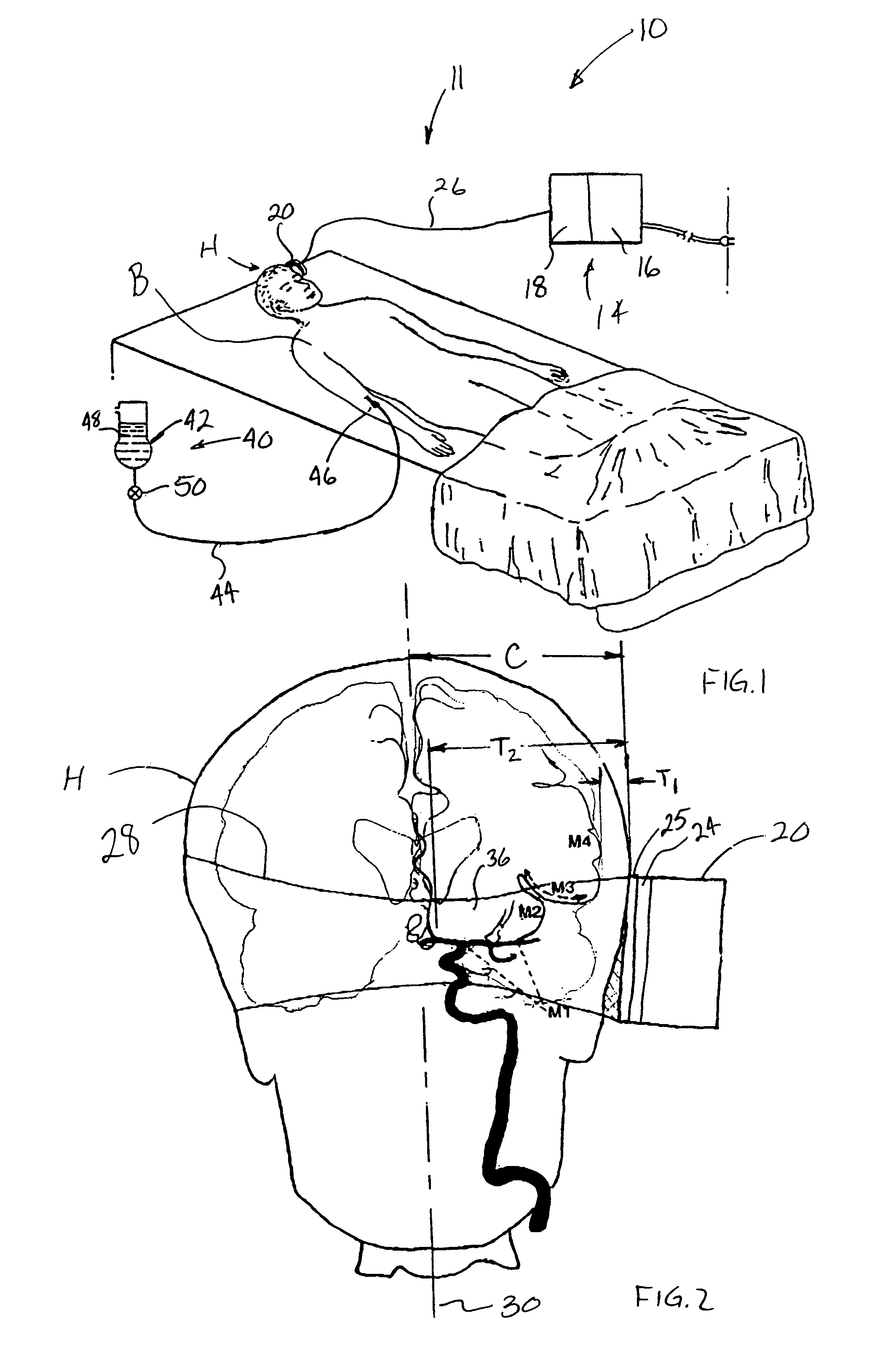

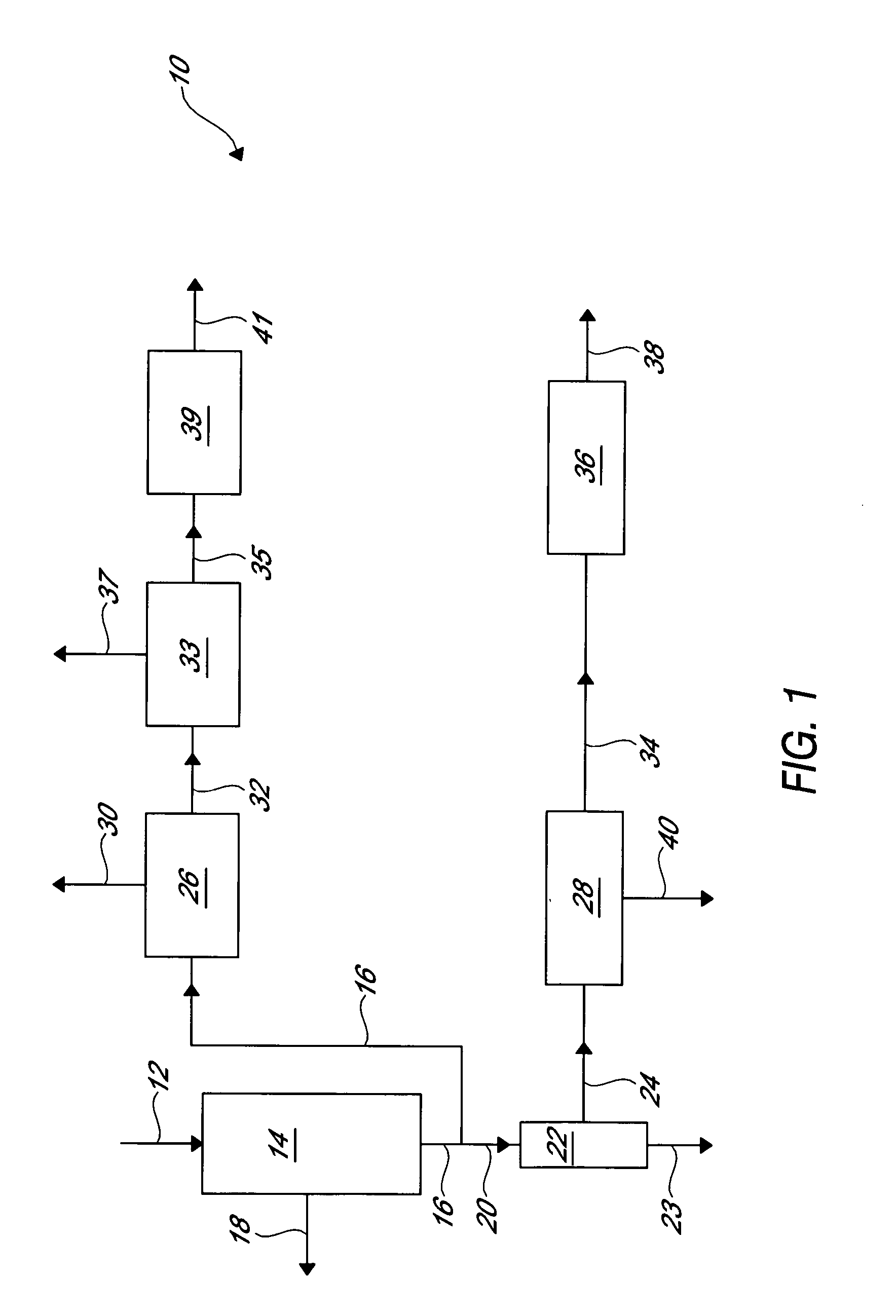

Transcranial ultrasound thrombolysis system and method of treating a stroke

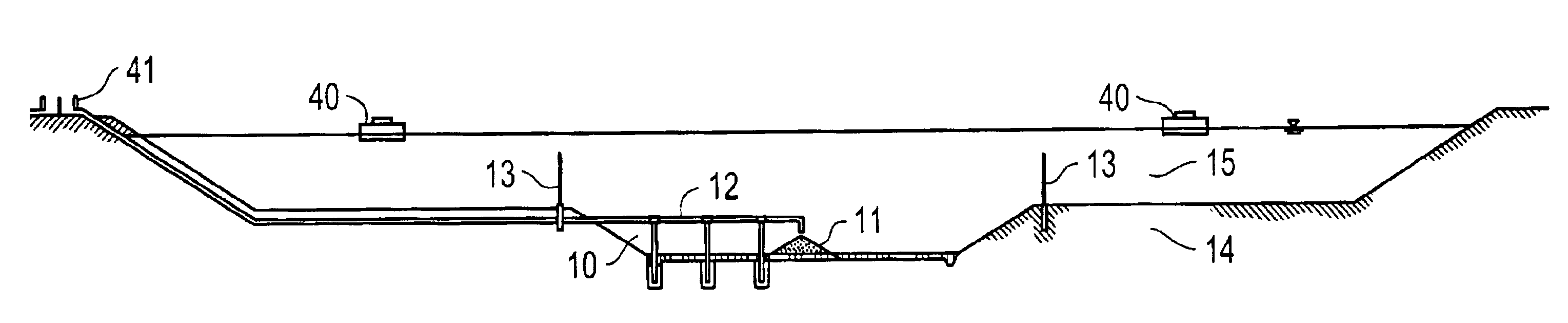

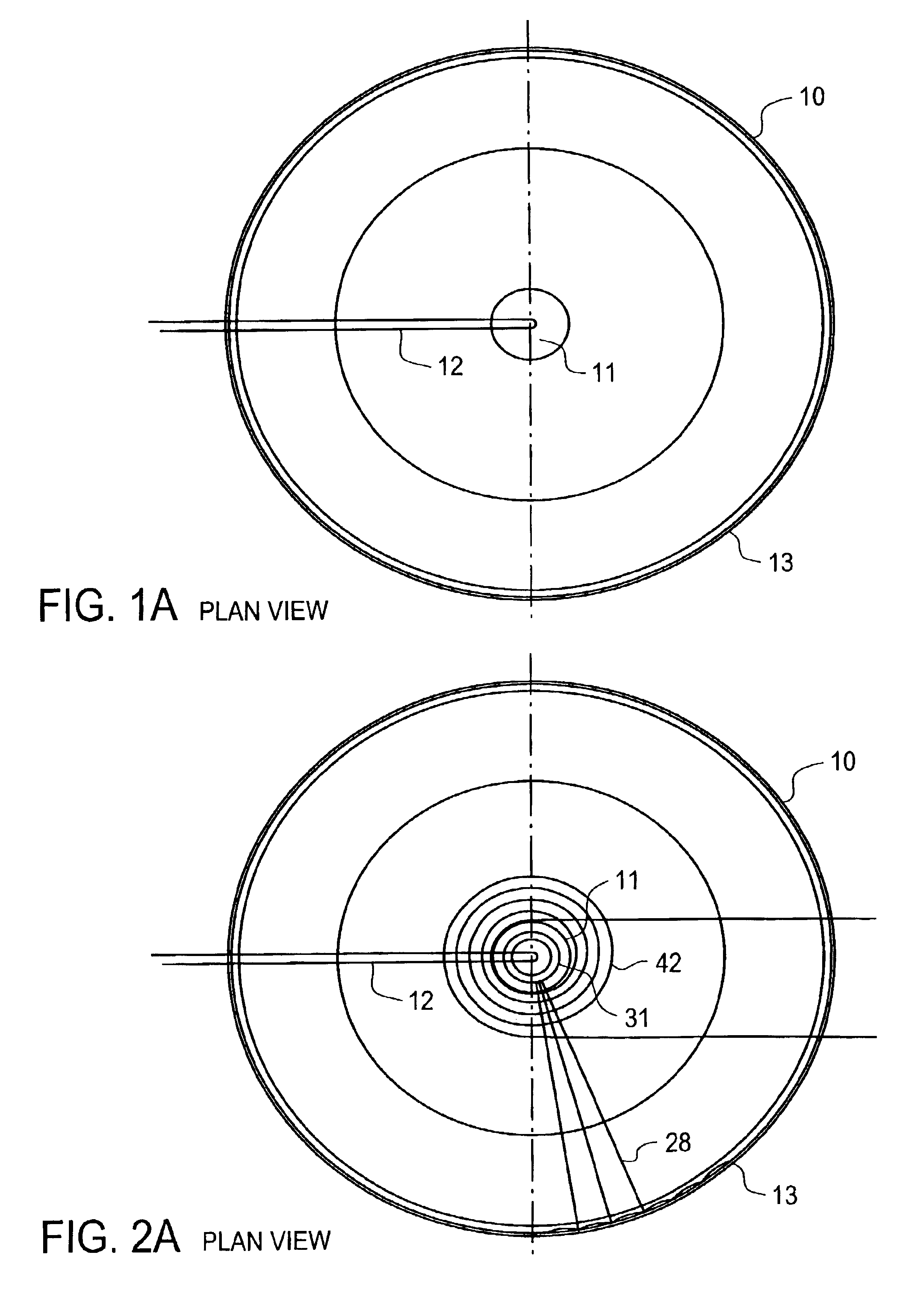

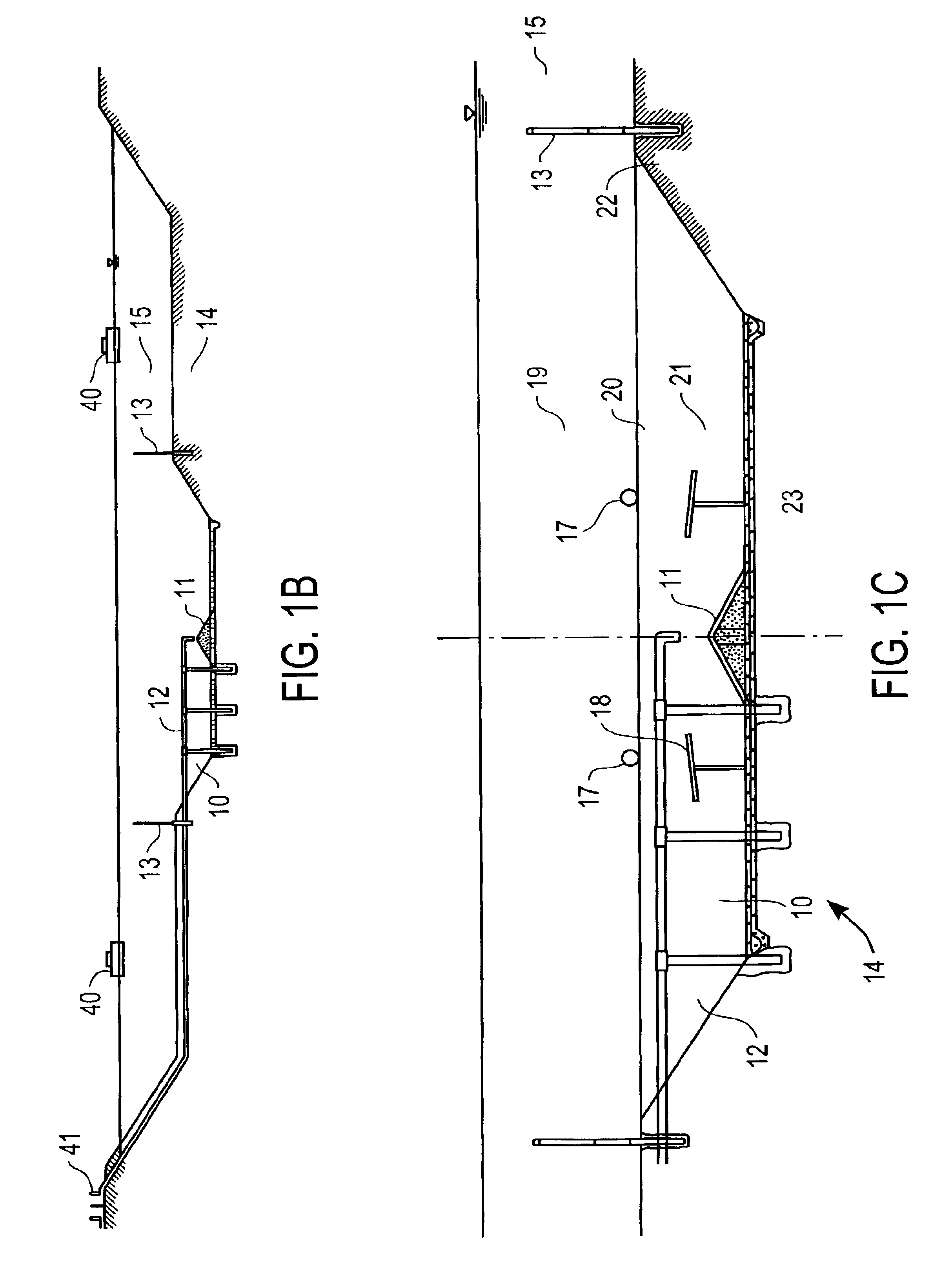

A method of transcranial ultrasound thrombolysis comprises the steps of providing a predetermined level of ultrasonic energy substantially throughout a primary treatment zone encompassing the M1 branch and M2 branches of the middle cerebral artery of an individual. A thrombolytic agent is also administered to the individual. A transcranial ultrasound thrombolysis system (10) is also provided that includes a transducer (20). The transducer is adapted to provide a predetermined level of ultrasonic energy substantially throughout a primary treatment zone encompassing at least a substantial portion of the M1 branch and the M2 branches of the middle cerebral artery in one hemisphere of a brain.

