Patents

Literature

685results about "Zinc sulfides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanocrystal doped matrixes

ActiveUS20070034833A1Good miscibilityInhibit aggregationMaterial nanotechnologyIndividual molecule manipulationAnti-reflective coatingSemiconductor nanocrystals

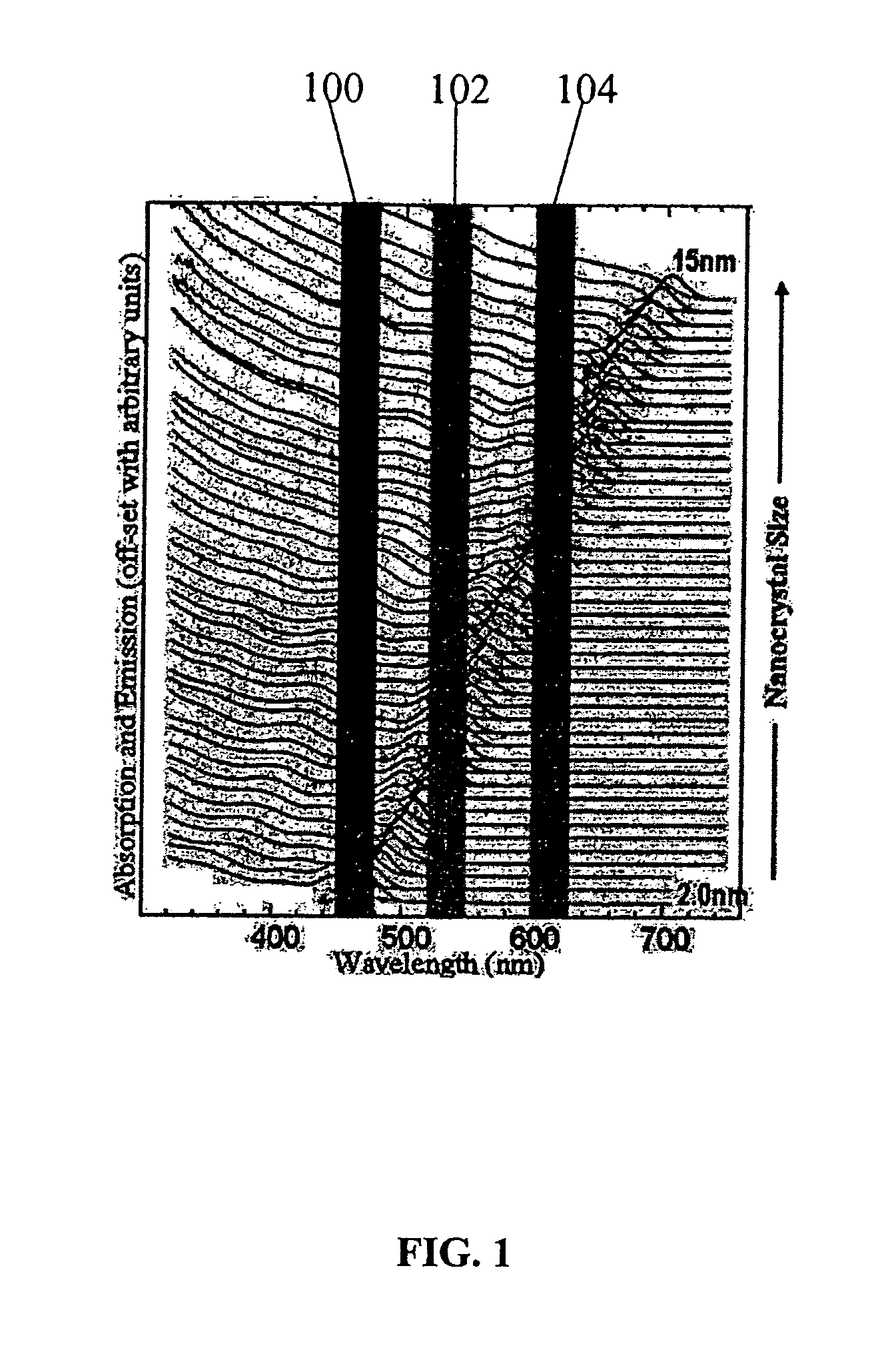

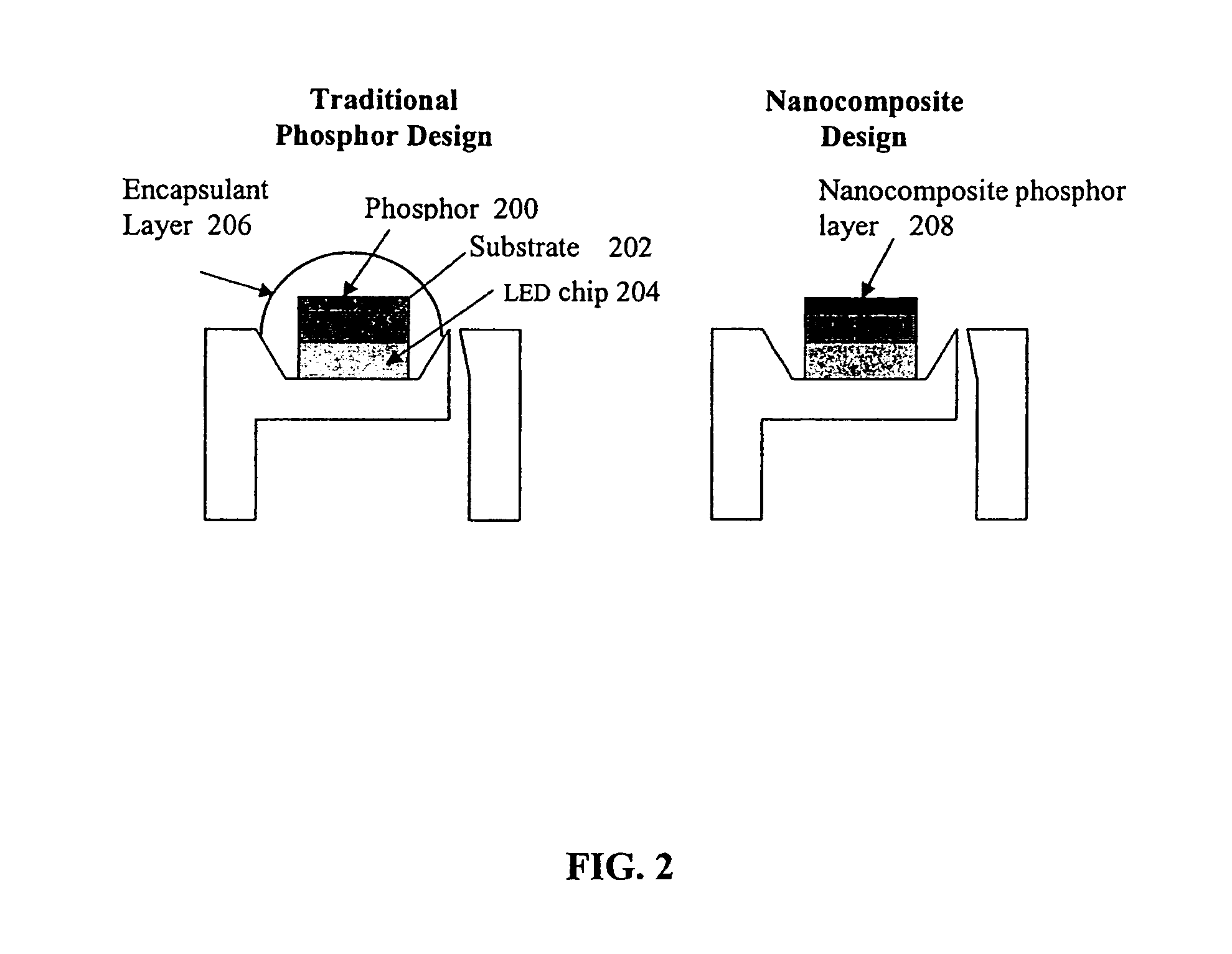

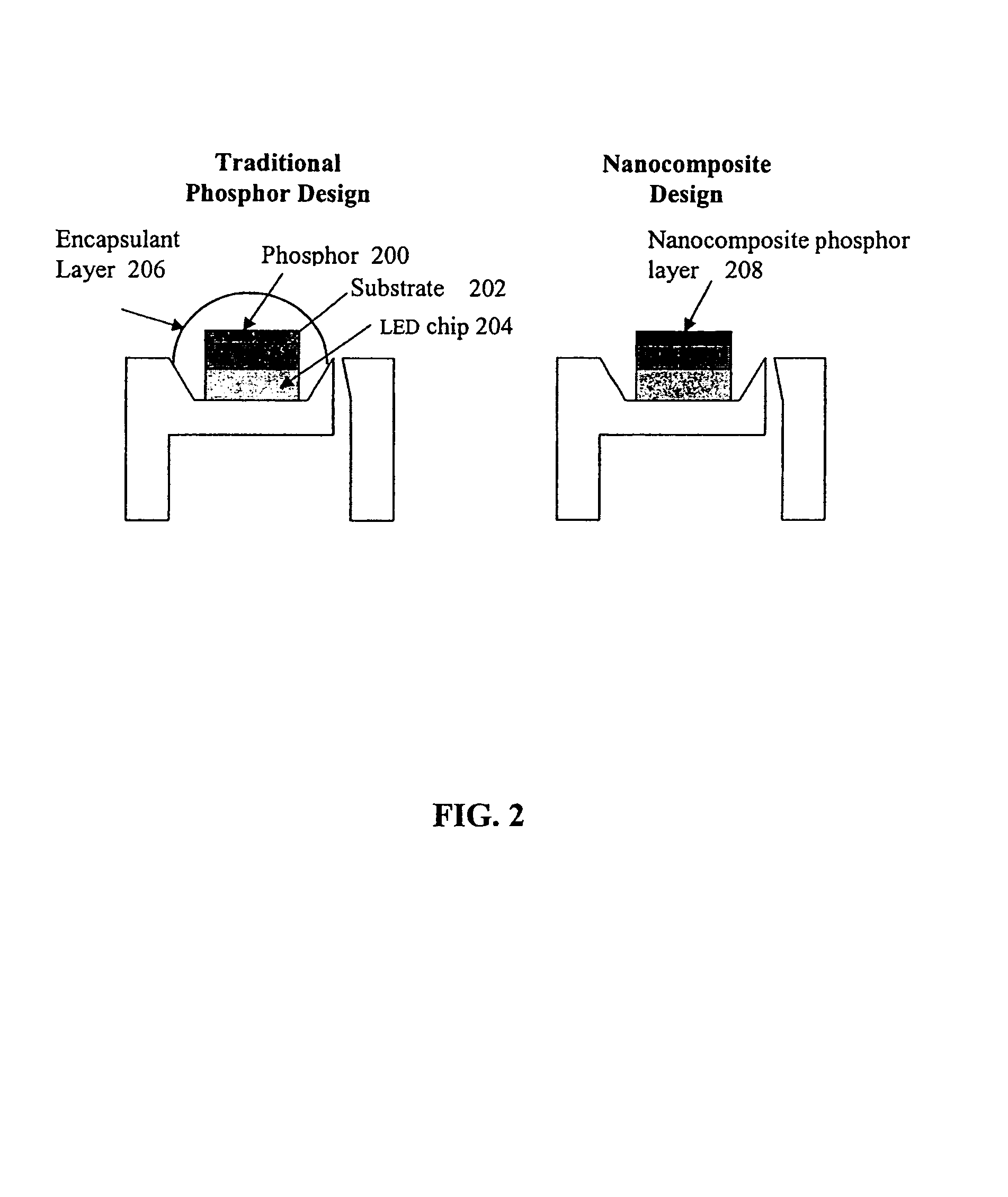

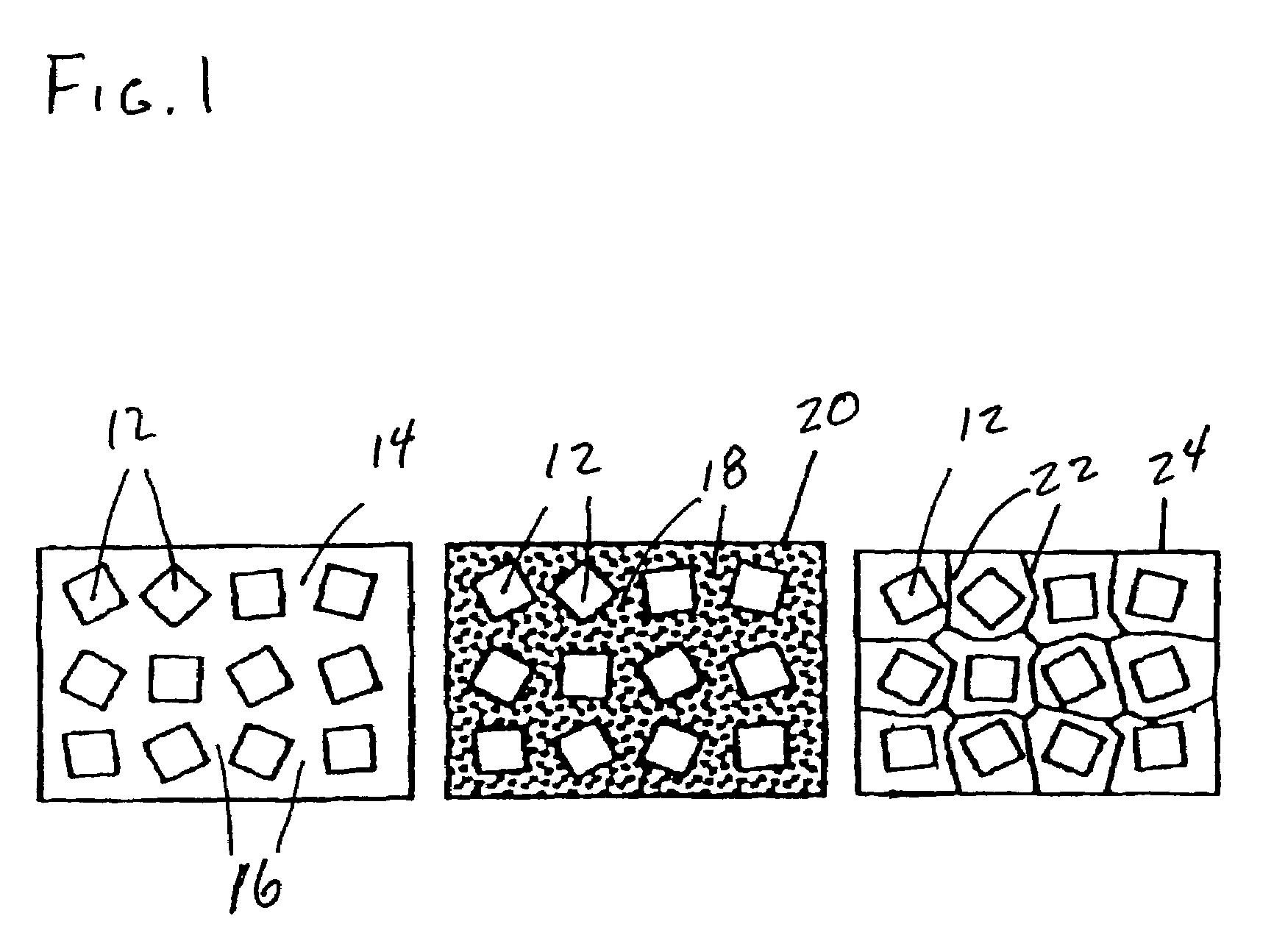

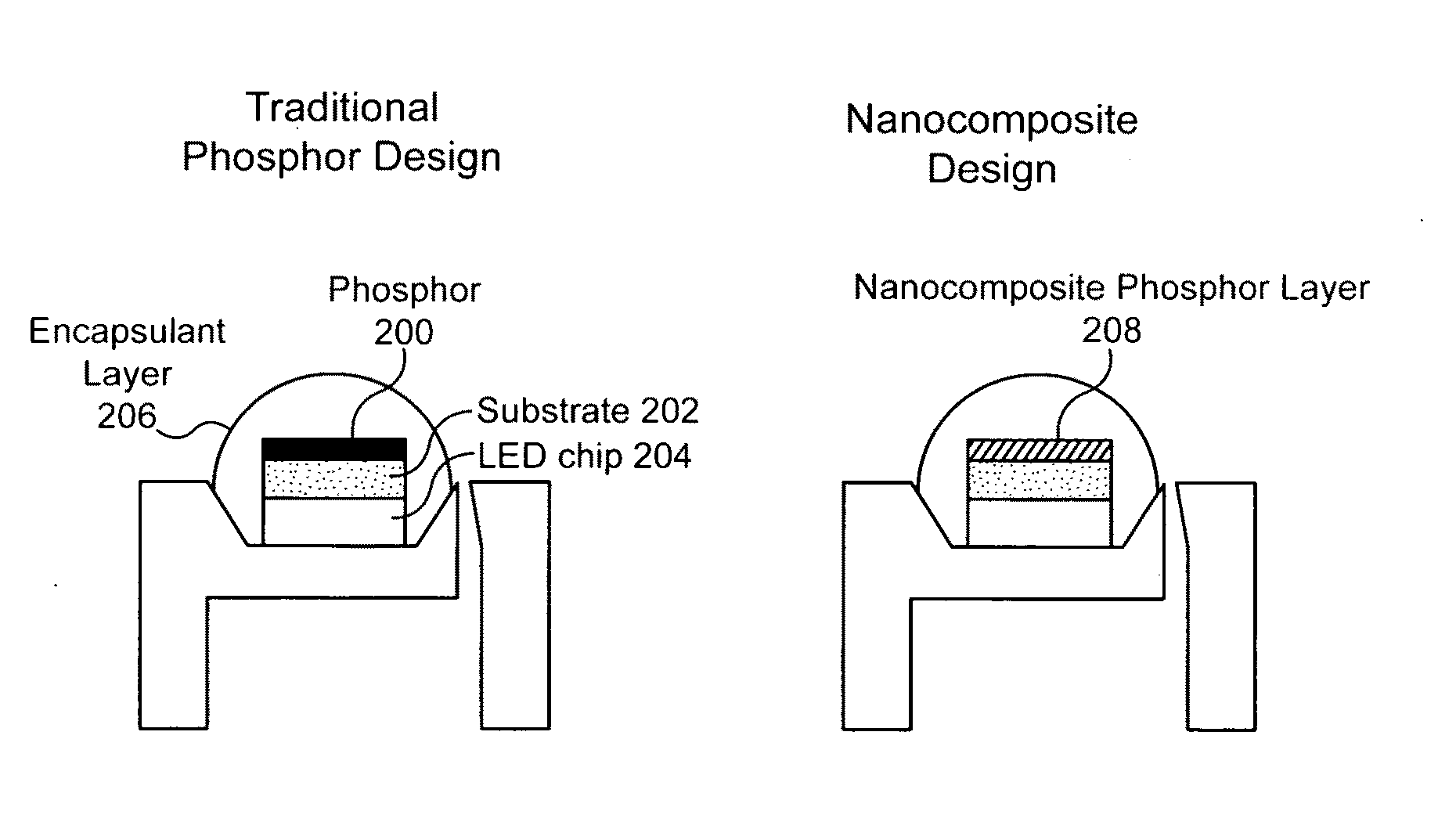

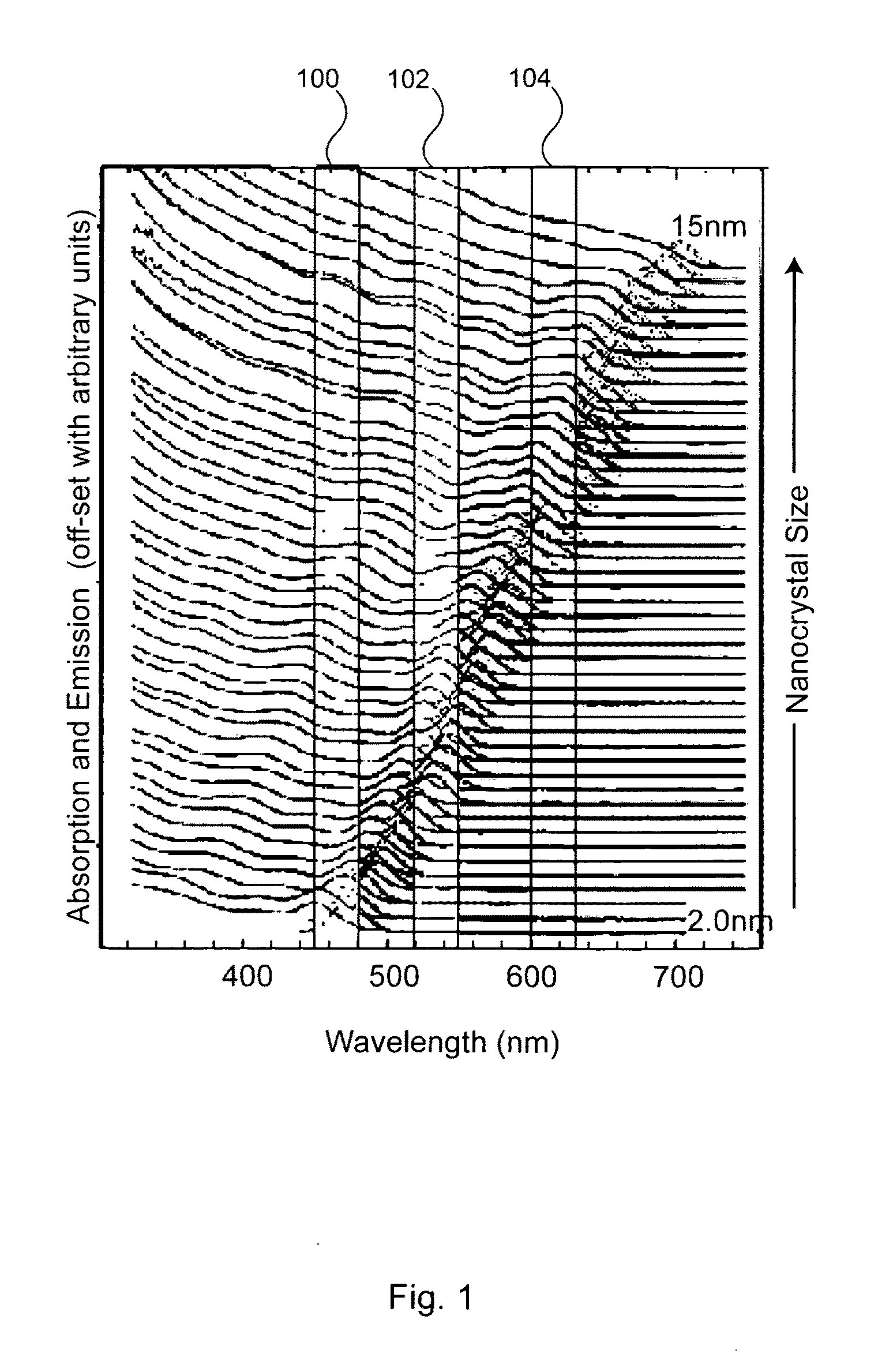

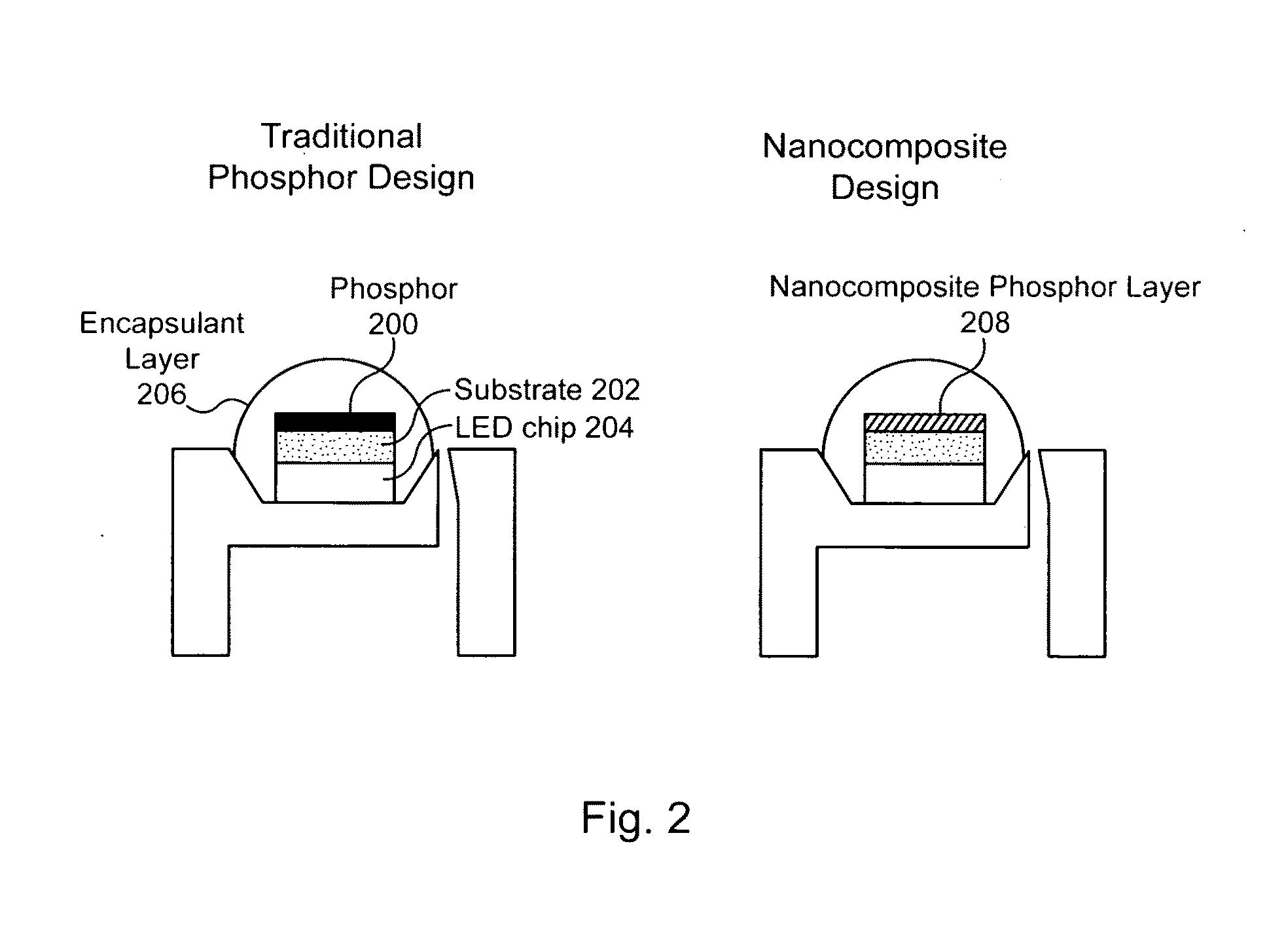

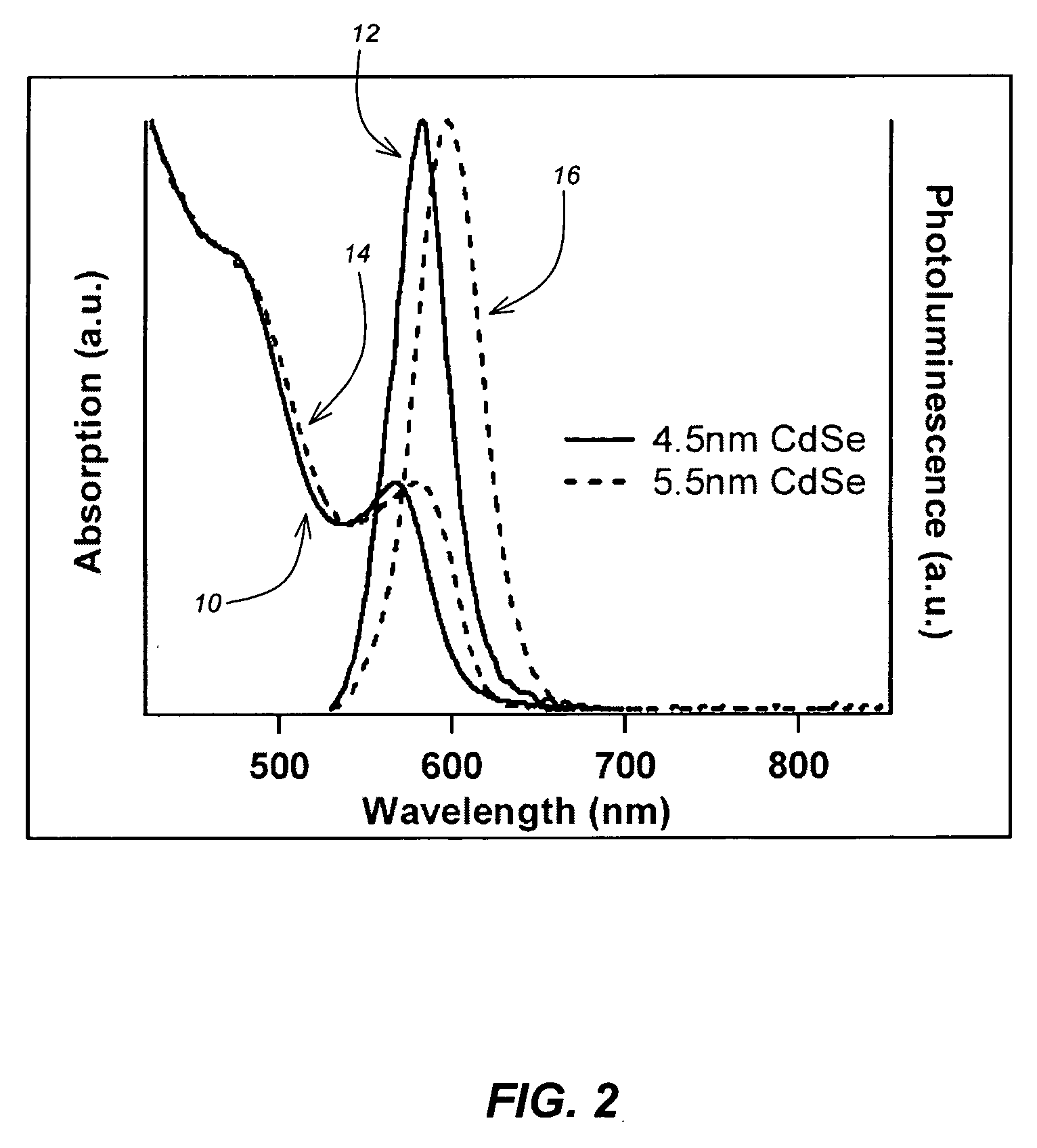

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:SAMSUNG ELECTRONICS CO LTD

Nanocrystal doped matrixes

ActiveUS7645397B2Good miscibilityInhibit aggregationMaterial nanotechnologyIndividual molecule manipulationAnti-reflective coatingQuantum efficiency

Owner:SAMSUNG ELECTRONICS CO LTD

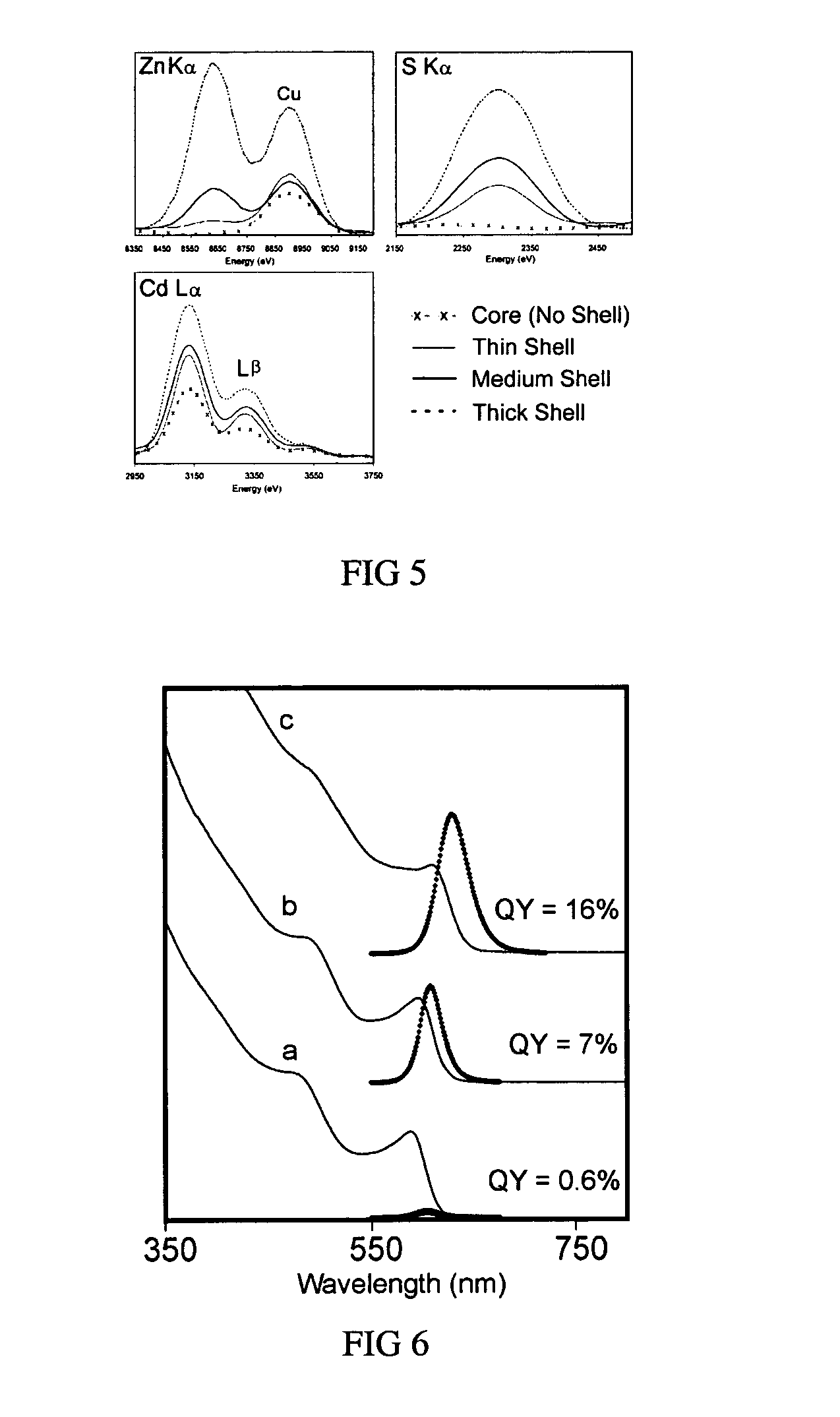

Graded core/shell semiconductor nanorods and nanorod barcodes

InactiveUS20050054004A1Improve quantum efficiencyIncrease in photoluminescence QYMaterial nanotechnologyNanosensorsGroup iiSemiconductor

