Patents

Literature

155results about How to "Continuous coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

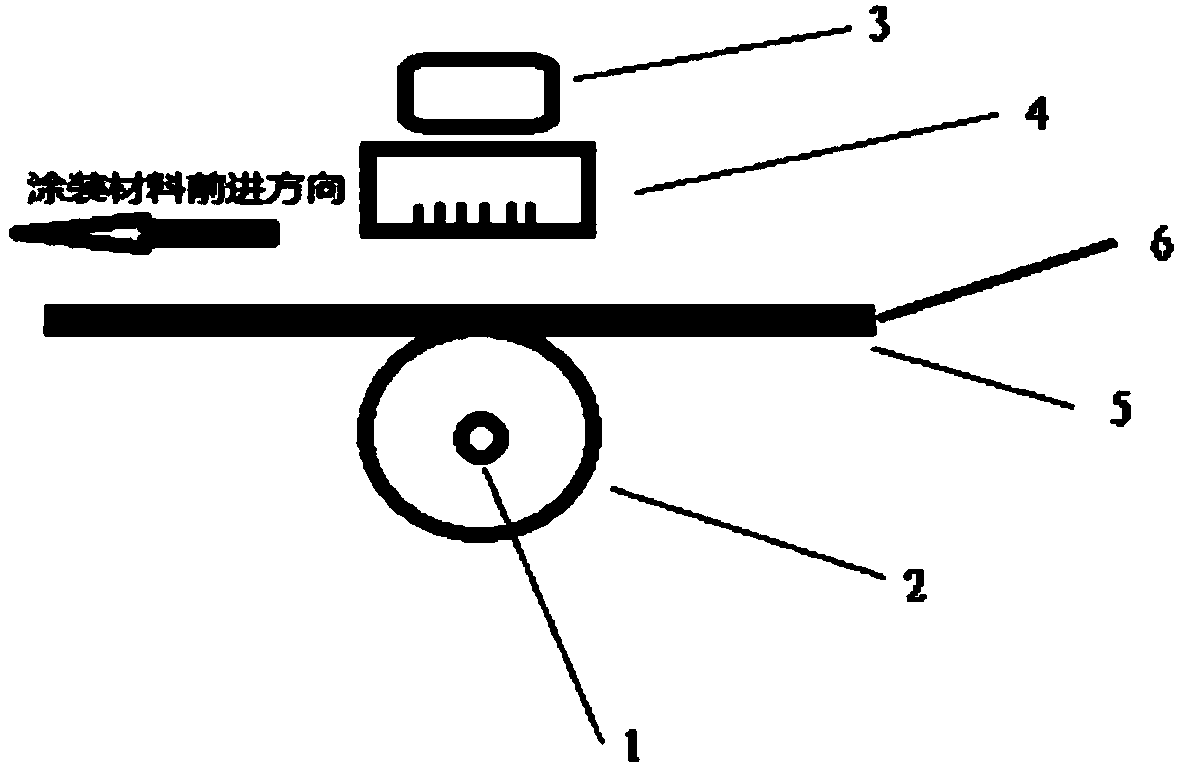

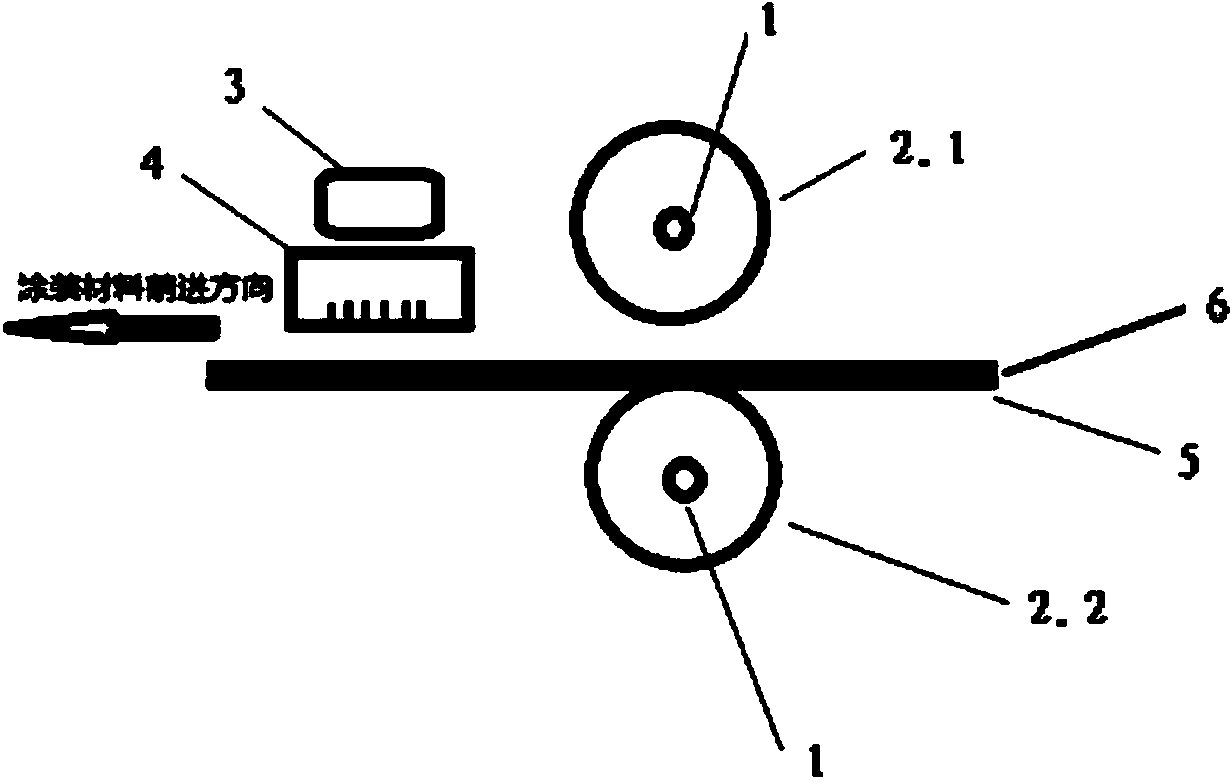

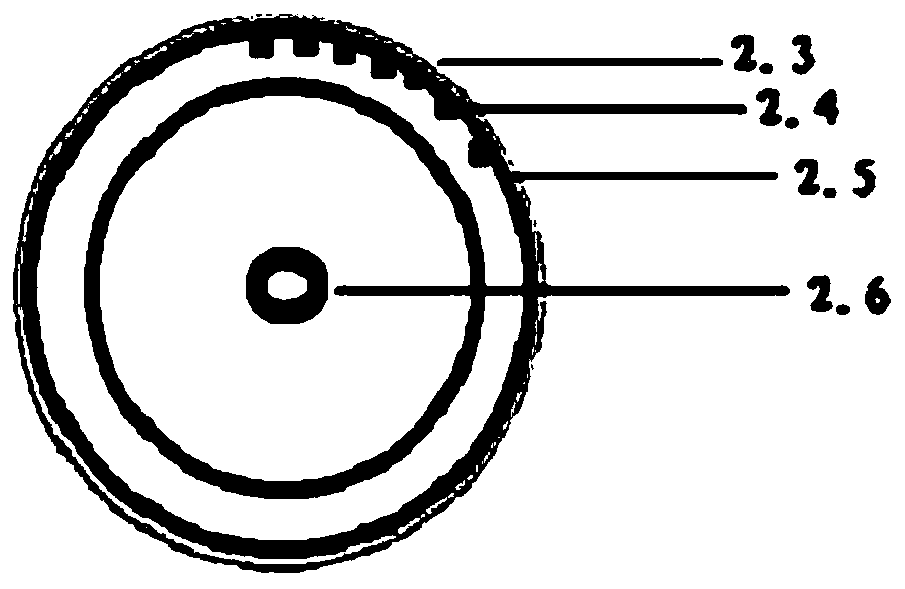

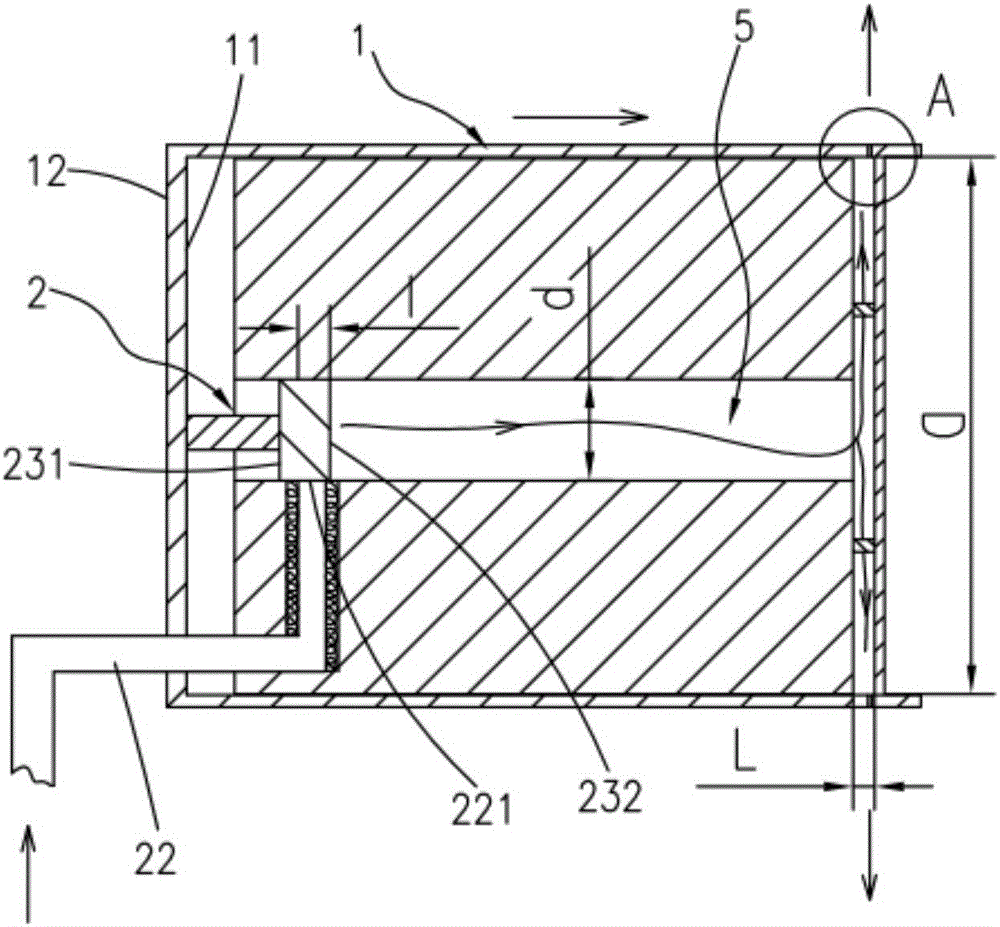

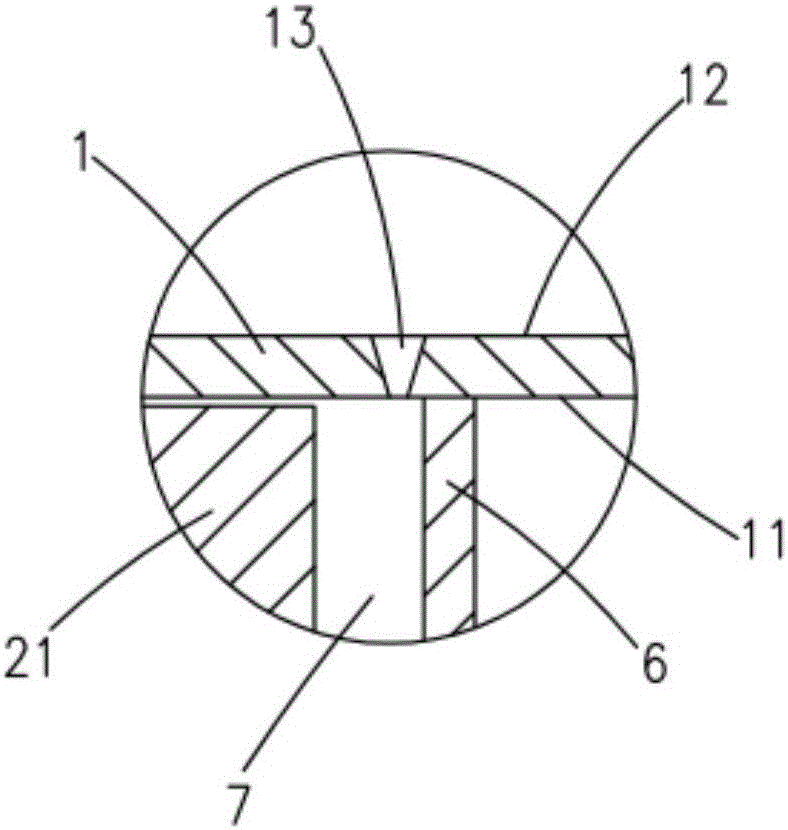

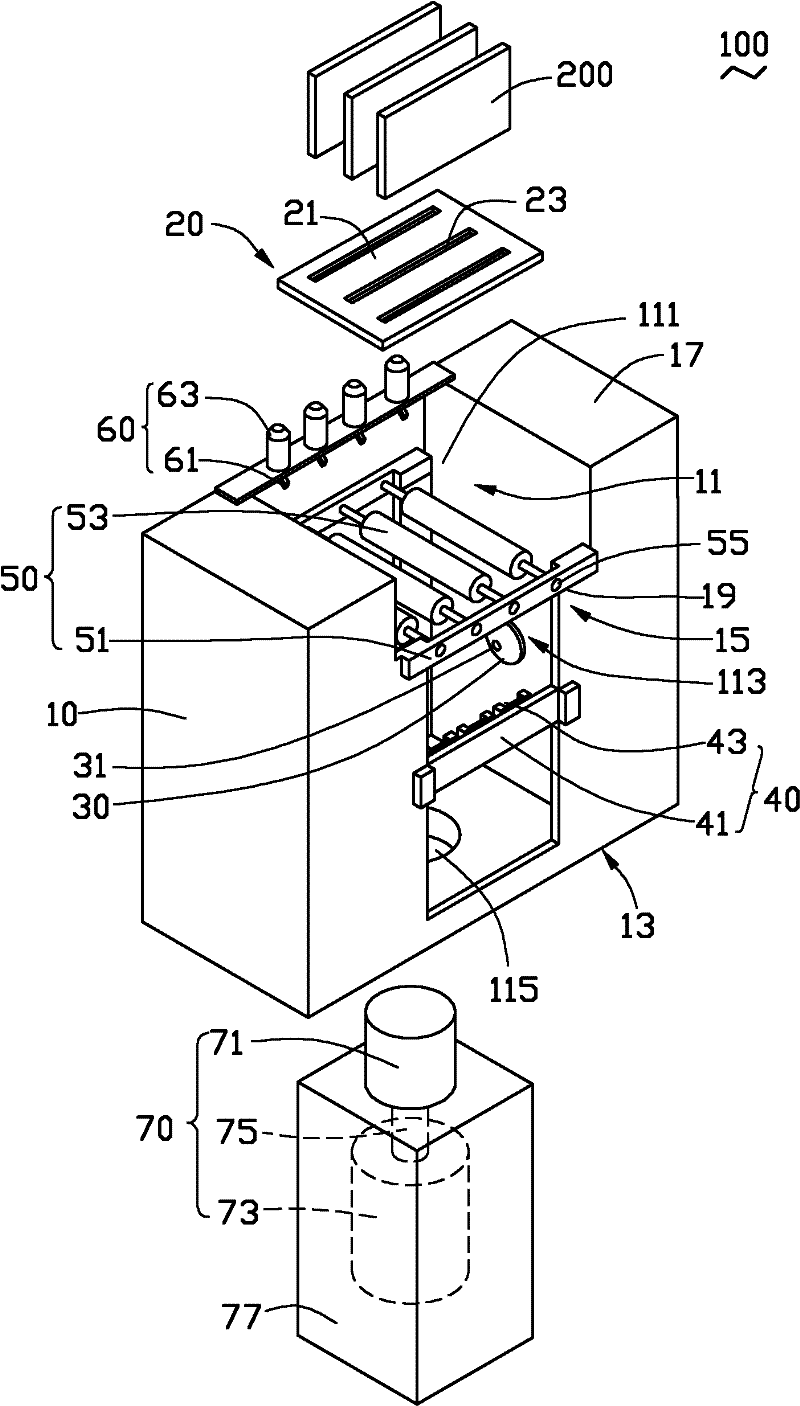

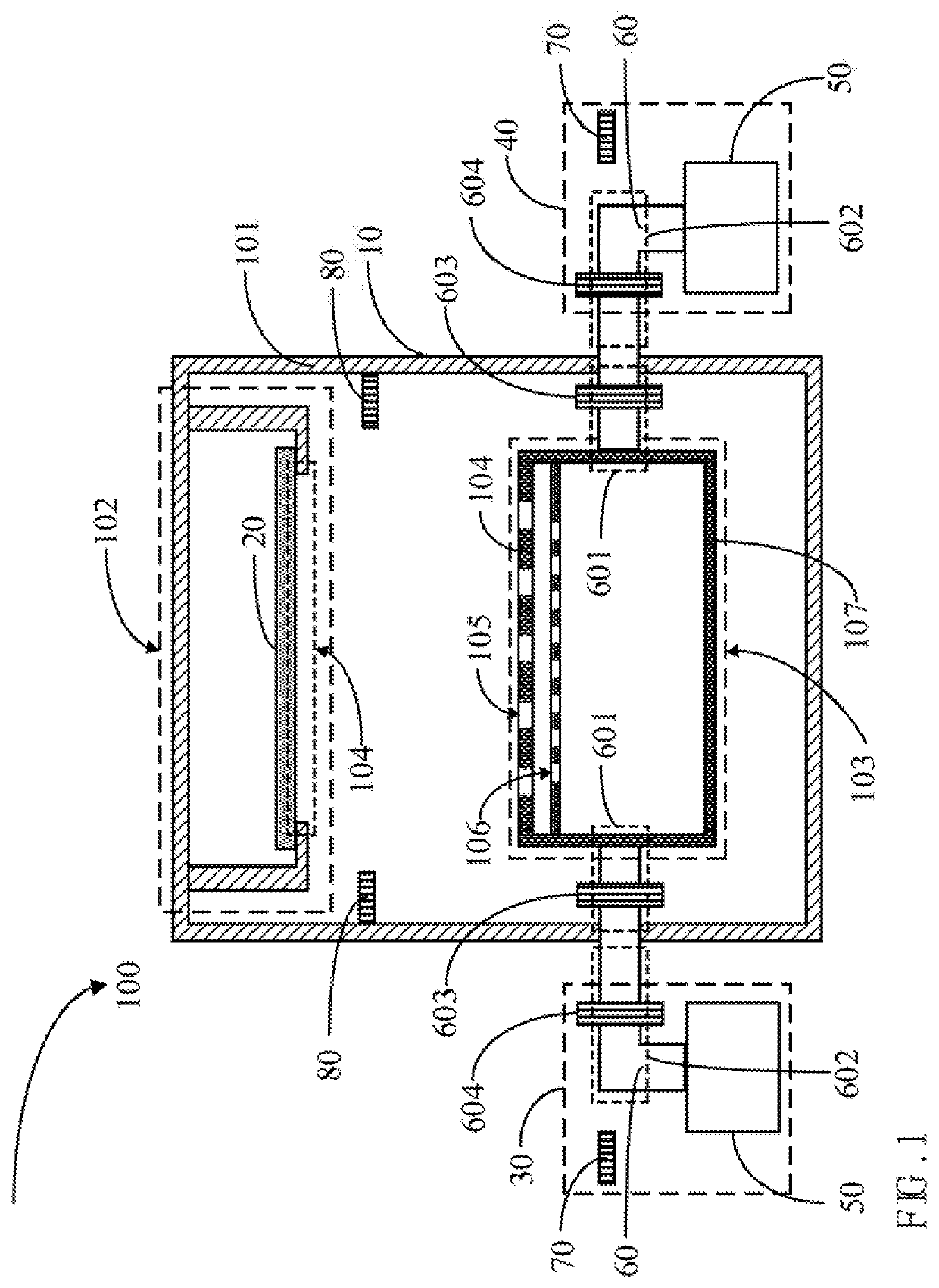

Painting equipment and technology of magnetic pigment

The invention discloses painting equipment of magnetic pigment. A painting device, a magnetic orienting device and a magnetic setting device used for setting of the magnetic pigment are sequentially arranged in the forward direction of magnetic pigment painting material, wherein the painting device is used for continuously painting the painting material with the magnetic pigment, and the magnetic orienting device is used for orienting the magnetic pigment. According to the painting equipment, the magnetic pigment can be continuously and rapidly