Patents

Literature

682results about "Cadmium sulfides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of producing nano-scaled graphene and inorganic platelets and their nanocomposites

ActiveUS20080206124A1Readily captured and re-usedReduce impactCarbon compoundsSelenium/tellurium compundsLiquid mediumPhysical chemistry

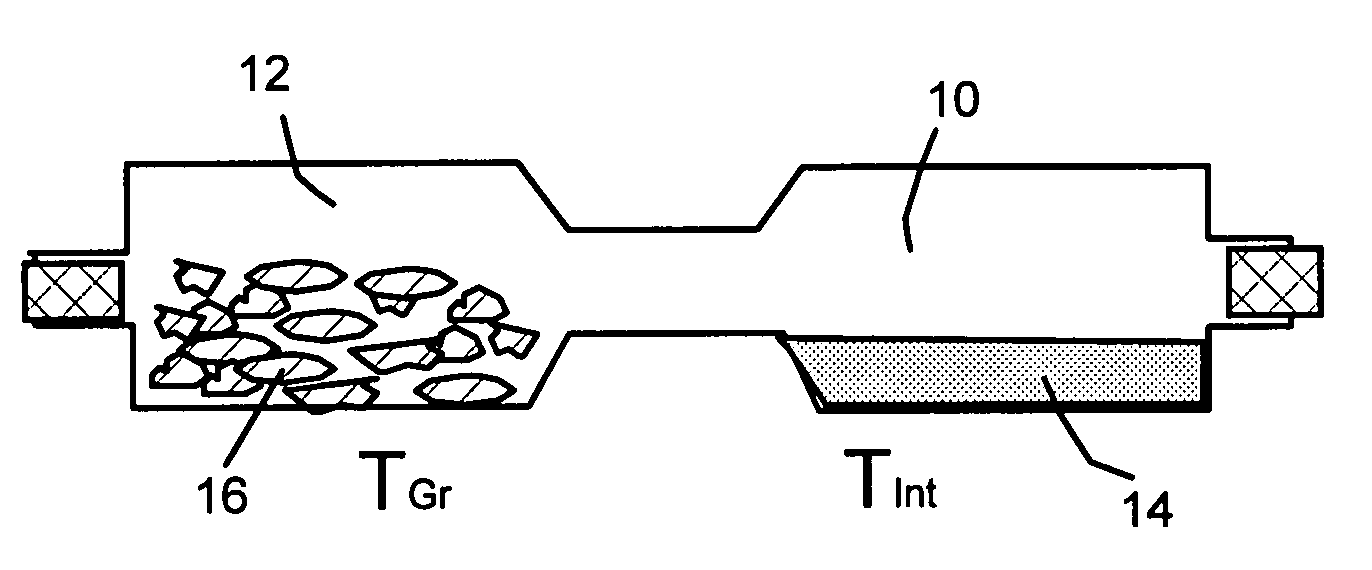

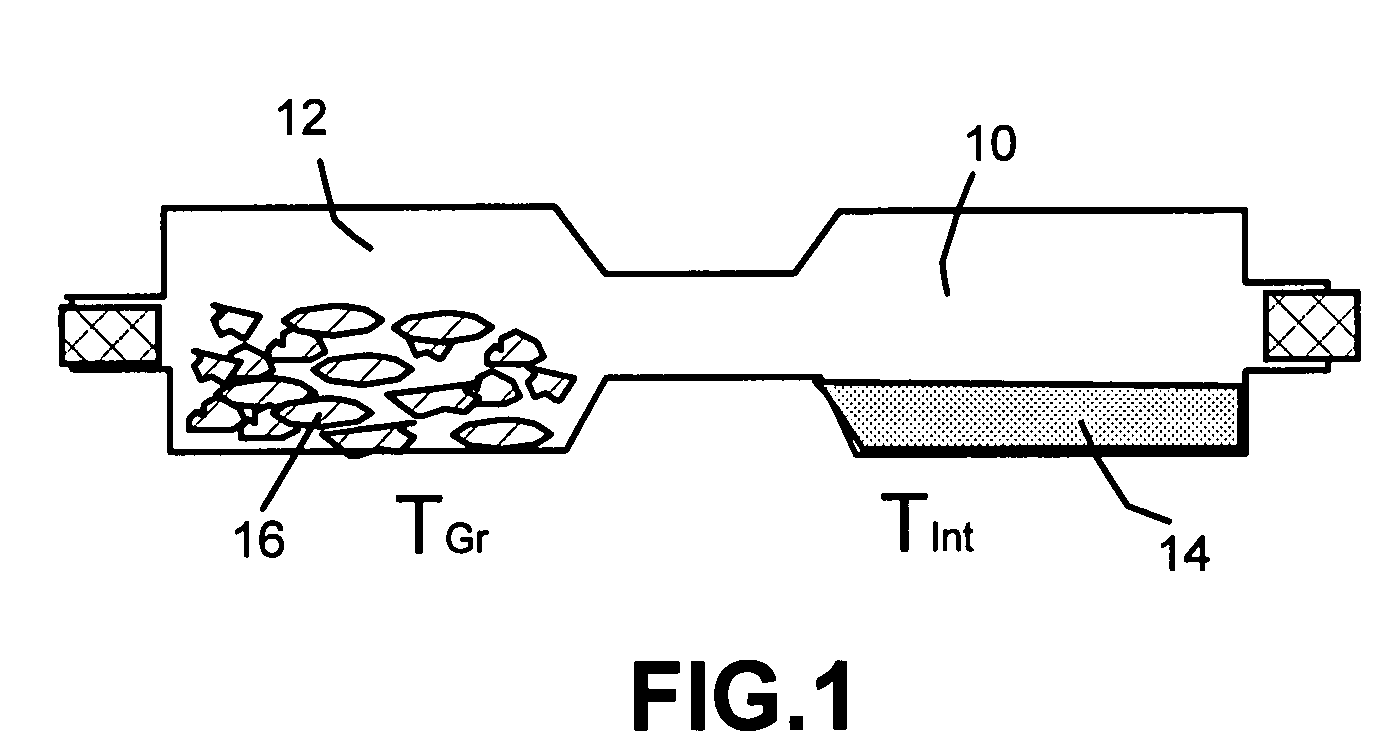

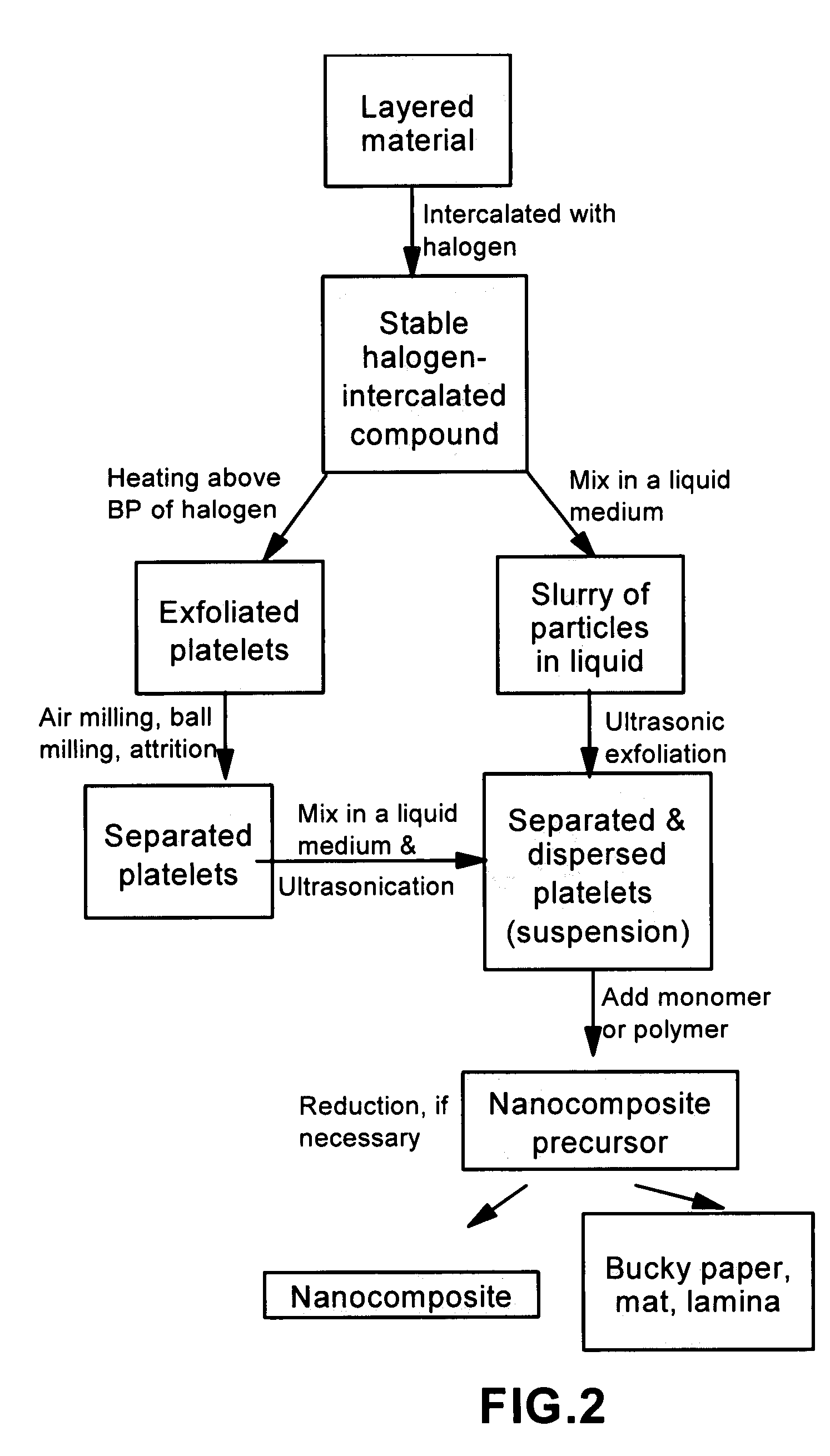

Disclosed is a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The method comprises: (a) subjecting the layered material in a powder form to a halogen vapor at a first temperature above the melting point or sublimation point of the halogen at a sufficient vapor pressure and for a duration of time sufficient to cause the halogen molecules to penetrate an interlayer space of the layered material, forming a stable halogen-intercalated compound; and (b) heating the halogen-intercalated compound at a second temperature above the boiling point of the halogen, allowing halogen atoms or molecules residing in the interlayer space to exfoliate the layered material to produce the platelets. Alternatively, rather than heating, step (a) is followed by a step of dispersing the halogen-intercalated compound in a liquid medium which is subjected to ultrasonication for exfoliating the halogen-intercalated compound to produce the platelets, which are dispersed in the liquid medium. The halogen can be readily captured and re-used, thereby significantly reducing the impact of halogen to the environment. The method can further include a step of dispersing the platelets in a polymer or monomer solution or suspension as a precursor step to nanocomposite fabrication.

Owner:GLOBAL GRAPHENE GRP INC

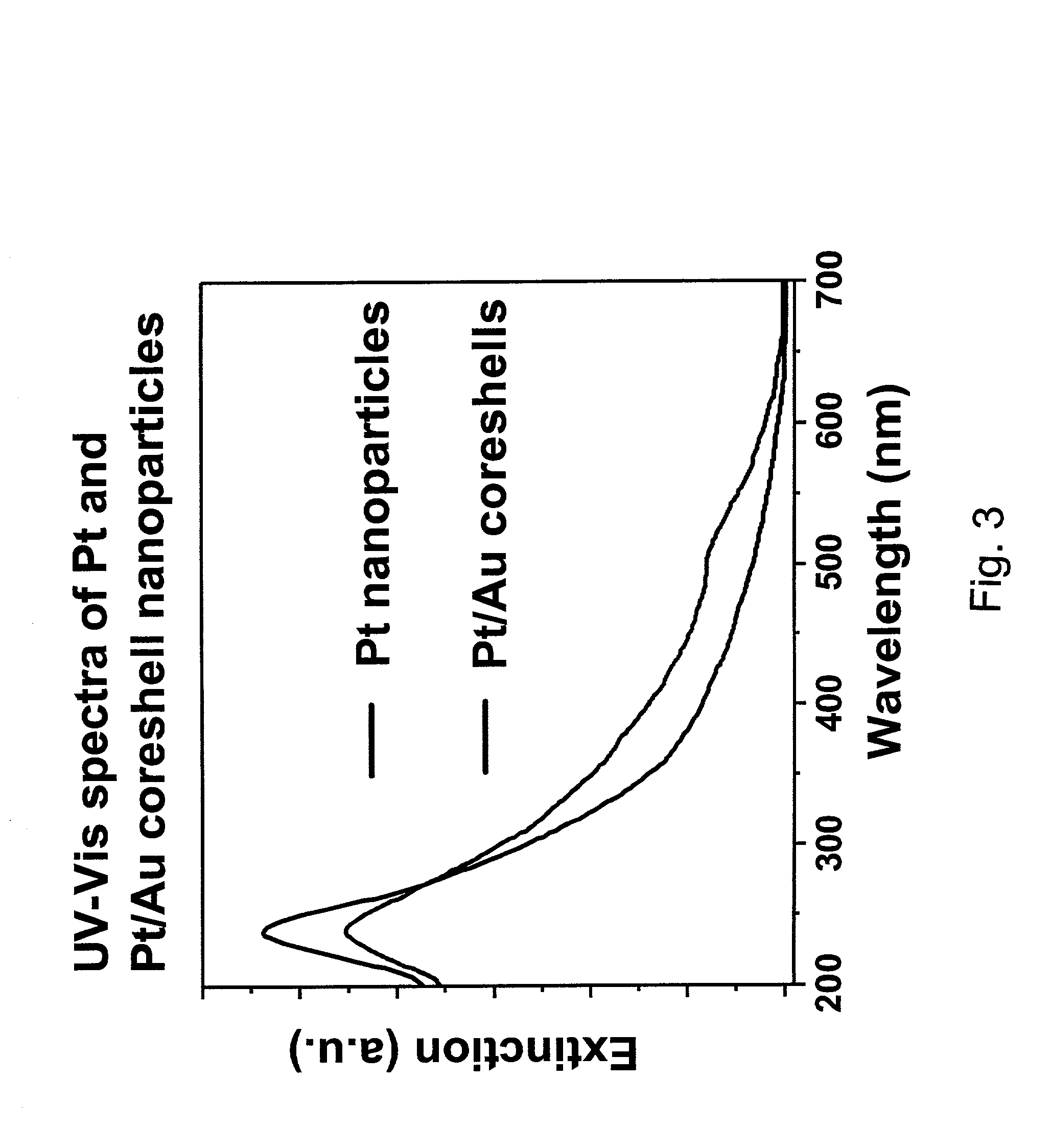

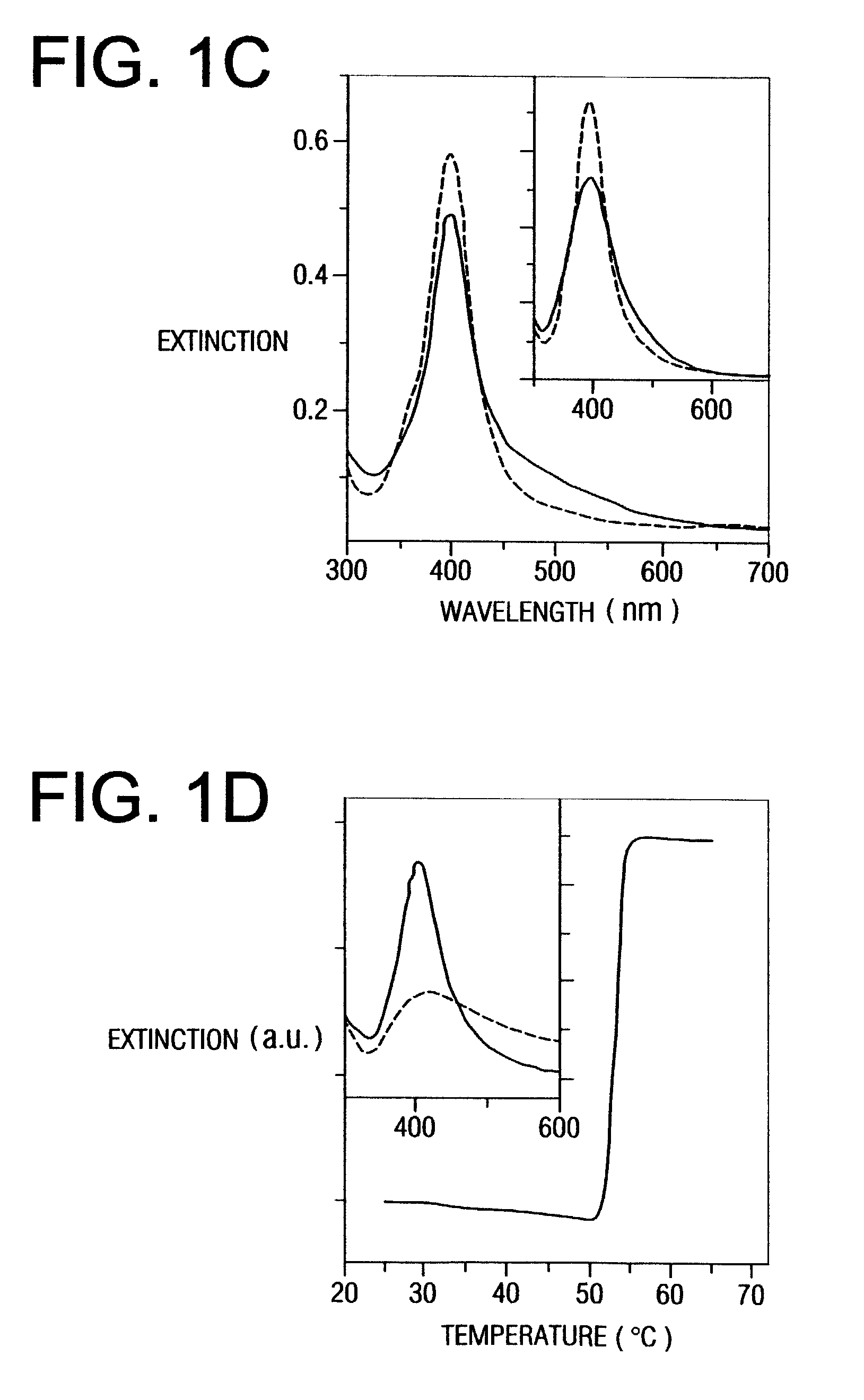

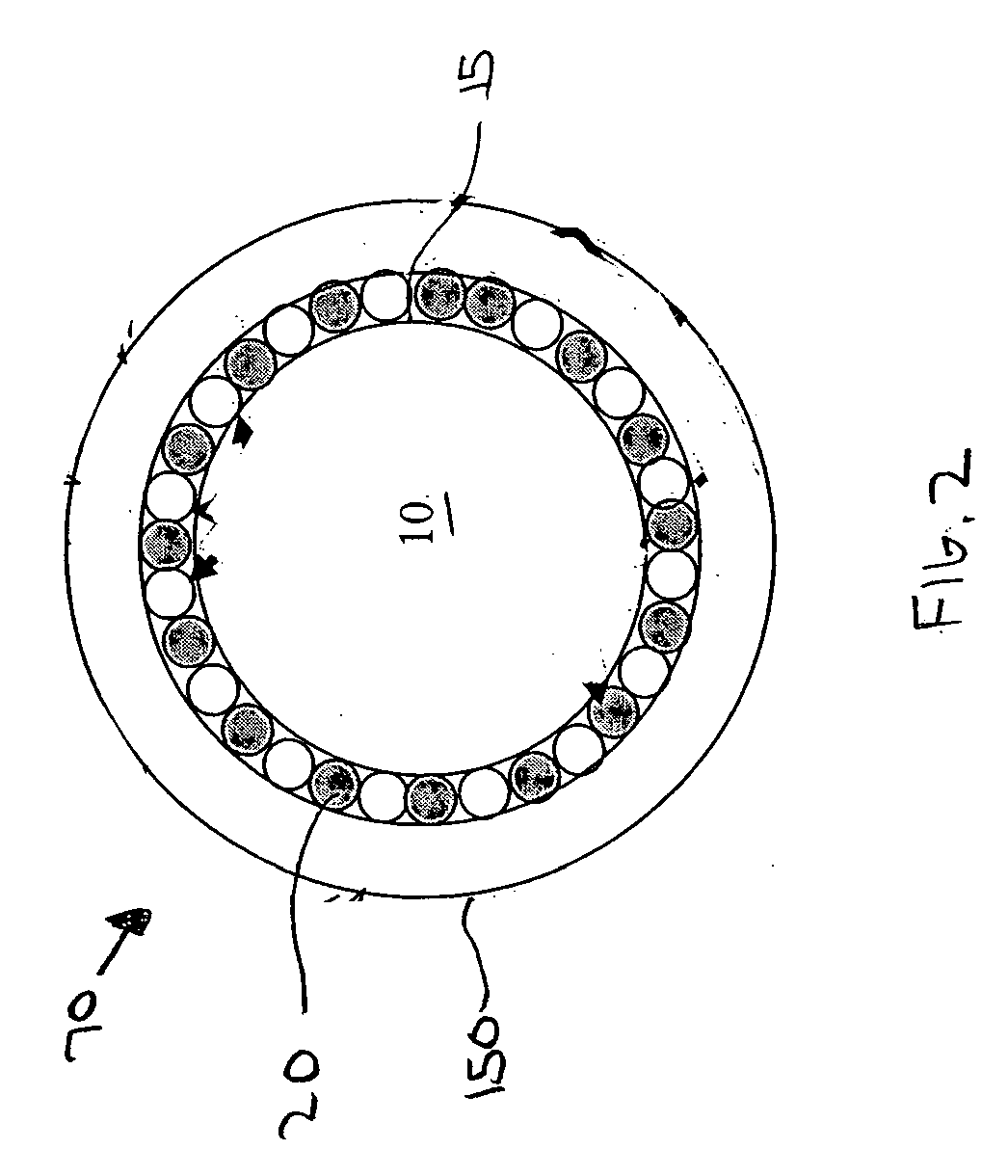

Non-alloying core shell nanoparticles

The present invention relates composite core / shell nanoparticles and a two-step method for their preparation. The present invention further relates to biomolecule-core / shell nanoparticle conjugates and methods for their preparation. The invention also relates to methods of detection of biomolecules comprising the biomolecule or specific binding substance-core / shell nanoparticle conjugates.

Owner:NORTHWESTERN UNIV

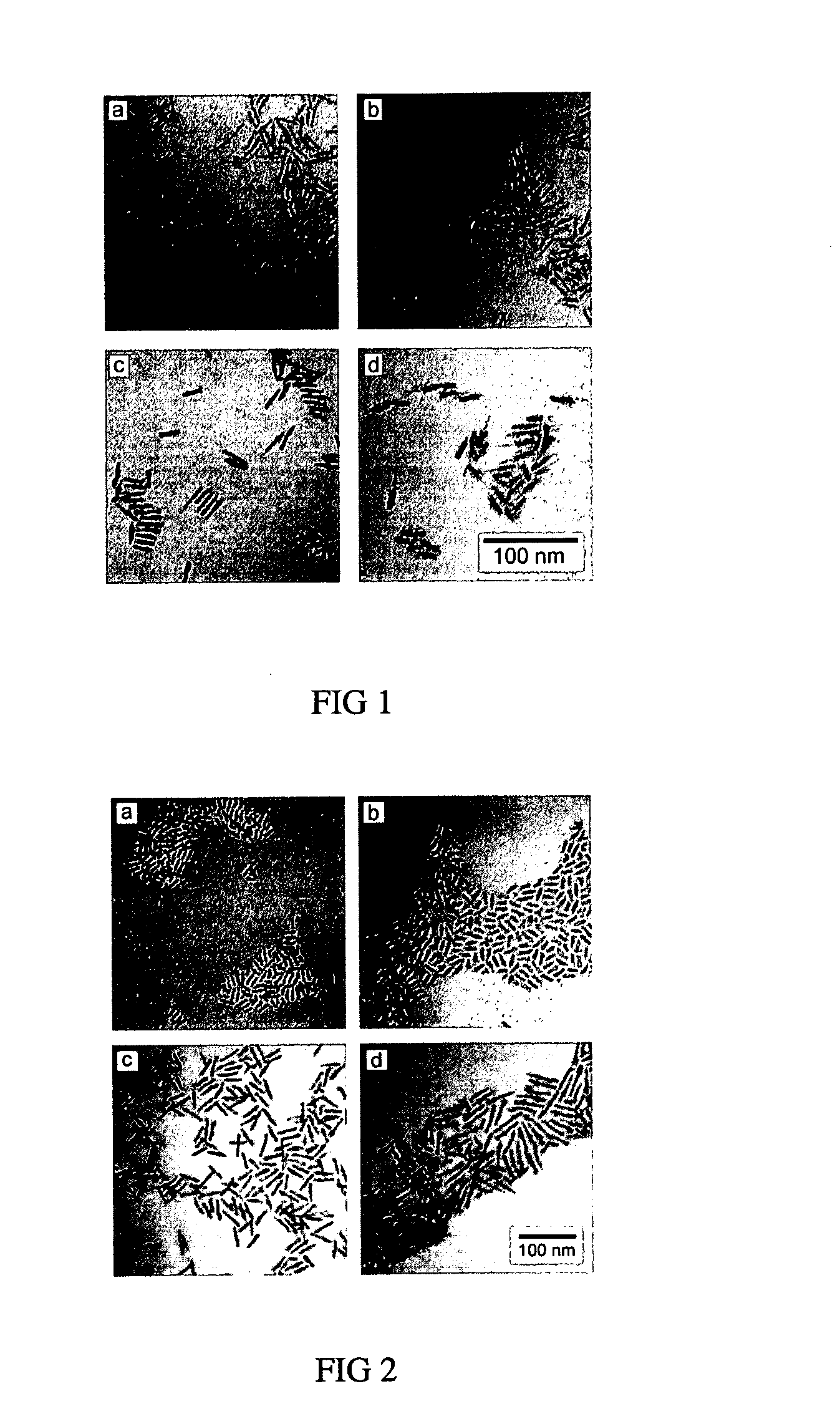

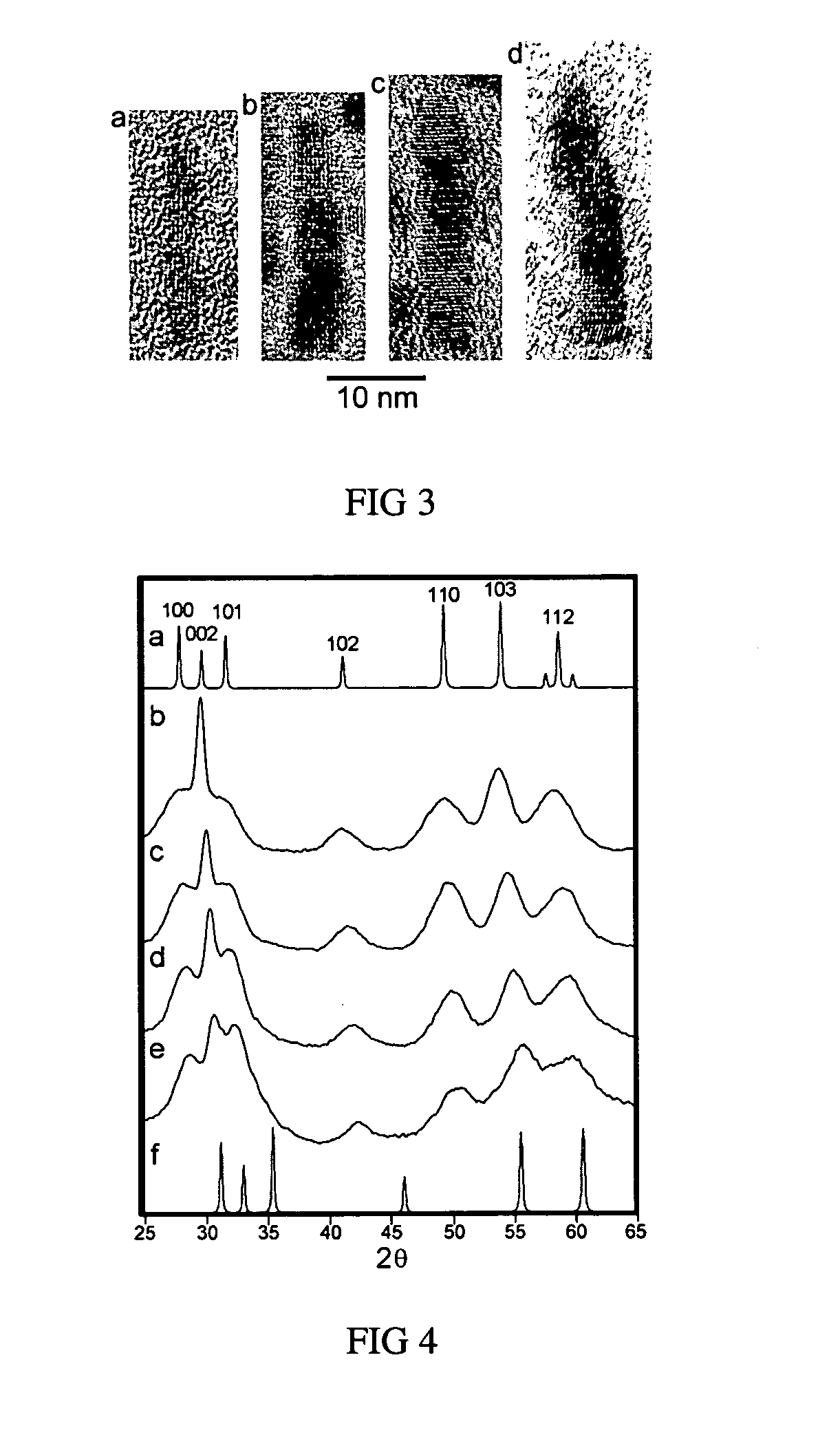

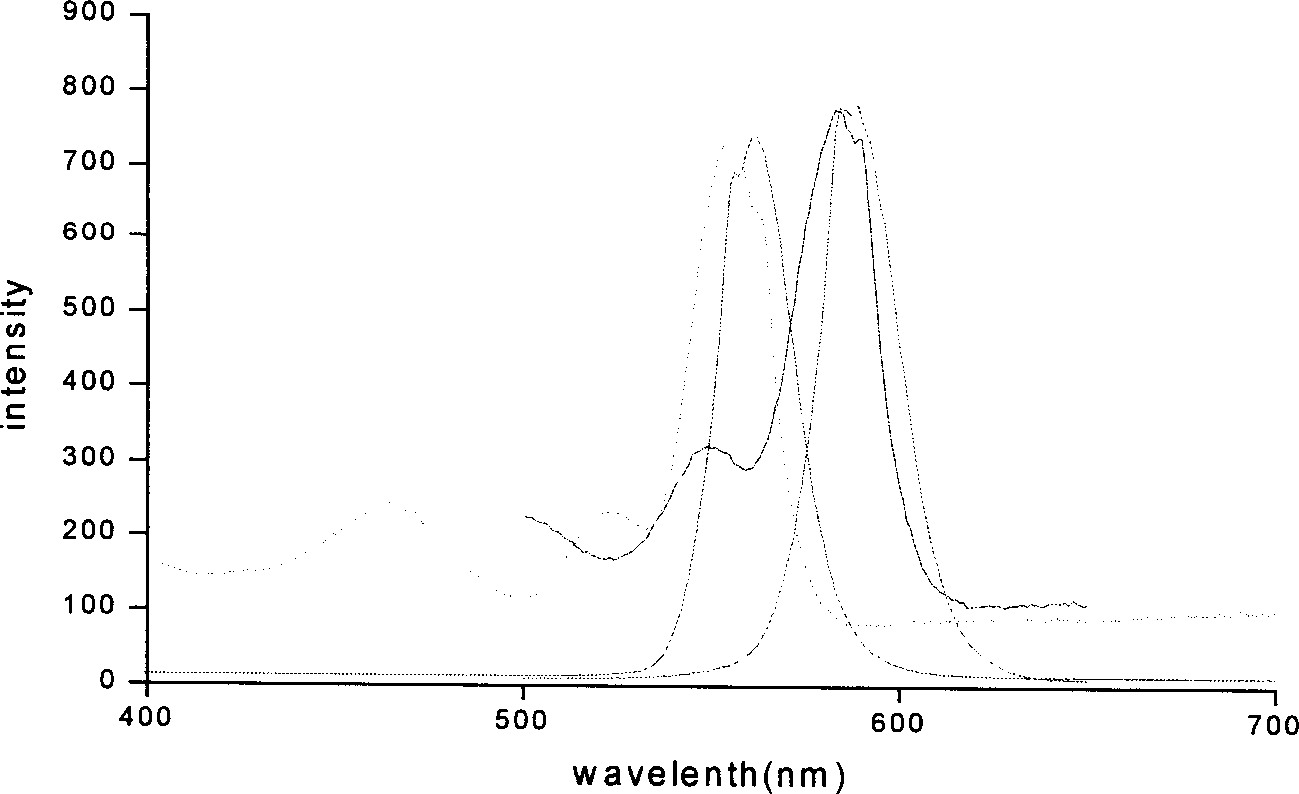

Graded core/shell semiconductor nanorods and nanorod barcodes

InactiveUS20050054004A1Improve quantum efficiencyIncrease in photoluminescence QYMaterial nanotechnologyNanosensorsGroup iiSemiconductor

Disclosed herein is a graded core / shell semiconductor nanorod having at least a first segment of a core of a Group II-VI, Group III-V or a Group IV semiconductor, a graded shell overlying the core, wherein the graded shell comprises at least two monolayers, wherein the at least two monolayers each independently comprise a Group II-VI, Group III-V or a Group IV semiconductor.