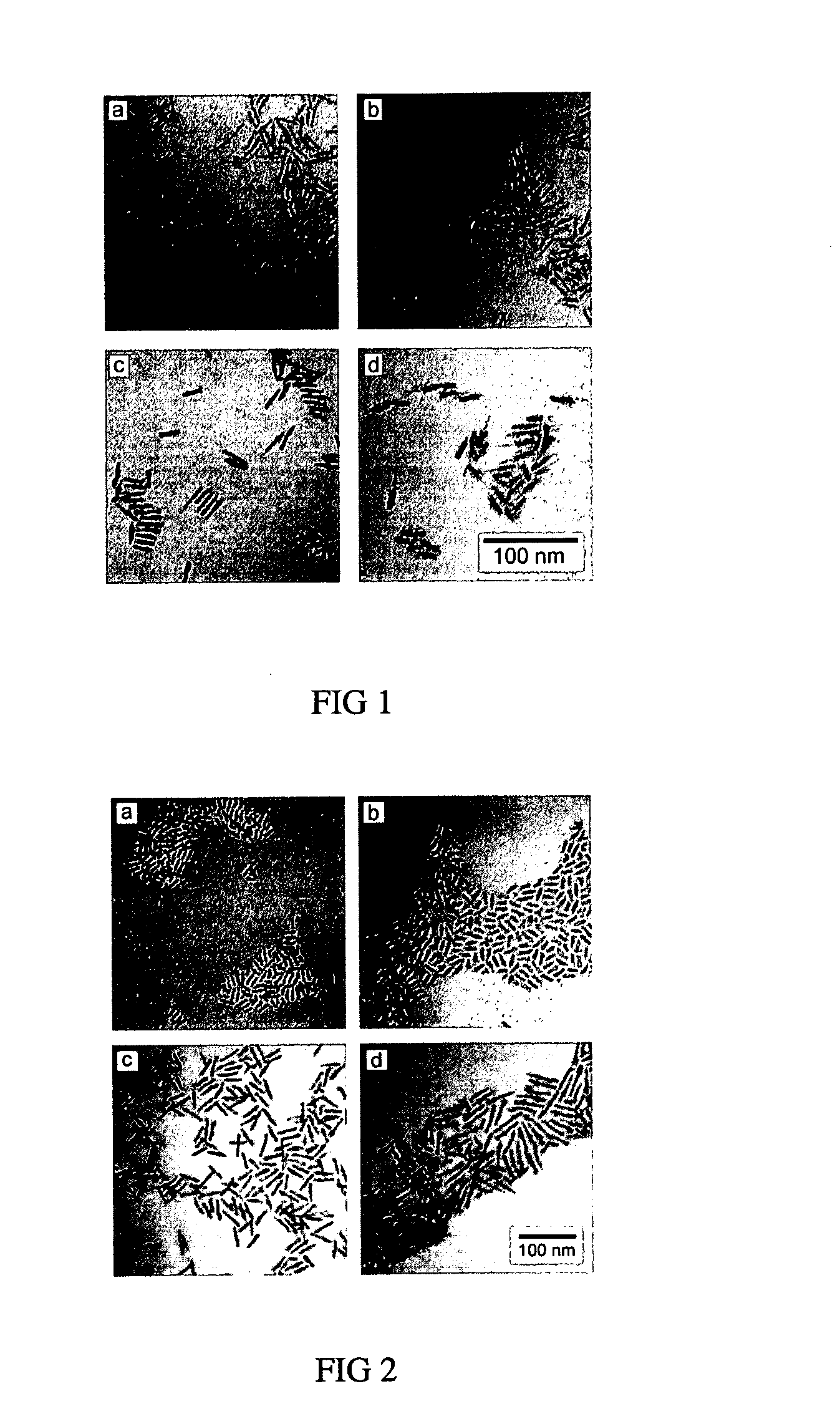

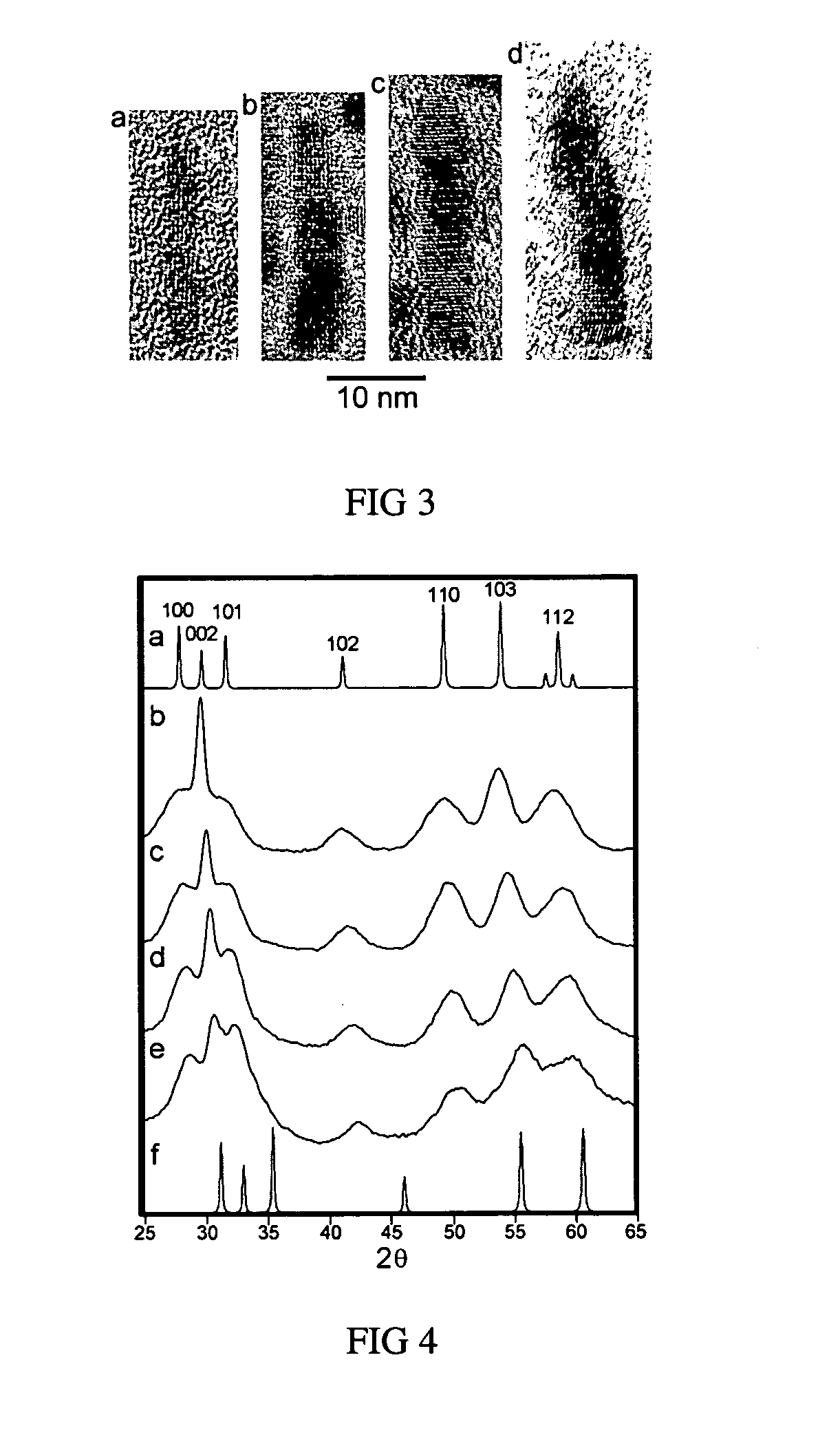

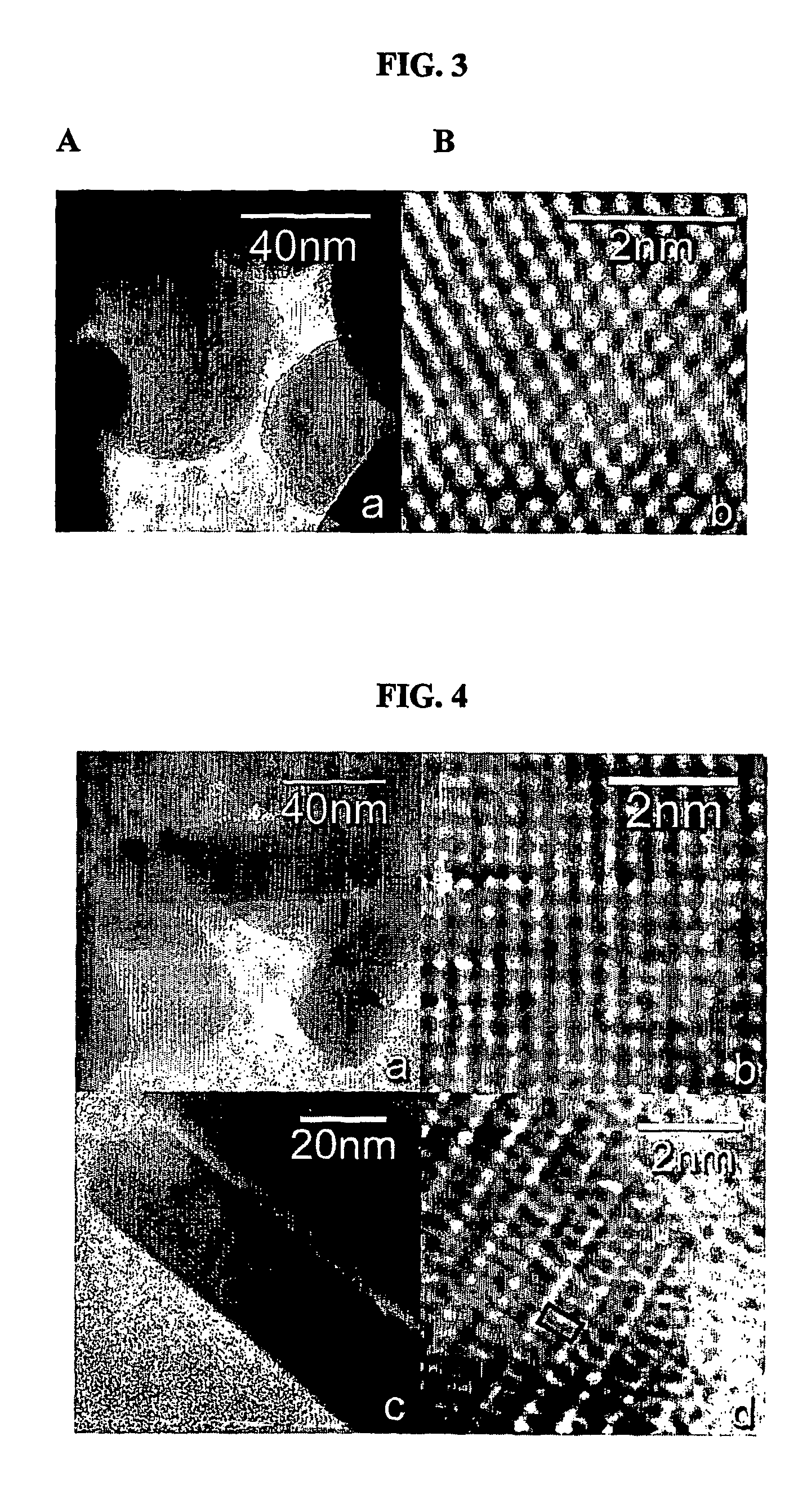

Disclosed herein is a graded core / shell semiconductor nanorod having at least a first segment of a core of a Group II-VI, Group III-V or a Group IV semiconductor, a graded shell overlying the core, wherein the graded shell comprises at least two monolayers, wherein the at least two monolayers each independently comprise a Group II-VI, Group III-V or a Group IV semiconductor.

Owner:RGT UNIV OF CALIFORNIA

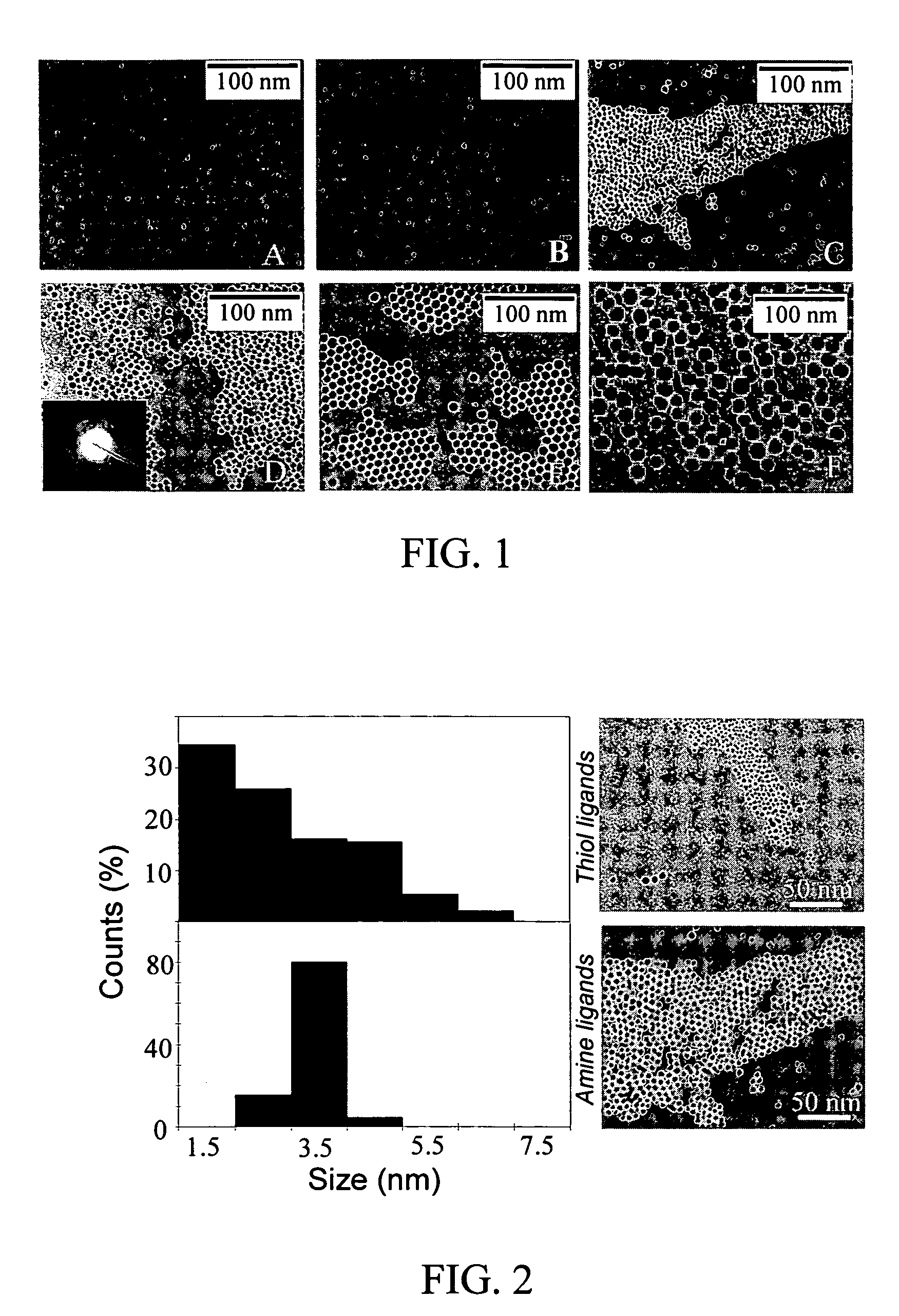

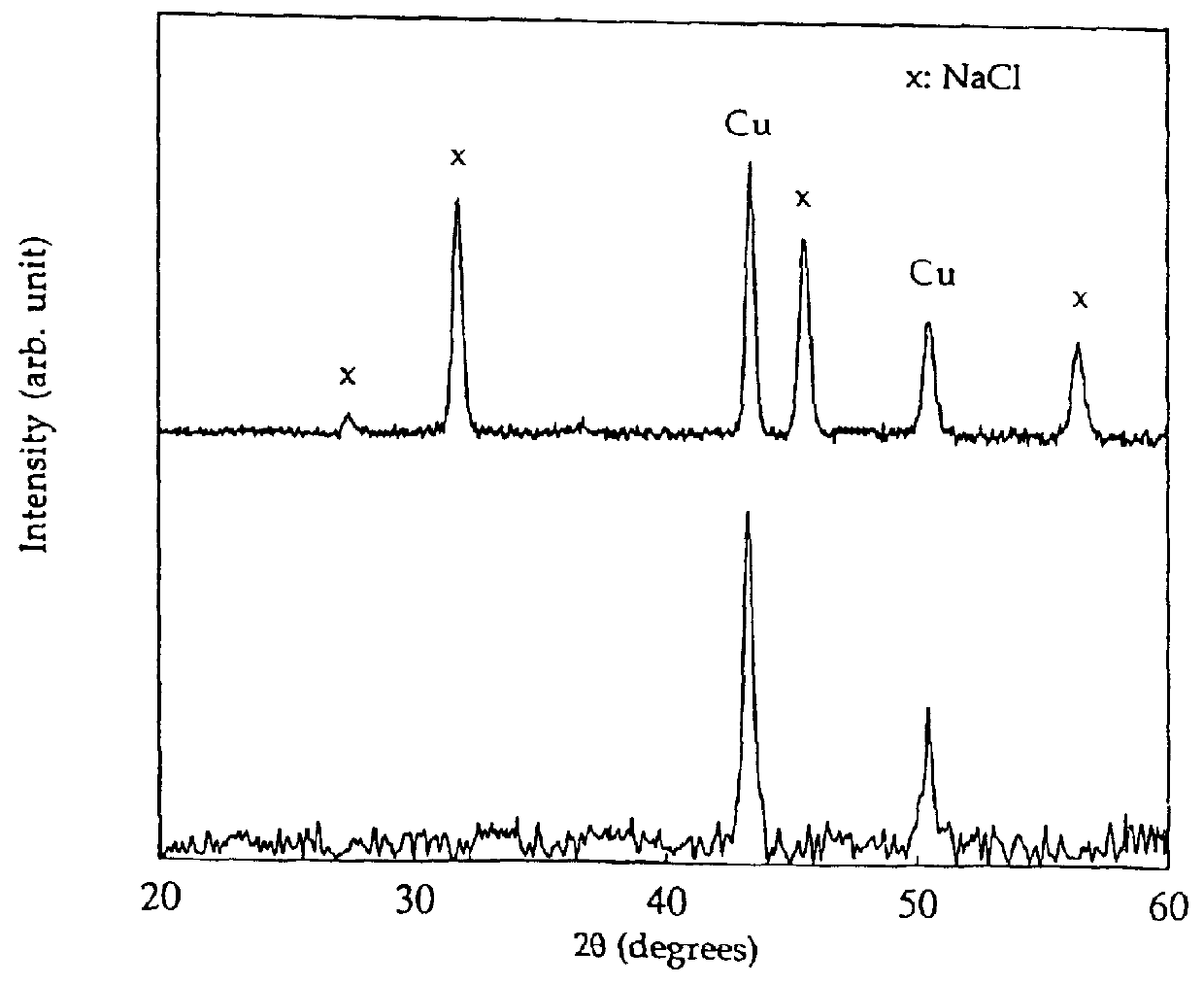

Monodisperse noble metal nanocrystals

Nanoparticle compositions of noble metals, and methods of making them, are described. The nanoparticle compositions are made by reacting a salt or complex of a noble metal, such as Au, Ag, Cu or Pt, with a weak ligand, and a reducing agent, in a single liquid phase. The noble metal is typically provided as a halide or carboxylate. The ligand is preferably a fatty acid or aliphatic amine. The reducing agent is preferably a borohydride reagent, hydrazine, or a mixture thereof. Nanocrystals in the size range of 1 nm to 20 nm are produced, and can be made in substantially monodisperse form.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

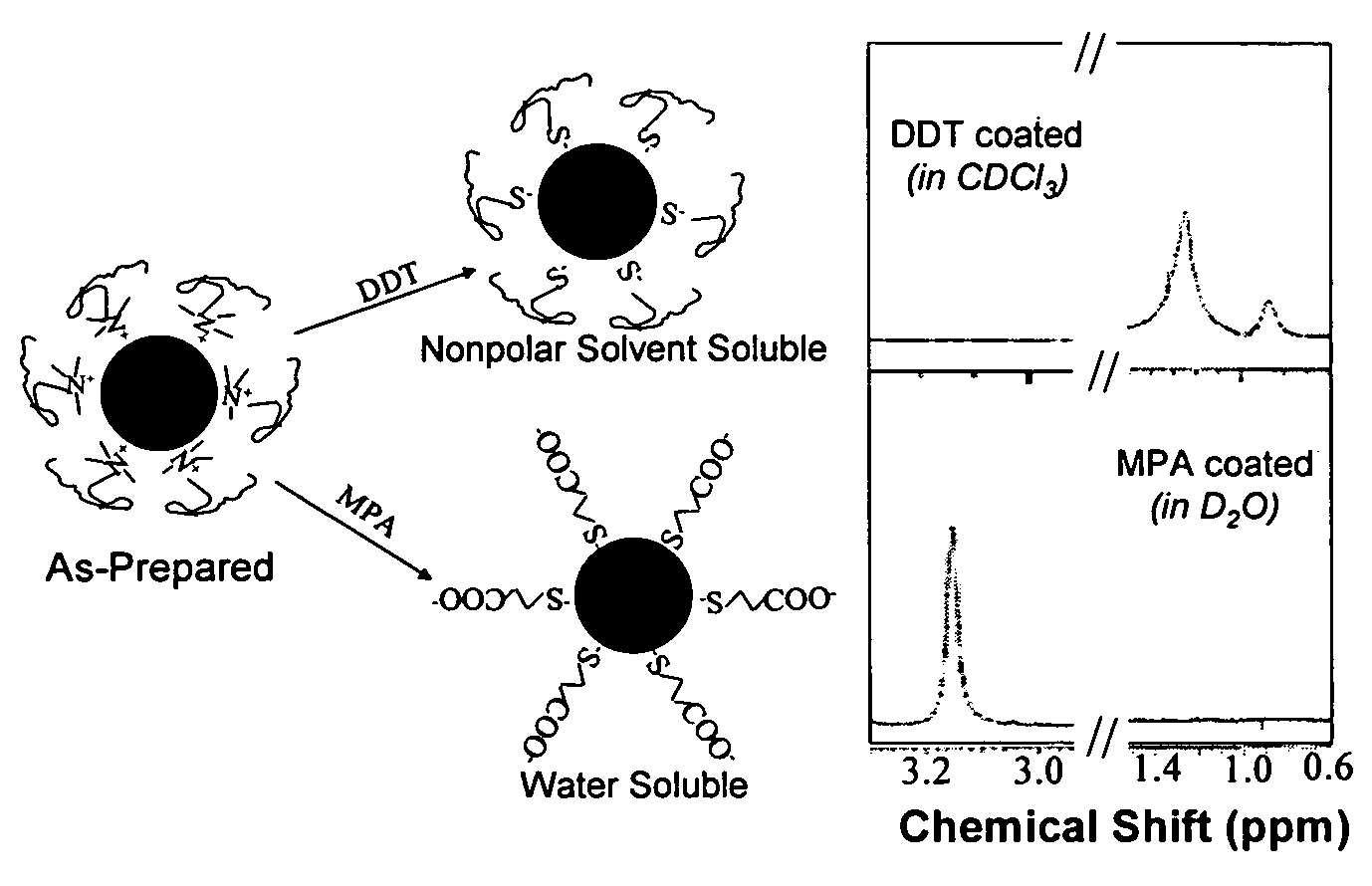

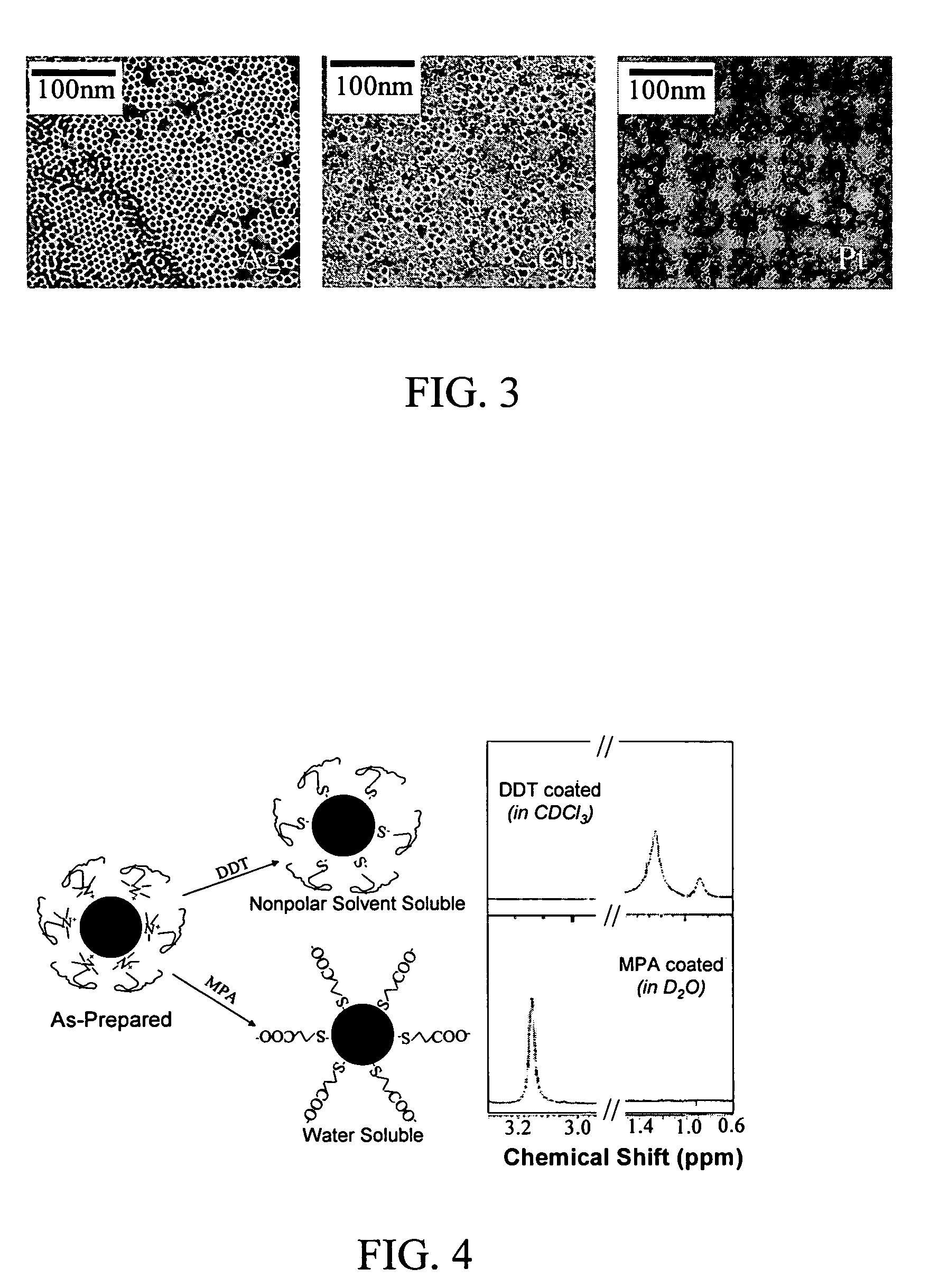

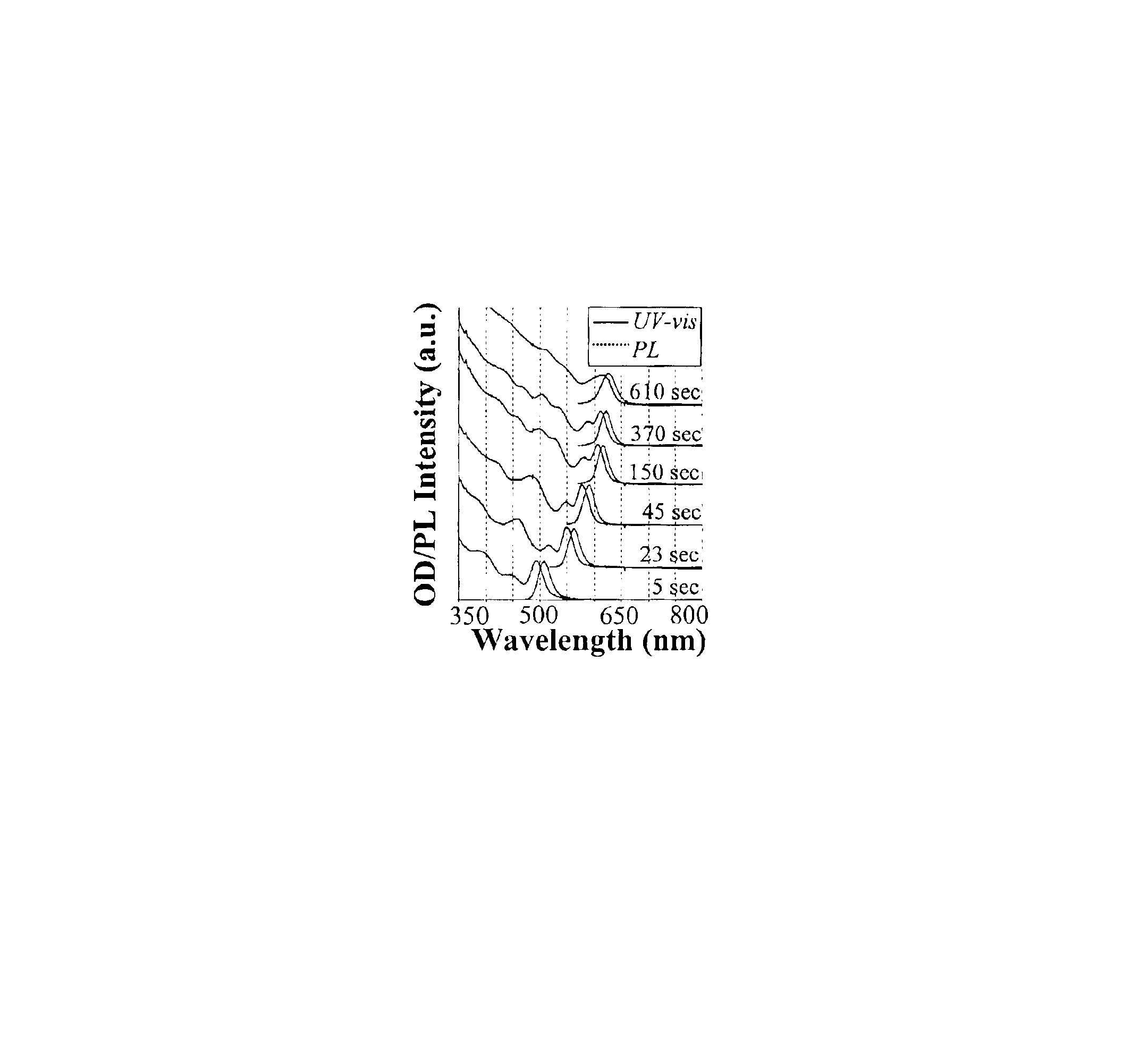

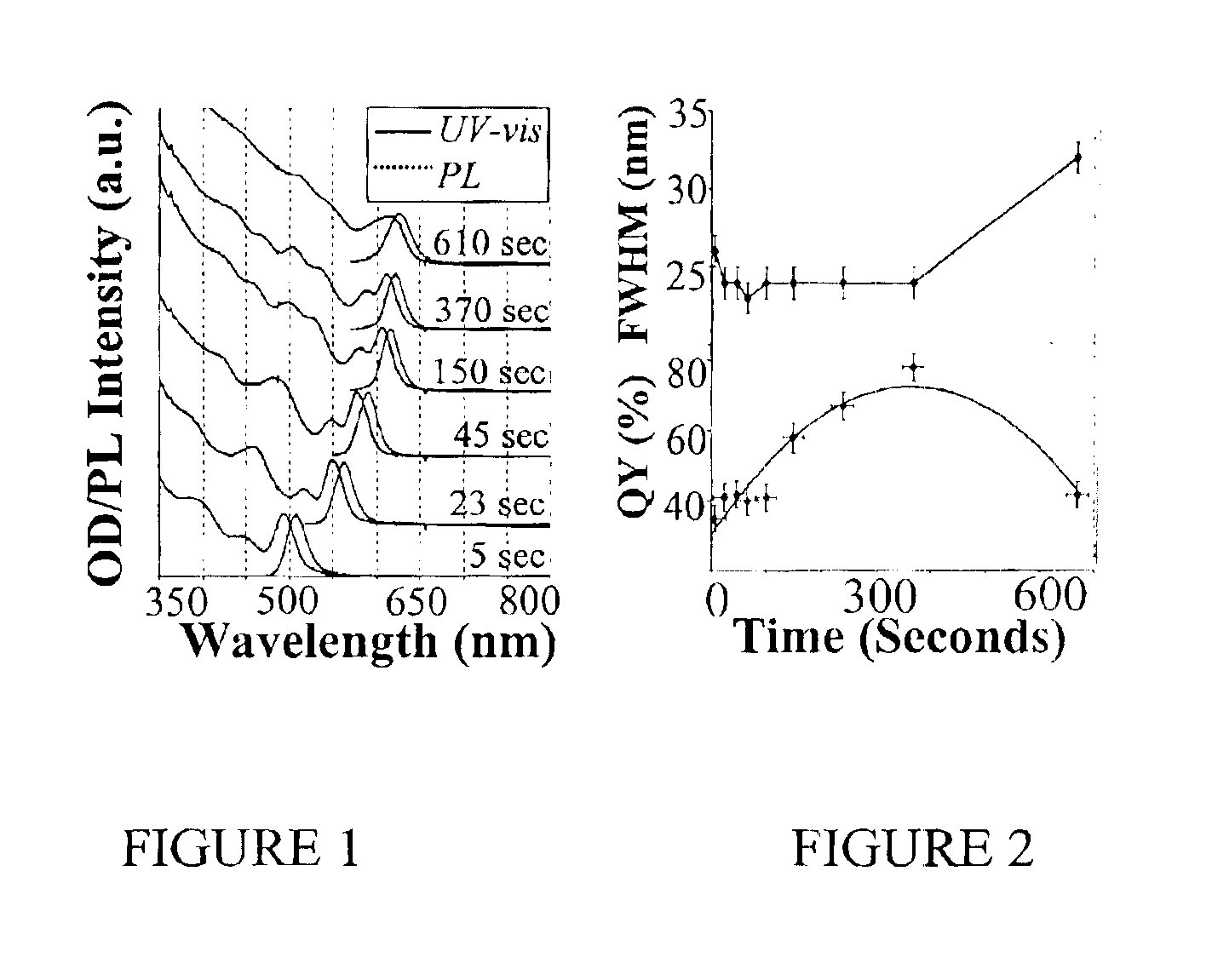

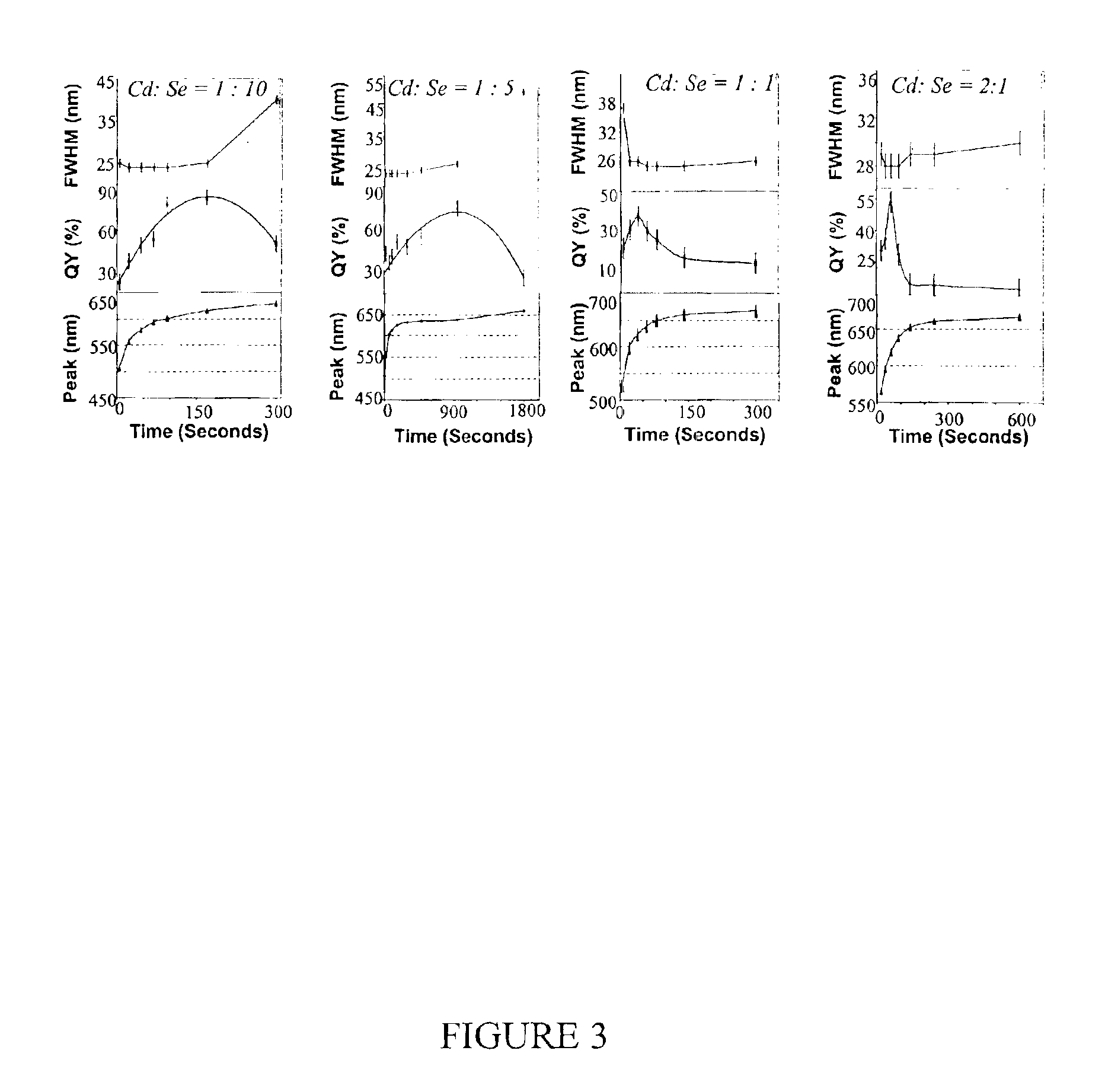

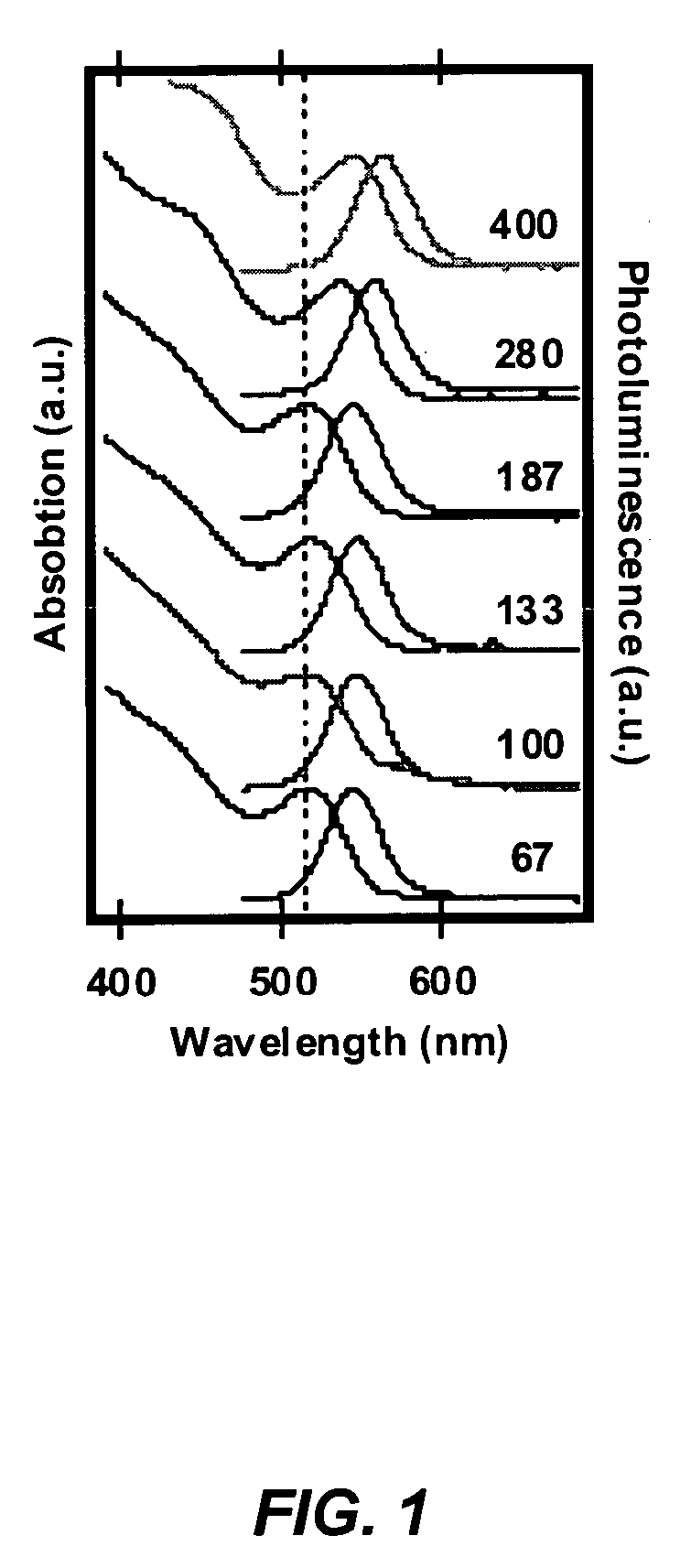

Colloidal nanocrystals with high photoluminescence quantum yields and methods of preparing the same