Owner:UNIVERSITY OF CINCINNATI

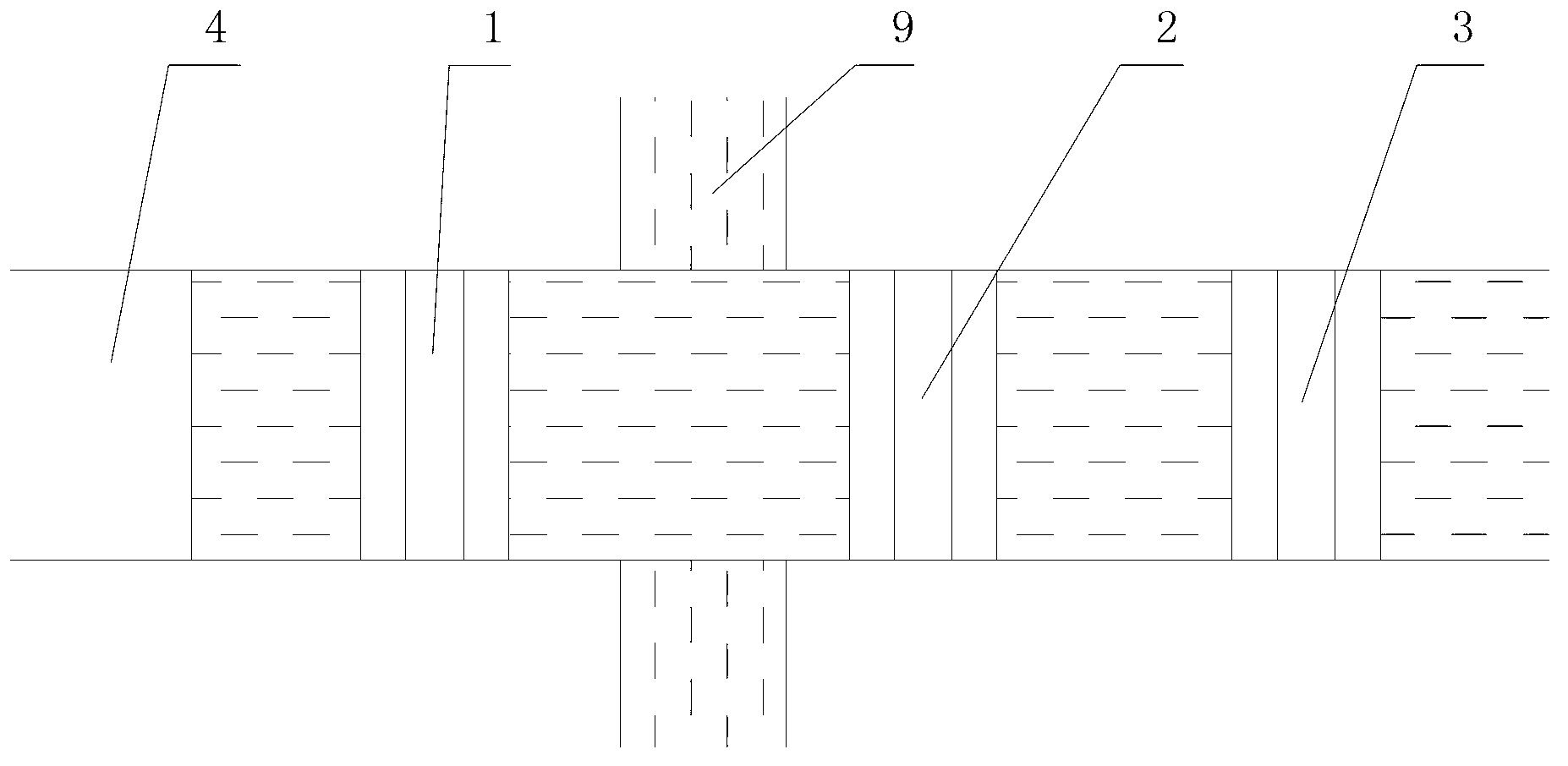

Method of purifying fischer-tropsch derived water

InactiveUS7166219B2Simplify and reduce costsTreatment using aerobic processesUltrafiltrationDistillationAerobic digestion

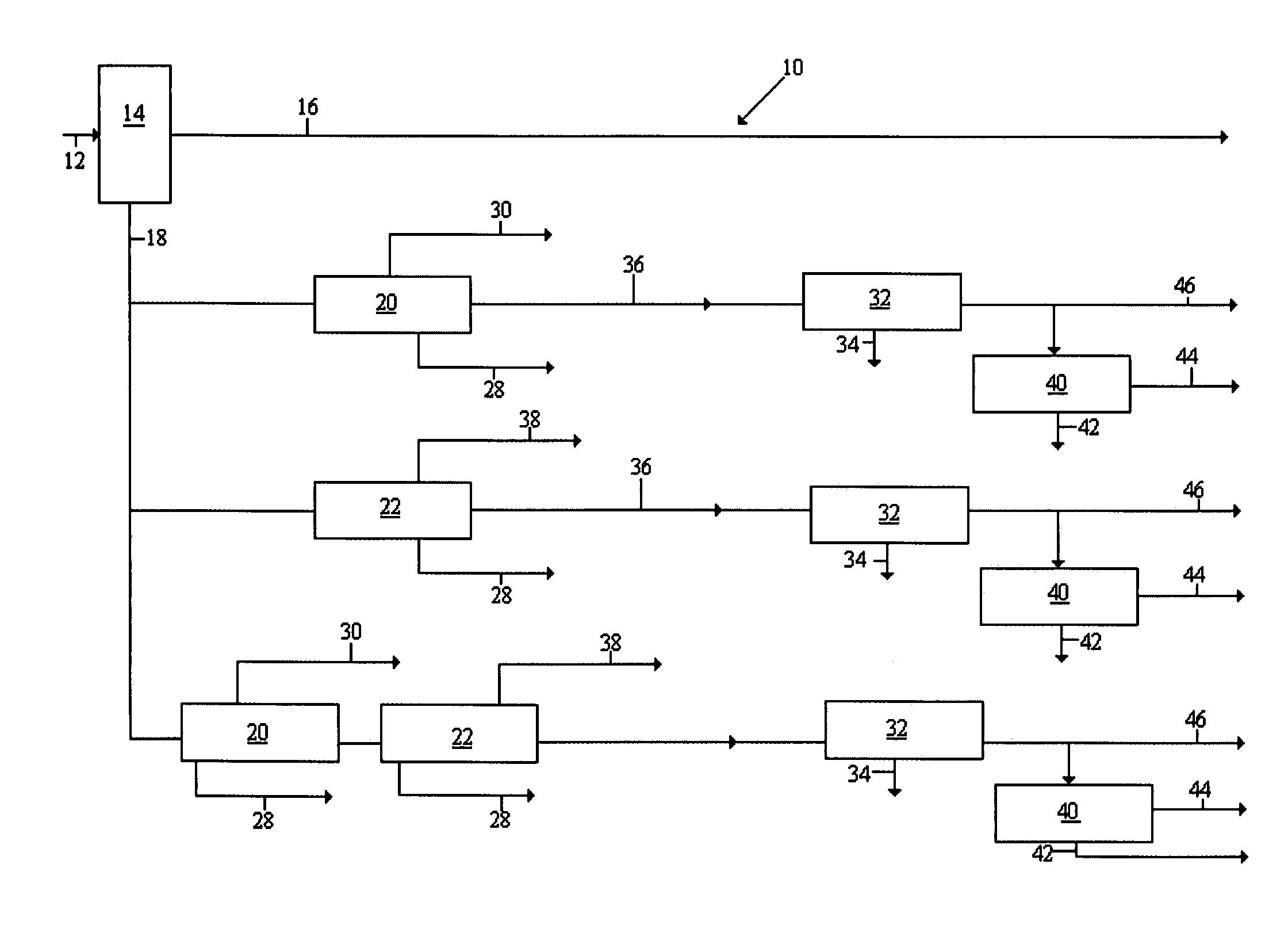

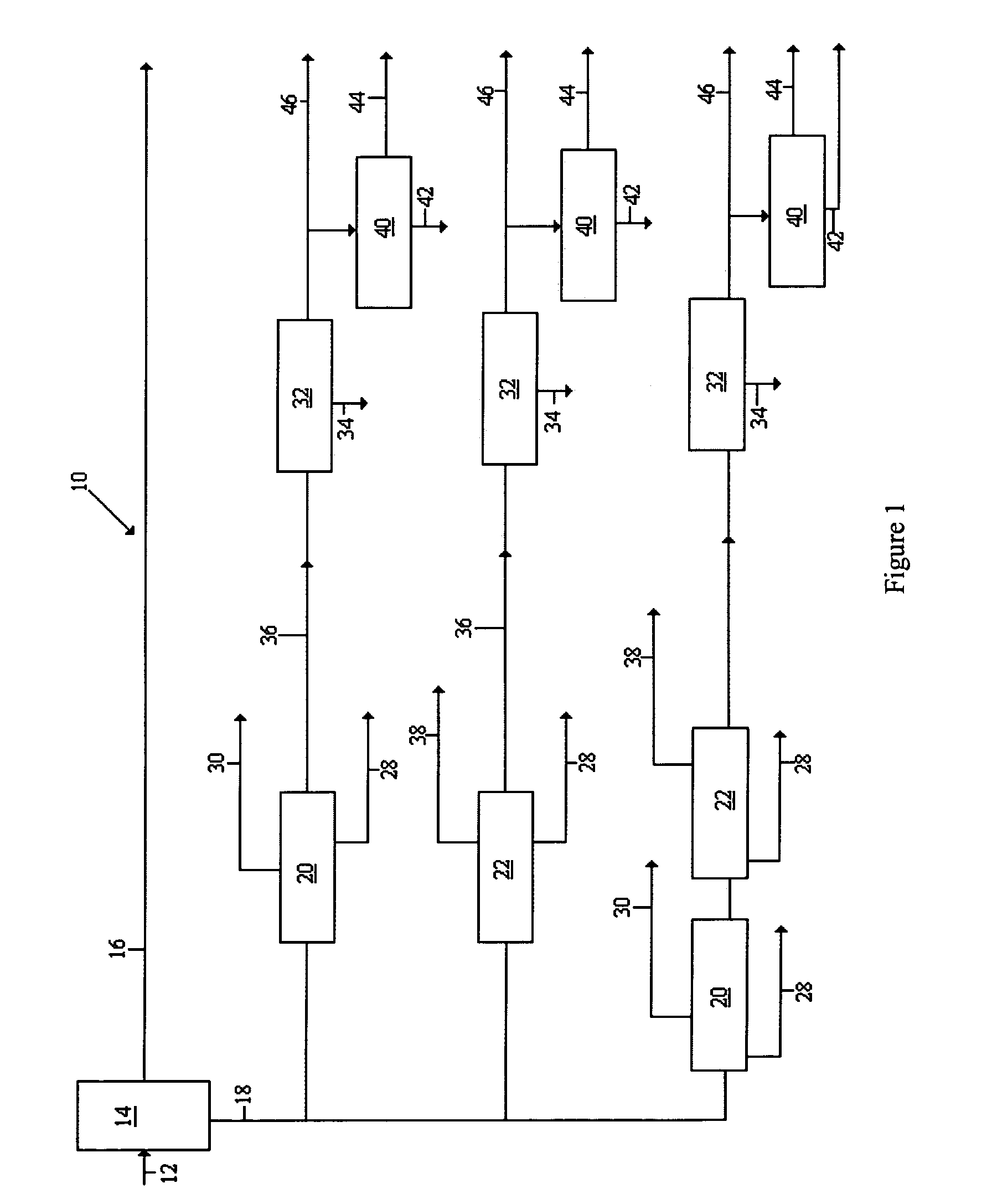

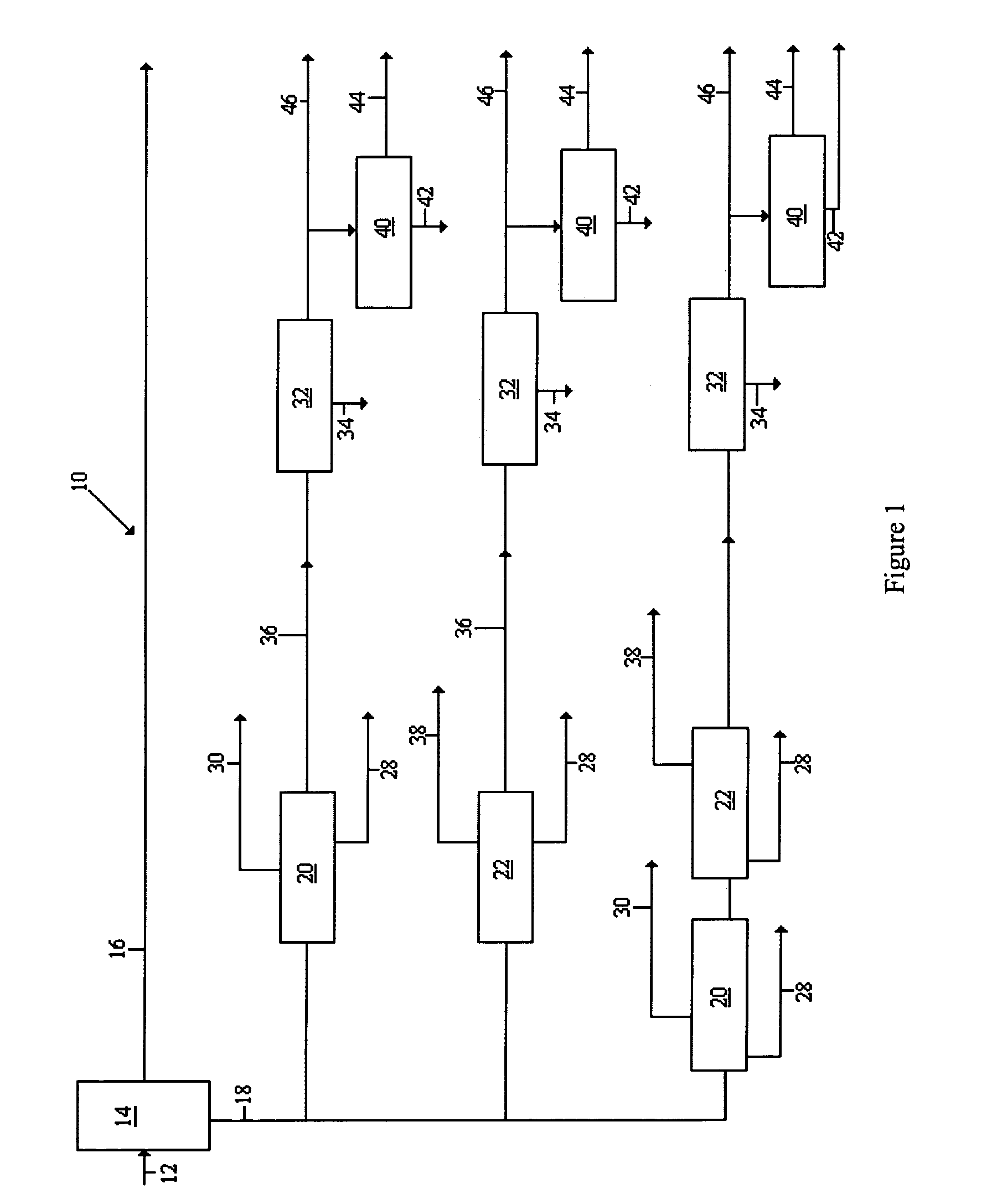

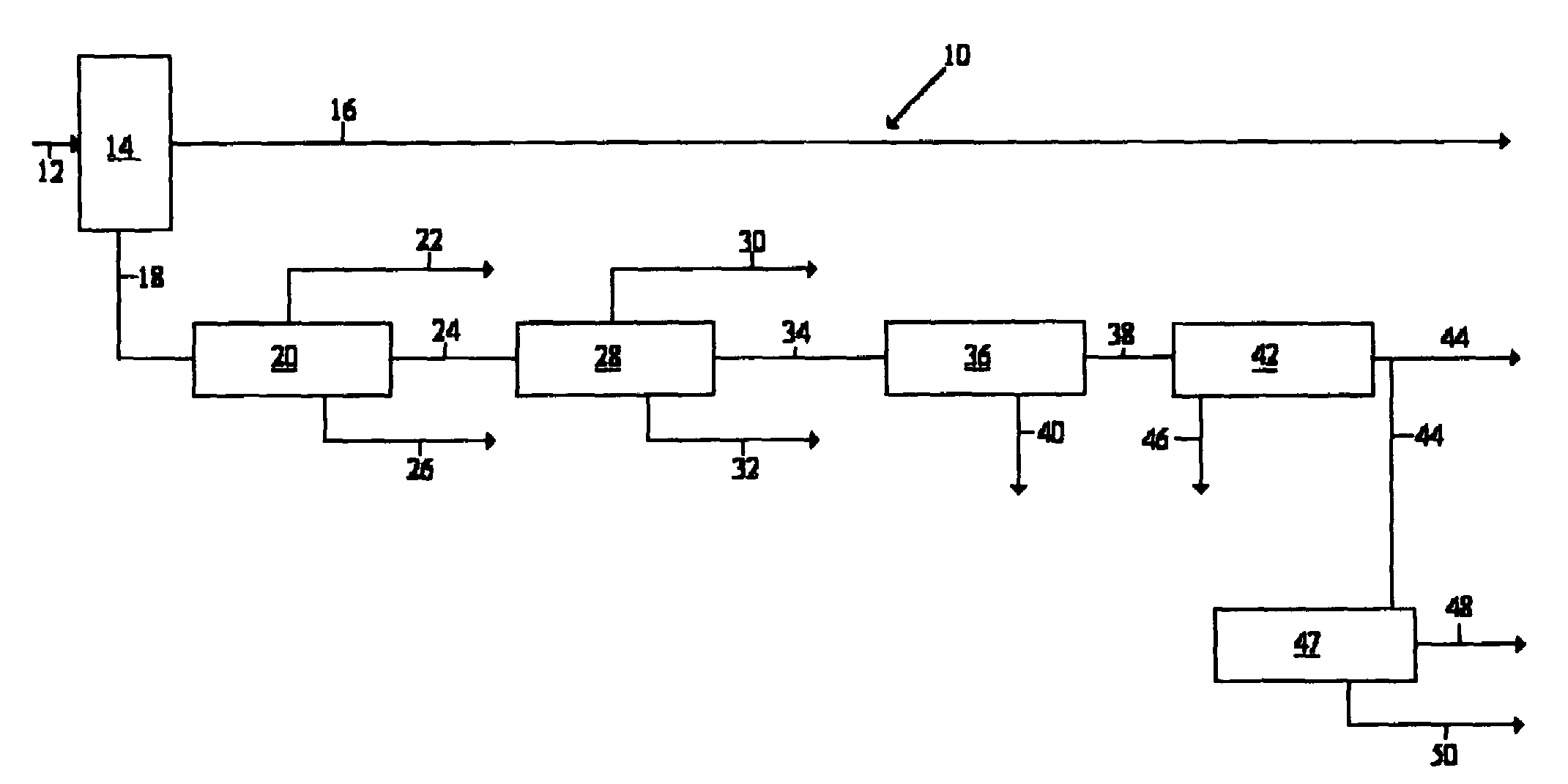

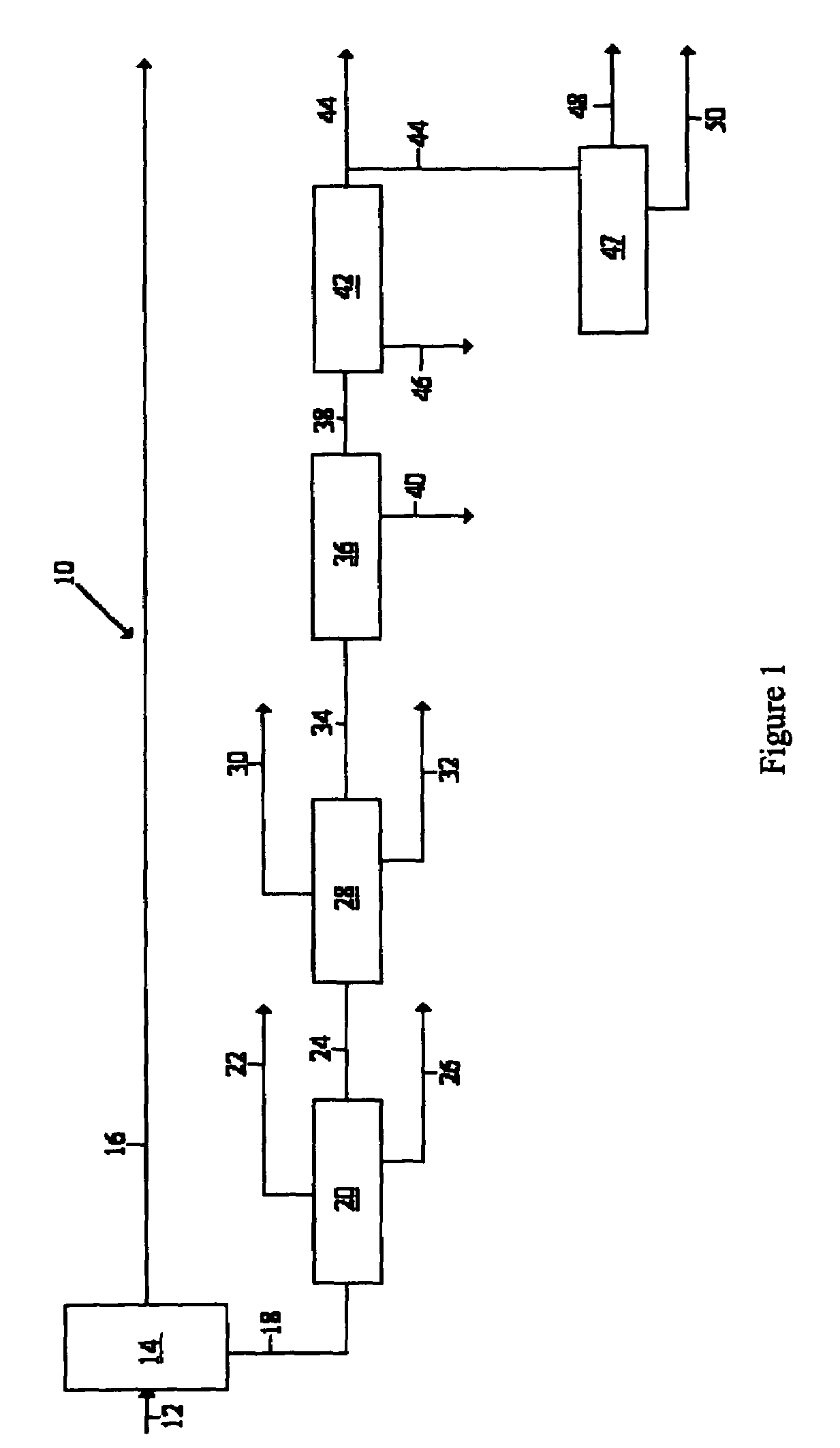

A process for the production of highly purified water 44 from Fischer-Tropsch reaction water 12 includes distillation 14 as a primary treatment stage, biological treatment including anaerobic digestion 20 and aerobic digestion 22 as a secondary treatment stage, solid-liquid separation 32 as a tertiary treatment stage and a dissolved salt and organic removal stage 40 as final treatment stage.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Method and system for treating wastewater

