Patents

Literature

33results about How to "Solve the problem of low work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

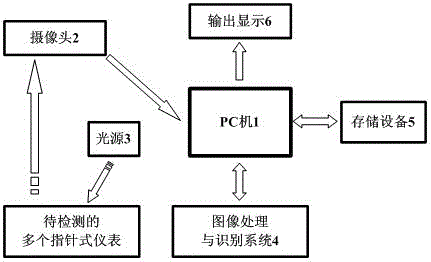

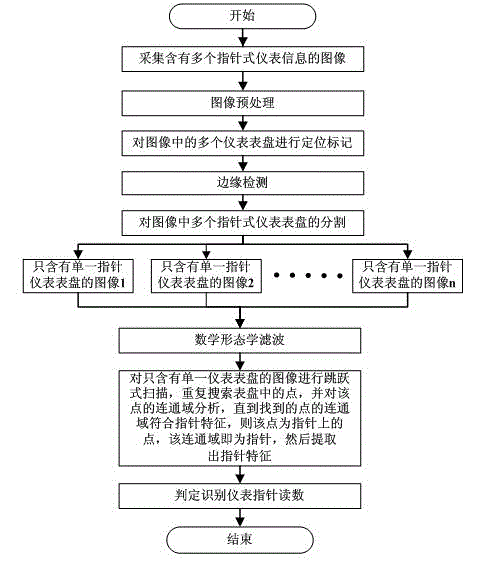

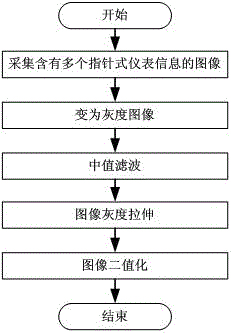

Machine vision method for identifying dial plate information of multi-pointer instrument

ActiveCN102176228AAvoid human errorReduce labor intensityCharacter and pattern recognitionMachine visionMorphological filtering

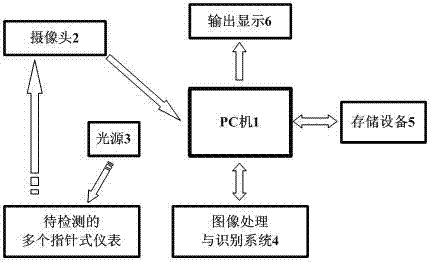

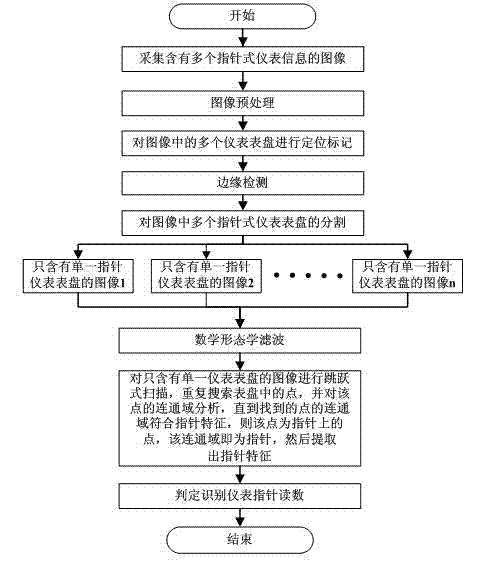

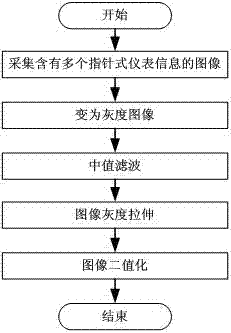

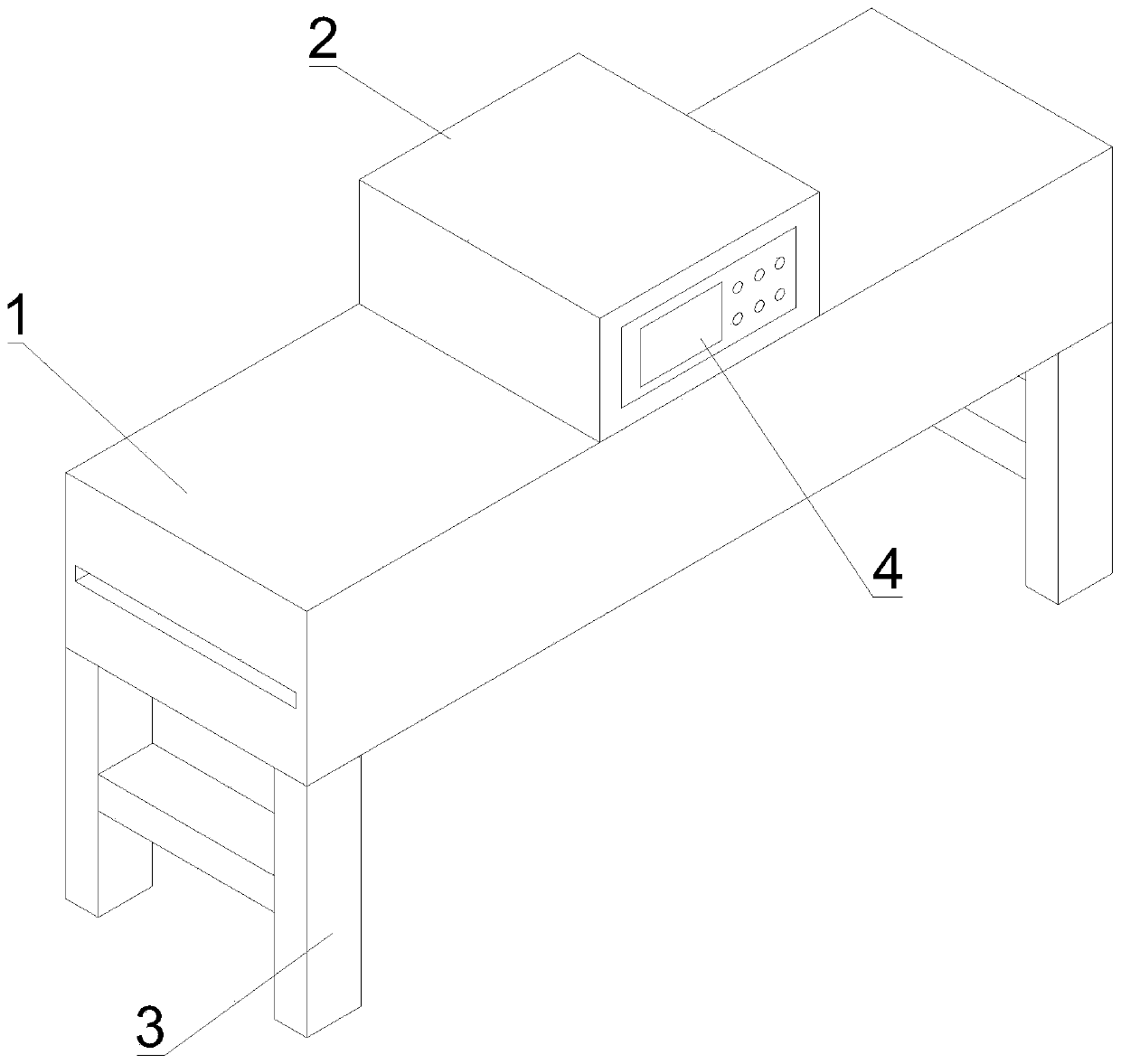

The invention provides a machine vision method for identifying the dial plate information of a multi-pointer instrument. The machine vision method mainly comprises the following steps of: acquiring an image containing information of the multi-pointer instrument, preprocessing the acquired image, positioning and marking a dial plate of the multi-pointer instrument in the image, segmenting the dialplate of the instrument in the image of the dial plate of the multi-pointer instrument, carrying out mathematical morphological filtering, extracting pointer characteristics in the dial plate by means of a human-eye-vision based jumping searching pointer and a human-eye-vision staring characteristic, calculating readings of the pointers of the instrument and the like. The machine vision method provided by the invention can be used for automatically carrying out vision identification on the information of the dial plate of the multi-pointer instrument in one image, and has the advantages of high degree of automation, accuracy in measurement, high efficiency and the like; and compared with the detection method in which one image and one instrument are provided in single-pointer instrument detection at present, the invention improves the utilization rate of the pointer instrument detection equipment and reduces the instrument detection cost.

