Patents

Literature

131results about How to "Achieve coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

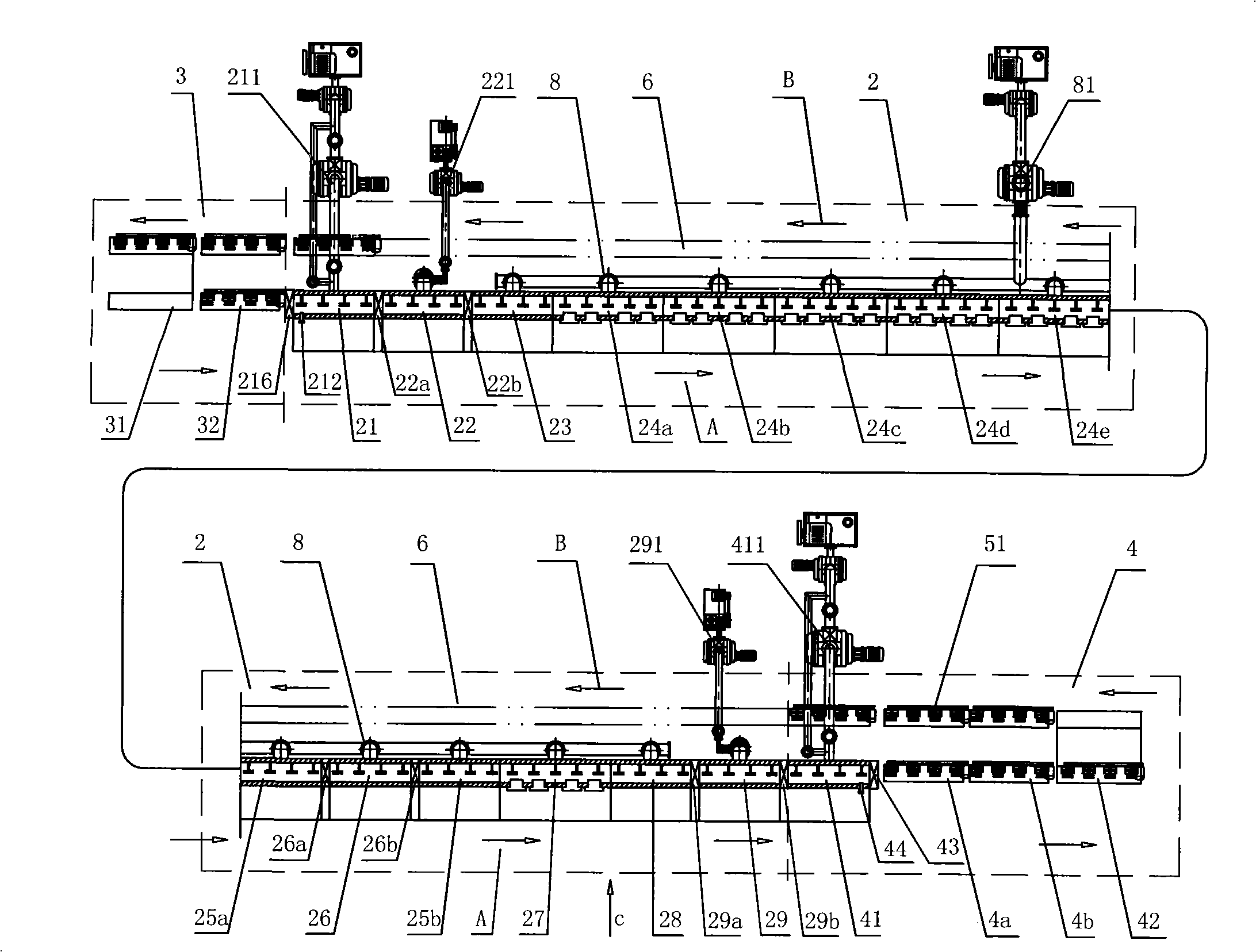

Large area anti-reflection conductive film continuous magnetron sputtering film coating production line

ActiveCN101353782AOvercome the defects of small transmission speed conversion ratio and low production efficiencyEffective isolationVacuum evaporation coatingSputtering coatingProduction lineTransmittance

The invention relates to a continuous magnetic control sputtering coating production line of a large-area anti-reflection conductive film, which comprises a plurality of vacuum chamber blocks which are adjacent in sequence, deployed in the transverse direction of a bedplate and communicated with a pumping system and comprise a pre-vacuum chamber and the like, a film advancing area and a film discharging area closely adjacent to the film advancing area, wherein, the film advancing area consists of a translational-motion rack for film advancing and the like, and the film discharging area consists of a translational-motion rack for film discharging and the like; magnetic-steering transport devices are arranged on the vacuum chamber blocks, the film advancing area and the film discharging area, together with an adaptive workpiece backing up rack form a production loop which runs continuously and circularly along the coating direction of a running loading frame and the backing up direction of the running loading frame so as to realize the technical proposal of continuous magnetic control sputtering coating of the large-area anti-reflection conductive film for a substrate. The production line of the invention overcomes the defects of the traditional transparent conducting film production line, namely, the transmittance range is narrow, no transport room is provided, the conversion ratio of transport speed of the substrate loading rack is small and production efficiency is low and the like. The production line of the invention is applicable to the production of the large-area sputtering coatings of transparent conductive films, anti-reflection films and high-reflection films and the like of various display panels, solar panels and decoration panels.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

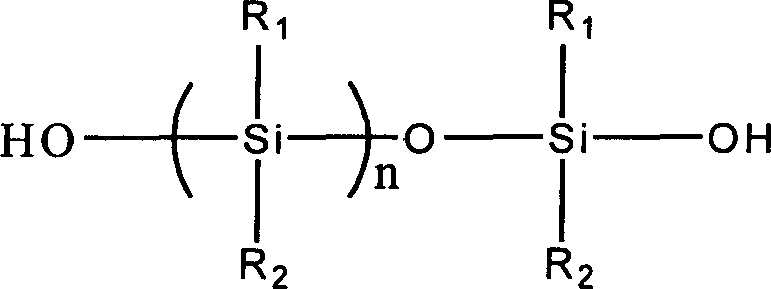

Bicomponent normal temperature crosslinked aqueous organosilicon rubber waterproof paint and method for preparing same

InactiveCN1670098AStrong adhesionAchieve coatingAntifouling/underwater paintsPaints with biocidesPolymer scienceEmulsion

The invention relates to a dual-component environment-friendly type organic silicon rubber waterproofing paint and its preparation process. The paint contains component A which is made of organosilicon emulsion, strengthening agents, fillers and catalyst, and component B which is made of polyfunctional group organosilicon cross linking agents and tackiness agent. The dual-component environment-friendly type organic silicon rubber waterproofing paint is preparing by compounding of the said components A and B in definite proportions. The tensile strength of the said organic silicon rubber waterproofing paint solidified film is more than 2.0 MPa and the elongation percentage is more than 500%. It also has strong adhesive force for the surface of many base materials such as metal, treatment or untreatment wood, tar mats, ceramic tiles, roofing and asphalt felts.

