Patents

Literature

44results about How to "Realize automatic coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

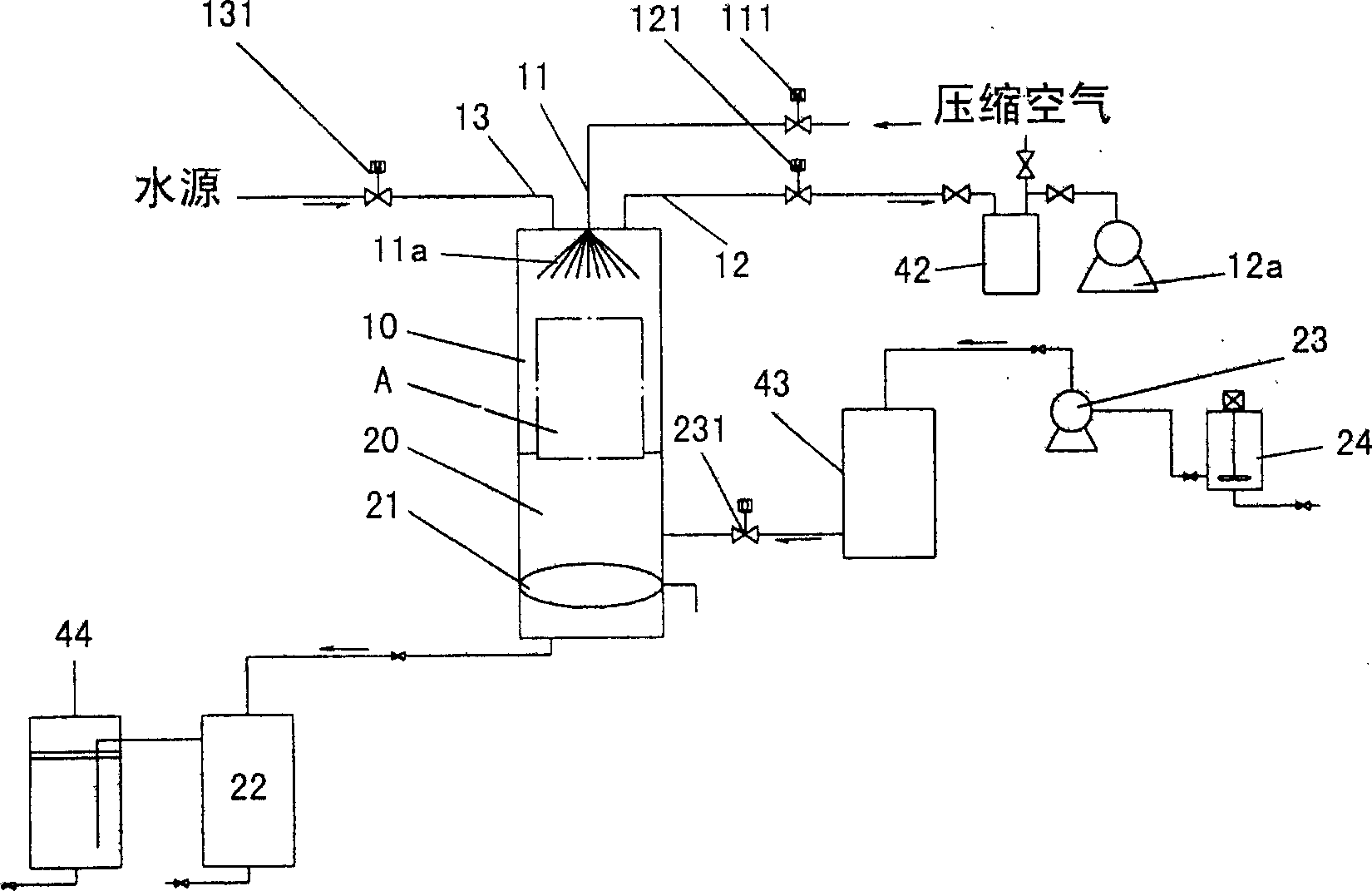

Method and equipment for coating slurry layer on cellular carrier of ceramics

InactiveCN1660508AImprove efficiencyControl thicknessLiquid surface applicatorsCoatingsAutomatic controlPositive pressure

A process for coating the slurry on the surface of cellular ceramic carrier inclues such steps as arranging the cellular ceramic carrier to a particular working position by automatic fixture, sealing it, delivering the slurry via tube, negative-pressure coating, and positive-pressure scavenge to remove excessive slurry.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

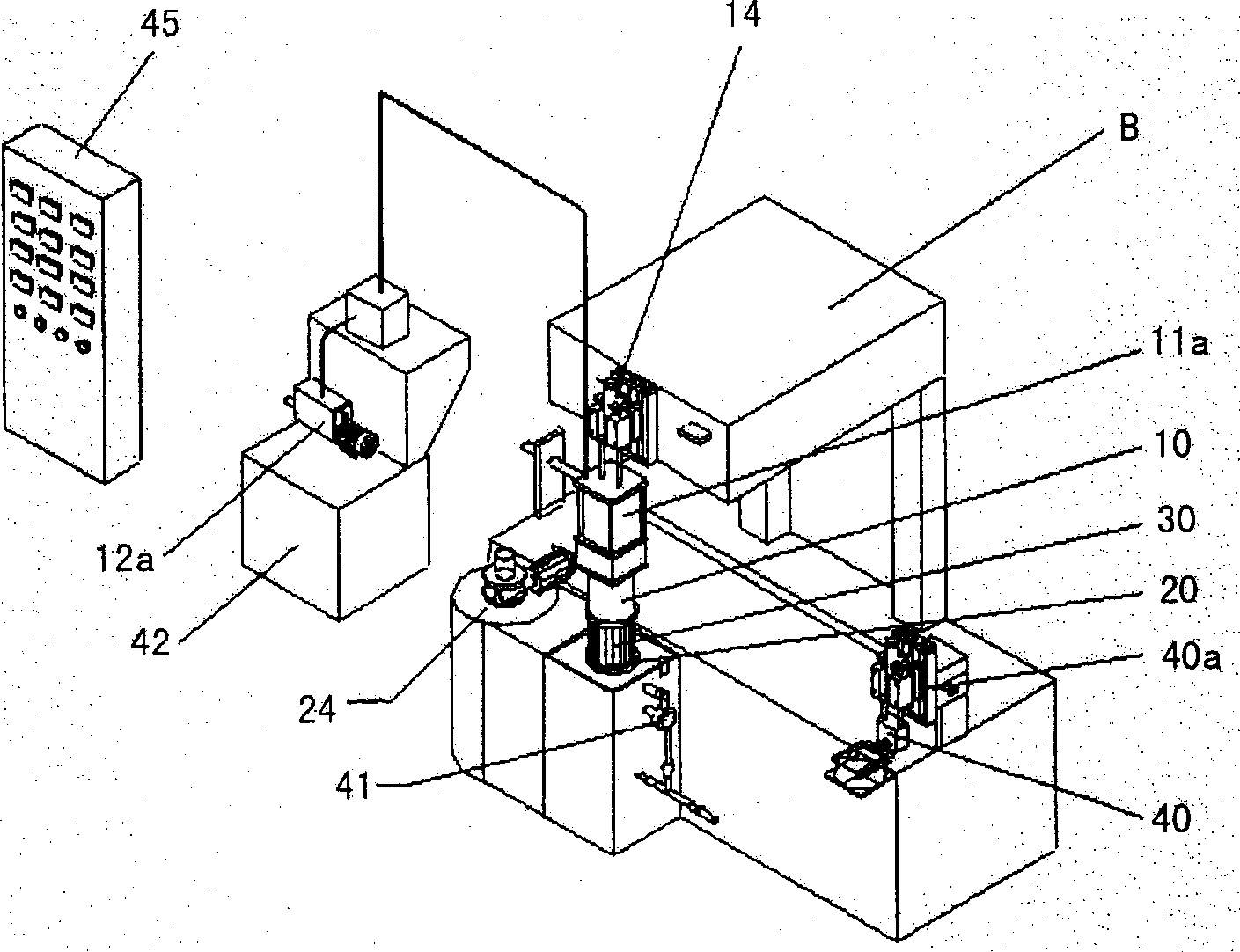

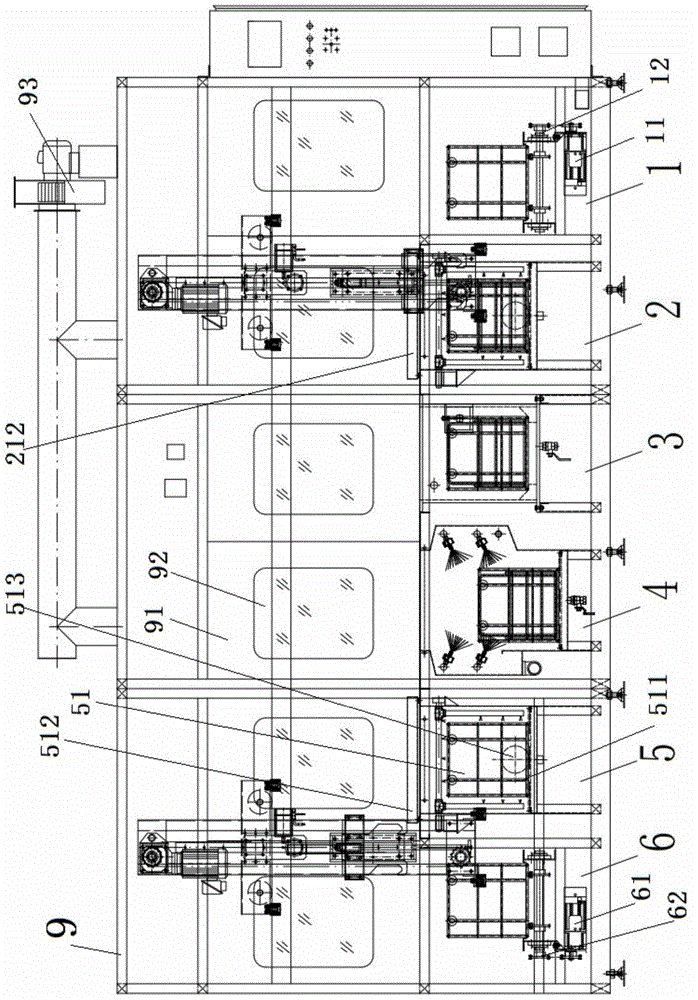

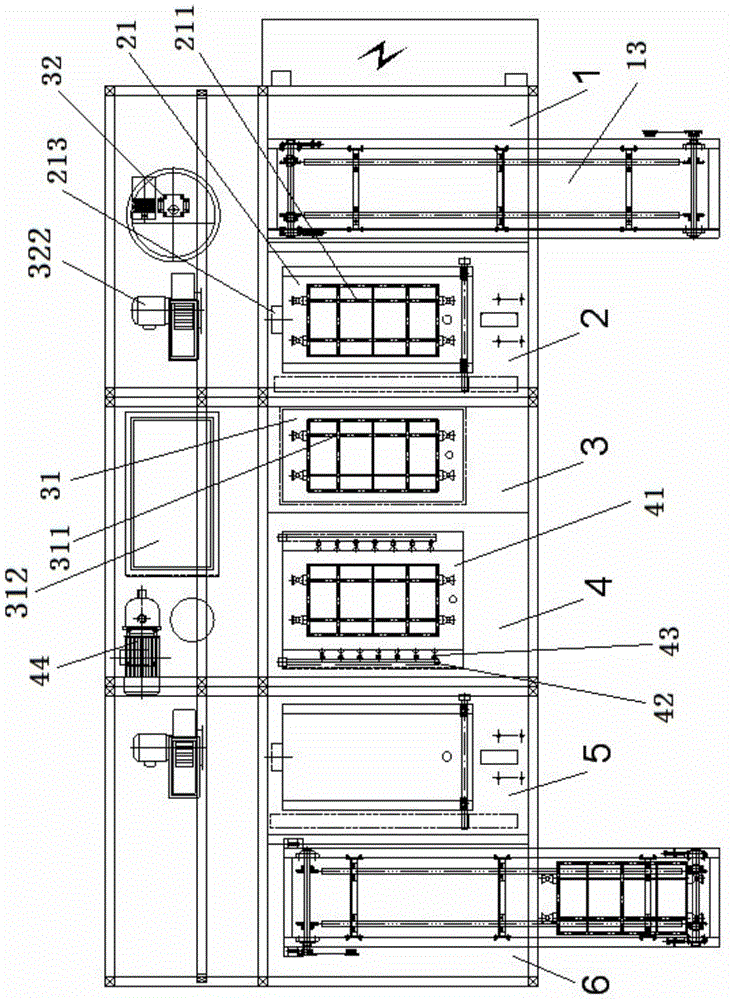

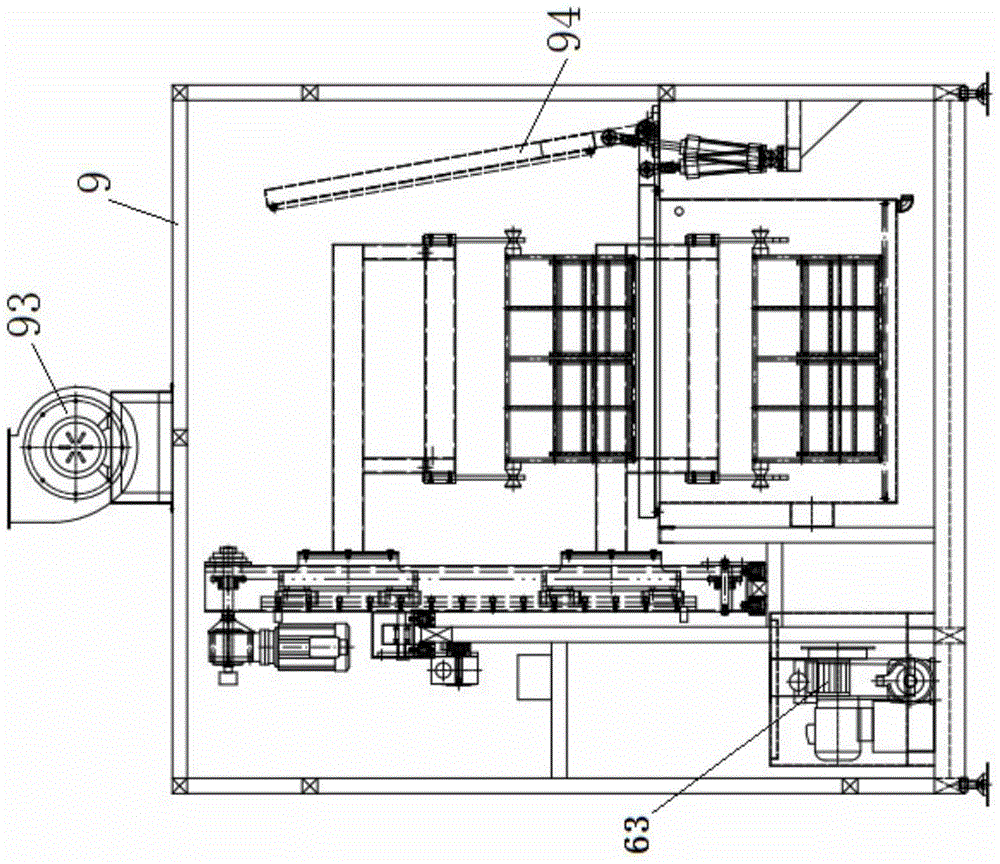

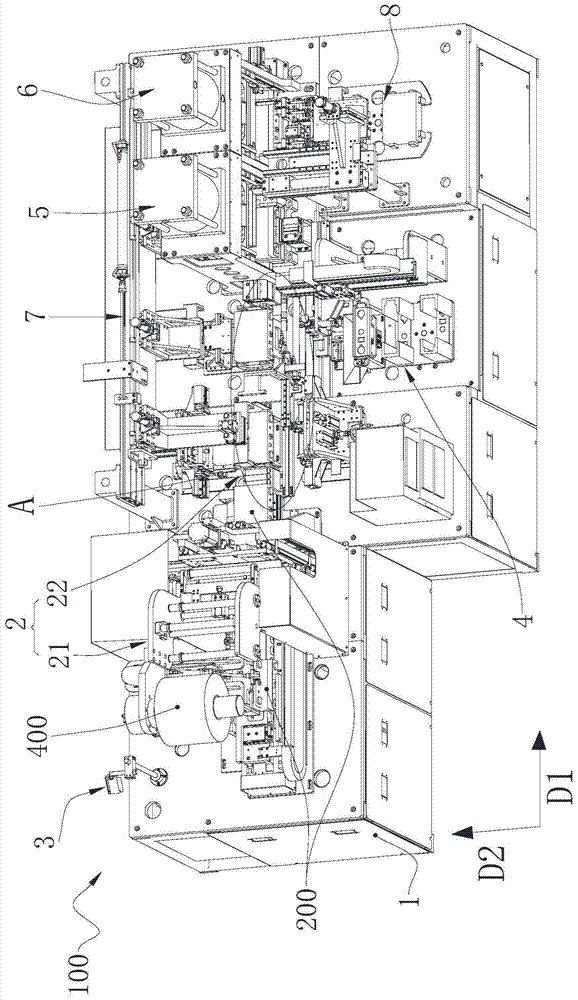

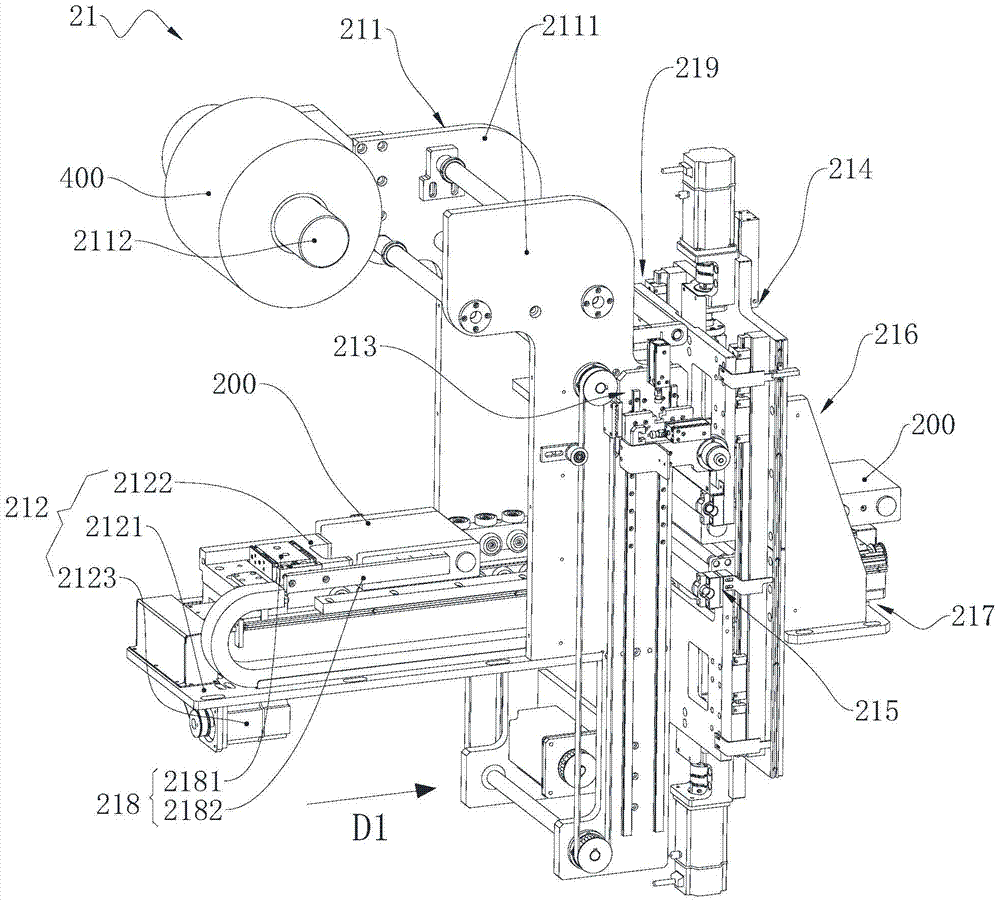

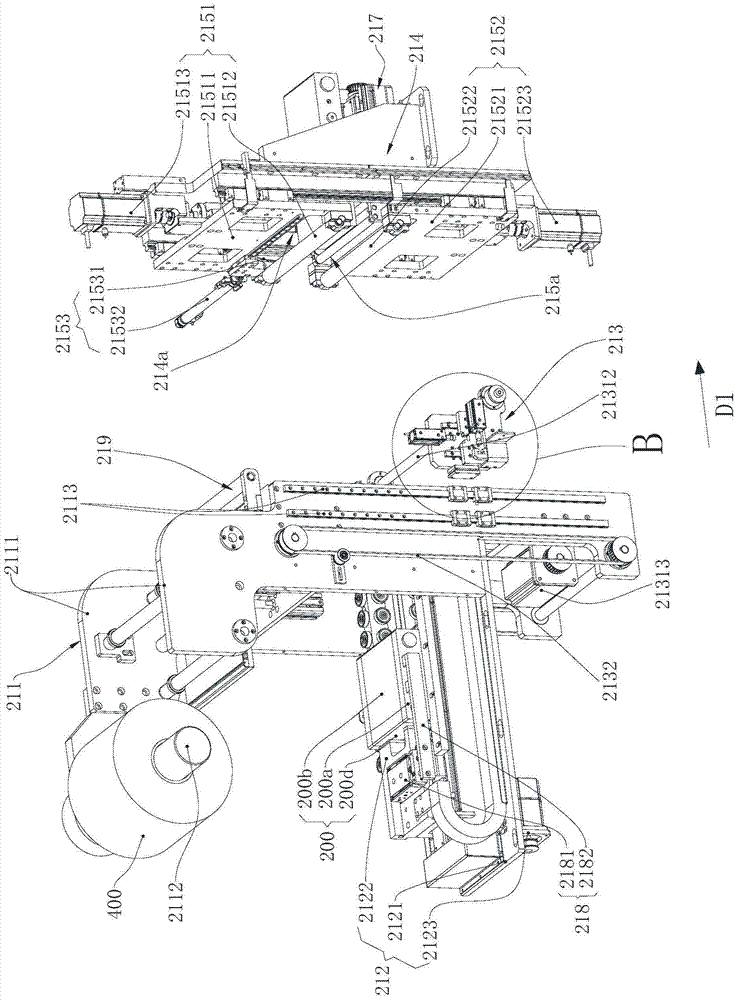

Automatic film coating system and method for precious metal coins

InactiveCN104451845ARealize automatic coatingReduce manual interventionSuperimposed coating processProduction lineEngineering

The invention discloses an automatic film coating system and an automatic film coating method for precious metal coins. The automatic film coating system comprises a production line main body as well as a loading assembly, a dust blowing assembly, a film coating assembly, a rinsing-spraying assembly, a blow-drying assembly and an unloading assembly which are sequentially connected, wherein the loading assembly is used for loading; the dust blowing assembly is used for blowing dust; the film coating assembly is used for coating the surfaces of the precious metal coins with films; the rinsing-spraying assembly is used for carrying out rinsing and spraying after the film coating; the blow-drying assembly is used for removing moisture; the unloading assembly is used for unloading; the production line main body is further provided with a mechanical arm control device which is used for placing a cleaning basket accommodating the precious metal coins to a preset station. According to the automatic film coating system and the automatic film coating method, by virtue of the loading assembly, the dust blowing assembly, the film coating assembly, the rinsing-spraying assembly, the blow-drying assembly and the unloading assembly which are sequentially connected, the automatic film coating of the precious metal coins can be realized, and manual intervention is reduced, so that the inconsistency of the film coating caused by the manual operation can be avoided, meanwhile, the continuous film coating is achieved, and the efficiency is increased.

Owner:SHENZHEN GUOBAO MINT

Improved structure of storage battery plate group automatic film coating machine

InactiveCN103123963ASimple structureMovement precisionElectrode manufacturing processesAgricultural engineeringFilm-coated tablet

The invention discloses an improved structure of a storage battery plate group automatic film coating machine. A separation space is arranged between a horizontal board and a back horizontal board; a battery case blanking barrel is vertically arranged at the right side of the separation space; a battery case positioning cylinder is vertically arranged right below the separation space; a plate group transmission rack is arranged at the left side of the separation space; the horizontal board and the back horizontal board are provided with plate group-into-battery case guide mechanisms for guiding plate groups, which are arranged at the front side and back side of the separation space; the back side of the horizontal board is provided with a transverse film cut-off clearance; the horizontal board is provided with a cut-off knife moving mechanism which is arranged below the film cut-off clearance and is provided with a cut-off knife; a plate group output rail is arranged below the back horizontal board; a plate group output cylinder is arranged below the horizontal board; and a piston rod of the plate group output cylinder is connected with a push board. The storage battery plate group automatic film coating machine disclosed by the invention is simple in structure and accurate in movement, realizes the automatic film coating of storage battery plate groups, lowers the labor intensity and improves the film coating efficiency.

Owner:赵芳

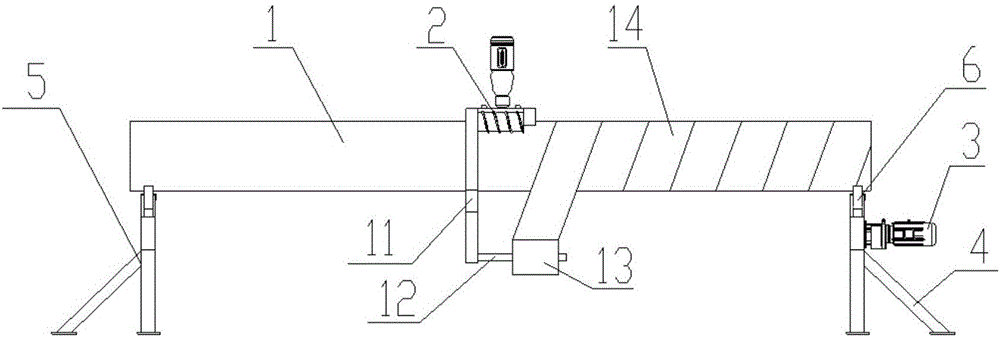

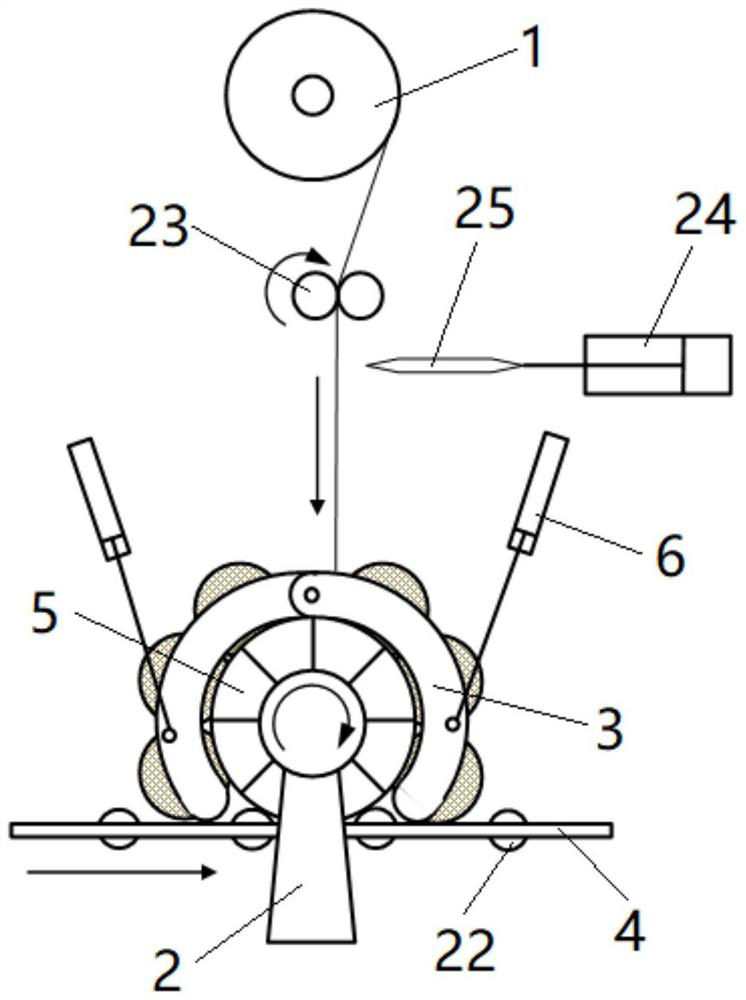

Film wrapping machine

The invention relates to a film wrapping machine which comprises a pipe, a film covering component and a motor. A first support and a second support are arranged on two sides of the lower end of the pipe respectively, a flat roller is arranged at the upper end of each of the first support and the second support, and each of the first support and the second support supports the pipe to roll through the flat rollers; the film covering component is movably arranged at the upper end of the pipe, the motor is arranged on the first support, and an output shaft of the motor drives the flat roller on the first support to rotate. Compared with the prior art, the film wrapping machine has the advantages of small size, convenience in moving and simplicity in operation.

Owner:LIUZHOU YUHUA TECH

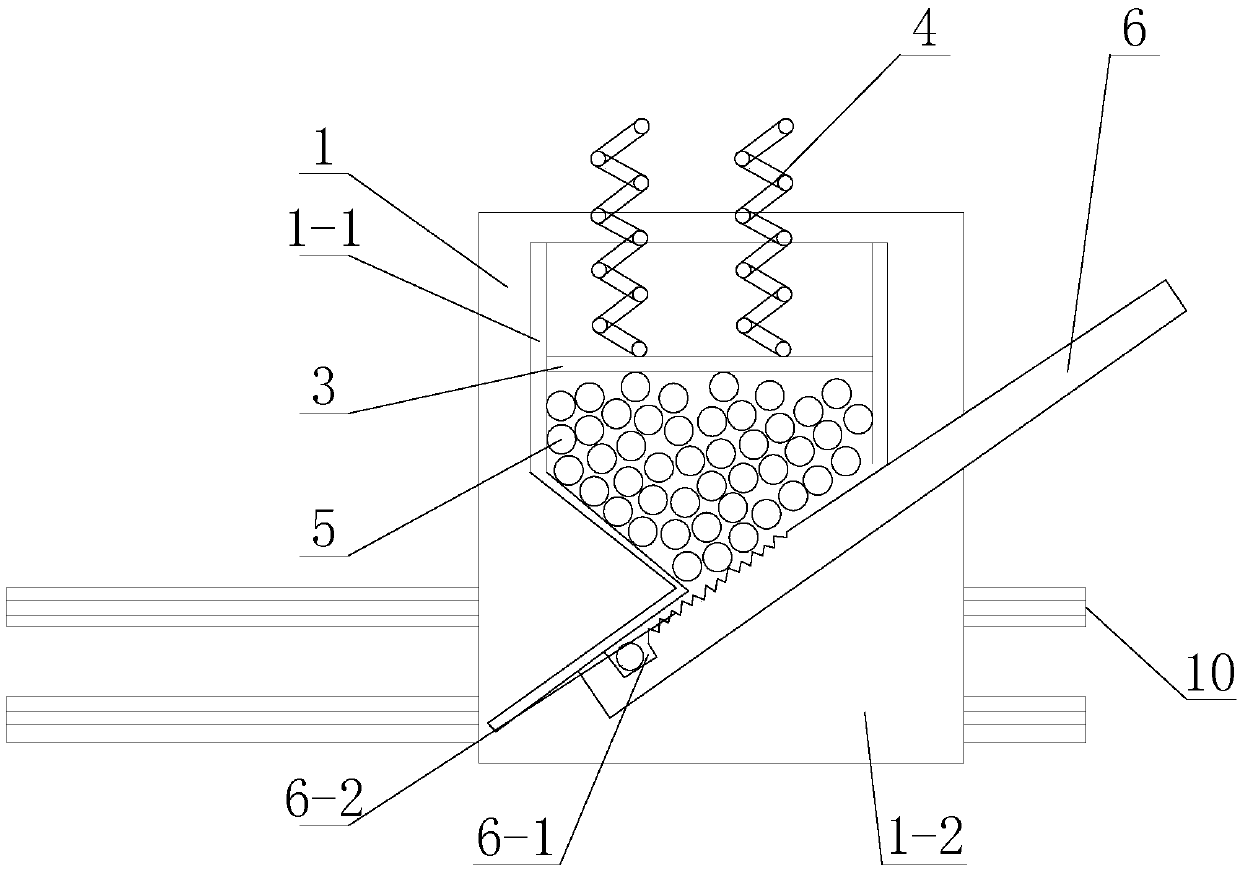

Automatic film wrapping machine film wrapping method for storage battery plate groups

ActiveCN103137998ASimple structureMovement precisionFinal product manufactureSecondary cells manufactureManipulatorEngineering

The invention discloses an automatic film wrapping machine film wrapping method for storage battery plate groups. A film conveying mechanism conveys films continuously, a film receiving mechanism receives the films, and then the films are pressed by a film pressing plate, and a cutting knife cuts across a film cutting groove to cut the films. Simultaneously, battery cases in a battery case blanking barrel are dropped on a battery case conveying slide rail one by one, and the battery cases are sent to a battery case locating air cylinder by a material pushing air cylinder. Plate groups are caught by a plate group catching mechanical hand, a vertical air cylinder and the plate group catching mechanical hand are driven by a horizontal air cylinder to horizontally move to an upward side of a separated space, then the vertical air cylinder moves downwards so that the plate groups are enabled to enter a guiding mechanism for the plate groups entering the battery cases. The plate groups are let go by the plate group catching mechanical hand, so that the plate groups and the films are enabled to enter the battery cases below the separated space, and a film wrapping movement and an entering battery cases movement are finished. When the films are wrapped, a pushing plate moves backwards so as to push the battery cases to a plate group output rail, and then the battery cases are output. By means of the automatic film wrapping machine film wrapping method for the storage battery plate groups, automatic film wrapping of the storage battery plate groups is achieved, labor intensity is relieved, and film wrapping efficiency is improved.