Owner:HOHAI UNIV CHANGZHOU

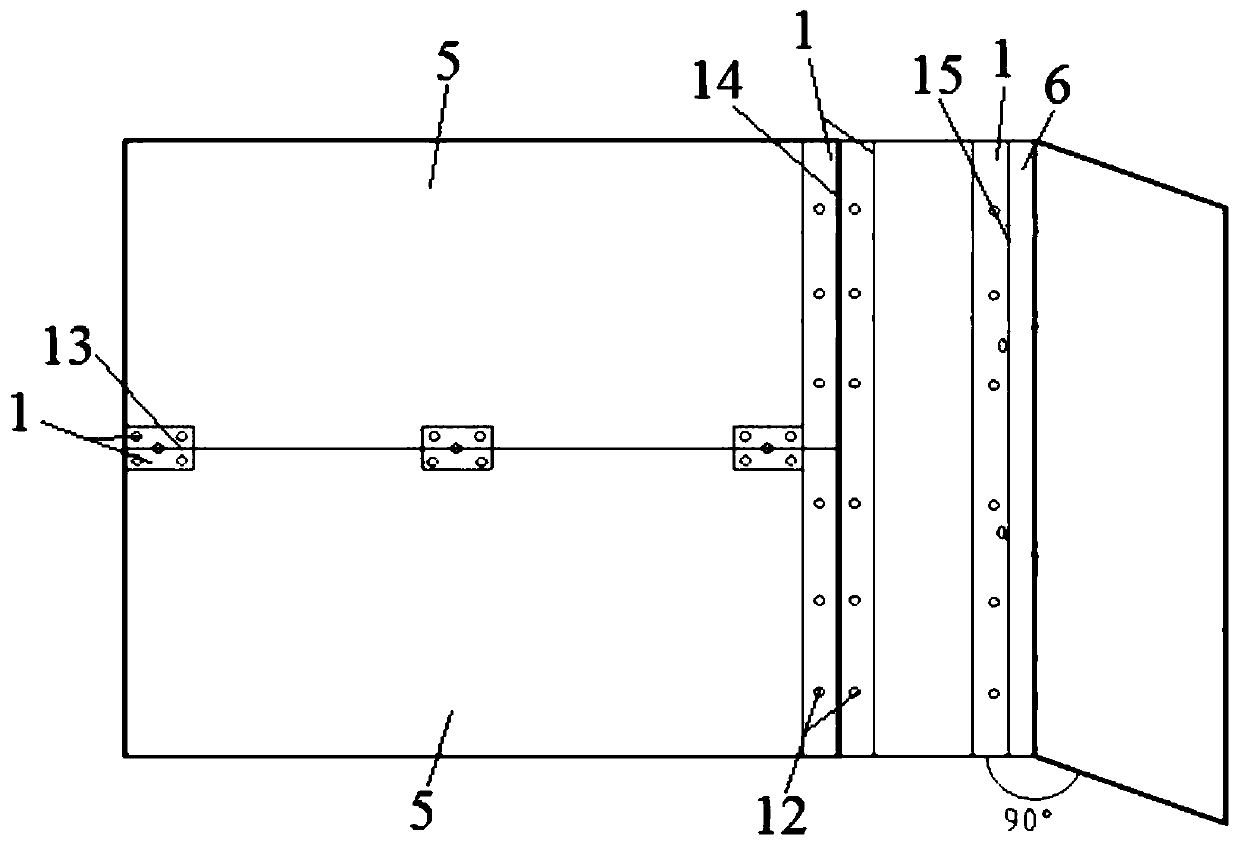

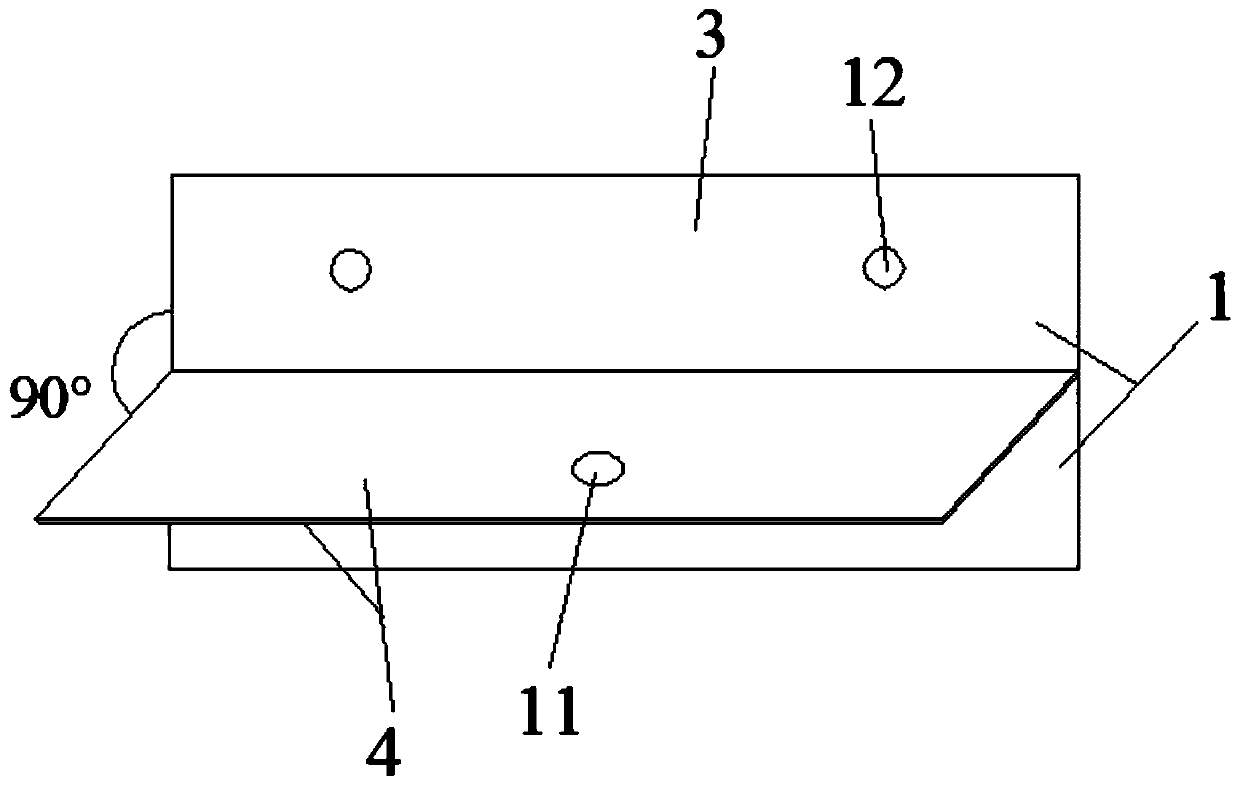

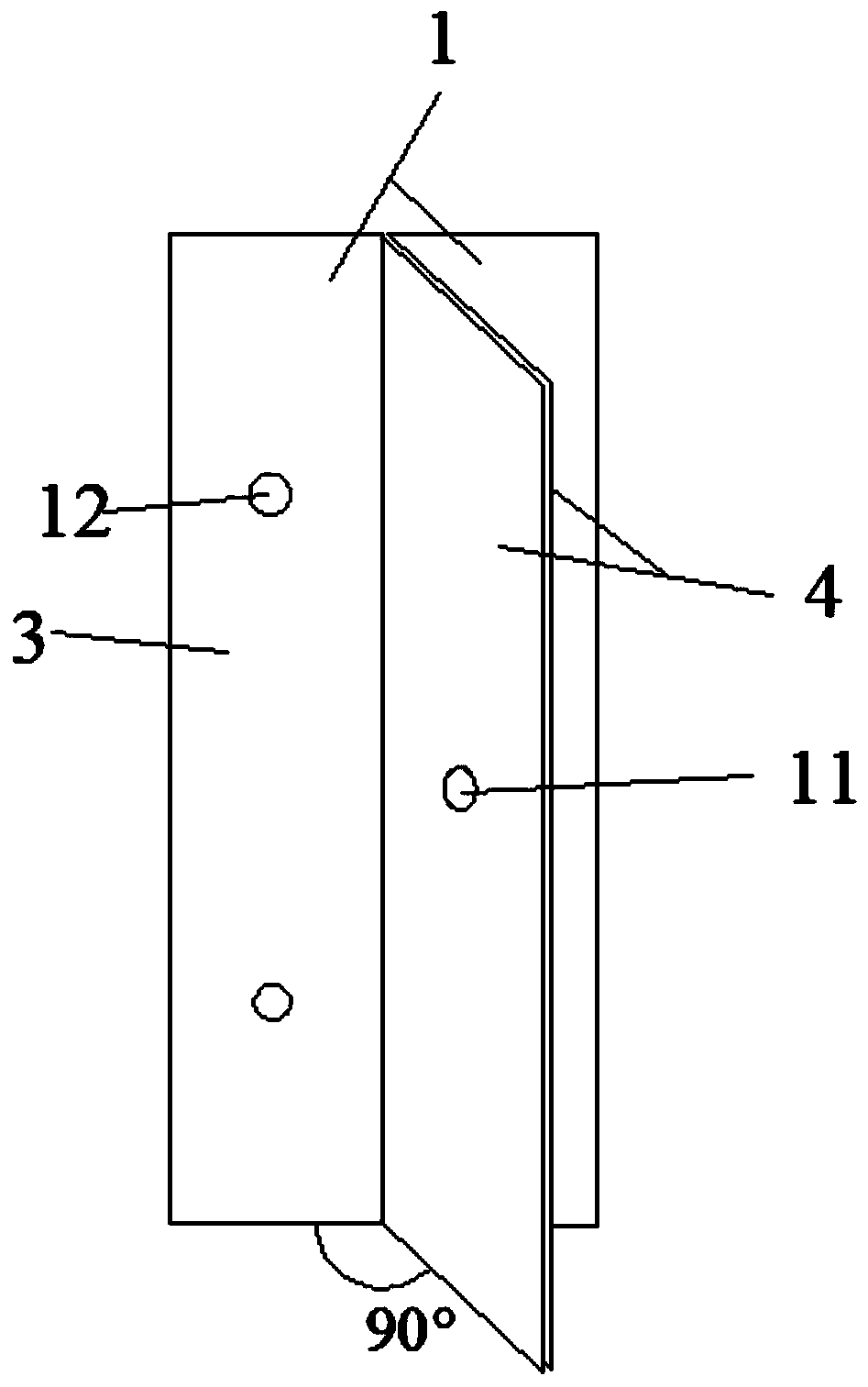

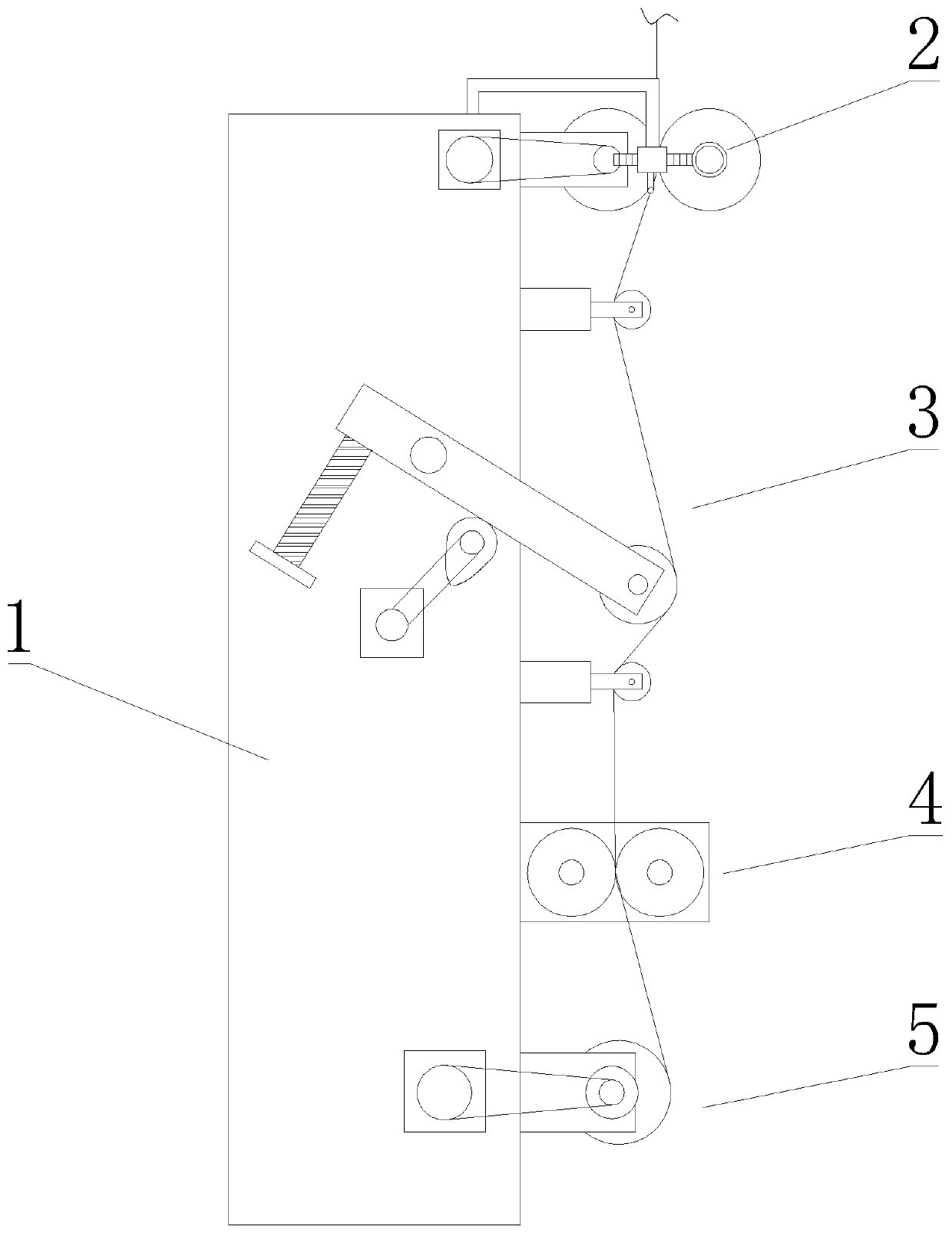

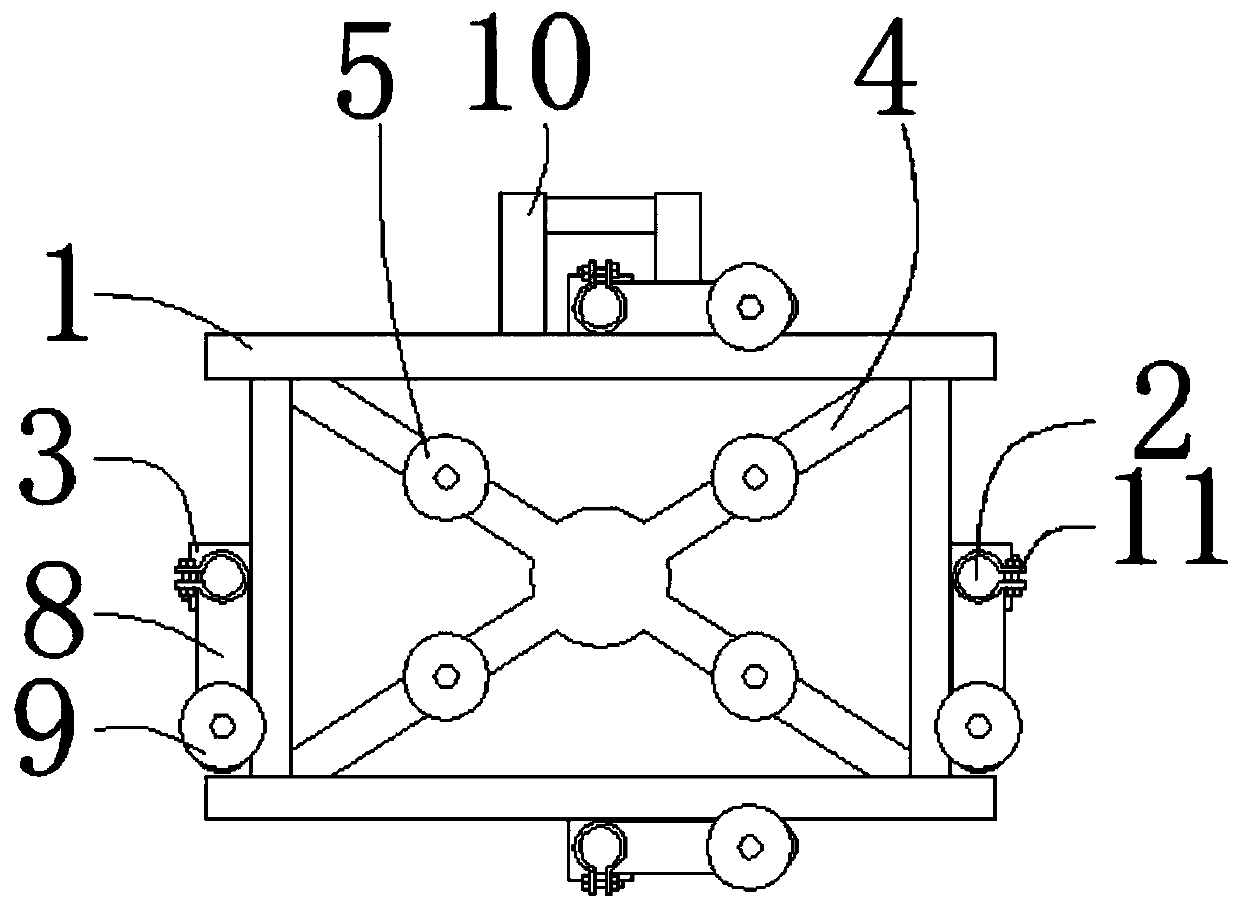

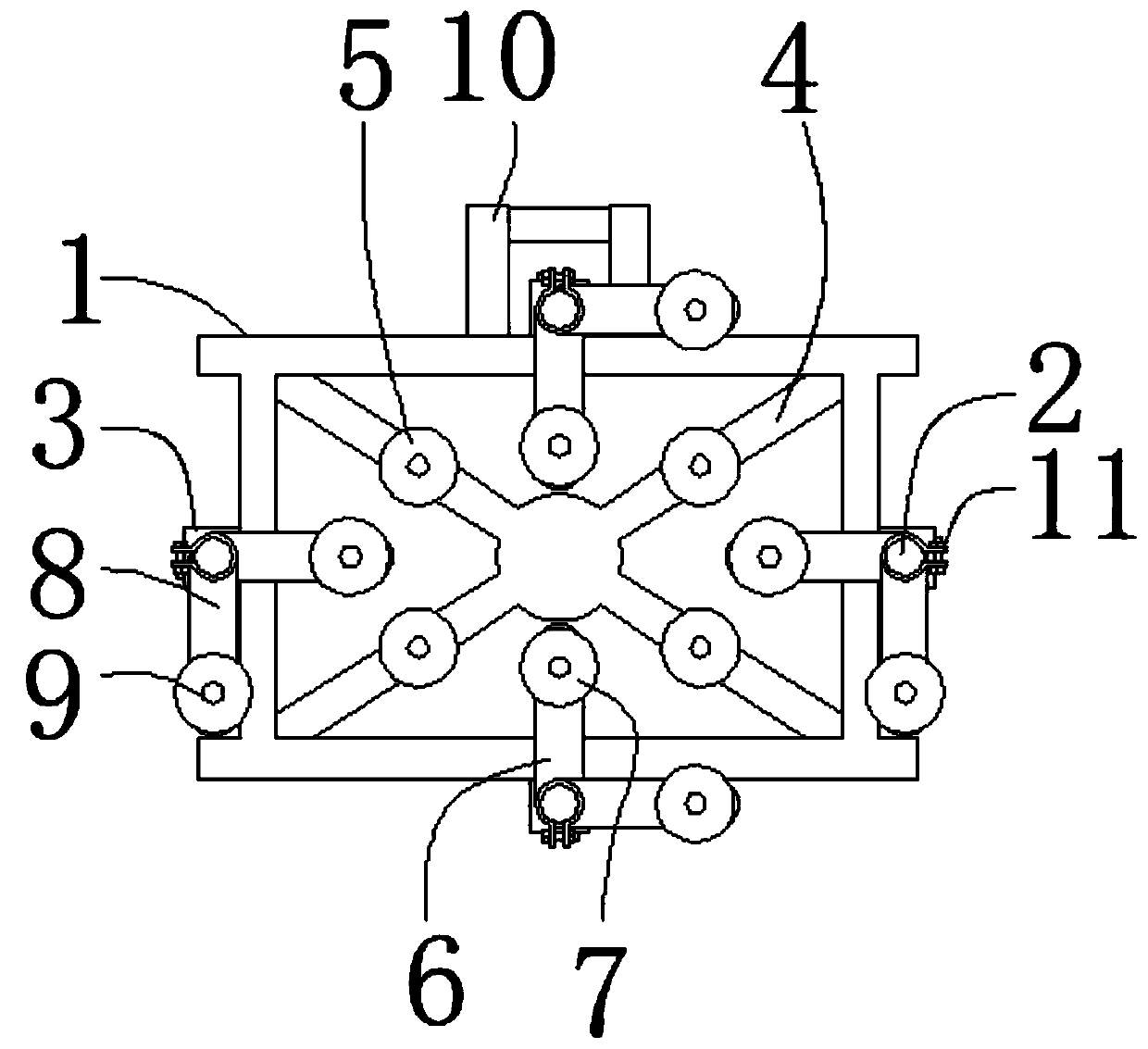

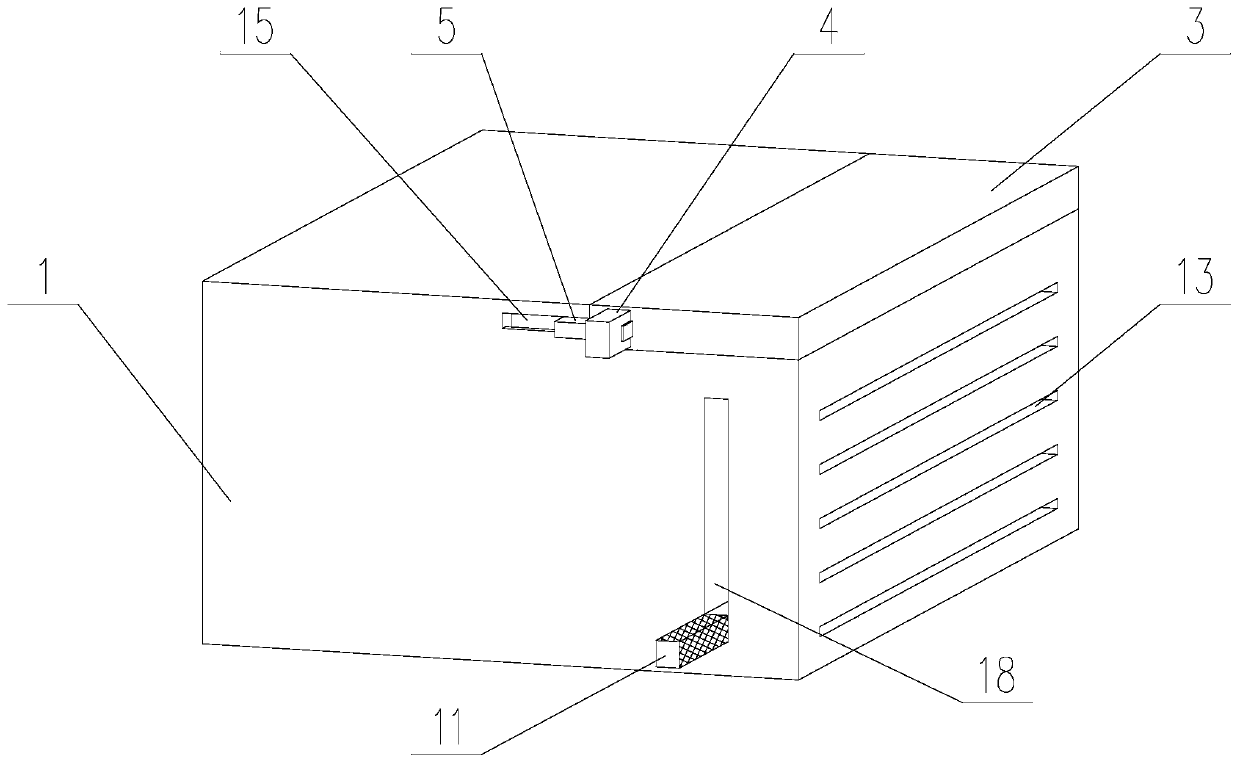

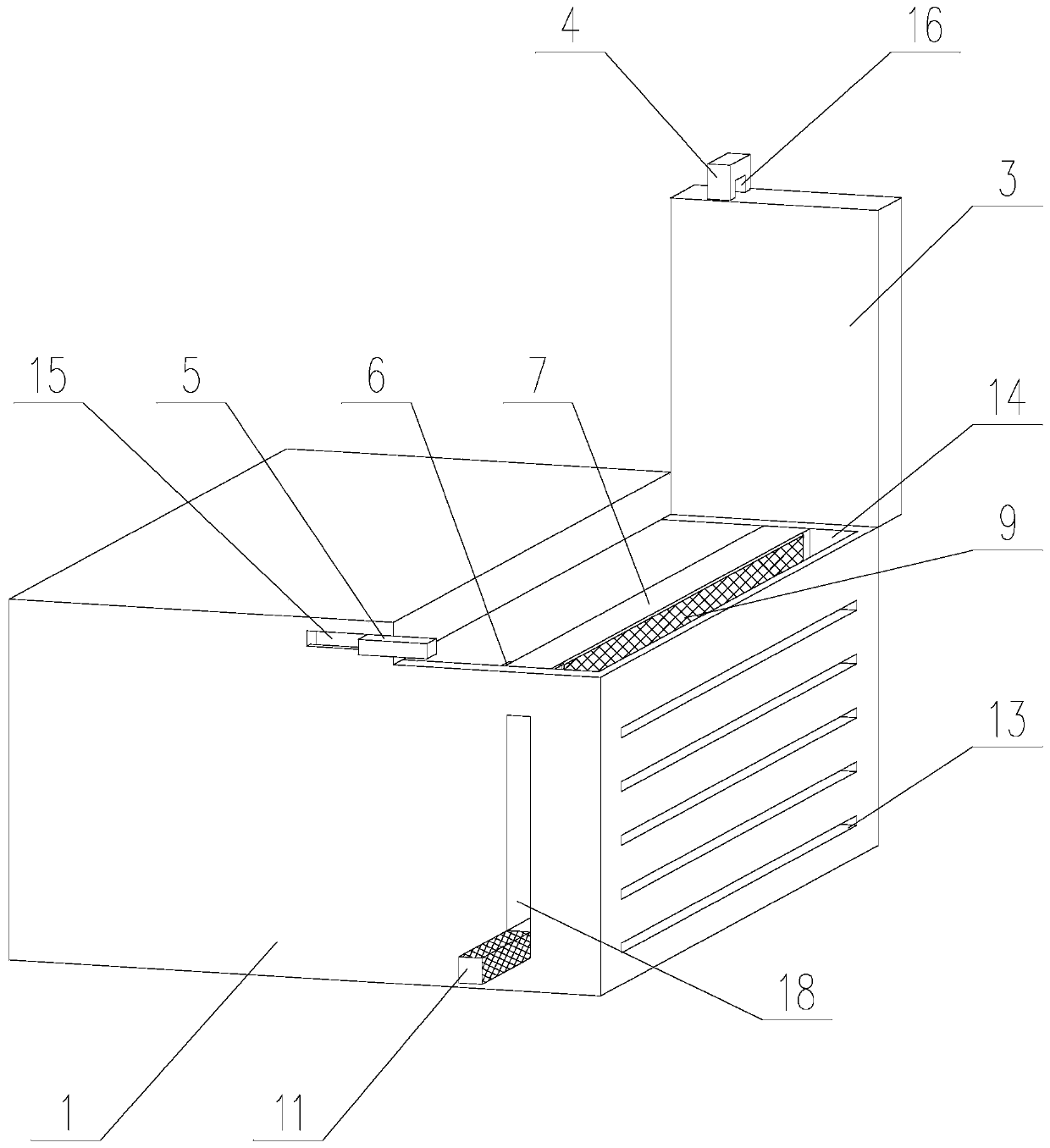

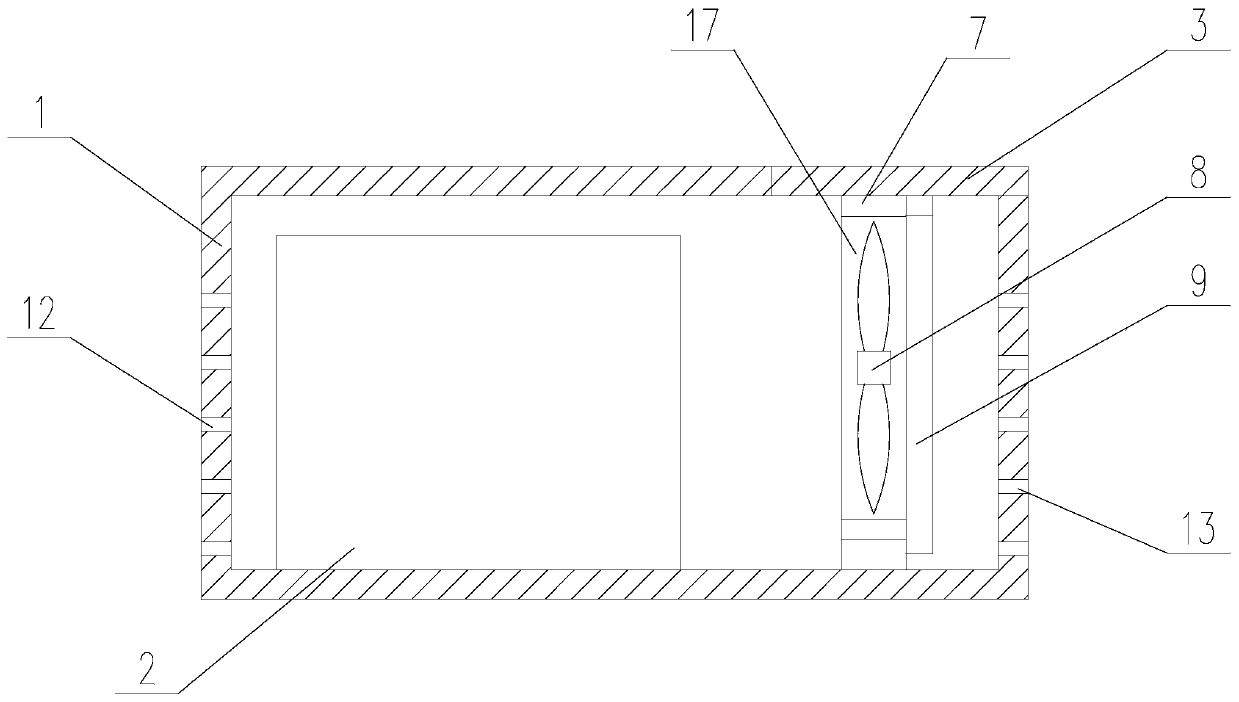

Drying and wrinkle removing integrated device for cotton yarn

InactiveCN110470122ASolve the problem of low work efficiencyAchieve anti-wrinkleDrying gas arrangementsDrying machines with progressive movementsWrinkle skinHydraulic cylinder

The invention provides a drying and wrinkle removing integrated device for cotton yarn. The drying and wrinkle removing integrated device comprises a machining box. A fabric inlet is formed in the left side of the machining box, a fabric outlet is formed in the right side of the machining box, and a wrinkle removing mechanism and a drying mechanism are arranged in the machining box. The output endof a hydraulic cylinder is connected with a movable plate, the movable plate is connected with the inner wall of the machining box through a buffer part, the two sides of the top face of the movableplate are connected with a fixing shell through elastic connecting parts, and an iron is arranged in the fixing shell. A platform is arranged on the bottom face in the machining box. Shells are symmetrically arranged in the machining box, the shells are mounted on the inner walls of box bodies through supporting rods, drying mechanisms are arranged in the shells, rotary shafts are sleeved with multiple sets of driving bevel gears at equal intervals, the driving bevel gears are in engaged connection with driven bevel gears, the driven bevel gears are connected with rotary rods, the rotary rodspenetrate through the box bodies and are rotationally connected with the box bodies, and fan blades are arranged on the rotary rods. Wrinkle removing and drying of fabric are integrated, and the treatment effect of the fabric is good.

Owner:XUZHOU HUAYUN TEXTILE CO LTD

Steel angel set, steel channel set for splicing of timber formwork, and construction method

InactiveCN110130638ASolve the problem of reduced turnover rate and increased costSolve the problem that the flatness is difficult to guaranteeAuxillary members of forms/shuttering/falseworksMetallurgyBuilding construction