Owner:SOUTH CHINA UNIV OF TECH

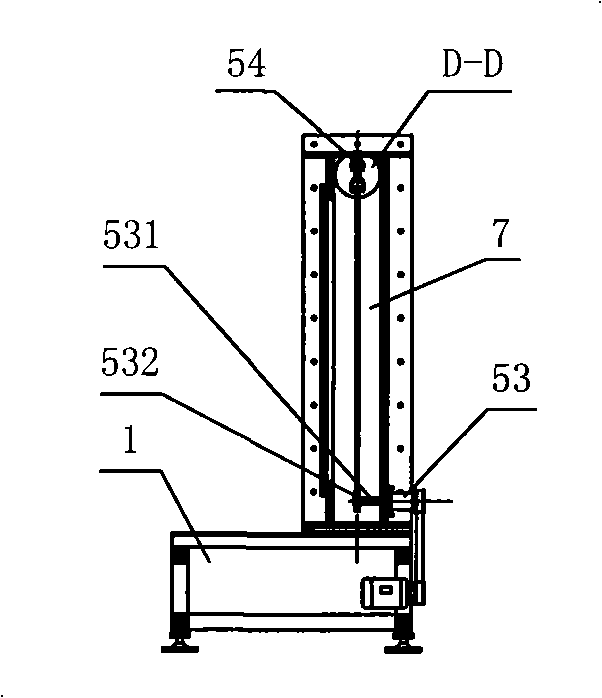

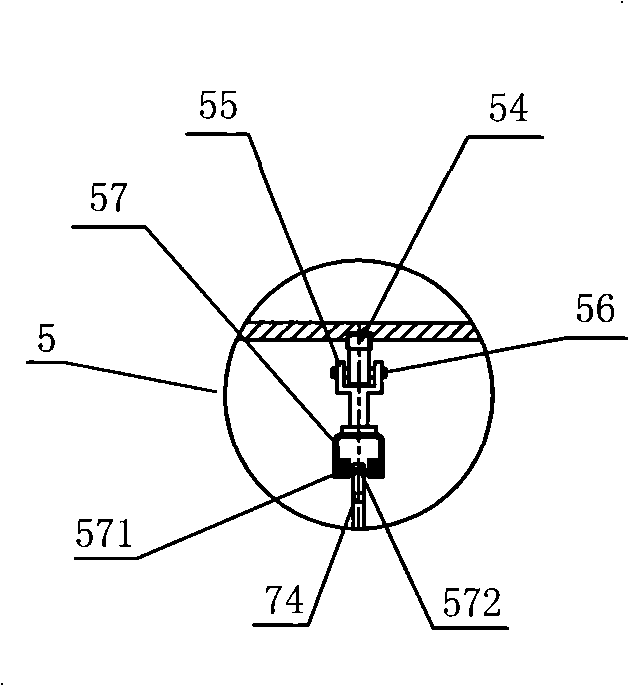

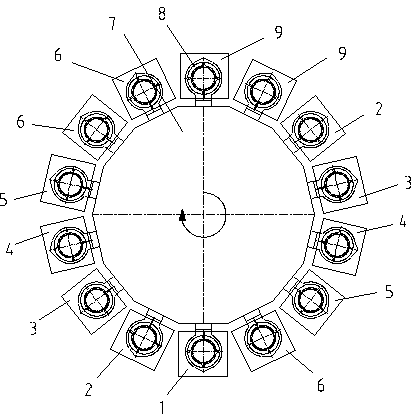

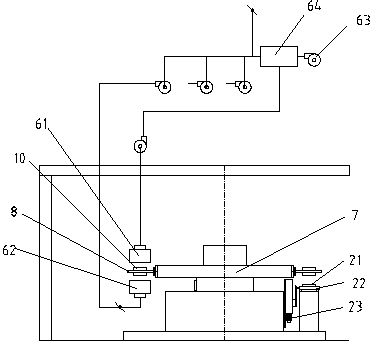

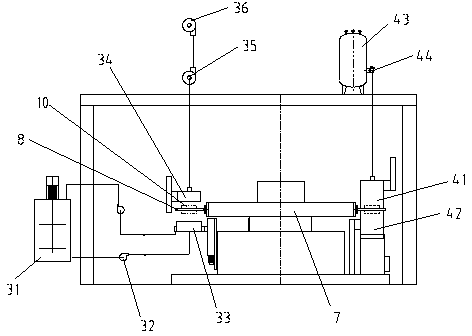

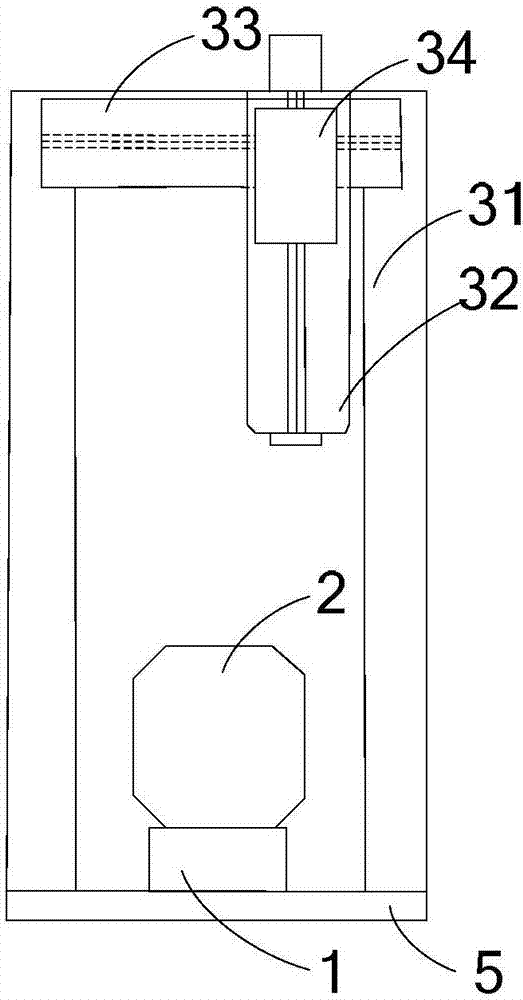

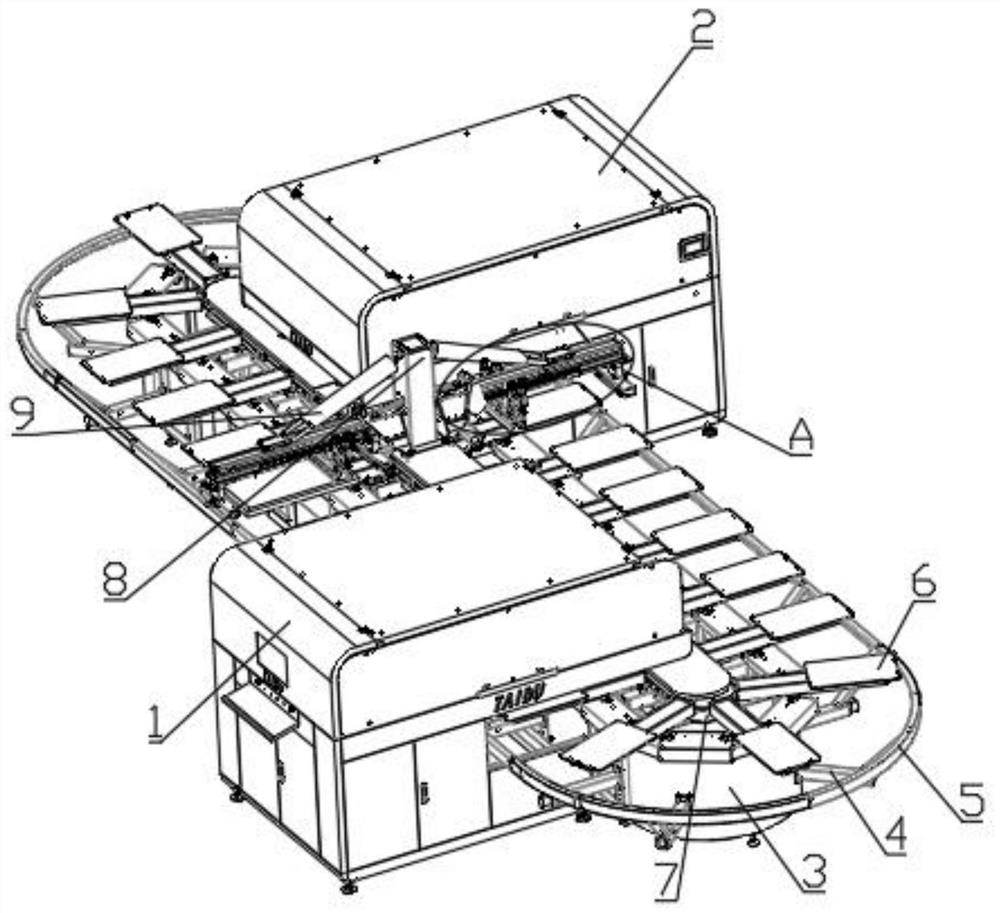

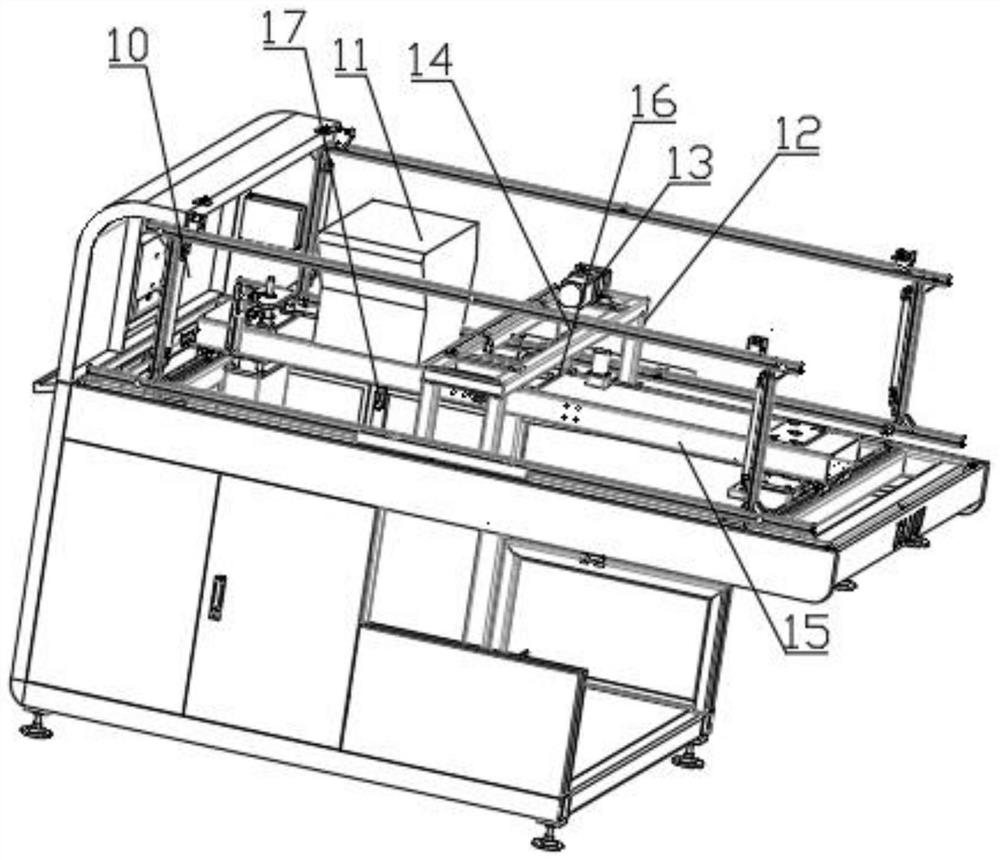

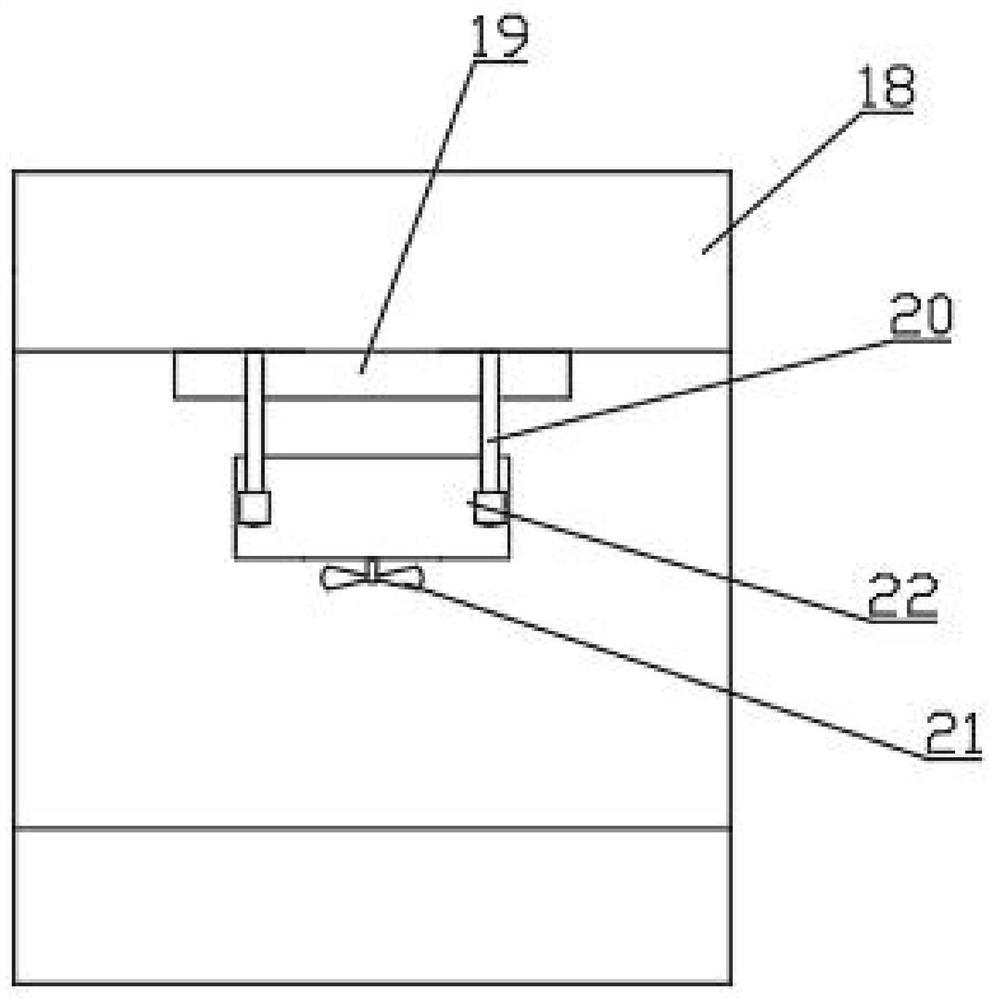

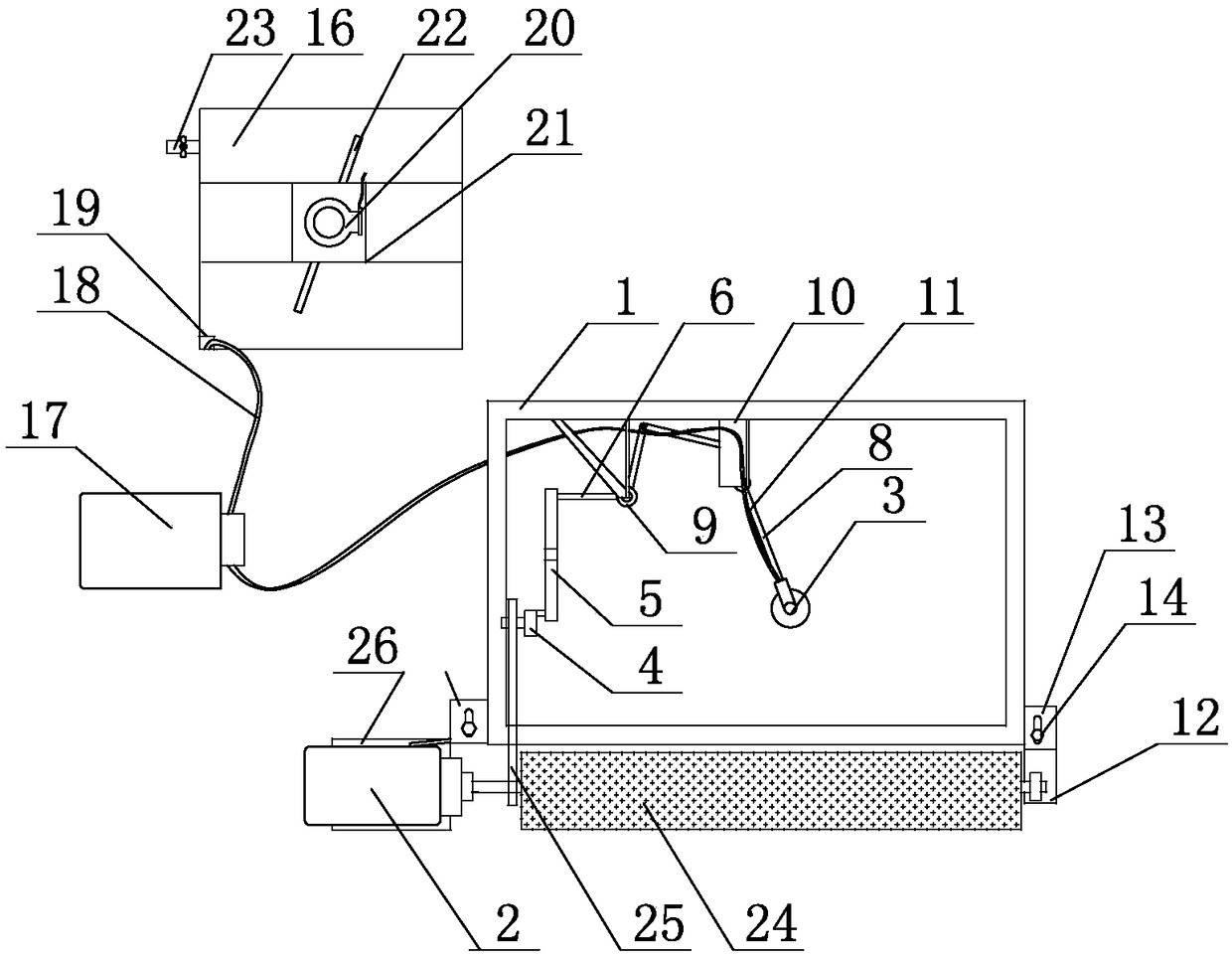

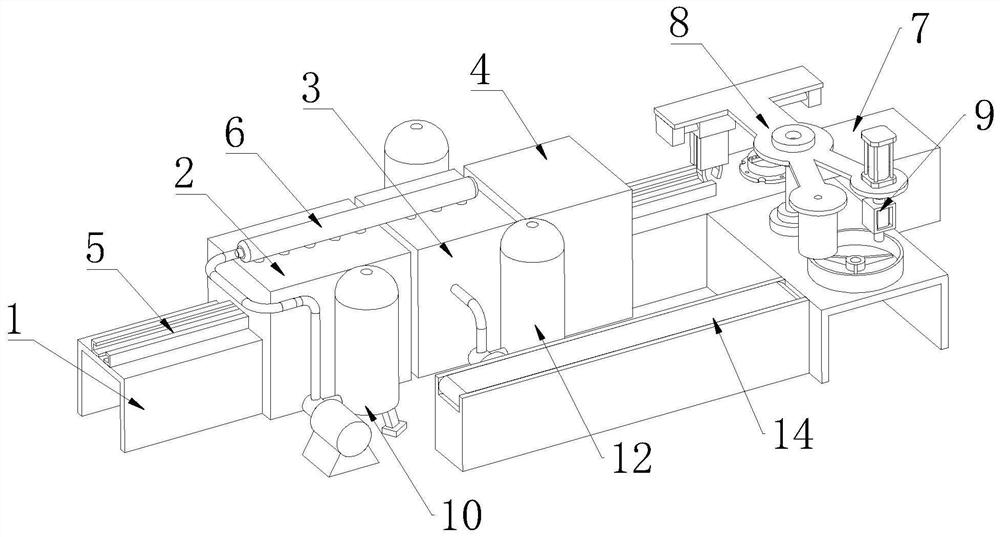

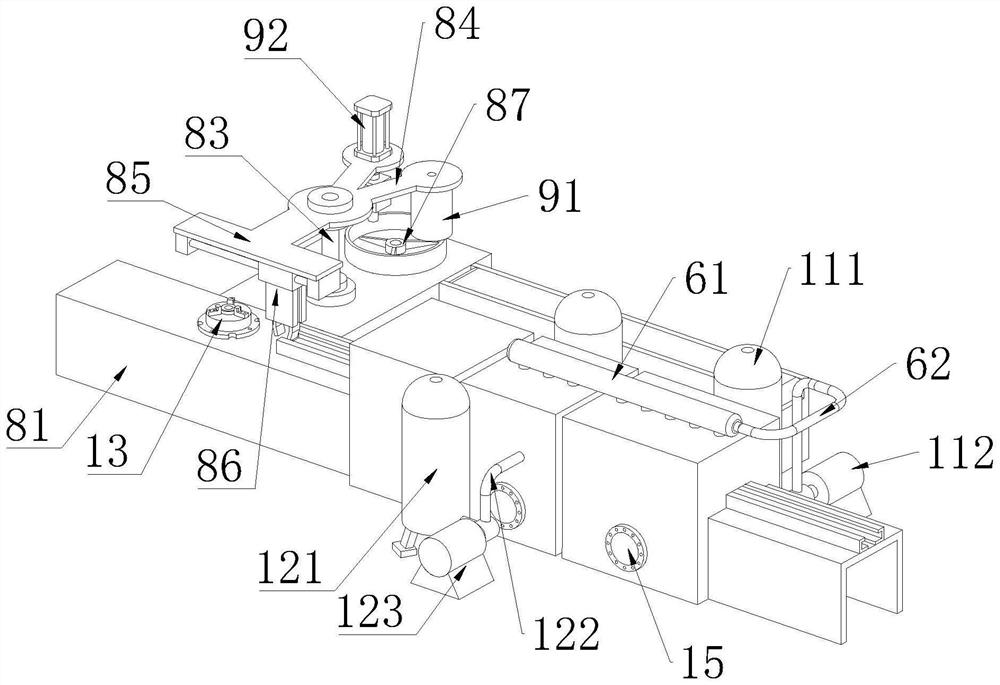

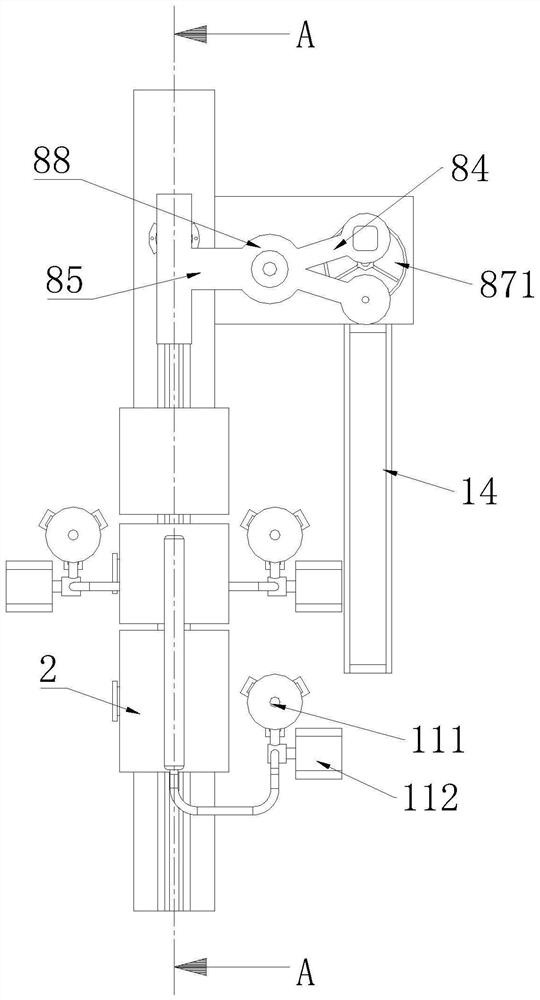

Automatic multi-station catalyst coating device

ActiveCN103752466AImprove processing efficiencyHigh degree of automationConveyorsPretreated surfacesMachiningElectrical and Electronics engineering

The invention relates to an automatic multi-station catalyst coating device. The device comprises a conveying device for conveying a carrier and positioning and detecting the carrier, an upper line-lower line carrier robot for catching and conveying the carrier, a transmission device for receiving the carrier from the upper line-lower line carrier robot and transmitting the carrier to different processing stations, and a coating station for coating the carrier, wherein the coating station comprises a primary coating station, a secondary coating station and a cooling device. The transmission device is tightly cooperated with each coating device, so that the automatic degree is high, the mechanical process precision is high, the stability of the whole device is good, and the quality of the produced products is good. The coating device has an open type operation window, a carrier clamp can be exchanged, so as to achieve multiple kinds of coating and secondary coating, so that the automatic multi-station catalyst coating device is multifunctional, and has wide application range.

Owner:CHANGZHOU FANQUN DRY EQUIP CO LTD

Polymeric Resin Composition For the Production of Coatings

InactiveUS20080194735A1Efficiently attachedLow costPlastic/resin/waxes insulatorsFilm/foil adhesivesPolymer resinPolymer concrete

Disclosed herein is a resin composition for the manufacture of coatings such as polymeric concretes, terrazzos and finishes, comprising: a) from 15 to 50% by weight of methyl methacrylate (MMA) monomer; b) from 25 to 75% by weight of a mixture of equal parts of polyester resins of: i) an isophthalic polyester resin; ii) an orthophthalic polyester resin; and iii) a neopentyl polyester resin; c) up to 8% by weight of an epoxy resin obtained from bisphenol A and epichlorohydrin; and d) up to 5% by weight of an aliphatic or aromatic polyurethane resin.

Owner:VERDUGO PEREZ JOSE ANGEL +1

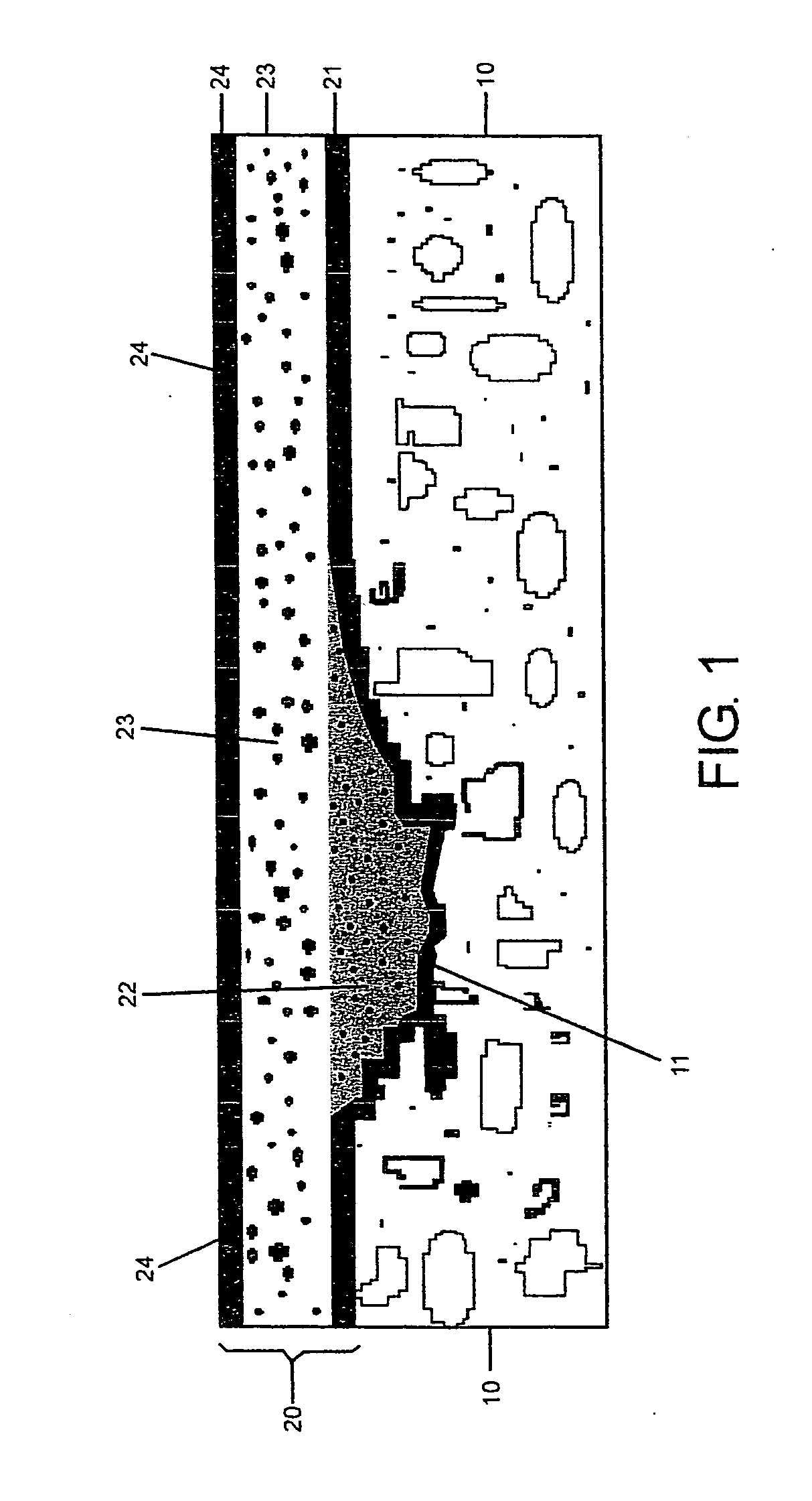

Powder rotating CVD (chemical vapor deposition) device

InactiveCN103668112AUniform coatingAchieve coatingChemical vapor deposition coatingEngineeringReaction chamber

The invention discloses a powder rotating CVD (chemical vapor deposition) device which comprises a support and a furnace tube fixed on the support, wherein a main electric furnace surrounds the furnace tube; two ends of the furnace tube are connected with a feed gas inlet device, a current-carrying gas inlet device and a waste gas treatment device respectively; a movable rotating shaft is arranged in the furnace tube; a cylindrical reaction chamber is fixed on the rotating shaft and provided with a plurality of stirring blades which extend from the inner wall surface to the axis side and are used for stirring a powder base; and a plurality of thermal couplers are arranged in the rotating shaft. According to the powder rotating CVD device, the reaction chamber rotates in the coating process, further, the stirring blades drive a powder material to turn over continuously, so that the powder surface is uniformly coated, the coating thickness can be controlled by controlling technological parameters such as a rotating period and the like, the surface of powder with any size can be coated, and the powder rotating CVD device is applicable to coating of inorganic substances including metal, nonmetal and ceramic powder.

Owner:WUHAN UNIV OF TECH

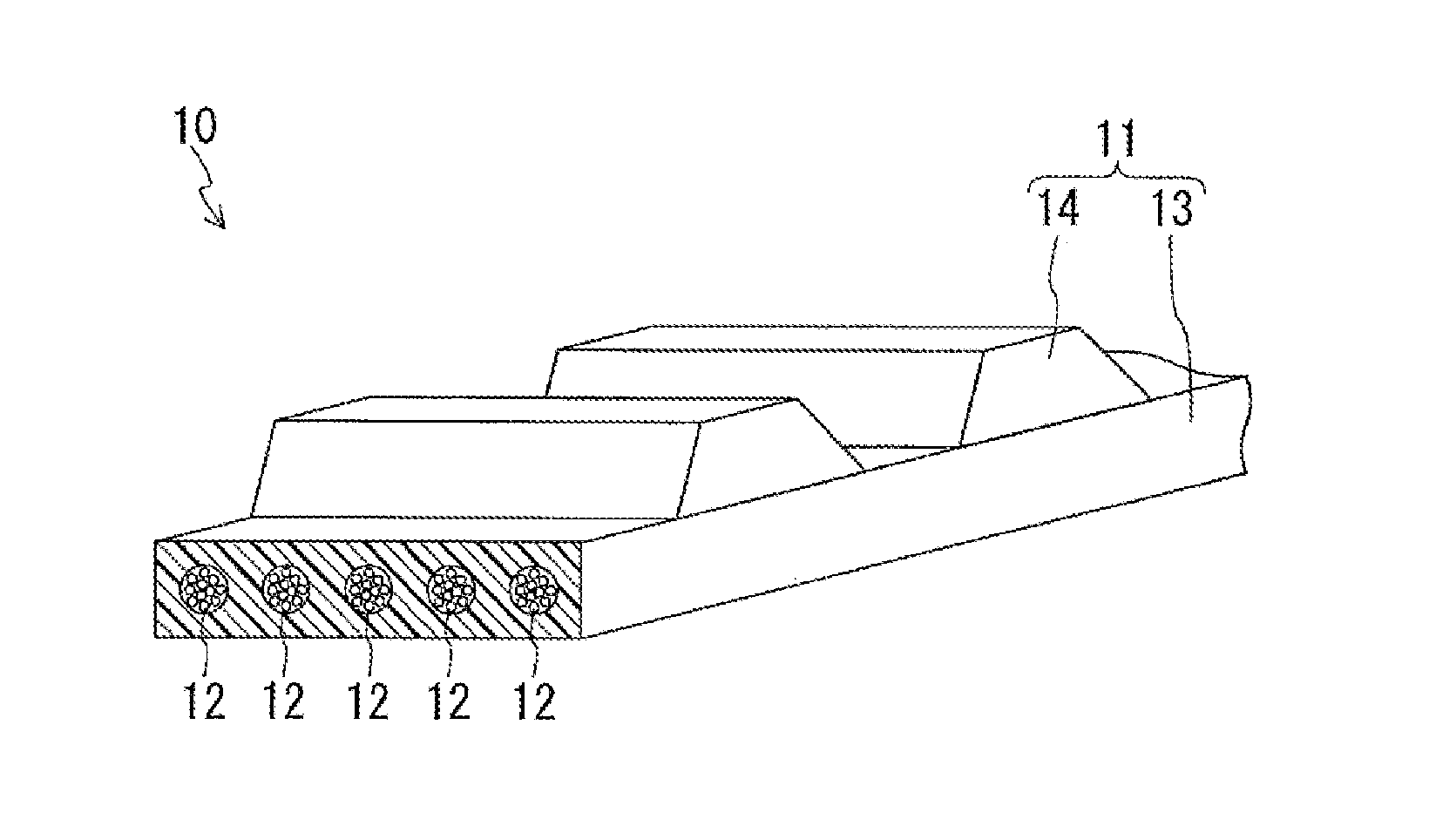

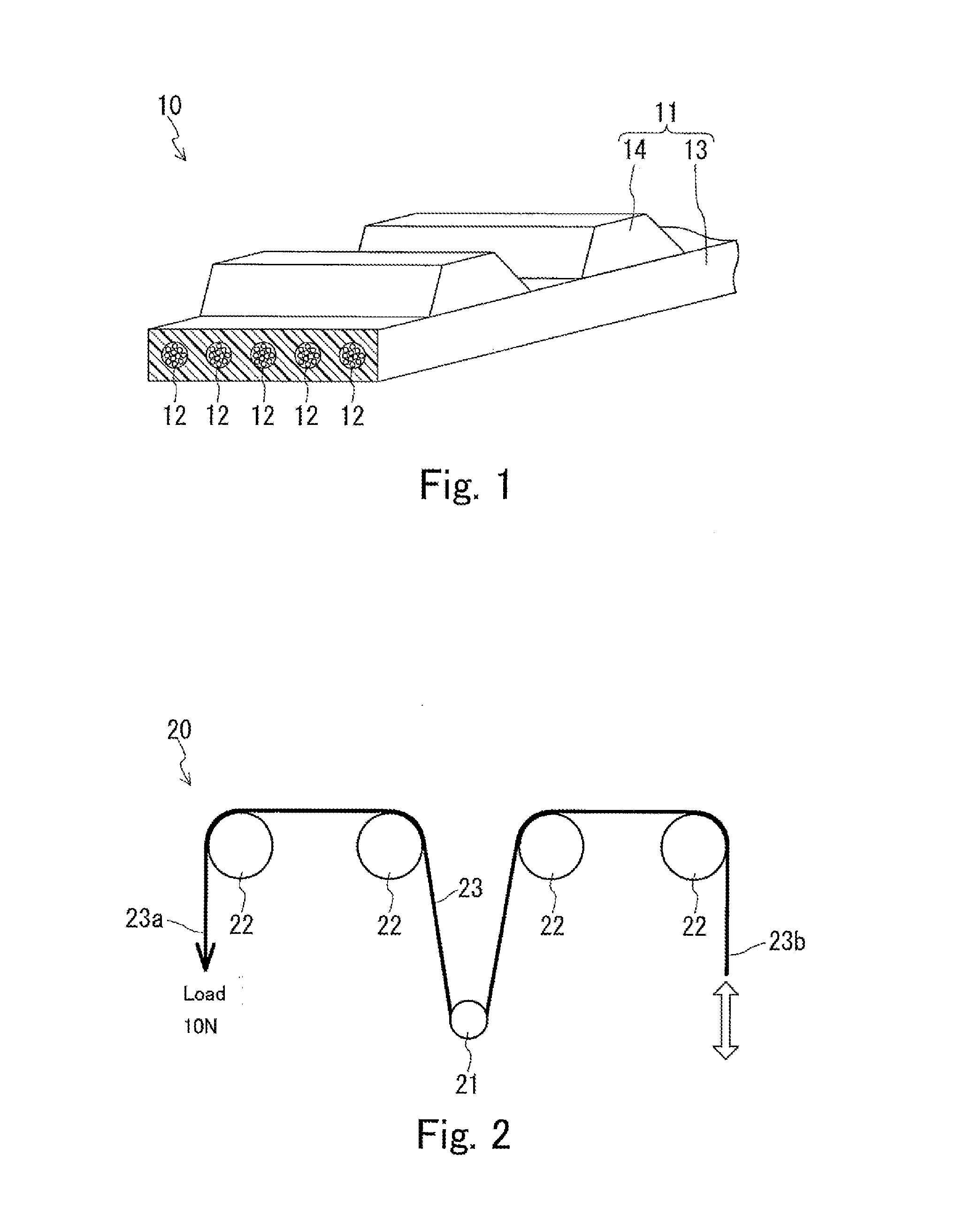

Reinforcement cord for reinforcing rubber product, and rubber product using same

ActiveUS20140093729A1Good bending fatigueAdhesion of coating be achievedV-beltsCarbon fibresCarbon fibersMedicine

The reinforcing cord of the present invention includes at least one strand. The strand includes a bundle of filaments that are bundled and twisted together in one direction, and a coating layer that is formed on at least the surface of the bundle. The bundle consists essentially of carbon fiber filaments. The coating layer is a coating layer that is formed from an aqueous treatment agent containing a rubber latex and a crosslinking agent as essential components and a filler as an optional component. In the aqueous treatment agent, the total of the mass of the crosslinking agent and the mass of the filler is in a range of 1 to 50% of the mass of rubber in the rubber latex.

Owner:NIPPON SHEET GLASS CO LTD

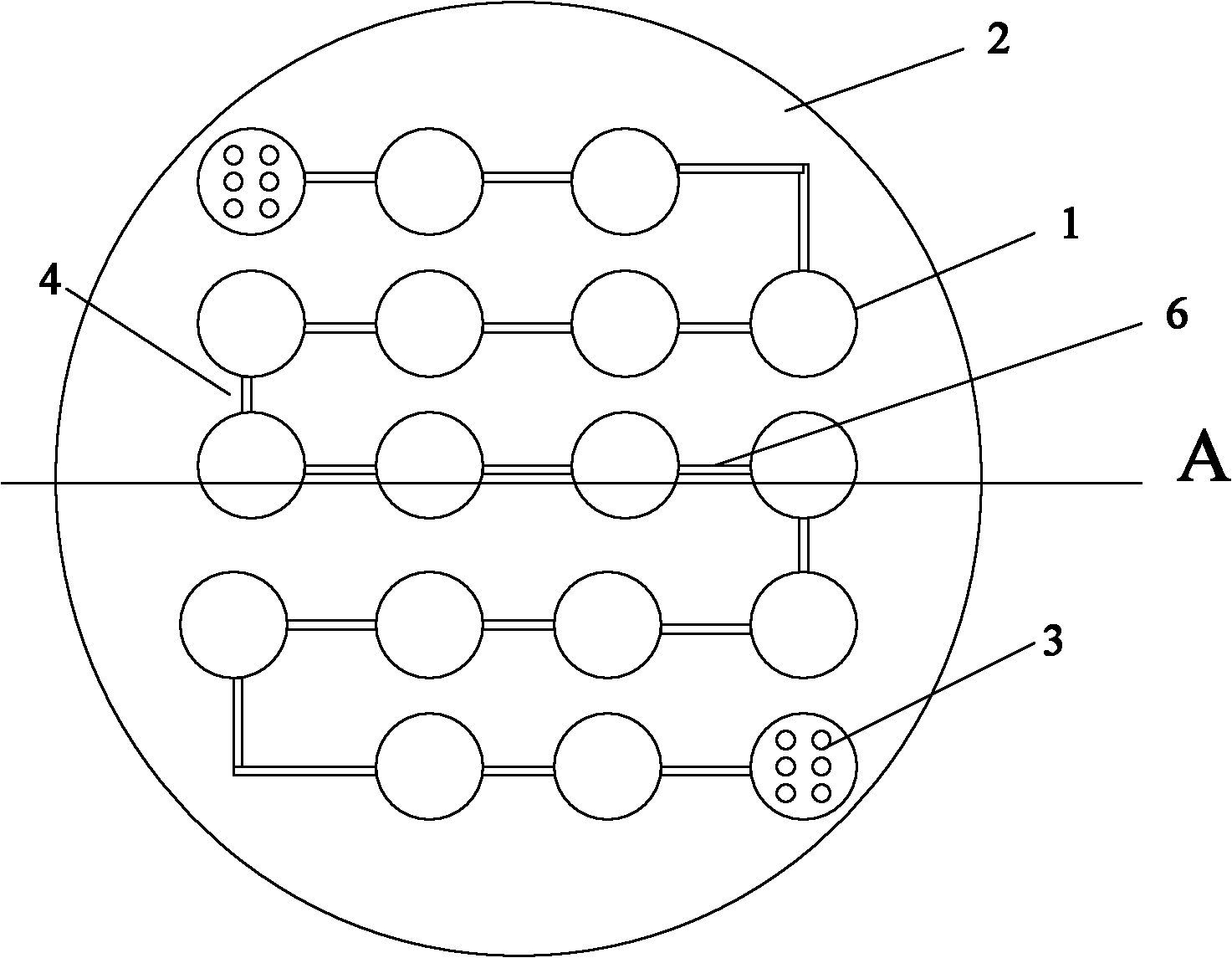

Method for packaging wafer level glass micro-cavity of light-emitting diode (LED)

ActiveCN102110750AReduce optical interfaceGood optical performanceSolid-state devicesSemiconductor devicesLed arrayLight beam

The invention discloses a method for packaging a wafer level glass micro-cavity of a light-emitting diode (LED), and the method comprises the following steps: (1) etching a micro-slot array corresponding to the pattern of a packaged LED array on a silicon wafer, wherein the micro-slots are communicated through a micro-channel, and a proper amount of heat gas releasing agent is arranged inside the micro-slots; (2) forming a closed cavity; (3) heating the bonded wafer in the air to form a spherical glass micro-cavity and a cylindrical glass micro-channel connected with the spherical glass micro-cavity, cooling to room temperature, annealing, and removing silicon to obtain a wafer level glass micro-cavity; (4) sputtering a metal layer on the silicon wafer, and preparing a metal lead through photolithography, so as to obtain a lead substrate, wherein the position of the metal lead corresponds to the position of the micro-channel of the glass micro-cavity; (5) mounting an LED chip on the lead substrate, and leading; (6) bonding the wafer level glass micro-cavity with the substrate to form a bonded wafer; and (7) filling the gap between the LED chip and the wafer level glass micro-cavity with silicone through the glass micro-channel. According to the invention, the light emitting efficiency is high, and a packaged glass lens realizes beam collimation.