Owner:珠海市四海久源科技有限公司

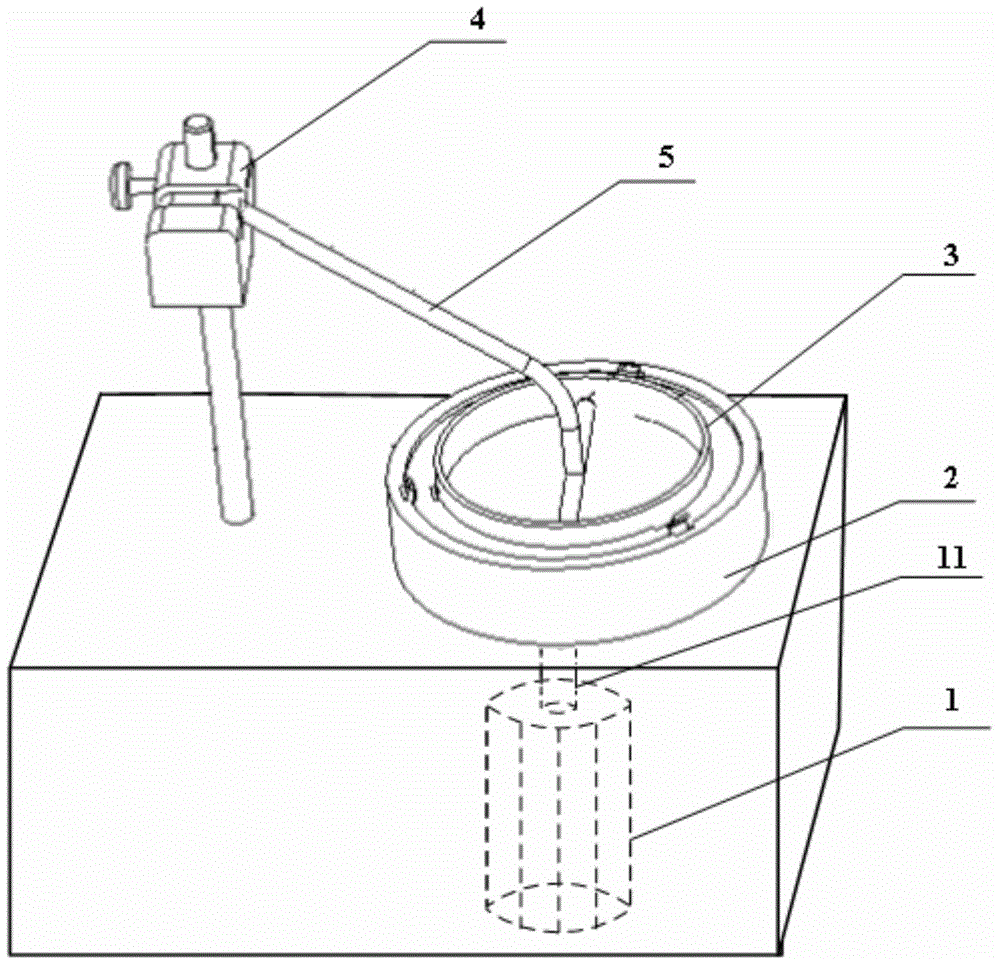

Spin coating device

InactiveCN104152343ARealize automatic coatingImprove uniformityBioreactor/fermenter combinationsBiological substance pretreatmentsLaboratory cultureMotor drive

The invention relates to the technical field of microbial instruments, and discloses a spin coating device. The spin coating device is used for coating operations of microbial culture. The spin coating device comprises a motor, a tray, a fixed mechanism and a coating bar, wherein the tray is connected with an output shaft of the motor, is used for fixing a culture dish, and is horizontally arranged; the coating bar is fixedly arranged on the fixed mechanism, and the coating end of the coating bar extends into the culture dish. By adopting the technical scheme of the spin coating device, the motor can be used for driving the tray to horizontally rotate, and the coating end of the coating bar which is fixedly arranged on the fixed mechanism extends into the culture dish; when microbial coating needs to be performed, a tester only needs to start the motor, the motor drives the tray to rotate, and the coating bar is used for coating bacterial liquid on a culture medium in the culture dish, so that the automatic coating of microorganisms can be achieved, and the coating efficiency can be greatly increased; in addition, because the culture dish rotates at a constant speed automatically, the tester does not need to coat on the culture medium back and forth by holding the coating bar in a hand, so that the coating uniformity can be increased.

Owner:北京赛智创业科技有限公司

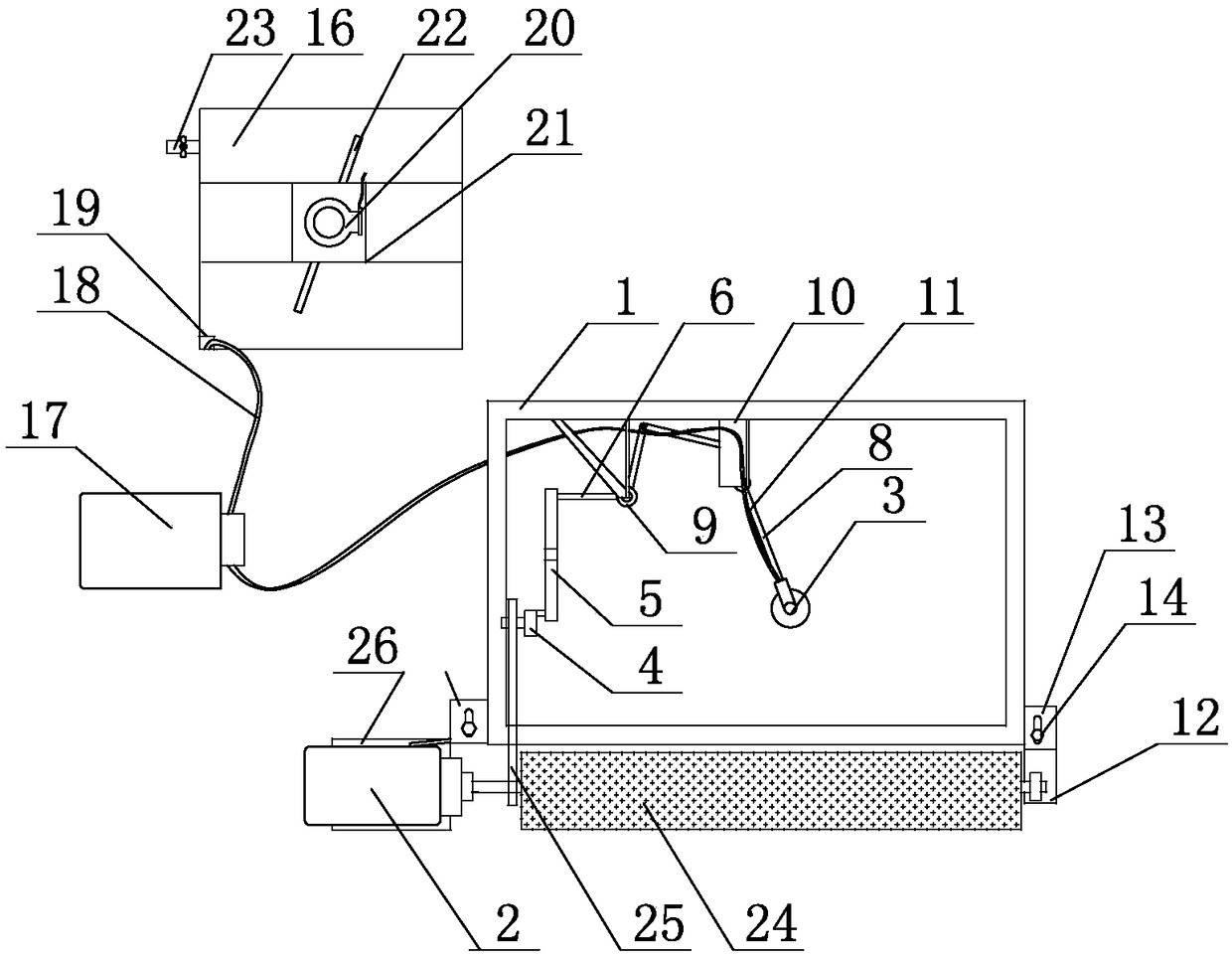

Automatic interfacial agent coating device for thermal insulation plate

InactiveCN108636691AAchieve full coverageRealize automatic coatingLiquid surface applicatorsCoatingsCouplingThermal insulation

The invention relates to a coating device, in particular to an automatic interfacial agent coating device for a thermal insulation plate. The automatic interfacial agent coating device comprises a material feeding part, a material coating part and a supporting frame; the material feeding part is used for feeding a material to the material coating part; the material coating part is supported through the supporting frame and comprises a driving motor, a material coating connection rod and a material coating brush; the material coating connection rod comprises a cranking bar, a coupling, a V-shaped rod, a connection rod and a coating rod; one end of the cranking bar is connected with a rotary shaft of the driving motor, and the other end of the cranking bar is connected with one end of the V-shaped rod through the coupling; the V-shaped rod is connected with the coating rod through the connection rod, and the inflection point position of the V-shaped rod is movably connected with the supporting frame through a connection ring; the middle of the coating rod is movably connected with the supporting frame through a connection ring; and the coating rod fixes a material coating brush and inclines downwards, and the material coating brush communicates with the feeding part through a feeding pipe. According to the automatic interfacial agent coating device for the thermal insulation plate, a groove does not need to be carved in the thermal insulation plate, the adhesion fastness is ensured while automatic coating of an interfacial agent for the thermal insulation plate is achieved, the production cost is reduced, and the production efficiency is improved.

Owner:崔致需

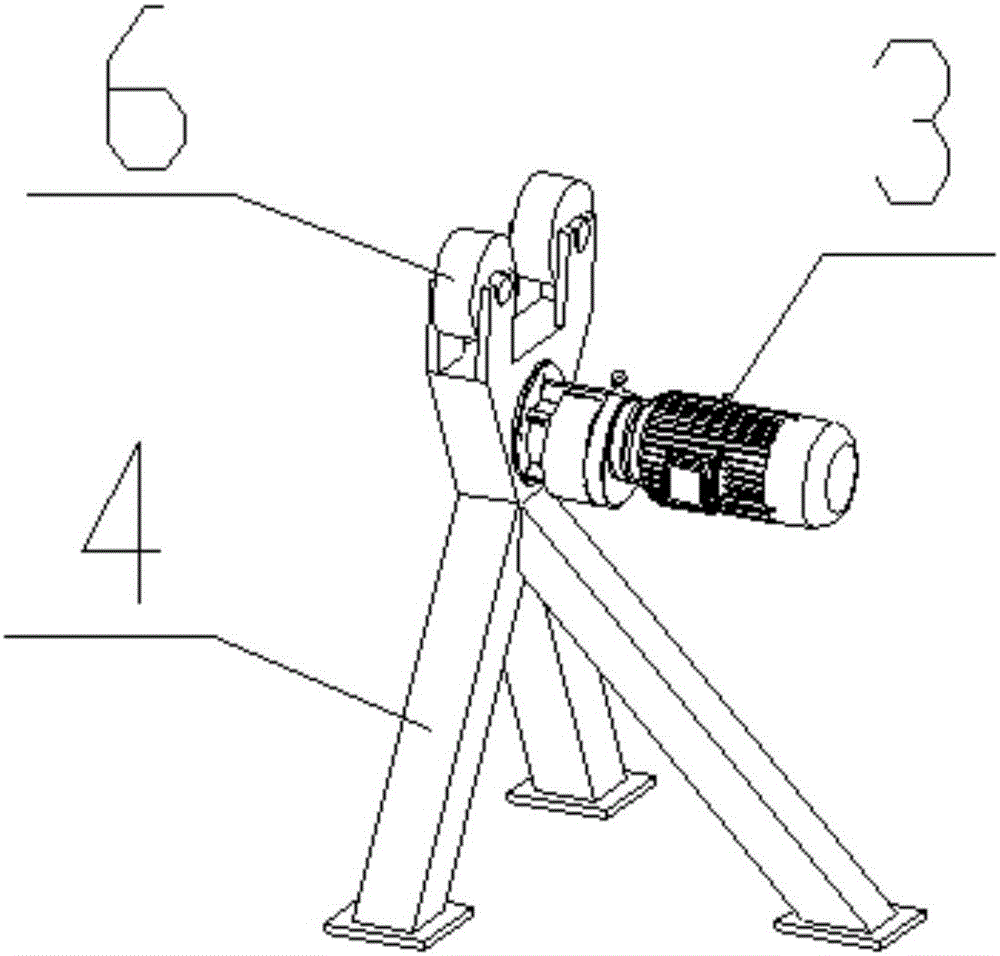

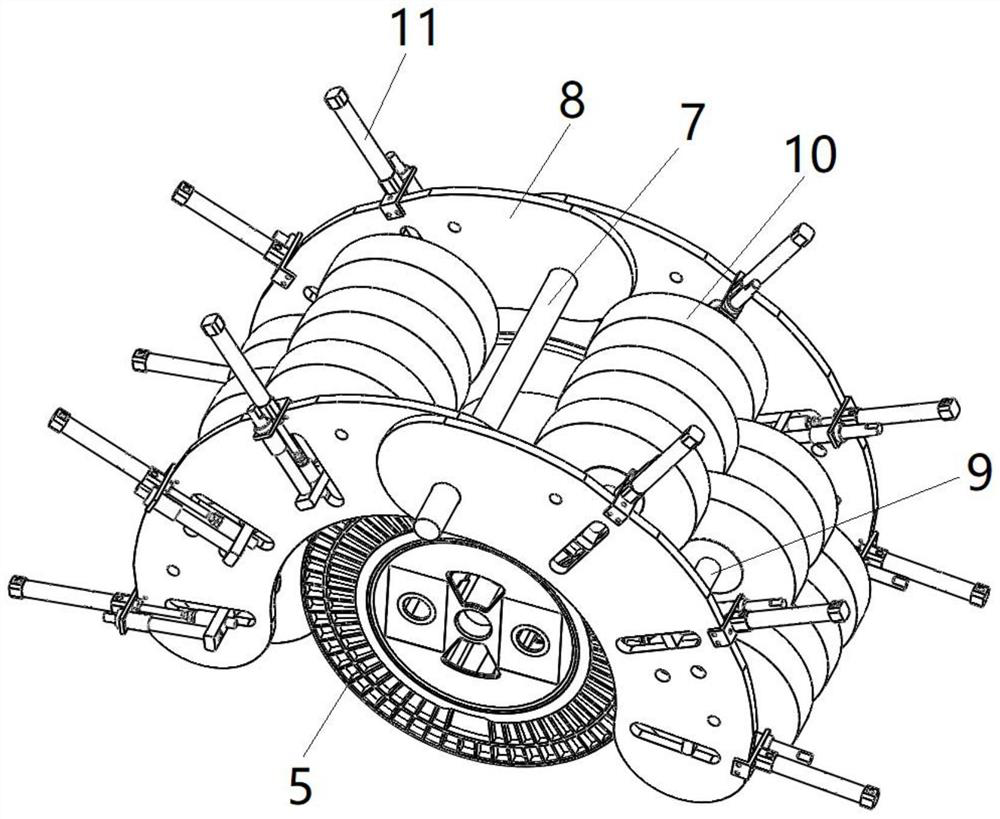

Rotatable automatic enameller

The invention provides a rotatable automatic enameller. The rotatable automatic enameller comprises an underframe, a rotatable frame, a motor used for driving the rotatable frame to rotate, and an enamel spraying device, wherein a support used for supporting the rotatable frame is arranged on the underframe; the rotatable frame is movably connected with support; the rotatable support comprises a rotatable shaft, a plurality of ratchet and I-shaped frames; the ratchetes are arranged surrounding the rotatable shaft uniformly; one end of each ratchet is fixed onto the rotatable shaft; the other end of each ratchet is connected with each I-shaped frame; the enamel spraying device is fixed onto the underframe, and comprises an enamel box, a pump, and a plurality of spraying pipes; the inlet of the pump is communicated with the enamel box; the output of the pump is communicated with the spraying pipes. The rotatable automatic enameller can realize automatic enameling of workblanks, and can effectively increase enameling of the workblanks by separating uploading and blanking for the I-shaped frames through the rotatable I-shaped frames.

Owner:简厚诚

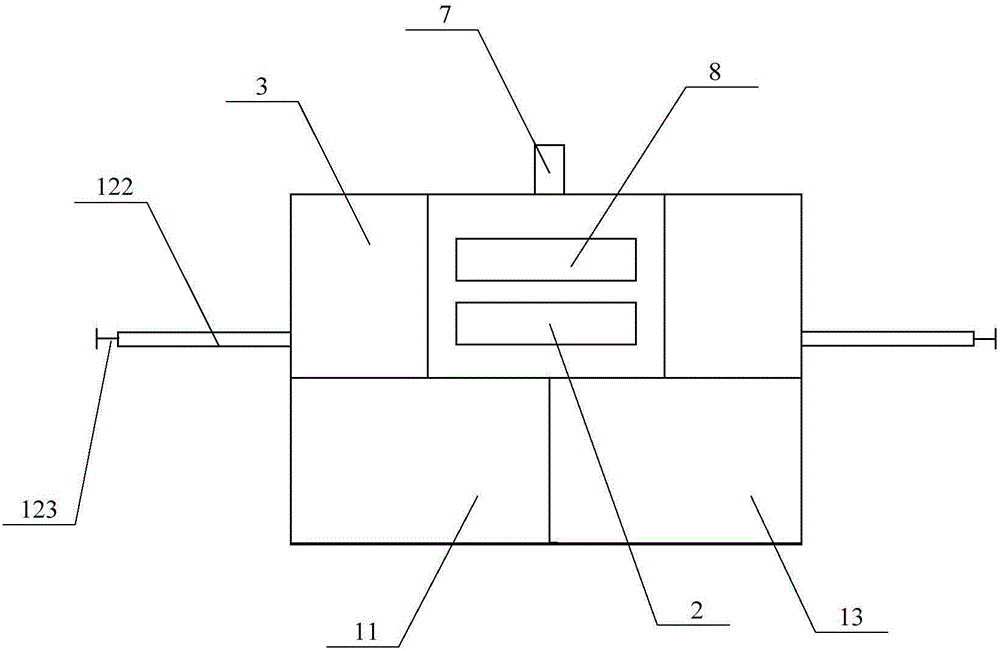

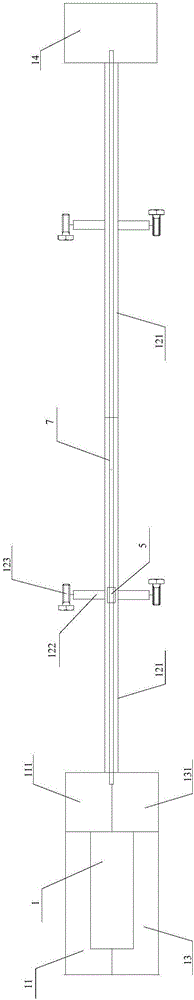

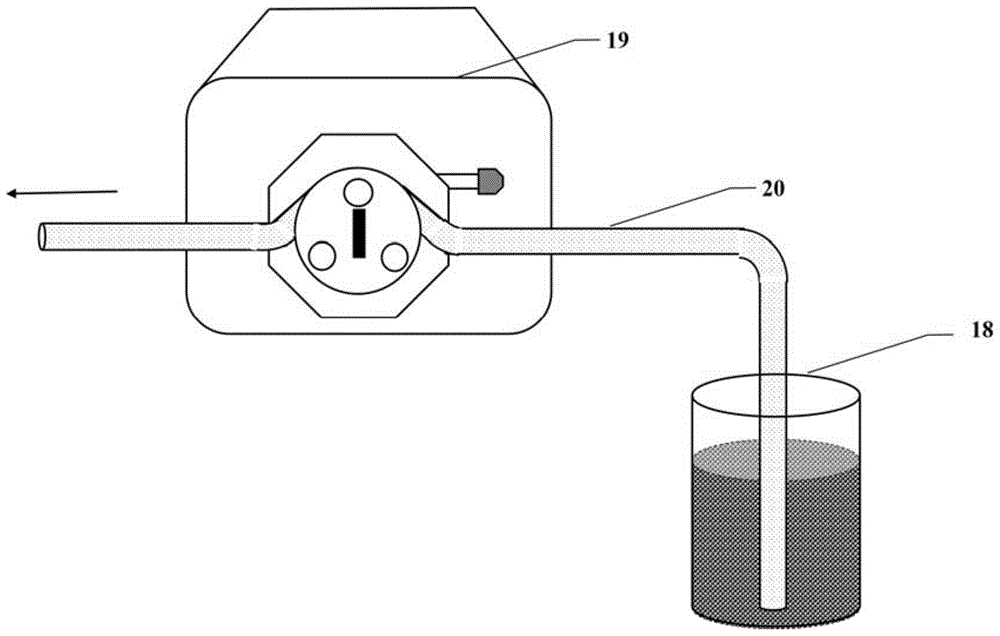

Automatic mantle applying mechanism for ultrasonic probe

ActiveCN107397559AImprove convenienceRealize automatic coatingUltrasonic/sonic/infrasonic diagnosticsSurgical furniturePhysicsEngineering

Owner:WUXI PEOPLES HOSPITAL

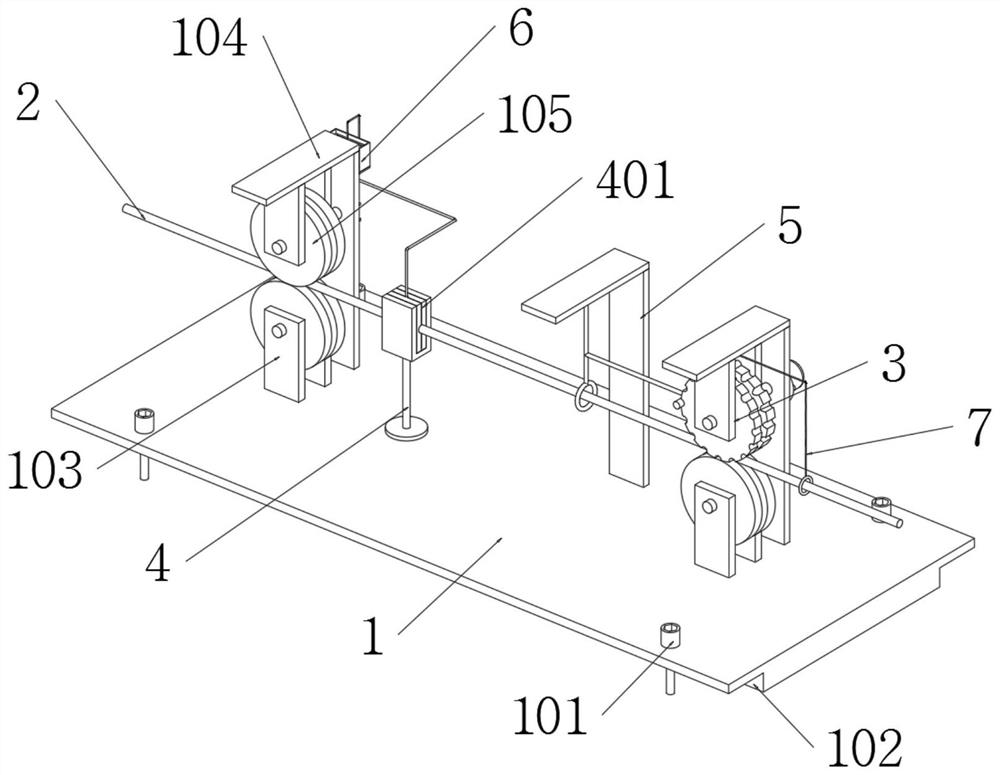

Automatic coating apparatus and operation method thereof

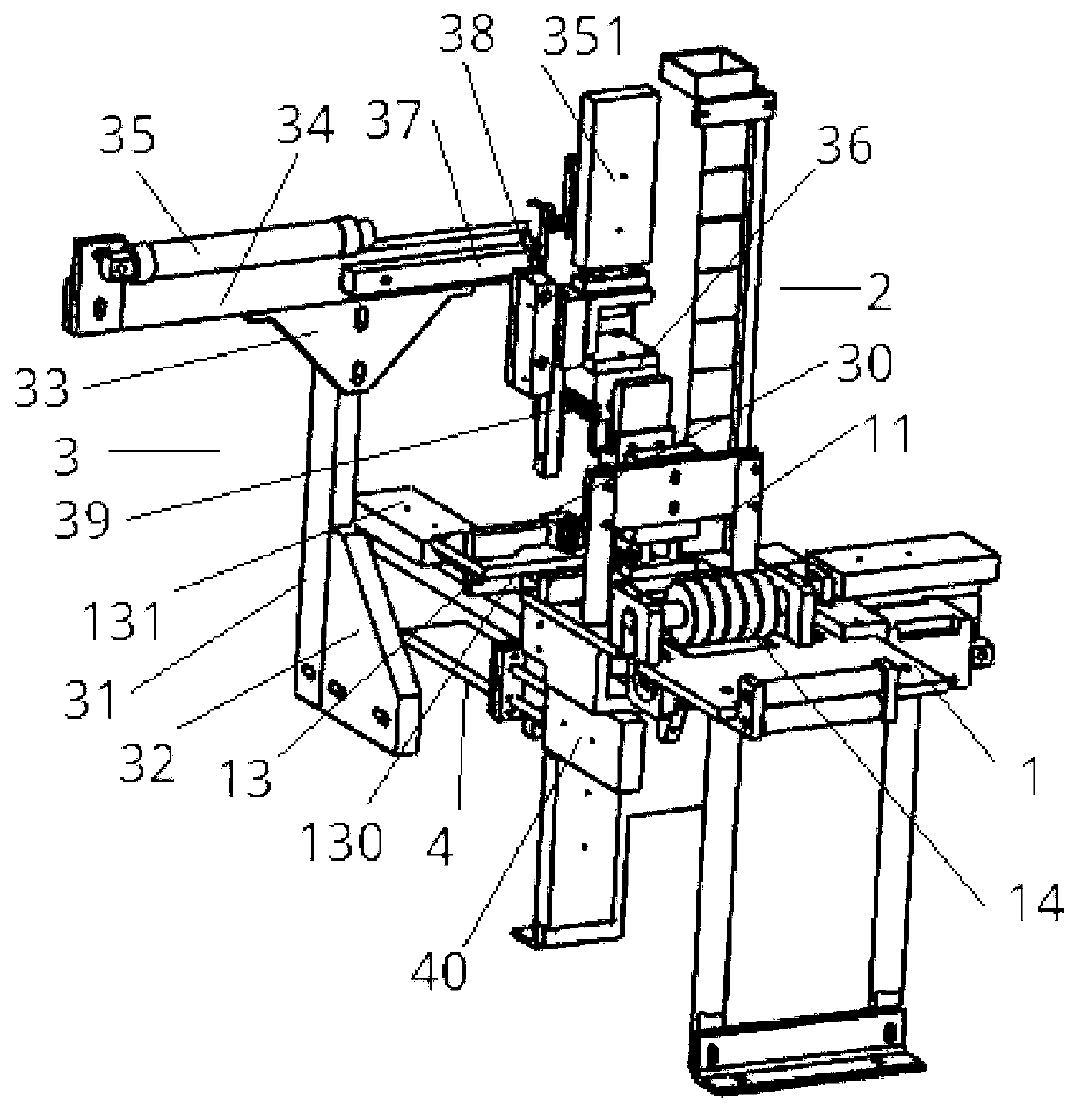

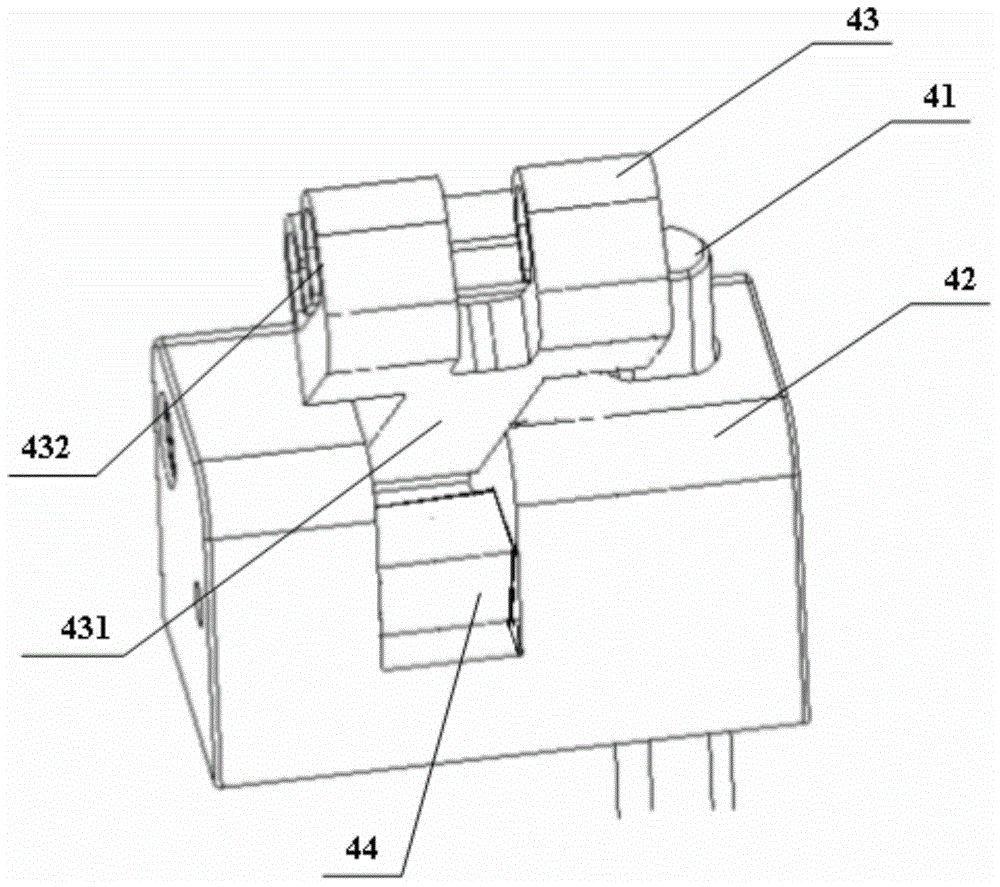

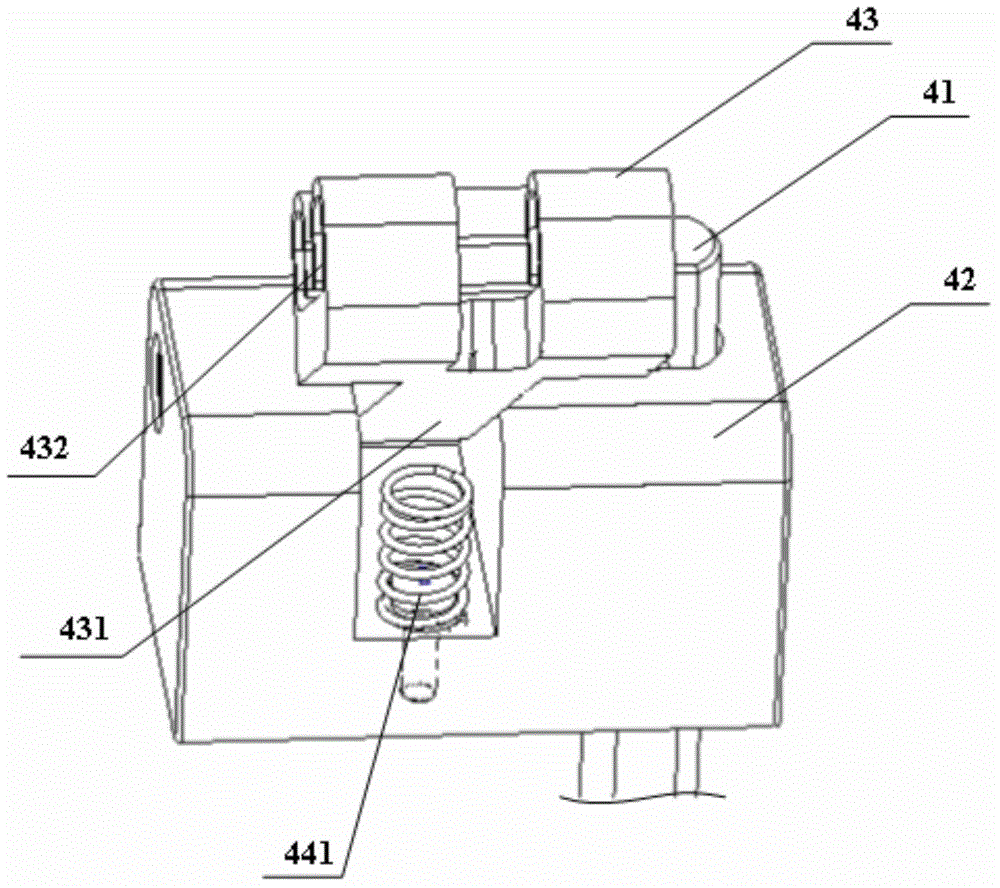

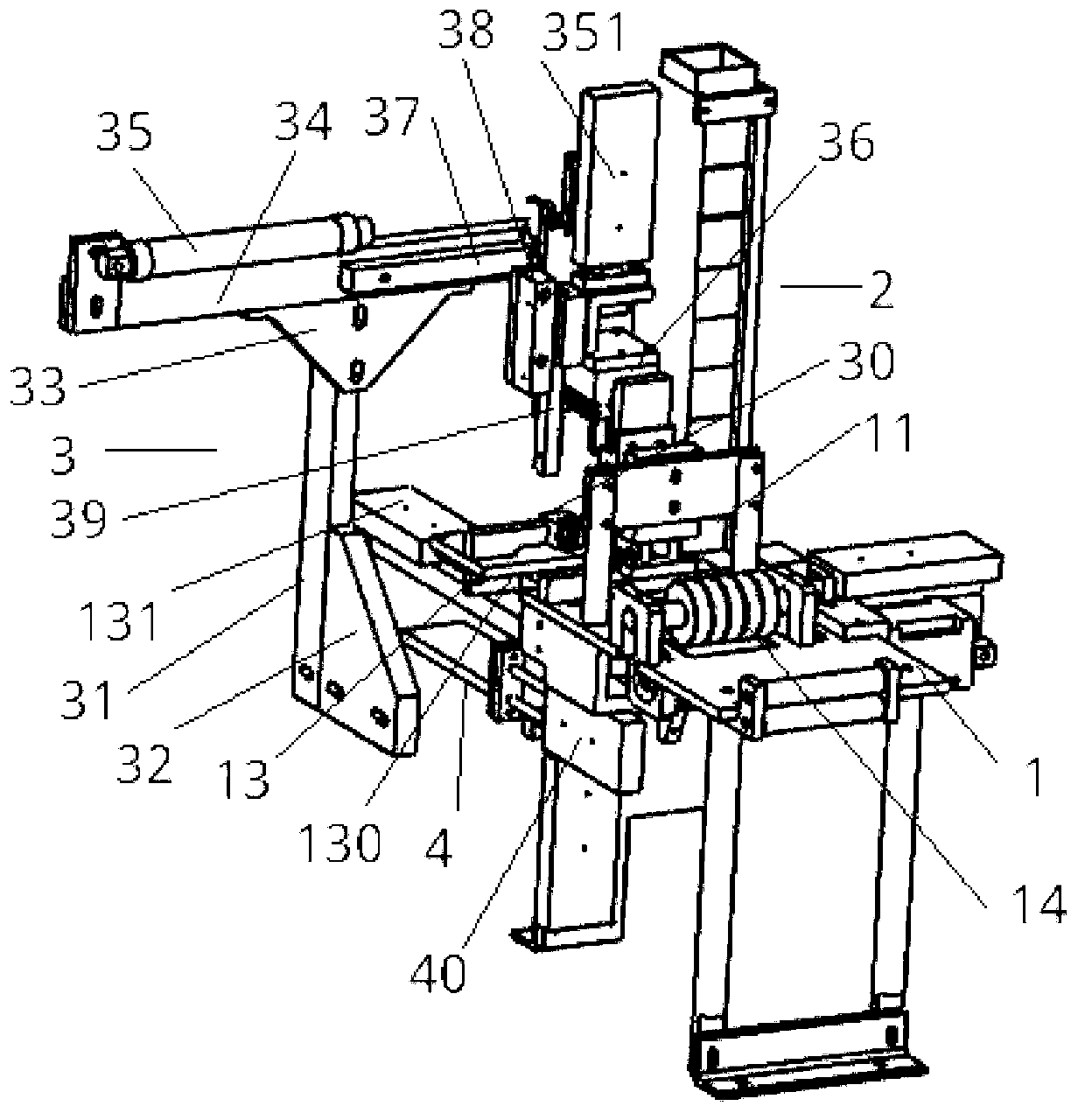

ActiveCN107837986ARealize automatic deliveryRealize automatic clampingLiquid surface applicatorsCoatingsGear wheelControl engineering