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

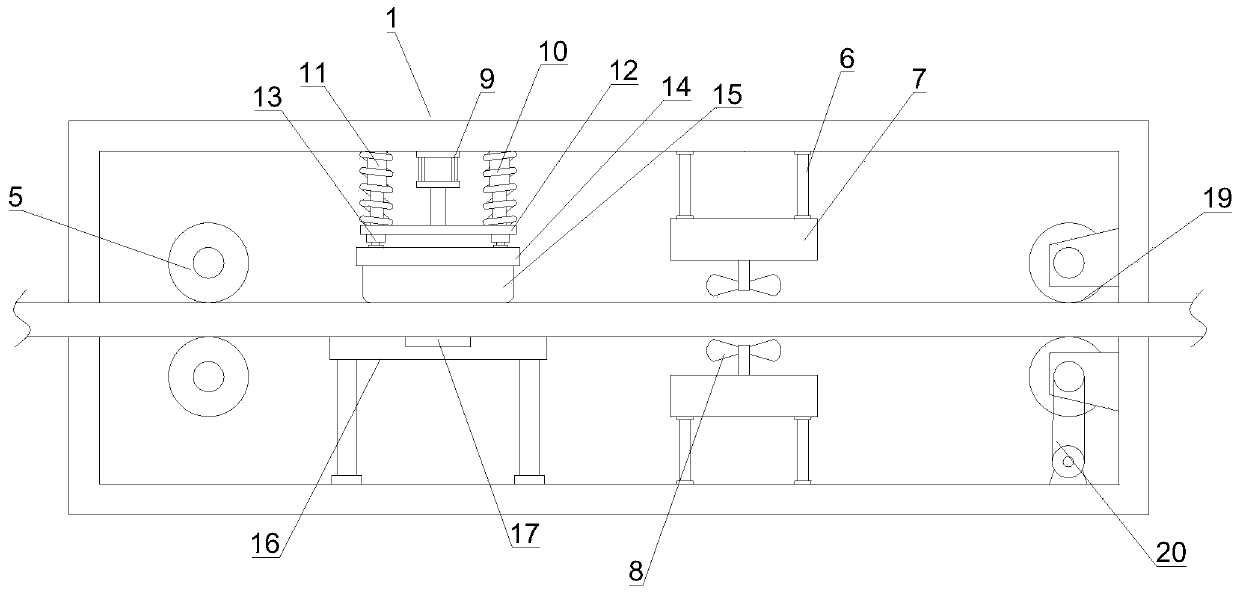

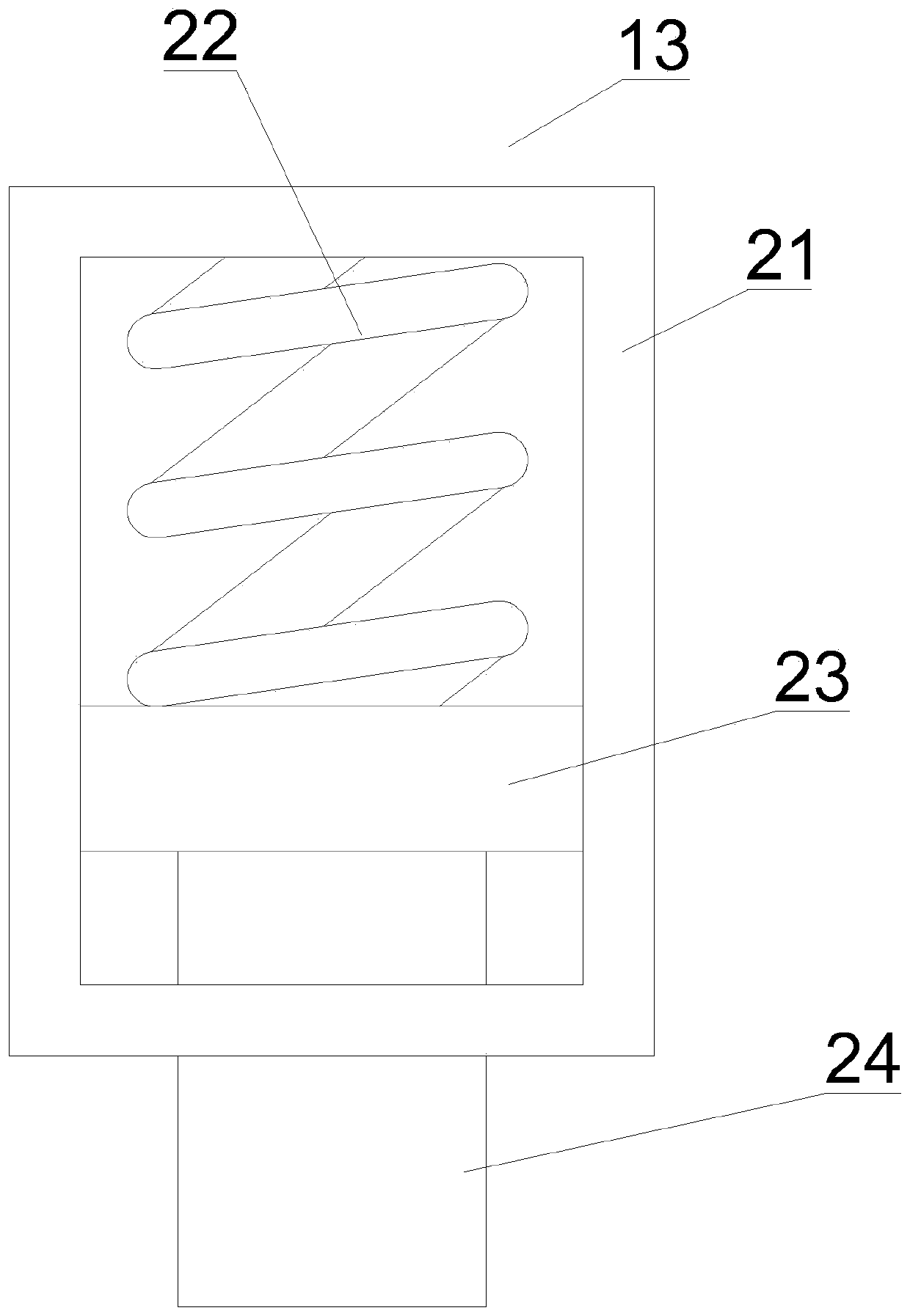

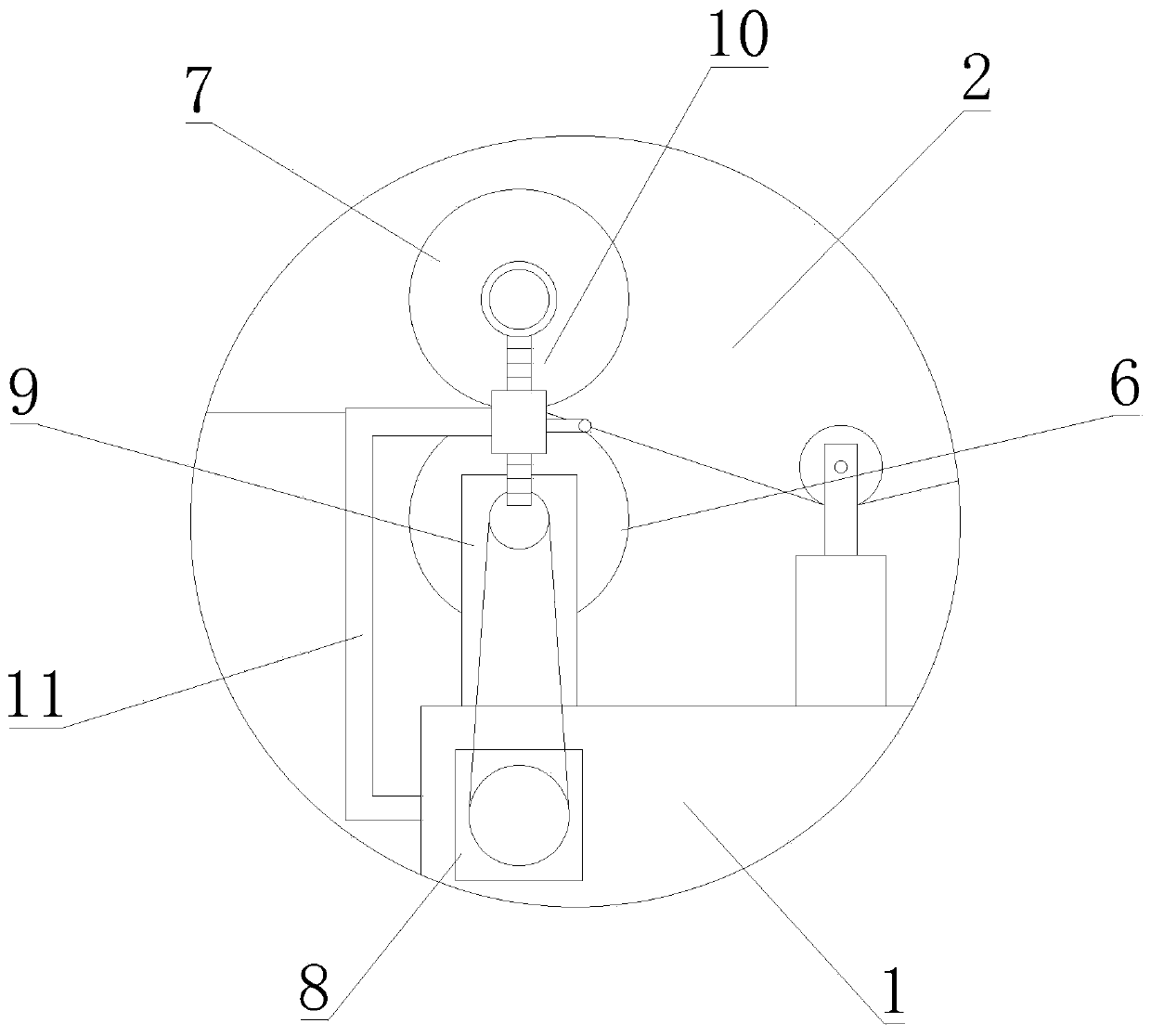

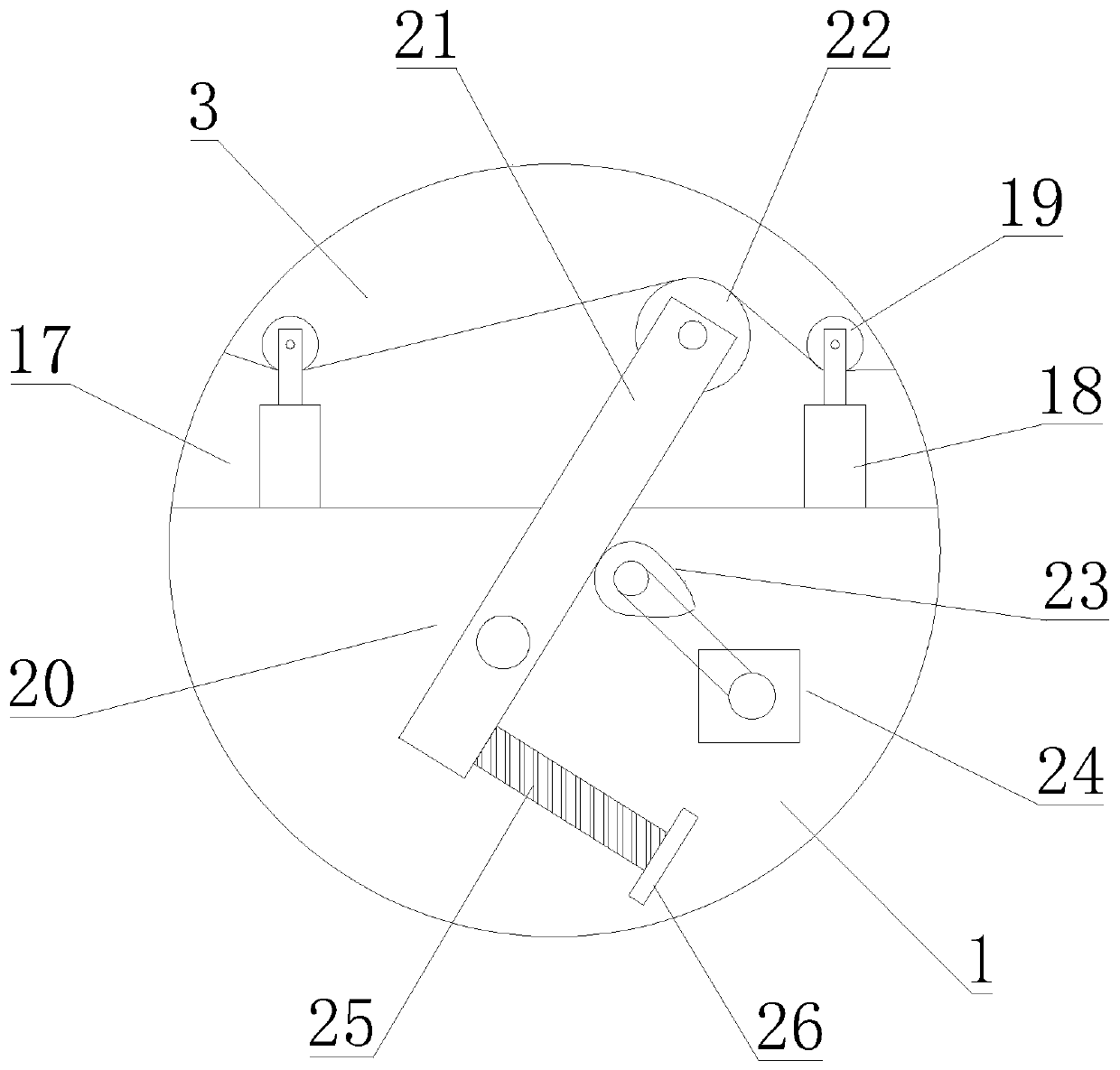

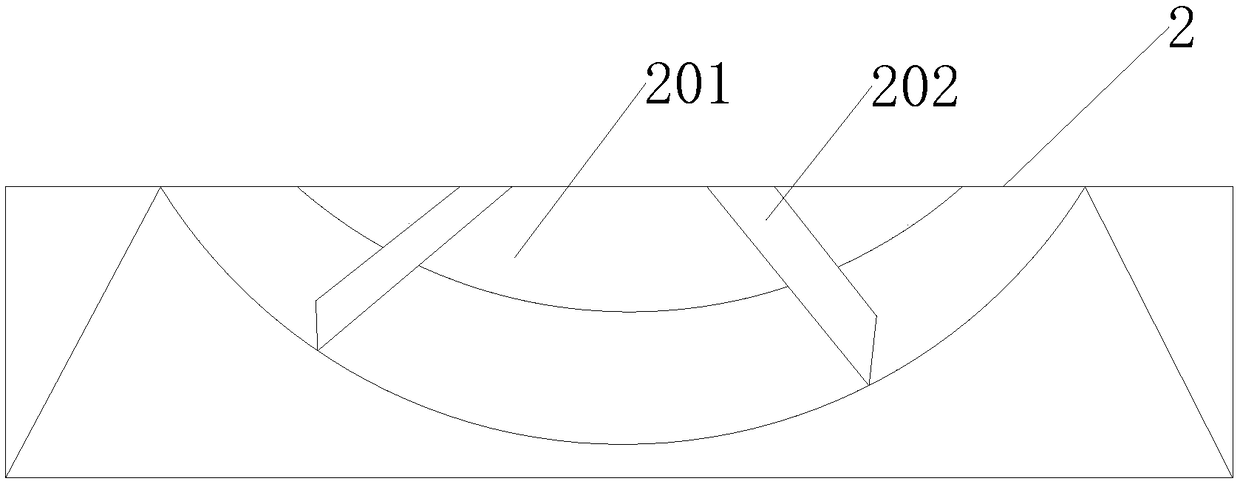

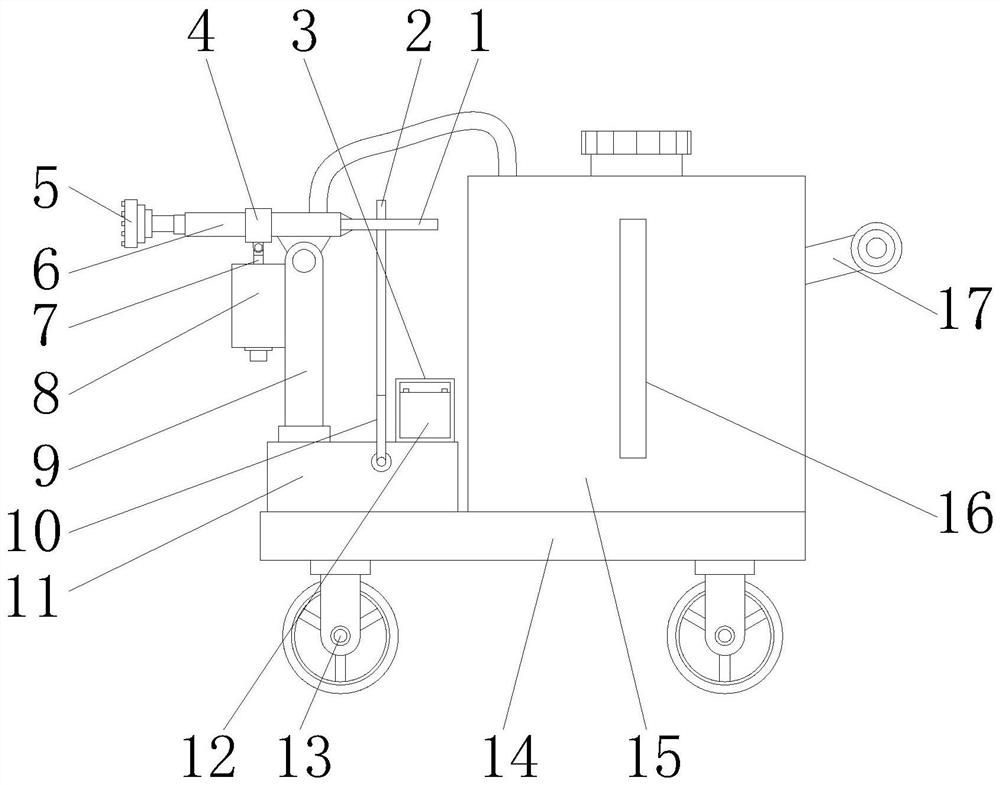

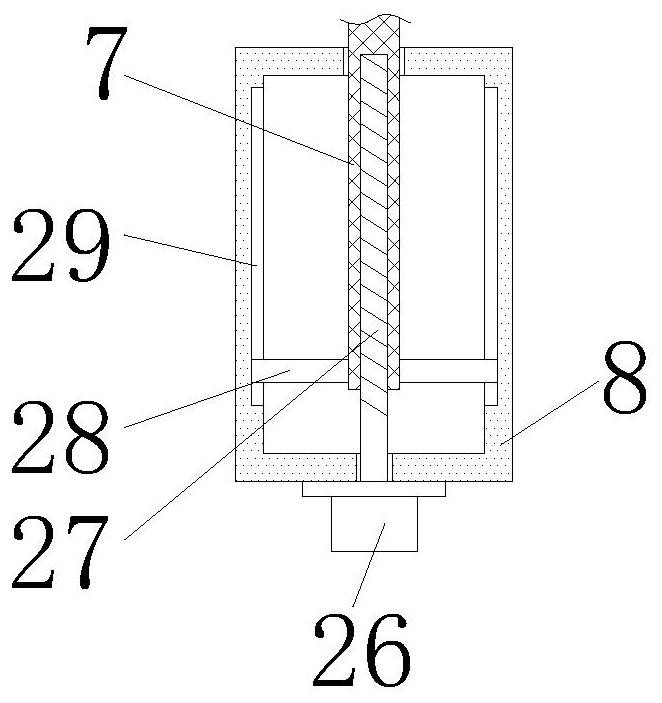

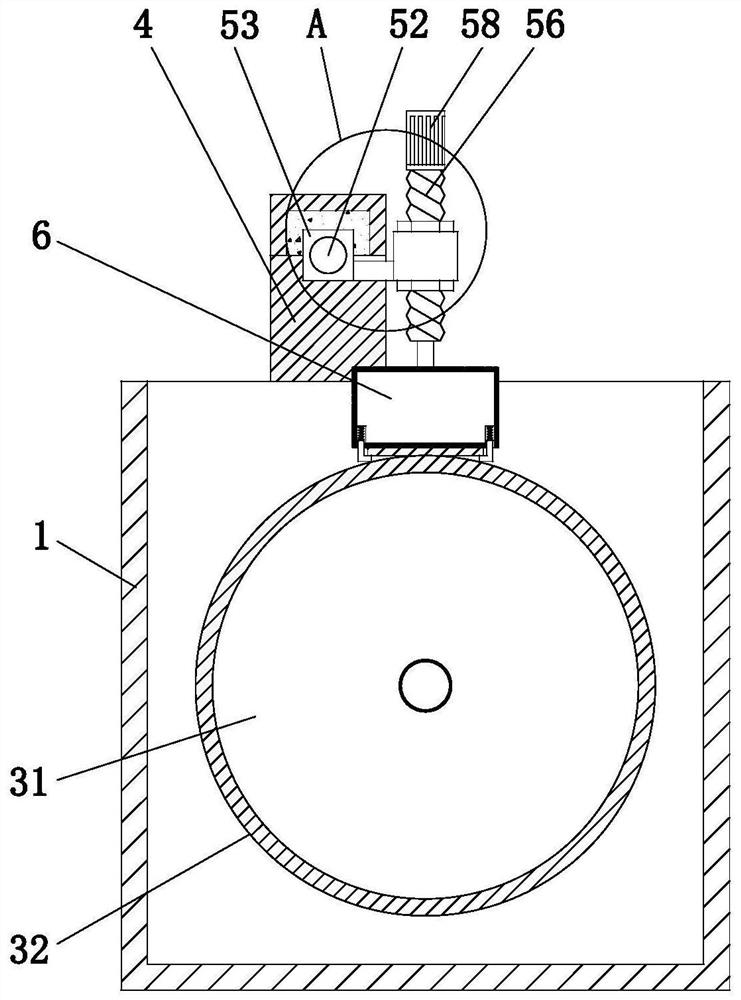

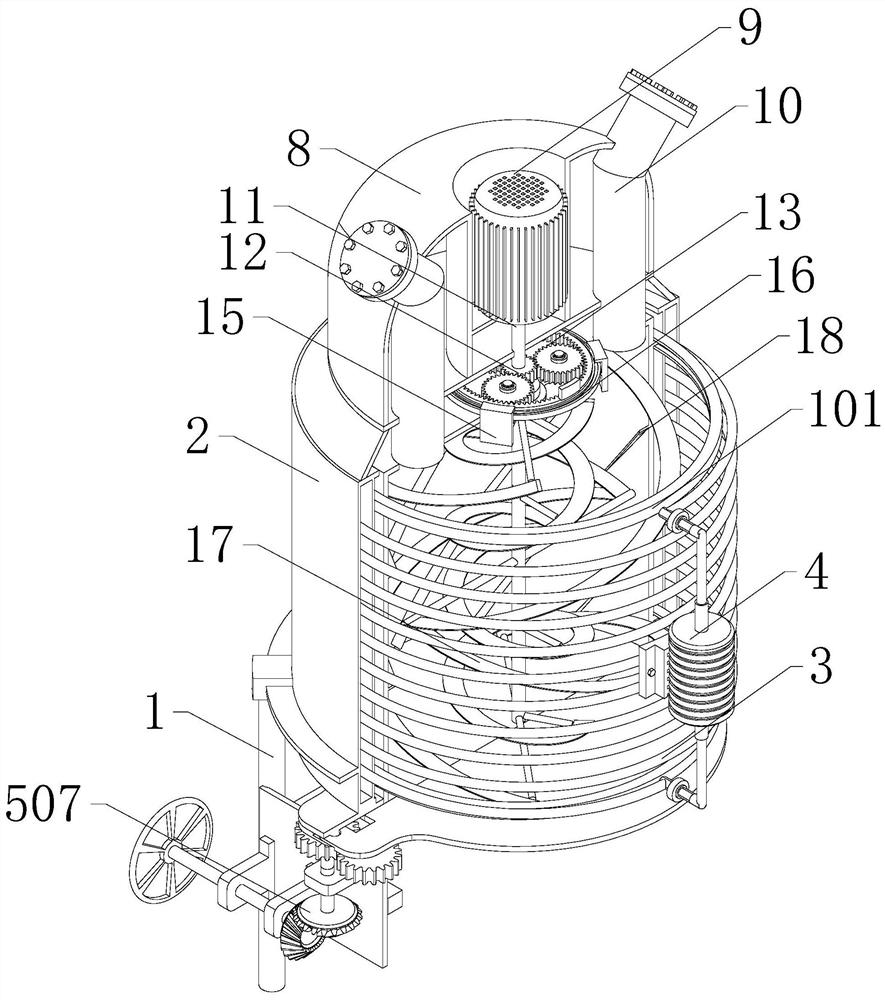

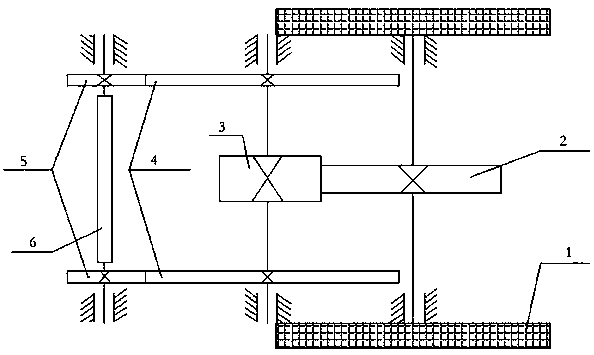

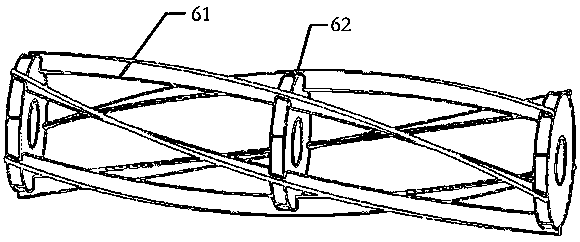

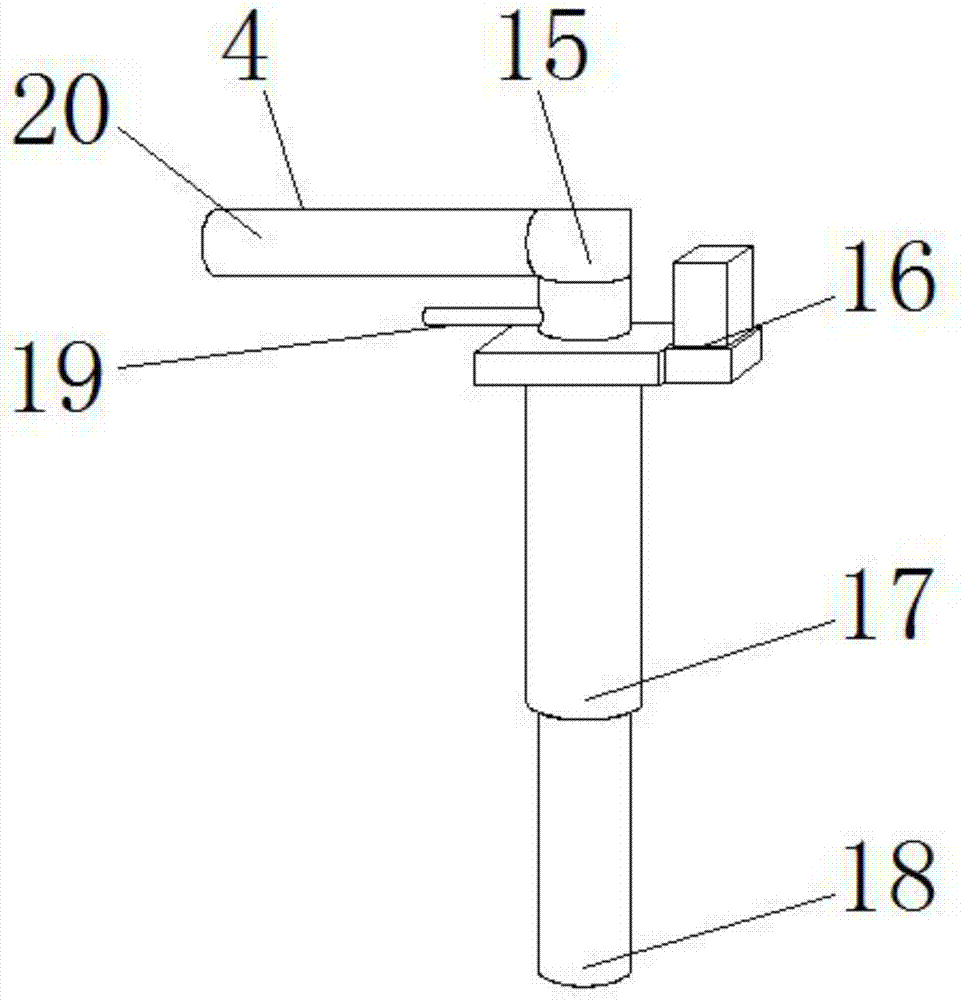

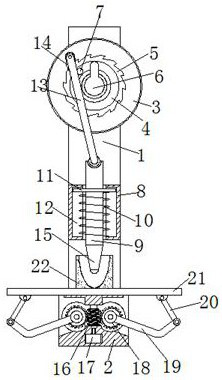

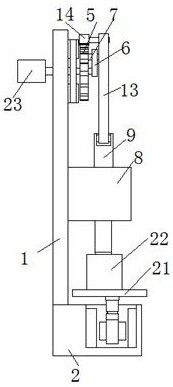

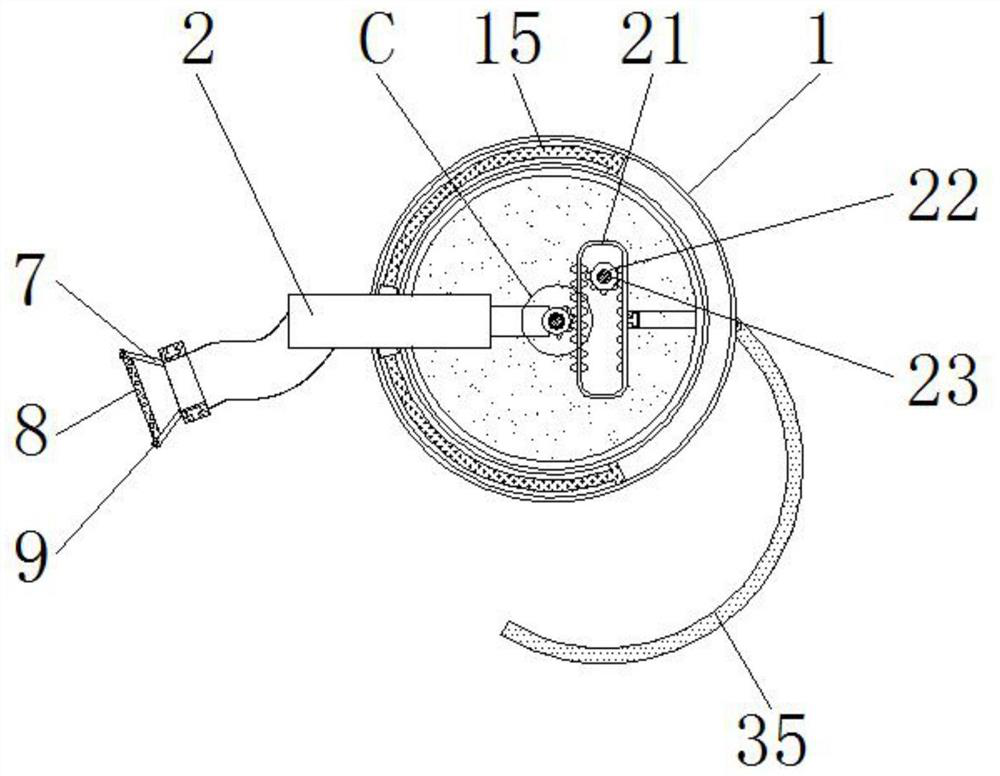

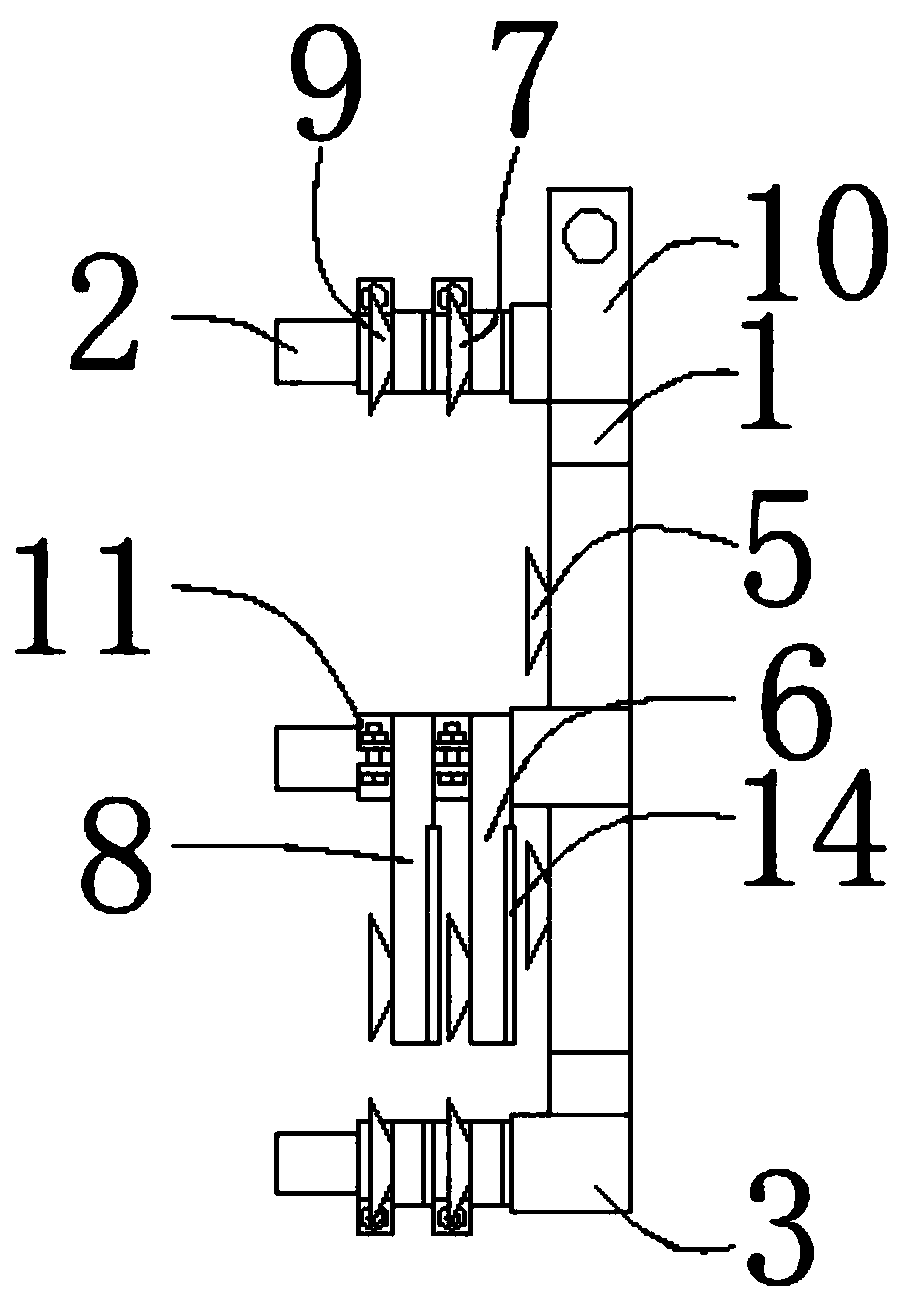

Tensioning and winding mechanism for blended yarns

InactiveCN110342338ASolve the problem of low work efficiencyLong adjustment distanceFilament handlingYarnConductor Coil