painted and can be continuously, rapidly and magnetically oriented and set, production efficiency is improved, accuracy of magnetic patterns is improved, and product cost is reduced. The invention further discloses a painting technology, a sheet coated with the magnetic pigment is sequentially magnetically oriented and set and completely solidified through a drying oven, and the sheet having a stereoscopic and dreamlike visual effect is formed. The method can greatly increase production speed of the magnetic pigment and reduce production cost, and the manufactured sheet is excellent in magnetic stereoscopic effect, the magnetic patterns are distinct, and accuracy is high.

Owner:吕嘉明 +1

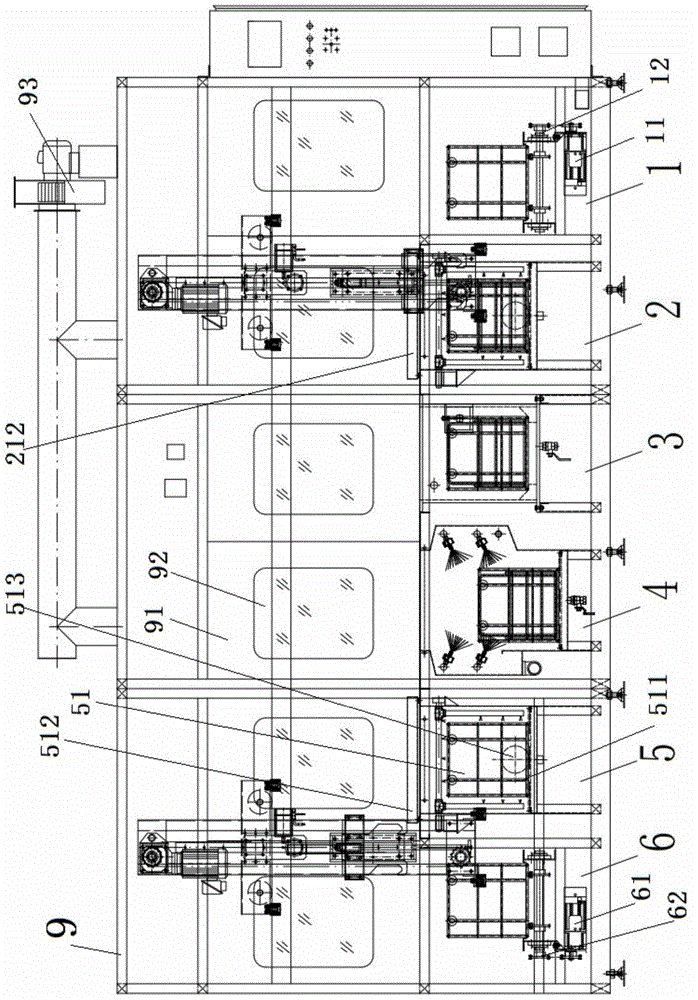

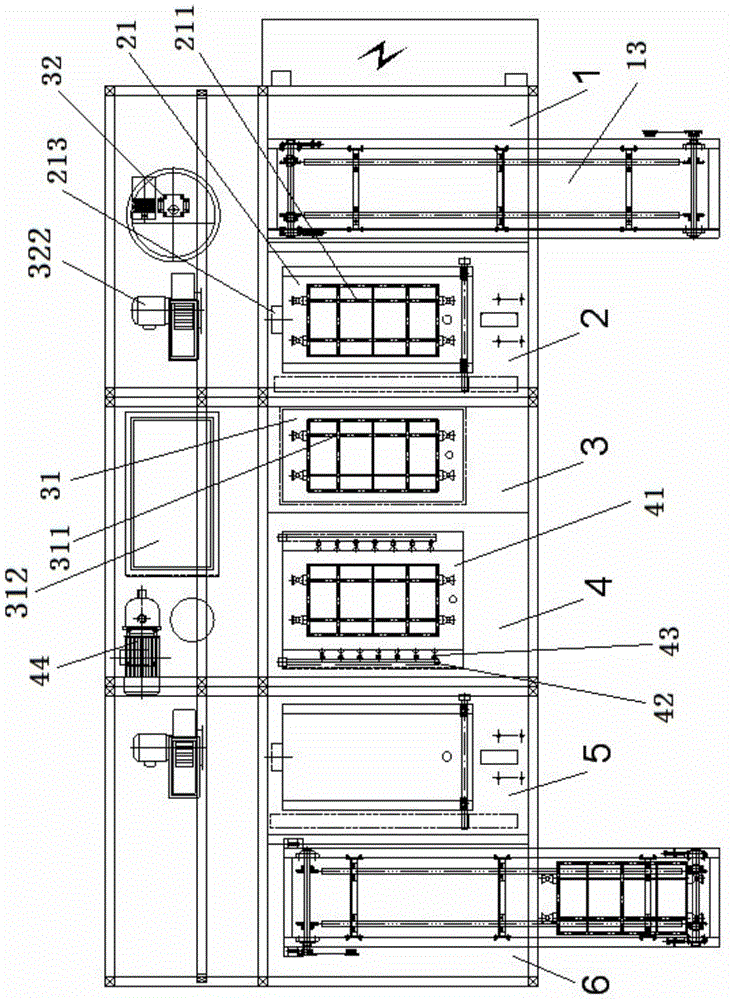

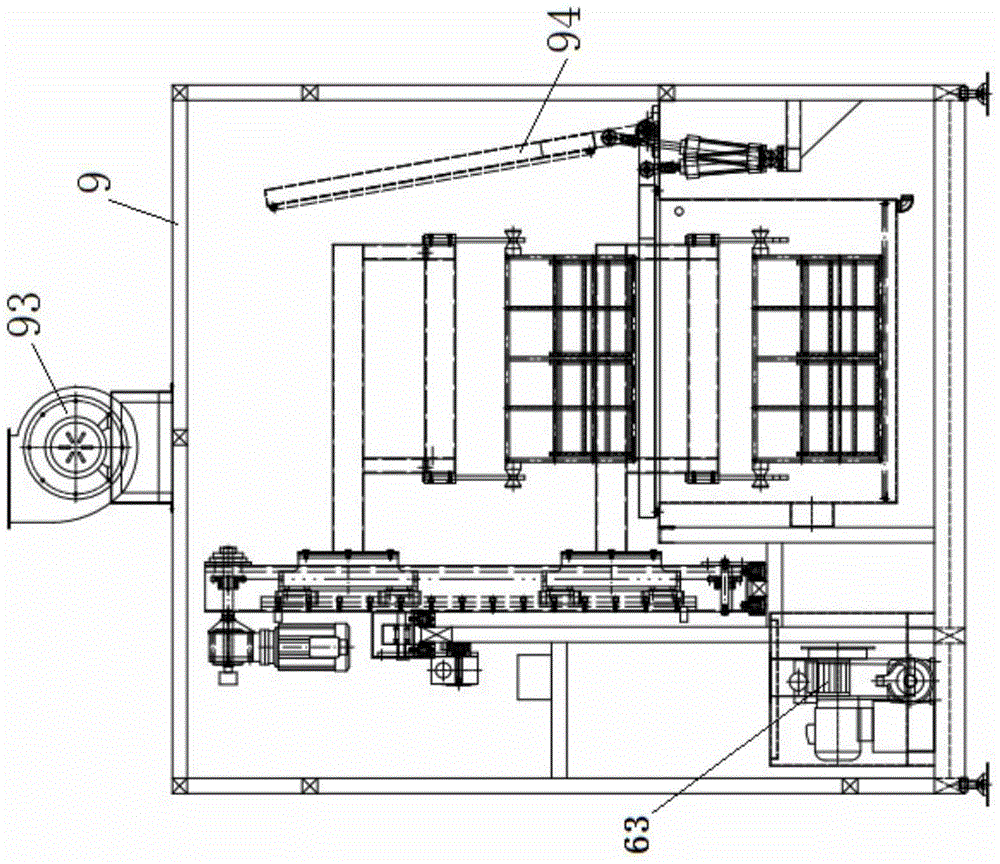

Automatic film coating system and method for precious metal coins

InactiveCN104451845ARealize automatic coatingReduce manual interventionSuperimposed coating processProduction lineEngineering