The invention relates to an automatic coating apparatus and an operation method thereof. The automatic coating apparatus comprises a paint barrel and a swinging device, wherein the swinging device comprises an arc-shaped rack, a swinging motor and a fixed shaft; the arc-shaped rack is arranged above the paint barrel; the output shaft of the swinging motor is fixedly connected with a first gear; the first gear is engaged with the arc-shaped bottom end of the arc-shaped rack; the fixed shaft is connected with a bearing located at the axle center of the arc-shaped rack; when the swinging motor cyclically rotates in forward and reverse directions, the arc-shaped rack is driven to swing around the fixed shaft in a reciprocating way; and an actuating arm is mounted on the outer side surface of the arc-shaped rack and connected with a workpiece to be coated, so when the arc-shaped rack is swinging, the to-be-coated workpiece is driven to swing in the paint barrel so as to complete coating.

Owner:黄翔鸥

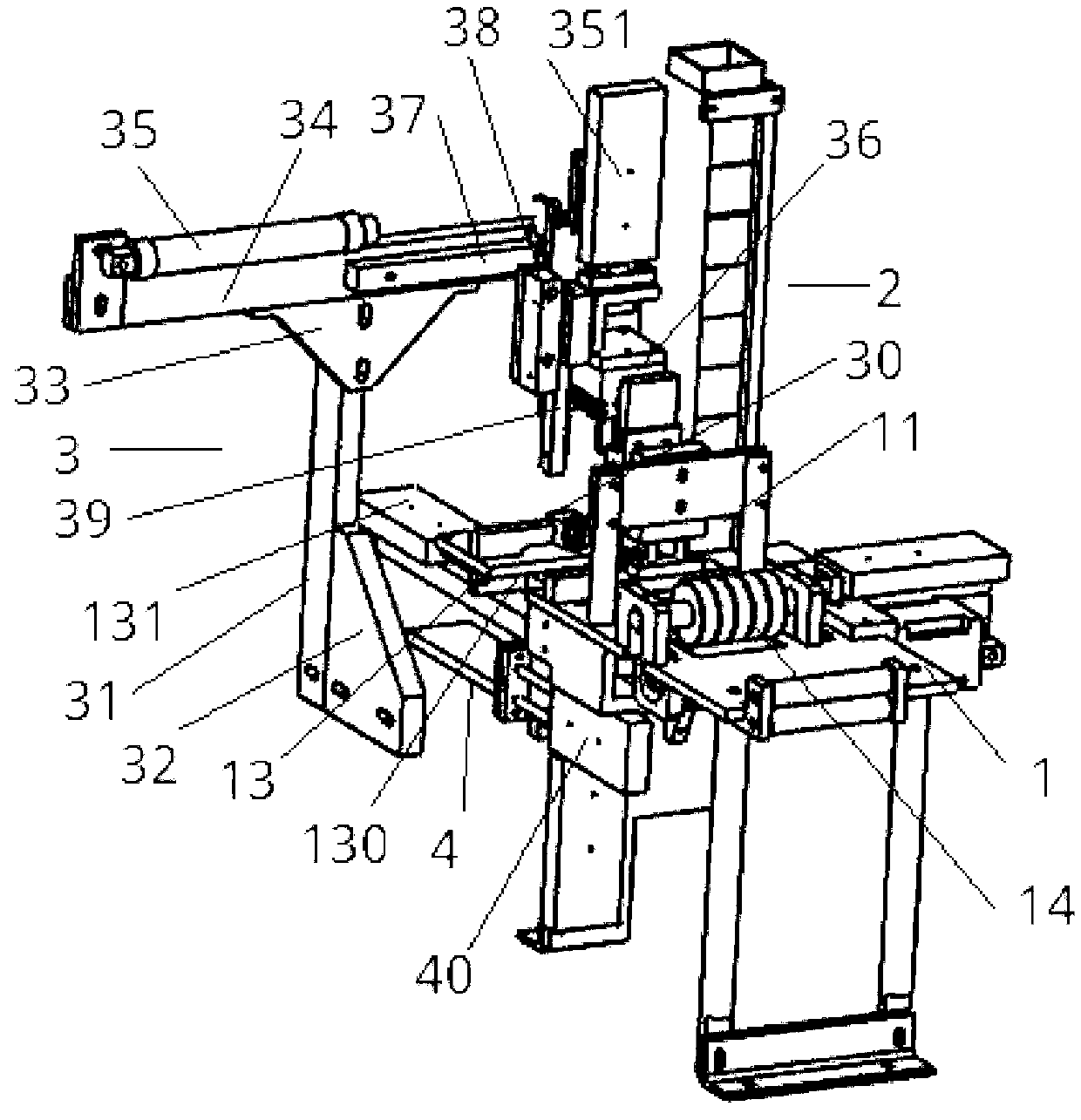

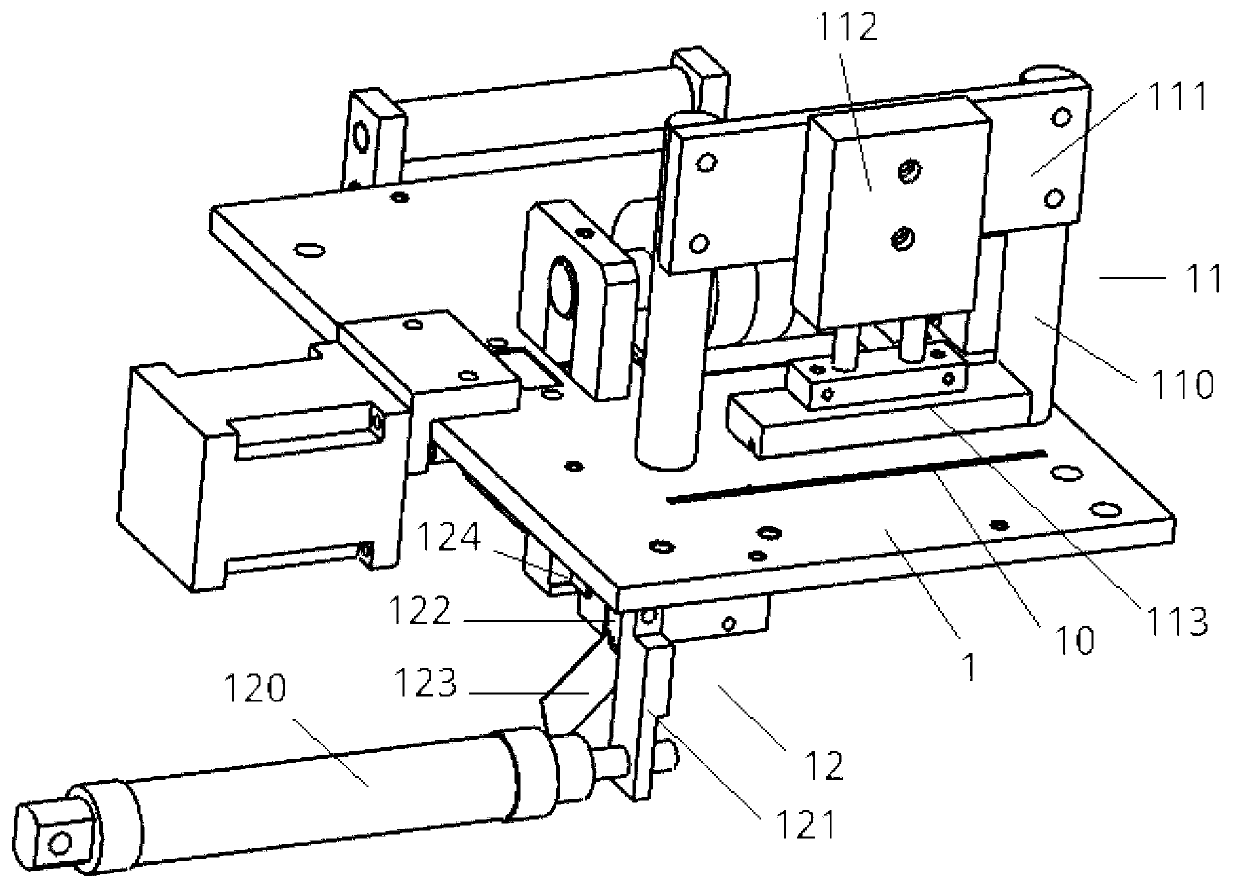

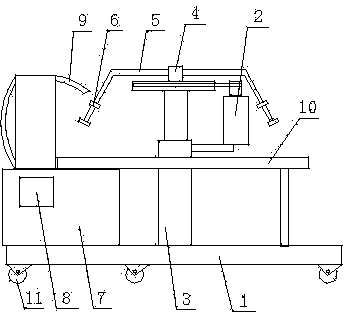

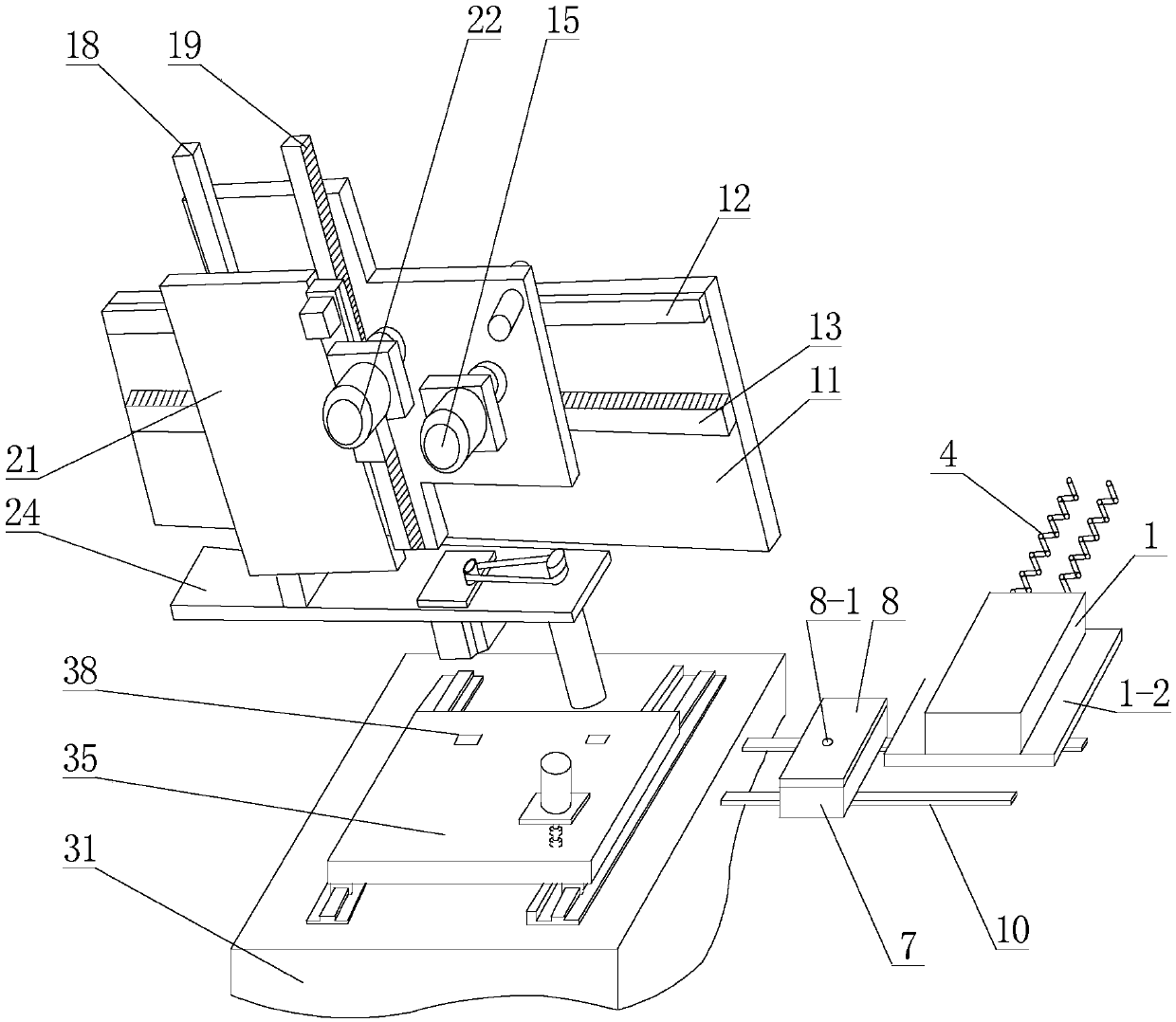

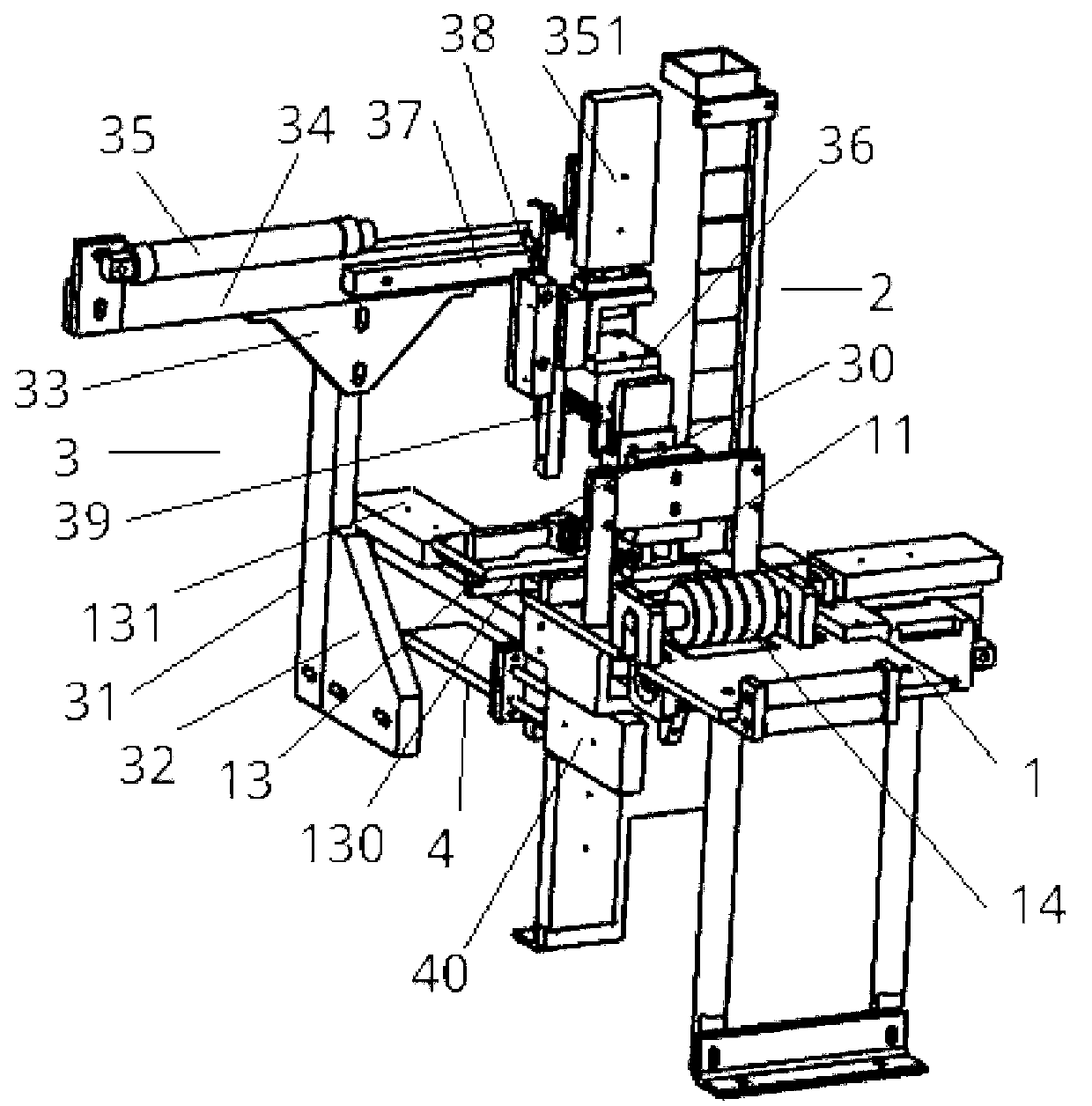

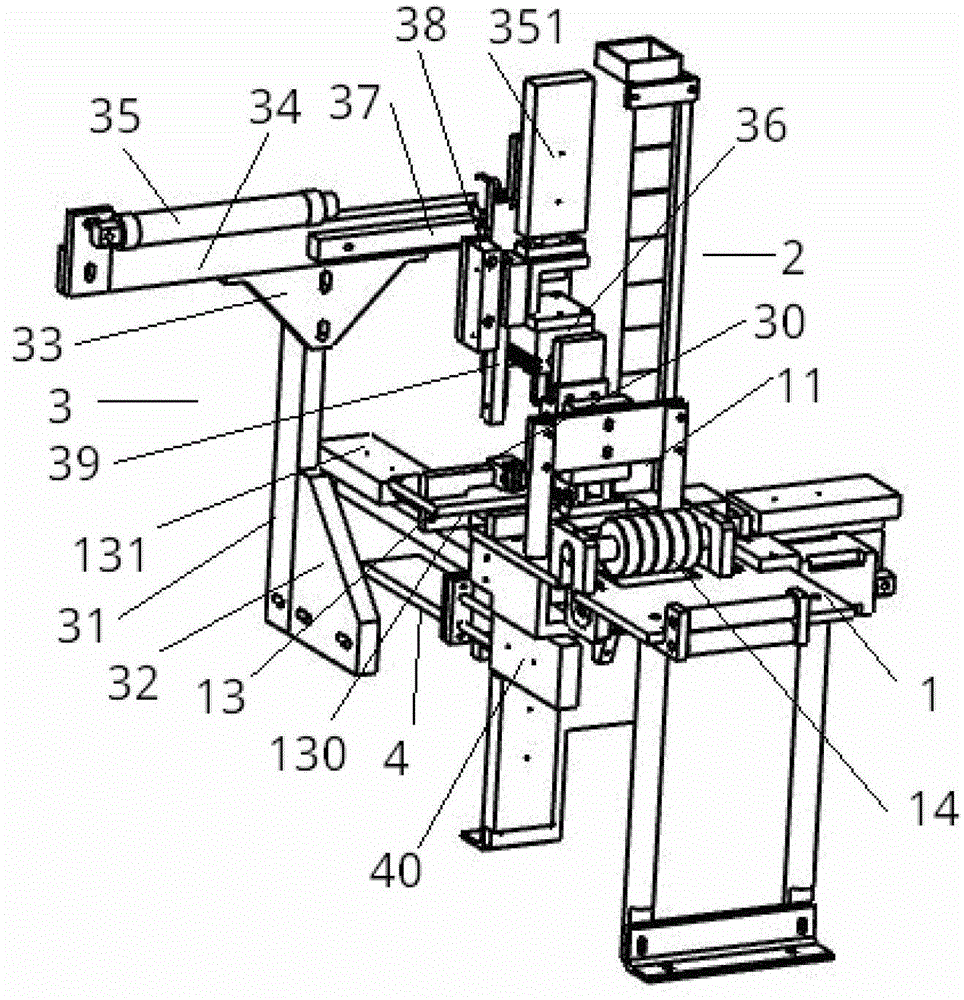

Storage battery plate group automatic film coating machine

InactiveCN103123979ASimple structureMovement precisionFinal product manufactureSecondary cells manufactureAgricultural engineeringManipulator

The invention discloses a storage battery plate group automatic film coating machine which comprises a horizontal board, wherein a back horizontal board placed on the same plane with the horizontal board is arranged behind the horizontal board; a separation space is arranged between the horizontal board and the back horizontal board; a battery case blanking barrel is vertically arranged at the right side of the separation space; a plate group transmission rack is arranged at the left side of the separation space; the upper end of the plate group transmission rack is provided with a horizontal support beam; the horizontal support beam is provided with a horizontal cylinder; a piston rod of the horizontal cylinder is connected with a perpendicular cylinder; a piston rod of the perpendicular cylinder is connected with a plate group grabbing manipulator; the back side of the horizontal board is provided with a transverse film cut-off clearance; the horizontal board is provided with a cut-off knife moving mechanism which is arranged below the film cut-off clearance and is provided with a cut-off knife; the front side of the horizontal board is provided with a film conveying mechanism; and the back horizontal board is provided with a film receiving mechanism. The storage battery plate group automatic film coating machine disclosed by the invention is simple in structure and accurate in movement, realizes the automatic film coating of storage battery plate groups, lowers the labor intensity and improves the film coating efficiency.

