Sulfide coated particle as well as preparation method and application thereof

A sulfide, coating type technology, applied in the field of chemistry, can solve the problems of expensive raw materials, difficult industrialization promotion, complicated process, etc., and achieve the effect of simple coating method, strong universality, and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

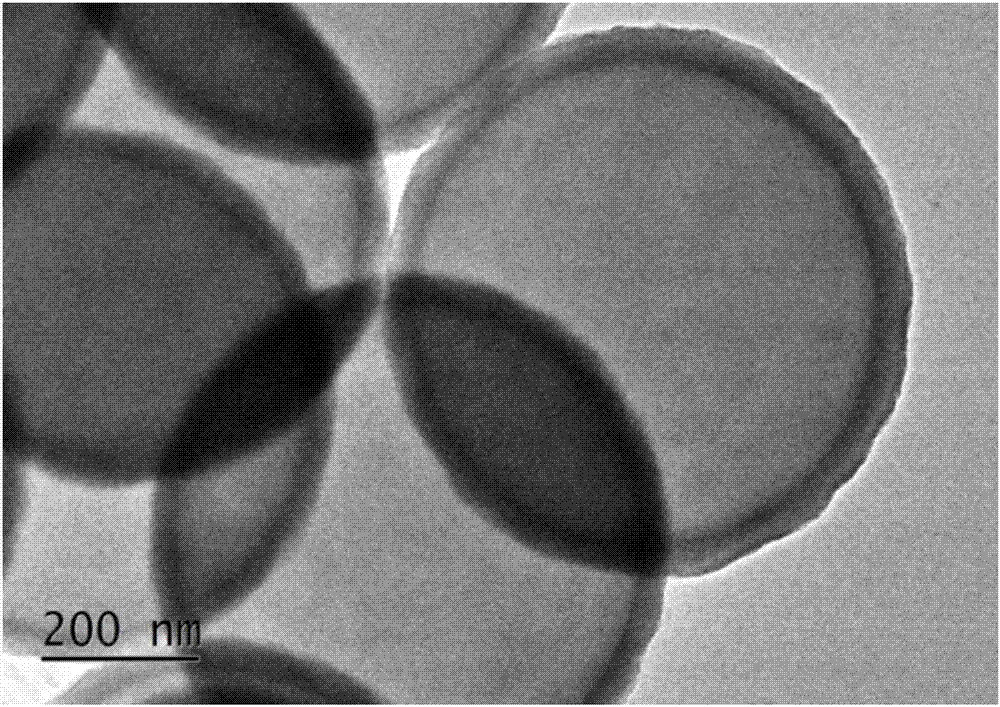

[0044] Preparation of cobalt sulfide-coated polystyrene

[0045] 0.2g of polystyrene particles (average particle diameter of 500nm), 0.124g of cobalt acetate (1*10 -3 mol / L) reducing agent hydrazine hydrate 400 microliters, sulfur source thioacetamide 0.075g (2*10 -3 mol / L) in 50 ml of solvent water, and reflux at 40° C. for 12 h under stirring for hydrolysis reaction, centrifugation, washing, and drying to obtain cobalt sulfide-coated polystyrene particles.