Owner:RGT UNIV OF CALIFORNIA

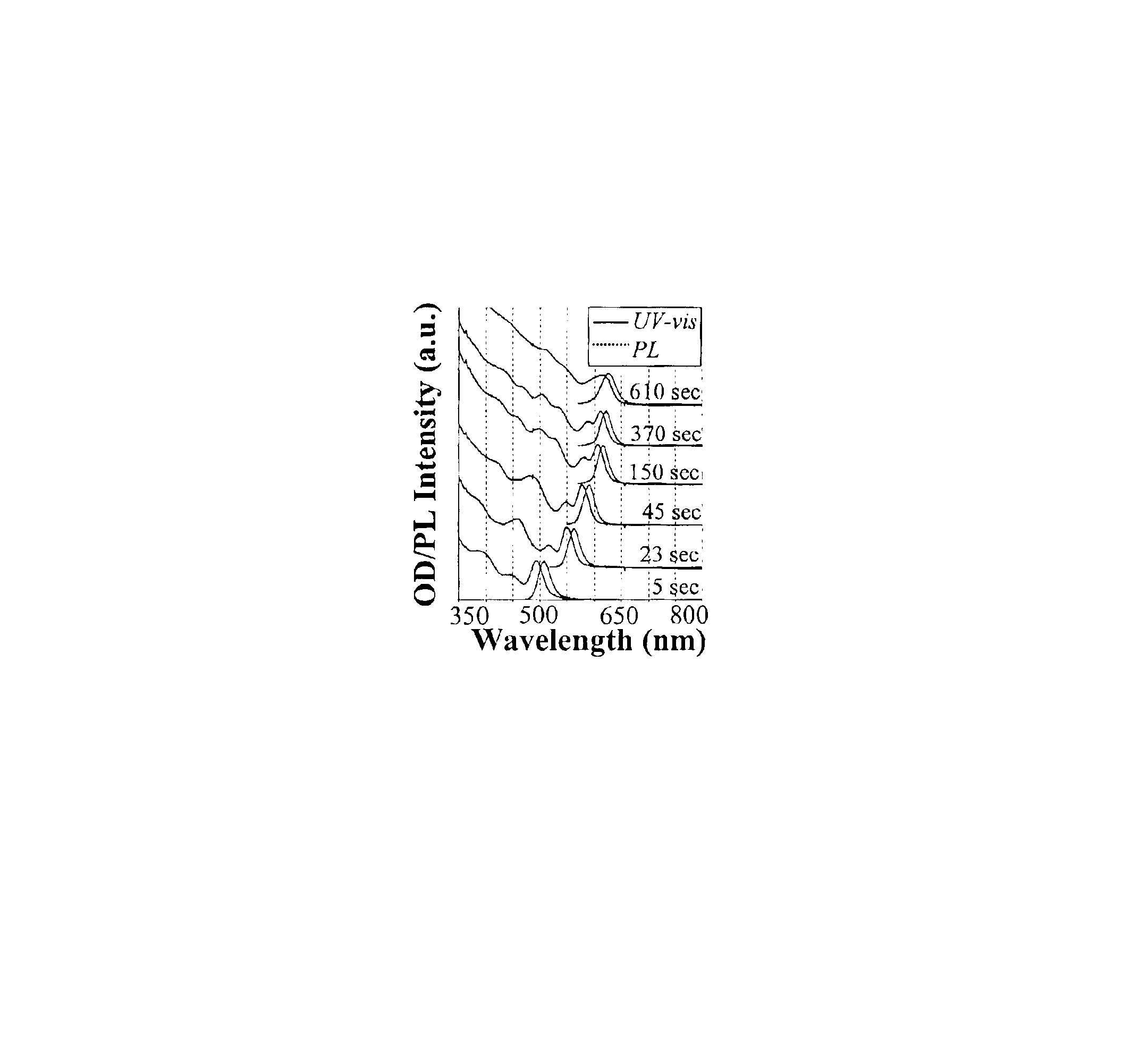

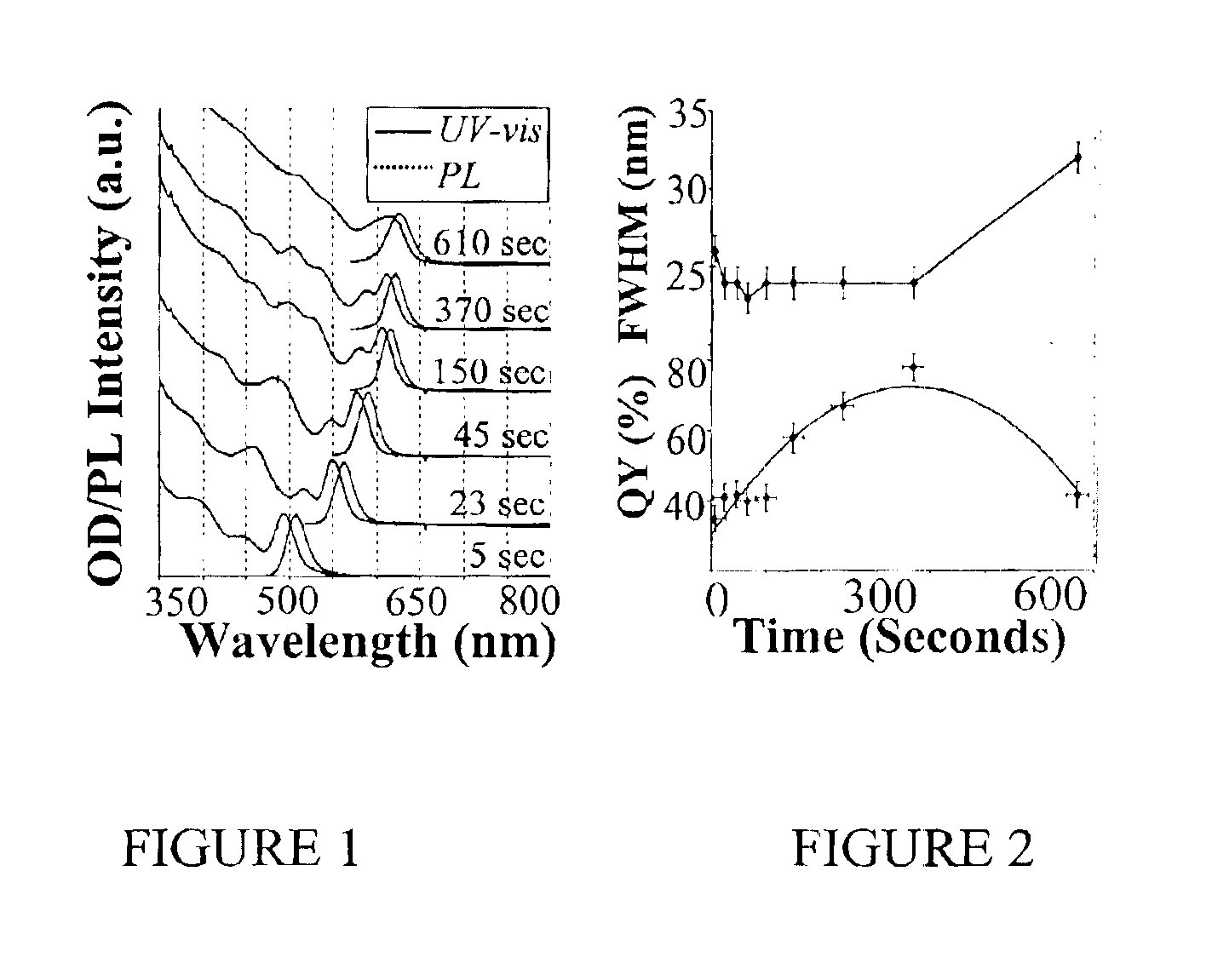

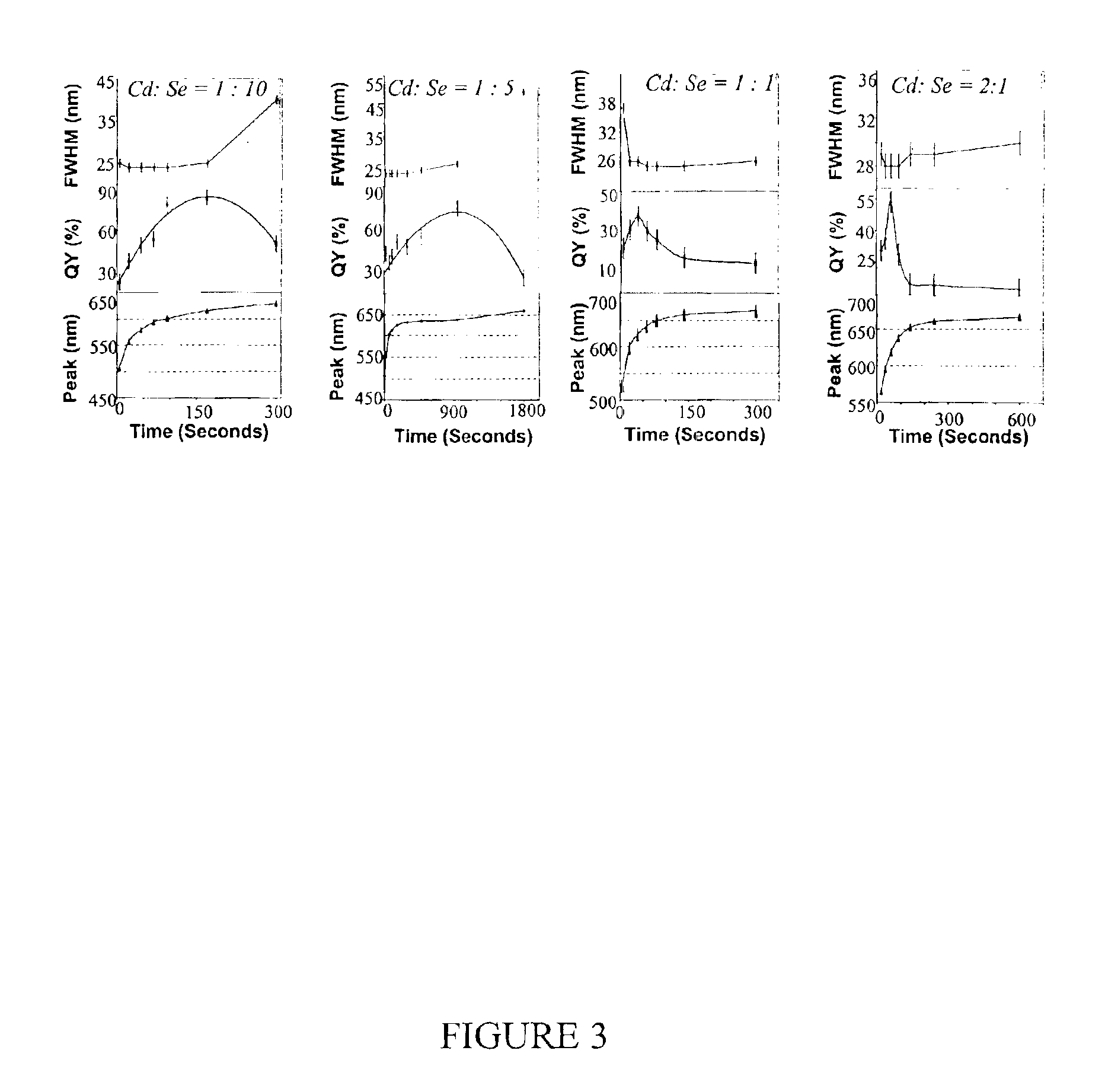

Colloidal nanocrystals with high photoluminescence quantum yields and methods of preparing the same

InactiveUS6869545B2Good monodispersityImprove launch performanceMaterial nanotechnologyNanoopticsQuantum yieldPhotoluminescence

The present invention provides new compositions containing colloidal nanocrystals with high photoluminescence quantum yields, new synthetic methods for the preparation of highly luminescent colloidal nanocrystals, as well as methods to control the photoluminescent properties of colloidal nanocrystals. The new synthetic methods disclosed herein allow photoemission brightness (quantum yield) to be correlated with certain adjustable nanocrystal growth parameters associated with a given synthetic scheme.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

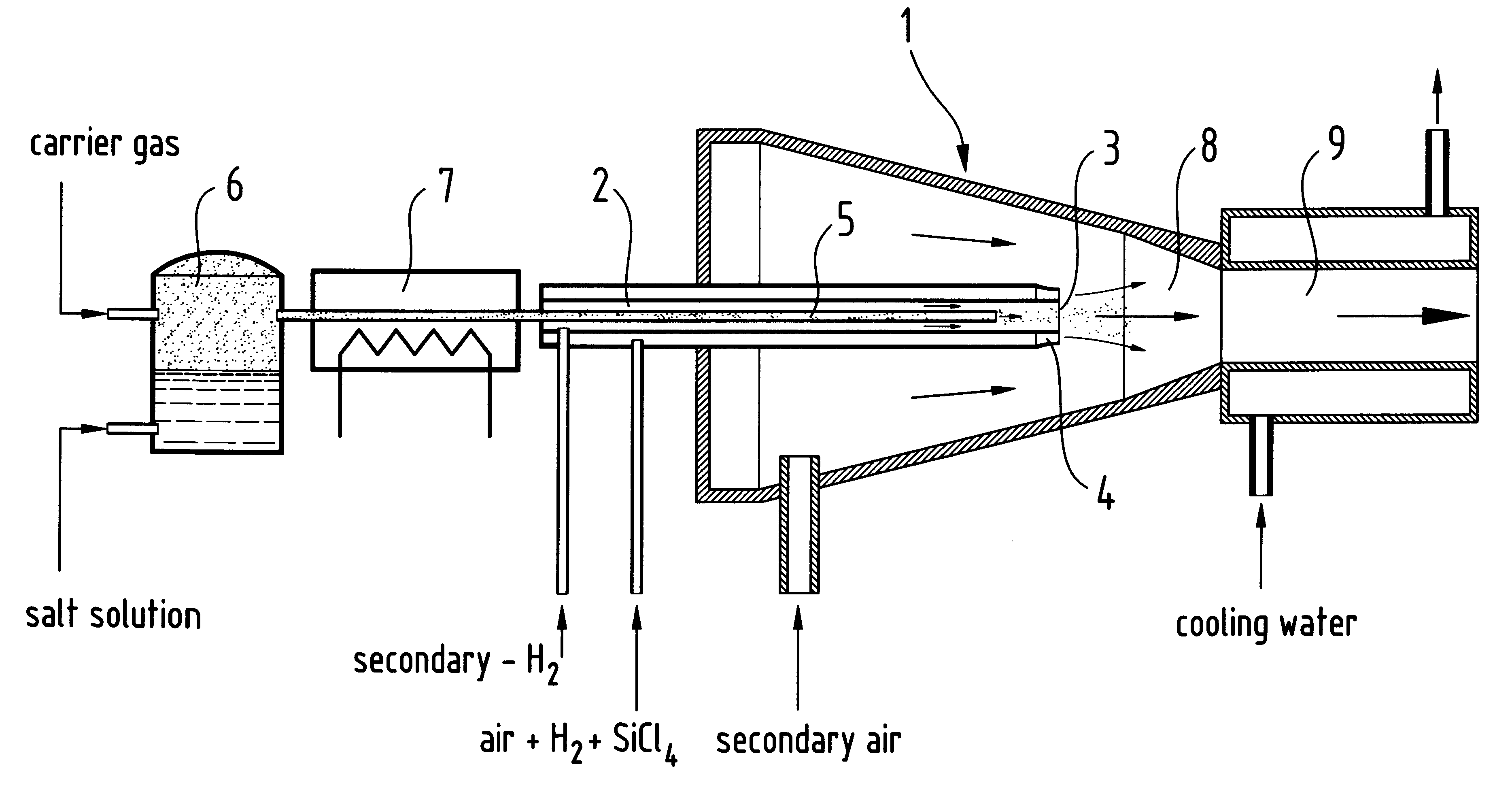

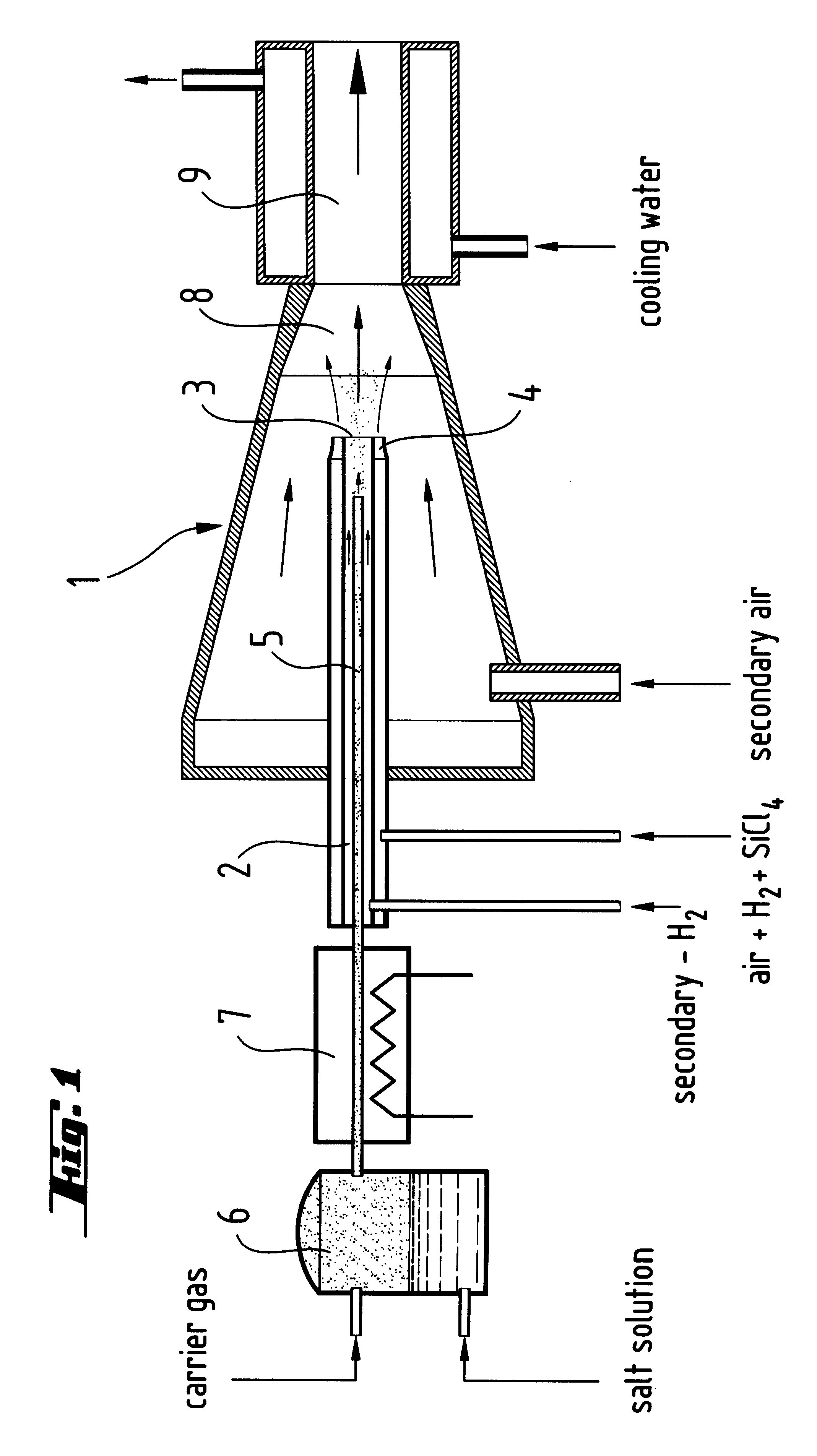

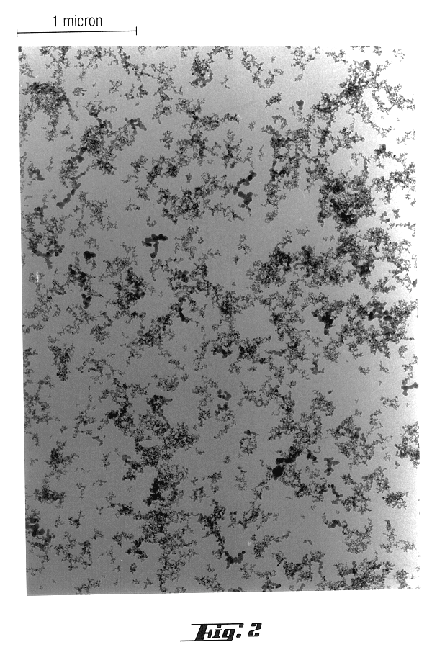

Doped, pyrogenically prepared oxides

InactiveUS6328944B1Germanium dioxidePipe protection by thermal insulationDoped oxideAqueous solution

Doped, pyrogenically prepared oxides of metals and / or non-metals which are doped with one or more doping components in an amount of 0.00001 to 20 wt. %. The doping component may be a metal and / or non-metal or an oxide and / or a salt of a metal and / or a non-metal. The BET surface area of the doped oxide may be between 5 and 600 m2 / g. The doped pyrogenically prepared oxides of metals and / or non-metals are prepared by adding an aerosol which contains an aqueous solution of a metal and / or non-metal to the gas mixture during the flame hydrolysis of vaporizable compounds of metals and / or non-metals.

Owner:EVONIK DEGUSSA GMBH

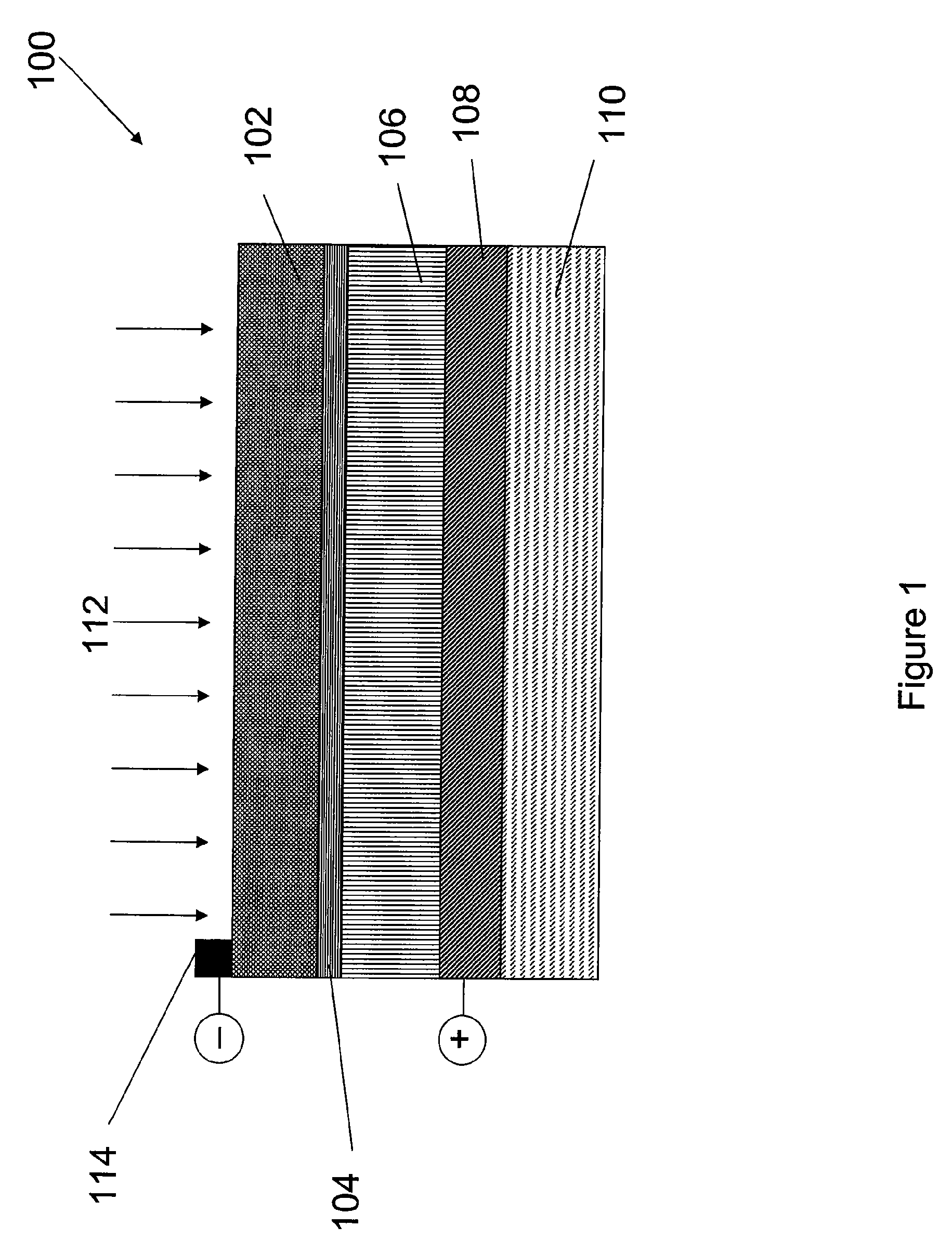

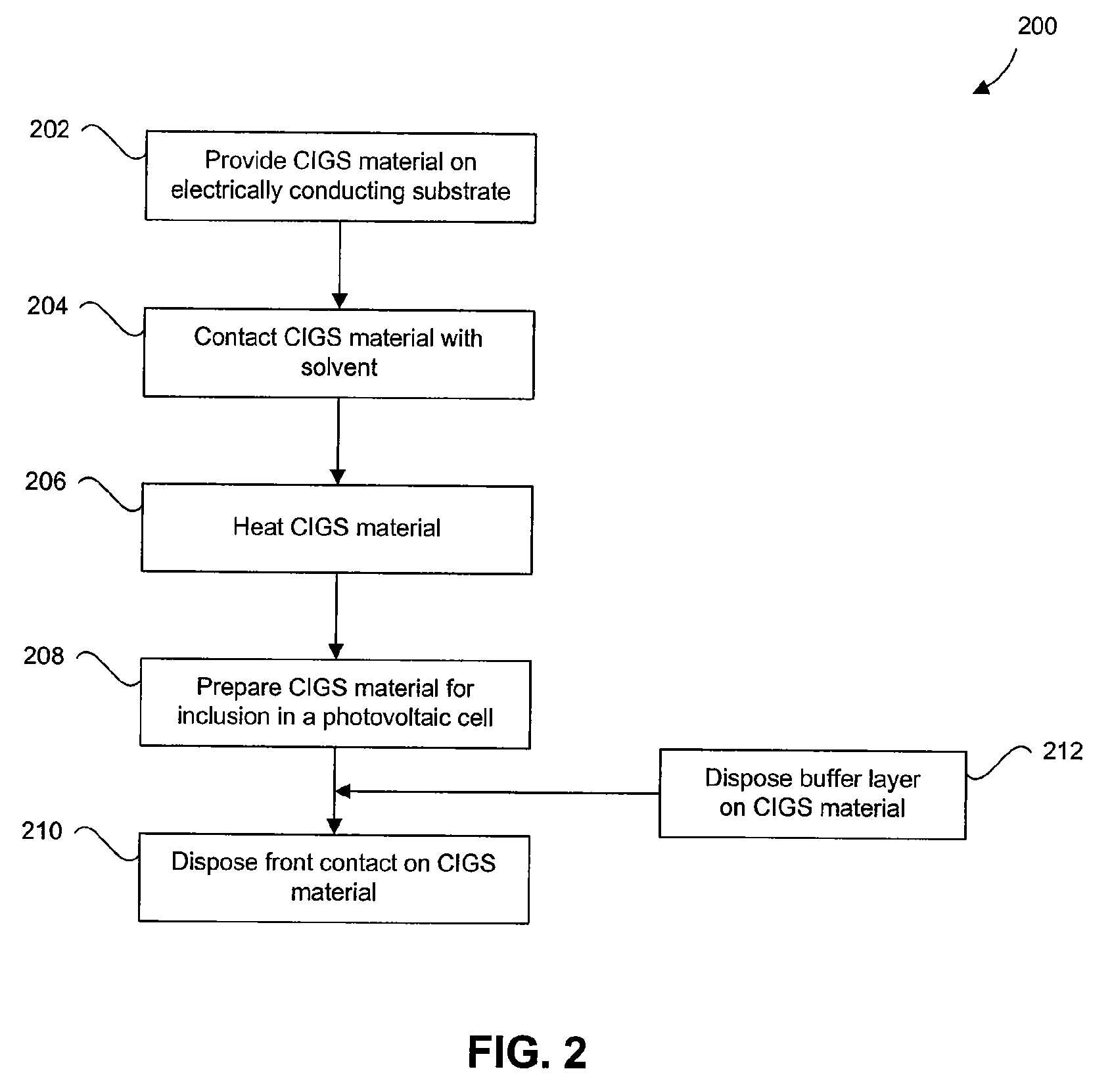

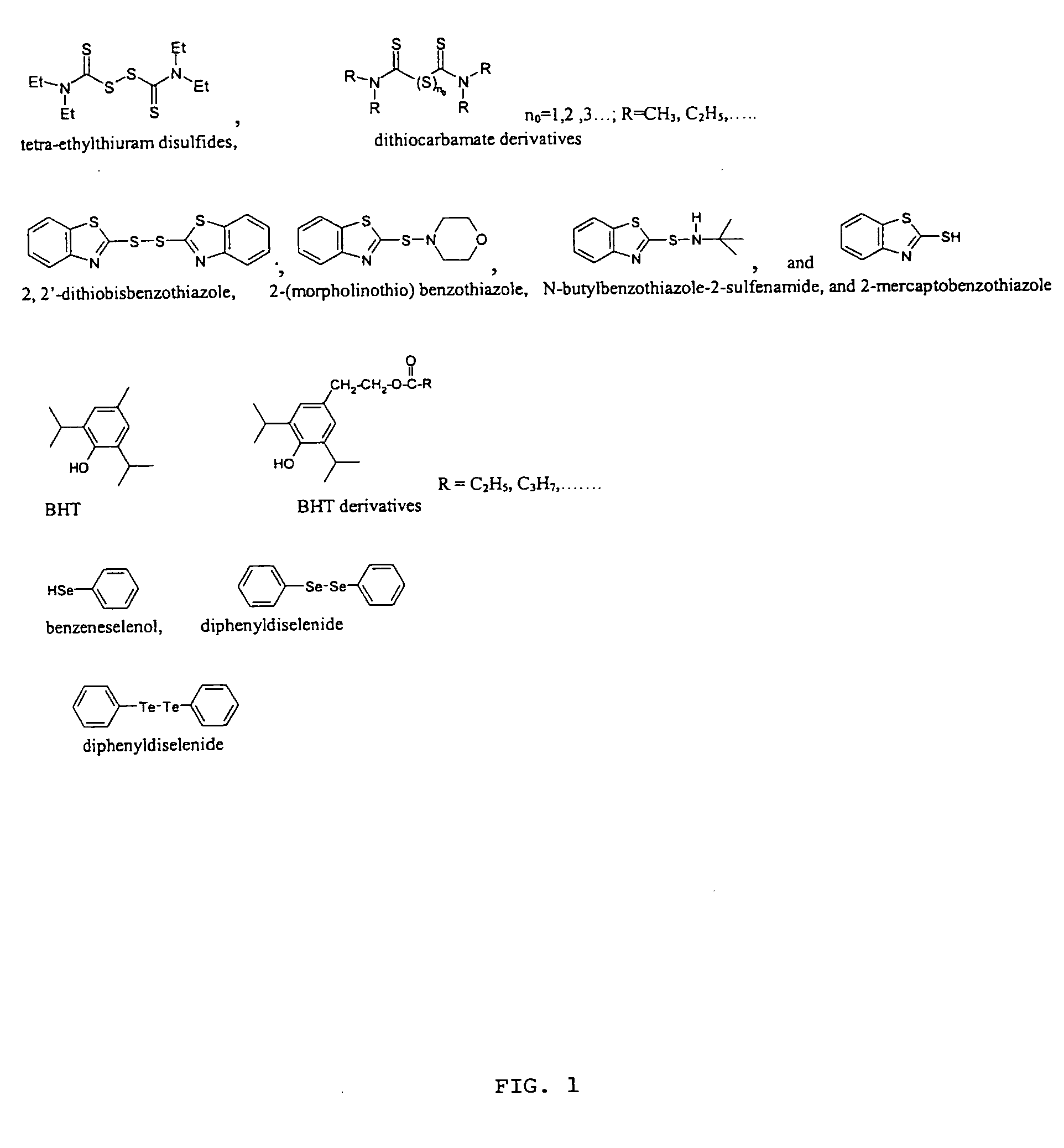

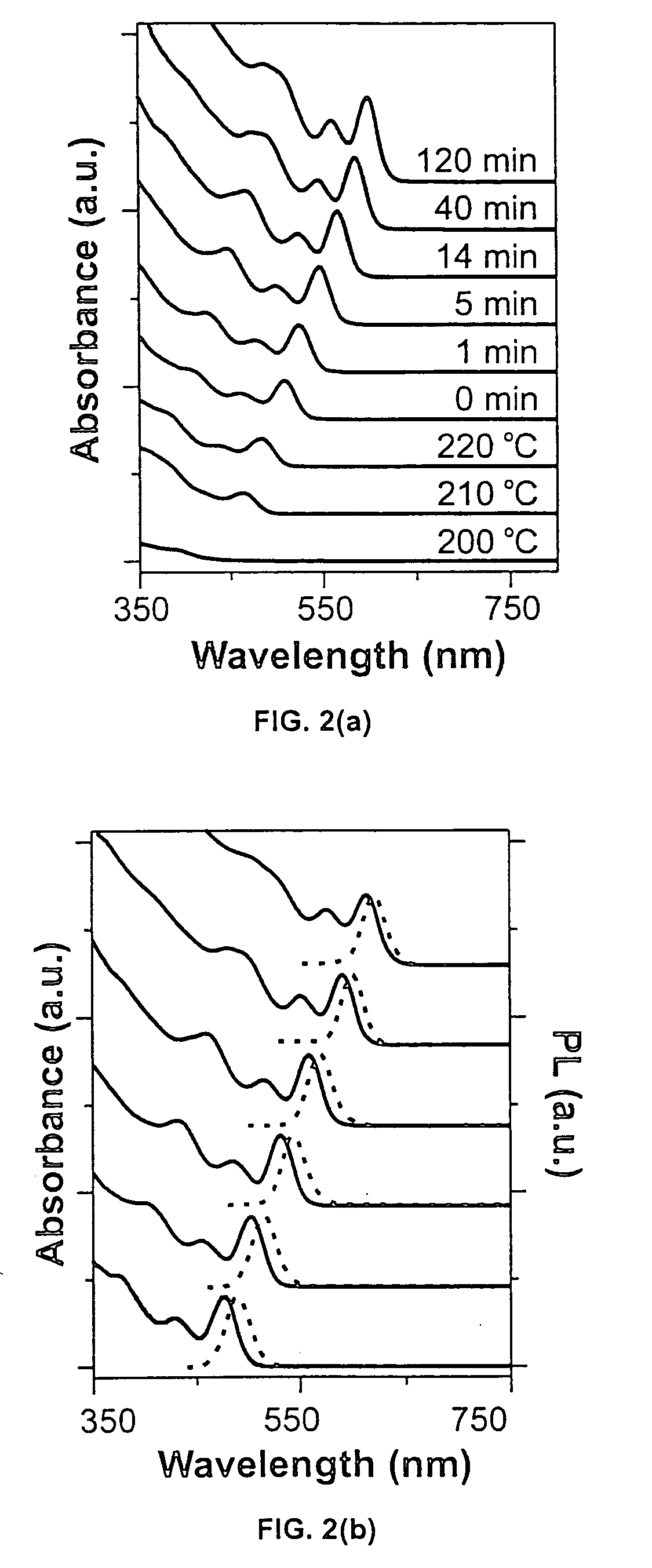

Chemical Treatments to Enhance Photovoltaic Performance of CIGS

InactiveUS20090235987A1Enhance solar cell conversion efficiencyReduce surface defect densityLighting and heating apparatusPhosphorus sulfur/selenium/tellurium compoundsChemical treatmentSolvent

The present invention provides method of treating semiconductor surfaces (e.g., CIGS) using various solvents (including ionic solvents and eutectics), and methods preparing photovoltaic cells comprising treated CIGS materials.