InactiveUS6869545B2Good monodispersityImprove launch performanceMaterial nanotechnologyNanoopticsQuantum yieldPhotoluminescence

The present invention provides new compositions containing colloidal nanocrystals with high photoluminescence quantum yields, new synthetic methods for the preparation of highly luminescent colloidal nanocrystals, as well as methods to control the photoluminescent properties of colloidal nanocrystals. The new synthetic methods disclosed herein allow photoemission brightness (quantum yield) to be correlated with certain adjustable nanocrystal growth parameters associated with a given synthetic scheme.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

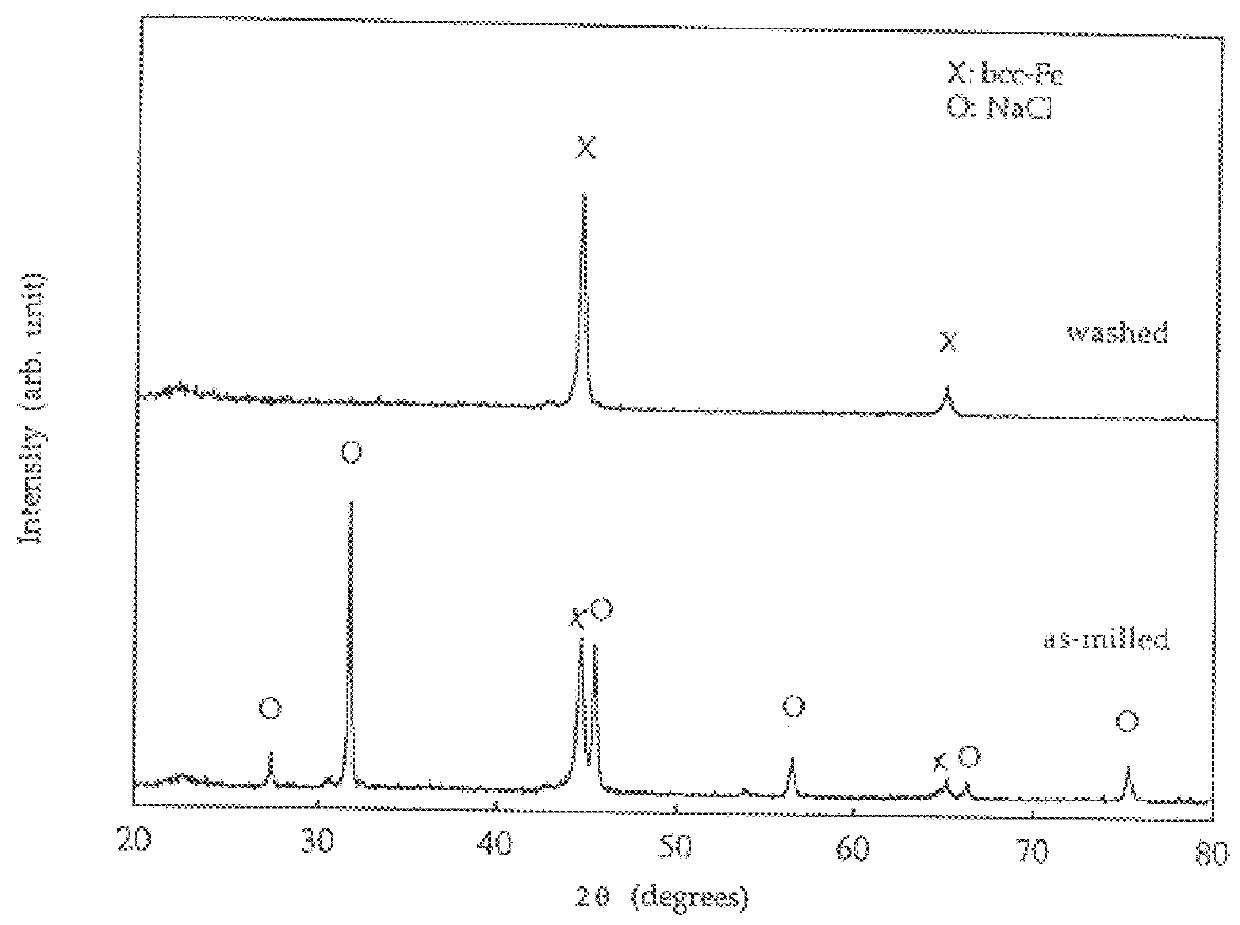

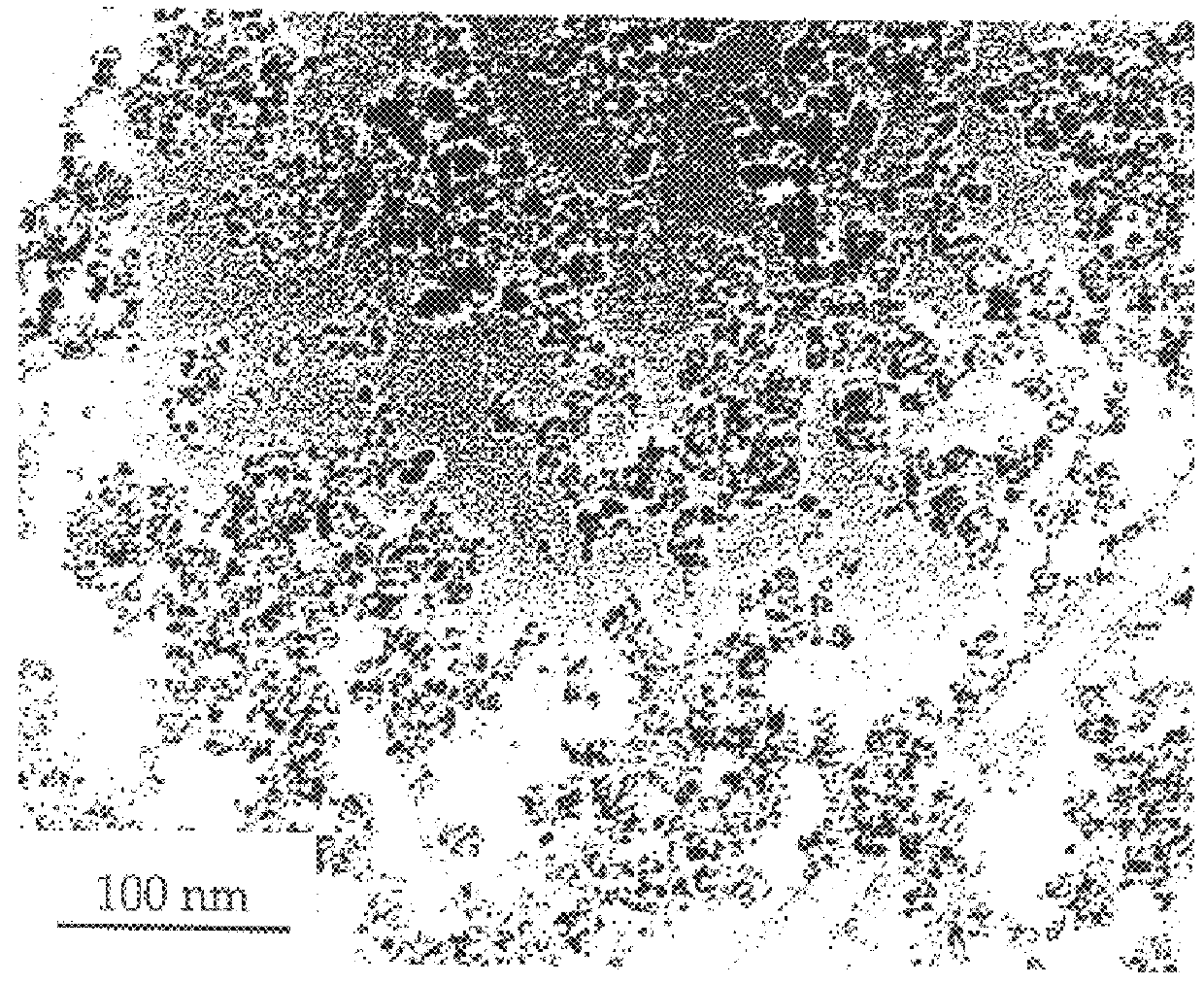

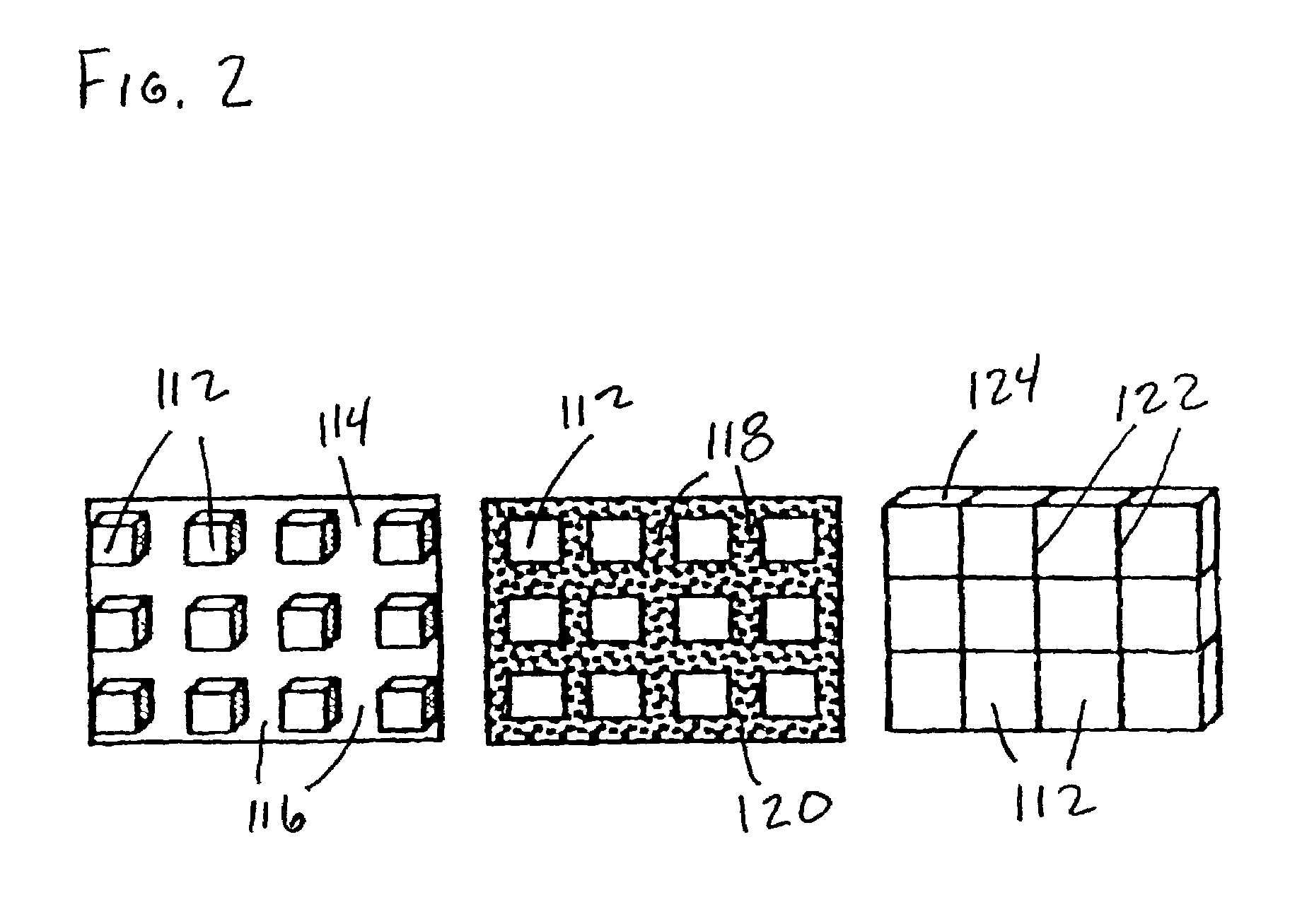

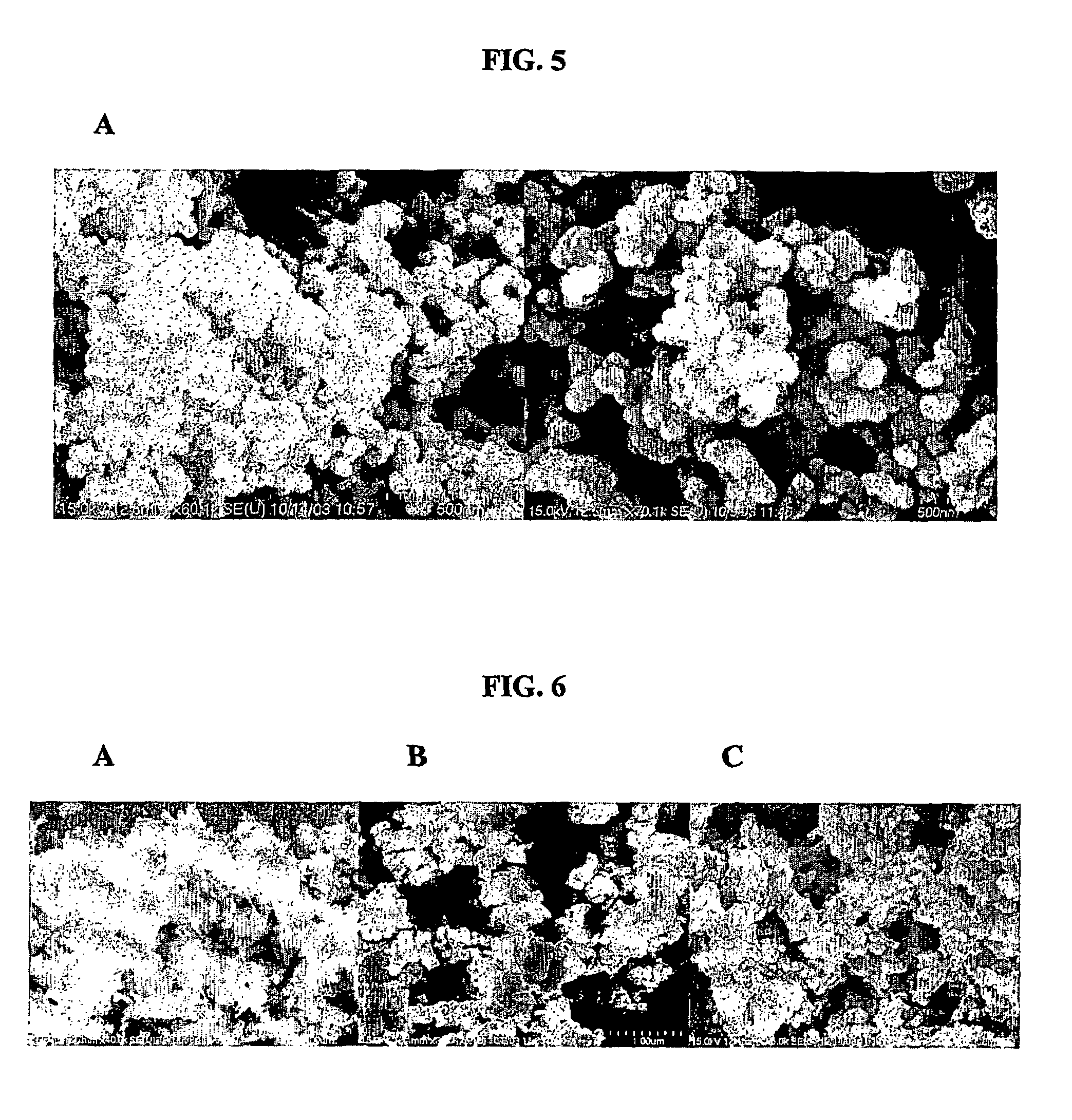

Process for the production of ultrafine particles

A new, cost effective process for the production of ultrafine particles which is based on mechanically activated chemical reaction of a metal compound with a suitable reagent. The process involves subjecting a mixture of a metal compound and a suitable reagent to mechanical activation to increase the chemical reactivity of the reactants and / or reaction kinetics such that a chemical reaction can occur which produces a solid nano-phase substance. Concomitantly, a by-product phase is also formed. This by-product phase is removed so that the solid nano-phase substance is left behind in the form of ultrafine particles. During mechanical activation a composite structure is formed which consists of an intimate mixture of nano-sized grains of the nano-phase substance and the reaction by-product phase. The step of removing the by-product phase, following mechanical activation, may involve subjecting the composite structure to a suitable solvent which dissolves the by-product phase, while not reacting with the solid nano-phase substance. The process according to the invention may be used to form ultrafine metal powders as well as ultrafine ceramic powders. Advantages of the process include a significant degree of control over the size and size distribution of the ultrafine particles, and over the nature of interfaces created between the solid nano-phase substance and the reaction by-product phase.

Owner:WESTERN AUSTRALIA UNIV OF THE

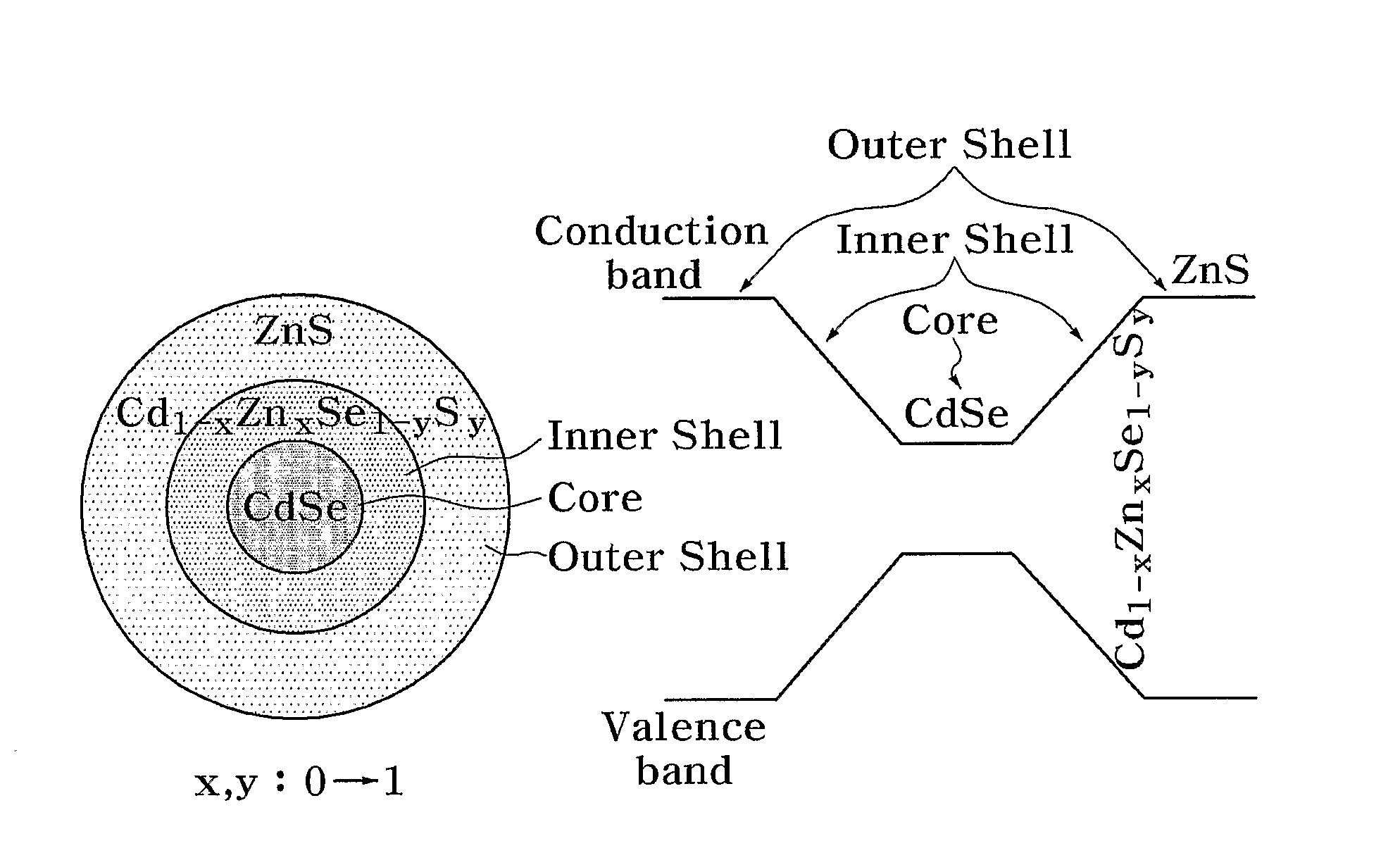

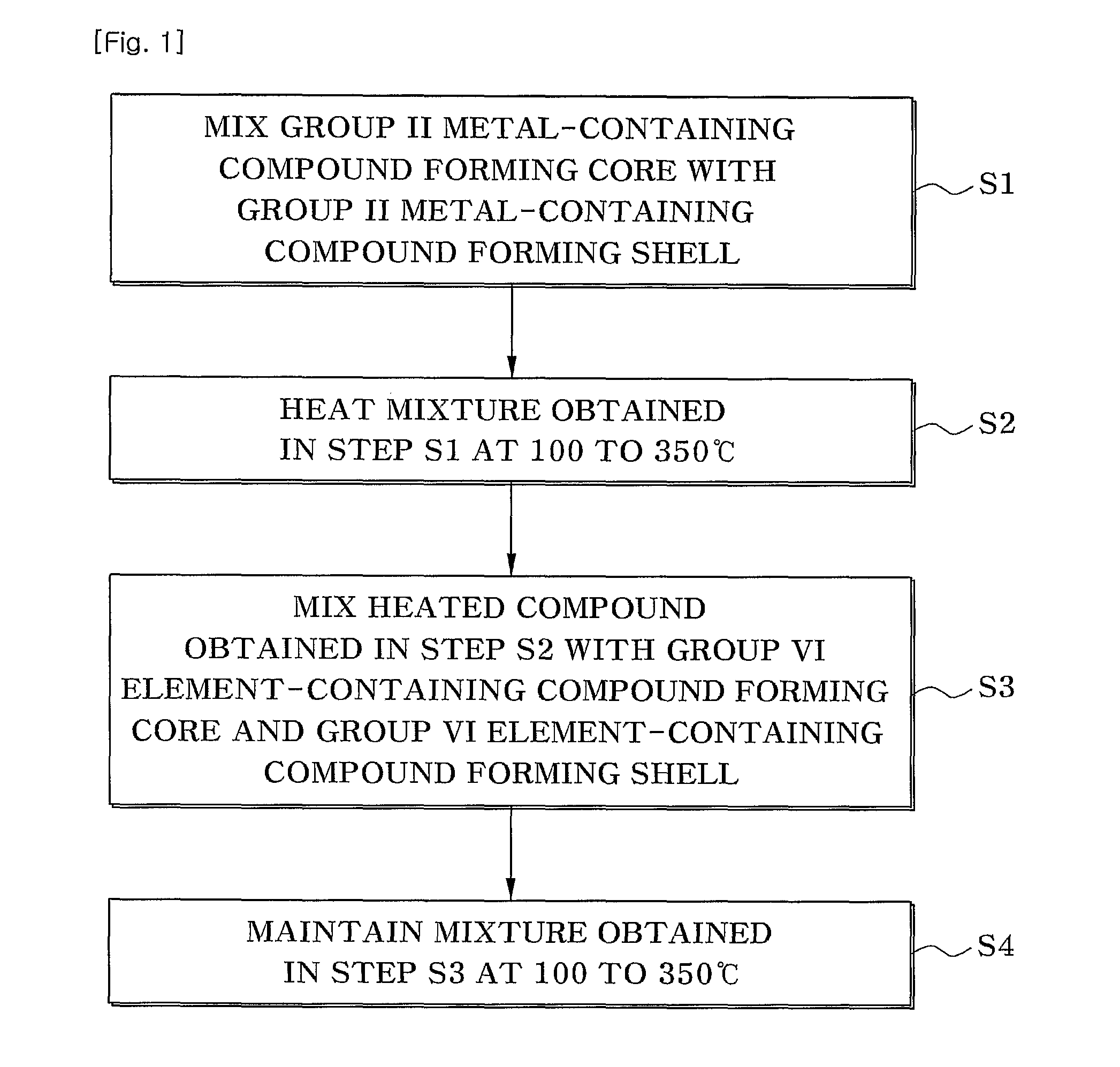

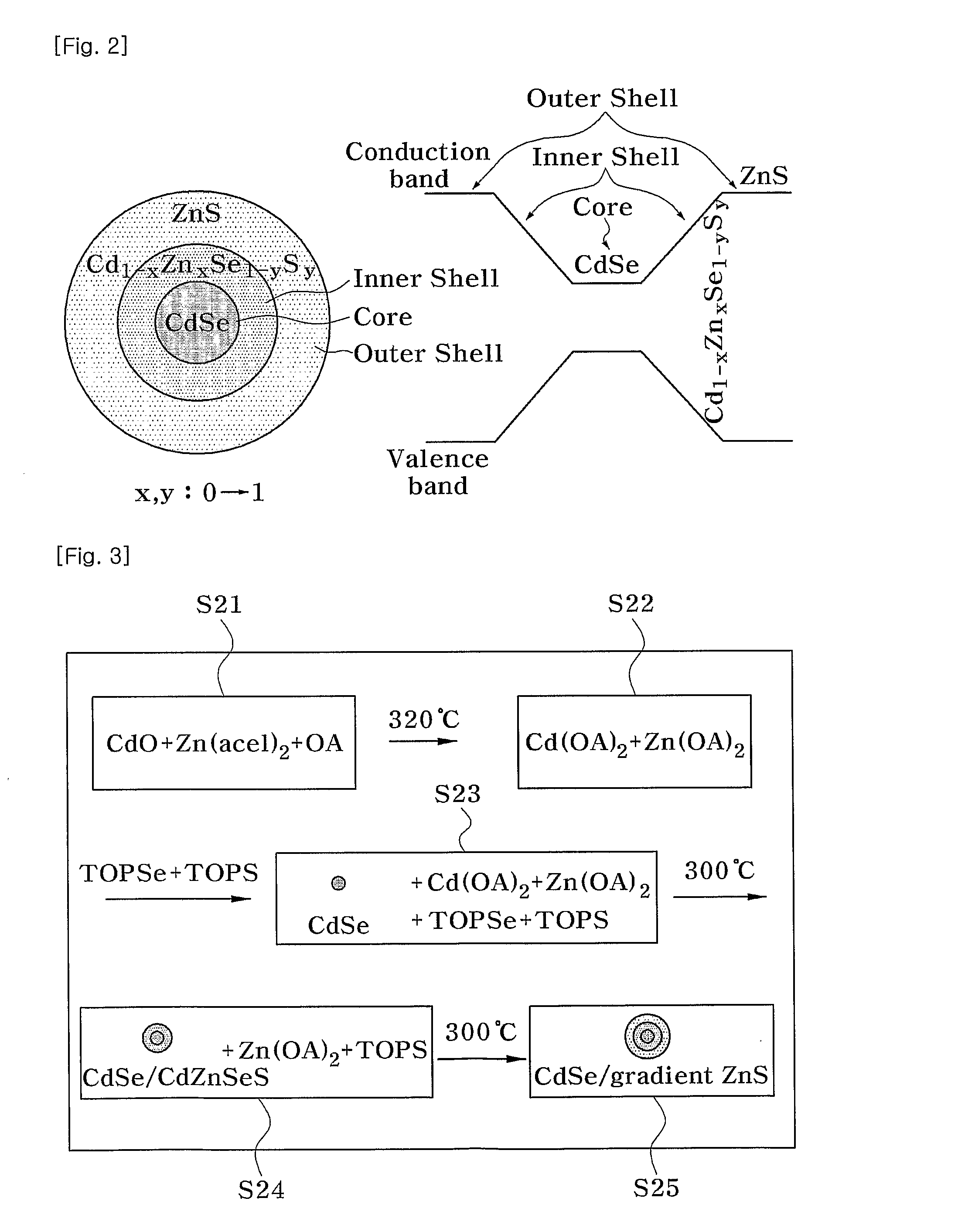

Quantum dots having composition gradient shell structure and manufacturing method thereof

InactiveUS20100140586A1Low costSolve low luminous efficiencyMaterial nanotechnologyCadmium sulfidesElectron holeLattice mismatch

Provided are quantum dots having a gradual composition gradient shell structure which have an improvedluminous efficiency and optical stability, and a method of manufacturing the quantum dots in a short amount of time at low cost. In the method, the quantum dots can be manufactured in a short amount of time at low cost using a reactivity difference between semiconductor precursors, unlike in uneconomical and inefficient conventional methods where shells areformed after forming cores and performing cleaning and redispersion processes. Also, formation of the cores is followed by formation of shells having a composition gradient. Thus, even if the shells are formed to a large thickness, the lattice mismatch between cores and shells is relieved. Furthermore, on the basis of the funneling concept, electrons and holes generated in the shells are transferred to the cores to emit light, thereby obtaining a high luminous efficiency of 80% or more. The quantum dot structure is not limited to Group II-IV semiconductor quantum dots but can be applied to other semiconductors quantum dots, such as Group III-V semiconductors quantum dots and Group IV-IV semiconductors quantum dots. Also, the manufacturing method can be utilized in the development of semiconductor quantum dots having different physical properties, and in various other fields.

