Quantum dots having composition gradient shell structure and manufacturing method thereof

a technology of composition gradient and quantum dots, which is applied in the direction of luminescent compositions, selenium/tellurium compounds with other elements, and nano-informatics. it can solve the problems of reducing the quantum efficiency of quantum dots, requiring expensive equipment, and difficult to produce large quantities of quantum dots with a uniform size through conventional semiconductor fabrication methods. , to achieve the effect of high luminous efficiency, low cost and short manufacturing tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

exemplary embodiment 1

[0042]Synthesis of Quantum Dots with CdSe Cores And ZnS Shells

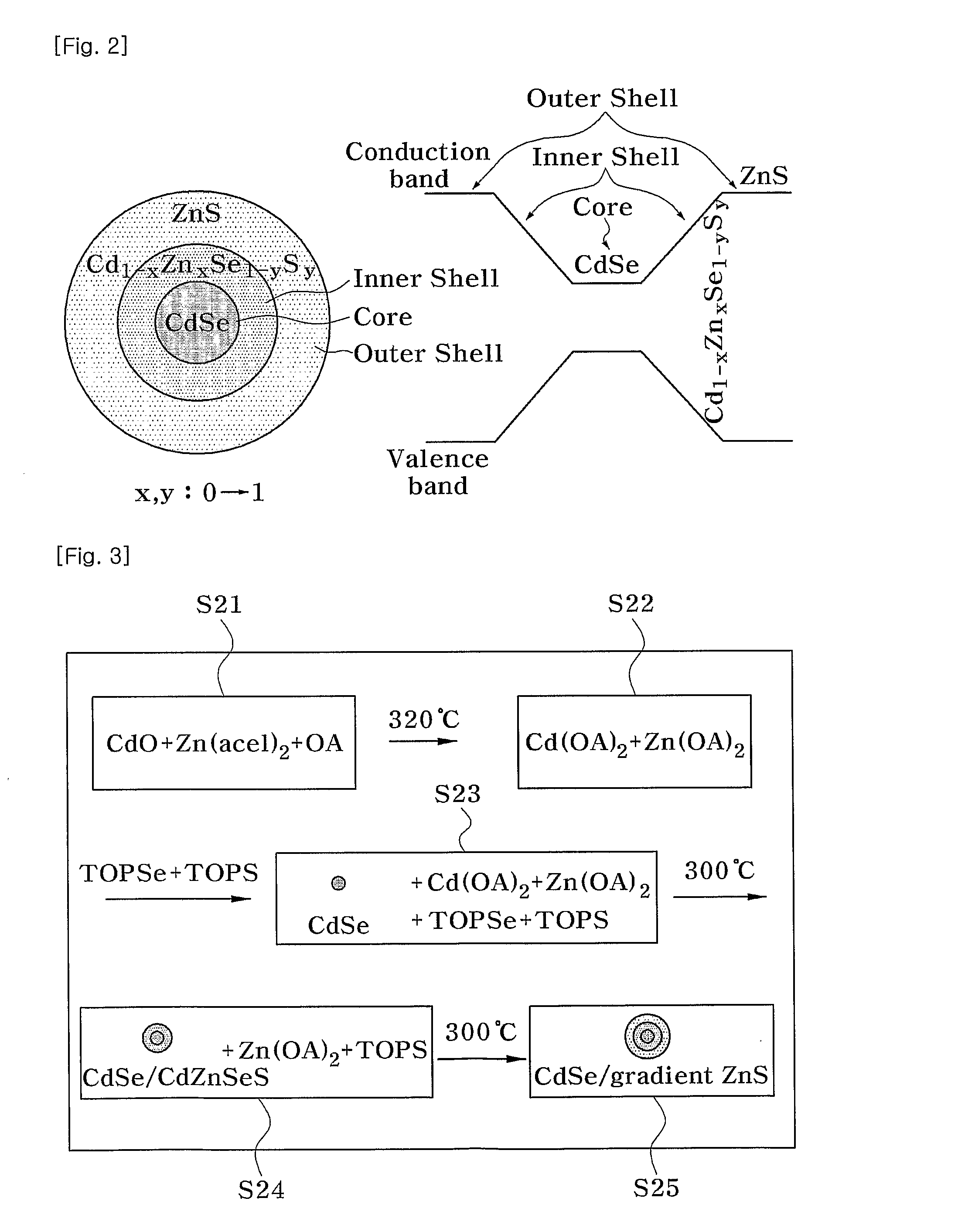

[0043]FIG. 3 is a diagram illustrating a process of manufacturing quantum dots according to an exemplary embodimentof the present invention, and FIG. 4 is a diagram of experimental equipment used for manufacturing quantum dots according to the present invention. Hereinafter, a process of synthesizing quantum dots with CdSe cores and ZnS shells will be described with reference to FIGS. 3 and 4.

[0044]In step S21, 0.0512 g (0.4 mmol) of solid cadmium oxide (purity: 99.998%), 0.732 g (4 mmol) of zinc acetate, 4.4 ml (17.6 mmol) of oleic acid, and 13.6 ml of 1-octadecene (CH2=CH(CH2)15CH3)were put in a 100 ml round-bottom flask 101 including a syringe 101, a thermometer 104, and a cooler 103. In step S22, the mixture was heated at a pressure of 1 ton and a temperature of about 320° C. for 20 minutes to synthesize a cadmium-oleic acid complex and a zinc-oleic acid complex and remove remaining oxygen from the complexes.

[0045]The...

exemplary embodiment 2

[0048]Synthesis of Quantum Dots with CdSe Cores and ZnSe Shells

[0049]In the present exemplary embodiment, quantum dots were manufactured in the same manner as in the first exemplary embodiment except that 2 ml of 2M trioctylphosphine selenide solution was used instead of the mixtureof trioctylphosphine selenide and trioctylphosphine sulfide used in the first exemplary embodiment.

exemplary embodiment 3

[0050]Synthesis of Quantum Dots with CdTe Cores and ZnS Shells

[0051]In the present exemplary embodiment, quantum dots were manufactured in the same manner as in the first exemplary embodiment except that a 2 ml mixture of 0.2 ml of 2M trioctylphosphine telluridesolution and 1.8 ml of 2M trioctylphosphine sulfide solution was used instead of the mixture of trioctylphosphine selenide and trioctylphosphine sulfide used in the first exemplary embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com