Owner:邳州市博睿投资管理有限公司

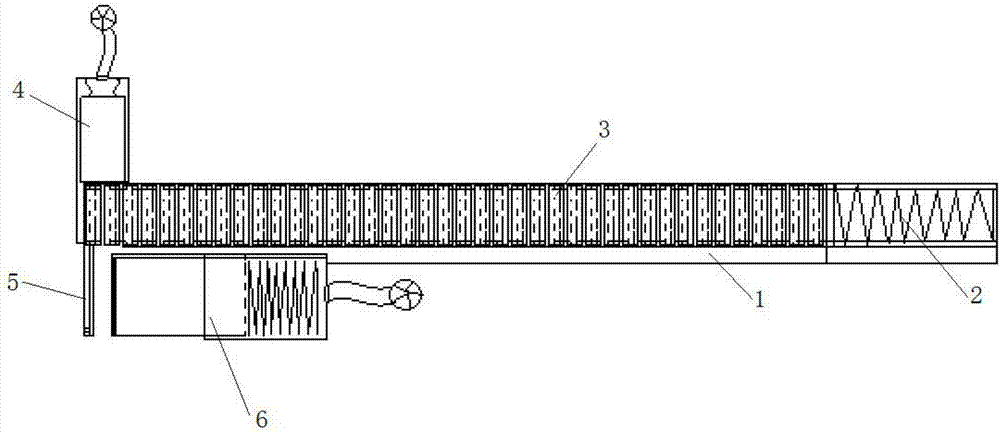

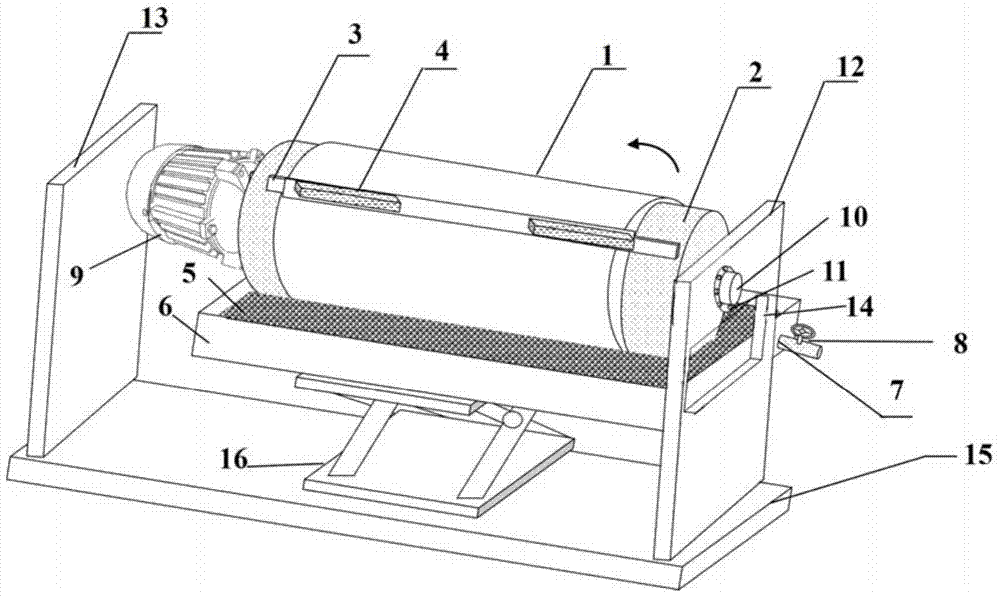

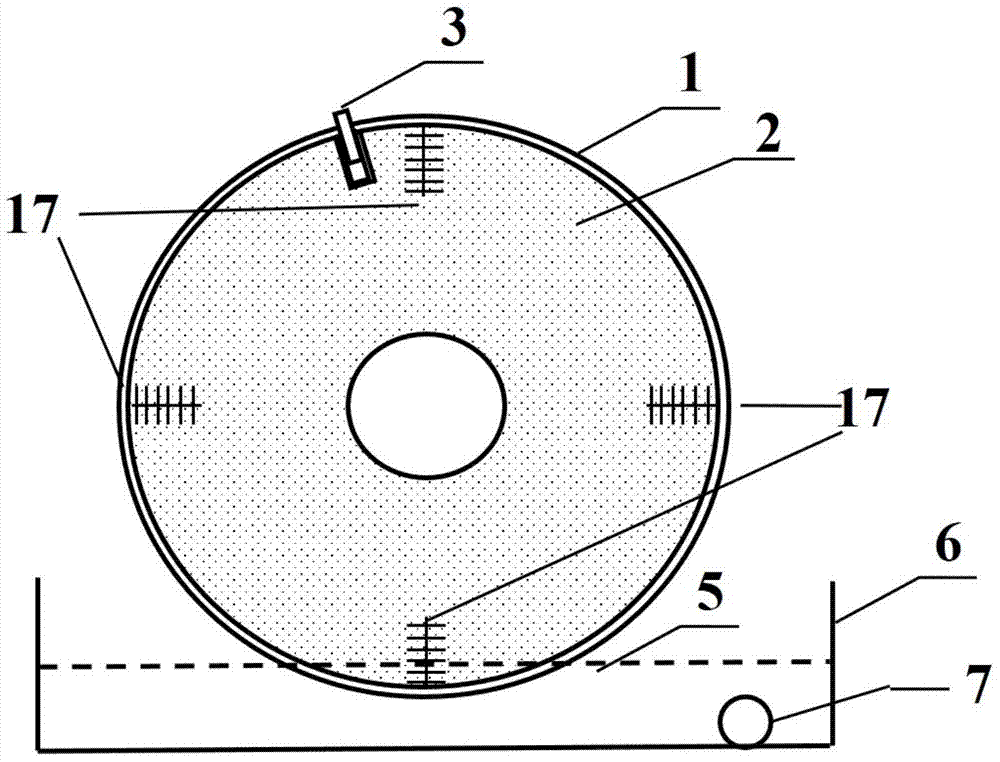

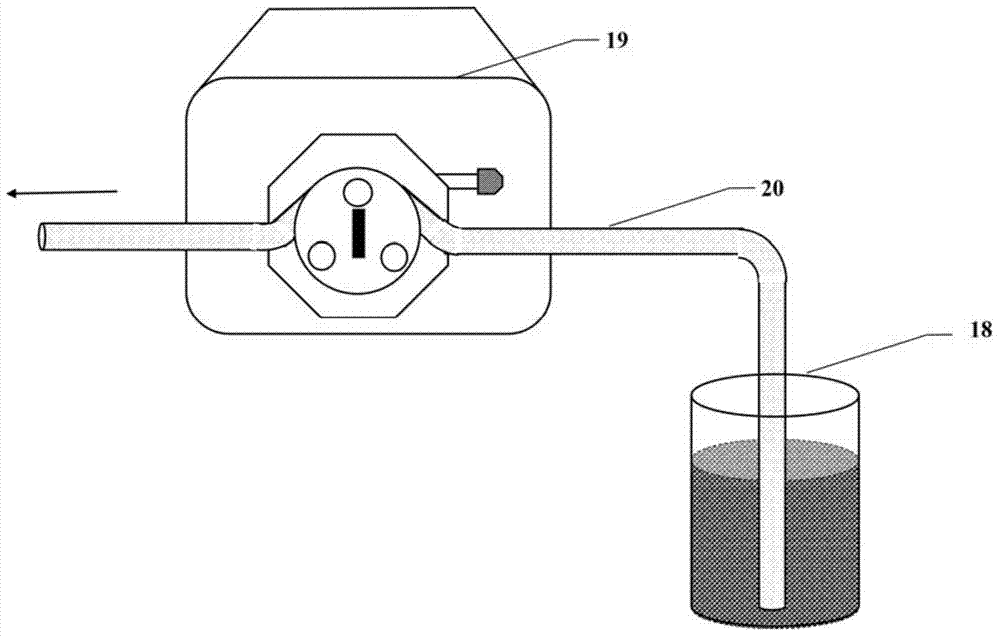

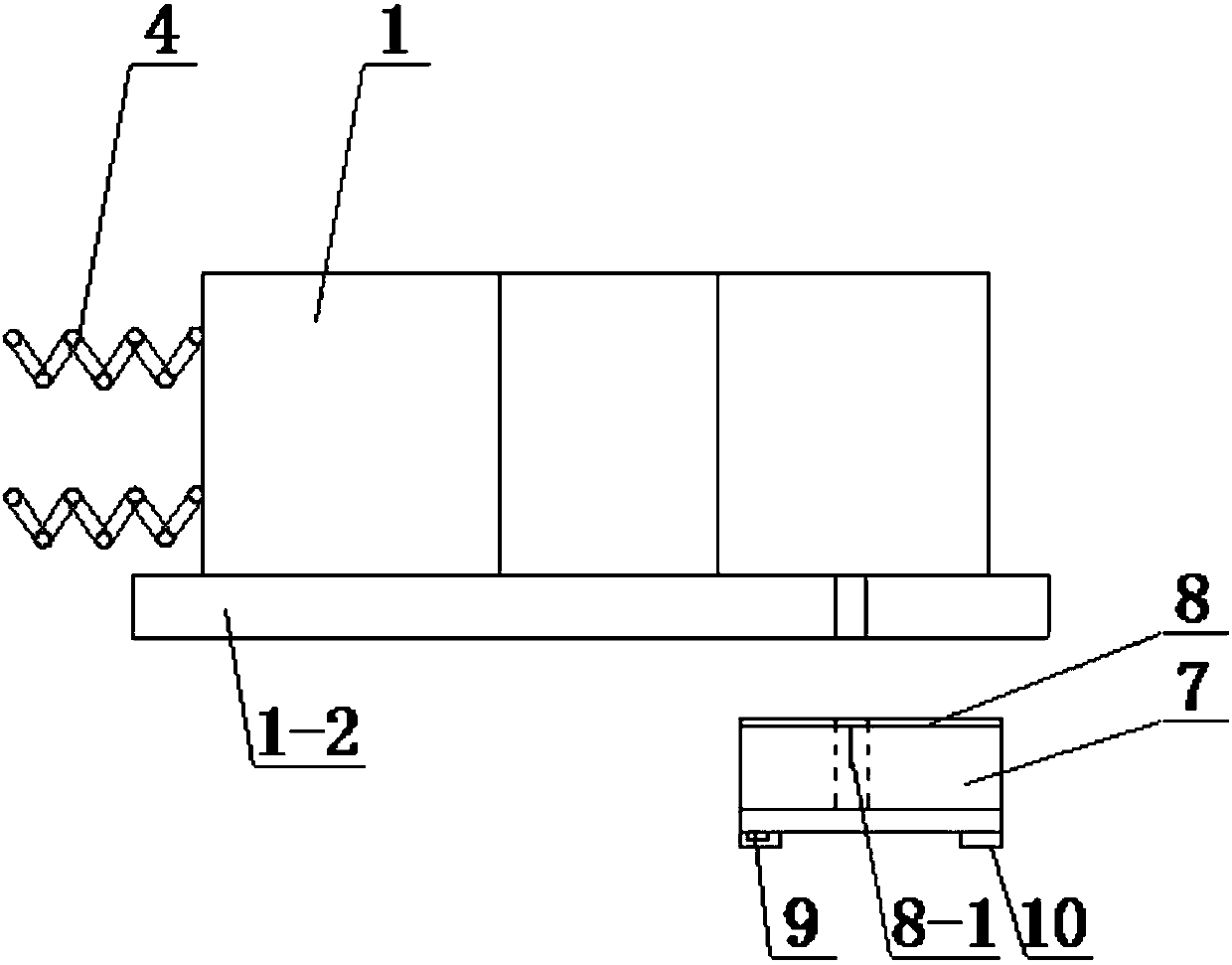

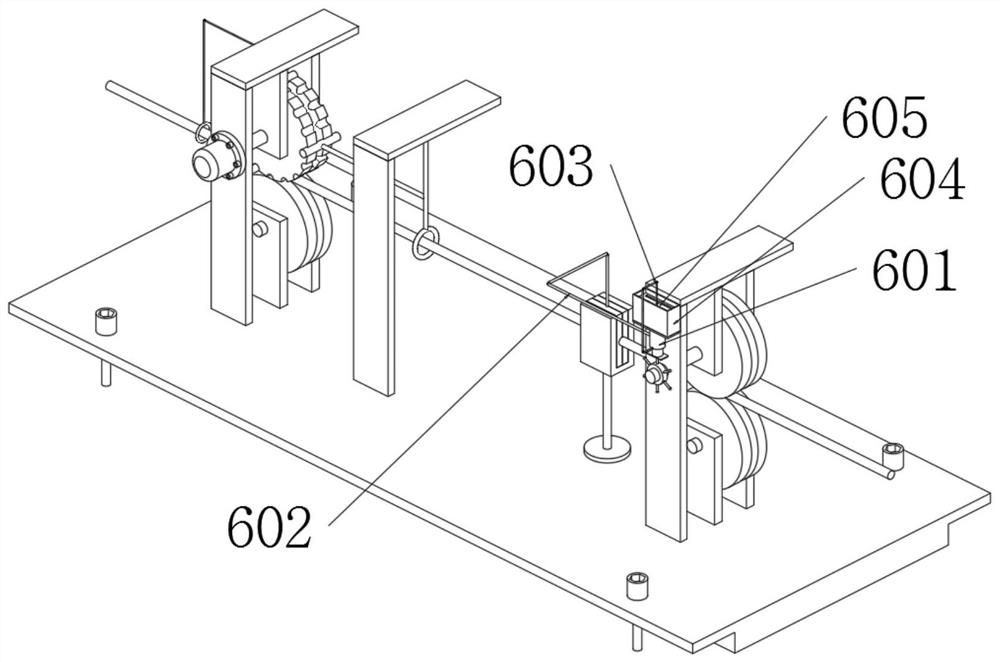

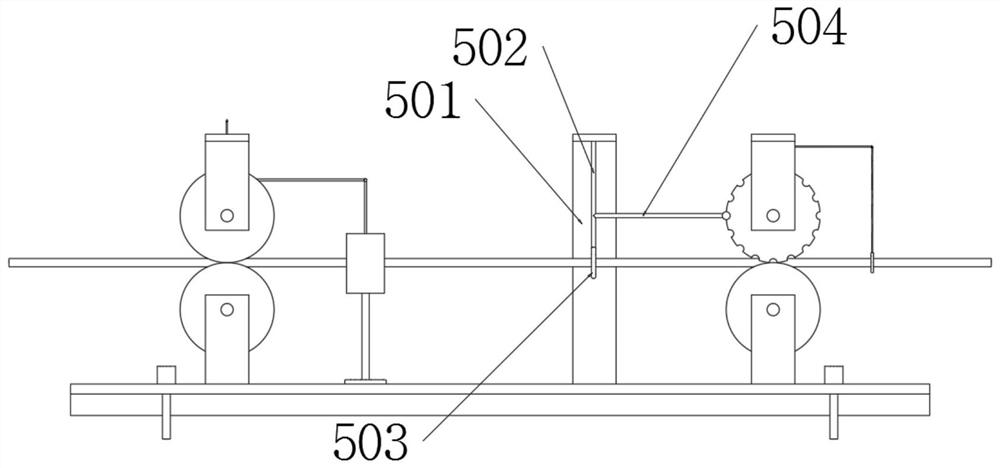

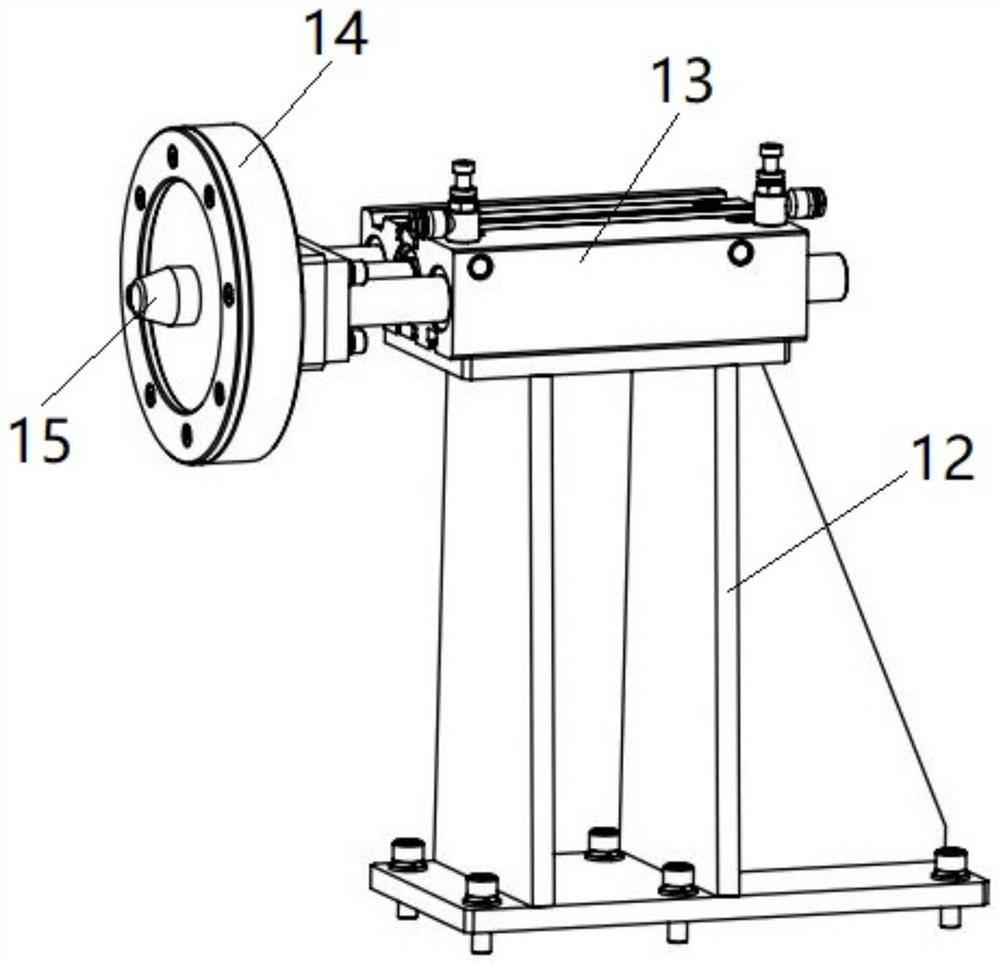

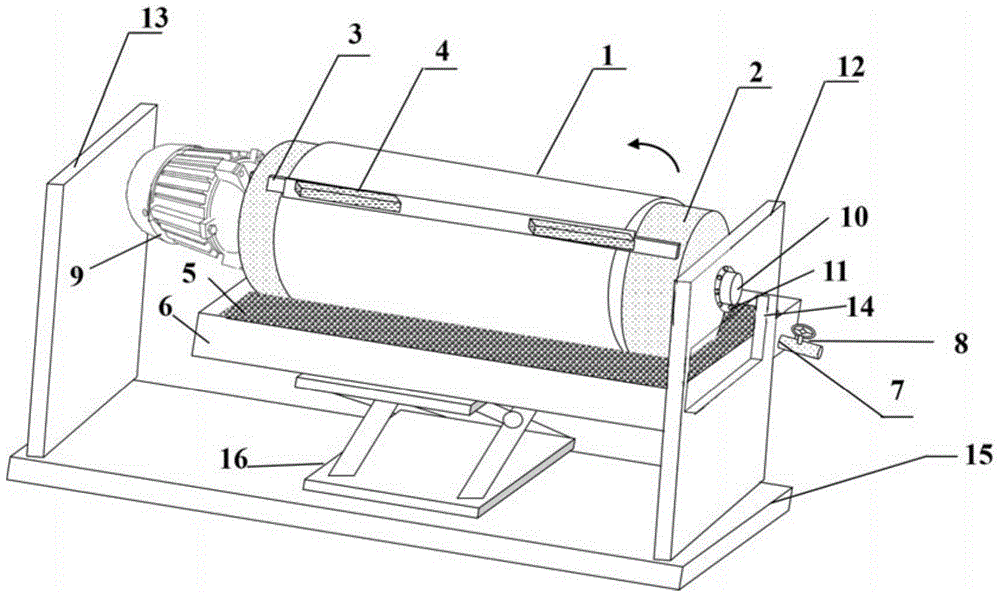

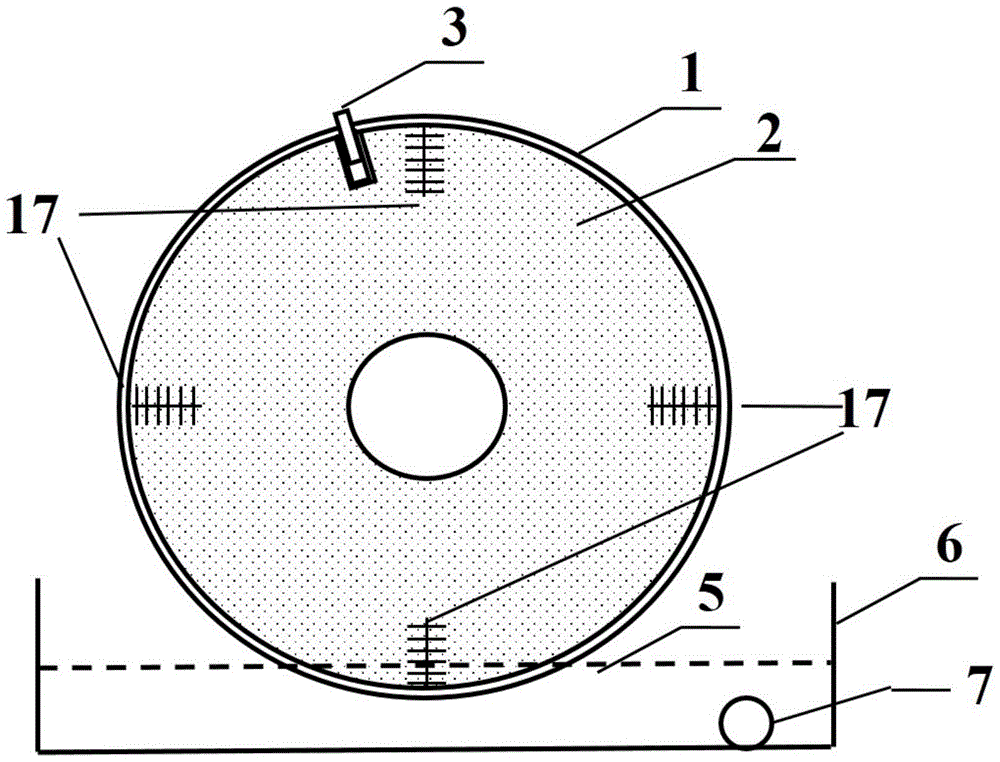

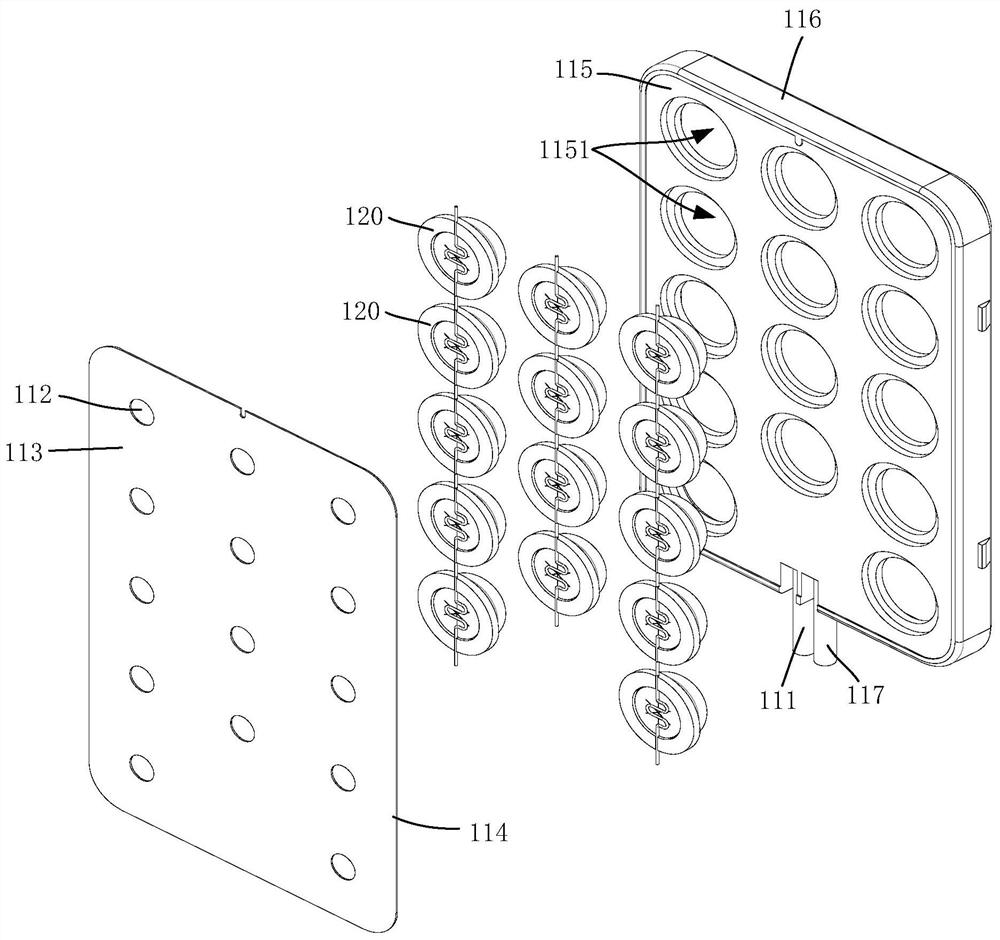

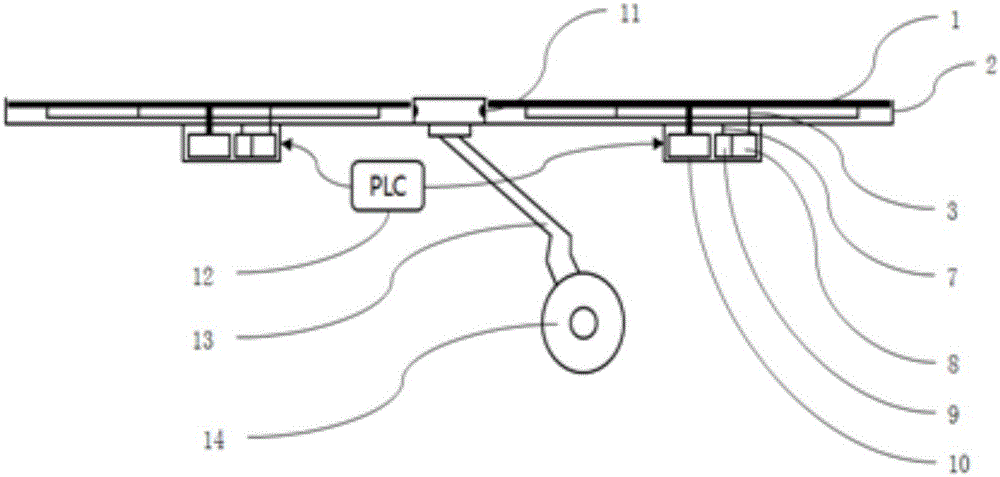

Automatic roll-coating method and automatic roll-coating device of ethanol-permselective composite membrane

InactiveCN104722211AIntegrity guaranteedControl and reduce thicknessSemi-permeable membranesLiquid tankPermeation

The invention discloses an automatic roll-coating method and device of an ethanol-permselective composite membrane, belonging to the technical field of membrane coating of separation membranes. A coating device comprises a roller, a gear, a support plate, a base, a motor, a feed liquid tank, a lifting table and the like. The coating method provided by the invention comprises the following steps: pouring membrane preparing liquid into a storage tank, conveying the feed liquid to the feed liquid tank through an automatic feeding device, adjusting the height of the feed liquid tank by using the lifting table and the scale marks at one end of the roller; rotating the roller through the driving of the motor so as to uniformly coat a base membrane with the feed liquid. Through the adoption of the method and the device disclosed by the invention, the thickness of a separation layer can be effectively controlled and reduced, the permeation flux is greatly improved, and the automatic coating of the ethanol-permselective composite membrane is realized.