Owner:SEOUL NAT UNIV R&DB FOUND

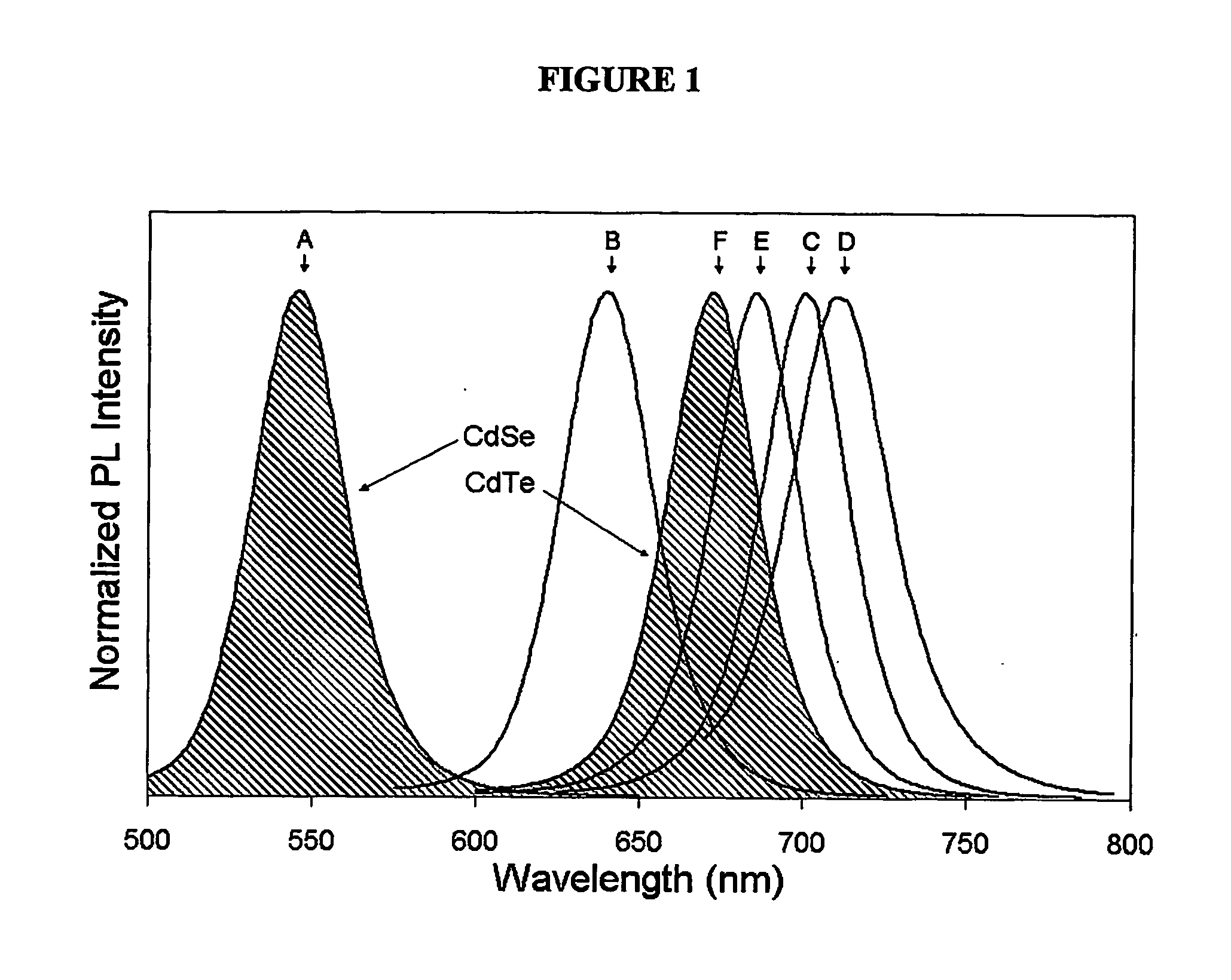

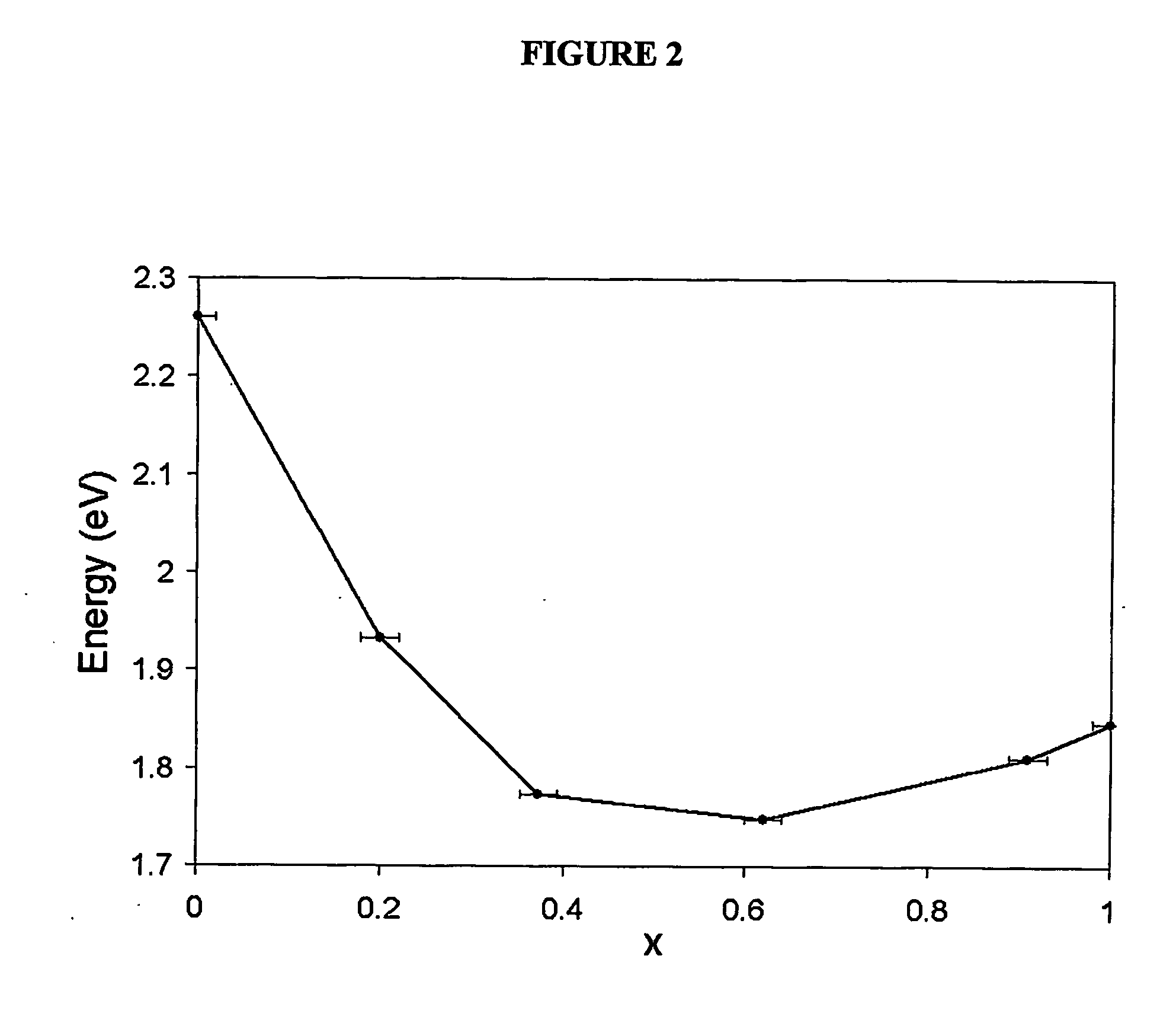

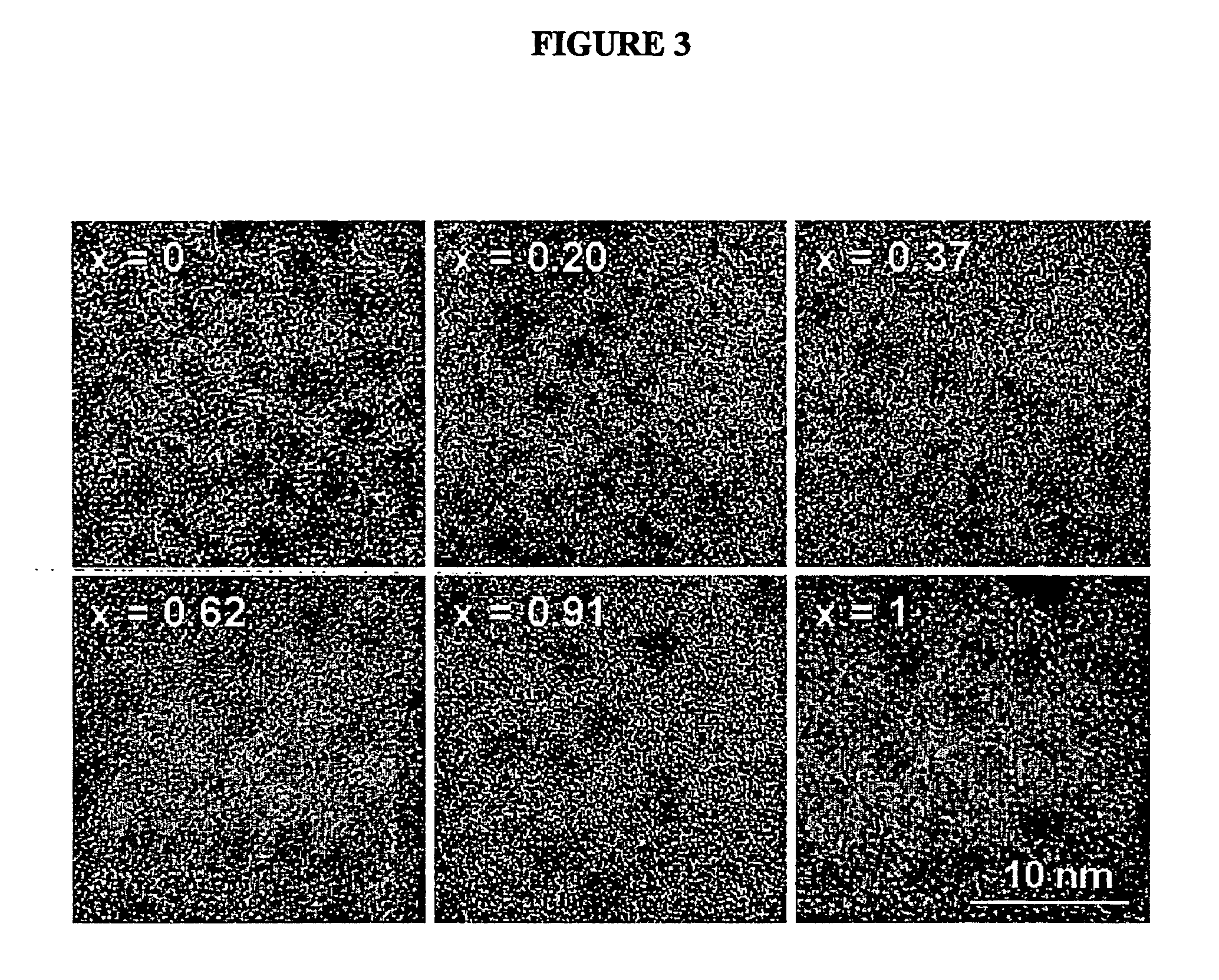

Alloyed semiconductor quantum dots and concentration-gradient alloyed quantum dots, series comprising the same and methods related thereto

An alloyed semiconductor quantum dot comprising an alloy of at least two semiconductors, wherein the quantum dot has a homogeneous composition and is characterized by a band gap energy that is non-linearly related to the molar ratio of the at least two semiconductors; a series of alloyed semiconductor quantum dots related thereto; a concentration-gradient quantum dot comprising an alloy of a first semiconductor and a second semiconductor, wherein the concentration of the first semiconductor gradually increases from the core of the quantum dot to the surface of the quantum dot and the concentration of the second semiconductor gradually decreases from the core of the quantum dot to the surface of the quantum dot; a series of concentration-gradient quantum dots related thereto; in vitro and in vivo methods of use; and methods of producing the alloyed semiconductor and concentration-gradient quantum dots and the series of quantum dots related thereto.

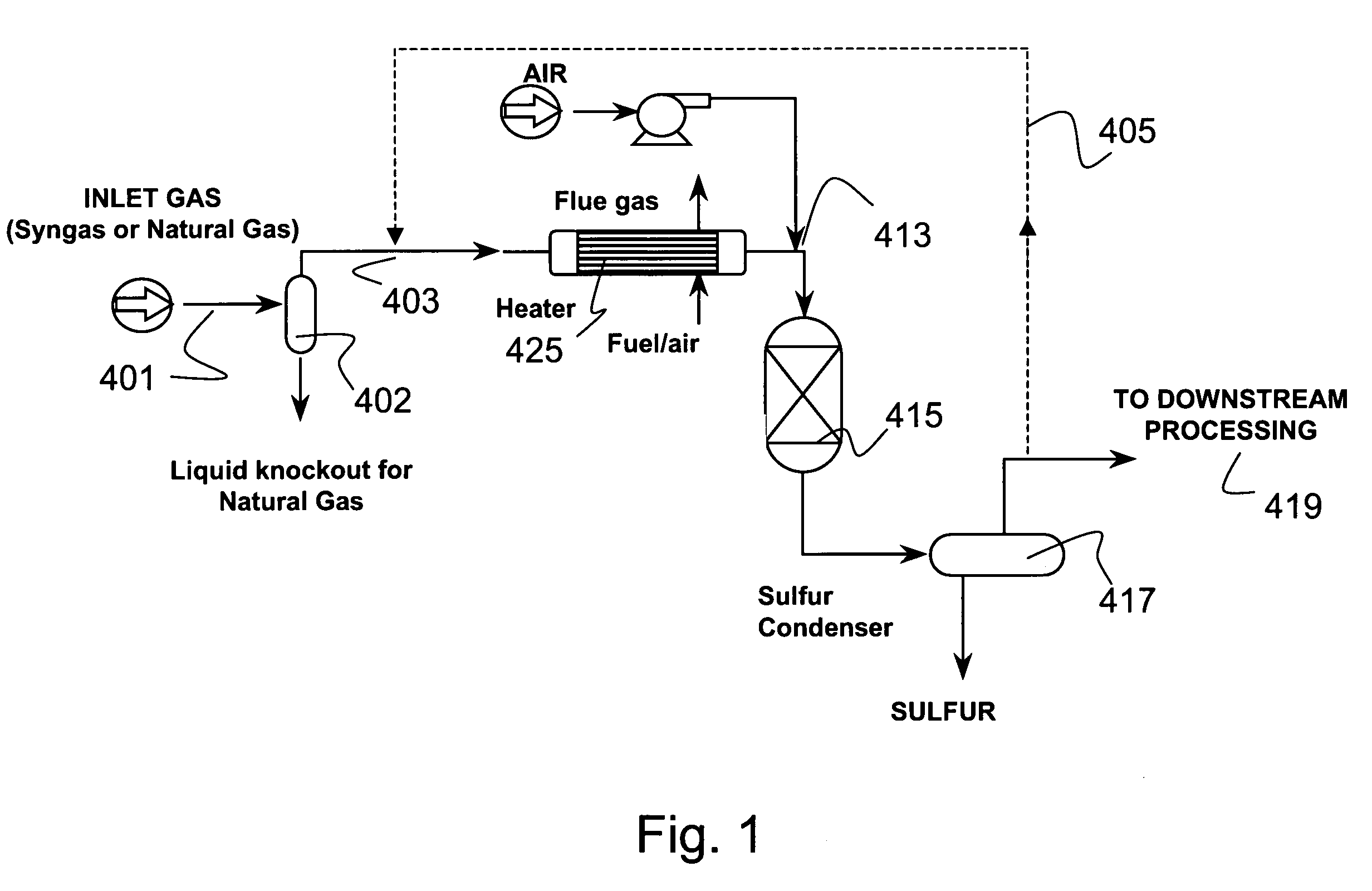

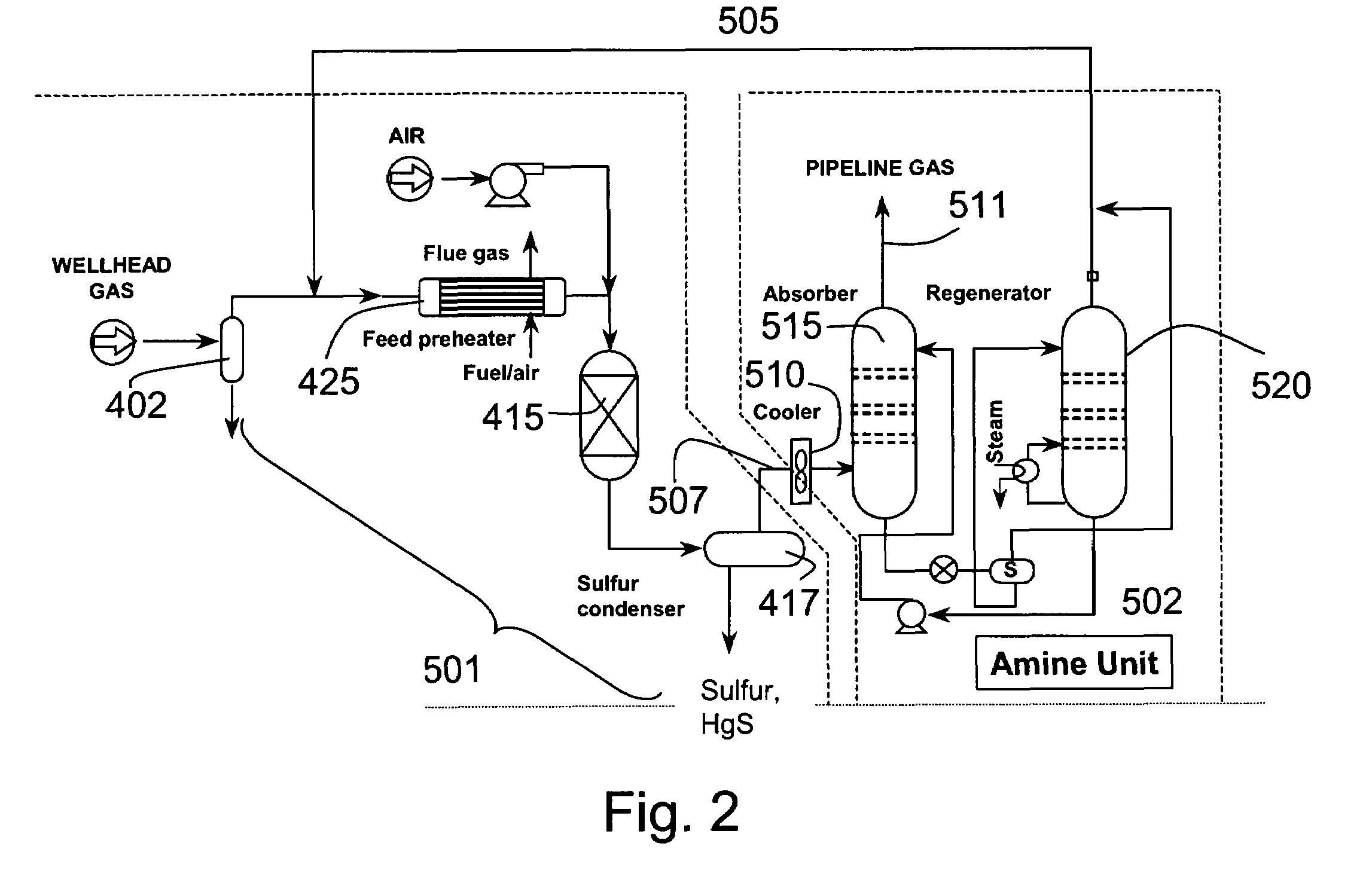

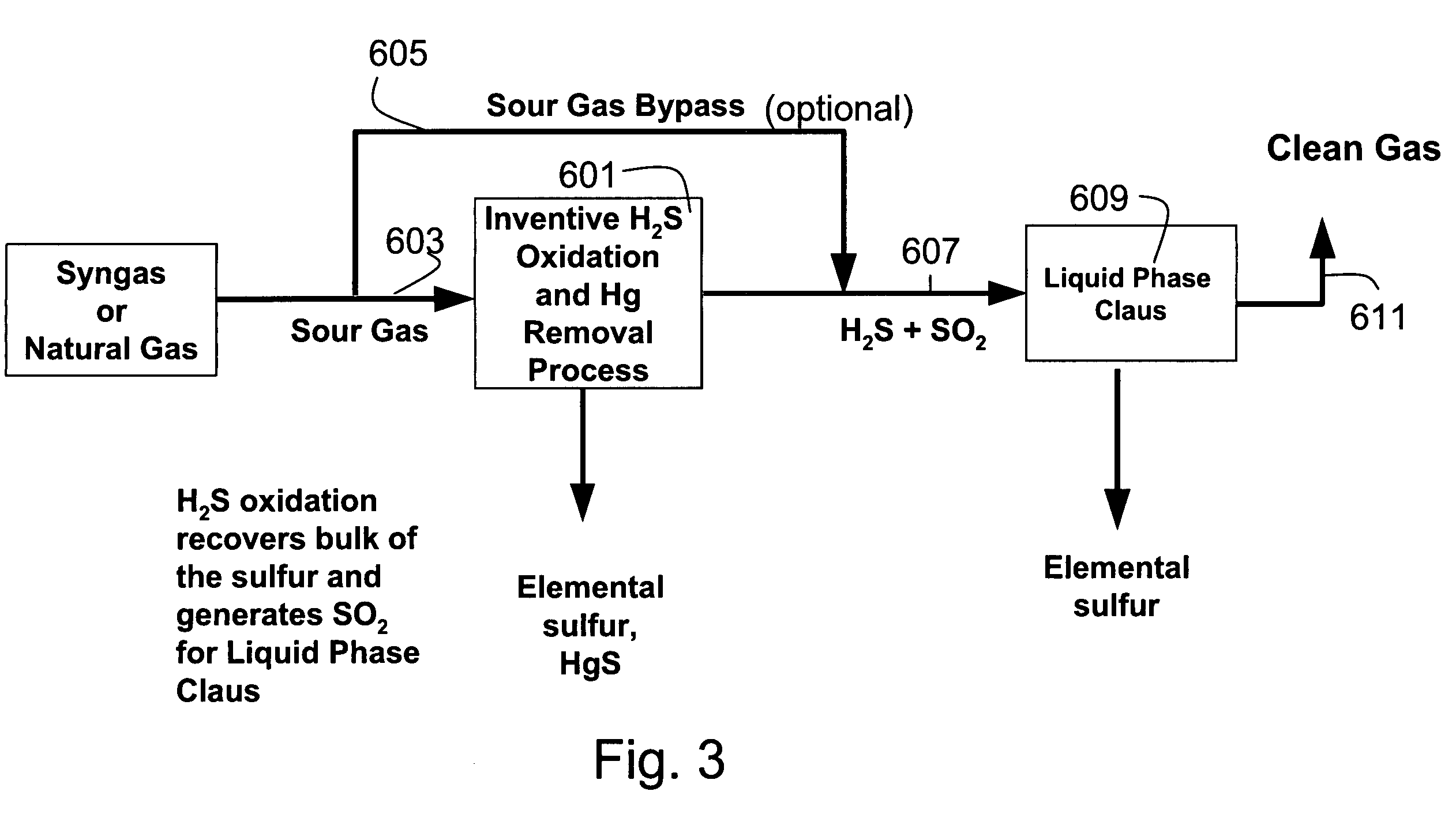

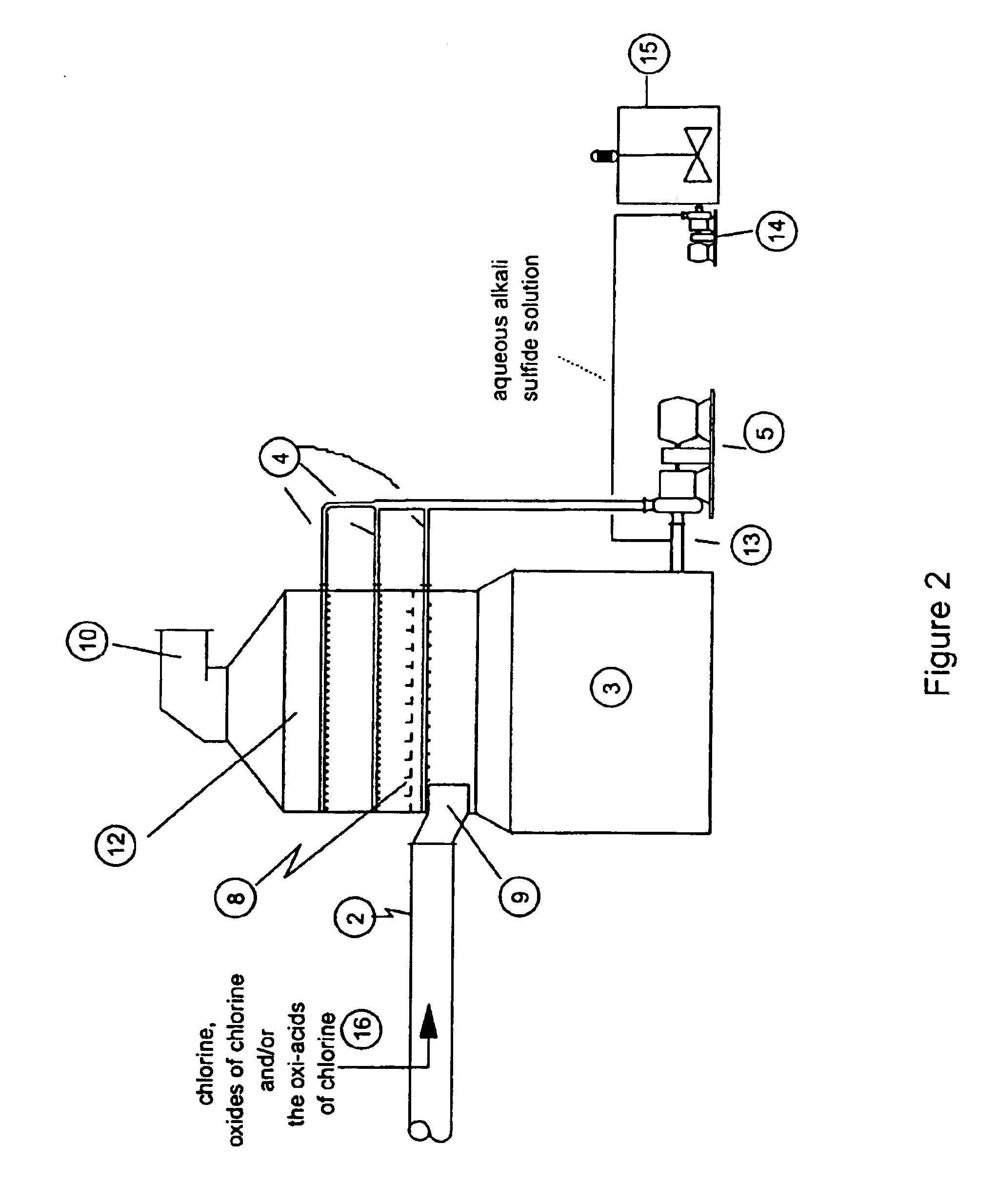

Process for the simultaneous removal of sulfur and mercury

InactiveUS7060233B1Lower capitalReduce operating costsGas treatmentUsing liquid separation agentSulfur containingInorganic sulfide

A process for removing hydrogen sulfide, other sulfur-containing compounds and / or sulfur and mercury from a gas stream contaminated with mercury, hydrogen sulfide or both. The method comprises the step of selective oxidation of hydrogen sulfide (H2S) in a gas stream containing one or more oxidizable components other than H2S to generate elemental sulfur (S) or a mixture of sulfur and sulfur dioxide (SO2). The sulfur generated in the gas stream reacts with mercury in the gas stream to generate mercuric sulfide and sulfur and mercuric sulfide are removed from the gas stream by co-condensation.

Owner:TDA RES

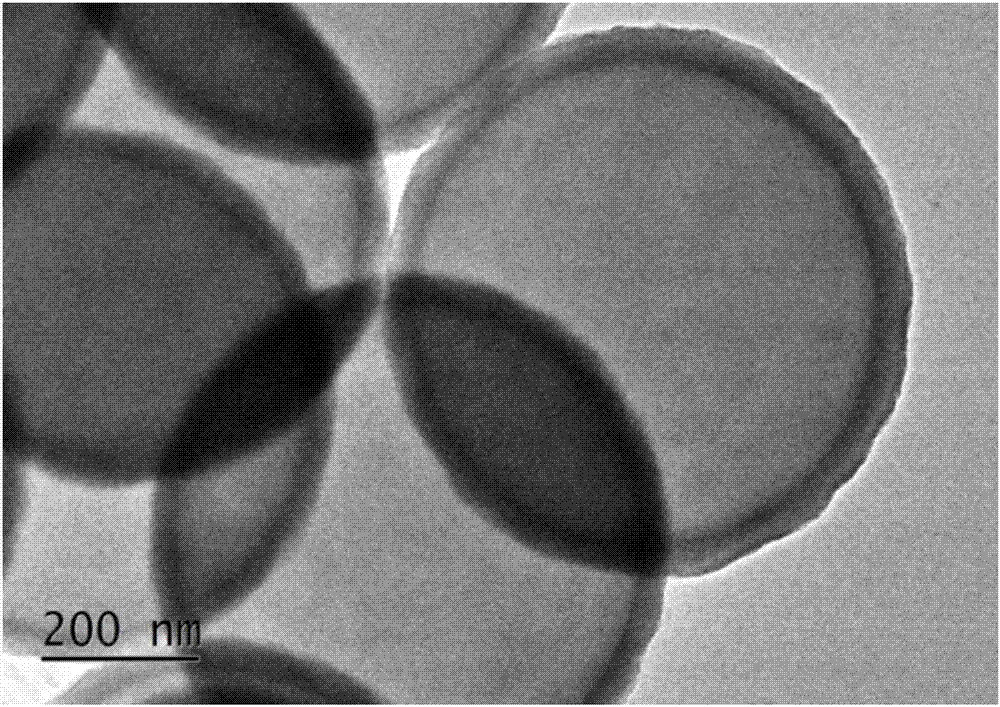

Sulfide coated particle as well as preparation method and application thereof

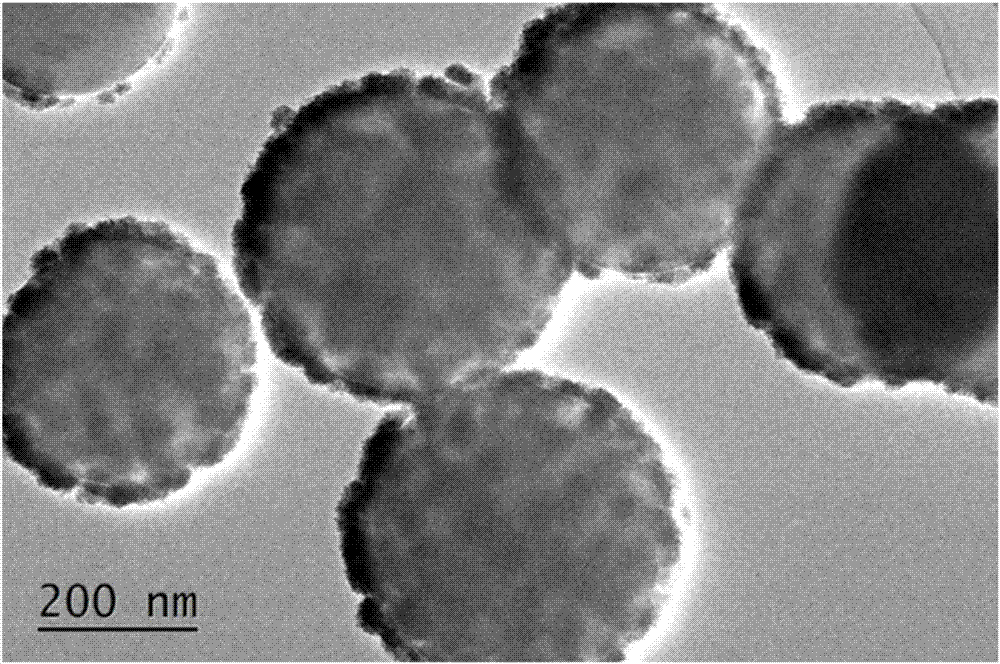

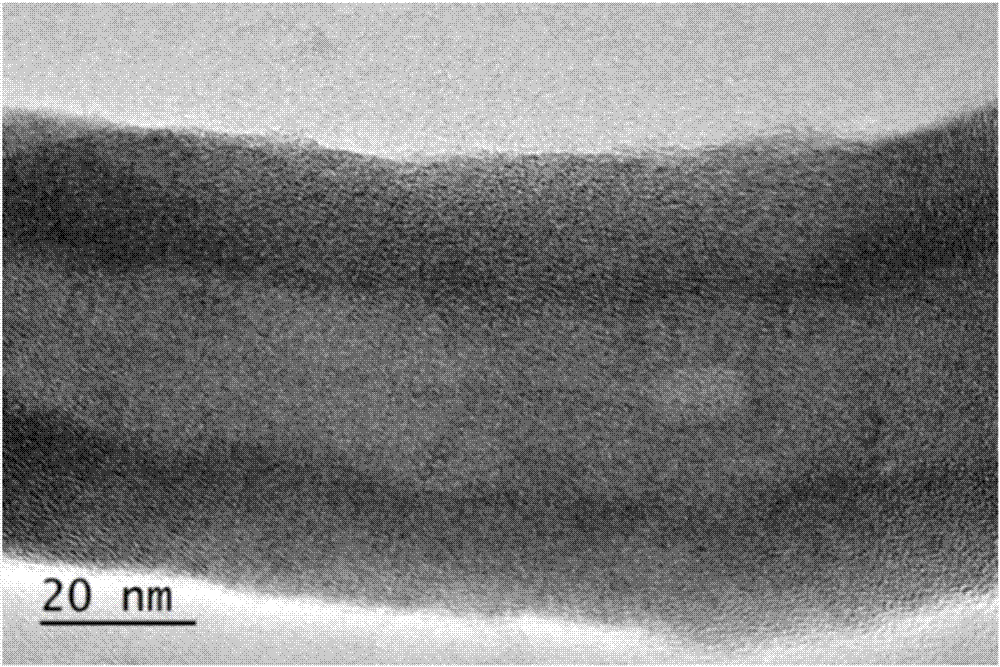

InactiveCN107983272AUniform thicknessThickness is easy to controlCobalt sulfidesZinc sulfidesMetallic sulfideLithium-ion battery

The invention discloses a sulfide coated particle as well as a preparation method and an application thereof. The sulfide coated particle comprises a core and a shell coating the core, wherein the core is prepared from at least one of metal, oxide, metal hydroxide, metal inorganic salt, elemental carbon or oxysome thereof, carbide, nitride, semiconductor and organic matter; the shell is prepared from metal sulfide. The to-be-coated core is mixed with the metal salt, a reducing agent and a sulfur source with a liquid phase method, metal sulfide is precipitated to the particle surface through in-situ reduction, and uniform, continuous and controllable coating of the core surface with metal sulfide is realized. The coating method is simple, reaction conditions are mild, universality is high,a coating layer is controllable in thickness, complete and uniform, and the sulfide coated particle has quite broad practical application prospect in the fields of electrocatalysis, lithium ion batteries, biomedicine and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

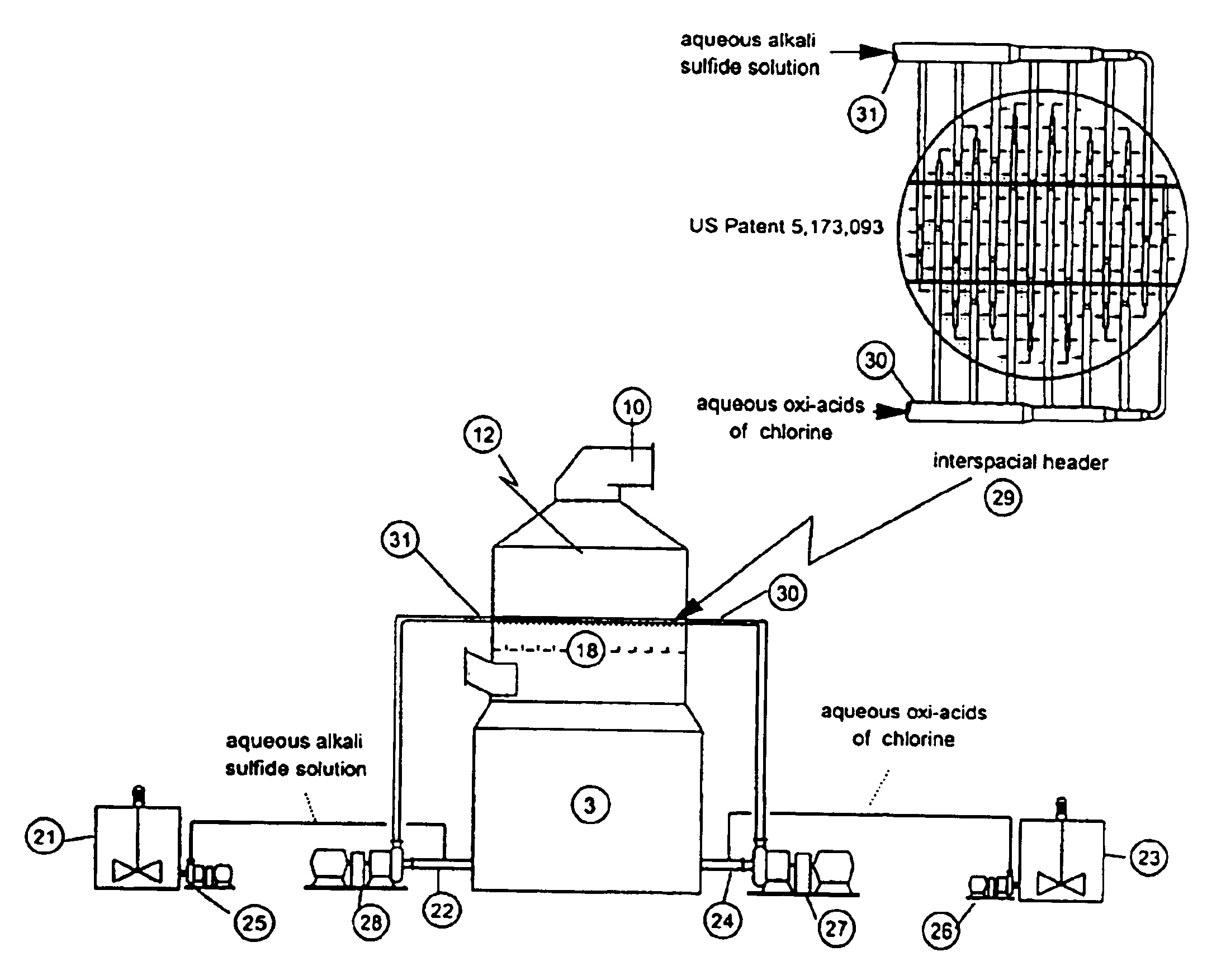

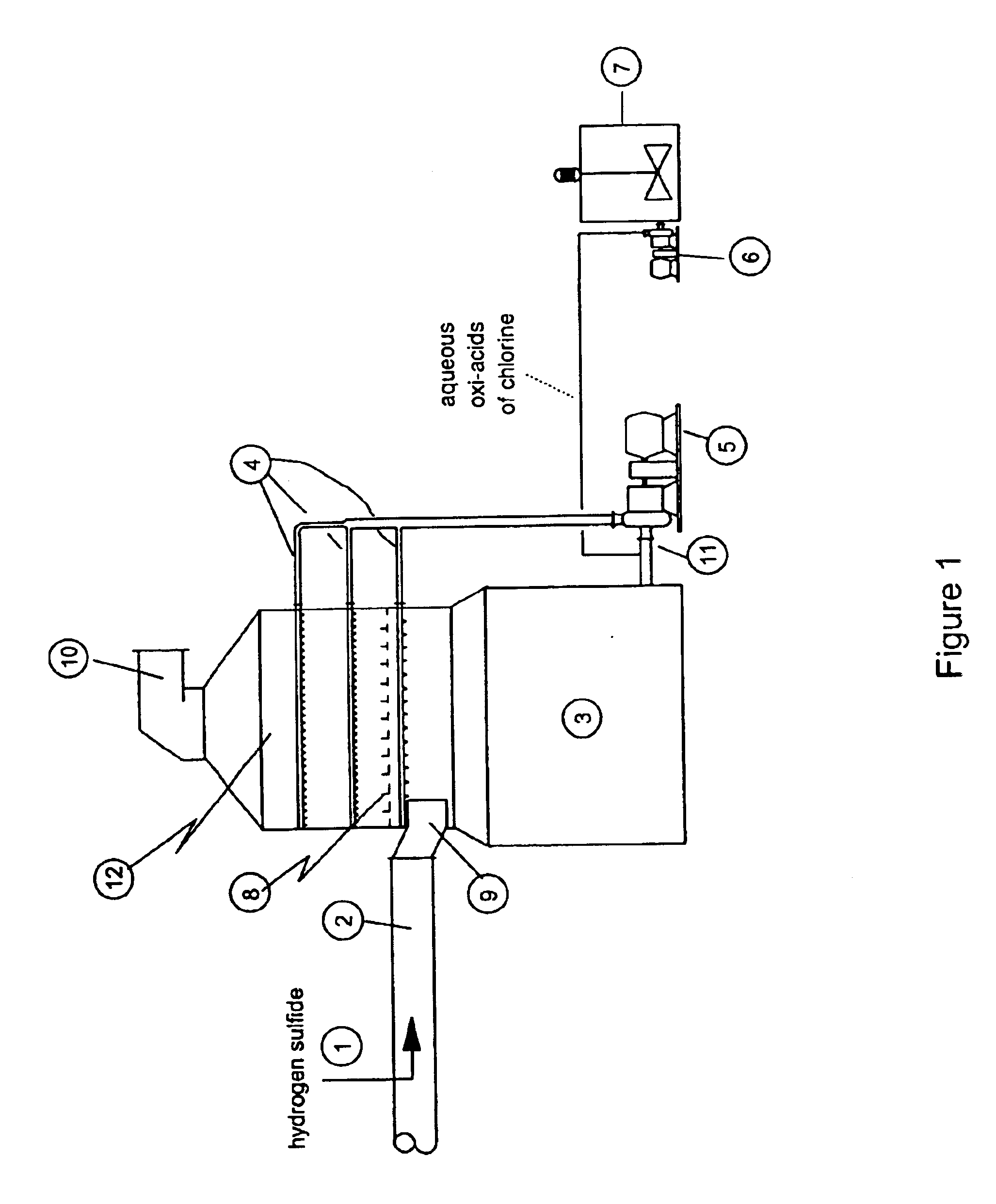

Method for controlling elemental mercury emissions

InactiveUS6855859B2Simple equipmentReduce oxidationGas treatmentExhaust apparatusElemental mercuryPrecipitation

Chlorine and sulfide species are separately introduced to a flue gas passing through a scrubber in order to remove the elemental and oxidized mercury from the gas through the precipitation of mercuric sulfide at near 100% efficiency.

