Automatic interfacial agent coating device for thermal insulation plate

A technology for automatic coating and thermal insulation of boards, which is applied to devices and coatings for coating liquids on the surface, which can solve problems such as the impact of production costs and production efficiency, increase production links, thermal insulation injection molding boards and cement cracking, etc. Production efficiency, automatic coating guarantee, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

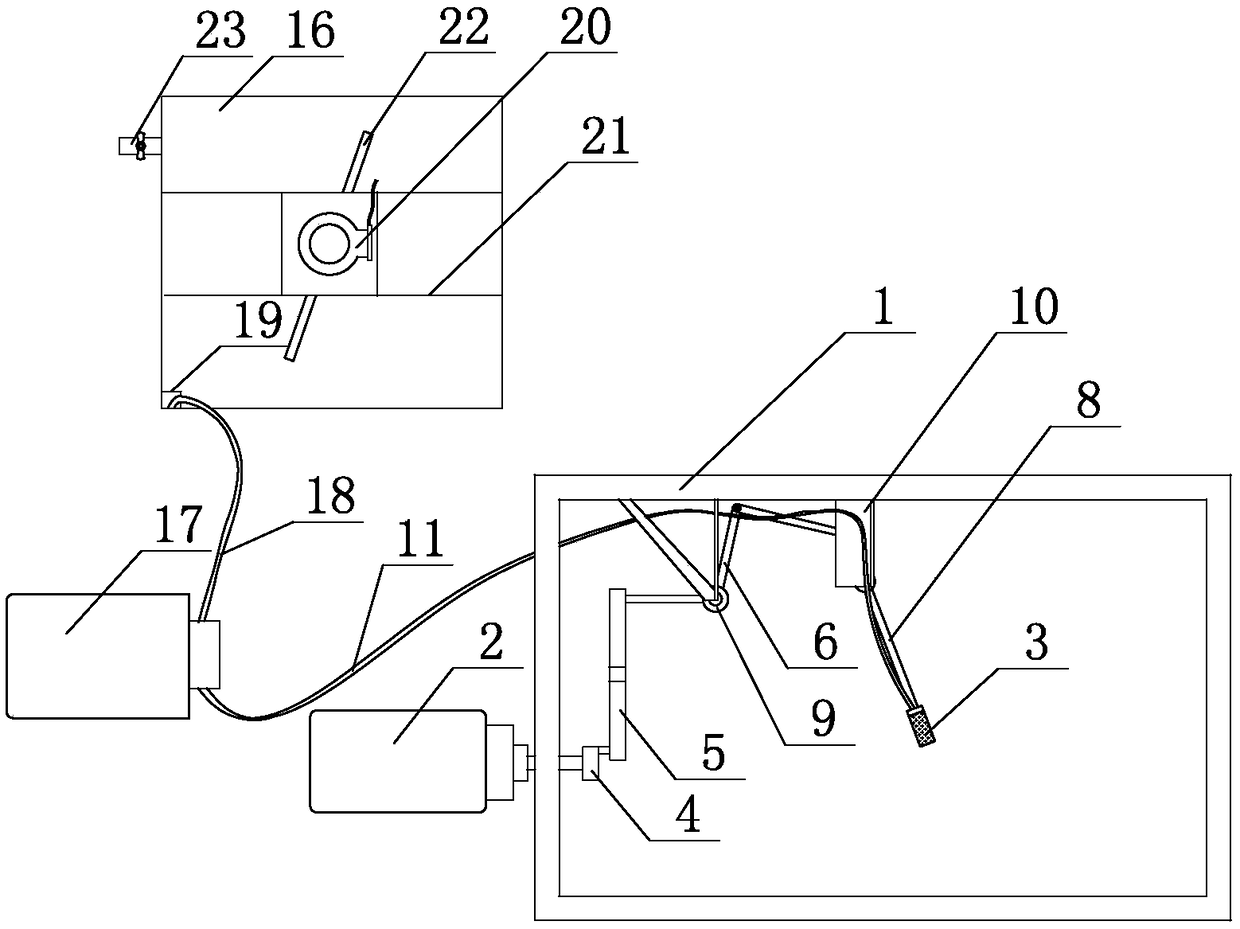

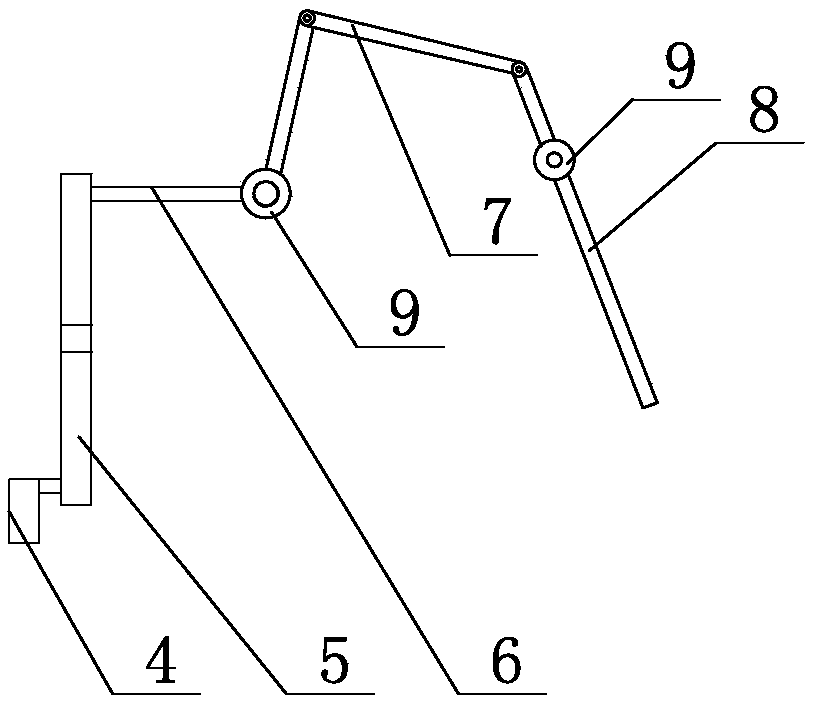

Embodiment 1

[0026] Such as Figure 1-2 As shown, the interface agent automatic coating device for thermal insulation boards described in this embodiment includes a feeding part, a coating part and a support frame 1, the feeding part is the feeding part of the coating part, and the coating part is supported by the support frame 1, and the coating part Including drive motor 2, paint connecting rod and paint brush 3, described paint connecting rod includes rocking handle 4, coupling 5, V-shaped bar 6, connecting rod 7 and coating rod 8, and described rocking handle 4 one end and driving The rotating shaft of the motor 2 is connected, the other end of the rocker 4 is connected to one end of the coupling 5, the other end of the coupling 5 is connected to one end of the V-shaped rod 6, and the other end of the V-shaped rod 6 is hinged to one end of the coating rod 8 through the connecting rod 7, V-shaped The position of the inflection point of the rod 6 is movably connected with the support fra...