Owner:BEIJING UNIV OF TECH

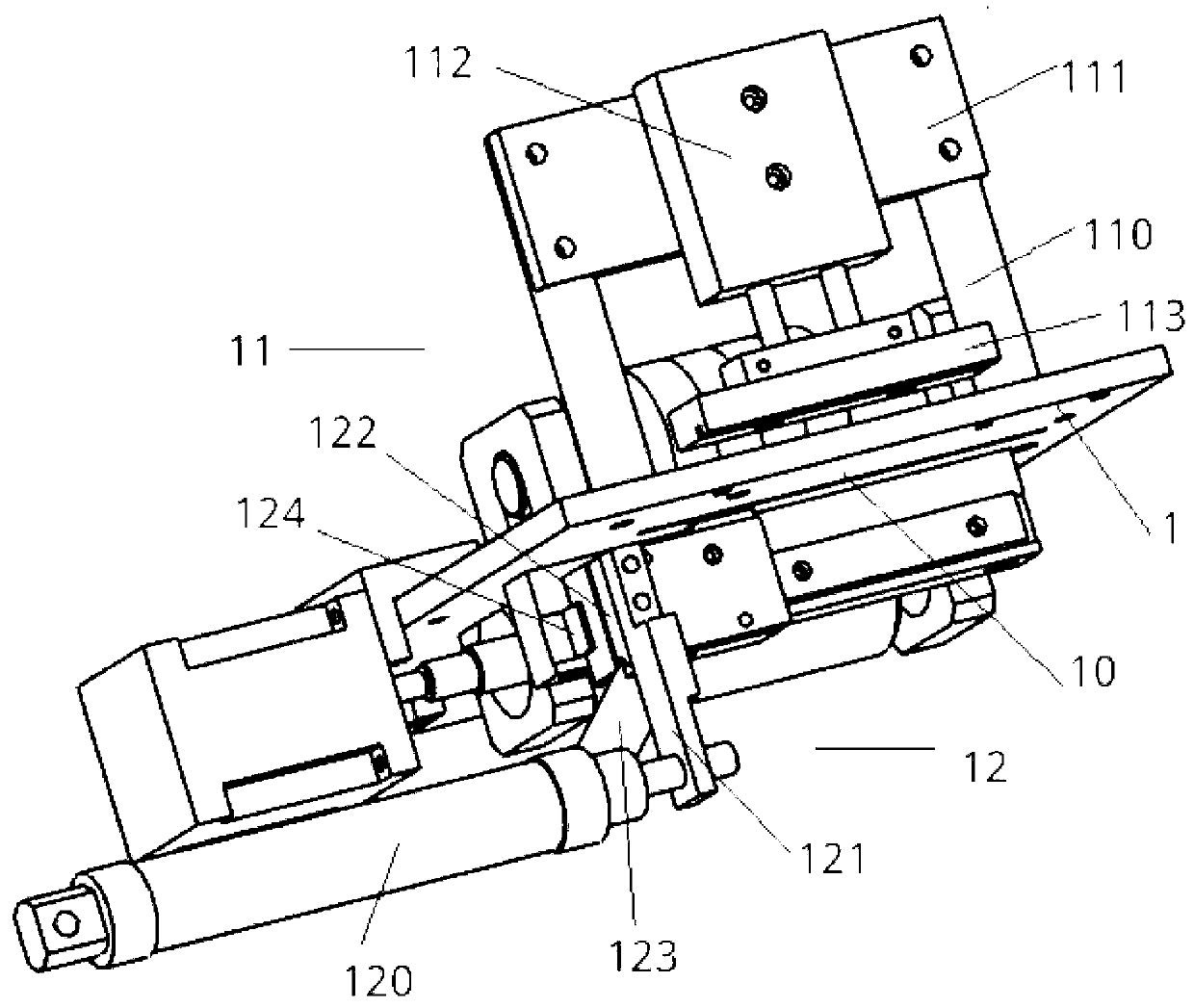

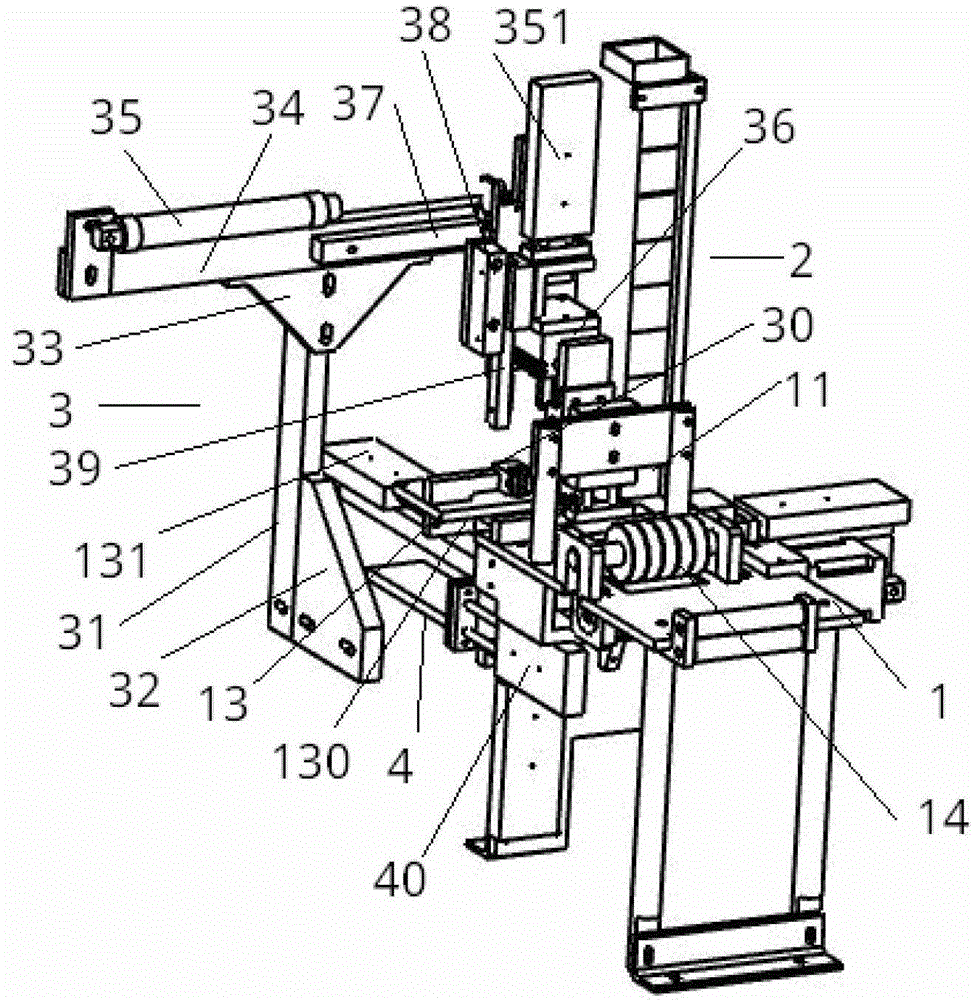

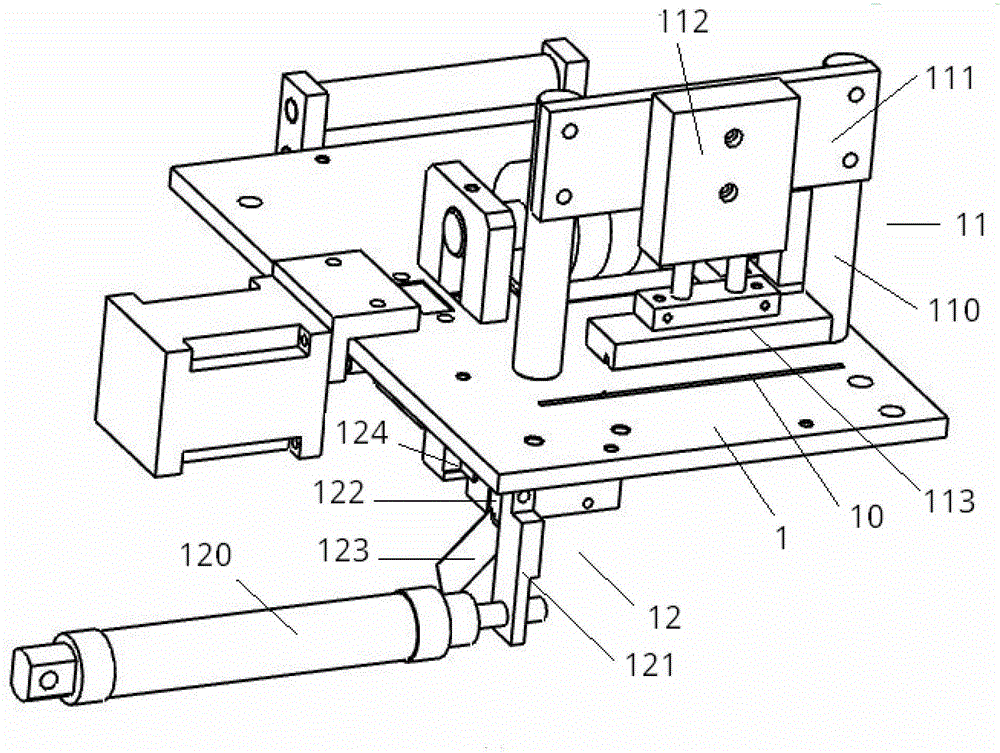

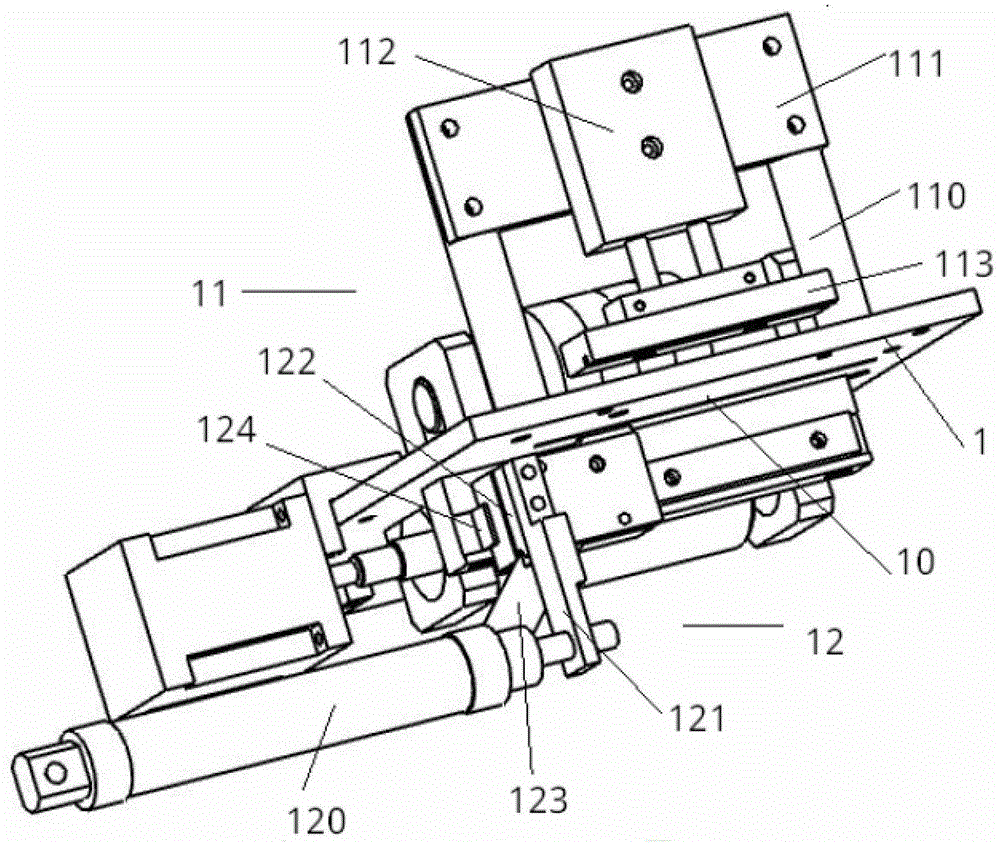

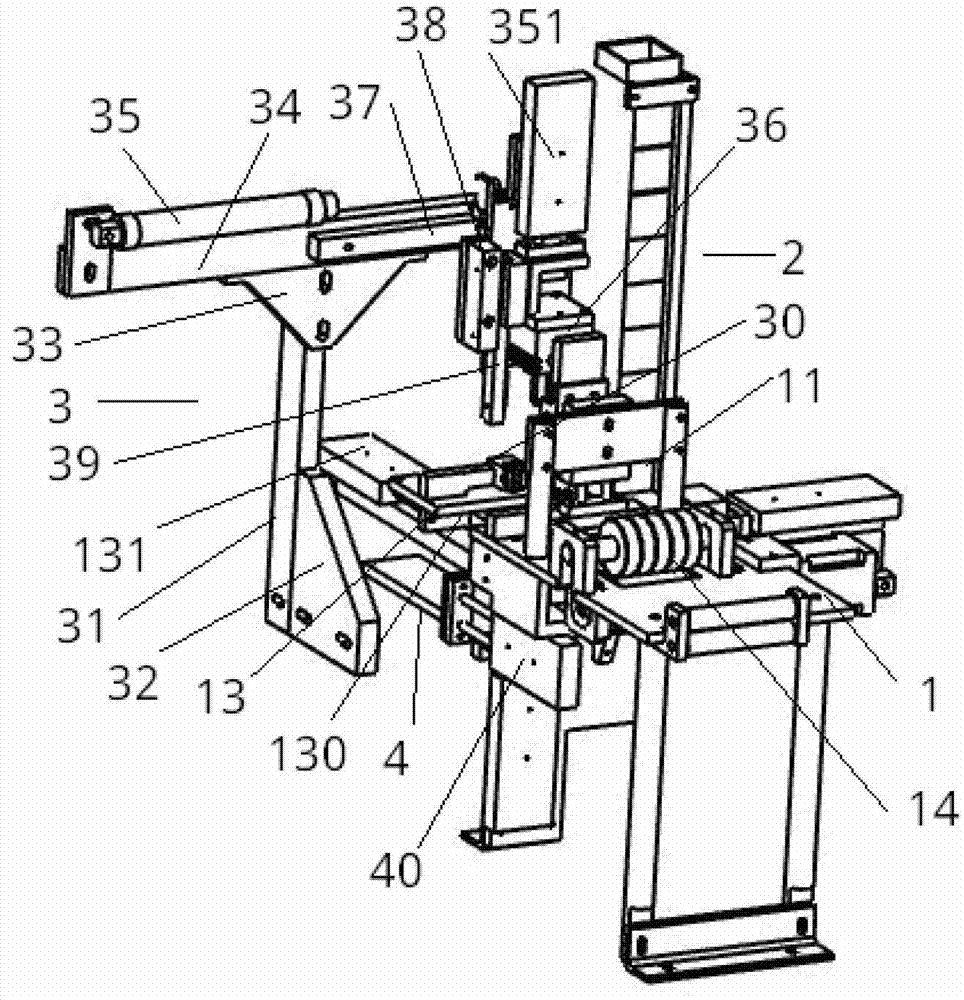

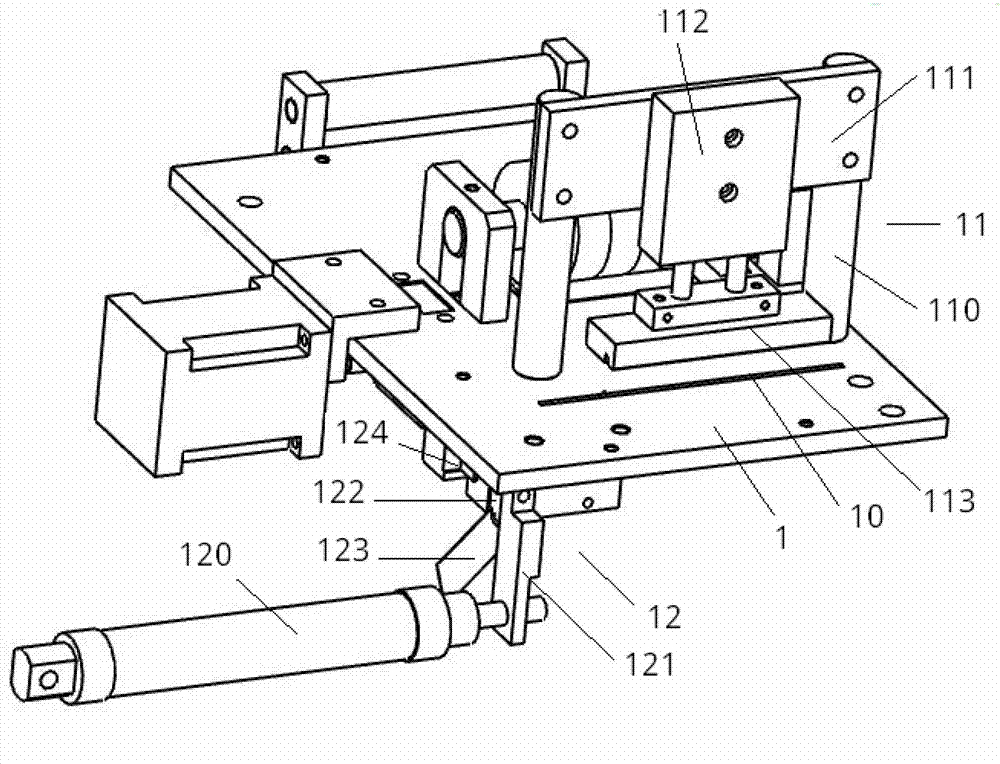

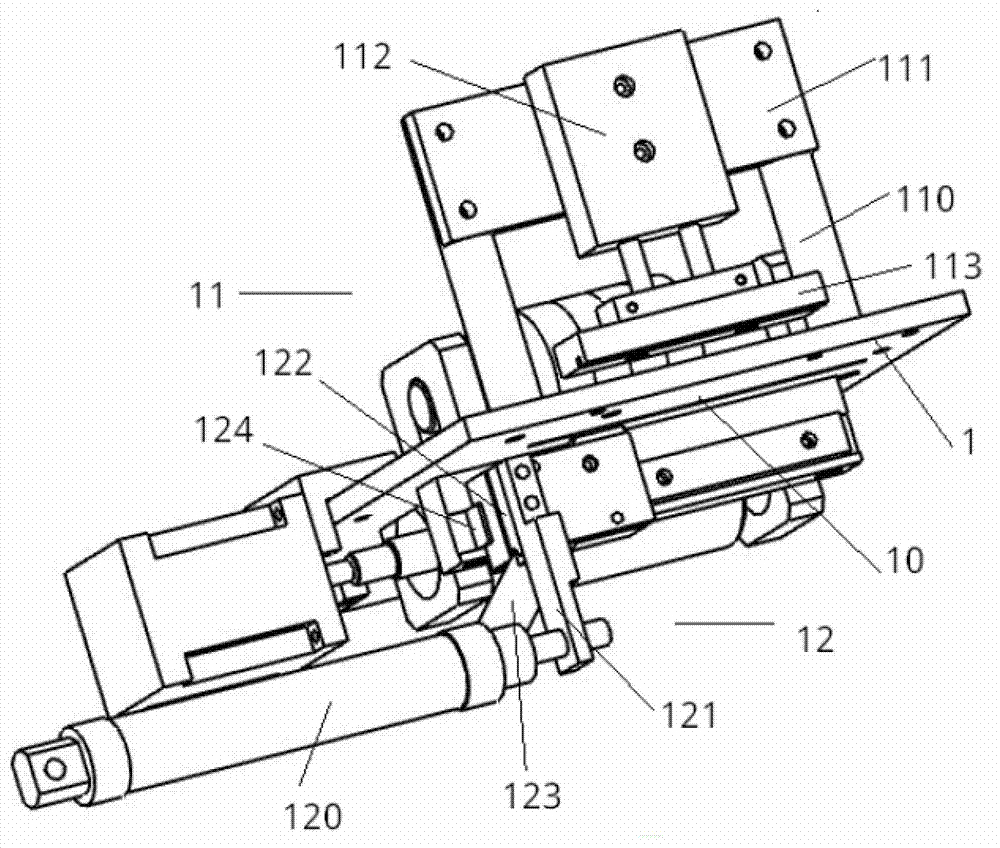

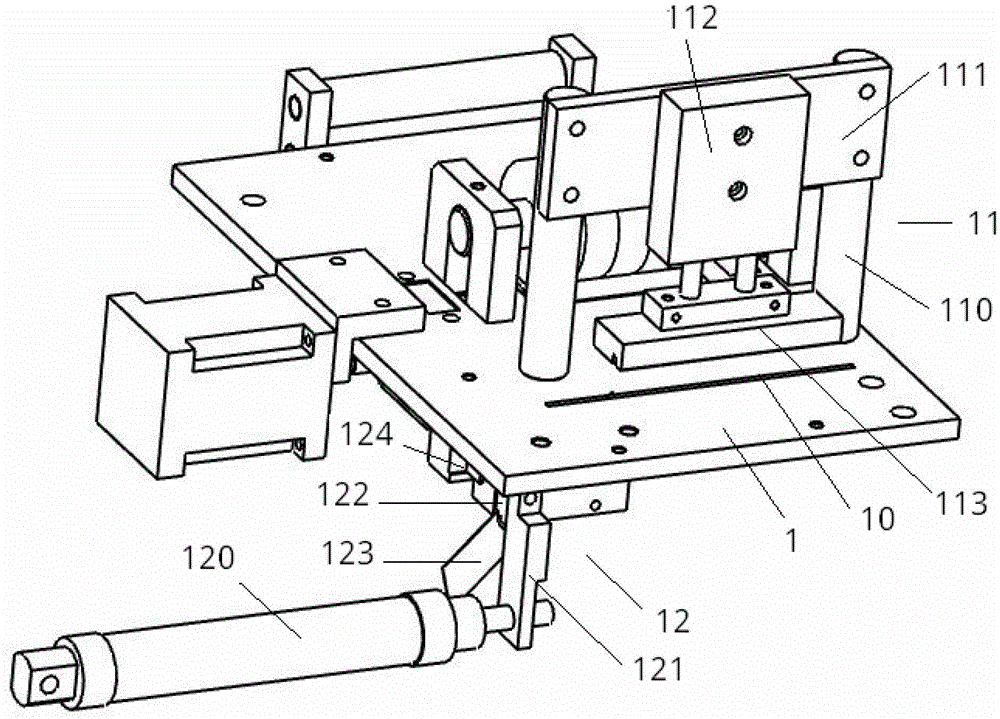

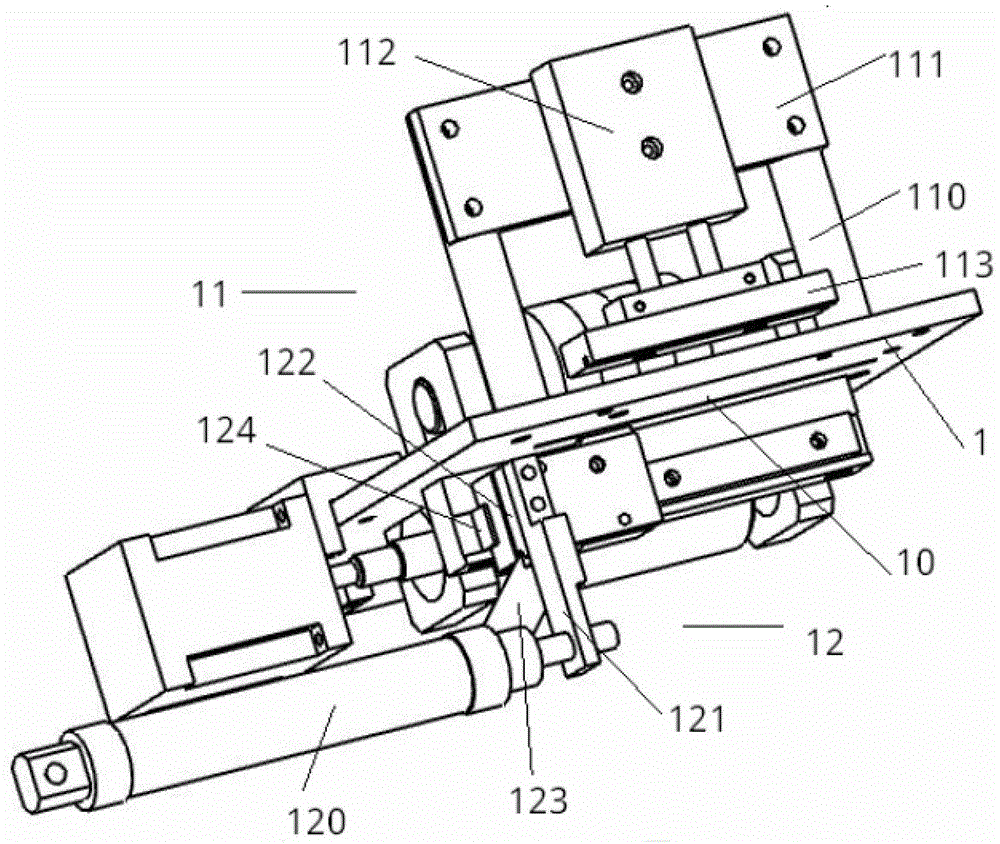

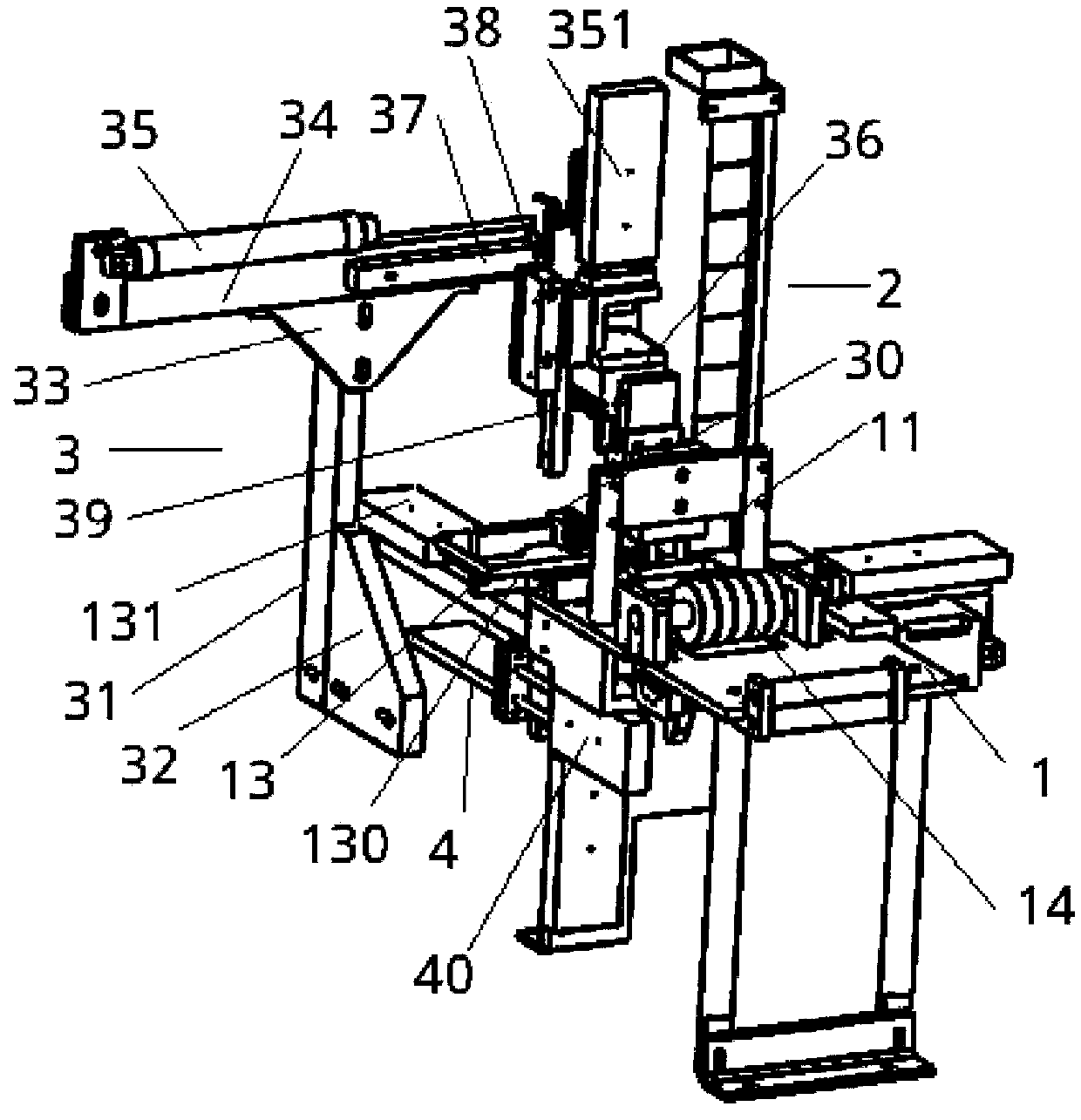

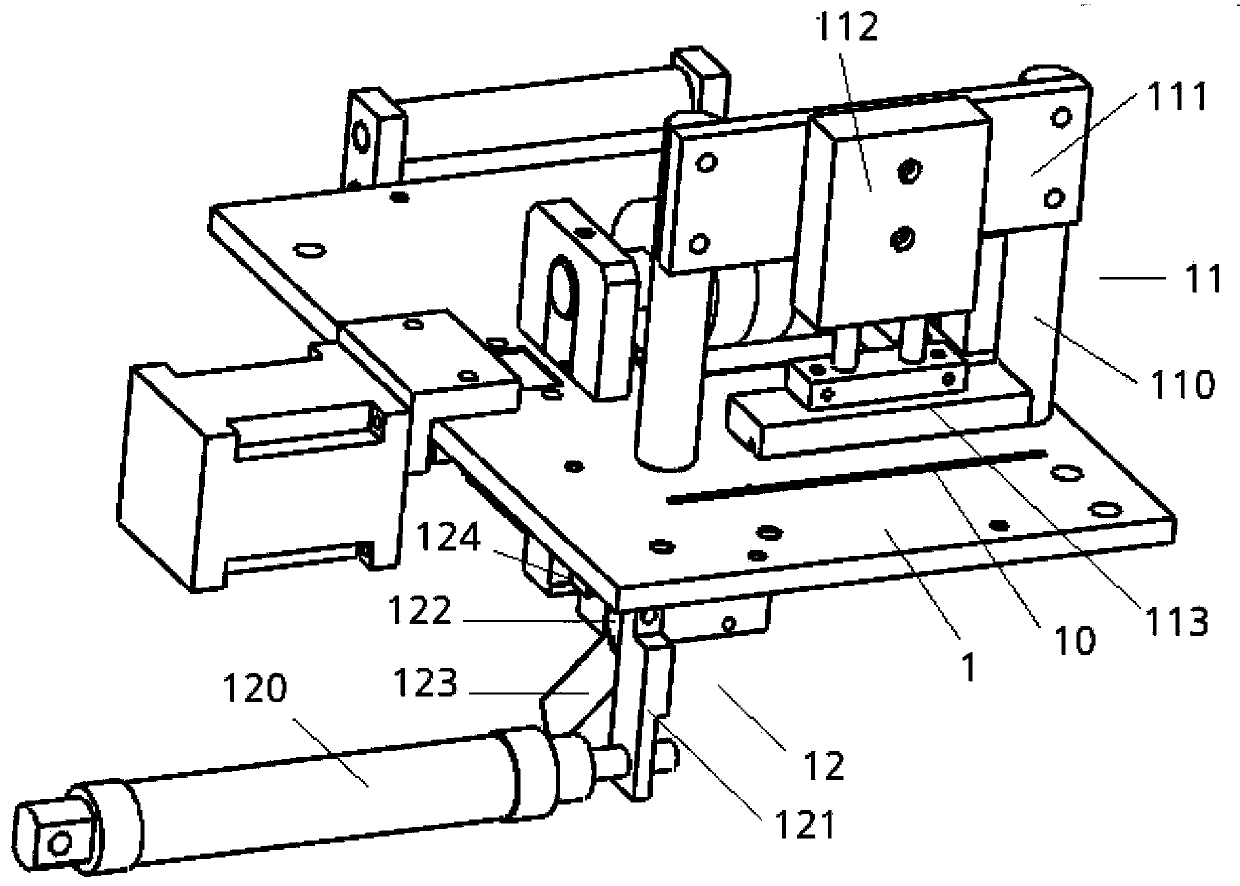

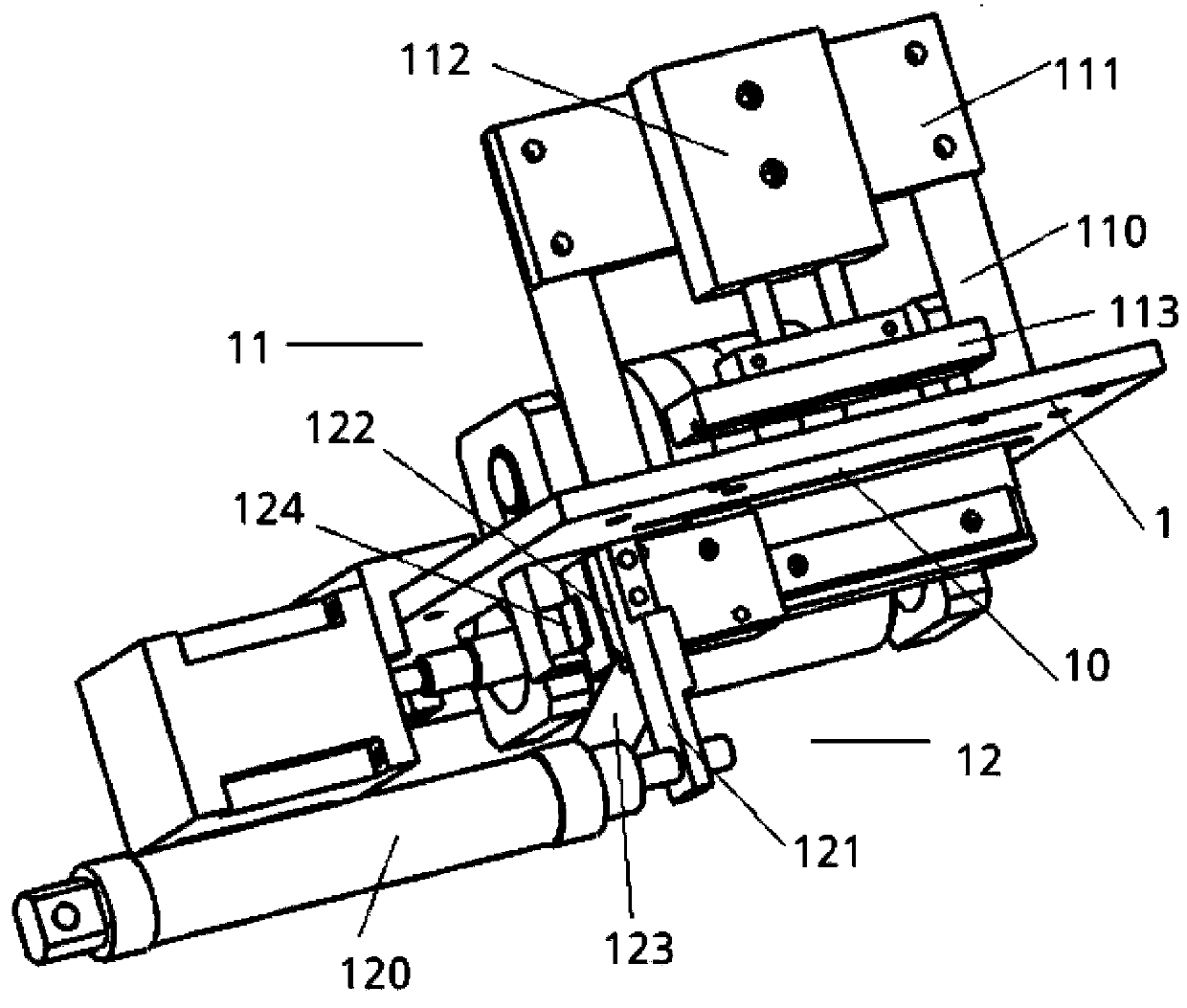

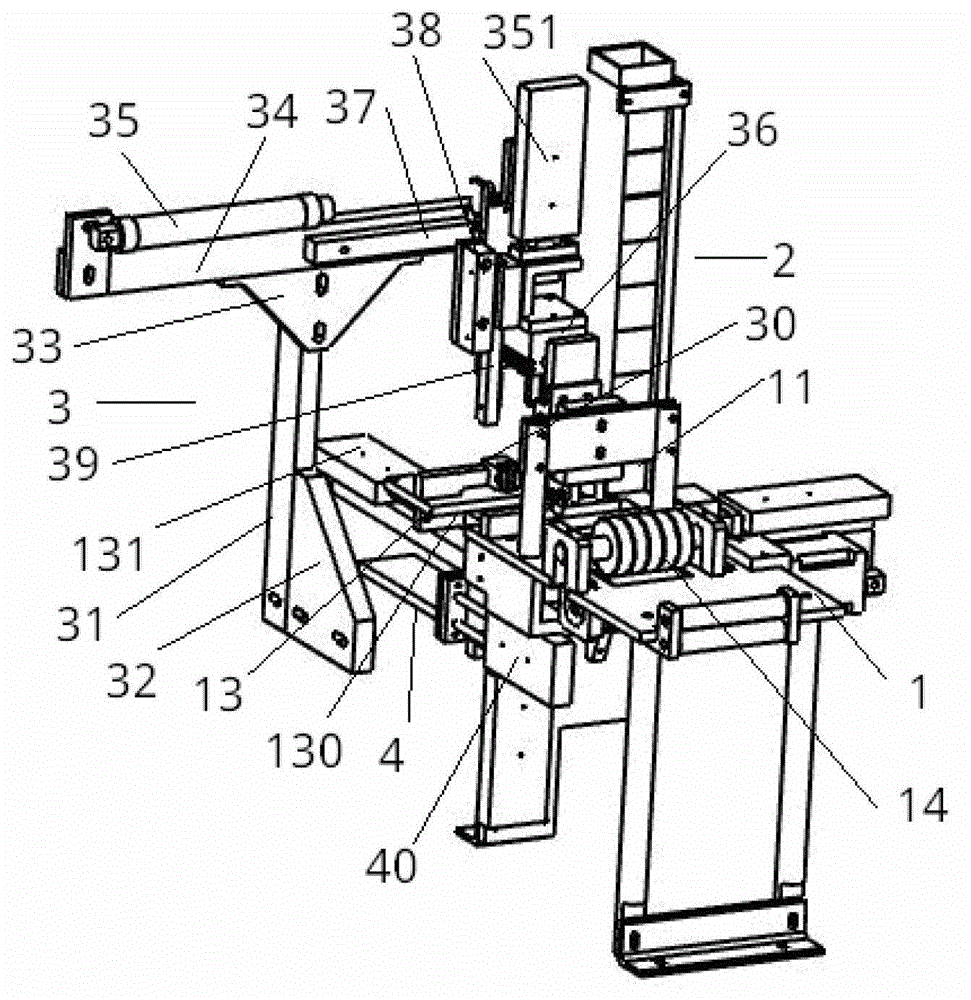

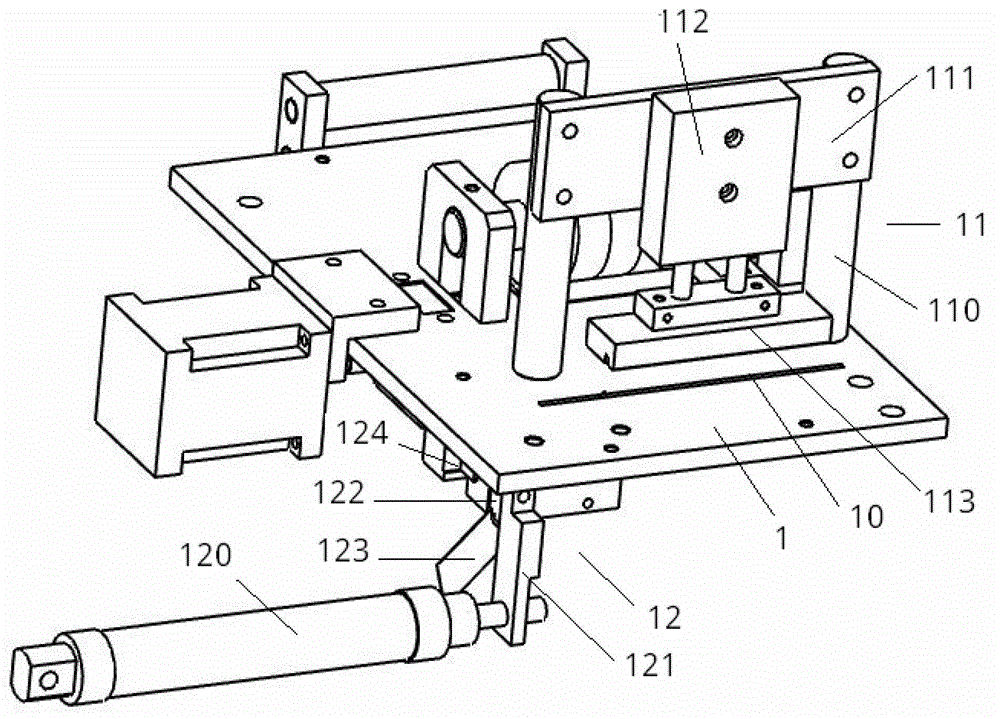

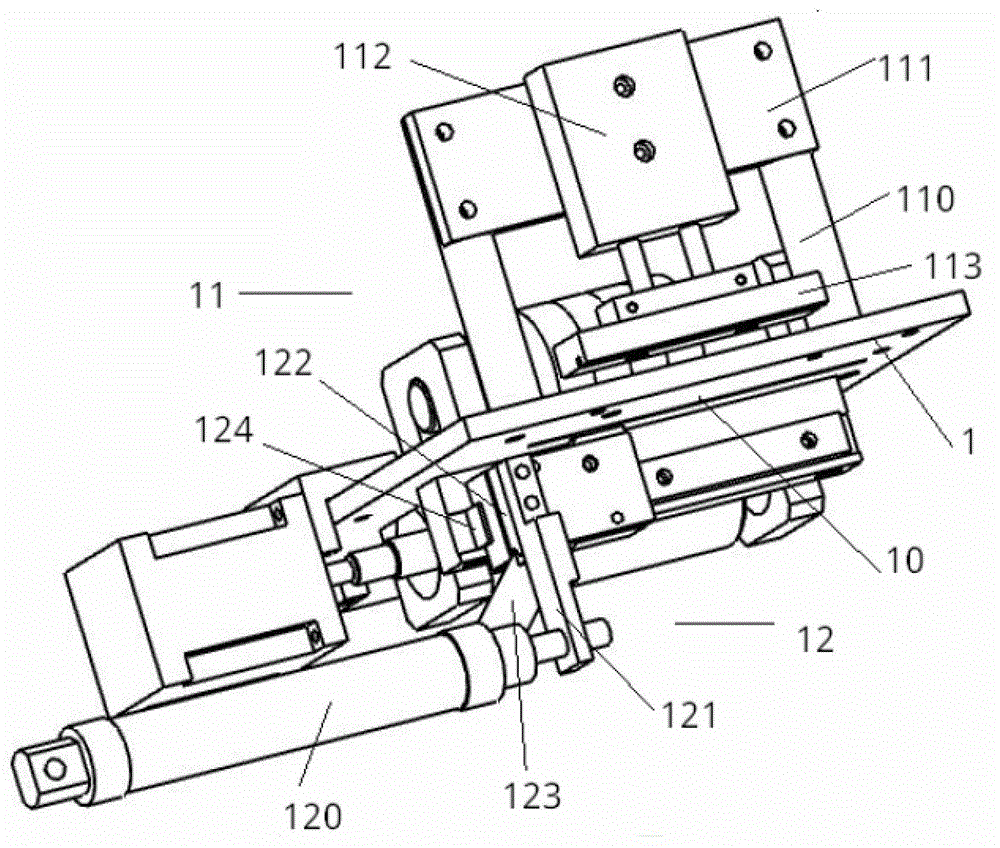

Device for copper column gate array interconnection device column implanting process

ActiveCN107611064ARealize automatic separationRealize automatic coatingSemiconductor/solid-state device manufacturingGate arrayImplanted device

A device for the copper column gate array interconnection device column implanting process is disclosed. The invention relates to a column implanting process device and particularly relates to a device for the copper column gate array interconnection device column implanting process. The invention aims to solve problems that a welding column is easy to be scratched, the high precision centering and positioning of the welding column are difficult, and the customization of different molds is needed by different specifications of devices and production cycle and cost are increased according to anexisting column implanting device and a used column implanting method. The device comprises a drill chuck translation movement mechanism, a drill chuck rotation movement assembly, an object stage assembly and a feeding assembly, the drill chuck rotation movement assembly is installed on the drill chuck translation movement mechanism, the drill chuck rotation movement assembly is arranged above the object stage assembly, and the feeding assembly is arranged at a side of the drill chuck rotation motion assembly. The device belongs to the field of electronic products.

Owner:HARBIN UNIV OF SCI & TECH

Insulating coating coating device for wire processing

PendingCN114864192APrevent slippingRealize automatic dryingInsulating conductors/cablesEngineeringMaterials science

The invention provides an insulating coating coating device for wire processing, which relates to the technical field of wire processing and comprises a base, a driving part, a drying part, a supply part and an auxiliary part, the base is fixedly connected to the workbench through four fixing bolts, and two riding wheels A are installed on the top end face of the base. A mounting frame A is mounted on the top end face of the base, the mounting frame A is aligned with the riding wheel A on the left side, and a riding wheel B is mounted on the mounting frame A. A connecting rod is welded to the bottom end face of the frame body, and a heating wire is installed at the tail end of the connecting rod. The heating wire is in an annular state after deformation, the heating wire is connected to the outer side of the electric wire in a sleeving mode, and the heating wire is located at the position 20 cm away from the right side of the coating cotton, so that when the electric wire moves, automatic drying of the electric wire can be achieved through the heating wire, and the problem that even though drying can be conducted after coating is conducted when the electric wire insulating layer is coated is solved. However, after a drying structure is used for a period of time, the performance is reduced, and then the drying efficiency is reduced.