Owner:THE BABCOCK & WILCOX CO

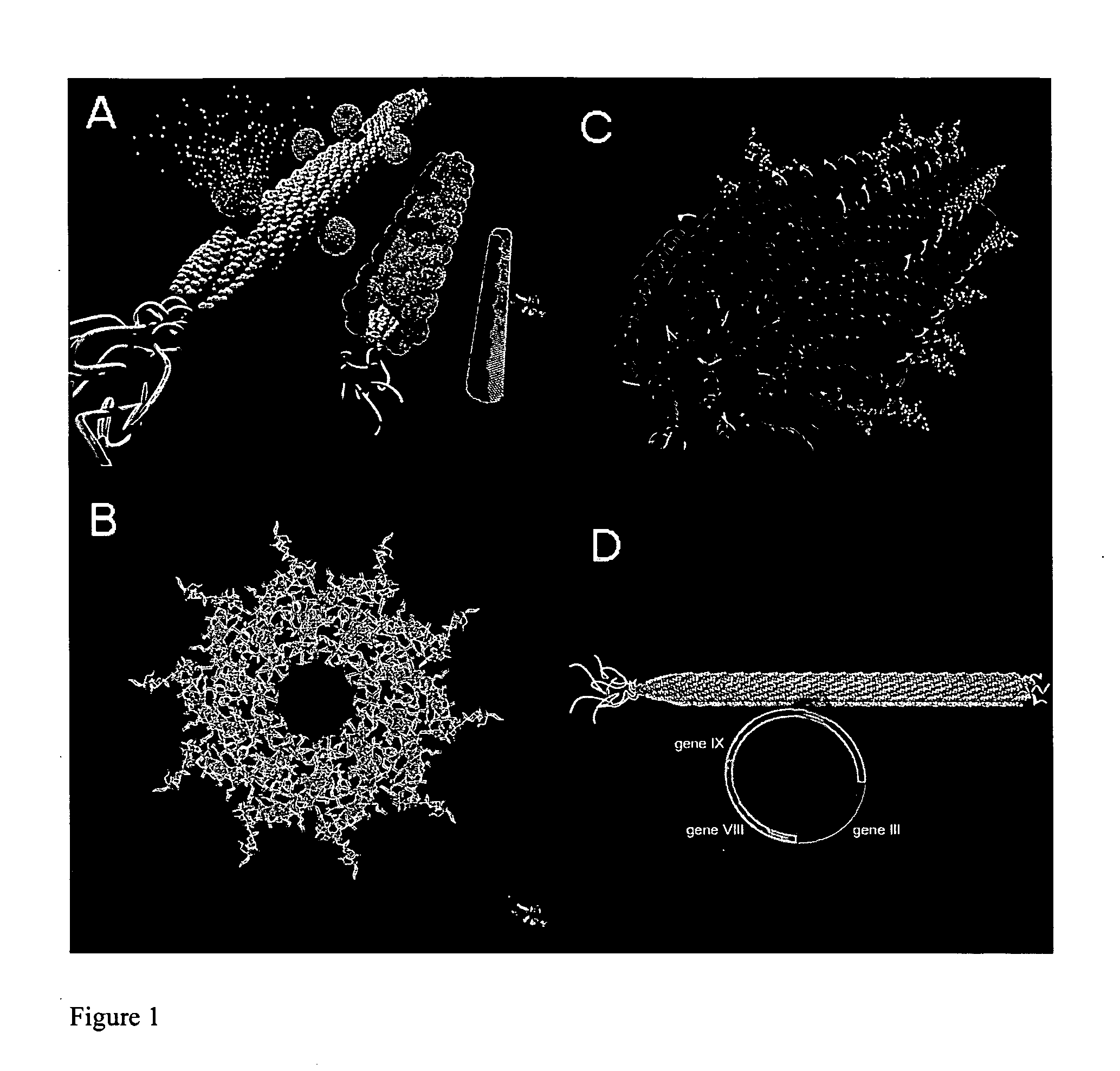

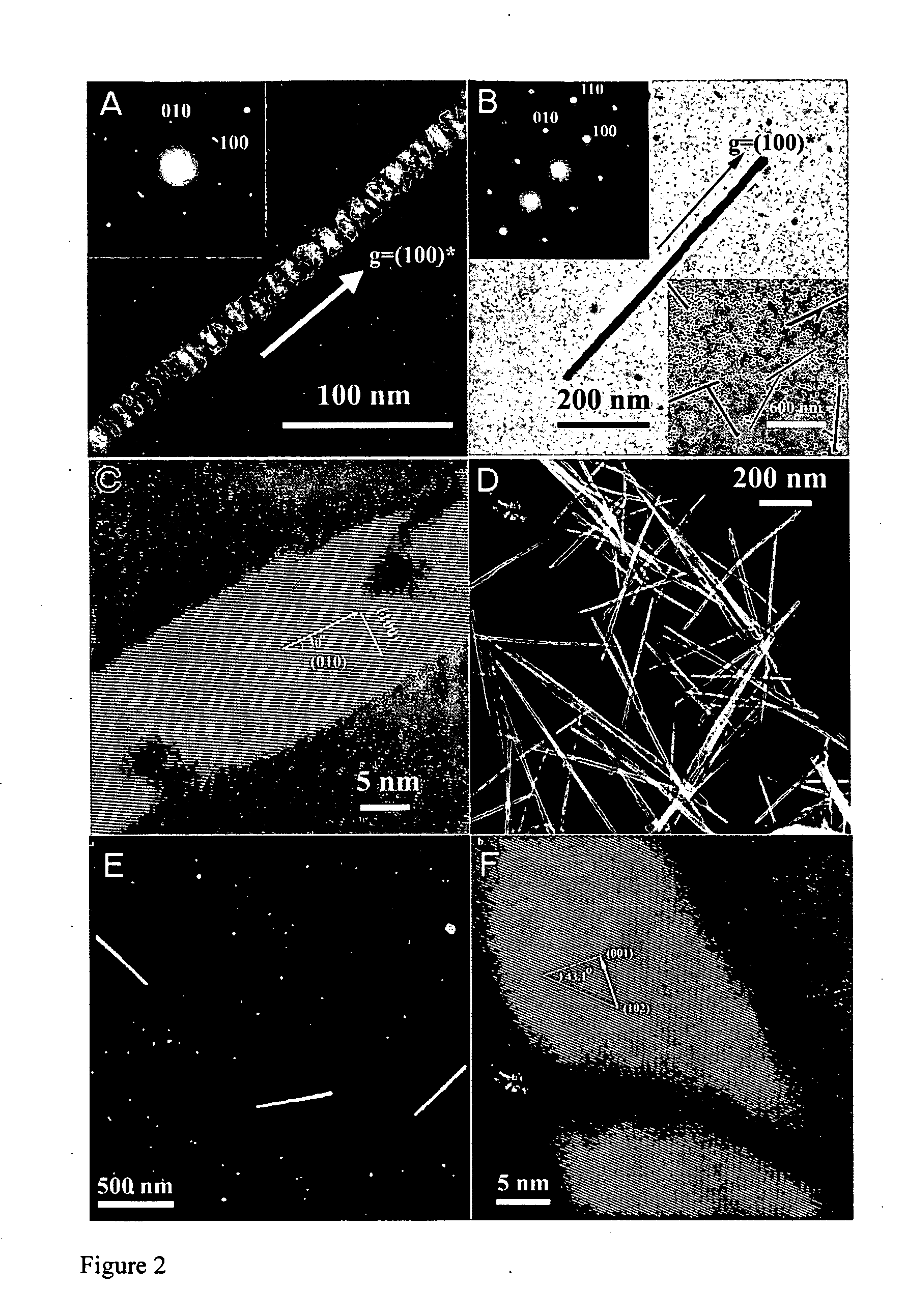

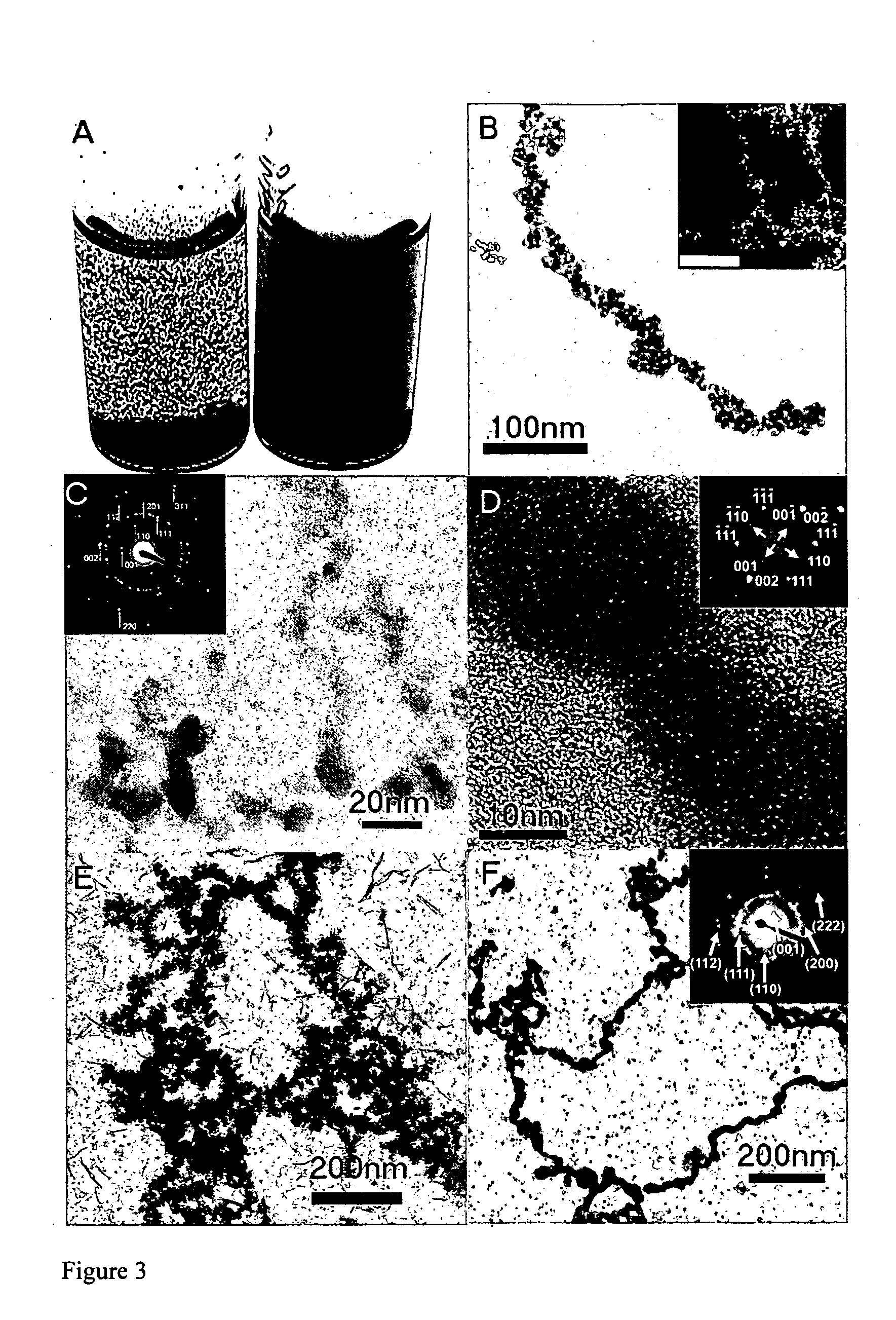

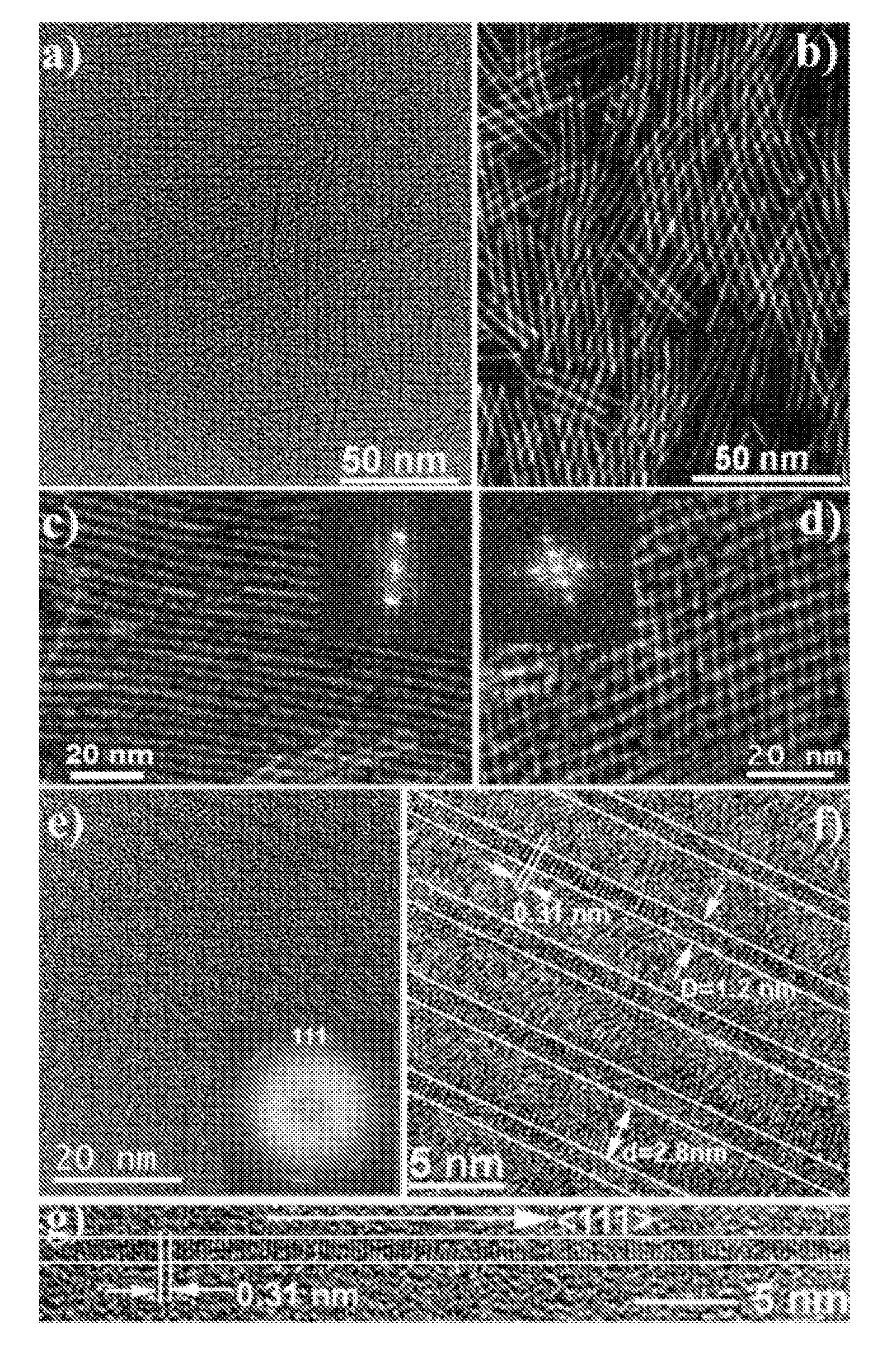

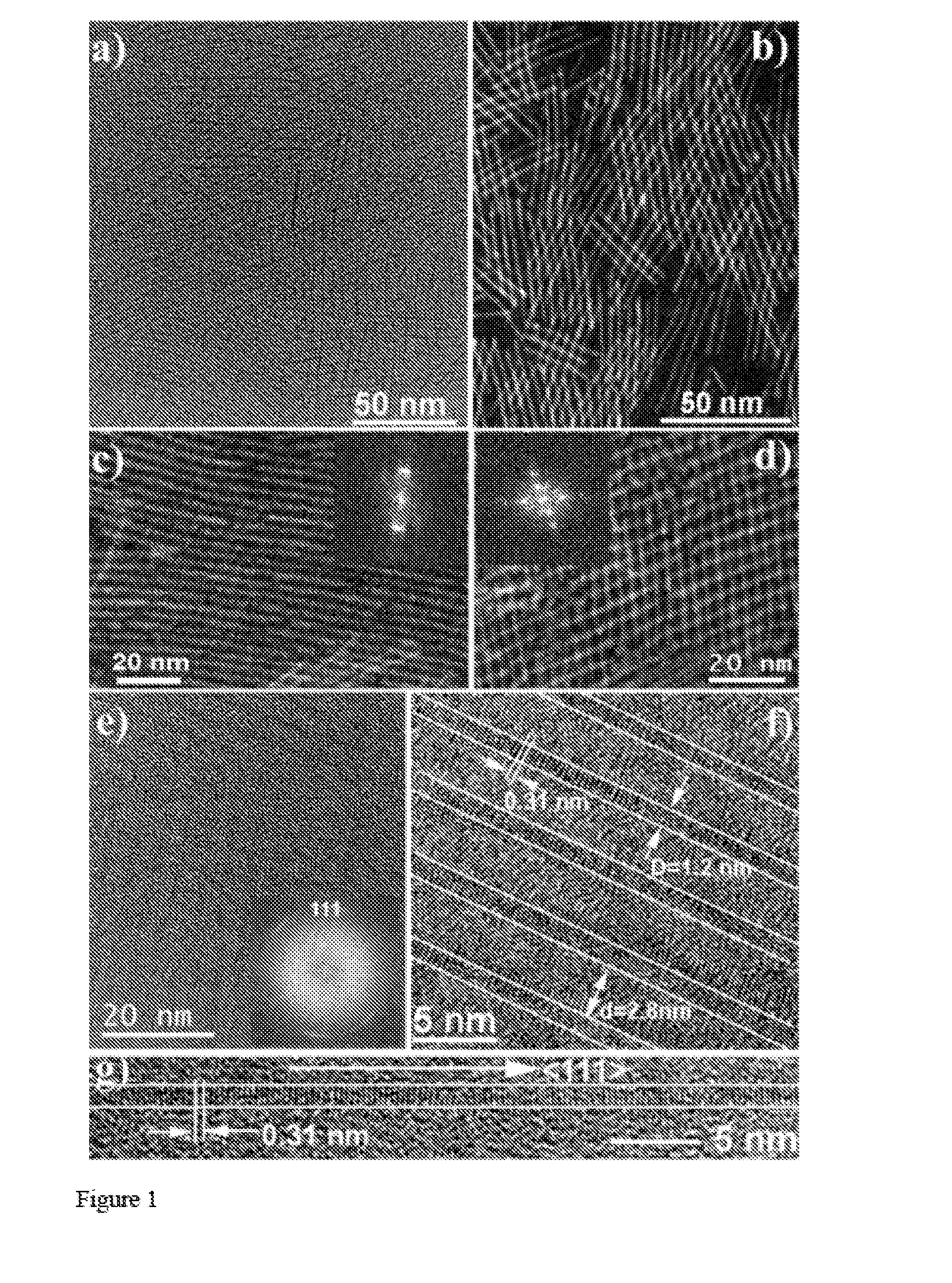

Inorganic nanowires

InactiveUS20050221083A1Good monodispersityHigh degreeMaterial nanotechnologyNanoinformaticsNanowireSingle crystal

An inorganic nanowire having an organic scaffold substantially removed from the inorganic nanowire, the inorganic nanowire consisting essentially of fused inorganic nanoparticles substantially free of the organic scaffold, and methods of making same. For example, a virus-based scaffold for the synthesis of single crystal ZnS, CdS and free-standing L10 CoPt and FePt nanowires can be used, with the means of modifying substrate specificity through standard biological methods. Peptides can be selected through an evolutionary screening process that exhibit control of composition, size, and phase during nanoparticle nucleation have been expressed on the highly ordered filamentous capsid of the M13 bacteriophage. The incorporation of specific, nucleating peptides into the generic scaffold of the M13 coat structure can provide a viable template for the directed synthesis of a variety of materials including semiconducting and magnetic materials. Removal of the viral template via annealing can promote oriented aggregation-based crystal growth, forming individual crystalline nanowires. The unique ability to interchange substrate specific peptides into the linear self-assembled filamentous construct of the M13 virus introduces a material tunability not seen in previous synthetic routes. Therefore, this system provides a genetic tool kit for growing and organizing nanowires from various materials including semiconducting and magnetic materials.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

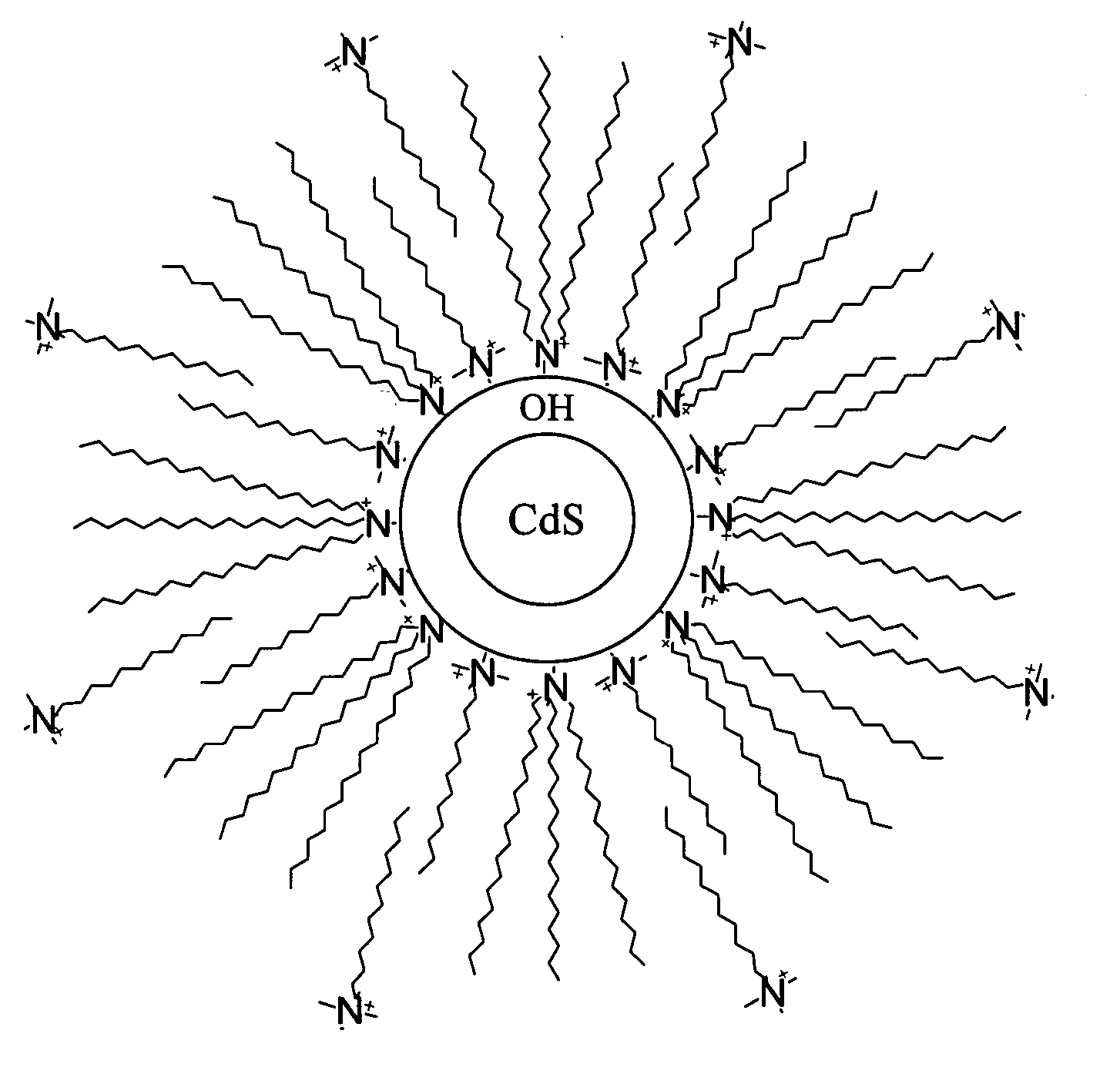

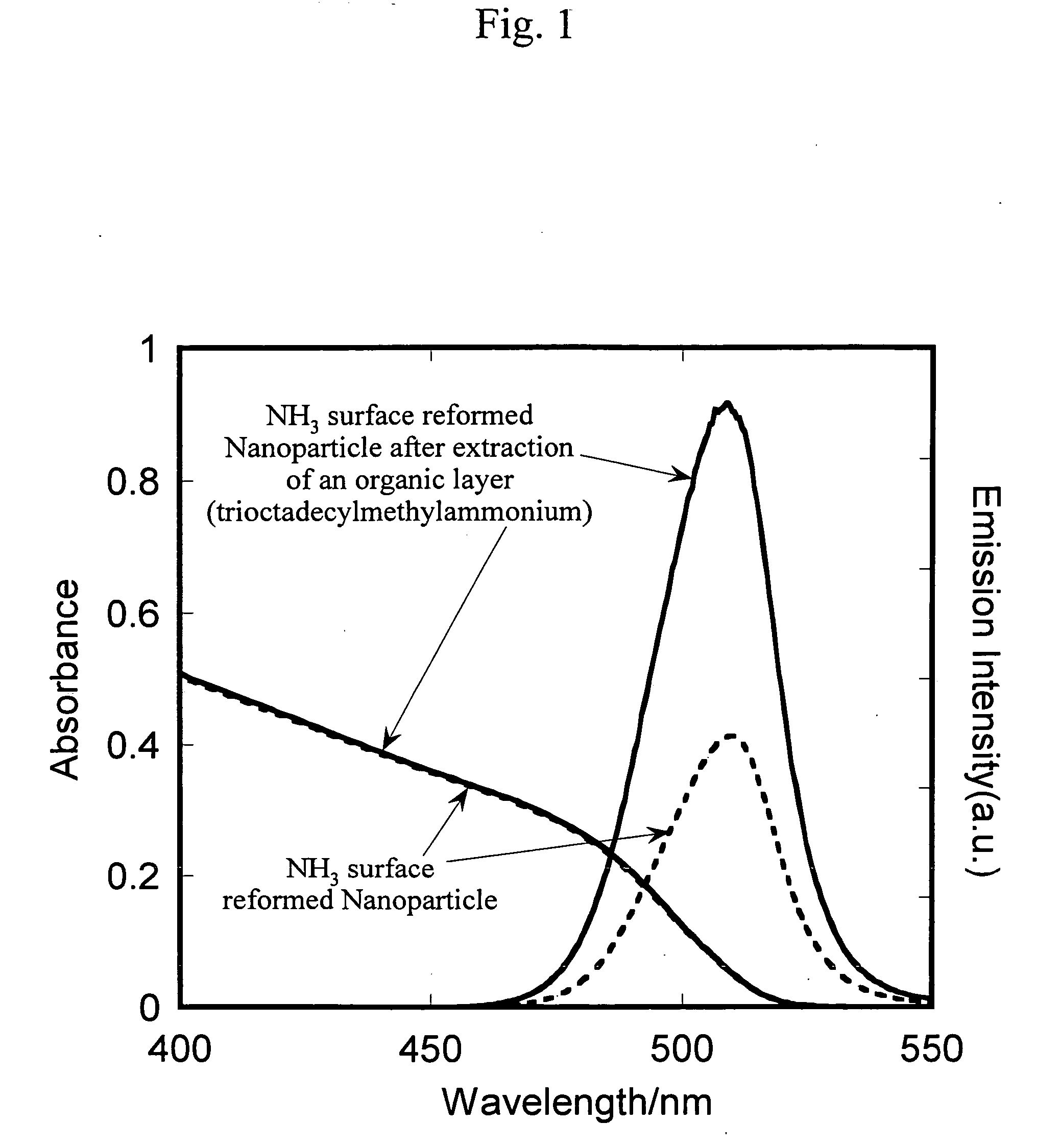

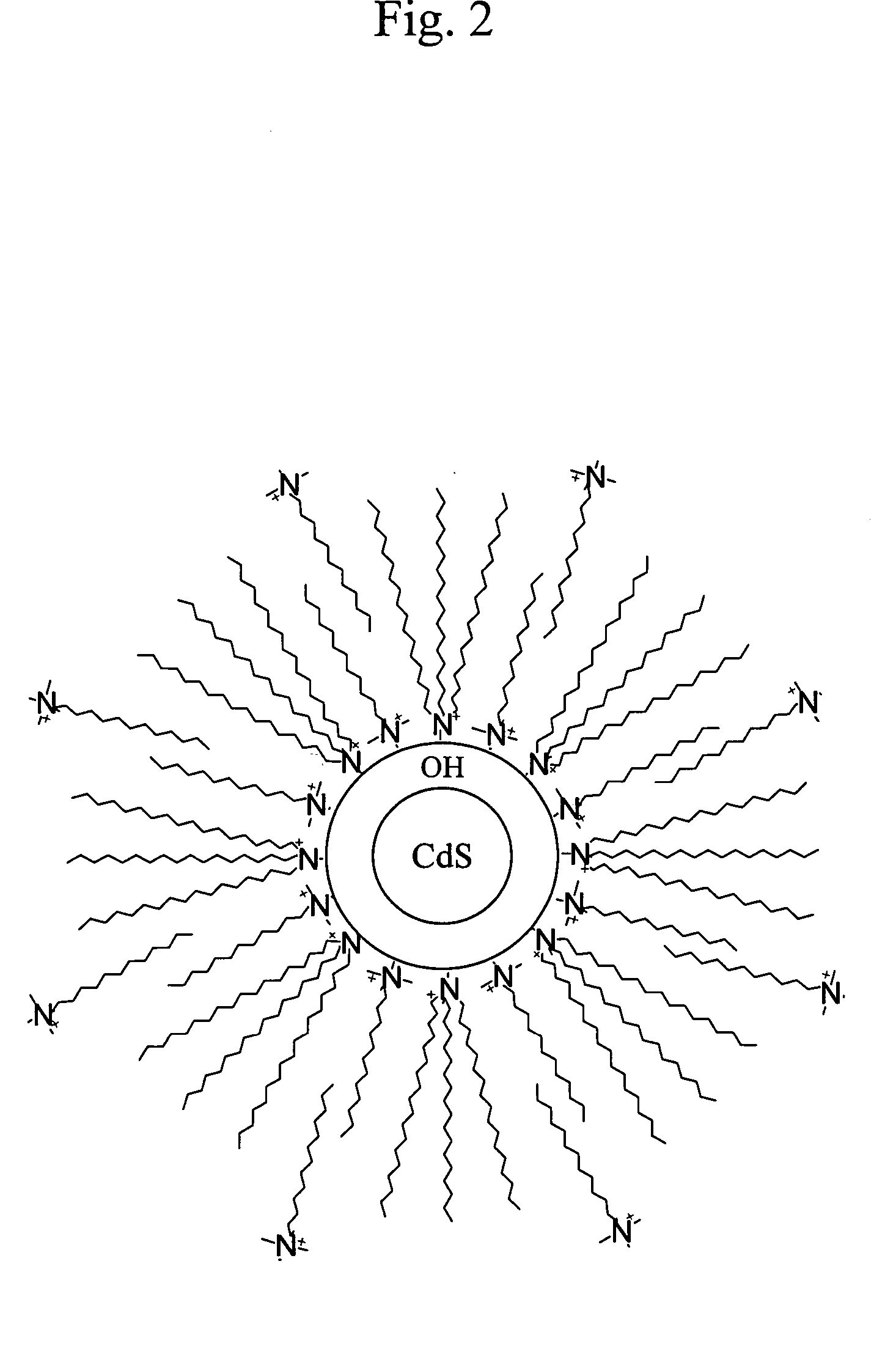

Semiconductor nanoparticle surface modification method

InactiveUS20070131905A1Improve luminous performanceMaterial nanotechnologySemiconductor/solid-state device detailsBiopolymerSemiconductor Nanoparticles

Semiconductor nanoparticles having high luminescence properties that are preferable for applications and uses of biotechnology are provided. With the use of electric charges on the surfaces of particles, the particles and selected polymers are allowed to electrostatically bind to each other, such that the surfaces of the particles are coated. The polymers are allowed to crosslink to each other, resulting in the improved durability of the particles. Further, functional groups contained in the polymers are exposed on the surfaces of the particles. Accordingly, semiconductor nanoparticles that are preferably utilized for applications such as staining and labeling of biopolymers have been synthesized.

Owner:HITACHI LTD

Single-crystal-like materials

InactiveUS7022303B2Improve fracture toughnessReadily apparentMagnesium fluoridesCalcium/strontium/barium fluoridesMetallurgySingle crystal

Polycrystalline materials of macroscopic size exhibiting Single-Crystal-Like properties are formed from a plurality of Single-Crystal Particles, having Self-Aligning morphologies and optionally ling morphology, bonded together and aligned along at least one, and up to three, crystallographic directions.

Owner:RUTGERS THE STATE UNIV

III-V semiconductor nanocrystal complexes and methods of making same

ActiveUS20060001119A1High Luminescence Quantum YieldMaterial nanotechnologyFrom normal temperature solutionsLuminescence quantum yieldSemiconductor nanocrystals

A semiconductor nanocrystal complex that is stable and has high luminescent quantum yield. The semiconductor nanocrystal complex has a semiconductor nanocrystal core of a III-V semiconductor nanocrystal material. A method of making a semiconductor nanocrystal complex is also provided. The method includes synthesizing a semiconductor nanocrystal core of a III-V semiconductor nanocrystal material, and forming a metal layer on the semiconductor nanocrystal core after synthesis of the semiconductor nanocrystal core.