The invention discloses an automatic film coating system and an automatic film coating method for precious metal coins. The automatic film coating system comprises a production line main body as well as a loading assembly, a dust blowing assembly, a film coating assembly, a rinsing-spraying assembly, a blow-drying assembly and an unloading assembly which are sequentially connected, wherein the loading assembly is used for loading; the dust blowing assembly is used for blowing dust; the film coating assembly is used for coating the surfaces of the precious metal coins with films; the rinsing-spraying assembly is used for carrying out rinsing and spraying after the film coating; the blow-drying assembly is used for removing moisture; the unloading assembly is used for unloading; the production line main body is further provided with a mechanical arm control device which is used for placing a cleaning basket accommodating the precious metal coins to a preset station. According to the automatic film coating system and the automatic film coating method, by virtue of the loading assembly, the dust blowing assembly, the film coating assembly, the rinsing-spraying assembly, the blow-drying assembly and the unloading assembly which are sequentially connected, the automatic film coating of the precious metal coins can be realized, and manual intervention is reduced, so that the inconsistency of the film coating caused by the manual operation can be avoided, meanwhile, the continuous film coating is achieved, and the efficiency is increased.

Owner:SHENZHEN GUOBAO MINT

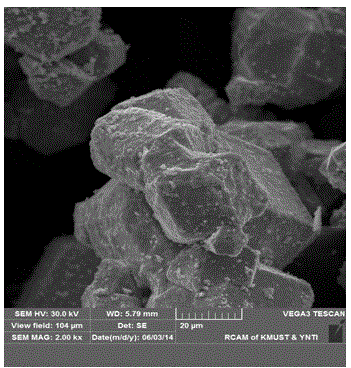

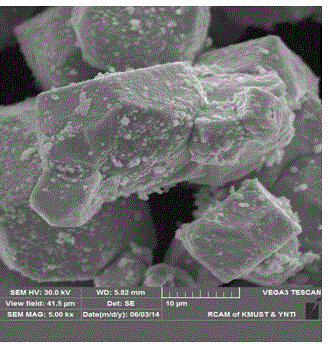

Tungsten powder surface copper plating method

ActiveCN104831257AImprove preprocessing effectEvenly distributedLiquid/solution decomposition chemical coatingChemical platingCopper plating

The present invention relates to a tungsten powder surface copper plating method, and belongs to the technical field of ultrasonic wave applications and tungsten powder surface plating treatment. The method comprises: carrying out a surface pretreatment on tungsten powder, preparing a mixed solution of a copper sulfate pentahydrate solution, potassium sodium tartrate, and disodium ethylenediaminetetraacetate, adjusting the pH value to 11-13 with a 10 wt.% sodium hydroxide solution, adding sodium thiosulfate to control the sodium thiosulfate concentration at 9-15 mg / L to obtain a chemical electroplating solution, adding the surface pretreated tungsten powder to the chemical electroplating solution to carry out plating, and drying in a vacuum drying oven at a temperature of 90-100 DEG C to obtain the dried and pure copper-plated tungsten powder. With the method of the present invention, the problems of slow copper plating, non-uniform, non-compact and non-solid plating layer, and the like during the powder copper plating process in the prior art are solved.