Owner:SOUTHEAST UNIV

Method for packaging glass-silicon wafer-grade chiponboard (COB) of light emitting diode (LED)

ActiveCN102097545AReduce luminous attenuationImprove performanceSolid-state devicesSemiconductor devicesHeat resistanceSilica gel

The invention discloses a method for packaging a glass-silicon wafer-grade chiponboard (COB) of a light emitting diode (LED). The method comprises the following steps: 1, etching a silicon micro slot array with the micro slots communicated with each other through micro channels, and placing a proper amount of heat outgas agent in the micro slots; 2, performing anodic bonding on the Si wafer with patterns and the heat outgas agent and borosilicate glass wafer in air or in vacuum to form a sealed cavity; 3, heating and preserving heat to form a spherical glass micro cavity, cooling the cavity to normal temperature, annealing and removing silicon to obtain a wafer-grade glass micro cavity; 4, preparing a lead substrate; 5, mounting a chip and leading a wire; 6, carrying out wafer-grade bonding; and 7, filling silica gel to realize the wafer-grade packaging of the LED. By achieving the integration with the wafer-grade LED reflecting cup, the method reduces heat resistance and cost.

Owner:SOUTHEAST UNIV

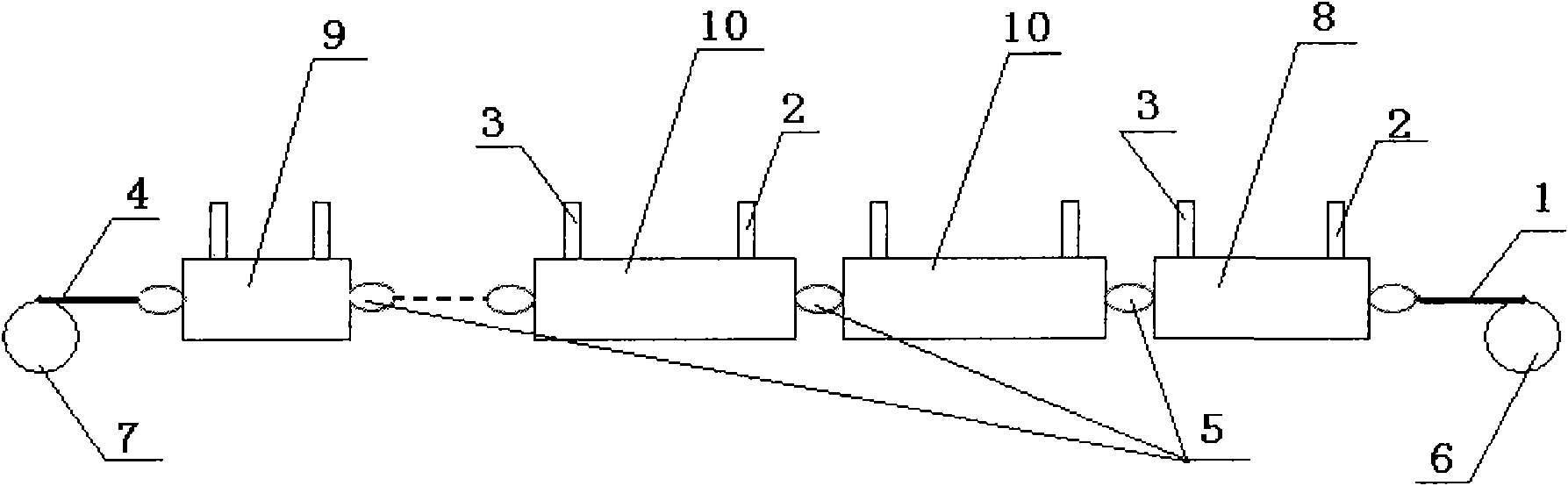

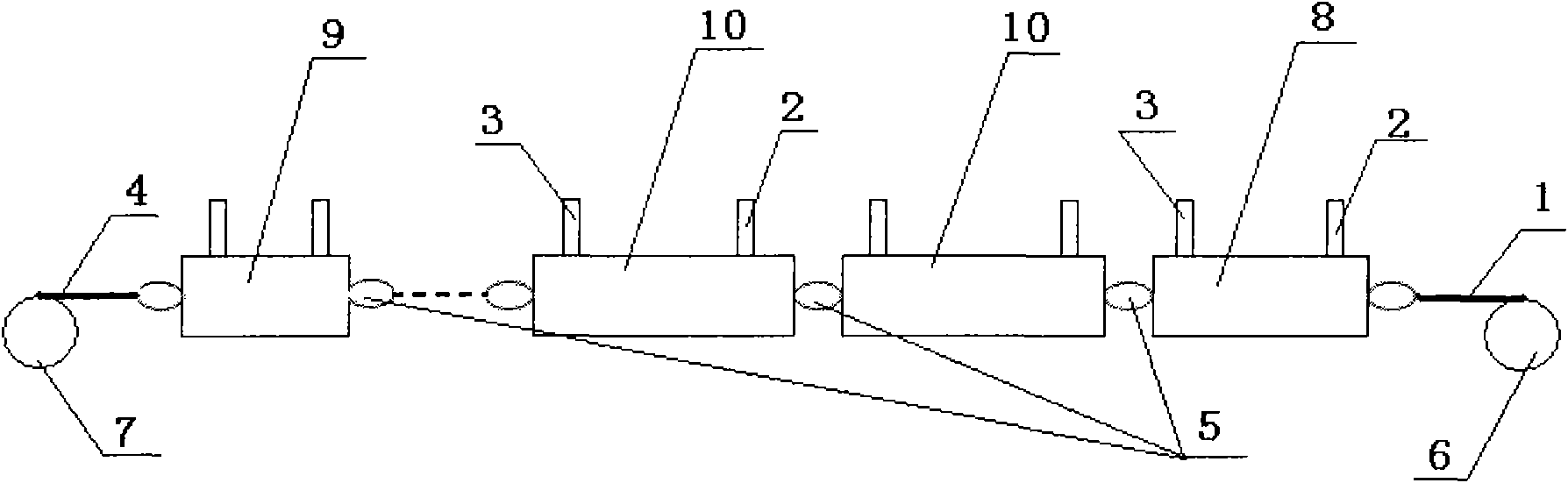

Device for preparing silicon carbide fiber by direct current heating CVD method and preparation method of silicon carbide fiber

InactiveCN102127753AGuaranteed performanceSmall temperature differenceChemical vapor deposition coatingSic fiberChemical vapor deposition

The invention belongs to a preparation technology of a silicon carbide fiber, and relates to improvements on a device for preparing the silicon carbide fiber by a direct current heating chemical vapor deposition (CVD) method and a preparation method of the silicon carbide fiber. The preparation device comprises an unwinding disc [6], a winding disc [7], a pretreatment chamber [8] made of a glass tube, a coating chamber [9] made of a glass tube, and deposition chambers [10] and mercury seals [5] which are positioned between the pretreatment chamber [8] and the coating chamber [9], and is characterized in that: 2 to 4 deposition chambers [10] are arranged between the pretreatment chamber [8] and the coating chamber [9]; and the mercury seals [5] are arranged among adjacent deposition chambers [10]. By the device which is provided with a plurality of deposition chambers and is used for preparing the silicon carbide fiber by the direct current heating CVD method and the preparation method of the silicon carbide fiber, a temperature difference between the front and rear ends of each deposition chamber is reduced, and the structural homogeneity of SiC coatings is improved; coatings with a large deposition temperature difference are coated by controlling the temperature of each deposition chamber; and the mixing uniformity of gas in each deposition chamber is improved, the influence of gas impurities on the deposition process is reduced, and the performance of the fiber is ensured.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

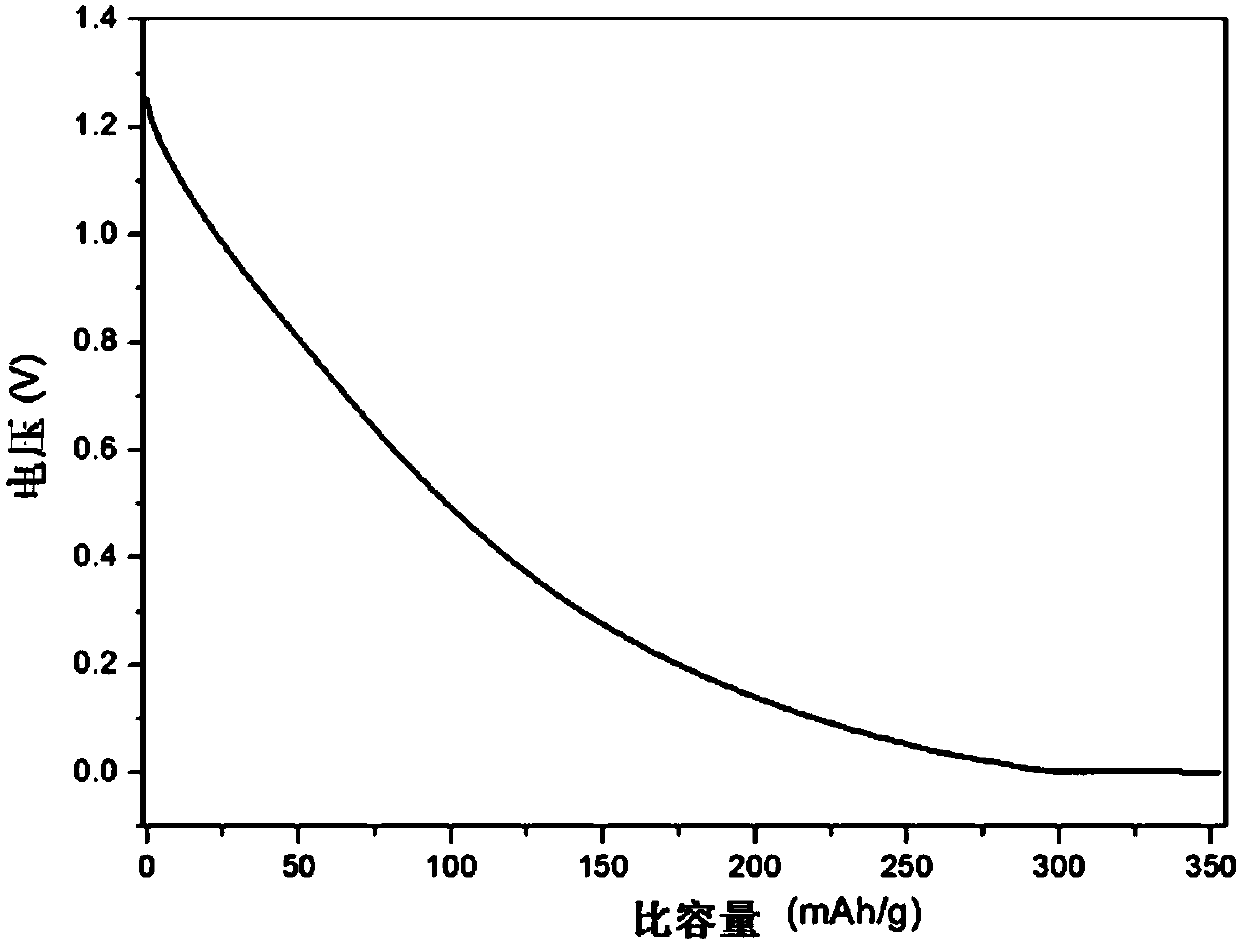

Negative electrode material with high temperature resistance, preparation method of negative electrode material and application of negative electrode material in lithium-ion battery

ActiveCN107919472AUniform coatingAchieve coatingSecondary cellsNegative electrodesHigh temperature storageCarbon coating

The invention discloses a negative electrode material with high temperature resistance, a preparation method of the negative electrode material and an application of the negative electrode material ina lithium-ion battery. The negative electrode material comprises soft carbon and / or hard carbon powder particles as a core, a carbon coating and a nano coating, wherein the carbon coating and the nano coating sequentially coat the surface of the core from inside to outside; and the carbon coating is transformed from a multifunctional group polymer material. The method comprises the steps of (1) preparing a material formed by coating soft carbon and / or hard carbon with the multifunctional group polymer material; (2) forming a nano material coating on the surface of the material; and (3) and burning to obtain the negative electrode material. The method disclosed by the invention is simple and feasible in process and low in manufacturing cost, and massive production can be implemented; and the prepared negative electrode material has very excellent electrochemical properties, especially high-temperature cycle performance and high-temperature storage performance, the capacity retention ratio after 50 charge-discharge cycles at high temperature of 45 DEG C and 1C can reach 93.3%, and the capacity retention ratio after discharge at room temperature and 0.1C can reach 98.3%.

Owner:深圳贝特瑞钠电新材料科技有限公司

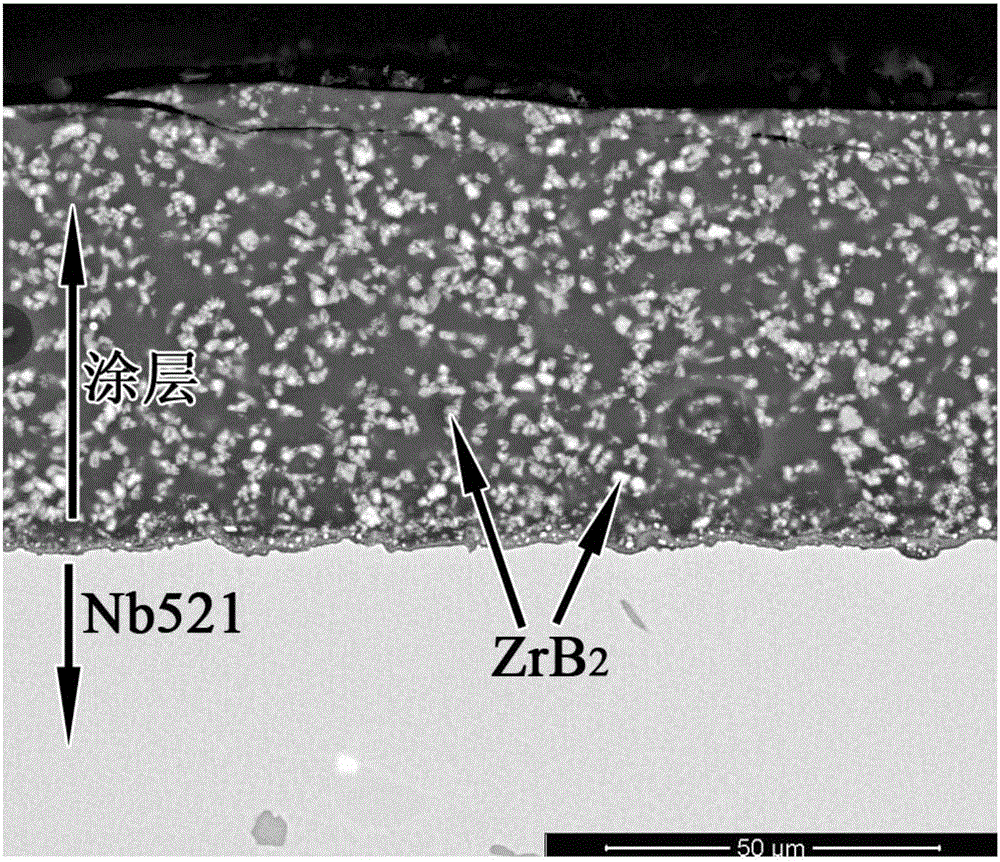

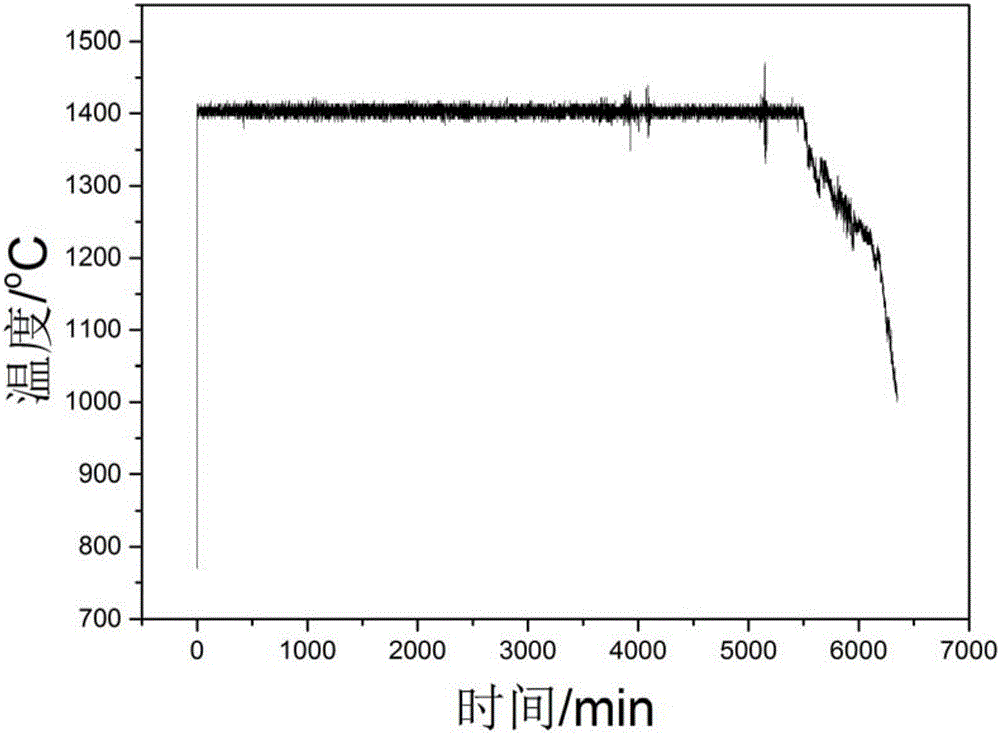

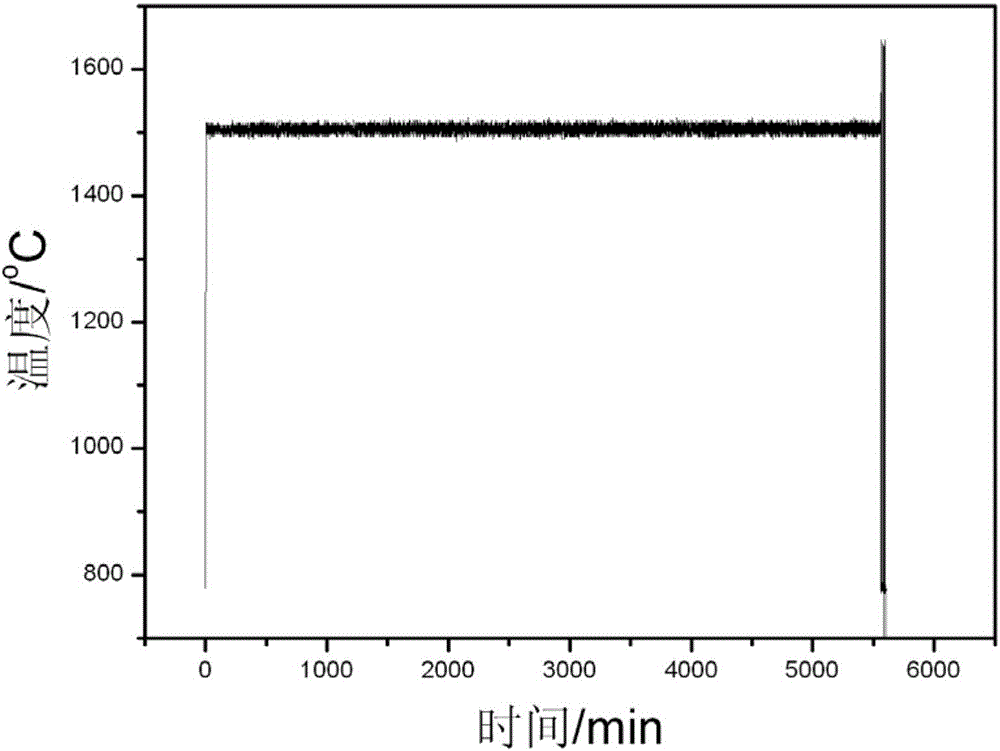

Boride modified glass ceramic based composite high-temperature oxidation resisting coating and preparation method thereof

ActiveCN106587629AGood heat erosion resistanceWide protection temperature rangeOxidation resistantBoride

The invention discloses a boride modified glass ceramic based composite high-temperature oxidation resisting coating. The composite high-temperature oxidation resisting coating fired on the surface of a refractory metal matrix is prepared from boride and silicate glass, wherein the boride is at least one or two of HfB2, ZrB2 and TiB2; besides, the invention further discloses a preparation method of the coating. The method comprises steps as follows: 1, the surface of the refractory metal matrix is treated; 2, boride particle modified glass ceramic composite slurry is prepared; 3, a preset layer is obtained by presetting the slurry on the surface of the refractory metal matrix, and the boride modified glass ceramic based composite high-temperature oxidation resisting coating is obtained vacuum high-temperature firing. The composite high-temperature oxidation resisting coating is used for high-temperature protection of the refractory metal matrix and can continuously protect the refractory metal matrix at the protection temperature of 400-1,600 DEG C for 5 h or longer.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

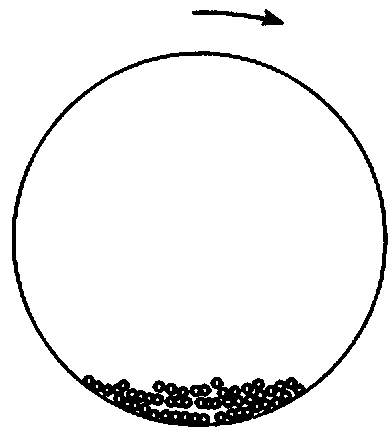

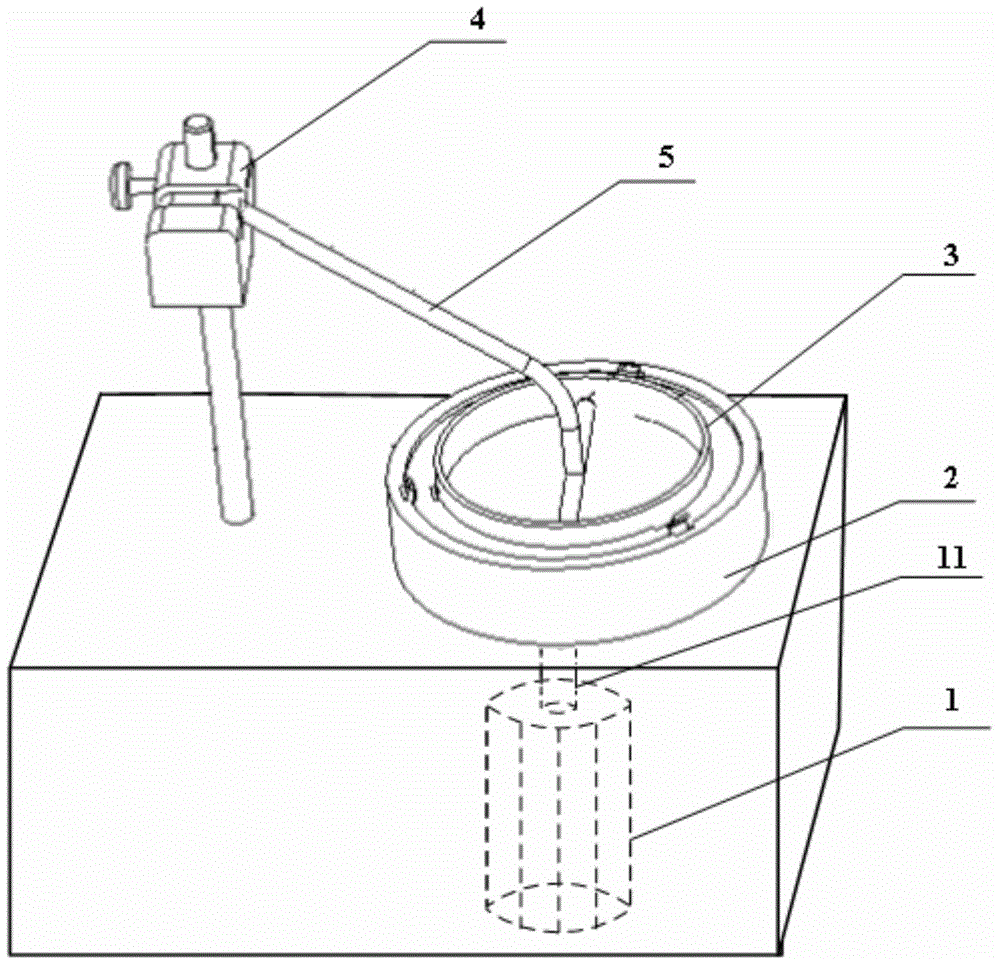

Spin coating device

InactiveCN104152343ARealize automatic coatingImprove uniformityBioreactor/fermenter combinationsBiological substance pretreatmentsLaboratory cultureMotor drive

The invention relates to the technical field of microbial instruments, and discloses a spin coating device. The spin coating device is used for coating operations of microbial culture. The spin coating device comprises a motor, a tray, a fixed mechanism and a coating bar, wherein the tray is connected with an output shaft of the motor, is used for fixing a culture dish, and is horizontally arranged; the coating bar is fixedly arranged on the fixed mechanism, and the coating end of the coating bar extends into the culture dish. By adopting the technical scheme of the spin coating device, the motor can be used for driving the tray to horizontally rotate, and the coating end of the coating bar which is fixedly arranged on the fixed mechanism extends into the culture dish; when microbial coating needs to be performed, a tester only needs to start the motor, the motor drives the tray to rotate, and the coating bar is used for coating bacterial liquid on a culture medium in the culture dish, so that the automatic coating of microorganisms can be achieved, and the coating efficiency can be greatly increased; in addition, because the culture dish rotates at a constant speed automatically, the tester does not need to coat on the culture medium back and forth by holding the coating bar in a hand, so that the coating uniformity can be increased.