Owner:SAMSUNG ELECTRONICS CO LTD

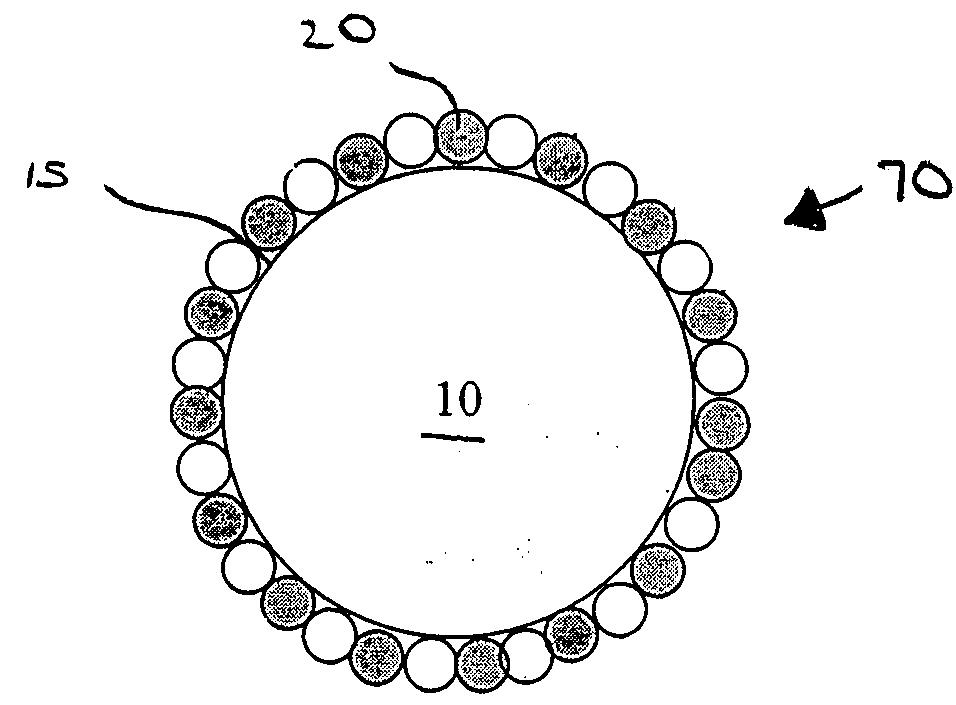

Nanocluster-based white-light-emitting material employing surface tuning

A method for making a nanocrystal-based material capable of emitting light over a sufficiently broad spectral range to appear white. Surface-modifying ligands are used to shift and broaden the emission of semiconductor nanocrystals to produce nanoparticle-based materials that emit white light.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Semiconductor nanocrystal complexes and methods of making same

ActiveUS20060014040A1Material nanotechnologyLiquid surface applicatorsLattice mismatchSemiconductor nanocrystals

A semiconductor nanocrystal complex including a metal layer formed on the outer surface of a semiconductor nanocrystal core after synthesis of the semiconductor nanocrystal core and a method for preparing a nanocrystal complex comprising forming a metal layer on a semiconductor nanocrystal core after synthesis of the semiconductor nanocrystal core. The metal layer may passivate the surface of the semiconductor nanocrystal core and protect the semiconductor nanocrystal core from the effects of oxidation. Also provided is a semiconductor nanocrystal complex with a shell grown onto the metal layer formed on the semiconductor nanocrystal core. In this embodiment, the metal layer may prevent lattice mismatch between the semiconductor shell and the semiconductor nanocrystal core.

Owner:SAMSUNG ELECTRONICS CO LTD

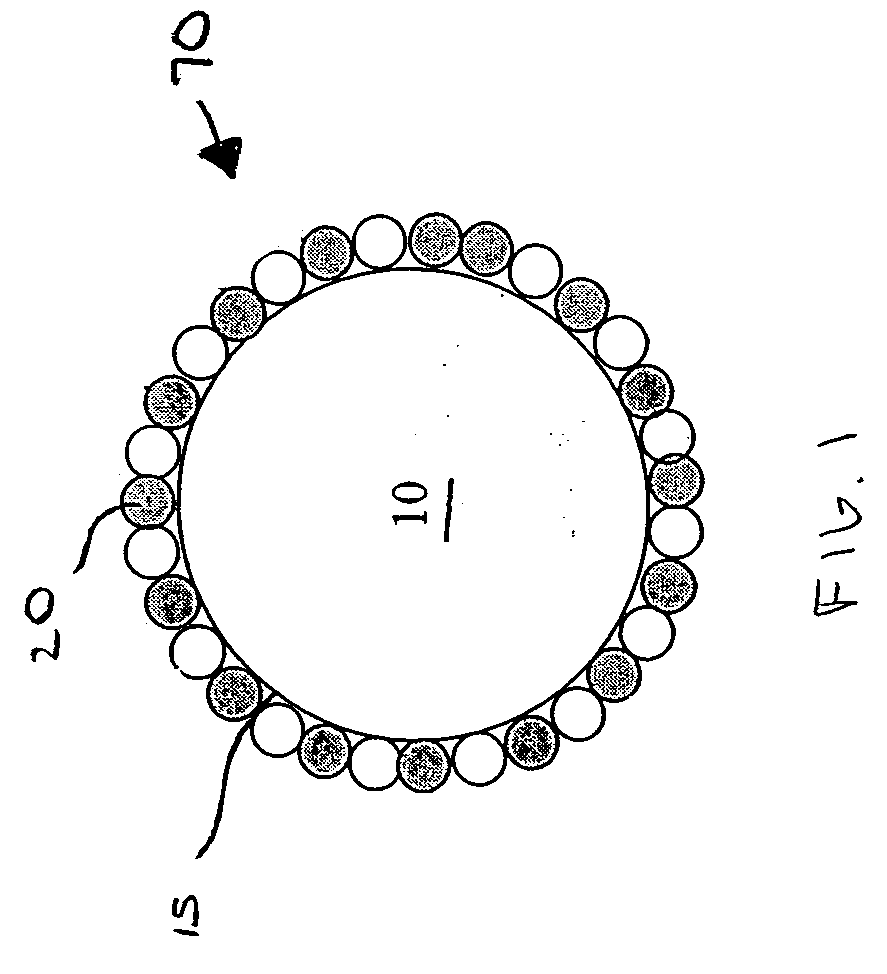

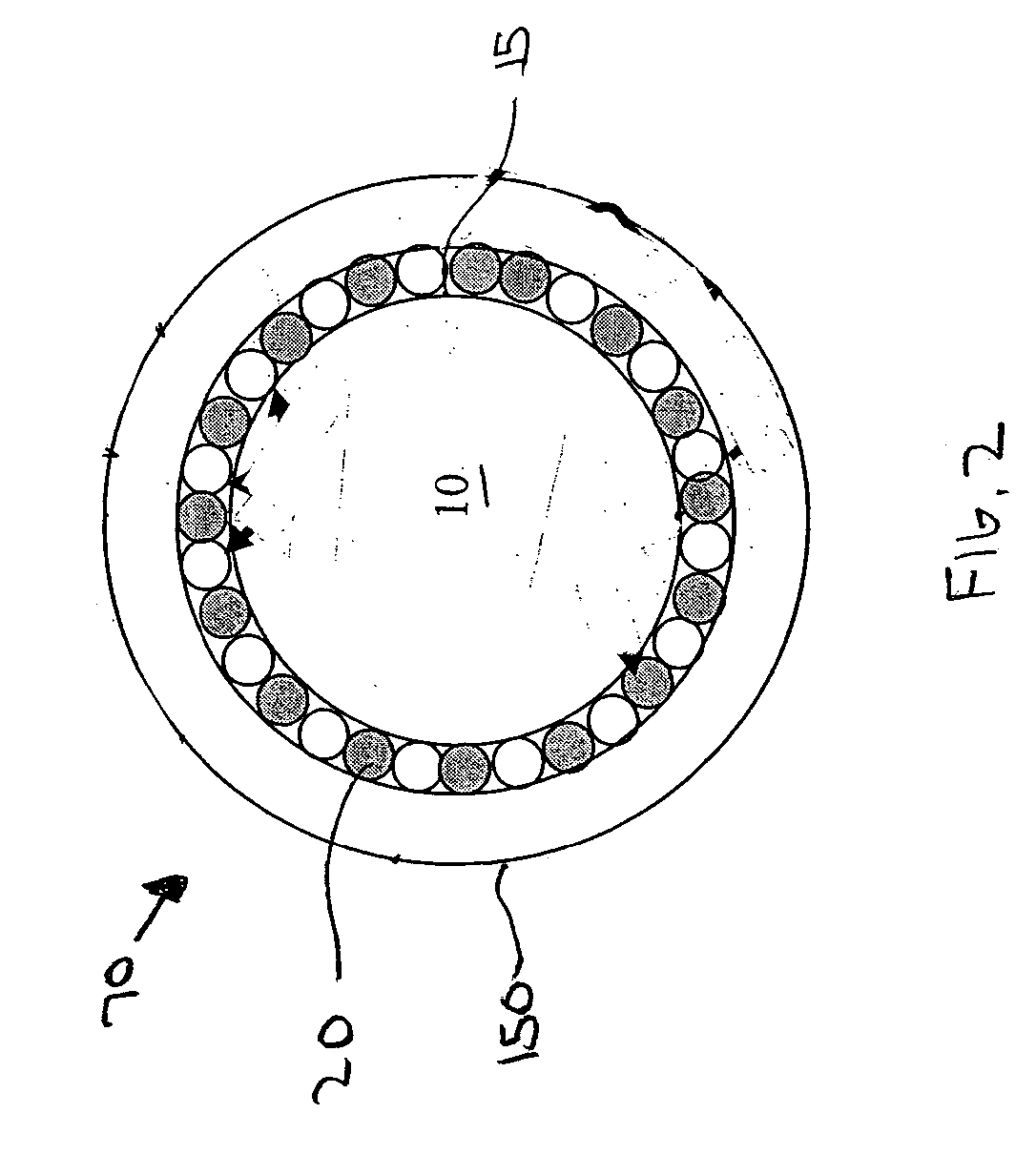

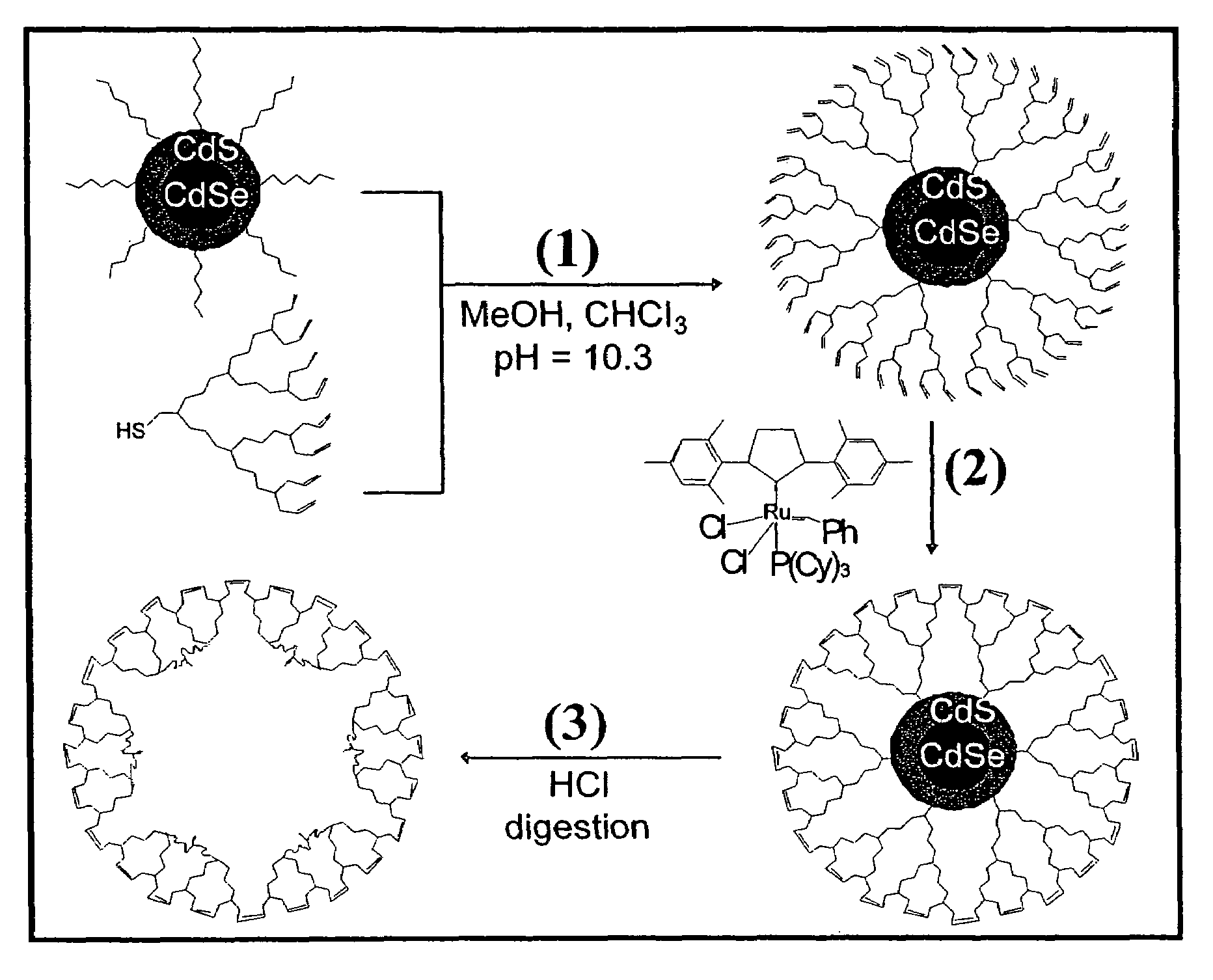

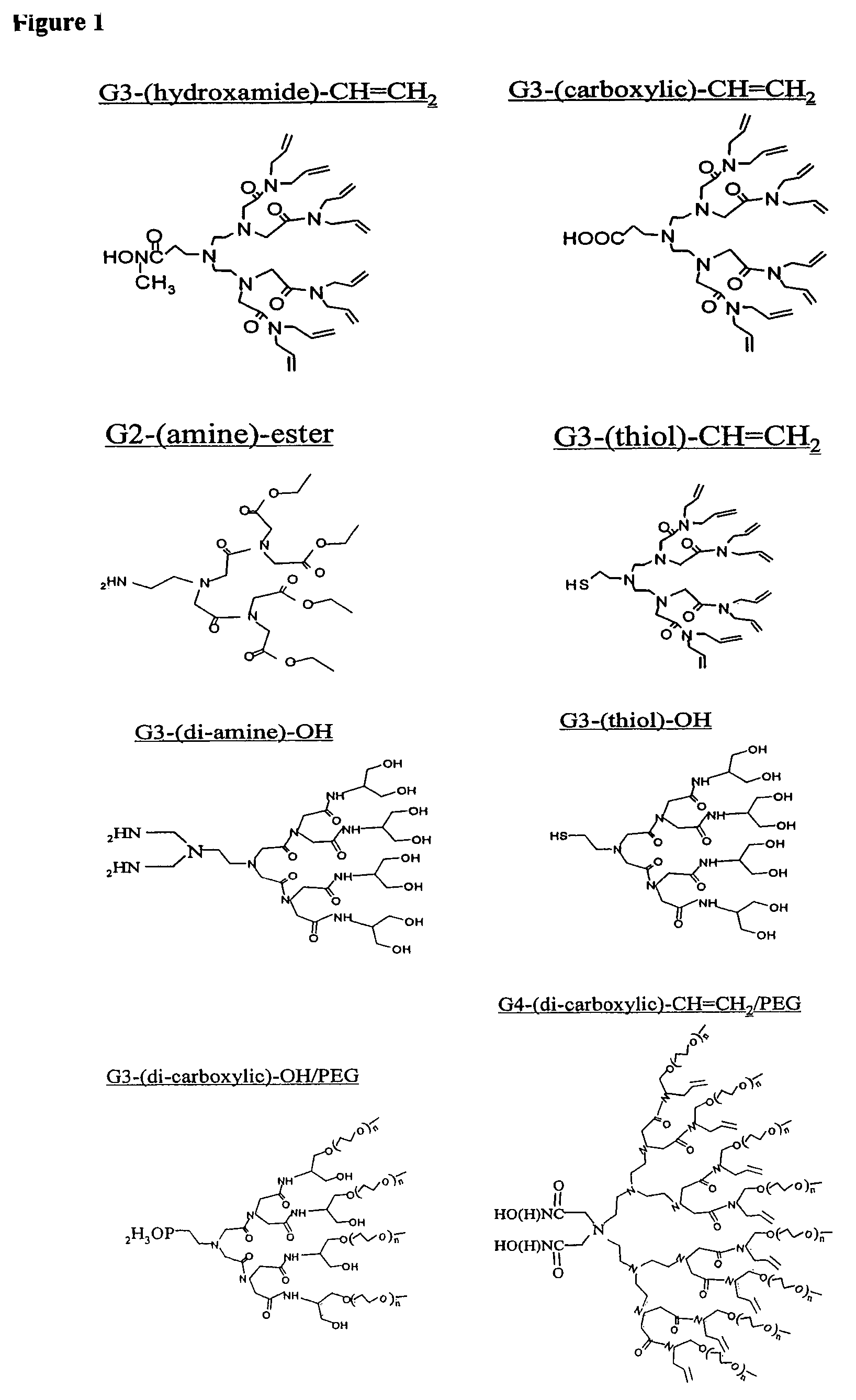

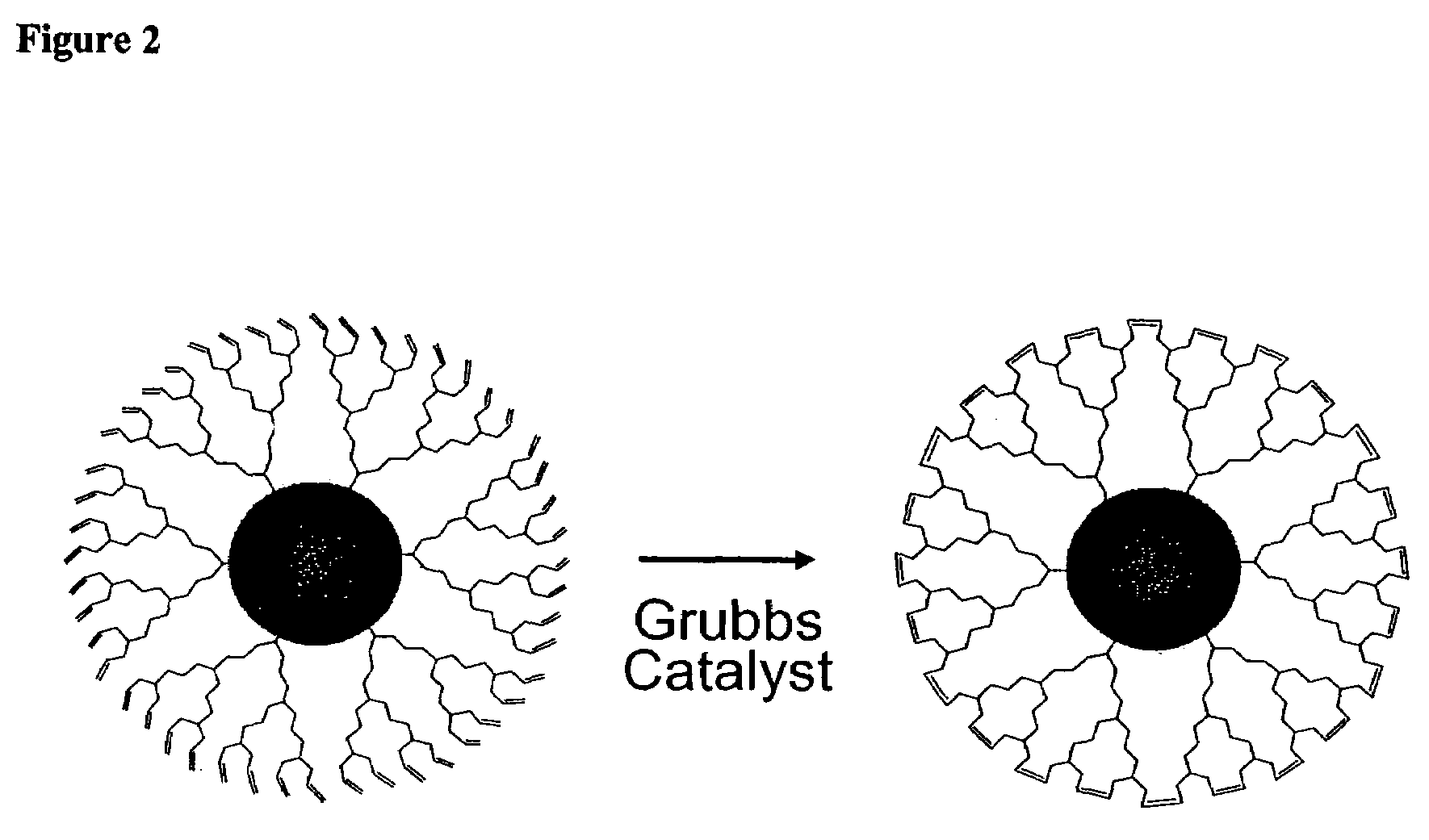

Nanocrystals in ligand boxes exhibiting enhanced chemical, photochemical, and thermal stability, and methods of making the same

ActiveUS7273904B2Improve stabilityEasy to detectMaterial nanotechnologyFrom normal temperature solutionsDendrimerCross-link

Dendron ligands or other branched ligands with cross-linkable groups were coordinated to colloidal inorganic nanoparticles, including nanocrystals, and substantially globally cross-linked through different strategies, such as ring-closing metathesis (RCM), dendrimer-bridging methods, and the like. This global cross-linking reaction sealed each nanocrystal within a dendron box to yield box-nanocrystals which showed dramatically enhanced stability against chemical, photochemical and thermal treatments in comparison to the non-cross-linked dendron-nanocrystals. Empty dendron boxes possessing a very narrow size distribution were formed by the dissolution of the inorganic nanocrystals contained therein upon acid or other etching treatments.

Owner:BEIJING JINGTAI MEIKANG BIOTECH CO LTC +1

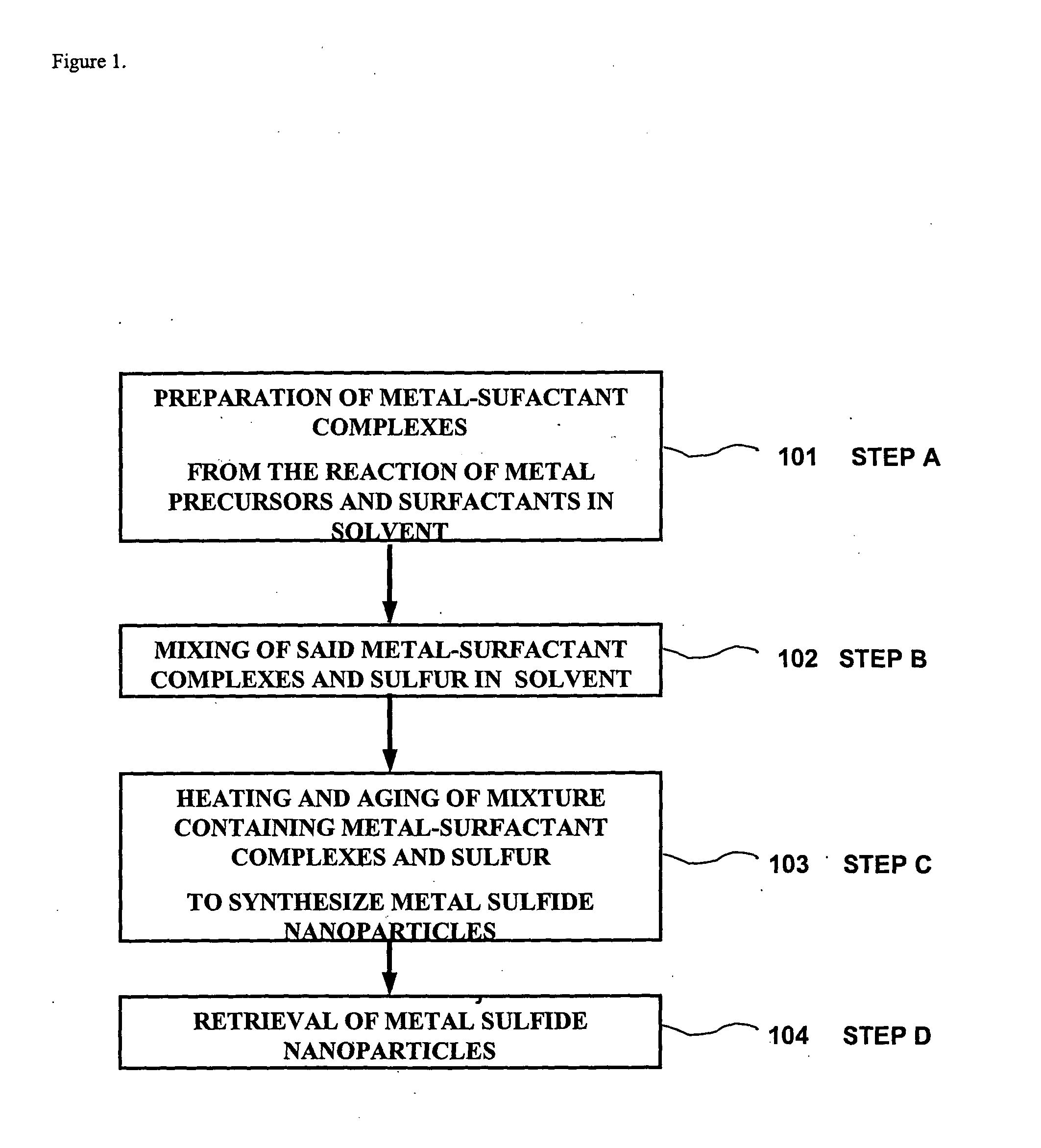

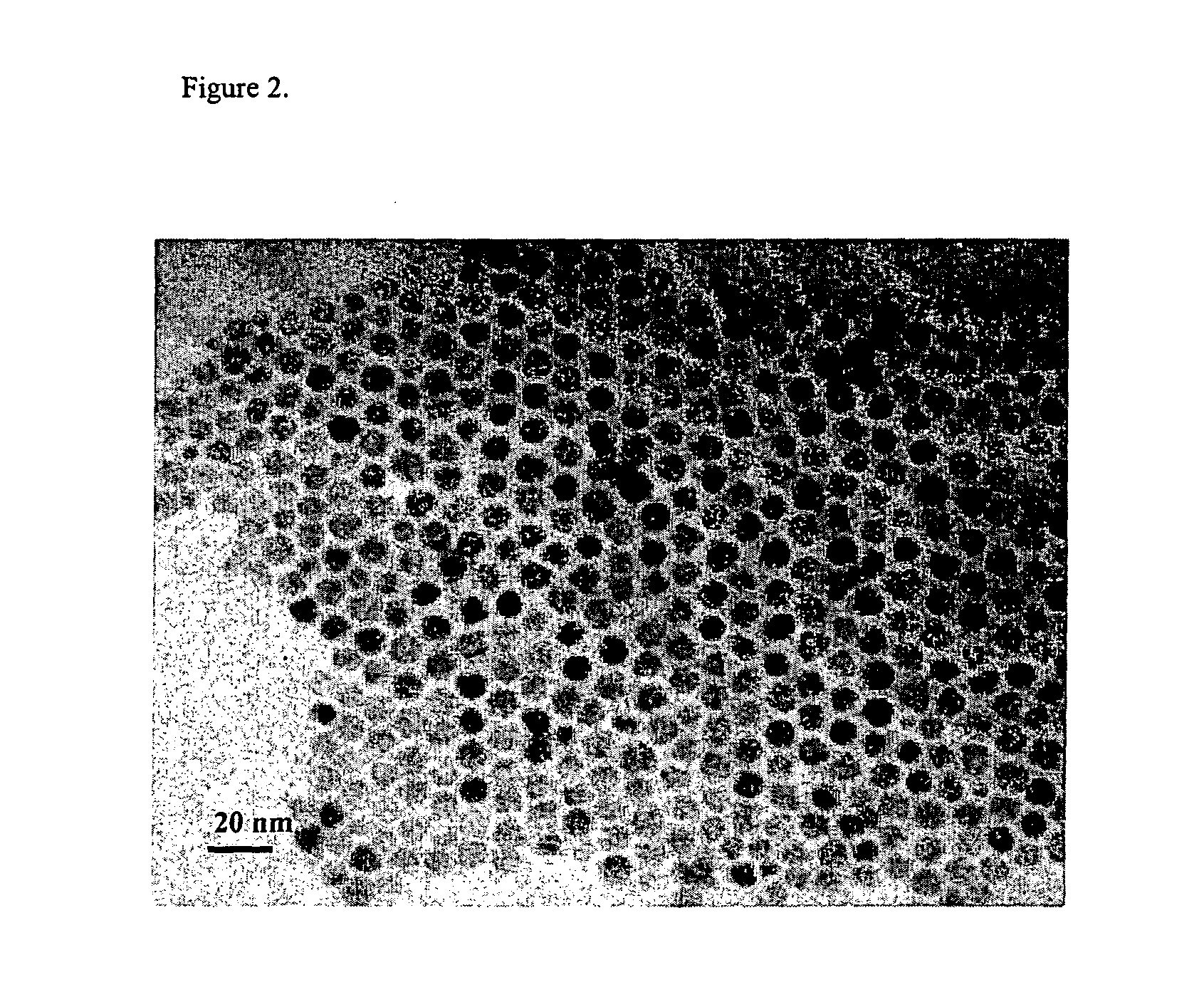

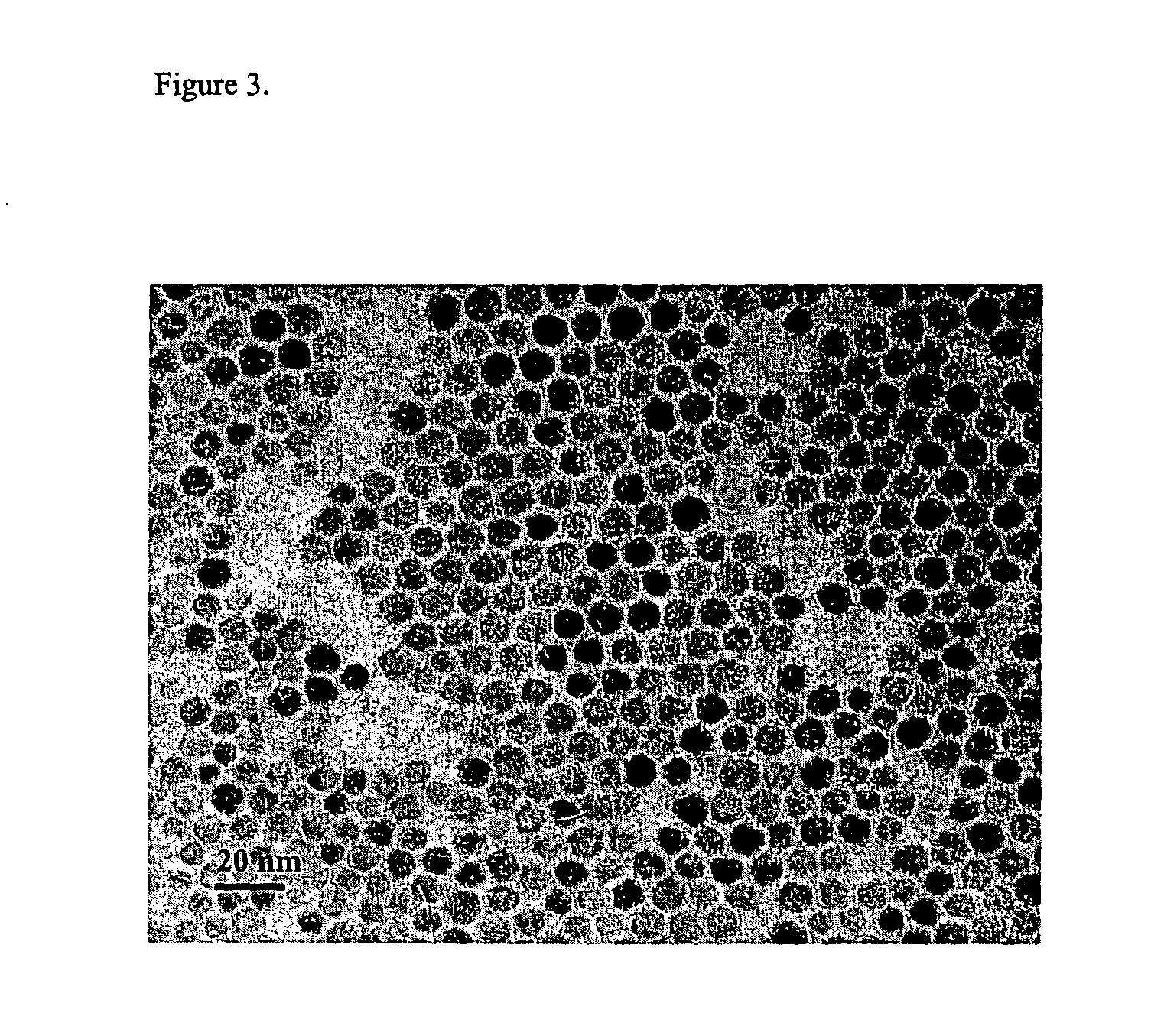

Method for synthesizing nanoparticles of metal sulfides

A synthetic method of fabricating highly crystalline and uniform nanoparticles of metal sulfides, doped metal sulfides, and multi-metallic sulfides disclosed, using no-toxic and inexpensive reagents. A typical synthetic method comprises the steps of, synthesis of metal-surfactant complexes from the reaction of metal precursors and surfactant, addition of sulfur reagent to the solution containing said metal-surfactant complexes followed by heating to high temperature, aging at that temperature to produce metal sulfide nanoparticles and completing the formation of synthesis of nanoparticles metal sulfides and multi-metallic sulfides by adding a poor solvent followed by centrifuging.

Owner:SEOUL NATIONAL UNIVERSITY

One-pot synthesis of high-quality metal chalcogenide nanocrystals without precursor injection

InactiveUS20060019427A1Material nanotechnologyPolycrystalline material growthSulfurMetal chalcogenides

A method of homogeneously forming metal chalcogenide nanocrystals includes the steps combining a metal source, a chalcogenide source, and at least one solvent at a first temperature to form a liquid comprising assembly, and heating the assembly at a sufficient temperature to initiate nucleation to form a plurality of metal chalcogenide nanocrystals. The plurality of metal chalcogenide nanocrystals are then grown without injection of either the metal source or the chalcogenide source at a temperature at least equal to the sufficient temperature, wherein growth proceeds substantially without nucleation to form a plurality of monodisperse metal chalcogenide nanocrystals. An optional nucleation initiator can help control the final size of the monodisperse crystals. Such synthesis, without the need for precursor injection, is suitable for the industrial preparation of high-quality nanocrystals.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Metal chalcogenide composite nano-particles and layers therewith

A metal chalcogenide composite nano-particle comprising a metal capable of forming p-type semiconducting chalcogenide nano-particles and a metal capable of forming n-type semiconducting chalcogenide nano-particles, wherein at least one of the metal chalcogenides has a band-gap between 1.0 and 2.9 eV and the concentration of the metal capable of forming p-type semiconducting chalcogenide nano-particles is at least 5 atomic percent of the metal and is less than 50 atomic percent of the metal; a dispersion thereof; a layer comprising the nano-particles; and a photovoltaic device comprising the layer.