The invention belongs to the field of weaving, particularly relates to a tensioning and winding mechanism for blended yarns, and solves the problem that an existing tensioning and winding mechanism for blended yarns is often inflexible in design and low in flexibility of operation, resulting in low working efficiency. The invention proposes a scheme as follows: the tensioning and winding mechanismfor blended yarns comprises a base, a yarn feeding component, a tensioning component, a length counter and a winding component; the yarn feeding component and the winding component are separately arranged at two ends of the base; the tensioning component and the length counter are arranged between the yarn feeding component and the winding component; the tensioning component is close to a yarn feeding end; and the length counter is close to a yarn discharging end. The yarn feeding component is arranged to conveniently adjust the distance between a driving roller and a driven roller, and is flexible to use, so that the working efficiency is improved; through the arrangement of the tensioning component, the height of a downward pressing part is adjusted through the operation of an electrictelescopic rod, an upper ejecting part is rotated through an eccentric wheel to push a rotating rod to rotate to adjust the inclined angle, so that the tensioning position and the tensioning degree are adjusted at last to meet production requirements of different yarns and improve the working efficiency.

Owner:徐州嘉搏纺织股份有限公司

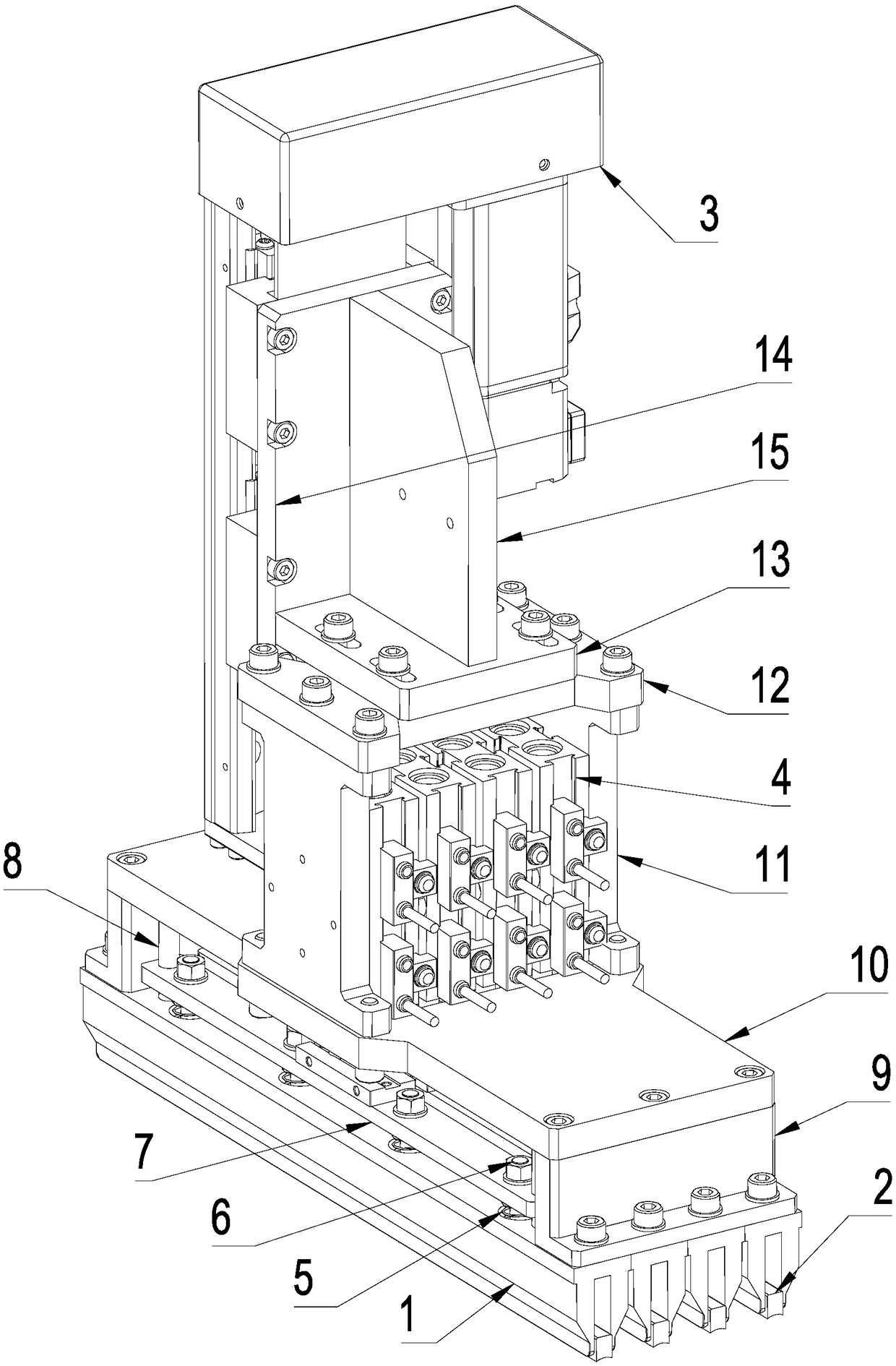

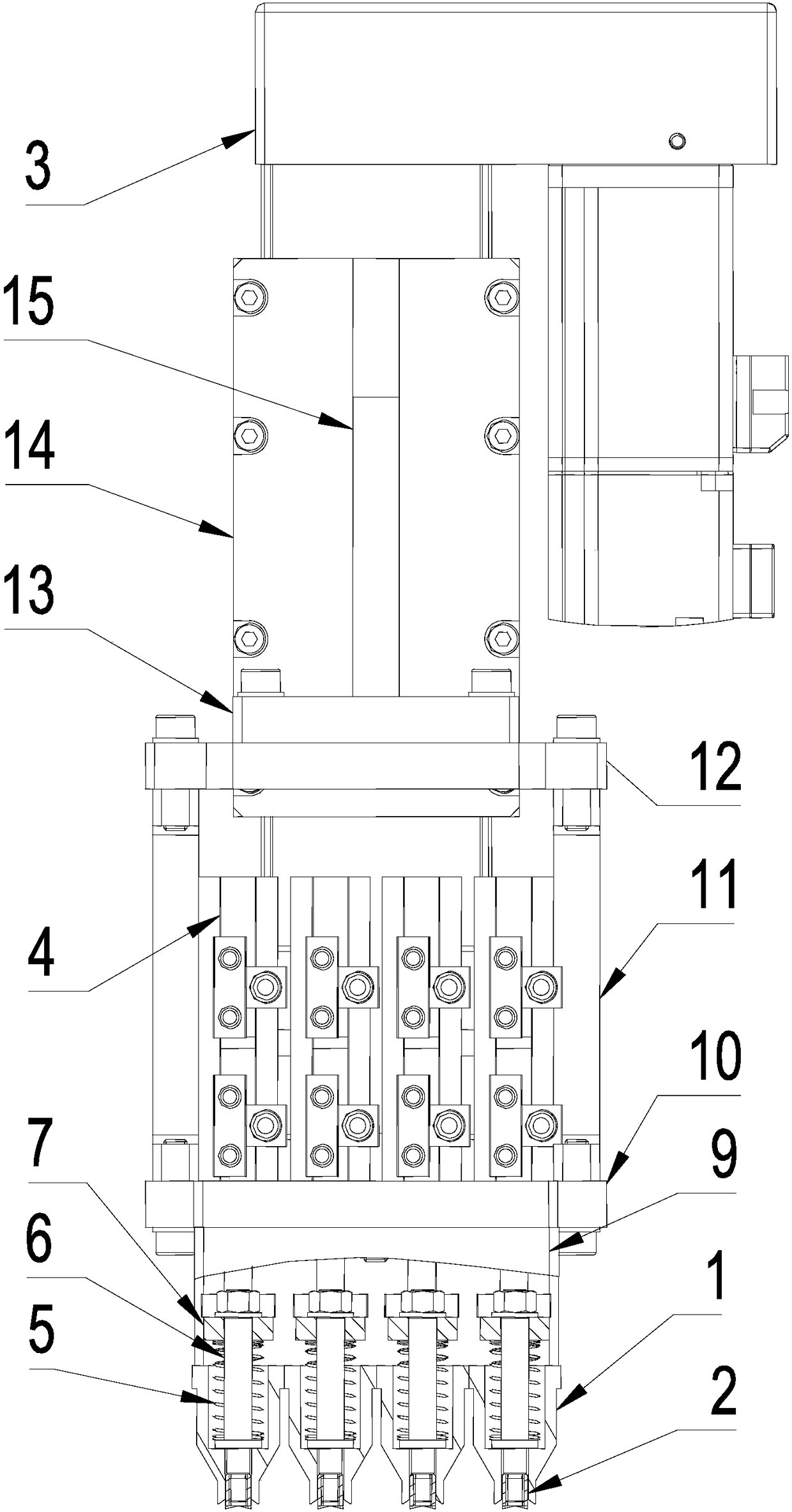

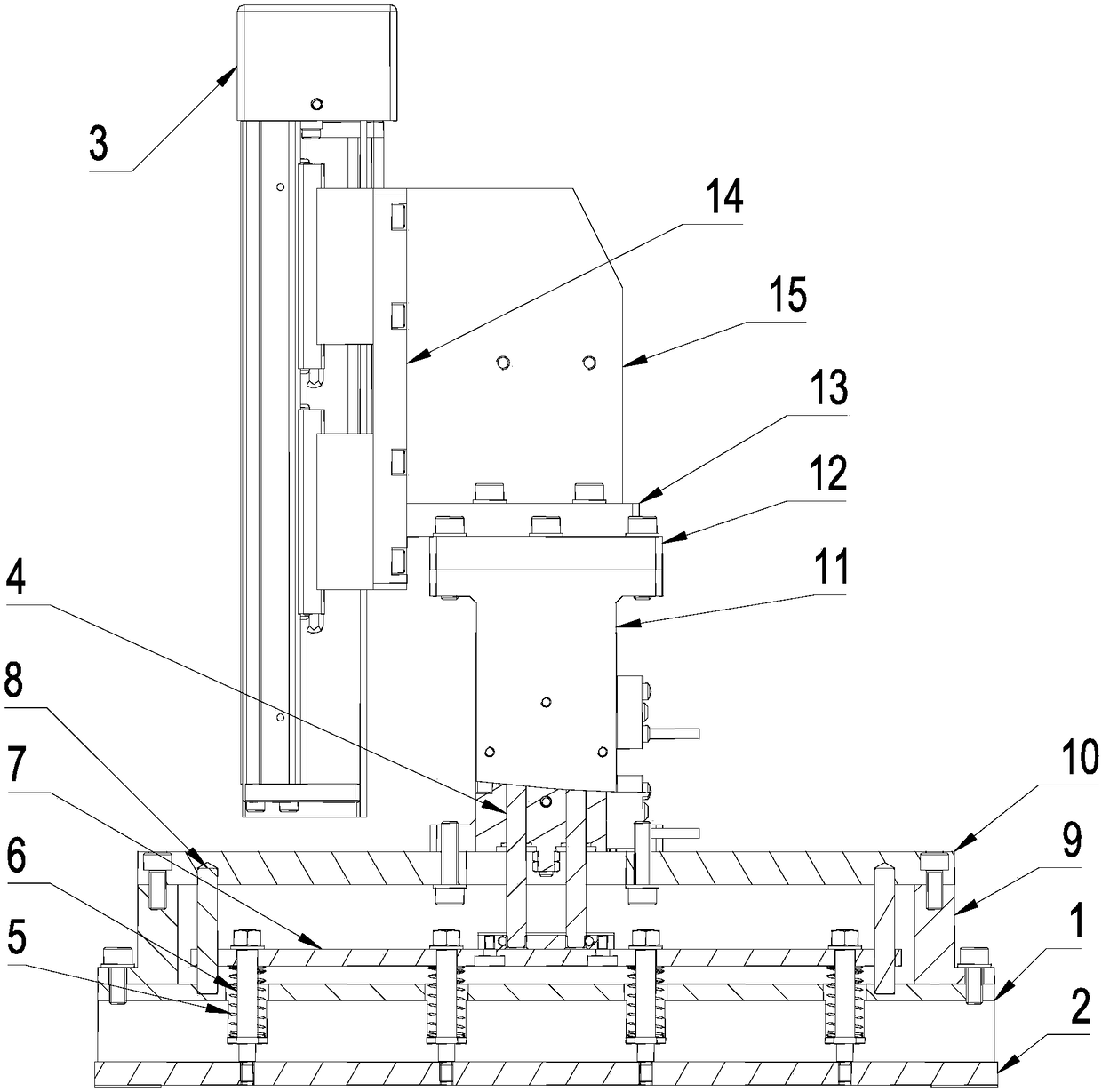

Magnetic stripe obtaining and storing mechanism

The invention discloses a magnetic stripe obtaining and storing mechanism which comprises a linear module, a material obtaining block, a suction block, a cylinder and a pull plate. The linear module is connected with the material obtaining block, the material obtaining block is driven by the linear module to move up and down integrally, the suction block is arranged in the center of the material obtaining block, the suction block is used for sucking a magnetic stripe with magnesium, a guiding screw is arranged on the suction block, the pull plate is sleeved with the upper end of the guiding screw, the pull plate is connected with the cylinder, the pull plate is driven by the cylinder to ascend, and the magnetic strip and the suction block are disengaged. The pull plate is independent, theguiding screw on each suction block is independently connected with one pull plate, each pull plate is connected with a cylinder, each pull plate can independently ascend under the drive of the cylinder, and magnetic stripes can be released independently. The guiding screw is sleeved with at least two springs, and the suction block has the certain drift rate. The magnetic stripes can be independently grabbed, lifted at the same time, lowered at the same time and released simultaneously or independently, and the applicability is high; the mechanism is compact in structure, simple, exquisite, high in precision, good in stability and high in automatic degree.

Owner:成都华聚科技有限公司

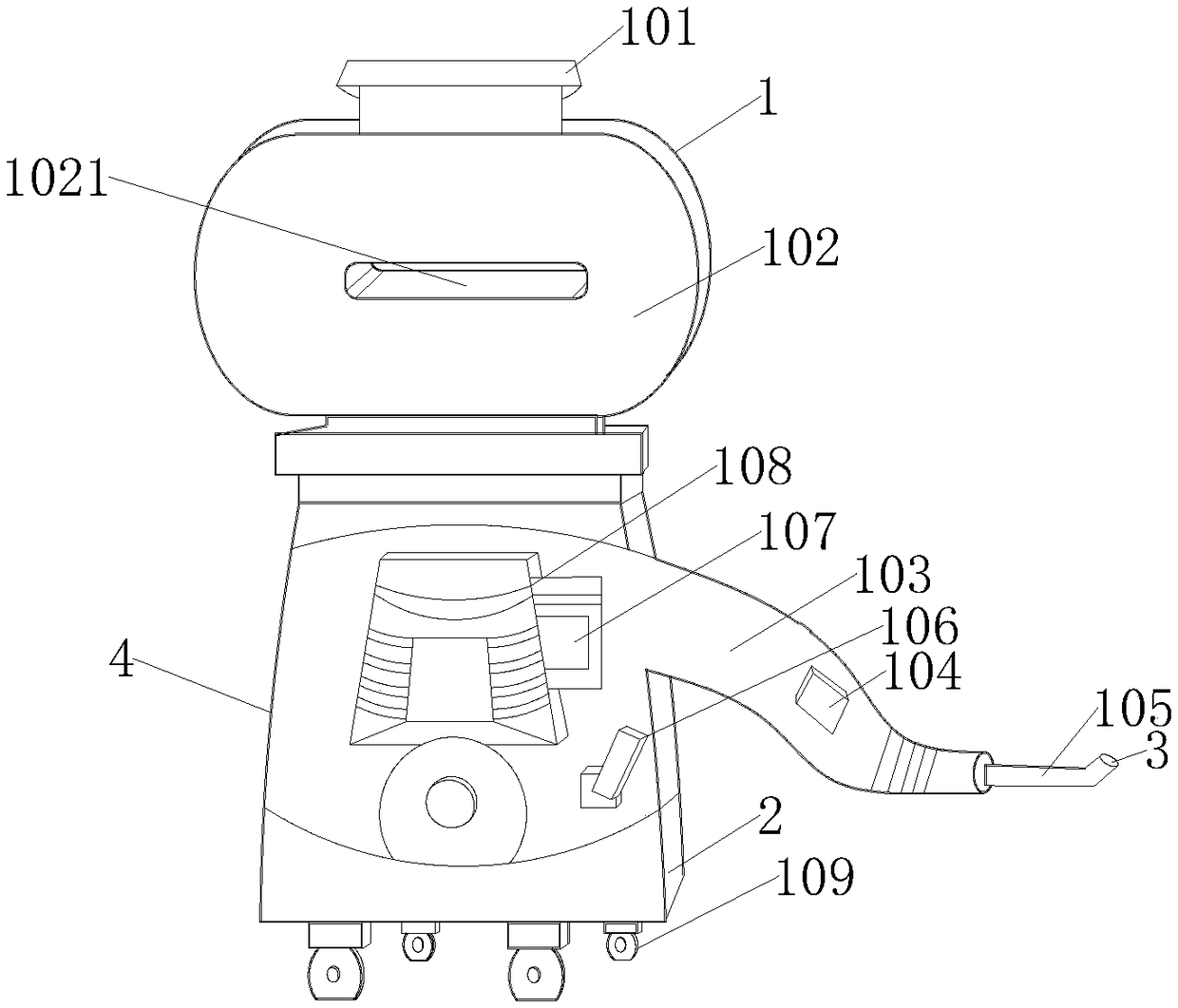

Efficient fertilization mode

PendingCN108713380AAvoid collectingAvoid manual entrySpadesFertiliser distributersAgricultural engineeringFan blade

The invention discloses an efficient fertilization mode, belonging to the field of fertilization modes. The technical scheme comprises the following key points: the efficient fertilization mode is characterized by comprising a fertilization integrated machine, a solid material hole, a nozzle plane and a pressing hammer, wherein a nozzle connecting pipe is fixedly connected to the outer wall of thefertilization integrated machine, and an arc-shaped spray head is movably connected to one side, far from the fertilization integrated machine, of the nozzle connecting pipe; the solid material holeis fixedly connected to the outer surface of the fertilization integrated machine, and rotating fan blades are movably connected to the center in the solid material hole; and the pressing hammer is fixedly connected to the outer surface of the fertilization integrated machine, and a grinding hammer surface is movably connected to the outer wall of the pressing hammer. By utilizing the arc-shaped spray head, a liquefied fertilizer can be atomized, so that the utilization rate of the fertilizer is effectively increased; and the arc-shaped spray head can rotate, so that the contact area between the fertilizer sprayed out in an arc manner and crops can be increased, and then the problem that a fertilization integrated machine is low in working efficiency is solved.

Owner:QINGDAO AGRI UNIV

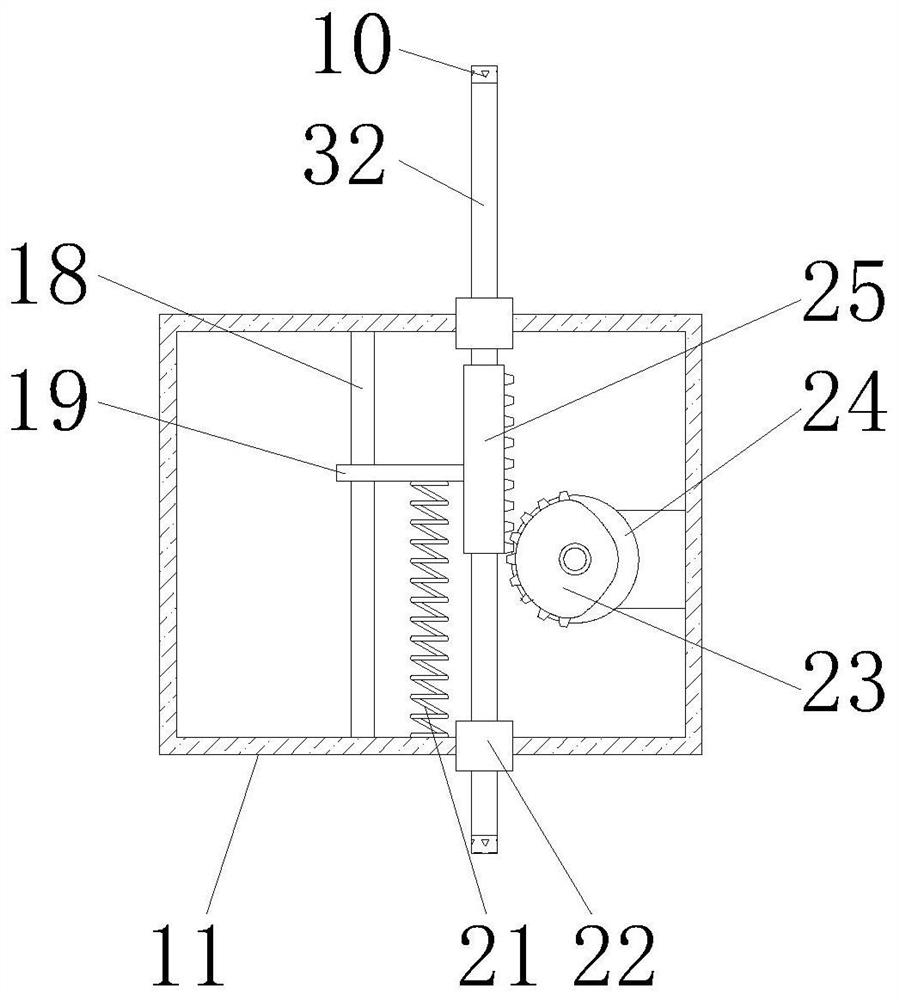

Pipeline butt joint operation bin for peritoneal dialysis

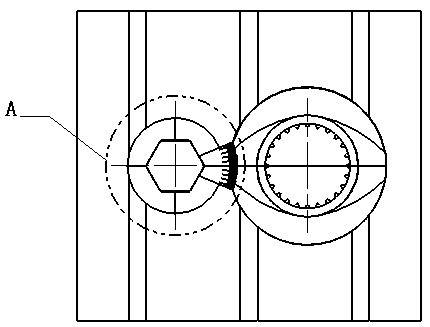

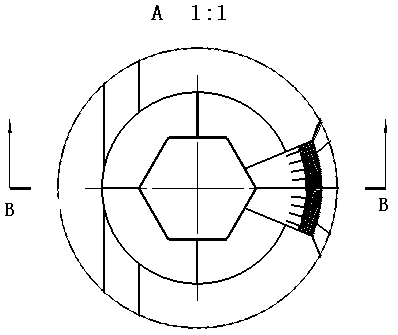

PendingCN114288485ASolve the problem of low work efficiencyQuick pullCatheterPeritoneal dialysisRubber ringGear wheel

The invention relates to the technical field of peritoneal dialysis, in particular to a peritoneal dialysis pipeline butt joint operation bin which comprises an operation bin body, a guide plate, a butt joint pipe seat, a rotating column, a wheel ring and a gear are arranged in the operation bin body, a sliding block is slidably connected to the inner side of the guide plate, and a connecting sleeve is arranged on one side of the sliding block; a rubber ring is arranged on the inner wall of the connecting sleeve, the end of the movable connecting pipe is inserted into the butt-joint pipe seat and is in butt joint with the end of the fixed pipe on the other side of the butt-joint pipe seat, and the problems that during peritoneal dialysis, the butt-joint project of pipelines in the butt-joint operation bin is troublesome, and the working efficiency is not high are solved. Under the driving of the servo motor, the external dialysate tube arranged in the sliding block can linearly slide, can be quickly butted with the short dialysate tube on the other side, can be quickly pulled out and replaced, and is simple and practical.