Owner:NEW MILLENNIUM SOLAR EQUIP CORP

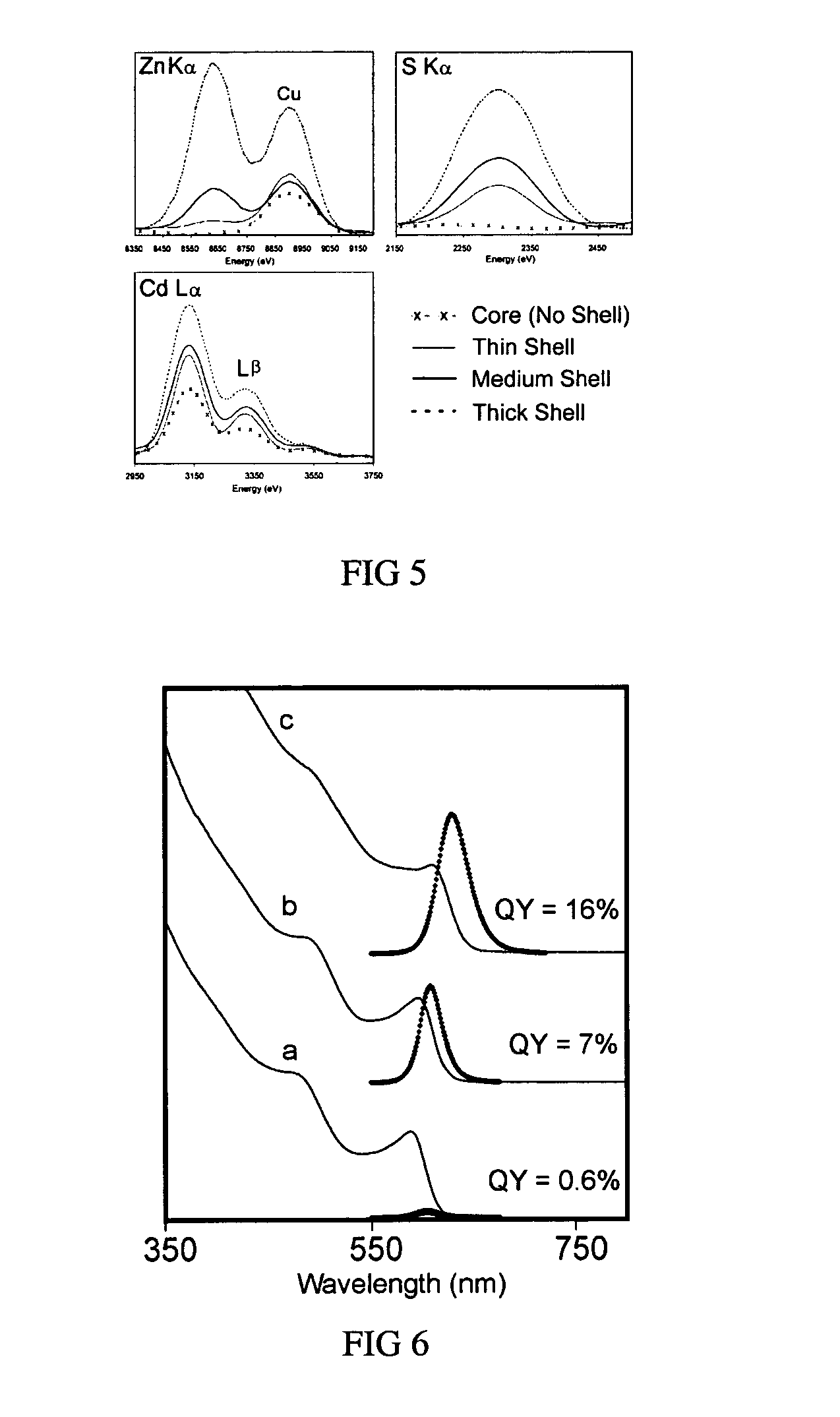

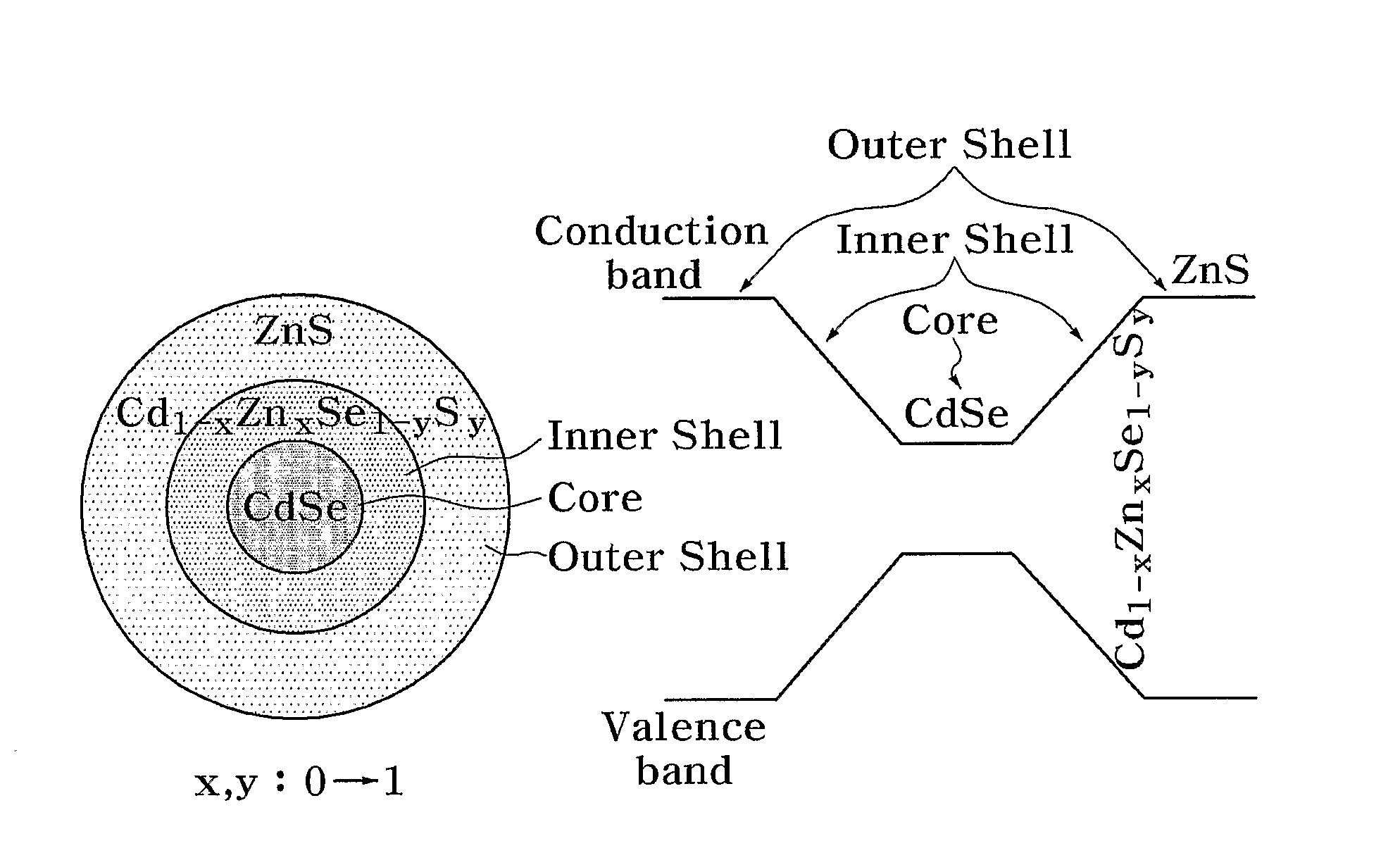

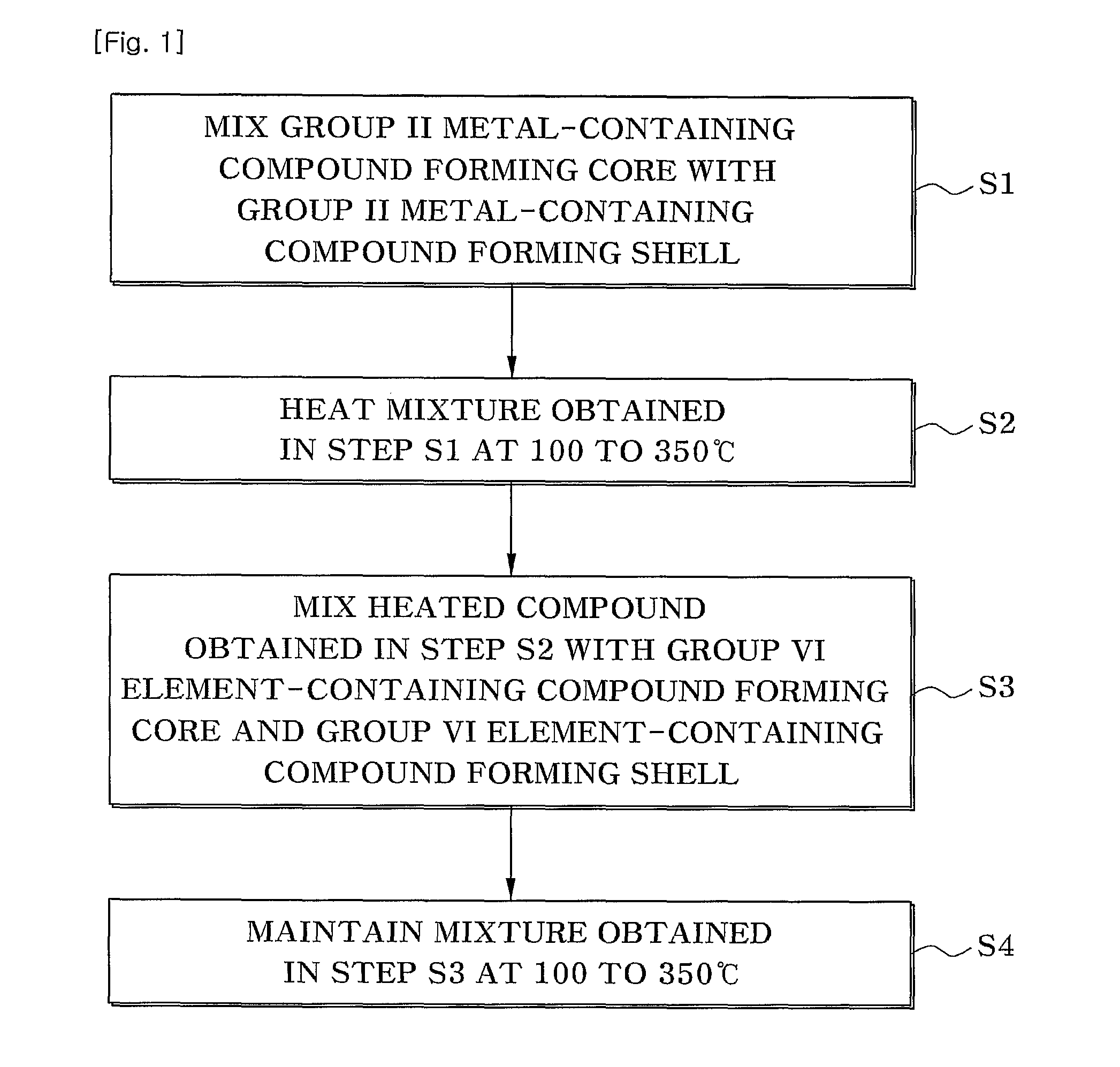

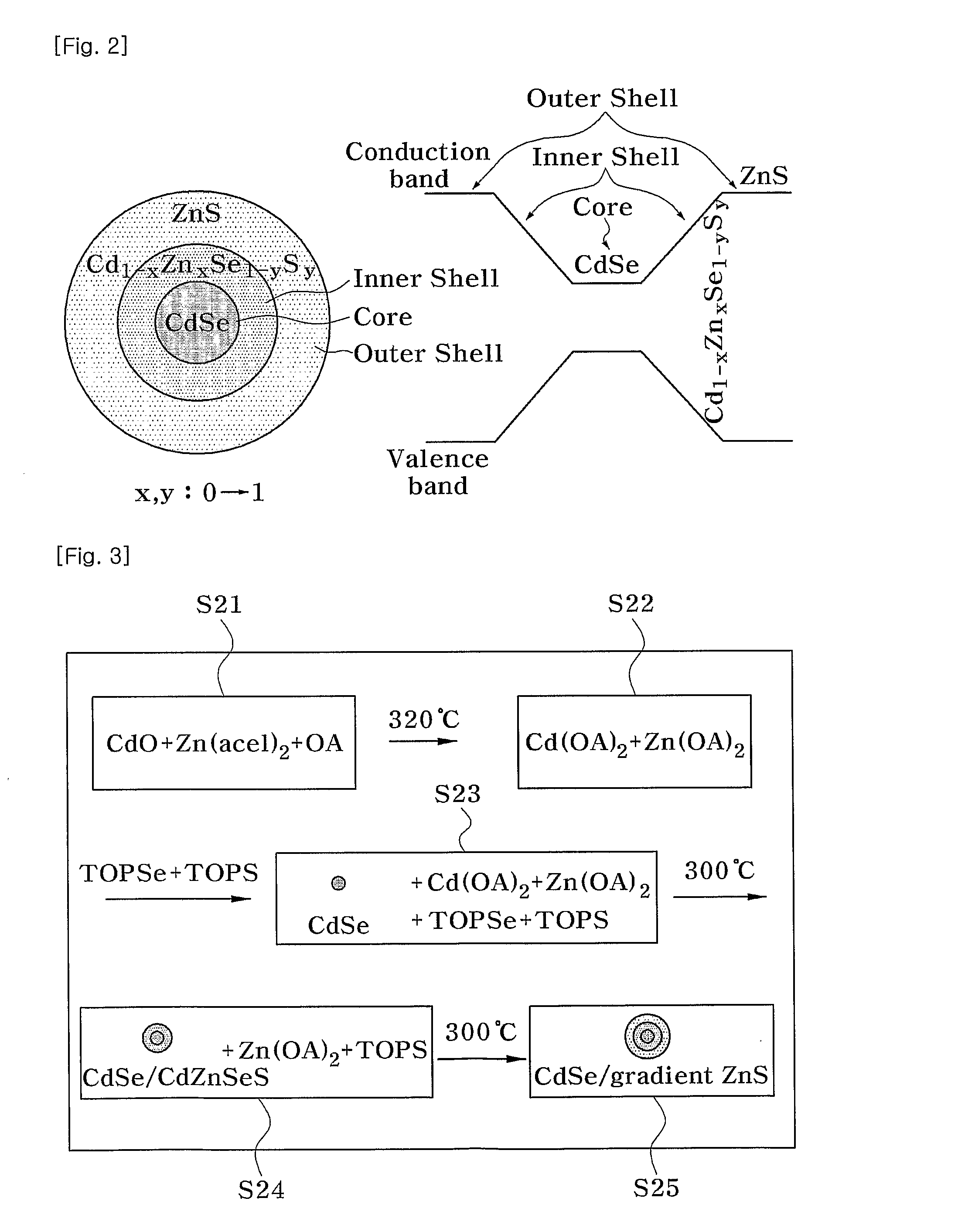

Quantum dots having composition gradient shell structure and manufacturing method thereof

InactiveUS20100140586A1Low costSolve low luminous efficiencyMaterial nanotechnologyCadmium sulfidesElectron holeLattice mismatch

Provided are quantum dots having a gradual composition gradient shell structure which have an improvedluminous efficiency and optical stability, and a method of manufacturing the quantum dots in a short amount of time at low cost. In the method, the quantum dots can be manufactured in a short amount of time at low cost using a reactivity difference between semiconductor precursors, unlike in uneconomical and inefficient conventional methods where shells areformed after forming cores and performing cleaning and redispersion processes. Also, formation of the cores is followed by formation of shells having a composition gradient. Thus, even if the shells are formed to a large thickness, the lattice mismatch between cores and shells is relieved. Furthermore, on the basis of the funneling concept, electrons and holes generated in the shells are transferred to the cores to emit light, thereby obtaining a high luminous efficiency of 80% or more. The quantum dot structure is not limited to Group II-IV semiconductor quantum dots but can be applied to other semiconductors quantum dots, such as Group III-V semiconductors quantum dots and Group IV-IV semiconductors quantum dots. Also, the manufacturing method can be utilized in the development of semiconductor quantum dots having different physical properties, and in various other fields.

Owner:SEOUL NAT UNIV R&DB FOUND

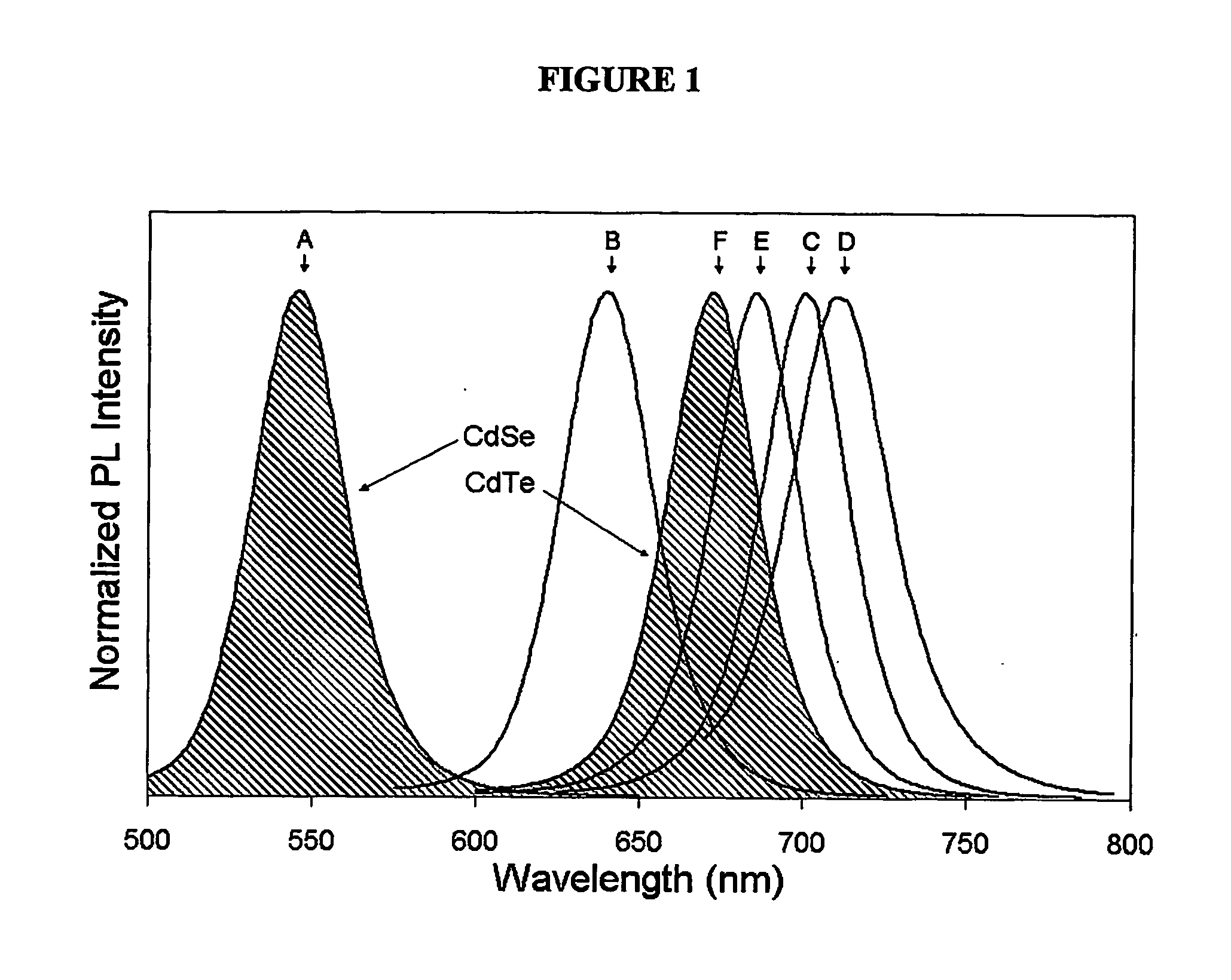

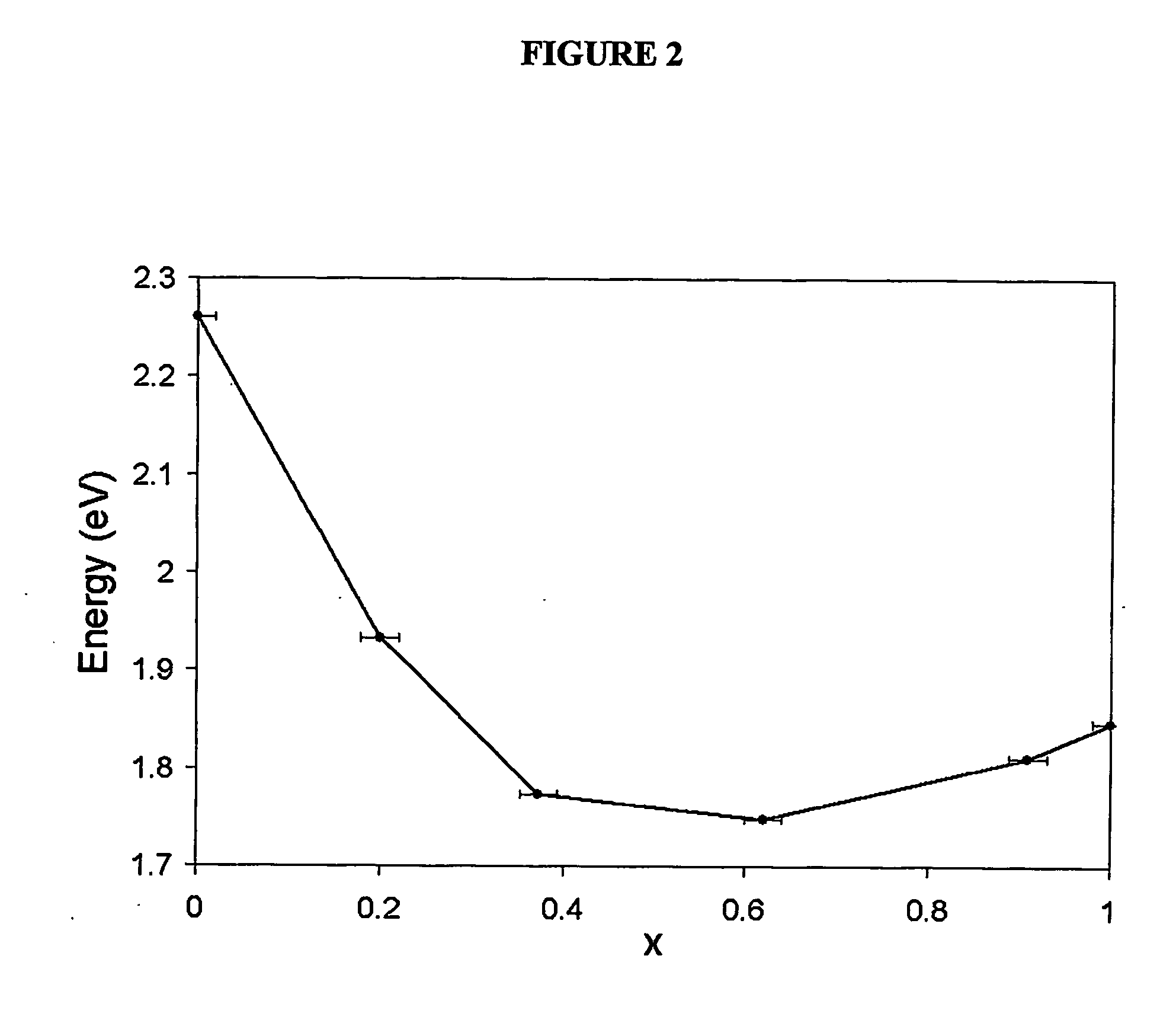

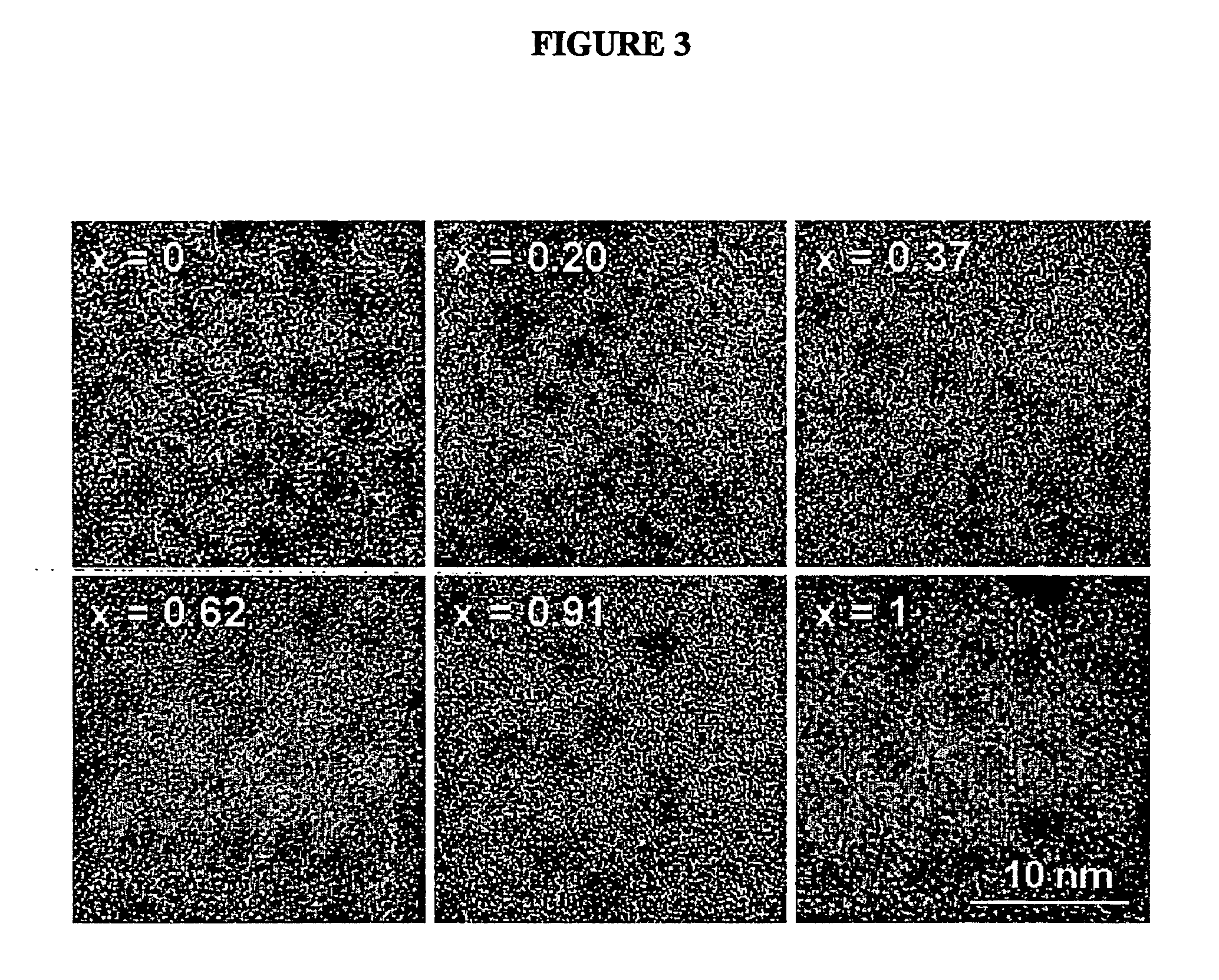

Alloyed semiconductor quantum dots and concentration-gradient alloyed quantum dots, series comprising the same and methods related thereto

An alloyed semiconductor quantum dot comprising an alloy of at least two semiconductors, wherein the quantum dot has a homogeneous composition and is characterized by a band gap energy that is non-linearly related to the molar ratio of the at least two semiconductors; a series of alloyed semiconductor quantum dots related thereto; a concentration-gradient quantum dot comprising an alloy of a first semiconductor and a second semiconductor, wherein the concentration of the first semiconductor gradually increases from the core of the quantum dot to the surface of the quantum dot and the concentration of the second semiconductor gradually decreases from the core of the quantum dot to the surface of the quantum dot; a series of concentration-gradient quantum dots related thereto; in vitro and in vivo methods of use; and methods of producing the alloyed semiconductor and concentration-gradient quantum dots and the series of quantum dots related thereto.

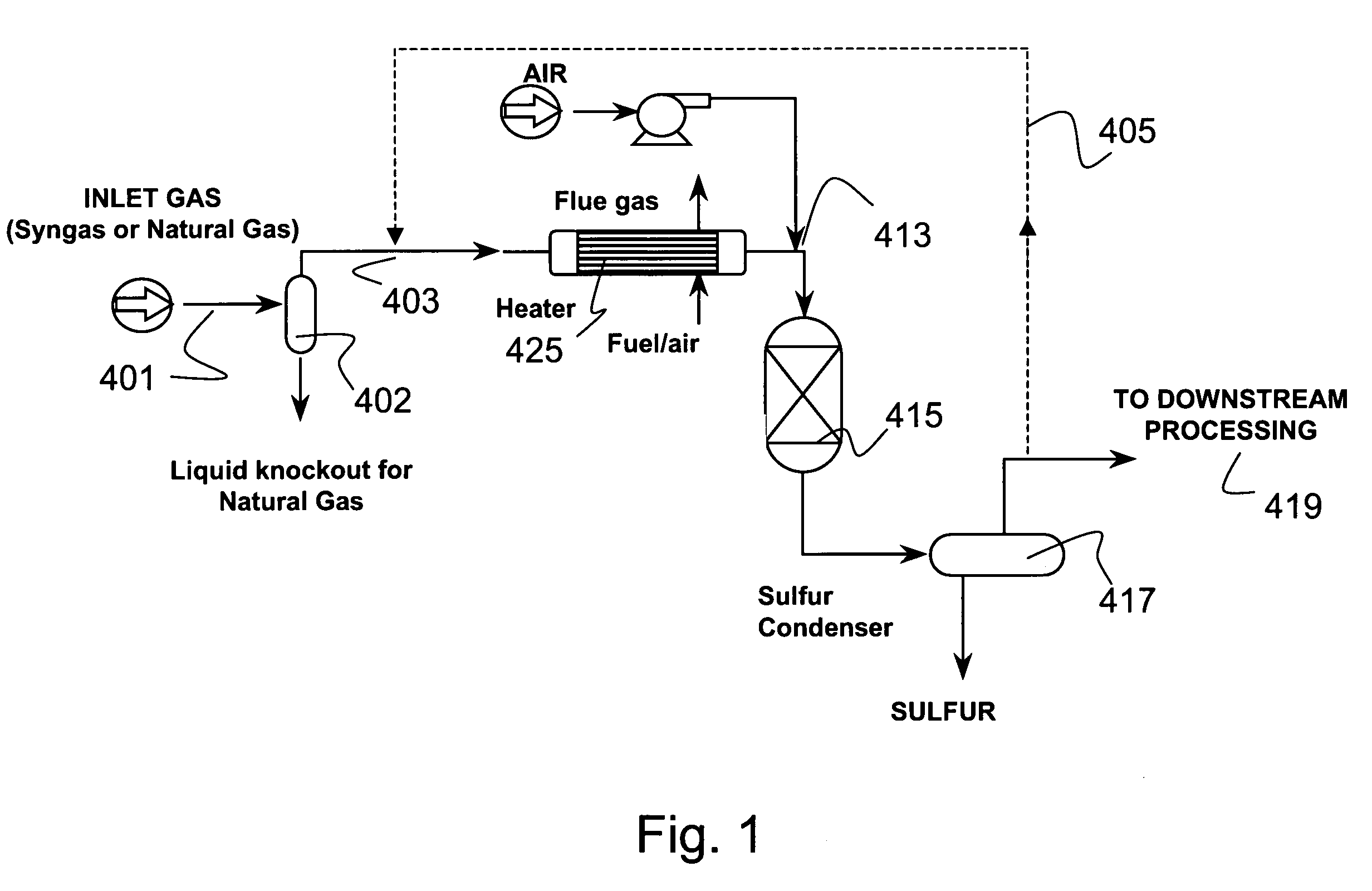

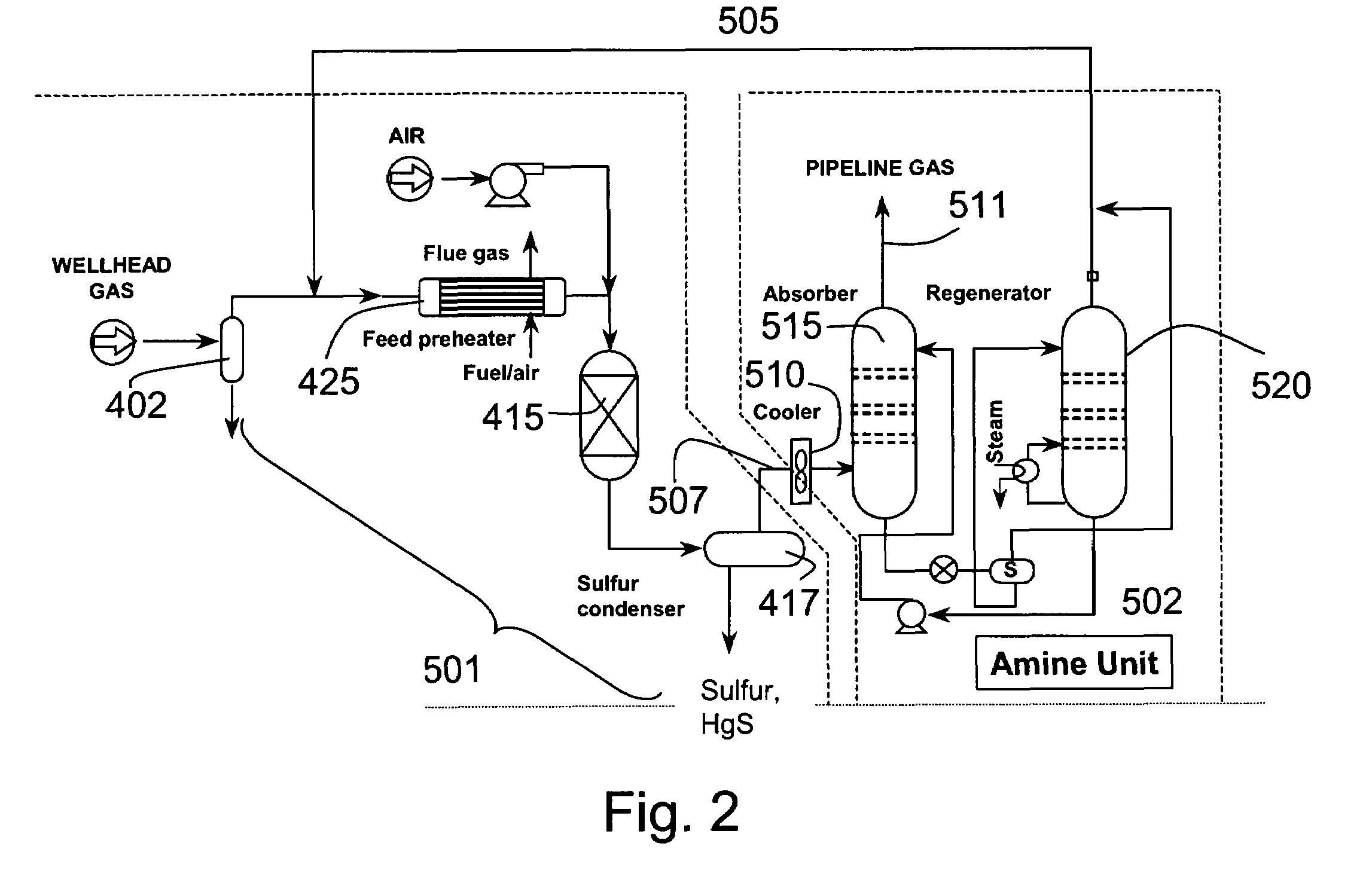

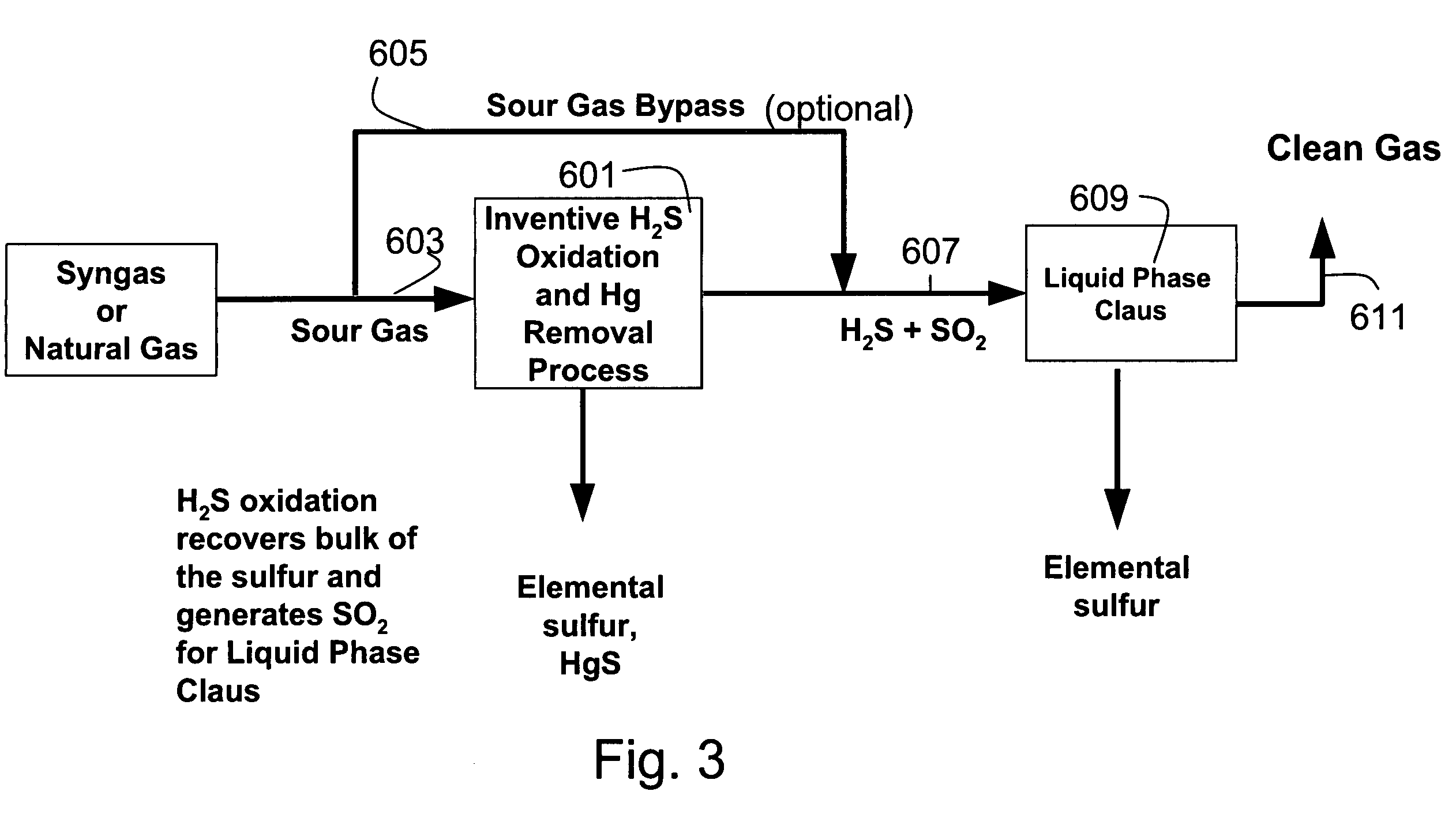

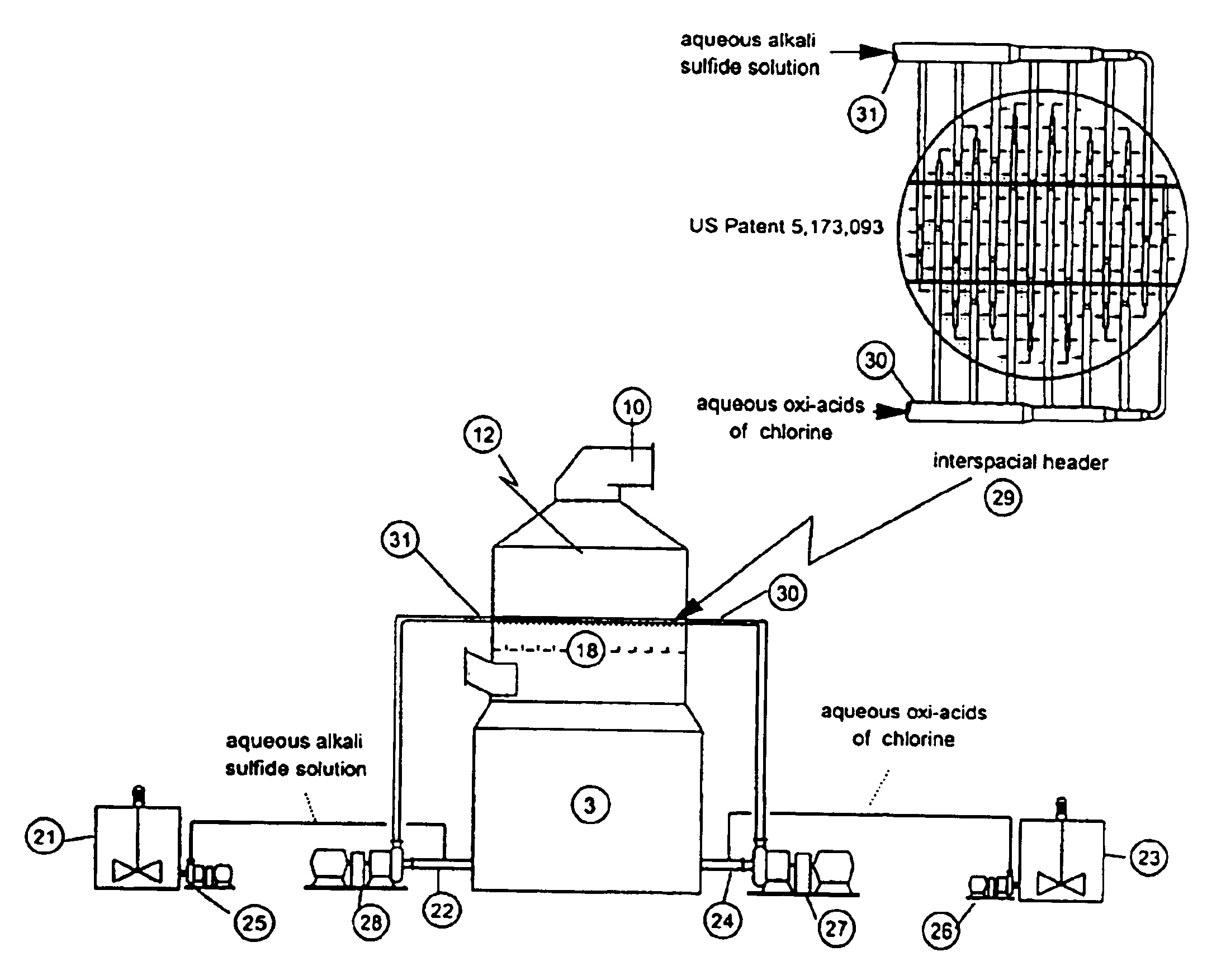

Process for the simultaneous removal of sulfur and mercury

InactiveUS7060233B1Lower capitalReduce operating costsGas treatmentUsing liquid separation agentSulfur containingInorganic sulfide

A process for removing hydrogen sulfide, other sulfur-containing compounds and / or sulfur and mercury from a gas stream contaminated with mercury, hydrogen sulfide or both. The method comprises the step of selective oxidation of hydrogen sulfide (H2S) in a gas stream containing one or more oxidizable components other than H2S to generate elemental sulfur (S) or a mixture of sulfur and sulfur dioxide (SO2). The sulfur generated in the gas stream reacts with mercury in the gas stream to generate mercuric sulfide and sulfur and mercuric sulfide are removed from the gas stream by co-condensation.