Owner:KUNMING UNIV OF SCI & TECH

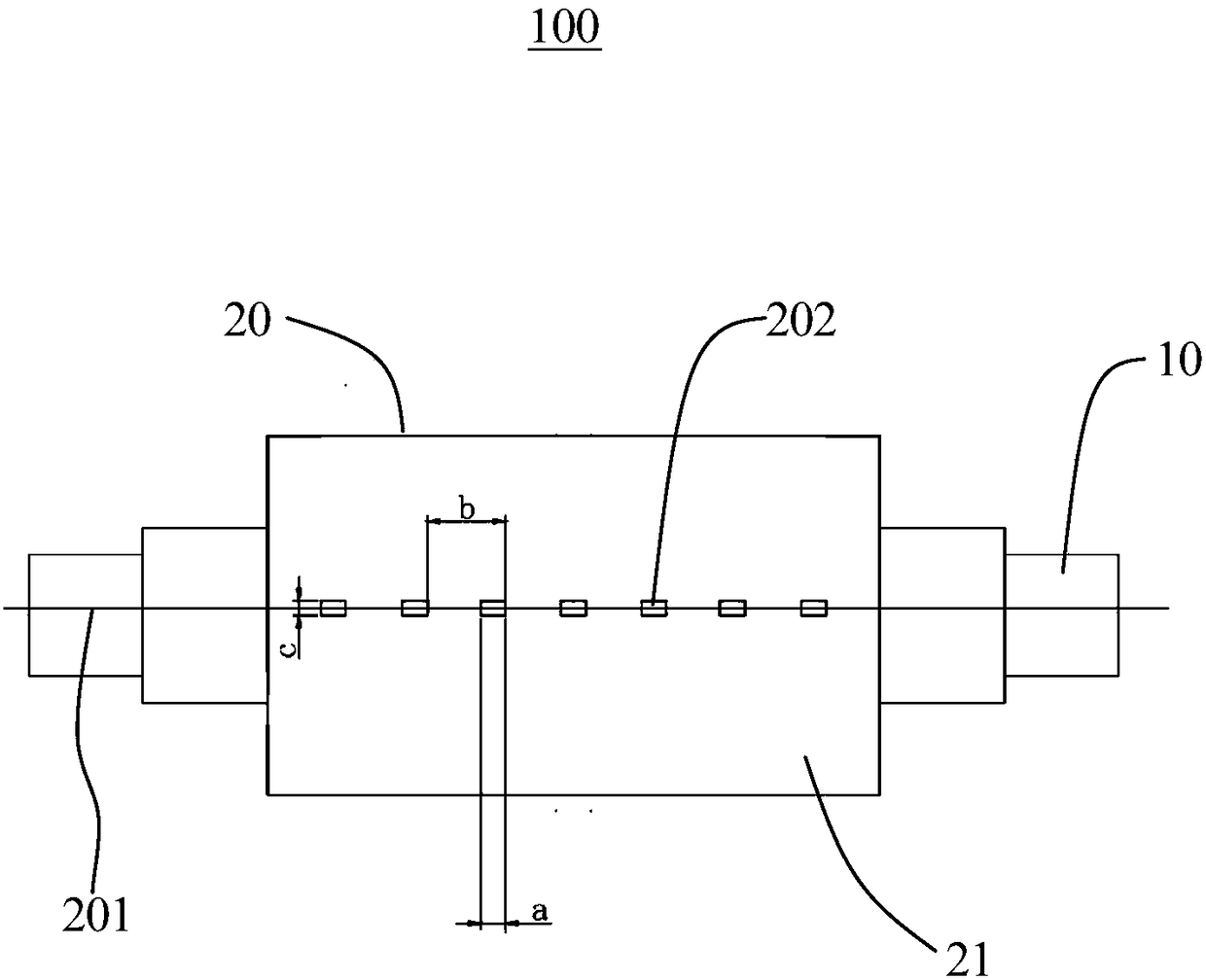

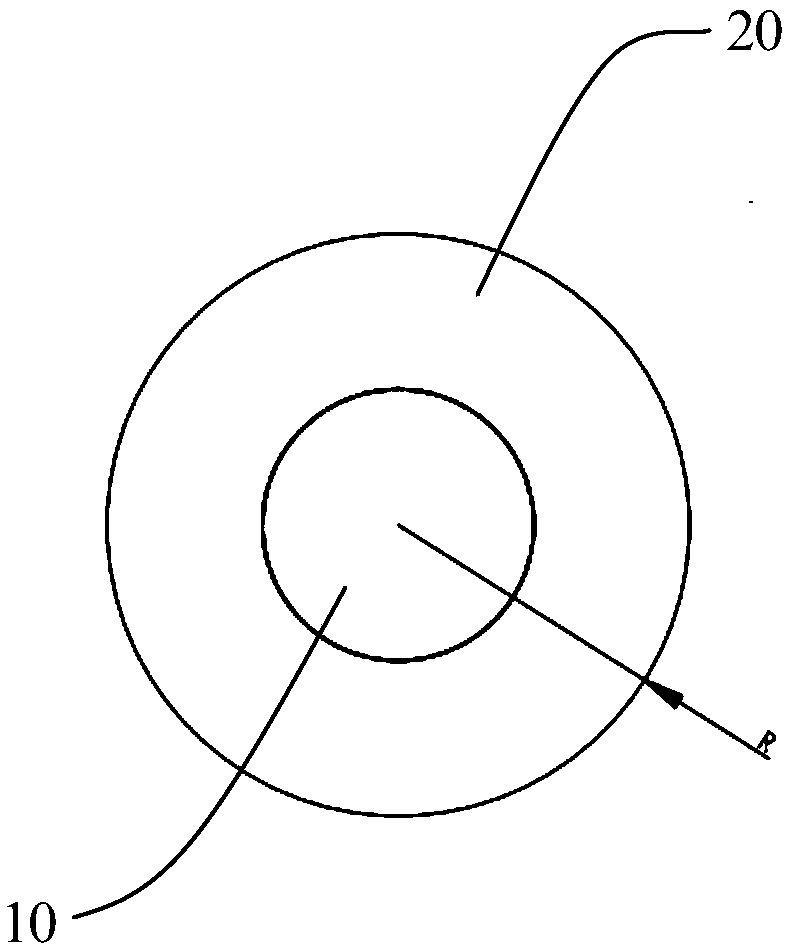

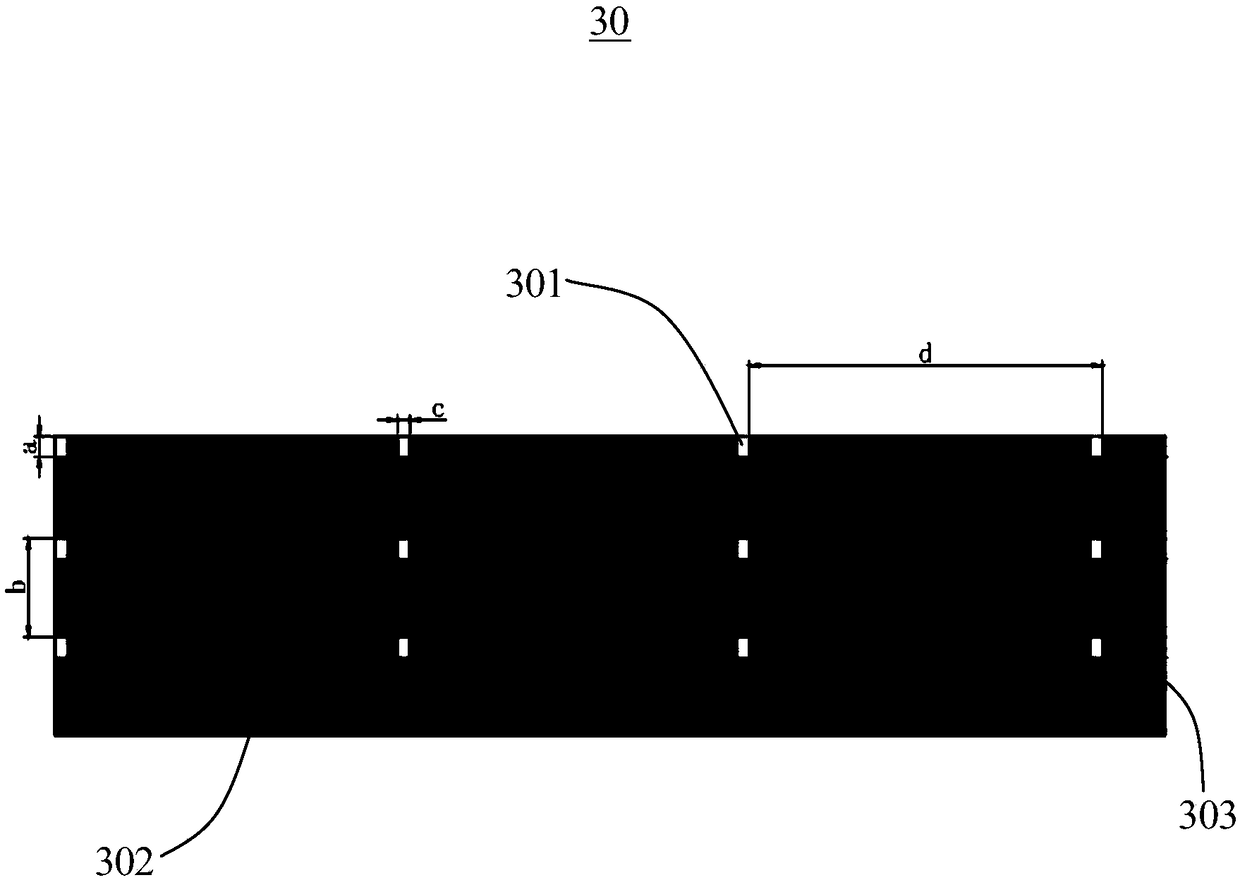

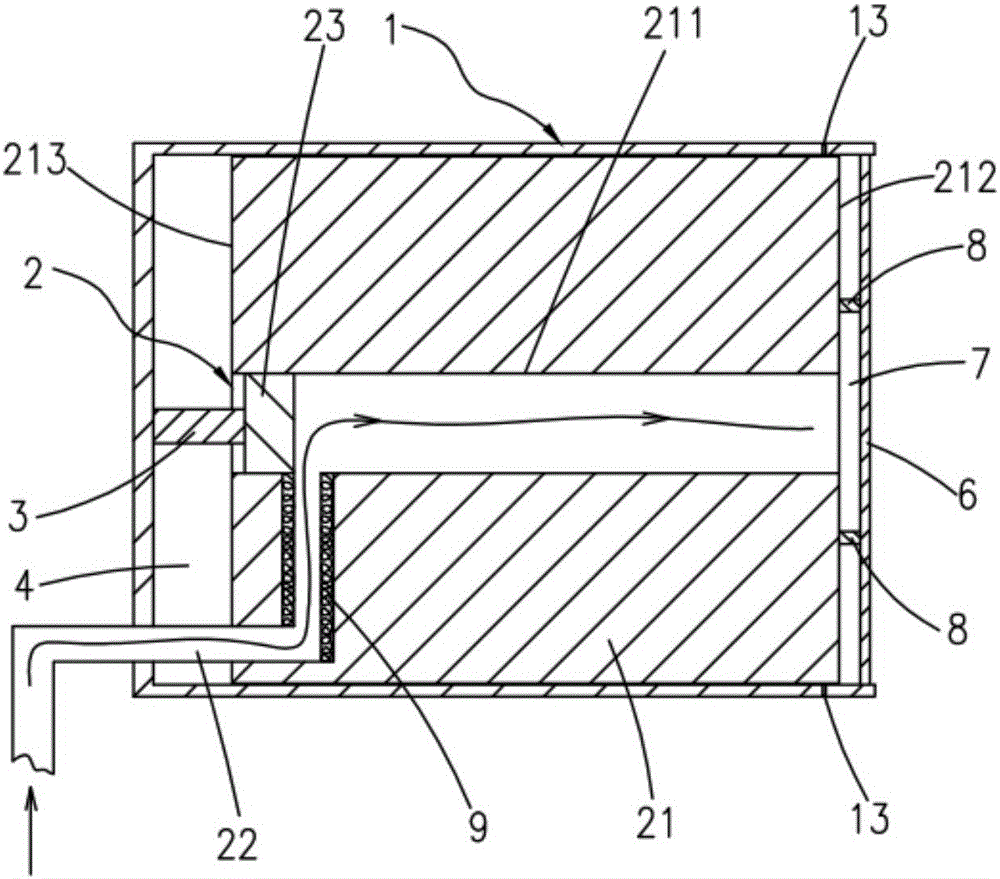

Coating roller for multi-pole battery coating machine and coating method for multi-pole battery pole piece

PendingCN108311335AContinuous coatingPrevent lithiumLiquid surface applicatorsElectrode manufacturing processesLithiumPole piece

The invention provides a coating roller for a multi-pole battery coating machine. The coating roller comprises a rotating shaft and a coating roller body. The rotating shaft is sleeved with the coating roller body and the coating roller body rotates around the rotating shaft. The coating roller body is in a cylindrical shape and is provided with a central shaft, and a plurality of grooves is formed in the outer peripheral wall of the coating roller body in the direction closing to the central shaft. The multiple grooves are arranged side by side in the direction of the central shaft. The invention further discloses a coating method for a multi-pole battery pole piece. According to the coating roller for the multi-pole battery coating machine and the coating method for the multi-pole battery pole piece, a backing roll does not need to be intermittently flicked, and the continuous coating of the coating machine is realized, the coating efficiency is high, the dressing area of the pole edge is increased, the lithium precipitation at the pole of a negative electrode is prevented, and the safety performance is high.

Owner:OPTIMUM BATTERY CO LTD

Battery sealing agent spray head

ActiveCN105665205ASmall volumeSpray evenlyLiquid surface applicatorsLiquid spraying apparatusEngineeringMechanical engineering

The invention relates to a battery sealing agent spray head. The spray head comprises a spraying cover and a sealing agent pushing mechanism, wherein the sealing agent pushing mechanism comprises an agent cylinder, an agent-passing pipe and a piston; a through hole is formed in the agent cylinder; the piston is hermetically and glidingly arranged in the through hole and is fixedly connected with the spraying cover through a connecting rod; an air cavity is formed between the outer end of the piston and the inner wall of the spraying cover; a storage cavity is formed between the inner end of the piston and the inner wall of the agent cylinder; the agent-passing pipe is communicated with the storage cavity; a limiting plate is arranged at the front end part of the agent cylinder; an accommodating cavity is formed between the limiting plate and the front end part of the agent cylinder and is communicated with the storage cavity; and a plurality of spraying holes are uniformly formed in the side walls of the spraying cover in the circumferential direction. According to the spray head, the spraying cover moves relative to the agent cylinder to synchronously drive the piston to be pushed forwards, so that the volume in the storage cavity is reduced and the pressure in the accommodating cavity is increased; and by utilizing the change of the pressure difference, a sealing agent in the accommodating cavity is sprayed instantly and simultaneously through the spraying holes, so that the spraying is uniform, continuous and efficient.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