Owner:常州市武进人民医院

Ecological slope protection maintenance device for water conservancy project

InactiveCN113463568AUniform cycle workTo achieve the effect of watering and maintenanceWatering devicesSpraying apparatusGear wheelElectric machinery

The invention discloses an ecological slope protection maintenance device for a water conservancy project. The device comprises a bottom plate; the left end of the top of the bottom plate is fixedly connected with a base; the left end of the top of the outer surface of the base is movably connected with a supporting rod through a bearing; the top of the supporting rod is movably connected with a telescopic spray pipe through a movable pin; a spray head is fixedly installed on the left side of the telescopic spray pipe; and a shifting plate is fixedly connected to the right side of the telescopic spray pipe. Under the action of mutual cooperation of a water pump, a water tank, the telescopic spray pipe, the spray head, an adjusting box, a second motor, a threaded rod, an adjusting rod, a movable sleeve, the supporting rod, a first motor, a gear, a toothed plate, a fixed rod, a limiting sleeve, a fixed plate, a spring, a U-shaped fixed frame, a shifting rod, the shifting plate and the base, the device has an adjusting function, the operation range of the device is greatly widened, the operation efficiency is effectively improved, and the use requirements of the water conservancy project are met.

Owner:孙作壮

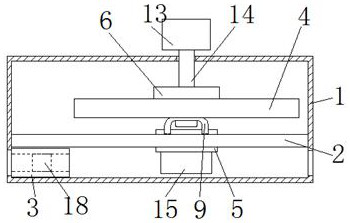

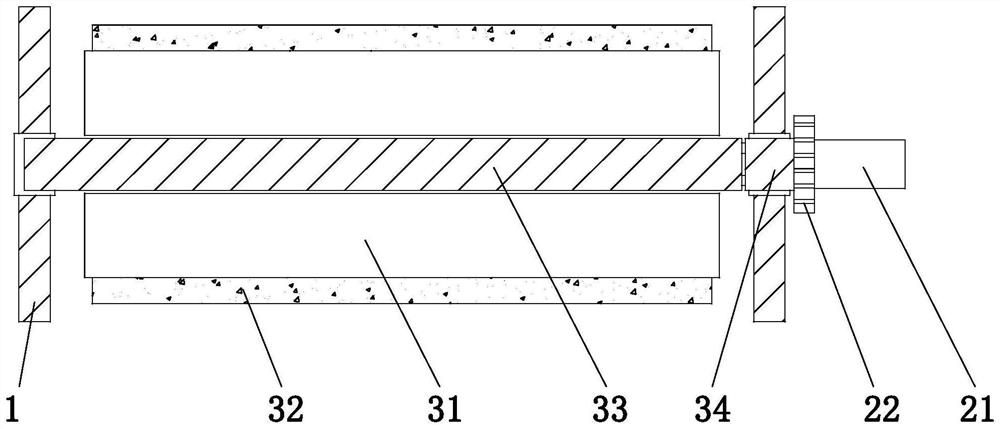

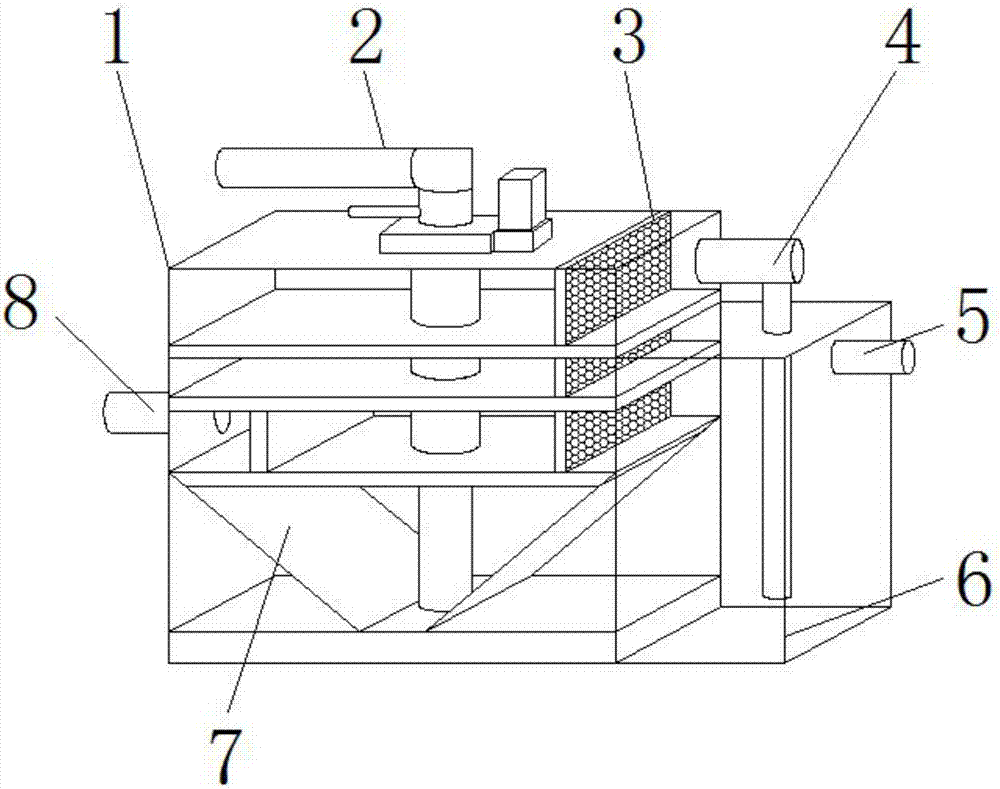

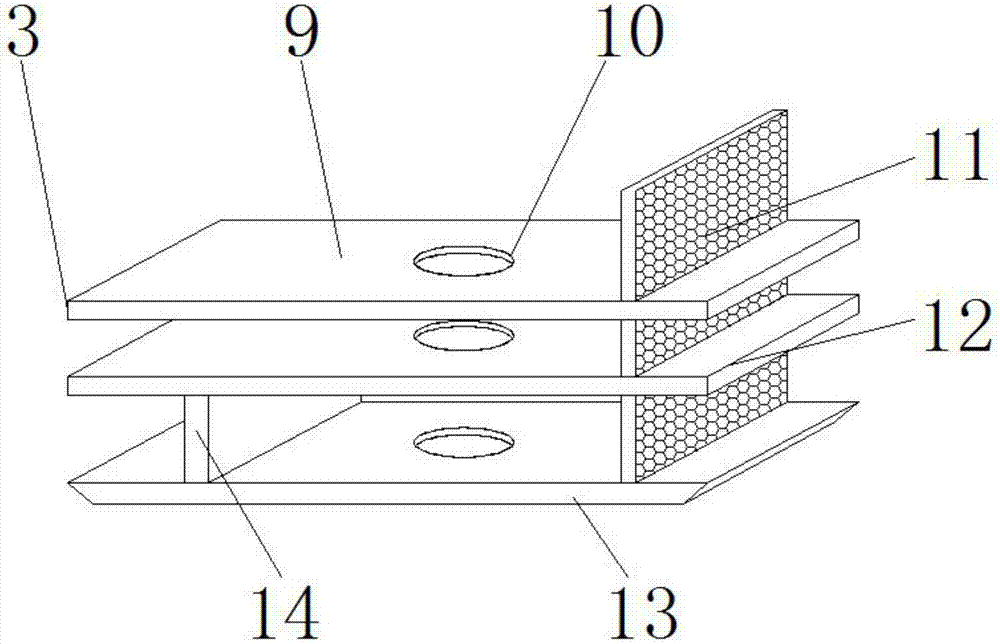

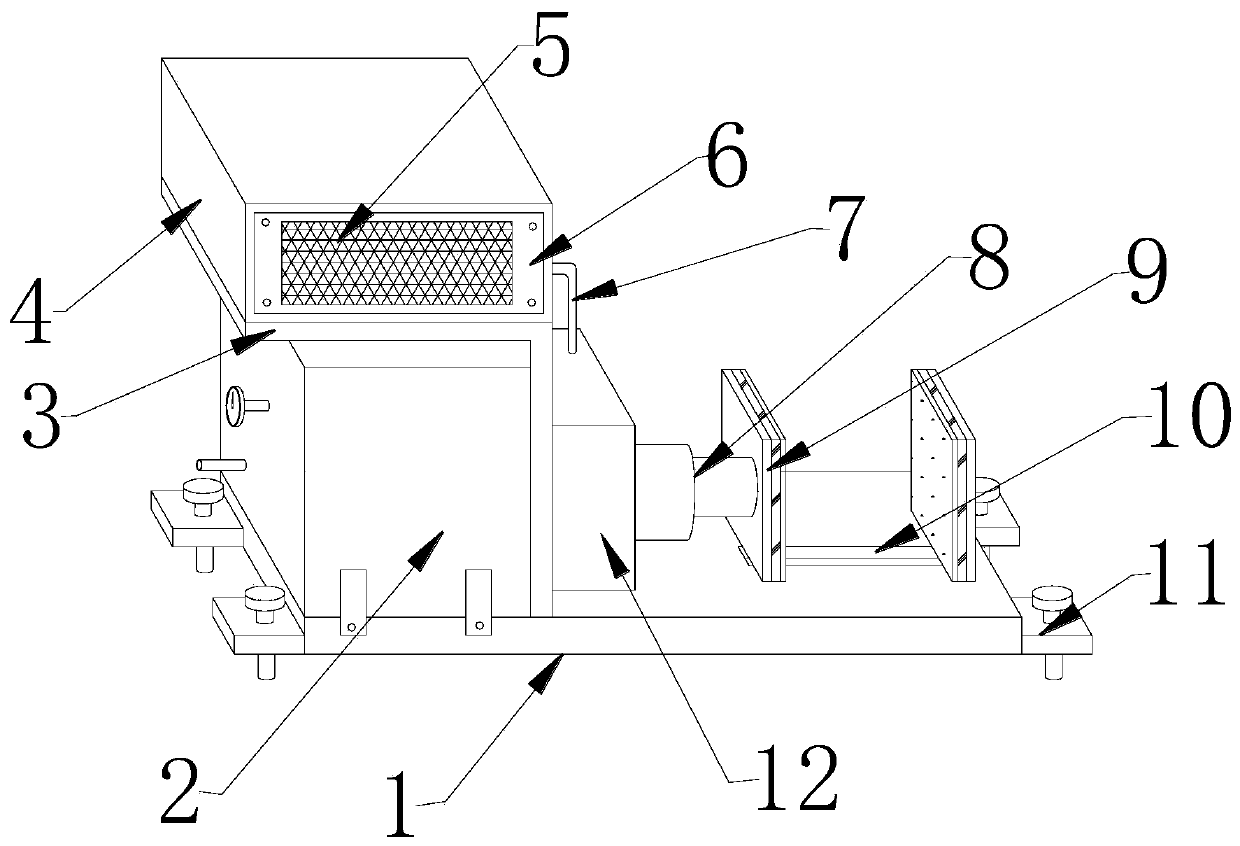

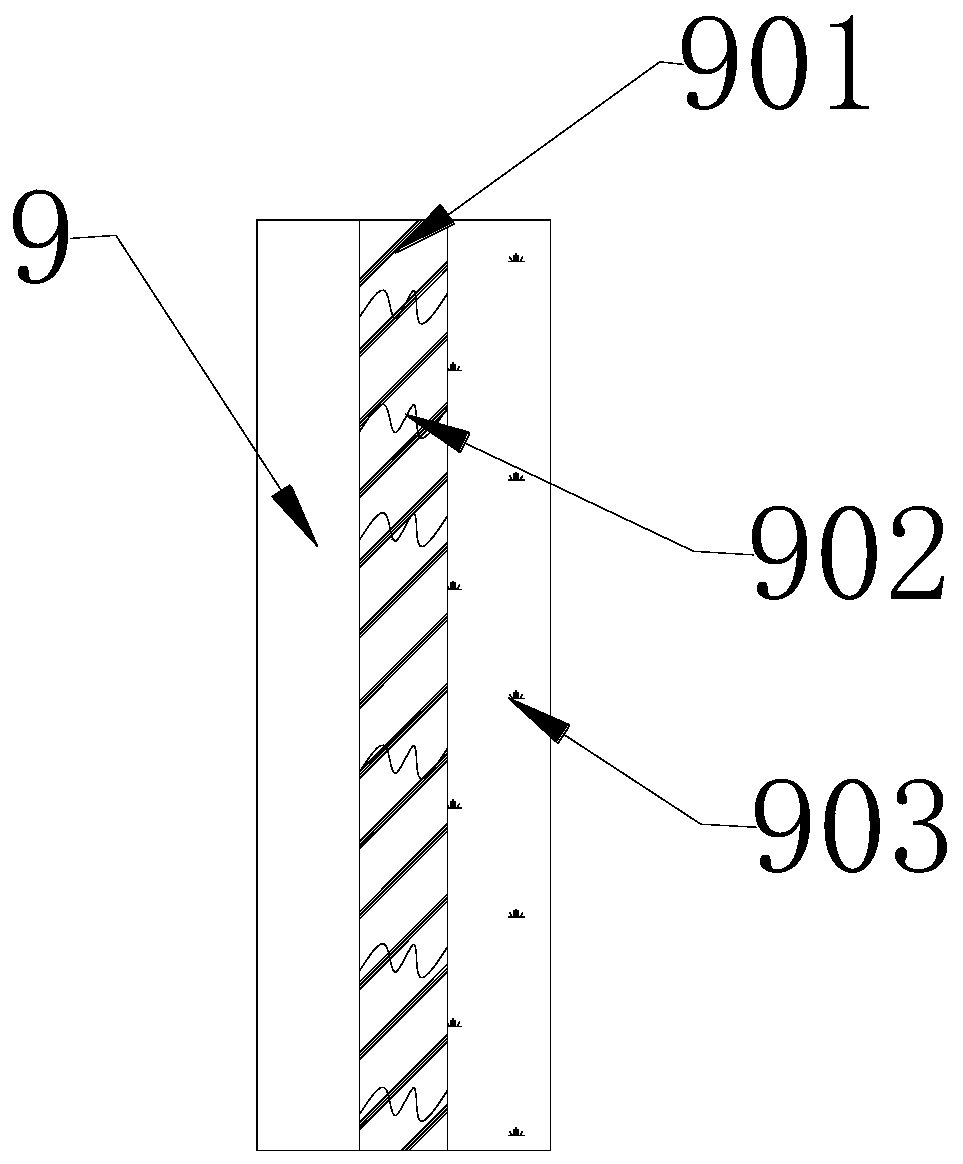

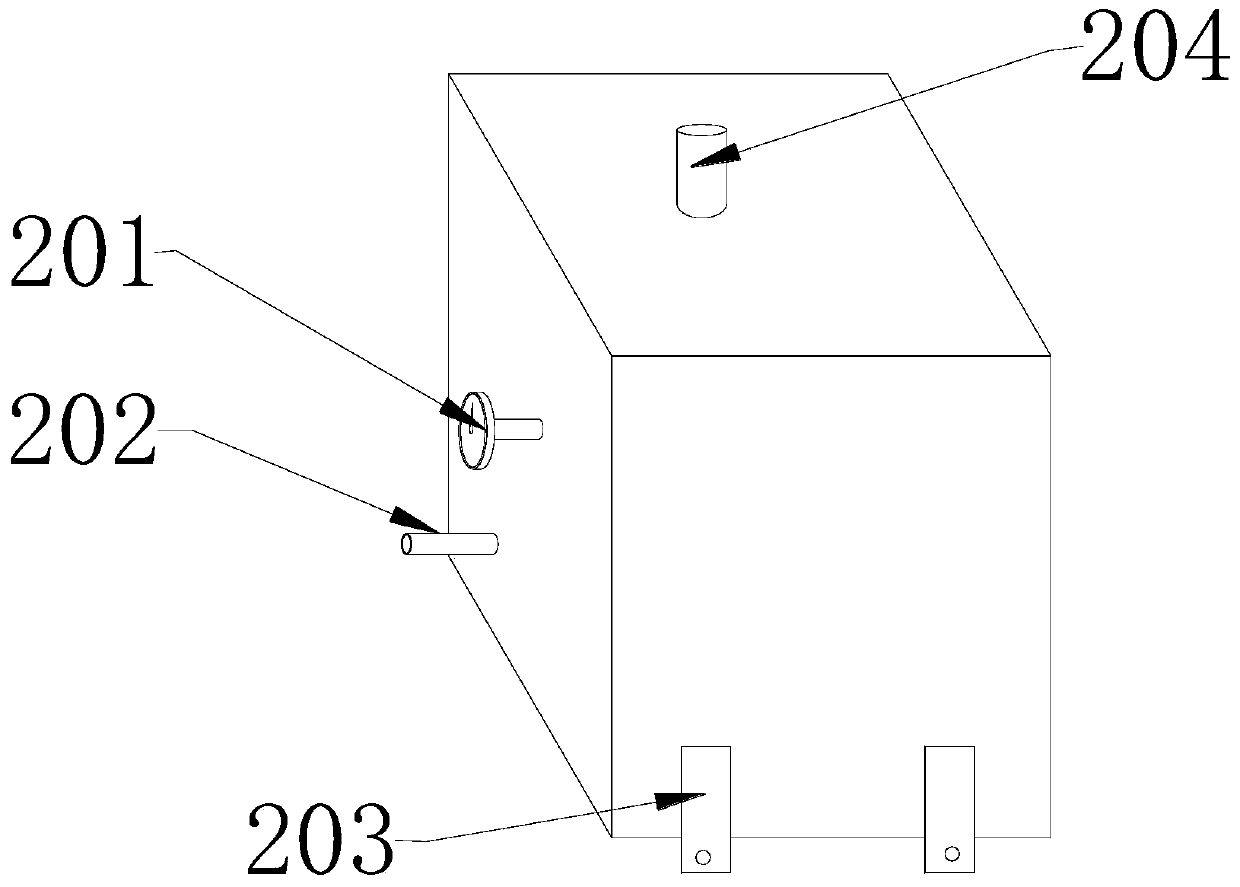

Synthetic leather performance detection equipment and detection method thereof

InactiveCN111638152ADetection of wear resistanceChange the friction intensityInvestigating abrasion/wear resistanceProcess engineeringWear resistance

The invention provides synthetic leather performance detection equipment and a detection method thereof. The synthetic leather performance detection equipment comprises a mounting frame, a driving mechanism, a friction mechanism, a top plate, a wear resistance detection mechanism and a clamping mechanism, the clamping mechanism can rapidly clamp a synthetic leather sample, and the problem that inthe prior art, the work efficiency is not high due to the fact that clamping of the synthetic leather sample is very slow is solved; in addition, the wear resistance detection mechanism can be used for adjusting the distance between the clamping mechanism and the friction mechanism, so that the friction strength between the synthetic leather sample and the friction mechanism can be changed; meanwhile, pin rollers are detachable, so that friction abrasive paper is convenient to replace, various friction conditions in real life are simulated by using the friction abrasive paper with different friction coefficients, and therefore the real abrasion resistance of the synthetic leather can be detected.