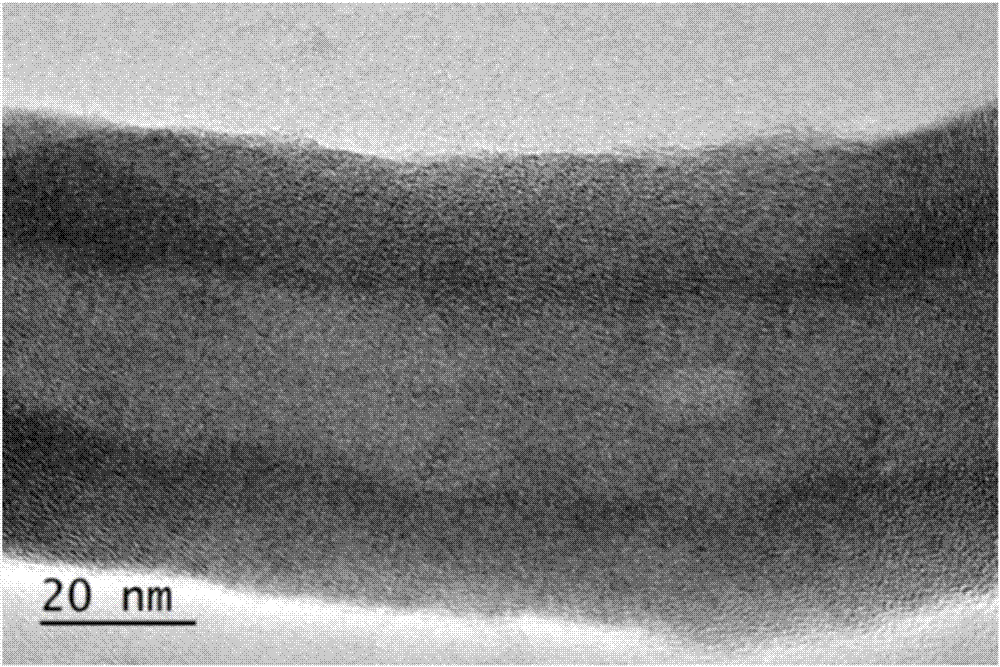

[0046] The cobalt sulfide-coated polystyrene particles have a core-shell structure, and its electron micrograph is shown in figure 1 shown. The material constituting the core is polystyrene with a particle size of about 500nm, and the material constituting the shell is cobalt sulfide in crystal phase with a thickness of about 30nm, and the cobalt sulfide uniformly covers the surface of polystyrene.

Embodiment 2

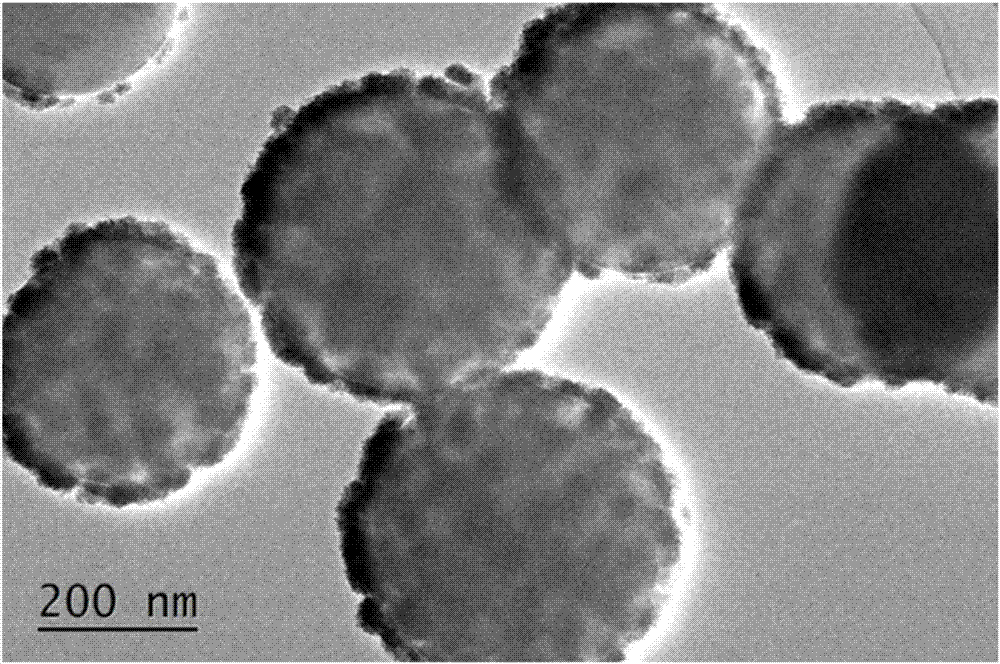

[0048] Zinc sulfide coated silica particles

[0049] Silica particles 0.1g (average particle diameter is 400nm), zinc nitrate hexahydrate 0.149g (1*10 -3 mol / L) reducing agent hydrazine hydrate 400 microliters, sulfur source thiourea 0.076g (2*10 -3 mol / L) in 50 ml of solvent water, and reflux at 55° C. for 8 h under stirring for hydrolysis reaction, centrifugation, washing, and drying to obtain zinc sulfide-coated silica particles.

[0050] The zinc sulfide-coated silica particles have a core-shell structure, and its electron micrograph is as follows: figure 2 shown. The material constituting the core is silicon dioxide spheres with a particle size of about 400nm, and the material constituting the shell is zinc sulfide in the crystalline phase with a thickness of about 20nm; and the zinc sulfide uniformly covers the surface of the silicon particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com