Owner:TDA RES

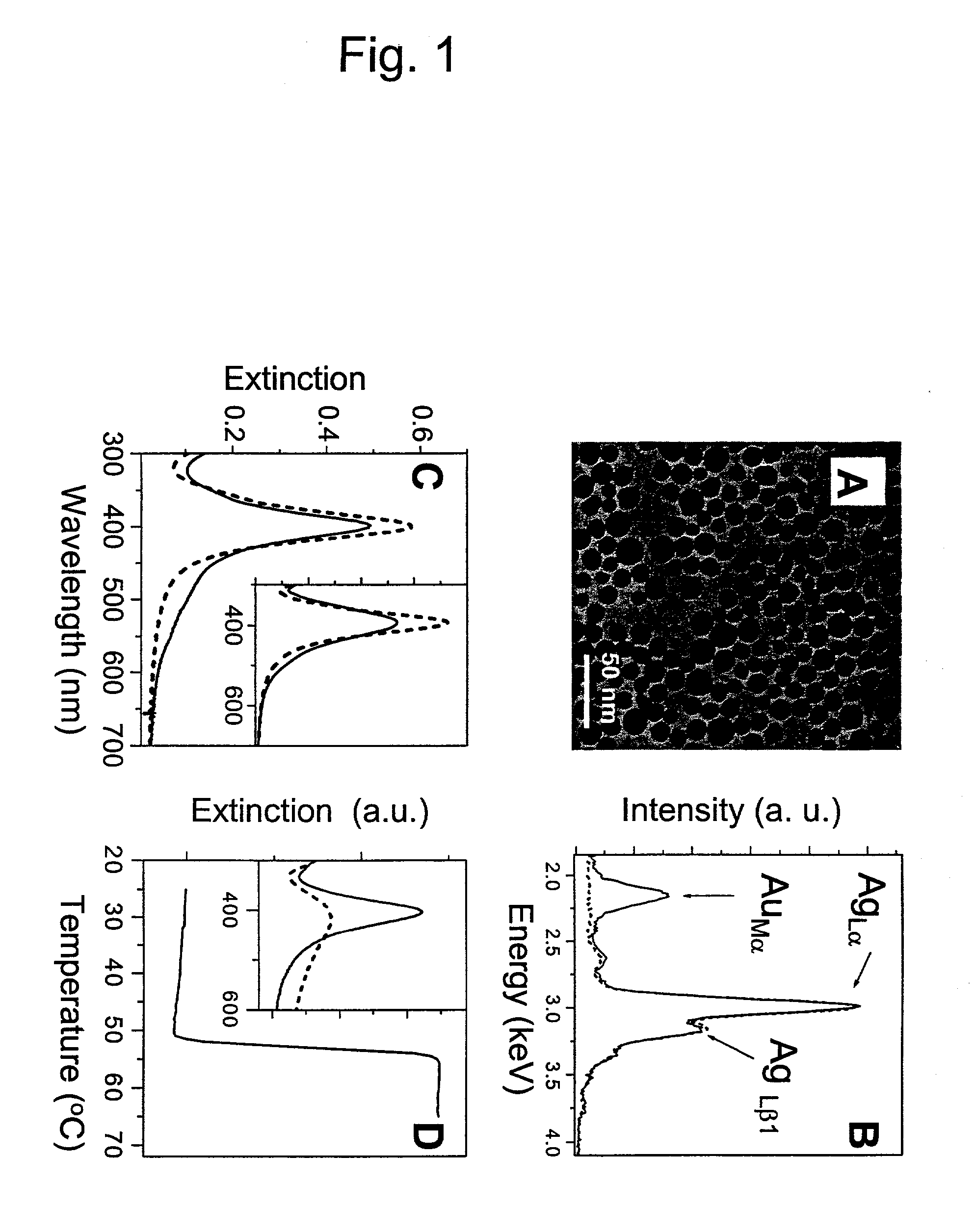

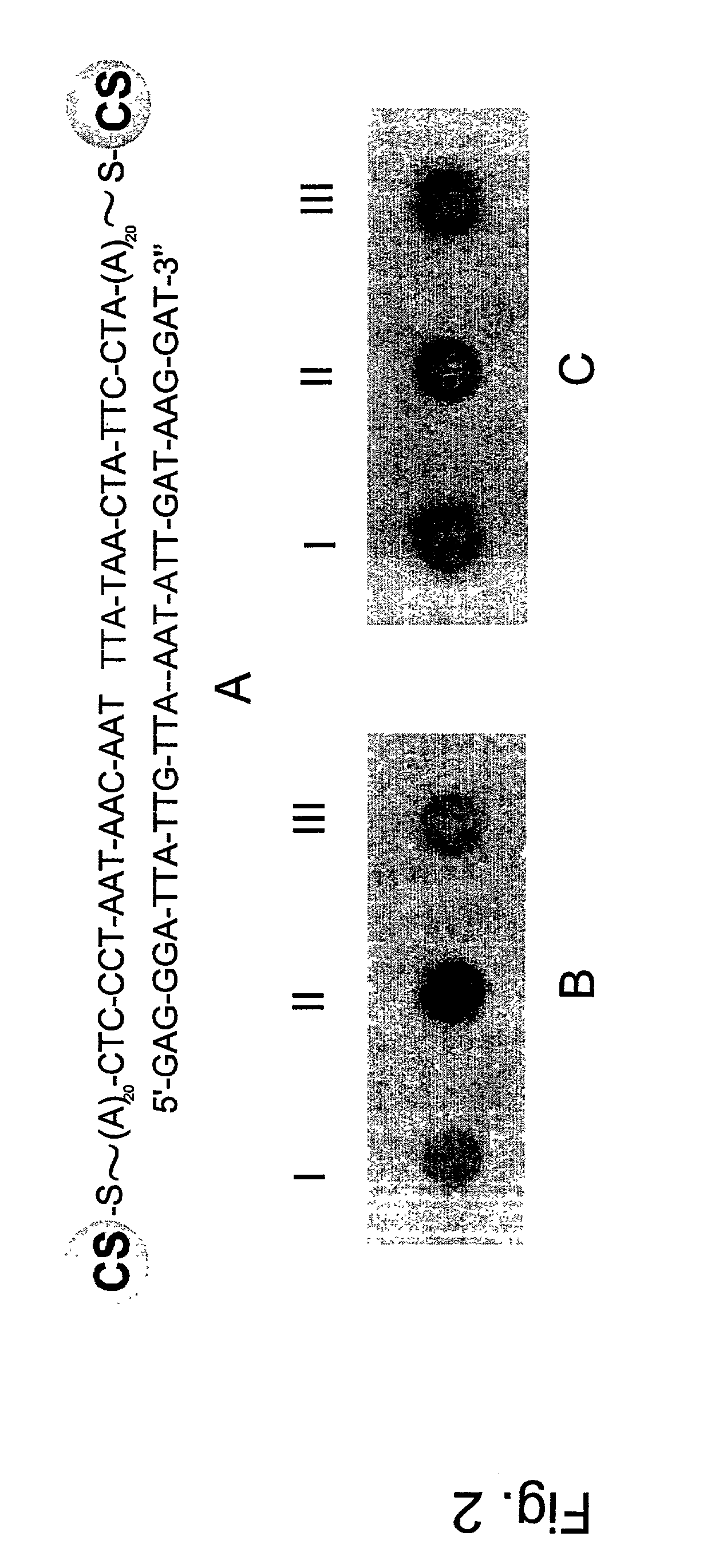

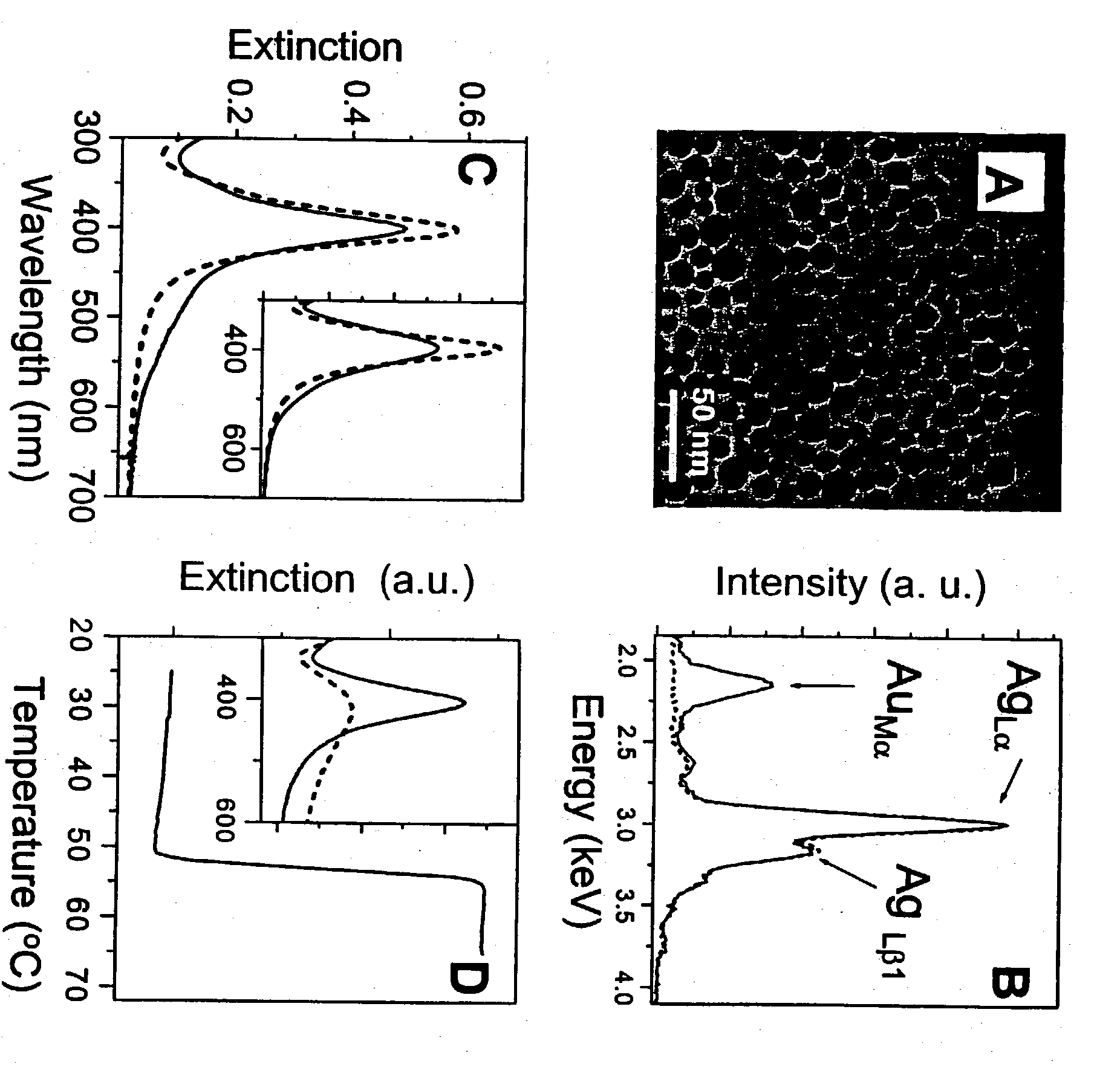

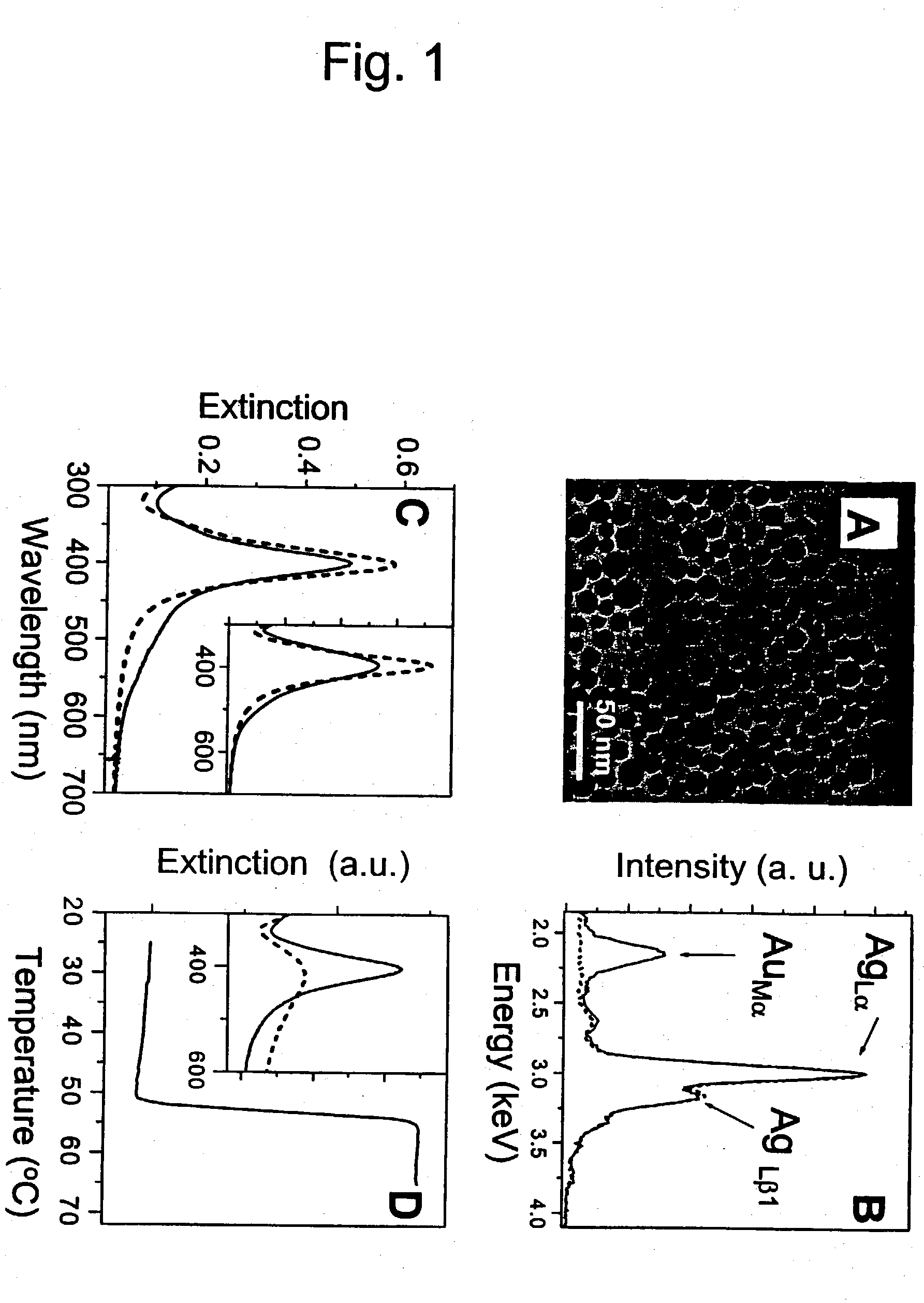

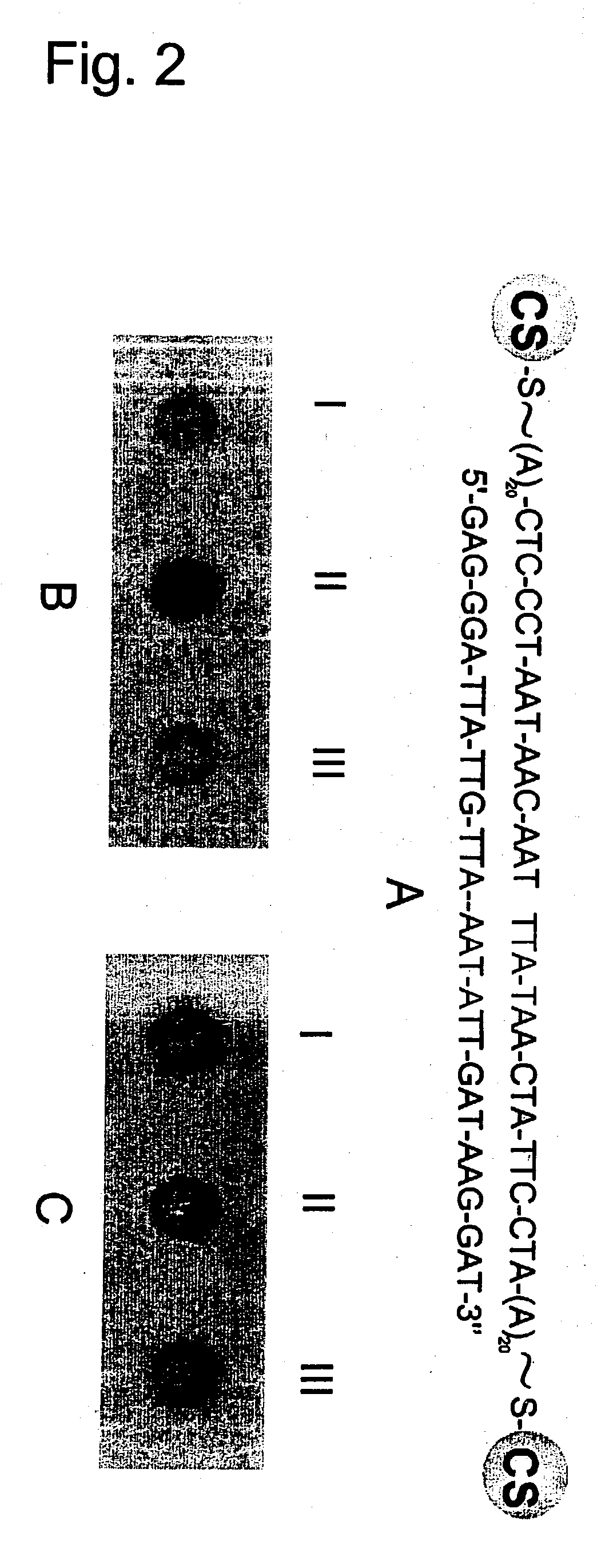

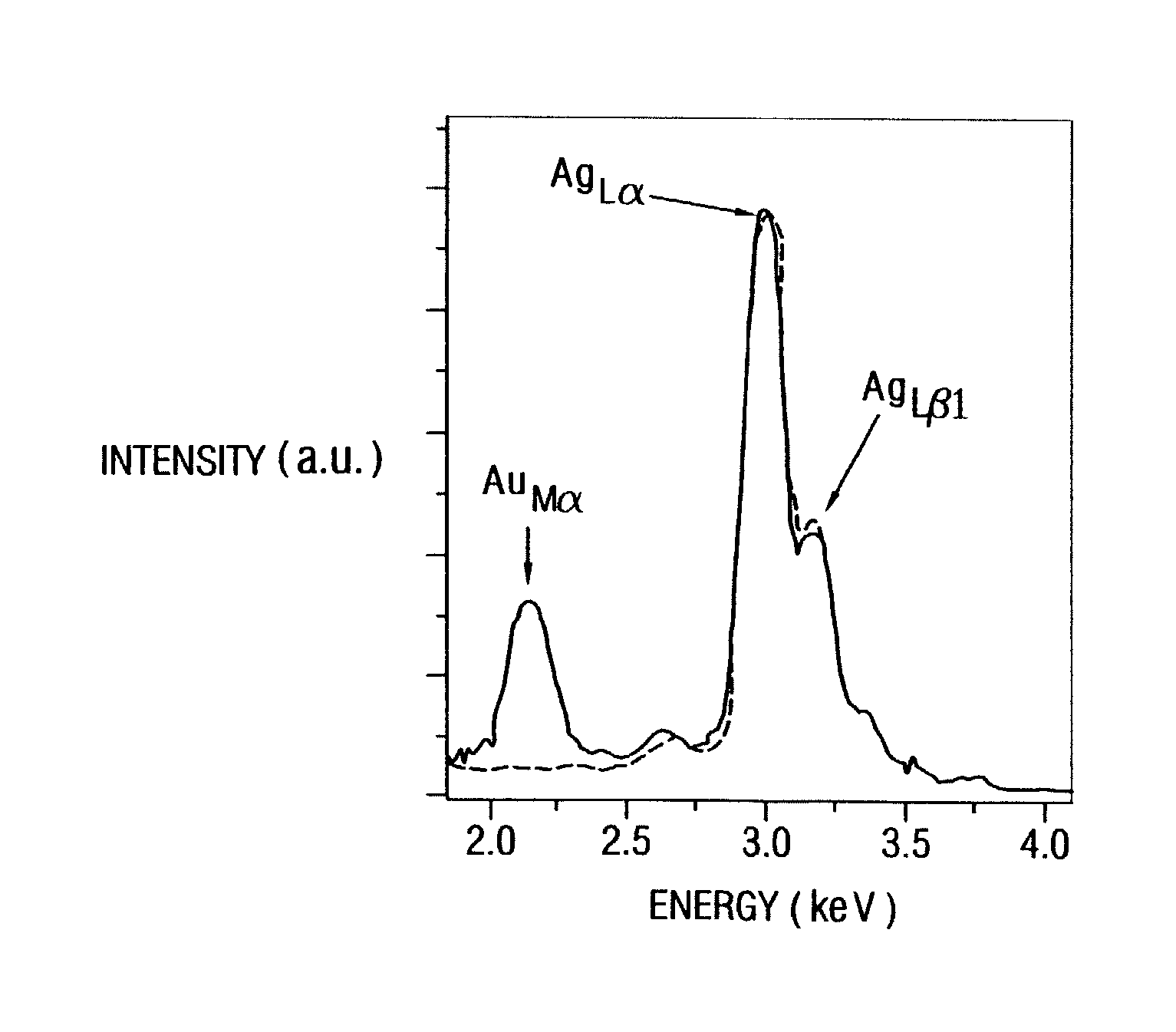

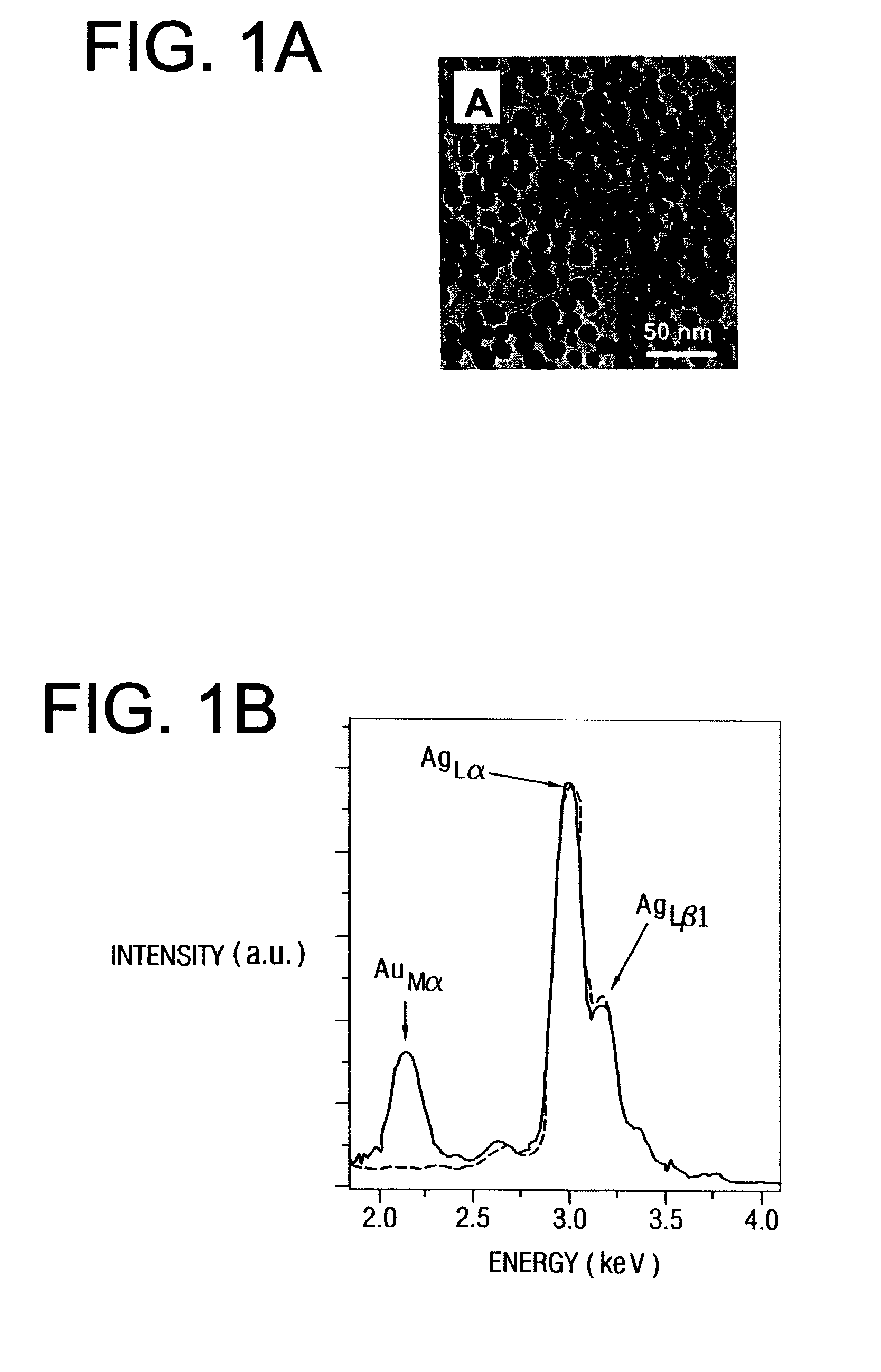

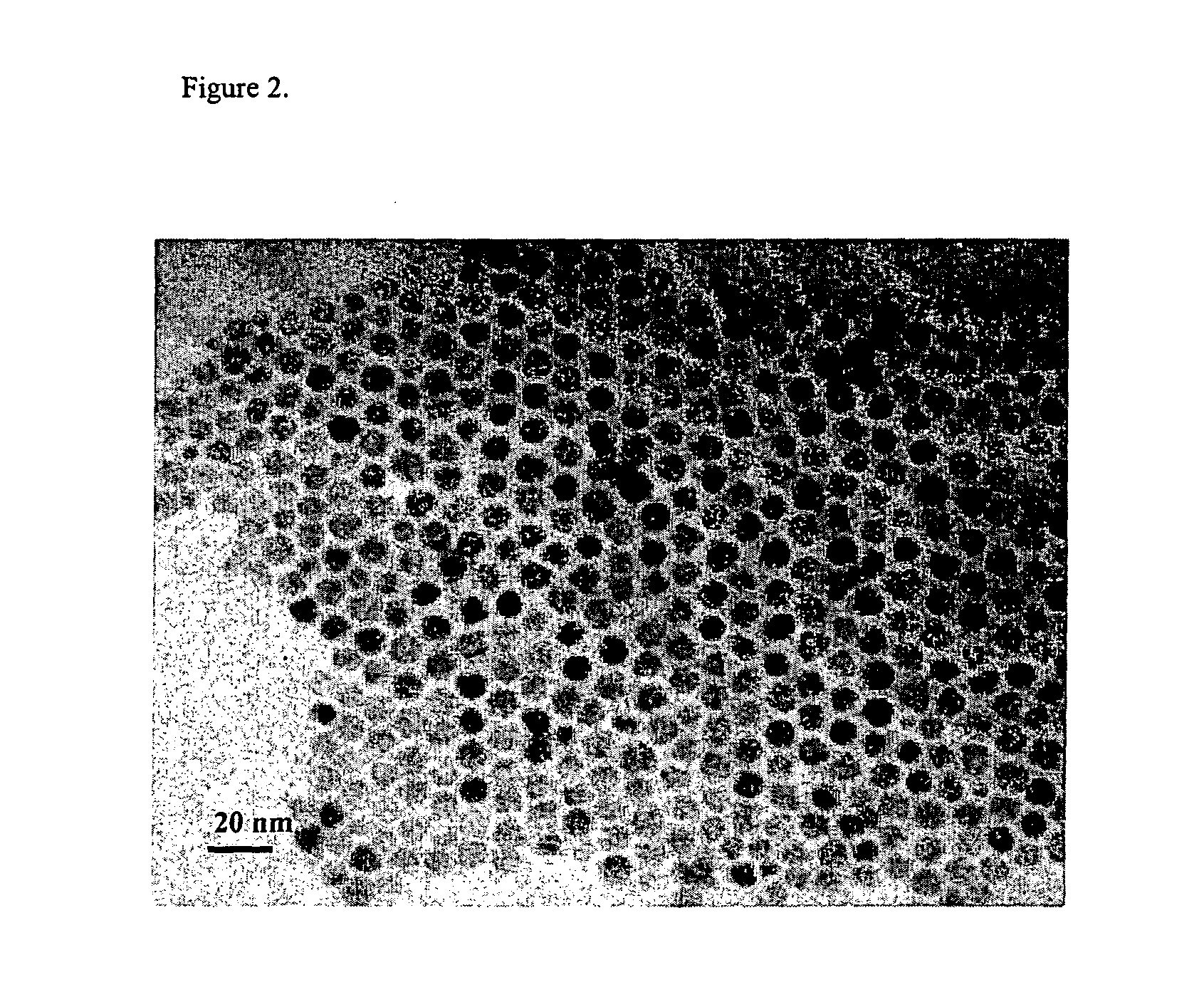

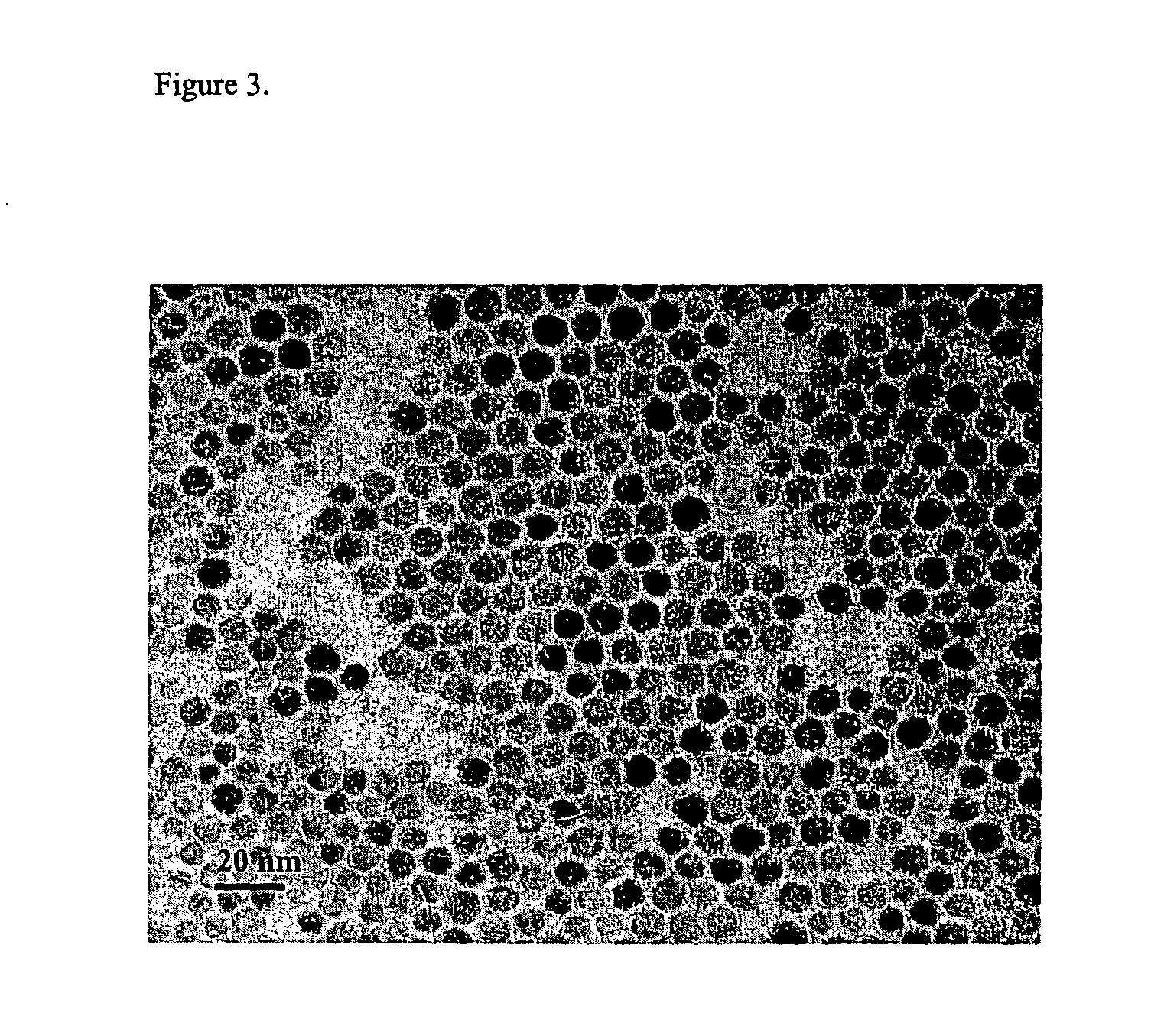

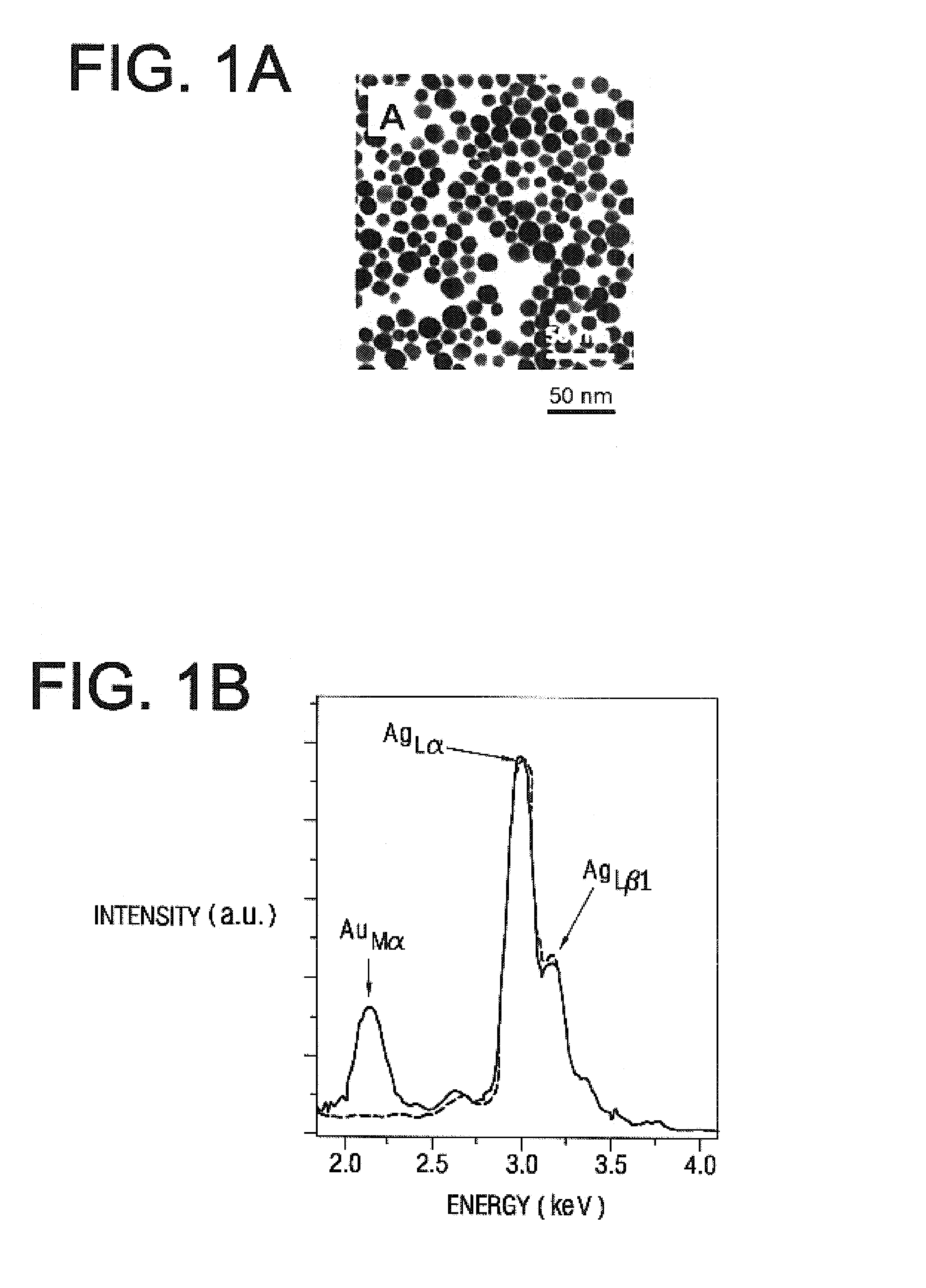

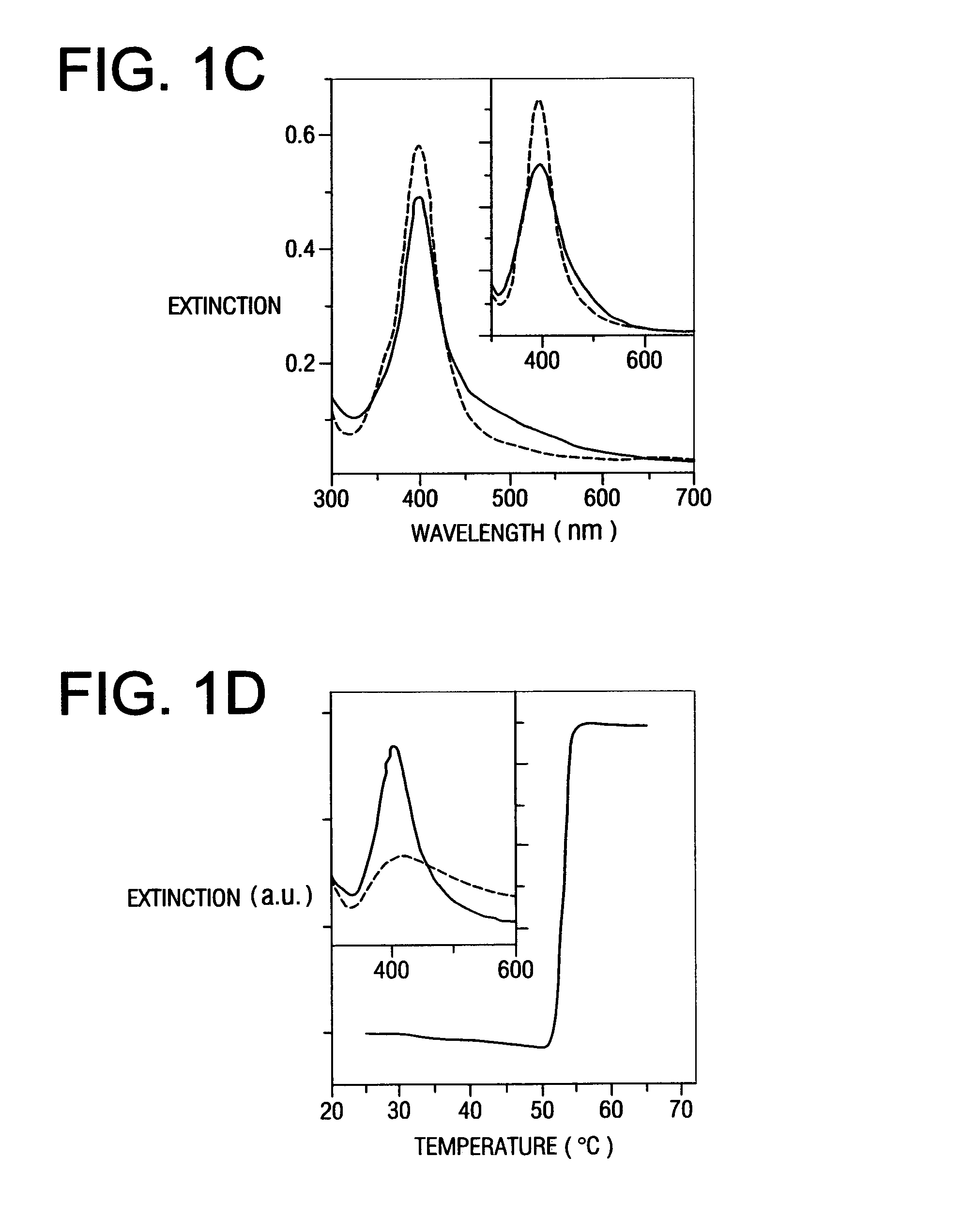

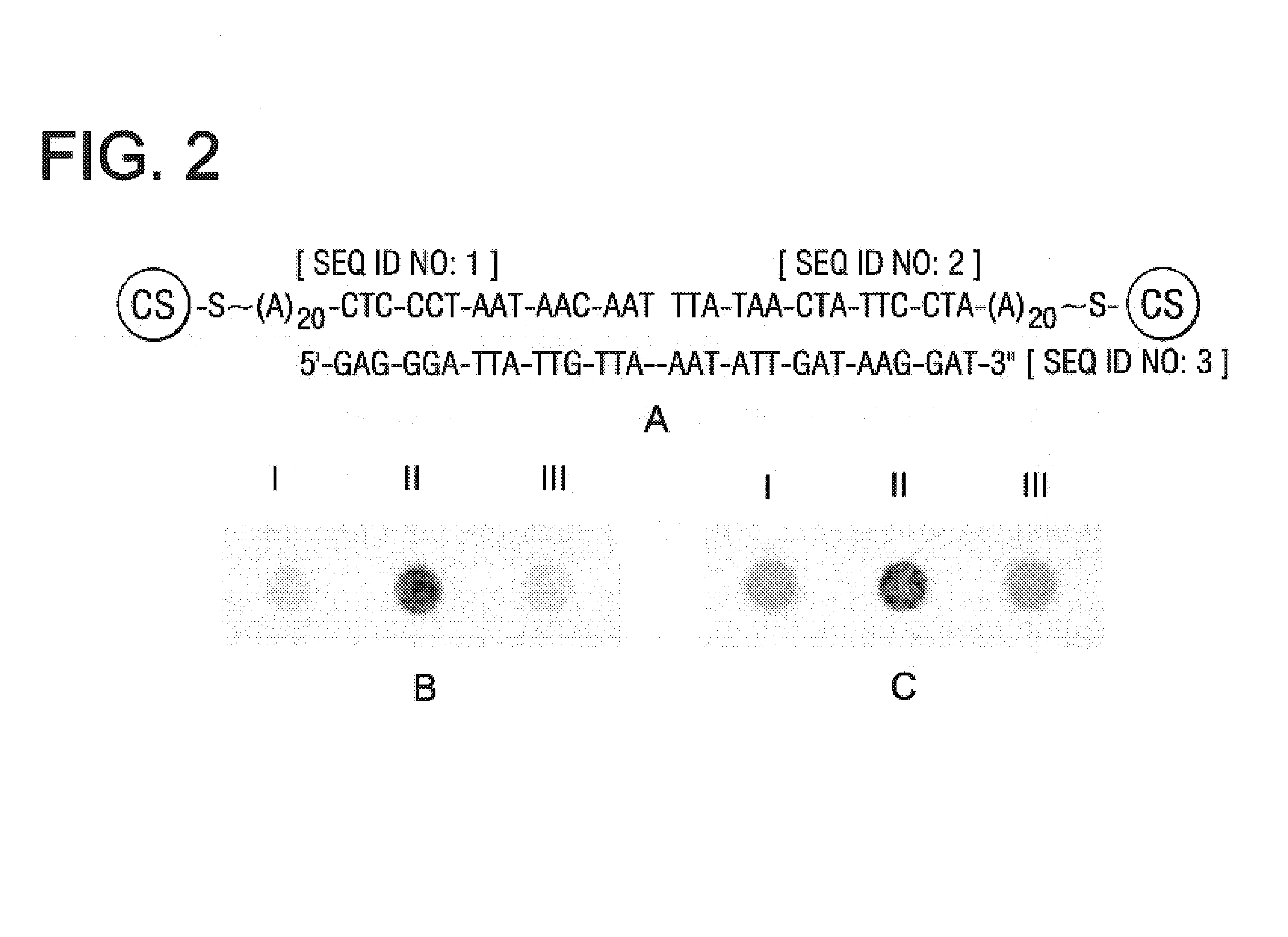

Non-alloying core shell nanoparticles

The present invention relates composite core / shell nanoparticles and a two-step method for their preparation. The present invention further relates to biomolecule-core / shell nanoparticle conjugates and methods for their preparation. The invention also relates to methods of detection of biomolecules comprising the biomolecule or specific binding substance-core / shell nanoparticle conjugates.

Owner:NORTHWESTERN UNIV

Non-alloying core shell nanoparticles

The present invention relates composite core / shell nanoparticles and a two-step method for their preparation. The present invention further relates to biomolecule-core / shell nanoparticle conjugates and methods for their preparation. The invention also relates to methods of detection of biomolecules comprising the biomolecule-core / shell nanoparticle conjugates.

Owner:NORTHWESTERN UNIV

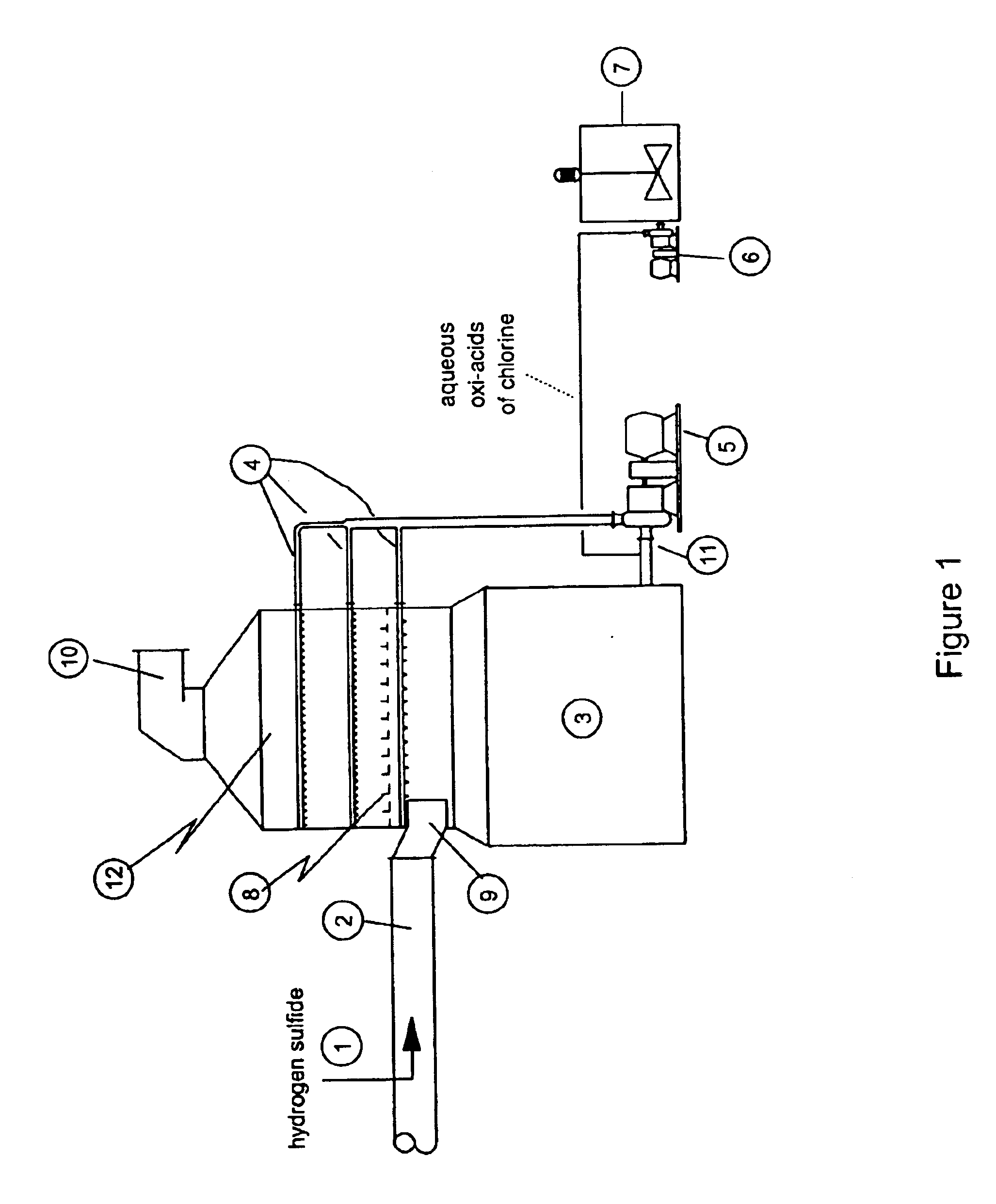

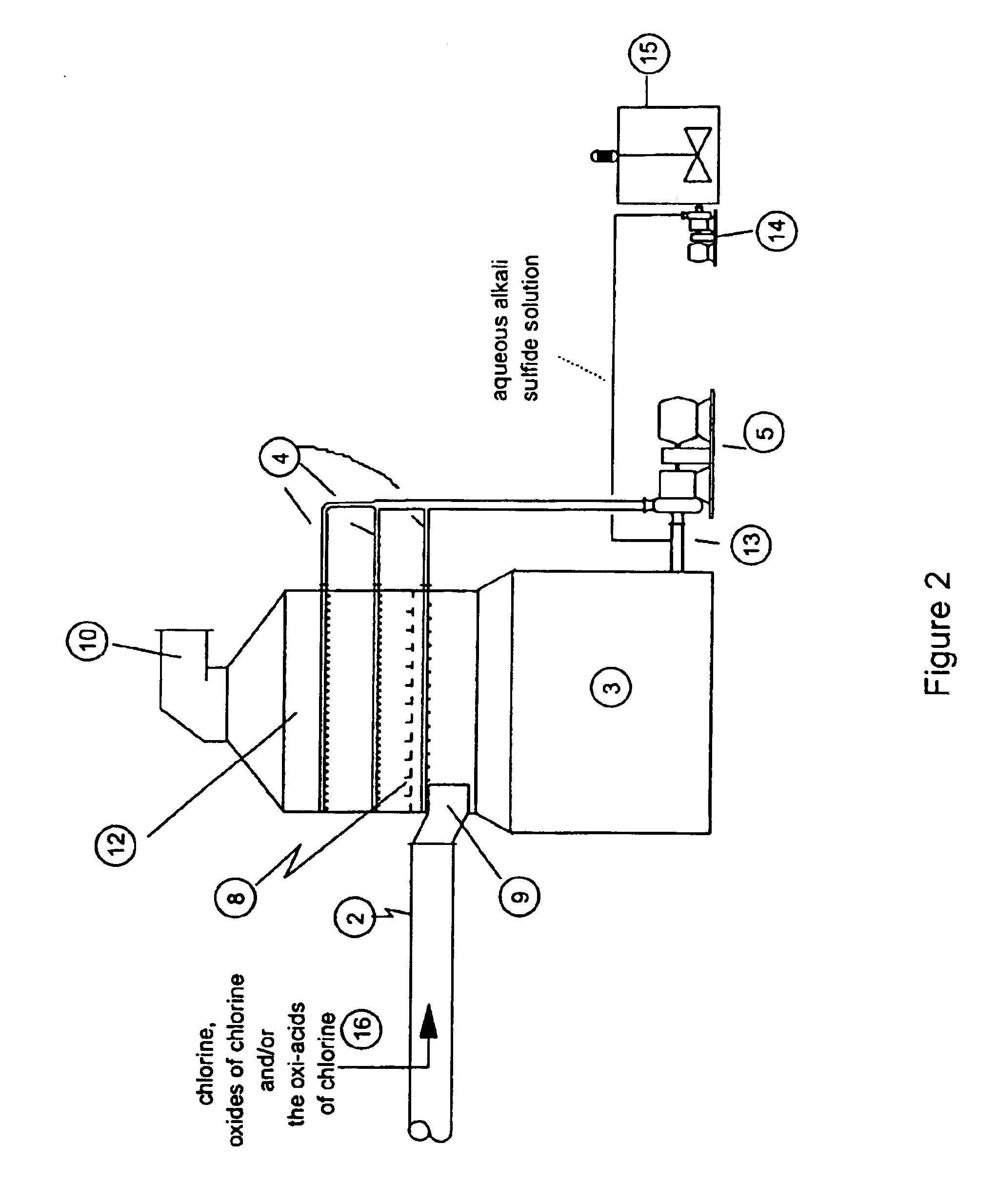