Owner:郭华民

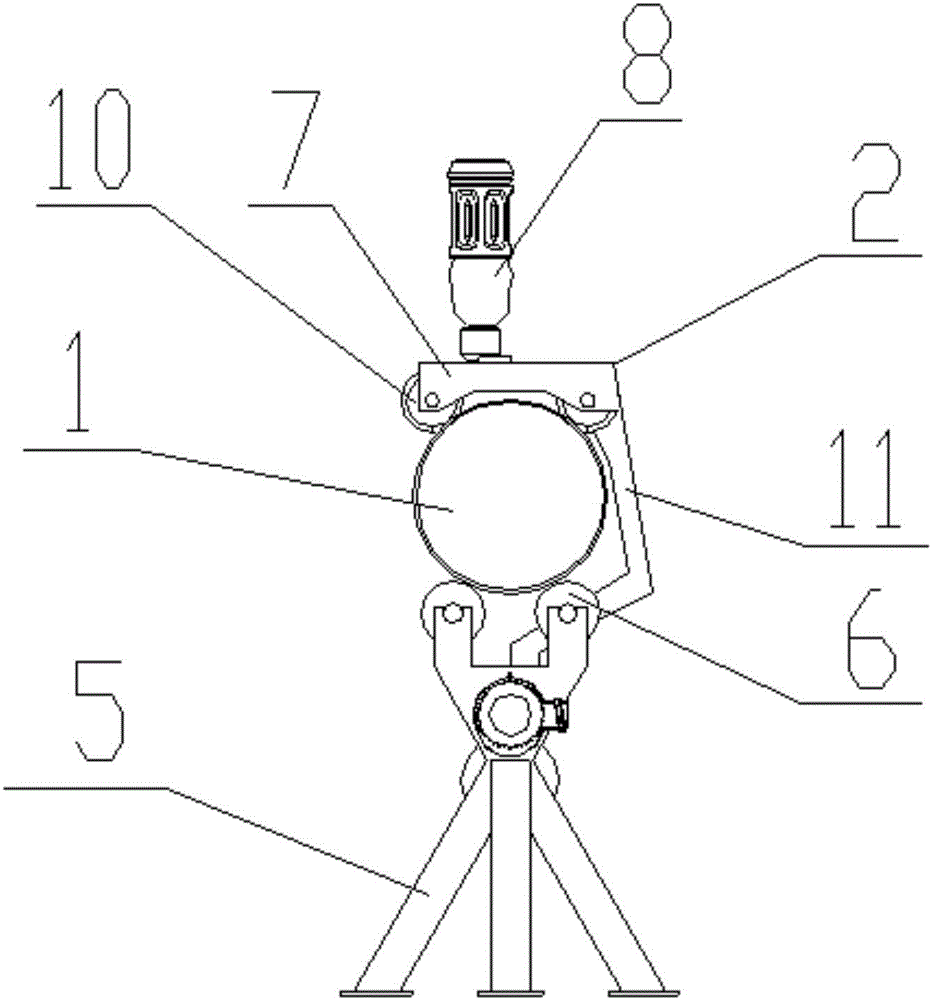

RTV anti-pollution-flashover coating apparatus for coating insulator

The invention provides an RTV anti-pollution-flashover coating apparatus for coating an insulator. The RTV anti-pollution-flashover coating apparatus comprises a bearing mechanism, an input apparatus and a control apparatus, wherein the bearing mechanism is used for detachably hooking the insulator; the input apparatus is used for inputting coating parameters; the control apparatus is connected with the input apparatus and used for receiving the coating parameters and determining coating time according to the coating parameters; the control apparatus is also connected with the bearing mechanism and used for controlling the rotation of the bearing mechanism to enable the insulator to be impregnated in an RTV container, and controlling the bearing mechanism to rotate to enable the insulator to move out of the RTV container after the coating time is reached; and the RTV container is used for accommodating the RTV anti-pollution-flashover coating. By adoption of the RTV anti-pollution-flashover coating apparatus, the automatic coating for the insulator is realized without requiring manual control of an operator in real time, so that the workload of the operator is greatly reduced and the error rate is lowered; in addition, the control apparatus can determine the coating time according to the coating parameter; therefore, the time for coating the RTV anti-pollution-flashover coating on the insulator can be effectively ensured, thereby further improving the coating quality for the insulator; and moreover, the usage amount of the RTV anti-pollution-flashover coating can be effectively reduced.

Owner:CHINA ELECTRIC POWER RES INST +1

Automatic film wrapping device

The invention provides an automatic film wrapping device, which comprises: a conveying assembly provided with a conveying belt suitable for bearing an optical fiber disc, wherein the conveying belt is suitable for circularly running in the length direction of the conveying belt; a film disc rotationally arranged over the conveying belt, wherein the winding film of the film disc is suitable for moving downwards to make contact with the circumferential direction of the optical fiber disc; a cutting assembly provided with a telescopic cutting piece, wherein the cutting piece is used for cutting off the winding film; a clamping assembly provided with a clamping disc which is rotatably arranged, wherein the clamping disc is suitable for being axially connected with the optical fiber disc and driving the optical fiber disc to axially rotate; and a film pressing assembly provided with a film pressing part which is rotationally arranged, wherein the film pressing part has a first state of swinging downwards to be pressed and attached to the optical fiber disc and a second state of swinging upwards to enable the optical fiber disc to pass through. According to the invention, manual participation is not needed in the whole film wrapping process, automatic film wrapping is achieved, and the film wrapping efficiency is improved by adjusting the matching speed of all the assemblies.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

Storage battery plate group automatic film coating machine

ActiveCN103123978ASimple structureMovement precisionFinal product manufactureSecondary cells manufactureEngineeringUltimate tensile strength

The invention discloses a storage battery plate group automatic film coating machine. A separation space is arranged between a horizontal board and a back horizontal board; a battery case blanking barrel is vertically arranged at the right side of the separation space; a battery case positioning cylinder is vertically arranged right below the separation space; a plate group transmission rack is arranged at the left side of the separation space; the back side of the horizontal board is provided with a transverse film cut-off clearance; the horizontal board is provided with a cut-off knife moving mechanism which is arranged below the film cut-off clearance and is provided with a cut-off knife; the horizontal board is provided with a film press board which is arranged above the film cut-off clearance and can be moved in the vertical direction; a plate group output rail is arranged below the back horizontal board; a plate group output cylinder is arranged below the horizontal board; a piston rod of the plate group output cylinder is connected with a push board; and the push board can be moved backwards to push a battery case on the battery case positioning cylinder to the plate group output rail for output. The storage battery plate group automatic film coating machine disclosed by the invention is simple in structure and accurate in movement, realizes the automatic film coating of storage battery plate groups, lowers the labor intensity and improves the film coating efficiency.

Owner:CHENZHOU NAIPU POWER SUPPLY CO LTD

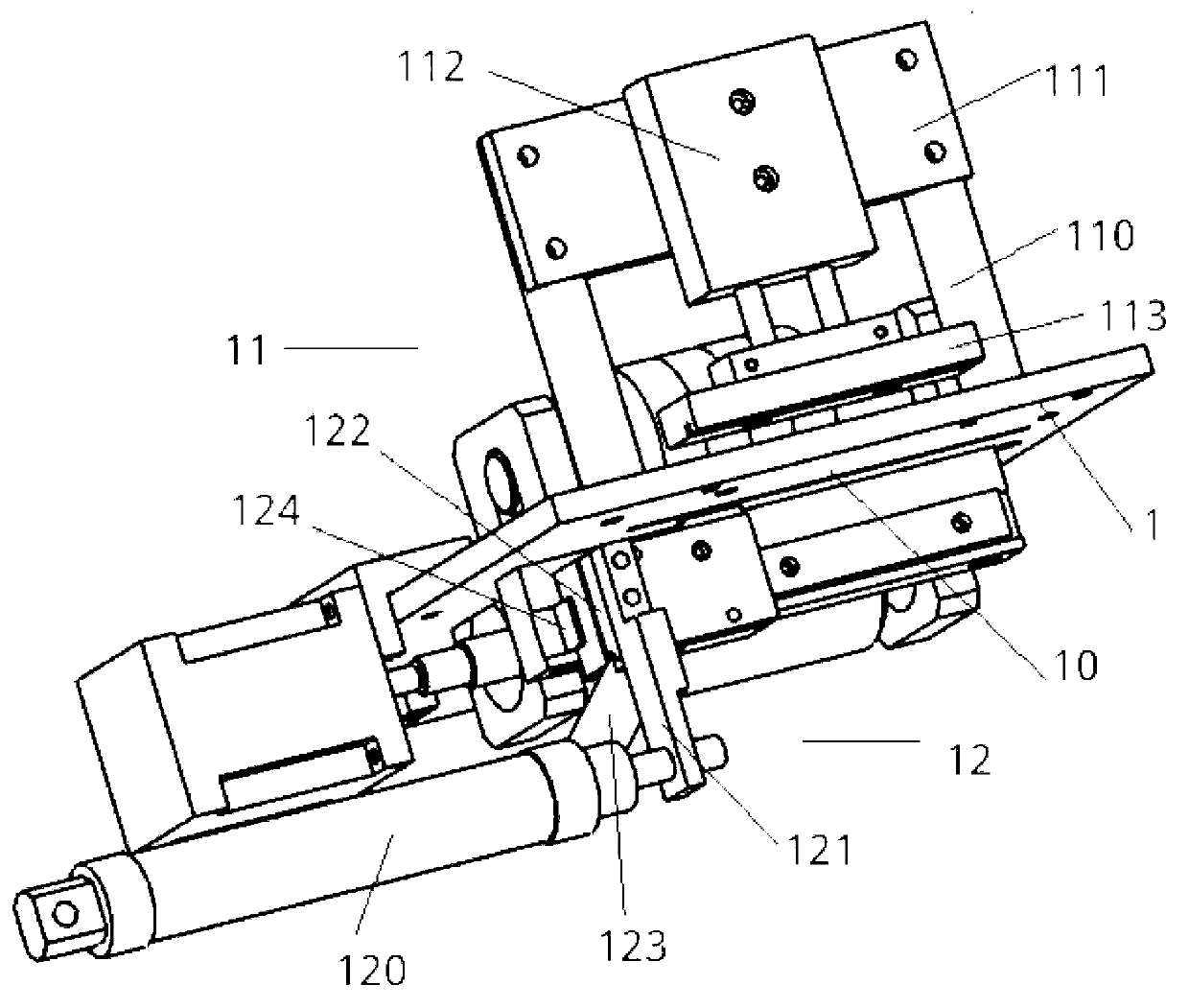

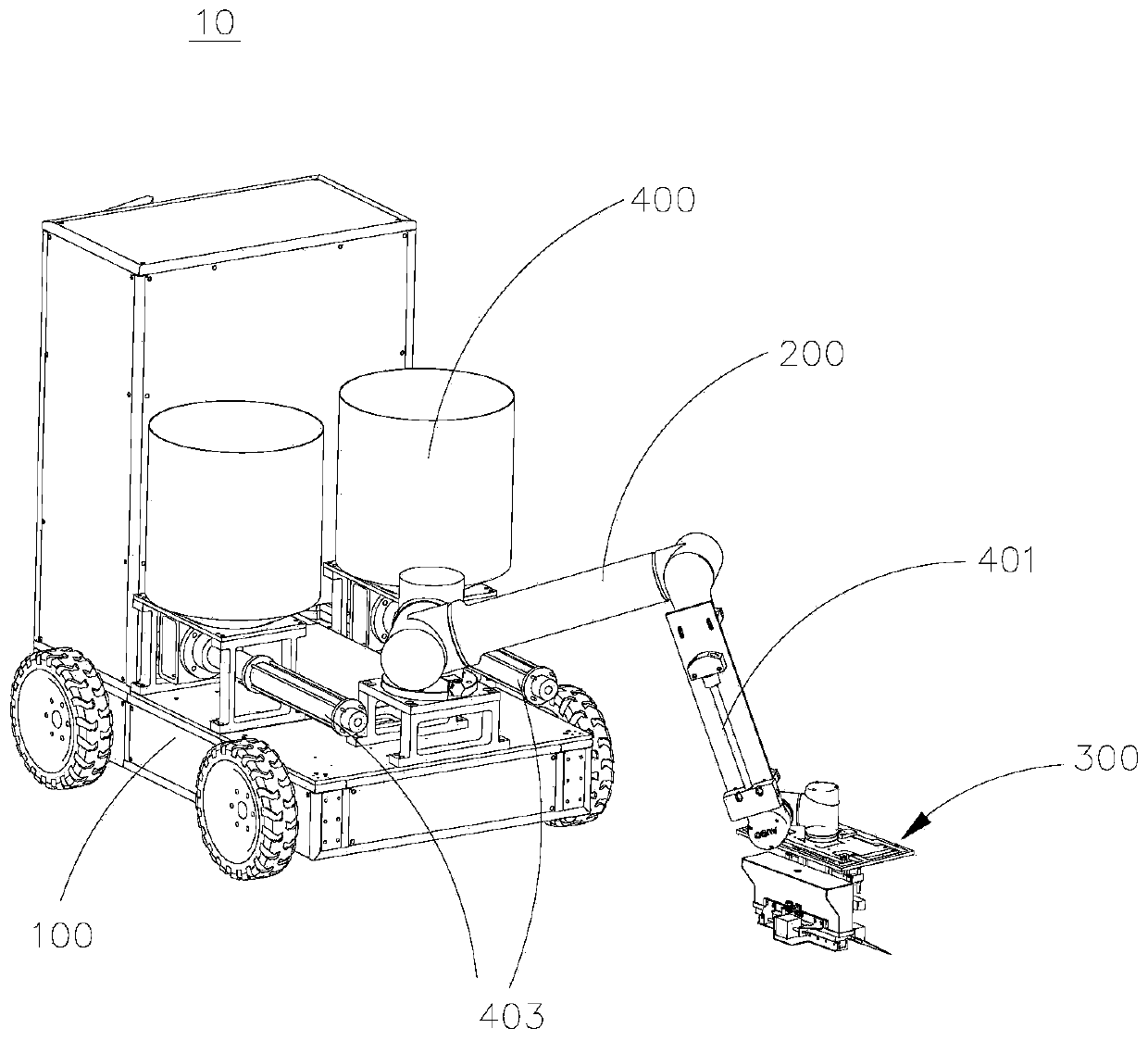

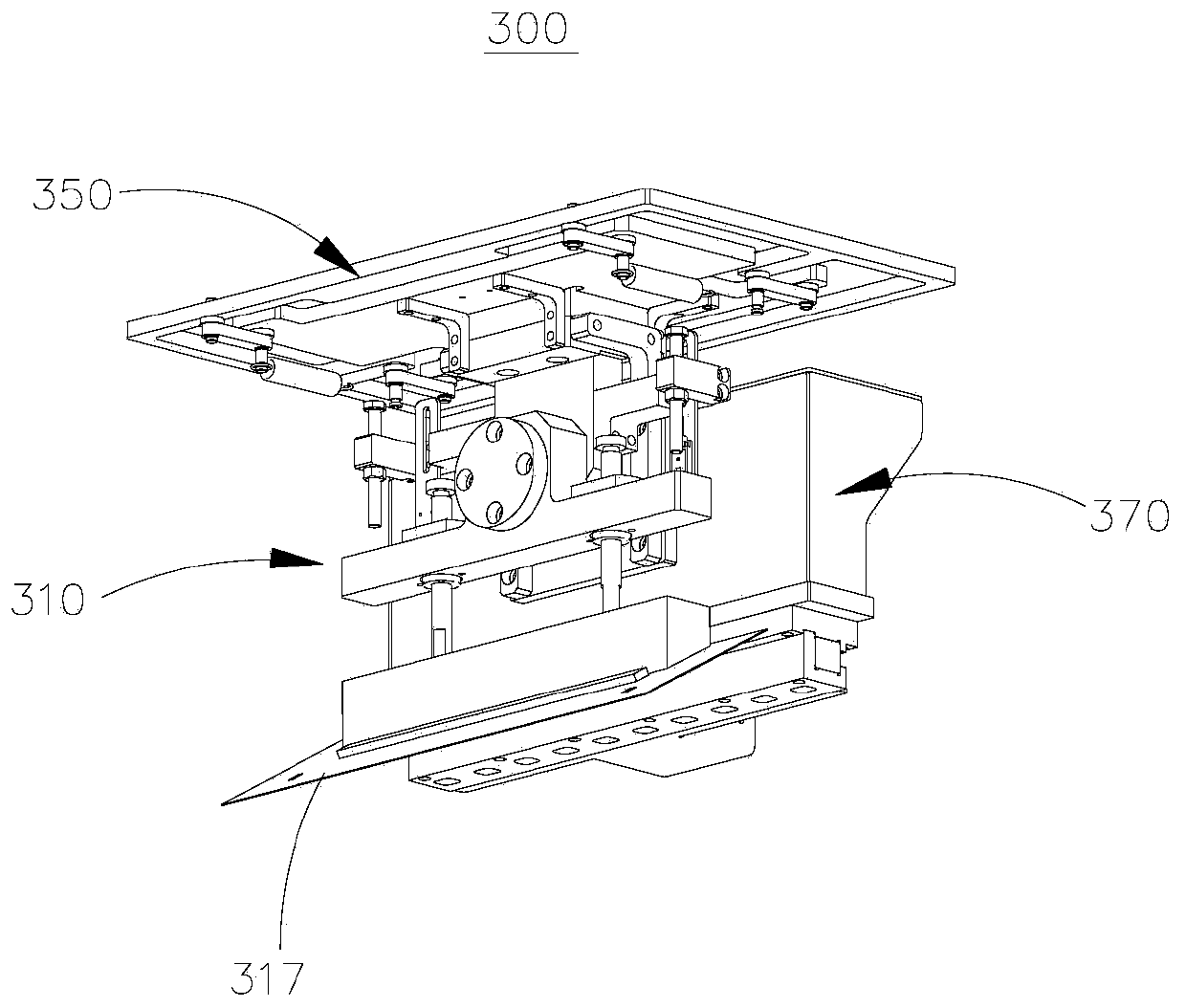

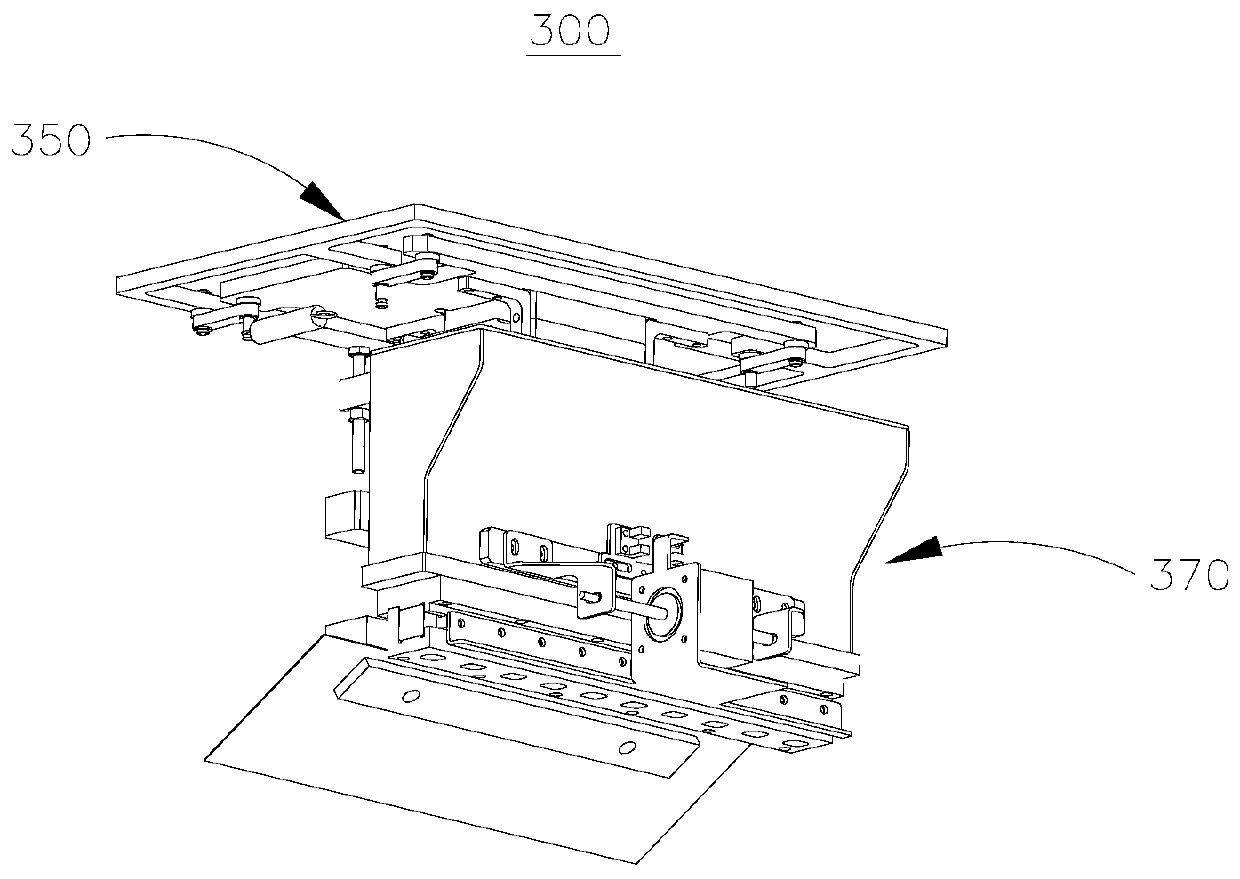

Coating and scraping mechanism and coating device

ActiveCN111530688AClose contactImprove coating qualityLiquid surface applicatorsBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a coating and scraping mechanism and a coating device, and relates to the field of robots. The coating and scraping mechanism comprises a fixing seat, a swing seat, a scraper and an elastic part, and wherein the swing seat is rotatably connected with the fixing seat through a pivot rotating shaft; the scraper is obliquely arranged from a first end to a second end in the extending direction of the pivot rotating shaft, a guiding column is arranged on the scraper, and the guiding column is vertically and slidably arranged on the swing seat in a penetrating mode; and the two ends of the elastic part are correspondingly connected with the scraper and the swing seat. According to the coating and scraping mechanism, the self-adaption of the scraper to a working surface can be achieved to ensure the coating quality, meanwhile automatic coating of the coating device is achieved, and the problems of harm to health, high labor intensity, complex process, high cost and thelike in existing manual operation are effectively solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