Owner:杜秀兰

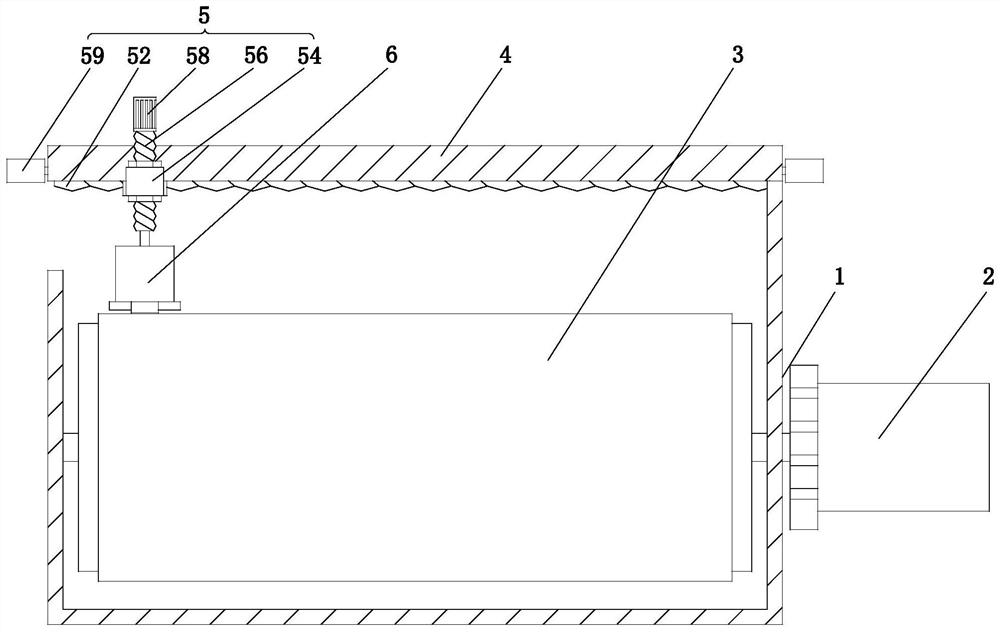

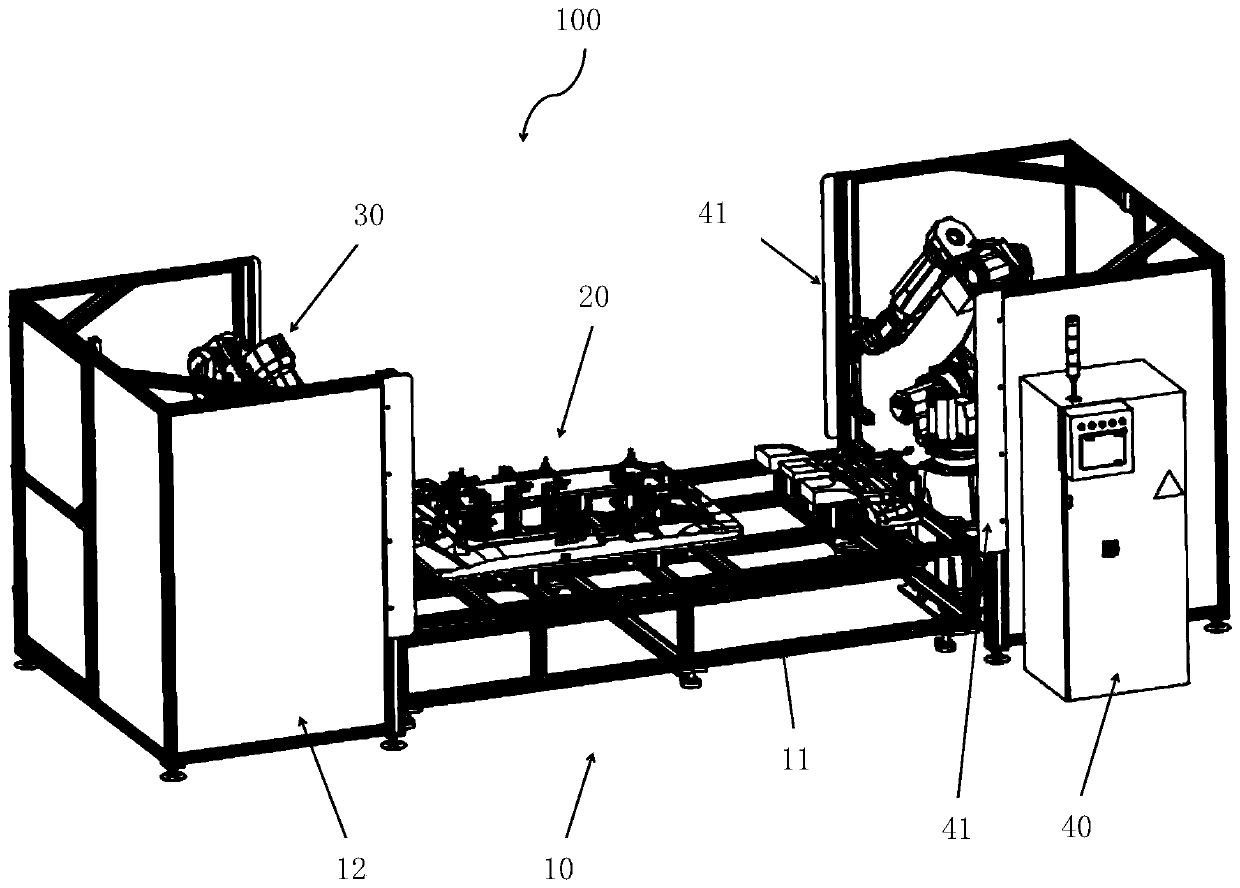

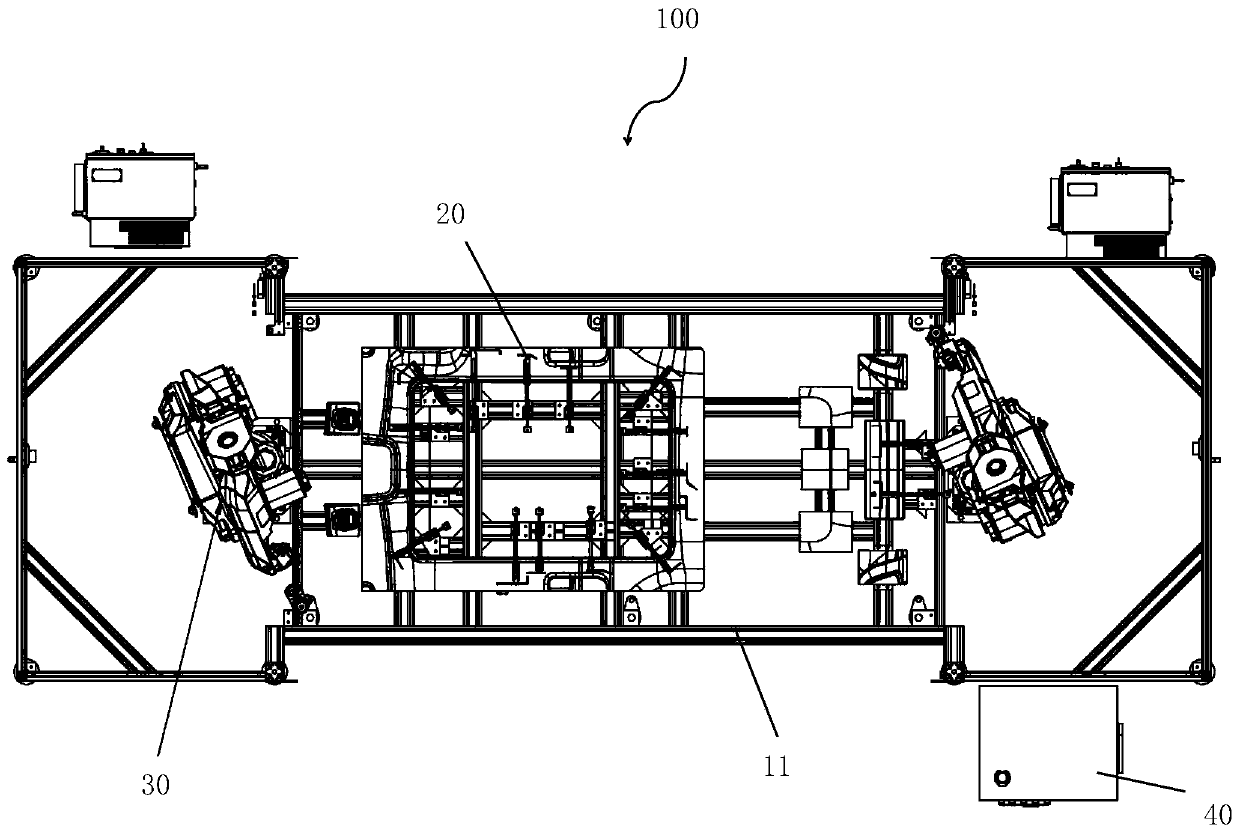

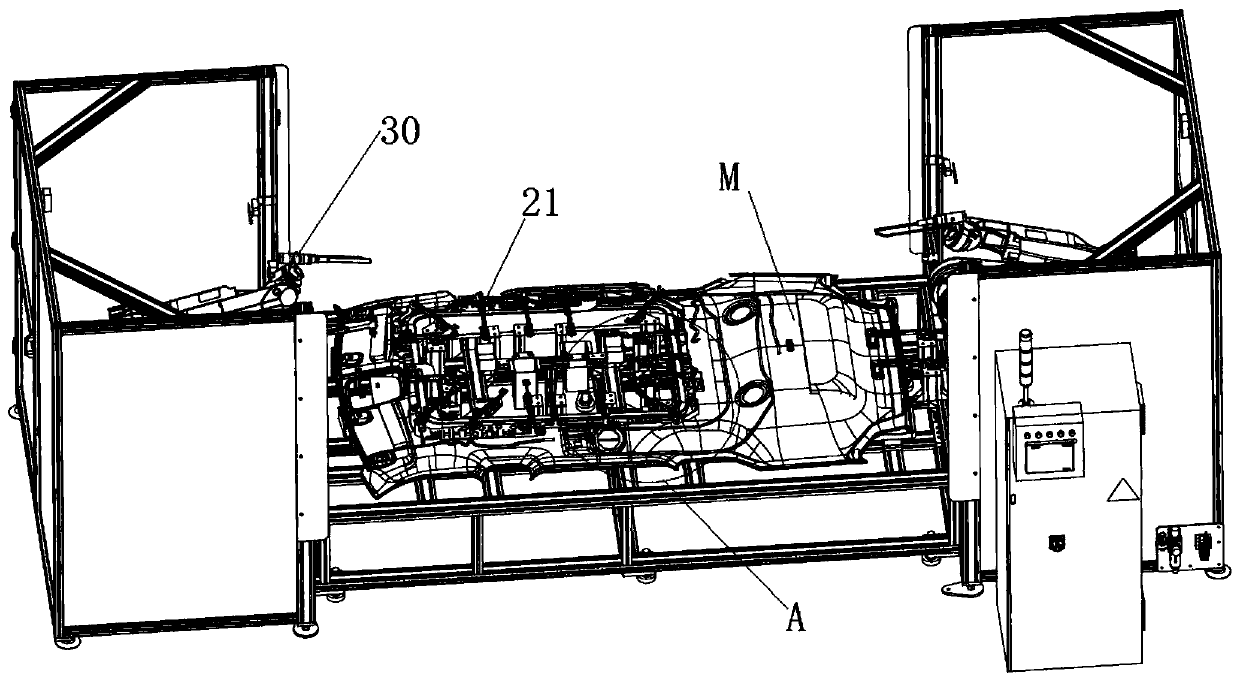

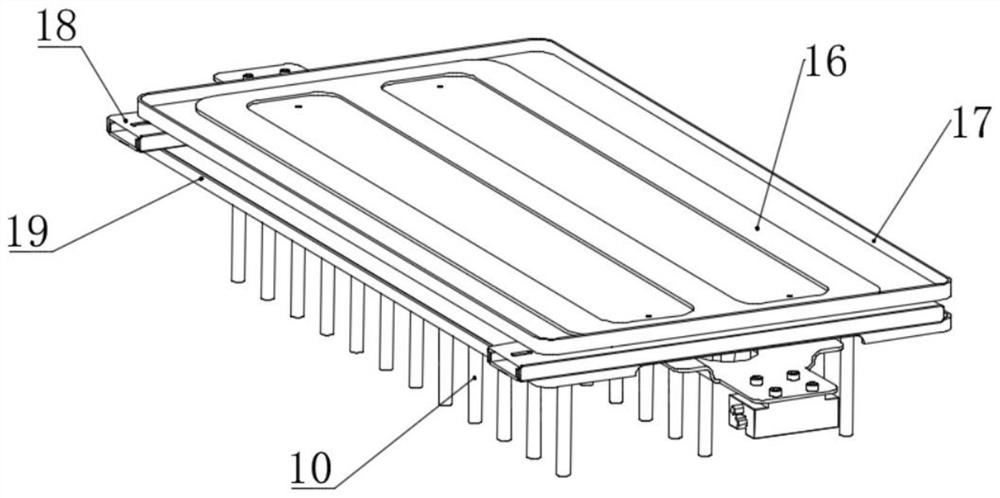

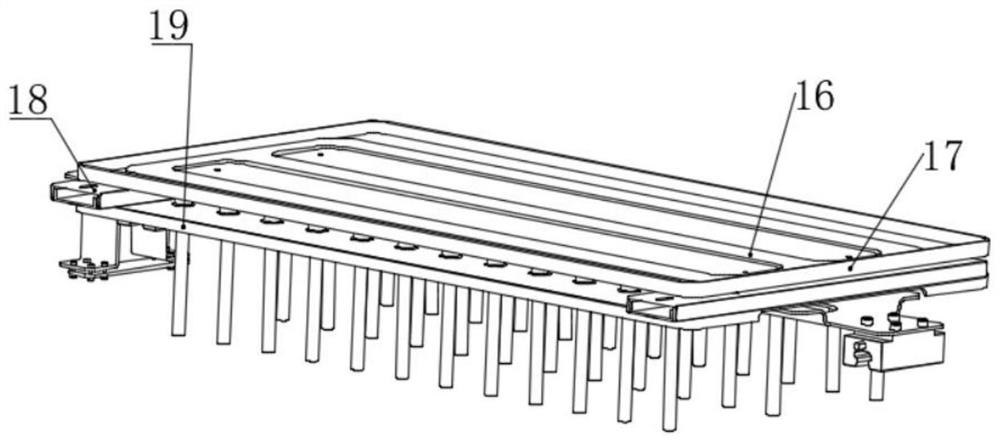

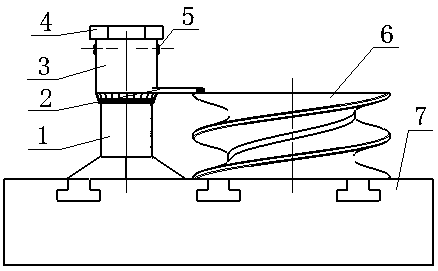

Ceiling plastic frame and fabric base material welding device

PendingCN110978531ASolve the problem of low work efficiencyPaste quality is stableDomestic articlesStructural engineeringManufacturing engineering

The invention discloses a ceiling plastic frame and fabric base material welding device. The ceiling plastic frame and fabric base material welding device comprises a rack part, a clamping part and two ultrasonic welding parts, wherein the clamping part is provided with a fabric base material mold and a plurality of clamping components, and the two ultrasonic welding parts are symmetrically arranged at the two ends of a bottom support correspondingly; a control part is in communication connection with the two ultrasonic welding parts; the fabric base material mold is arranged on the upper partof the bottom support and used for fixing and supporting a fabric base material; the plurality of clamping components are used for fixing a ceiling plastic frame to the supported fabric base material; each ultrasonic welding part comprises a mechanical arm and an ultrasonic welding unit arranged at the end of the mechanical arm; each ultrasonic welding unit comprises an ultrasonic welding gun; each ultrasonic welding gun comprises a welding head and a gun body; one end of each gun body is connected with the corresponding welding head, and the other end of each gun body is fixedly connected with the end of the corresponding mechanical arm through a connecting piece; and the control part controls the heads of the ultrasonic welding guns to conduct ultrasonic welding at the preset position of the ceiling plastic frame according to a set program, and the ceiling plastic frame and the fabric base material are connected.

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

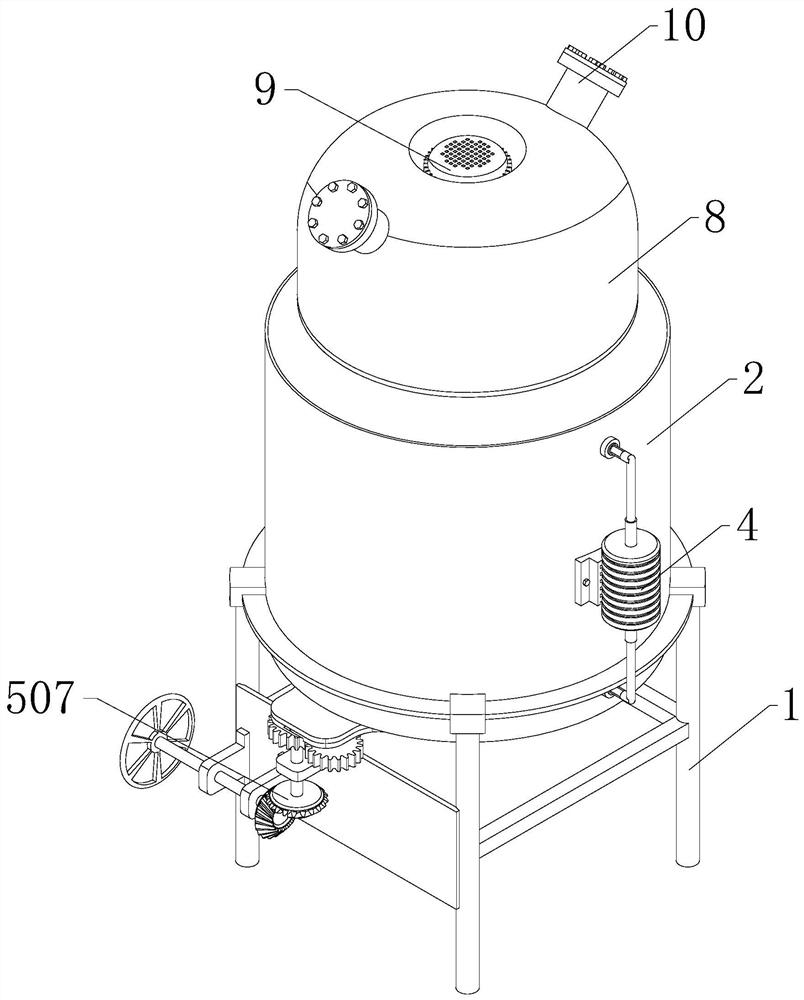

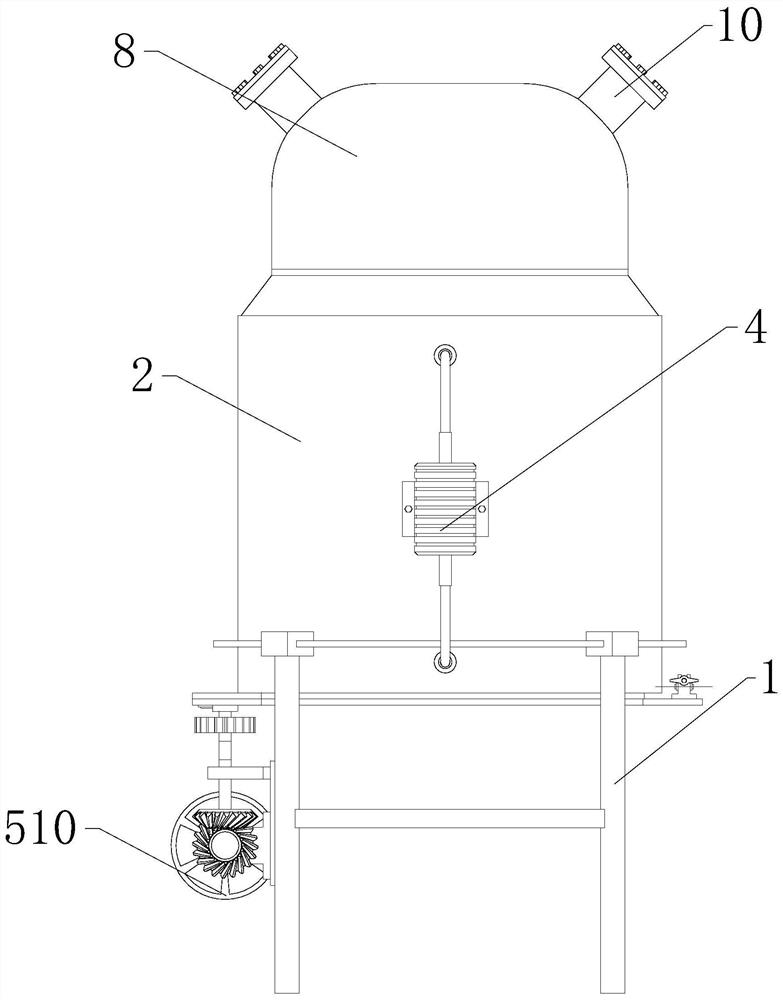

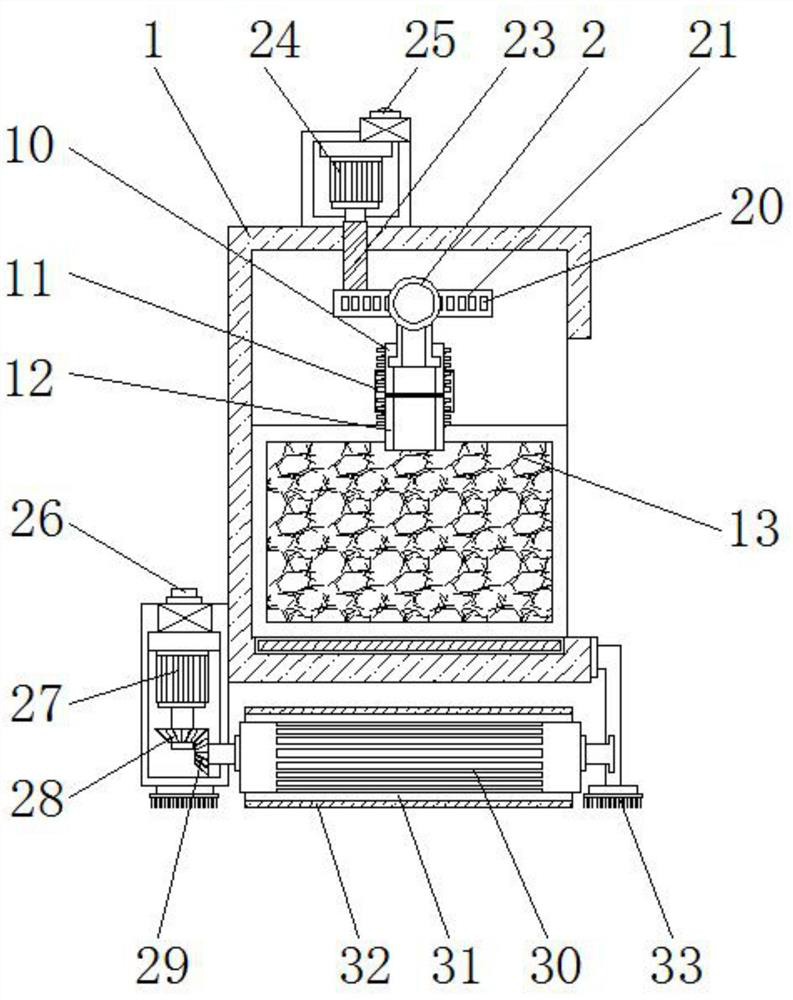

Preparation device of environment-friendly packaging material

PendingCN114192028AWill not affect work efficiencySolve work efficiencyRotating receptacle mixersTransportation and packagingPack materialMechanical engineering

The invention relates to the technical field of industrial instruments, in particular to an environment-friendly packaging material preparation device which comprises a base, a condensation box is connected to the end face of the base, and a condensation pipe is arranged on the side wall of an interlayer of the condensation box. A condensation pipe is arranged on the side wall of the interlayer of the condensation box body, and the two ends of the condensation pipe penetrate through the side wall of the condensation box body and extend to the exterior of the condensation box body to be connected with a condenser. According to the environment-friendly packaging material preparation device, the working efficiency is not influenced by over-high temperature caused by friction generated during stirring, so that the problem that the working efficiency is influenced by over-high temperature is solved, a gear structure is adopted in the device, and the stirring box and the stirring blades move back to back, so that the environment-friendly packaging material preparation material is fully stirred, and meanwhile, the stirring efficiency is greatly improved. And the working efficiency is improved, so that the problem of low working efficiency is solved.