Method for controlling elemental mercury emissions

InactiveUS6855859B2Simple equipmentReduce oxidationGas treatmentExhaust apparatusElemental mercuryPrecipitation

Chlorine and sulfide species are separately introduced to a flue gas passing through a scrubber in order to remove the elemental and oxidized mercury from the gas through the precipitation of mercuric sulfide at near 100% efficiency.

Owner:THE BABCOCK & WILCOX CO

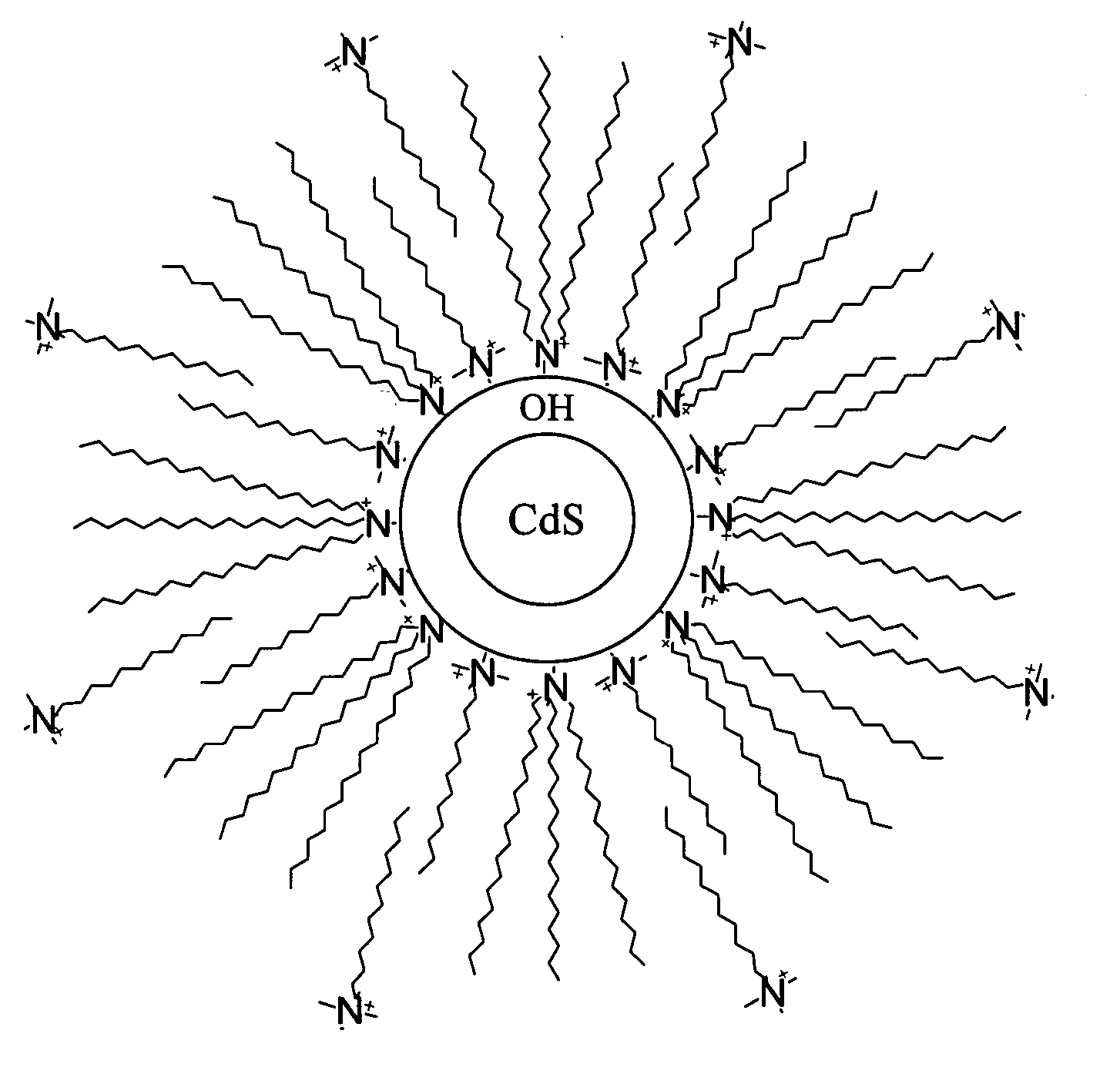

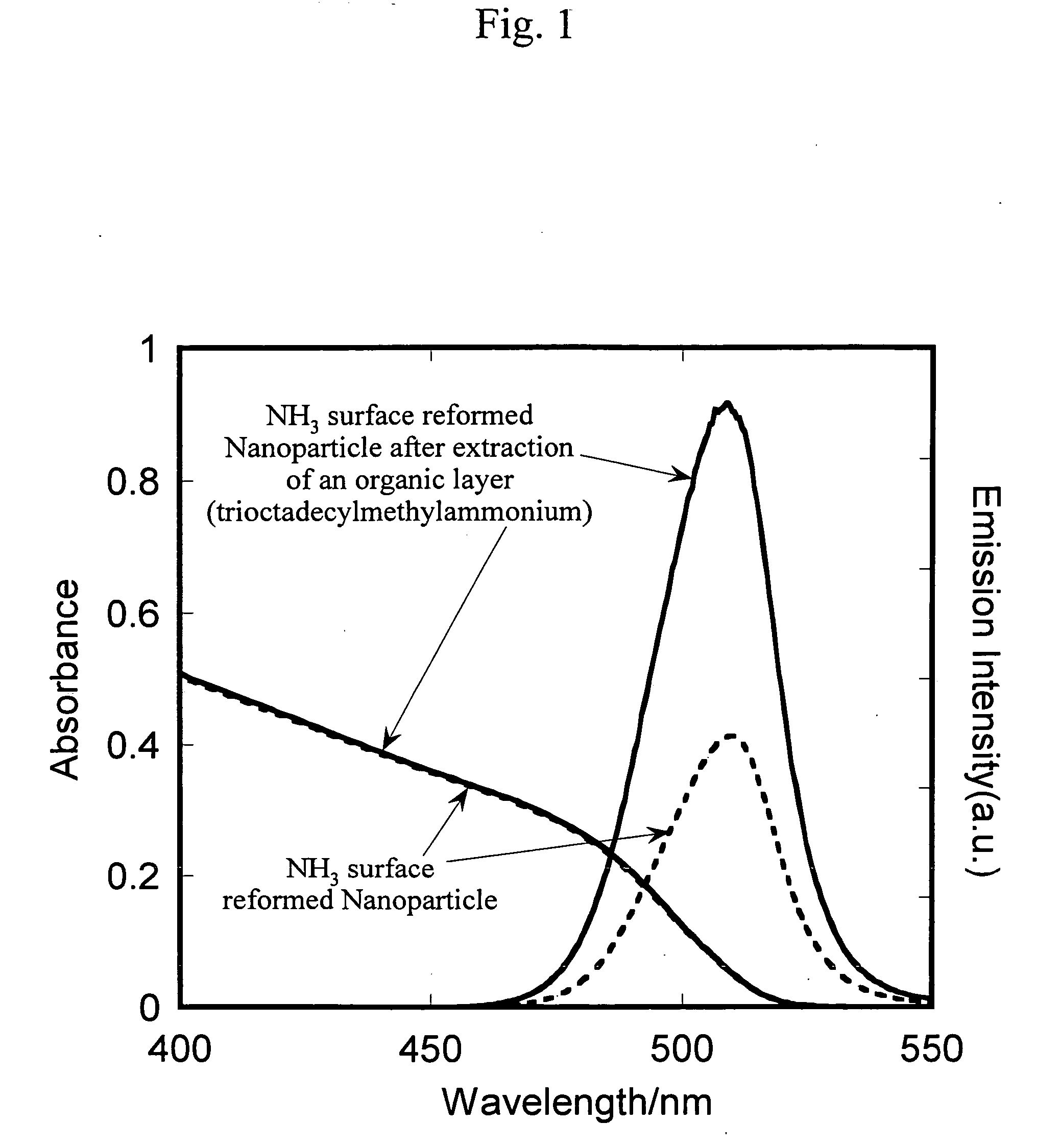

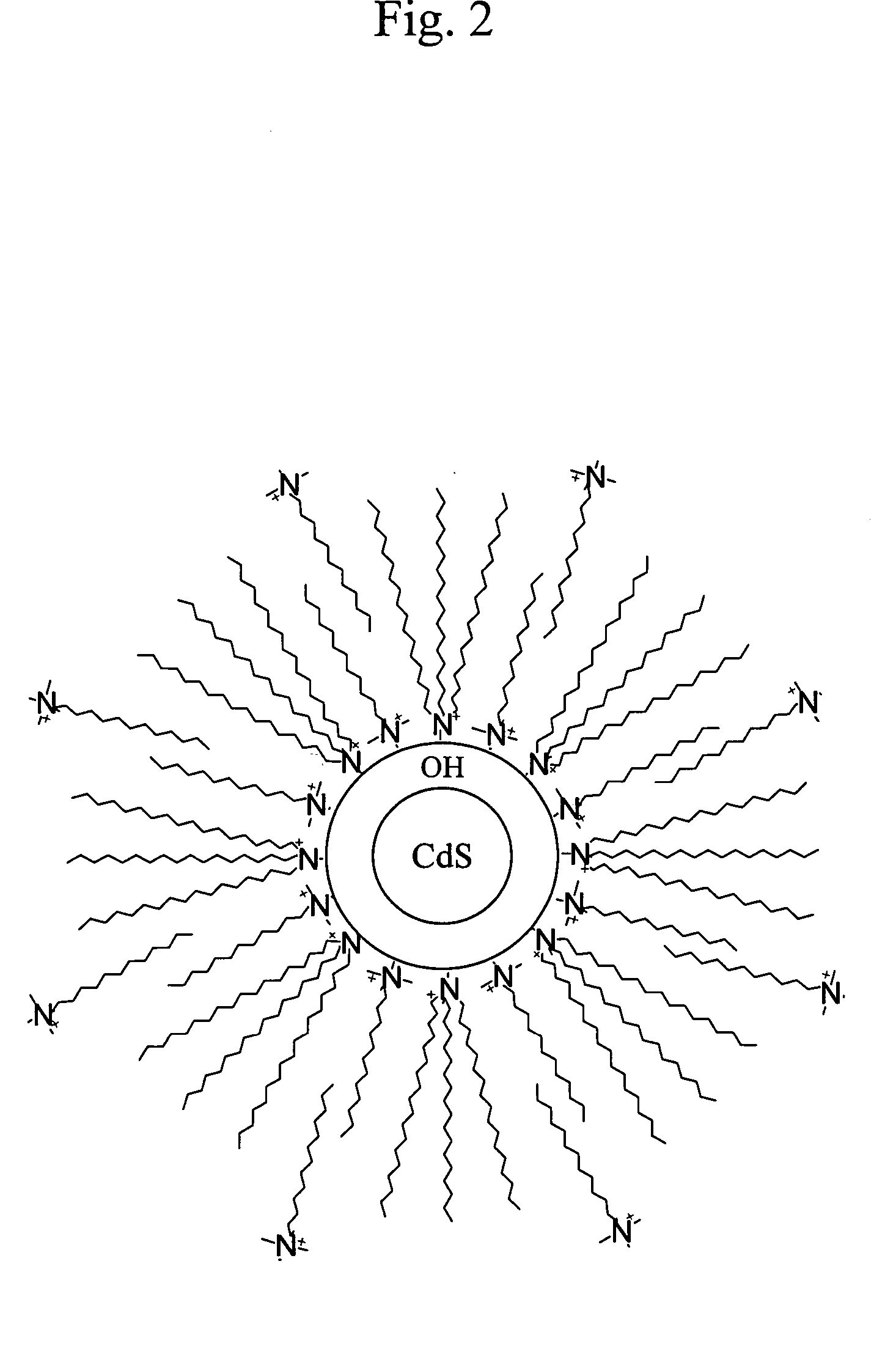

Semiconductor nanoparticle surface modification method

InactiveUS20070131905A1Improve luminous performanceMaterial nanotechnologySemiconductor/solid-state device detailsBiopolymerSemiconductor Nanoparticles

Semiconductor nanoparticles having high luminescence properties that are preferable for applications and uses of biotechnology are provided. With the use of electric charges on the surfaces of particles, the particles and selected polymers are allowed to electrostatically bind to each other, such that the surfaces of the particles are coated. The polymers are allowed to crosslink to each other, resulting in the improved durability of the particles. Further, functional groups contained in the polymers are exposed on the surfaces of the particles. Accordingly, semiconductor nanoparticles that are preferably utilized for applications such as staining and labeling of biopolymers have been synthesized.