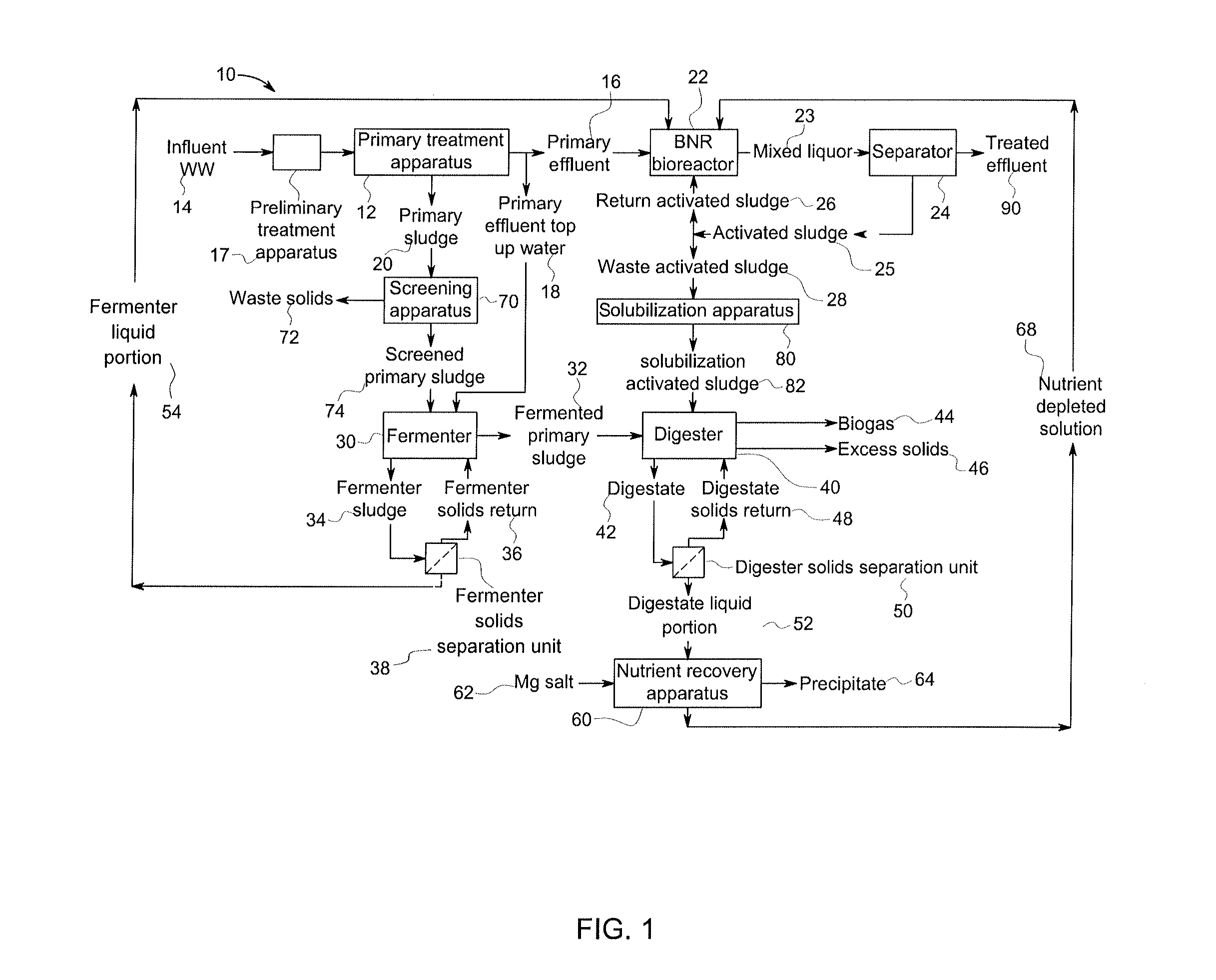

InactiveUS20130134089A1Water treatment parameter controlSpecific water treatment objectivesActivated sludgeVolatile fatty acids

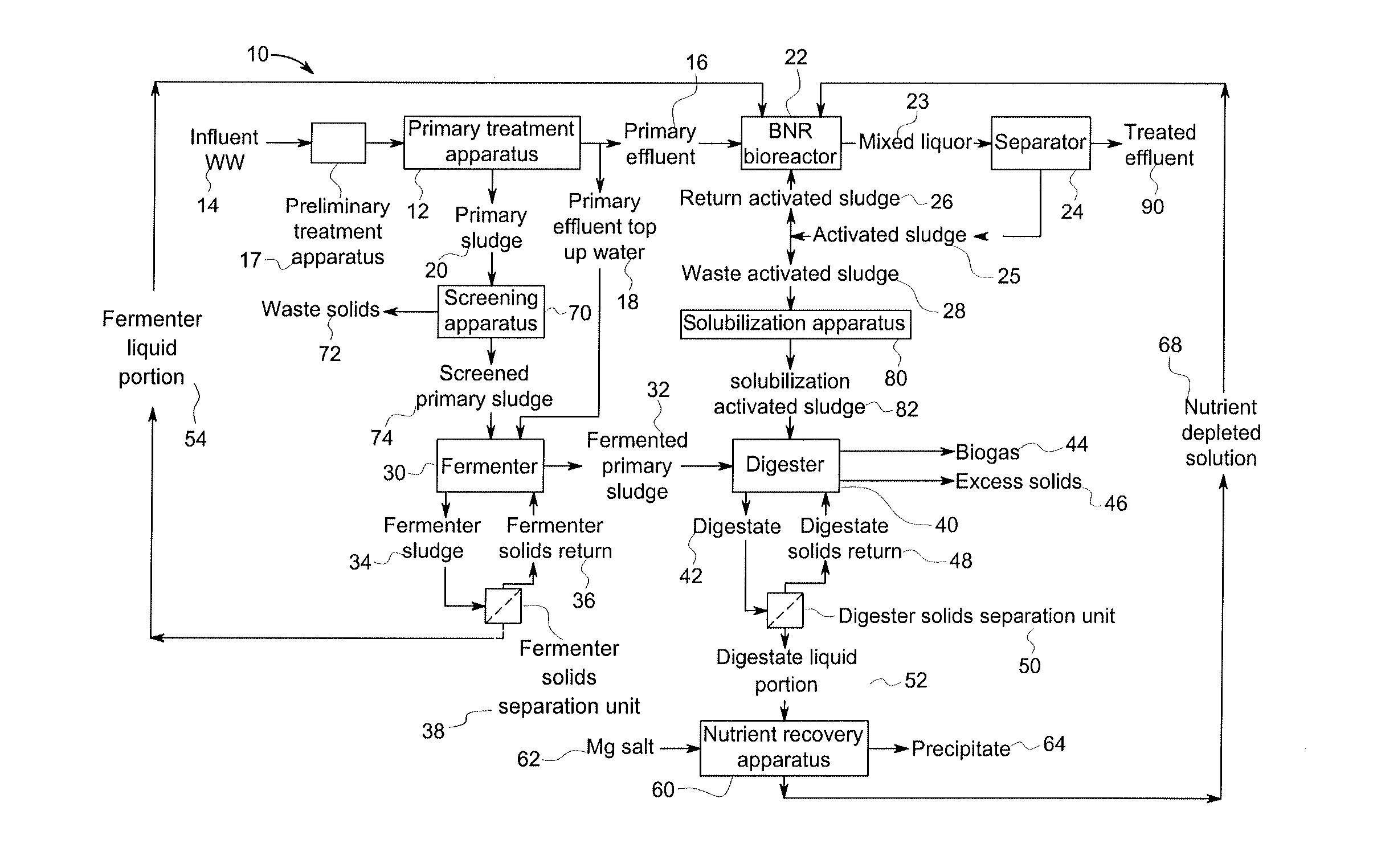

A wastewater treatment process uses enhanced primary treatment to remove suspended solids from raw wastewater. Primary sludge is treated in a fermenter. Primary effluent is treated by biological nutrient removal (BNR) to produce a treated effluent and waste activated sludge (WAS). The WAS is treated in an anaerobic digester, which also treats sludge from the fermenter. Anaerobic digestate is separated to provide a liquid effluent. The liquid effluent is stripped of phosphorous and returned to the BNR as a source of readily biodegradable carbon. Liquid in the fermenter may also be separated to provide a liquid rich in volatile fatty acids (VFAs). This liquid is returned to the BNR when additional VFAs are required.

Owner:GENERAL ELECTRIC CO

Systems and methods for treating obesity and other gastrointestinal conditions

InactiveUS20090118699A1Reduce morbidityIncrease satietyElectrotherapyPeptide/protein ingredientsReflexREFLEX DECREASE

Owner:RESPIRATORY DIAGNOSTICS

Method of purifying fischer-tropsch derived water

ActiveUS20050131086A1Simplify and reduce costsTreatment using aerobic processesUltrafiltrationDistillationAerobic digestion

A process for the production of highly purified water 44 from Fischer-Tropsch reaction water 12 includes distillation 14 as a primary treatment stage, biological treatment including anaerobic digestion 20 and aerobic digestion 22 as a secondary treatment stage, solid-liquid separation 32 as a tertiary treatment stage and a dissolved salt and organic removal stage 40 as final treatment stage.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Method of purifying fischer-tropsch derived water

InactiveUS7150831B2Simplify and reduce costsTreatment using aerobic processesUltrafiltrationOrganic acidTotal dissolved solids

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

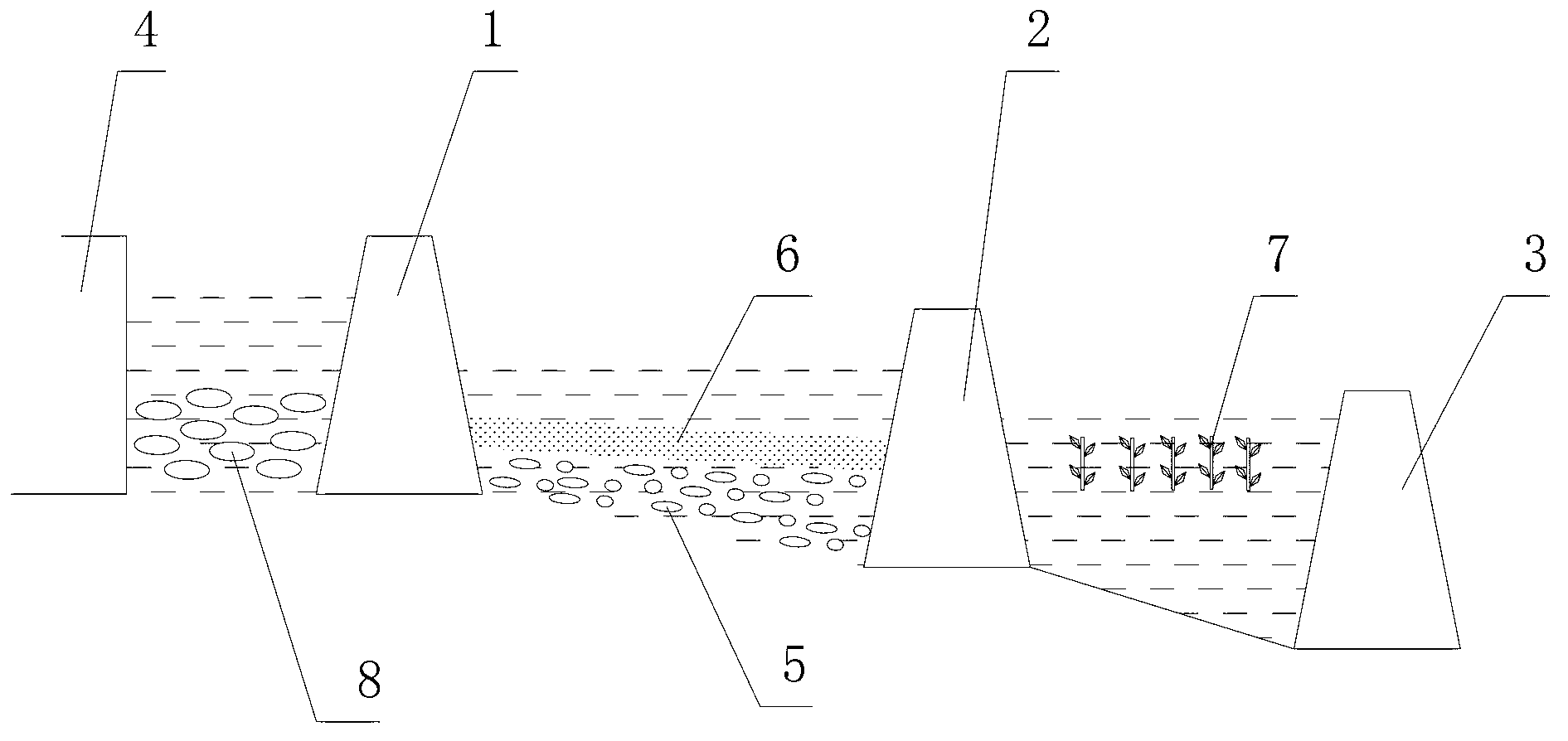

Method for utilizing buffer strip to control agricultural non-point source pollution of tidal river network area of plain

ActiveCN101555071AImprove water qualityQuality improvementSustainable biological treatmentBiological water/sewage treatmentBuffer stripWater source

The invention relates to a method for utilizing a buffer strip to control agricultural non-point source pollution of a tidal river network area of a plain, belonging to the technical field of environmental protection. The method comprises the following steps of: selecting buffer strip areas, carrying out primary treatment to the buffer strip, setting a water distribution system of the buffer strip, selecting and planting plants in the buffer strip and introducing water source into the buffer strip. The method has the characteristics of simpleness, convenience, practicability, good purifying effect and free maintenance management.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

Systems and methods for applying a selected treatment agent into contact with tissue to treat disorders of the gastrointestinal tract

Systems and methods that treat disorders of the gastrointestinal tract by applying one or more treatment agents to tissue at or near the region where abnormal neurological symptoms or abnormal tissue conditions exist. The treatment agent is selected to either disrupt the abnormal nerve pathways and / or to alleviate the abnormal tissue conditions. The treatment agent can include at least one cytokine and / or at least one vanilloid compound to evoke a desired tissue response. The systems and methods can be used a primary treatment modality, or as a neoadjuvent or adjuvant treatment modality.

Owner:MEDERI RF LLC

Magnetorheological fluid recycling device and control method and component manufacturing method thereof

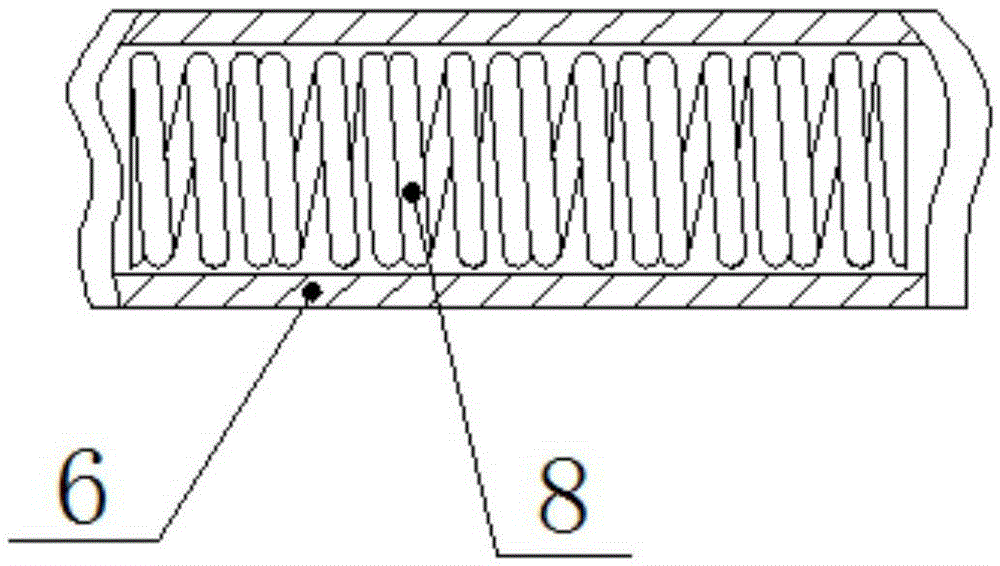

PendingCN105417834AEasy to separateIncrease contact rateTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsFiltrationMagnetorheological fluid

The invention discloses a magnetorheological fluid recycling device and a control method and component manufacturing method thereof, and belongs to the technical field of mechanical manufacturing. The magnetorheological fluid recycling device comprises an inlet stop valve, an upper shell, a lower shell, an electrostatic filter plate, upper adsorption pipes, lower adsorption pipes, rib pipes, coils, heaters, stirrers, a pump, a return pipe and an outlet stop valve. The upper shell is connected with the lower shell through bolts, seal rings are arranged on the attached positions of the upper shell and the lower shell, and the inlet stop valve is arranged on the upper shell. Meanwhile, the invention further provides the control method and key component manufacturing method of the magnetorheological fluid recycling device. According to the magnetorheological fluid recycling device and the control method and component manufacturing method thereof, primary treatment on mixed liquid is completed through filtration and adsorption of the electrostatic filter plate, and then treatment on the mixed liquid is further completed through adsorption of the upper adsorption pipes, the lower adsorption pipes and the rib pipes; the heaters, the stirrers and a circulatory system are additionally arranged, and the purpose of thoroughly separating magnetic substances from solvent is achieved.