Owner:YUYAO SUN RAIN SPRAYER

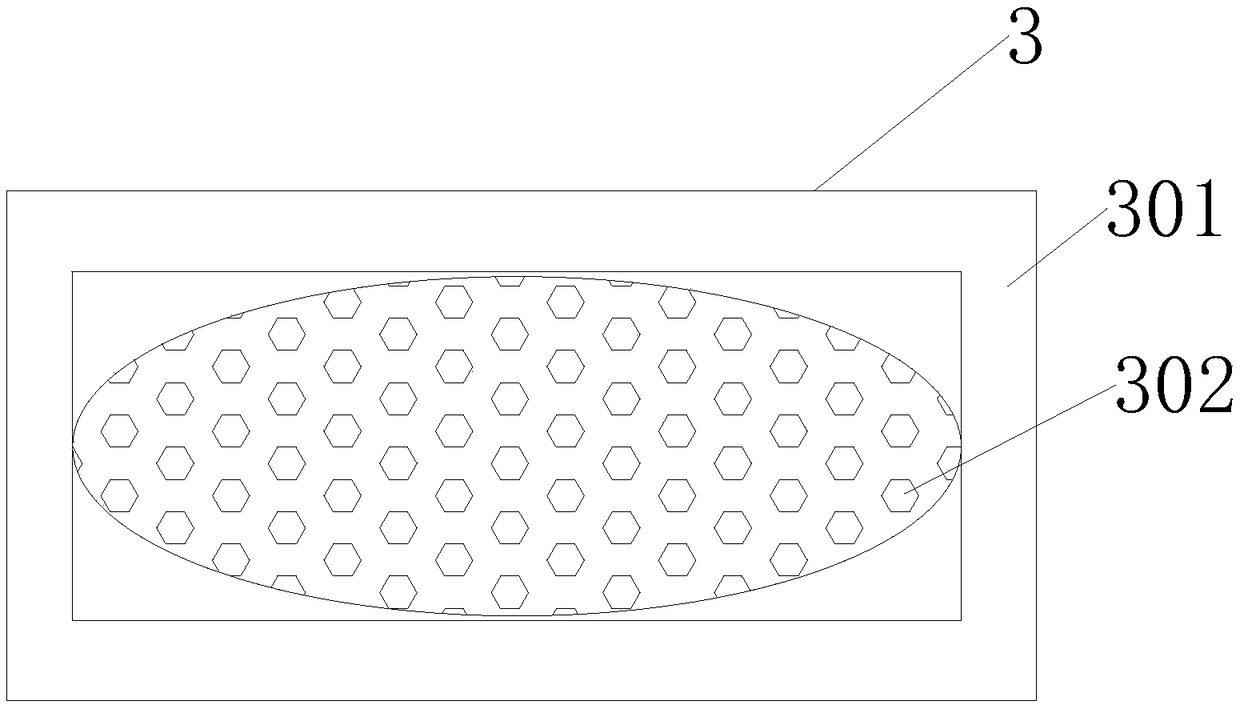

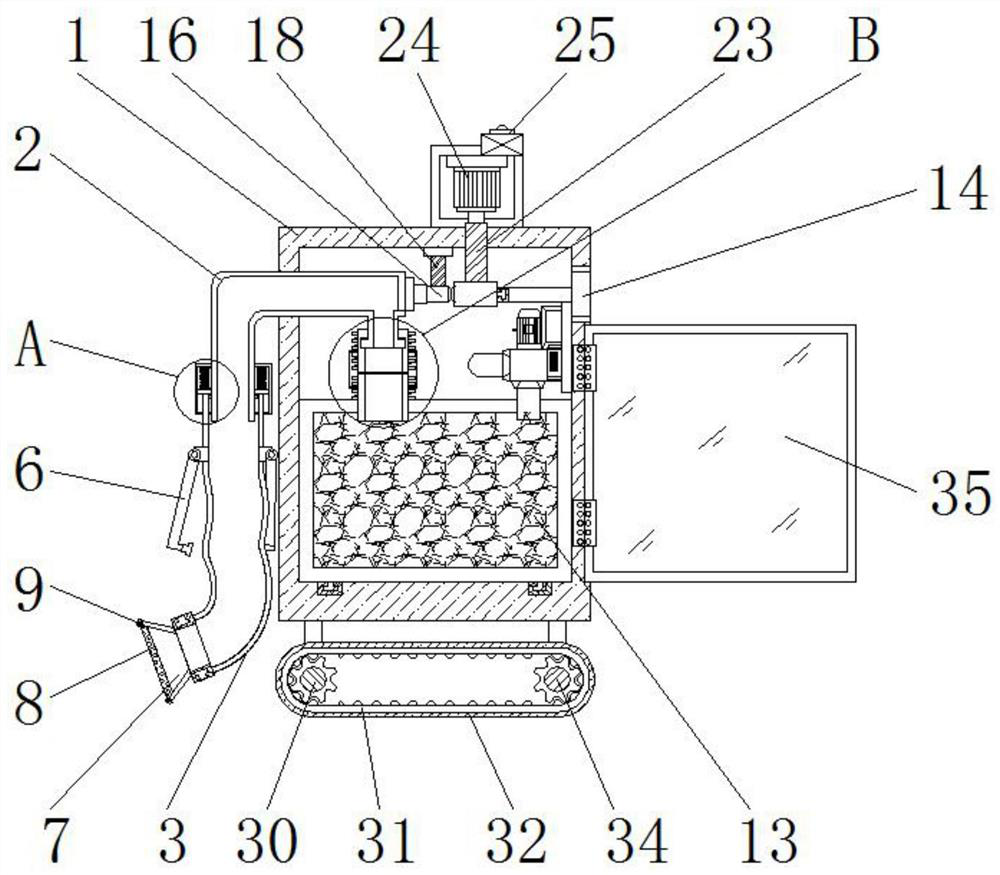

A quantitative filling equipment for insect eggs based on biological control

The invention discloses a quantitative filling device for insect eggs based on biological control, which includes an equipment frame, on which an insect ball splint and a leaking plate located on the insect ball splint are fixed, and an insect egg ball is provided with a The slotted holes for insect eggs; the leaking plate includes an upper plate for placing insect eggs and a lower plate matched with the upper plate. hole; when placing eggs, the upper plate and lower plate are in a dislocation state, and the through holes of the upper plate are not connected to the through holes of the lower plate; when releasing eggs, slide the upper plate to align with the lower plate, and the through holes of the upper plate The holes communicate with the through holes of the lower plate in one-to-one correspondence, and become a release channel for releasing the eggs stored on the upper plate, and the eggs slide down to the slots on the egg ball through the release channel. Through the optimized design of the leaking plate, the present application can not only realize rapid and large-scale filling of insect eggs, but also precisely control the quantitative filling and release of insect eggs, and significantly improve the filling efficiency.

Owner:湖南植保无人机技术有限公司

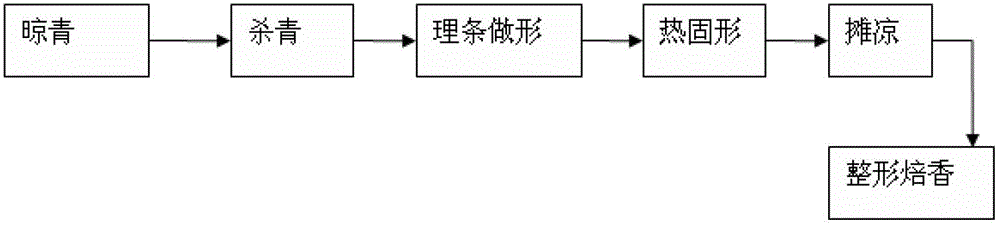

Processing process for Yungu Dafang tea

InactiveCN102742679AImprove qualityEasy to processPre-extraction tea treatmentTemperature controlAgricultural engineering

The present invention discloses a processing process for Yungu Dafang tea, which comprises the following steps: a green leaf drying and fragrance improving step, a ventilation-smothering-combined water removing step, a leaf tidying temperature-controlled shaping step, a thermal shape fixing step, a shaping and torrifying step, etc. The ventilation-smothering-combined water removing step is performed by an electrothermal roller water removing machine. The leaf tidying temperature-controlled shaping step is performed by a hot-wind leaf tidying machine and a semi-pot type tea flattening machine. The thermal shape fixing step is performed by a specific temperature-controlled heating device. The shaping and torrifying step is performed by the semi-pot type tea flattening machine. The Yungu Dafang tea which is processed by the processing process of the invention has the following advantages: strong fragrance, combination of chestnut fragrance and flower fragrance, mellow and fresh fragrance, remarkably improved quality than the traditional Dafang tea, reduced labor intensity and remarkably improved processing efficiency as a continuous water removing step is adopted in the processing process.

Owner:黄山茶业集团有限公司 +1

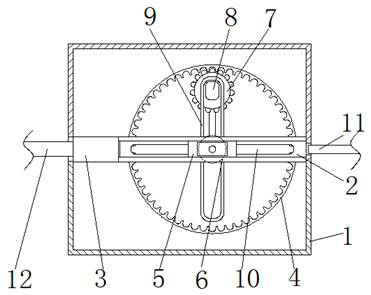

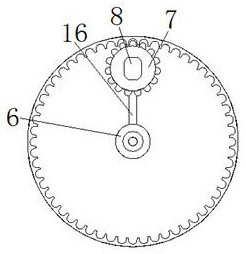

Environment-friendly lawn mower

The invention discloses an environment-friendly lawn mower. The environment-friendly lawn mower is characterized by comprising wheels, a large gear, a small gear, a large chain wheel, a small chain wheel and a hob, wherein the wheels are meshed with the large gear, and the large gear is meshed with the small gear; the small gear is meshed with the large chain wheel, the large chain wheel is meshedwith the small chain wheel, and the hob is arranged on the small chain wheel. The lawn mower is free of engine driving, saves energy, and is free of pollution (noise and waste gas). An environment-friendly design is utilized; a gear-chain wheel mechanism is adopted to achieve speed increasing, the working efficiency of the whole mower is improved, and the problem that the working efficiency of amanual mower is not high is solved; the hob is adopted, the grass mowing effect is ideal, the cost is low, and the lawn mower is the first selected product of small-area lawn mowing.

Owner:宁夏源浩科技服务有限公司

A novel synchronous measuring device for the height and phase angle of the helical element

ActiveCN106568369BSolve the problem of low accuracy of measuring positionSolve the problem of low product qualityAngles/taper measurementsMechanical thickness measurementsMeasurement deviceEngineering

The invention discloses a novel screw element height and phase angle synchronization measurement device, which comprises a height measurement seat, a sector measurement plate, an angle measurement sleeve, a screw rod, a screw element and a working platform, wherein the screw element is positioned on the working platform; the height measurement seat is placed on the working platform; the height measurement seat is in threaded connection with the screw rod; the sector measurement plate and the angle measurement sleeve are in an integrated structure; the angle measurement sleeve is connected with the screw rod through a clamping pin; and the height measurement seat is moved, and the sector bottom plane of the sector measurement plate is placed on the plane of the screw element in the height direction. According to the novel screw element height and phase angle synchronization measurement device of the invention, the problem that the corresponding relationship between the height and the screw section phase angle is cut caused as the original measurement structure separately measures the height and the phase angle can be solved, the problem that the position measurement precision is not high is solved, and the problem that the product quality is not high after the screw element is combined and assembled can be solved.

Owner:大连橡胶塑料机械有限公司

Pretreatment sediment box for sewage treatment

InactiveCN107352672AEasy dischargeImprove work efficiencyTreatment involving filtrationMultistage water/sewage treatmentThree phase asynchronous motorSewage

The invention discloses a pretreatment sediment box for sewage treatment. The pretreatment sediment box comprises a protective shell, a sand discharge main body is fixed to the center of the upper end face of the protective shell, the sand discharge main body comprises a first sand guiding pipe, a sand lifting pipe is connected to the center of the lower end face of the first sand guiding pipe in a penetrating mode, a three-phase asynchronous motor is fixed to the upper end face of the first sand guiding pipe, a water suction pump is fixed to the upper end face of the three-phase asynchronous motor, a sediment main body is fixed to the interior of the protective shell and comprises a third filter screen, a buffer plate is fixed to the upper end face of the third filter screen, a cable support shell is fixed to the end, deviating from the buffer plate, of the third filter screen, a second filter screen is fixed to the upper end face of the buffer plate, and a first filter screen is fixed to the upper end face of the second filter screen. Accordingly, by arranging the protective shell, the sand discharge main body and the sediment main body, the work efficiency of sewage treatment can be improved, and meanwhile the sewage can be sedimented rapidly.

Owner:范科晨

Traditional Chinese medicine smashing pretreatment equipment based on traditional Chinese medicine pounding process

InactiveCN113877664ASolve the problem of low work efficiencyImprove work efficiencyGrain treatmentsRatchetPharmacy medicine

The invention relates to the technical field of traditional Chinese medicine pretreatment, and particularly relates to traditional Chinese medicine smashing pretreatment equipment based on a traditional Chinese medicine pounding process. The traditional Chinese medicine smashing pretreatment equipment comprises a fixing frame and a control box. A mounting disc and a mounting box are arranged on the side face of the fixing frame. A rotatable ratchet wheel is arranged in the center of the mounting disc. A movable column capable of elastically ascending and descending is arranged in the mounting box. A pawl matched with ratchets of the ratchet wheel is hinged to the top end of a connecting column. A pounding rod is arranged at the bottom end of the movable column. A supporting table capable of ascending and descending is placed on the control box. A pounding mortar is mounted on the supporting table and located under the pounding rod. The traditional Chinese medicine smashing pretreatment equipment solves the problem that the work efficiency is not high when a pounding pretreatment manner is adopted for traditional Chinese medicine. According to the pretreatment equipment, through a mechanical transmission structure, medicine pounding work can be continuously conducted, the work intensity of workers is lowered, time is saved, and meanwhile the work efficiency can be improved.

Owner:江阴市中医院

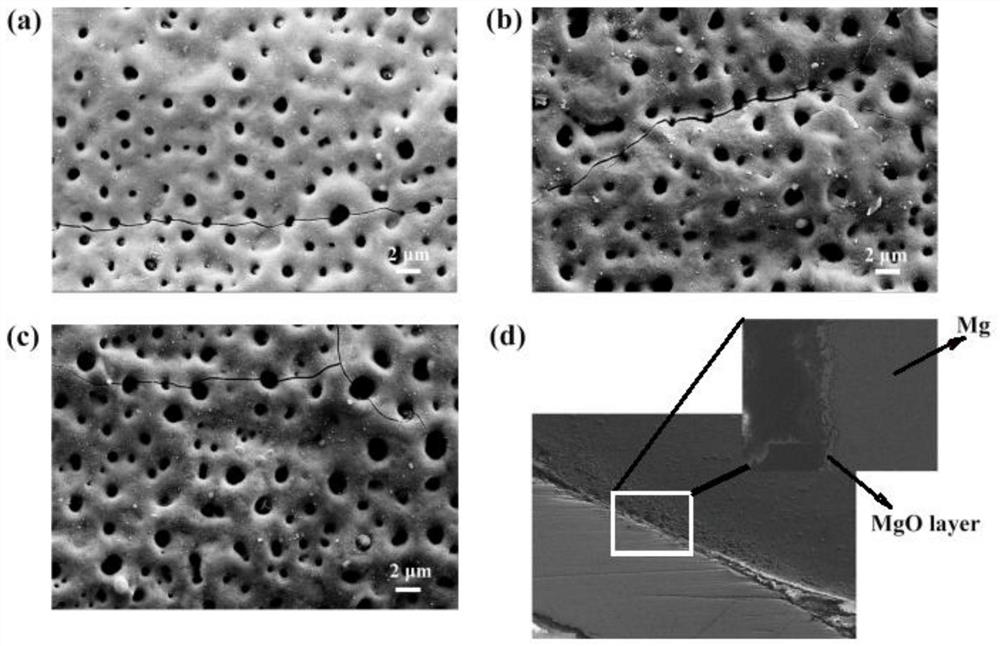

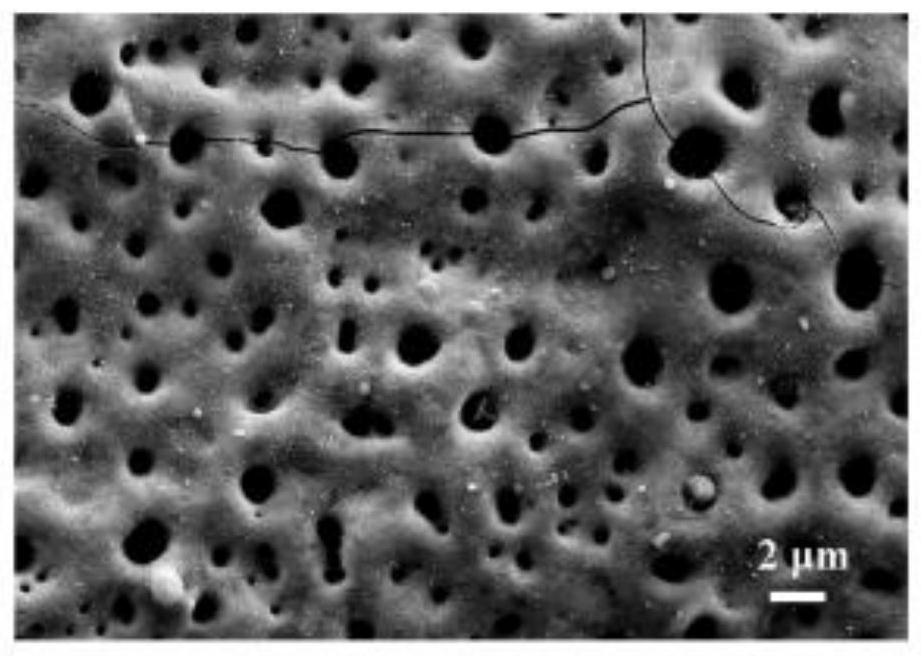

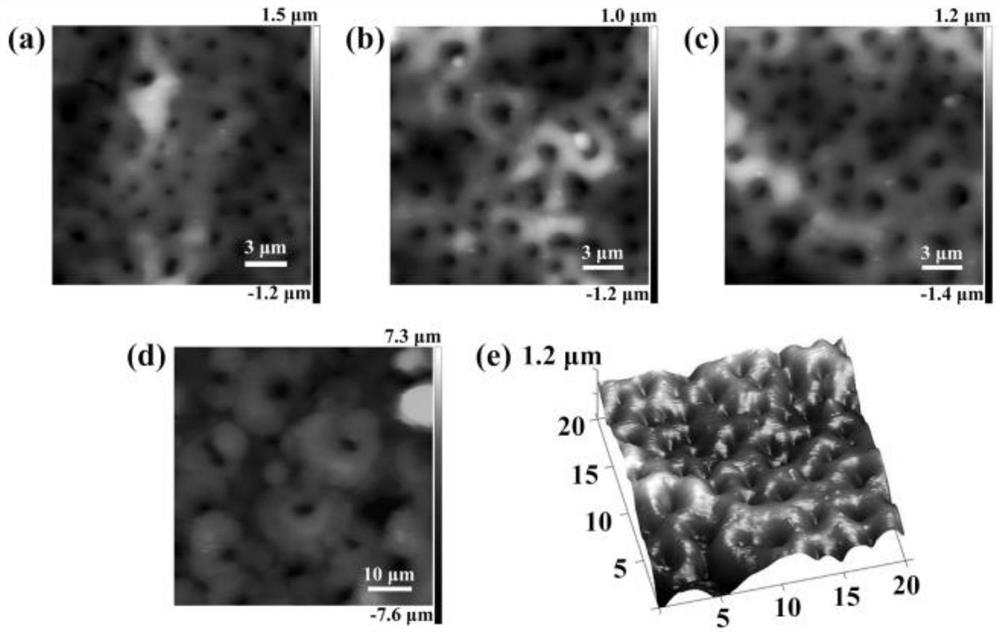

A kind of substrate material, Raman surface enhancement substrate, preparation method, application

ActiveCN111876813BImprove efficiencyLow costAnodisationRaman scatteringElectrolytic agentNano structuring

The invention relates to the field of micro-nano structure processing, and specifically discloses a substrate material, a Raman surface enhanced substrate, a preparation method, and an application. The substrate material is obtained by anodizing magnesium ingots in an electrolyte, and can be controlled The energization time can then control the geometric parameters of its surface structure, realize high-efficiency processing that can obtain the expected surface structure, and can prepare Raman surface-enhanced substrates with fixed specifications at high efficiency and low cost; and the preparation method provided is simple, only need to select The material is polished and cleaned, the preparation work is significantly reduced, and the work efficiency is improved. The prepared substrate material can be retained for a long time, and can also be prepared as a Raman surface-enhanced substrate, which is used in the detection of surface-enhanced Raman spectroscopy and the detection of different biological reagents Being applied, the preparation of the existing Raman surface enhanced substrate needs to prepare a lot of work in the early stage, and the problem of low work efficiency exists, and has broad market prospects.

Owner:CHANGCHUN UNIV OF SCI & TECH

A dust removal device for industrial automation equipment

ActiveCN109107993BSolve the problem of low work efficiencyExpand the vacuum rangeDirt cleaningCleaning using toolsGear wheelDust control

The invention discloses a dust removal device for industrial automation equipment, which comprises a box body, a first fixed pipe, a second fixed groove, a second switch, an inspection door and a blower. The upper end of the lower dust suction pipe is hingedly connected with a fixed Rod, the inner side of the lower end of the dust suction head is engaged with a filter screen, the first fixed pipe is located at the right lower end of the upper dust suction pipe, and the right end of the upper dust suction pipe is fixedly connected with a first runner, so The second switch is located at the rear side of the lower end of the box, the lower end of the second motor is welded and connected with a driving gear, brushes are installed on the front and rear sides of the first rotating roller, and the inspection door is located on the outside of the box , the blower is located above the collection box. The dust removal device of the industrial automation equipment solves the problem of low working efficiency of most dust removal devices, and the problem that general dust removal devices cannot perform dust removal while moving, and ordinary dust removal devices cannot be adjusted. Angle problem.

Owner:芜湖英特杰智能科技有限公司

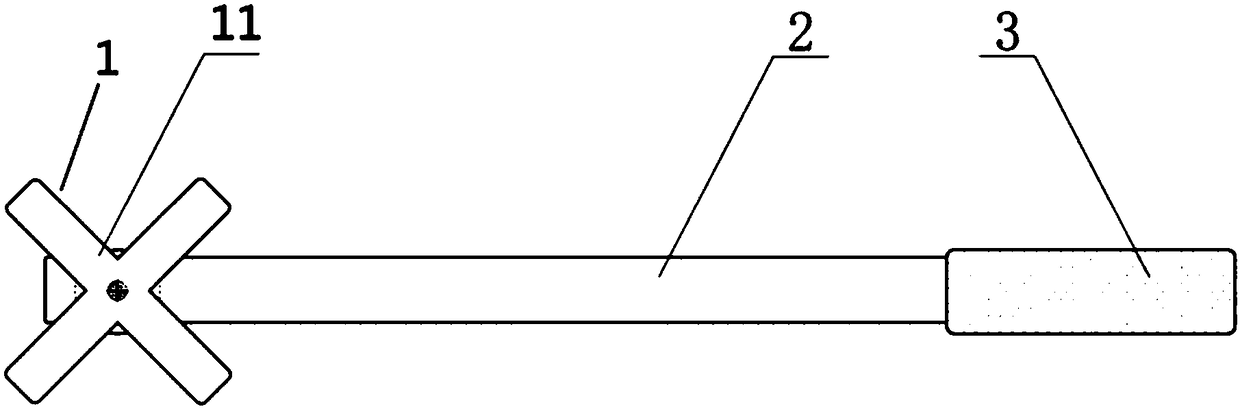

Butt joint clamping groove mechanism for loader

InactiveCN109108879ASolve the problem of low work efficiencyImprove work efficiencySpannersWrenchesButt jointLoading unloading

The invention discloses a butt joint clamping groove mechanism for a loader. A loading-unloading tool comprises a rod body and a working head fixed to one end of the rod body, wherein the working headis clamped to a groove on an external thread protector, when the working head is clamped to the groove on the external thread protector, and the axis of the rod body is perpendicular to a rotating shaft of the external thread protector. The mechanism is simple in structure, is convenient to operate, solves the problem that the working efficiency is not high when the external thread protector of an external thread joint of a petroleum drilling tool is loaded and unloaded, enables the working efficiency of operation of the petroleum drilling tool to be greatly improved, and enables the workingintensity to be reduced.

Owner:XIAN ANT PETROLEUM TECH

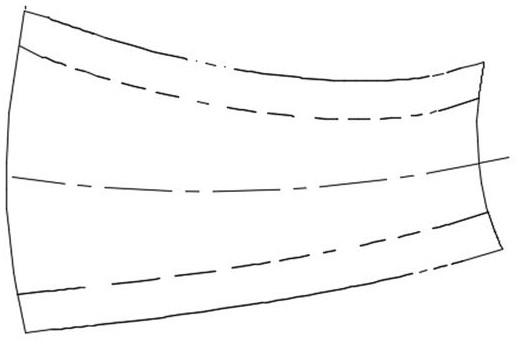

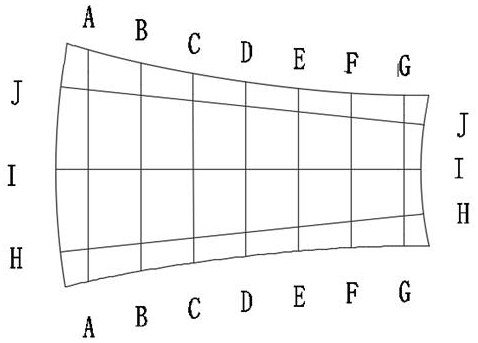

A processing method of hyperboloid forming equipment

ActiveCN112541226BImprove bending efficiencyInhibit deteriorationGeometric CADShaping toolsMechanical modelsDouble curvature

The invention discloses a processing technology of double-curvature forming equipment, which includes: establishing a mechanical model of cold forming and studying the mechanical properties of special plates, deriving the rebound radius of material processing and forming; fitting the curved surface of double-curvature plates and performing Mathematical characterization: finite element numerical simulation to determine the springback of the shape of the double-curvature molding die: processing and manufacturing the curved plate die outer plate: the part of the outer plate whose curvature is not processed enough is thermally trimmed: install the special mold on the storage rack , assembled according to the number and partition of the base surface panel and fixed by spot welding; using the optical surface scanning measurement technology to reconstruct the shape of the hyperboloid after each bending: making a sample box for real-time measurement and control of the shape accuracy of the plate forming, the present invention Grasp the amount of springback compensation more accurately, ensure the quality of the product, better guarantee the accuracy of the curved surface, significantly improve the efficiency of bending and forming, reduce the manual workload, greatly shorten the working hours and save costs, and improve the quality of the product.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU +4

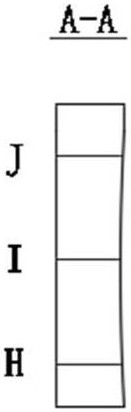

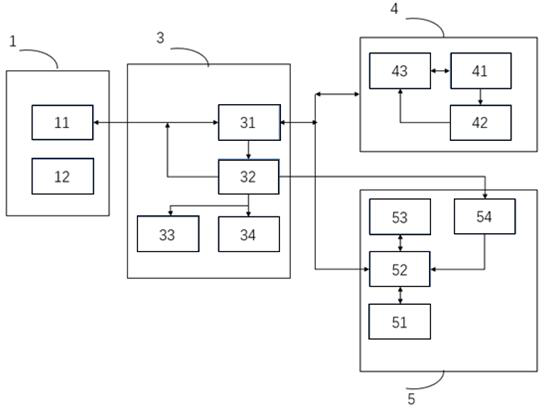

Intelligent system fusion platform and working method thereof

PendingCN112306001AGood manpower arrangement planReduced staffingTotal factory controlProgramme total factory controlLogic cellControl engineering

The invention discloses an intelligent system fusion platform and a working method thereof. The platform comprises field positioning equipment and a control center, the field positioning equipment comprises an intelligent bracelet / mobile terminal and a sensor. The intelligent bracelet / mobile terminal detects the real-time condition of the worker and performs signal interaction with the control center; the sensor detects field equipment and performs signal interaction with the control center; the control center comprises a logic unit, a command unit, a manual unit and a work order unit; the logic unit receives the uploaded detection signal, generates a logic command and outputs the logic command to the command unit; the command unit automatically feeds back a control command to the field positioning equipment according to the logic command / accesses the manual unit / activates the work order unit; the manual unit realizes remote information interaction between the intelligent system fusionplatform and the worker; and the work order unit automatically generates and distributes work orders after being activated. According to the invention, intelligent property equipment management, personnel management and energy management can be realized.