Owner:HITACHI LTD

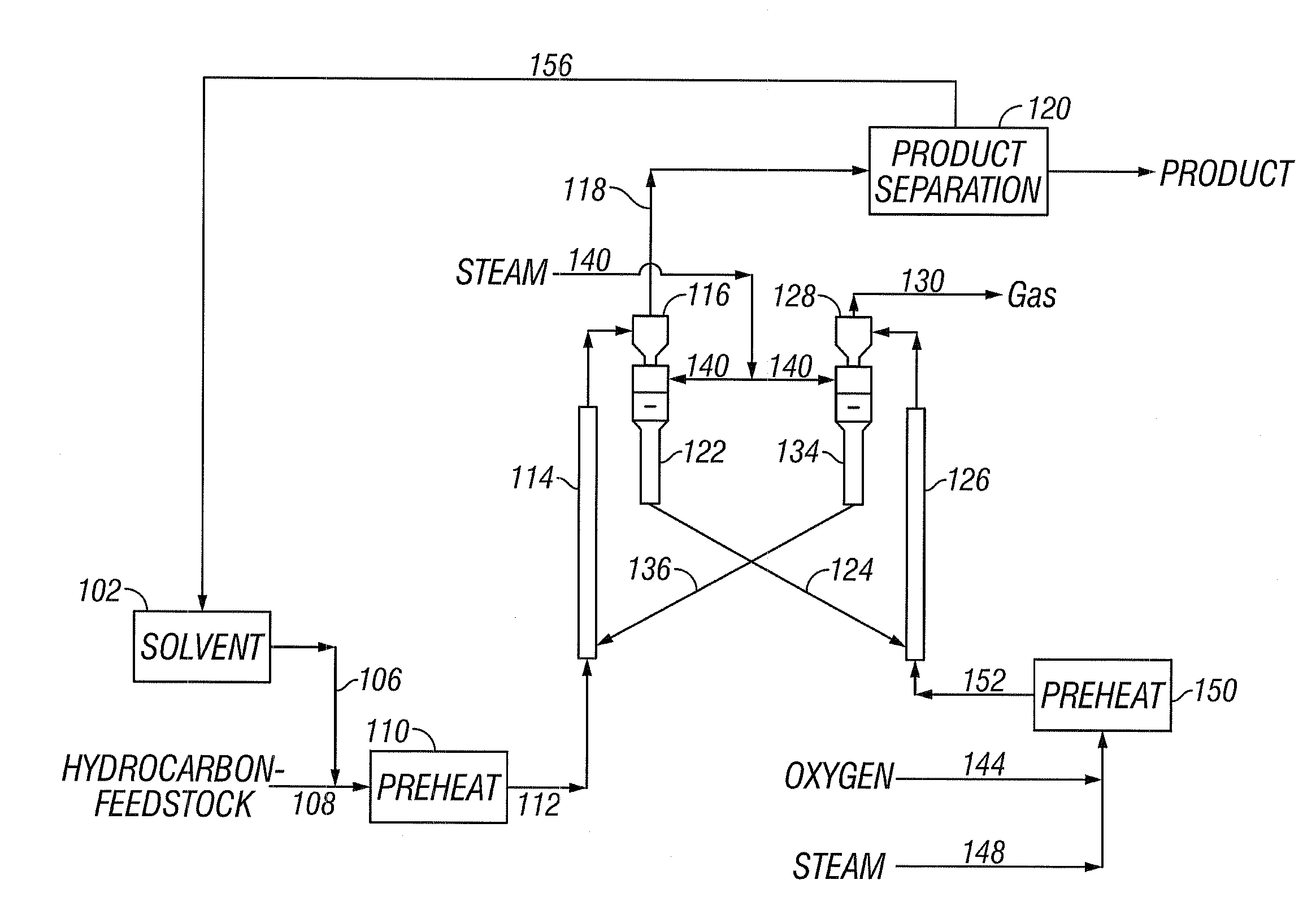

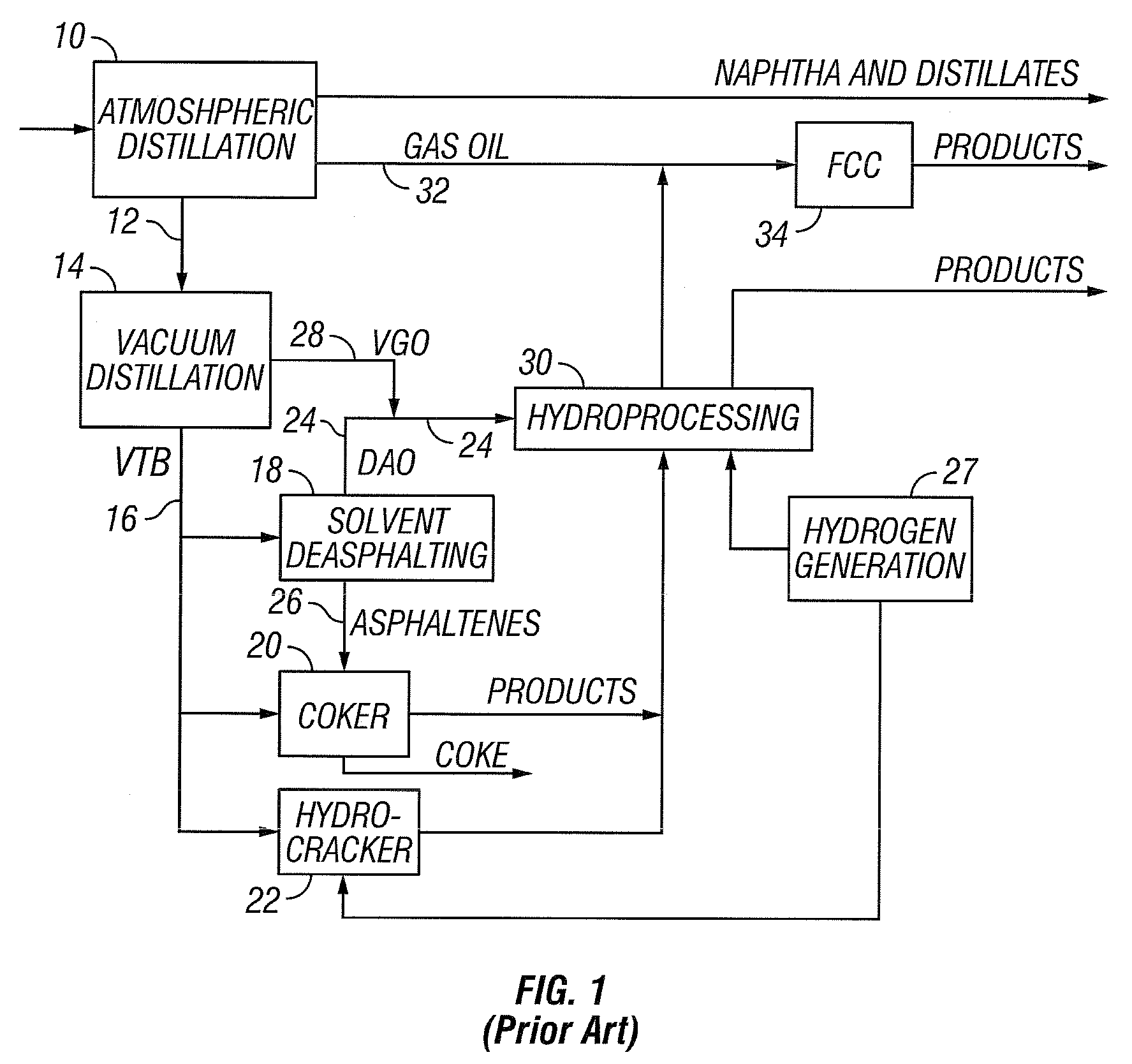

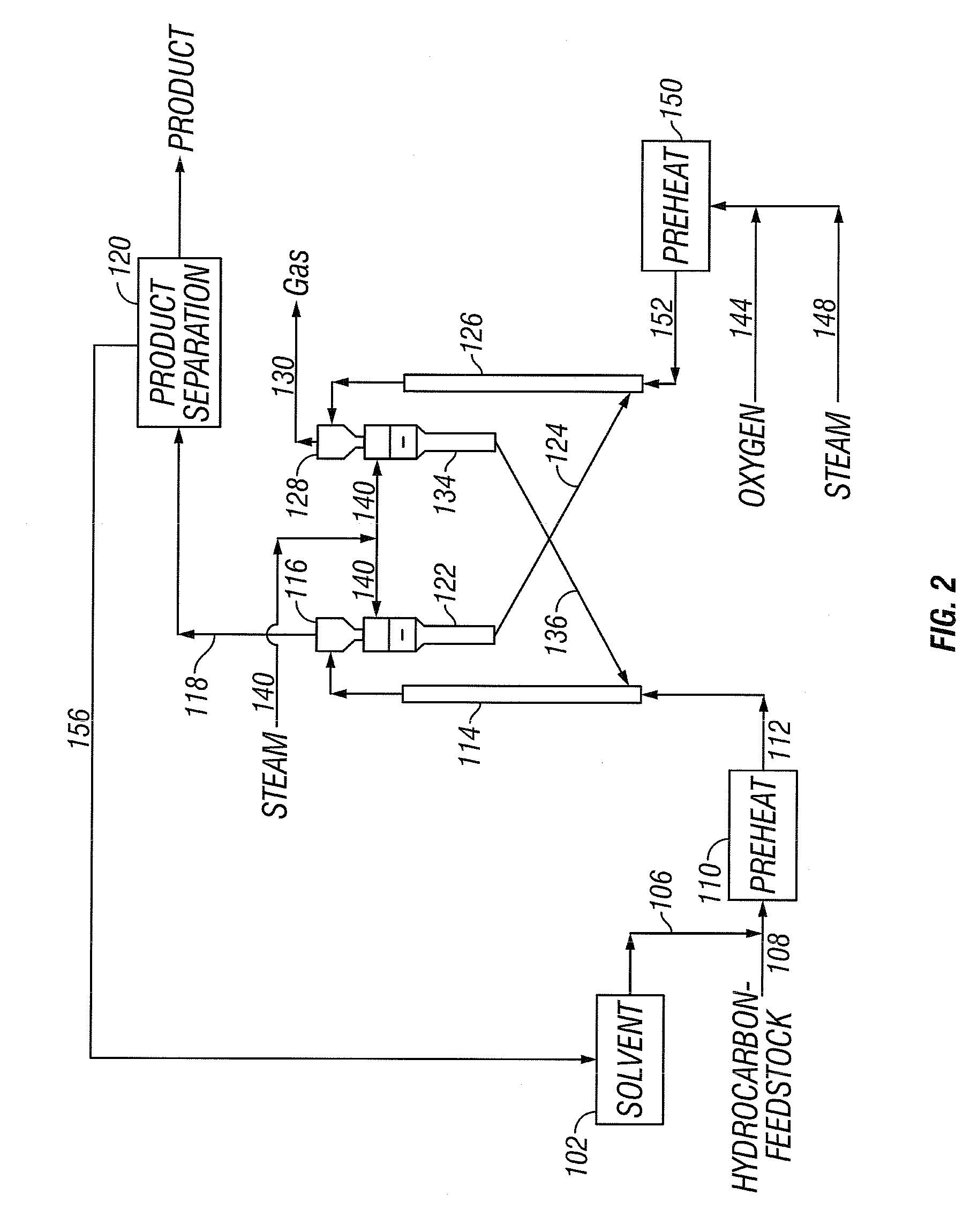

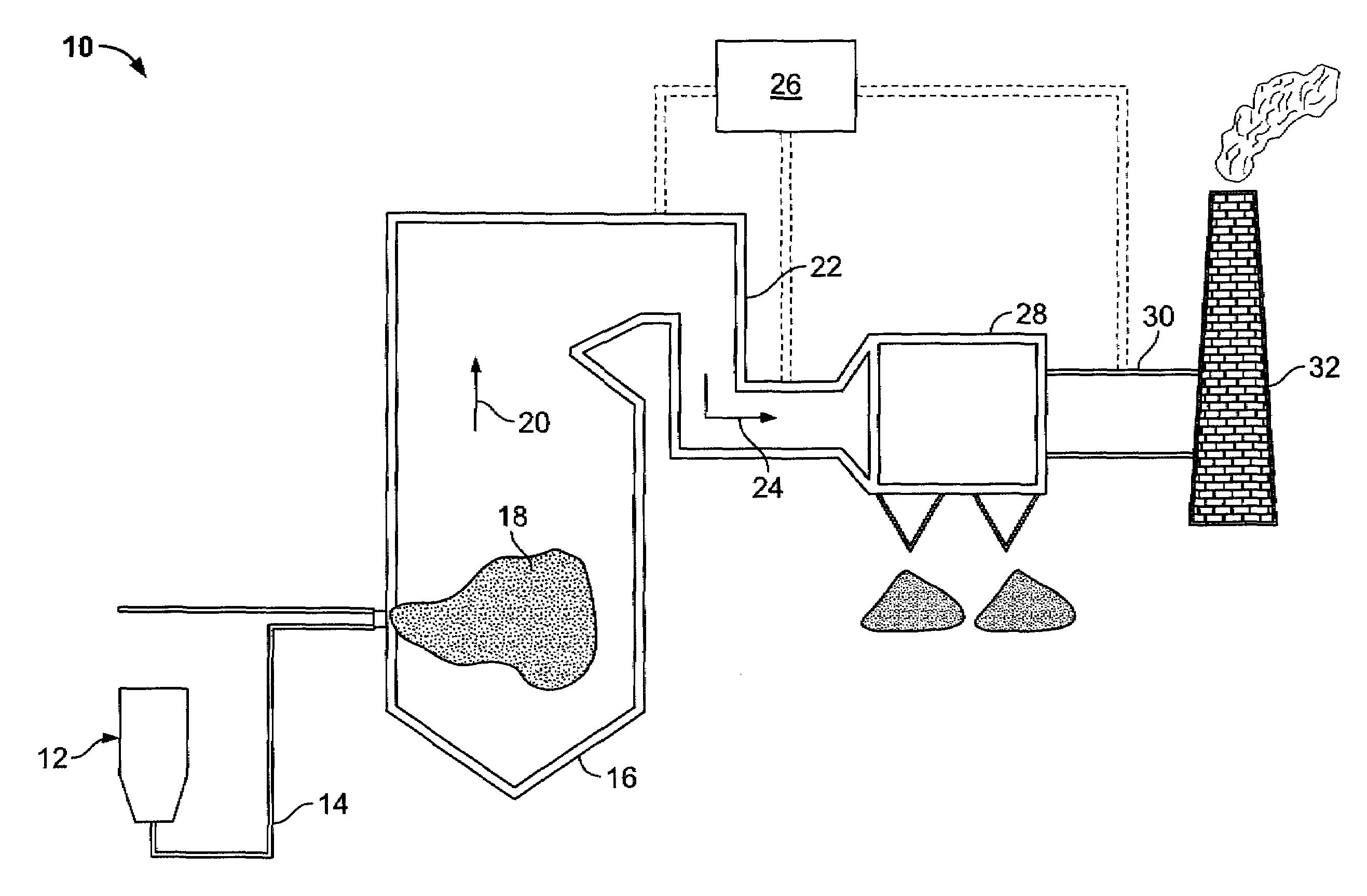

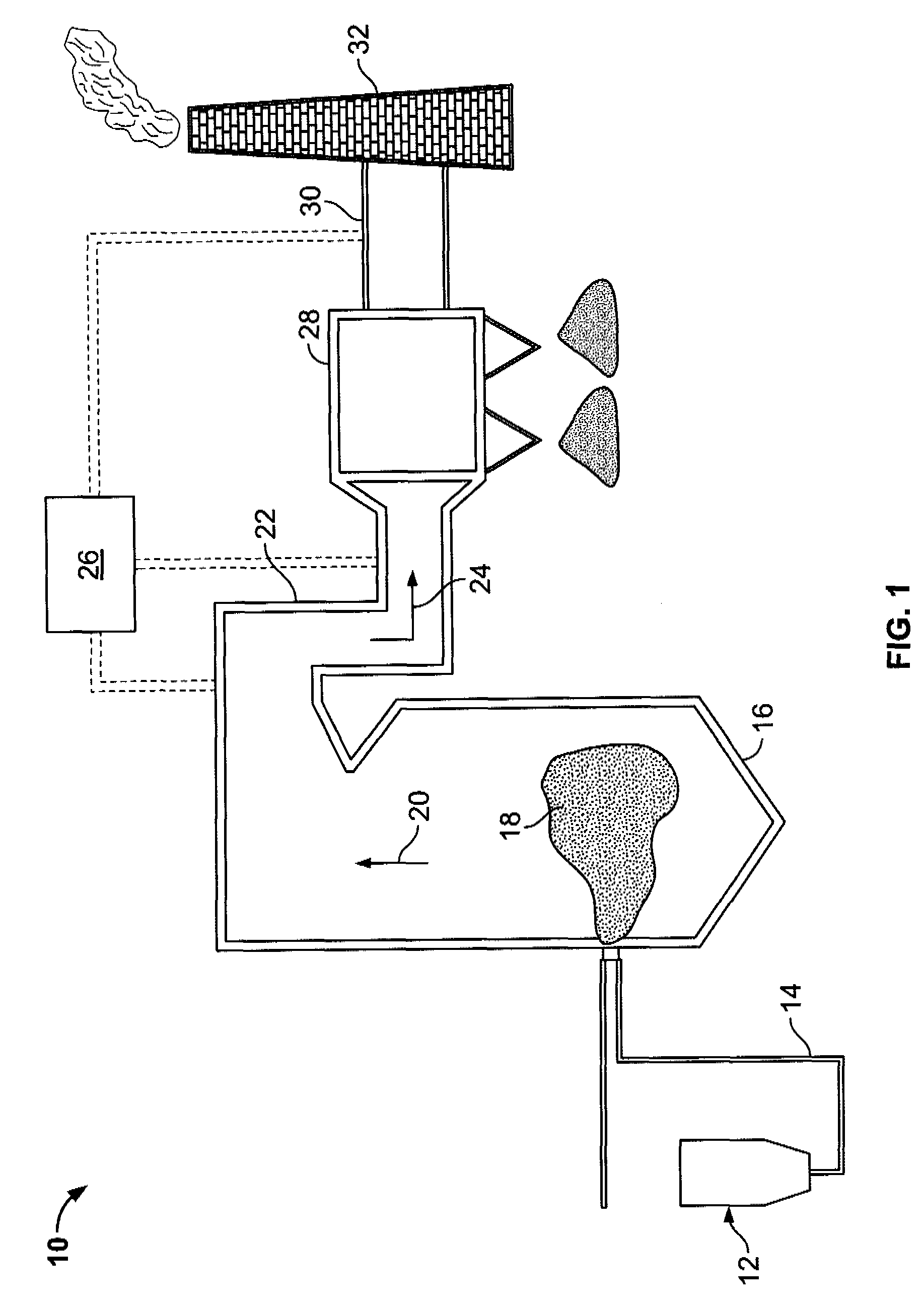

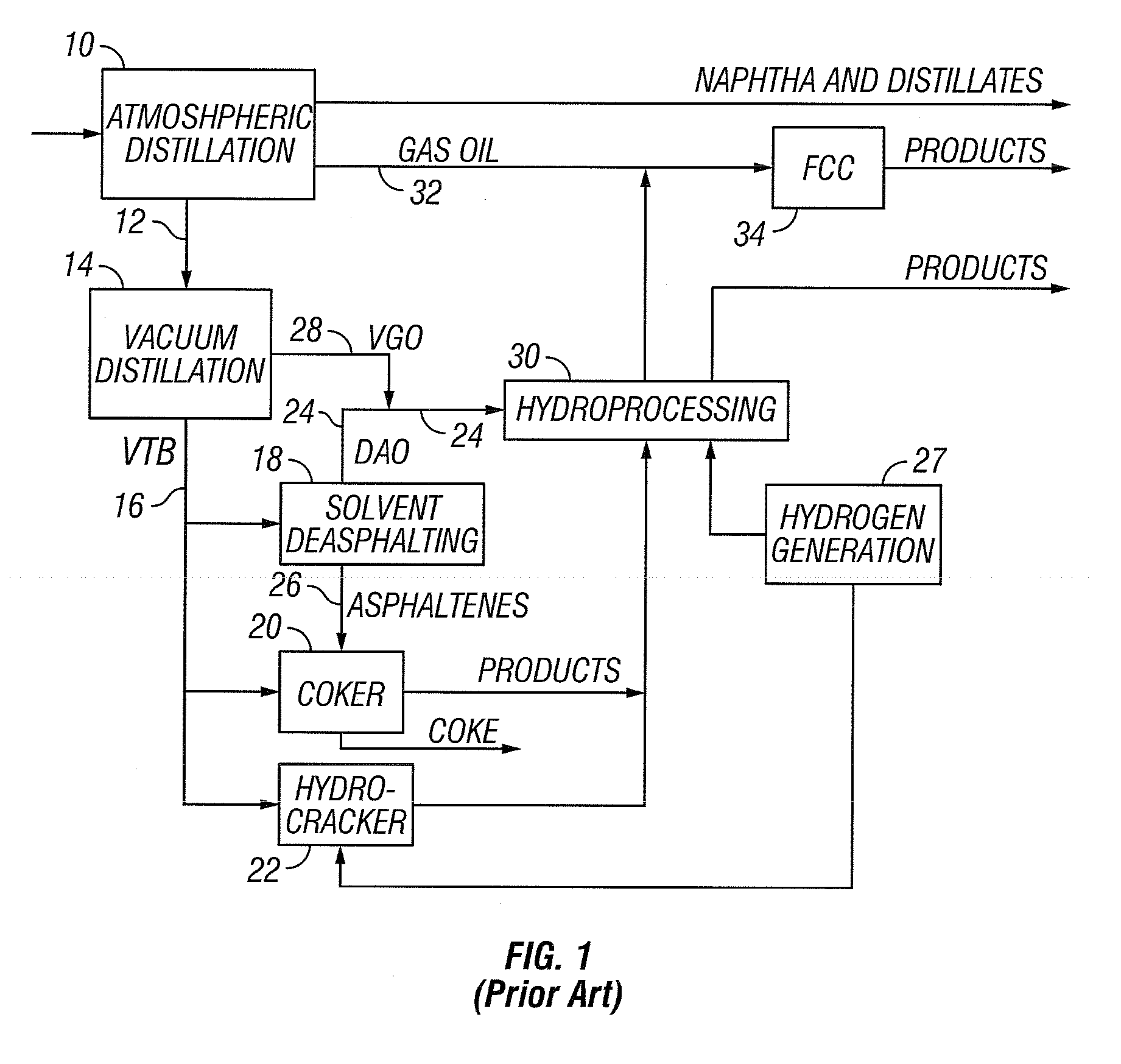

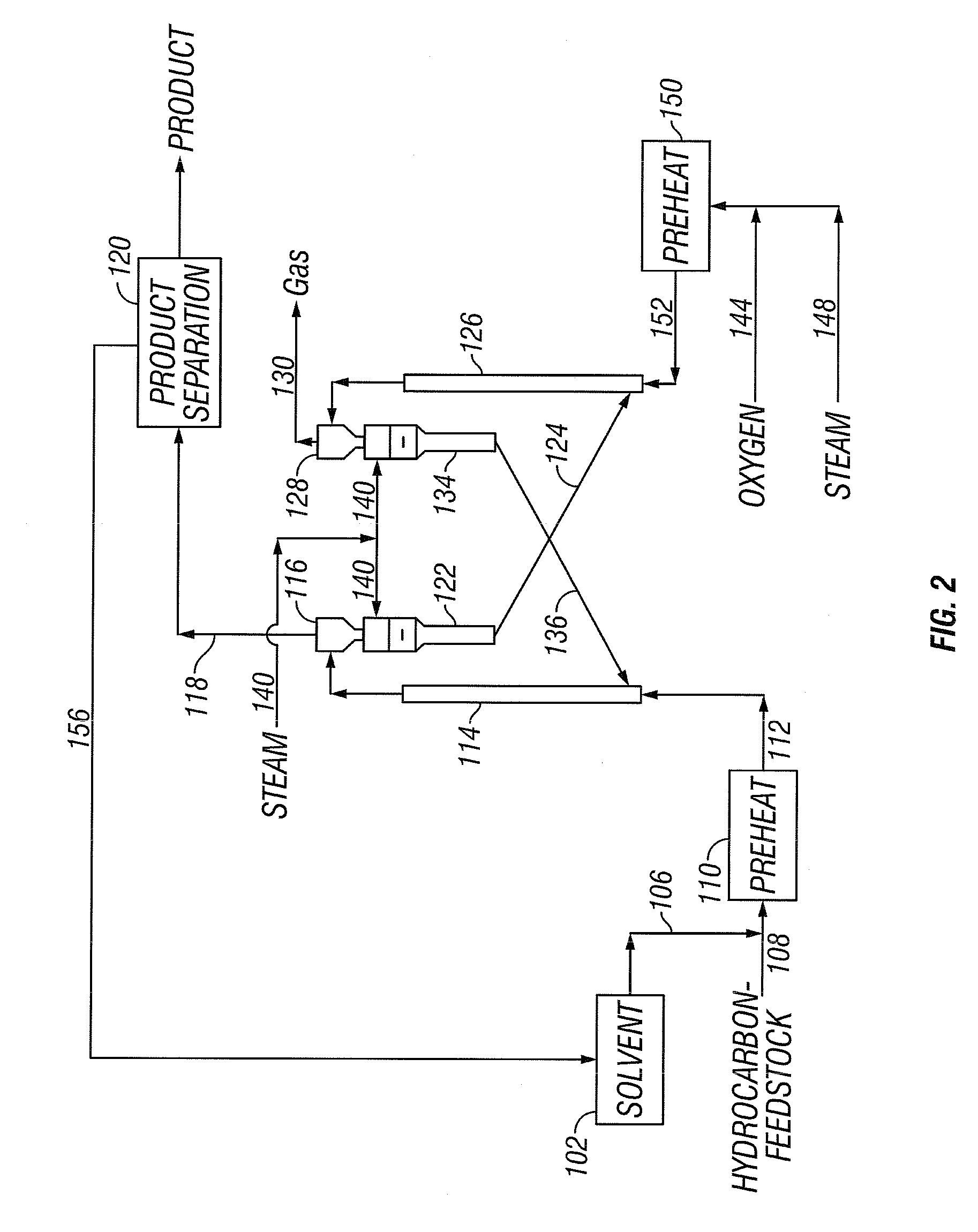

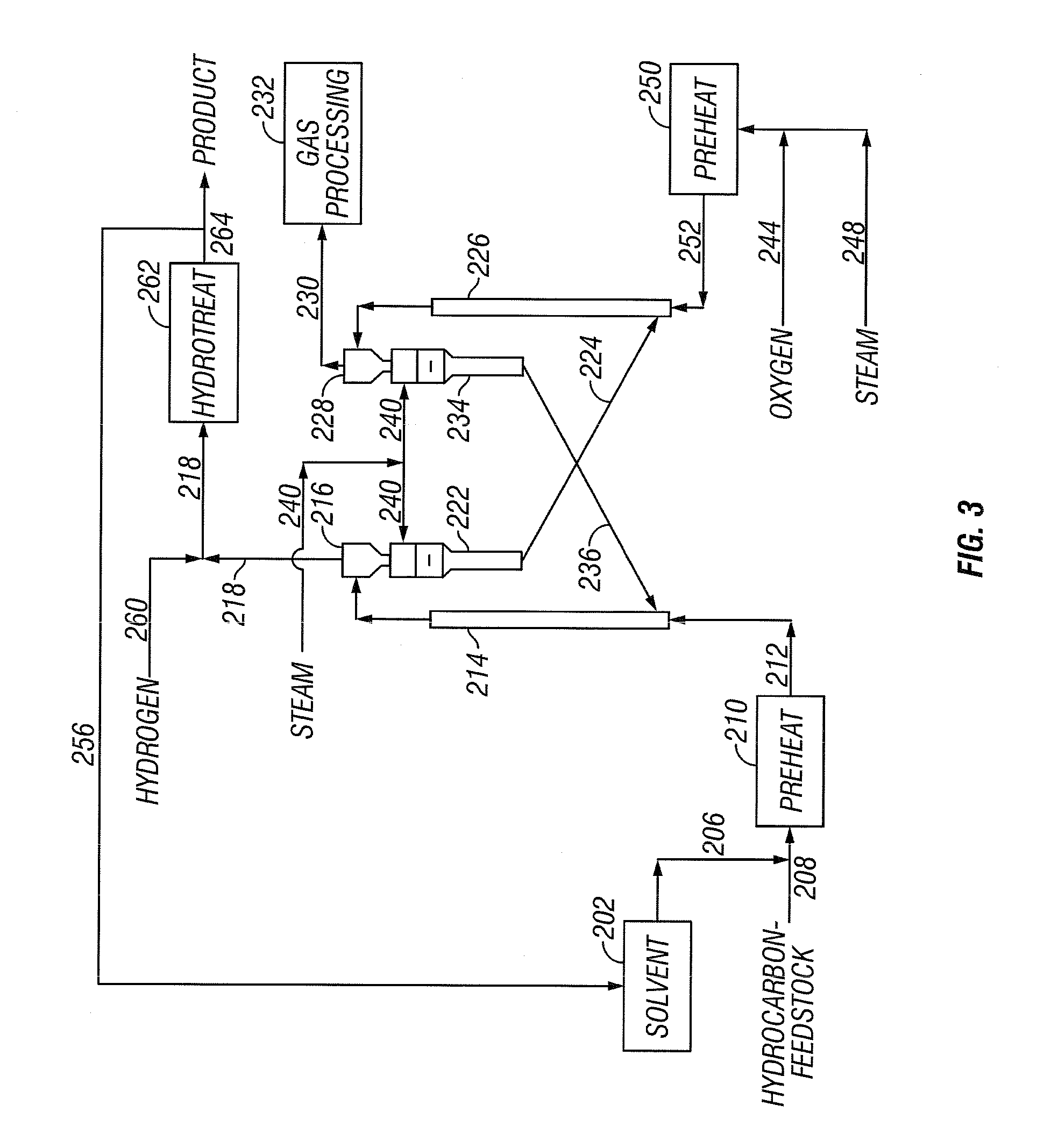

Supercritical hydrocarbon conversion process

ActiveUS7144498B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

Sorbents and sorbent composition for mercury removal

A system for removing mercury from combustion gas. The system includes a combustion device, a stack, and a duct system that couples the combustion device to the stack. The system further comprises an injection system that is coupled to the duct system. The injection system injects sorbents including alkali-based sorbents and carbon-based sorbents into the duct system.

Owner:GENERAL ELECTRIC CO

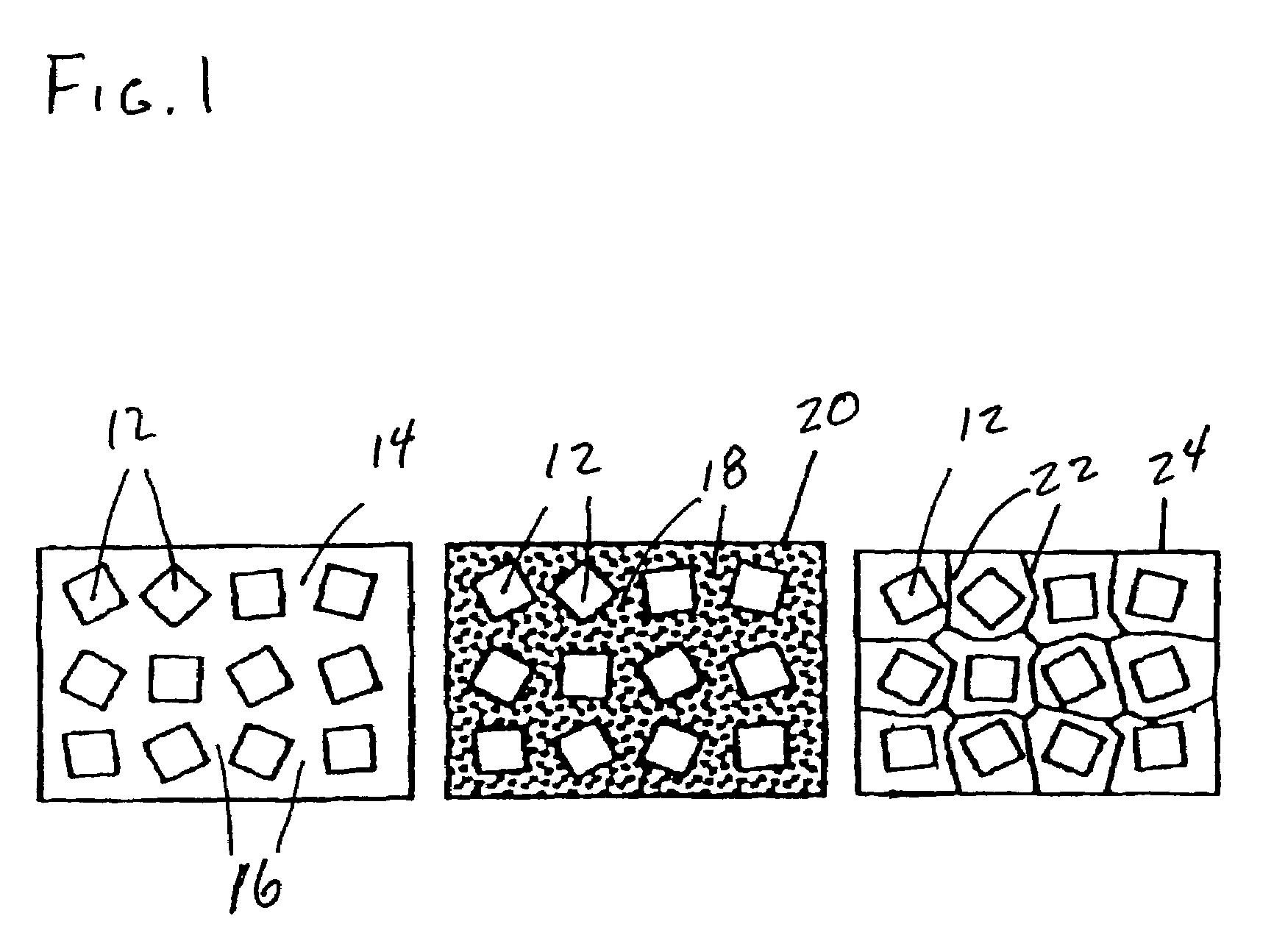

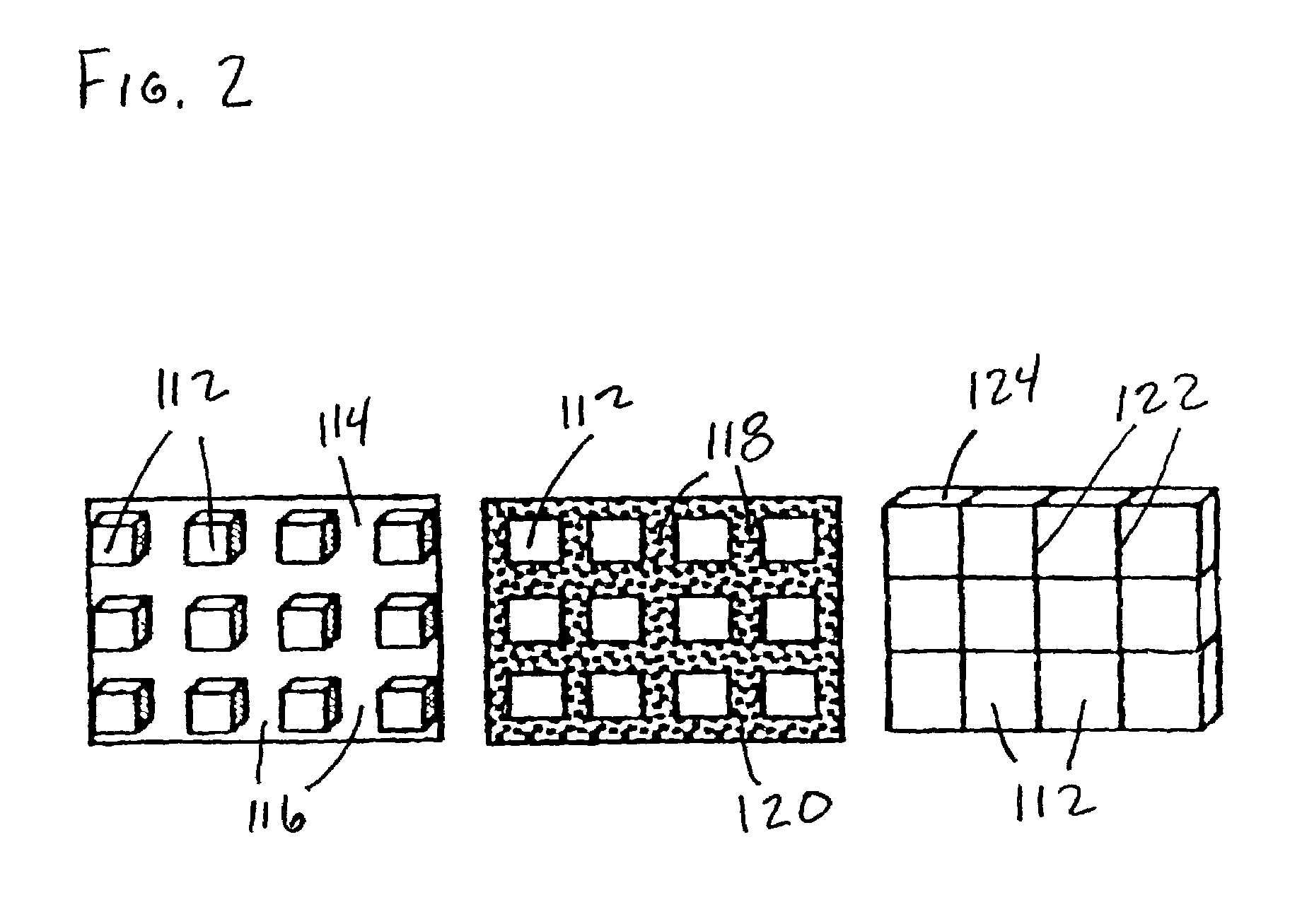

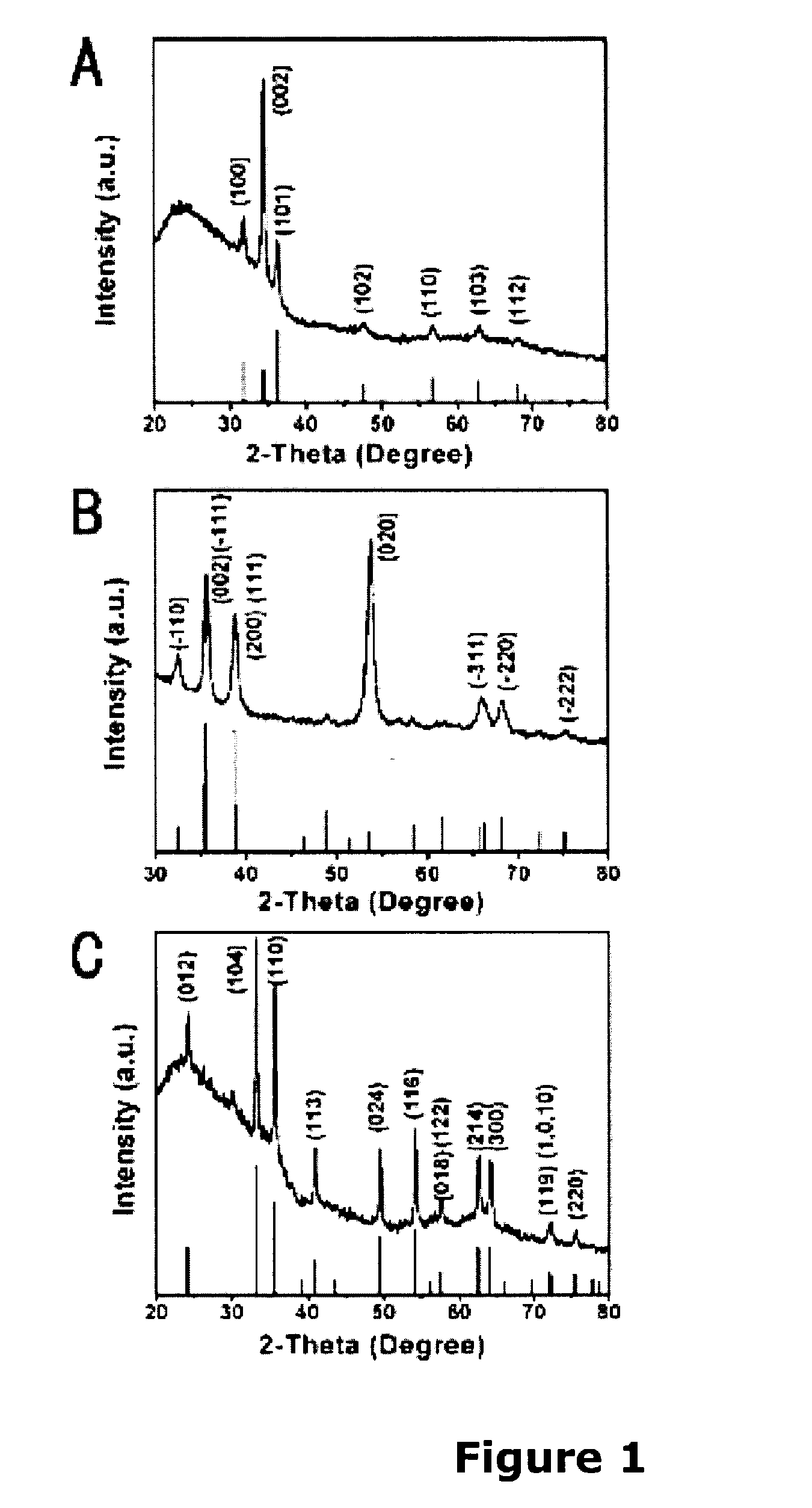

Single-crystal-like materials

InactiveUS7022303B2Improve fracture toughnessReadily apparentMagnesium fluoridesCalcium/strontium/barium fluoridesMetallurgySingle crystal

Polycrystalline materials of macroscopic size exhibiting Single-Crystal-Like properties are formed from a plurality of Single-Crystal Particles, having Self-Aligning morphologies and optionally ling morphology, bonded together and aligned along at least one, and up to three, crystallographic directions.

Owner:RUTGERS THE STATE UNIV

III-V semiconductor nanocrystal complexes and methods of making same

ActiveUS20060001119A1High Luminescence Quantum YieldMaterial nanotechnologyFrom normal temperature solutionsLuminescence quantum yieldSemiconductor nanocrystals

A semiconductor nanocrystal complex that is stable and has high luminescent quantum yield. The semiconductor nanocrystal complex has a semiconductor nanocrystal core of a III-V semiconductor nanocrystal material. A method of making a semiconductor nanocrystal complex is also provided. The method includes synthesizing a semiconductor nanocrystal core of a III-V semiconductor nanocrystal material, and forming a metal layer on the semiconductor nanocrystal core after synthesis of the semiconductor nanocrystal core.