Owner:北京赛智创业科技有限公司

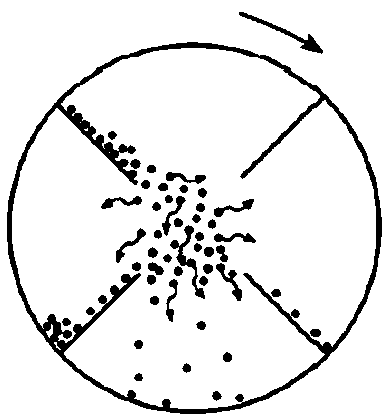

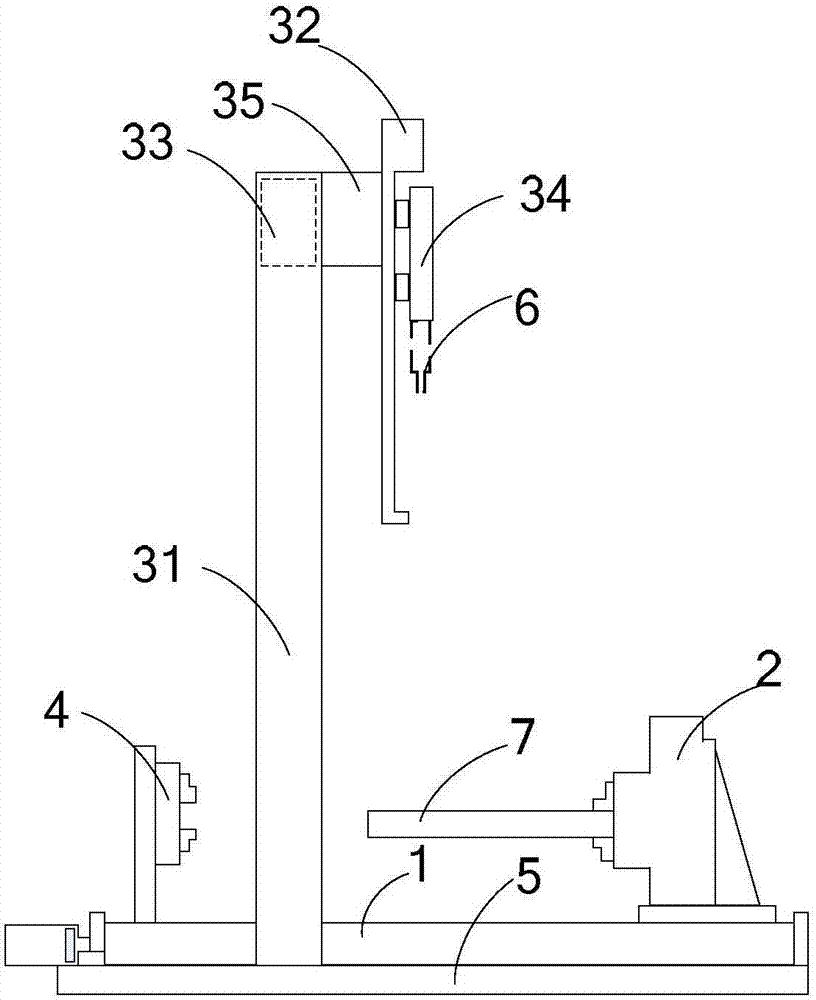

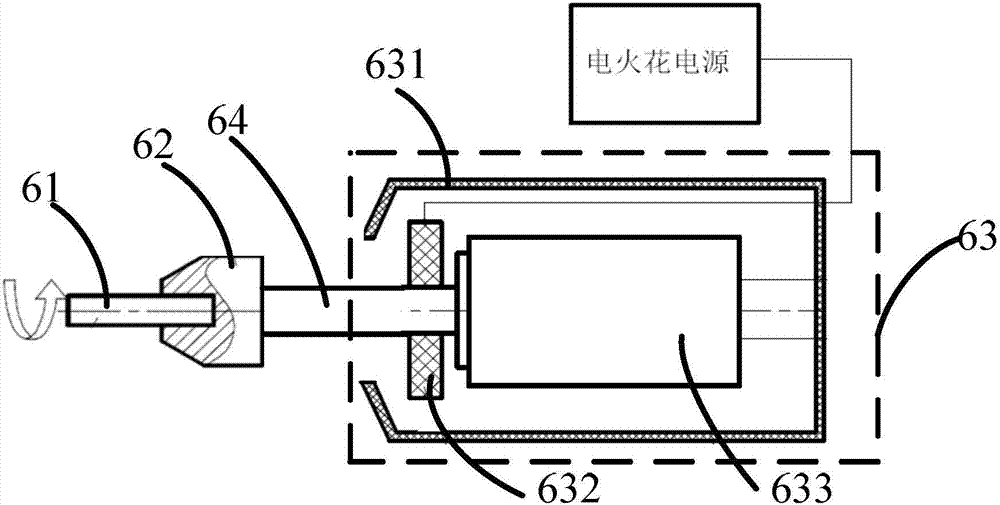

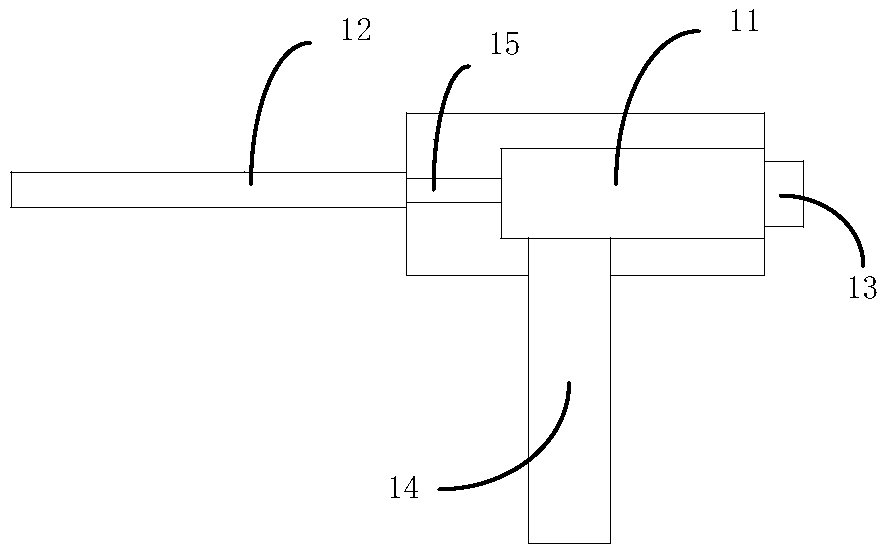

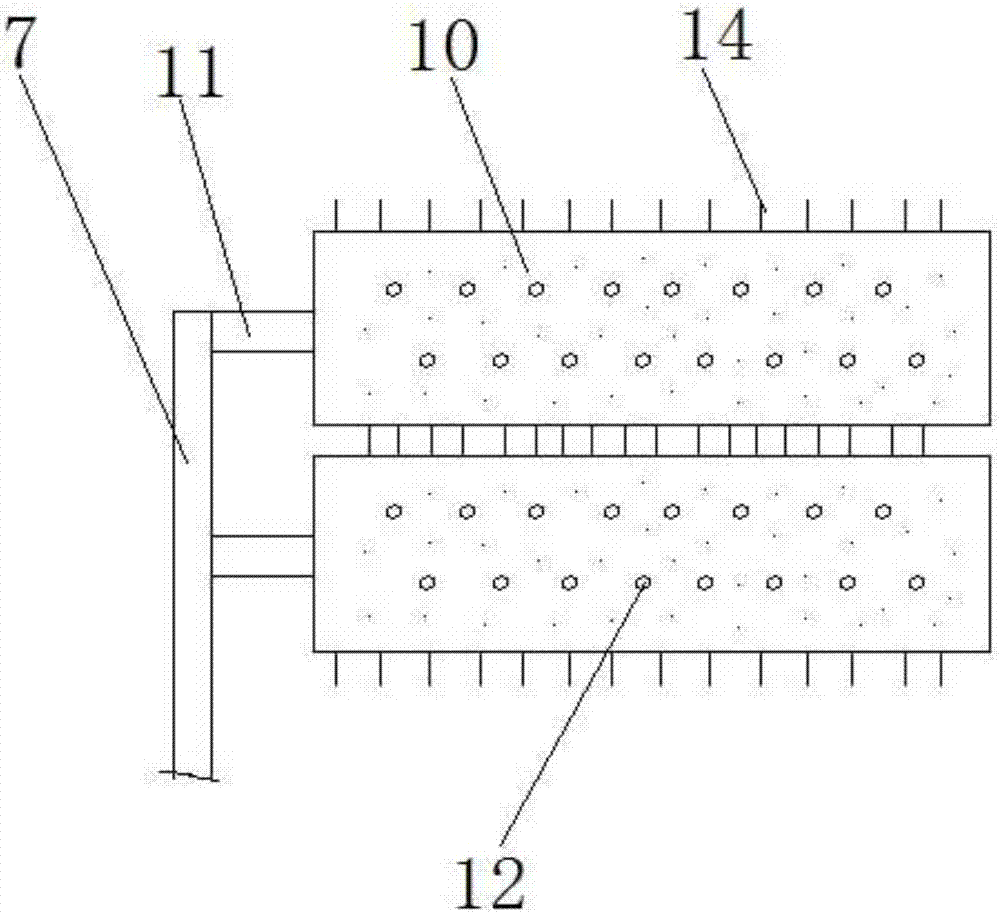

Pipe fitting automatic electric spark treatment device and method

InactiveCN106944757AAchieve coatingImprove uniformityMetallic material coating processesWelding apparatusControl systemPipe fitting

Aiming at the problems of low efficiency during large-area coating, high labor intensity and poor uniformity caused by manual operation of an electric spark welding gun, the invention provides a pipe fitting automatic electric spark treatment device and method and belongs to the technical field of mold and casting surface defect restoration. The treatment device comprises a main mobile platform, a rotary chuck and a control system. The rotary chuck is connected with one end of a to-be-treated pipe fitting and arranged on the main mobile platform. An electrode of the welding gun makes contact with the outer surface or the inner surface of the to-be-treated pipe fitting. The treatment method comprises the steps that the welding gun is controlled to conduct electric spark treatment; meanwhile, the control system controls the rotary chuck to drive the to-be-treated pipe fitting to rotate; when the to-be-treated pipe fitting rotates by a set number of laps, the main mobile platform is controlled to move by a set stepping distance in the axial direction of the to-be-treated pipe fitting; and the steps are repeated till the discharging point of the electrode covers the outer surface or the inner surface of the to-be-treated pipe fitting. By adoption of the pipe fitting automatic electric spark treatment device and method, electric spark automatic treatment on the outer surface or the inner surface of the pipe fitting is achieved, complete coating is achieved, and the coating uniformity is good.

Owner:HARBIN INST OF TECH

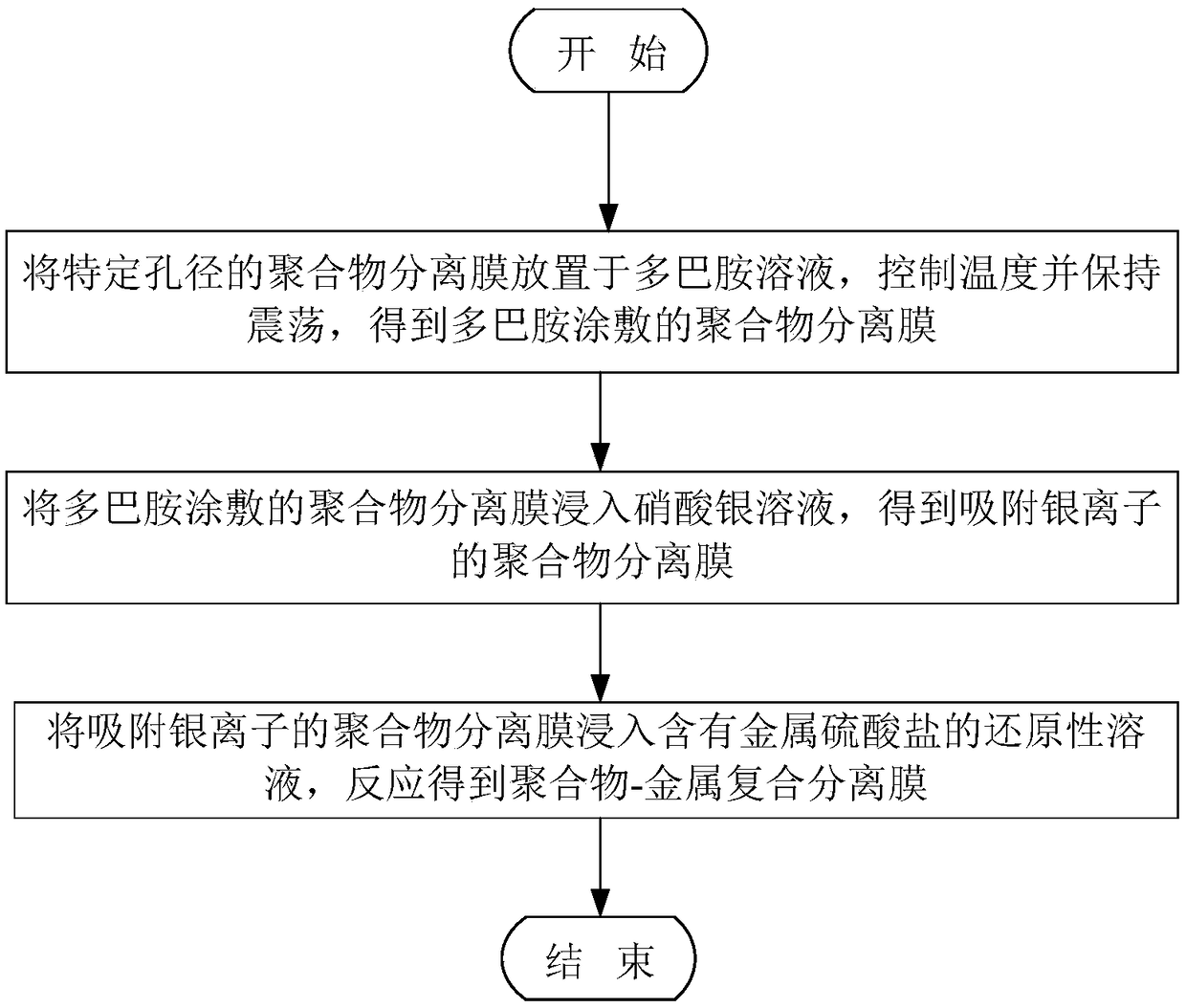

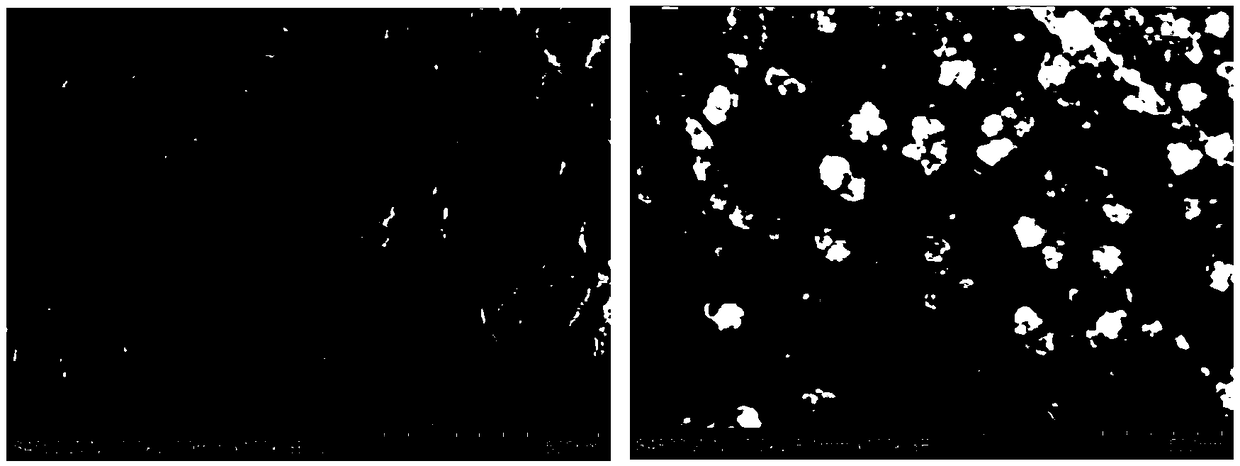

Preparation method and application of polymer-metal composite separation membrane

ActiveCN108636130AControl Separation PropertiesIncreased sensitivityMembranesSemi-permeable membranesCongo redMicrofiltration membrane

The invention relates to a preparation method and an application of a polymer-metal composite separation membrane. The method comprises the following steps: coating a polyvinylidene fluoride microfiltration membrane with dopamine to endow the membrane with the capacity of adsorbing silver ions; then, immersing the membrane adsorbing the silver ions into a reducing solution containing nickel sulfate, and compounding nickel on a polymer separation membrane through reaction to prepare the polymer-metal composite separation membrane. The obtained polymer-metal composite separation membrane realizes sensitivity of Congo red interception rate to an electric field and also has interception stability, and is suitable for selective separation as interception efficiency increases with the enhancement of the electric field, and the separation characteristic of the membrane can be conveniently controlled by changing intensity of the environmental electric field. The method is simple to operate andlow in cost, facilitates industrial application and has great significance in application to printing and dyeing wastewater.

Owner:HUZHOU SENNUO FLUORINE MATERIAL TECH

Control system and method of inhomogeneous film layer product film coating equipment

ActiveCN109182995AAchieve coatingAdjustable speedVacuum evaporation coatingSputtering coatingPower controllerControl signal

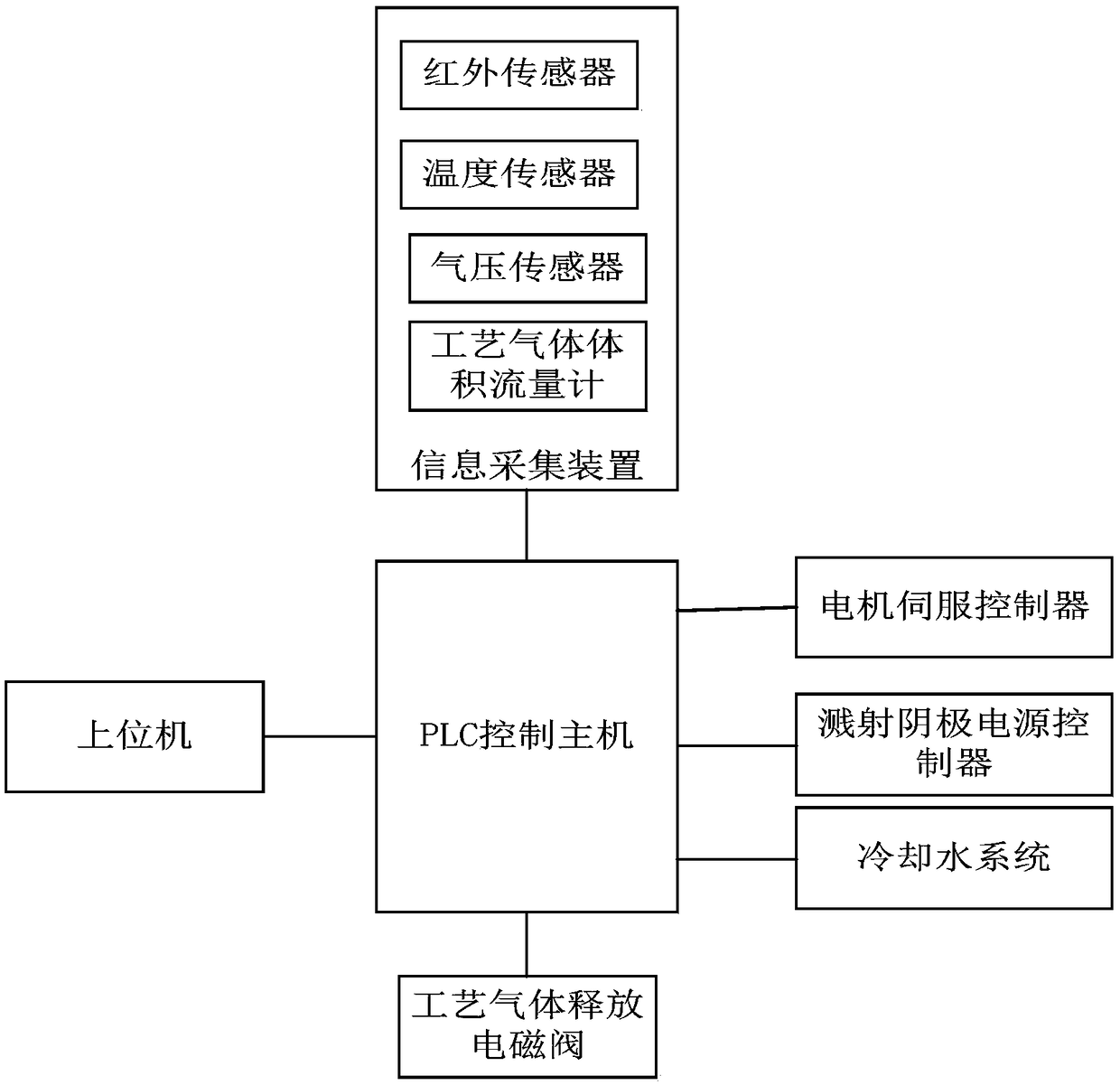

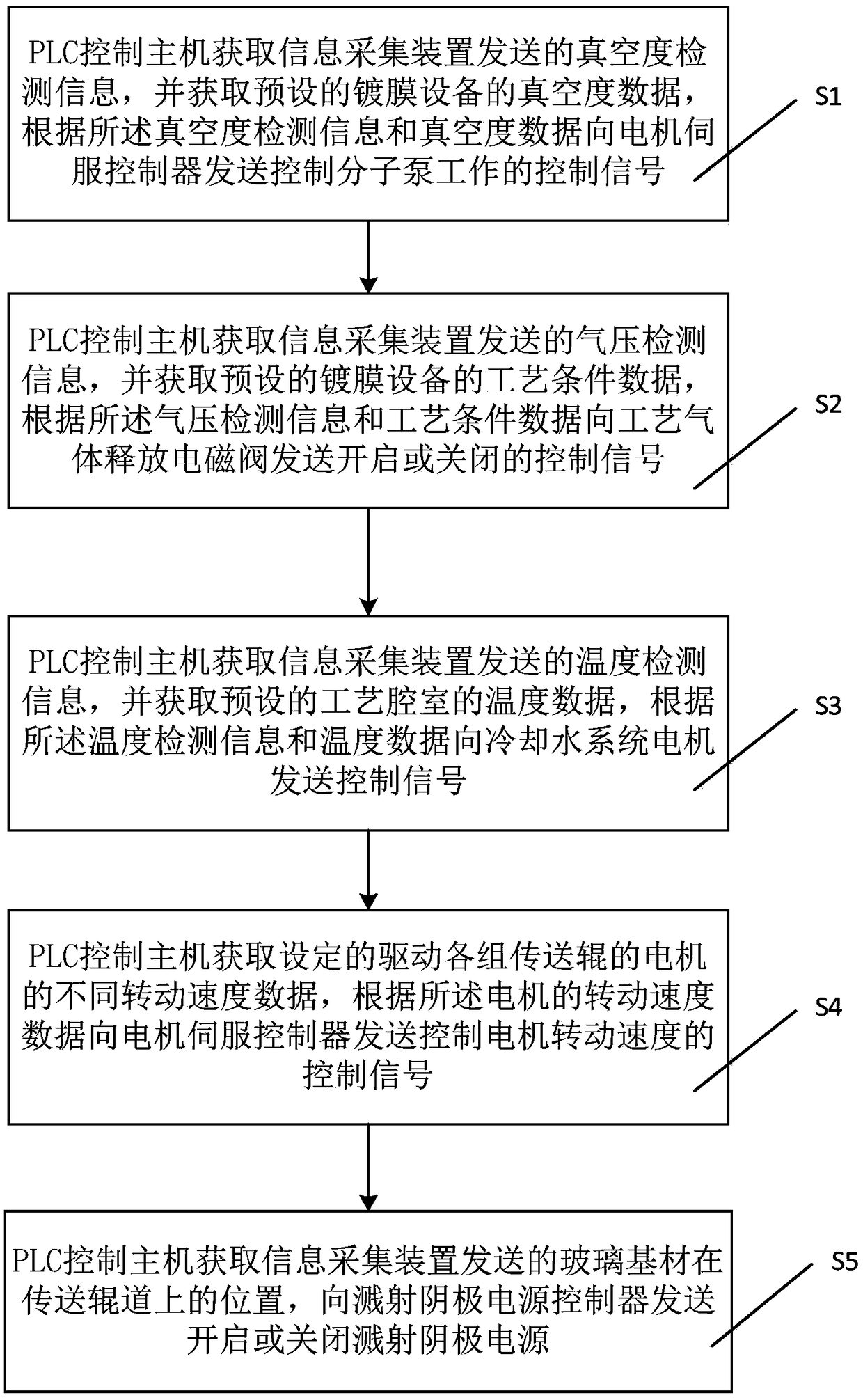

The invention discloses a coating control system of an inhomogeneous film layer product. The control system comprises an upper computer, a PLC control host, an information acquisition device, a motorservo controller and a sputtering cathode power supply controller; the information acquisition device is used for detecting positions of a glass substrate on conveying roller ways, and temperature andair pressure information in process cavities, and the PLC control host is used for receiving detection information sent through the information acquisition device; the motor servo controller and thesputtering cathode power supply controller are controlled to work according to the detection information; and the motor servo controller is used for sending control signals to motors and controlling the motors to rotate according to different set speed curves. According to the coating control system of the inhomogeneous film layer product, the motor servo controller controls the motors to rotate according to the set motor rotating speed curves so that n conveying rollers corresponding to each layer of films can be independently adjusted and controlled, then the speed of the glass substrate under the corresponding sputtering cathode can be adjusted, then the thickness of a coated film layer can be changed controllably, and the effect that a coated film of the inhomogeneous film layer product can be continuously produced in a large scale is realized.