Embodiment 2

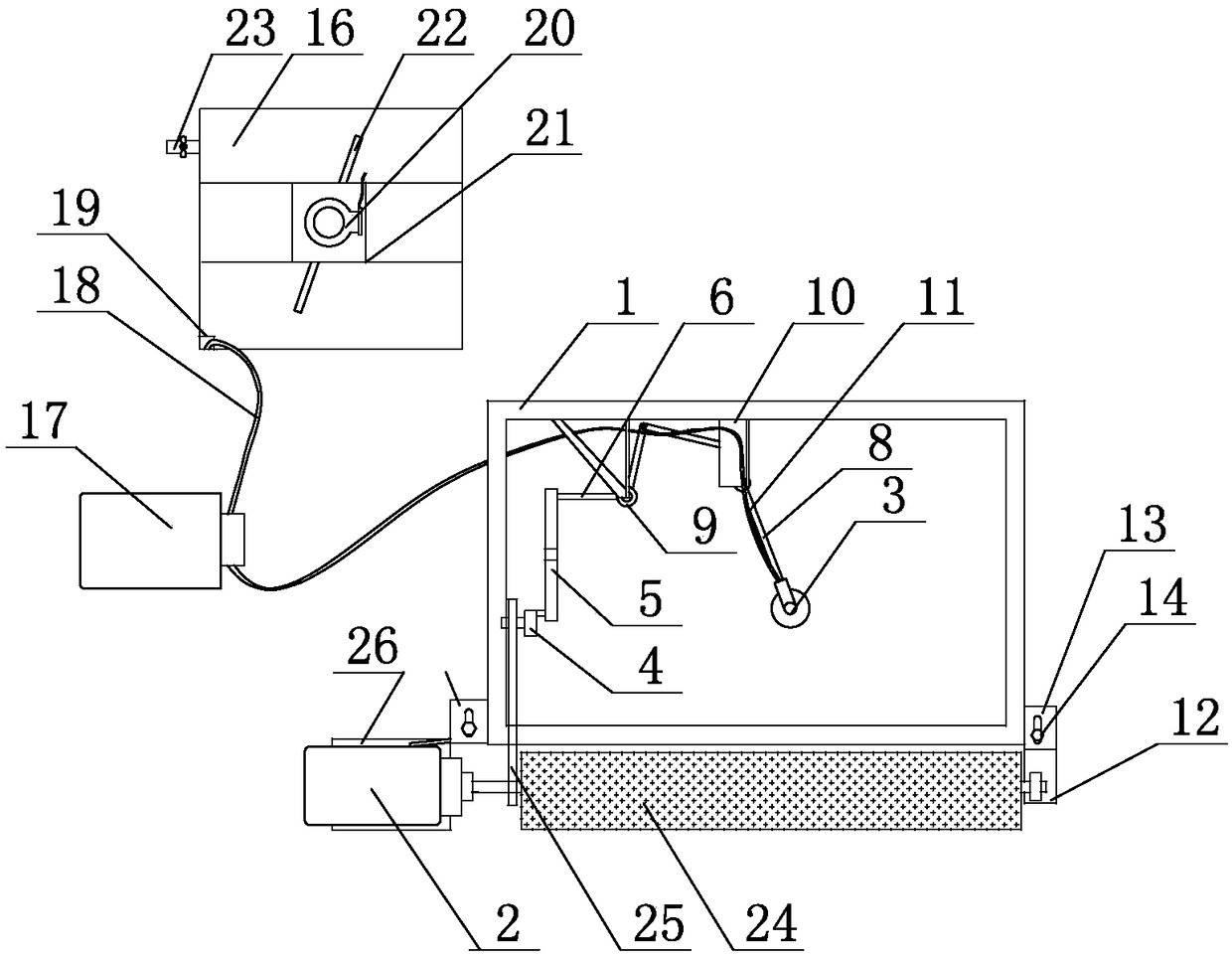

[0031] Such as Figure 3-4 As shown, in this embodiment, a coating roller 24 is added on the basis of Embodiment 1, and the installation position of the driving motor 2 is adaptively modified. The roller shaft of the coating roller 24 is connected to the rotating shaft of the driving motor 2, and the rotating shaft of the driving motor 2 passes through The transmission gear and the transmission chain 25 are connected to the crank handle 4, and the coating roller 24 carries out secondary uniform distribution and extrusion of the surfactant brushed by the paint brush 3, and the hard bristles are also arranged on the coating roller 24, which is driven by the drive motor 2 Simultaneously drive the coating roller 24 and the paint brush 3 to act. In this embodiment, the paint brush 3 does not need to be consistent with Embodiment 1, and its shape can be more diverse. It can adopt the same structure as the shower head, but the diameter of the discharge hole Set larger than the shower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com