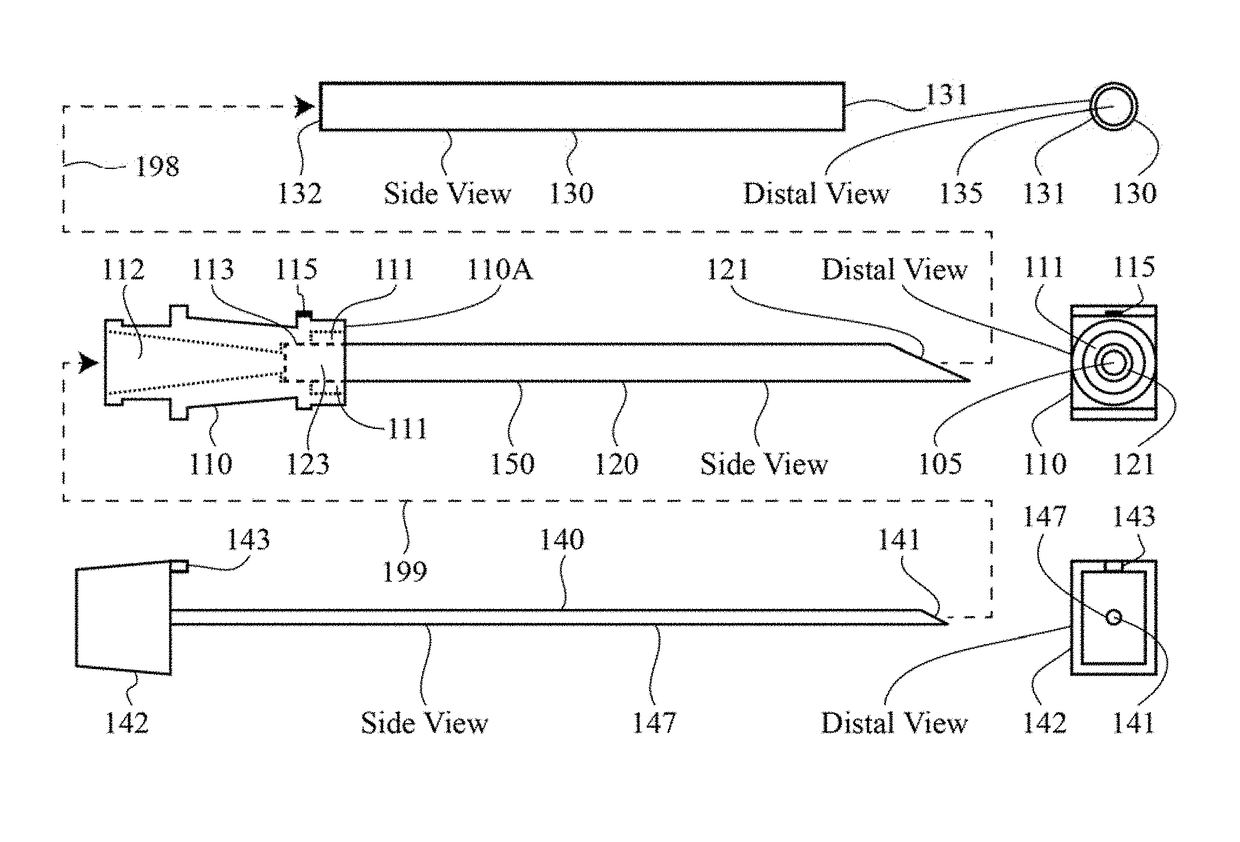

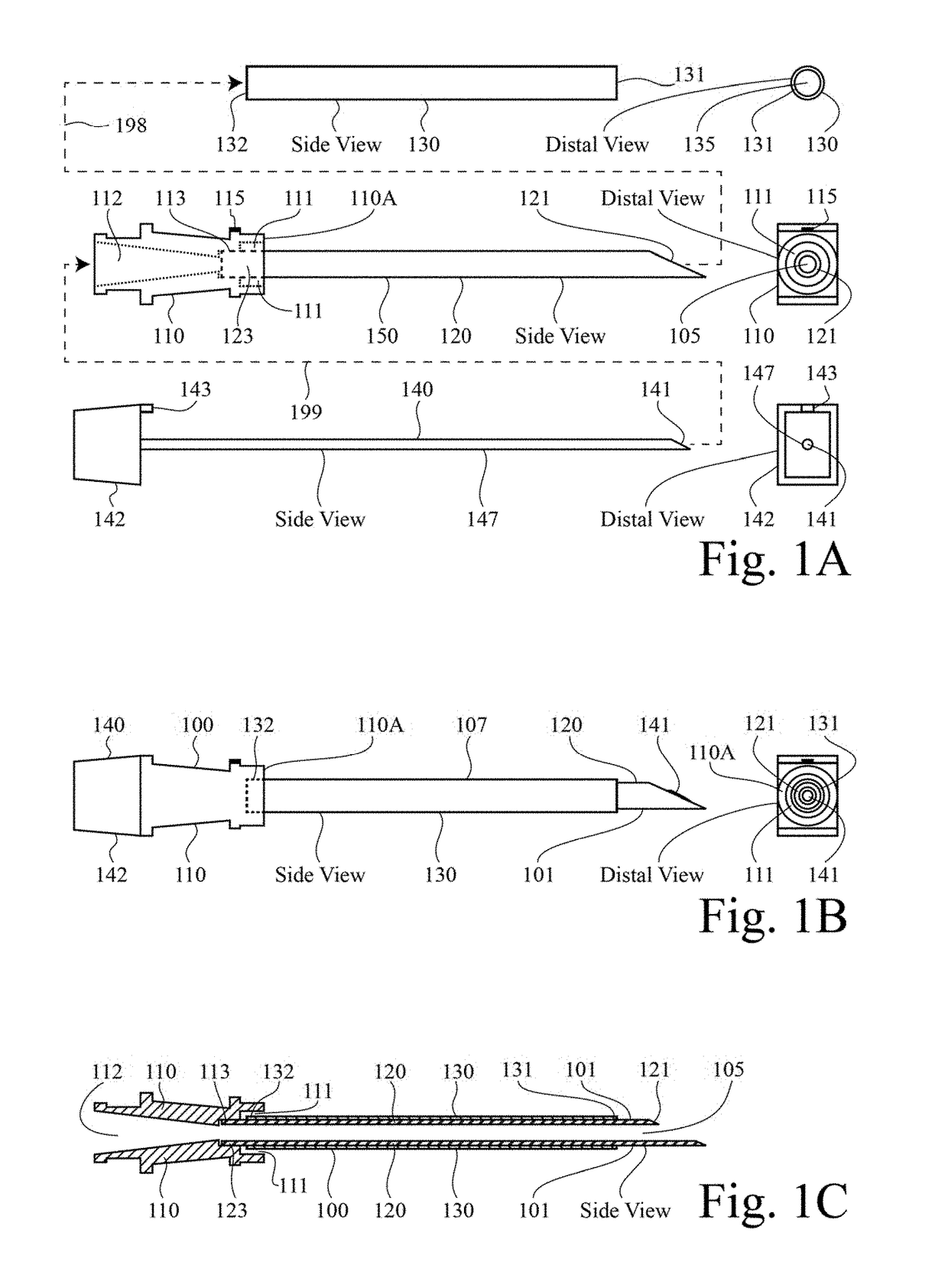

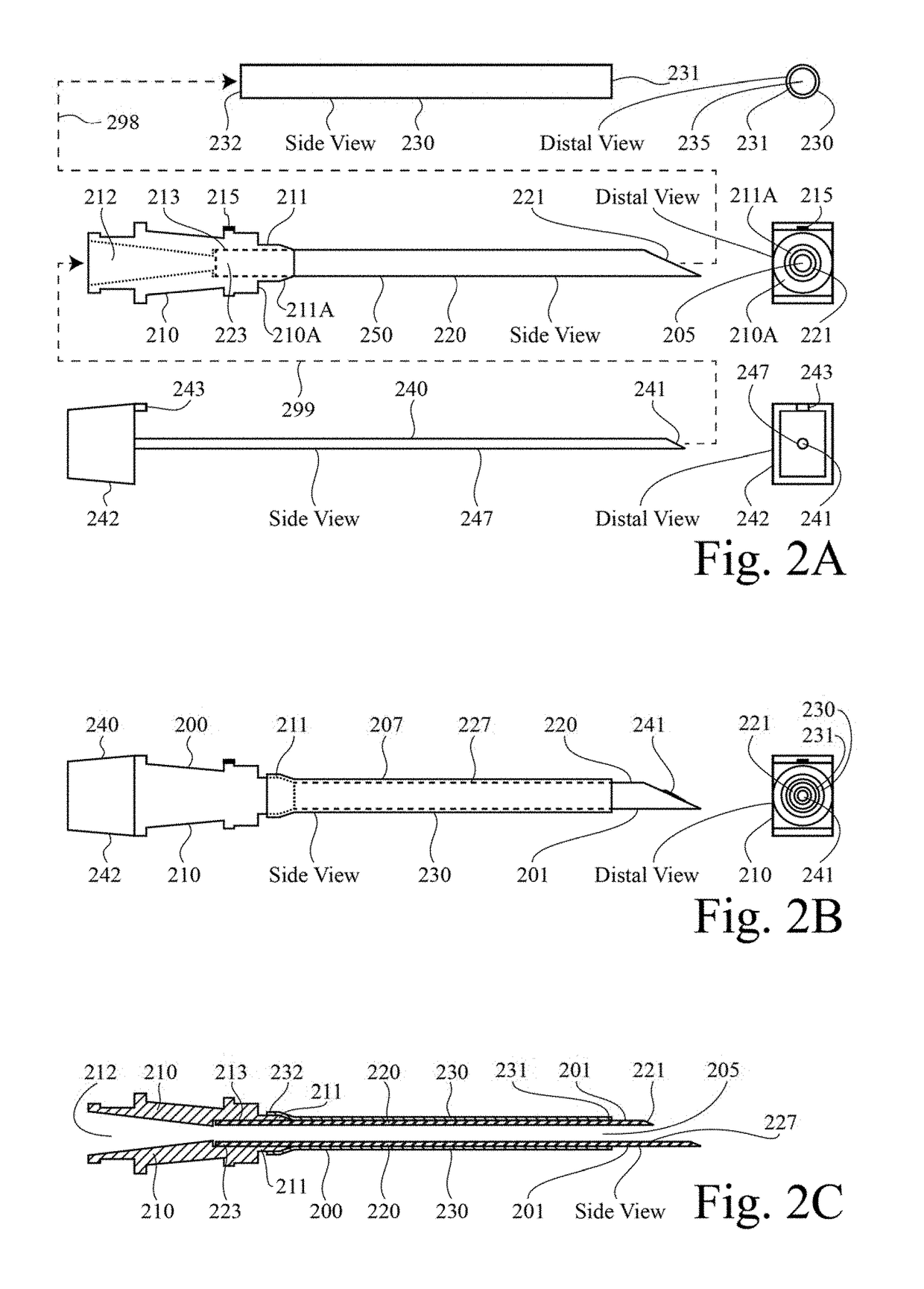

Electrosurgical generator

ActiveUS20180036060A1Continuous coatingSurgical needlesSurgical instruments for heatingLiving bodyBiomedical engineering

A system and method for applying energy, particularly high-frequency (HF) energy, such as radiofrequency (RF) electrical energy, to a living body can include a cannula hub.

Owner:COSMAN MEDICAL INC

Rotation type quantitative spraying equipment

ActiveCN105709996ATake advantage ofContinuous sprayingLiquid surface applicatorsCoatingsSpray nozzleEngineering

The invention relates to rotation type quantitative spraying equipment. The rotation type quantitative spraying equipment comprises a spraying support, a conveying mechanism and a spraying nozzle; the conveying mechanism is communicated with the spraying nozzle through an agent passing pipe, the spraying nozzle comprises a spraying cover and an agent cylinder, and a transmission mechanism and a rotation mechanism are installed at the back end of the spraying nozzle; a through hole is formed inside the agent cylinder, a piston is arranged in the through hole, an air containing cavity is formed between the outer side end of the piston and the inner wall of the spraying cover, a storage cavity is formed between the inner side end of the piston and the inner wall of the agent cylinder, a limiting plate is arranged at the front end of the agent cylinder, and a containing cavity is formed between the limiting plate and the front end of the agent cylinder; and the side wall of the spraying cover is evenly provided with four spraying openings capable of being communicated with the containing cavity when the pressure of the storage cavity changes in the circumferential direction. According to the rotation type quantitative spraying equipment, instantaneous pressure changes inside the storage cavity and the containing cavity are used, so that the spraying openings simultaneously conduct jetting instantaneously; and a rotation mechanism is used in a combined manner to drive the spraying cover to rotate by 90 degrees, a wiping brush is used in a matched manner to evenly spray the surface of a steel battery shell with a sealing agent, spraying is even and continuous, and the using rate of the sealing agent is high.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

Inside coating technology for plastic woven bag

InactiveCN108014986AImprove liquidityImprove corrosion resistanceFireproof paintsPretreated surfacesLow-density polyethyleneEngineering

The invention discloses an inside coating technology for a plastic woven bag. According to the technology, firstly, finished ribbon-like filaments are sent into a weaving machine for weaving of wovenbag fabric used as film-coated weaving base fabric, then the inner side of the weaving base fabric is coated with paint, a lining is formed, and the paint is prepared from raw materials in parts by mass as follows: 60-70 parts of homo-polypropylene, 20-30 parts of low-density polyethylene, 8-10 parts of anti-aging master batch, 3-5 parts of polyethylene wax, 3-5 parts of organic silicone oil and 0.5-1 part of nano Au28(SCH3)20 clusters. The coating technology comprises steps as follows: (1) preparation of the paint, (2) preheating, (3) spraying and (4) aftertreatment. The sprayed paint adoptedin the technology is a novel environment-friendly material, is sprayed on the inner side of the base fabric of the woven bag and has the characteristics that the coating is dense, continuous and seamless, so that the coated woven bag has the characteristics of high strength, low price, durability and the like. According to the coating technology for the woven bag, spraying is the main technology,the method is simple in technology, low in equipment input and high in production efficiency, and environmental protection is facilitated.

Owner:安徽省临泉县万隆塑料包装有限公司

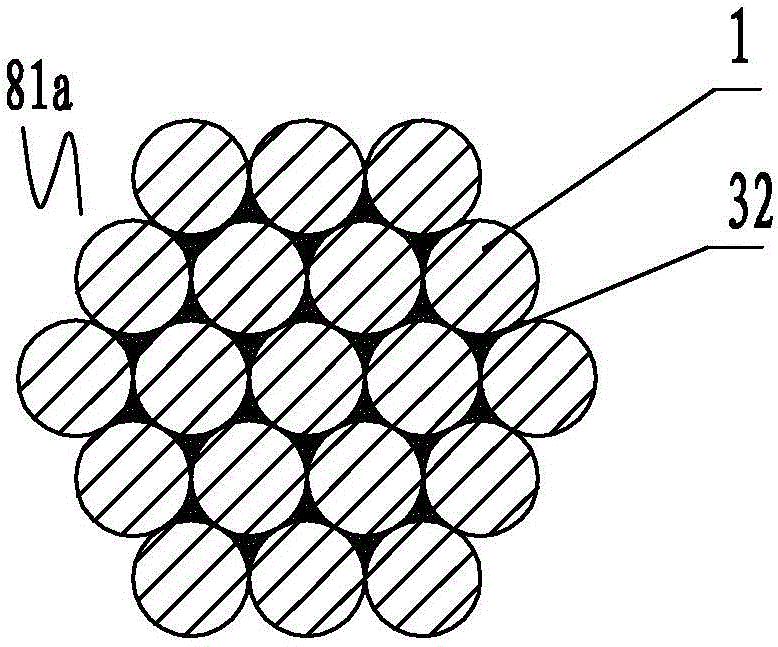

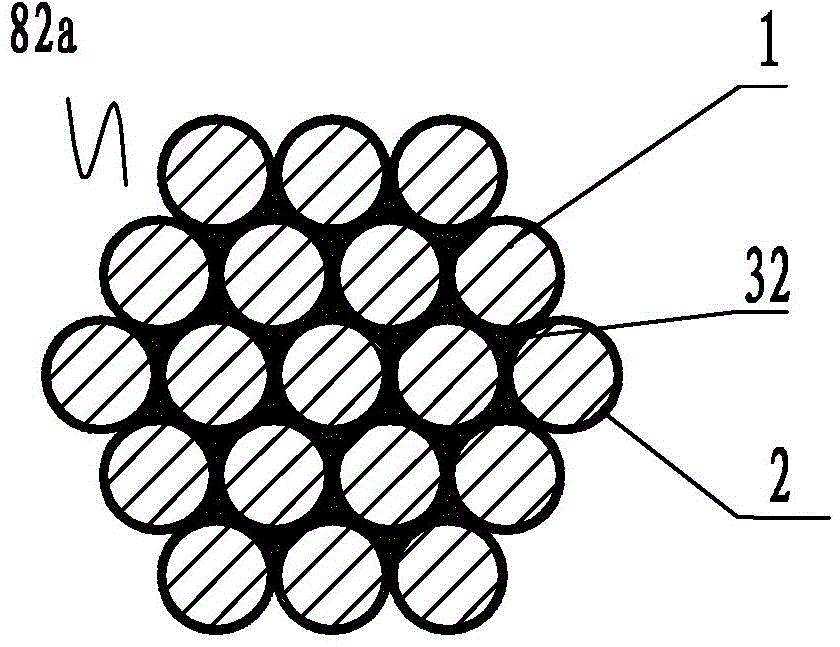

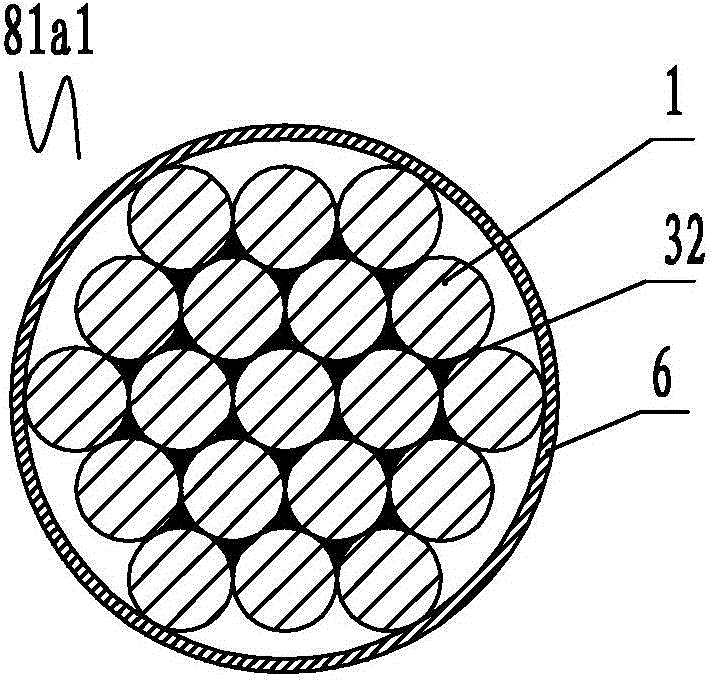

Manufacturing method for steel wire inhaul cable filled or coated with polyurea protective materials

ActiveCN105088947AImprove shock absorptionImprove skid resistanceRope making machinesBridge structural detailsPolymer scienceProtection layer

The invention relates to a manufacturing method for a steel wire inhaul cable filled or coated with polyurea protective materials. The manufacturing method includes the steps that after steel wires are pretreated, steel wire combinations are molded through drying, coiling, wire dividing, polyurea material filling and coalescence, and steel wire inhaul cable bodies Ia or IIa filled or coated with the polyurea protective materials are formed, wherein gaps at the portions, in the middle portions of the n steel wires, between the steel wires are filled with the polyurea materials; the outer layer of the steel wire inhaul cable bodies Ia or IIa is coated with a polyurea protective coating I through the polyurea material extrusion coating working procedure to form steel wire inhaul cable bodies Ib or II b filled or coated with the polyurea protective materials; on the basis of the steel wire inhaul cable bodies of the two structures, the steel wire inhaul cable which has multiple protection layers and is provided with the polyurea protective coatings is formed through one or more of the wrapping and packaging molding working procedure, the PE sleeve extrusion molding working procedures I and II and polyurea material coating working procedures II and III. The steel wire inhaul cable which is manufactured with the method and provided with the polyurea protective coatings is compact in structure and antiseptic, reduces shocks, and is good in skid resistance and abrasive resistance.