Owner:马鞍山清净环保科技有限公司

Process for removing thallium from thallium-containing heavy metal wastewater through neutralization and flocculation

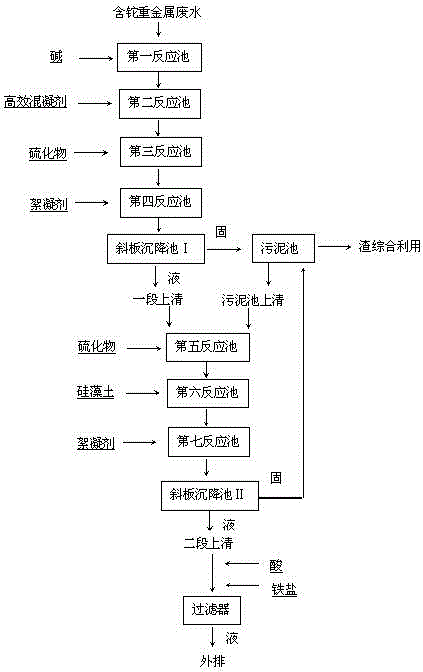

InactiveCN104445732AGuaranteed deep removalRealize deep purificationWater contaminantsMultistage water/sewage treatmentFlocculationIron salts

The invention discloses a process for removing thallium from thallium-containing heavy metal wastewater through neutralization and flocculation. The process comprises the following steps: performing primary treatment, namely adjusting the pH value of thallium-containing heavy metal wastewater to be more than 7through acid and alkali, adding an efficient coagulant, sulfide and a flocculant, and performing solid-liquid separation through a slanting board sedimentation pool; performing secondary treatment, namely adding sulfide, diatomite and the flocculant into supernatant purified water after primary treatment, and performing solid-liquid separation through the slanting board sedimentation pool; adjusting the purified water subjected to secondary treatment to be neutral, adding iron salt, and finally filtering through a filter and directly discharging to the outside. Due to the adoption of the technical scheme, the removal rate of thallium and other heavy metal ions in the heavy metal wastewater can be effectively increased, the environmental pollution can be avoided, and the medicament cost can be reduced.

Owner:ZHUZHOU SMELTER GRP

Process for Purification Treatment of Wastewater Containing Organic Substance

InactiveUS20070256972A1Pressurized chemical processTreatment involving filtrationFiltrationPrimary treatment

There is provided a process for purification treatment of wastewater containing an organic substance. There is provided a process for purification treatment of wastewater containing an organic substance by carrying out supercritical treatment or subcritical treatment, which comprises subjecting the wastewater to at least one solid-liquid separation pretreatment selected from separation treatment with a flocculant, sedimentation treatment, flotation treatment and filtration treatment; and then subjecting the wastewater to primary treatment as biological treatment; and subsequently purifying the wastewater by treatment including secondary treatment as supercritical treatment or subcritical treatment.

Owner:KANSAI PAINT CO LTD

Methods of treating tardive dyskinesia and other movement disorders

InactiveUS7498361B2Decreases postsynaptic responseSpread the wordBiocideHydroxy compound active ingredientsNR1 NMDA receptorAcamprosate

The present invention describes a novel treatment for movement disorders, including tardive dyskinesia, tic disorders, Tourette's syndrome, and blepharospasm, and other focal dystonias. The treatment of the present invention utilizes agents that simultaneously act as NMDA-type glutamate receptor antagonists and GABA-A receptor agonists. Preferably these two activities are characteristic of a single agent, for example acamprosate. Alternatively, separate agents having these activities can be combined and administered together. The invention also provides a third agent that acts as a non-competitive NMDA-receptor blocking agent or ion channel blocker that augments the effect of the primary treatment. A particularly preferred ion channel blocking agent is magnesium. Alternatively, magnesium can be administered alone for prevention and treatment of movement disorders.

Owner:SYNCHRONEURON

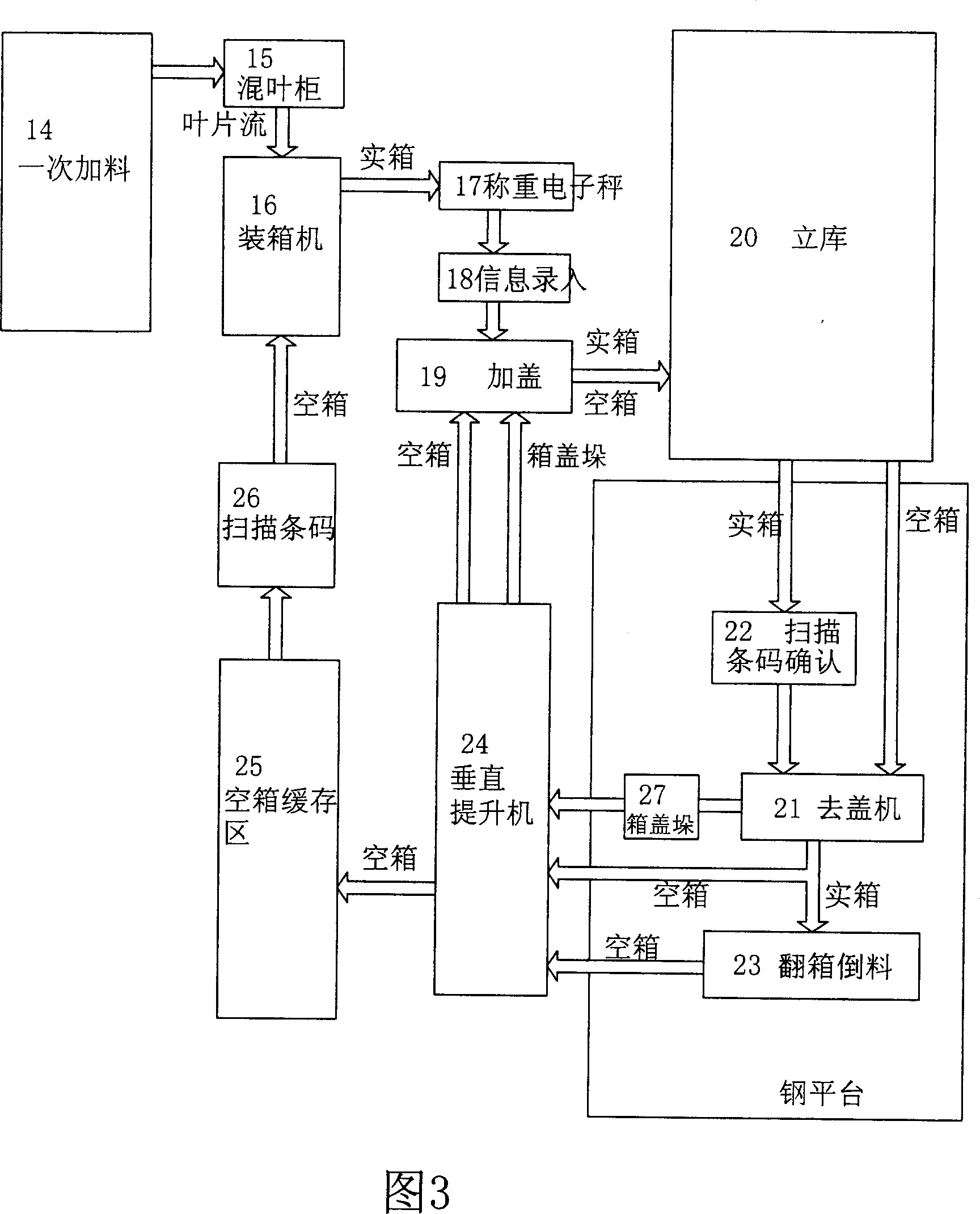

Chamber type leaves-storing process for tobacco processing line

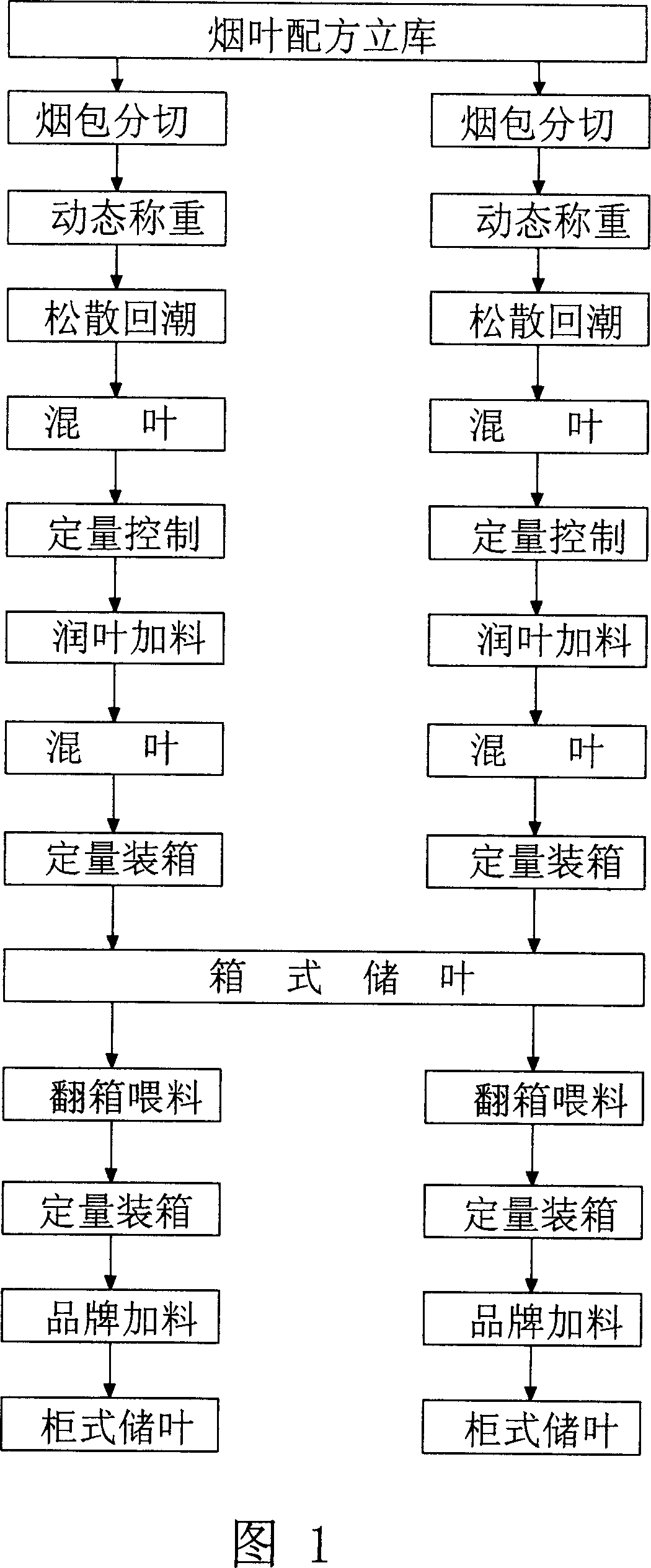

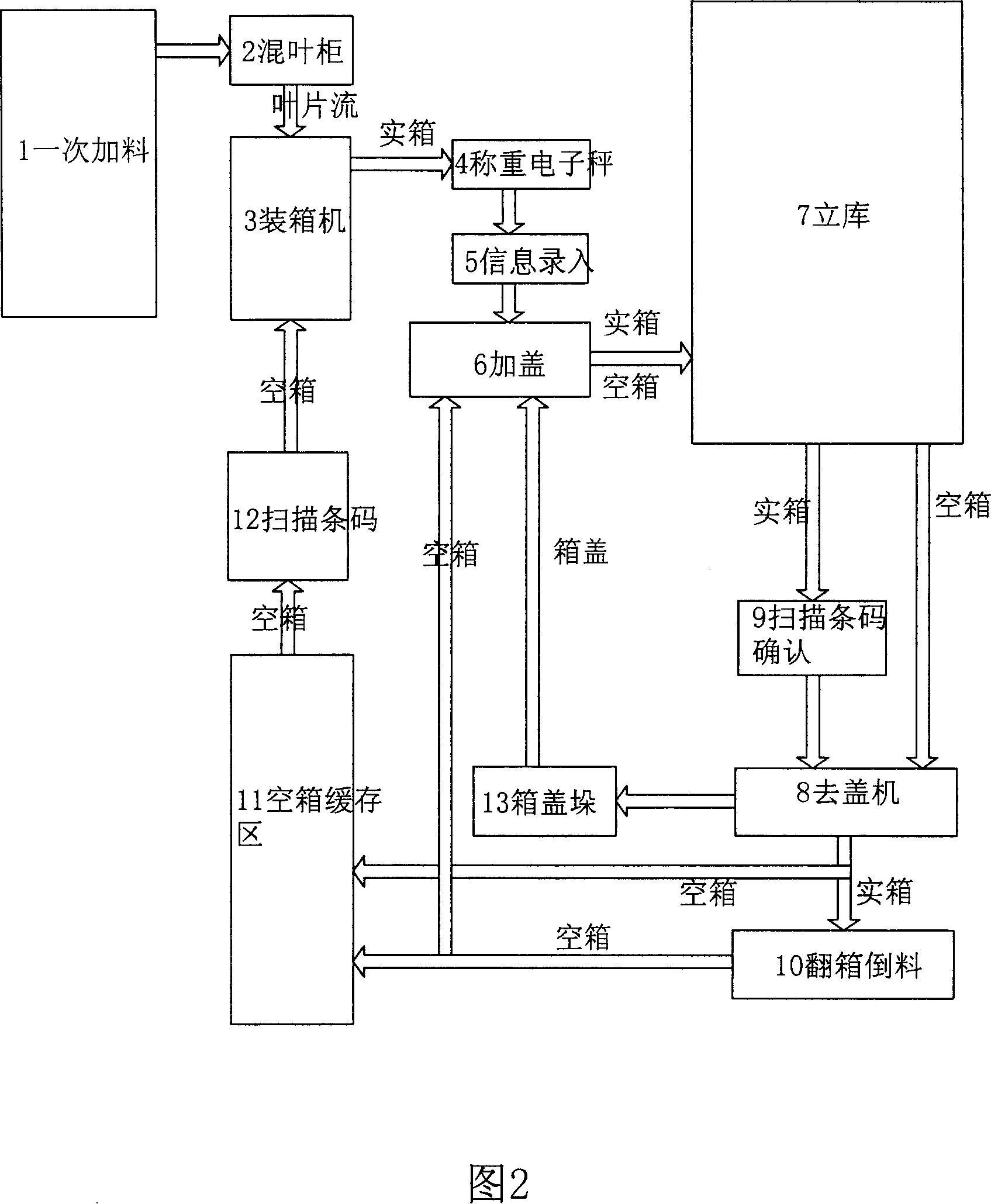

InactiveCN101077215AIncrease flexibilityImprove continuityTobacco preparationSolid materialEngineeringPrimary treatment

The present invention discloses one kind of box type tobacco storing process in tobacco shred producing line. The box type tobacco storing process includes the primary treatment of tobacco material comprising cutting tobacco package, weighing, loosening and remoistening, mixing, rationing, feeding and re-mixing; the subsequent rationing and boxing in 50-400 Kg boxes and marking; the tobacco storing in box type warehouse at constant temperature and constant humidity for the required period; and taking out the tobacco storing box from the warehouse and storing in storing cabinet.