Owner:上海韦英霍文智能科技有限公司

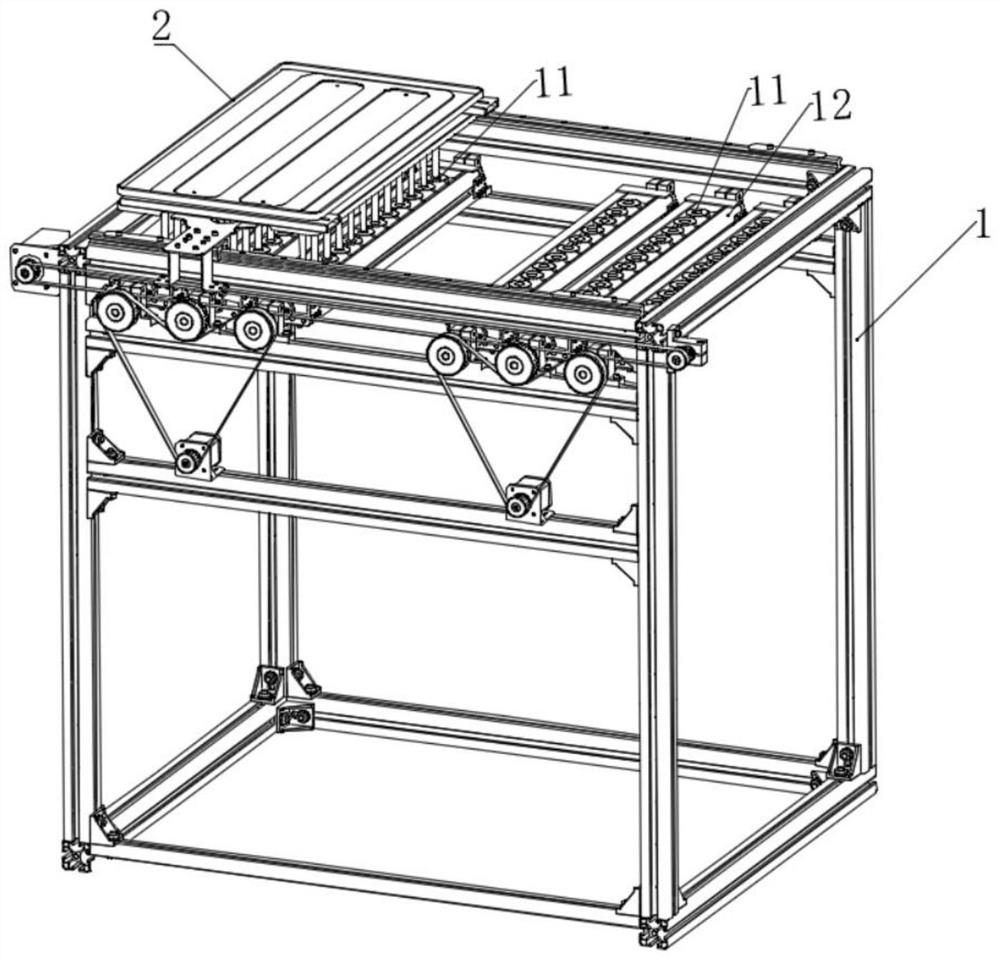

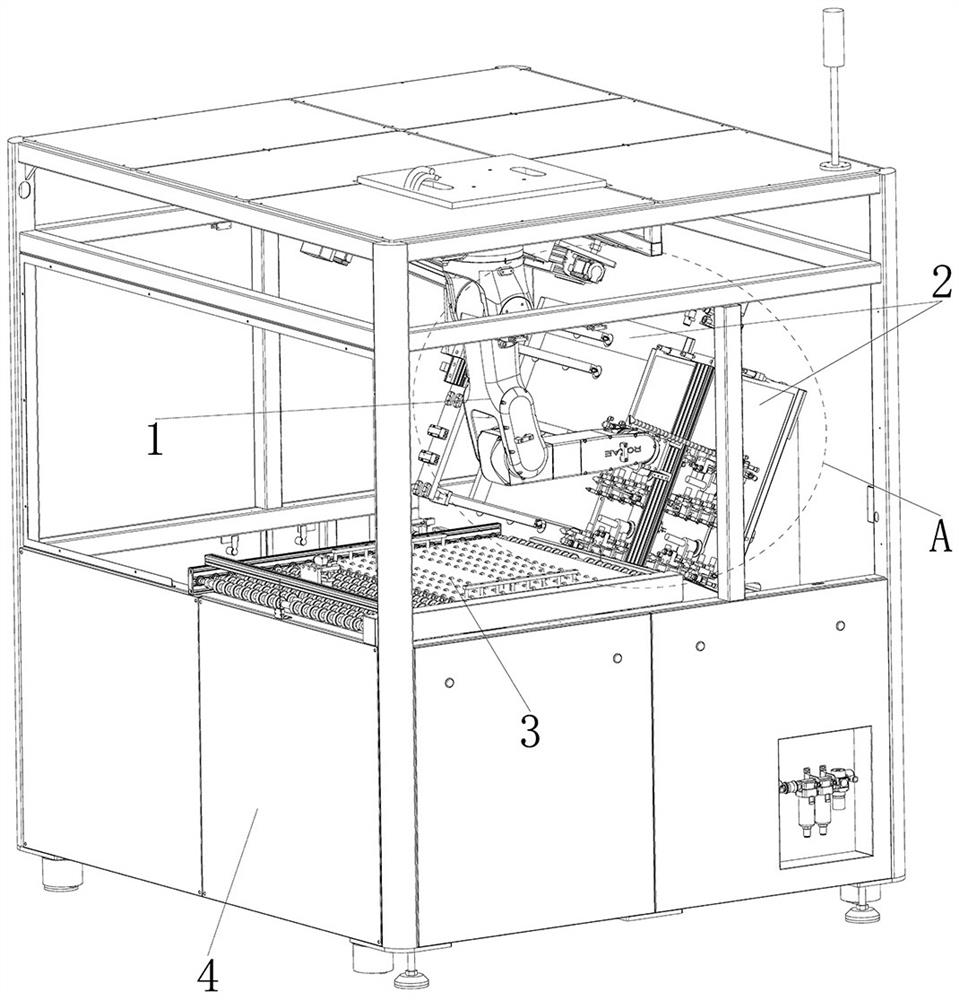

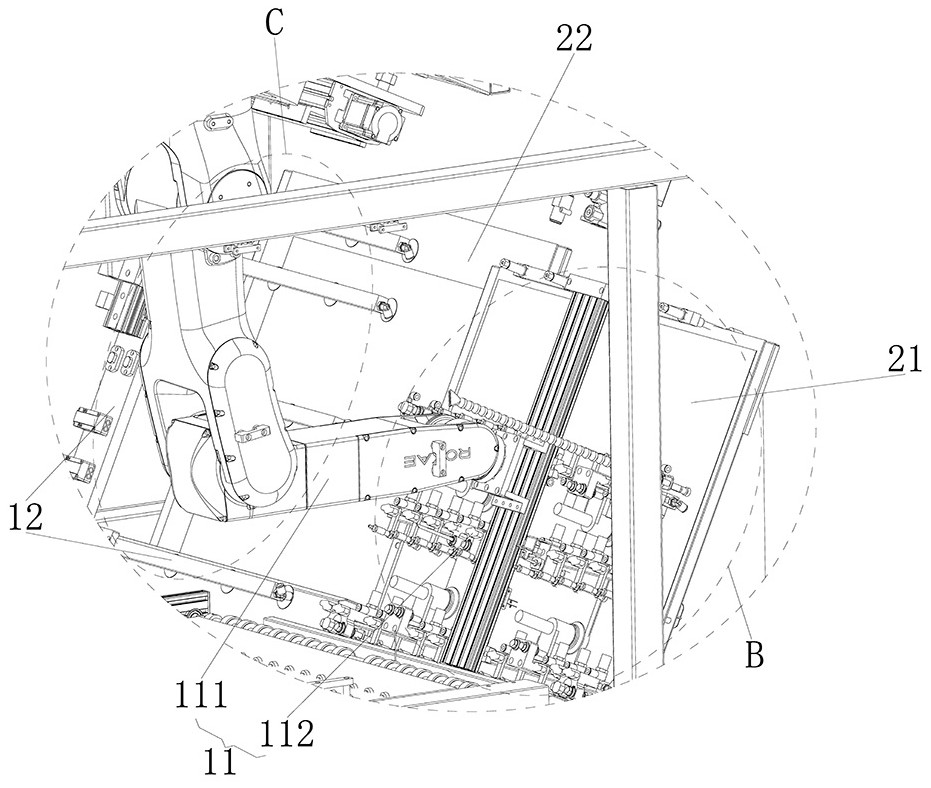

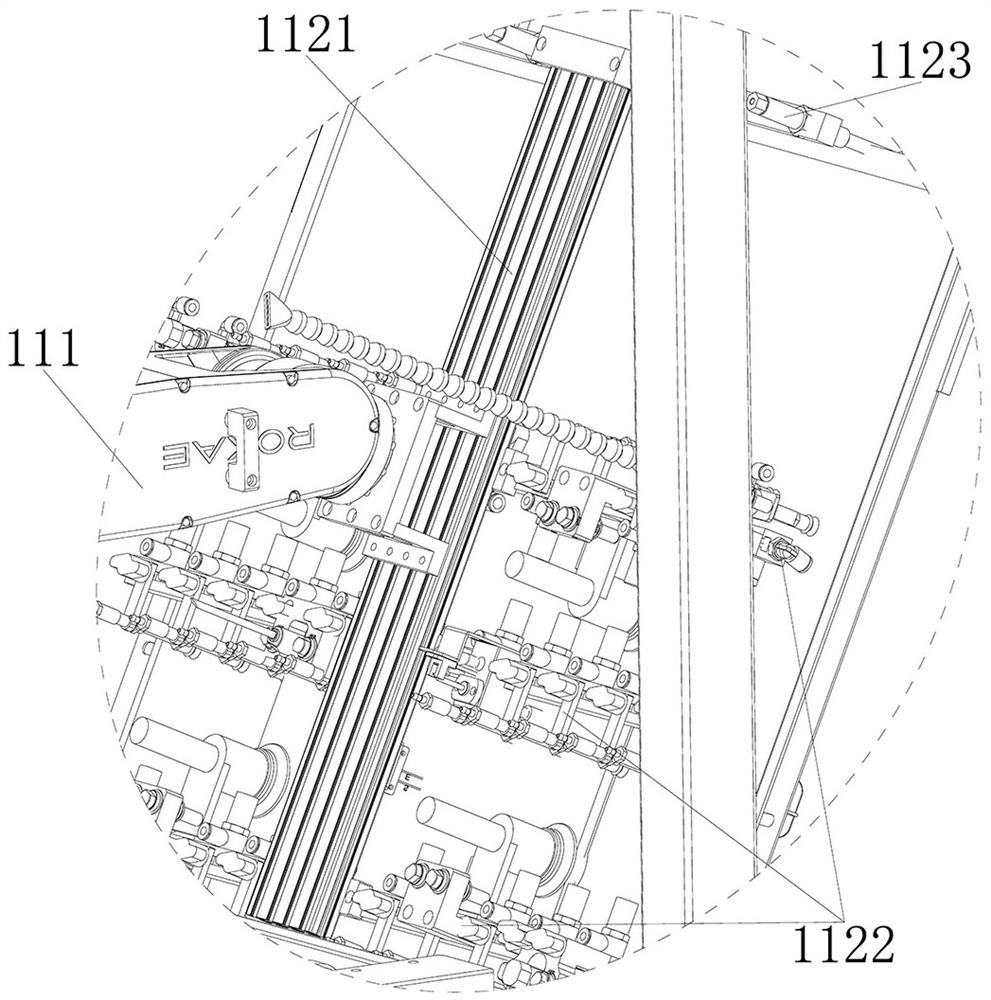

Efficient plate collecting and gummed paper releasing device

PendingCN114030865AReduce labor costsEasy to operateArticle unpackingConveyor partsTransfer mechanismElectrical and Electronics engineering

The invention discloses an efficient plate collecting and gummed paper releasing device which comprises a transferring mechanism. The transfer mechanism comprises a plate moving part and a gummed paper moving part arranged on one side of the plate moving part; the plate moving part comprises a manipulator and a first suction body connected with one end of the manipulator; the gummed paper moving part comprises a sliding body, a lifting body fixedly connected with one end of the sliding body, and a second suction body fixedly connected with one end of the lifting body. Through the arrangement of the plate collecting and gummed paper releasing device, the problem that the operation efficiency is low due to the fact that the operation of separating a circuit board from gummed paper is tedious is solved; the circuit board and the scratch-resistant gummed paper can be automatically separated, the labor cost is reduced, the operation is simple and rapid, the automation degree is effectively improved, the operation efficiency is improved, the circuit board damage caused by the separation operation can be effectively prevented, and the quality of the circuit board is effectively ensured.

Owner:HUIZHOU CHENGTAI AUTOMATION TECH CO LTD

Machine vision method for identifying dial plate information of multi-pointer instrument

ActiveCN102176228BAvoid human errorReduce labor intensityCharacter and pattern recognitionMachine visionMorphological filtering

Owner:HOHAI UNIV CHANGZHOU

a glass hanger

ActiveCN109335688BSolve the problem of low work efficiencyAvoid hittingCharge manipulationConveyor partsStructural engineeringMechanical engineering

Owner:FOSHAN UNIVERSITY

Furniture cutting and edge sealing device

InactiveCN112873469ASolve the problem of low work efficiencyStable jobOther plywood/veneer working apparatusDrilling machinesDrill holeStructural engineering

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

Pneumatic clamp for metal plate fixing

InactiveCN110695741ASolve the problem of low work efficiencyImprove work efficiencyWork clamping meansPositioning apparatusThin metalGas cylinder

The invention discloses a pneumatic clamp for metal plate fixing. The clamp comprises a bottom plate, a gas bottle, a supporting frame and an air cylinder are fixedly connected to the top of the bottom plate, one side of the air cylinder is fixedly connected with a piston, one side of the piston is fixedly connected with a clamping plate, a sliding groove is embedded in the top of the bottom plate, mounting plates are welded to the two sides of the bottom plate, one side of the clamping plate is fixedly connected with a buffer cotton and a spring, one side of the buffer cotton is fixedly connected with a rubber pad, an air exhaust pipe is arranged on the top of the gas bottle in a penetrating manner, one side of the air cylinder is welded with an air pressure meter and an inflation pipe, fixed plates are welded to the front face and the back face of the gas bottle, an air pump box is fixedly mounted on the top of the supporting frame, an overhauling plate is embedded on the front faceof the air pump box, a cooling net is arranged on the front face of the overhauling plate in a penetrating manner, and a connecting pipe is arranged on one side of the air pump box in a penetrating manner. The buffer cotton, the spring and the rubber pad are arranged to solve the problem that an existing clamp easily causes stress deforming to a thin metal plate.

Owner:江苏亚飞机械制造有限公司

Gear operating device for drilling machine

InactiveCN109108886ASolve the problem of low work efficiencyImprove work efficiencyMetal-working hand toolsRotational axisGear wheel

The invention discloses a gear operating device for a drilling machine. A loading-unloading tool comprises a rod body and a working head fixed to one end of the rod body, wherein the working head is clamped to a groove on an external thread protector, when the working head is clamped to the groove on the external thread protector, and the axis of the rod body is perpendicular to a rotating shaft of the external thread protector. The gear operating device is simple in structure, is convenient to operate, solves the problem that the working efficiency is not high when the external thread protector of an external thread joint of a petroleum drilling tool is loaded and unloaded, enables the working efficiency of operation of the petroleum drilling tool to be greatly improved, and enables the working intensity to be reduced.

Owner:XIAN ANT PETROLEUM TECH

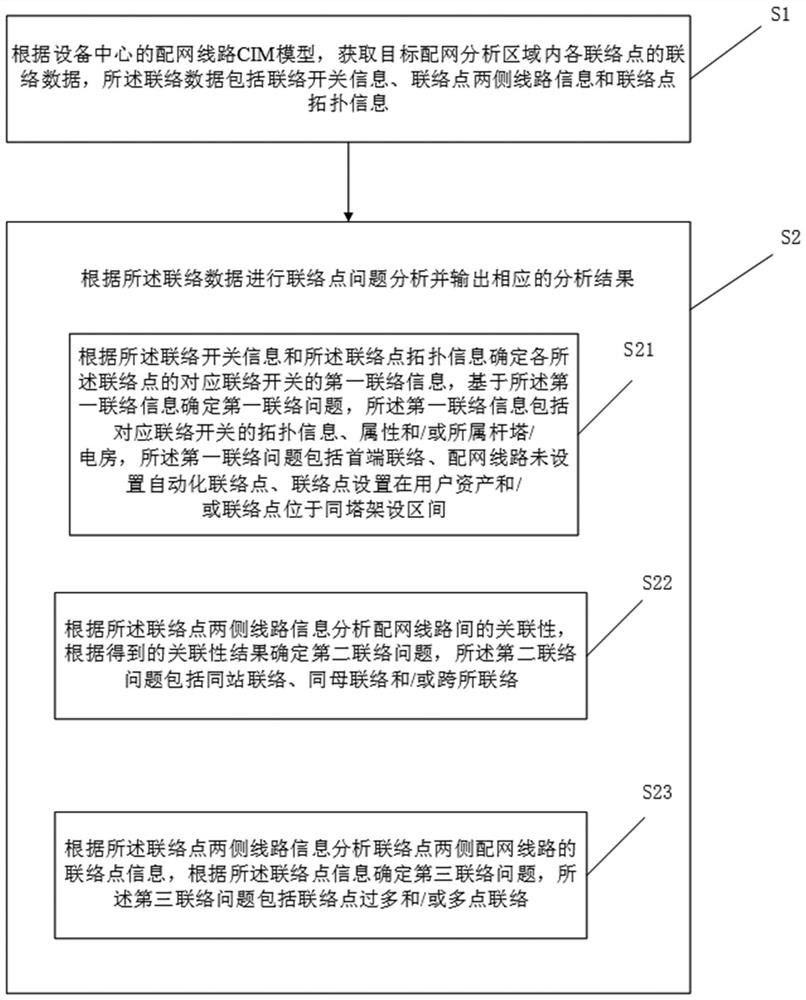

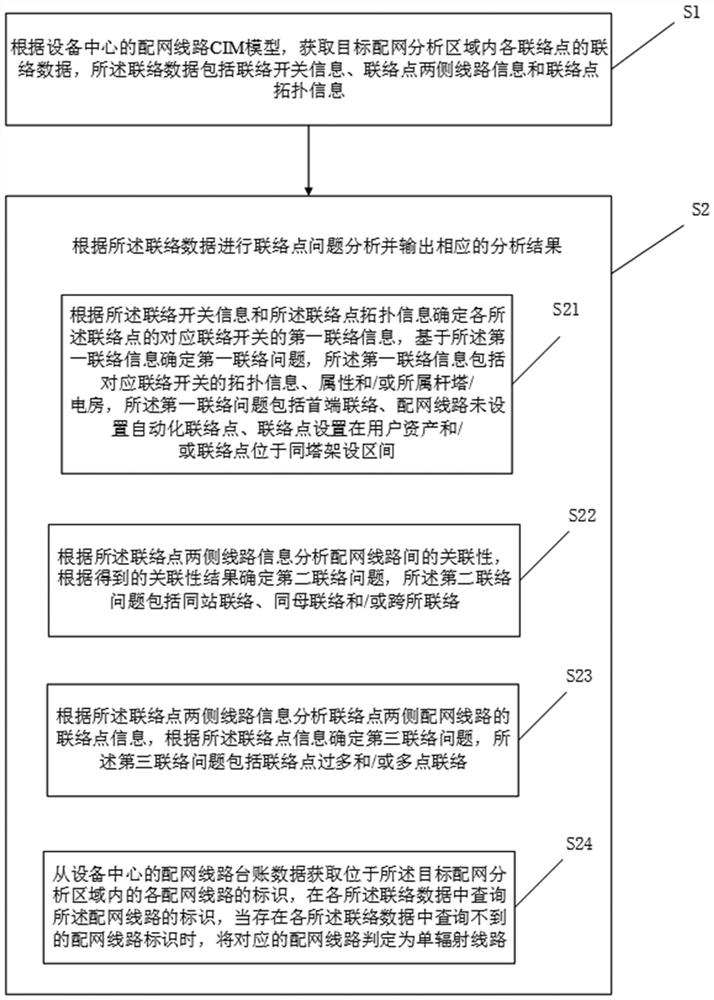

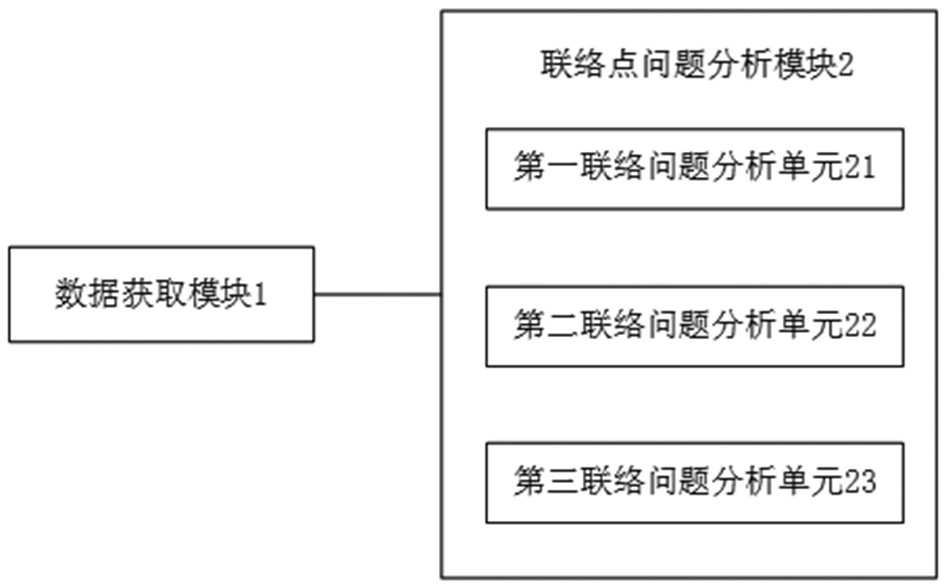

Intelligent analysis method, system and equipment for distribution network line contact point problem

ActiveCN114693185ASolve the problem of low work efficiencySolve the low accuracy of analysisResourcesInformation technology support systemReal-time computingNetwork analysis

The invention relates to the technical field of distribution network analysis, and discloses a distribution network line contact point problem intelligent analysis method, system and device. The method comprises the following steps: acquiring contact data of each contact point in a target distribution network analysis area according to a distribution network line CIM model of an equipment center; analyzing a contact point problem, including analyzing a corresponding contact switch of the contact point according to the contact switch information and the contact point topological information to determine whether the contact problem includes head end contact, no automatic contact point of the distribution network line, the contact point being arranged in the user assets and / or the contact point being located in the same tower erection interval; analyzing the relevance between the distribution network lines according to the information of the lines on the two sides of the contact point to determine whether the contact problem comprises co-station contact, co-bus contact and / or cross-station contact; and / or analyzing the distribution network lines on the two sides of the contact points to determine whether the contact problem comprises excessive contact points and / or multi-point contact. According to the invention, efficient and accurate analysis of the distribution network line connection problem is realized.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com