Owner:LIUZHOU OVM MASCH CO LTD

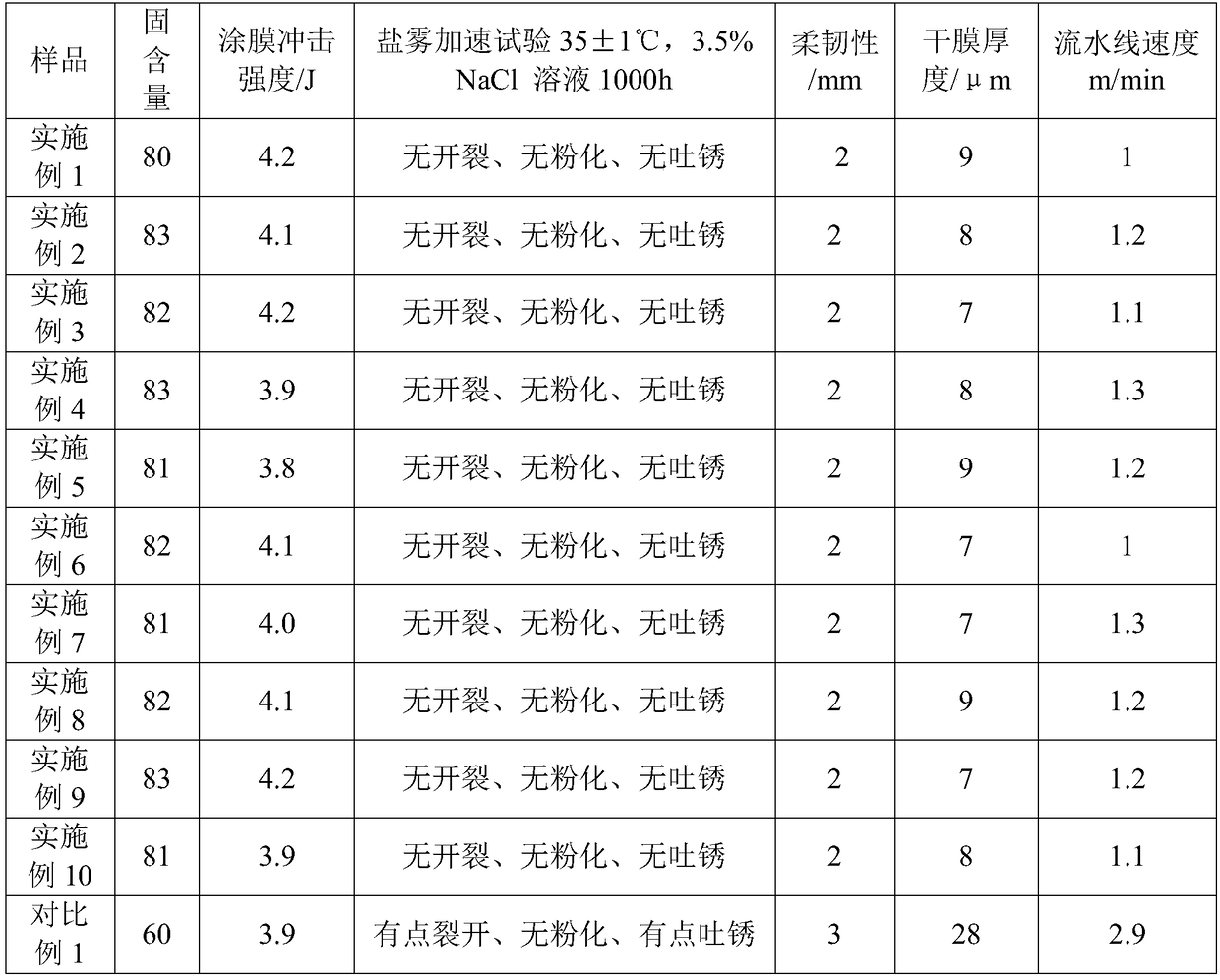

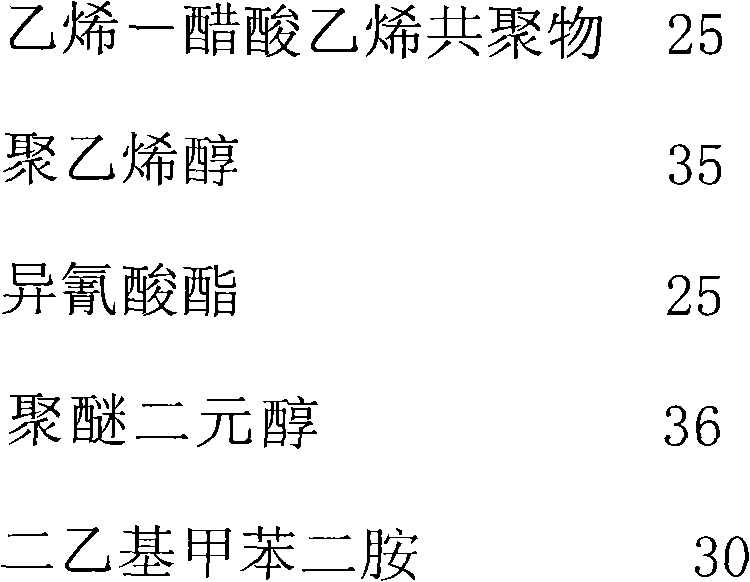

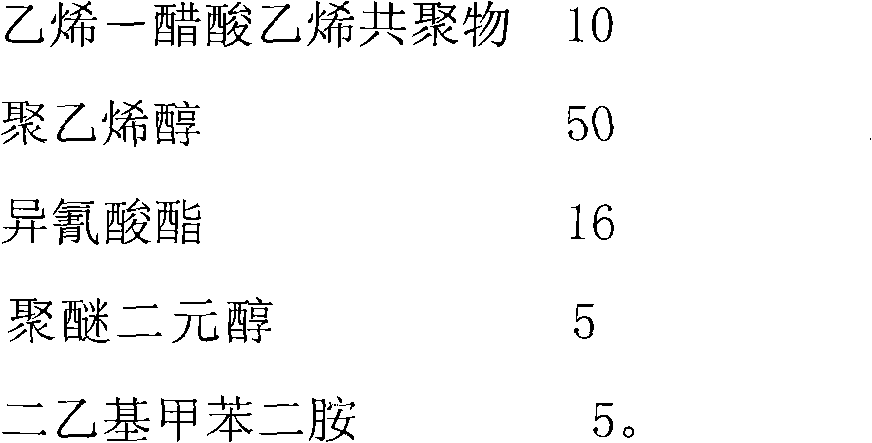

Coating method of woven bag

The invention provides a coating method of a woven bag. The method comprises the following steps of: weaving warps and wefts made of fibrous material into a cylindrical fibrous braid on a circular weaving machine; then spraying coatings which are prepared on site on the inside of the braid to form a liner, wherein the coatings comprise the following components in parts by mass: 11-15 parts of ethylene-vinyl acetate copolymer, 26-35 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-15 parts of polyether glycol, and 5-12 parts of diethyl methyl benzene diamine; and then drying to obtain an inner sprayed woven bag product.