Owner:红云烟草(集团)有限责任公司 +1

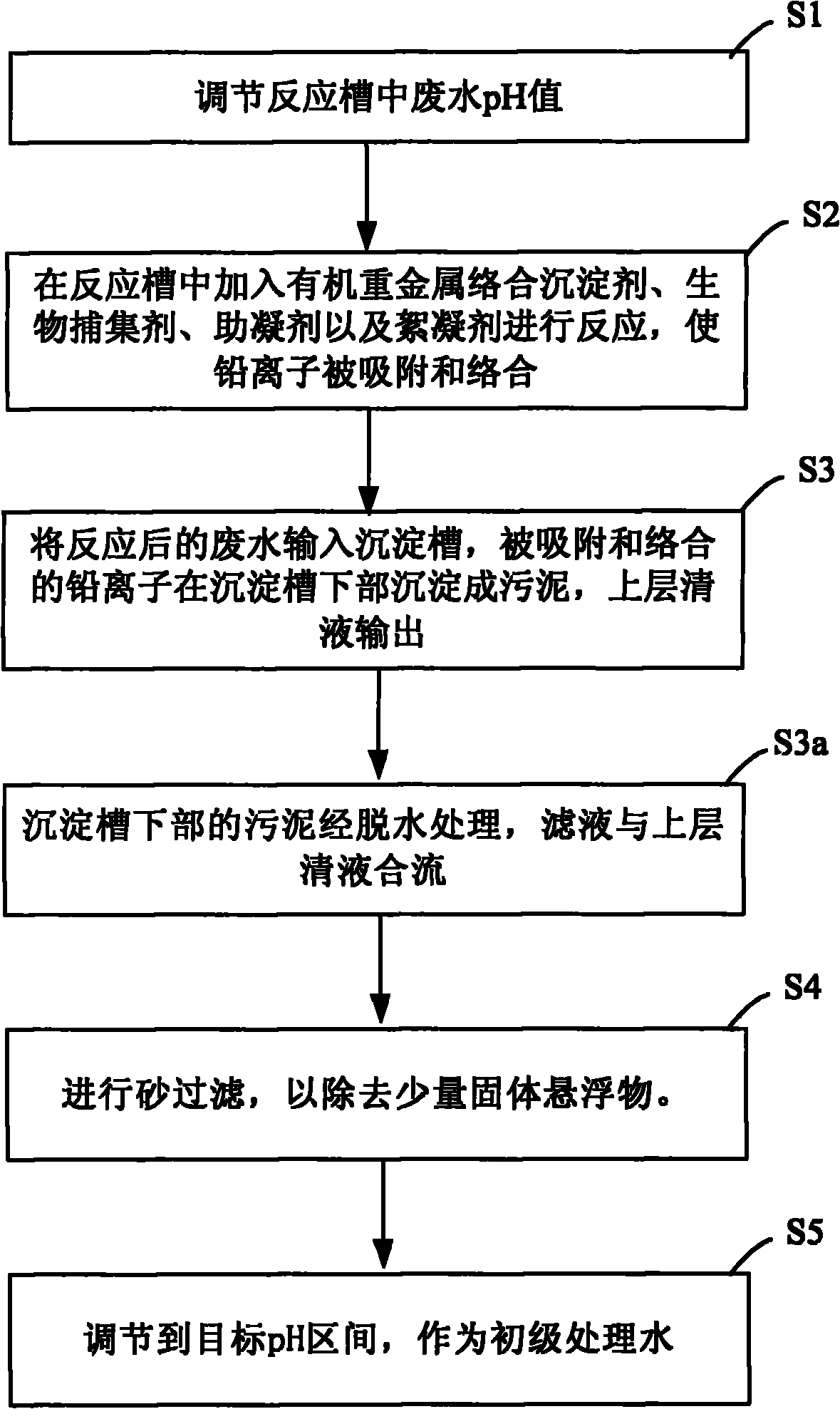

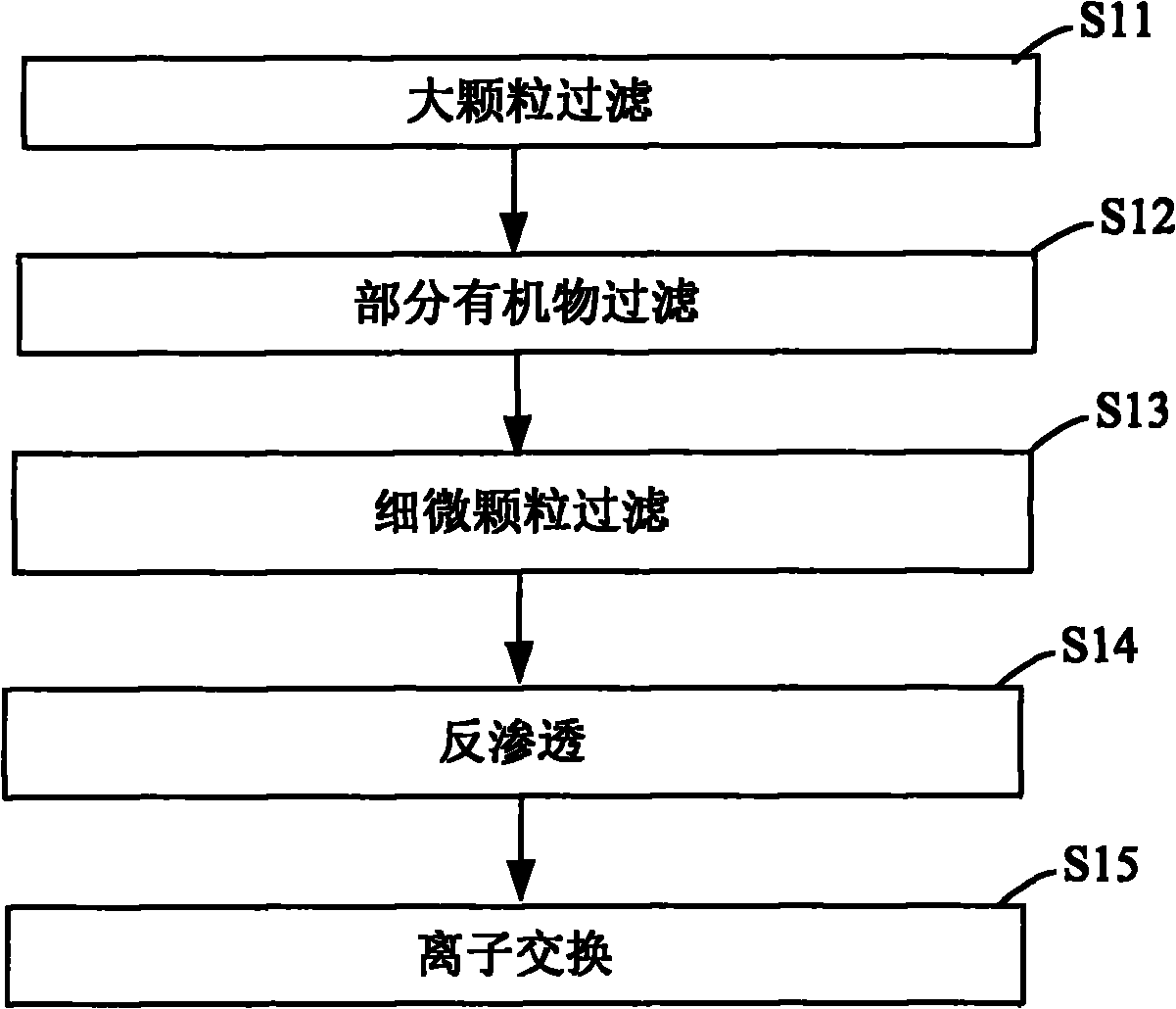

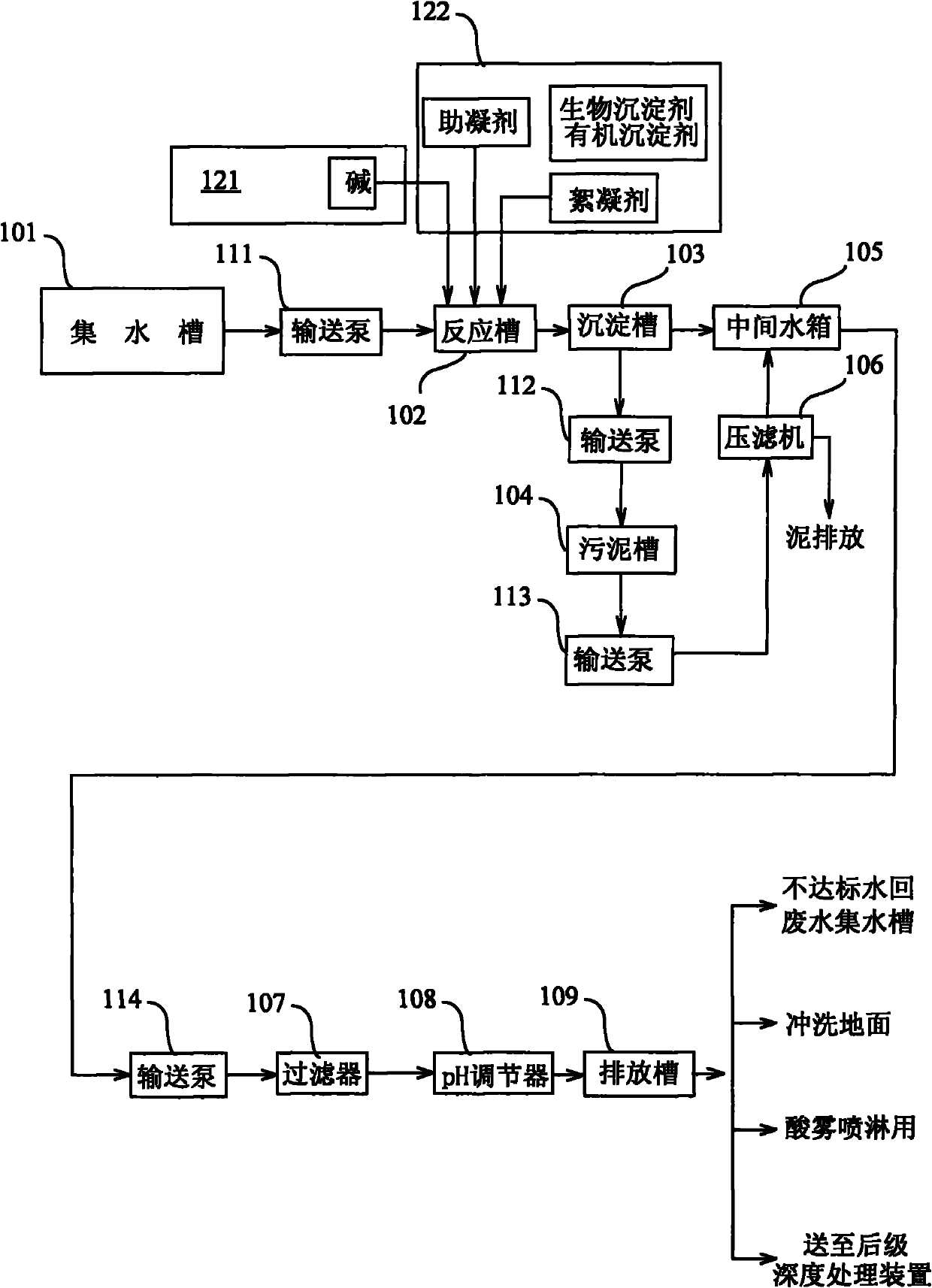

Method for recycling waste water of lead-acid storage battery

InactiveCN102020374ALead ion content decreasedReduce the burden onDispersed particle separationWater/sewage treatment by ion-exchangeSludgeReverse osmosis

The invention relates to a method for recycling waste water of a lead-acid storage battery, which is used for realizing harmless treatment of the waste water of the lead-acid storage battery and recycling of water resources. The method comprises the following steps of: inputting lead-containing waste water into a reaction tank, adding an organic heavy metal complex precipitant or a biological precipitant into the reaction tank and adding a coagulant aid and a flocculating agent for reacting so as to realize adsorption or complexation of lead ions; inputting reacted waste water into a precipitation tank, precipitating the adsorbed or complex lead ions into sludge on the lower part of the precipitation tank and outputting supernatant; adjusting the pH value of the supernatant to a target range and outputting the supernatant serving as primary treatment water; and performing reverse osmosis treatment on the primary treatment water to remove salt in the waste water and outputting advanced treatment water serving as water for production of storage batteries.

Owner:SHANGHAI LIGHT IND RES INST

System for auxiliarily treating acid mine waste water by utilizing stepped interception dams and process thereof

InactiveCN102701545AAvoid damageEasy to handleWaste water treatment from quariesMultistage water/sewage treatmentThree levelChemical reaction

The invention discloses a system for auxiliarily treating acid mine waste water by utilizing stepped interception dams and a process thereof. The system for auxiliarily treating the acid mine waste water by utilizing the stepped interception dams comprises at least three levels of interception dams, wherein the interception dams are distributed in a shape of naturally falling trapezoid so as to carry out primary treatment, neutralization treatment, reducing treatment and impurity eliminating treatment on the acid mine waste water. The system and the process disclosed by the invention have theadvantages that the stepped interception dams are established on a natural ditch by utilizing natural falls, and the functions of obstruction of the stepped dams, physical and chemical reaction of microorganisms, filtering and adsorption of plant roots and the like are also utilized, so that the process is a subsequent auxiliary and deep treatment method, the treating effect is improved, the complexity and treating difficulty of the traditional method are simplified, the cost is reduced, the water quality is improved, the heavy metal content and the acidity are further reduced, and the damages of the mine waste water to water source areas and ecological environment are reduced.

Owner:GUIZHOU NORMAL UNIVERSITY

Method of purifying fischer-tropsch derived water

InactiveUS20050139555A1Reduce the amount requiredMaximizes and removalUsing liquid separation agentUltrafiltrationPurified waterPrimary treatment

A process for the production of highly purified water 38 from Fischer-Tropsch reaction water 12, includes at least the steps of a primary treatment stage comprising an equilibrium staged separation process 14 having at least one stage for removing at least a fraction of non-acid oxygenated hydrocarbons from the Fischer-Tropsch reaction water 12 to produce a primary water-enriched stream 16, a secondary treatment stage comprising at least one membrane separation process 28 for removing at least some suspended solids and acidic oxygenated hydrocarbons from at least a portion of the primary water-enriched stream 16 to produce a secondary water-enriched stream 34 and a tertiary treatment stage comprising a dissolved salt and organic removal stage 36 for removing at least some dissolved salts and organic constituents from at least a portion of the secondary water-enriched stream 34.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

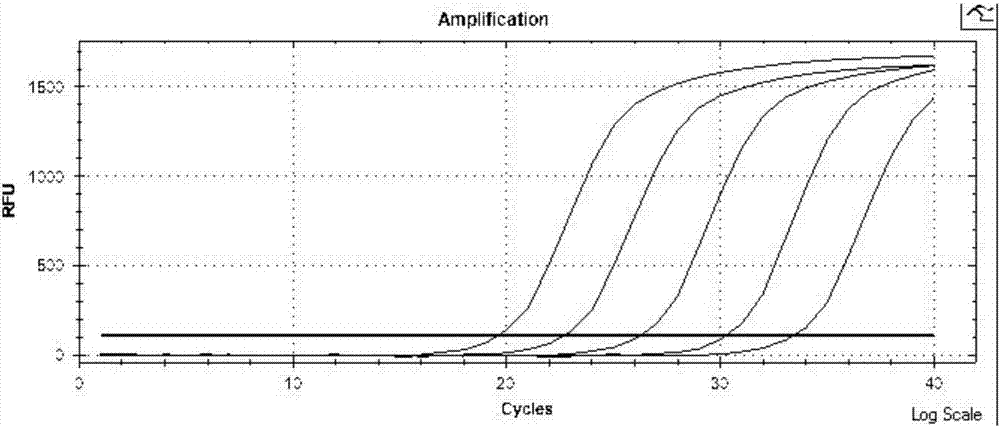

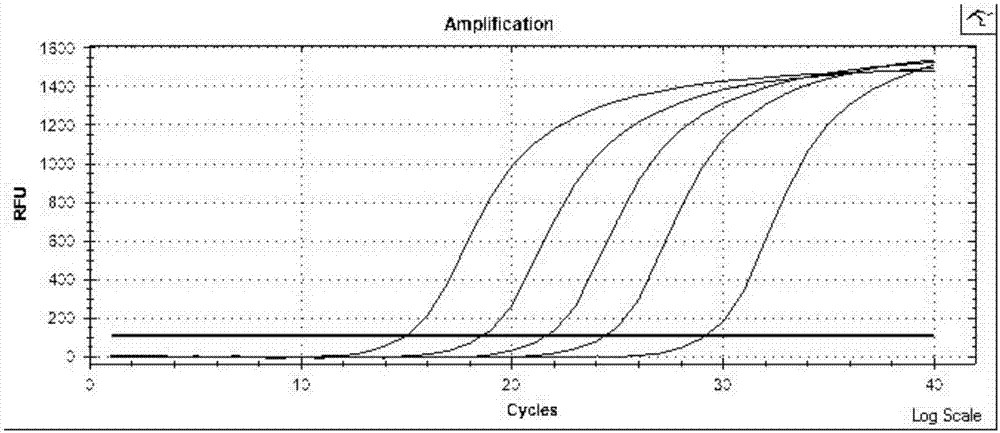

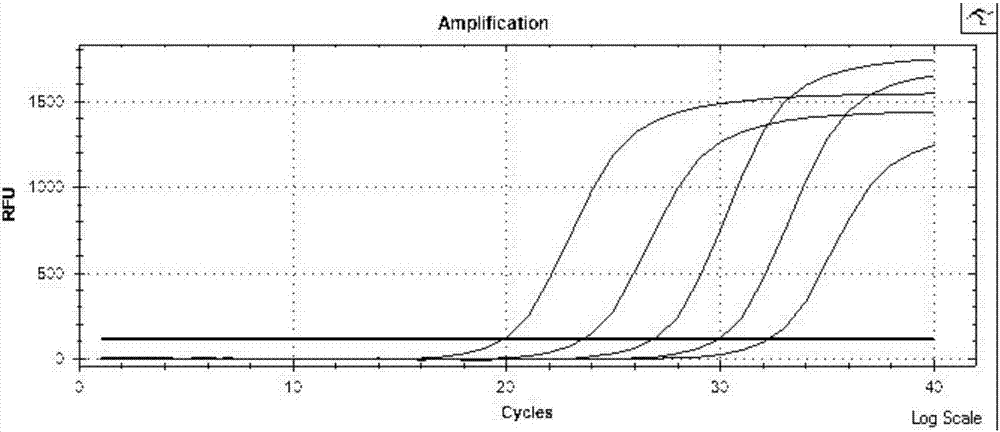

Kit for detecting methylation of colorectal cancer related gene multi-sites and application of kit

ActiveCN106893777AMeet the requirements of early screeningHigh sensitivityMicrobiological testing/measurementDNA/RNA fragmentationMulti siteA-DNA

The invention discloses a kit for methylation of colorectal cancer related gene multi-sites and application of the kit. A primer combination and a probe can specifically detect the methylation degrees of a plurality of colorectal cancer related gene sites. The invention further provides application and a method of the primer combination and the probe for detecting the methylation in colorectal cancer and precancerous polyps screening. The method comprises the steps that a cell lysis solution is added to cell sediment and mixed uniformly, then PVPP is added for crude extraction, a cell sediment sample after primary treatment contains a little protein and RNA, protease K and RNA enzyme are added for completely removing the protein and the RNA, cell lysate is added to a centrifugal column with an adsorption film, after impurities are washed by a DNA rising solution, a DNA eluent is added to elute the DNA in the absorption film, and finally a DNA solution is collected through centrifugation. Efficient pipe collection detection is performed aiming at the plurality of gene sites, the flexibility and the specificity are improved, and the tumor early screening requirement can be improved.

Owner:WUHAN AIMISEN LIFE TECH CO LTD

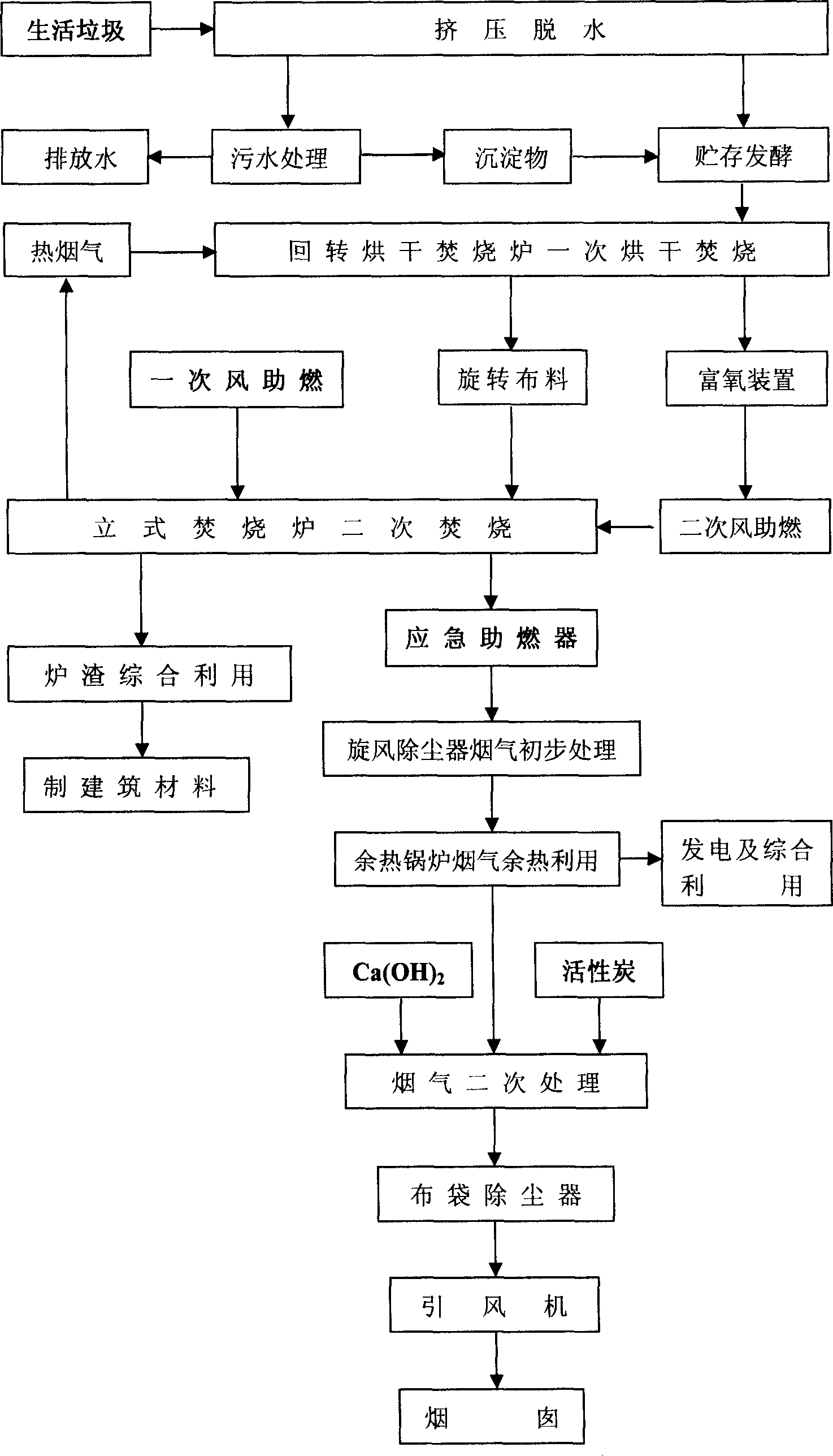

Life-garbage comprehensive treatment technology

InactiveCN1850370AIncrease temperatureExtended burn timeSolid waste disposalIncreasing energy efficiencySlagEnvironmental engineering

The present invention relates to a comprehensive treatment process of house refuse. Said treatment process includes the following steps: (1), squeezing and dehydrating; (2), storing and making fermentation, (3), using rotary baking incinerator to make firest incineration; (4), using vertical incinerator to make secondary incineration; (5), smoke primary treatment; (6), smoke waste heat utilization for power goneration and heating water; (7), secondary treatment of smoke; and (8), utilization of incinerator slag to make building material.