Owner:AGFA GEVAERT AG

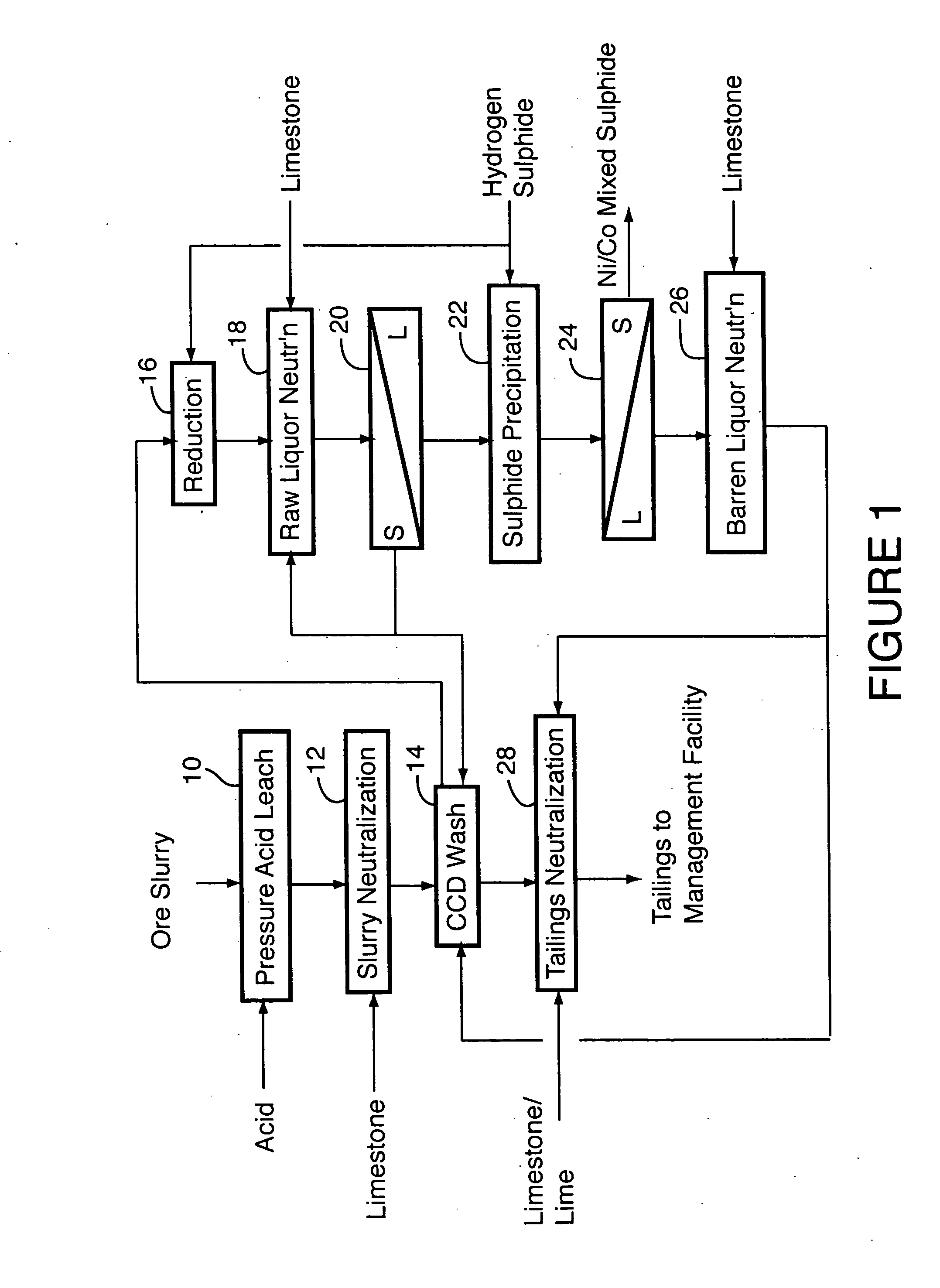

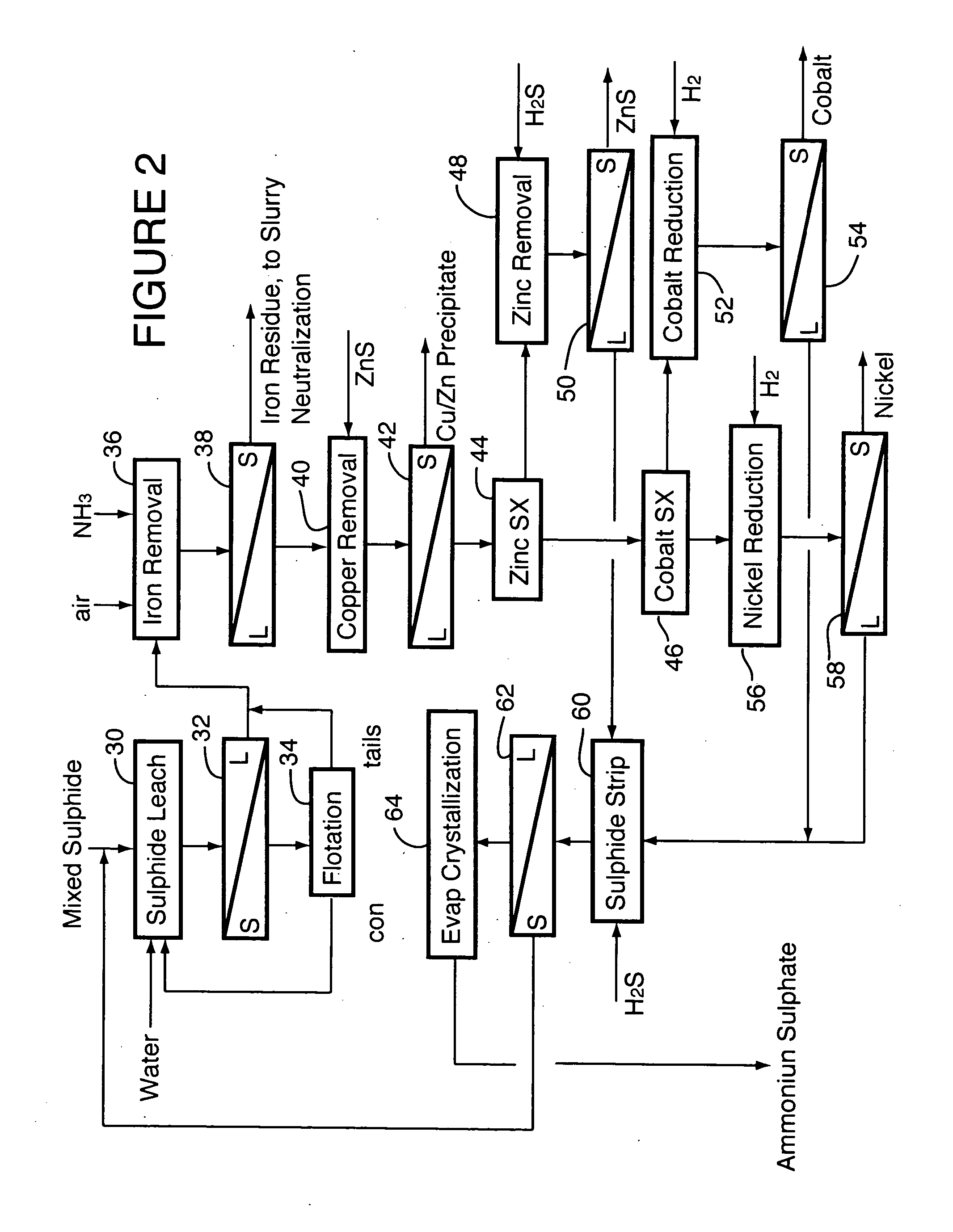

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

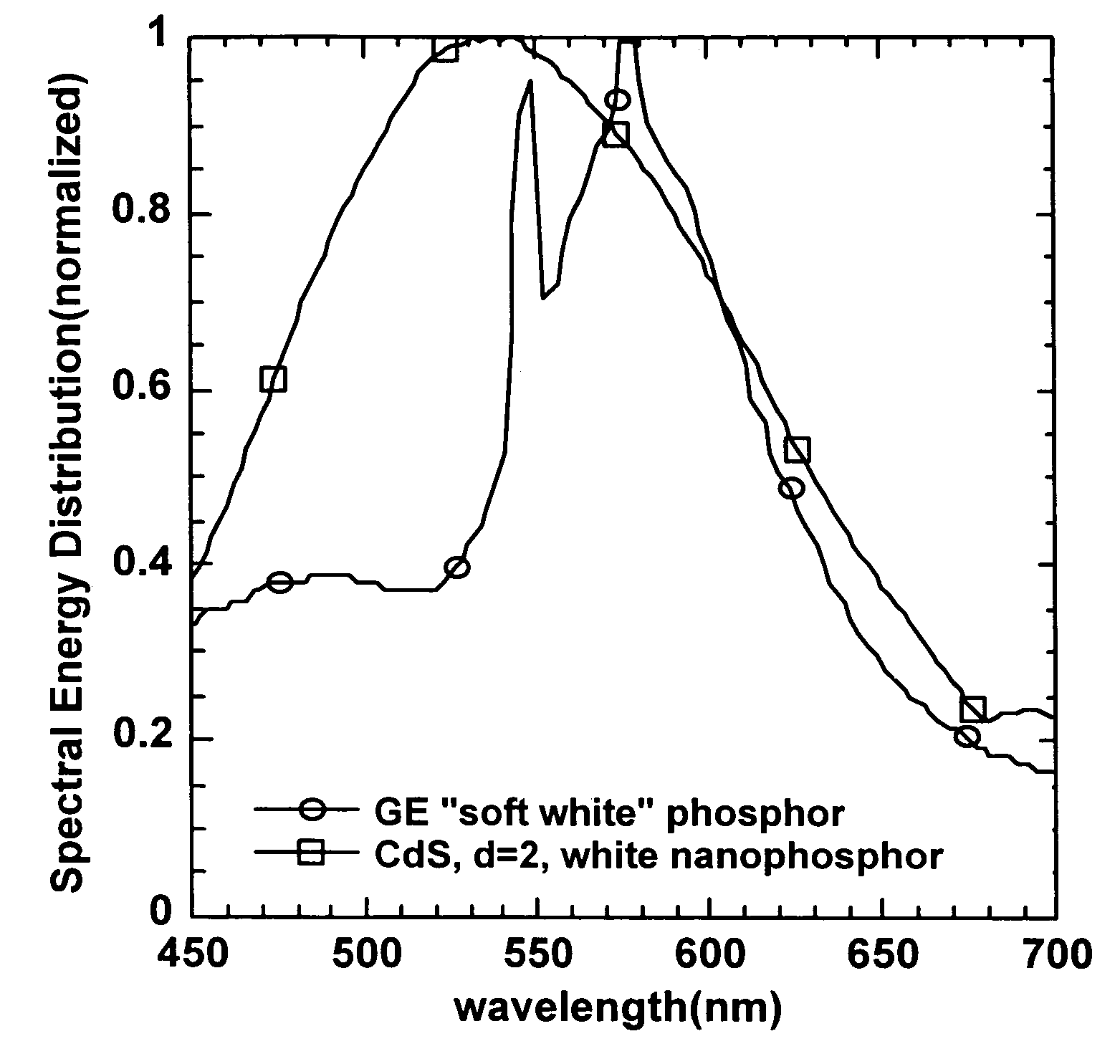

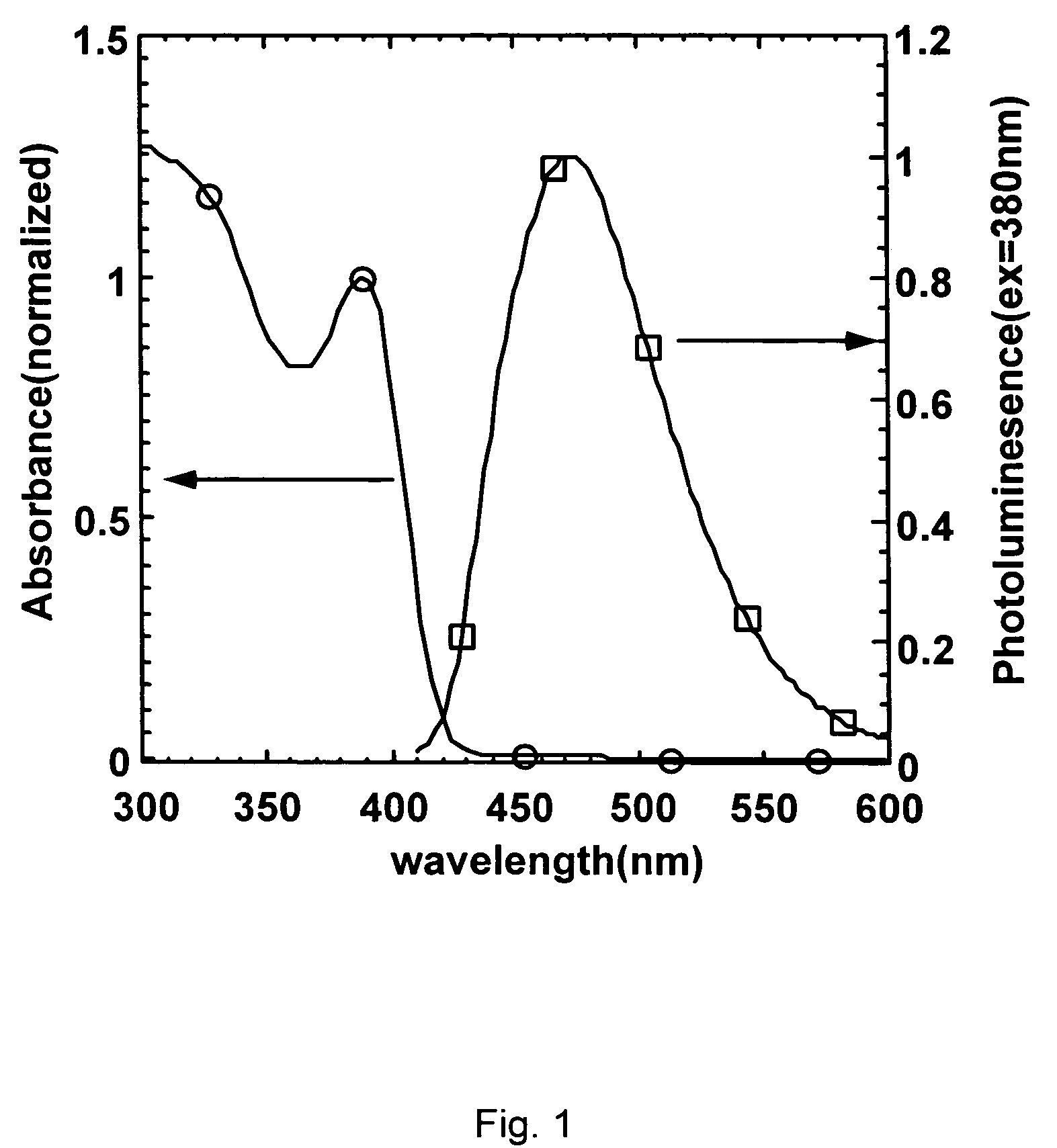

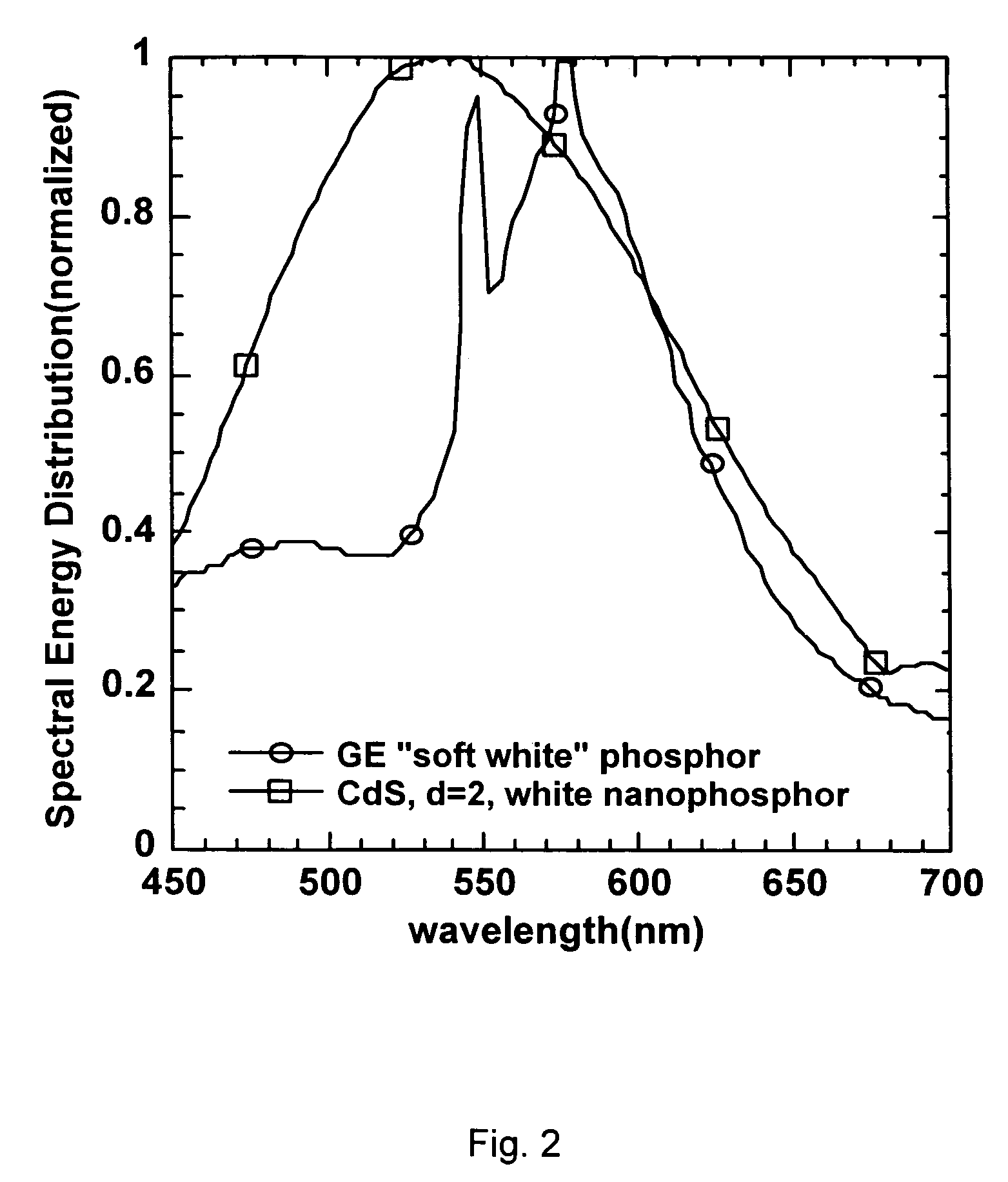

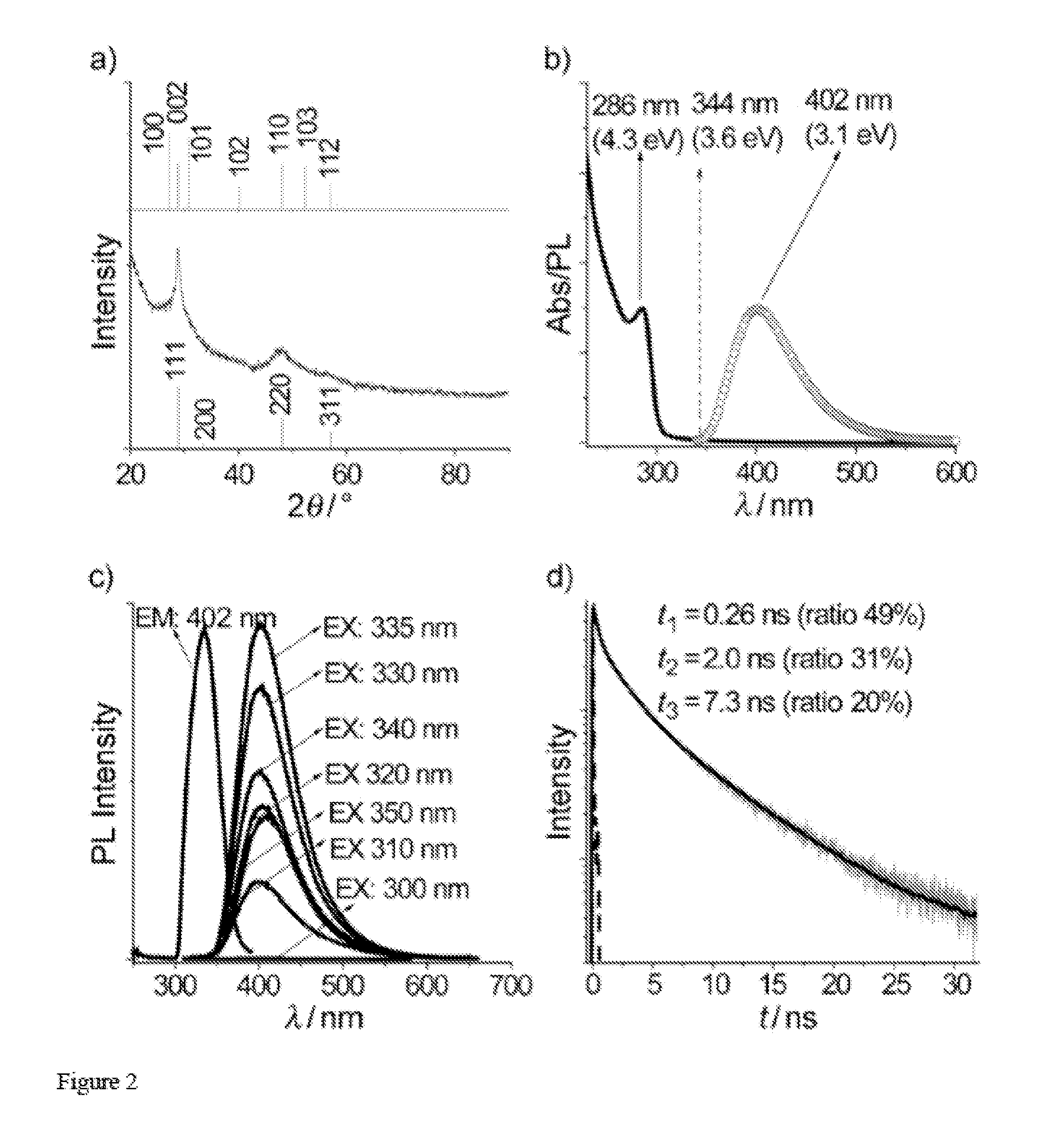

Method of preparing cadmium sulfide nanocrystals emitting light at multiple wavelengths, and cadmium sulfide nanocrystals prepared by the method

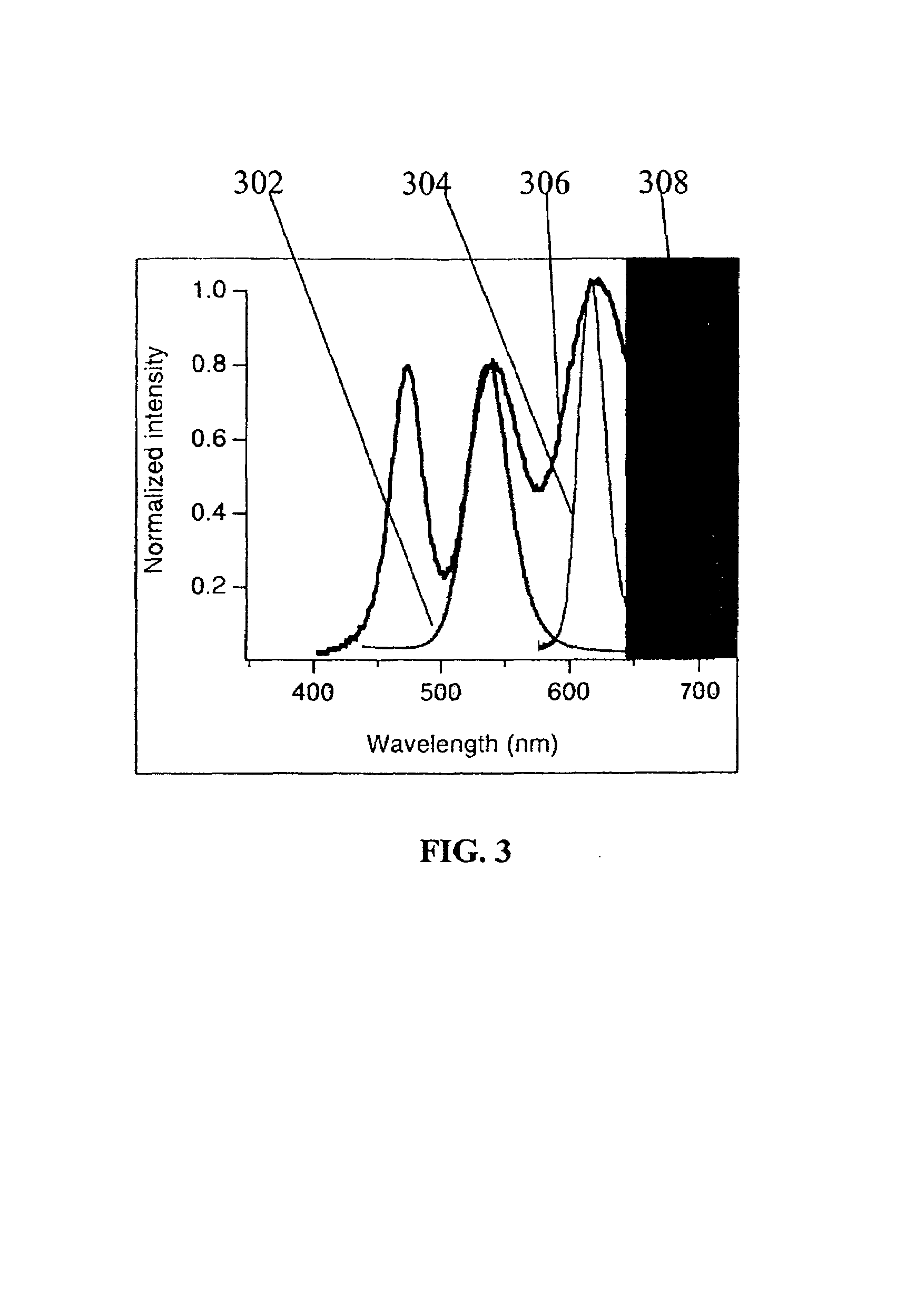

A method for preparing cadmium sulfide nanocrystals emitting light at multiple wavelengths. The method comprises the steps of (a) mixing a cadmium precursor and a dispersant in a solvent that weakly coordinates to the cadmium precursor, and heating the mixture to obtain a cadmium precursor solution, (b) dissolving a sulfur precursor in a solvent that weakly coordinates to the sulfur precursor to obtain a sulfur precursor solution, and (c) feeding the sulfur precursor solution to the heated cadmium precursor solution maintained at a high temperature to prepare cadmium sulfide crystals, and growing the cadmium sulfide crystals. Further, cadmium sulfide nanocrystals prepared by the method. The cadmium sulfide nanocrystals have uniform size and shape and can emit light close to white light simultaneously at different wavelengths upon excitation. Due to these characteristics, the cadmium sulfide nanocrystals can be applied to white light-emitting diode devices.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

Nanocrystal doped matrixes

ActiveUS20100140551A1Good miscibilityInhibit aggregationMaterial nanotechnologyLiquid surface applicatorsAnti-reflective coatingSemiconductor nanocrystals

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:SAMSUNG ELECTRONICS CO LTD

Quantum dots, rods, wires, sheets, and ribbons, and uses thereof

ActiveUS20140252316A1Improve stand-alone performanceImprove mobilityMaterial nanotechnologyNanoinformaticsQuantum dotNanocrystal

Described are ZnxCd1-xSySe1-y / ZnSzSe1-z core / shell nanocrystals, CdTe / CdS / ZnS core / shell / shell nanocrystals, optionally ally doped Zn(S,Se,Te) nano- and quantum wires, and SnS quantum sheets or ribbons, methods for making the same, and their use in biomedical and photonic applications, such as sensors for analytes in cells and preparation of field effect transistors.