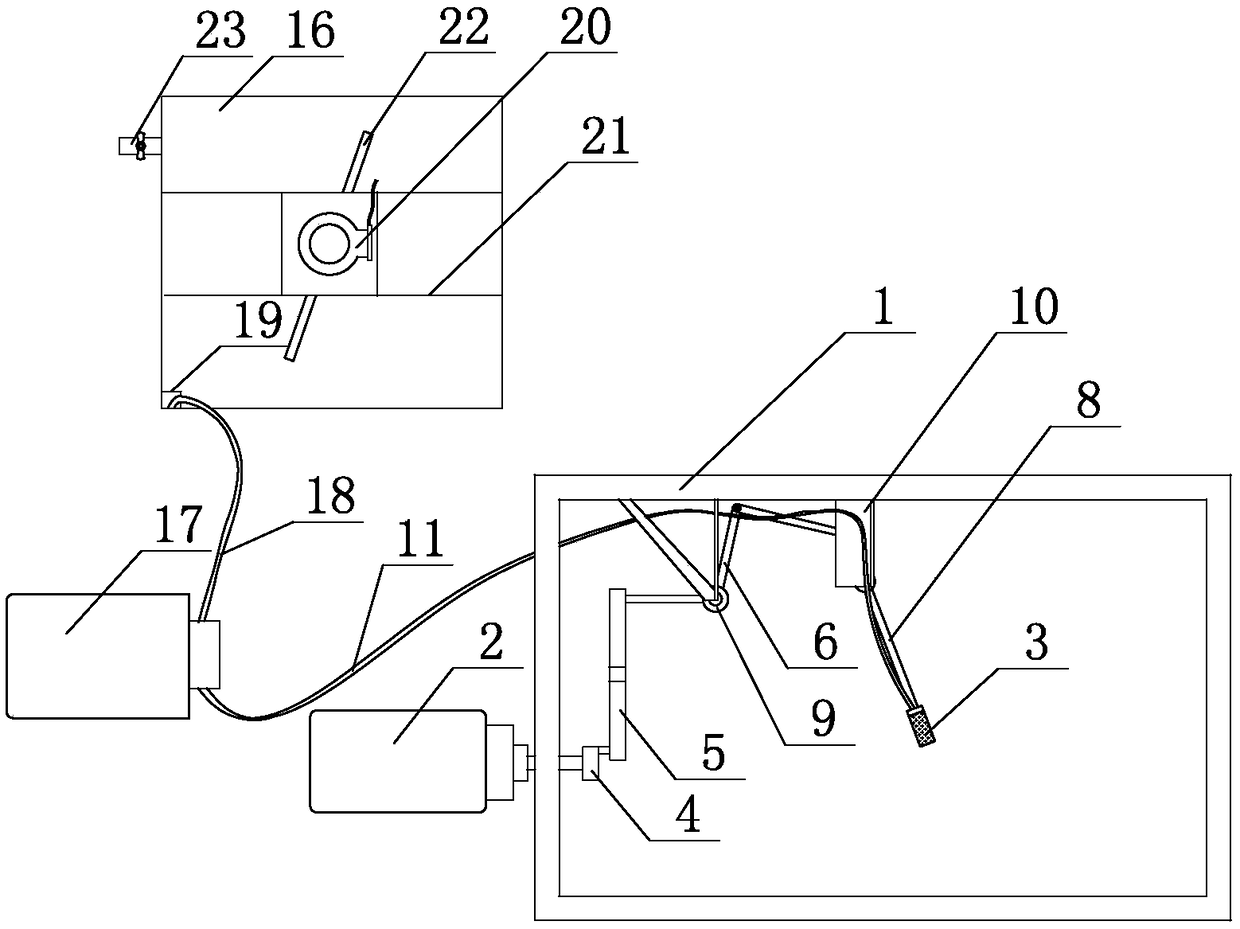

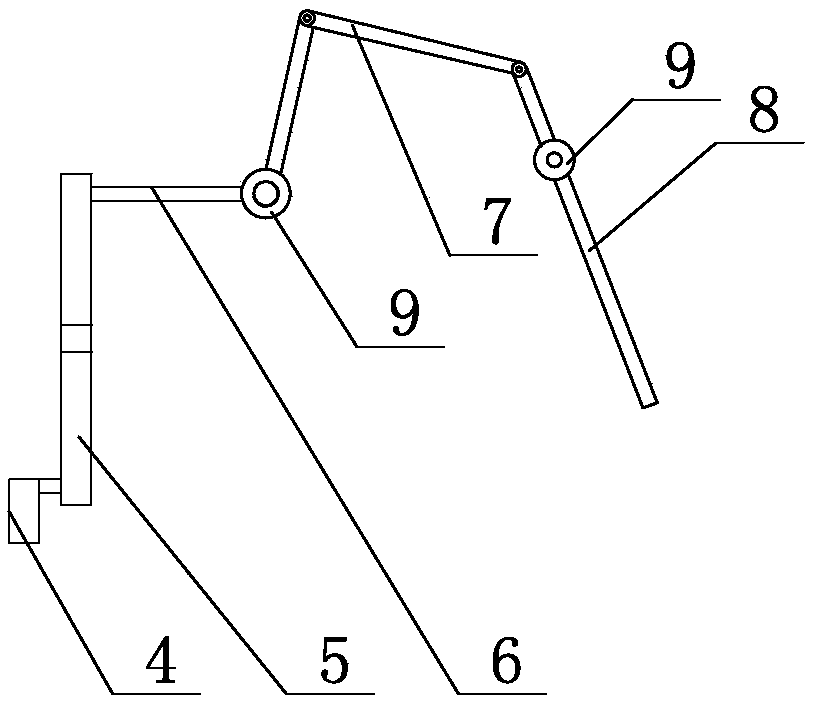

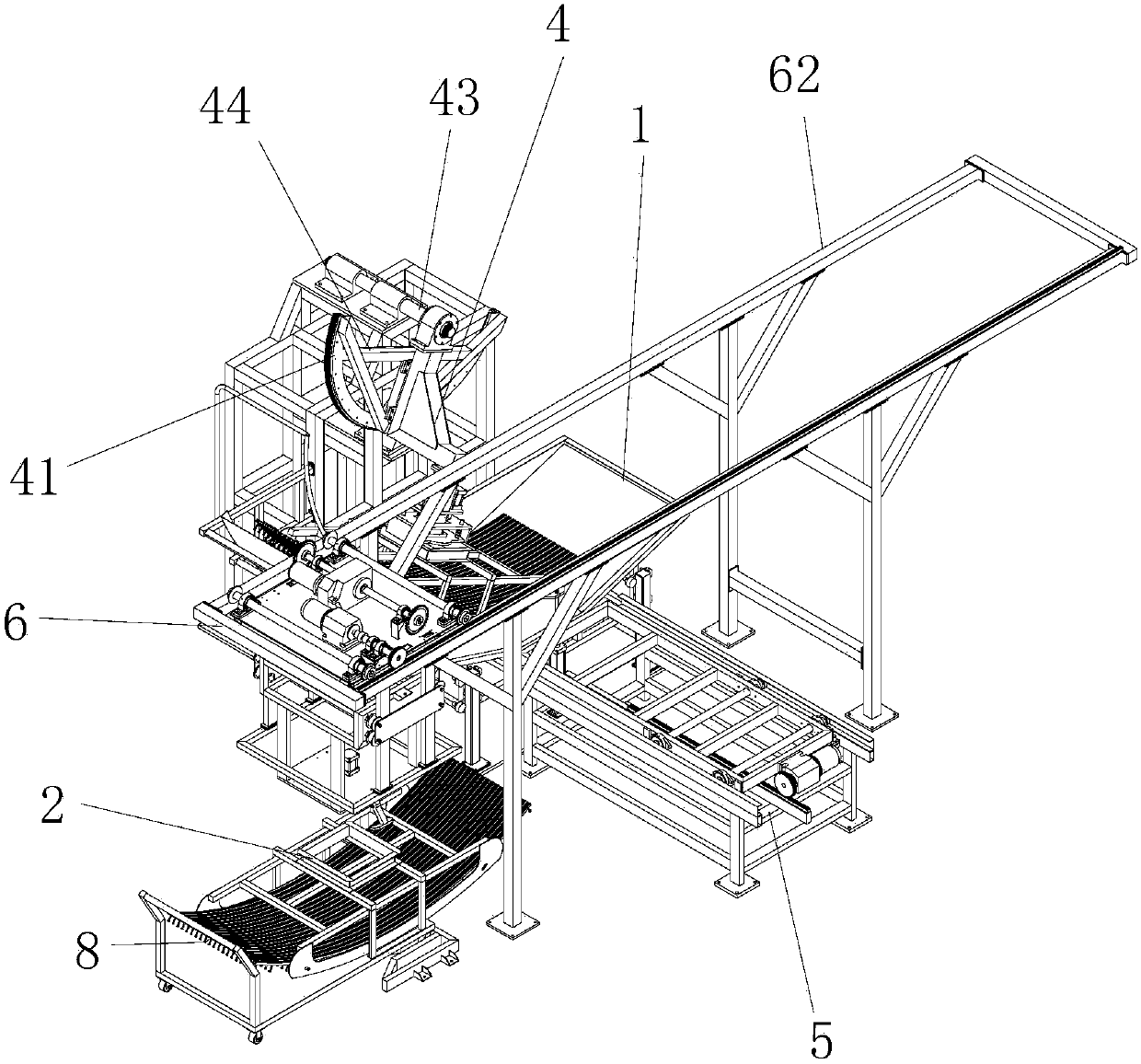

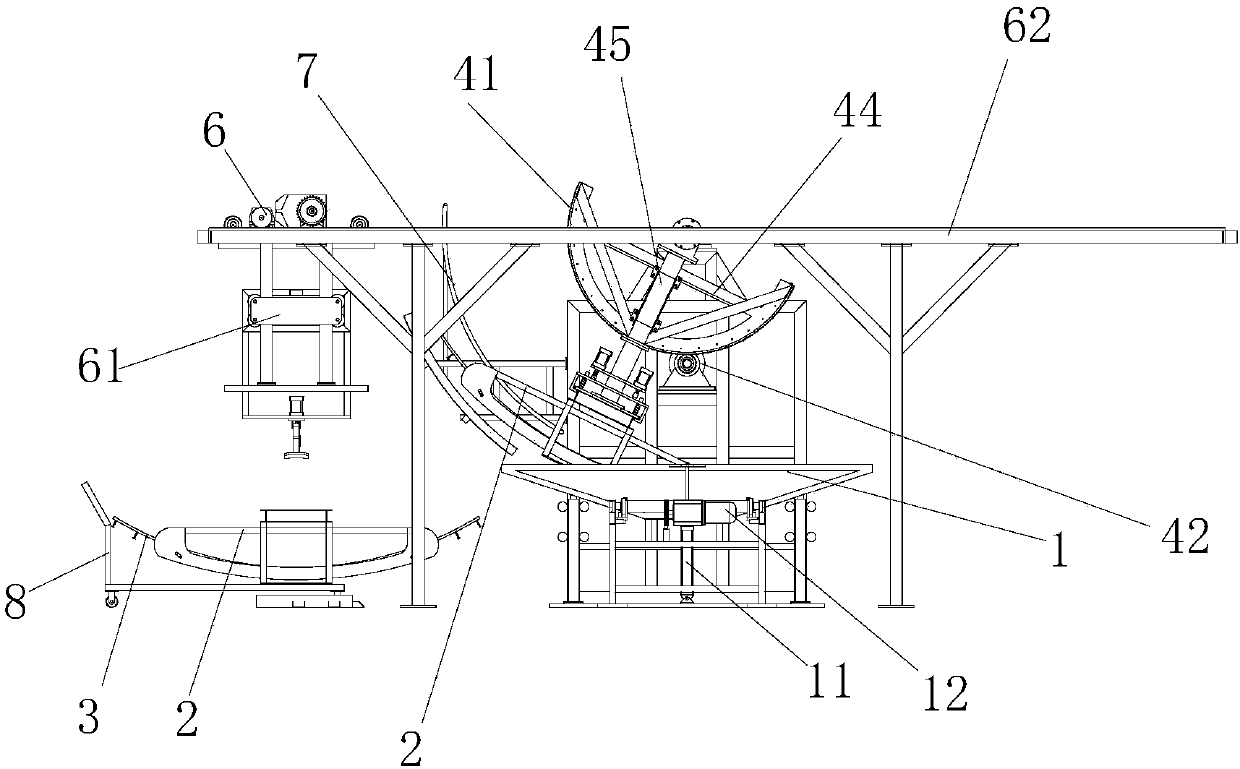

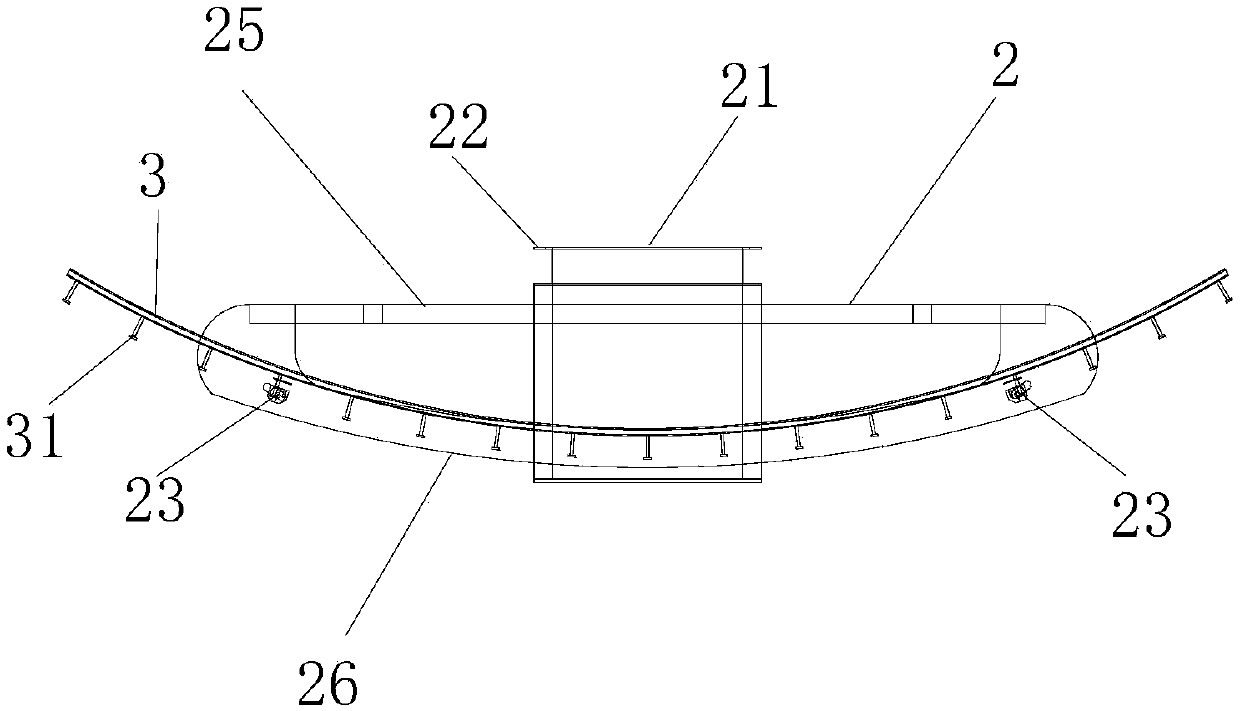

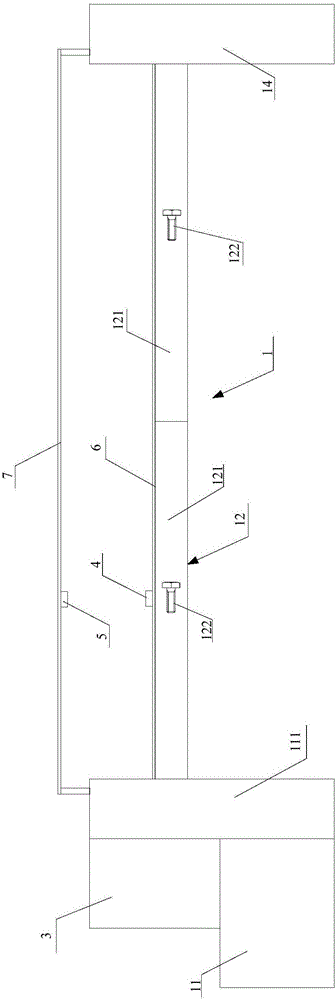

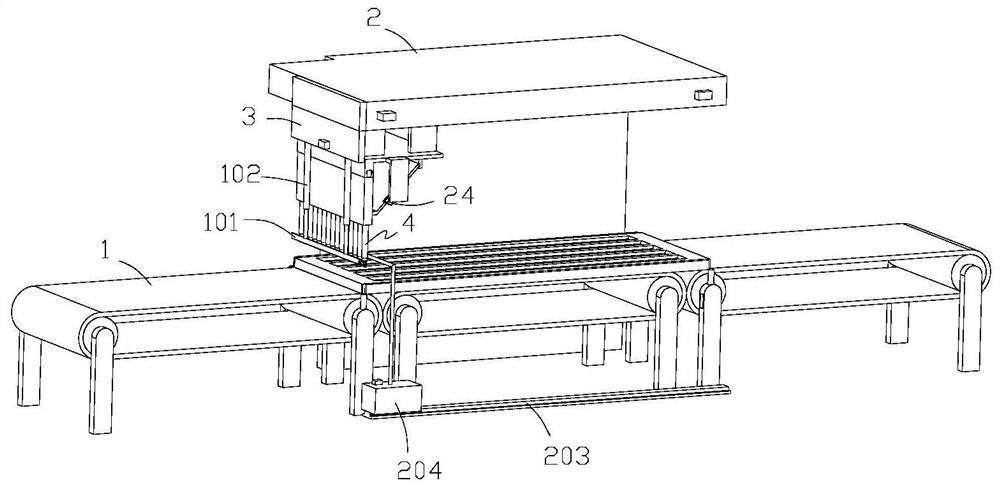

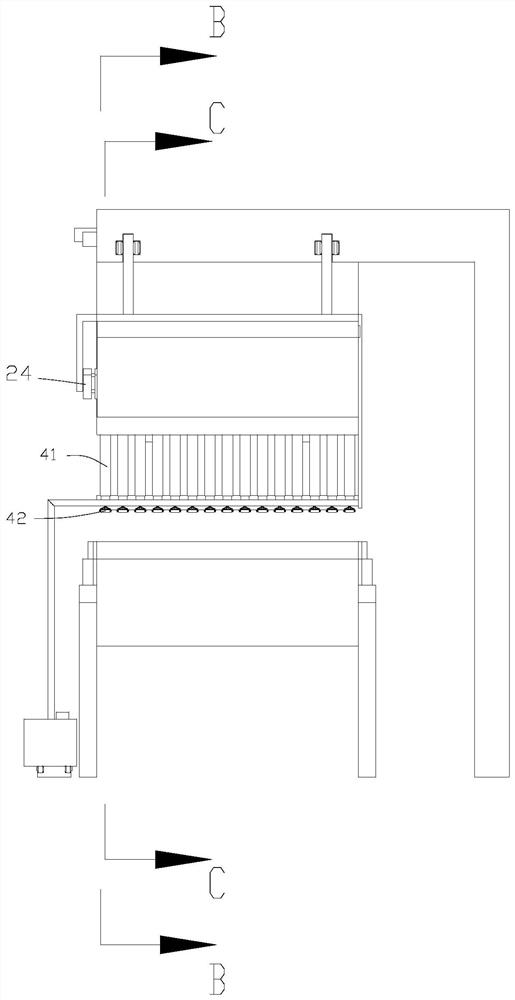

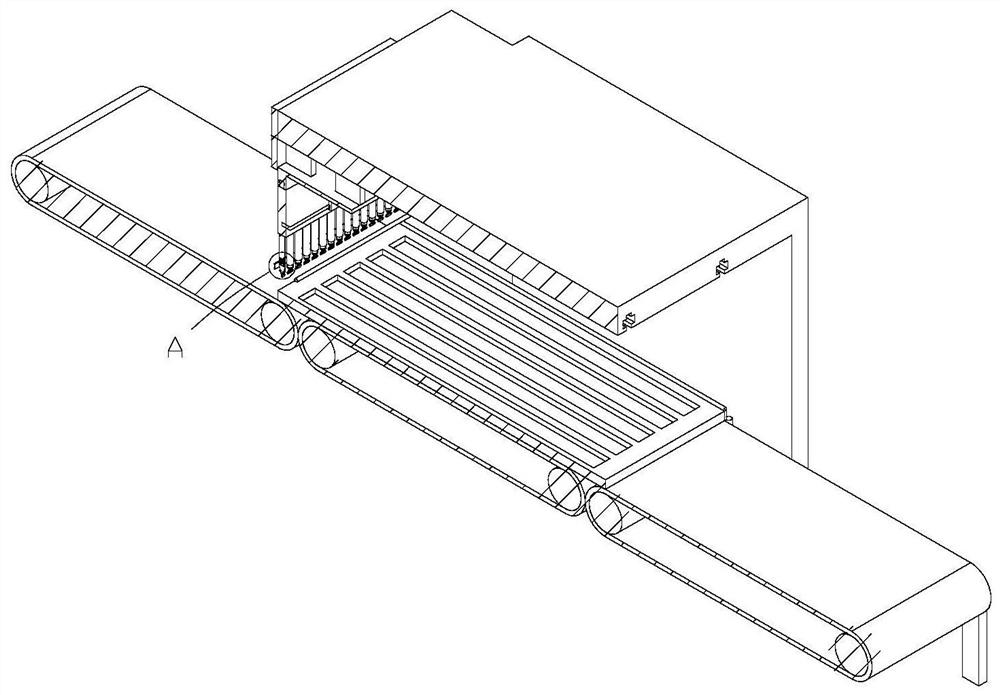

A processing equipment for the production of FRP wall panels

ActiveCN111195577BRealize automatic feedingRealize automatic coatingLiquid surface applicatorsCoatingsGlass fiberGelcoat

The invention discloses processing equipment for glass fiber reinforced plastic wallboard production. The processing equipment comprises a conveying belt, a material pressing device and a gluing device, wherein the conveying belt is used for conveying a to-be-processed wallboard; the material pressing device is used for pressing at least one end of to-be-processed glass fiber cloth on the wallboard; the gluing device is used for coating gel coat resin on the glass fiber cloth covering the wallboard, and the gluing device comprises a support, a gluing component and a gluing component, wherein the gluing component and the gluing component can reciprocate relative to the support in the length direction of the support; and the gluing component comprises an installation base and multiple gluingpieces arranged on the installation base, wherein each gluing piece comprises a gluing arm, a gluing head arranged below the gluing arm, a telescopic structure used for enabling the gluing head to float up and down relative to the length direction of the gluing arm as well as an angle adjusting structure used for enabling the gluing head to turn over by 180 degrees in the left-right direction relative to the gluing arm. According to the processing equipment for glass fiber reinforced plastic wallboard production, automatic feeding of the wallboard and automatic coating of the gel coat are achieved, the working efficiency is high, and the quality of the wallboard obtained through final machining is effectively improved.

Owner:浙江联丰冷却塔有限公司

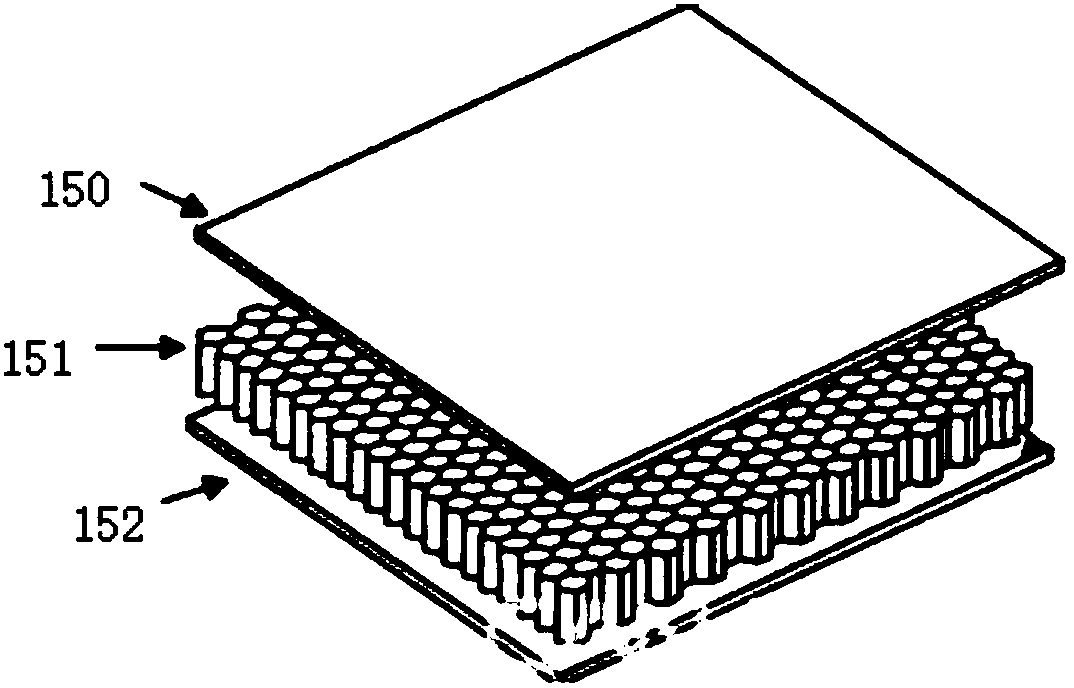

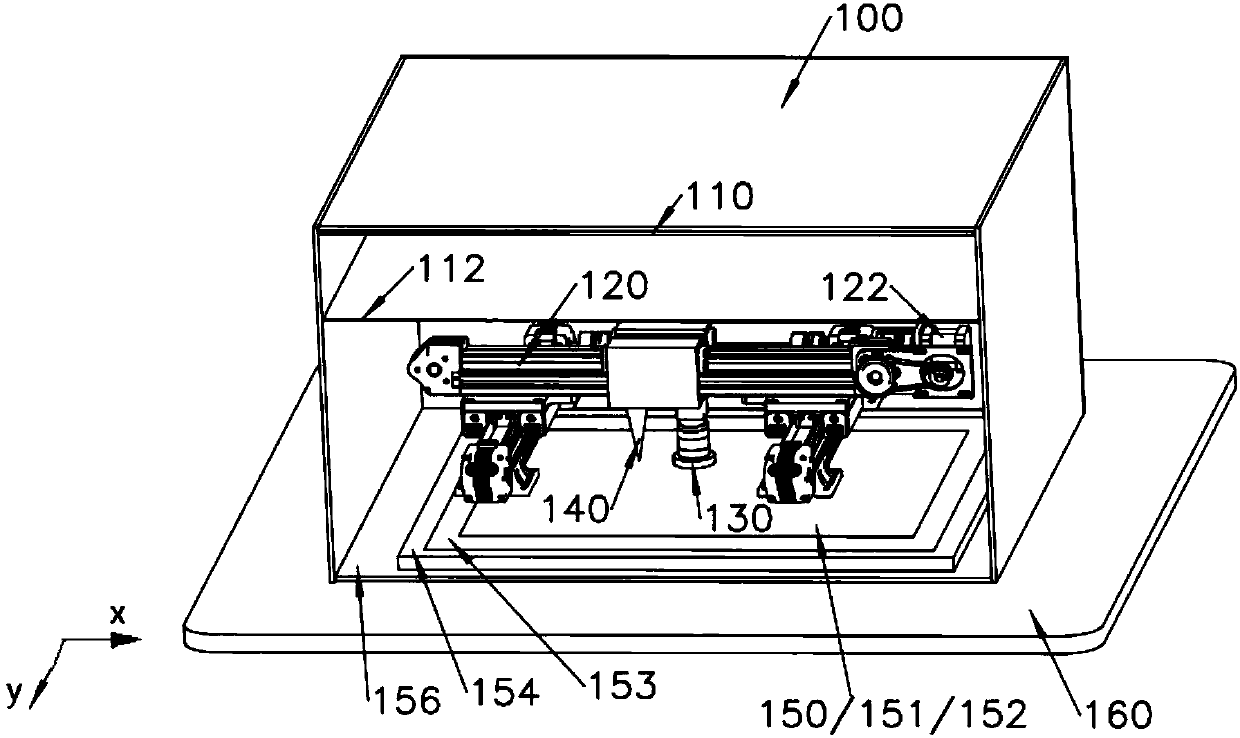

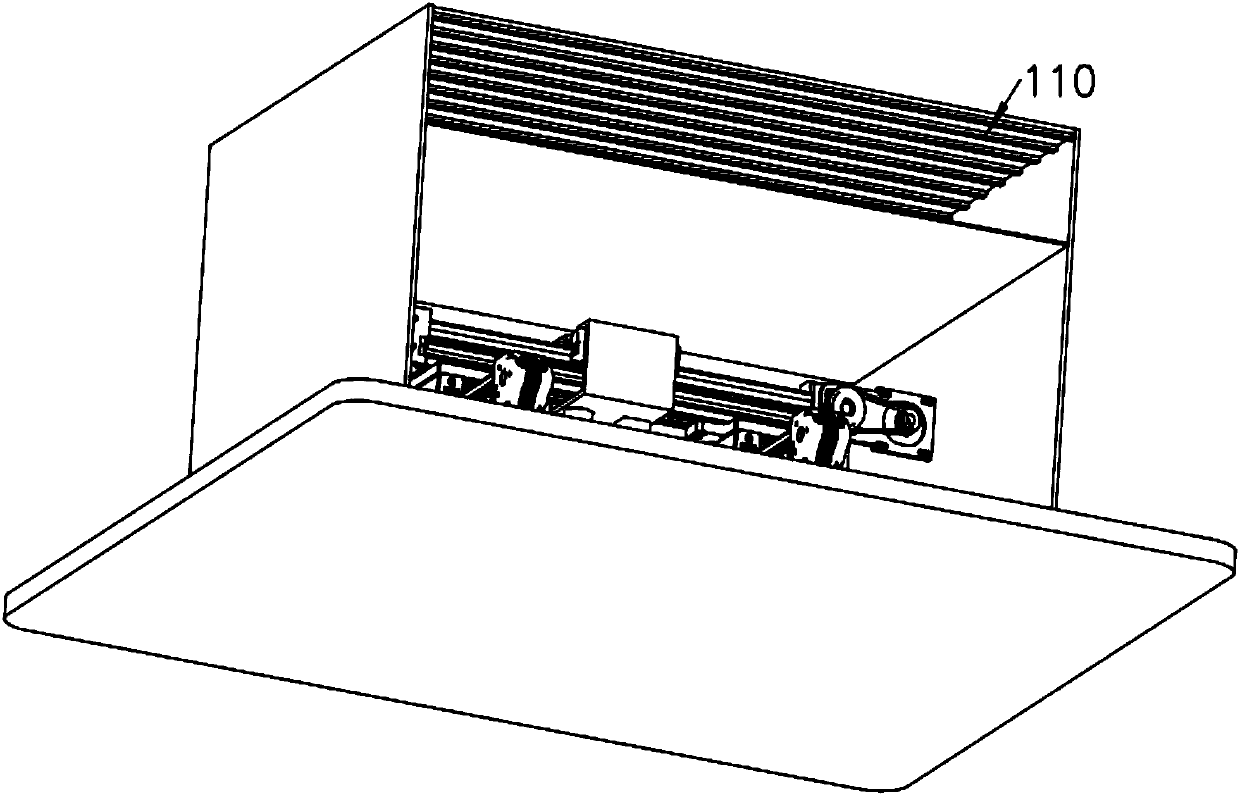

Device and method for coating honeycomb plate

ActiveCN108014962ALess corrosiveIncrease profitLiquid surface applicatorsCoatingsHoneycombStructural engineering

The invention discloses a device and a method for coating a honeycomb plate. The device comprises: a supporting frame; a darkroom cover plate arranged on the supporting frame and used for forming a darkroom; a light source arranged in the darkroom; a slide table module arranged in the darkroom cover plate and moving relative to the supporting frame along a horizontal Y direction; an imager arranged on the slide table module, being able to slide relative to the slide table module along a horizontal X direction and used for imaging the honeycomb plate; a nozzle arranged on the slide table moduleand sliding relative to the slide table module along a horizontal X direction and used for coating with a combined material; a clamp arranged, on the upper surface of the supporting frame, in the darkroom cover plate and used for fixing at least one of the upper plate, the lower plate and the honeycomb core of the honeycomb plate, wherein a calibrating frame is arranged surrounding the clamp, andthe calibrating frame is provided with a scale; an image processor used for processing the shot image of the imager; and a servo motor used for controlling the movement of the slide table module andthe sliding of the imager and the nozzle.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD

A kind of automatic roll coating method and device of alcohol-preferred composite film

InactiveCN104722211BIntegrity guaranteedControl and reduce thicknessSemi-permeable membranesAlcoholLiquid tank

The invention discloses an automatic roll-coating method and device of an ethanol-permselective composite membrane, belonging to the technical field of membrane coating of separation membranes. A coating device comprises a roller, a gear, a support plate, a base, a motor, a feed liquid tank, a lifting table and the like. The coating method provided by the invention comprises the following steps: pouring membrane preparing liquid into a storage tank, conveying the feed liquid to the feed liquid tank through an automatic feeding device, adjusting the height of the feed liquid tank by using the lifting table and the scale marks at one end of the roller; rotating the roller through the driving of the motor so as to uniformly coat a base membrane with the feed liquid. Through the adoption of the method and the device disclosed by the invention, the thickness of a separation layer can be effectively controlled and reduced, the permeation flux is greatly improved, and the automatic coating of the ethanol-permselective composite membrane is realized.

Owner:BEIJING UNIV OF TECH

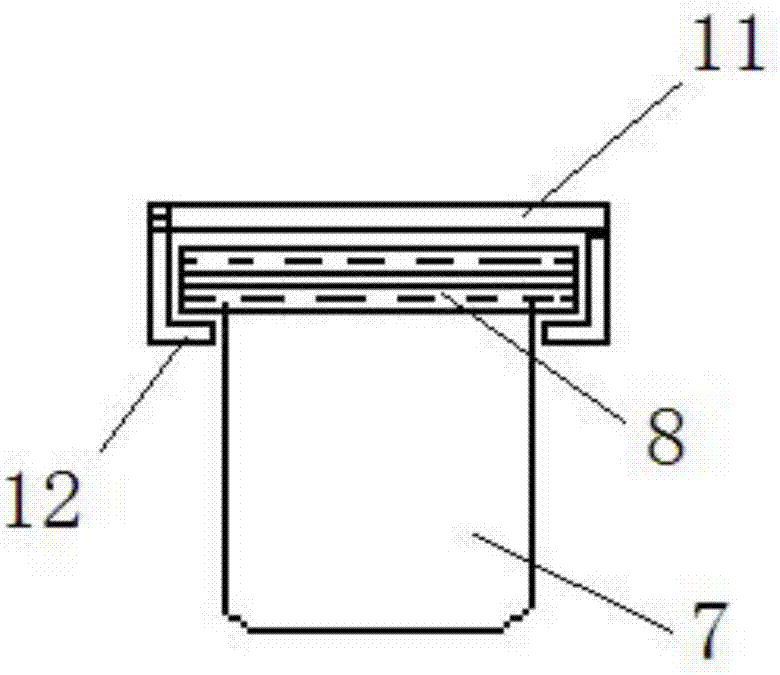

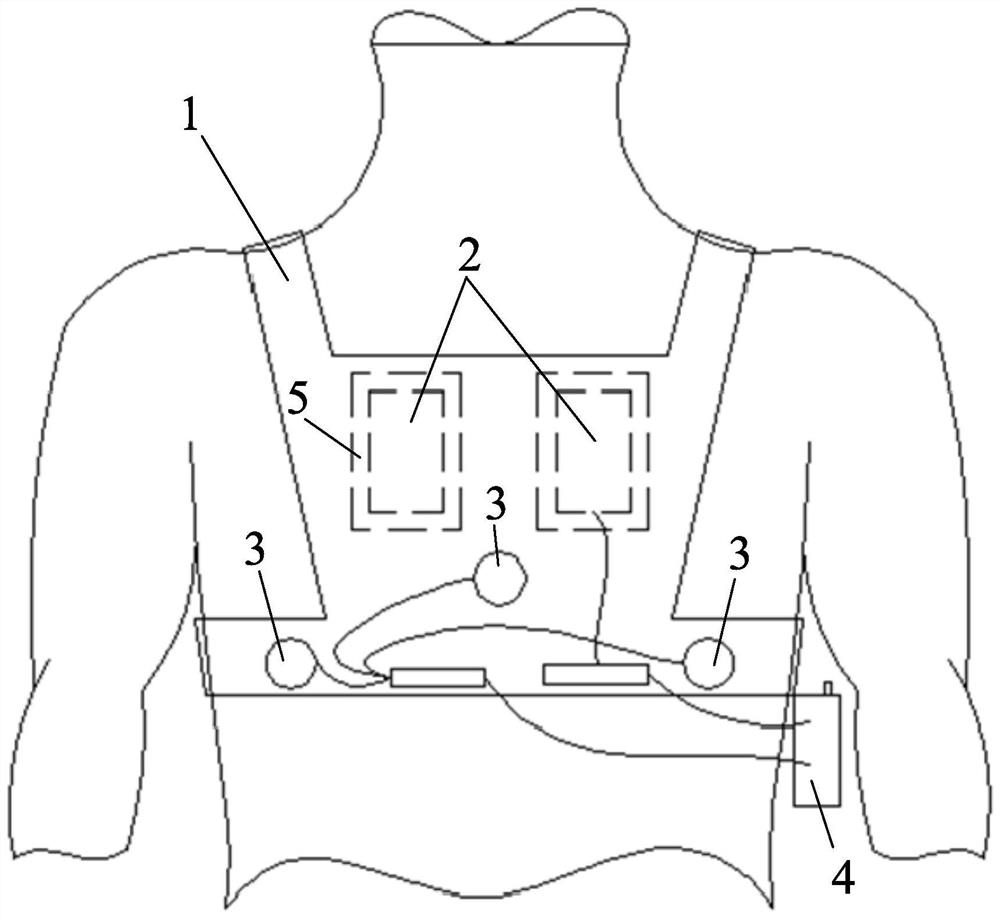

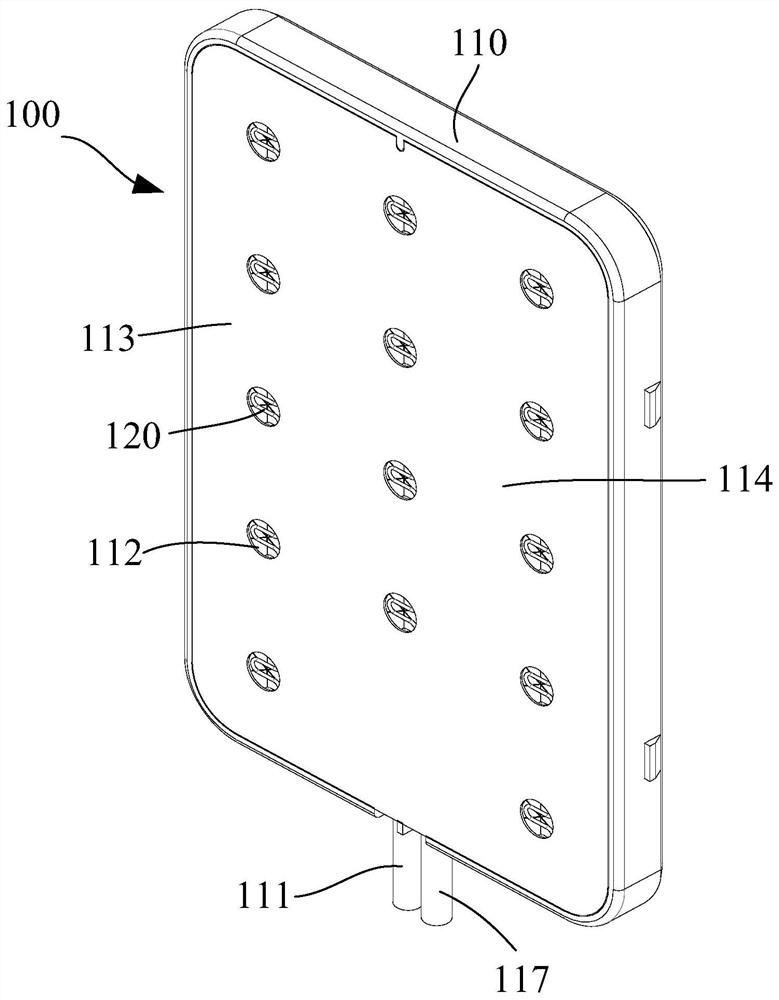

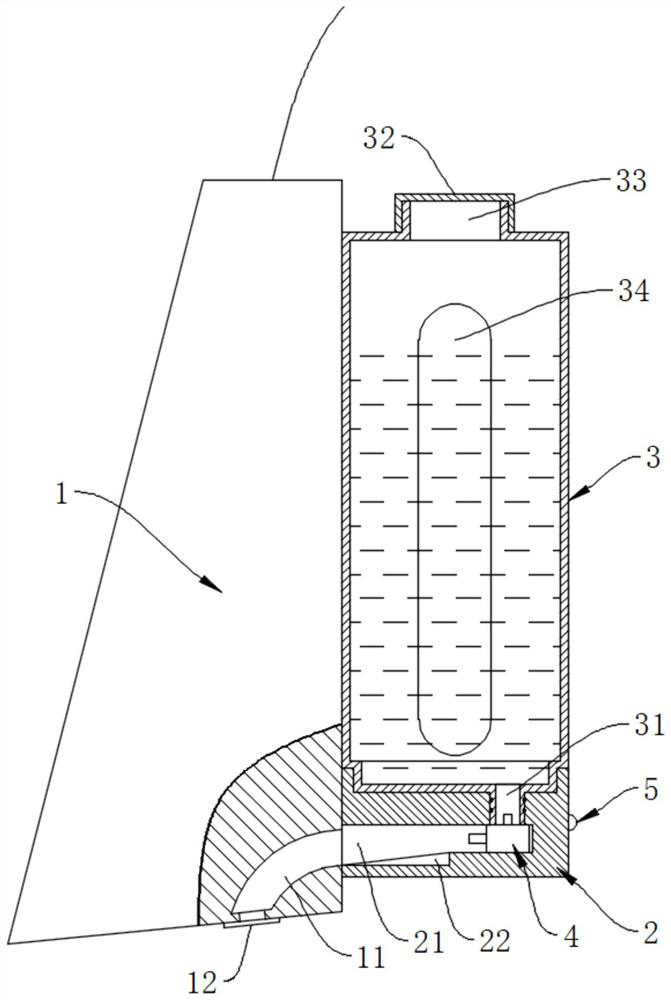

Electrode plate and wearable defibrillation device

PendingCN113730810ATimely protectionImprove securityLiquid surface applicatorsEngine sealsElectrically conductiveBiomedical engineering

The invention relates to an electrode plate and a wearable defibrillation device. The electrode plate comprises a sealing shell and capsules arranged in the sealing shell; the sealing shell is provided with an inflation port and glue overflow ports; the glue overflow ports are formed in an exposed surface of the sealing shell and the exposed surface has conductivity; the capsule comprises a body and a cover, the body is provided with a hollow cavity and an outlet communicating with the cavity, and the cavity is used for storing a conductive paste, and isolated from an empty cavity of the sealing shell; the cover is arranged at an outlet and used for sealing the outlet; and a gap formed after the cover is broken communicates with the outlet and the glue overflow port, such that the conductive paste in the cavity flows out to the exposed surface through the outlet, the gap of the cover and the glue overflow port in sequence. The device has advantages of automatically coating the conductive paste, protecting a patient in time, and improving release safety of the conductive paste.