Owner:滕清华 +1

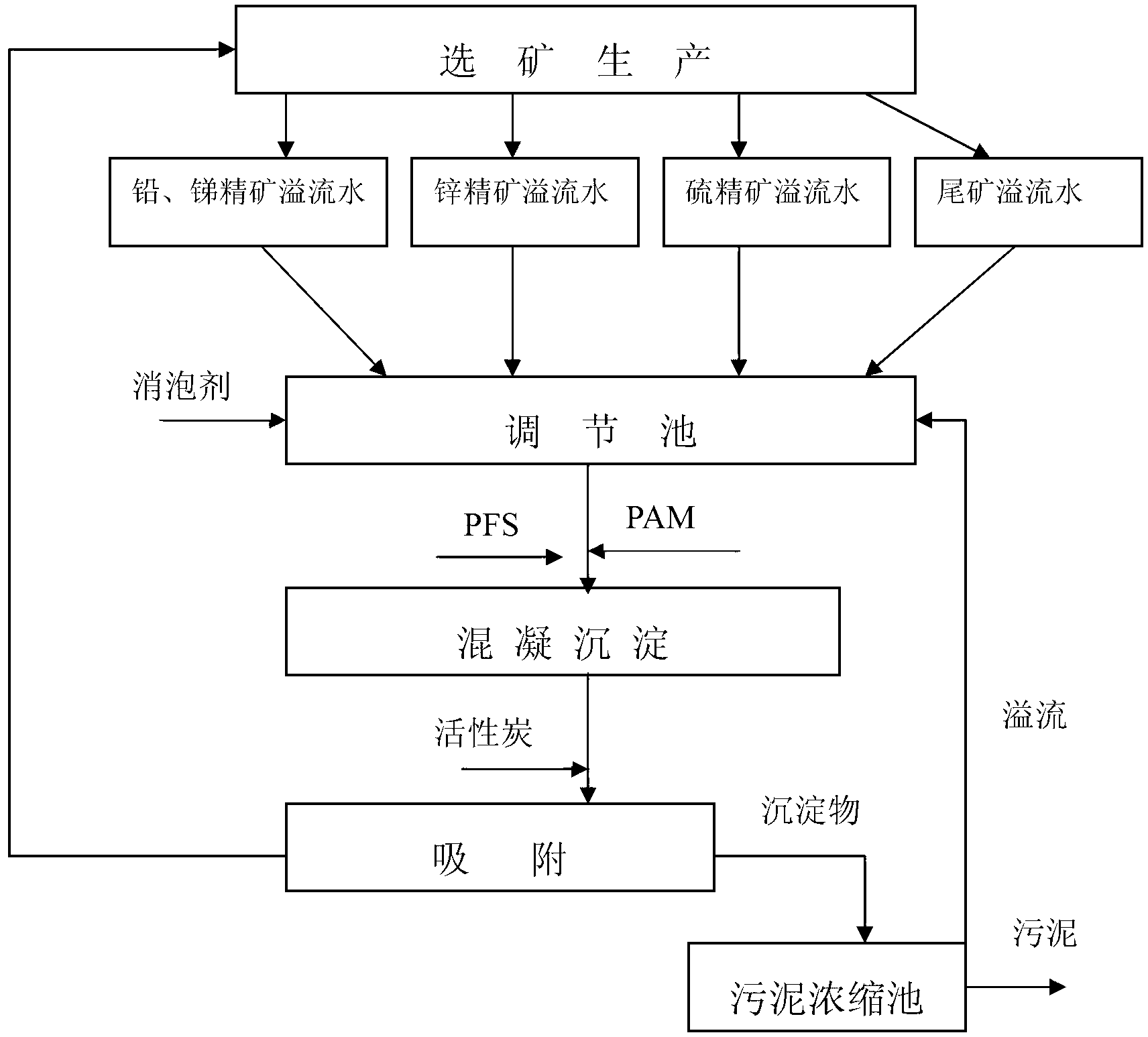

In-process circular and comprehensive recovery technology for mineral processing wastewater of tin-lead-zinc polymetallic sulphide ores

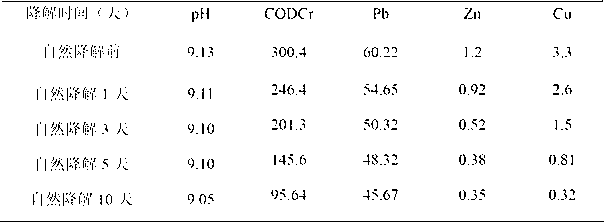

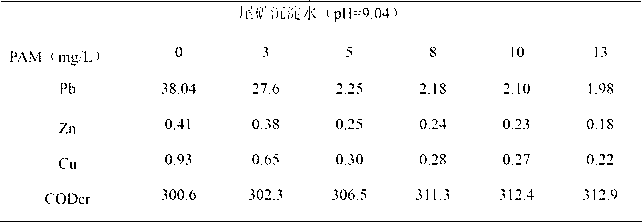

InactiveCN102936068AReduce dosageGood effectWaste water treatment from quariesMultistage water/sewage treatmentChemical oxygen demandSludge

The invention discloses an in-process circular and comprehensive recovery technology for mineral processing wastewater of tin-lead-zinc polymetallic sulphide ores. The technology includes primary treatment and secondary treatment, wherein the primary treatment is to coagulate and precipitate, comprising the step of adding a coagulant to remove suspended solid and metal ion, wherein some organic pollutants are removed at the same time; the secondary treatment is to carry out an adsorption method to remove flotation agent in the wastewater so as to further reduce the CODCr (Chemical Oxygen Demand) and foamability of the wastewater; and all water generated in the secondary treatment is recycled. The technology has the advantages of being simple in equipment, high in processing efficiency, high in adaptability, less in occupied area, and few in resulting sludge, and has higher effect of processing the mineral processing wastewater of tin-lead-zinc polymetallic sulphide ores; the polymeric ferric sulfate (PFS) and polyacrylamide (PAM) are selected and used as the compound coagulant to remove the pollutants such as the suspended solid and the metal ion during precipitating and removing the pollutants in the wastewater; and compared with single inorganic coagulant, the compound coagulant of the PFS and the PAM is low in dosage, good in effect, low in cost, and safe and nontoxic, and has no secondary pollution.

Owner:GUANGXI GAOFENG MINE IND

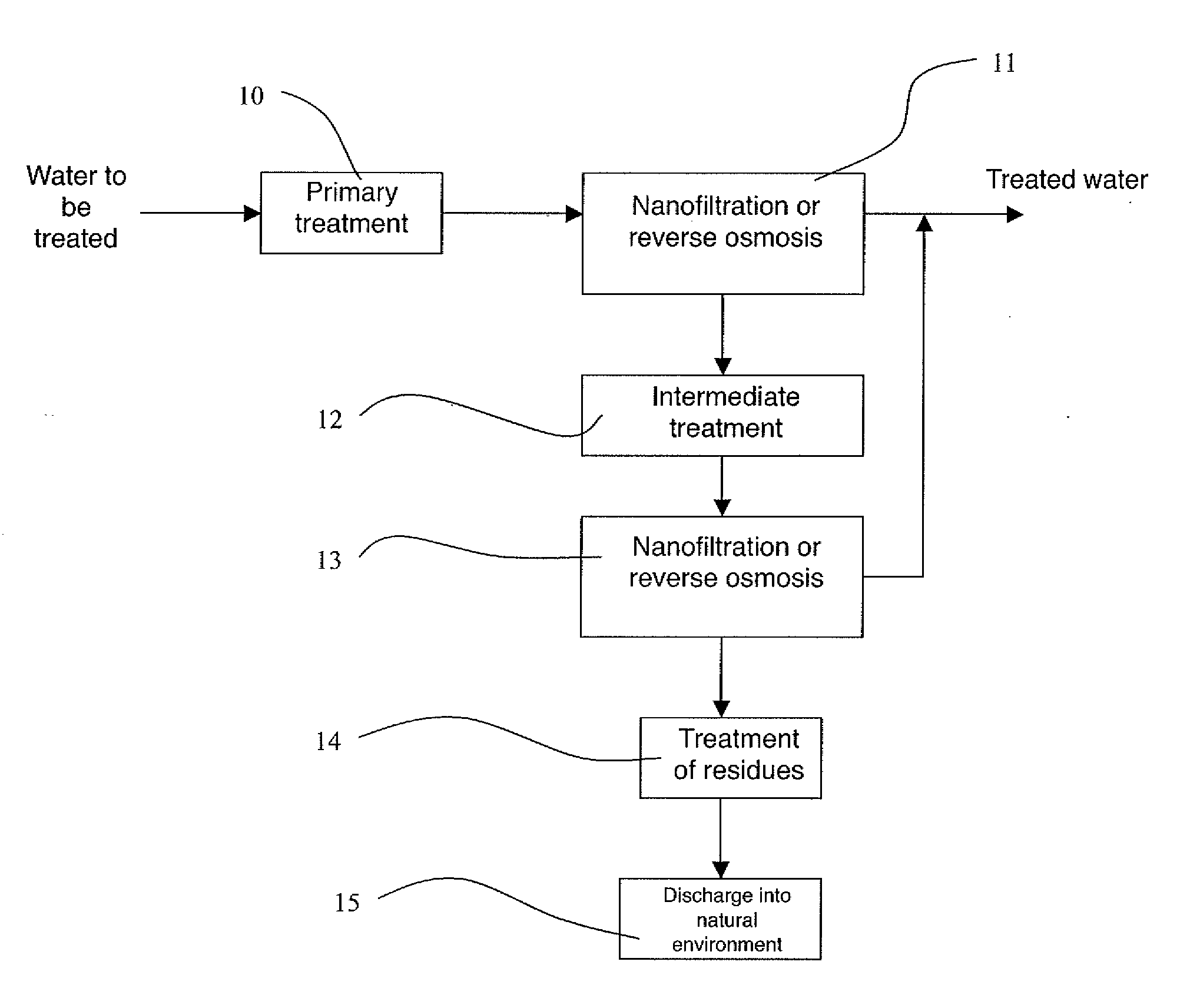

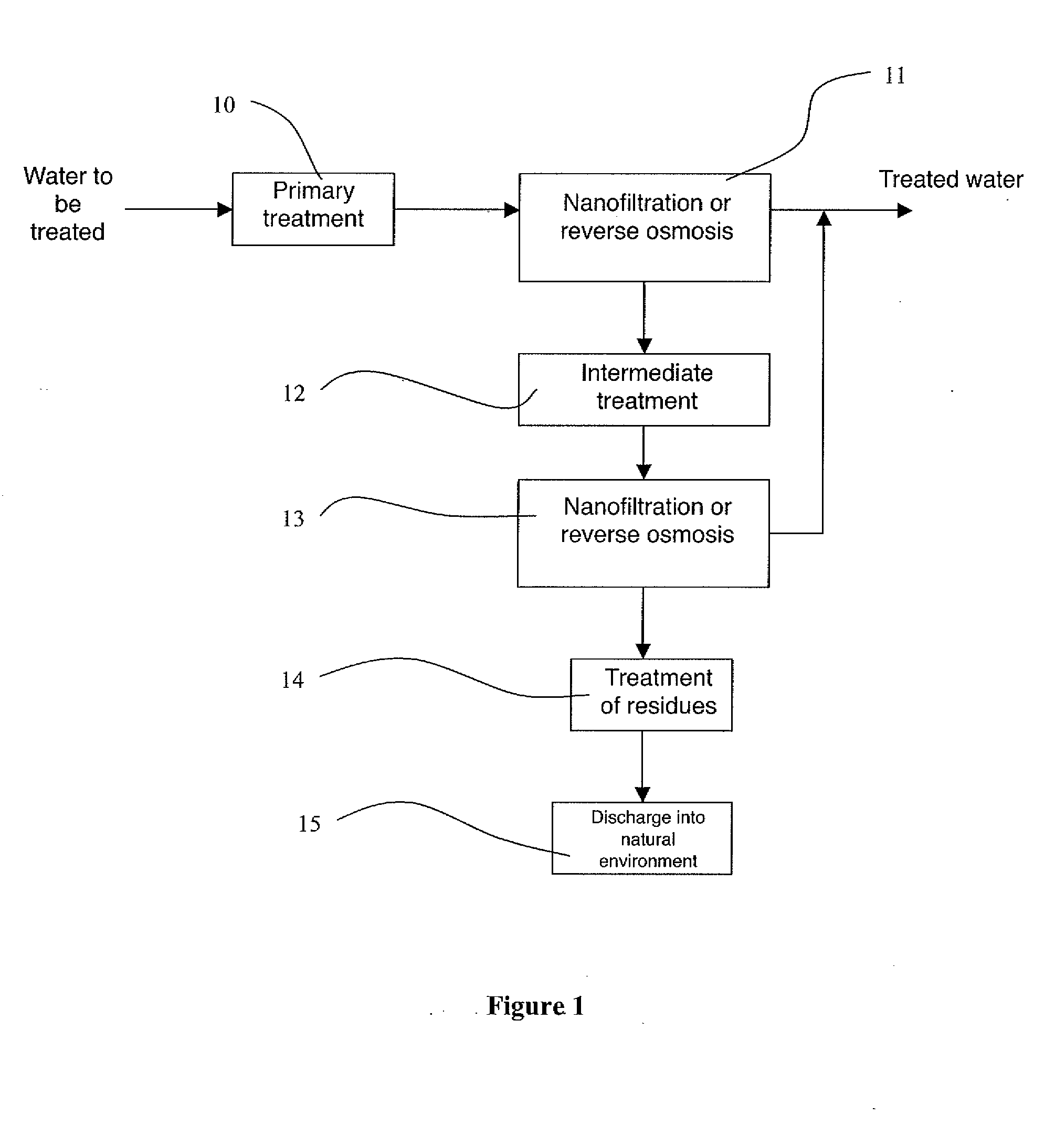

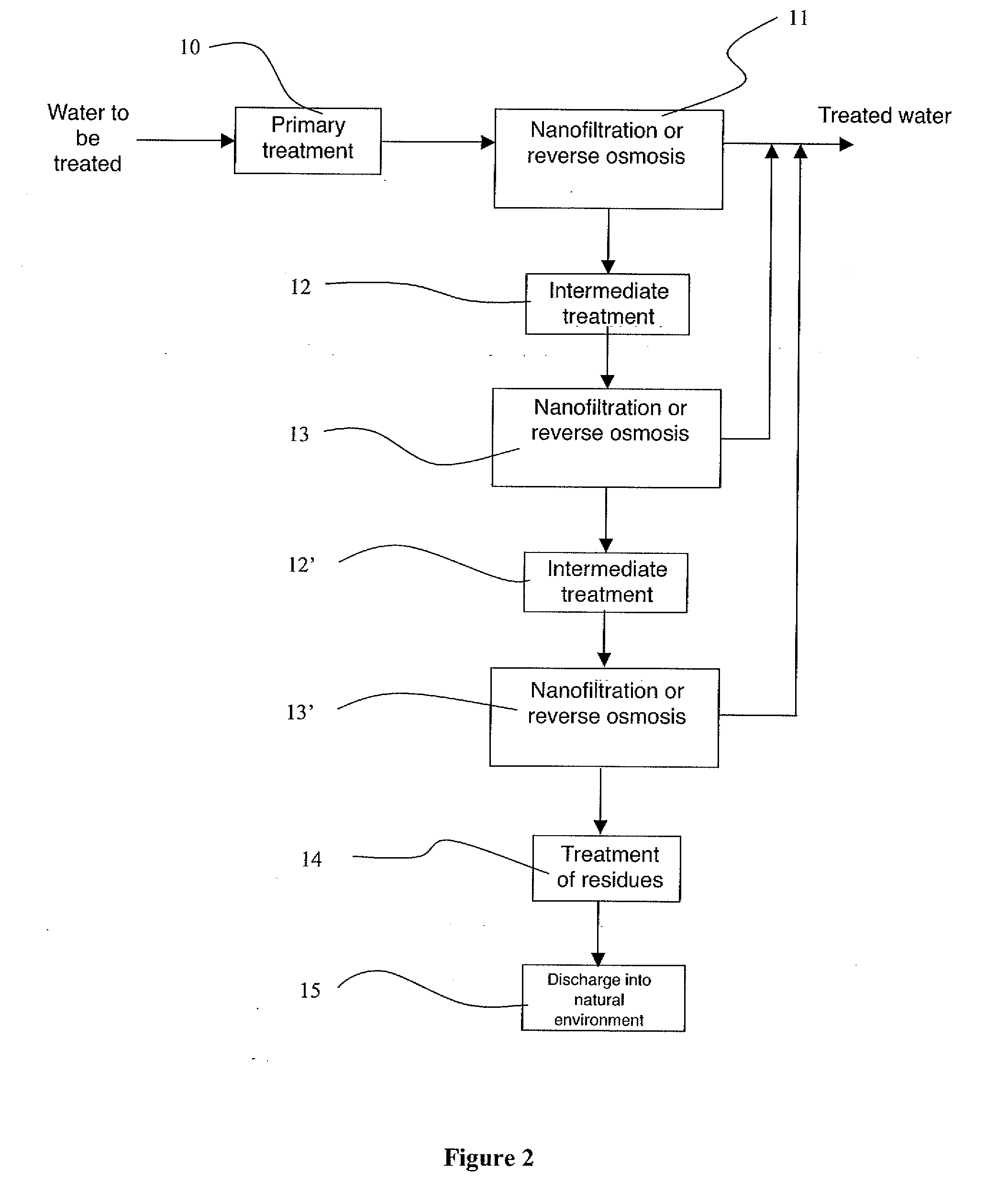

Process for treating water by a nanofiltration or reverse osmosis membrane system enabling high conversion rates due to the elimination of organic matter

InactiveUS20110062079A1Increase conversion rateReduce the amount of solutionTreatment using aerobic processesGeneral water supply conservationFresh water organismFiltration

The invention relates to a process for treating freshwater, sea water, brackish water or water exiting a drinking water treatment plant containing organic matter, with a view to the potabilization thereof, recycling thereof, desalination thereof, or with a view to the purification thereof for an industrial application, said process comprising at least a first step (11) of filtration, by a nanofiltration or reverse osmosis, of a flow coming in from a primary treatment step (10) and a second step (13) of filtration, by nanofiltration or reverse osmosis, of a concentrate coming from said first filtration step (11). According to the invention, such a process comprises a step (12, 12′) of intermediate treatment that includes a biological and / or oxidation treatment and / or a coagulation at low pH of said concentrate coming from said first filtration step (11) and / or of said concentrate coming from said second filtration step (13).

