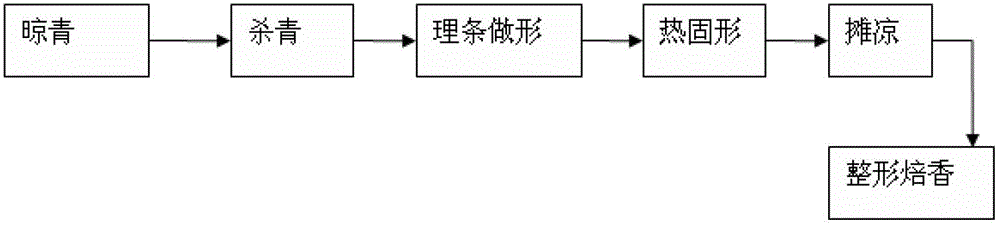

Processing process for Yungu Dafang tea

A kind of tea processing and generous technology, applied in the field of Yungu Dafang tea processing technology, can solve the problems that the leaves are difficult to kill evenly and thoroughly, difficult to process and produce in batches, and the leaf edges are easy to dry, so as to improve the processing efficiency and the quality of the greening. , rich aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A processing technology of Yungu Dafang tea,

[0025] (1) Drying the green tea to enhance the fragrance, by spreading the fresh leaves moderately to make the dried tea have a floral fragrance.

[0026] (2) Penetrating and stuffy combined degreening, which is composed of an electric heating roller degreening machine, the temperature is controlled from high to low, and the leaves enter the high temperature part of the degreening machine (about 280 ℃) to quickly lose moisture and inactivate the activity of enzymes, and then enter the lower temperature part at the back (About 200°C), further lose water, make the contained components moderately transformed, until the greening is moderate.

[0027] (3) The strips are shaped by temperature control, which is formed by connecting a hot-air strip machine and a half-pot flat tea machine. The leaves first enter the hot-air strip machine (about 140°C) to straighten the tea strips, and then enter the flat tea Machine (about 110°C) f...

Embodiment 2

[0031] A processing technology of Yungu Dafang tea, comprising the following steps:

[0032] (1) Air-drying to enhance fragrance: Under the condition of controlling a certain temperature (about 25°C), the fresh leaves are moderately air-dried to promote the effective transformation of their aroma precursors, and the dried tea has a floral aroma.

[0033] (2) Penetrating and stuffy combined degreening: It is composed of an electric heating drum degreening machine. The temperature is controlled first high and then low. The leaves enter the high temperature part of the degreening machine with a temperature of about 280°C to quickly lose water and inactivate the activity of the enzyme, and then enter the back The lower temperature part of the cylinder with a temperature of about 200°C further loses water and moderately transforms the contained components until the greening is moderate, and the leaves are moderately greening;

[0034] (3) Stretching and temperature control to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com