Automatic film coating system and method for precious metal coins

A coating system and precious metal coin technology, applied in metal material coating process, superimposed layer coating, coating, etc., can solve the problems of low coating efficiency and poor consistency, achieve continuous coating, improve efficiency, and reduce manual intervention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

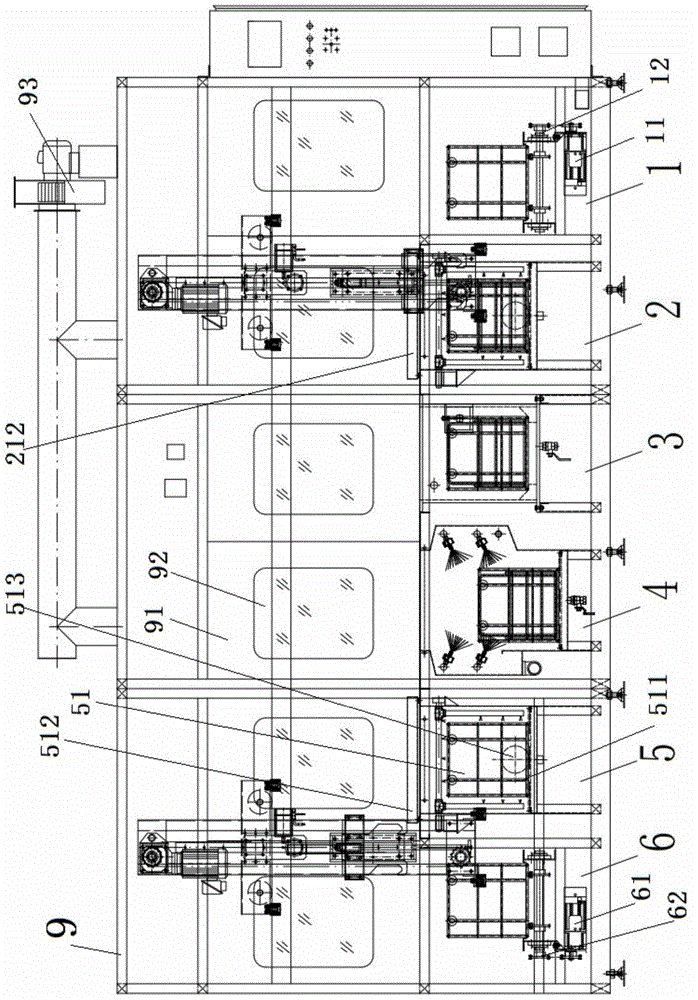

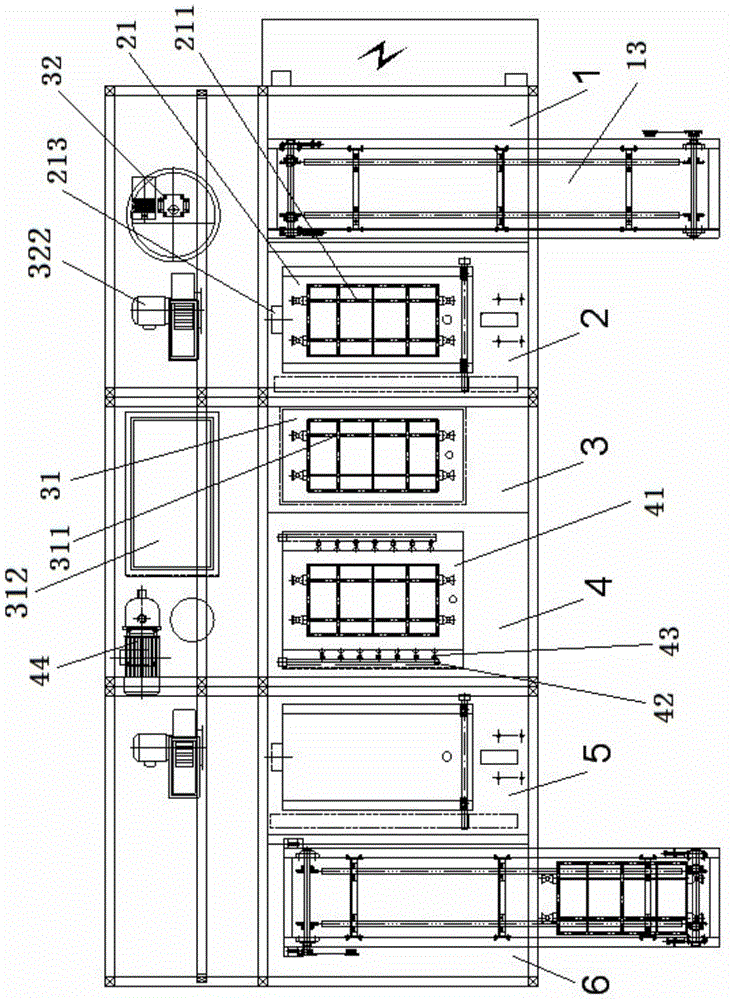

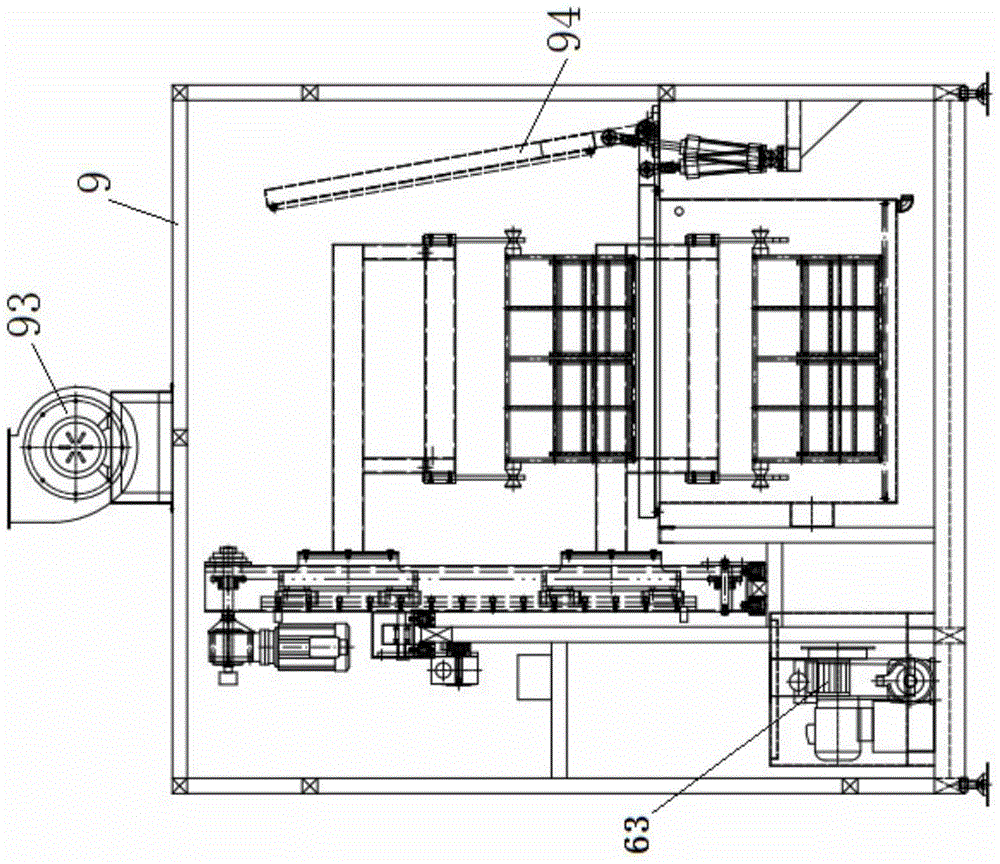

[0033] Such as Figure 1-3 Shown is an automatic production line for precious metal coin coating, which includes a production line main body 9 and sequentially connected feeding assembly 1, dust blowing assembly 2, coating assembly 3, dipping and spraying assembly 4, drying assembly 5 and unloading assembly 6, The main body of the production line includes a loading station, a dust blowing station, a coating station, a dipping and spraying station, a drying station and a blanking station, which are respectively used to place the feeding assembly, dust blowing assembly, Coating assembly, dipping and spraying assembly, drying assembly and unloading assembly, the main body of the production line is also equipped with a manipulator control device for picking and placing the washing basket containing precious metal coins to a predetermined station; wherein:

[0034] Such as Figure 1-3 As shown, the main body 9 of the production line includes a feeding station, a dust blowing stati...

Embodiment 2

[0049] Such as Figure 8 As shown, the precious metal coin automatic coating method of this embodiment adopts the precious metal coin automatic coating system as described above, including the following steps:

[0050] Loading, that is, placing the washing basket containing precious metal coins at the predetermined station by the robot, and then transporting it to the dust blowing station.

[0051] Dust blowing, air blowing at the dust blowing station, and then transported to the coating station. The dust blowing step uses compressed air filtered by a high-efficiency filter, and the filtration accuracy is preferably about 1 μm.

[0052] Coating, at the coating station, the coating is soaked in the coating solution, and then transported to the dipping and spraying station. The coating step also preferably includes an automatic dosing step, which includes the following sub-steps: pH value detection; when it is detected that the pH value of the coating solution exceeds a preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com