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

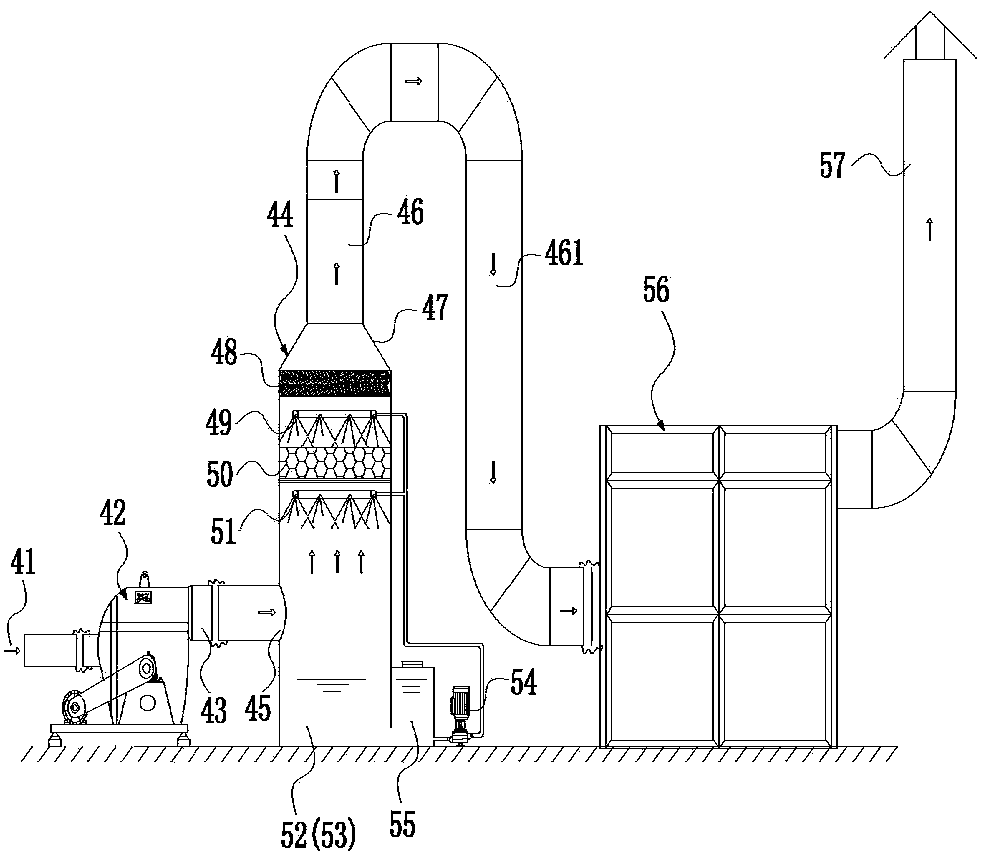

VOC (volatile organic compound) waste gas treatment system

ActiveCN104028086AEasy to handleImprove efficiencyCombination devicesUsing liquid separation agentActivated carbonEnvironmental engineering

The invention discloses a VOC (volatile organic compound) waste gas treatment system. The VOC waste gas treatment system sequentially comprises a fan, a padding spray tower device, an ultraviolet activated carbon integrated device and a purified gas discharge opening, wherein the fan is connected with a VOC waste gas source; the padding spray tower device is connected with an air outlet of the fan; the ultraviolet activated carbon integrated device is connected to an air outlet of the padding spray tower device; the purified gas discharge opening is connected to the ultraviolet activated carbon integrated device. Waste gas is treated efficiently by the design of combining the padding spray tower with the ultraviolet activated carbon integrated purifier. Firstly, the padding spray tower is used for spraying washing; organic waste gas is dissolved into a purifying liquid well by multi-surface hollow spheres; then air water of a defogging layer is matched to share efficiently, so that gas after primary treatment is obtained by the padding spray tower. The gas after primary treatment is treated by the ultraviolet activated carbon integrated purifier, and clean gas reaching the standard is discharged out. The size of the device is reduced; the waste gas treatment efficiency is high; the purification cost is reduced; the purification standard reaching effect is ensured.

Owner:DONGGUAN CITY HUANSHUN ENVIRONMENTAL PROTECTION EQUIP IND

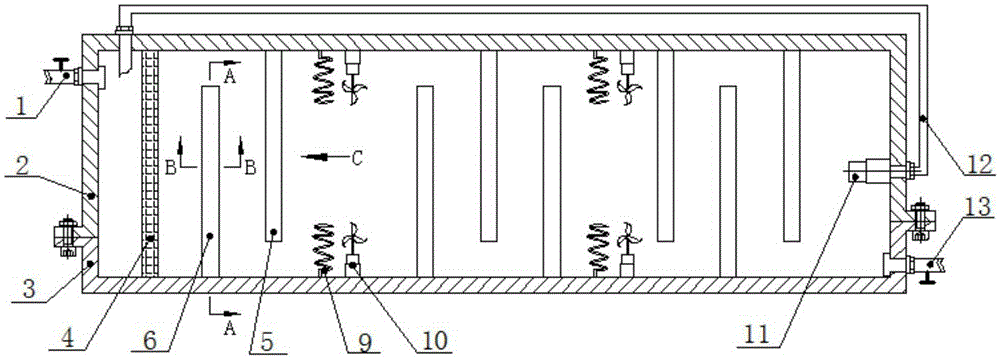

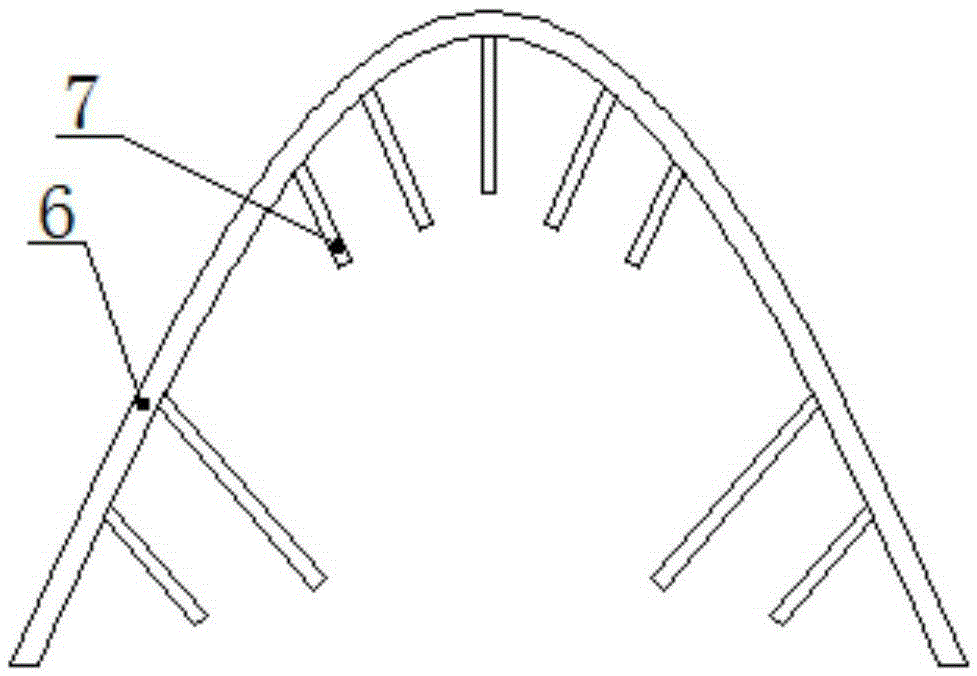

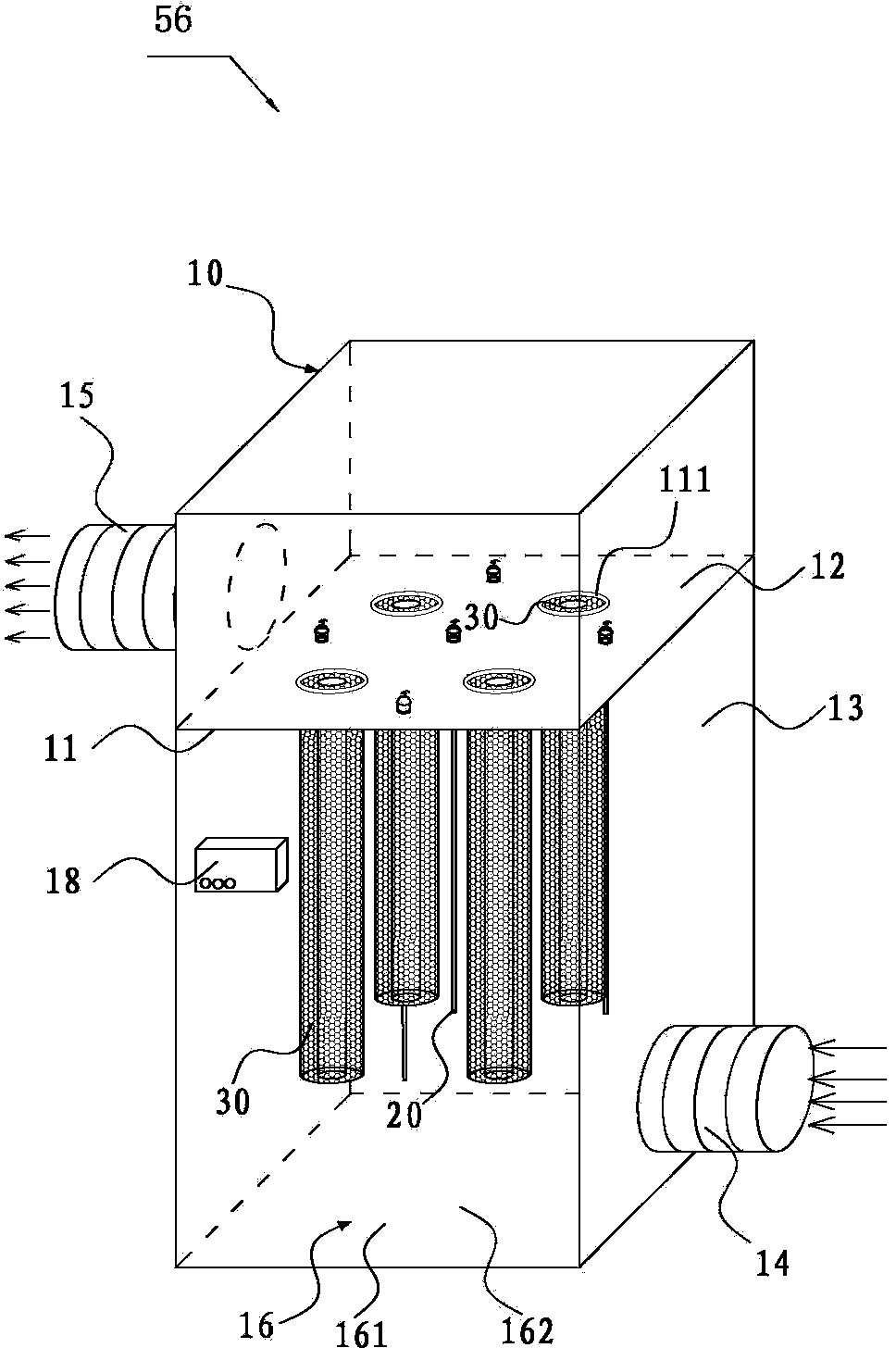

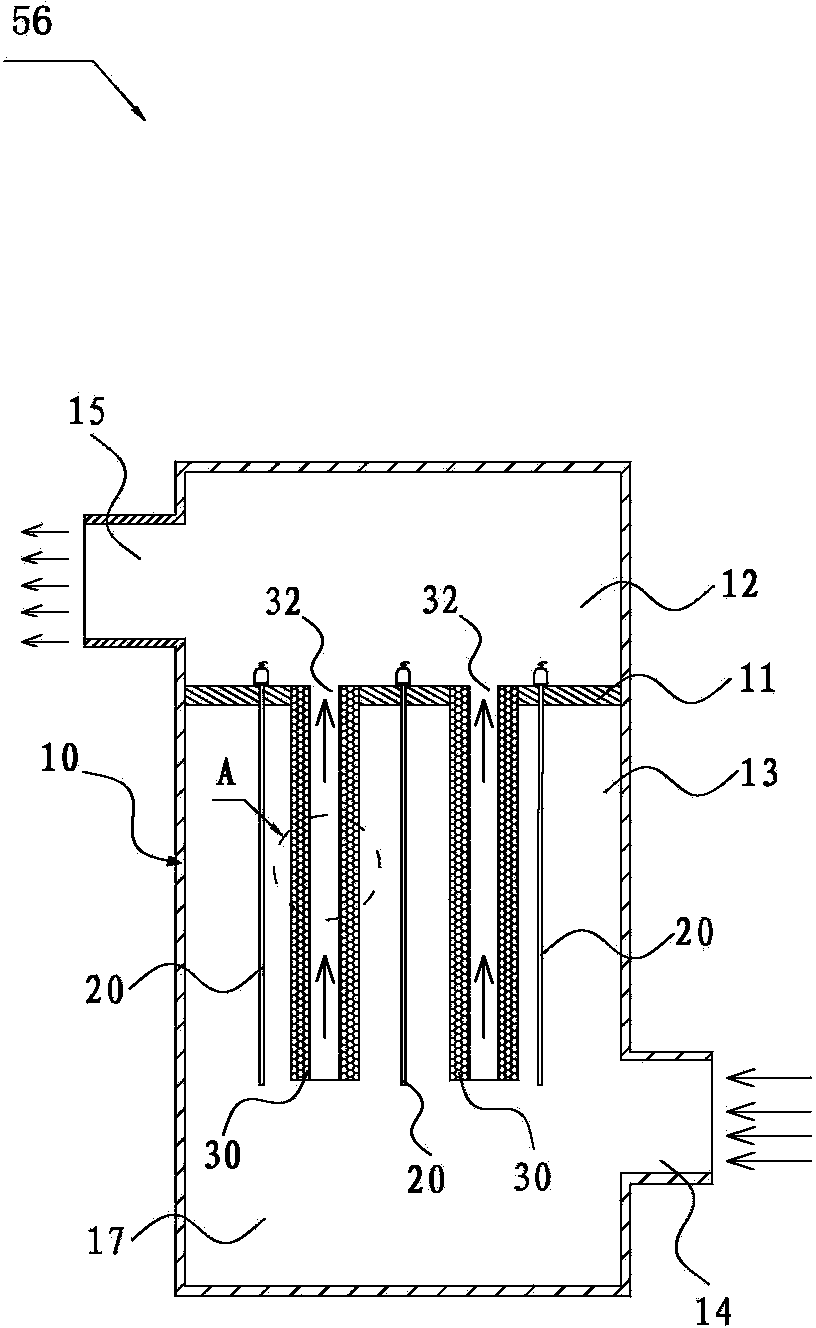

Fluid Treatment Apparatus

ActiveUS20120085691A1Water/sewage treatment by irradiationOther chemical processesMultiple treatmentsEnvironmental engineering