Owner:QINGDAO BAIZHONG CHEM TECH

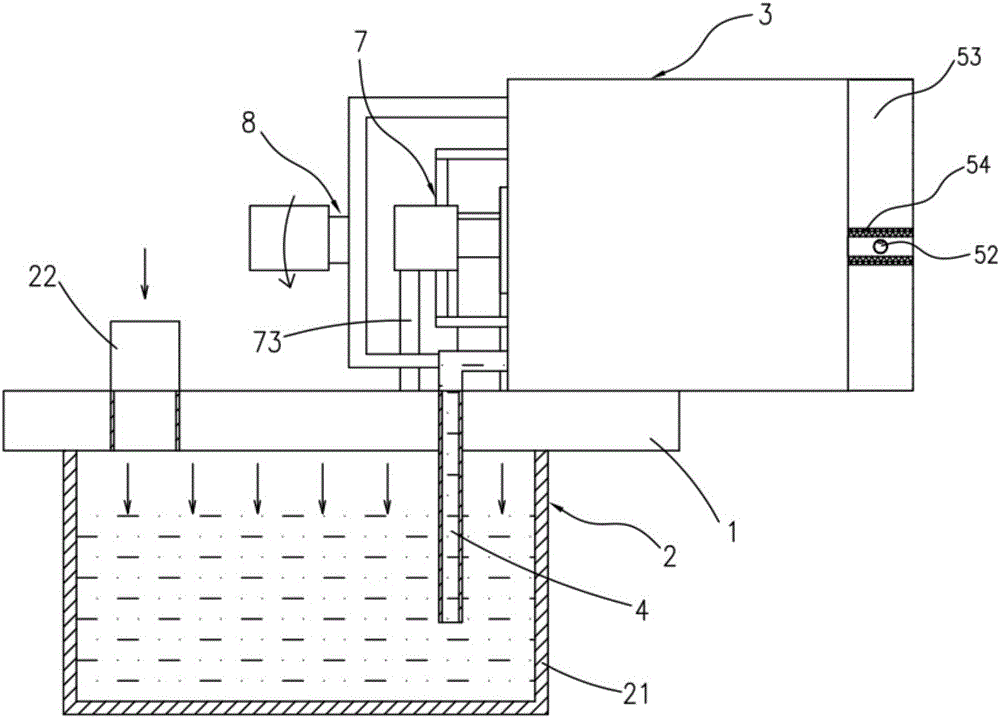

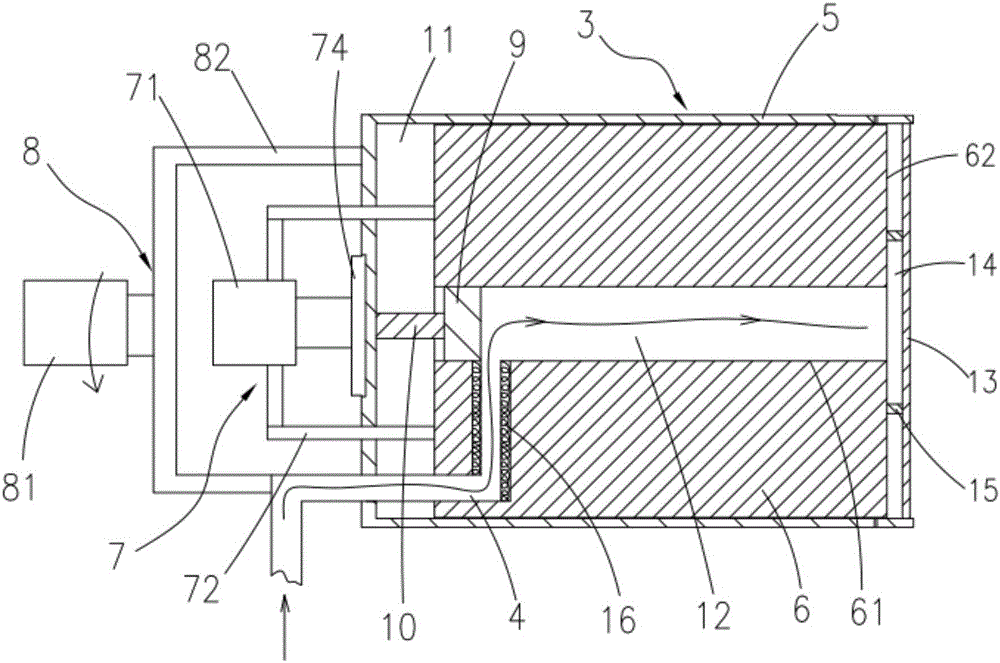

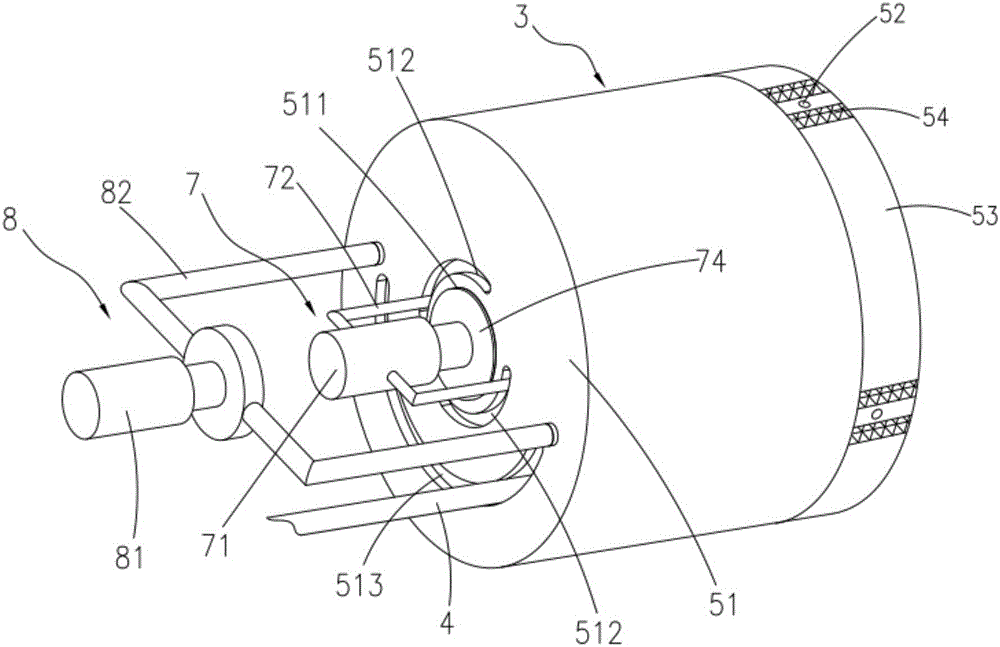

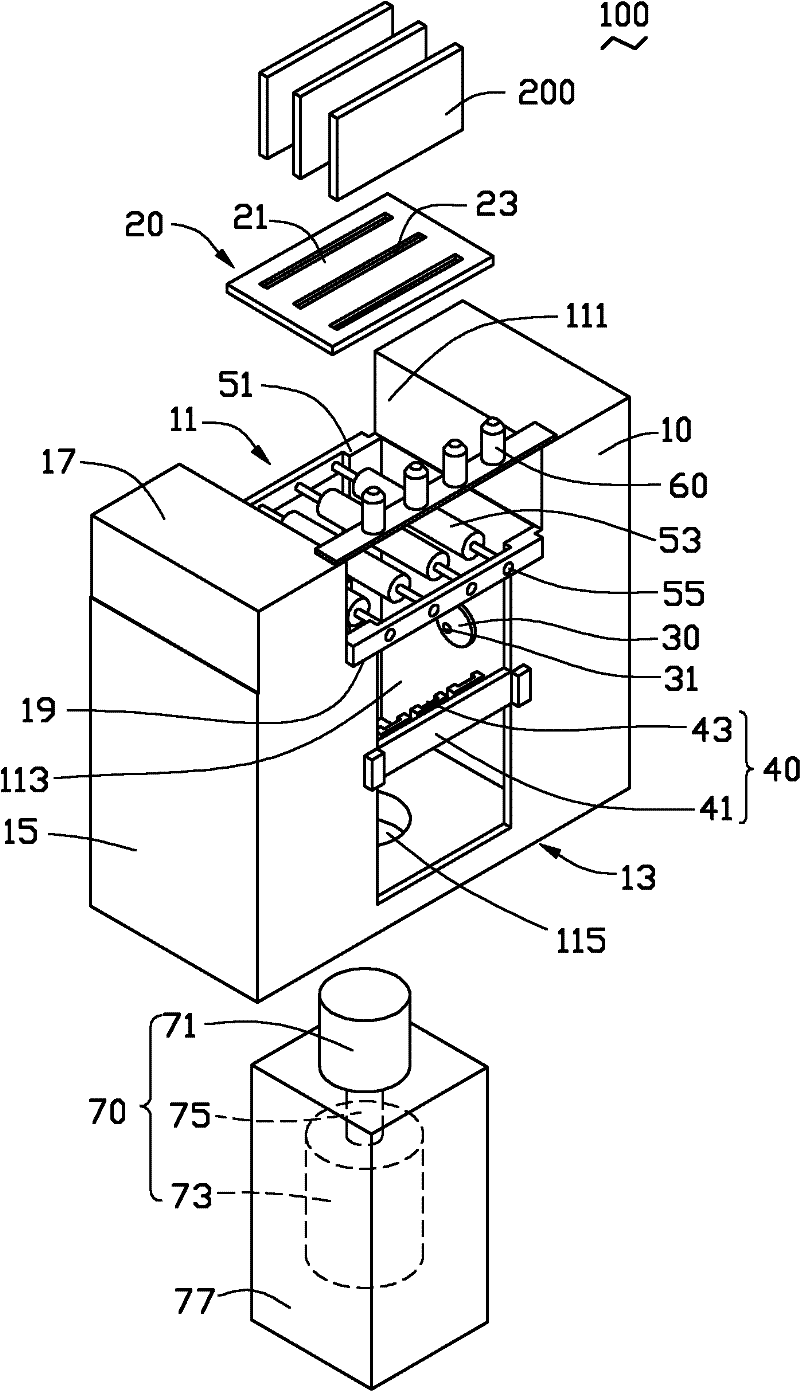

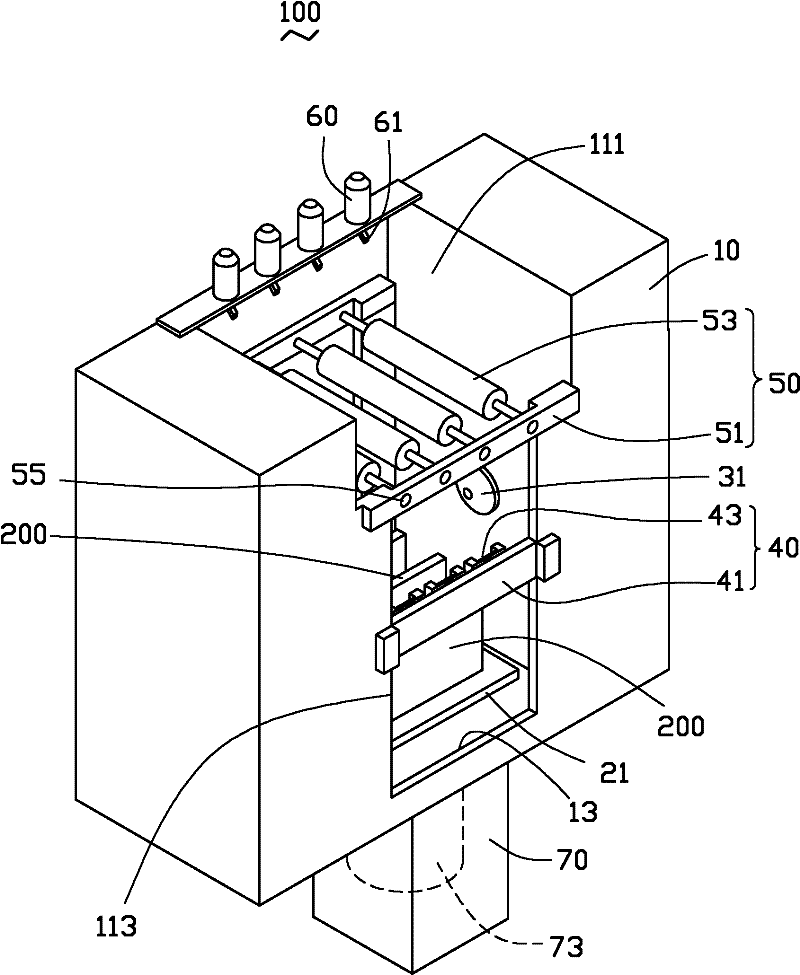

Drum-type film coating equipment

InactiveCN102327839AContinuous coatingImprove coating efficiencyLiquid surface applicatorsCoatingsEngineeringAtmospheric pressure

The invention discloses drum-type film coating equipment, which is used for coating a film on a substrate in atmospheric pressure environment. The film coating equipment comprises a bearing device, a base, a cleaning device, a heating device, a drum device, a liquid spray device and a driving device, wherein an accommodating groove is formed on the bearing device; the base is arranged at the bottom of the accommodating groove, and is used for supporting at least one substrate; the cleaning device and the heating device are arranged in the accommodating groove, and are fixedly arranged on the middle part of the bearing device; the drum device is arranged above the cleaning device and the heating device, and comprises a plurality of drums which are arranged at intervals side by side; the distance between adjacent drums is equal to the thickness of the substrate; the liquid spray device is arranged above the drum device, is fixedly arranged above the bearing device, and is used for providing liquid to be coated for the substrate; and the driving device is connected with the base, and is used for driving the base to rotate relative to the accommodating groove and move up and down, so that the substrate cleaned by the cleaning device passes through the drum device among the drums for film coating with the drum and the liquid spray device, and is dried by the heating device after being coated with a film, so that the efficiency is increased, and the film coating quality is ensured.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Internal direct coating process of composite plastic woven bag and preparation method thereof

InactiveCN109487566ADense coatingOptimizing Control ParametersTextiles and paperPolypropyleneControl parameters

The invention discloses an internal direct coating process of a composite plastic woven bag and a preparation method thereof. The preparation method is characterized by comprising the following steps:first sending finished product ribbon-like filaments into a weaving machine to form a piece of woven bag cloth serving as laminated woven basic cloth, and then smearing the paint on the inner side ofthe woven basic cloth to form a liner. The paint is prepared from the following raw materials in parts by weight: 40 to 60 parts of polypropylene powder, 5 to 8 parts of cooling master batch, 3 to 5parts of coating-type polyethylene, 1 to 2 parts of modifier, and 1 to 2 parts of aid. All raw materials are mixed at a high speed, heated, extruded, coated with a film, laminated, cut, and sewed. Thespraying paint adopted in the invention is a novel environment-friendly material and is sprayed on the inner side of the coating film of the woven bag. The composite plastic woven bag has the characteristics of compactness, continuity and no seam of the coating. The produced woven bag is resistant to corrosion, resistant to high temperature and durable. The woven bag coating process provided in the invention adopts a high-efficiency continuous production technology; and by optimizing control parameters of a processing process, the continuous production can be realized, and the production efficiency can be improved.

Owner:温州晨光集团有限公司

Coating method for inside of woven bag

The invention discloses a coating method of a woven bag. The coating method comprises the following steps of: firstly weaving warps and wefts made of fiber materials into a barrel-shaped fiber weaving layer on a circular weaving machine; then spraying paint prepared on site on the inner side of the weaving layer to form lining, wherein the paint comprises the following components in parts by weight: 16-20 parts of ethylene-vinyl acetate copolymer, 26-35 parts of polyving akohol, 30-45 parts of isocyanate, 20-35 parts of polyether glycol and 10-20 parts of diethyl methyl benzene diamine; and drying and obtaining a woven bag product with internal spraying.

Owner:湖南安福环保科技股份有限公司

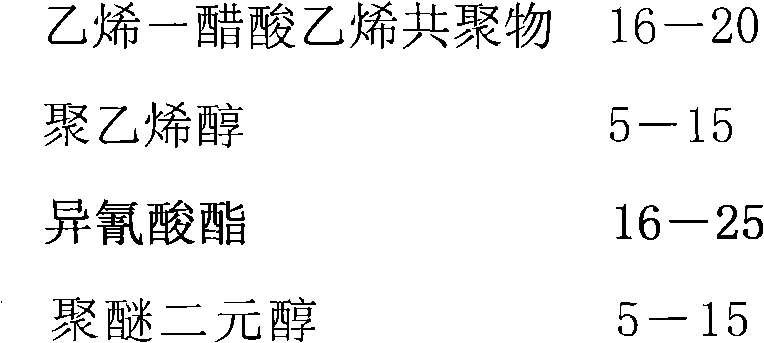

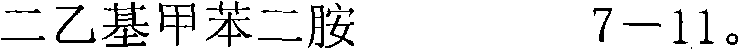

Internal coating technology for woven bag

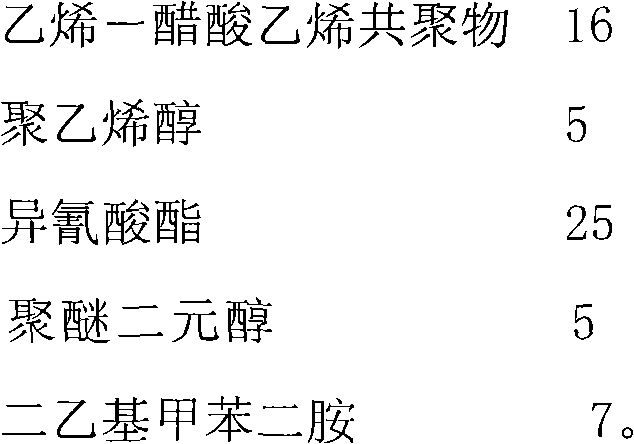

InactiveCN103046354AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberPolyvinyl alcohol

The invention relates to an internal coating technology for a woven bag. The internal coating technology for the woven bag comprises the following steps: weaving warps and wefts made of fiber materials into a cylindrical fiber woven layer on a circular weaving machine; spraying coating prepared on site on the inner side of the woven layer to form lining, wherein the coating comprises the following components in part by weight: 16 to 20 parts of ethylene-vinyl acetate copolymer, 5 to 15 parts of polyvinyl alcohol, 16 to 25 parts of isocyanate, 5 to 15 parts of polyether glycol and 7 to 11 parts of diethyltoluenediamine; and drying to obtain the internally coated woven bag product.

Owner:青岛天鹅新材料织造有限公司

High voltage switch aluminium casing friction powder-spraying coating technique

InactiveCN101234376AContinuous coatingUniform coatingPretreated surfacesCoatingsHigh pressureRubbing

The invention relates to a rubbing, dusting and coating process of high pressure switch aluminum shell, the process is characterized in that the process is a technique which completes the coating of the aluminum shell of the high pressure switch products by utilizing the method of rubbing and dusting. The rubbing, dusting and coating process can replace the general paint coating technique, so the thickness of the primary coating film is increased, the coating processing cycle is shortened in double, the release of the volatiles (VOC) in the process of paint coating is reduced and even stopped and the environmental pollution is reduced.

Owner:CHINT ELECTRIC

Rebar powder coating and production technology thereof

InactiveCN109181501AWith continuous coatingImprove economyAnti-corrosive paintsPowdery paintsEpoxyCross-link

The invention discloses a rebar powder coating and a production technology thereof and relates to the field of coatings. The rebar powder coating is used for solving the problems of thicker coating layer, incapability of continuously coating and long curing time of the coatings in the prior art. The rebar powder coating comprises the following components in parts by weight: 56-84 wt% of film forming matter, 5-20 wt% of cross-linking agent, 0.5-1.0 wt% of accelerant and 10-26 wt% of modified filler; the film forming matter includes at least two of polyester resin, novolac epoxy and acrylic resin; the cross-linking agent includes any one of polytetrafluoroethylene and C6; the accelerant includes any one of triphenylphosphonium bromide and methyltriphenylphosp; the modified filler includes any one of wollastonite and calcium carbonate. The rebar powder coating has the advantages of thin coating layer, continuous coating, short curing time, high adhesion and suitability for coating of high-temperature fast curing rebar, has a certain economic effect and social effect and is simple in production process.