Owner:布勒莱宝光学设备(北京)有限公司

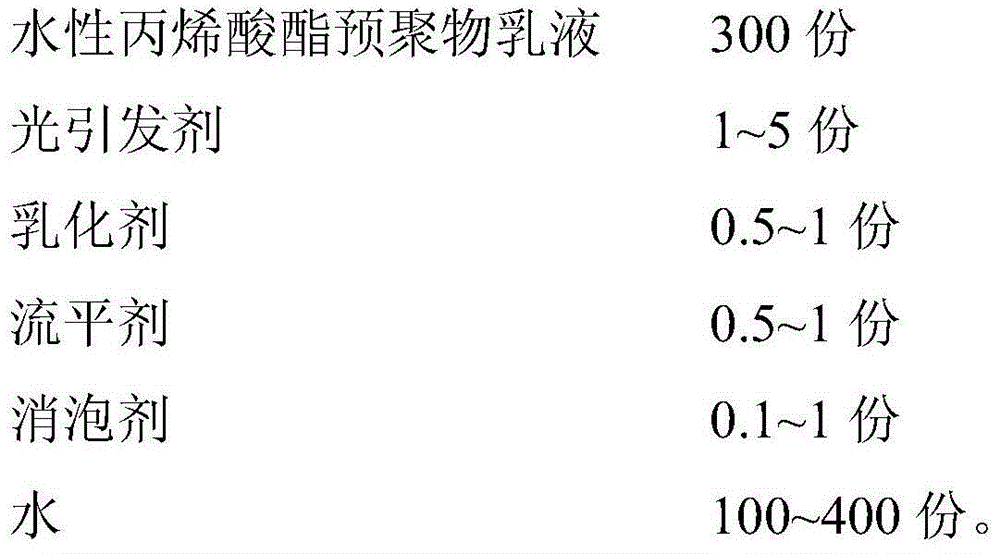

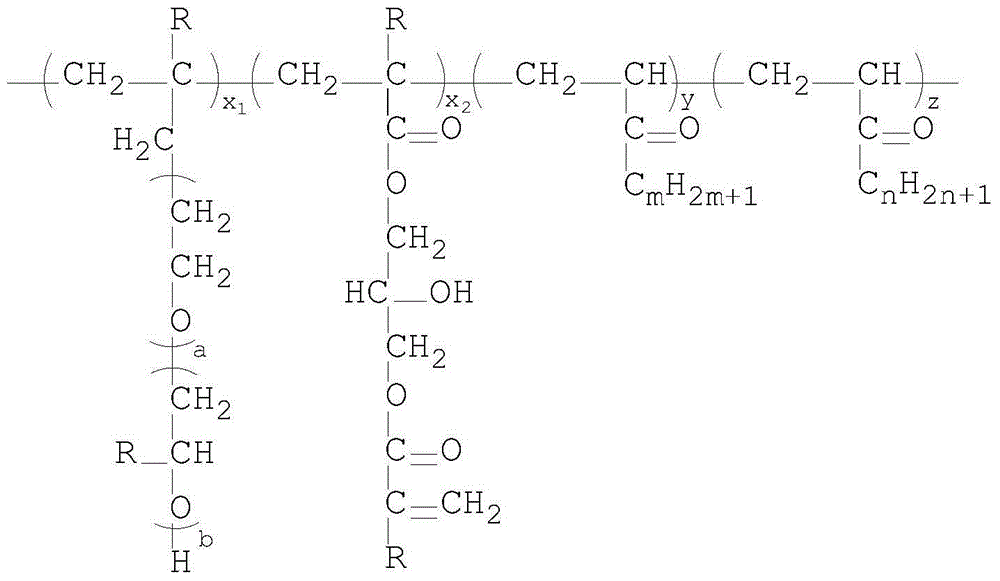

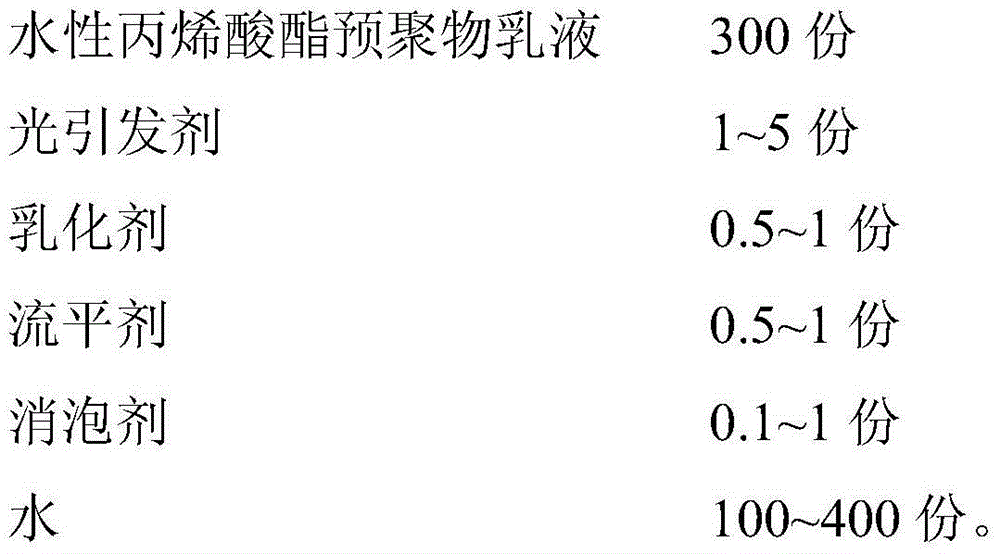

UV (ultraviolet)-curable acrylate polymer water emulsion for coating polypropylene film

The invention belongs to the technical field of acrylate polymer water emulsion, and discloses a UV (ultraviolet)-curable acrylate polymer water emulsion for coating a polypropylene film, and a preparation method and application thereof. The polymer water emulsion comprises the following components in parts by weight: 300 parts of water-based acrylic emulsion prepolymer, 1 to 5 parts of photoinitiator, 0.5 to 1 part of emulsifier, 0.5 to 1 part of flatting agent, 0.1 to 1 part of de-foaming agent, and 100 to 400 parts of water. The structure of the acrylate polymer water emulsion disclosed by the invention contains rich ester groups and alkyl groups, and can form acting force with the inorganic materials, such as glass, and organic interfaces, such as BOPP (biaxially-oriented polypropylene) plastic film; the polyether segment has high flowability and is soluble in water; the spreadability property of the emulsion on the BOPP film and the bonding property, the durability and the like of the emulsion on a cured film are improved; the UV-curable acrylate polymer water emulsion is favorable for the adhesive sealing and the fixing between the BOPP film and other plastics, glass, wood, metal, biological tissues and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

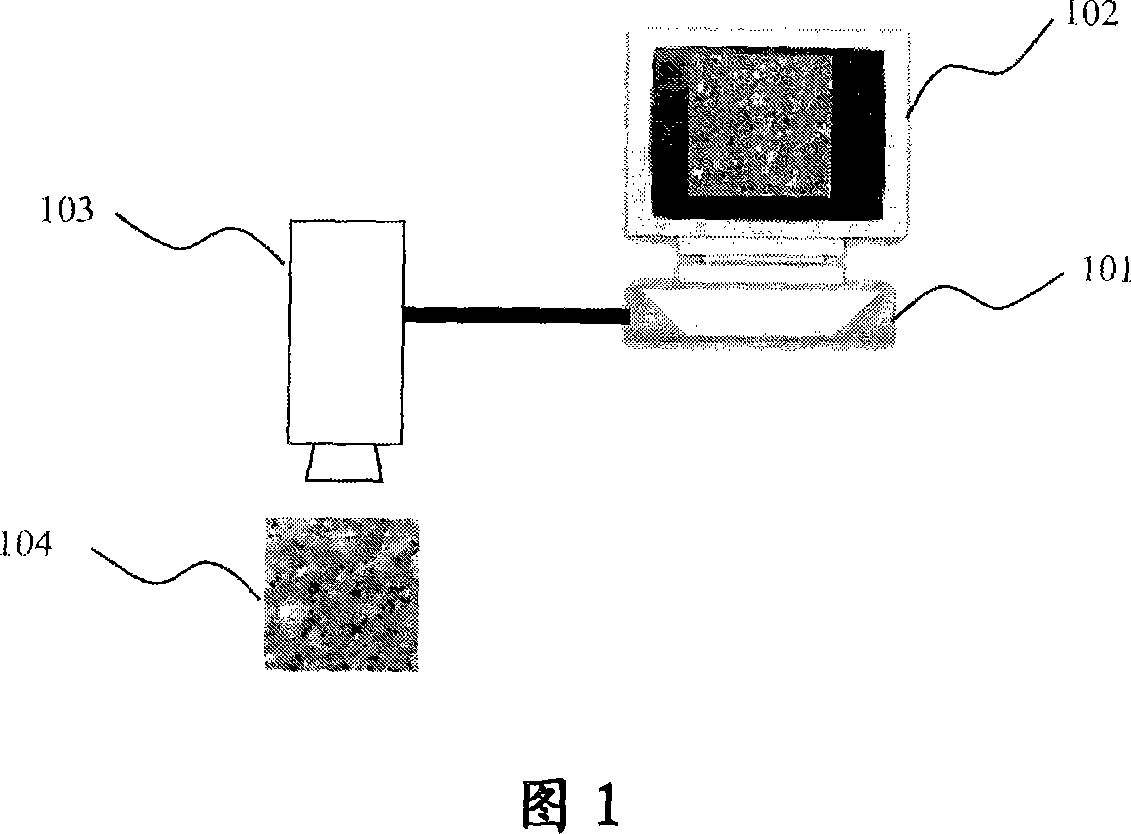

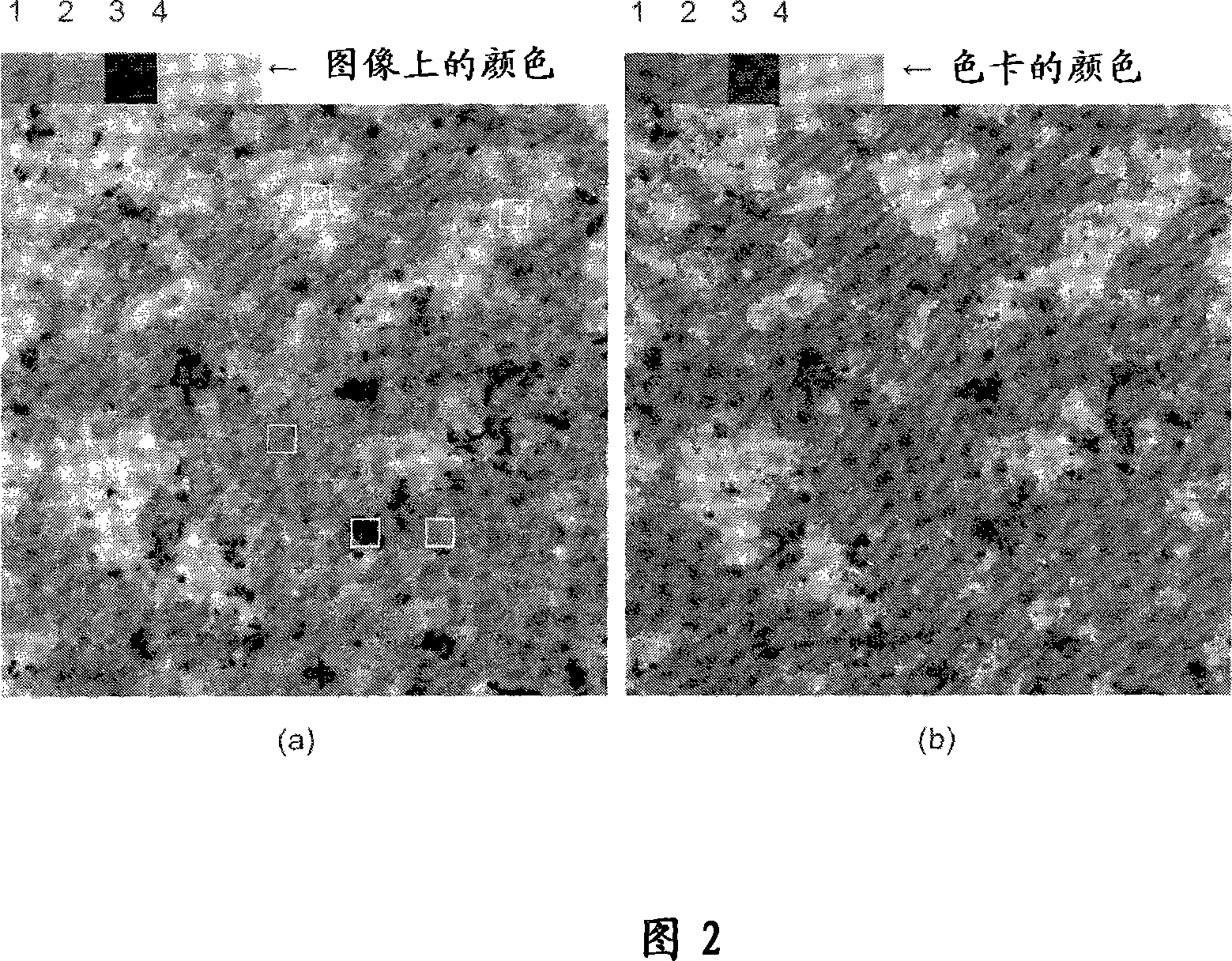

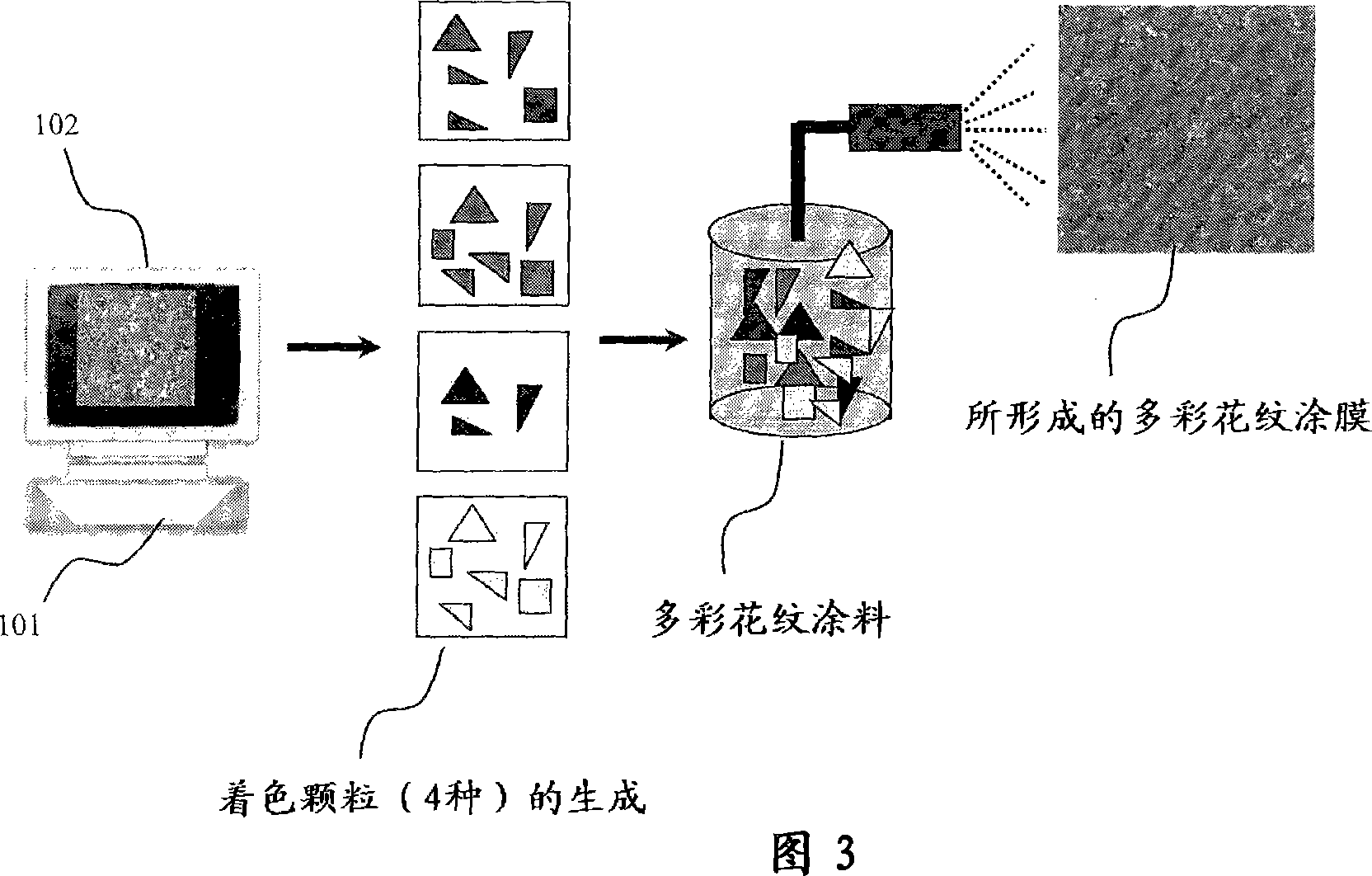

Determining method of colorful riffled paint compound information and base material visual information

InactiveCN101049592AHigh simulationHigh precisionArtistic surface treatmentCoatingsColor imageComputer science

The present invention provides the determined method, procedure and recording medium of the coating combining information and the substrate visual information to generate the needed multicolour pattern coating film. This determined method is be in the computer possessing controlling unit and displaying unit, the controlling unit determines the visual information of the multiple dot-blots on the multicolour image of the multicolour pattern as well as the coloring particles and substrate(s2) of the visual information reappearing the dot-blots, making one of the arbitrary visual information among the multi visual information corresponding to each pixel of the coloring image. According to the number of the pixel corresponding to the equal visual information, determining the combining ratio(s3) of the coloring particles. Then obtaining the conditions(s4,s6) using for generating multicolour pattern image data through the visual information corresponding to the coloring particle as well as the visual information, combining ratio, coloring particle size corresponding to the substrate, based on the obtained conditions, generating multicolour pattern image data and displaying on the displaying unit(s5,s7).

Owner:KANSAI PAINT CO LTD

Coating equipment for coated glass production

PendingCN111960684AAchieve installationSolve the problem of low work efficiencyChain linkMaterials science

The invention discloses coating equipment for coated glass production. The coating equipment comprises a coating box, a drying box, a clamping mechanism, a conveying chain and a glass body; a conveying chain is annularly arranged on the side wall of a base; the conveying chain is in transmission connection with the base; a plurality of groups of clamping mechanisms for fixing the glass body are arranged on the conveying chain at equal intervals; the coating box for coating the glass body is arranged on one side of the base; a coating mechanism is arranged in the coating box, the drying box used for drying the glass body is arranged on the other side of the base, a support is vertically arranged on the base, the top end of the support is connected with the top end of a connecting rod, the bottom end of the connecting rod is connected with one end of a shell, and the other end of the shell is installed on the support. The glass body is comprehensively coated by the coating equipment under the condition that the glass body is not disassembled, and the coating equipment has the advantages that the automation degree is high, the manual operation is little, and the manpower is greatly saved.