Owner:SAMSUNG ELECTRONICS CO LTD

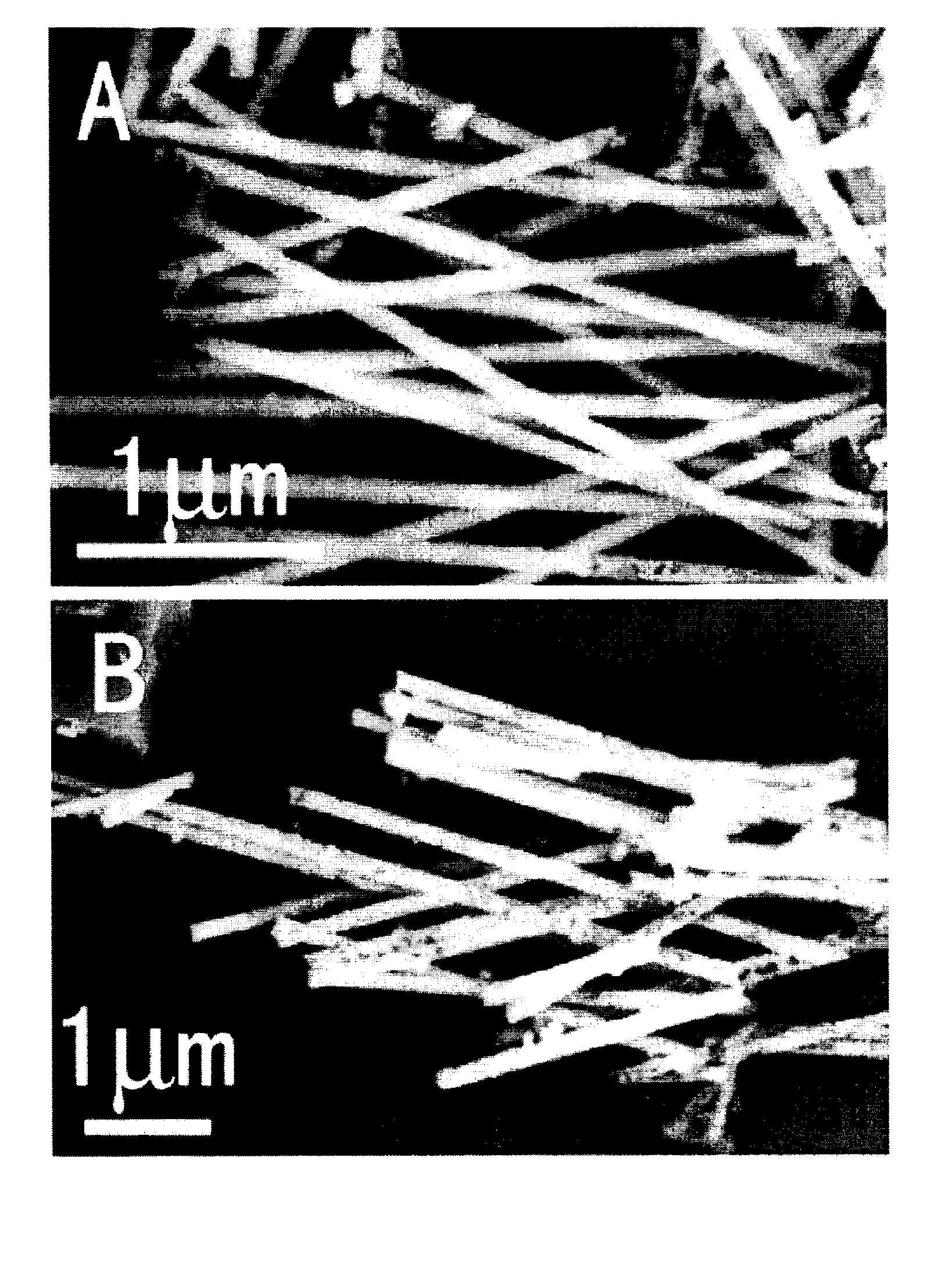

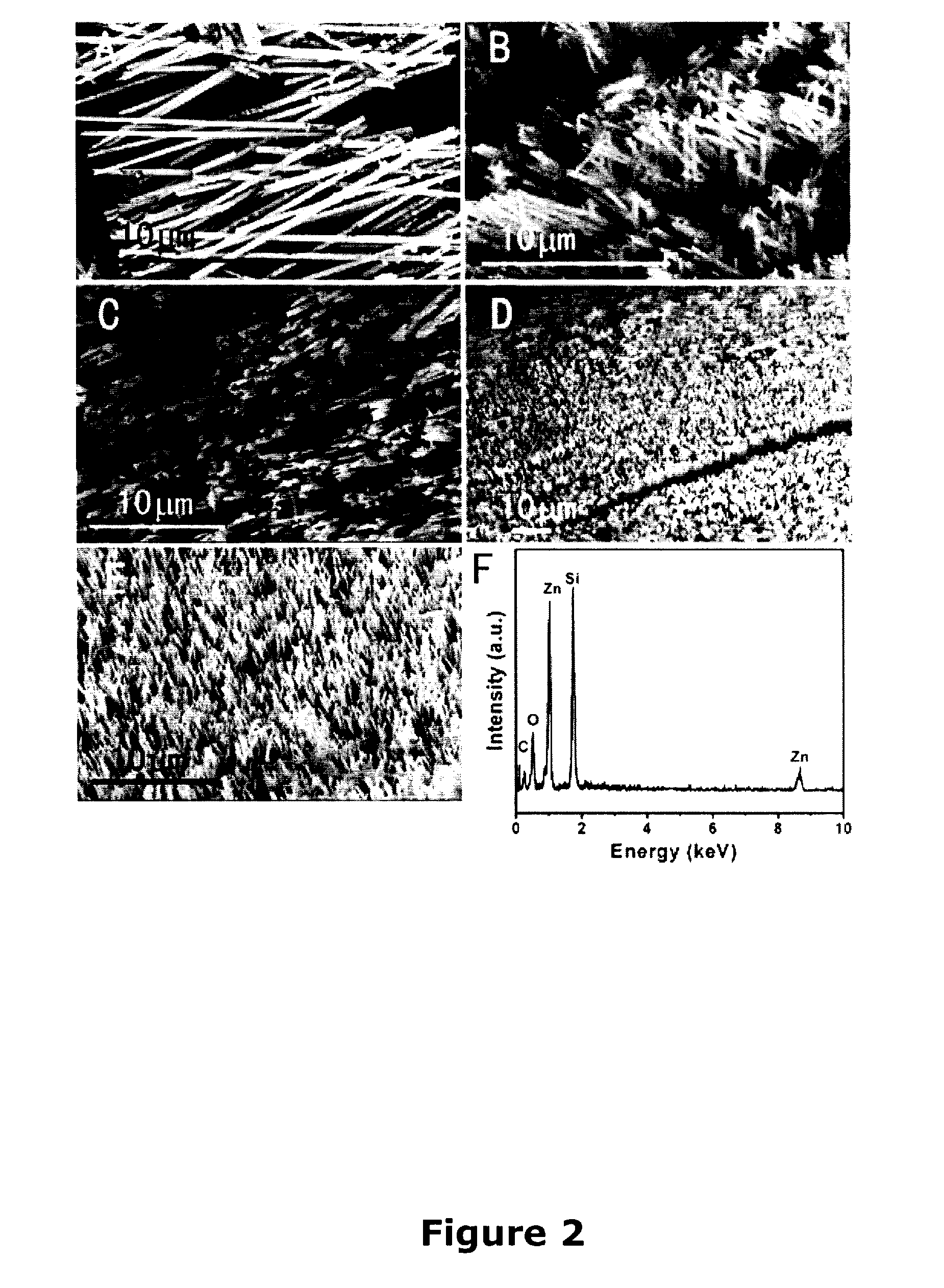

Methods of Making Binary Metal Oxide Nanostructures and Methods of Controlling Morphology of Same

ActiveUS20100278720A1Reduce crystallinityControl dimensionalityCopper oxides/halidesManganese oxides/hydroxidesPorous membraneNanostructure

The present invention includes a method of producing a crystalline metal oxide nanostructure. The method comprises providing a metal salt solution and providing a basic solution; placing a porous membrane between the metal salt solution and the basic solution, wherein metal cations of the metal salt solution and hydroxide ions of the basic solution react, thereby producing a crystalline metal oxide nanostructure.

Owner:WONG STANISLAUS S +1

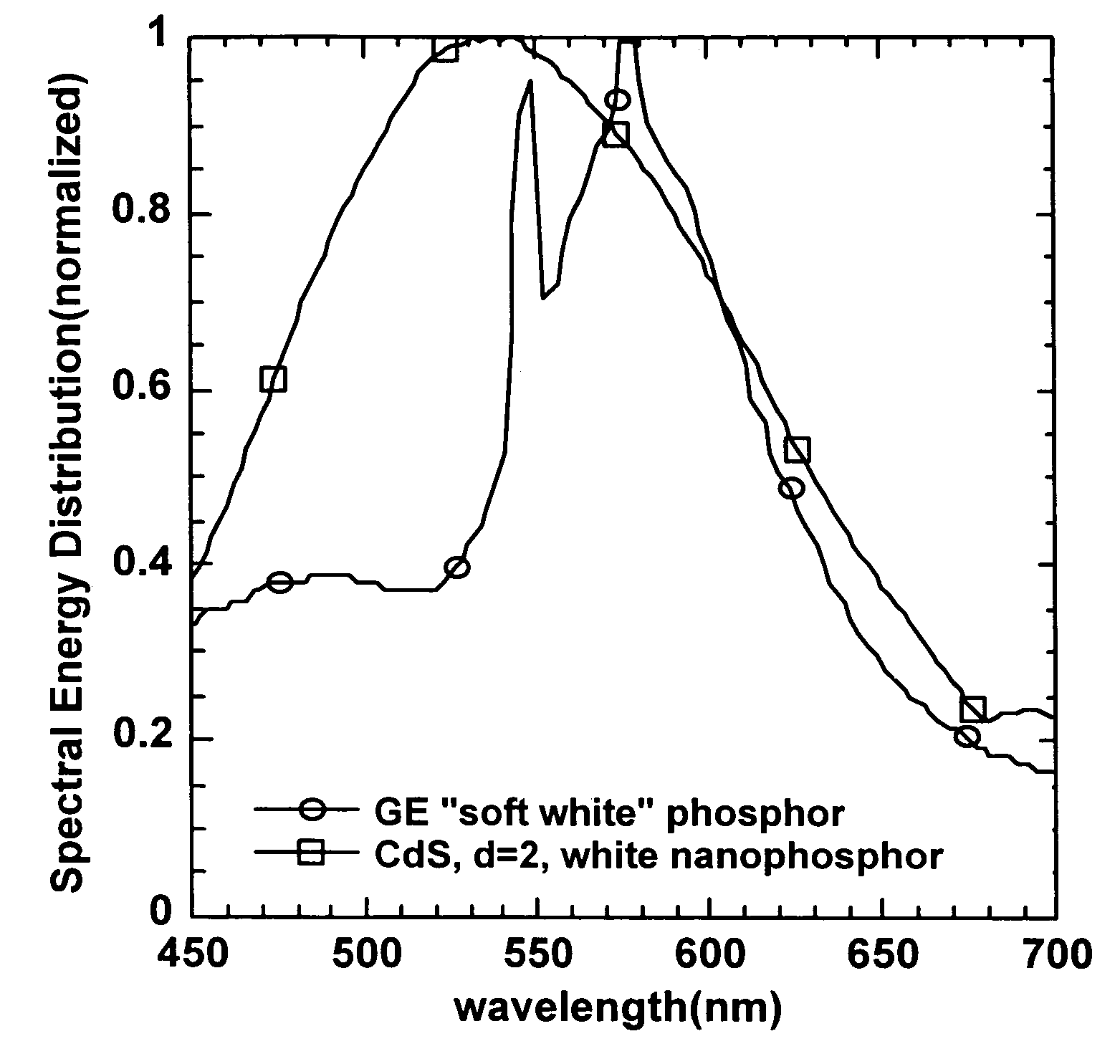

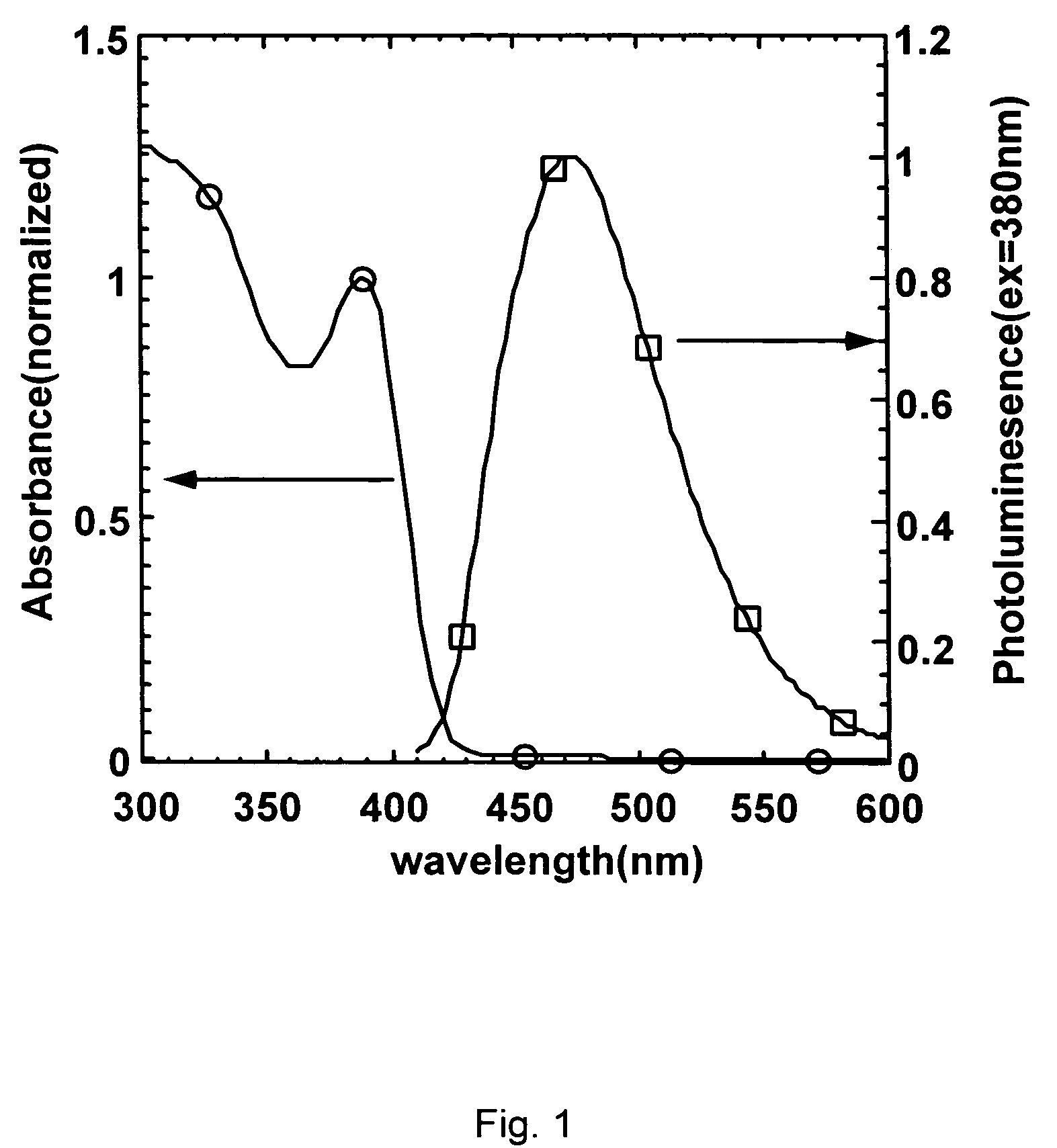

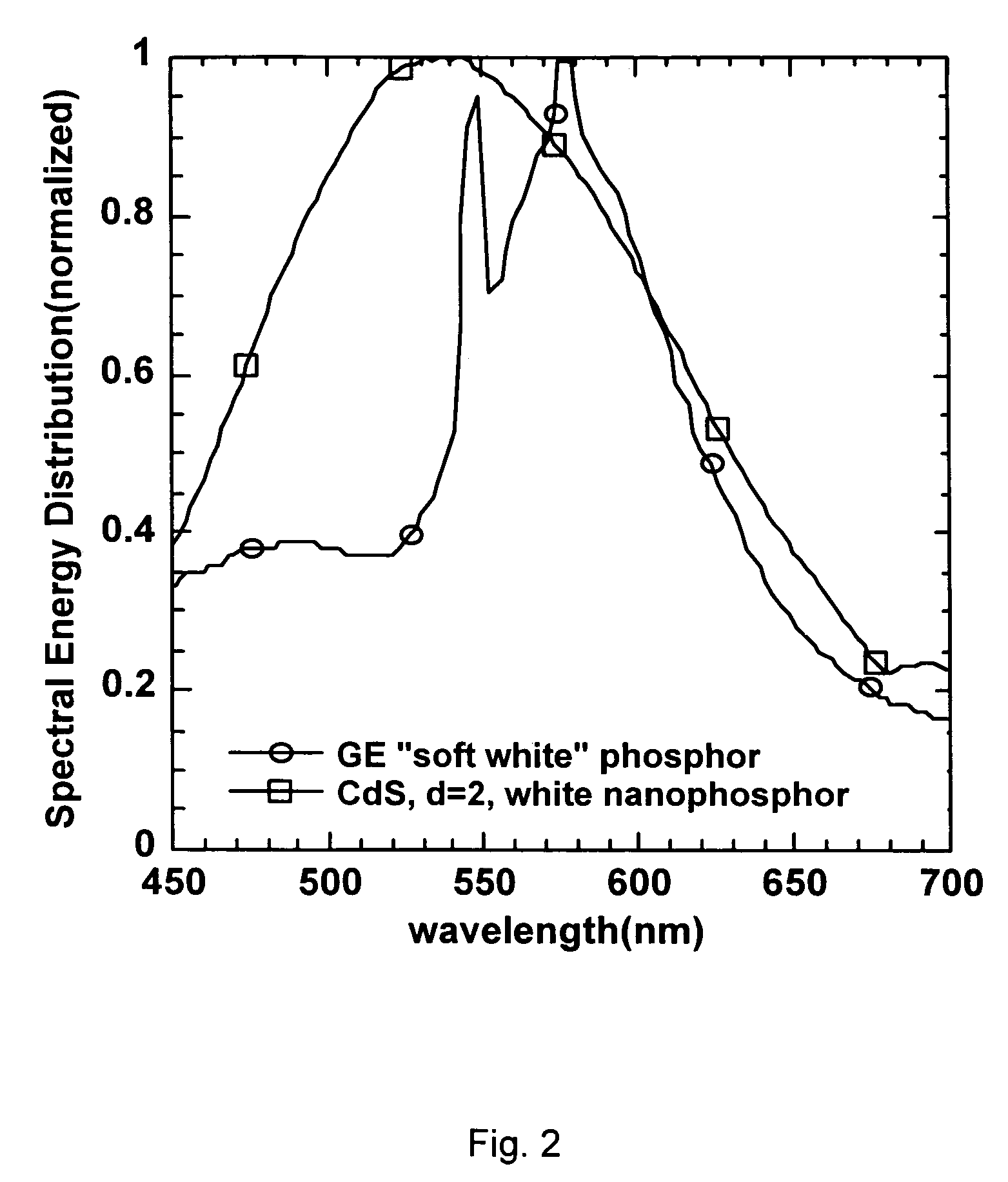

Nanocluster-based white-light-emitting material employing surface tuning

A method for making a nanocrystal-based material capable of emitting light over a sufficiently broad spectral range to appear white. Surface-modifying ligands are used to shift and broaden the emission of semiconductor nanocrystals to produce nanoparticle-based materials that emit white light.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

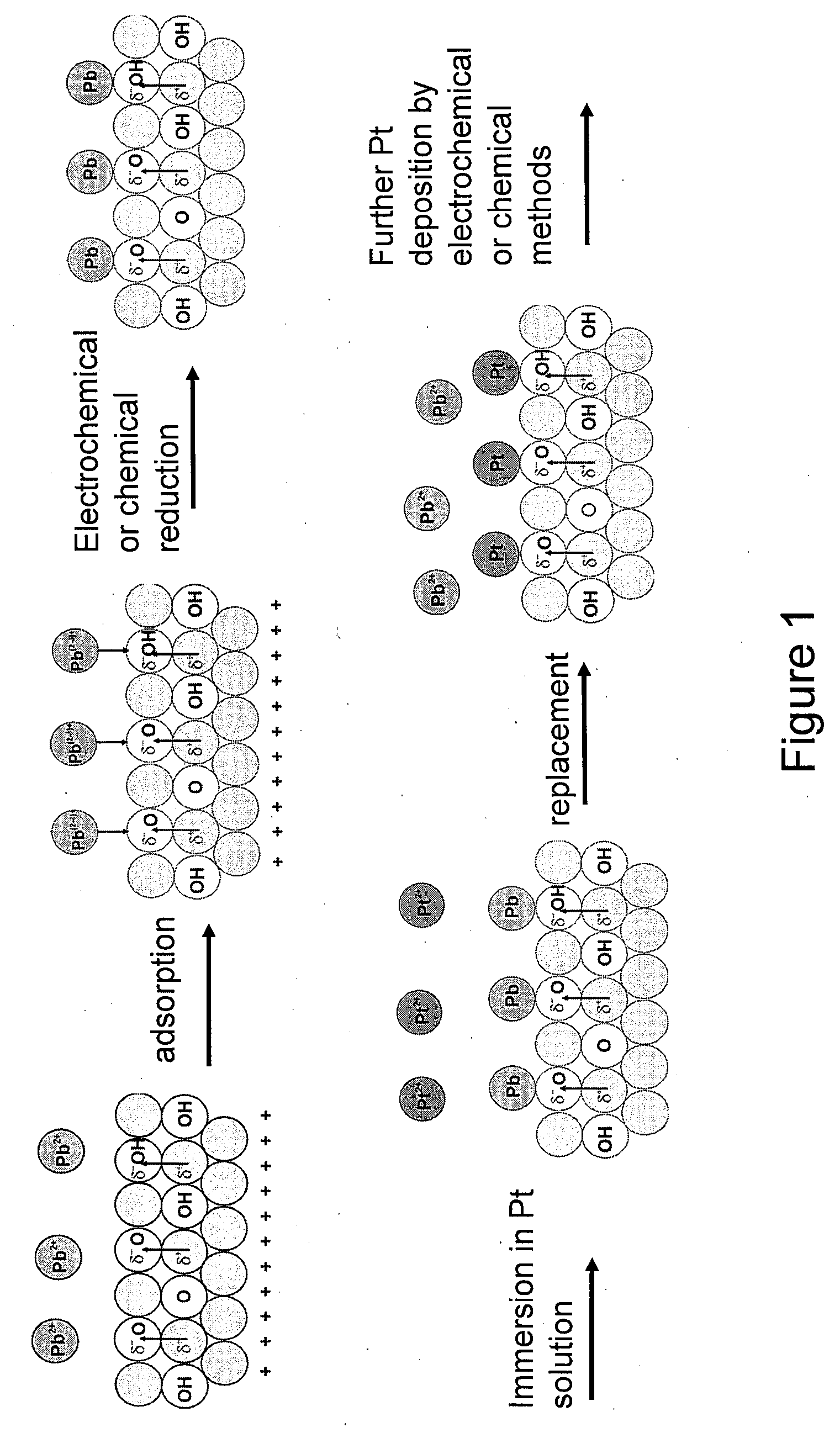

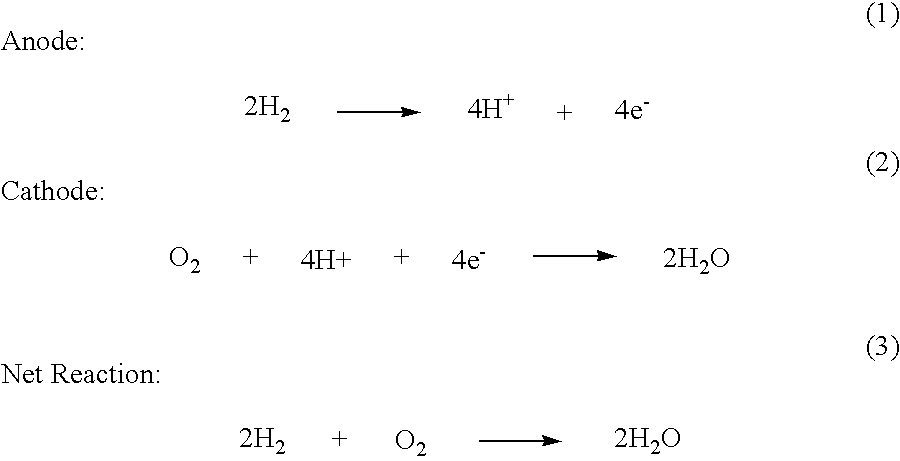

Synthesis of Metal-Metal Oxide Catalysts and Electrocatalysts Using a Metal Cation Adsorption/Reduction and Adatom Replacement by More Noble Ones

InactiveUS20070264189A1Improve stabilityReducing and preventing oxidationCell electrodesGold compoundsHydrogenFuel cells

The invention relates to platinum-metal oxide composite particles and their use as electrocatalysts in oxygen-reducing cathodes and fuel cells. The invention particularly relates to methods for preventing the oxidation of the platinum electrocatalyst in the cathodes of fuel cells by use of these platinum-metal oxide composite particles. The invention additionally relates to methods for producing electrical energy by supplying such a fuel cell with an oxidant, such as oxygen, and a fuel source, such as hydrogen. The invention also relates to methods of making the metal-metal oxide composites.

Owner:BROOKHAVEN SCI ASSOCS

Semiconductor nanocrystal complexes and methods of making same

ActiveUS20060014040A1Material nanotechnologyLiquid surface applicatorsLattice mismatchSemiconductor nanocrystals

A semiconductor nanocrystal complex including a metal layer formed on the outer surface of a semiconductor nanocrystal core after synthesis of the semiconductor nanocrystal core and a method for preparing a nanocrystal complex comprising forming a metal layer on a semiconductor nanocrystal core after synthesis of the semiconductor nanocrystal core. The metal layer may passivate the surface of the semiconductor nanocrystal core and protect the semiconductor nanocrystal core from the effects of oxidation. Also provided is a semiconductor nanocrystal complex with a shell grown onto the metal layer formed on the semiconductor nanocrystal core. In this embodiment, the metal layer may prevent lattice mismatch between the semiconductor shell and the semiconductor nanocrystal core.

Owner:SAMSUNG ELECTRONICS CO LTD

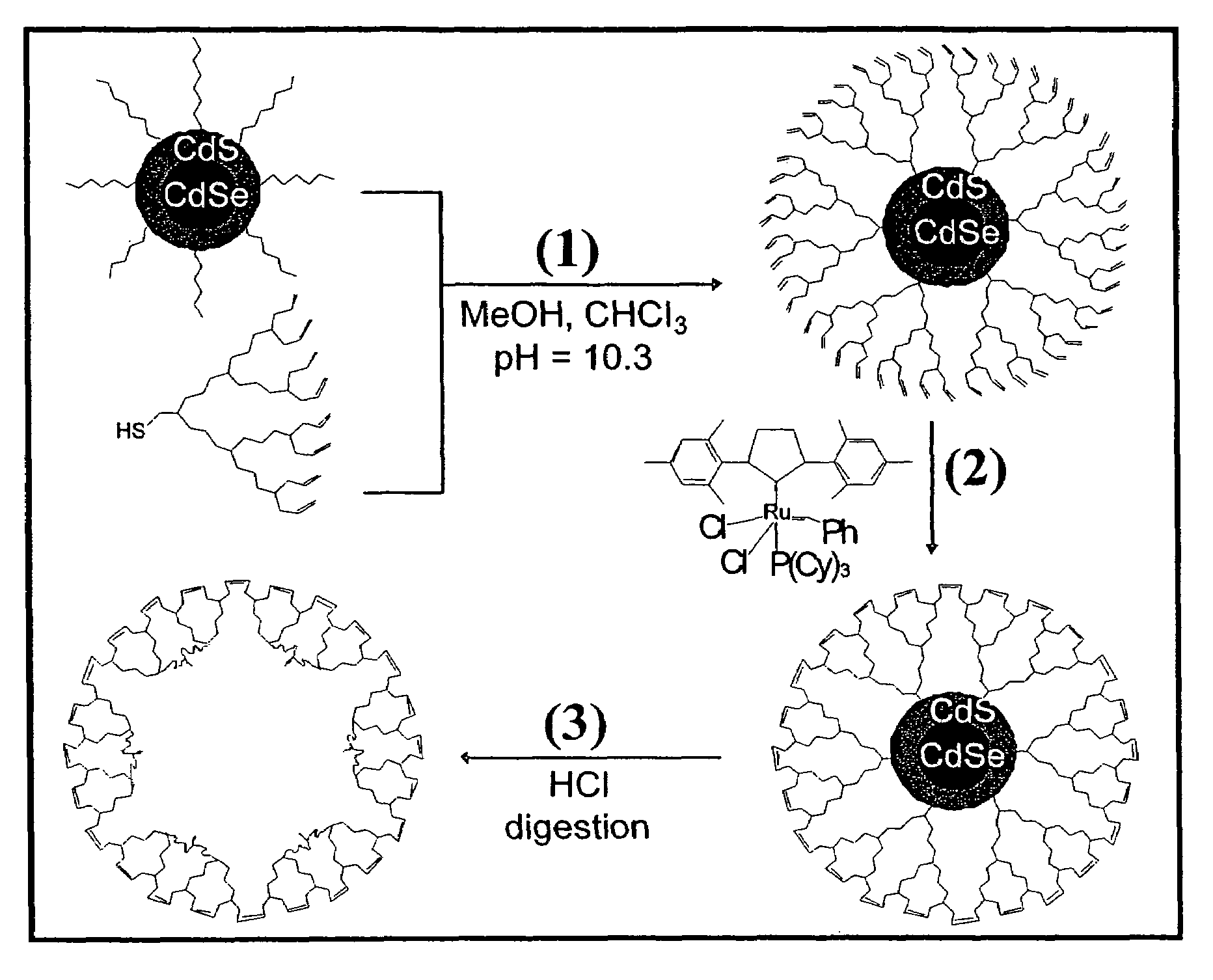

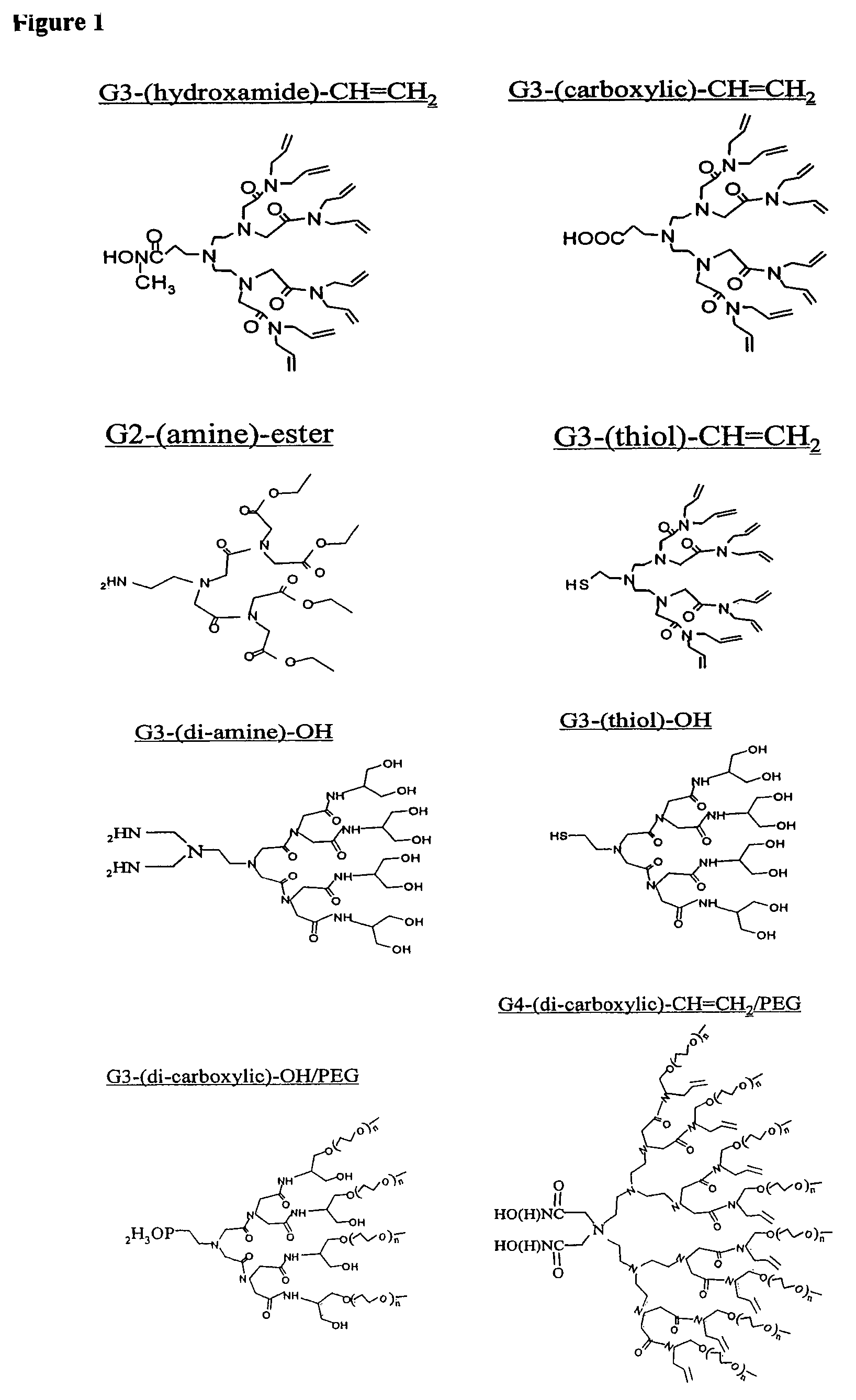

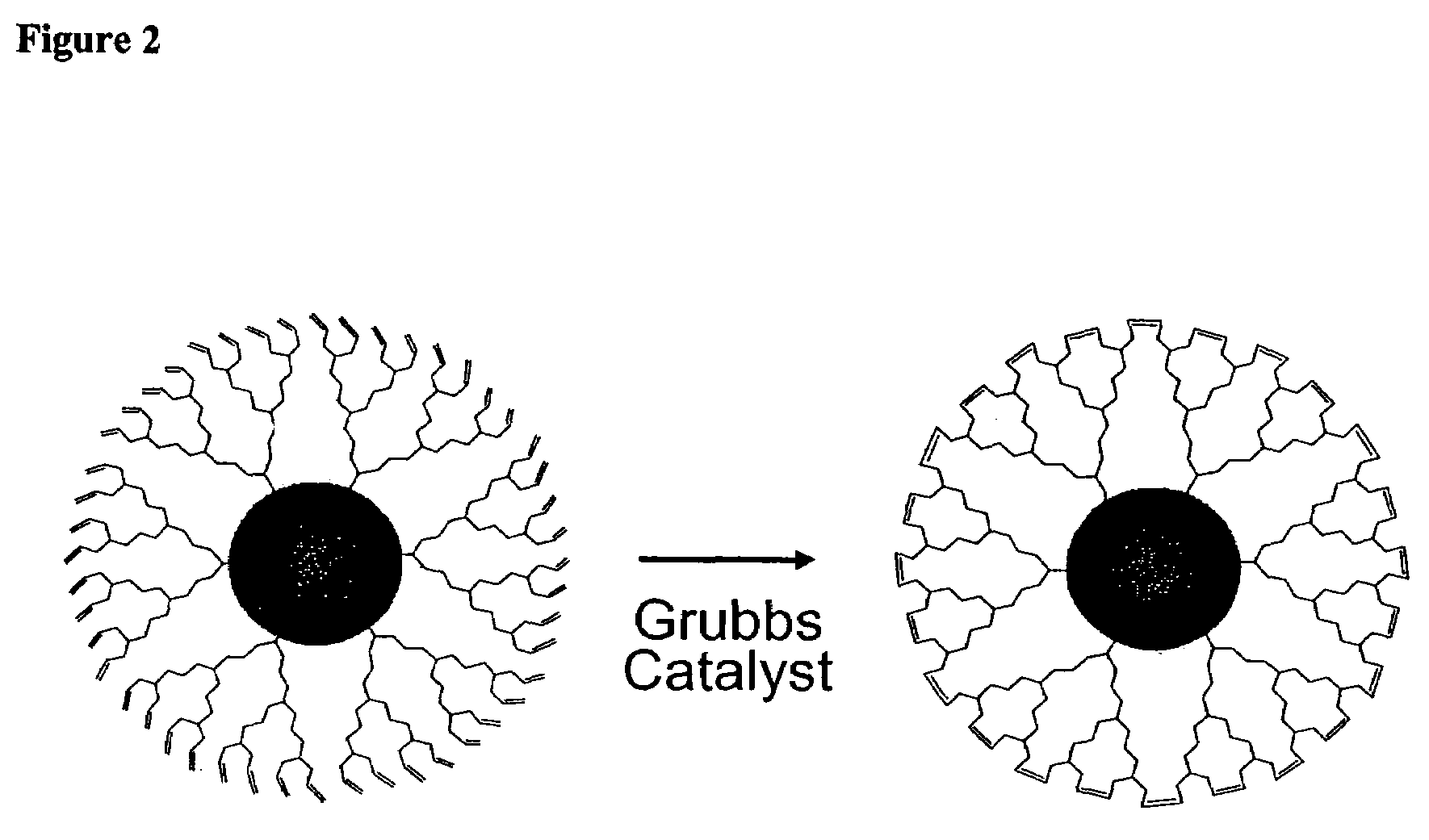

Nanocrystals in ligand boxes exhibiting enhanced chemical, photochemical, and thermal stability, and methods of making the same

ActiveUS7273904B2Improve stabilityEasy to detectMaterial nanotechnologyFrom normal temperature solutionsDendrimerCross-link

Dendron ligands or other branched ligands with cross-linkable groups were coordinated to colloidal inorganic nanoparticles, including nanocrystals, and substantially globally cross-linked through different strategies, such as ring-closing metathesis (RCM), dendrimer-bridging methods, and the like. This global cross-linking reaction sealed each nanocrystal within a dendron box to yield box-nanocrystals which showed dramatically enhanced stability against chemical, photochemical and thermal treatments in comparison to the non-cross-linked dendron-nanocrystals. Empty dendron boxes possessing a very narrow size distribution were formed by the dissolution of the inorganic nanocrystals contained therein upon acid or other etching treatments.

Owner:BEIJING JINGTAI MEIKANG BIOTECH CO LTC +1

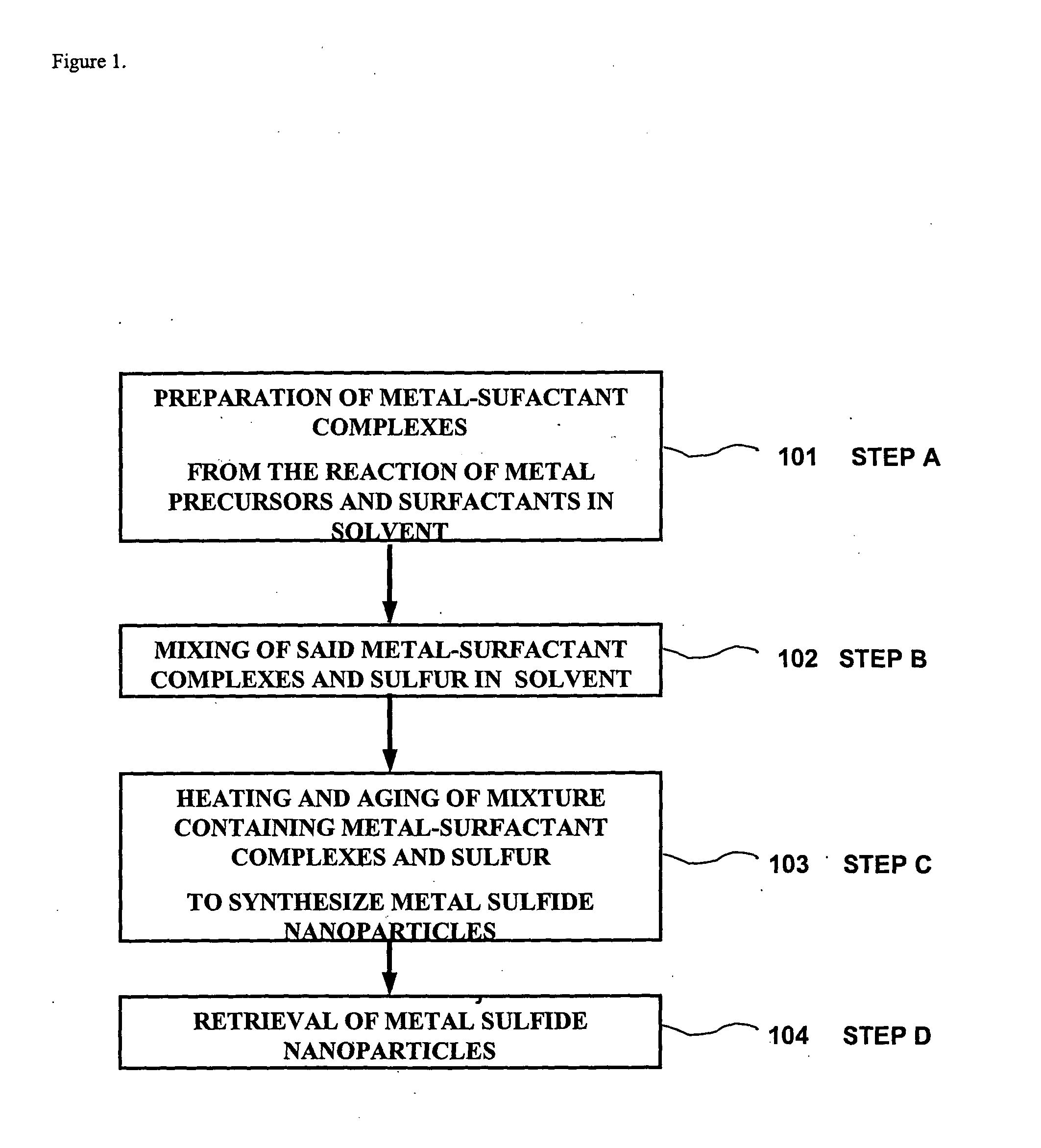

Method for synthesizing nanoparticles of metal sulfides

A synthetic method of fabricating highly crystalline and uniform nanoparticles of metal sulfides, doped metal sulfides, and multi-metallic sulfides disclosed, using no-toxic and inexpensive reagents. A typical synthetic method comprises the steps of, synthesis of metal-surfactant complexes from the reaction of metal precursors and surfactant, addition of sulfur reagent to the solution containing said metal-surfactant complexes followed by heating to high temperature, aging at that temperature to produce metal sulfide nanoparticles and completing the formation of synthesis of nanoparticles metal sulfides and multi-metallic sulfides by adding a poor solvent followed by centrifuging.