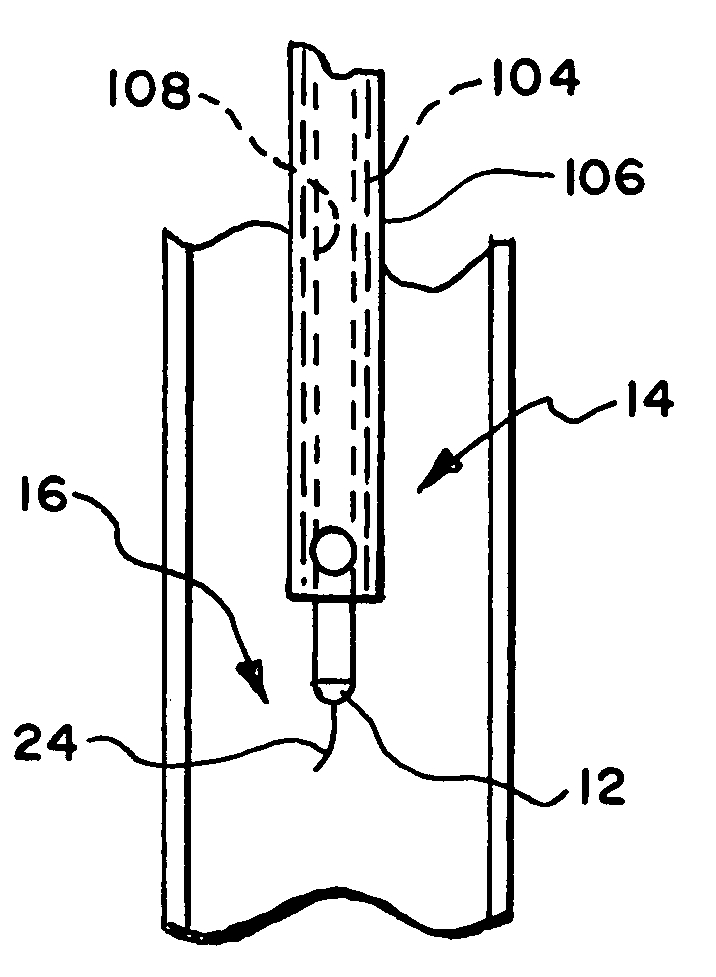

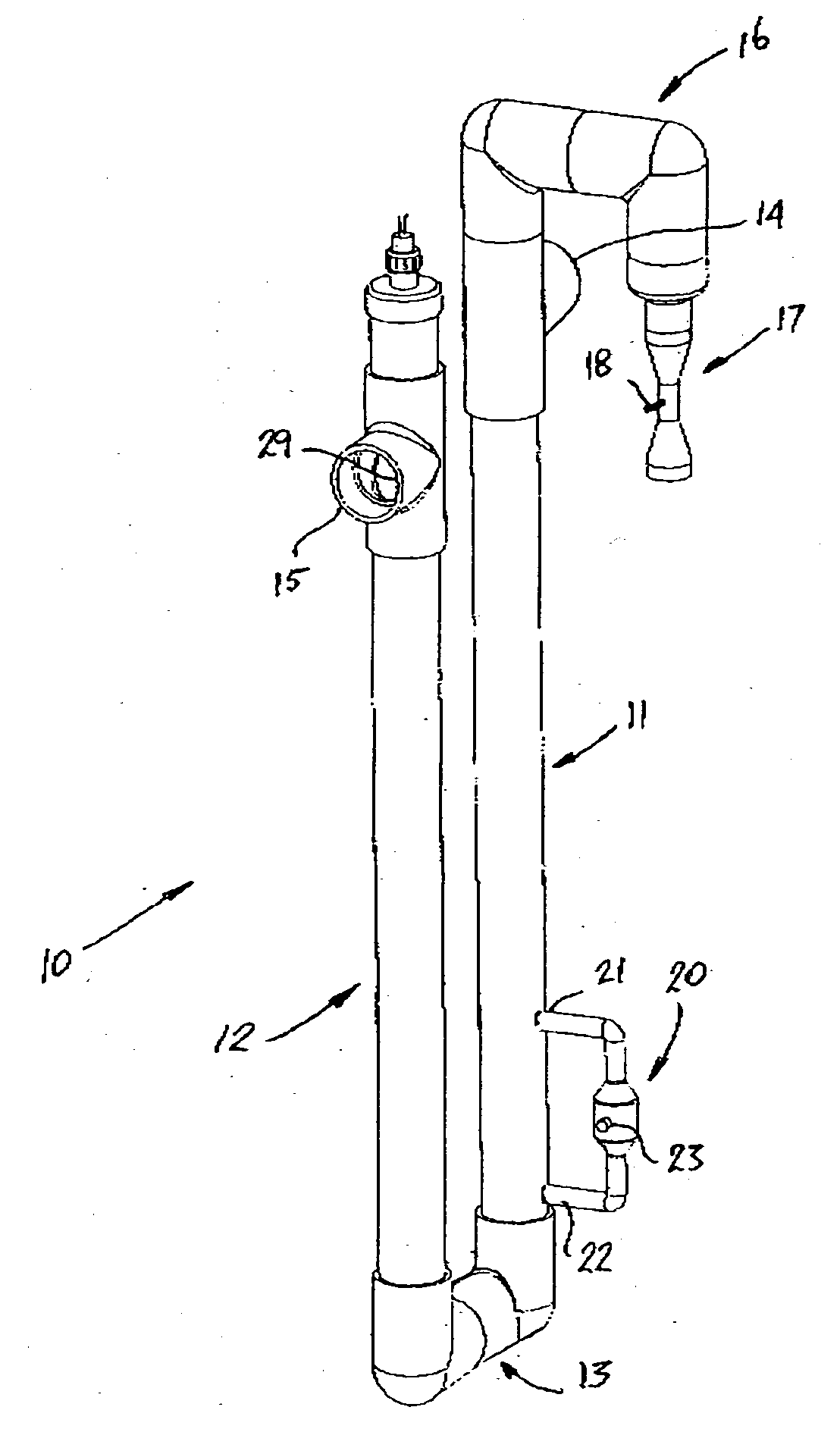

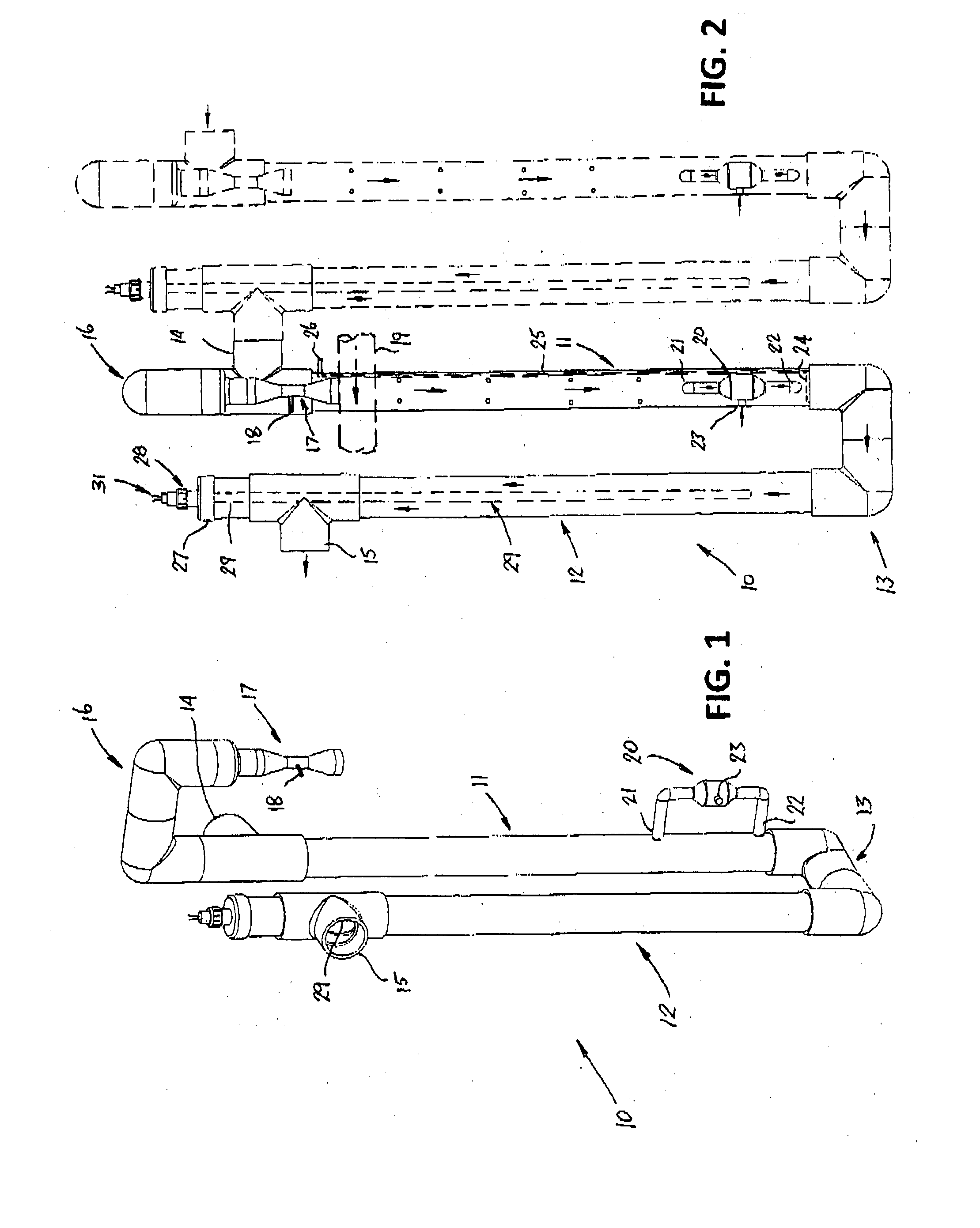

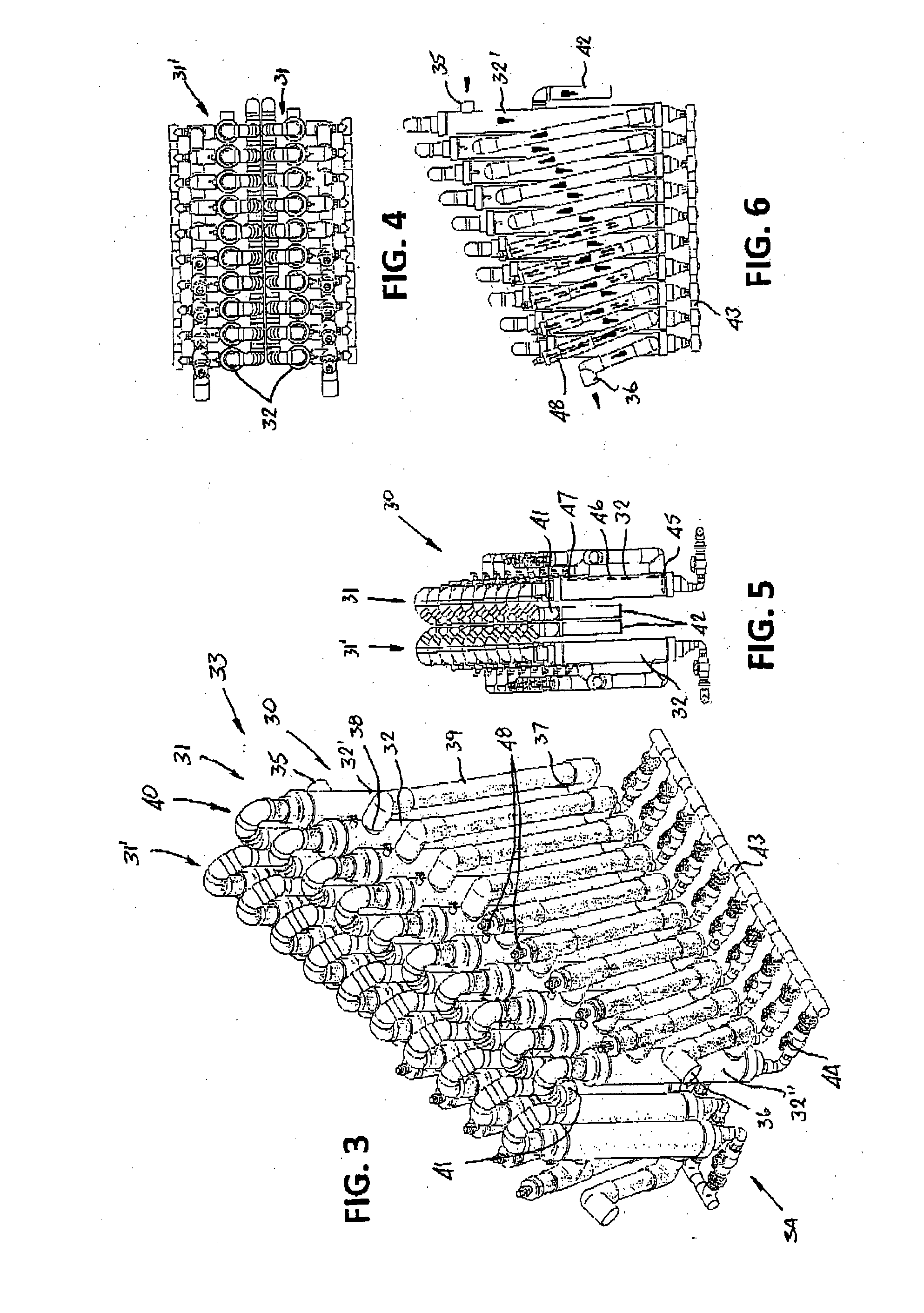

Fluid purification or treatment apparatus (10) for treating or purifying contaminated liquids such as water which includes at least one upright elongated primary treatment chamber (11) having an inlet (14) for fluid to be treated at an upper end of the chamber (11) such that fluid flows downwardly through the chamber (11) and means (20 or 24) for introducing a sterilizing agent such as ozone or ozone enriched air into a lower end of the chamber (11) for bubbling upwardly through liquid flowing downwardly through the chamber (11), means (16) at the upper end of the chamber (11) for removing waste and an ultraviolet lamp (29) for UV treatment of the liquid, the ultraviolet lamp (29) being located in a separate chamber (12) connected to the primary treatment chamber (11) or within the primary treatment chamber (11). A plurality of chambers (11) and (12) may be provided for multiple treatment of the liquid.

Owner:INTPROP LTD INC +2

Methods for treatment of wastewater

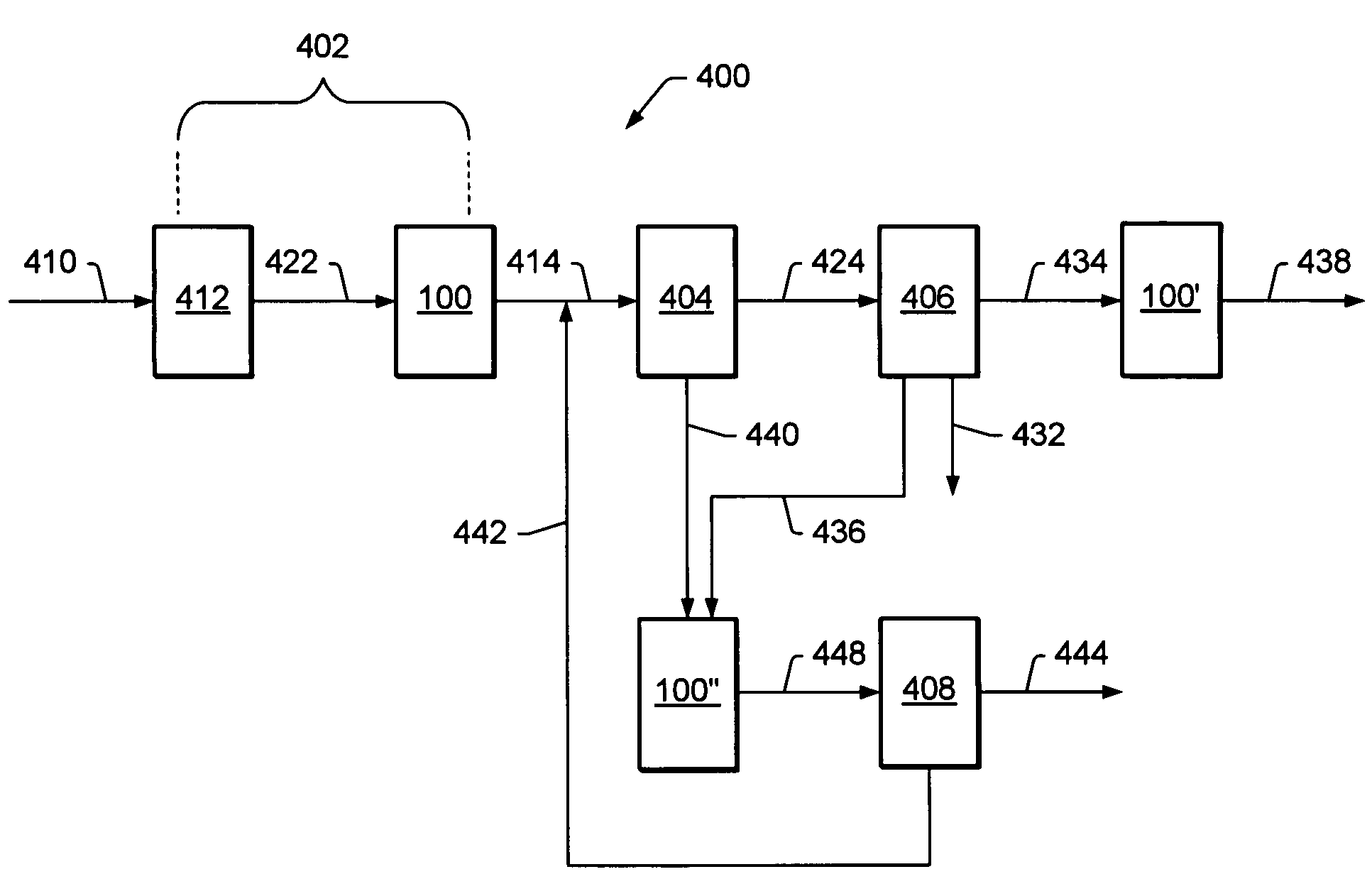

InactiveUS7651614B2Water/sewage treatment by centrifugal separationTreatment using aerobic processesMedicineWastewater systems

Systems and methods to treat wastewater are described herein. A wastewater treatment system may include a primary treatment system, a secondary treatment system, a disinfection treatment system, a solids treatment system, one or more fluid treatment systems, or combinations thereof.

Owner:WATERCOOLTOWER LLC

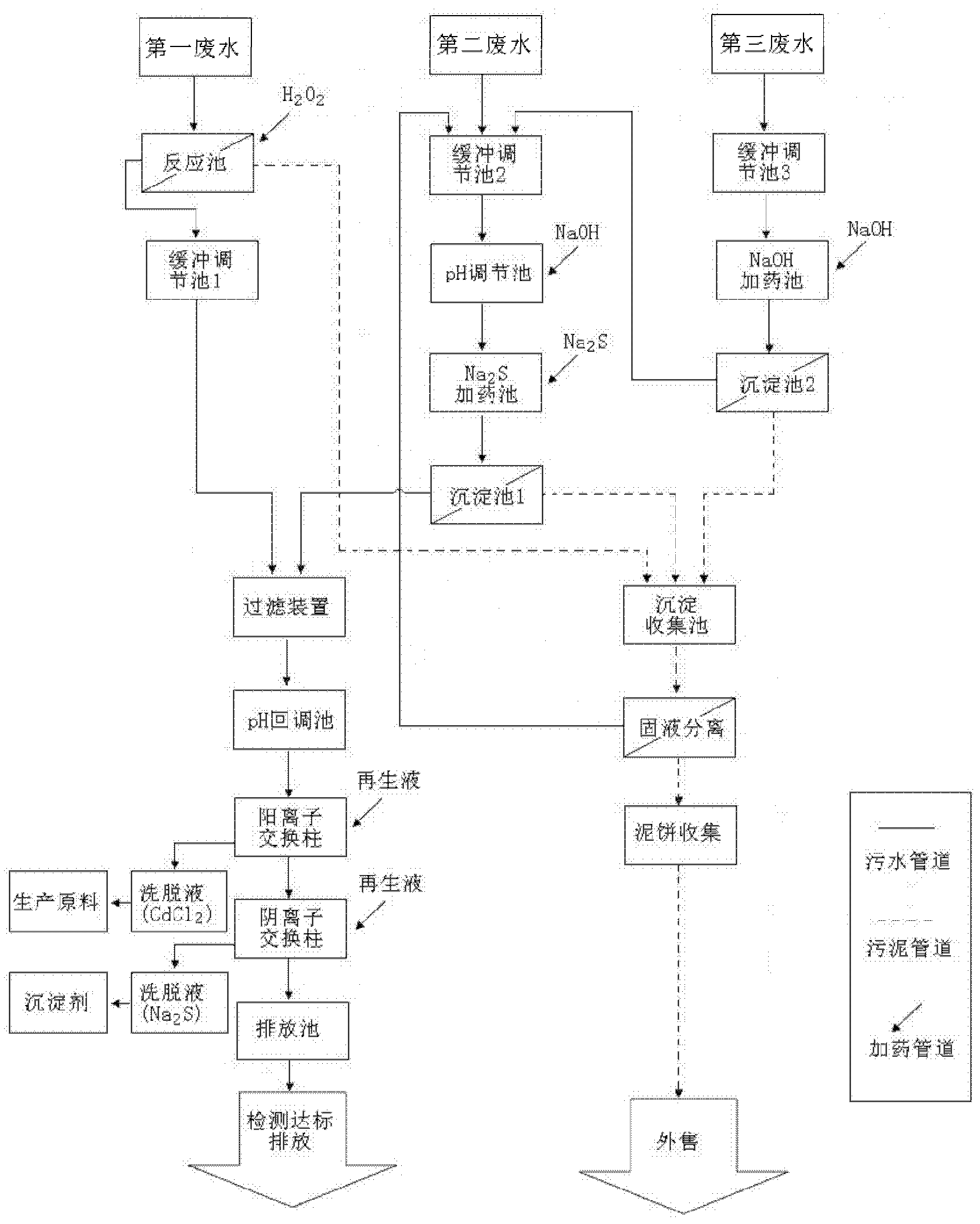

Cadmium-containing wastewater treatment method

The present invention provides a cadmium-containing wastewater treatment method, which comprises the following steps that: (1) cadmium-containing wastewater generates CdS, and precipitate separation is performed; and (2) the precipitate-separated wastewater is subjected to an anion and cation exchange treatment. According to the wastewater treated by the method, a cadmium content in the effluent is controlled to less than 0.03 mg / L, is far less than the national emission standard, and effective cadmium recovery is achieved with the whole process; although the primary treatment adopts the CdS precipitation method, sulfur is recycled through the ion exchange column in the secondary treatment so as not to introduce the contamination ion sulfur to the water, and the precipitation process does not adopt any flocculants, such that the treated cadmium precipitate dehydration solid is easily recycled.

Owner:WUXI SUNTECH POWER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com