Owner:安徽艺云玻璃有限公司

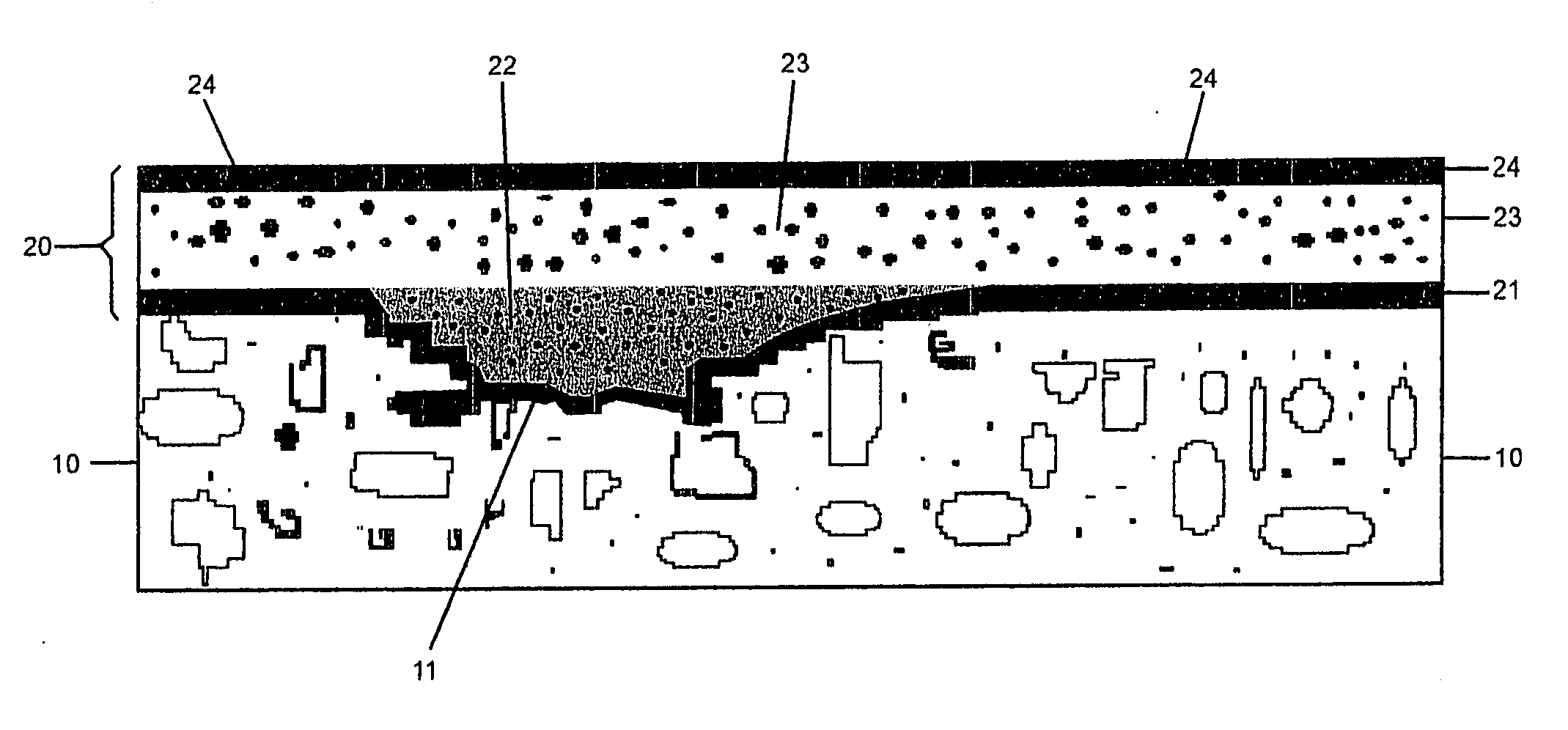

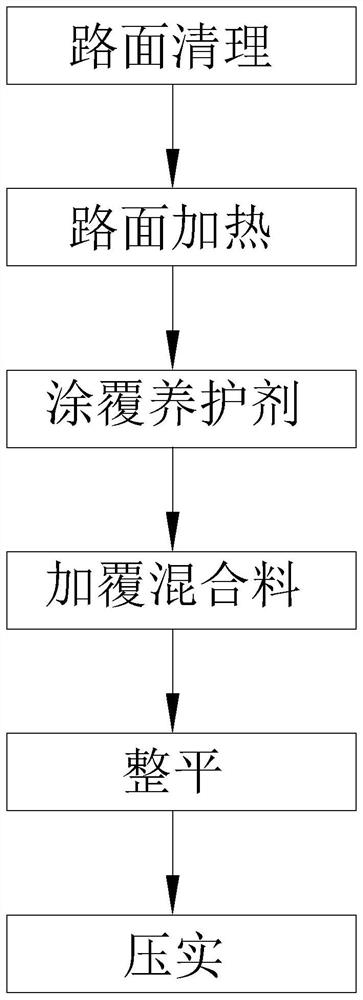

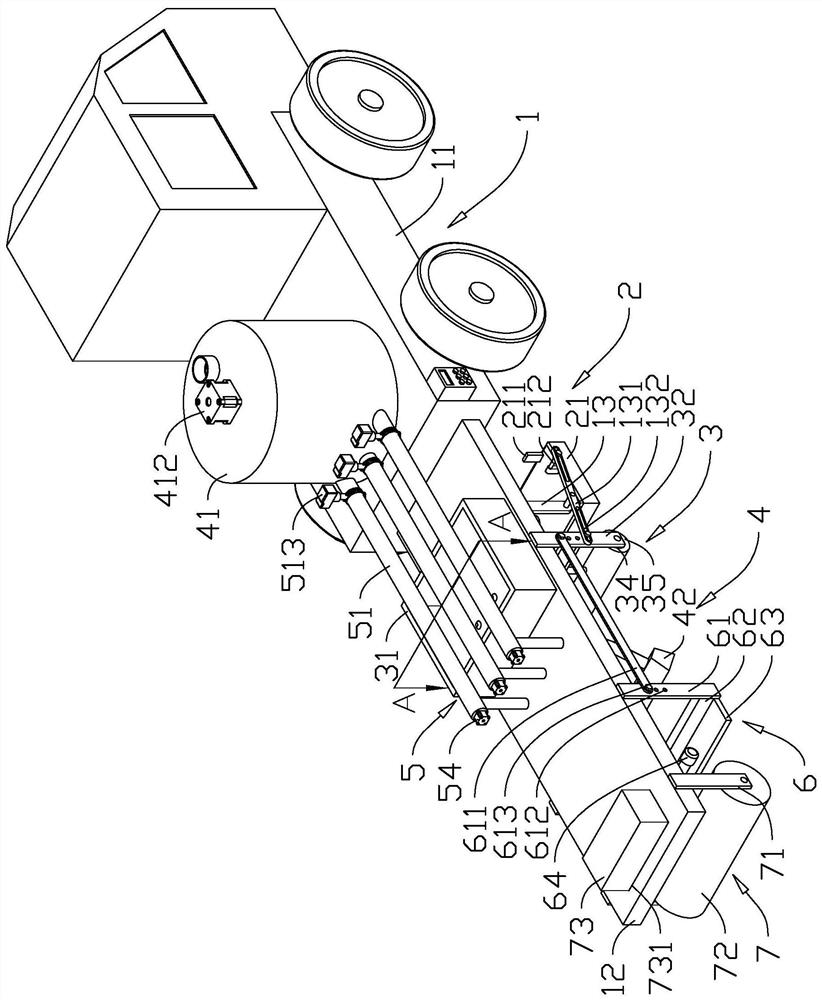

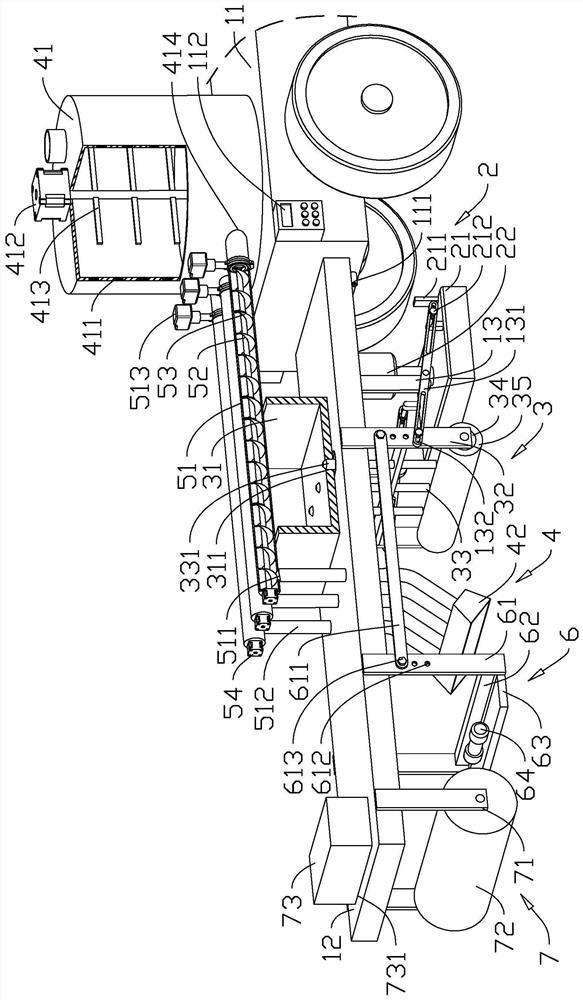

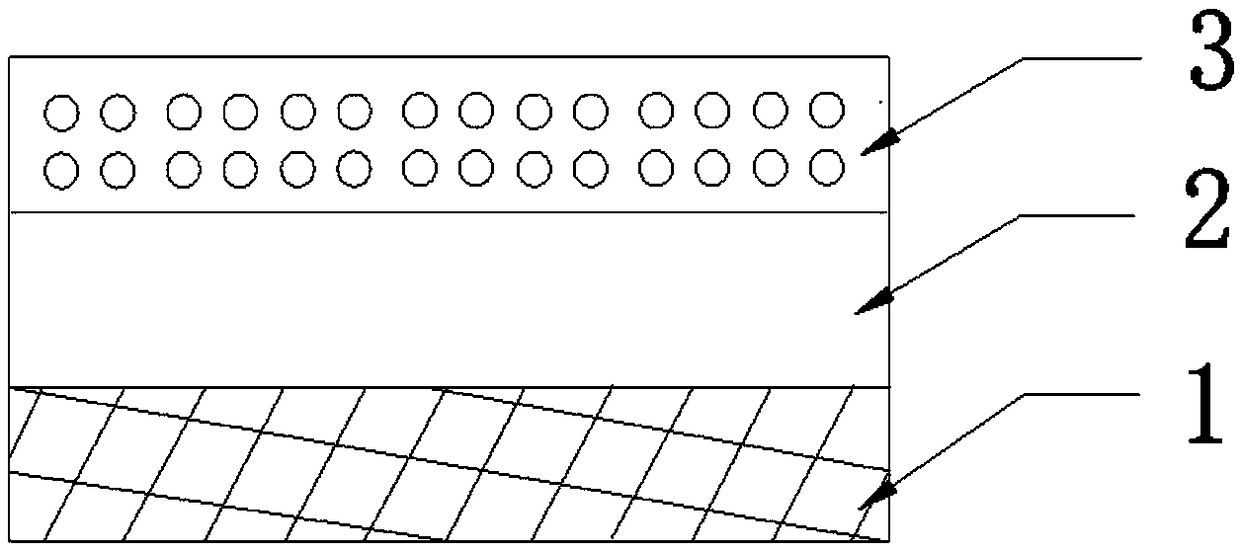

Preventive maintenance method for asphalt concrete pavement

ActiveCN112982109ADelay asphalt agingReduce the possibilityRoads maintainenceGeotechnical engineeringStructural engineering

The invention relates to a preventive maintenance method for an asphalt concrete pavement. According to the method maintenance operation is implemented based on a maintenance truck. The method comprises the following specific operation steps: S1, pavement cleaning: removing sundries on the pavement; S2, pavement heating: heating and softening the pavement by using a heating mechanism; S3, coating of a curing agent: coating the pavement with the curing agent by using a curing mechanism; S4, adding and covering of a mixture: subjecting the pavement to adding and covering with a new and hot asphalt mixture through an adding and covering mechanism; S5, leveling: flattening the new and hot asphalt mixture through a leveling mechanism; and S6, compacting: rolling the new and hot asphalt mixture by a compacting mechanism to obtain a protective layer. According to the invention, heating softening of the pavement induces self-repairing of disease parts, pavement diseases are filled and repaired by coating with the curing agent, excavation of a damaged asphalt concrete pavement is not needed, and curing efficiency is improved; and the pavement is covered with the new and hot asphalt mixture, a compact and flat protective layer is formed after flattening and rolling, the protective layer and the pavement form an integral new pavement, so the effect of prolonging the service life of the asphalt concrete pavement is facilitated.

Owner:蚌埠市思创沥青路面工程有限公司

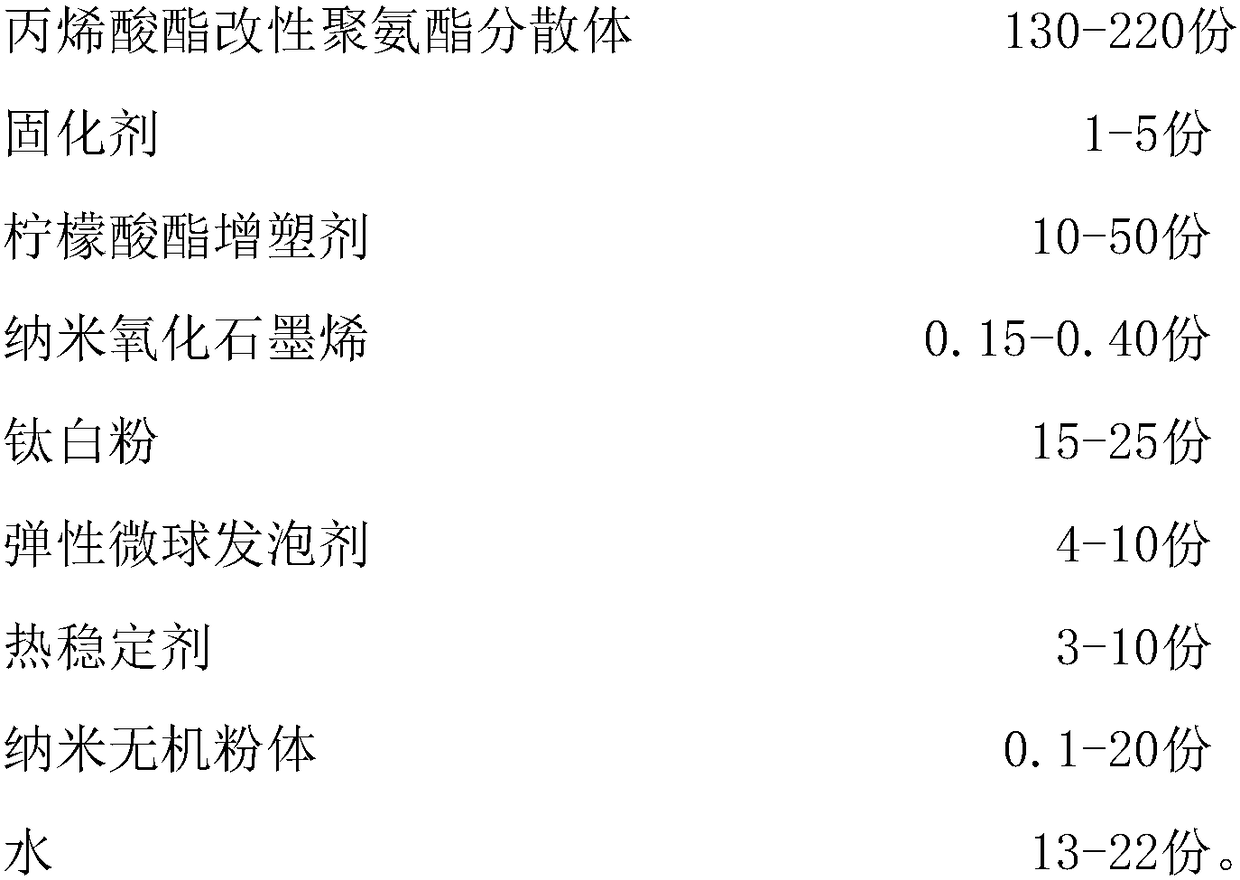

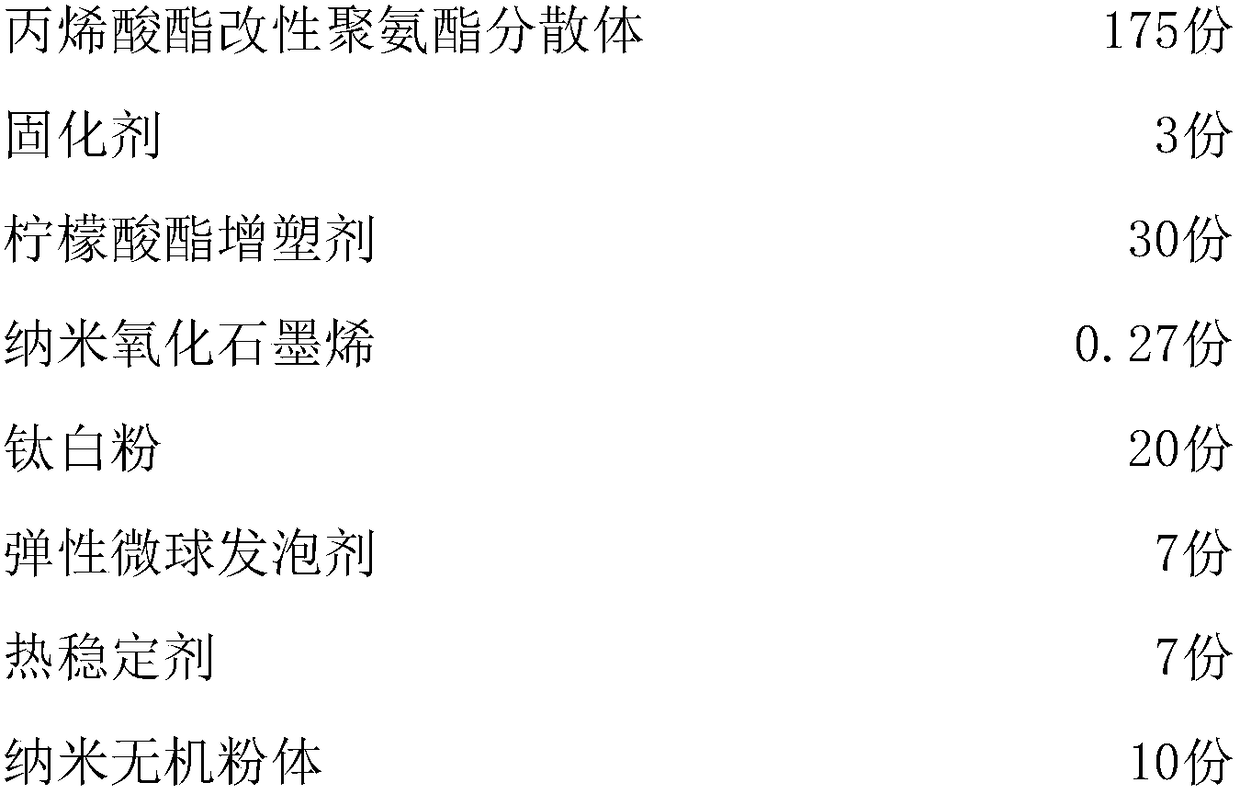

Anti-scratching foaming wall cloth

ActiveCN108978236AGood adsorption performanceUniform thicknessTextiles and paperActivated carbonWoven fabric

The invention relates to the technical field of wall cloth, and particularly relates to anti-scratching foaming wall cloth, comprising an activated carbon non-woven fabric layer, an anion layer compounded on the activated carbon non-woven fabric layer, and an anti-scraping foaming layer compounded on the anion layer, wherein the anti-scratching foaming layer is formed by anti-scratching foaming slurry, and the anti-scratching foaming slurry contains the following materials: an acrylic ester modified polyurethane dispersion, a curing agent, a citrate plasticizer, nanometer graphene oxide, titanium dioxide, an elastic microsphere foaming agent, a heat stabilizer, nanometer inorganic powder, and water. The wall cloth disclosed by the invention has the advantages of high hardness, scratching resistance and difficulty in falling-off of the coating, and the wall cloth disclosed by the invention also comprises the activated carbon non-woven fabric layer, which has strong 'physical adsorption'and 'chemical adsorption' effects, can effectively adsorb harmful gas, and is remarkable in antitoxin and deodorization effects.

Owner:GUANGDONG YULAN GRP

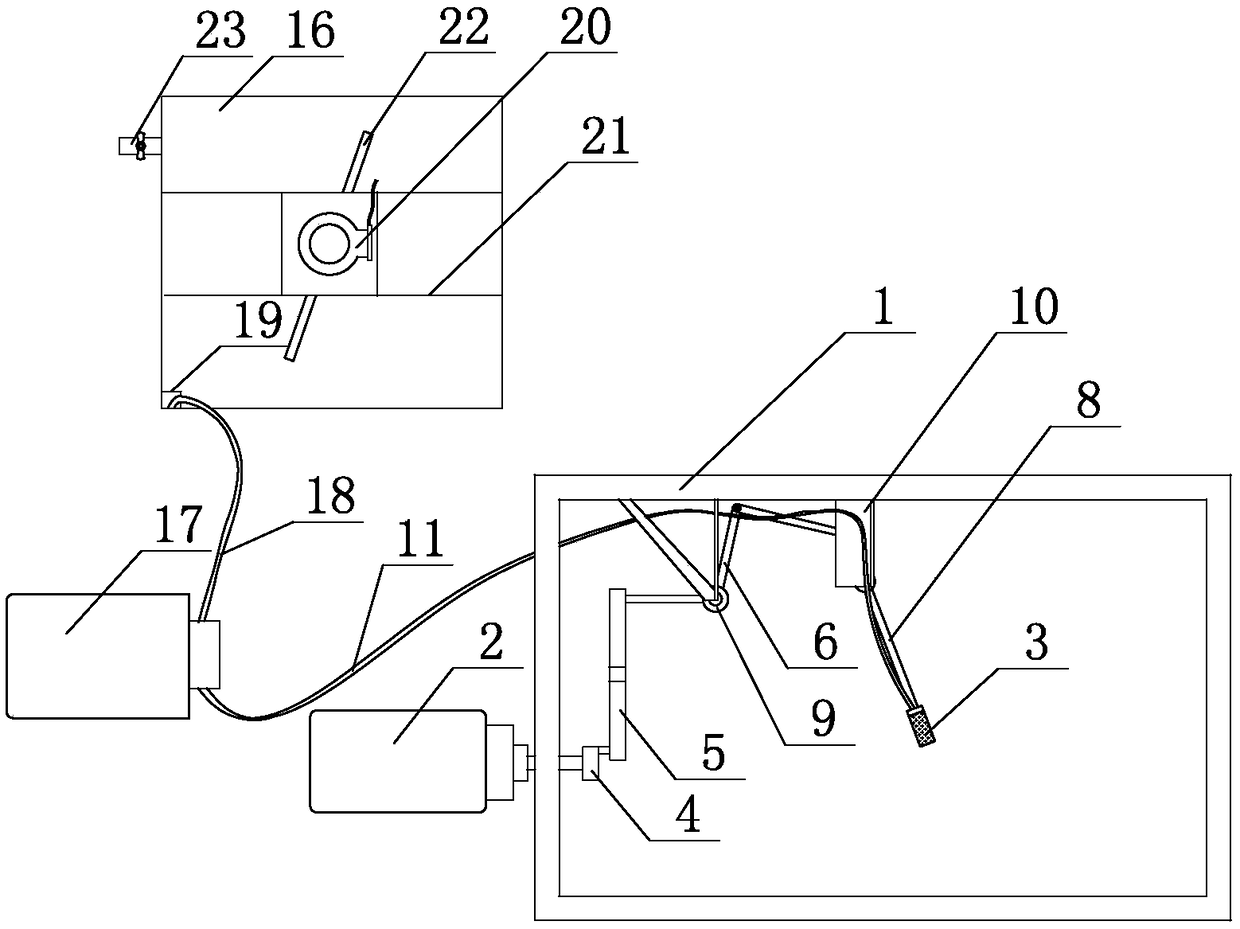

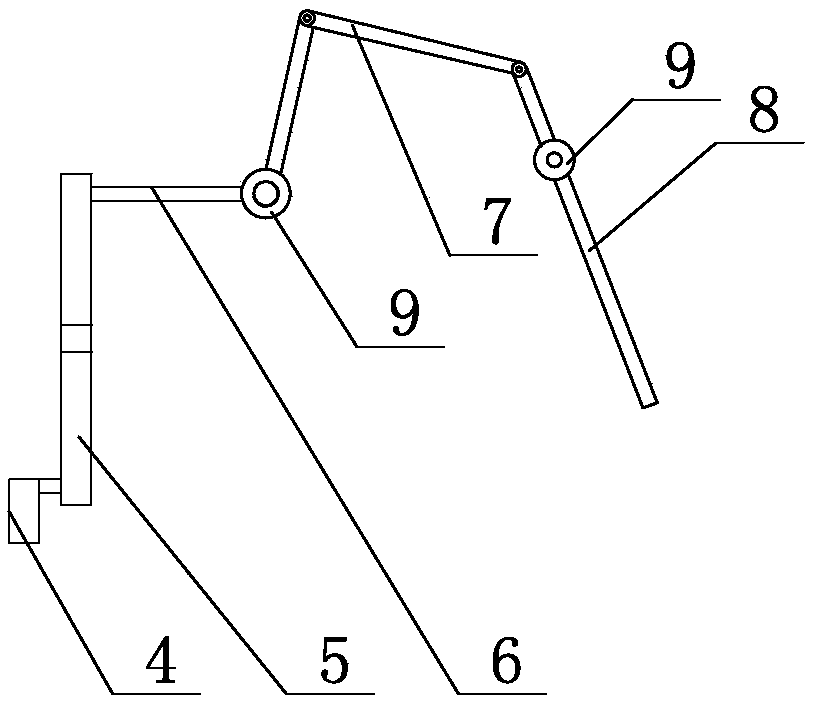

Automatic interfacial agent coating device for thermal insulation plate

InactiveCN108636691AAchieve full coverageRealize automatic coatingLiquid surface applicatorsCoatingsCouplingThermal insulation

The invention relates to a coating device, in particular to an automatic interfacial agent coating device for a thermal insulation plate. The automatic interfacial agent coating device comprises a material feeding part, a material coating part and a supporting frame; the material feeding part is used for feeding a material to the material coating part; the material coating part is supported through the supporting frame and comprises a driving motor, a material coating connection rod and a material coating brush; the material coating connection rod comprises a cranking bar, a coupling, a V-shaped rod, a connection rod and a coating rod; one end of the cranking bar is connected with a rotary shaft of the driving motor, and the other end of the cranking bar is connected with one end of the V-shaped rod through the coupling; the V-shaped rod is connected with the coating rod through the connection rod, and the inflection point position of the V-shaped rod is movably connected with the supporting frame through a connection ring; the middle of the coating rod is movably connected with the supporting frame through a connection ring; and the coating rod fixes a material coating brush and inclines downwards, and the material coating brush communicates with the feeding part through a feeding pipe. According to the automatic interfacial agent coating device for the thermal insulation plate, a groove does not need to be carved in the thermal insulation plate, the adhesion fastness is ensured while automatic coating of an interfacial agent for the thermal insulation plate is achieved, the production cost is reduced, and the production efficiency is improved.