Owner:ARIZONA STATE UNIVERSITY

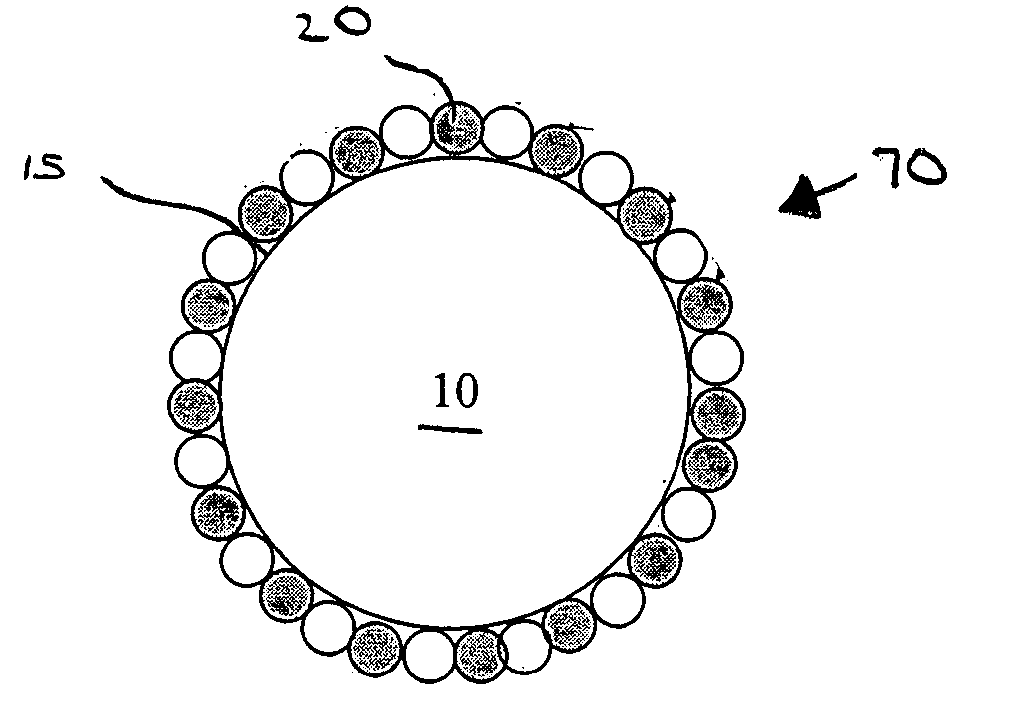

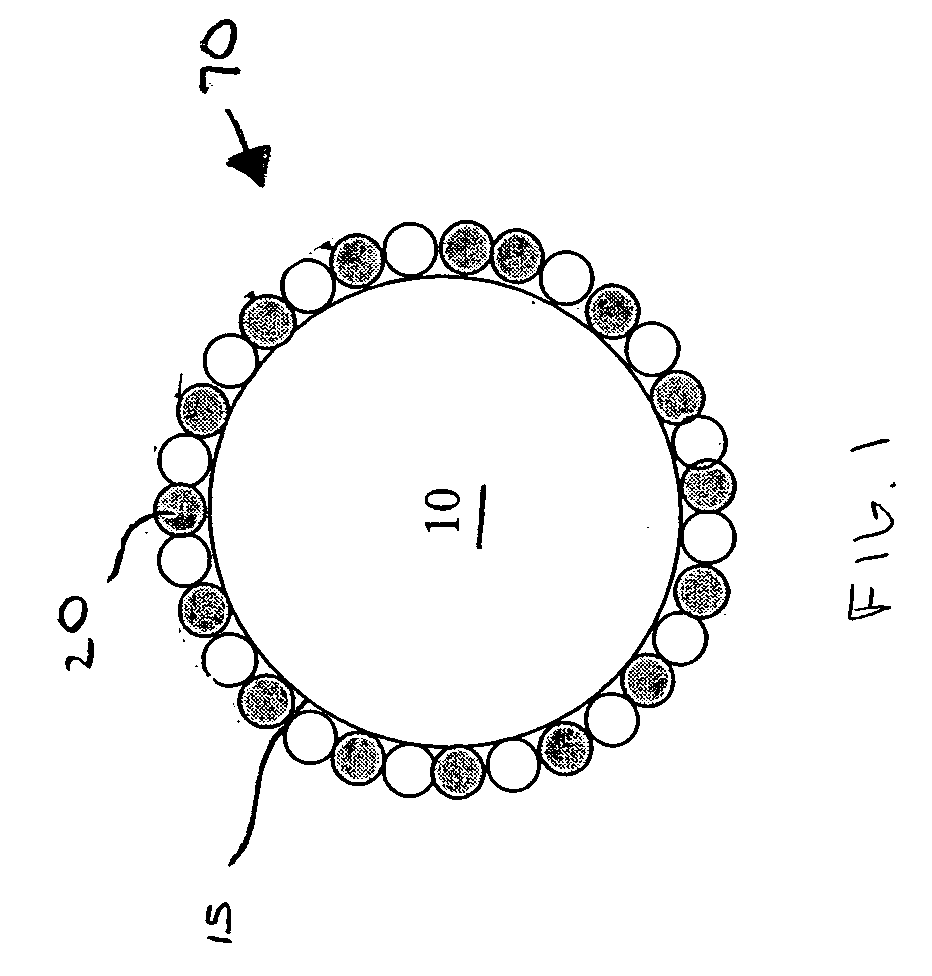

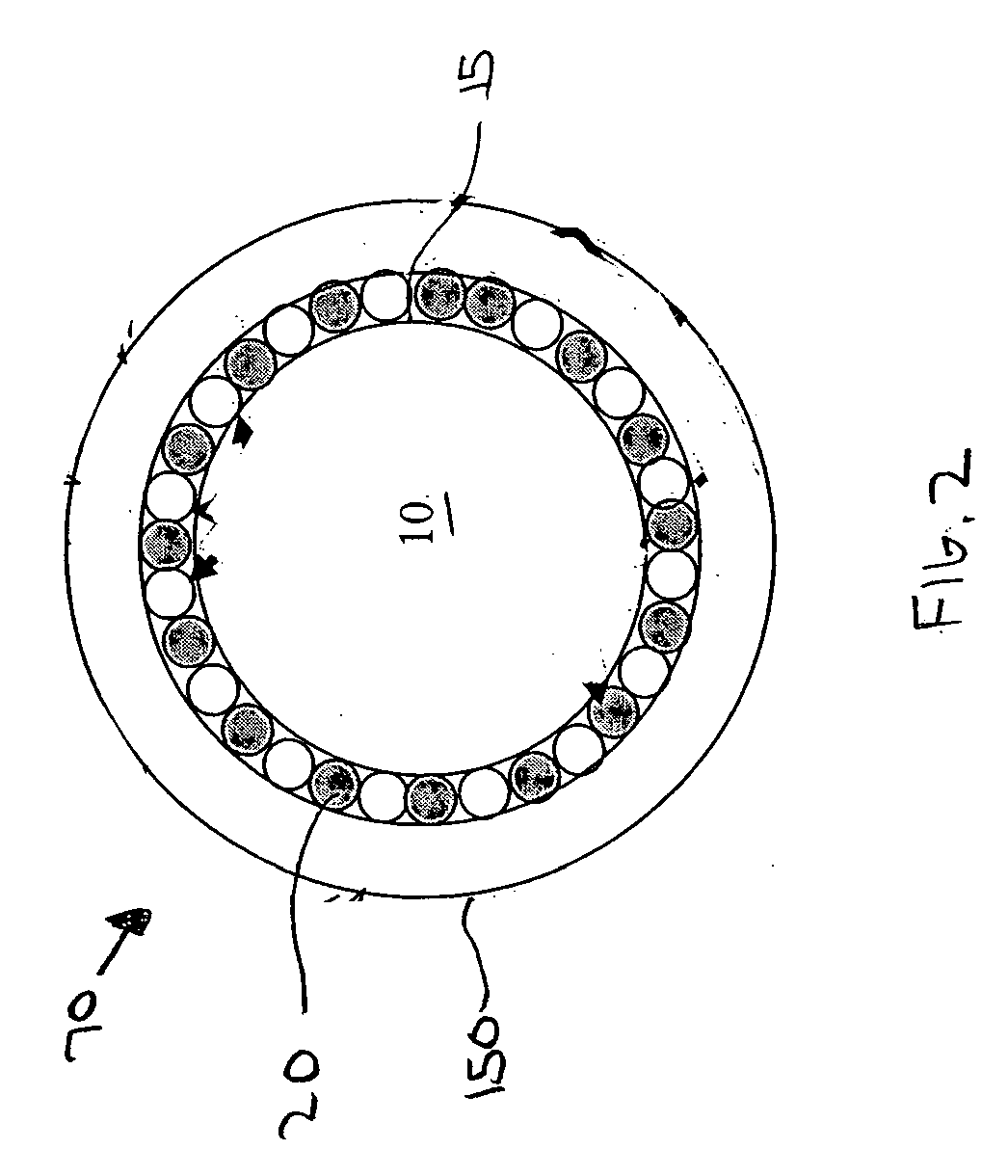

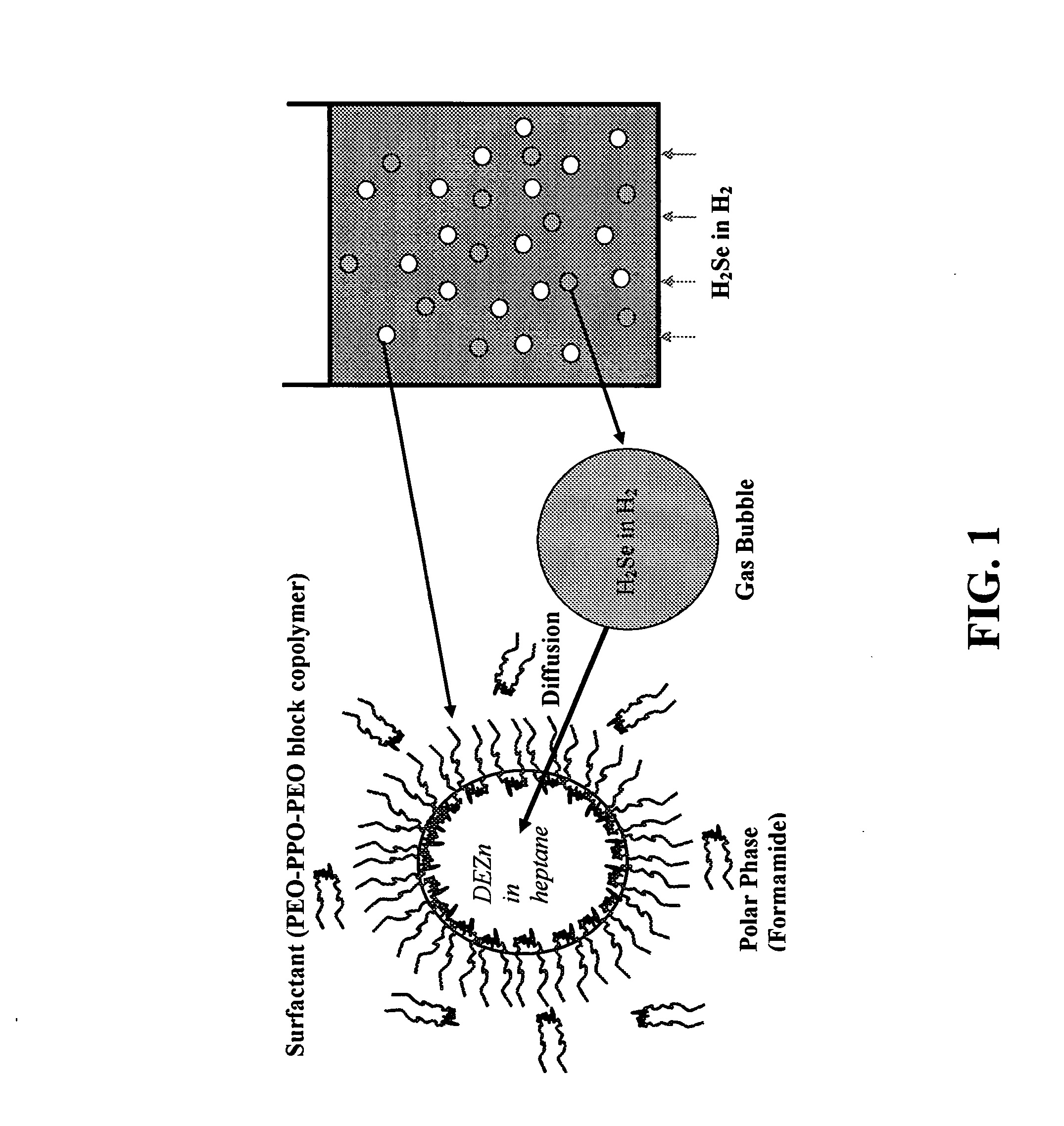

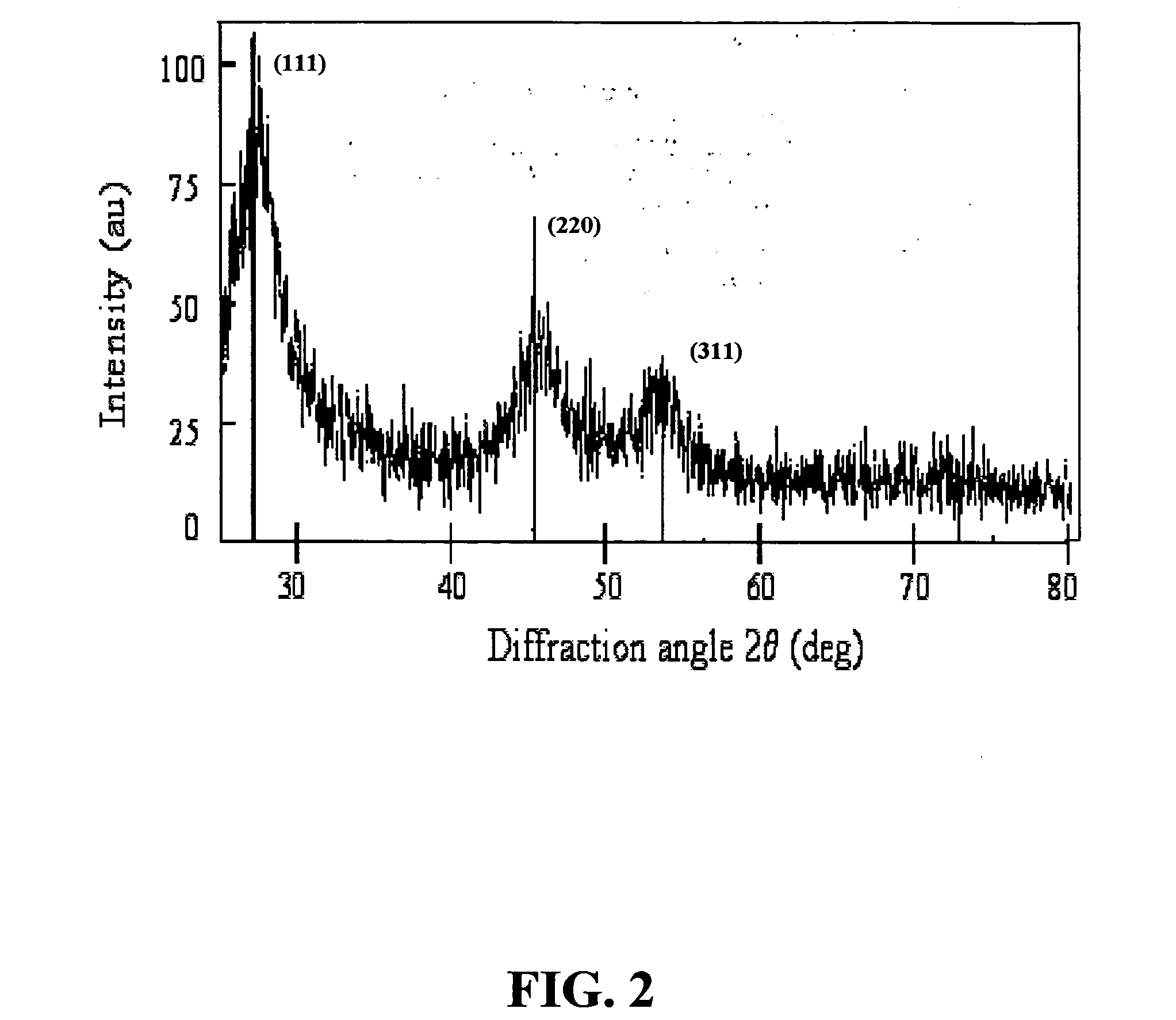

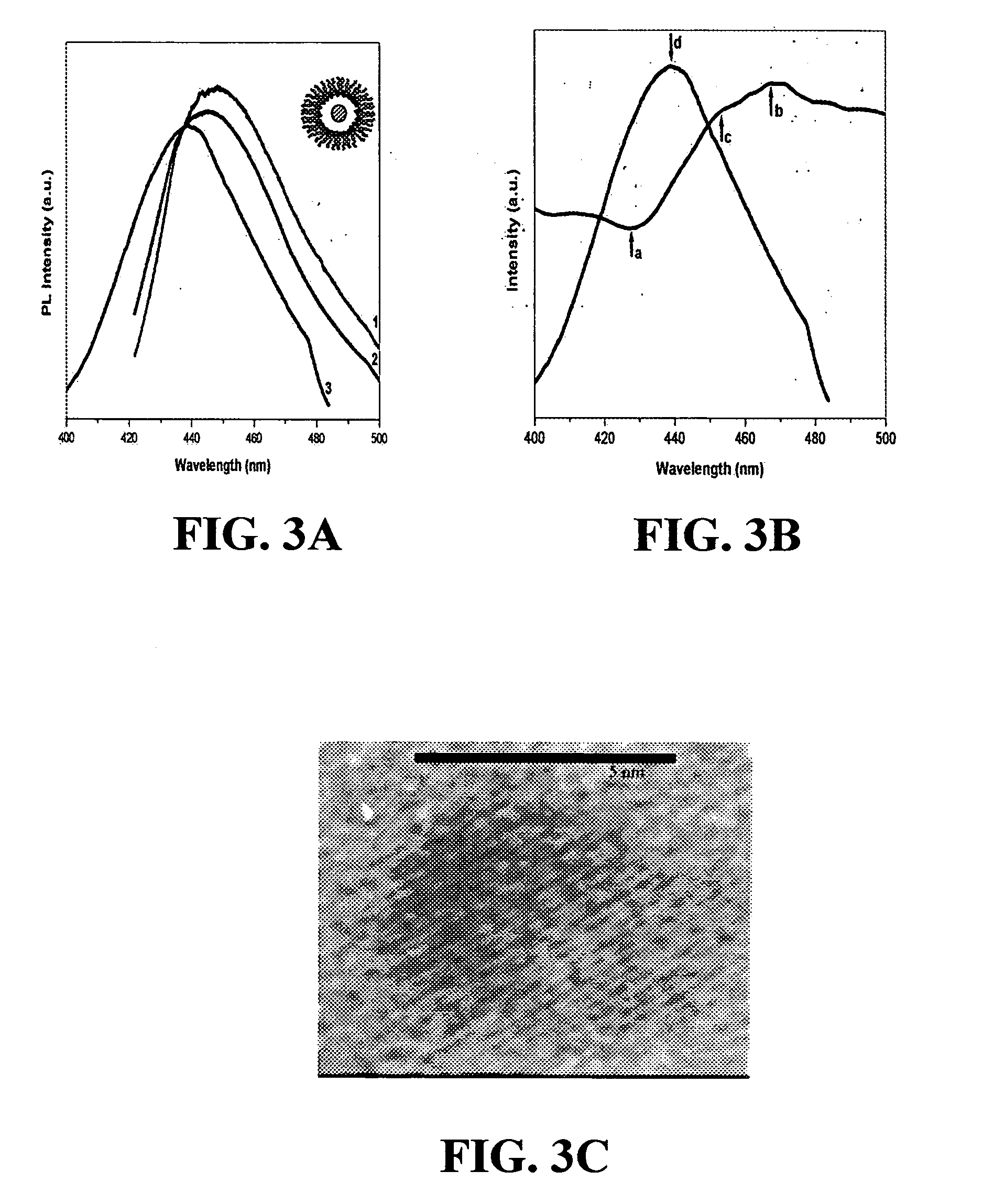

Synthesis of nanoparticles by an emulsion-gas contacting process

ActiveUS20050006800A1Easy to controlEasily scaled-upPowder deliveryMaterial nanotechnologyEmulsionGas phase

The present invention is directed to a process for synthesizing nanoparticles. This process involves providing a stable emulsion containing a plurality of droplets suspended in a continuous phase. The droplets, which are encapsulated by an interfacially-active material, contain a first reactant dissolved in a dispersed phase. The process also involves contacting a gas phase containing a second reactant diluted in a carrier gas with the stable emulsion under conditions effective to permit the first reactant and second reactant to react and form nanoparticles. The present invention further relates to nanoparticle-loaded emulsions and their uses in formulations for various purposes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

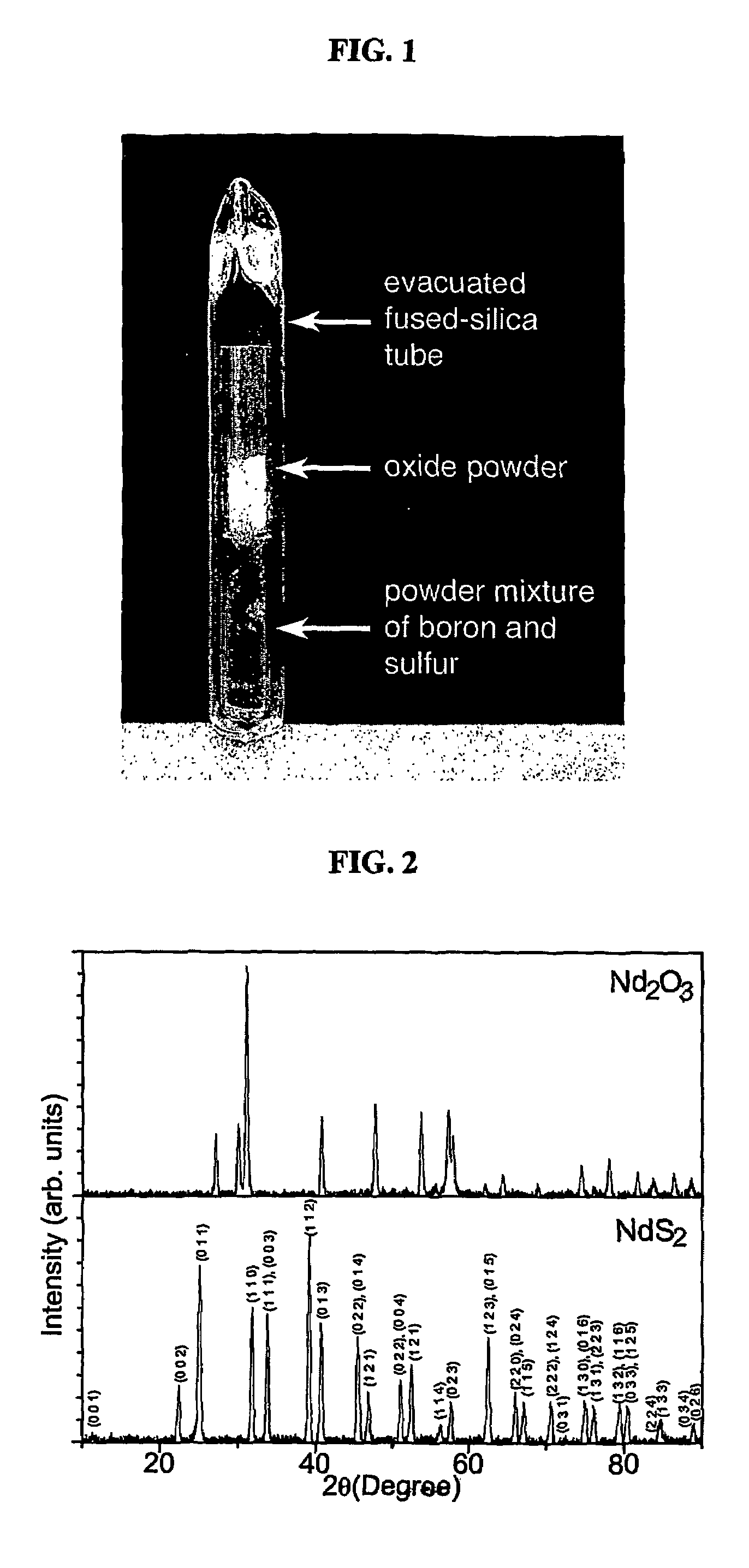

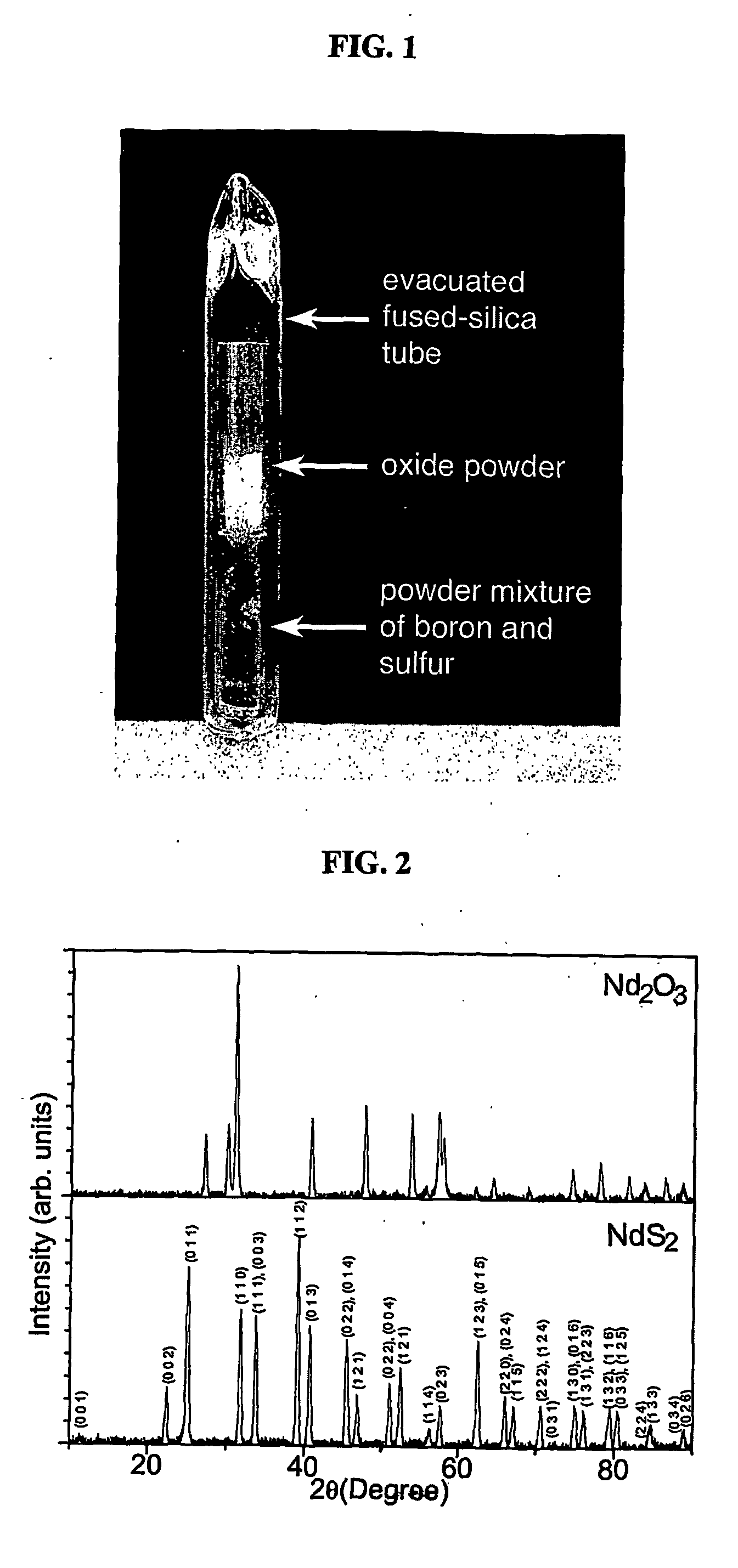

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

InactiveUS20060239882A1Rare earth metal sulfidesSelenium/tellurium compundsSufficient timeNanoparticle

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

Synthesis of water soluble nanocrystalline quantum dots and uses thereof

InactiveUS20060078490A1Improved emission spectrumAccelerate emissionsMaterial nanotechnologyHybrid immunoglobulinsPhotoluminescenceSynthesis methods

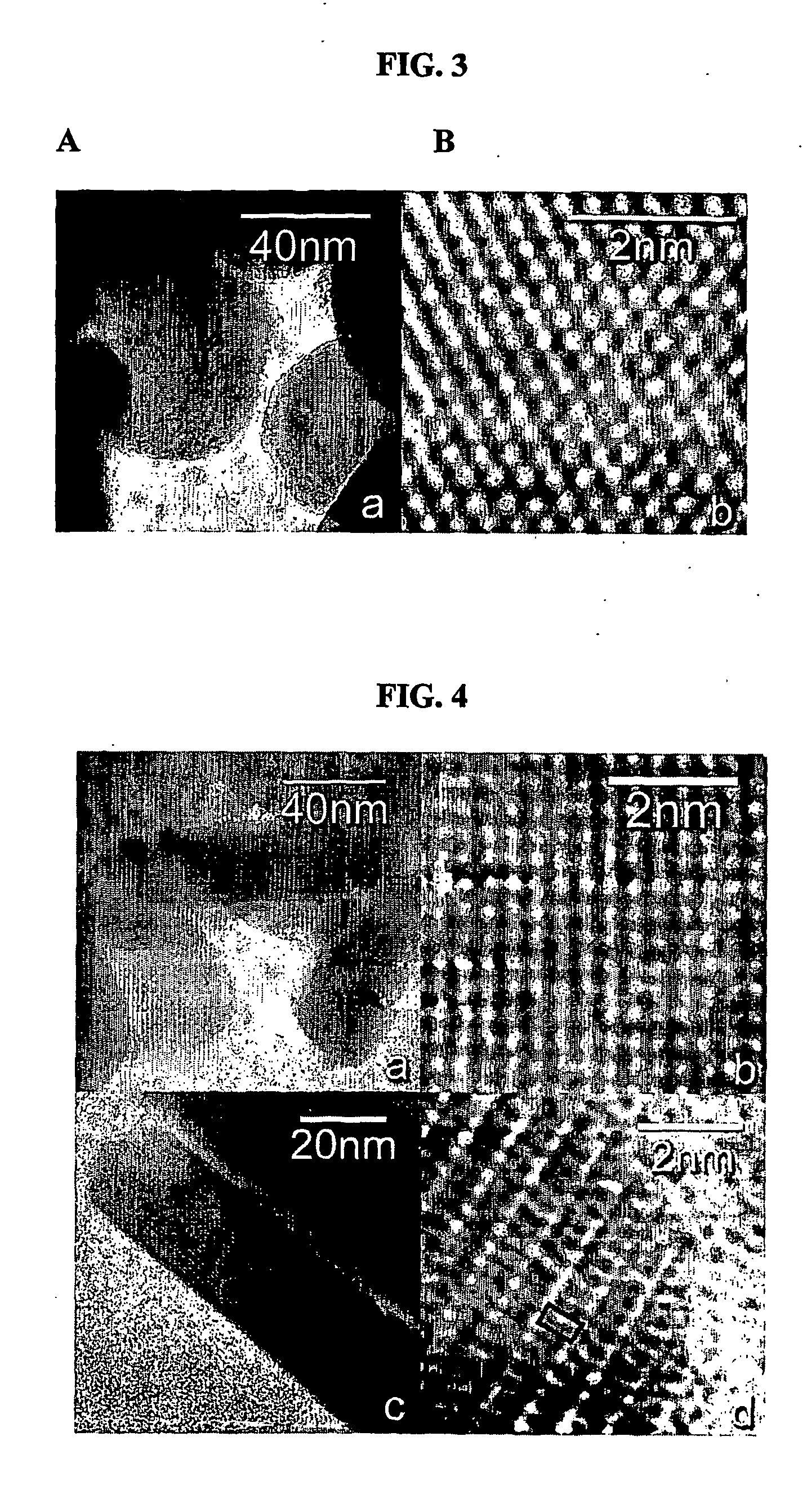

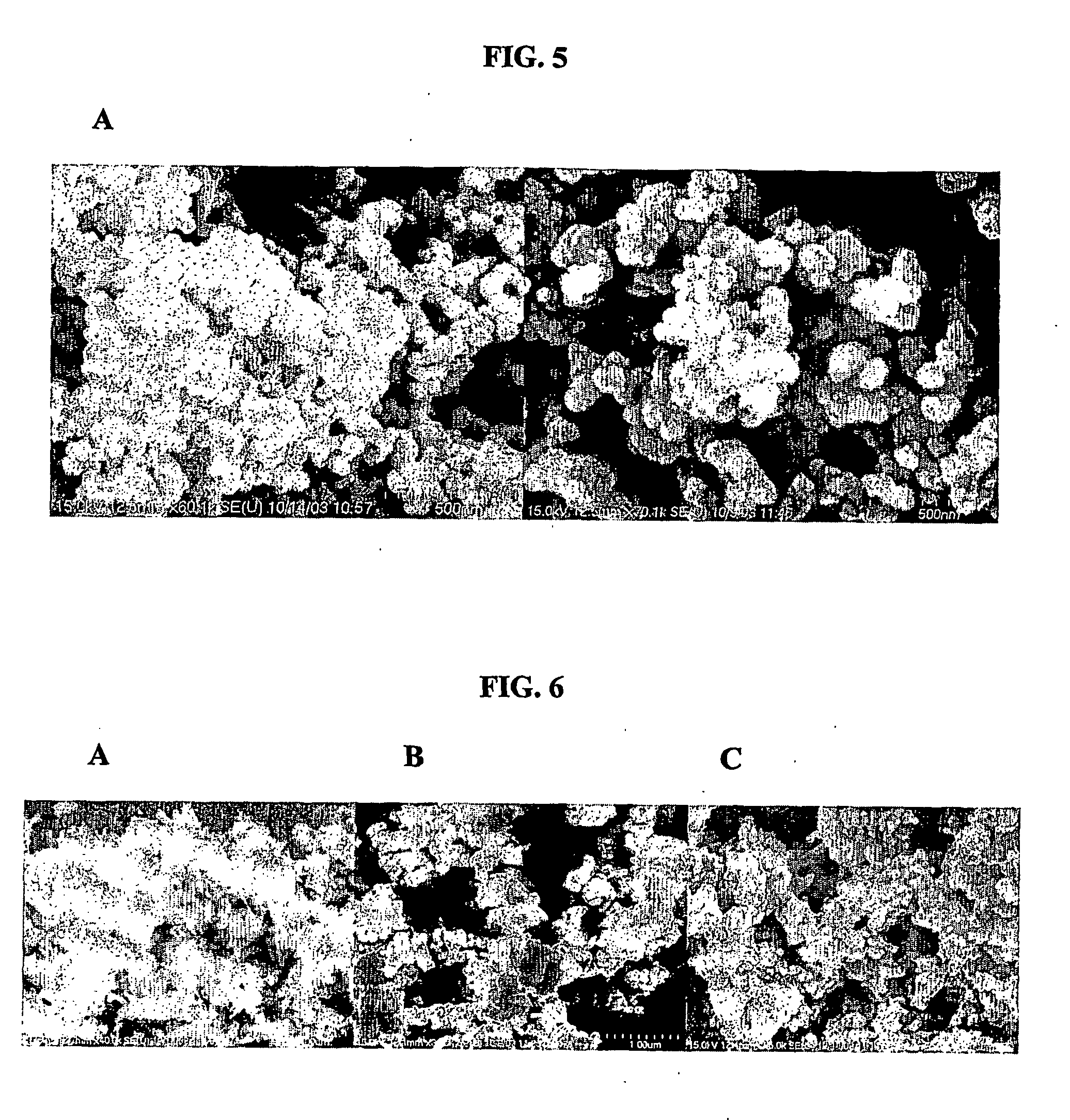

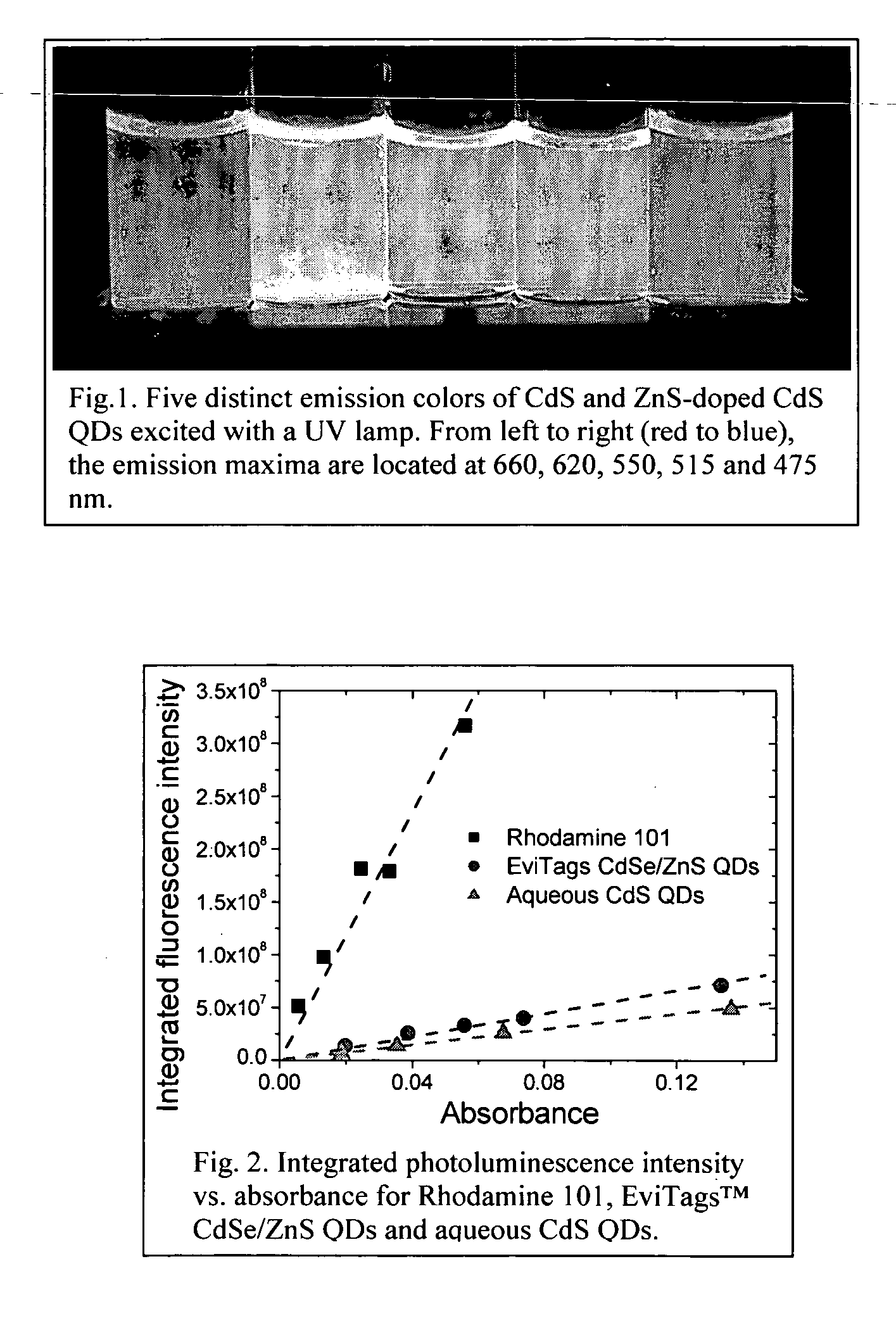

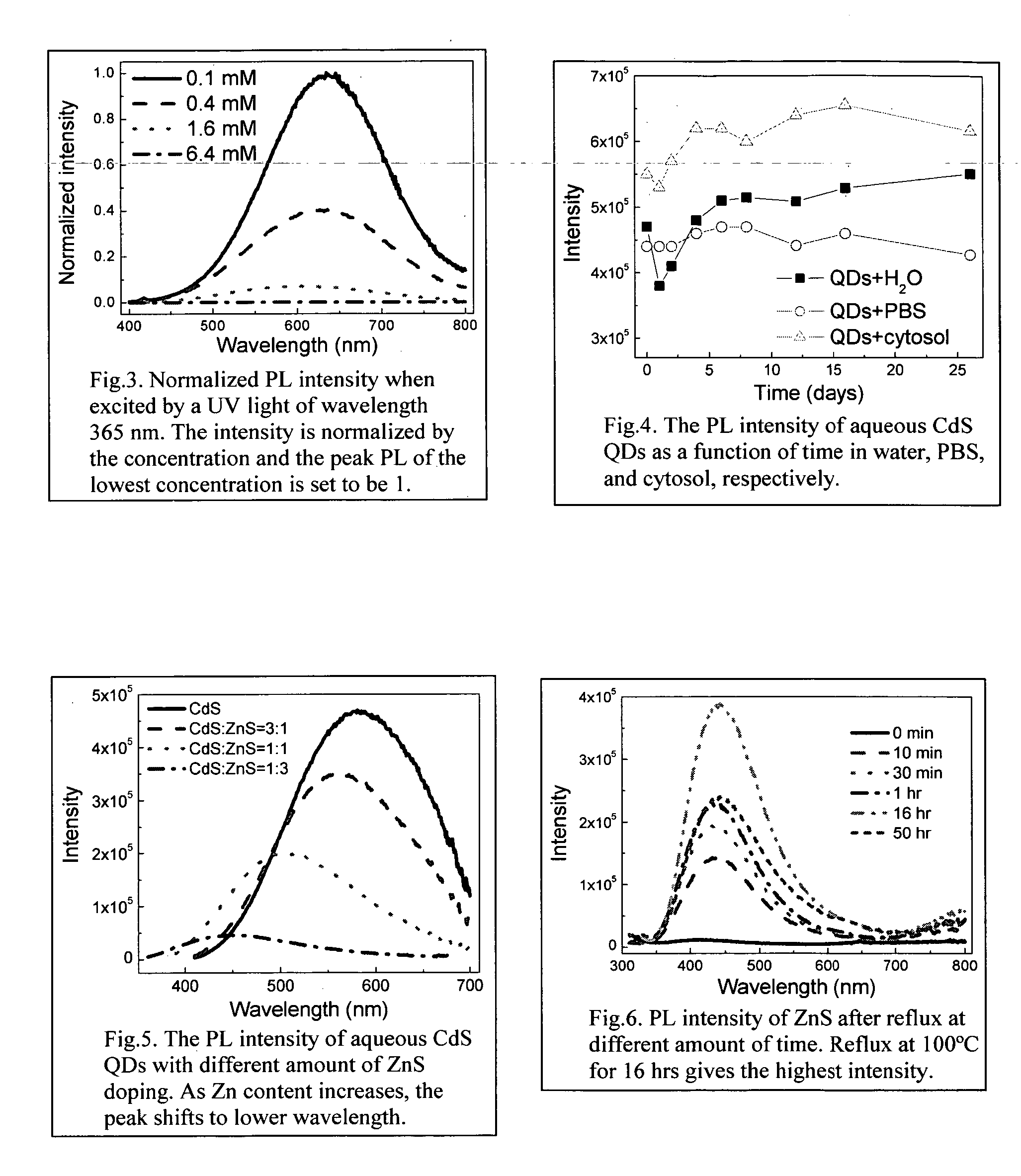

An economic, direct synthetic method for producing water soluble QDs that are ready for bioconjugation is provided. The method can produce aqueous QDs with emission wavelengths varying from 400 nm to 700 nm. Highly luminescent metal sulfide (MS) QDs are produced via an aqueous synthesis route. MS QDs are capped with thiol-containing charged molecules in a single step. The resultant MS QDs exhibit the distinctive excitonic photoluminescence desired of QDs and can be fabricated to avoid undesirable broadband emissions at higher wavelengths. This provides a significant improvement over the present complex and expensive commercial processes for the production of QDs. The aqueous QDs are stable in biological fluids over a long period of time. In addition, nontoxic ZnS QDs have been produced with good photoluminescence properties by refluxing the ZnS QD suspensions over a period of time.

Owner:DREXEL UNIV

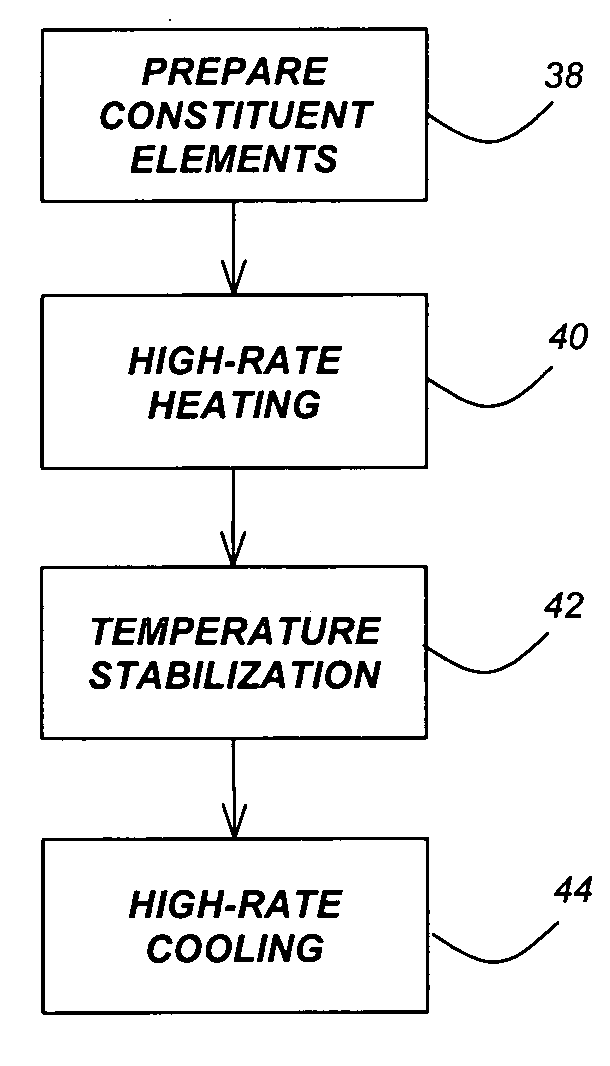

Method for synthesis of colloidal nanoparticles

InactiveUS20060060998A1Large-scale, safe, convenient, reproducible, and energy-efficient productionHigh crystallinityDielectric heatingNanoinformaticsColloidal nanoparticlesContinuous flow

A method for synthesis of high quality colloidal nanoparticles using comprises a high heating rate process. Irradiation of single mode, high power, microwave is a particularly well suited technique to realize high quality semiconductor nanoparticles. The use of microwave radiation effectively automates the synthesis, and more importantly, permits the use of a continuous flow microwave reactor for commercial preparation of the high quality colloidal nanoparticles.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com