Owner:MICROPORT SORIN CRMSHANGHAICO LTD

Storage battery plate group automatic film coating machine

ActiveCN103123978BSimple structureMovement precisionFinal product manufactureSecondary cells manufactureEngineeringUltimate tensile strength

The invention discloses a storage battery plate group automatic film coating machine. A separation space is arranged between a horizontal board and a back horizontal board; a battery case blanking barrel is vertically arranged at the right side of the separation space; a battery case positioning cylinder is vertically arranged right below the separation space; a plate group transmission rack is arranged at the left side of the separation space; the back side of the horizontal board is provided with a transverse film cut-off clearance; the horizontal board is provided with a cut-off knife moving mechanism which is arranged below the film cut-off clearance and is provided with a cut-off knife; the horizontal board is provided with a film press board which is arranged above the film cut-off clearance and can be moved in the vertical direction; a plate group output rail is arranged below the back horizontal board; a plate group output cylinder is arranged below the horizontal board; a piston rod of the plate group output cylinder is connected with a push board; and the push board can be moved backwards to push a battery case on the battery case positioning cylinder to the plate group output rail for output. The storage battery plate group automatic film coating machine disclosed by the invention is simple in structure and accurate in movement, realizes the automatic film coating of storage battery plate groups, lowers the labor intensity and improves the film coating efficiency.

Owner:CHENZHOU NAIPU POWER SUPPLY CO LTD

Improved structure of storage battery plate group automatic film coating machine

InactiveCN103123963BSimple structureMovement precisionElectrode manufacturing processesAgricultural engineeringFilm-coated tablet

The invention discloses an improved structure of a storage battery plate group automatic film coating machine. A separation space is arranged between a horizontal board and a back horizontal board; a battery case blanking barrel is vertically arranged at the right side of the separation space; a battery case positioning cylinder is vertically arranged right below the separation space; a plate group transmission rack is arranged at the left side of the separation space; the horizontal board and the back horizontal board are provided with plate group-into-battery case guide mechanisms for guiding plate groups, which are arranged at the front side and back side of the separation space; the back side of the horizontal board is provided with a transverse film cut-off clearance; the horizontal board is provided with a cut-off knife moving mechanism which is arranged below the film cut-off clearance and is provided with a cut-off knife; a plate group output rail is arranged below the back horizontal board; a plate group output cylinder is arranged below the horizontal board; and a piston rod of the plate group output cylinder is connected with a push board. The storage battery plate group automatic film coating machine disclosed by the invention is simple in structure and accurate in movement, realizes the automatic film coating of storage battery plate groups, lowers the labor intensity and improves the film coating efficiency.

Owner:赵芳

Blood flow velocity detection device with coupling agent coating function

InactiveCN114403923ARealize automatic coatingImprove detection efficiencyBlood flow measurement devicesInfrasonic diagnosticsBlood flowEngineering

The invention relates to a blood flow velocity detection device with a coupling agent coating function, which comprises a probe body, the probe body is electrically connected with a detection host, the lower part of one side of the probe body is provided with a mounting seat, the top of the mounting seat is provided with a liquid collection container, the liquid collection container is filled with a coupling agent, the bottom of the liquid collection container is provided with an insertion port, and the insertion port is connected with the probe body. The top of the mounting base is provided with a channel which is connected with the socket in an inserted mode. A liquid collecting cavity and a liquid feeding mechanism for communicating the liquid collecting cavity with the channel are further arranged in the mounting seat, and a switch for driving the liquid feeding mechanism to work is arranged on the outer side of the mounting seat; a liquid conveying channel is arranged in the probe body, one end of the liquid conveying channel is communicated with the liquid collecting cavity, and the other end of the liquid conveying channel penetrates through the bottom of the probe body to form a liquid conveying opening. The device has a coupling agent coating function, and the detection efficiency can be improved.

Owner:刘浩

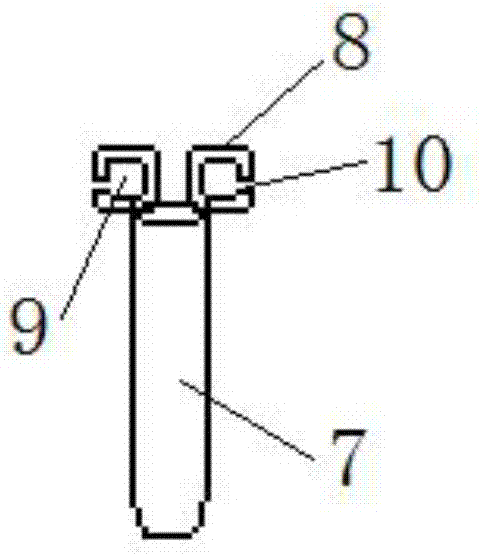

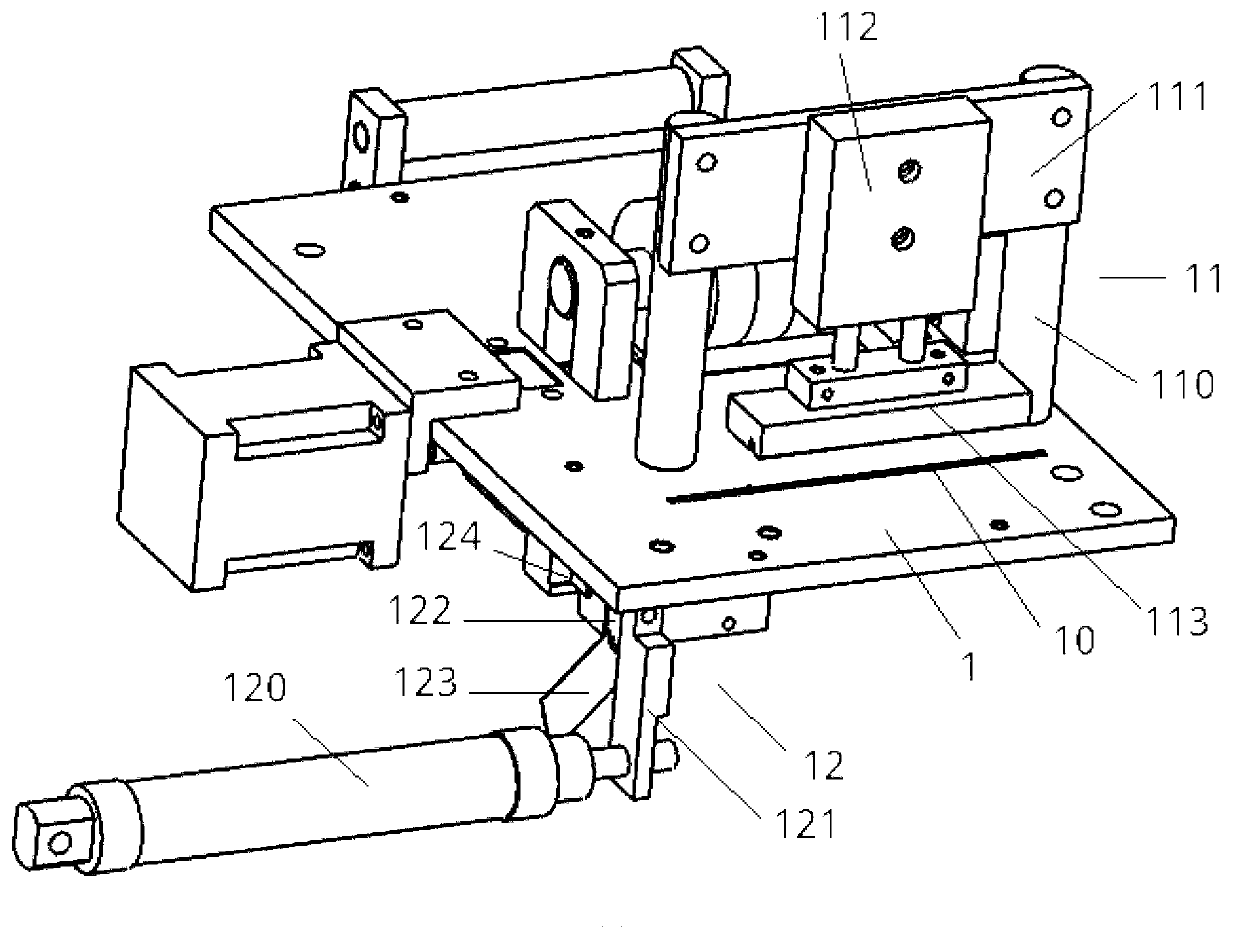

Storage battery plate group automatic coating machine improved structure

ActiveCN103151552BSimple structureMovement precisionFinal product manufactureSecondary cells manufactureMechanical engineeringVertical cylinder

The invention discloses a storage battery plate group automatic coating machine improved structure. A separated space is formed between a horizontal plate and a rear horizontal plate, a battery case blanking cylinder is vertically arranged on the right side of the separated space, a battery case locating cylinder is vertically arranged under the separated space, a plate group conveying frame is arranged on the left side of the separated space, a horizontal supporting beam is arranged at the upper end of the plate group conveying frame, a horizontal cylinder is arranged on the horizontal supporting beam, a piston rod of the horizontal cylinder is connected with a vertical cylinder, a piston rod of the vertical cylinder is connected with a mechanical arm used for grabbing plate groups, and guiding mechanisms of plate group to the battery case used for guiding the plate groups are arranged on the front side and the rear side of the separated space by the horizontal plate and the rear horizontal plate. A horizontal thin film cut gap is reserved on the rear side of the horizontal plate, and a cutting knife moving structure provided with a cutting knife is arranged below the thin film cut gap of the horizontal plate. The storage battery plate group automatic coating machine improved structure has the advantages of being simple in structure, accurate in motion and capable of achieving automatic coating of the storage battery plate groups, reducing labor intensity and improving coating efficiency.

Owner:广东贤畅环保科技有限公司

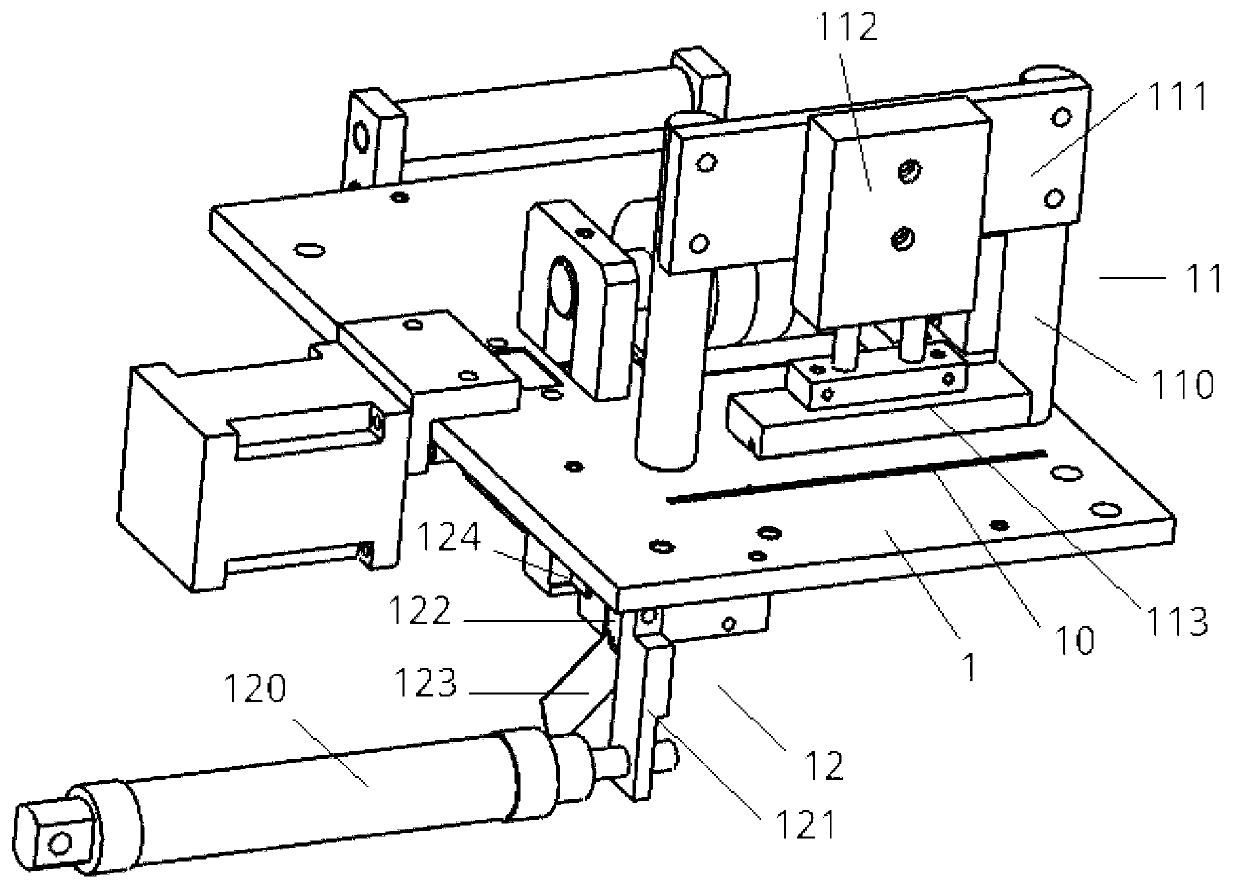

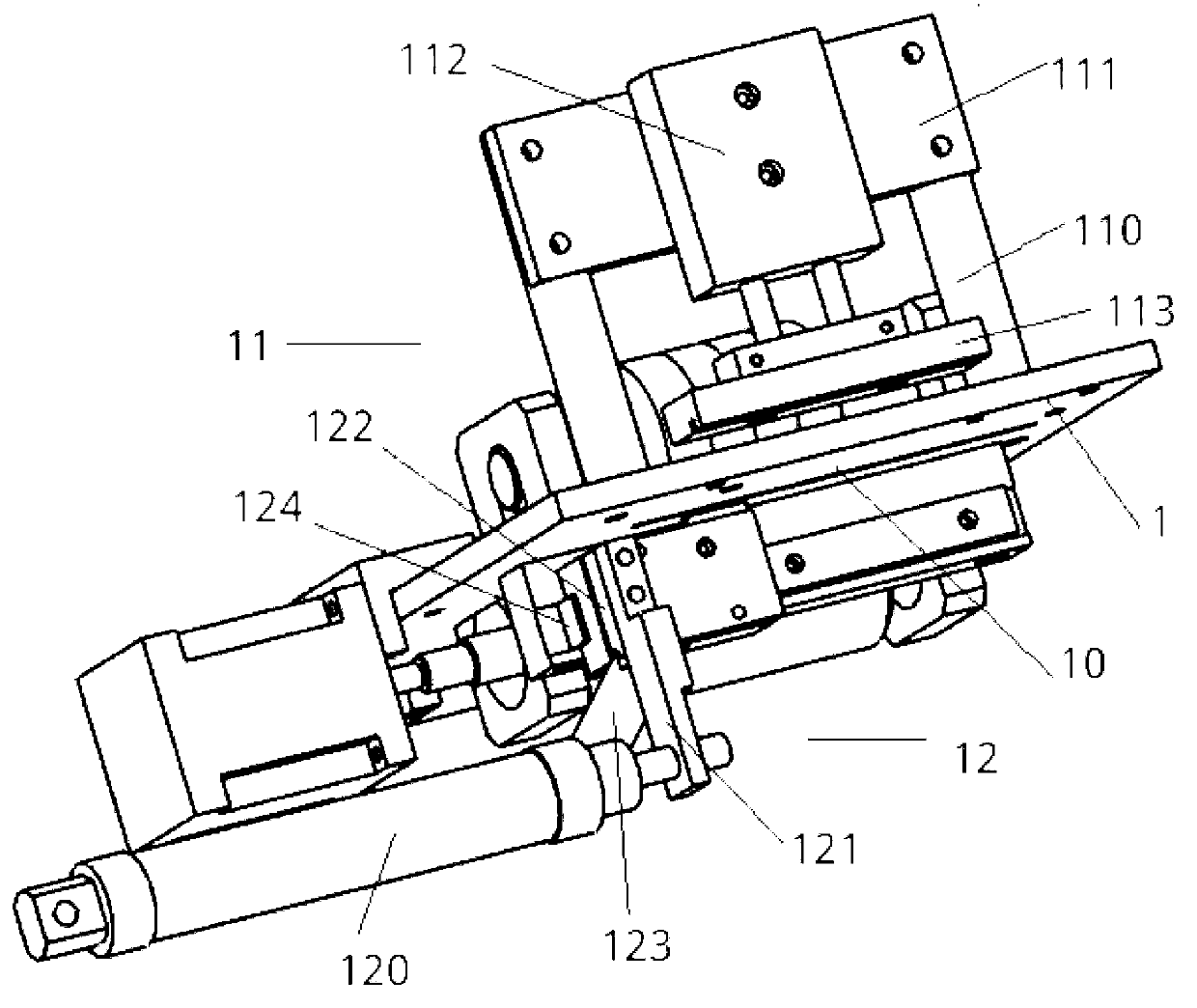

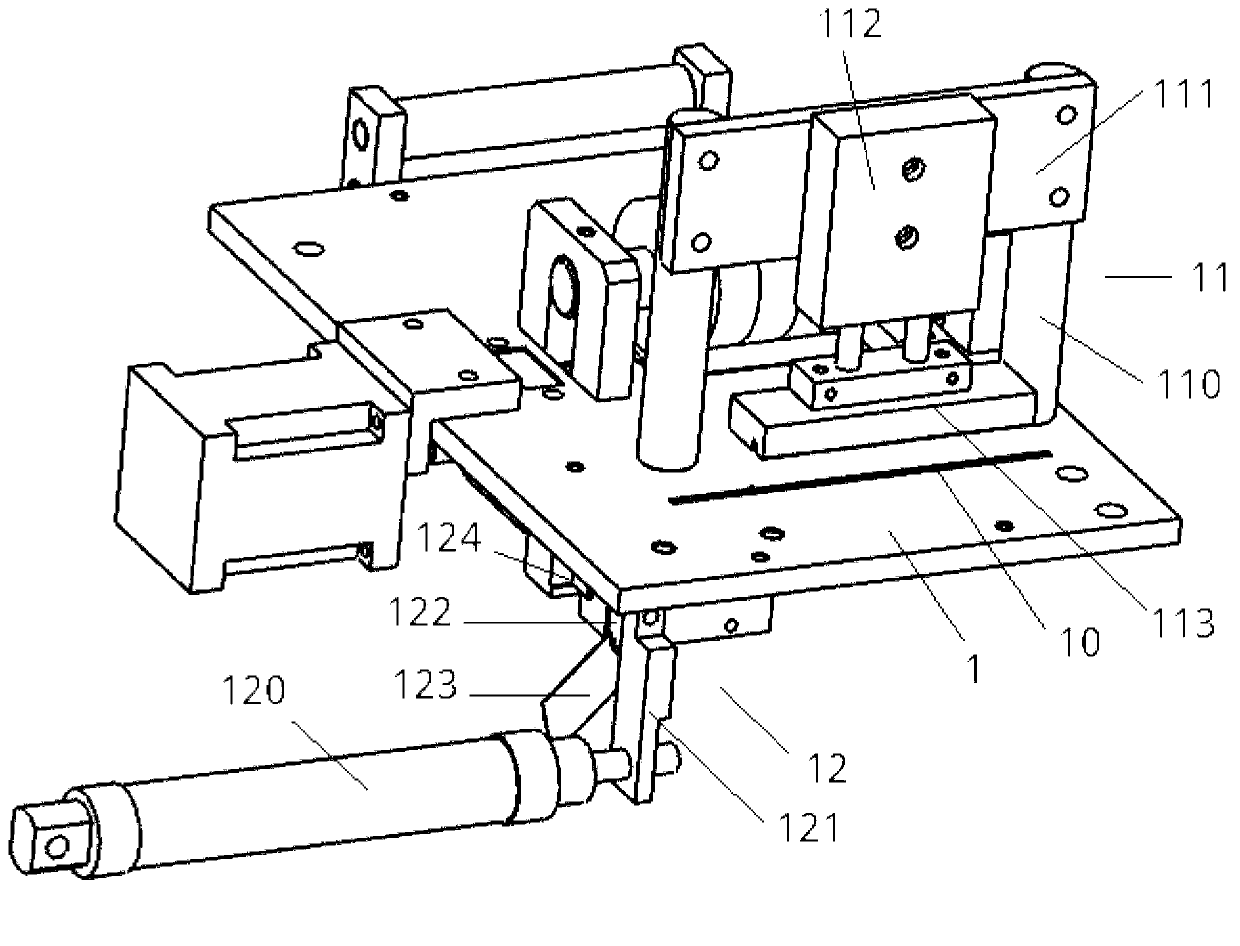

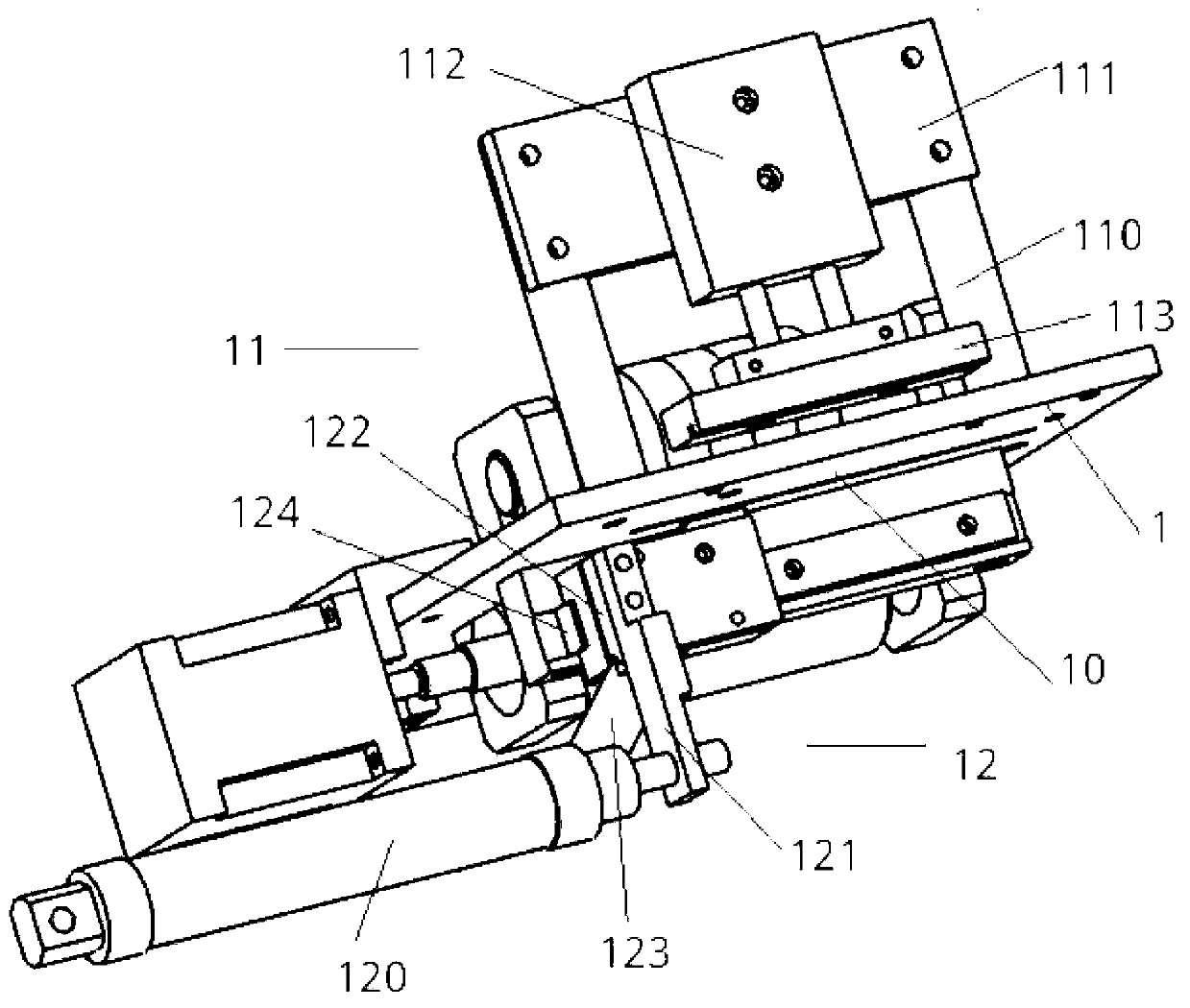

Battery coating device and coating equipment

ActiveCN105514477BRealize automatic coatingAvoid contactPrimary cell manufactureAssembling battery machinesElectrical batteryUltimate tensile strength

The invention relates to the technical field of battery coating, and provides a battery coating device and coating equipment. The battery coating device provided by the present invention includes a side coating device for sticking a film on the side of the battery, and the side coating device includes a first mounting frame, a second mounting frame, a film pulling mechanism, a battery pushing mechanism, a first coating mechanism, a battery discharge mechanism and a second coating mechanism. Compared with the prior art, the battery coating device provided by the present invention realizes the automatic coating of batteries, reduces labor intensity, has high production capacity and high production efficiency, and avoids contact between workers and batteries, eliminating hidden dangers in quality. The coating equipment provided by the invention realizes the sticking of insulating sheet, insulation test and size measurement on the battery, which can effectively improve the yield rate of the battery and ensure the production quality.

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

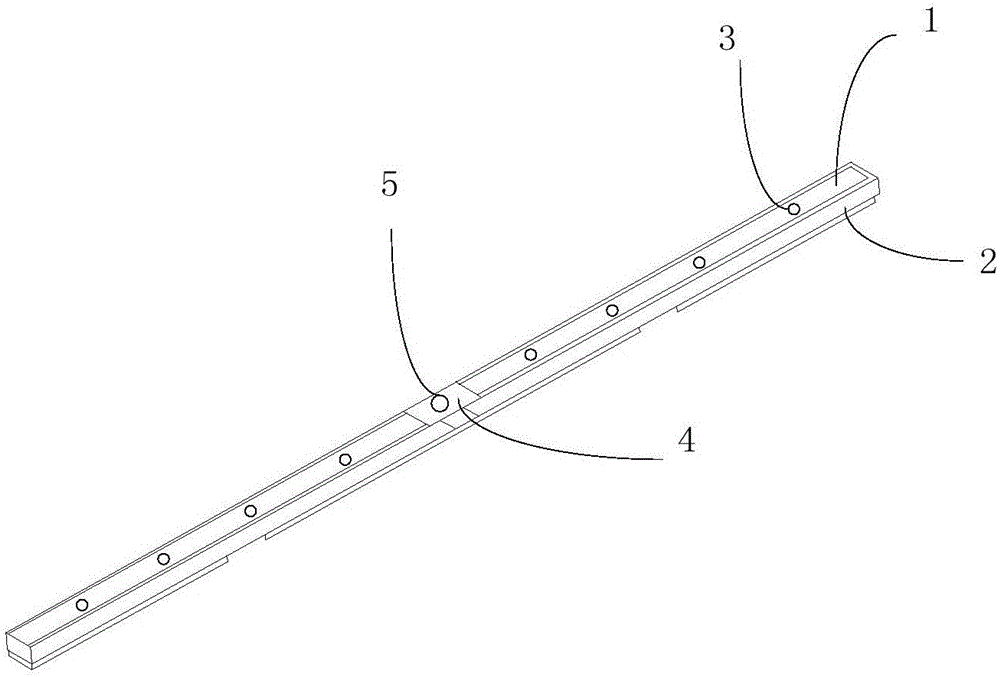

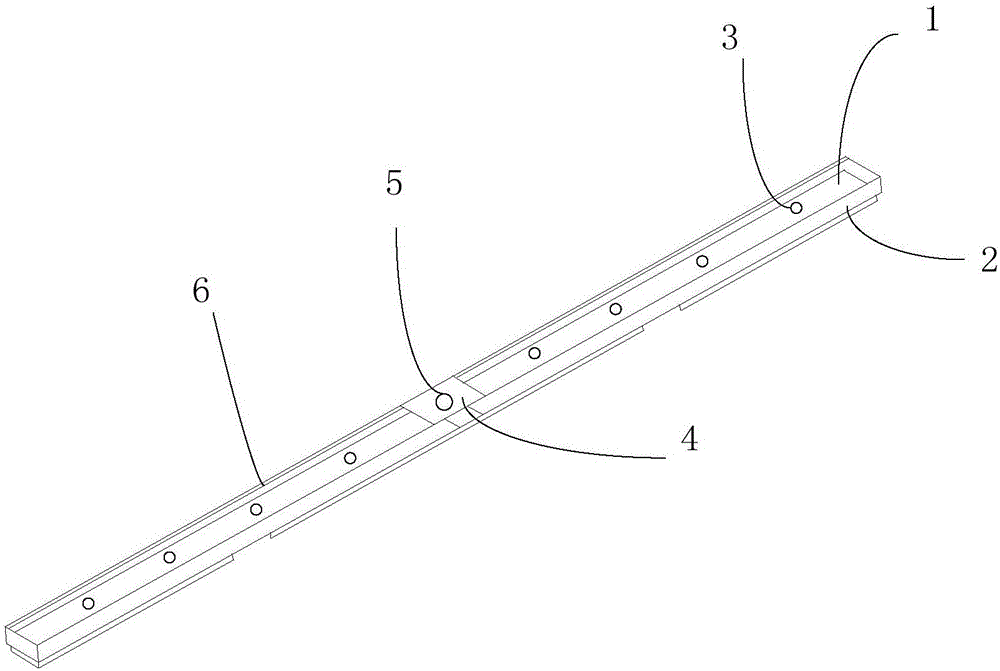

Substrate supporting rod and antistatic liquid coating method

ActiveCN106444110ARealize automatic coatingAvoid pollutionLiquid surface applicatorsSemiconductor/solid-state device manufacturingSoftware engineeringSupport surface

The invention relates to a substrate supporting rod. The substrate supporting rod comprises an outer supporting rod, an inner supporting rod, a lifting structure and an antistatic liquid coating structure, wherein the outer supporting rod adopts a box structure with an opening in one surface; the inner supporting rod is accommodated inside the outer supporting rod, and has a supporting surface for supporting a substrate; the lifting structure is used for controlling the inner supporting rod to do lifting movement so as to change the inner supporting rod between a first state and a second state; the lifting structure comprises a connecting rod running through the bottom of the outer supporting rod so as to support the inner supporting rod; the antistatic liquid coating structure is used for coating antistatic liquid onto the inner supporting rod when the inner supporting rod is in the first state; in the first state, the inner supporting rod is completely positioned inside the outer supporting rod; in the second state, the supporting surface of the inner supporting rod is flush with the surface, having the opening, of the outer supporting rod. The invention further relates to an antistatic liquid coating method. With the antistatic liquid coating method, automatic coating of the antistatic liquid is achieved, and during antistatic liquid coating, pollution to the substrate and the like is prevented and personal hazards are avoided.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Automatic film wrapping machine film wrapping method for storage battery plate groups

ActiveCN103137998BSimple structureMovement precisionFinal product manufactureSecondary cells manufactureEngineeringManipulator

The invention discloses an automatic film wrapping machine film wrapping method for storage battery plate groups. A film conveying mechanism conveys films continuously, a film receiving mechanism receives the films, and then the films are pressed by a film pressing plate, and a cutting knife cuts across a film cutting groove to cut the films. Simultaneously, battery cases in a battery case blanking barrel are dropped on a battery case conveying slide rail one by one, and the battery cases are sent to a battery case locating air cylinder by a material pushing air cylinder. Plate groups are caught by a plate group catching mechanical hand, a vertical air cylinder and the plate group catching mechanical hand are driven by a horizontal air cylinder to horizontally move to an upward side of a separated space, then the vertical air cylinder moves downwards so that the plate groups are enabled to enter a guiding mechanism for the plate groups entering the battery cases. The plate groups are let go by the plate group catching mechanical hand, so that the plate groups and the films are enabled to enter the battery cases below the separated space, and a film wrapping movement and an entering battery cases movement are finished. When the films are wrapped, a pushing plate moves backwards so as to push the battery cases to a plate group output rail, and then the battery cases are output. By means of the automatic film wrapping machine film wrapping method for the storage battery plate groups, automatic film wrapping of the storage battery plate groups is achieved, labor intensity is relieved, and film wrapping efficiency is improved.

Owner:珠海市四海久源科技有限公司

Storage battery plate group automatic coating machine improved structure

ActiveCN103151552ASimple structureMovement precisionFinal product manufactureSecondary cells manufactureEngineeringMechanical engineering

The invention discloses a storage battery plate group automatic coating machine improved structure. A separated space is formed between a horizontal plate and a rear horizontal plate, a battery case blanking cylinder is vertically arranged on the right side of the separated space, a battery case locating cylinder is vertically arranged under the separated space, a plate group conveying frame is arranged on the left side of the separated space, a horizontal supporting beam is arranged at the upper end of the plate group conveying frame, a horizontal cylinder is arranged on the horizontal supporting beam, a piston rod of the horizontal cylinder is connected with a vertical cylinder, a piston rod of the vertical cylinder is connected with a mechanical arm used for grabbing plate groups, and guiding mechanisms of plate group to the battery case used for guiding the plate groups are arranged on the front side and the rear side of the separated space by the horizontal plate and the rear horizontal plate. A horizontal thin film cut gap is reserved on the rear side of the horizontal plate, and a cutting knife moving structure provided with a cutting knife is arranged below the thin film cut gap of the horizontal plate. The storage battery plate group automatic coating machine improved structure has the advantages of being simple in structure, accurate in motion and capable of achieving automatic coating of the storage battery plate groups, reducing labor intensity and improving coating efficiency.

Owner:广东贤畅环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com