Owner:崔致需

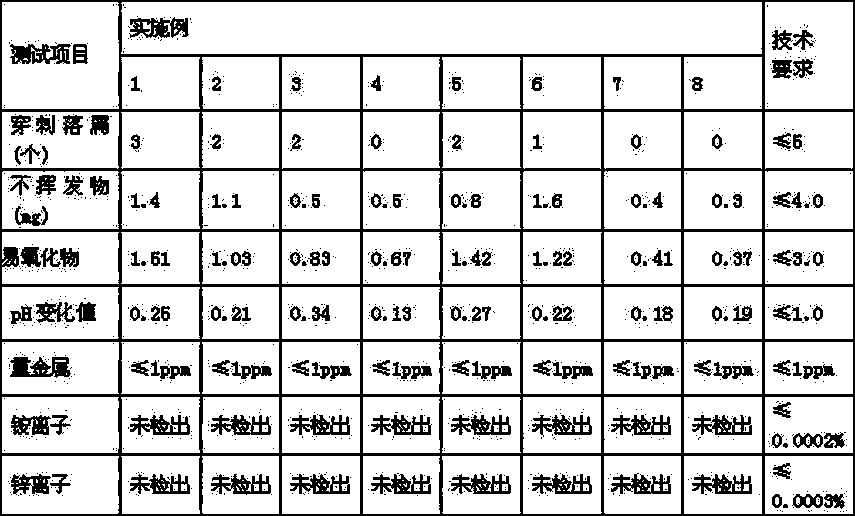

Surface-modified rubber plug and preparation method thereof

InactiveCN103405335AImprove sealingImprove securityPharmaceutical containersMedical packagingEmulsionThermoplastic elastomer

The invention discloses a surface-modified rubber plug and a preparation method thereof. The rubber plug comprises a rubber plug body and a modification layer on the surface of the rubber plug body. The modification layer is modified through PVDC (polyvinyl dichloride) emulsion. Chemical modification is performed on the surface of the rubber plug by the aid of the corona-aided high polymer material surface modification technology, oxygen-blocking and dampness-blocking features of the PVDC is utilized to increase negative pressure maintaining capacity of a vacuum container, block the contact of the rubber plug body and medicines and blood, and increase safety and biocompatibility of the rubber plug. The method is suitable for the existing rubber plugs available on the market, thermoplastic elastomer rubber plugs and surface modification of sealing parts with complex shapes.

Owner:SHANDONG WEIGAO GROUP MEDICAL POLYMER

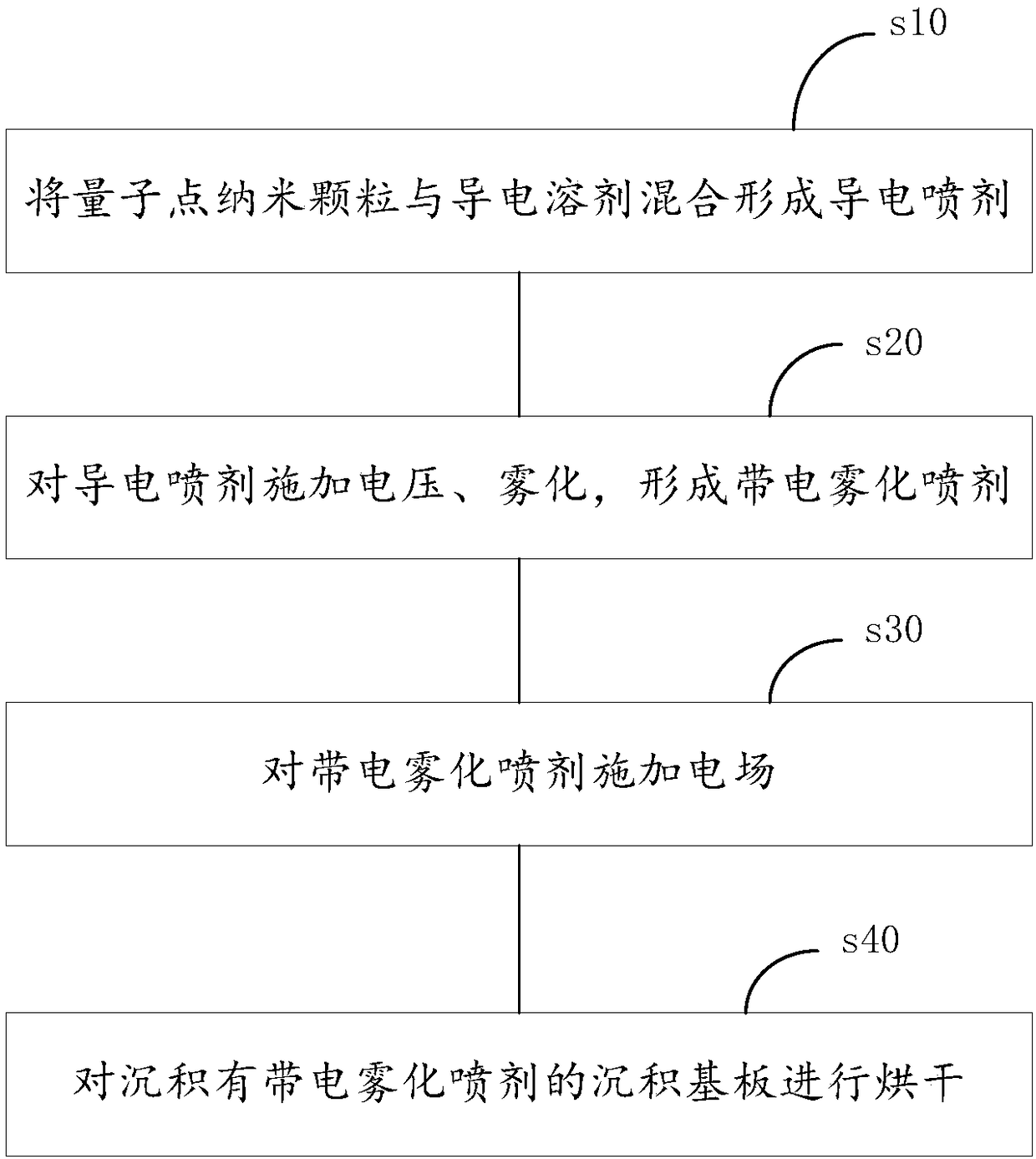

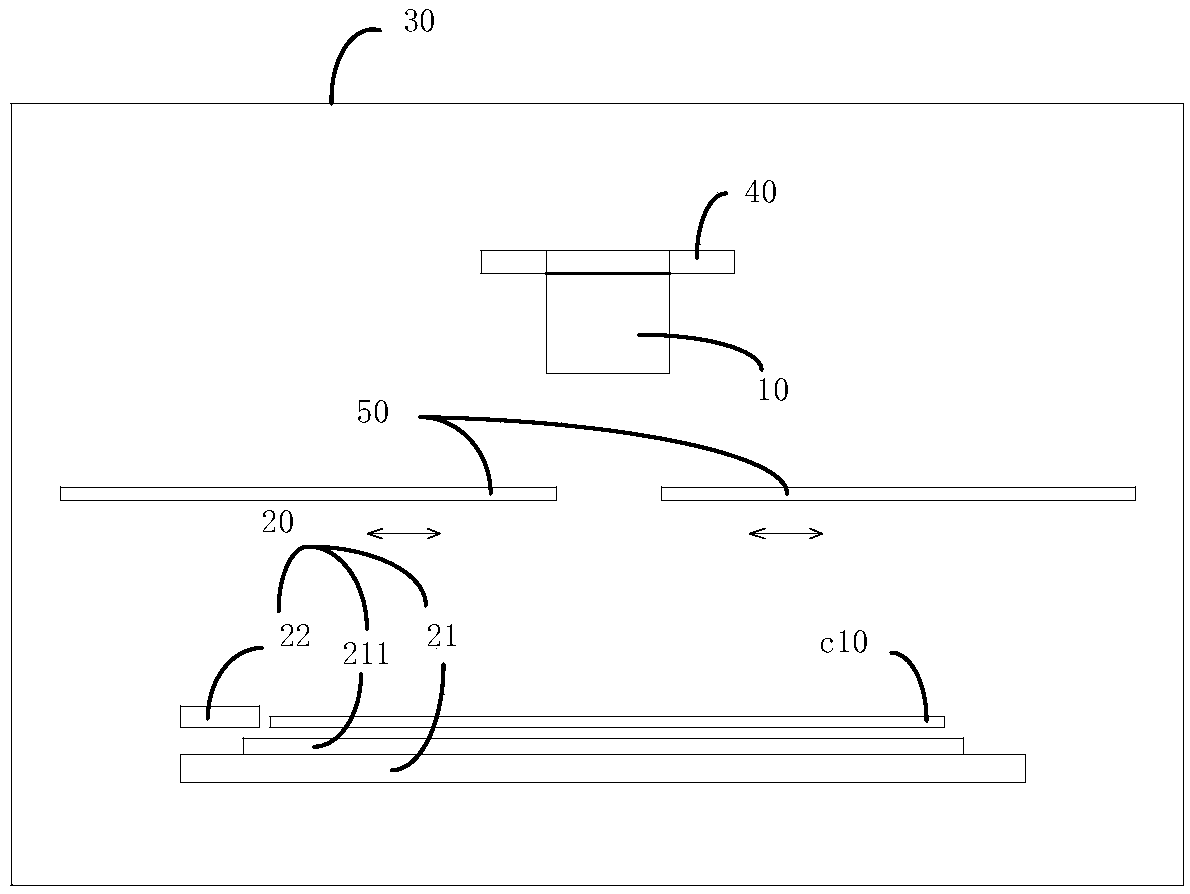

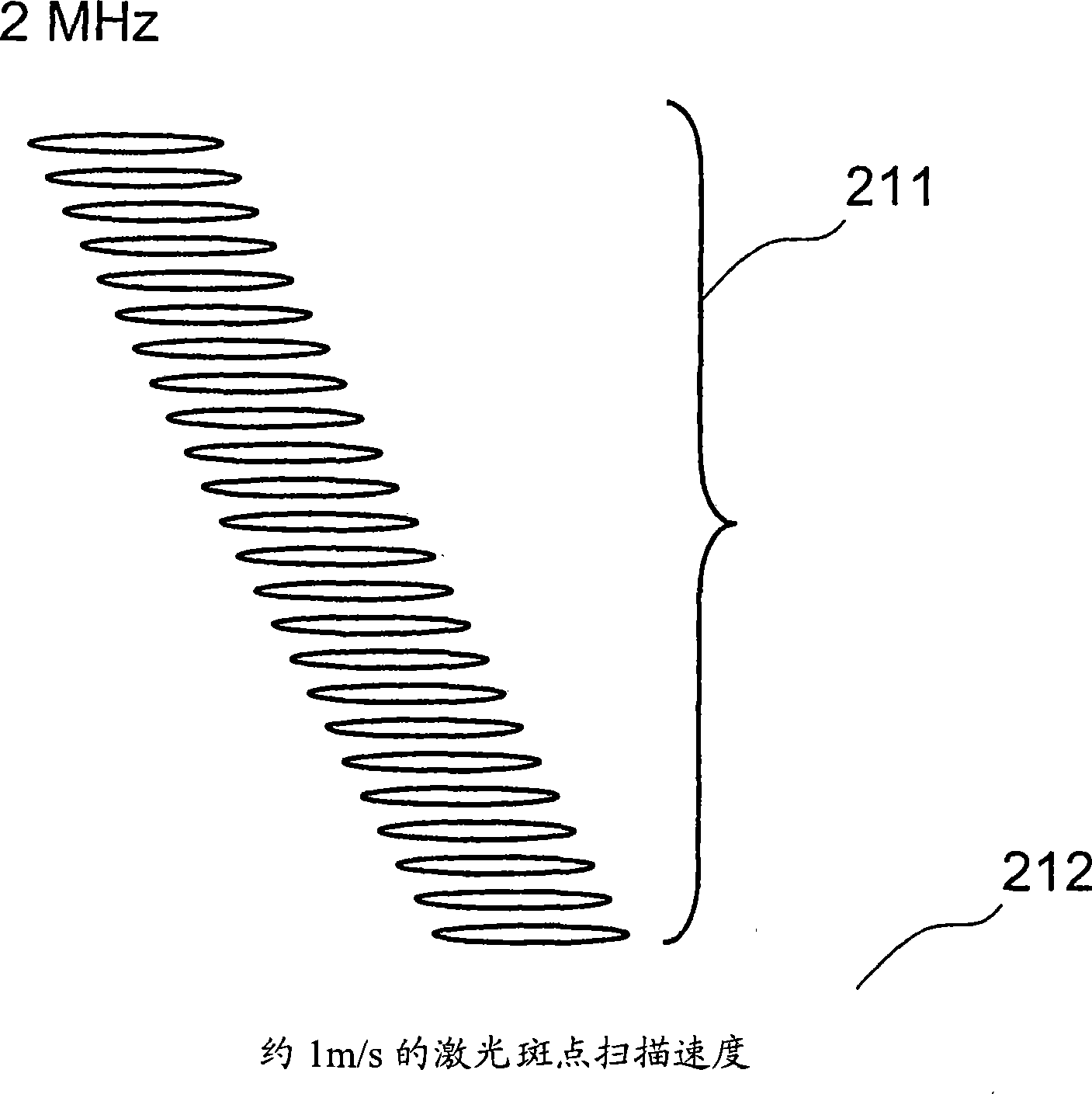

Quantum dot film coating method and system

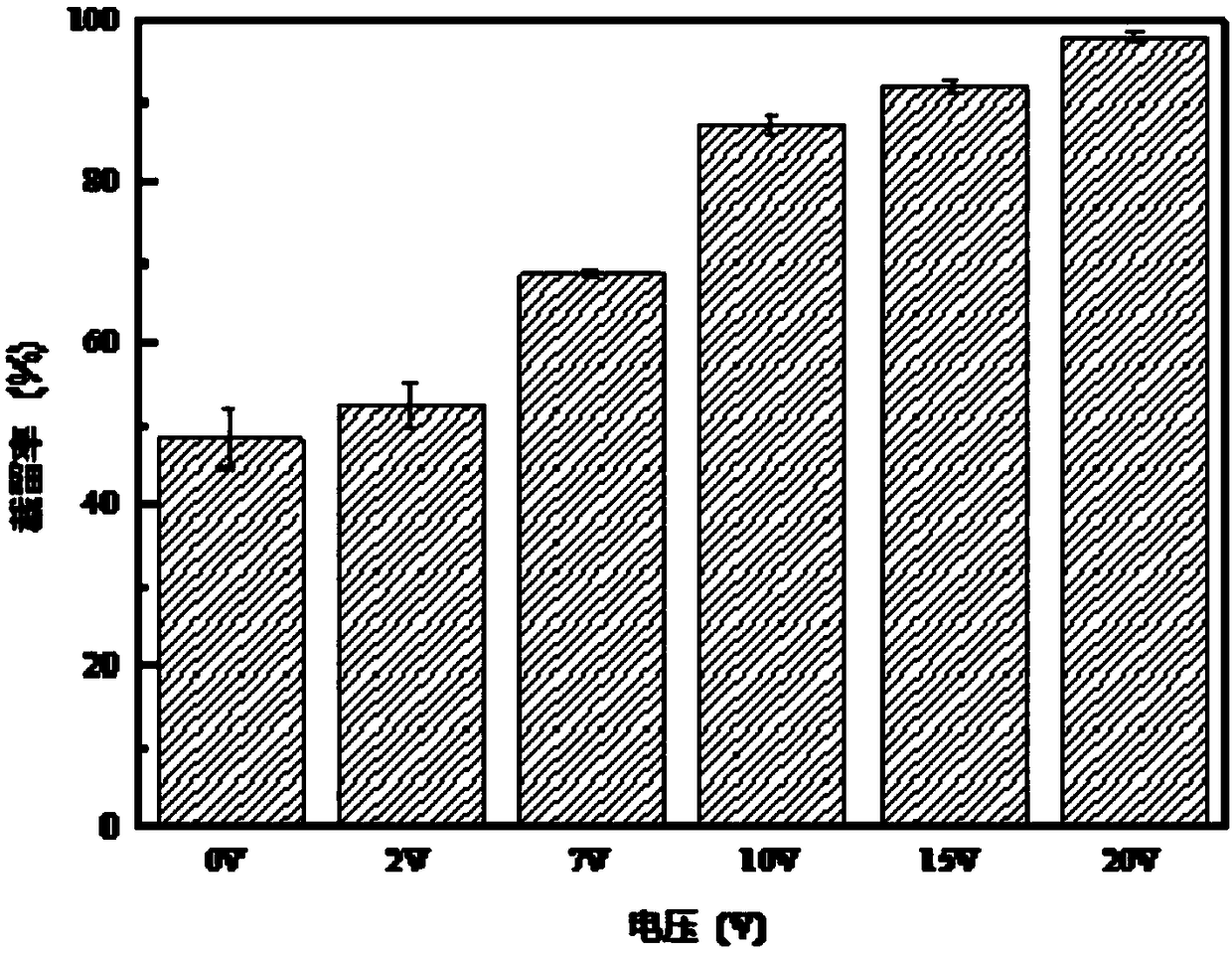

The invention relates to a quantum dot film coating method and system and relates to the technical field of quantum dot film coating. The quantum dot film coating method and system mainly achieve thetechnical effect that film coating can be conducted on quantum dot nano particles. According to the main technical scheme, the quantum dot film coating system comprises a voltage application atomization unit and an electric field application unit, wherein the voltage application atomization unit is used for applying the voltage to an electrically-conducting spray for atomization, so that an electrified atomization spray is formed; and the electric field application unit is used for applying an electric field to the electrified atomization spray. In the nano quantum dot film coating process, the quantum dot nano particles can be mixed with electrically-conducting solvent in the first place, so that the electrically-conducting spray is formed, and then the voltage is applied to the electrically-conducting spray for atomization, so that the electrified atomization spray is formed; under the effect of the applied electric field, the electrified atomization spray is deposited onto a deposition substrate; and then, drying can be conducted on the electrified atomization spray deposited on the deposition substrate, so that a quantum dot film layer is formed on the deposition substrate. Compared with the prior art, quantum dot film coating can be achieved.

Owner:BOE TECH GRP CO LTD

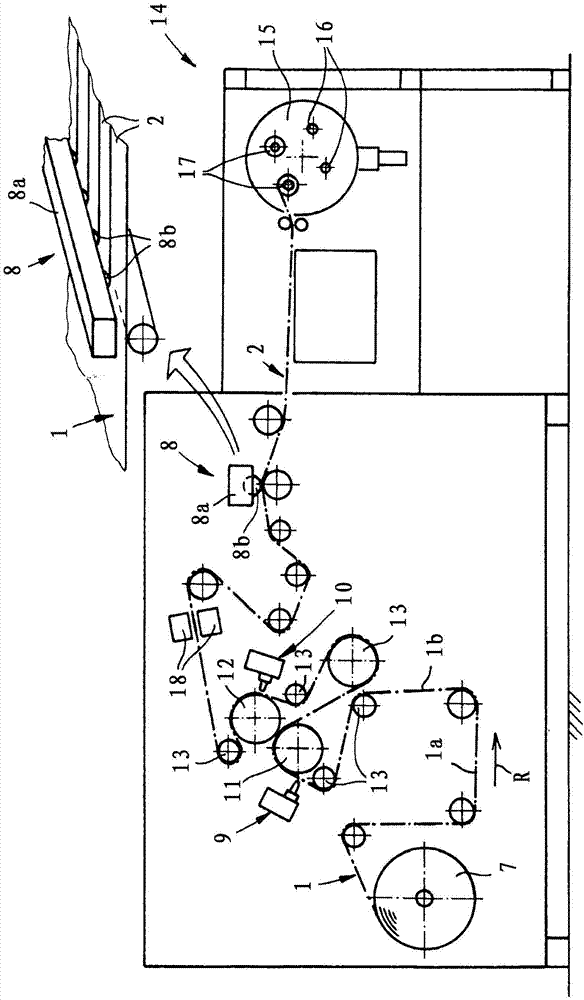

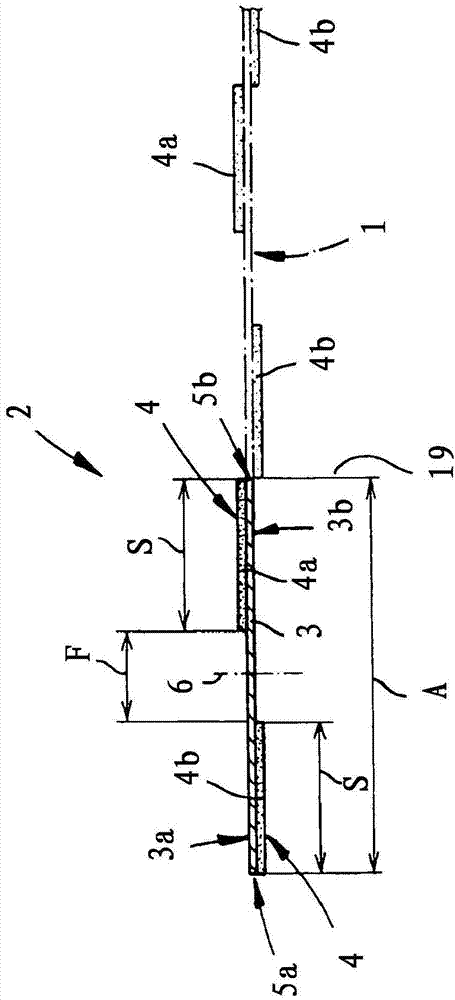

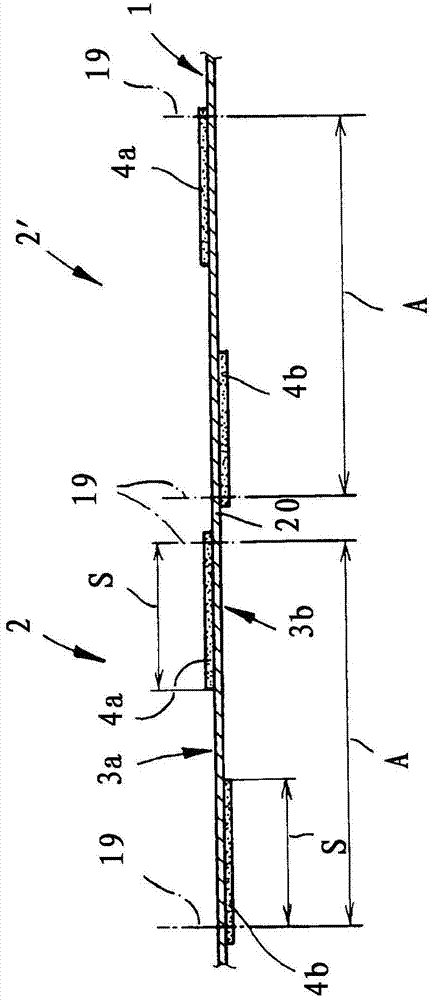

Method for producing an adhesive tape

ActiveCN103781862AAchieve coatingFor precise cuttingFilm/foil adhesivesCoatingsReverse orderAdhesive

The present invention relates to a method for producing an adhesive tape (2). The adhesive tape (2) possesses a tapelike carrier (3) and at least one strip (4; 4a, 4b) of adhesive which is applied to the carrier (3) on at least one side. Here, first of all, a carrier web (1), coming from a supply unit (7), is supplied to at least one coating unit (9, 10). The coating unit (9, 10) then generates the at least one strip (4; 4a, 4b) of adhesive on the carrier web (1) in its longitudinal extent, by carrying out coating with an adhesive. Lastly, the carrier web (1) is slit in the longitudinal direction into the individual adhesive tapes (2), and the two last-mentioned method steps may also be run in the opposite order.