Owner:SEOUL NATIONAL UNIVERSITY

Composition and method for oxidizing mercury in combustion processes

InactiveUS7413719B2Emission reductionExcessive emissionUsing liquid separation agentEmission preventionCombustion chamberCombustor

The invention can be summarized as follows. There is provided a method for oxidizing elemental mercury in a combustion process comprising, adding a composition comprising an aluminum silicate to a combustion chamber, boiler or kiln downstream from the burner region combustion zone. There is further provided a method for reducing the emission of one or more heavy metals in a combustion process by adding a composition comprising an aluminum silicate to a combustion chamber downstream from the burner region combustion zone. There is also provided a composition comprising an aluminum silicate that may be employed to oxidize elemental mercury generated in a combustion process. The composition also may be employed to reduce the emission of one or more heavy metals generated in a combustion process.

Owner:DIGDON WILLIAM TROY

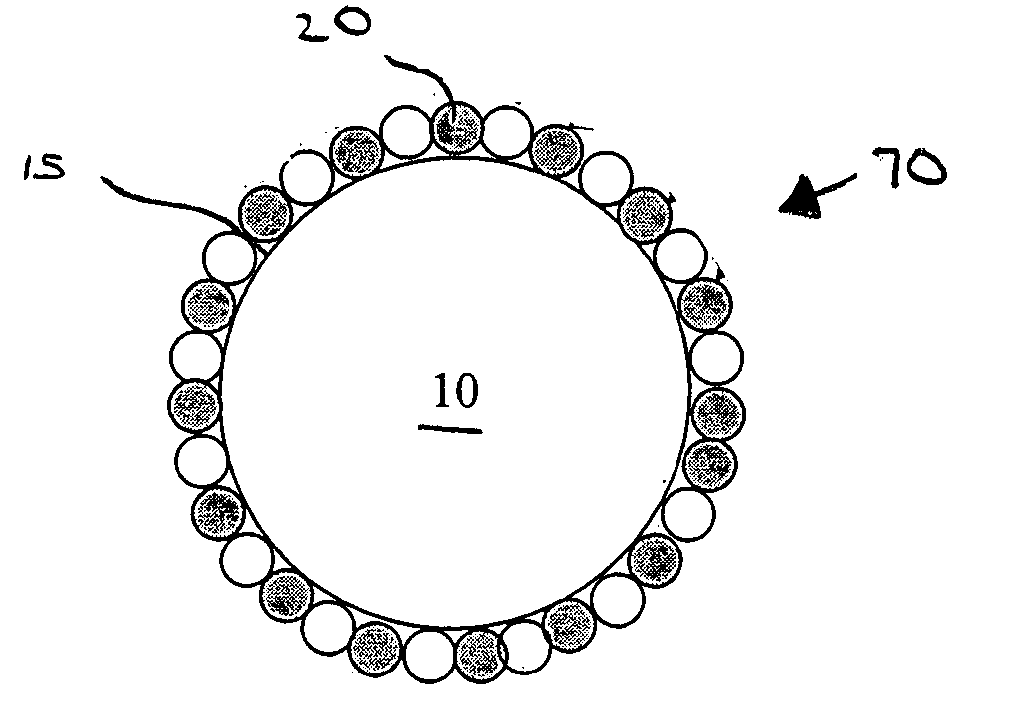

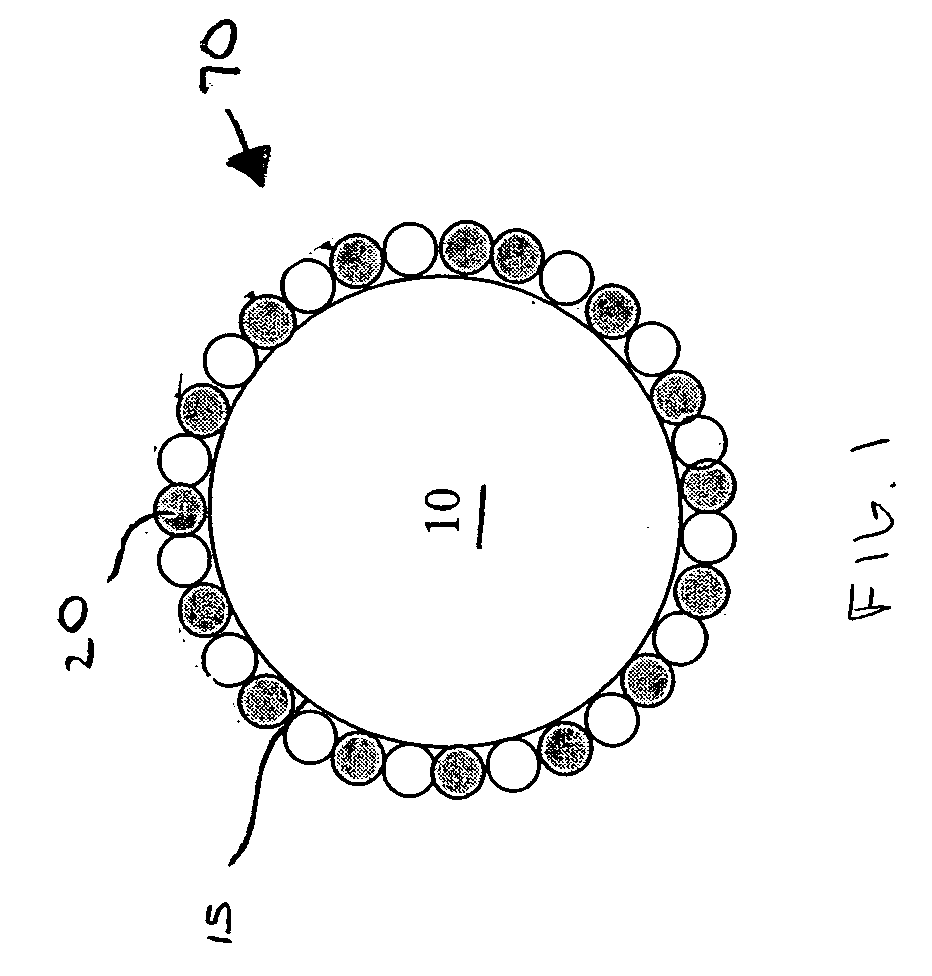

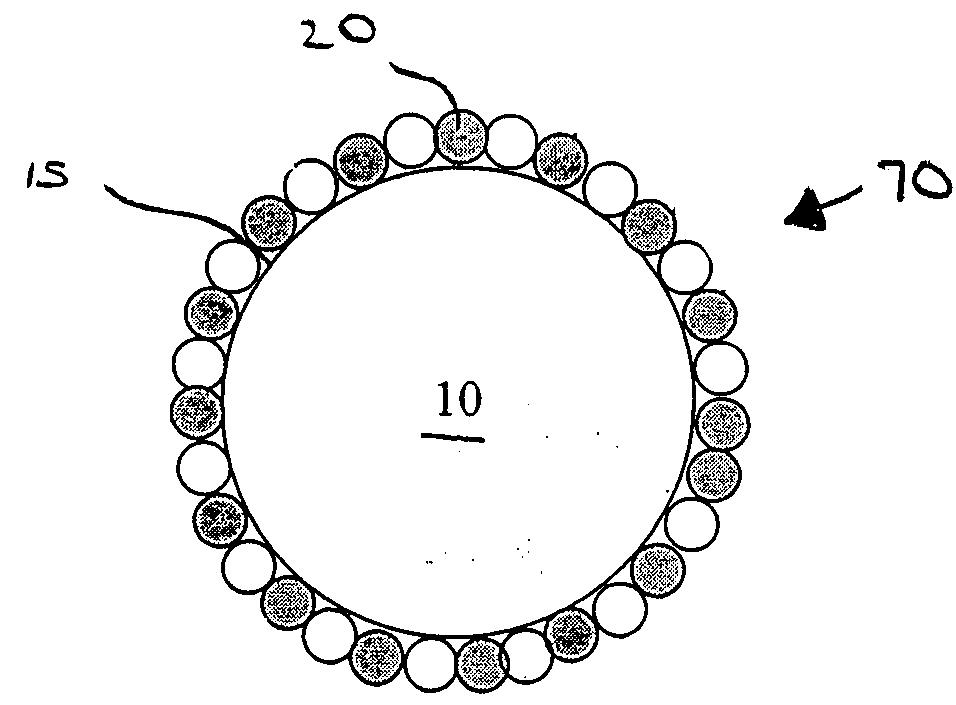

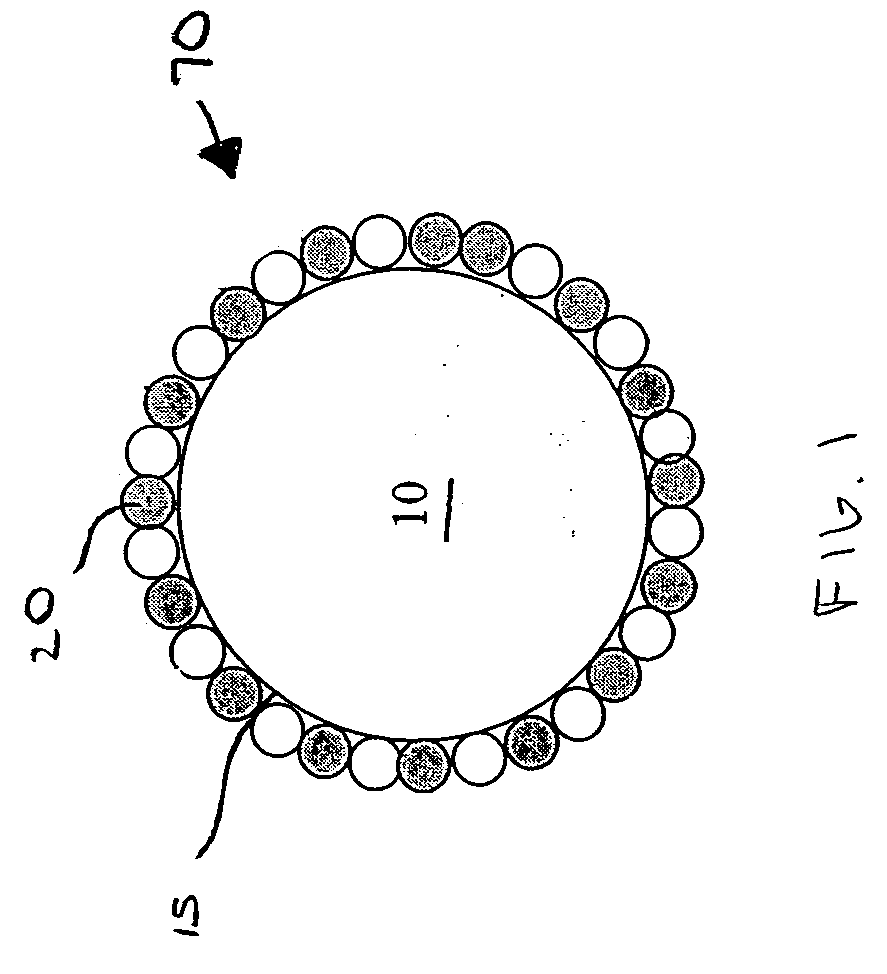

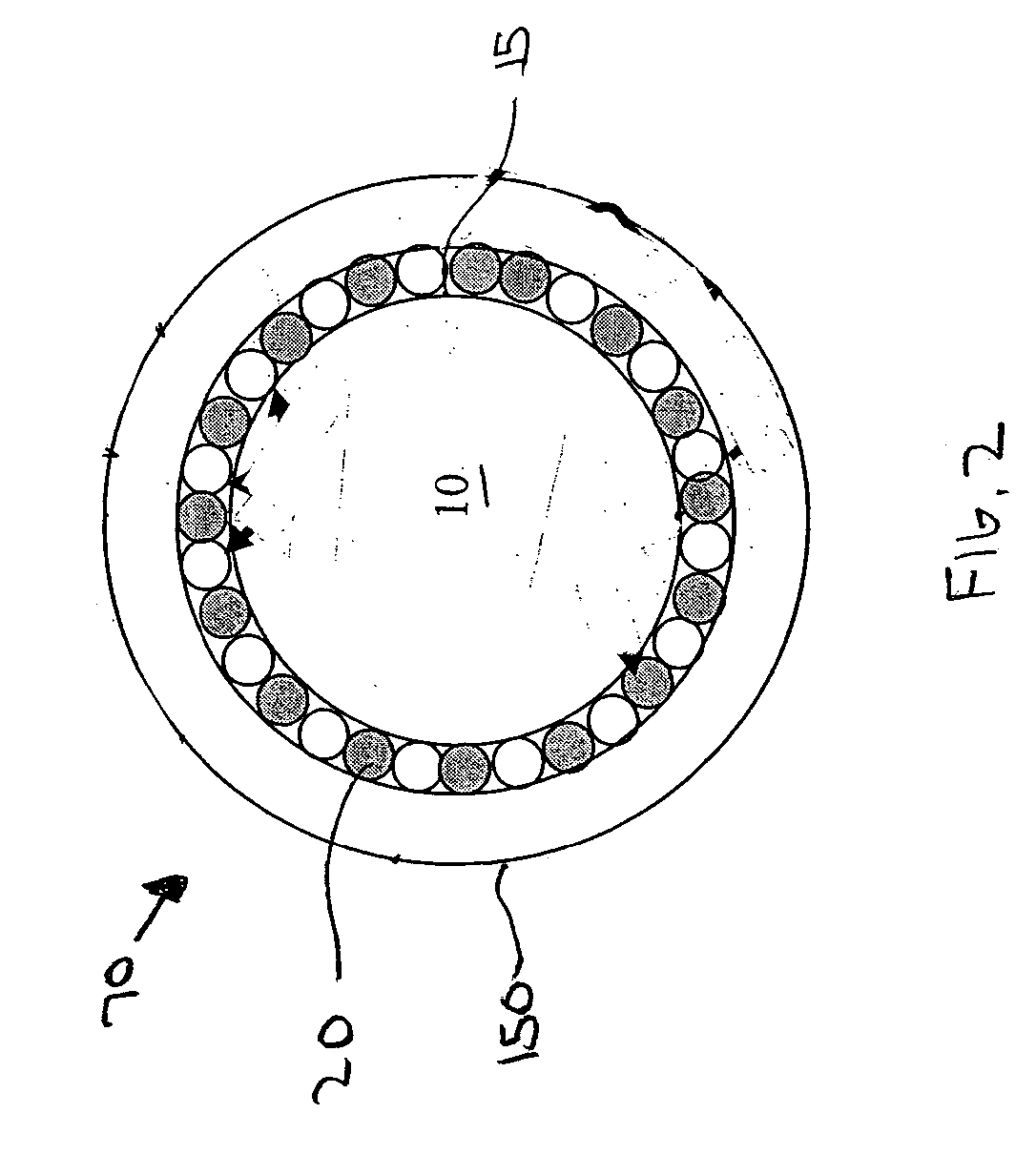

Non-alloying core shell nanoparticles

InactiveUS7147687B2Useful propertyMaterial nanotechnologyPowder deliveryCore shell nanoparticlesNanometre

The present invention relates composite core / shell nanoparticles and a two-step method for their preparation. The present invention further relates to biomolecule-core / shell nanoparticle conjugates and methods for their preparation. The invention also relates to methods of detection of biomolecules comprising the biomolecule-core / shell nanoparticle conjugates.

Owner:NORTHWESTERN UNIV

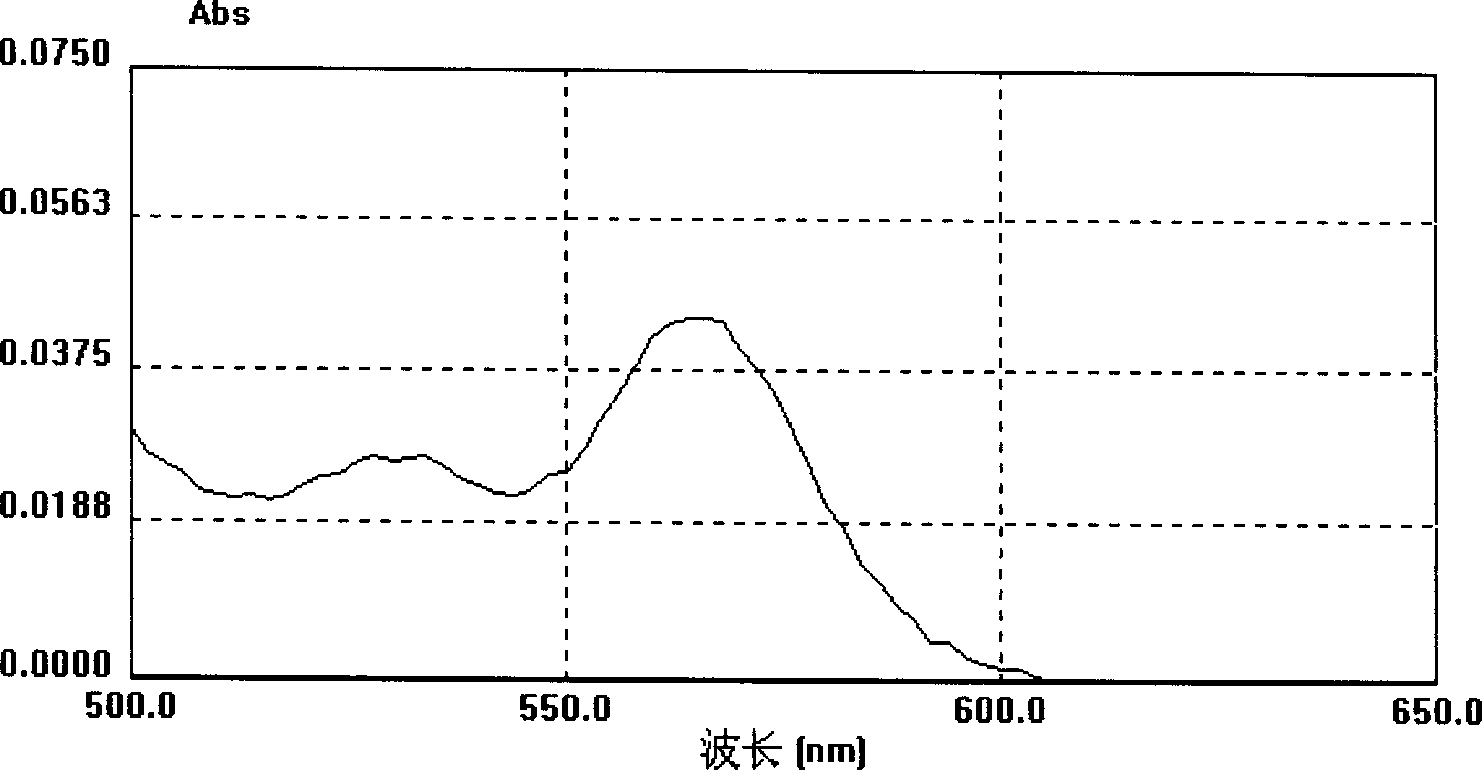

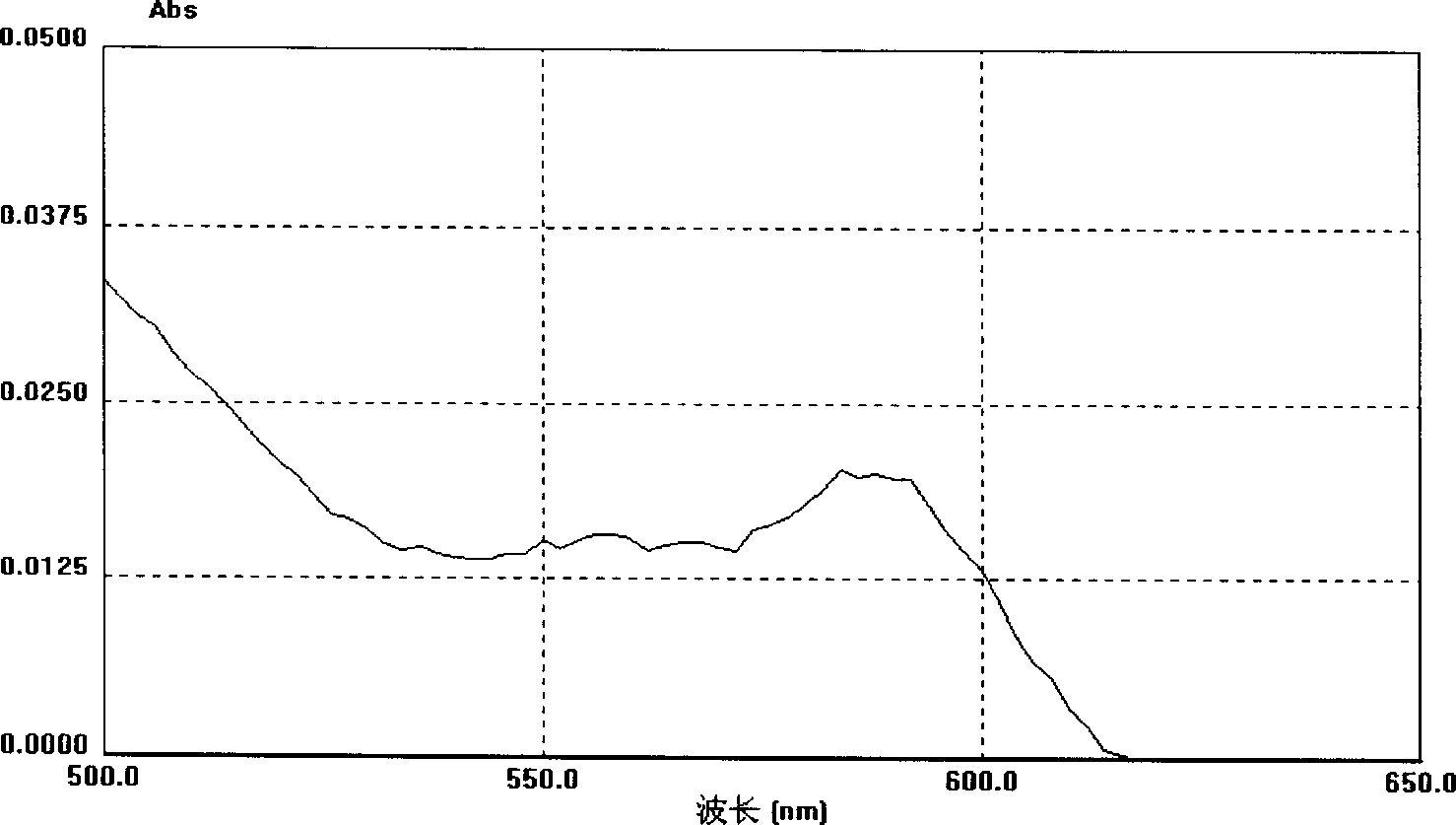

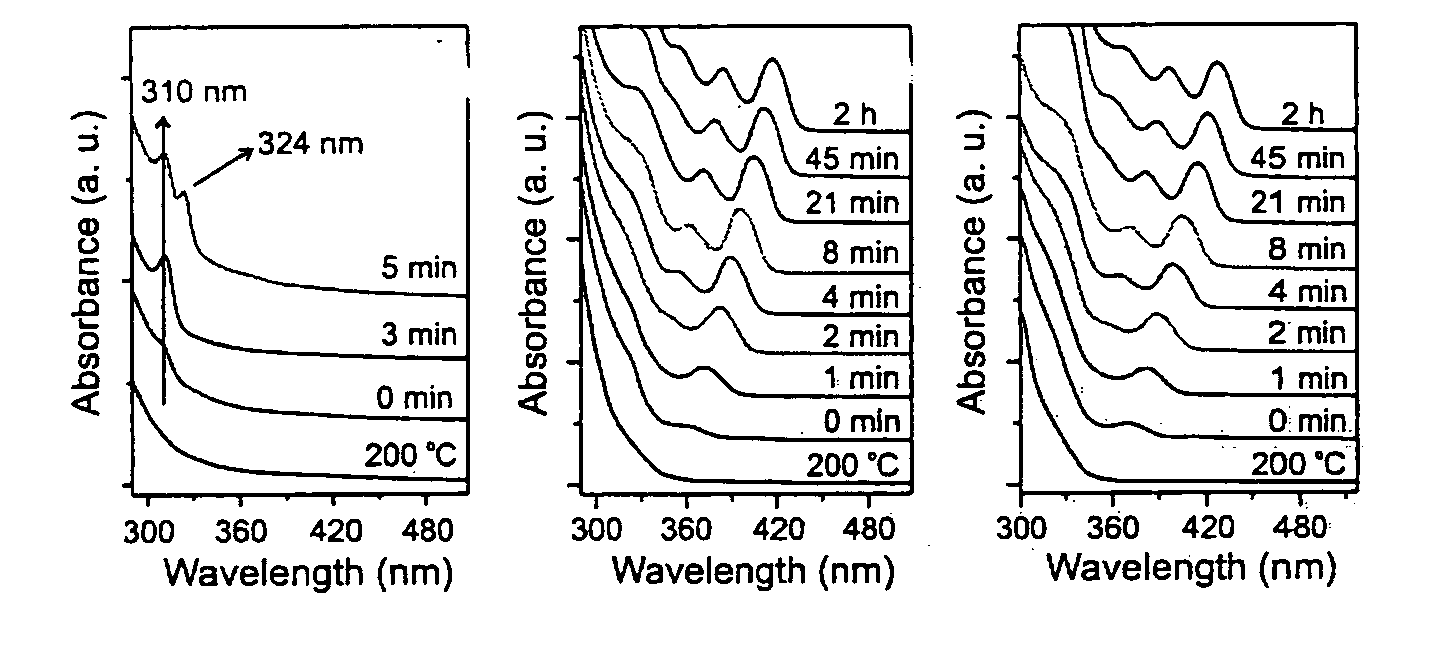

Prepn of CdSe/CdS or CdSe/ZnS core-shell quantum dot

InactiveCN1403379ARaw materials are safe and easy to obtainLow priceFrom normal temperature solutionsCadmium sulfidesQuantum yieldQuantum dot

The present invention discloses the preparation process of CdSe / CdS, CdSe / ZnS and other II-VI type core-shell quantum dot. The CdSe / CdS and CdSe / ZnS core-shell quantum dot are prepared with cadmium acetate, zinc acetate or other inorganic compound, instead of Cd(CH3)2, Zn(CH3)2 or other inflammable, detonable and expensive organic metal compound, as material. The prdouct has excellent single dispersivity, improved fluorescent property, high quantum yield, high stability, and may be used widely as the fluorescent mark for biological detection and analysis.

Owner:WUHAN UNIV

One-pot synthesis of high-quality metal chalcogenide nanocrystals without precursor injection

InactiveUS20060019427A1Material nanotechnologyPolycrystalline material growthSulfurMetal chalcogenides

A method of homogeneously forming metal chalcogenide nanocrystals includes the steps combining a metal source, a chalcogenide source, and at least one solvent at a first temperature to form a liquid comprising assembly, and heating the assembly at a sufficient temperature to initiate nucleation to form a plurality of metal chalcogenide nanocrystals. The plurality of metal chalcogenide nanocrystals are then grown without injection of either the metal source or the chalcogenide source at a temperature at least equal to the sufficient temperature, wherein growth proceeds substantially without nucleation to form a plurality of monodisperse metal chalcogenide nanocrystals. An optional nucleation initiator can help control the final size of the monodisperse crystals. Such synthesis, without the need for precursor injection, is suitable for the industrial preparation of high-quality nanocrystals.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

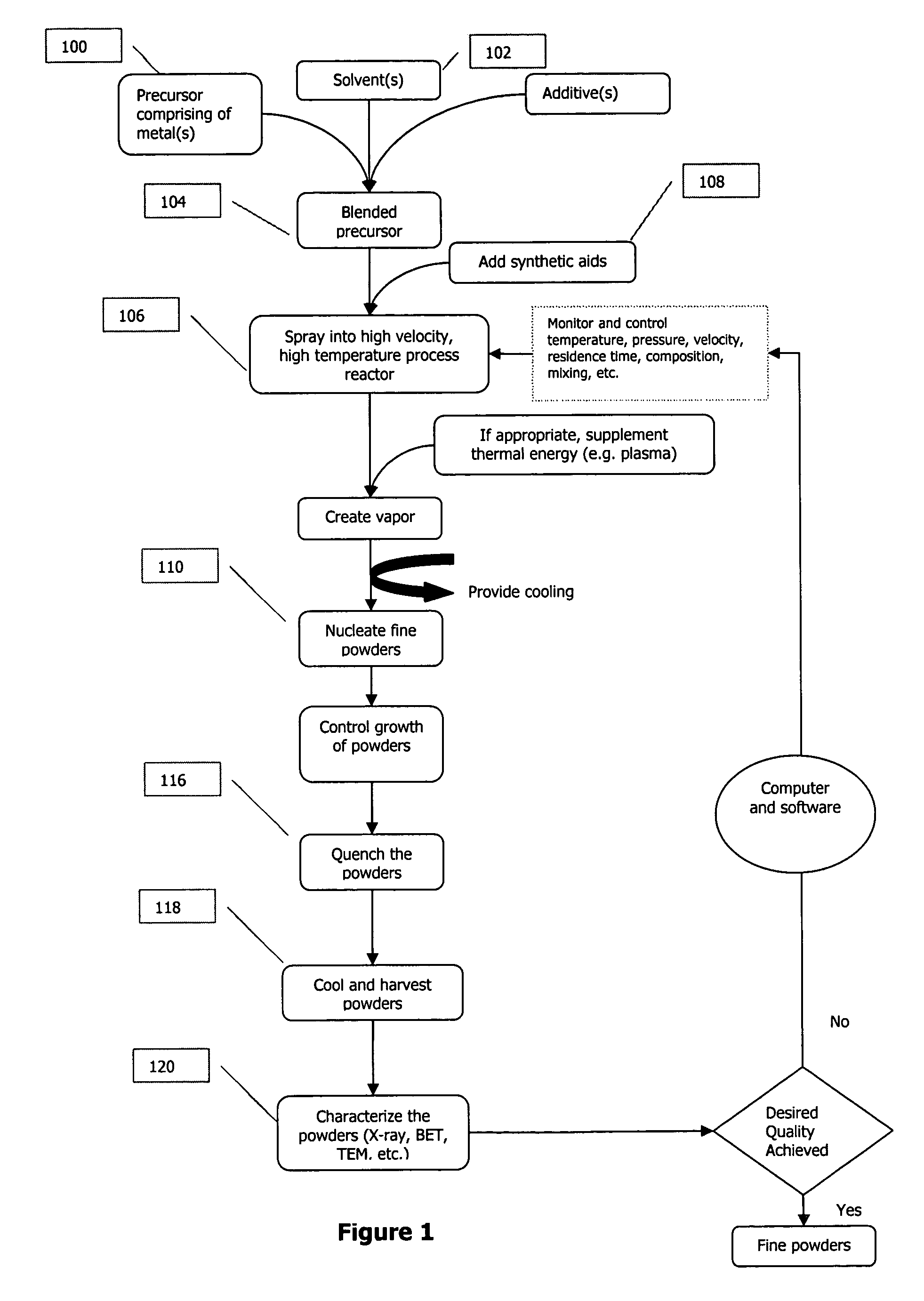

Titanium comprising nanoparticles and related nanotechnology

ActiveUS7232556B2Increase volumeLow cost productionNitrogen compoundsGermanium dioxideNanoparticleTitanium metal

Owner:PPG IND OHIO INC

Supercritical Hydrocarbon Conversion Process

ActiveUS20050167333A1Reduce molecular weightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

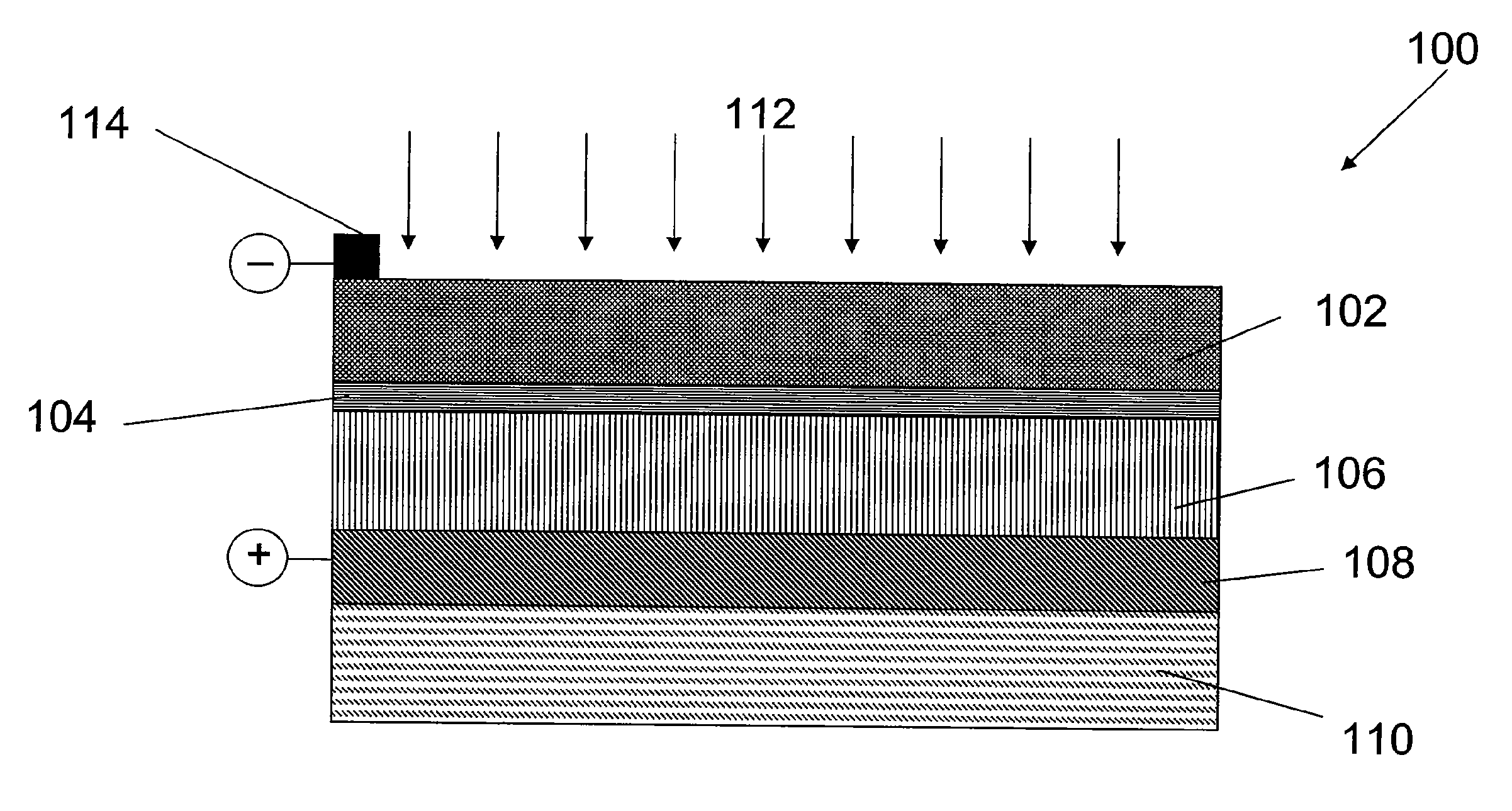

Metal chalcogenide composite nano-particles and layers therewith

A metal chalcogenide composite nano-particle comprising a metal capable of forming p-type semiconducting chalcogenide nano-particles and a metal capable of forming n-type semiconducting chalcogenide nano-particles, wherein at least one of the metal chalcogenides has a band-gap between 1.0 and 2.9 eV and the concentration of the metal capable of forming p-type semiconducting chalcogenide nano-particles is at least 5 atomic percent of the metal and is less than 50 atomic percent of the metal; a dispersion thereof; a layer comprising the nano-particles; and a photovoltaic device comprising the layer.

Owner:AGFA GEVAERT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com