Owner:厦门唯丽固新材料科技有限公司

Flow for coating polyether glycol composition inside woven bag

InactiveCN102978951AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberPolymer science

The invention provides a flow for coating a polyether glycol composition inside a woven bag, comprising the following steps of: firstly, weaving warps and wefts made of fiber materials into a cylindrical fiber woven layer on a circular weaving machine; then spraying a coating which is prepared in the field at the inner side of a woven layer to form a lining, wherein the coating comprises the following components in parts by mass: 16-20 parts of ethylene-vinyl acetate copolymer, 16-25 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 26-35 parts of polyether glycol and 7-11 parts of diethyl methyl benzene diamine; and drying to obtain an internally sprayed woven bag product.

Owner:QINGDAO PENGHAI SOFT CO LTD

Woven bag coating method

InactiveCN102978942AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberPolyvinyl alcohol

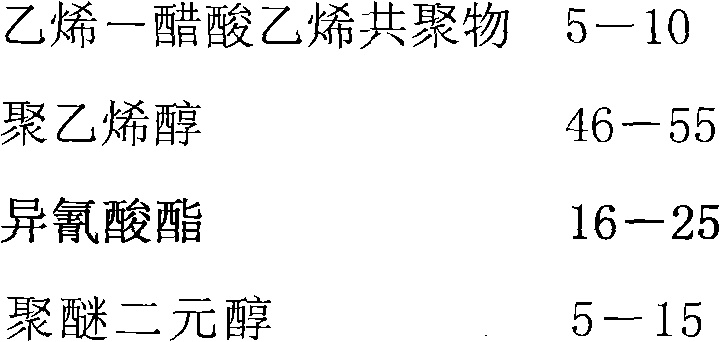

The invention provides a woven bag coating method. The method comprises the steps of firstly weaving warps and wefts, which are made of fiber materials, to prepare a tubular fiber woven layer on a circular weaving machine, then spraying a coating prepared on site on the inner side of the woven layer to form a lining and obtaining the internally sprayed woven bag product after drying, wherein the coating comprises the following components in parts by weight: 11-15 parts of ethylene-vinyl acetate copolymers, 46-55 parts of polyvinyl alcohol, 10-14 parts of isocyanate, 5-15 parts of polyether diol and 5-12 parts of diethyltoluenediamine.

Owner:QINGDAO BAIZHONG CHEM TECH

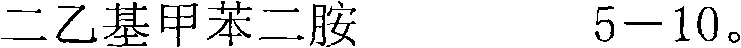

Method for coating woven bag

The invention discloses a method for coating a woven bag. The method comprises the following steps of: weaving warps and wefts made of a fiber material into a cylindrical fiber woven layer on a circular weaving machine; spraying a coating prepared in situ onto the inner side of the woven layer to form an inner lining, wherein the coating comprises the following components in parts by mass: 5-10 parts of ethylene-vinyl acetate copolymer, 5-15 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-10 parts of polyether glycol and 5-10 parts of diethyl methyl benzene diamine; and drying to obtain an internally-sprayed woven bag product.

Owner:QINGDAO BAIZHONG CHEM TECH

Evaporation Device

InactiveUS20210332471A1Increase productivityReduce maintenance timeVacuum evaporation coatingSputtering coatingPhysicsEngineering

An evaporation device includes a primary chamber and two or more secondary chambers at both sides of the primary chamber. The secondary chamber is configured to supply the disposition material in a disposition process. One or more of the secondary chambers serve as an alternative disposition source. When the disposition material in one or more of the secondary chambers is nearly empty, the alternative disposition source in the other secondary chamber starts to operate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Polymeric mineral joint mixture for engine containment ring and preparation method of polymeric mineral joint mixture

ActiveCN112480787ASuitable bonding strengthUniform coatingFireproof paintsLiquid surface applicatorsGlass fiberPolymer science

The invention discloses a room-temperature curing type polymerized mineral joint mixture for an engine containment ring, and the mixture comprises a surface adhesive and a bottom adhesive, wherein thesurface adhesive is a putty-like material composed of a two-component material, and the component A is composed of bisphenol A epoxy resin, nitrile butadiene rubber and aluminum oxide; the componentB is prepared from polyamide resin, aliphatic amine, a silane coupling agent and glass fiber powder; the mass ratio of the component A to the component B is 2: 1-2.5: 1; the primer is a C and D double-component material, and the C component is composed of bisphenol A type epoxy resin and nitrile butadiene rubber; the component D is prepared from polyamide resin, aliphatic amine and a silane coupling agent; and the mass ratio of the component C to the component D of the primer is 1.5: 2-2: 1. The protective material has proper bonding strength, can be used for the inner surface of an accommodating ring of an engine fan casing, and is suitable for the working temperature of -60 to 120 DEG C.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Inner coating technology of woven bag

InactiveCN102965949AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberMethyl benzene

The invention provides an inner coating technology of a woven bag. The inner coating technology comprises the following steps: weaving wraps and wefts, which are made of fiber materials, through a circular weaving machine, so as to obtain a cylindrical fiber woven layer; spraying the coating prepared at site on the inner side of the woven layer to form a liner, wherein the coating comprises the following components (mass): 5 to 10 parts of ethylene-vinyl acetate copolymer, 5 to 15 parts of polyving akohol, 16 to 25 parts of isocyanate, 36 to 45 parts of polyether glycol, and 5 to 10 parts of diethyl methyl benzene diamine; and drying, thus obtaining the inner-coated woven bag.

Owner:QINGDAO VLAND BIOTECH GRP

Woven bag coating method

InactiveCN102978919AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberPolyvinyl alcohol

The invention provides a woven bag coating method. The method comprises the steps of firstly weaving warps and wefts, which are made of fiber materials, to prepare a tubular fiber woven layer on a circular weaving machine, then spraying a coating prepared on site on the inner side of the woven layer to form a lining and obtaining the internally sprayed woven bag product after drying, wherein the coating comprises the following components in parts by weight: 11-15 parts of ethylene-vinyl acetate copolymers, 5-15 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-15 parts of polyether diol and 5-10 parts of diethyltoluenediamine.

Owner:QINGDAO BAIZHONG CHEM TECH

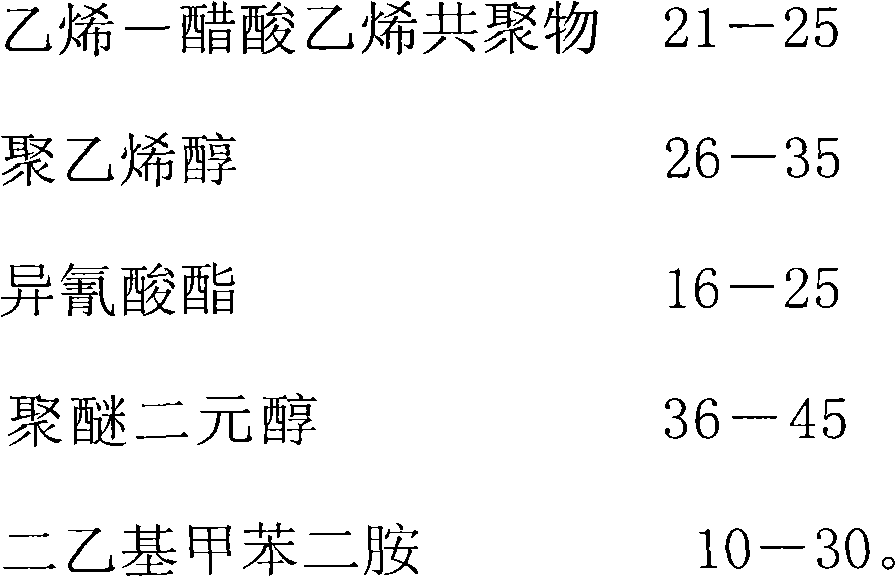

Process for coating inside woven bag

InactiveCN103266487AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberMethyl benzene

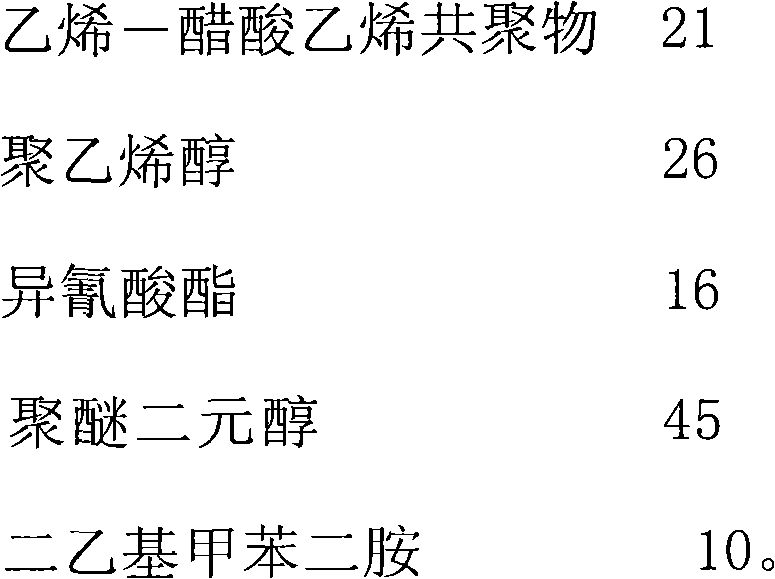

The invention discloses a process for coating inside a woven bag. The process comprises the following steps: firstly, weaving warps and wefts made of fiber materials into a cylindrical fiber braid on a circular weaving machine; then spraying a coating prepared on site on the inner side of the braid to form a liner, wherein the coating comprises the following components in parts by mass: 21-25 parts of ethylene-vinyl acetate copolymer, 26-35 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 16-25 parts of polyether glycol and 10-30 parts of diethyl methyl benzene diamine; and drying to obtain the woven bag which is inside coated with the coating.

Owner:卜迪迪

Technology for coating inside woven bag

InactiveCN102978949AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberPolymer science

The invention discloses a technology for coating inside a woven bag. The technology comprises the following steps of: firstly, weaving a cylindrical fiber woven layer by using warps and wefts, both of which are made of fiber materials, on a circular weaving machine, then, spraying the coating prepared on site to the inner side of the woven layer to form a liner, and drying to obtain an inside-sprayed woven bag product, wherein the coating comprises the following components in parts by weight: 21-25 parts of ethylene-vinyl acetate copolymer, 26-35 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 36-45 parts of polyether glycol, and 10-30 parts of diethyl toluenediamine.

Owner:QINGDAO PENGHAI SOFT CO LTD

Coating method of woven bag

The invention provides a coating method of a woven bag. The method comprises the following steps of: weaving warps and wefts made of fibrous material into a cylindrical fibrous braid on a circular weaving machine; then spraying coatings which are prepared on site on the inside of the braid to form a liner, wherein the coatings comprise the following components in parts by mass: 11-15 parts of ethylene-vinyl acetate copolymer, 36-45 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-15 parts of polyether glycol, and 5-12 parts of diethyl methyl benzene diamine; and then drying to obtain an inner sprayed woven bag product.

Owner:QINGDAO BAIZHONG CHEM TECH

Coating technology for inner part of woven bag

InactiveCN103046371AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberPolyvinyl alcohol

A coating technology for the inner part of a woven bag comprises the following steps: first, weaving warps and wefts, which are made of fiber materials on a circular weaving machine, into a tube-shaped fiber weaving layer; then, spraying paint on the spot is sprayed on the inner side of the weaving layer to form a lining, wherein the paint comprises the following components in part by weight: 26 to 30 parts of ethylene-vinyl acetate copolymer, 46 to 55 parts of polyvinyl alcohol, 16 to 25 parts of isocyanate, 26 to 35 parts of polyether glycol, and 10 to 30 parts of diethyltoluenediamine; and after the lining is dried, obtaining a woven bag product with the spray-coated inner part.

Owner:QINGDAO SHENGHAN CHROMATOGRAPH TECH CO LTD

Internal coating method for woven bags

InactiveCN103046369AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberAdditive ingredient

The invention relates to an internal coating method for woven bags. The method comprises the following steps: weaving warp and weft made of fiber materials into a tubular fiber woven layer on a circular weaving machine, then coating paint prepared on site onto the inner side of the woven layer to form a lining, and finally drying to obtain the inner-coating woven bag product. The pain comprises the following ingredients in part by weight (shown as the specifications).

Owner:QINGDAO SEACON WATER SERVICE TECH

Process for coating inside woven bag

InactiveCN102995442AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberMethyl benzene

The invention discloses a process for coating inside a woven bag. The process comprises the following steps of: firstly, weaving warps and wefts made of fiber materials into a cylindrical fiber braid on a circular weaving machine; then spraying a coating prepared on site on the inner side of the braid to form a liner, wherein the coating comprises the following components in parts by mass: 16-20 parts of ethylene-vinyl acetate copolymer, 16-25 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 5-15 parts of polyether glycol and 7-11 parts of diethyl methyl benzene diamine; and drying to obtain the woven bag the inside of which is coated with the coating.

Owner:青岛天鹅新材料织造有限公司

Woven bag coating method

InactiveCN102978941AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberPolyvinyl alcohol

The invention provides a woven bag coating method. The method comprises the steps of firstly weaving warps and wefts, which are made of fiber materials, to prepare a tubular fiber woven layer on a circular weaving machine, then spraying a coating prepared on site on the inner side of the woven layer to form a lining and obtaining the internally sprayed woven bag product after drying, wherein the coating comprises the following components in parts by weight: 11-15 parts of ethylene-vinyl acetate copolymers, 16-25 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-15 parts of polyether diol and 5-12 parts of diethyltoluenediamine.

Owner:QINGDAO BAIZHONG CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com