Owner:CERTOPLAST VORWERK & SOHN

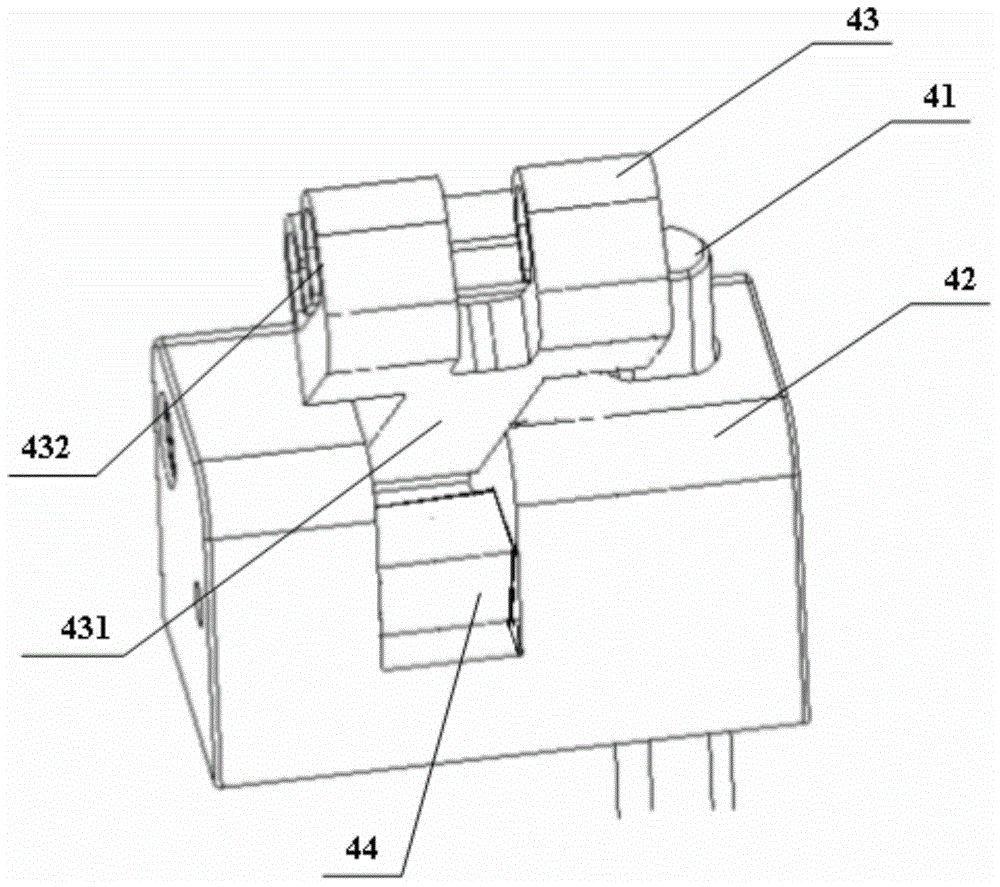

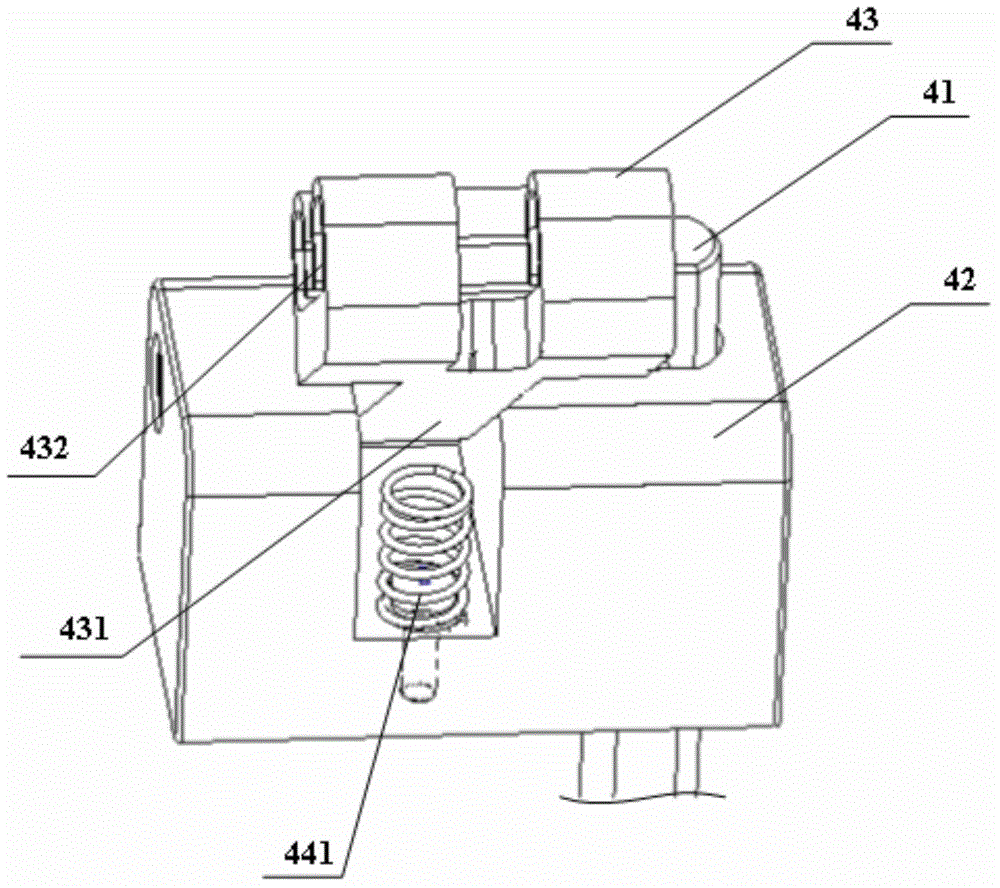

Bearing cleaning and painting robot

InactiveCN113634429AEasy to sprayImprove spraying effectLiquid surface applicatorsCleaning using toolsEngineeringVALVE PORT

The invention discloses a bearing cleaning and painting robot, and relates to the field of bearing machining equipment. The bearing cleaning and painting robot comprises a front supporting rack, a brushing chamber, a rinsing chamber, a drying chamber, a conveying track, a showering mechanism, a rear supporting rack, a rotating mechanism and a painting mechanism. The front supporting rack and the rear supporting rack are located at the two ends of the conveying track respectively, the conveying track sequentially penetrates through the brushing chamber, the rinsing chamber and the drying chamber, a brushing mechanism is arranged in the brushing chamber, a first water supply mechanism communicated with the painting mechanism is arranged beside the brushing chamber, rinsing mechanisms are arranged on the two sides of the rinsing chamber, and a triangular chuck for positioning a bearing is arranged on the top of the rear supporting rack. A conveyer belt is arranged on one side of the rotating mechanism, and water outlet valve ports are arranged on the brushing chamber and the rinsing chamber respectively. The bearing cleaning and painting robot is high in automation degree, the integrated operation of precise cleaning, drying, transferring, painting and discharging of inner and outer rings of the bearing can be achieved, the manual labor force is reduced, and the production efficiency is improved.

Owner:南京智慧阳光科技有限公司

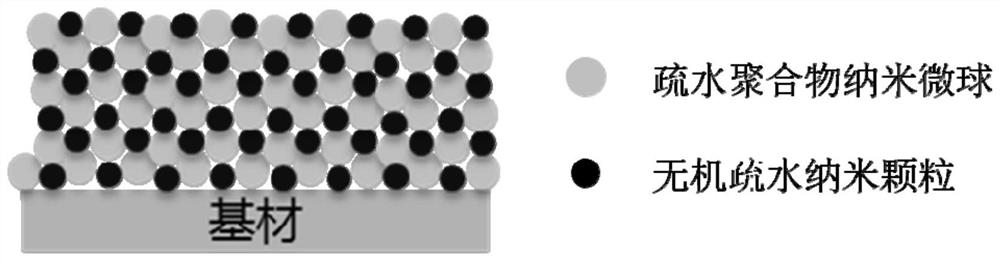

Super-hydrophobic coating as well as preparation method and application thereof

PendingCN113004749AHomogeneous nanostructureImprove adhesionAntifouling/underwater paintsPaints with biocidesPolymer scienceHydrophobic polymer

The invention belongs to the technical field of functional materials, and particularly relates to a super-hydrophobic coating as well as a preparation method and application thereof. The super-hydrophobic coating is of a three-dimensional porous nano composite structure. The three-dimensional porous nano composite structure comprises a construction unit and a bonding unit, wherein the construction unit is formed by inorganic hydrophobic nanoparticles; the bonding unit is formed by hydrophobic polymer nano microspheres; and the inorganic hydrophobic nano-particles and the hydrophobic polymer nano-microspheres are mutually connected to form uniform pores. The durable super-hydrophobic coating of a novel composite structure is researched and designed from the essence of the super-hydrophobic coating, the durable super-hydrophobic coating is not limited by a spraying process and can be treated through a dip-coating or roll-coating process, coating of coiled materials and special-shaped parts can be achieved, the comprehensive performance of the obtained coating is good, and the application field of the coating is expanded.

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +2

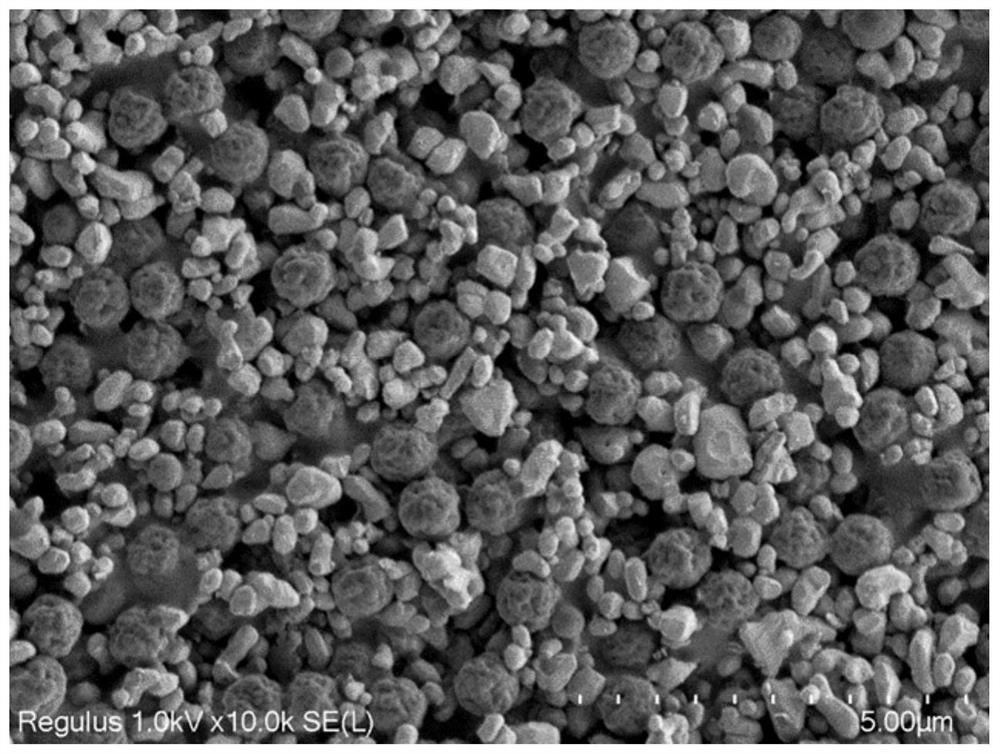

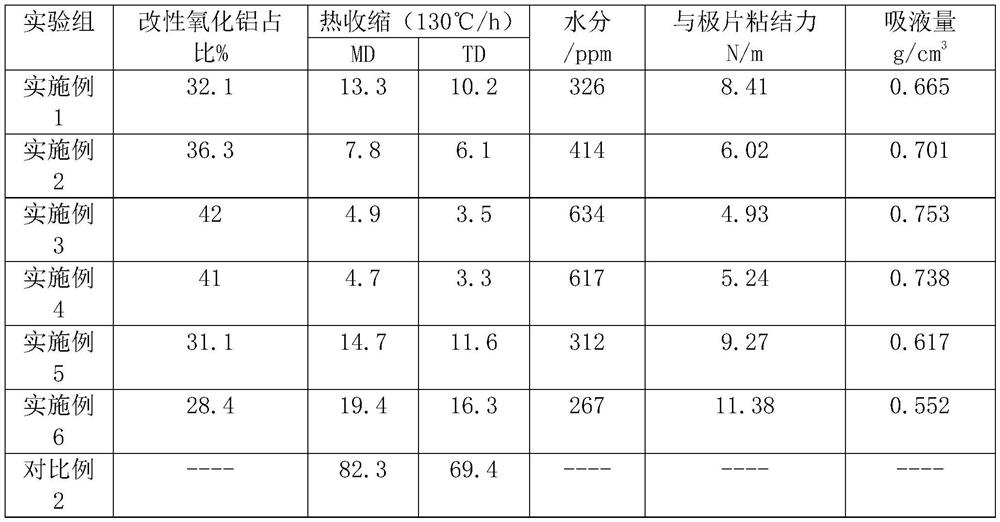

Preparation method of modified aluminum oxide and PMMA mixed slurry coated diaphragm

ActiveCN114050375AInhibition of agglomerationNot prone to dark spotsCell component detailsAdhesiveSilanes

The invention discloses a preparation method of a modified aluminum oxide and PMMA mixed slurry coated diaphragm, which comprises the following steps: taking a silane coupling agent, adding an ethanol solution, adding aluminum oxide powder, heating and stirring to obtain a mixed solution; carrying out suction filtration and drying on the mixed solution to obtain modified aluminum oxide powder particles; adding the modified aluminum oxide powder into deionized water, adding a thickening agent, adding an adhesive and adding an auxiliary agent to obtain slurry; and coating a base membrane with the obtained slurry to obtain the diaphragm. The coupling agent is used for modifying aluminum oxide, a part of groups in molecules of the coupling agent can react with various functional groups on the surface of powder to form powerful chemical bonds, and the other part of groups can be physically wound in a slurry system, so that agglomeration of particles is inhibited, the coated diaphragm is not prone to generating black spots, the surface of the aluminum oxide is organized, the hydrophobic purpose is achieved, and the effect of reducing the moisture of a coating film is achieved.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

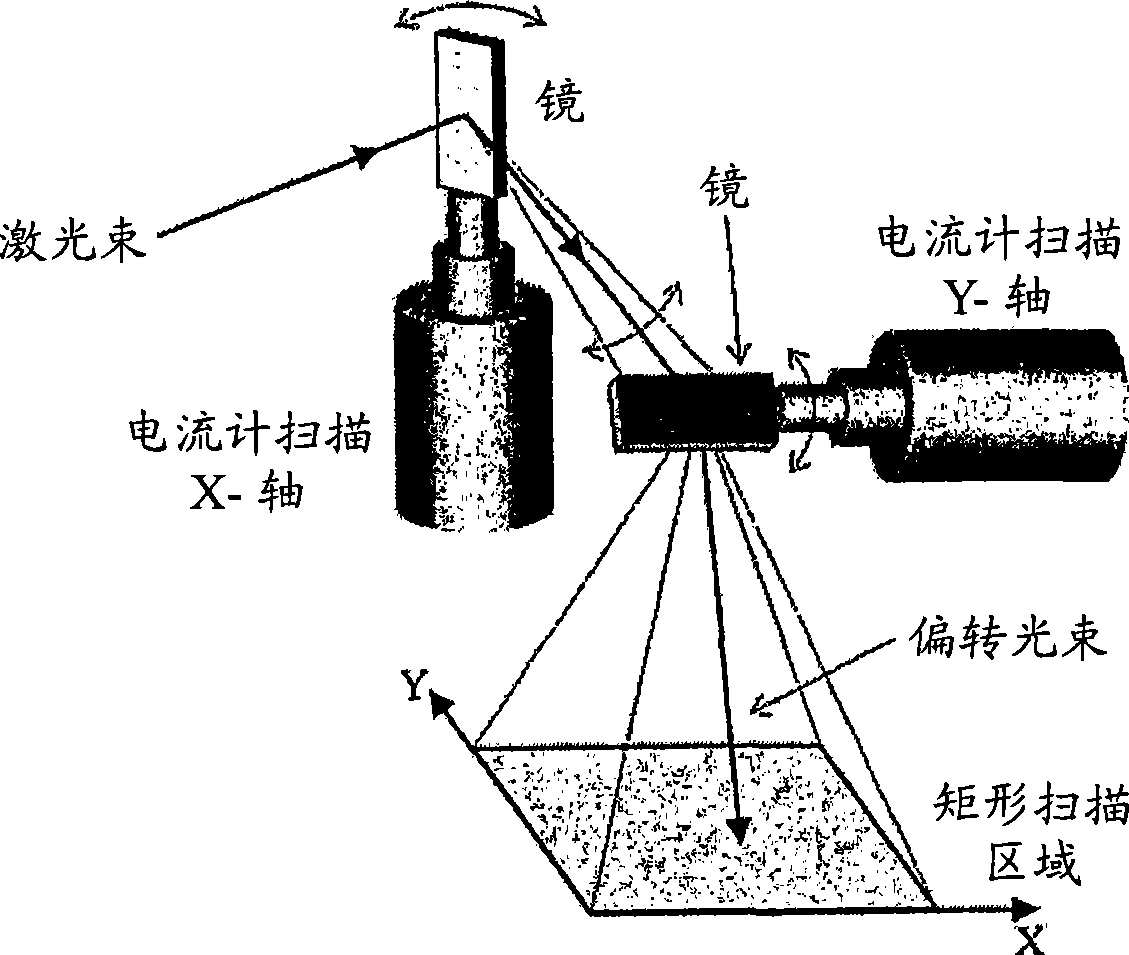

Coating with carbon nitride and carbon nitride coated product

InactiveCN101389440AGood optical performanceGood chemical resistanceVacuum evaporation coatingSputtering coatingProduction rateMetallurgy

The invention relates in general level to a method for coating articulating surfaces of medical products. The invention also relates to coated medical products manufactured by the method. The coating is carried out by employing ultra short pulsed laser deposition wherein pulsed laser beam is preferably scanned with a rotating optical scanner comprising at least one mirror for reflecting said laser beam. The invention has several both industrially and qualitatively advantageous effects such as high coating production rate, excellent coating properties and overall low manufacturing costs.

Owner:PICODEON OY

Corrosion-prevention grease coating device

InactiveCN107464640AAchieve coatingSimple structureInsulating conductors/cablesCorrosion preventionFuel tank

The invention discloses an anti-corrosion grease coating device, which comprises a machine frame, a workbench, an oil tank, a coating box, a bracket, a guide wheel, an oil feeding pipe, an oil return pipe, an oil pump, a coating roller, an oil inlet pipe and an oil outlet hole. The upper end of the frame is provided with a workbench, the workbench is provided with a coating box, the lower part of the workbench is provided with an oil tank, the two sides of the oil tank are symmetrically provided with supports, the top of the support is provided with guide wheels, and the wires pass through The guide wheel passes through the middle of the coating box, and the coating box is provided with two coating rollers arranged tangentially up and down, and the outer wall of the coating roller is uniformly provided with oil outlet holes, and the coating roller ends are There is an oil inlet pipe at the bottom, the oil inlet pipe is connected to the oil pipe, the lower end of the oil pipe is inserted into the bottom of the oil tank, the oil pump is arranged on the oil pipe, the oil return pipe is connected to the bottom of the coating tank, and the lower end of the oil return pipe is into the fuel tank. The invention has the advantages of simple structure, convenient use, good coating uniformity, high work efficiency, and the grease can be recycled and reused.

Owner:蒙玛特(天津)铜业有限公司

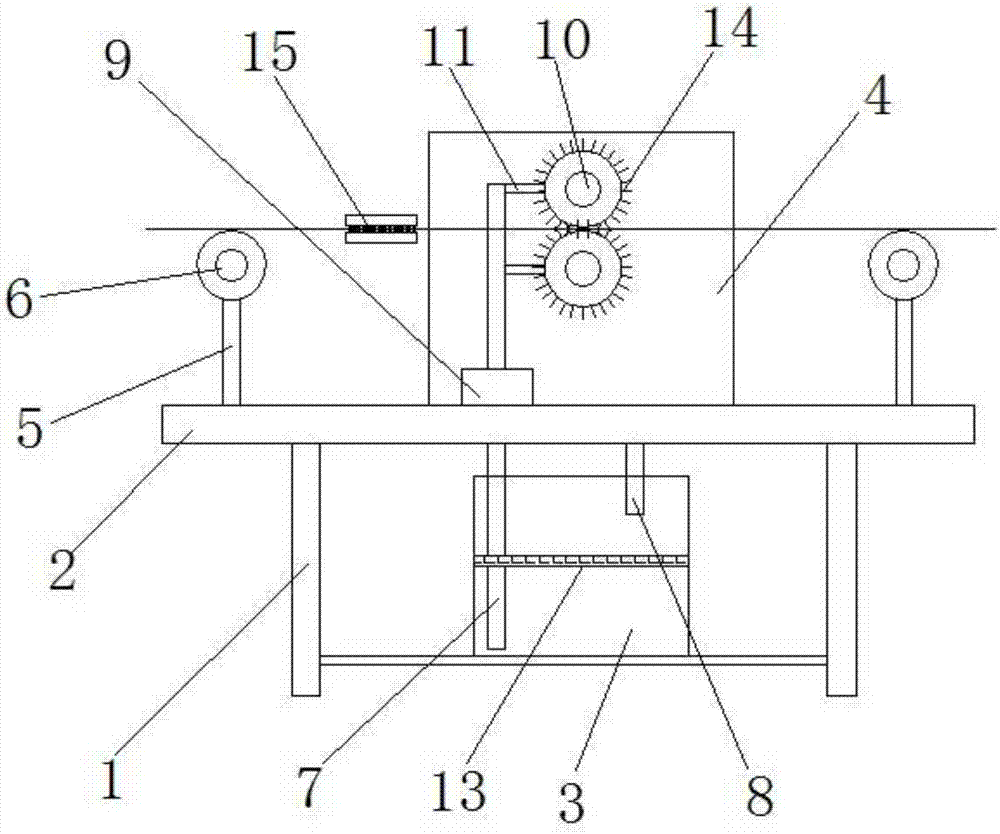

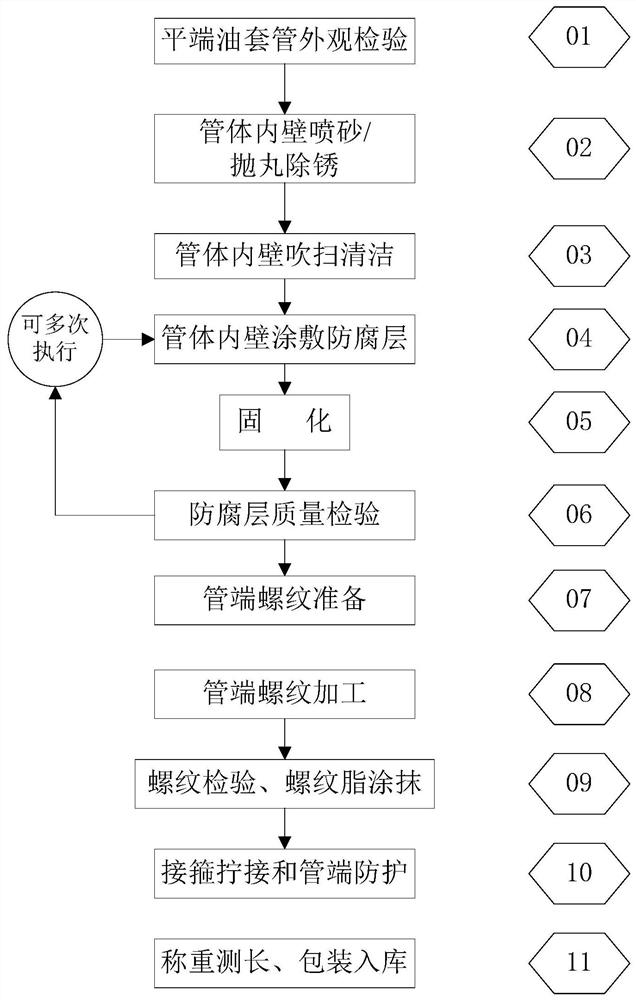

Anti-corrosion coating process in oil casing pipe

ActiveCN112439678AReduce excessive frictionGuaranteed friction strengthThread cutting machinesHollow article cleaningMachine partsMachining process

The invention provides an anti-corrosion coating process in an oil casing pipe. The process comprises the following steps that firstly, the inner wall of the flat-end oil casing is cleaned; secondly,anti-corrosion layer coating treatment and curing treatment are conducted on the inner wall of a flat-end oil casing pipe body; thirdly, threads at the pipe end of the oil casing pipe are machined; inthe thread machining process, the highest temperature of the inner wall of the thread machining part does not exceed 90% of the upper limit value of the temperature resistance of an anti-corrosion layer of the pipe body in terms of the celsius degree; cutting fluid used for thread machining does not damage the anti-corrosion layer coated on the inner wall of the oil casing pipe; and fourthly, theoil casing pipe is subjected to coupling tightening and pipe end protection, and the whole anti-corrosion coating process in the oil casing pipe is completed. The technological process is simple, thedefective product generation probability is low, and the anti-corrosion coating process can be well suitable for coating in the oil casing pipe of high-temperature-resistant anti-corrosion paint, andcoating in the low-end and conventional paint oil casing pipe for temporary storage and transportation is achieved at a low price.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com